Static-dynamic automatic feeding method in converter smelting process

A technology of automatic feeding and converter smelting, which is applied in the manufacture of converters, etc., can solve problems such as inaccuracy, instability, and untimely manual feeding, and achieve the effects of reducing operation difficulty, improving hit rate, and saving feeding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

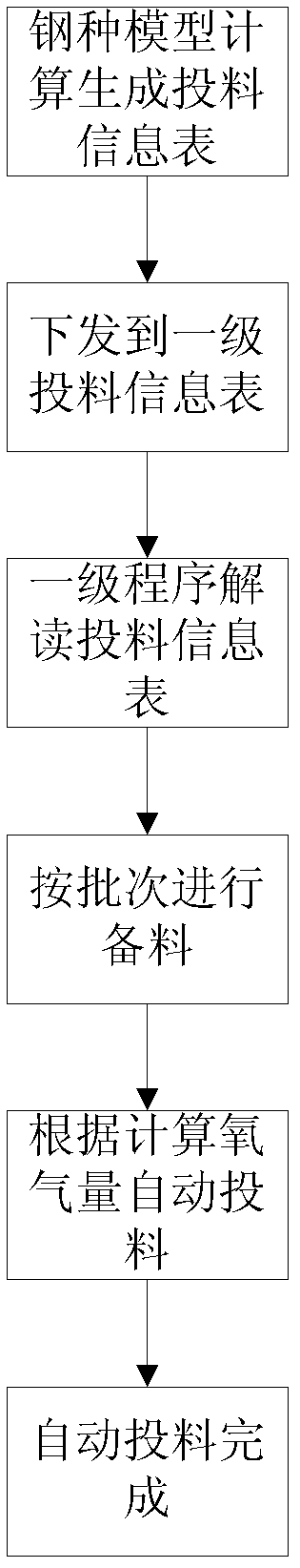

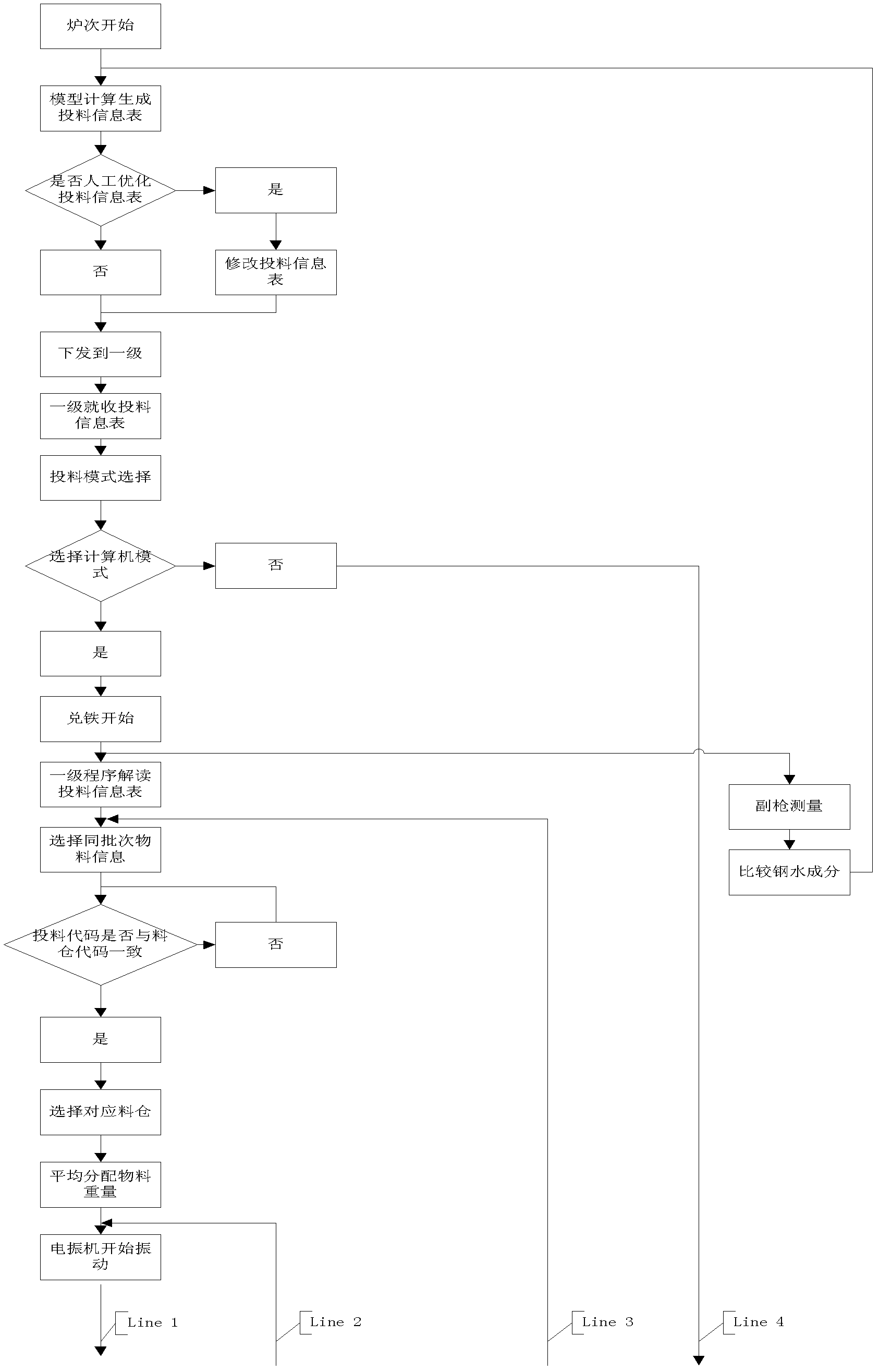

Method used

Image

Examples

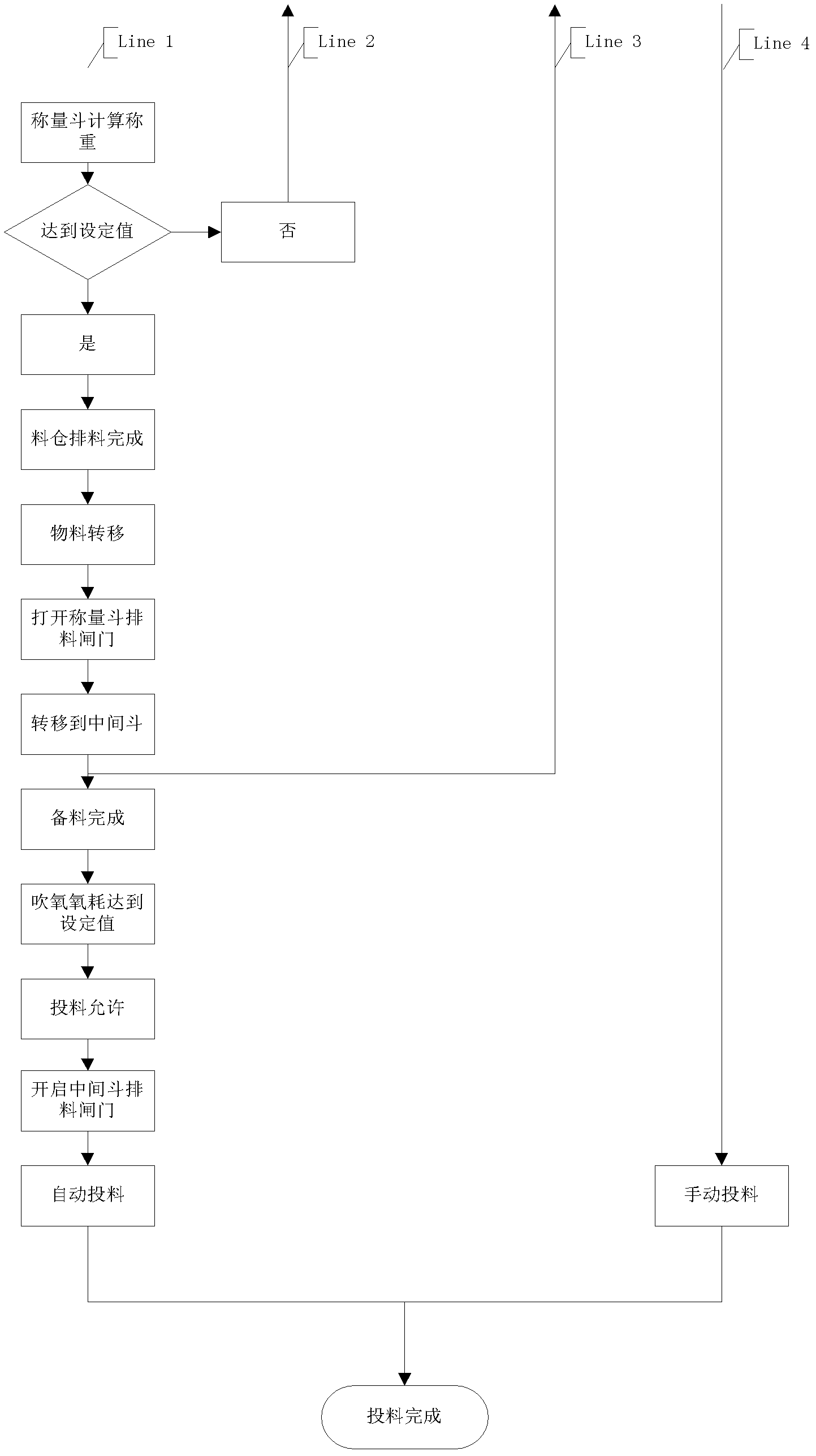

Embodiment Construction

[0019] Take the automatic feeding method of metallurgical lime as an example:

[0020] Metallurgical lime is a commonly used material in the feeding process of auxiliary raw materials for converter steelmaking. It is always placed in 6#, 7#, and 11# bins in the auxiliary raw material system. The preparation and feeding process of metallurgical lime is: the first-level program calls program block FC2000 , and according to the data of DB2001, it is known that the metallurgical lime is required to feed 1500Kg in the second level, and the oxygen blowing amount reaches 1500m 3 The batch of metallurgical lime was put in at that time. The program FC2000 will select silos 6#, 7#, and 11# of auxiliary raw materials, and each silo needs to prepare 500Kg of materials. At the same time start the program FB703, FB704 to start material preparation. Program FB703 starts 6#, 7# silos and WH4 weighing hopper to start material preparation, program FB704 starts 11# silo and WH3 weighing hopper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com