Patents

Literature

30results about How to "Guaranteed high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wet-type high cracking resistance, high wear resistance and high peel strength polyurethane resin and preparation thereof

The invention discloses a wet polyurethane resin with high flexing resistance, high wear resistance and high peeling strength, and a preparation method thereof. During a synthetic process of the polyurethane (PU) resin, proper soft polyurethane segment and hard polyurethane segment materials and a brand-new synthesis process route by quasi prepolymerization are selected to prepare the wet polyurethane resin based on fully considering effect of separate soft and hard segment structure, crystallinity and intermolecular cohesive energy density distribution of the PU resin on aggregation structure relationship formed by coagulation of PU resin solution in dimethylformamide (DMF) aqueous solution. The wet PU resin with high flexing resistance, high wear resistance and high peeling strength fully solves the defect that the existing common PU resin can not reach three performance indexes which are high flexing, high wear resistance, high peeling strength at the same time. Synthetic leather made from the wet PU resin with high flexing resistance, high wear resistance and high peeling strength can meet three performance indexes of high flexing resistance, high wear resistance, high peeling strength at the same time, and can greatly improve durability of shoes products.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

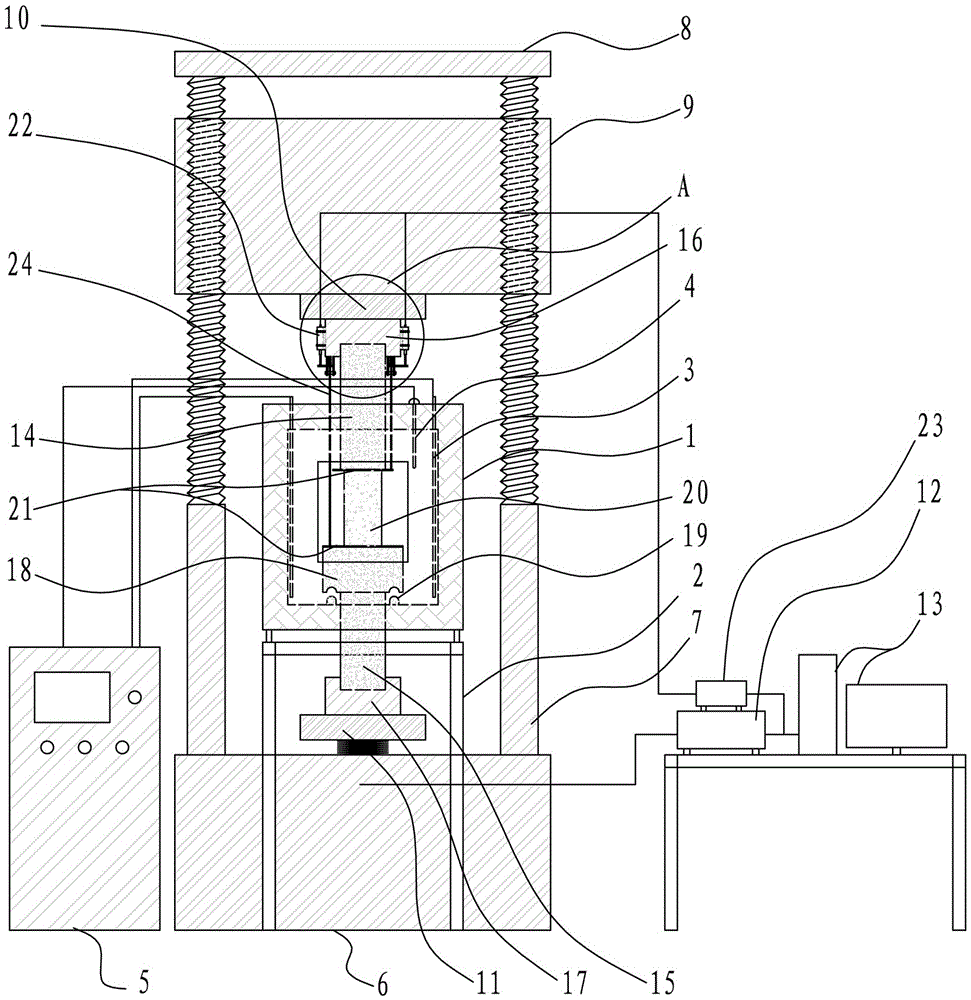

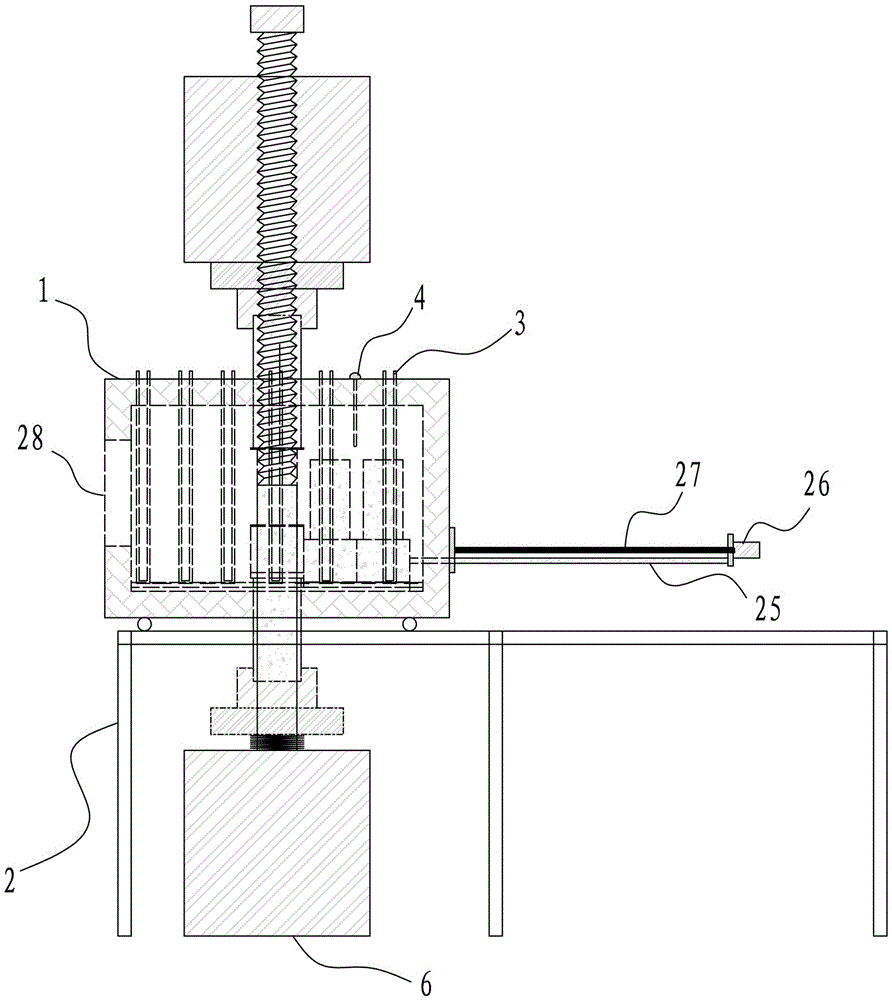

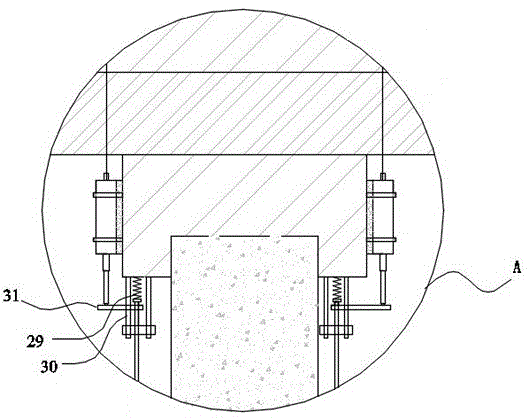

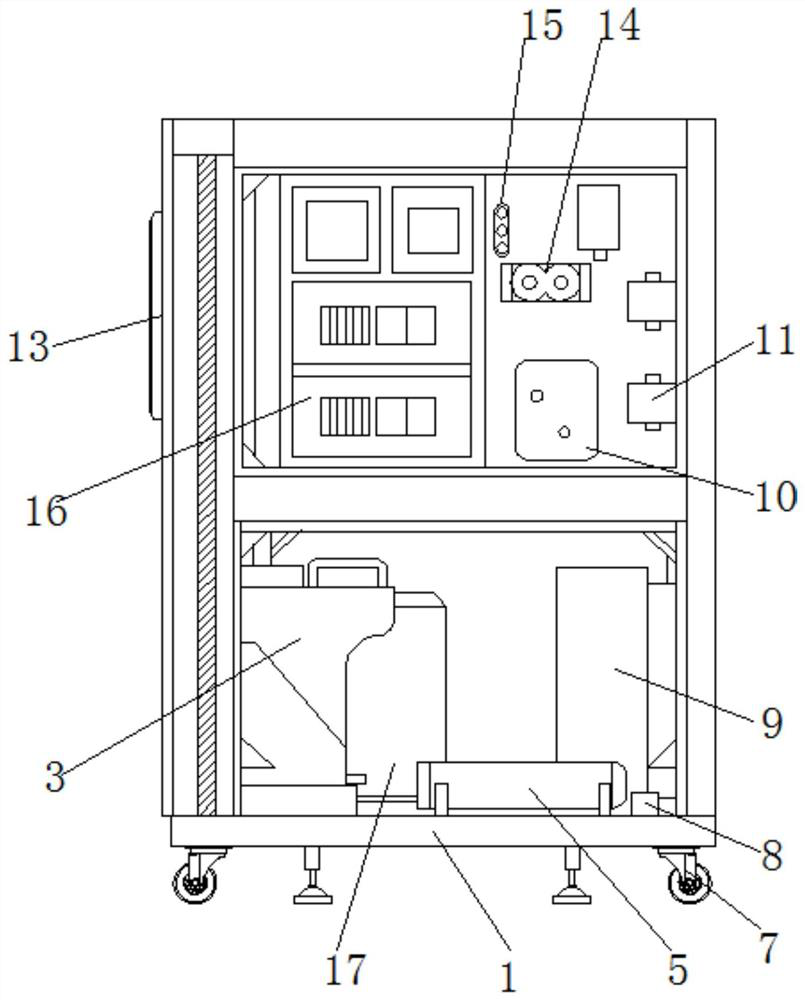

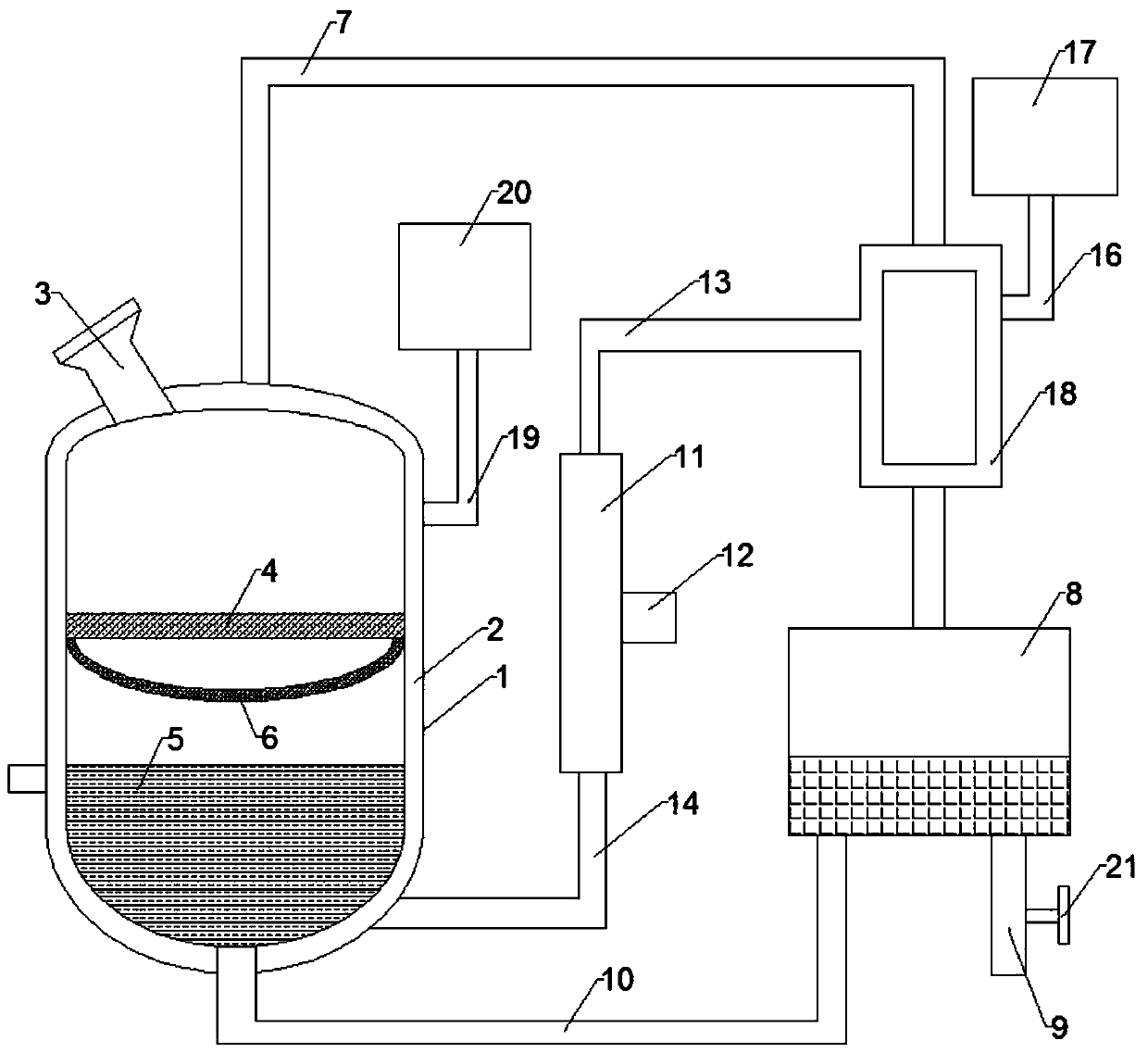

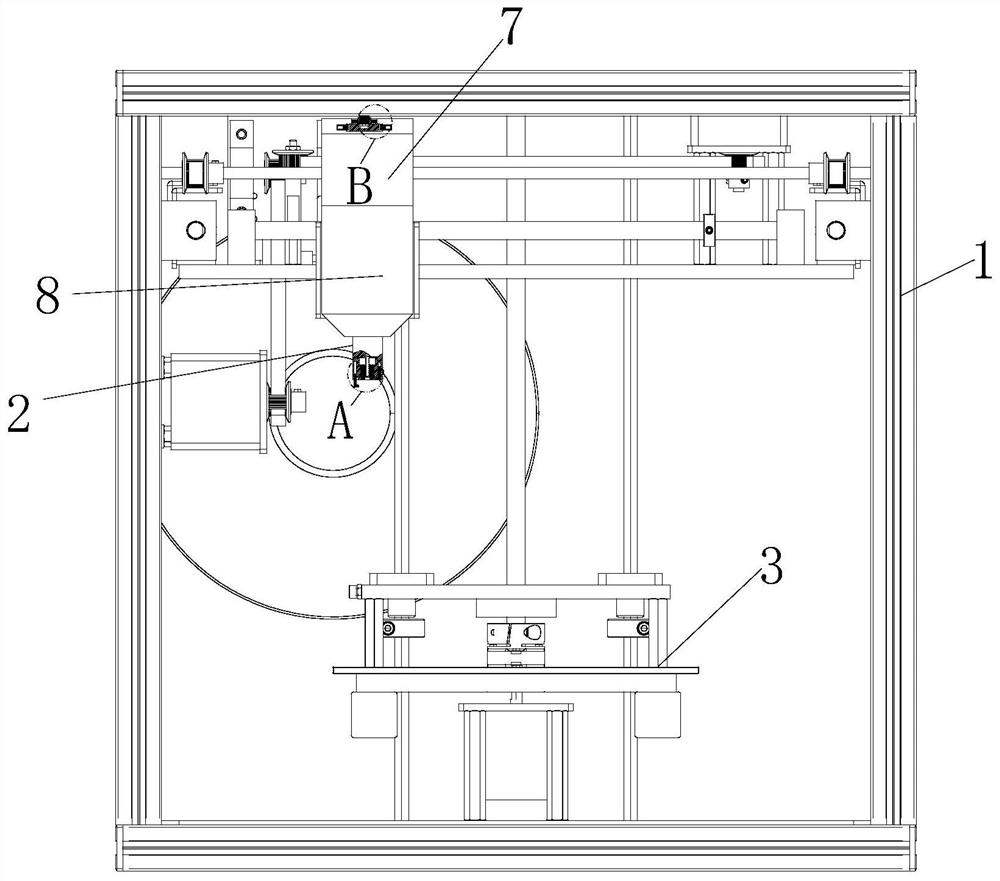

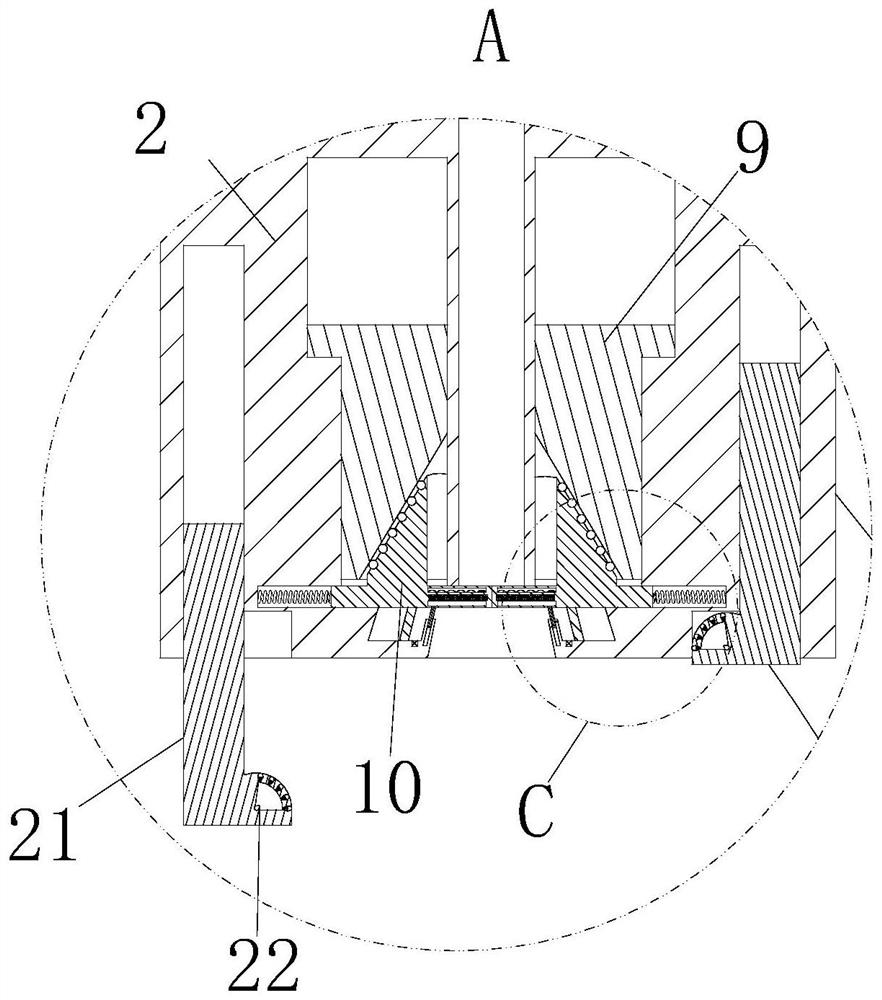

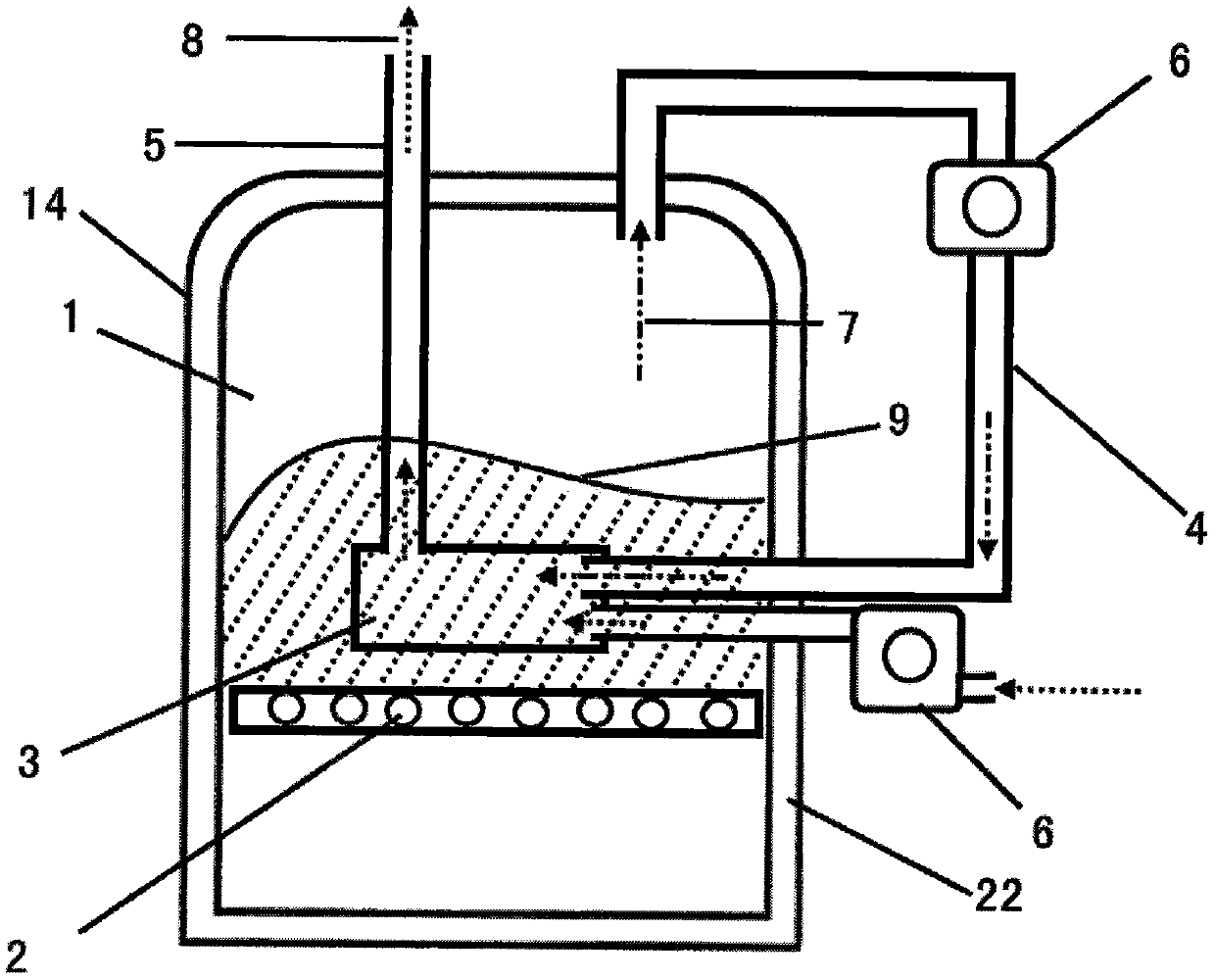

Concrete material in-high-temperature compression testing machine and in-high-temperature compression testing method

ActiveCN105424498AGuaranteed high temperatureGuaranteed fire resistanceMaterial strength using tensile/compressive forcesEngineeringFire resistance

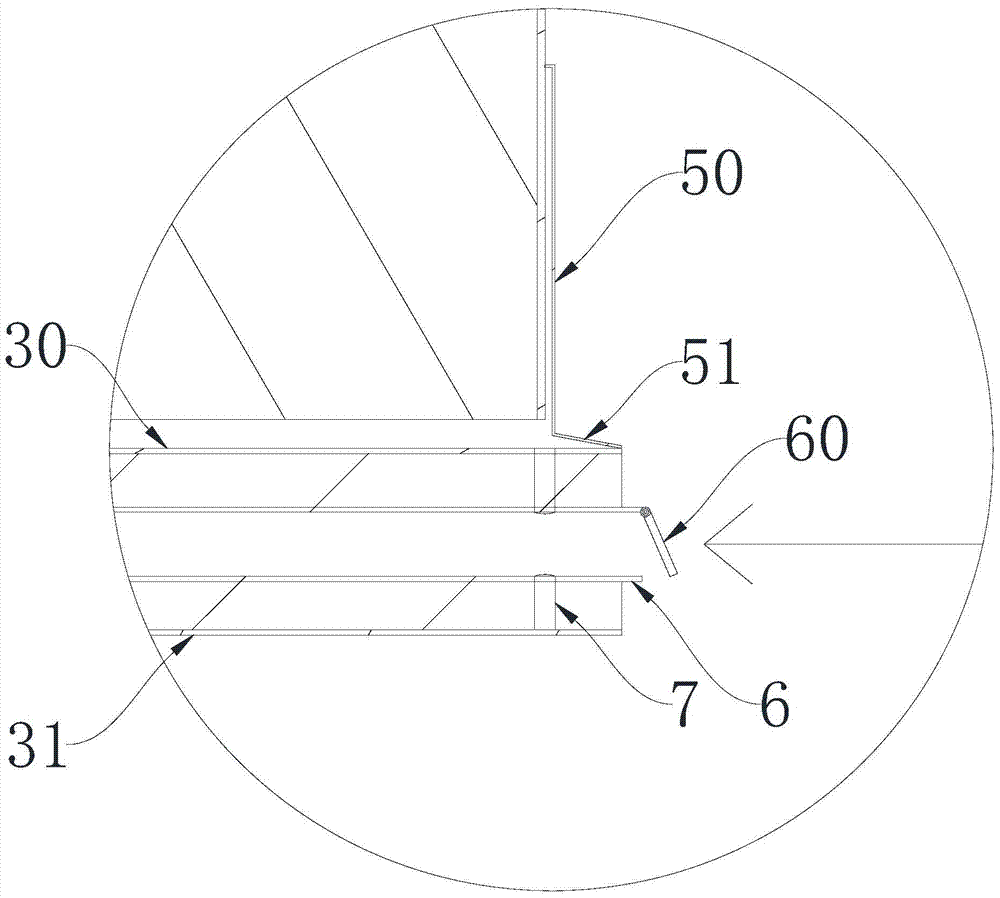

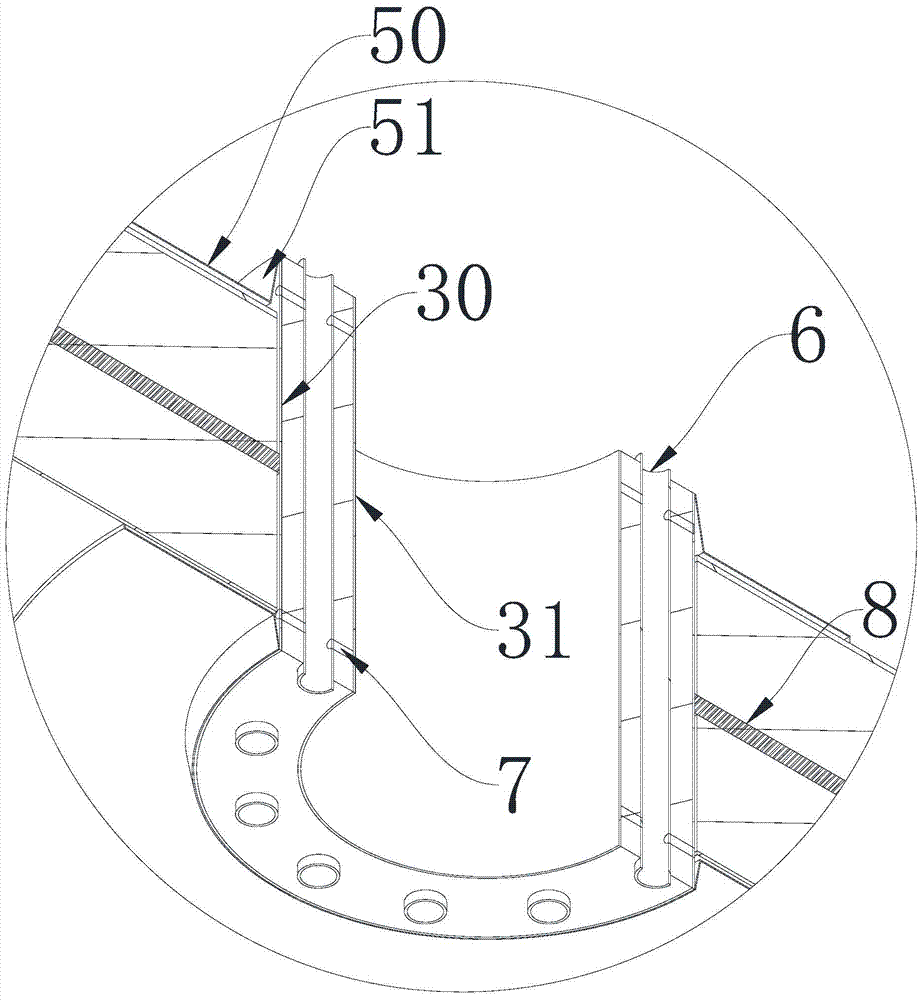

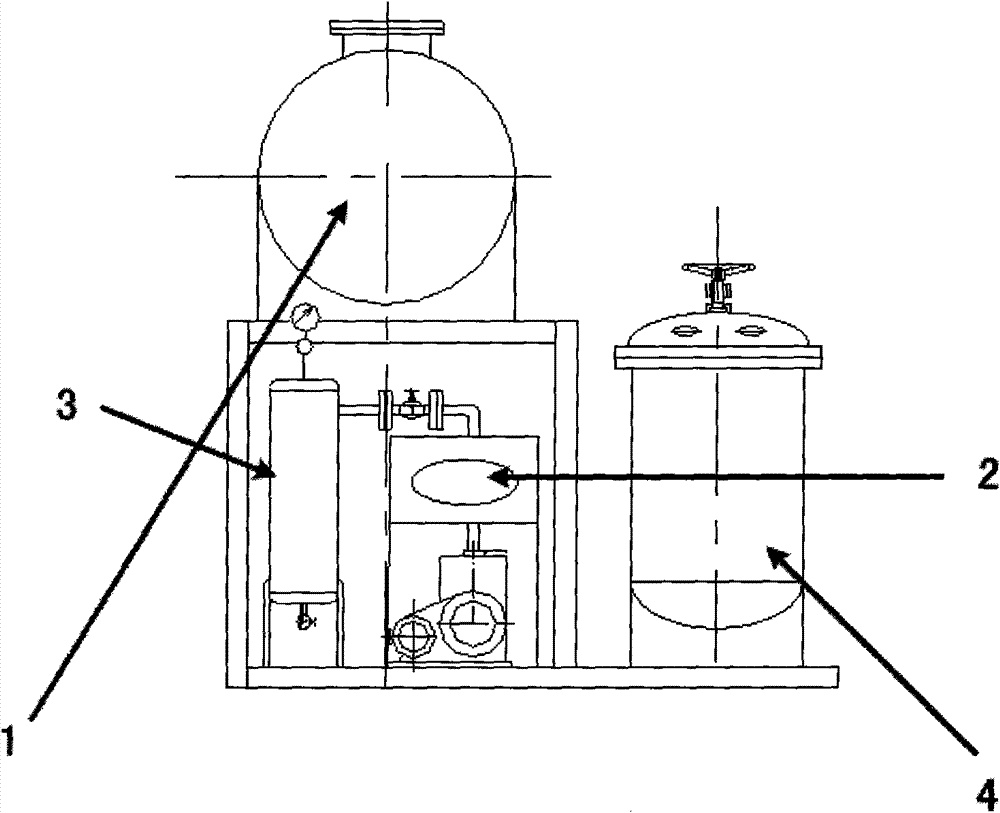

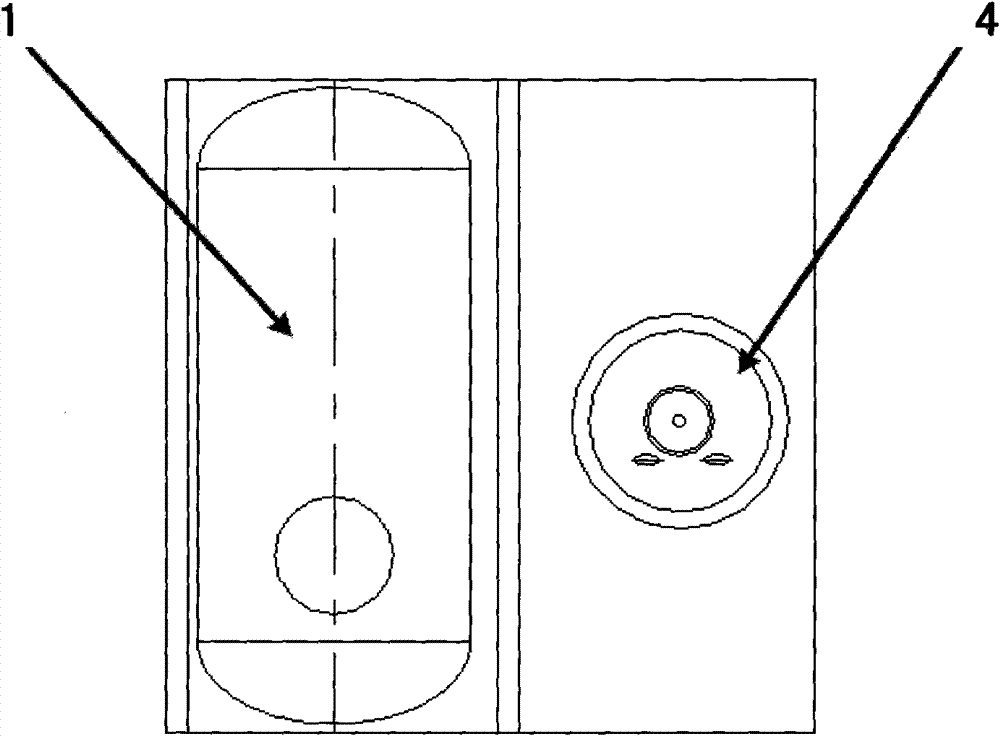

The invention provides a concrete material in-high-temperature compression testing machine and an in-high-temperature compression testing method. The concrete material in-high-temperature compression testing machine comprises loading equipment for applying pressure on a concrete test-piece, heating equipment for heating the concrete test-piece, and a displacement acquisition device for measuring the deformation of the concrete test-piece. According to the concrete material in-high-temperature compression testing machine, the heating equipment and the loading equipment for concrete testing are skillfully combined together, and are assisted by the displacement acquisition device, so that a comprehensive testing system capable of being used for concrete test-piece in-high-temperature compression testing is formed, synchronization of heating and loading is realized, a concrete environment in high temperature due to fire can be truly simulated, a test result obtained by performing a concrete material test through the concrete material in-high-temperature compression testing machine is very close to actual compressive property of concrete in high temperature due to fire, and a guarantee is provided for researching high temperature performance and fire resistance of a concrete material.

Owner:HENAN INST OF ENG +1

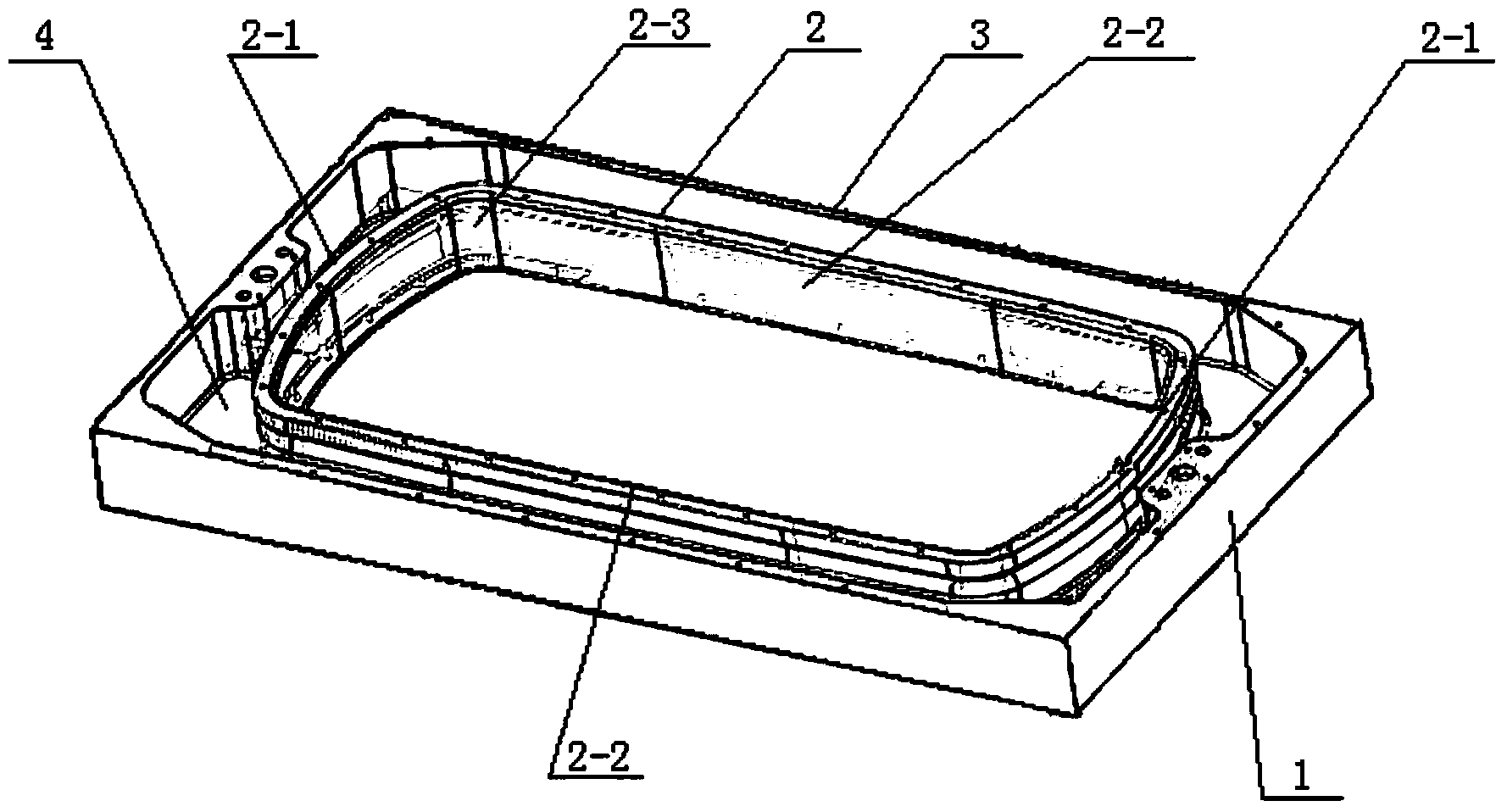

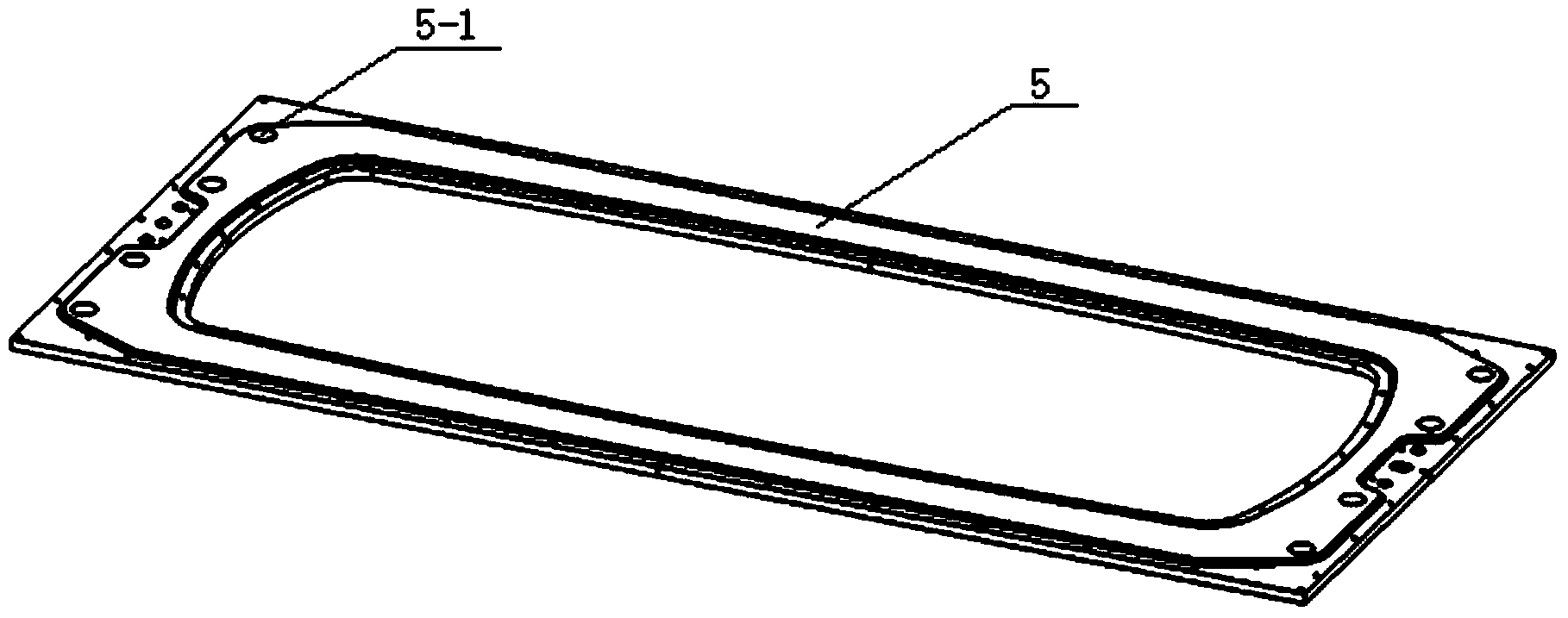

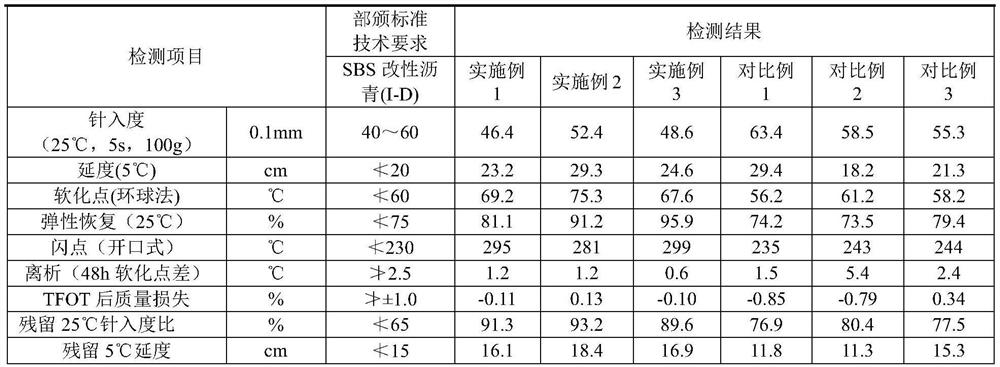

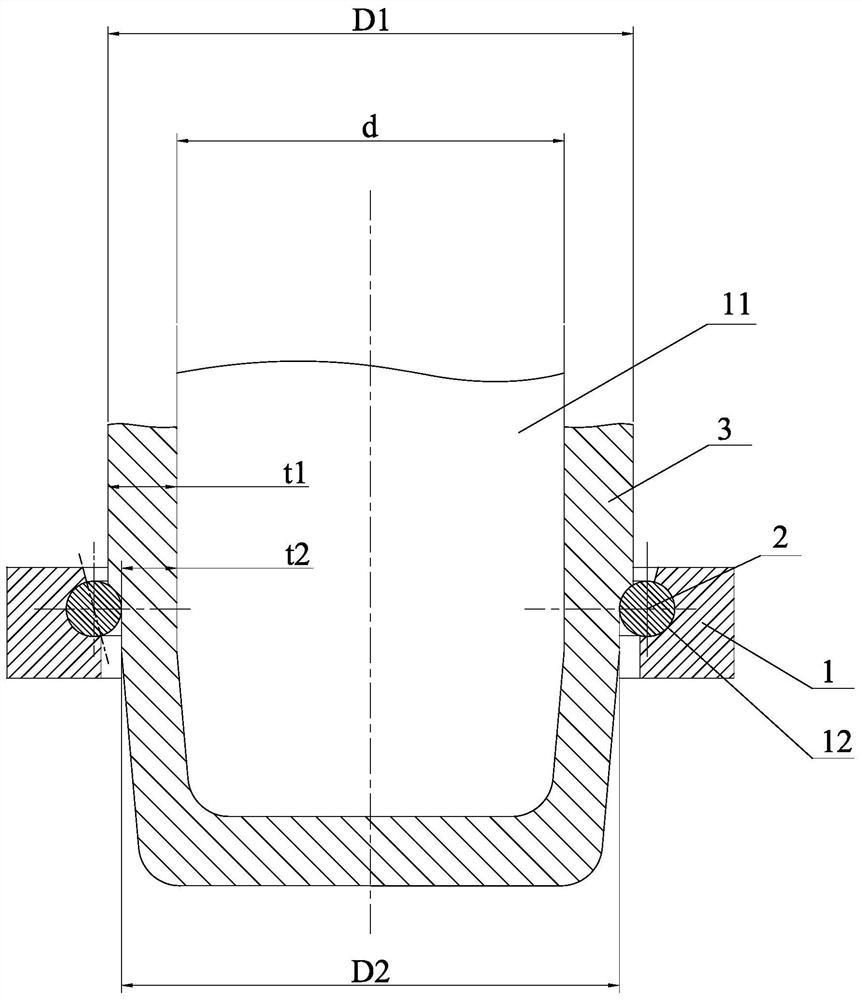

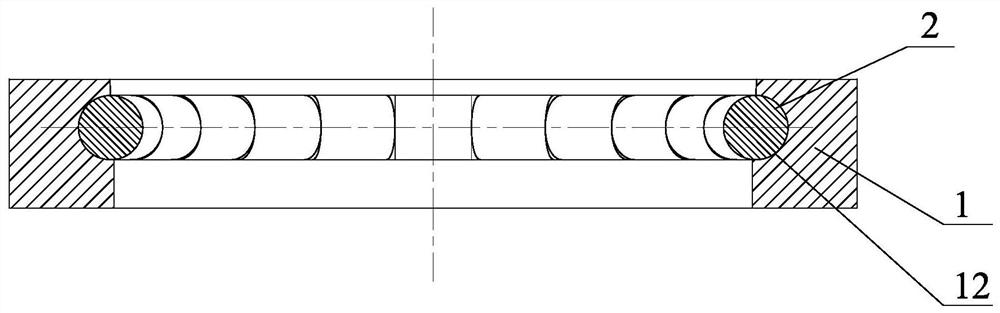

Crystallizer for preparing superhard aluminum alloy flat cast ingot and use method of crystallizer

The invention discloses a crystallizer for preparing a superhard aluminum alloy flat cast ingot and a use method of the crystallizer and relates to a tool for preparing the superhard aluminum alloy flat cast ingot and a use method of the tool.The crystallizer aims at solving the problem that superhard aluminum alloys produced by the existing casting tool have high possibility of crack rejects. The crystallizer for preparing the superhard aluminum alloy flat cast ingot comprises a crystallizer water chamber, a water chamber gland, a secondary water distribution plate and an oil gland, wherein the crystallizer water chamber comprises a water chamber internal wall, a water chamber external wall and a water chamber base; a plane is arranged at a junction between the internal surface and the upper surface of the water chamber internal wall; water outlet holes are formed in the plane; water inlet holes are formed at the two ends of the water chamber gland in a length direction; and a lubricating oil channel is arranged on the water chamber base and located close to the water chamber internal wall on the plane on the outer side of a cavity.The use method comprises the step of arranging a water baffle in a down direction of the cast ingot below the crystallizer when in use.The method reduces crack tendency.

Owner:NORTHEAST LIGHT ALLOY CO LTD

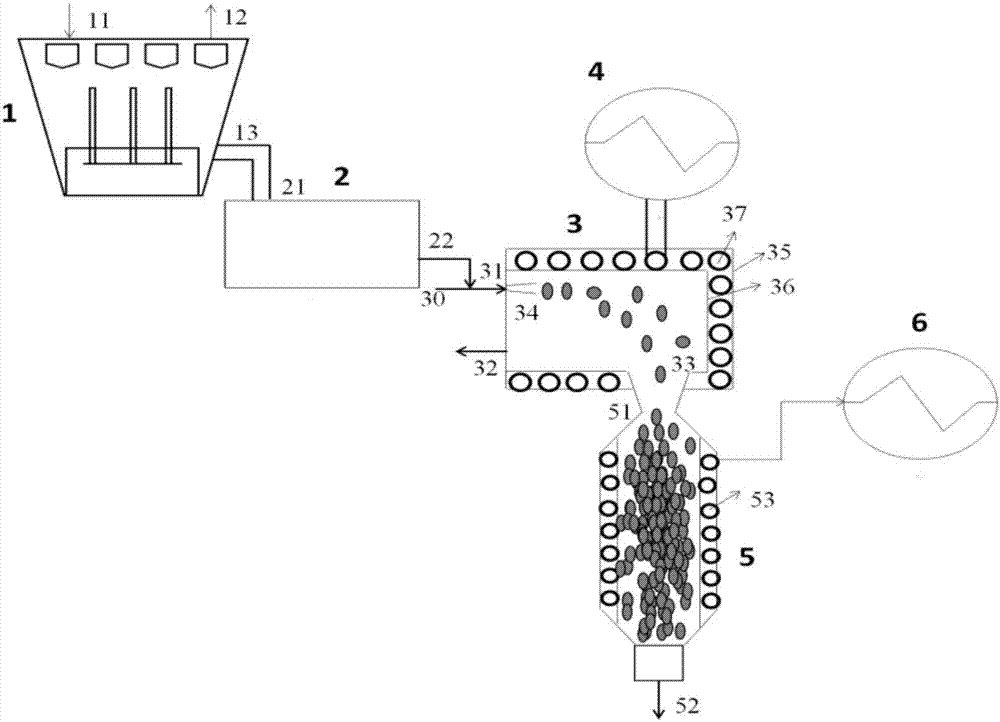

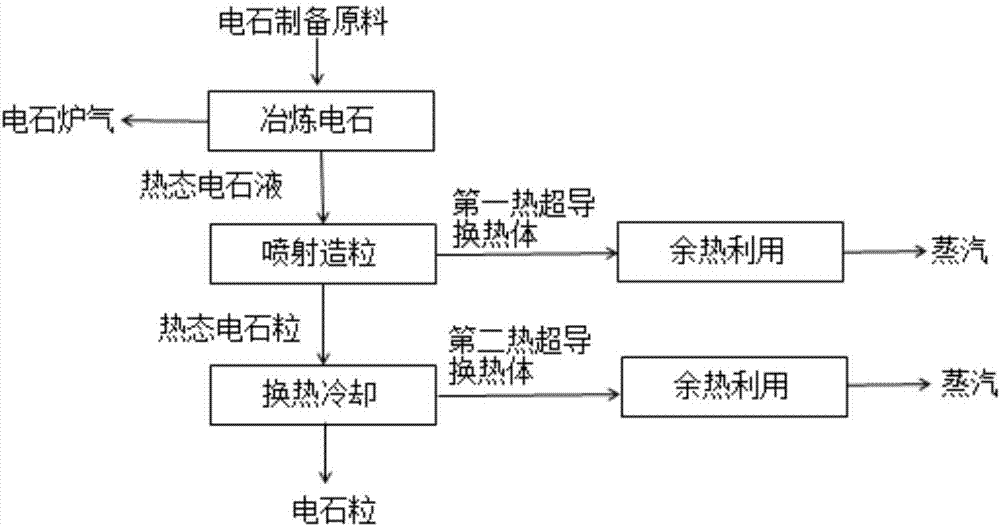

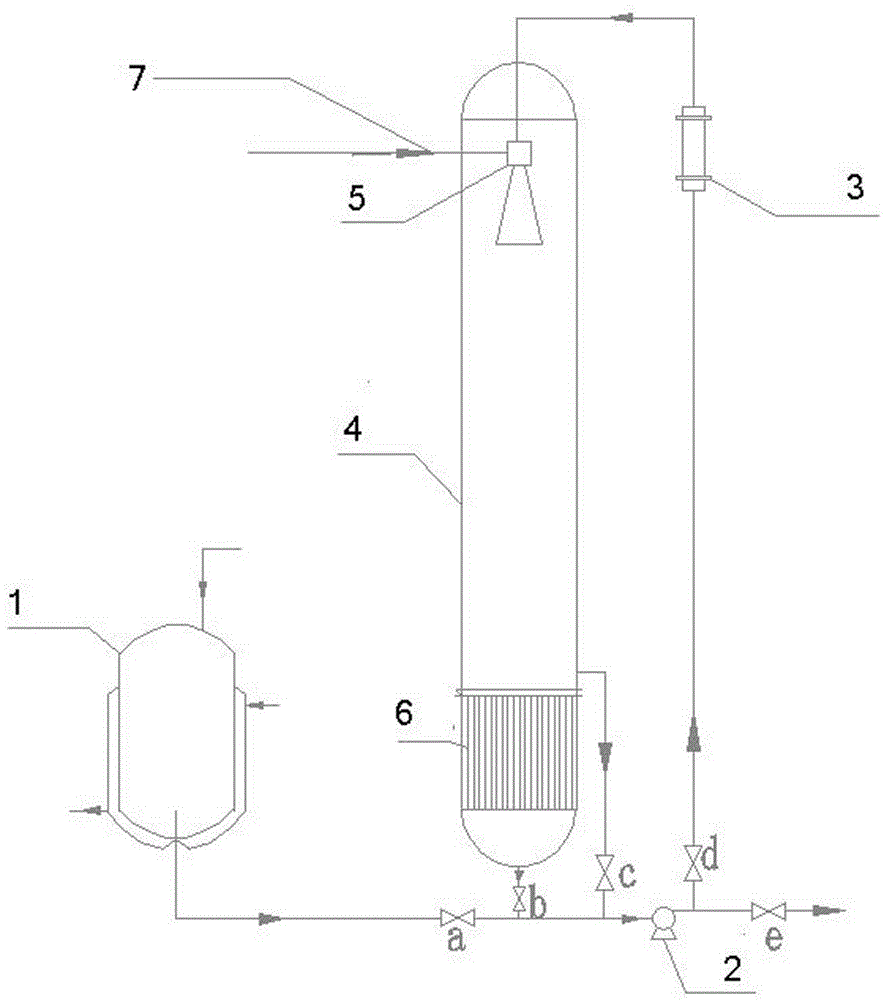

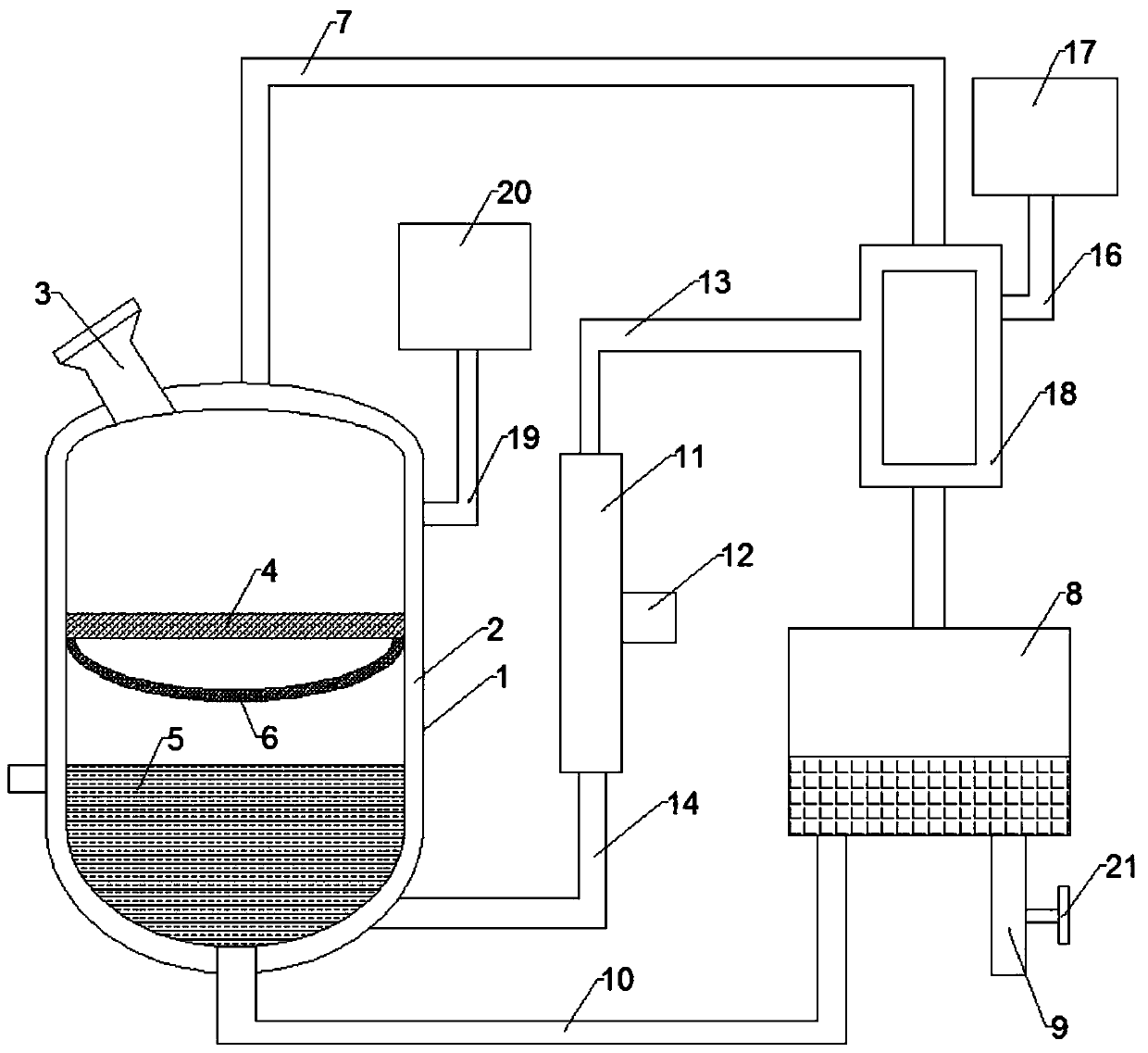

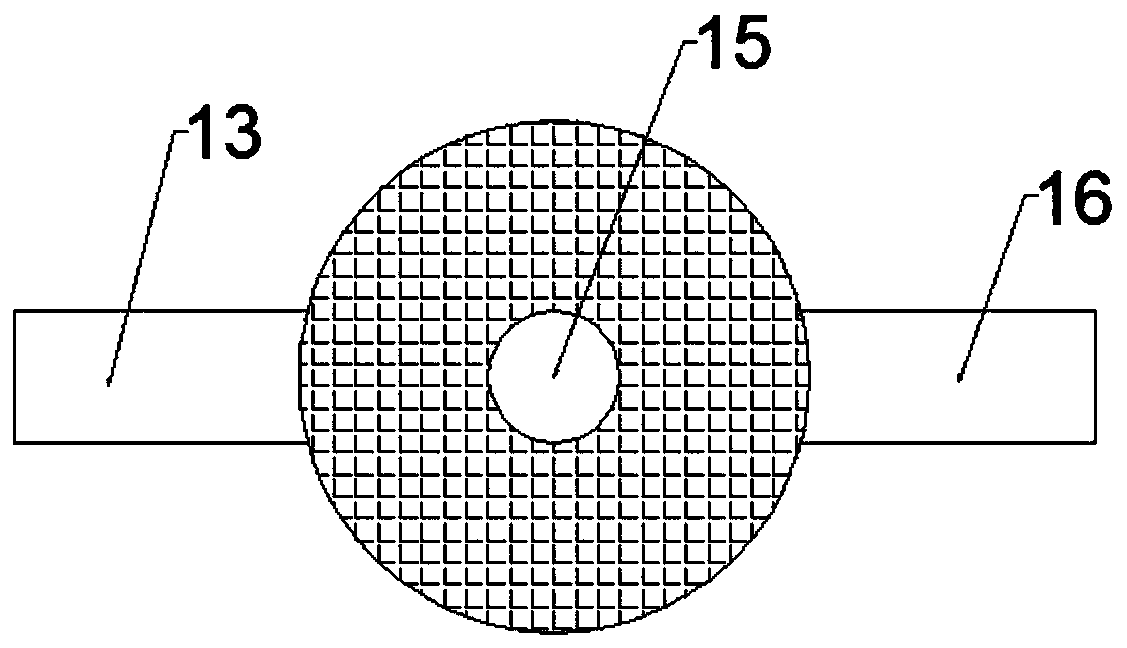

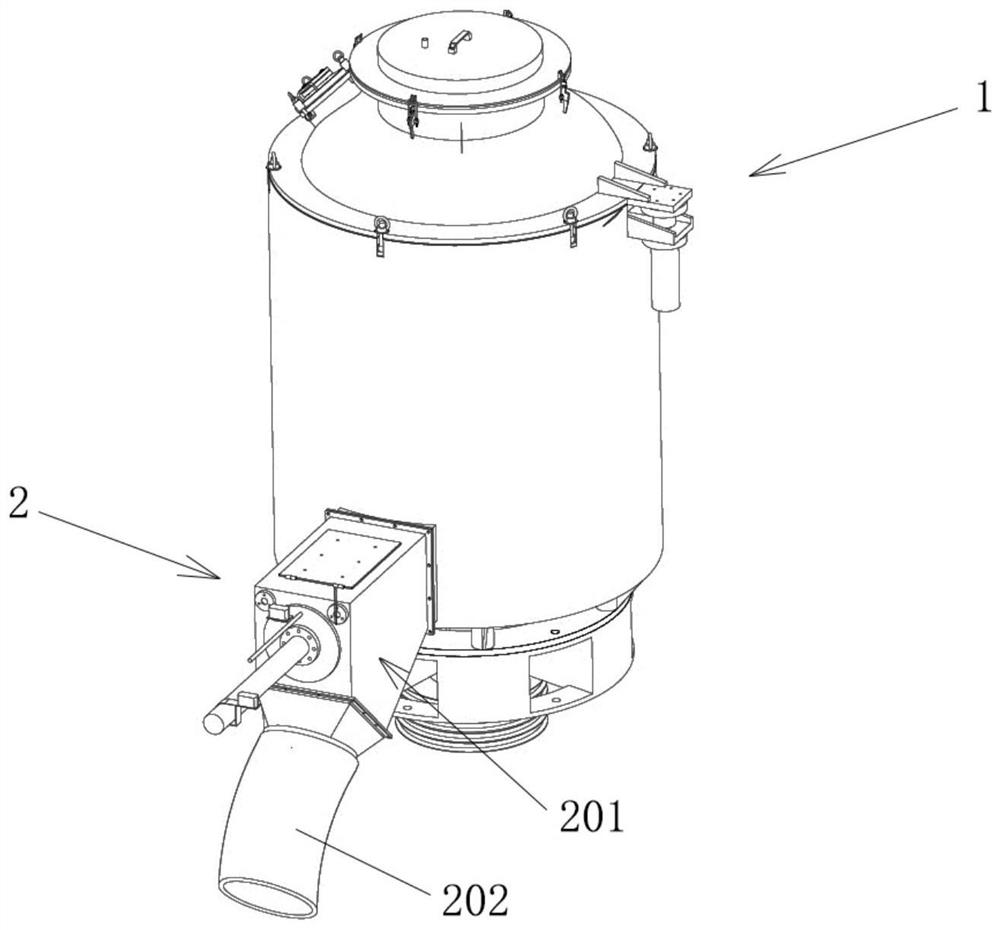

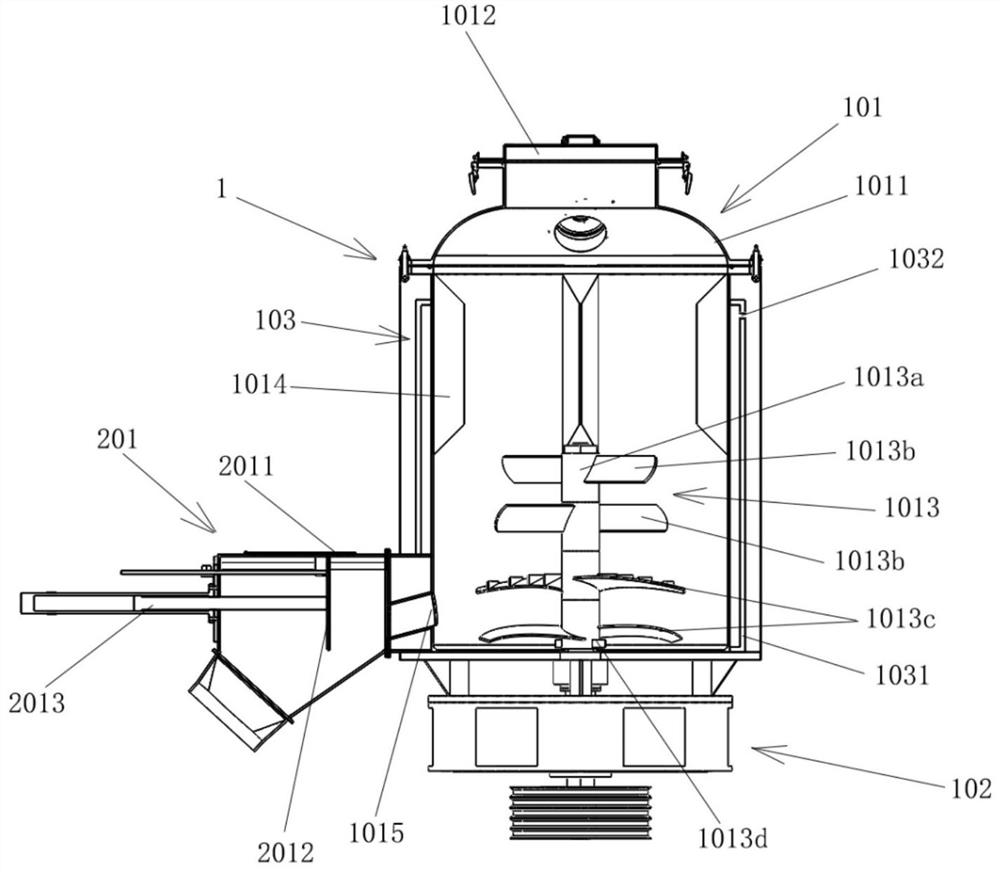

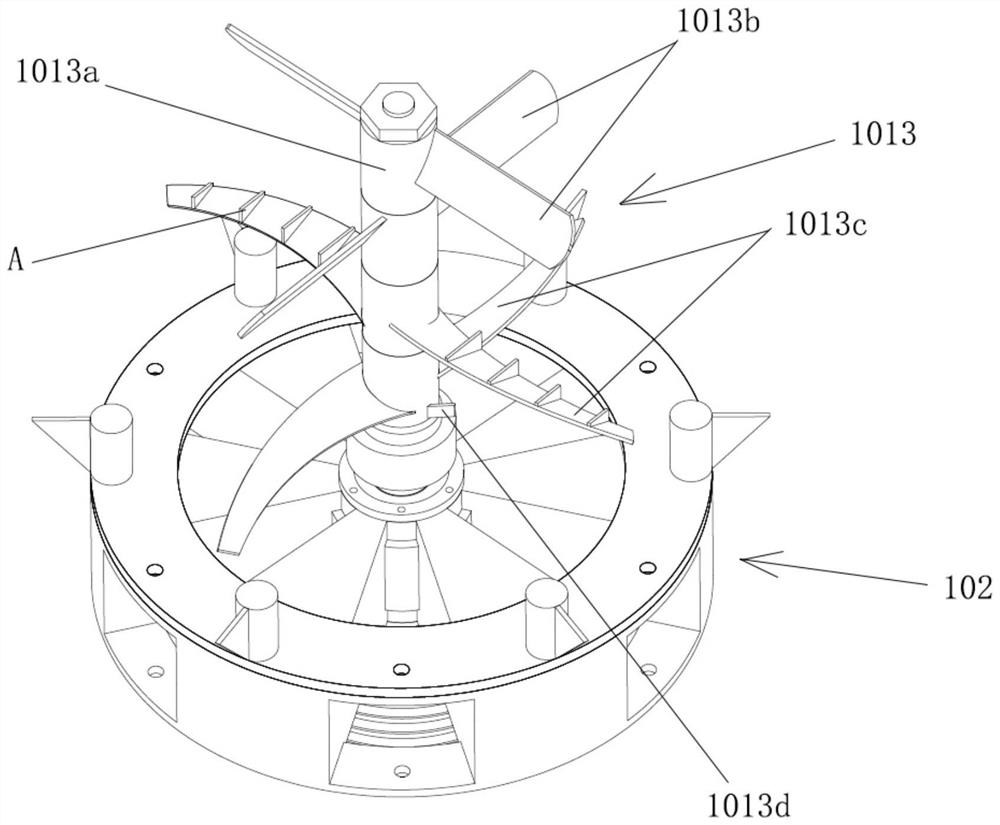

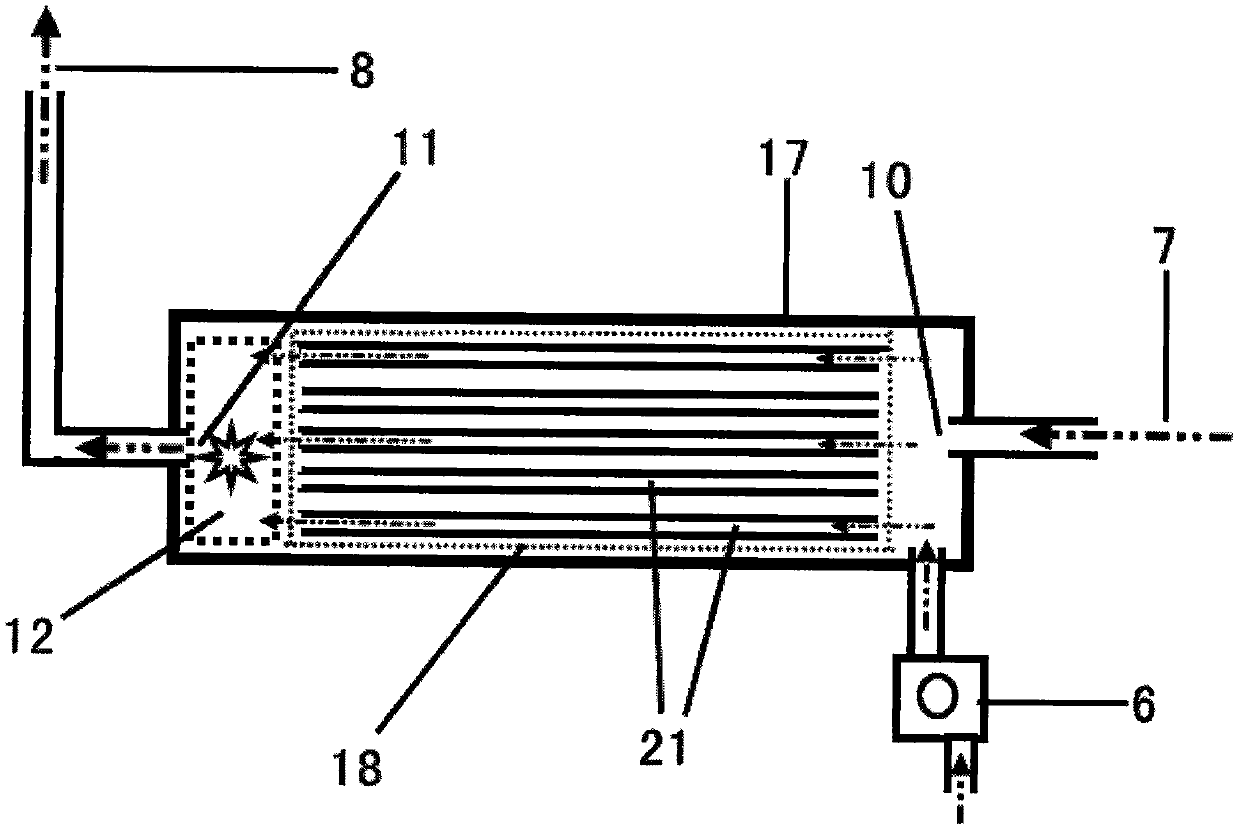

Calcium carbide liquid jet granulation and waste heat utilization system and method

PendingCN107416832ARapid cooling granulationAchieve recyclingEnergy inputGranulation by liquid drop formationLiquid jetThermal state

The invention relates to a calcium carbide liquid jet granulation and waste heat utilization system and method. The system comprises a jet granulation device, a first steam boiler, a heat exchange device and a second steam boiler, wherein the jet granulation device comprises a thermal-state calcium carbide liquid inlet and a thermal-state calcium carbide particle outlet, an injector is arranged at the thermal-state calcium carbide liquid inlet, and multiple horizontally arranged seamless steel tubes are arranged between the outer wall and the inner wall of the jet granulation device and filled with first thermal superconductive heat exchange bodies connected with the first steam boiler; the heat exchange device comprises a thermal-state calcium carbide particle inlet and a thermal-state calcium carbide particle outlet, the thermal-state calcium carbide particle inlet is connected with the thermal-state calcium carbide particle outlet of the jet granulation device, and multiple horizontally arranged seamless steel tubes are arranged between the outer wall and the inner wall of the heat exchange device and filled with second thermal superconductive heat exchange bodies connected with the second steam boiler. With the adoption of the system and method, quick cooling and granulation of a calcium carbide liquid can be realized, and waste heat of the calcium carbide liquid can be effectively utilized.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

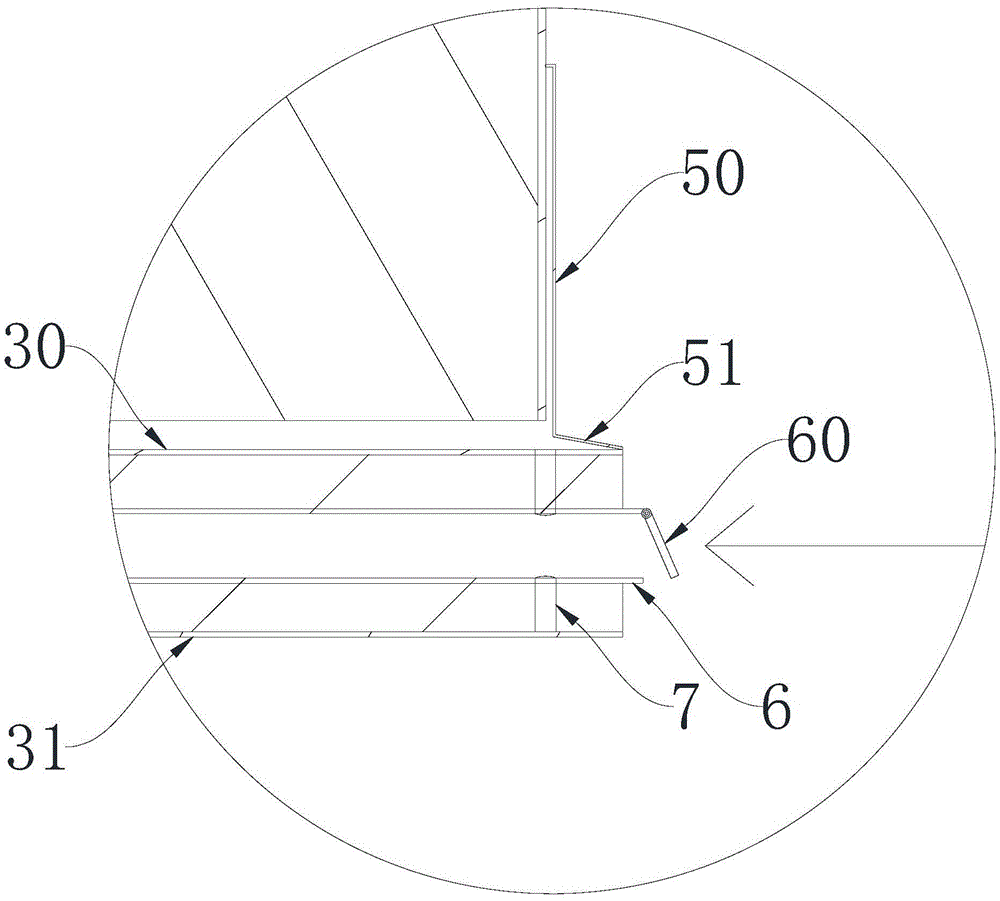

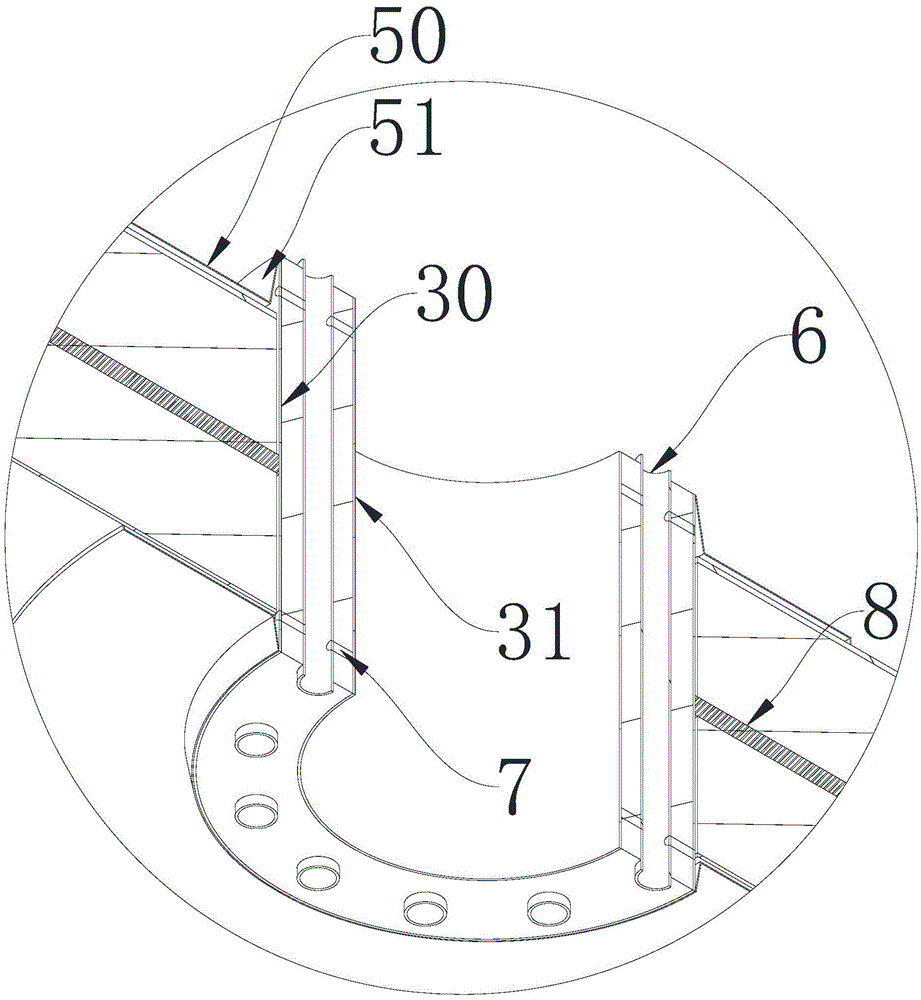

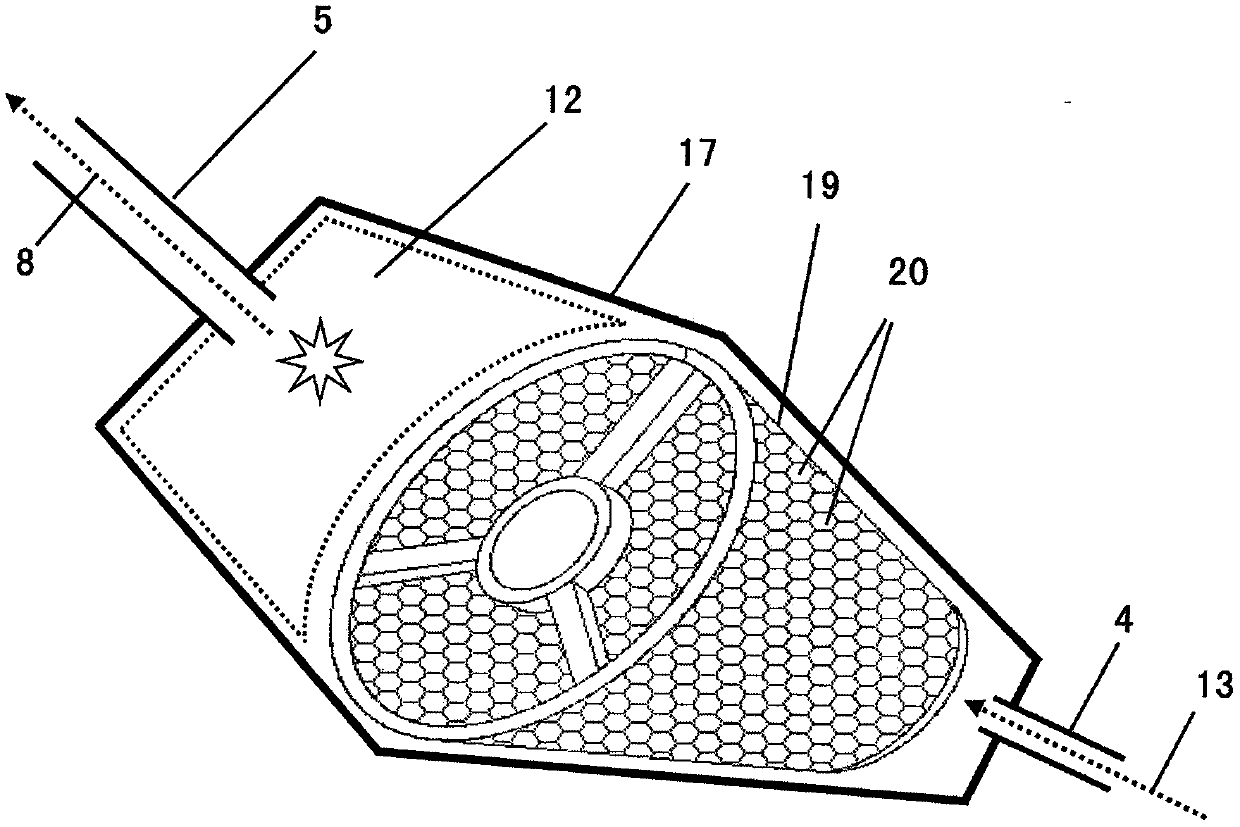

Oxygen supply and thermal insulation device and flammable gas combustion chamber with same

ActiveCN105465773ANo swellingImprove stabilityAir/fuel supply for combustionCombustion chamberThermal insulation

The invention discloses an oxygen supply and thermal insulation device and a flammable gas combustion chamber with the same. After being inlaid in an inlet of the combustion chamber, the oxygen supply and thermal insulation device connects an inner cavity of the combustion chamber with a flame jetting opening of a combustion device. The oxygen supply and thermal insulation device comprises a gas inlet cylinder formed by mutually nesting an inner cylinder and an outer cylinder. An oxygen supply pipe is inserted between the inner cylinder and the outer cylinder, and the space between the inner cylinder and the outer cylinder is filled with temperature-resistant castable. The inner cylinder, the outer cylinder and the oxygen supply pipe are mutually fixed through supporting rings. A pipe cap used for adjusting the gas inflow of the combustion chamber is installed at the gas inlet end of the oxygen supply pipe. According to the oxygen supply and thermal insulation device and the flammable gas combustion chamber with the same, flammable gas can be fully burnt, and the burning temperature can be above 1000 DEG C, so that energy in the flammable gas can be fully used. Through a special sealing structure at the inlet of the combustion chamber, heat loss is avoided, so that heat energy generated by burning the flammable gas is used furthest. In addition, the inlet of the combustion chamber is welded in a sealed mode through a hubbed flange structure, so that the functions that the service life of the combustion chamber, the gas inlet cylinder and other parts is prolonged are achieved.

Owner:潘汉祥

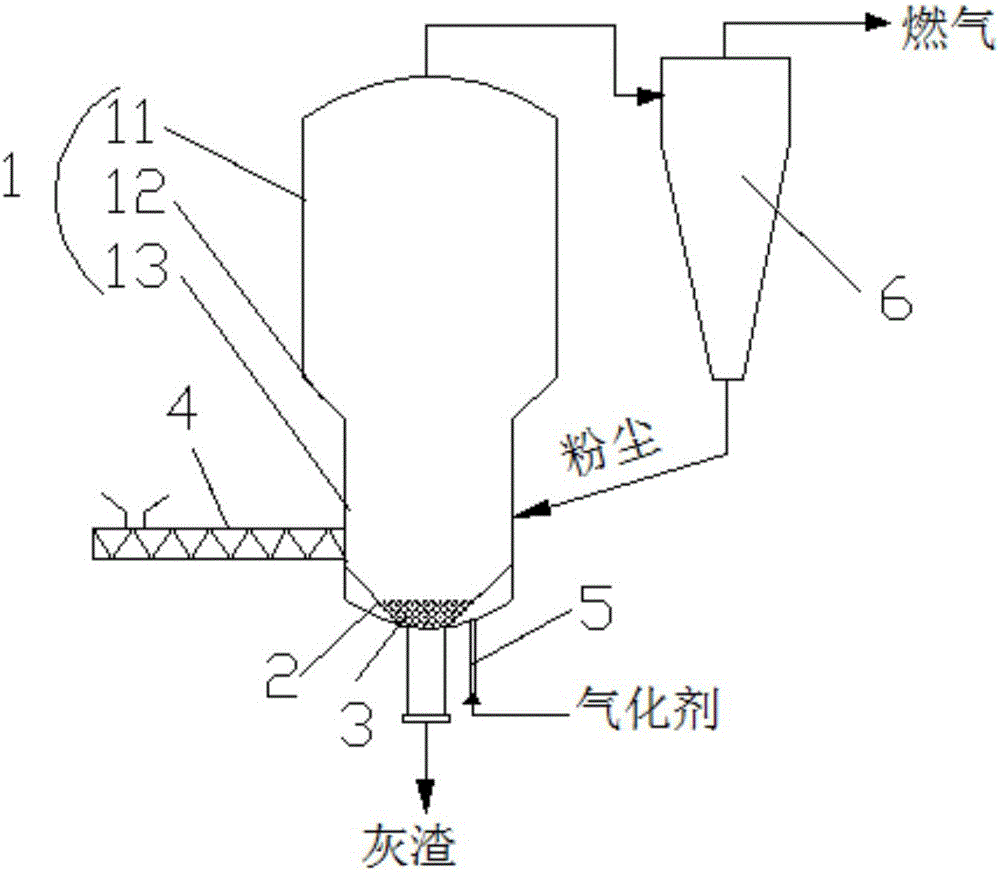

Fluidized-bed gasification furnace for treating biomass

InactiveCN106336905ALight weightSmall specific surface areaGasifier feeding meansGasifier mechanical detailsFluidized bed gasifierRound table

The present invention discloses a fluidized-bed gasification furnace for treating biomass. According to the fluidized-bed gasification furnace, the fluidized-bed gasification furnace body comprises an upper cylinder having a cylindrical structure, a lower cylinder having a cylindrical structure, and a connection section for connecting the upper cylinder and the lower cylinder; and the fluidized-bed gasification furnace is characterized in that the diameter ratio of the upper cylinder to the lower cylinder is 1.5-2:1, the connection section has a top-removing cone structure, the inclination angle of the connection section is 45-75 DEG, the bottom portion of the lower cylinder is provided with a wind distribution plate, the wind distribution plate has a hollow round table structure having the large upper portion and the small lower portion, and the included angle between the wind distribution plate and the bottom portion of the lower cylinder is 20-55 DEG. According to the present invention, the biomass raw material can be subjected to the large-scale treatment with the fluidized-bed gasification furnace, the fluidized-bed gasification furnace has the high energy conversion rate, the tar content in the produced fuel gas is low, and the secondary pollution cannot be generated.

Owner:武汉高斯生态能源技术有限公司

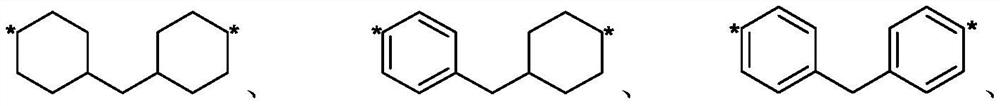

Hydrogenation reaction device

ActiveCN105237357AReduce lossesGuaranteed high temperaturePreparation by hydrogenationChemical industryHydrogenation reactionTower

The invention discloses a hydrogenation reaction device and belongs to the field of chemical equipment. The device comprises a raw material dissolving kettle, a circulating pump, a preheater and a hydrogenation filter, wherein the bottom of the raw material dissolving kettle is sequentially connected with the bottom of the hydrogenation filter and the circulating pump; the other end of the circulating pump is connected with the preheater, and the preheater is connected with the top of the hydrogenation filter through a pipeline; the hydrogenation filter is composed of a jet-loop reactor, a hydrogen tube and a filter; the hydrogenation filter is tower type and is sequentially divided into a hydrogenation reaction region and a filter region from bottom to top internally, respectively; the two regions are connected and communicated with each other by virtue of flanges; in the hydrogenation reaction region, the hydrogen tube is connected with the jet-loop reactor which is fixedly arranged at the top of the tower and is connected with the preheater through a pipeline; various inlet-outlet pipes connected with the circulating pump are provided with control valves. The hydrogenation reaction device disclosed by the invention fully carries out hydrogenation, is high in yield, and does not need to recycle escaped hydrogen. In particular in an application of hydrogenation production of hydrogenated bisphenol A by bisphenol A, the hydrogenation reaction device is energy-saving, high in work efficiency and stable in product quality.

Owner:PUYANG HUICHENG ELECTRONICS MATERIAL

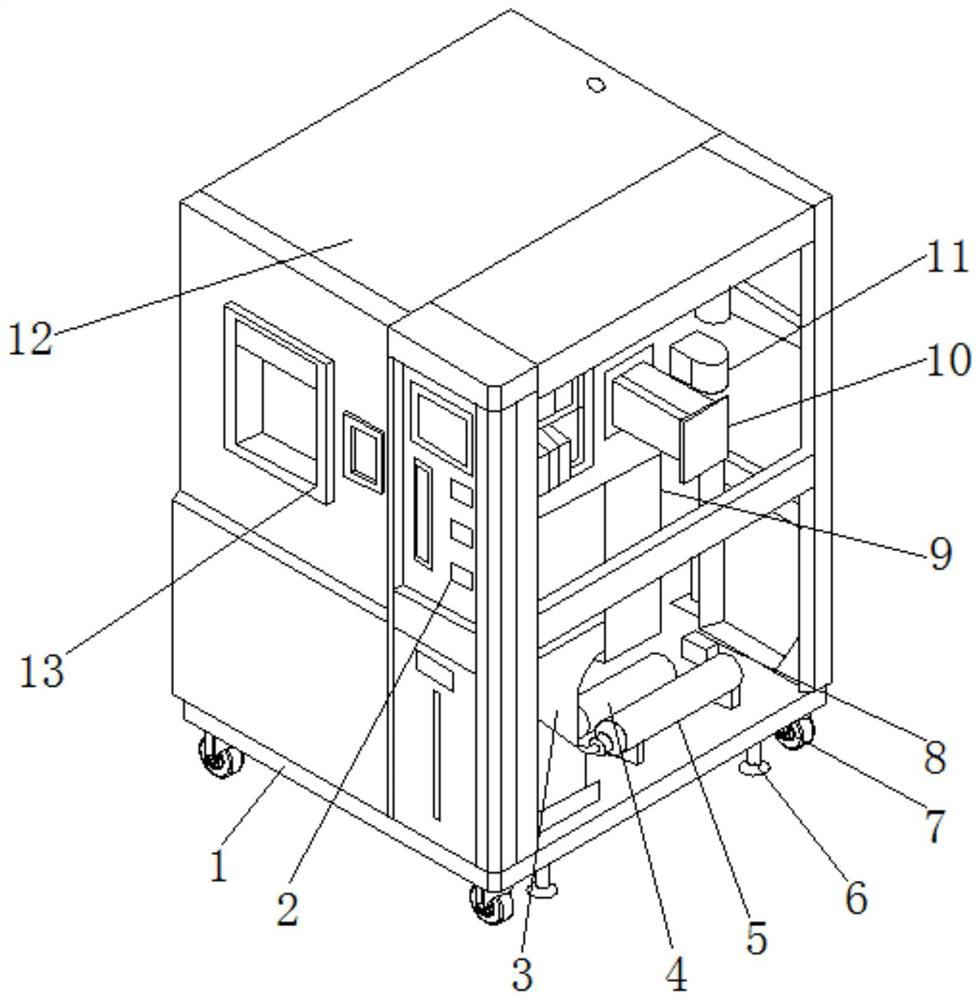

Constant temperature and moisture test box

InactiveCN112517087AReduce interactionGuaranteed high temperatureHeating or cooling apparatusEnclosures/chambersTemperature controlEngineering

The invention discloses a constant temperature and moisture test box, comprising a bottom plate, wherein a cabinet body is welded to the outer wall of the top of the bottom plate; a test bin and an accessory bin are arranged on the outer wall of one side of the cabinet body; an experiment bin is arranged on the outer wall of one side of the cabinet body; a sealing door is fixed to the outer wall of the experiment bin through hinges; a control cabinet is arranged on the side, close to the experiment bin; and a humidifying box, a water cup group, an EZO over-temperature protection element and aswitchboard are arranged on the inner wall of the test bin. According to the invention, through the EZO over-temperature protection element and temperature and moisture sensors, a temperature controlarea and a moisture control area are changed separately; meanwhile, mutual influence of temperature and moisture is reduced in the temperature and moisture changing process, and constant-temperature water mist is formed in the internal water cup group; and when the water cup group works, entered to-be-atomized liquid is atomized and quantified, the temperature of an overall atomized substance is regulated and controlled, and the temperature and moisture of the water mist injected into the experiment bin reach a constant standard, so constant-temperature and constant-moisture effects are achieved.

Owner:无锡市恒升试验设备有限公司

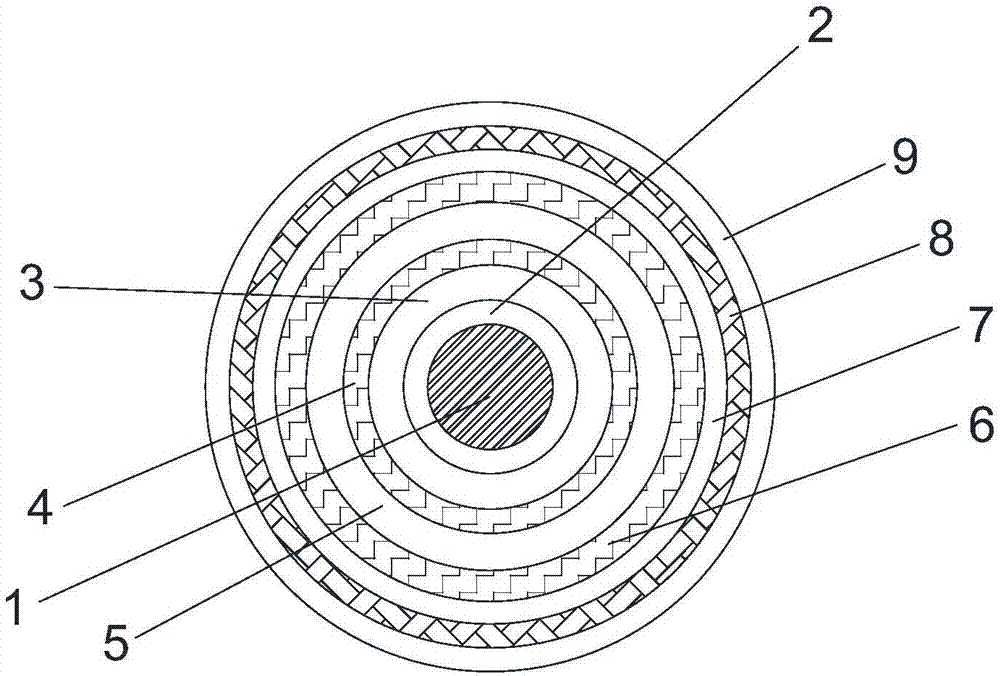

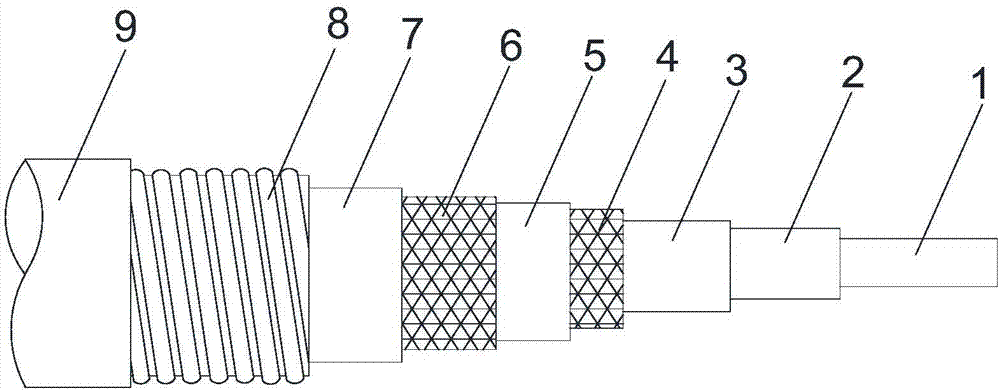

Coaxial cable for nuclear power station

ActiveCN107204215AGuaranteed irradiationWarranty requirementsPlastic/resin/waxes insulatorsConcentric cablesPoly ether ether ketonePolyolefin

The invention relates to the field of a cable, and particularly to a coaxial cable for a nuclear power station. The cable comprises a conductor. A first insulating layer, a second insulating layer, a first woven shielding layer, a first inner sheath, a second woven shielding layer, a second inner sheath, a metal corrugated pipe and an outer sheath successively wrap the external surface of the conductor. The first insulating layer is made of a thin-wall extruded poly-ether-ether-ketone modified cable insulating material. The second insulating layer is made of radiating crosslinked polyolefin. The thickness ratio between the first insulating layer and the second insulating layer is 1:3-20. The coaxial cable satisfies a requirement for signal transmission among a reactor workshop neutron detector and a junction box and a through member and among an auxiliary workshop through member and a pre-amplifier and a signal processing cabinet in a Chinese third-generation nuclear power plant instrument system. Furthermore the coaxial cable satisfies a requirement for executing a safe function in a designed reference accident environment condition of the third-generation nuclear power plant.

Owner:CHANGZHOU BAYI CABLE

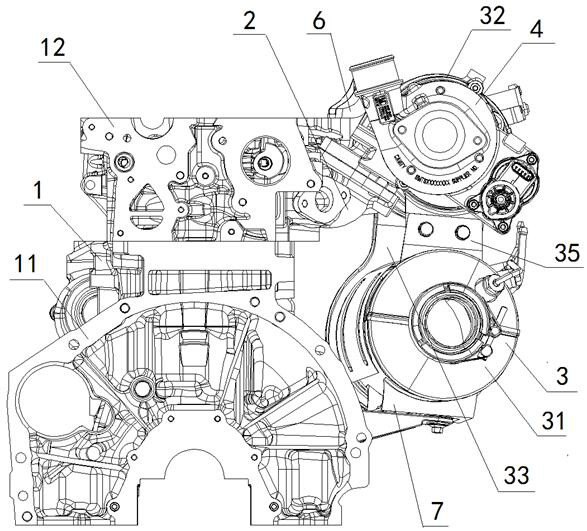

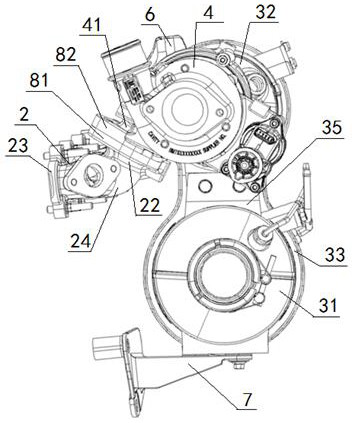

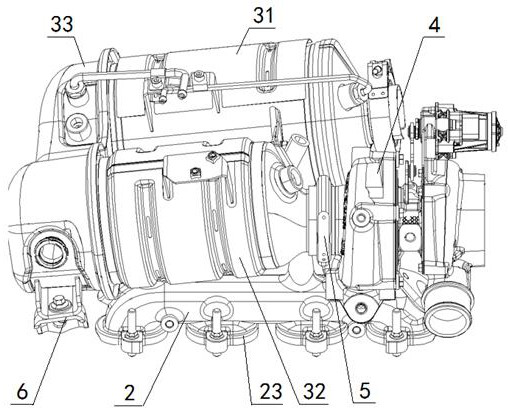

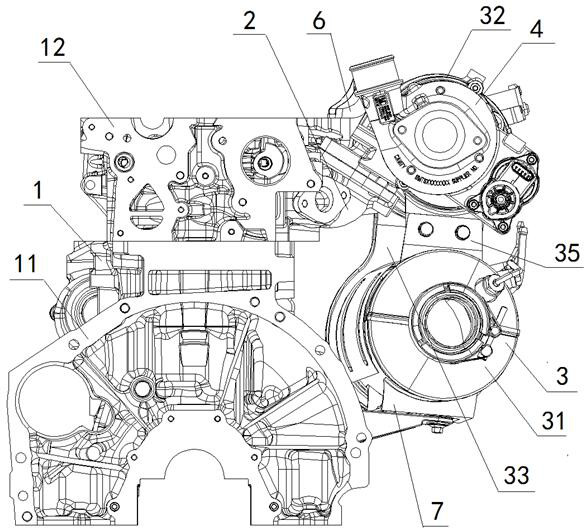

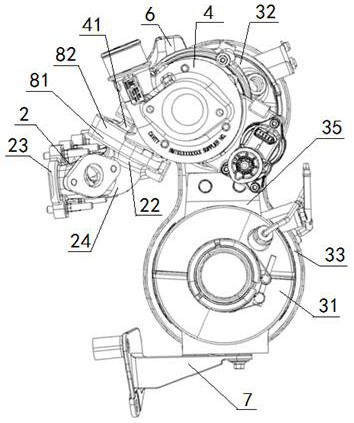

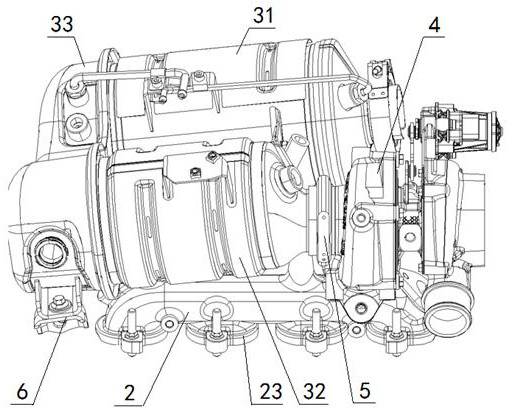

Tightly-arranged engine tail gas treatment system

ActiveCN112648046AGuaranteed high temperatureReduce temperature lossInternal combustion piston enginesExhaust apparatusParticulatesPtru catalyst

A tightly-arranged engine tail gas treatment system comprises an exhaust manifold, a post-treatment assembly and a supercharger which are fixedly arranged on one side of an engine, wherein the post-treatment assembly comprises a particulate matter catcher for selective catalytic reduction, an oxidation catalytic converter and a mixer assembly; the rear end of the particulate matter catcher for selective catalytic reduction is communicated with the rear end of the oxidation catalytic converter through the mixer assembly, and the particulate matter catcher for selective catalytic reduction, the oxidation catalytic converter and the mixer assembly are arranged in a U shape; the exhaust manifold is arranged between the engine and the oxidation catalytic converter, the front portion of the exhaust manifold is communicated with the front end of the oxidation catalytic converter through the supercharger, and the exhaust manifold, the supercharger and the particulate matter catcher 31 for selective catalytic reduction are arranged in a U shape; and the side part of the exhaust manifold is communicated with an engine exhaust port in the side part of the engine. The design is compact in arrangement, a waste gas flowing path is short, the waste gas heat loss is small, the conversion efficiency of catalysts is high, and strict emission standards are met.

Owner:DONGFENG AUTOMOBILE COMPANY

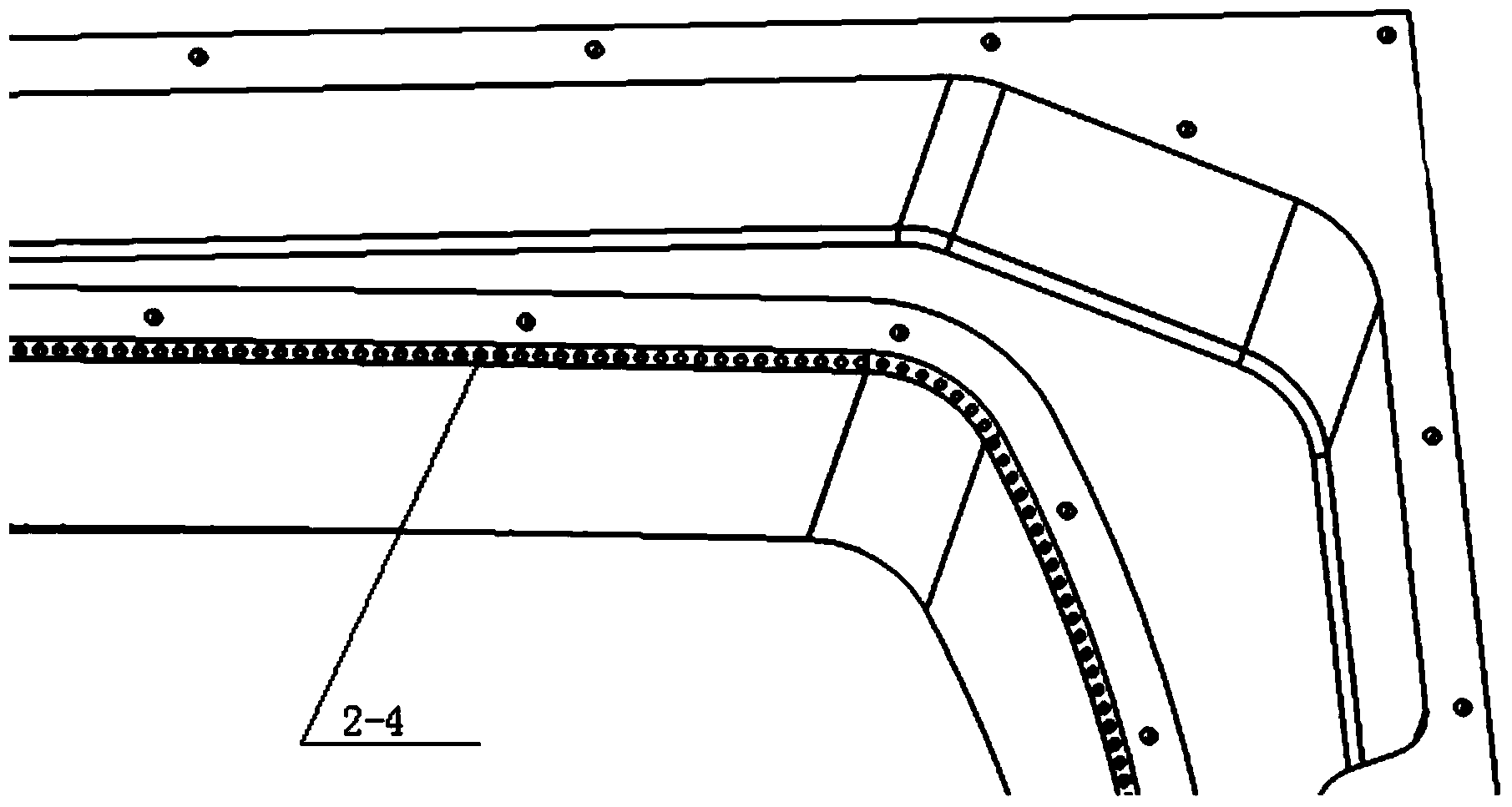

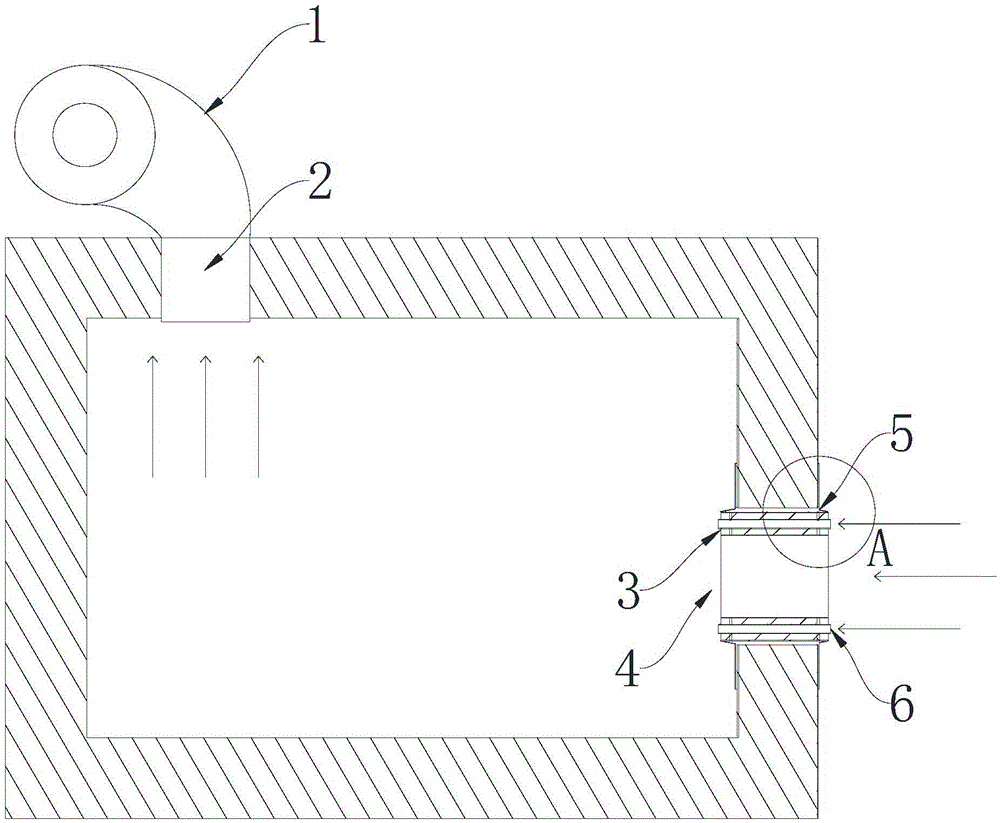

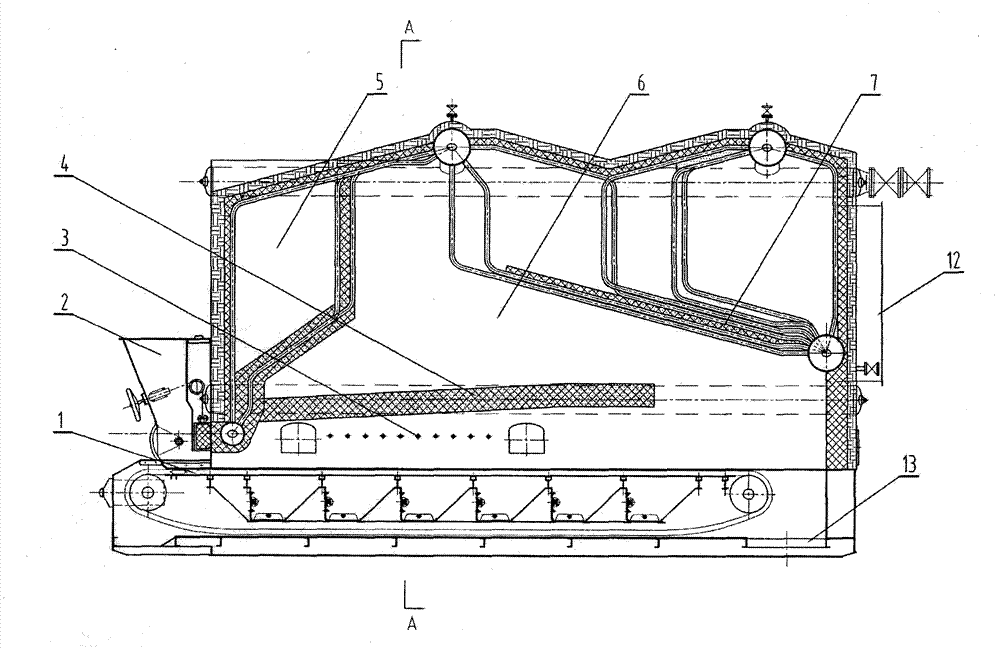

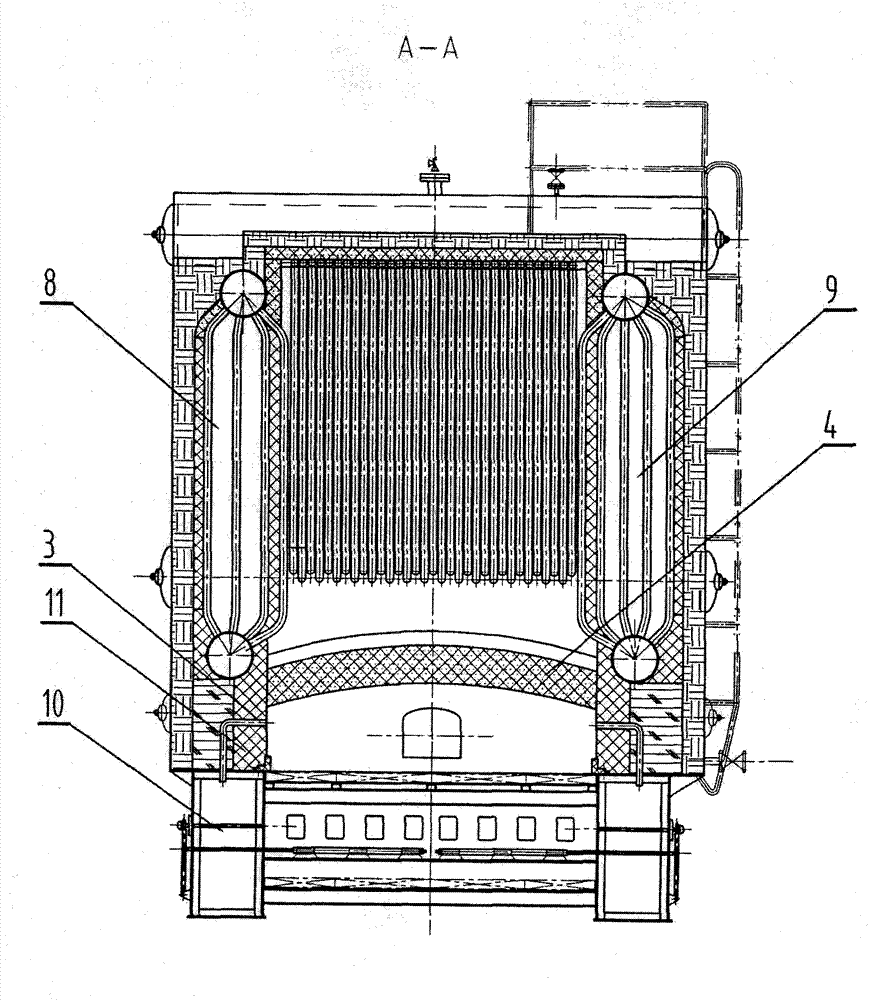

Long front arch and secondary air composite structure of lignite-fired traveling grate boiler

InactiveCN102954485AImprove combustion efficiencyGuaranteed burnoutCasings/liningsNon-combustible gases/liquids supplyOxygen deficiencyBrown coal

The invention discloses a long front arch and secondary air composite structure of a lignite-fired traveling grate boiler. The structure comprises a traveling grate stoker, a lignite hopper, a single long front arch, composite secondary air exhaust pipes and a smoke guide arch, wherein the single long front arch is arranged inside a hearth from front to back, the composite secondary air exhaust pipes are arranged on a side wall of the hearth and positioned below the long front arch, and the smoke guide arch is used for guiding high-temperature smoke to an upper hearth. Lignite can be quickly ignited under the action of thermal radiation of the long front arch after being fed into the hearth along with the traveling grate stoker, and flame generated by combustion of the lignite and the high-temperature smoke skim through along an integral lignite bed of the traveling grate stoker from front to back and are discharged from a long front arch outlet positioned at the rear of the hearth, so that the integral lignite bed which is positioned below the long front arch and arranged on the traveling grate stoker is in a high-temperature state, and high combustion efficiency can be realized. Besides, air delivered by an air blower is sprayed into the upper side of the lignite bed positioned below the long front arch via the composite secondary air exhaust pipes, so that high-volatility matters in the lignite are guaranteed against generating black smoke due to oxygen deficiency during combustion.

Owner:哈尔滨工大格瑞环保能源科技有限公司

Plant raw pulp extraction technology

PendingCN110016385AGuaranteed circulationGuaranteed high temperatureFatty-oils/fats productionCold airDistillation

The invention relates to a plant raw pulp extraction technology. The technology comprises a distillation tank, and the technology is characterized in that: the inner wall of the distillation tank is provided with a hollow layer, the distillation tank is provided with a feeding port, the interior of the distillation tank is provided with a baffle net layer, the bottom of the baffle net layer is provided with a support net, the bottom of the distillation tank is provided with distilled water, the top end of the distillation tank is provided with a flow guiding pipe, the flow guiding pipe is connected with an oil-water separation apparatus, one side of the distillation tank is provided with a vortex pipe, the bottom end of the vortex pipe is provided with a hot air pipe, an air inlet pipe isarranged on the vortex pipe, a cold air pipe is arranged at the bottom end of the vortex pipe, the cold air pipe is connected with a cooling apparatus, the interior of the cooling apparatus is provided with a passage hole, the cooling apparatus is connected with a cold discharge pipe, the hollow layer is connected with a heat discharge pipe, and the oil-water separation apparatus communicates withthe distillation tank through a backflow pipe. The technology has the advantages of convenient operation, good extraction effect and resource saving.

Owner:邹红媚

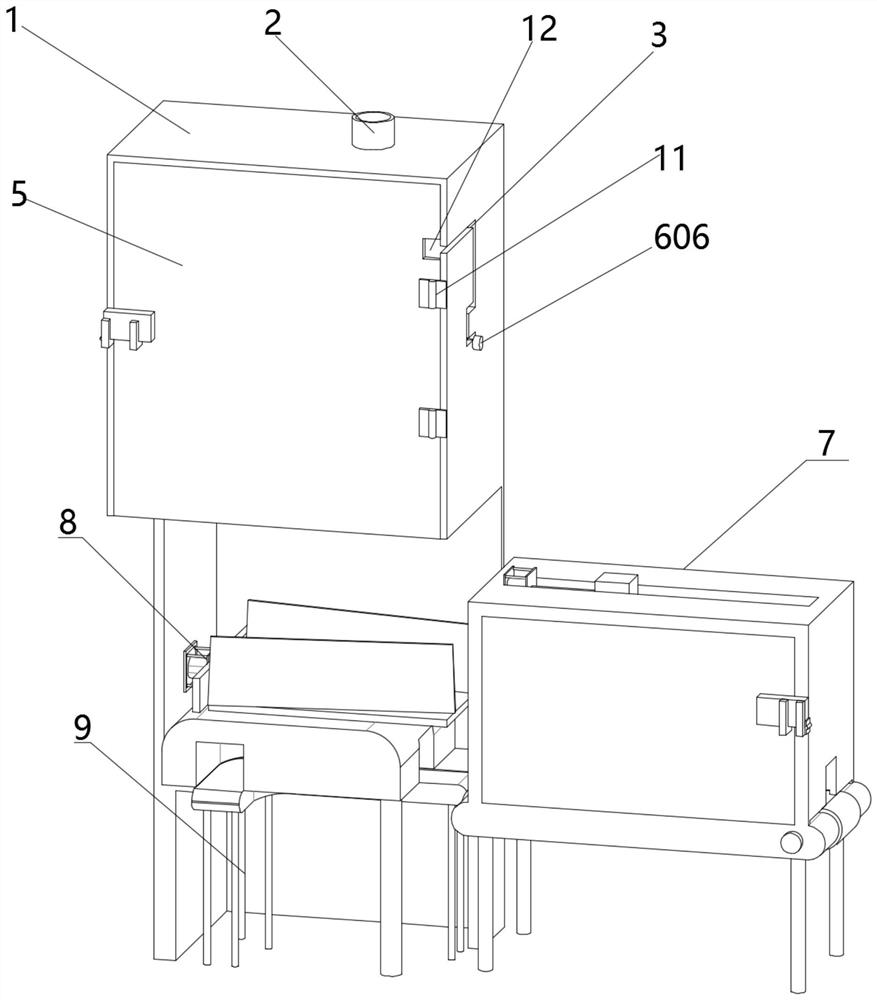

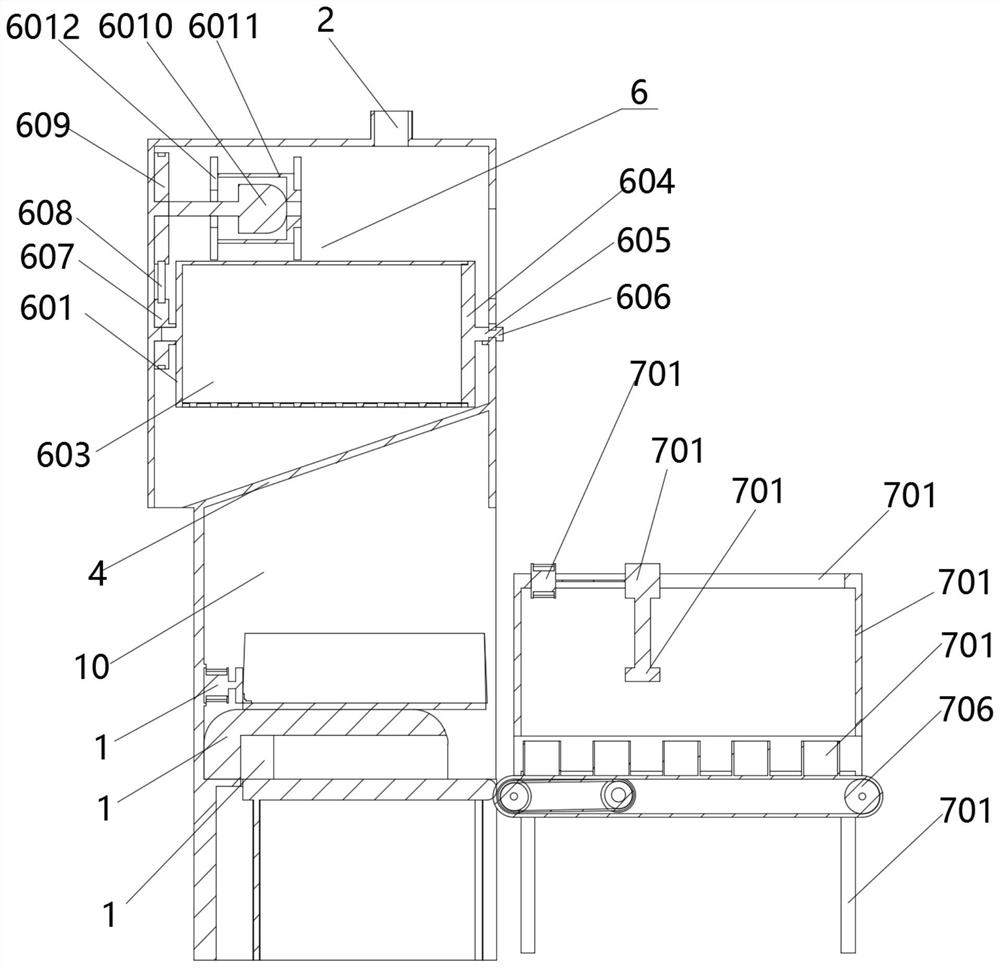

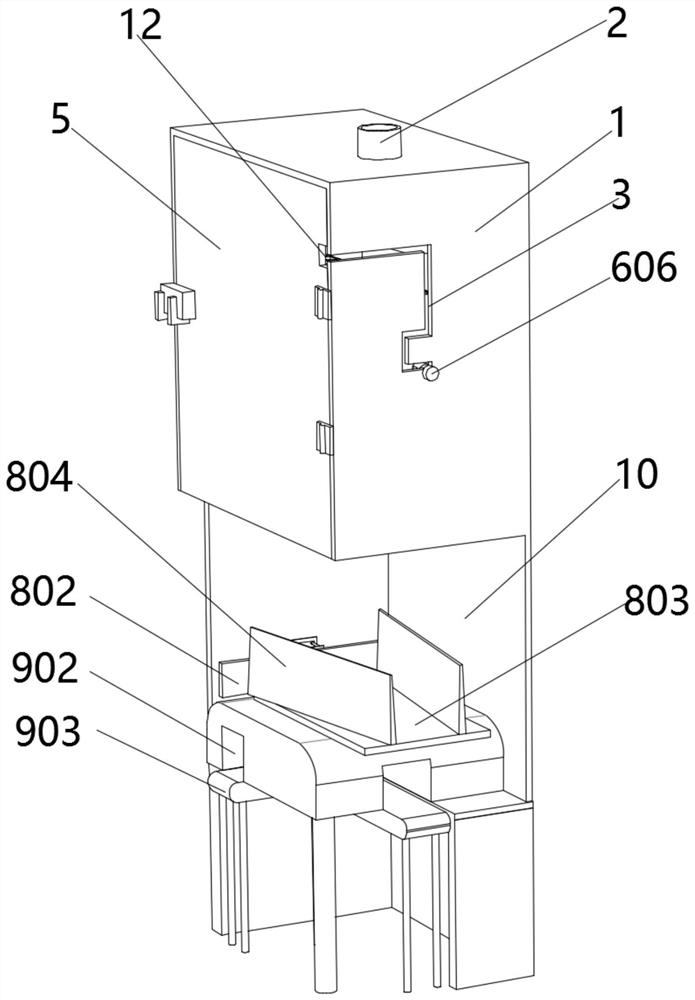

Intelligent traditional Chinese medicine residue recovery equipment for aromatherapy block preparation and aromatherapy block preparation technology

PendingCN113183517AEfficient dryingTake advantage ofDrying solid materials without heatDrying gas arrangementsAromatherapyProcess engineering

The invention relates to the technical field of traditional Chinese medicine residue treatment, in particular to intelligent traditional Chinese medicine residue recovery equipment for aromatherapy block preparation and an aromatherapy block preparation technology. The intelligent traditional Chinese medicine residue recovery equipment comprises a drying box, an air inlet is fixedly formed in the top end of the drying box, a first sliding rail is arranged on one side of the drying box, and a drainage wall is fixedly arranged at the bottom end of the drying box; a waterproof plate is movably arranged on the opening side of the drying box, a turnover device is arranged in the drying box, a fixing plate is fixedly arranged at the bottom end of the drying box, a medicine residue conveying device is arranged below the drying box, and a mold conveying device is arranged below the medicine residue conveying device; and a pressing mechanism is arranged on one side of the medicine residue conveying device and the mold conveying device, the pressing mechanism comprises processing supporting legs, and a first heating layer and a second heating layer are fixedly arranged at the tops of the processing supporting legs. According to the intelligent traditional Chinese medicine residue recovery equipment, medicine residues can be fully utilized and prevented from being wasted, the indoor environment can be optimized, and environmental protection is facilitated.

Owner:赵航

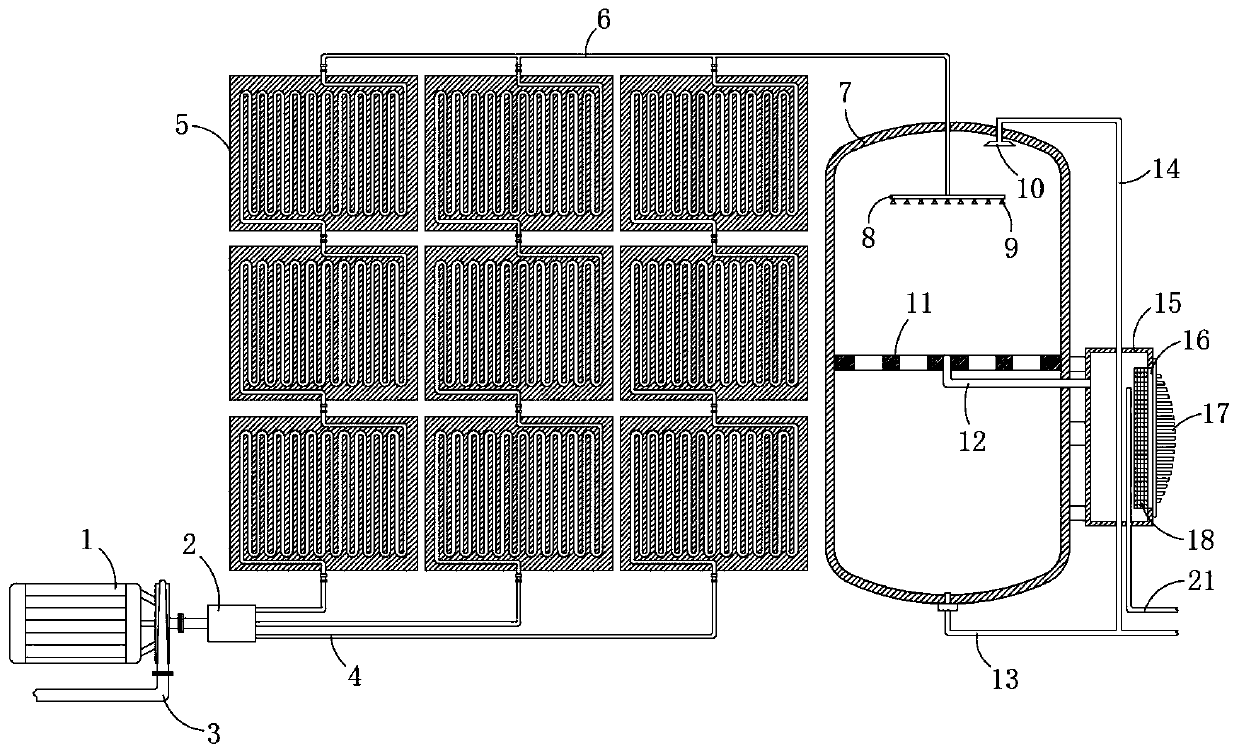

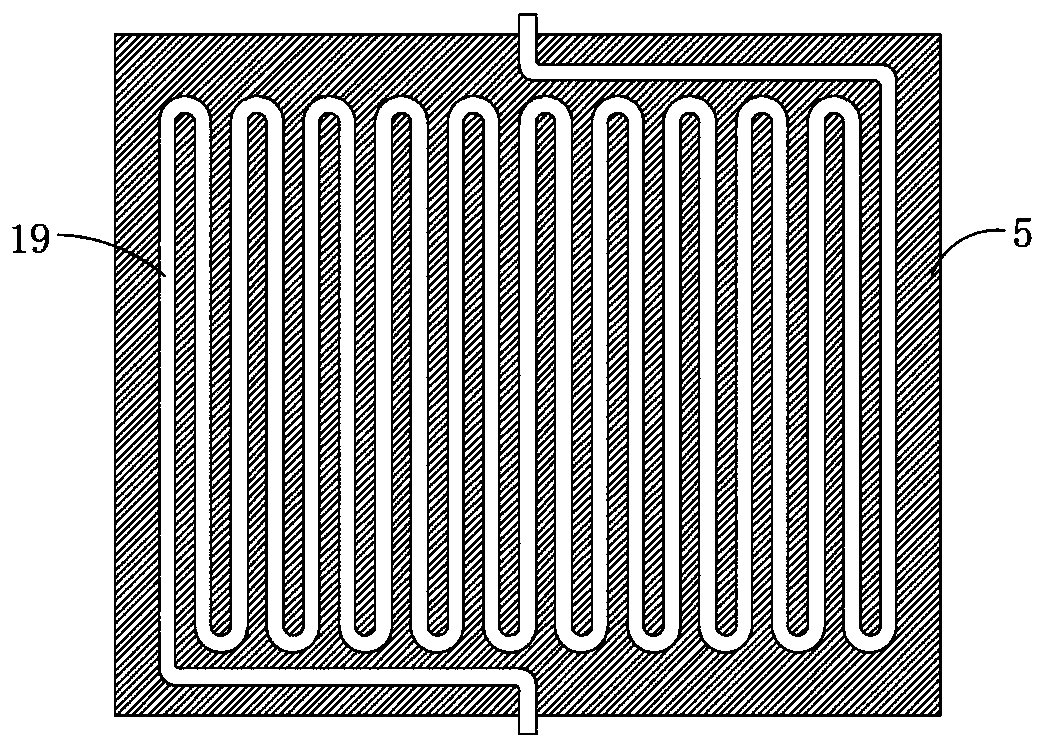

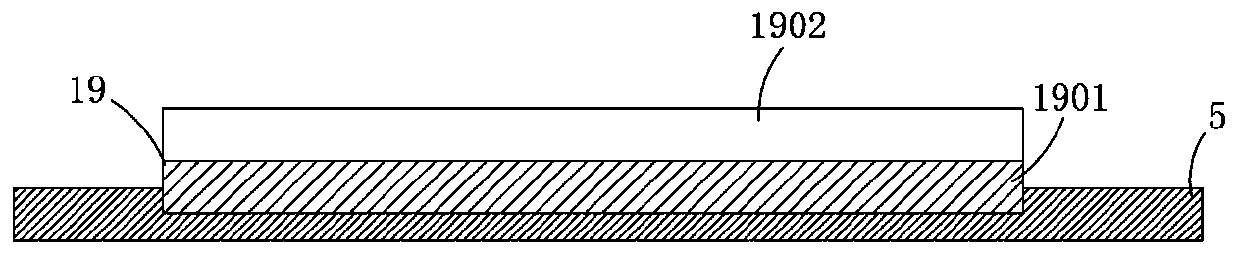

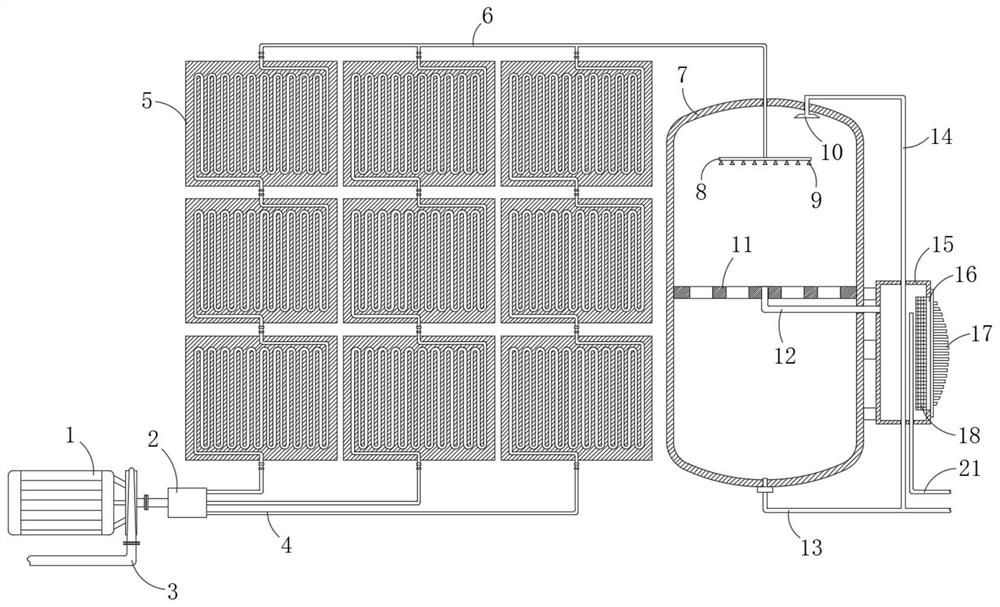

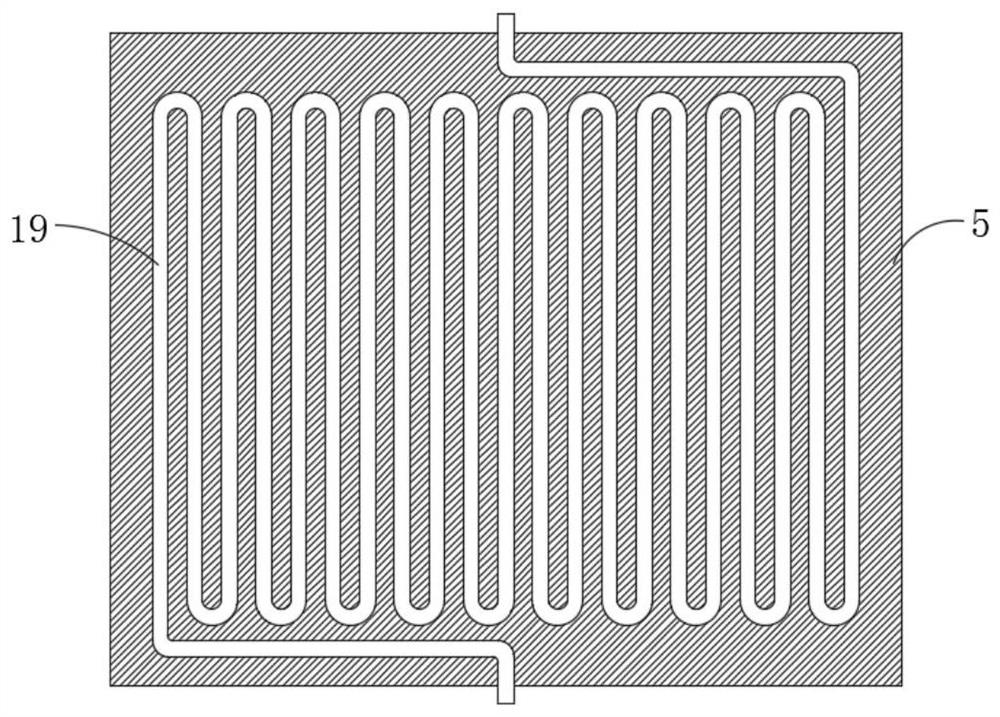

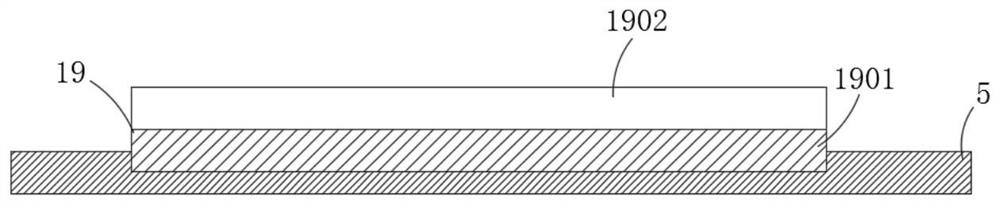

Low-energy consumption seawater desalting system and method

ActiveCN110563234AFast heatingReduce energy consumptionGeneral water supply conservationSeawater treatmentSeawaterHigh concentration

The invention discloses a low-energy consumption seawater desalting system which comprises a seawater pump and a seawater desalting tank, wherein a diversion valve is connected with a discharge end ofthe seawater pump; a plurality of diversion tubes are connected with the diversion valve; an optical energy heating mechanism is connected with the plurality of the diversion tubes together; and theoptical energy heating mechanism comprises a plurality of seawater heating mechanisms which are arranged in a matrix manner. The invention further discloses a low-energy consumption seawater desaltingmethod which comprises the following steps: S1, sucking seawater; S2, performing diversion heating; S3, performing confluence; S4, performing reverse osmosis filtration; S5, performing vapor condensation; and S6, collecting fresh water. As seawater is heated by using a sooting metallic plate and a sooting metallic semicircular tube, the cost of equipment can be lowered; due to adoption of atomization nozzles, the evaporation speed and the evaporation amount of seawater can be increased, and the seawater is further desalted through a reverse osmosis membrane; in addition; precipitate is not separated from salt in the seawater, high-concentration seawater after desalting is taken as a condensation agent of vapor, the material cost can be lowered, and in addition, energy consumption can be reduced.

Owner:衡阳远通物流有限公司

An oxygen supply heat insulation device and a combustible gas combustion chamber with the device

ActiveCN105465773BNo swellingImprove stabilityAir/fuel supply for combustionCombustion chamberThermal insulation

The invention discloses an oxygen supply and thermal insulation device and a flammable gas combustion chamber with the same. After being inlaid in an inlet of the combustion chamber, the oxygen supply and thermal insulation device connects an inner cavity of the combustion chamber with a flame jetting opening of a combustion device. The oxygen supply and thermal insulation device comprises a gas inlet cylinder formed by mutually nesting an inner cylinder and an outer cylinder. An oxygen supply pipe is inserted between the inner cylinder and the outer cylinder, and the space between the inner cylinder and the outer cylinder is filled with temperature-resistant castable. The inner cylinder, the outer cylinder and the oxygen supply pipe are mutually fixed through supporting rings. A pipe cap used for adjusting the gas inflow of the combustion chamber is installed at the gas inlet end of the oxygen supply pipe. According to the oxygen supply and thermal insulation device and the flammable gas combustion chamber with the same, flammable gas can be fully burnt, and the burning temperature can be above 1000 DEG C, so that energy in the flammable gas can be fully used. Through a special sealing structure at the inlet of the combustion chamber, heat loss is avoided, so that heat energy generated by burning the flammable gas is used furthest. In addition, the inlet of the combustion chamber is welded in a sealed mode through a hubbed flange structure, so that the functions that the service life of the combustion chamber, the gas inlet cylinder and other parts is prolonged are achieved.

Owner:潘汉祥

Lithium ion battery

ActiveCN114464959AGuaranteed high temperatureGuaranteed normal temperature cycle performanceCell seperators/membranes/diaphragms/spacersSecondary cells charging/dischargingElectrolytic agentInorganic particle

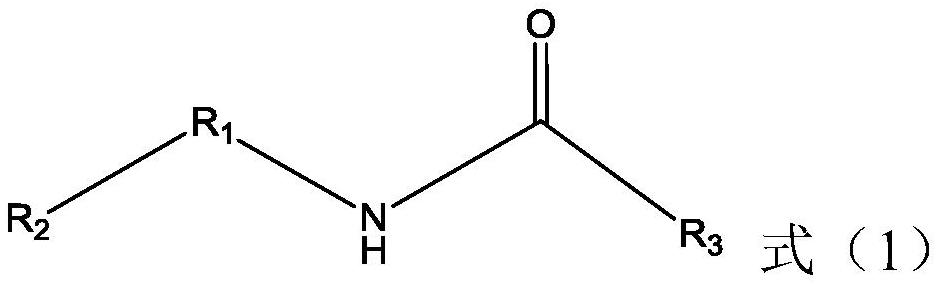

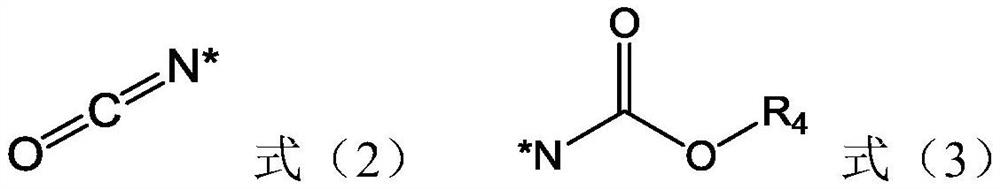

The present invention relates to the technical field of lithium ion batteries, and discloses a lithium ion battery, the lithium ion battery comprises a positive electrode, a negative electrode, a separator arranged between the positive electrode and the negative electrode, and a non-aqueous electrolyte, the separator comprises a substrate and a coating, the coating is coated on at least one surface of the substrate, and the coating comprises inorganic particles and / or PVDF, the nonaqueous electrolyte solution contains an organic solvent, a lithium salt, and a compound represented by formula (1). According to the lithium ion battery, the diaphragm with the coating is used, so that the safety performance of the battery is ensured, and meanwhile, the cycle performance and the quick charge performance of the battery are remarkably improved.

Owner:SHENZHEN CAPCHEM TECH

A tightly arranged engine exhaust gas treatment system

ActiveCN112648046BGuaranteed high temperatureReduce temperature lossInternal combustion piston enginesExhaust apparatusThermodynamicsPtru catalyst

A tightly arranged engine exhaust gas treatment system includes an exhaust manifold fixed on one side of the engine, an aftertreatment assembly and a supercharger, and the aftertreatment assembly includes a particulate matter trap for selective catalytic reduction, an oxidation catalyst and a mixing The rear end of the selective catalytic reduction particulate matter trap is connected to the rear end of the oxidation catalyst through the mixer assembly, and the selective catalytic reduction particulate matter trap, oxidation catalytic converter and mixer assembly are in the form of U-shaped arrangement; the exhaust manifold is arranged between the engine and the oxidation catalyst, the front of the exhaust manifold communicates with the front end of the oxidation catalyst through the supercharger, and the exhaust manifold, the supercharger and the selector The catalytic reduction particulate trap 31 is arranged in a U shape; the side of the exhaust manifold communicates with the engine exhaust port on the side of the engine. The design is compact, and the path of exhaust gas flow is short, the heat loss of exhaust gas is small, the conversion efficiency of catalyst is high, and it meets strict emission standards.

Owner:DONGFENG AUTOMOBILE COMPANY

A low energy consumption seawater desalination system and method

ActiveCN110563234BReduce lossLow costGeneral water supply conservationSeawater treatmentSteam condensationFiltration

The invention discloses a low-energy seawater desalination system, which comprises a seawater pump and a seawater desalination tank. A light energy heating mechanism is commonly connected to the tube, and the light energy heating mechanism includes a plurality of seawater heating mechanisms arranged in a matrix; the present invention also discloses a low-energy seawater desalination method, which includes the following steps: S1: seawater extraction; S2 : split heating; S3: confluence; S4: reverse osmosis filtration; S5: steam condensation; S6: fresh water collection. The present invention heats seawater through blackened metal plates and blackened metal semicircular tubes, reduces equipment costs, increases seawater evaporation speed and evaporation through atomizing nozzles, and further desalinizes seawater through reverse osmosis membranes without analyzing salt in seawater Desalinated high-concentration seawater is used as a condensing agent for water vapor, which reduces material costs and energy consumption.

Owner:衡阳远通物流有限公司

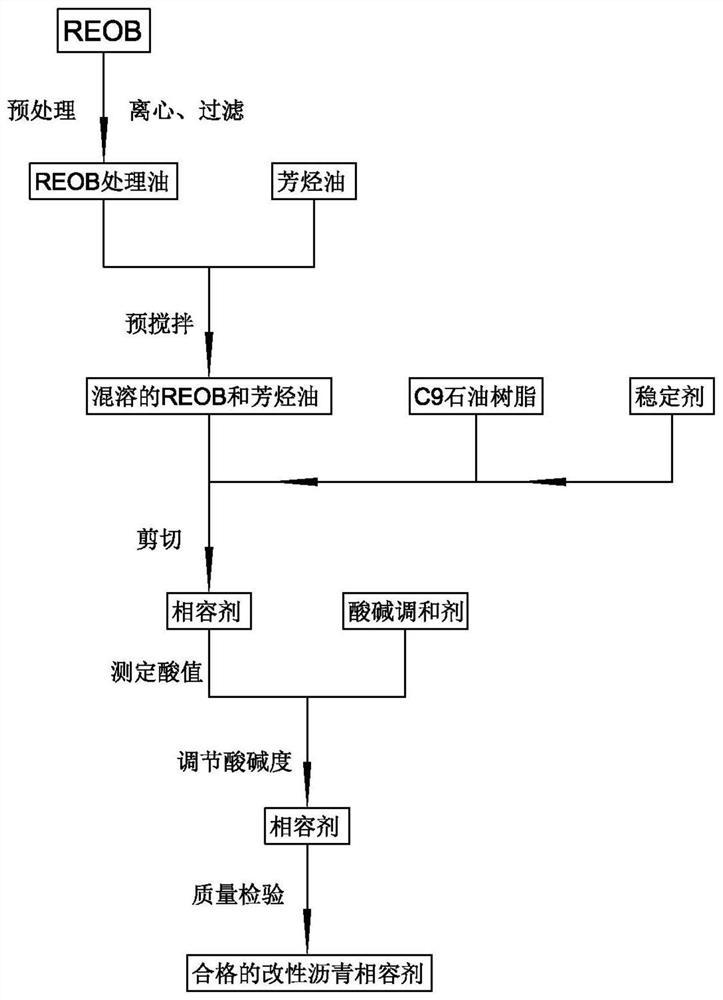

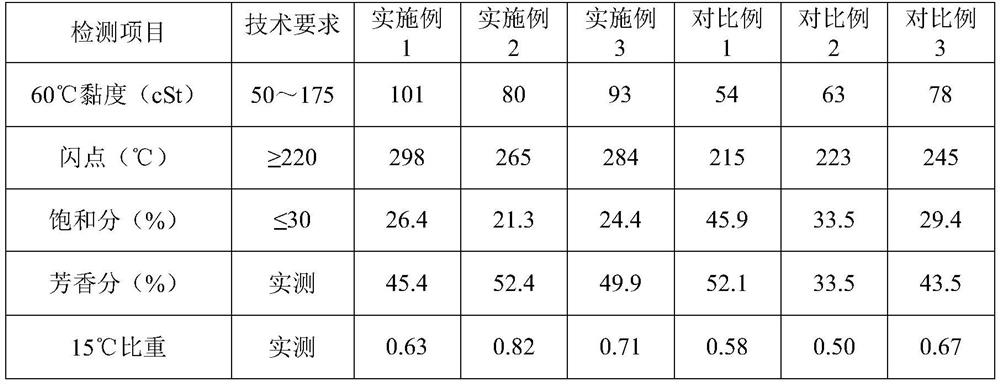

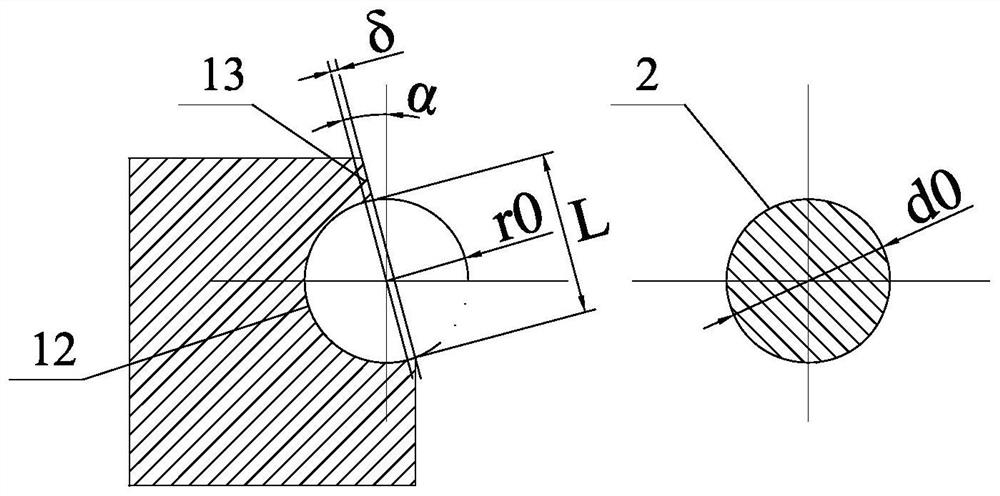

Modified asphalt compatilizer and preparation method thereof

ActiveCN113337134ARealize secondary effective useReduce processing costsBuilding insulationsPetroleum resinProcess engineering

The invention discloses a modified asphalt compatilizer and a preparation method thereof, and belongs to the technical field of asphalt processing. The modified asphalt compatilizer is prepared from the following raw materials in parts by mass: 40-80 parts of waste engine oil residues, 10-30 parts of aromatic hydrocarbon oil, 5-20 parts of C9 petroleum resin and 1-15 parts of a stabilizer. The modified asphalt compatilizer is prepared through the steps of pretreatment, pre-stirring, shearing, pH value adjustment and the like. According to the technical scheme, a large amount of waste engine oil residues can be recycled, the preparation cost of the compatilizer is reduced, secondary effective utilization of the waste engine oil residues is achieved, the treatment cost of the waste engine oil residues is reduced, and pollution of the waste engine oil residues to the environment is avoided.

Owner:SHANDONG JIAOTONG UNIV

Labor-saving thinning stretching method adopting rolling shaft structure

PendingCN113042604AExtended service lifeEasy to storeShaping toolsStructural engineeringFriction force

The invention discloses a labor-saving thinning stretching method adopting a rolling shaft structure. A stretching piece moves downwards along with a stretching punch, the stretching piece enters an annular working belt from a stretching piece channel, firstly the stretching piece makes contact with a cylindrical rolling shaft and starts to be meshed with the cylindrical rolling shaft, and the cylindrical rolling shaft can generate and keep rotating in a groove due to the friction force between the stretching piece and the cylindrical rolling shaft along with the increase of the meshing area. And in the subsequent deformation process, the rolling shaft and the feeding movement of the stretching piece synchronously rotate, so that thinning stretching without sliding friction is realized until the stretching piece completely passes through the annular working belt. According to the scheme, an annular die is particularly adopted for metal thinning stretching, the structure is simple, flexibility is high, the mode is novel, sliding friction between the metal stretching piece and a die ring is weakened, and therefore the advantages that labor-saving thinning stretching is achieved, single-pass deformation is large, and the stretching piece is not prone to damage are achieved.

Owner:ZHONGBEI UNIV

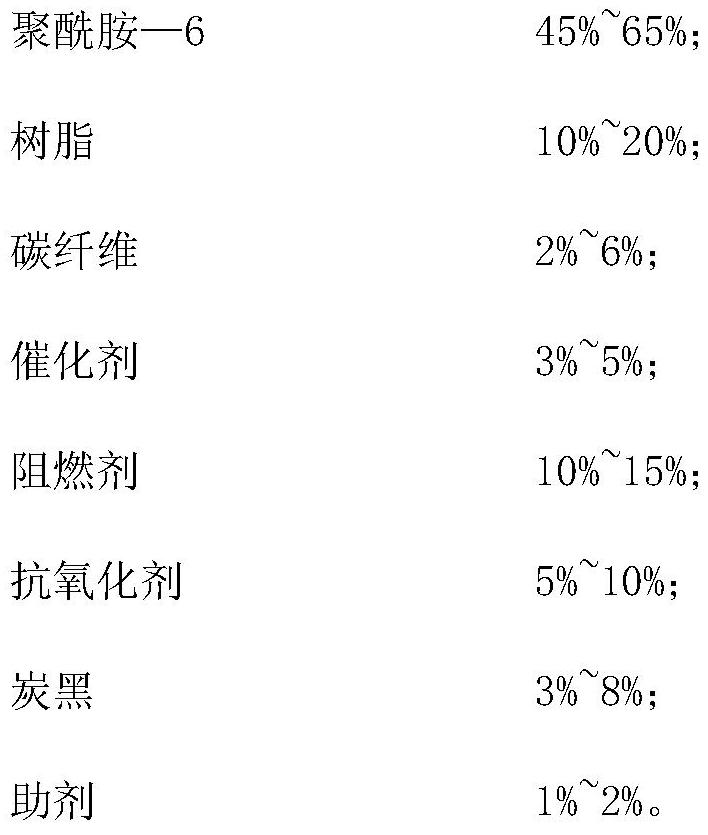

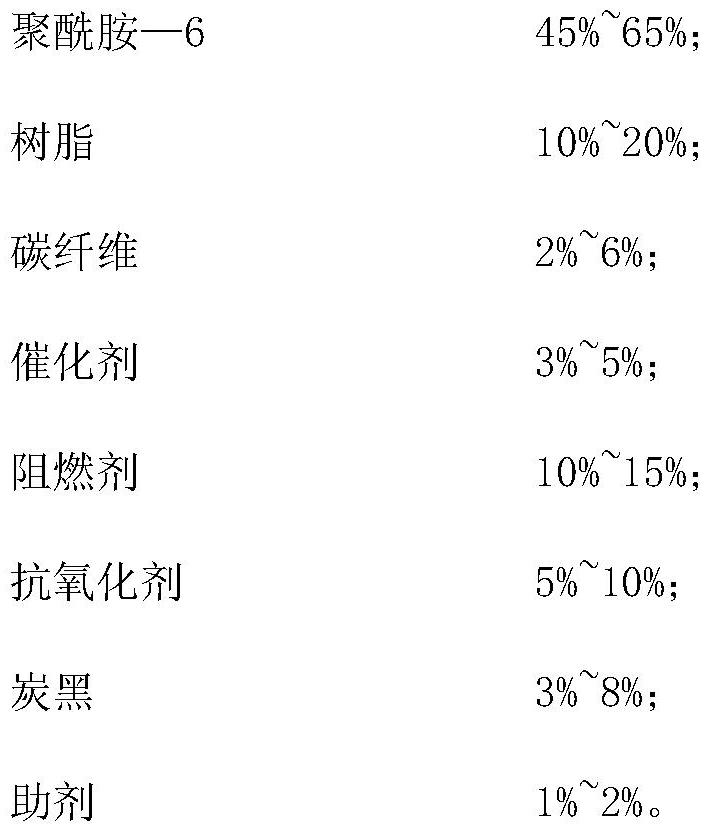

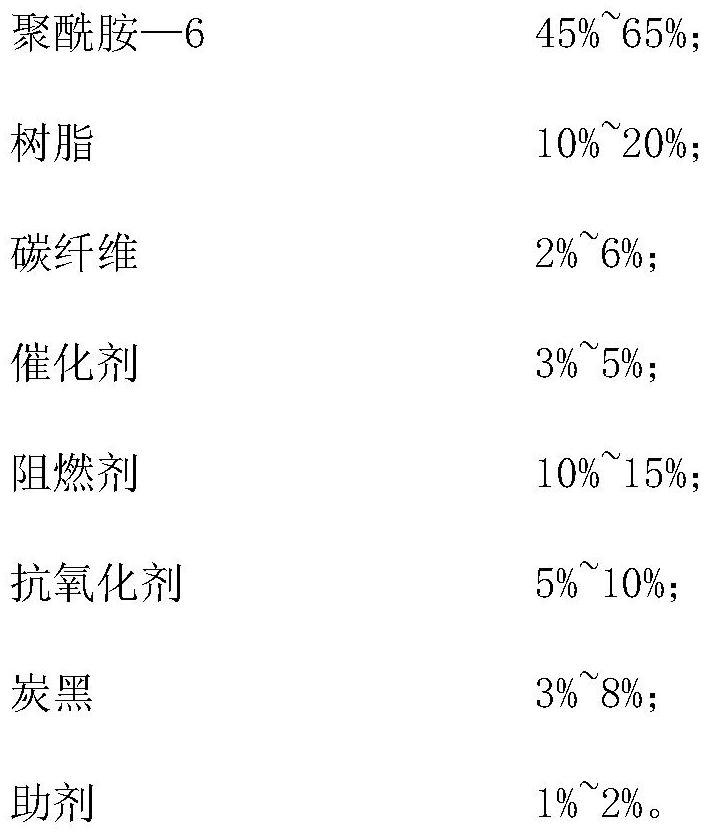

Preparation method of high-strength nylon

The invention provides a preparation method of high-strength nylon. The preparation method comprises the steps: 1, polyamide-6 is packaged through a vacuum bag, during using, the polyamide-6 is addedinto a drying machine to be dried at a high temperature of 200 to 300 DEG C, and after drying is completed, impurities in the polyamide-6 are filtered through a nylon filter net; 2, resin is heated at200 DEG C, after heating, the resin is mixed with the polyamide-6, and after still standing for 20 min, carbon fibers are added for stirring for 30 to 40 min; 3, an antioxidant is added into a mixture, after stirring and still standing, a fire retardant is added, after stirring for 20 to 30 min, still standing is conducted for 30 min, and an assistant is added for stirring; 4, it is ensured thatthe processing temperature is maintained at 300 to 320 DEG C, carbon black is added, and after stirring for 25 to 30 min, still standing is conducted; and 5, during injection molding, the injection molding duration is prolonged, the injection speed is 50 to 60 cm3 / s, a catalyst is added during injection molding, and during extrusion, the temperature of an extruding outlet is controlled to be 260 to 300 DEG C.

Owner:中平神马江苏新材料科技有限公司

Stirring and discharging device

ActiveCN112354419BEffective controlGuaranteed high temperatureRotary stirring mixersTransportation and packagingProcess engineeringControl switch

Owner:北京艾科美特新材料开发有限公司

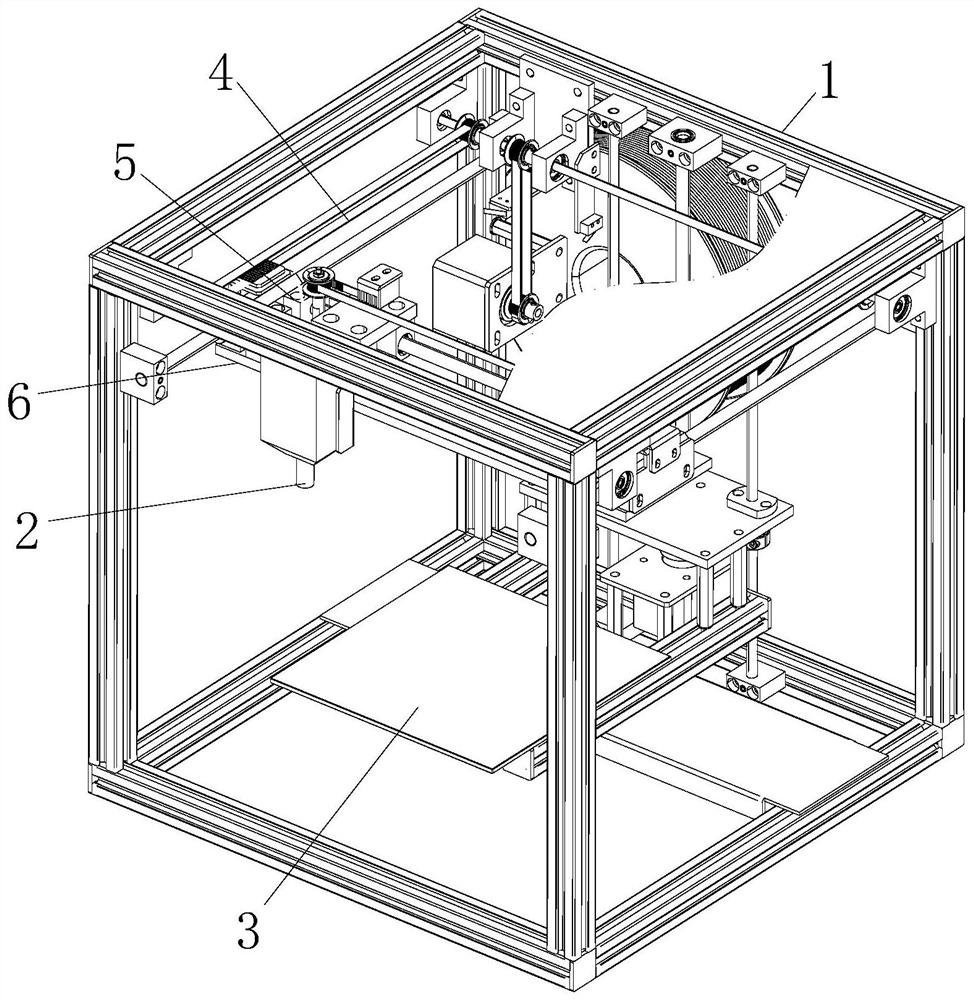

Multi-material 3D printer

InactiveCN113183453ARealize automatic opening and closingAvoid dripping and drawing problems3D object support structuresApplying layer meansComputer printing3d printer

The invention belongs to the technical field of advanced manufacturing, and particularly relates to a multi-material 3D printer. The multi-material 3D printer comprises a supporting frame, a spray head and a bottom plate, wherein the bottom plate is arranged at the position, close to the bottom face of the supporting frame, in the supporting frame; the top of the supporting frame is fixedly connected with a first guide rail; the interior of the first guide rail is slidably connected with a first sliding block; a second guide rail is arranged on the surface of the first sliding block; the inner bottom surface of the second guide rail is in sliding connection with a second sliding block; the bottom face of the second sliding block is fixedly connected with a support rod; the spray head is fixedly connected to the bottom surface of the supporting rod; a guide block is arranged in the spray head; by means of the multi-material 3D printer, automatic opening and closing of a spraying hole of a 3D printer are effectively achieved, the problem that when the position of the spraying head is switched, remaining molten materials in the spraying hole drip and wiredraw are avoided, meanwhile, it is guaranteed that the remaining molten materials are kept in a high-temperature state, the bottom hardening phenomenon of the remaining molten materials is avoided, and the product quality is improved.

Owner:李杰

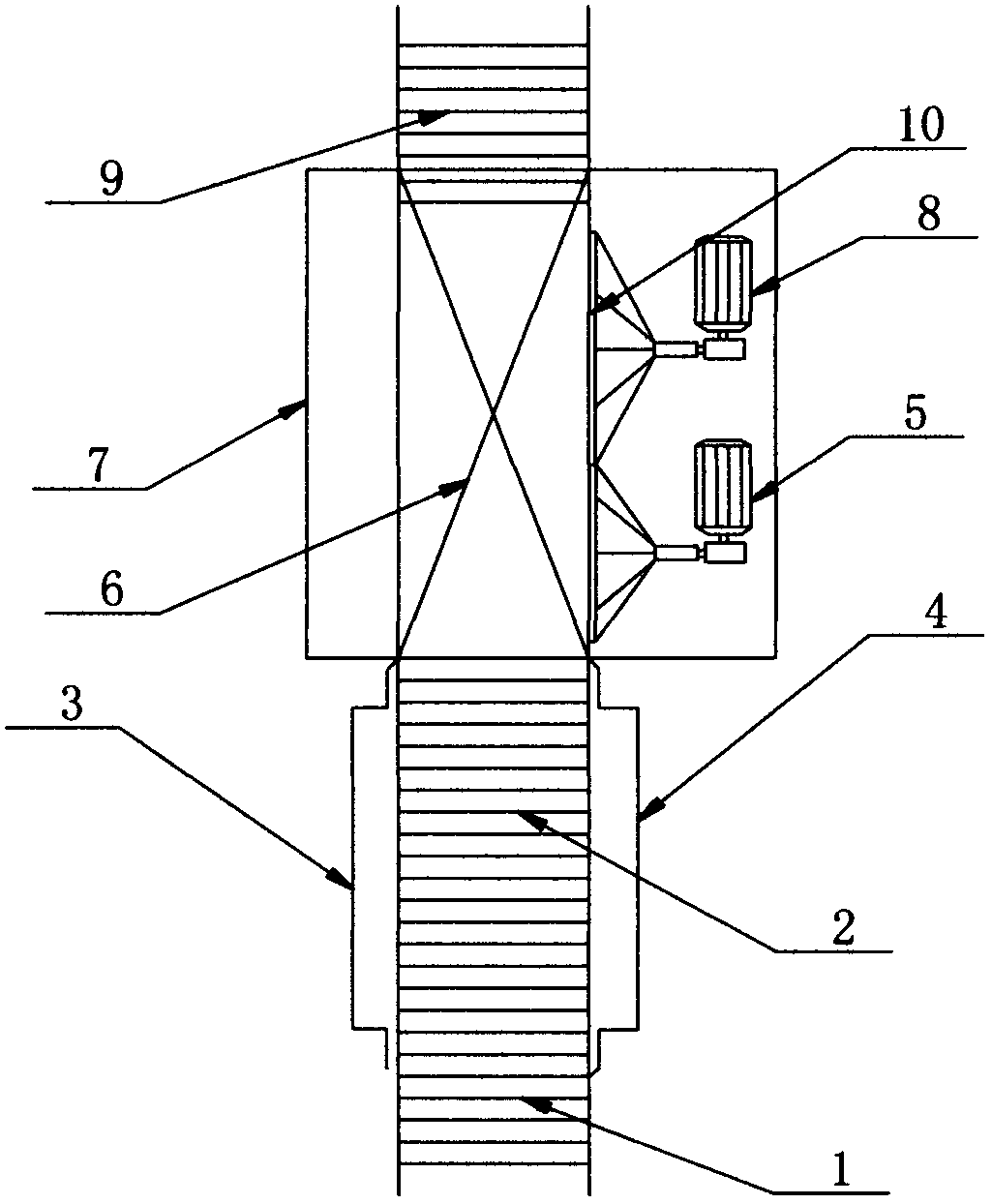

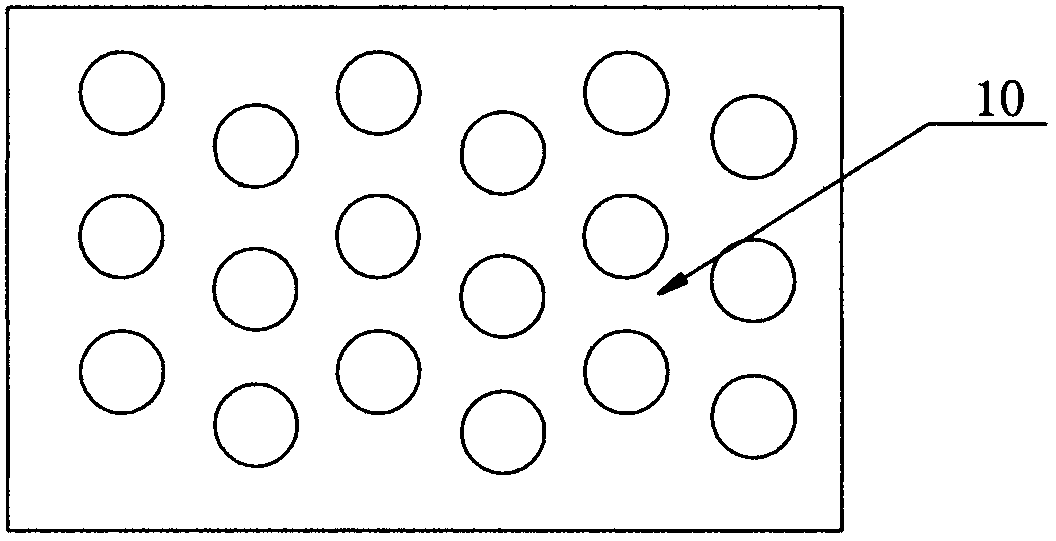

2.5 mm glass tempering process

InactiveCN103910483ARadiation area is largeShorten heating timeGlass tempering apparatusHeating timeEngineering

The invention discloses a 2.5 mm glass tempering process, which relates to the technical field of thin glass tempering. A heating zone roller way (2) is arranged at one side of a sheet loading roller way (1), a left air convection device (3) and a right air convection device (4) are respectively arranged at two sides of the heating zone roller way (2), a tempering cooling part (6) is arranged at the rear end of the heating zone roller way (2), a sound insulation room (7) is arranged at one side of the tempering cooling part (6), the other side of the tempering cooling part (6) is respectively provided with a quenching fan (5) and a cooling fan (8), the quenching fan (5) and the cooling fan (8) are respectively provided with a plurality of air nozzles (10), a sheet unloading zone roller way (9) is arranged at the rear end of the tempering cooling part (6); and the 2.5 mm glass tempering process is as follows: 1, sheet loading, 2, heating, 3, quenching, 4, cooling, 5, sheet unloading test, and 6 packaging. The2.5 mm glass tempering process can reduce the heating time, increase the air flow rate, make the temperature more uniform and guarantee the product quality and finished product rate.

Owner:SHANGHAI CHUNGE GLASS

Wet-type high cracking resistance, high wear resistance and high peel strength polyurethane resin and preparation thereof

The invention discloses a wet polyurethane resin with high flexing resistance, high wear resistance and high peeling strength, and a preparation method thereof. During a synthetic process of the polyurethane (PU) resin, proper soft polyurethane segment and hard polyurethane segment materials and a brand-new synthesis process route by quasi prepolymerization are selected to prepare the wet polyurethane resin based on fully considering effect of separate soft and hard segment structure, crystallinity and intermolecular cohesive energy density distribution of the PU resin on aggregation structure relationship formed by coagulation of PU resin solution in dimethylformamide (DMF) aqueous solution. The wet PU resin with high flexing resistance, high wear resistance and high peeling strength fully solves the defect that the existing common PU resin can not reach three performance indexes which are high flexing, high wear resistance, high peeling strength at the same time. Synthetic leather made from the wet PU resin with high flexing resistance, high wear resistance and high peeling strength can meet three performance indexes of high flexing resistance, high wear resistance, high peelingstrength at the same time, and can greatly improve durability of shoes products.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

Smoke secondary combustion furnace

PendingCN110081415AGuaranteed high temperatureCombustion-air/flue-gas circulation for stovesSolid fuel combustionHearthEngineering

The invention belongs to the field of combustion furnaces, and particularly relates to a smoke secondary combustion furnace. At present, in the use process of an ordinary combustion furnace, the mainpollution is that in the fuel adding process of the combustion furnace, particularly relates to a civilian combustion furnace, when a fire coal is added and stirred, emission of smoke reaches the highest peak, the high emission duration of the smoke dust can be up to several minutes or even more than ten minutes, in this case, due to the hearth is in a smoldering state, so that the temperature ofthe hearth is lower than the internal temperature of the fire coal in the furnace, therefor, the smoke dust at the moment is difficult to burn out. According to the smoke secondary combustion furnace,smoke dust combusted in the hearth of the combustion furnace is introduced into a smoke preheater above a furnace grate in the hearth again through a chimney, the smoke preheater is always located inwrapping of the fire coal in the hearth, and therefore it can be guaranteed that the smoke preheater is always in a high-temperature state; when the oxygen-containing smoke dust passes through a preheating cavity of the smoke dust preheater, the oxygen-containing smoke dust is heated to be higher than the ignition point by a high temperature, the oxygen-containing smoke dust is combusted, and finally clean gas is discharged.

Owner:姚舜

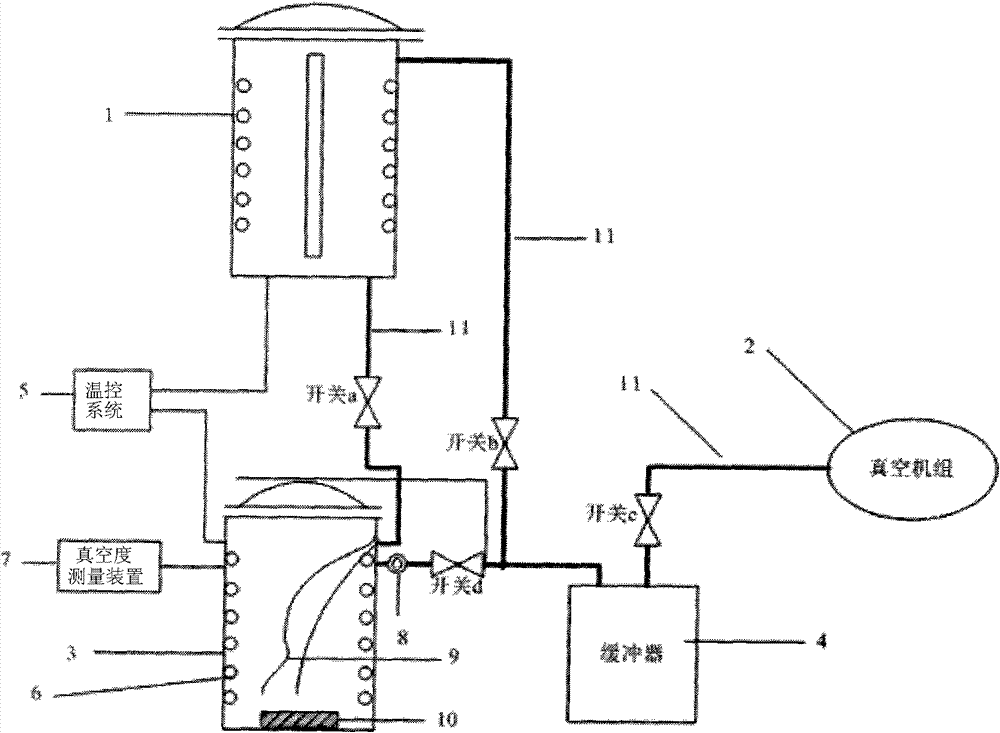

Vacuum insulation oil impregnating device and method thereof

ActiveCN101950642BFull overflowPrevent secondary entryInsulatorsCoils manufactureCardboardTherapeutic effect

Owner:CHINA ELECTRIC POWER RES INST +1

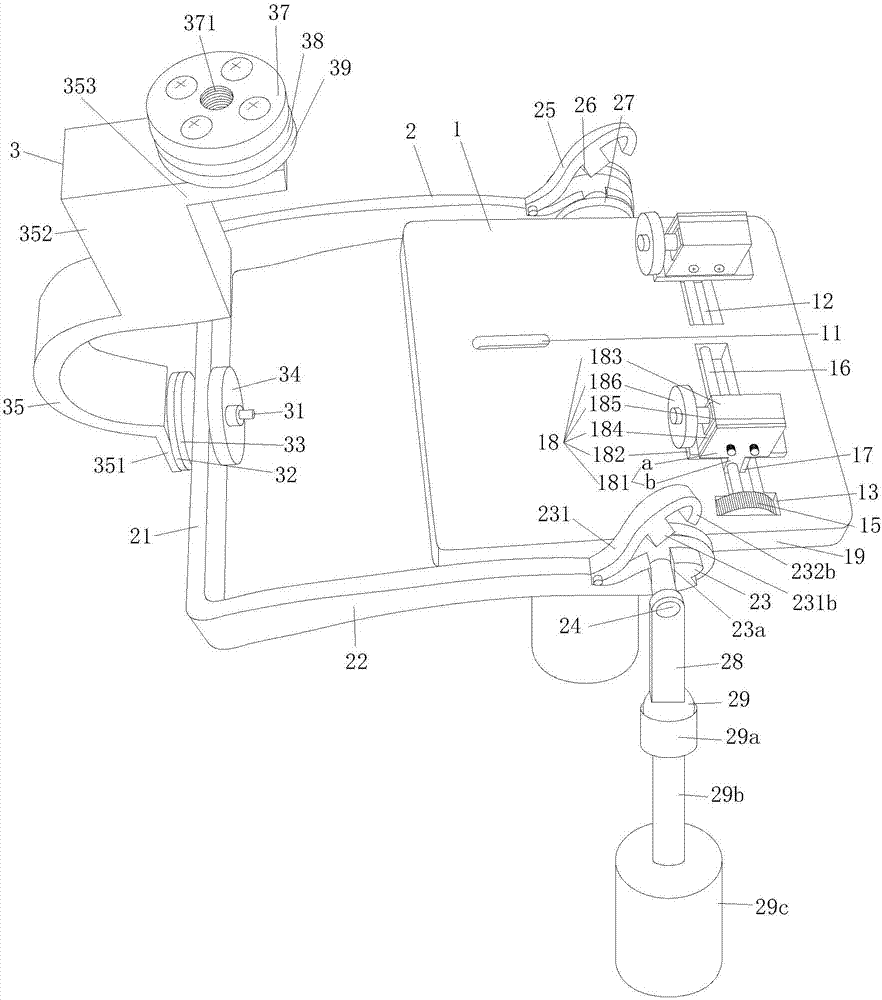

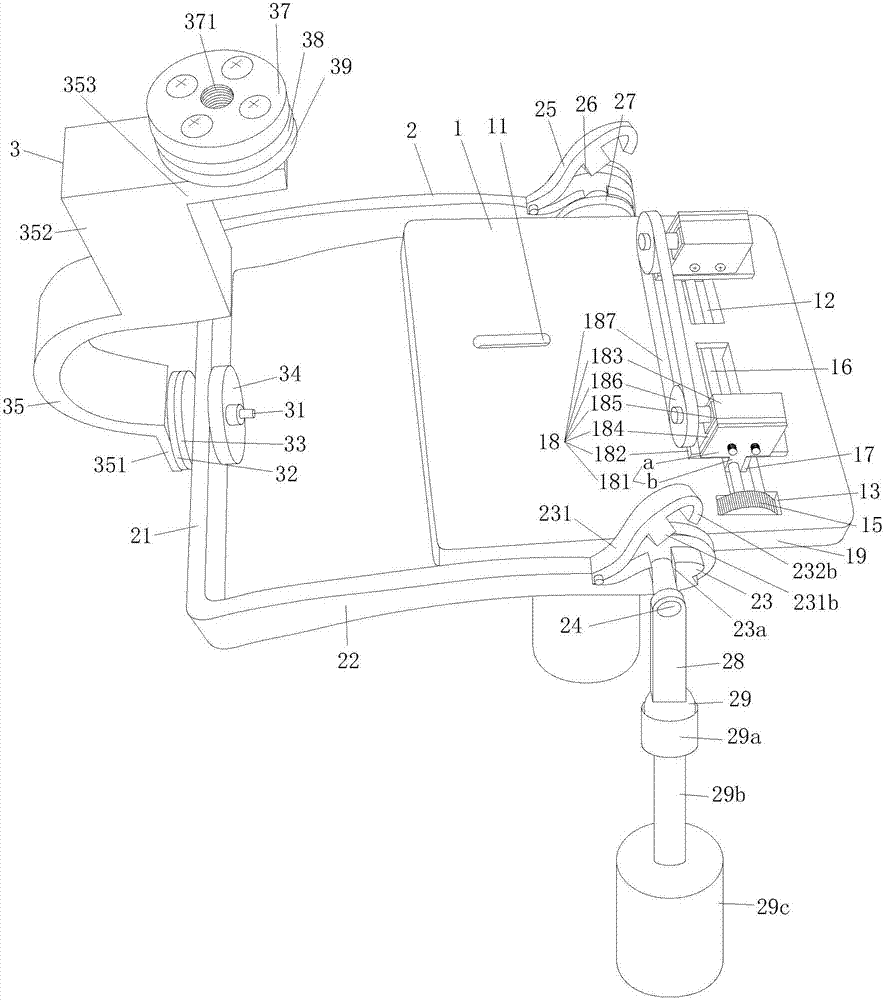

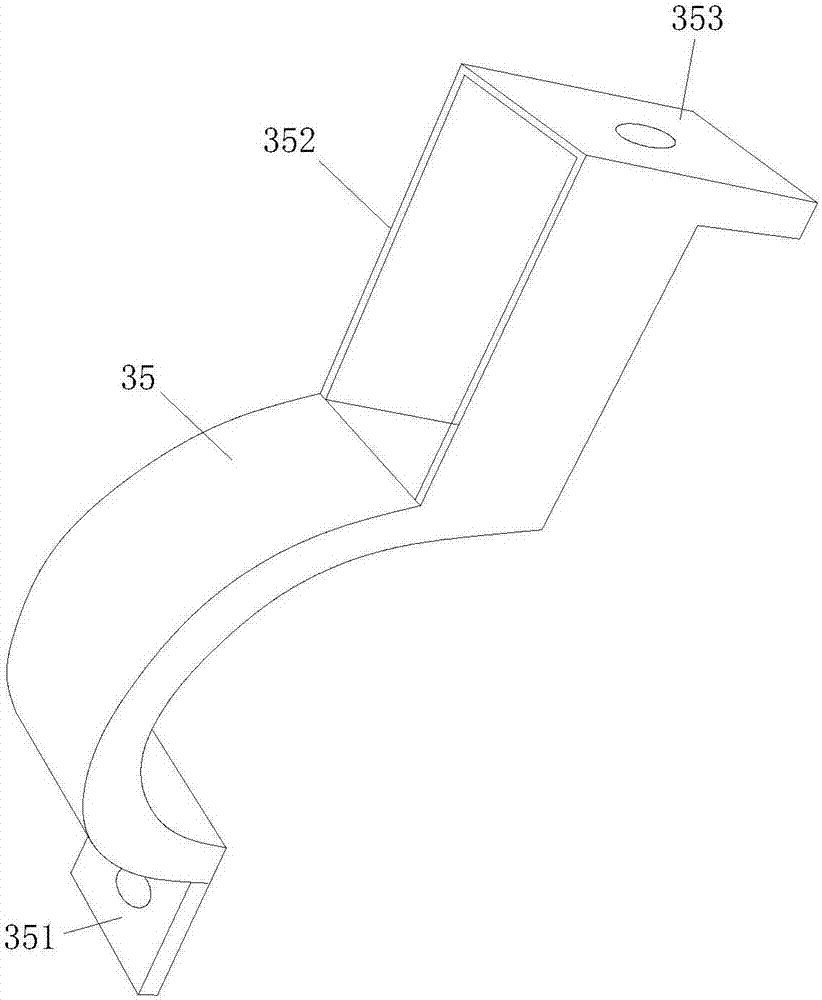

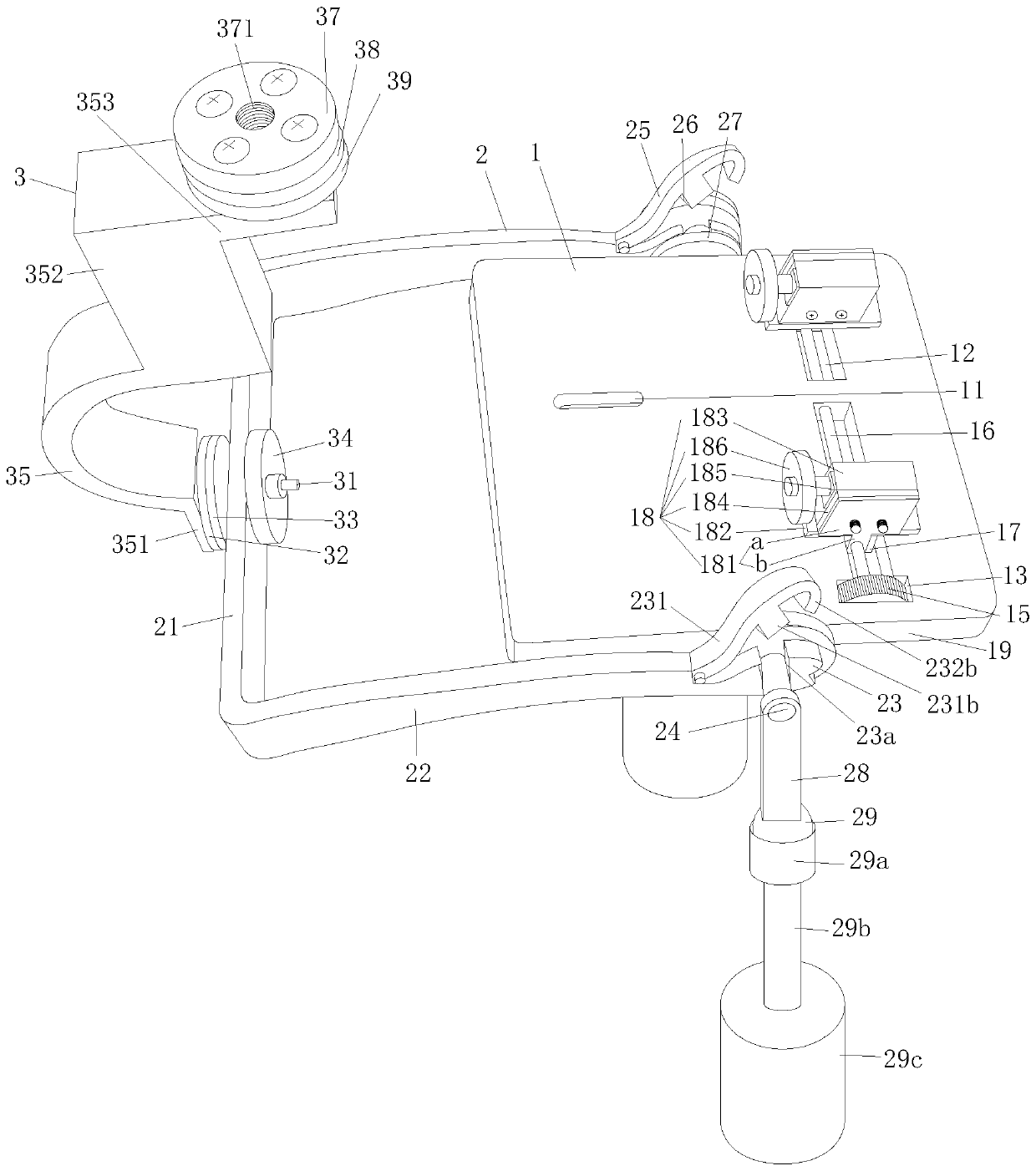

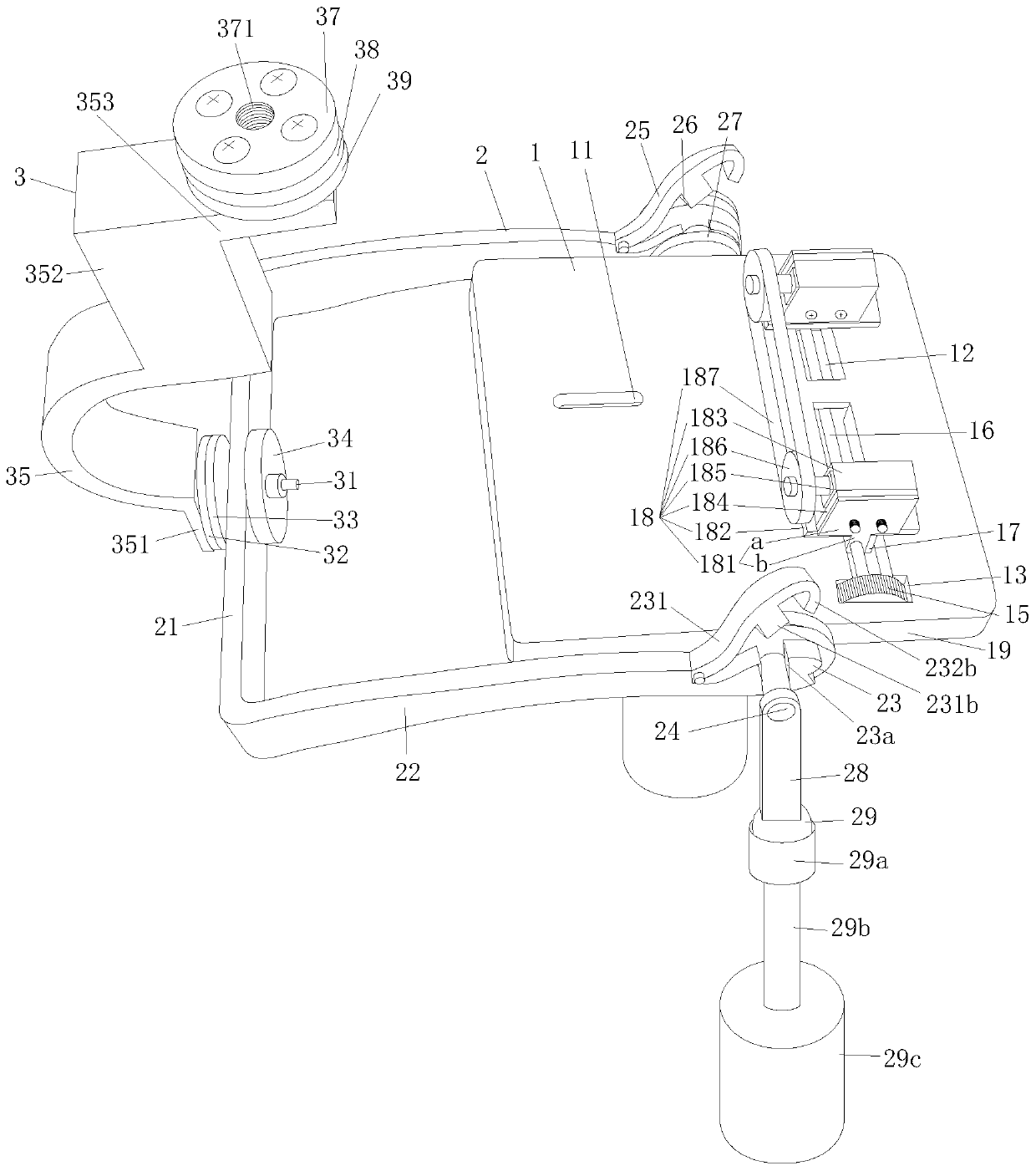

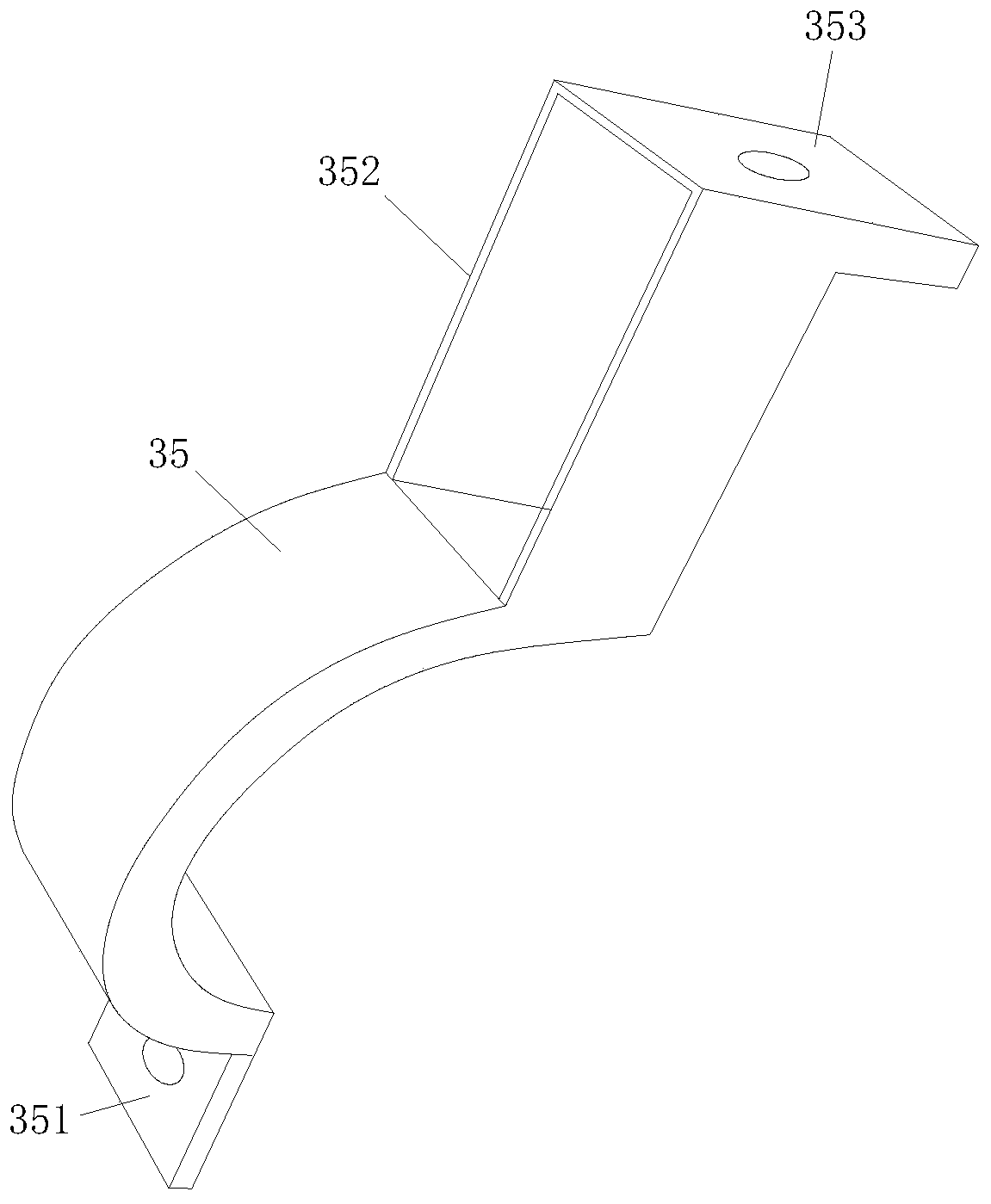

Movable-static integrated zoom intelligent shooting device

ActiveCN107071280AReduce lossesReduce volumeTelevision system detailsColor television detailsEngineering

The invention discloses a movable-static integrated zoom intelligent shooting device. The intelligent shooting device comprises a photography platform composed of a horizontal platform, a horizontal platform bracket and a special-shaped floor stand and a remote controller. The movable-static integrated zoom intelligent shooting device disclosed by the invention is small in volume, light in weight, convenient for carrying, easy to mounting, high in intelligent level and convenient for operation.

Owner:韩瑞丰

Liquid state slag removal method of high-temperature oriented silicon steel heating furnace

InactiveCN103453773BImprove liquidityGuaranteed liquidityCharge manipulationLiquid stateHeating furnace

The invention discloses a liquid state slag removal method of a high-temperature oriented silicon steel heating furnace. The liquid stage slag removal method comprises the following steps of uniformly paving a coke particle layer on the surfaces of the furnace bottoms of a second heating section and a soaking section of the heating furnace after slag removal when the stepped heating furnace is stopped; opening a burner nozzle of a slag removal hole, and uniformly adding deslagging agent particles on the furnace bottoms of the second heating section and the soaking section of the heating furnace till slag accumulated on the furnace bottom rises to cause that the burning flame shape of burner nozzles at the lower parts of the second heating section and the soaking section of the heating furnace and the temperature uniformity of the upper part and the lower part of the furnace cannot meet the normal heating quality requirement of high-temperature oriented silicon steel; and stopping heating the high-temperature oriented silicon steel of the heating furnace. According to the liquid state slag removal method, the heating furnace does not need to be transformed, and the liquid state slag can be efficiently and rapidly removed by using an existing liquid stage slag removal device; the liquid state slag removal method disclosed by the invention has the advantages of simple method, convenience for operation, excellent liquid state slag removal effect and the like; the comprehensive purposes of reducing the slag melting point, the molten slag viscosity and the maintenance cost of the high-temperature oriented silicon steel heating furnace, improving the molten slag fluidity, liquid state slag removal quantity, cycle heating quantity of the heating furnace and production efficiency of high-temperature oriented silicon steel heating furnace and the like are finally achieved.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com