A preparing method of a three-way catalyst

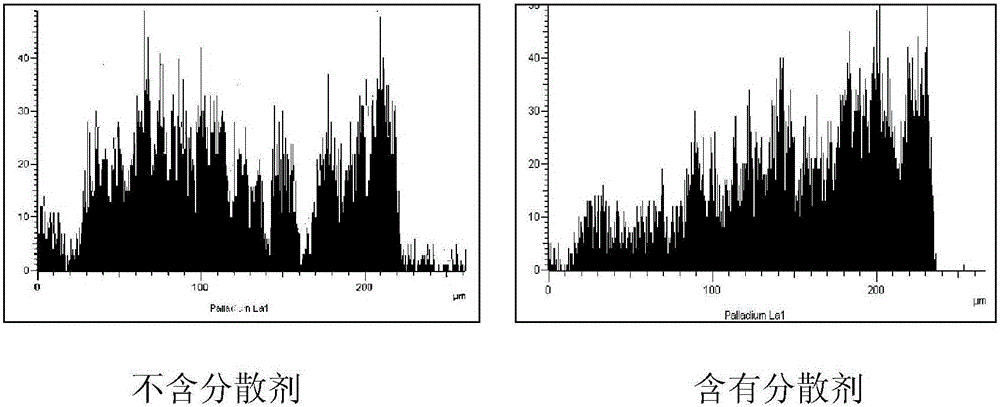

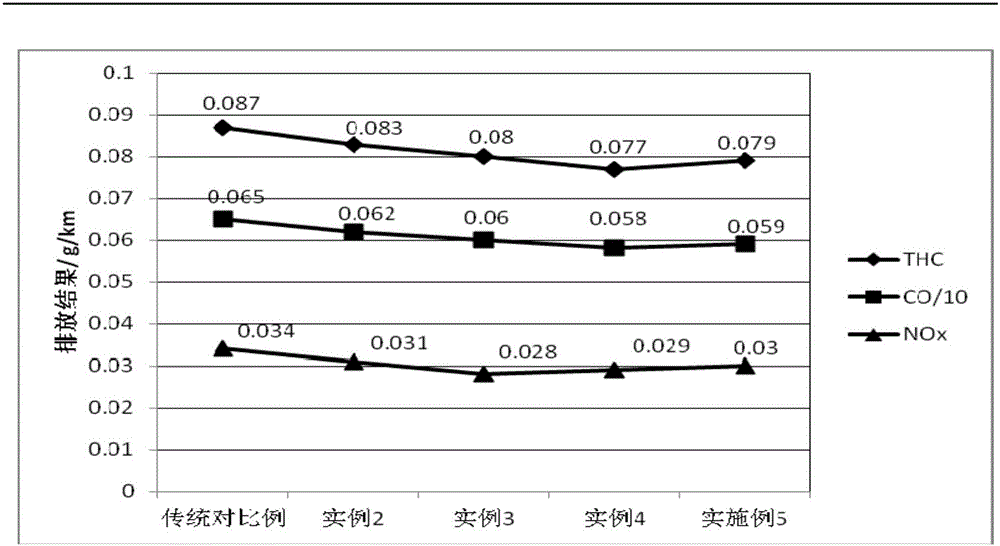

A three-way catalyst and dispersing aid technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. It can achieve the effect of high utilization rate of precious metals, excellent three-way catalytic activity, and fast light-off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Adopt the preparation process of dipping method of the present invention:

[0031] (1) Preparation of precious metal Pd impregnation solution: Take 1 part of methylcellulose as a dispersing aid, add it to 90 parts of water, stir for 3 hours, then add 8 parts of palladium nitrate solution dropwise, and continue stirring for 3 hours until it is evenly mixed , the viscosity of the dipping solution is 105 centipoise;

[0032] (2) Coating of the first coating slurry: take a blank carrier of φ103*130mm, coat the first coating slurry on it with a coating amount of 120g / L, and dry it in an oven at 150°C for 5h, 500 Roasting at ℃ for 2 hours;

[0033] The components in the first coating slurry are 50 parts by weight of alumina, 30 parts of cerium-zirconium powder, 10 parts of lanthanum nitrate, and 10 parts of cerium nitrate;

[0034] (3) Traditional method of precious metal Pd impregnation: according to the partition ratio of carrier length ratio of 1:1, only the front end is...

Embodiment 2

[0044] A preparation method of a three-way catalyst, characterized in that: comprising the steps of:

[0045] (1) Preparation of precious metal Pd impregnation solution in the front area: Take 1.6 parts of hydroxyethyl cellulose as a dispersing aid, add it to 90 parts of water, stir for 3 hours, then add 8 parts of palladium nitrate solution dropwise, and continue stirring for 2 hours to It is mixed evenly, and the viscosity of the dipping solution is 120 centipoise;

[0046] (2) Preparation of precious metal Pd impregnating solution in the rear area: Take 0.4 parts of polyurethane as a dispersion aid, add it to 94 parts of water, stir for 3 hours, then add 4 parts of palladium nitrate solution dropwise, and continue stirring for 2 hours until it is evenly mixed. The viscosity of the dipping solution is 115 centipoise;

[0047] (3) Coating of the first coating slurry: take a blank carrier of φ103*130mm, apply the first layer of slurry without active components on it according...

Embodiment 3

[0057] A preparation method of a three-way catalyst, characterized in that: comprising the steps of:

[0058] (1) Preparation of precious metal Pd impregnation solution in the front area: Take 2 parts of methylcellulose as a dispersing aid, add it to 89.8 parts of water, stir for 3 hours, then add 10 parts of palladium nitrate solution dropwise, and continue stirring for 2 hours until it reaches its peak. Mix evenly, and the viscosity of the dipping solution is 130 centipoise;

[0059] (2) Preparation of precious metal Pd impregnating solution in the back area: Take 0.2 parts of methylcellulose as a dispersing aid, add it to 96 parts of water, stir for 3 hours, then add 2 parts of palladium nitrate solution dropwise, and continue stirring for 2 hours until it reaches its peak. Mix evenly, the viscosity of the dipping solution is 115 centipoise;

[0060] (3) Coating of the first coating slurry: take a blank carrier of φ103*130mm, coat the first coating slurry on it with a coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com