Patents

Literature

408results about How to "Fast ignition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

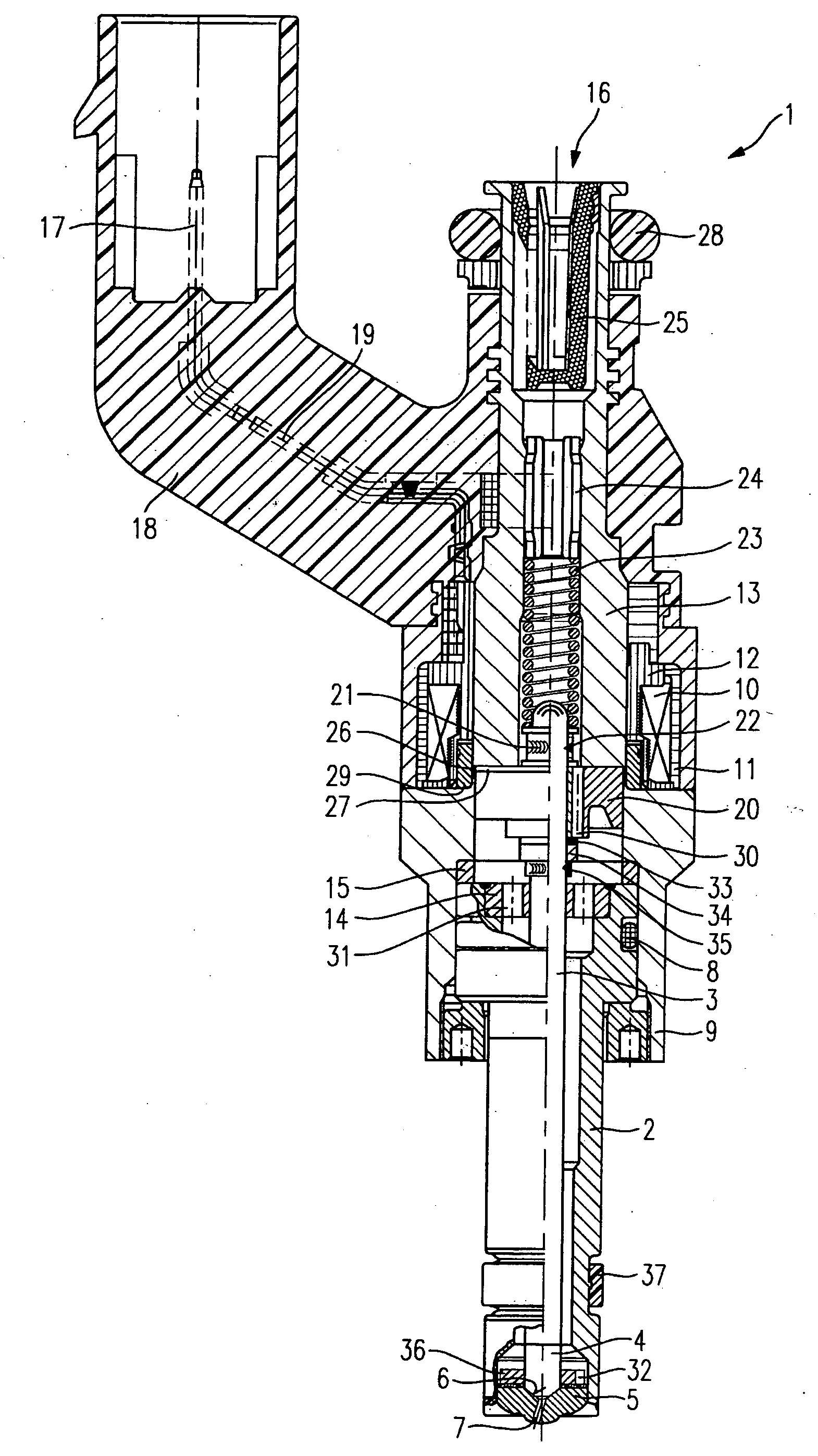

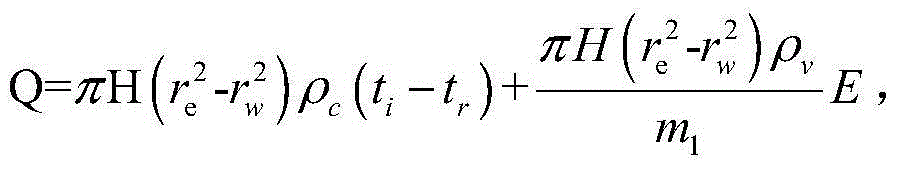

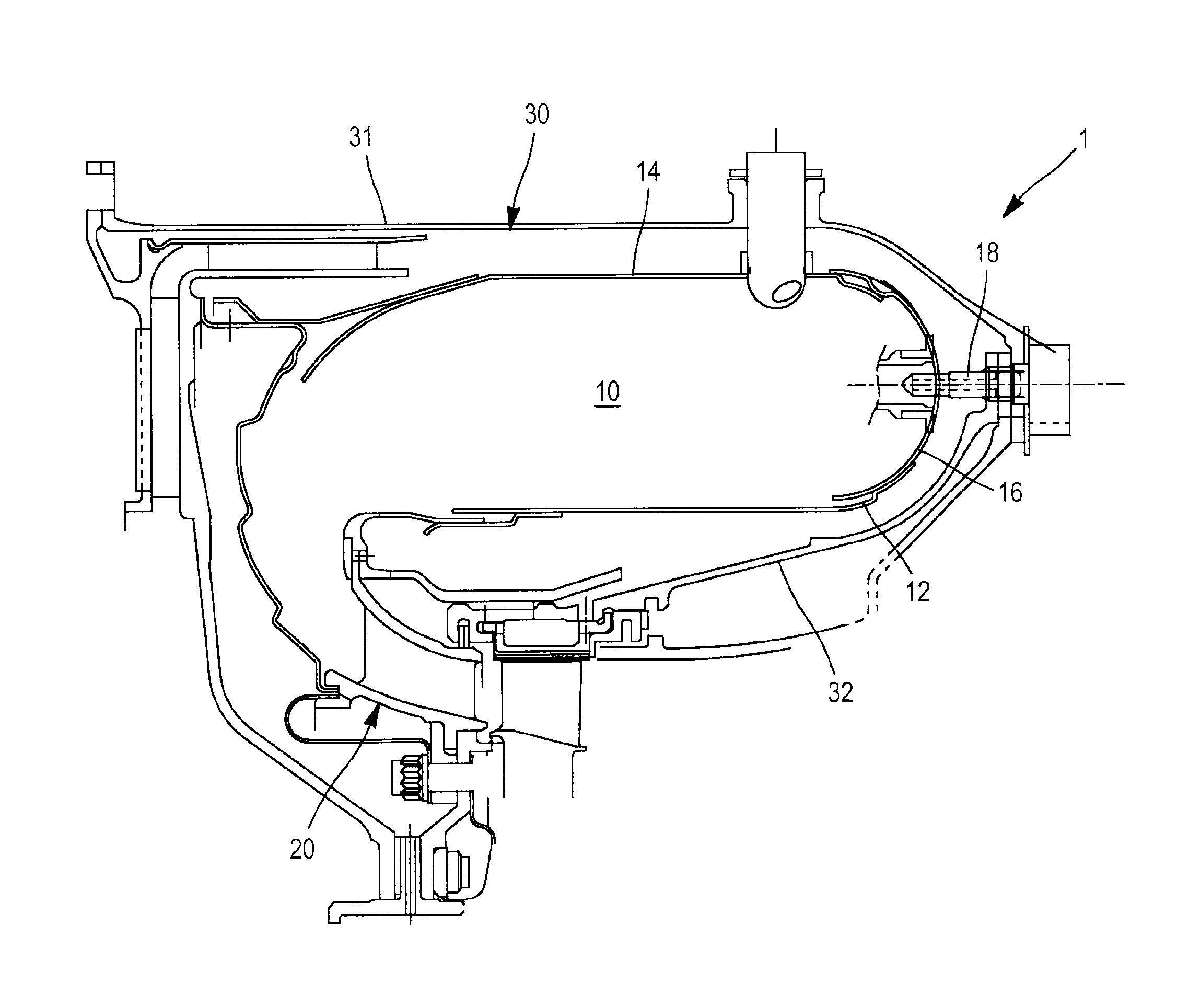

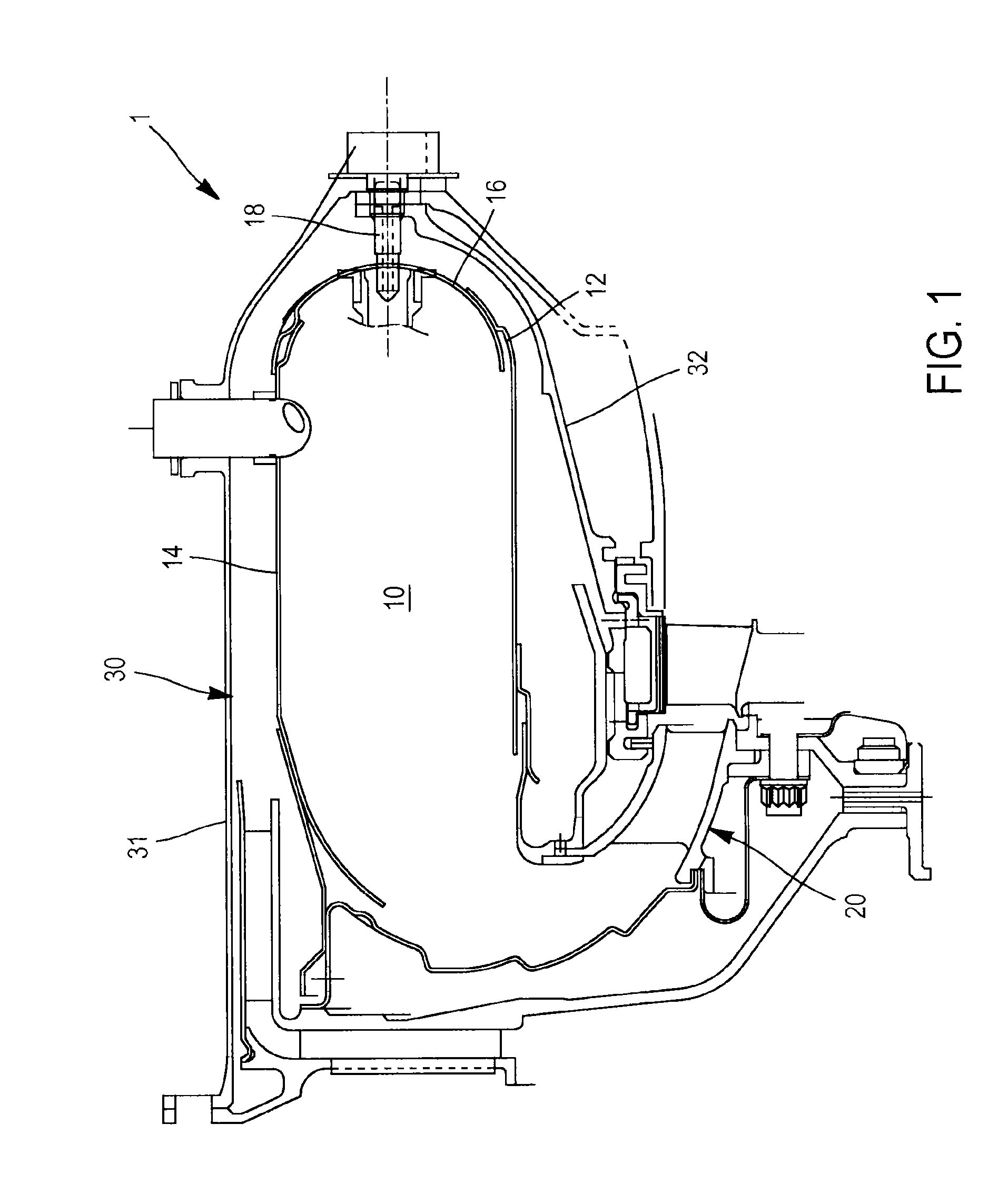

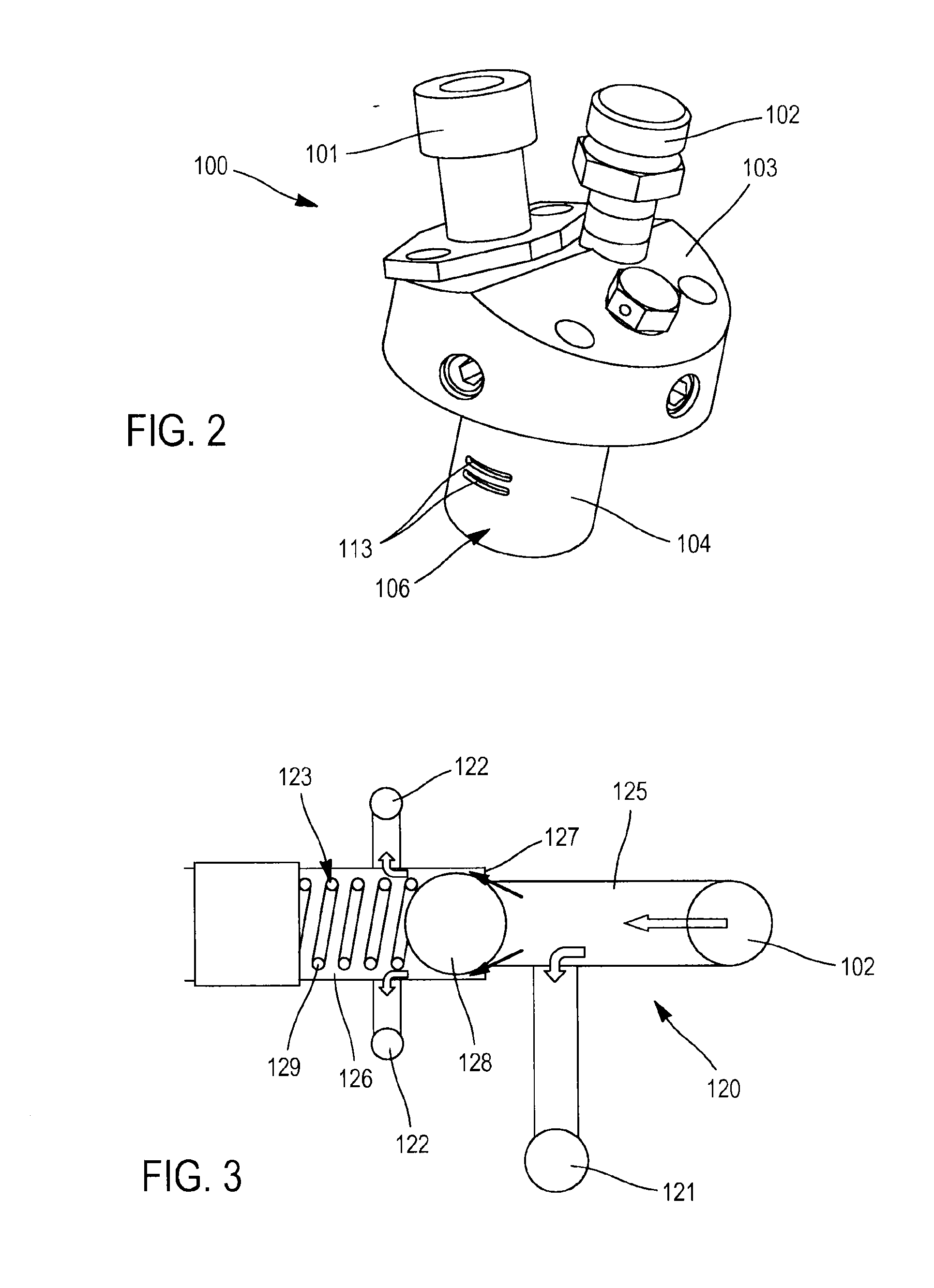

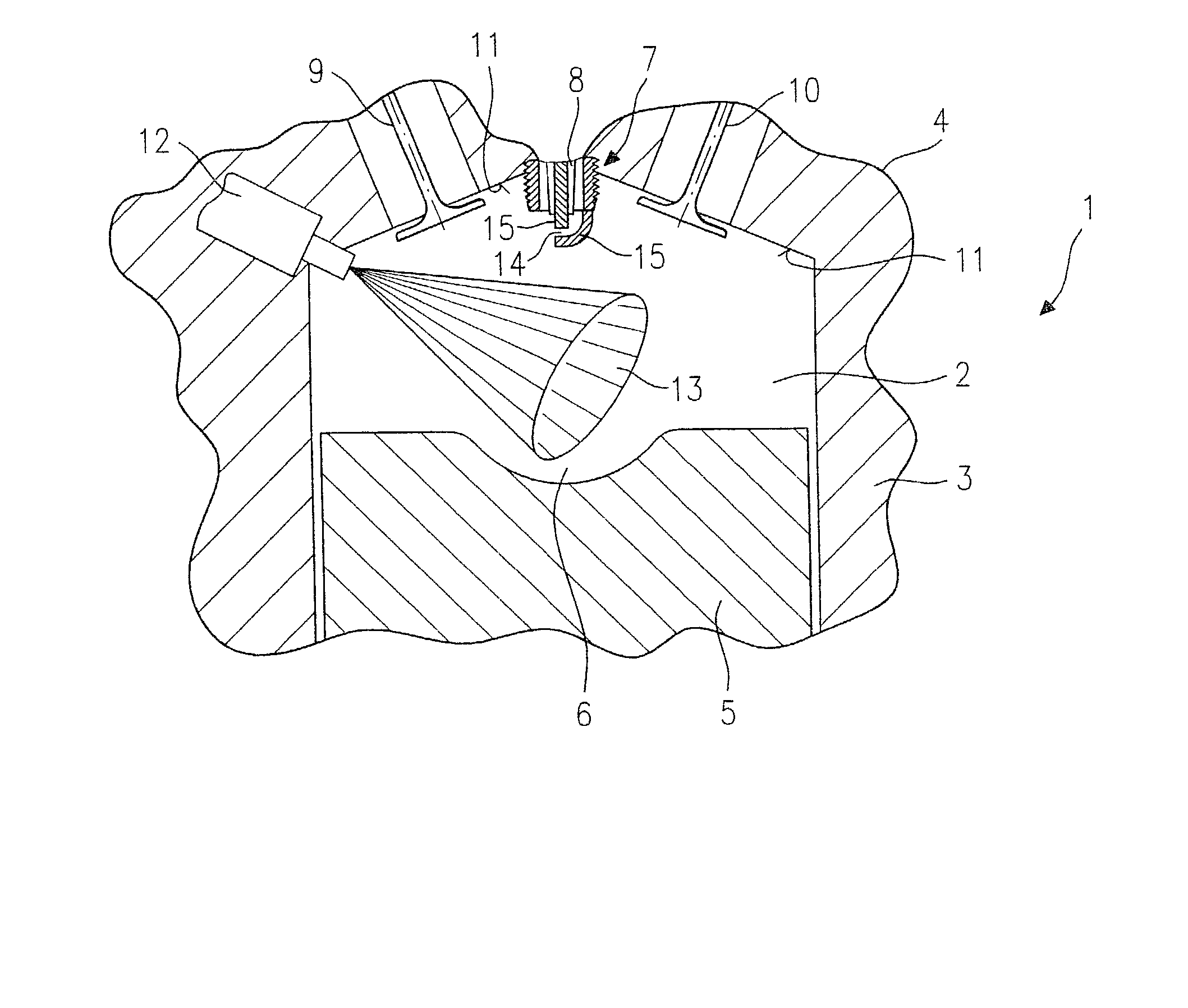

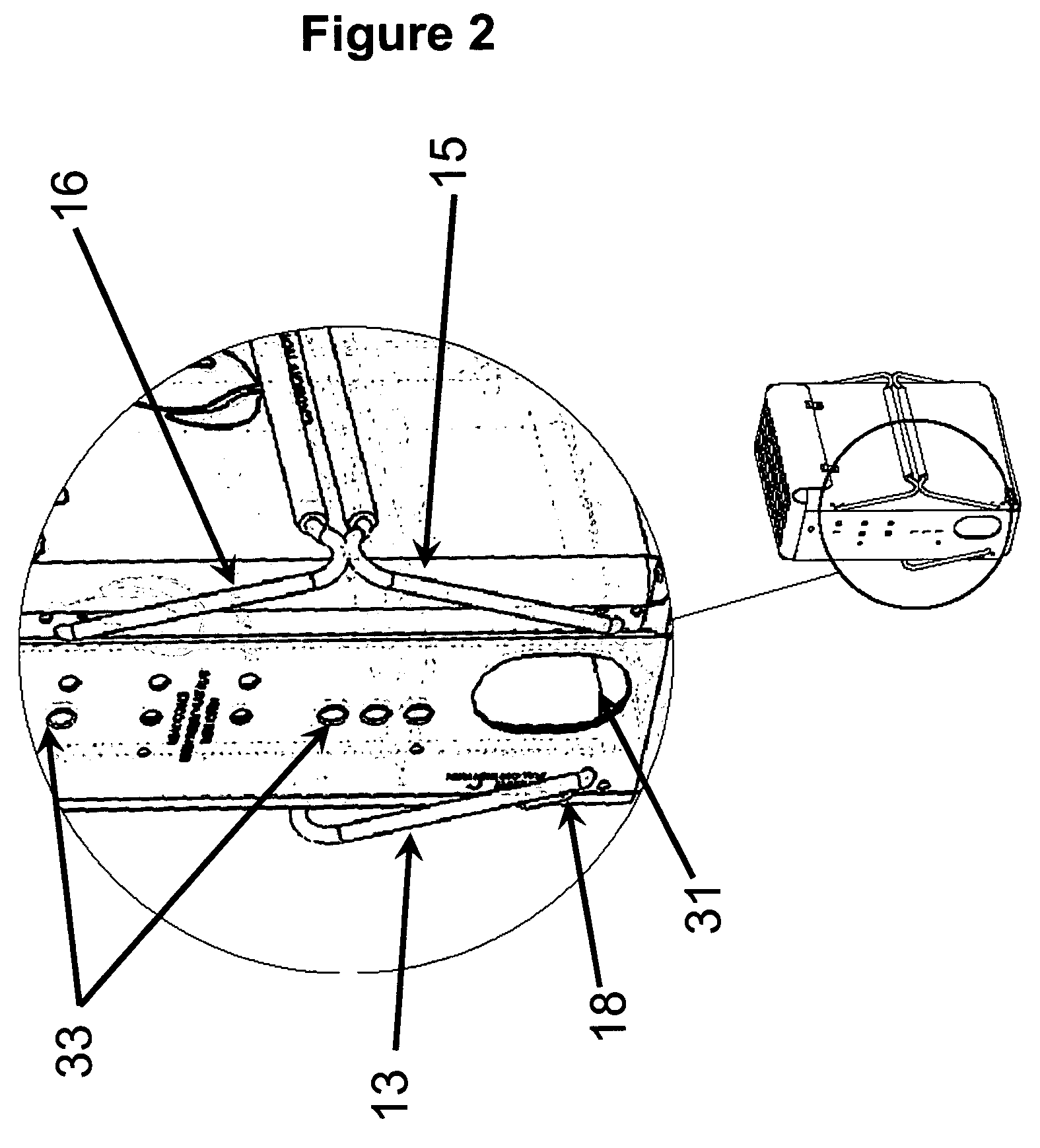

Fuel Injector Having an Integrated Ignition Device

InactiveUS20080072871A1Reduce thicknessEasy to monitorMachines/enginesFuel injection with sensorsCombustion chamberElectrode pair

A fuel injector having an integrated ignition device includes a first electrode pair for igniting fuel which is injected directly into a combustion chamber of an internal combustion chamber through spray-discharge orifices of the fuel injector. The first electrode pair is made up of a ground electrode and a center electrode which are set apart by a spark gap. The fuel injector and the ignition device are situated in a shared housing. The ignition device has at least one additional spark gap and / or an additional electrode pair.

Owner:ROBERT BOSCH GMBH

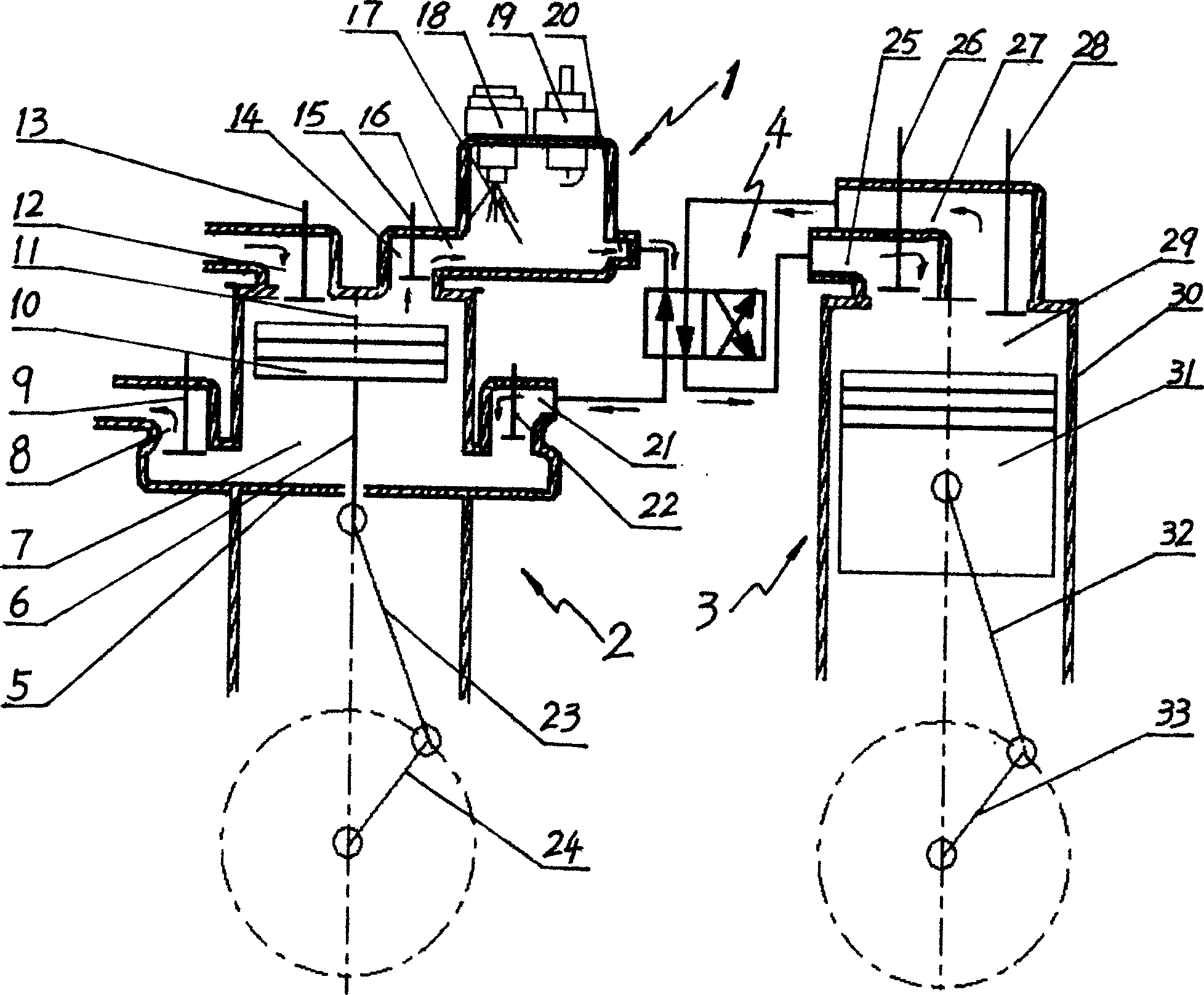

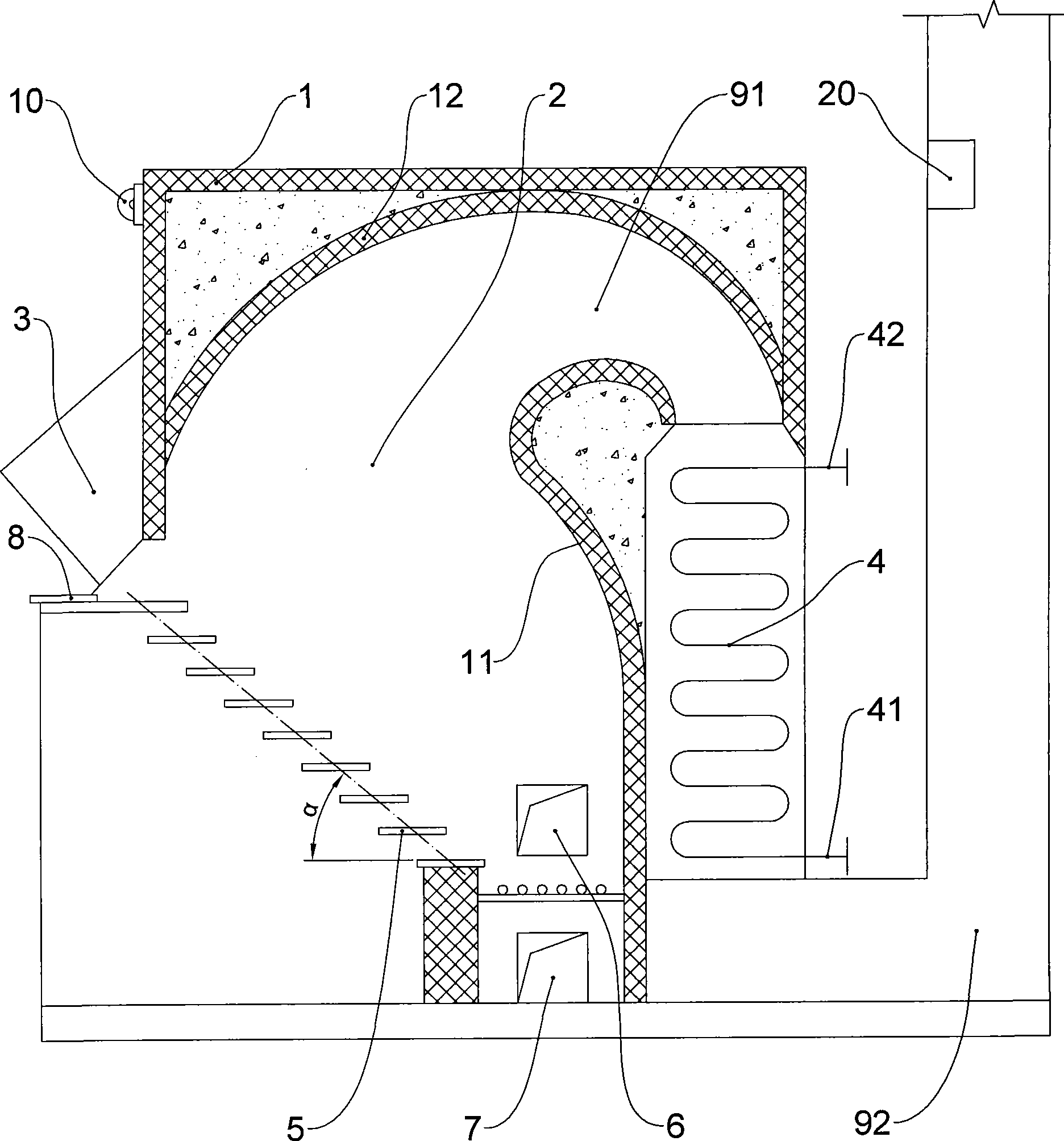

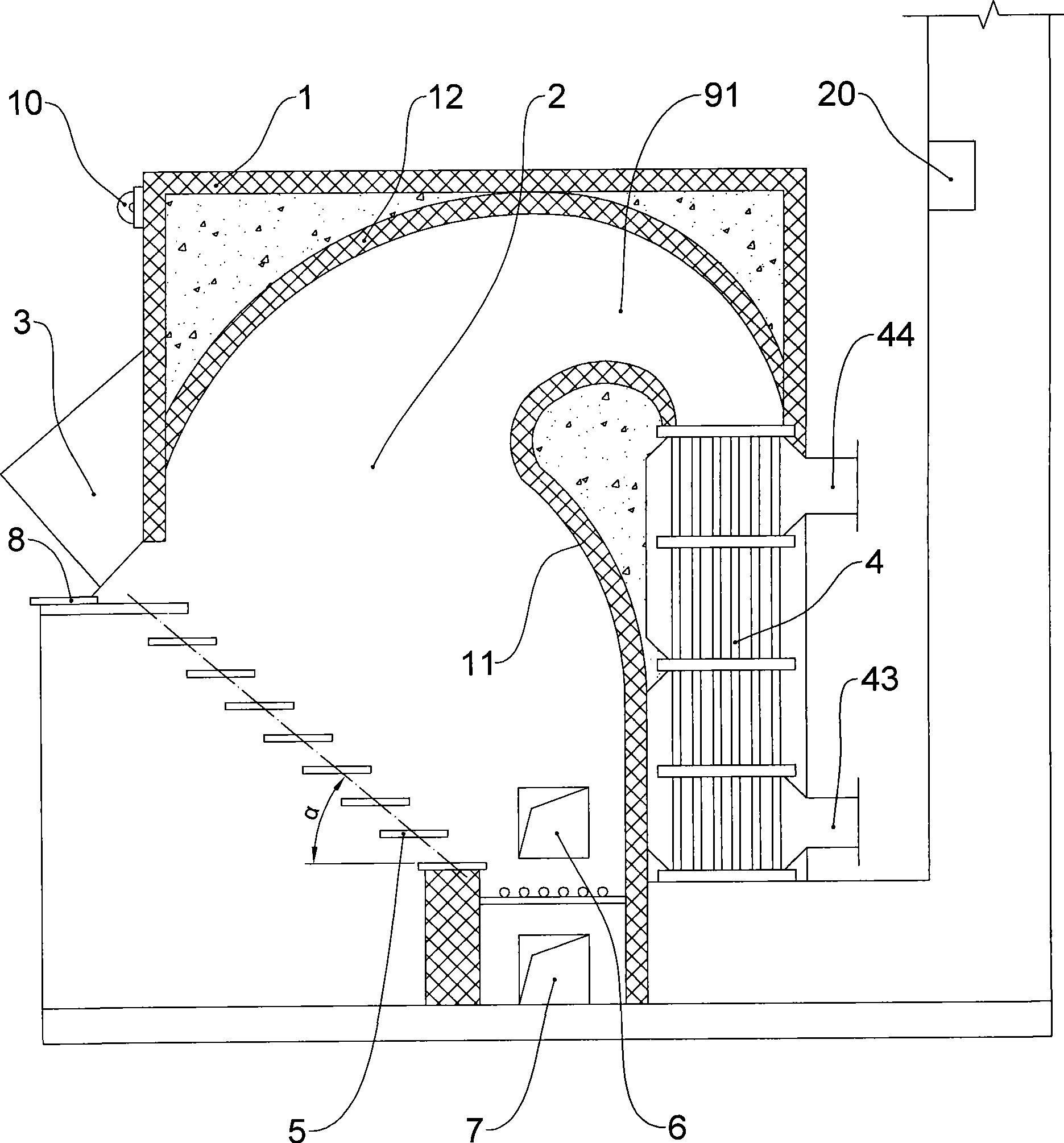

Continuous combustion constant power engine

InactiveCN1821557ATroubleshoot hard-to-start issuesEmission reductionInternal combustion piston enginesDetonationCombustor

The present invention relates to continuous combustion constant power engine. There are one independent continuous combustor outside the cylinder, two sets of link rod-piston mechanisms with gas compressing device and expansion device, and one gas exchange valve for connecting these two mechanisms to the continuous combustor, to constitute one complete thermal engine. The present invention can reach ideal low temperature multiple fuel clean combustion with less noise, no smoke and no combustion detonation, and has raised compression ratio, raised expansion ratio, high heat efficiency, and reduced exhaust of harmful gas. The independent combustor of the present invention can realize fast ignition and self starting without compression and in the condition of low temperature.

Owner:李岳

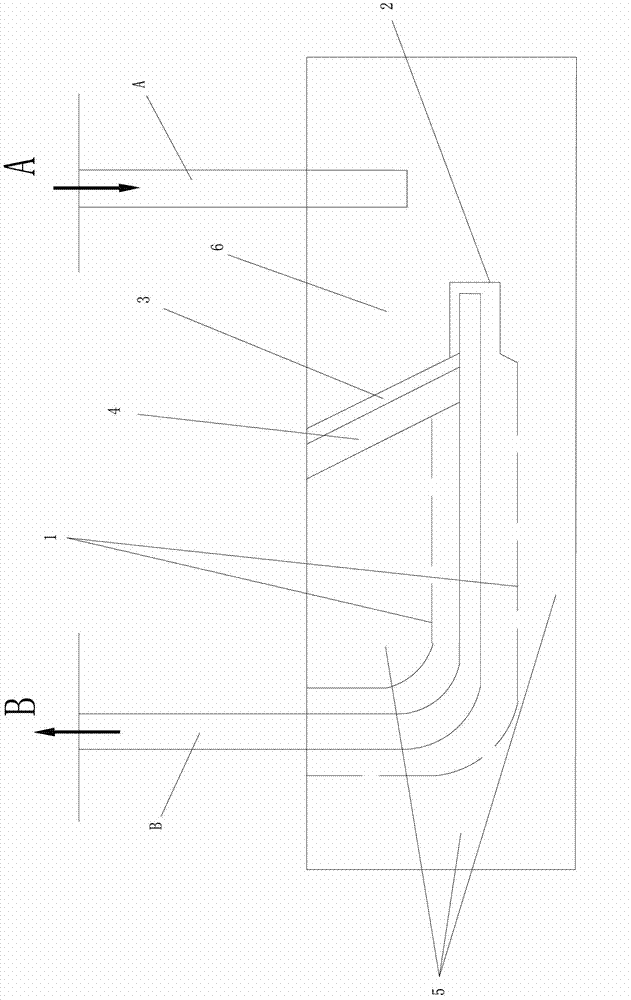

Dense Phase Swirl Pulverized Coal Burner

InactiveUS20130112120A1Simple primary air channel structureImprove wear resistancePulverulent fuel combustion burnersCombustionFlue gas

A dense phase swirl pulverized coal burner comprises a primary air channel, a direct flow secondary air channel and a outermost swirl secondary air channel; and multiple levels of pulverized coal concentration rings are arranged axially at intervals along the oil gun casing in a straight tube section of the primary air channel, so that pulverized coal air flow is distributed thickly outside and thinly inside the primary air nozzle. In the invention, dense phase pulverized coal outside the primary air nozzle passes through guide vanes, forms disturbed flow, is ejected into a furnace and mixes with high temperature backflow flue gas rapidly and sufficiently at an outlet. Meanwhile, dilute pulverized coal air flow at the center is ejected into the furnace by direct flow, ensuring subsequent mixing and combustion of pulverized coal flow. The primary air nozzle and the secondary air nozzle are provided with cone flaring structures with certain angle to effectively control appropriate mixing of secondary air and pulverized coal. The invention has advantages of strong ignition and combustion stability, good coal adaptability, low nitric oxide emission, simple primary air channel structure and small resistance, which effectively slows wear rate of parts.

Owner:LI YUEHUA

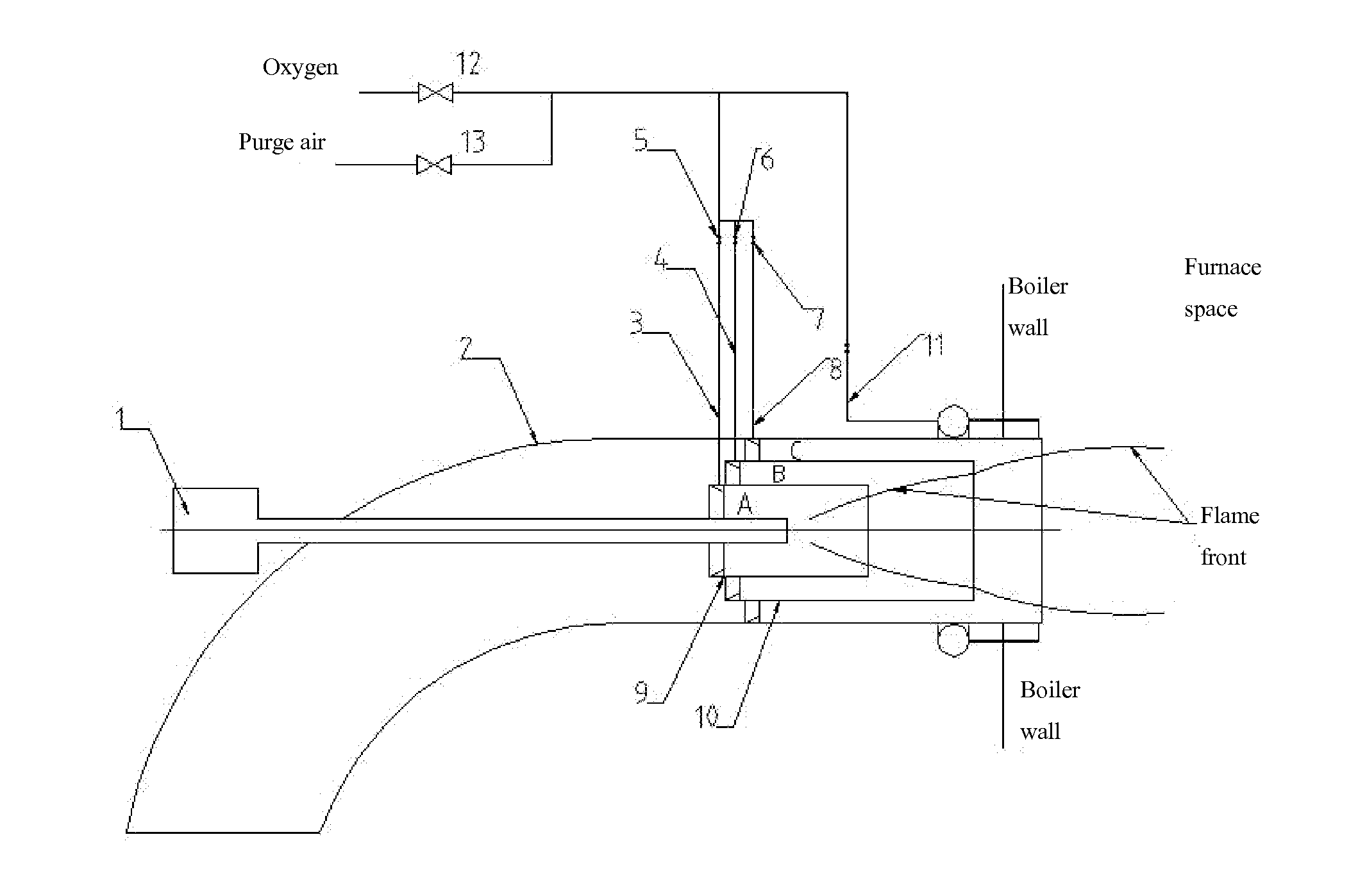

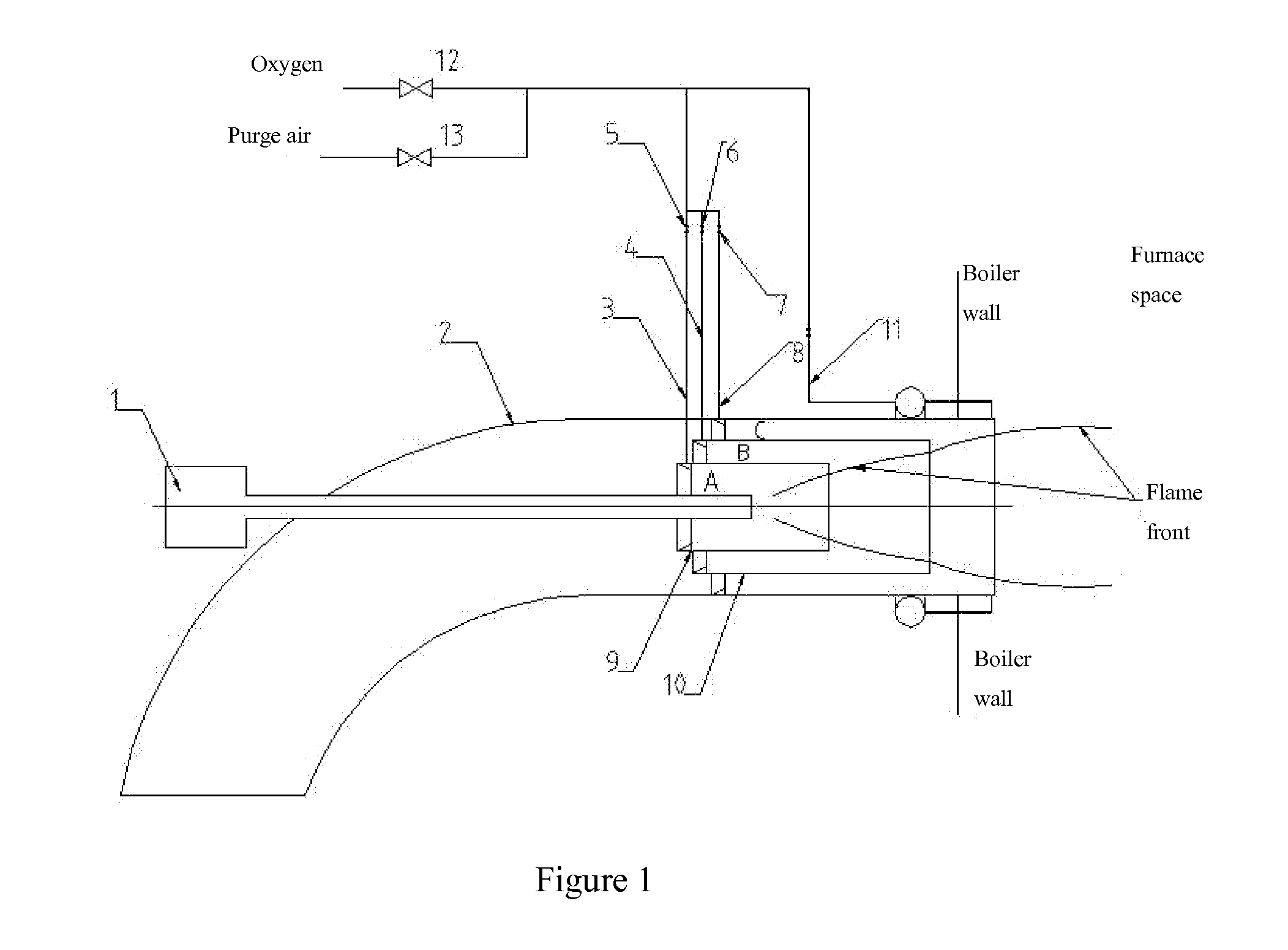

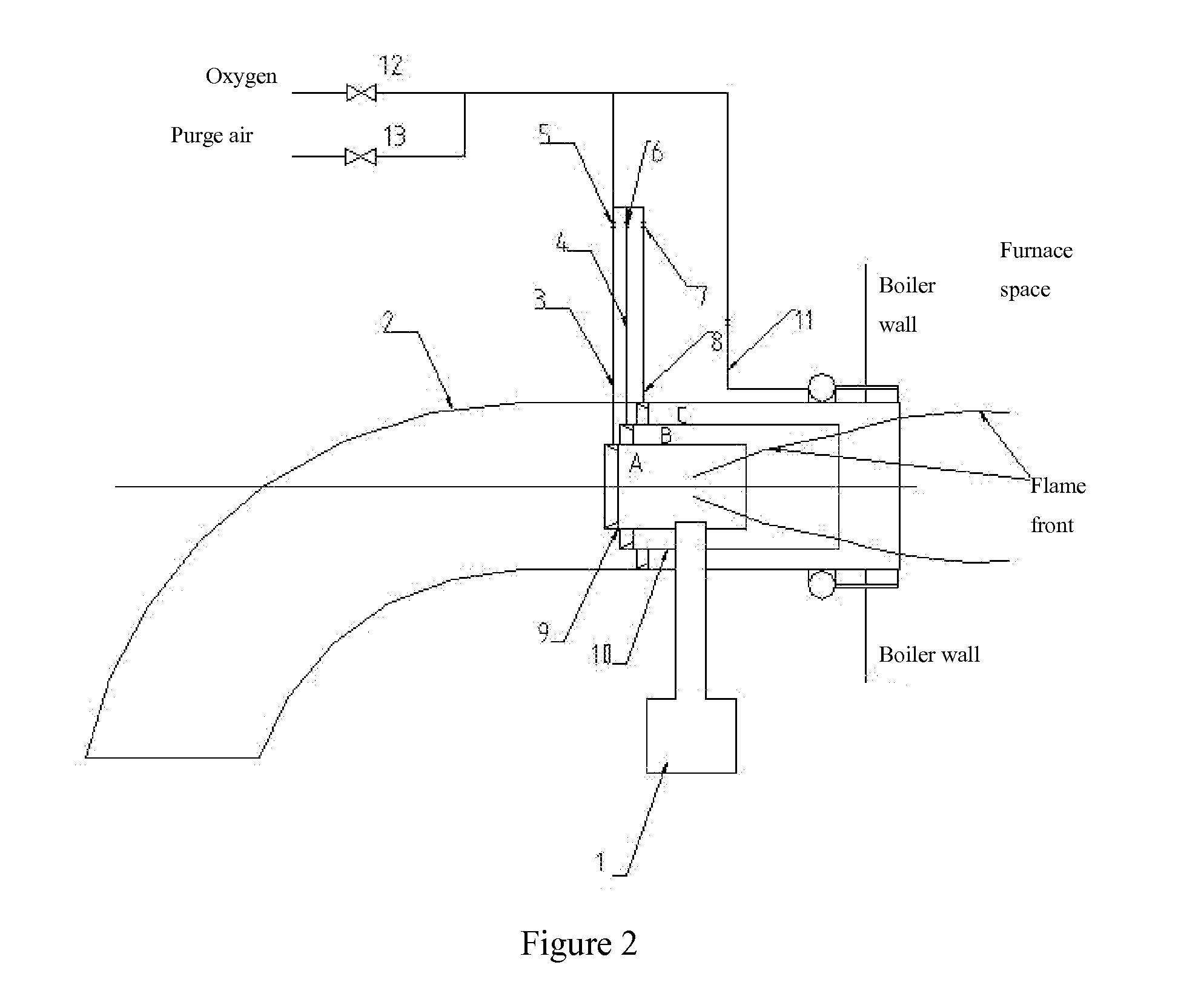

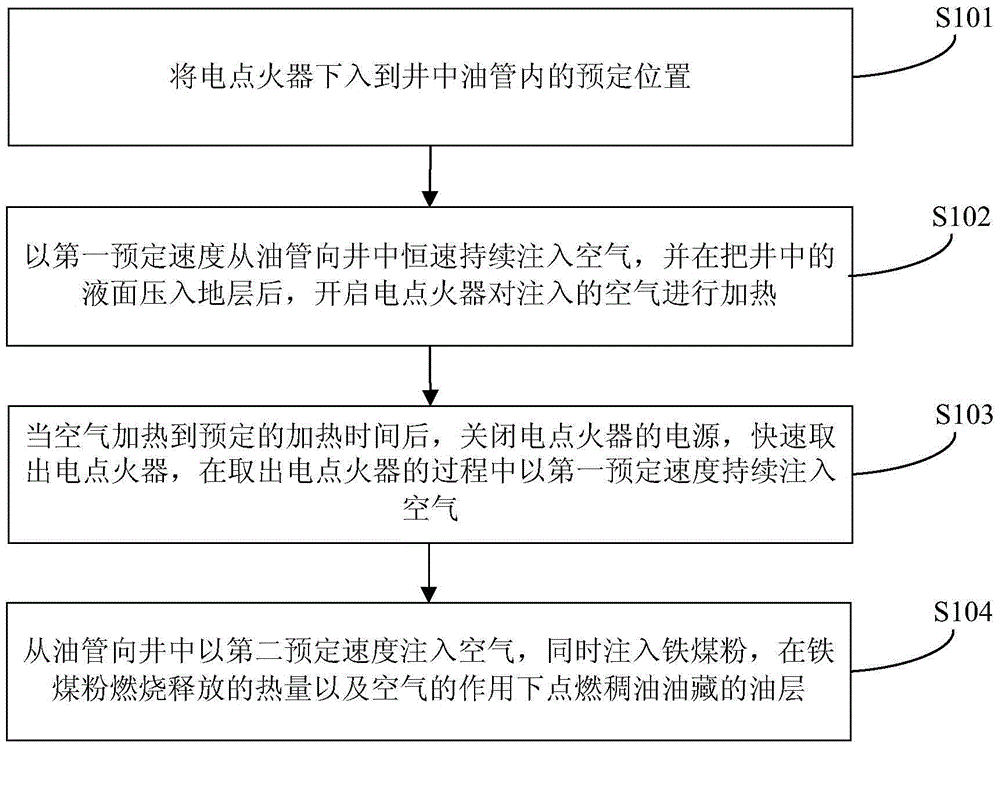

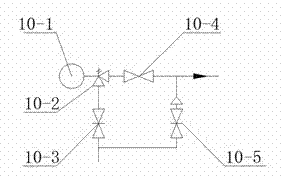

In-situ combustion combustion-supporting ignition method

ActiveCN104453817AReduce moisturePlay the role of profile control and channel sealingFluid removalElectricityHeating time

The invention discloses an in-situ combustion combustion-supporting ignition method. The method comprises the steps that an electric igniter is tripped in the preset position in an oil tube in a well; air is continuously injected into the well from the oil tube at a first preset speed, and after a liquid level in the well is pressed into a stratum, the electric igniter is started to heat the injected air; after the air is heated by the preset heating time, a power source of the electric igniter is turned off, the electric igniter is taken out, and the air is continuously injected at the first preset speed in the process of taking out the electric igniter; air is injected into the well from the oil tube at a second preset speed, meanwhile, iron pulverized coal is injected, and an oil layer of a heavy oil reservoir is ignited under the action of heat released by combustion of the iron pulverized coal and the air. Through the electric igniter, the oil layer is preheated, and water of near bore zones is reduced. The iron pulverized coal has the functions of profile correction and channeling blocking, combustion products are stored in holes, a gas entry profile continues to be adjusted, ignition is facilitated better, gas channeling is reduced, and meanwhile fast ignition is achieved.

Owner:PETROCHINA CO LTD

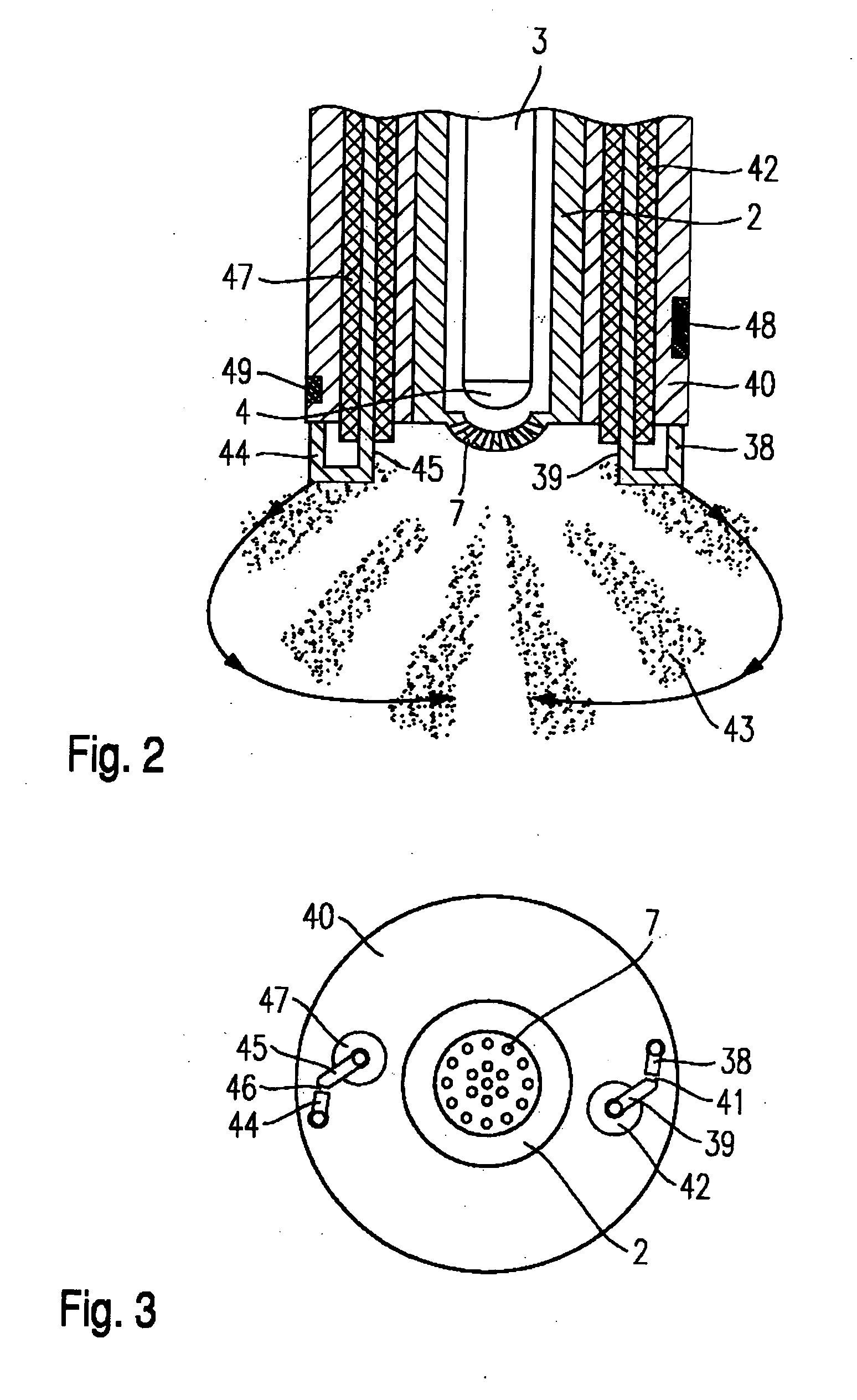

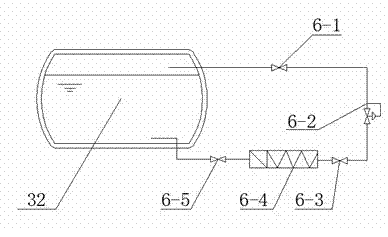

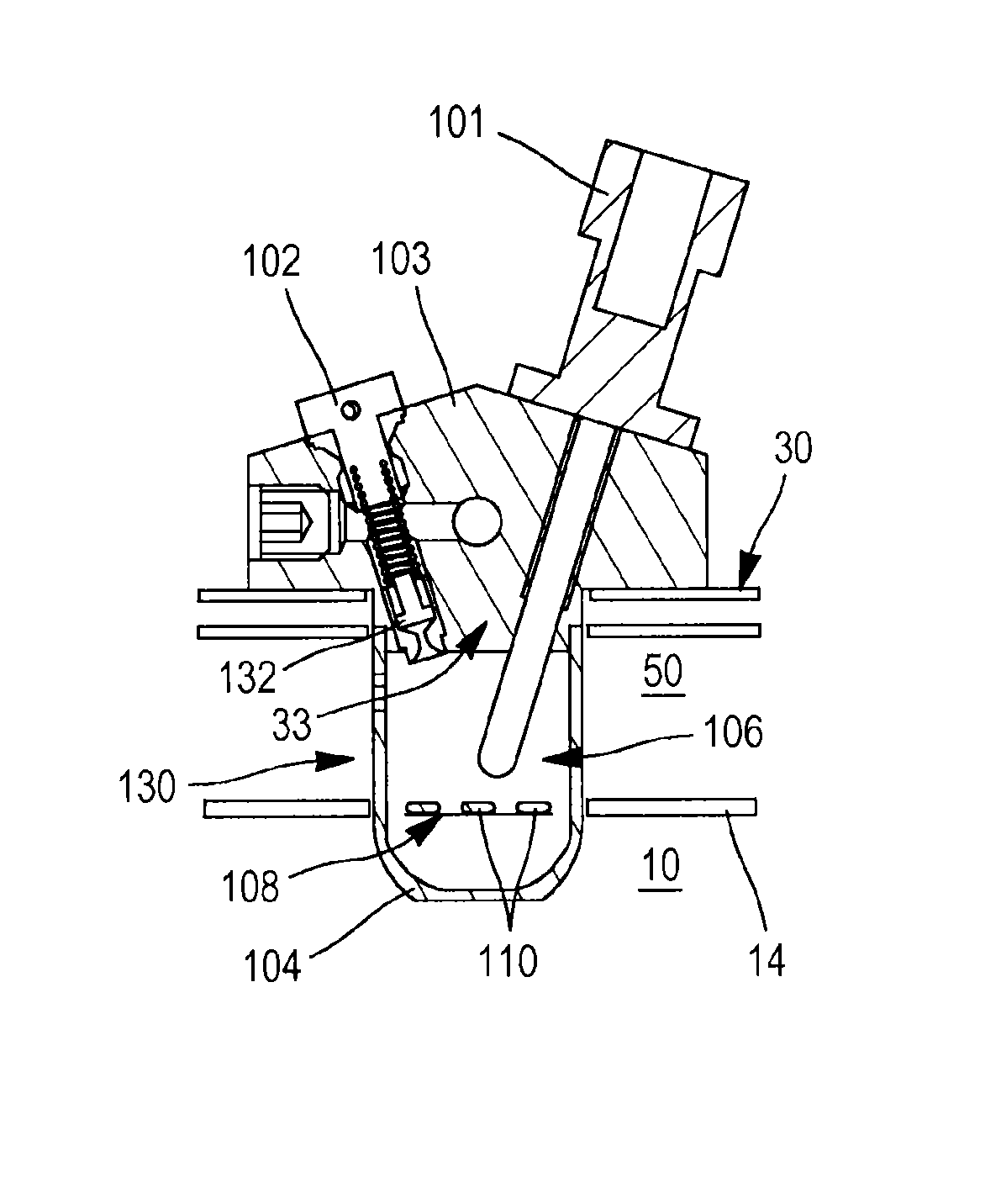

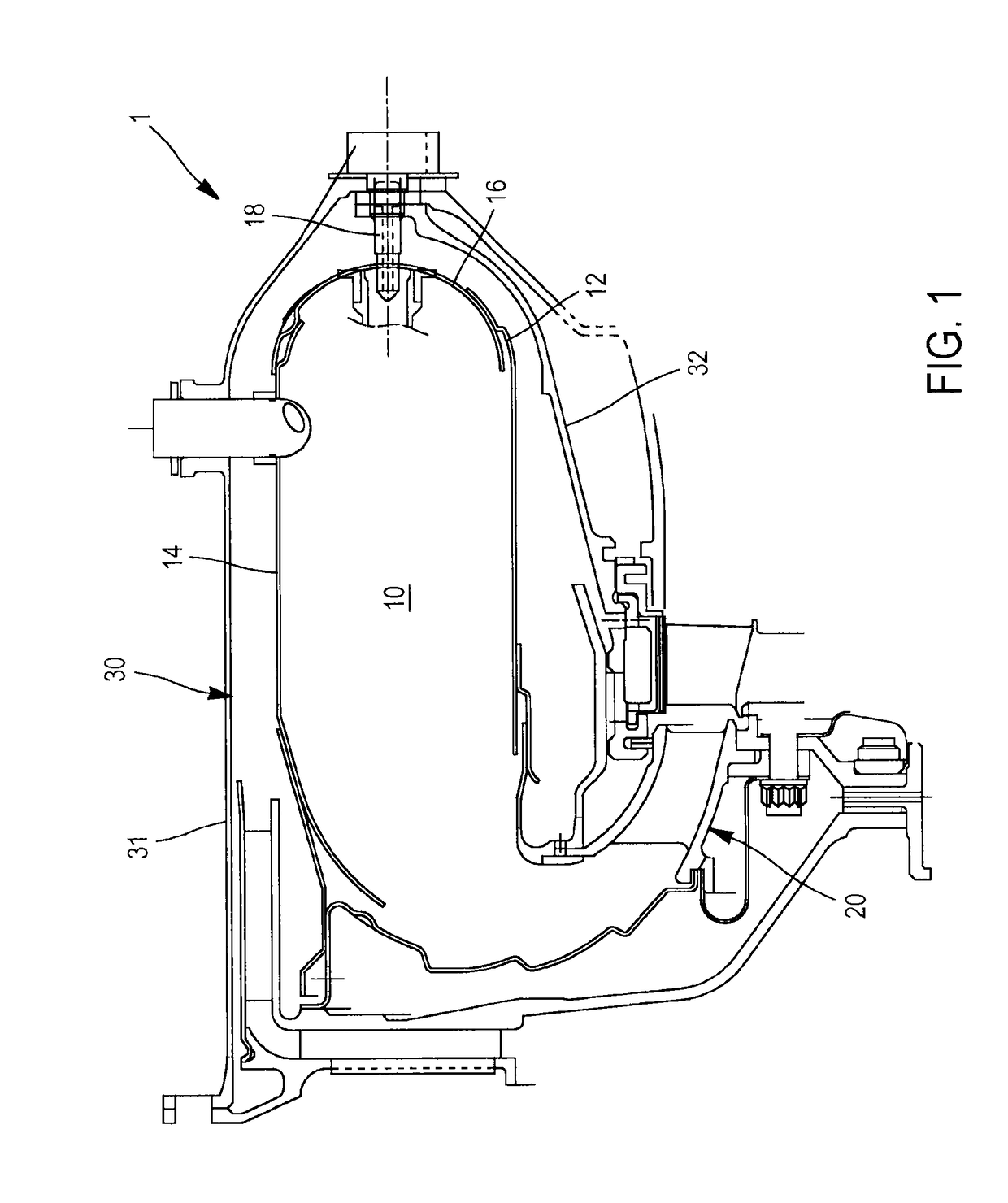

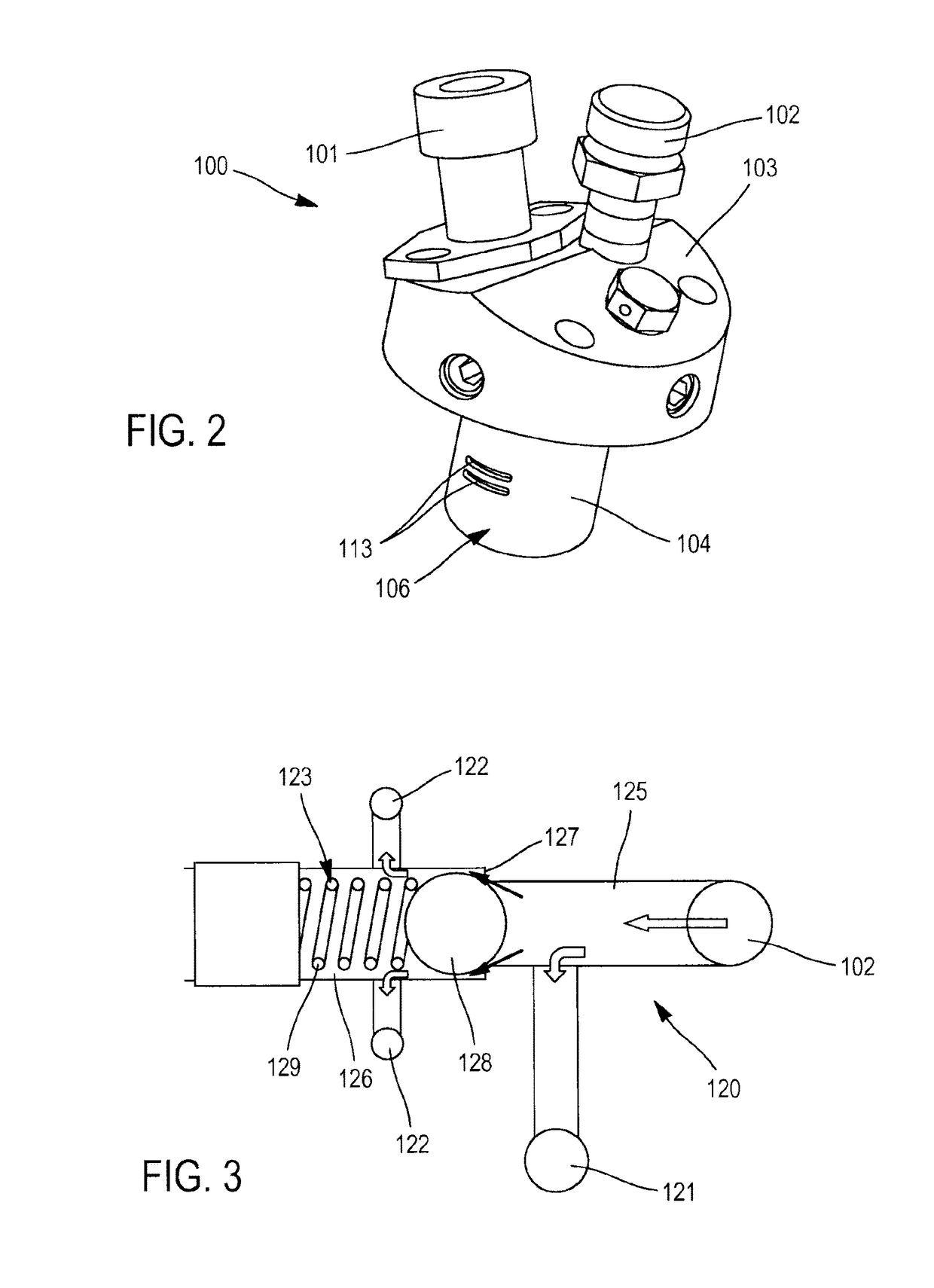

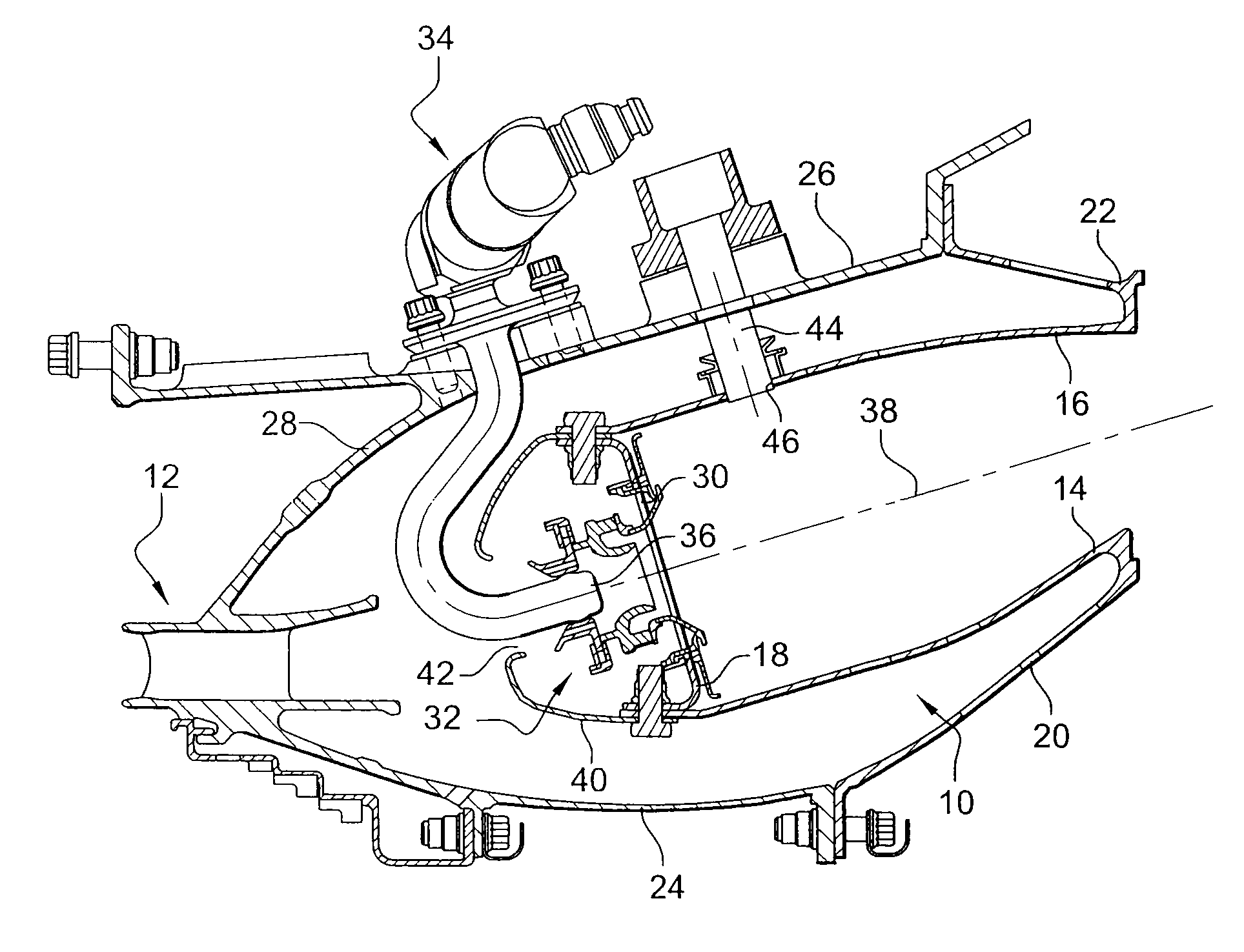

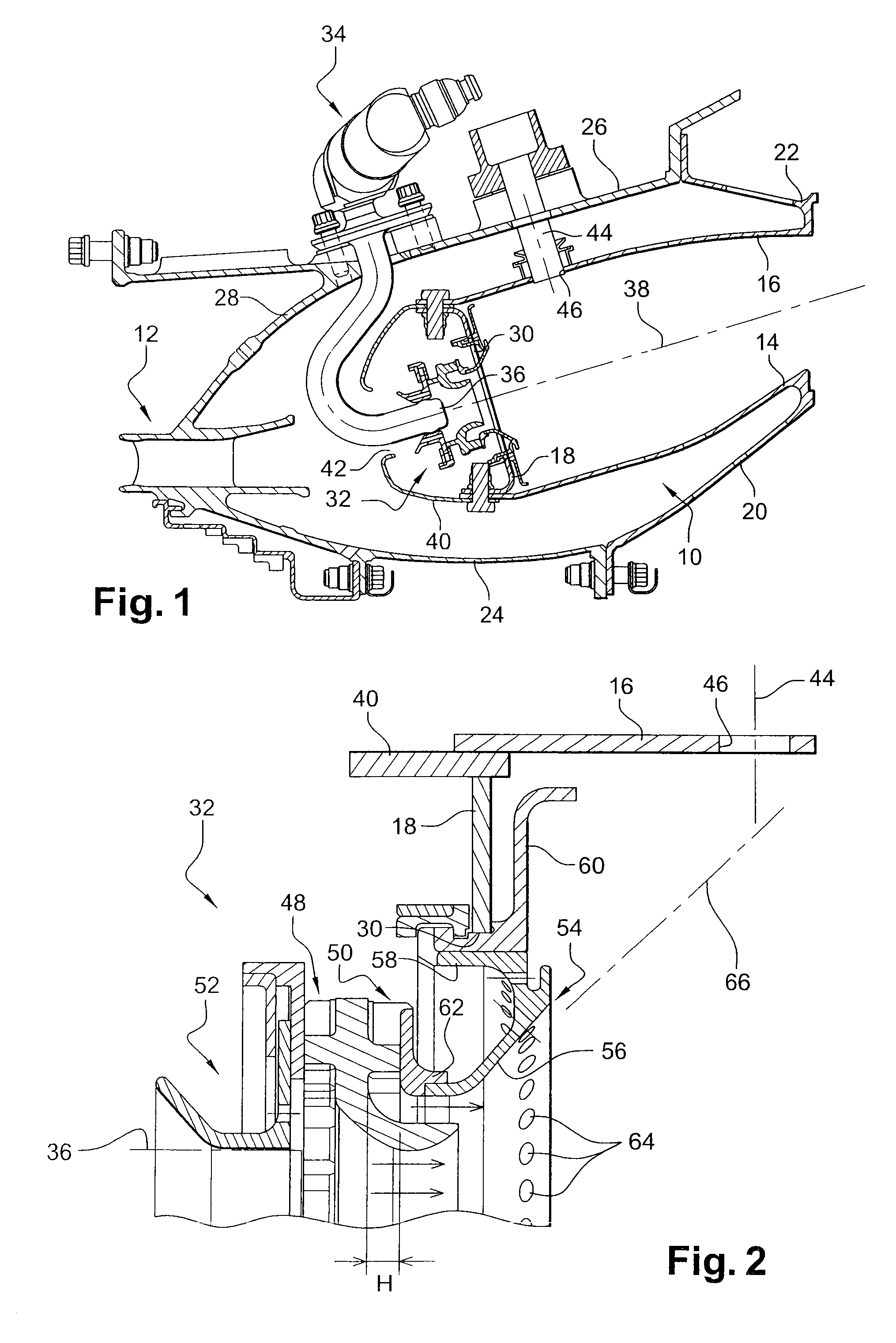

Two-circuit injector for a turbine engine combustion chamber

ActiveUS20150260406A1Fast ignitionFuel economyContinuous combustion chamberCombustion typesCombustion chamberTurbine

A start-up injector for a turbine engine combustion chamber, said injector including a fuel injection circuit; and a fuel ignition circuit including a fuel injector supplied by the fuel injection circuit and a spark plug for igniting the injected fuel. The start-up injector also includes a partitioned enclosure including a first compartment in which the fuel is ignited by the spark plug and a second compartment separated from the first compartment by a thermally conductive partition; and a main combustion start-up circuit which includes at least one fuel injector supplied by the fuel injection circuit and opens into the second compartment of the enclosure such as to inject the fuel against the wall.

Owner:SAFRAN HELICOPTER ENGINES

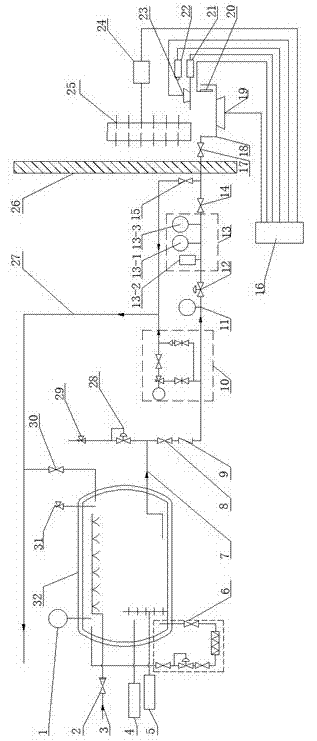

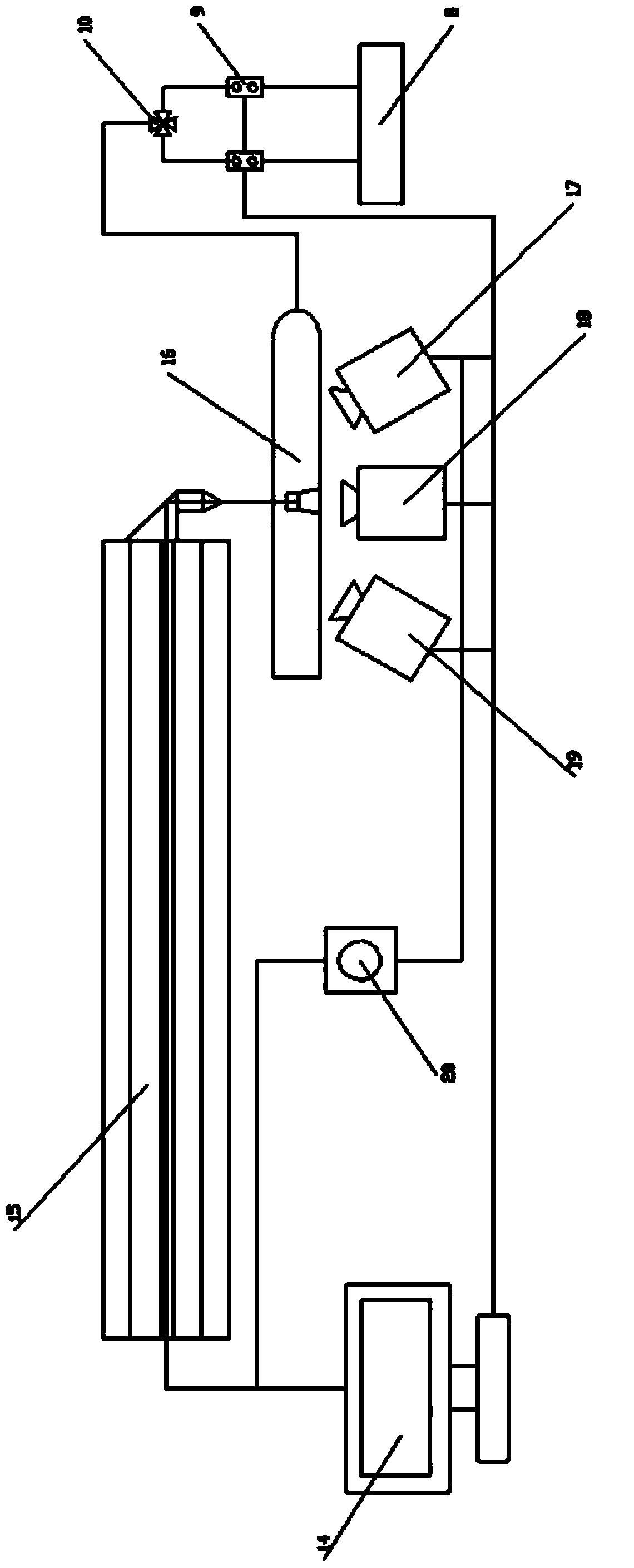

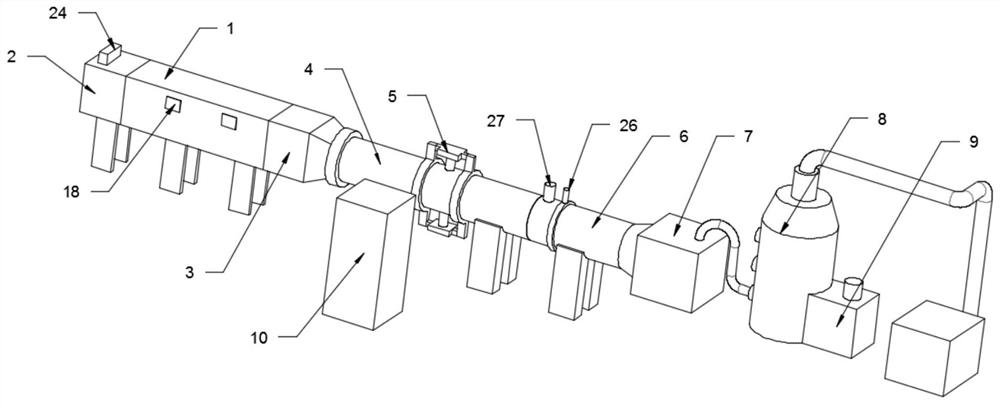

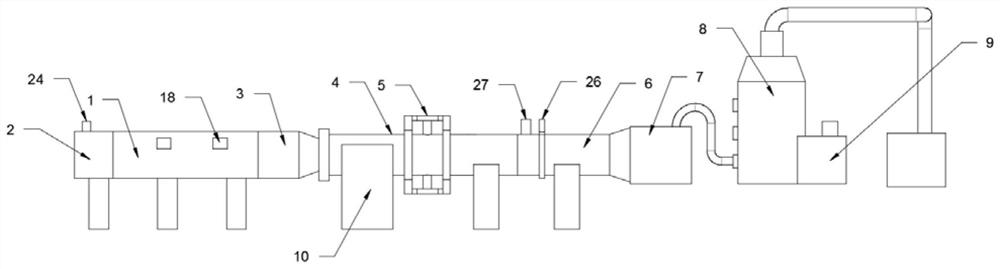

Liquefied natural gas (LNG) drain diffusion and pool fire combustion simulated experimental platform and LNG drain diffusion and pool fire combustion simulated experimental method

ActiveCN102879305AAvoid suffocation damageAvoid cold damageSurface/boundary effectData acquisitionEngineering

The invention relates to a liquefied natural gas (LNG) drain diffusion and pool fire combustion simulated experimental platform and an LNG drain diffusion and pool fire combustion simulated experimental method. The platform comprises an experimental system, a testing system and a control system, wherein the experimental system consists of an LNG storage tank, heat-insulation pipes, experimental devices and an anti-explosion isolating wall; the testing system consists of an electronic balance, an ignition system, a methane concentration detector, a thermocouple tree, a data acquirer and a camera; and the control system consists of a programmable logic controller (PLC) system, various display instruments and a control valve. By designing an angle-adjustable LNG surface spreading experimental device with a changeable surface material, spreading and gasification diffusion experimental simulation of LNG on surfaces of different substances and at different flowing speeds can be carried out; and by matching the ignition system and the methane concentration detector, LNG gas cloud concentration change monitoring and gas cloud ignition can be realized, and data and images are acquired automatically. The platform has the advantages of short experimental time, low cost, high experimental efficiency and the like. By the design, experimental steps are less, experimental safety is guaranteed under the condition of severe monitoring and control, the platform is easy and convenient to operate, and experimental repeatability is high.

Owner:应急管理部天津消防研究所

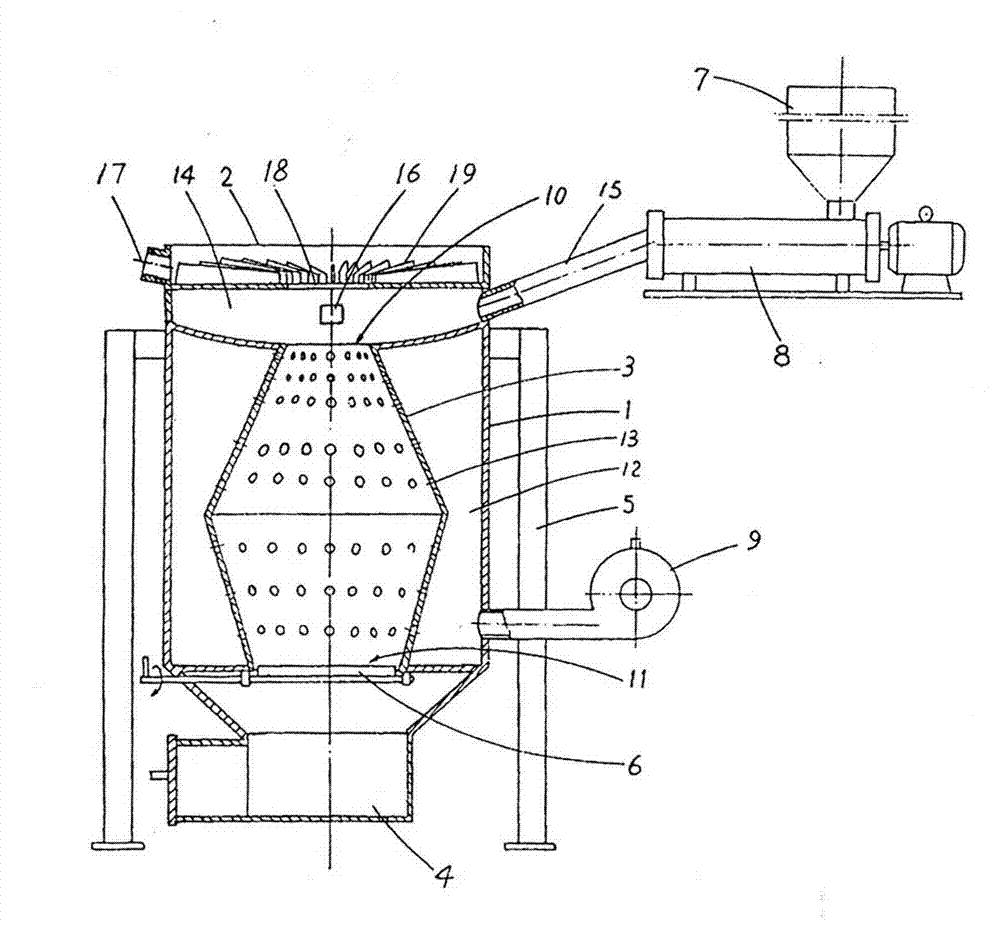

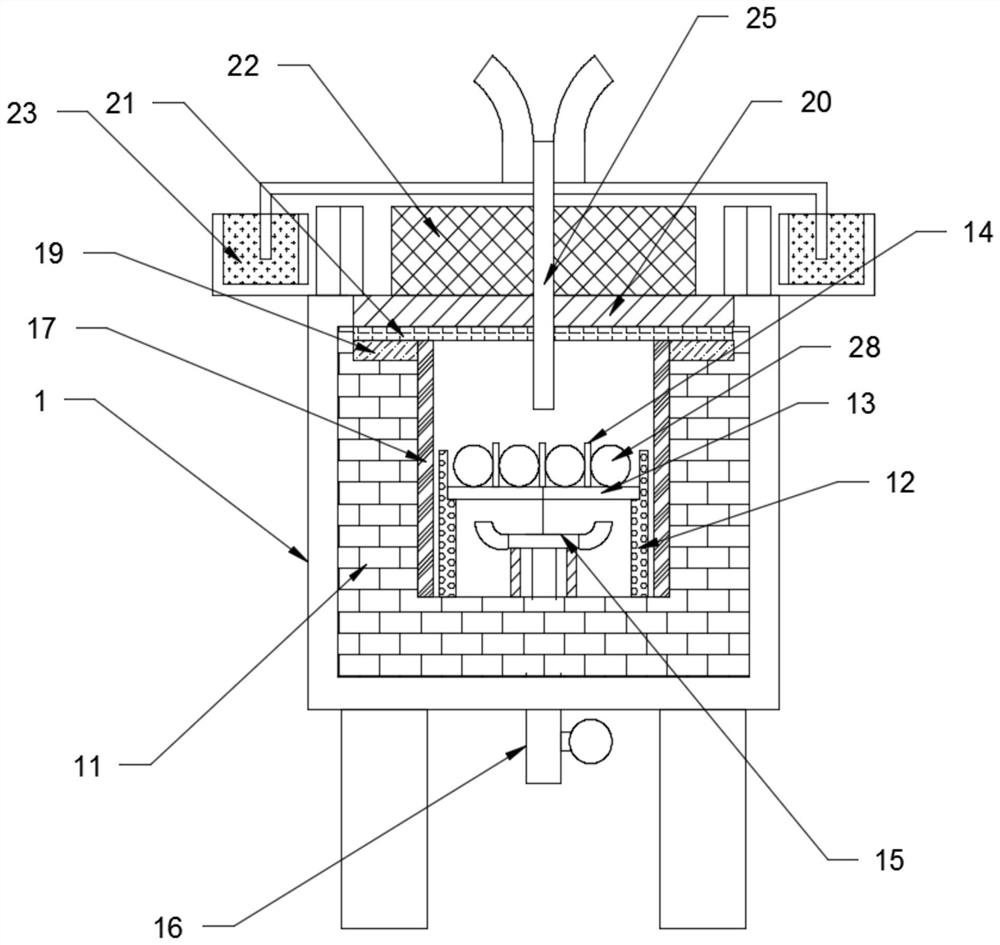

Combustor for gasification combustion of biomass formed particles

InactiveCN102818256ALow priceNo pollution in the processSolid fuel combustionCombustion apparatusCombustorEngineering

The invention discloses a combustor for gasification combustion of biomass formed particles. The combustor comprises a furnace body, a furnace head, a furnace pipe, an ash collecting box and a support, and is characterized in that the combustor further comprises a mobile ash discharging plate, a hopper, a screw feeder and a blower fan, wherein the furnace pipe is of the shape of a truncated rhombus, an upper through hole is of a fire outlet hole, a lower through hole is of an ash discharge hole, the whole furnace pipe is arranged at the middle of the furnace body and forms a closed wind box with the furnace body, the blower fan is communicated with the wind box through a ventilation pipe, a plurality of wind holes are uniformly formed on the furnace pipe, the top surface of the furnace body is of the shape of a cauldron, the furnace body and the furnace head form a feeding cavity, the screw feeder is connected with the hopper and connected with the feeding cavity on the side wall between the top surface of the furnace body and the furnace head through a material conveying pipe, an ignition hole is formed on the feeding cavity, a fire through hole is formed at the center of a bottom plate of the furnace head, the rotating ash discharging plate is arranged on the ash discharge hole on the bottom surface of the furnace pipe, and a smoke exhaust port is arranged on the side wall of the furnace head. The combustor takes biomass as fuel, fuel sources are abundant, and environmental pollution is avoided; and furthermore, the combustor has the advantages of reasonable structure, fast ignition, full combustion, high calorific value and great convenience in operation, and is particularly suitable for boilers, tobacco curing furnaces and other drying equipment.

Owner:曾巨泓

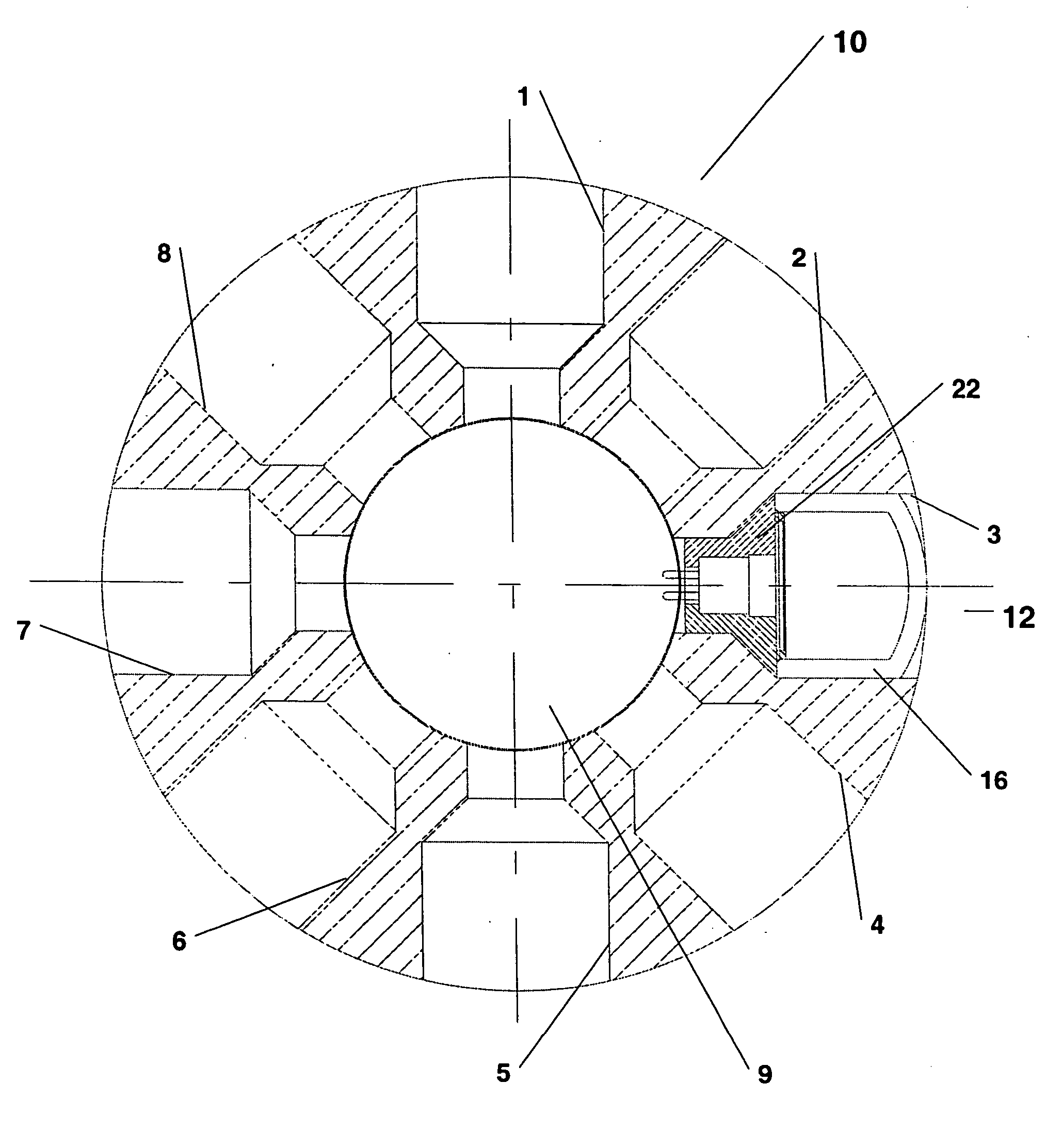

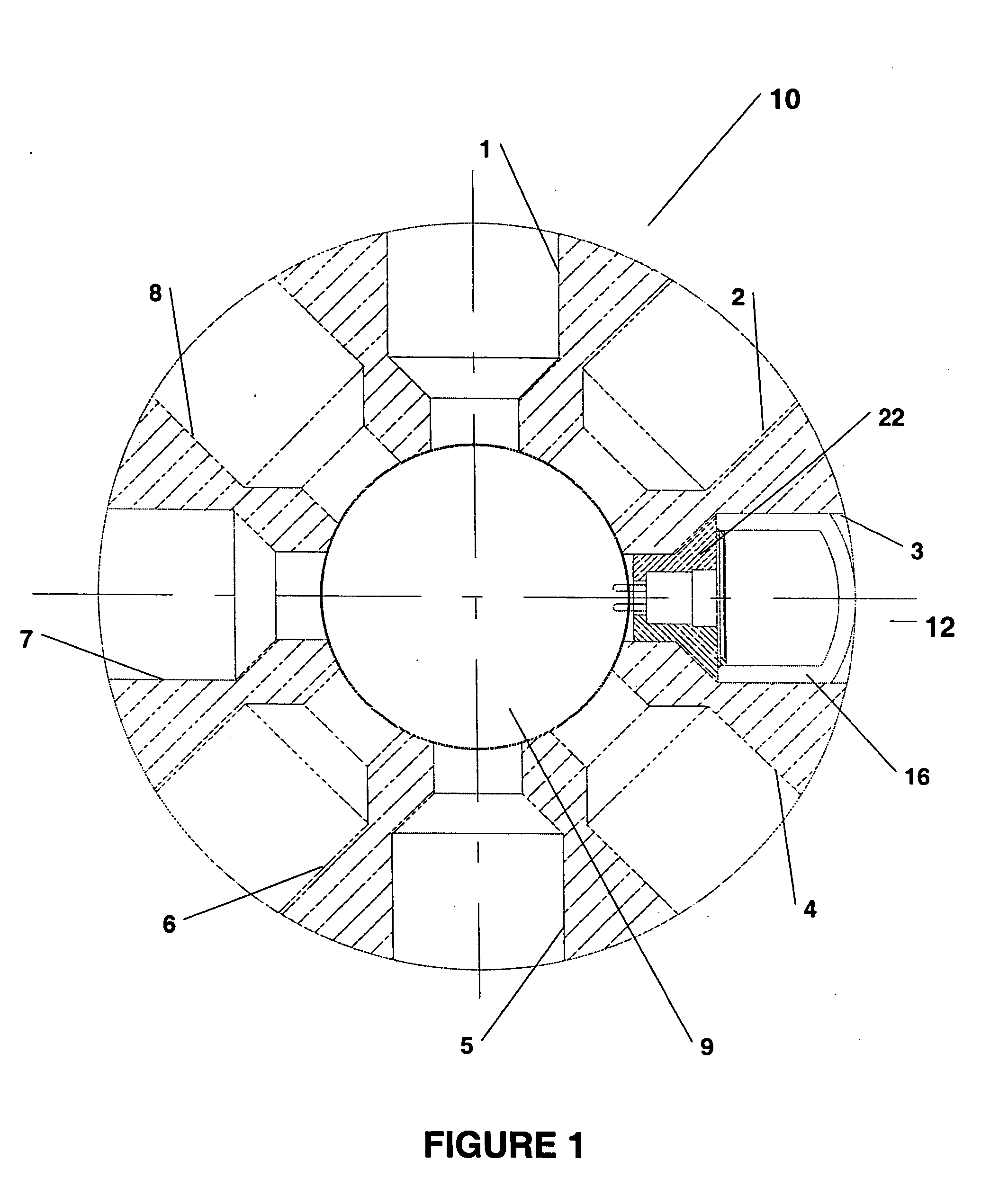

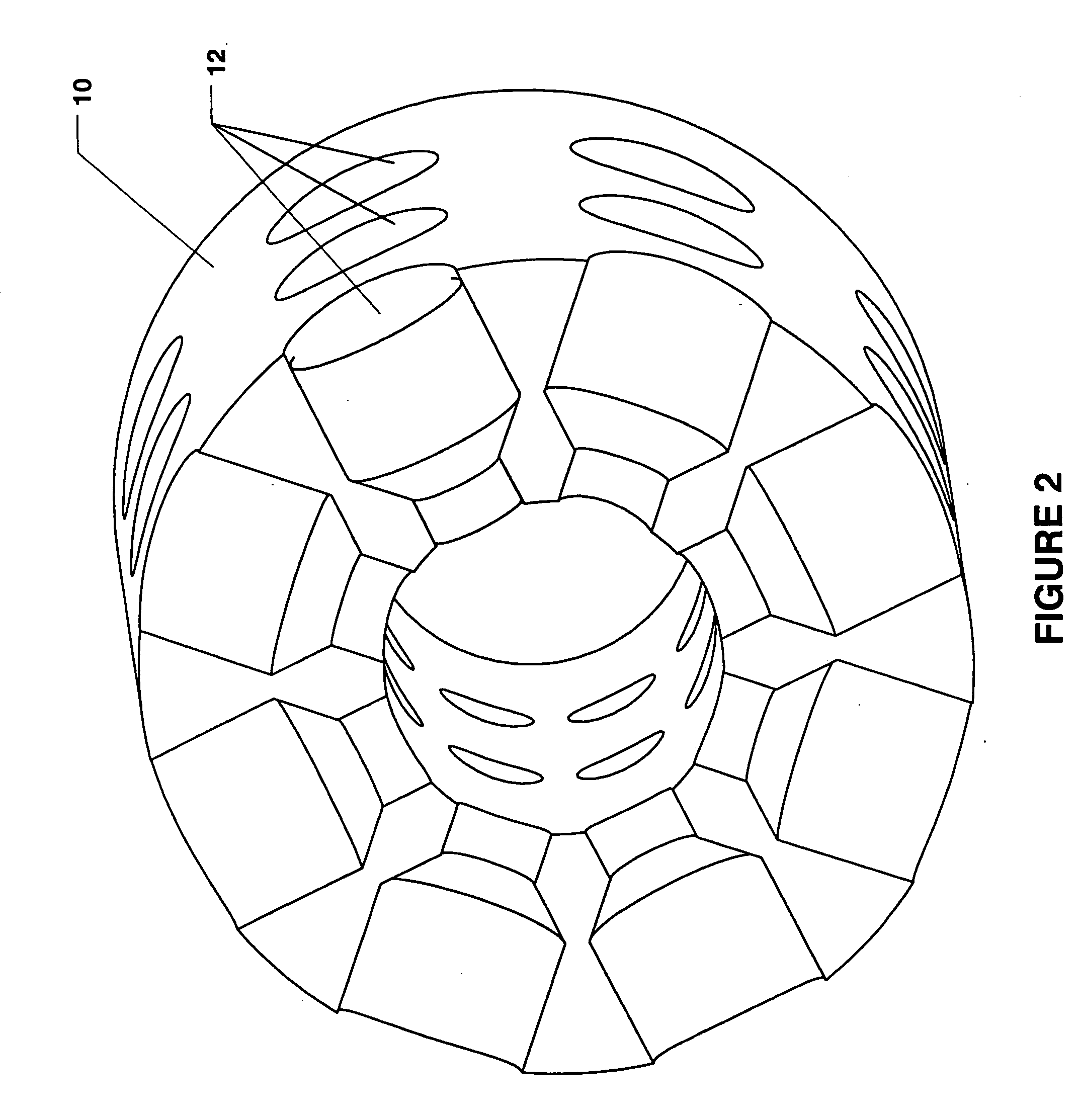

Projectile diverter

InactiveUS20050103925A1Low costFast ignitionAmmunition projectilesDirection controllersGuidance systemElectricity

The present invention provides a fast, low-cost, small diverter capable of generating a relatively high impulse (1-5 N-sec) over a short time period. The diverter is adapted for installation in a projectile for steering the projectile in flight by ejecting an end cap or hot burning gases in response to control signals from a guidance system. In one embodiment, multiple diverters are arranged in one or more bands about a flying projectile such as a rocket. Each diverter includes a header assembly providing support for a plurality of electrical leads, a mounting surface either on the header assembly or on a sealing assembly, a reactive semiconductor bridge mounted on the mounting surface and providing an electrical path for the electrical leads at a certain voltage across the bridge, a diverter body supporting the header assembly and containing a prime, wherein the reactive semiconductor bridge and the prime permit a gap, and an end cap or a sealing assembly attached to the diverter body containing the propellant.

Owner:QUANTIC INDS

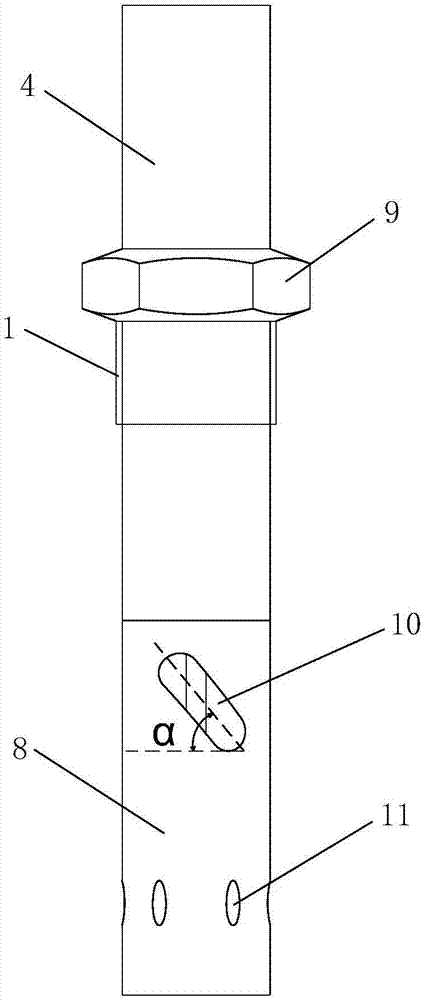

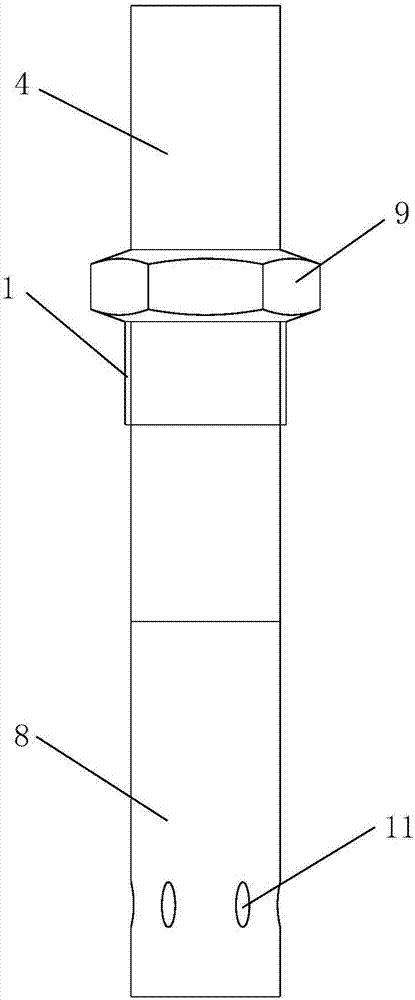

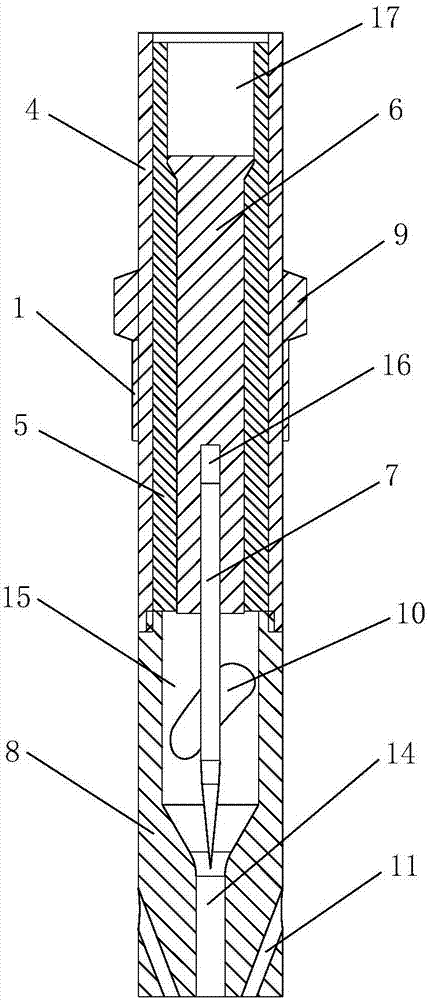

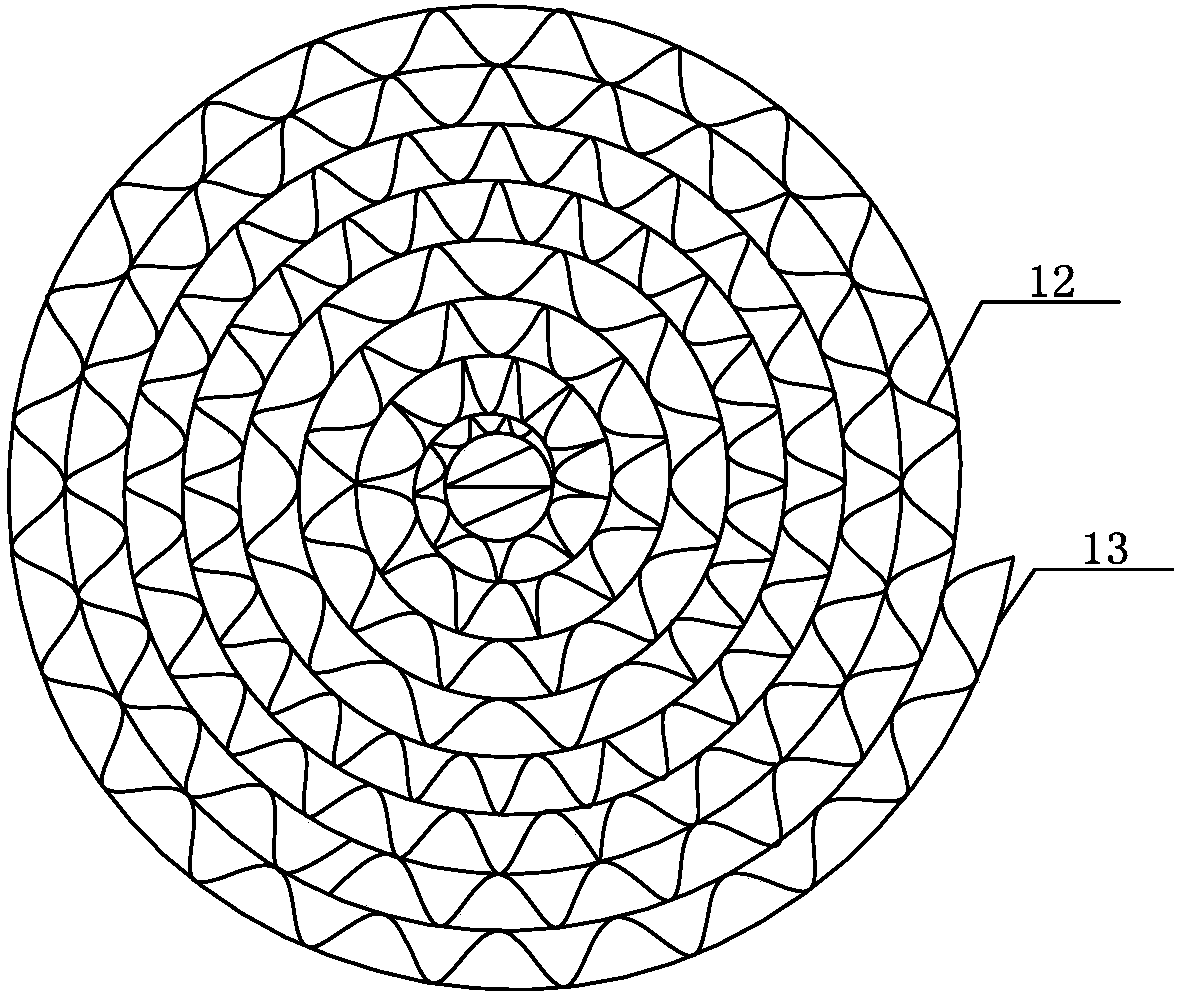

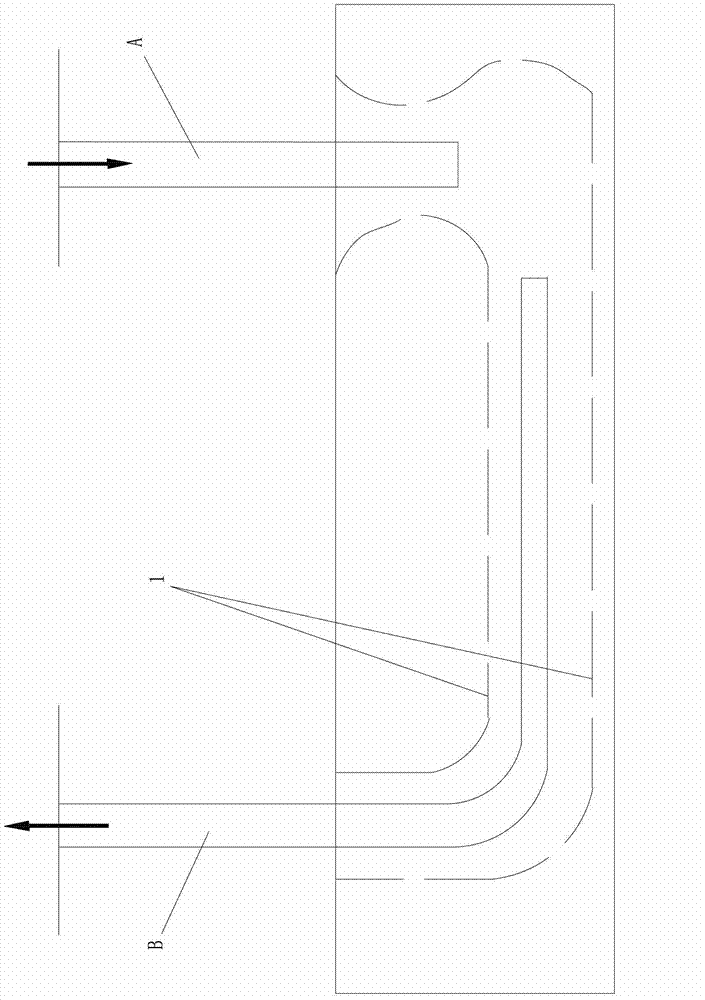

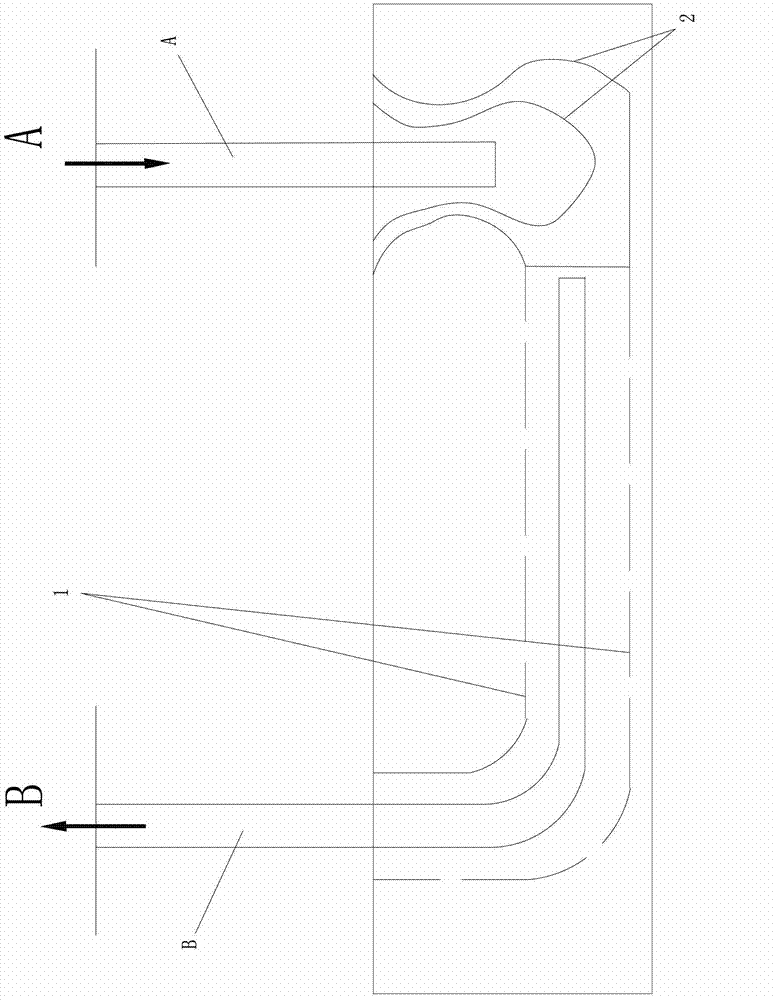

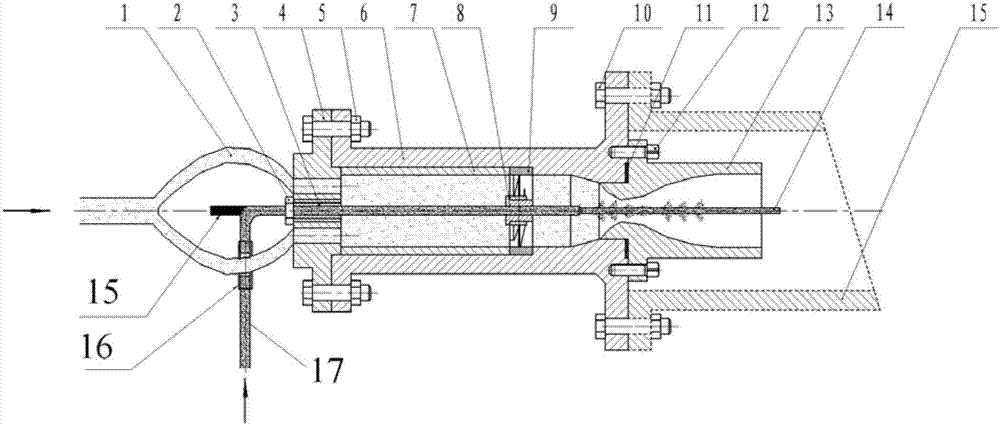

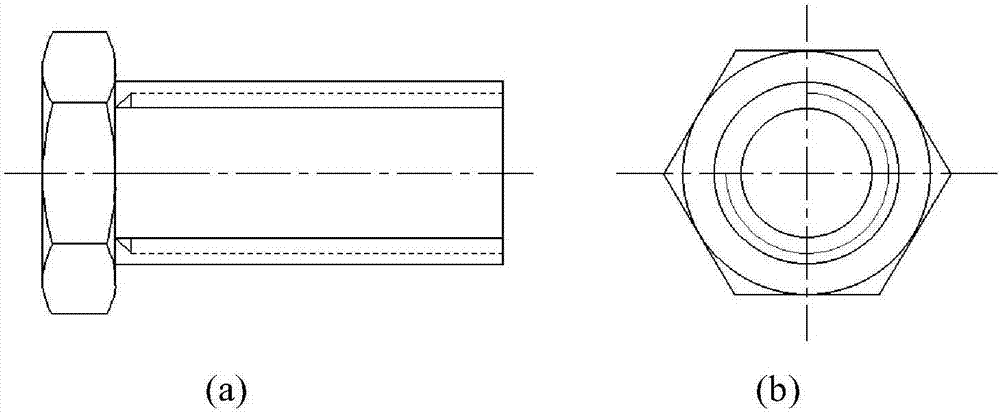

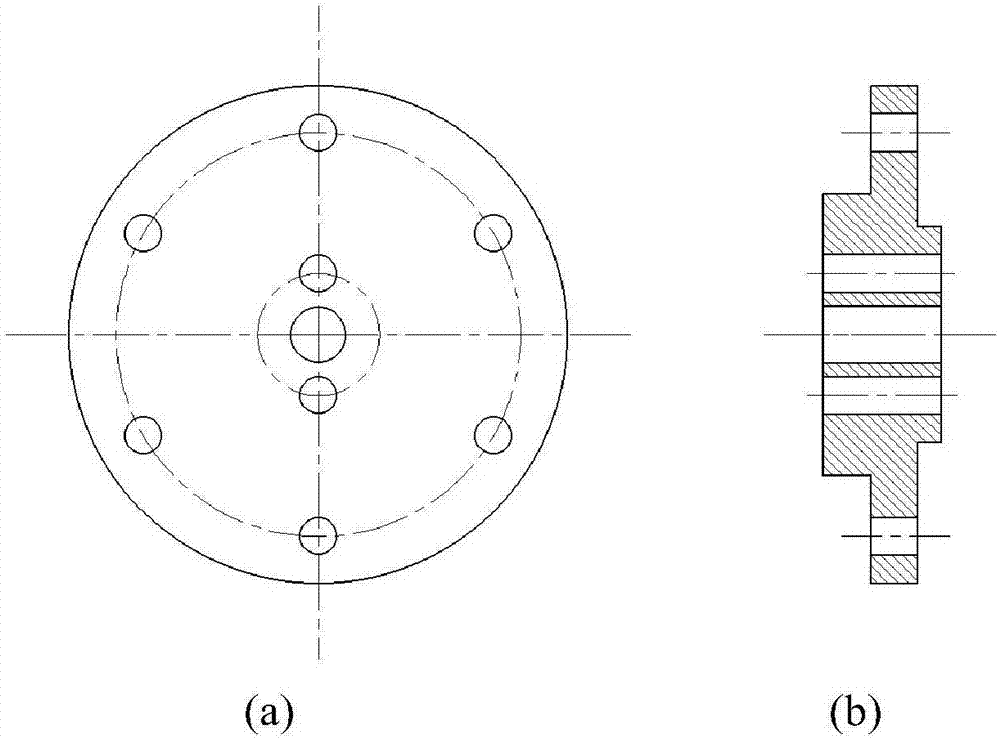

Self-air-entrainment-based plasma jet igniter of aero-engine

ActiveCN108005790ASimplify the intake structureReduce weightGas turbine plantsJet propulsion plantsPlasma jetCombustion chamber

The invention discloses a self-air-entrainment-based plasma jet igniter of an aero-engine. The plasma jet igniter comprises an outer pipe, an insulating inner pipe, a conducting copper pipe, a cathodeand an anode; the lower end of the outer pipe is fixedly connected with the upper end of the anode; the outer pipe is internally sleeved with the insulating inner pipe; the insulting inner pipe is internally sleeved with the conducting copper pipe; the upper part of the cathode has threaded connection with a groove formed in the lower part of the conducting copper pipe; a hollow structure insidethe upper part of the cathode is an ionization region; the hollow structure inside the lower part of the anode is a flow jet region; the outer sidewall of the ionization region is provided with an igniter air inlet for leading air which is inside a main combustion chamber or mixed rotational air flow which is inside an afterburner into the ionization region; the upper part of the cathode is positioned inside the conducting copper pipe; and the lower part of the cathode is positioned inside the ionization region. The plasma jet igniter disclosed by the invention needs not to be externally connected with an air entraining device; the air flow in two channels of the main combustion chamber or the air flow in the afterburner is directly led into the plasma jet igniter, so the structure of an igniting device is simplified, and the weight and volume of the igniting device are reduced.

Owner:AIR FORCE UNIV PLA

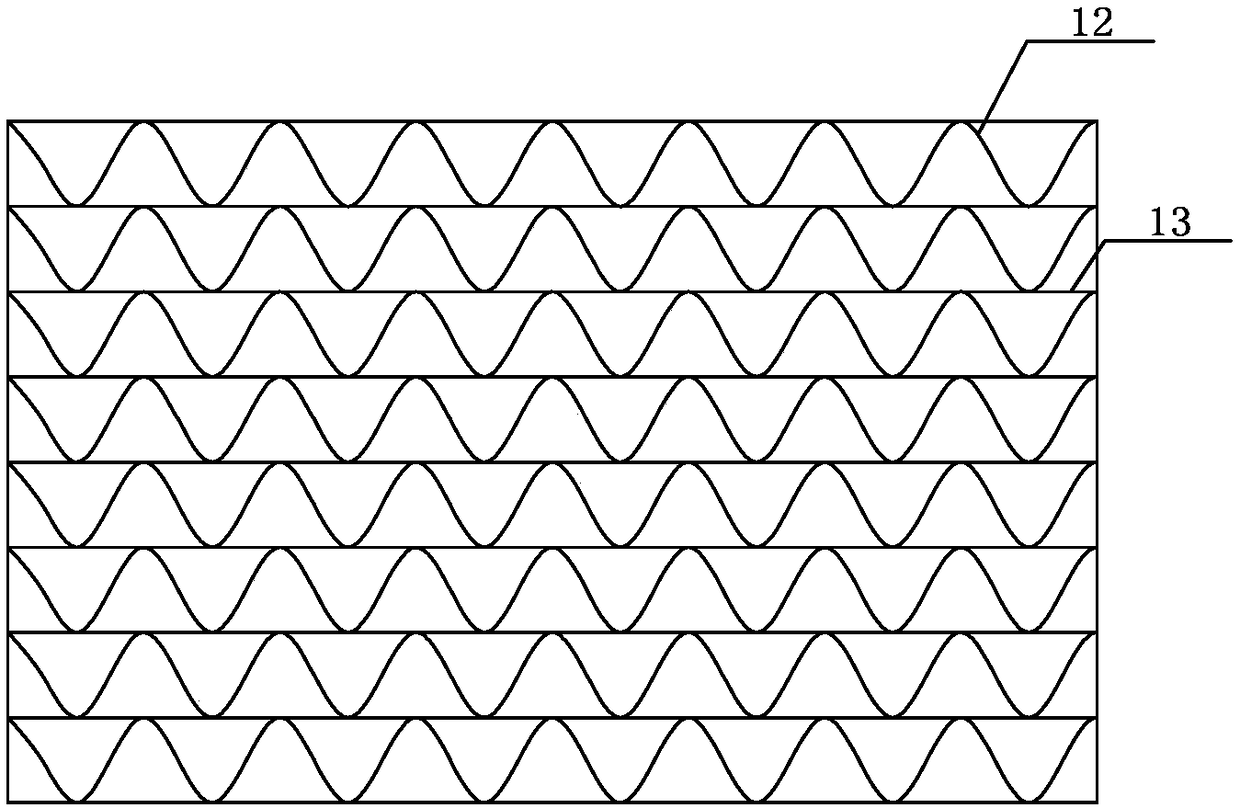

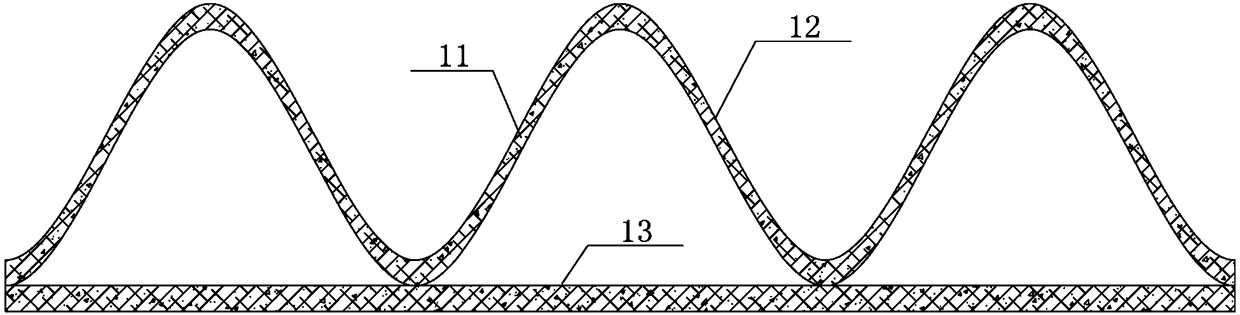

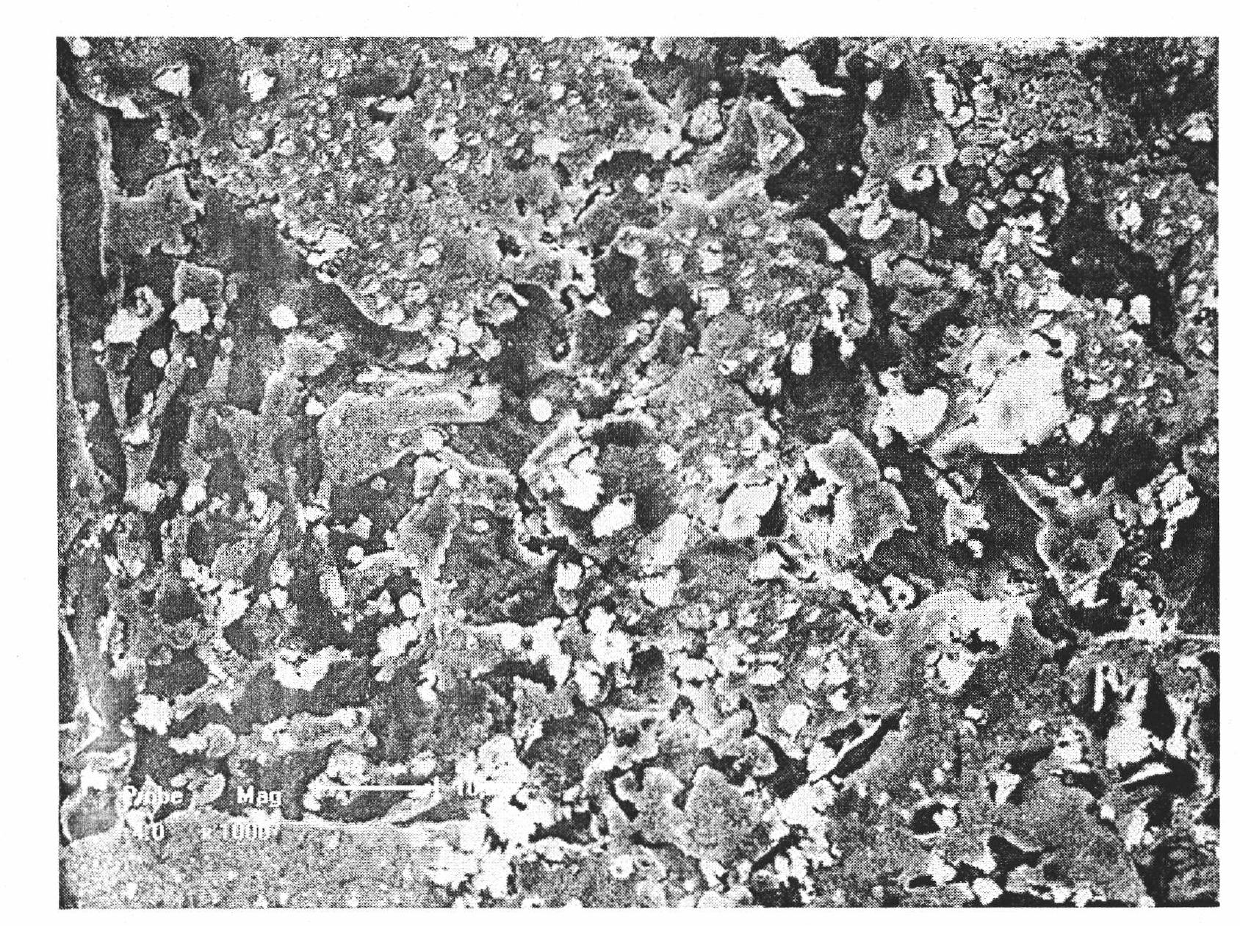

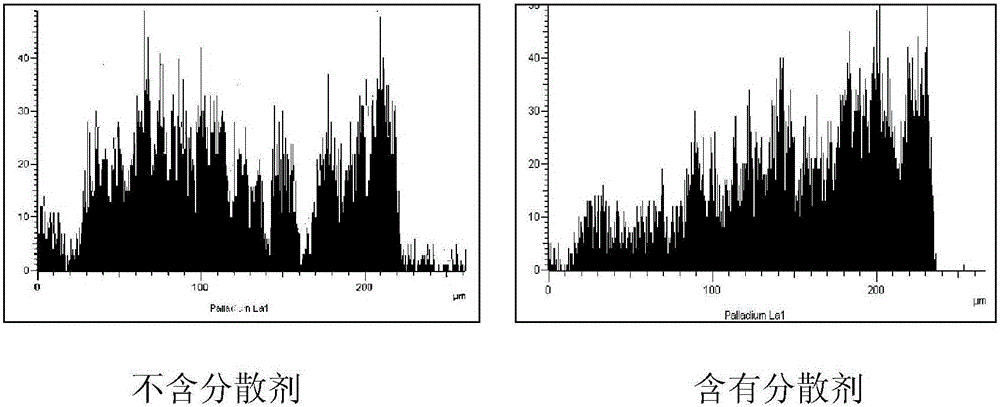

Monolithic oxidation catalyst for VOCs and preparation method of oxidation catalyst

PendingCN108579745ASimple processLow costHeterogenous catalyst chemical elementsDispersed particle separationFiberActive component

The invention relates to a monolithic oxidation catalyst for volatile organic compounds (VOCs) and a preparation method of the oxidation catalyst. The monolithic oxidation catalyst for the VOCs comprises a carrier, a catalyst coating uniformly embedded into the carrier and uniformly distributed on the surface of the carrier, and an active component and an auxiliary agent which are uniformly dispersed in the catalyst coating, wherein the carrier is a monolithic corrugated fiber paper carrier formed by rolling or laminating a corrugated fiber paper substrate. The preparation method of the catalyst provided by the invention has a simple process, low costs and easy industrialized realization; and the monolithic oxidation catalyst for the VOCs prepared by the method has excellent catalytic activity, thermal stability and water resistance, a high geometric specific surface area and a low catalyst density which is 60%-70% of that of a conventional cordierite material, and can be quickly ignited, thereby facilitating a quick catalytic oxidation reaction.

Owner:QINGDAO HSJ ENVIRONMENTAL PROTECTION TECH CO LTD

Fleeing sealing sand-prevention ignition method of fireflooding oil extraction

ActiveCN103161437AShorten ignition timeHigh porosityFluid removalEconomic benefitsShale oil extraction

The invention provides a fleeing sealing sand-prevention ignition method of fireflooding oil extraction which comprises preheating an oil layer, coking the oil layer, adjusting coking zone hole permeability degrees, oxygen-enriched ignition and the other steps. The fleeing sealing sand-prevention ignition method of the fireflooding oil extraction is suitable for ignition of heavy oil reservoir fireflooding oil extraction. Due to the steam preheating oil layer, ignition time of an oil layer is reduced; due to gas injection well (ignition well) immediate vicinity of wellbore coking, a role of fleeing sealing sand-prevention function can be played, and coking products (petroleum coke) is used as fuel; due to oxygen-enriched combustion, rapid ignition can be achieved; due to adjusting coking zone hole permeability degrees, hole permeability degrees and permeability of a coking zone of a gas injection well are increased; success rate of ignition is improved, and fleeing sealing sand-prevention ignition method of the fireflooding oil extraction is of great significance of improving economic benefits of the fireflooding oil extraction.

Owner:PETROCHINA CO LTD

Civil use synthetic liquid fuel and its preparation method

A synthetic liquid fuel for civil purpose is prepared from alcohol, H2O2, acetone, camphor extract or essence, and multifunctional additive through proportioning, sequentially mixing and stirring for 3-8 min. Its advantages are low cost, high heat value and no carbon deposit.

Owner:黄海静

Two-circuit injector for a turbine engine combustion chamber

ActiveUS9927125B2Fast ignitionFuel economyContinuous combustion chamberCombustion typesCombustion chamberTurbine

A start-up injector for a turbine engine combustion chamber, said injector including a fuel injection circuit; and a fuel ignition circuit including a fuel injector supplied by the fuel injection circuit and a spark plug for igniting the injected fuel. The start-up injector also includes a partitioned enclosure including a first compartment in which the fuel is ignited by the spark plug and a second compartment separated from the first compartment by a thermally conductive partition; and a main combustion start-up circuit which includes at least one fuel injector supplied by the fuel injection circuit and opens into the second compartment of the enclosure such as to inject the fuel against the wall.

Owner:SAFRAN HELICOPTER ENGINES

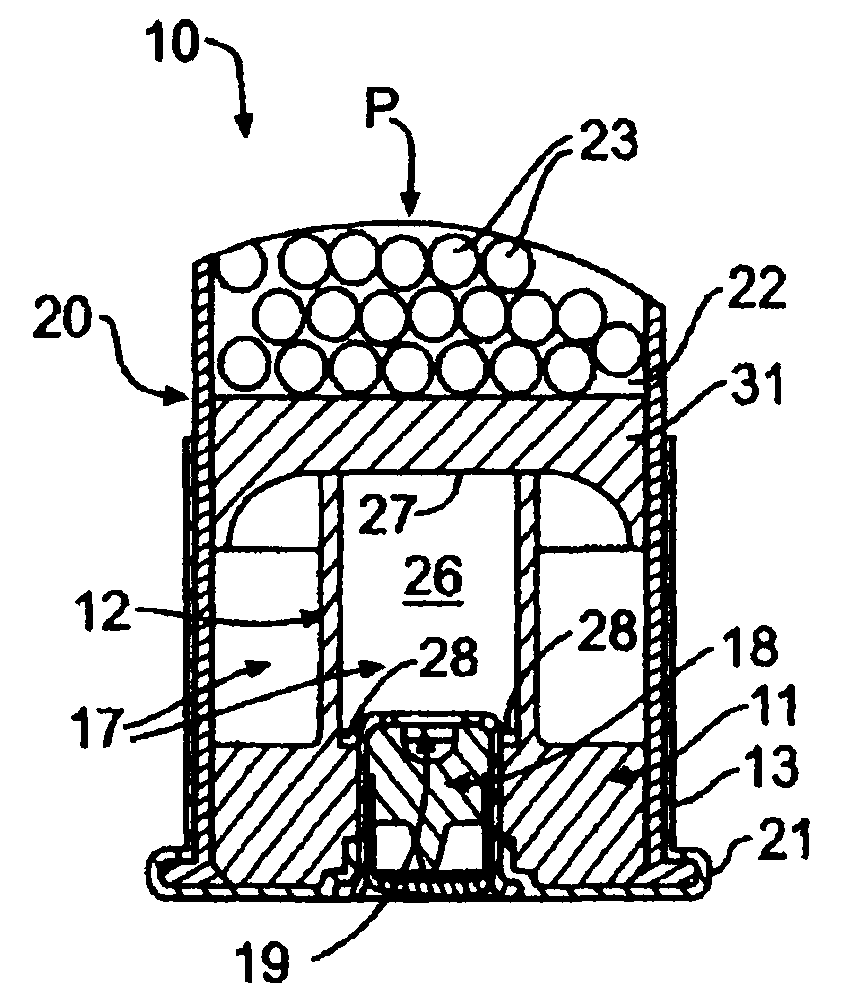

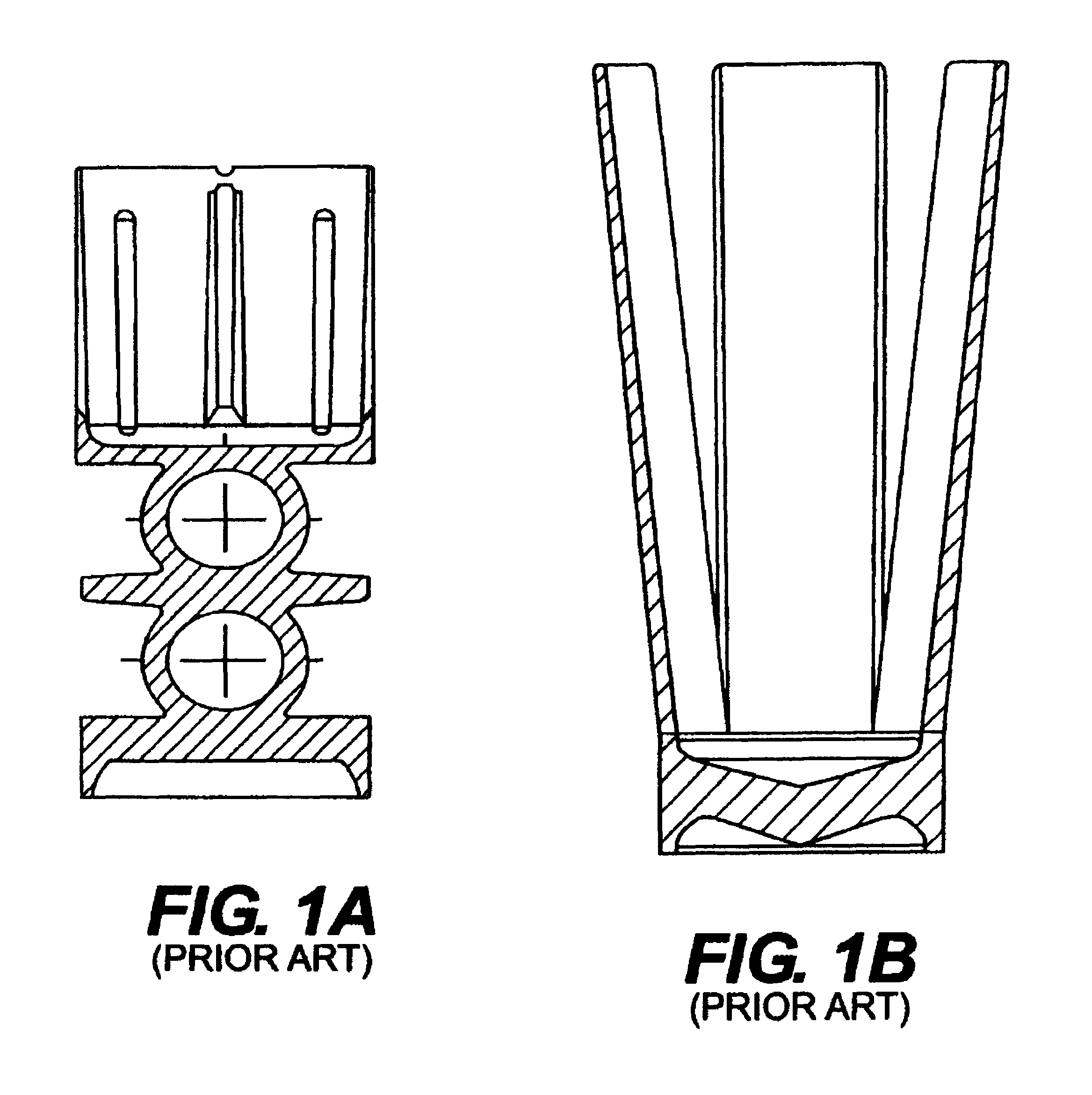

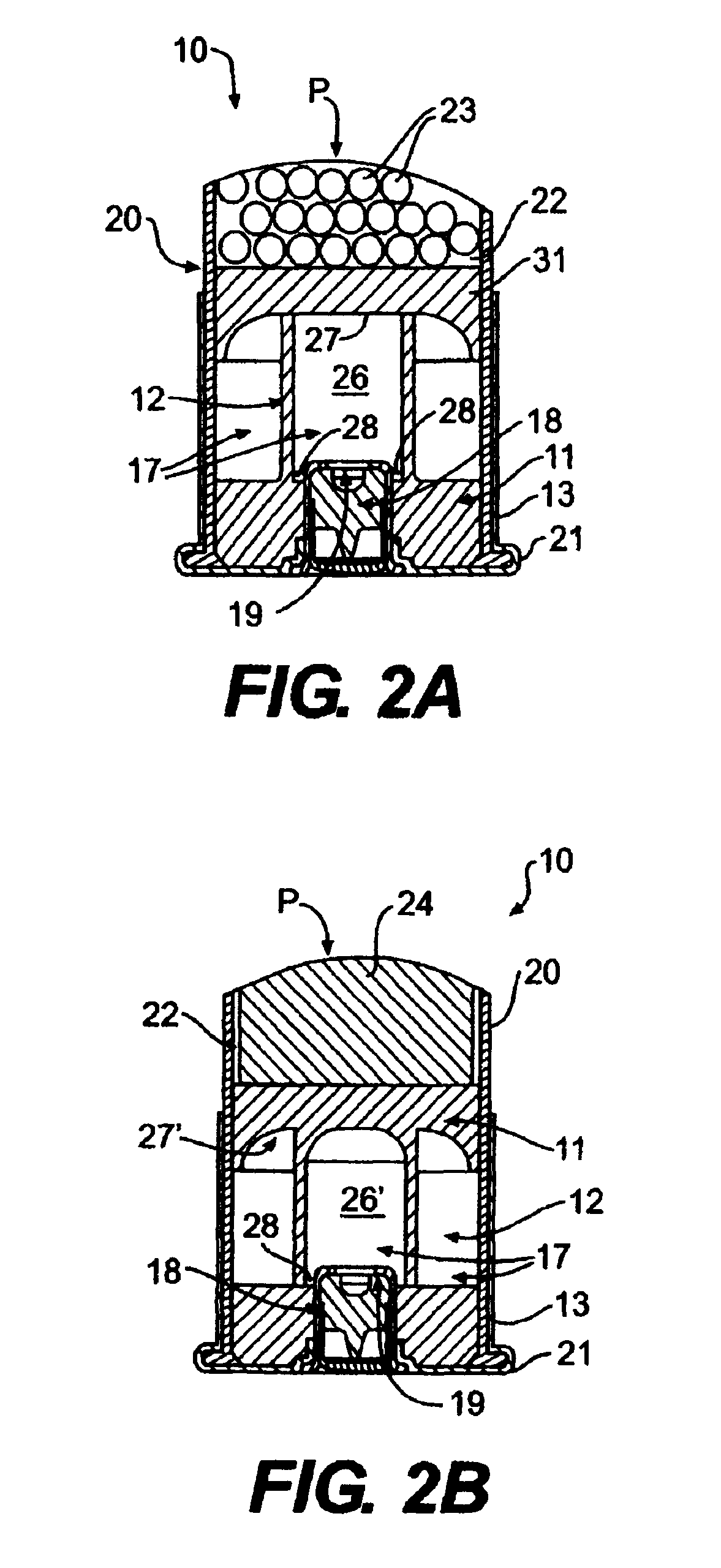

Wad with ignition chamber

ActiveUS8800449B2Easy to igniteIncreased local pressureAmmunition projectilesShotgun ammunitionPropellantRecoil

A wad or basewad for ammunition includes an ignition chamber. The ignition chamber can be integrally formed with the payload wad, basewad, or battery cup or can be attached to the payload wad, basewad, or battery cup. The ignition chamber communicates with a primer of the ammunition to receive and contain the primer blast for at least an initial period of time. This facilitates faster initial ignition of the propellant of the ammunition, and consequently allows higher performance levels to be achieved. Other advantages regarding other applications of this invention include cleaner burning loads, greater economy, and lower perceived recoil.

Owner:AMMUNITION OPERATIONS LLC

Sliding arc combustion supporting device producing atmospheric pressure non-equilibrium plasmas

The invention provides a sliding arc combustion supporting device producing atmospheric pressure non-equilibrium plasmas. The sliding arc combustion supporting device producing the atmospheric pressure non-equilibrium plasmas comprises a pressure gas pipeline, a center electrode pipe, a Laval spraying pipe, a cyclone and the like; a plurality of small holes are formed in the tail end of the center electrode pipe, fuel is sprayed out of the small holes to be atomized, and is fully mixed in the Laval spraying pipe with combustion-supporting gas rectified by the cyclone. The left end of the center electrode pipe is connected with a high voltage power source to serve as an anode; the Laval spraying pipe is grounded to serve as a cathode; the center electrode pipe and the wall face of the Laval spraying pipe perform discharging to generate the plasmas; arc columns of sliding arcs generate a catalysis reaction in a gas mixing area to perform combustion; and flames are sprayed out of the Laval spraying pipe to act on an external connection device. The sliding arc combustion supporting device producing the atmospheric pressure non-equilibrium plasmas is compact in structure, convenient to machine, high in combustion supporting efficiency and capable of being used for combustion supporting of a matched combustion device.

Owner:航天神洁(北京)科技发展有限公司 +1

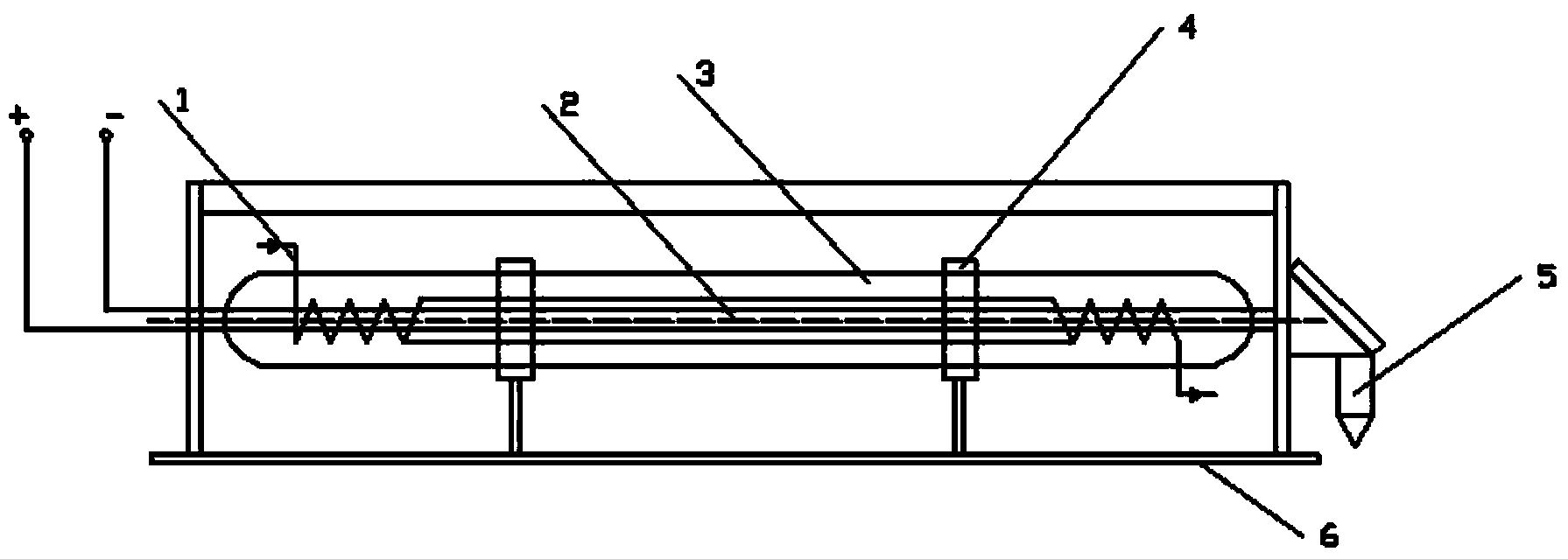

Device for ignition and combustion of primary boron product with high energy density laser

The invention relates to an ignition and combustion testing device, and aims to provide a device for ignition and combustion of a primary boron product with high energy density laser. The device comprises an ignition module, an atmosphere control module, a combustion diagnostic module, and a data recording module, wherein the ignition module comprises a high energy density laser device and a transparent ignition combustion tube, a laser tube is fixed on a base via a laser tube support frame, the transparent ignition combustion tube is arranged on an iron stand, and a sample bracket is arranged in the center of the transparent ignition combustion tube. The device provided by the invention can rapidly heat a primary boron product sample to a temperature above the boiling point of boron oxide in several milliseconds, which is far better than the conventional electric heating ignition manner, and can realize rapid ignition and complete combustion of the primary boron product. The laser device has low electric power, and can be used after being supplied with 220V family electricity, resulting in good generality. The laser heating range is centralized, and the energy utilization efficiency is high.

Owner:ZHEJIANG UNIV

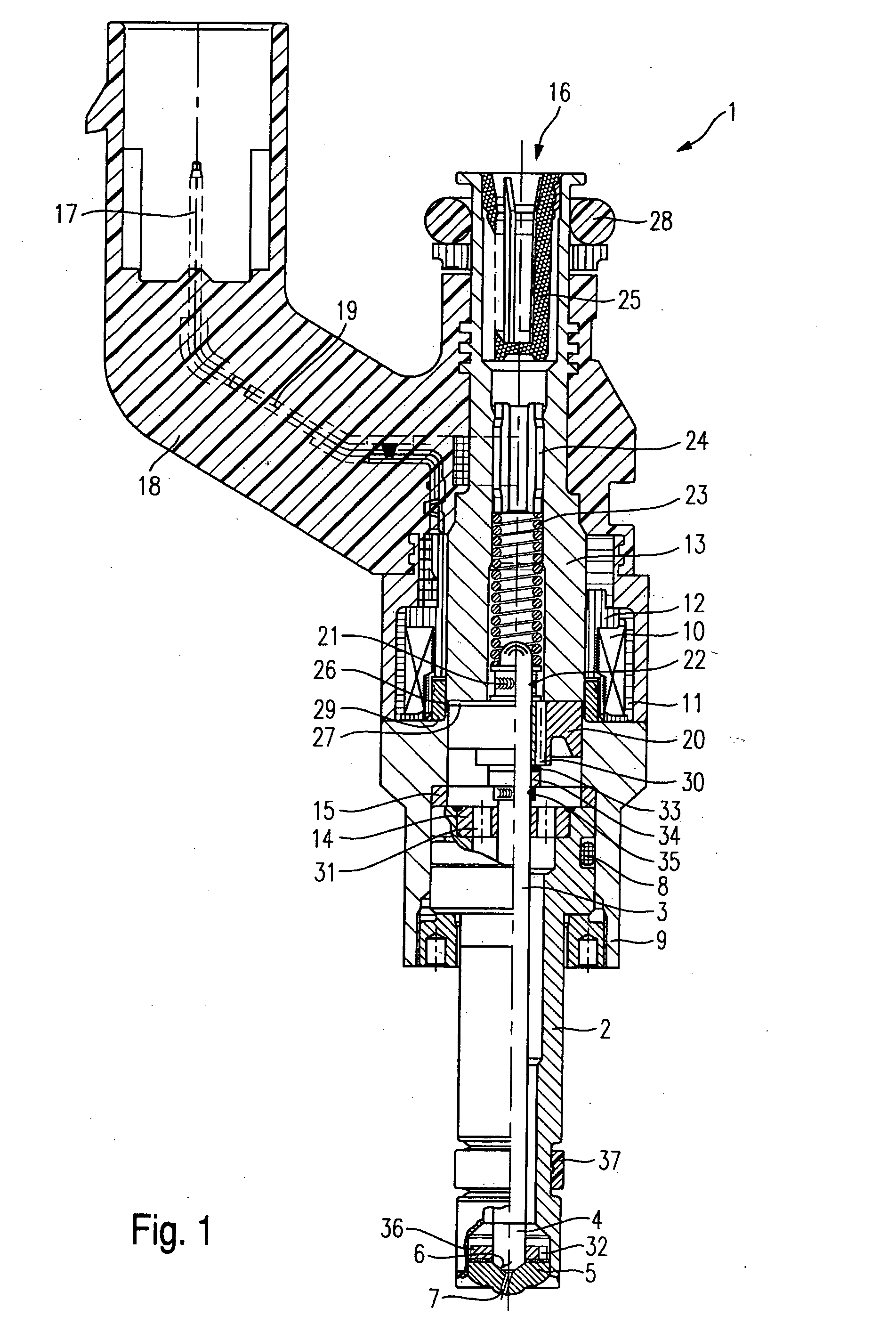

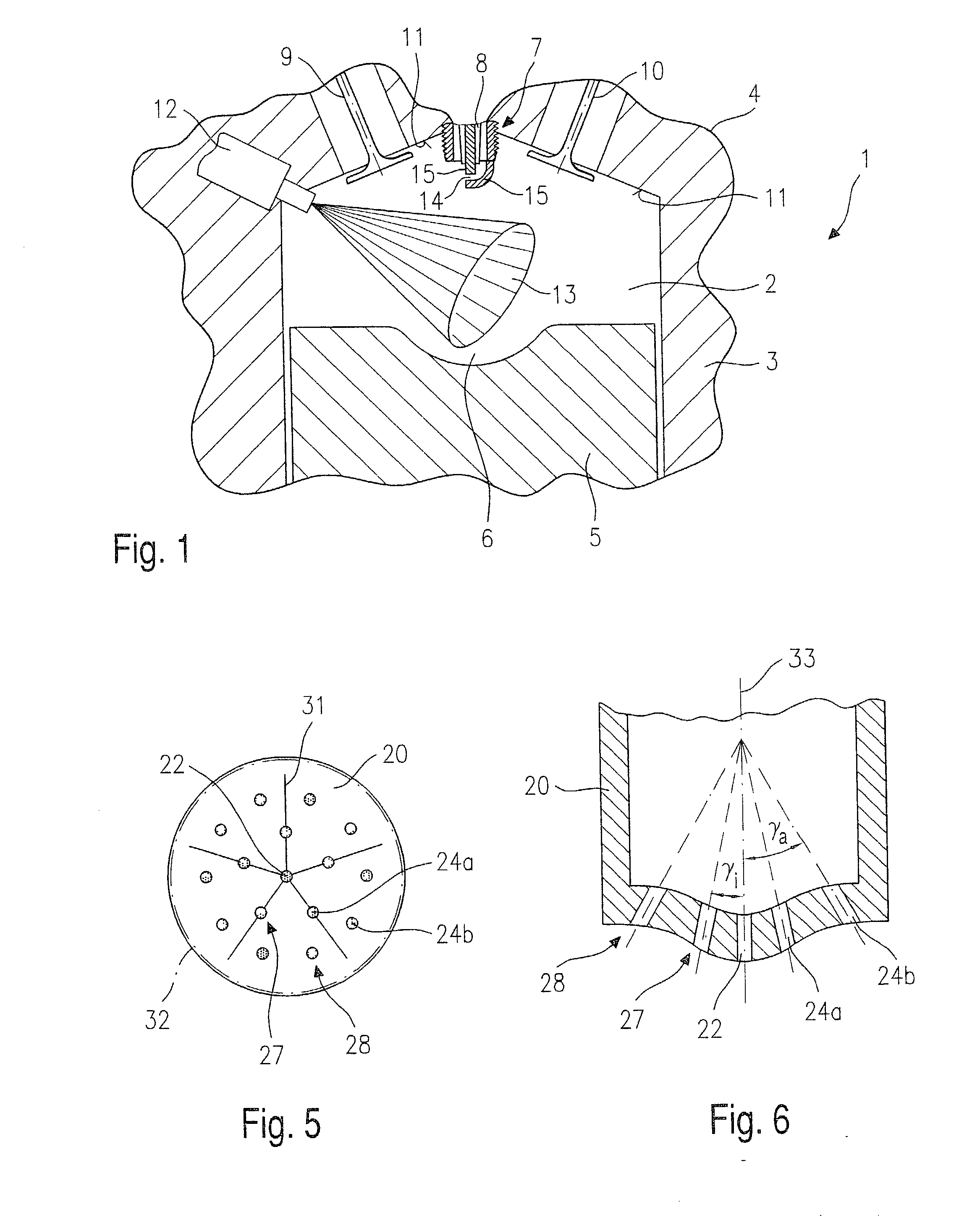

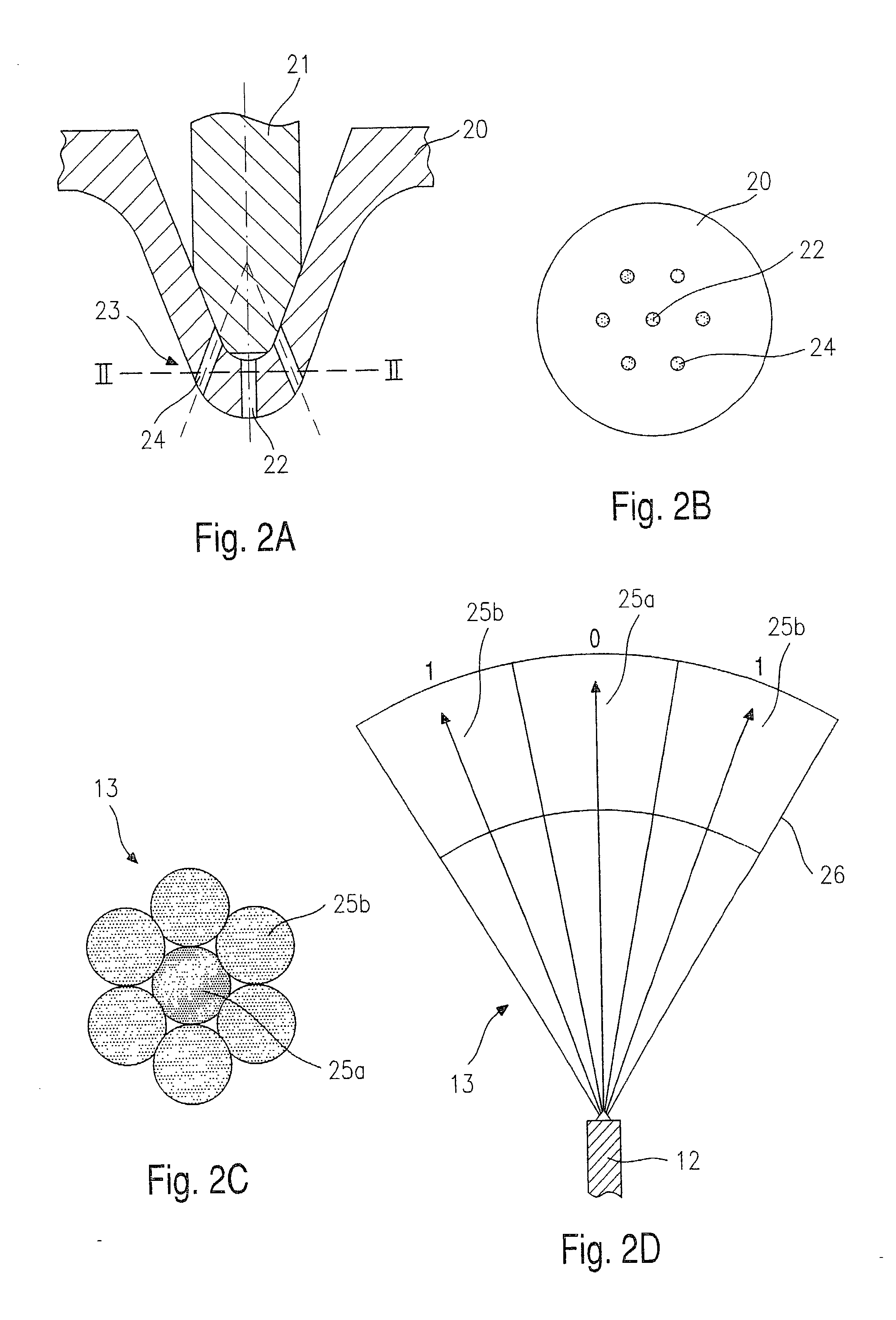

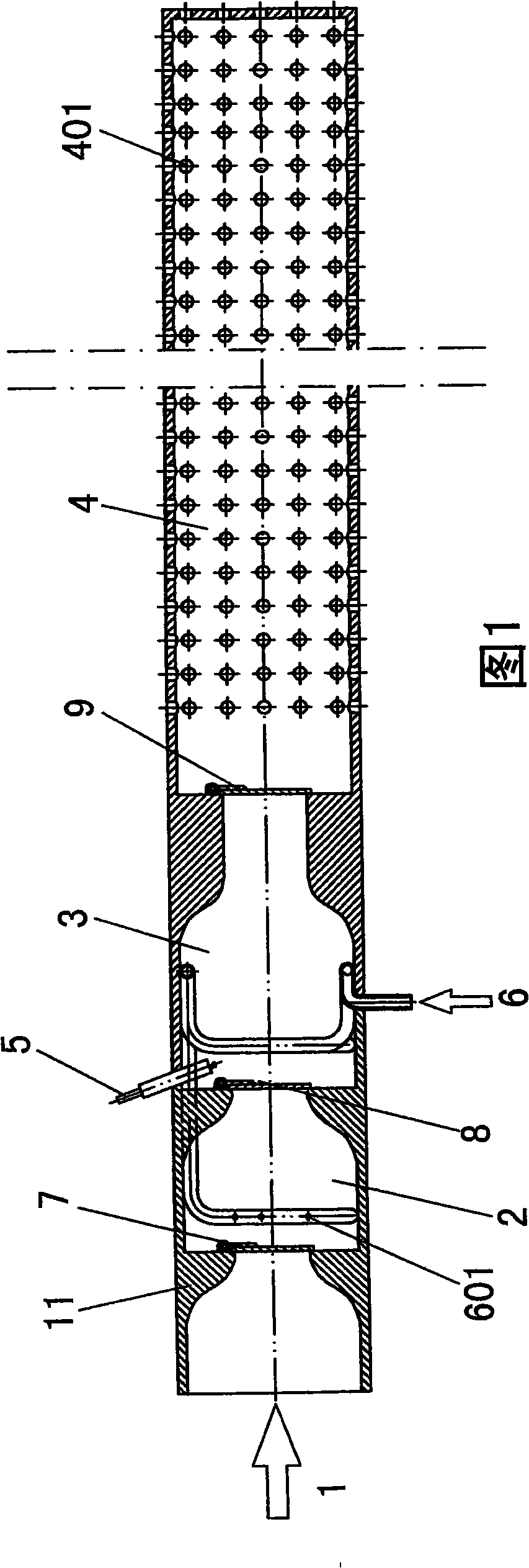

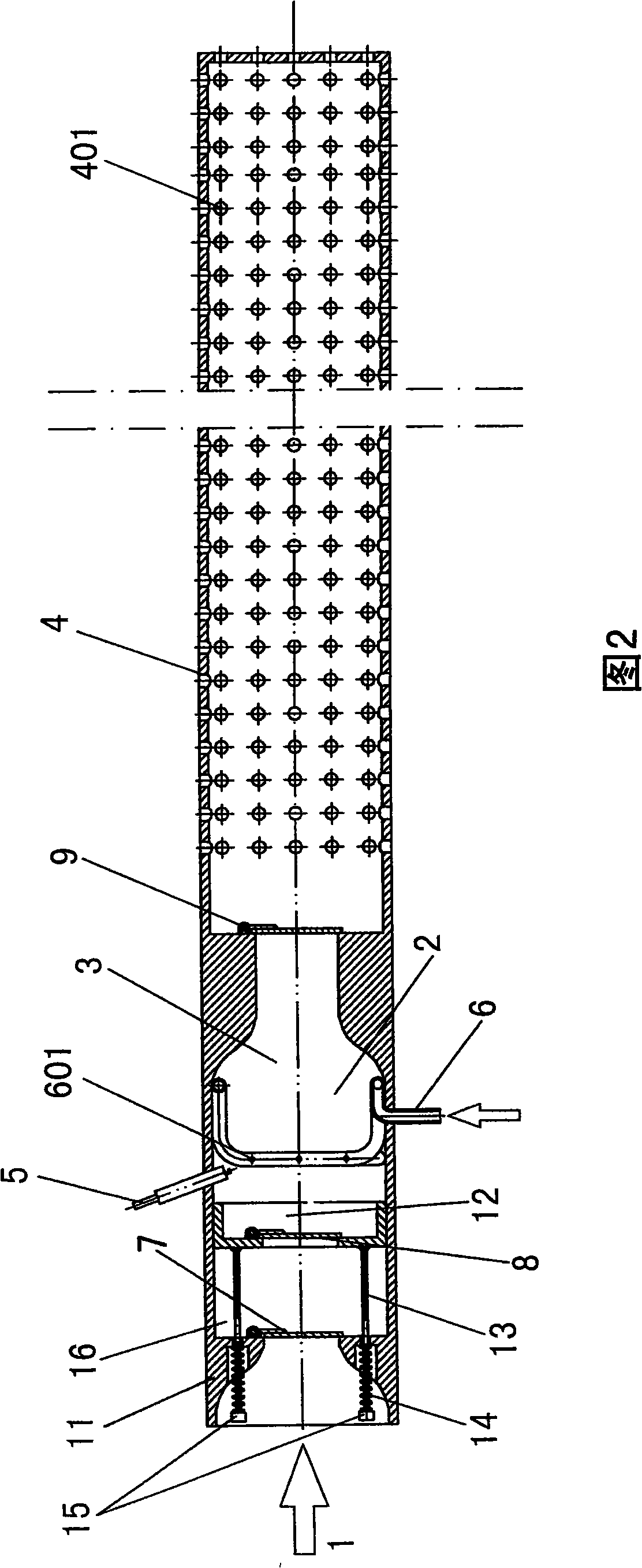

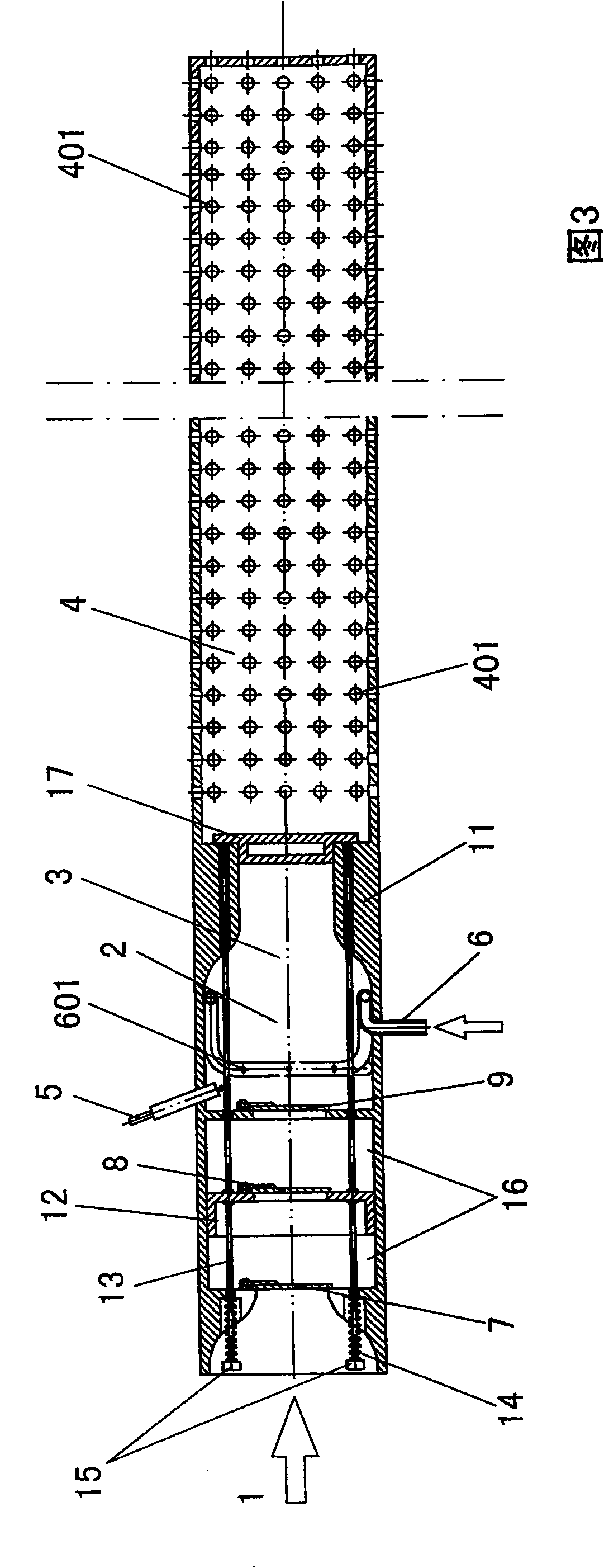

Fuel injection system

InactiveUS20020185104A1Emission reductionNegligible nitrogen oxide emissionInternal combustion piston enginesCylinder headsCombustion chamberInternal combustion engine

A fuel injection system for internal combustion engines comprises a fuel injector that injects fuel into a combustion chamber, the combustion chamber being delimited by a cylinder wall in which a piston is guided, and a spark plug that protrudes into combustion chamber. The fuel injector produces a conical mixture cloud in the combustion chamber through at least one row of injection orifices arranged circumferentially on a valve body of the fuel injector. The valve body also provides a centrally arranged injection orifice that produces a central area of the mixture cloud directed towards the spark plug.

Owner:ROBERT BOSCH GMBH

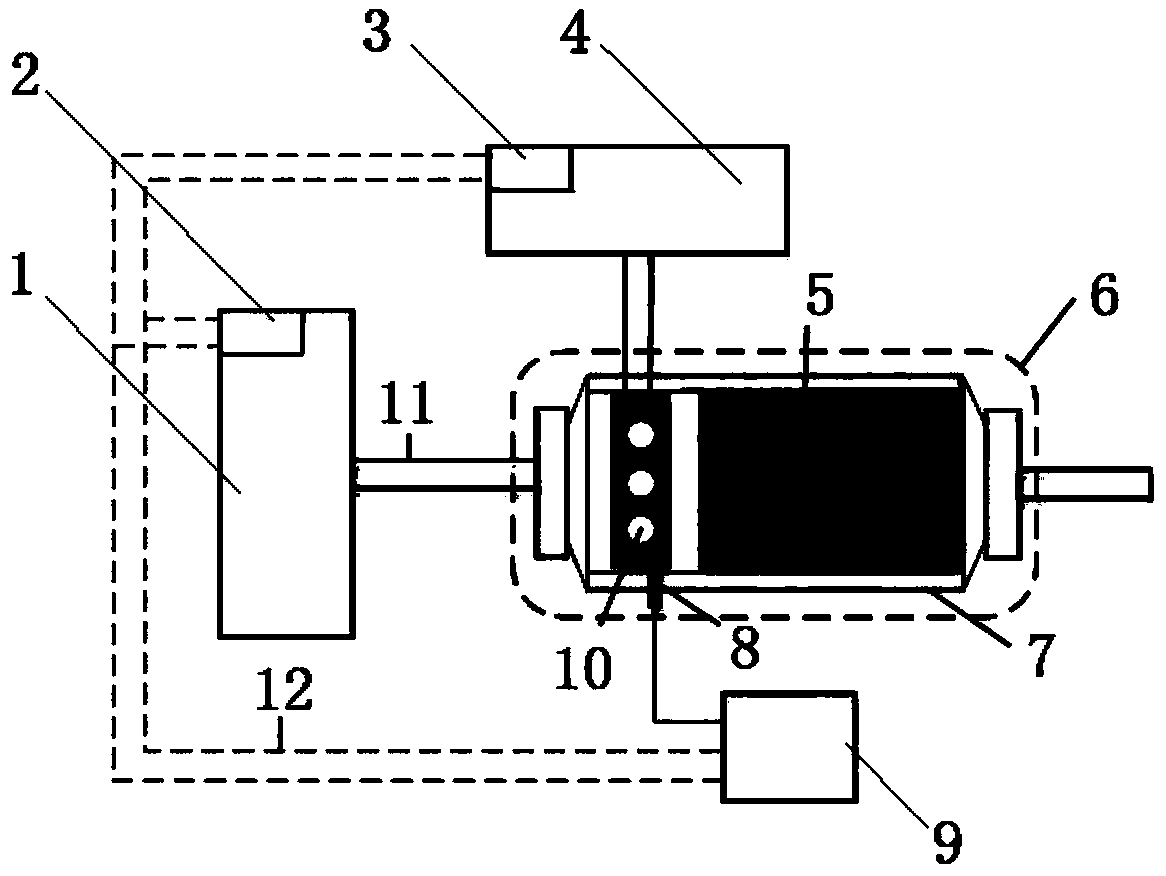

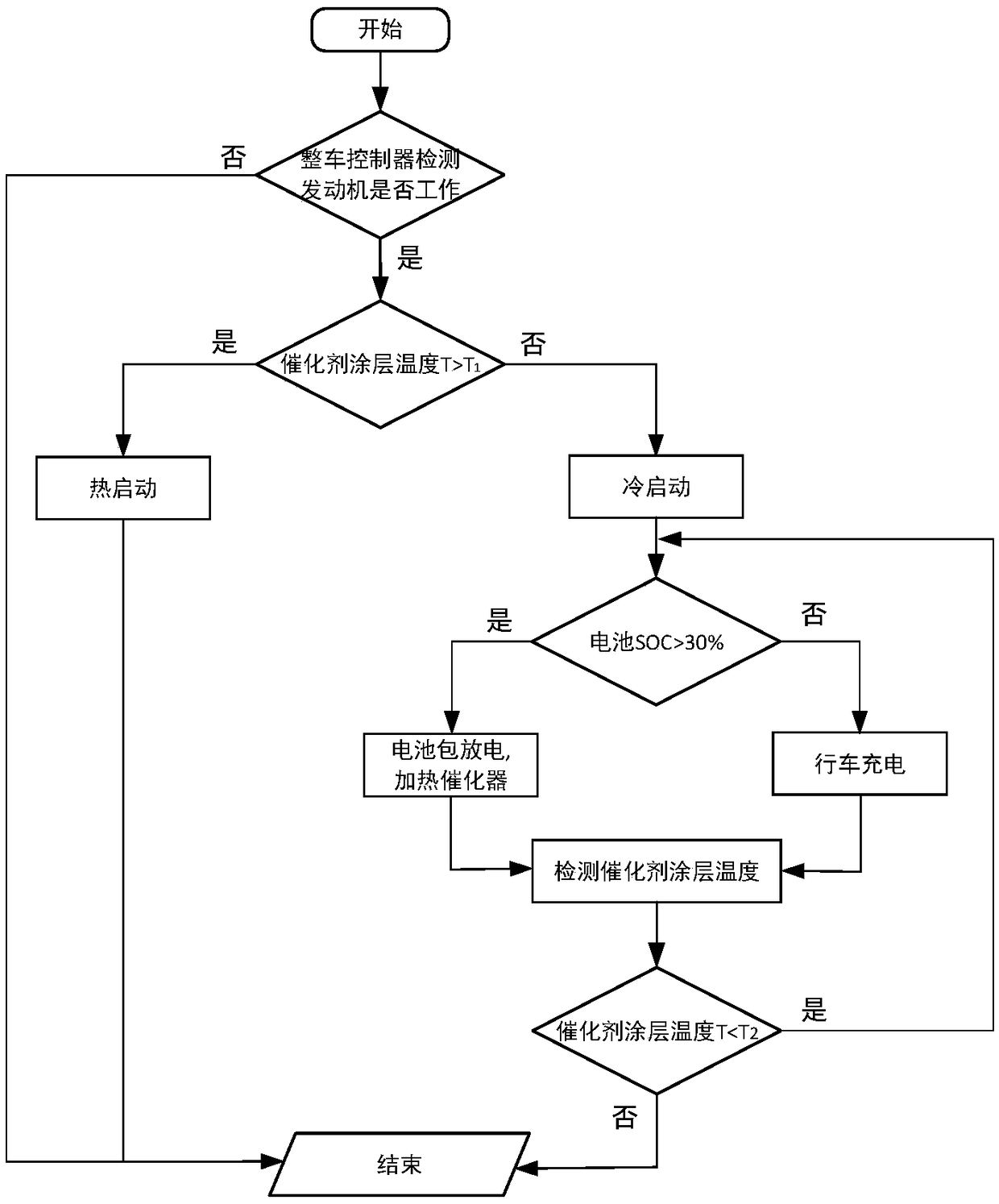

Control method for reducing cold start emission based on hybrid electric vehicle

InactiveCN108590818AReduce pollutionFast ignitionExhaust apparatusSilencing apparatusElectrical batteryElectric vehicle

The invention provides an electric heating type three-way catalytic converter structure and a control method for reducing cold start emission based on a hybrid electric vehicle. The control method comprises the steps that a whole vehicle controller detects whether an ECU controls an engine to start or not through a CAN bus, if the fact that the engine starts is detected, the whole vehicle controller reads the current temperature T of a three-way catalytic converter and a battery SOC, and the current temperature T is compared with the set initiation temperature T1; if the current temperature Tis larger than the initiation temperature T1, it is judged that the engine is in a hot start state, the three-way catalytic converter does not need electric heating, and electric heating is stopped; and if the current temperature T is less than the initiation temperature T1, the engine is in a cold start state, at this time, the state of the battery SOC is judged based on CAN bus communication. The further processing method is also disclosed. According to the electric heating type three-way catalytic converter structure and the control method for reducing cold start emission based on the hybrid electric vehicle, an external heat source is provided for the three-way catalytic converter by utilizing a large capacity battery and high-voltage equipment on the hybrid electric vehicle, under thepremise that the dynamic property is met, the purpose that whole vehicle emission at the cold start stage is reduced is achieved, and accordingly the low-pollution property superiority of the hybridelectric vehicle is further exerted.

Owner:CHENGDU RAJA NEW ENERGY AUTOMOTIVE TECH CO LTD

Biomass briquette fuel

InactiveCN104745266AReduce sulfur contentReduce nitrogen contentBiofuelsSolid fuelsCombustionEngineering

The invention provides a biomass briquette fuel. The biomass briquette fuel is formed by mixing biomass raw material particles with fuel additives, and then crushing, mixing, drying, extruding and granulating; the weight percentage of the biomass raw material particles is 90-95%; the weight percentage of the fuel additive is 5-10%; the biomass raw material particles are composed of saw dust, bamboo dust, straws and rice straws; and the fuel additives are composed of quick lime, a combustion improver and high clay. The biomass briquette fuel is low in dust content which is greatly lower than the dust content of the fuel coal, and also high in combustion value and advantageous for improving the efficiency and the output of a boiler.

Owner:LINAN JICHEN BIOMASS ENERGY TECH CO LTD

Method for synthesizing in-situ formed ceramic particle reinforced iron-aluminum-based composites by laser combustion

InactiveCN101906572AIncrease profitImprove performanceSelf-propagating high-temperature synthesisIron powder

The invention discloses a method for synthesizing in-situ formed ceramic particle reinforced iron-aluminum-based composites by laser combustion, belonging to the technical field of materials. The in-situ formed ceramic particle reinforced iron-aluminum-based composites are prepared by the following steps of: putting tungsten ore powder, iron powder, aluminum powder and carbon powder in a ball mill for milling to obtain a mixed powder material; and compressing the mixed powder material into a pressed compact, transmitting a high-energy laser beam by employing a CO2 laser processing machine to ignite the surface of the pressed compact and trigger self-propagating high temperature synthesis of the pressed compact. By the invention, two ceramic particle reinforced phases are simultaneously formed on one substrate, which shortens the preparation process of the composites, lowers material manufacture cost and facilitates large-scale production and application.

Owner:LIAONING TECHNICAL UNIVERSITY

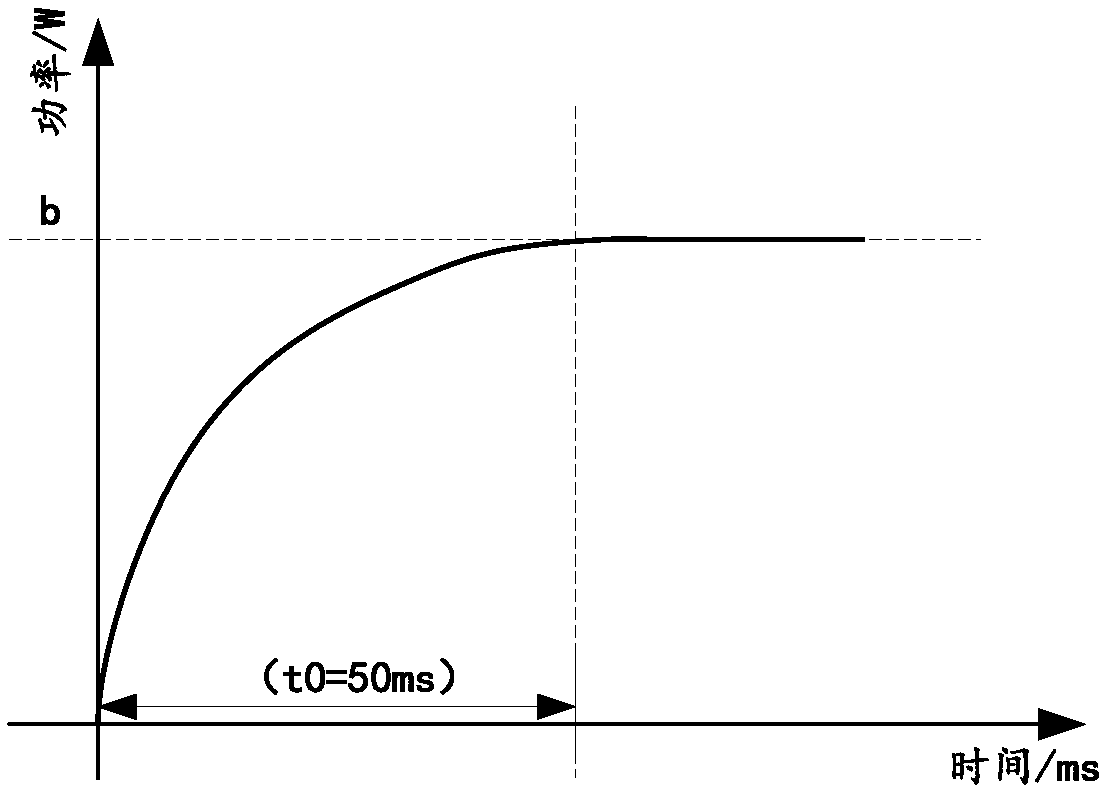

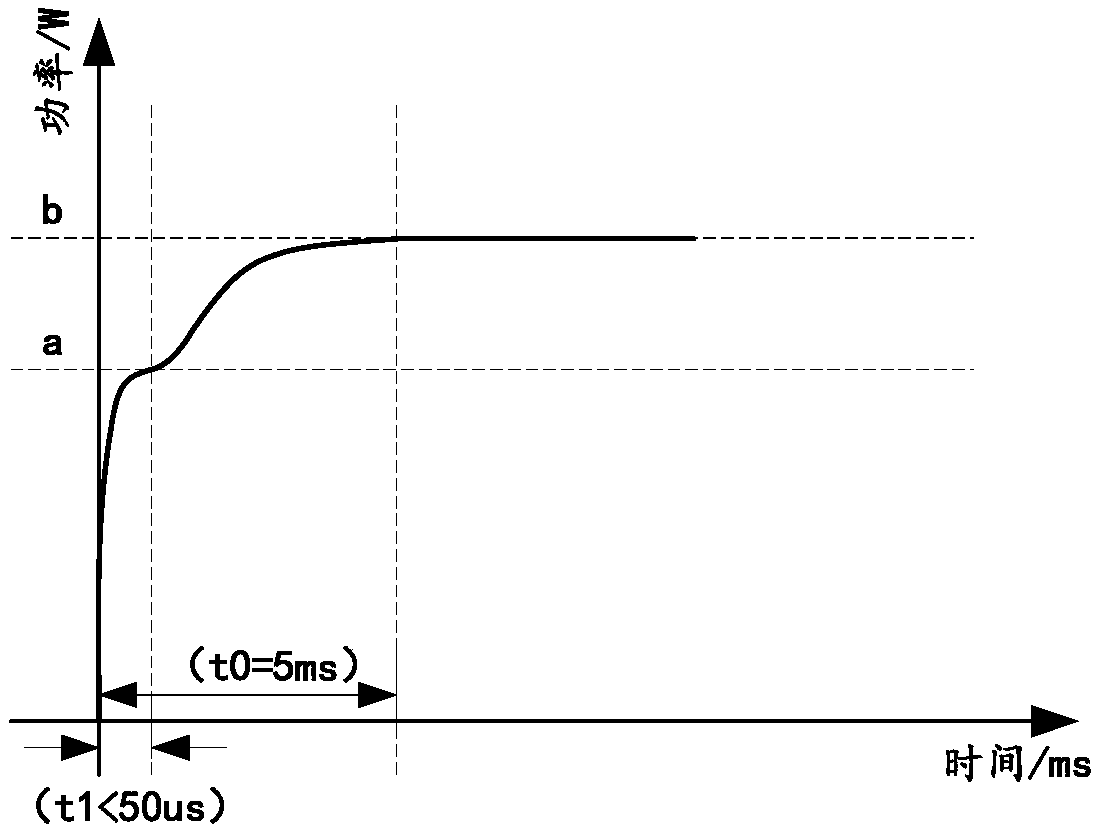

Electronic-cigarette power control method and electronic cigarette

ActiveCN108835718AShorten the smoking timeFast ignitionTobacco devicesElectric variable regulationPower controlRise time

The embodiment of the invention relates to the technical field of electronic cigarettes, in particular to an electronic-cigarette power control method and an electronic cigarette. The electronic-cigarette power control method is used for controlling a power supply device to output power to a heating element, and includes the steps that target power is determined; middle power is set according to the target power, wherein the middle power is smaller than the target power; the power supply device is controlled to output power to the heating element, and power output by the power supply device directly reaches the middle power in the first stage; power output by the power supply device is adjusted so that the power reaches the target power in the second stage, wherein the continuous time of the first stage is shorter than the continuous time of the second stage; the power supply device is controlled to constantly output the target power to the heating element in the third stage. Accordingto the mode, the electronic-cigarette power control method in the mode can shorten power rise time, and the ignition speed of the electronic cigarette is increased.

Owner:SHENZHEN FIRST UNION TECH CO LTD

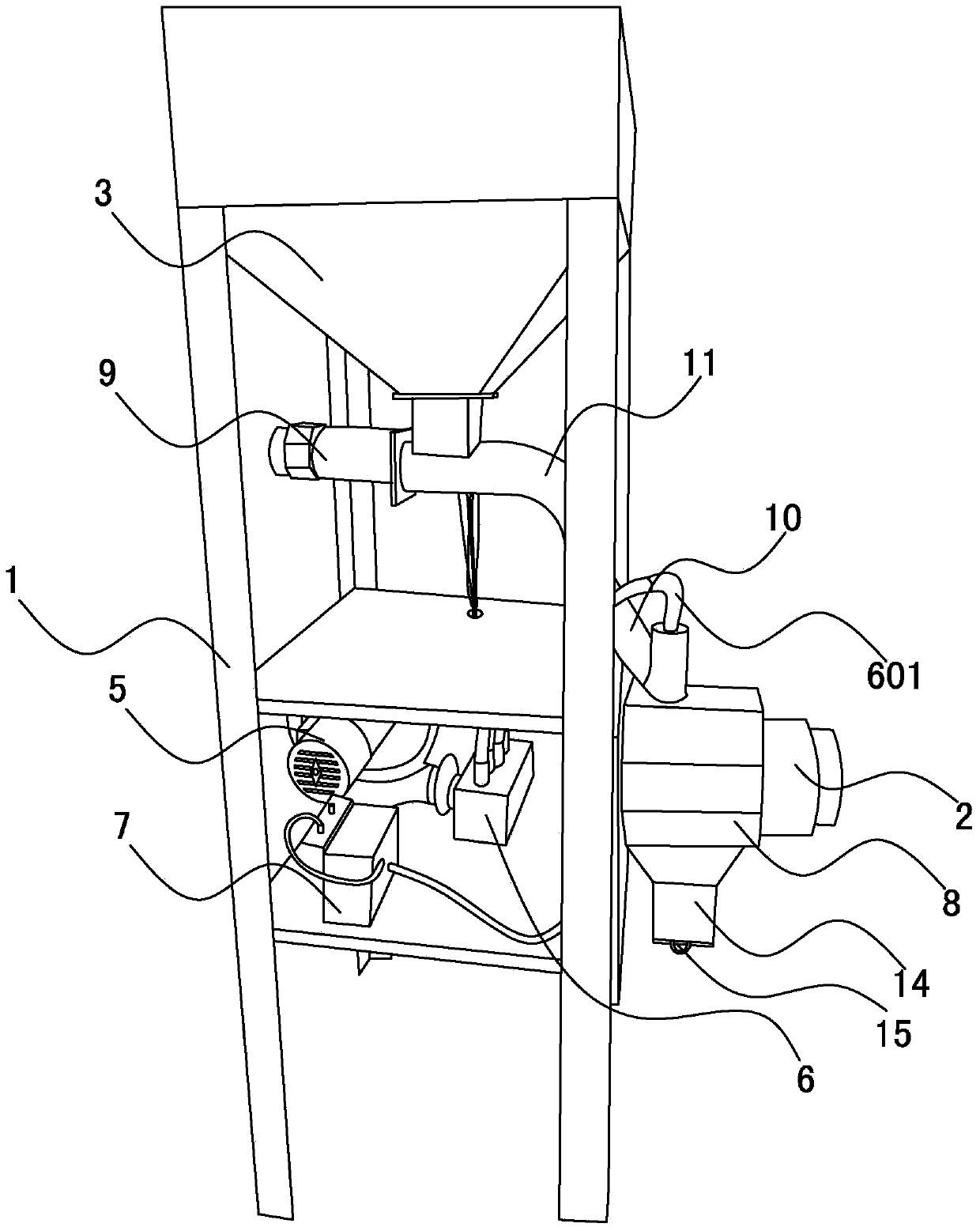

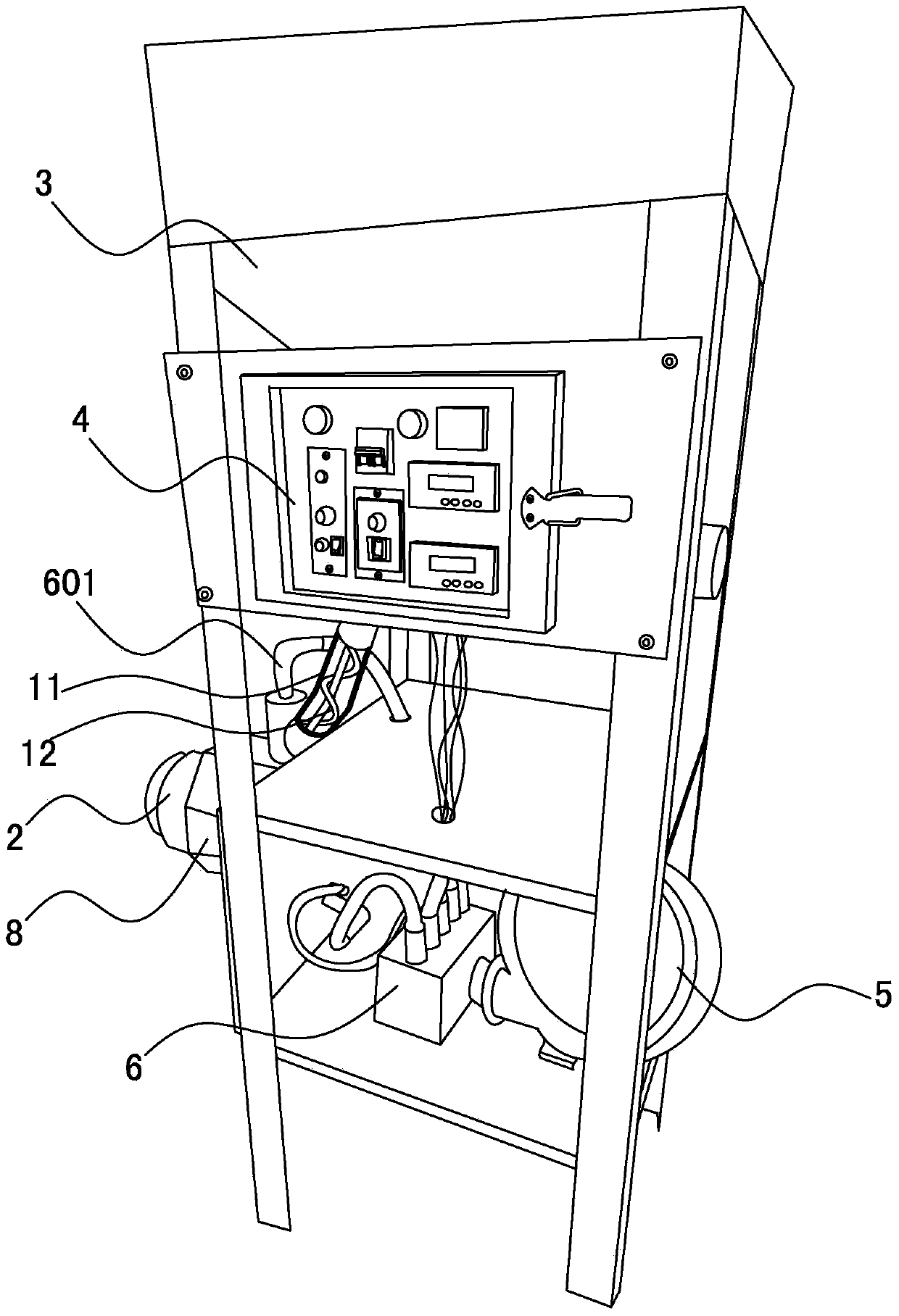

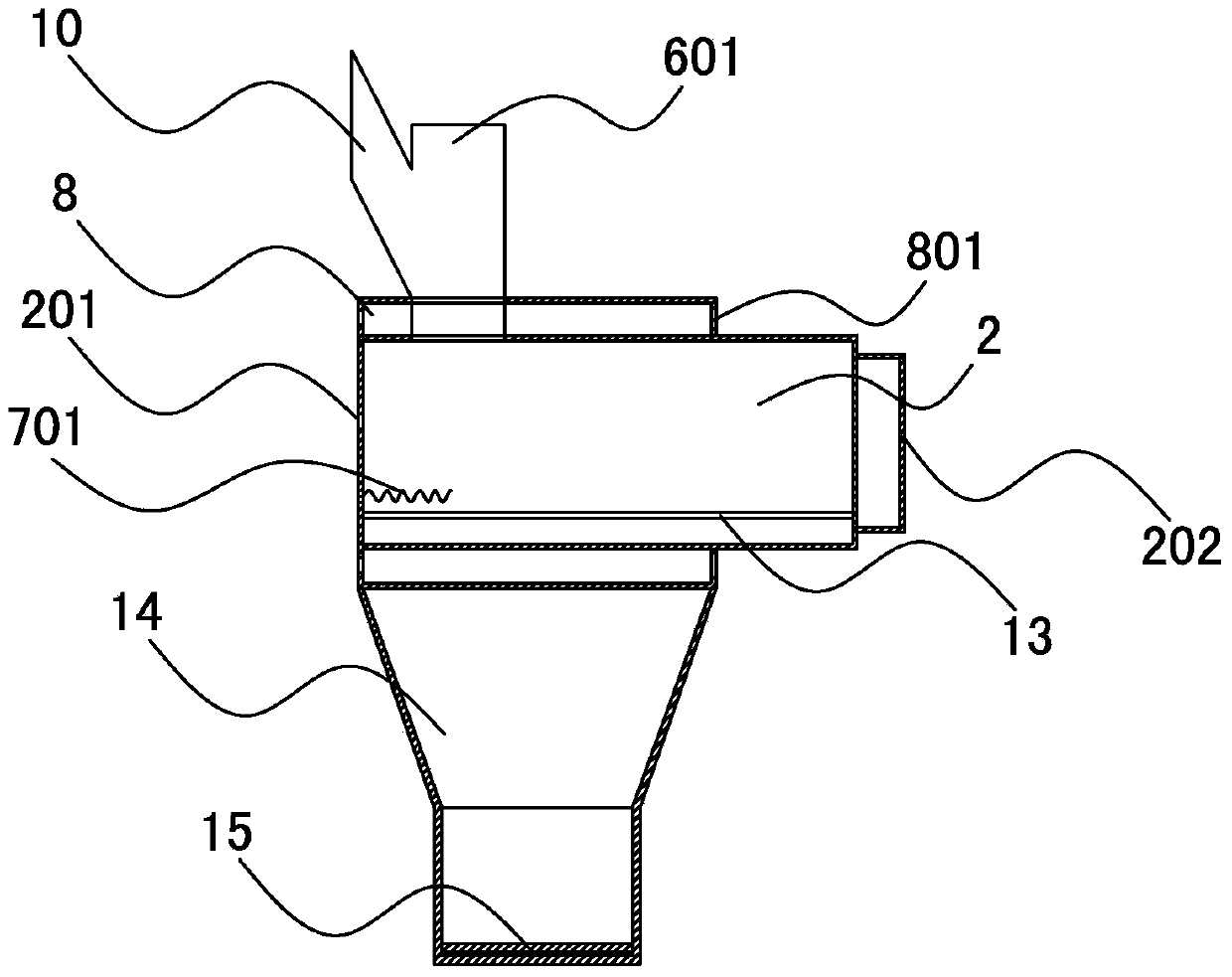

Bio-particle fuel burner

InactiveCN103438434AIncrease profitImprove the protective effectFuel supply regulationIncandescent ignitionCombustion chamberTransformer

The invention relates to fuel-burning equipment and provides a bio-particle fuel burner. According to the bio-particle fuel burner, the burner fast to ignite can reduce fuel loss, improve the utilization efficiency of fuel, save energy and protect environment, a machine table operates safely and stably, the burning power is large and the automatic level is high. The bio-particle fuel burner comprises a machine frame, a combustion chamber, a bin, a PLC, a temperature sensor and an air blower, wherein the combustion chamber, the bin, the PLC, the temperature sensor and the air blower are arranged on the machine frame. The bio-particle fuel burner further comprises an adjustable-air flow-distributing device and an ignition device. The bin is provided with a discharge device. The combustion chamber is provided with a feed pipe communicated with the discharge device of the bin. The air blower is communicated with an air inlet of the combustion chamber through the adjustable-air flow-distributing device. A flow-distributing output pipe air outlet of the adjustable-air flow-distributing device is further communicated with a feed pipe discharge opening of the combustion chamber. The ignition device comprises an ignition transformer and an electric stove wire connected with the ignition transformer. The electric stove wire is arranged in the combustion chamber. The PLC is connected with the discharge device, the ignition transformer, the temperature sensor and the adjustable-air flow-distributing device respectively.

Owner:蔡春祥

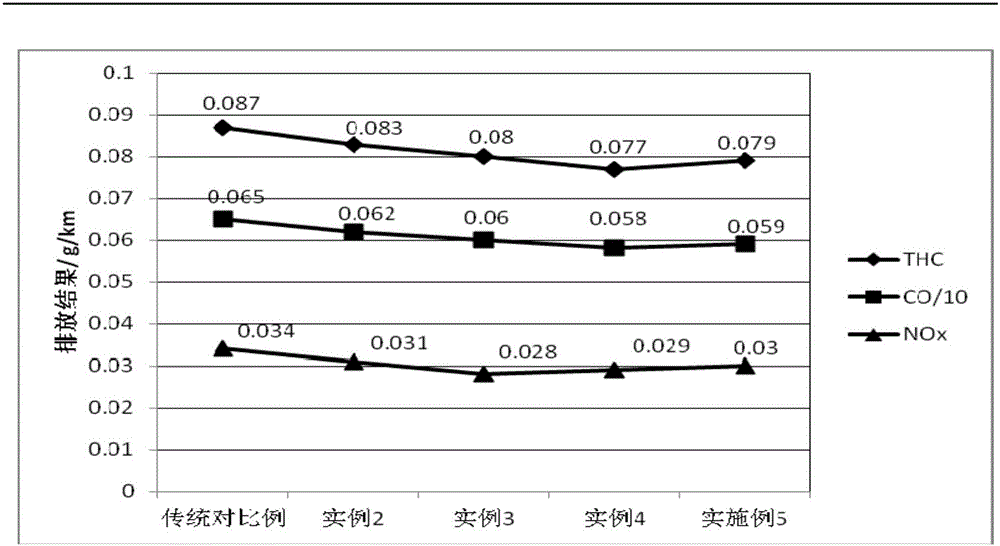

A preparing method of a three-way catalyst

ActiveCN106076331AIncrease profitLow costCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMetallurgyActive component

The invention relates to a preparing method of a three-way catalyst. The method includes preparing a front-zone precious metal solution and a rear-zone precious metal solution, coating a carrier with a first slurry layer with the coating amount being 100-140 g / L, drying, calcinating, dipping the front end of the carrier in 50-300 g of the precious metal solution, dipping the rear end of the carrier in 100-500 g of the precious metal solution, drying in a drying oven having a temperature of 100-150 DEG C for 4-8 h, calcinating at 400-600 DEG C for 1-3 h, coating the carrier with a second slurry layer with the coating amount being 60-100 g / L, drying, and calcinating to obtain the catalyst. The method is simple and easily controllable in steps. Both ends of the carrier are respectively dipped in the precious metal solutions by a dipping manner. Active components are controllable in distribution and mostly distributed on the surface of a pore channel structure. The catalyst is high in catalytic conversion capability and still shows excellent three-way catalytic activity after high-temperature ageing. Compared with traditional three-way catalysts, the catalyst is rapid in ignition, high in precious metal utilization rate and low in cost.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

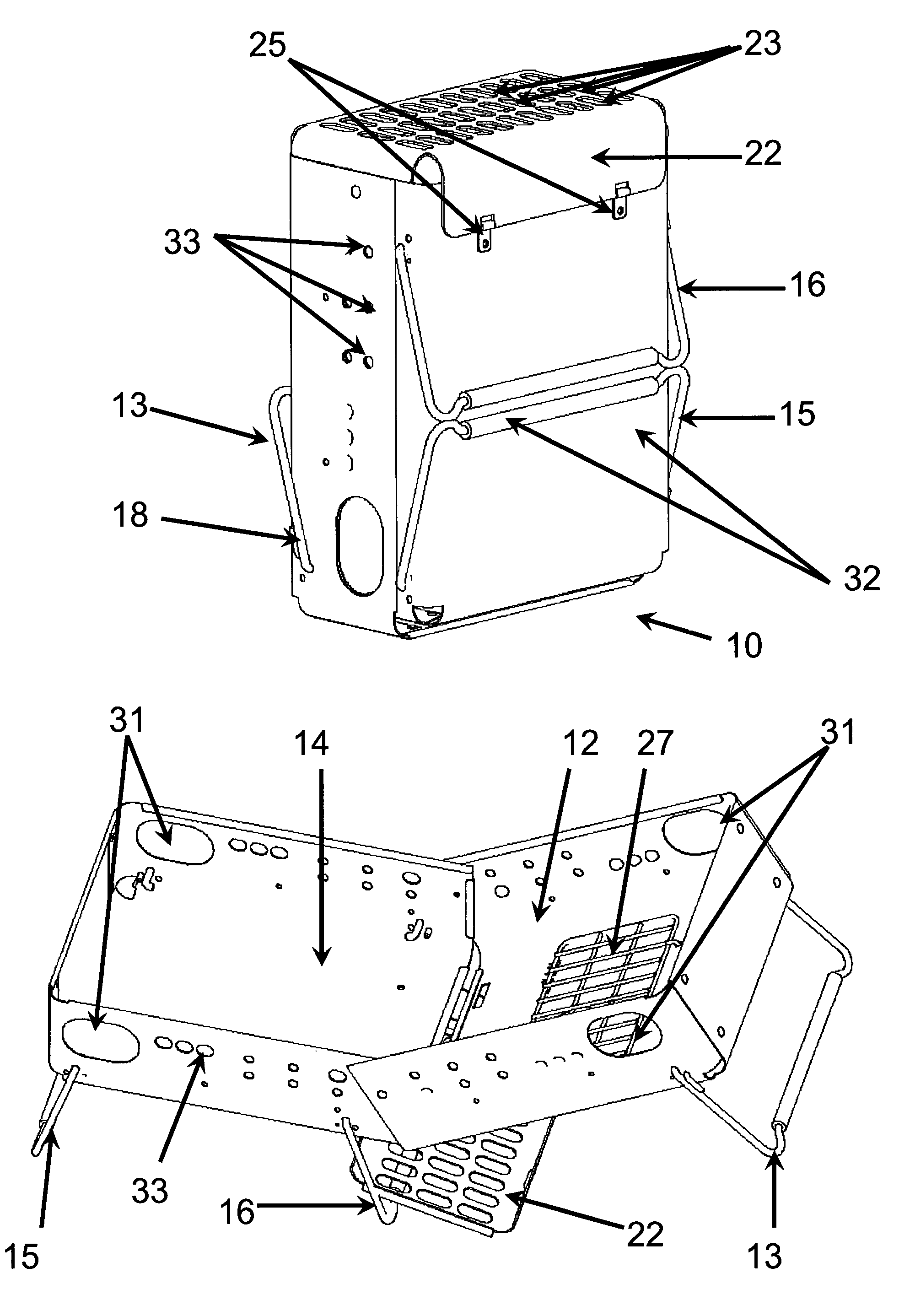

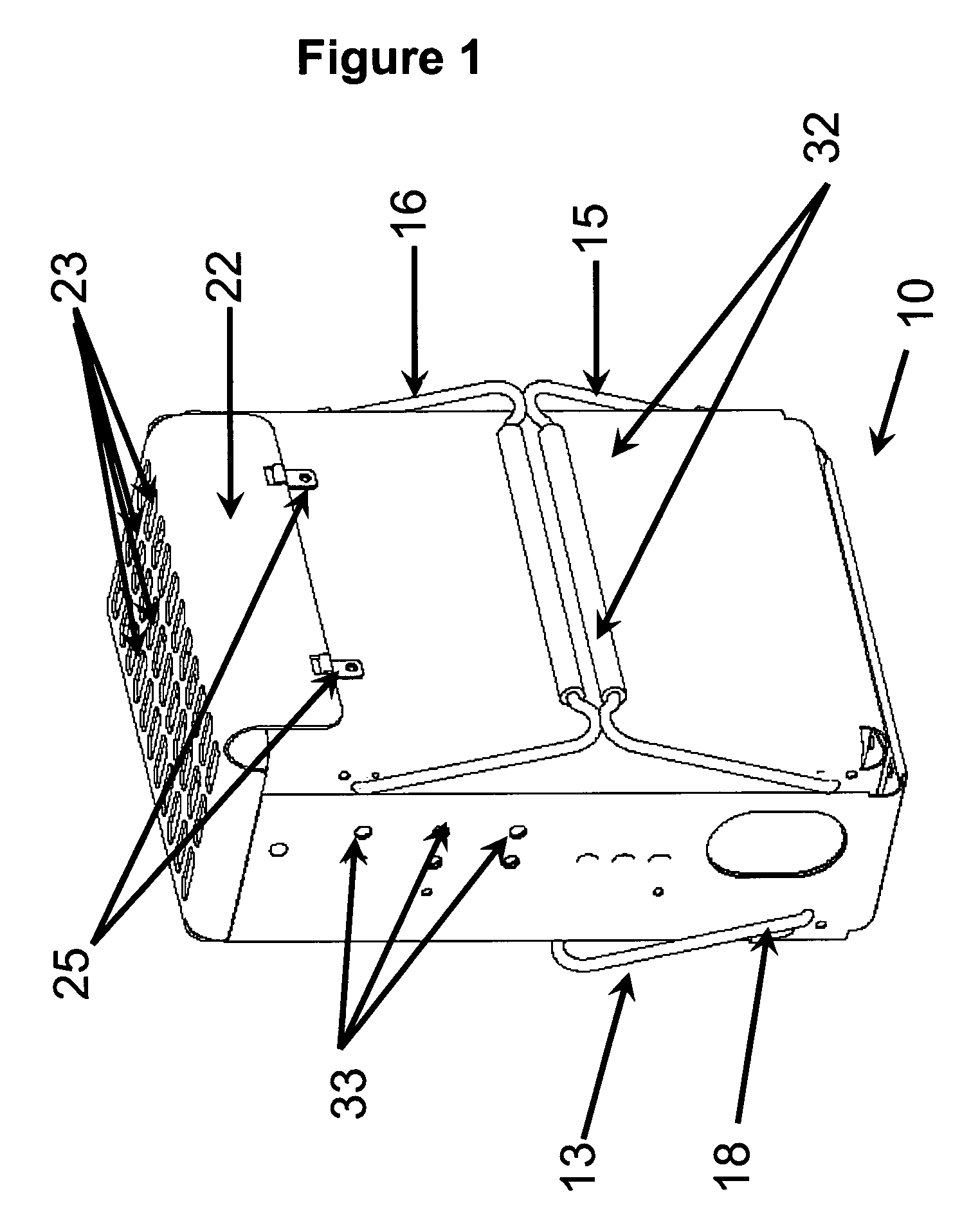

Portable charcoal grill

InactiveUS7237548B2Fast ignitionIncrease the areaDomestic stoves or rangesLighting and heating apparatusEngineeringCharcoal

Some embodiments of the present invention relate to a portable charcoal grill where, in the closed position, charcoal may be supplied through an opened chimney lid located at the top of the grill, and lit paper or other kindling material may be inserted through an opening to an ignition area located at the bottom of the grill in order to ignite the charcoal. The chimney effect created by the shape and directionality of the closed portable grill may aid in heating and igniting the charcoal. Once the charcoal is at the proper burning point, the portable grill may be safely opened up and a large grilling area may be available for cooking. The legs, which can be used as carrying handles for the grill, may be secured in place by a unique joint that has two or more distinct positions.

Owner:SHIRYONIT HOSEM TECH 1999

Wire and cable horizontal combustion test device and test method thereof

PendingCN113376209ARealize automatic data collectionAchieving processing powerMaterial heat developmentProgramme control in sequence/logic controllersHuman–machine interfaceData acquisition

The invention discloses a wire and cable horizontal combustion test device and a test method thereof. The wire and cable horizontal combustion test device comprises a combustion furnace, an exhaust transition section is arranged at the other end of the combustion furnace, an exhaust pipeline is arranged on one side of the exhaust transition section, a smoke density measuring mechanism is arranged on the exhaust pipeline, a waste gas pipe is arranged on one side of the exhaust pipeline, a smoke exhaust fan is arranged on one side of the waste gas pipe, and a waste gas treatment mechanism is arranged on one side of the smoke exhaust fan. PLC programming, a human-computer interface and computer control are adopted, test data can be checked in real time in the control test process, automatic data acquisition and processing, data storage and determination result output can be achieved, the whole test process is controlled through a computer, the test time, the test frequency, the delayed combustion time and the like can be set and recorded in the computer, automatic detection control is achieved, and detection work is automatically completed.

Owner:应急管理部四川消防研究所 +1

Pulse vector high-pressure burner

A pulse vector high pressure burner is composed of an air compression part, an oil and gas mixing chamber part, a combustion chamber part and a flame jet pipe communicated with each other in turn. The cavity of the combustion chamber is connected with a fuel sucker, a spark plug; the tube wall of the flame jet pipe is densely covered with a flame jet; the air compression part, the oil and gas mixing chamber part, the combustion chamber part are provided with a device composed of a check valve using the gas and oil pressure change to generate the pulse to supply air, wherein the device has 3-4 groups of check valves, except a group of check valves toward the flame jet pipe direction at the pressure entrance just in not out, the directions of the others just out not in; the invention can realize the fast pressurizing heating, large spray pressure, high temperature, good stability, which is suitable for the boimass compression moulding process and the required pressure heating or pressure combustion-supporting process.

Owner:ZEROQ SCI & TECH

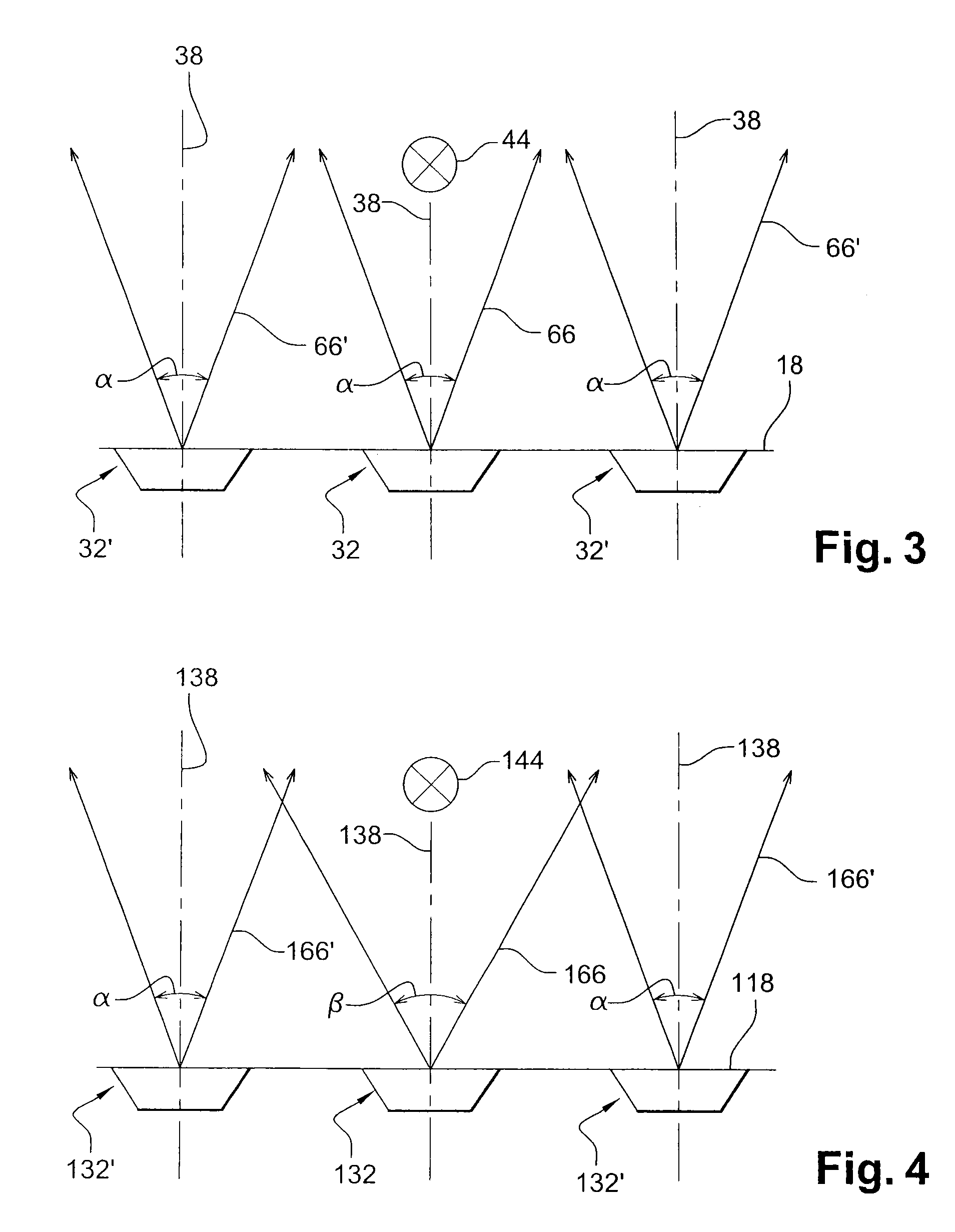

Fuel injection systems in a turbomachine combustion chamber

ActiveUS20100229559A1Simple and effective and economicSimple and effective and economic solutionContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustion chamberEngineering

Turbomachine, comprising a combustion chamber provided with systems (132, 132′) for injecting fuel into the chamber, and with at least one spark plug (144), the injection system (132) located as close as possible to the spark plug being configured in order to produce a pool (166) of fuel having an angle of opening (β) of a greater value than that (α) of the pools (166′) produced by the other injection systems (132′), and having a flow of fuel greater than that of the other injection systems (132′).

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

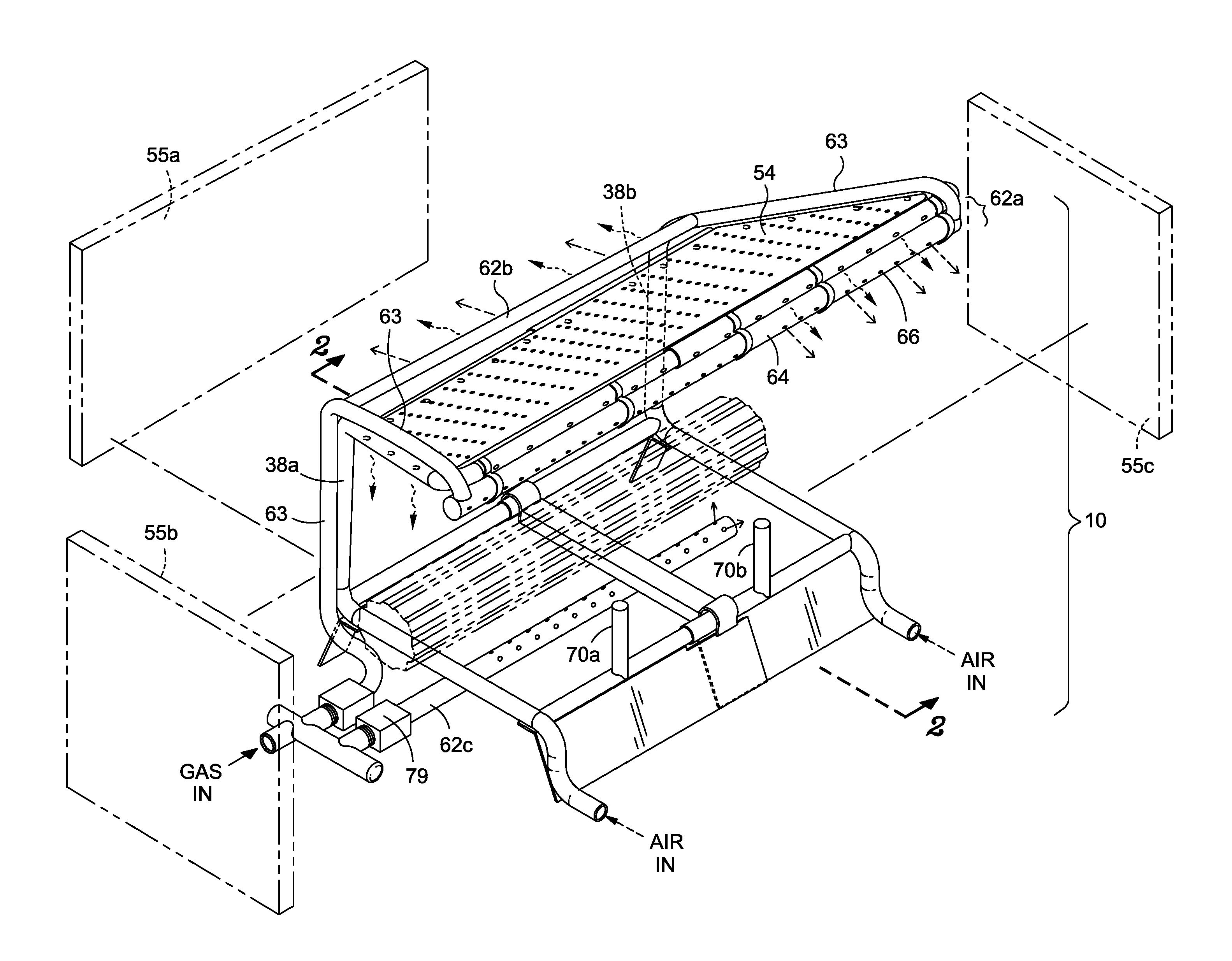

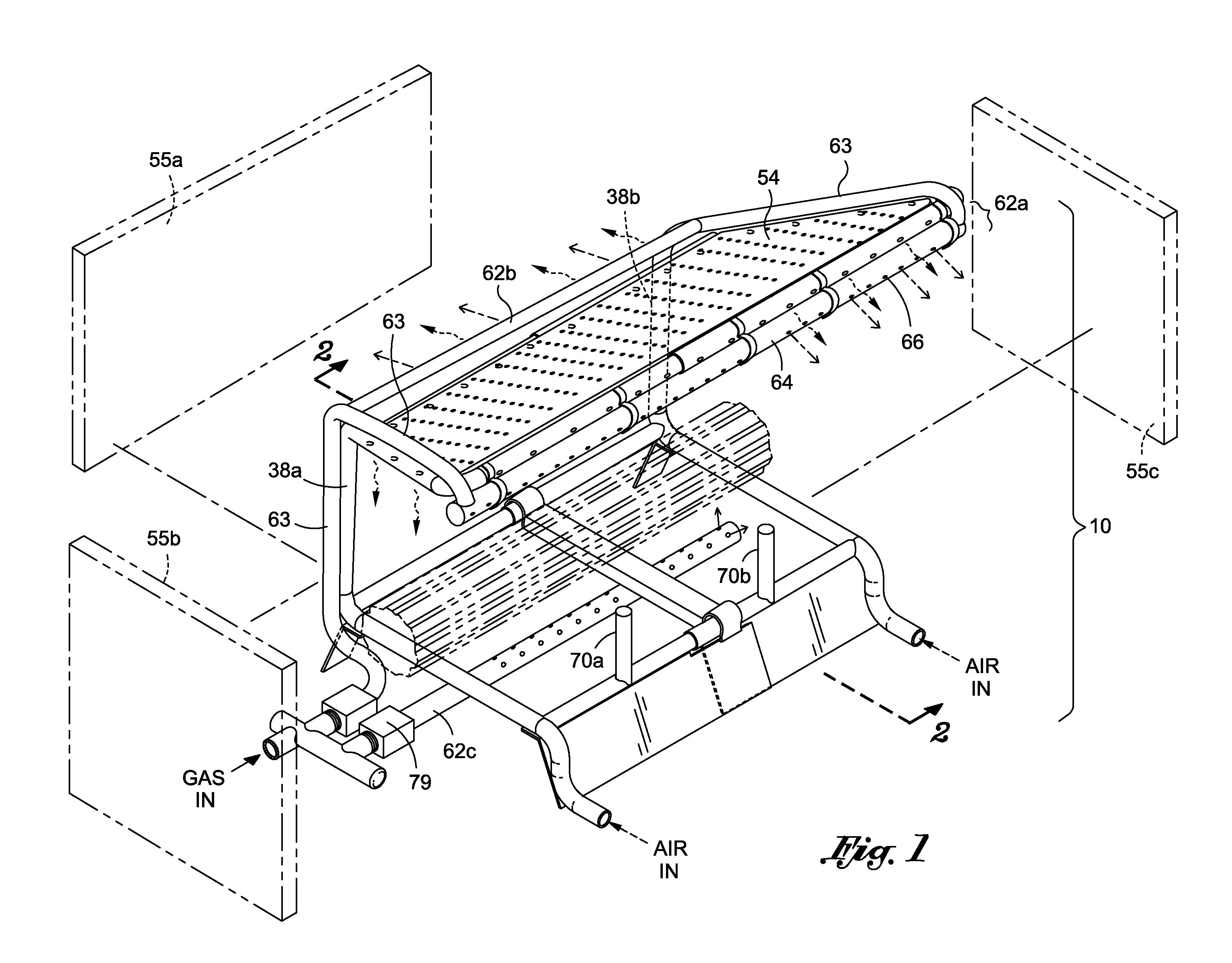

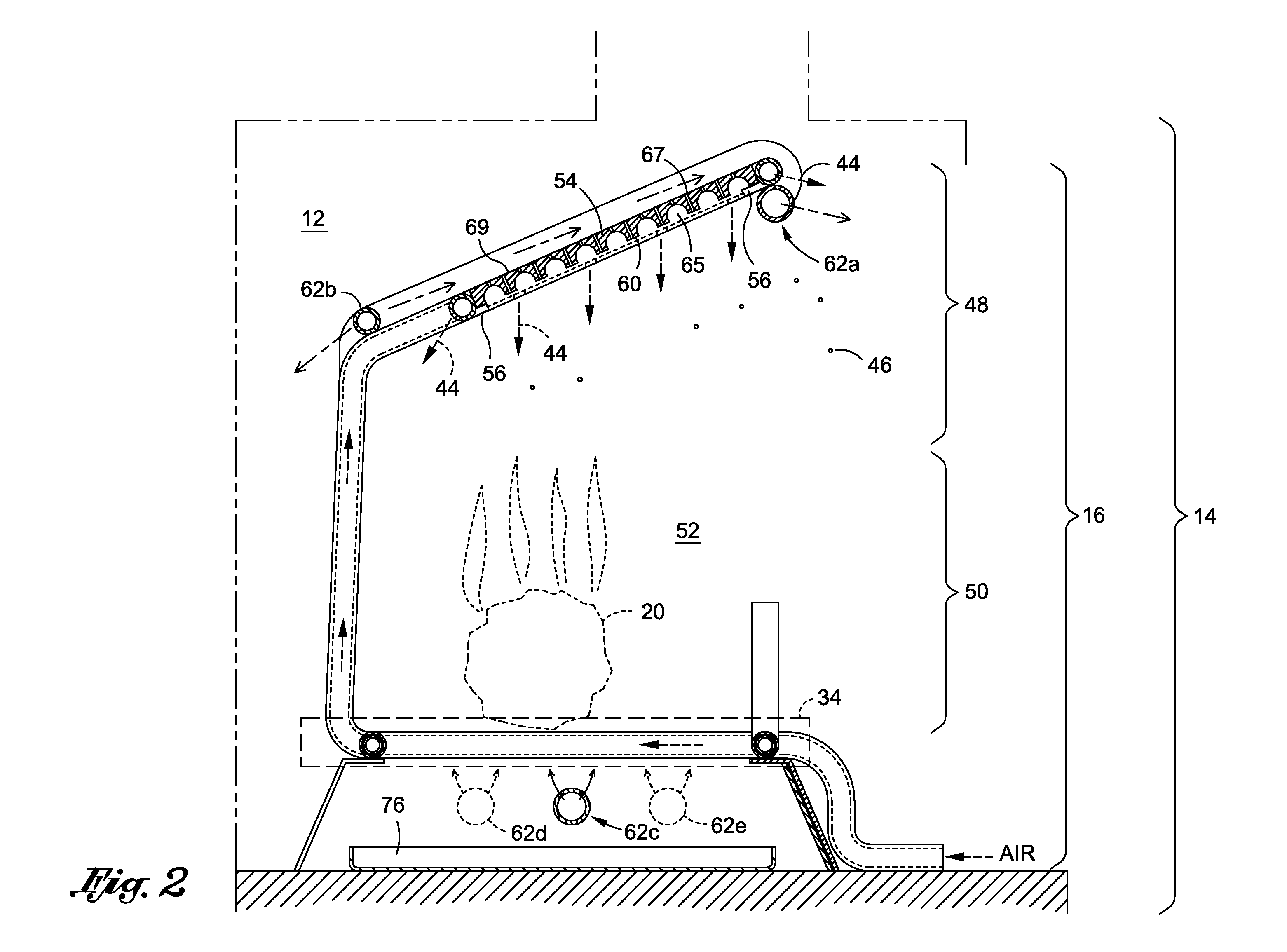

Biomass boiler monitoring system

The invention discloses a biomass boiler monitoring system which can monitor the charge and discharge in a real time manner. The biomass boiler monitoring system can ensure that only biomass fuel is used by the biomass boiler to avoid using fuel with high-pollution emission. The biomass boiler monitoring system comprises a biomass boiler body and a smoke evacuation passage (92). The biomass boiler body is equipped with a camera (10) for monitoring a feed port, and the smoke evacuation passage (92) is equipped with a gas induction monitor (20). The camera (10) and the gas induction monitor (20) are connected with a signal receiver (30), and the signal receiver (30) is connected with a signal recorder (40). The biomass boiler monitoring system can be widely applied to the boiler field.

Owner:ZHUHAI HUISHENG ENERGY SOURCE TECH DEV

Exothermic heat-preservation feeder for casting and preparation method of feeder

ActiveCN103551515AReduce consumptionProlong clotting timeFoundry mouldsFoundry coresRed mudCasting defect

The invention relates to an exothermic heat-preservation feeder for casting and a preparation method of the feeder, belongs to the casting field, and solves the problems that an existing feeder has a poor heat insulating effect and insufficient heat, so as to shorten the solidification time of molten metal in the feeder, reduce casting defects such as casting shrinkage cavities and shrinkage porosity and promote the product yield. The feeder is prepared from expanded vermiculite, magnesite powder, quartz sand, aluminite powder, graphite powder, magnesium powder, ferric oxide powder, sodium nitrate, fluorite powder, sodium silicate, red mud and lignin. The preparation method comprises the following steps of weighing; placing the expanded vermiculite, the magnesite powder, 40% of sodium nitrate, 40% of red mud and 40% of lignin into a runner wheel sand mixer and mixing, then adding the quartz sand, the aluminite powder, the graphite powder, the magnesium powder, the ferric oxide powder, sodium nitrate and fluorite powder, mixing, adding the remained red mud, the lignin and the sodium silicate and mixing; and filling into a mold and compacting, dehydrating and demoulding after hardening. The feeder is used for casting.

Owner:欧区爱铸造材料(中国)有限公司

Fire Grate for Enhanced Combustion with Vertical and Horizontal Expansion Sleeves

InactiveUS20110005509A1Reduce harmful emissionsHarmful emissionDomestic stoves or rangesWater heatersParticulatesCombustion chamber

An improved fire grate may provide fresh oxygen rich air to a secondary combustion zone, created by the improved fire grate, of a combustion chamber where a combustion gas stream is typically oxygen starved assisting in the burning process of incompletely burned particulates and reducing other harmful emissions. A baffle plate may be introduced in the secondary combustion zone to increase a combustion chamber temperature, encourage mixing of oxygen starved air with oxygen rich air and increase a residence time of the combustion gas within the combustion chamber. These aspects of the baffle plate promote more efficient burning of the biomass / fuel. Additionally, log lighter(s) may be disposed in the secondary combustion zone to increase a temperature of the combustion chamber for the purposes of reducing harmful emissions. The improved fire grate may be horizontally and vertically adjusted to fit within different sized fireplace combustion chambers.

Owner:EARTHS FLAME

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com