Equipment and method for detecting burst tendency of glass of curtain wall

A detection equipment and glass technology, which is applied in the field of curtain wall glass bursting tendency detection equipment, can solve the problems of deflection coefficient drop, detection or stop, flatness change, etc., and achieve the effects of reducing measurement error, rapid measurement, and low measurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical characteristics of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

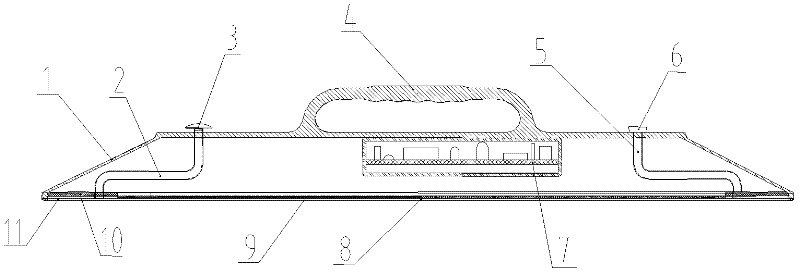

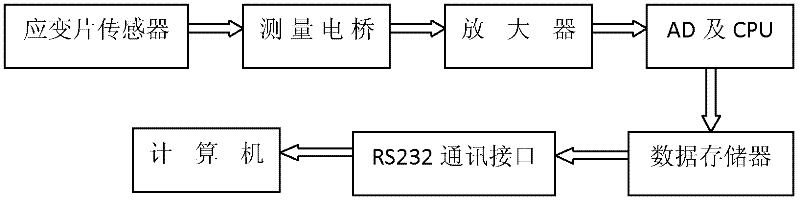

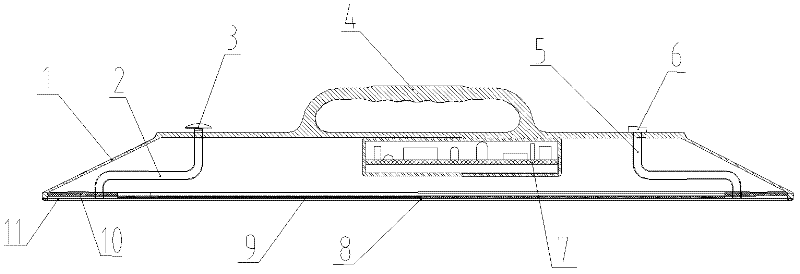

[0030] Such as figure 1 Described: a detection device for the tendency of curtain wall glass to burst, including: a measuring device for online detection, processing, and storage of glass deformation data; and a computer for storing, processing, and analyzing the data detected by the measuring device; the measuring device includes: housing electronic measuring device The casing 1 of the circuit 4, the top of the casing 1 is provided with a handle 4; the bottom of the casing 1 is a flexible substrate 8 that can be in contact with the glass to be detected, and the flexible substrate 8 is covered with a strain gauge pressure sensor 9; The electronic measuring circuit 7 which has a resistance effect and amplifies and processes the signal is electrically connected to the strain gauge pressure sensor 9; a gap sufficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com