Flux-free aluminium alloy additive agent and preparation method

An additive and aluminum alloy technology, which is applied in the field of flux-free aluminum alloy additives and preparation, can solve problems such as air, soil and water pollution, and achieve the effects of improved purity of melt, simple addition method, and stable content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

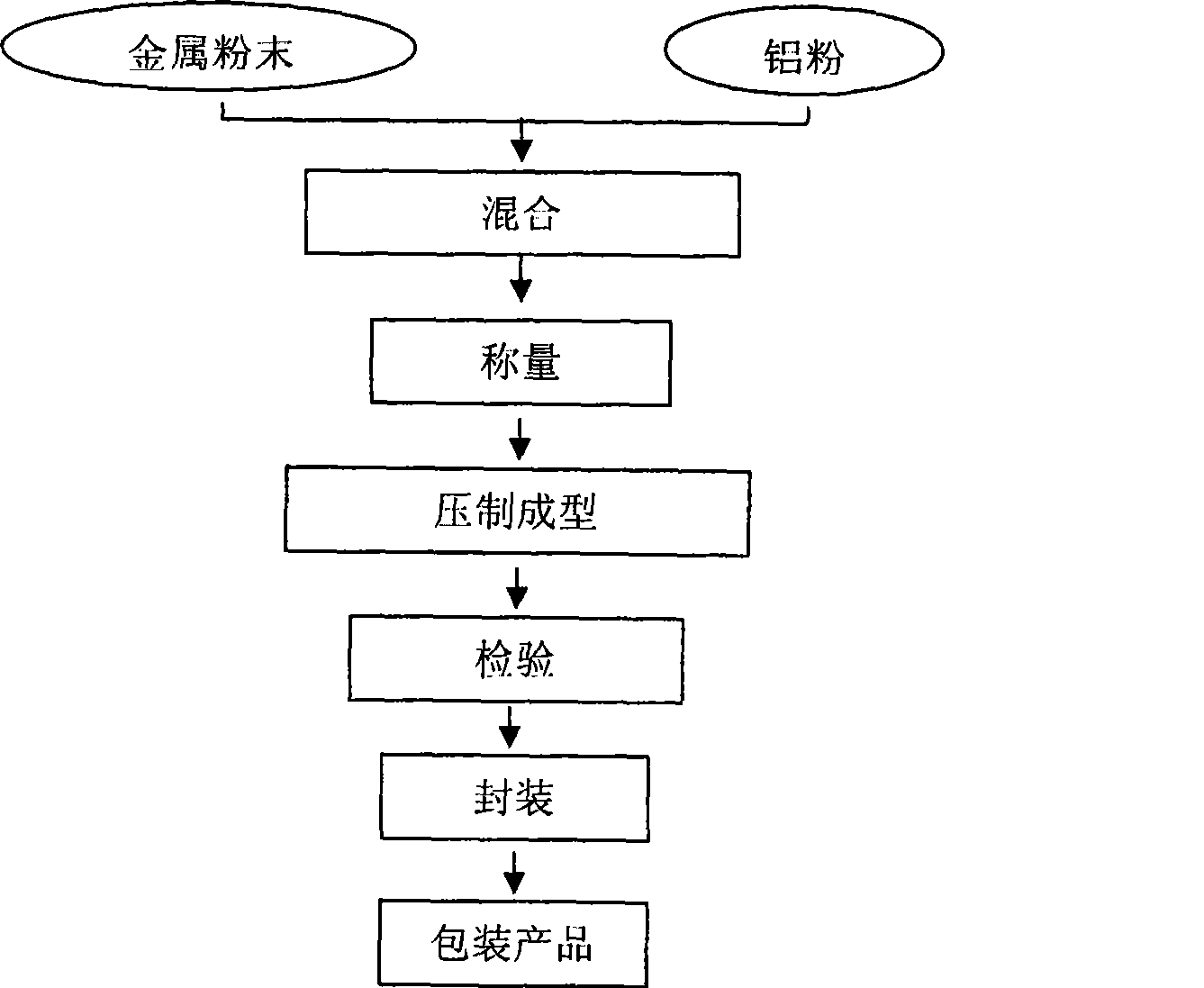

[0023] 2. Preparation of Additives

[0024] Add 5% to 30% aluminum powder to the metal powder, mix well and press it into a briquette of 50 to 500g with a press after weighing. After passing the inspection, it is sealed and packaged.

Embodiment 1

[0025] Example 1 Iron additive

[0026] (1) Using known methods to prepare iron powder with a purity of not less than 98% and an average particle size of the powder between 0.01 and 0.5 mm, and aluminum powder with a purity of not less than 95% and an average particle size of the powder between 0.01 and 0.5 mm;

[0027] (2) by 80% iron powder, the proportioning of 20% aluminum powder mixes raw material in mixer;

[0028] (3) After fully mixing evenly, press it into a 200g briquette with a press for weighing, and seal the package.

Embodiment 2

[0029] Example 2 Manganese additive

[0030] (1) Manganese powder with a purity of not less than 98% and an average powder particle size of 0.01 to 0.5 mm and an aluminum powder with a purity of not less than 95% and an average powder particle size of 0.01 to 0.5 mm are prepared by known methods;

[0031] (2) by 85% iron powder, the proportioning of 15% aluminum powder is mixed with raw material in mixer;

[0032] (3) After fully mixing evenly, press into a 50g briquette with a press for weighing, and seal the package.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com