Smoke secondary combustion furnace

A secondary combustion and soot technology, applied in the field of combustion furnaces, can solve the problems of unsatisfactory secondary combustion effect, serious soot pollution, insufficient combustion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

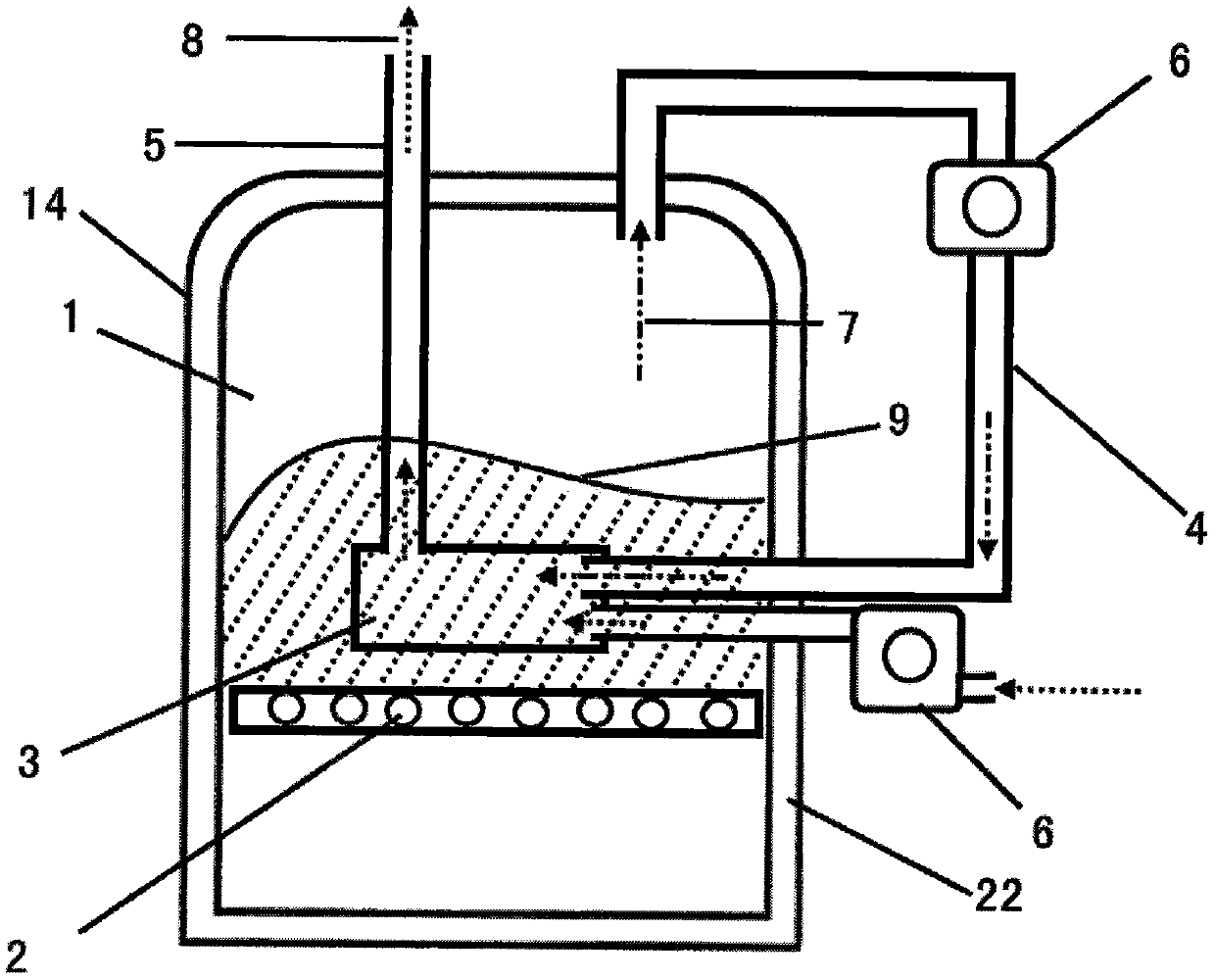

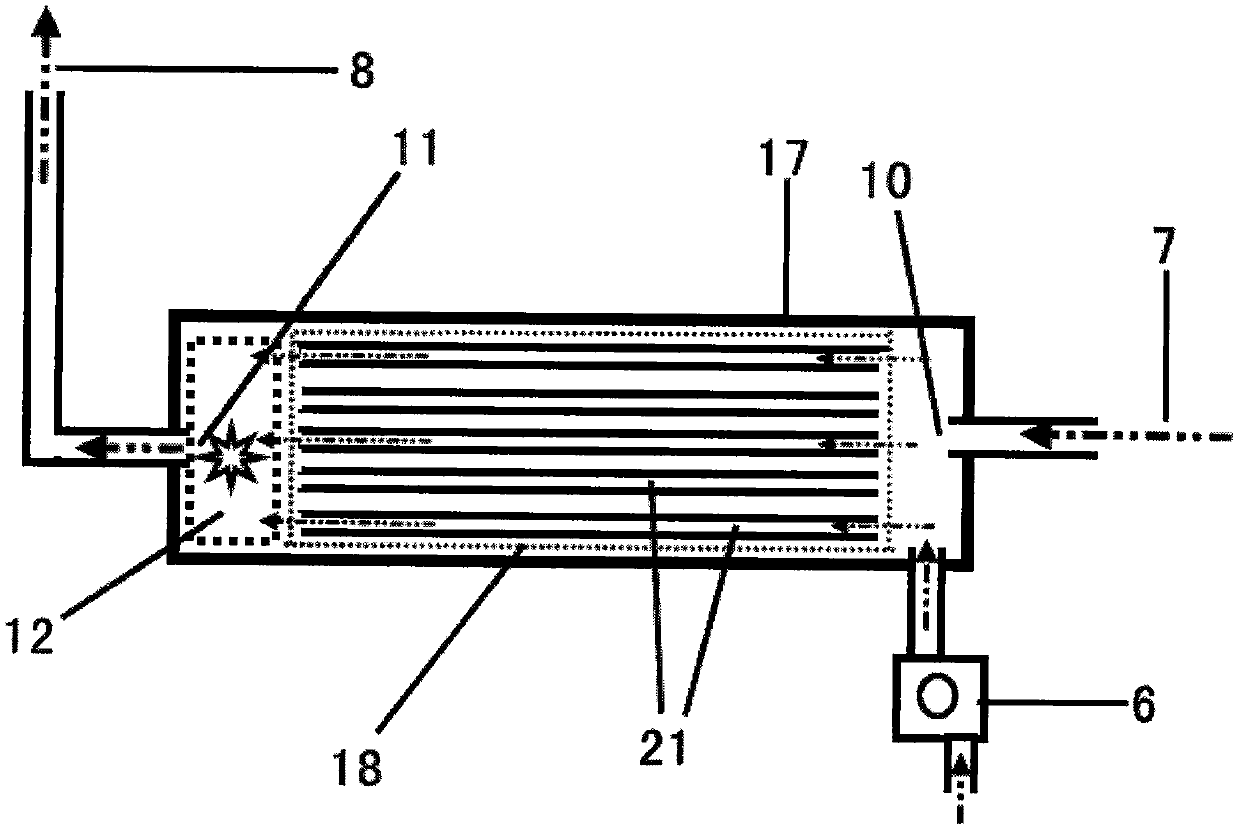

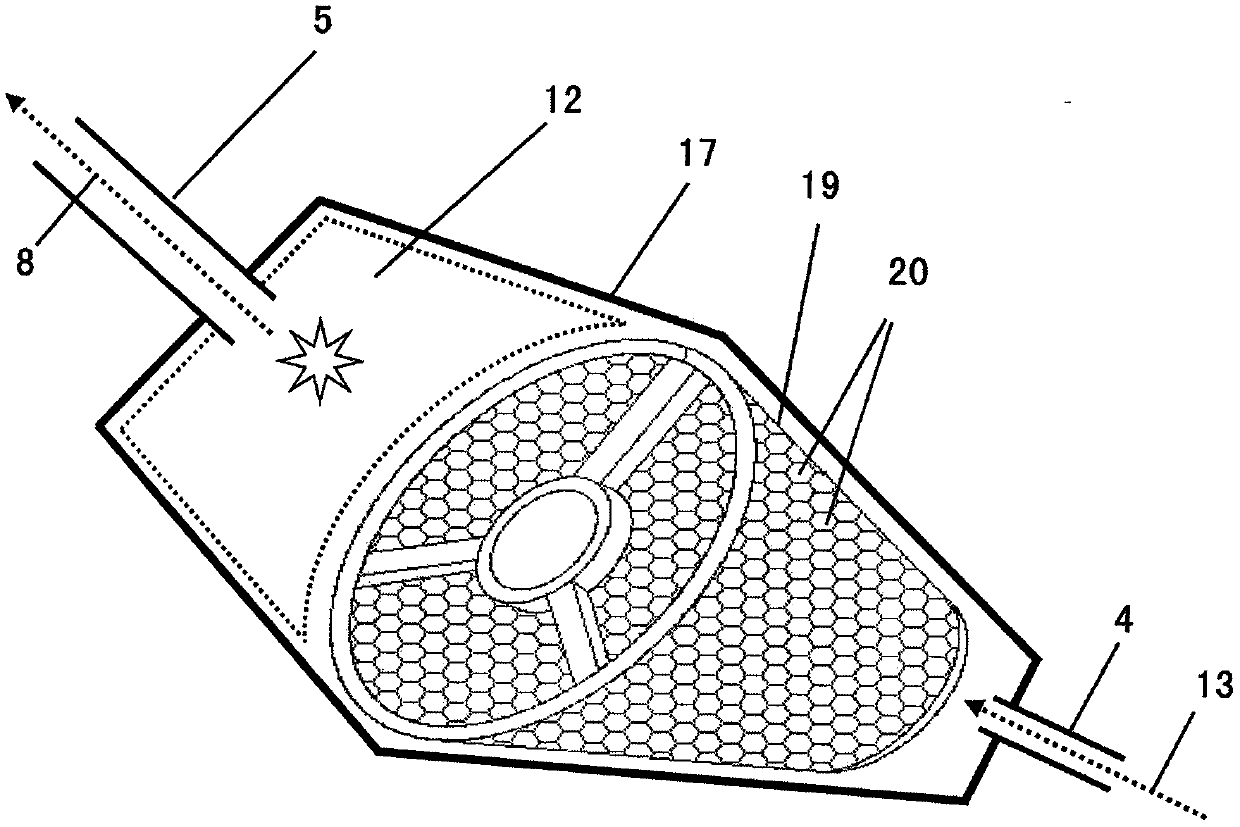

[0014] The present invention will be further described below in conjunction with accompanying drawing.

[0015] The preheating chamber 16 of the soot preheater 3 is a tubular body of high thermal conductivity material, called the preheating pipe 15, the preheating pipe 15 and the combustion chamber 12 form the soot preheater 3, and the front end of the preheating pipe 15 is connected to a primary combustion chamber. The smoke pipe 4 and the blower 6 are connected to the combustion chamber 12 at the rear end of the preheating pipe 15, and the combustion chamber 12 is connected to the secondary combustion smoke pipe 4 again.

[0016] The preheating chamber 16 of the soot preheater 3 is a hollow closed shell, the front end of the preheating chamber 16 is connected to the primary combustion pipe 4 and the blower 6, the rear end of the preheating chamber 16 is connected to the combustion chamber 12, and the combustion chamber 12 is connected to On the secondary combustion flue pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com