Combustor for gasification combustion of biomass formed particles

A technology of biomass and particles, which is applied in the fields of boilers, burners for gasification and combustion of biomass shaped particles, tobacco flue-cured furnaces and burners for various drying equipment. It can solve the problems of difficult application of biomass fuels and achieve petrochemical savings. The effect of fuel, high calorific value and cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

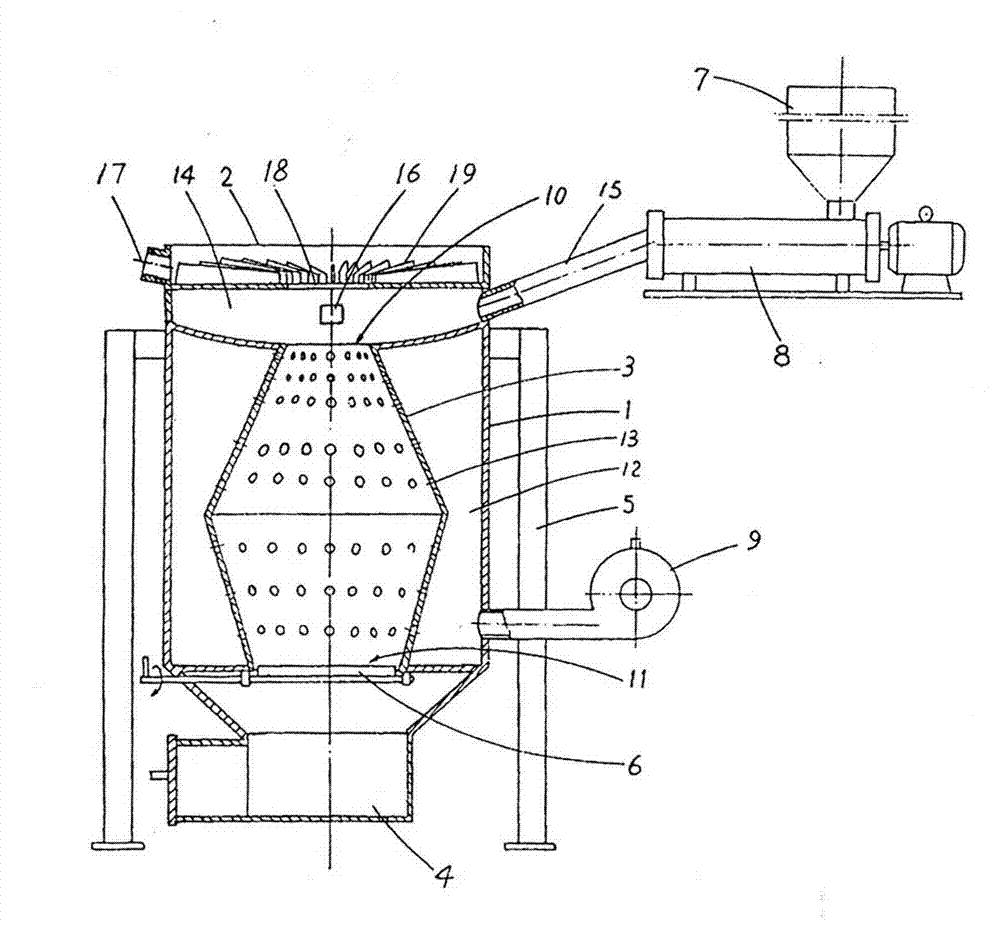

[0020] Embodiment 1, on the floor around the fire hole 18 of the burner 2, several fire distribution plates 19 arranged radially are uniformly arranged.

[0021] The furnace of the present invention is circular and welded with cast iron or steel plates. Some of its parameters are determined according to the size of the boiler and the flue-cured furnace. The following examples are available for reference (see Table 1)

[0022] Table 1

[0023] parameters example 1 Example 2 Example 3 Furnace height (mm) 470 600 750 Fire hole diameter (mm) 80 100 130 Furnace middle diameter (mm) 260 300 390 Ash discharge hole diameter (mm) 150 180 230 The diameter of the vent hole on the upper part of the furnace (mm) 5 5.5 6.0 Ventilation hole spacing on the upper part of the furnace (mm) 20 22 25 The diameter of the ventilation hole in the lower part of the furnace (mm)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com