Patents

Literature

1372results about How to "Precise feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

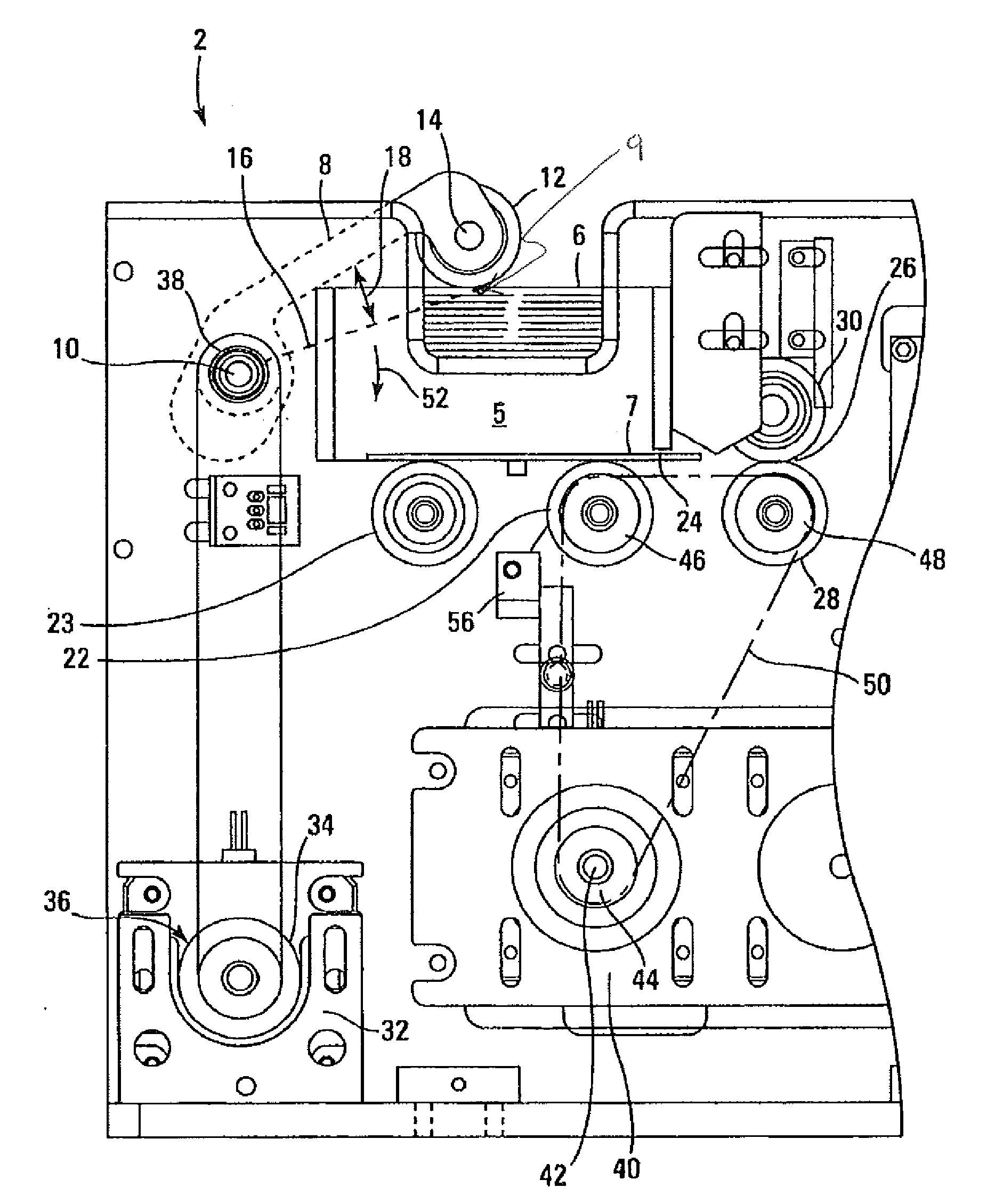

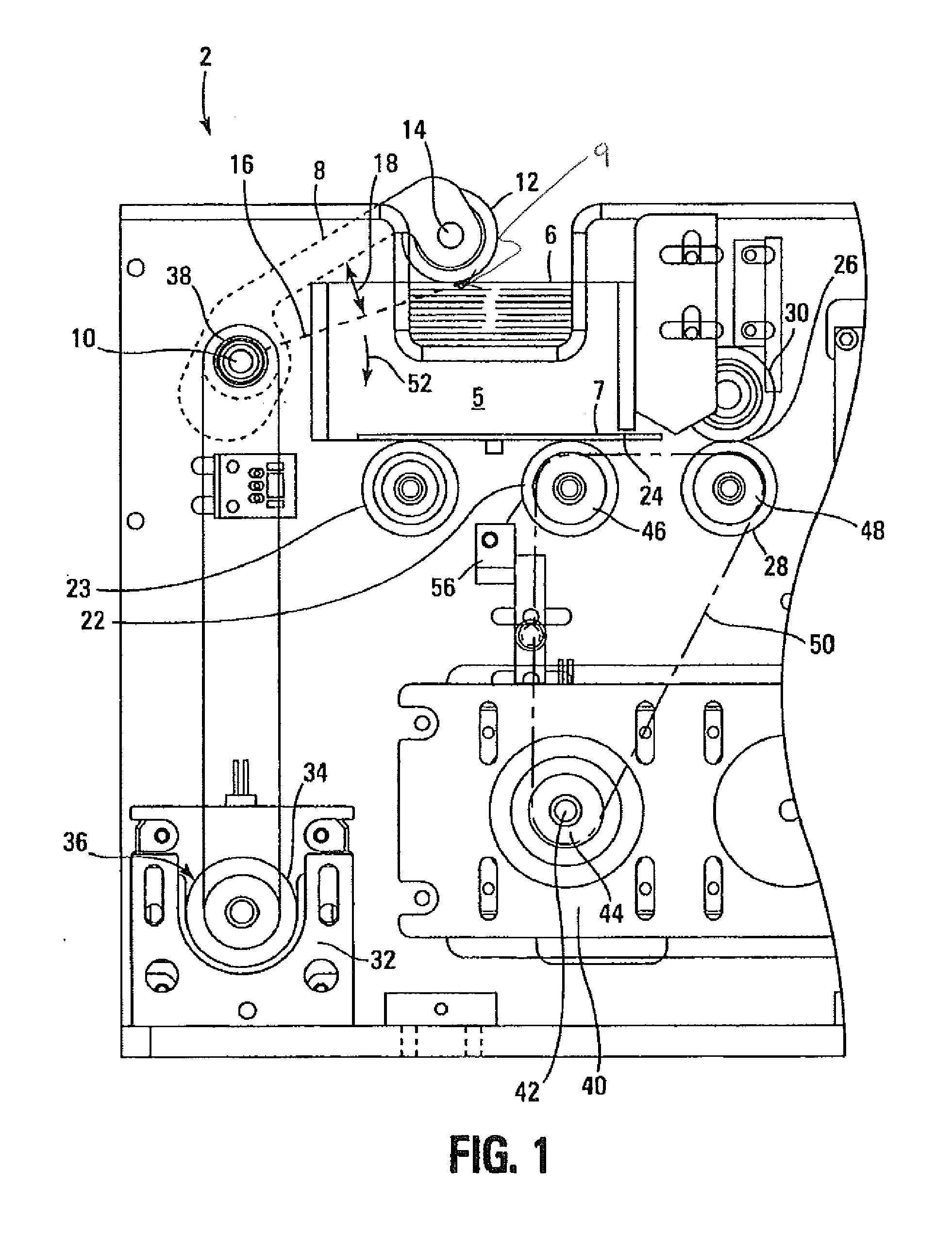

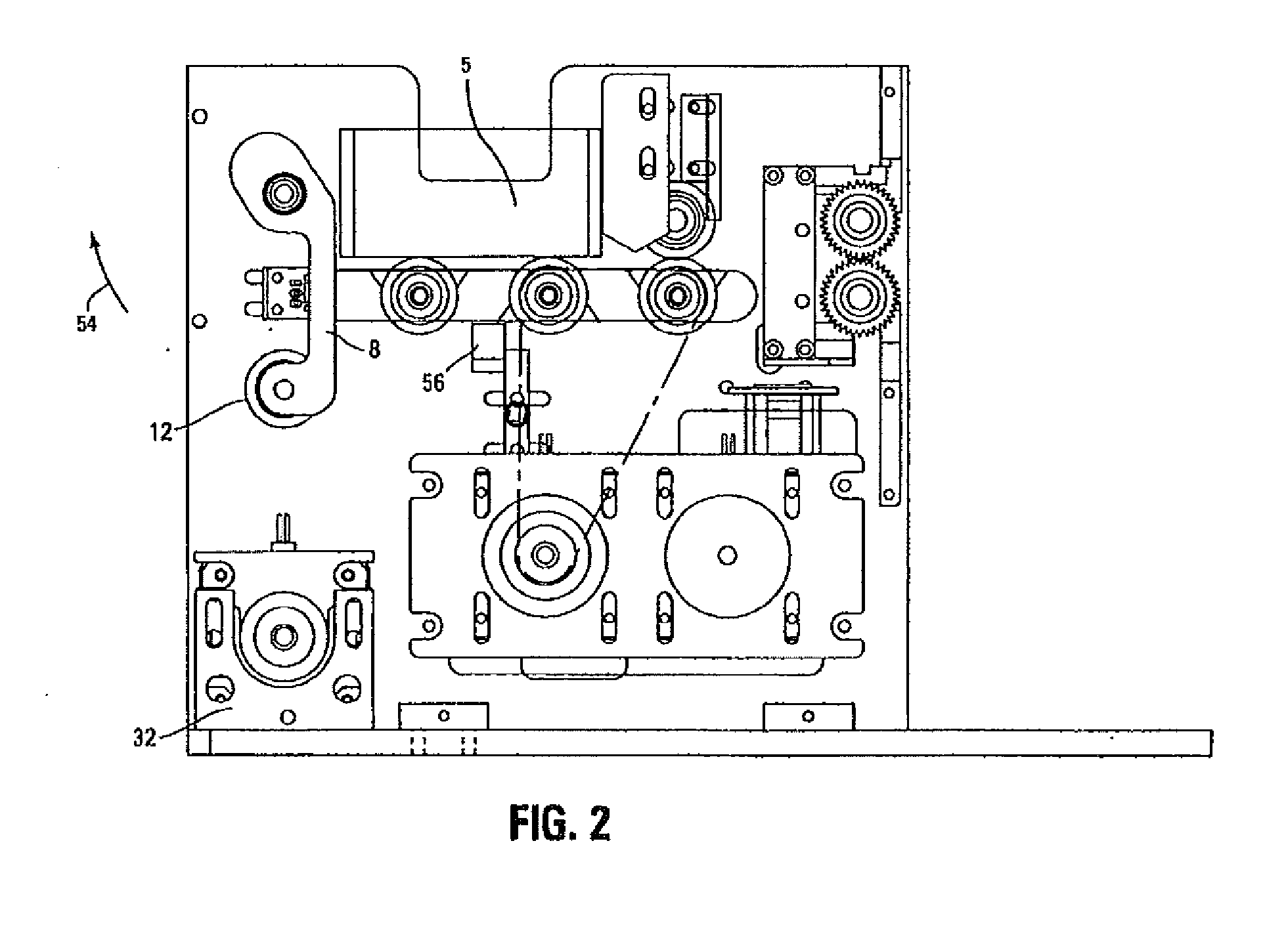

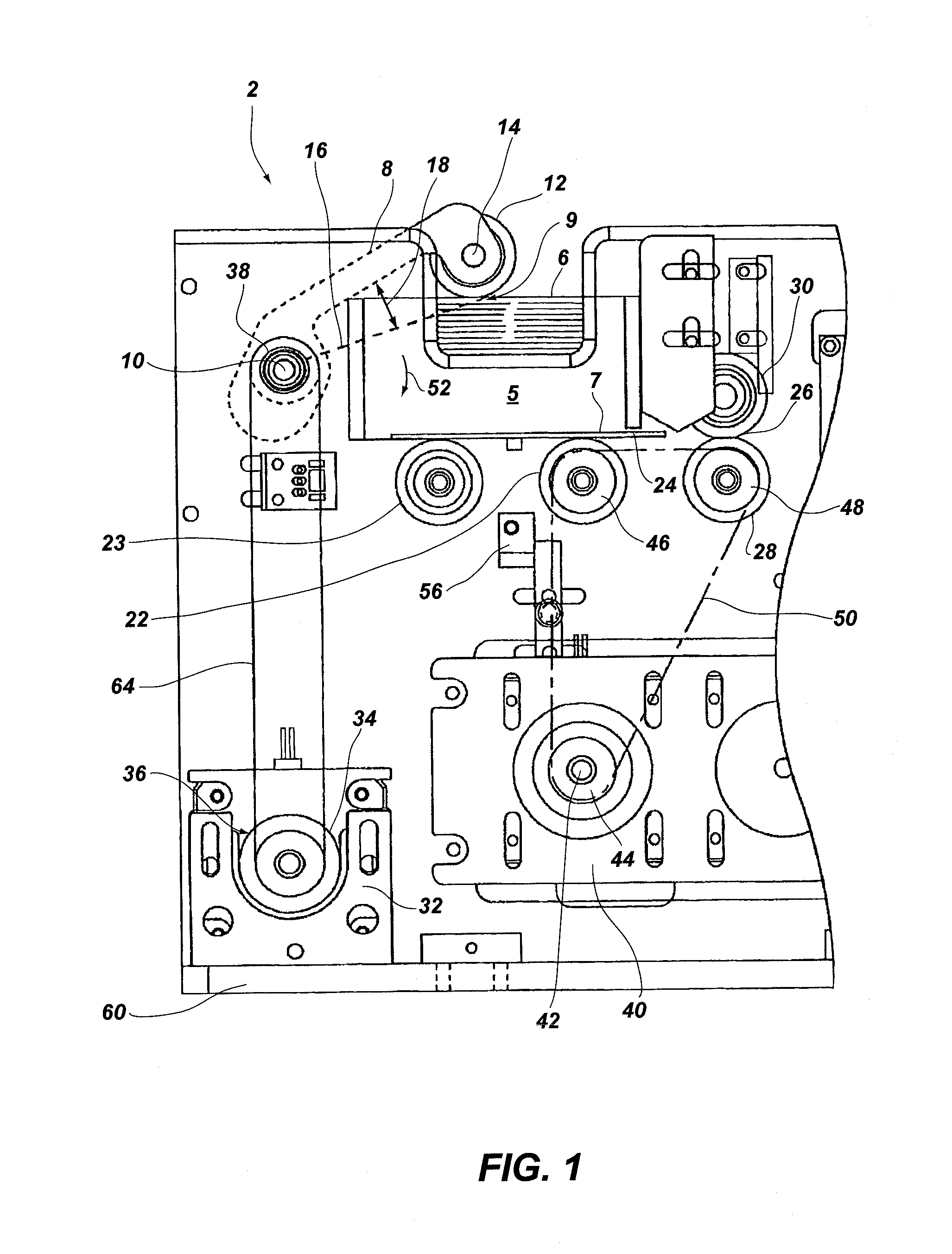

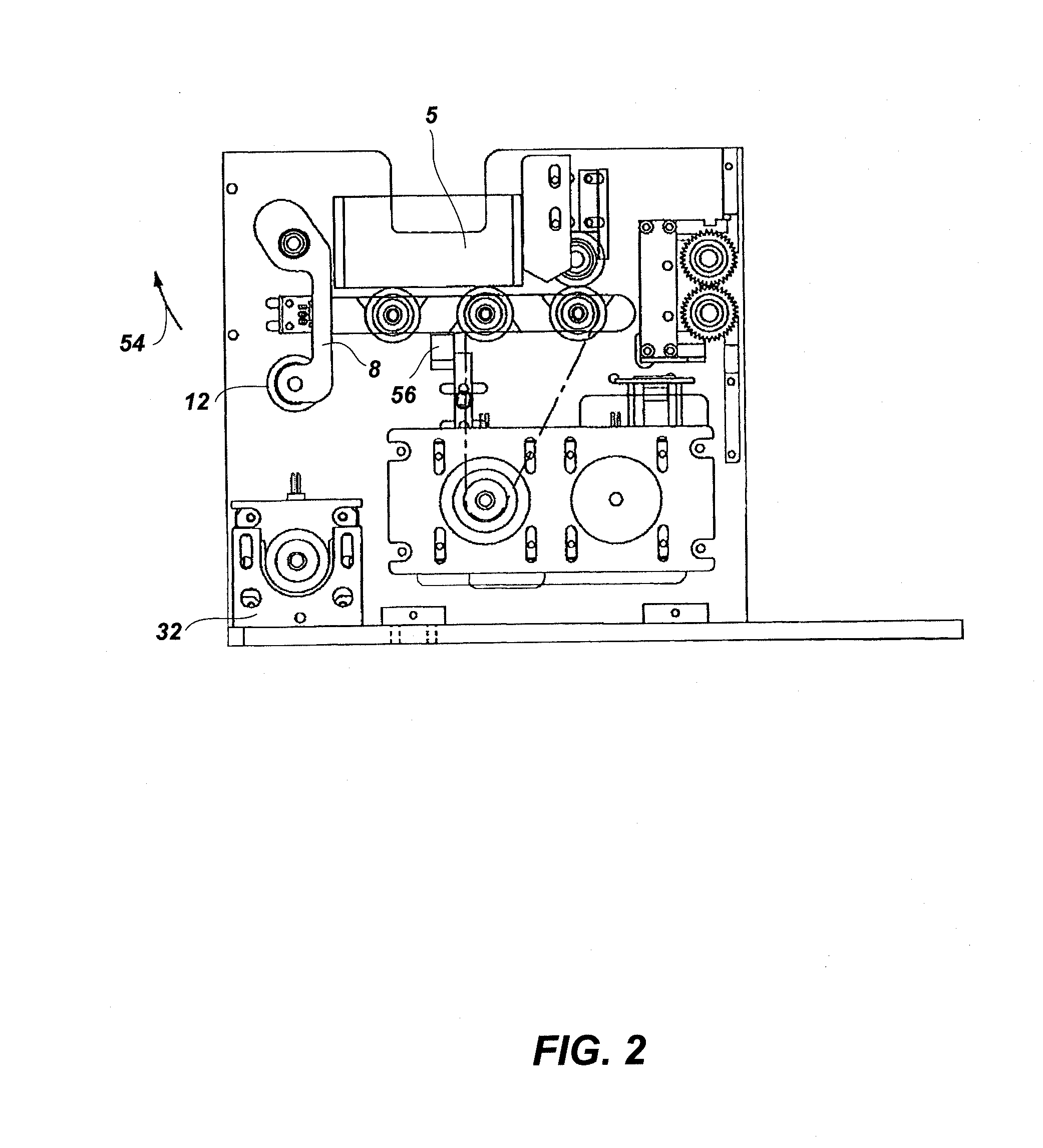

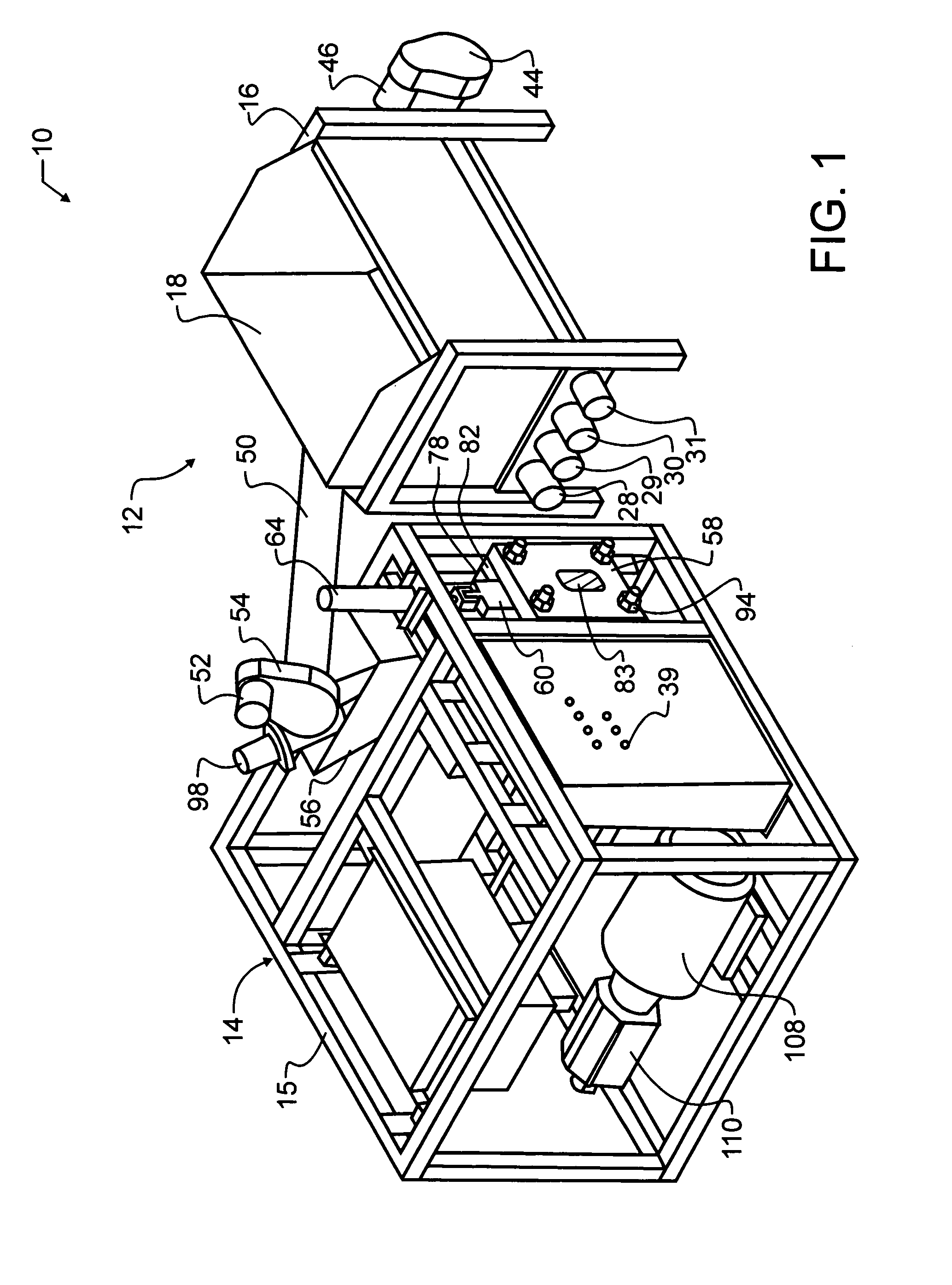

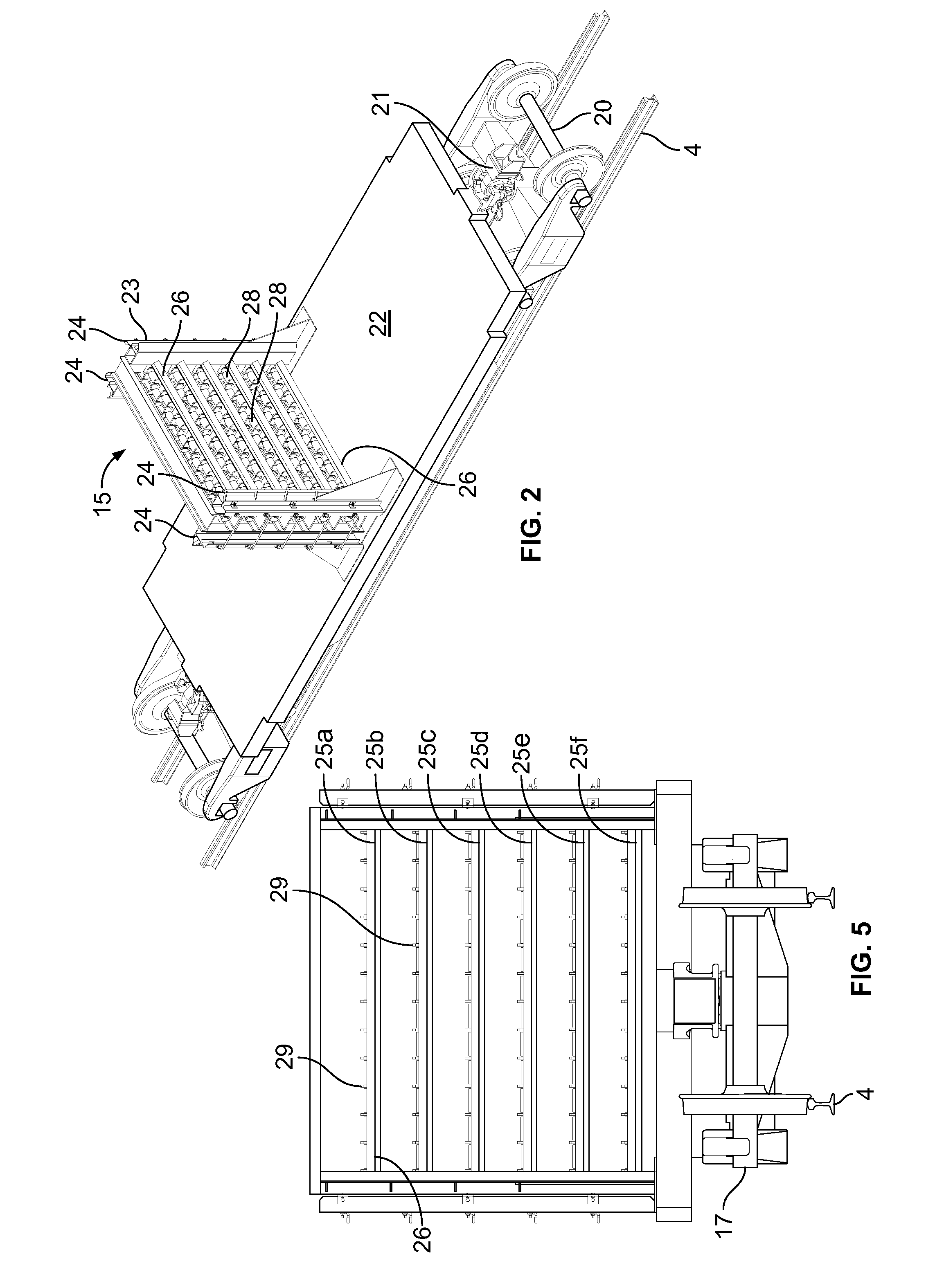

Automatic system and methods for accurate card handling

A playing card handling device is disclosed, comprising a card storing area that supports a stack of playing cards, the storing area having a playing card support surface. A card removing system is provided that removes playing cards individually from the bottom of the stack. A pivoting arm is automatically moved by a motor between at least two positions, wherein in a first position the end of the arm opposite a pivot is disengaged from a playing card at the top of the stack and in a second position the end of the arm is engaged with a playing card at the top of the stack. A processor in the playing card handling device directs movement of the pivoting arm between at least a first and second position when information is known to the processor that a predetermined number of cards is present in the card storing area of the card handling device. Methods of card handling employing the use of a pivotal arm are also disclosed.

Owner:LNW GAMING INC

Automatic system and methods for accurate card handling

A playing card handling device comprises a card storing area that supports a stack of playing cards, the card storing area having a playing card support surface. A card removing system is provided that removes playing cards individually from the bottom of the stack. A pivoting arm is automatically moved by a motor between at least two positions, wherein in a first position the end of the arm opposite a pivot is disengaged from a playing card at the top of the stack and in a second position the end of the min is engaged with a playing card at the top of the stack. A processor in the playing card handling device directs movement of the pivoting arm between at least a first and second position when information is known to the processor that a predetermined number of cards is present in the card storing area of the card handling device. Methods of card handling employing the use of a pivotal arm are also disclosed.

Owner:LNW GAMING INC

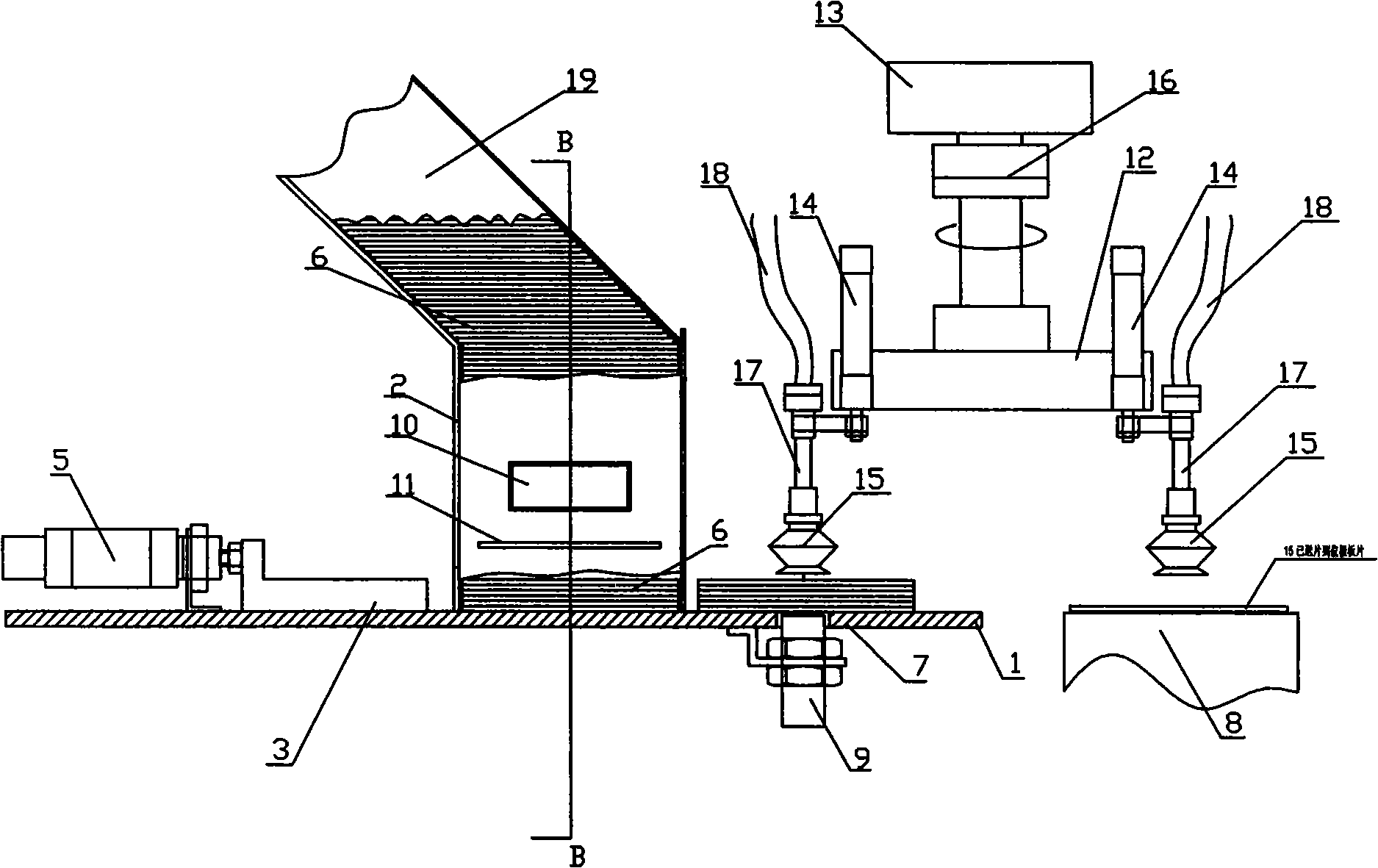

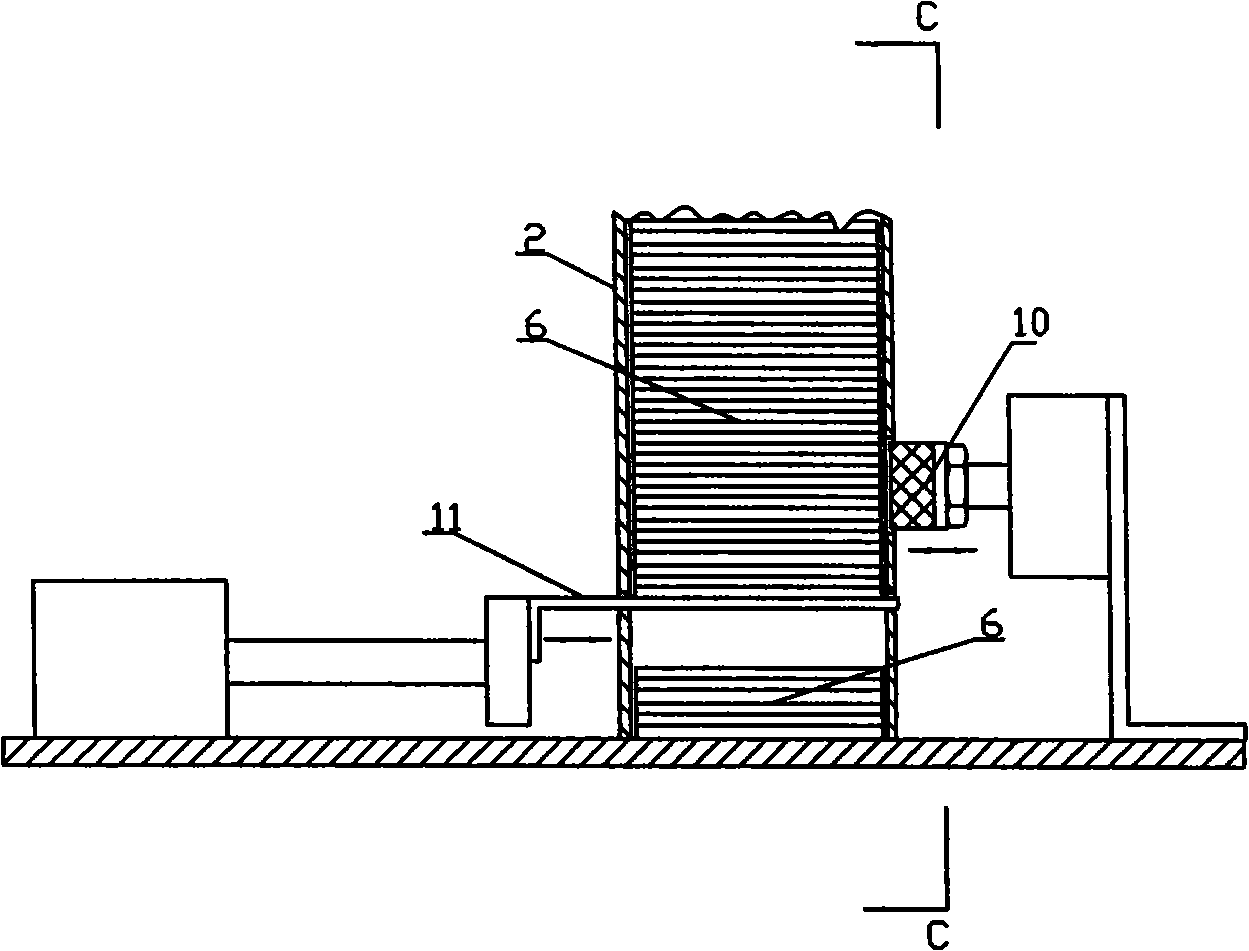

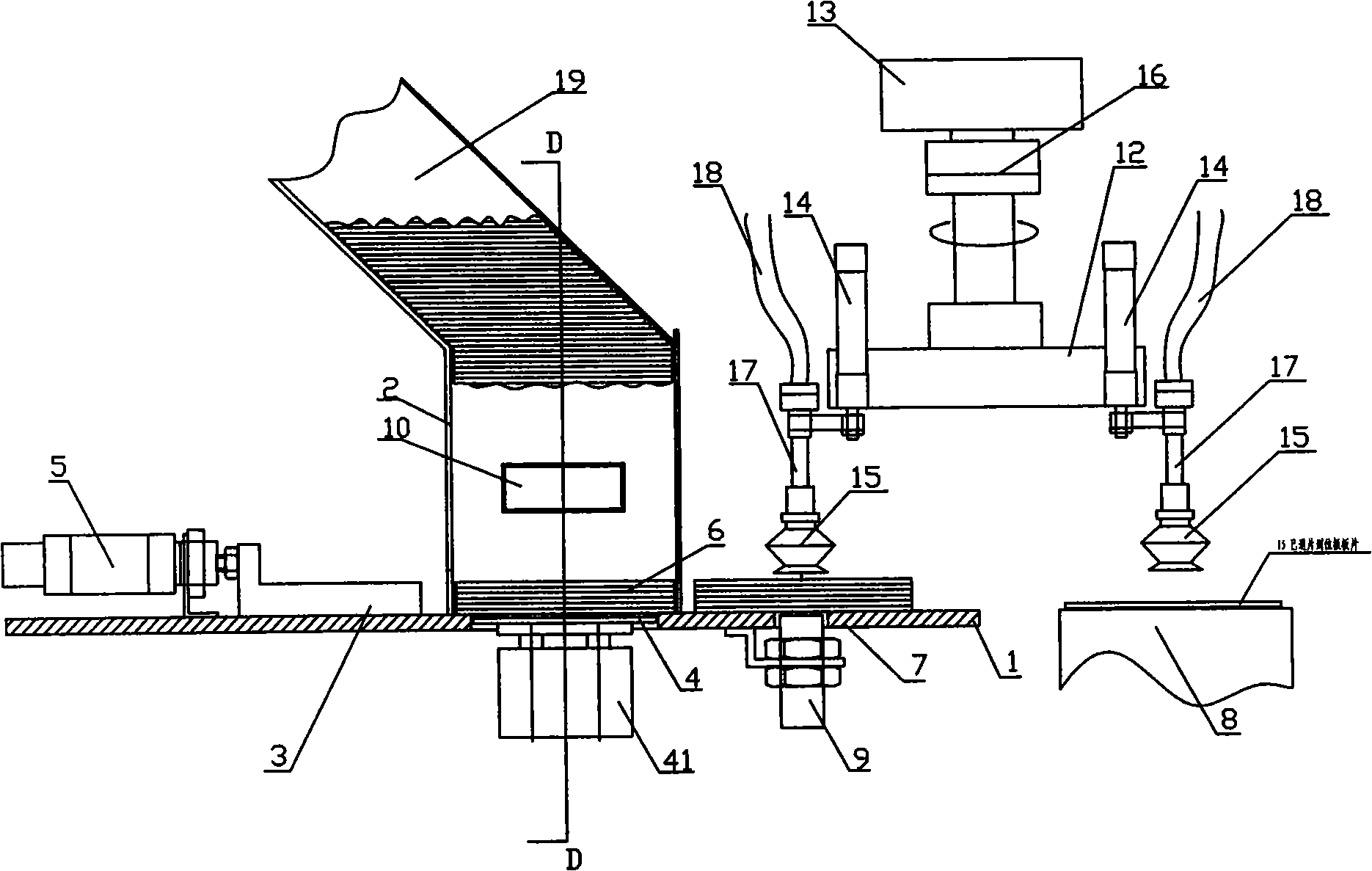

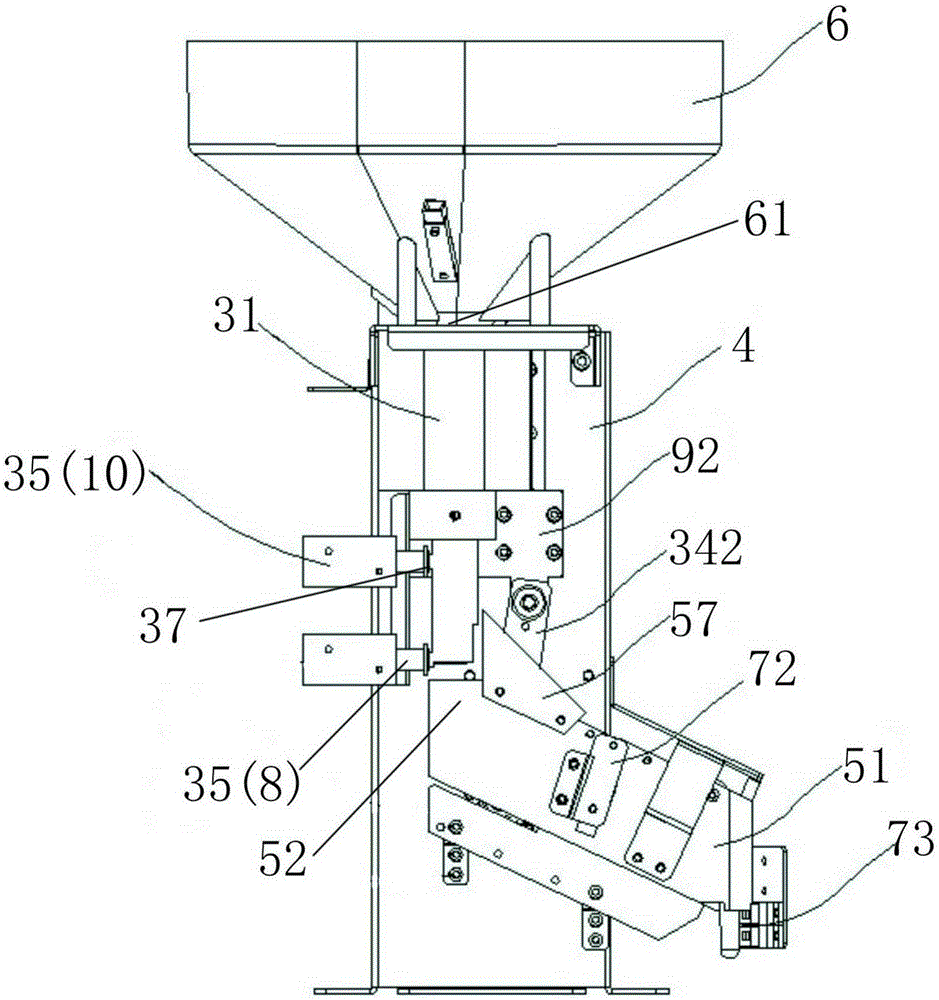

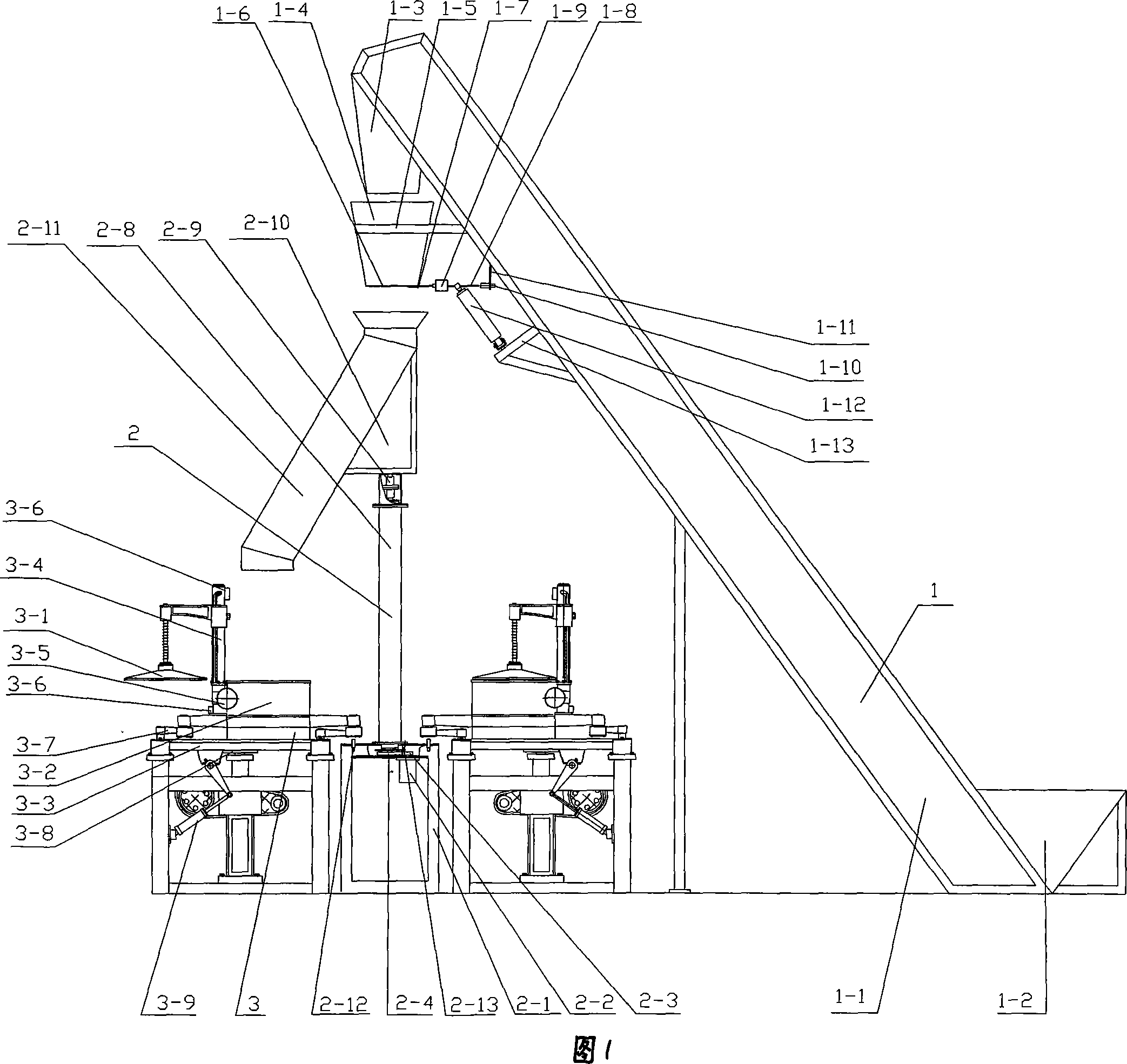

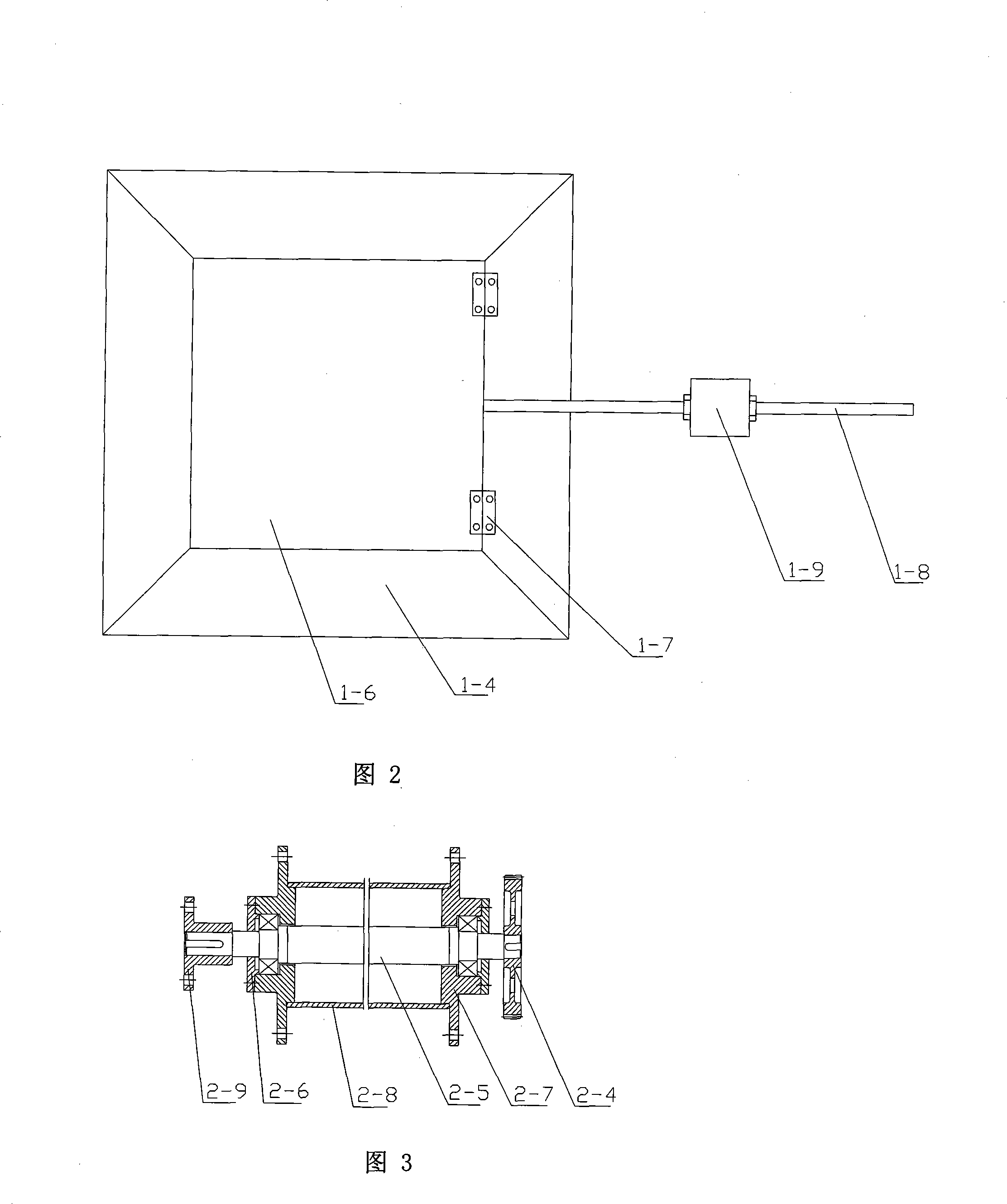

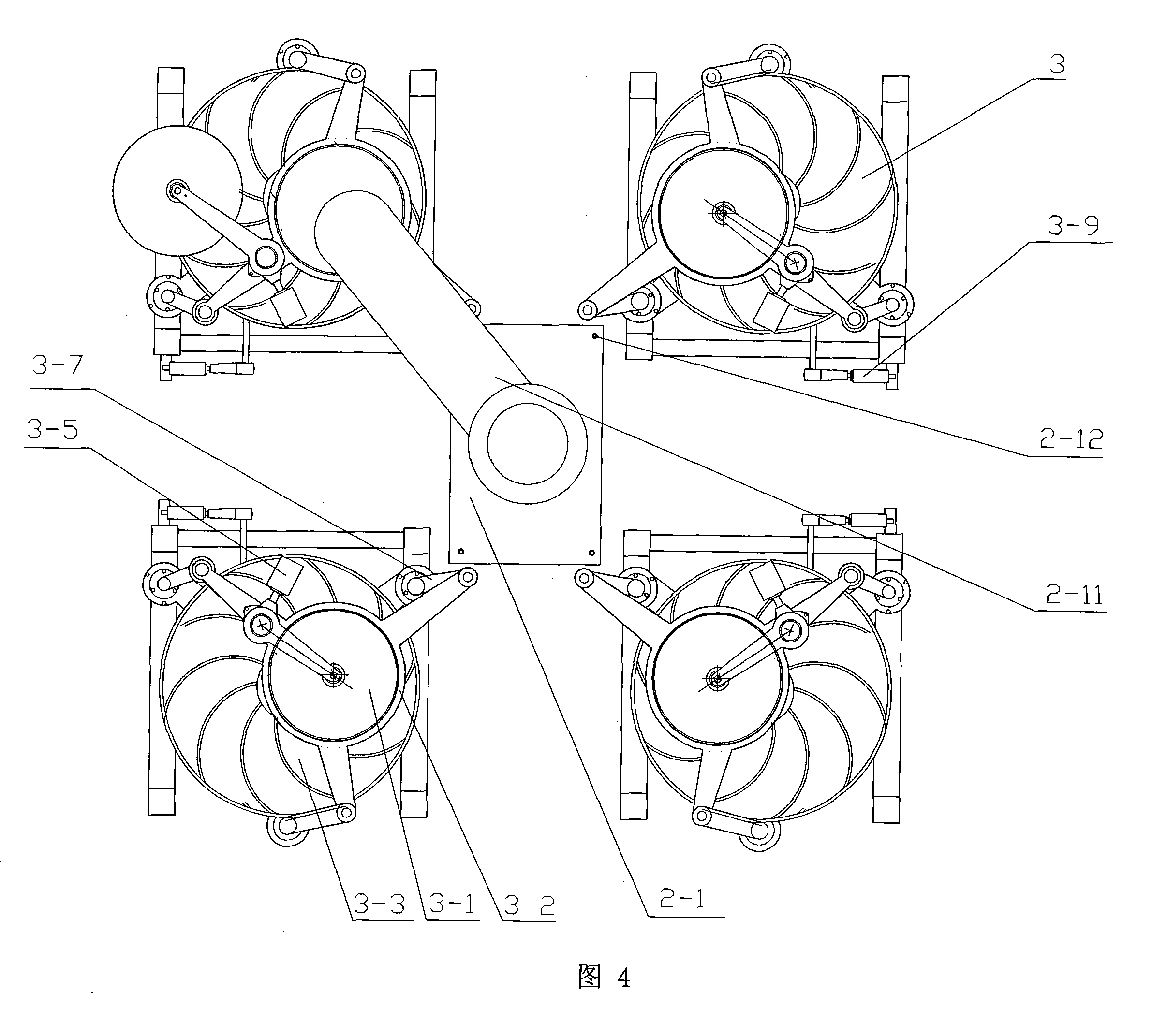

Feeding device of sorter of batteries plate

InactiveCN101357717ASimple structureCooperate wellGripping headsDe-stacking articlesBattery electrodeEngineering

The invention discloses a battery electrode sorting machine sheet conveying device, consisting of a material conveying platform, a vertical material bin, a material feeding pushing plate and a reciprocating swing sheet conveying mechanism; the vertical material bin is arranged above the middle part of the material conveying platform; the material conveying pushing plate is arranged at the rear part of the vertical material bin of the material conveying platform; the material conveying pushing plate is pushed by a material conveying cylinder and can slide forwards and backwards; the batter electrodes which are piled at the bottom of the vertical material bin are sent into the sheet taking positions of the reciprocating swing sheet conveying mechanism; the reciprocating swing sheet conveying mechanism is arranged above the front part of the material conveying platform; the battery electrodes piled at the sheet taking positions are sent to a feeding working position of the battery electrode sorting machine one after another. The battery electrode sorting machine sheet conveying device of the invention has simple structure, can quickly, exactly and safely send the battery electrodes into the inlet of the sorting machine one after another, and realizes the high-efficiency matching of the battery electrode sorting machine, thus ensuring that the battery electrode sorting machine sufficiently exerts the working efficiency.

Owner:NANJING NORMAL UNIVERSITY

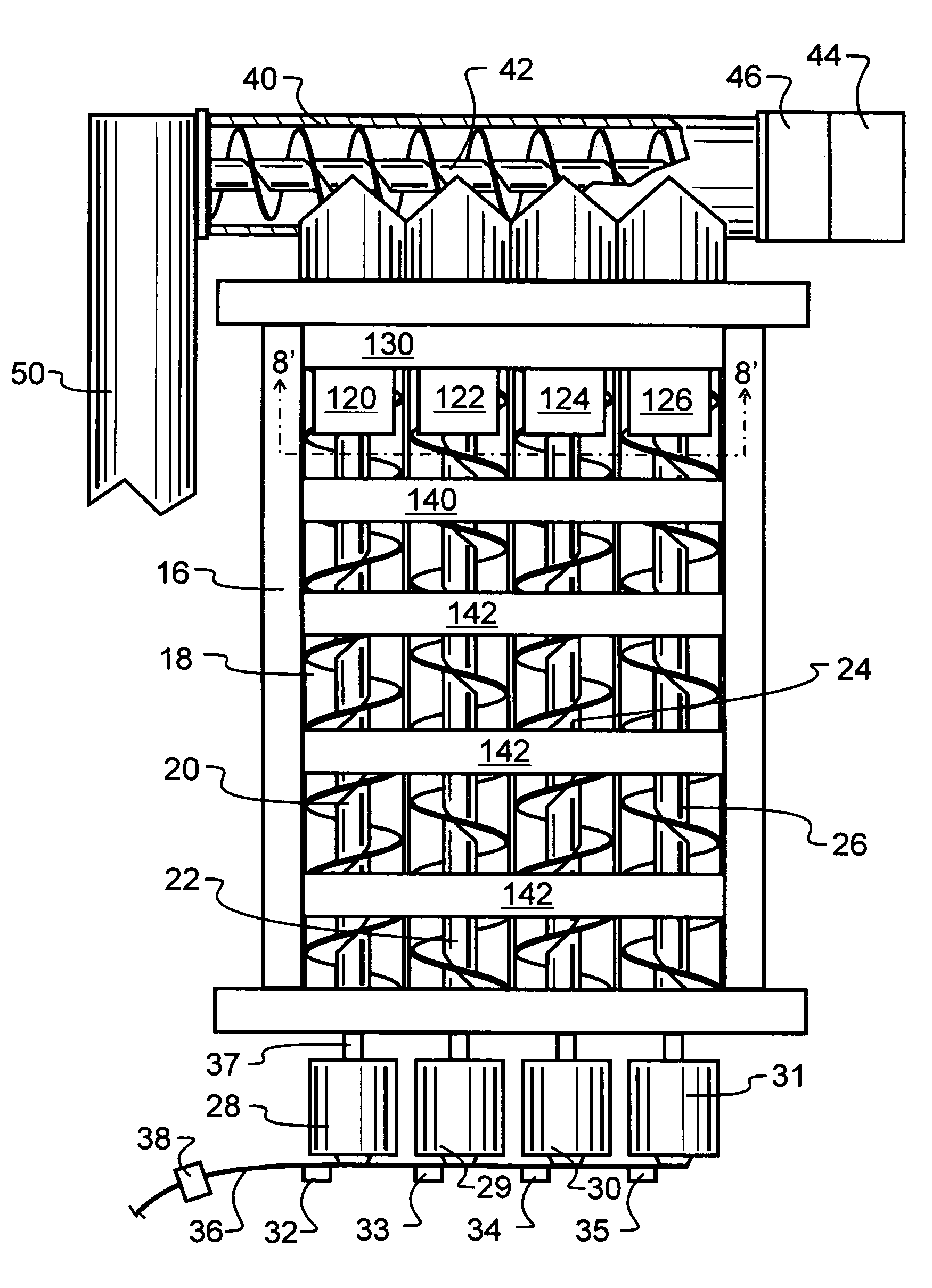

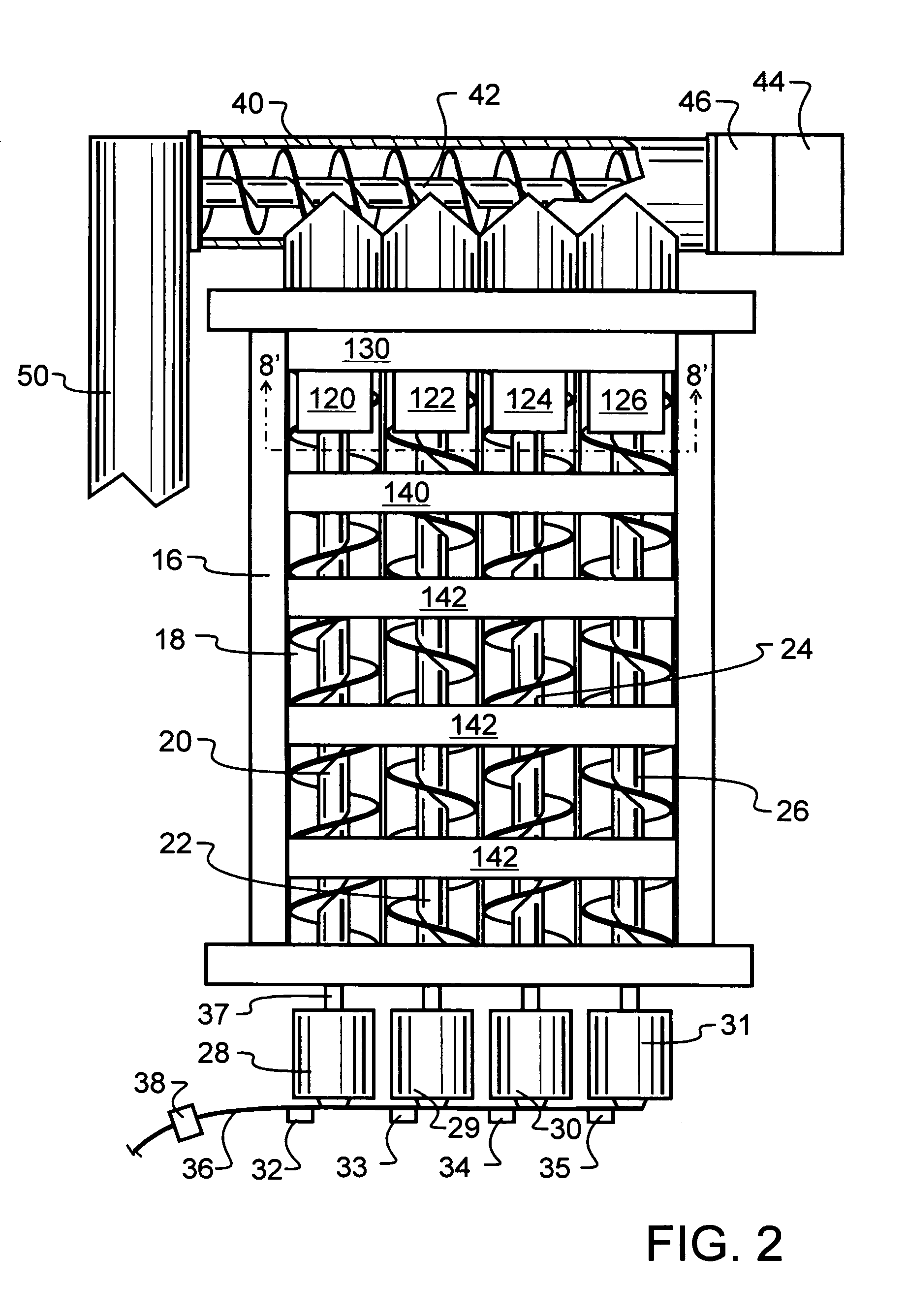

Automatic System and Methods for Accurate Card Handling

A playing card handling device comprises a card storing area that supports a stack of playing cards, the card storing area having a playing card support surface. A card removing system removes playing cards individually from the bottom of the stack. A pivoting arm is automatically moved by a motor between at least two positions, wherein in a first position the end of the arm opposite a pivot is disengaged from a playing card at the top of the stack and in a second position the end of the arm is engaged with a playing card at the top of the stack. A processor in the playing card handling device directs movement of the pivoting arm between at least the first and second positions when a predetermined number of cards is present in the card storing area. Methods of card handling include employing the use of such a pivotal arm.

Owner:LNW GAMING INC

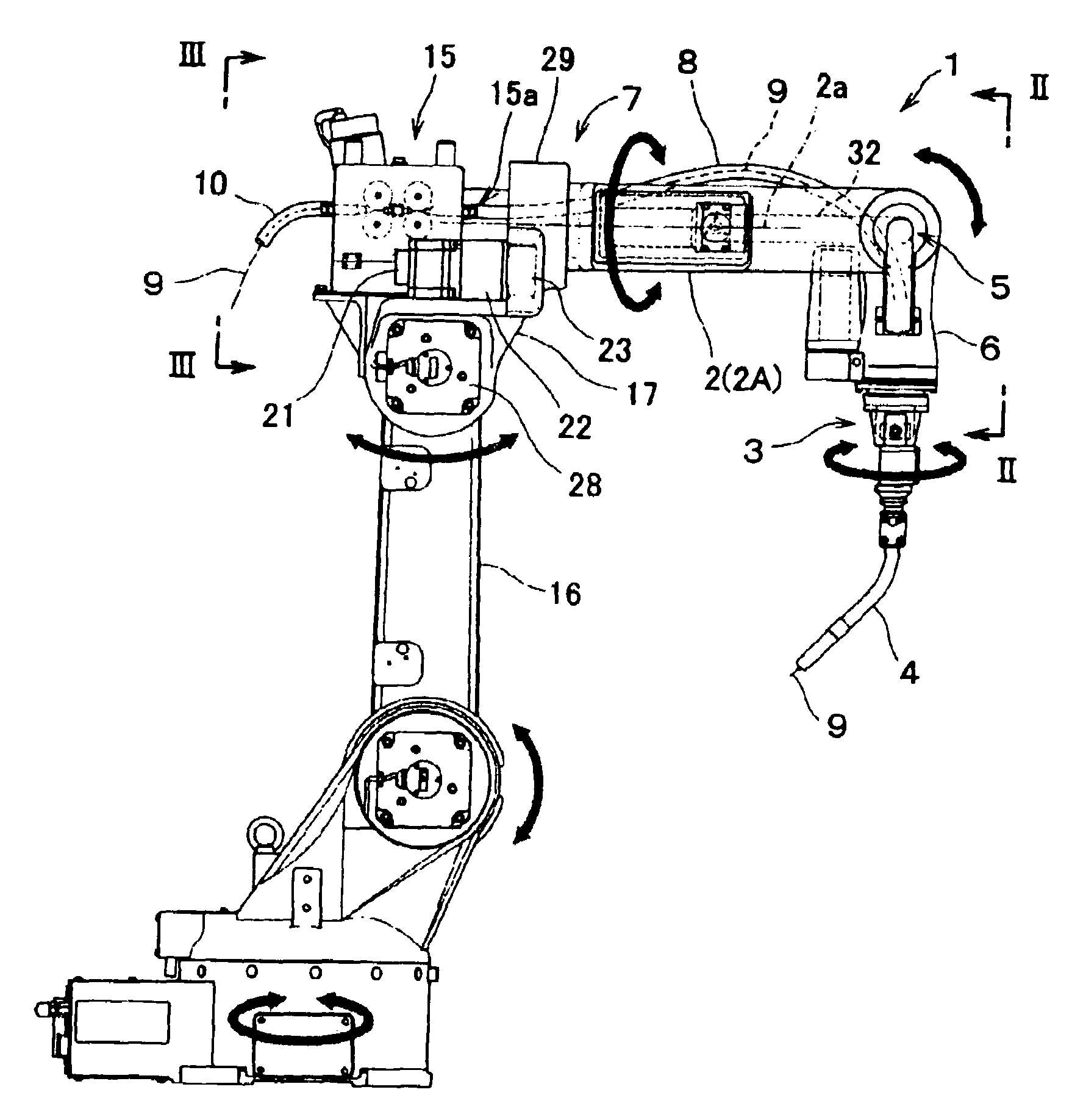

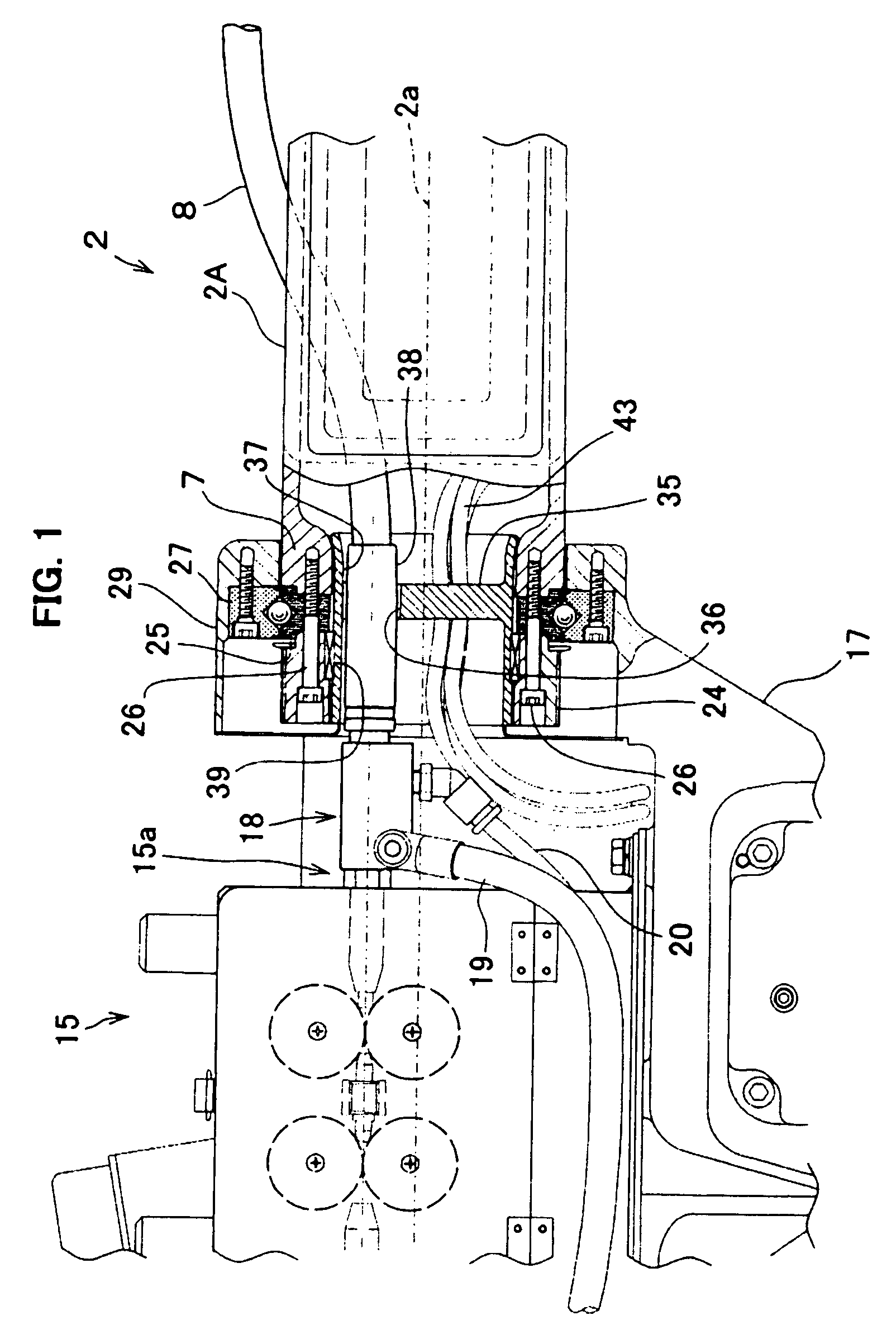

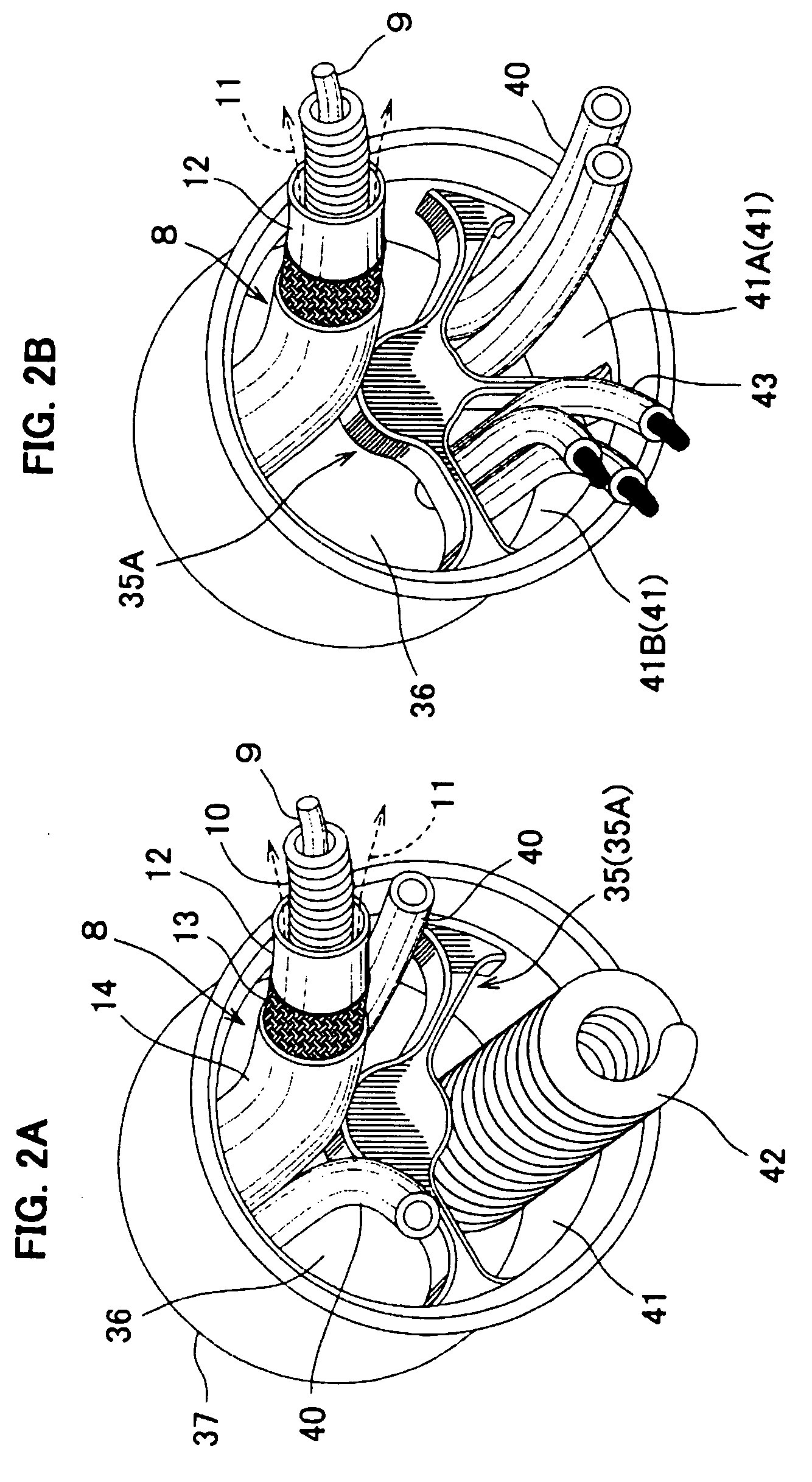

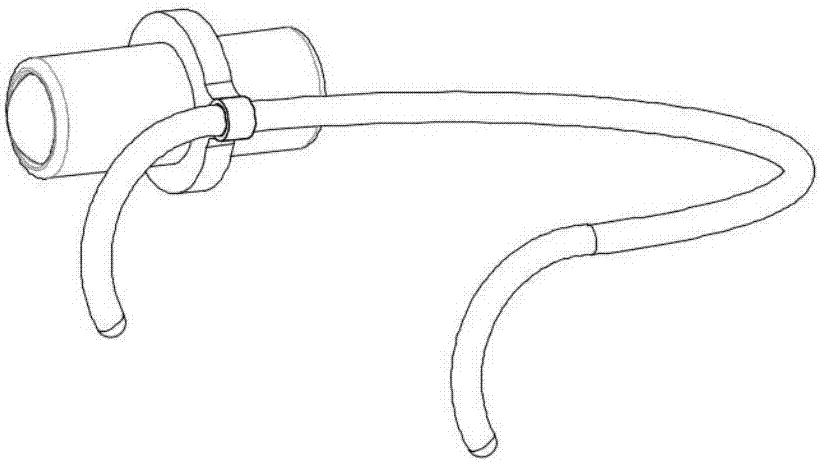

Cable arrangement for robot arm, and industrial robot utilizing the same

ActiveUS7202442B2Minimize impactImprove mobilityProgramme-controlled manipulatorWelding accessoriesPower cableEngineering

A cable arrangement for a robot arm is provided, which includes a rotation arm and a line member such as a power cable. The rotation arm has a front end and a base end, the front end being provided with a swing shaft, the base end being provided with a rotational shaft rotatable about a longitudinal axis. The line member extends from the base end toward the front end of the arm. The rotational shaft includes a line offset member formed with at least one through-hole for passing the line member. The through-hole as a whole is offset from the axis of the rotational shaft.

Owner:DAIHEN CORP

Iron oxide black granular pigment and preparation method thereof

InactiveCN101691456APollution suppressionSettling fastPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsDispersityIron oxide black

The invention belongs to the field of chemical pigments, and in particular relates to an iron oxide black granular pigment and a manufacturing method thereof. The iron oxide black granular pigment comprises a main component iron oxide black (Fe3O4) which is coated with an additive coating layer, and the main component iron oxide black is combined with the additive coating layer to form the granular pigment; and the pigment is prepared by the following steps: firstly preparing aqueous solution of an additive, and performing heating until 30 to 100 DEG C; and sending the iron oxide black into a granulator, evenly spraying the prepared aqueous solution of the additive onto powder, gradually forming small granules, and screening and drying the prepared granules with a vibrating screen to prepare a finished product. The granular pigment prepared by the method is not easy to diffuse so as to effectively prevent dust pollution, has high luster retention, good flowability and dispersity, and low cost, and is suitable to be widely applied in industry.

Owner:HANGZHOU XIAOXIANG PIGMENT CHEM

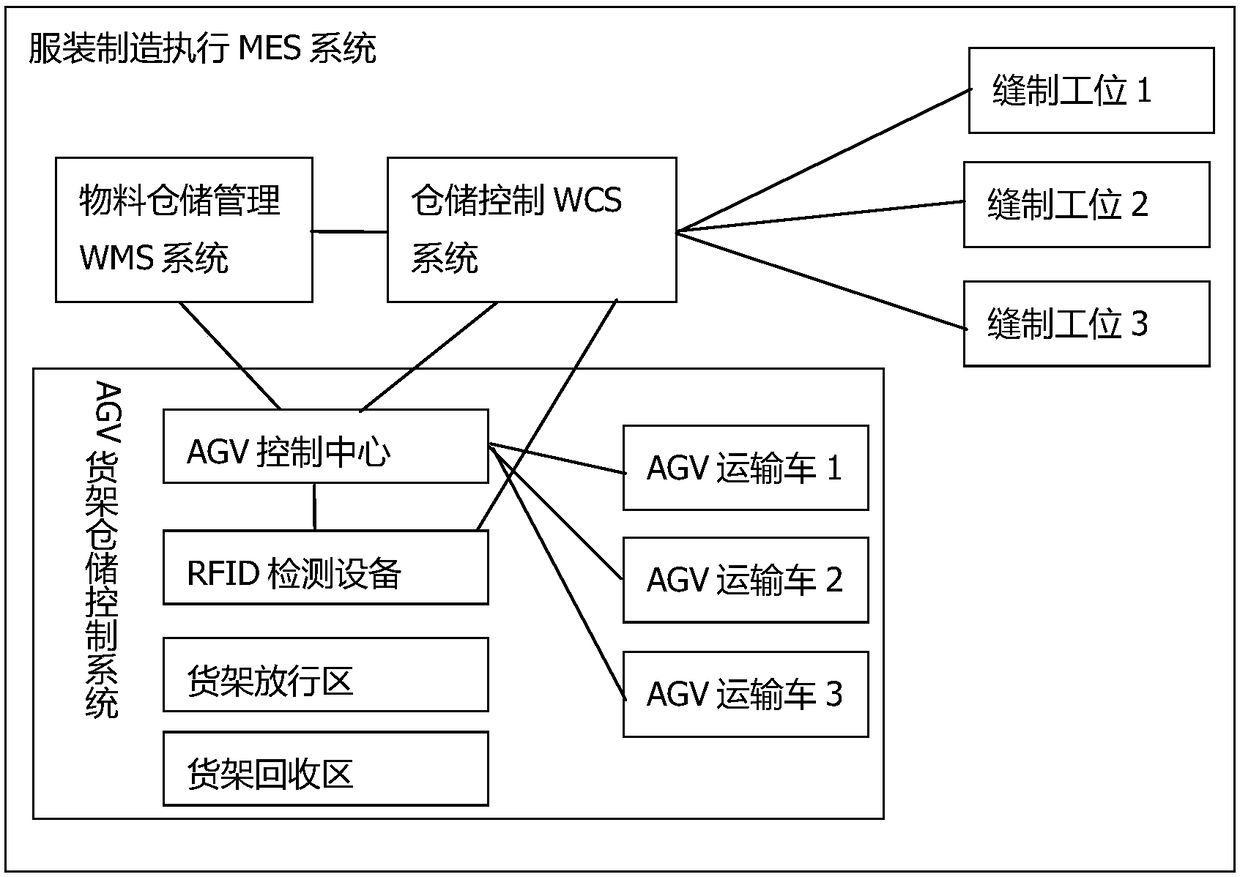

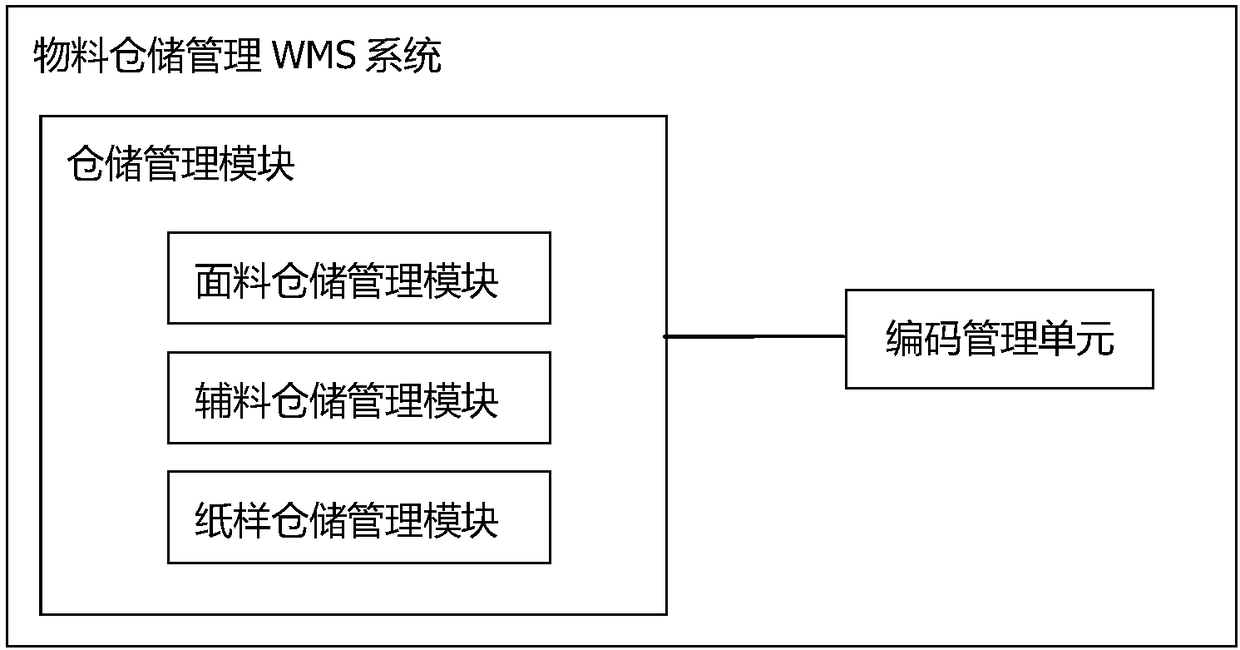

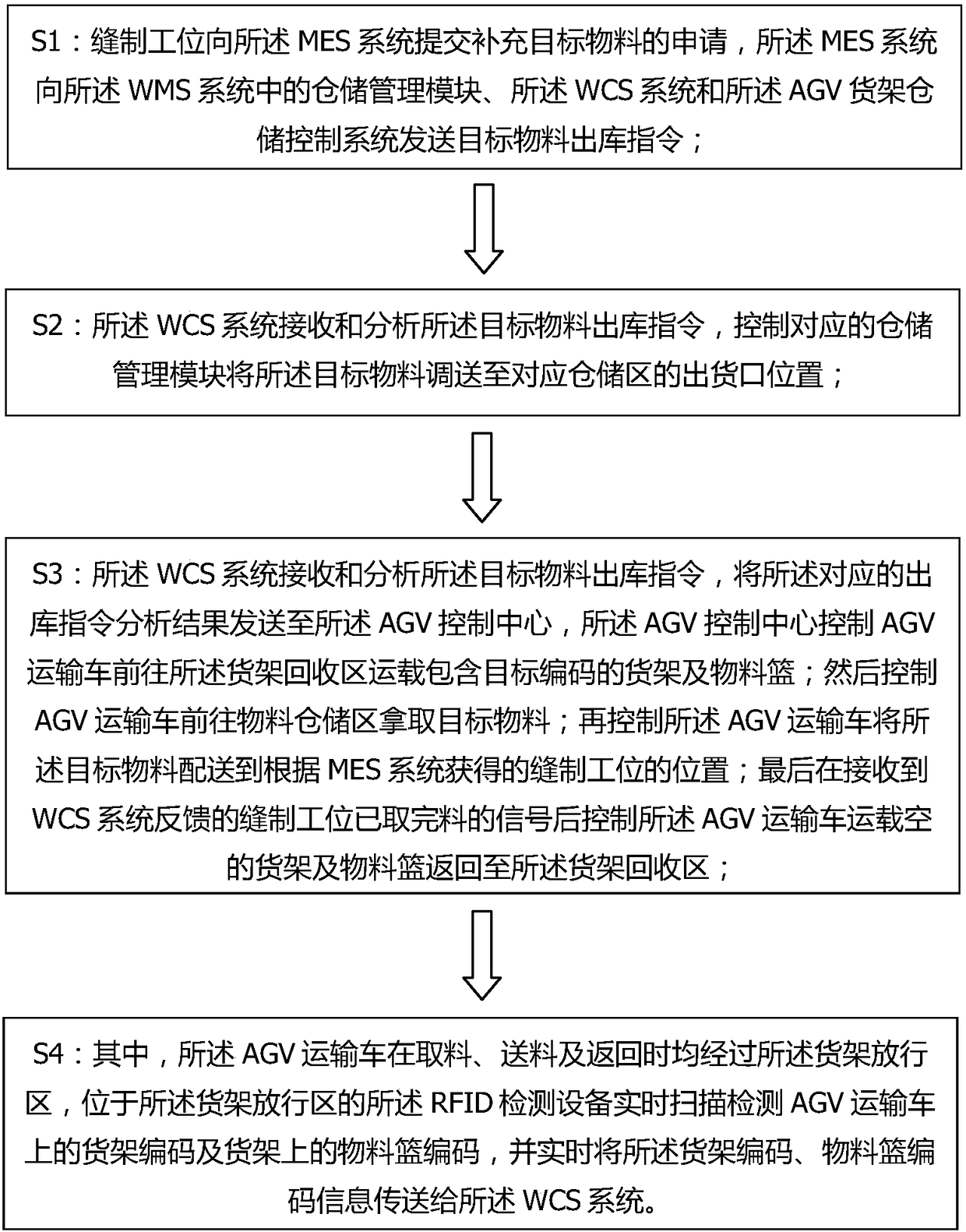

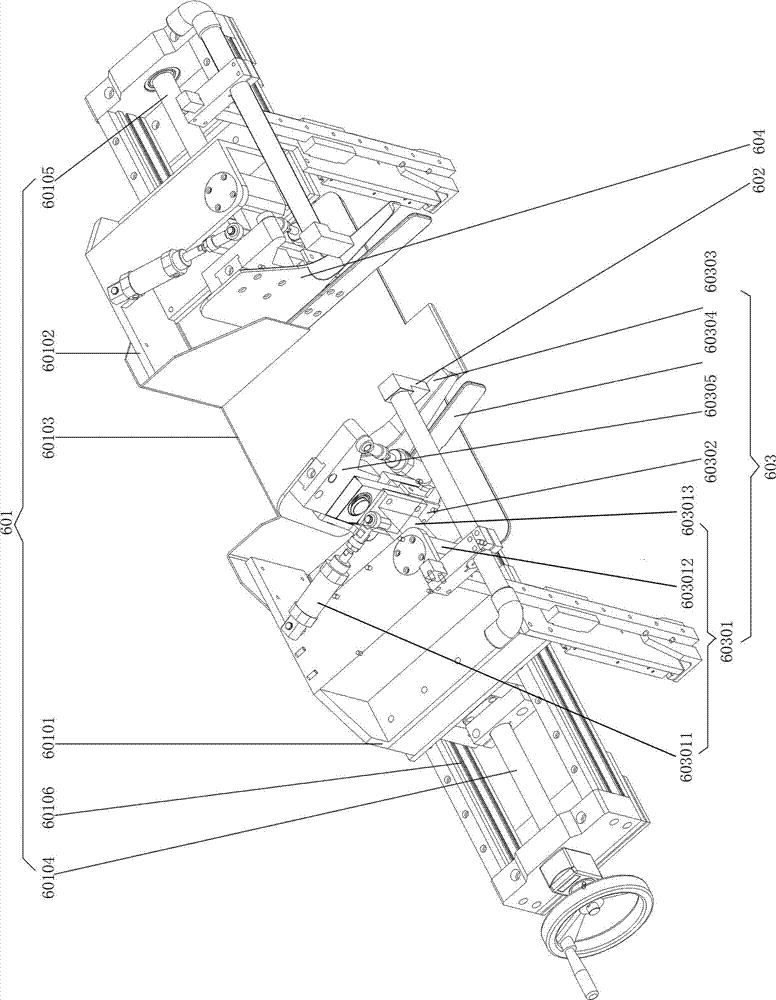

AGV shelf storage control system and method

ActiveCN108089557AImprove automationImprove intelligenceElectric/hybrid propulsionTotal factory controlControl systemTransport engineering

The invention discloses an AGV shelf storage control system and method, which are applied to an MES system for garment manufacturing. The control system includes an AGV control center, a shelf recovery area, a shelf release area, and an RFID detection device; the AGV control center is used to control an AGV transport vehicle to go to the shelf collection area to carry shelves and material basketsand go to a material storage area to take target materials according to a target material delivery instruction of the MES system, to control the AGV transport vehicle to deliver the target materials to the position of a sewing station obtained according to the MES system, and to control the AGV transport vehicle to carry the empty shelves and the material baskets back to the shelf collection areaafter receiving a signal from the sewing station and fed back by a WCS system, wherein the signal indicates that the materials are taken; and an RFID detection device is used to detect shelf codes andmaterial basket codes on the AGV transport vehicle and the information of the shelf codes and the material basket codes are transmitted to the WCS system. The system and the method can realize the high automation of material transportation and shelf management in the manufacturing process of clothes and greatly improve the production efficiency.

Owner:南京新标特仓储设备有限公司

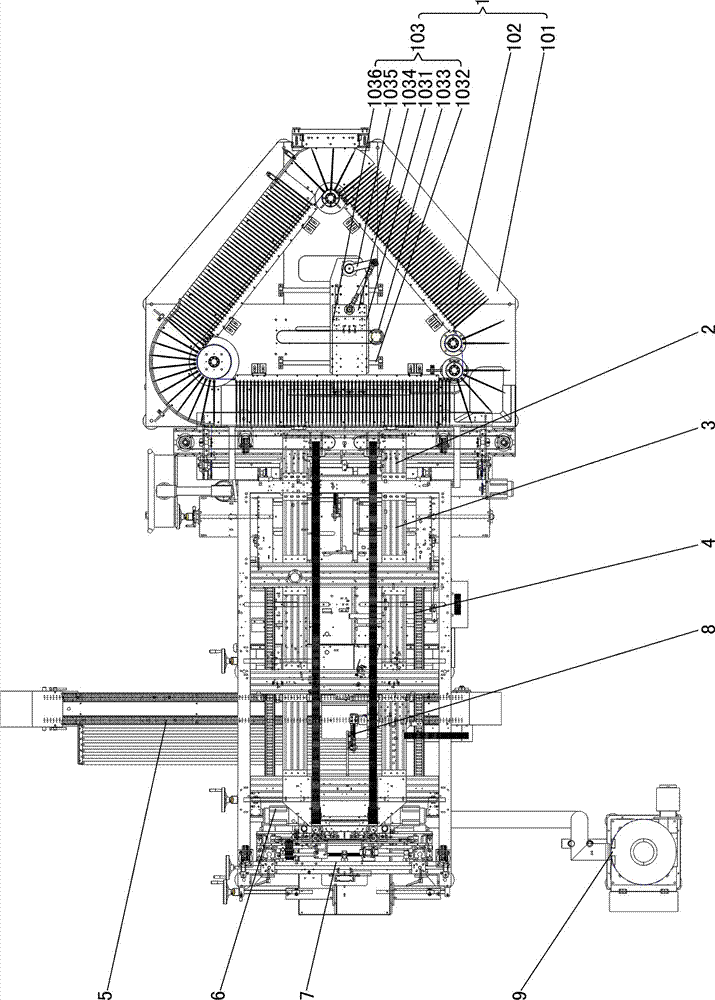

Full-automatic paper diaper packaging production line

ActiveCN104843248APrecise feedingAvoid getting stuckIndividual articlesStack machineCompression device

The invention relates to a full-automatic paper diaper packaging production line which comprises a stacking machine, pre-compression device, a transition mechanism, a secondary compression device, a bag feeding device, a bag opening device, a packaging, sealing and cutting-off device, a pushing mechanism and an offcut collecting device. The pre-compression device comprises a support, a support plate, a left compression mechanism, a right compression mechanism and a push out mechanism, wherein each of the left compression mechanism and the right compression mechanism comprises a compression translation mechanism, an upper push block and a lower push block, the upper push block and the lower push block are respectively connected with the power output end of the compression translation mechanism, and the upper push block is located above the lower push block. The full-automatic paper diaper packaging production line has the advantages that the upper push blocks and the lower push blocks are respectively driven by independent compression translation mechanisms and are fixed in the middle to perform pre-compression, paper diapers are prevented from being deviated and stuck, production smoothness is increased, and production efficiency is increased; the upper push blocks are separated from the lower push blocks, the friction between the paper diapers and the upper push blocks and the lower push blocks is reduced, and abrasion and scratch of the paper diapers are avoided.

Owner:孙少光

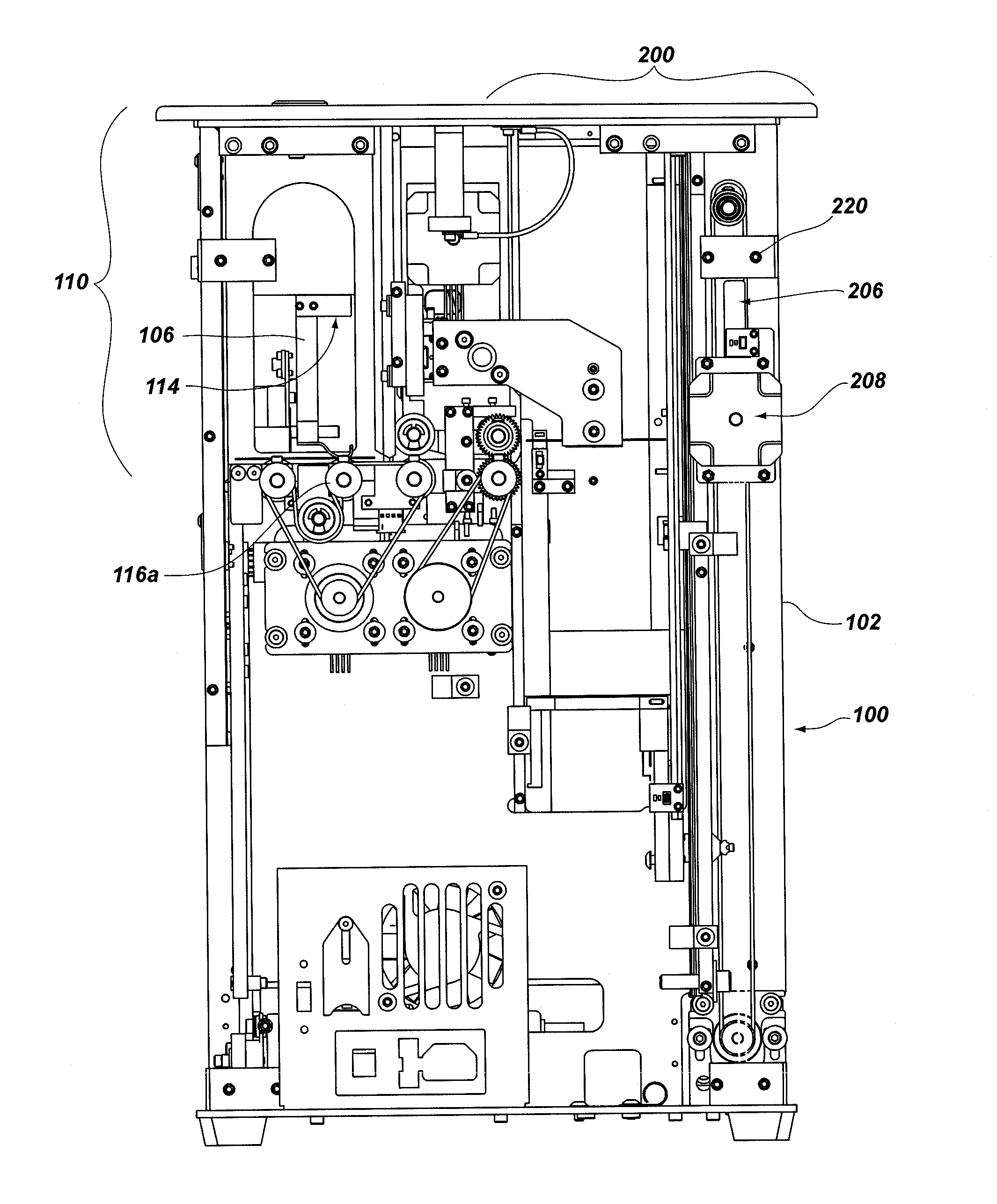

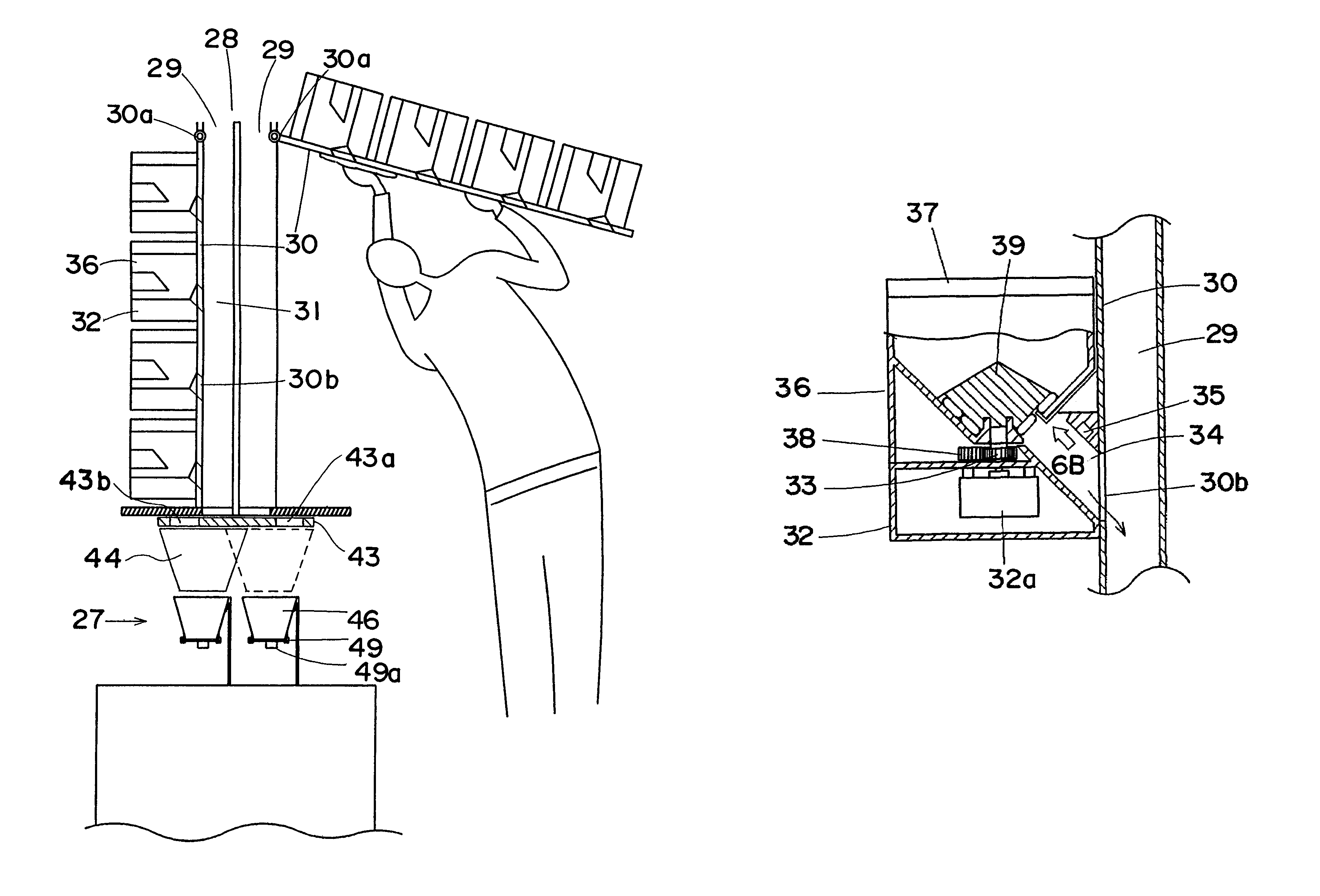

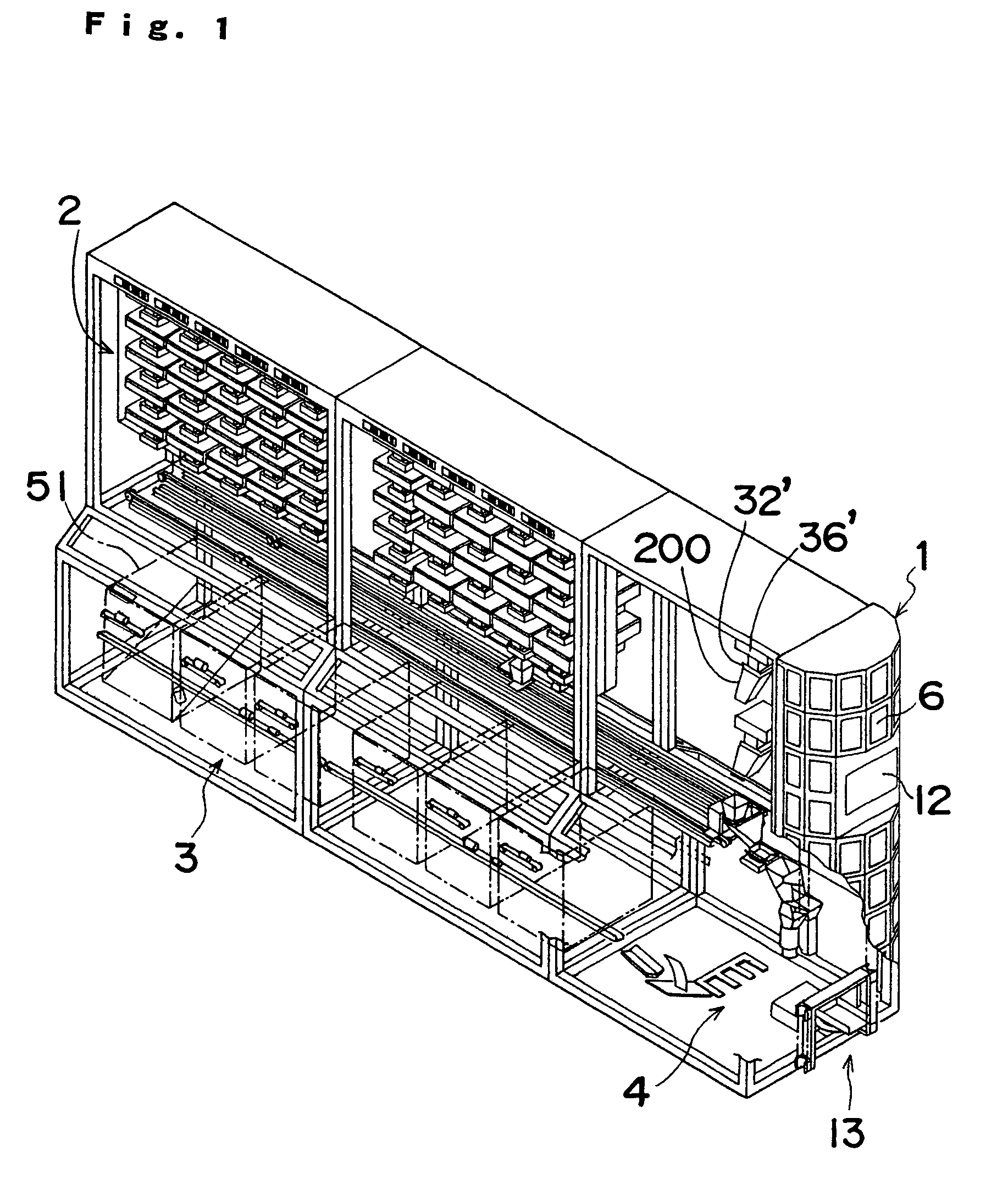

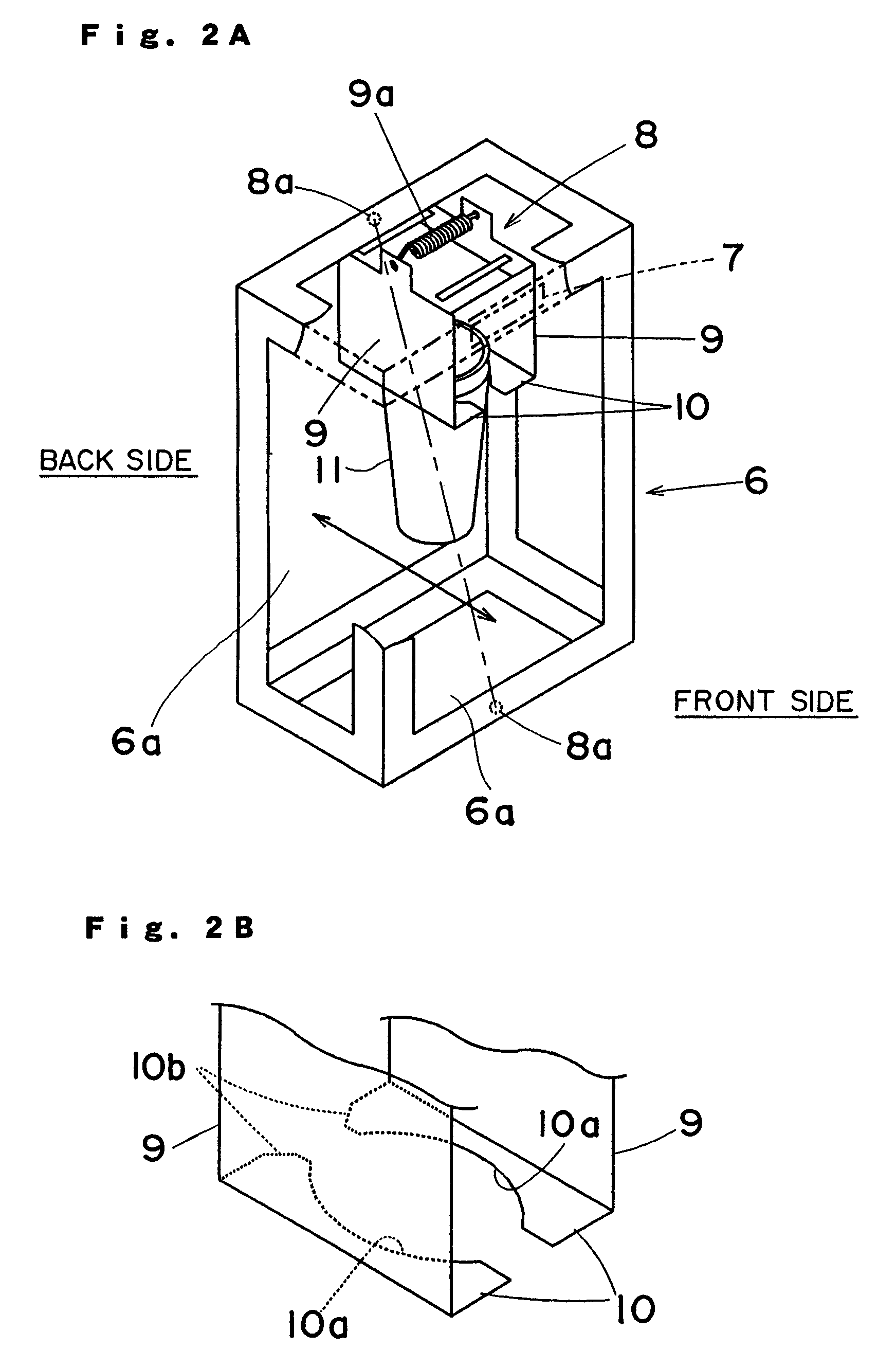

Tablet packing apparatus

InactiveUS7040070B2Easy to openEasy to pushCoin-freed apparatus detailsPharmaceutical product form changeEngineeringElectrical and Electronics engineering

A tablet packing apparatus in which there is no risk that next tablets will be mixed into tablets previously discharged. The packing apparatus includes a plurality of feeder vessels (36) containing the tablets, a plurality of mounting bases (32) on which respective feeder vessels (36) are mounted, and a tablet reserving member (200) disposed below the mounting base (32) and reserving the tablets fed from the feeder vessels (36) and a shutter (203,300) which is movable to open and close the lower opening of the tablet reserving member (200). The apparatus further comprises a LED (201) which is turned on when the tablets are fed to the tablet reserving member (200) and a sensor (206, 301a, 301b) for detecting opening or closing operation of the shutter (203), whereby when the sensor (206, 301a, 301b) detects the opening operation of the shutter (203,300), the LED (201) is turned off.

Owner:YUYAMA MFG CO LTD

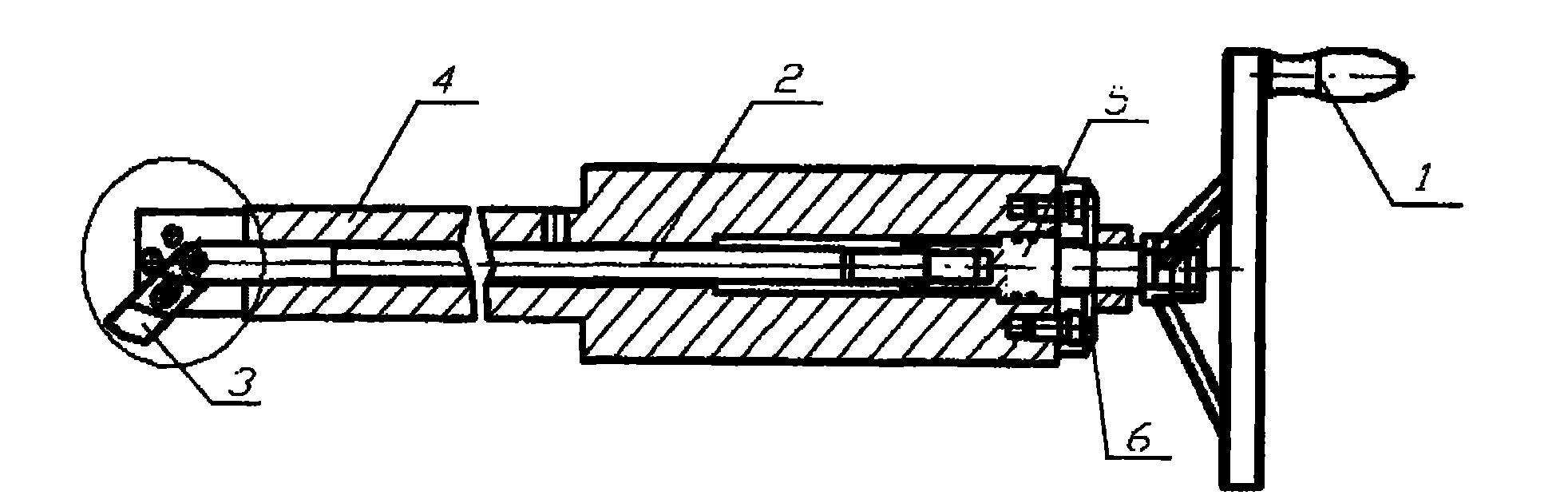

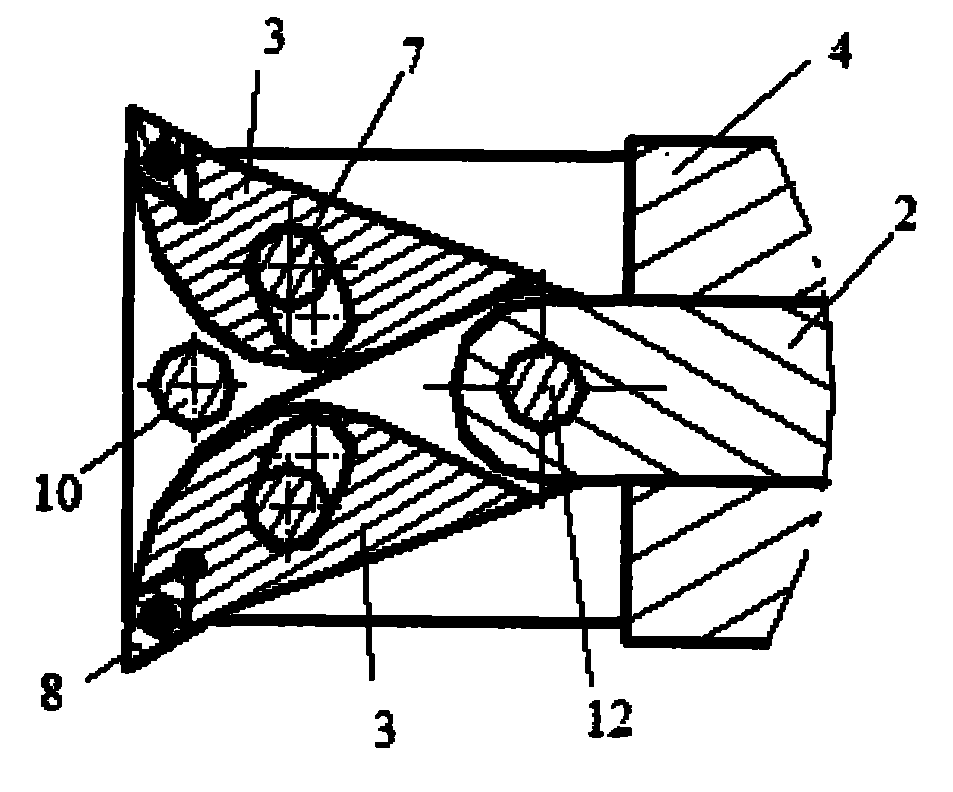

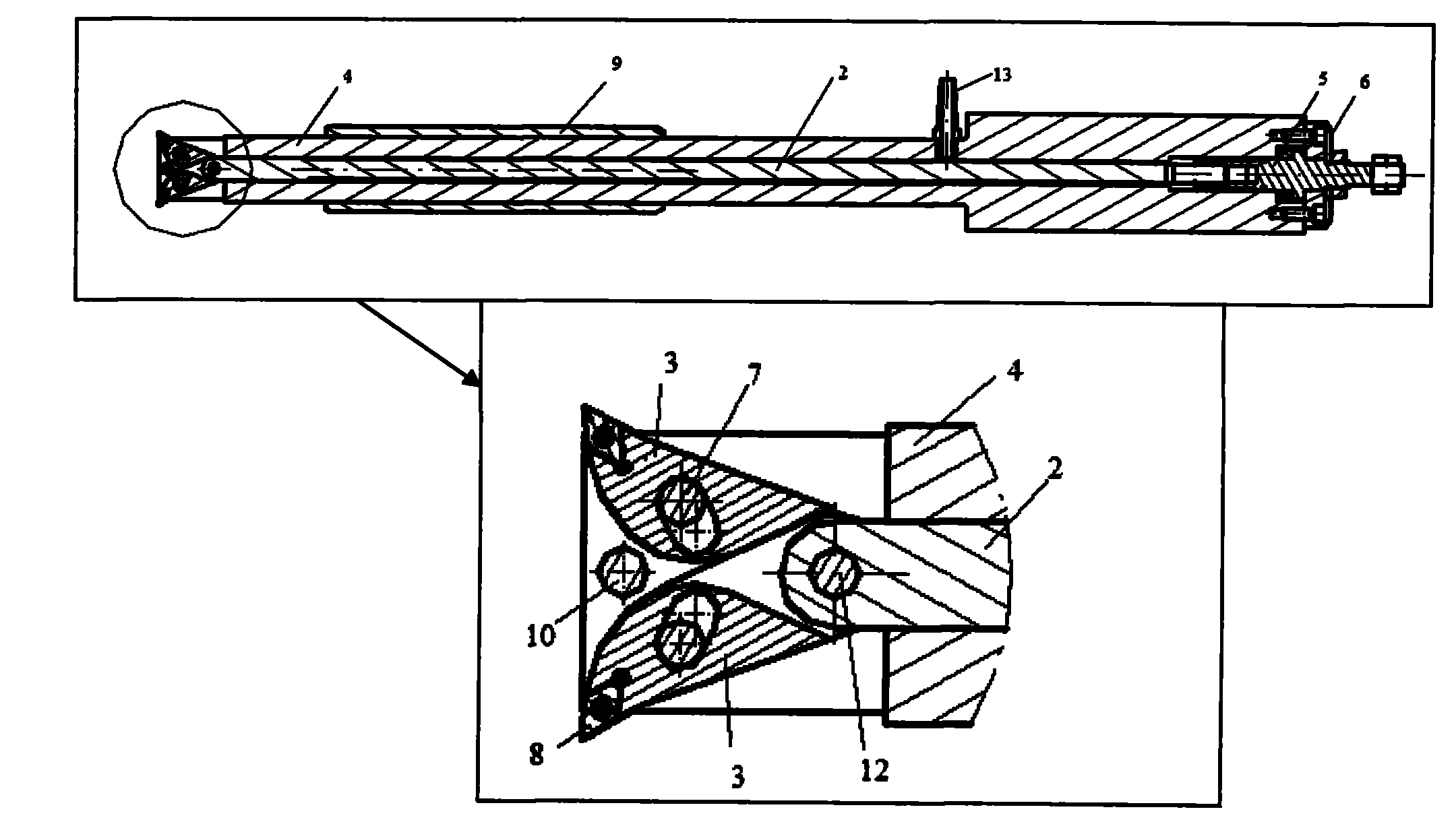

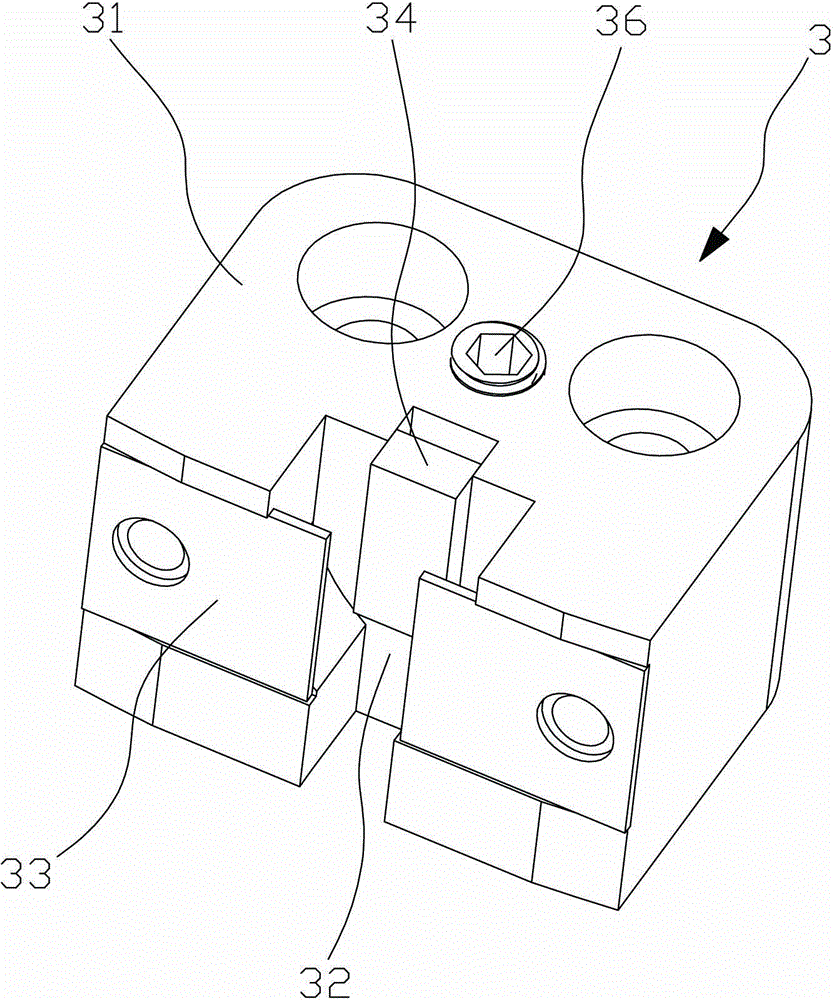

Telescopic double-edged deep-hole boring cutter

The invention provides a telescopic double-edged deep-hole boring cutter, aims to provide a deep-hole drilling boring cutter which has large length-diameter ratio, small self-excited vibration of a boring bar, reliable and stable feeding operation, no radial motion of a cutter arbor, and radial feeding of a cutting edge in a cutting process, and solves the problem that the deep-hole bottle cavity with large length-diameter ratio has large processing difficulty. The boring cutter comprises the boring bar which can extend to the deep-hole bottle cavity, wherein the central axis of the boring bar is provided with a through hole which runs through the central axis; a push rod (2) which is connected with a radial feeding device of the head of the boring bar is arranged in the through hole; the rear end of the push rod (2) is provided with a rotating handle; the rotating handle rotates a screw (5) and pushes the push rod (2) to do radial telescopic motion in the through hole of the boring bar; and the push rod (2) moves by way of pushing or pulling to drive the radial feeding device connected with the push rod and adjust the cutting edge of the double-edged boring cutter on a cutter block (3) to radically feed in the deep-hole bottle cavity.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP +1

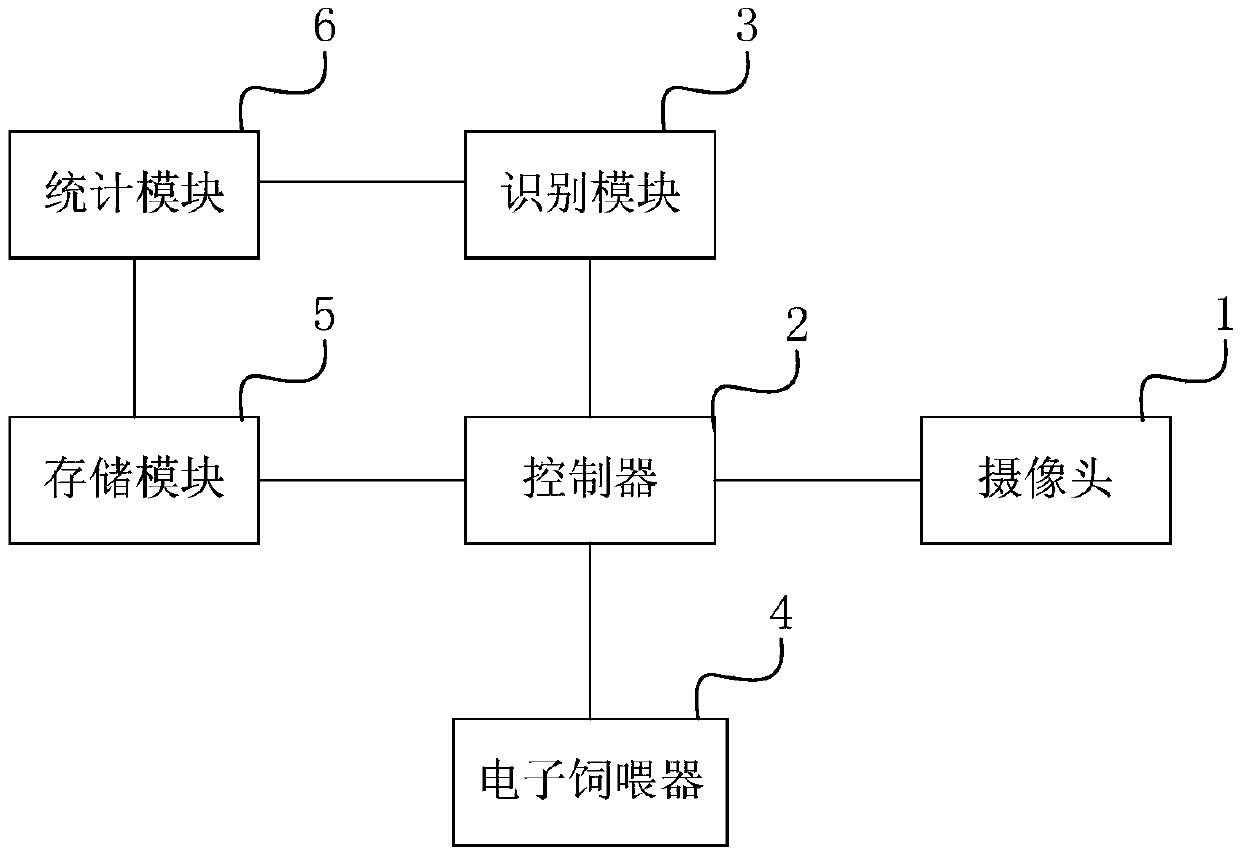

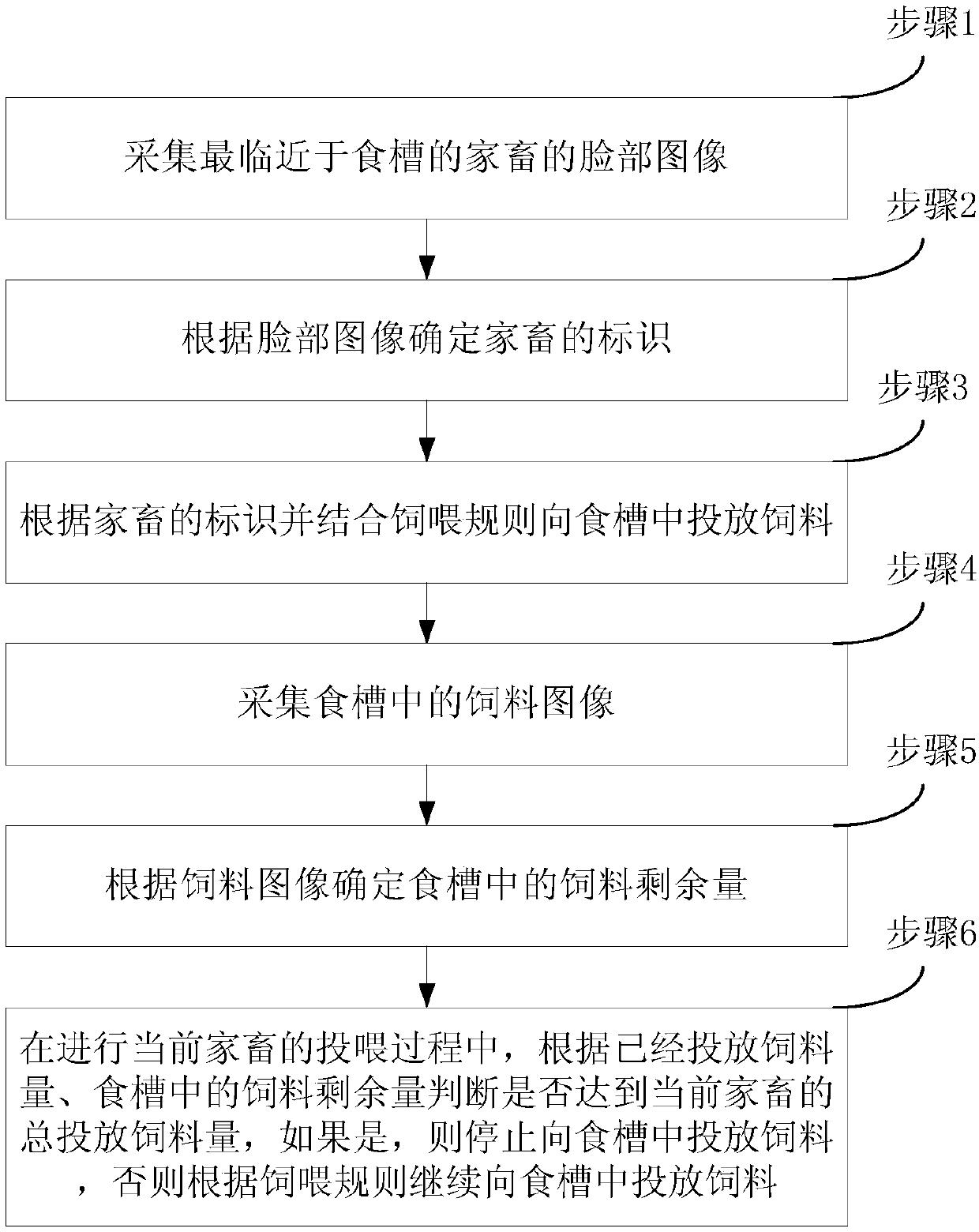

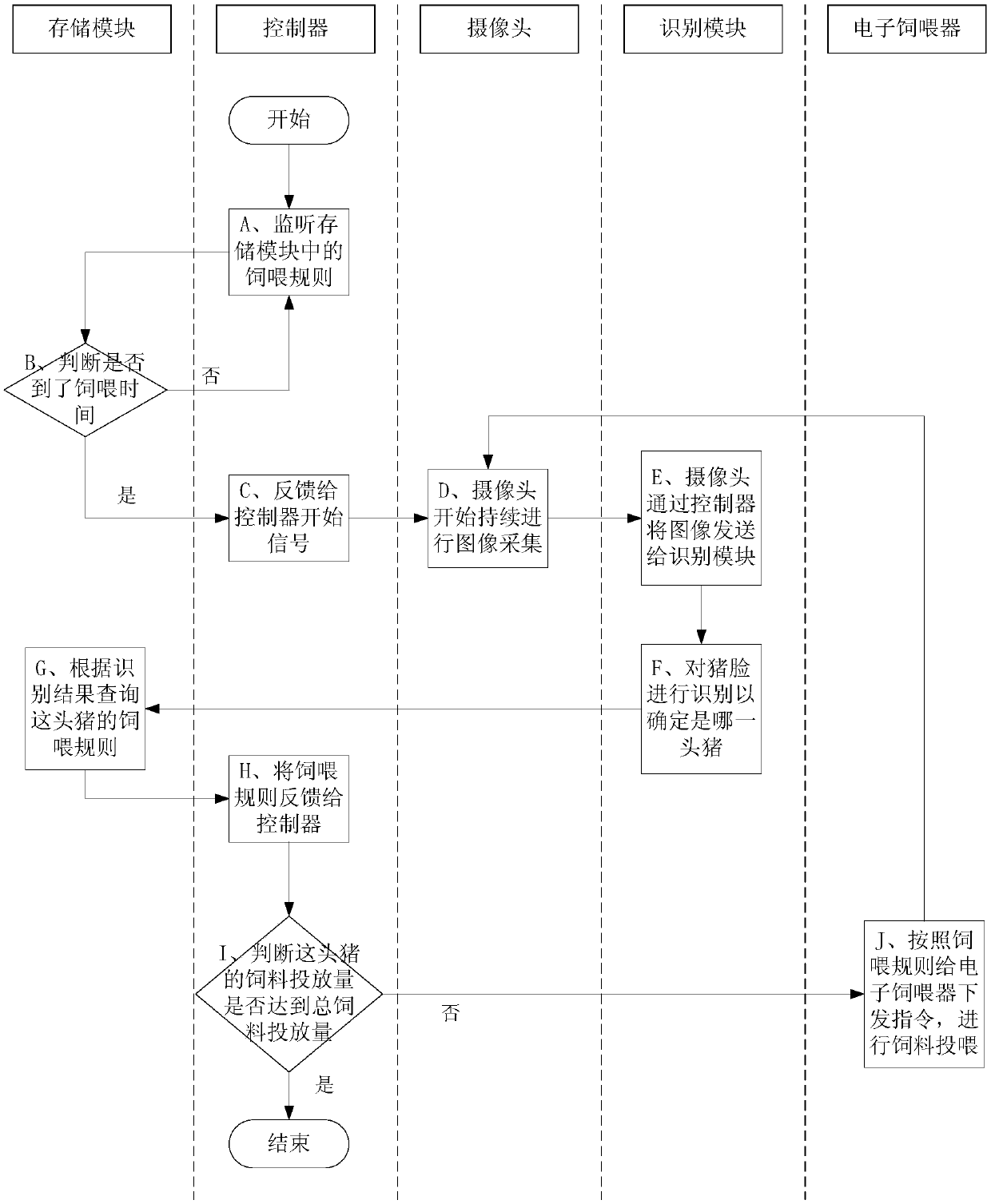

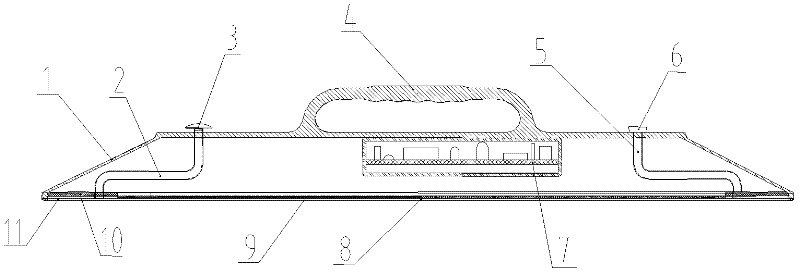

Intelligent feeding system and method for livestock

ActiveCN109618961AEasy to formulateEasy to adjustData processing applicationsAnimal feeding devicesComputer moduleComputer science

The invention discloses an intelligent feeding system and method for livestock. The system comprises a storage module, a camera, an identification module, an electronic feeder and a controller. The storage module is used for storing a feeding rule of livestock; the camera is installed above a trough and collects a face image of the livestock which are closest to the trough when a shooting instruction is received; the identification module is used for determining an identifier of the livestock according to the face image; the electronic feeder is installed on the trough and adds feed to the trough according to a received discharging instruction; the controller is used for sending the shooting instruction to the camera according to the feeding rule of the storage module, receiving the face image and a feed image from the camera, transmitting the face image and the feed image to the identification module, receiving the identifier of the livestock and the feed surplus amount of the troughfrom the identification module and sending the discharging instruction to the electronic feeder according to the identifier of the livestock in combination with the feeding rule. According to the intelligent feeding system, all the livestock are distinguished through a face identification technology of artificial intelligence, the livestock individuals are remotely and precisely fed and controlled, and the feeding rule is conveniently made and adjusted.

Owner:JINGDONG TECH HLDG CO LTD

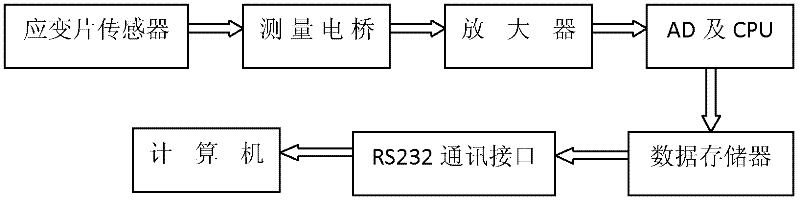

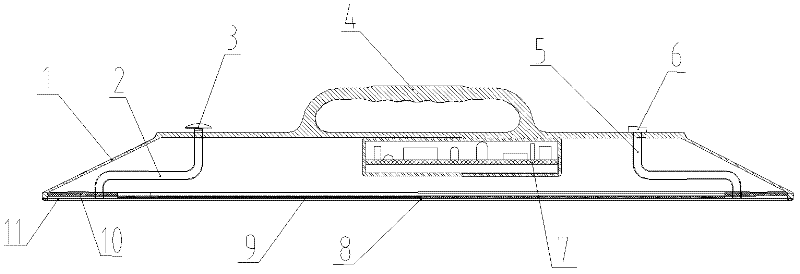

Equipment and method for detecting burst tendency of glass of curtain wall

ActiveCN102565309AEasy to measureReduce measurement errorElectrical/magnetic solid deformation measurementMaterial testing goodsMeasurement costEngineering

The invention discloses equipment and a method for detecting the burst tendency of glass of a curtain wall. A strain material is used for detecting the distortion degree of the glass, a strain gauge pressure sensor is closely contacted with the surface of the glass to be measured by a negative pressure absorption device, the deformation of a strain gauge is completely consistent with that of the glass in an ideal state, the deformation degree of the glass of the curtain wall can be determined by processing a deformation signal by using a measurement detection circuit, and the magnitude of stress inside the glass is indirectly obtained through calculation, so that the safety of the glass of the curtain wall can be conveniently and quickly detected in real time on the spot. The invention has the advantages that: 1, by the measurement method, the function of real-time, on-site, quantitative and quick measurement is realized, and the method is low in measurement cost and is safe, convenient, efficient and accurate; and 2, measured data can be accurately and timely sent into a computer, and an intact detection database is established so as to store the measured data, so that a good reference basis is provided for the regular measurement and evaluation in the future.

Owner:SHANGHAI LANBAO SENSING TECH

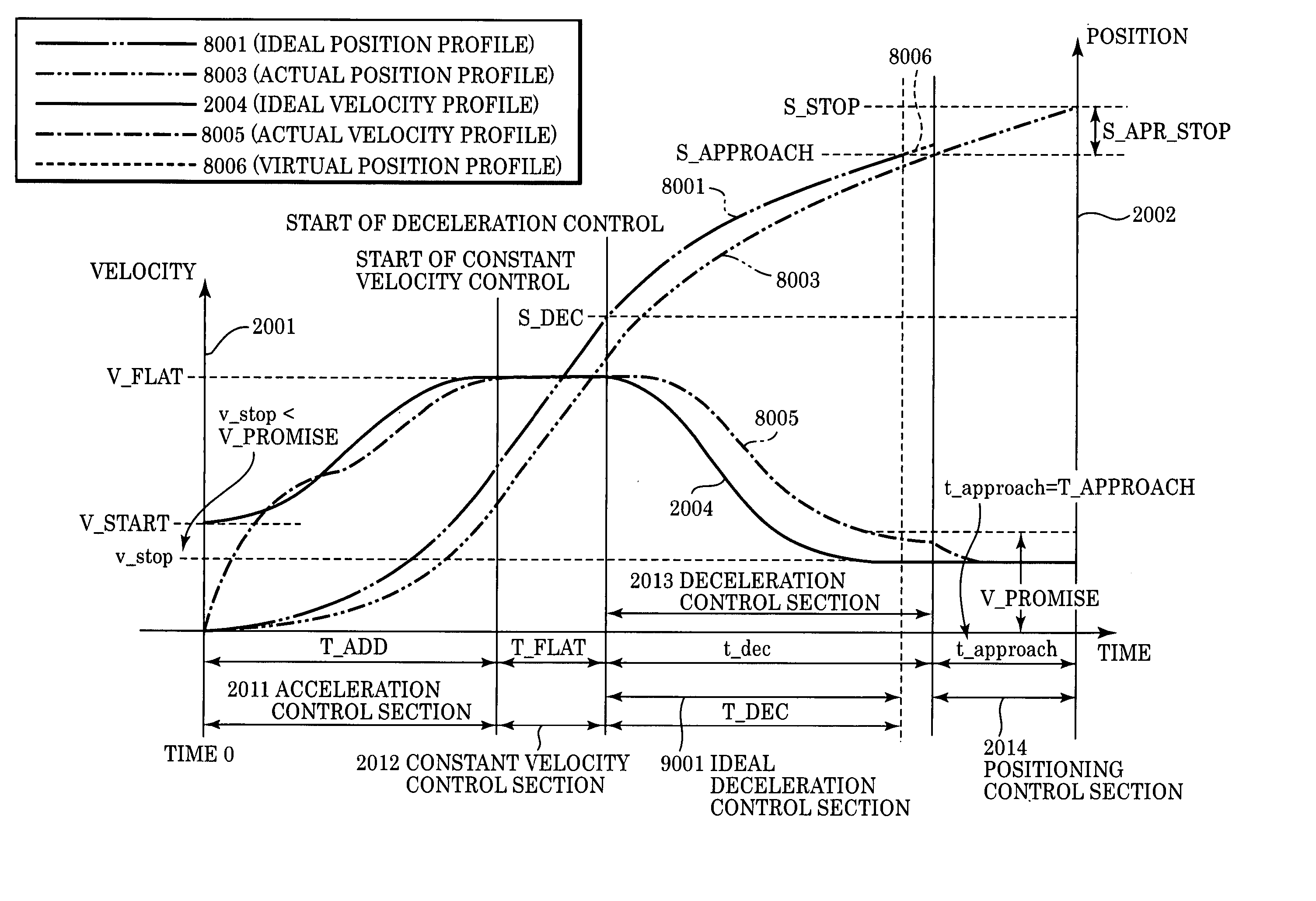

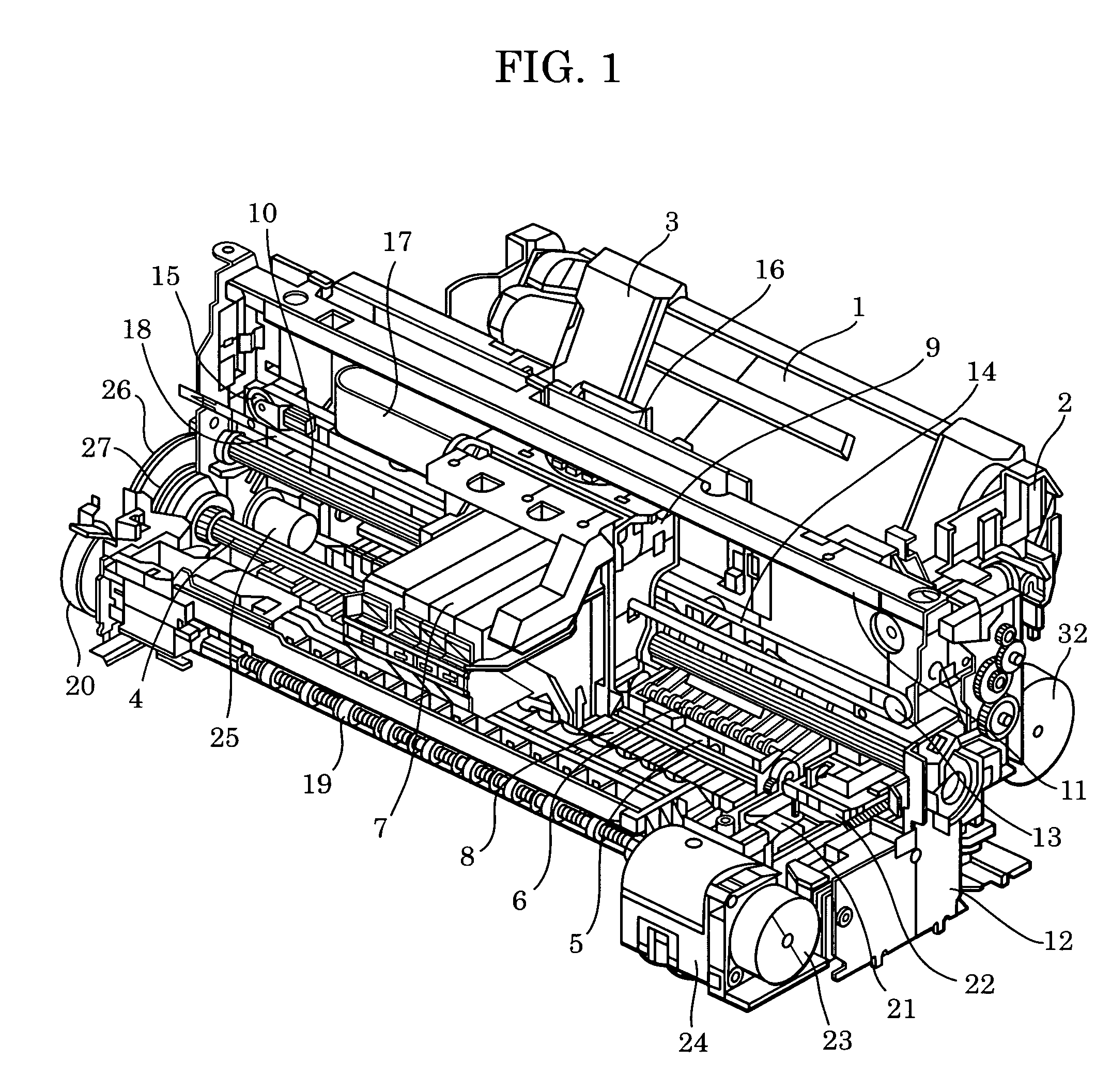

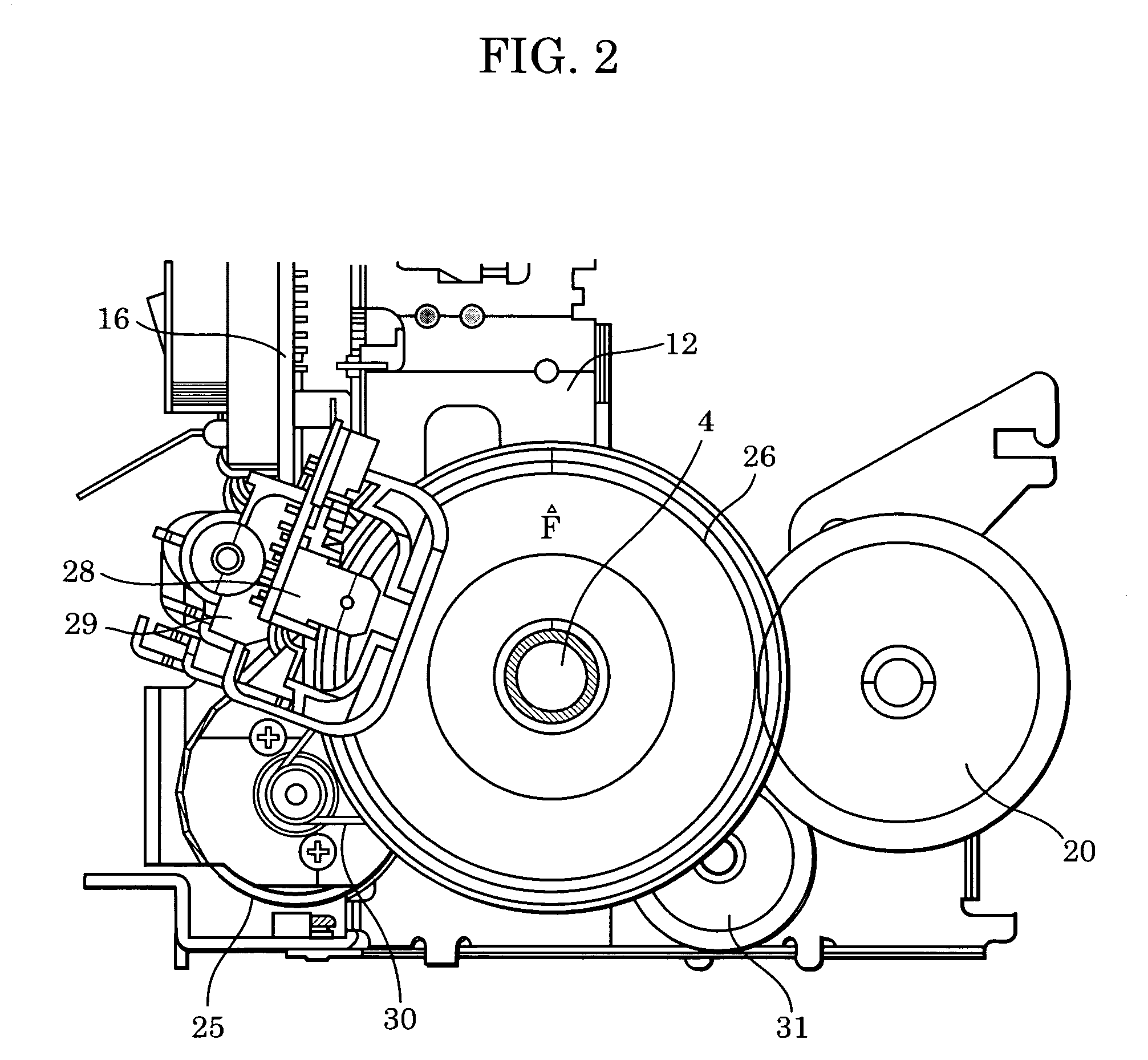

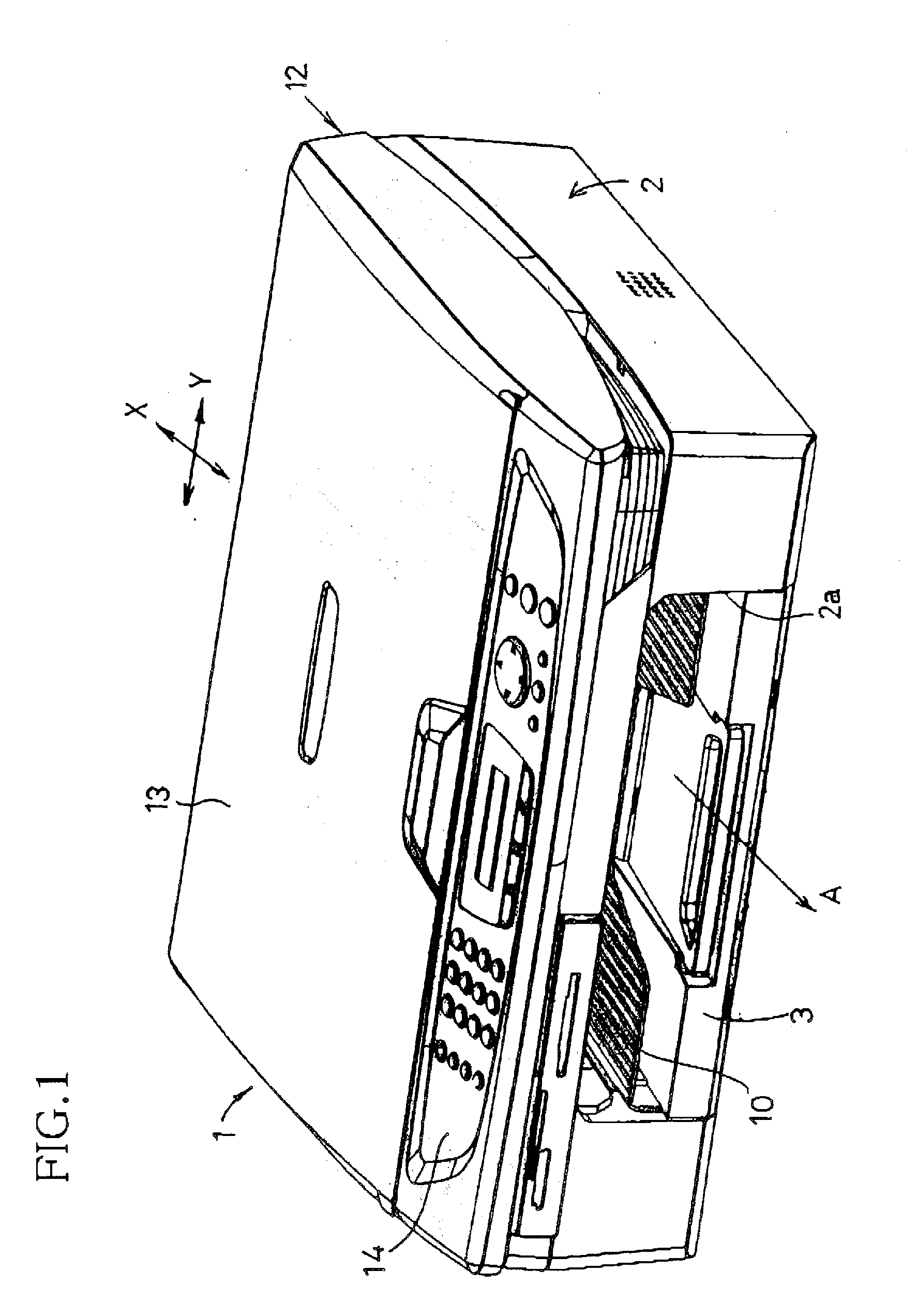

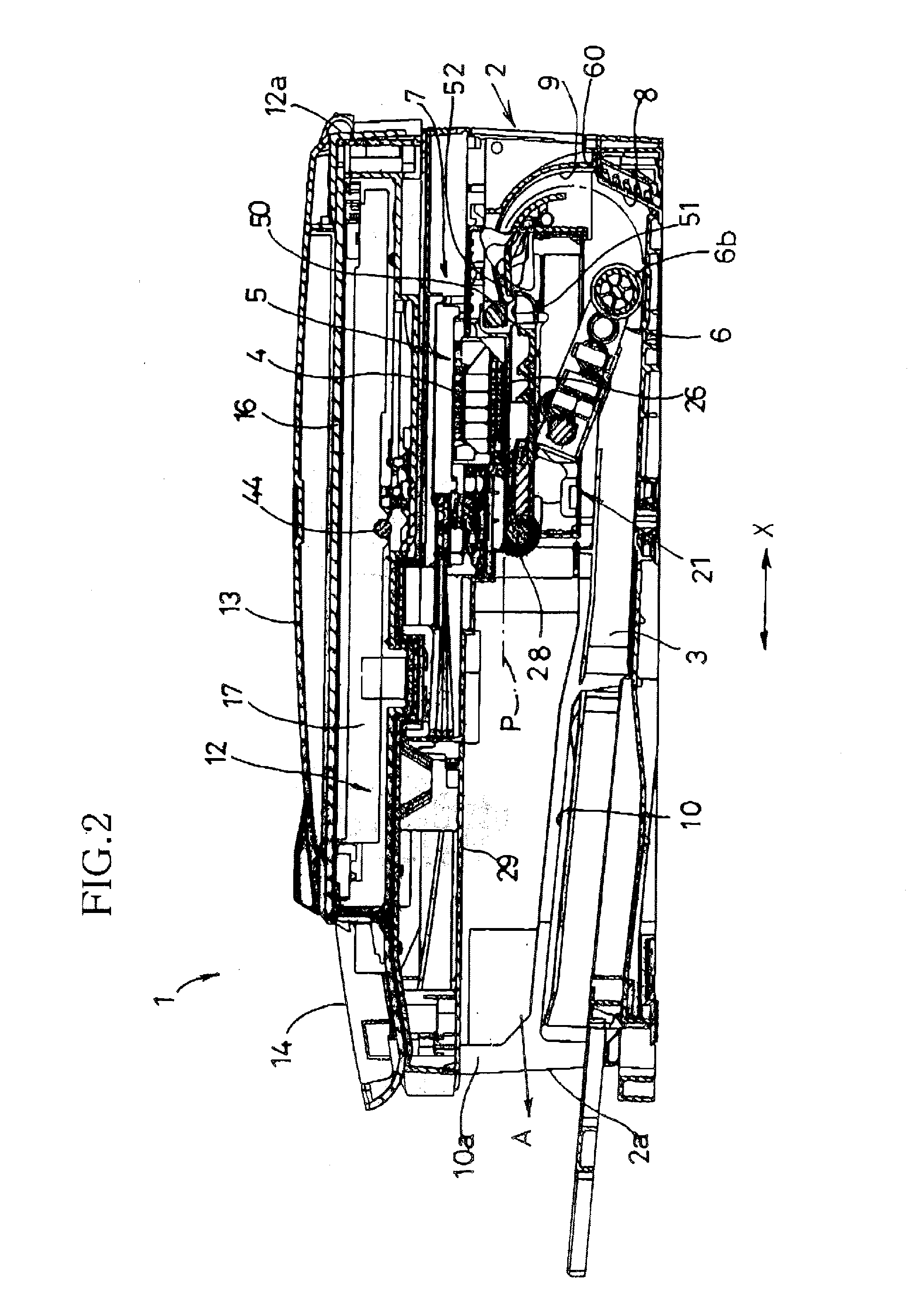

Printer and paper feed controller

InactiveUS7014378B2High resolutionPrecise feedingSpacing mechanismsOther printing apparatusControl signalSignal edge

High accuracy is achieved in paper feed control without increasing the size of an encoder, which would result in an increase in cost. The velocity of a paper feeding mechanism is calculated from an edge signal that is generated by the encoder in response to the motion of the paper feeding mechanism. Based on the calculated velocity, a calculation is performed as to the time needed to reach a stop position since a detection of an encoder signal edge immediately before the stop position. Based on the calculated time, a control signal for stopping the paper feeding mechanism is generated.

Owner:CANON KK

Particulate ferric oxide red pigment and method for producing the same

InactiveCN1521220ASolving Dispersion ProblemsSolve the problem of easy cakingPigmenting treatmentPolyvinyl alcoholSulfate

The present invention is granular iron oxide red pigment of grain size of 5-100 mesh and its preparation process. The preparation process includes the following steps: compounding water solution of additive in the concentration of 0.3-10 % and heating to 30-100 deg.c; spraying the water solution to iron oxide red in a pelletizing machine to form the granular pigment gradually with the weight ratio of iron oxide red to the water solution being 100 to 15-40; and vibration sieving and stoving to obtain the product. The additive is the combination of two or more of CMCNa, PVA, sodium silicate, glutin, sodium lignosulfonate and ferrous sulfate. The granular iron oxide red pigment has the same performance and use effect as the powdered iron oxide red pigment and is favorable to prevent dust pollution, and may be used to replace powdered iron oxide red pigment.

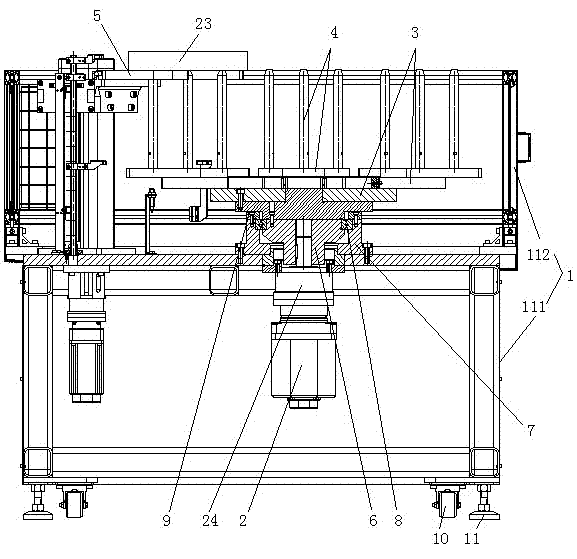

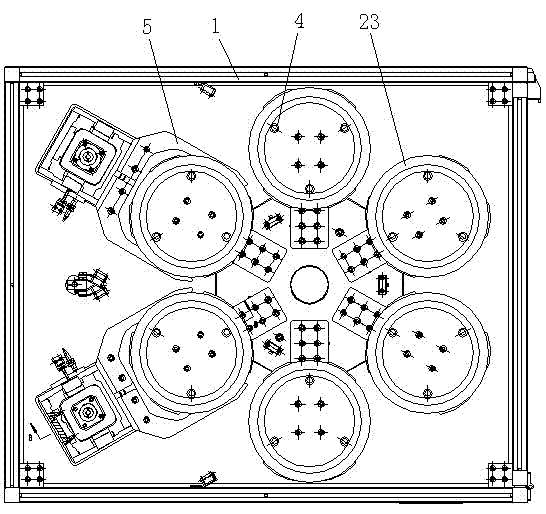

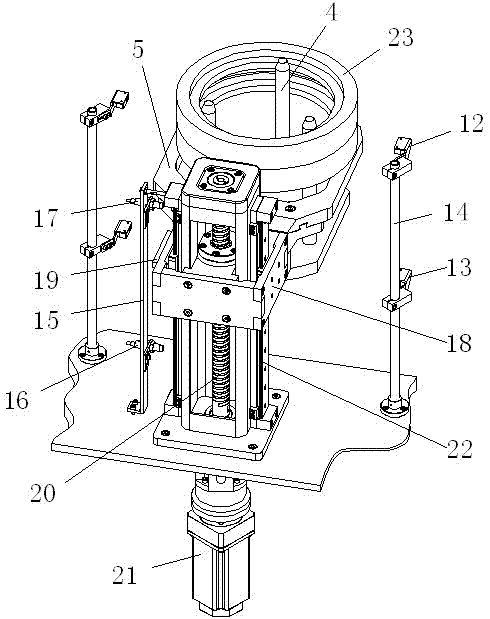

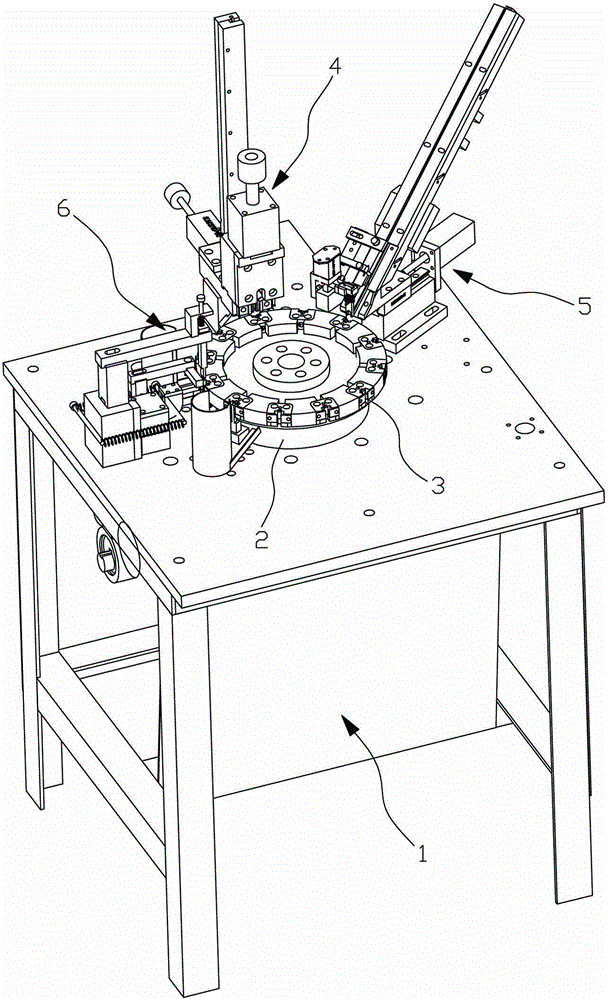

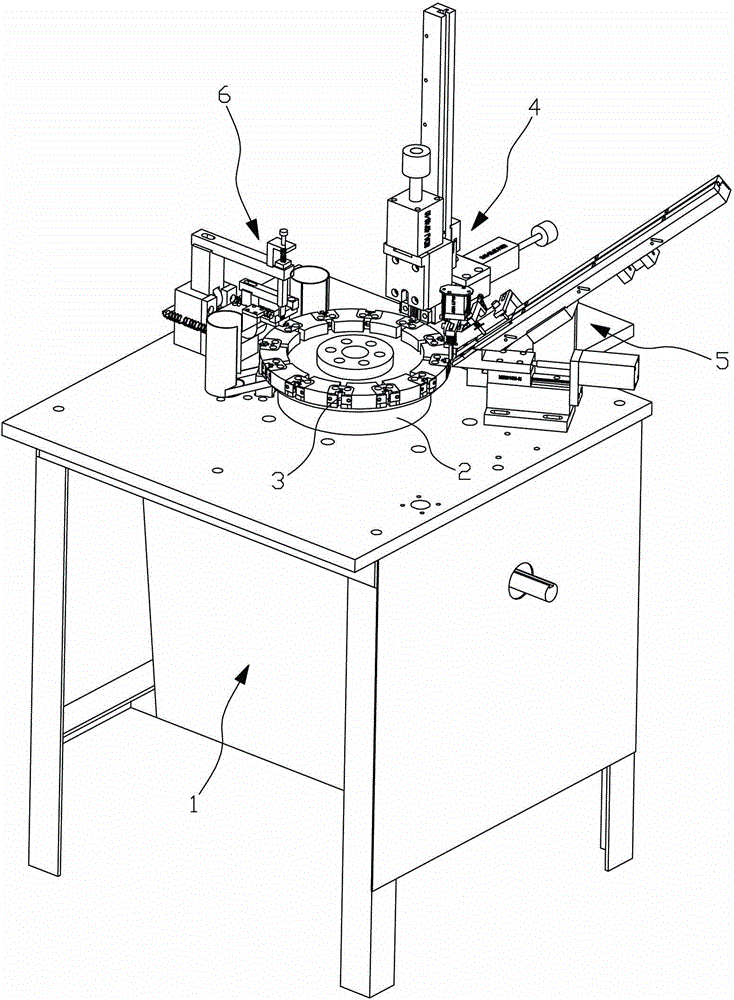

Accurate positioning storage bin

ActiveCN103028998AIncrease loading capacitySmall footprintMetal working apparatusMotor driveSmall footprint

The invention discloses an accurate positioning storage bin. The accurate positioning storage bin comprises a storage bin frame, workpiece lifting mechanisms and a workpiece horizontal rotary conveying mechanism; the workpiece horizontal rotary conveying mechanism comprises a first motor which is arranged on the storage bin frame, a rotary disc which is connected with a first motor rotor and workpiece loading mechanisms which are arranged along the peripheral direction of the rotary disc at equal intervals; and two sets of workpiece lifting mechanisms are arranged and are distributed opposite to the two sets of workpiece loading mechanisms, and each workpiece lifting mechanism comprises a clamping jaw for conveying workpieces on the workpiece loading mechanisms and a drive device for driving the clamping jaw to lift and descend. According to the accurate positioning storage bin, the first motor drives the rotary disc so as to drive the workpiece loading mechanisms to rotate horizontally, so that the transmission error existing in conventional storage bin chain wheel and chain transmission is eliminated, the repeat positioning precision along the horizontal direction is high, and a manipulator of processing equipment can accurately take and store materials; and moreover, a plurality of workpiece loading mechanisms can be arranged on the same rotary disc, the loading capacity of the storage bin is large and the storage bin occupies a small area.

Owner:CHONGQING MACHINE TOOL GROUP

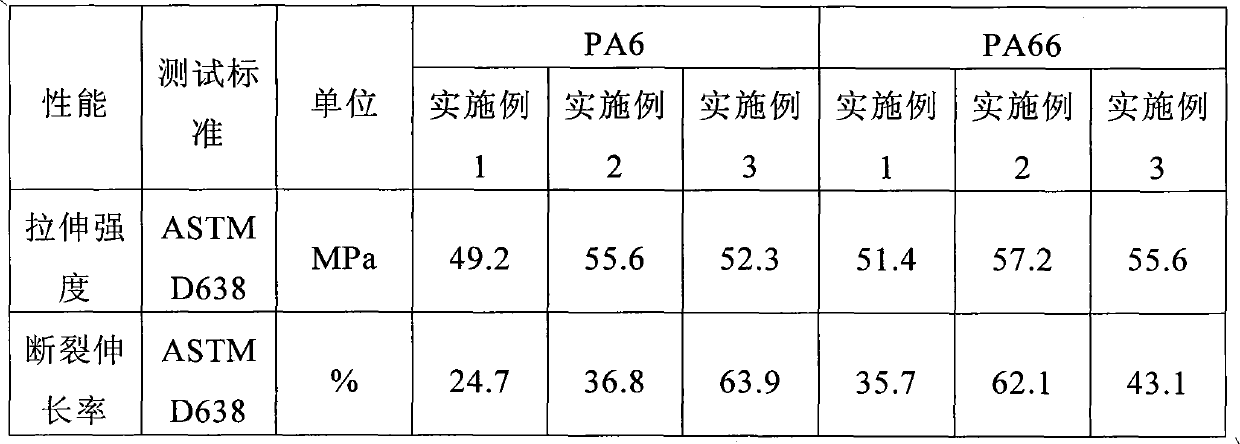

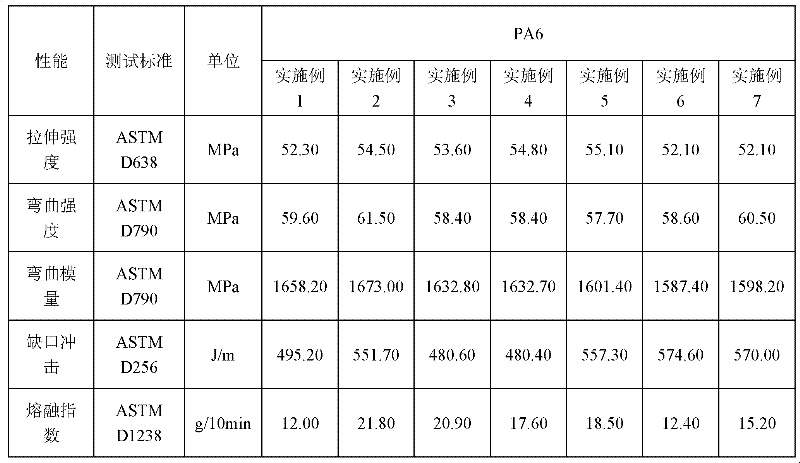

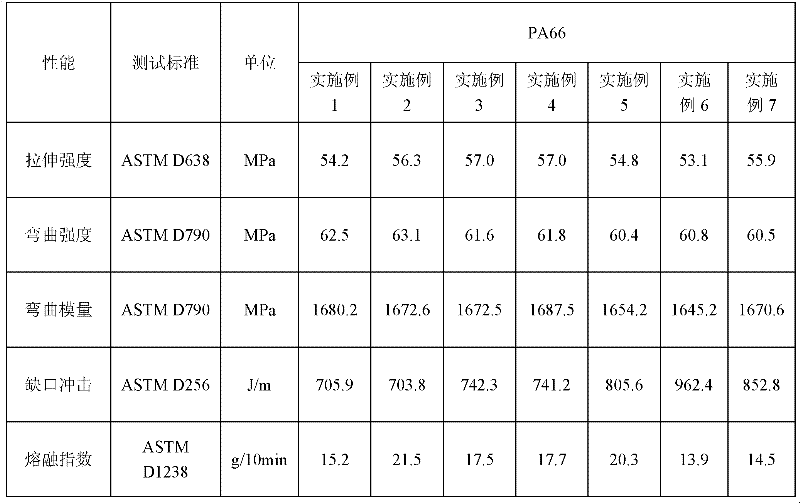

Low temperature impact resistant nylon flexibilizer and preparation method of low temperature impact resistant nylon flexibilizer

The invention relates to a low temperature impact resistant nylon flexibilizer and a preparation method of the low temperature impact resistant nylon flexibilizer. The low temperature impact resistant nylon flexibilizer comprises the following components in parts by weight: 50-95 parts of ethylene-alpha-octylene copolymer resin, 4-40 parts of polypropylene copolymer, 1-30 parts of linear low density polyethylene, 0.5-10 parts of graft monomer, 0.01-2 parts of initiator, 0.1-1 part of lubricator, 0.1-1 part of antioxidant and 0.1-2 parts of liquid additive. The preparation method of the low temperature impact resistant nylon flexibilizer comprises the steps of: mixing the above components except for the initiator, and adding into a double-screw extruder; laterally feeding and metering the initiator, and adding into the extruder; and extruding and pelletizing to obtain the low temperature impact resistant nylon flexibilizer as a product. The graft ratio of the flexibilizer is increased and the gel content of the flexibilizer is reduced by the lateral feeding technology; after the flexibilizer is applied to nylon (nylon 6, nylon 66), the flexibilizer is good in comprehensive performance and more excellent in low temperature impact performance; and the notch impact strength of the flexibilizer can reach 600J / m at a temperature of -30 DEG C, so that the flexibilizer can be applied to the fields of auto accessories and bumpers, railway equipment and the like under low temperature resistance.

Owner:SHANGHAI SUNNY

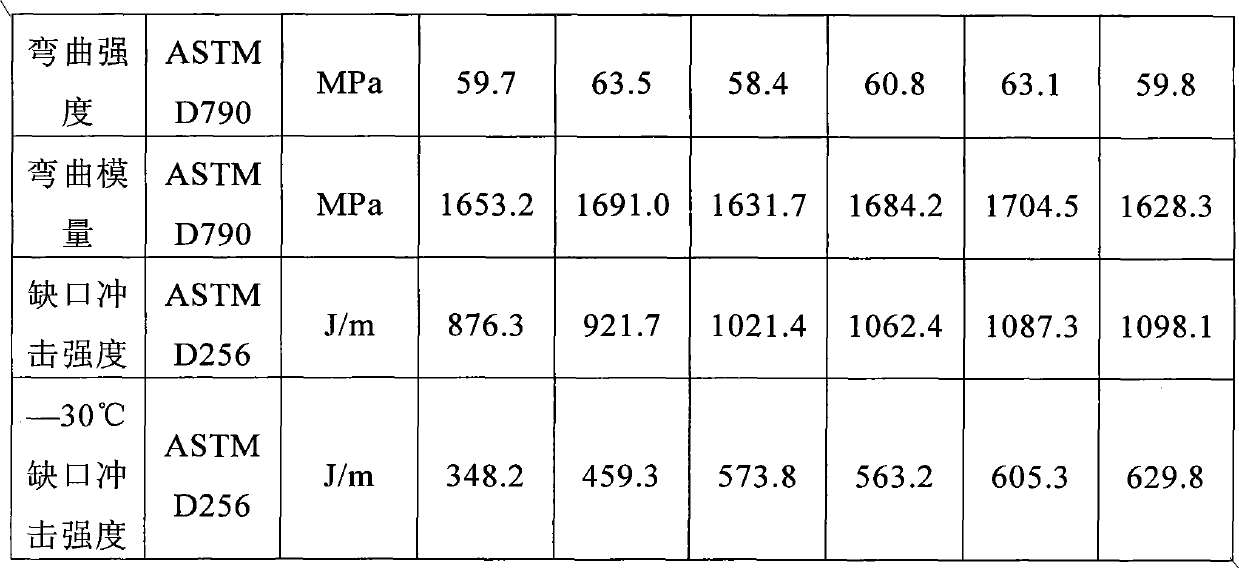

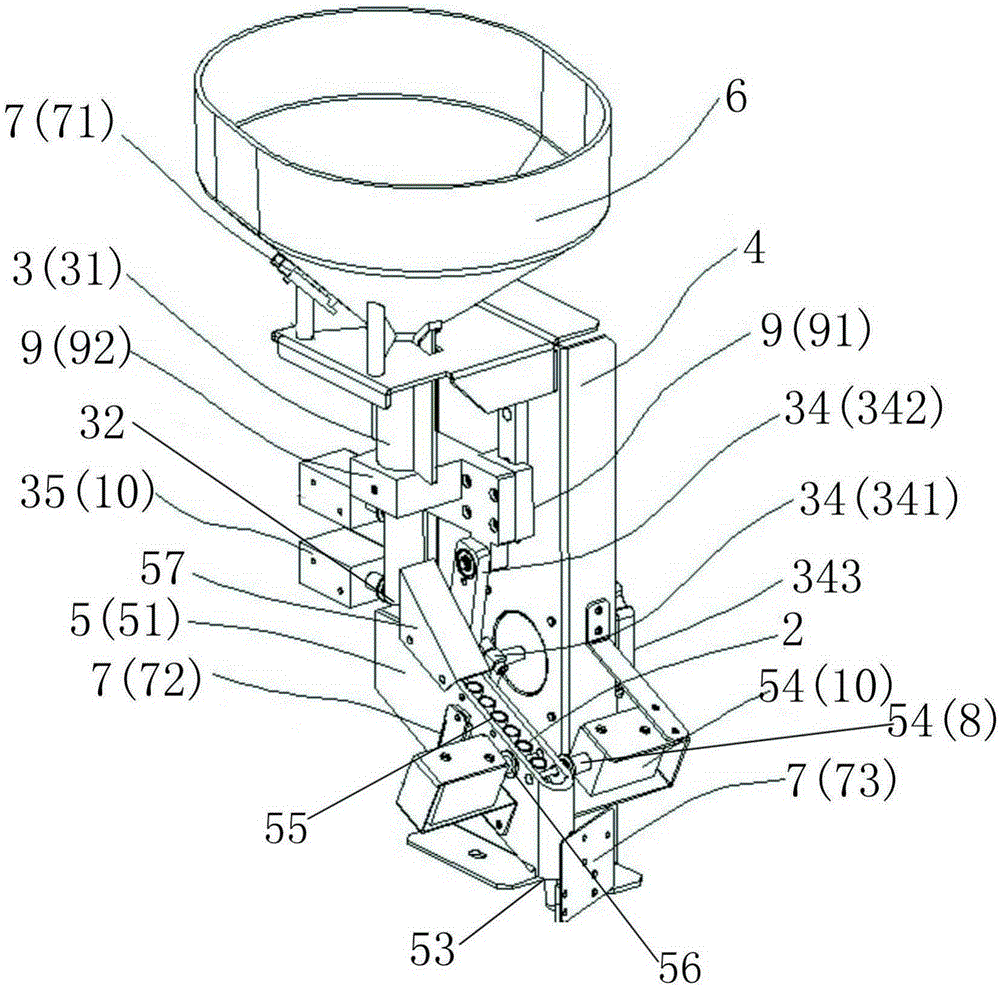

Multifunctional assembly machine allowing pull tabs to be automatically fitted into non-lock sliders

ActiveCN104905499ASavings in the deburring processImprove assembly efficiencySlide fastenersAssembly machineEngineering

A multifunctional assembly machine allowing pull tabs to be automatically fitted into non-lock sliders comprises a frame, a circular turnplate and slider fitting cores. The peripheral side of the round turnplate is provided with a slider conveyer, a pull tab conveyer and a riveting device; the slider conveyer comprises a slider rail, a slider cavity, a deburring blade and a slider vertical-push mechanism, wherein the slider cavity is provided right below the slider rail, the deburring tool is disposed right above the corresponding slider fitting core, and the rear of the slider cavity is further provided with a slider horizontal-push mechanism; the pull tab conveyer comprises a pull tab rail; the tail end of a discharge outlet of the pull tab rail is provided with a pull tab bearing capable of moving back to forth; a holding mechanism capable of moving up and down is further disposed in front of the pull tab bearing. The multifunctional assembly machine allows the sliders to be deburred at the premise of ensuring that the sliders are accurately fed into the slider fitting cores, the non-lock sliders can be avoided deforming during riveting, and product assembly efficiency and yield can be greatly increased.

Owner:QUANZHOU LICHENG DISTRICT ZHAN AUTOMATION EQUIP

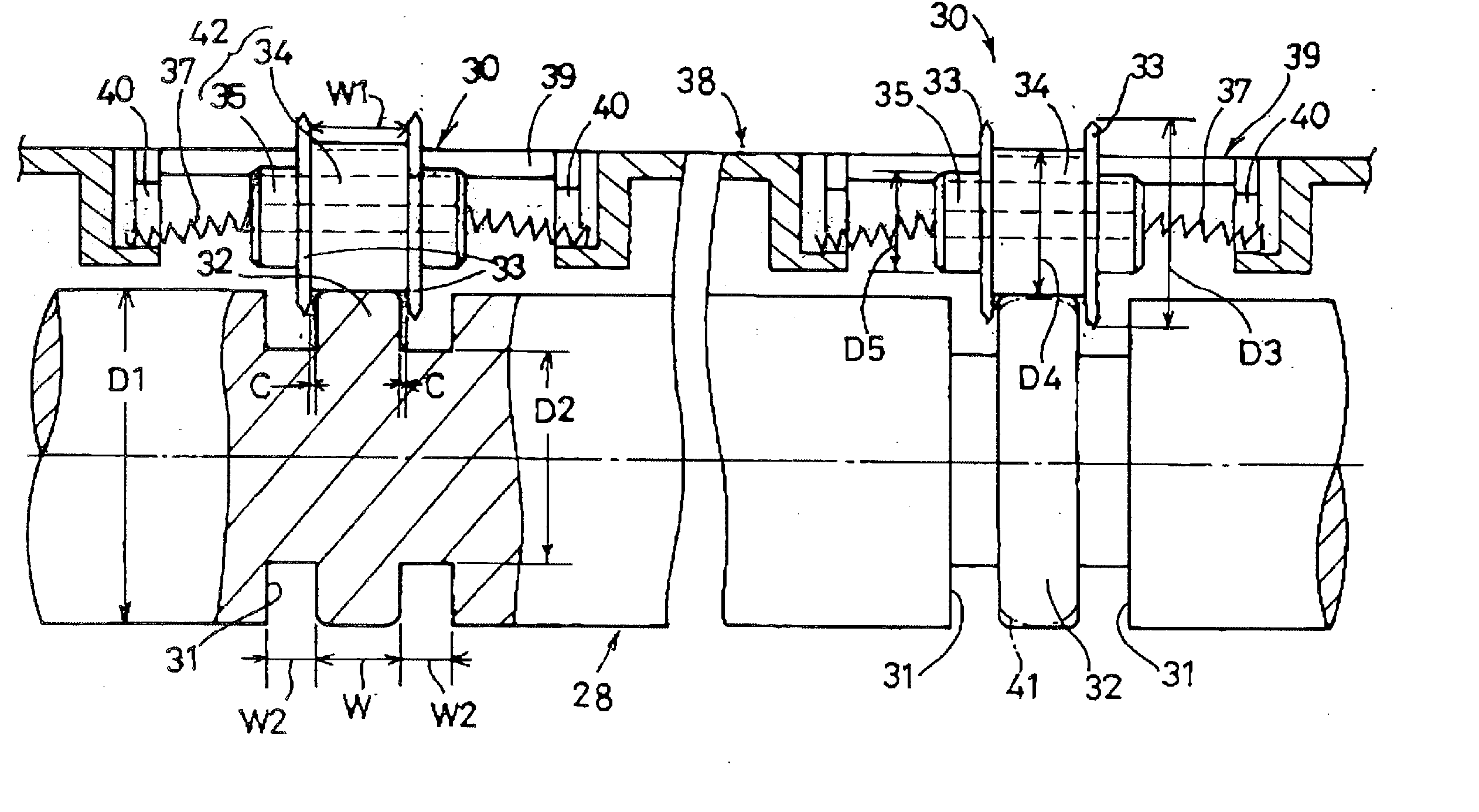

Feeding Device And Image Recording Apparatus Equipped With The Feeding Device

ActiveUS20060163803A1Weak elasticityReduction in sheet feeding forceArticle feedersArticle deliveryImage recordingEngineering

A feeding device including a drive roller and a driven roller opposed to the drive roller and biased toward the drive roller, such that the drive and driven rollers cooperate to feed a sheet while holding the sheet therebetween. The driven roller includes a toothed wheel portion and a contactable portion having a diameter smaller than that of the toothed wheel portion. The drive roller includes first and second portions. A radially outer end of the second portion is more distant from an axis of the drive roller than a radially outer end of the first portion. During absence of the sheet between the drive and driven rollers, the contactable portion of the driven roller is held in contact at its circumferential surface with a circumferential surface of the second portion of the drive roller, while a radially outer end of the toothed wheel portion is not in contact with a circumferential surface of the first portion. Also disclosed is an image recording apparatus including the above-described feeding device.

Owner:BROTHER KOGYO KK

Breeding method and pond for improving commercial specification and yield of procambarus clarkii in pond

ActiveCN105994027AEasy plantingIncrease coverageClimate change adaptationPisciculture and aquariaShrimpProcambarus clarkii

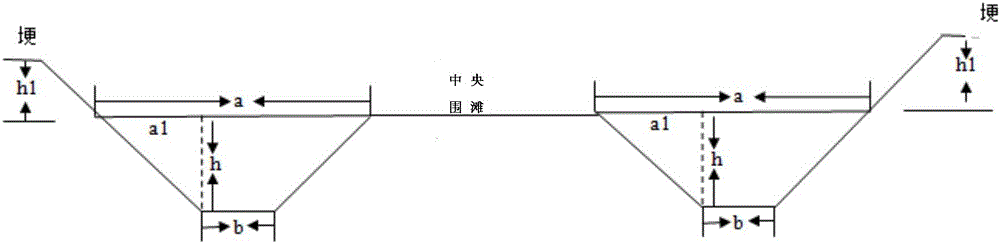

The invention provides a breeding method and a pond for improving the commercial specification and the yield of procambarus clarkii in the pond. The breeding method comprises the following steps: drying the pond under the sun; putting young procambarus clarkii into the pond for the first time; performing catch rotation on commercial procambarus clarkii for the first time; putting young procambarus clarkii into the pond for the second time; performing catch rotation on commercial procambarus clarkii for the second time; and thoroughly draining water of the pond, and catching all commercial procambarus clarkii. The pond comprises a circular groove which is digged along the periphery of the pond, wherein the circular groove has an upper bottom width of 6 to 10 meters, a lower bottom width of 1 to 5 meters, a depth of 0.8 to 1 meter, a ridge height of 0.8 to 1 meter and a slope ratio of 1: 3; the area of the circular groove accounts for 20 to 30% of the total area of the pond; the a region, located at the inner side of the circular groove, of the pond is piled with a central enclosed beach; and the distance between the water level of the pond and the central enclosed beach is in a range of 10 to 70 cm. The invention has the following beneficial technical effects: by adopting the method provided by the invention, 200 to 250 kg of commercial procambarus clarkii can be harvested in two seasons, wherein the proportion of the commercial procambarus clarkii with a specification of 40 g or more reaches 60 to 70%.

Owner:FISHERIES RES INST ANHUI ACAD OF AGRI SCI

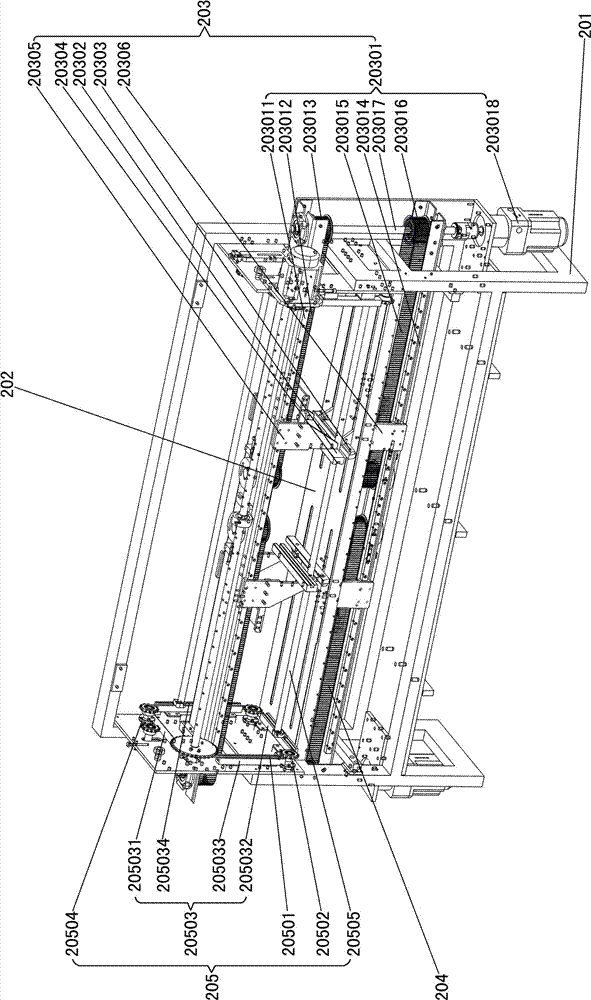

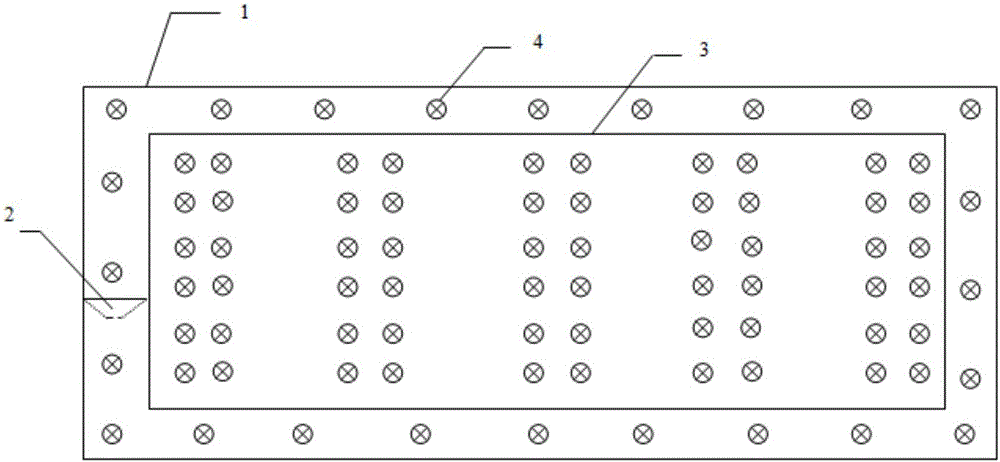

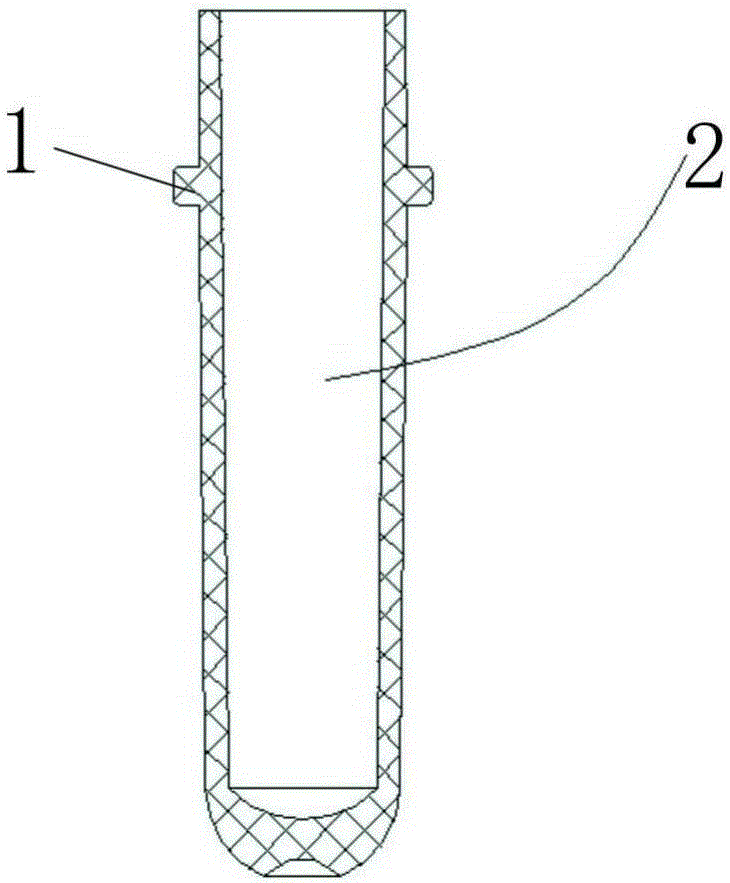

Reaction cup loading system for automatically conveying reaction cups to analysis device

InactiveCN105181985ACompact structureSimple operation and controlMaterial analysisEngineeringGuide tube

The invention provides a reaction cup loading system for automatically conveying reaction cups to an analysis device. The reaction cup loading system comprises a rack, as well as a cup storage cabin, a cup fetching mechanism and a cup conveying mechanism which are fixedly arranged on the rack and are arranged in sequence along a conveying direction of the reaction cups, wherein a cup outlet is formed in the bottom of the cup storage cabin; the cup fetching mechanism comprises a guide pipe, a driver for driving the guide pope to hoist to enable the guide pipe to stretch into the cup storage cabin from the cup outlet to take the cups, and a first mechanical switch for controlling the reaction cups in the guide pipe to fall off one by one from a first outlet; the cup conveying mechanism comprises a slide groove and a second mechanical switch for controlling the reaction cups in the slide groove to slide out one by one from a second outlet; the reaction cup loading system further comprises a cup detection mechanism arranged on the cup fetching mechanism and / or the cup conveying mechanism. A reaction cup automatic conveying device provides guarantees to full-automatic operation of a biological sample analysis system, has a compact whole structure, is simple to operate and control, has low operation fault rate and is accurate and reliable to convey; the device can be continuously operated for a long time with the matching of the detection mechanism, so that the conveying efficiency is improved and the operation cost is reduced.

Owner:SYSCAN MEDICAL TECH SUZHOU

Compacting apparatus

InactiveUS7028610B1Efficient and economical recyclingEasy to removeGrain huskingGrain polishingControlled drainageMetal recycling

A machining waste metal recycling machine has an in-feed hopper. The hopper uses paired augers to move the waste metal through the hopper to a cutting and transporting auger. The hopper augers are powered independently from each other, and may be individually reversed or reversed as a group to clear jams. In the event a jam is not cleared through one or more reversal cycles, the remaining augers may be operated to clear the hopper, thereby avoiding the need for manual unloading. Within the hopper are one or more shear bars that are provided to sever bunches or bundles of machining waste and thereby clear tangles which might otherwise jam the augers. The cutting and transporting augers ultimately feed a reciprocating compactor having a movable gate with one or more grooves for controlled drainage of machining oil and other liquid, as the machining waste metal is compressed into pellets.

Owner:RALICKI DANIEL J

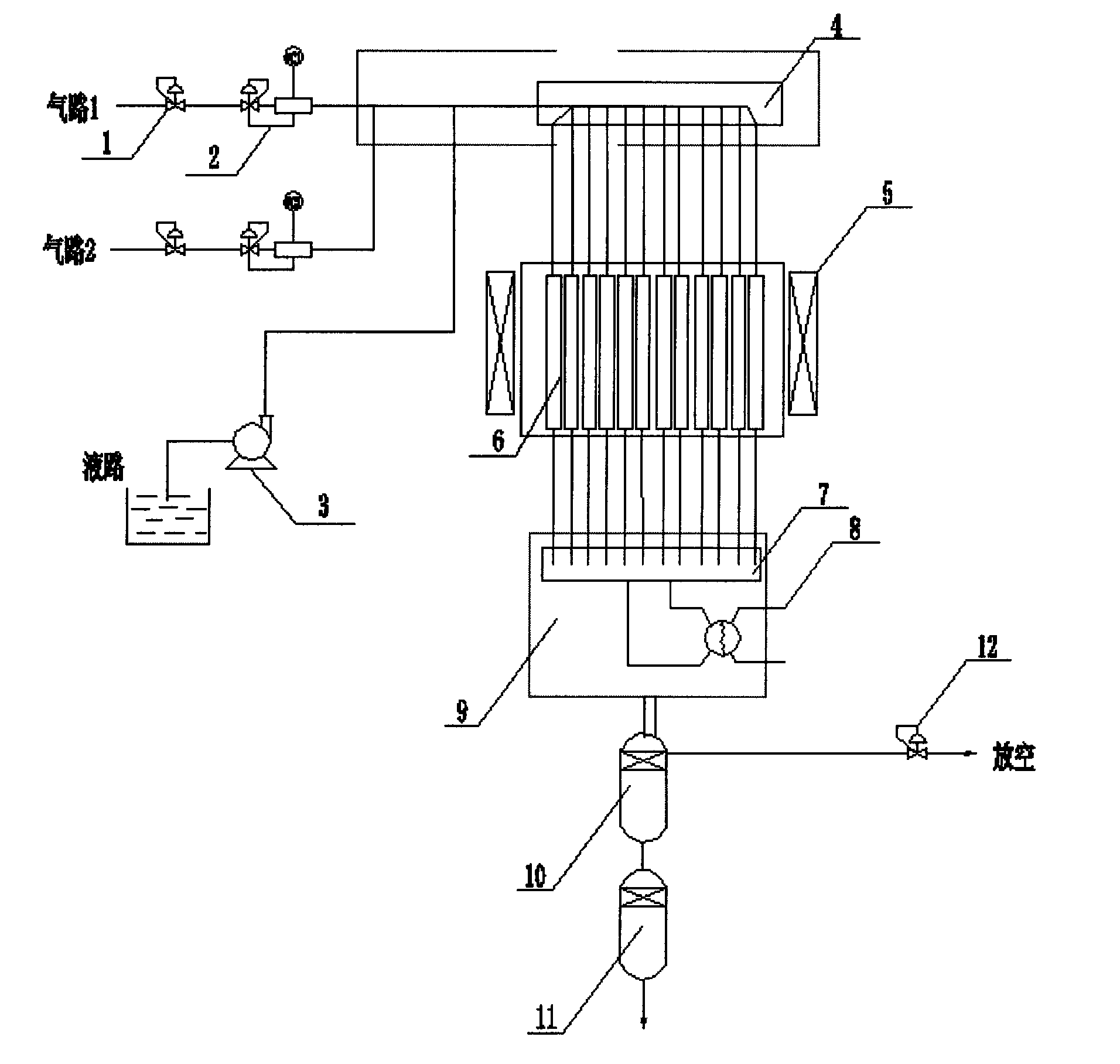

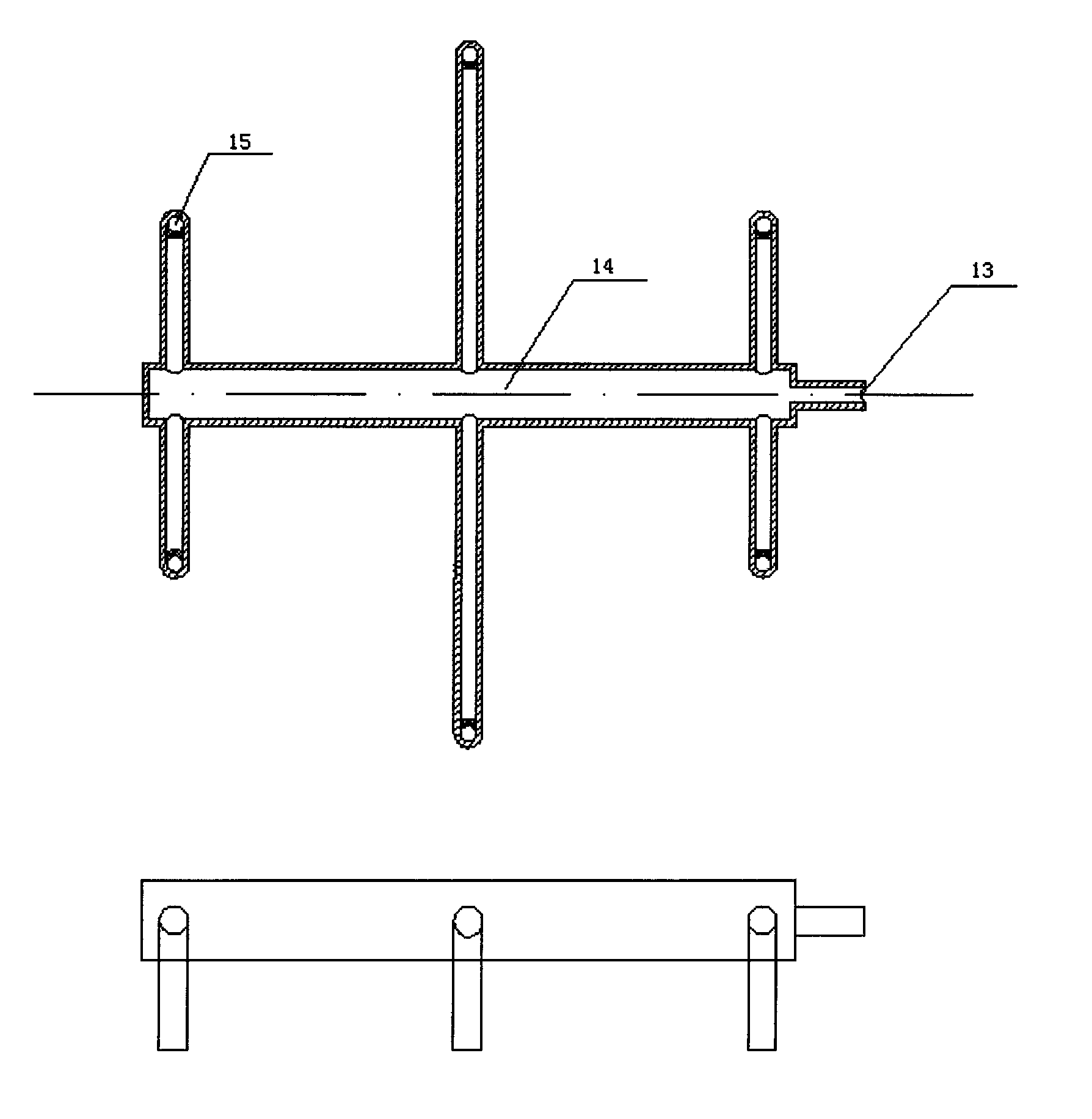

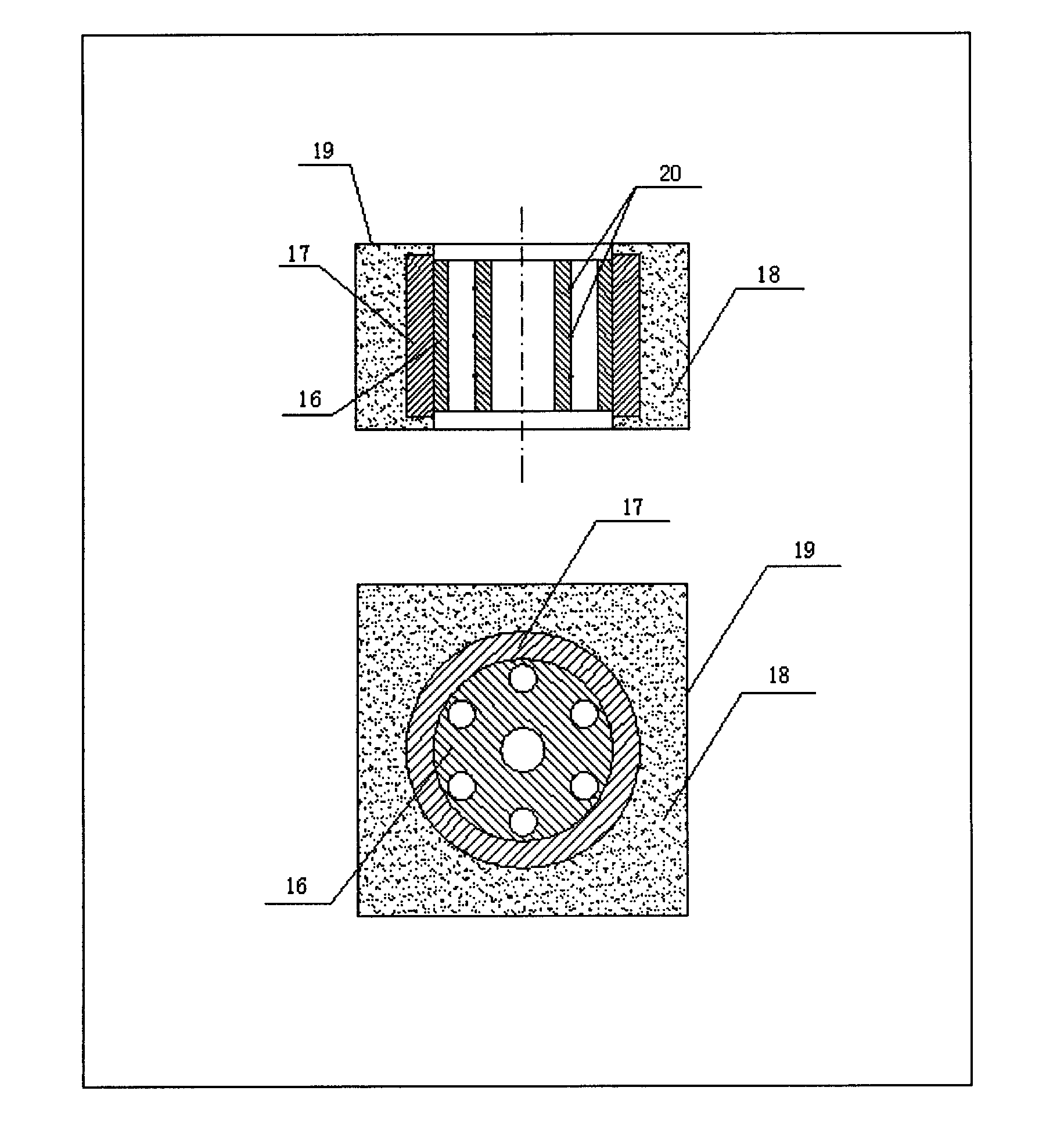

A multi-channel differential reaction device

ActiveCN102266742AImprove efficiencyImprove the level ofComponent separationChemical/physical/physico-chemical processesAutomatic controlGas phase

The invention discloses a multi-channel differential reaction device, and belongs to catalyst analysis and evaluation reaction device. The multi-channel differential reaction device comprises four systems of a gas-liquid charging system of (1)-(3), a multi-channel reactor system of (4)-(6), an automatic control system (7) and an on-line analysis system (8). The multi-channel differential reaction device adopts a high pressure distributor (4) to distribute a raw material into reaction tubes (6) of all channels. Temperatures of the all reaction tubes (6) are controlled unitedly by a heating furnace (5). The multi-channel differential reaction device is provided with the automatic control system (7) and the on-line analysis system (8) and can satisfy that in a reaction process, at any time, reaction products in all channel reaction tubes can be taken out on line simultaneously, are placed respectively in corresponding quantitative rings and are analyzed orderly through use of a gas chromatography. The catalyst analysis and evaluation reaction device can evaluate a catalyst rapidly and also evaluate and screen multiple catalysts simultaneously under a condition thus saves time spent on research and exploitation of a novel catalyst.

Owner:TIANJIN GOLDEN EAGLE TECH

Ultrahigh-mobility propenyl elastomer grafting copolymer and preparation method thereof

The invention relates to an ultrahigh-mobility propenyl elastomer grafting copolymer and a preparation method thereof. The copolymer comprises the following components in percentage by weight (wt%): 50-100wt% of propenyl elastomer resin, 0-50wt% of polyolefin resin, 0.5-5wt% of grafted monomer, 0.01-2wt% of initiator, 0.1-1wt% of crosslinking inhibitor, 0.1-1wt% of antioxygen and 0.1-2wt% of liquid accessory ingredient, wherein other components except the initiator are mixed in a high-speed mixer at a certain ratio and are added into a double-screw extruder by main feeding; the initiator is added into the extruder by side feeding; and a product is obtained by fusing, plastifying, kneading, mixing, extruding from a handpiece, bracing, cooling, pelletizing and drying. Compared with the prior art, the ultrahigh-mobility propenyl elastomer grafting copolymer disclosed by the invention has the advantages of higher product grafting ratio, lower gel content, excellent comprehensive performance and excellent impact performance by the side feeding technology, and is especially suitable for thin-wall products and large producing pieces in the fields, such as interior / exterior trim parts ofautomobiles, bumpers, railway equipment and the like.

Owner:SHANGHAI SUNNY

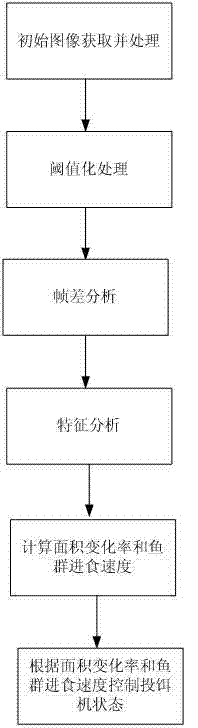

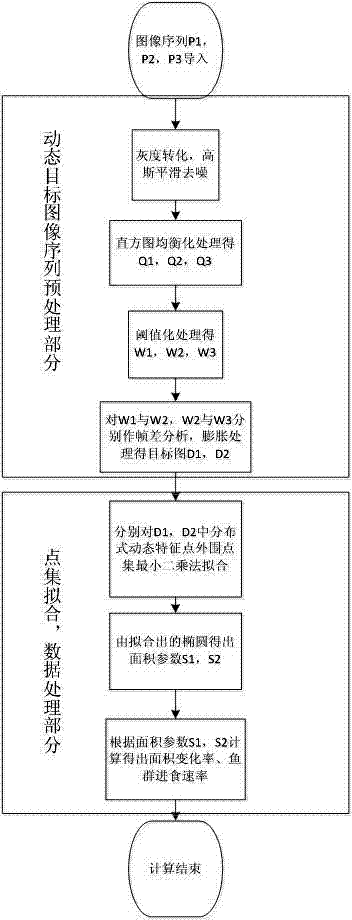

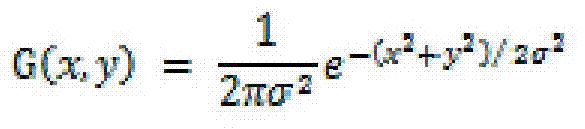

Automatic fish school feeding control method based on video streaming image distributed dynamic characteristic technology

The invention discloses an automatic fish school feeding control method based on a video streaming image distributed dynamic characteristic technology; compared with the prior art, the automatic fish school feeding control method solves the problem that in the existing automatic feeding control method does not reasonably utilize characteristic information of a fish school. The method comprises the following steps of: obtaining and processing an initial image, thresholding, analyzing frame difference, analyzing characteristics, computing an area change rate and a fish school eating speed, and controlling the state of a feeder according to the area change rate and the fish school eating speed. According to the automatic fish school feeding control method based on the video streaming image distributed dynamic characteristic technology, fish school eating parameters are identified and analyzed and a lower computer is controlled to feed by a real-time image processing method.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

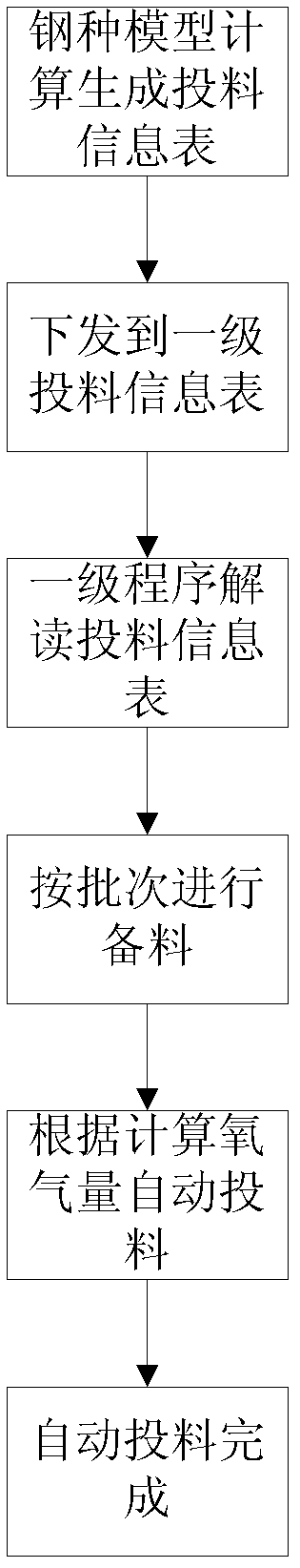

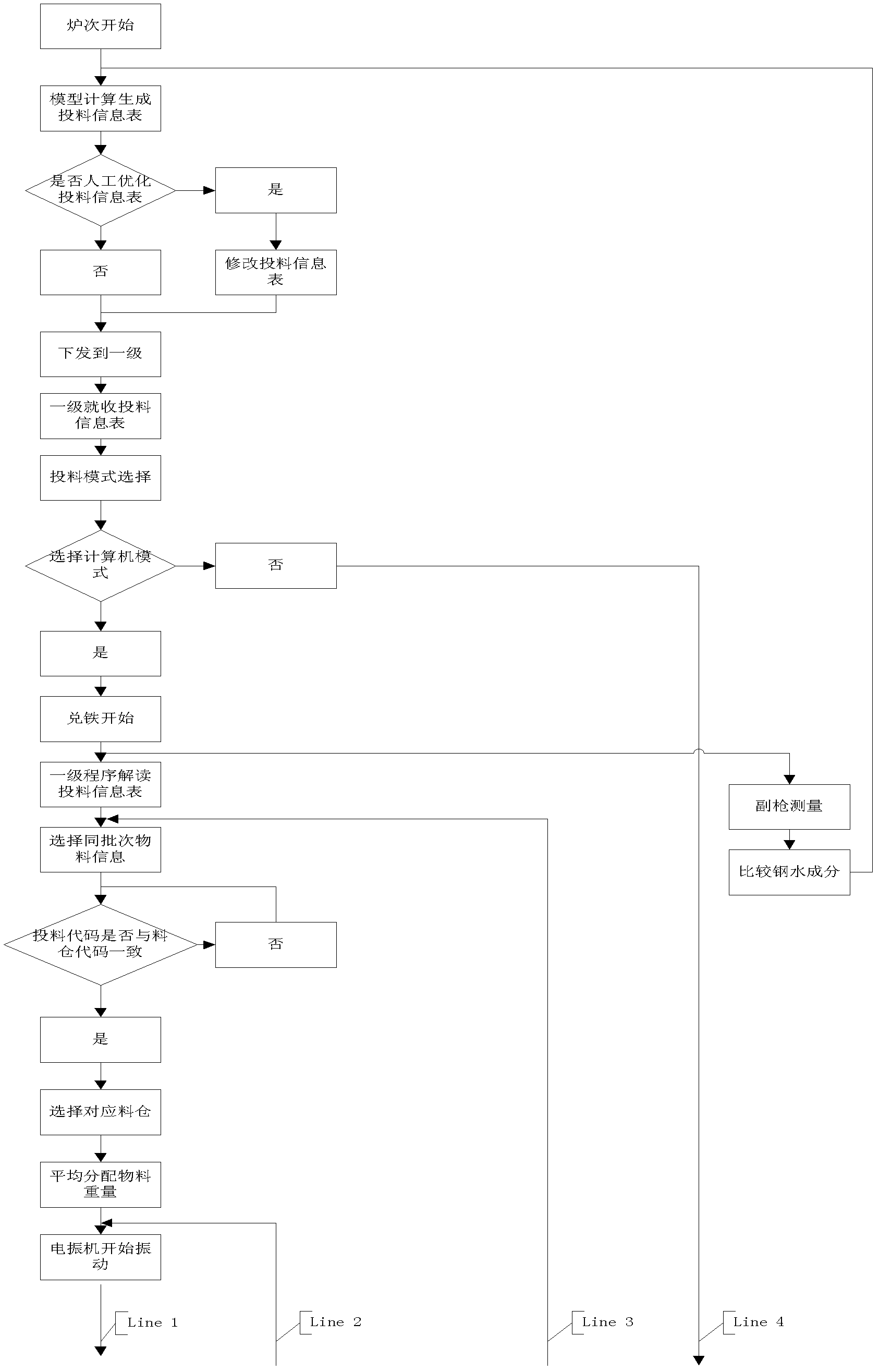

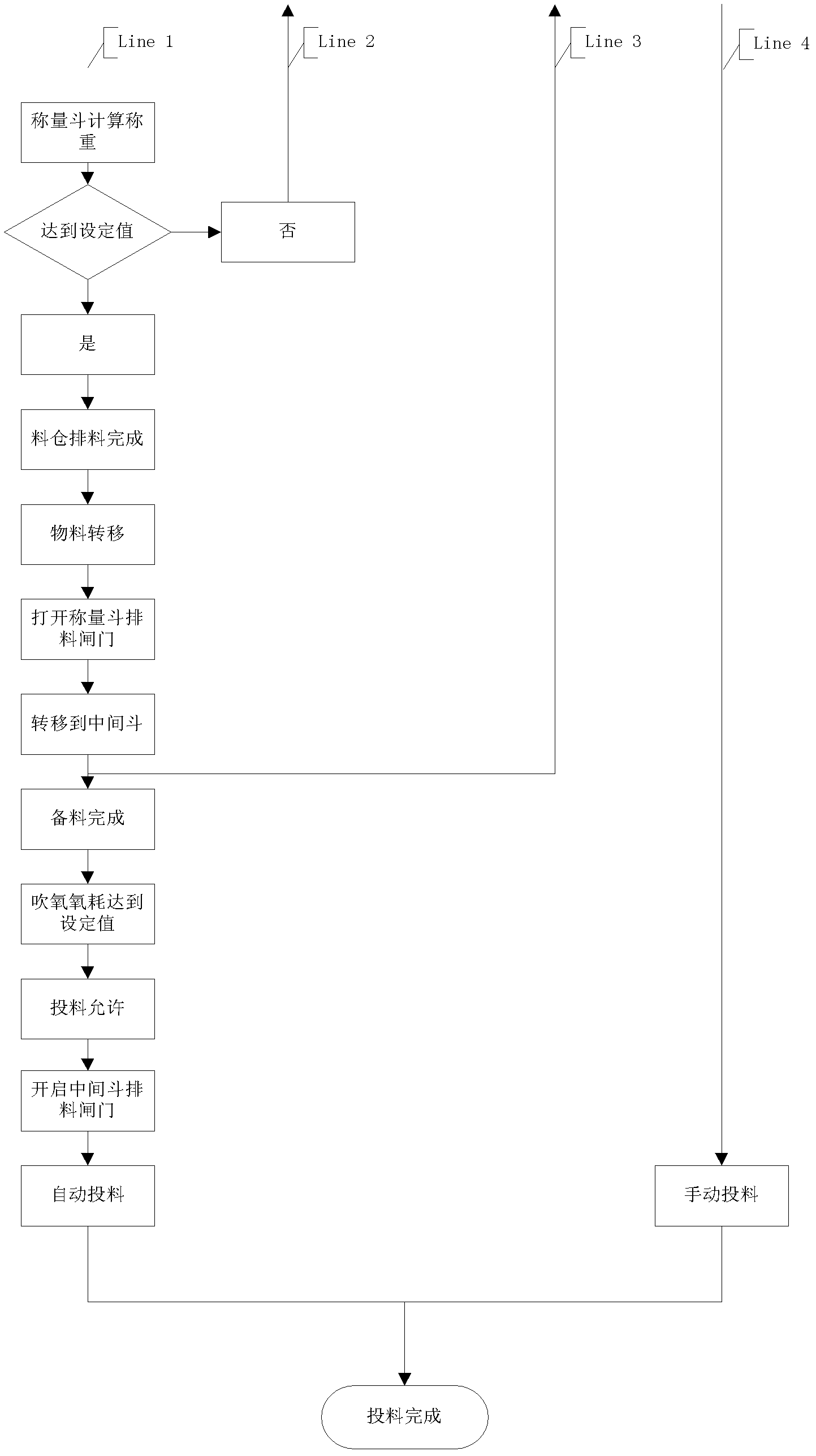

Static-dynamic automatic feeding method in converter smelting process

ActiveCN102586535AReduce the difficulty of operationPrecise feedingManufacturing convertersMaterials preparationAutomatic control

A static-dynamic automatic feeding method in the converter smelting process belongs to the technical field of automatic control. In the converter smelting process, according to various factors such as components of loaded molten iron, added scrap steel amount and remaining slag amount and by calculation of a secondary steel grade model, a static feeding information sheet is generated and issued to a primary programmable logic controller (PLC) control procedure. The primary PLC control procedure receives material information of the feeding information sheet, prepares materials for secondary material information according to the technological requirements and the principle that an identical material is equally distributed in an identical bin, performs material transfer in real time and automatically carries out converter feeding according to smelting oxygen-blowing amount. After sublance converting medium-term measurement is finished, molten steel components are measured. According to comparing difference between measurement components and target components, the secondary steel grade model undergoes calculation again to generate a dynamic feeding information sheet, the dynamic feeding information sheet is issued to the primary PLC control procedure, and material preparation and feeding are automatically carried out. The static-dynamic automatic feeding method has the advantages of effectively solving the problems that manual feeding is not timely, unstable and inaccurate and the like, improves working efficiency and smelting hit rate, reduces feeding cost, shortens smelting cycle, effectively reduces labor and guarantees continuous and stable high-level automatic production.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

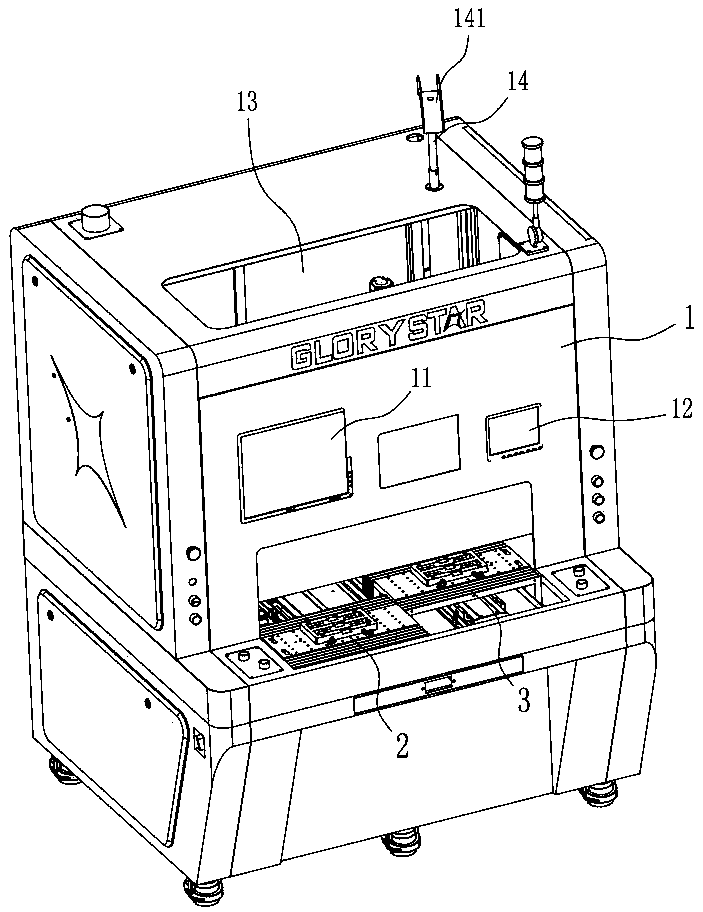

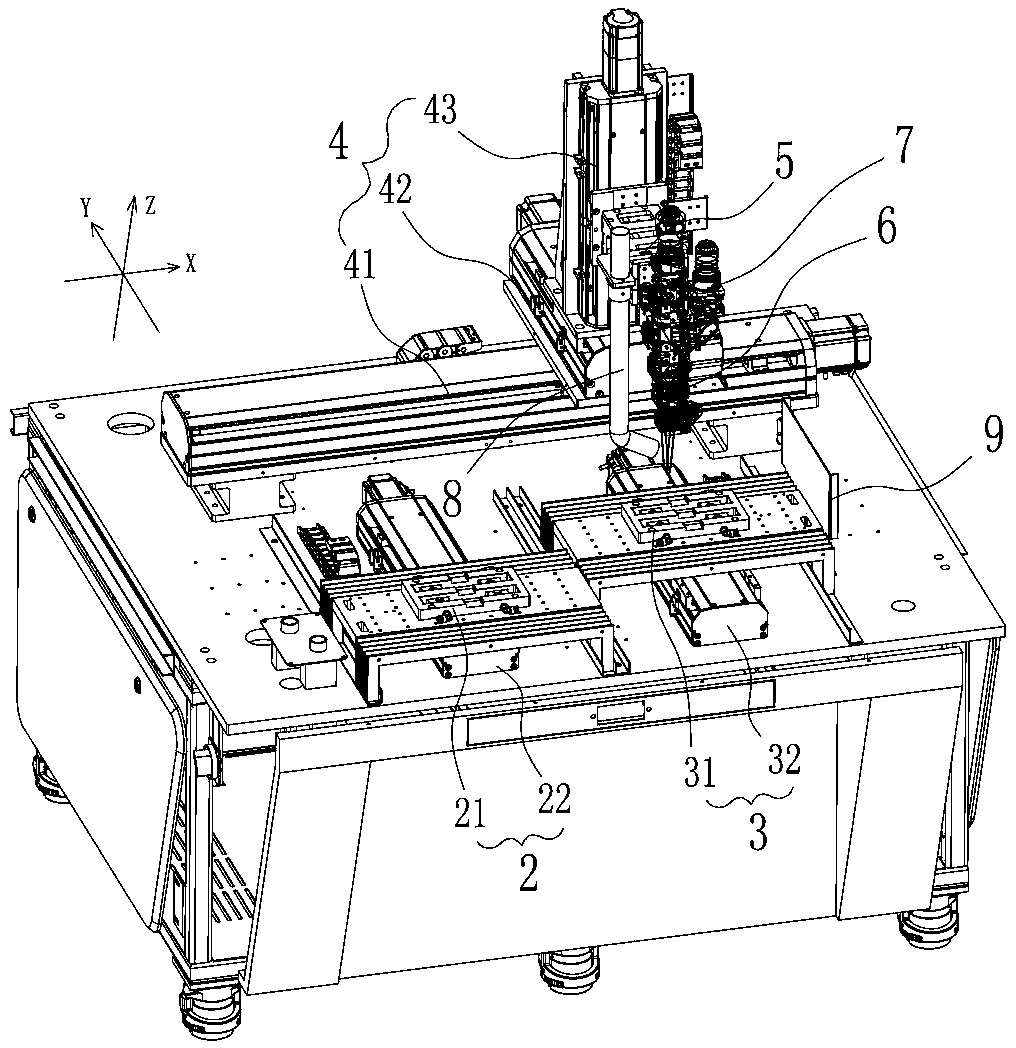

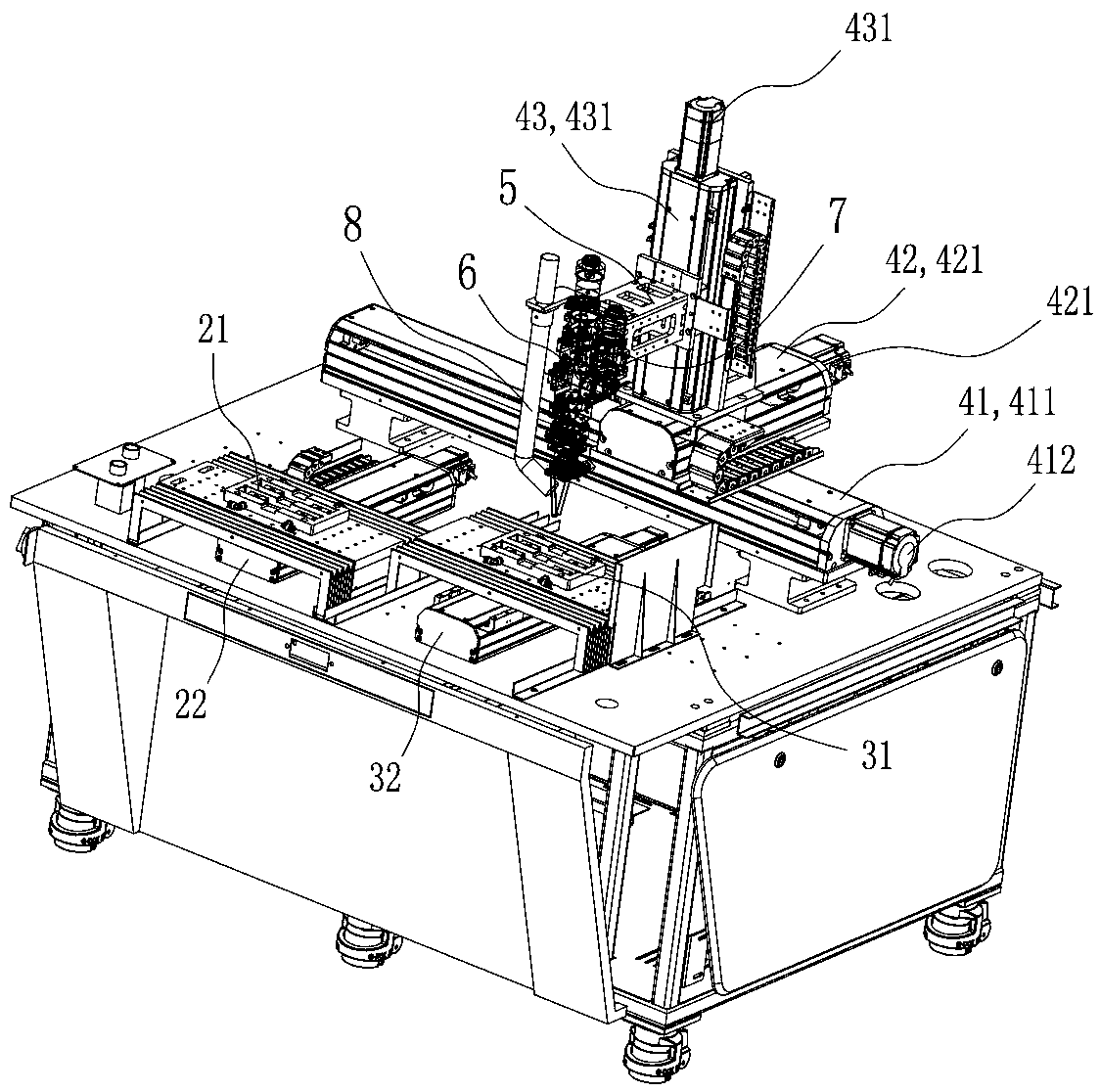

Double-station power battery cover plate laser welding machine and welding method

PendingCN107790879AWeld firmlyPrecision weldingLaser beam welding apparatusPower batteryElectrical battery

The invention discloses a double-station power battery cover plate laser welding machine and a welding method. The power battery cover plate laser welding machine comprises a control system, and a first power battery cover plate feeding system, a second power battery cover plate feeding system, an XYZ-axle transmission system, a welding machine head, a laser welding system and a CCD positioning system electrically connected with the control system; and the first power battery cover plate feeding system and the second power battery cover plate feeding system are mounted in the X-axle directionside by side. The power battery cover plate laser welding machine is convenient to feed and high in welding efficiency, realizes movement in X, Y and Z directions, can adjust distances from the laserwelding device to products, can fix the products through vacuum absorption, can determine positioning errors through CCD positioning, and can compensate error values from the X, Y and Z directions.

Owner:DONGGUAN GLORYSTAR LASER TECH

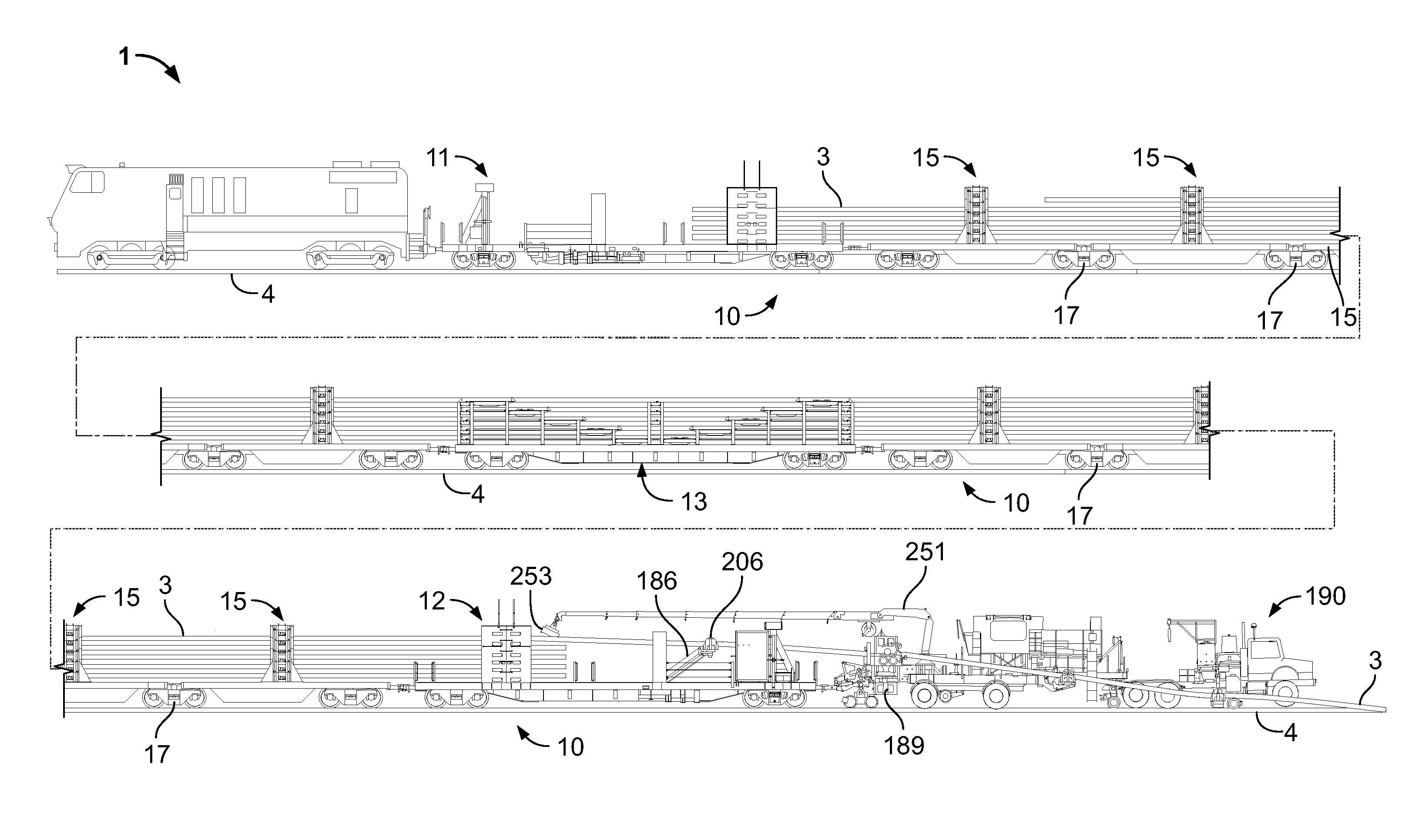

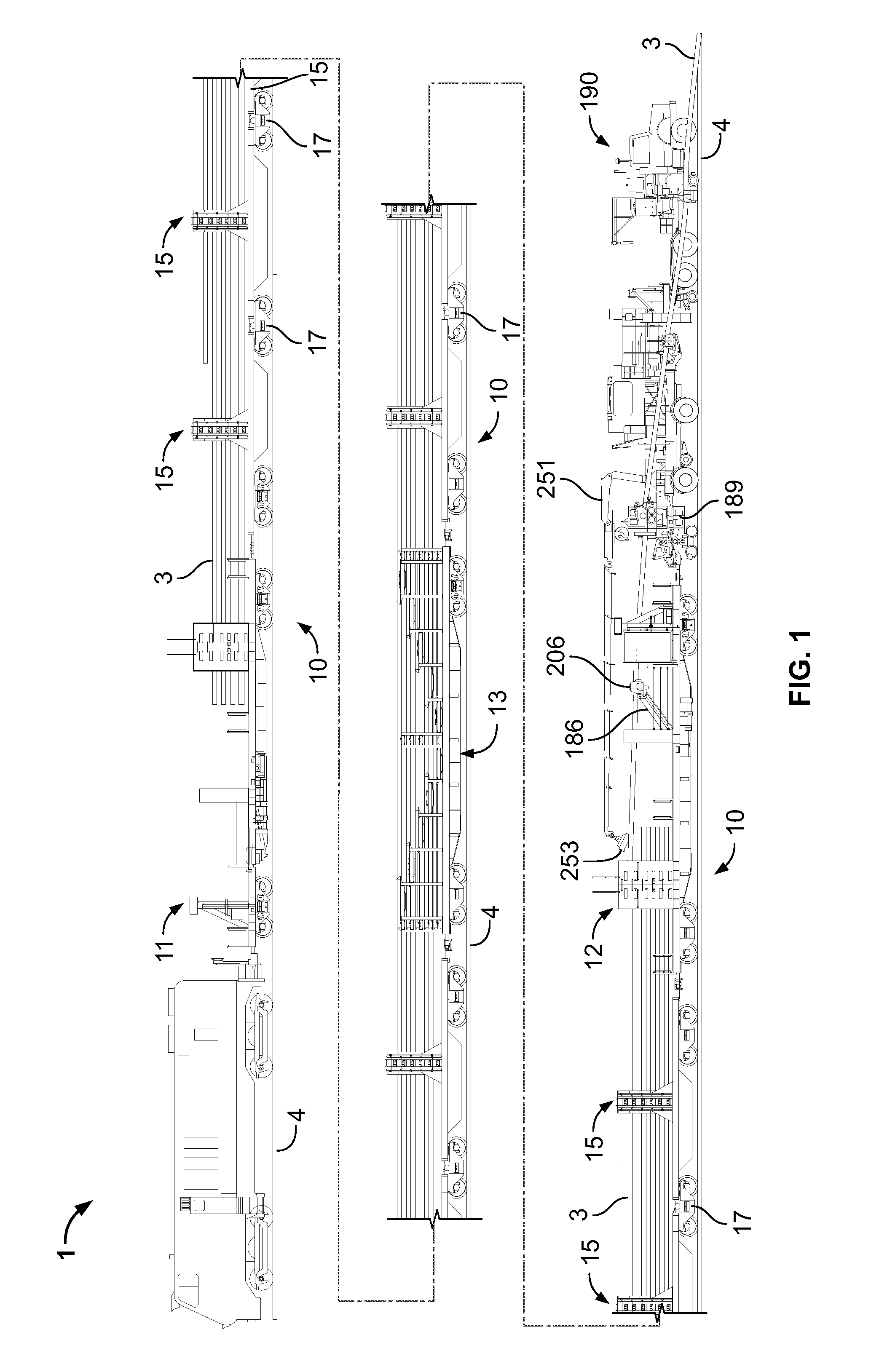

Rail train

ActiveUS8181577B2Load minimizationPrecise feedingSnap fastenersClothes buttonsVehicle frameEngineering

A rail train for supporting multiple sticks of ribbon rail comprises a plurality of rail support cars having a single, centrally positioned rail support stand wherein adjacent rail support cars are supported on shared trucks. End cars include a tunnel for supporting the rails near their ends and one or more rail support arms pivotal at a first end about two axis and supporting a rail guide assembly at a second end for supporting a rail as it is pulled of the rail train. A rail tie-down car utilizes spring-loaded, hydraulically actuated clamp assemblies to clamp individual rails to the tie-down car. Each clamp assembly incorporates at least two clamp members which act opposite one another to prevent the rail secured in place by the clamps from sliding in either longitudinal direction.

Owner:HERZOG CONTRACTING

Tea rolling device with multi stations

InactiveCN101223923ASimple structureIncrease productivityPre-extraction tea treatmentAutomatic controlMechanical engineering

The invention relates to a multi-station tea leaves rolling device which comprises a rolling machine (3). The device is characterized in that a transmission weighing mechanism (1) and a rotary material-feeding mechanism (2) are additionally arranged near the rolling machine (3); the material outlet end of the transmission weighing mechanism (1) is matched with the material inlet end of the material-feeding mechanism (2); the outlet end of the material-feeding mechanism (2) is matched with the inlet end of the rolling machine (3). The multi-station tea leaves rolling device of the invention has simple and reasonable structure, can automatically, continuously, effectively and exactly carry out weighing, feeding and rolling, can realize circular operation of a plurality of rolling machines at will and meet rolling requirement for different scales, achieves continuous and automatic control of rolling tea procedure, thereby greatly improving the production efficiency of tea rolling and relieving labor intensity; besides, the invention has little equipment investment and convenient production.

Owner:CHONGQING ACAD OF AGRI SCI

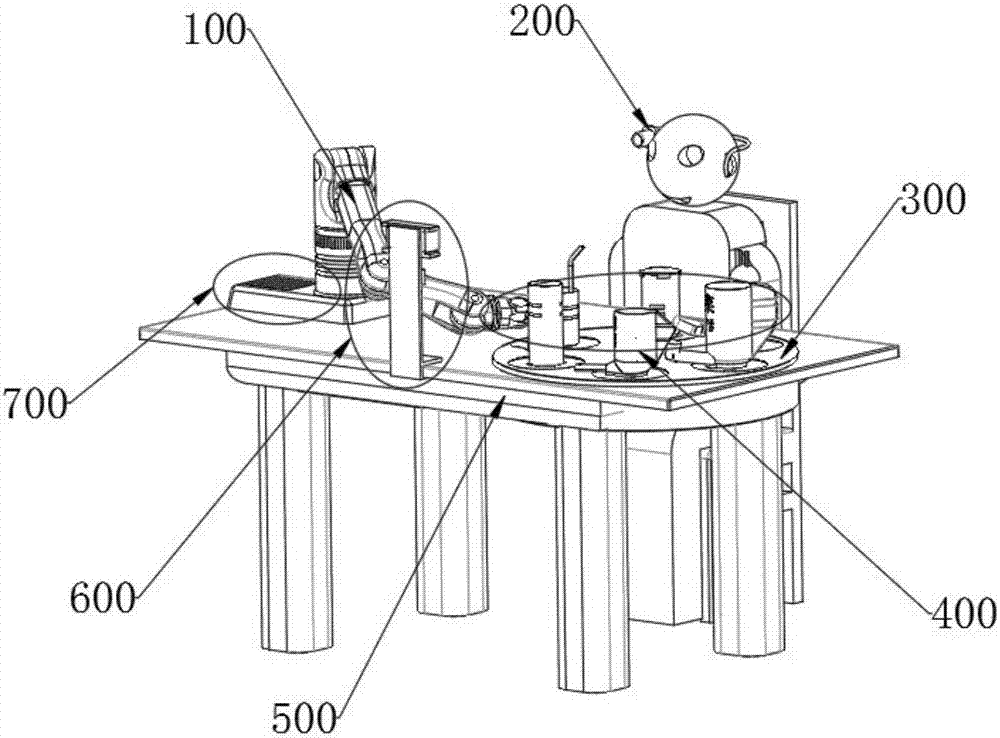

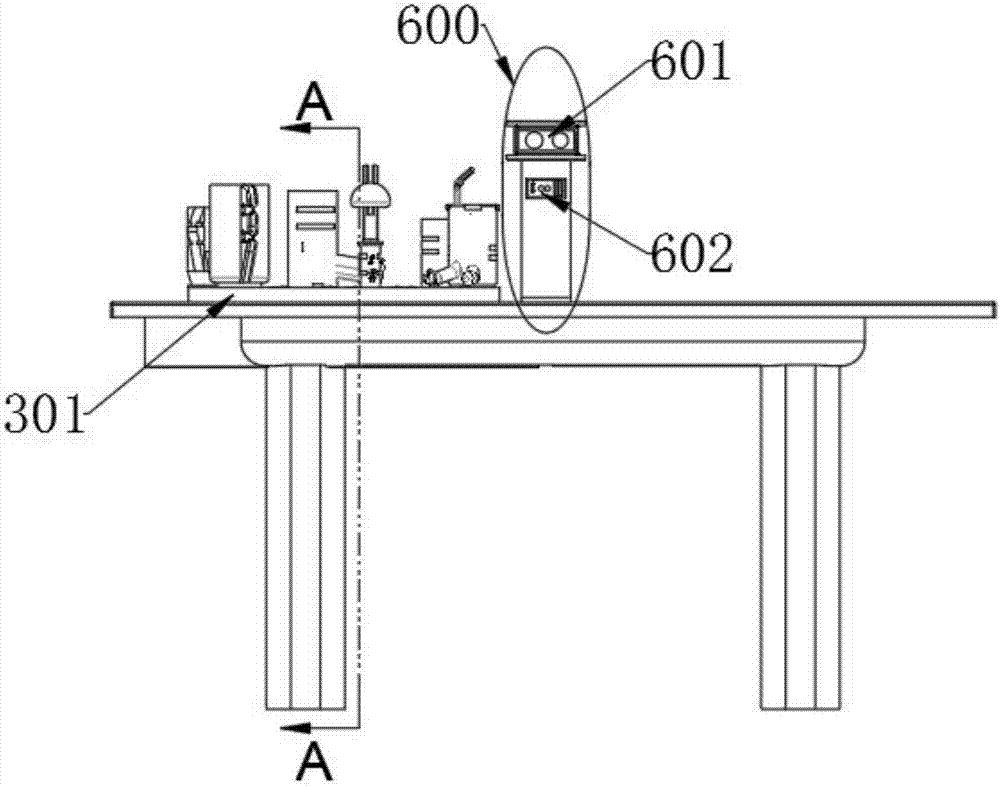

Mechanical arm system assisting person with upper limb disability in dining and work method of system

InactiveCN106976094ASolve the problem of not being able to adapt to changes in work objectsSolve the shortcomings of a large number of operating instructionsManipulatorSimulationUpper limb

The invention discloses a mechanical arm system assisting a person with upper limb disability in dining and a work method of the system. The system comprises a mechanical arm, an instruction input device, a rotating disc system, a plurality of special feeders, a work platform, a mouth positioning device and a controller; request signals are transmitted to the controller through the instruction input device; the controller controls a rotating disc to rotate, the feeders are rotated to the work position close to a mechanical arm, and according to voice instructions sent out by the aided person, the controller controls the mechanical arm to achieve action of special feeder grabbing. The teaching reappearing control method is reasonably combined with the man-machine interaction control method, the problem that robot teaching reappearing operation cannot adapt to changes of a work object is solved, the defect that generally, only the man-machine interaction type control method is used for operating, and operation instructions are tedious is overcome effectively, and design of the special feeders is fully used for greatly reducing the requirement of operation action complexity.

Owner:SHANDONG UNIV OF SCI & TECH

Iron oxide yellow granular pigment and manufacturing method thereof

InactiveCN101691455APollution suppressionSettling fastPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsAqueous solutionDust pollution

The invention belongs to the field of chemical pigments, in particular to an iron oxide yellow granular pigment and a manufacturing method thereof, the related iron oxide yellow granular pigment comprises a main component of iron oxide yellow, an additive coating layer is arranged outside the main component of the iron oxide yellow, and the main component of the iron oxide yellow and the coating layer are combined together for constituting the granular pigment; and the pigment is realized by the following steps: firstly preparing additive water solution, heating to 30-100 DEG C, sending the iron oxide yellow into a granulator, evenly spraying the prepared additive water solution on powder materials, gradually forming small grains, further sieving the prepared grains by using a vibration sieve and drying, thereby preparing a finished product. The prepared granular pigment is difficult to diffuse, thereby effectively preventing dust pollution, having the advantages of high color retaining performance, good fluidity, good dispersion and low cost, and being applicable to extensive application on the industry.

Owner:HANGZHOU XIAOXIANG PIGMENT CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com