Feeding mechanism of biomass fuel furnace

A biomass fuel and feeding cylinder technology, applied in fuel supply, combustion methods, combustion equipment, etc., can solve the problems of low thermal efficiency, black smoke, environmental pollution, etc., and achieve full combustion, no black smoke, and high thermal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

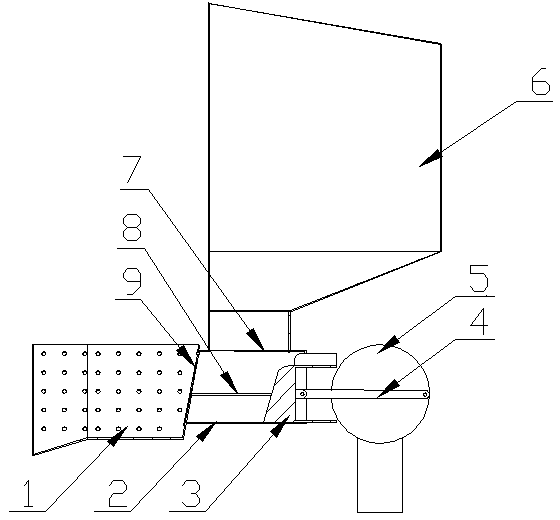

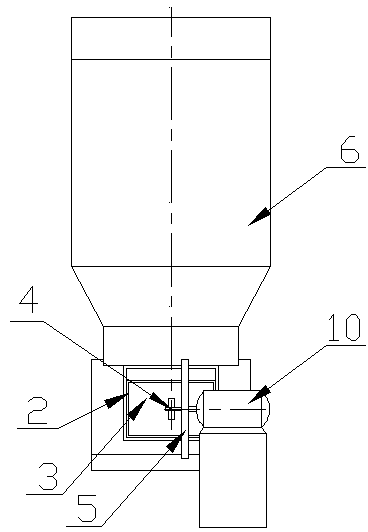

[0009] As shown in the figure, the feeding mechanism of the biomass fuel furnace is composed of a storage box 6, a feeding barrel 2, a piston 3, and a motor 10. The shaft end of the motor 10 has a wheel 5, and the piston 3 is slidingly matched with the feeding barrel 2, and the feeding barrel 2 In the lower part of the storage box 6, there is a receiving port on the feeding barrel 2, and the lower part of the storage box 6 has a funnel-shaped outlet. The outlet of the storage box 6 matches the receiving port of the feeding barrel 2. The discharge port of the storage box 6 is hinged with a discharge door 7, the piston 3 and the combustion chamber door 9 of the combustion chamber 1 of the biomass fuel furnace are connected by a rod 8. A connecting rod 4 is hinged on the piston 3, and the connecting rod 4 The other end is hinged on the edge of the wheel 5. The wheel 5 and the connecting rod 4 constitute a crank-connecting rod mechanism. When the motor 10 drives the wheel 5 to rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com