Patents

Literature

360results about How to "Realize continuous feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

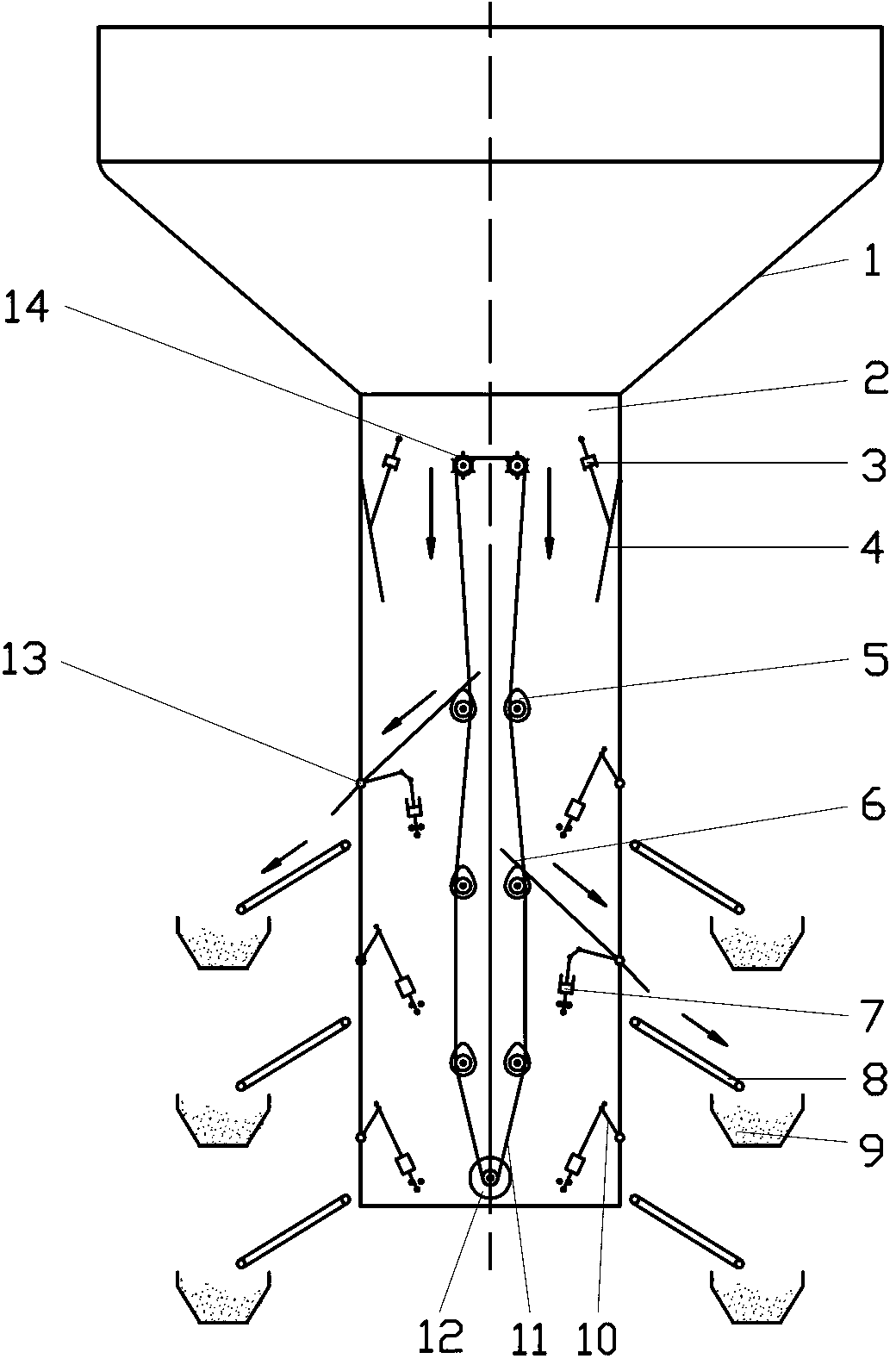

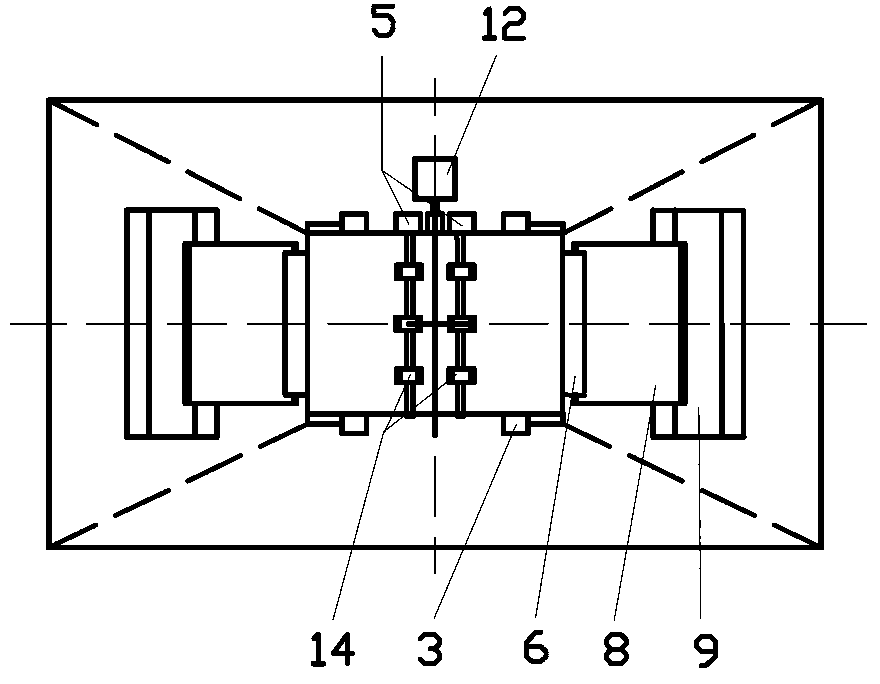

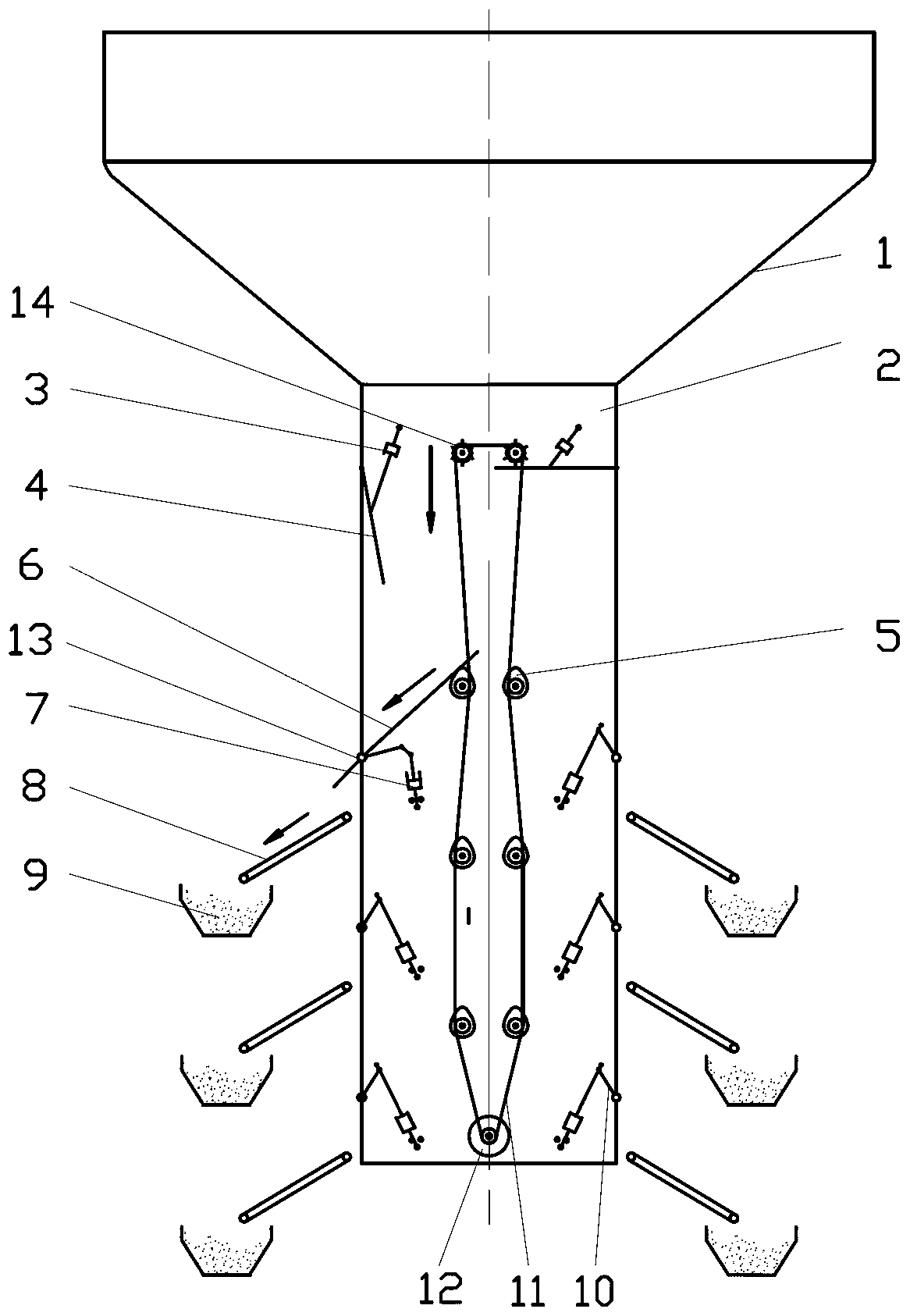

Efficient burning furnace with rotary fluidization grate

InactiveCN101532667ATurn overWith self-cleaning functionRevolving grateRocking grateCombustion systemFlue gas

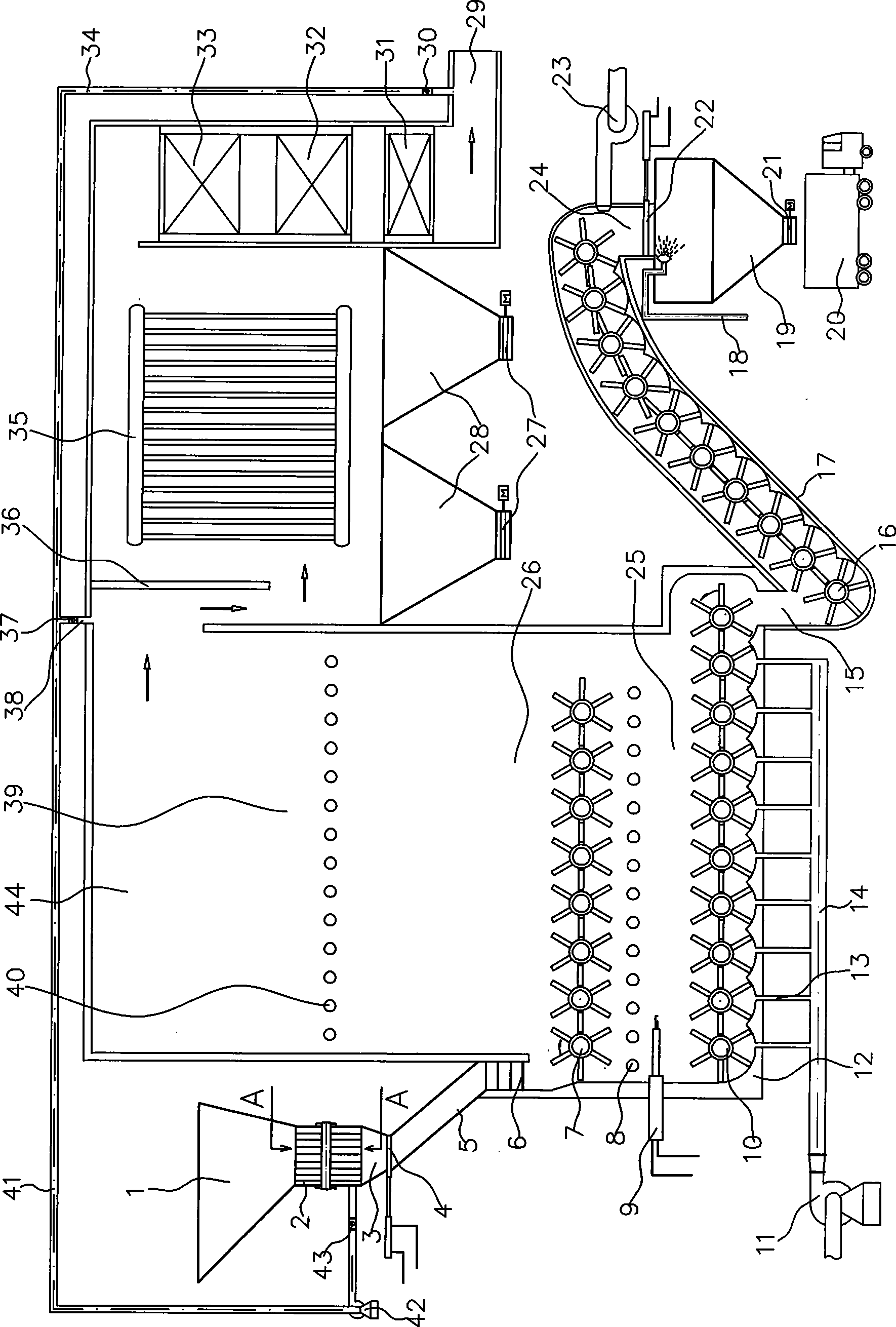

The invention relates to an efficient burning furnace with a rotary fluidization grate. The burning furnace with the rotary fluidization grate consists of a feeding system, a burning system and a slagging system; moreover, a waste heat boiler and a flue gas treatment system are connected with the burning furnace to form a complete garbage burning and generating system. The feeding system consists of a feeding hopper, a pre-drying conveying device, an aggregate bin, a chute and a charge distributor. The feeding hopper is a receiving opening for feeding garbage into the burning furnace and is arranged in a garbage storage pit close to one side of the burning furnace. An outlet of the feeding hopper is connected with an inlet of the pre-drying conveying device. A material level switch is arranged in the feeding hopper, and gives an alarm to prompt an operator to feed materials when the material level is lower than a set value so as to ensure that the hopper is not empty. The outlet of the hopper can be selectively provided with a feeding device. The burning furnace has the advantages of high burning speed, high burning efficiency, high slag burning degree, easy control, lower energy consumption, low pollution, low cost and investment conservation, and is applicable to domestic garbage with low thermal value and high moisture; and the garbage does not need to be pretreated.

Owner:新乡锅炉制造有限公司

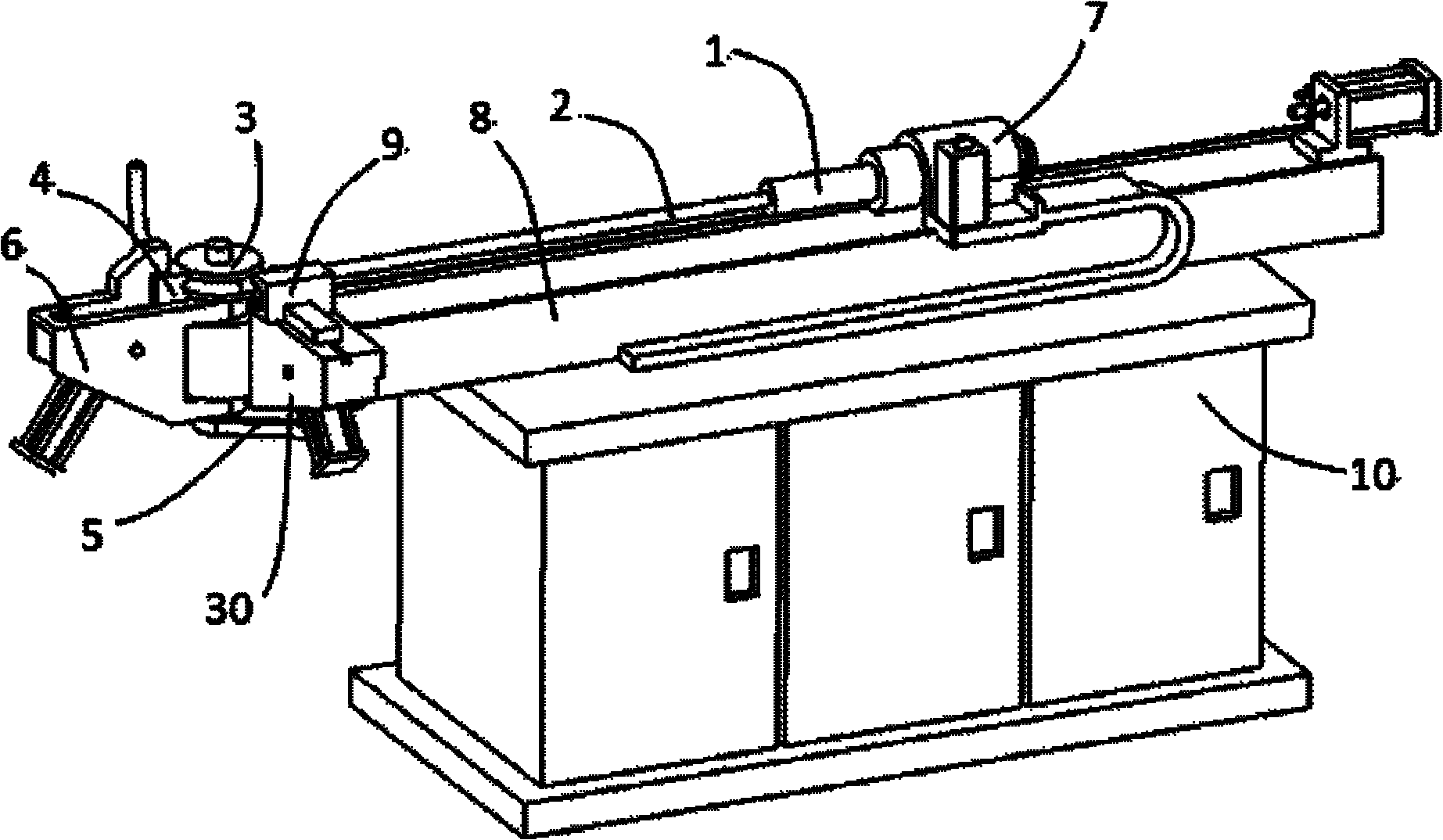

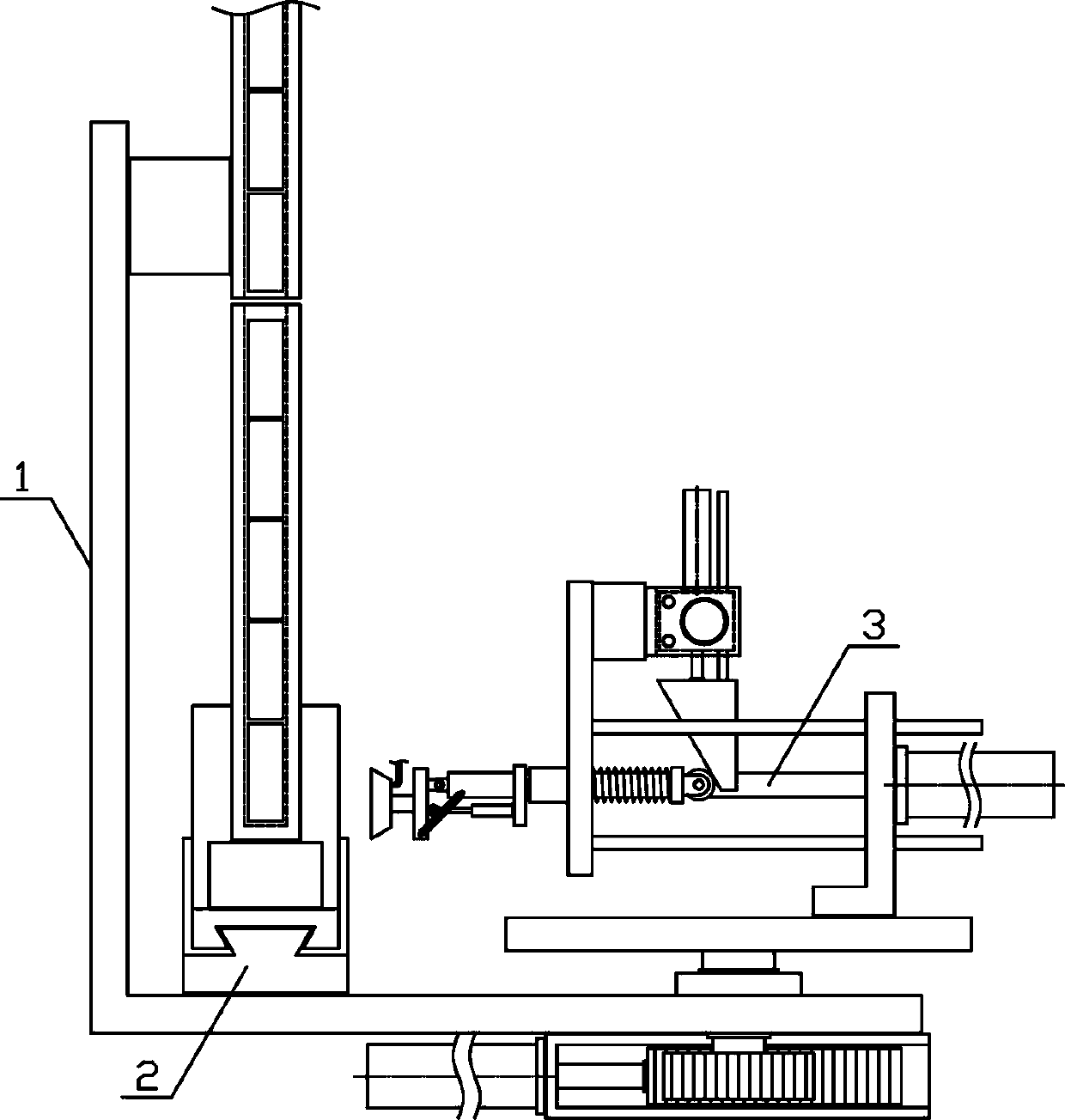

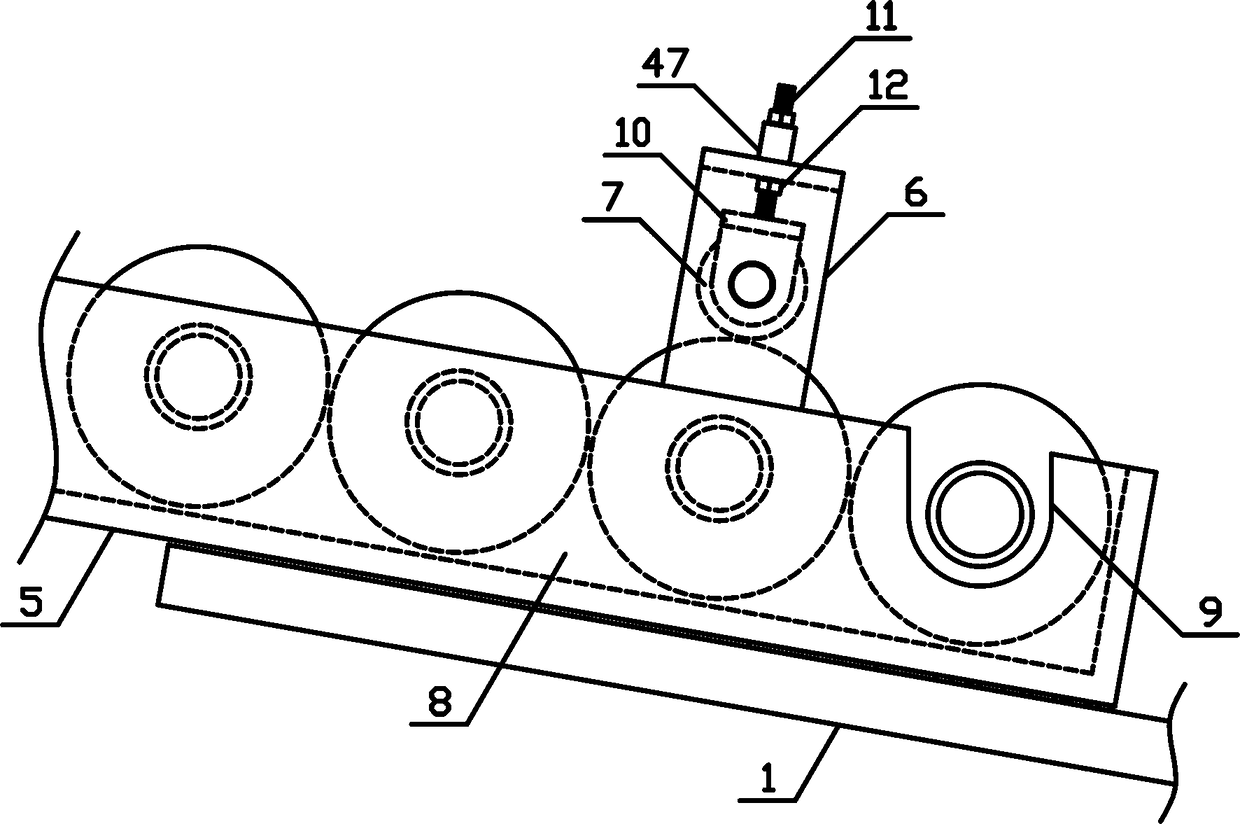

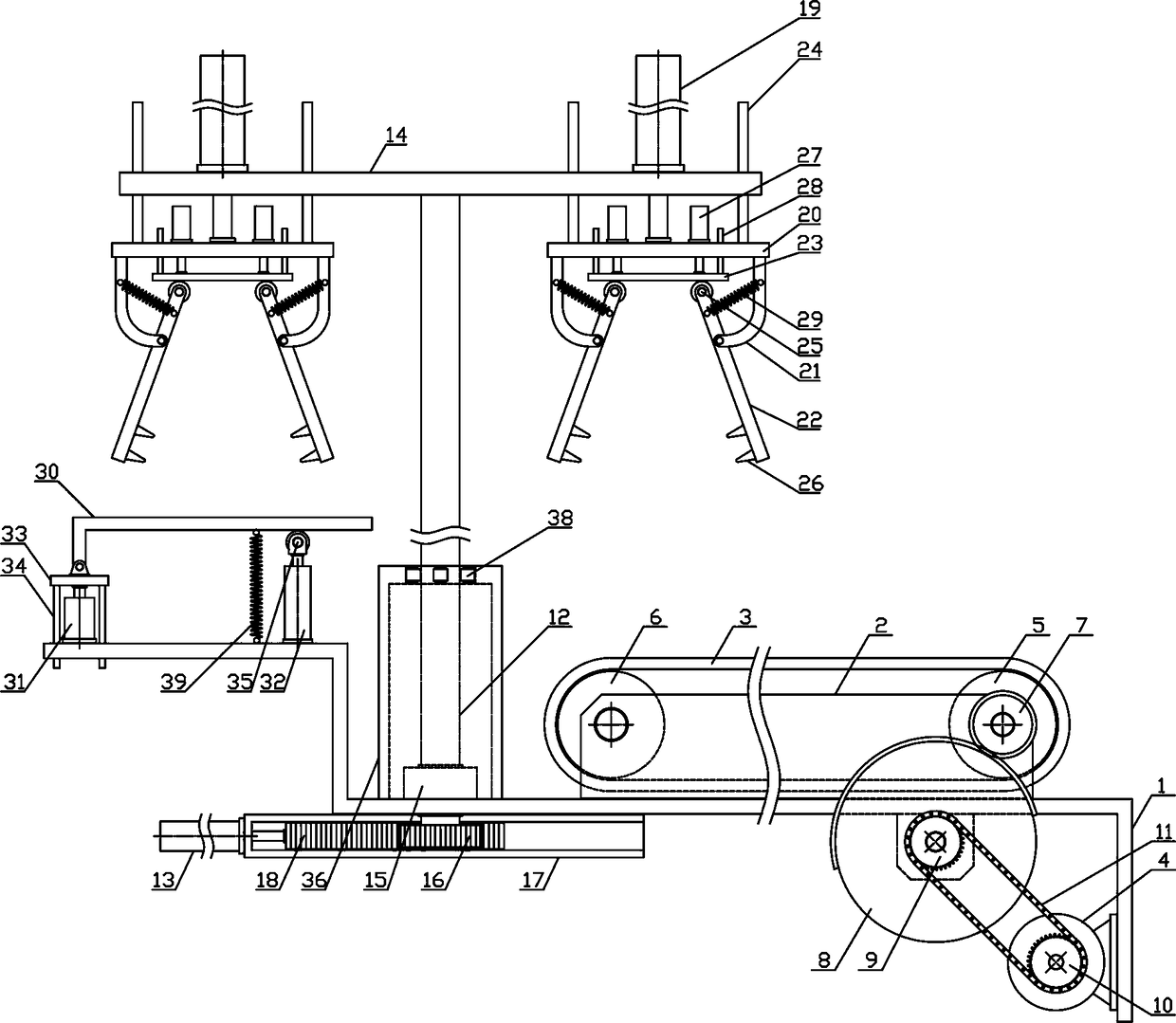

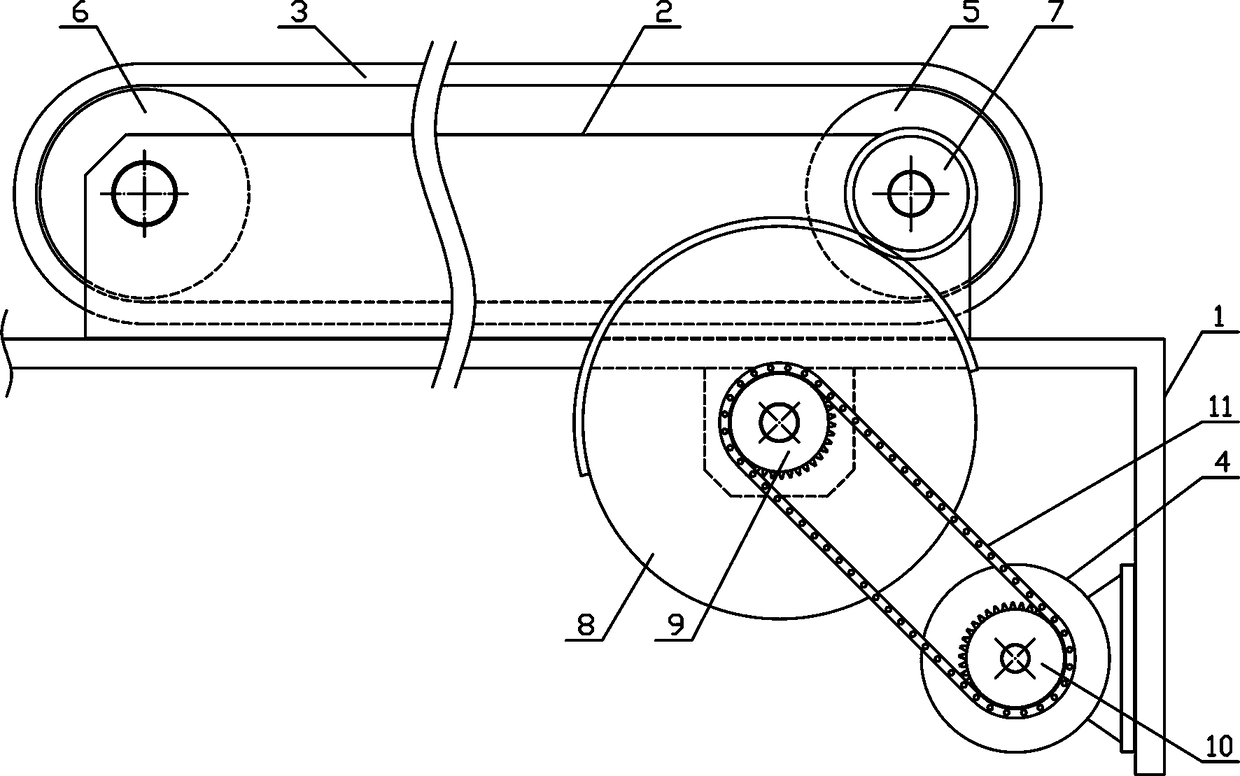

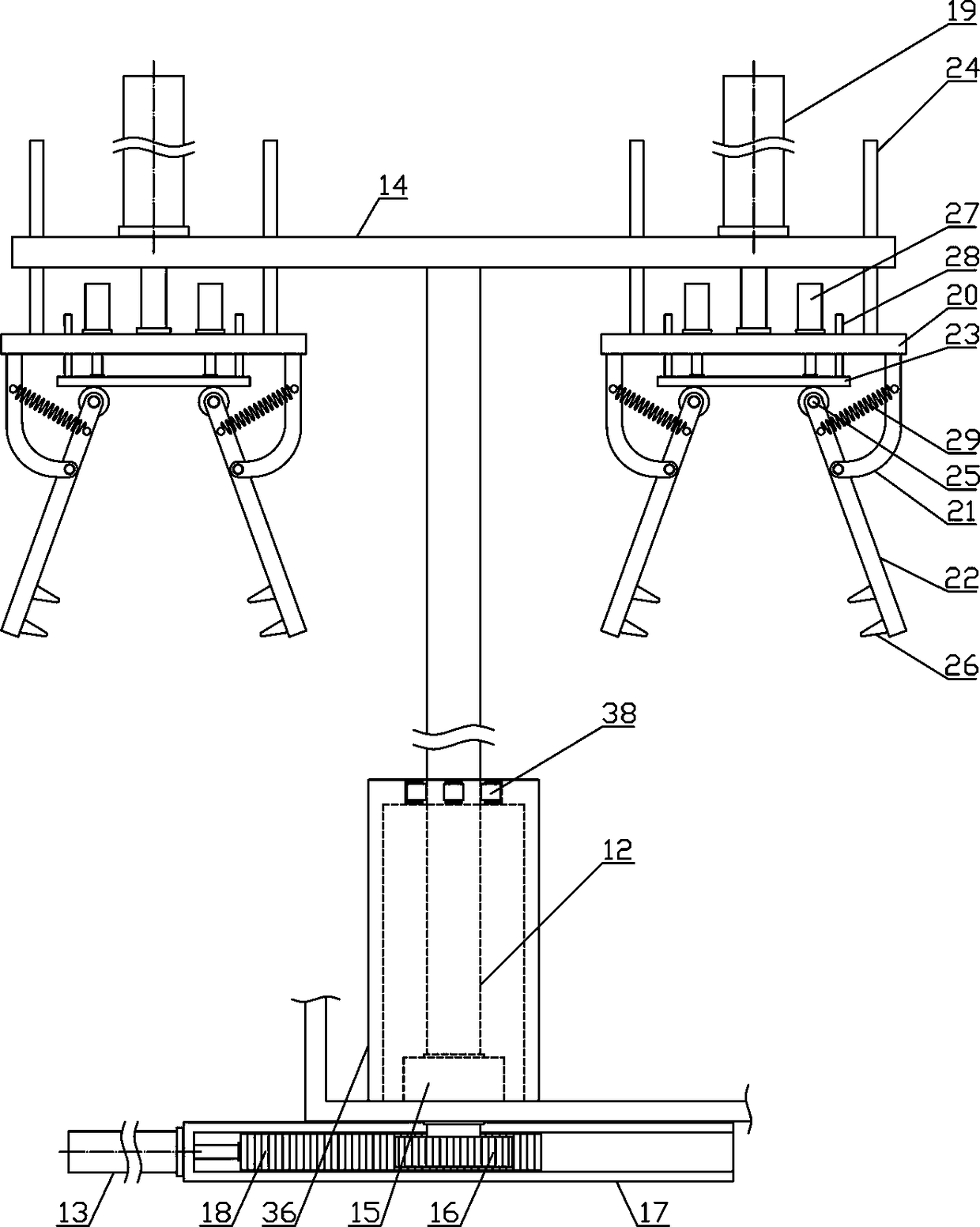

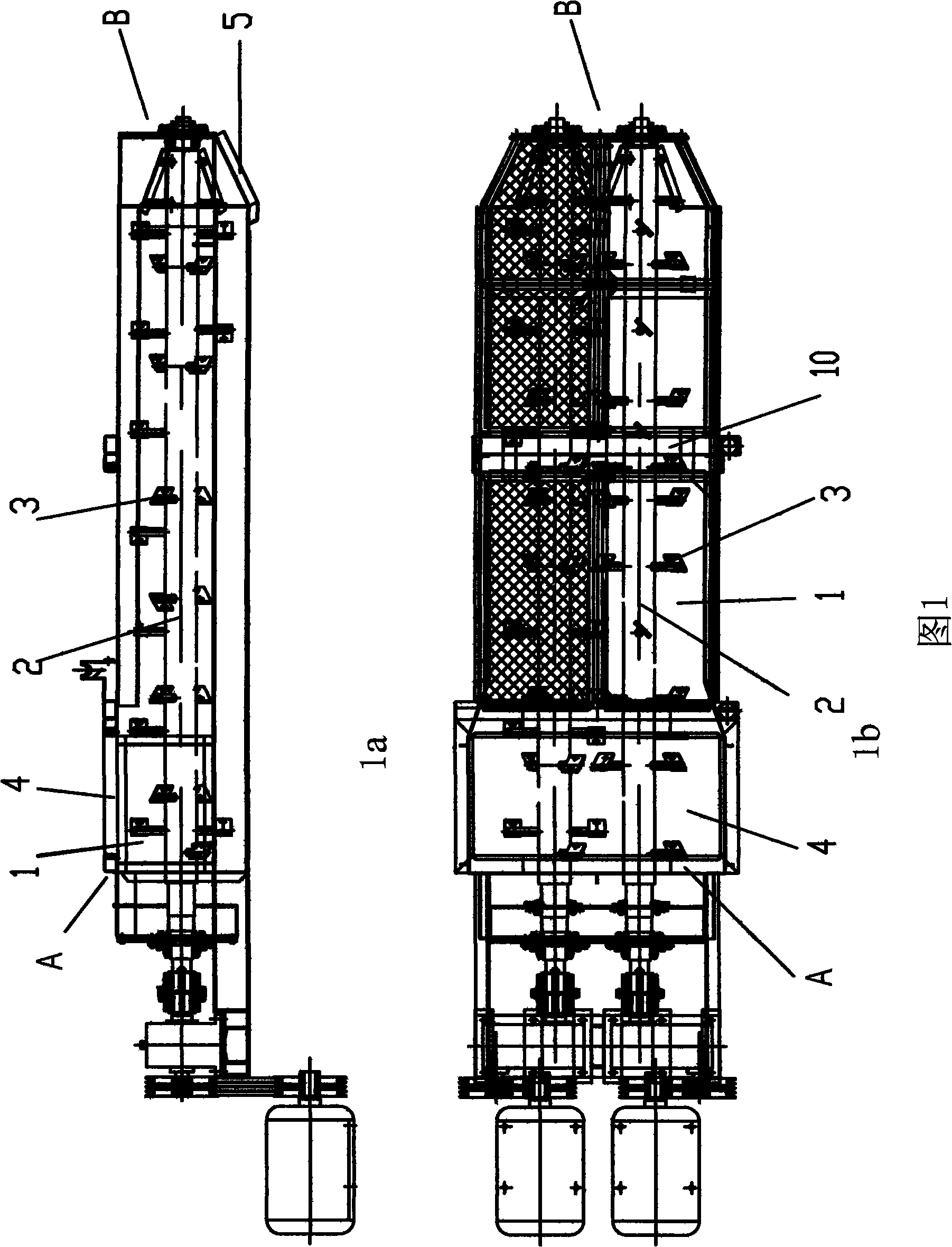

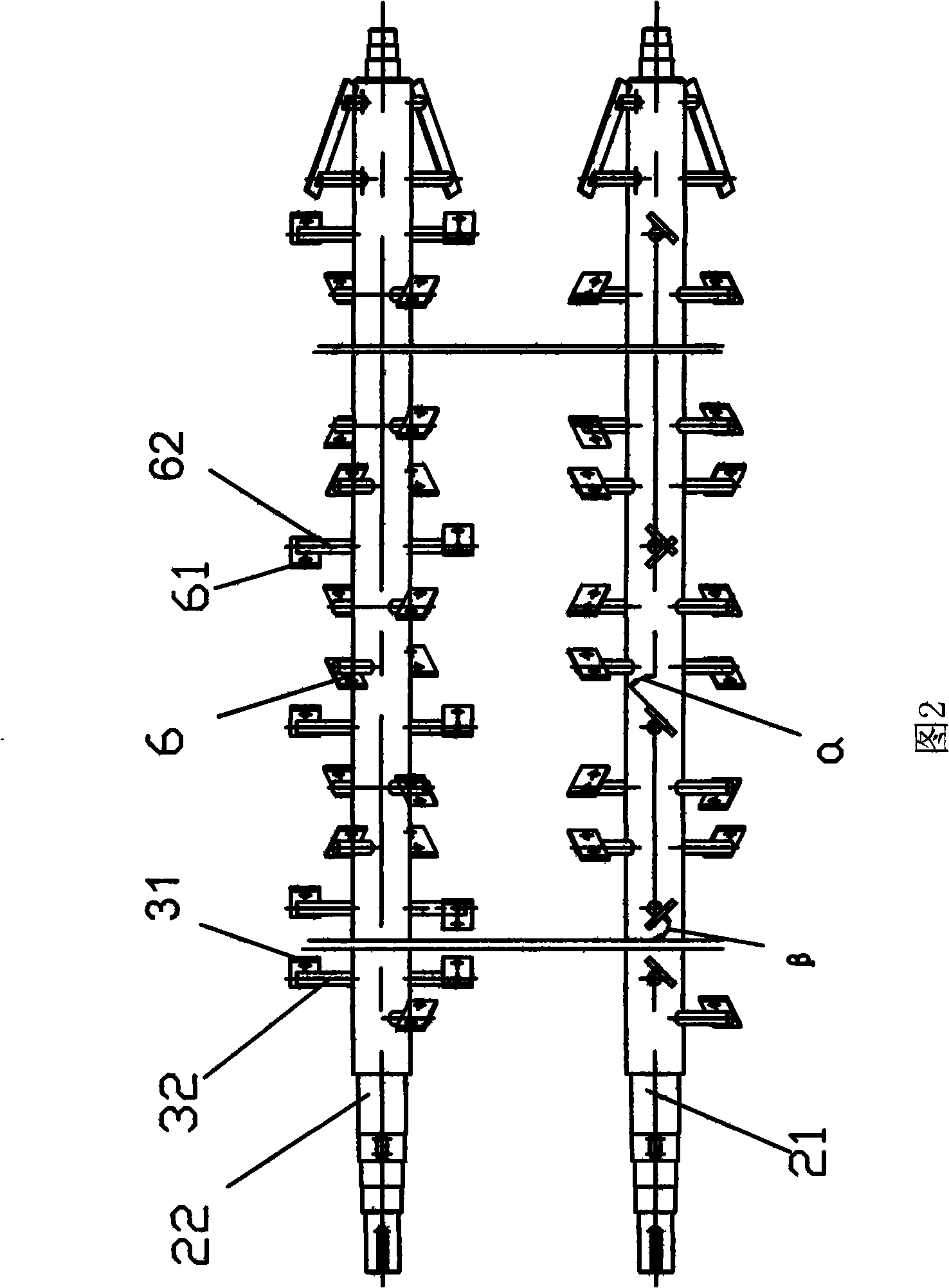

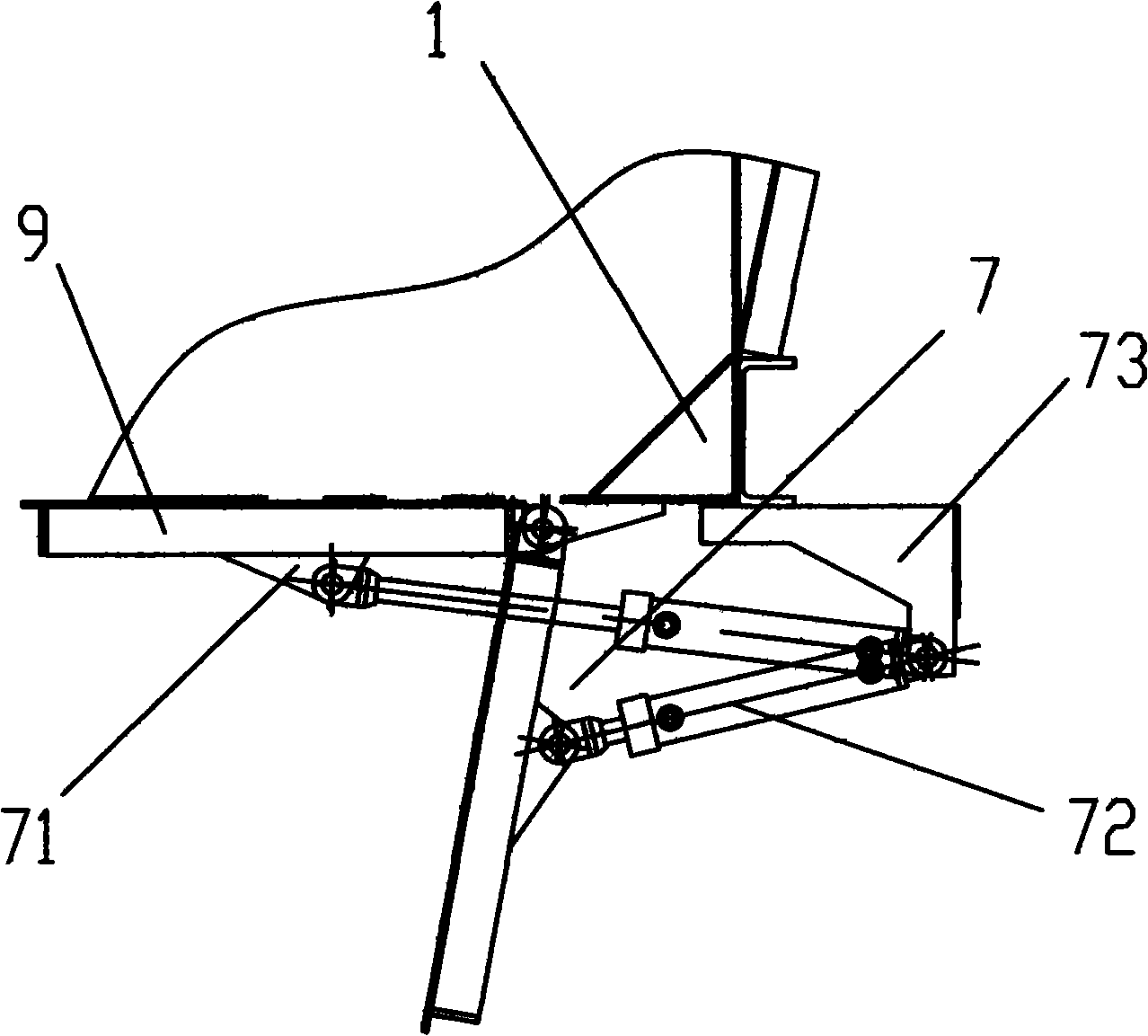

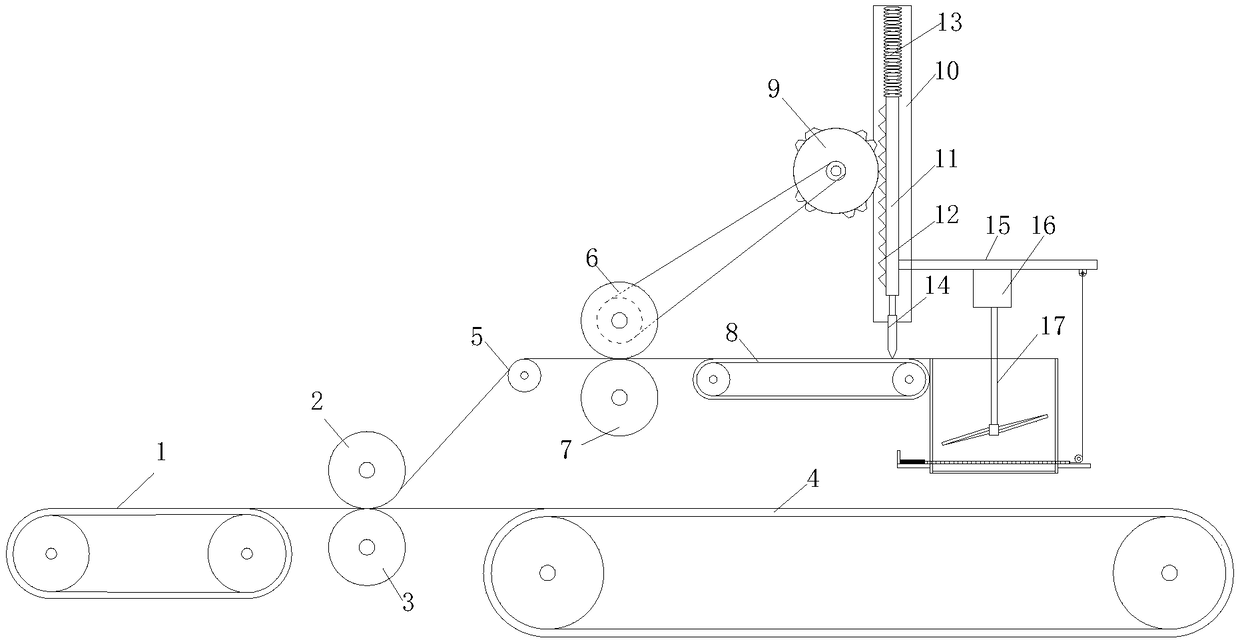

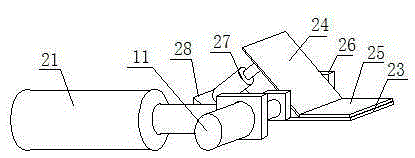

Alternated plate feeding device

InactiveCN102745459ARealize clamping and conveyingCompact structureConveyorsReciprocating motionEngineering

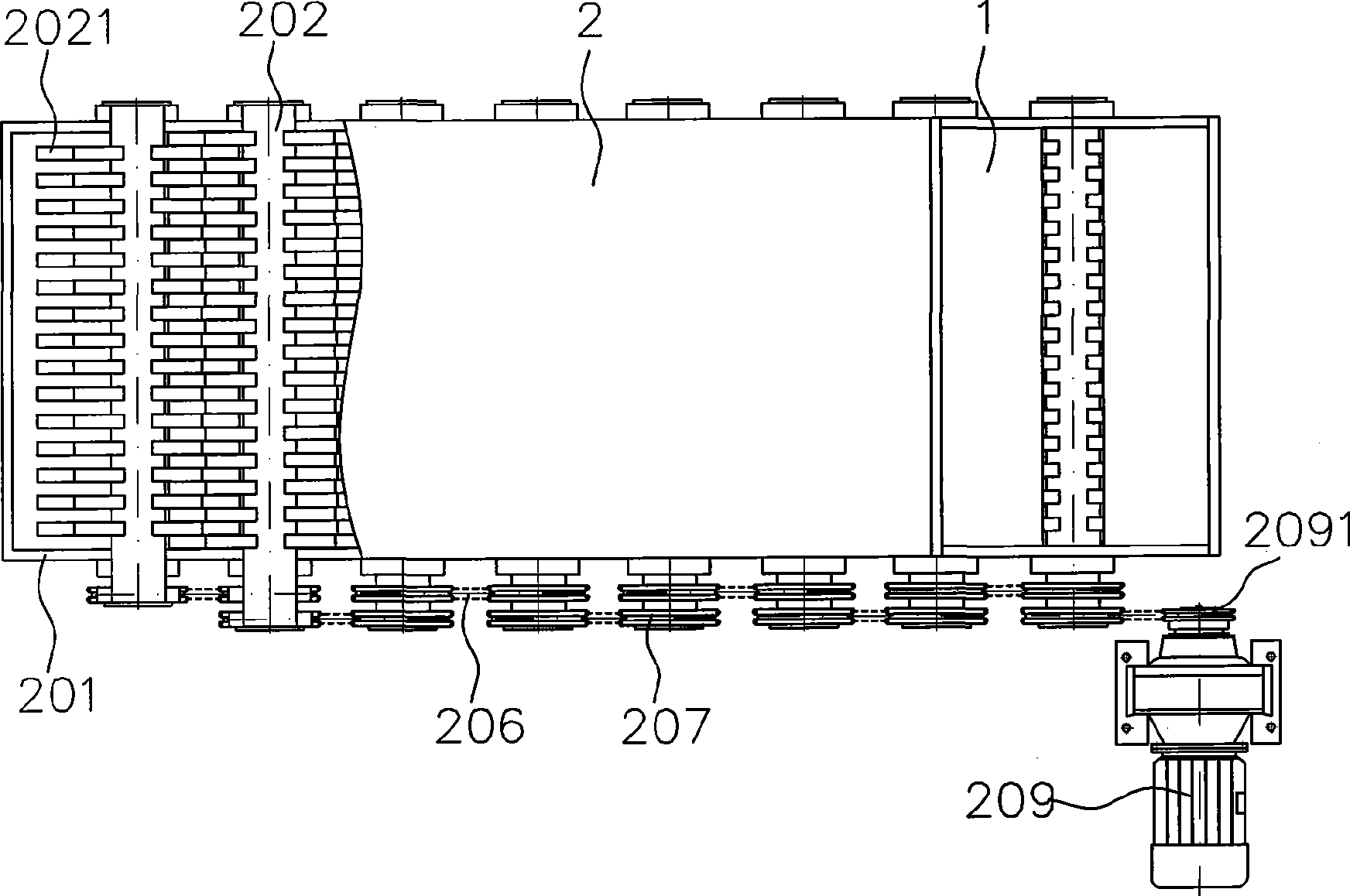

The invention discloses an alternated plate feeding device, which comprises a conveyor belt, at least two plate clamping mechanisms and a slide rail, wherein the conveyor belt comprises a plurality of working sections arranged in parallel, and at least two of all the working sections have opposite conveying directions; the plate clamping mechanisms are fixedly connected to different working sections; and the slide rail is used for bearing reciprocating motion of the plate clamping mechanisms. The alternated plate feeding device does not slip during clamping; and the feeding distance can be conveniently calculated through the conveying distance of the conveyor belt, so that the feeding precision is greatly promoted. In the optimal technical scheme, a first plate clamping mechanism and a second plate clamping mechanism are adopted, so that idle travel is avoided in the feeding process, uninterrupted feeding is realized, and the feeding efficiency is greatly improved; and only one clamping part is required in one feeding stroke, so that the surface of a material is scratched little. The device has the advantages of convenience in control, high feeding precision, little surface scratch, high feeding efficiency and the like.

Owner:ZHEJIANG UNIV

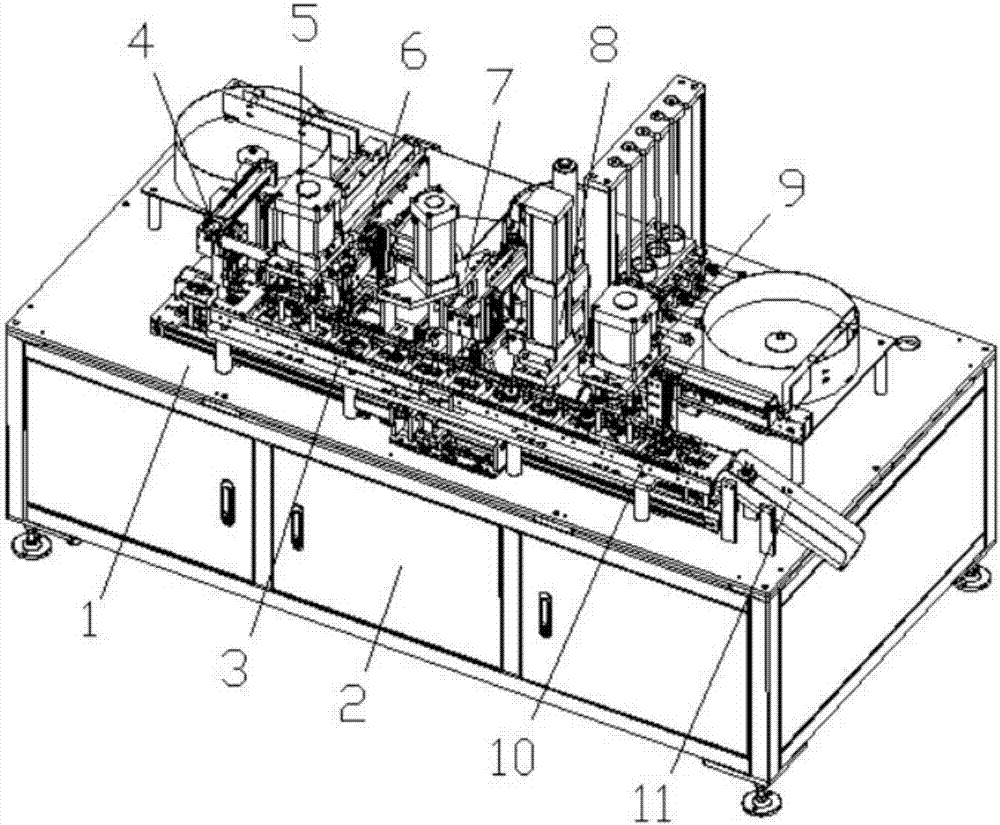

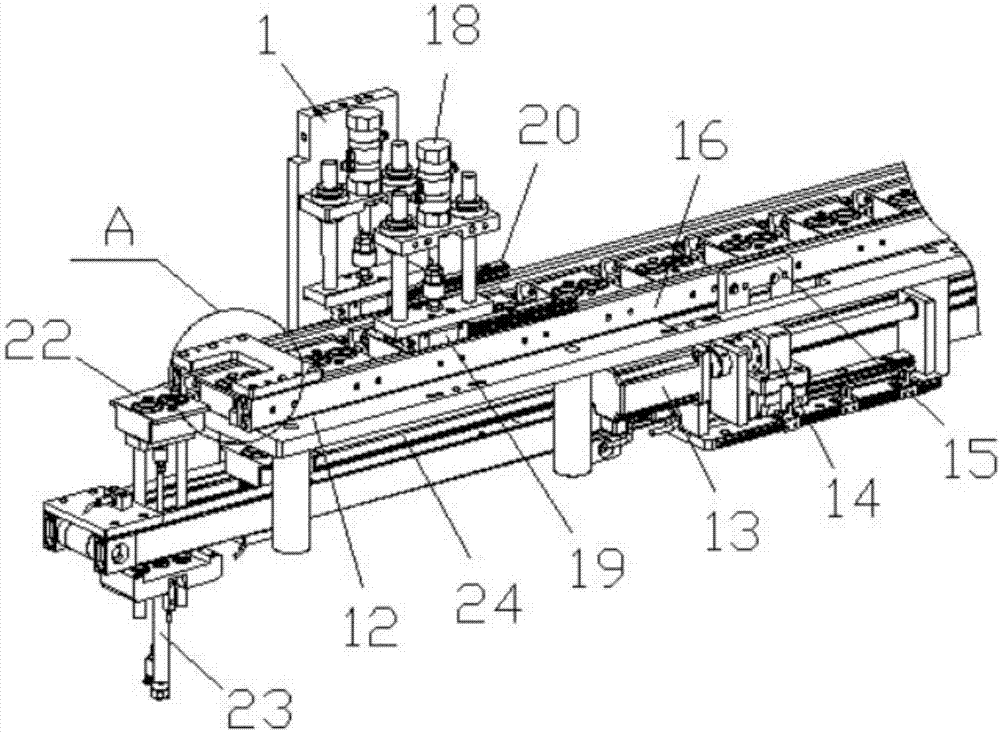

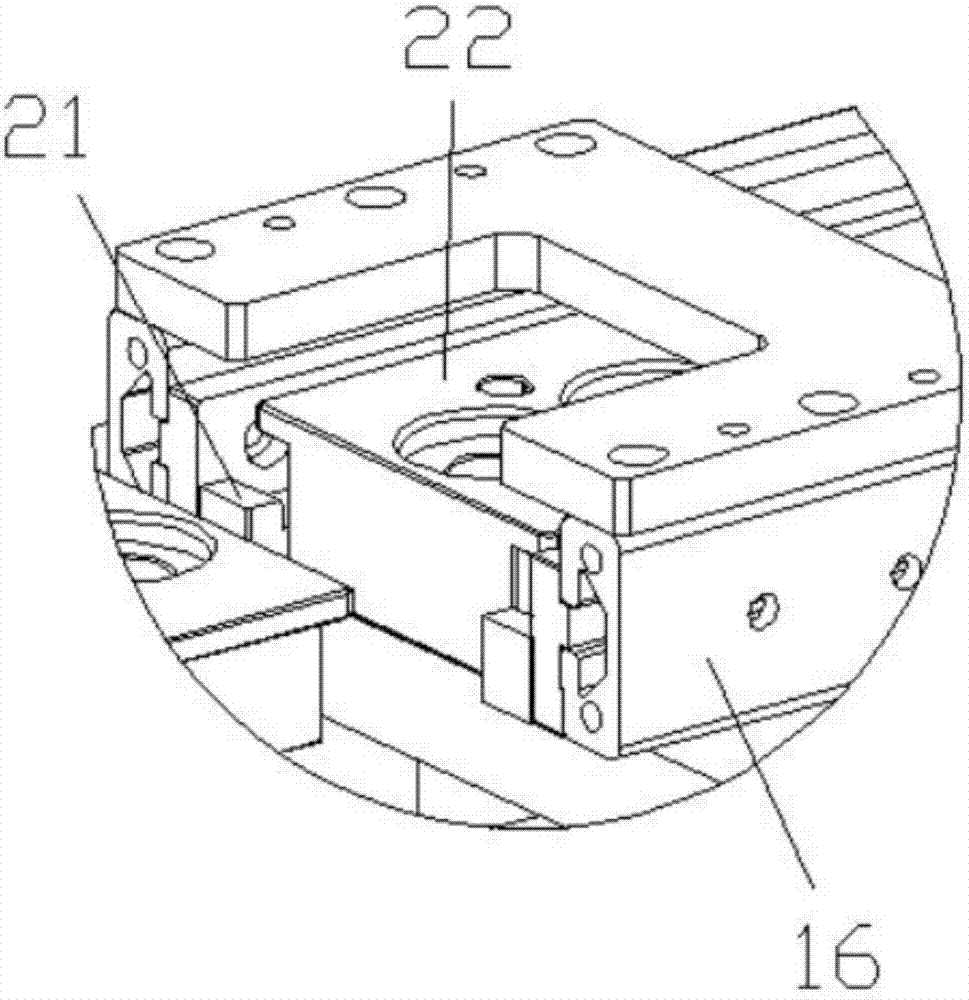

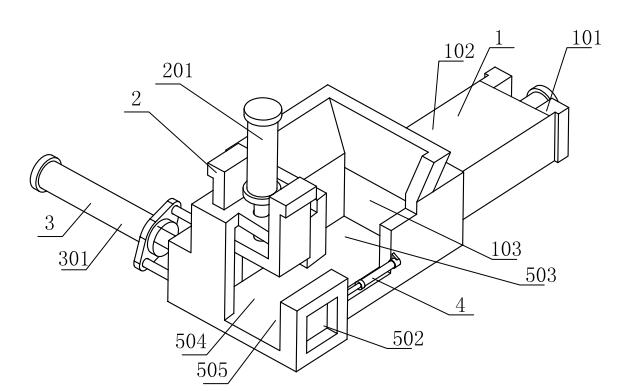

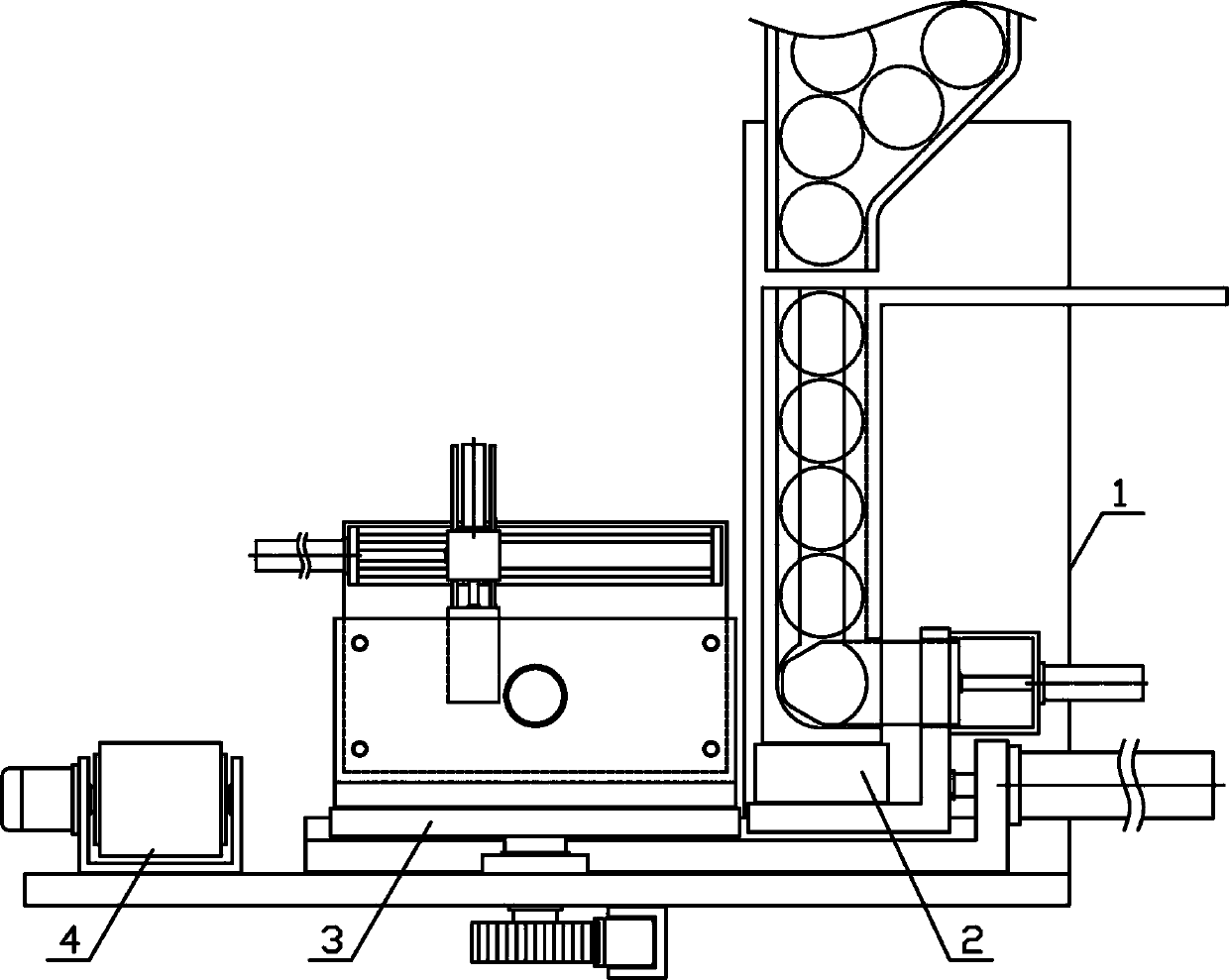

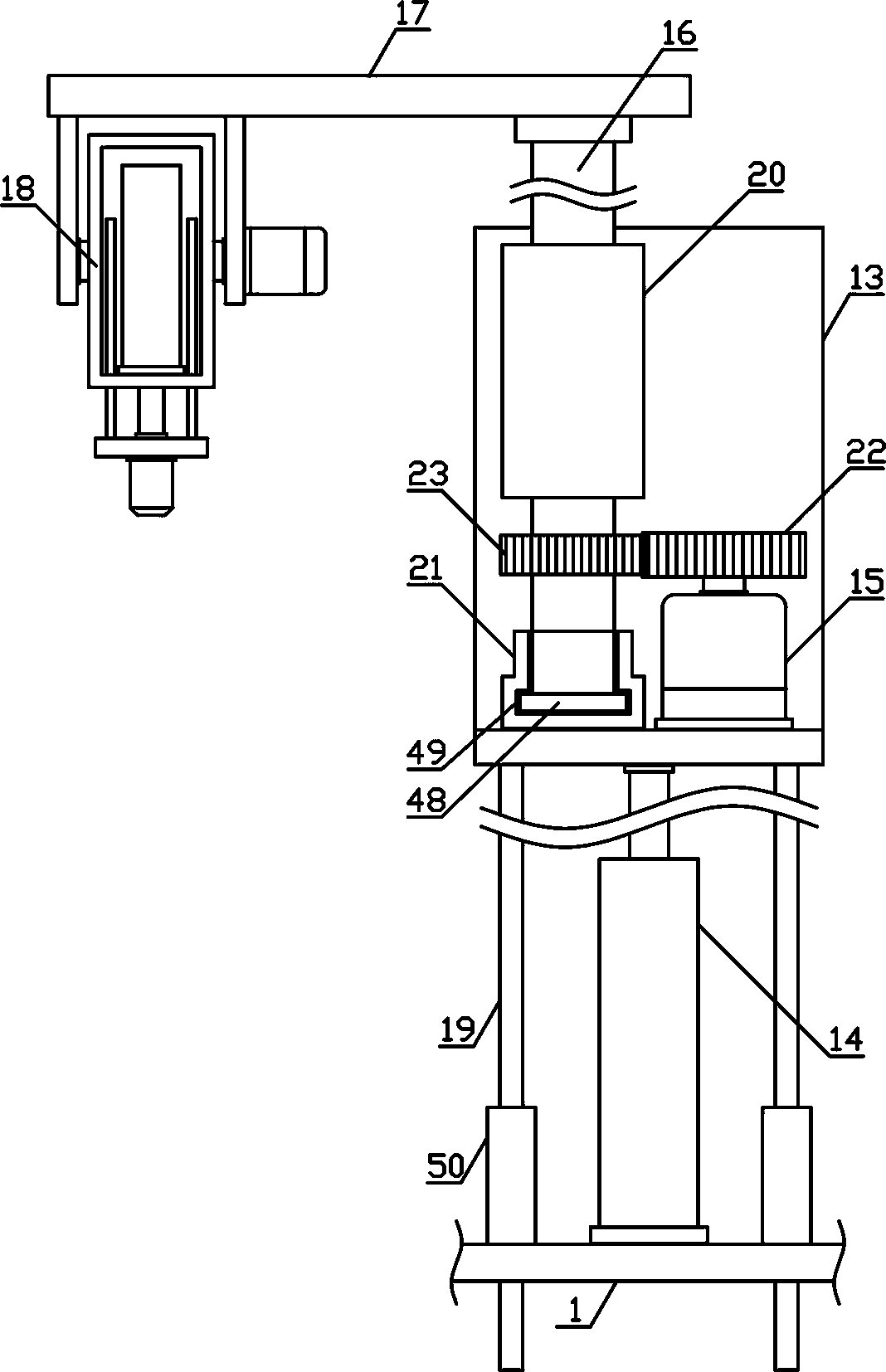

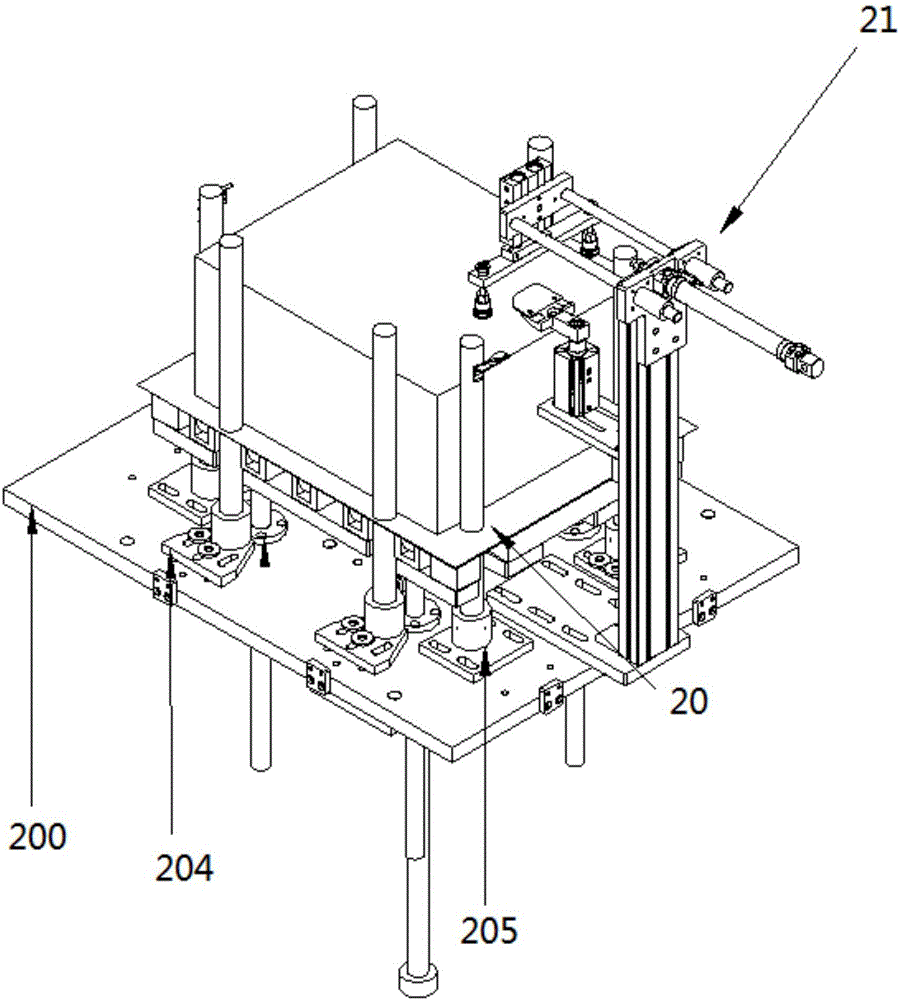

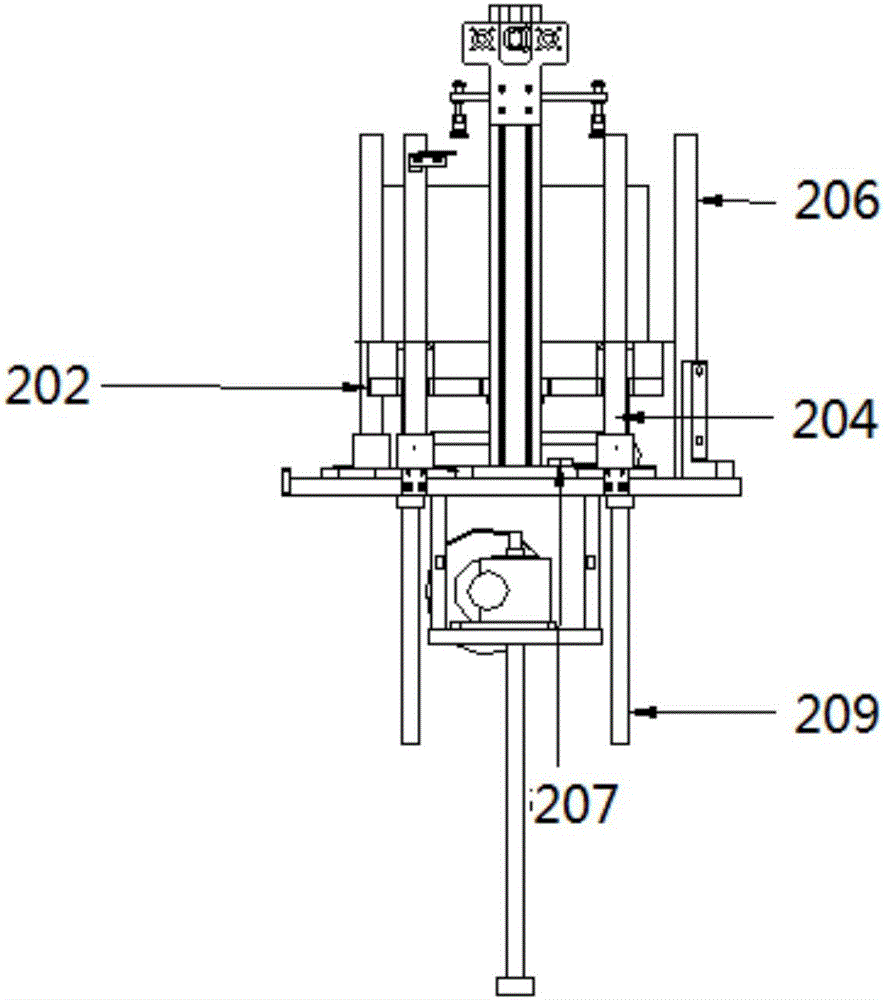

Automatic gear shaft assembling machine

InactiveCN107571008AHigh matching precisionImprove assembly efficiency and yieldAssembly machinesManipulatorBall bearing

The invention relates to an automatic gear shaft assembling machine. The rack is provided with a carrier conveying device. The carrier conveying device comprises a carrier conveying base. Carrier feeding movable air cylinders are arranged on the front side and the rear side of the carrier conveying base and connected with a carrier feeding movable base. The carrier feeding movable base is connected with a carrier feeding movable block. A carrier feeding clamping block matched with a carrier is arranged on the inner side of the carrier feeding movable block. A carrier feeding lifting matched sliding rail is arranged at the upper portion of the carrier feeding movable block and matched with a carrier feeding lifting matched sliding block. The upper portion of the carrier feeding lifting matched sliding block is matched with a carrier feeding lifting air cylinder on the rack. The rack is provided with a ball bearing feeding device, a shaft rod feeding device, an overturning device, a clamping ring feeding device, a gear feeding device, a clamping bearing feeding device and a discharging mechanical arm. According to the automatic gear shaft assembling machine, automatic ball bearing and shaft rod assembling can be achieved, and the assembling efficiency and the yield are greatly improved.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

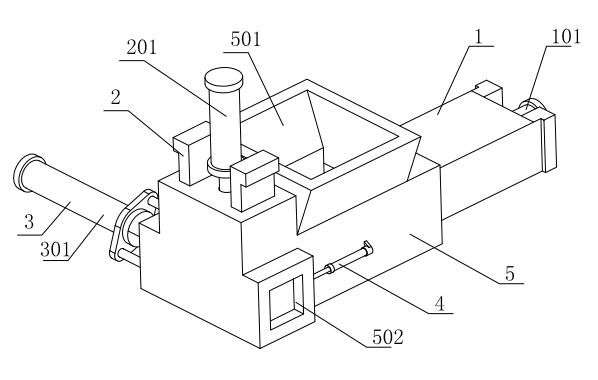

Scrap metal briquetting machine

The invention relates to a scrap metal briquetting machine which comprises a machine body and a three-way hydraulic device, wherein an inlet hopper bin is arranged on the top of the machine body, an outlet is arranged in front of the lower part, a door opening device is arranged at the outlet, and the inside part of the machine body is divided into a pre-extrusion cavity, a secondary extrusion cavity and a third extrusion cavity; the three-way hydraulic device comprises a lateral hydraulic device, a vertical hydraulic device and a longitudinal hydraulic device. Scrap metal is extruded in three ways through the three-way hydraulic device, the compression mode is reasonable, the compression force is great, great compression ratio can be achieved, and the compression efficiency is high. The continuous feeding of the hopper bin can be realized, a lateral pusher head can directly enter the next working cycle after resetting, so that the cycle time is greatly saved, and the working efficiency of the machine is high. A groove is adopted between the pusher head and the inner wall of the machine body for cooperation, therefore, better cooperation can be realized, the service life is long, and the security is good.

Owner:JIANGYIN RUIFENG HYDRAULIC MACHINE CO LTD

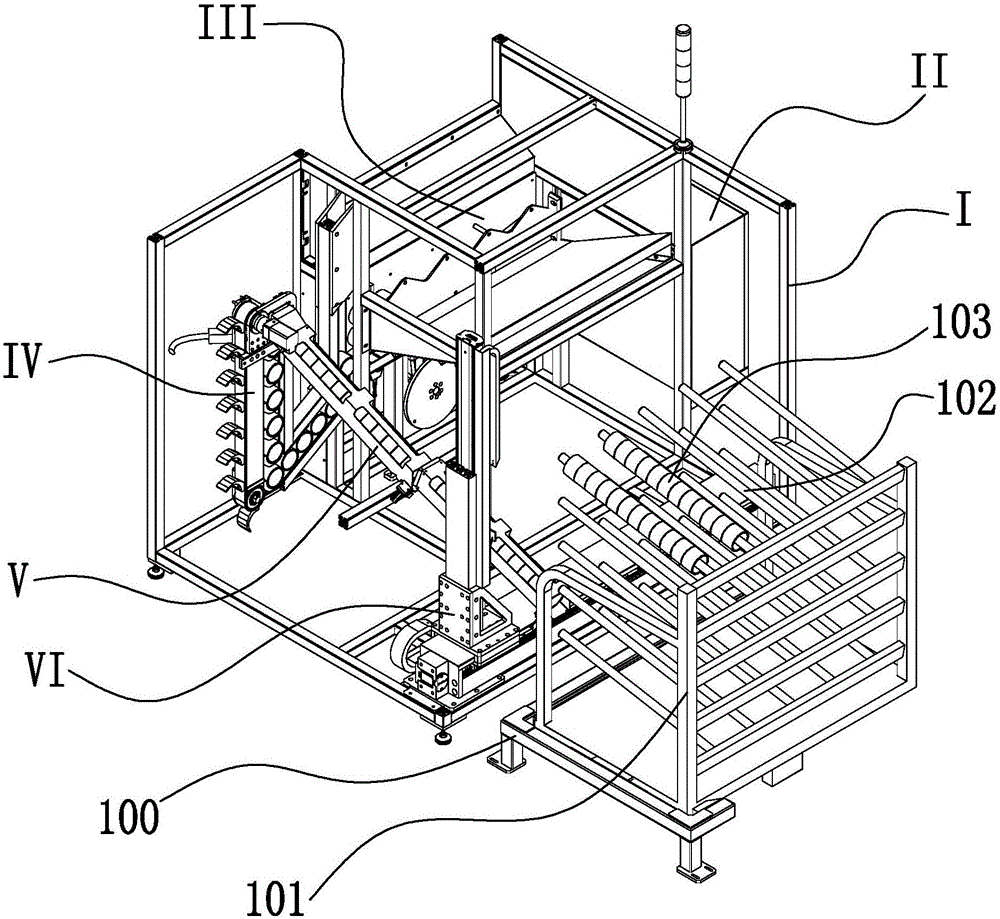

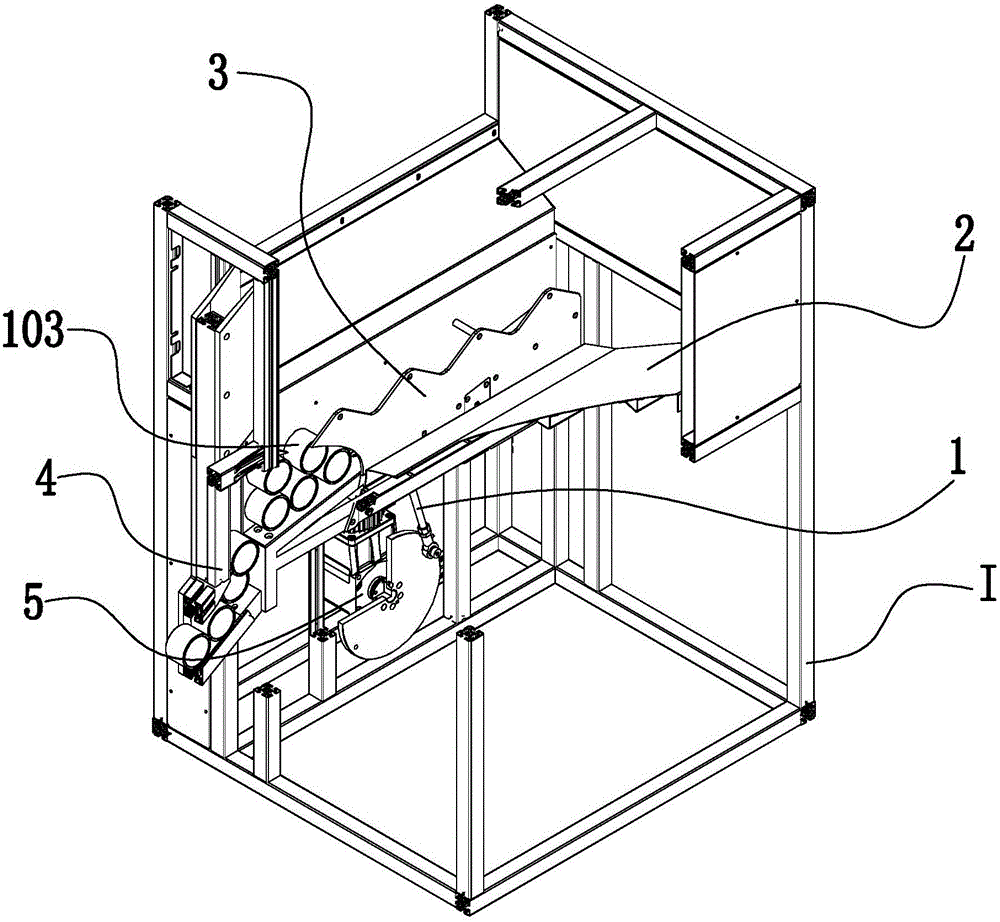

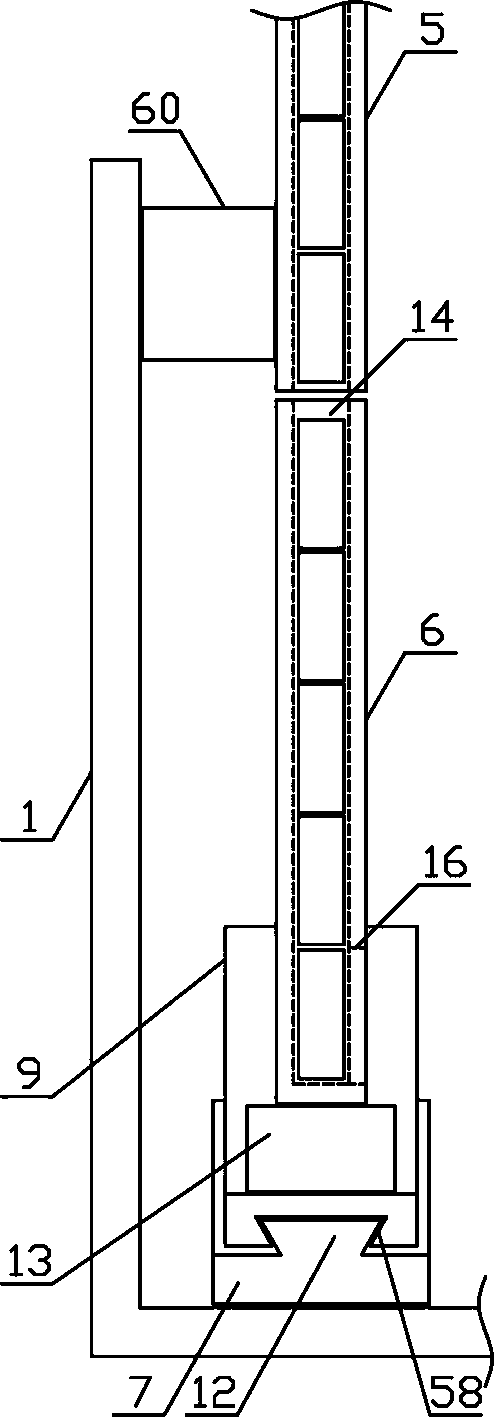

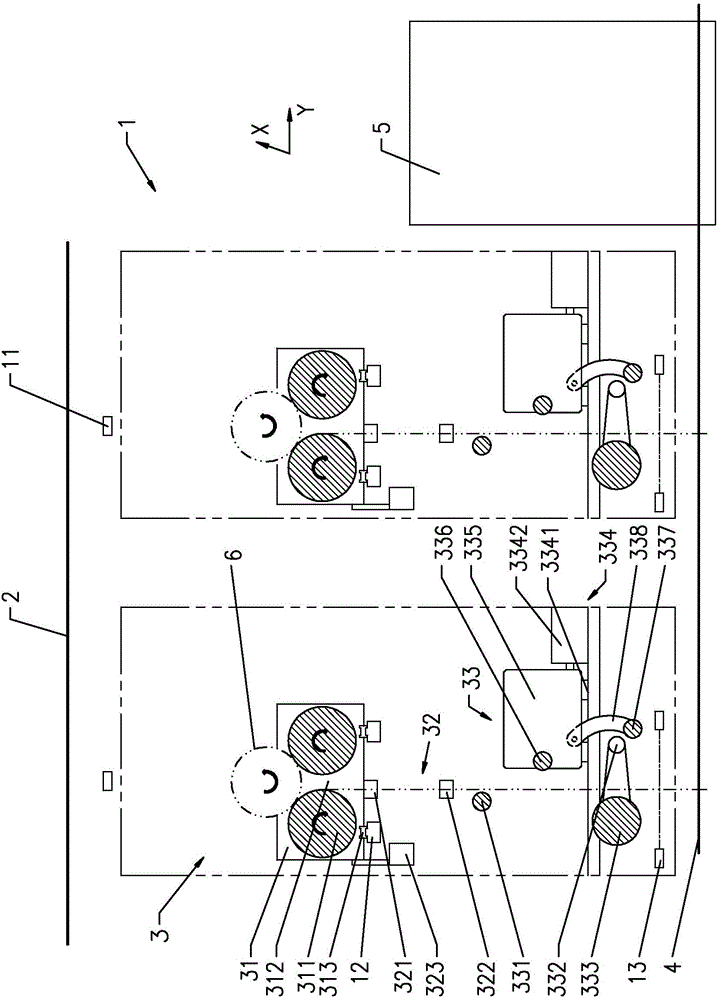

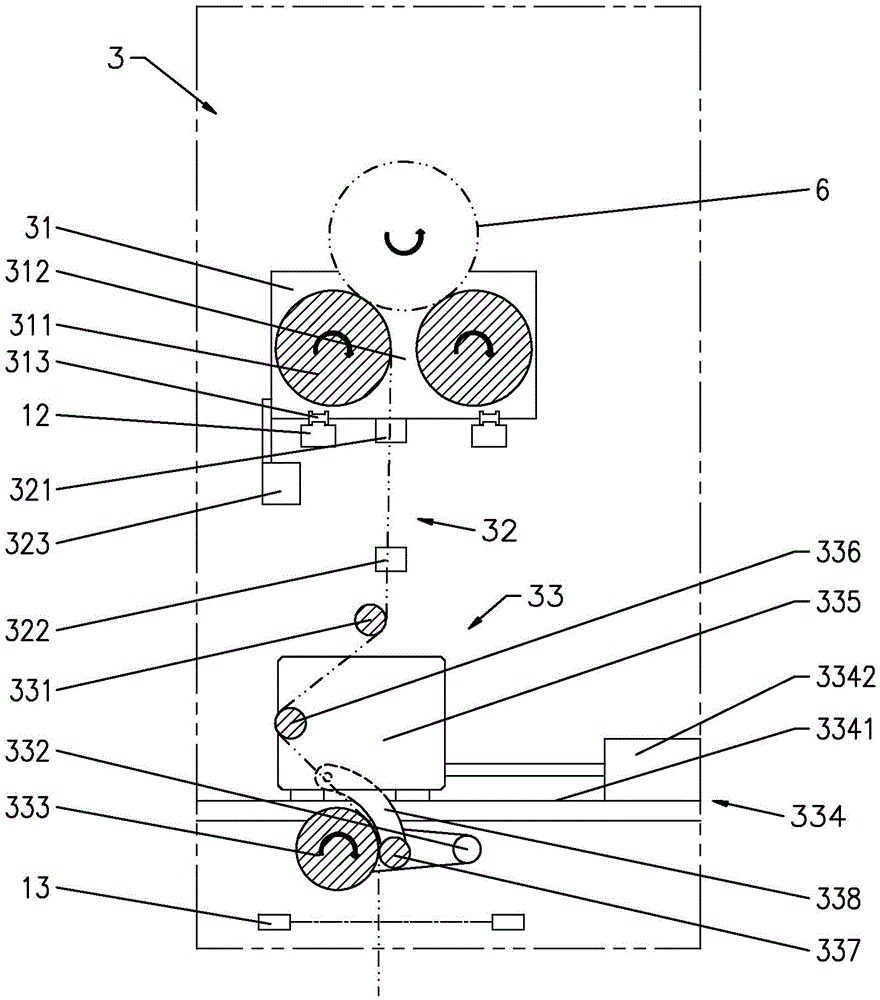

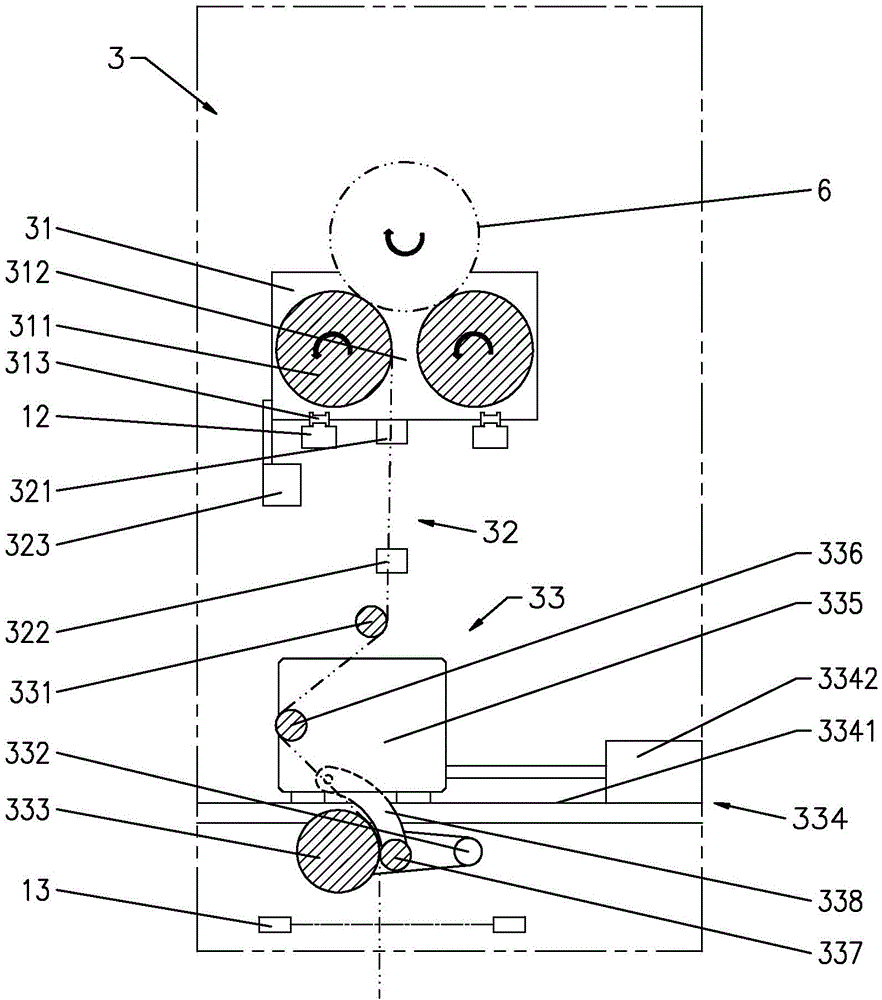

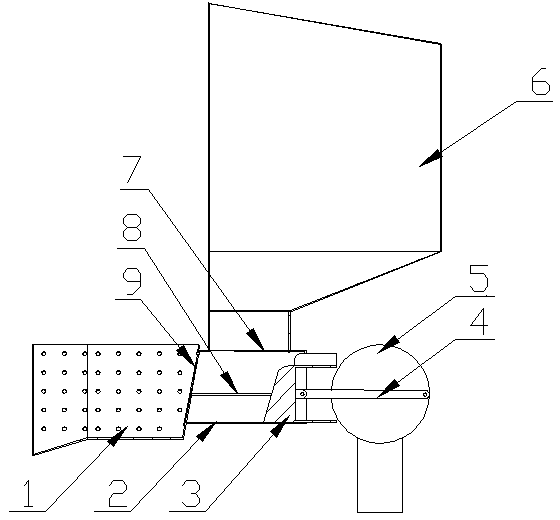

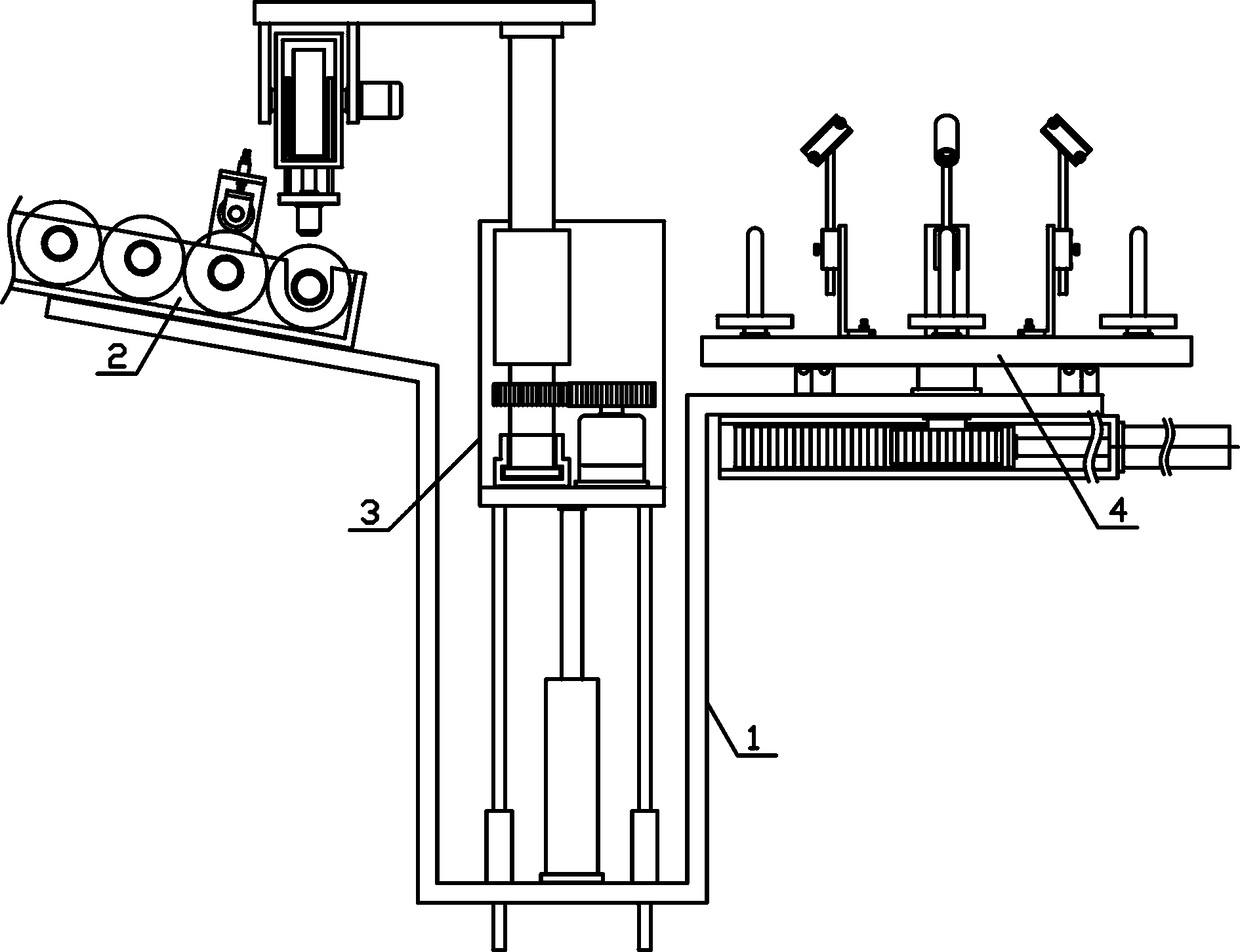

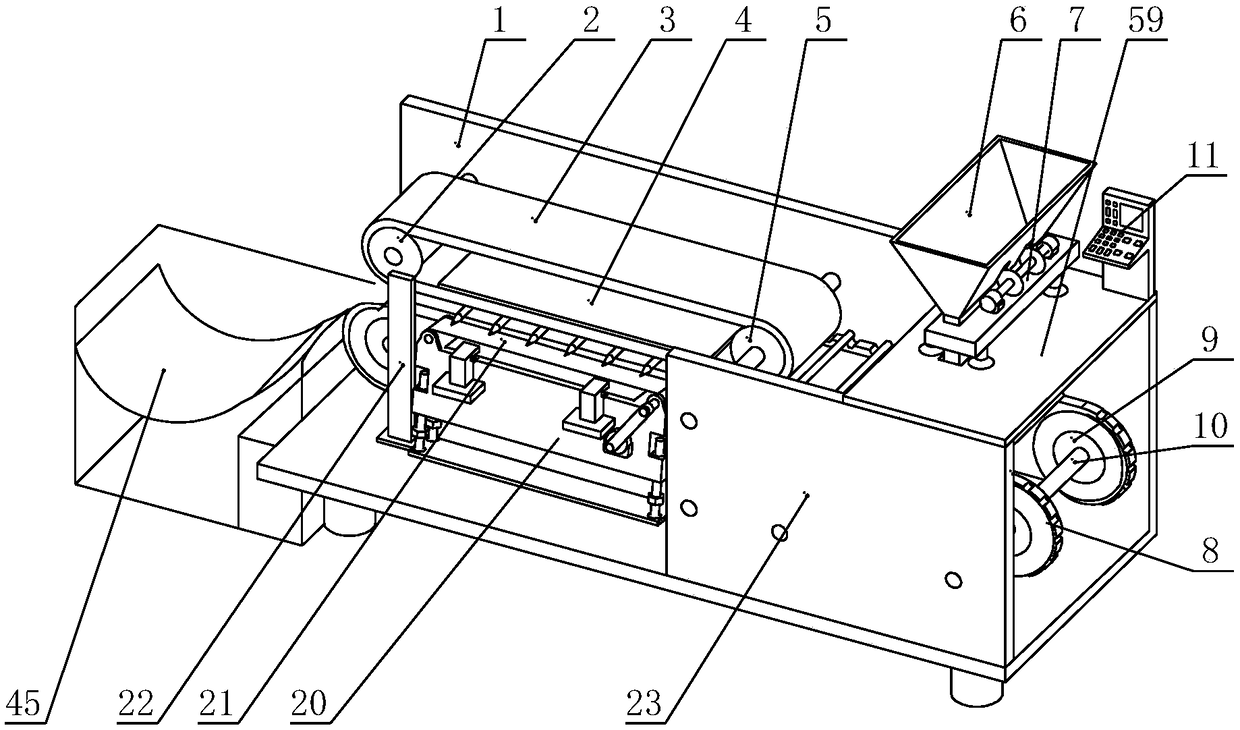

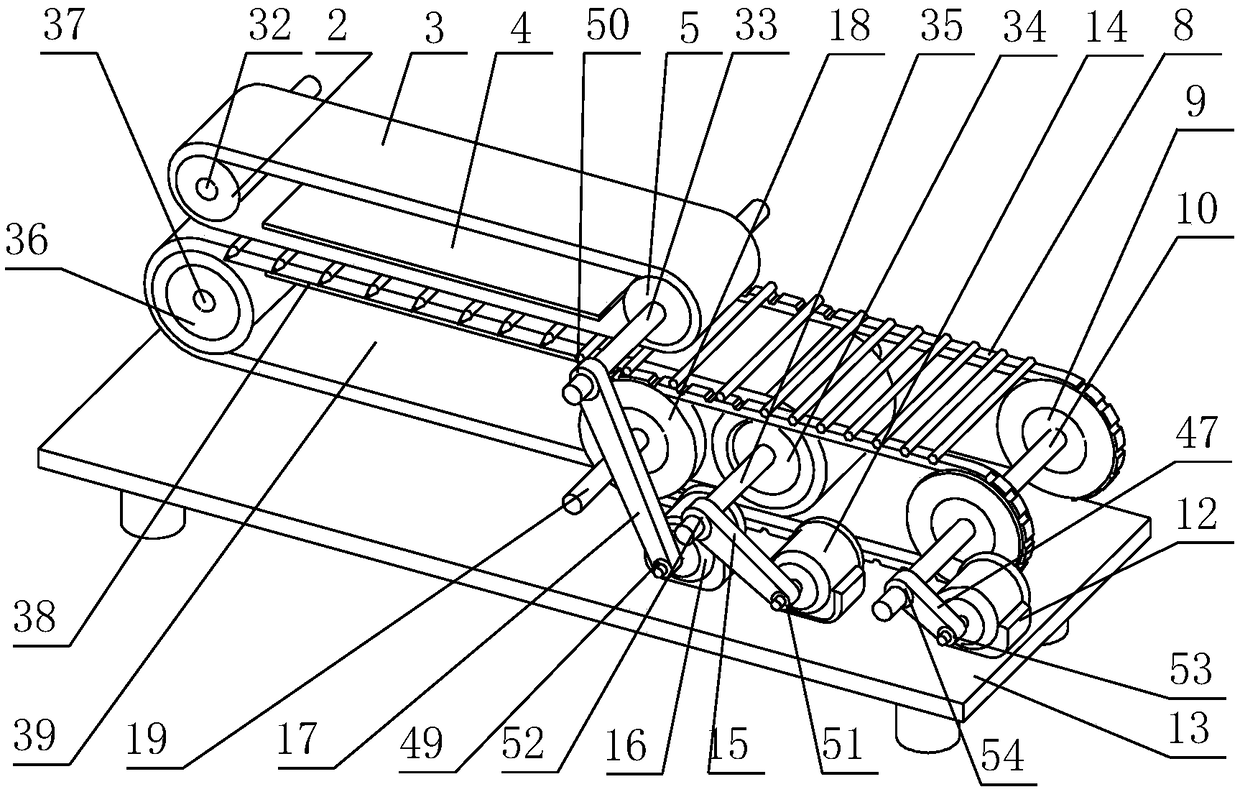

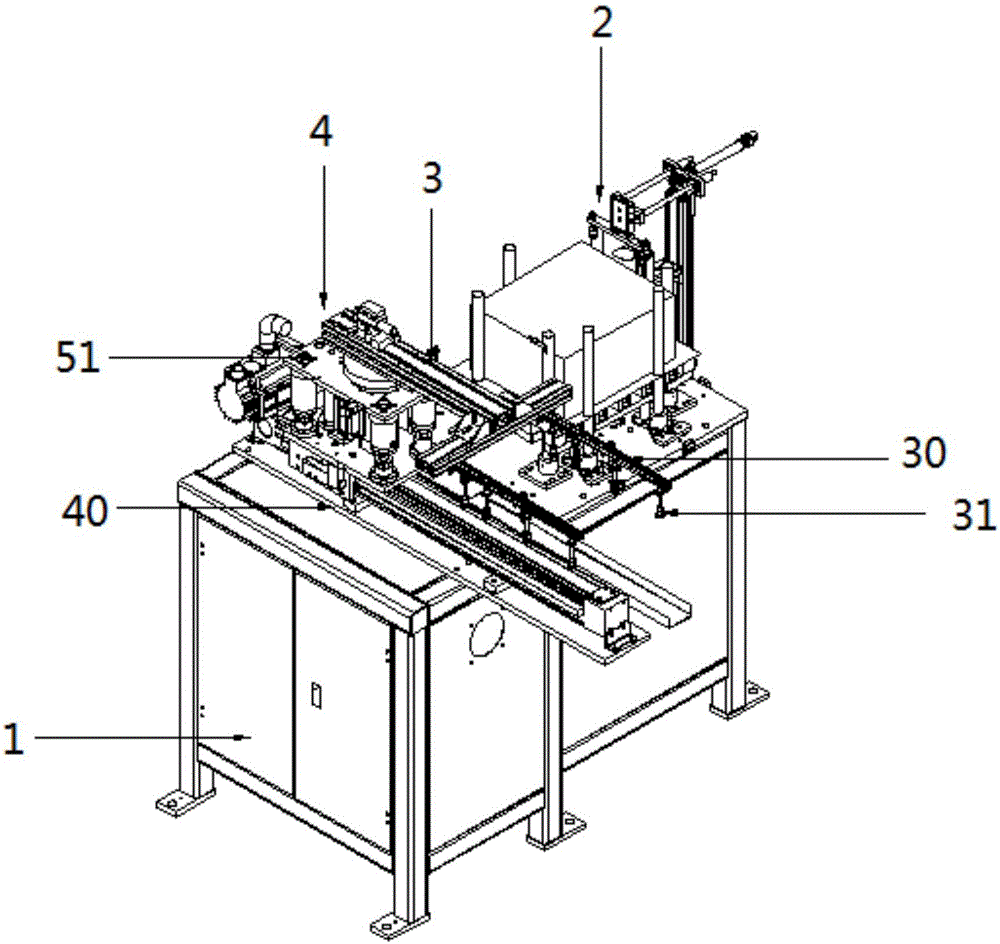

Automatic code spraying and stacking machine for spandex filament paper pipes and use method of automatic code spraying and stacking machine

ActiveCN105712100ARealize continuous feedingStrong market demandConveyorsStacking articlesEngineeringStorage material

The invention relates to an automatic code spraying and stacking machine for spandex filament paper pipes and a use method of the automatic code spraying and stacking machine. The automatic code spraying and stacking machine for spandex filament paper pipes comprises a machine frame, a material distribution module, a lifting and code spraying module, a buffer material way module and a perpendicular cross-shaped slide table discharge module, and the material distribution module, the lifting and code spraying module, the buffer material way module and the perpendicular cross-shaped slide table discharge module are installed on the machine frame. A paper pipe table positioning frame is arranged outside the machine frame. A finished product paper pipe trolley and material rods are installed on the paper pipe table positioning frame. A discharge port of the material distribution module corresponds to a feed port of the lifting and code spraying module. A discharge port of the lifting and cod spraying module corresponds to a feed port of the slow-storage material way module. The buffer material way module is obliquely installed on the perpendicular cross-shaped slide table discharge module. The automatic code spraying and stacking machine has the beneficial effects that the ingenious lifting material distribution and a C-shaped guide shoe lifting mechanism are adopted, and therefore continuous spandex filament paper pipe supply is achieved, and the code spraying and stacking efficiency is high. In addition, the automatic code spraying and stacking machine further has the beneficial effects of being low in manufacturing cost, reliable in mechanism, stable in running, easy to operate, and the like.

Owner:HANGZHOU DIANZI UNIV

Method for smelting vanadium-rich pig iron from vanadium-containing steel slag

The invention discloses a method for smelting vanadium-rich pig iron from vanadium-containing steel slag, which comprises the following steps: adding 63-67 parts of vanadium-containing steel slag, 14-18 parts of iron powder, 8-12 parts of silica, 4-6 parts of carbon powder and 3-4 parts of aluminum shot into a smelting furnace, and heating to melt the mixture; and after the reaction is finished, separating furnace slag from molten iron, and cooling the molten iron to obtain the vanadium-rich pig iron, wherein the vanadium-containing steel slag is slag left after smelting vanadium-containing molten iron in a converter. The method can enrich 85% of vanadium in the vanadium-containing steel slag into pig iron to obtain the vanadium-rich pig iron, well utilizes the steel slag, has the advantages of simple production technique, strong operability and low production cost, and is convenient for development in industrial production.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

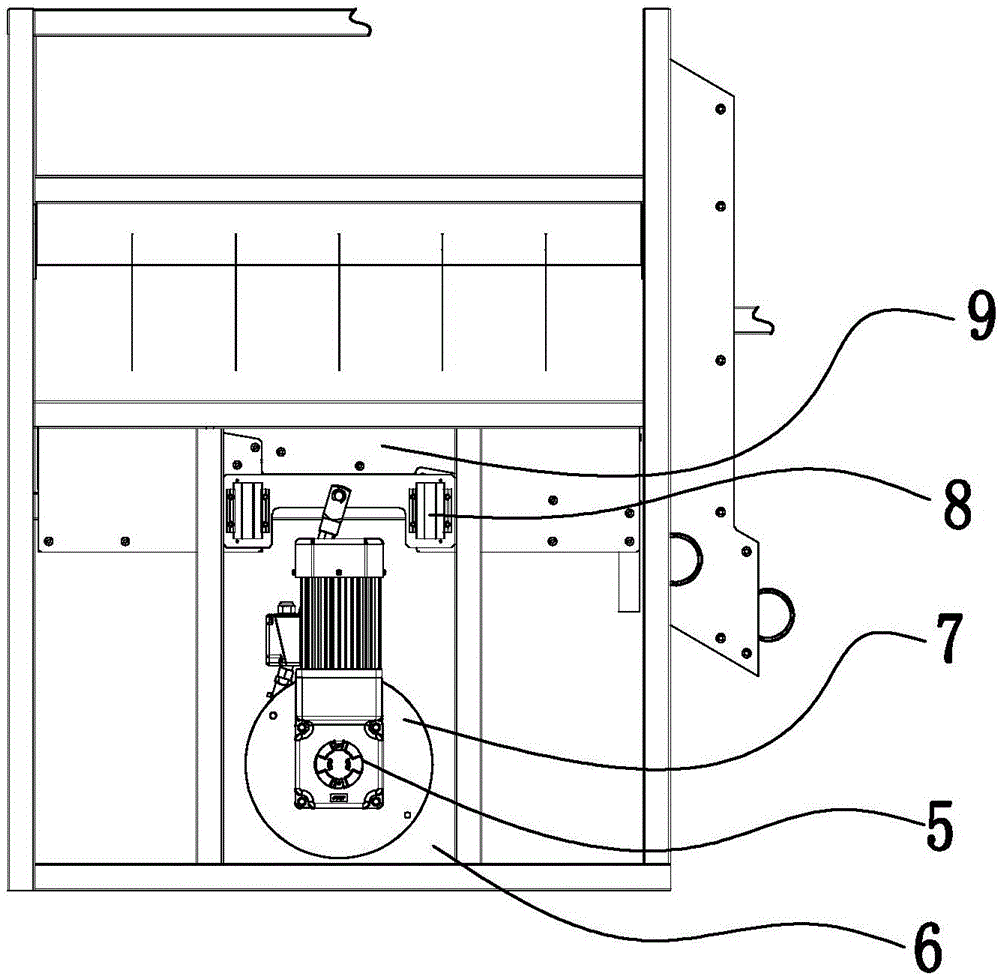

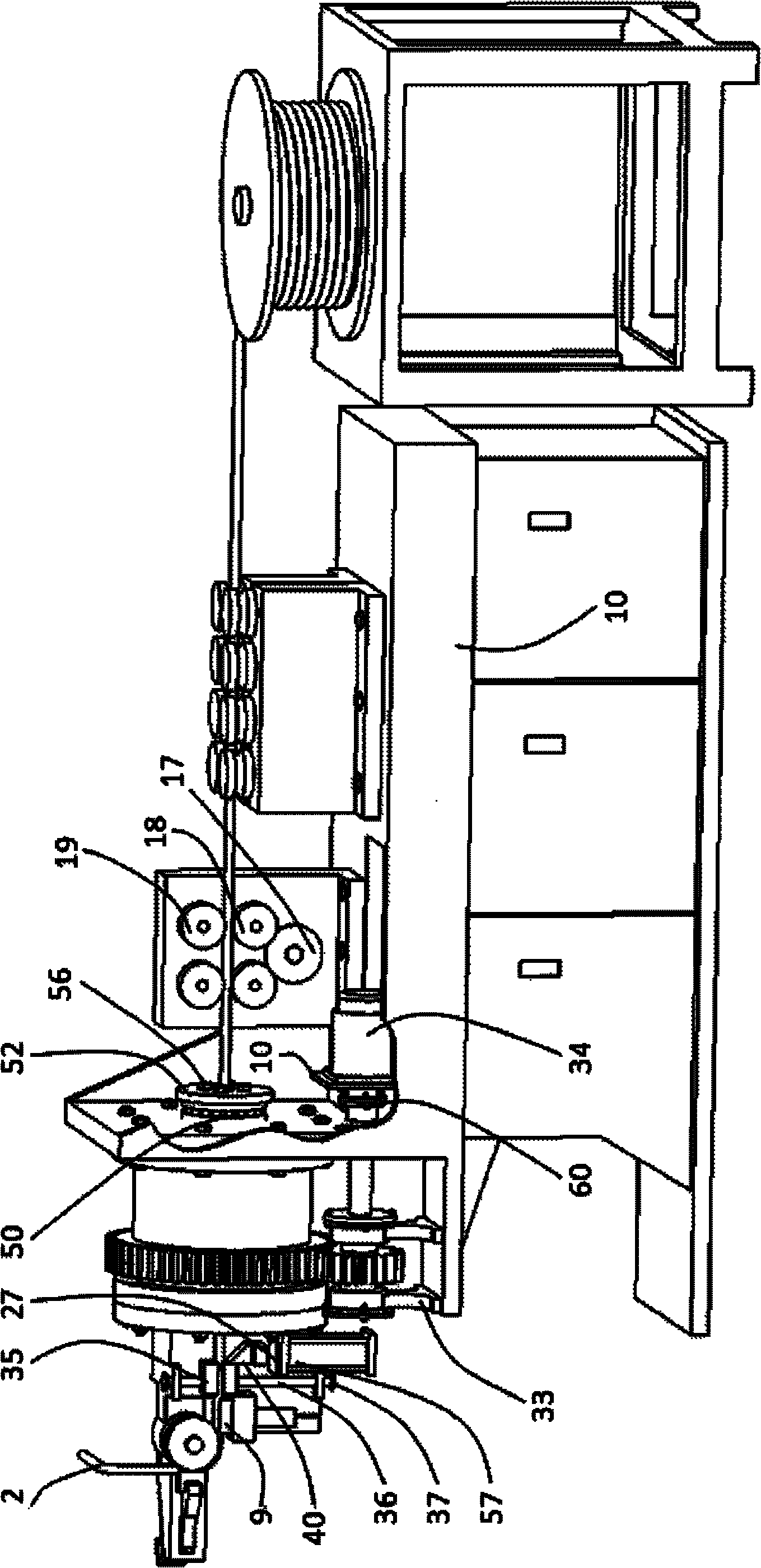

Rotary machine head type wire bending equipment

InactiveCN101862800AContinuous processingHigh equipment flexibilityMetal-working feeding devicesPositioning devicesRotary machineElectric machinery

The invention discloses rotary machine head type wire bending equipment, which comprises a machine frame, a material feeding mechanism, a fixed mold seat and a bending hand mechanism, wherein the material feeding mechanism, and the fixed mold seat and the bending hand mechanism are arranged on the machine frame and are used for wire bending on wire materials. The invention is characterized in that a straightening device and a feeding device are arranged on the machine frame, the conveying end of the feeding device is connected with a rotating device, a driven gearwheel arranged on the rotating device is engaged with a driving pinion connected on the machine frame, a wheel shaft of the driving pinion is connected with a motor output shaft fixed on the machine frame for realizing motive power transmission, in addition, the end surface of the rotating device is connected with a machine head frame, the bending hand mechanism, a shearing device and a support mold are arranged on the machine head frame, the bending hand mechanism and the shearing device are matched with the support mold for realizing the bending and the shearing on the wire materials, the wire bending equipment uses a motor to output the motive power, the driving pinion drives the driven gearwheel, a rotary joint and the machine head frame to rotate, the rotation movement of the machine head frame correspondingly to the wire materials is realized, the rotary machine head type wire bending equipment is matched with the feeding mechanism to realize the continuous processing, and the equipment flexibility is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

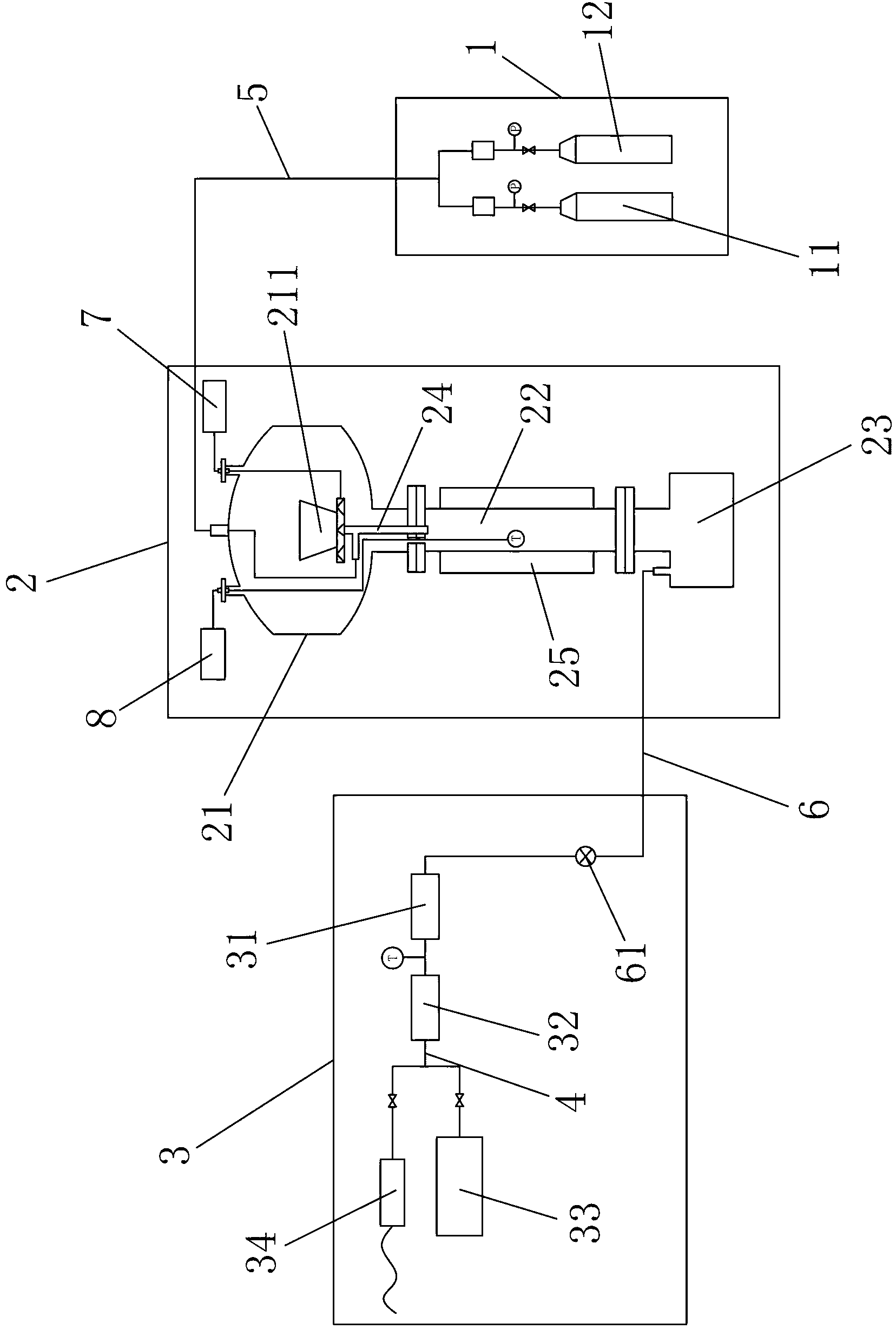

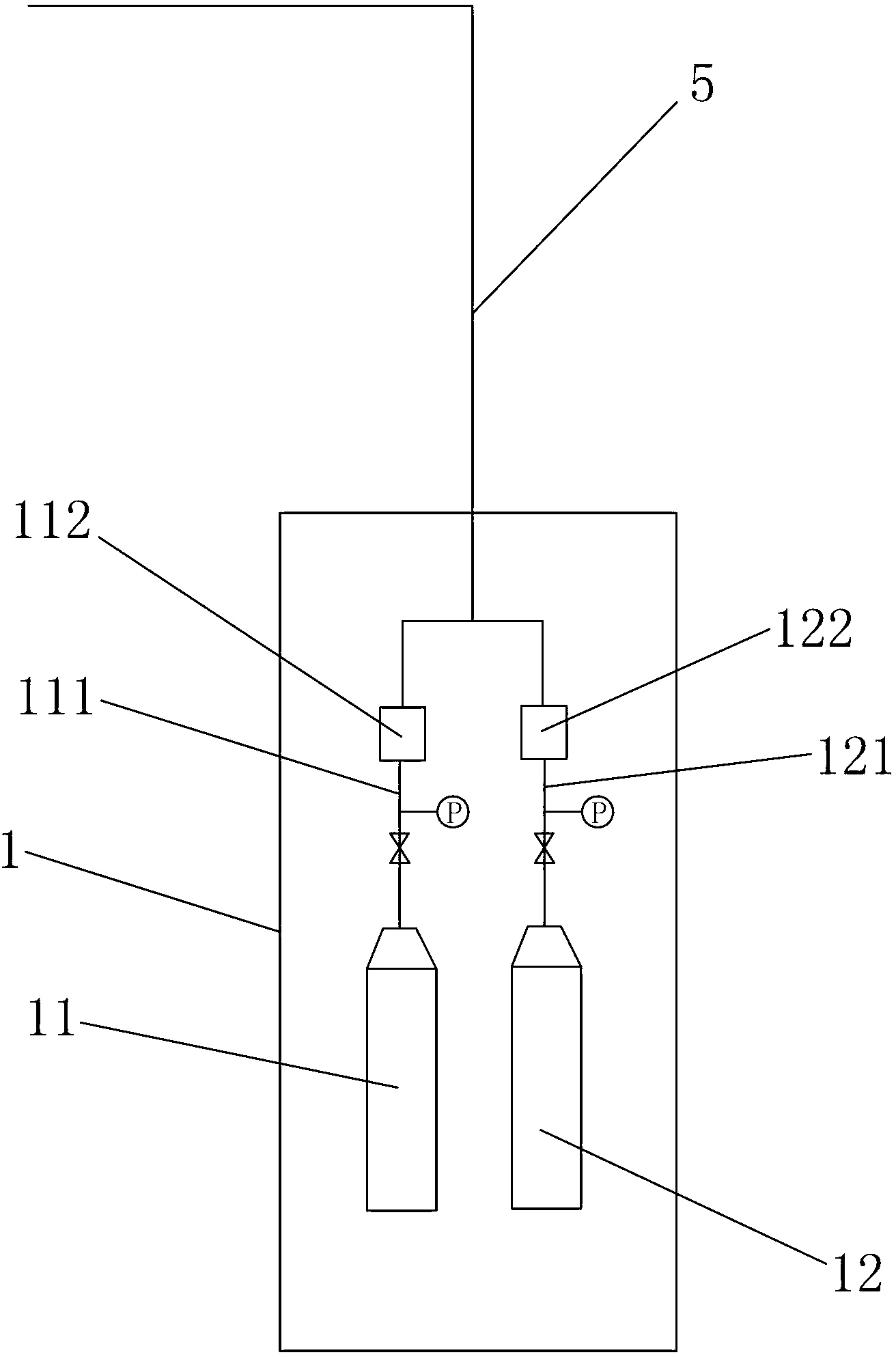

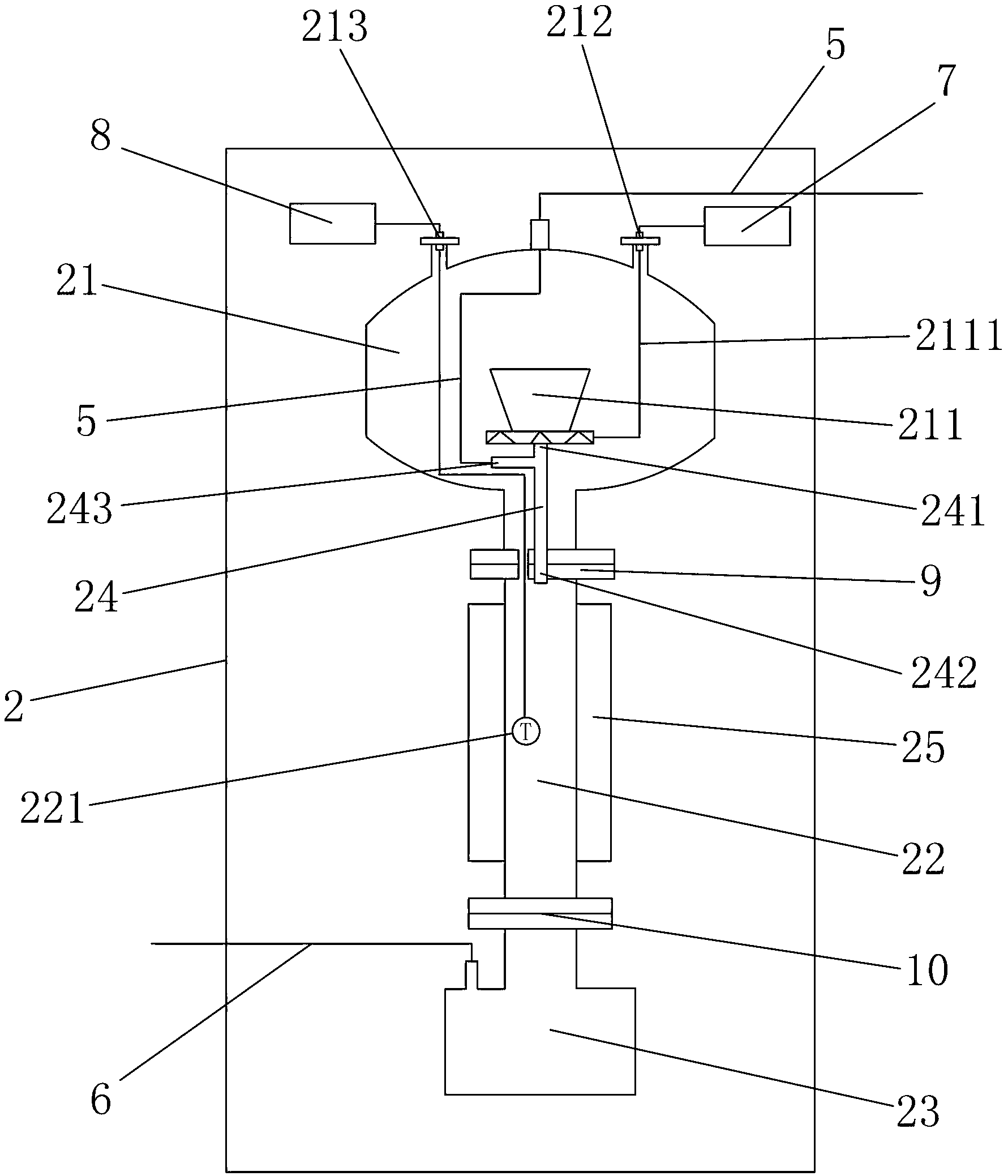

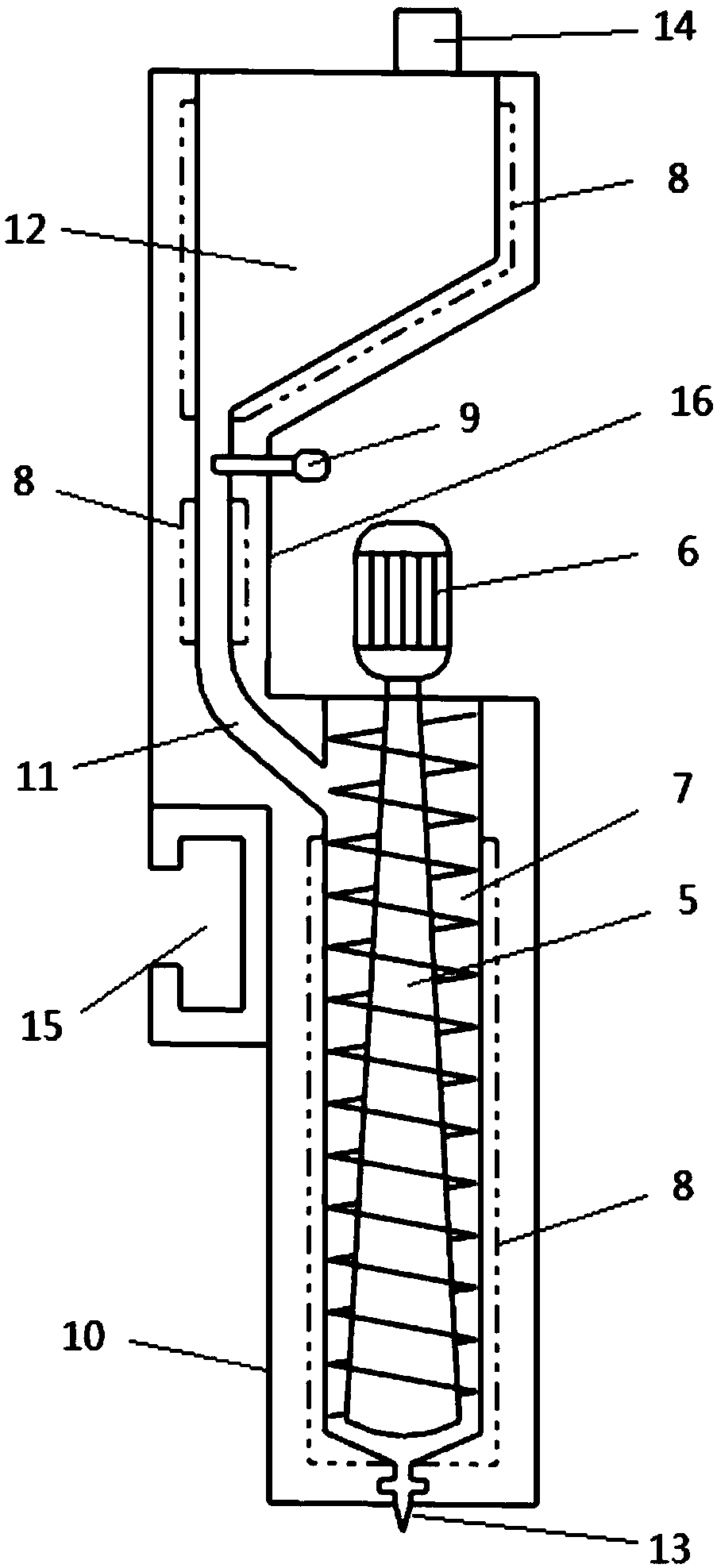

Coal powder pressurizing oxygen-enriched combustion settling furnace experimental device

InactiveCN103076361ARealize continuous feedingGet generated featuresMaterial heat developmentInvestigating phase/state changeSlagCoal

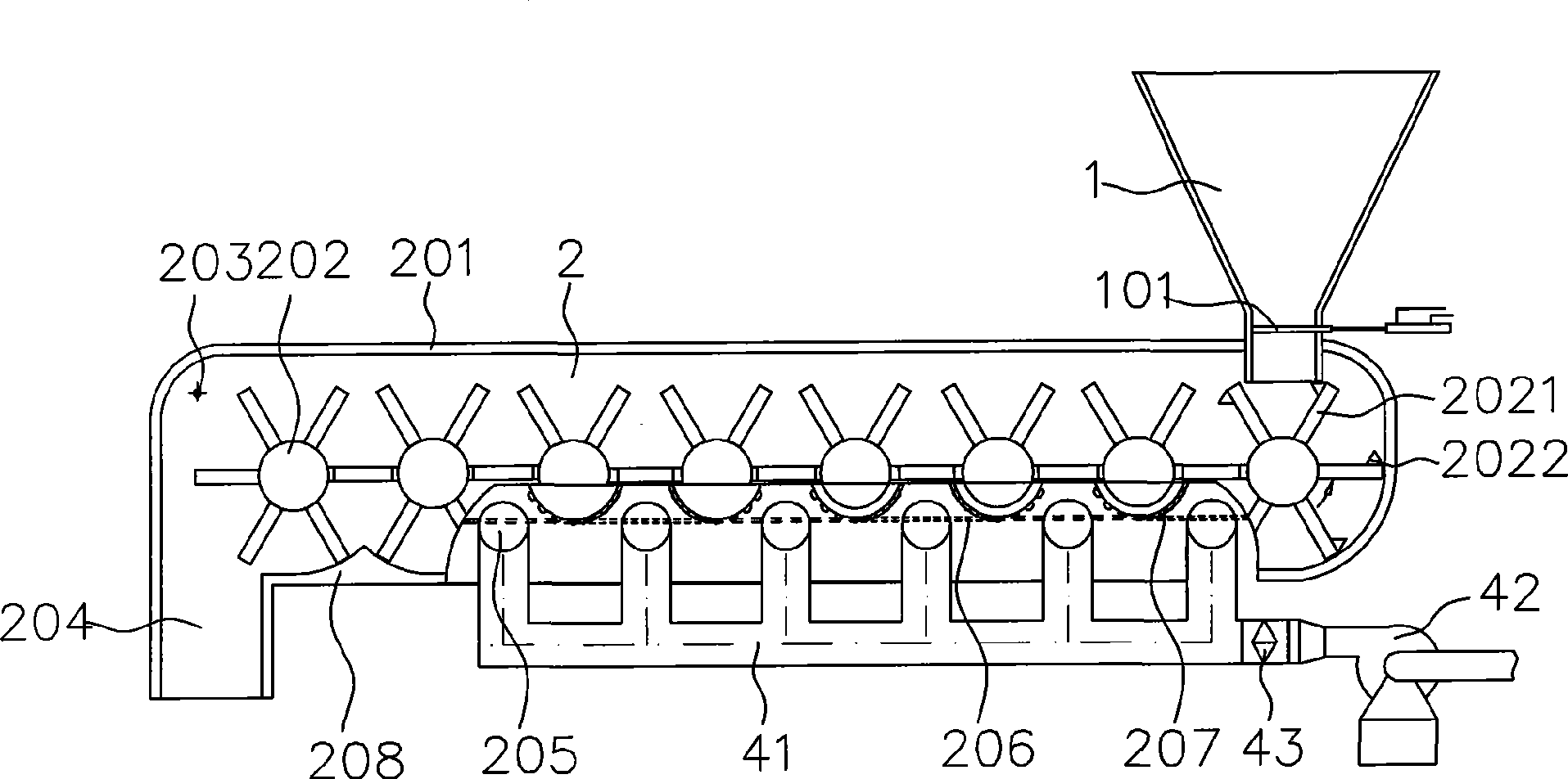

The invention discloses a coal powder pressurizing oxygen-enriched combustion settling furnace experimental device. A gas inlet system comprises an oxygen supplying unit and a carbon dioxide supplying unit; a settling furnace comprises a pressure container, a reaction pipe and a slag storage tank which are connected sequentially from the top down, wherein a coal powder feeding machine is fixedly arranged inside the pressure container, and is communicated with the reaction pipe through a blanking pipe, and a heating furnace is arranged on the outer wall of the reaction pipe in a sleeving way; a flue gas analysis system comprises a cooling device, a flue gas flowmeter and a flue gas analysis instrument which are connected sequentially through a pipeline; the gas inlet system is communicated with the blanking pipe through a gas inlet pipeline; and the slag storage tank is communicated with the cooling device through a gas outlet pipeline. According to the invention, continuous feeding of coal powder under the conditions of pressurizing and oxygen enrichment is realized, combustion characteristic parameters of ignition point, combustion temperature, burnout rate of carbon and the like of coal powder under the conditions of different pressures and different O2 / CO2 proportions can be accurately obtained, and meanwhile, flue gas components of coal powder combustion can be analyzed, so as to obtain the generation characteristics of pollutants under the conditions of pressurizing and oxygen enrichment.

Owner:BEIJING JIAOTONG UNIV

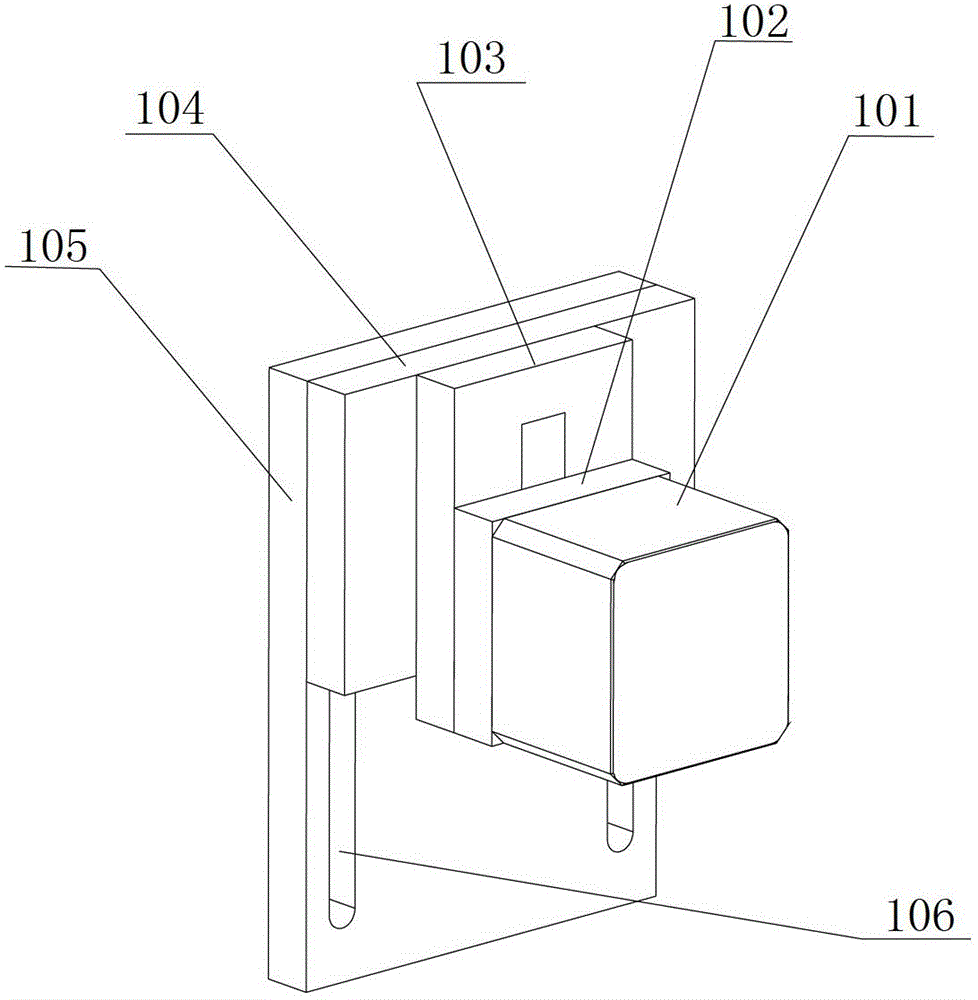

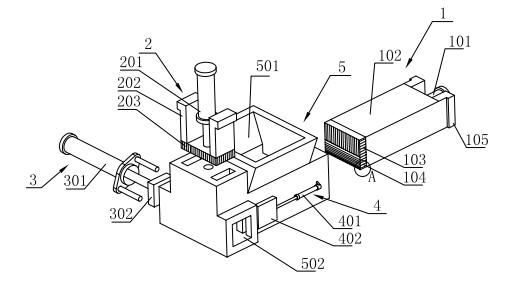

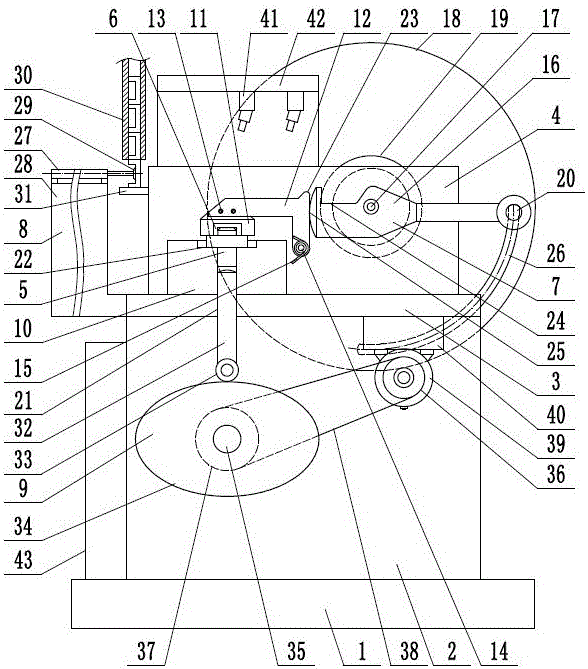

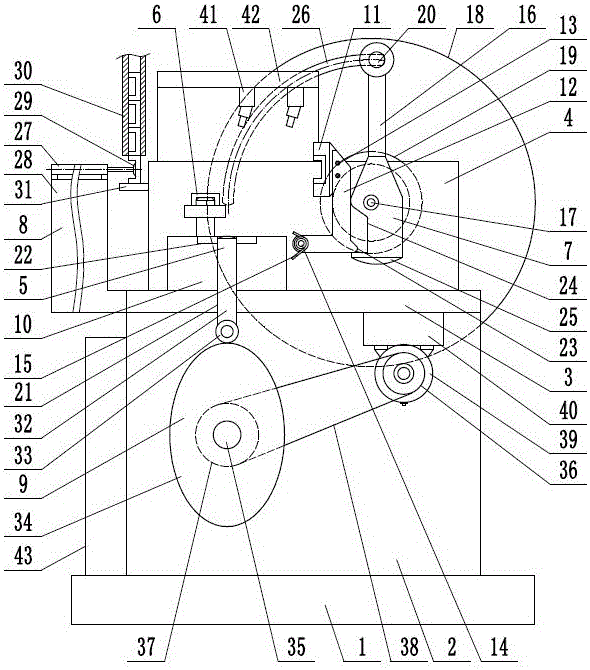

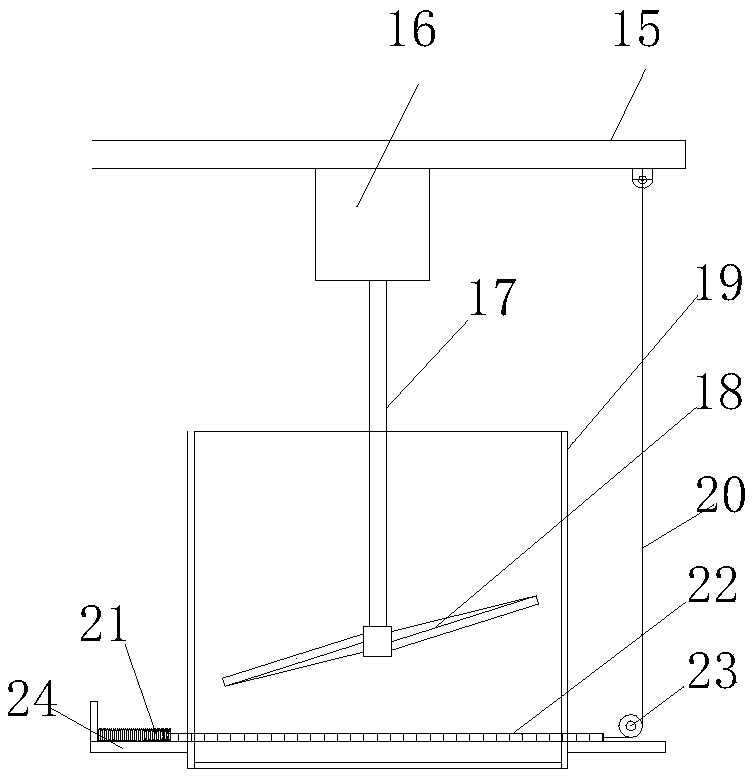

Sheet workpiece continuous feeding mechanism

InactiveCN109648378AReasonable structural designRealize continuous feedingMetal working apparatusEngineeringMechanical equipment

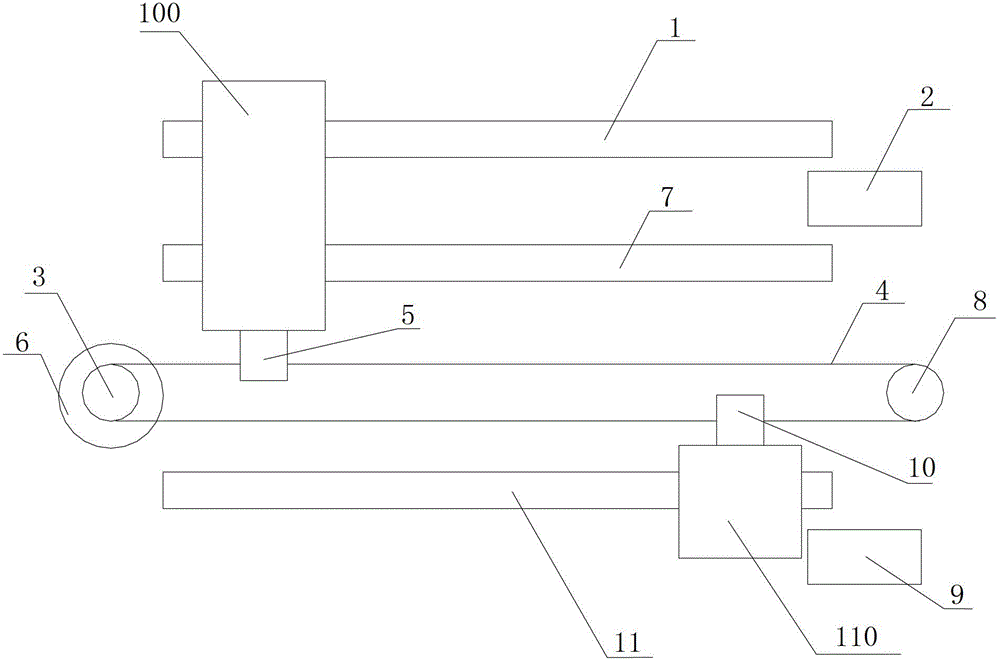

The invention discloses a sheet workpiece continuous feeding mechanism and belongs to the field of workpiece machining and conveying mechanical equipment. A feeding mechanism body and a material conveying mechanism of the feeding mechanism are sequentially arranged on the part, on one side of a material guiding mechanism, of a fixing bracket in the horizontal direction; a translation bracket is horizontally arranged on the part, on the lower side of a storage hopper, of the fixing bracket; a translation connecting plate is slidably arranged on a translation guide bar in the horizontal direction; the middle of the lower side of a rotating disc is fixedly connected with the upper end of a feeding rotating shaft; a material suction guiding plate is vertically arranged on one side of a material suction bracket; the output end of a material suction air cylinder is fixedly connected with the middle of one side of the material suction guiding plate; a plurality of material suction mechanismsare sequentially and uniformly arranged on the material suction guiding plate in the horizontal direction; and a material conveying belt is arranged on the upper side of a material conveying bracket.The feeding mechanism is reasonable in structure design, a plurality of sheet workpieces can be sequentially sucked and fixed, and the multiple sucked and fixed sheet workpieces can be synchronously transferred and conveyed, so that the sheet workpiece feeding automation degree is increased, and the machining demands are met.

Owner:嘉兴汉羿文化传播有限公司

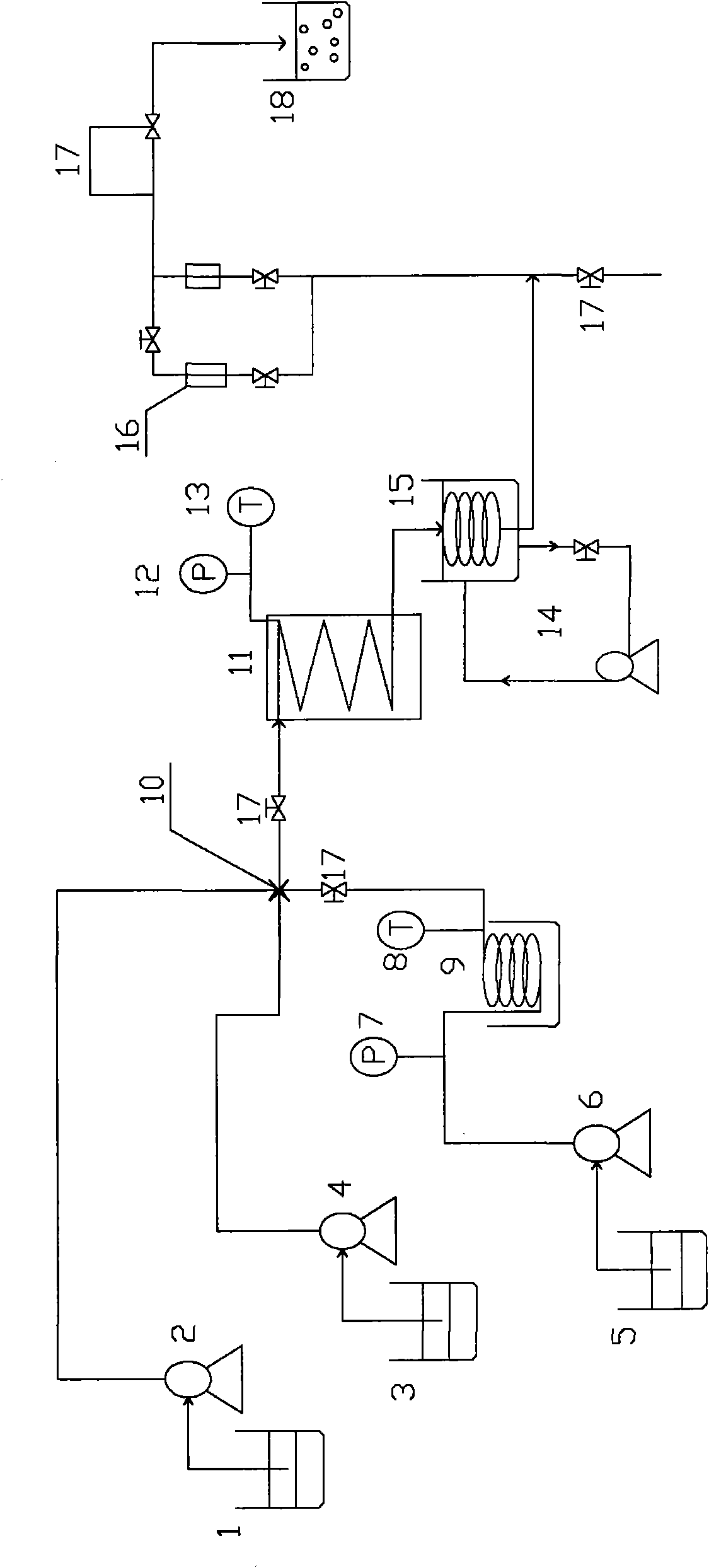

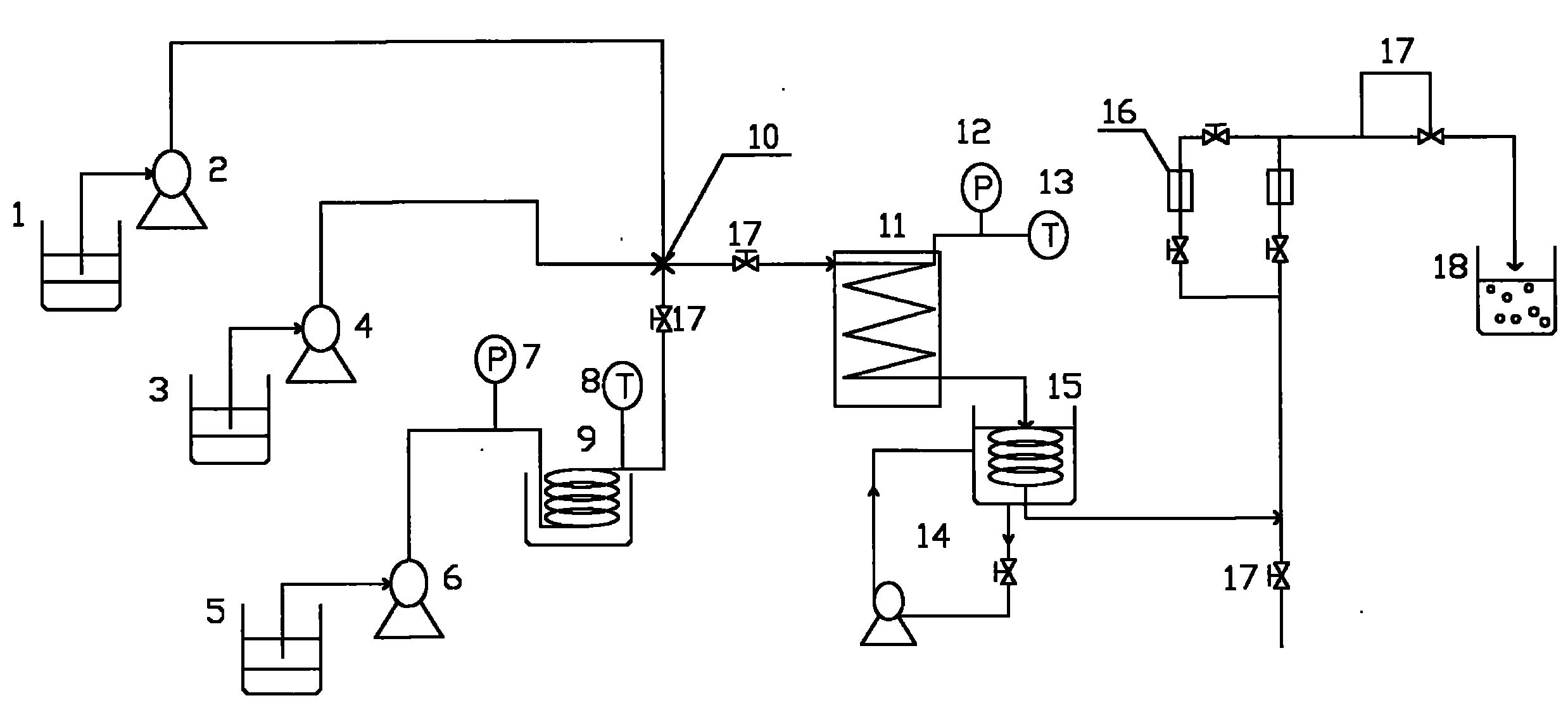

Process for preparing power type lithium-ion battery anode material by using supercritical/subcritcal water thermal process

InactiveCN101807698AIncrease the reaction areaIncrease production per unit timeCell electrodesPhosphorus compoundsElectrical batteryPhosphoric acid

The invention relates to a process for preparing a power type lithium-ion battery anode material by using a supercritical / subcritcal water thermal process. The process comprises the following steps of: (1) continuously injecting two fluids of a raw material lithium source and a mixed liquid consisting of an iron source / manganese source and a phosphoric acid source into a mixer for mixing; (2) preheating a third fluid formed by deionized water, and adding the third fluid into the mixer to be mixed with the two fluids in the step (1); (3) leading the mixed liquid of the three fluids discharging from the mixer in the step (2) to enter a high temperature and high pressure reaction kettle for carrying out hydrothermal crystallization reaction; (4) cooling a product liquid obtained from the hydrothermal crystallization reaction through a heat exchanger, filtering by a filter to remove large-grain particles and impurities, and leading the filtrate into a solid-liquid separator; (5) continuously collecting particles precipitated in the solid-liquid separator, and drying to obtain dry powder of the battery anode material. The process can be carried out continuously and is beneficial to improving the operation efficiency and reducing the energy consumption.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

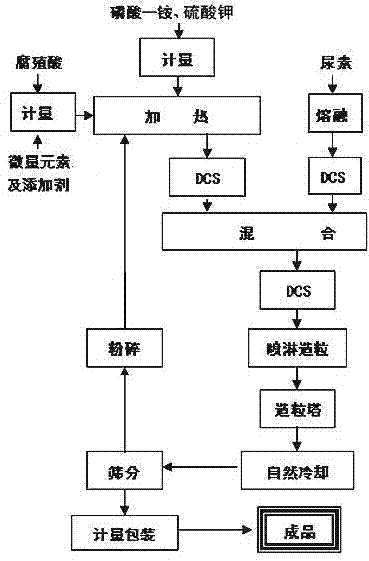

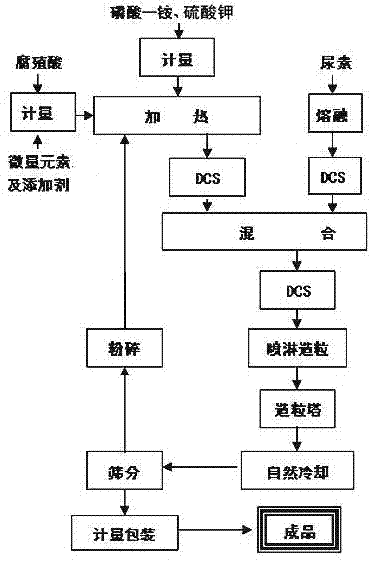

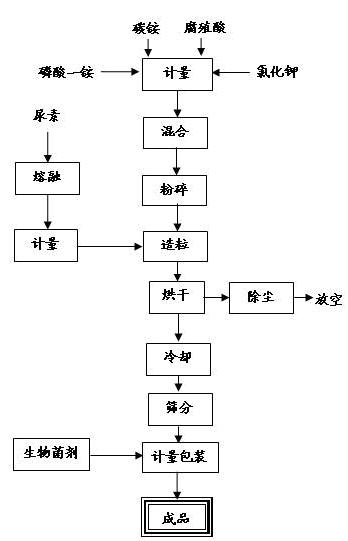

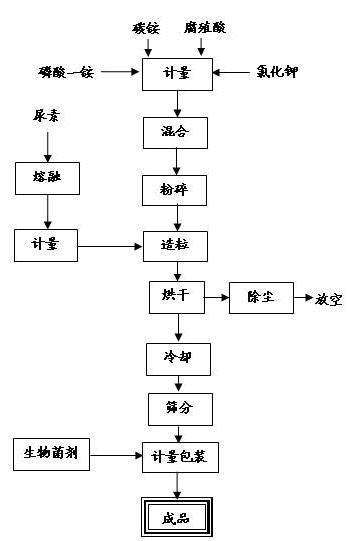

Melt granulation humic acid functional fertilizer special for corns and preparing method thereof

ActiveCN102503639AAdvanced technologyRealize continuous feedingFertiliser formsFertilizer mixturesPhosphateCaking

The invention discloses a melt granulation humic acid functional fertilizer special for corns and a preparing method thereof. The melt granulation humic acid functional fertilizer adopts raw materials of urea, monoammonium phosphate, potassium sulfate, humic acid, calcium magnesium phosphate, ethylene diamine tetra acetic acid (EDTA) chelating zinc, EDTA chelating ferrite, EDTA chelating boron, ammonium molybdate and additives, all the raw materials are dosed according to a specified ratio, and finished products are obtained through mixing, stirring, heating, filtering, granulating, cooling, sieving, anti-caking processing and measurement packaging of the raw materials. The melt granulation humic acid functional fertilizer special for corns has the advantages of being environment-friendly, balanced in nutrition, fast in fertilizer effect, high in crop absorption rate and capable of prolonging valid period of nitrogen nutrient and improving the soil, is a novel fertilizer for agricultural sustainable development and green food production, and has important meaning for promoting development of the ecological agriculture.

Owner:STANLEY AGRI GRP CO LTD

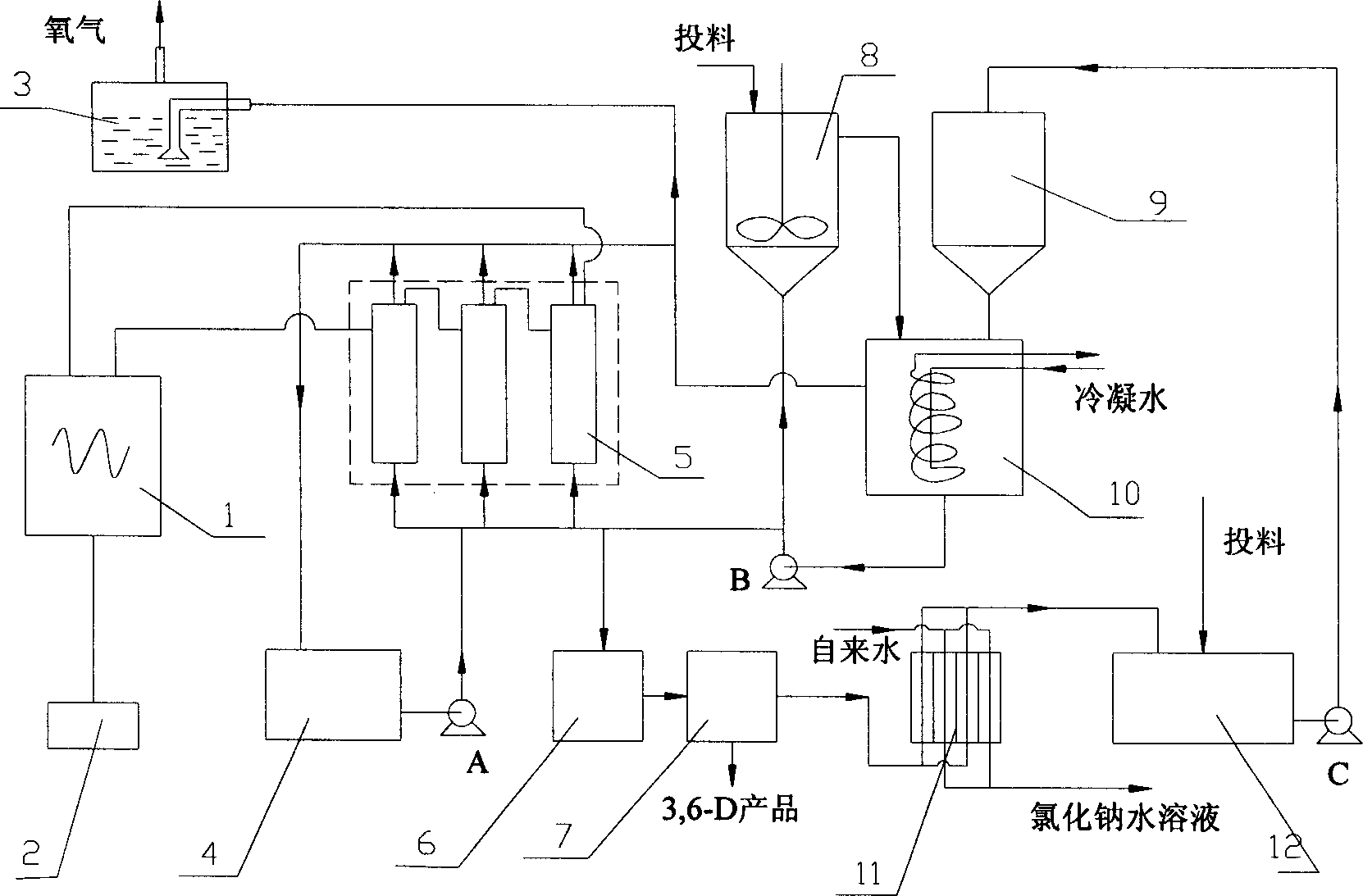

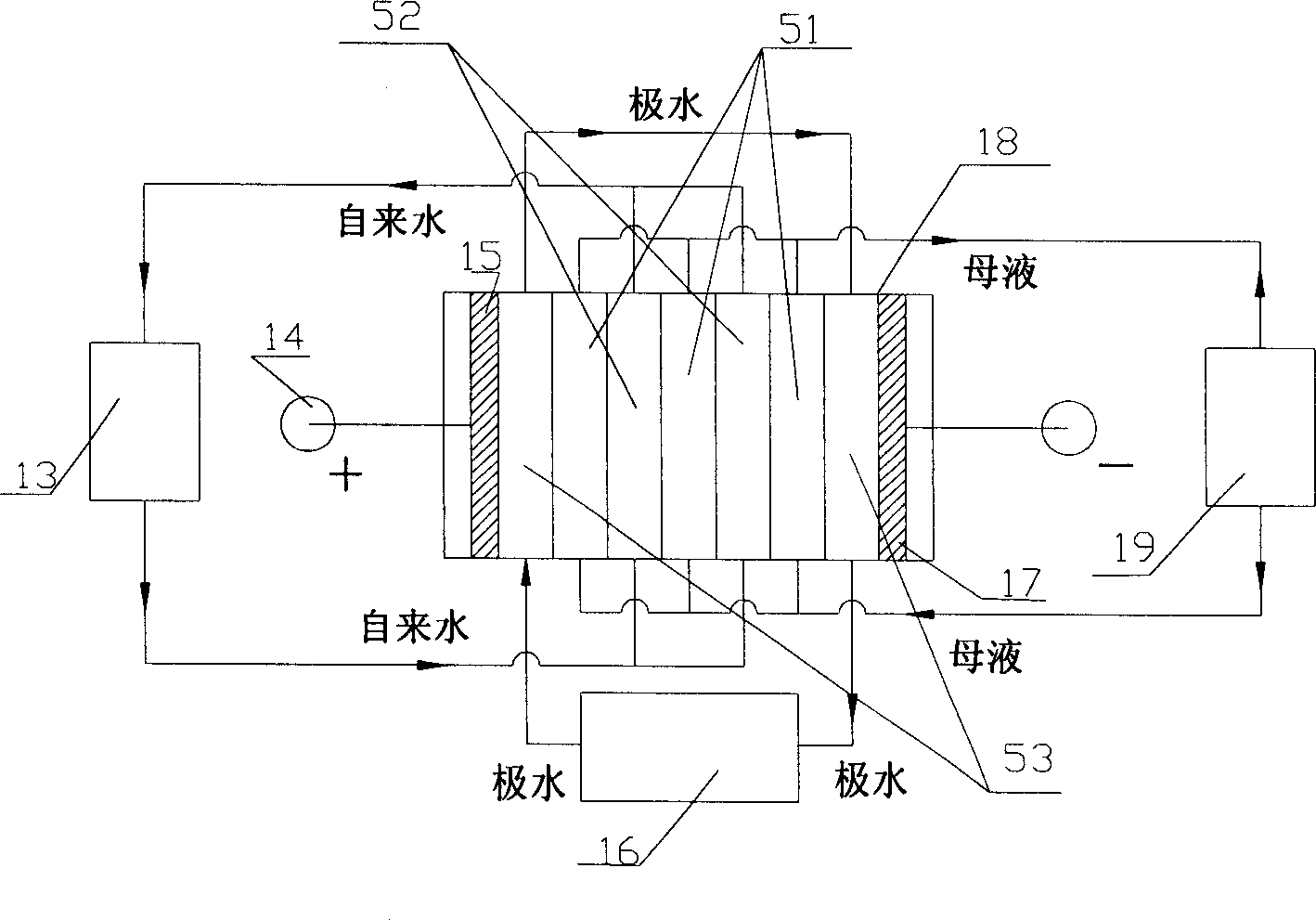

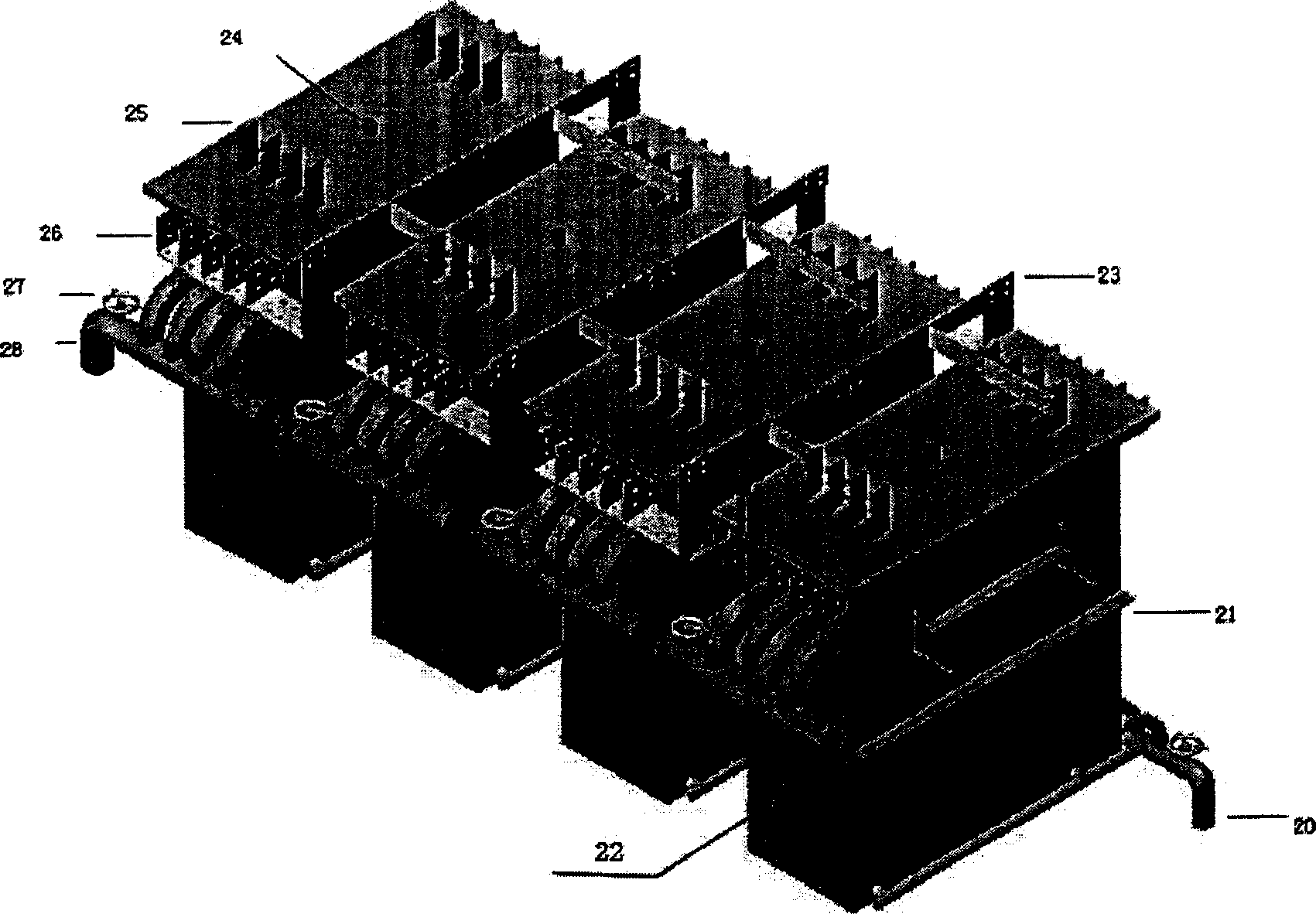

Method and apparatus for electrolytic synthesis of 3,6-dichloropyridine-carboxylic acid

InactiveCN1807691ALow energy consumption in the production processLess side effectsOrganic chemistryElectrolysis componentsElectrolysisSynthesis methods

The invention discloses a 3, 6- dichloro pyridine methanamine electrolytic synthesis method and device, which comprises the following steps: using 3, 4, 5, 6-tetrachloro pyridine aminic acid for main electrolysis material; placing electrolytic solution in electrolysis bath to electrolyze; getting 3, 6- dichloro pyridine methanamine by neutralizing, cooling, crystallizing, filtering and drying; carrying on toughening treatment for cathode of electrolysis bath by periodic reversible power of thyristors. The device is composed of power, dosage bunker, electrolysis bath, wherein the power is stabilized voltage and permanent flow, which can control the cycle reverse power; the power connects to current commutator; program control unit is installed for current commutator; the anode of power is connected to anode of electrolysis bath; the minus pole of power connects to cathode of electrolysis bath.

Owner:ZHEJIANG UNIV OF TECH

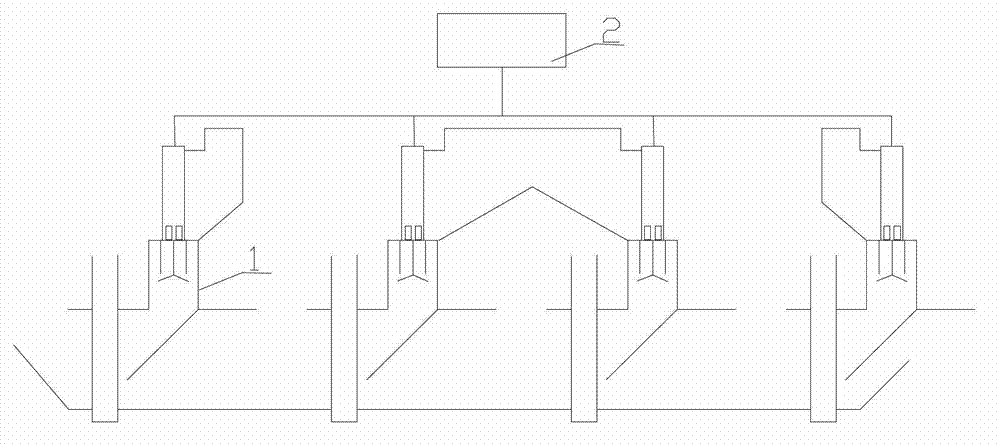

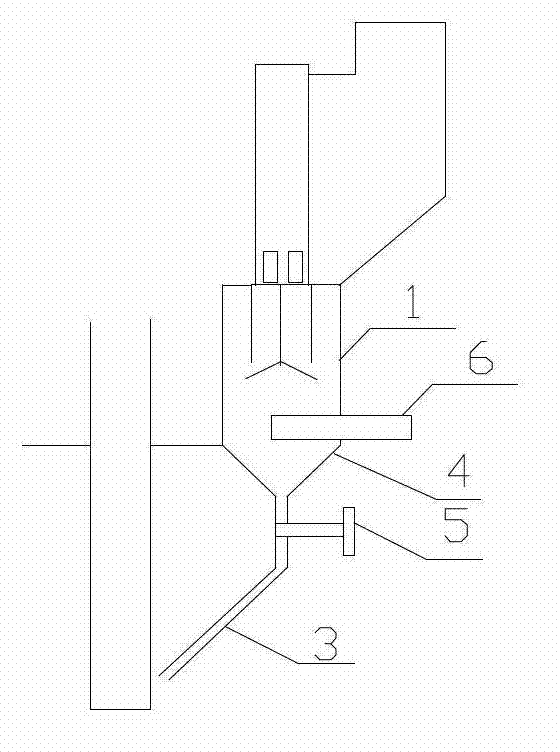

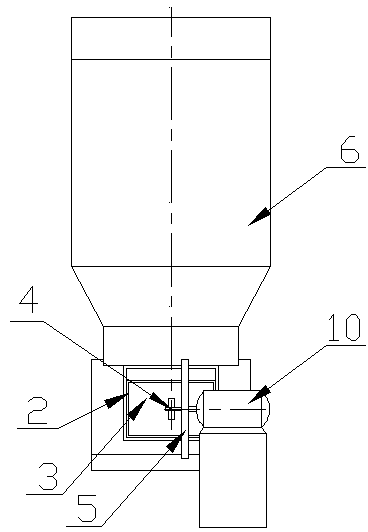

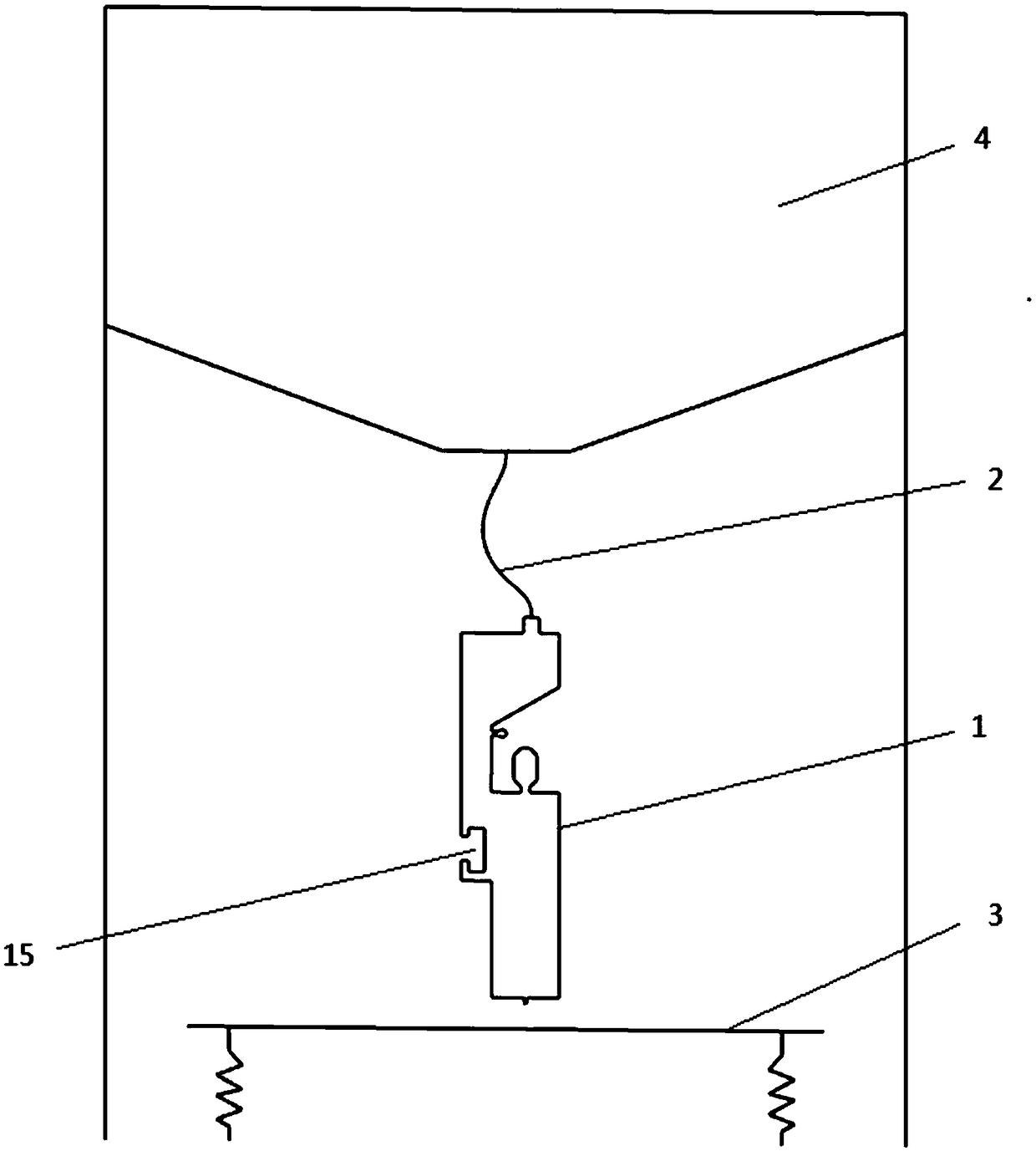

Continuous feeding device for aluminum electrolysis cell and electrolysis cell with same

The invention belongs to the technical field of aluminum electrolysis cells, and particularly relates to a continuous feeding device for an aluminum electrolysis cell and an electrolysis cell with the same. The continuous feeding device for the aluminum electrolysis cell is capable of improving the stability of the electrolysis cell, lowering energy consumption, reducing sediment and pressure drop at the furnace bottom and prolonging the service life of the cell. According to the technical scheme, the continuous feeding device for the aluminum electrolysis cell comprises a sleeve, a funnel and an upper delivery pipe, wherein the open end of the funnel is fixedly connected with the bottom of the sleeve; and the outlet end of the funnel is fixedly connected with one end of the upper delivery pipe. Since the funnel is arranged at the bottom of the sleeve, so that the flow velocity of fed materials can be reduced, continuous feeding is realized, and the problem caused when alumina powder which is not completely dissolved sinks into the aluminum liquid is avoided.

Owner:HUNAN CHUANGYUAN ALUMINUM IND

Flexible material processing and production equipment

The invention discloses flexible material processing and production equipment, which comprises a machine frame, wherein the machine frame is provided with a material input mechanism, a plurality of discharging and collection mechanisms, a material output mechanism and processing equipment, wherein each discharging and collection mechanism comprises two power rolls and a tension mechanism, each tension mechanism comprises at least one fixing roll, a traction roll, a second movement frame, at least one movement roll and a press roll, each traction roll is driven by a second power device, each second movement frame is driven by a Y-axis movement mechanism, and each movement roll and each fixing roll are vertically staggered. The flexible material processing and production equipment has the advantages that the structure is compact, and the space is saved; a material coil can be conveniently and rapidly charged; the flexible material is discharged and collected according to requirements, and a plurality of coils of flexible material can be flexibly and quickly replaced according to requirements.

Owner:GOERTEK INC

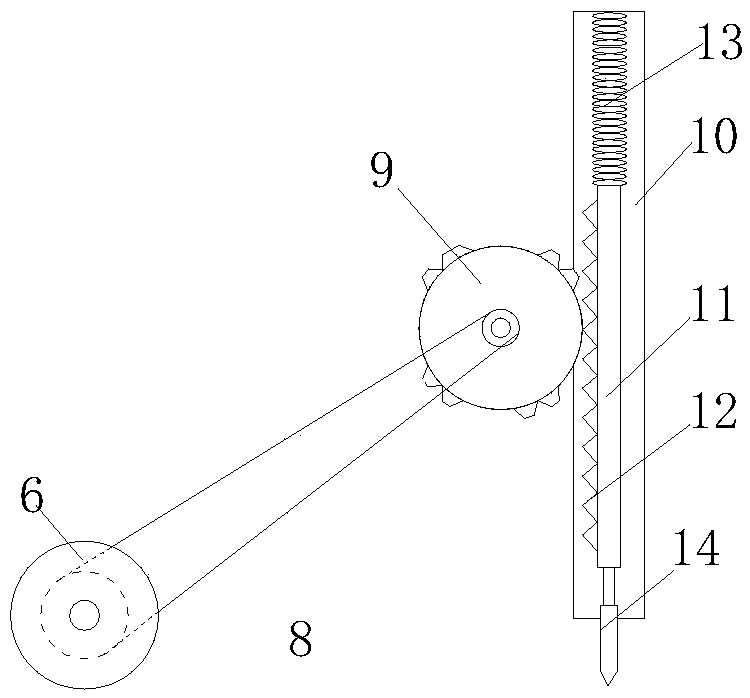

Feeding mechanism of biomass fuel furnace

InactiveCN103776048ABurn fullyImprove thermal efficiencyLump/pulverulent fuel feeder/distributionCombustion chamberReciprocating motion

The invention discloses a feeding mechanism of a biomass fuel furnace. The feeding mechanism comprises a storage tank, a feeding tube, a piston and a motor, wherein a wheel is arranged at the shaft end of the motor; the motor is matched with the feeding tube in a sliding manner; the feeding tube is arranged at the lower part of the storage tank; a receiving opening is formed in the feeding tube; a funnel-shaped material outlet is formed in the lower part of the storage tank; the material outlet of the storage tank is matched with the receiving opening of the feeding tube; a material outlet door is hinged to the material outlet of the storage tank; the piston is connected with the door of a combustion chamber of the biomass fuel furnace through a rod; a connecting rod is hinged to the piston; the other end of the connecting rod is hinged to the edge of the wheel; the wheel and the connecting rod form a crank connecting rod mechanism; when the motor drives the wheel to rotate, the wheel drives the piston to perform reciprocating motion in the feeding tube through the connecting rod; when the piston moves forward, the material outlet door is closed and the door of the combustion chamber is opened, and biomass fuel in the feeding tube is rapidly fed into the combustion chamber; conversely, when the position moves backwards, the door of the combustion chamber is closed and the material outlet door is opened, and biomass fuel in the feeding tube rapidly drops into the feeding tube.

Owner:河北老樵夫生物质能源有限公司

Chemical fiber bobbin yarn transferring and placing mechanism

InactiveCN109205393ARealize continuous feedingEasy and efficient replacementFilament handlingYarnFiber

The invention discloses a chemical fiber bobbin yarn transferring and placing mechanism, and belongs to the field of chemical fiber conveying and processing machine equipment. A bobbin transferring mechanism is vertically arranged on a fixing support between a bobbin guiding mechanism and a yarn placing mechanism. A discharging material pipe is obliquely downwards arranged on the upper side of thefixing support. The output end of a lifting air cylinder is vertically and fixedly provided with a lifting support. A bobbin transferring rotation rod is vertically and rotationally connected to a rotation rod sleeve. One end of the lower side of a reciprocating rotating plate is fixedly connected with the upper end of the bobbin transferring rotation rod. A bobbin taking mechanism is fixedly arranged at the other end of the lower side of the reciprocating rotation plate. A plurality of bobbin placing circular plates are evenly arranged at the outer end of the upper side of a yarn guiding rotation disc. A plurality of yarn guiding mechanisms are evenly arranged on the upper side of the yarn guiding rotation disc. The bobbin placing circular plates and the yarn guiding mechanism are sequentially arranged in the radial direction of the yarn guiding rotation disc from exterior to interior. The chemical fiber bobbin yarn transferring and placing mechanism is reasonable in structural design, a plurality of chemical fiber bobbin yarns can be continuously transferred and replaced conveniently and efficiently, a plurality of strands of chemical fiber filaments can be stably, accurately and synchronously conveyed, the automation degree is high, and the production and usage requirements are met.

Owner:桐乡市宏力纺织股份有限公司

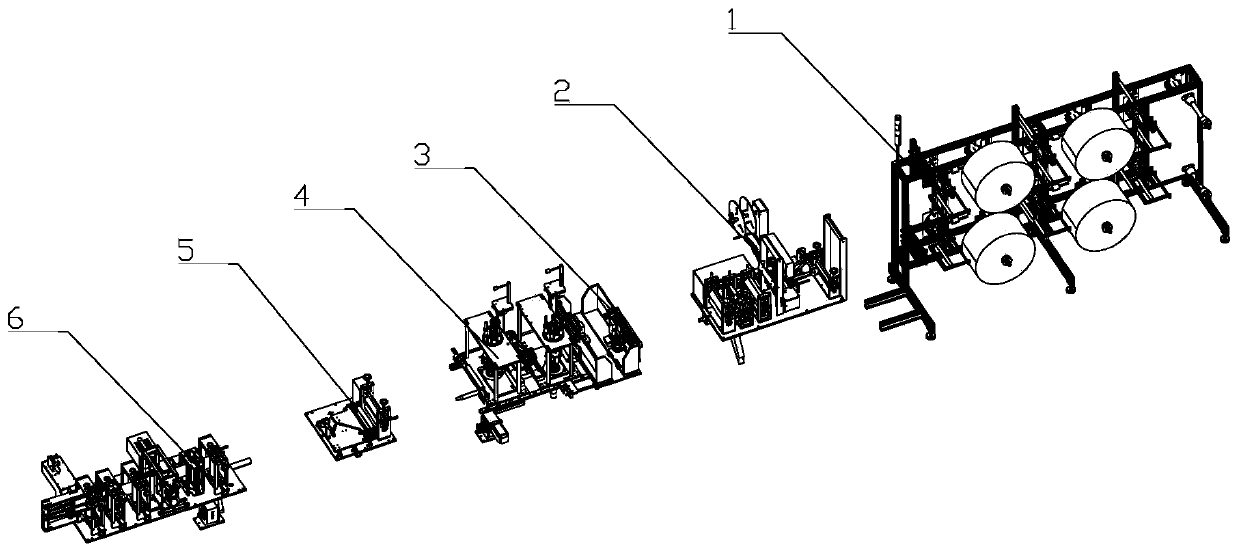

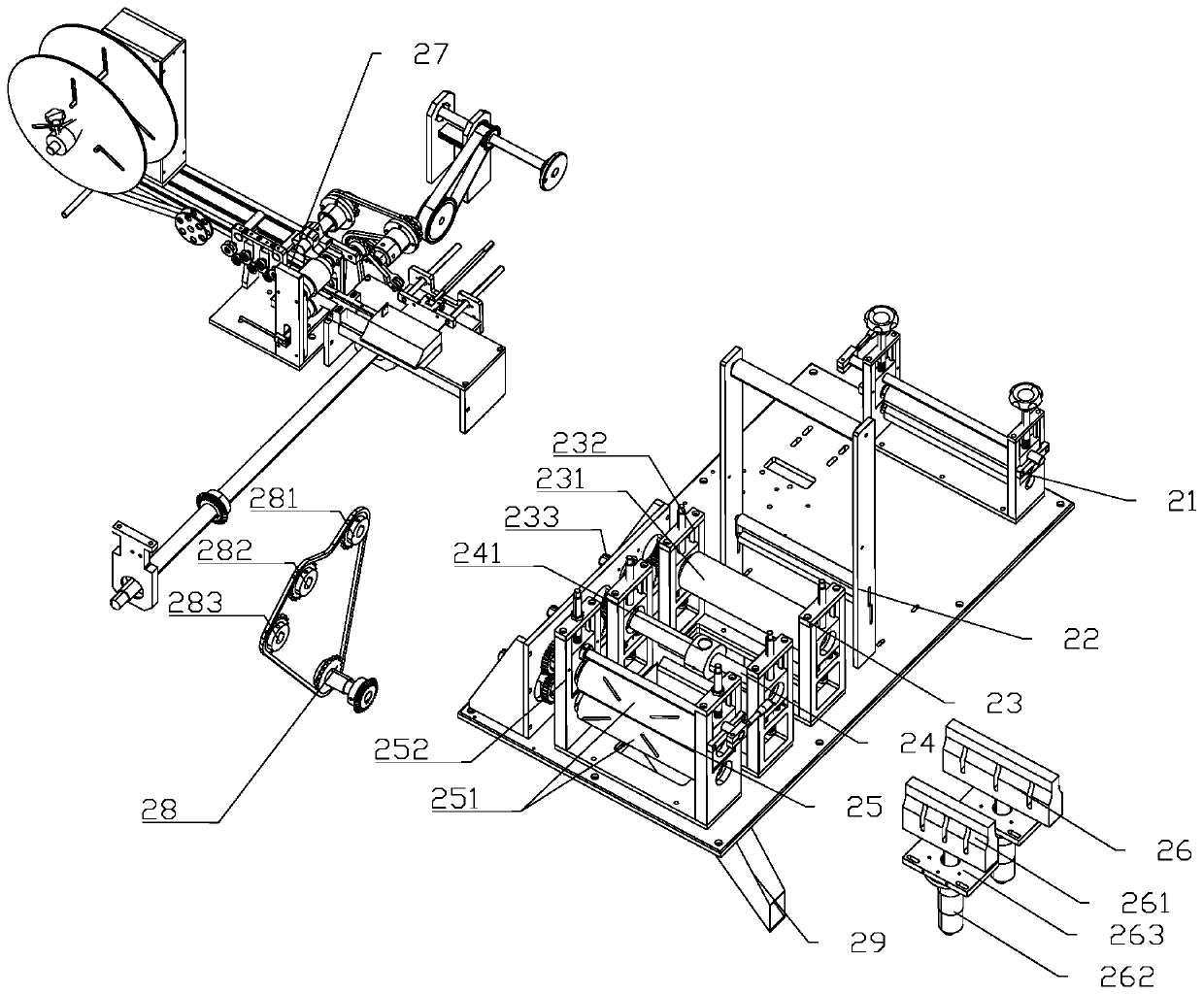

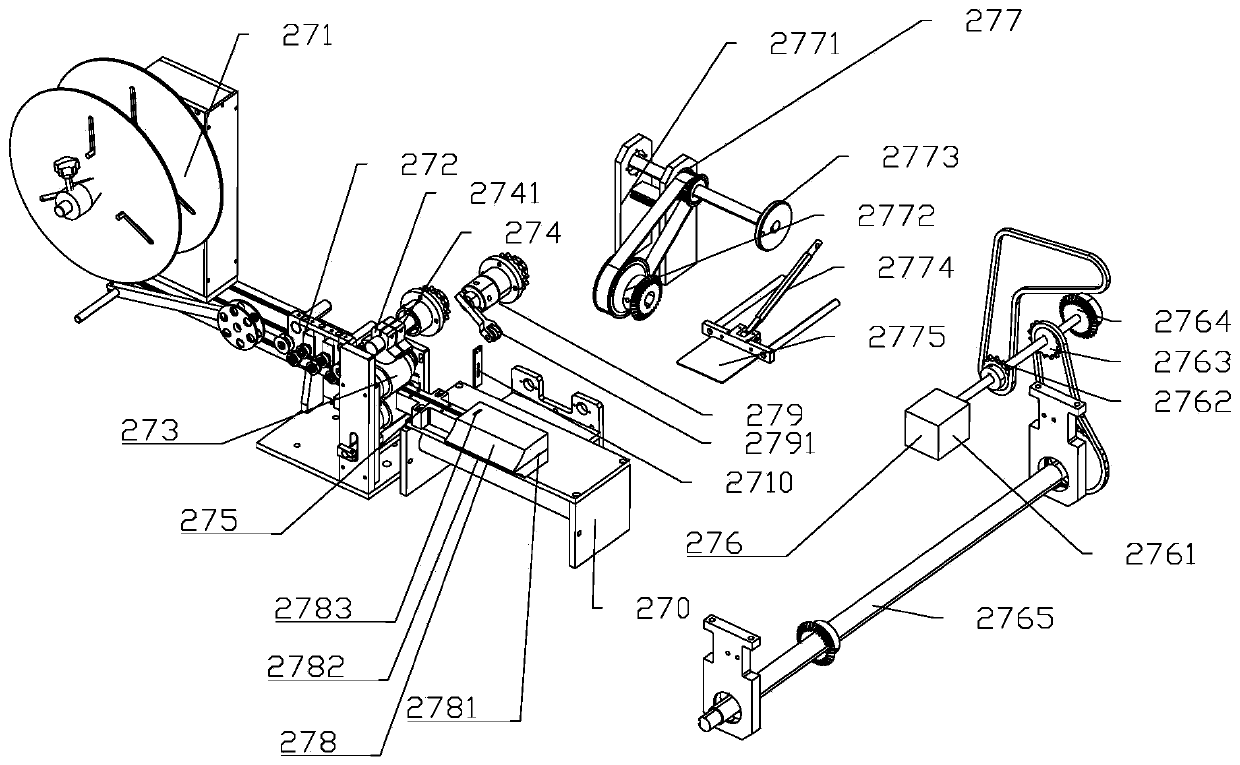

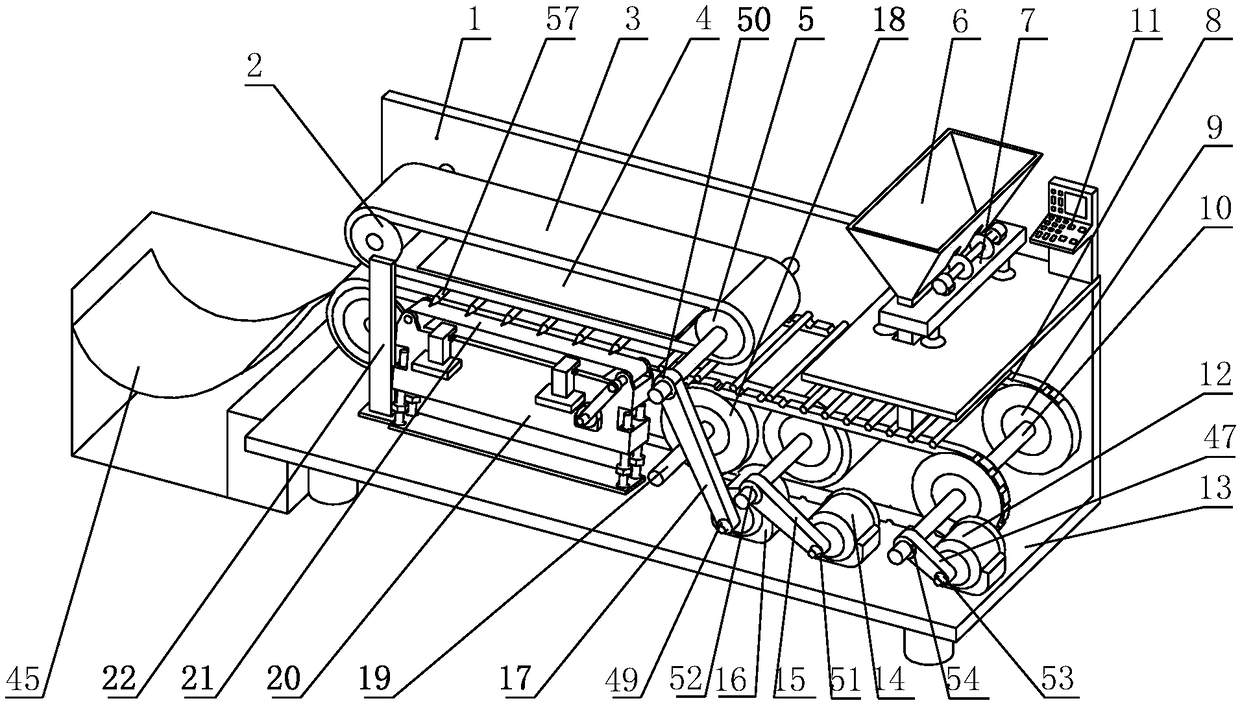

Mask and full-automatic mask production machine and production method thereof

InactiveCN111391345AIncrease the feeding speedRealize intermittent driveDomestic articlesMetal working apparatusIndustrial engineeringFully automated

The invention relates to the field of mask production, and discloses a full-automatic mask production machine. The full-automatic mask production machine comprises a cloth feeding device, a welding device, a transfer printing device, an ear band welding device, a pressing folding device and a die-cutting shaping device, wherein the cloth feeding device, the welding device, the transfer printing device, the ear band welding device, the pressing folding device and the die-cutting shaping device are sequentially connected in the processing direction; the ear band welding device is used for welding two ear bands on two sides of a mask, the pressing folding device is used for pressing and folding the mask, and the die-cutting shaping device is used for shaping the mask and cutting an outer contour. The full-automatic mask production machine has the advantages of being efficient in nose strip connection, reliable in cloth connection, diversified in cloth processing, reliable and efficient inear band welding, compact in structure and easy to stack masks.

Owner:林阿香

Pencil sharpening machine

ActiveCN108790520ARealize continuous automatic feed cuttingImprove cutting efficiencySharpenersEngineeringSharpening

The invention belongs to the technical field of pencil sharpening, and relates to a pencil sharpening machine. The problem that production efficiency of an existing pencil sharpening device is low dueto the fact that the existing pencil sharpening device usually adopts a method that clamping is performed on each pencil is solved, pencils can be continuously fed and sharpened, and pencil sharpening efficiency is improved. The pencil sharpening machine comprises a supporting part, a pencil feeding part, a rolling feeding part, a sharpening part and a collection part. The sharpening part is installed on the front side of the rolling feeding part, the collection part is installed on the left side of the rolling feeding part, the pencil feeding part is installed on the right side of the rolling feeding part, an anti-bridging device of the pencil feeding part is installed on the right side of a pencil feeding funnel, the rolling feeding part enables the pencils to rotate and also roll fromright to left, and continuous sharpening is realized.

Owner:李冠余

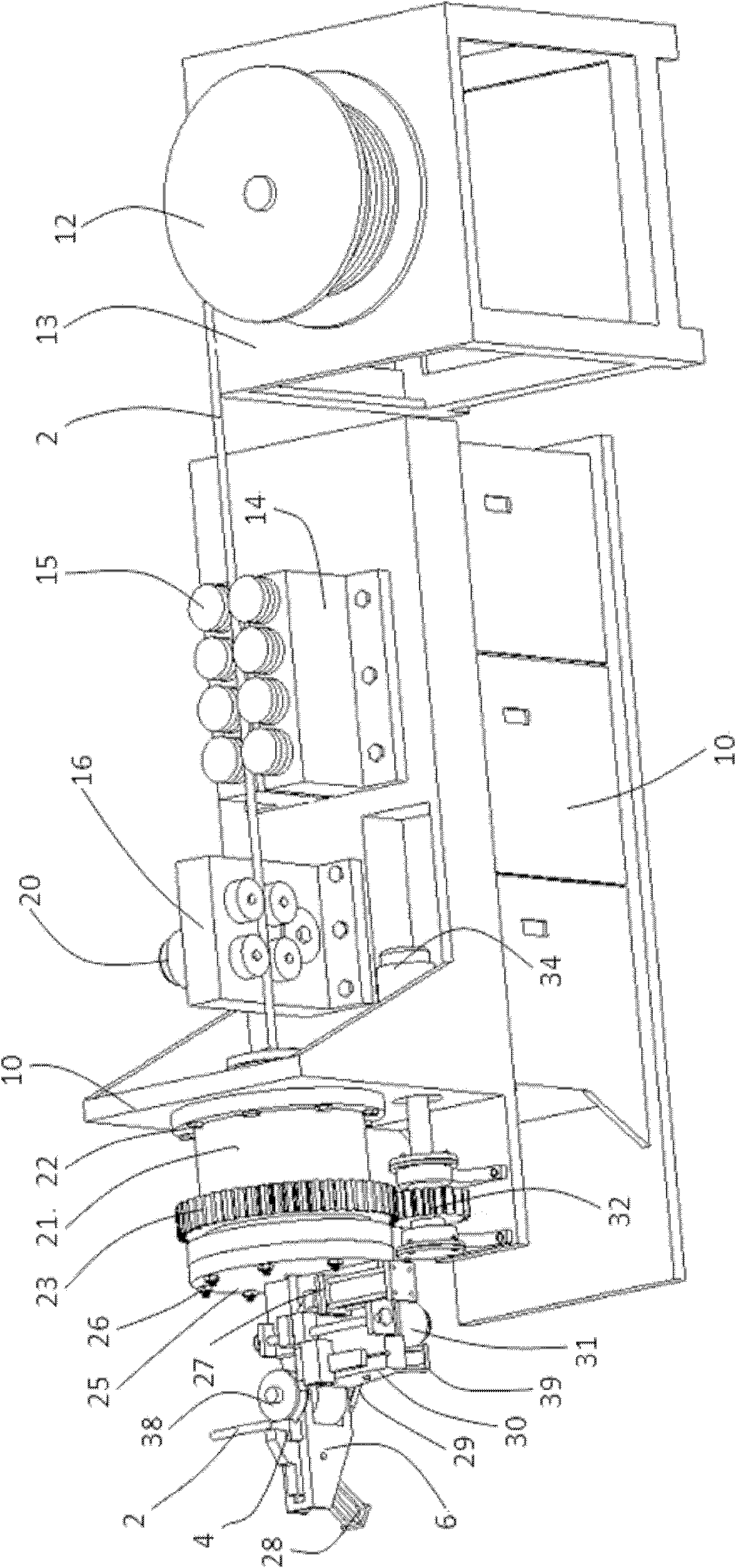

Flax coil continuous loading mechanism

InactiveCN108946035AReasonable structural designHigh degree of automationMechanical conveyorsMaterial transferLeather belt

The invention discloses a flax coil continuous loading mechanism and belongs to the field of textile processing machinery equipment. A material transferring mechanism and a bearing carrying mechanismare horizontally arranged on the two sides of the lower side of the loading mechanism respectively; the two sides of a material conveying belt are connected to a main conveying roll and an auxiliary conveying roll which are on the two sides of a fixed bracket in a coiling manner respectively; a drive gear which is adapted to a conveying gear is vertically and rotationally connected to the fixed bracket on the lower side of the conveying gear; a loading rotary shaft is vertically and rotationally connected to the middle part of a rotation truncated cone; a rotation disc is horizontally arrangedat the upper end of the loading rotary shaft; the two sides of the rotation disc are vertically and symmetrically provided with coil clamping mechanism in a radial direction of the rotation disc; oneend of a bearing carrying rotary plate is hinged to the middle part of the supper side of a carrying plate bracket; and a push plate rotary wheel is vertically and rotationally connected to the output ends of a push plate cylinder on the two sides of the lower side of one end of the material carrying rotary plate. The flax coil continuous loading mechanism provided by the invention is reasonablein structure design, can rapidly, efficiently, continuously and smoothly perform conveying and loading on a flax coil, increases the processing automation degree of the flax coil and meets the demandof production use.

Owner:戴杰

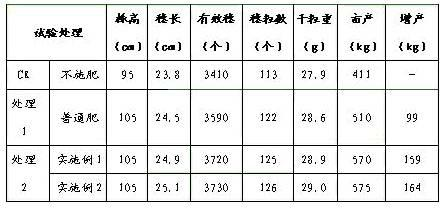

Special bio-compound fertilizer for rice and production method thereof

InactiveCN102503729AIncrease profitIncrease productionFertilizer mixturesCalcium silicateEthylene diamine

The invention discloses a special bio-compound fertilizer for rice and a production method thereof, relating to the technical field of the production of bio-compound fertilizers. According to the production method, the characteristics of fertilizer requirement of the rice are followed, urea, potassium chloride, monoammonium phosphate, biological additives, humic acid, ammonium bicarbonate, calcium silicate, and EDTA (Ethylene Diamine Tetraacetic Acid) chelated zinc are mixed according to a formulated mixture ratio, and the special bio-compound fertilizer is obtained through even mixing, pelleting, drying, cooling, screening, blending and then packaging. The special fertilizer has the advantages of comprehensiveness in nutrients, high utilization ratio, performance in increase of rice yield and rice quality and no pollution.

Owner:STANLEY AGRI GRP CO LTD

Full-automatic plastic sucking machine, and plastic sucking machine loading and unloading method

ActiveCN106493909ARealize continuous feedingImprove delivery response speedCoatingsEngineeringTransfer mechanism

The invention discloses a full-automatic plastic sucking machine. The full-automatic plastic sucking machine comprises a machine support, and a feeding device, a collecting device, and a transferring device which are arranged on the machine support; the feeding device comprises a loading pushing mechanism, and a material pressing separating mechanism matching the loading pushing mechanism; the loading pushing mechanism is used for pushing materials to a preset feeding position; the material pressing separating mechanism is used for separating the materials at the preset feeding position into single materials; the collecting device comprises a collecting jig; the collecting jig comprises a plurality of vacuum grip devices used for collecting; the transferring device comprises a lifting rotating mechanism and a horizontal transferring mechanism; the lifting rotating mechanism is provided with a collecting device installation position; the lifting rotating mechanism is arranged on a horizontal transferring mechanism installation position, and is used for controlling rotating and lifting movement of the collecting device; the horizontal transferring mechanism is used for controlling the horizontal movement of the collecting device. The invention also discloses a full-automatic plastic sucking machine loading and unloading method.

Owner:东莞市信瑞智能科技有限公司

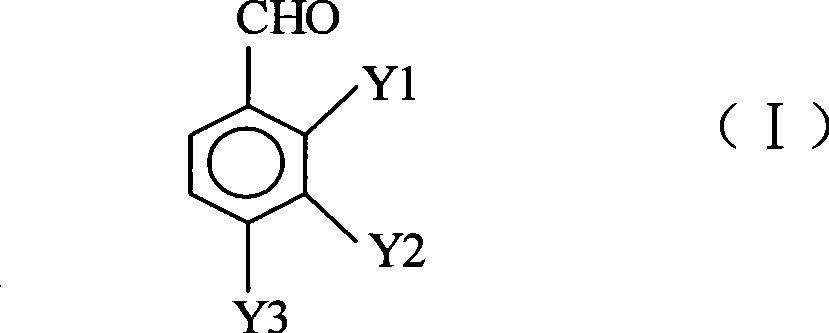

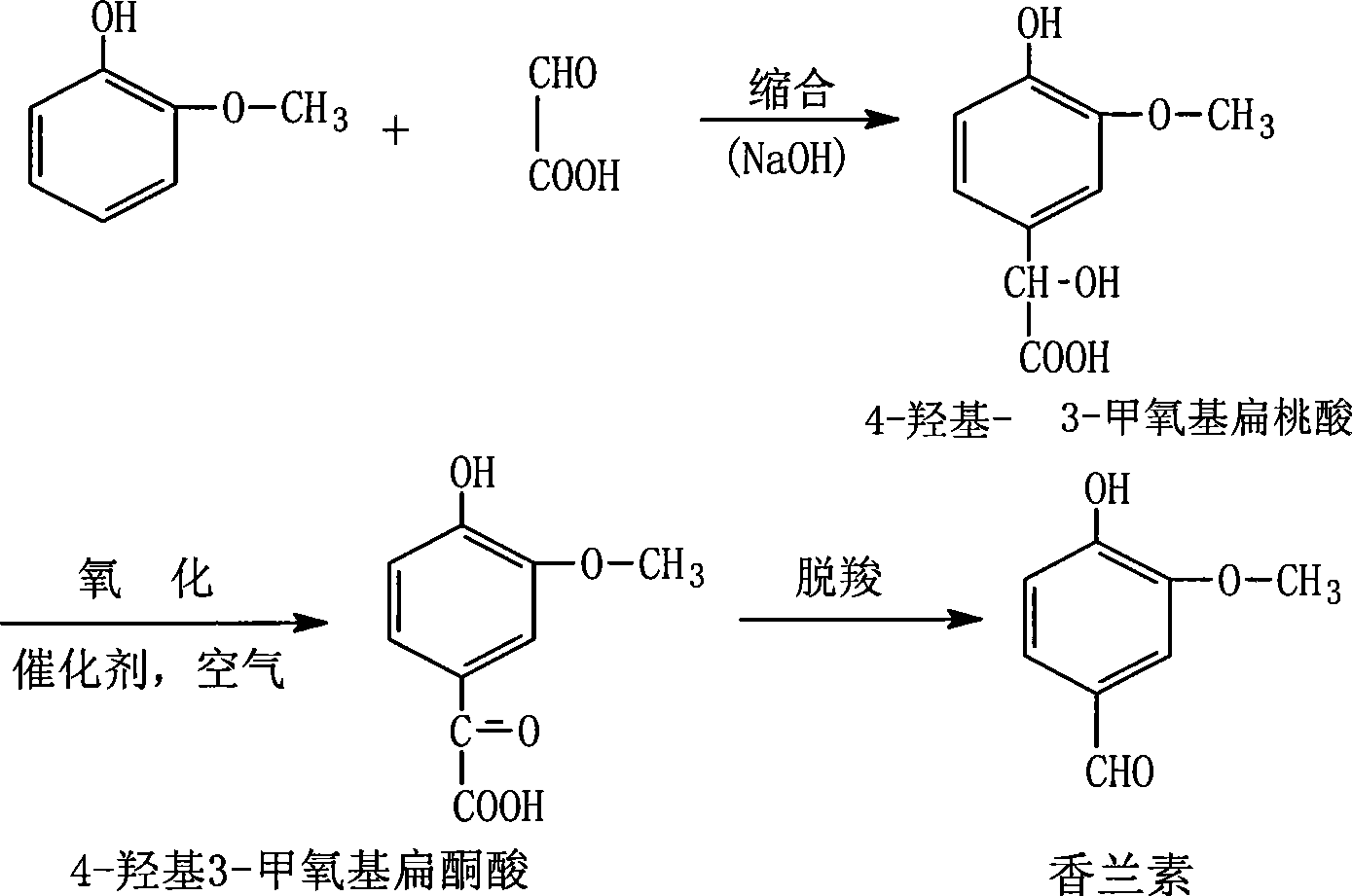

Carbon dioxide supercritical continuous extraction of vanillic aldehyde and derivates thereof from acidic water solution

ActiveCN101386571ASignificant progressSignificant positive effectCarbonyl compound separation/purificationBulk chemical productionGlyoxylic acidAqueous solution

The invention provides a carbon dioxide supercritical method for continuously extracting vanillin and derivatives thereof in acidic aqueous solution. The method is characterized in that glyoxylic acid and phenolic compounds are used as raw materials, condensed and oxidized so as to obtain an acidic aqueous solution containing 2 to 7 percent of the vanillin and the derivatives thereof; the acidic aqueous solution and carbon dioxide supercritical fluid are continuously and reversely mixed in an extraction column, enter separation tanks, and are decompressed and separated so as to obtain a product; the liquid flow rate of the acidic aqueous solution is between 2 and 6 Kg / h; the flow rate of the carbon dioxide fluid is between 10 and 25 Kg / h; the pressure is between 20 and 35 MPa; the temperature is between 40 and 65 DEG C; the separation pressures of the two separation tanks are between 5.5 and 7.0 MPa and between 4.5 and 5.5 MPa respectively; the temperatures of the two separation tanks are between 50 and 65 DEG C and between 30 and 45 DEG C respectively; and the method is simple to operate, improves product content, has the extraction efficiency over 95 percent, has the product content more than 95 percent, realizes the continuous feeding of supercritical extraction, and has good industrialization prospect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Pressing machining device

ActiveCN106736409ARealize automatic feeding processRealize continuous pressingMetal working apparatusEngineeringCam

The invention provides a pressing machining device, and belongs to the technical field of machining. The pressing machining device comprises a pressing mechanism, a material feeding mechanism and a material discharging mechanism, wherein a step shaft of the pressing mechanism is inserted into a through hole in a concave table; one end of a pressing plate is hinged to a supporting plate through a pressing plate pin shaft; a torsional spring and the pressing plate pin shaft are coaxially arranged; a driving handle is hinged to the supporting plate through a handle pin shaft; a driving disk is arranged on the rear side of the supporting plate in a rotatable manner; an insertion pin of the driving handle is inserted into a 1 / 4 arc slot in the driving disk; a vacuum feeder is arranged at the right end of a piston rod of a material feeding cylinder of the material feeding mechanism; a carrying plate is fixed on one side of the supporting plate; a material channel is fixed above the carrying plate; a material discharging mandril of the material discharging mechanism is arranged in a through hole in the concave table and a fixed platform in a manner of sliding up and down; a cam is attached to a mandril roller; and gas nozzles are mounted on a gas nozzle bracket. The pressing machining device quickly realizes pressing machining of the step shaft and an end cover, and is reasonable in structure, high in automaton degree and high in production efficiency.

Owner:佛山市鹏城五金有限公司

Flexible three-dimensional forming printing device based on screw extrusion

PendingCN108748979ASolve the blockage and discharge lagReduce weight3D object support structuresApplying layer meansEngineeringNozzle

The invention discloses a flexible three-dimensional forming printing device based on screw extrusion which comprises a pulse nozzle, a large material bin, a small material bin, wherein the large material bin is independently supported above the nozzle; the small material bin is integrated on the nozzle; the large material bin is connected to the small material bin below through a telescopic flexible conveying pipe; the lower portion of the small material bin is connected and fixed to an extrusion bin through a feeding pipe; a material limiting valve is arranged on the feeding pipe; a screw running vertically is arranged in the extrusion bin; a motor is arranged at the top of the extrusion bin; the motor is connected to the top of the screw and controls the screw to rotate about its own central axis; a heating module is arranged on the periphery of the extrusion bin; and the pulse nozzle is arranged at the bottom of the extrusion bin. The flexible three-dimensional forming printing device based on screw extrusion disclosed by the invention can effectively solve the problems of delay and blocking, is simple in structure, can improve efficiency and reduce the cost and runs stably.

Owner:SHANGHAI UNIV OF ENG SCI +1

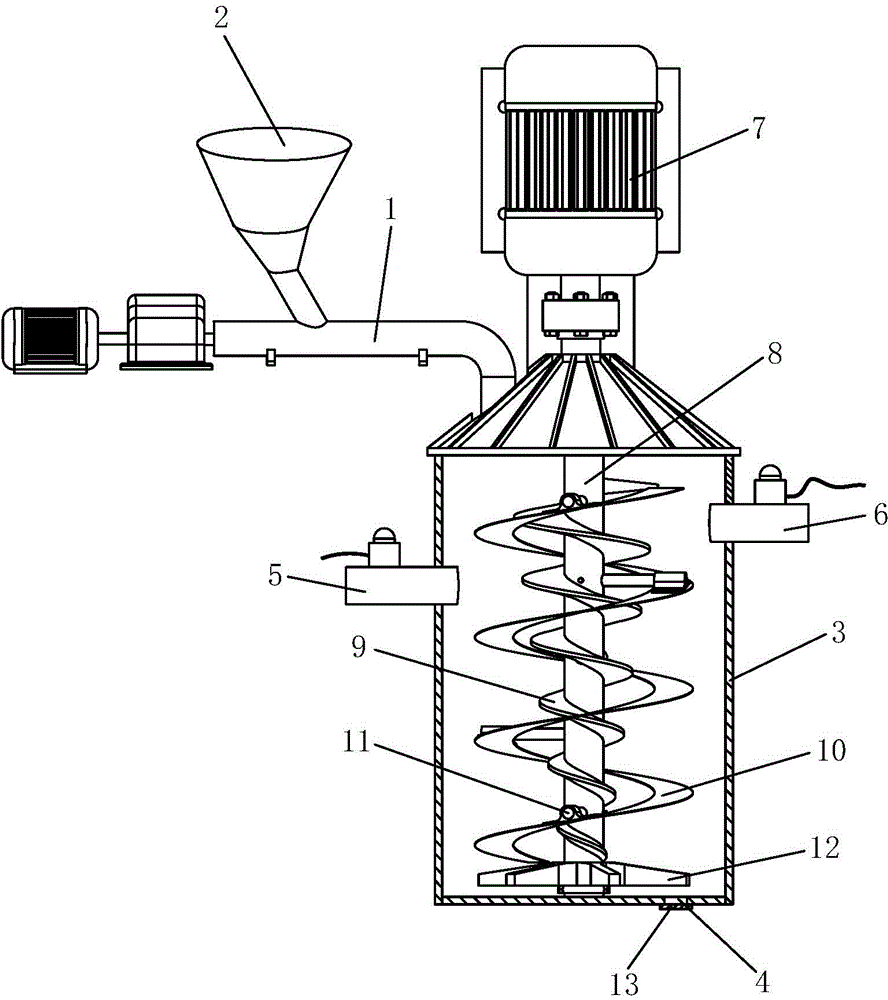

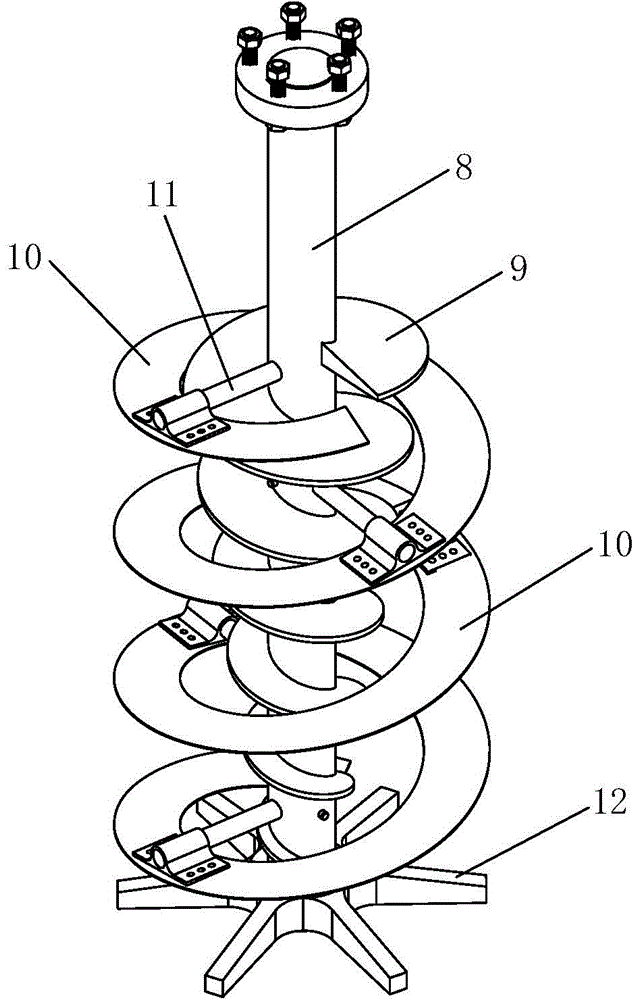

Stirring cylinder of cold-regeneration stirring apparatus for asphalt mixture

InactiveCN101314934ARealize continuous feedingStir wellRoads maintainenceBiochemical engineeringAsphalt

The invention discloses an agitating tank of bituminous mixture cold regeneration and agitation equipment, which comprises a tank body and an inlet and an outlet formed on the tank body, wherein two rotatable agitating shafts are arranged inside the tank body; at least three agitating blade devices are arranged on each agitating shaft; each agitating blade device comprises an agitating blade and a holder; the inlet is formed above one end in the axial direction of the agitating shaft of the tank body; the outlet is formed below the other end in the axial direction of the agitating shaft of the tank body; and the plane of the agitating blade and the axial line of the agitating shaft form an included angle Alpha. Compared with the prior art, the inlet and the outlet of the tank body are formed on the two ends in the axial direction of the agitating shaft of the tank body; the agitating blades and the axial direction of the agitating shaft incline to form the included angle; materials to be agitated enter the inlet, are output from one end of the agitating shaft to the other end thereof in a mixed way under the agitating action of the inclined agitating blades, and meanwhile, during the agitating process, the agitating tank can realize continuous feeding after the materials to be agitated are mixed.

Owner:ZHENJIANG HUACHEN HUATONG ROAD MASCH CO LTD

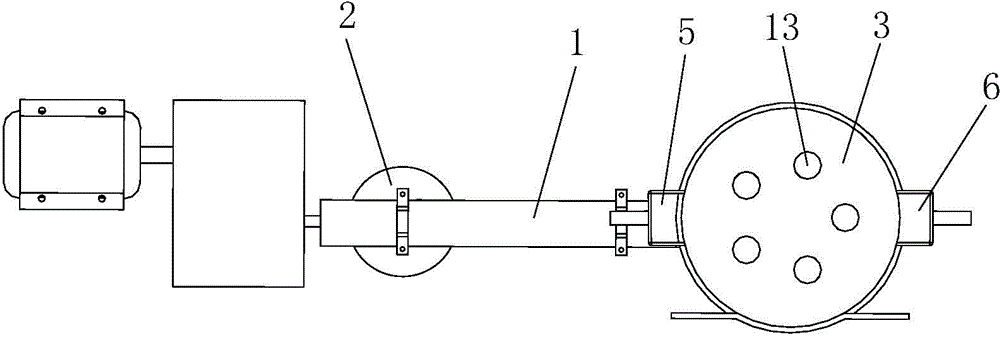

Dry and wet double-purpose stirring ball mill

ActiveCN104984790ASmall granularityRealize three-dimensional circulationGrain treatmentsEngineeringDrive motor

The invention discloses a dry and wet double-purpose stirring ball mill. The dry and wet double-purpose stirring ball mill comprises a stirring ball mill device and a dry material feeding device, wherein the stirring ball mill device comprises a stirring barrel and a stirring ball mill mechanism; a dry material feeding opening is arranged on the a stirring barrel over, and a dry material discharging opening is formed in the bottom of the stirring barrel; a slurry flowing-in pipe and a slurry flowing-out pipe are arranged on the side wall of the stirring barrel; the stirring ball mill mechanism comprises a driving motor, a stirring shaft, a first helical belt and a second helical belt; the first helical belt is wound on the stirring shaft and is fixed to the stirring shaft into a whole, and the first helical belt is sleeved with the second helical belt; the second helical belt is connected with the stirring shaft through a connecting stick, the first helical belt is a left helical belt, and the second helical belt is a right helical belt; the lower end of the stirring shaft penetrates into the barrel over, and a scraper blade is fixed to the stirring shaft; and the first helical belt and the second helical belt are both located in the stirring barrel. The shearing, friction and grinding efficiency needed by the materials is strengthened, the aim of homogenizing crushing of the materials is achieved, the crushing efficiency is high, and dry and wet materials can be crushed.

Owner:XIAN UNIV OF SCI & TECH

Recovery equipment for paperboard leftover materials

InactiveCN109454087AAchieve pre-crushingAvoid entanglementSolid waste disposalGrain treatmentsPaperboardEngineering

The invention relates to recovery equipment for paperboard leftover materials. The recovery equipment is used on a paperboard slitting machine and is used for recycling the leftover materials generated in the slitting process. The recovery equipment comprises a guide roller, a feeding mechanism, a cutting mechanism and a crushing mechanism. The feeding mechanism comprises an upper pressing rollerand a lower pressing roller which are matched with each other, and the upper pressing roller is driven to rotate by a first motor. The cutting mechanism comprises a conveyor belt, a bracket, a liftingrod and a cutter, wherein the lifting rod is slidably connected to the bracket and can move up and down relative to the bracket, the cutter is connected to the bottom of the lifting rod and positioned above the conveyor belt, and the conveyor belt is positioned on the discharging side of the feeding mechanism. The lifting rod and the upper pressing roller are connected through a first transmission mechanism. The crushing mechanism comprises a crushing box, wherein a crushing shaft is arranged in the crushing box, a crushing blade sleeves the bottom of the crushing shaft, the top of the crushing shaft is rotatably connected to a lifting plate and supported by the lifting plate, the crushing shaft is driven to rotate by a second motor, and the lifting plate is connected with the lifting rod.

Owner:句容市南山包装制品有限公司

Anti-wrinkling film covering and forming device

InactiveCN105415848ARealize continuous feedingRealize continuationLamination ancillary operationsLaminationActivated carbonConductor Coil

The invention provides an anti-wrinkling film covering and forming device which comprises a film covering assembly, a glue extruding assembly, a drying assembly, a winding type cooling assembly and an exhaust gas recycling and treating assembly. The discharge end of the film covering assembly is provided with the glue extruding assembly, the discharge end of the glue extruding assembly is provided with the drying assembly, and the discharge end of the drying assembly is provided with the winding-type cooling assembly; the film covering assembly comprises a film covering rack, a glue dipping tank, a glue dipping roller, a lower film guide roller, a lower film covering part, an upper film guide roller and an upper film covering part, and the exhaust gas recycling and treating assembly comprises a recycling pipeline, a cyclone separator, a condenser, a heat exchanger, a plasma processor, an activated carbon sponge filter and an exhaust pipeline. According to the device, exhaust gas generated in production is treated and then recycled, liquid asphalt in production is cooled through the recycled gas to enable the asphalt to be at the appropriate temperature which is more suitable for film covering operation, therefore, the wrinkling phenomenon generated after film covering is performed is effectively avoided, and the processing quality can be guaranteed.

Owner:安徽五星凯虹防水建材科技有限公司

Continuous production process for amino trimethylene phosphonic acid

ActiveCN103275121ARealize continuous feedingIncrease production capacityGroup 5/15 element organic compoundsPhosphorous acidWater vapor

The invention relates to a continuous production process for an amino trimethylene phosphonic acid. The continuous production process comprises the steps of adding ammonium chloride, phosphorous acid and formaldehyde in a mixing kettle according to a certain molar ratio; adding reverse osmosis water; mixing uniformly at the temperature of 35 DEG C; pumping into a tubular reactor at a certain flow rate; reacting thoroughly; then introducing into a spraying absorption tower; and spraying from the top of the tower so as to contact with rising high temperature water vapor, condensing amino trimethylene phosphonic acid being cooled to enter the tower unreacted ammonium chloride, formaldehyde and hydrogen chloride vapor entering a rectification apparatus to be separated by rectification from the top of the tower. Continuous feeding and discharging production process is employed, and conventional intermittent production process employing single kettle mixing material is changed, so that utilization rate of the equipment is increased; production period is shorten; productivity is increased; performance is more stable; comprehensive energy consumption is reduced; and large-scale industrialized production can be achieved easily.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

Automatic material dividing device with anti-blocking function

ActiveCN103256617AReduce in quantitySimple structureConveyor partsLump/pulverulent fuel feeder/distributionEngineeringThrough transmission

The invention discloses an automatic material dividing device with an anti-blocking function. A storage hopper is arranged at the top end of a material dividing box. A material blocking board is arranged at the lower end of a connecting part of the storage hopper and the material dividing box. Material stirring wheels are arranged at the upper end near a closing position of the material blocking board. The material blocking board is connected with a material blocking board driving device. Material dividing units are symmetrically arranged on two sides of the material dividing box. Each set of material dividing units comprises a cam mechanism, a material dividing board, a material dividing board dividing device, a conveyor belt and a small storage hopper. Positions of the cam mechanisms correspond to positions of the material stirring wheels. Each material dividing board is arranged on one side, near a box body of the material dividing box, of each cam mechanism. The material dividing board driving devices are connected with the material dividing boards. An opening is formed in a position, corresponding to the material dividing boards, of the material dividing box. The material dividing boards are arranged on rotary shafts arranged at the lower end of the opening of the material dividing box. The conveyor belts and the small storage hoppers are arranged around the opening. A variable frequency motor is arranged at the bottom end of the material dividing box, and is connected with the cam mechanisms and the material stirring wheels through transmission chains. A material storage function and the anti-blocking function are combined, and the automatic material dividing device with the anti-blocking function has the advantages of being capable of dividing materials continuously, high in efficiency and strong in anti-blocking ability.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com