Concrete material in-high-temperature compression testing machine and in-high-temperature compression testing method

A technology for compressive testing and concrete specimens, applied in the direction of analyzing materials, using stable tension/pressure testing material strength, measuring devices, etc., can solve problems such as differences in concrete compressive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

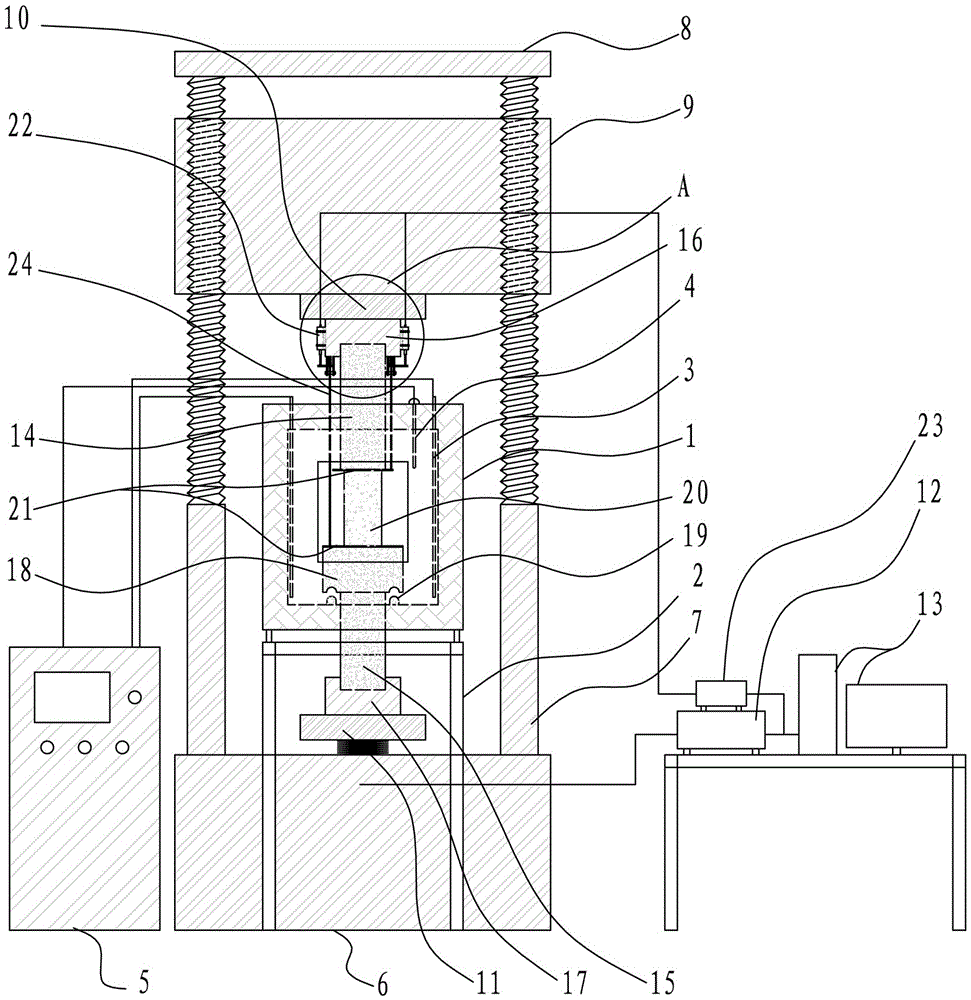

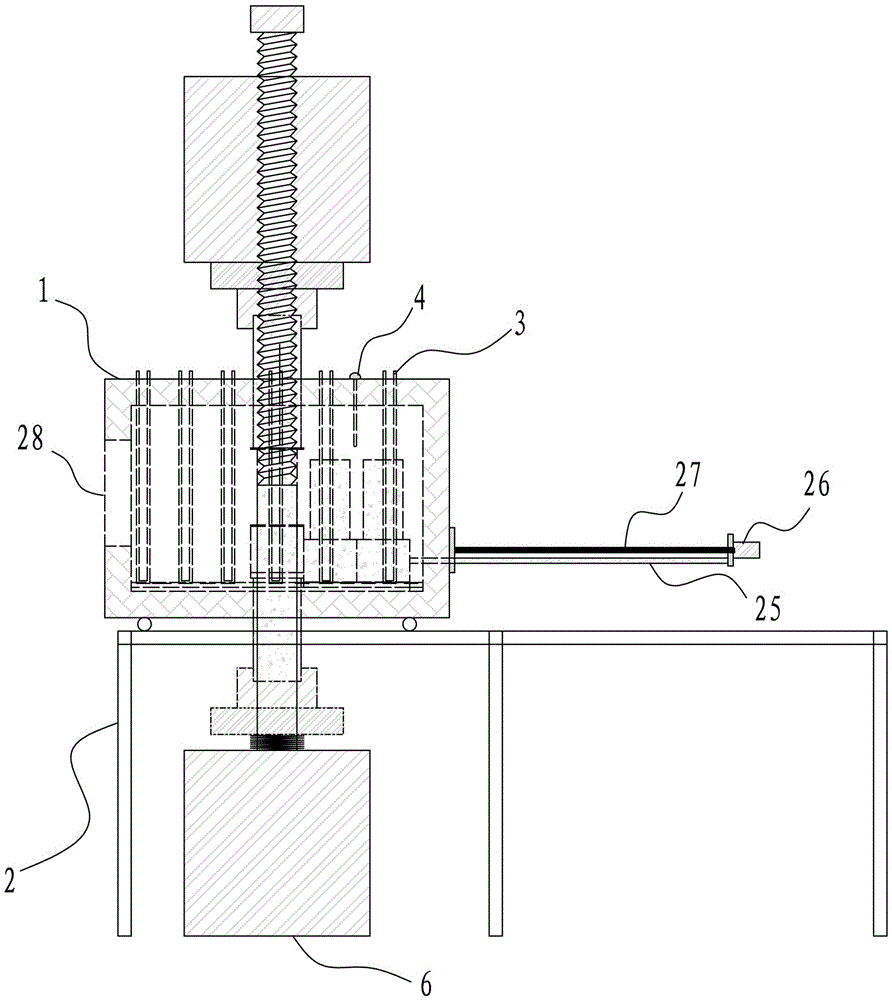

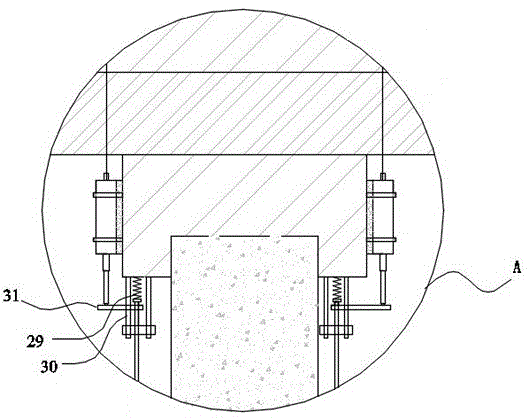

[0041] High temperature and medium compression testing machine for concrete materials, such as Figure 1~3 As shown, it includes loading equipment for applying pressure to the concrete specimen, heating equipment for heating the concrete specimen, displacement acquisition device for measuring the deformation of the concrete specimen, and a device for pushing the concrete specimen to move toward the furnace mouth. The pushing device; the loading device includes a base 6, a column 7 fixed on the base 6, a crossbeam 9 which is arranged on the column 7 and moves up and down along the column 7 and positioned, an upper platen 10 fixed on the bottom of the beam, and fixed on the upper platen The high-temperature-resistant upper pressure head at the bottom, the lower pressure plate 11 located on the base 6, the high-temperature-resistant lower pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com