Patents

Literature

76results about How to "Low cost of measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and method for detecting the coagulation functions of global, especially primary hemostasis

InactiveUS20030130596A1Effect of viscosity can be correctedRealize automatic adjustmentUltrasonic/sonic/infrasonic diagnosticsDiagnostic recording/measuringPiston cylinderPlatelet-rich plasma

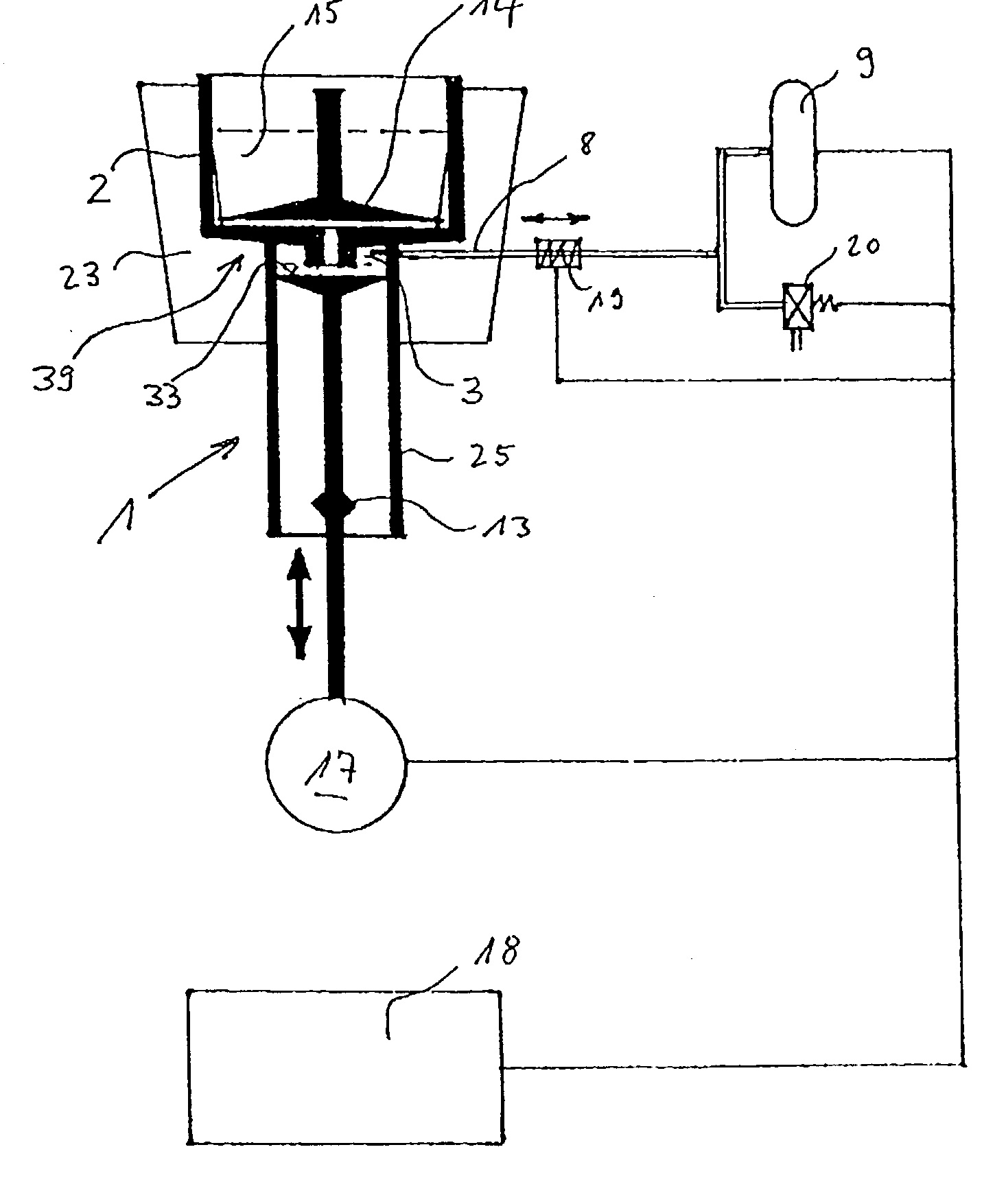

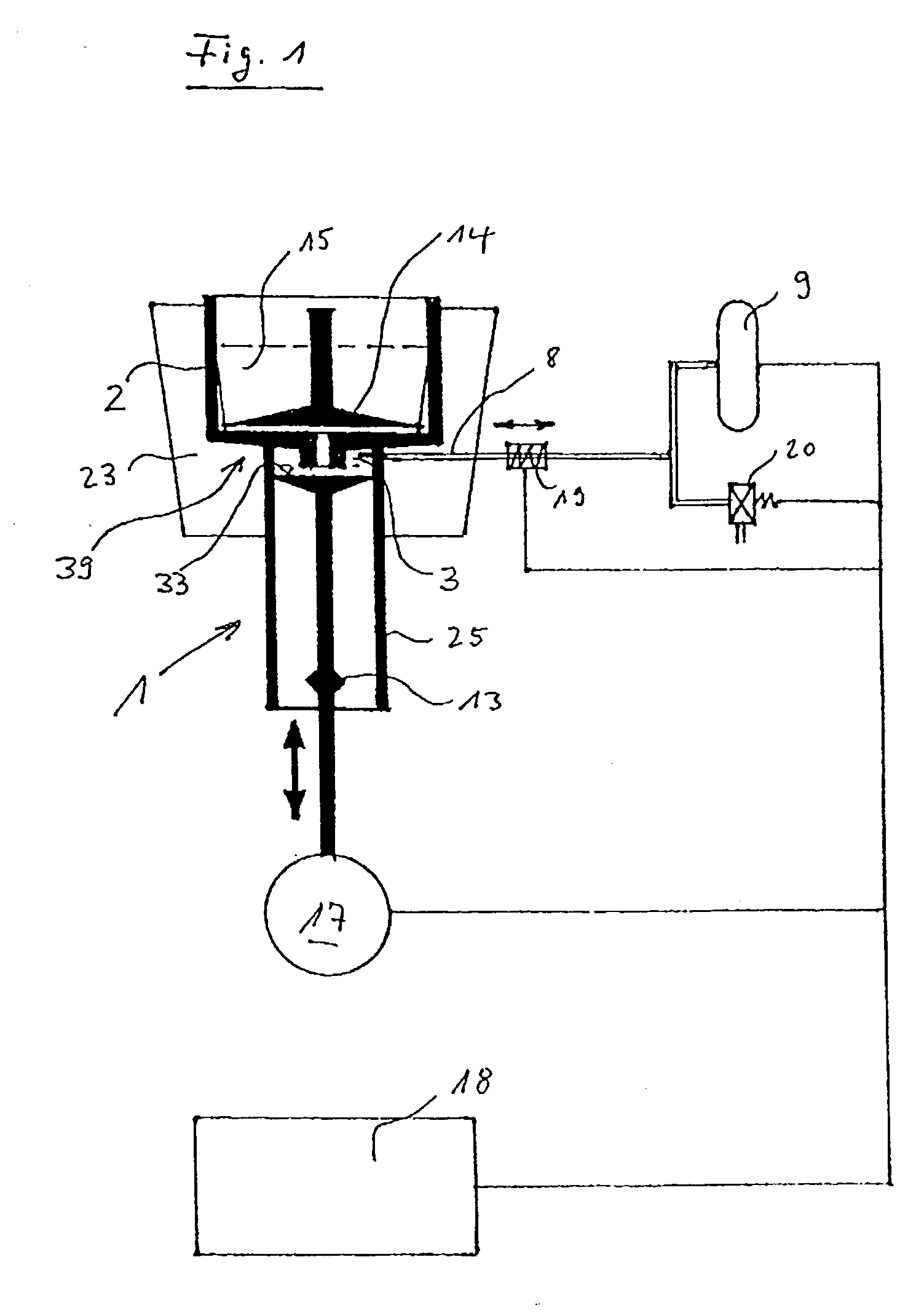

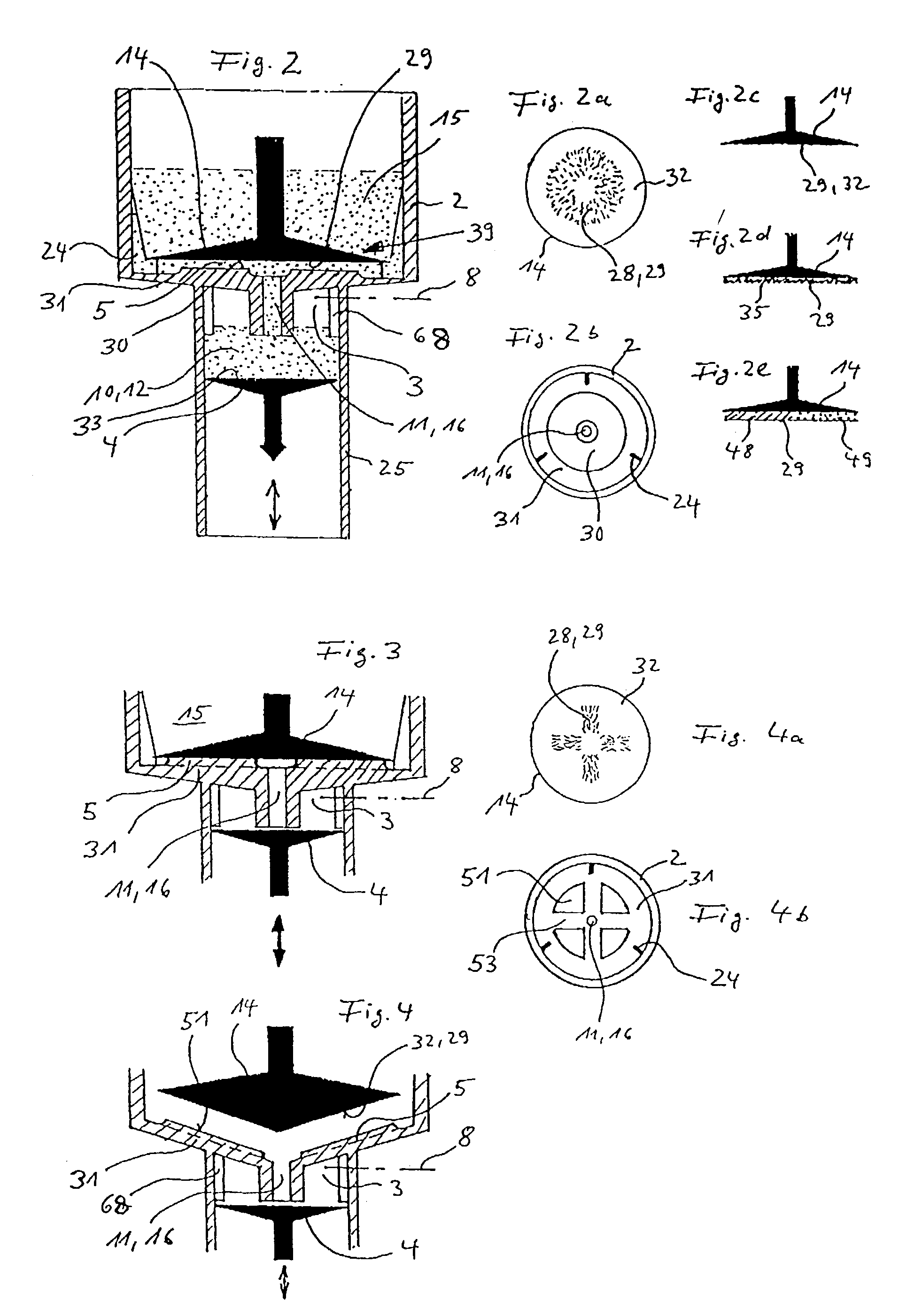

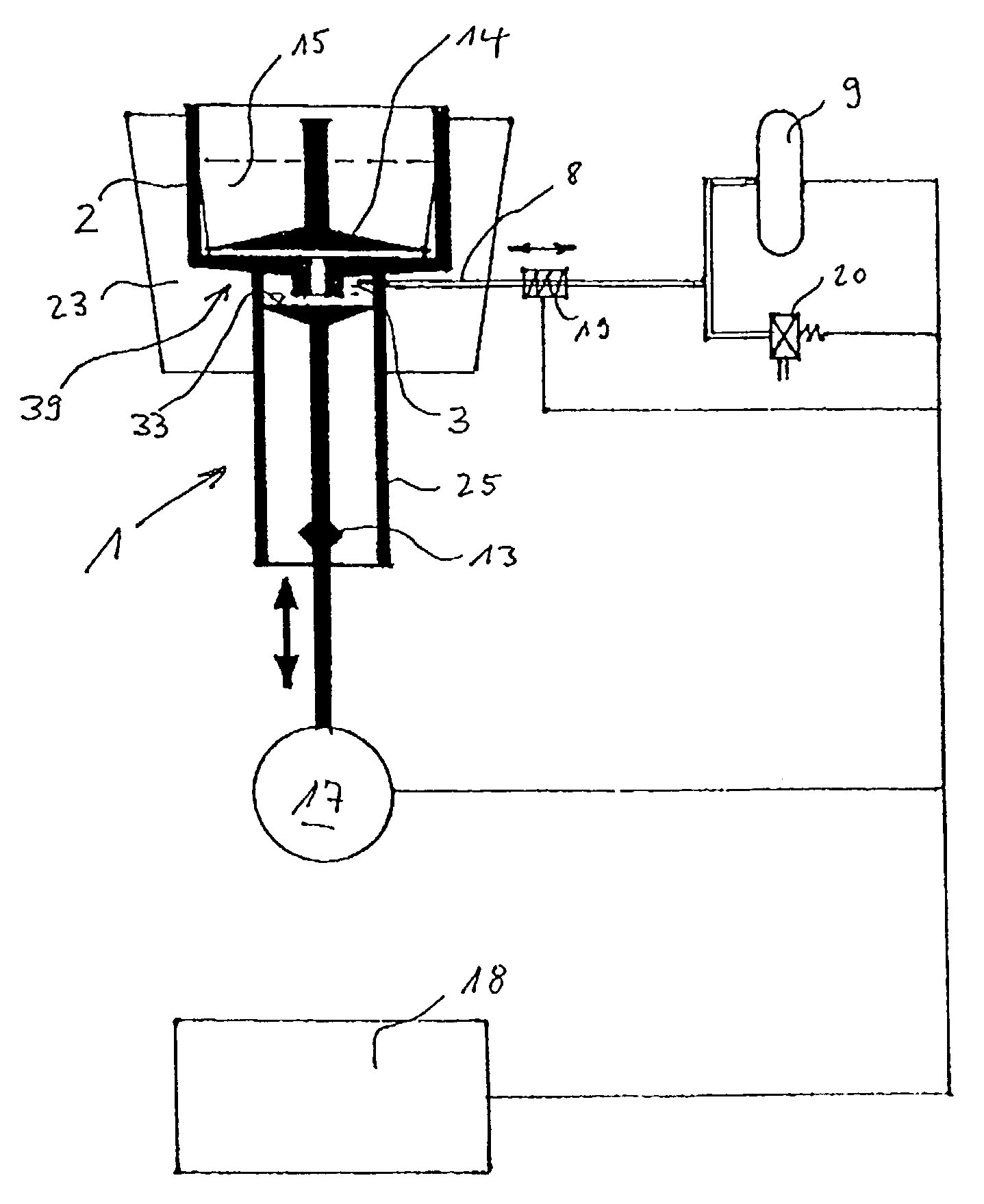

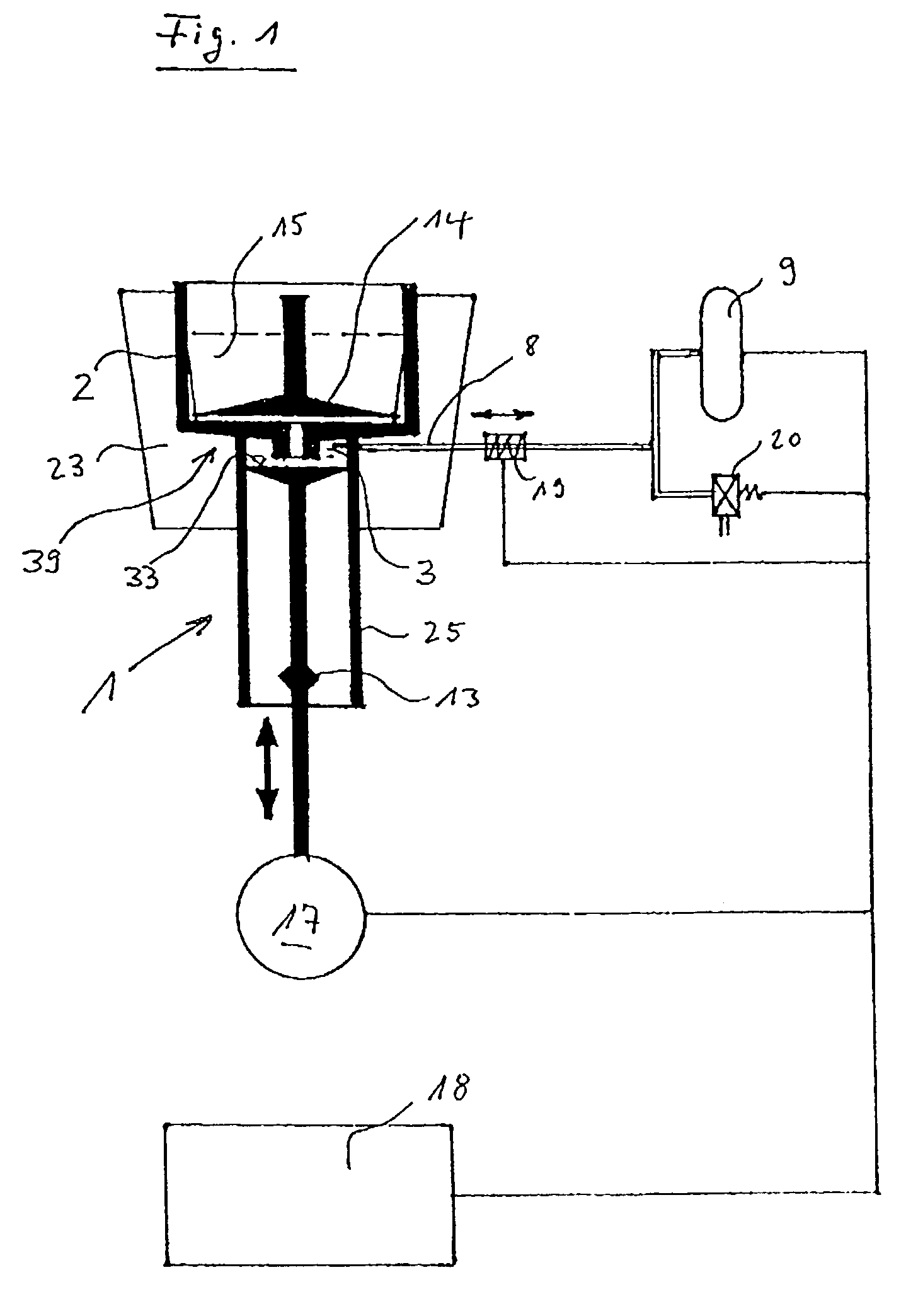

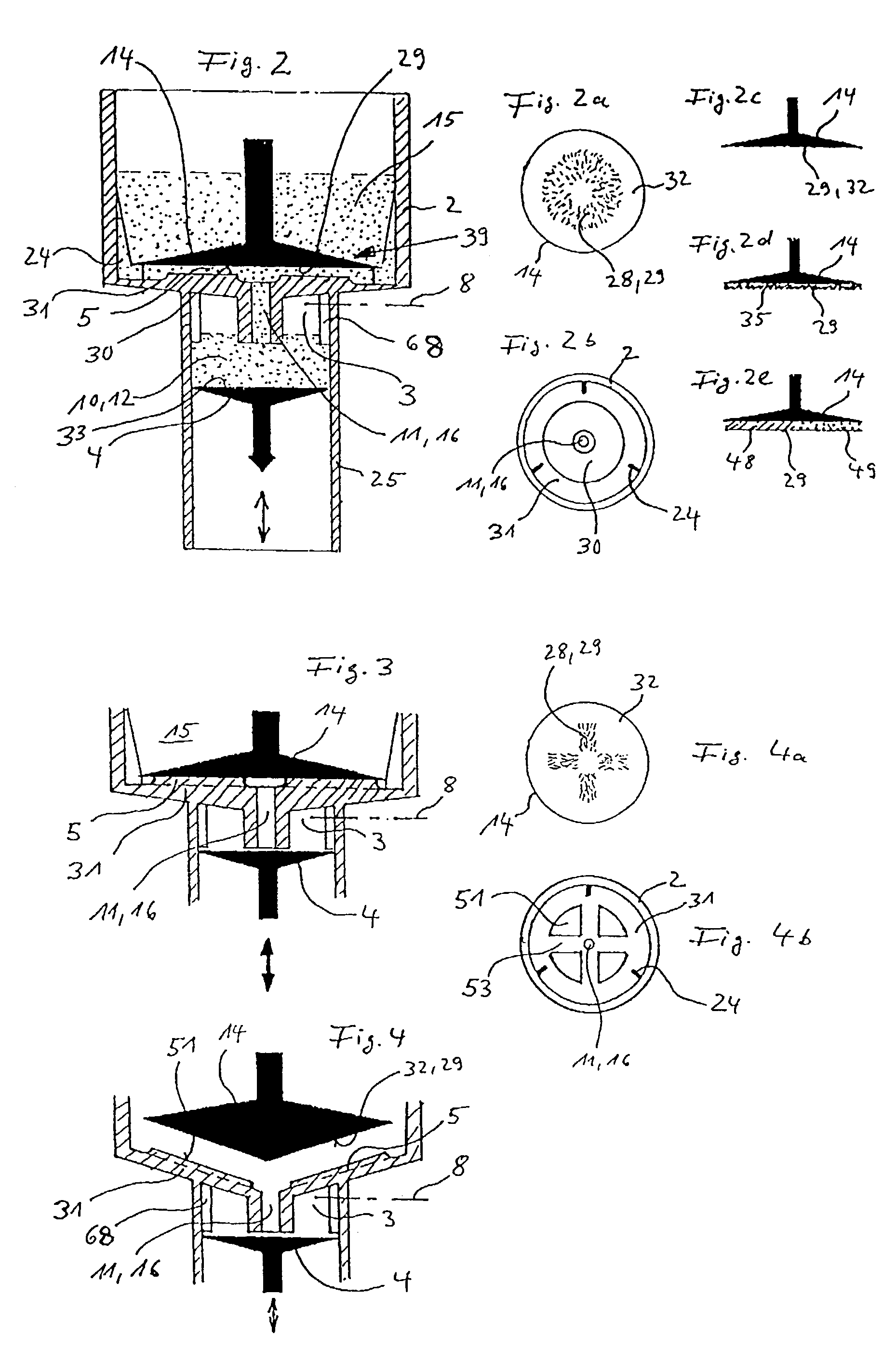

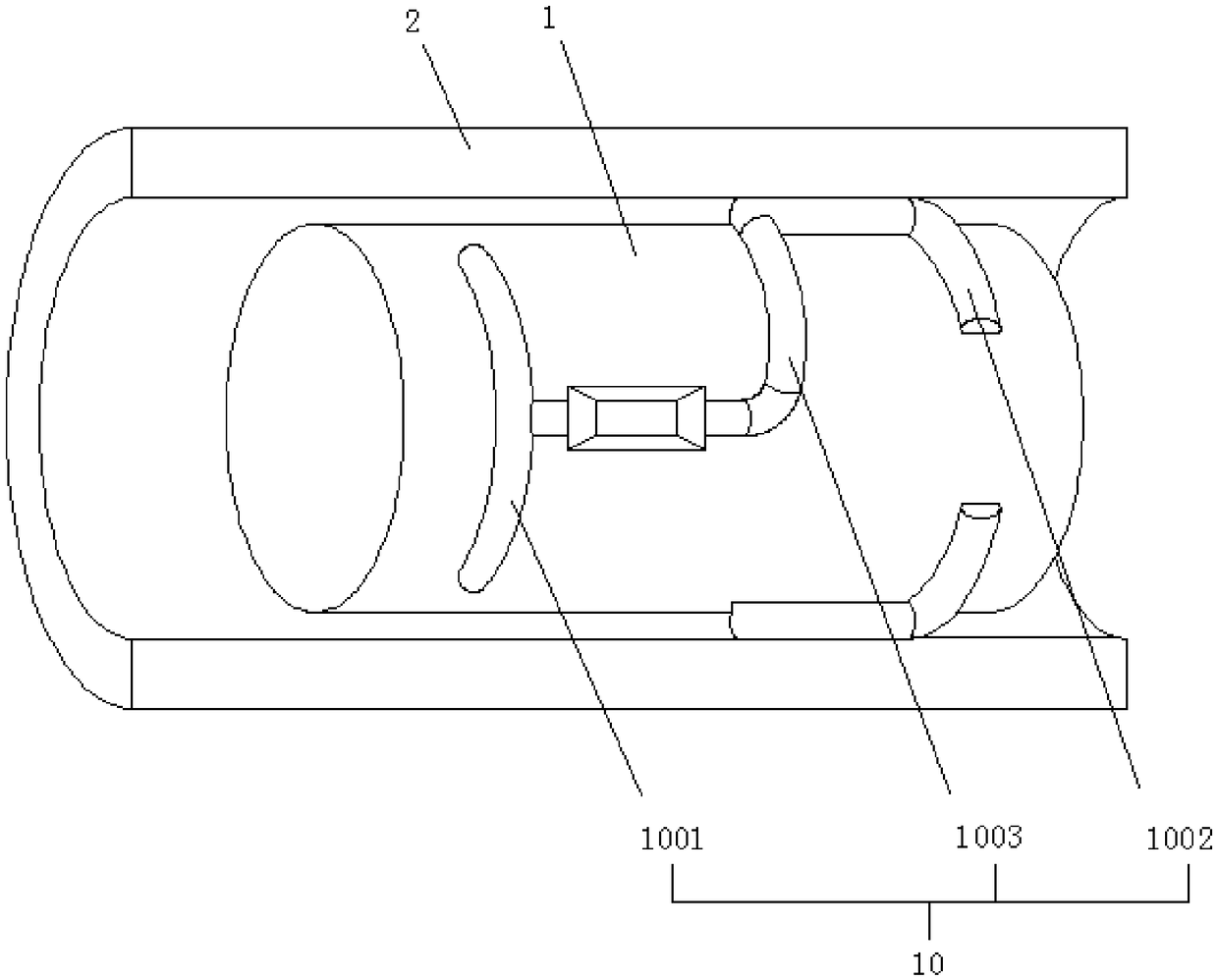

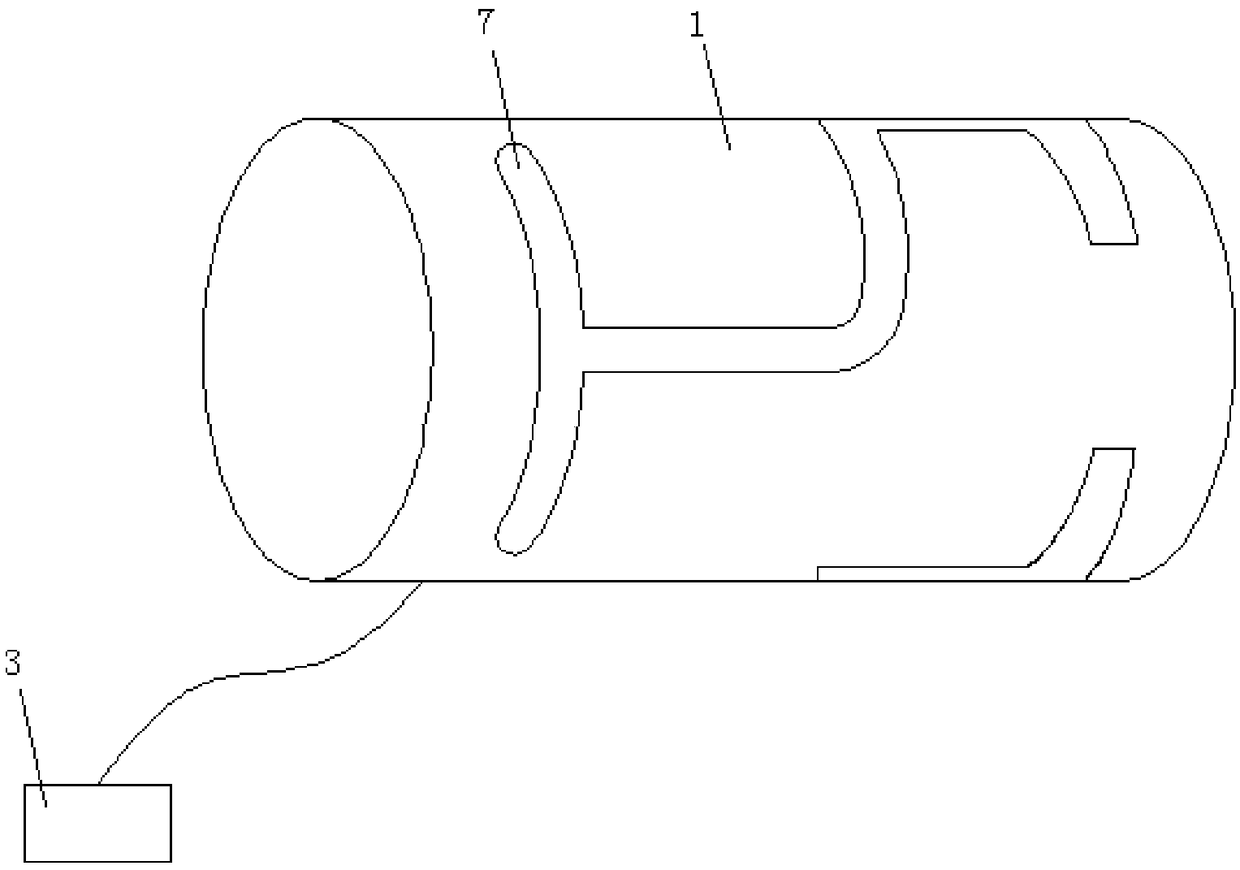

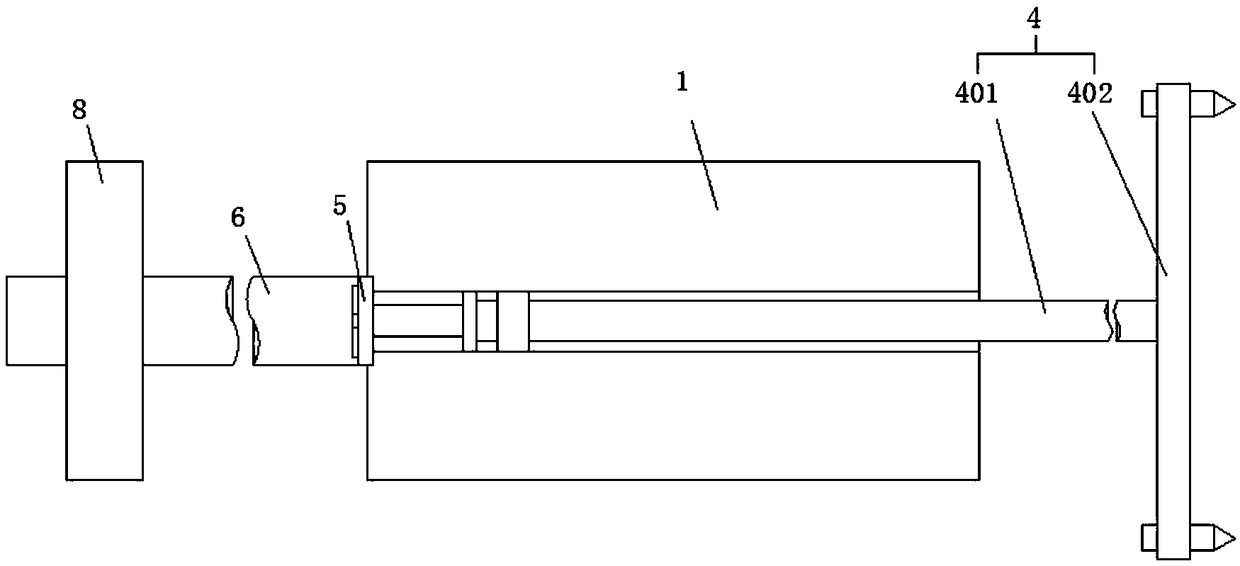

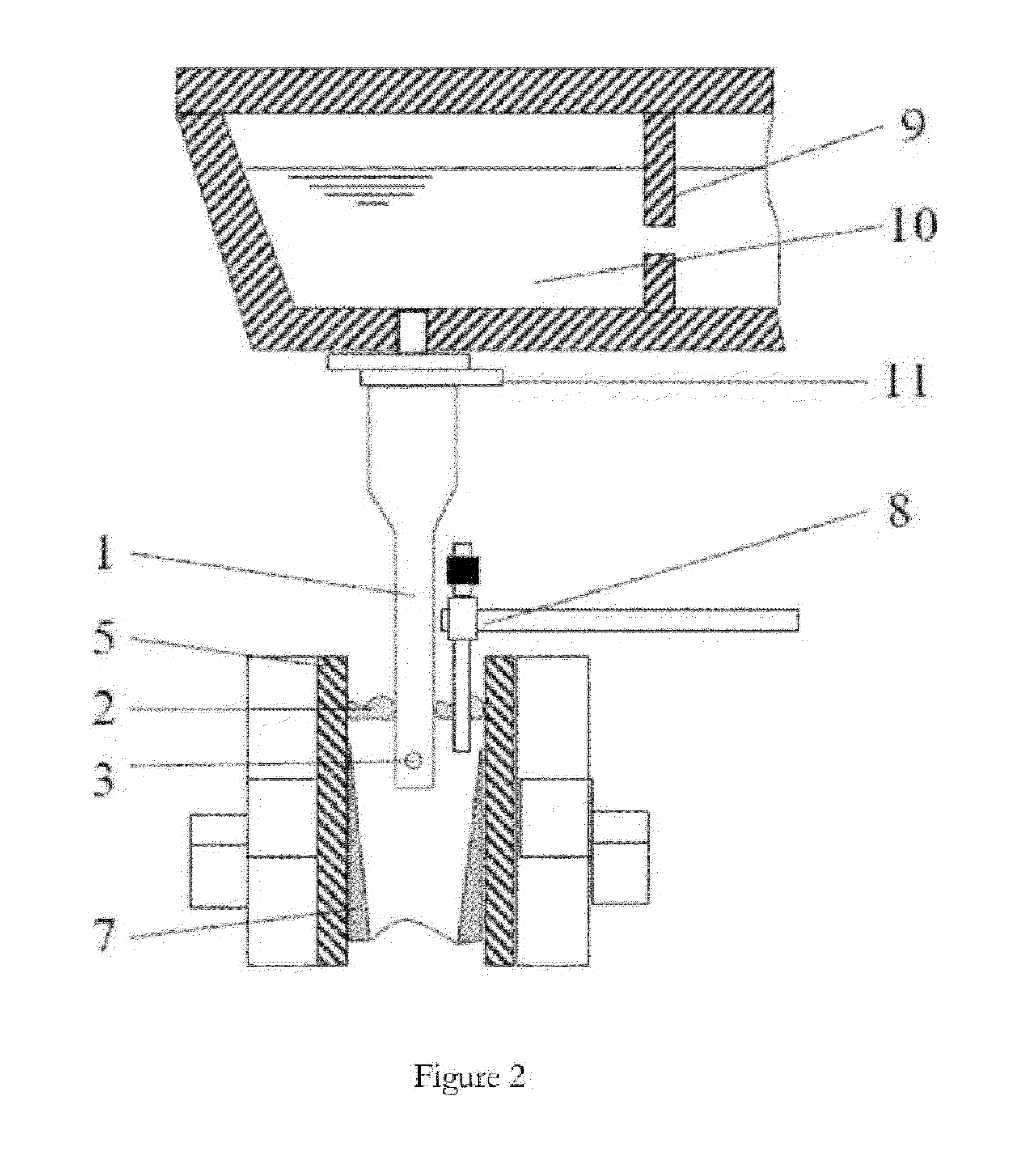

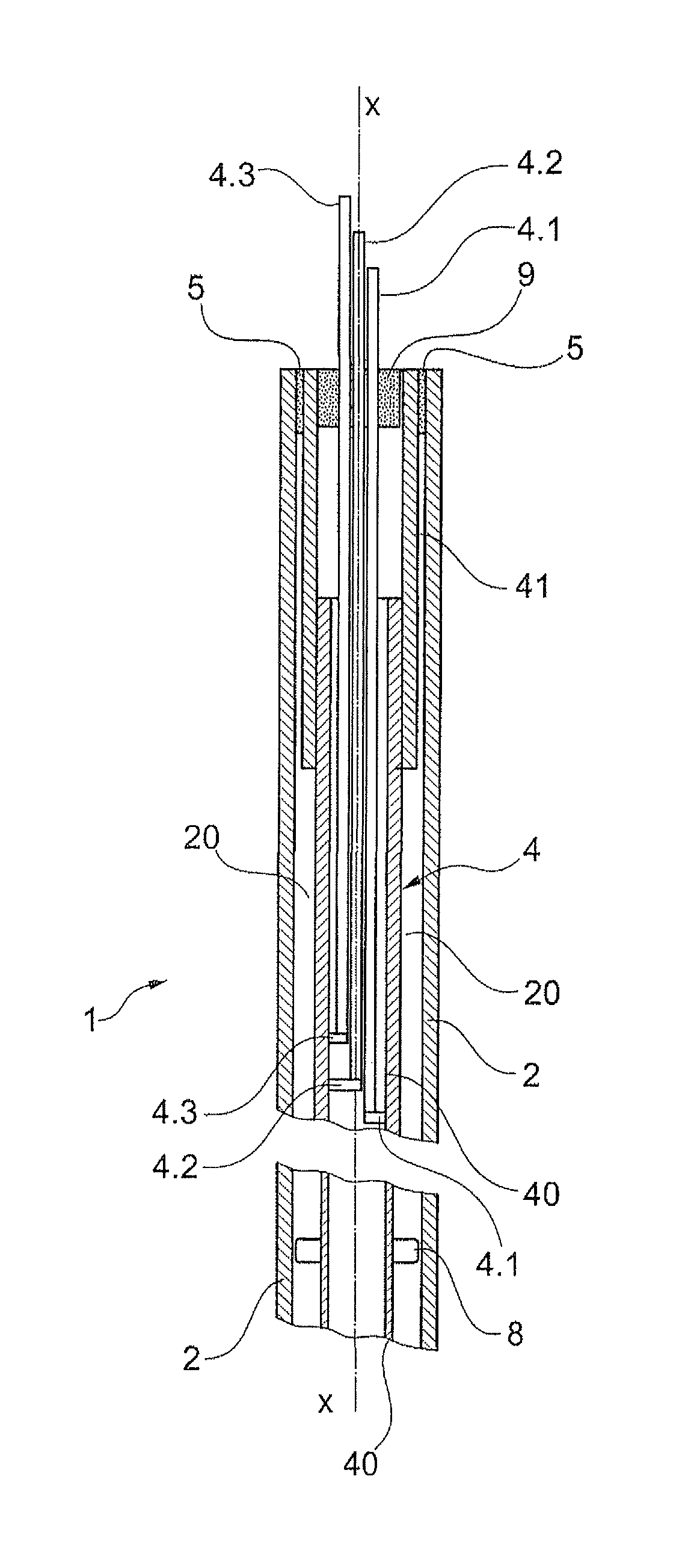

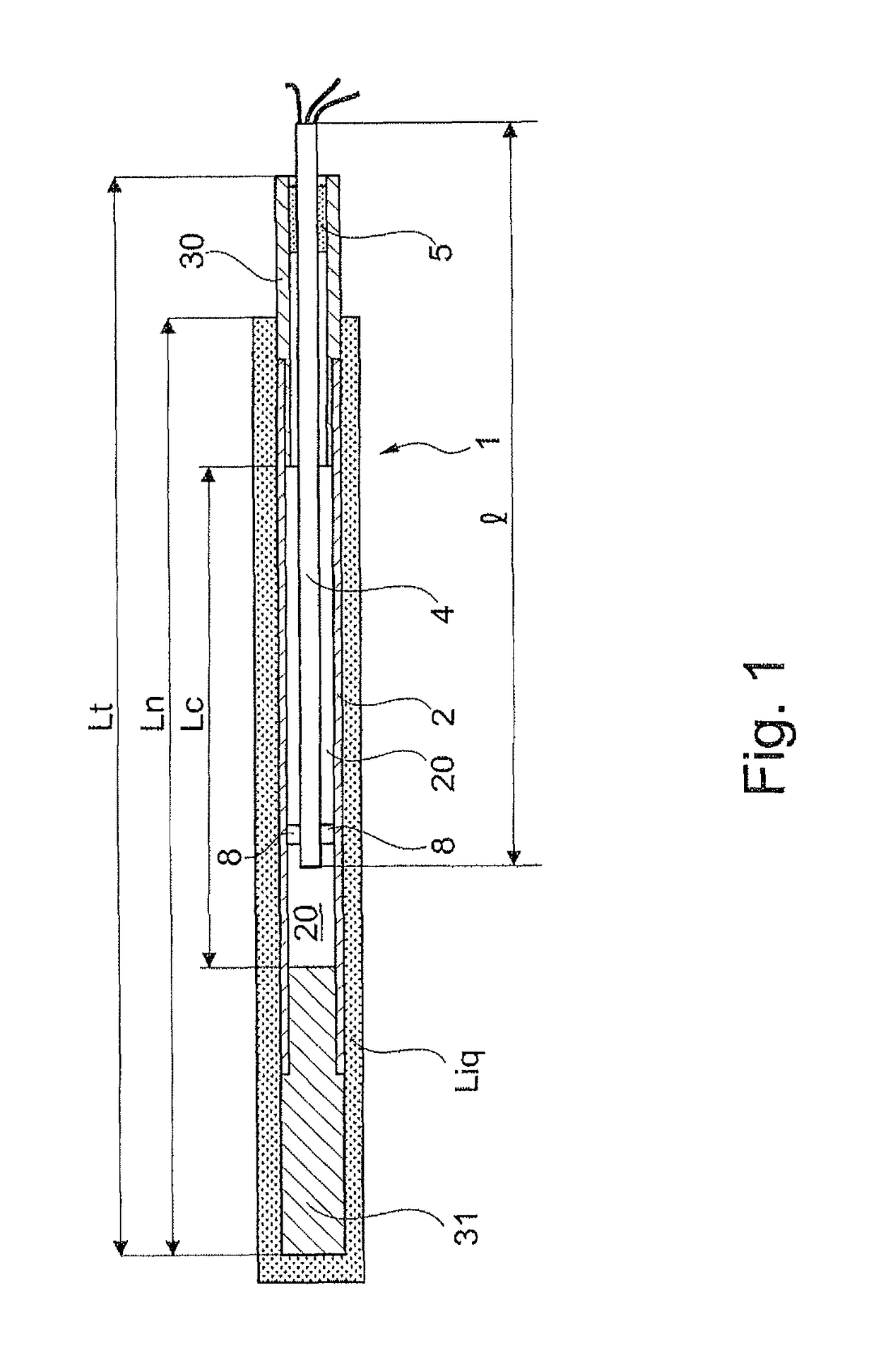

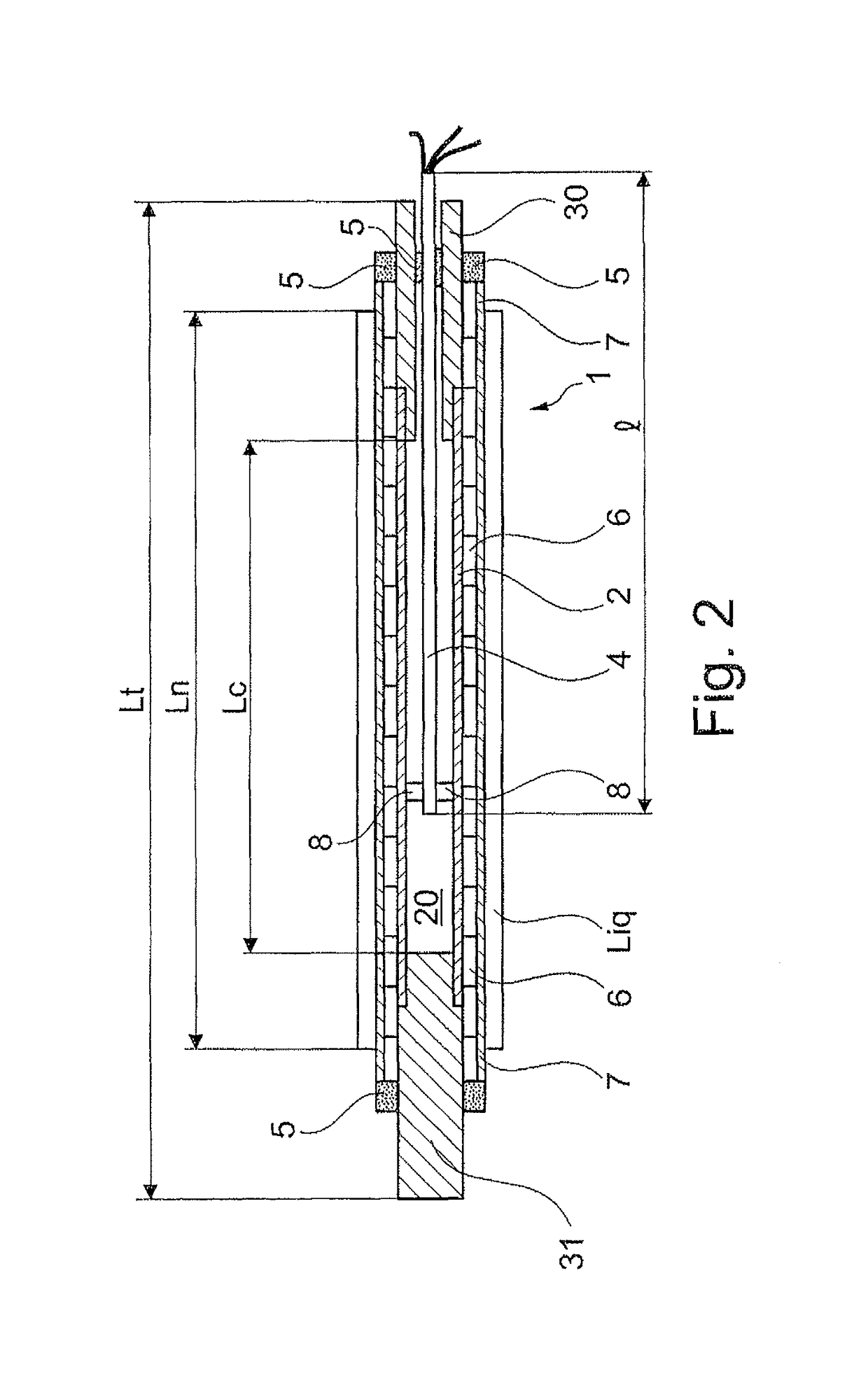

The invention relates to a method and to a device for examining the properties of the global, in particular the primary, hemostasis functions in whole blood or platelet-rich plasma, comprising a storage chamber (15) for the blood to be examined, a reaction device (39) having at least one flow path (5, 16) via which the blood to be examined is transported for carrying out certain reactions, a conveyor device (1) which conveys a volumetric flow for the transport of the blood through the reaction device (39), thereby generating a conveyor pressure, a pressure gauge (8, 9) which in a blood-free pressure gauge chamber (3) measures changes in the conveyor pressure which appear depending on the reactions of the blood to be examined which have taken place in the reaction device (39), a blood collection chamber (10) for collecting the blood transported through the reaction device (39), the conveyor pressure in a pressure-sealed working chamber (12) being generated by a piston-cylinder system (1), a working surface (33) of the piston (4) forming a boundary of the working chamber (12), and the working chamber (12) being formed by the blood collection chamber (10) and the blood-free pressure gauge chamber (3). According to the method of the invention, the volumetric flow is preferably adjusted, depending on the measured pressure of the volumetric flow, in such a way that the shear rate or the shear force, whose action in the reaction opening causes blood components, in particular thrombocytes, to deposit, follows a predetermined characteristic curve and in particular is held constant.

Owner:FREIHERR VON DER GOLTZ VOLKER

Device and method for detecting the coagulation functions of global, especially primary hemostasis

InactiveUS7223365B2Low cost of measurementSimple and low-maintenance techniqueUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsBlood plasmaPlasma rich platelet

A method and a device are provided for examining the properties of the global, in particular the primary, hemostasis functions in whole blood or platelet-rich plasma. A volumetric blood flow is preferably adjusted, depending on the measured pressure of the volumetric flow, so that the shear rate or the shear force, whose action in the reaction opening causes blood components, in particular thrombocytes, to deposit, follows a predetermined characteristic curve and in particular is held constant.

Owner:FREIHERR VON DER GOLTZ VOLKER

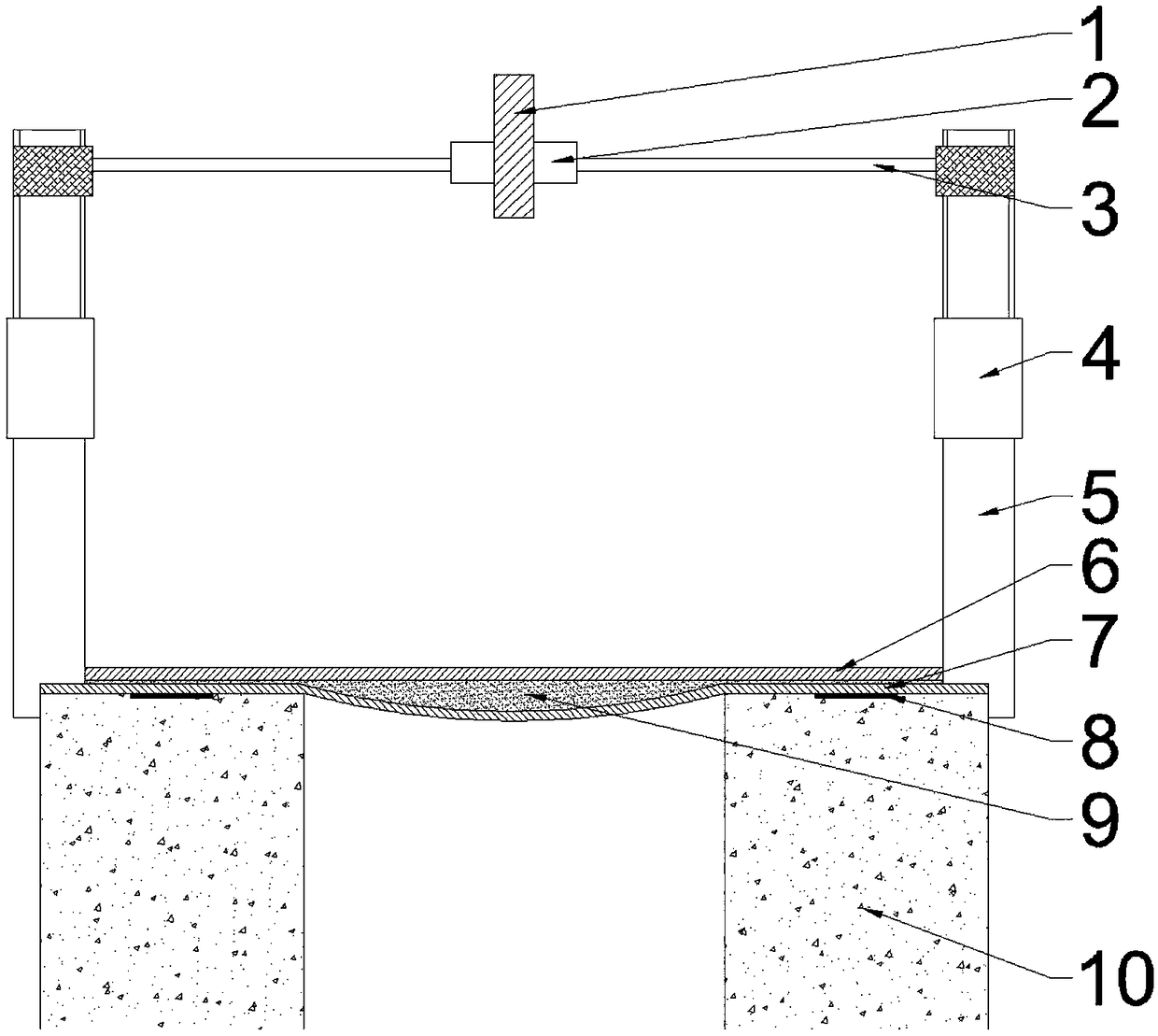

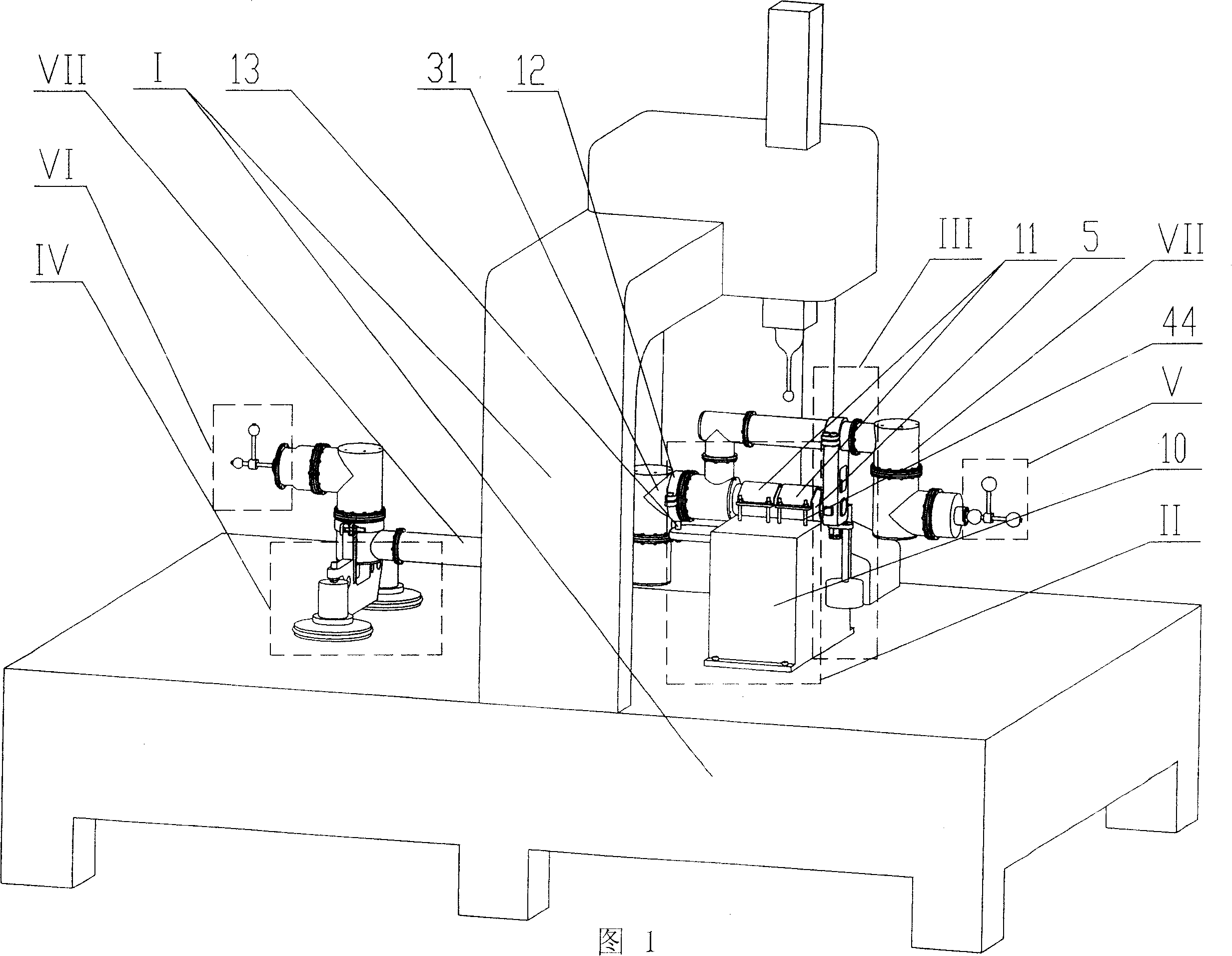

Method for detecting quality of large-diameter tubular pile at low strain

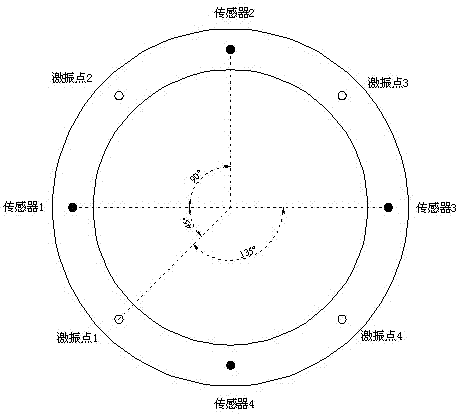

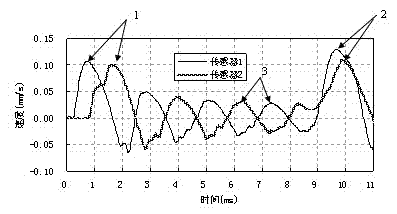

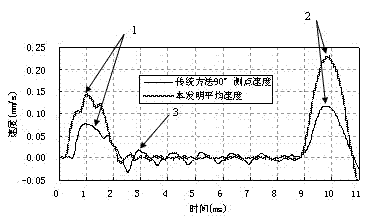

ActiveCN102877490AEliminate the effects of 3D effectsEliminate high-frequency interference wave problemsFoundation testingControl theoryInterference wave

The invention discloses a method for detecting the quality of a large-diameter tubular pile at a low strain. A plurality of acceleration sensors are arranged on the top of the tubular pile; a central angle corresponding to two adjacent acceleration sensors is 90 DEG; central angles between exciting points and all the acceleration sensors are 45 DEG or 135 DEG; acceleration responses are obtained through the measurement of the acceleration sensors, and speed responses are obtained through acceleration response integrals; an average value is obtained by superposing the speed responses obtained through the measurement at all measuring points to obtain an average speed response curve; and the integrity of a pile body is determined according to the obtained average speed response curve. By the method, a plurality of sensors are use for multipoint measurement, so that the propagation law of stress waves along the circumferential direction of a pile wall can be obtained, and the influence of a three-dimensional effect is eliminated; and due to the adoption of the average speed response curve, the problem of high-frequency interference waves can be completely solved, and the excitation of the points which form an angle of 45 DEG or 135 DEG with the acceleration sensors is better than the conventional excitation of the points which form an angle of 90 DEG with the sensors. The method for detecting the quality of the large-diameter tubular pile is easy to operate, convenient to implement, low in measurement cost, high in measurement accuracy and high in efficiency.

Owner:HOHAI UNIV +1

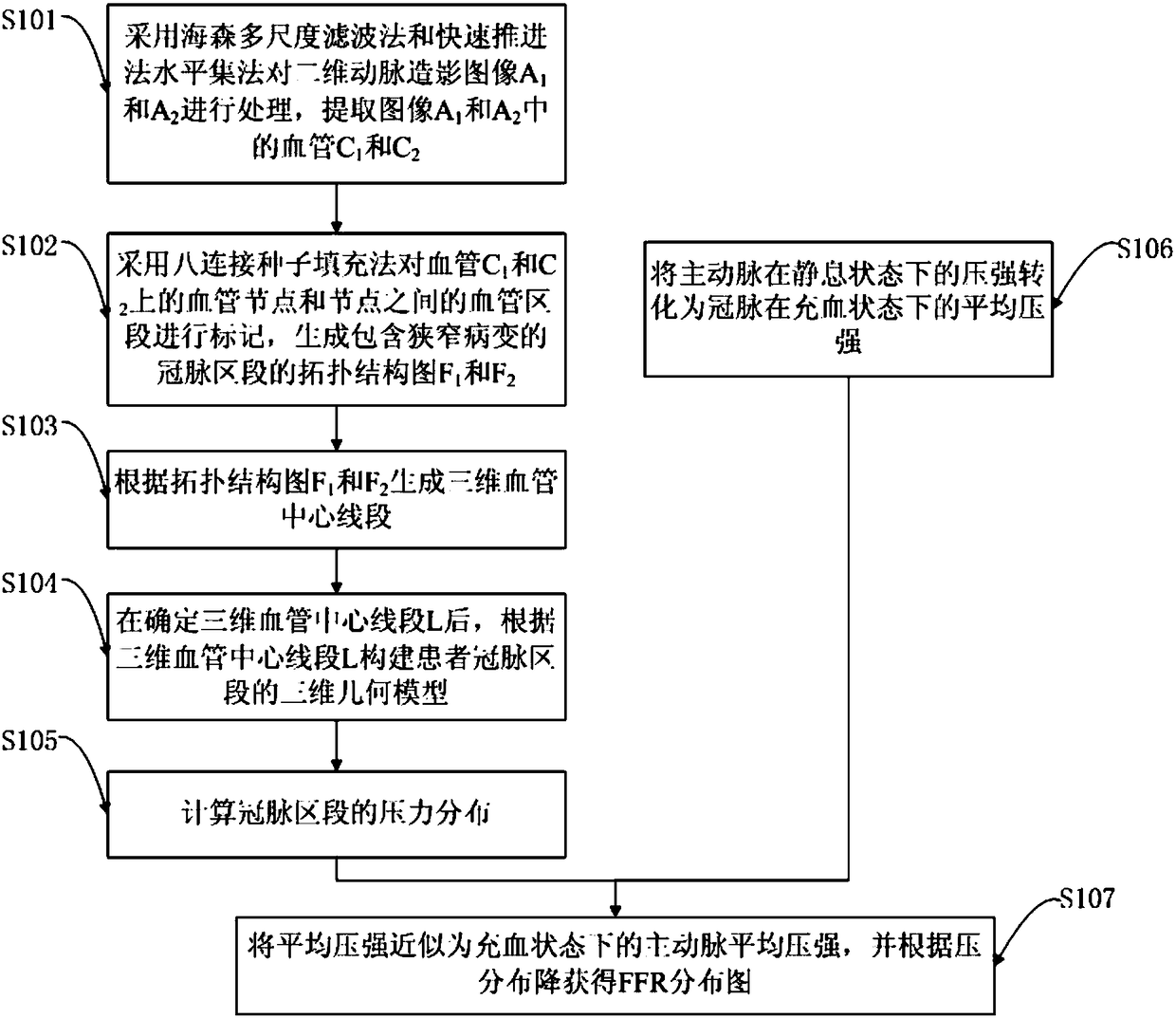

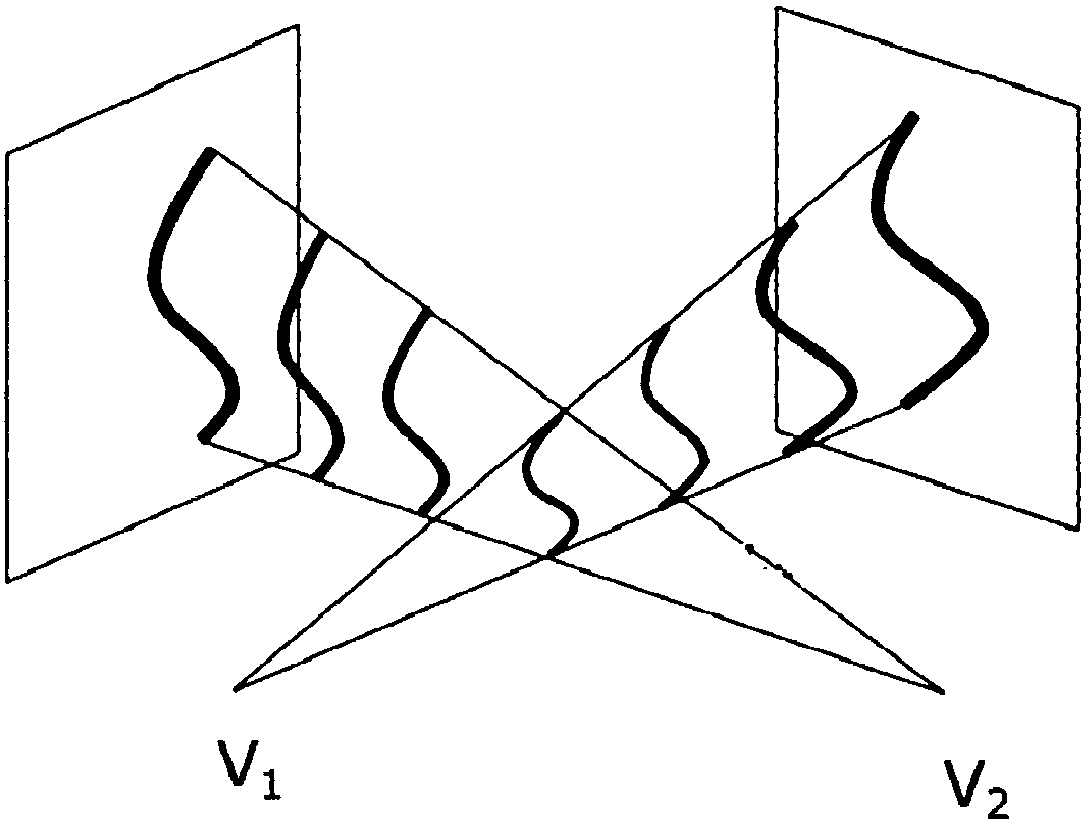

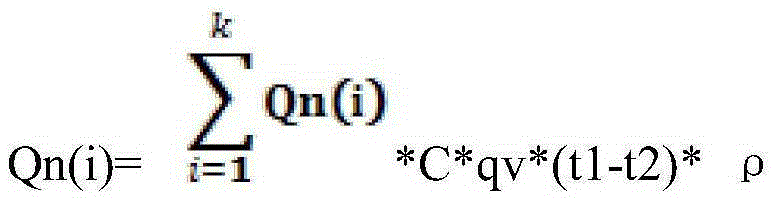

System for calculating coronary fractional flow reserve based on arteriography images

ActiveCN108186038AReduce security risksImprove universalityDiagnostic recording/measuringSensorsComputerized systemVolumetric Mass Density

The invention discloses a system for calculating coronary fractional flow reserve based on arteriography images. The system comprises at least one computer system and is characterized in that each computer system receives the arteriography images and electrocardiogram signals; corresponding two sequences of two-dimensional arteriography images under the identical electrocardiogram signal are selected; after the blood vessels of the arteriography images are determined, the topological structure diagram of coronary sections is generated, three-dimensional blood vessel central line sections are generated according to the topological structure diagram, and uniform rational b-spline curves are applied to the central line sections to build the three-dimensional geometrical model of the coronarysections; after inlet blood flow rate is determined according to the gray value change of two optional points at a model inlet in the dynamic arteriography images, computational fluid mechanics simulation analysis is performed according to the three-dimensional geometrical model having grids, the outlet / inlet blood flow rate, blood viscosity and blood density to obtain the pressure distribution ofthe coronary sections; aorta average pressure intensity in a congestive state is simulated, and the coronary fractional flow reserve distribution is determined according to the aorta average pressureintensity.

Owner:HANGZHOU ARTERYFLOW TECH CO LTD

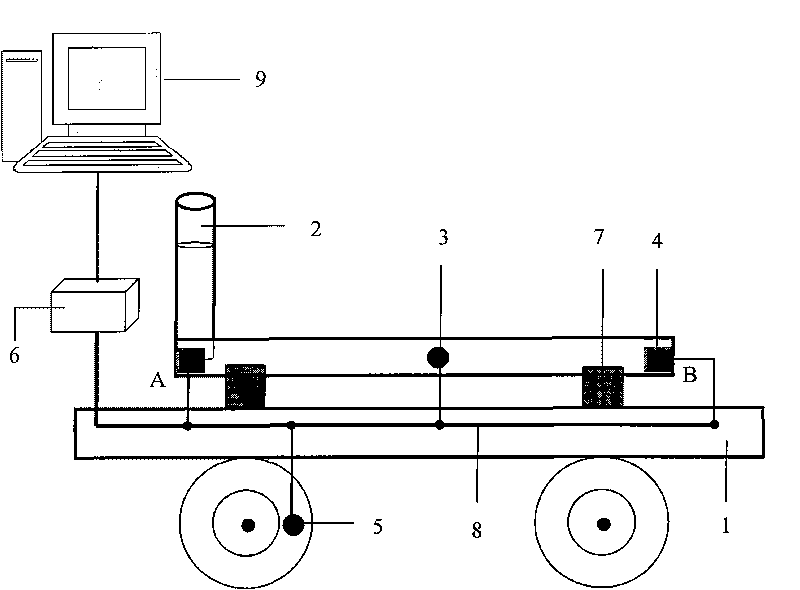

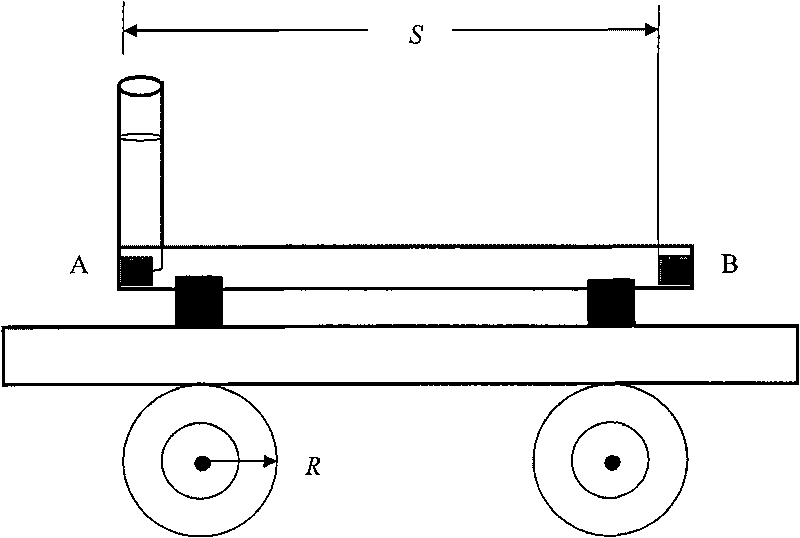

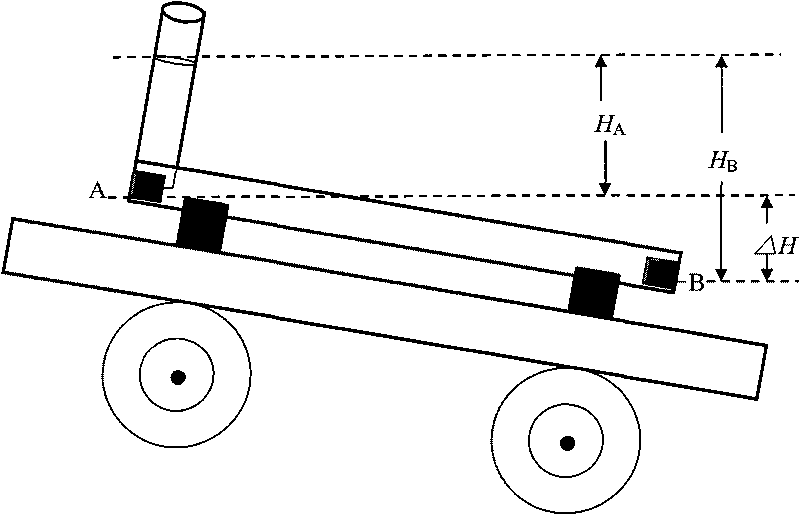

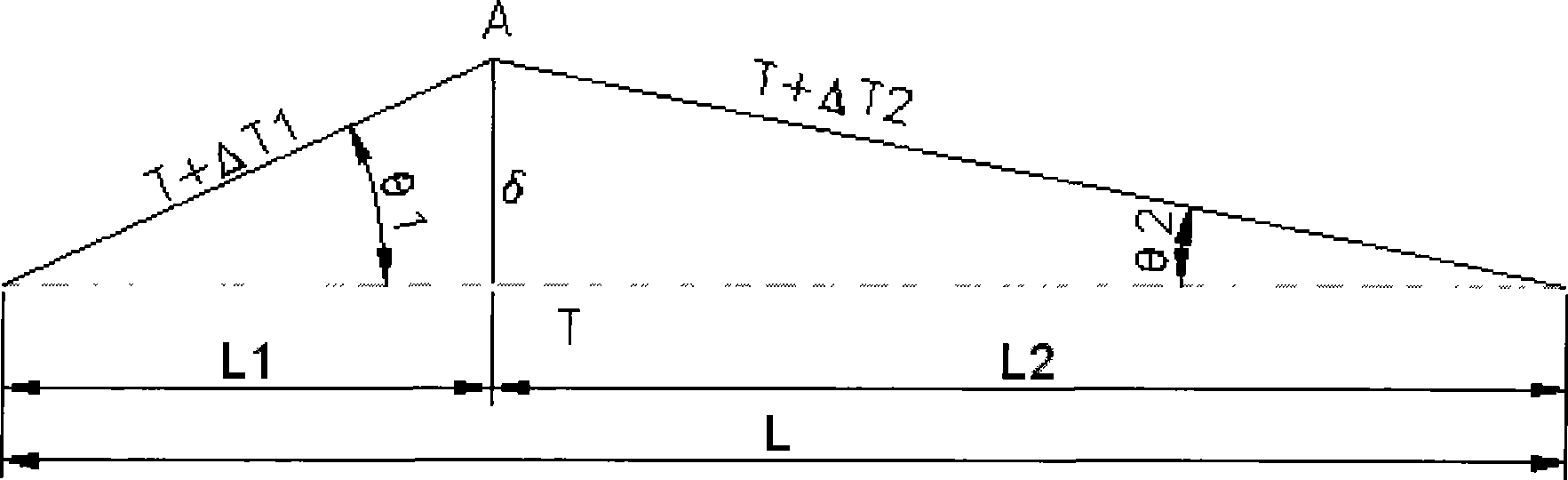

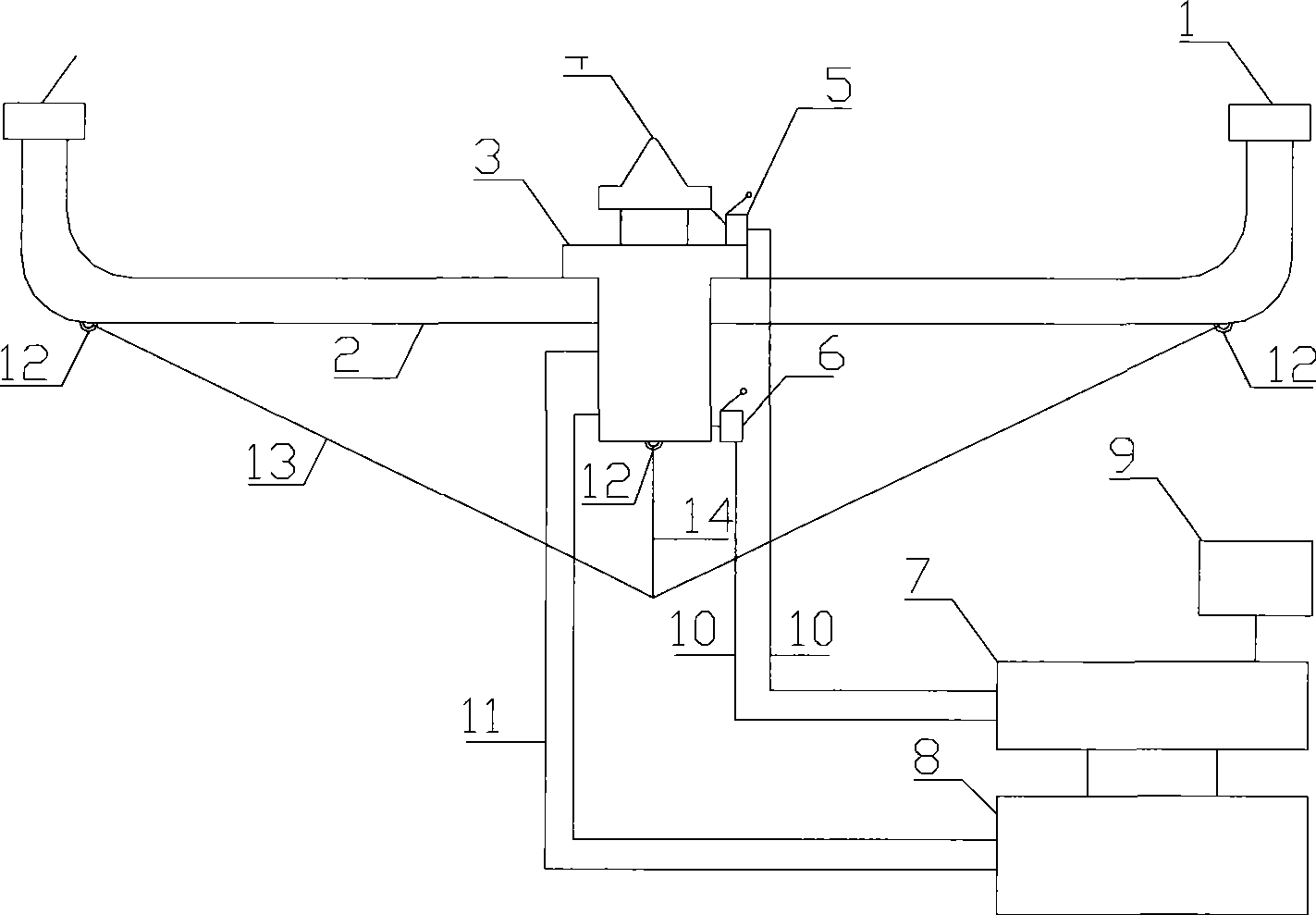

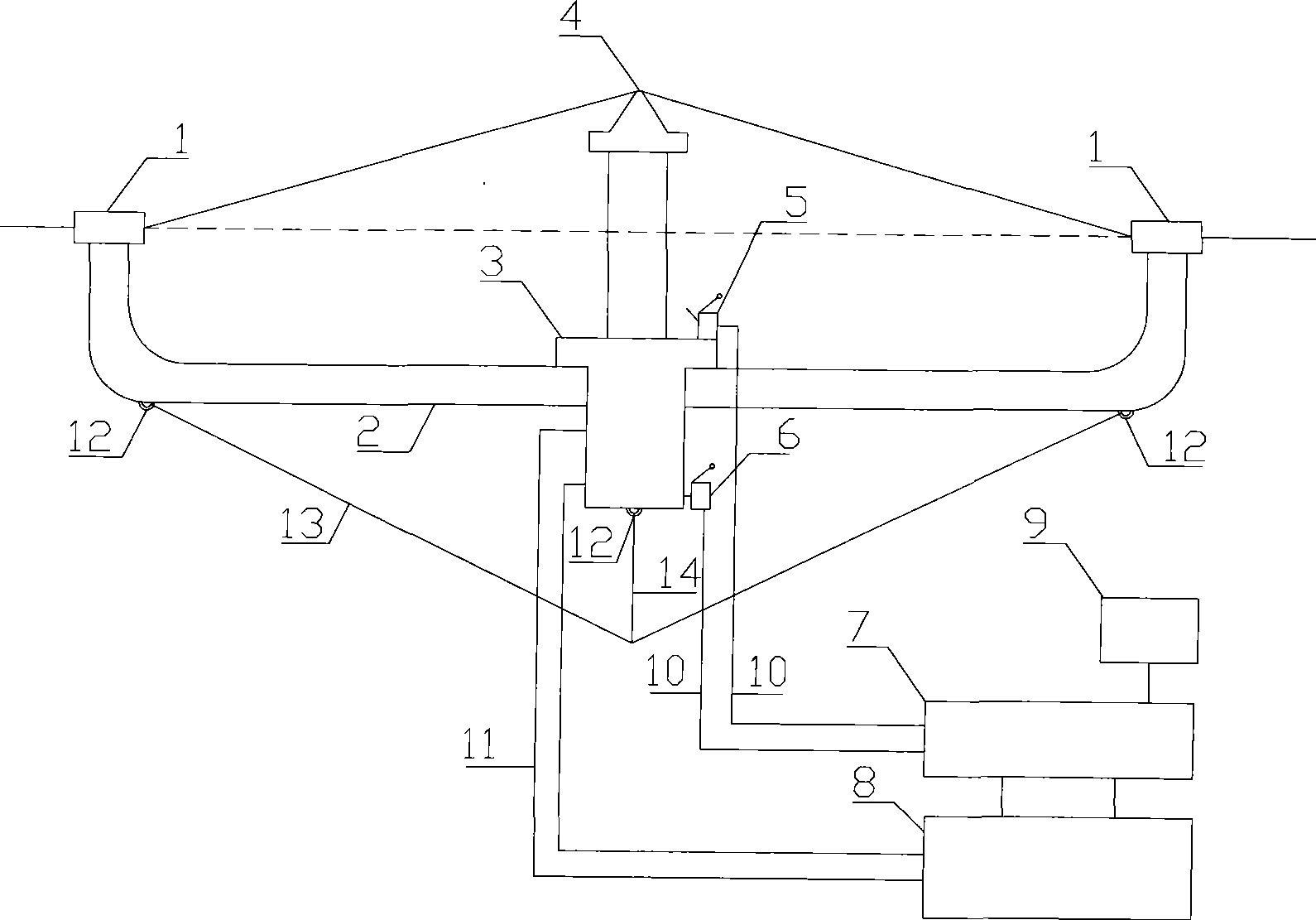

Device for measuring deflection/ displacement line shape by pressure difference and method thereof

InactiveCN101718543AWide measurement rangeFast measurementHydrostatic levellingElasticity measurementLiquid densityControl system

The invention provides a device for measuring deflection / displacement line shape by pressure difference and a method thereof. The device comprises a trolley and an L-shaped pipeline filled with liquid, wherein the horizontal section of the L-shaped pipeline is arranged on the trolley along the length direction of the trolley; the two ends of the horizontal section of the L-shaped pipeline are respectively provided with pressure sensors A and B, and the bottom is provided with a temperature sensor; a wheel of the trolley is provided with a displacement transducer; the temperature sensor, the pressure sensors A and B and the displacement transducer are connected with a control system provided with an interface and a memorizer by a data bus; and the displacement transducer is used for controlling the measurement to start for once after the trolley rotates for N rounds. The two pressure sensors are used for measuring the pressure difference at the two ends of the pipeline, and calculating by the liquid density at the different temperatures, thus measuring the vertical altitude difference between two points. The invention has the advantages of wide measuring plane, high accuracy, no influence by light interference, high degree of automation, low measuring cost, etc.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

Method for detecting coaxiality and verticality of large container by optical instrument

ActiveCN101929852AEasy and fast measurementRealize autonomous measurementUsing optical meansOptical axisEngineering

The invention relates to a method for detecting coaxiality and verticality of a large container by an optical instrument. The large petrochemical containers have common characteristics such as complicated structure, large geometric dimension and high manufacturing precision requirement. The method for detecting coaxiality and verticality of the large container by the optical instrument comprises the two steps of: (1) establishing a datum axis line by using a micro-alignment telescope, mounting a triangular centre bracket at a measured seal head, and reading an offset value of the bracket centre relative to the datum axis line by a micro-drumwheel; and (2) arranging a verticality measuring scale at the end face of the measured seal head, enabling an auto-collimation image to be completely superposed with a local image with an auto-collimation method when a reflector or a large reflection object in front of the telescope is vertical to the principal optical axis of the telescope, if the auto-collimation image is not superposed with the local image, adjusting the included angle between the large reflection object and the principal optical axis of the telescope to enable the auto-collimation image to be completely superposed with the local image, and computing the value of the verticality by using the scale value of a displacement graticule on the telescope and the read value of the micro-drumwheel. The invention is used for detecting the coaxiality and the verticality of the large container.

Owner:HARBIN BOILER

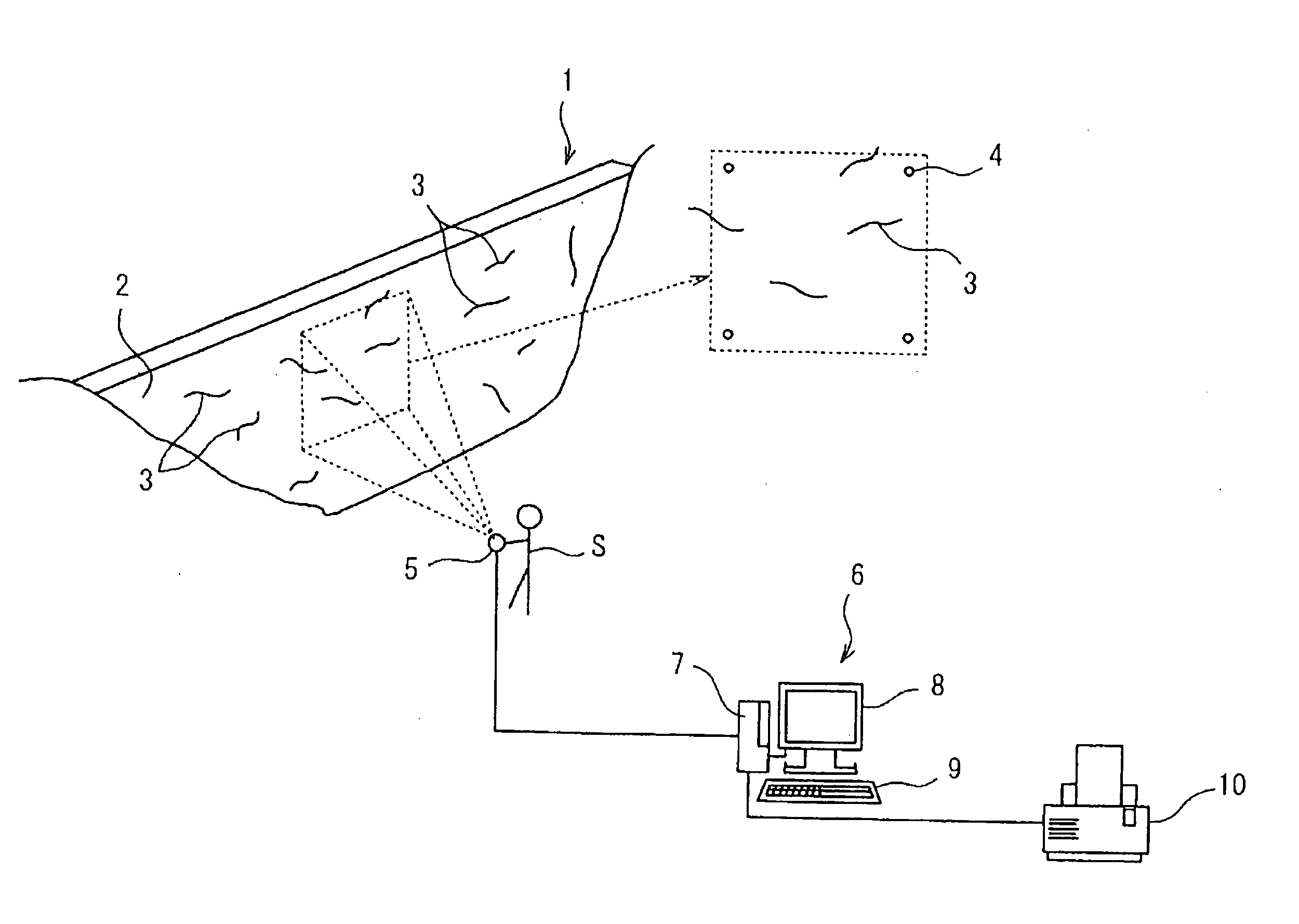

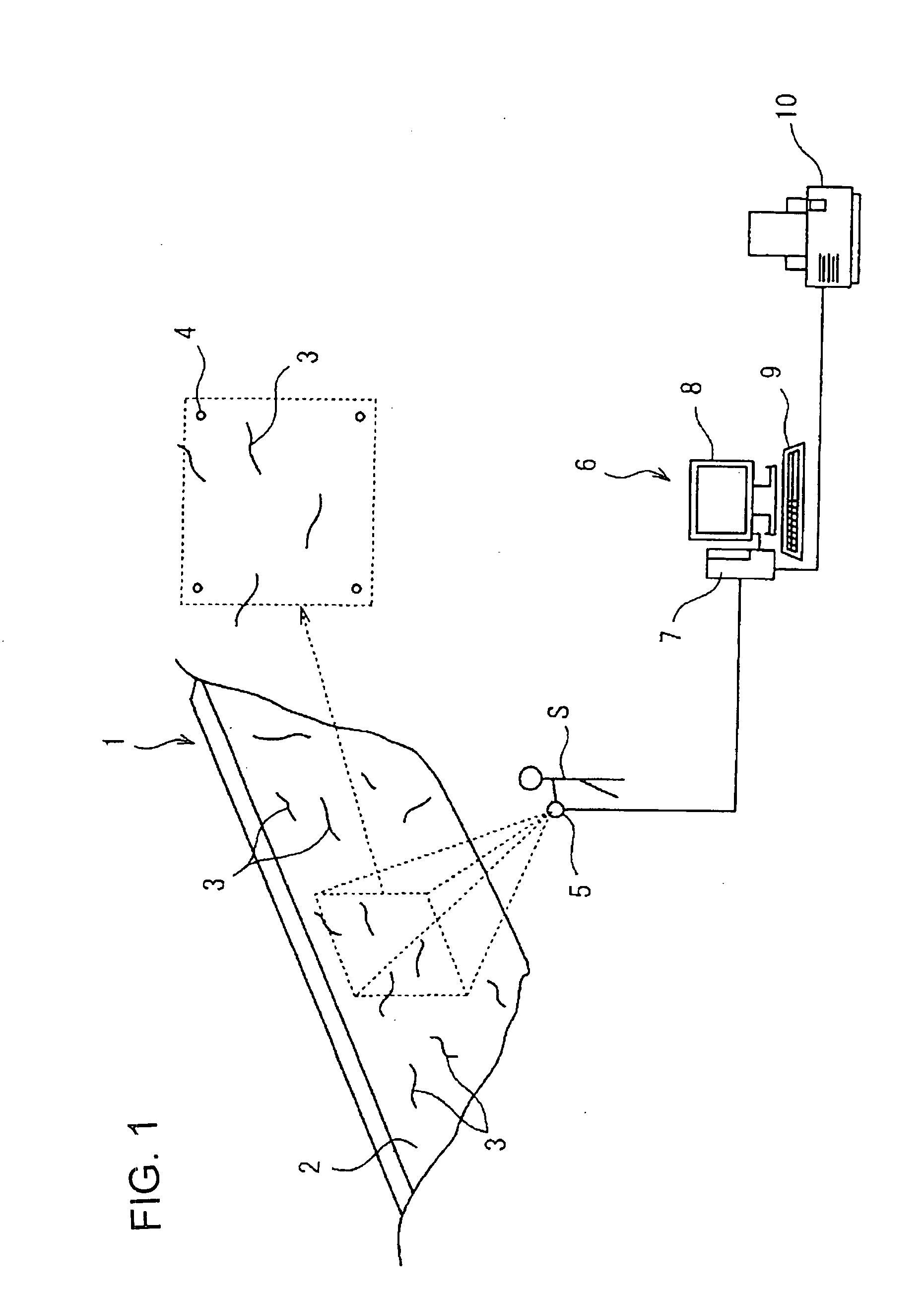

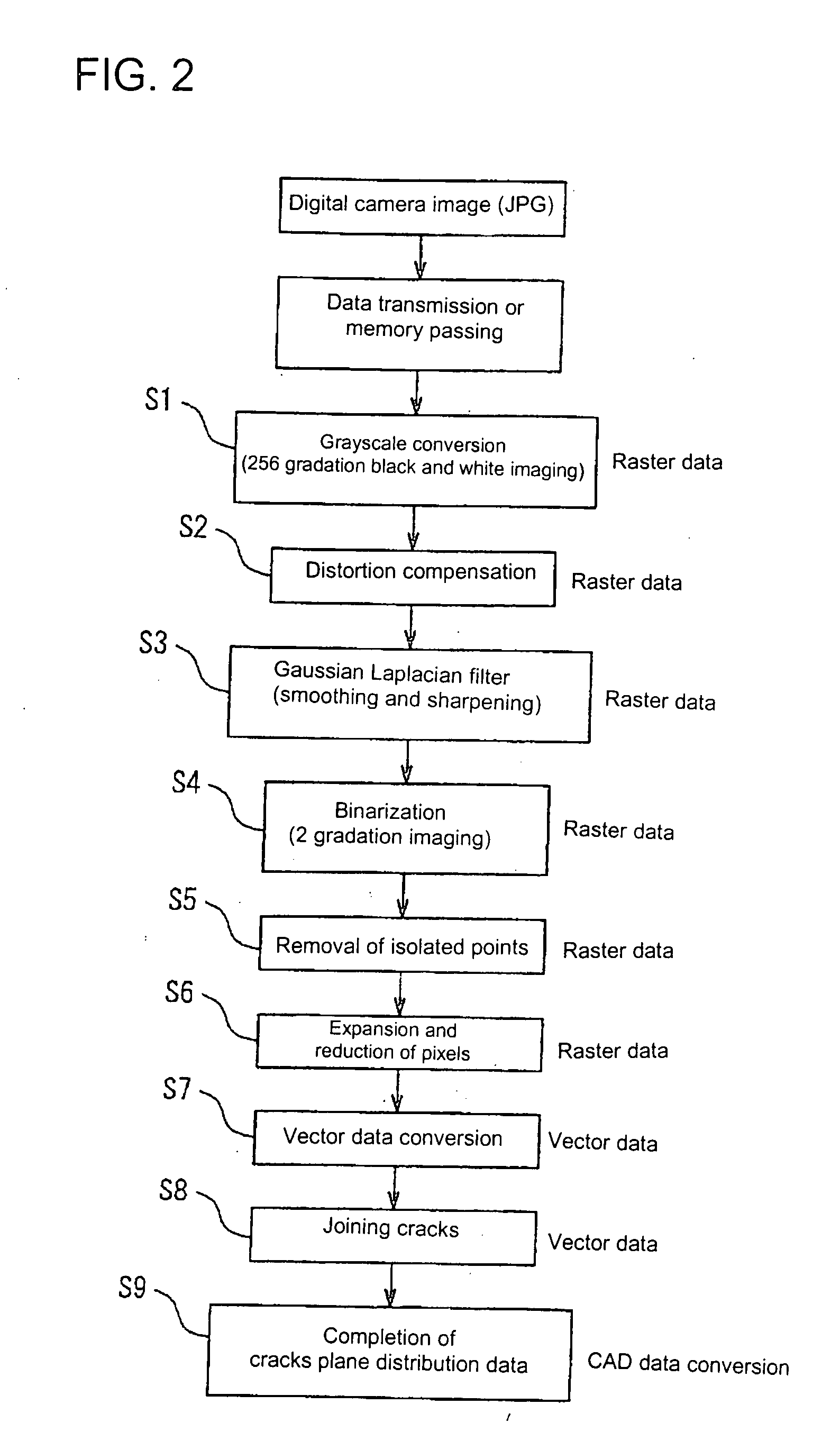

Concrete Structure Crack Inspection Device and Crack Inspection Method

InactiveUS20080195330A1Small amountAccurate outputMaterial analysis using sonic/ultrasonic/infrasonic wavesImage analysisComputer hardwareRaster data

A crack inspection device (6) for a concrete structure (1) includes: storage means for storing raster data obtained by imaging a surface (2) of the concrete structure (1) having a crack (3); conversion means for performing raster vector conversion on the data obtained by digitizing the raster data; data superimposing means for superimposing the vector data of the crack (3) obtained by the conversion means on the graphic data of the surface (2) of the concrete structure (1) while matching the coordinates; and output means for outputting the superimposed data obtained by the data superimposing means.

Owner:HARA TOORU

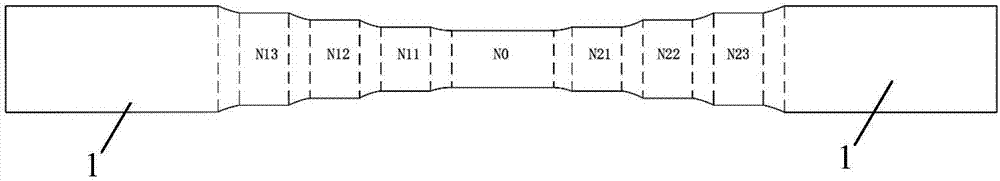

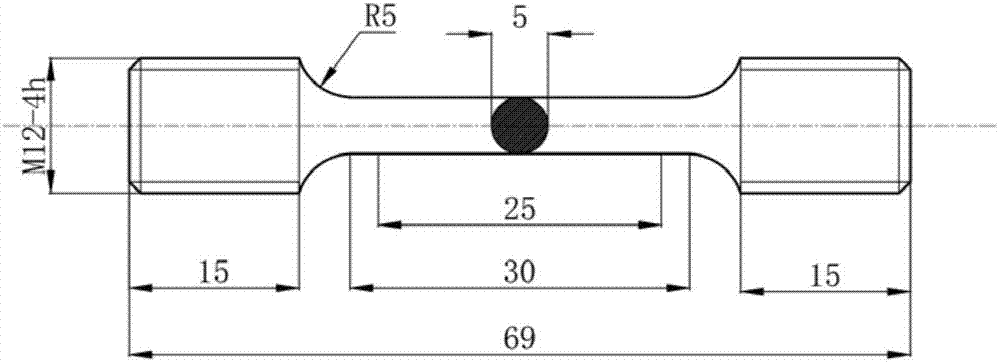

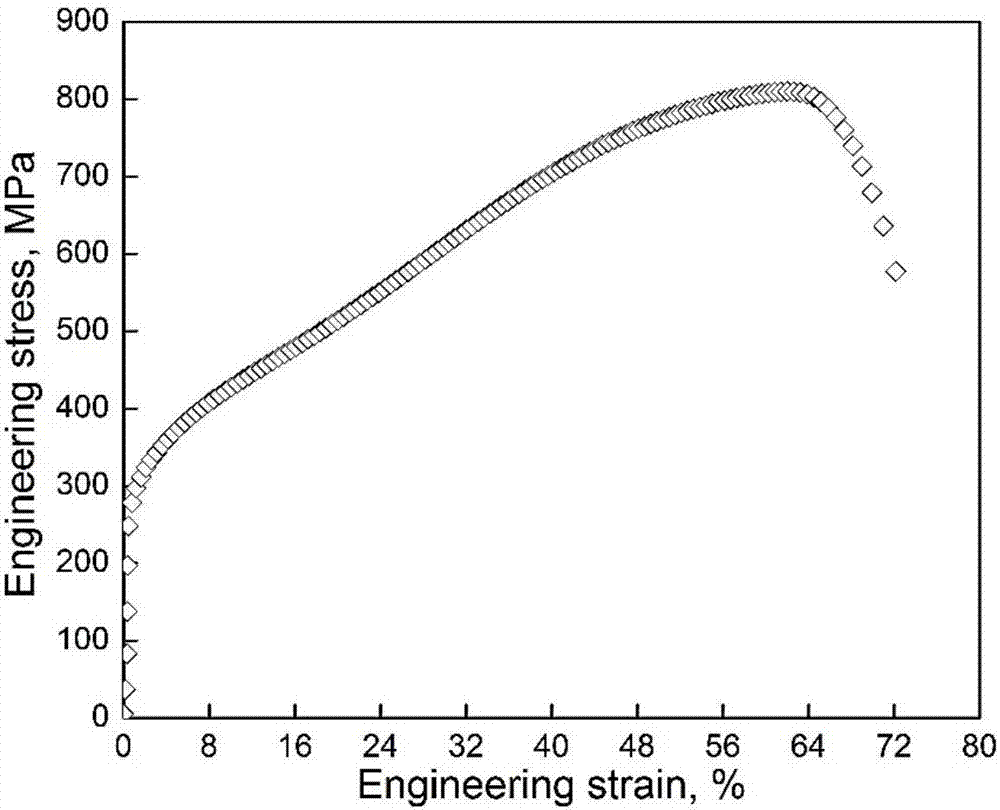

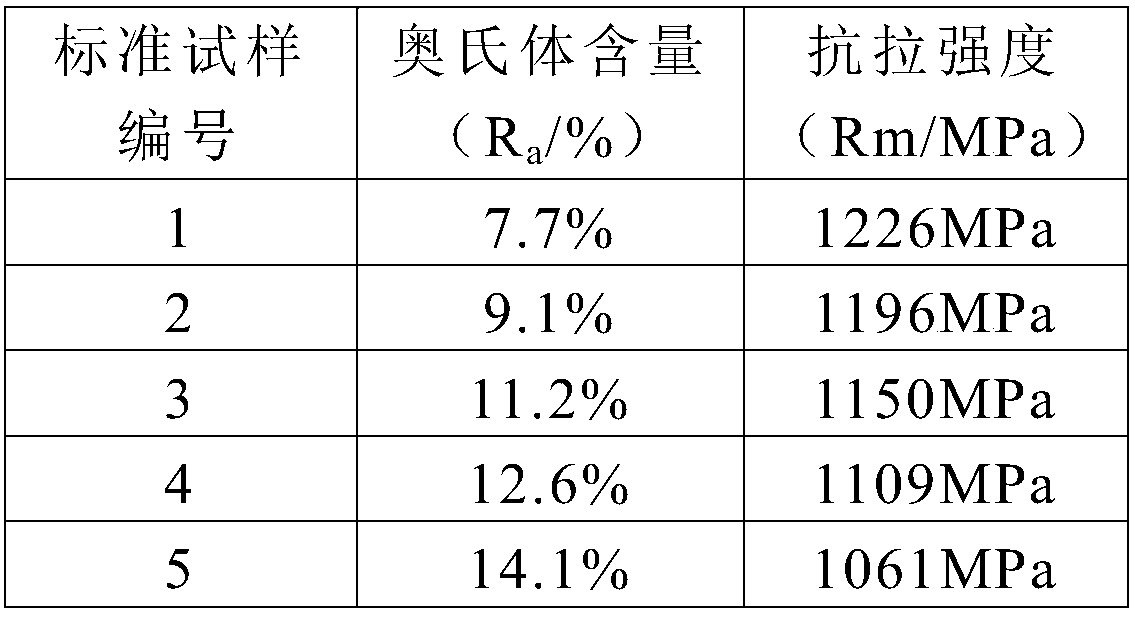

Method for determining strain-induced martensite phase transformation kinetics curve

ActiveCN107991179ALow cost of measurementHigh speedMaterial strength using tensile/compressive forcesMartensite transformationTest sample

The invention relates to a method for determining a strain-induced martensite phase transformation kinetics curve. The method comprises the following steps: S1, preparing a metal material containing ametastable austenite phase into a standard stretching test sample, and performing the stretching test to obtain a stress-strain curve; S2, preparing the metal material containing the metastable austenite phase into a stepped stretching test sample with N deformation sections, performing the stretching test under a same environment and strain rate with the step S1 until the test sample is broken;S3, determining a strain-induced martensite content fa' of N deformation section characteristic parts in the step S2; S4, obtaining N groups of strains sigma corresponding to a determination positionin step S3; and S5, obtaining a strain-induced martensite phase transformation kinetics curve containing a metastable austenite phase metal material. The method has the advantages that aiming at the metastable austenite phase metal material, while the metastable austenite phase metal material stress-strain curve data is measured, the strain-induced martensite transformation kinetics curve of the metalstable austenite phase metal material can also be measured, so that double benefits can be achieved.

Owner:HEFEI GENERAL MACHINERY RES INST +1

Method for measuring internal force of guy cable in active service and measuring device using same

ActiveCN101532893AEasy to operateLow cost of measurementTension measurementMeasurement deviceInternal forces

Owner:GUANGZHOU CONSTR ENG +1

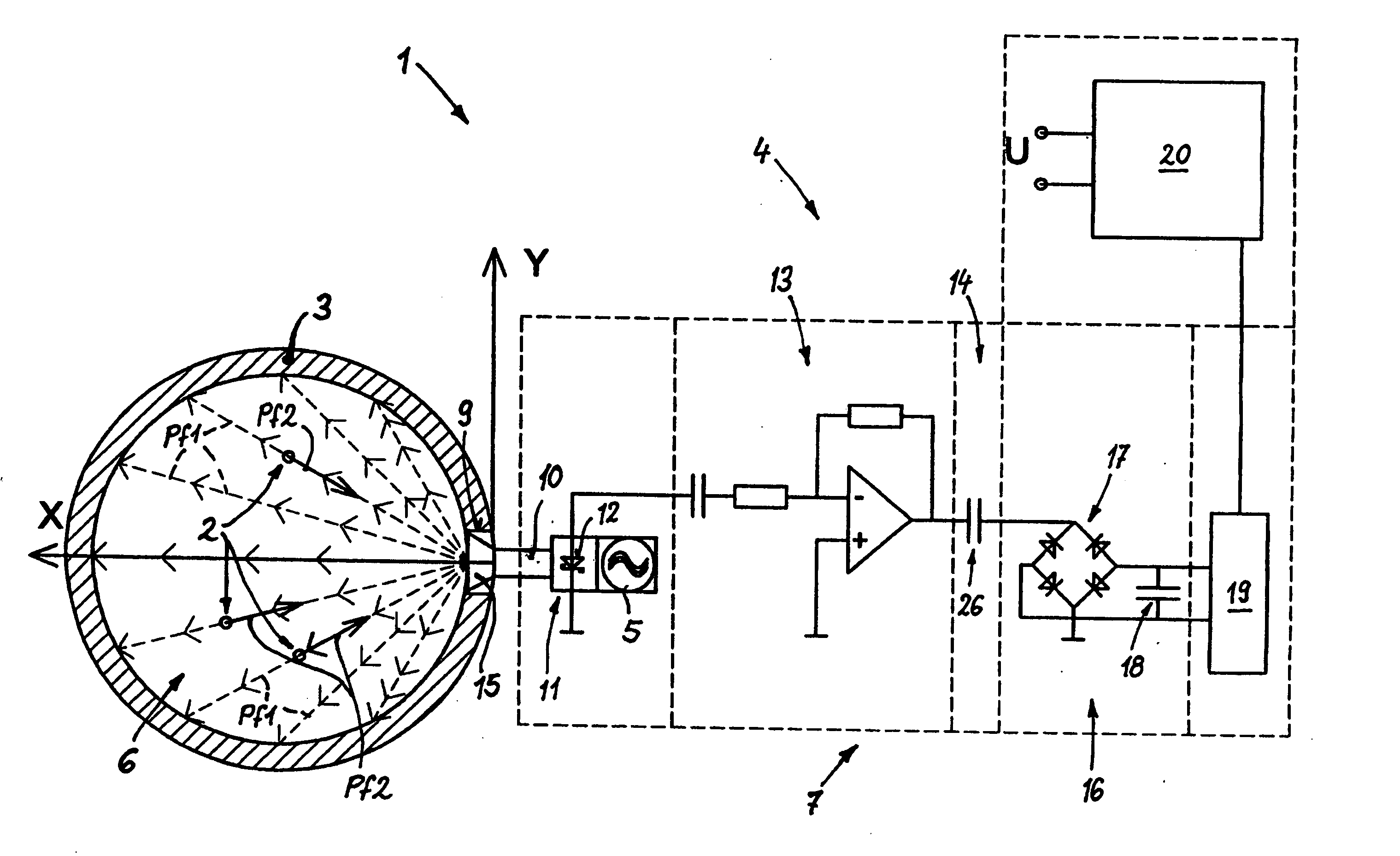

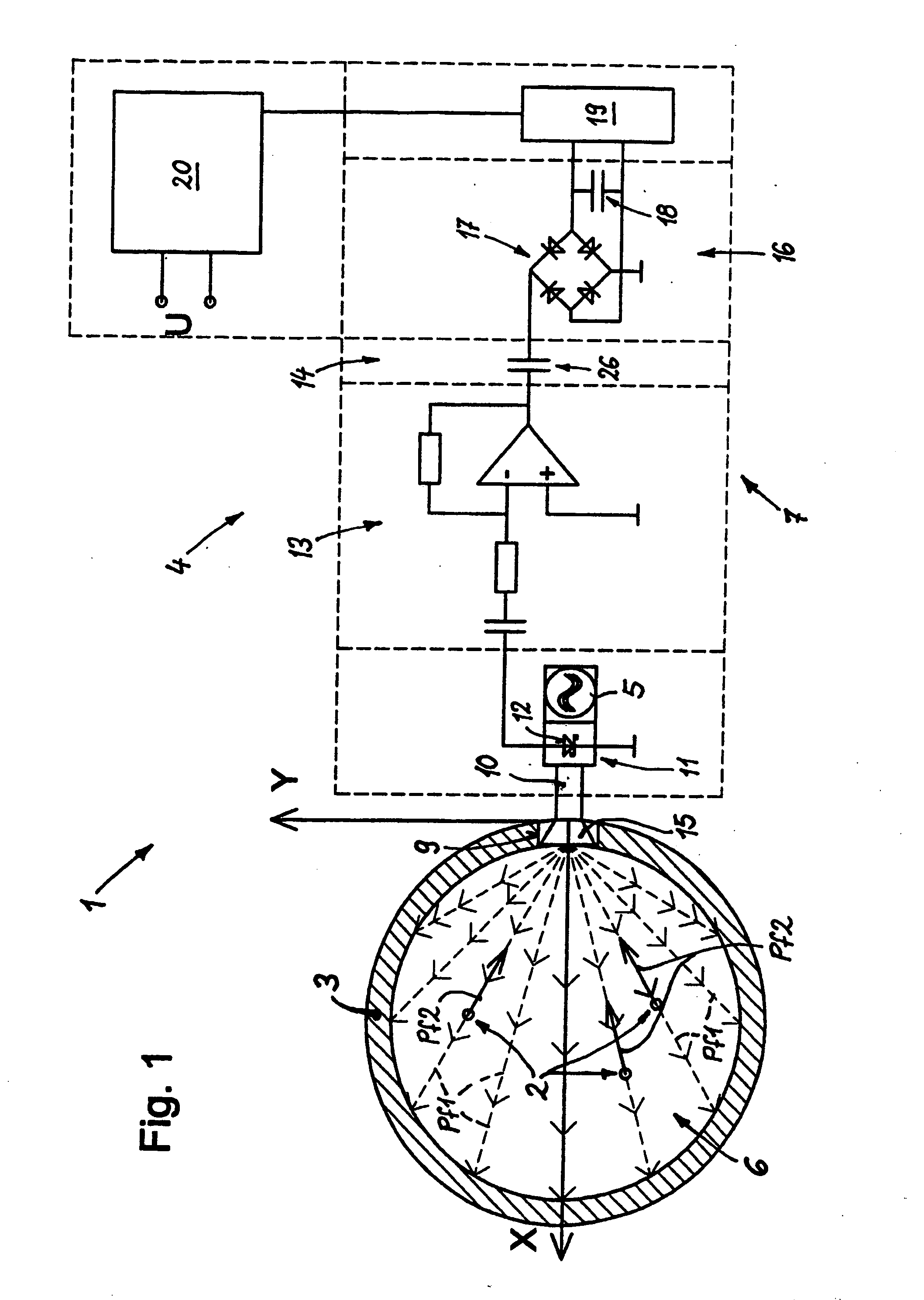

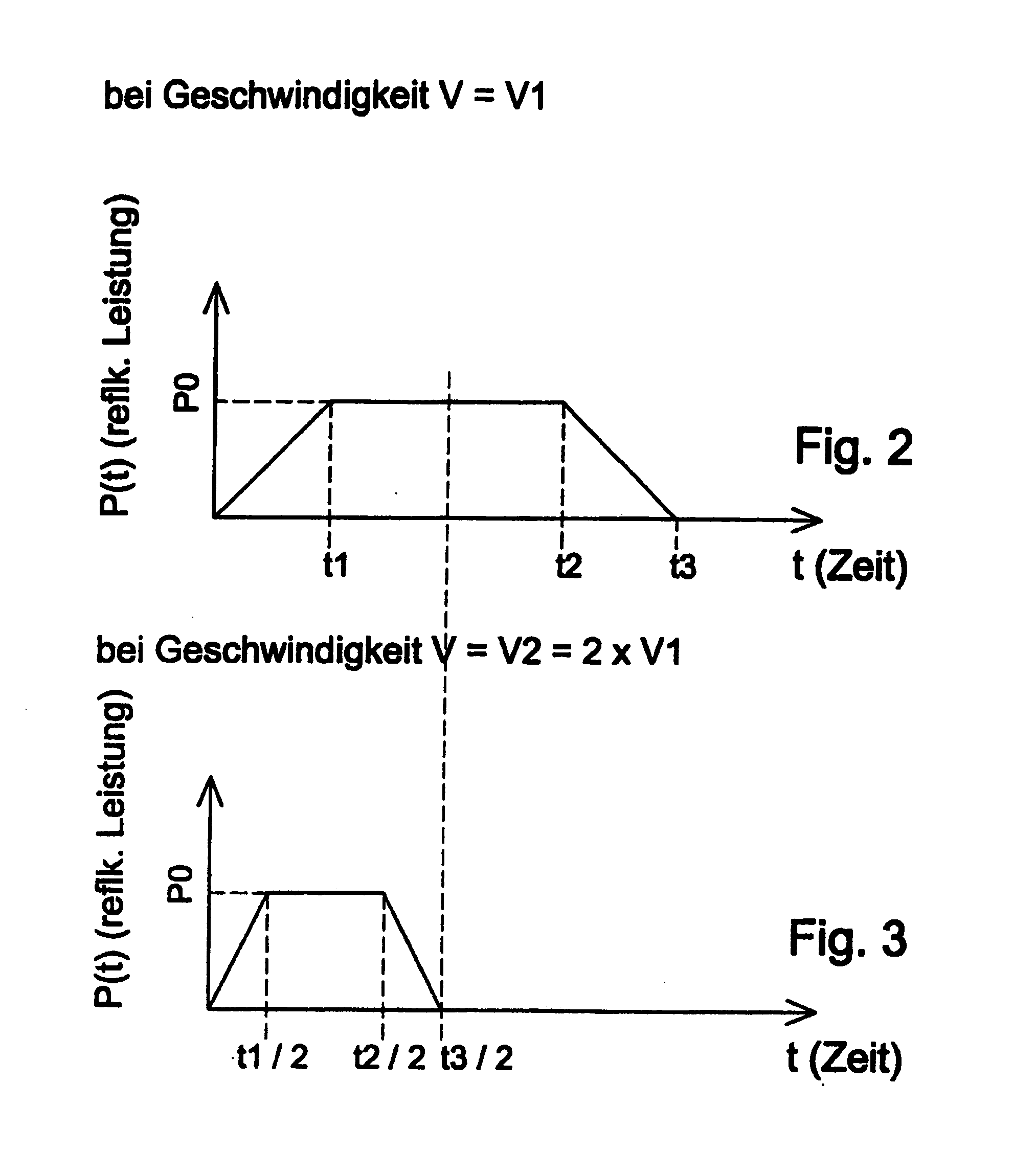

Method and device for measuring a mass flow

InactiveUS20050001169A1Simple measureReduce expensesMaterial analysis using microwave meansScattering properties measurementsPhysicsElectromagnetic field

A device used to measure the mass flow of a particulate transported with the aid of a gas. The device includes an arrangement which is used to create an electromagnetic field, with a measuring area being defined therein. An evaluation device for electromagnetic radiation which is reflected at least off of the solid(s) is connected to a detector. The evaluation device is provided with a differentiator which is connected to the detector for detecting reflected electromagnetic radiation. A rectifier is connected to the differentiator in order to determine an amount, whereby mass flow is obtained from the reflection amount. The reflection is measured, at least from the solid(s) within the measuring area of the magnetic field, whereupon the differential quotient is determined as a function of time from the chronological progression of the measuring signal and the amount is obtained therefrom. A measuring signal is obtained from the non-homogeneity of the electromagnetic field, forming the integral over time of the amount of the reflected power per time. The measuring signal is proportional to the mass flow.

Owner:MIC MEASURING IDEAS CONSULTING

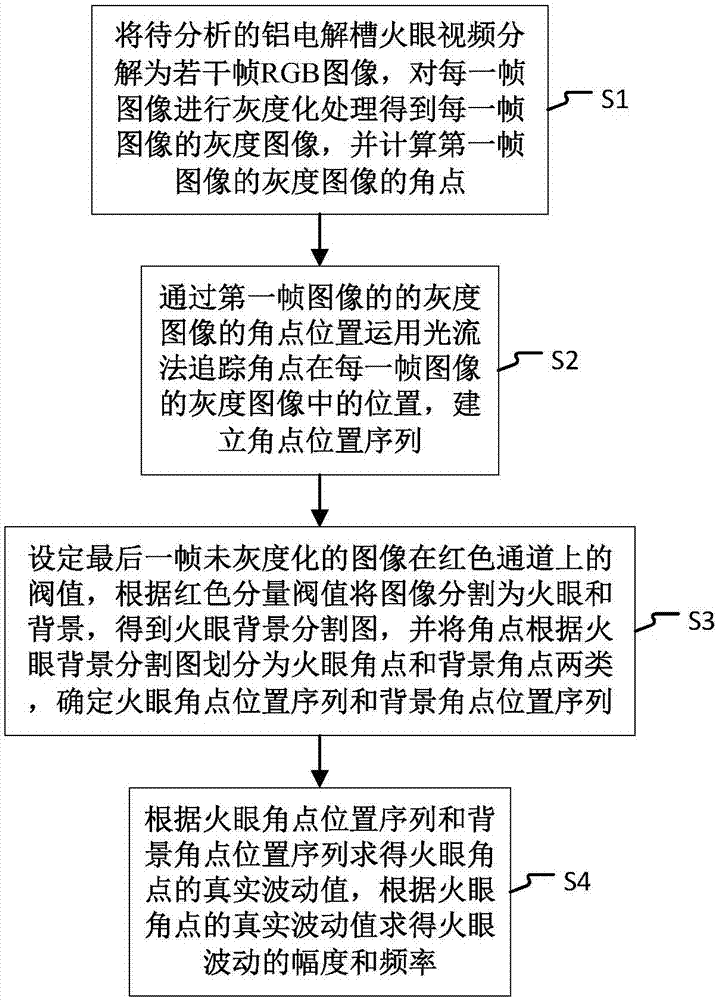

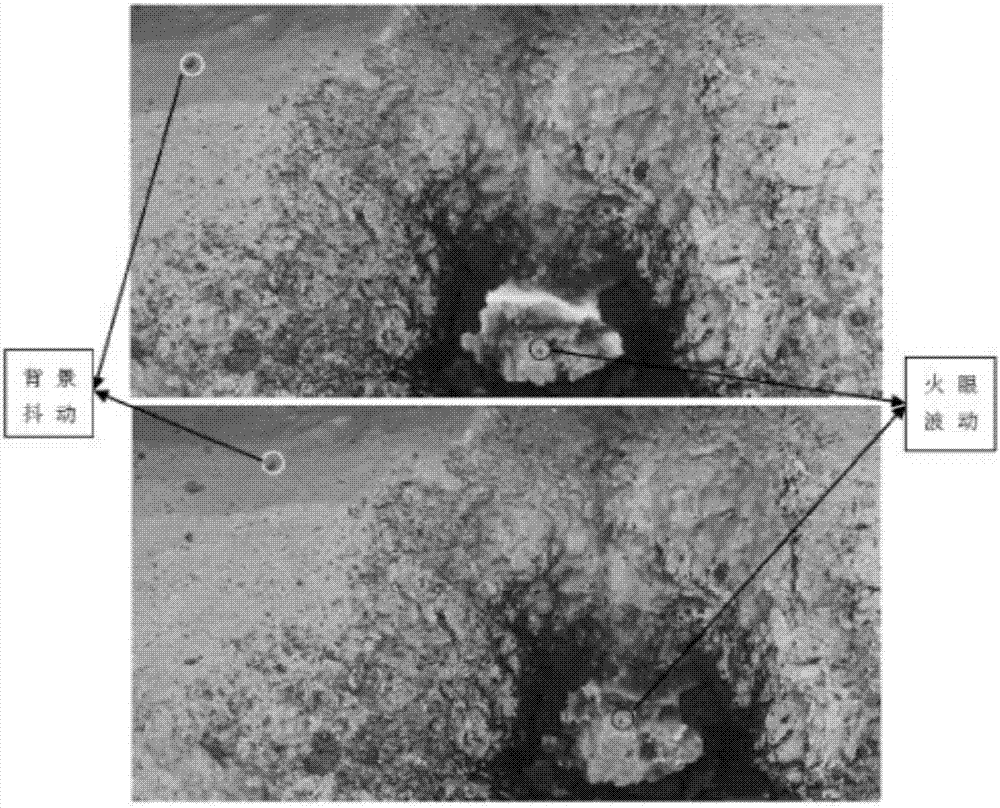

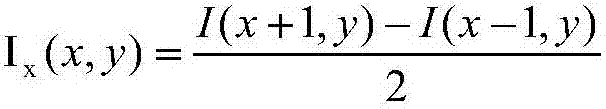

Method and system for identification of aluminum reduction cell burner video dynamic characteristics

The present invention discloses a method and system for identification of aluminum reduction cell burner video dynamic characteristics. The method and system are configured to extract burner fluctuation characteristics and provide guidance effect for determination of the size of the degree of superheat. The method comprises: decomposing the aluminum reduction cell burner video to be analyzed into a plurality of RGB images, and performing gray-scale processing of each image to obtain the gray image matrix of each image; calculating angular points of the gray image of each image according to the corner detection algorithm, employing an optical flow method to track the positions of angular points in each image through the position of the angular points of each image, and establishing an angular point position sequence; analyzing the red component value of any one image without graying, performing segmentation of a burner and a background, obtaining a burner background binary image, and dividing the angular points into two classes of burner angular points and background angular points; and solving the actual fluctuating values of the burner angular points according the angular point position sequence and the background angular point position sequence, and solving the amplitude and the frequency of the burner fluctuation according to the actual fluctuating values of the burner angular points.

Owner:CENT SOUTH UNIV

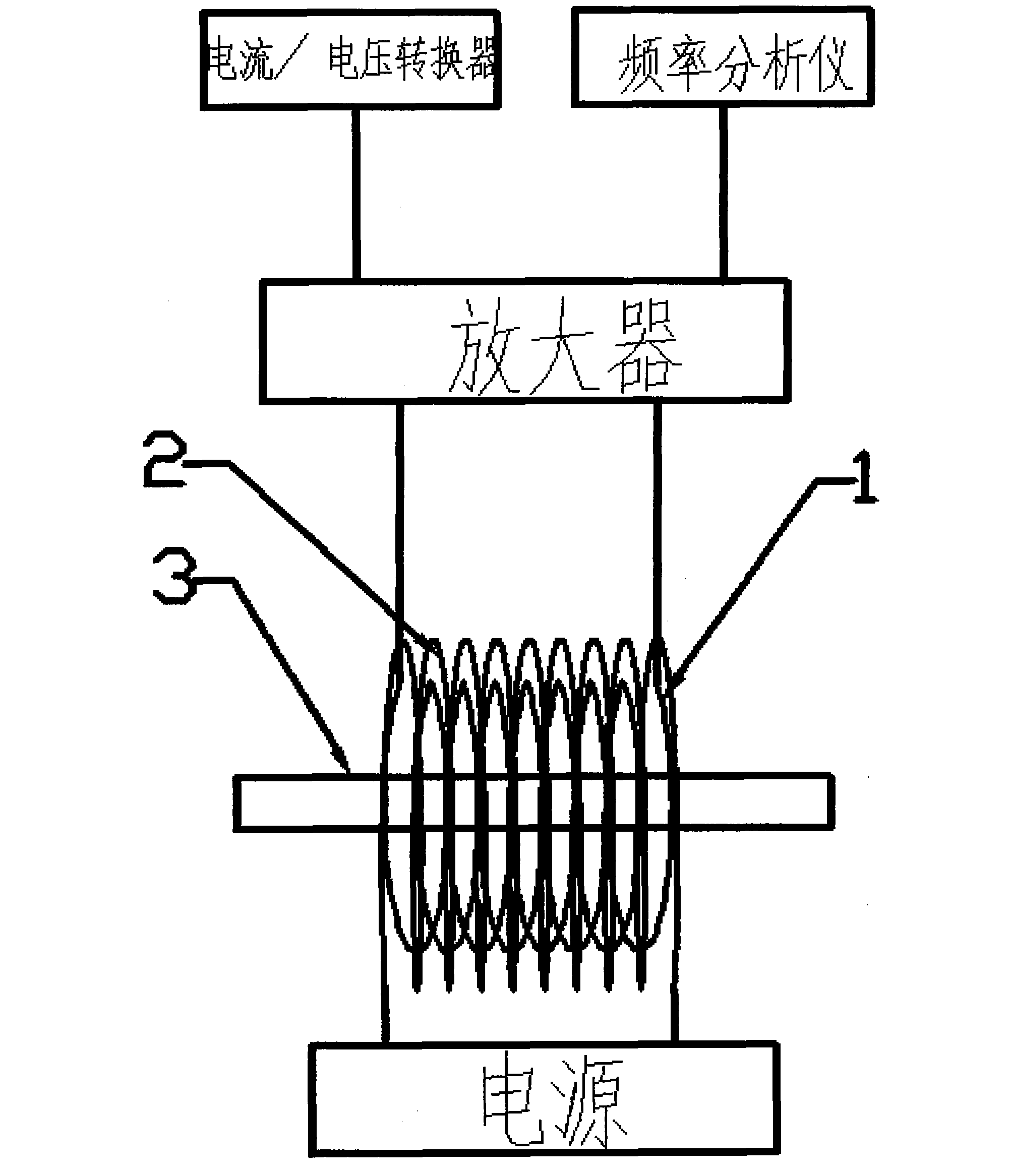

Nondestructive flaw detection device for metal wire/pipe

InactiveCN104165923AAchieving Relative MeasurementsEasy to measureMaterial magnetic variablesVoltage converterPower flow

The invention discloses a nondestructive flaw detection device for a metal wire / pipe. The device comprises a measurement coil and a magnetic field coil that are mutually nested. The magnetic field coil is connected to a power source, and an amplifier is connected to the measurement coil and transmits the measurement signal to a frequency analyzer and a current / voltage converter respectively. The nondestructive flaw detection method includes the steps of: (1) energizing the magnetic field coil by the power source to form an electromagnetic field; (2) establishing measurement standards, passing the to-be-measured metal wire / pipe through the magnetic field coil and the measurement coil to do longitudinal motion, performing real-time measurement and induction of the frequency information and current / voltage information of a coil measurement signal, and selecting a most stable frequency value and current / voltage value as standard values; and (3) repeating the longitudinal motion of the to-be-measured metal wire / pipe along the coils, conducting real-time measurement of frequency information and current / voltage information and performing comparison with the standard values, when the difference between the measured frequency or current / voltage value and the standard values is more than + / -10%, emitting alarm information by an alarm prompt module. According to the invention, by measuring the magnetic field change signals when different positions of the to-be-measured member stretch into a high frequency magnetic field, whether a position has a flaw can be determined, thus realizing relative measurement of the quality defect of the whole to-be-measured member. The measurement method is simple, and the result is reliable.

Owner:北京谷德广告有限公司

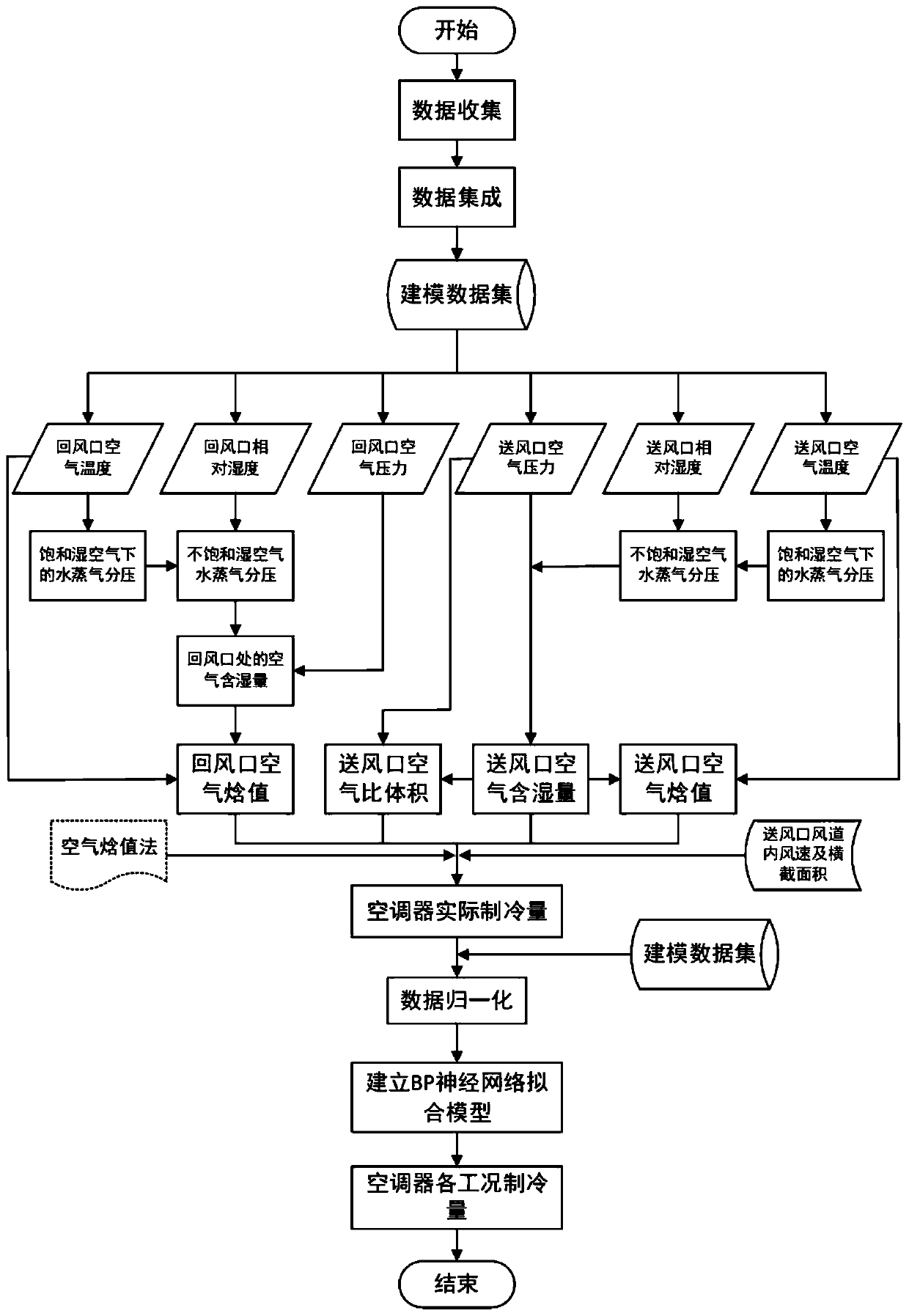

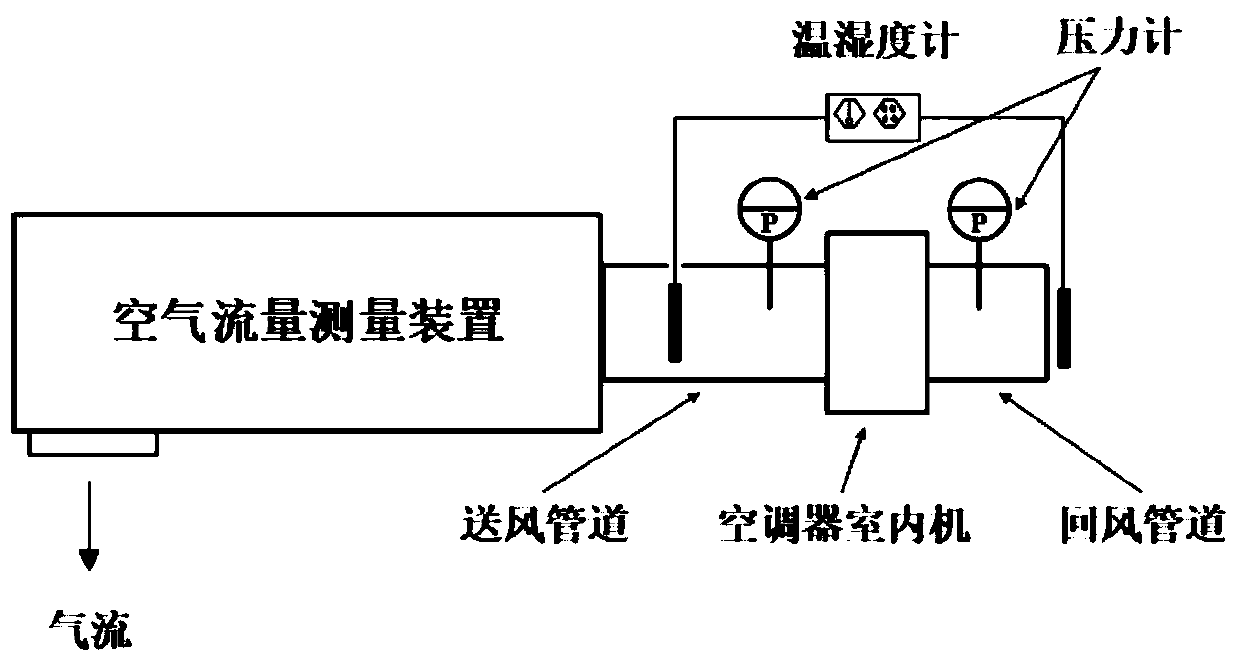

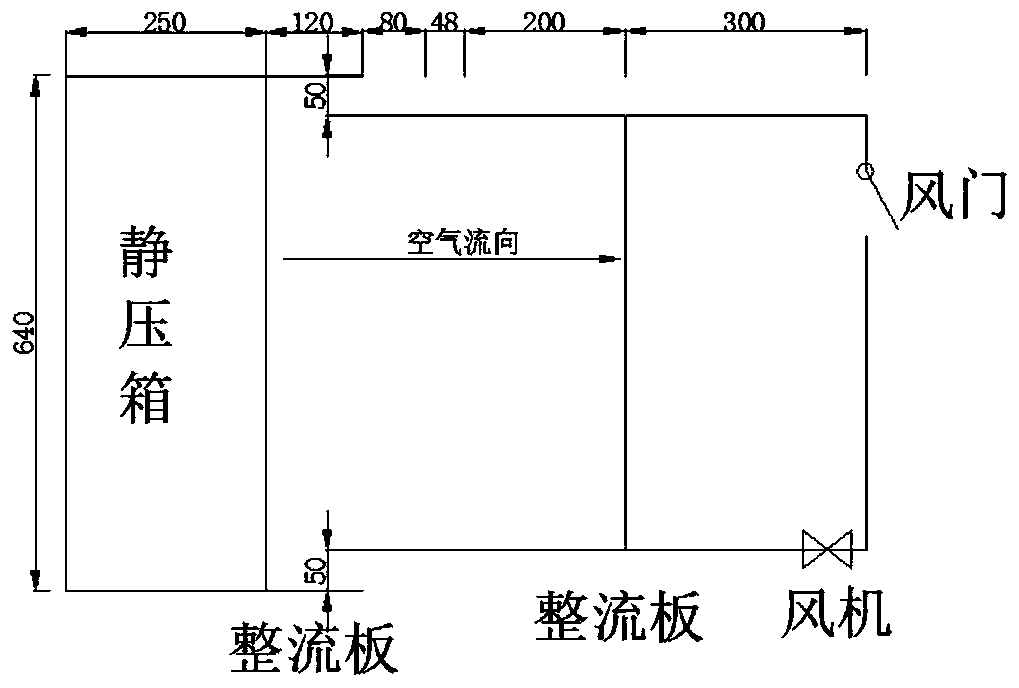

Method for measuring refrigeration capacity of air conditioner based on BP neural network fitting model

InactiveCN110715405AConducive to high-precision performance testingGood for instrumentationMechanical apparatusSpace heating and ventilation safety systemsData acquisitionProcess engineering

The invention belongs to the technical field and discloses a method for measuring a refrigeration capacity of an air conditioner based on a BP neural network fitting method. The method comprises the steps that data at an air return hole and an air feeding hole of an indoor unit of the air conditioner is collected and integrated; indexes such as air enthalpy values at the air return hole and the air feeding hole of the indoor unit of the air conditioner are computed; the actual refrigeration capacity of the air conditioner is computed based on an air enthalpy value method; and steps such as detection of the actual refrigeration capacity based on the BP neural network fitting model are carried out. The method disclosed by the invention has the beneficial effects that the refrigeration capacity of the air conditioner can be detected without any dismounting of the air conditioner and without use of an expensive enthalpy difference lab; in addition, in comparison with other modeling algorithms, experimental devices needed are simple, and more accurate and controllable detection results can be obtained; and the method and results are reliable.

Owner:HUAZHONG UNIV OF SCI & TECH

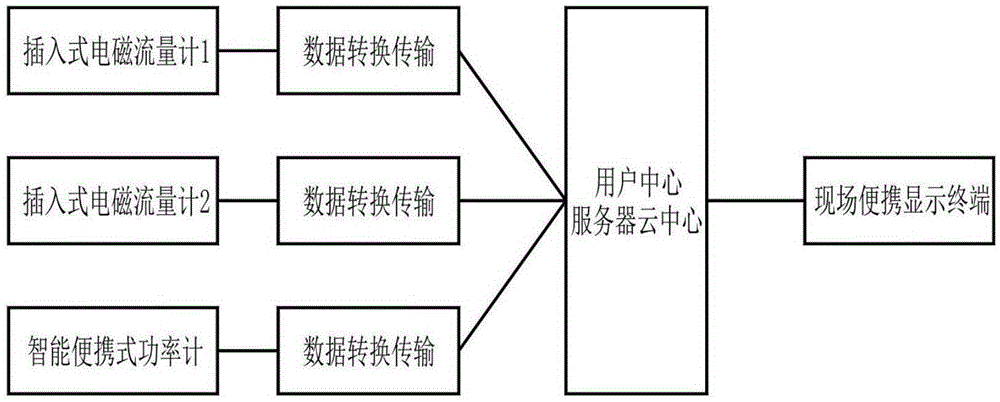

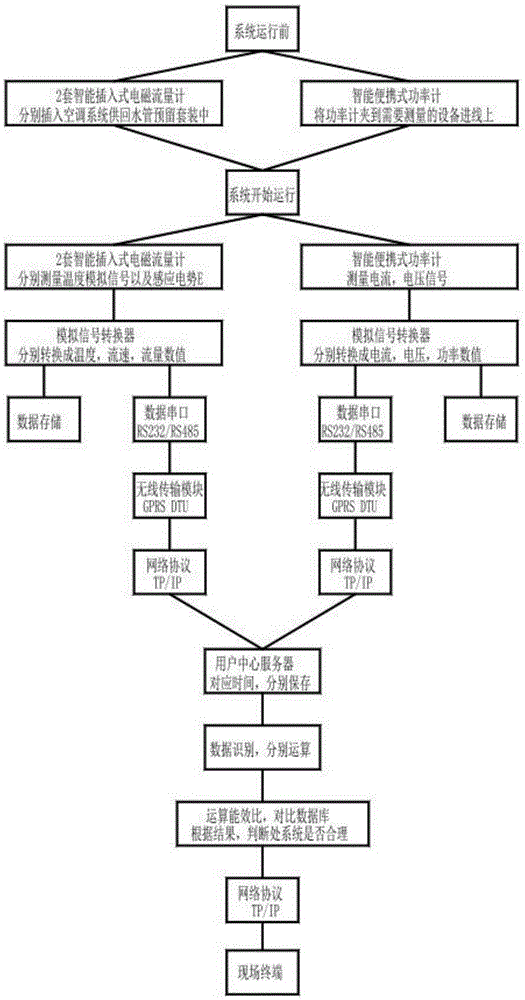

Portable intelligent energy efficiency ratio determination system

InactiveCN105277383AEasy to useReduce mistakesStructural/machines measurementSite monitoringTraffic capacity

The invention relates to a portable intelligent energy efficiency ratio determination system, which comprises at least two sets of plug-in type flowmeters and at least a power meter. The system can transmit the data detected by the flowmeters and the power meter to a background server in real time through the network transmission technology, the server records, identifies and organizes the data, the air-conditioning system real time energy efficiency ratio and comprehensive energy efficiency ratio in a period of time are computed, and the computed result is fed back to an on-site portable display terminal through the network transmission, so that the on-site staff can check and solve the problem conveniently in real time. The system has the advantages of simple mounting, convenient and fast detecting and convenient on-site monitoring and processing.

Owner:NOVELAND CORP

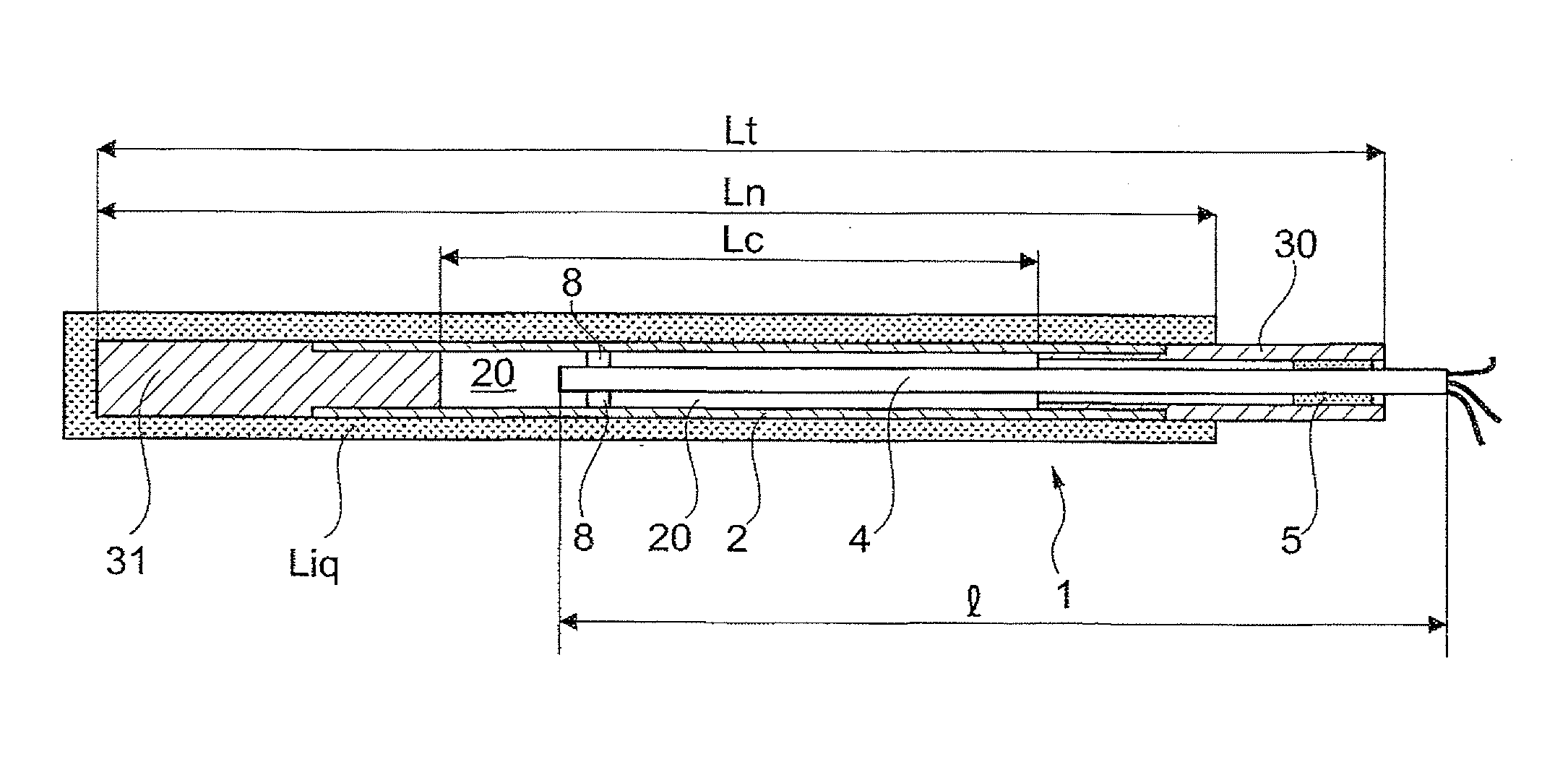

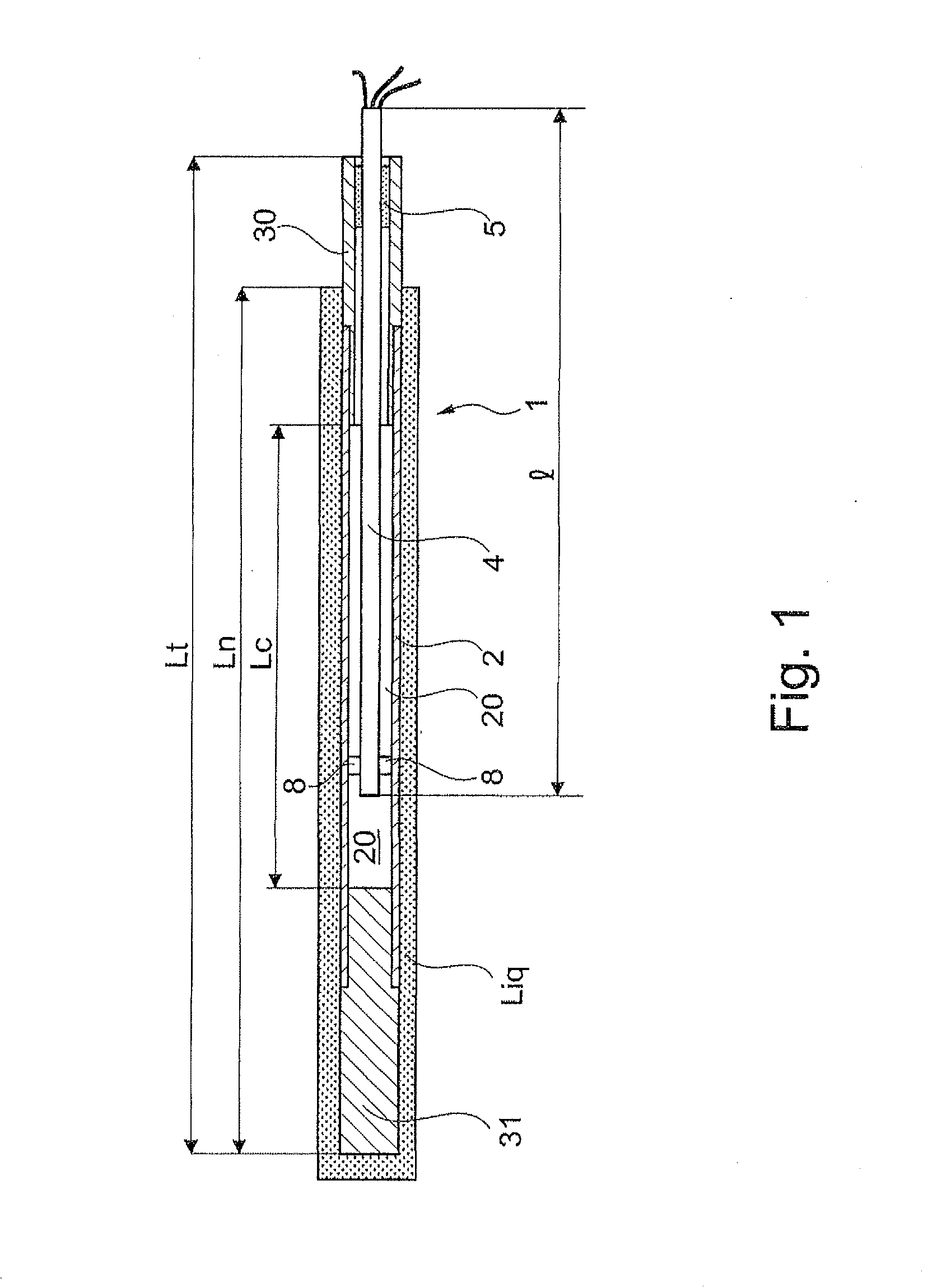

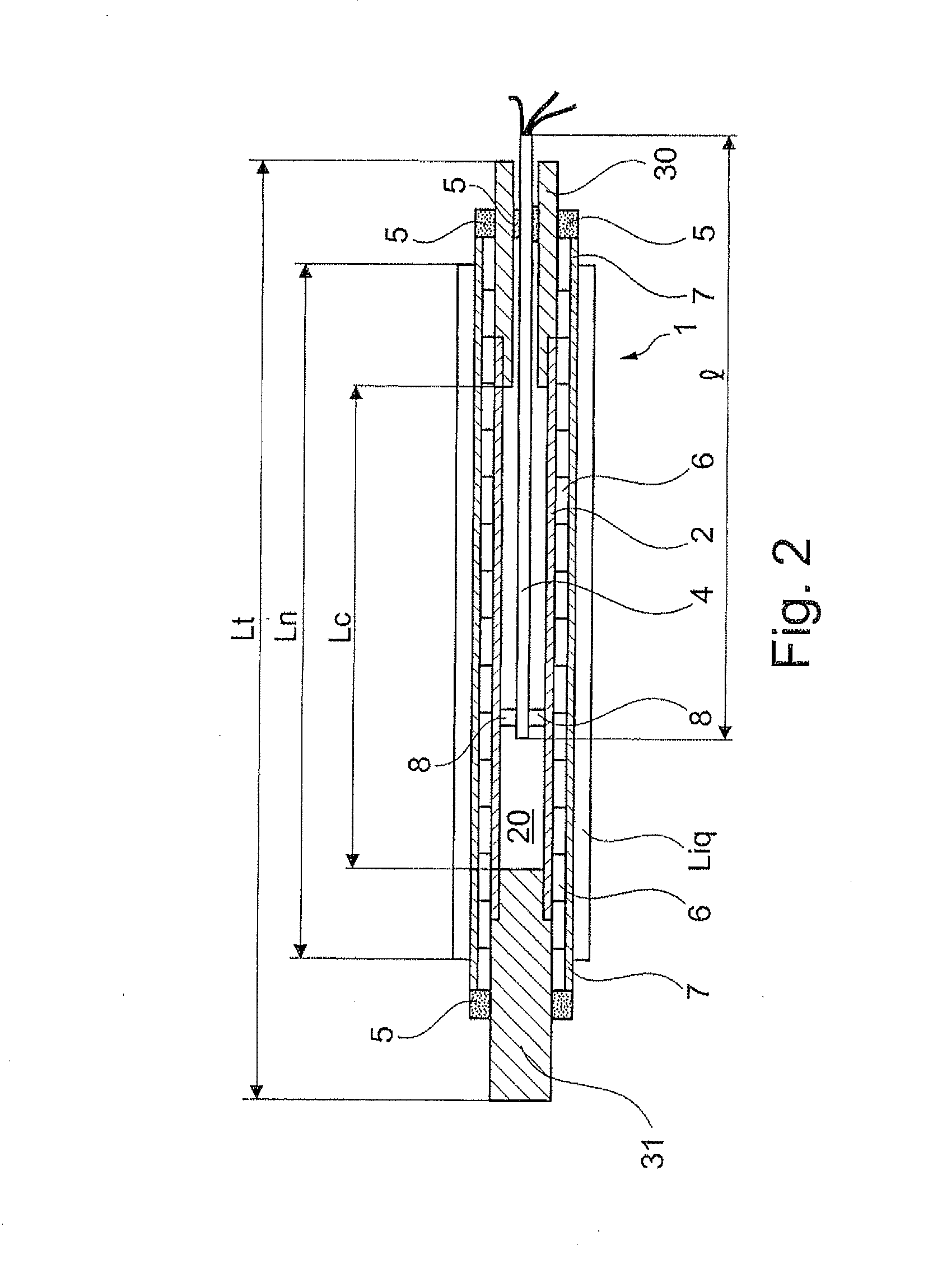

Rod thermometer device for detecting a temperature, use for the electrical simulation of nuclear fuel rods

InactiveUS20150323390A1Short response timeQuickly detect occurrenceThermometer detailsLine/current collector detailsElectricityThermocouple

The invention relates to rod thermometer device for detecting a temperature, including a plurality of temperature-sensitive elements and a protective sheath having an axis X in which the sensitive elements are partially inserted. The sheath is made of a metal constituting one of the two metals of a thermocouple, and the sensitive elements of a plurality of wires made of a metal other than that of the sheath and constituting the other one of the two metals of a thermocouple, one of the ends of each one of the wires being welded inside the sheath forming a junction for measuring a given thermocouple, the welded ends of the wires being distributed along a plurality of axial and azimuth positions relative to the axis X inside the sheath, each one of the wires extending out of the sheath by at least one of the ends thereof.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

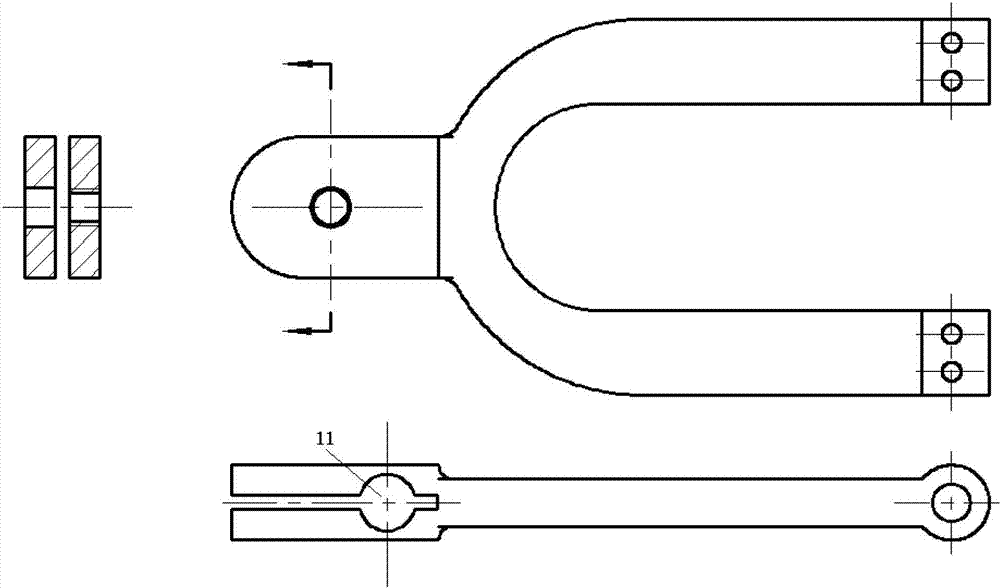

Low-strain quality detection measuring tool and testing method thereof

ActiveCN109208657AReducing Diffusion EffectsReduce mistakesFoundation testingEngineeringStandardization

The invention discloses a low-strain quality detection measuring tool and a test method based on a test die. The measuring tool is arranged on the top of the exposed pipe pile in a sleeved mode when in use, and the measuring tool includes an impact disc and a positioning support, a sensor is arranged on the lower surface of the impact disc and serves as a detection point, the upper surface is provided with a sand layer, and the surface of the sand layer is leveled and is provided with an impact plate; the positioning support comprises a cross-shaped support and a telescopic rod body, a movablevibration excitation hammer body installation support is arranged on the cross-shaped support so as to locate and install a vibration excitation hammer body to perform vibration excitation impact. According to the method, auxiliary measurement is carried out through the measuring tool, and data collection is carried out through quantitative and standardized operation, through the cooperation of the sand layer and the reasonably arranged detection point, the spread of strain in the horizontal plane and the influences of errors between materials can be buffered and counteracted, and then afterthe data is amplified, the accurate measurement data of the tube pile can be obtained.

Owner:湖南湘建智科工程技术有限公司

Method for measuring three-dimensional scene data

InactiveCN110132131AQuick measurementImprove efficiencyImage enhancementImage analysisMeasurement costComputer vision

The invention relates to the technical field of data measurement, in particular to a method for measuring three-dimensional scene data, and the method comprises the following steps of exploring and analyzing a three-dimensional scene measurement area; setting up a measurement tool on the station control point; selecting a low-altitude aerial drone of a suitable model according to the three-dimensional spot scene, wherein the drone performs aerial survey to acquire panoramic real-time images of high-precision image data, sorts the obtained image information, and extracts and comprehensively analyzes the measurement information; and organically blending the three-dimensional model in S7 and the panoramic real-time images in S5 to achieve stereoscopic data measurement of the 3D scene. The method provided by the invention can quickly measure the data of the three-dimensional scene, and the obtained three-dimensional scene is accurate in measurement data and high in efficiency, thereby greatly reducing the labor intensity of the measuring personnel and reducing the measurement cost of the three-dimensional scene data.

Owner:XIAN TECHNOLOGICAL UNIV

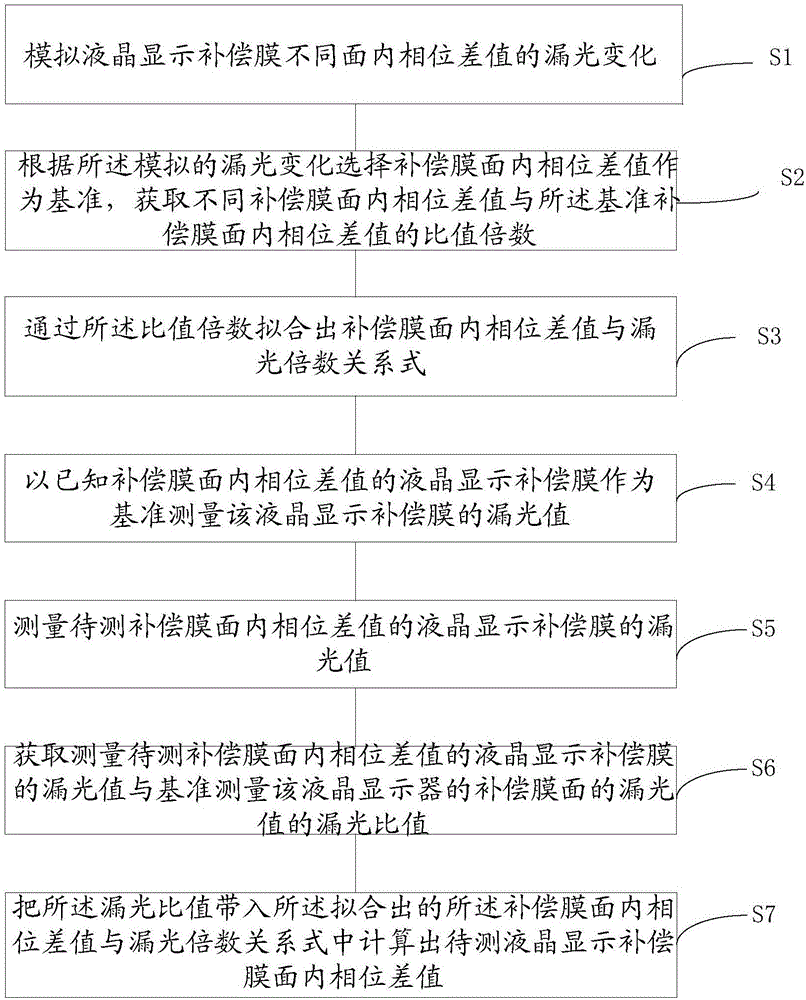

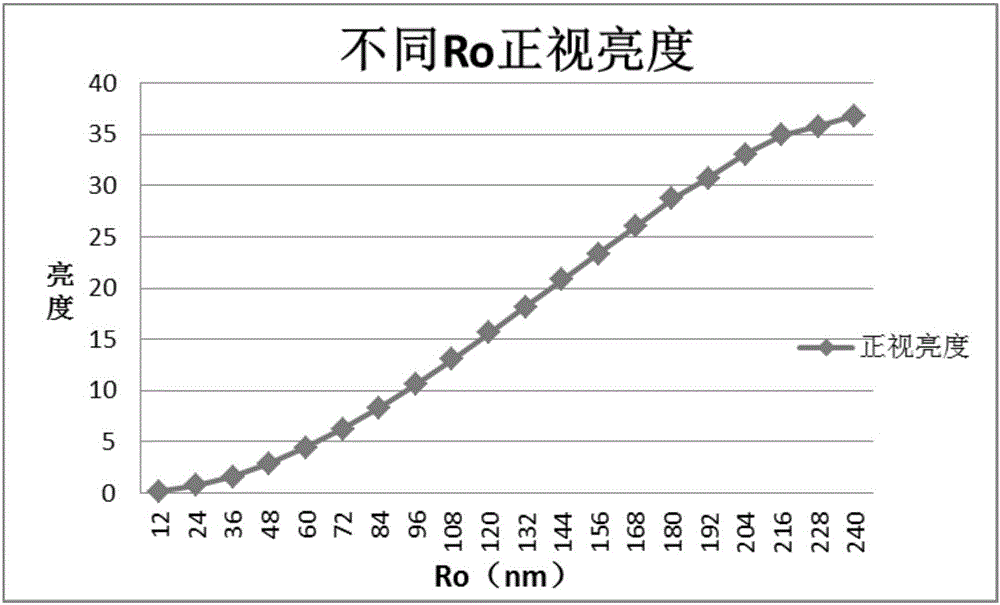

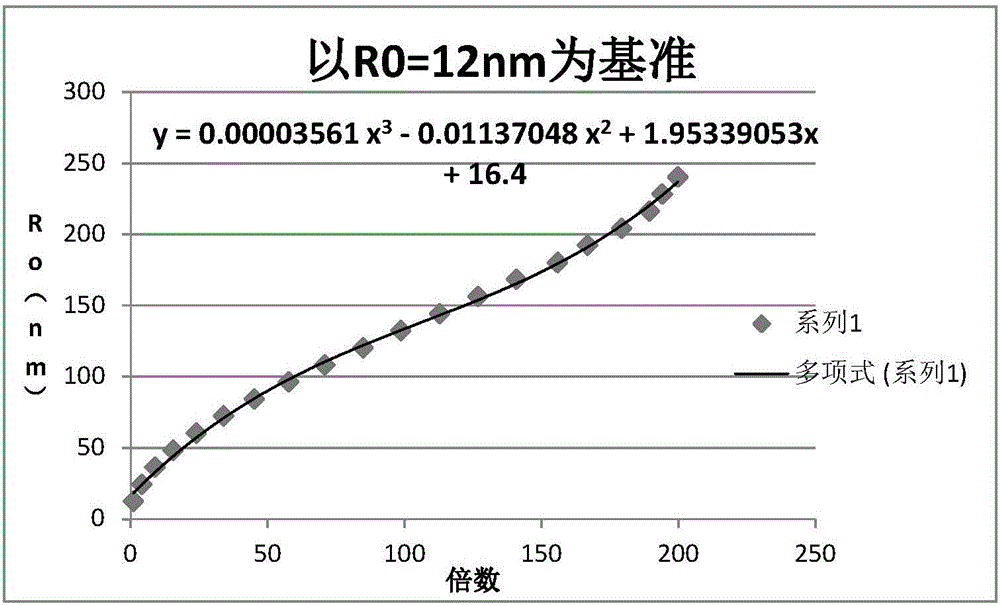

Method and device for measuring liquid crystal display compensation film in-plane phase difference values

The invention discloses a method for measuring liquid crystal display compensation film in-plane phase difference values. The method includes simulating light leakage variation of the different liquid crystal display compensation film in-plane phase difference values; selecting compensation film in-plane phase difference values to be used as standards according to the simulated light leakage variation and acquiring ratio multiples of different compensation film in-plane phase difference values and standard compensation film in-plane phase difference values; fitting relational expressions of the compensation film in-plane phase difference values and light leakage multiples by the aid of the ratio multiples; utilizing liquid crystal display compensation films with known compensation film in-plane phase difference values as standards and measuring light leakage values of the liquid crystal display compensation films; measuring light leakage values of liquid crystal display compensation films with to-be-measured compensation film in-plane phase difference values; acquiring light leakage ratios of the measured light leakage values of the liquid crystal display compensation films with the to-be-measured compensation film in-plane phase difference values to standard light leakage values for measuring compensation film surfaces of liquid crystal displays; substituting the light leakage ratios into the fitted relational expressions of the compensation film in-plane phase difference values and the light leakage multiples to calculate the to-be-measured liquid crystal display compensation film in-plane phase difference values.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Method for measuring heat sealability of glass paper

ActiveCN101852710ASolve specification measurement problemsAvoid compromising qualityFlow propertiesMeasurement costSpring scale

The invention relates to a method for measuring heat sealability of glass paper, which comprises the following steps: cutting a plurality of long stripped samples on glass paper to be measured; after the middle part of each sample is folded in the transverse direction, placing the samples on a heat sealing intensity test instrument; carrying out hot adhesion on proper parts; after the samples are cooled through placement, clamping one edge of the opening end of the samples by a clamping device at the lower end of a spring scale; pinching the other edge by hand for tightly tearing the samples until the adhesion parts are completely peeled off; reading and recording the peeling load; and finally, calculating the average value to be used as the heat sealability data of the glass paper to be measured after all measurements are completed. The invention has the advantages that the operation is simple and convenient, the used tool and equipment are simple and can be easily obtained, the measurement cost is low, the measuring data is accurate, and the invention can provide the importance assurance for the quality improvement of the glass paper.

Owner:SHANDONG HENGLIAN NEW MATERIALS CO LTD

Experimental method for studying reverse fault ground stress of coal mine roadway

InactiveCN108756795ASame drilling angleGuaranteed accuracyBorehole/well accessoriesCore removalExperimental methodsRock core

The invention discloses an experimental method for studying the reverse fault ground stress of a coal mine roadway. The experimental method comprises the following steps that S1, rock cores are drilled on a coal mine roadway site; S2, in a laboratory, required rock core test blocks are drilled in the drilled rock cores of 1-1, 1-2, 2-1 and 2-2 correspondingly; S3, an MTS test machine is combined with an acoustic emission testing device, the secondarily drilled rock core test blocks are subjected to single-axis compression testing correspondingly, and Kaiser effect points of all the test blocksand the positive stress corresponding to the Kaiser effect points are obtained; S4, the acoustic emission ground stress is calculated to obtain the magnitude of the principal stress; and S5, according to the Kaiser effect points and the principal stress, the influences of the reverse fault ground stress on laying of the coal mine roadway are analyzed. According to the experimental method, the accuracy of obtained reverse fault ground stress data can be guaranteed, and an effective and reasonable basis is provided for laying of the coal mine roadway.

Owner:NORTH CHINA INST OF SCI & TECH

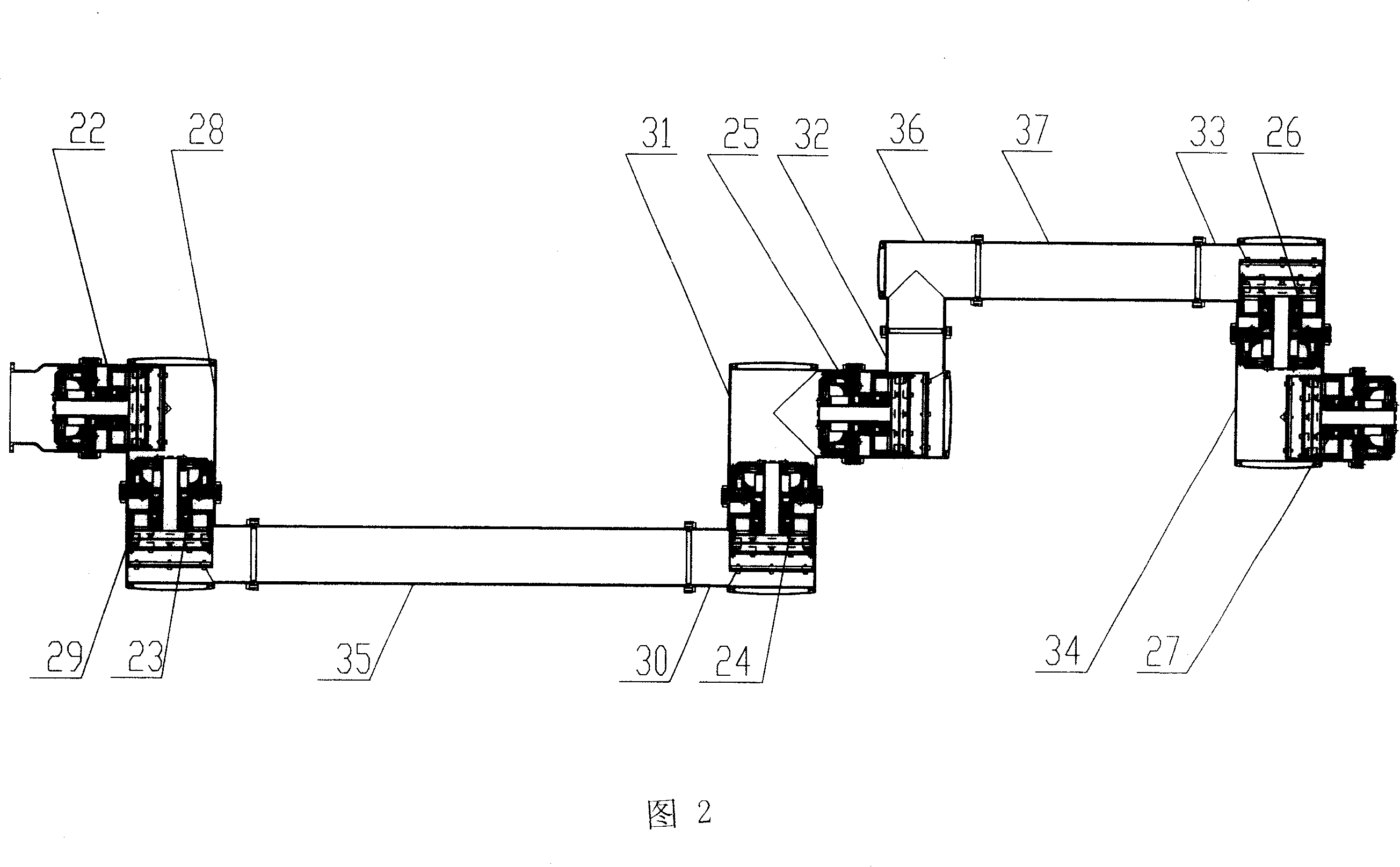

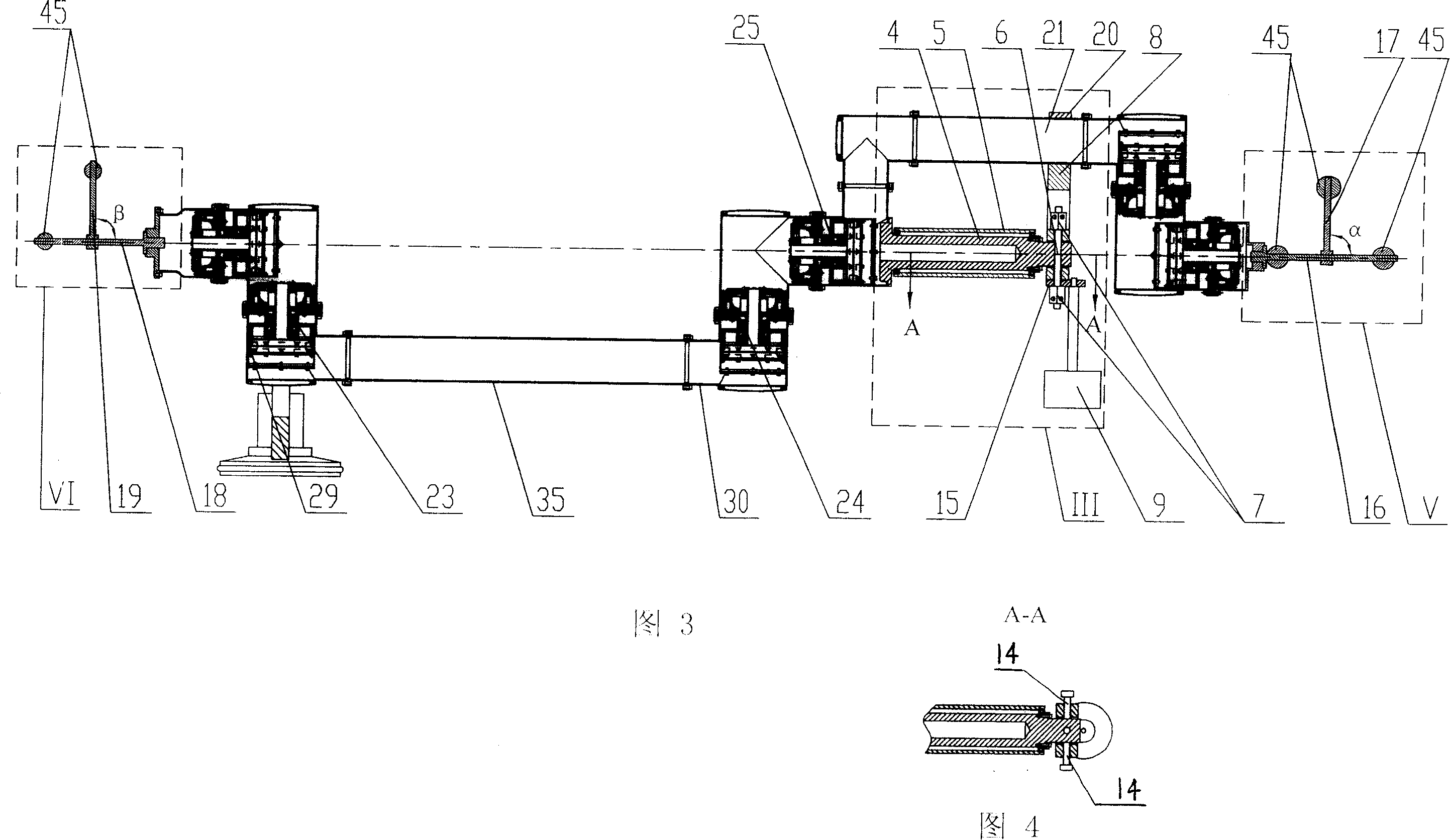

Precisive determining system of mechanical arm location and gesture in space

Owner:HARBIN INST OF TECH

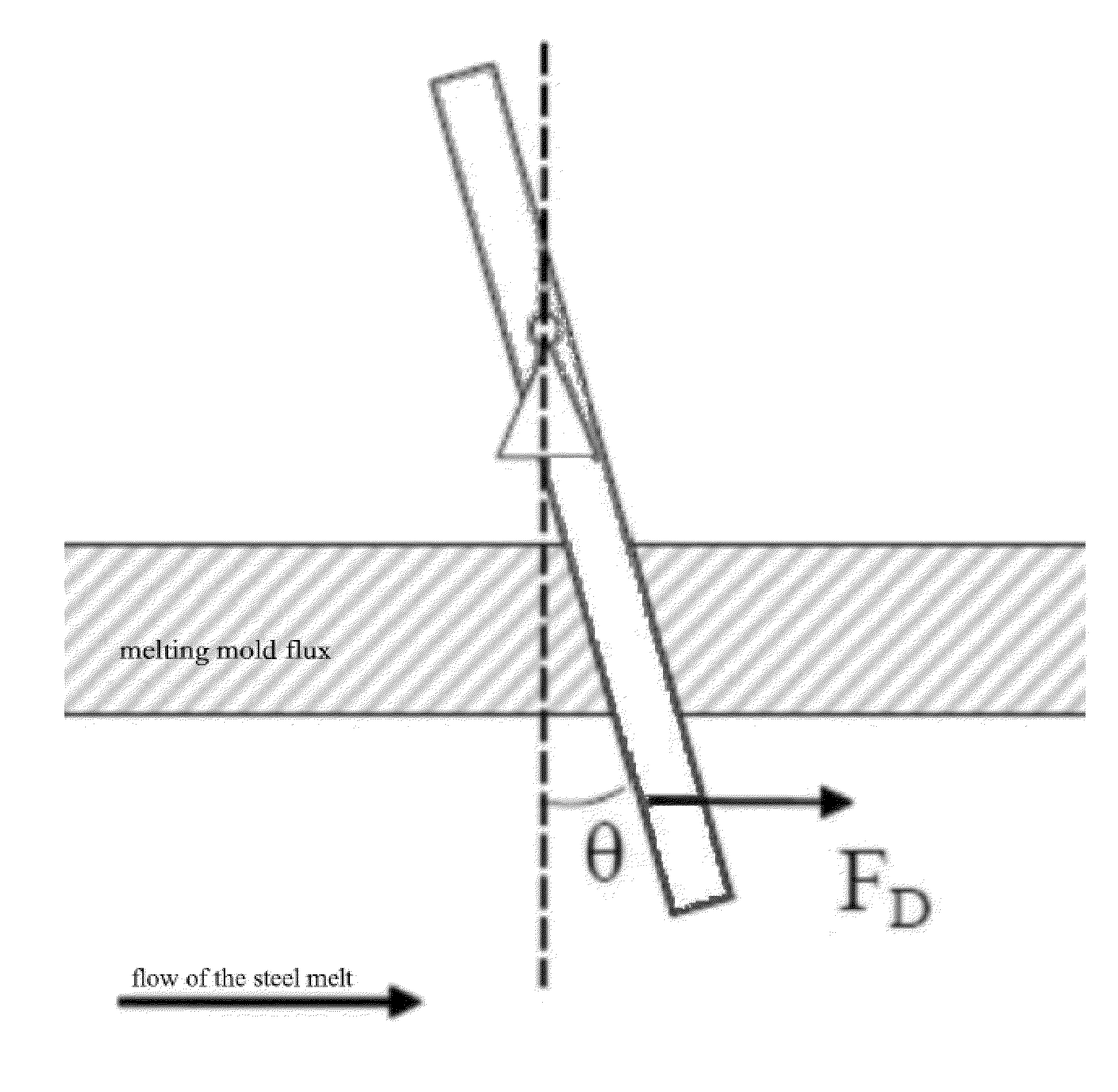

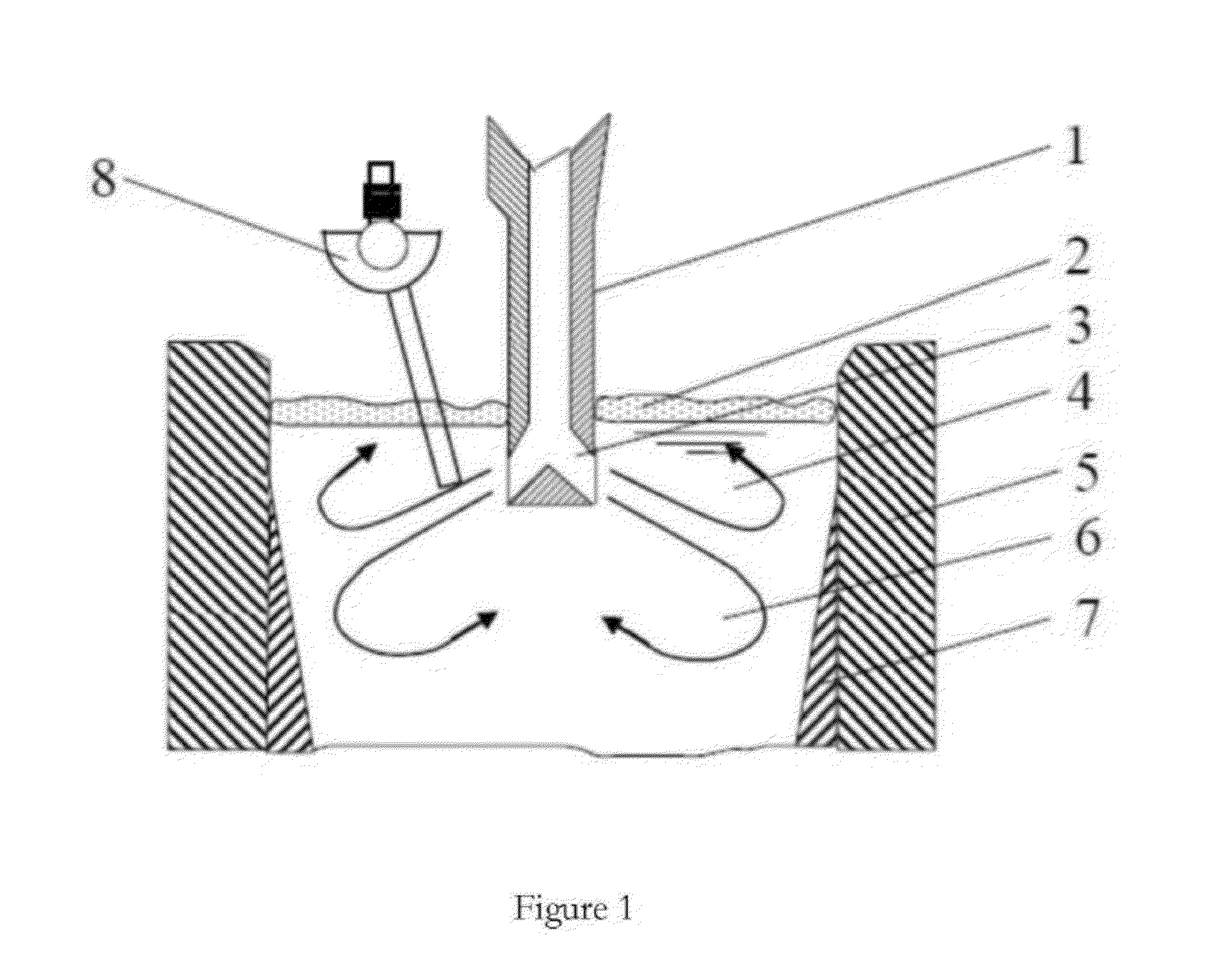

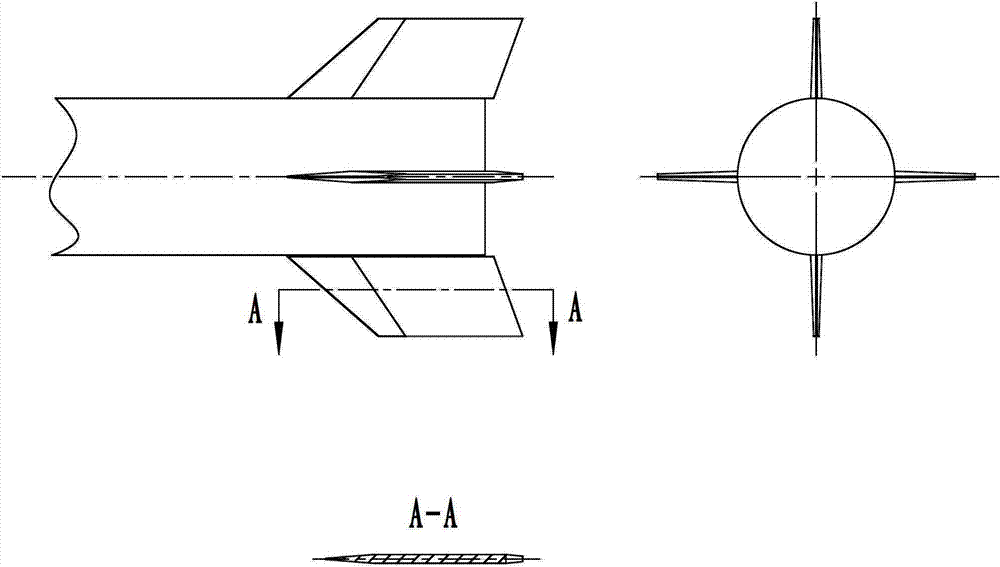

Device and method for measuring flow rate of steel melt near the surface thereof

ActiveUS20150300849A1Rotational sensitivity of be maximizeAccurately measureVolume/mass flow by dynamic fluid flow effectFluid speed measurementDeflection angleEngineering

A device for measuring the flow rate of steel melt near the surface thereof. The device has a flow rate detecting rod and a deflection device for the flow rate detecting rod. The deflection device for the flow rate detecting rod has a flow rate detecting rod counterweight, a deflection bearing sleeve, a deflection bearing, a deflection angle indicating board, a deflection angle pointer and a the flow rate detecting rod fastening bolt.

Owner:BAOSHAN IRON & STEEL CO LTD

Independent wheel suspension

InactiveCN101535068AAvoid damageReaction time achievedResilient suspensionsPivoted suspension armsEngineeringNeutral position

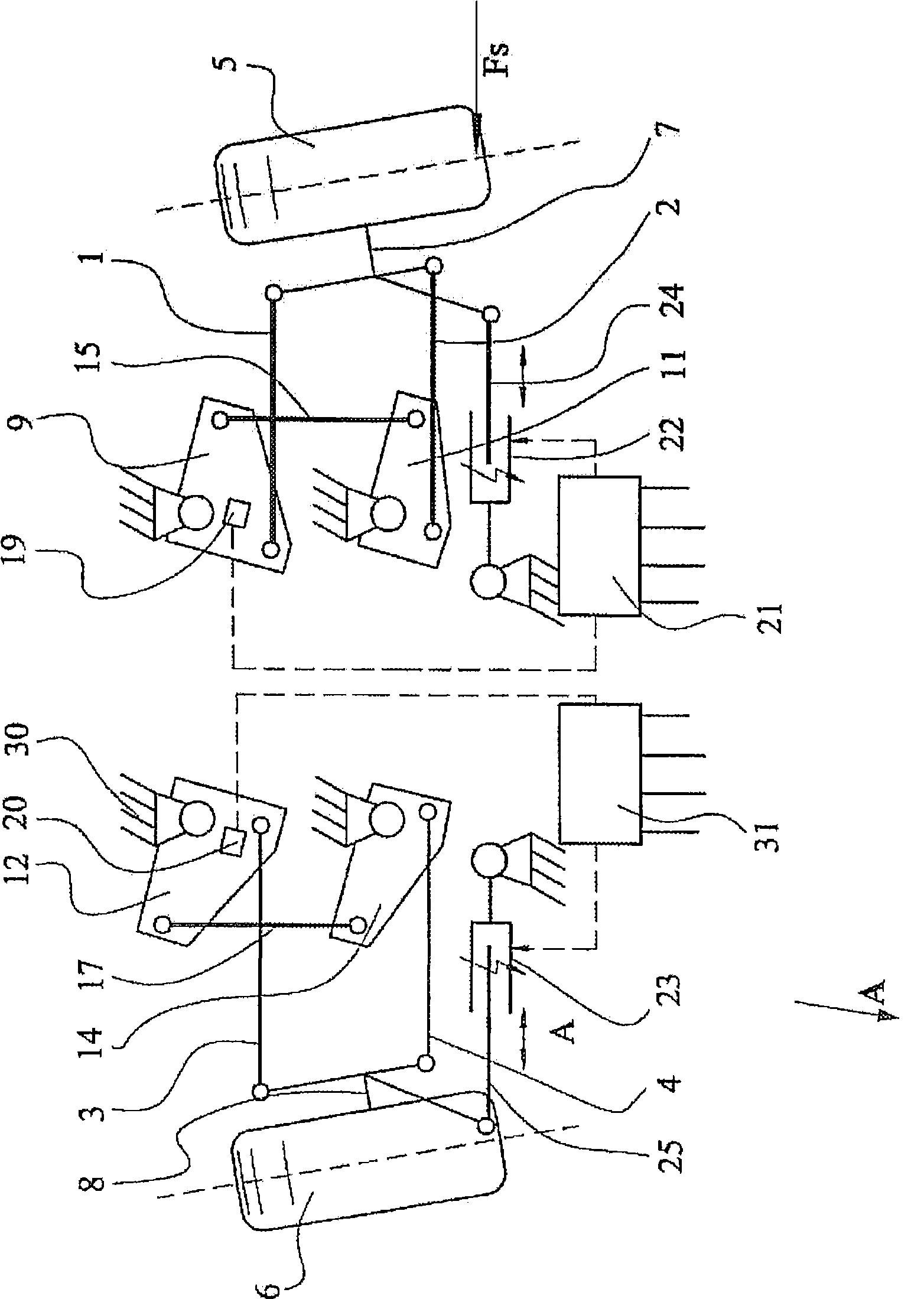

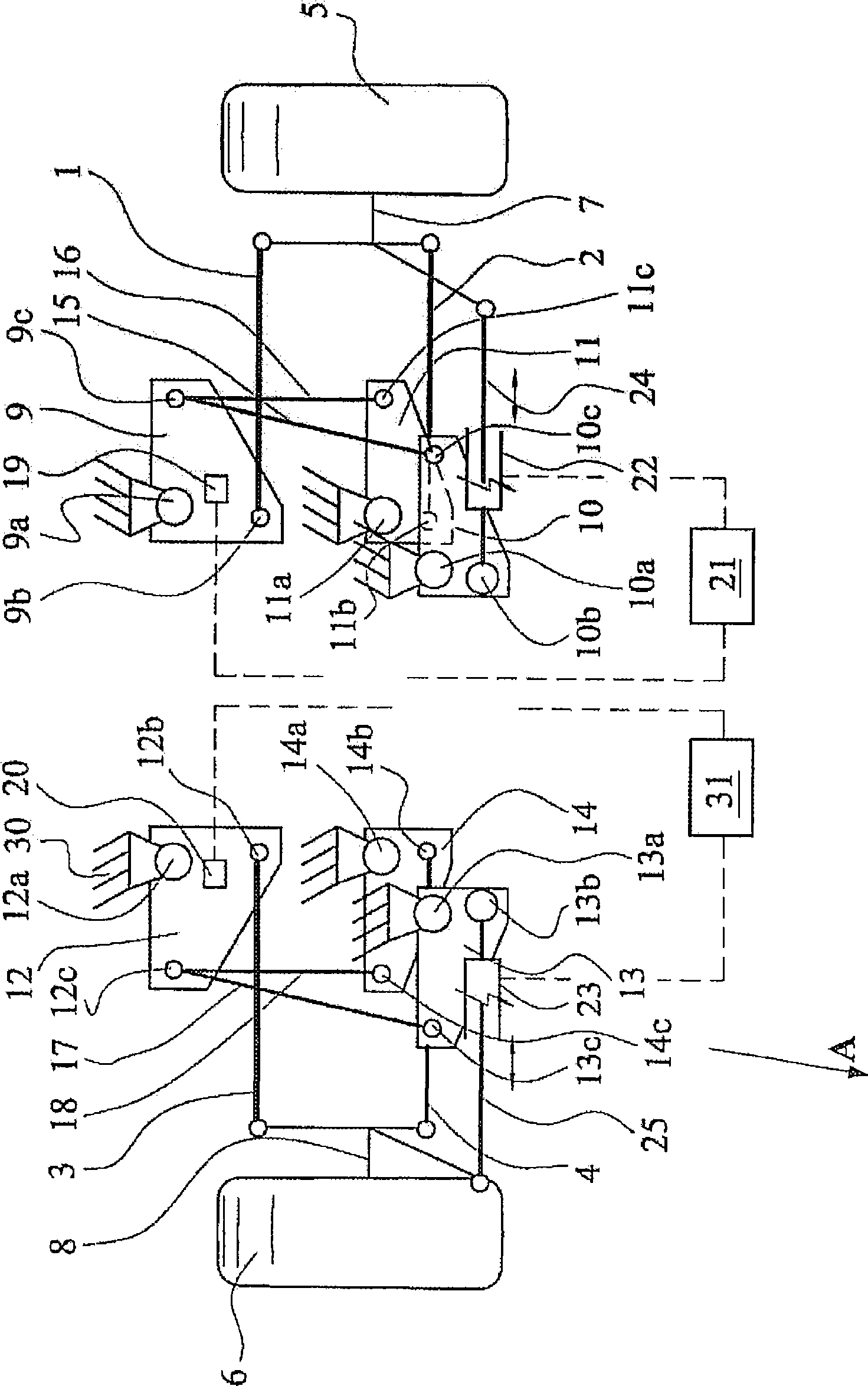

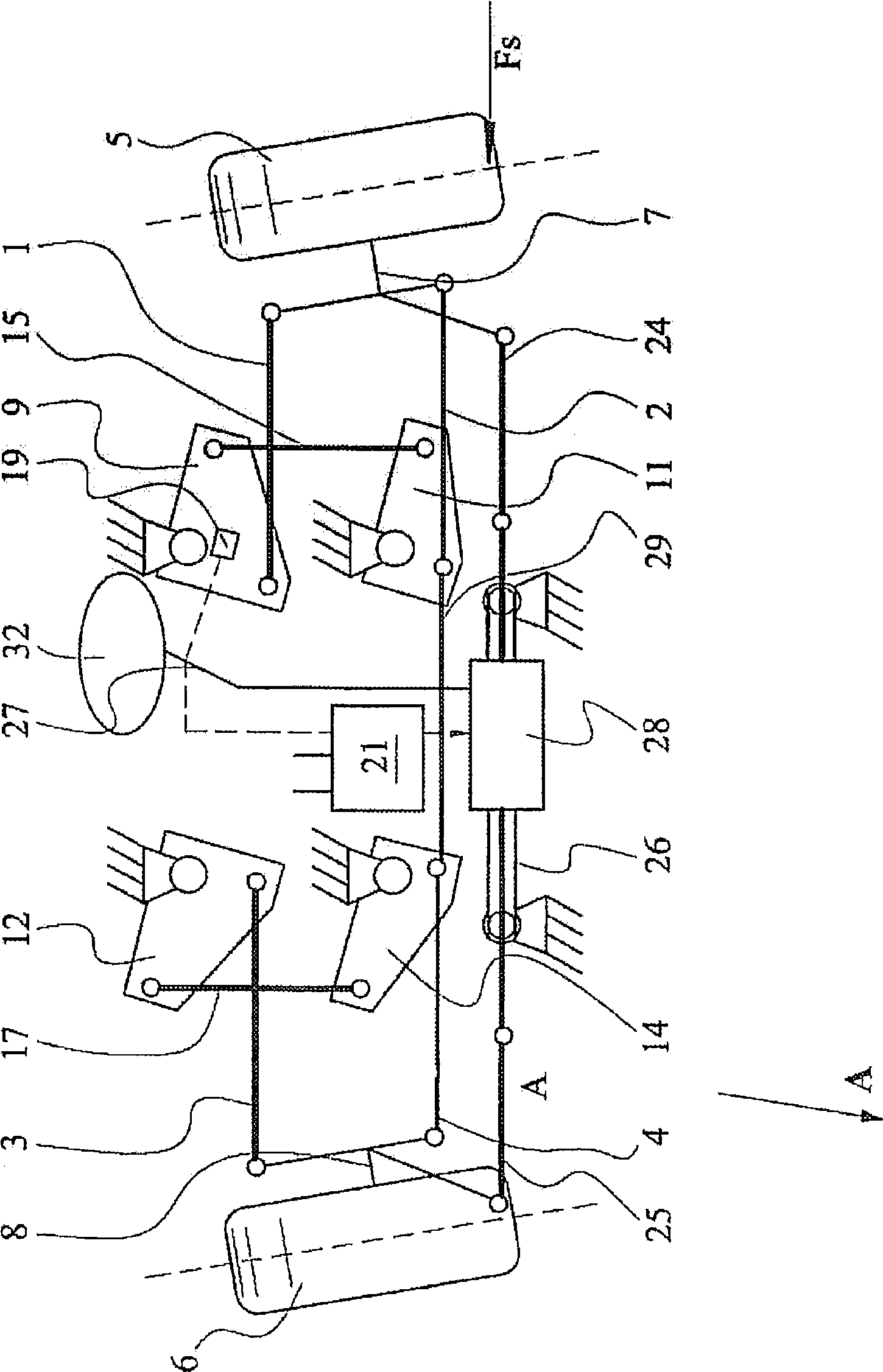

Proposed is an independent wheel suspension for a motor vehicle, in which at least one first and at least one second link (1, 2, 3, 4) are in each case articulatedly coupled to a wheel carrier (7, 8) which supports a vehicle wheel (5, 6). The independent wheel suspension has compensating means (9, 10, 11, 12, 13, 14) for correcting wheel positions, wherein at least the first and the second link (1, 2, 3, 4) have a compensating means (9, 10, 11, 12, 13, 14) or are connected to a compensating means (9, 10, 11, 12, 13, 14), and at least two compensating means (9, 10 and 12, 13 respectively) of one wheel are connected to one another by means of at least one coupling element (15, 16, 17, 18). According to the invention, a wheel position of at least one of the vehicle wheels (5, 6) which differs from the neutral position can be sensed by means of a sensor unit (19, 20), composed of a measured value emitter and a measured value pick-up, which is arranged on at least one of the compensating means (9, 10, 11, 12, 13, 14) of the respective vehicle wheel (5, 6) or which is assigned to at least one of the compensating means (9, 10, 11, 12, 13, 14).

Owner:ZF FRIEDRICHSHAFEN AG

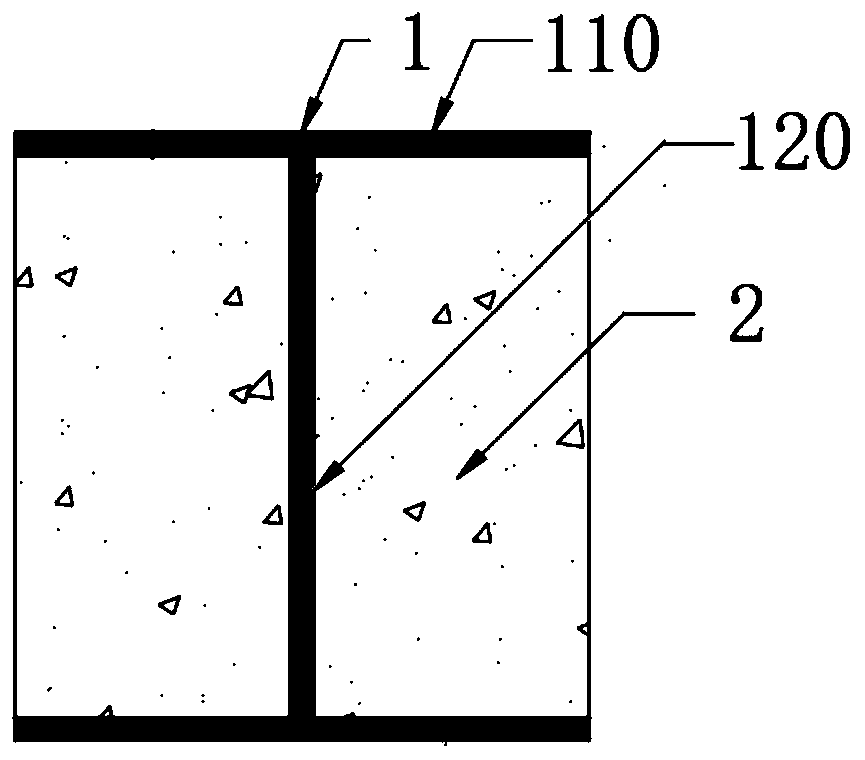

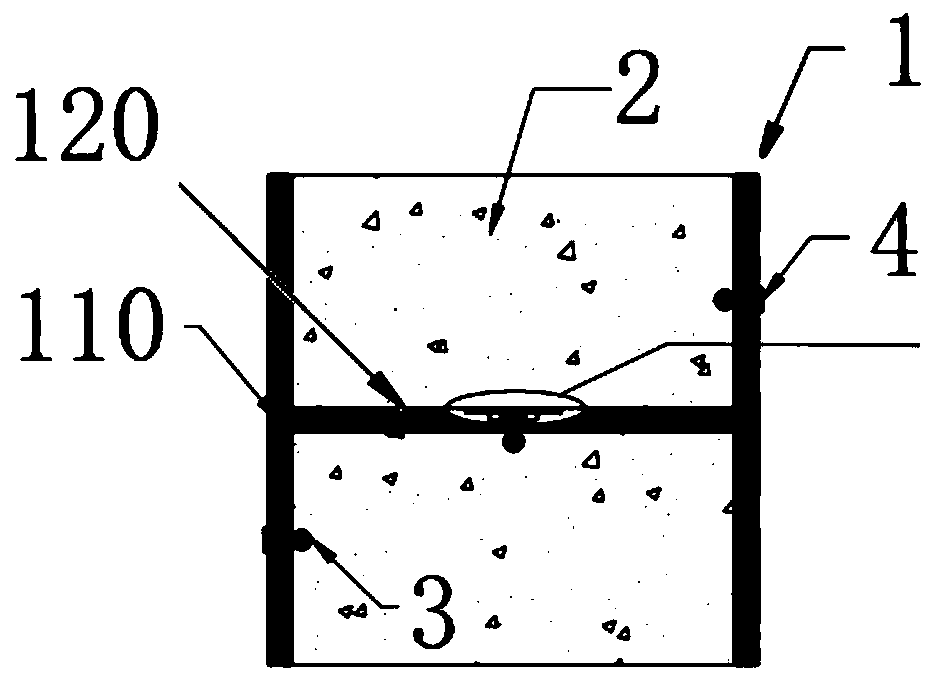

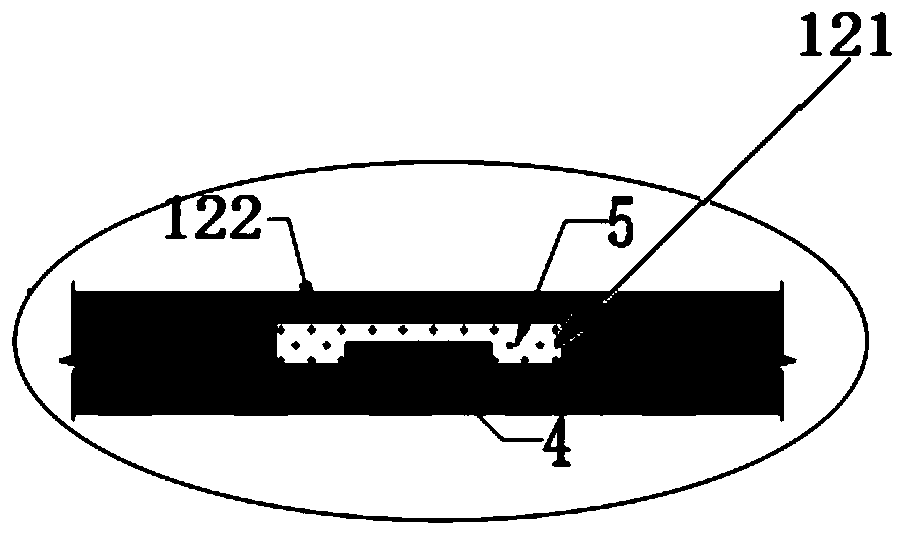

Method for directly measuring bonding performance of PEC type steel reinforced concrete bonding surface

PendingCN110274872AAddressing the Effects of Adhesive PropertiesGuaranteed bonding areaMaterial strength using tensile/compressive forcesUsing mechanical meansReinforced concreteStrain gauge

The invention discloses a method for directly measuring the bonding performance of a PEC type steel reinforced concrete bonding surface. The PEC type steel reinforced concrete is formed by arranging H-shaped steel between flanges and pouring concrete at the two sides of a web. The method comprises: step one, pasting a strain gauge pair including a metal strain gauge for measuring the strain of the H-shaped steel and a non-metal strain gauge for measuring the strain of a concrete structure at each measuring point of the H-shaped steel; step two, pouring concrete between the flanges of the H-shaped steel at the two sides the web to obtain a structural steel-reinforced concrete test piece; and step three, loading the structural steel-reinforced concrete test piece, colleting strain values of all metal strain gauges and corresponding non-metal strain gauges, and analyzing the bonding performance of the bonding surface of the PEC type steel reinforced concrete based on the collected strain values. According to the invention, the strain of the concrete on the contact surface between the H-shaped steel and the concrete can be measured directly and accurately, so that the bonding performance of the bonding surface of the PEC type steel reinforced concrete is obtained.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

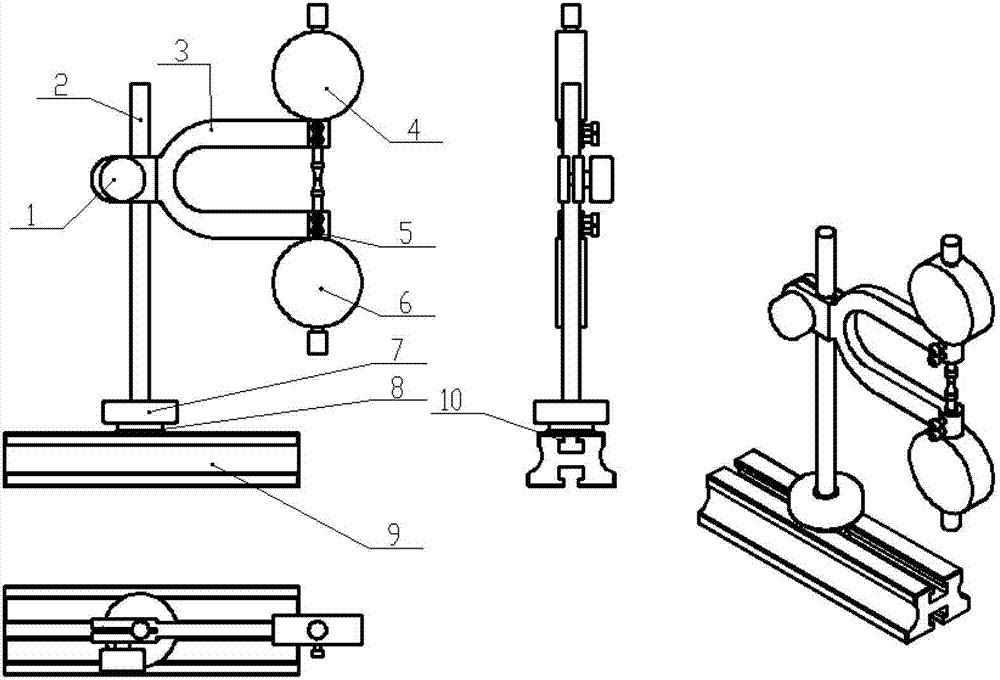

Device used for testing guided missile model wing or rudder assembling precision

ActiveCN103398651AEasy to measureHigh measurement accuracyAngles/taper measurementsMeasurement costRudder

The invention relates to a device used for testing the guided missile model wing or rudder assembling precision, and belongs to the technical field of the guided missile model detection. The device comprises a locking screw, a stand column, a U-shaped dial indicator bracket, an upper dial indicator, a puller screw, a lower dial indicator, a locking nut, a gasket, a base and a T-shaped slot nut. The double-dial-indicator structure in the device disclosed by the invention has the advantages of simple structure, high measurement precision, low measurement cost and simple measurement process, any position of the whole wing surface can be measured, and measurement data can be displayed constantly.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

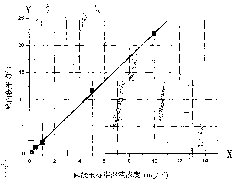

Method for measuring phosphorus content of polysaccharide phosphate ester

InactiveCN101799459AGood compatibilityWide linear rangeComponent separationPreparing sample for investigationChemistryMeasurement cost

The invention discloses a method for measuring the phosphorus content of polysaccharide phosphate ester. In the method, sample solution which is processed is detected by the high-efficiency liquid phase chromatography, and the phosphorus content of the detected polysaccharide sample is calculated by preparing gradient standard solution by using through detection, making a standard curve and establishing a regression equation. The method has the advantages of good compatibility of the detected polysaccharide solution and mobile phase mixed liquid, wide linear range of the standard curve, accurate and reliable detection result, simplification of detection steps, measurement time conservation, low measurement cost and easy popularization and implementation. The method overcomes the defects of complicated operation, serious impurity interference, unsatisfactory accuracy and sensitivity, narrow linear range and the like in the conventional process of measuring the phosphorus content.

Owner:TIANSHUI NORMAL UNIV

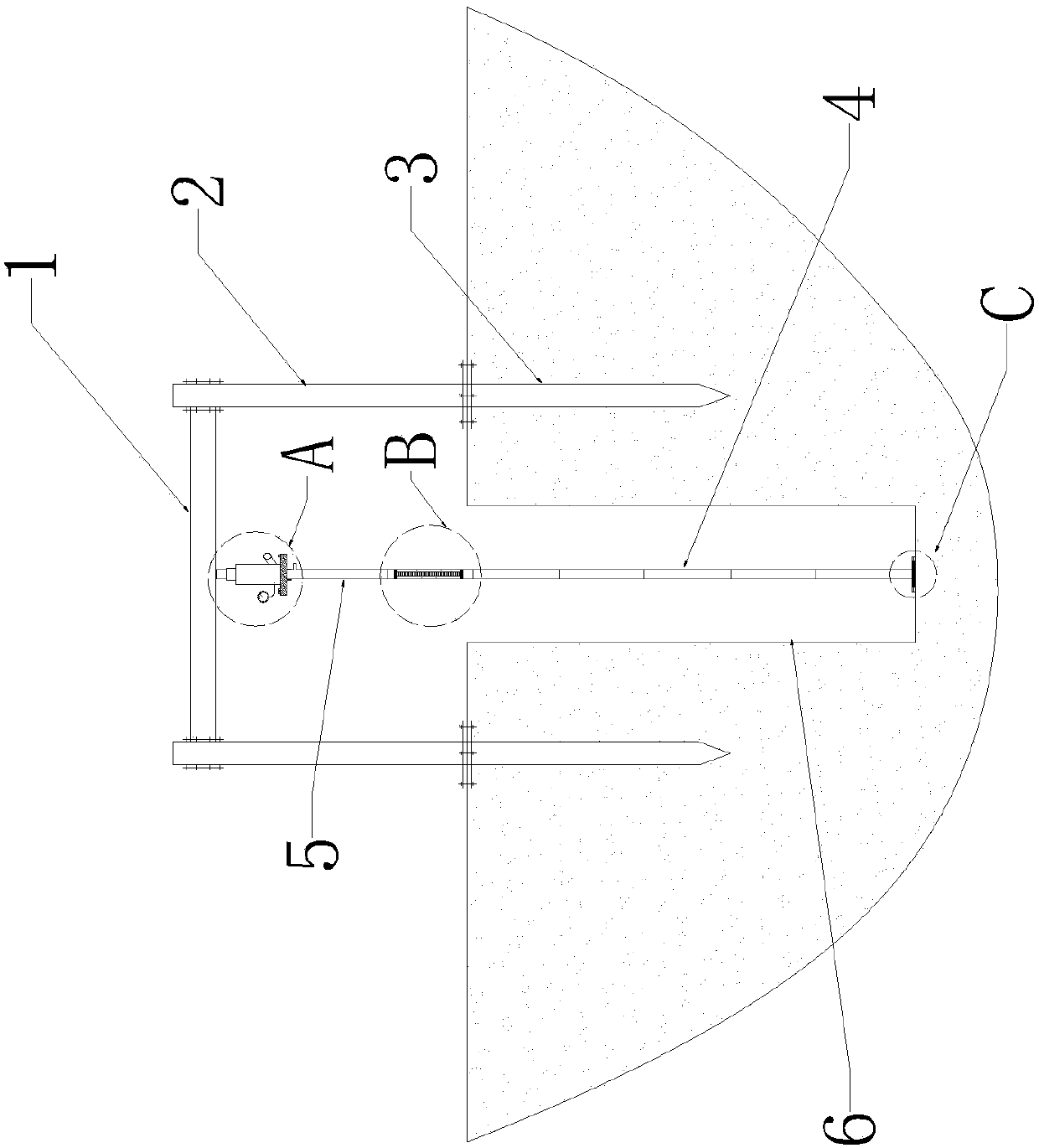

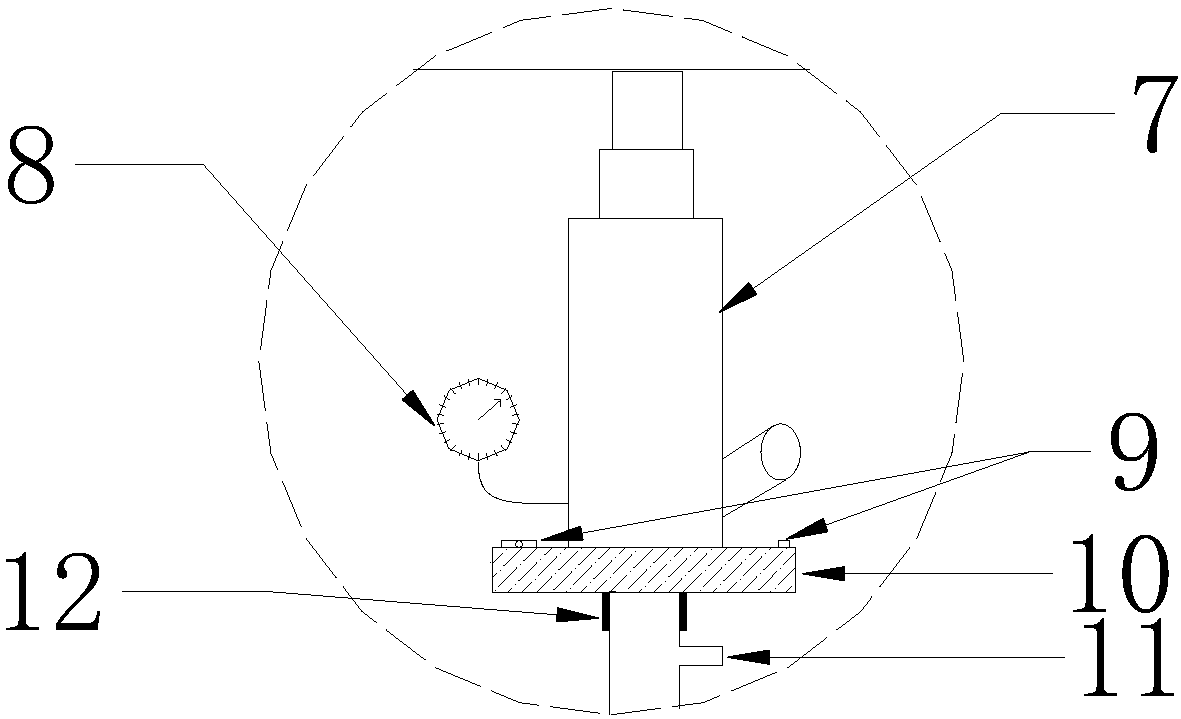

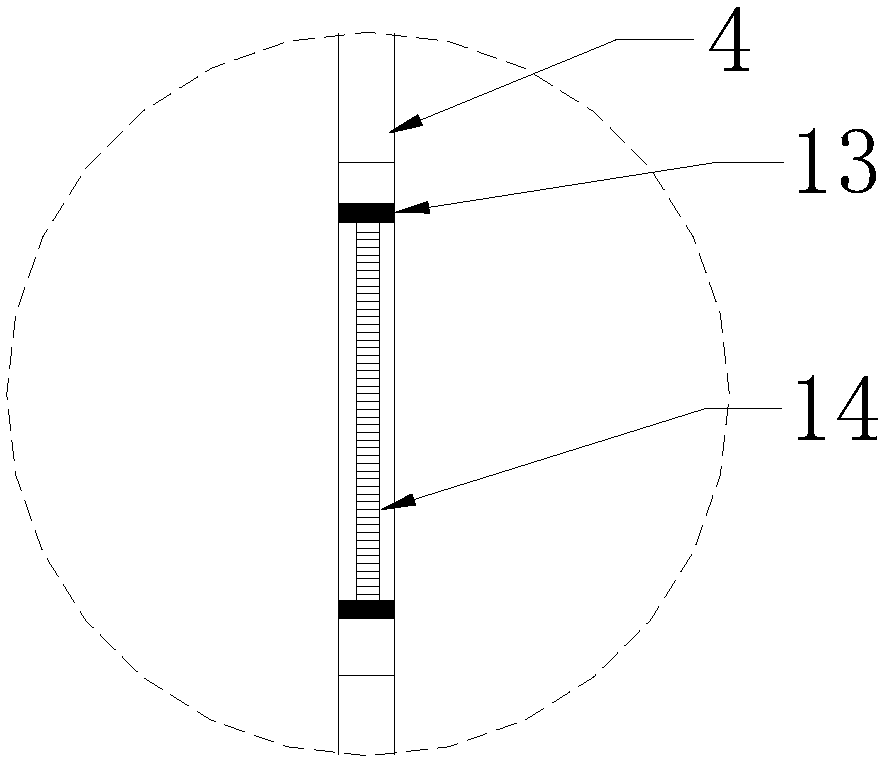

Equipment and method for measuring coefficient of collapsibility of loess

PendingCN108020460AReduce the probability of trial failureLow cost of measurementMaterial strength using tensile/compressive forcesSteel columnsLoess

The invention discloses equipment and method for measuring the coefficient of collapsibility of loess, and relates to the field of civil engineering measurement equipment. The equipment comprises a reaction frame, a vertical oil jack, a centering bearing plate, a dowel steel, a bottom bearing plate and observation equipment, wherein the reaction frame comprises a reaction cross beam, a stand column and a spiral steel column; the vertical oil jack is provided with a hydraulic pressure indicator, bubble levels are arranged at four corners of the centering bearing plate; the observation equipmentcomprises a digital level and an indium steel ruler matched with the digital level; and the indium steel ruler is fixed on the dowel steel through a ruler hoop. According to the equipment, the problem that loading is easily eccentric due to existence of a force-measuring loop in the prior art can be effectively controlled by using the hydraulic gauge, and the dowel steel is directly used as waterdelivery pipe for delivering water to an exploratory well, each part of the reaction frame is connected by adopting screws with simple assembly and disassembly, and the counter force provided by utilizing the spiral steel column and the pulling resistance of a soil mass is better than that provided by utilizing dead weight of overloading.

Owner:ANHUI UNIV OF SCI & TECH

Rod thermometer device for detecting a temperature, use for the electrical simulation of nuclear fuel rods

InactiveUS9835497B2Low cost of measurementLow costThermometer detailsNuclear energy generationElectricityThermocouple

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

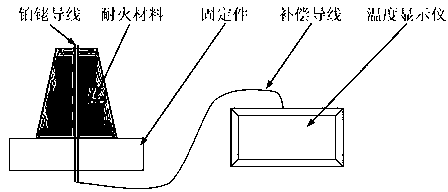

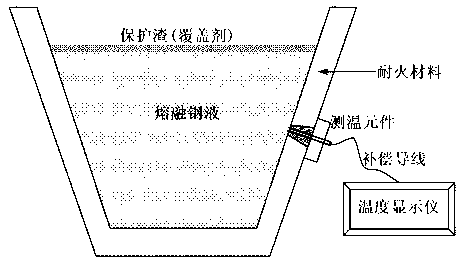

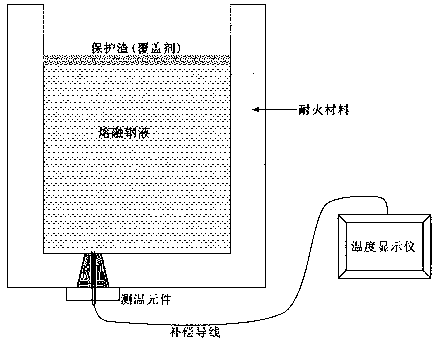

Method for continuously measuring temperature of molten metal

InactiveCN103278254AThe temperature is accurately obtainedEasy to operateThermometers using electric/magnetic elementsUsing electrical meansContinuous measurementPlatinum

The invention provides a method for continuously measuring the temperature of molten metal, and belongs to the technical field of measurement and detection. A measuring structure adopted in the method comprises three parts including a temperature measuring element, a display instrument and a compensation conducting wire, wherein the temperature measuring element is formed by two platinum-rhodium conducting wires which are buried in fire-resistance materials and the ends of which are exposed out, the display instrument is used for displaying the temperature of the molten metal in real time, and the compensation conducting wire is connected with the temperature measuring element and the temperature display instrument. Before the measurement, the temperature measuring element is fastened at the side wall or the bottom of a container for containing molten metal, and the two exposed platinum-rhodium conducting wires and the molten metal are enabled to form a thermocouple loop in the measurement process, so the continuous and precise measurement on the temperature of the molten metal can be realized.

Owner:沈阳东大高温材料有限公司

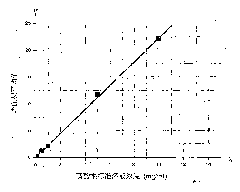

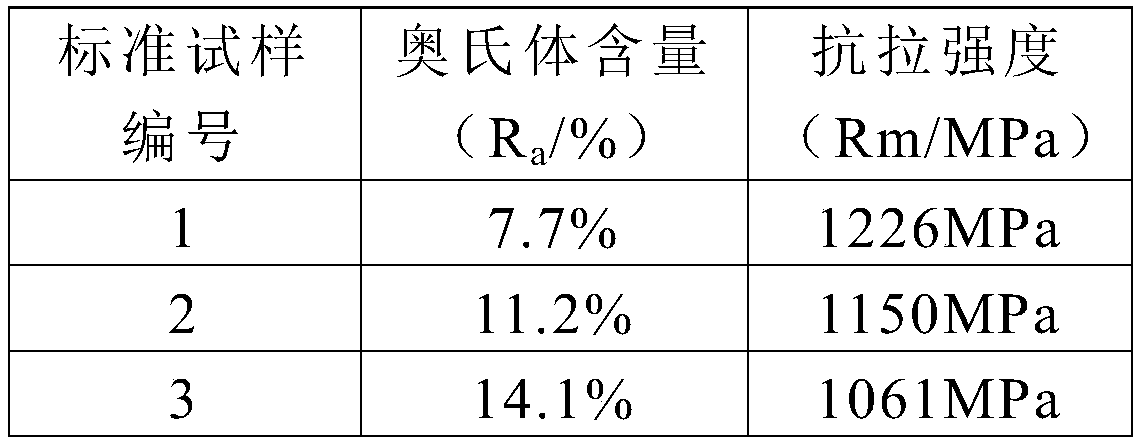

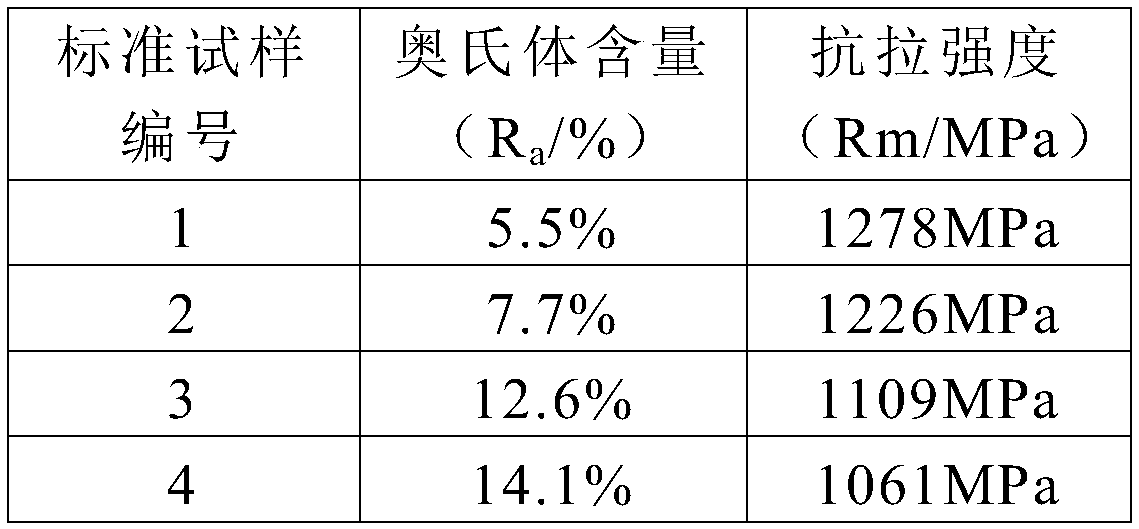

Measurement method of retained austenite content in high nickel alloy steel

ActiveCN106198221BLow cost of measurementHigh speedMaterial strength using tensile/compressive forcesTest sampleX ray analysis

The invention discloses a method for measuring the content of residual austenite in high-nickel alloy steel. The method comprises the following steps: selecting N high-nickel alloy steel standard samples; measuring the content of the residual austenite and the tensile strength of each high-nickel alloy steel standard sample by adopting an X-ray analysis technology and utilizing a tensile testing machine; drawing points about data of the content of the residual austenite and the tensile strength of N groups in a coordinate axis, fitting the points in the coordinate axis according to coefficients related to linear fitting, forming a fitting straight line, and obtaining a fitting straight line equation Rm=ARa+B; carrying out a tensile test on a high-nickel alloy steel test sample on the tensile testing machine, measuring the tensile strength, substituting the tensile strength in the fitting straight line equation Rm=ARa+B, and obtaining the content of the residual austenite. Aiming at the high-nickel alloy steel, the content of the residual austenite in the high-nickel alloy steel can be measured while the tensile strength of the high-nickel alloy steel is measured by adopting the tensile testing machine, two results can be obtained through one operation, and the measuring cost is reduced; the speed is fast, and the measuring efficiency is increased.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com