Patents

Literature

176 results about "Compression testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

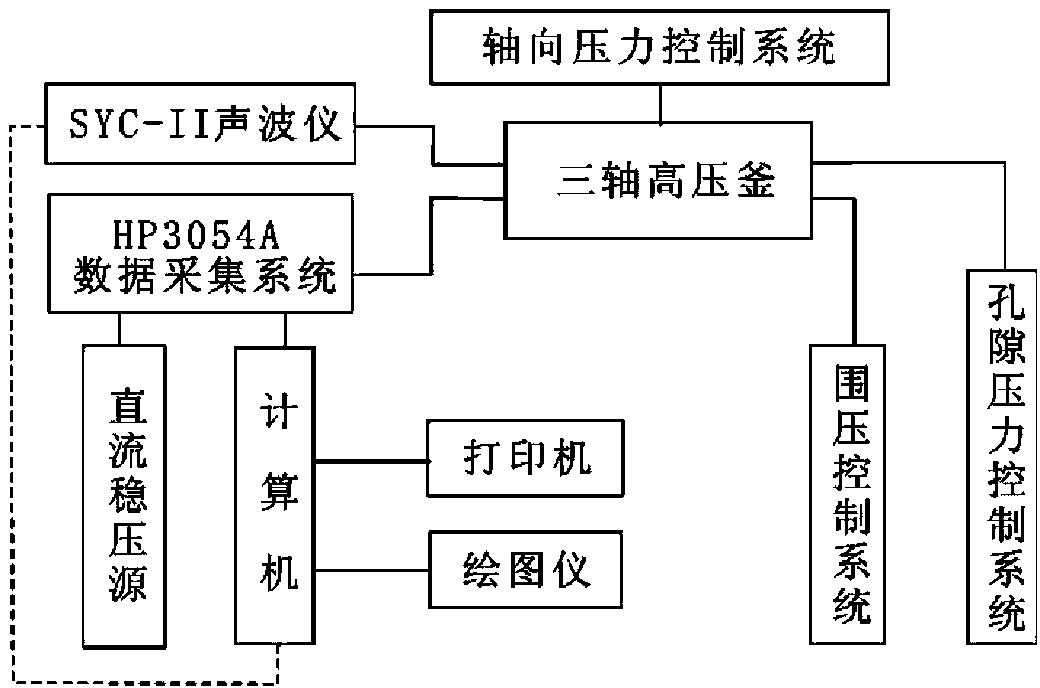

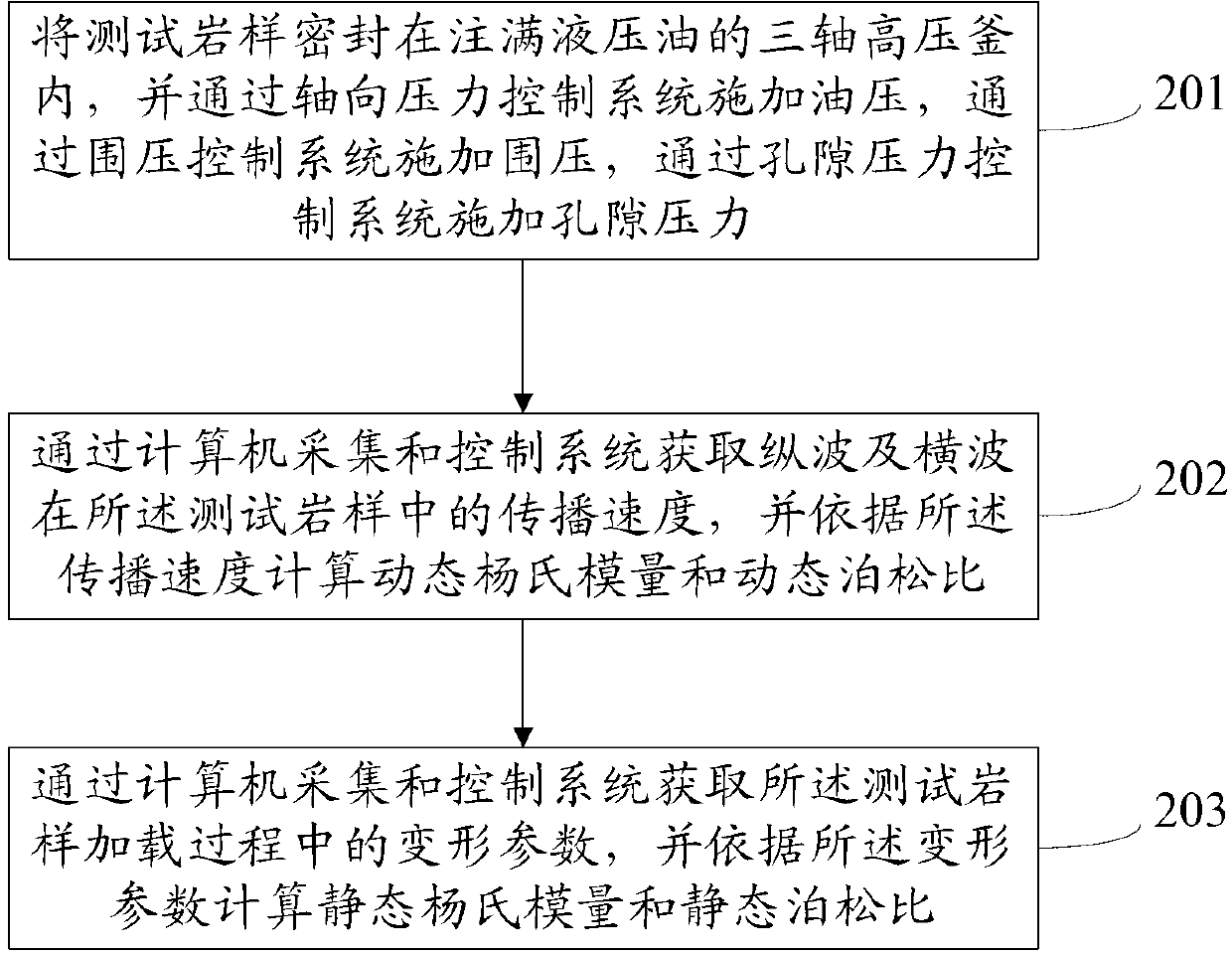

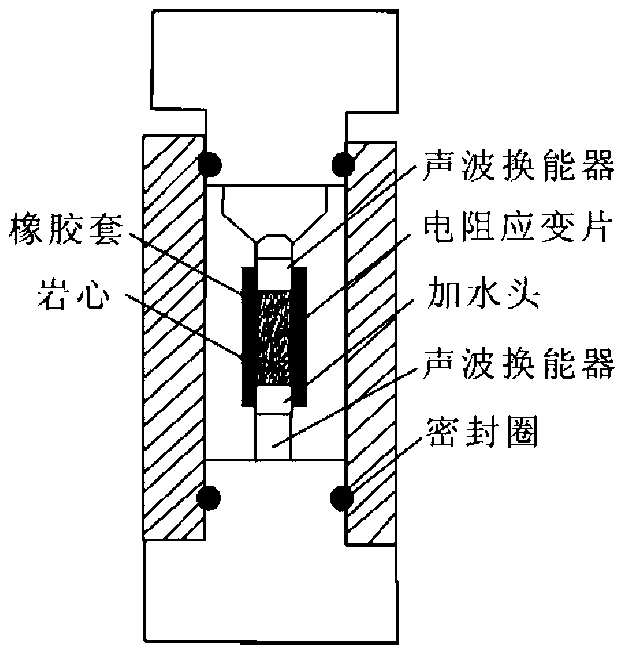

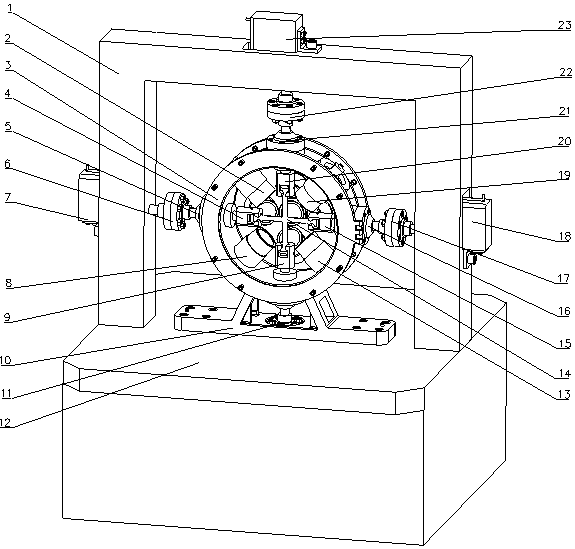

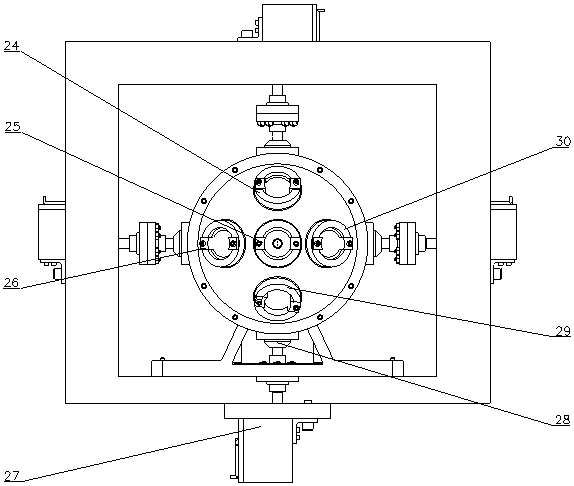

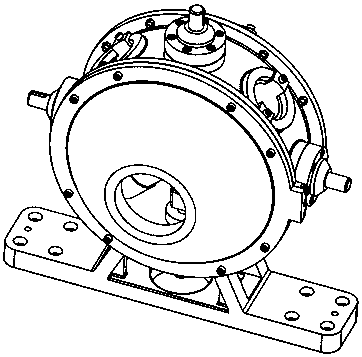

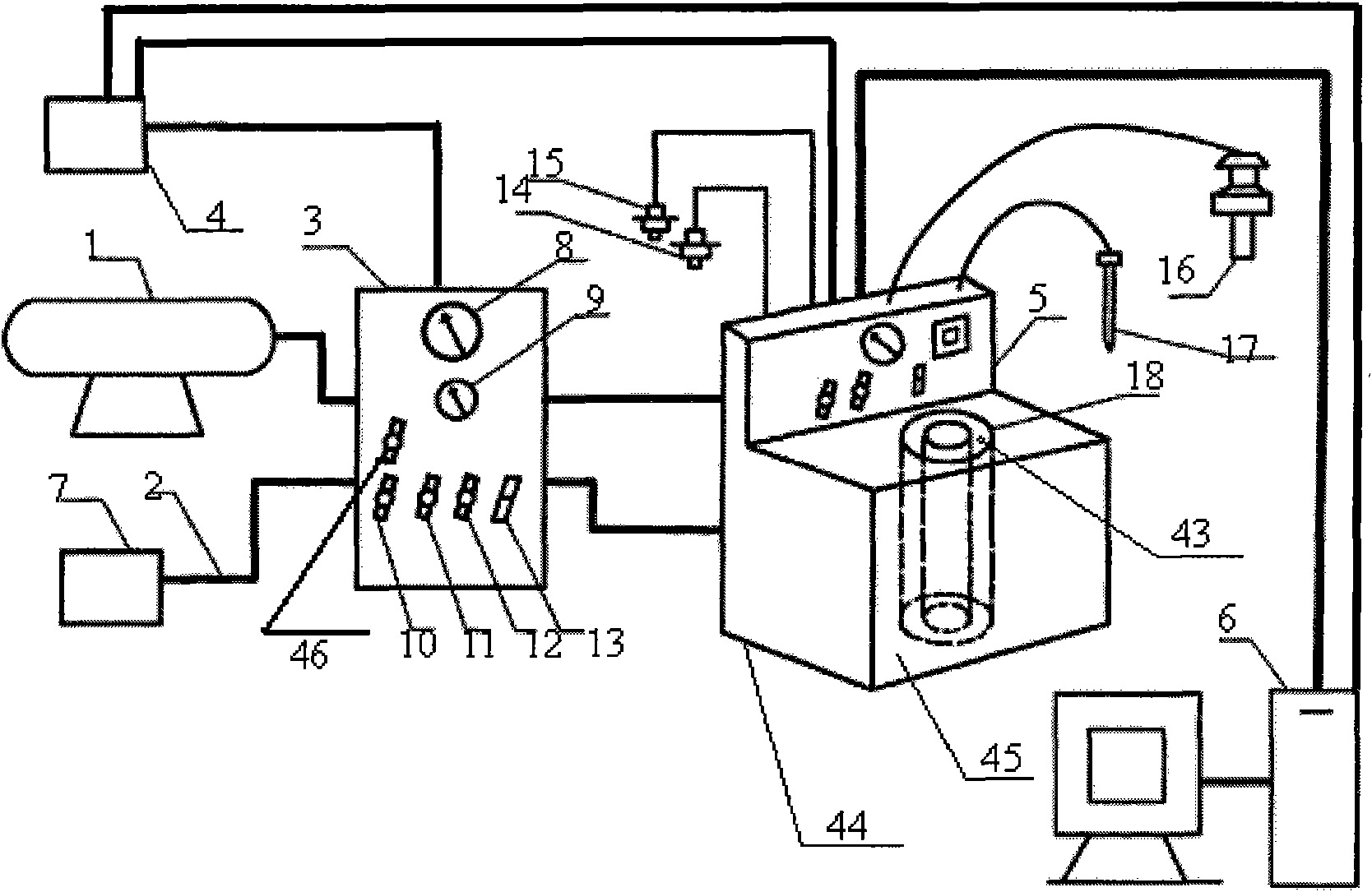

Method for synchronous measurements on dynamic and static elastic parameters of rocks

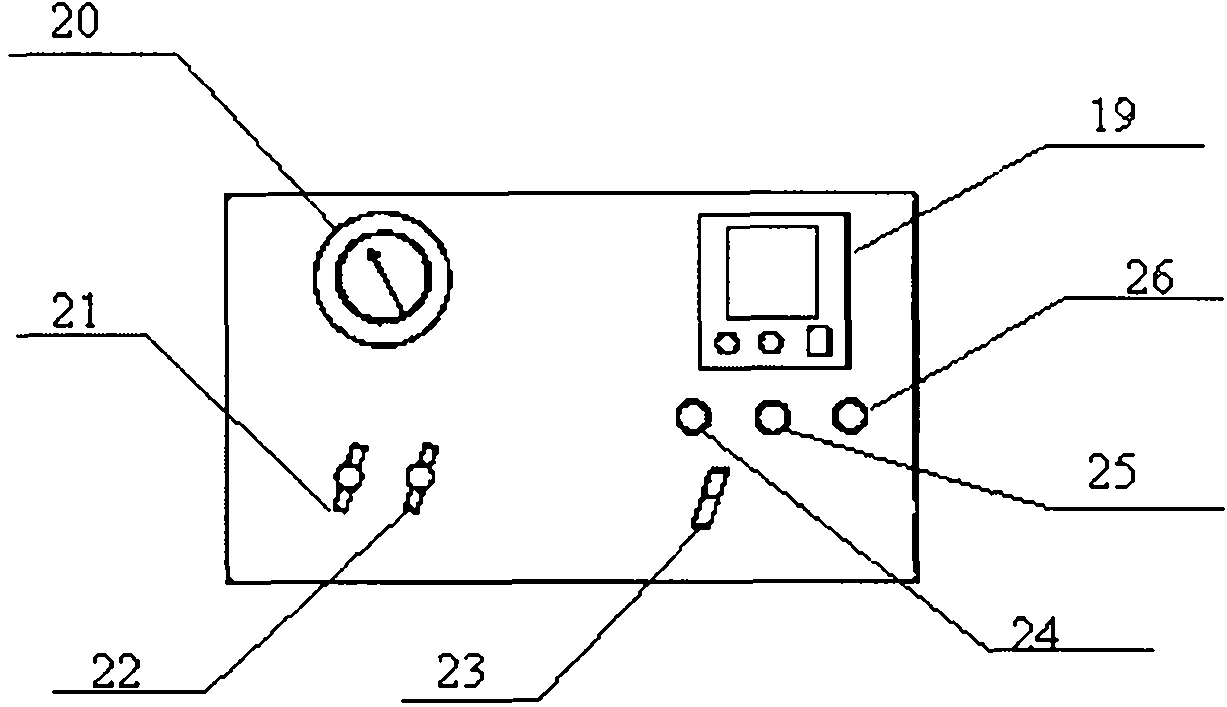

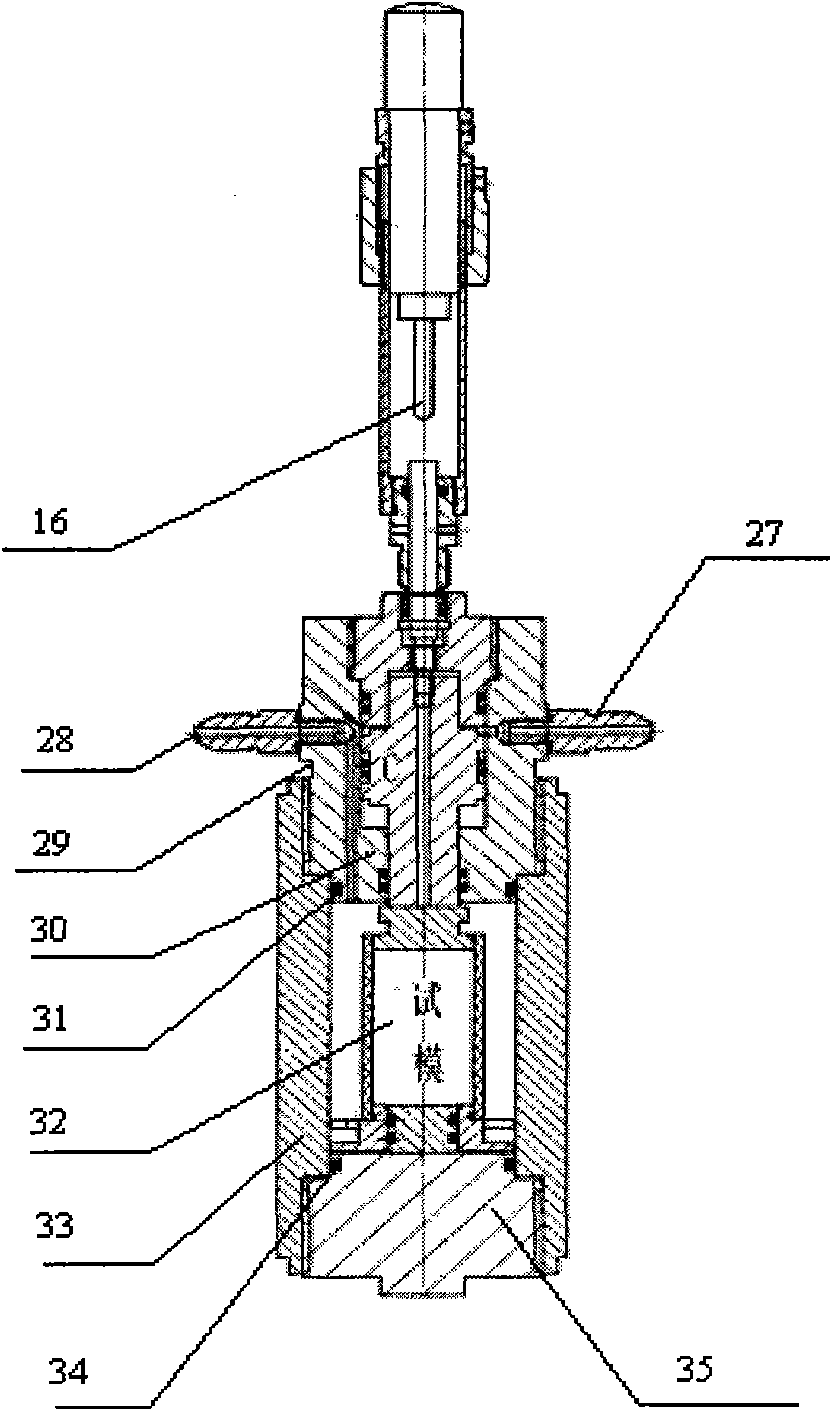

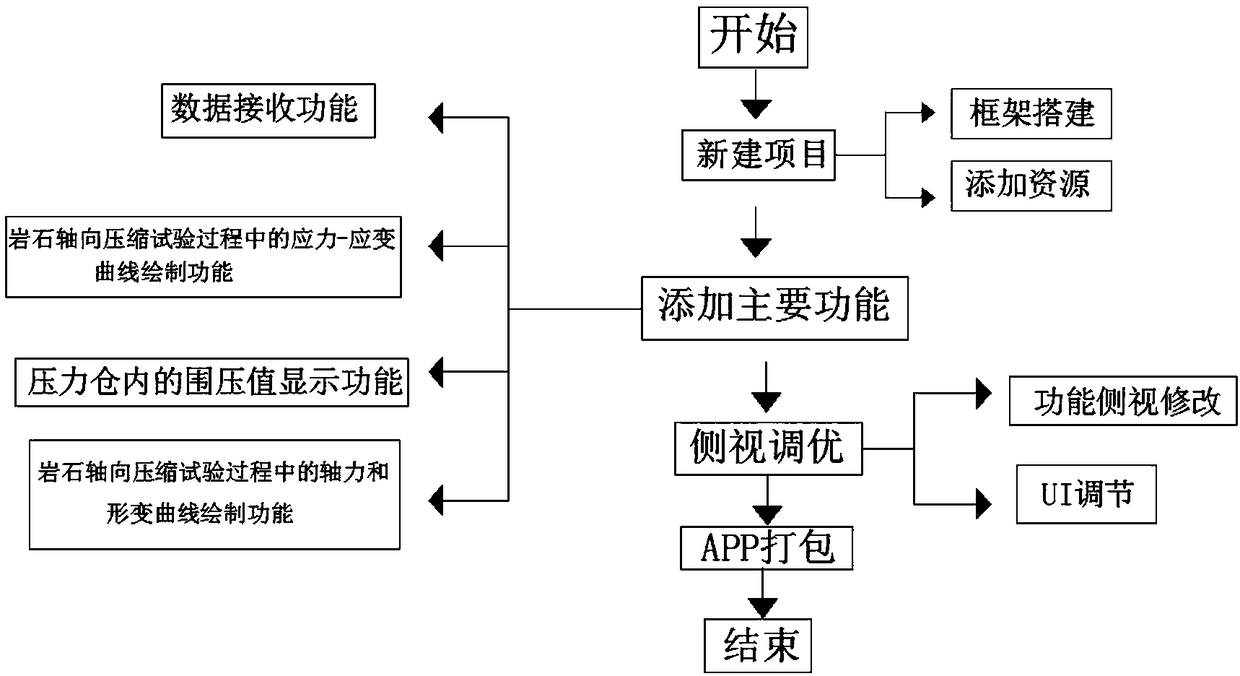

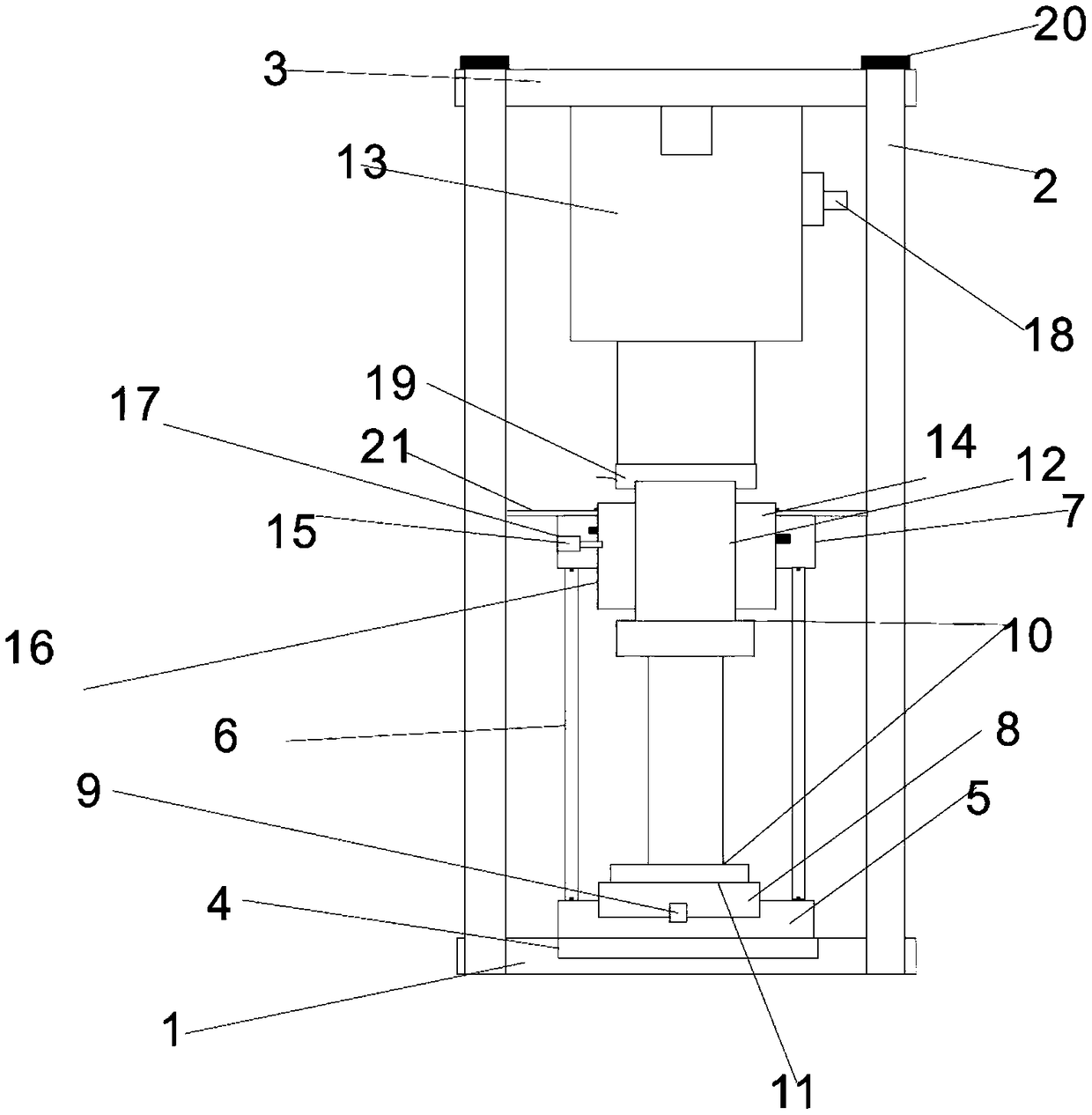

InactiveCN103278389AGuaranteed validityGuaranteed accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using tensile/compressive forcesControl systemAxial pressure

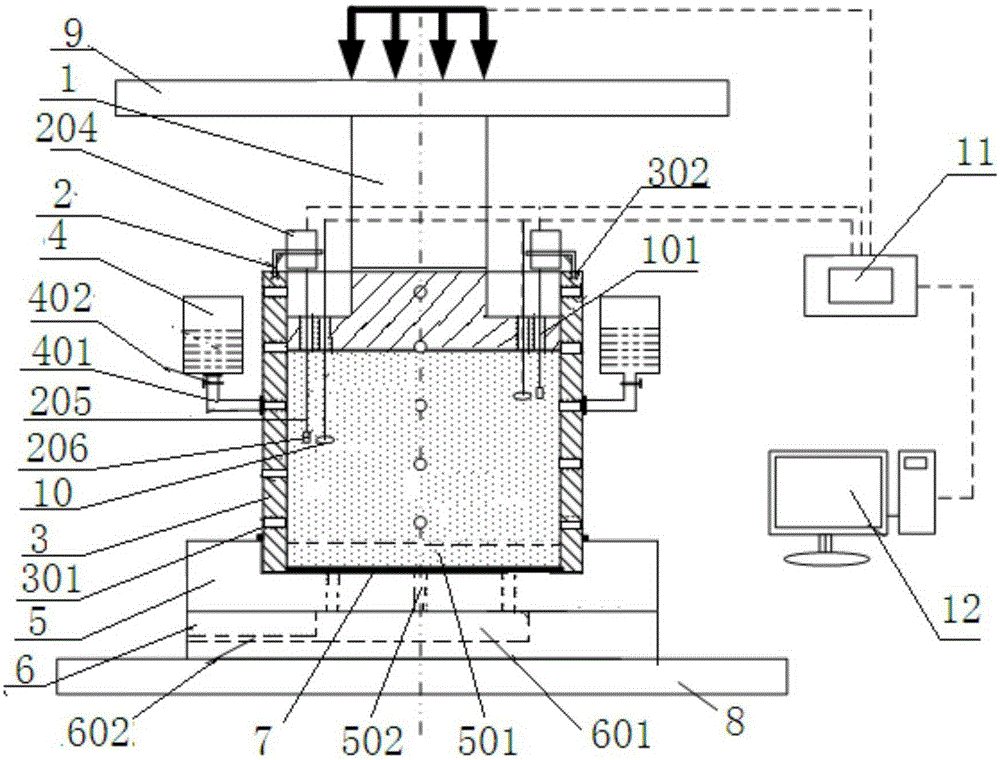

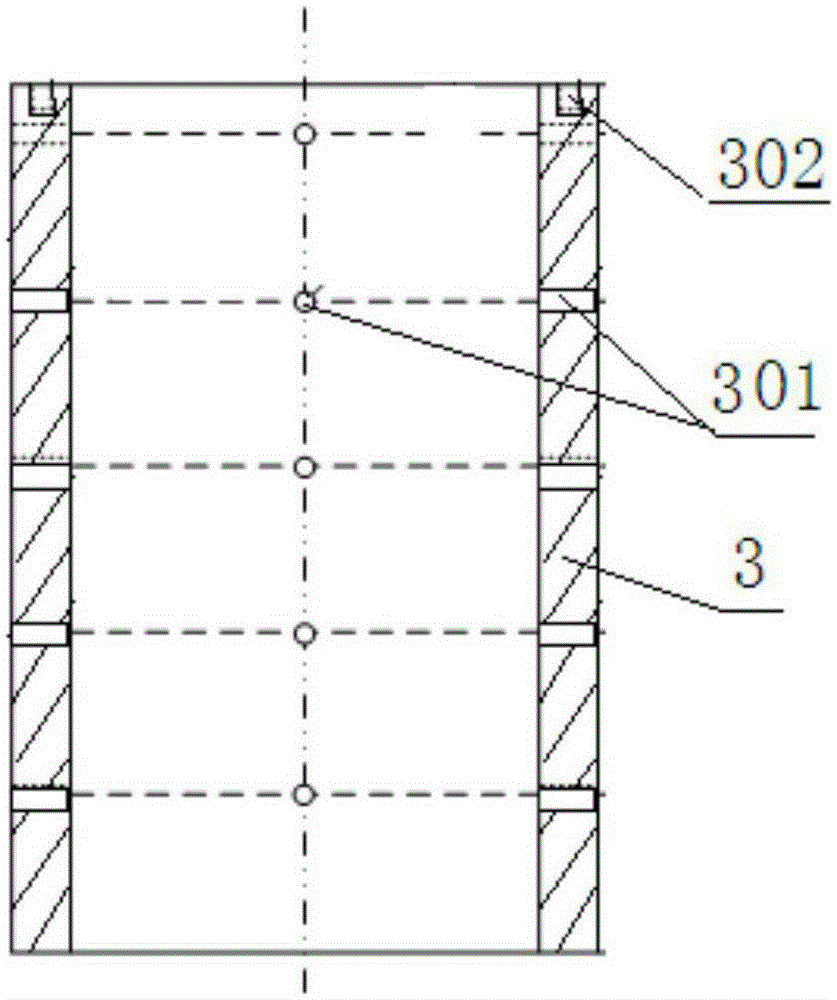

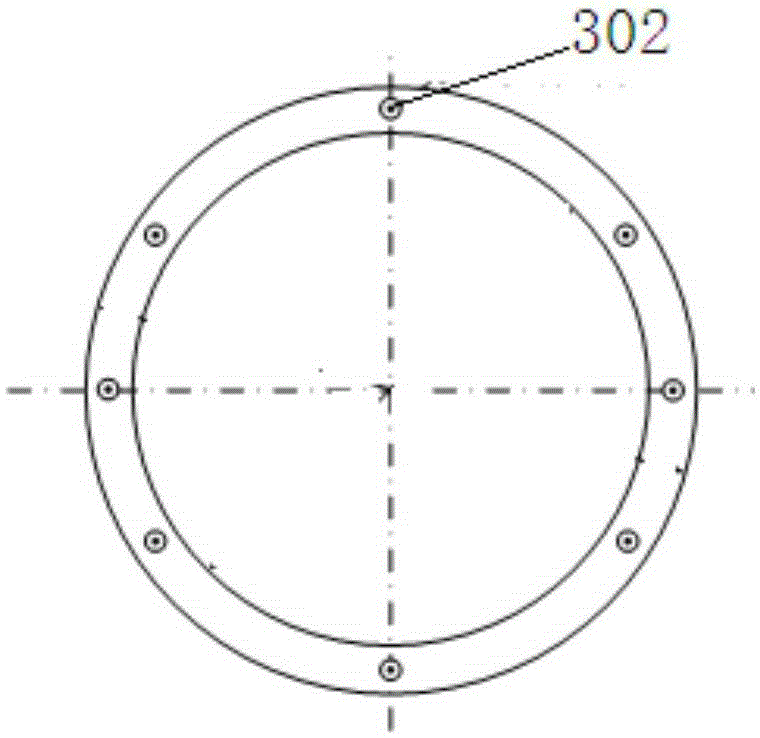

The invention provides a method and a device for synchronous measurements on dynamic and static elastic parameters of rocks by using a rock triaxial anti-compression testing device. The method comprises: sealing a test rock sample in a triaxial autoclave filled with hydraulic oil, applying an oil pressure by an axial pressure control system, applying a confining pressure by a confining pressure control system, and applying a pore pressure by a pore pressure control system; acquiring propagation speeds of longitudinal waves and transverse waves in the test rock sample by a computer acquisition and control system, and calculating the dynamic Young modulus and the dynamic Poisson ratio according to the propagation speeds; and acquiring deformation parameters of the test rock sample during a loading process by the computer acquisition and control system, and calculating the static Young modulus and the static Poisson ratio according to the deformation parameters. The method and the device can ensure validity and accuracy of hydrocarbon reservoir rock mechanical parameter measurements in thousands of meters deep underground and under the conditions of complex confining pressure, high temperature, high pore pressure and polyphase fluid.

Owner:PEKING UNIV

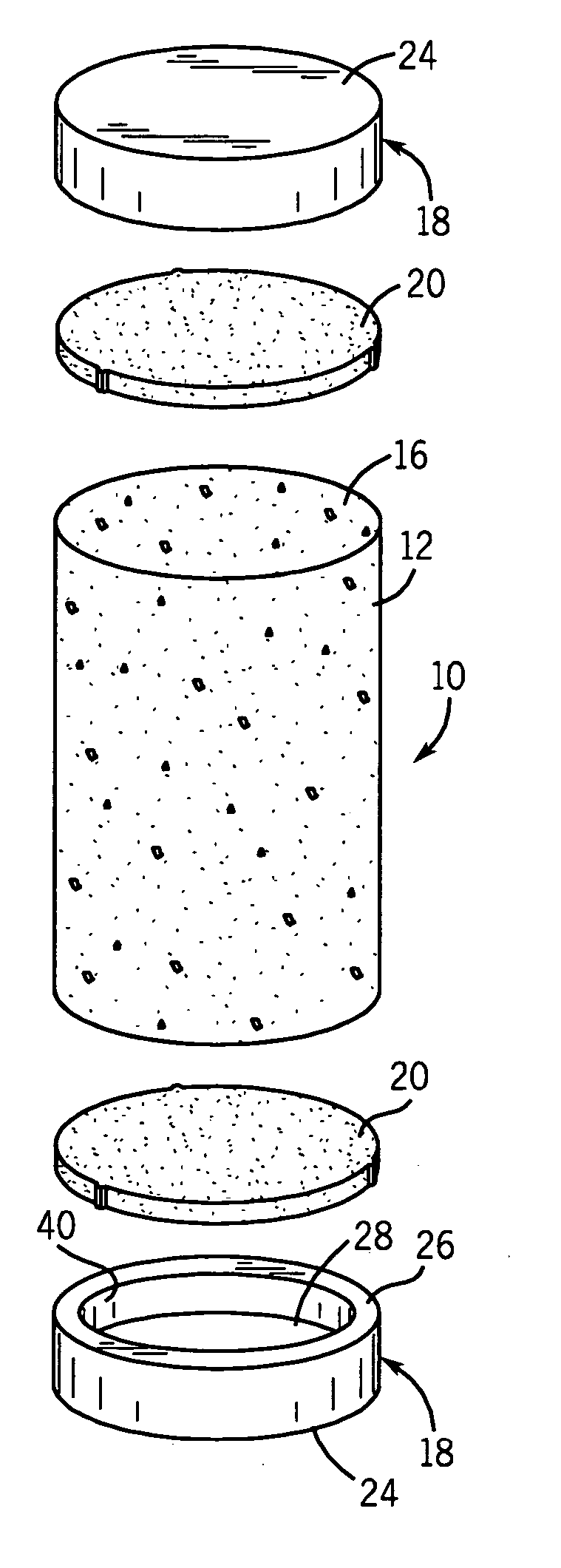

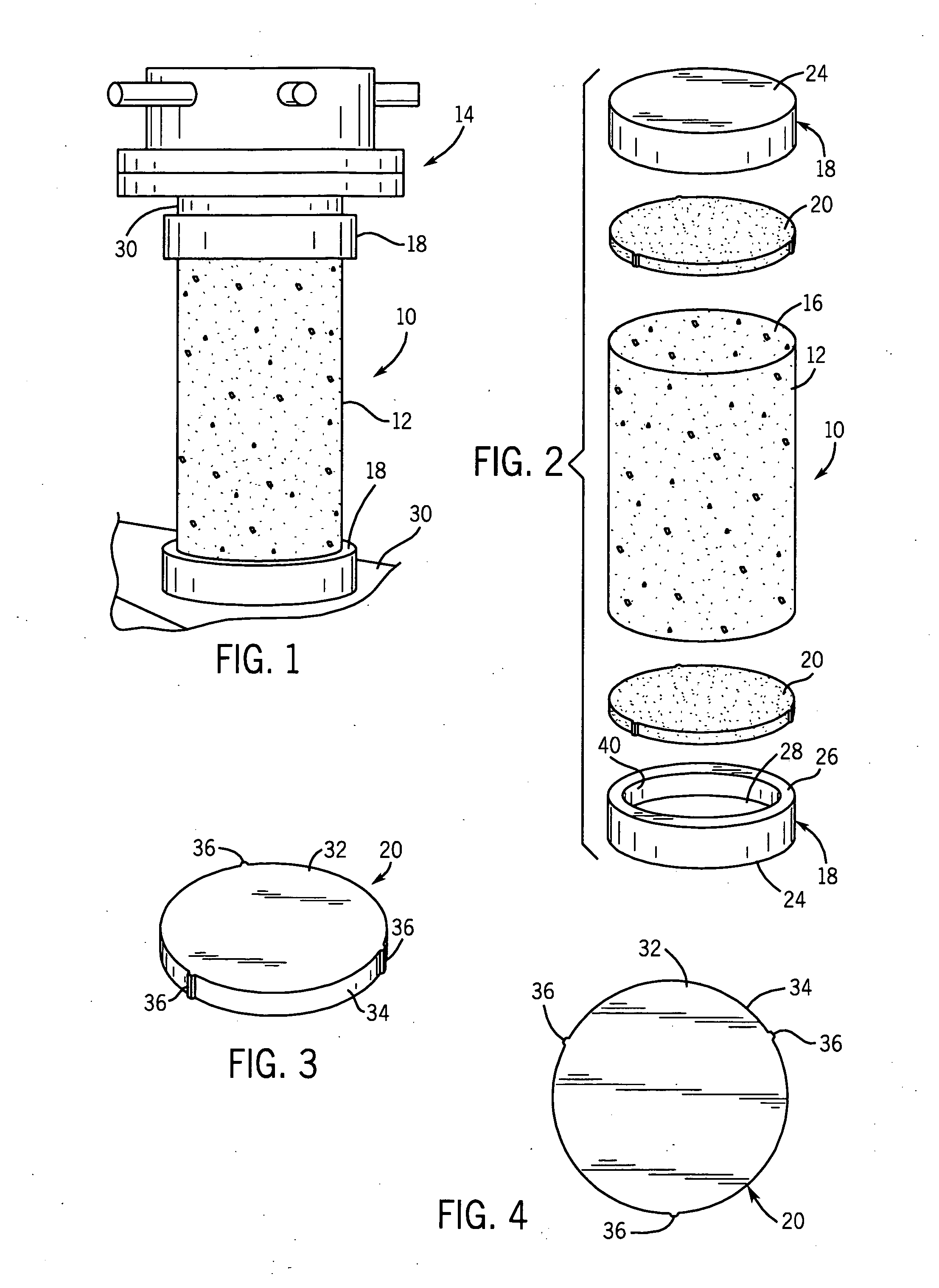

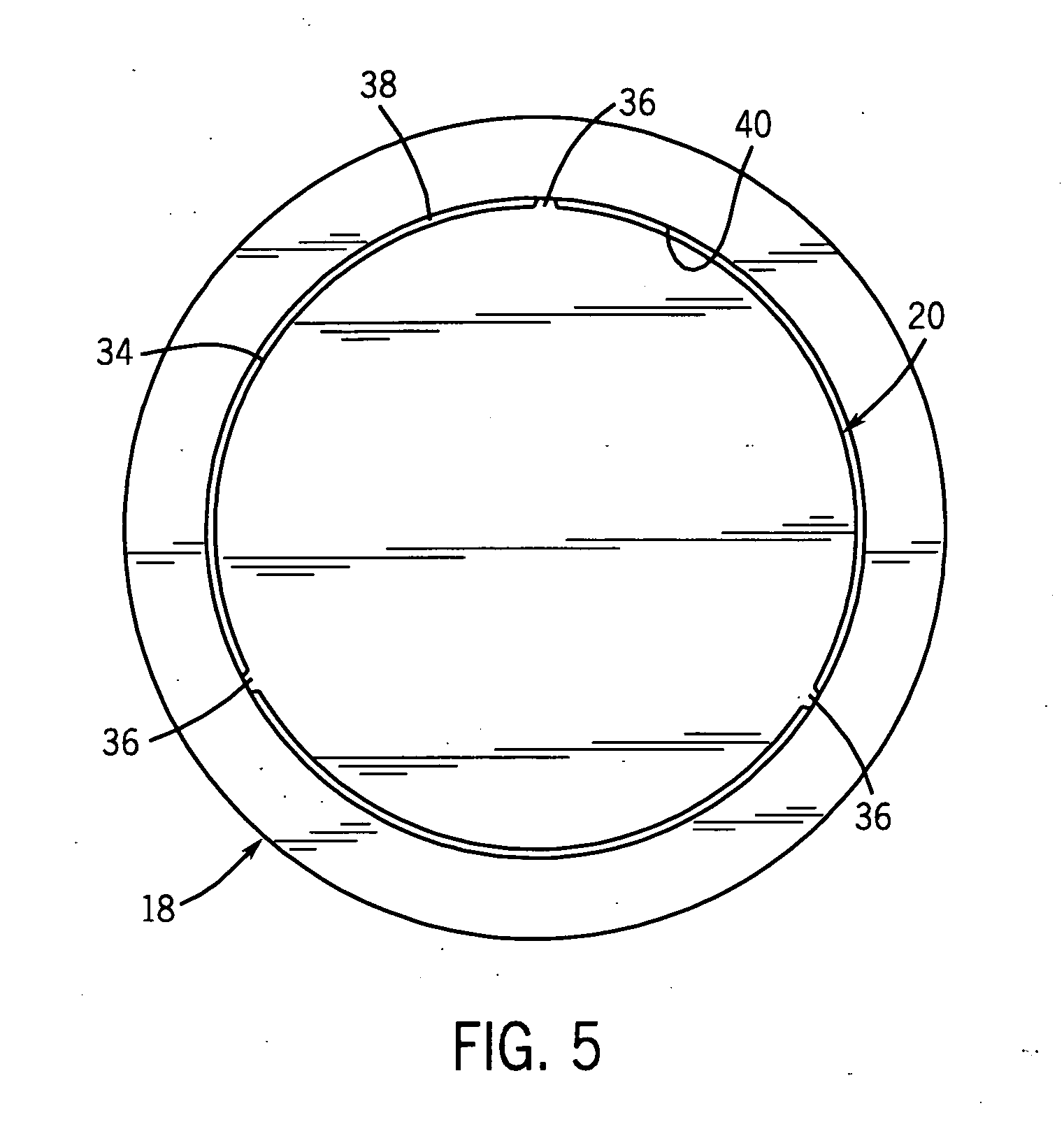

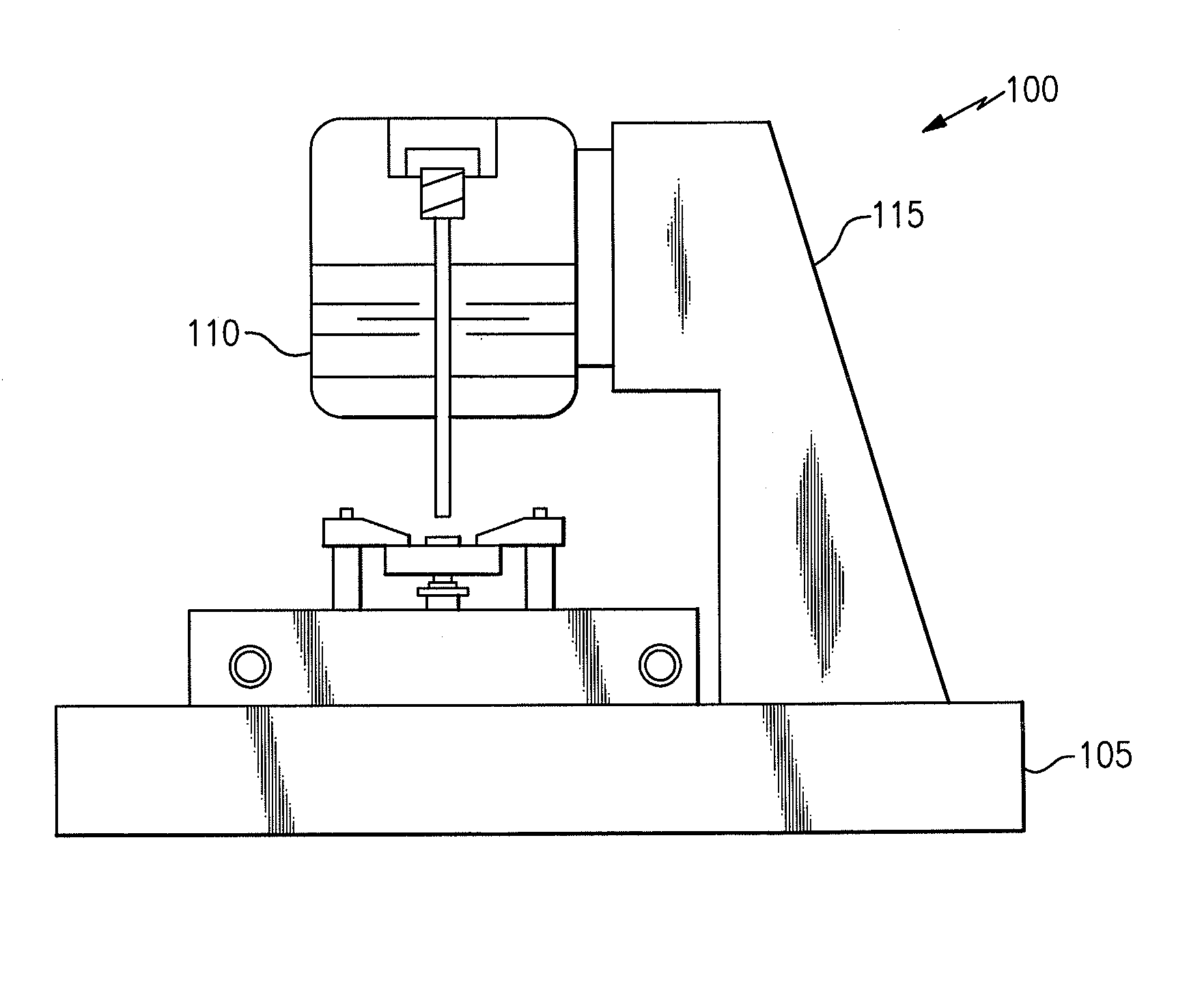

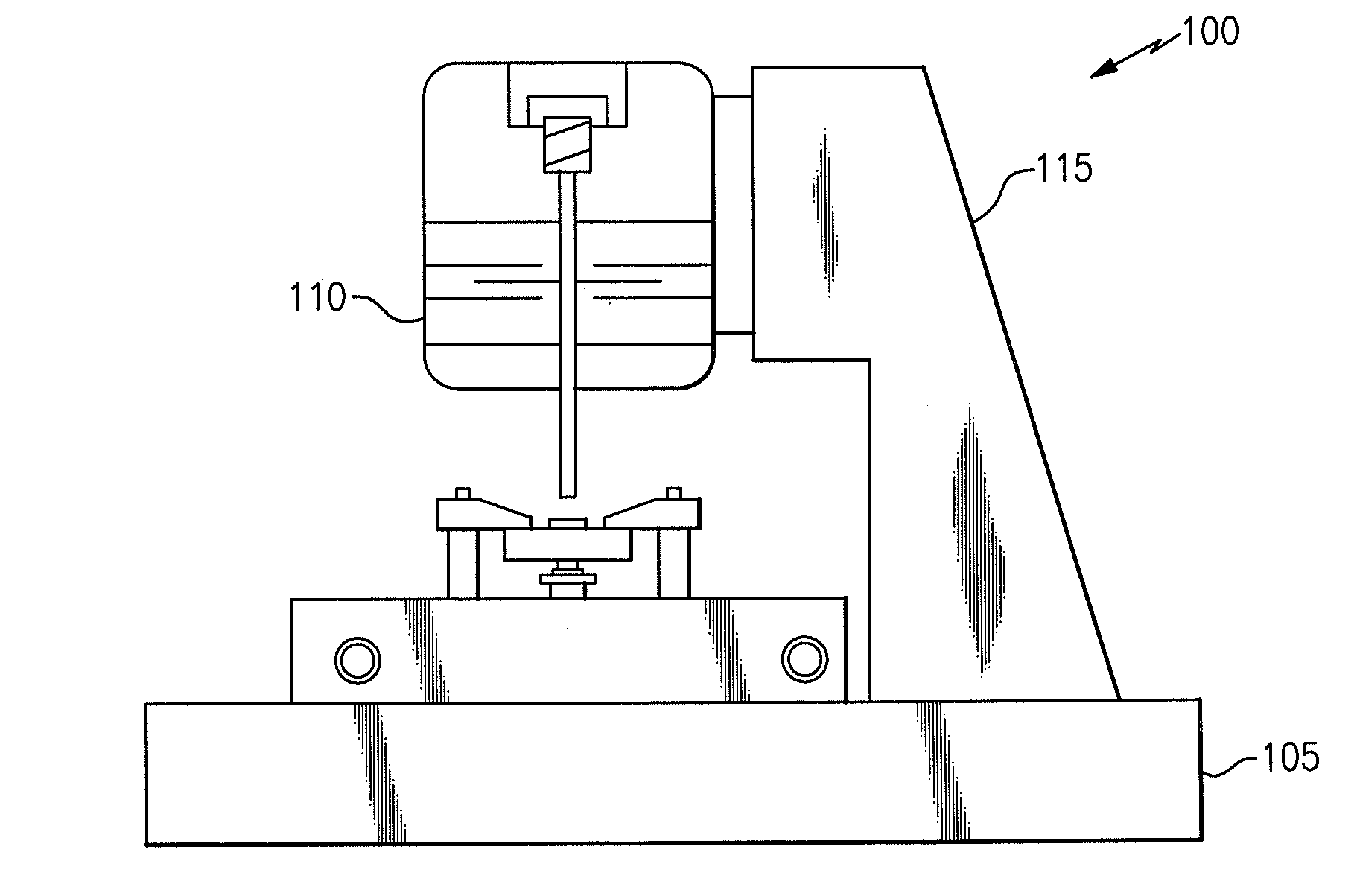

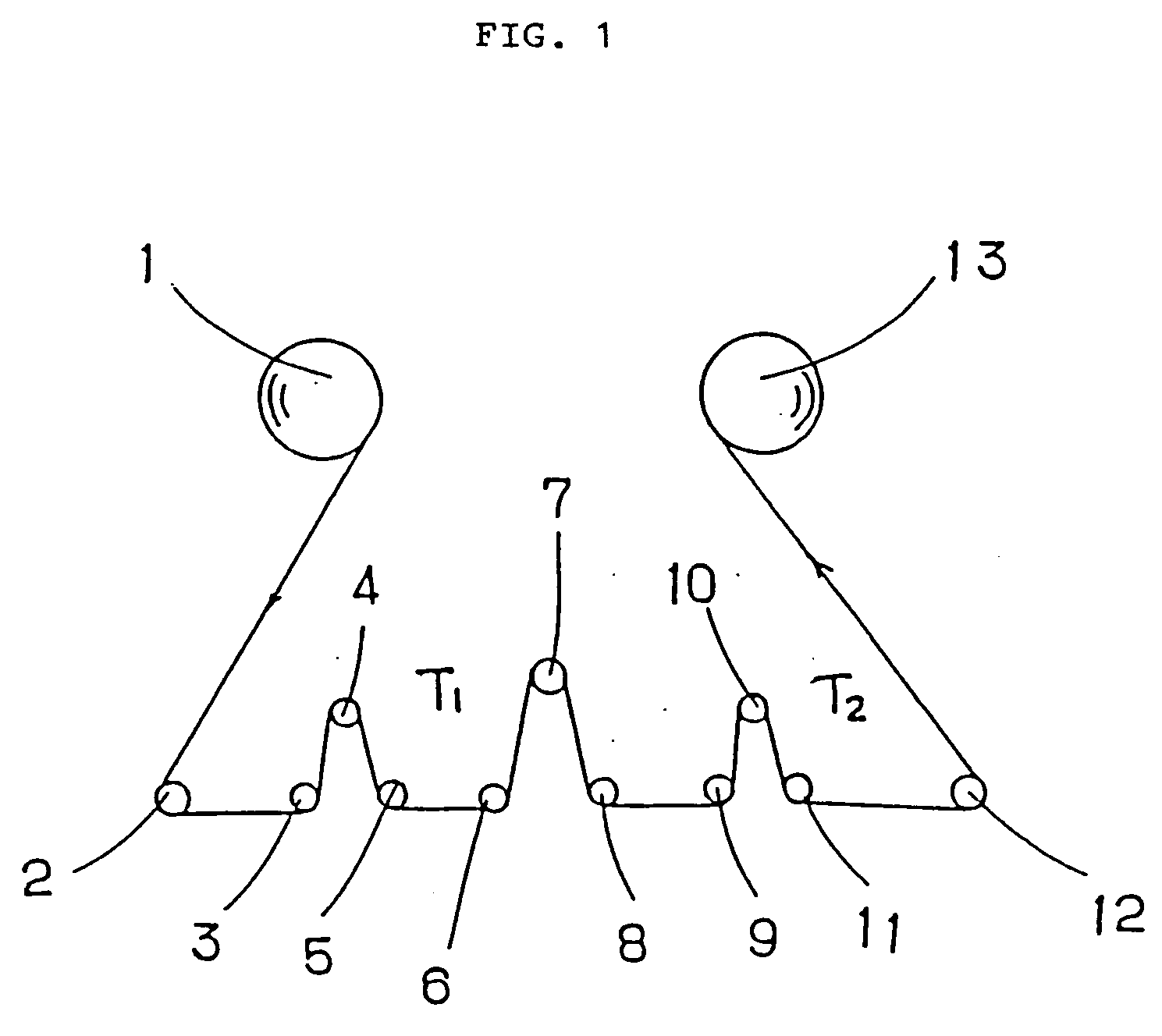

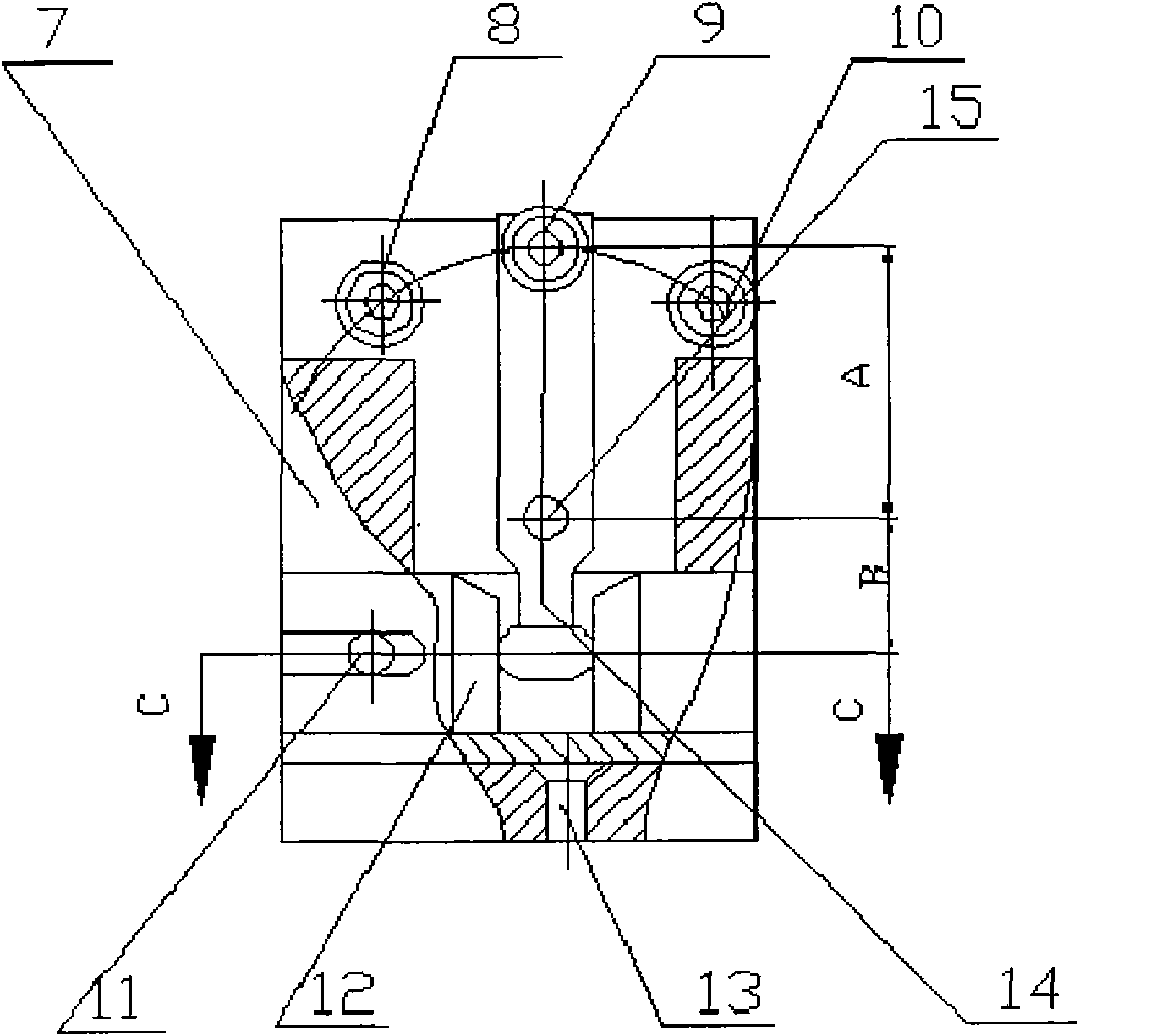

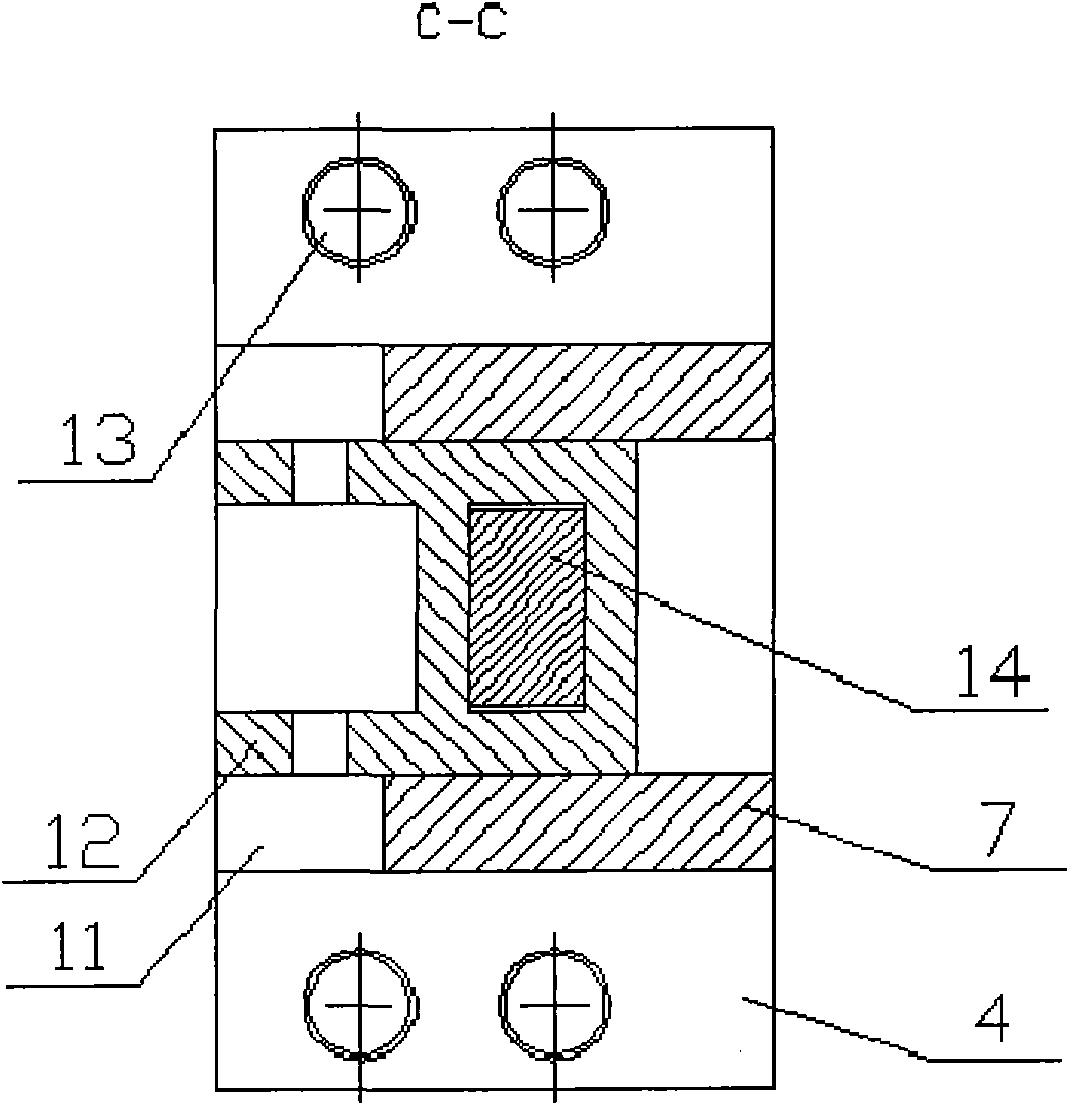

Unbonded system for strength testing of concrete cylinders

InactiveUS20050103118A1Fluid pressure measurement using elastically-deformable gaugesMaterial strength using tensile/compressive forcesEngineeringUltimate tensile strength

An unbonded capping system for compression testing of concrete cylinders comprises first and second retaining cups comprising metal blocks each having opposite parallel planar surfaces. A first of the planar surfaces is engageable by a test apparatus, in use. A second of the planar surfaces has a cylindrical cavity of a first select diameter for receiving one end of the concrete cylinder. First and second cylindrical compression pads are each to be received in one of the retaining cup cavities to abut an end of the concrete cylinder, in use. The compression pads are of a second select diameter smaller than the first select diameter of the cavity to define a circumferential space therebetween. Nubs are provided for gripping the cavity to prevent the compression pads from falling out of the cavities.

Owner:DESLAURIERS

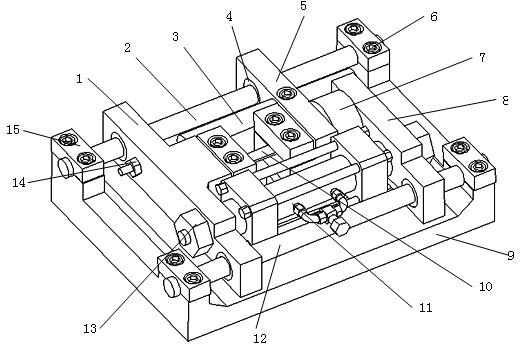

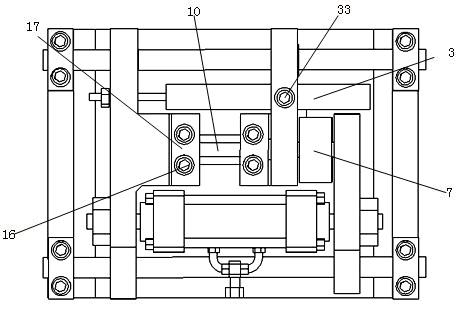

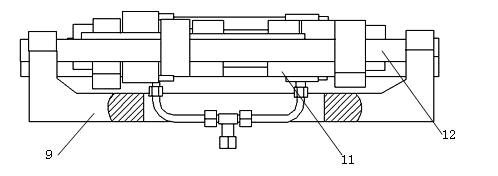

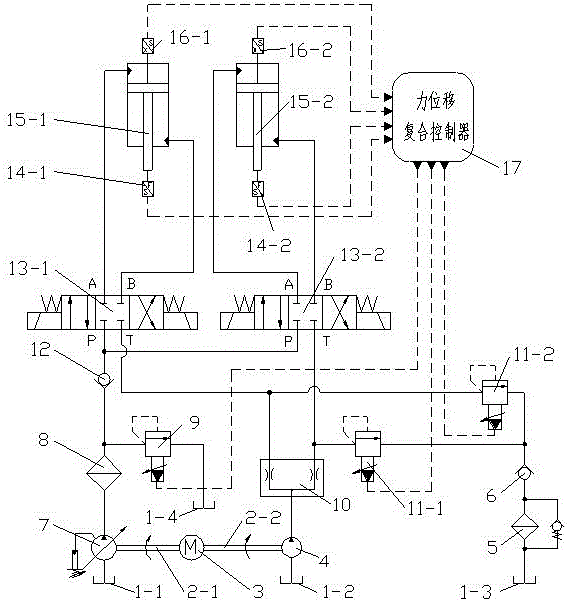

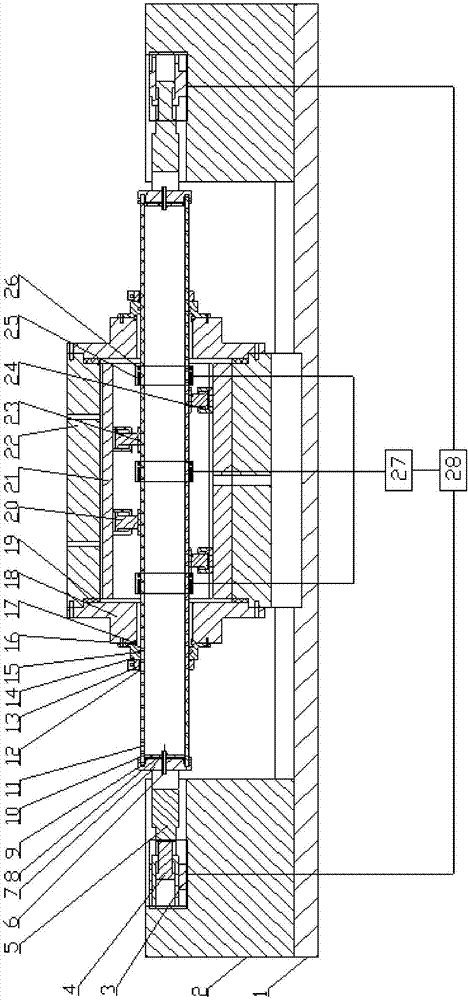

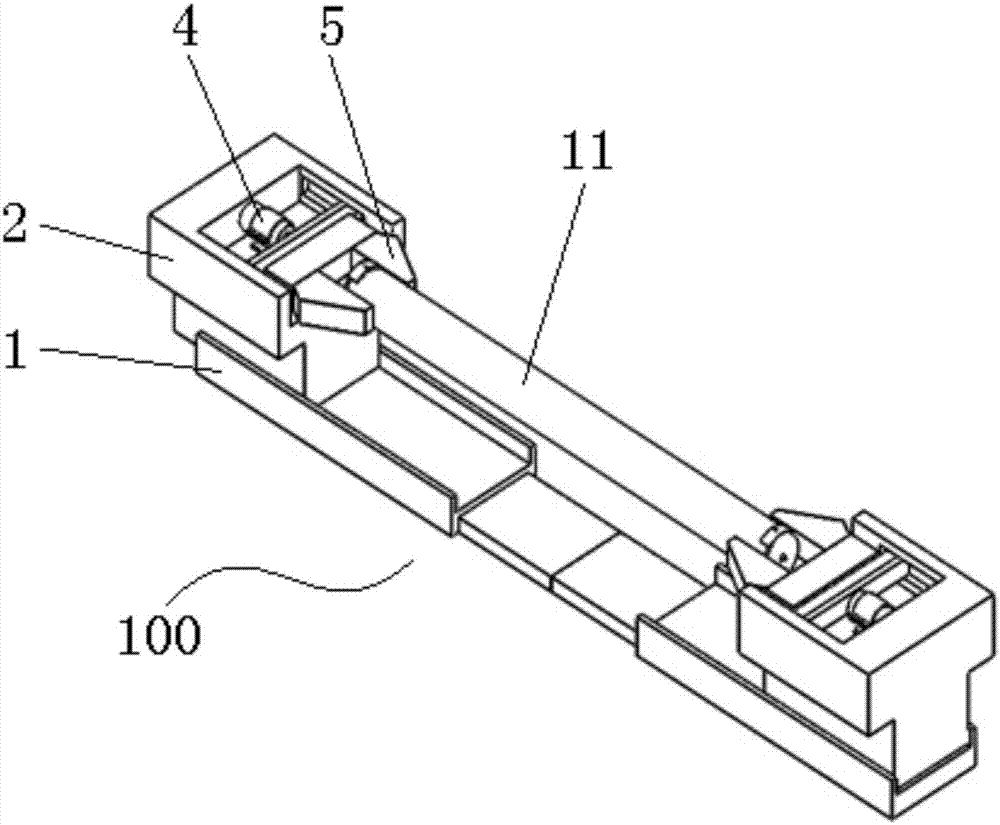

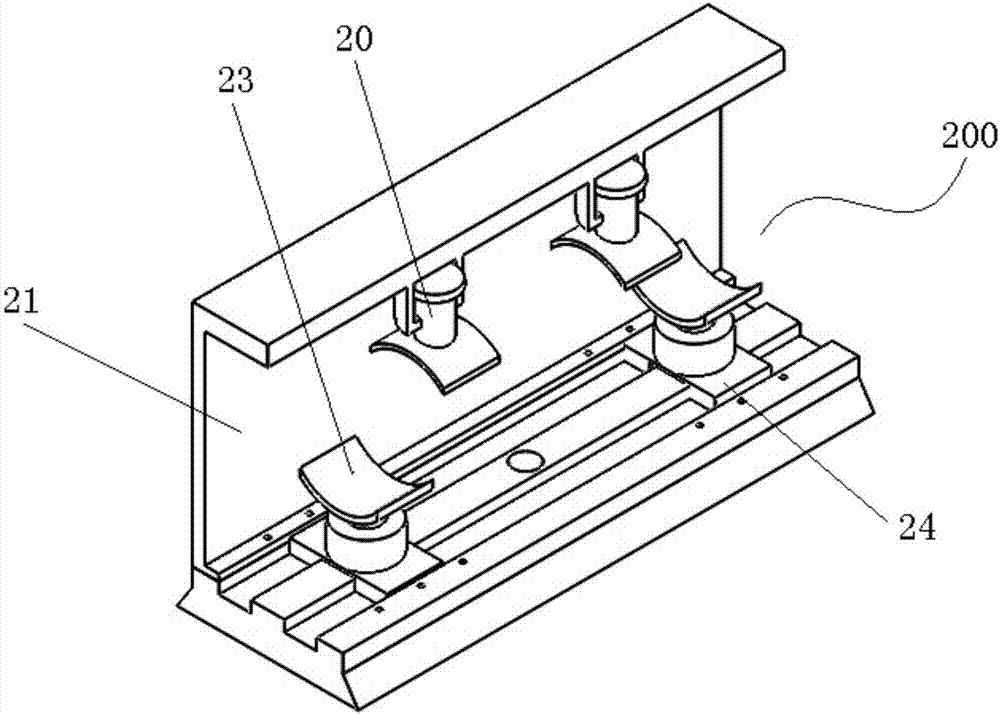

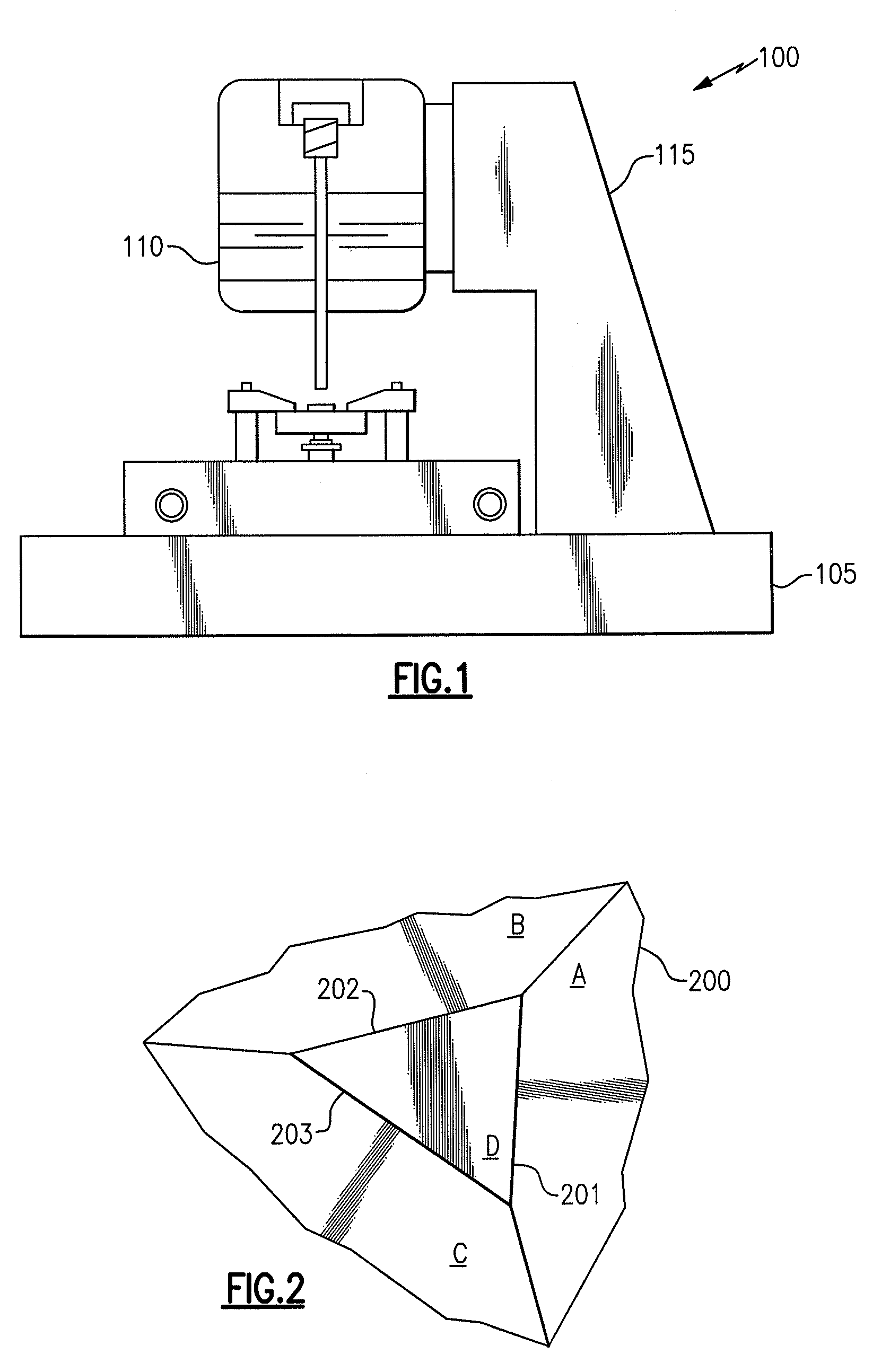

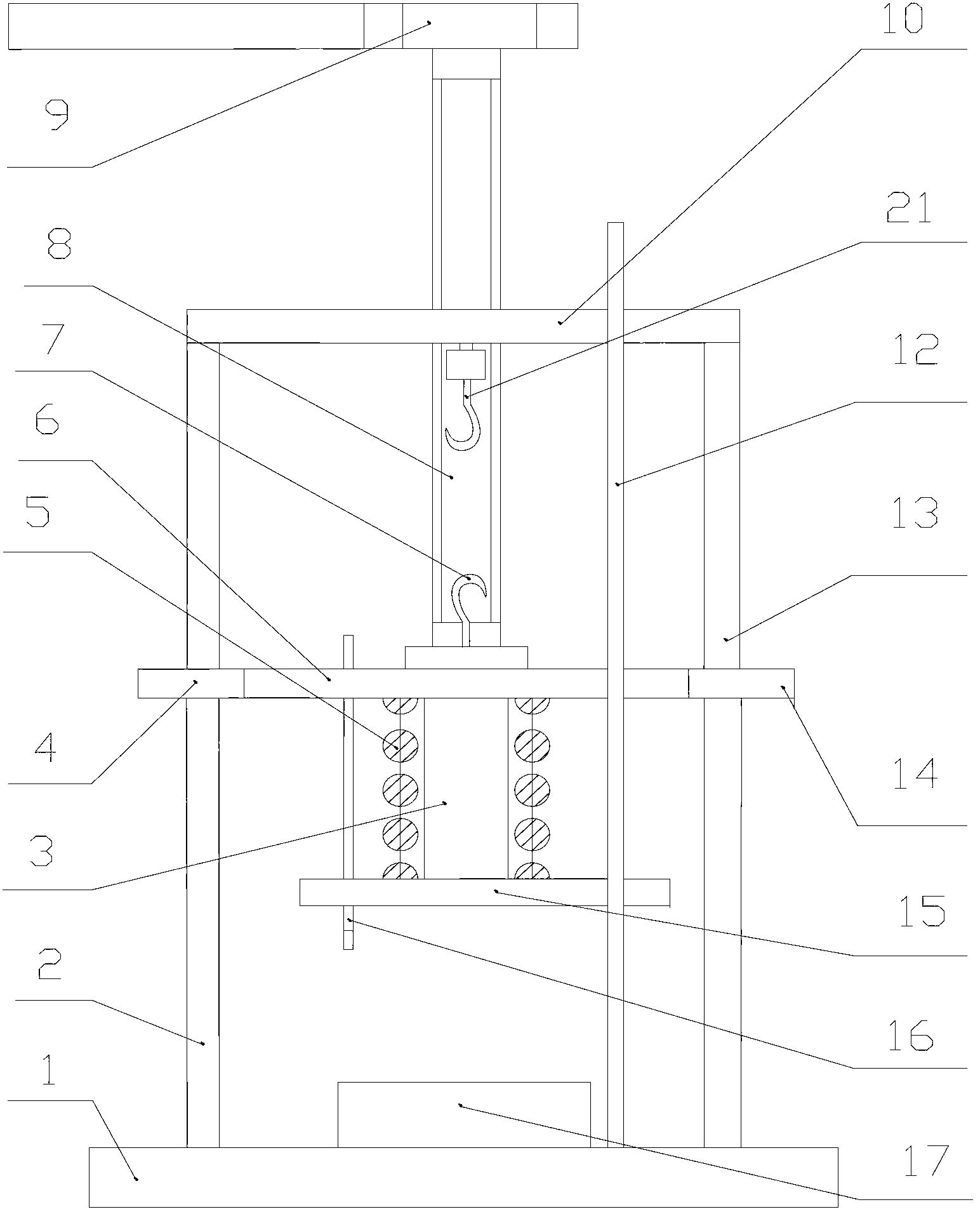

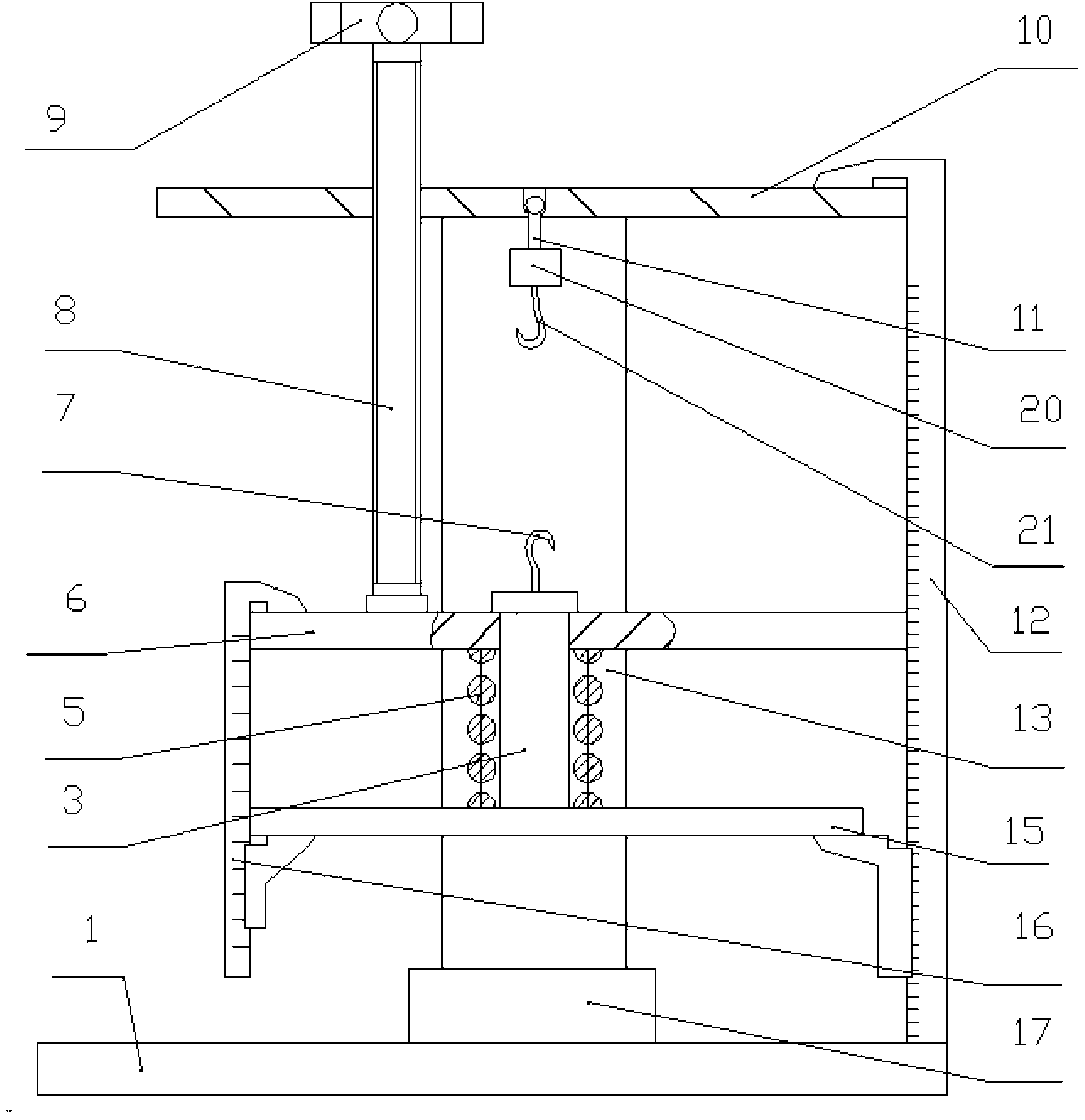

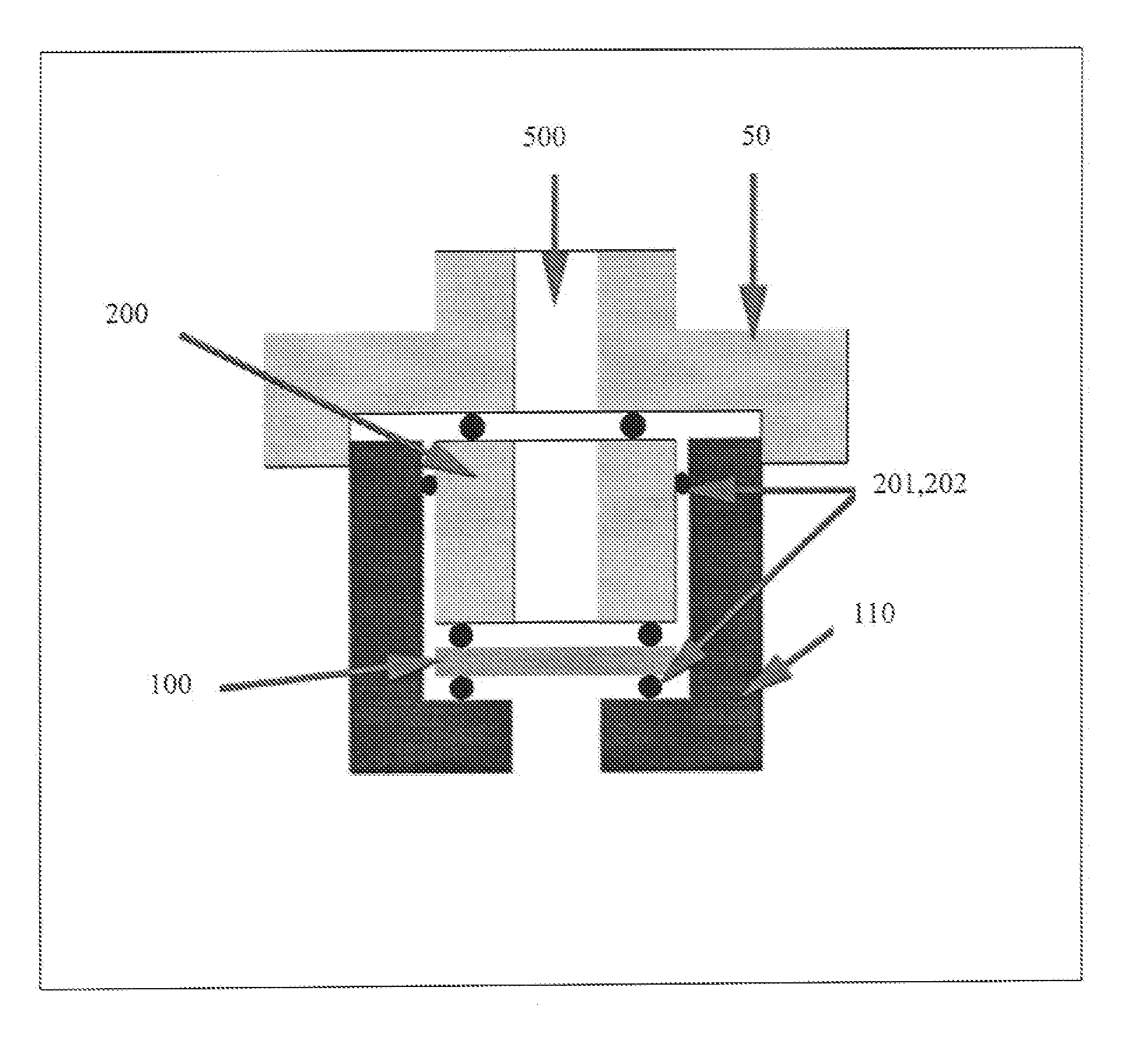

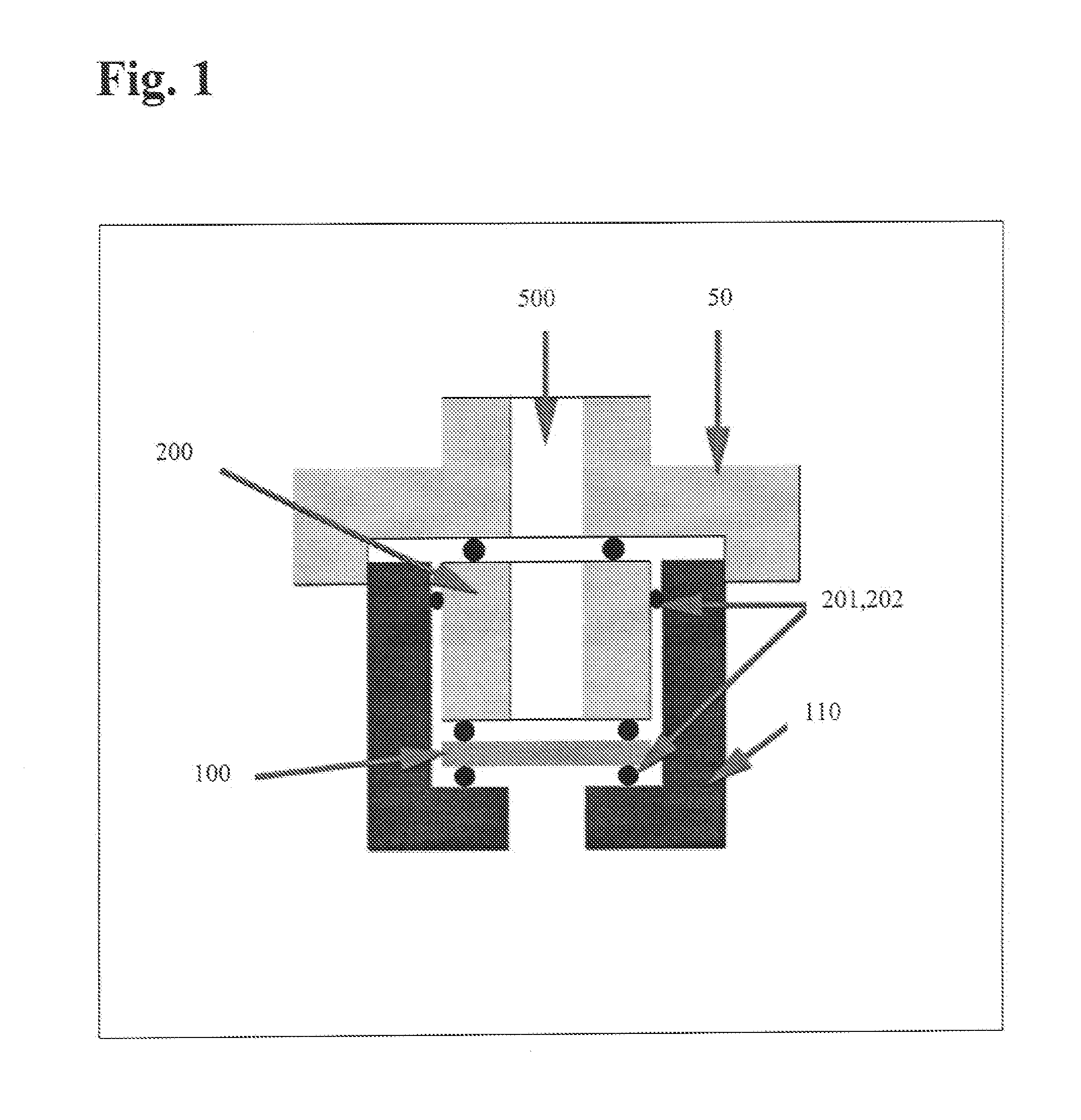

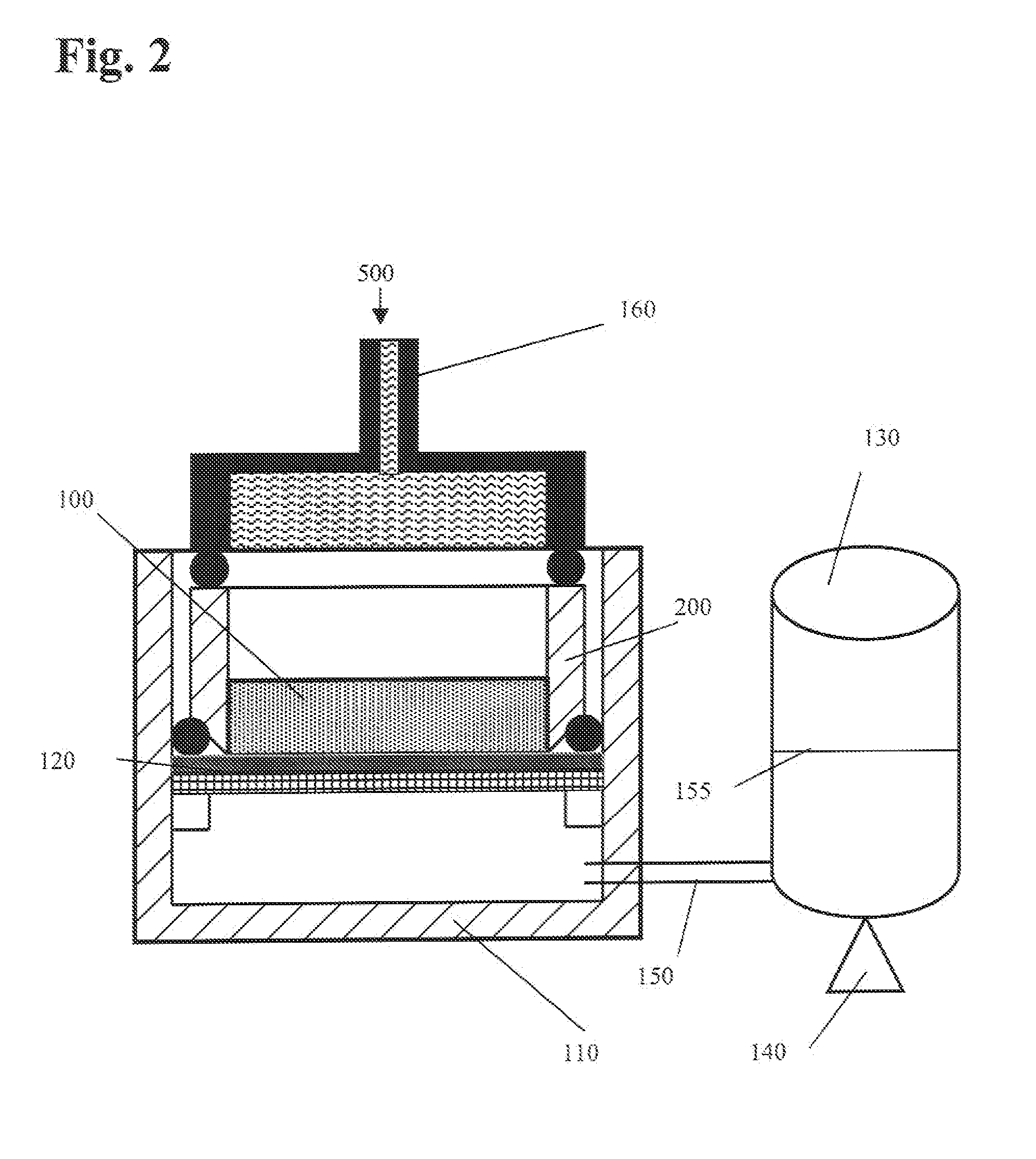

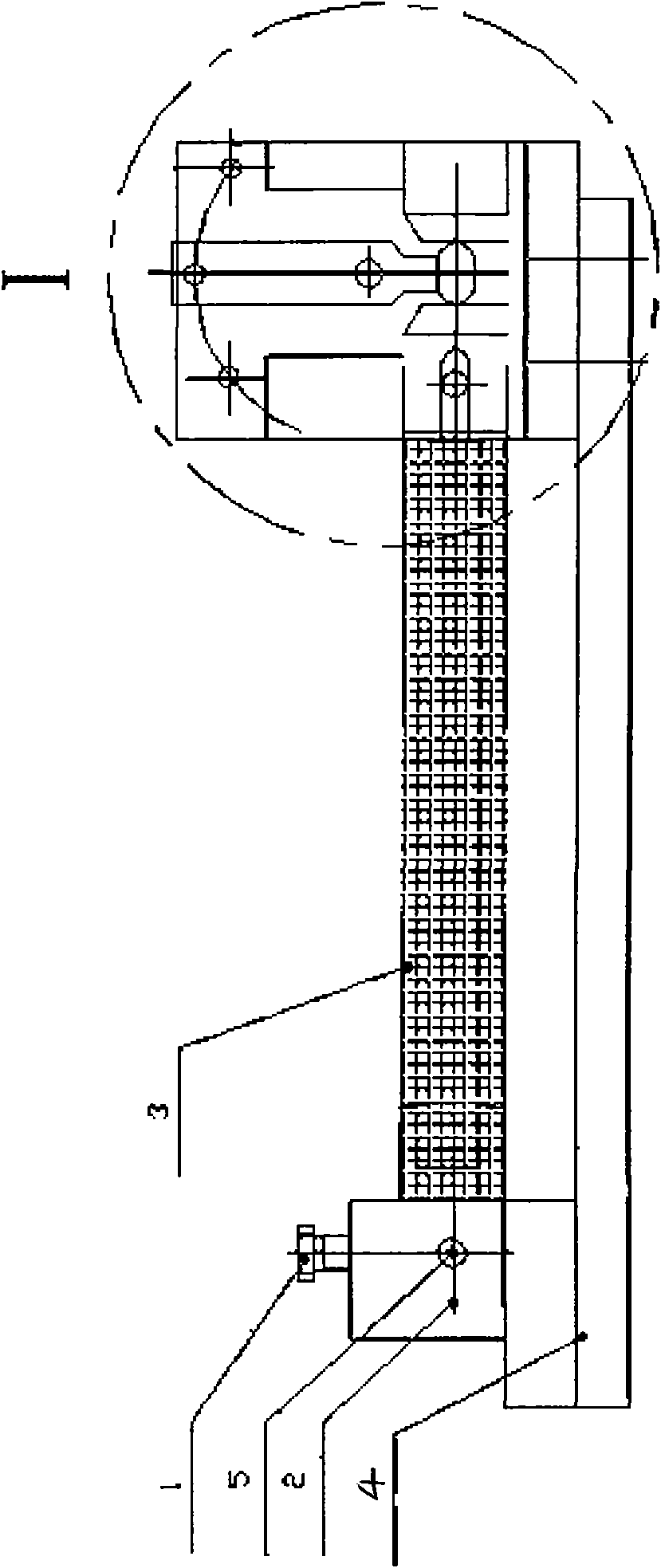

Hydraulic-driving mode based in situ tensile/compression testing platform under scanning electron microscope

InactiveCN102435493AGood structural compatibilityImprove compatibilityStrength propertiesElectromechanicsScanning tunneling microscope

The invention relates to a hydraulic-driving mode based in-situ tensile / compression testing platform under a scanning electron microscope, and belongs to the field of electromechanics. The hydraulic-driving mode based in-situ tensile / compression testing platform under the scanning electron microscope comprises a hydraulic driving unit consisting of a hydraulic cylinder, an oil tank, an oil filter, a motor, a hydraulic pump, an overflow valve, a throttle valve and an electro-hydraulic servo valve, a load / displacement signal detection and control unit consisting of a displacement sensor and a pull and pressure sensor, and a clamping and supporting unit consisting of light bars, fixture body supporting racks, base linear bearings, pressure plates, a force sensor supporting rack and a specimen. The hydraulic-driving mode based in-situ tensile / compression testing platform under the scanning electron microscope has the advantages of small volume, compact structure, large output load, continuously variable transmission loading, and good structural compatibility with a microscopic imaging system with an open space structure, such as an optical microscope, a Raman spectrometer and an X-ray diffractometer and the like, and also can used for deep study on the micro-mechanical behavior and the deformation and damage mechanism of the specimen with a centimeter-level characteristic size under the action of tensile / compression loads by combination with the instruments.

Owner:JILIN UNIV

Bent casing pipe non-uniform collapse strength simulation test method and device

InactiveCN105352807AMaterial strength using tensile/compressive forcesReciprocating motionThrust bearing

The invention discloses a bent casing pipe non-uniform collapse strength simulation test method and device. Through a thrust bearing and a right clamp, additional bending moment is applied for a casing pipe fixed by a left clamp and a support, the right clamp produces up-down reciprocating motion under the action of the thrust bearing so that the casing pipe is bent and produces a certain overall angle change rate, through a front movement pressure head and a rear movement pressure head of a compression-testing machine, non-uniform load is applied for the bent casing pipe, the casing pipe strains under different loads are recorded by a strain gage and a strain meter on the outer wall of the casing pipe, based on the test data, a relationship curve of the non-uniform loads and the casing pipe strains is drawn, non-uniform collapse strength of the casing pipe at the overall angle change rate is calculated, and through change of the overall angle change rate, non-uniform collapse strength values of the casing pipe at different overall angle change rates are obtained. The test method and device are suitable for test and research of non-uniform collapse strength of a casing pipe in a crooked hole.

Owner:SOUTHWEST PETROLEUM UNIV

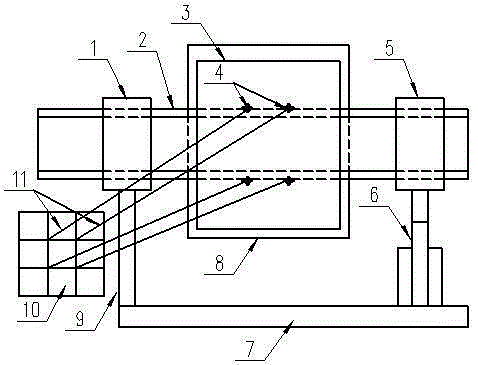

Tension and compression testing machine hydraulic loading system adopting differential control of proportional overflow valves

InactiveCN106015139AAvoid the problem of controlling the dead zoneHigh control precisionServomotor componentsServomotorsHydraulic cylinderSynchronous control

The invention discloses a tension and compression testing machine hydraulic loading system adopting differential control of proportional overflow valves. The system comprises a hydraulic pump station, a low-pressure filter, an oil return one-way valve, the high-pressure proportional overflow valve, a flow dividing valve, the two low-pressure proportional overflow valves, an oil inlet one-way valve, two electromagnetic reversing valves, two tension and compression force sensors, two hydraulic cylinders, two displacement sensors and a force and displacement compound controller. The differential control of the proportional overflow valves and compound control over the pressure and displacement of the hydraulic cylinders by pressure valves are adopted, and the micro force control and loading force control precision of a testing machine is improved; and during static and quasi-static loading of the tension and compression force testing machine, the loading force and the hydraulic cylinder synchronous displacement in the loading process are controlled in real time, and control over any loading curve and synchronous control over the multiple hydraulic cylinders are achieved. By means of the tension and compression testing machine hydraulic loading system adopting differential control of the proportional overflow valves, the tension and compression testing machine can adapt to various complicated loading work conditions. The tension and compression testing machine hydraulic loading system adopting differential control of the proportional overflow valves is suitable for the occasion where the loading force changing range is wide, the adjusting precision is high, and the hydraulic cylinders frequently need to perform synchronous control during static and quasi-static loading.

Owner:ZHEJIANG UNIV

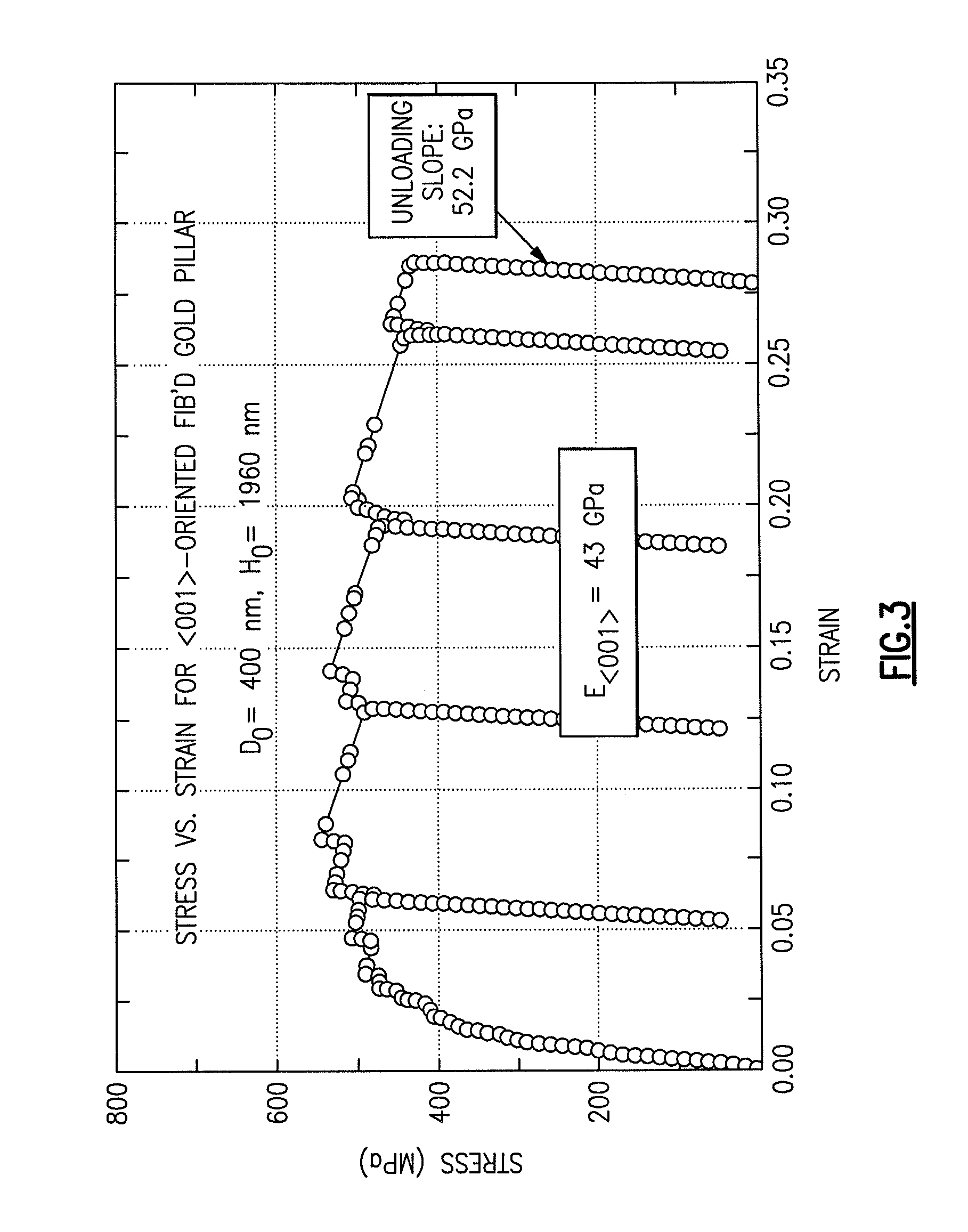

Nanoindenter tip for uniaxial tension and compression testing

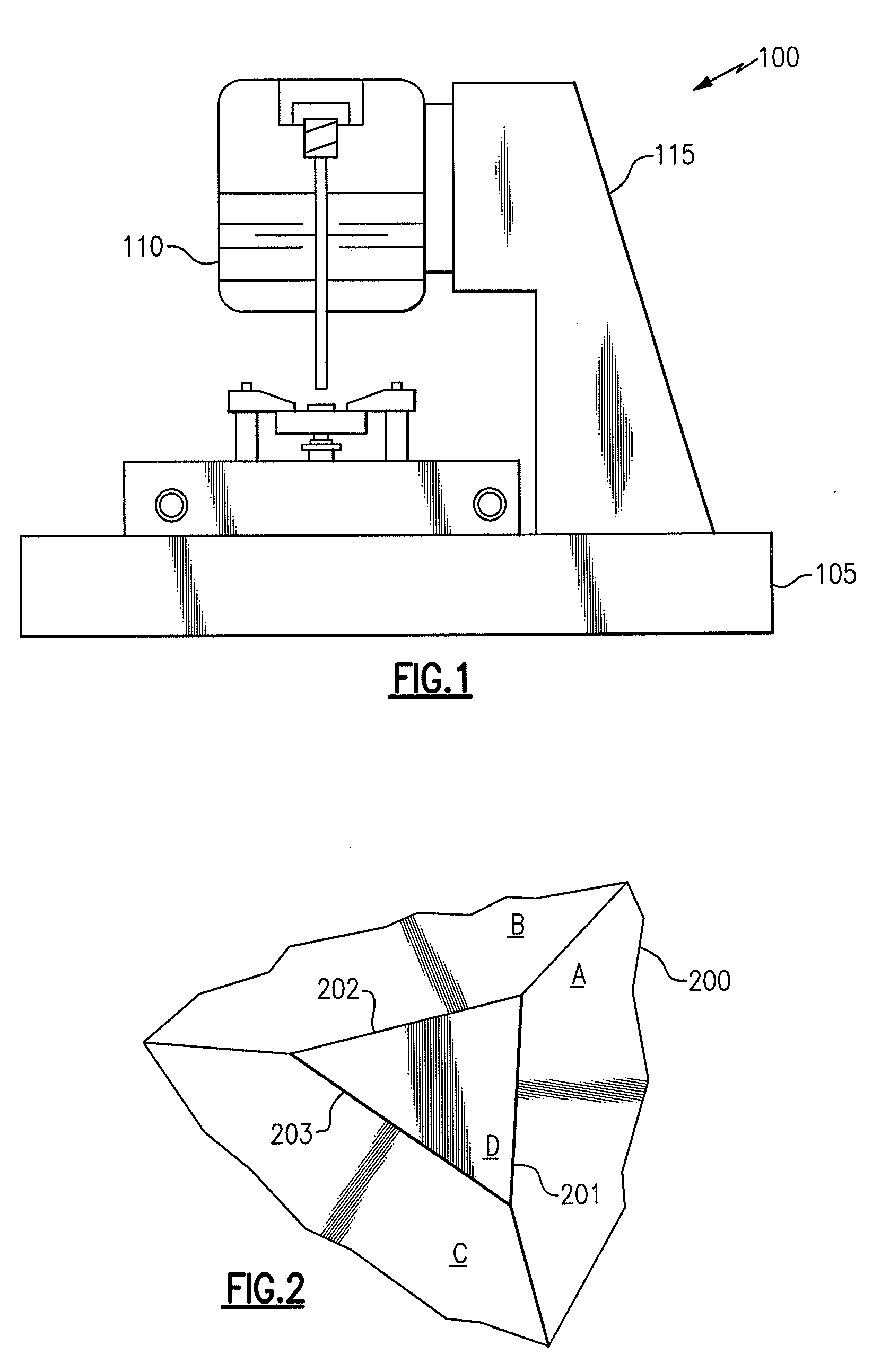

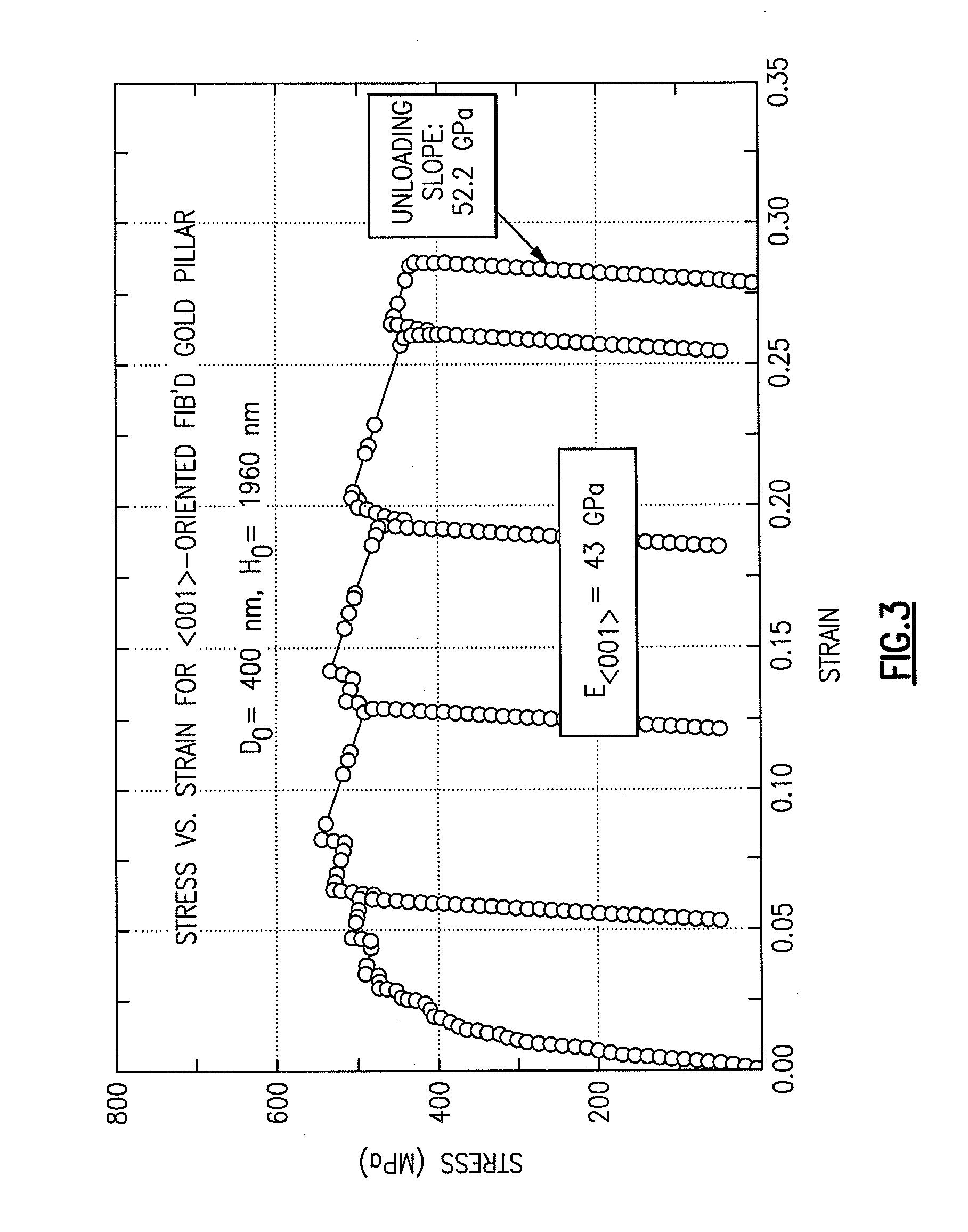

InactiveUS20100281963A1Force measurementMaterial strength using tensile/compressive forcesScanning tunneling microscopeScanning electron microscope

The invention is an indenter tip that is modified to permit both compression testing and tensile testing on samples having dimensions smaller than approximately 1 μm. The modified indenter tip has both a surface that can be used to apply compressive forces, and tines that can be used to engage a free end of a specimen to be tested in tension. The apparatus used to perform the tests includes elements of a scanning electron microscope that permit visualization of the specimen to be tested and the modified indenter tip, so as to permit appropriate alignment and engagement of the same. The apparatus also includes elements of a microindenter that provide mechanical manipulation of the relative position and orientation of the modified indenter tip and of the specimen to be tested, as well as the necessary controls and instrumentation to perform the test and to collect, record and manipulate data.

Owner:CALIFORNIA INST OF TECH

Experimental device for comprehensive testing of marine pipeline mechanical properties

ActiveCN107515150AImprove the shortcomings of the single test contentImprove the disadvantages of simplificationStrength propertiesCompression actionInternal pressure

The invention relates to an experimental device for comprehensive testing of marine pipeline mechanical properties, wherein the experimental device includes a tension and compression testing device, a four-point bending testing device, an external pressure testing device, an internal pressure testing device and a groove type base; the tension and compression testing device includes two groups of tension and compression testing components oppositely arranged on the groove type base, and the tension and compression testing components are used for achieving a clamping action and a tension and compression action on a test pipe; the four-point bending testing device adopts a four-point bending principle and is used for achieving the four point bending effect on the test pipe; the external pressure testing device is used for applying external hydraulic pressure to the periphery of the test pipe; the internal pressure testing device is used for applying internal hydraulic pressure to the inner periphery of the test pipe. The four sets of testing sub-devices have no direct relation and can be arbitrarily combined with other testing sub-devices, so that the arbitrary combination of tension, compression, bending, internal and external pressures can be realized, the shortcoming of single testing contents of a traditional experimental device is improved, the experimental device is more diverse in experimental forms, powerful in functions and complete in performance.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

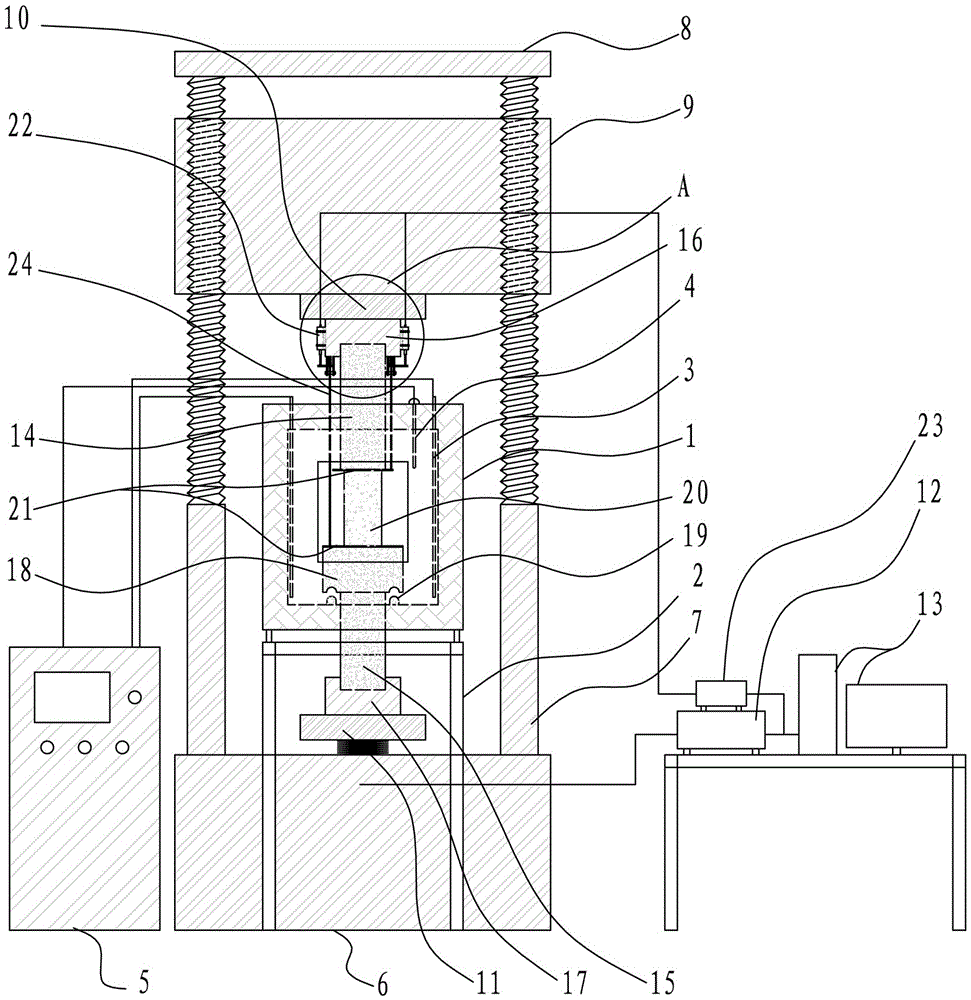

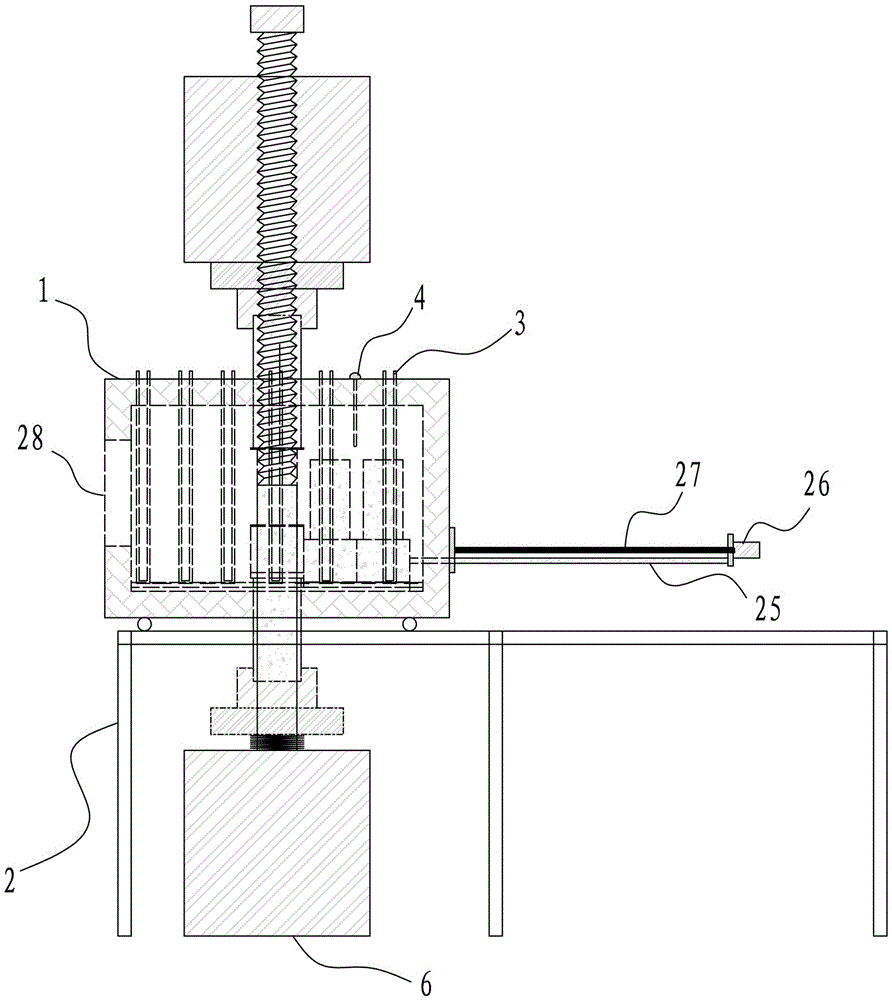

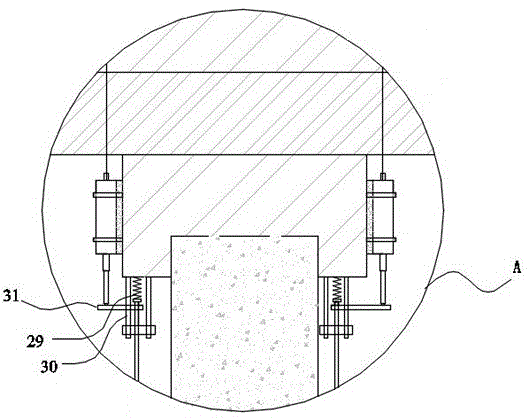

Concrete material in-high-temperature compression testing machine and in-high-temperature compression testing method

ActiveCN105424498AGuaranteed high temperatureGuaranteed fire resistanceMaterial strength using tensile/compressive forcesEngineeringFire resistance

The invention provides a concrete material in-high-temperature compression testing machine and an in-high-temperature compression testing method. The concrete material in-high-temperature compression testing machine comprises loading equipment for applying pressure on a concrete test-piece, heating equipment for heating the concrete test-piece, and a displacement acquisition device for measuring the deformation of the concrete test-piece. According to the concrete material in-high-temperature compression testing machine, the heating equipment and the loading equipment for concrete testing are skillfully combined together, and are assisted by the displacement acquisition device, so that a comprehensive testing system capable of being used for concrete test-piece in-high-temperature compression testing is formed, synchronization of heating and loading is realized, a concrete environment in high temperature due to fire can be truly simulated, a test result obtained by performing a concrete material test through the concrete material in-high-temperature compression testing machine is very close to actual compressive property of concrete in high temperature due to fire, and a guarantee is provided for researching high temperature performance and fire resistance of a concrete material.

Owner:HENAN INST OF ENG +1

Water-containing gangue compression testing device and testing method thereof

InactiveCN105181463AChange wetting methodGet compressionMaterial strength using tensile/compressive forcesWater contentEngineering

The invention discloses a water-containing gangue compression testing device and a testing method thereof. The water-containing gangue compression testing device comprises a steel barrel for storing gangues, wherein the steel barrel is divided into a plurality of layers from the whole height; a pressure sensor and a stay wire displacement sensor are arranged on each layer; the steel barrel is put on a testing machine to be subjected to a compression test so as to obtain a compression ratio and force magnitude relation of gangues on different-height layers; the same batch of gangues are tested again, but the difference is as follows: a fixed amount of water is injected at the height of a certain layer, and a compression test is carried out; the compression ratio and force magnitude relations of the gangues before and after the water is added are compared to obtain the influences on a compression process by the moisture content of the gangues on the certain layers; by that analogy, a plurality of times of tests are carried out to obtain the influences on the compression process by the moisture content of the gangues at different-height positions. The water-containing gangue compression testing device and the testing method thereof, disclosed by the invention, not only can be used for underground engineering of gangue mining with filling and the like, but also can be used for the fields of building and traffic engineering including geotechnical side slope stability analysis, gravel foundation treatment, roadbed deformation calculation and the like.

Owner:SHANDONG UNIV OF SCI & TECH

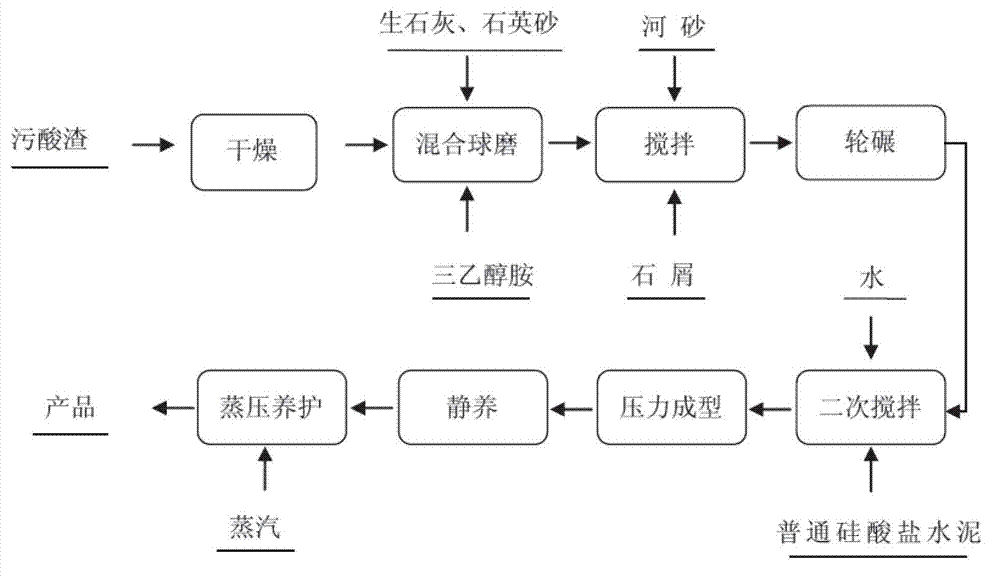

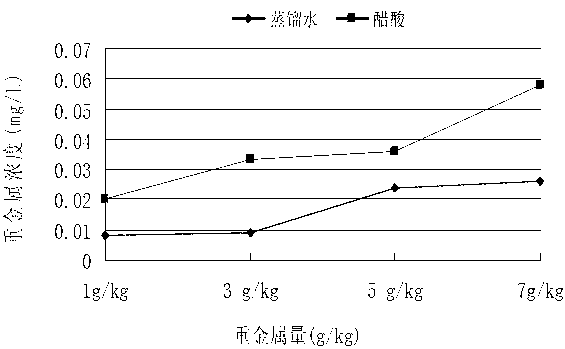

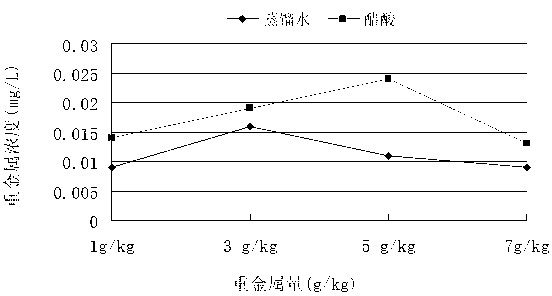

Method for manufacturing autoclaved bricks by utilizing contaminated acid sludge

InactiveCN102775113ASolve ecological and environmental problemsWide variety of sourcesBrickPortland cement

The invention discloses a method for manufacturing autoclaved bricks by utilizing contaminated acid sludge. The method comprises the steps of: I. drying: collecting and drying contaminated acid sludge; II. ball-milling: placing the dried contaminated acid sludge in a ball mill, adding a grinding additive and a chemical excitant to carry out ball milling; III. stirring: adding the ball-milled materials in a stirrer for stirring; IV. wheel milling: conveying the stirred materials in a wheel mill, adding ordinary Portland cement and adding water for wheel milling; V. compressing moulding: loading the wheel-milled materials in a standard brick mould, and placing a compression testing machine for pressure maintaining and then demoulding to obtain brick blanks; VI. static curing: placing the stamping formed brick blanks into a cement standard curing chamber for static curing; and VII. autoclaved curing: placing the brick blanks subjected to static curing into an autoclaved kettle, introducing vapor, carrying out high-temperature constant-pressure autoclaved curing, naturally cooling and taking out of the kettle to obtain the autoclaved bricks. The method solves the problem that the acidsludge pollutes biological environment and achieves the effect of changing wastes into valuables.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

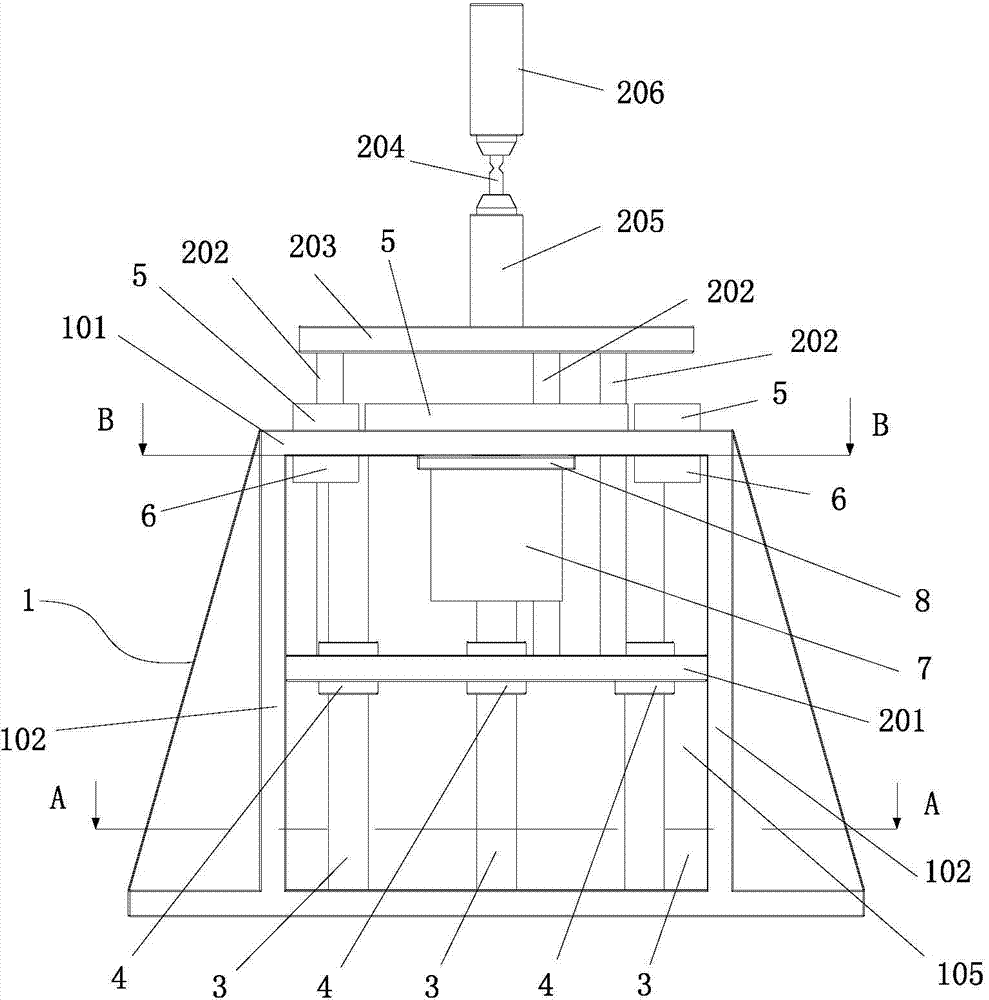

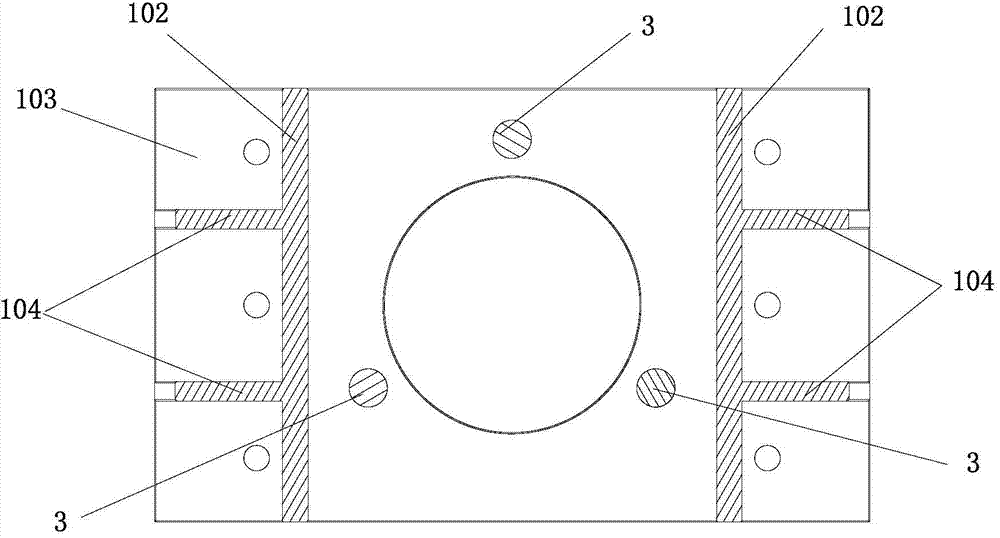

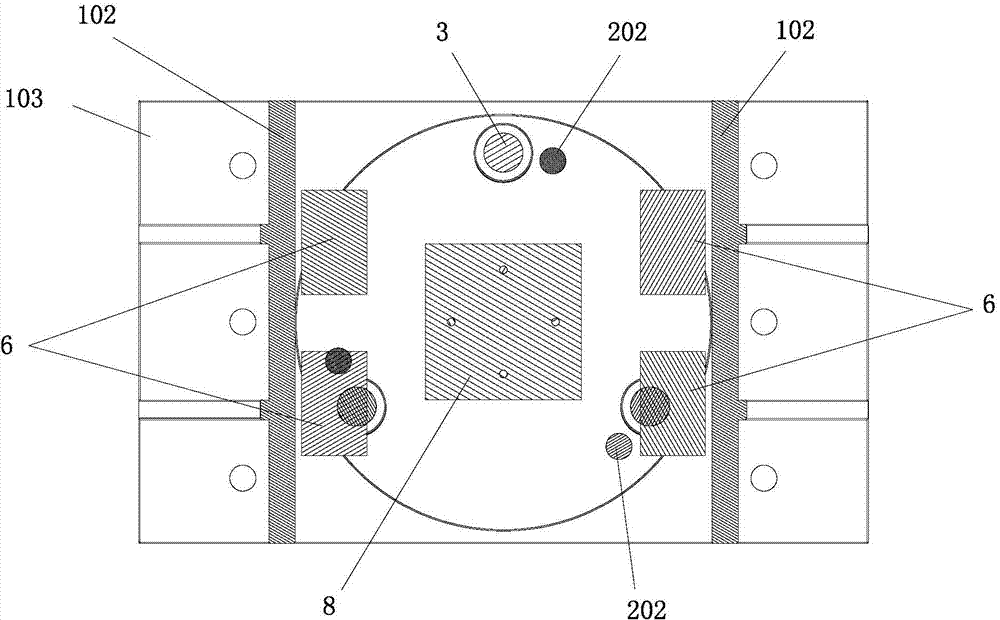

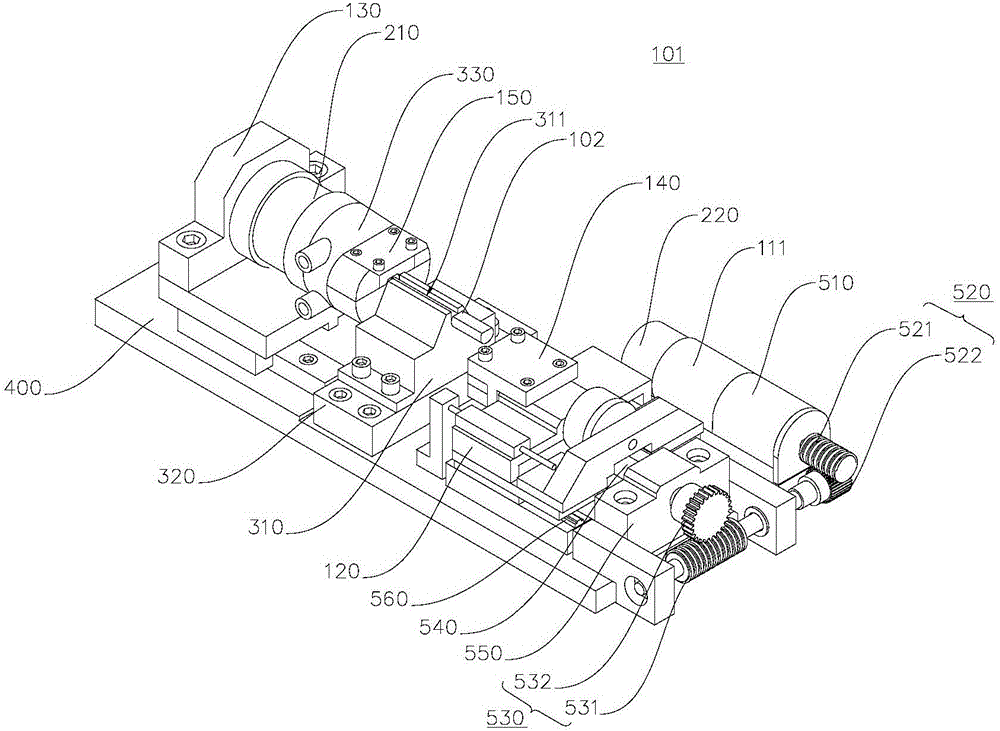

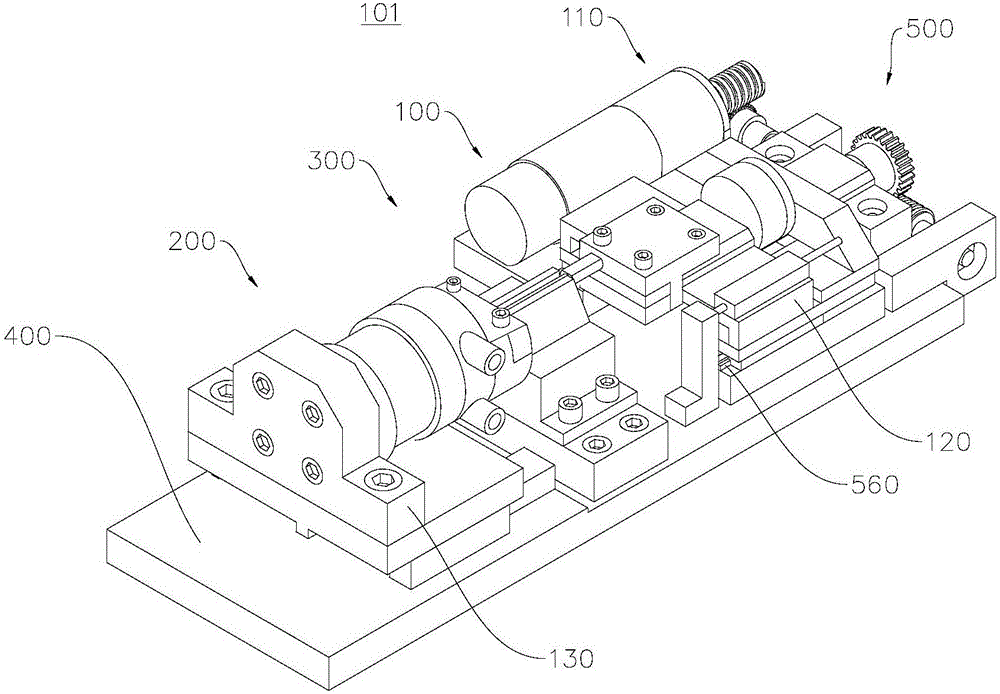

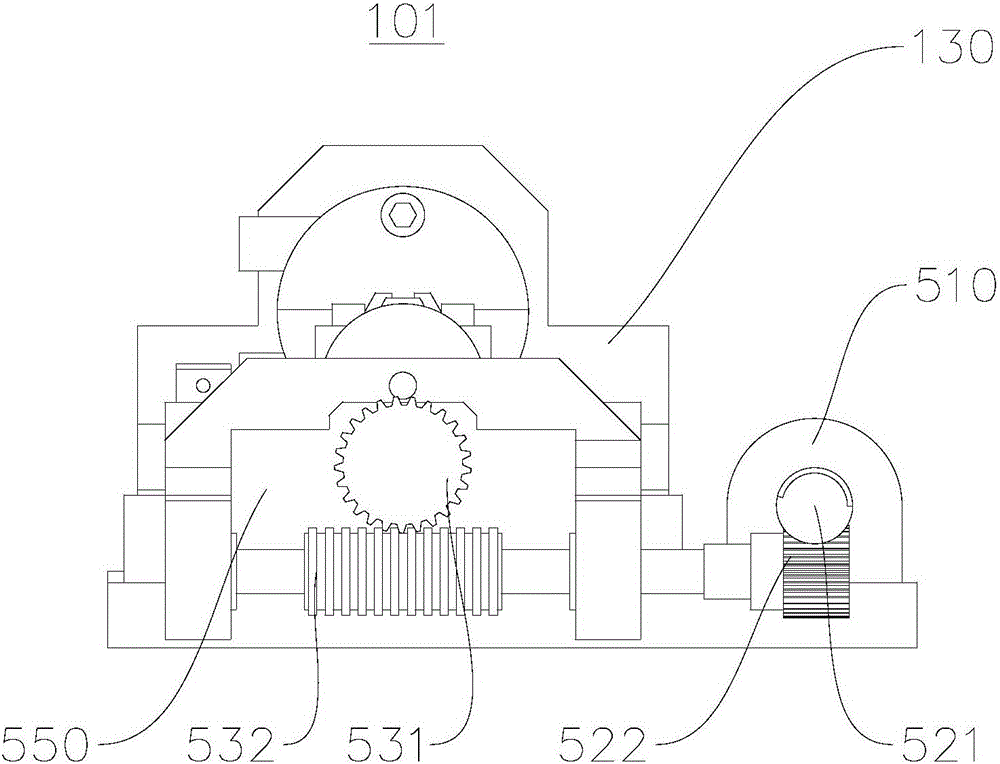

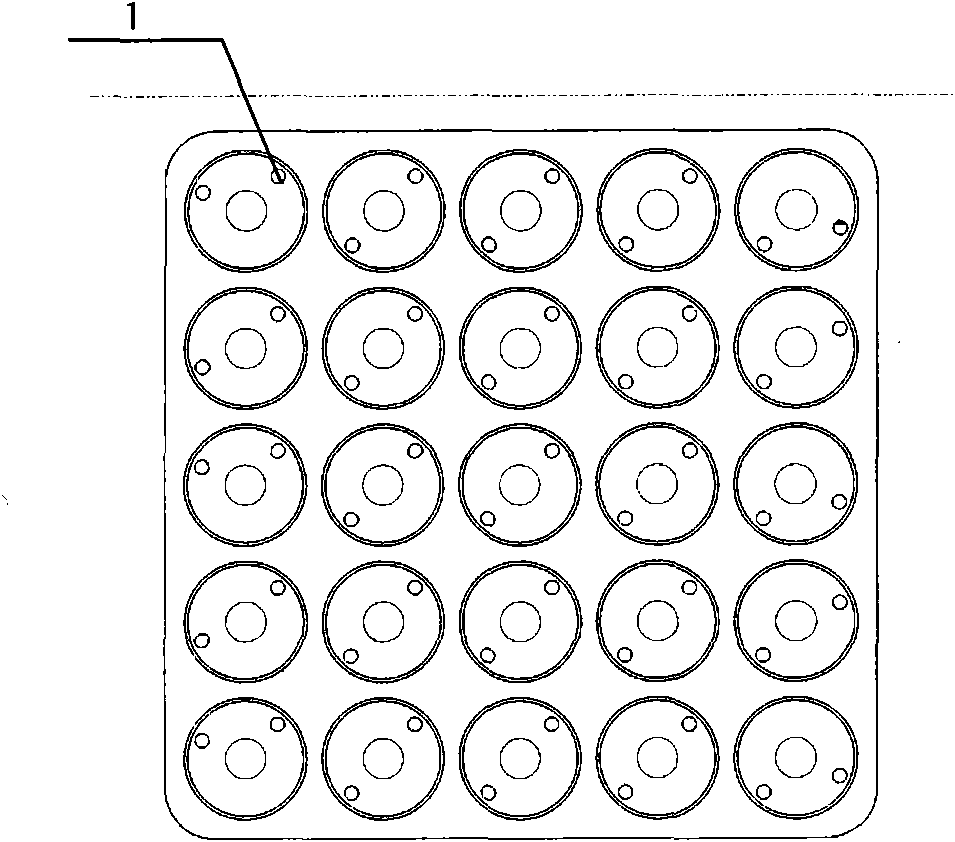

Biaxial tensile compression testing device under ultrahigh temperature complex load

PendingCN107607409ATo achieve multi-function loadingRealize linkage controlMaterial strength using tensile/compressive forcesStatic modeHot Temperature

The invention relates to a biaxial tensile compression testing device under an ultrahigh temperature complex load, and belongs to the technical field of mechanical performance testing of materials. The device comprises a bidirectional tensile / compressive load applying unit, a bidirectional signal detection and control unit, an ultrahigh temperature loading unit, a clamping unit and the like, and is of a vertical gantry structure. Drive, transmission and detection units on each shaft of the device are independent and do not interfere with one another. The bidirectional tensile / compressive loadapplying unit is driven by an electric actuating cylinder, a high-precision direct current servo motor in the bidirectional tensile / compressive load applying unit is used as a driving power source, high speed reduction ratio and torque increase are realized by a miniature multi-stage speed reduction mechanism, in combination with a stress change feedback technology, sufficient loading capacity isensured on the premise of compact structure, and application of the precise load in a quasi-static mode is realized. Real working conditions of material components can be simulated to the maximum extent, and effective means and method are provided for mechanical performance testing of the materials in the high-temperature service state.

Owner:JILIN UNIV

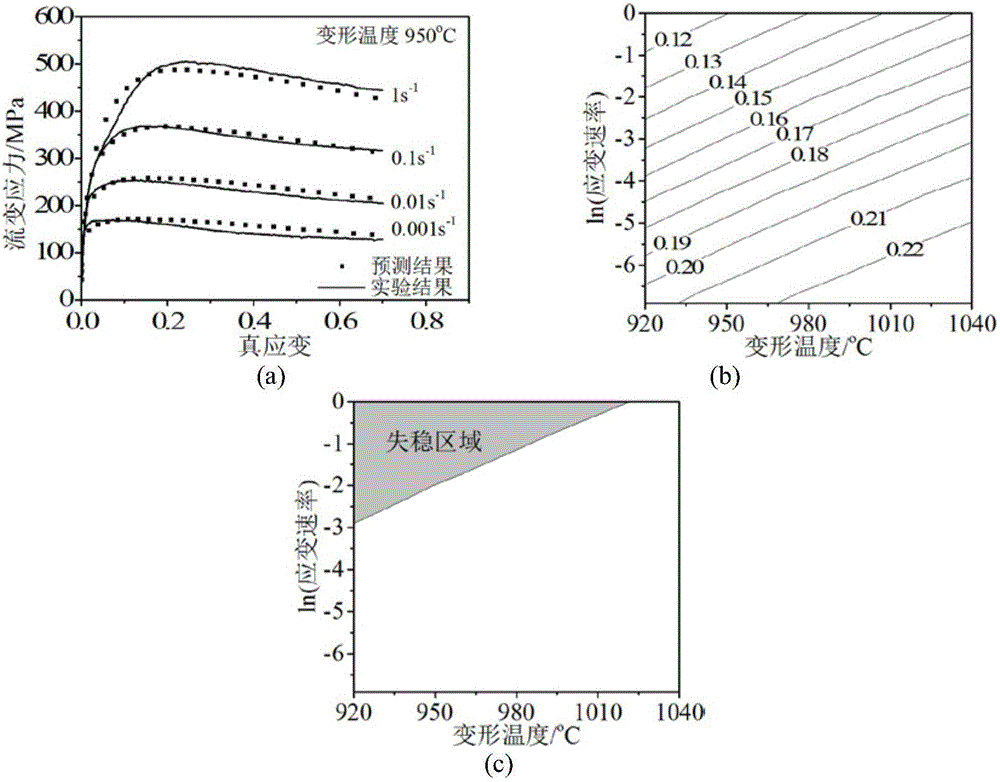

Nanoindenter tip for uniaxial tension and compression testing

InactiveUS7878071B2Force measurementMaterial strength using tensile/compressive forcesScanning tunneling microscopeScanning electron microscope

The invention is an indenter tip that is modified to permit both compression testing and tensile testing on samples having dimensions smaller than approximately 1 μm. The modified indenter tip has both a surface that can be used to apply compressive forces, and tines that can be used to engage a free end of a specimen to be tested in tension. The apparatus used to perform the tests includes elements of a scanning electron microscope that permit visualization of the specimen to be tested and the modified indenter tip, so as to permit appropriate alignment and engagement of the same. The apparatus also includes elements of a microindenter that provide mechanical manipulation of the relative position and orientation of the modified indenter tip and of the specimen to be tested, as well as the necessary controls and instrumentation to perform the test and to collect, record and manipulate data.

Owner:CALIFORNIA INST OF TECH

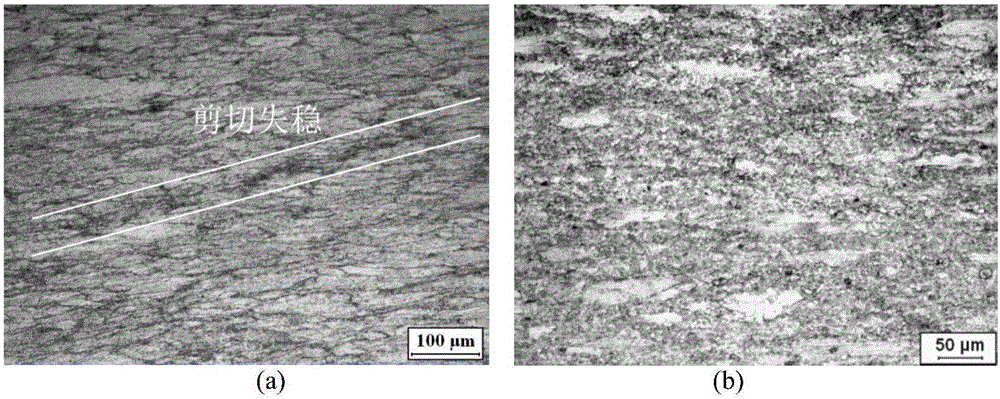

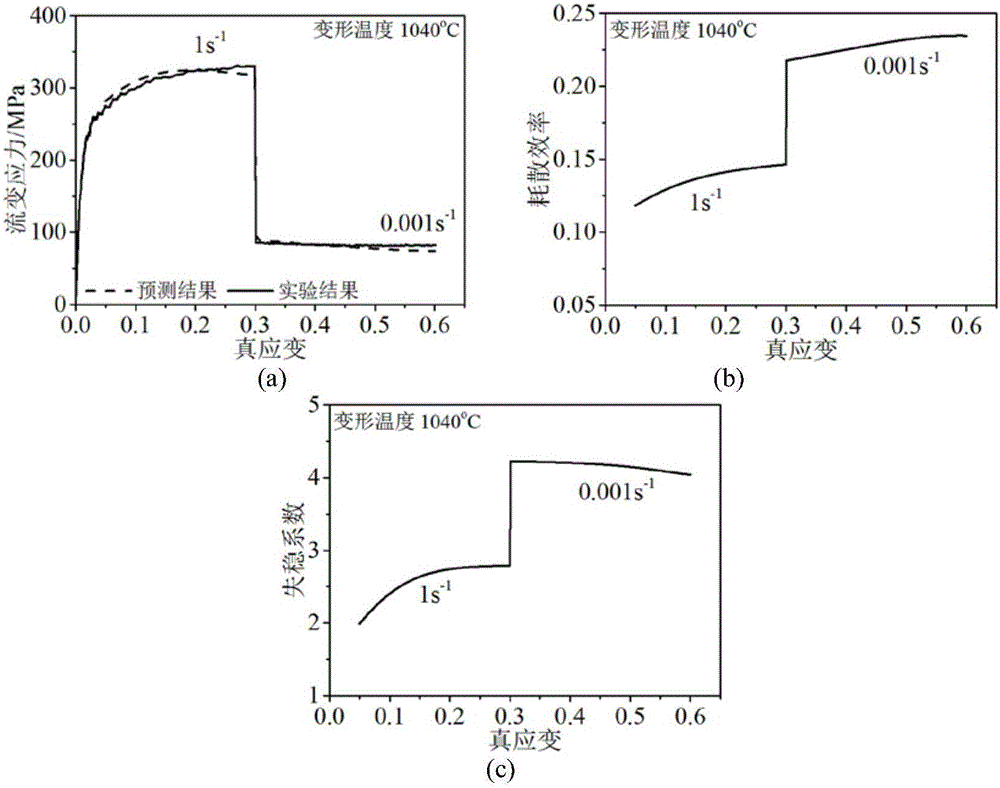

Method estimating hot-working performance of metal material

InactiveCN105651620AAccurate assessmentMaterial strength using tensile/compressive forcesFlow stressThermal deformation

The invention discloses a method estimating hot-working performance of a metal material. The method comprises the following steps: (1), subjecting the metal material to high-temperature compression testing under designed thermal deformation conditions so as to obtain tree-true strain data; (2), establishing a modified hyperbolic sine constitutive model for describing high-temperature flow stress of a metal material, through programming; (3), establishing a hot-working dissipation efficiency estimation model and an instability judging module of the metal material, through programming; (4), using a high temperature flow stress prediction model established in steps (2) and (3), hot-working dissipation efficiency estimation model and instability judging model to predict flow stress of the metal material, hot-working dissipation rate and instability coefficient under any condition so that hot-working performance of the metal material is comprehensively estimated under any deformation condition. The method enables the hot-working performance of the metal material to be accurately and quickly estimated, and significant technical guidance is provided for reasonable arrangement of the-working process of the metal material is reasonably formulated.

Owner:CENT SOUTH UNIV

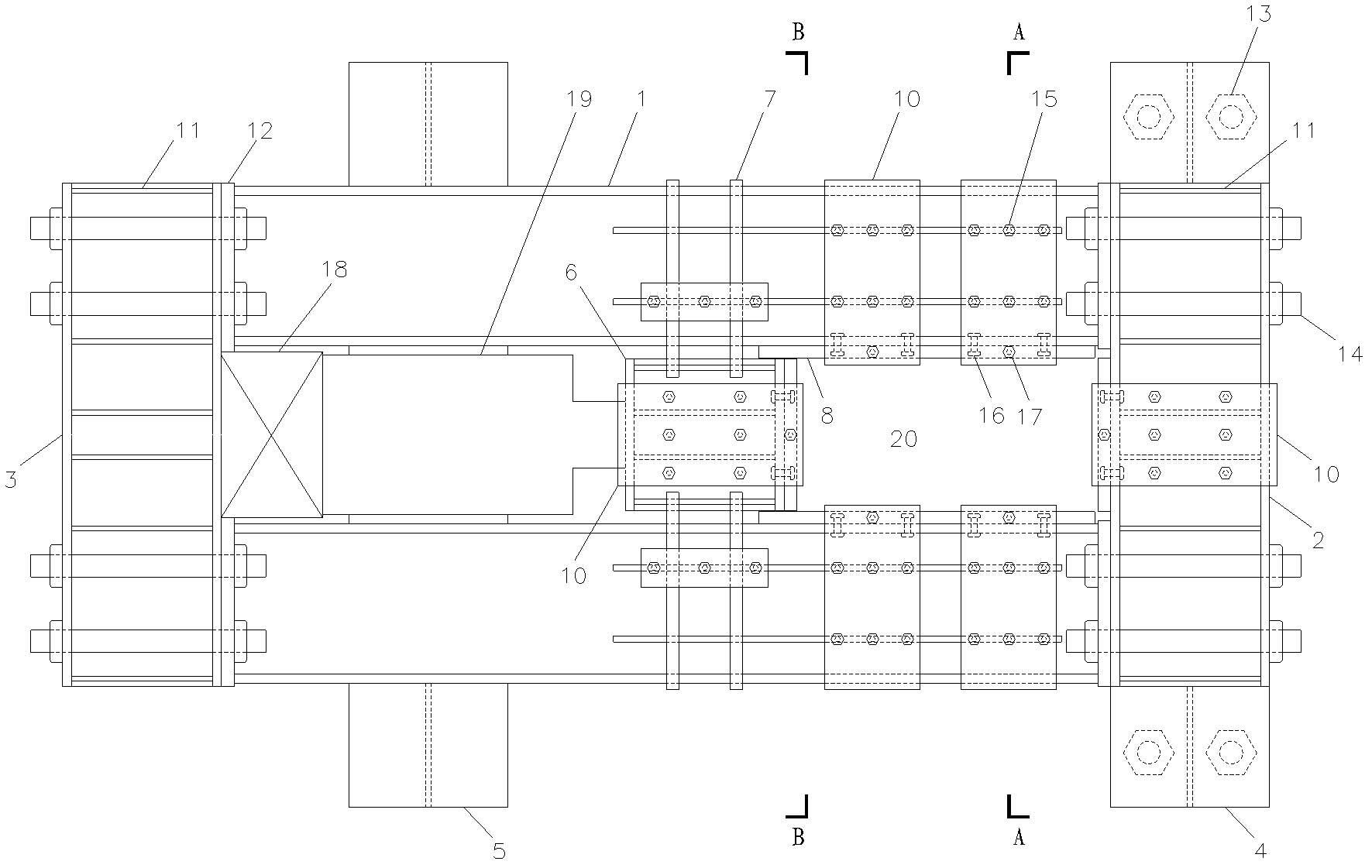

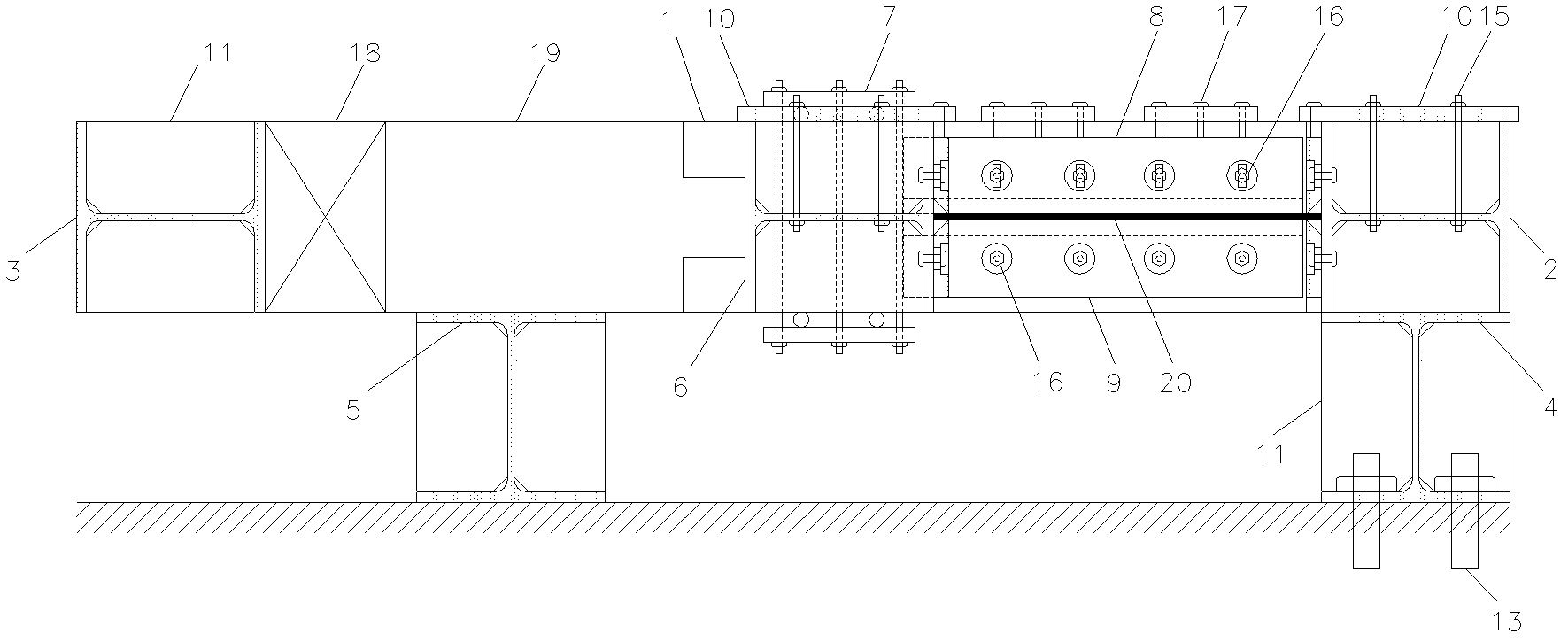

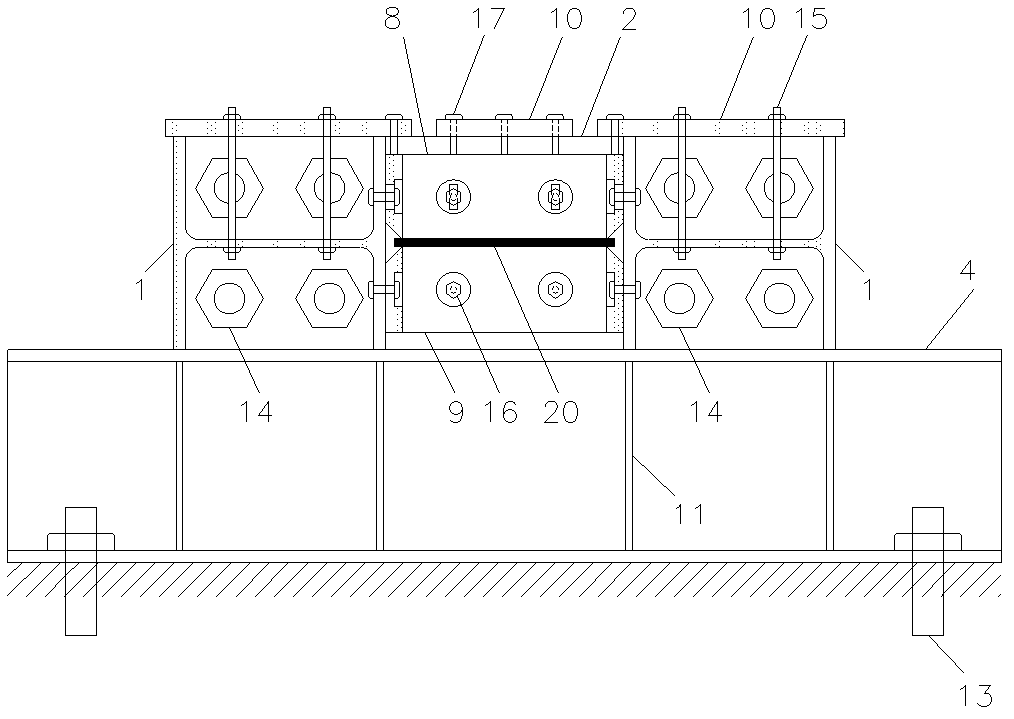

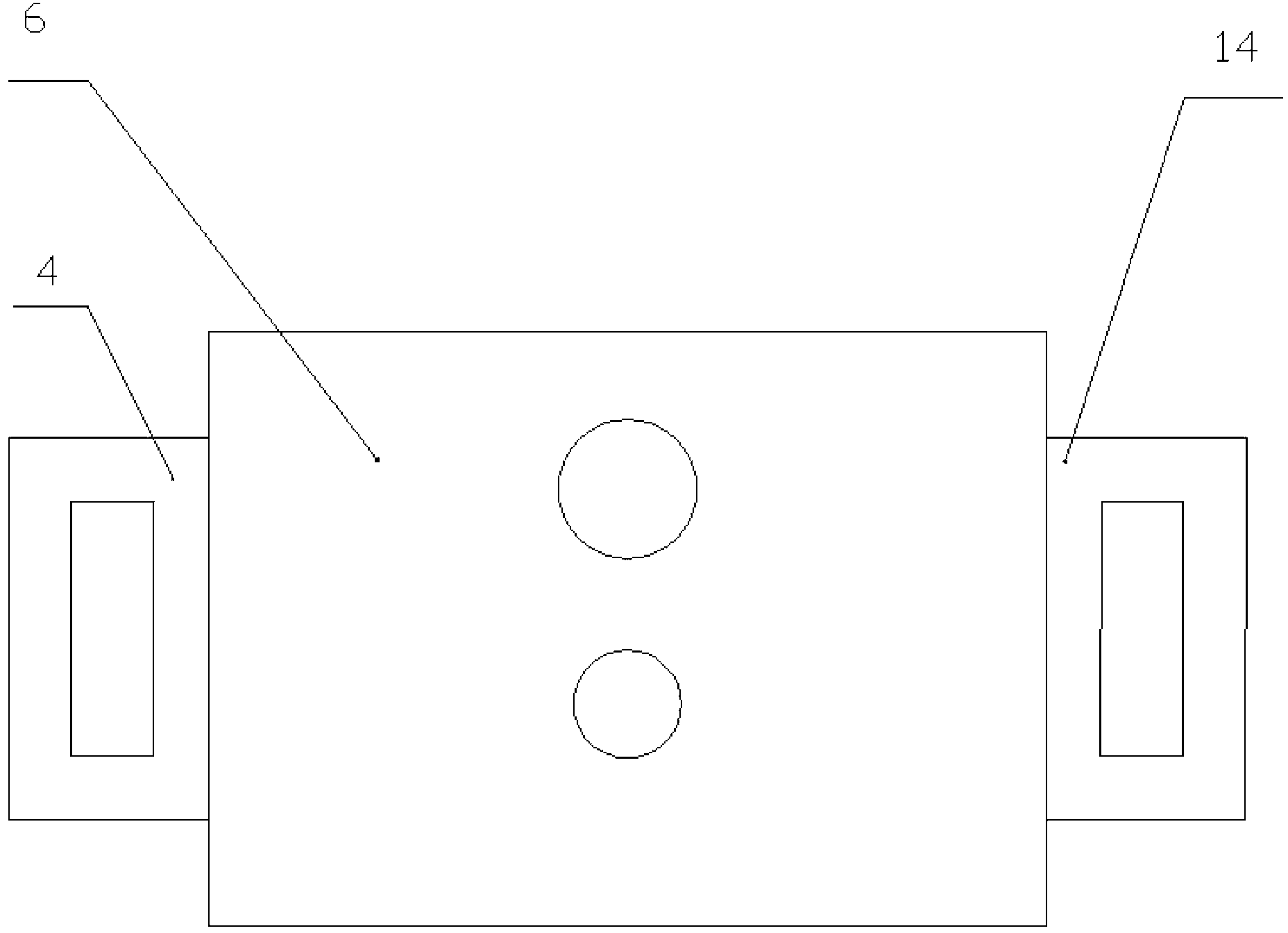

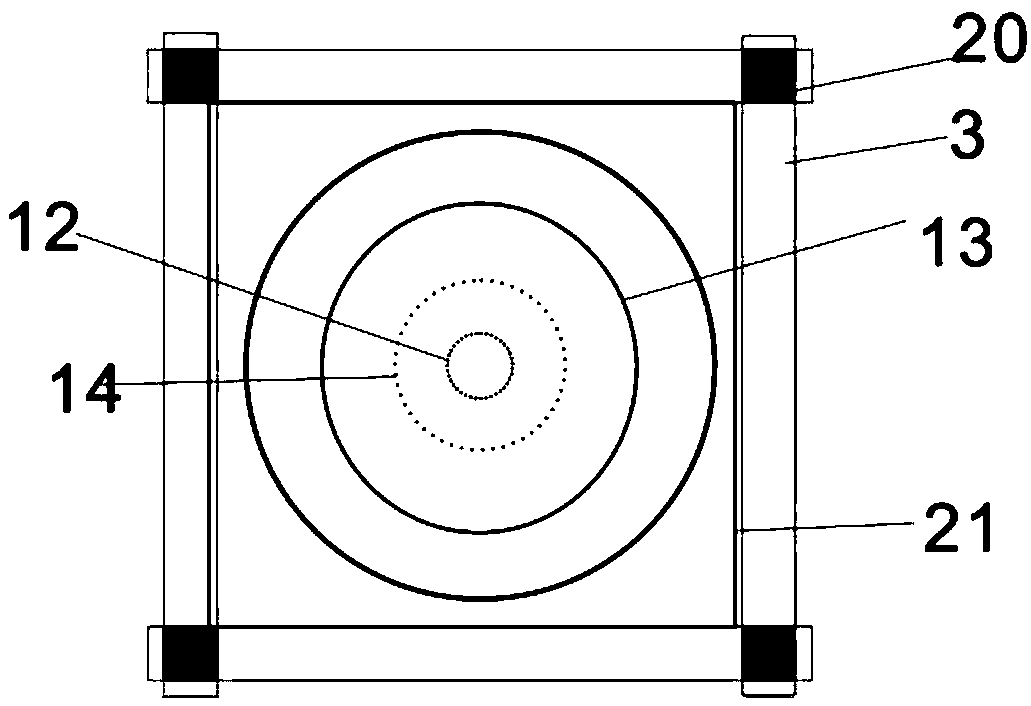

Device for testing compression in rectangular steel plate surface

InactiveCN102539243AMeet the requirements of scientific experimentsRealize the loadMaterial strength using tensile/compressive forcesSheet steelRigid block

The invention discloses a device for testing compression in a rectangular steel plate surface, belonging to the field of civil engineering professional testing devices. The device is formed by connecting a square main frame with H-shaped steel through a bolt, and can be used for self-balance in a test load. In the device, a load guide rigid block is arranged between a hydraulic jack and a steel plate loading edge, so that uniform compression loading is realized, and off-plate simple support constraint conditions are provided for four sides of a test steel plate through a wedge-shaped support plate. In the entire testing device, the size of a component can be adjusted flexibly according to the size of a test piece, so that the loading requirements of steel plates of different sizes are met. Due to the adoption of the device, uniform compression testing in the rectangular steel plate surface is more convenient, and the batch testing requirements of test pieces are met simultaneously; and the device can be applied to civil engineering teaching and scientific research testing.

Owner:SHANGHAI JIAO TONG UNIV

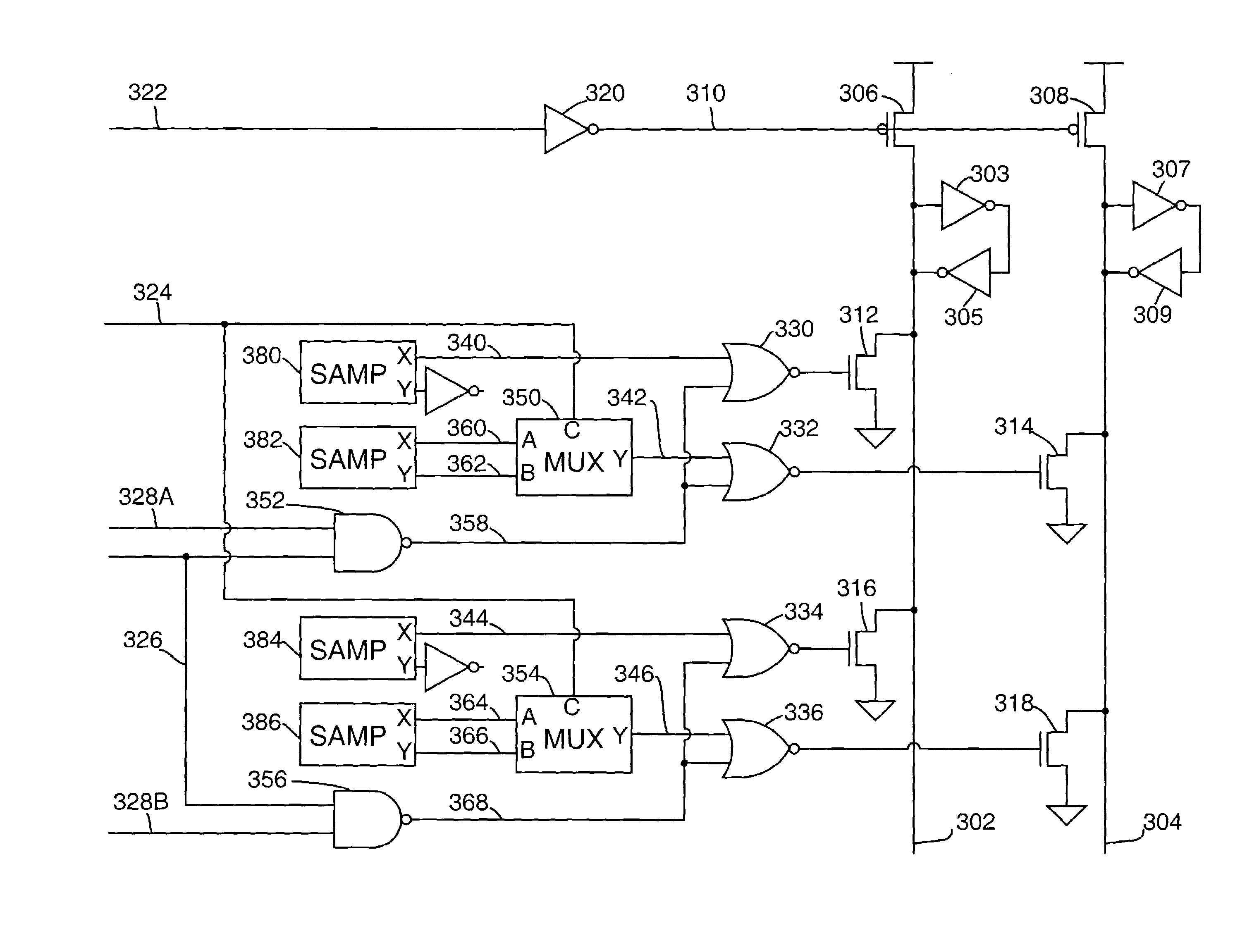

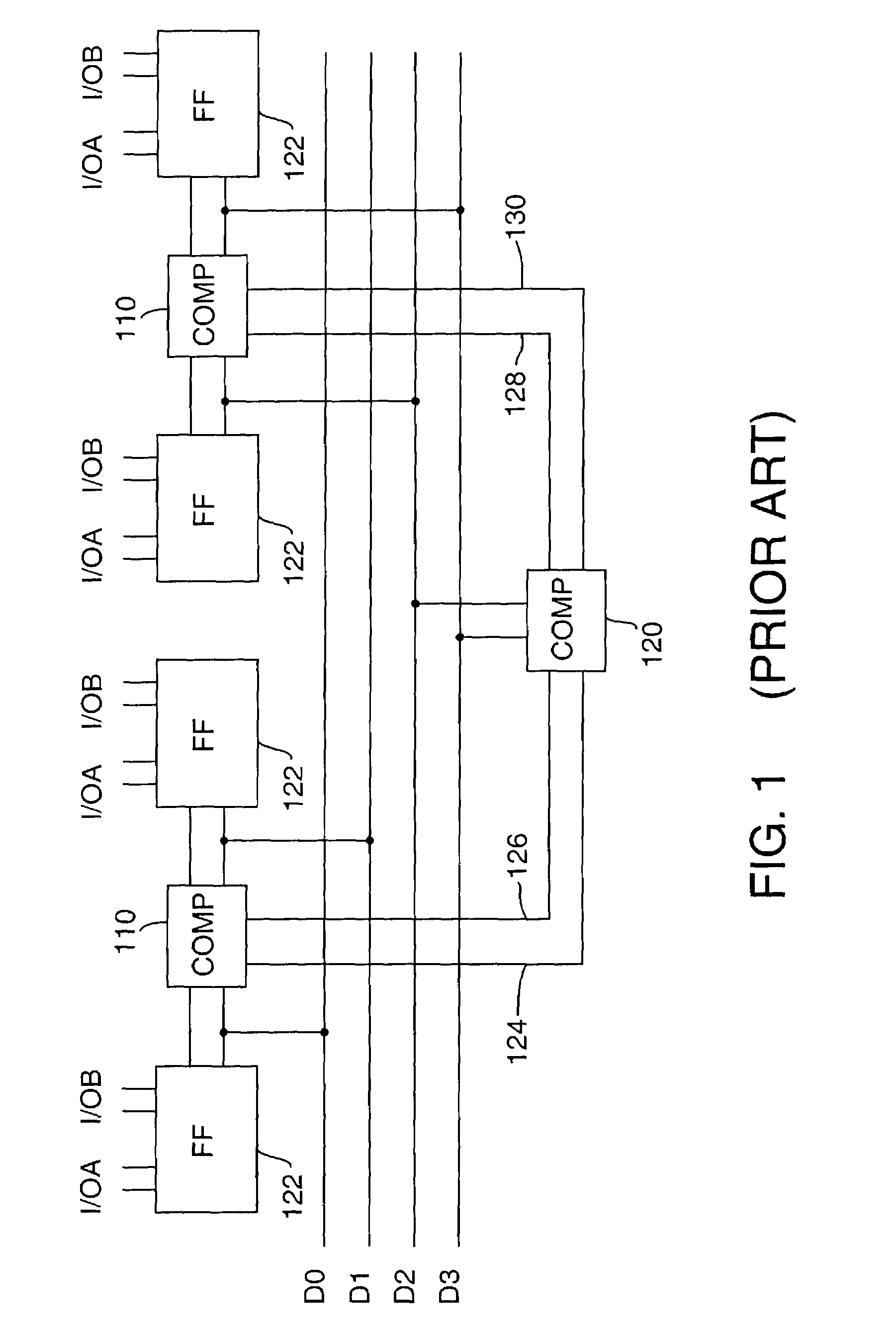

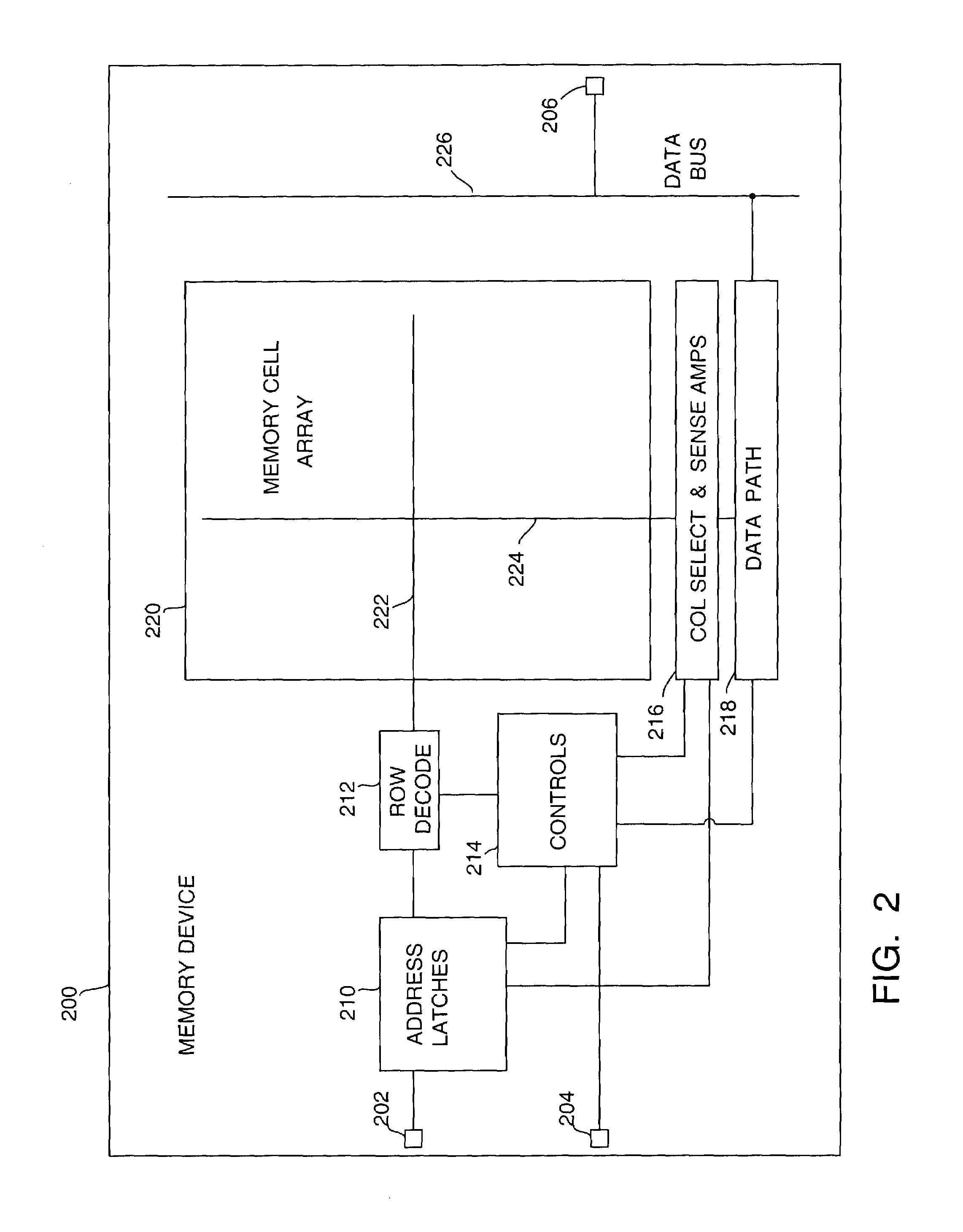

Memory data path circuit

InactiveUS7032143B1Improve scalabilityIncrease the compression ratioDigital storageDatapath circuitsNOR logic

A memory device with a data path circuit having support in the sense-amp region for compression testing of the device. The data path circuit uses NOR logic compression to provide a scalable design which may be extended to large circuits.

Owner:WALLER WILLIAM KENNETH

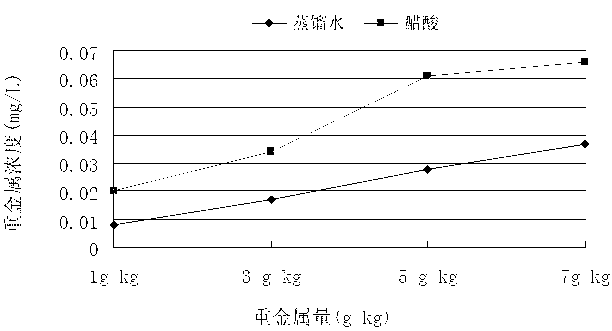

Preparation method of heavy metal solid waste curing agent

InactiveCN102989741AReduce leaching concentrationSolve resource problemsSolid waste disposalMonopotassium phosphateCompressive strength

Owner:YANCHENG INST OF TECH

Manual spring tension and compression testing machine

InactiveCN103292969AReduce usageLow manufacturing and maintenance costsElasticity measurementElectronic componentCalipers

The invention discloses a manual spring tension and compression testing machine which aims to solve the problems that spring elasticity coefficients are detected by special equipment mostly made of electronic components currently and the special equipment is not applicable to field operation and the like. The manual spring tension and compression testing machine comprises a frame, a measuring mechanism, a transmission mechanism and a tension and compression clamp mechanism. The measuring mechanism comprises a wide-range vernier caliper (12), a small-range vernier caliper (16) and a spring (5). The spring (5) is sleeved on an upper pressing plate guide rod (3), the upper end of the spring (5) is fixed with a middle crossbeam (6), the lower end of the spring (5) is fixed with an upper spring pressing plate (15) of the tension and compression clamp mechanism, an upper measuring jaw of the small-range vernier caliper (16) is fixed with the middle crossbeam (6), a lower measuring jaw of the small-range vernier caliper (16) is fixed with the lower surface of the upper spring pressing plate (15), an upper measuring jaw of the wide-range vernier caliper (12) is fixed with the upper surface of an upper crossbeam (10), and a lower measuring jaw of the wide-range vernier caliper (12) is fixed with the lower surface of the upper spring pressing plate (15).

Owner:JILIN UNIV

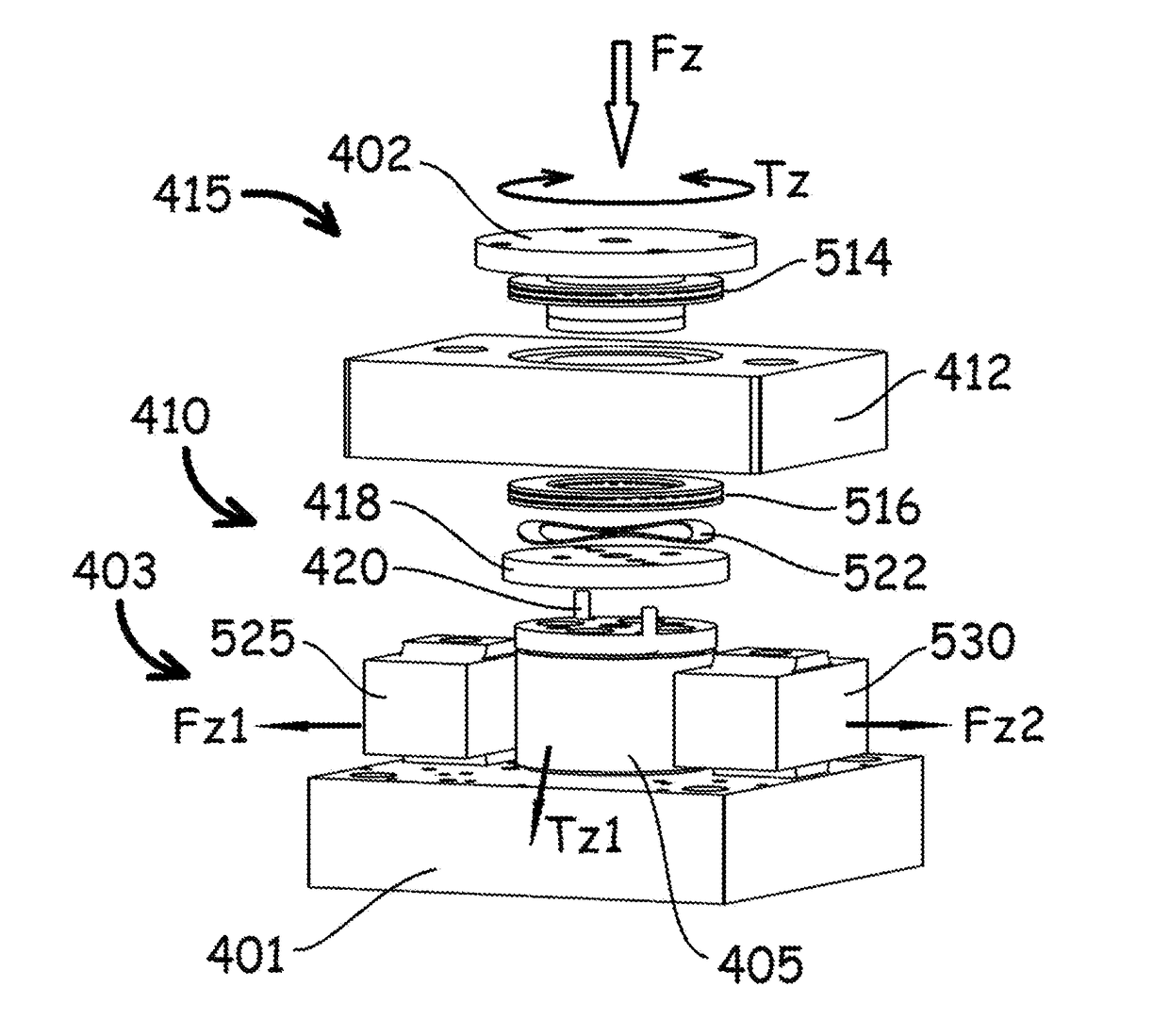

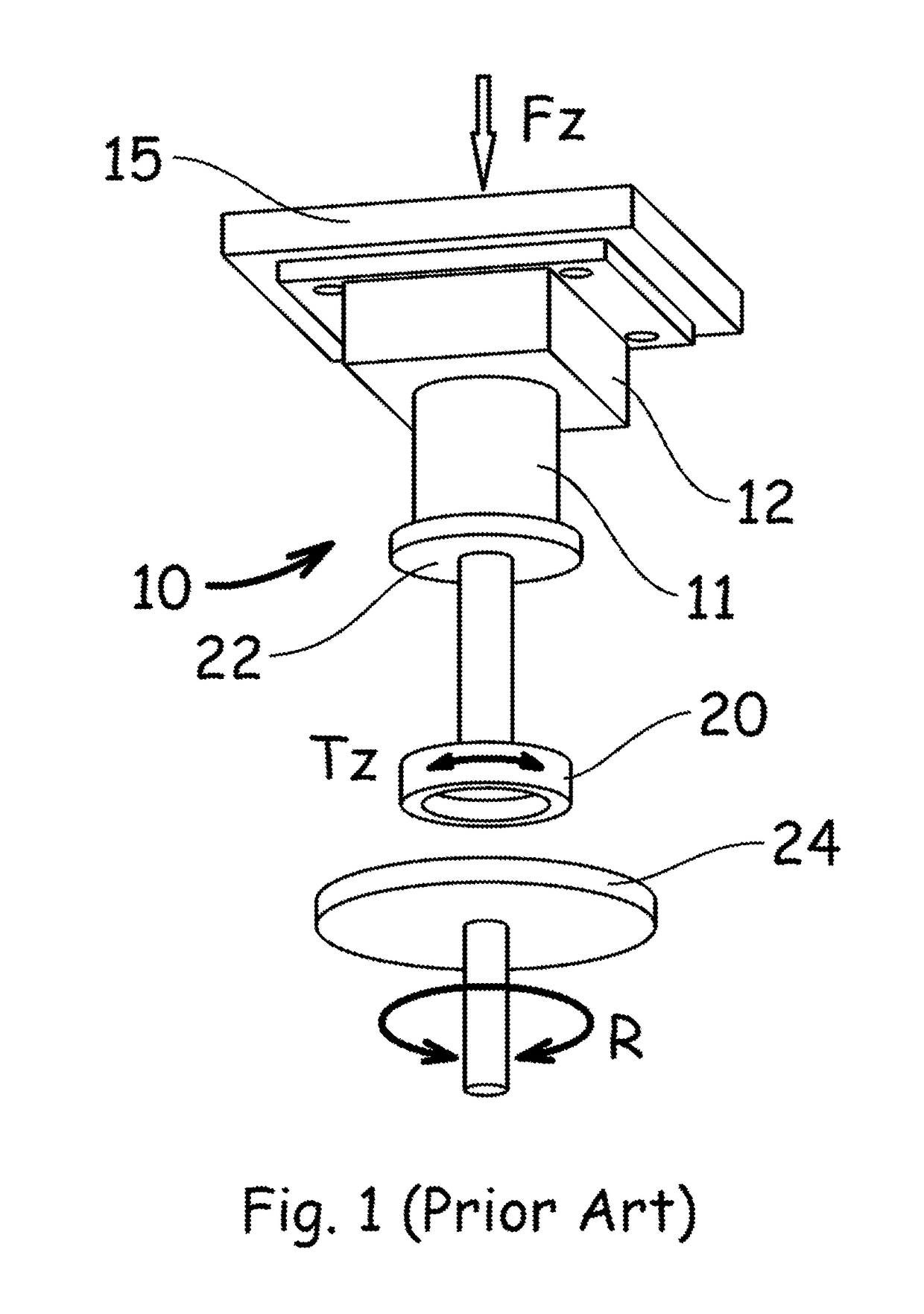

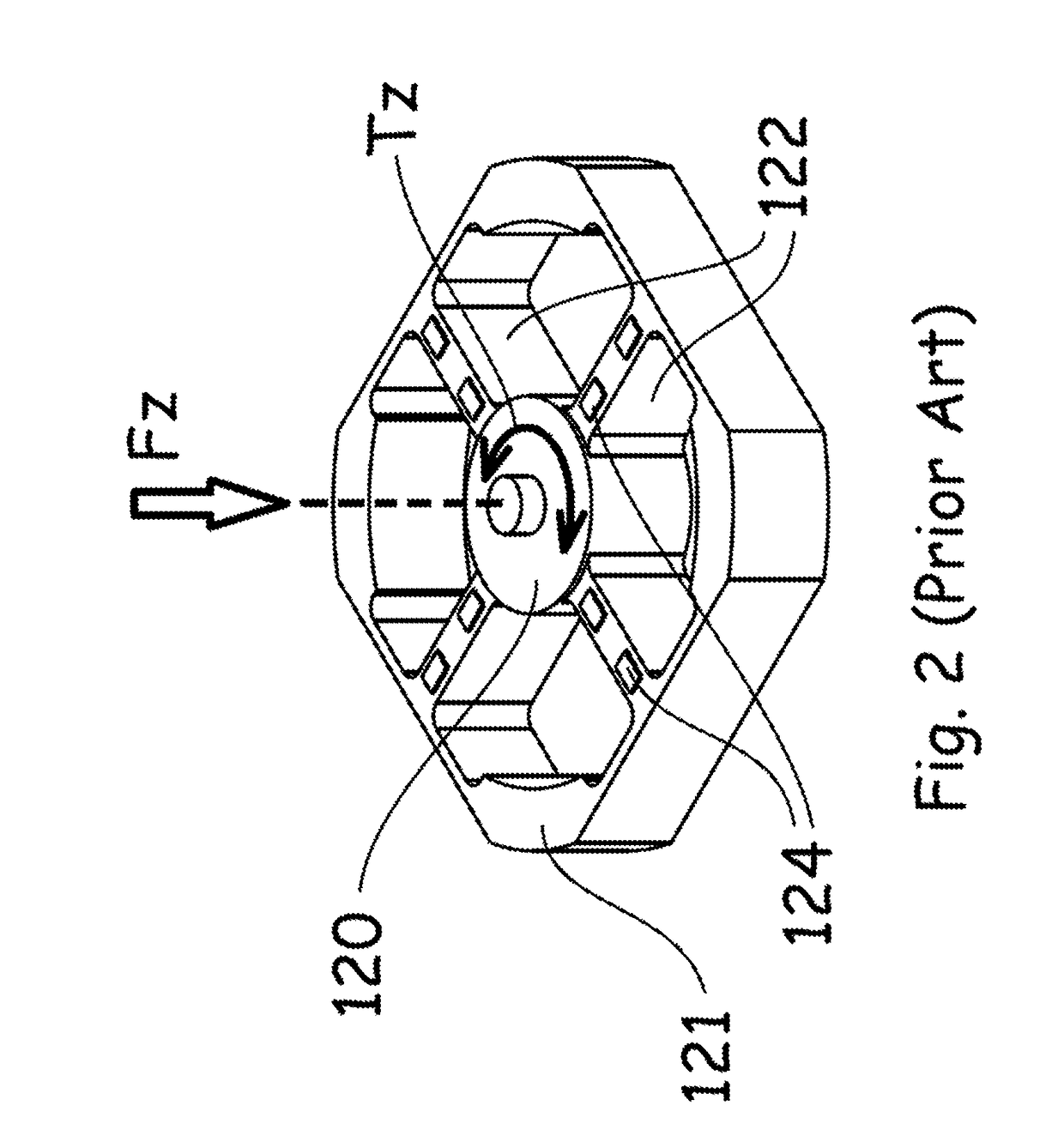

Multi-component force-torque sensing device with reduced cross-talk for twist-compression testing machine

ActiveUS20170191888A1Improve mechanical stabilityCost-effective and reliableMaterial strength using steady torsional forcesMeasurement of force componentsControl theoryCompression testing

Owner:VINOGRADOV NURENBERG MICHAEL

Agglomerate and resin composition containing the same

InactiveUS20060052503A1Good anti-blocking property propertyGood property slipping propertyCalcium/strontium/barium carbonatesPigmenting treatmentInorganic compoundUltimate tensile strength

An agglomerate comprising fine primary particles of an inorganic compound except for silica is provided, satisfying dp50: the average particle diameter [μm] of the agglomerate measured by Microtrac-FRA, a laser analysis type particle size distribution measurement apparatus, a: the value calculated by dividing the difference between the particle diameter d90 of cumulative 90% minus sieve particles of the agglomerate and the particle diameter d10 of cumulative 10% minus sieve particles of the agglomerate calculated by the Microtrac-FRA, Sw: the BET specific surface area [m2 / g]of the agglomerate, St: the tensile strength [MPa] required to break the agglomerate with the particle diameter 4 μm, and, Sta: the tensile strength [MPa] required to break 30% of the particle diameter of the agglomerate with the particle diameter 4 μm, both St and Sta being measured by a micro compression testing machine manufactured by Shimadzu Corporation. The agglomerate of the present invention provides a resin composition excellent in the anti-blocking property and the stretching resistance property.

Owner:MARUO CALCIUM COMPANY

Determination of pore structure characteristics of absorbent materials under compression

InactiveUS20150047418A1Readily apparentImprove abilitiesMaterial strength using tensile/compressive forcesPermeability/surface area analysisCylindrical channelRadial compression

Compression testing apparatus for analyzing porous materials includes a cylindrical channel having a central bore, solid outside, upper and lower walls, the inner edge of the channel being open to the inner bore. A flexible sealing member having a central bore concentric to the bore of the cylindrical channel opposes the edge of the channel. The flexible walls of the flexible member overlap with and are sealingly affixed to the upper and lower surfaces of the channel. The central bore of the flexible sealing member thus forms a sample chamber for porous material to be tested. Top and bottom sealing members cover the sample chamber and a gas inlet enters through the outside wall of the cylindrical channel for applying biaxial or radial compression on the test material. Triaxial compression is applied with addition of a weight or piston sealingly engaged within the central bore of the flexible sealing member.

Owner:POROUS MATERIALS INC

Quantitative tension and compression testing device

InactiveCN101881716ARealize tension and compression loadingControl precisionMaterial strength using tensile/compressive forcesMaterials testingEngineering

The invention relates to a quantitative tension and compression testing device which belongs to the technical field of material testing. The device comprises a fixed base, a support stand, a loading support stand, a quantitative tension and compression rod and three fixed pulleys. The device has simple structure, can be used together with other testing instruments, has strong extension applicability, and realizes very high testing precision and larger loading and moment increase by ingeniously arranging the positions of the three fixed pulleys and the length ratio of the tension and compression rods with geometric and leverage principles. The positions of the three fixed pulleys must be relatively on the same circular arc with a round pin hole at the middle part of a quantitative loading rod; and when a weight is quantitatively loaded and applied, the three fixed pulleys are still on the same circle of center so as to fully ensure the loading precision. The length ratio of quantitative loading rods A and B decides the loading torque ratio.

Owner:JIANGSU UNIV

Agglomerate and resin composition containing the same

InactiveUS7199173B2Inhibit deteriorationGood anti-adhesionCalcium/strontium/barium carbonatesPigmenting treatmentInorganic compoundUltimate tensile strength

An agglomerate comprising fine primary particles of an inorganic compound except for silica is provided, satisfying dp50: the average particle diameter [μm] of the agglomerate measured by Microtrac-FRA, a laser analysis type particle size distribution measurement apparatus, α: the value calculated by dividing the difference between the particle diameter d90 of cumulative 90% minus sieve particles of the agglomerate and the particle diameter d10 of cumulative 10% minus sieve particles of the agglomerate calculated by the Microtrac-FRA, Sw: the BET specific surface area [m2 / g] of the agglomerate, St: the tensile strength [MPa] required to break the agglomerate with the particle diameter 4 μm, and, Sta: the tensile strength [MPa] required to break 30% of the particle diameter of the agglomerate with the particle diameter 4 μm, both St and Sta being measured by a micro compression testing machine manufactured by Shimadzu Corporation.The agglomerate of the present invention provides a resin composition excellent in the anti-blocking property and the stretching resistance property.

Owner:MARUO CALCIUM COMPANY

High-speed dynamic compression testing device

ActiveCN104237015AAvoid damageDynamic compression test lowMaterial strength using tensile/compressive forcesEngineeringTensile testing

The invention relates to a high-speed dynamic compression testing device. The high-speed dynamic compression testing device comprises a base for mounting a test piece and a loading mechanism for performing compression loading on the test piece; the loading mechanism comprises a pressing plate for compressing the test piece and a connecting rod of which one end portion is fixedly connected with the pressing plate; the base is provided with a cavity for holding the test piece and the pressing plate, and a mounting plate for mounting the test piece; one end portion of the connecting rod is located in the cavity, while the other end portion of the connecting rod penetrates through the mounting plate and extends out of the cavity, and the connecting rod is arranged in such a manner of sliding relatively to the mounting plate; the loading mechanism further comprises a loading plate of which one surface is fixedly connected with the other end portion of the connecting rod, and an unloading rod which is fixedly connected with the other side surface of the loading plate. The high-speed dynamic compression testing device can be directly applied to a high-speed tensile testing machine, is capable of realizing high-speed dynamic compression at low, medium and high different strain rates, and is safe and reliable.

Owner:AUTOMOBILE RES INST OF TSINGHUA UNIV IN SUZHOU XIANGCHENG

Oil well cement high-temperature high-pressure compressive stress strain system

ActiveCN102401769AStable pressure outputAutomatic pressure reductionThermometers using electric/magnetic elementsMaterial strength using tensile/compressive forcesPressure curveStress–strain curve

The invention relates to an oil well cement high-temperature high-pressure compressive stress strain system comprising a cement compression testing module, a power source, a pressure controlling unit, a temperature controlling unit, a signal controlling and processing unit, and pipelines. With the invention, temperature and pressure of bottom hole maintenance can be simulated. The compressive stress of oil well cement stones can be continuously measured under the temperature and pressure, and a temperature-pressure curve and a compressive stress-strain curve can be recorded. With the system and the method, anti-compression properties of different cement slurry systems can be directly measured and compared. The system and the method are beneficial for the design of cement slurry formulas. With the system and the method, cement slurry systems satisfying in-field construction requirements can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

In-situ method for obtaining rock parameters

PendingCN109141960AEasy to useVersatileWithdrawing sample devicesPreparing sample for investigationAngle grinderRock sample

Owner:SHAOXING UNIVERSITY

Cement compression resistance clamp for compression testing machine and usage method of clamp

ActiveCN104483191ASimple structureEasy to operateMaterial strength using tensile/compressive forcesSoftware engineeringCompressive strength

The invention discloses a cement compression resistance clamp for a compression testing machine and a usage method of the clamp. The cement compression resistance clamp for the compression testing machine includes a shell body, a telescopic rod, a bearing plate, a sliding block, a test piece position calibrating column, a pressure head and a plurality of springs, wherein an opening is formed in one side surface of the shell body; a through hole is formed in the top of the shell body; the upper end of the telescopic rod is fixedly connected with the bearing plate; the lower end of the telescopic rod penetrates through the through hole and is inserted into the shell body; the upper part of the sliding block is connected with the lower end of the telescopic rod; the pressure head is fixed at the bottom of the sliding block; one end of each spring is connected with the inner side surface at the top of the shell body; the other end of each spring is fixed at the upper part of the sliding block; the bearing plate is mounted on the compression testing machine; the test piece position calibrating column and a cement mortar test piece to be tested are fixed on the inner side at the bottom of the shell body; the cement mortar test piece to be tested is in contact with one side of the test piece position calibrating column; the pressure head is positioned right above the cement mortar test piece to be tested. When the compressive strength of the cement mortar test piece is tested, the cement mortar test piece to be tested can be clamped by the cement compression resistance clamp.

Owner:CHANGAN UNIV

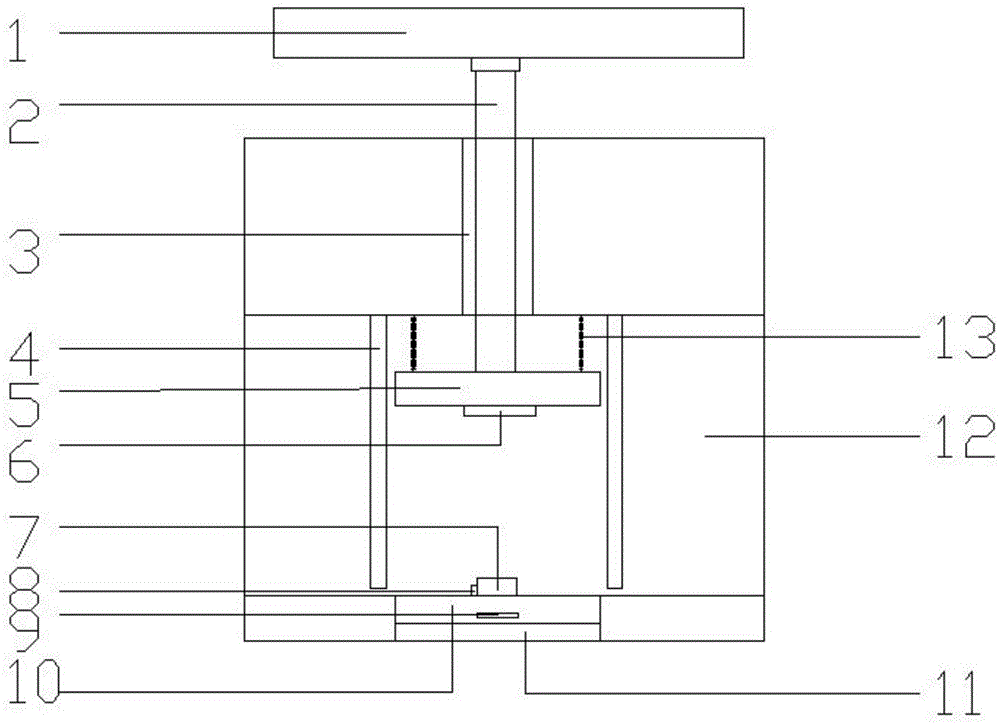

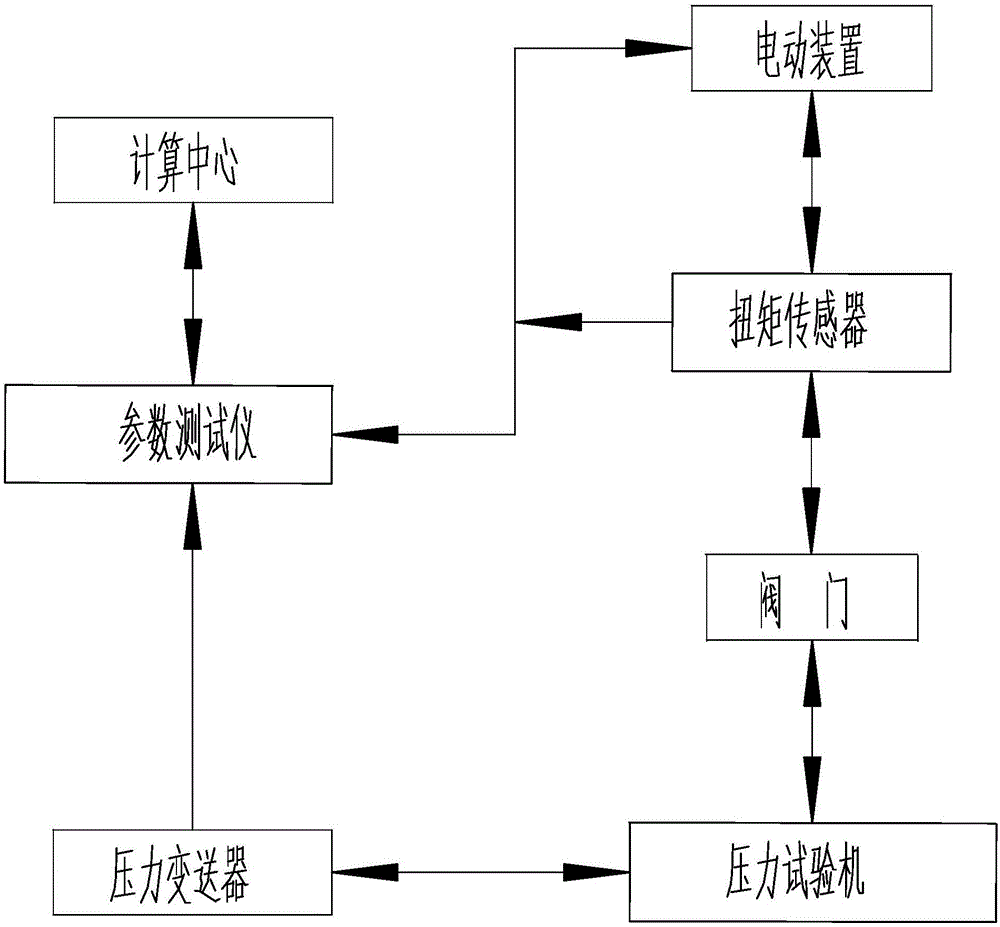

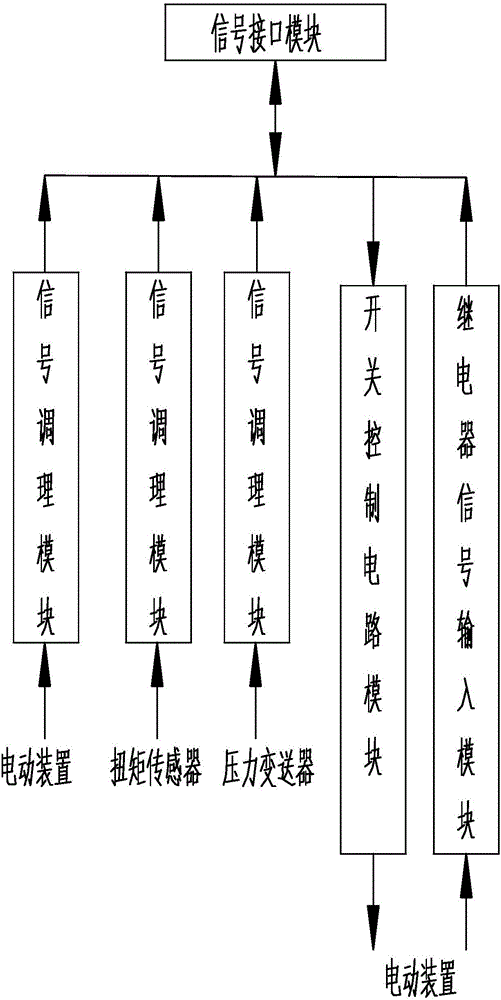

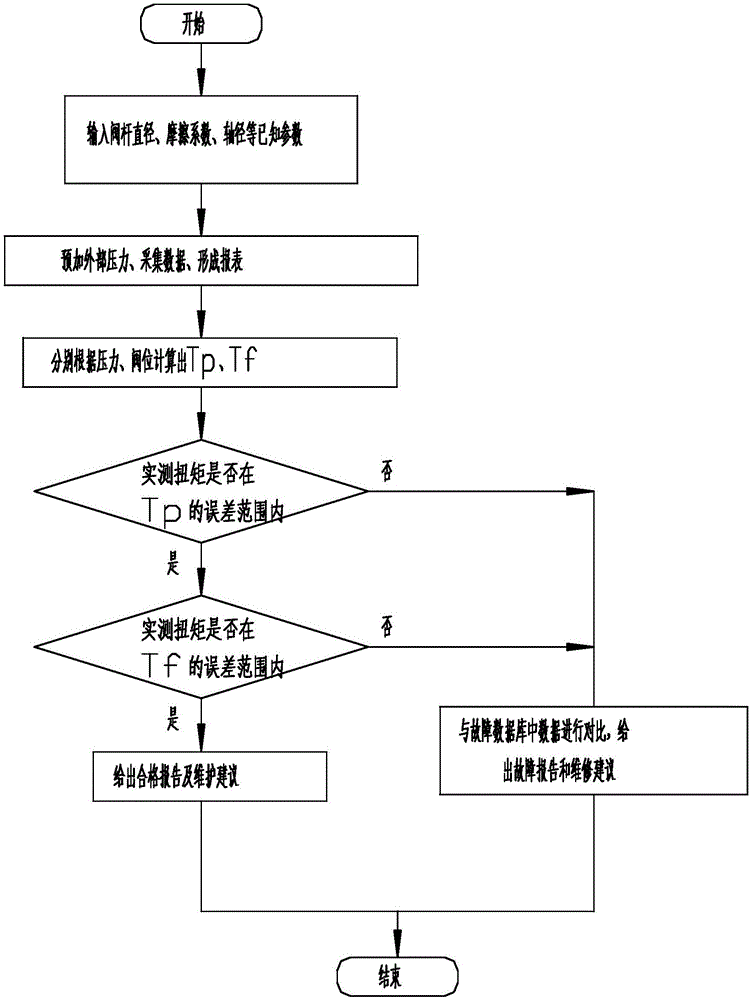

Valve state on-line monitoring system and working method thereof

ActiveCN106197558AEasy to calculateAccurate calculationMeasurement devicesPower flowWorking pressure

The invention discloses a valve state on-line monitoring system and a working method thereof. The invention relates to the field of industry process control and detection, and in particular to improvements of technology of valve state on-line monitoring and fault diagnosis. The valve state on-line monitoring system has exquisite structure, is easy to use and has high reliability, and can use valve position (i.e., valve caliber and opening amount of a valve gate) and valve pressure to calculate a theoretical torque so as to compare the theoretical torque and actual torque and finally provide accurate determination of the state of the valve. An electric apparatus is connected to the valve, and is intended for driving the valve to perform opening and closing movement. A torque sensor is connected between the electric apparatus and the valve, and is intended for acquiring the current torque of the valve. A pressure transmitter is connected to a compression testing machine, and is intended for measuring current working pressure of the valve, and converts the pressure to a current signal. According to the invention, the system as a whole is characterized by exquisite structure, easy usage and high reliability.

Owner:YANGZHOU ELECTRIC POWER EQUIP MFG FACTORY CO LTD

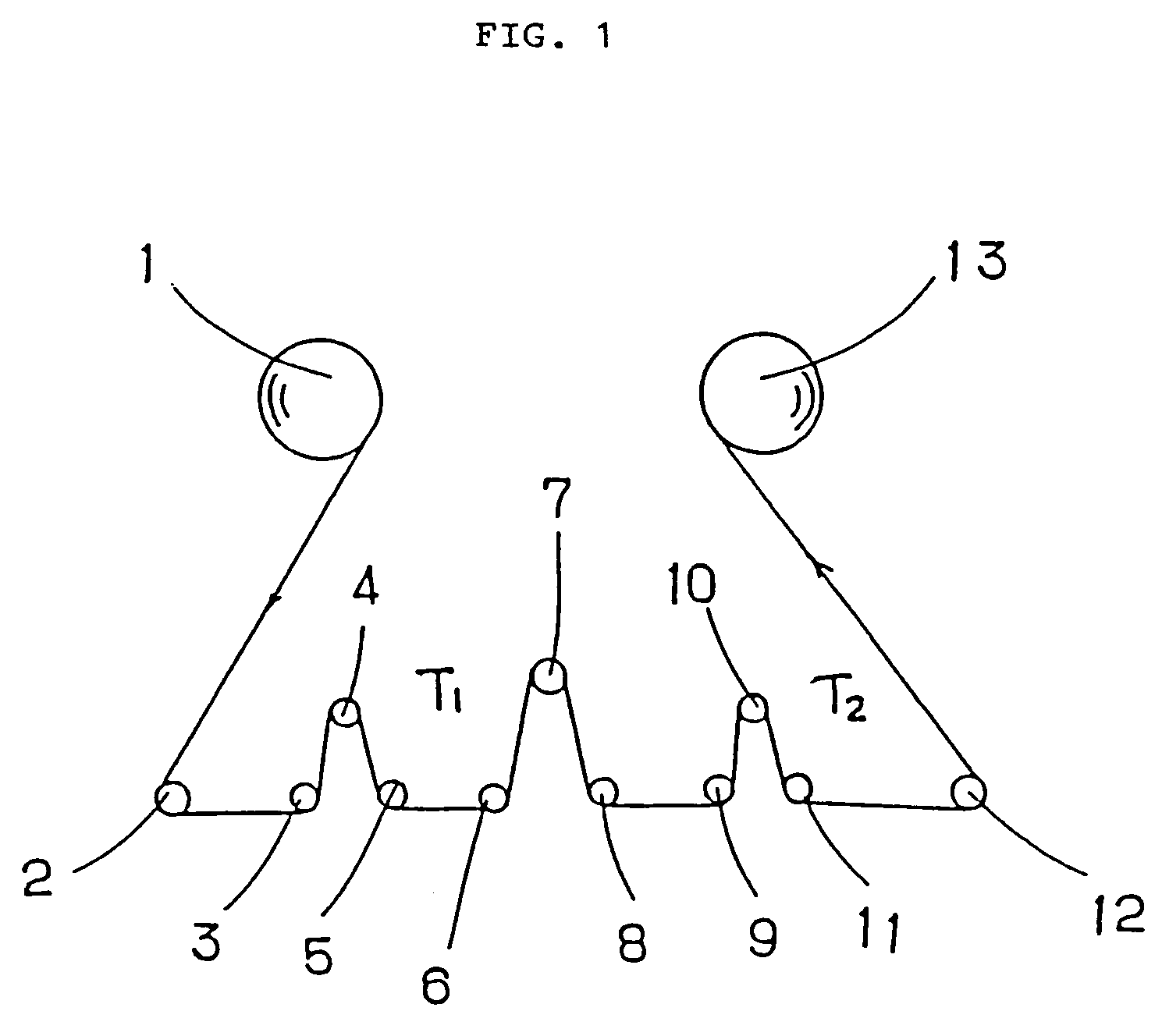

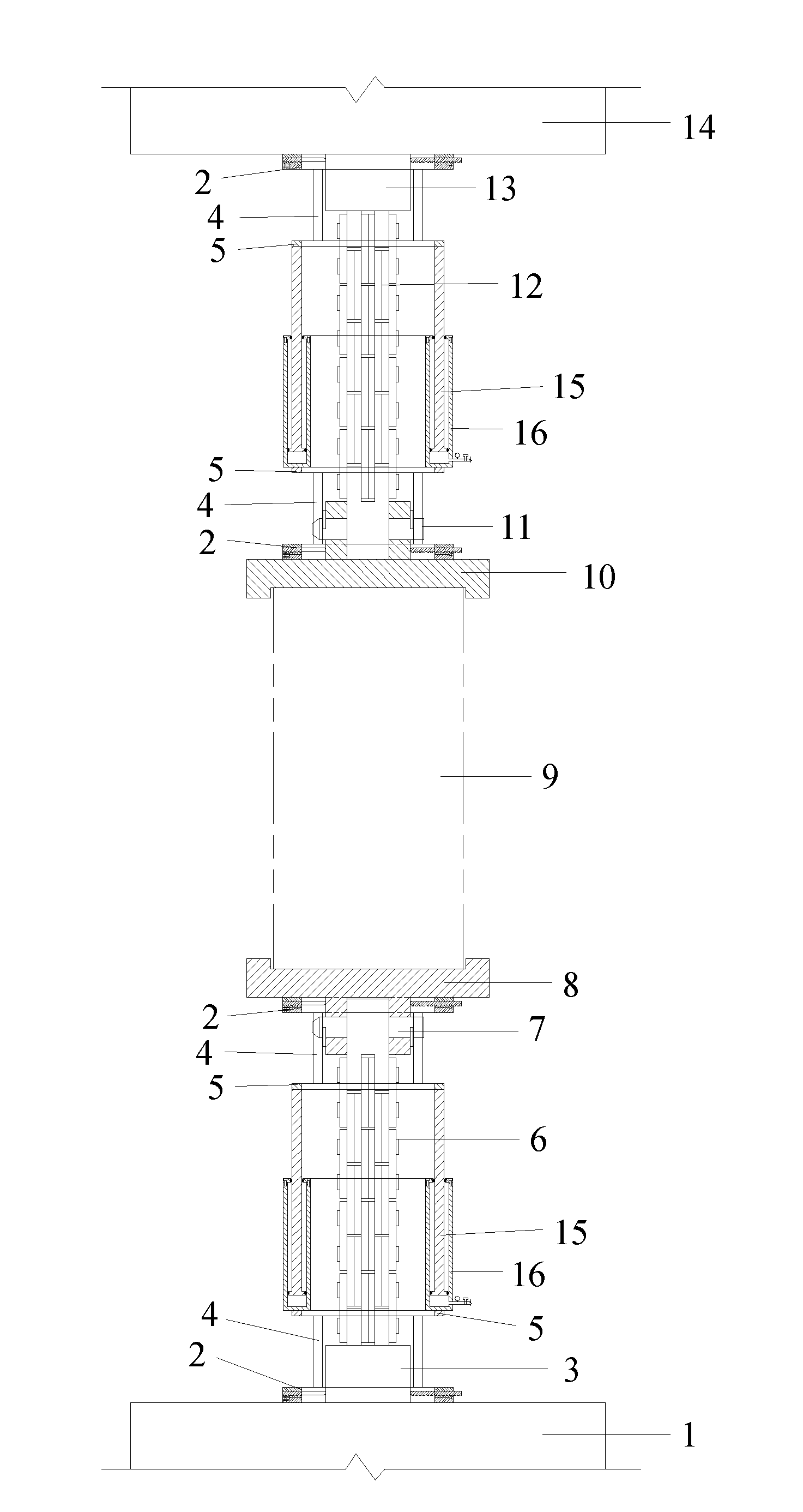

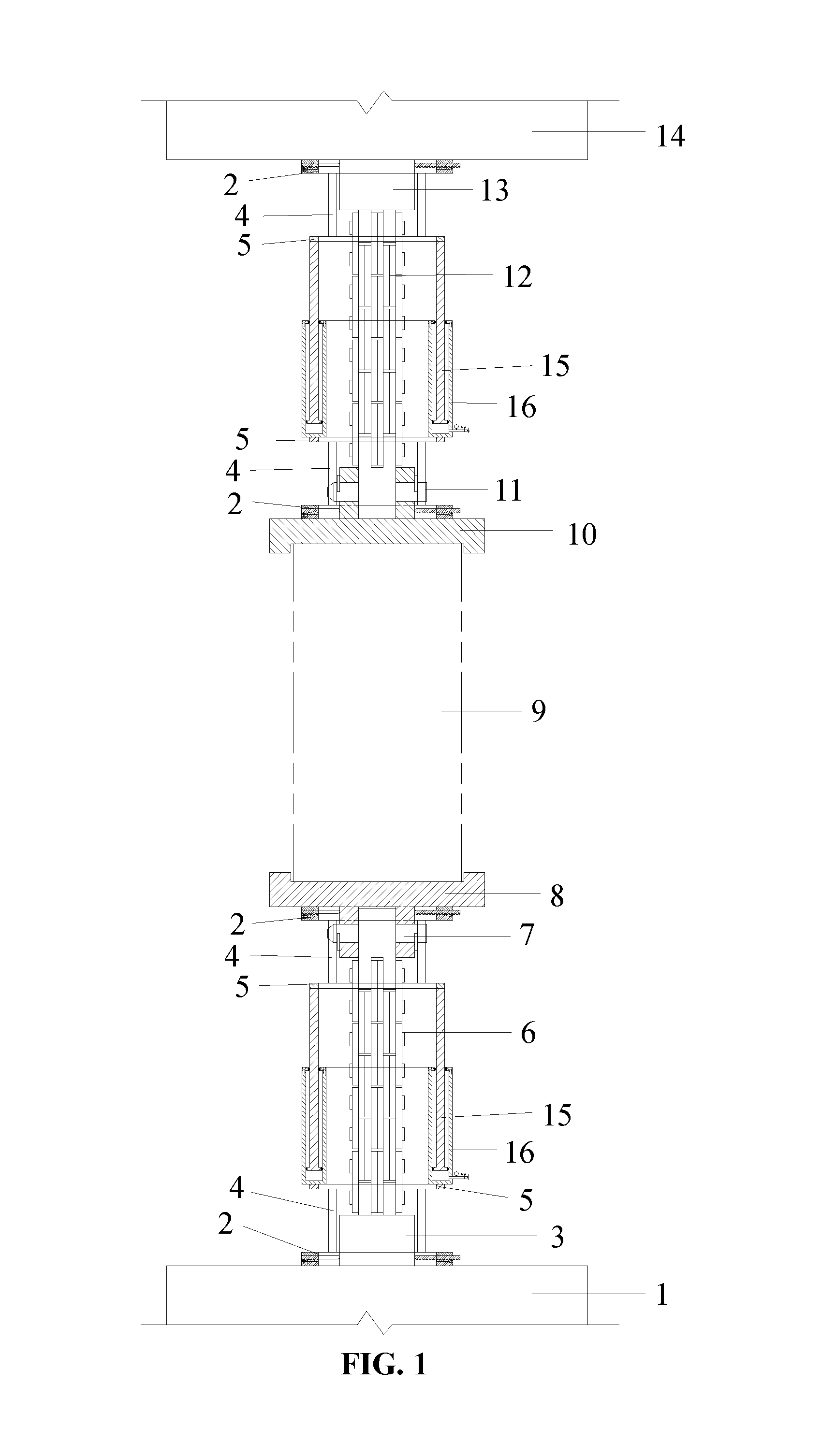

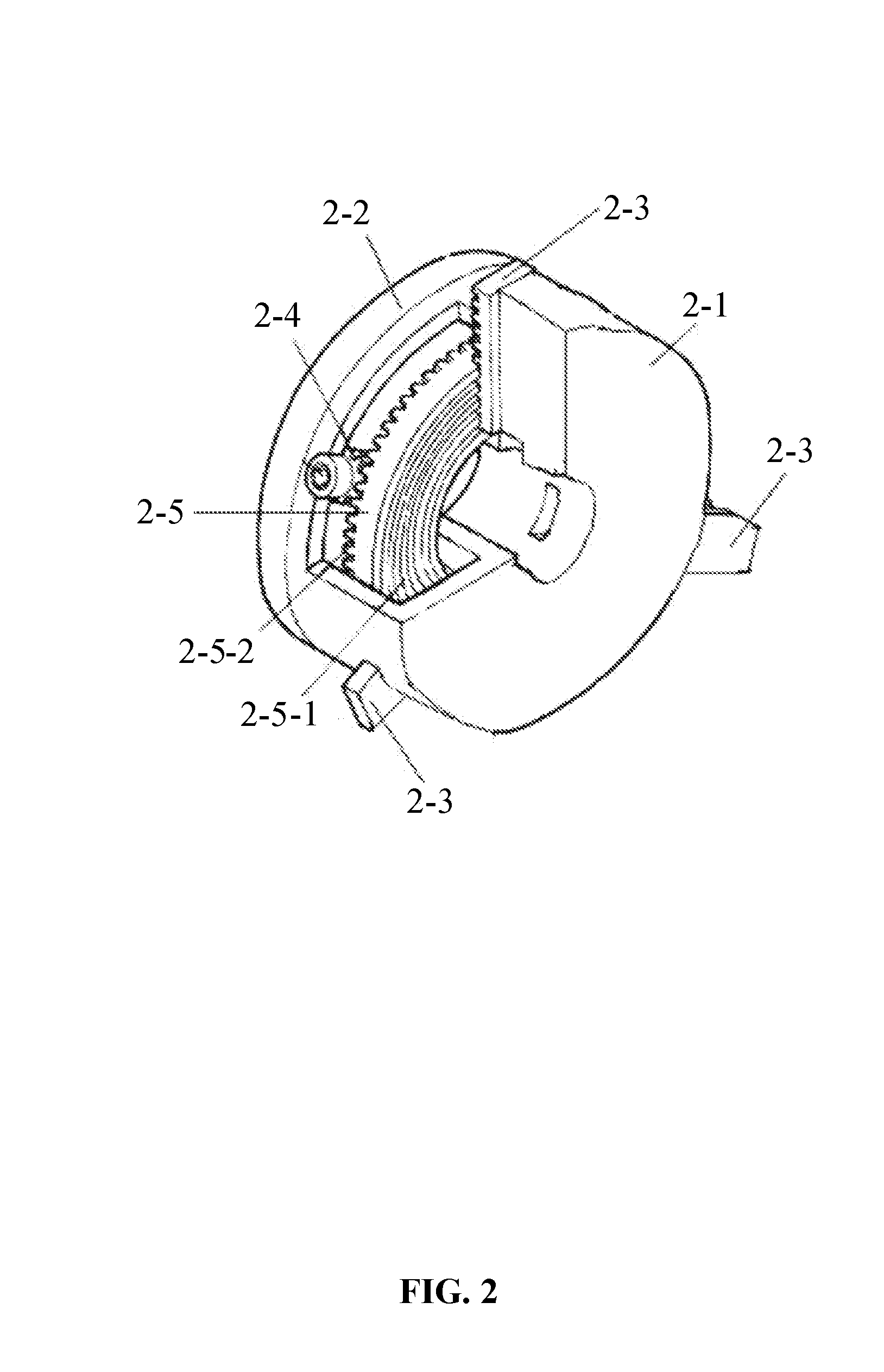

Device for fixing rock samples

ActiveUS20160231216A1Overcomes shortcomingSimple methodMaterial strength using tensile/compressive forcesCyclic tensionRock sample

A rock sample fixing device with a three-jaw chuck for cyclic tension and compression testing including: a lower clamp and an upper clamp; the lower clamp including a lower connector connected to a loading base at a bottom of a testing machine, a lower end cap for fixing samples, a lower chain connecting the lower connector and the lower end cap, a first central position-limit mechanism, a second central position-limit mechanism, and a first hydraulic mechanism; the upper clamp including an upper connector connected to a loading base at a top of the testing machine, an upper end cap for fixing samples, an upper chain connecting the upper connector and the upper end cap, a third central position-limit mechanism, a fourth central position-limit mechanism, and a second hydraulic mechanism.

Owner:SICHUAN UNIV

In-situ tension and compression testing platform and observation system

PendingCN106370521AOverall small sizeImprove test accuracyMaterial strength using tensile/compressive forcesTension compressionScientific instrument

The invention provides an in-situ tension and compression testing platform and an observation system, and relates to the field of precision scientific instruments. The in-situ tension and compression testing platform comprises a tension and compression loading unit, a detection unit, a temperature loading unit and a base, wherein the tension and compression loading unit comprises a power assembly, a first support body and a first clamp body which are matched with each other, and a second support body and a second clamp body which are matched with each other; the temperature loading unit is arranged between the first clamp body and the second clamp body; the power assembly comprises a direct current servo motor and a transmission mechanism; and the detection unit comprises a tension-compression sensor and a photoelectric encoder connected which is connected with the direct current servo motor. Through the in-situ tension and compression testing platform, in-situ observation can be performed on the micromechanical characteristics and damage mechanisms of the material in the tension and compression loading process of a sample under the action of a thermal field; and the in-situ tension and compression testing platform has the advantages of ingenious volume, high measuring accuracy, favorable microscope equipment compatibility and the like. The invention also provides an observation system using the in-situ tension and compression testing platform.

Owner:YANCHENG INST OF TECH

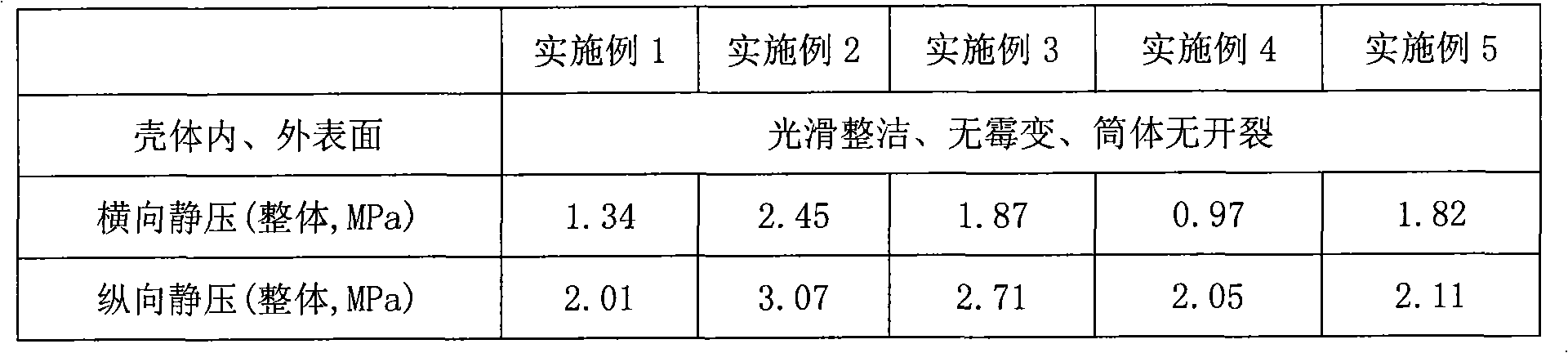

Set-off shell material for fireworks and crackers and preparation method thereof

InactiveCN101592460AHigh mechanical strengthImprove stress resistanceFireworksFireworksVegetable fibers

The invention discloses a set-off shell material for fireworks and crackers, which is prepared from the following raw materials in portion by weight: 1 to 2.5 portions of starch, 1.5 to 3 portions of vegetable fiber, 4.5 to 8 portions of clay, 0.09 to 1.0 portion of activating agent, and 0.1 to 0.9 portion of stabilizing agent. The shell material takes the clay as a base material and the starch and the vegetable fiber as auxiliary materials and can be biodegraded in the natural environment, which is advantageous for environmental protection, and the prepared shells of the fireworks and the crackers have high strength, are high-temperature resistant, reduce the possibility of undershooting during the of setting off, and reach the standard of 'method for compression and stacking tests by a compression testing machine' of GB / T4857.4-2008. The fireworks and the crackers made from the set-off shell material prepared by the method have high strength, strong set-off performance and high safety performance, and reach the standards of GB10631-2004, GB19593-2004 and GB19594-2004.

Owner:王会军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com