Patents

Literature

226results about How to "Shorten the smelting cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

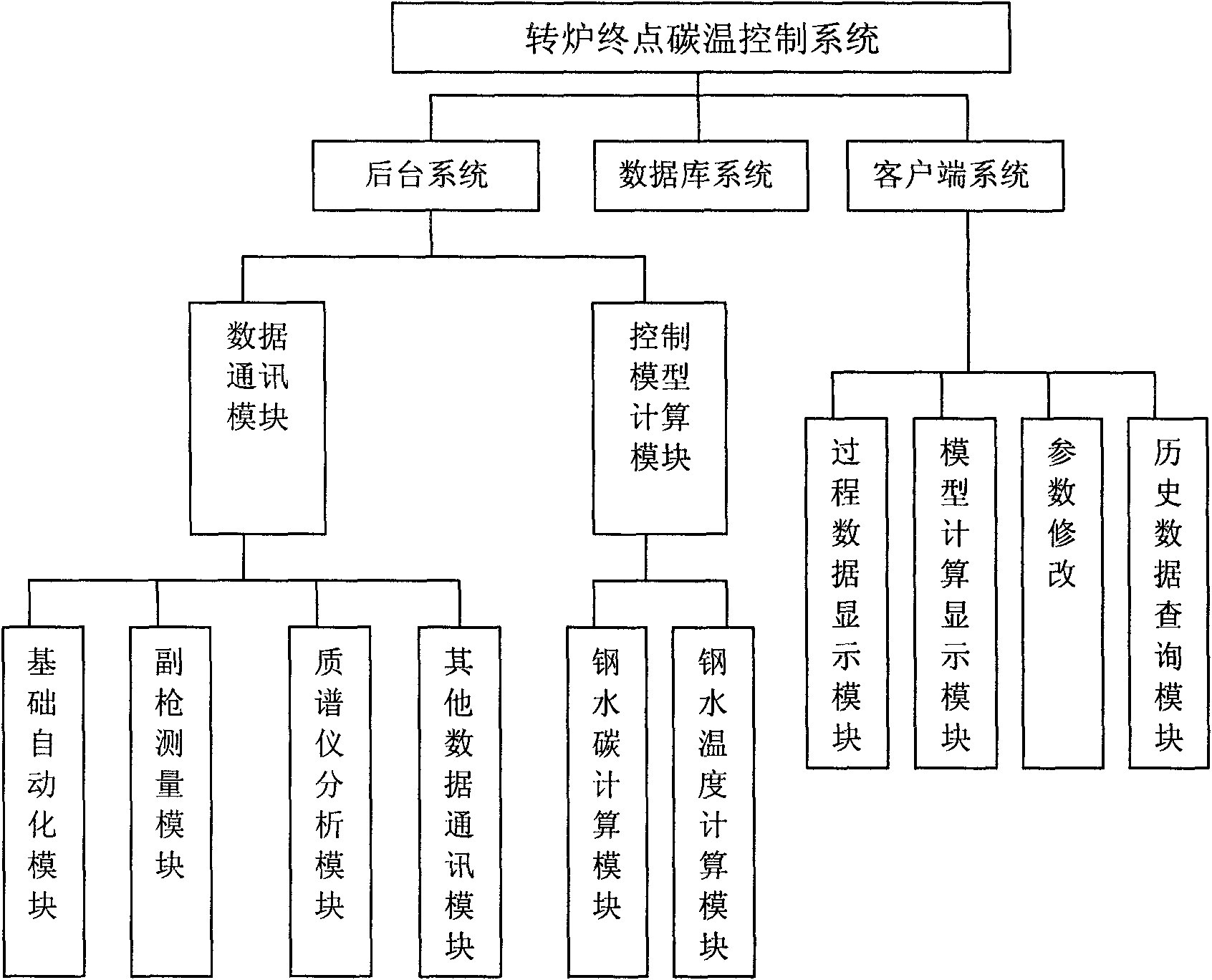

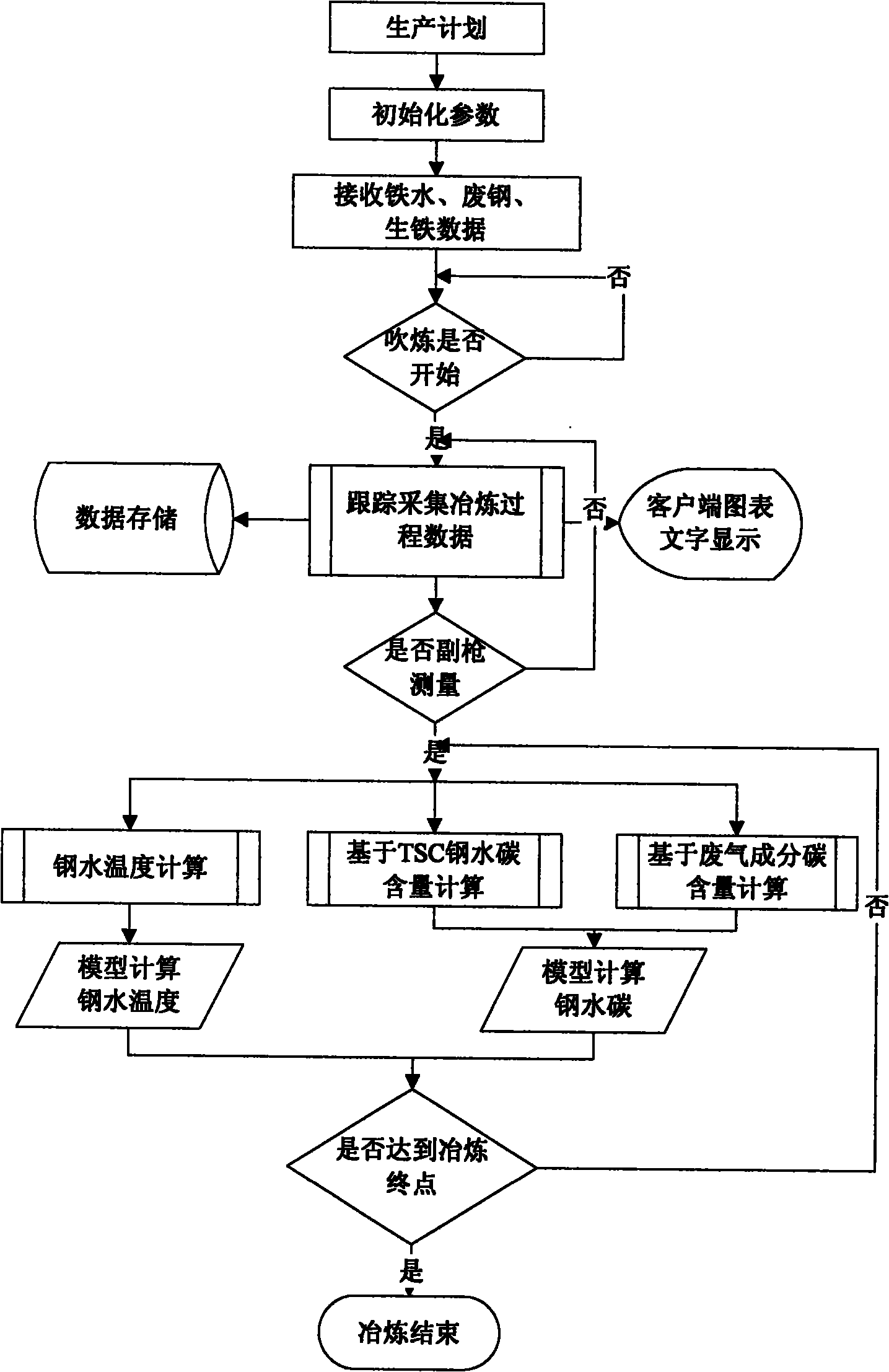

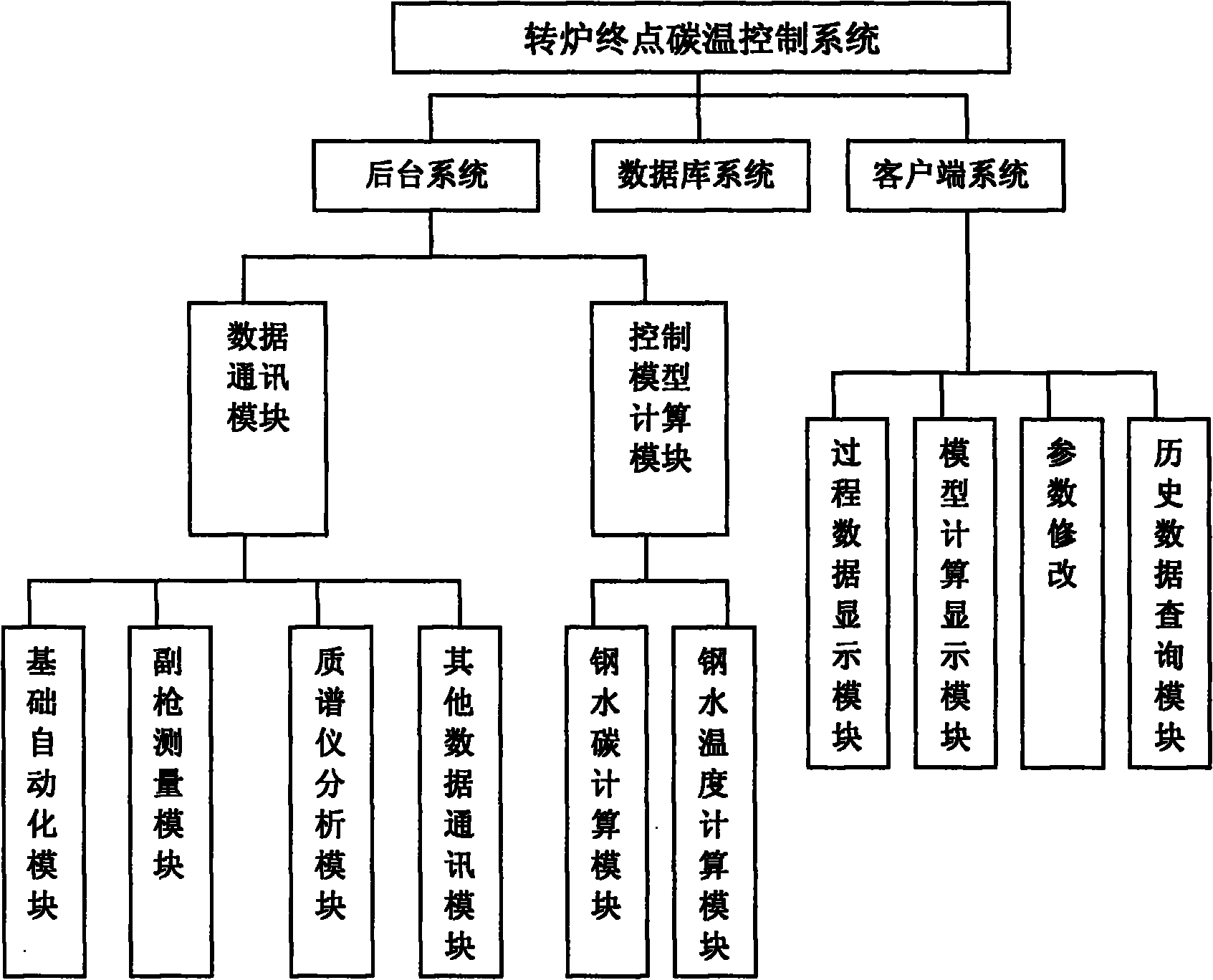

Converter smelting endpoint molten steel carbon and temperature control system and method thereof

ActiveCN101845531AEffective controlUnderstand clearlyManufacturing convertersSteelmakingTemperature control

The invention discloses a converter smelting endpoint molten steel carbon and temperature control system and a method thereof, and belongs to the technical field of converter steelmaking automation control. The converter smelting endpoint molten steel carbon and temperature control system comprises hardware equipment and a software processing module, and is characterized in that: the hardware equipment comprises converter sublance measuring equipment and converter exhaust gas analysis equipment; the software processing module comprises a converter production process data acquisition module, a converter smelting endpoint carbon calculation module, a converter smelting endpoint temperature calculation module, and an information display module; the software processing module is operated on a computer; and the hardware equipment and the software module are connected with a converter production process database through an Ethernet to realize data interaction. The control system and the method thereof have the advantages of accurately controlling the converter smelting endpoint molten steel carbon content and the molten steel temperature, along with stable operation, cost conservation, and wide application range.

Owner:HEBEI SHOUGANG QIAN AN IRON & STEEL CO LTD +2

Slag adjusting and furnace protecting method for controlling rising of converter bottom and furnace wall slag deposition

InactiveCN102127612AIncrease the content of MgOImprove furnace protection effectManufacturing convertersSteelmakingSludge

The invention belongs to the technical field of steelmaking and provides a slag adjusting and slag splashing furnace protecting method for controlling rising of a converter bottom and furnace wall slag deposition, solving the problems that the effective volume is reduced and the center of gravity of a furnace body shifts as slag stacked at the converter bottom rises and slag deposits at the lining of the furnace wall when the traditional slag splashing furnace protecting process is adopted. The method provided by the invention is characterized by adopting a two-step slag adjusting method, primary slag adjusting is carried out before molten steel is tapped, a boric sludge-magnesia slag adjusting agent is added into a furnace to reduce the viscosity of the slag, slag deposition at the lining of the unilateral furnace wall and slagging at the converter bottom in the tapping process can be prevented, the slag remaining and no steel remaining operation is adopted in the follow-up tapping process; and secondary slag adjusting is carried out after tapping, namely a magnesia carbon slag adjusting agent (coke powder and material containing magnesium oxide) is added into the slag remained in the furnace, and then the slag splashing slag protecting process is carried out. By adopting the method provided by the invention, the rising of the converter bottom and thickening of slag depositedon the furnace wall can be controlled, the thickness uniformity of the furnace wall can be guaranteed, and the slag splashing furnace protecting effect is obviously improved, thus the service life ofthe lining of a converter can be greatly prolonged.

Owner:JIANGSU UNIV

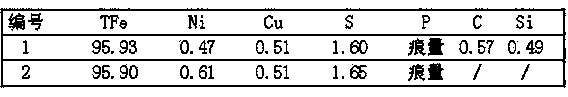

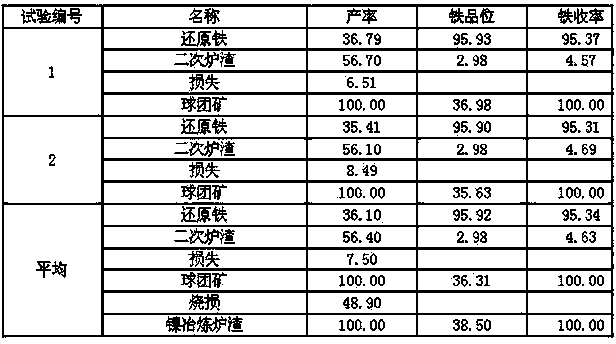

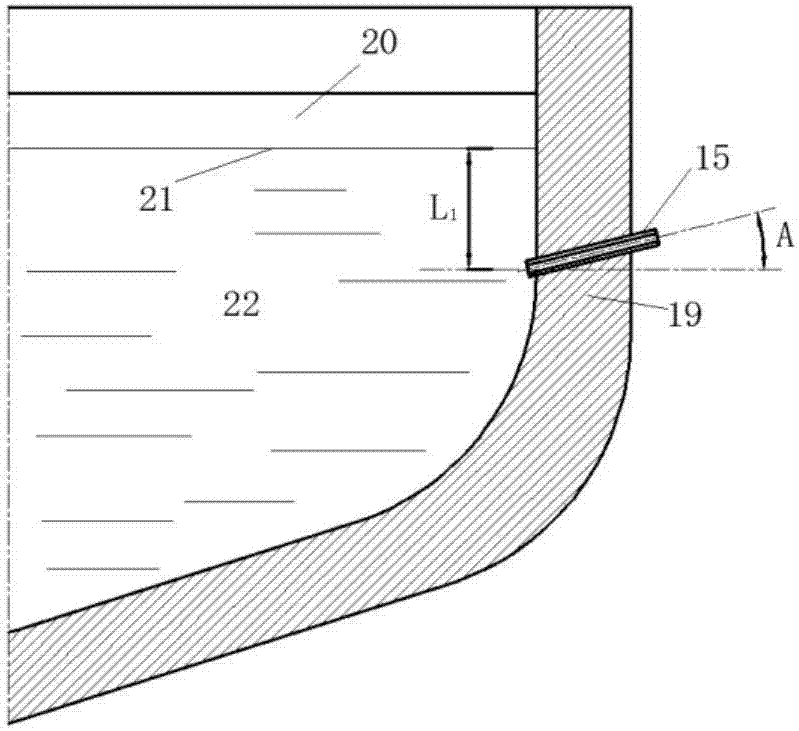

Method for treating nickel smelting furnace slag

The invention method provides a method for treating nickel smelting furnace slag and relates to a method for treating nickel smelting furnace slag by a rotary hearth furnace reduction-gas furnace melting separation combined process. The method is characterized by sequentially comprising the following process steps: (1) adding a reducing agent, a fusing agent and an adhesive into the nickel smelting furnace slag and mixing; (2) pressing into pellets; (3) drying the pressed pellets; (4) charging the dried carbon-containing pellets into a preheating section of a rotary hearth furnace and preheating; (5) reducing the carbon-containing pellets in a reducing section of the rotary hearth furnace to obtain thermal-state metallized pellets; and (6) adding the hot pellets into the gas furnace for melting separation to realize final reduction and scrap iron melting separation. By the method, valuable elements in the nickel smelting furnace slag can be comprehensively recovered, continuity of a preparation process is realized, molten iron for steel-making can be provided, and secondary slag for developing and producing products such as slag micropowder, foamed ceramic and aerated concrete blocks also can be provided, and zero emission of solid wastes is realized.

Owner:JINCHUAN GROUP LIMITED

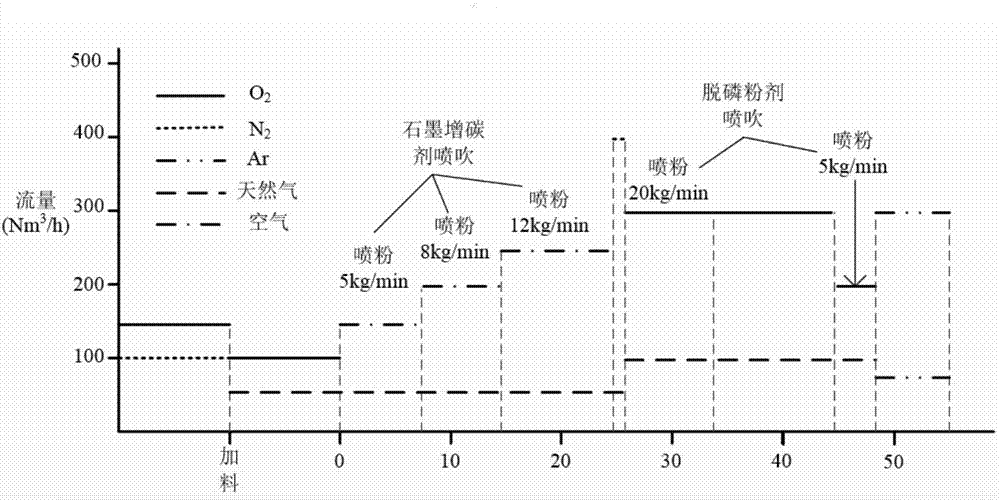

Full-steel-scrap electric arc furnace cleanness rapid smelting method

ActiveCN107502702AImprove cleanlinessShorten the smelting cycleProcess efficiency improvementElectric furnaceSteelmakingElectric arc furnace

The invention belongs to the technical field of electric arc furnace steelmaking and particularly relates to a full-steel-scrap electric arc furnace cleanness rapid smelting method which is applicable to the 30-300t full-steel-scrap electric arc furnace smelting process. According to the full-steel-scrap electric arc furnace smelting process, spray guns buried in refractory materials on the side faces of the furnace bottom of an electric arc furnace are used for blowing different types of media at different smelting stages; at the stage of recarburization and melting acceleration, melting-down of a molten pool is accelerated through carburization, and the carbon content of the molten pool is increased. At the stage of high-efficiency dephosphorization and deep denitrification, molten pool reaction is intensified to conduct high-efficiency dephosphorization and deep denitrification. Accordingly, the smelting rhythm of the full-steel-scrap electric arc furnace is accelerated, the dephosphorization and denitrification effects are improved, the cleanness of molten steel is improved, and full-steel-scrap electric arc furnace cleanness rapid smelting is realized.

Owner:UNIV OF SCI & TECH BEIJING

Rapid desulfurization refining method for ladle furnace

The invention discloses a rapid desulfurization refining method for a ladle furnace (LF). The method comprises the following steps of: 1) performing desulfurization refining in the LF, wherein the LF treatment starting temperature is between 1,570 and 1,605 DEG C; 2) after a ladle argon blowing device of the LF is turned on, blowing argon from the bottom of the ladle; 3) after finishing adjusting the temperature, inserting a desulfurization powder spraying gun into a molten steel liquid for spraying a desulfurizing agent; 4) after finishing spraying powder, switching the spraying gun to a functional stage of blowing the argon, blowing the argon from the top, simultaneously blowing the argon from the bottom of the ladle, and performing strong stirring desulfurization operation; 5) alloying, namely after desulfurization is finished, lifting the desulfurization powder spraying gun, adjusting a ladle bottom blowing flow, and performing alloy configuration to meet a target requirement on final components of a steel grade; and 6) after finishing adjusting components, performing soft stirring operation, measuring the temperature, sampling, and turning off the ladle argon blowing device to finish treating. The method realizes rapid desulfurization of the LF, and can shorten an overall melting cycle and improve the number of continuous casting furnaces and production efficiency.

Owner:BAOSHAN IRON & STEEL CO LTD

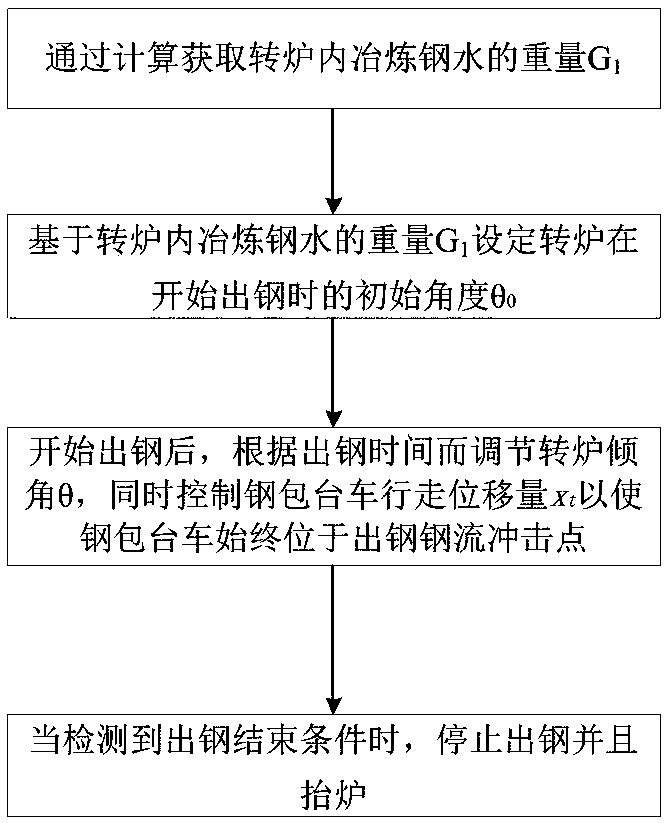

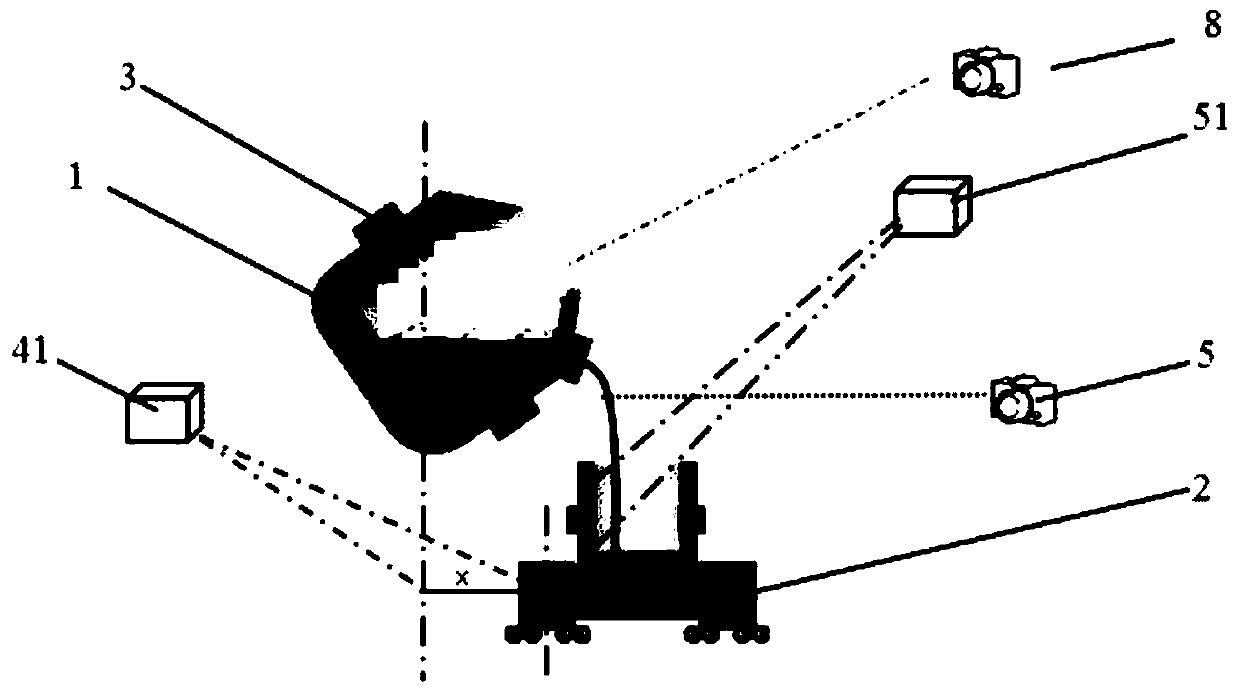

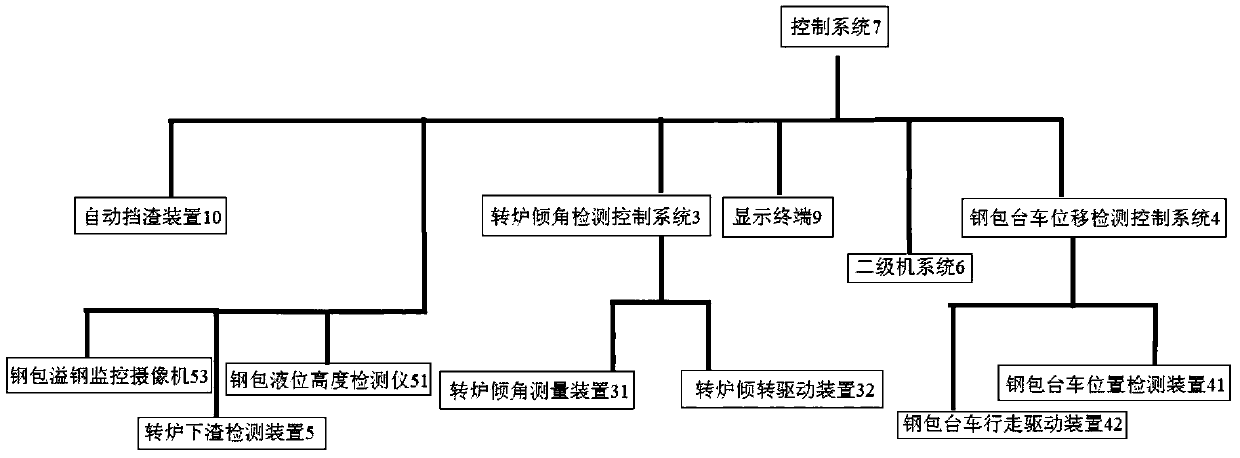

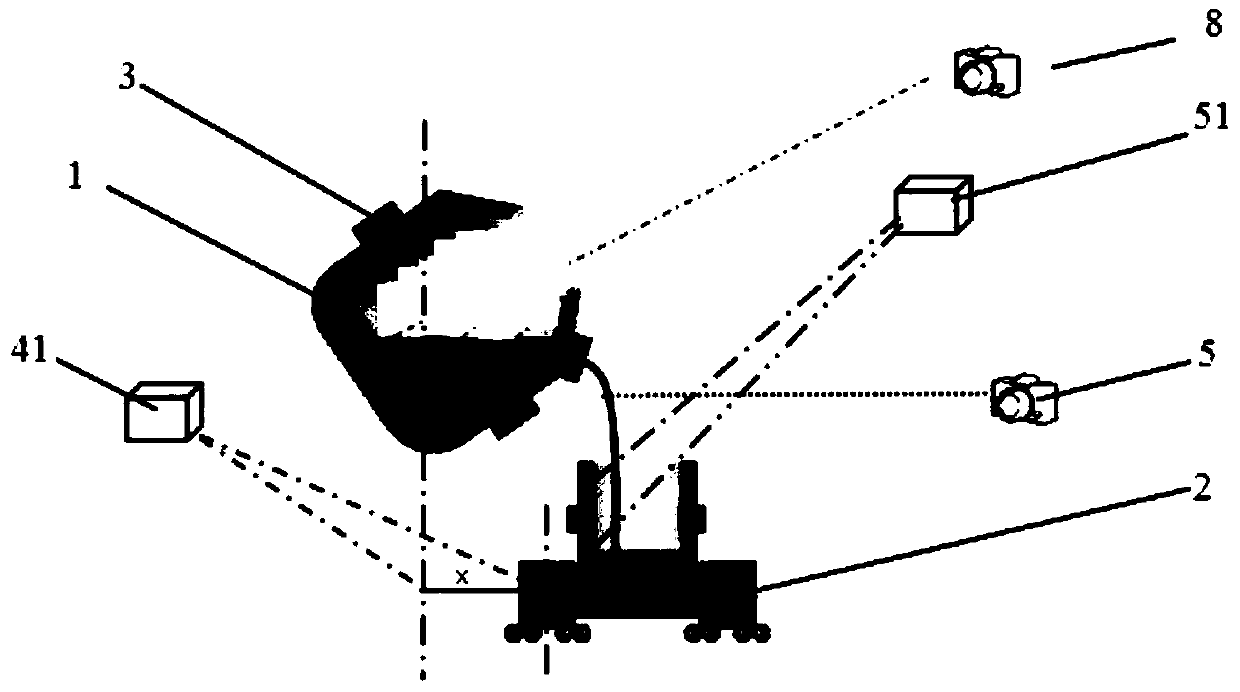

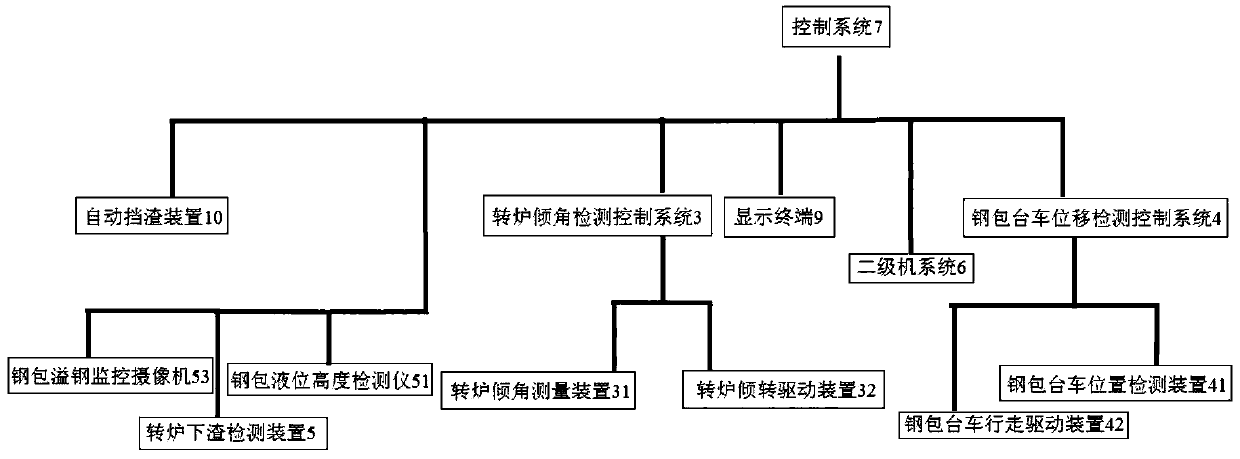

Full-automatic steel tapping method and system of converter

InactiveCN110616288AReduce incidenceLess investmentSteel manufacturing process aspectsManufacturing convertersMeasurement deviceMicrocomputer system

The invention discloses a full-automatic steel tapping method of a converter. The method comprises the steps of (1) obtaining the weight G1 of smelting molten steel in the converter through calculation; (2) based on the weight G1 of the smelting molten steel in the converter, setting the initial angle theta 0 when steel tapping of the converter begins; (3) after steel tapping begins, adjusting theinclination angle theta of the converter according to the steel tapping time, and meanwhile, controlling the walking displacement xt of a steel ladle trolley, so that the steel ladle trolley is located at a steel tapping steel flow impact point all the time; (4) when a steel tapping end condition is detected, stopping steel tapping and lifting up the converter. The invention further discloses a full-automatic steel tapping system of the converter. The system comprises the converter, the steel ladle trolley, a second-level microcomputer system storing steel grade smelting information, a converter inclination angle measurement device for measuring the inclination angle of the converter, a converter tilting driving device connected with the converter, a steel ladle trolley position detectiondevice for detecting the position of the steel ladle trolley in the walking direction, a steel ladle trolley walking driving device connected with the steel ladle trolley, a slag discharging device and a control system.

Owner:BAOSHAN IRON & STEEL CO LTD

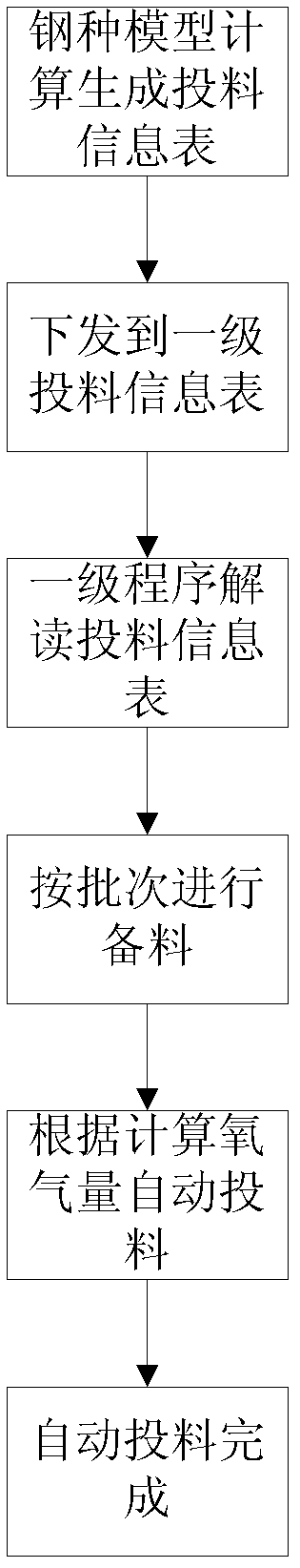

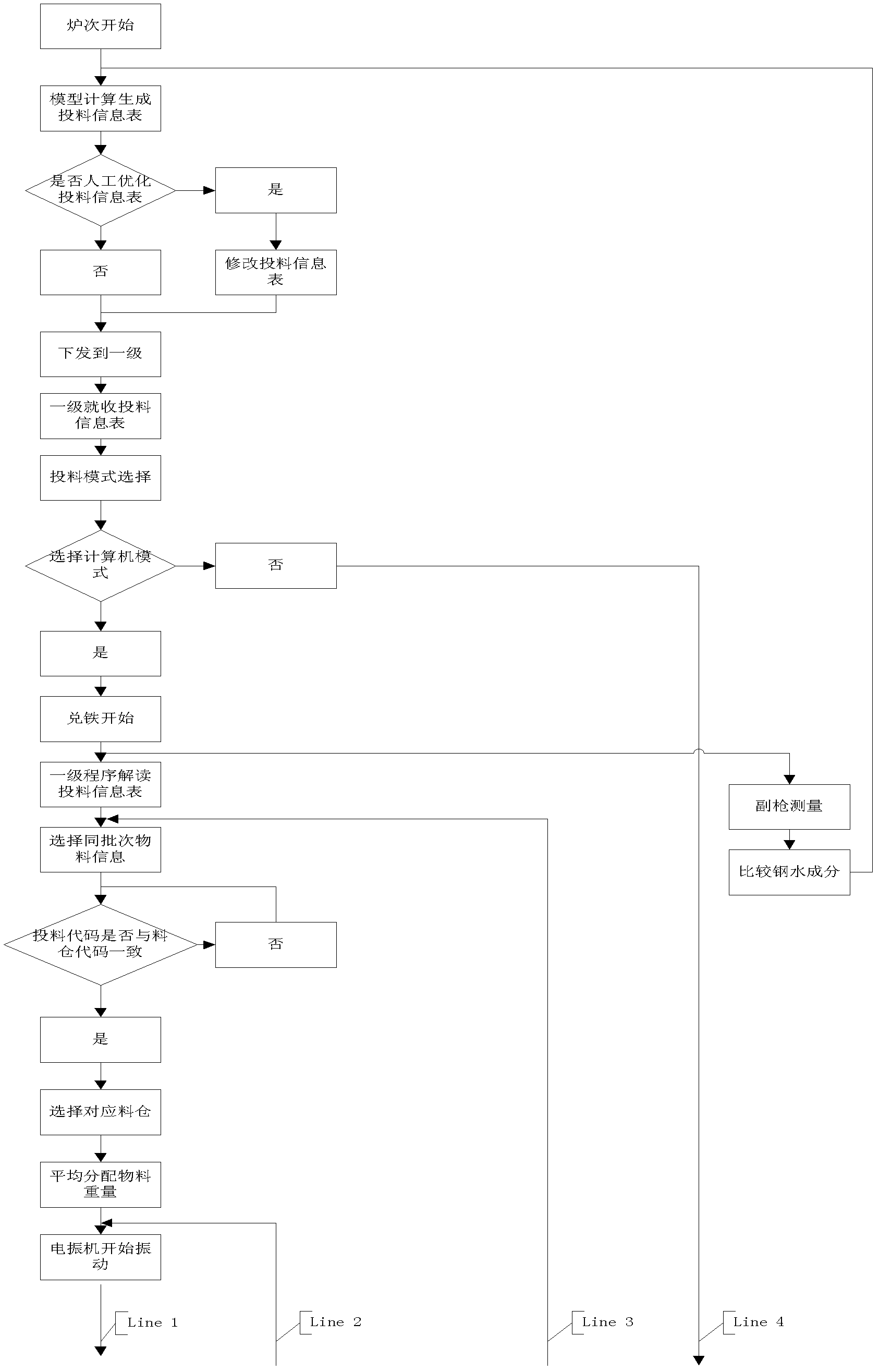

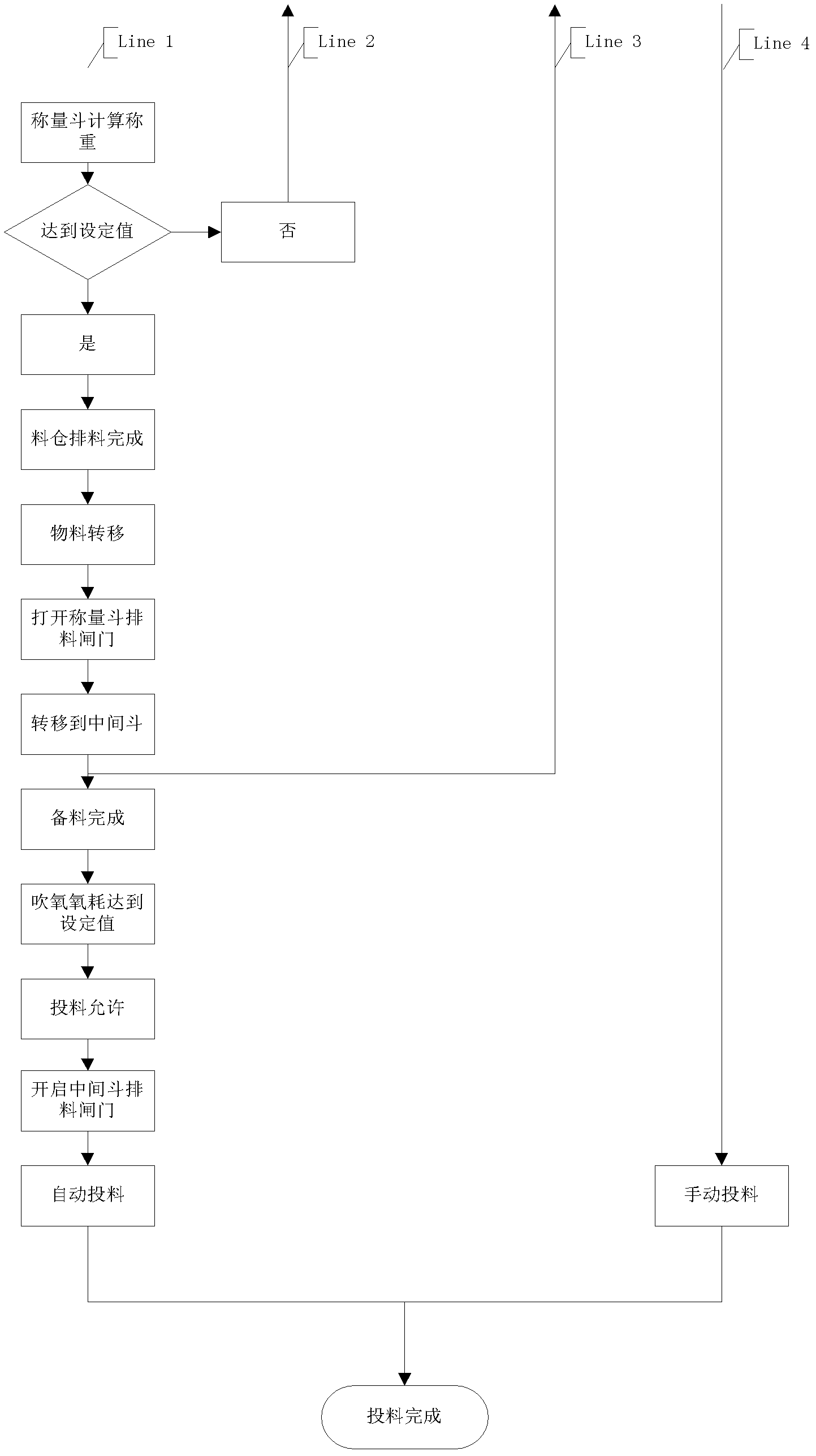

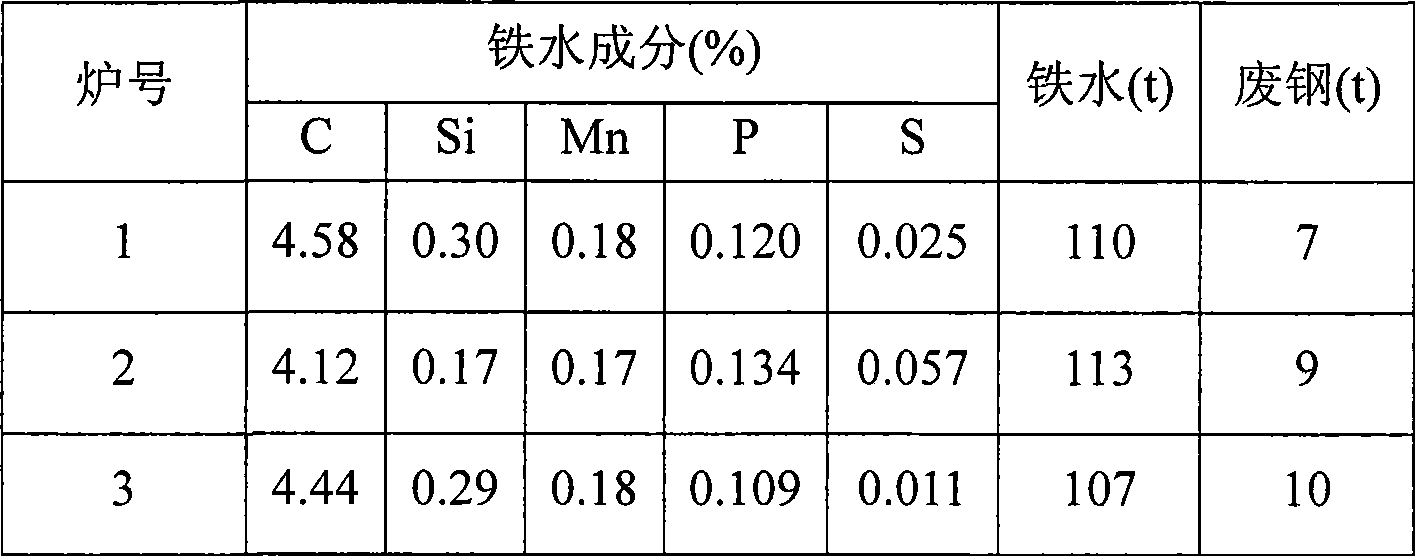

Static-dynamic automatic feeding method in converter smelting process

ActiveCN102586535AReduce the difficulty of operationPrecise feedingManufacturing convertersMaterials preparationAutomatic control

A static-dynamic automatic feeding method in the converter smelting process belongs to the technical field of automatic control. In the converter smelting process, according to various factors such as components of loaded molten iron, added scrap steel amount and remaining slag amount and by calculation of a secondary steel grade model, a static feeding information sheet is generated and issued to a primary programmable logic controller (PLC) control procedure. The primary PLC control procedure receives material information of the feeding information sheet, prepares materials for secondary material information according to the technological requirements and the principle that an identical material is equally distributed in an identical bin, performs material transfer in real time and automatically carries out converter feeding according to smelting oxygen-blowing amount. After sublance converting medium-term measurement is finished, molten steel components are measured. According to comparing difference between measurement components and target components, the secondary steel grade model undergoes calculation again to generate a dynamic feeding information sheet, the dynamic feeding information sheet is issued to the primary PLC control procedure, and material preparation and feeding are automatically carried out. The static-dynamic automatic feeding method has the advantages of effectively solving the problems that manual feeding is not timely, unstable and inaccurate and the like, improves working efficiency and smelting hit rate, reduces feeding cost, shortens smelting cycle, effectively reduces labor and guarantees continuous and stable high-level automatic production.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

Method for reducing and smelting titania slag by utilizing vanadium-titanium-iron ore concentrates in molten state

The invention provides a method for reducing and smelting titania slag by utilizing vanadium-titanium-iron ore concentrates in a molten state. The method comprises the following steps: mixing the vanadium-titanium-iron ore concentrates with titanium ore concentrates and adding a carbonaceous reducing agent and a binder, thus forming a mixture; reducing the mixture and then performing slag-iron separation treatment, thus obtaining semisteel and titanium slag; and spraying water to the surface of the titanium slag obtained through slag-iron separation treatment so as to rapidly cool the titanium slag to 600-850 DEG C in a cooling process, thus forming the acidsoluble titania slag. The method provided by the invention can be used for efficiently utilizing the Fe and TiO2 in the vanadium-titanium-iron ore concentrates and has the advantages of stable molten-state reduction process, good effect in smelting and separating process, stable furnace condition, short smelting period, low power consumption level, low production cost and the like.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

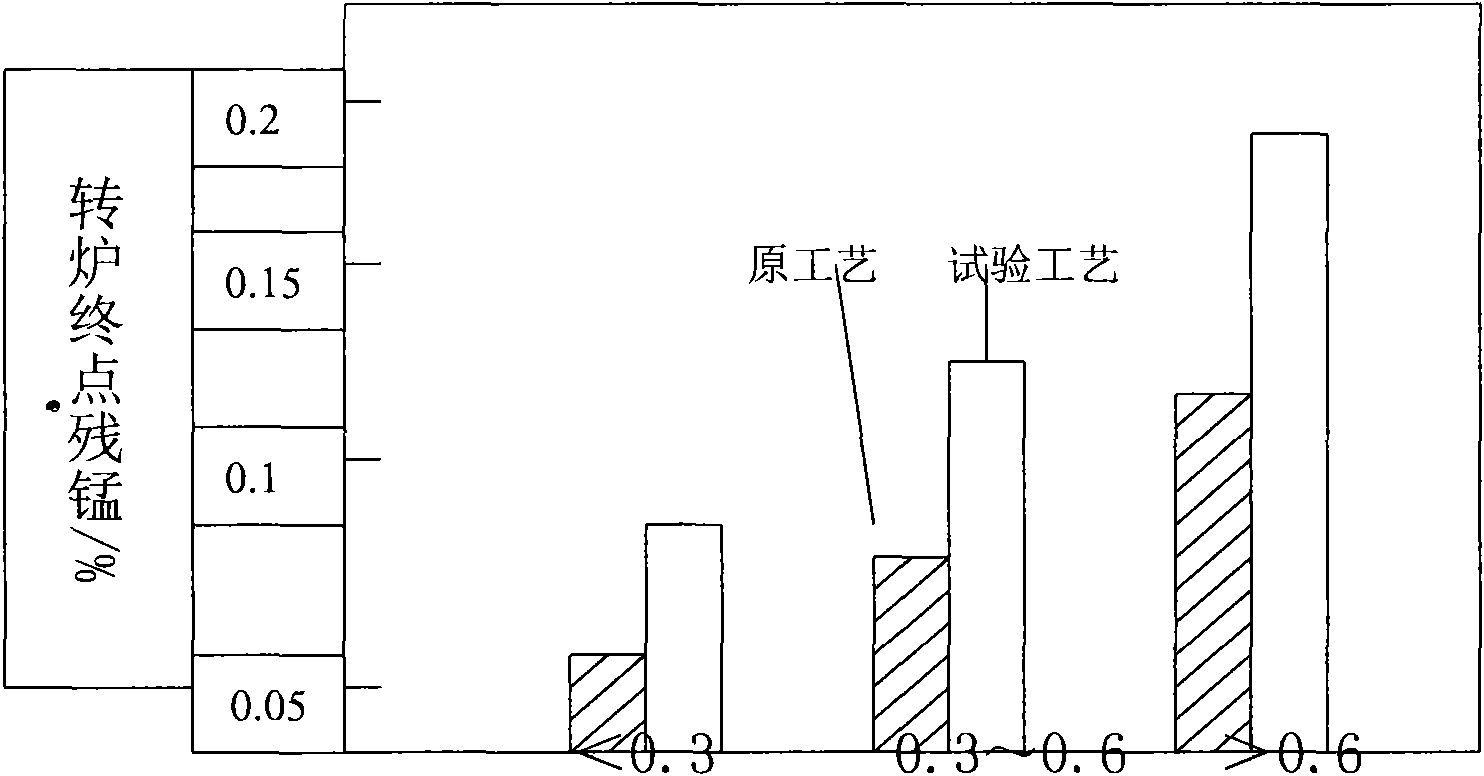

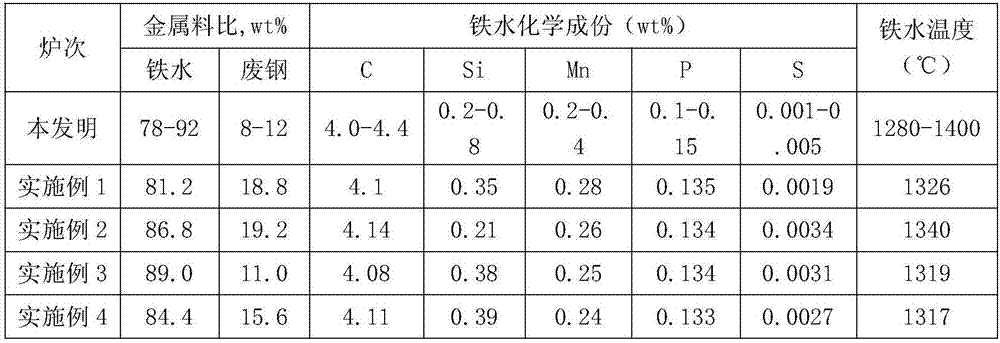

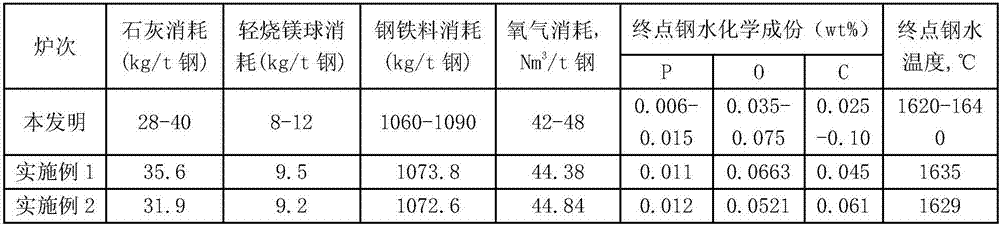

Efficient smelting technology for producing low-phosphorous clean steel through converter

ActiveCN109897933AEfficient separationReduce lossManufacturing convertersProcess efficiency improvementSlagDolomite

The invention discloses an efficient smelting technology for producing low-phosphorous clean steel through a converter. According to the technology, furnace slag of last furnace is subjected to slag splashing treatment, final slag is totally or partially left in the furnace, raw materials are added for smelting, during the one-time gun going and blow beginning stage, the gun position and flow of an oxygen gun are controlled, after the gun goes down and is ignited, an iron oxide ball adding and mine returning begin, then lime and light calcined dolomite are added, after all is added, the gun position is gradually hoisted up, and slag is poured; and the gun position and flow of the oxygen gun are controlled secondly, after fire is on, the lime begins to be added, the slag is adjusted in time, the position and the oxygen supply amount of the oxygen gun are controlled, finally, furnace pouring is carried out, the gun is lifted, and finally, the furnace slag is totally left in the converterfor slag and phosphorous curing, and used for smelting in next furnace. According to the technology, the slag added when the converted smelts the low-phosphorous clean steel is adjusted in time, thegun position and the oxygen supply amount of the oxygen gun are controlled, the final point steel tapping condition can meet the high-cleanness low-phosphorous steel converter final point control condition with C larger or equal to 0.12% and P smaller than or equal to 0.006%.

Owner:ZENITH STEEL GROUP CORP

Total-converting steelmaking method of electric furnace

ActiveCN102534112AReduce noise and radiation pollutionReduce smelting costProcess efficiency improvementElectric furnaceDeoxidizationScrap

The invention discloses a total-converting steelmaking method of an electric furnace. The method achieves the purposes of energy saving and consumption reducing through the working procedures containing adjustment for ratio of raw materials and strict control for the converting process. The method specifically comprises the following steps of: controlling the proportion of molten iron to be 71-79 percent; adding steel scraps through a furnace mouth for one time, and adding the molten iron through an iron exchanging mouth for two times; preheating, warming and decarburizing the steel scraps and molten steel in a furnace through a nozzle of an oxygen-burning system 3 installed on a furnace wall; during converting, regulating a corresponding gear according to demands, meanwhile converting with a furnace door oxygen gun, and making the converting efficiency to be maximized; adding slag making materials such as lime into the electric furnace to make slag; and when the molten steel achieves the temperature and components needed by steel grades, carrying out ladle deoxidization for steel tapping. Compared with the general steelmaking method of the electric furnace, the total-converting steelmaking method of the electric furnace has the advantages that electrode heating is cancelled, the consumptions of the electric energy, electrode and steel scrap are greatly reduced, the smelting cost per ton of steel is greatly reduced, the pollution is decreased, meanwhile the contents of harmful elements in the steel are reduced, and the product quality is increased.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

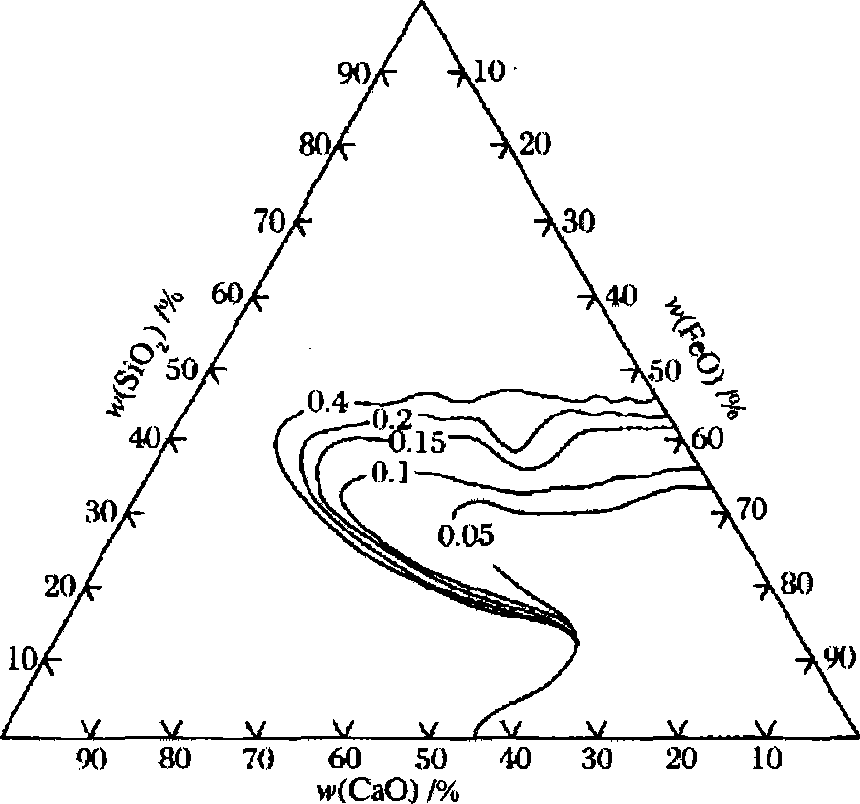

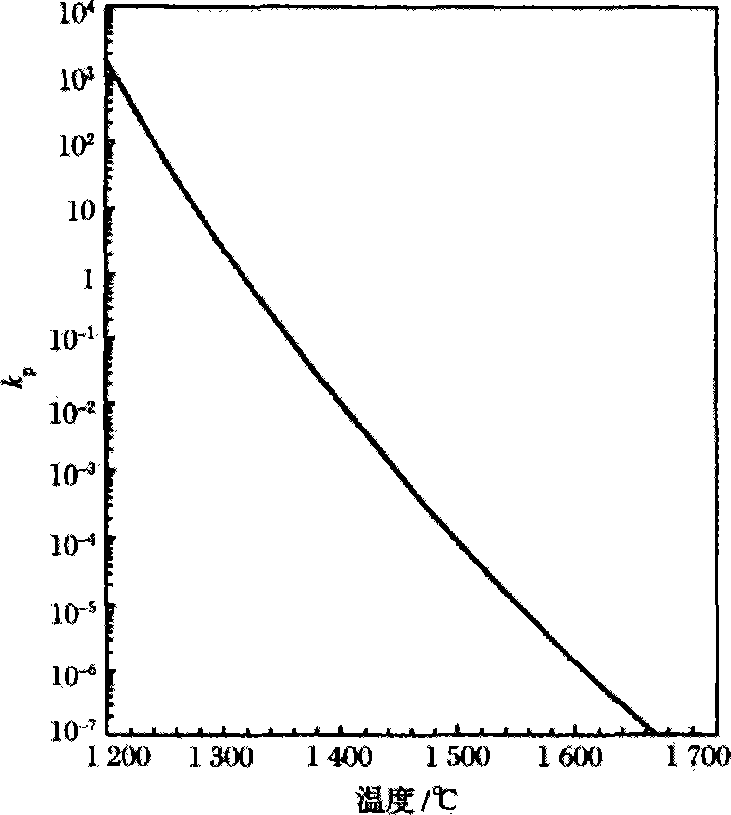

Converter smelting process using dephosphorization agent

InactiveCN101476013ALow investment costShorten the smelting cycleManufacturing convertersSteelmakingSmelting process

The invention pertaining to the field of convertor steelmaking technology provides a technique of converter smelting by using a dephosphorization agent. In a same convertor, dephosphorization is performed by using a CaO-base ephosphorization agent containing a few CaCl2 under favorable thermodynamics and combined-blowing dynamics conditions such as low temperature at the prior period, high content of iron oxide and the like, the prior period, desilication and dephosphorization slags of 50-70% are poured away in the molten iron preprocessing process, in the later period, decarburization process is performed and decarburization slag is formed and is then utilized as dephosphorization slag of the lower converter. According to the smelting technology, CaCl2 is added to the CaO-base ephosphorization agent to accelerate the burn-off rate of CaO by using the eutectic point character of CaCl2 and CaO binary system, the utilization ratio of lime is also improved, the utilizing of decarburization slag not only fully utilizes the physics heat brought by the decarburization slag, but also provides high content iron oxide for the dephosphorization of the prior period and accelerates the dephosphorization reaction.The invention has advantages of low cost of investment, shortened smelting period, carbon content of 0.4% at the end point of smelting, phosphorus content capable of being reduced to 0.006% and dephosphorization ratio up to 95.5%.

Owner:CHINA IRON & STEEL RES INST GRP +1

Composite slag for smelting stainless steel with back method at same time of desulfurization dephosphorization

ActiveCN101294235AImprove desulfurization effectReduce sulfur contentProcess efficiency improvementGranularitySlag

The invention provides composite slag which is used for smelting a stainless steel by using a return method and also used for desulfuration and dephosphorization at the same time. The composite slag comprises the components and proportioning by weight as follows: when the content of CaO is 1 part, BaO and / or BaCO3 is 0.6 to 1.8 parts, CaF2 and / or BaCl2 is 0.3 to 0.6 parts, and Fe2O3 is 0.01 to 0.15 parts. When limes are used as CaO material, the content of the CaO in the limes is more than 92 percent, the sulfur content is less than 0.025 percent, and the silicon dioxide content is less than 1 percent. The purity quotient of other components are demanded to reach more than 98 percent. The granularity of the composite slag is less than 1cm<3>.

Owner:WUHAN IRON & STEEL ENG TECH GROUP

Refined-smelting ladle furnace carbon control deep desulphurization method for ultra-low-carbon steel production

ActiveCN101323896ASolve the problem of adding CShorten desulfurization treatment timeProcess efficiency improvementAlkalinitySulfur

The invention discloses a method for controlling carbon and deep desulphurization by a refined-smelting ladle furnace in the production of extreme low carbon steel, pertaining to the technical field of ladle refining. The technology of the invention is that the amount of roughing slag of a converter is controlled and the thickness of the slag is 30 mm to 60mm; the temperature of molten steel in an LF furnace ranges from 1590 DEG C to 1640 DEG C and the content of Al in the steel is equal to 0.05 percent to 0.09 percent; 6 to 12 kg / ton of refining slag with high basicity and 0.4 to 1.0 kg / ton of Al granules are added; the flow of bottom-blowing argon gas is controlled during the rapid deep desulphurization refining process. On the condition that no electrode is available, argon gas with mass flow of 6 to 8NL / (min question mark t) is adopted for melting slag. After slag melting, the electrode is arranged to control the flow of argon gas to 4.8-6NL / (min question mark t) and carbon pickup of the molten steel occurs; when the refining is completed, the oxidizability of steel slag (FeO+MnO) is required to be less than or equal to 1.0 percent and the weight percentage of alkalinity of (CaO) / (SiO2) is equal to 5.5 to 8.0. The method of the invention has the advantages of solving the problem of carbon pickup during the refining in the LF furnace and controlling the weight percentage of carbon increment within 0.015 percent, thereby realizing rapid deep desulphurization with the content of sulfur[S] which is less than or equal to 0.0010 percent after desulphurization, and shortening the smelting time of the LF furnace.

Owner:SHOUGANG CORPORATION

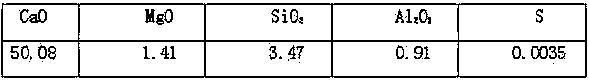

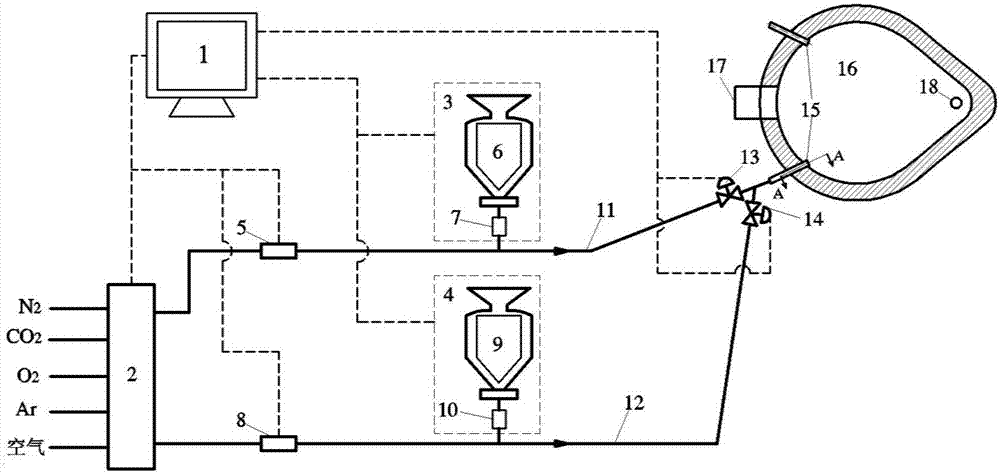

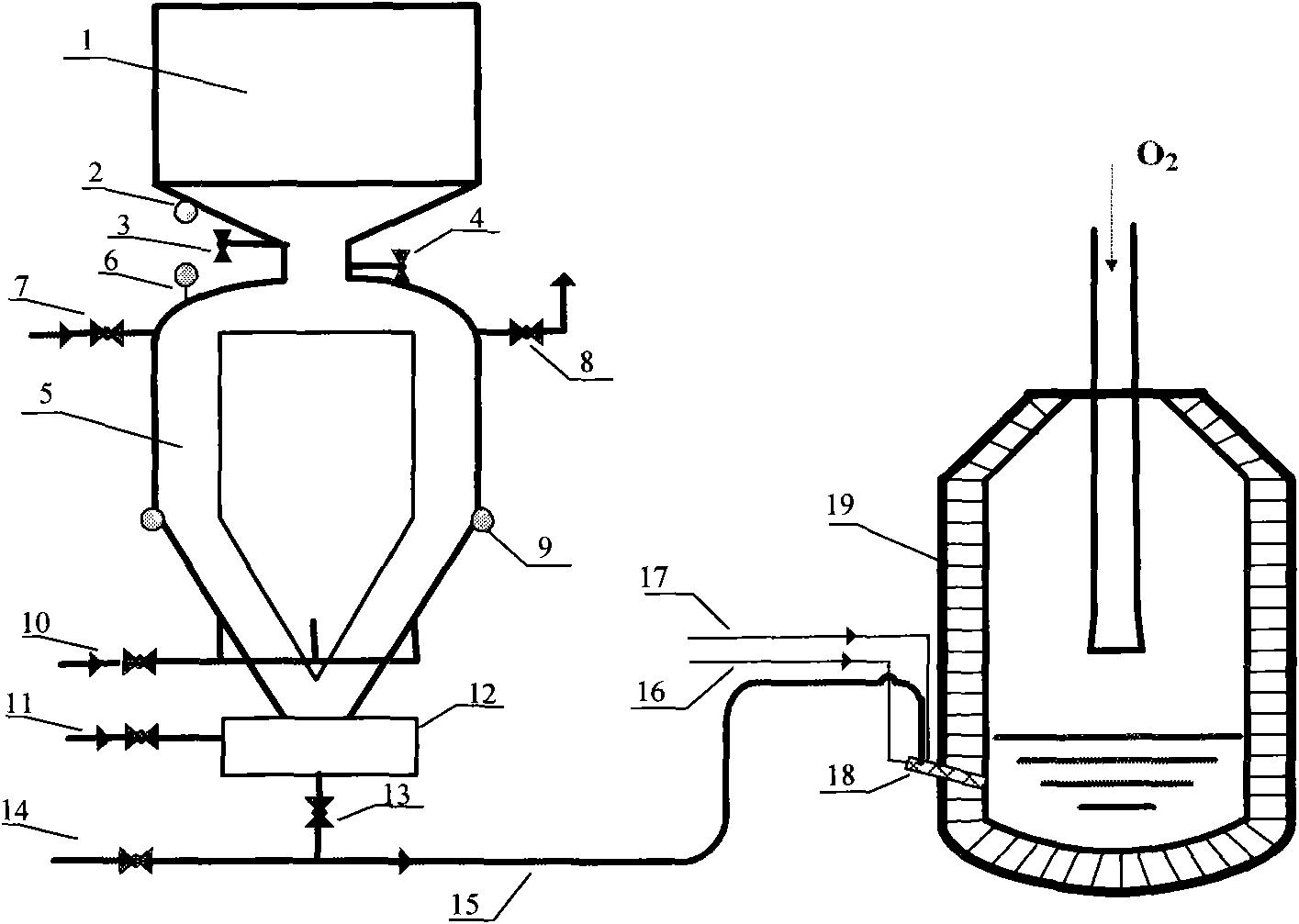

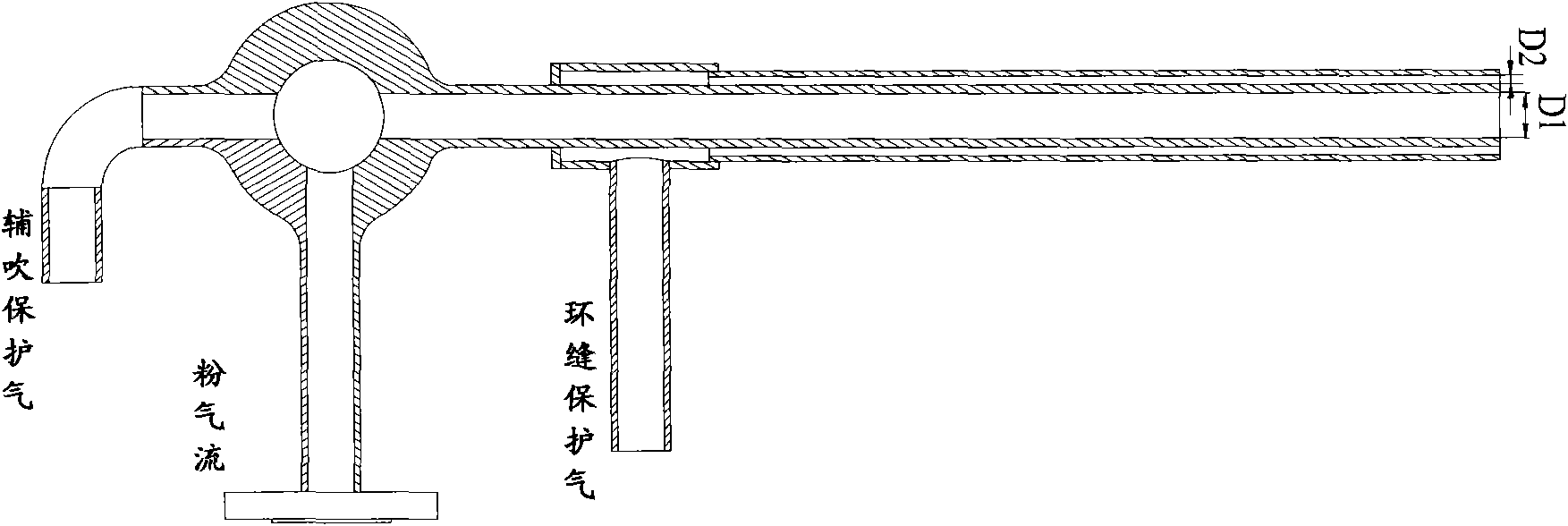

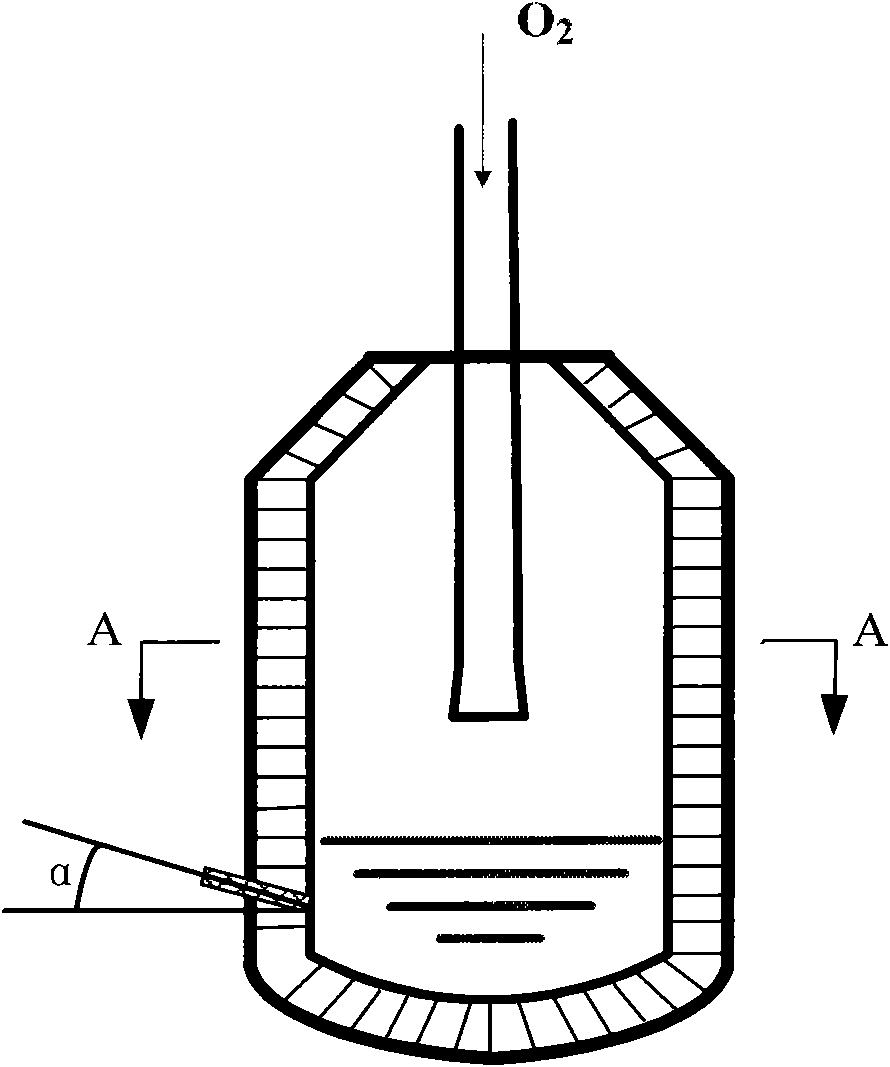

Powder spraying device and method for efficient vanadium extracting process of converter

ActiveCN101967532AImprove mechanical propertiesOptimizationCharge manipulationManufacturing convertersBrickSlag

The invention discloses a powder spraying device and a powder spraying method for an efficient vanadium extracting process of a converter, belongs to the technical field of metallurgy, and aims to solve the technical problems of poor dynamical condition, low oxidation conversion rate of vanadium and the like in the vanadium extracting process of the converter. The device comprises a powder spraying tank system, a PLC (programmable logic controller) control system, a gas adjusting valve set and a powder spraying gun. The powder spraying rate is accurately and continuously controlled by adjusting the frequency of a rotary feeding tray motor, the powder spraying gun has a double-sleeve structure, carrier gas powder spraying is adopted in a central pipe, meanwhile, auxiliary blowing gas ensures continuous operation of the powder spraying process, and circular seam blowing protective gas protects the powder spraying gun. The powder spraying gun is arranged on the side or the bottom of the vanadium extracting converter, and protective sleeve bricks are embedded around the powder spraying gun. The device is suitable for the vanadium extracting converter of 10 to 200 tons, can spray 50 to 200kg / min iron concentrate powder in the vanadium extracting process of the converter, improve the dynamical and thermodynamic conditions of vanadium extraction of the converter, reduce the content of half steel vanadium to be less than 0.03 percent and improve the content of vanadium slag (V2O5) by 2 to 5 percent, meanwhile, is favorable for shortening the vanadium extracting smelting period of the converter, and realizes efficient vanadium extraction of the converter.

Owner:HEBEI IRON AND STEEL +1

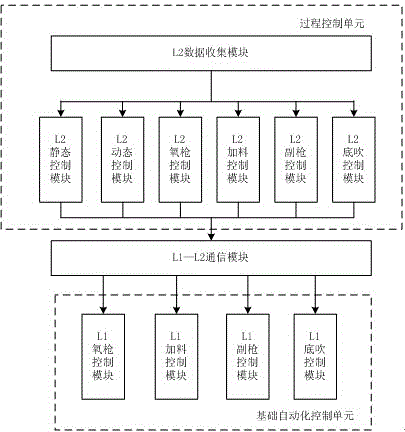

Full-automatic control system and method for converter single-slag process

ActiveCN104480248ARealize automatic controlReduce labor intensityManufacturing convertersProcess efficiency improvementAutomatic controlControl manner

The invention relates to a full-automatic control system and a full-automatic control method for a converter single-slag process. The method comprises the following steps: (1) preparing automatic control in a smelting process, namely selecting a control mode of associated modules and collecting base information; (2) starting a converting start switch, collecting the associated data by virtue of an L2 data collecting module, starting an L2 oxygen lance control process, an L2 charging control process, an L2 sub lance control process, an L2 bottom-blowing control process and a blowing stopping and lance-lifting control process. The full-automatic control system and the full-automatic control method for the converter single-slag process have the beneficial effects of simple structure, convenience in use, automatic control on the oxygen lance, the sub lance, charging and bottom-blowing, lowered labor intensity of the operation staff, high smelting end point control precision, shortened smelting period and lowered production cost.

Owner:SHANGHAI MEISHAN TECH DEV

Chrome-molybdenum metal self reduction pellet and preparation and direct steel liquid alloying methods thereof

The invention relates to alloy steel smelting, and particularly relates to a chrome-molybdenum metal self reduction pellet and preparation and direct steel liquid alloying methods thereof. The pellet comprises the following components according to mass percentage: 40-65 percent of high-carbon ferrochrome powder, 15-40 percent of molybdic oxide powder, 5-15 percent of a reductant and 3-5 percent of a flux. The self reduction pellet product is added to a ladle during electric furnace or convertor tapping, under the action of high-temperature molten steel and a pellet inner reductant, metal elements in the pellet are effectively reduced, as a result, the molten steel is directly alloyed; the self reduction pellet product is applied in alloy steel including stainless steel, wear resistant steel and the like, which contain elements Cr and Mo, and not only is the procedure for the production of ferro molybdenum saved, but also the elements Cr and Mo can be added at one time, so that the cost of adding alloy elements is lowered, the smelting cycle is shortened, meanwhile, the use range of high-carbon ferrochrome is widened, and furthermore, the problem that the element Mo is difficult to add and settle and great in volatilization during the steel smelting is solved.

Owner:JIANGSU UNIV

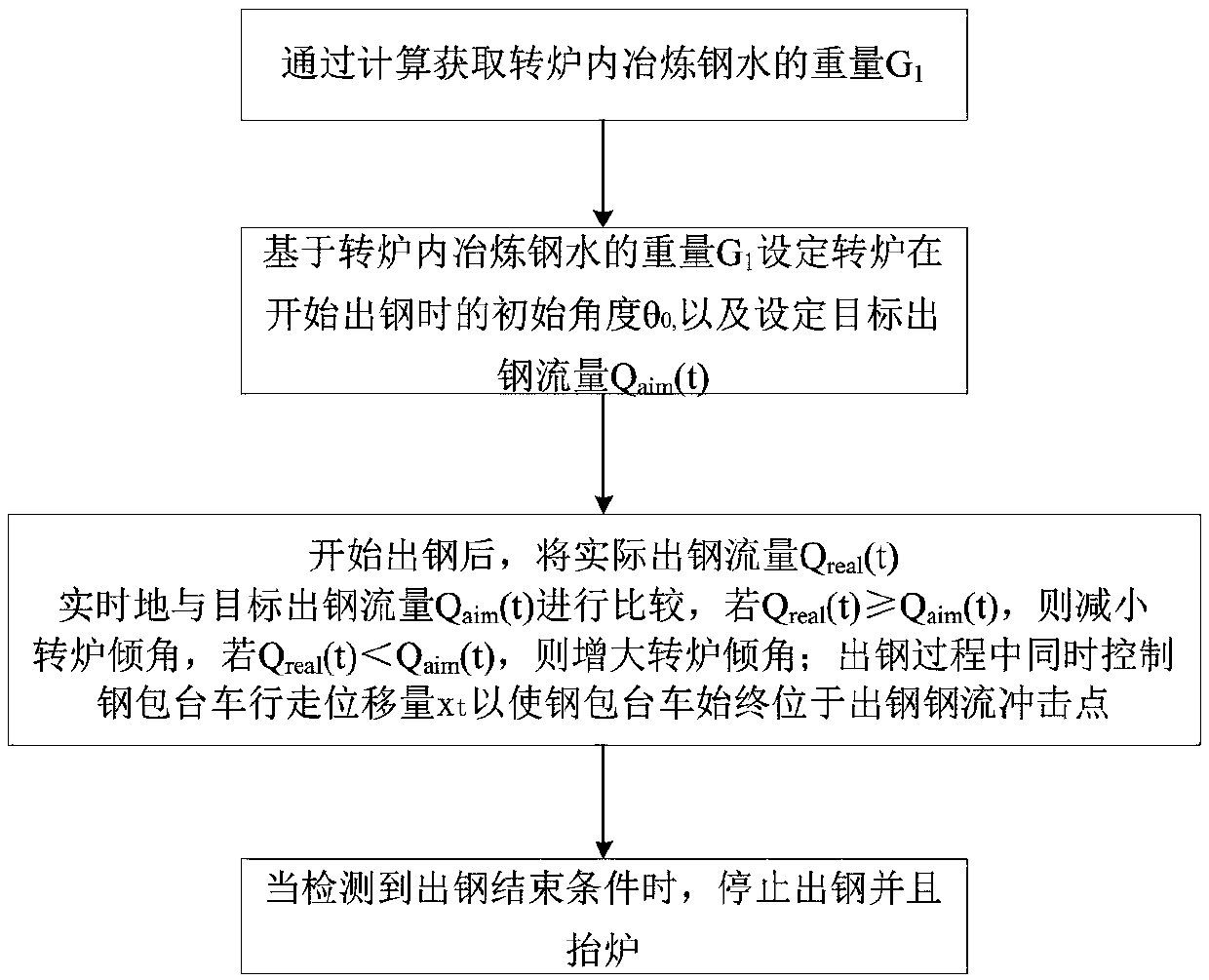

Tapping flow control method and system for full-automatic converter tapping

InactiveCN110616289ALess investmentReduce maintenance and repair costsManufacturing convertersSpecial data processing applicationsControl systemMolten steel

The invention discloses a tapping flow control method for full-automatic converter tapping. The method comprises the following steps that (1) the weight G 1 of molten steel in a converter is obtainedthrough calculation; (2) the initial angle Theta 0 of the converter when tapping starts is set based on the weight of the molten steel in the converter, and target tapping flow Q<aim> (t) is set; (3)when the tapping starts, actual tapping flow Q<real> (t) is compared with the target tapping flow the Q<aim> (t) in real time, if the Q<real> (t) is larger than or equal to the Q<aim> (t), the inclination of the converter is reduced, and if the Q<real> (t) is smaller than the Q<aim> (t), the inclination angle of the converter is increased; and in the tapping process, the walking displacement amount xt of a ladle trolley is controlled at the same time, so that the ladle trolley is always located at an impact point of tapping steel flow; and (4) when the condition that the tapping is finished isdetected, the is stopped and the converter is lifted. In addition, the invention further discloses a tapping flow control system for full-automatic converter tapping.

Owner:BAOSHAN IRON & STEEL CO LTD

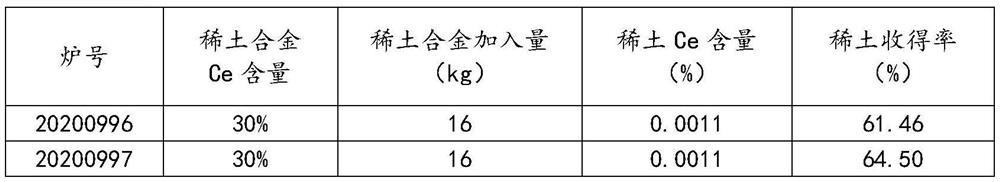

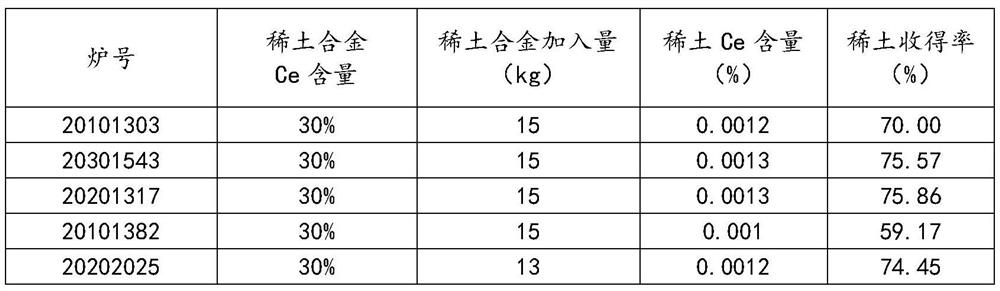

Rare earth adding control method for high-strength rare earth girder steel

InactiveCN112226578AImprove cleanlinessEvenly distributedManufacturing convertersSteelmakingMetallurgy

The invention discloses a rare earth adding control method for high-strength rare earth girder steel. The cleanliness of molten steel of rare earth high-strength girder steel and the yield of rare earth in the steel is improved by optimizing the steel-making process. In early-stage rare earth steel research, due to the fact that the key control processes such as a rare earth adding mode, adding time and the like are not completely mastered, the yield of rare earth is low and is about 35%; and meanwhile, the number of rare earth composite inclusions in steel is large, and the continuous castingpourability of a casting machine is poor. In order to increase the yield of the rare earth, the cleanliness of molten steel is guaranteed before the rare earth is added, and the component uniformityof the rare earth in the molten steel is guaranteed after the rare earth is added. Meanwhile, protective pouring is conducted in the casting process of a casting machine, secondary oxidation of the molten steel is prevented, and the yield of the rare earth in the steel can be remarkably increased.

Owner:BAOTOU IRON & STEEL GRP

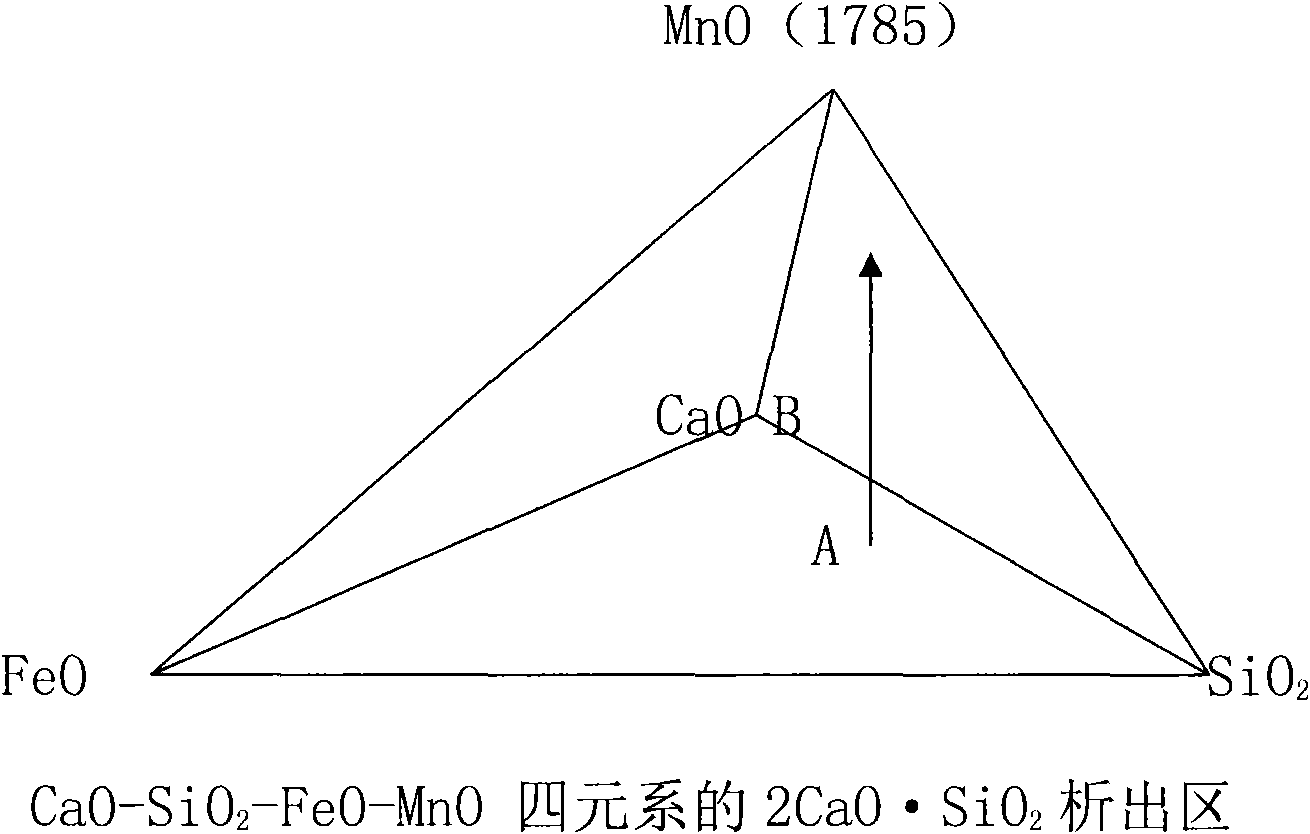

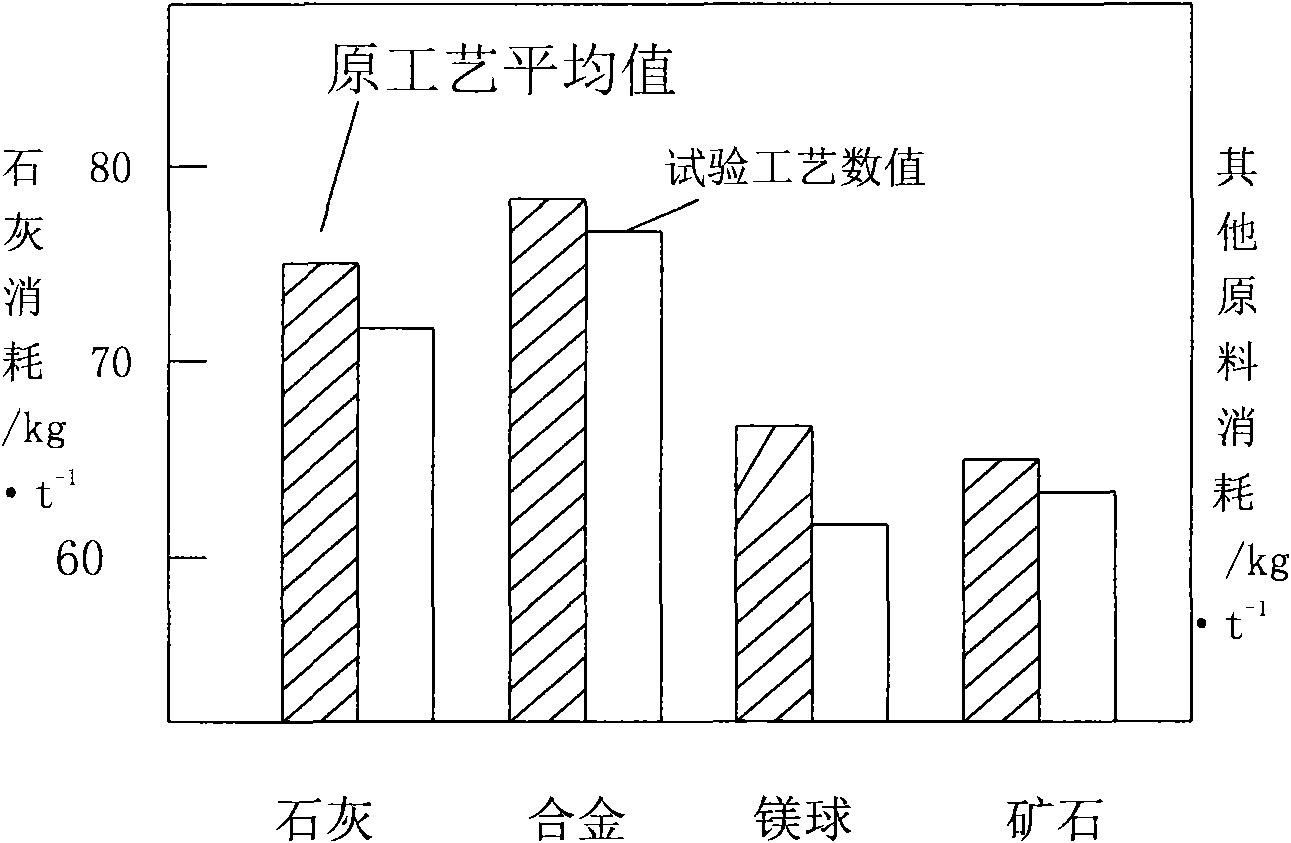

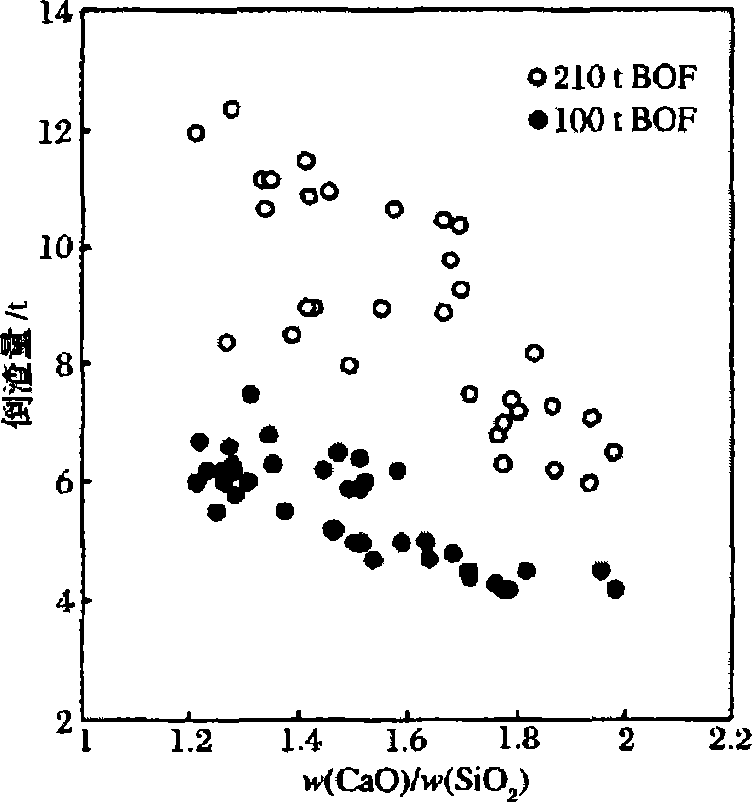

Compound slagging agent of converter and preparation method and applications thereof

The invention relates to a metallurgic refining flux and preparation method and applications thereof. A compound slagging agent of converter comprises the following components by weight percentage: 20to 50 percent of MnO, 3 to 6 percent of MgO, 5 to 8 percent of CaO, 10 to 15 percent of Fe, 7 to 10 percent of water and the balance of unavoidable impurities. The product has good smelting characteristic, so as to be capable of slagging ahead of time for 1 to 1.5 minutes, shortens the tap-to-tap cycle so as to improve the yield of steel, has good slagging effect in the whole process and almost does not cause splashing, re-drying or slag adhesion on oxygen lance so as to be capable of reducing ferrous charges consumption by 5 to 10 kilograms per ton, increases residual manganese of terminal molten steel by 0.04 to 0.08 percent by using 8 to 14 kilograms of compound slagging agent per ton so as to be capable of saving the alloy of Fe and Mn by 1 to 2 kilograms per ton, eliminates the pollution of fluorinion to environment and water resource, can directly lead to economic benefit in normal conditions according to the results of primary test, and has remarkable social benefit.

Owner:陆建荣

Zero-power consumption steel-making method using electric-arc furnace

ActiveCN103205529AIncrease profitPromote rapid formationProcess efficiency improvementElectric furnaceElectric arc furnaceSmelting process

The invention discloses a zero-power consumption steel-making method using an electric-arc furnace. The zero-power consumption steel-making method specially comprises the following steps of: controlling the proportion of steel scrap in a furnace burden structure at 20%-30% and the proportion of molten iron at 70%-80%; pushing the steel scrap in a vertical shaft into the furnace by a hydraulic device, wherein the pushing speed is 1-3t / min; adding the molten iron to the furnace at twice through a molten iron adding chute for the furnace wall, wherein the primary molten iron accounts for 40%-80% of the total amount of the molten iron, the iron addition speed is 15-30t / min, the secondary molten iron accounts for 20%-60% of the total amount of the molten iron, and the iron addition speed is 4.5-6.5t / min; simultaneously adding lime to the furnace for slagging, and blowing oxygen for smelting; and when the temperature and components of the molten iron meet the technological requirements, finishing smelting in the electric-arc furnace. The zero-power consumption steel-making method can prevent the molten iron and furnace slag from overflowing from a furnace gate, thus reducing the consumption of slag charges and steel in the smelting process.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Dephosphorizing process of electric furnace steel making

InactiveCN102251072AShorten the smelting cycleLow costProcess efficiency improvementElectric furnaceFerrous metallurgySmelting

The invention relates to a dephosphorizing process of electric furnace steel making, belonging to the field of ferrous metallurgy. The invention provides a dephosphorizing process of electric furnace steel making low cost, comprising a step of slag discharge, and the molten steel temperature is more than 1560 DEG C during the step of slag discharge. Compared with dephosphorizing processes existedin the prior art, the dephosphorizing process disclosed in the invention has no need of adding dephosphorization agent to strengthen dephosphorization, only needs the step of slag discharge once, andthe quantity of slag can be reduced by more than 30%, the smelting cycle can be reduced by more than 5%, thus greatly reducing the cost of dephosphorization in steel-making. The invention provides a novel method for dephosphorization in steel-making, with a wide application prospect.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

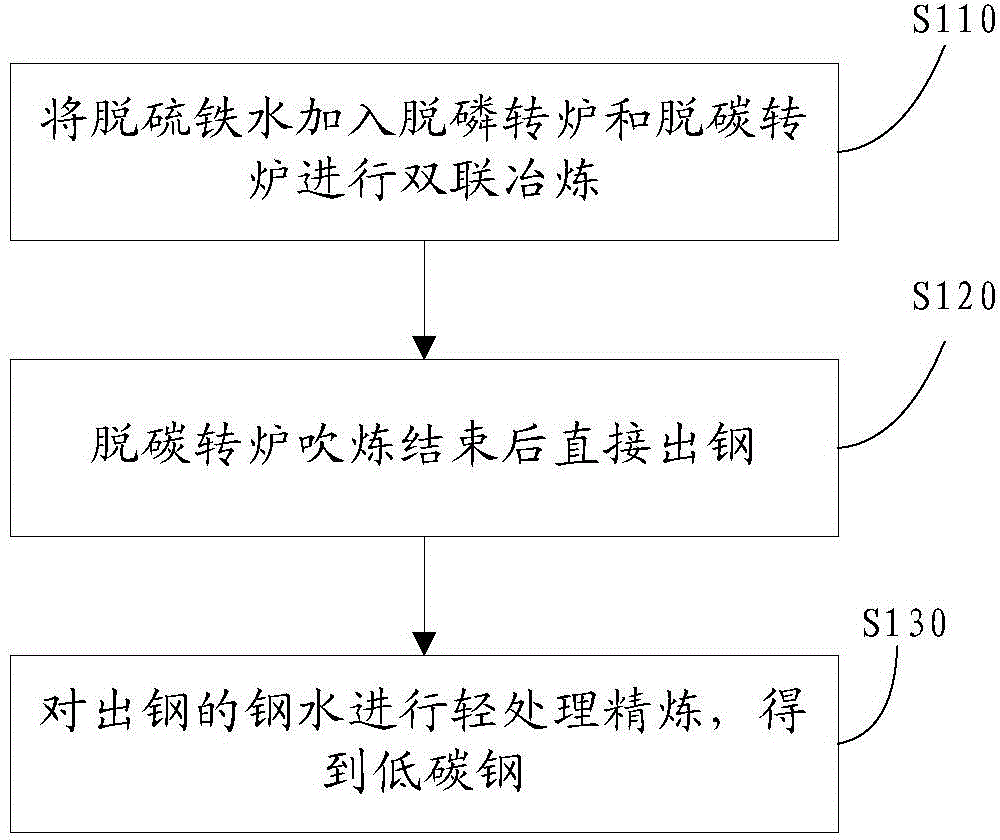

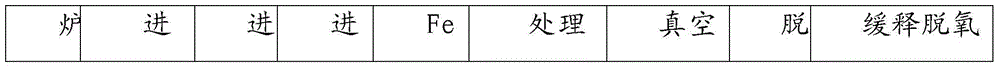

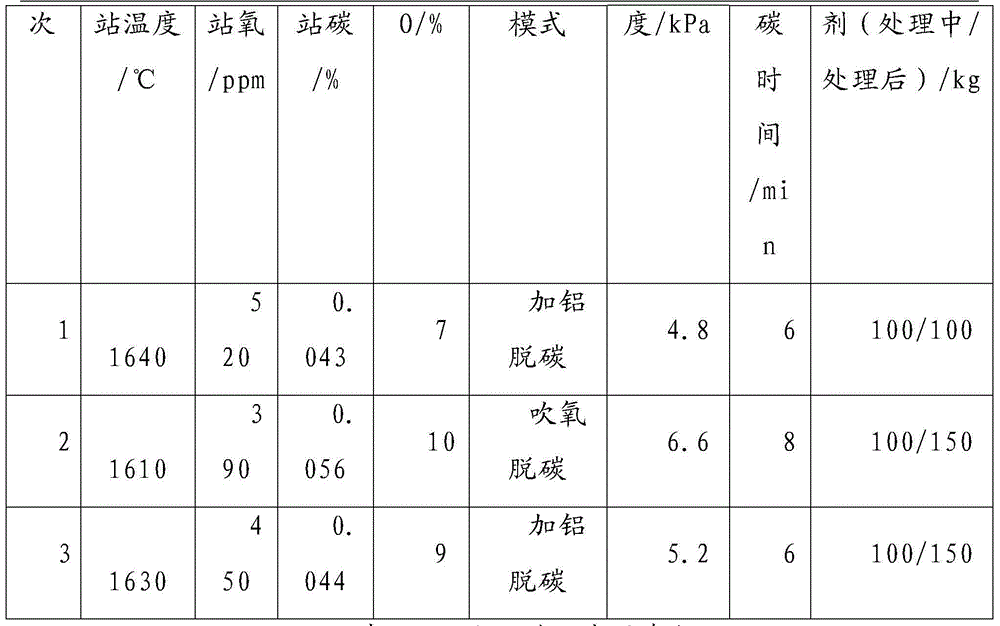

Production method of low-carbon steel

The invention discloses a production method of low-carbon steel. The production method mainly aims to solve the technical problems that normal pouring of a slab caster cannot be satisfied and the production cost of the low-carbon steel is high because inclusions in the low-carbon steel which is smelted by a converter are difficult to control in the prior art. According to the technical scheme, the production method comprises the following steps of performing convertor smelting, converter low-temperature tapping and deoxidation, performing molten steel treatment at an argon blowing station, and refining molten steel in a refining furnace. The molten steel produced by adopting the production method has high cleanliness, the average content of total oxygen in the molten steel is 16.5 ppm, the average content of phosphorus is 95 ppm, the content of phosphorus as a harmful element in the molten steel is greatly reduced, and the production cost of the molten steel per ton steel is reduced by 13 Yuan.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

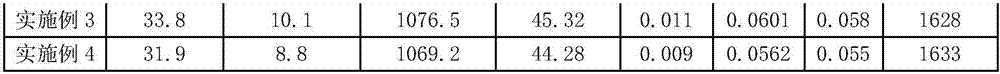

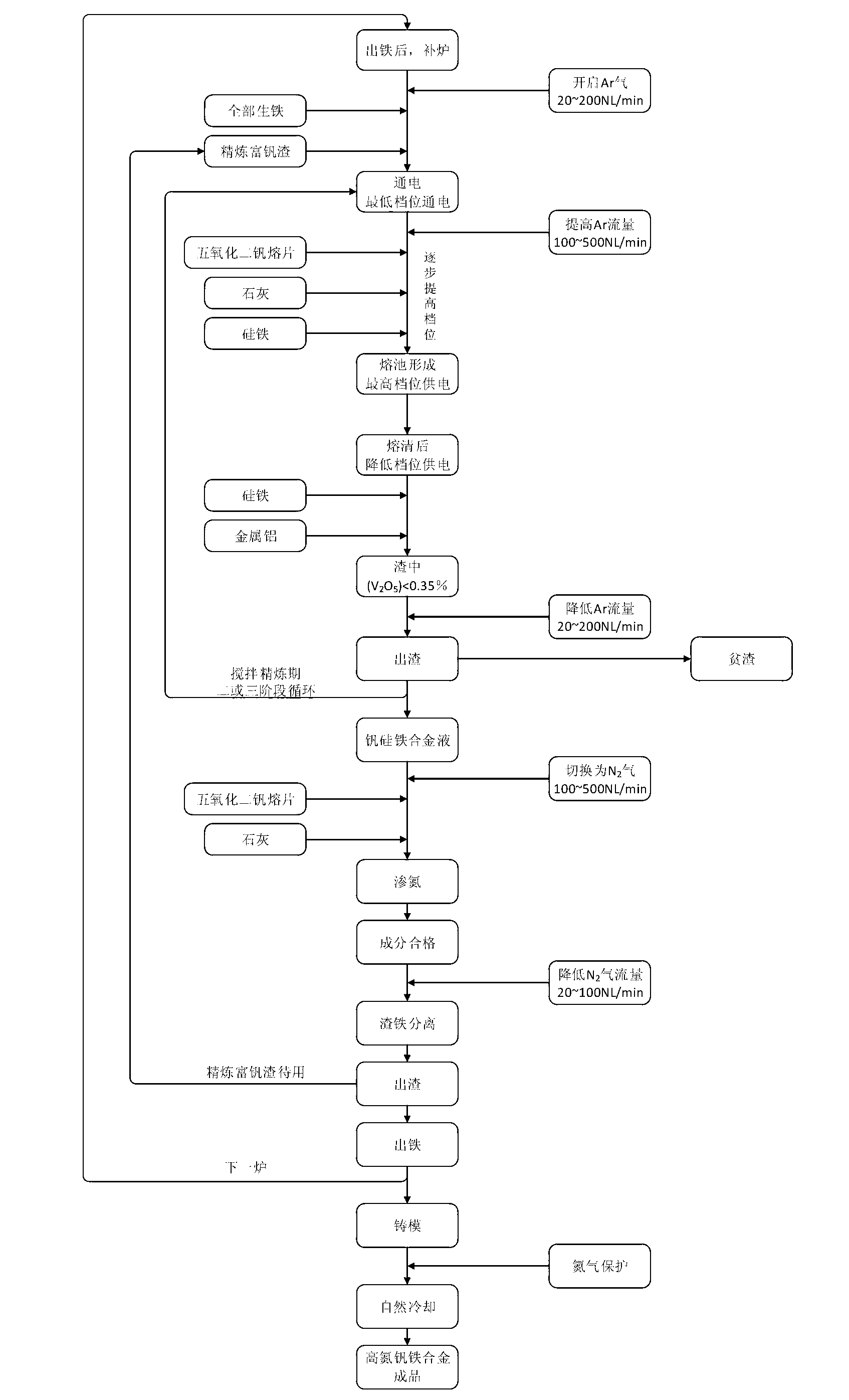

Method for generating nitrogenous ferrovanadium alloy through utilizing ferrovanadium electric-arc furnace

Owner:UNIV OF SCI & TECH BEIJING +1

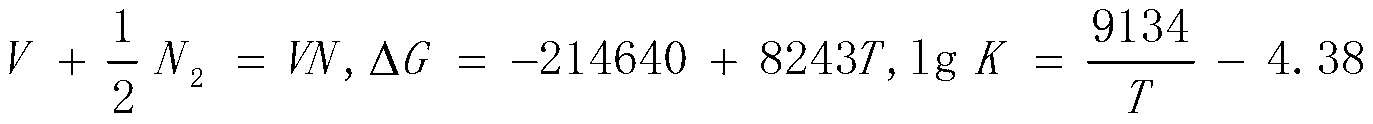

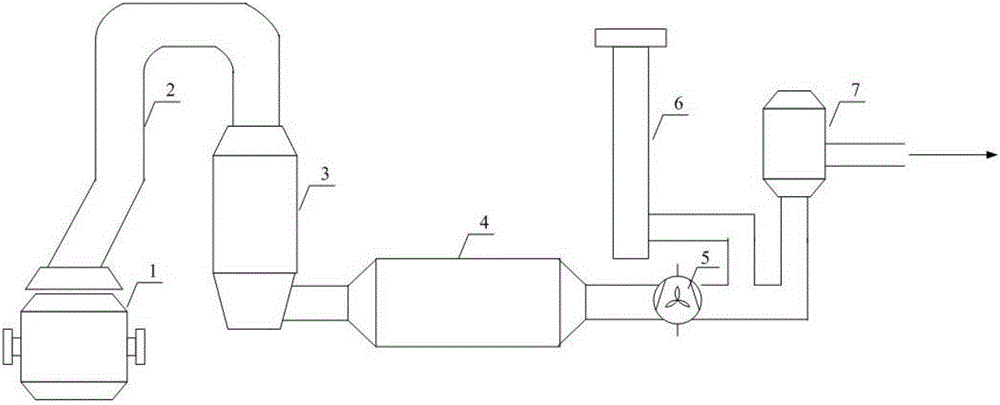

Oxygen blowing control method for dry dedusting explosion suppression of converter

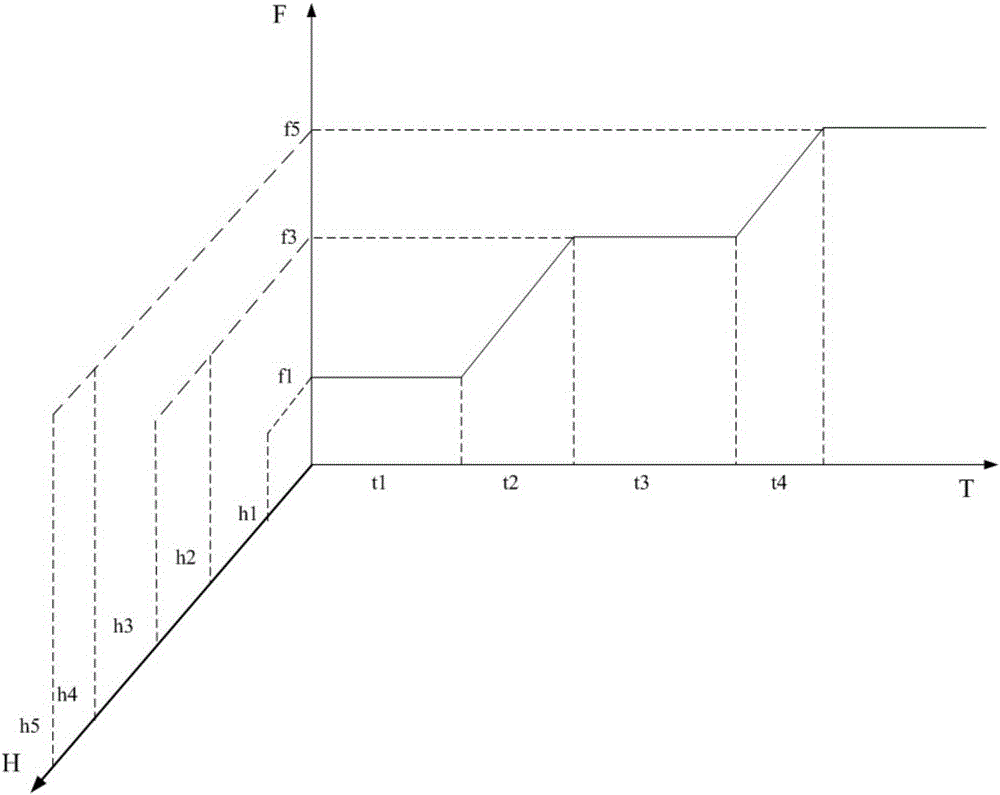

ActiveCN105274277AMeet ignition requirementsStable productionManufacturing convertersProcess engineeringEngineering

The invention discloses an oxygen blowing control method for dry dedusting explosion suppression of a converter. Multiple stepped climbing three-dimensional curves for controlling the oxygen blowing amount of the converter are established according to different steel types, and parameters of the curves are determined according to actual data of the production environment. The parameters of the curves are recorded in a database, the parameters in the database are corrected at any time according to the data of the actual production environment, and an optimal curve is obtained. Different stepped climbing three-dimensional curves are selected at different blowing stages, and the ascent control function of the oxygen flow at the initial blowing period, the middle blowing period, the rear blowing period and the reblowing stage is satisfied. According to the method, dry dedusting explosion caused by re-gun-discharge after blowing is interrupted can be effectively restrained, stable production of a converter smelting and dry dedusting system is guaranteed, the smelting period is shortened, and production efficiency is improved.

Owner:WISDRI ENG & RES INC LTD

Modification technology for steel slag in converter dephosphorization stage

InactiveCN104294003AThe use has been expandedImprove work rateManufacturing convertersSlagAdditional values

The invention discloses a modification technology for steel slag in converter dephosphorization stage. The modification technology comprises the following steps: adding an SiO2 material or a material taking SiO2 and Al2O3 as main components, or a Al2O3 material into a furnace from an overhead bunker so as to modify furnace slag before the blowing in the converter dephosphorization stage is finished, so that the basicity of the furnace slag is reduced and the foaming slag is pressed into thinned slag without foam. After the modification of the furnace slag is finished, foaming slag is not formed when the blowing in the converter dephosphorization stage is finished, the content of FeO in the slag is not required for addition in advance near the finishing of the blowing to form proper foaming slag to improve the mobility of the furnace slag, iron loss can be reduced, slag can be poured as soon as stopping of blowing, the slag pouring speed is fast, the slag discharging time is short and the melting period is shortened; the furnace slag is not foamed, so that a slag pressing agent is not required for being added in a slag tank when the slag is discharged, so that the cost is lowered, the labor intensity is reduced, and the operation rate of the slag tank can be improved; after being modified, the furnace slag is blast-furnace slagged, the utilization routes of the slag can be widened, the additional value is greatly increased, and the environment-friendly and utilization problems of the steel slag can be thoroughly solved; the dephosphorization slag can be fast and adequately poured out, so that the terminal full-remaining slag and continuous cycle of converter remaining slag-double slag technology can be guaranteed, so that the advantage of the converter remaining slag-double slag technology can be played to the greatest extent.

Owner:王虎

Low-carbon steel for deep drawing and smelting method thereof

InactiveCN104928558AShorten the smelting cycleReduce smelting costManufacturing convertersLight treatmentMolten steel

The present invention relates to the technical field of steel-making, and discloses a low-carbon steel for deep drawing and a smelting method thereof. The method comprises: adding desulfurized molten iron into dephosphorization converter and decarbonization converter for duplex smelting; blowing in decarbonization converter and directly tapping, which is tapping without converter deoxidation; carrying out light treatment refining process on the molten steel after tapping to obtain low-carbon steel for deep drawing. The method not only shortens the refining cycle, but also reduces the cost of smelting.

Owner:SHOUGANG CORPORATION

Method for smelting austenite stainless steel by using dephosphorized molten iron

The invention relates to a method for smelting austenite stainless steel by using dephosphorized molten iron. The method comprises the following steps of: (I) melting nickel-base alloy into a pre-solution by using a medium-frequency induction furnace, wherein the mass percentage of Ni in the nickel-base alloy is 4-99.5%, and the mass percentage of P in the nickel-base alloy is not higher than 0.045%; (II) pretreating molten iron so as to provide the dephosphorized molten iron, wherein the mass percentage of C in the dephosphorized molten iron is 2.5-4.0%, and the mass percentage of P in the dephosphorized molten iron is not higher than 0.01%; (III) blending the dephosphorized molten iron and the pre-solution with KOBMS and blowing, wherein the nickel-base alloy melted by the medium-frequency induction furnace and the dephosphorized molten iron are mixed, then are blended into the KOBMS and are subjected to oxygen-blowing decarburization melting in the KOBMS; (IV) carrying out VOD blowing and adjusting ingredients, wherein a VOD carries out blowing according to ingredients of outlet steel of the KOBMS and carries out alloying adjustment according to ingredients of steel types; and (V) carrying out LF refining, wherein an LF adjusts the ingredients and adjusts temperature to a target outbound temperature. The method for smelting the austenite stainless steel by using the dephosphorized molten iron has the advantages that the austenite smelting time of a stainless steel converter is shortened, and the operating efficiency of the stainless steel converter is increased.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

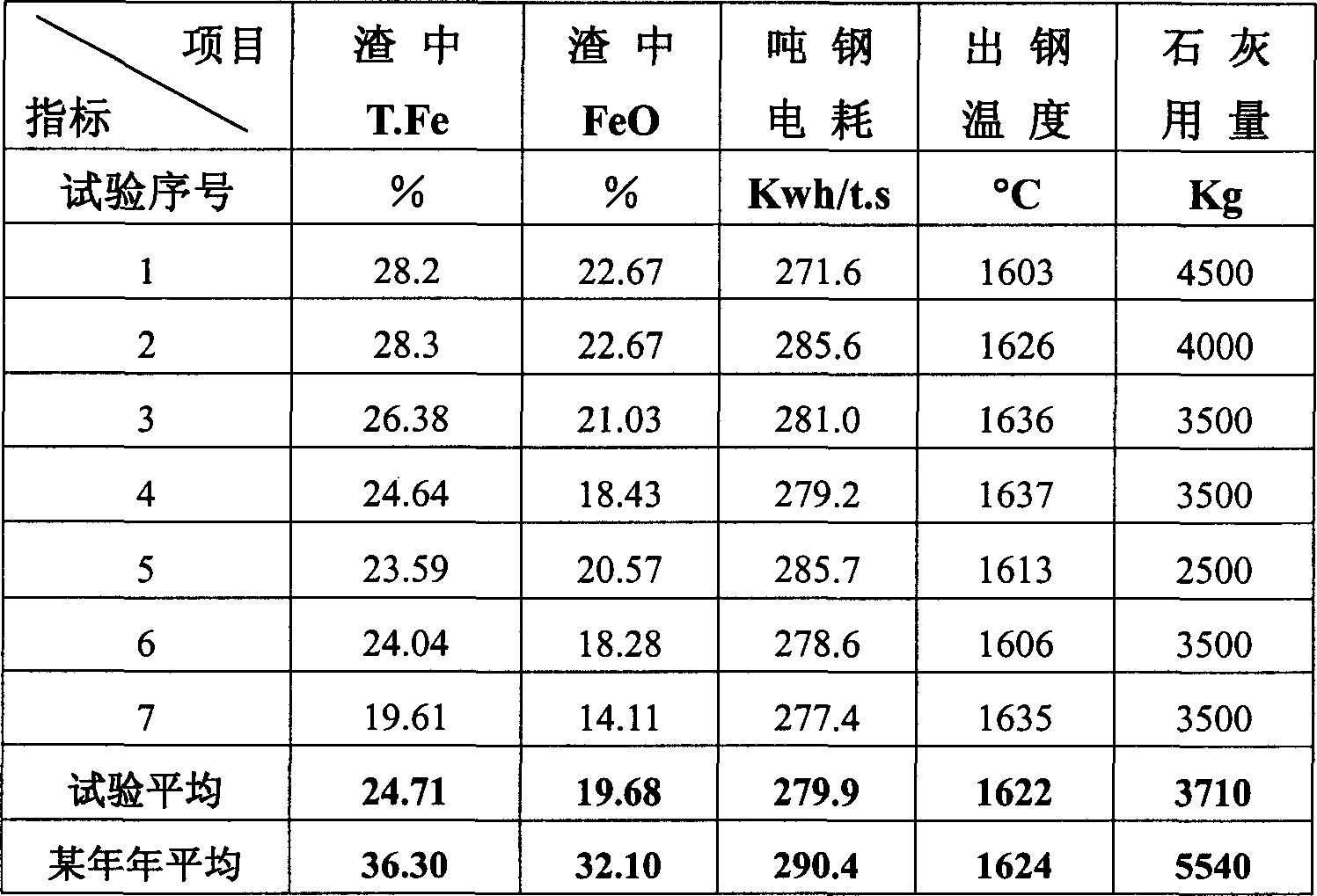

Slag regulating agent for super high power large electric furnace smelting

ActiveCN1782101AReduce iron contentTotal iron content dropped toProcess efficiency improvementElectric furnaceElectricityElectric arc furnace

The present invention relates to super high power arc furnace smelting technology, and is especially slag regulating agent for super high power large electric furnace. The present invention features that the slag regulating agent consists of C 30-35 wt%, Al 5-7 wt%, MgO 8-10 wt%, Al2O3 10-12 wt%, CaO 20-25 wt%, SiC 9-10 wt% and impurity the rest, and has bulk density of 1.8-2.0 g / cu cm. The slag regulating agent of the present invention can form homogeneous foamed slag continuously in the furnace to reduce FeO, Fe2O3, etc. in the slag layer, raise smelting yield, raise steel alloy yield, raise the heat efficiency of the furnace, lower power consumption, raise the dephosphorization capacity of the furnace and prolong the service life of the furnace.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for repairing converter through waste magnesia carbon bricks

ActiveCN109593909AImprove liquidityEffective bondingManufacturing convertersProcess efficiency improvementBrickSlag

The invention relates to a method for repairing a converter through waste magnesia carbon bricks. The method comprises the following steps that the to-be-repaired converter is tapped; terminal slag after tapping is directly poured without slag splashing until to-be-used brick fillers are covered with the terminal slag; a pre-calculated amount of brick fillers are added into the to-be-repaired converter, and forms a molten material together with the terminal slag; according to the converter repairing position, the converter is shaken, and thus the molten material can cover the to-be-repaired position; the to-be-repaired converter is sintered for 30 minutes or longer until the terminal slag is solidified; and iron is fed, and next batch of smelting is conducted. According to the method for repairing the converter, the problems of long sintering time, poor converter repairing effect, high converter repairing cost, serious environmental pollution and the like can be effectively solved, byreasonably controlling converter terminal slag, the effect that a mixture of the converter terminal slag remaining in the converter and the waste magnesia carbon bricks is effectively bonded to the repairing position of a converter lining is achieved, and finally the broken converter is repaired.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Efficient steel making process method

InactiveCN110484677AReduce splashReduce contentManufacturing convertersProcess efficiency improvementSlagHeat balance

The invention relates to the technical field of smelting, and in particular to an efficient steel making process method. The method comprises the following steps of feeding a fine material into a furnace; carrying out high scrap ratio and heat balance loading; carrying out a gun and pressure changing oxygen supplying technology; adopting a bomb dropping temperature measuring and carbon determiningtechnology at an end point; and optimizing the steel tapping process, and changing the converter slag pouring process flow. The process method is high in efficiency, low in cost, free of splashing and drying in the process, and stable in blowing.

Owner:YANCHENG LIANXIN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com