Patents

Literature

1129 results about "Ignition point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ignition point n. The minimum temperature at which a substance will continue to burn without additional application of external heat.

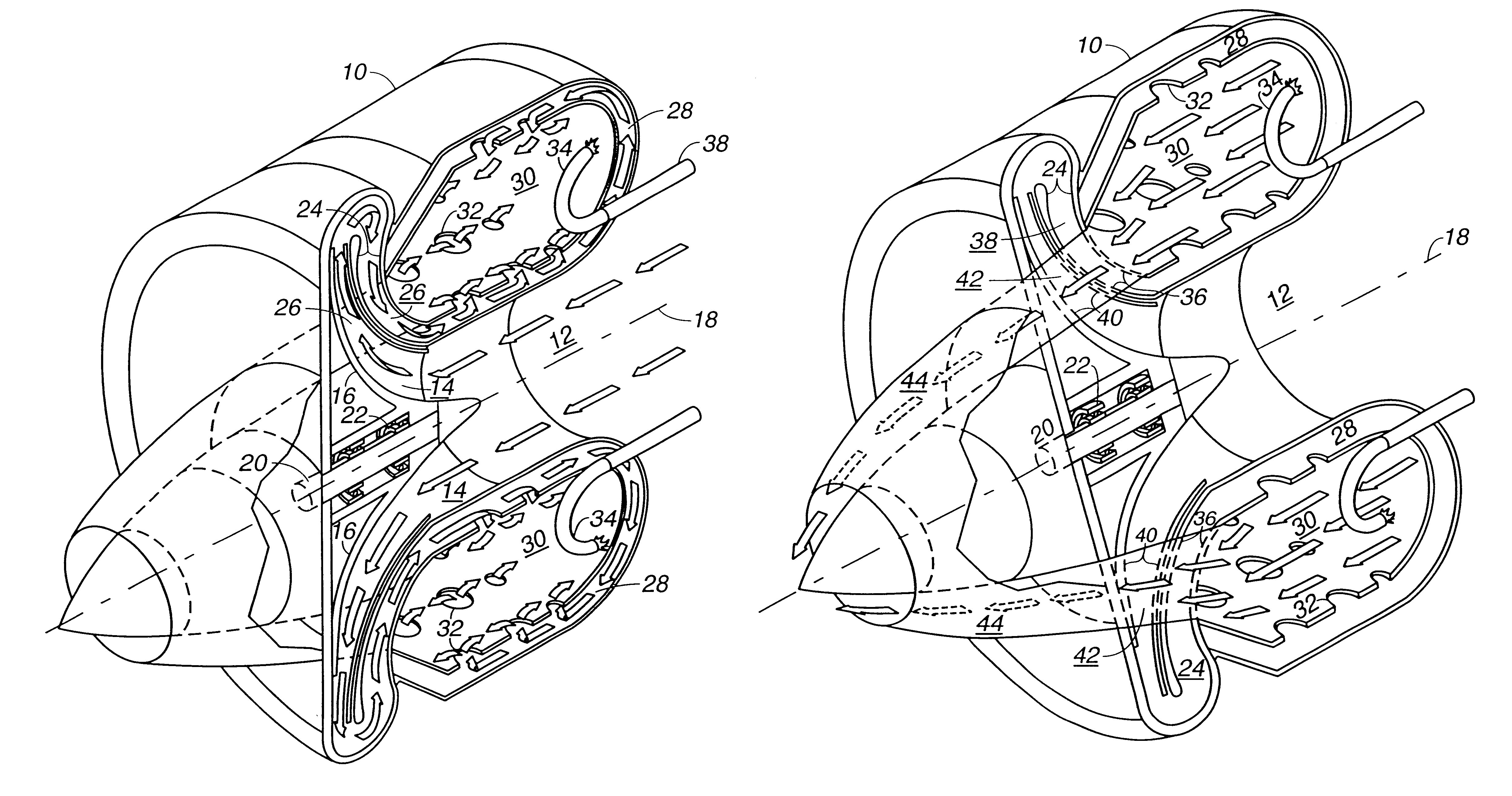

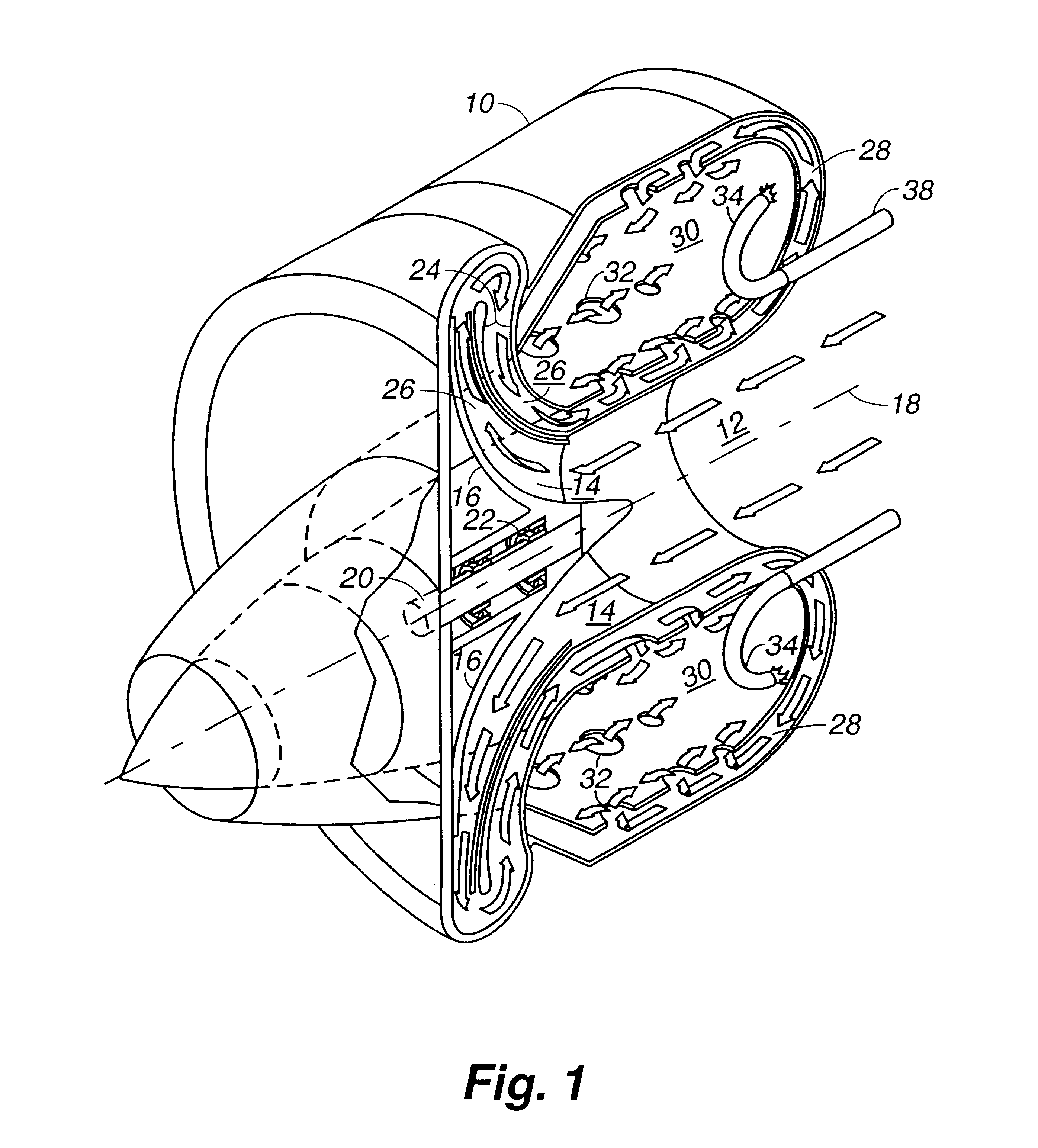

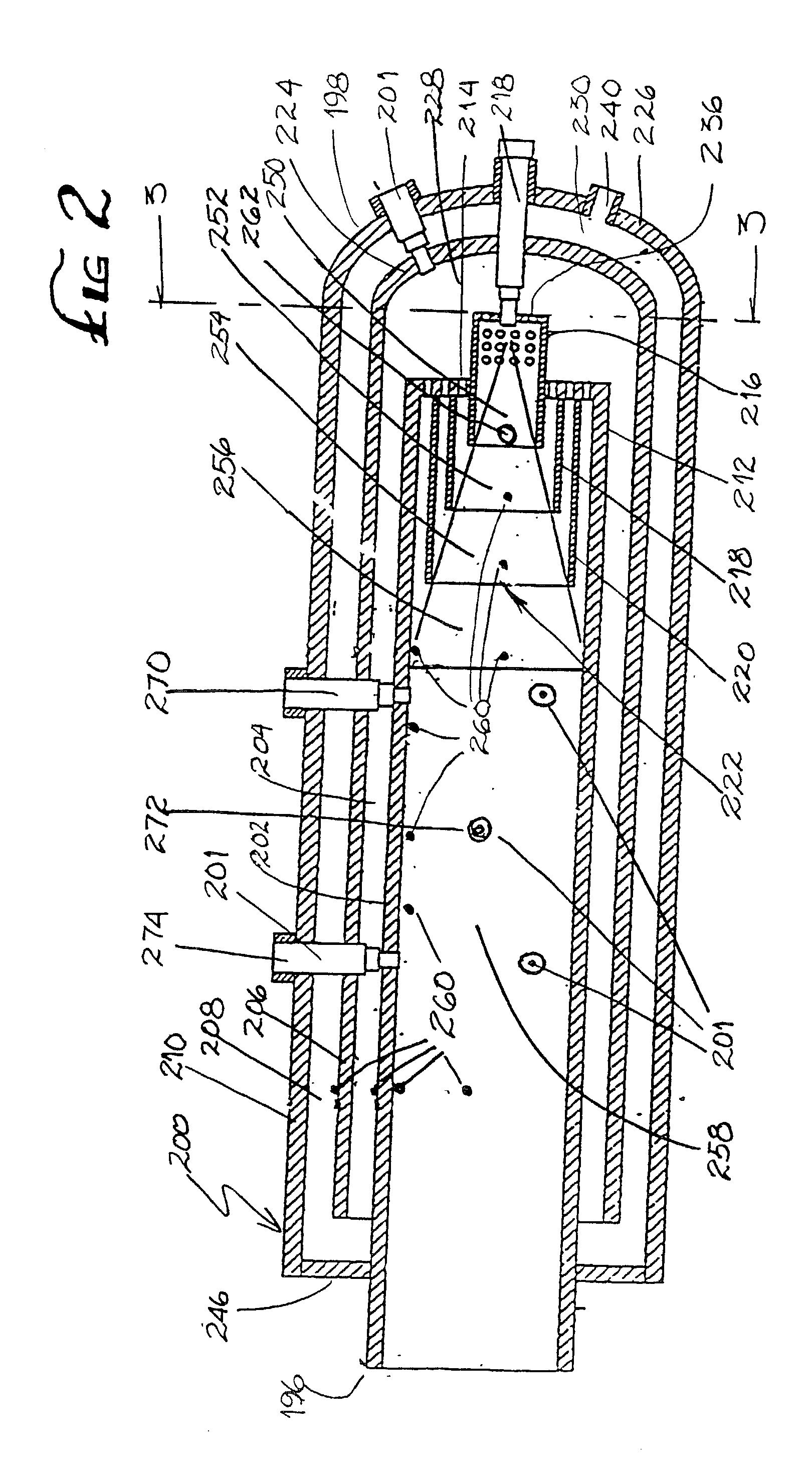

Single rotor turbine engine

There has been invented a turbine engine with a single rotor which cools the engine, functions as a radial compressor, pushes air through the engine to the ignition point, and acts as an axial turbine for powering the compressor. The invention engine is designed to use a simple scheme of conventional passage shapes to provide both a radial and axial flow pattern through the single rotor, thereby allowing the radial intake air flow to cool the turbine blades and turbine exhaust gases in an axial flow to be used for energy transfer. In an alternative embodiment, an electric generator is incorporated in the engine to specifically adapt the invention for power generation. Magnets are embedded in the exhaust face of the single rotor proximate to a ring of stationary magnetic cores with windings to provide for the generation of electricity. In this alternative embodiment, the turbine is a radial inflow turbine rather than an axial turbine as used in the first embodiment. Radial inflow passages of conventional design are interleaved with radial compressor passages to allow the intake air to cool the turbine blades.

Owner:LOS ALAMOS NATIONAL SECURITY

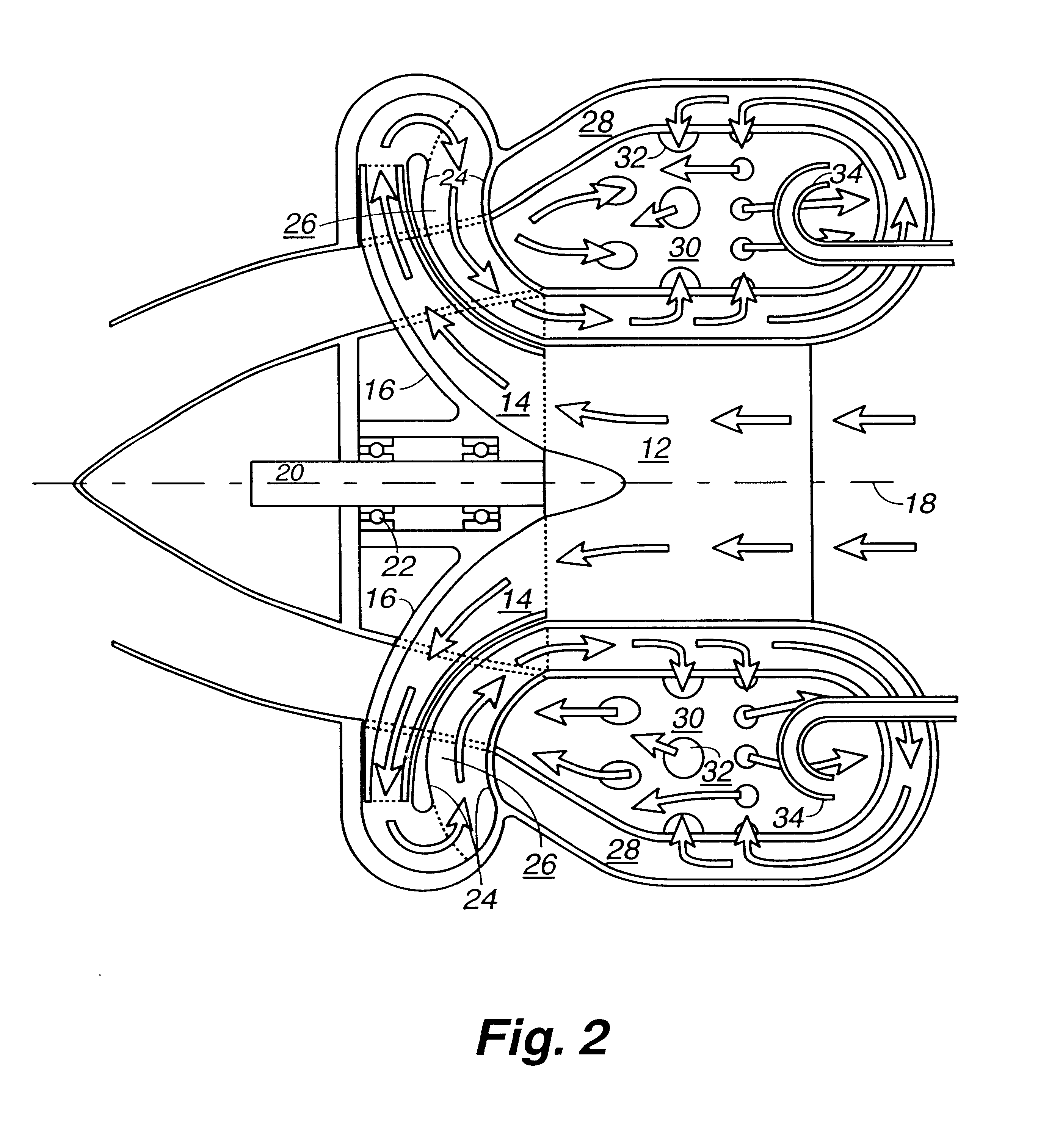

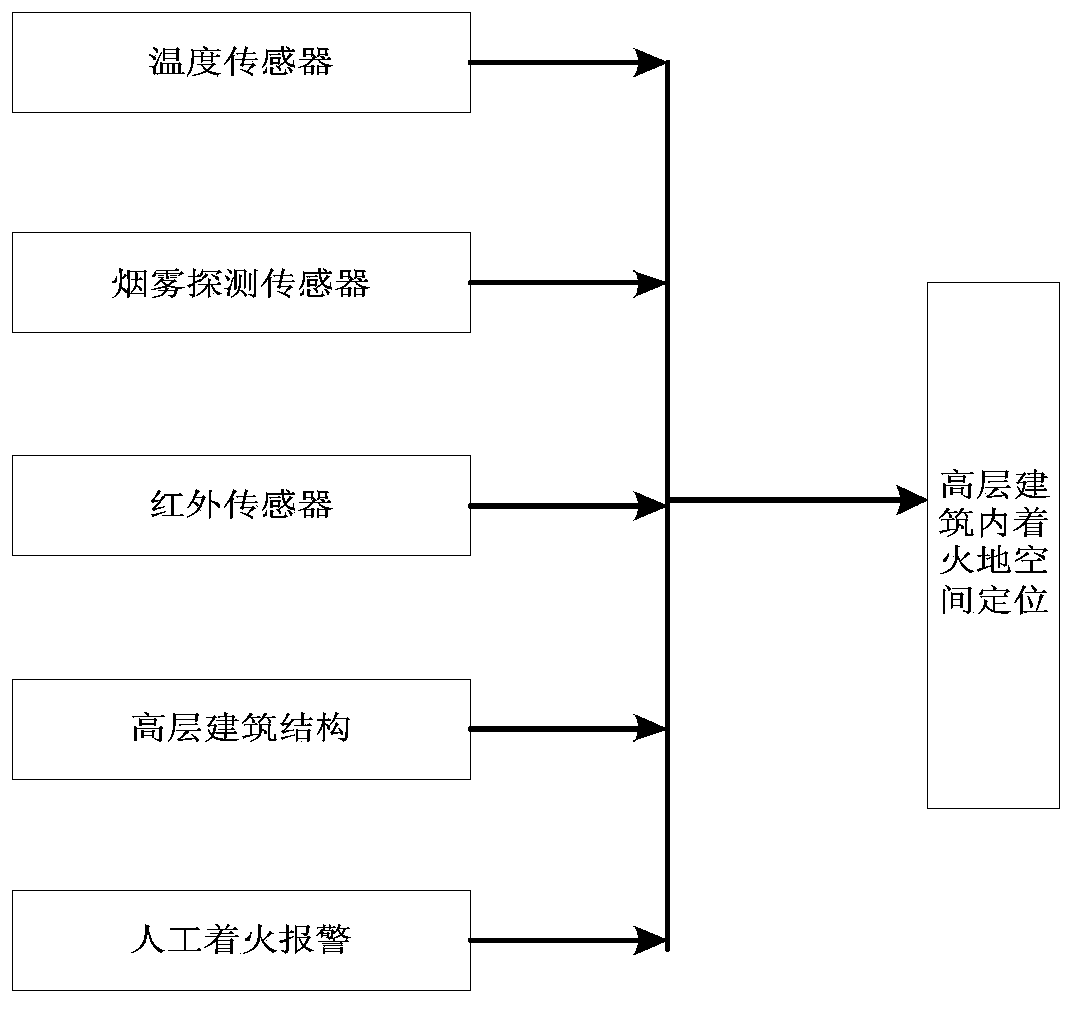

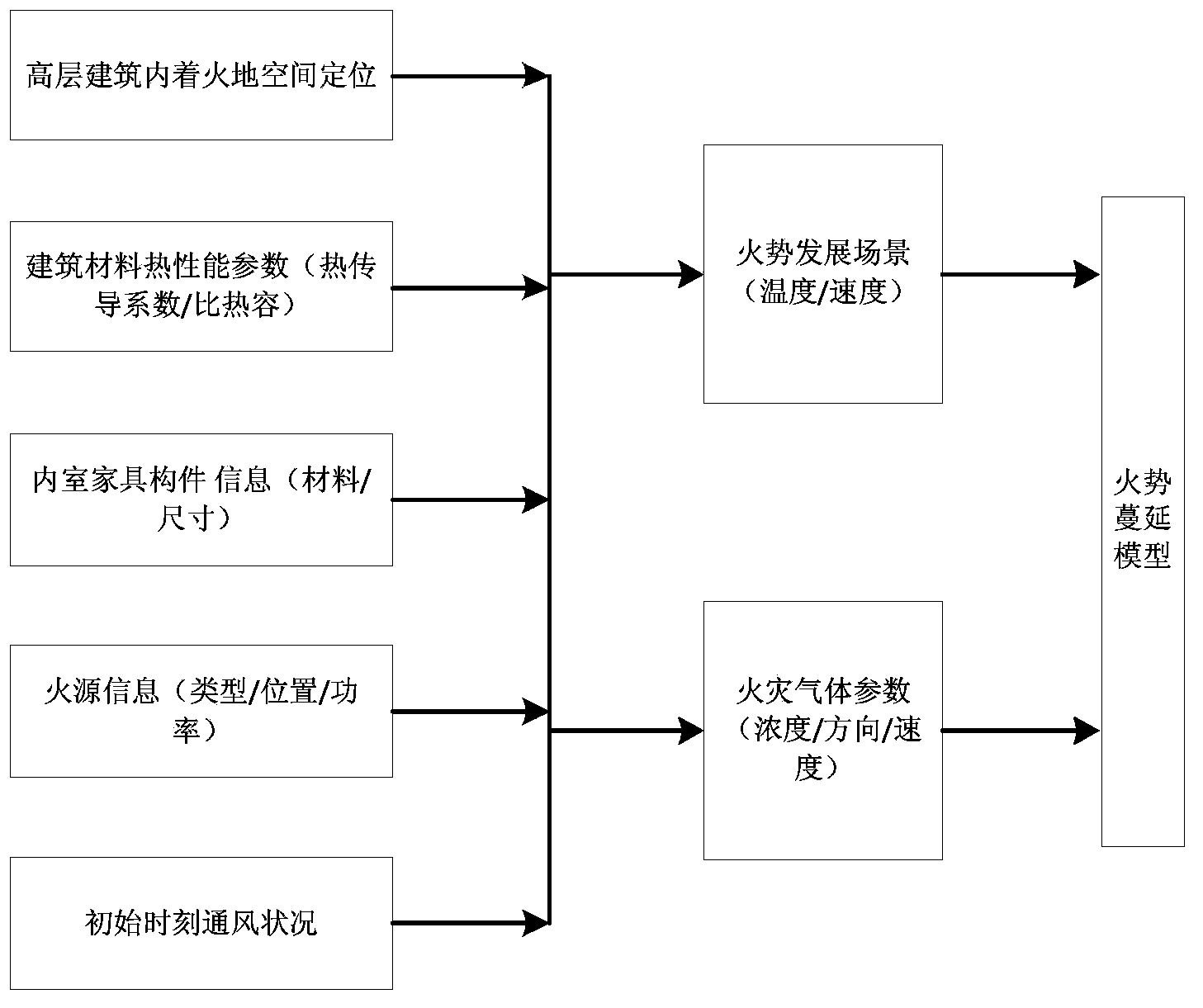

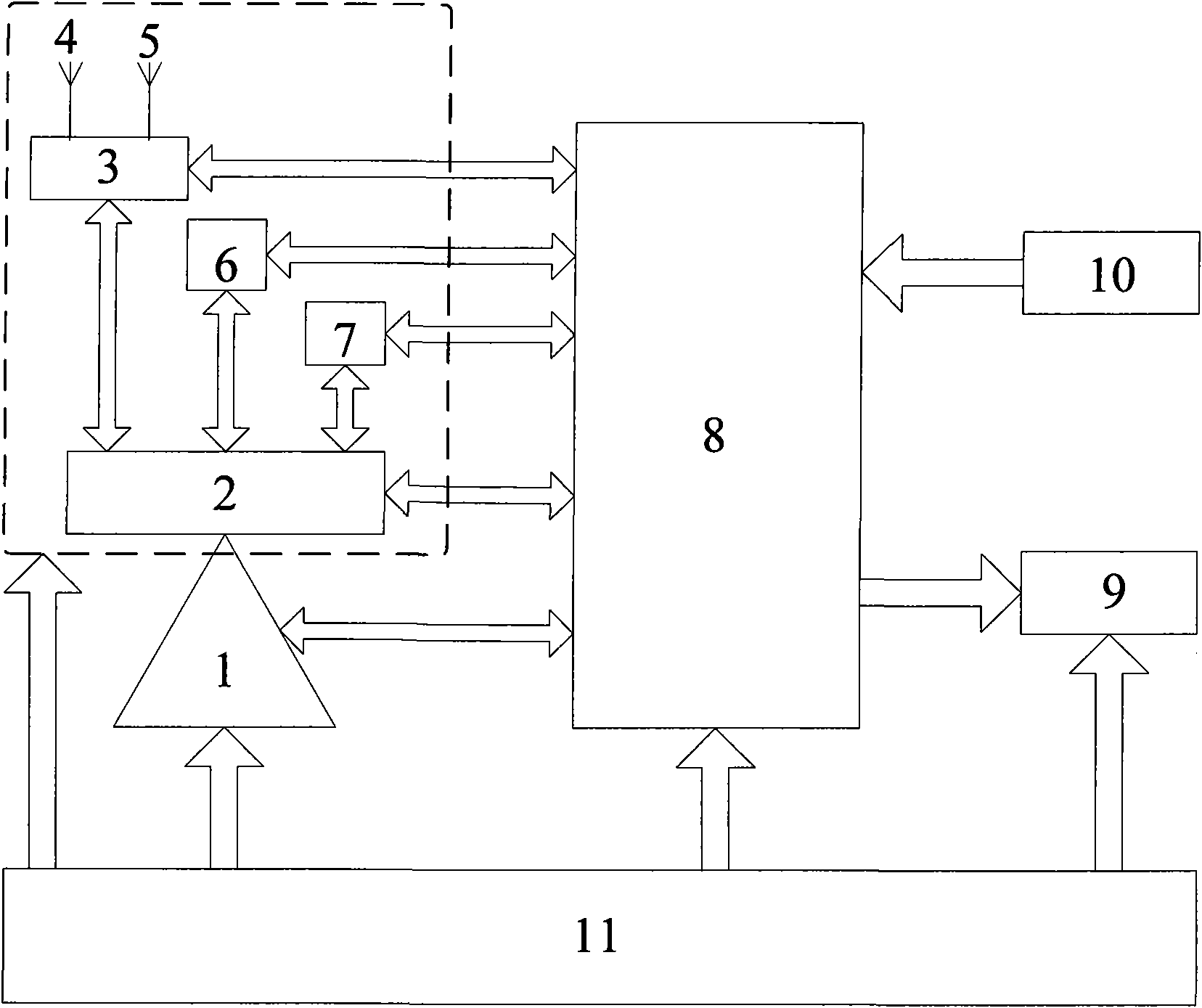

Large high-rise building indoor fire urgent evacuation indication escape method and system

ActiveCN103394171ASolve congestionSolve low timelinessBuilding rescueFire alarm smoke/gas actuationFire evacuationDynamic models

The invention discloses a large high-rise building indoor fire urgent evacuation indication escape method and system, and belongs to the field of high-rise building fire safety. The large high-rise building indoor fire urgent evacuation indication escape method comprises the following steps: step 1, a fire source is located; step 2, a dynamic module of fire spread is set up; step 3, according to the dynamic module of fire spread in combination with the structural information of a building, the spatial position of an ignition point and the spatial position of fire-fighting equipment in a large high-rise building are determined, predictions are made over fire spread paths, and evacuation escape routes are planned; step 4, according to the designed escape routes, site equipment is controlled in a selective mode for assisting people in evacuation. According to the large high-rise building indoor fire urgent evacuation indication escape method and system, the fire control escape routes are made based on specific fire behavior, so that evacuation time is shortened; the existing problems that when a fire breaks out, a fire control evacuation escape way is crowded , low in efficiency and disorderly and stampedes easily occur are solved fundamentally; the practical significance of improving the safe evacuation performance of the large high-rise building and reducing the property loss and casualties caused by the fire in the large high-rise building is quite high.

Owner:天津安博瑞尼科技股份有限公司

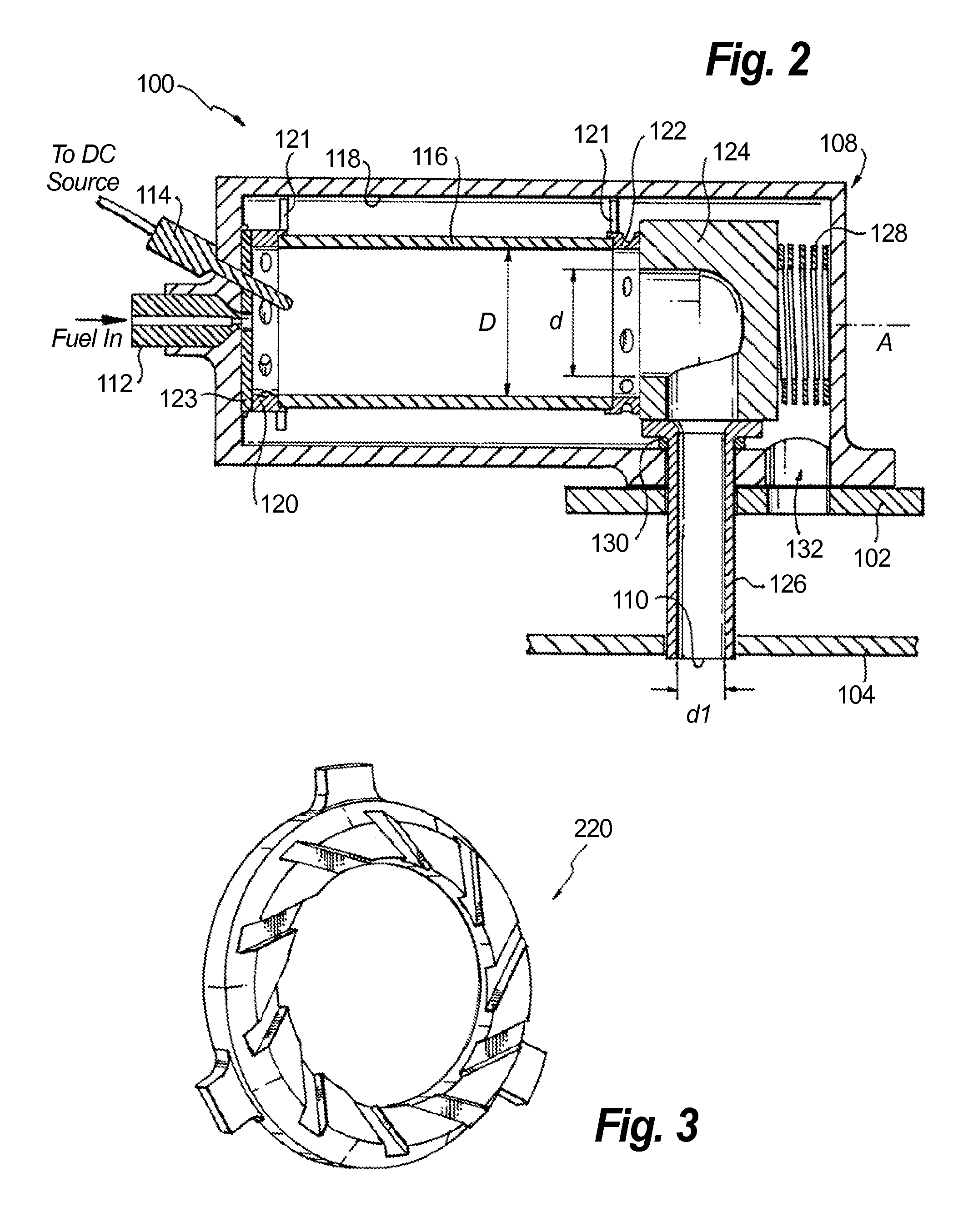

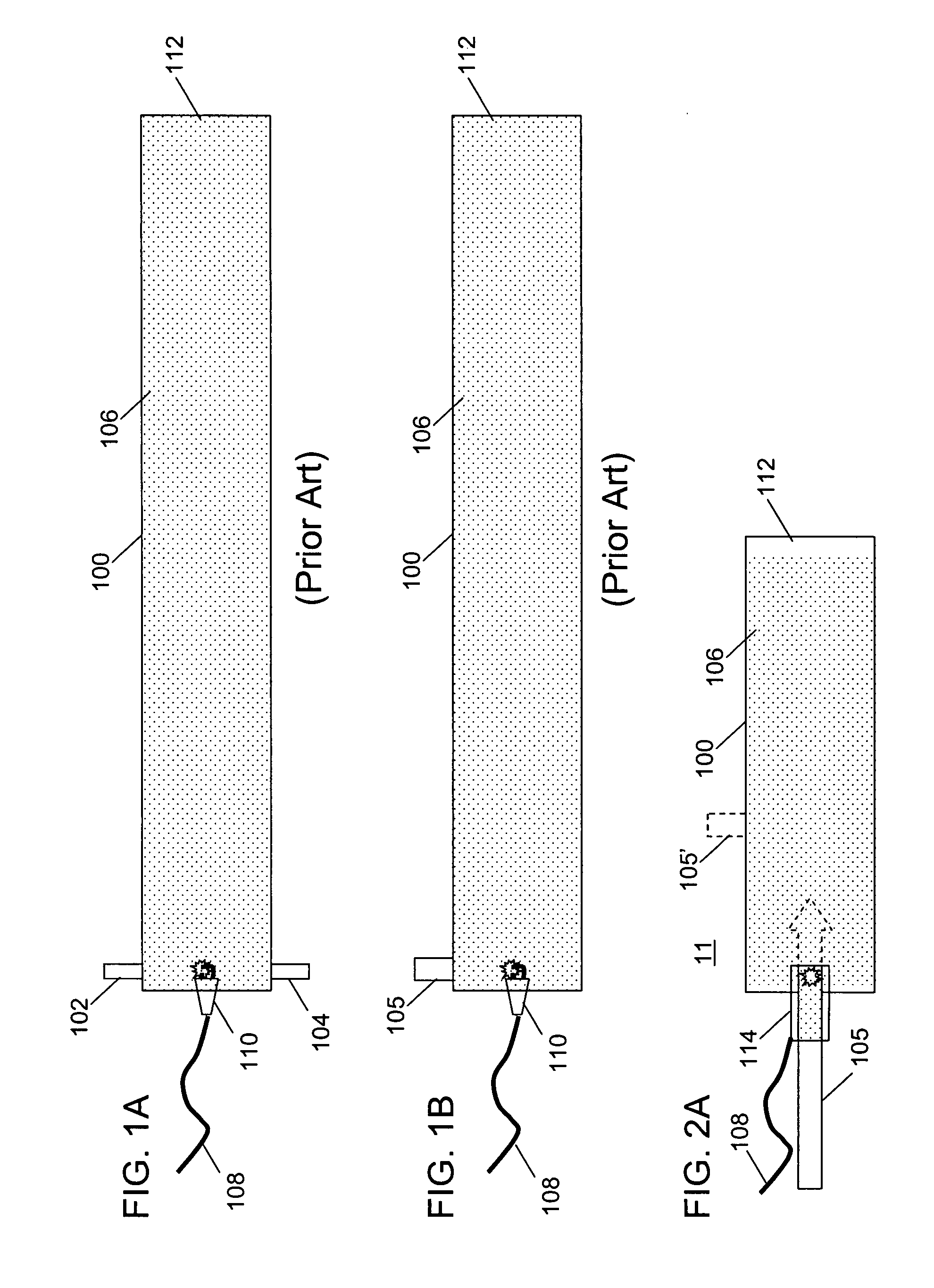

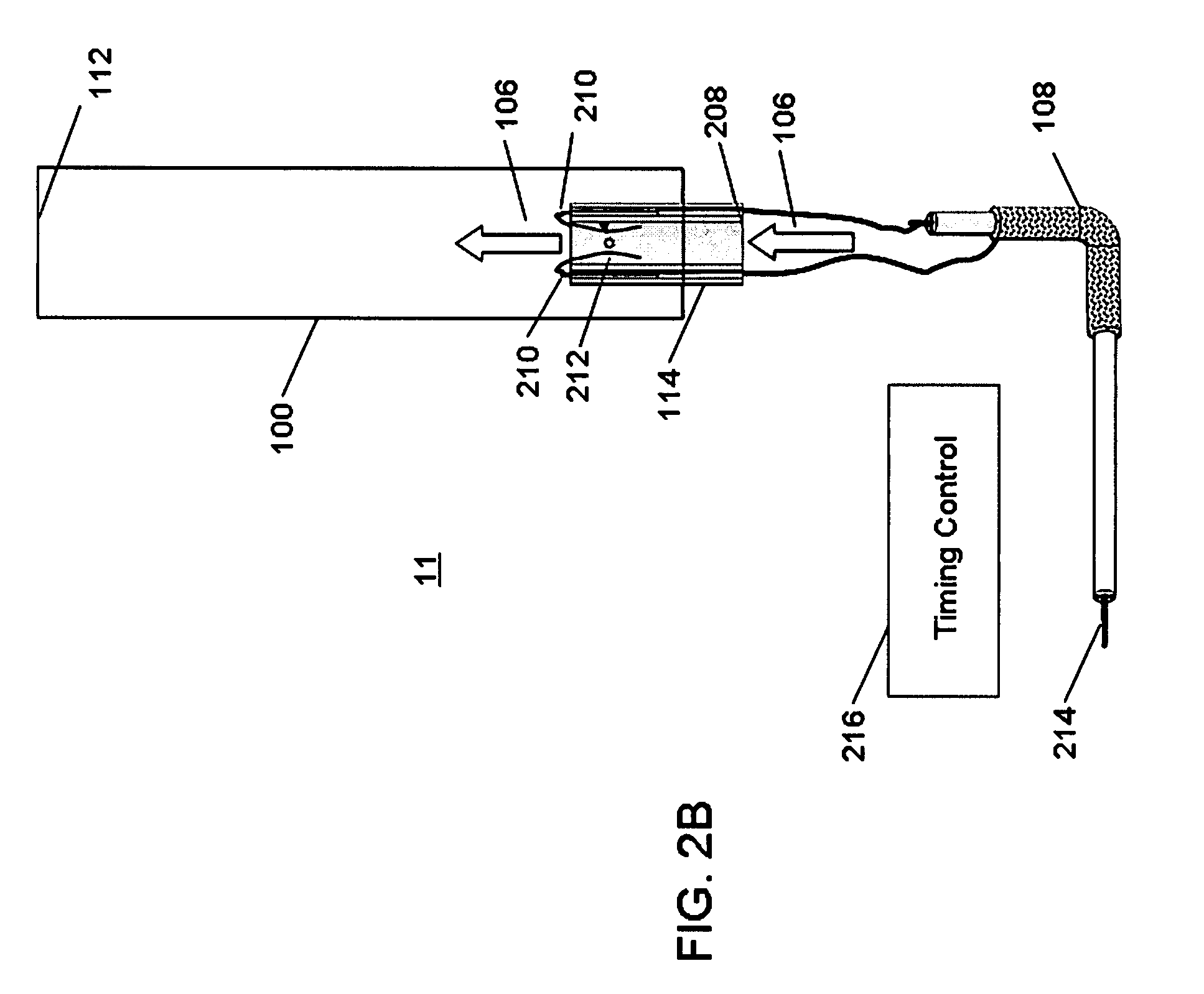

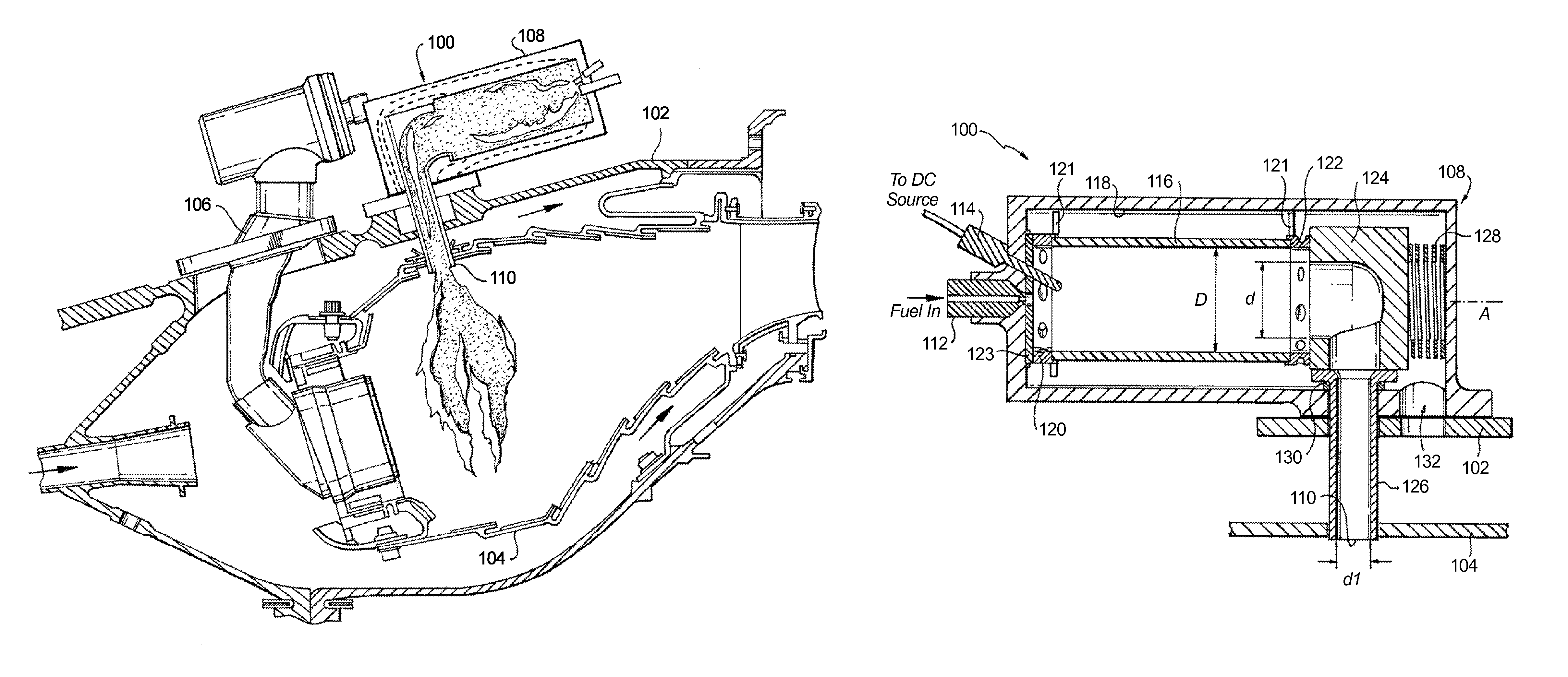

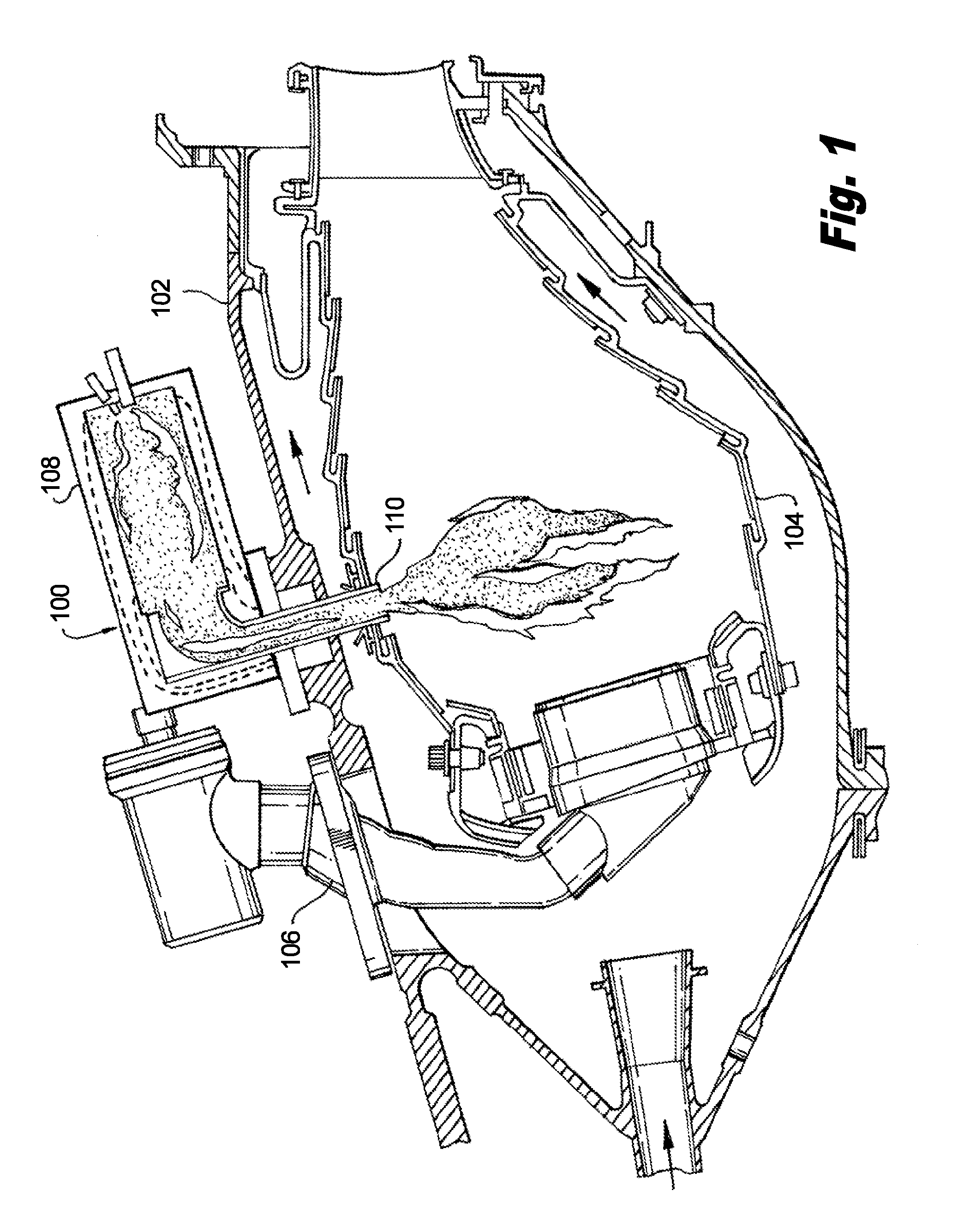

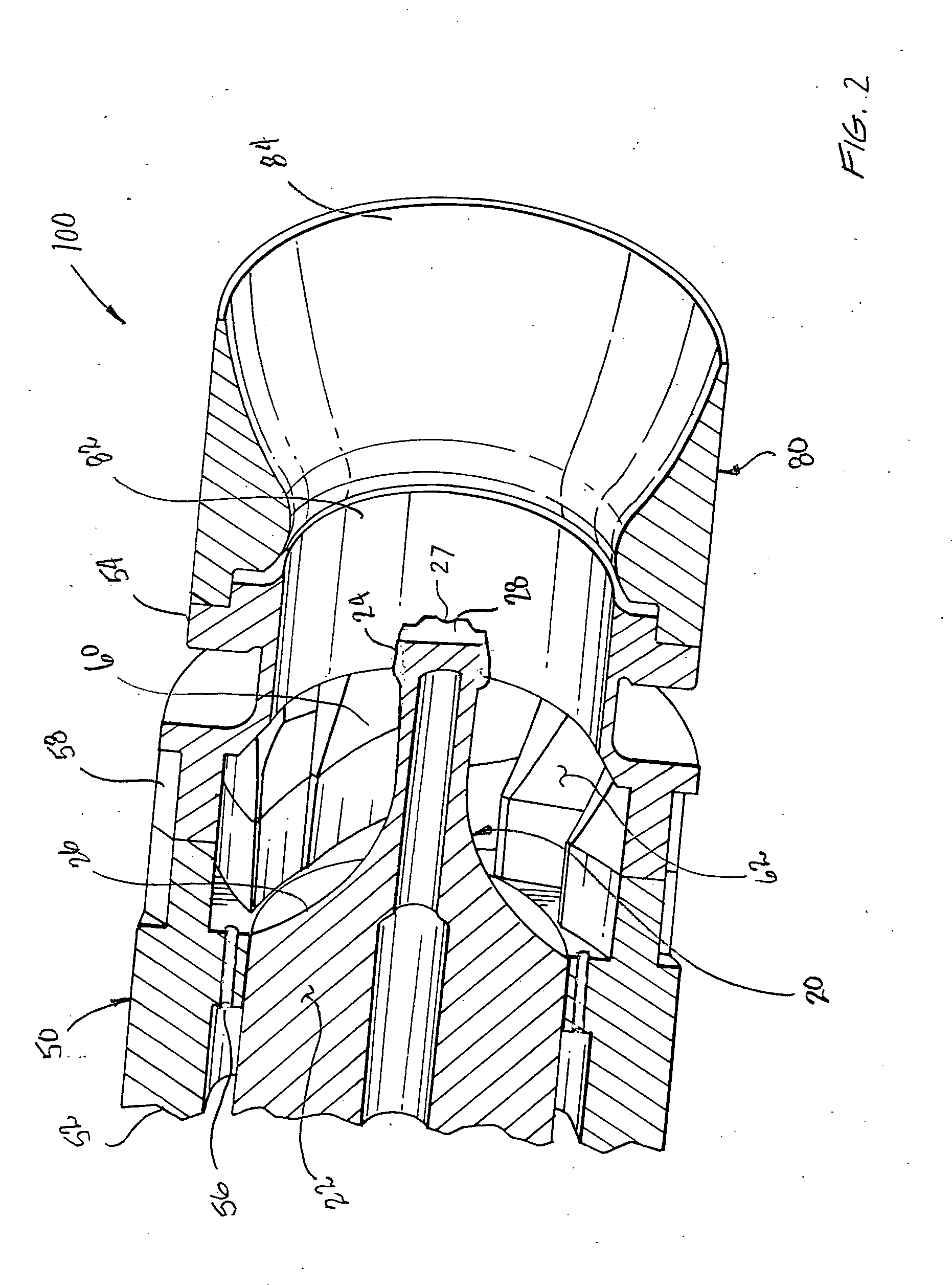

Continuous ignition

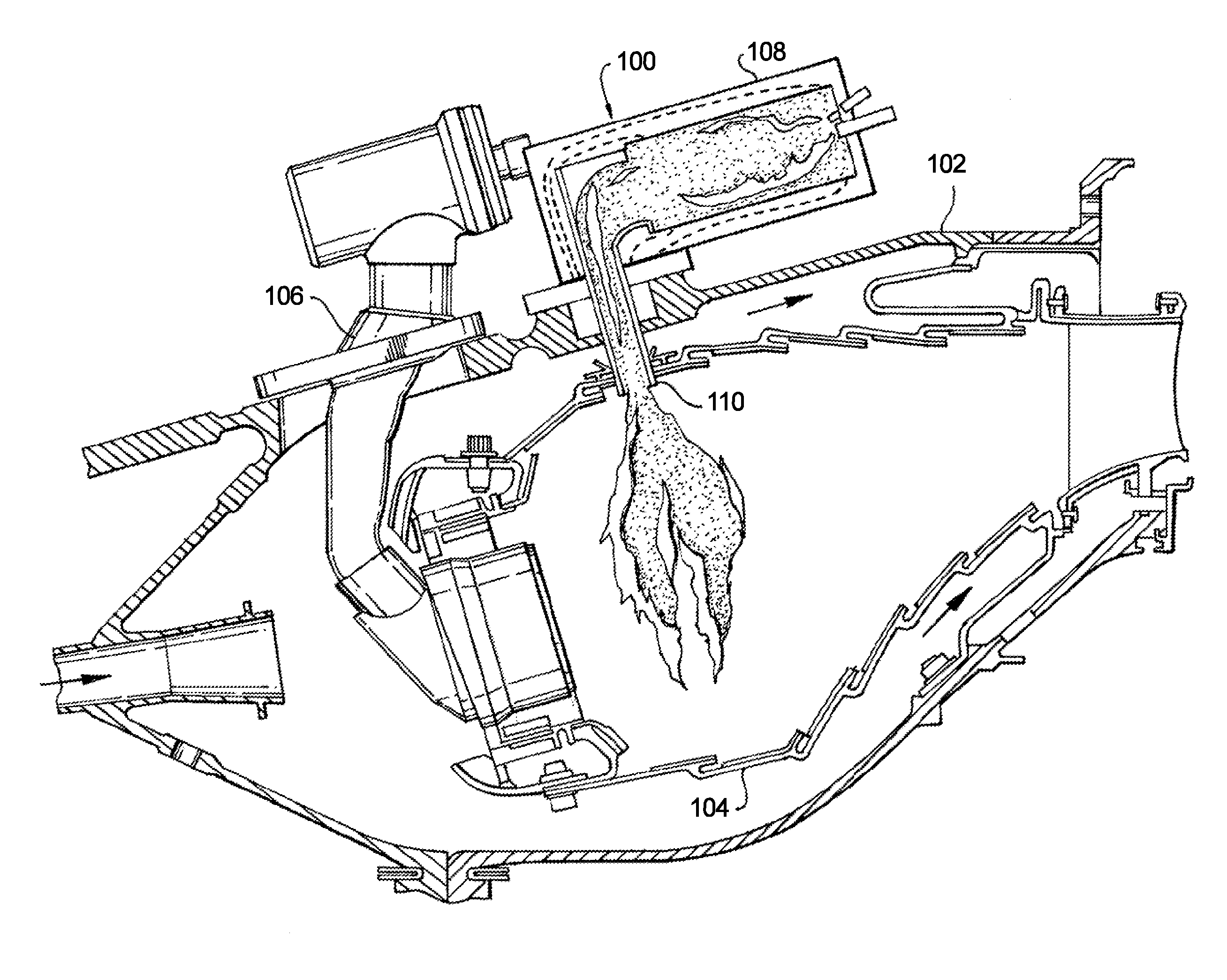

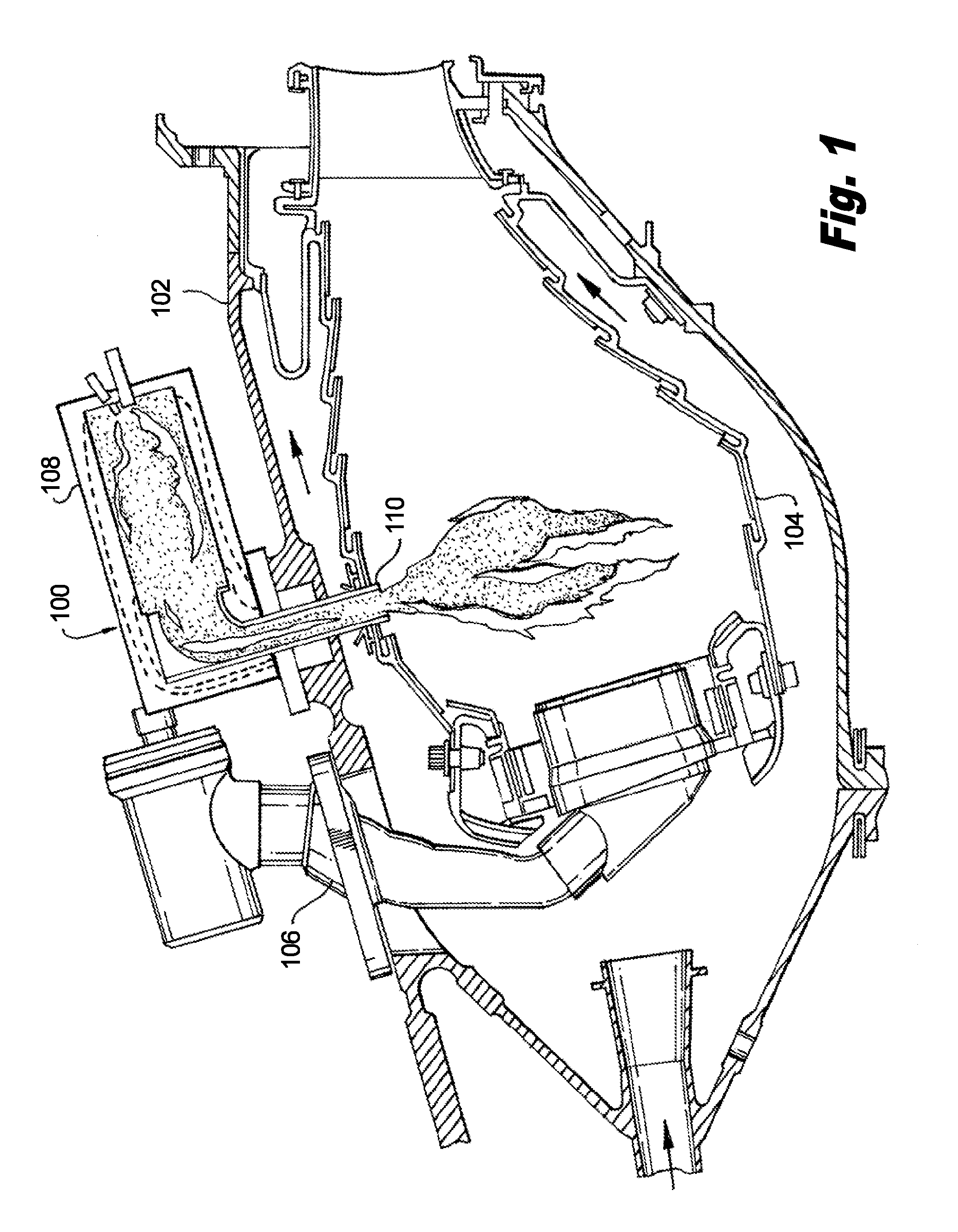

ActiveUS20140366551A1High flame intensityDecreasing flame strengthBurnersContinuous combustion chamberCombustorIgnition point

An ignition system includes a housing defining an interior and an exhaust outlet. The housing is configured and adapted to be mounted to a combustor to issue flame from the exhaust outlet into the combustor for ignition and flame stabilization within the combustor. A fuel injector is mounted to the housing with an outlet of the fuel injector directed to issue a spray of fuel into the interior of the housing. An igniter is mounted to the housing with an ignition point of the igniter proximate the outlet of the fuel injector for ignition within the interior of the housing.

Owner:COLLINS ENGINE NOZZLES INC

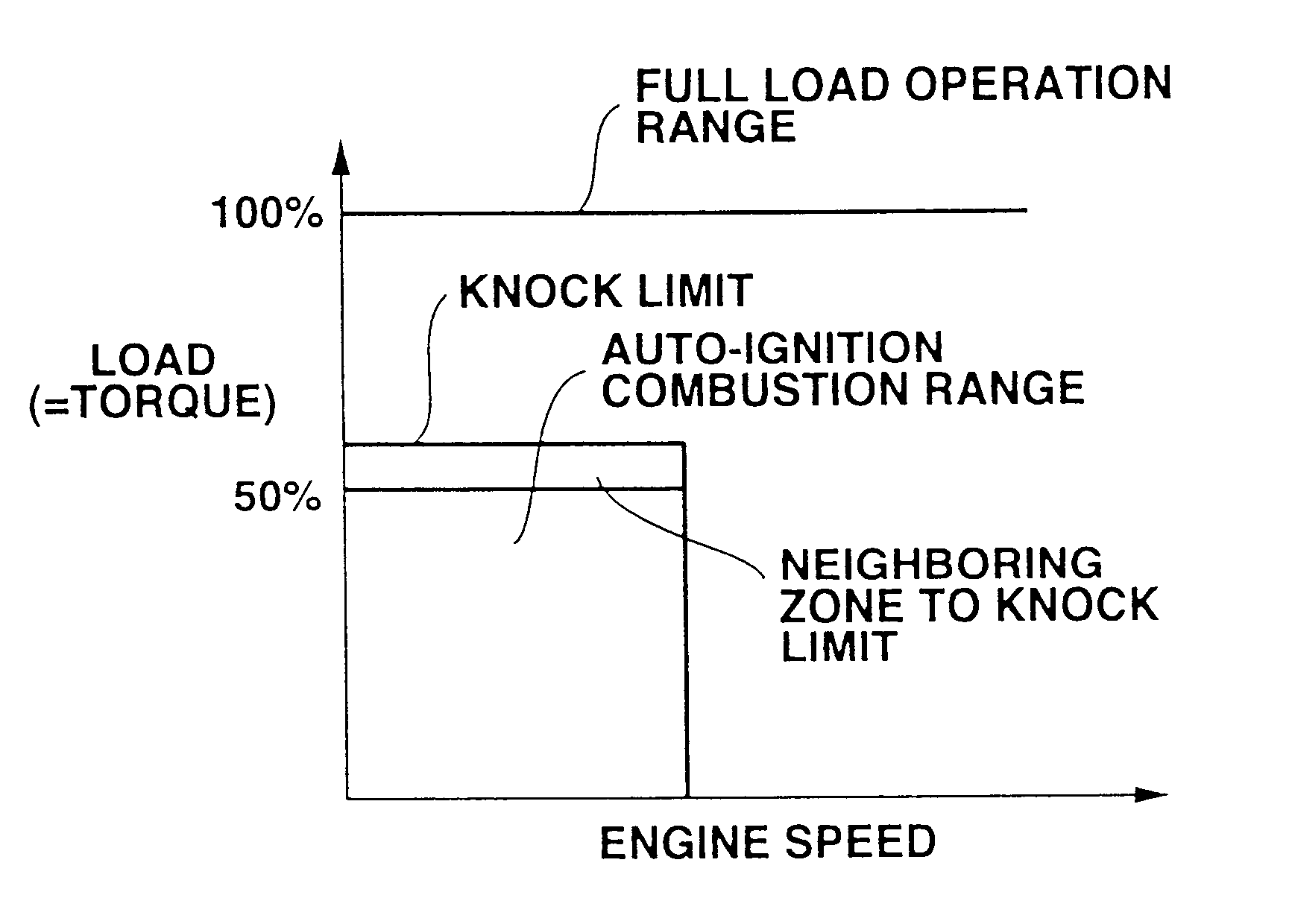

Auto-ignition combustion management in internal combustion engine

InactiveUS6401688B2High densityElectrical controlCombustion enginesCombustion chamberTop dead center

Owner:NISSAN MOTOR CO LTD

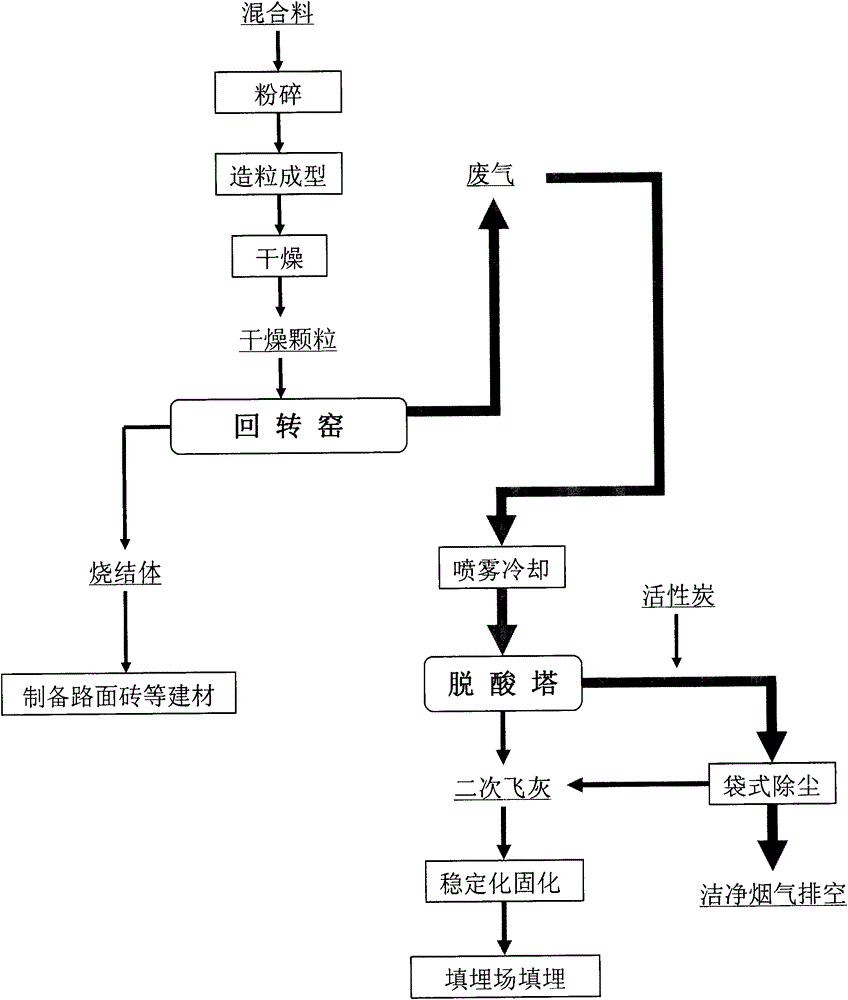

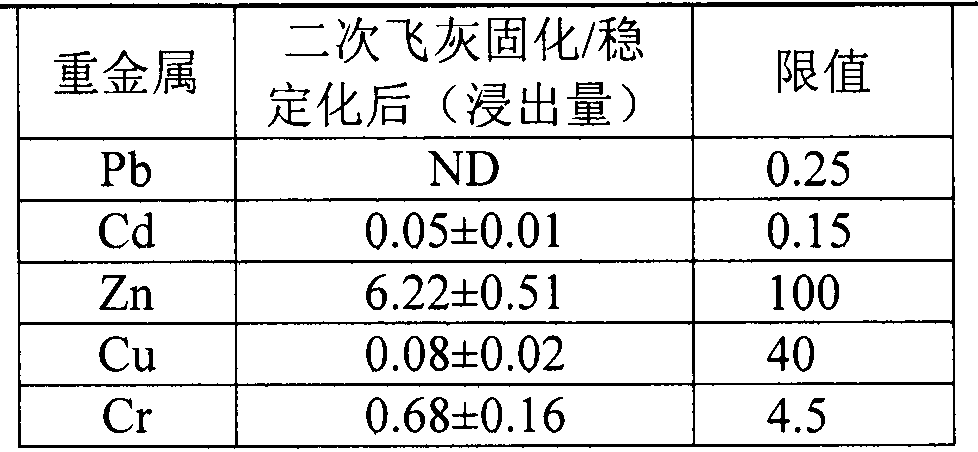

Garbage burning fly ash sintering harm-eliminating resource-utilization treatment system

The invention relates to a garbage burning fly ash sintering harm-eliminating resource-utilization treatment technology. According to the invention, garbage burning fly ash is mixed with premixed coal and auxiliary materials; the mixture is granulated and shaped; and the material is dried and is sintered in a rotary kiln. During the sintering process, when the temperature is increased and a coal ignition point is reached, the premixed coal is spontaneously combusted. Therefore, external coal dose can be reduced. Initial combustion of the premixed coal can provide a reductive atmosphere, such that dechlorination and detoxification of dioxin in fly ash can be benefited. Large amount of gas is produced by subsequent combustion, such that dust pores and holes are produced on inner and outer parts of the sintered body, and heavy metal volatilization can be promoted, and fly ash sintered body with low heavy metal content and leaching amount can be obtained. The sintered body has no potential harm to the environment, such that fly ash harm-eliminating and resource-utilization are sufficiently realized. During the processing process, smoke and secondary fly ash production amounts are low, and heavy metal and acidic component contents are high. In deacidification and heavy metal stabilization processes, agent utilization rate is improved. Compared with a traditional original fly ash curing / stabilizing process, a landfill amount can be reduced by 80-90%, such that pressure caused by serious landfill space shortage can be effectively relieved.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

Preparation method for coal combustion improver

The invention relates to a preparation method for a coal combustion improver. After common coal is added with coal additives for combustion, the effect of energy saving and emission reduction is obvious and effective. The preparation method comprises the following steps that: 1. high-stability sodium chlorate and potassium chloride react with each other to produce potassium chlorate when water is added and the sodium chlorate and the potassium chloride are dissolved; 2. leavening agent sodium acetate is introduced to conduct base exchange with humate in coal, low ignition point humate is produced and the ignition performance of the coal is reduced; and 3. ferric oxide required by the formula is compound insoluble in water. Thereby, ferric chloride and calcium oxide are used to react with each other to produce ferric oxide when water is added and the ferric chloride and the calcium oxide are dissolved. Other products in the market do not at all have the preparation and application characteristics of the three compounds.

Owner:GUANGHUA SCI & TECH SHANGHAI +1

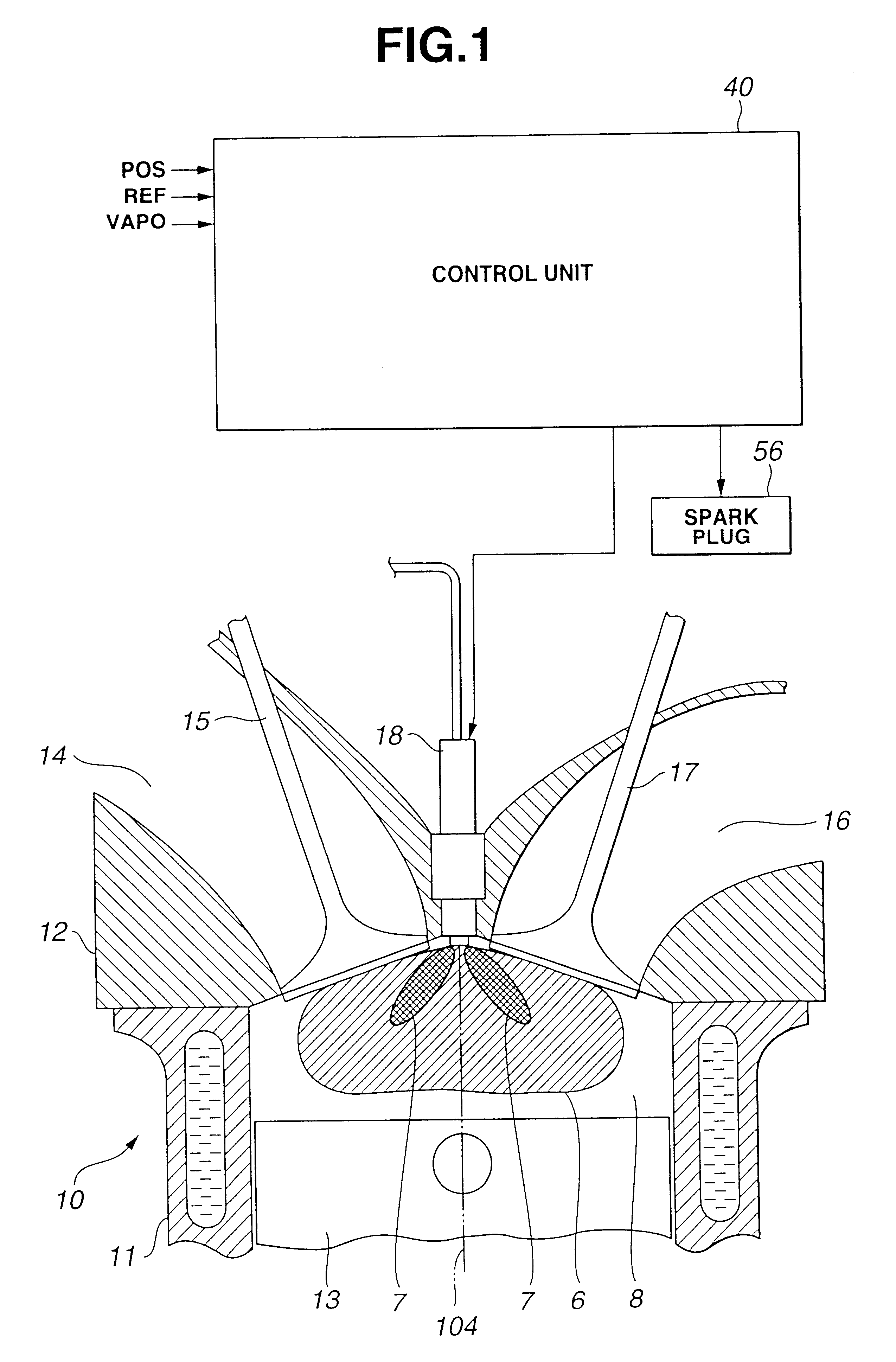

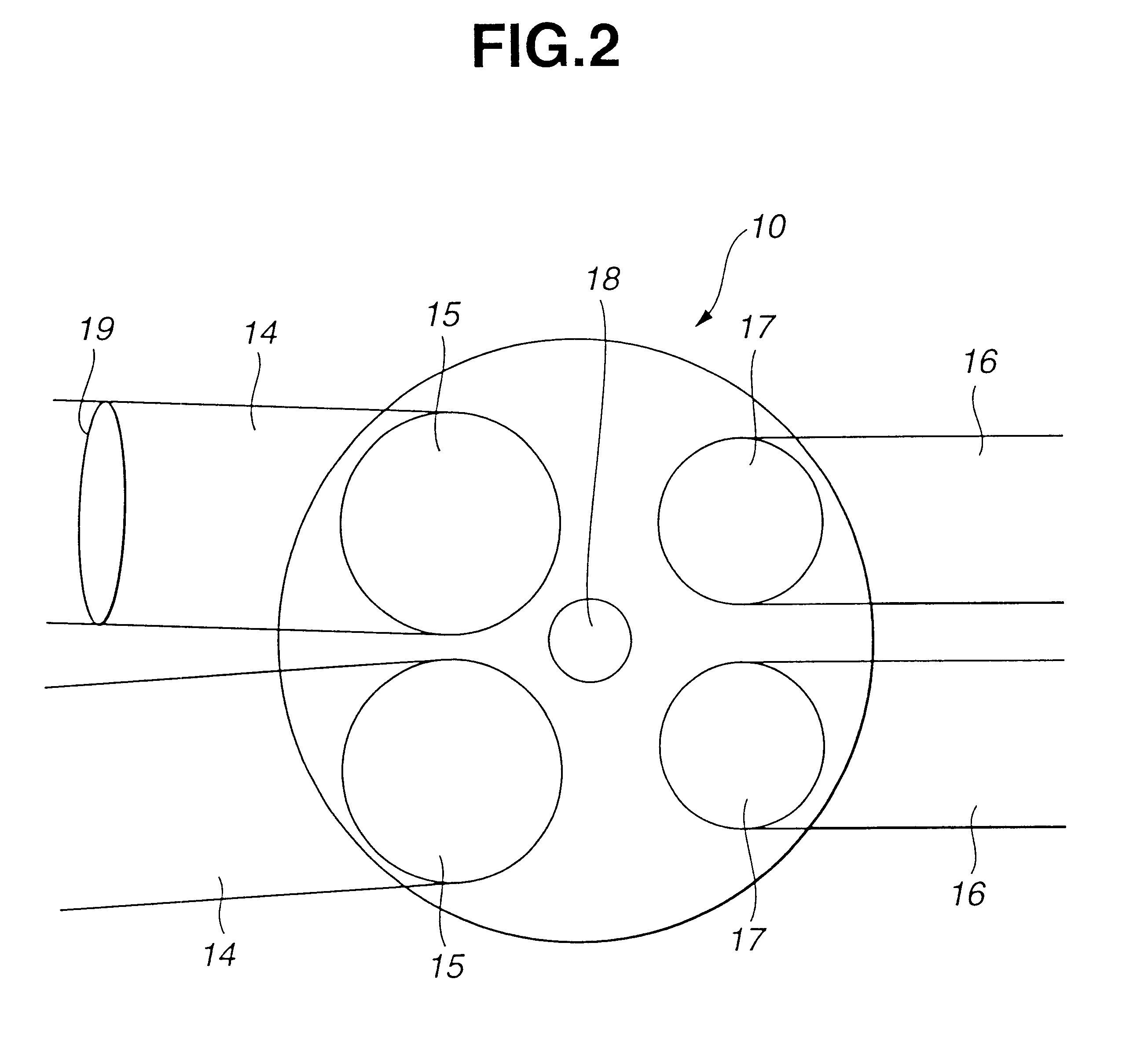

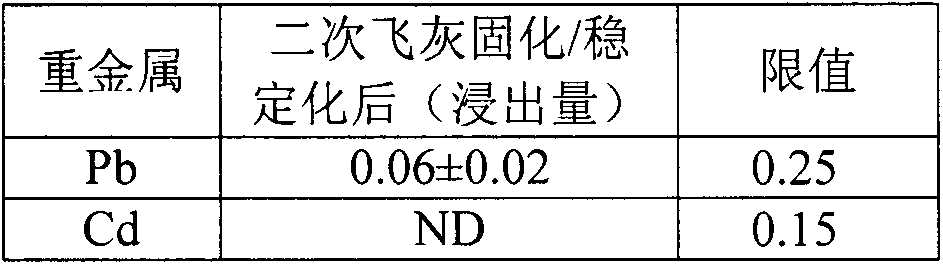

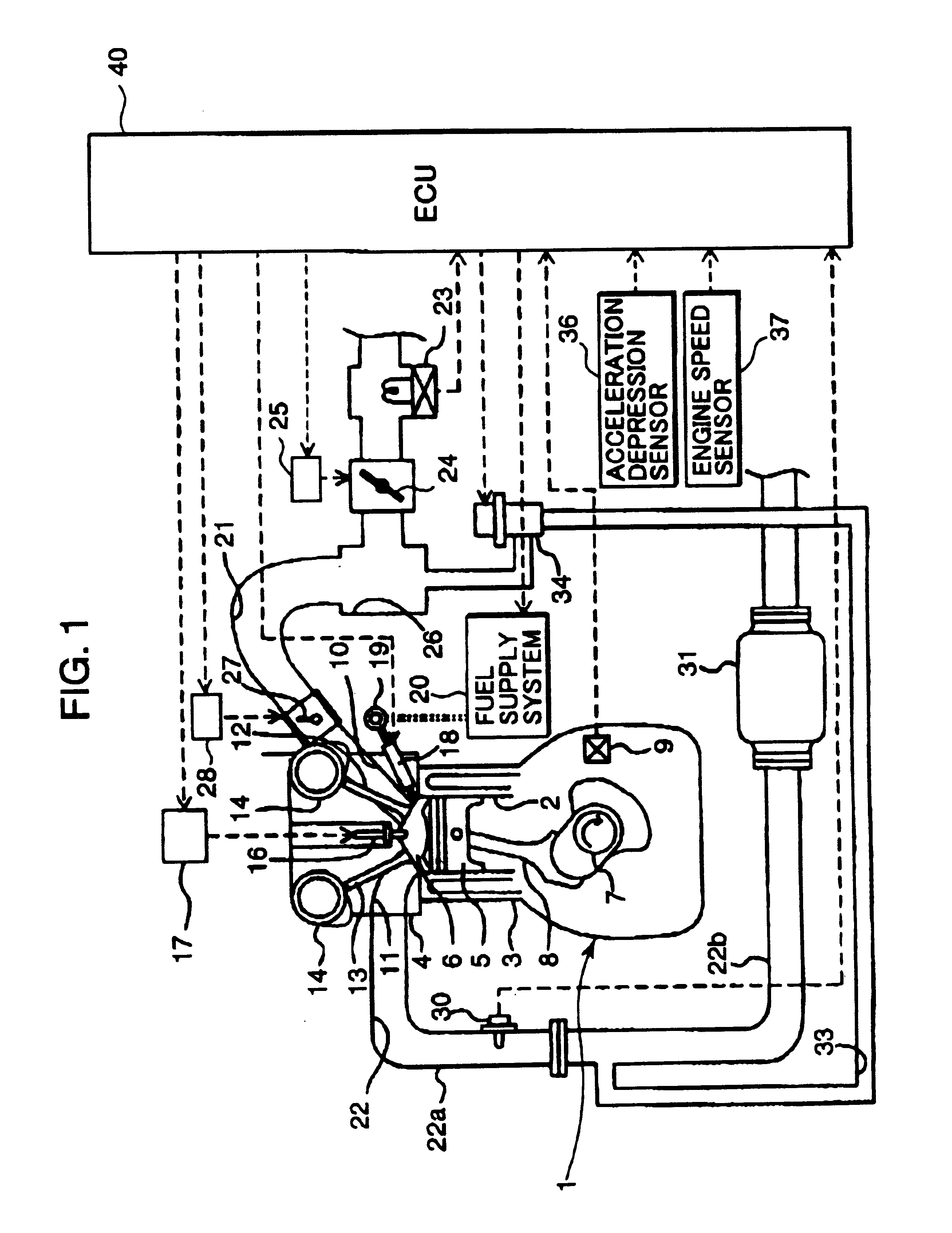

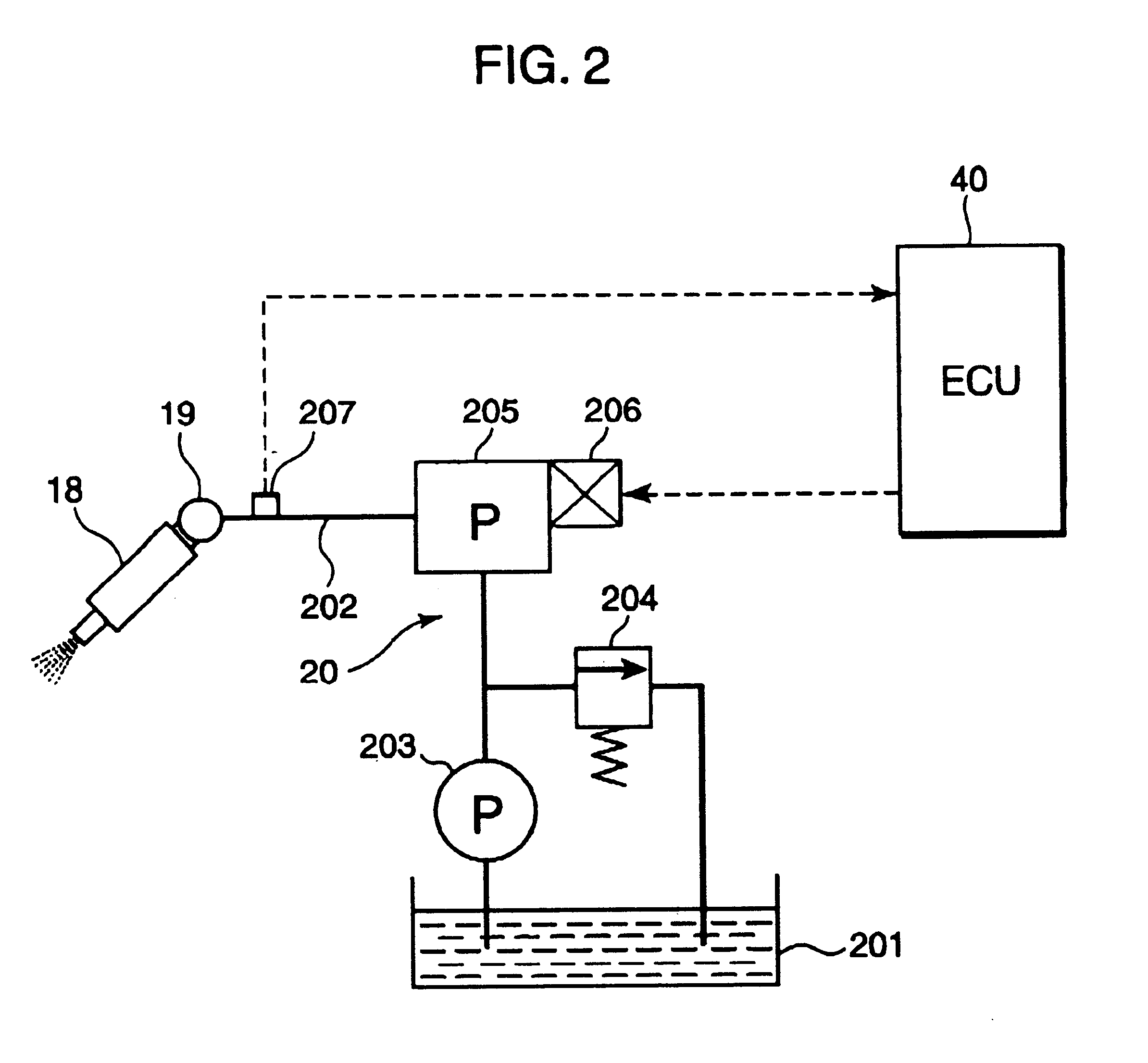

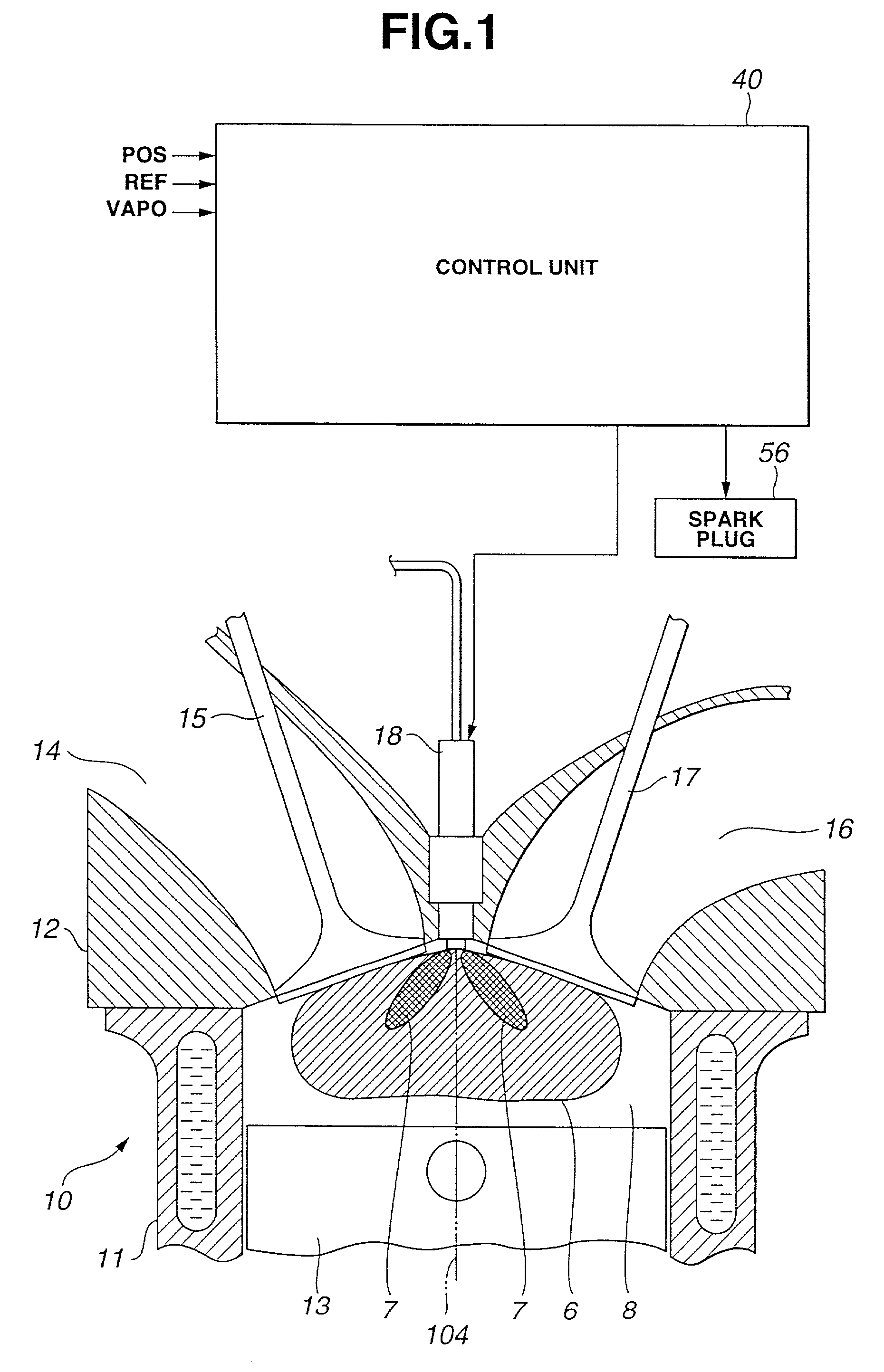

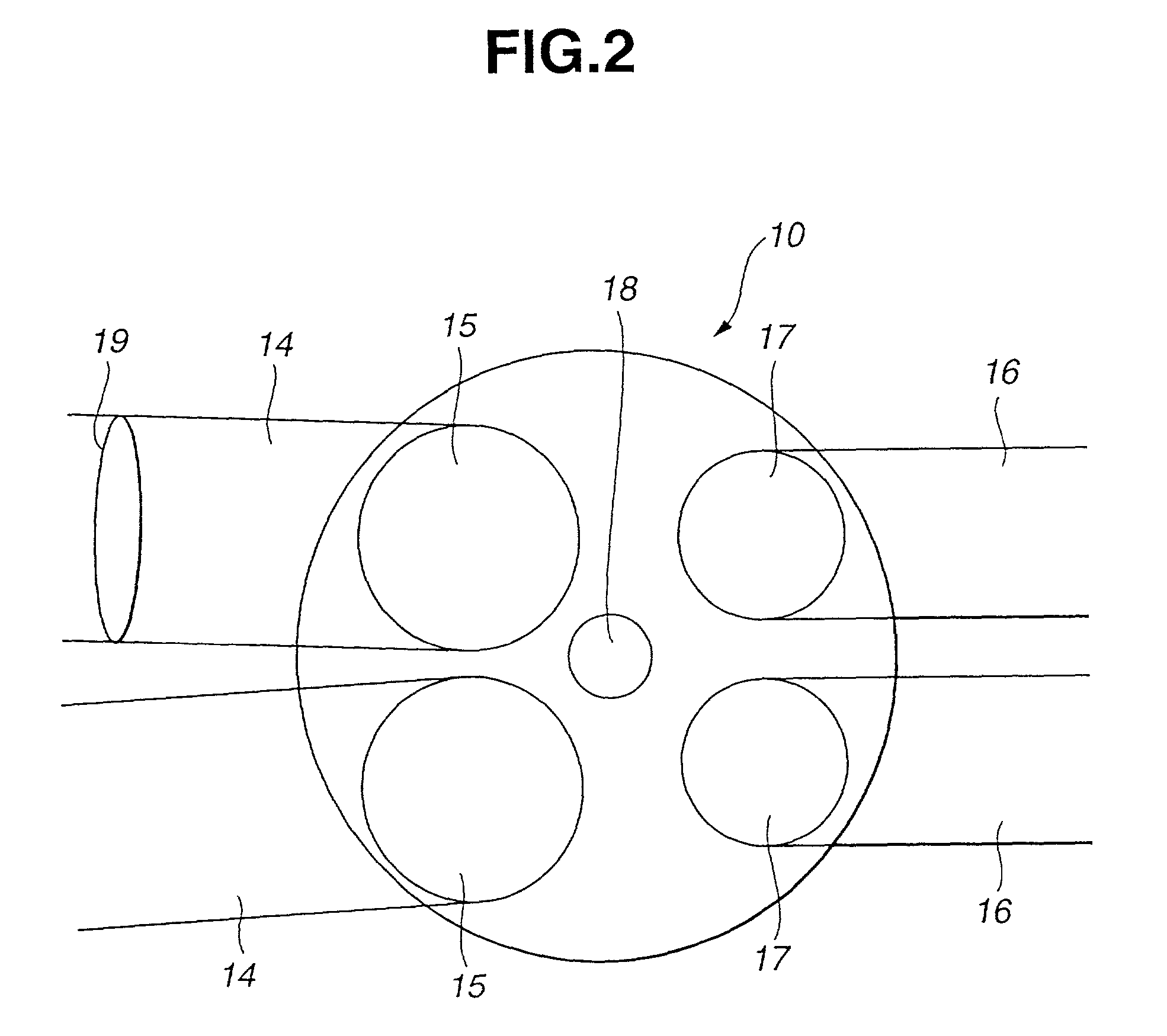

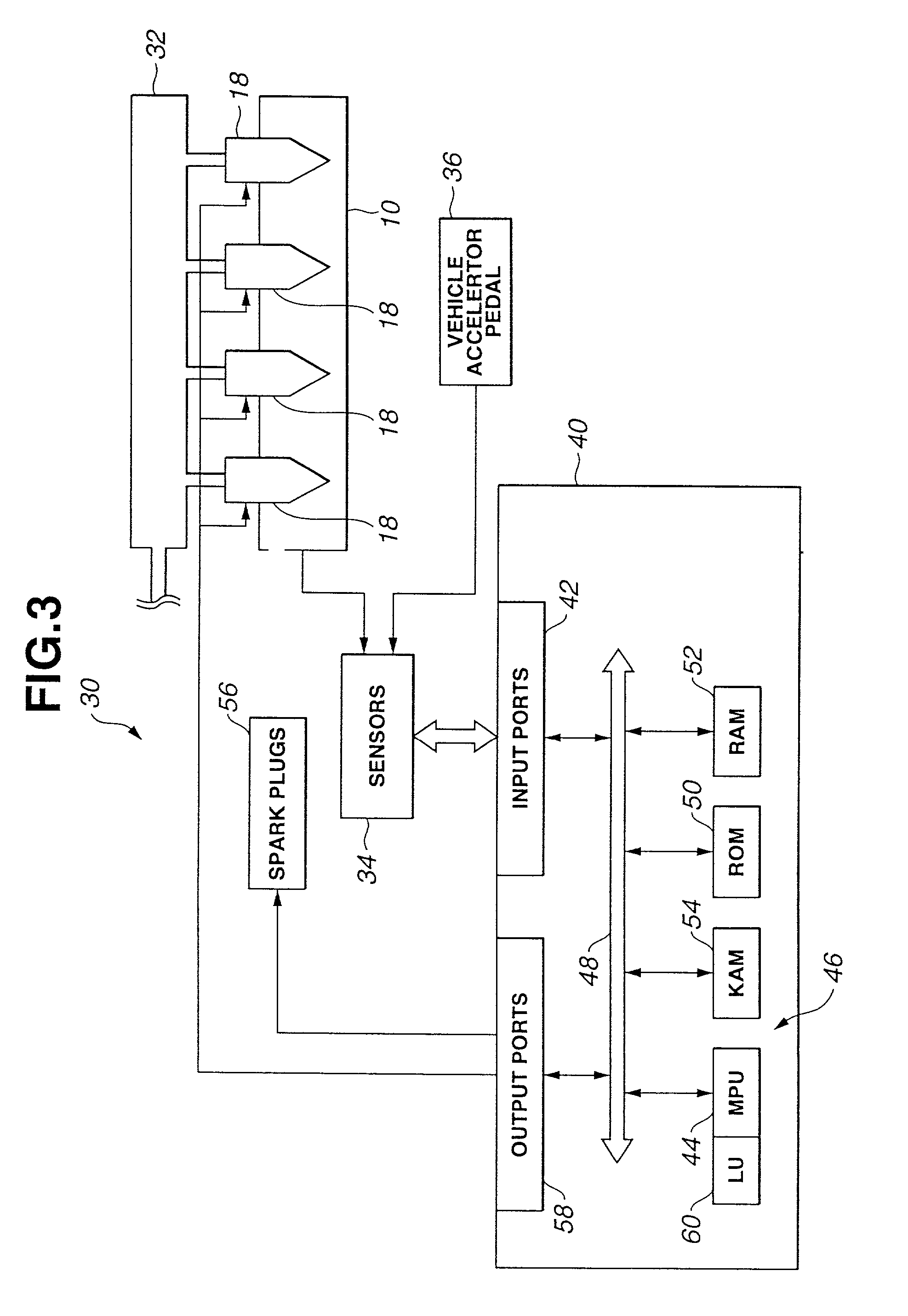

Control device for direct-injection spark-ignition engine and method of setting fuel injection timing of the same

InactiveUS6681739B2Improve fuel economyElectrical controlNon-fuel substance addition to fuelFuel injectionIgnition point

A direct-injection spark-ignition engine in which a combustible mixture is produced around a spark plug at an ignition point by causing a tumble and a fuel spray to collide with each other in a combustion chamber during stratified charge combustion comprises a fuel pressure controller which controls fuel pressure such that penetration of the fuel spray from a fuel injector is progressively intensified with an increase in engine speed in a stratified charge combustion region and means for controlling fuel injection timing including an injection timing setter. The means for controlling fuel injection timing controls the injection timing in such a way that the interval between a fuel injection ending point and the ignition point becomes progressively shorter as engine speed increases under the same engine load conditions in the stratified charge combustion region.

Owner:MAZDA MOTOR CORP

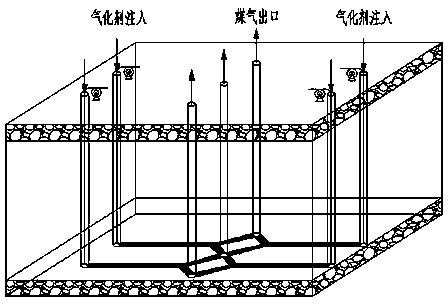

Coal underground gasification process system

InactiveCN104018820AIncrease horizontal widthIncrease widthConstructionsCoal gasificationThermodynamicsWater vapor

The invention relates to a coal underground gasification process system. The coal underground gasification process system comprises a gasification agent injection drill hole, coal gas outlet drill holes, a main gasification channel, branch gasification channels, a drill hole supporting tube, a gasification agent injection tube, a combustion agent injection tube, a sealing device and an ignition point shifter. The gasification agent injection drill hole is connected with the coal gas outlet drill holes through the main gasification channel and the branch gasification channels, and the combustion agent injection tube is sleeved with the gasification agent injection tube and is connected through the sealing device. A gasification process includes the steps of carrying out ignition, judging whether water vapor is fed into, feeding into water vapor, judging whether an ignition point is moved forward, starting the ignition point shifter and continuing to conduct combustion. The coal underground gasification process system has the advantages that the transverse gasification area and longitudinal gasification area can be enlarged, coal reserves for gasification are increased, autoignition and controllable back gas injection are achieved in a well-free coal underground gasification process, meanwhile the problem of short circuit of gasification agents in the gasification channels is solved, the probability of back mixing of product gas and the gasification agents is lowered, and safety operation of the gasification process is guaranteed.

Owner:北京中矿科能煤炭地下气化技术研究中心

System and method for ignition of a gaseous or dispersed fuel-oxidant mixture

An improved system and method for ignition of a gaseous or dispersive fuel-oxidant mixture is provided where a gaseous or dispersive fuel-oxidant mixture is supplied to a detonator tube having a fill point and an open end and an igniter placed at an ignition point within the detonator tube is ignited while the gaseous or dispersive fuel-oxidant mixture is flowing through the detonator tube. A detonation impulse is produced at the ignition point that propagates to the open end of said detonator tube where it can be supplied to a detonation tube having an open end, to an internal combustion engine, a combustion chamber, and to a pulse detonation engine.

Owner:SOUNDBLAST TECH

Auto-ignition combustion management in internal combustion engine

InactiveUS20010022168A1High densityElectrical controlCombustion enginesCombustion chamberTop dead center

An enhanced auto-ignition in a gasoline internal combustion engine, comprises a fuel injector directly communicating with said combustion chamber for spraying gasoline fuel. The fuel injector sprays a first injection quantity of gasoline fuel into a combustion chamber at first fuel injection timing, which falls in a range from the intake stroke to the first half of the compression stroke, thereby to form air / fuel mixture cloud that becomes a body of mixture as the engine piston moves from the first fuel injection timing toward a top dead center position of the compression stroke, and the fuel injector sprays a second injection quantity of gasoline fuel into the body of mixture at second fuel injection timing, which falls in the second half of the compression stroke, forming mixture cloud that is superimposed on a portion of said body of mixture, thereby to establish the cylinder content wherein the density of fuel particles within the superimposed portion is high enough to burn by auto-ignition at an ignition point in the neighborhood of the piston top dead center position of the compression stroke, causing temperature rise and pressure, which initiate auto-ignition of the fuel particles within the remaining portion of said body of mixture.

Owner:NISSAN MOTOR CO LTD

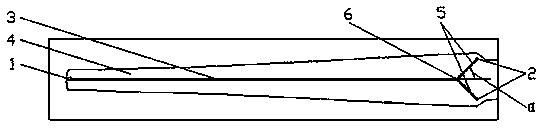

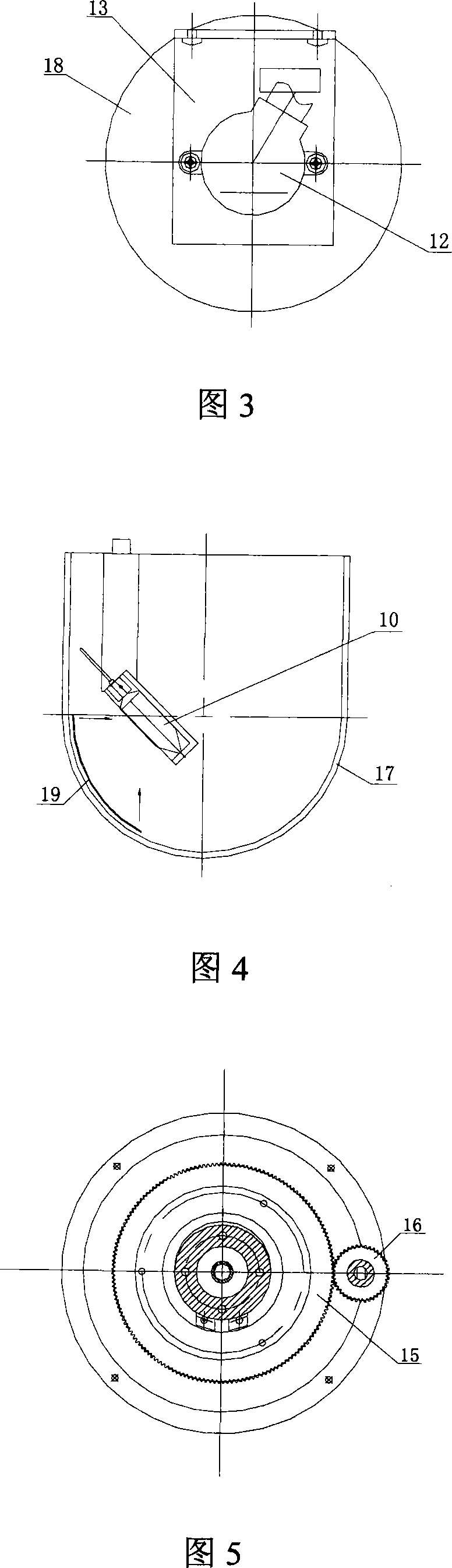

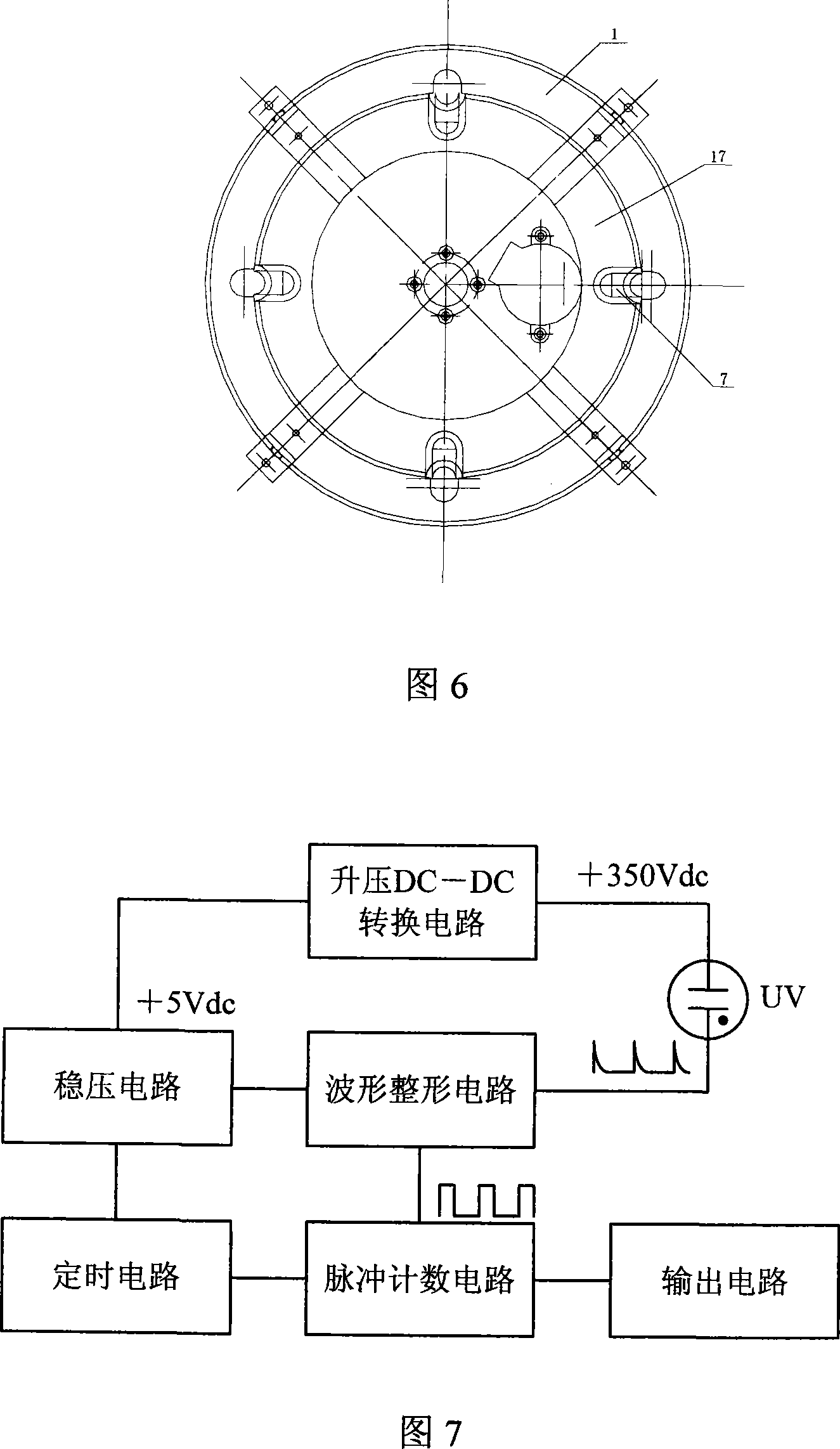

Fire disaster detector and detection positioning method

InactiveCN101236684AAvoid interferencePrecise positioningFire rescueFire alarm radiation actuationFire detectorFire - disasters

The present invention relates to a fire detector and a detection positioning method. The fire detector of the present invention comprises a real-time monitoring sensor, a horizontal positioning sensor and a vertical positioning sensor. When the real-time monitoring sensor monitors a fire signal, the horizontal positioning sensor scans at the horizontal direction and stops scanning when detecting the fire signal; then the vertical positioning sensor scans at the vertical direction and stops scanning when detecting the fire signal, so as to finish positioning an ignition point. The fire detector and the detection positioning method of the present invention utilizes an ultraviolet flame sensor to detect the occurrence of fire, can avoid the interference of sunlight, lamplight and other background light, reduce false alarm rate, and improve detection accuracy degree. The fire detector can accurately position the ignition point through the horizontal positioning sensor and the vertical positioning sensor, so as to provide accurate data for subsequent fire extinguishment and realize that extinguishing agent is accurately sprayed at the ignition point, which can prevent extinguishing agent from damaging unlighted property at the same time when saving extinguishing agent.

Owner:中国人民解放军第二炮兵装备研究院第三研究所

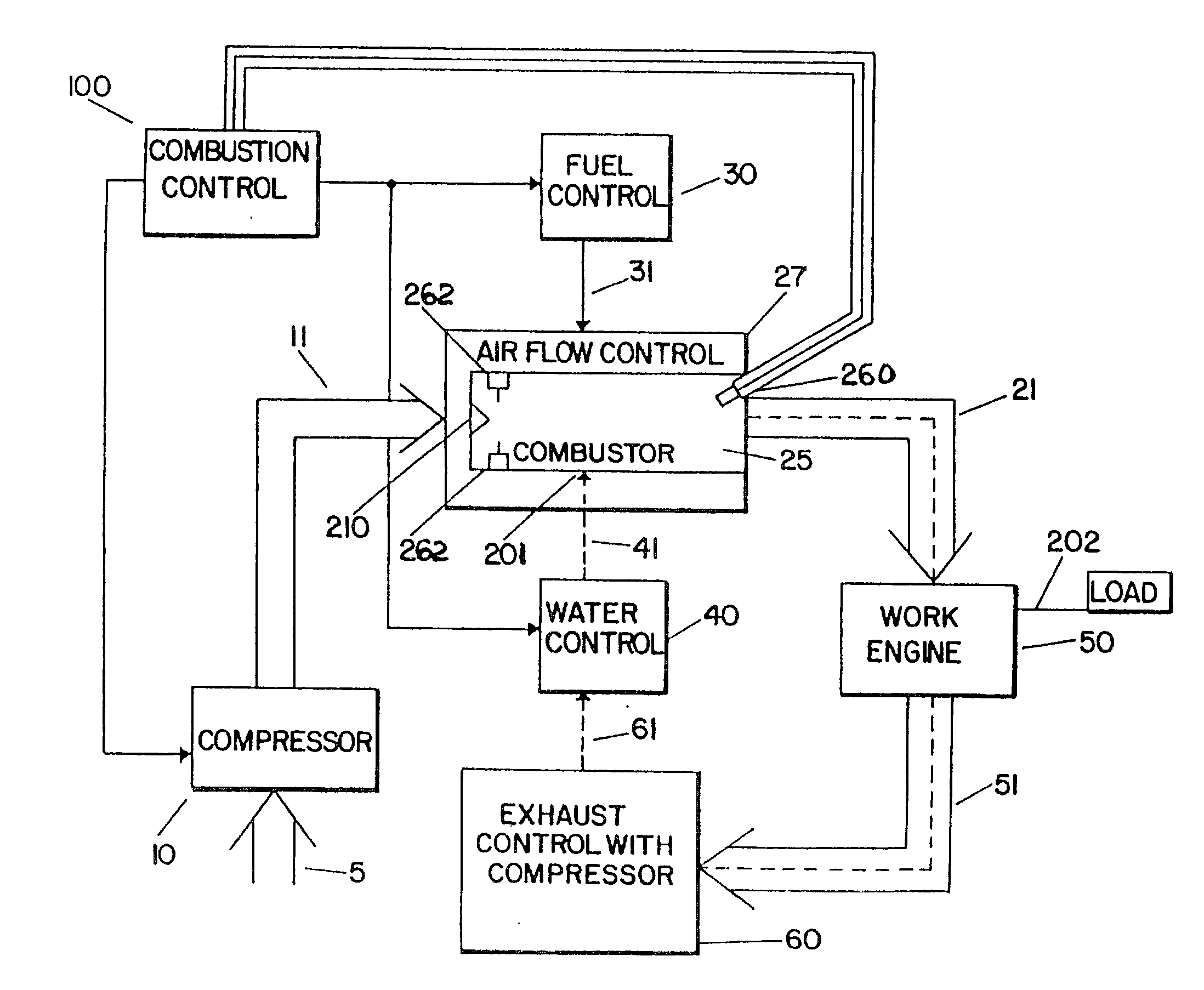

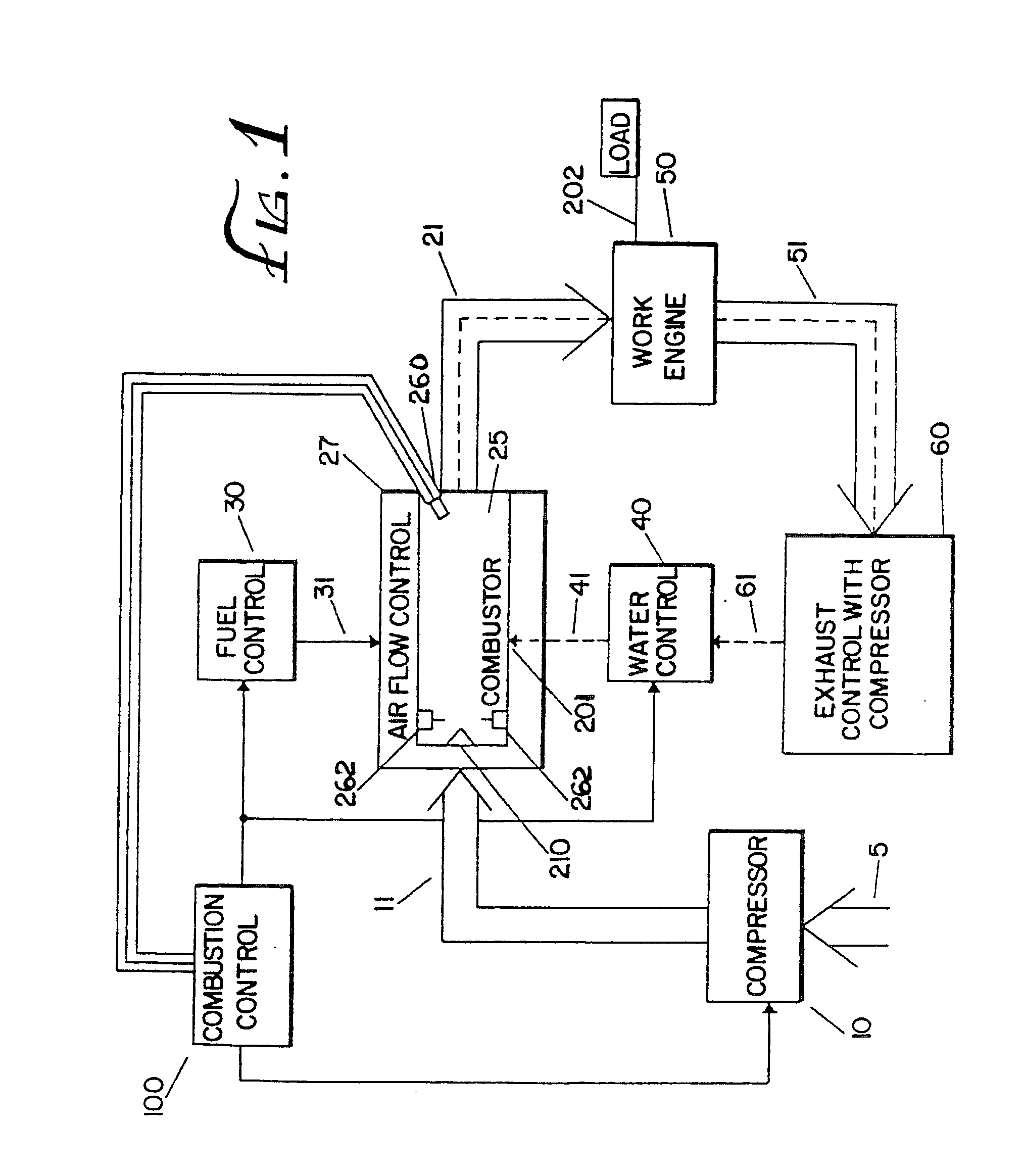

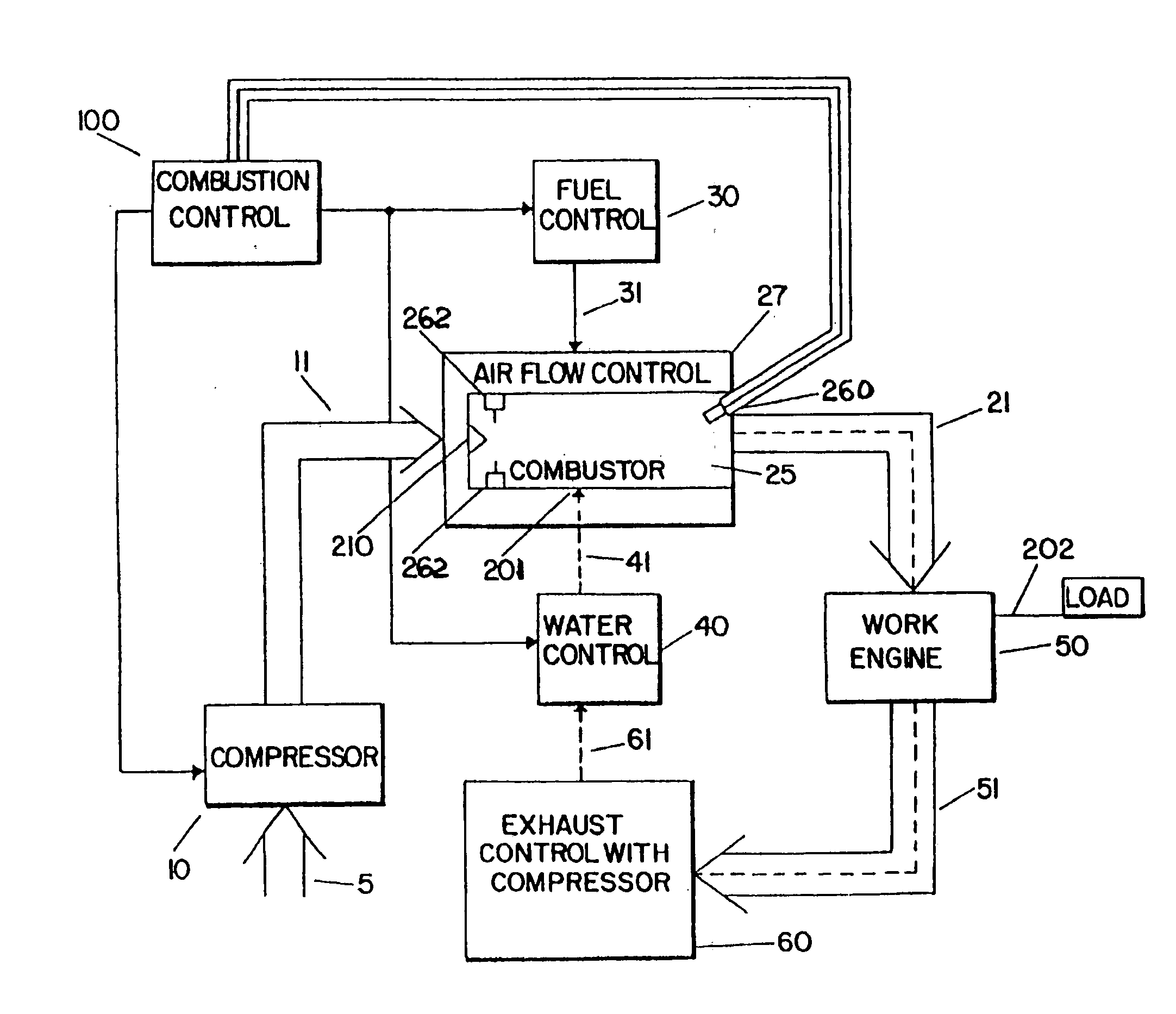

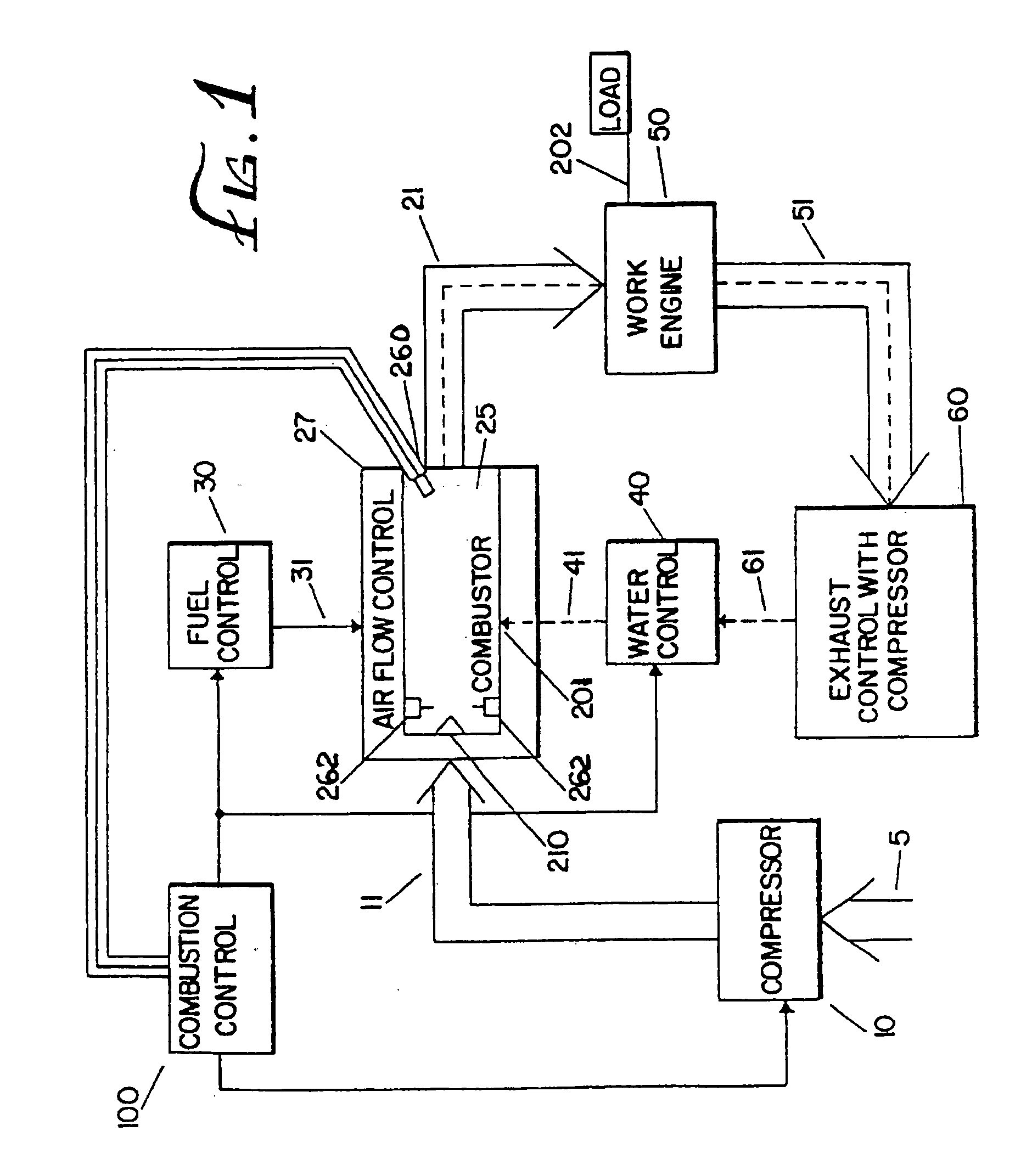

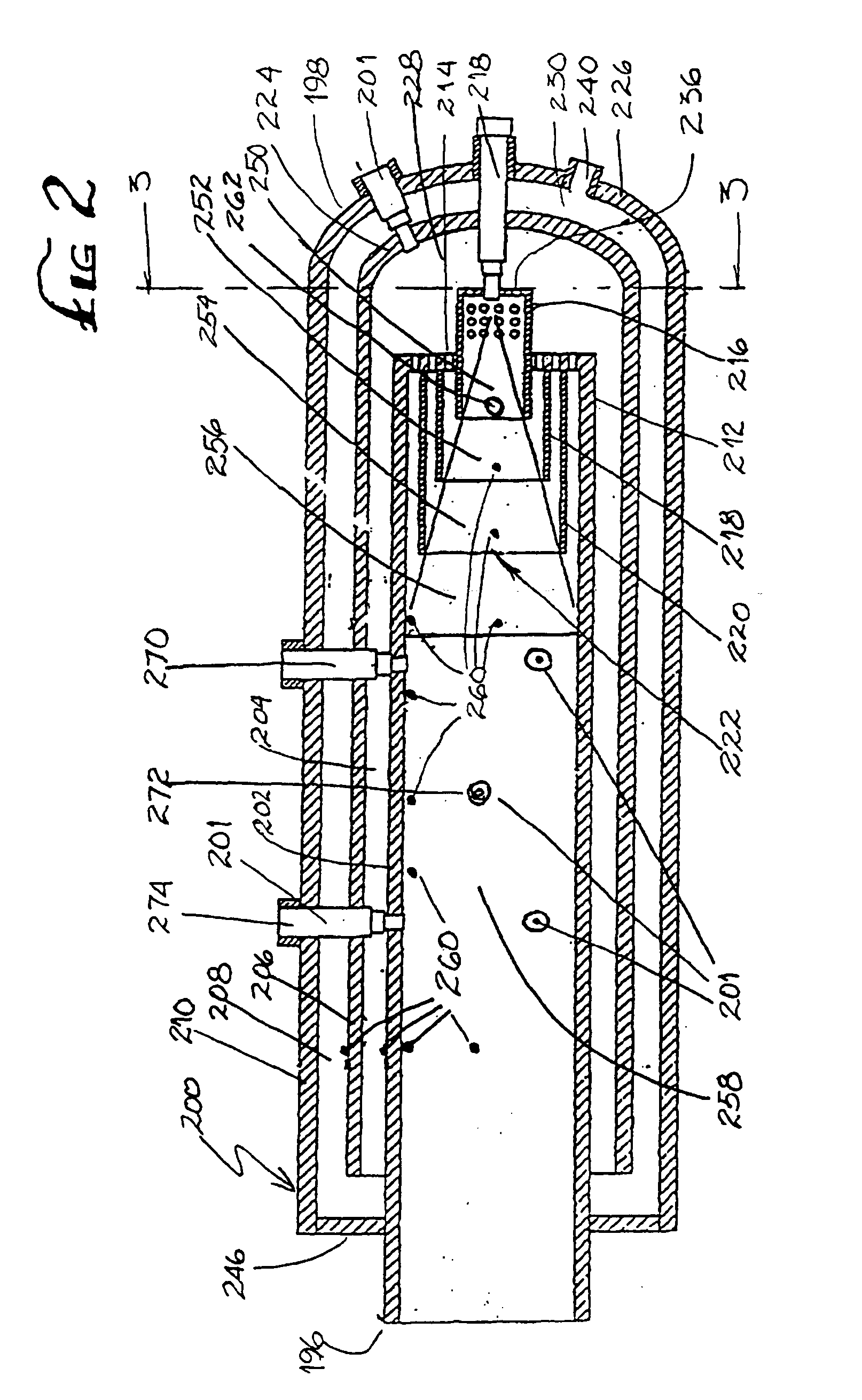

High efficiency low pollution hybrid brayton cycle combustor

InactiveUS20030014959A1Efficient and clean and pollution free powerIncrease horsepowerGas turbine plantsEfficient propulsion technologiesHybrid typeCombustion chamber

A power generating system and method operating at high pressure and utilizing a working fluid consisting of a mixture of compressed non-flammable air components, fuel combustion products and steam. The working fluid is substantially free of CO and NO.sub.x. Fuel and compressed air at an elevated temperature and at a constant pressure are delivered to a combustion chamber, the amount of air being chosen so that at least about 90% of the oxygen in the air is consumed during combustion. The quantity of air and fuel supplied to the combustion chamber may be varied provided a constant fuel to air ratio is maintained. Superheated water is delivered under pressure to the combustion chamber, and is converted substantially instantaneously to steam. The quantity of water delivered is controlled such that the latent heat of vaporization of the water maintains the temperature of the working fluid at a desired level. Heat may be transferred from the working fluid exiting the work engine to the water to heat the water to the desired temperature for delivery to the combustion chamber. The quantity, temperature and pressure of the air, fuel and water introduced in to the combustion chamber are independently controllable. A zoned burner may be employed in which a portion of the compressed air may be mixed with the fuel in a first zone prior to ignition, with the remaining compressed air being added at one or more locations downstream of the point of ignition.

Owner:GINTER J LYELL

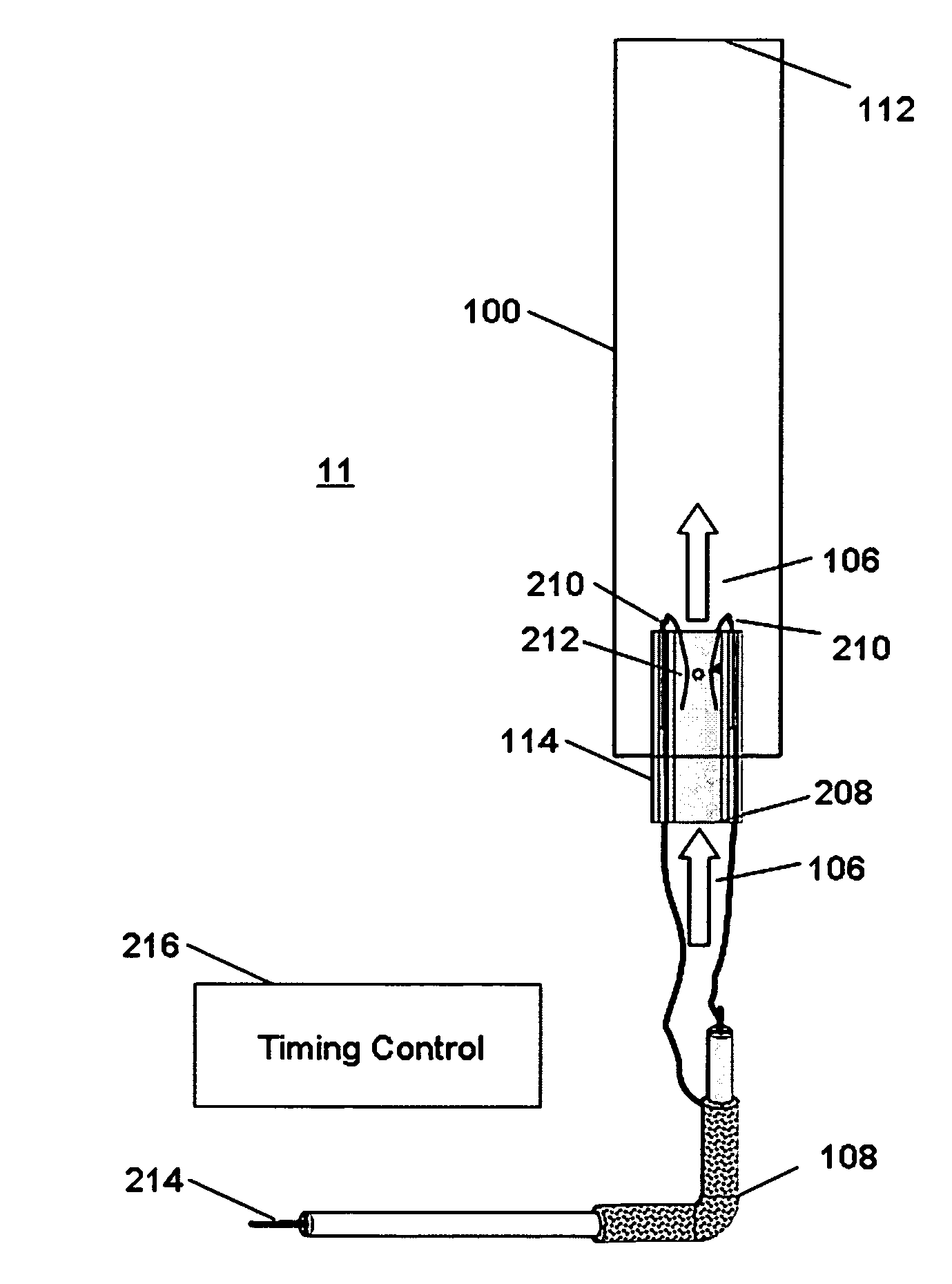

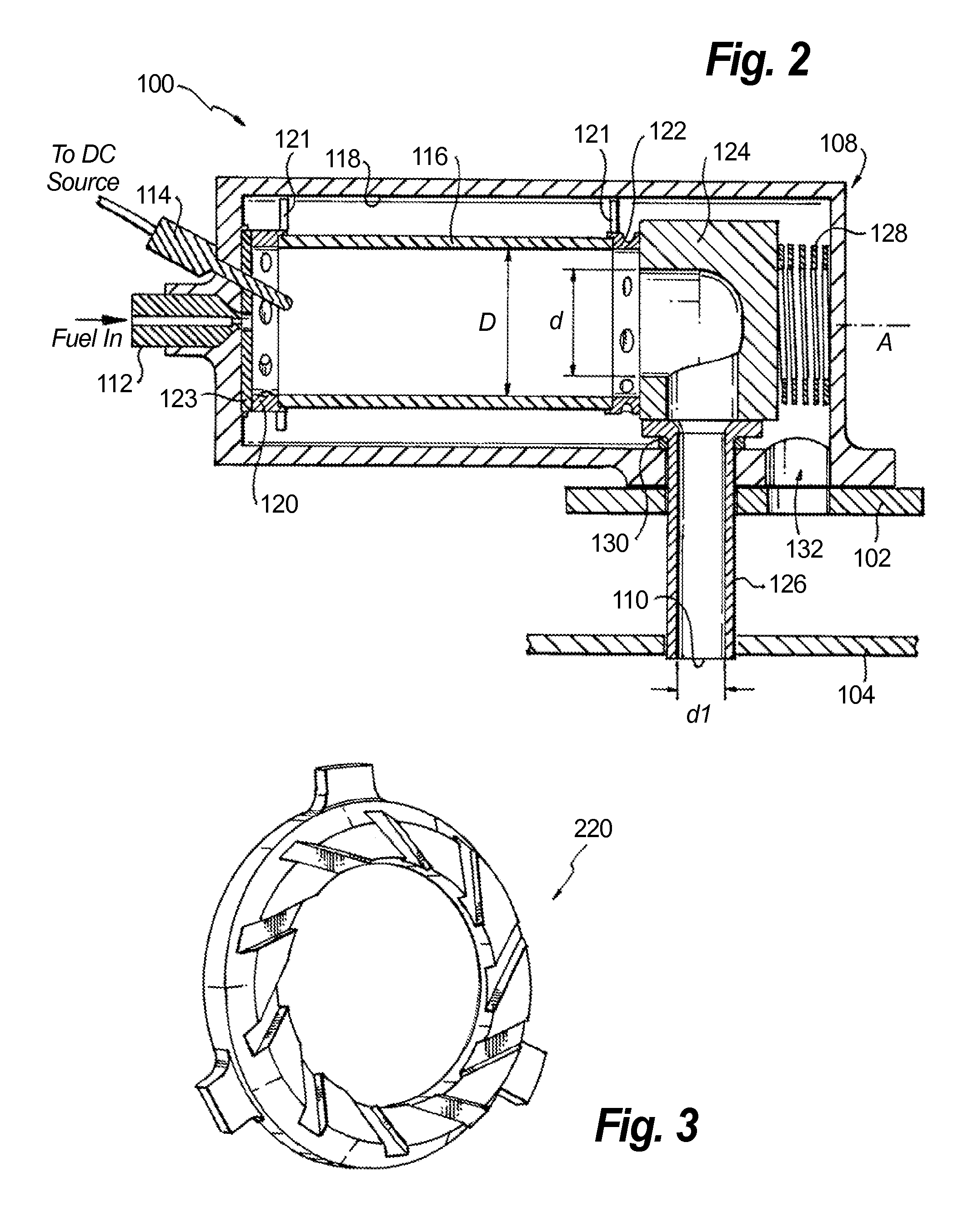

Continuous ignition

ActiveUS9080772B2High flame intensityReduced strengthBurnersContinuous combustion chamberCombustorIgnition point

An ignition system includes a housing defining an interior and an exhaust outlet. The housing is configured and adapted to be mounted to a combustor to issue flame from the exhaust outlet into the combustor for ignition and flame stabilization within the combustor. A fuel injector is mounted to the housing with an outlet of the fuel injector directed to issue a spray of fuel into the interior of the housing. An igniter is mounted to the housing with an ignition point of the igniter proximate the outlet of the fuel injector for ignition within the interior of the housing.

Owner:COLLINS ENGINE NOZZLES INC

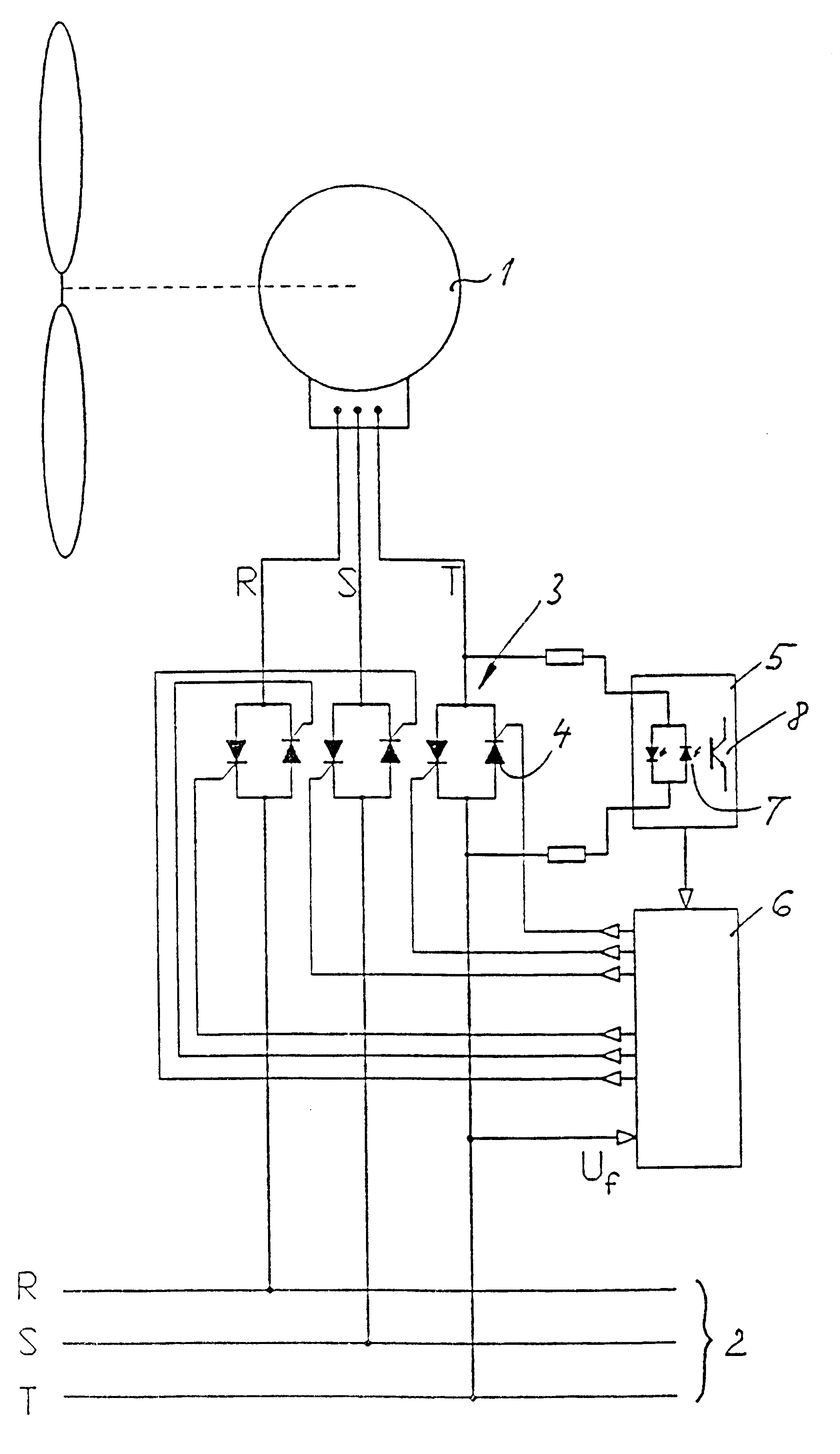

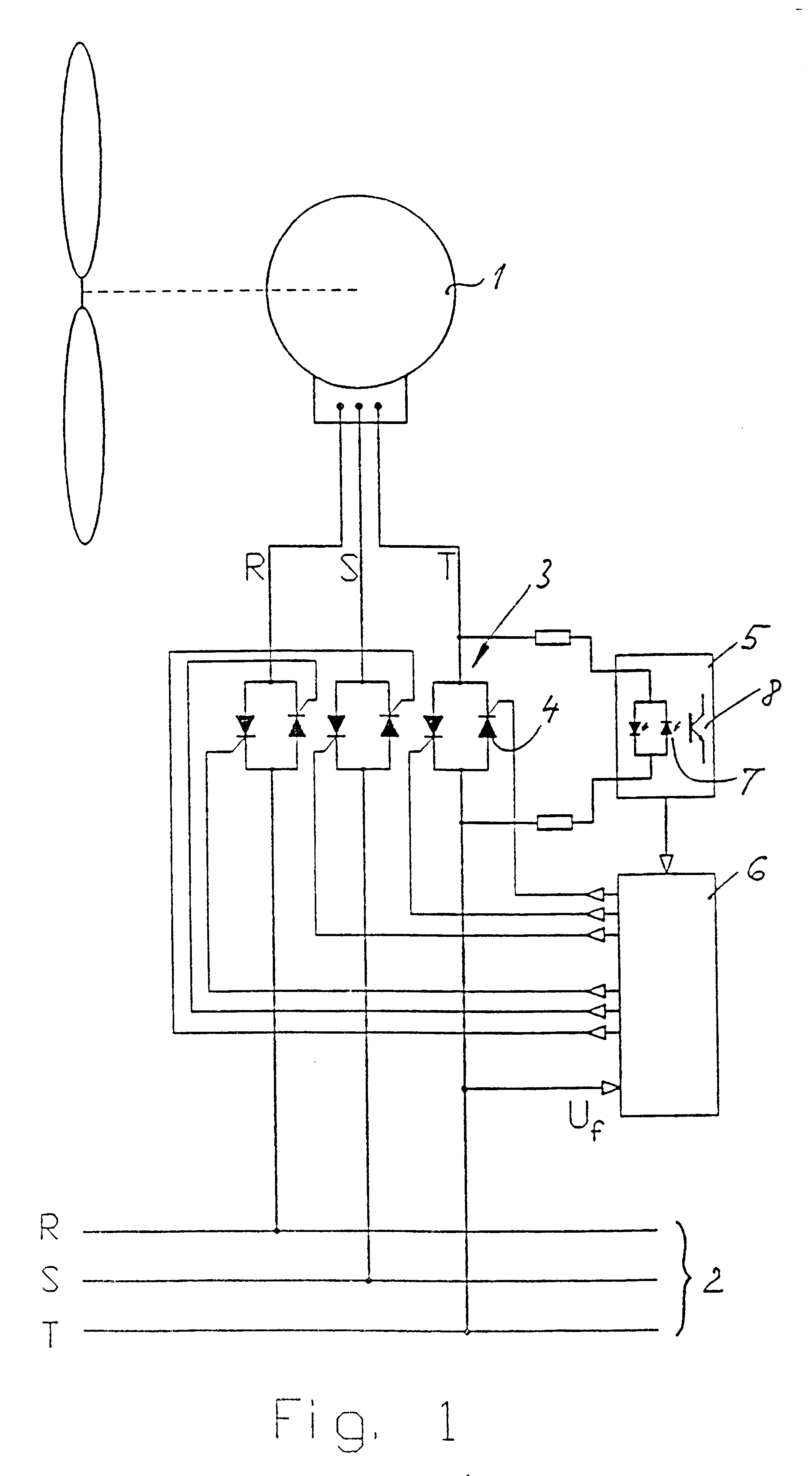

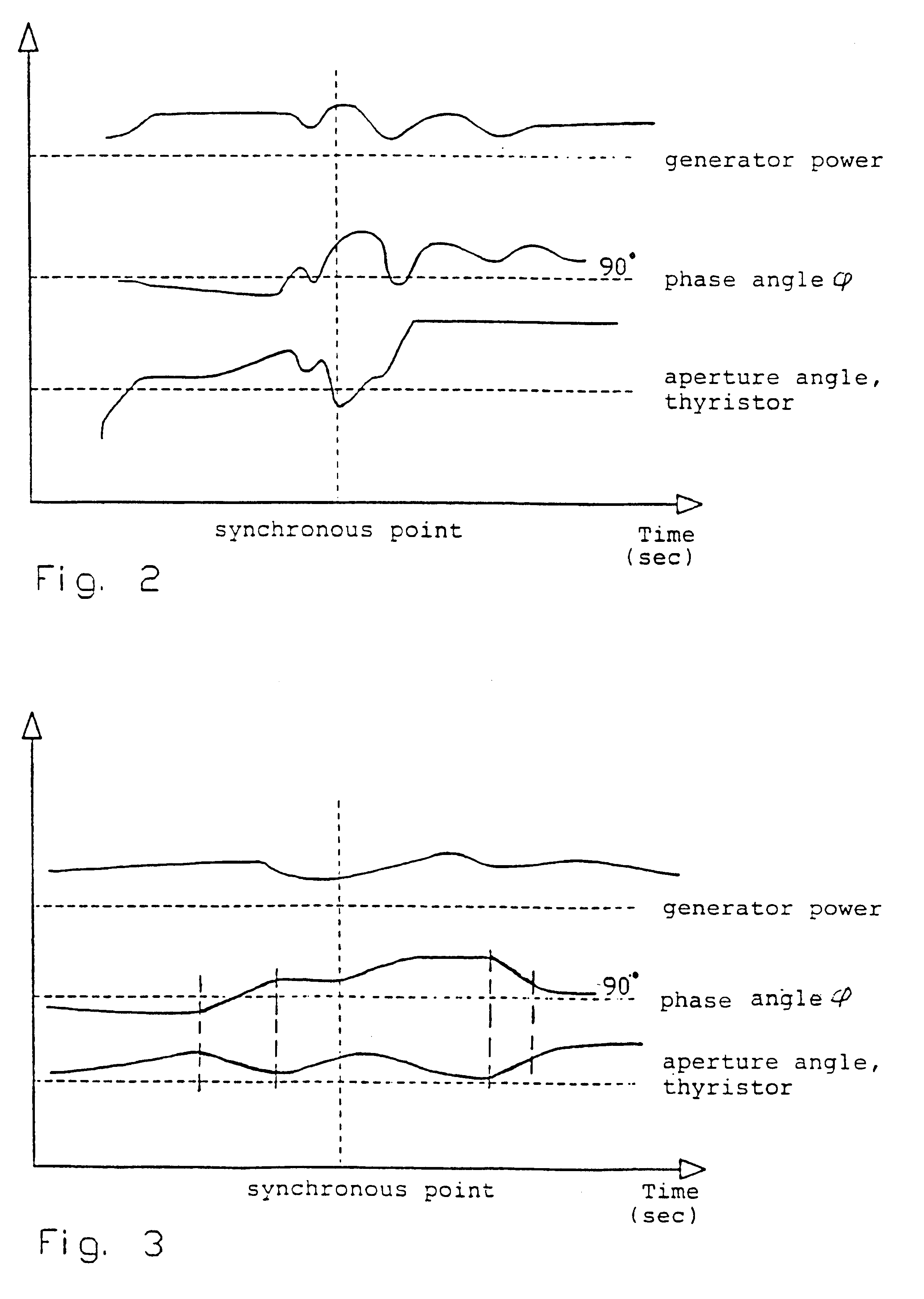

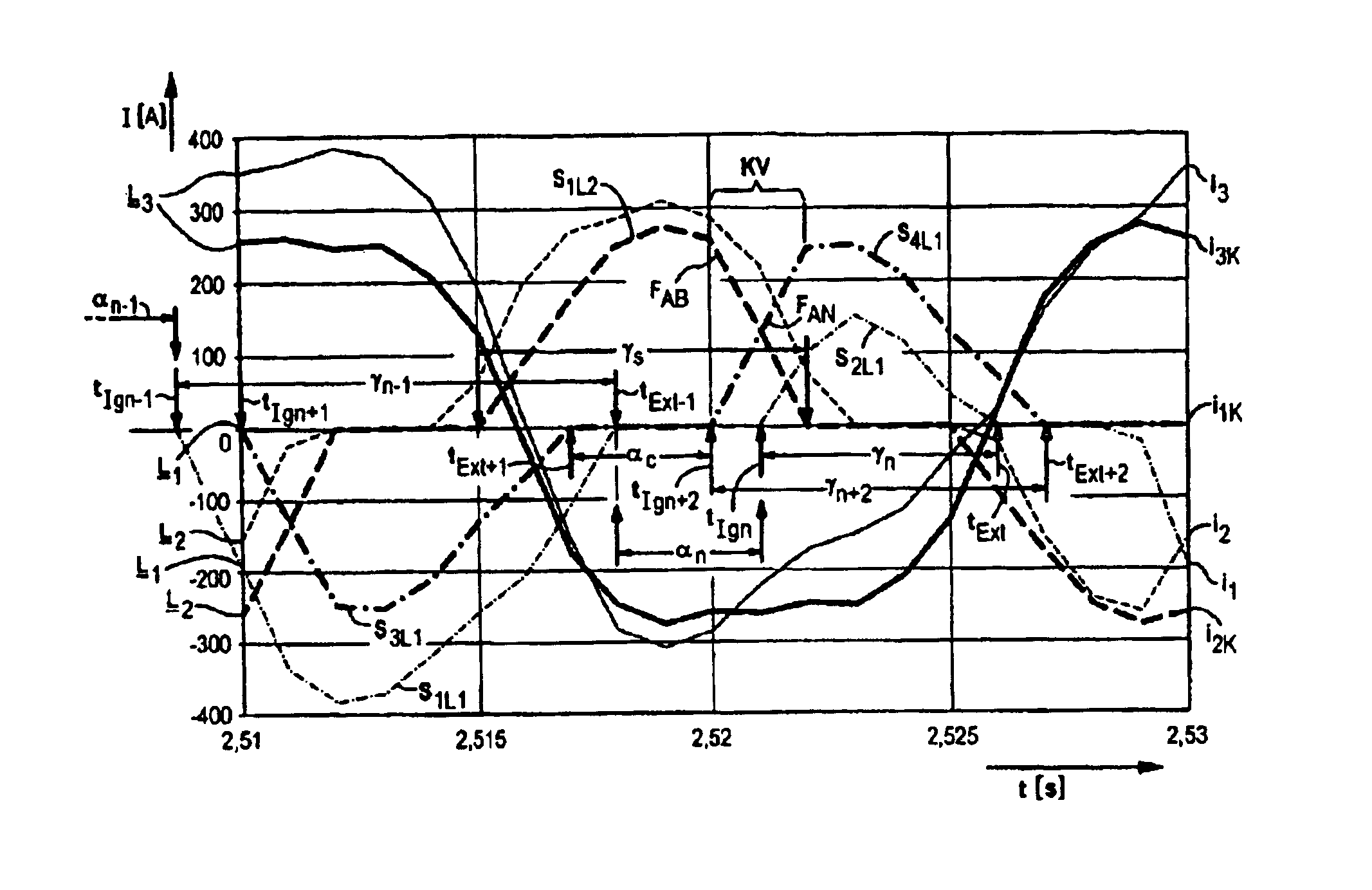

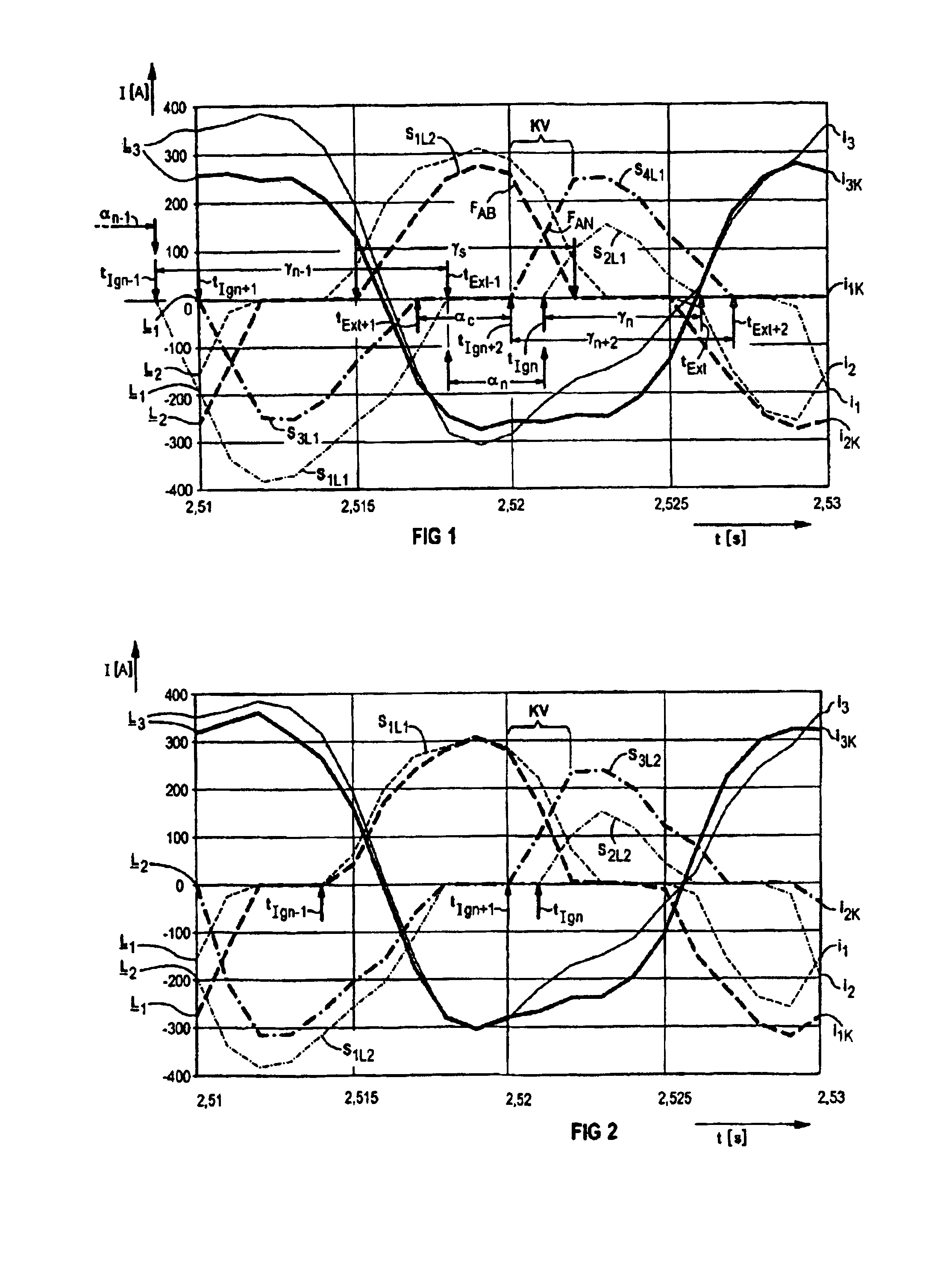

Procedure to connect an asynchronous generator on an alternating current and an electrical connecting for use at this procedure

InactiveUS6323624B1Thyristor aperture angle is reducedHigh degreeEmergency protective circuit arrangementsConversion without intermediate conversion to dcThyratronEngineering

The invention relates to a procedure of connecting a polyphased asynchronous generator on a polyphased alternating voltage network. The connecting is carried out by means of an adjustable, electronic connecting based on thyristors or similar variable (adjustable) connecting items, the connecting degree of which is varied during a controlled connecting course, which is controlled in consideration of the wish of a "soft" connecting on the network and a limitation of the maximum amperage during the connecting course. During the whole connecting course a continuous determination of the generator phase angle phi is carried out, and on basis of this determination a continuous adjustment of thyristors-the aperture angle is carried out, thus the aimed, successive load connection of the generator on the network (soft-connecting) is obtained. Furthermore the procedure include a new method to determine the generator phase angle phi by registering the time of zero circulation on the phase voltage, and at the same time detection of the respective thyristor voltage zero circulation point at a measuring method based on measuring of the thyristor voltage. The novelty of the invention consists in adjusting the ignition point of the thyristors successively to the phase angle phi, thus the connecting degree resulted to the thyristors is increased in a controlled speed regardless of the variations registered in the phase angle during the connecting course, i.e. in the principle the thyristor aperture angle is reduced, when phi increases and so on.

Owner:MITA TEKNIK

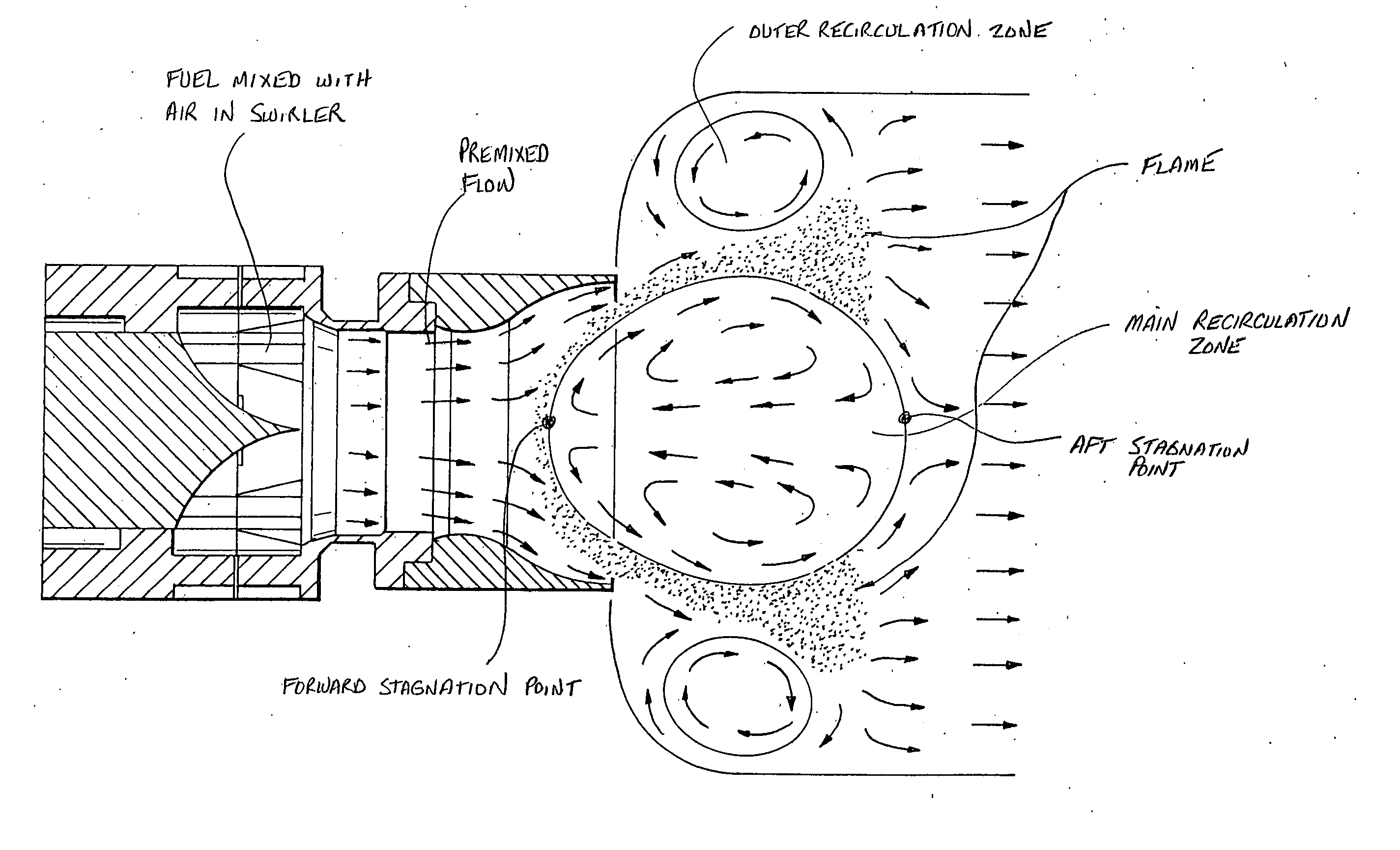

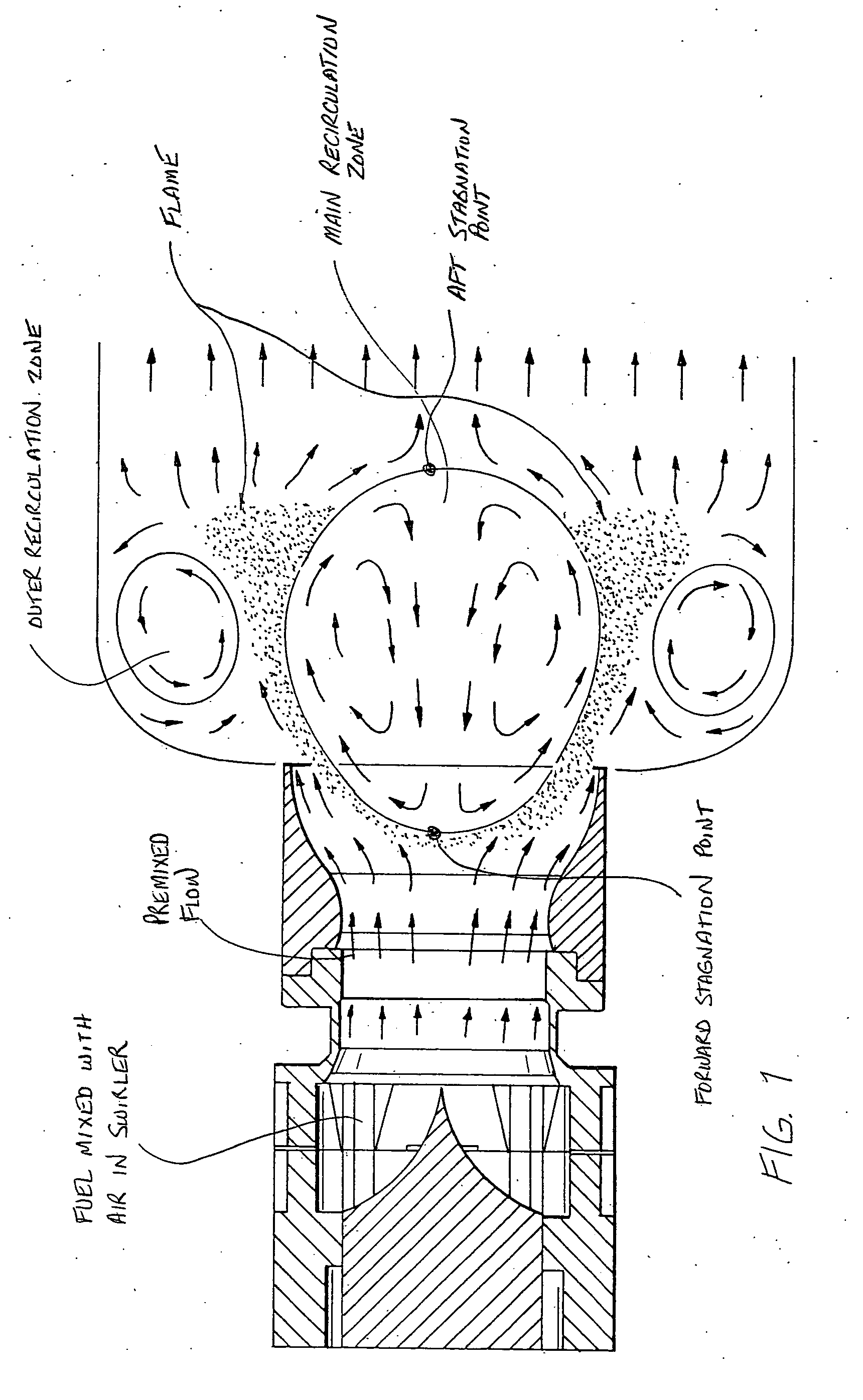

Device for stabilizing combustion in gas turbine engines

Disclose is a burner for a gas turbine combustor that uses a central bluff body flame holder and a quarl to shape the recirculation zone in order to stabilize the combustion process. The burner includes, among other elements, a cylindrical main body and a flame holder. The flame holder is disposed within a fuel-air mixing chamber and includes a base portion and an elongated bluff body. The base portion engages with the main body of the burner in a supporting manner and the elongated bluff body extends in an axially downstream direction from the base portion through the internal mixing chamber so as to position a combustion ignition point downstream of the internal mixing chamber. In a representative embodiment, the burner further includes a quarl device disposed adjacent to the downstream end portion of the burner main body. The quarl device defines an interior recirculation chamber and a burner exit. The interior recirculation chamber is adapted for receiving precombustion gases from the mixing chamber and for recirculating a portion of the combustion product gases in an upstream direction so as to aid in stabilizing combustion.

Owner:SIEMENS AG

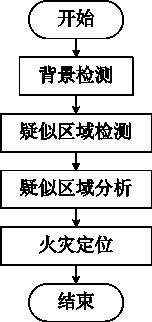

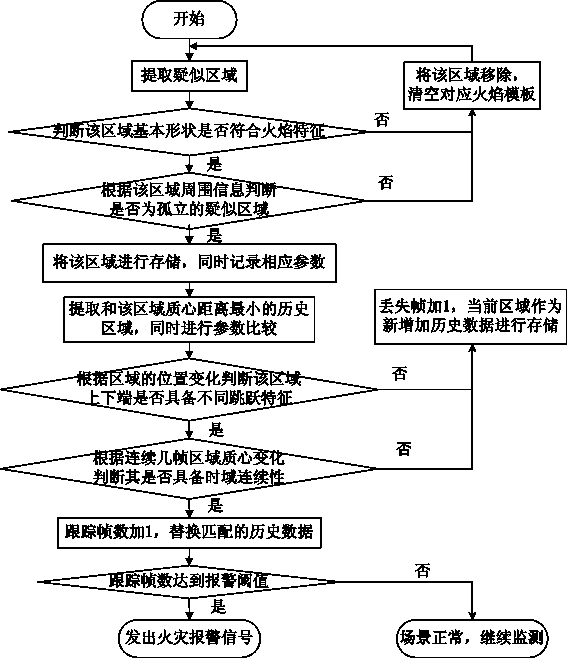

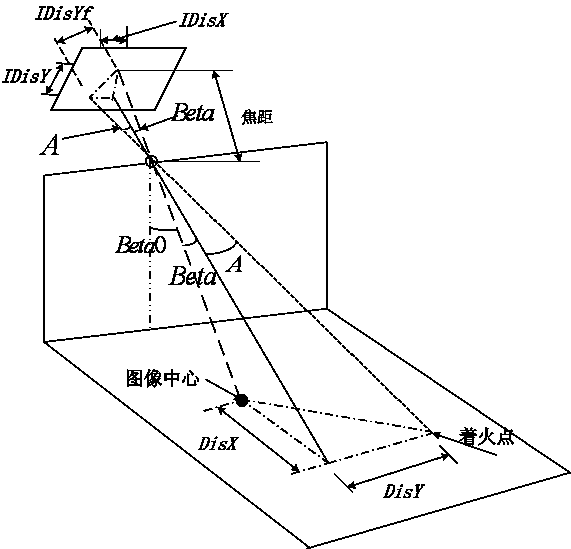

A method for detecting and locating fire based on double-waveband image

InactiveCN104408706ALive UpdateEfficient exclusionImage analysisCharacter and pattern recognitionColor imageFrame difference

A method for detecting and locating fire based on double-waveband image includes: performing background modeling using a way of weighted average, and greatly reducing an amount of calculation while ensuring real time updating of a scene; performing a flame suspected region detection based on a method of frame difference, to possibly detect more flame suspected regions; excluding unqualified suspected regions according to sensory features, airspace variability feature, time domain continuity feature, position derivable feature and distribution isolation feature of the flame, to reduce phenomenon of false reports; using a method of margin marking to map the flame region detected on an infrared image to a color image for the convenience of the monitoring staff to observe; and obtaining horizontal and vertical distances of an actual ignition point with respect to a certain reference object on the ground according to a coordinate of the flame in the image to achieve an aim of locating a fire. The advantages of the present invention are: being capable of in time and accurately determining the flame feature of the monitored occasion, providing a fire alarm, transmitting a most visual video image and targeting the fire scene.

Owner:TIANJIN ISECURE TECH

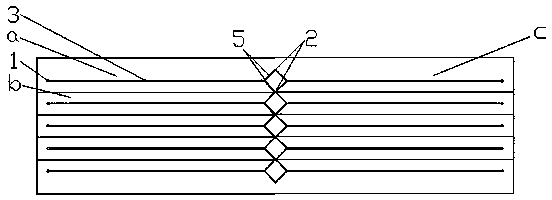

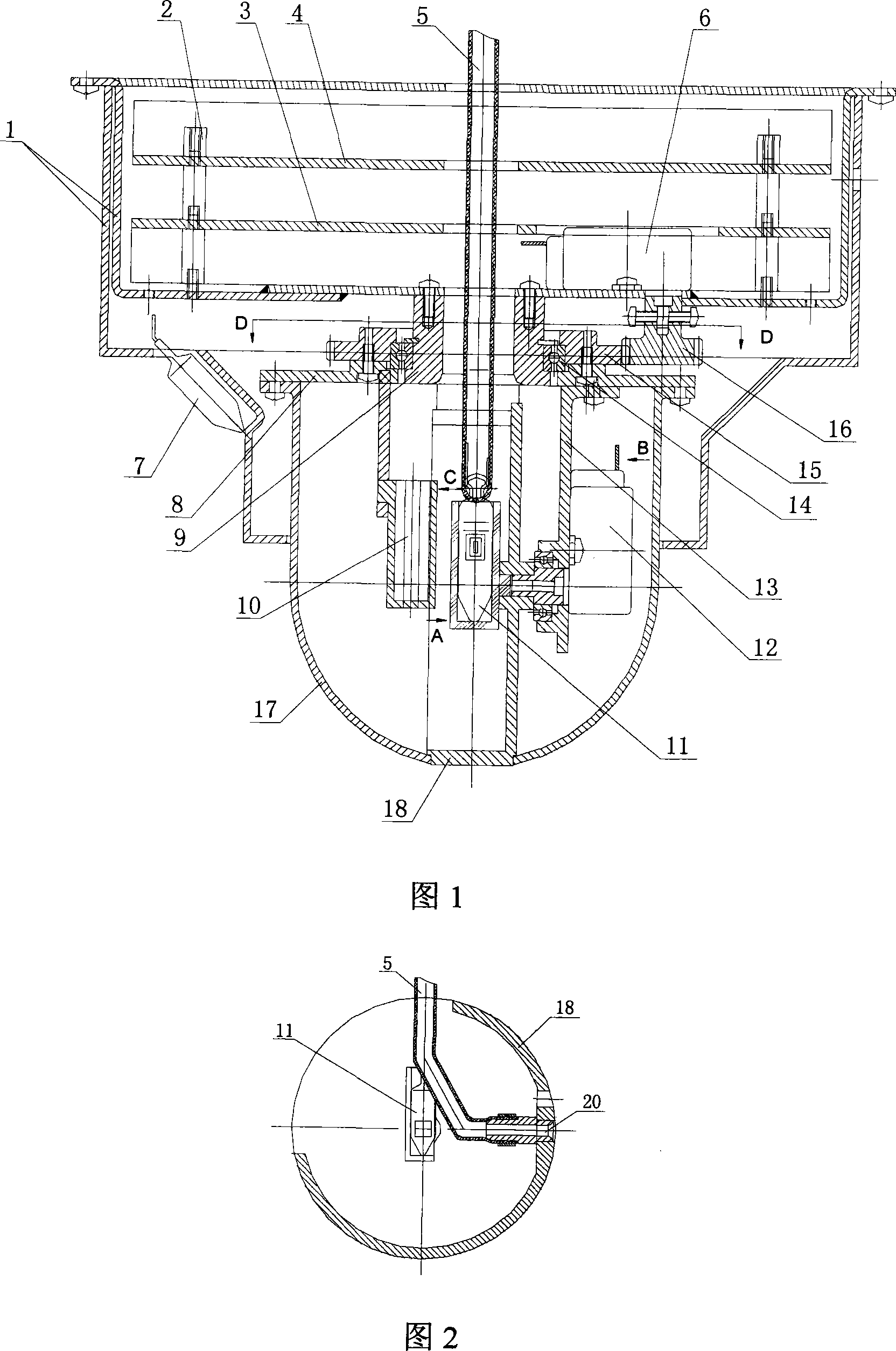

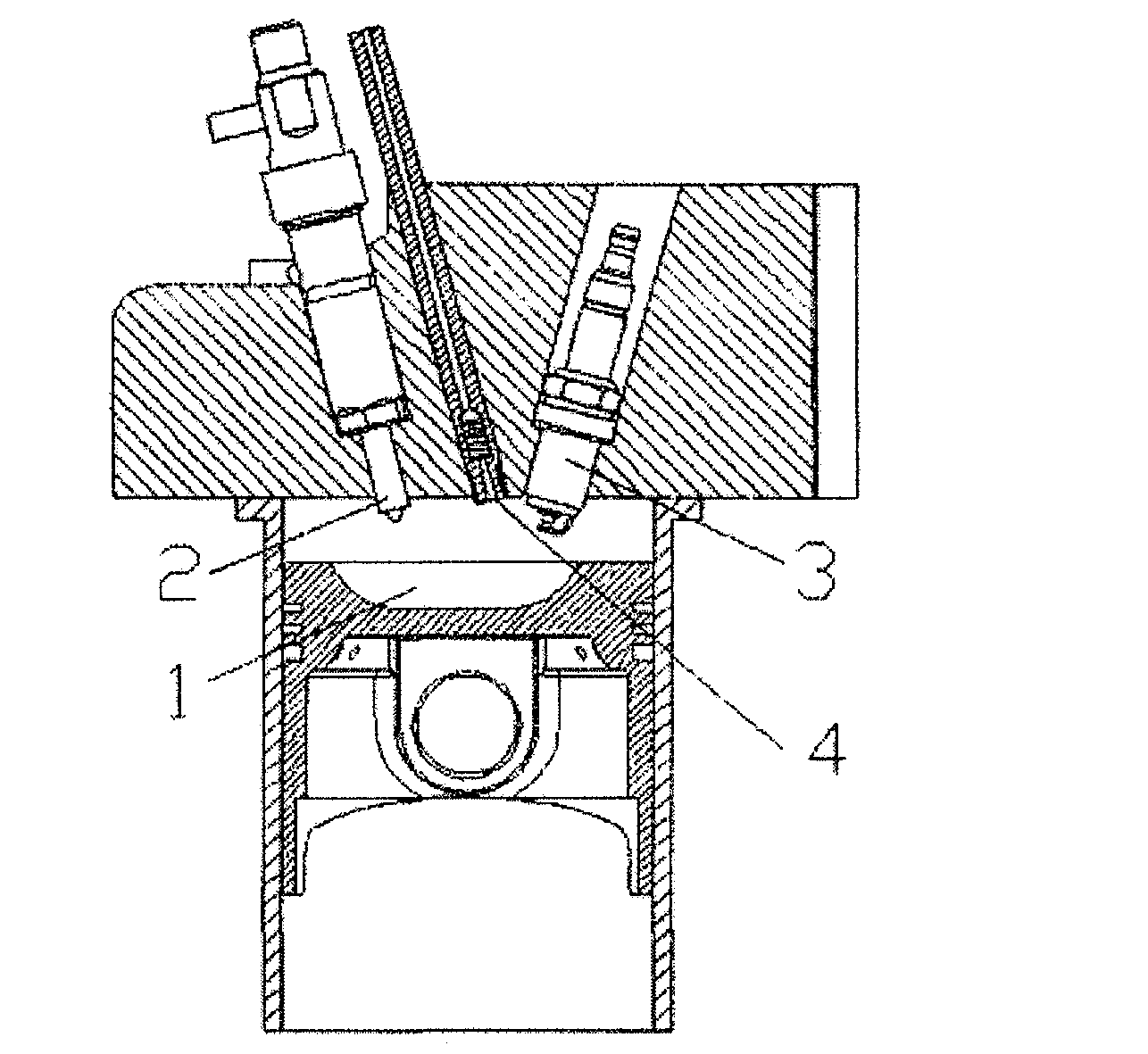

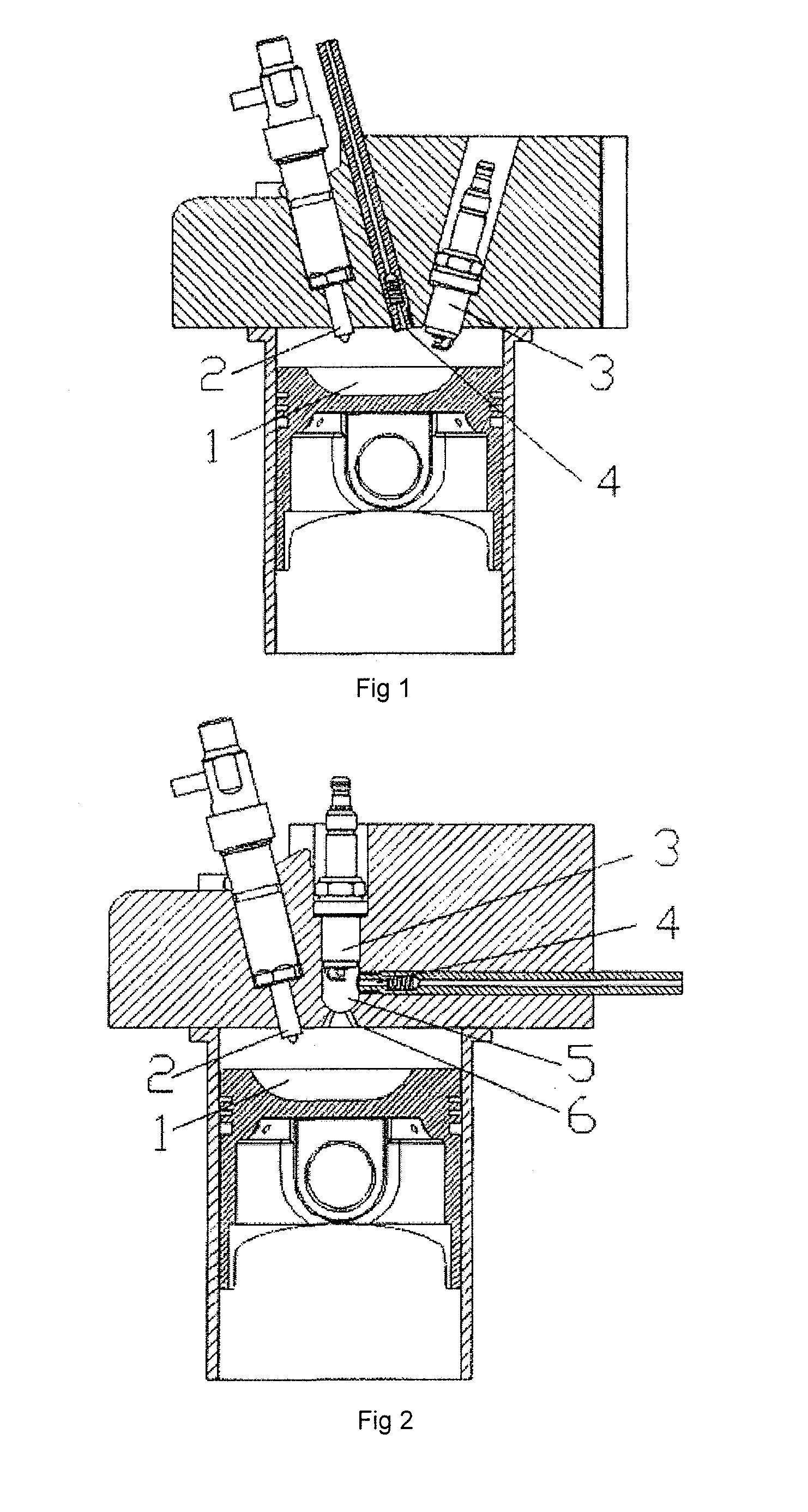

Multi-fuel pre-mixed combustion system of internal combustion engine

InactiveUS20130104850A1Improve performanceLow costInternal combustion piston enginesNon-fuel substance addition to fuelCombustion systemSpray nozzle

A multi-fuel pre-mixed combustion system of an internal combustion engine includes a main fuel spray nozzle (2), which injects a mixed fuel of compression-ignition-suitable fuels, spark-ignition-suitable fuel, or a wide cut fuel to form a homogeneous primary pre-mixed gas. An auxiliary spray nozzle (4) injects a spark-ignition-suitable fuel to form a secondary mixed gas, which is ignited by the spark plug (3) by means of spray guiding or an ignition chamber (5), and the primary pre-mixed gas in the combustion chamber (1) is compression ignited. Consequently, the ignition point of the primary mixed gas is effectively controlled and knock is avoided, and a homogeneous pre-mixed compression ignition is achieved over the whole range of operating conditions. The combustion rate is controlled by exhaust gas recirculation or spray of water into a cylinder or intake port, and high thermal efficiency is ensured by a high expansion ratio.

Owner:DALIAN UNIV OF TECH

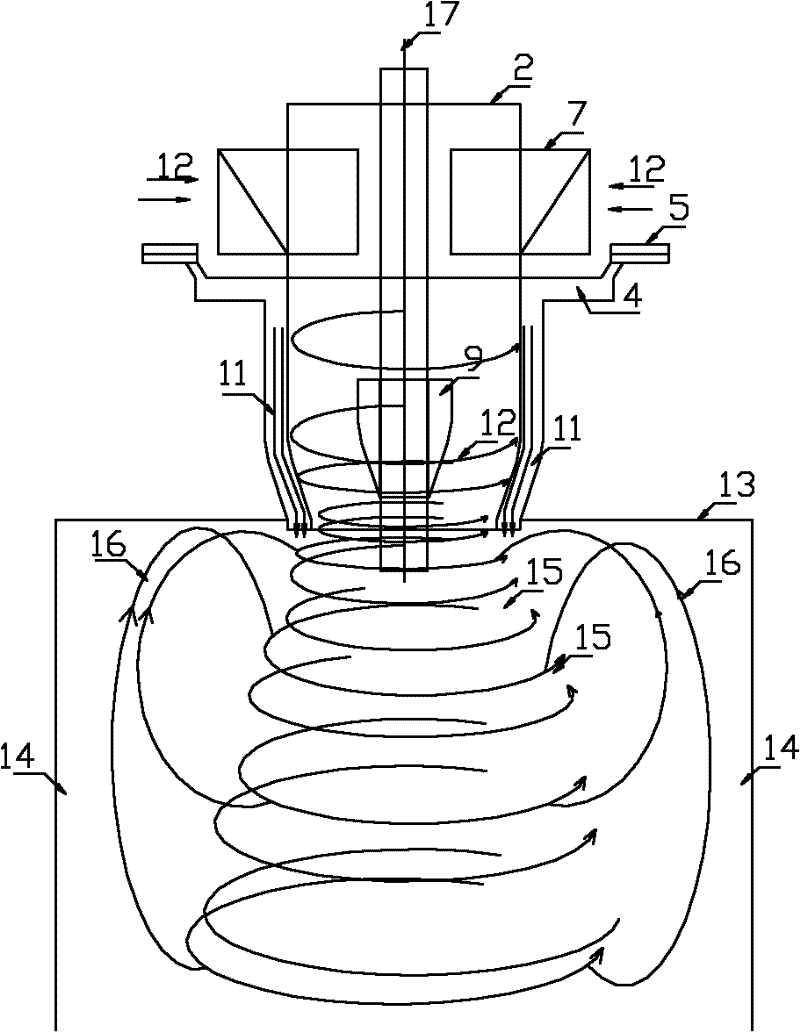

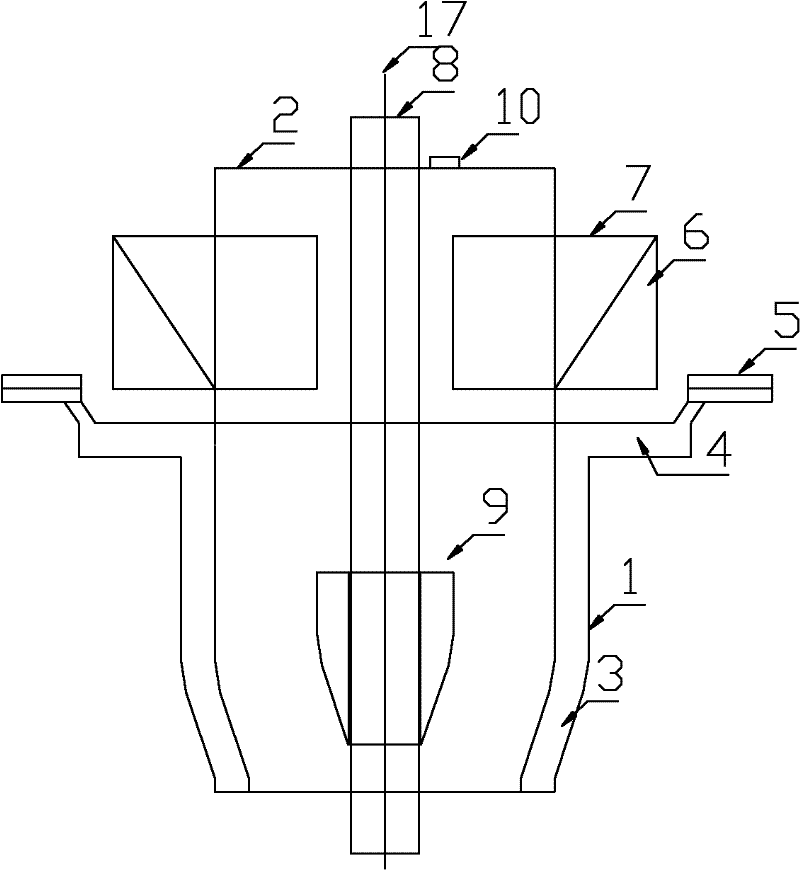

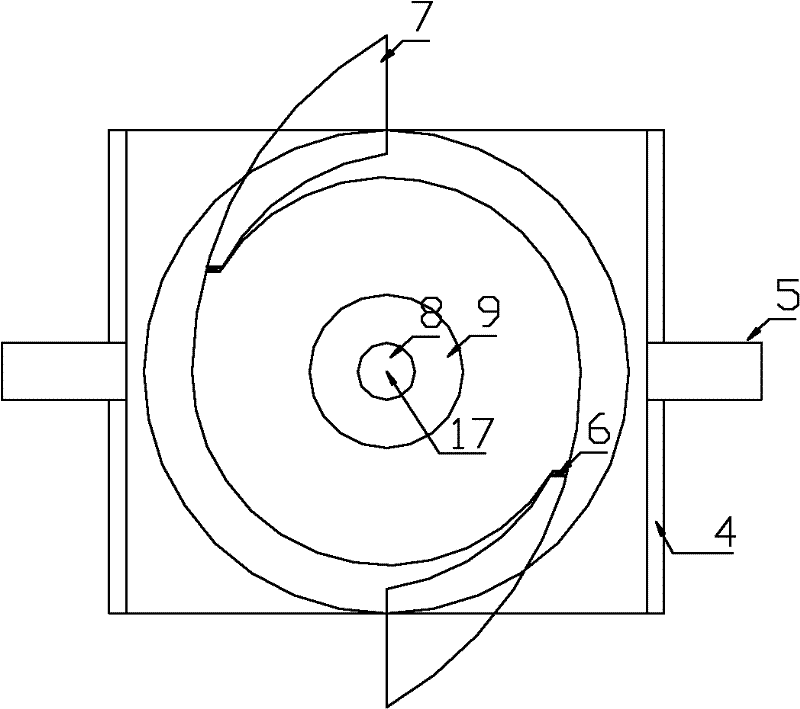

A spin-floating entrainment metallurgical process and its reactor

The invention relates a floating entrainment metallurgical process. In this process, the reaction gas and the powdery materials are injected into the reaction furnace, aiming to obtain a controllable highly rotating and floating state and reach the ignition point under the high-temperature radiation of the reaction furnace to combust intensely. Meanwhile, the rotating fluid injected in the reaction furnace will drive the furnace gas, and forms a relatively low-temperature circular backflow protection area around the rotating fluid. The reaction gas is tangentially fed into the rotating generator along numbers of rotary channels to form a controllable rotating airflow, in addition, a conical exit air controller that can be moved up and down is adopted to control the exit area of the rotating generator, thus controlling the velocity of the reaction gas into the reaction furnace; the powdery materials fall freely around the reaction gas and are involved in the high-speed rotating airflow, forming a rotating fluid, of which the powdery materials are highly dispersed into the reaction gas, moving downwards along the radial high-speed rotating axle. For the purpose of this invention, a steplessly adjusted reactor is as well referred to in this invention.

Owner:YANGGU XIANGGUANG COPPER

Method for reducing the influence of a DC current component in the load current of an asynchronous motor

InactiveUS6930459B2Enhance the imageSingle-phase induction motor startersAC motor controlPower controllerDc current

A method with which the load current and thus the load moment of an asynchronous motor that is controlled via a phase-controlled two-phase thyristor power controller, can be easily influenced so as to allow a smooth starting operation. According to a first embodiment, the ignition point is determined in the controlled phase in order to adapt the flow angles of the subsequent current half waves. According to a second embodiment, the ignition point of the subsequent current half waves is brought forward in both controlled phases.

Owner:SIEMENS AG

High efficiency low pollution hybrid brayton cycle combustor

InactiveUS20060064986A1Increase horsepowerFast accelerationEfficient propulsion technologiesGas turbine plantsHybrid typeCombustion chamber

A power generating system and method operating at high pressure and utilizing a working fluid consisting of a mixture of compressed non-flammable air components, fuel combustion products and steam. The working fluid is substantially free of CO and NOx. Fuel and compressed air at an elevated temperature and at a constant pressure are delivered to a combustion chamber, the amount of air being chosen so that at least about 90% of the oxygen in the air is consumed during combustion. The quantity of air and fuel supplied to the combustion chamber may be varied provided a constant fuel to air ratio is maintained. Superheated water is delivered under pressure to the combustion chamber, and is converted substantially instantaneously to steam. The quantity of water delivered is controlled such that the latent heat of vaporization of the water maintains the temperature of the working fluid at a desired level. Heat may be transferred from the working fluid exiting the work engine to the water to heat the water to the desired temperature for delivery to the combustion chamber. The quantity, temperature and pressure of the air, fuel and water introduced in to the combustion chamber are independently controllable. A zoned burner may be employed in which a portion of the compressed air may be mixed with the fuel in a first zone prior to ignition, with the remaining compressed air being added at one or more locations downstream of the point of ignition.

Owner:GINTER J LYELL +1

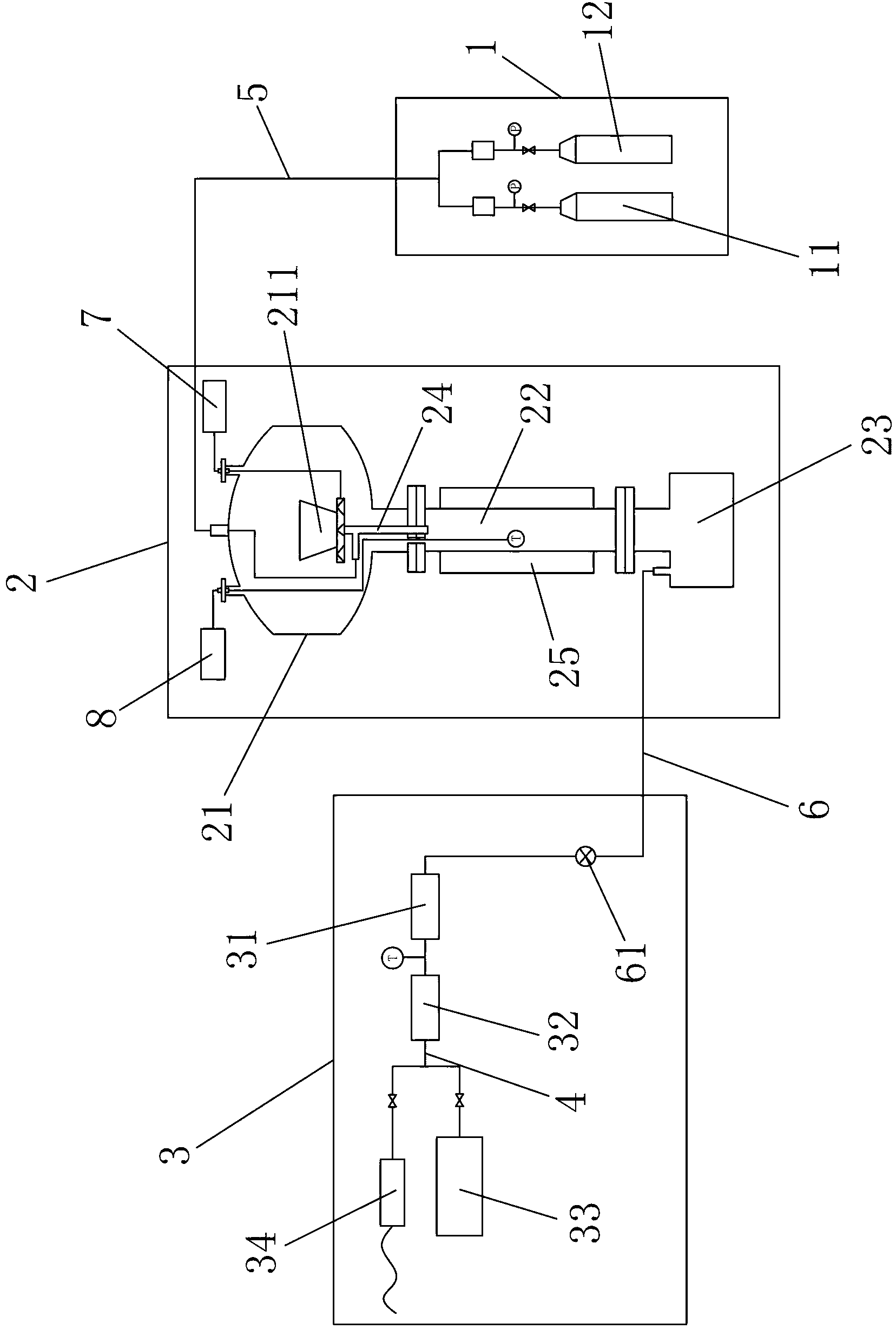

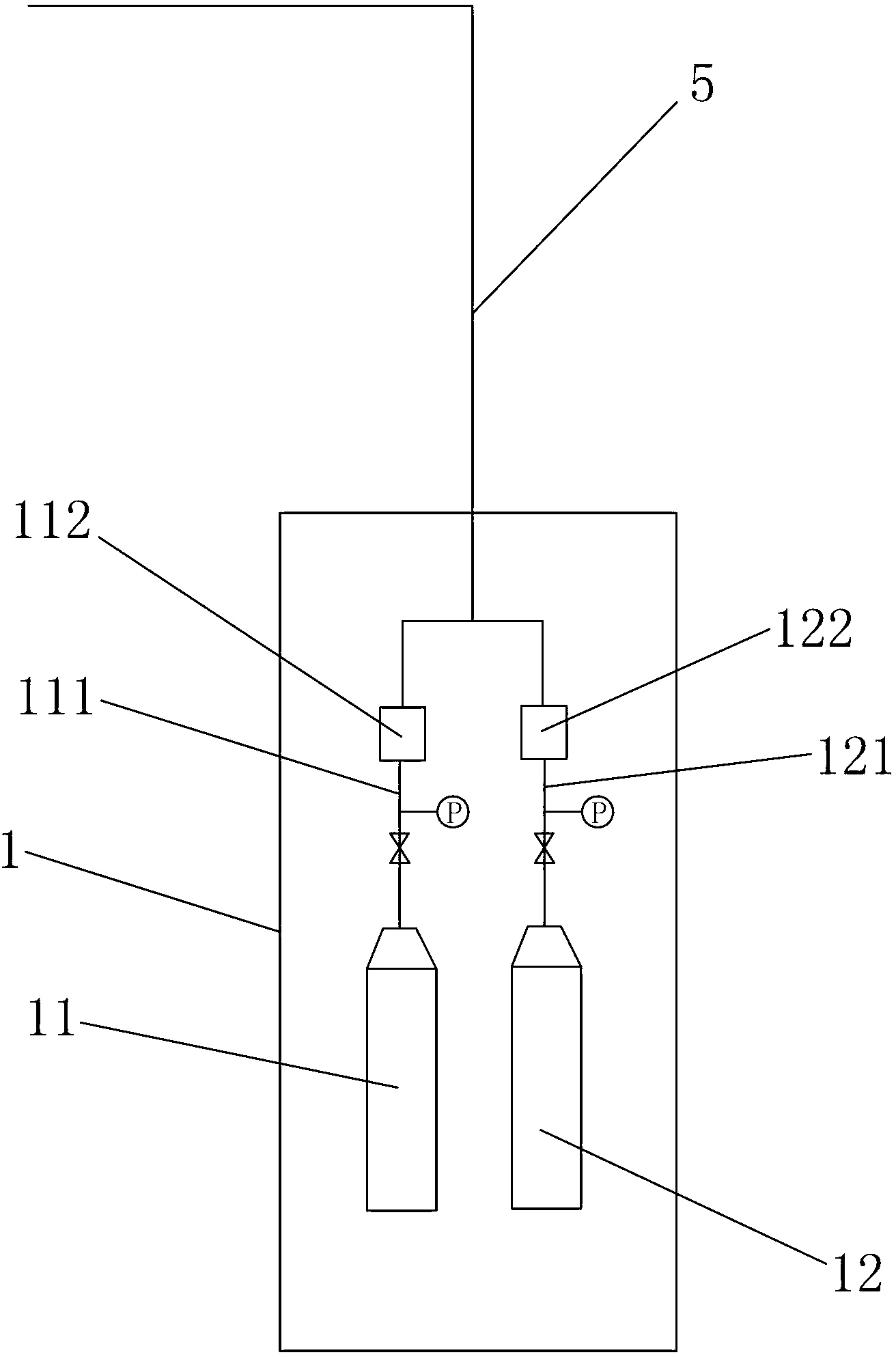

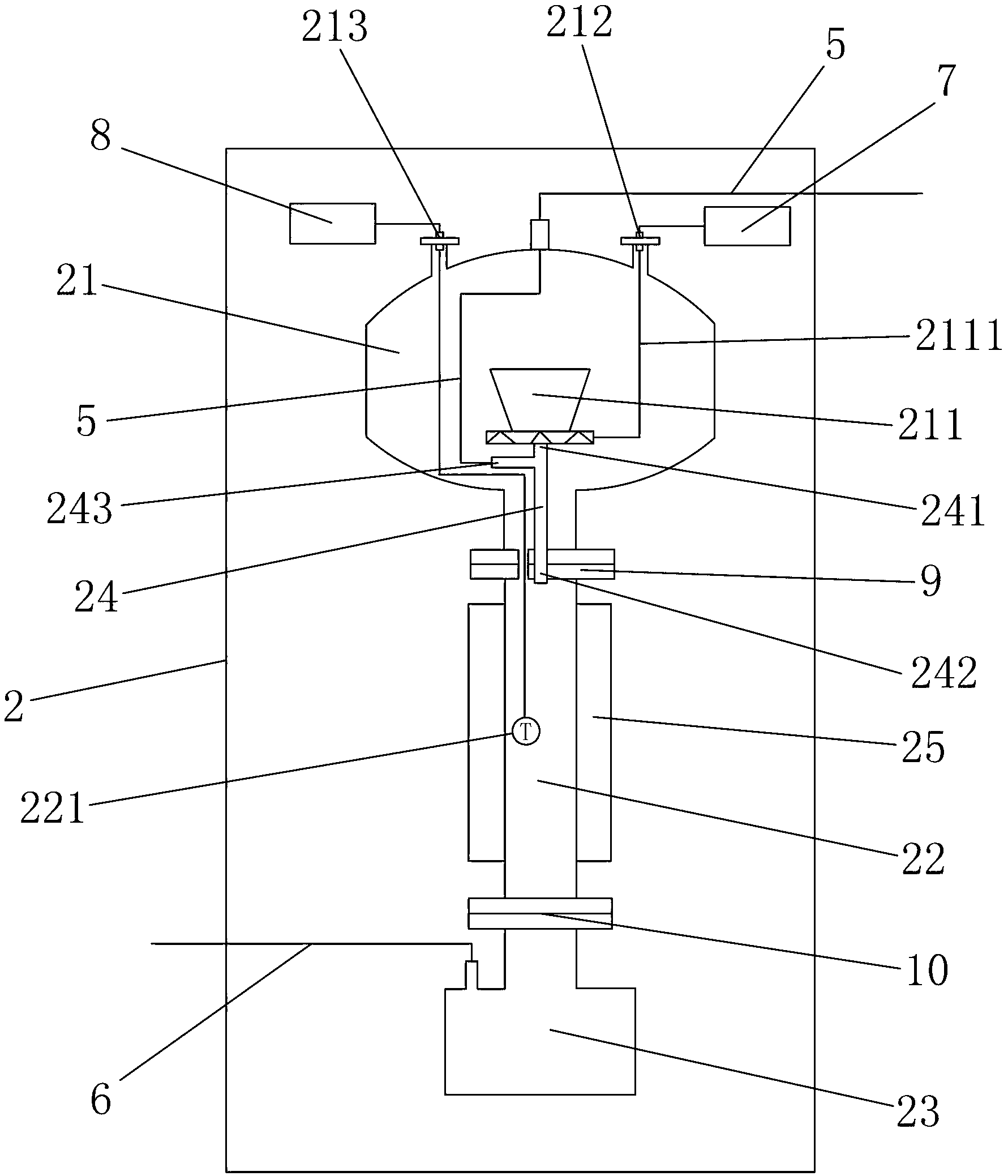

Coal powder pressurizing oxygen-enriched combustion settling furnace experimental device

InactiveCN103076361ARealize continuous feedingGet generated featuresMaterial heat developmentInvestigating phase/state changeSlagCoal

The invention discloses a coal powder pressurizing oxygen-enriched combustion settling furnace experimental device. A gas inlet system comprises an oxygen supplying unit and a carbon dioxide supplying unit; a settling furnace comprises a pressure container, a reaction pipe and a slag storage tank which are connected sequentially from the top down, wherein a coal powder feeding machine is fixedly arranged inside the pressure container, and is communicated with the reaction pipe through a blanking pipe, and a heating furnace is arranged on the outer wall of the reaction pipe in a sleeving way; a flue gas analysis system comprises a cooling device, a flue gas flowmeter and a flue gas analysis instrument which are connected sequentially through a pipeline; the gas inlet system is communicated with the blanking pipe through a gas inlet pipeline; and the slag storage tank is communicated with the cooling device through a gas outlet pipeline. According to the invention, continuous feeding of coal powder under the conditions of pressurizing and oxygen enrichment is realized, combustion characteristic parameters of ignition point, combustion temperature, burnout rate of carbon and the like of coal powder under the conditions of different pressures and different O2 / CO2 proportions can be accurately obtained, and meanwhile, flue gas components of coal powder combustion can be analyzed, so as to obtain the generation characteristics of pollutants under the conditions of pressurizing and oxygen enrichment.

Owner:BEIJING JIAOTONG UNIV

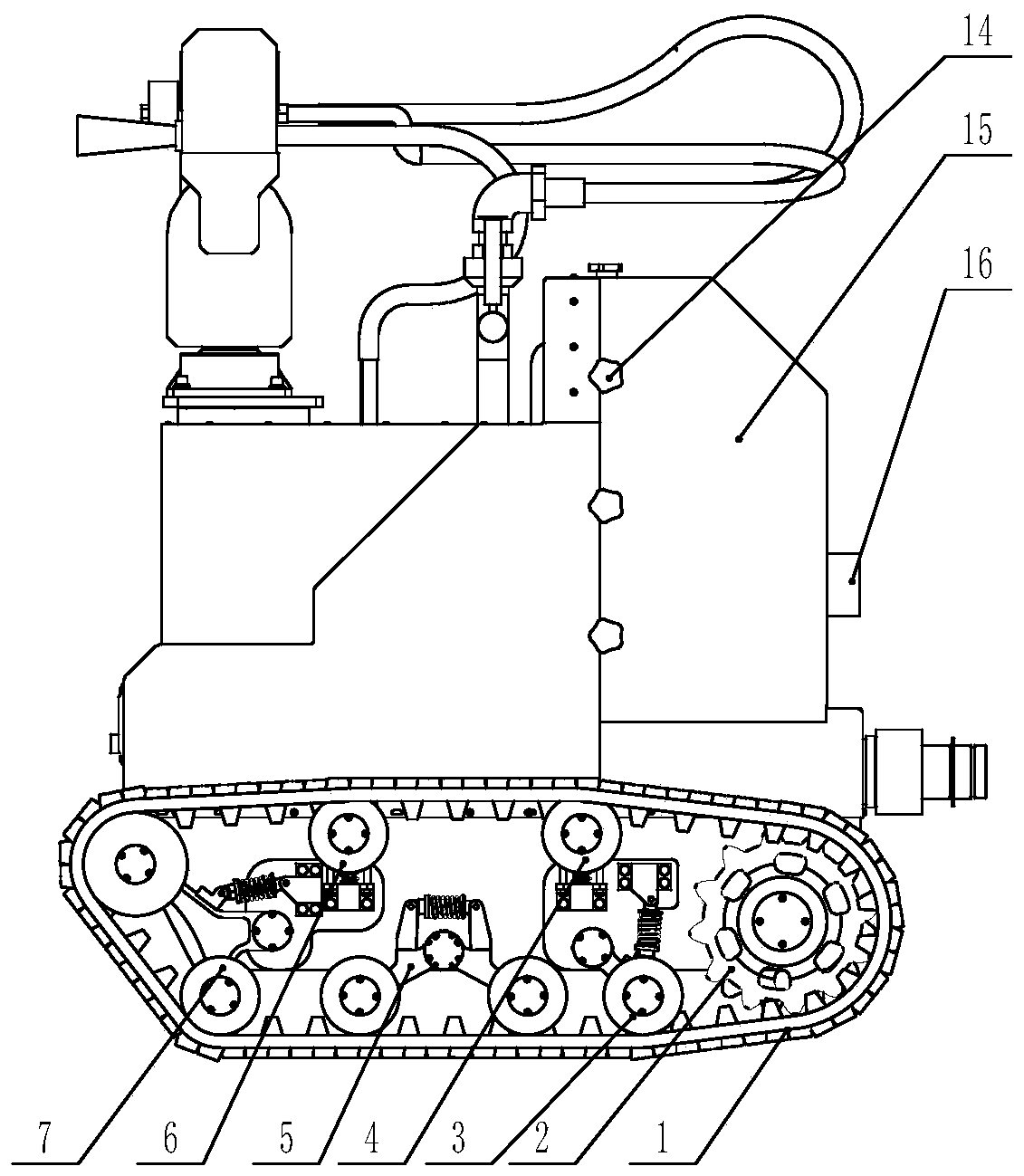

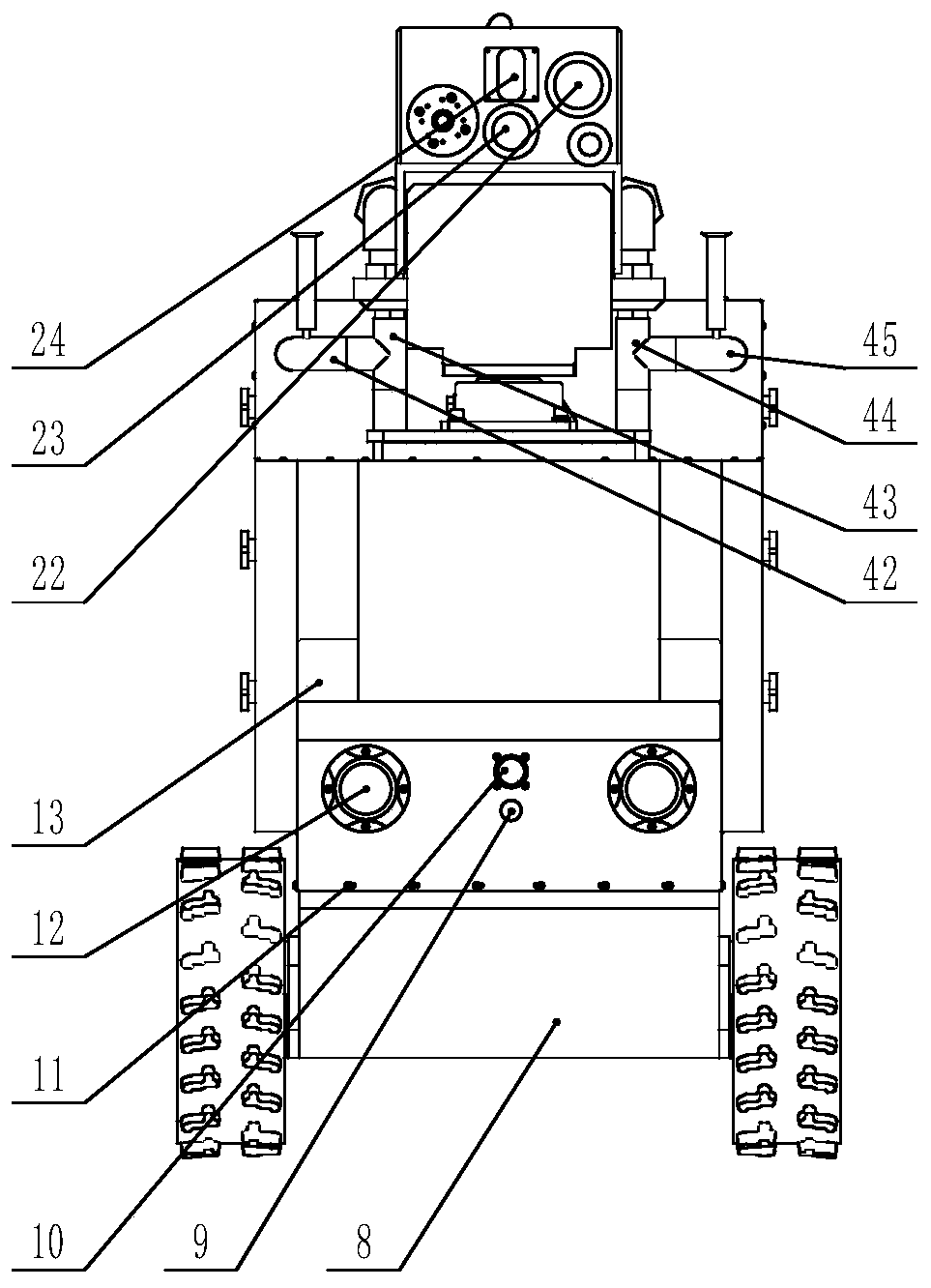

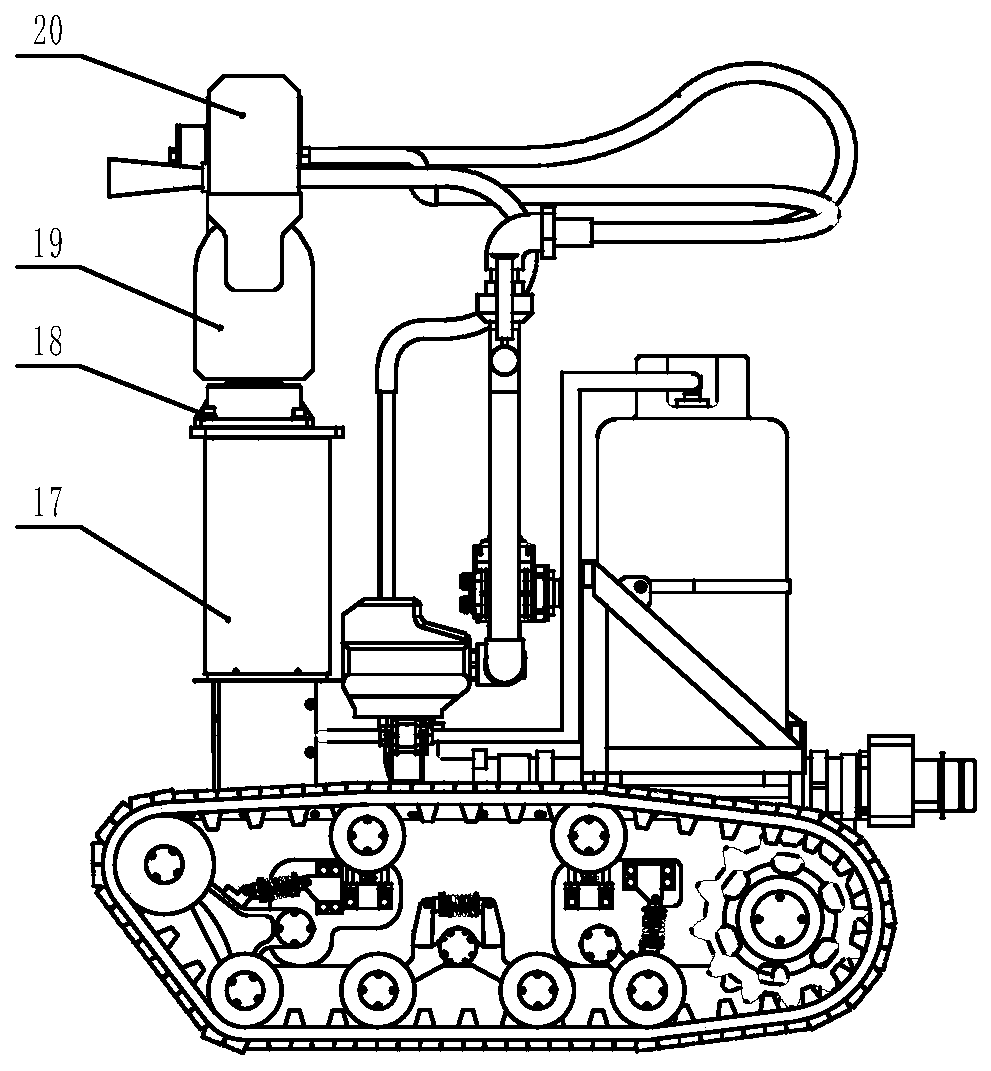

Intelligent fire-fighting system and method for transformer substation

The invention provides an intelligent fire-fighting system and method for a transformer substation. The intelligent fire-fighting system comprises a plurality of fire-fighting robots and fire-fightingmedium supply equipment as well as a control center, wherein the fire-fighting robots and the fire-fighting medium supply equipment are arranged on each area in the transformer substation in a spacedmode; the fire-fighting medium supply equipment can be fixed, and also can be movable; while a fire behavior occurs, ignition point information can be obtained according to a smoke / temperature sensorarranged on each area in the transformer substation, also can be obtained by sensors on the fire-fighting robots, and also can be detected by arranging an unmanned aerial vehicle. The control centerschedules the fire-fighting robot closest to the ignition point, so that the fire-fighting robot firstly goes to the ignition point to extinguish fire; and meanwhile, other fire-fighting robots closerto the ignition point or the fire-fighting medium supply equipment can be scheduled to go to the ignition point. The intelligent fire-fighting system realizes timely fire-extinguishing and adaptive fire-extinguishing.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

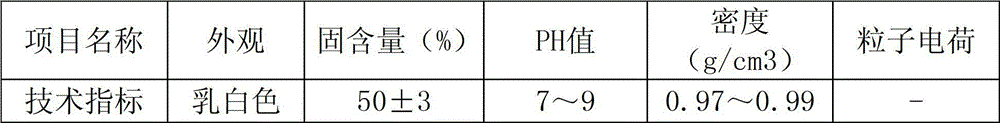

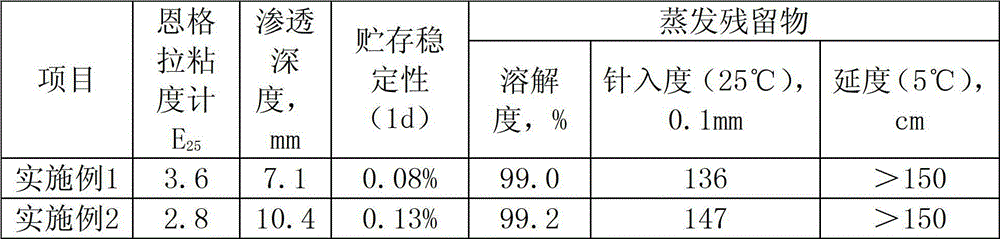

High-permeability anion modified emulsified asphalt and preparation method thereof

InactiveCN102911506AHigh ignition pointNot volatileBuilding insulationsEnvironmental resistanceEmulsion

The invention provides a high-permeability anion modified emulsified asphalt and a preparation method thereof. The high-permeability anion modified emulsified asphalt comprises asphalt, diluents, emulsifiers, penetrants, water, stabilizers and anion SBR (styrene-butadiene rubber) latex. The preparation method includes controlling proportioning and processing temperature of the materials and then emulsifying through a latex mill so as to obtain finished products. The prepared emulsified asphalt has good stability and strong permeability, and can meet the specification requirement of permeating a base by the depth of 5-10mm. The diluents are mixtures of industrial byproducts such as crude residual oil, white oil, processing light oil and the like which are distilled and extracted from crude oil or petroleum, and are high in ignition point, low in volatility and low in price, and therefore, the prepared high-permeability anion modified emulsified asphalt is environment-friendly and low-cost. In addition, owning to the compounded emulsifiers, emulsion performance is improved; and owning to the penetrants which are selected through relative permeability test, capillary permeability of the emulsified asphalt is improved.

Owner:CHANGAN UNIV

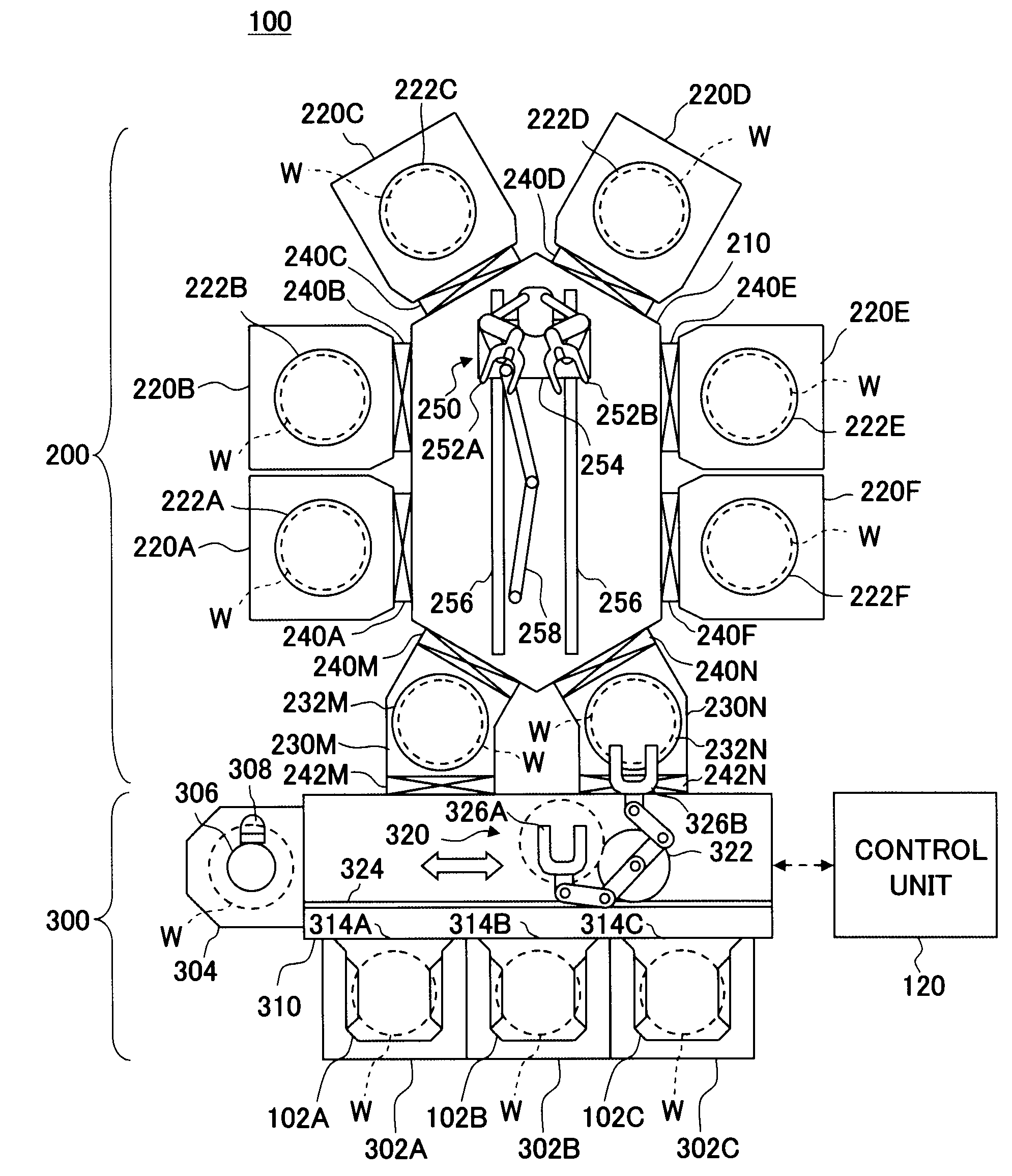

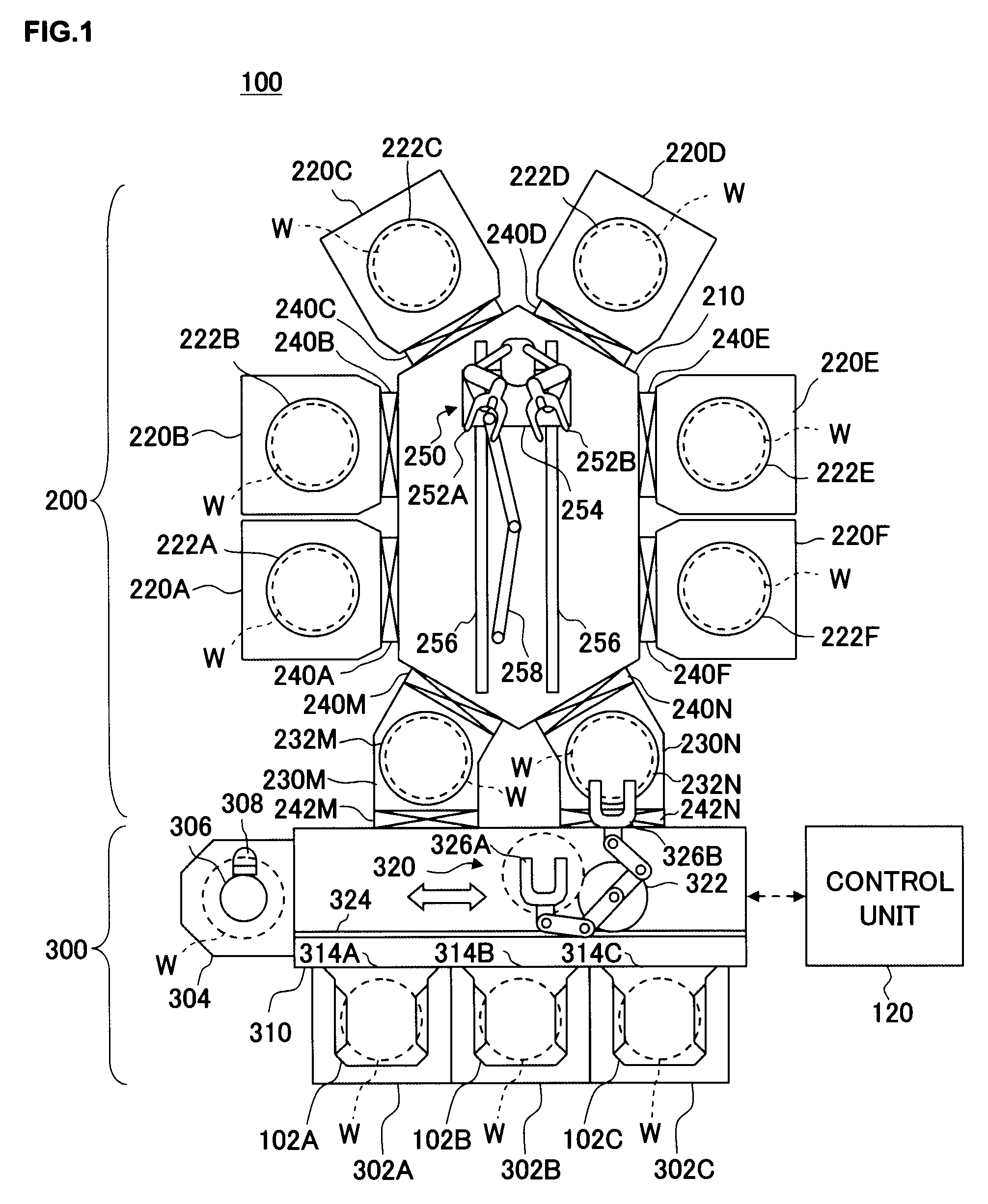

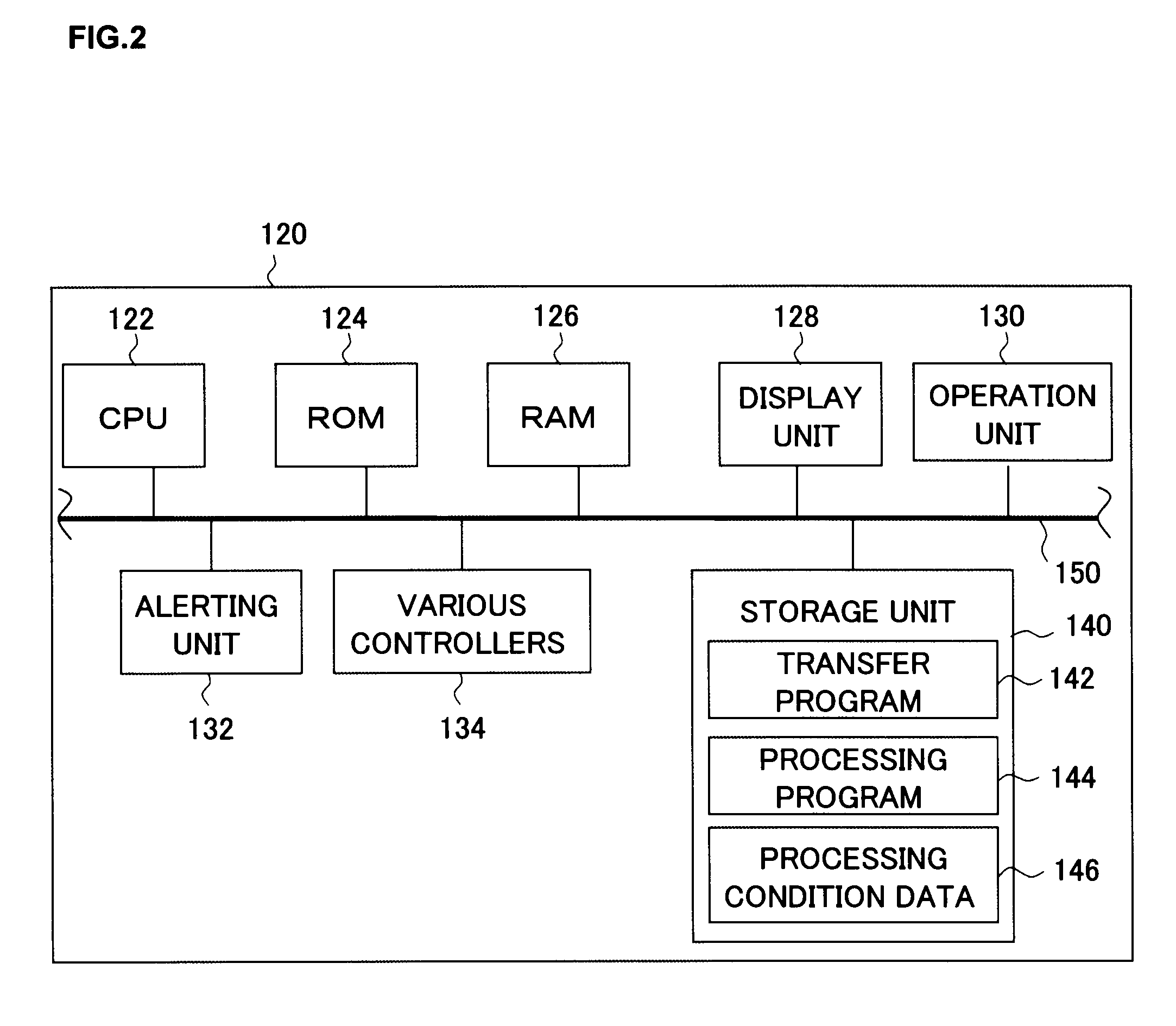

Substrate processing method, substrate processing apparatus and recording medium

ActiveUS20090179003A1Improve throughputRapid coolingElectric discharge tubesDecorative surface effectsEngineeringAshing

An ashing process in which an etching mask is removed through ashing by supplying hydrogen radicals toward a wafer W being heated to a predetermined temperature and a restoration process in which the film quality of a low dielectric constant insulating film having been damaged during an etching process is restored while, at the same time, rendering the low dielectric constant insulating film exposed at a recessed portion into a hydrophobic state by supplying a gas containing a β-diketone compound with an ignition point equal to or higher than 300° C. toward the wafer W having undergone the ashing process, are executed.

Owner:TOKYO ELECTRON LTD

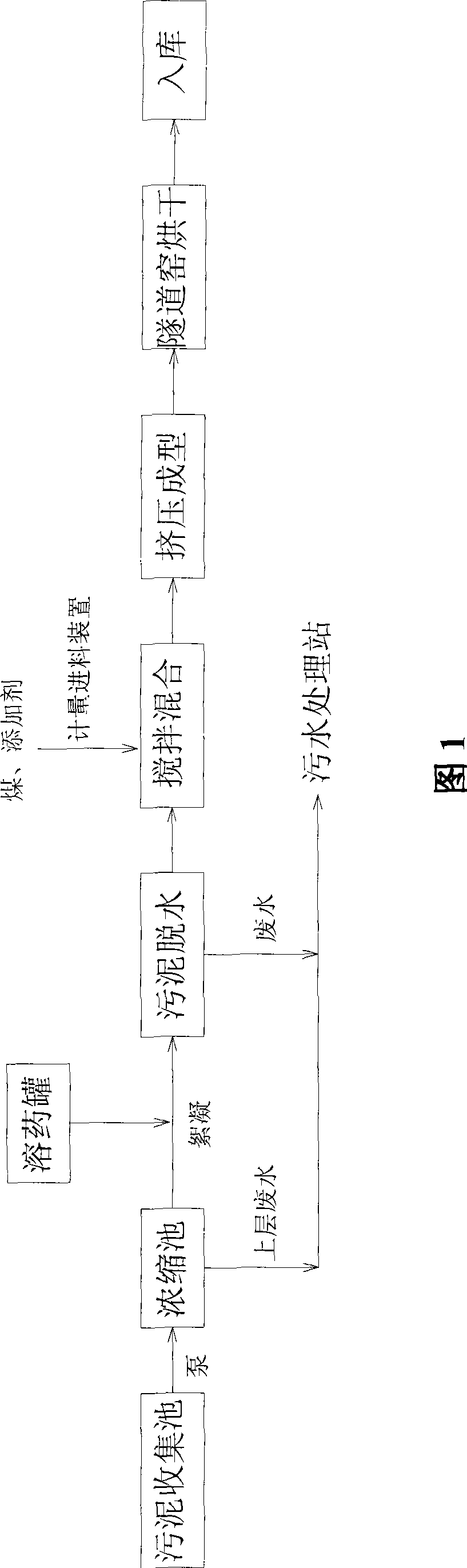

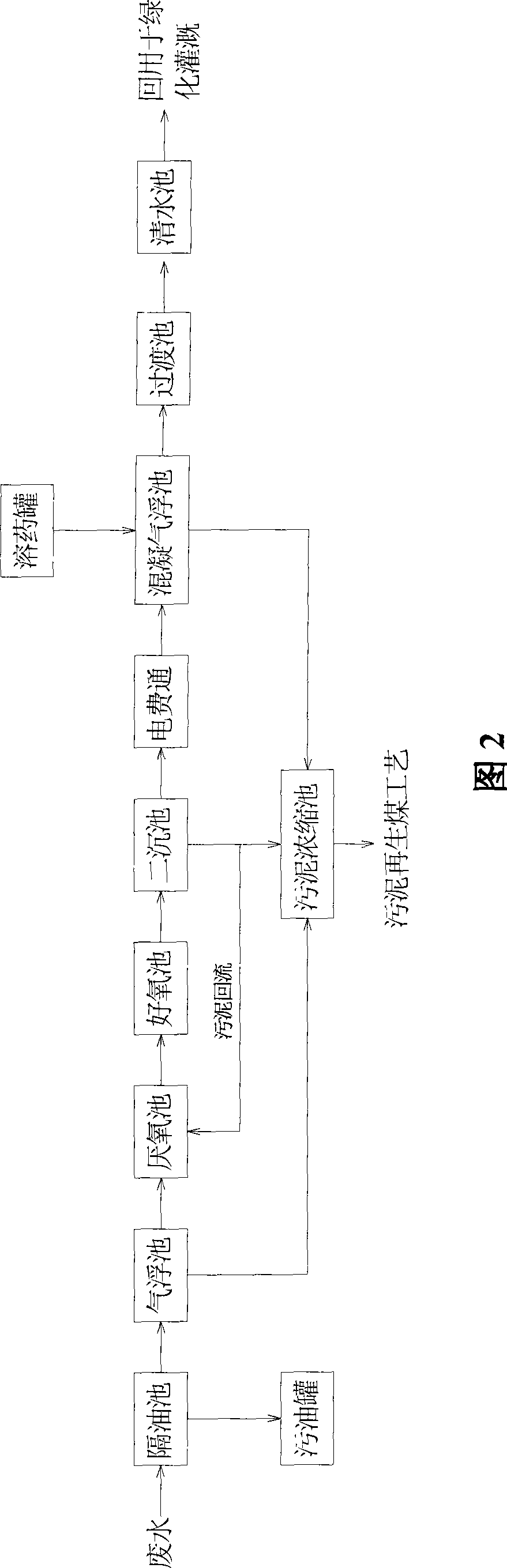

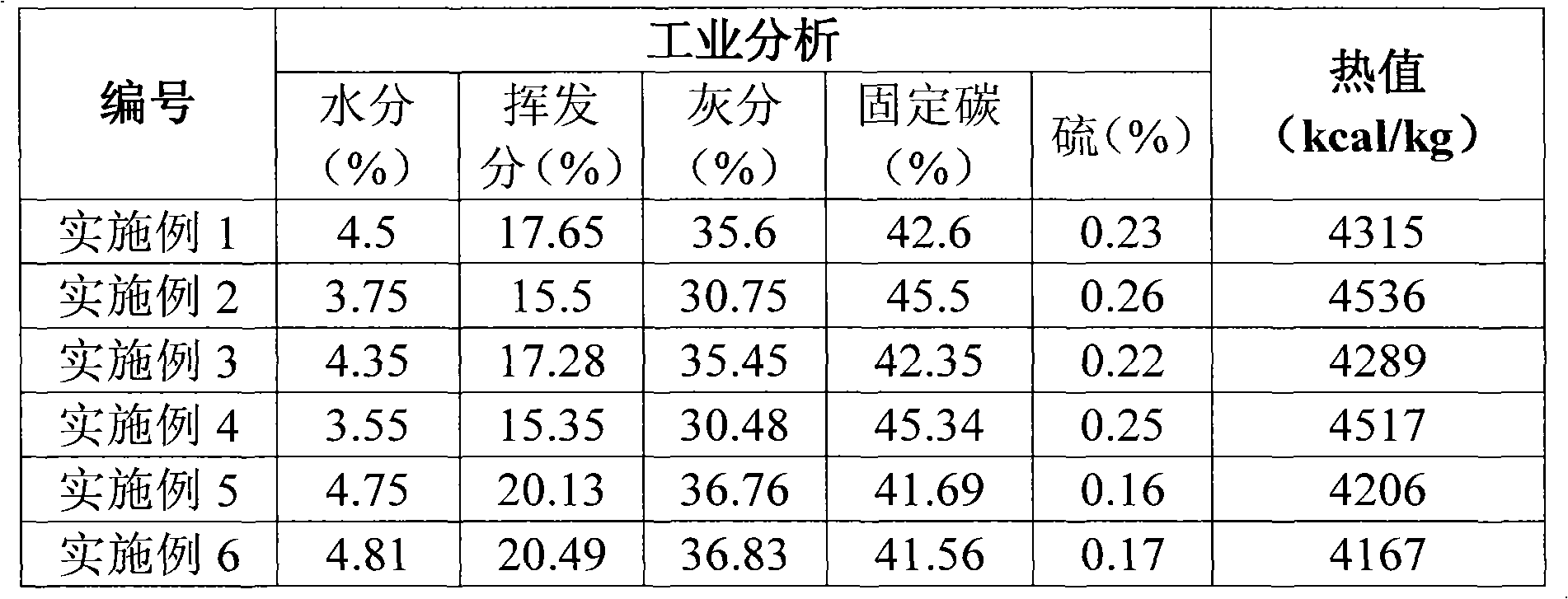

Regenerated coal prepared by oil-containing sludge from oil production field and oil-extraction plant and preparation technology thereof

The invention relates to an oily sludge renewable coal and a production technology thereof for an oil field and a refinery. The renewable coal composition is composed of 10 percent to 30 percent of oily sludge, 60 percent to 80 percent of coal, 3 percent to 6 percent of sulfur fixing matter and 1 percent to 5 percent of preservative according to the weight percentage. The production technology comprises the following steps: sludge thickening to flocculation reaction to sludge dehydration to stirring and mixing to extrusion forming and drying by a tunnel kiln. The production technology further comprises the disposal technology of wastewater containing oily sludge: wastewater to an oil separating tank to an air flotation tank to an anaerobic tank to an aerobic tank to a secondary sedimentation tank to a transition tank to an electricity charge payment device to a coagulation and air flotation tank to a clean water tank. The wastewater can achieve the national first level discharge standard after the treatment, and the outlet water is reused for green irrigation or car washing or toilet flushing. The oily sludge renewable coal has the advantages of high calorific value, low ignition point and low production cost, thereby truly realizing the purposes of reduction, harmlessness and resource utilization of the oily sludge.

Owner:深圳市宇力科技有限公司

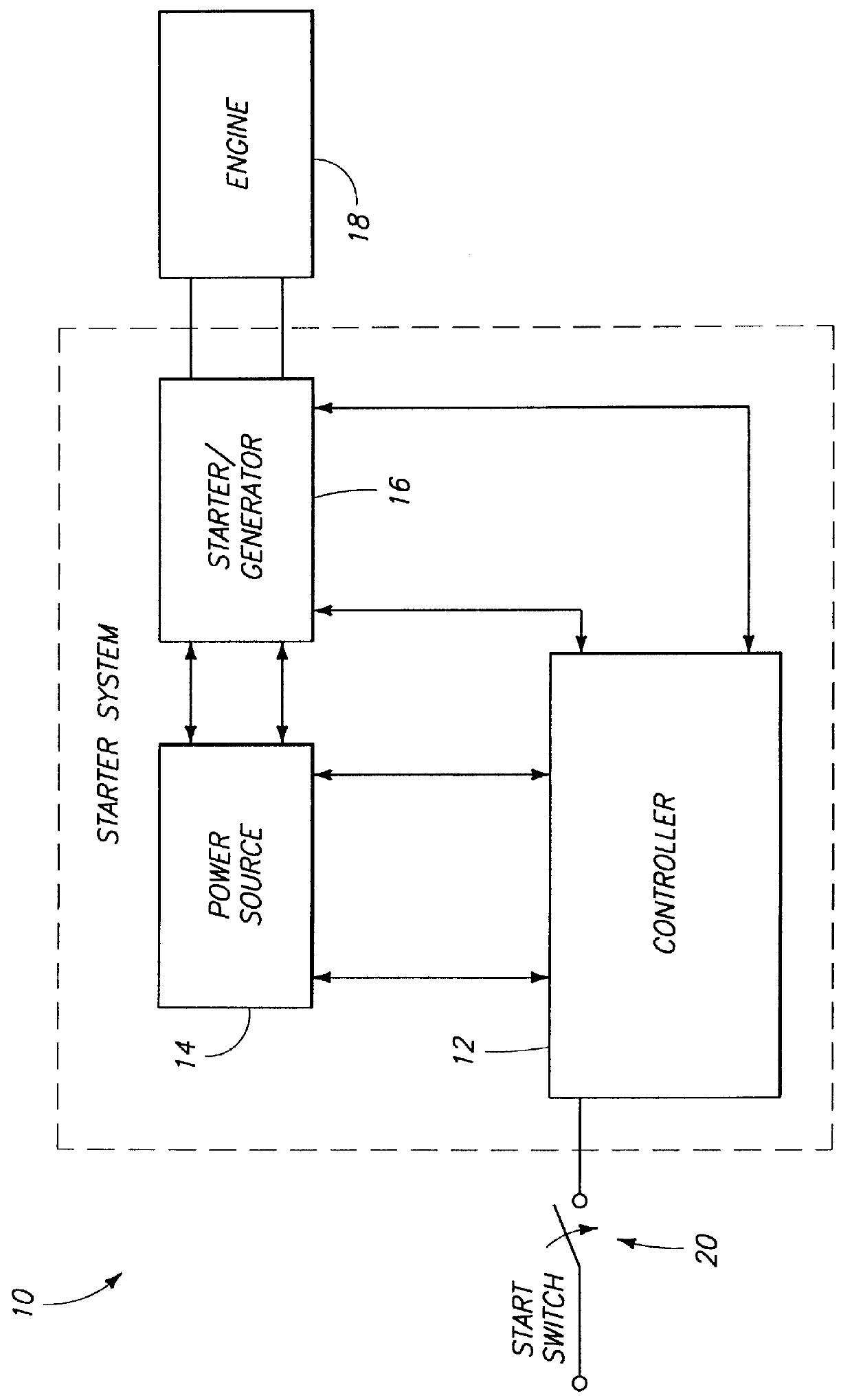

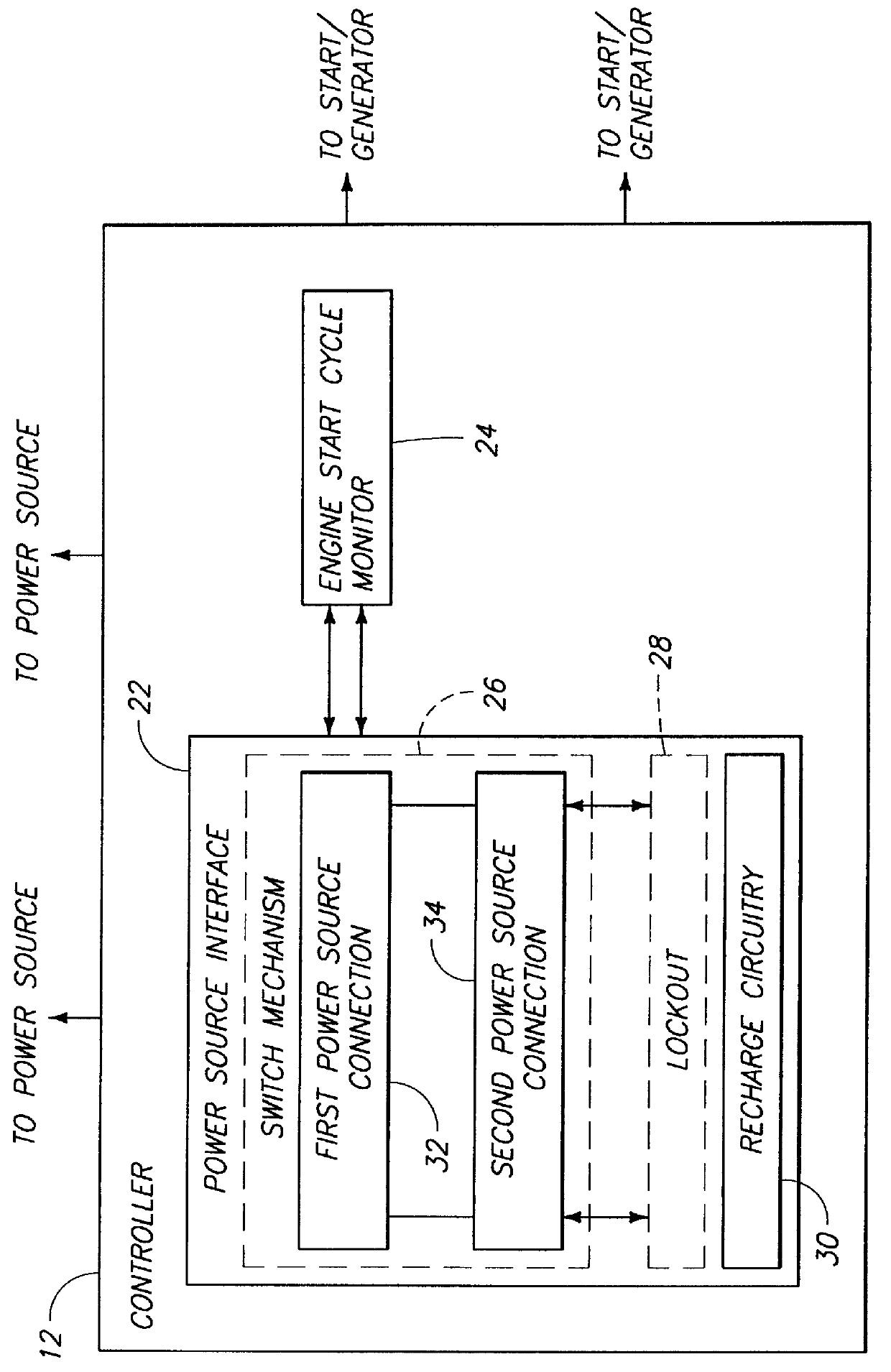

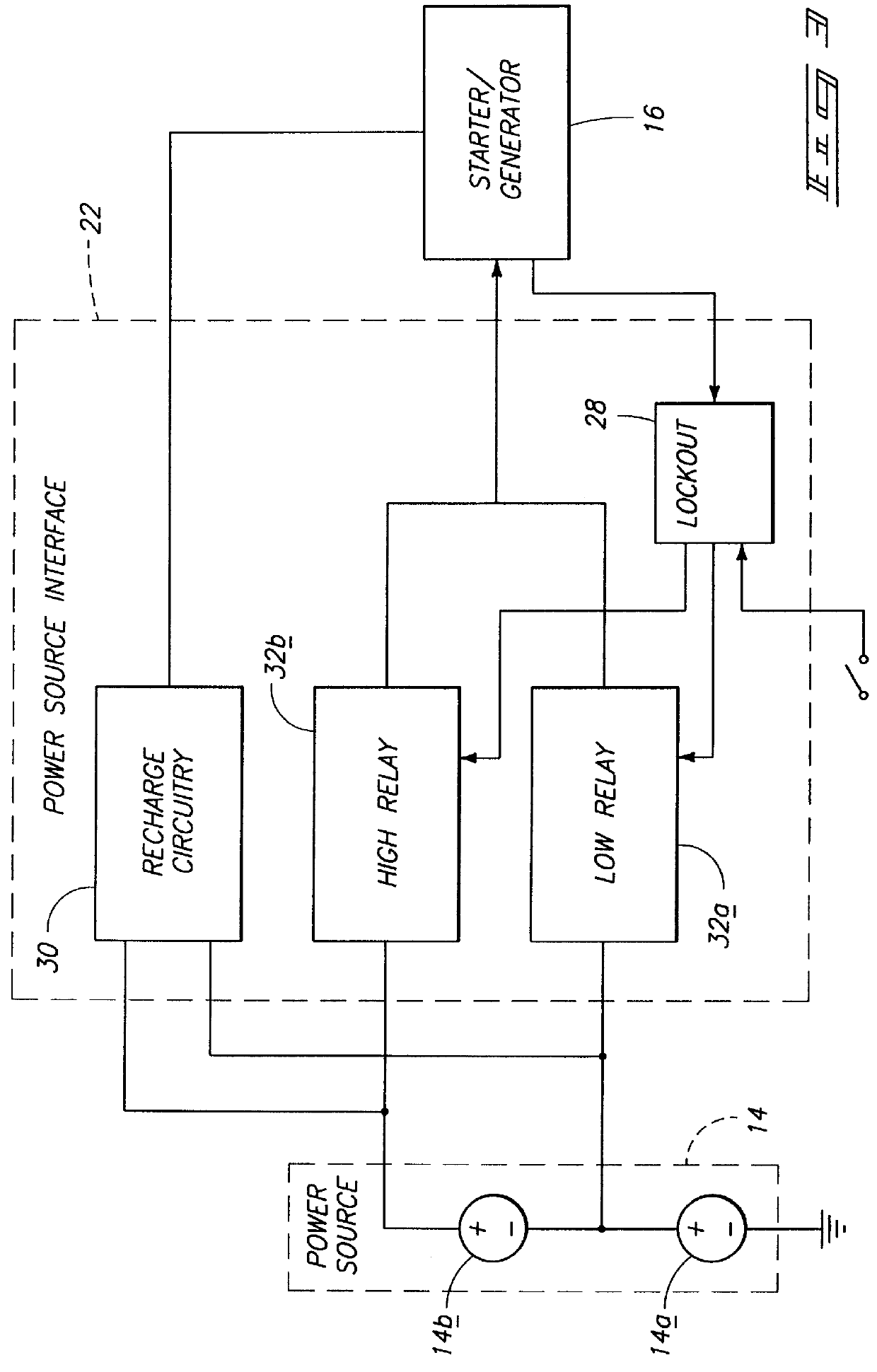

Electric starter system for turbine aircraft engines

InactiveUS6018941ADC motor speed/torque controlTurbine/propulsion engine ignitionJet aeroplaneElectricity

Turbine aircraft engine starter systems and controllers for use therewith, and methods of starting turbine aircraft engines are described. A starter is operably connected with an aircraft engine and configured to initiate an engine start cycle which includes engine rotation and a fuel ignition point. A power source is connected with the starter and is configured to provide power thereto in accordance with at least first and second settings which apply different magnitudes of voltage to the starter. The first setting initiates the engine start cycle and the second setting accelerates the engine through the start cycle after the fuel ignition point. A controller is operably connected with the starter and the power source and is configured to monitor the engine start cycle and responsive to a controller-determinable time during the engine start cycle changes the first setting to the second setting. In a preferred implementation, the power source comprises a pair of batteries which are permanently connected in series.

Owner:LAMAR TECH

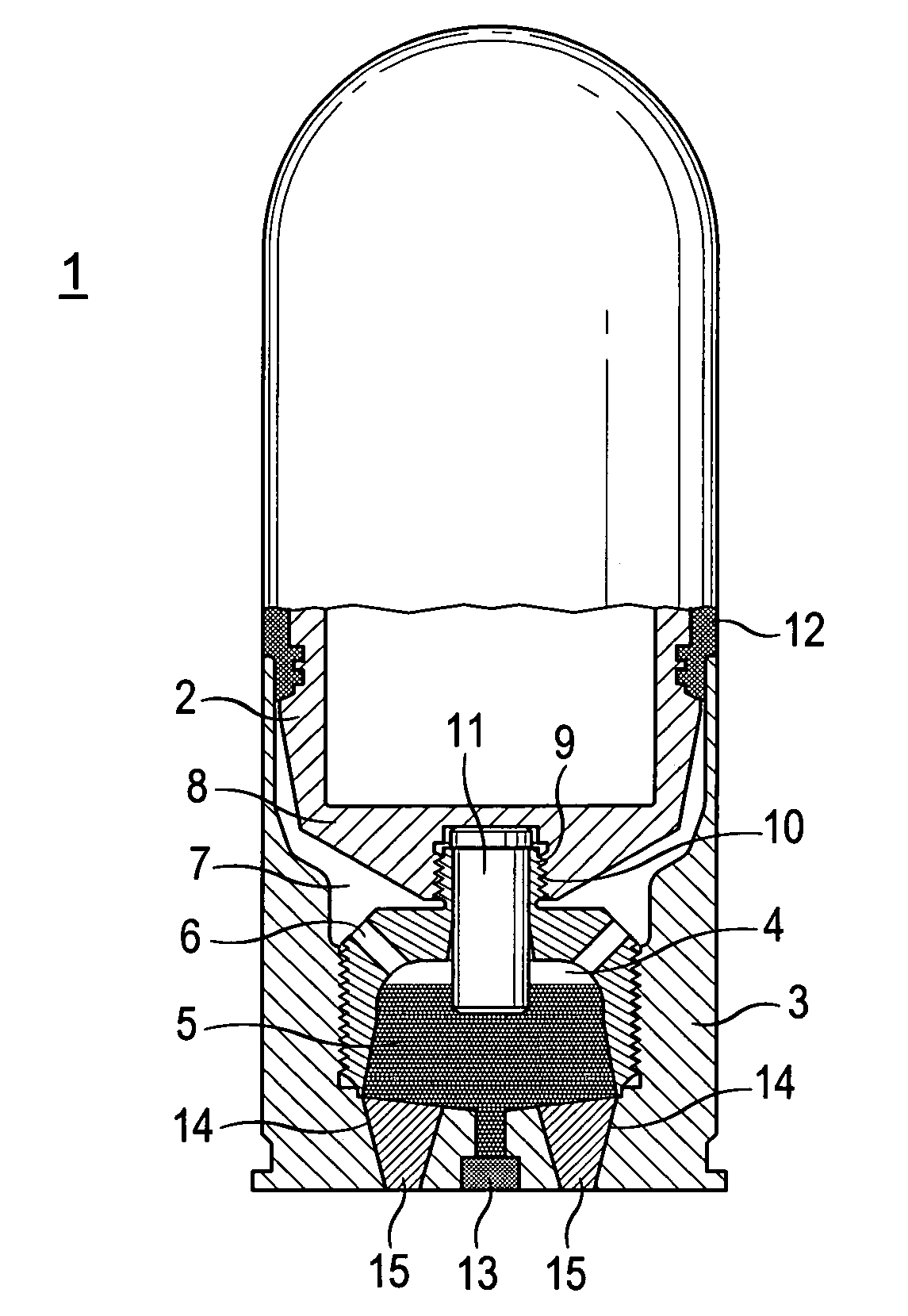

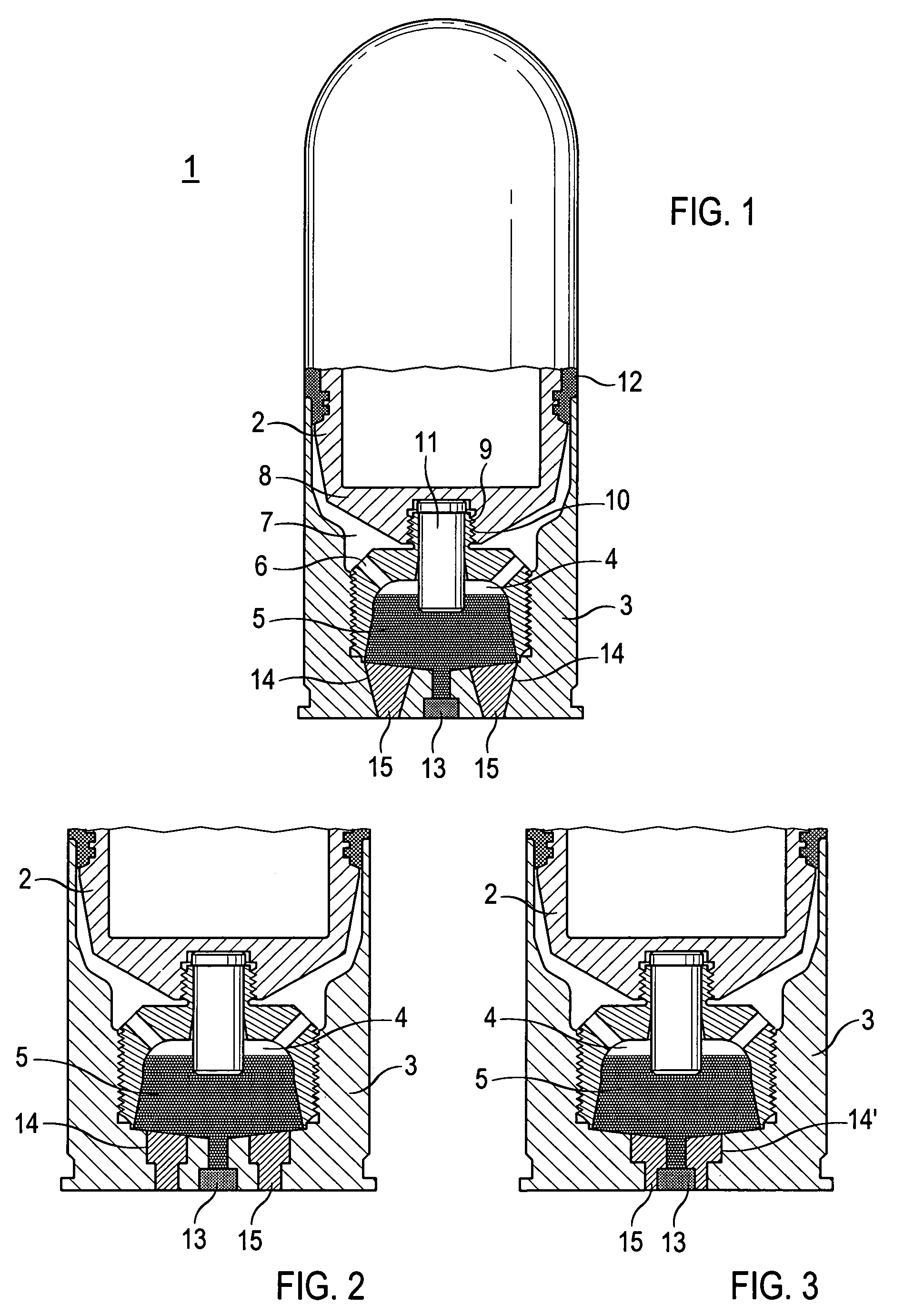

Cartridge munition, particularly one of medium caliber

ActiveUS7107909B2Avoid separationAvoid damageAmmunition projectilesTraining ammunitionEngineeringProjectile

A cartridge munition, particularly practice round, includes a cartridge shell (3) and a projectile (2) inserted into it. A propulsion chamber (4) is provided within the cartridge shell that receives a propulsive charge (5) that may be ignited by means of a pyrotechnic igniter (13) and that develops propulsive gases that act on the base (8) of the projectile, driving it out of the cartridge shell. In order to prevent the pyrotechnic igniter from igniting spontaneously, and from igniting the propulsive charge (5) because of the ambient temperature or because of a fire, which would cause the cartridge shell and projectile to be separated and fly apart, it is proposed by the invention to provide exhaust channels (14) between the propulsion chamber and the exterior of the cartridge shell (3) that are filled with a fusible material, particularly a fusible metal (15). The fusible material has a lower melting point than the ignition point of the igniter (13) and of the propulsive charge (5). If the ambient temperature of the cartridge shell rises above the melting point of the fusible material, it melts, releasing the exhaust channels (14), so that, upon delayed ignition of the propulsive charge, it burns without pressure buildup, and the cartridge shell and projectile remain together.

Owner:NICO PYROTECHNIK HANNS JUERGEN DIEDRICHS GMBH & CO KG

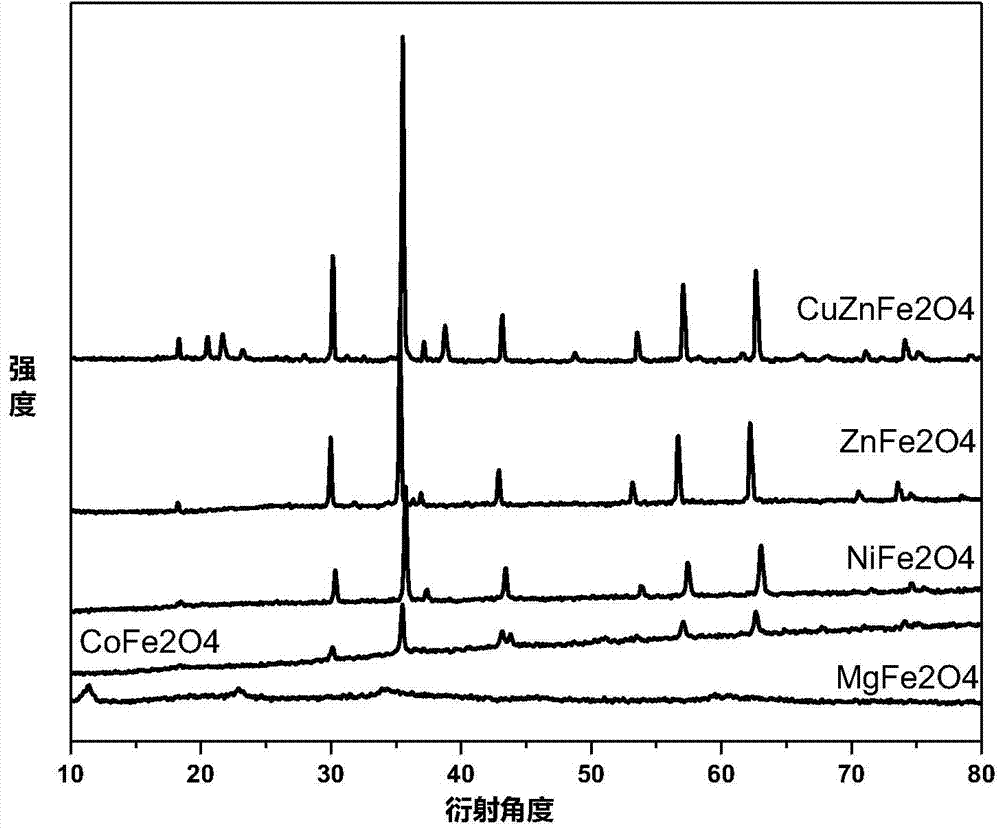

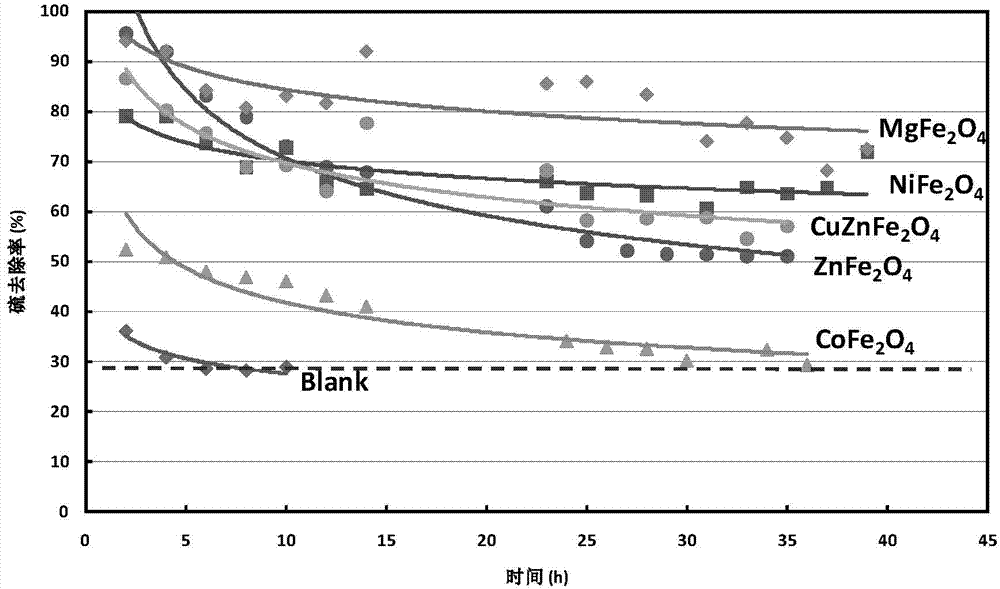

Novel nano ferrite adsorption desulfurization catalyst and preparation method thereof

InactiveCN104741123AHigh desulfurization selectivityRealize deep desulfurizationHydrocarbon oils refiningMetal/metal-oxides/metal-hydroxide catalystsFuel oilPetroleum

The invention belongs to the technical field of fuel processing and petroleum chemical engineering, and relates to a novel nano ferrite adsorption desulfurization catalyst MeFe2O4, wherein Me comprises but not the same with Mg, Zn, Ni, Co and Cu. The preparation method comprises the following steps: dissolving transition metal nitrate, Fe-containing nitrate and fuels in water, heating the obtained solution in a microwave furnace rapidly, decomposing so as to generate a great quantity of combustible gases and emit a great amount of heat, and combusting reactants reaching the spontaneous ignition point; and reacting so as to obtain a solid material, namely the novel nano ferrite adsorption desulfurization catalyst. The novel nano ferrite adsorption desulfurization catalyst is relatively high in desulfurization selectivity, can prevent the loss of octane value and cetane value due to olefins hydrogenation while deeply removing sulfocompound in fuel oil, and has relatively good industrial application prospect.

Owner:DALIAN UNIV OF TECH +1

Biomass moulded coal and preparation method thereof

InactiveCN101985575ALow calorific valueLow volatileBiofuelsSolid fuelsFixation agentSodium hydroxide

The invention provides a method for preparing biomass moulded coal by using biomass and inferior smokeless pulverized coal as raw materials. The biomass moulded coal is prepared by uniformly mixing the biomass, the inferior smokeless pulverized coal and additives (a sulfur fixation agent, a biomass binder, an oxidant and a waterproofing agent), and performing low-pressure compression moulding by a wet method, wherein the sulfur fixation agent is calcined lime CaO; the biomass binder is light yellow dope prepared by treating bagasse by using 1 to 2 percent sodium hydroxide solution; the oxidant is potassium permanganate; and the waterproofing agent is tar or a binder. The biomass moulded coal comprises following raw materials in part by mass: 40 to 65 parts of inferior smokeless pulverized coal, 25 to 55 parts of biomass and 5 to 10 parts of additive. The biomass moulded coal has the advantages of low cost, low ignition point, high burn-off rate and integrative desulfurization and water proofing performance, and has great significance of energy conservation and environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

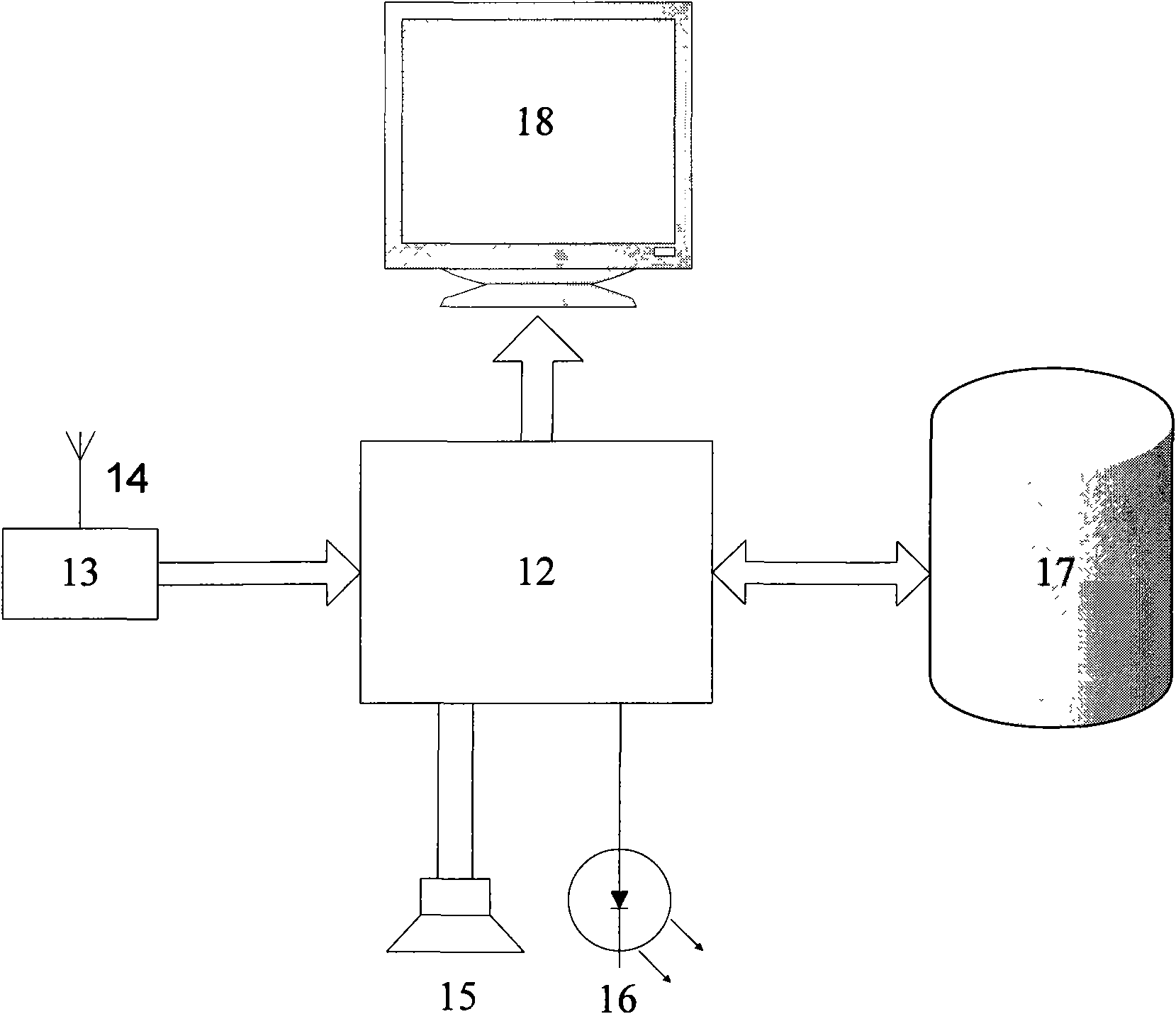

Fast forest fire detecting system by laser ranging positioning

InactiveCN101551458AHigh positioning accuracySolve the costAngle measurementPosition fixationLaser rangingTelecommunications link

The invention discloses a fast forest fire detecting system by laser ranging positioning, composed of a laser ranging positioning unit and a command information platform. The invention mainly discloses a laser ranging positioning unit integrating a laser ranging module, a digital compass, a dip circle and a GPS / Beidou double-module positioning communication module, and adopts short message communicating function of a Beidou first-generation satellite to send fire condition information. Advantages are as follows: compared with the traditional mapping tools, the laser ranging positioning unit more quickly measure three-dimensional coordinate of an ignition point distantly and saves precious time at the beginning of finding forest fire; the method of positioning by Beidou double-module positioning has higher positioning precision; Beidou first-generation communication link is safer, more reliable and stable, compared with wired communication network or other wireless communication ways; the command information platform monitoring system base on 3D-GIS database can accurately and directly display specific position of the fire and provide effective instruction for organizing to extinguish fire.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com