Patents

Literature

149results about How to "Controllable distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of large-size graphene oxide or graphene

ActiveCN105293476ASmall sizeQuality improvementMaterial nanotechnologySingle layer grapheneHigh energyReducing agent

The invention discloses a preparation method of large-size graphene oxide or graphene. The preparation method mainly utilizes graphite as a raw material and comprises that 1, under the action of an intercalator and an expanding agent, graphite fully releases interlayer spaces so that interlayer interaction is reduced and a graphene aggregate is obtained, 2, the graphene aggregate is oxidized by an oxidizing agent, and then the oxidized graphene aggregate is peeled in water under gentle mechanical action so that a large area of a dispersion liquid of graphene oxide is obtained, and 3, the peeled graphene oxide is reduced by a reducer or heat treatment so that high conductivity graphene is obtained. The preparation method utilizes cheap raw materials, has a simple process, can be controlled easily, realizes fast and high efficiency solid-liquid separation, is convenient for industrial large scale production, prevents graphene crystal structure destroy caused by high energy supersonic wave, high speed shearing or fluid crushing. The obtained graphene has a large size and high conductivity and can be popularized and used in fields of high efficiency heat management, flexible display, energy conversion and storage.

Owner:FUDAN UNIV

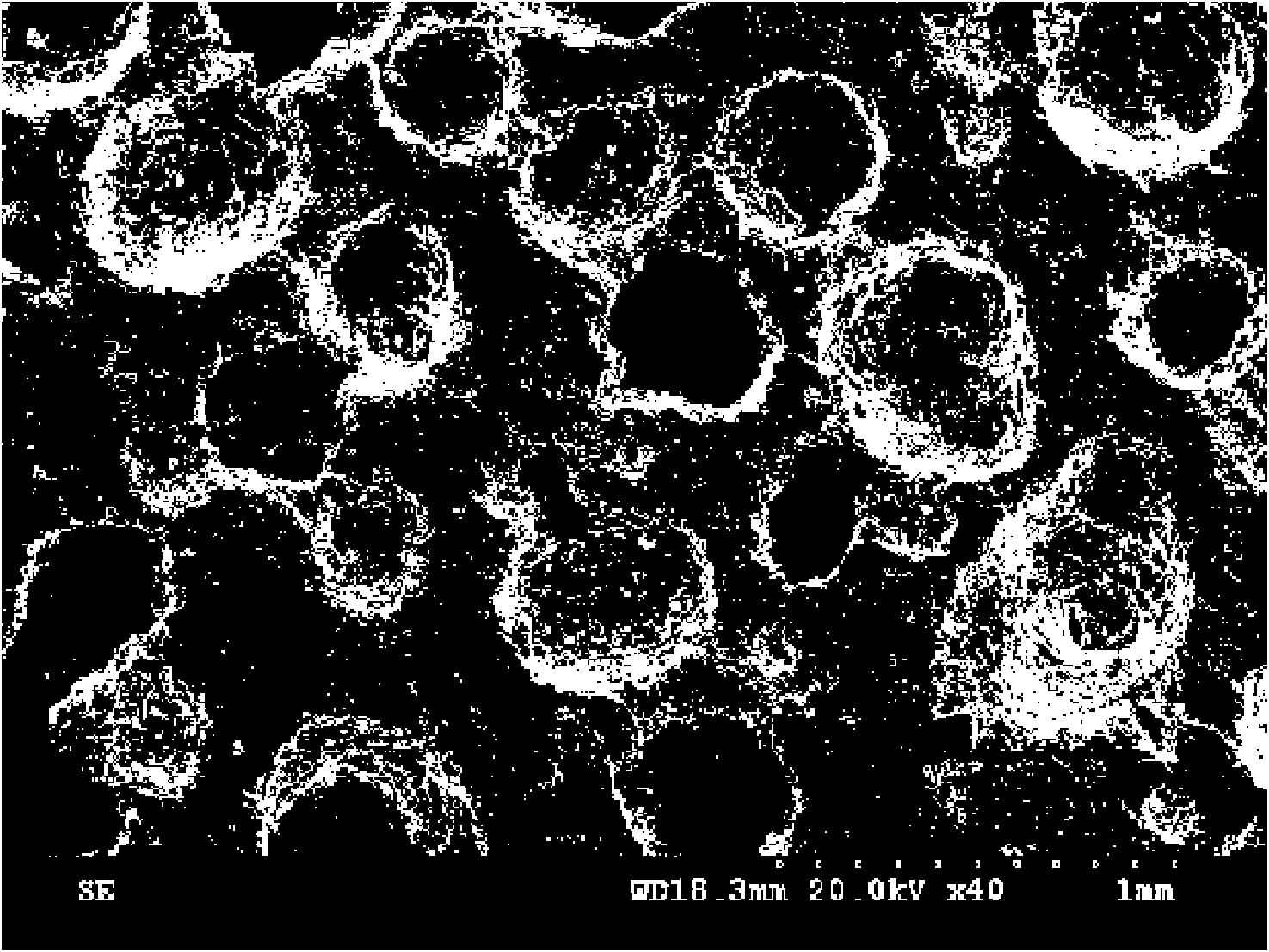

Nano-ceramic particle reinforced aluminum foam matrix composite material and preparation method thereof

A nano-ceramic particle reinforced aluminum foam matrix composite material and a preparation method thereof relates to an aluminum foam matrix composite material and a preparation method thereof. The invention solves the problem that in the preparation method of the ceramic particle reinforced aluminum foam matrix composite material, ceramic particles are micron-sized, the uniform distribution of nano-ceramic particles can not be realized, and the existing ceramic particle reinforced aluminum foam matrix composite material has wide aperture and low compressive yield strength. The aluminum foam matrix composite material of the invention is prepared from aluminum or aluminum alloy powder, CaCO3 and nano-ceramic particles. The preparation method comprises the following steps: using a ball mill to process raw material powder and stearic acid, mixing powder, then placing the mixture in a graphite mould to perform vacuum hot press sintering and obtain a perform, performing forward extruding to obtain a semi-finished product, heating and foaming to obtain the finished product. The aperture of the aluminum foam matrix composite material is less than 1mm, and the compressive yield strength is 50-98MPa which is 2-20 times of that of the existing aluminum foam matrix composite material. By using the method of the invention, the nano-ceramic particles can be uniformly distributed in the aluminum foam matrix composite material.

Owner:HARBIN INST OF TECH

Conductive plastic and its processing method and apparatus

Owner:BEIJING NASHENGTONG ADVANCED MATERIAL & TECH CO LTD

Lightweight periclase-magnesium aluminate spinel refractory material for rotary cement kiln and preparation method thereof

The invention relates to a lightweight periclase-magnesium aluminate spinel refractory material for a rotary cement kiln and a preparation method thereof. According to the scheme, the preparation method comprises the following steps of: uniformly dispersing 0.2 to 4wt% of magnesite micro powder and 0.2 to 4wt% of active alpha alumina micro powder into 5 to 8wt% of binding agent to obtain a modified binding agent; adding 50 to 70wt% of porous periclase-magnesium aluminate spinel ceramic particles to a vacuum agitating machine; vacuumizing to be below 2.5kPa; maintaining the constant pressure for 3 minutes; adding the modified biding agent to the vacuum agitating machine; agitating for 10 minutes; closing a vacuumizing system; then adding 10 to 25wt% of porous periclase-magnesium aluminate spinel ceramic fine powder, 4 to 20wt% of fine magnesia powder, and 1.5 to 4wt% of magnesium aluminate spinel fine powder to the vacuum agitating machine; uniformly agitating; mechanically pressing and modeling; drying; and maintaining the temperature of 1,500 to 1,650 DEG C for 2 to 10 hours. The lightweight periclase-magnesium aluminate spinel refractory material for the rotary cement kiln has the advantages of being low in heat conductivity, high in intensity, high in thermal shock resistance, high in kiln coating performance, and high in resistance to medium erosion.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing ceramic particle reinforced foamed aluminum-matrix composite material

The invention relates to a method for preparing a ceramic particle reinforced foamed aluminum-matrix composite material, which relates to a method for preparing a foamed aluminum-matrix composite material. The method solves the problems of high production cost and nonuniform pore distribution of the obtained foamed aluminum-matrix composite material due to a foaming agent TiH2 adopted in a conventional melt-foaming method which is expensive, needs pretreatment and has a difficultly controlled decomposition rate. The method comprises the following steps of: mixing aluminum alloy powder, ceramic particles and calcium carbonate (CaCO3) powder and placing a mixture into a graphite mould; placing the graphite mould into a vacuum hotpressing sintering furnace to prepare a prefabricated body; and performing forward extrusion, heating and foaming on the prefabricated body to obtain the ceramic particle reinforced foamed aluminum-matrix composite material. By using a powder metallurgic method and taking the CaCO3 powder as a foaming agent, the method has the advantages of low price, no pretreatment, simple process, stable decomposition rate, convenience for industrial production and uniform pore distribution of the obtained composite material which has a pore diameter of 0.5 to 2 mm, a porosity of 40 to 82 percent and a compressive yield strength of 36 to 70 MPa.

Owner:HARBIN INST OF TECH

Microencapsulation method for preparing hydrotropic substance serving as core material by using complex coacervation method

InactiveCN102580638AEnsure safetyImprove permeabilityMicroballoon preparationMicrocapsule preparationMass ratioFreeze-drying

The invention relates to a microencapsulation method for preparing a hydrotropic substance serving as a core material by using a complex coacervation method. The method is simple in process and low in cost, and the product has high encapsulation rate. The method comprises the following steps of: (1) weighing specific protein and polysaccharide in a certain ratio, stirring and dissolving in hot water to form a wall material solution; (2) weighing a certain mass of hydrotropic core material substance, adding an oil phase substance and an emulsifier in a certain mass ratio, and performing high-speed dispersion to form water / oil (W / O) emulsion; (3) directly pouring the emulsion into the wall material solution, stirring at the constant temperature of 45 DEG C, regulating pH by using 10 percent acid, and reacting for 15 minutes; (4) cooling to the temperature of below 15 DEG C, regulating the pH to 6.0, and adding glutamine transaminase for solidifying; and (5) filtering to obtain a wet capsule product. A dry microcapsule product can be obtained by freeze drying or spray drying.

Owner:山东省万兴食品有限公司 +1

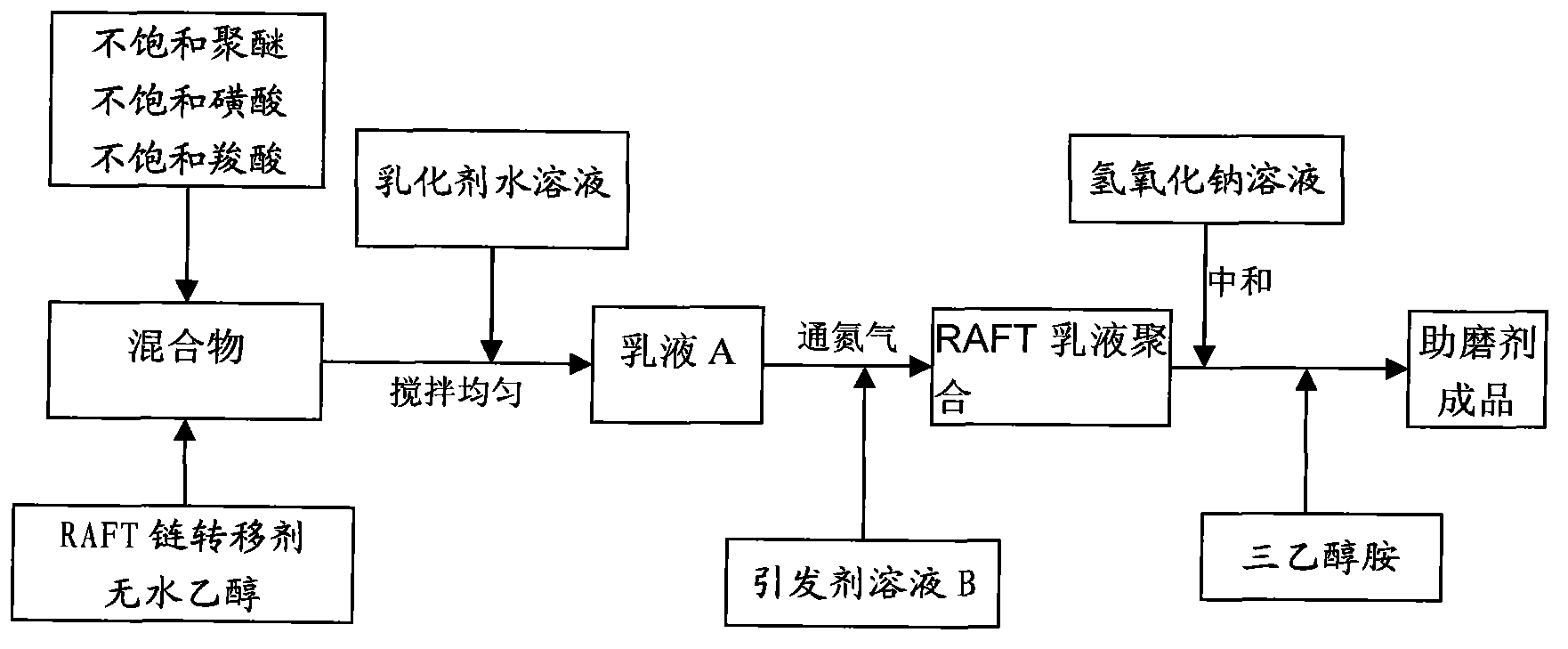

Preparation method of high efficiency controllable polycarboxylic acids series cement grinding aid

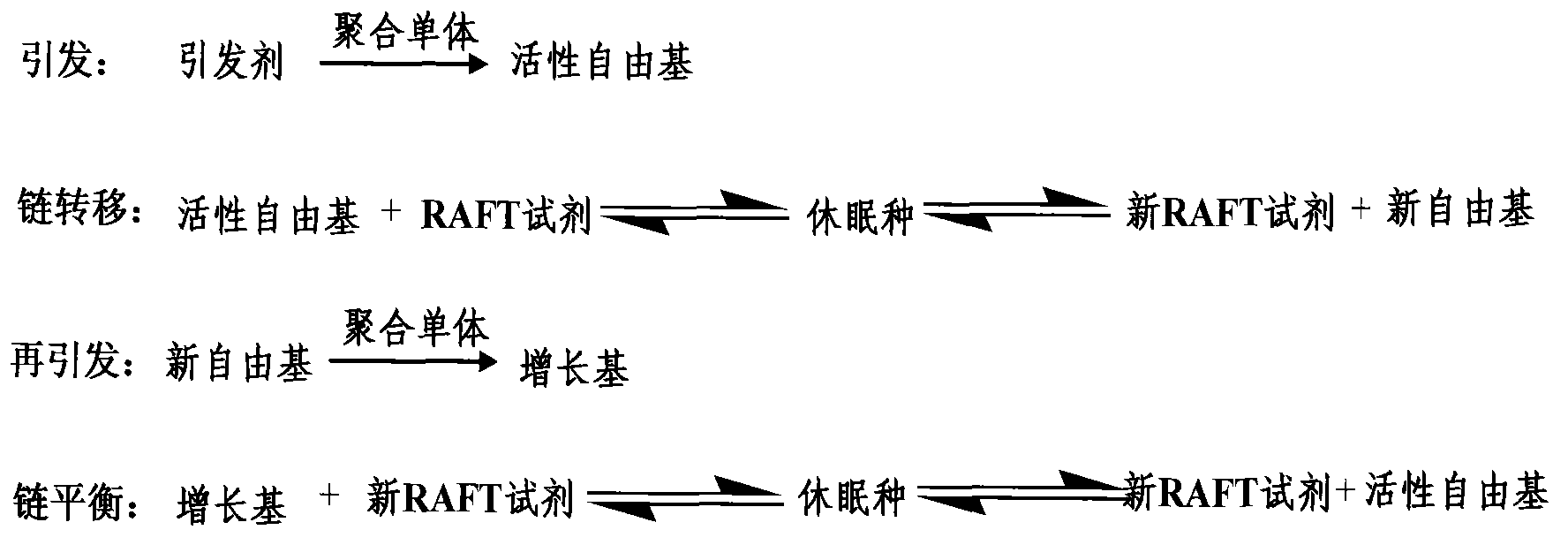

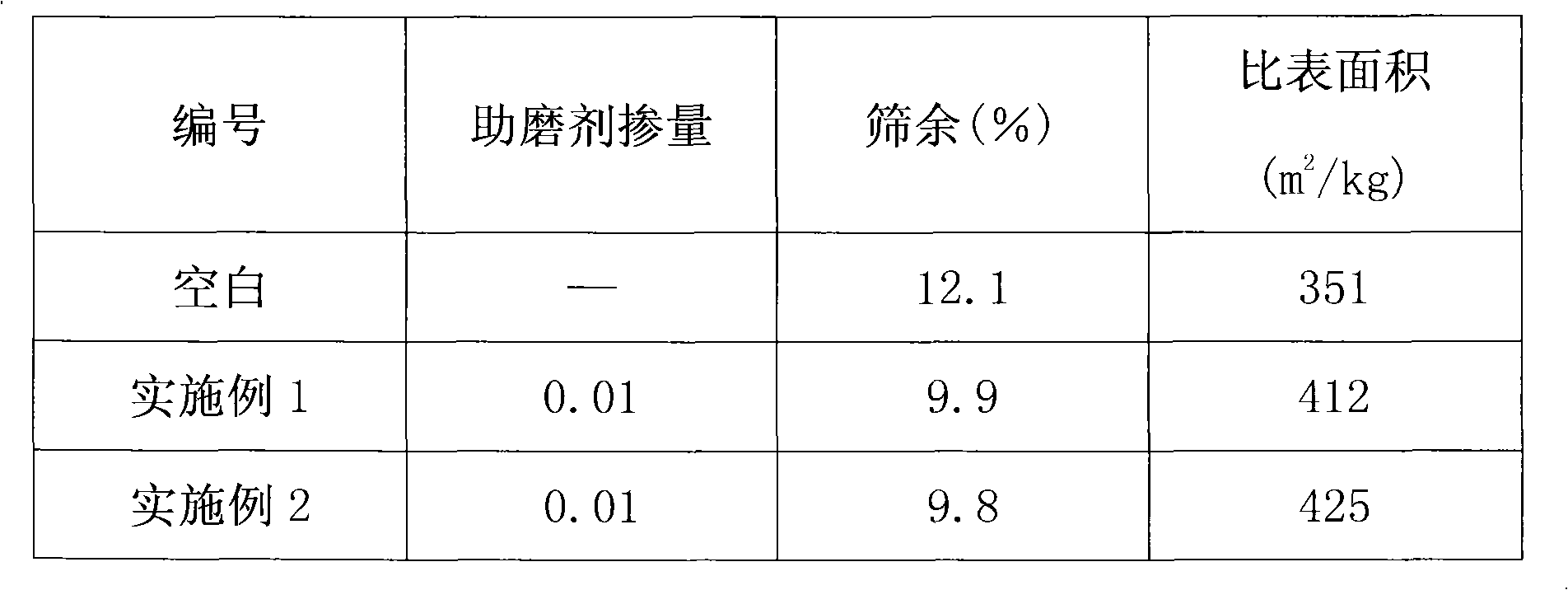

The invention relates to a preparation method of a high efficiency controllable polycarboxylic acids series cement grinding aid, which comprises the following steps: mixing nonsaturated polyether, nonsaturated sulfonic acid, unsaturated carboxylic acid, a RAFT chain transferring agent and absolute ethanol, adding an emulsifier aqueous solution, uniformly stirring and mixing to prepare an emulsion A; blending an initiator and water to obtain a solution B; under the condition that nitrogen is introduced in the emulsion A, heating to certain temperature and adding the solution B drop by drop, adjusting a flowmeter by finishing dropping after 1.0-2.5 hours, continuously reacting for 10-15 hours; after the reaction is finished, adding a sodium hydroxide solution with mass fraction of 30% and neutralizing to obtain the pH value between 6.5 and 7.5, adding triethanolamine which accounts for 3-7% of total mass of a reaction system in the solution drop by drop, and uniformly stirring to obtain the polycarboxylic acids series grinding aid product. The preparation principle is RAFT controllable / active free radical emulsion polymerization. The polycarboxylic acids series cement grinding aid has the advantages of low effective mixing amount and stable applicability, and has substantial effects for improving and enhancing the cement grinding aiding and cement physical properties.

Owner:LIAOCHENG TIANCHENG CEMENT TECH RES DEV

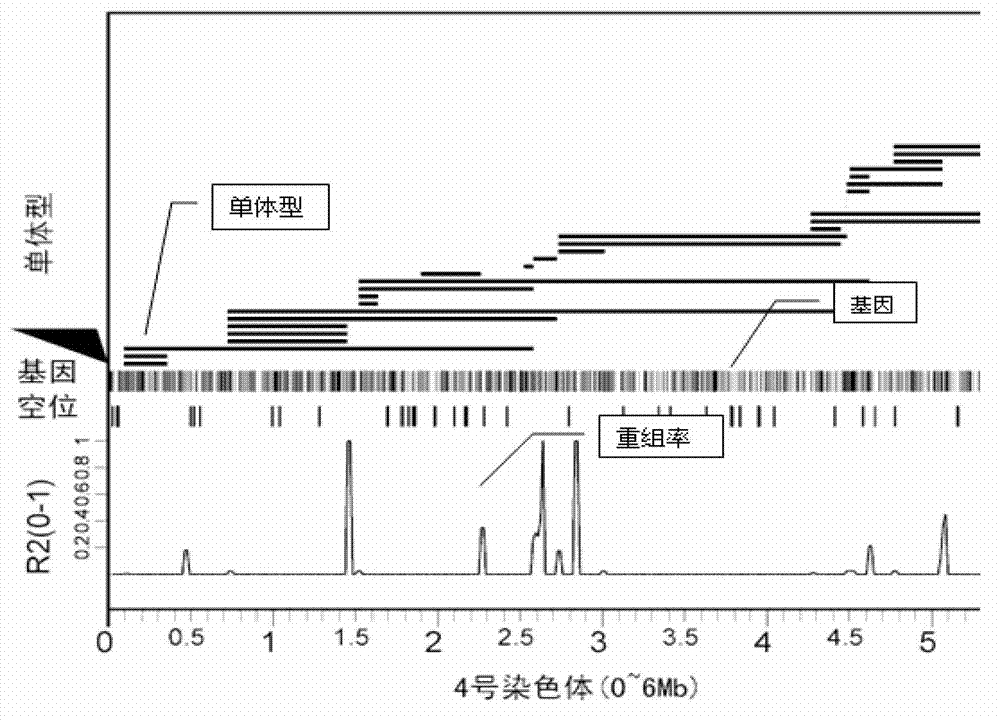

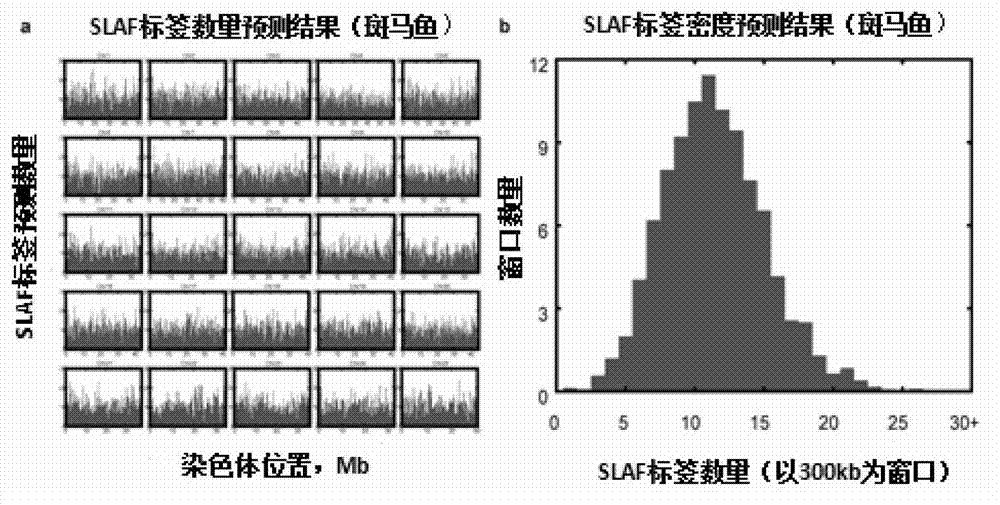

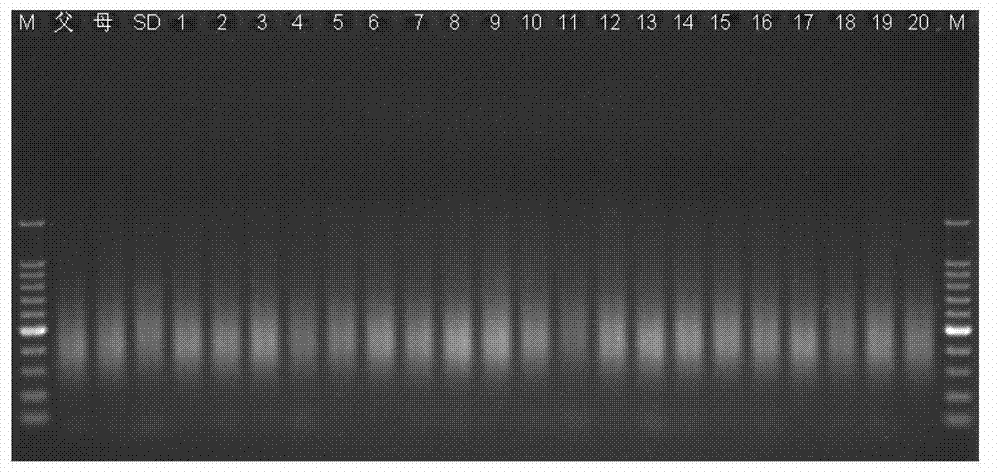

Large-scale genetic typing method based on SLAF-seq (Specific-Locus Amplified Fragment Sequencing) technology

ActiveCN103088120AGuarantee label qualityQuality assuranceMicrobiological testing/measurementGenotyping by sequencingGenome

The invention provides a method for carrying out large-scale gene typing based on an n SLAF-seq (Specific-Locus Amplified Fragment Sequencing) technology. Complexity of the genome is reduced by utilizing the SLAF-seq technology, and genetic typing is carried out on large-scale products. High-throughput sequencing is carried out on the genome, marker-developing, genetic map drawing and whole genome association analyzing are carried out on the samples by utilizing the technology. Compared with the conventional method, the large-scale genetic typing method disclosed by the invention has the advantages that the throughput is greatly improved, and the cost is greatly reduced. The method is mainly applied to marker-developing, genetic map drawing and whole genome association analyzing.

Owner:BIOMARKER TECH

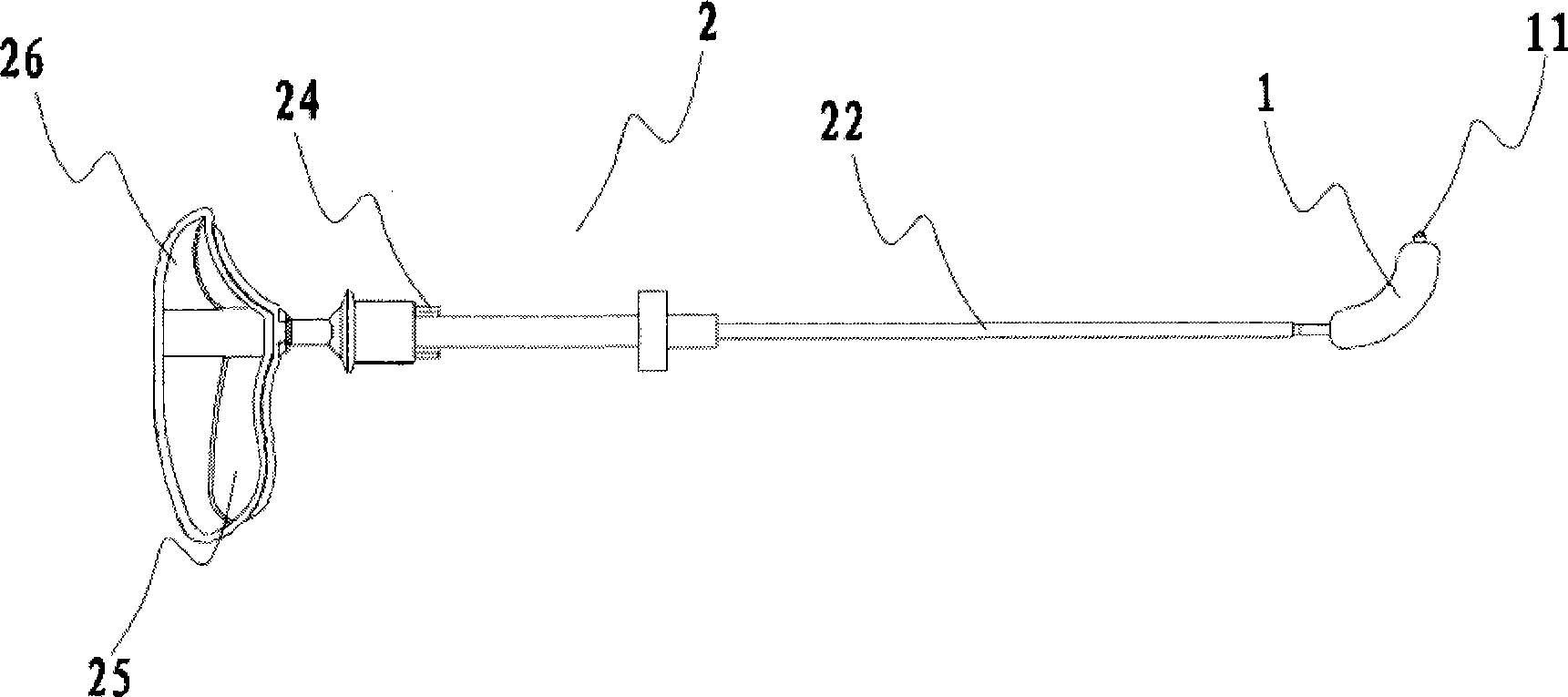

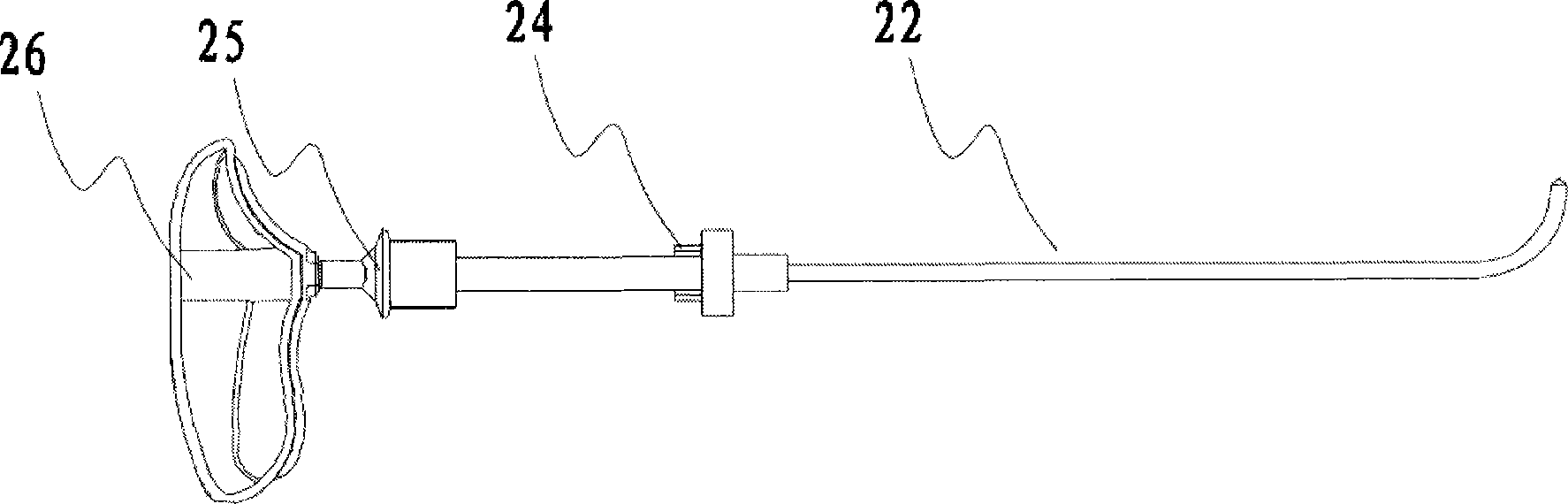

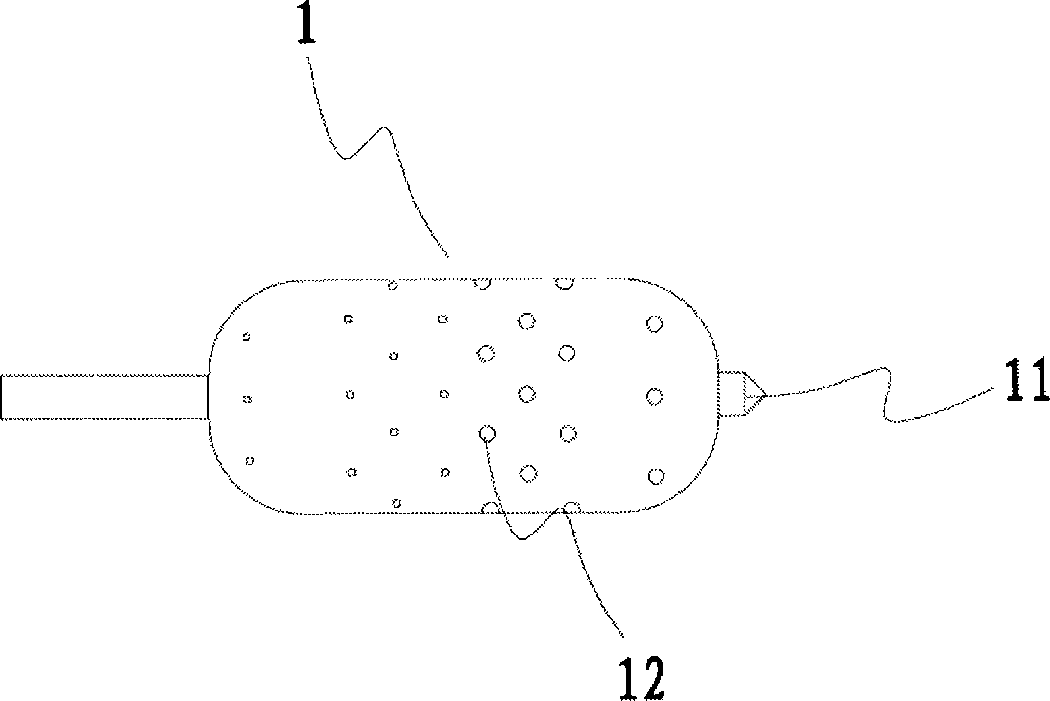

Implantation system for bone implants

ActiveCN103637842AConvenient operationReduce surgical riskInternal osteosythesisBone tissueBone implant

The invention relates to an implantation system for bone implants. The implantation system comprises a bag body and a conveying device. The far end of the bag body is fixedly connected with an end socket, the near end of the end socket is provided with a blind hole with an opening facing the interior of the bag body, and a micro hole is formed in the bag body. The conveying device comprises a lining core, a conveying pipe and a sleeve pipe. The conveying pipe is a rigid pipe, the far end of the conveying pipe is detachably connected with the near end of the bag body, the lining core is inserted into the conveying pipe in a sliding mode, the portion, extending out of the far end of the conveying pipe, of the far end of the lining core is a bent section, the far end of the lining core penetrates through the conveying pipe and the bag body and then is inserted into the blind hole, the far end of the sleeve pipe is a flexible section and is rigid in the radial direction, and the conveying pipe and the bag body are sleeved with the sleeve pipe. According to the implantation system for the bone implants, operation steps are simplified, the bone tissues are smoothly squeezed to be open in the conveying pipe, the bag body can be fed into the center of a centrum or the opposite of the centrum, bone cement is prevented from being leaked, and the centrum height can be recovered.

Owner:NINGBO HICREN BIOTECH

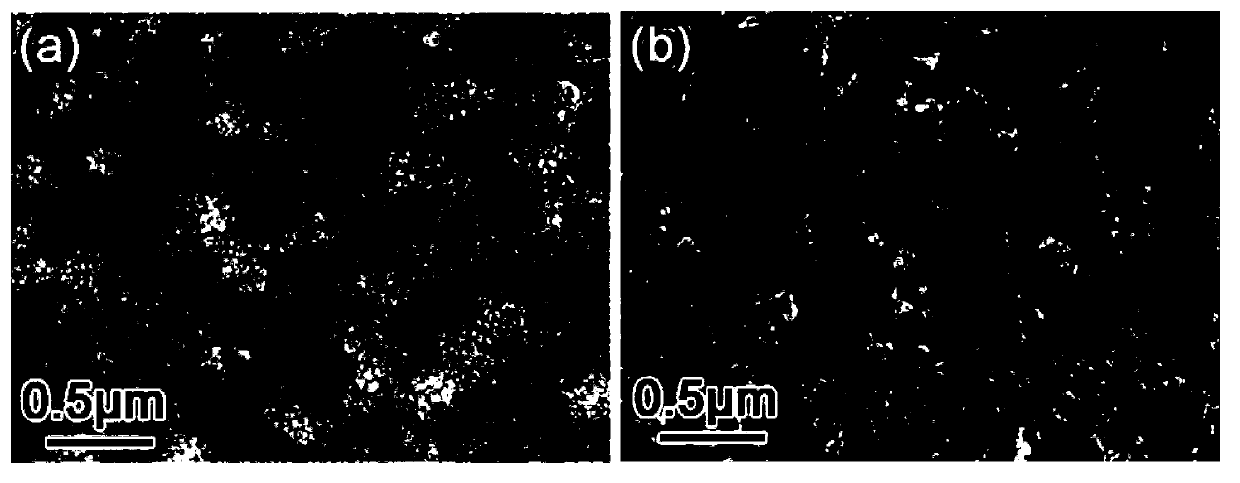

Abrasive grain CeO2 for chemical and mechanical buffing and method for preparing same

ActiveCN101284952AReduce surface roughnessImprove flatnessPigmenting treatmentSemiconductor/solid-state device manufacturingCrystal systemInorganic salts

The invention relates to a chemical mechanical polishing abrasive particle CeO2 and a method for preparing the same, belonging to the rare earth powder material chemical preparation technical field. The invention is to prepare the CMP abrasive particle by utilization of cerous inorganic salt solution and homogeneous precipitation agent. The method comprises the following steps that: the cerous inorganic salt and the precipitation agent are prepared into solution with certain proportion; the solution is uniformly mixed through ultrasonic vibration; deposits are generated after the solution is heated to a certain temperature; serum is kept stand, aged, filtered and calcined, and then the CeO2 abrasive particle is prepared. The method also accelerates the nucleation rate through addition of surface active agent so as to reduce the reaction temperature, and simultaneously the nodulizing degree of the abrasive particle obtained is also good. The method prepares the CMP abrasive particle, wherein, the CMP abrasive particle belongs to the single-phase cubic crystal system; the space group is O<5>H-FM3M; the dispersibility is good; the grain fineness distribution is uniform; the shape is similar to a sphere; and the specific surface area BET is more than 0 and less than 50m<2> / g.

Owner:GRIREM ADVANCED MATERIALS CO LTD

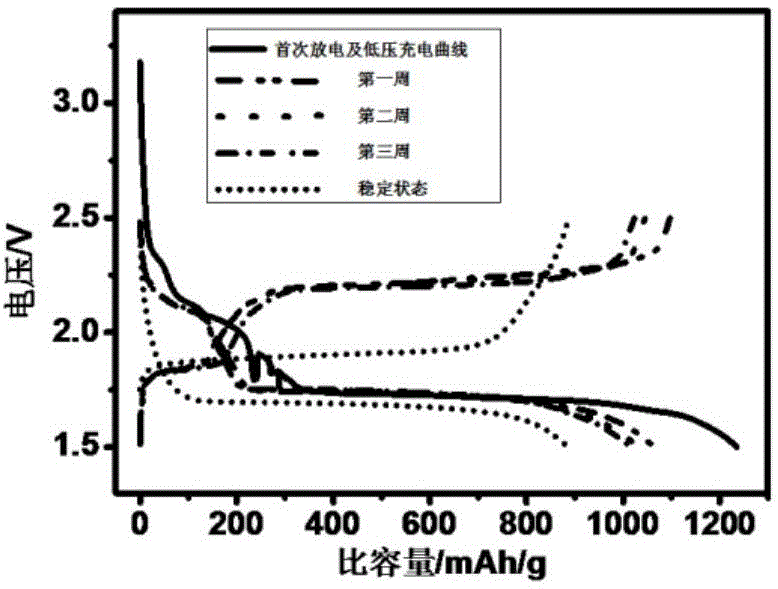

Manufacturing method for long-life lithium sulfur battery positive electrode

InactiveCN105304958ANo pollutionEasy to operateCell electrodesSecondary cells charging/dischargingLithium sulfideSulfide ions

The invention discloses a new method for on-site synthesis of a lithium ion conductive protection film for preventing poly-sulfide-ions diffusion on a surface of a lithium sulfur battery positive electrode, and an application therefor. The method is carried out by the steps of reducing the initial discharge voltage lower limit of a lithium sulfur battery taking a carbon sulfur composite as the positive electrode material to be lower than the normal working voltage 1.5V to generate the lithium ion conductive protection film; the film is quite high in the lithium ion conductivity and capable of preventing the poly-sulfide-ions from being dissolved in an electrolyte to enable the lithium sulfur battery to realize and maintain higher cycle performance, rate capability, coulombic efficiency and lower self discharge performance, so that the service life of the lithium sulfur battery is prolonged, and the use cost of the lithium sulfur battery is reduced; meanwhile, porous carbon with hierarchical pores used as the supporting material can accommodate the poly-sulfide-ions and lithium sulfide generated in charging and discharging processes of sulphur and the lithium sulfur battery; and the sulphur content in the carbon-sulfur composite material made from the porous carbon with the hierarchical pores is high, so that the comprehensive specific capacity of the carbon-sulfur composite product can be improved so as to further increase the overall energy density of the battery.

Owner:TSINGHUA UNIV

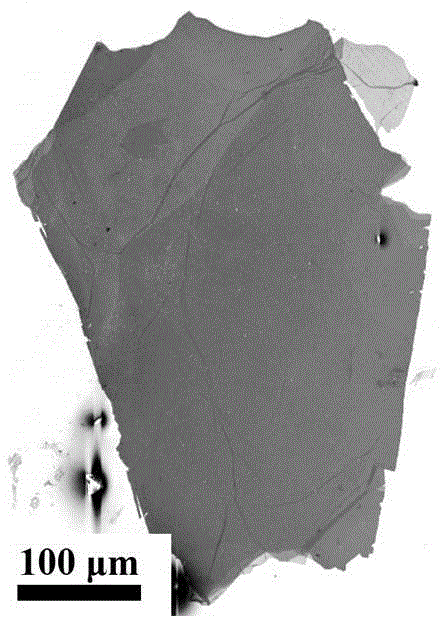

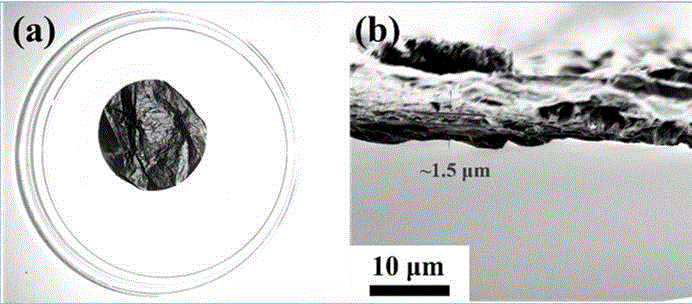

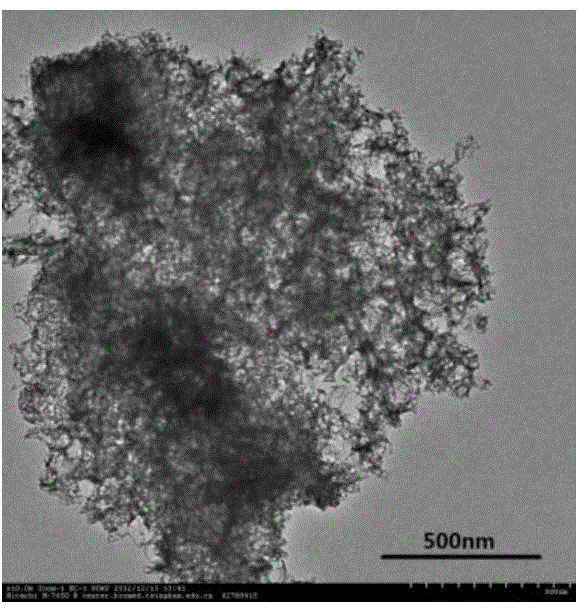

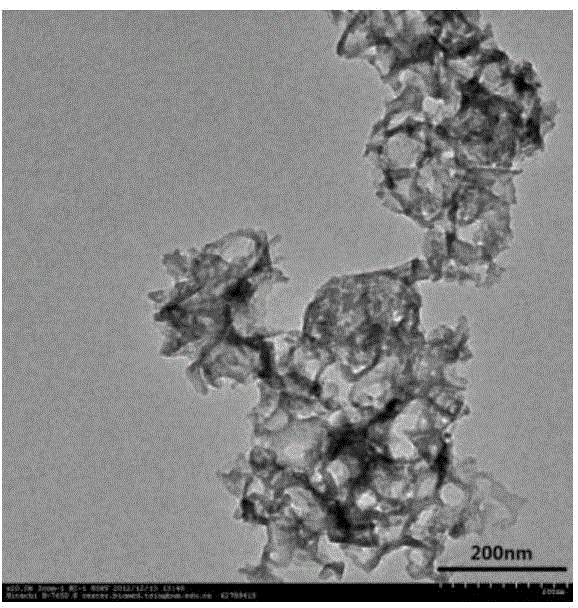

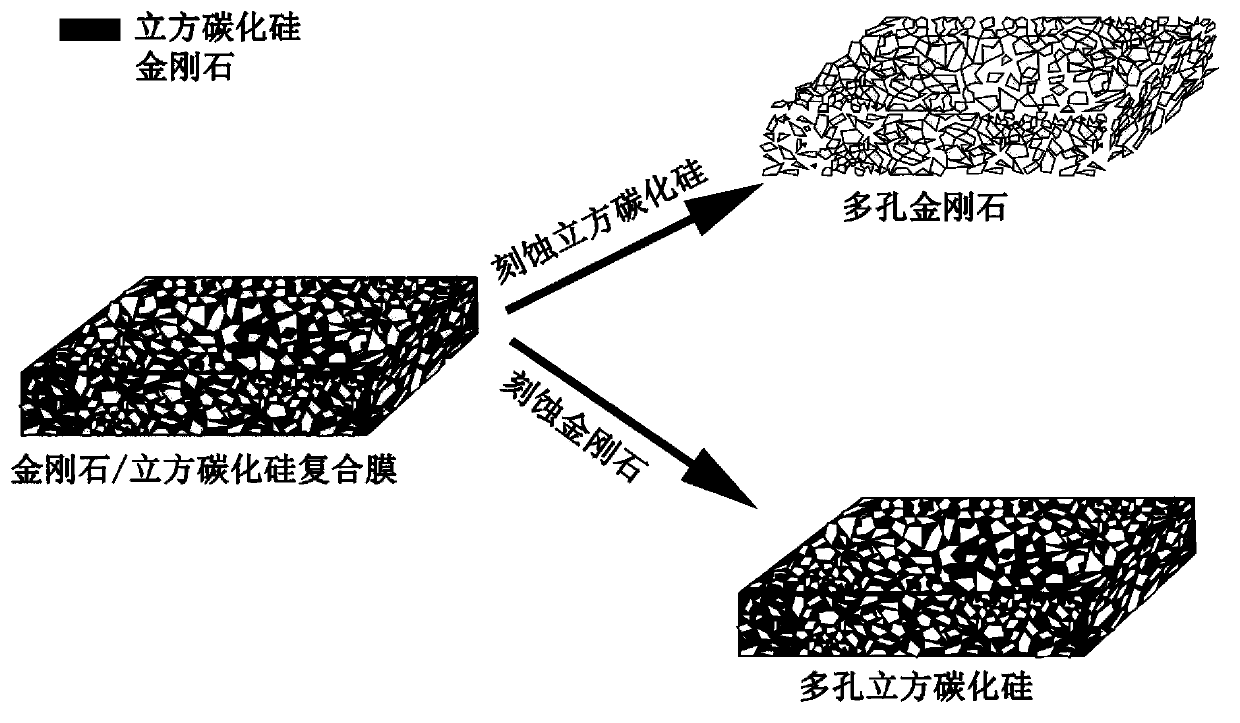

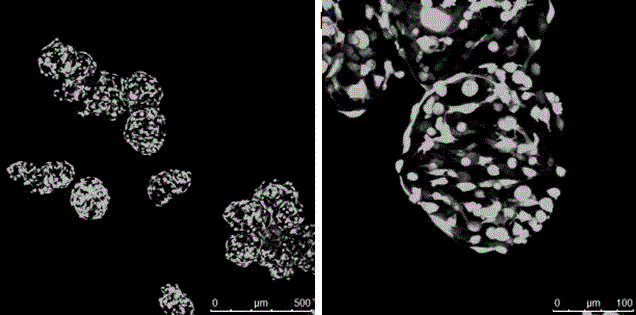

Method for manufacturing porous diamond or porous cubic silicon carbide self-supporting film

ActiveCN104178745AImprove stabilityControllable distributionChemical vapor deposition coatingPorosityComposite film

The invention discloses a method for manufacturing a porous diamond or porous cubic silicon carbide self-supporting film. The method comprises the steps that a base material is provided, and surface of the base material is pretreated to obtain a higher diamond-shaped nuclei rate; the pretreated base material is put into a microwave plasma chemical vapor deposition or hot filament chemical vapor deposition reactor, and at the temperature of 600 DEG C to 900 DEG C, a diamond / cubic silicon carbide composite film is manufactured; selective etching is performed on the obtained composite film, at the temperature above 70 DEG C, the composite film is etched in mixed corrosion liquid of hydrofluoric acid and nitric acid, and the porous diamond self-supporting film is obtained, at the temperature above 500 DEG C, the composite film is heated in the air containing oxygen gas, and the porous cubic silicon carbide self-supporting film is obtained. Under the condition that any template and any electrode material are not used, the obtained porous diamond self-supporting film and the porous cubic silicon carbide self-supporting film have the controllable aperture, the controllable porosity and the controllable thickness, and the method is suitable for industrial application and fundamental research.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

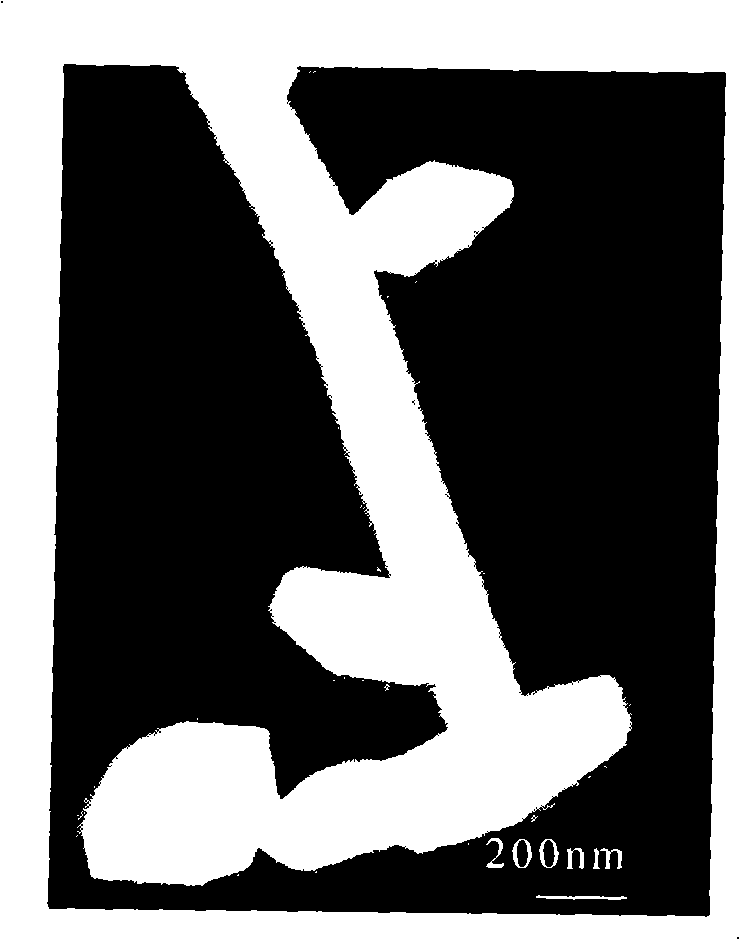

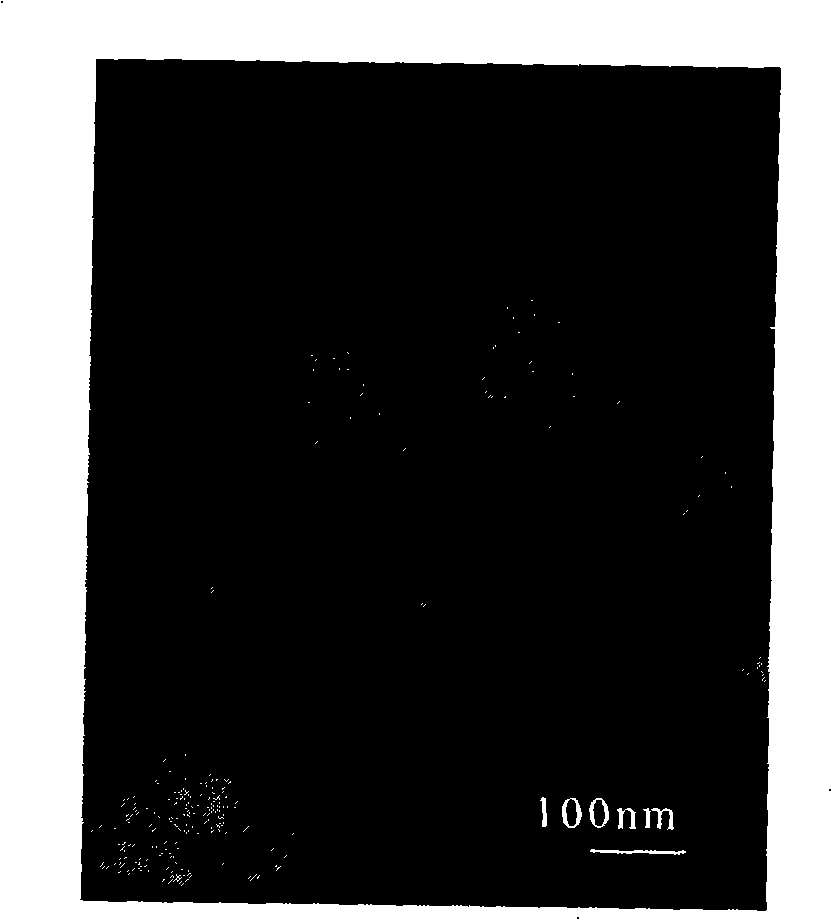

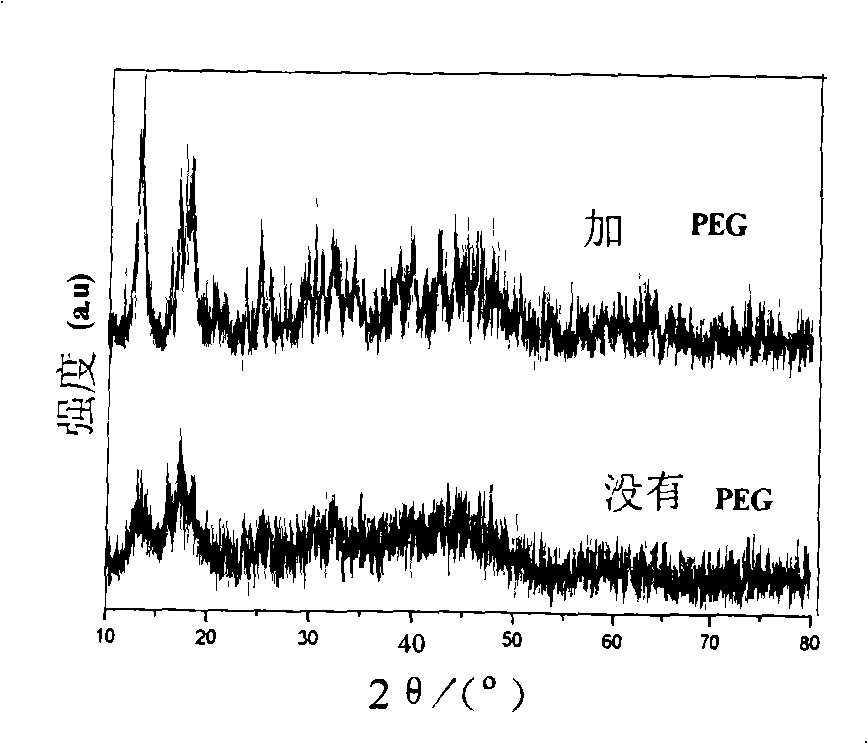

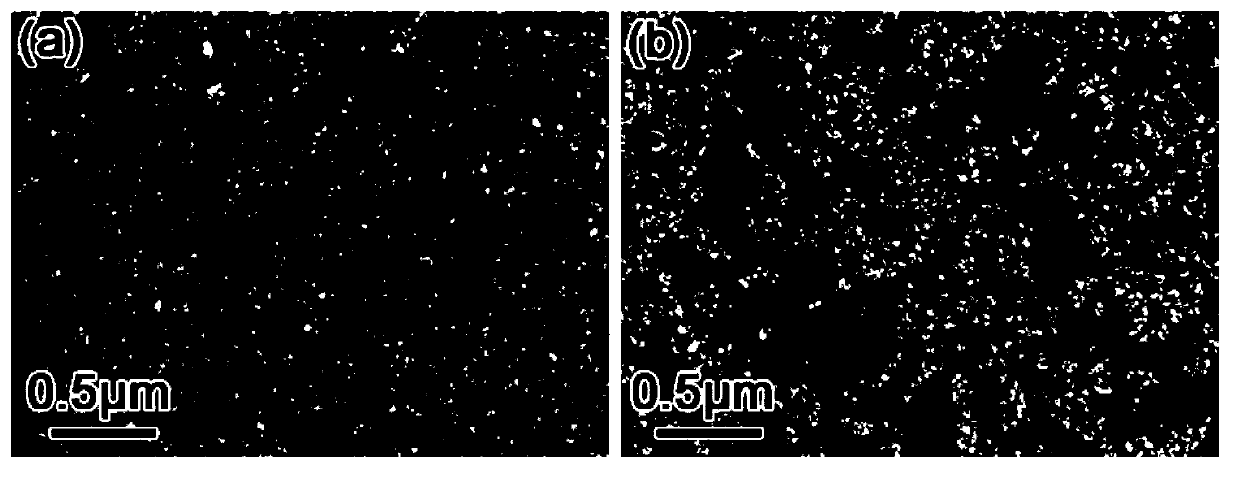

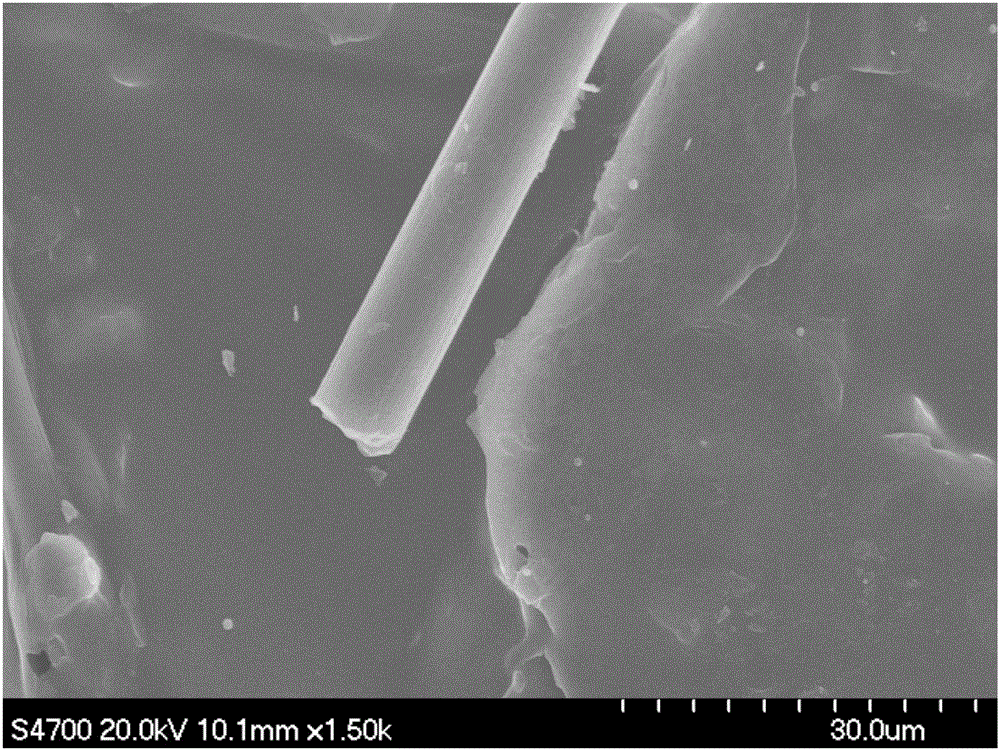

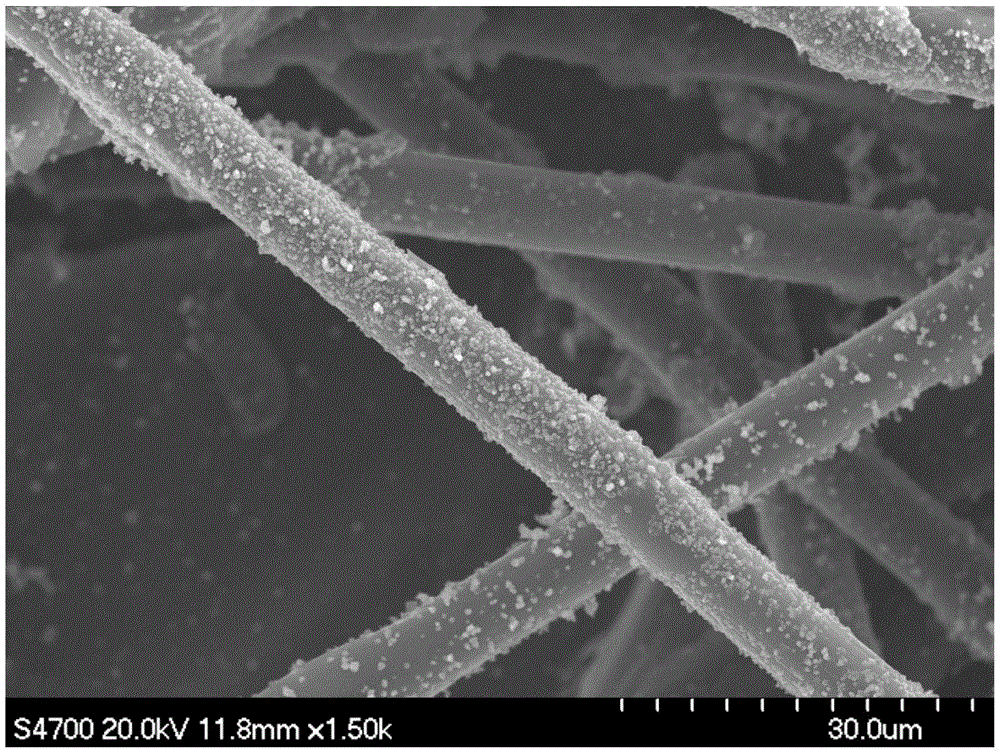

Method for modifying carbon nano-tube by nickel nanometer particles

InactiveCN101549865AShape is easy to controlControllable distributionMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureCarbon nanotube

The invention relates to a method for modifying carbon nano-tube by nickel nanometer particles, which comprises the steps of: dispersing carbon 1-40 weight parts of nano-tube into solvent medium, adding 1-100 parts of nickelion salt and 10-800 parts of reducing agent, reacting under the temperature of 40-120 degrees centigrade for 0.5-5 hours; cooling to room temperature after reaction; separating out carbon nano-tube modified by metal nickel nanometer particles, washing 3-5 times by deionized water, putting into a vacuum oven, drying under 30-50 degrees centigrade for 24 hours to obtain the carbon nano-tube modified by metal nickel nanometer particles. The invention loads nickel nanometer particles on the carbon nano-tube surface uniformly by chemical reduction method under mild reaction condition, is method and easy for operation, can obtain the carbon nano-tube modified by metal nickel nanometer particles with stronger magnetic responsiveness, and can control the morphology of the nickel nanometer particles and the distribution on the carbon nano-tube surface by adjusting the reaction temperature and feeding ratio.

Owner:FUDAN UNIV

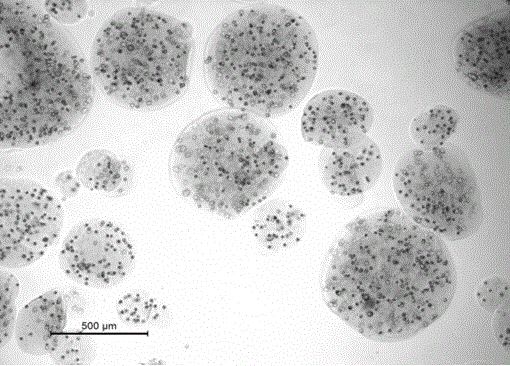

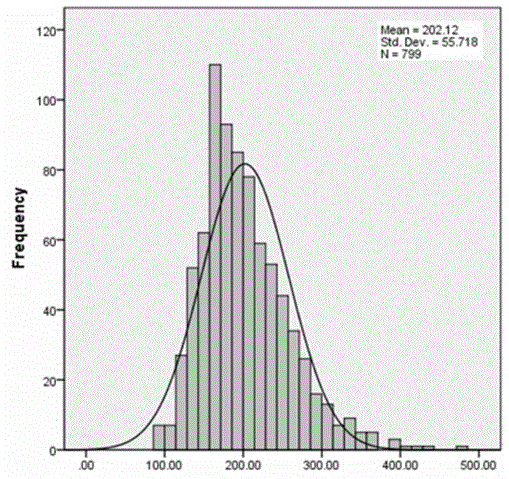

Cell-gel material composite microsphere as well as preparation method and application thereof

ActiveCN104436306AMaintain the biological properties of collagenEasy to prepareArtificial cell constructsSkeletal/connective tissue cellsMetaboliteMicrosphere

The invention discloses a cell-gel material composite microsphere as well as a preparation method and an application thereof and belongs to the field of biomedical materials. The cell-gel material composite microsphere is prepared from a gel microsphere and cells distributed in the gel microsphere. The preparation method comprises the following steps: dispersing a gel material-cell mixed solution in an oily solution, and carrying out emulsification and gelation treatment to obtain the cell-gel material composite microsphere. The cell-gel material composite microsphere is controllable in cell loading ratio, high in cell survival rate, small in volume shrinkage, difficult in breaking, good in transmitting capability of nutrients and metabolites, simple in preparation method and convenient in popularization and application and can also be used for preparing nonhomogeneous hydrogel so as to obtain a material with high biomimetic degree.

Owner:SICHUAN UNIV

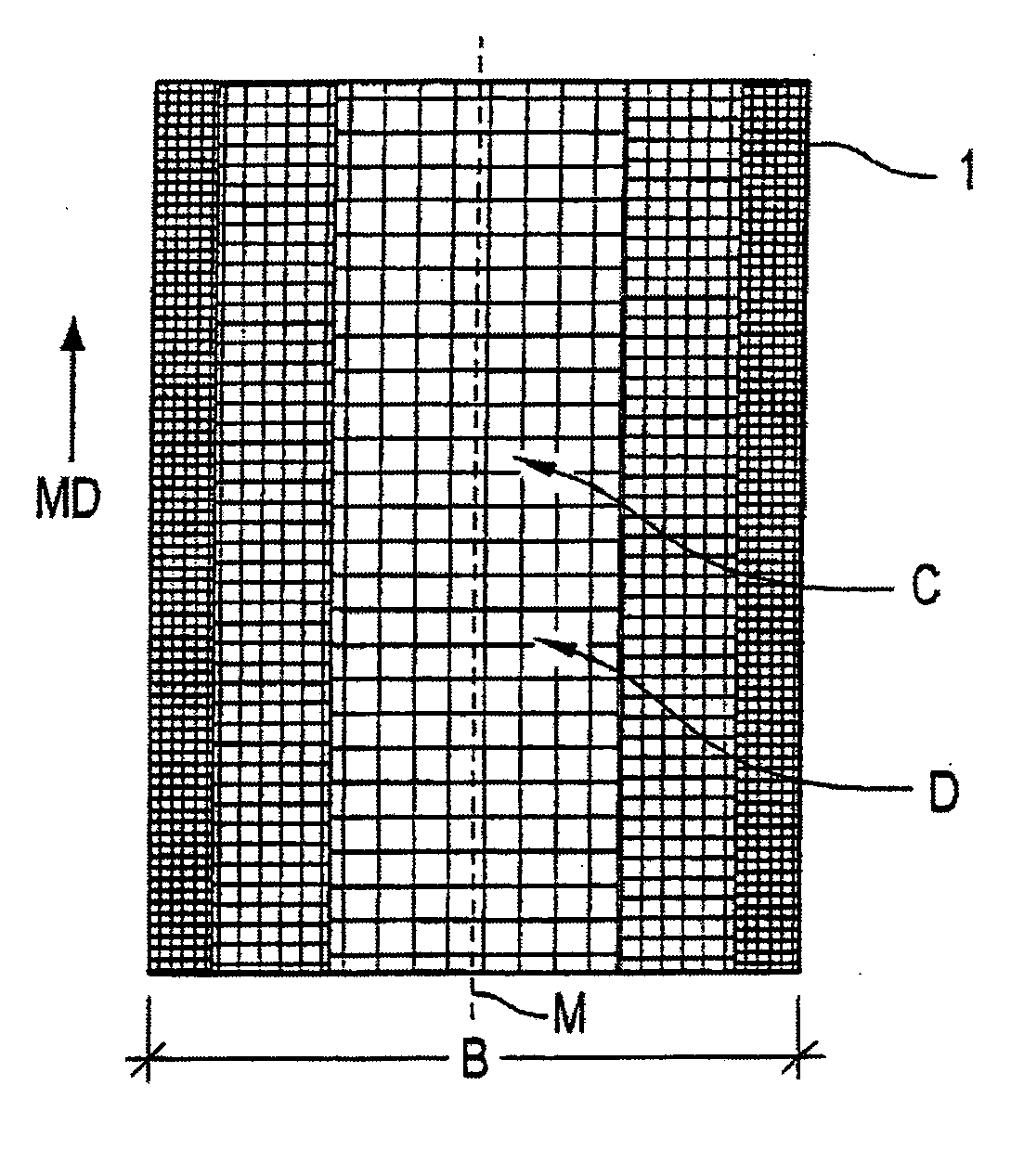

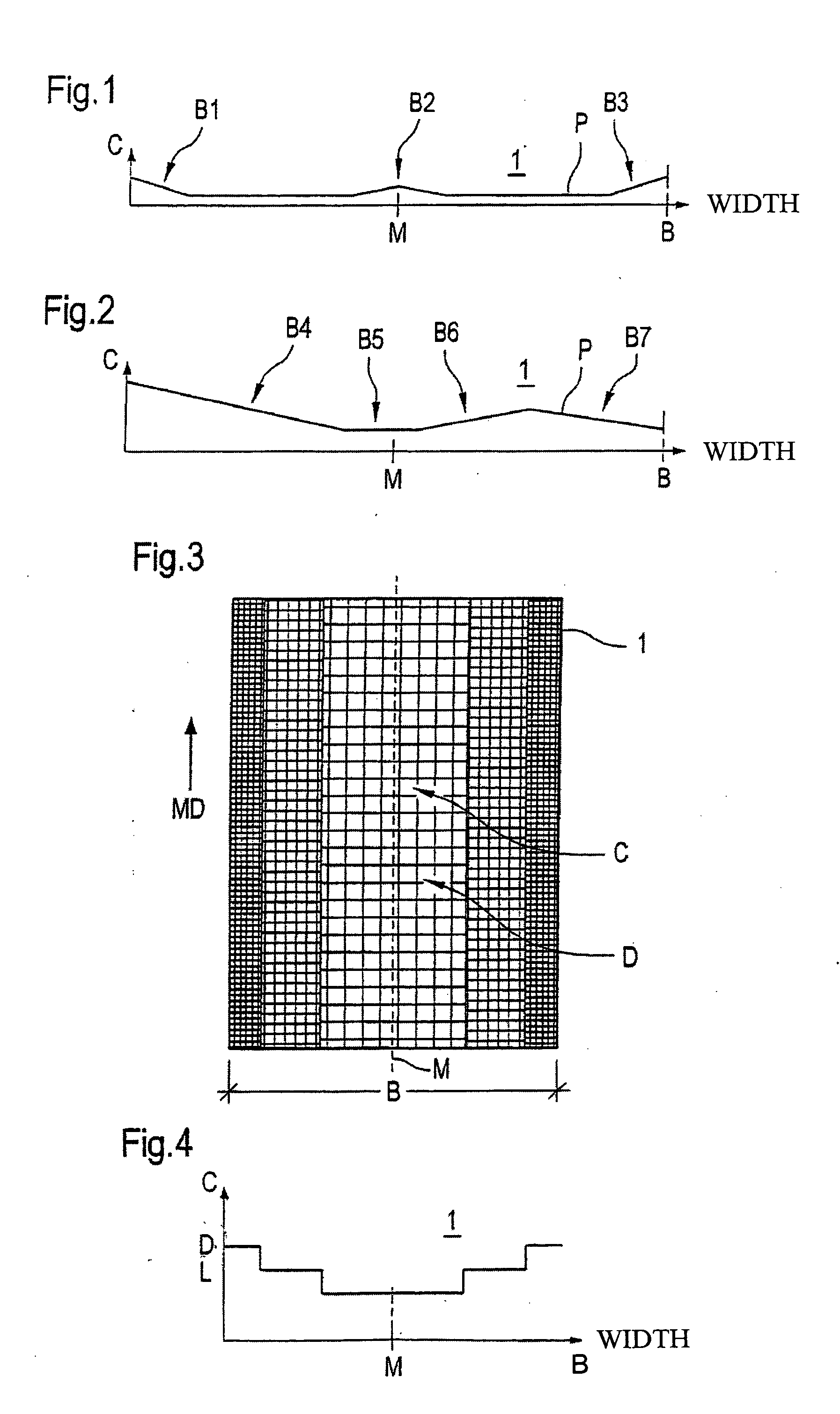

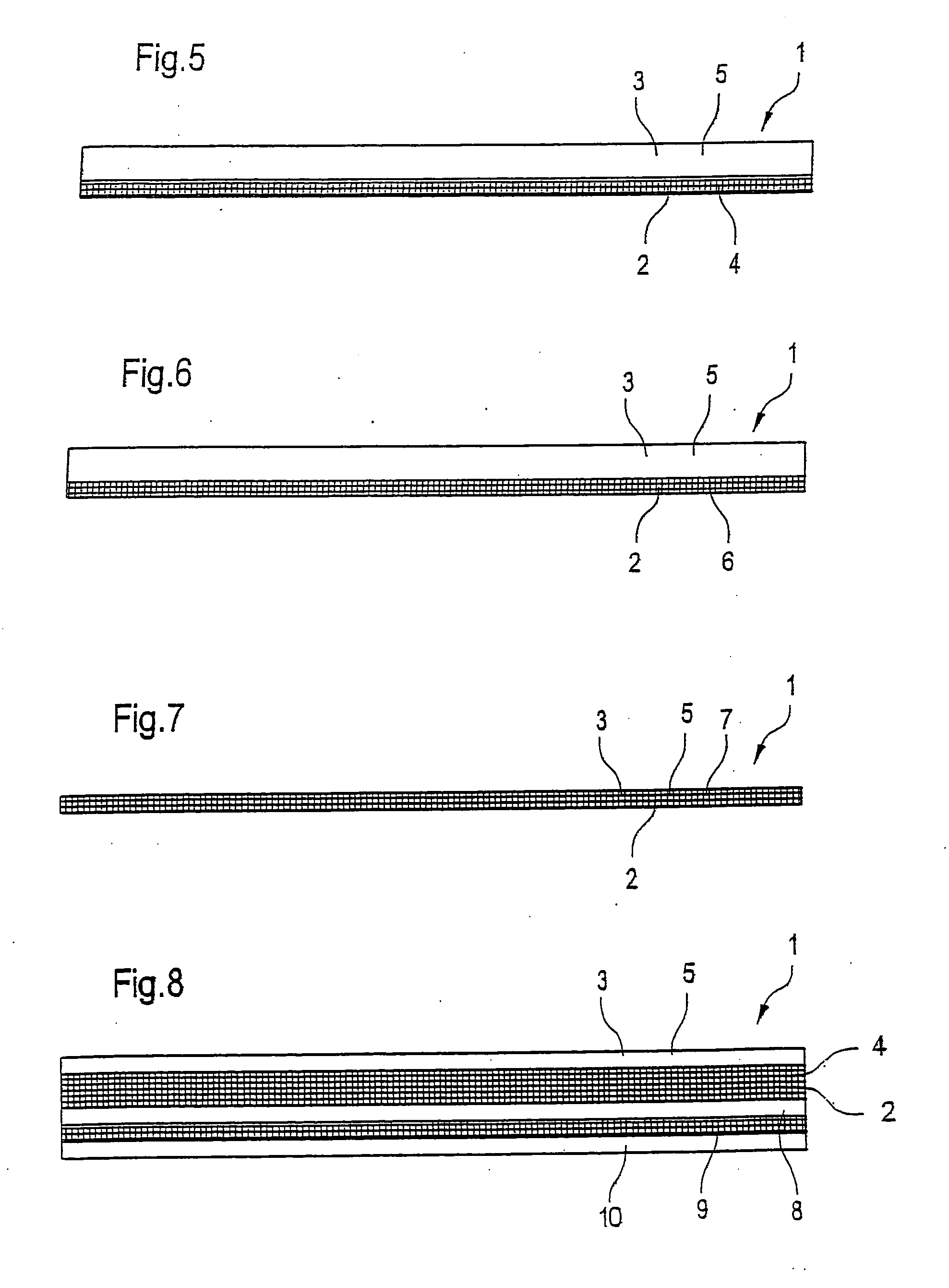

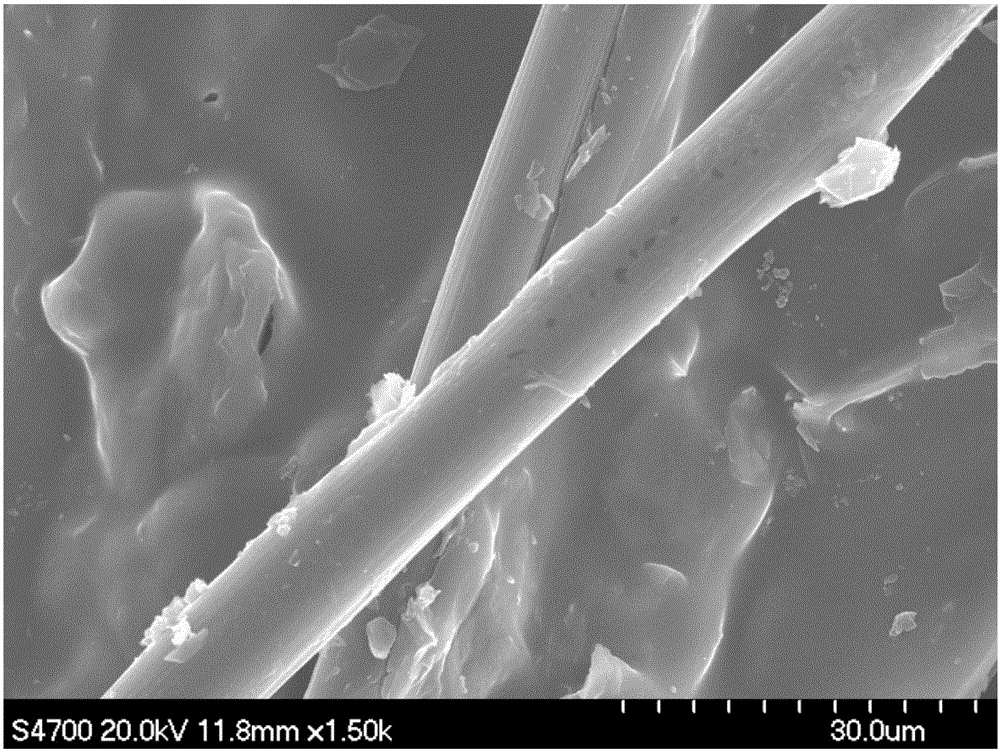

Belt for transferring an in-production fibrous web

InactiveUS20070074836A1Good allowanceQuality improvementSynthetic resin layered productsCellulosic plastic layered productsFiberCardboard

This invention relates to a belt for transferring an in-production fibrous web, in particular a paper web or paperboard web, in a machine area of a machine producing the fibrous web, in particular a paper machine or paperboard machine, including at least one textile substrate and a coating, which is applied to the substrate and touches the in-production fibrous web, for obtaining a partial or complete impermeability of the belt. The inventive belt has at least one continuously differencing characteristic in at least one region across its overall width. Also, this invention relates to a machine, in particular a paper machine or paperboard machine, for producing a fibrous web, in particular a paper web or paperboard web, as well as to a use of a belt for transferring an in-production fibrous web, in particular a paper web or paperboard web, in one machine area or between two machine areas of a machine producing the fibrous web, in particular a paper machine or paperboard machine.

Owner:VOITH PATENT GMBH

Polyvinylidene fluoride anti-pollution membrane and preparation method thereof

ActiveCN107149882AEasy to makeLow preparation equipment requirementsMembranesSemi-permeable membranesPhase conversionUltraviolet

The invention discloses a polyvinylidene fluoride anti-pollution membrane and a preparation method thereof, and belongs to the field of environmental functional membrane materials. The preparation method comprises: (1) self-polymerizing dopamine on the surface of polyvinylidene fluoride powder, and adhering the generated poly dopamine functional layer onto the surface of the polyvinylidene fluoride powder; (2) preparing a poly dopamine modified polyvinylidene fluoride membrane by using a phase conversion method; and (3) depositing a nano-TiO2 functional layer on the membrane prepared in the step (2) through a liquid phase deposition method to prepare the polyvinylidene fluoride anti-pollution membrane. According to the present invention, by combining the strong adhesion and the polyfunctional group of poly dopamine, the ultraviolet resistance and stable chemical performance of polyvinylidene fluoride, and the advantages of hydrophilicity, high photocatalytic activity and the like of nano-TiO2, the polyvinylidene fluoride anti-pollution membrane is developed; and the prepared polyvinylidene fluoride anti-pollution membrane has excellent pollution resistance, and can be used in various membrane separation fields.

Owner:天津鼎芯膜科技有限公司

Thermal treatment method used for improving duplex stainless steel welded structure

InactiveCN102560065AImprove pitting resistanceControl volumeFurnace typesHeat treatment furnacesHeat-affected zoneElectrical impulse

The invention discloses a thermal treatment method used for improving a duplex stainless steel welded structure, which comprises the following steps: 1) heating by an electric oven at the temperature lower or close to duplex stainless steel phase transition when a duplex stainless steel weld seam and a heat affected zone are heated by a thermal treatment technology, simultaneously carrying out electric pulse heating; 2) insulating for 10-60 minutes after heating, cooling with three phases, wherein in a first phase, the temperature of the welded structure is 850 DEG C and the cooling speed is controlled at 1-30 DEG C / s, simultaneously providing pulse current; in a second phase: the temperature is decreased to 800-500 DEG C, the cooling speed is controlled at 5-50 DEG C / s, and the cooling speed is greater than that of the first phase; in a third phase: the temperature is decreased below 500 DEG C and the cooling speed is controlled more than 30 DEG C / s. The thermal treatment for duplex stainless steel welded seam and the heat affected zone can control the volume fraction and existence form of ferrite, avoid the precipitation of a brittleness phase in ferrite / austenite, ferrite / ferrite crystal boundary, and enhance the capability of pitting corrosion resistance of the duplex stainless steel.

Owner:WENGFU (GRP) CO LTD

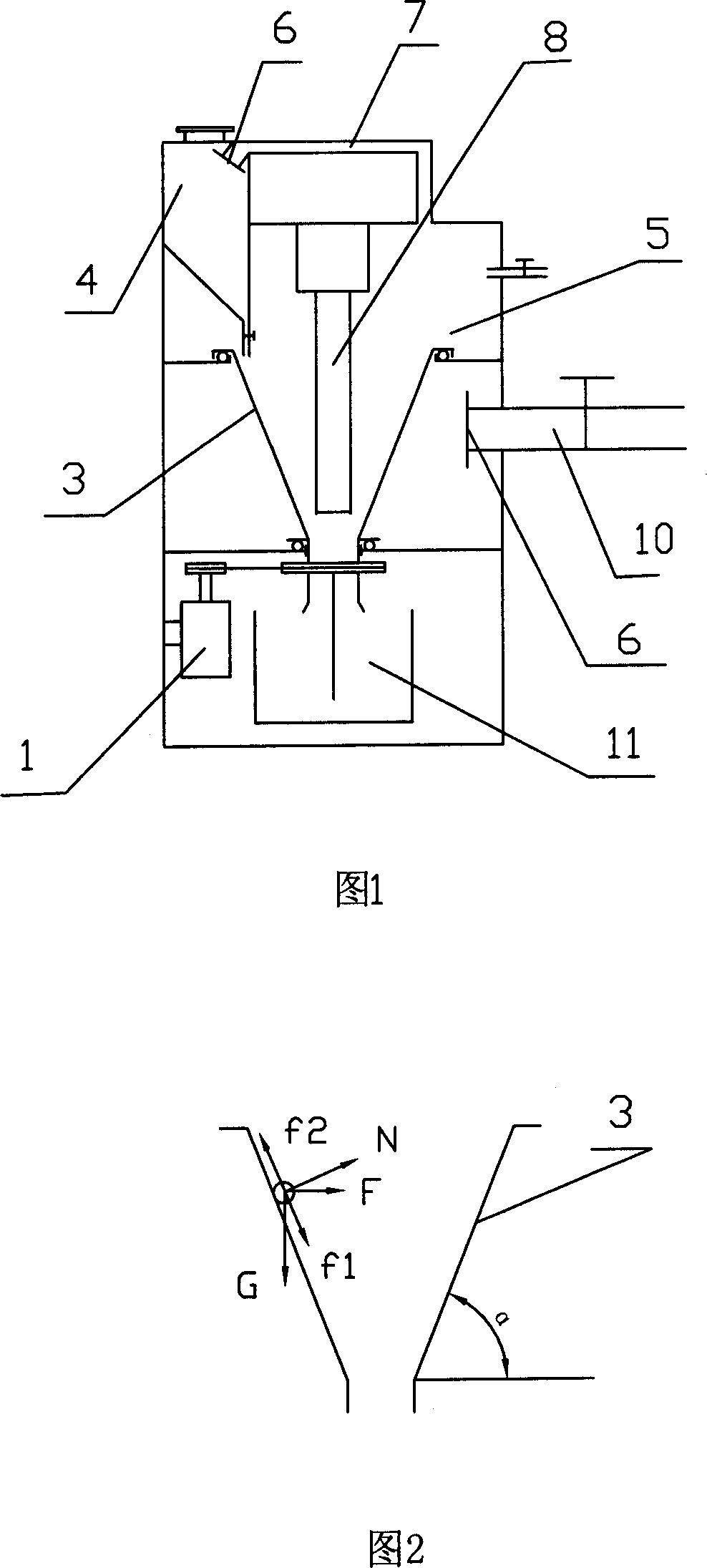

Technique for film plating on powder surface and equipment thereof

InactiveCN101082120AEasy flipWith speed control functionVacuum evaporation coatingSputtering coatingVacuum pumpingMetallurgy

The present invention is powder surface coating process and apparatus. During coating powder, the powder is made to fall spirally in a vacuum environment and a homogeneous cladding is formed on the surface of the powder. The apparatus for coating powder includes one vacuum chamber, a vacuum film coating source, and a vacuumizing system. Inside the vacuum chamber, there are one turned conic rotary hopper, one feeding chamber connected to the upper end of the hopper, and collecting chamber connected to its lower end. The vacuum film coating source mounted in the middle part inside the hopper has one speed adjustable motor for rotating the hopper. The present invention has great coating capacity and low running cost.

Owner:BYD CO LTD

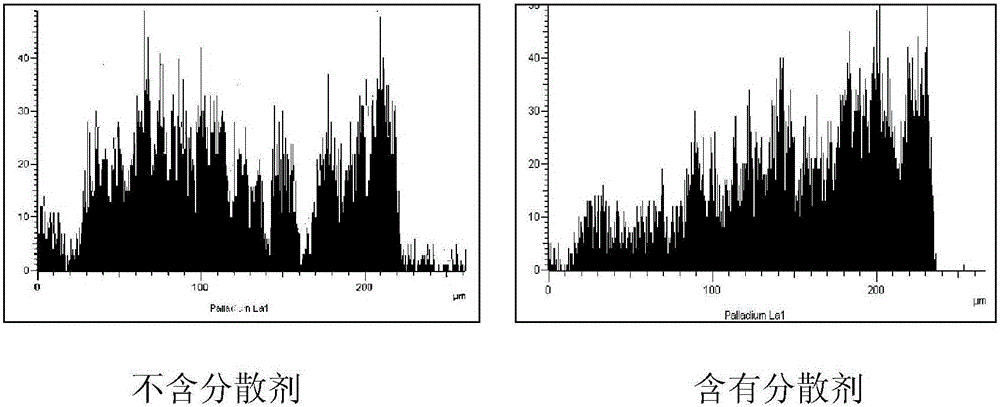

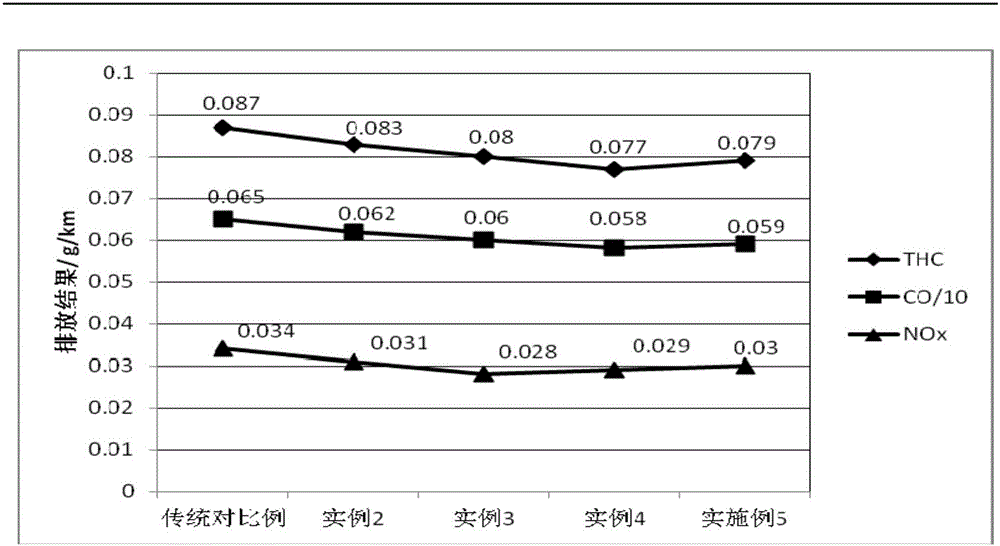

A preparing method of a three-way catalyst

ActiveCN106076331AIncrease profitLow costCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMetallurgyActive component

The invention relates to a preparing method of a three-way catalyst. The method includes preparing a front-zone precious metal solution and a rear-zone precious metal solution, coating a carrier with a first slurry layer with the coating amount being 100-140 g / L, drying, calcinating, dipping the front end of the carrier in 50-300 g of the precious metal solution, dipping the rear end of the carrier in 100-500 g of the precious metal solution, drying in a drying oven having a temperature of 100-150 DEG C for 4-8 h, calcinating at 400-600 DEG C for 1-3 h, coating the carrier with a second slurry layer with the coating amount being 60-100 g / L, drying, and calcinating to obtain the catalyst. The method is simple and easily controllable in steps. Both ends of the carrier are respectively dipped in the precious metal solutions by a dipping manner. Active components are controllable in distribution and mostly distributed on the surface of a pore channel structure. The catalyst is high in catalytic conversion capability and still shows excellent three-way catalytic activity after high-temperature ageing. Compared with traditional three-way catalysts, the catalyst is rapid in ignition, high in precious metal utilization rate and low in cost.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

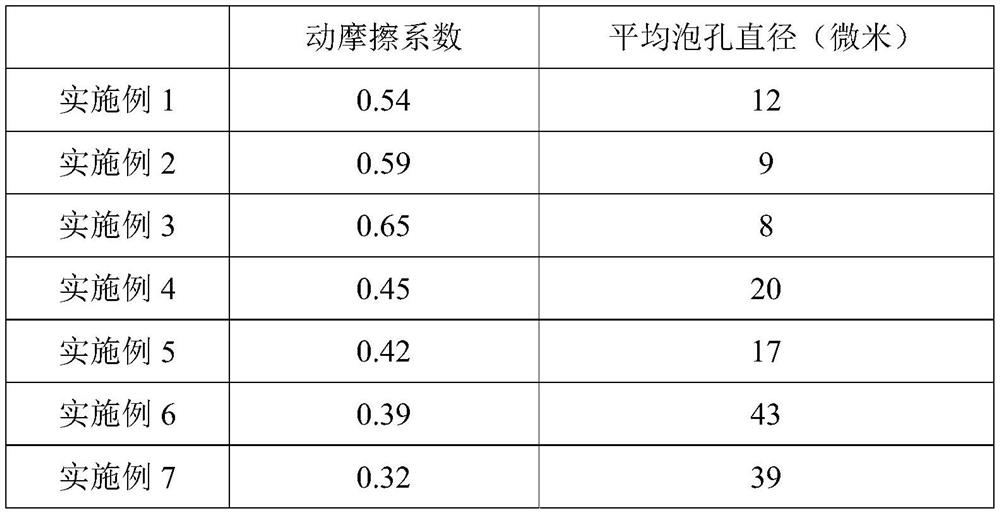

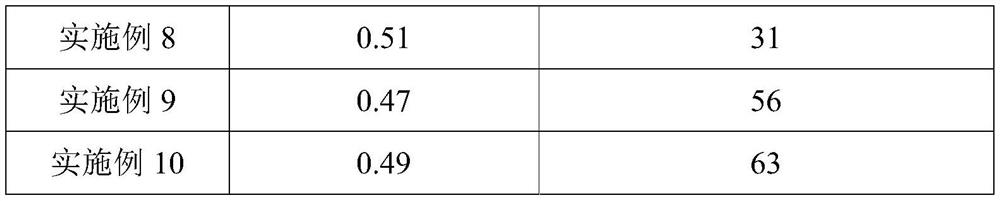

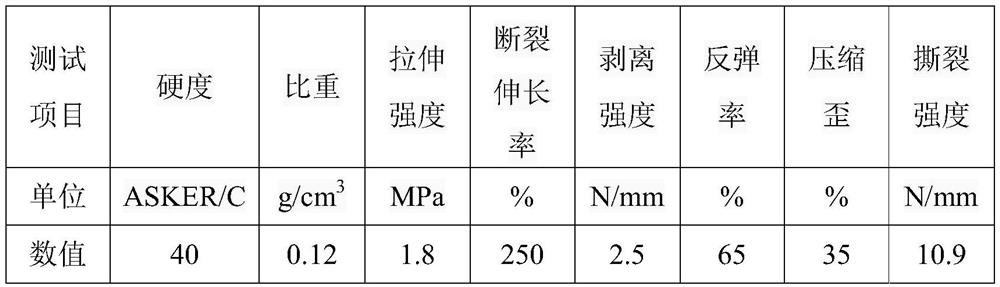

EVA/POE supercritical foaming composite shoe material and preparation method thereof

The invention belongs to the technical field of footwear products, and particularly relates to an EVA / POE supercritical foaming composite material for shoes and a preparation method thereof. The EVA / POE supercritical foaming composite shoe material in the invention at least comprises the following preparation raw materials in parts by weight: 30-40 parts of an ethylene-vinyl acetate copolymer, 20-30 parts of an ethylene-octene copolymer, 10-20 parts of a styrene-butadiene segmented copolymer, 1-3 parts of peroxide and 1.2-1.6 parts of a nucleating agent. Through a supercritical N2 foaming technology, a foaming temperature range is wide, foam holes are uniformly distributed, pore sizes are controllable, and the material has excellent mechanical properties and use performance such as light weight and high strength, and is high in tensile strength, large in elongation at break, good in tear resistance, low in density, extremely low in compression deformation and extremely good in wear resistance. The foaming process is environmentally friendly, a produced product has no odor of a foaming agent and a cross-linking agent, the same mechanical properties as the mechanical properties of achemical foaming material can be obtained, and the material has profound application prospects.

Owner:GUANGDONG GUOLI SCI & TECH CO LTD

Periclase-magnesium aluminate spinel refractory material for rotary cement kiln and preparation method thereof

The invention relates to a periclase-magnesium aluminate spinel refractory material for a rotary cement kiln and a preparation method thereof. according to the technical scheme, 75-95wt% of periclase-magnesium aluminate spinel composite material, 4-20wt% of magnesite and 0.5-5wt% of magnesium aluminate spinel are mixed together to obtain a mixture; a binder accounting which is 3-8wt% of the mixture is added to the mixture and mixed evenly, and then the final mixture is mechanically pressed and formed; the formed blank is dried at 110 DEG C for 8-36 hours and then fired at 1500-1650 DEG C, and furthermore, heat is preserved for 4-15 hours, and finally, the periclase-magnesium aluminate spinel refractory material for the rotary cement kiln is obtained. The preparation method of the periclase-magnesium aluminate spinel refractory material for the rotary cement kiln is simple; the periclase-magnesium aluminate spinel refractory material prepared has the characteristic of controllable distribution of magnesium aluminate spinel, and also the characteristics of good coating formation property, good thermal shock resistance and high medium erosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

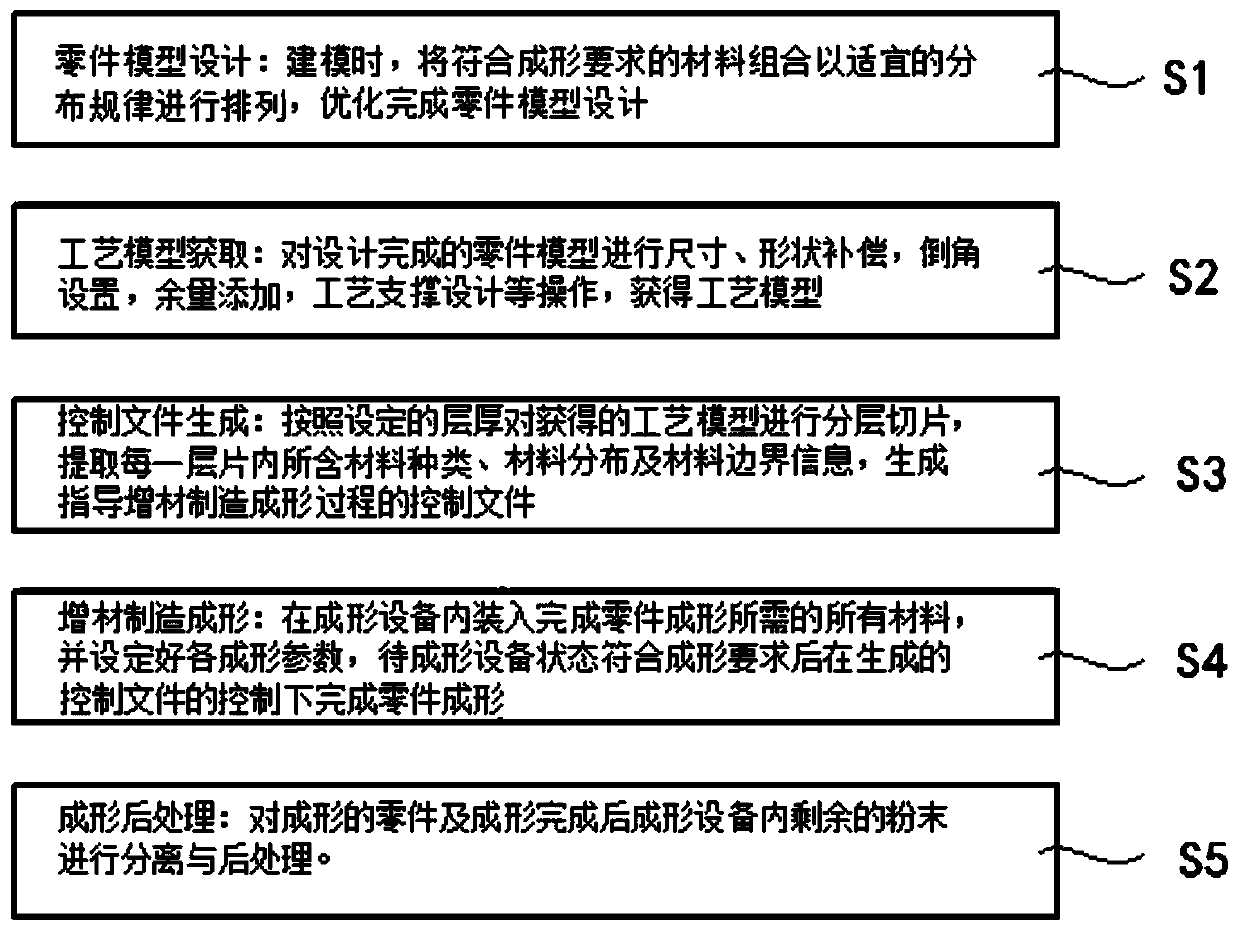

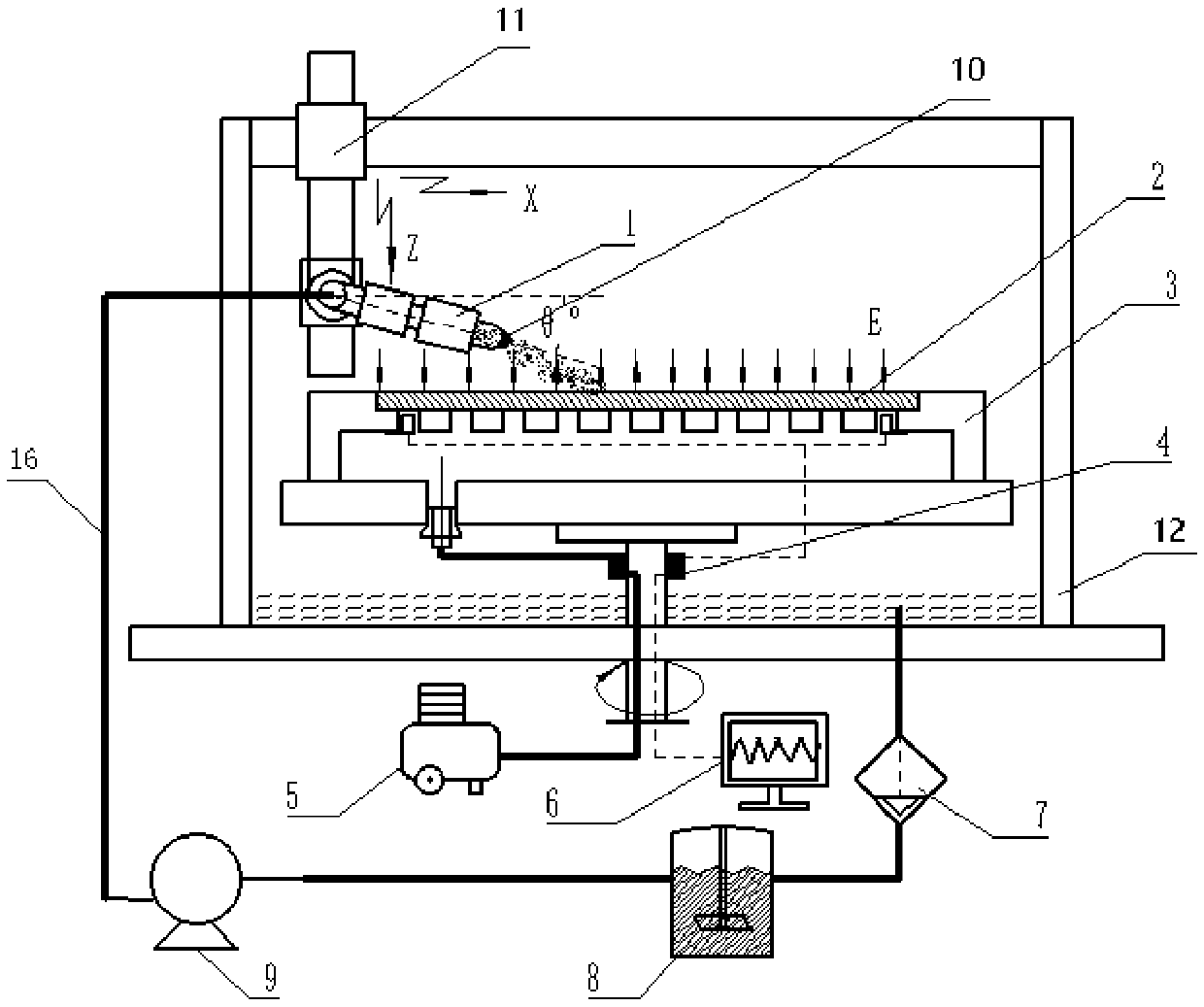

Selective laser melting forming method of multi-material part

InactiveCN111036901ASolve the problem of low bonding strengthQuality improvementAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingProcess engineering

The invention relates to the field of a part forming process, and discloses a selective laser melting forming method of a multi-material part. The method comprises the following steps of S1, part model design, wherein during modeling, materials meeting forming needs are combined to be arranged according to the proper distribution rule, and part model design is finished in an optimized manner; S2,process model obtaining, wherein a designed part model is subjected to size and shape compensation, chamfering, remaining adding, process support design and the like, and a process model is obtained;S3, control file generation, wherein the obtained process model is subjected to layered slicing, the material kind, material distribution and material boundary information contained in each layer areextracted, and a control file guiding an additive manufacturing forming process is generated; S4, additive manufacturing forming; and S5, forming aftertreatment. According to the method, through the selective laser melting forming technology, the high-precision high-quality multi-material part can be formed.

Owner:XIAN SPACE ENGINE CO LTD

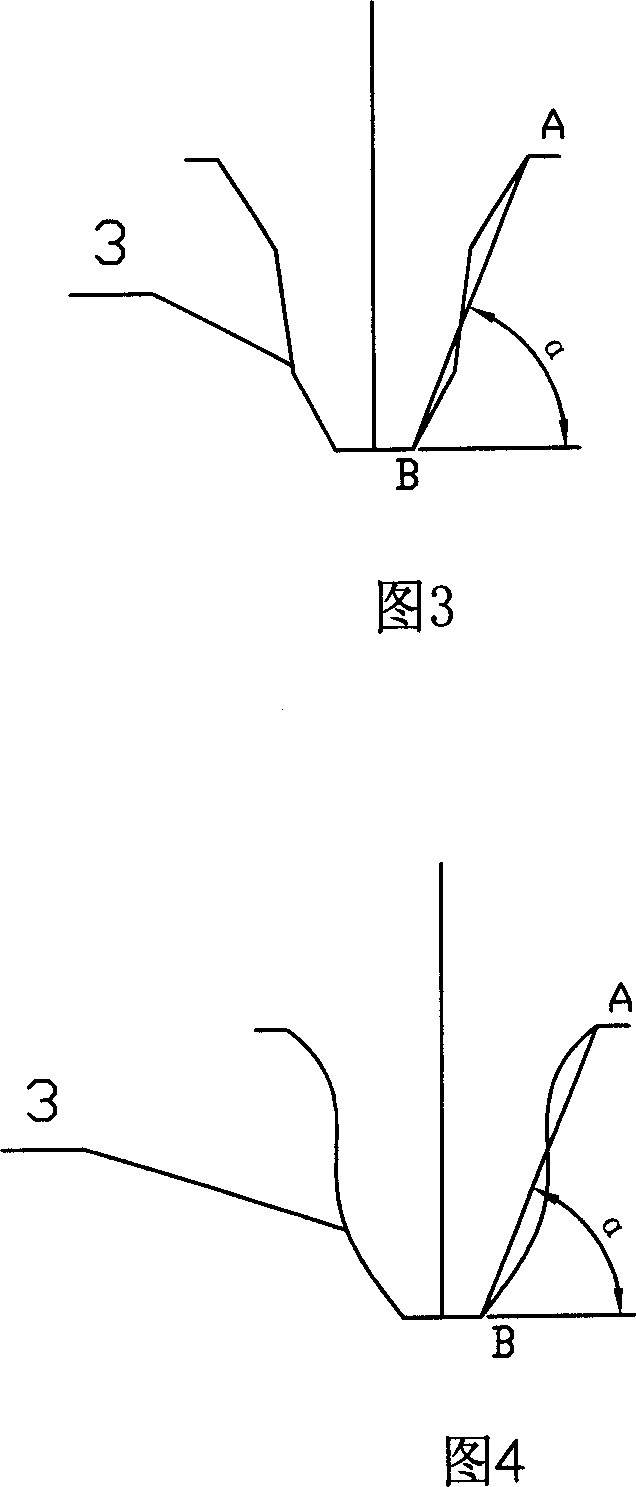

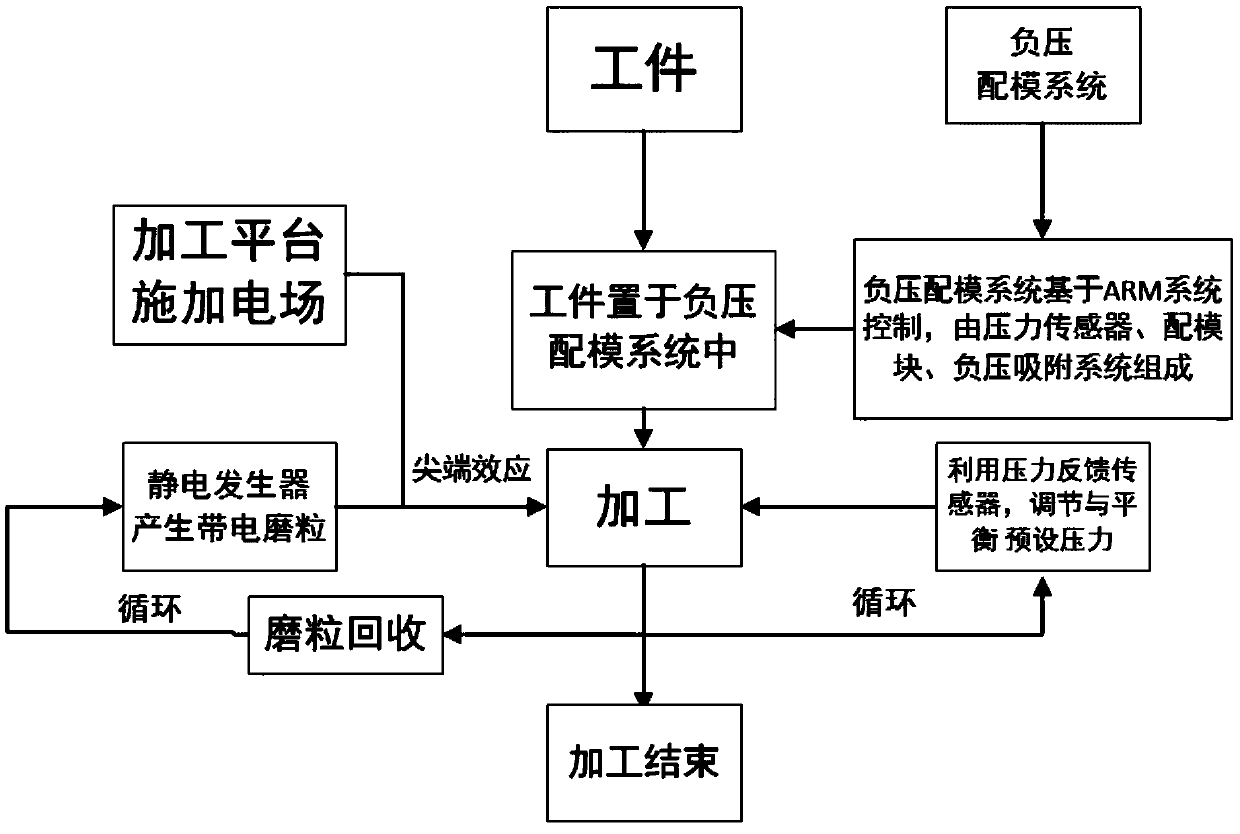

Static electricity controllable abrasive particle flow processing method based on charge tip aggregation effect

ActiveCN109551374AControllable distributionReduce particle size unevennessAbrasive machine appurtenancesMicroscopic scaleHigh pressure

The invention discloses a static electricity controllable abrasive particle flow processing method based on a charge tip aggregation effect. An abrasive particle flow with non-electrolyte as a carrieris subjected to a high-voltage electrostatic field to be charged, so that the distribution of the abrasive particles in the flow field can be controlled, and negative influences produced by abrasiveparticle size unevenness and large-particle-size abrasive particles in the processing process are reduced; an electric field is applied to the flow field, the distribution characteristics of the abrasive particles with the negative charge on the collision area on the surface of a workpiece with the positive charge are changed through the electric charge tip aggregation effect, the possibility of collision of the abrasive particles to the microscopic surface crest of the workpiece is increased, workpiece surface crest removal is accelerated, the flow-in angle of the abrasive particles is periodically swung in a pulse mode, the optimal polishing alternating force acting on the workpiece is obtained by effectively adjusting and controlling the pulse frequency and the swing angle, and it is ensured that the high-quality surface is obtained on the premise of efficient removal.

Owner:ZHEJIANG UNIV OF TECH

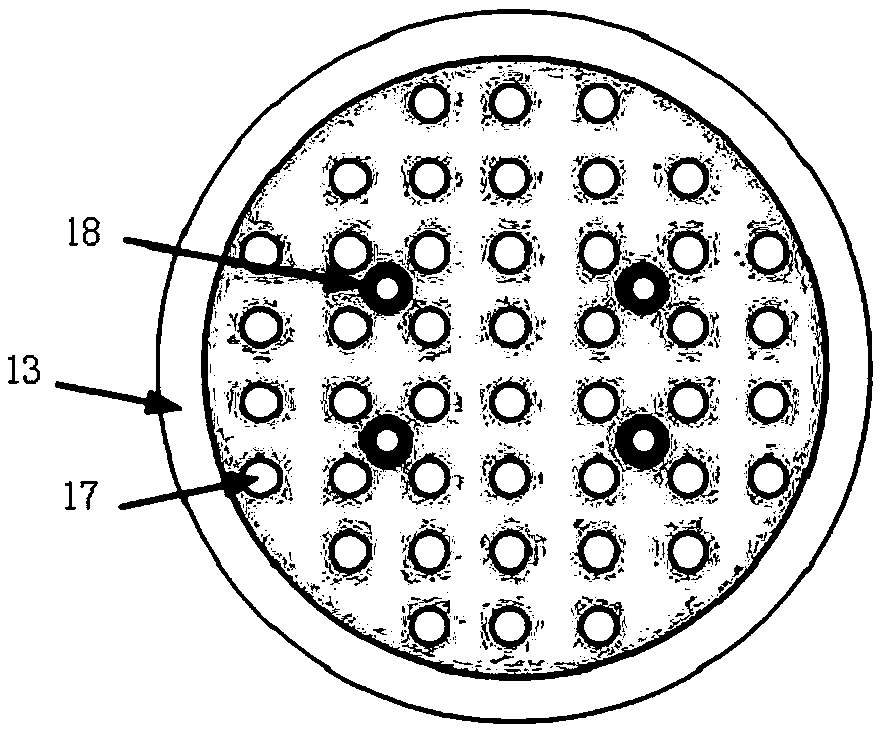

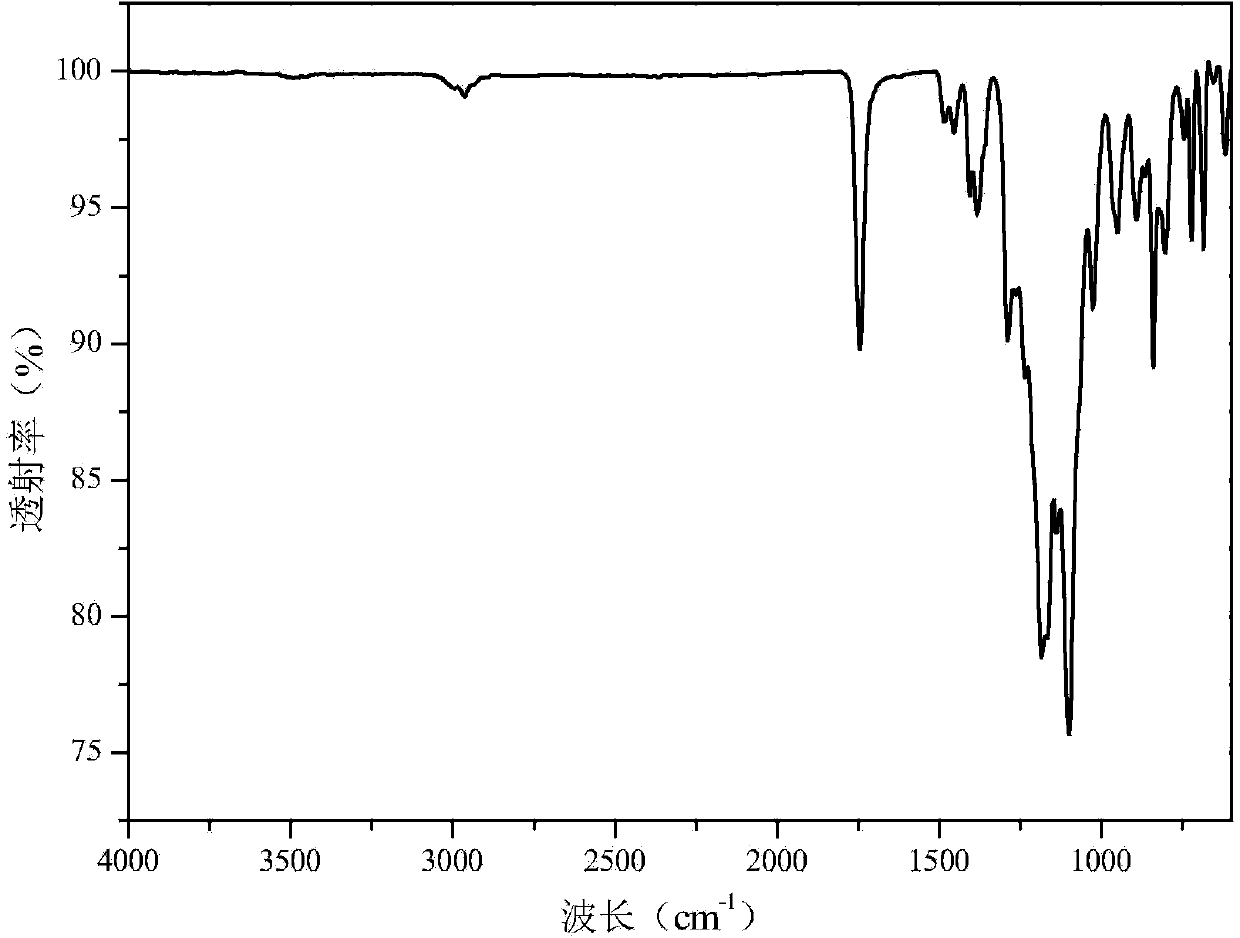

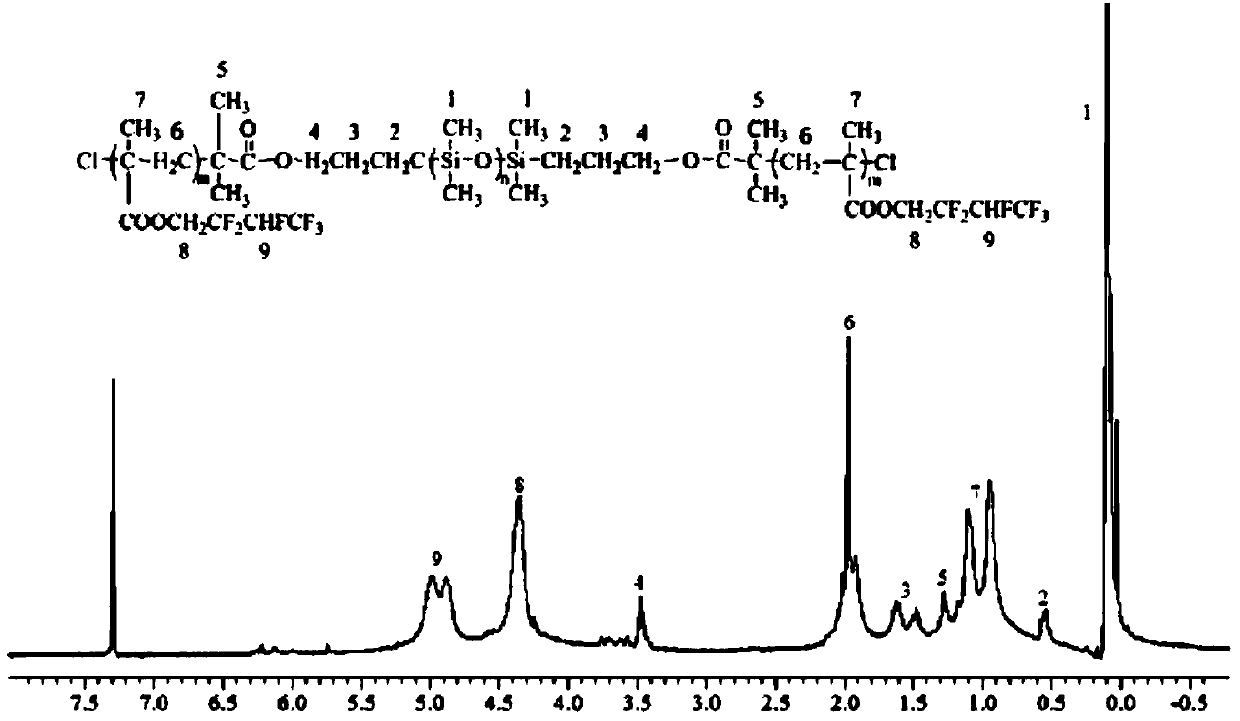

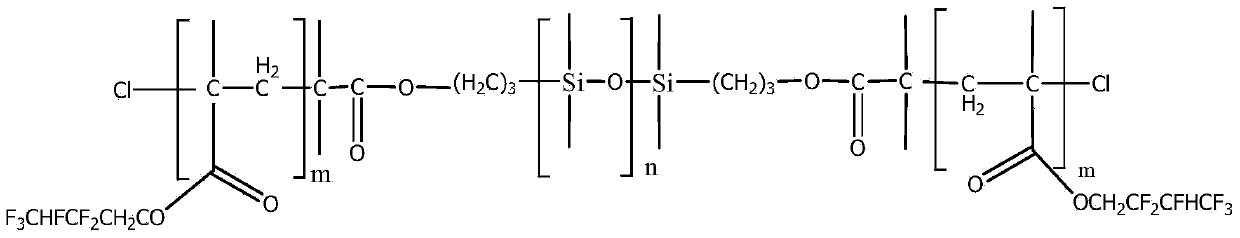

Hydrophobic/oleophobic fluorosilicone triblock polymer and preparation method thereof

ActiveCN104193923AControllable Molecular WeightControllable distributionAntifouling/underwater paintsPaints with biocidesMethacrylatePolymer science

The invention discloses a hydrophobic / oleophobic fluorosilicone triblock polymer and a preparation method thereof. The structural formula of the polymer is as shown in the specification, in the structural formula, m is an integer from 10 to 50, n is an integer from 20 to 50, and a target polymer, namely, hexafluorobutyl methacrylate-b-polydimethylsiloxane-b-polyhexafluorobutyl methacrylate is synthesized by taking chloro-polydimethylsiloxane as a chain initiator under the co-catalysis of a catalyst CuCl and catalyst ligands 2,2'-dipyridyl and N-(2-pyridine methylene)-1-propylamine or tetramethylethylenediamine by using an atom transfer radical polymerization method. According to the hydrophobic / oleophobic fluorosilicone triblock polymer, microwave radiation heating is adopted, the operation is simple and convenient, the reaction condition is gentle, the molecular weight and the distribution of a reaction product can be controlled, and the synthesized hydrophobic / oleophobic fluorosilicone triblock polymer is excellent in hydrophobic and oleophobic property and is wide in application prospect in anti-flouring coating.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

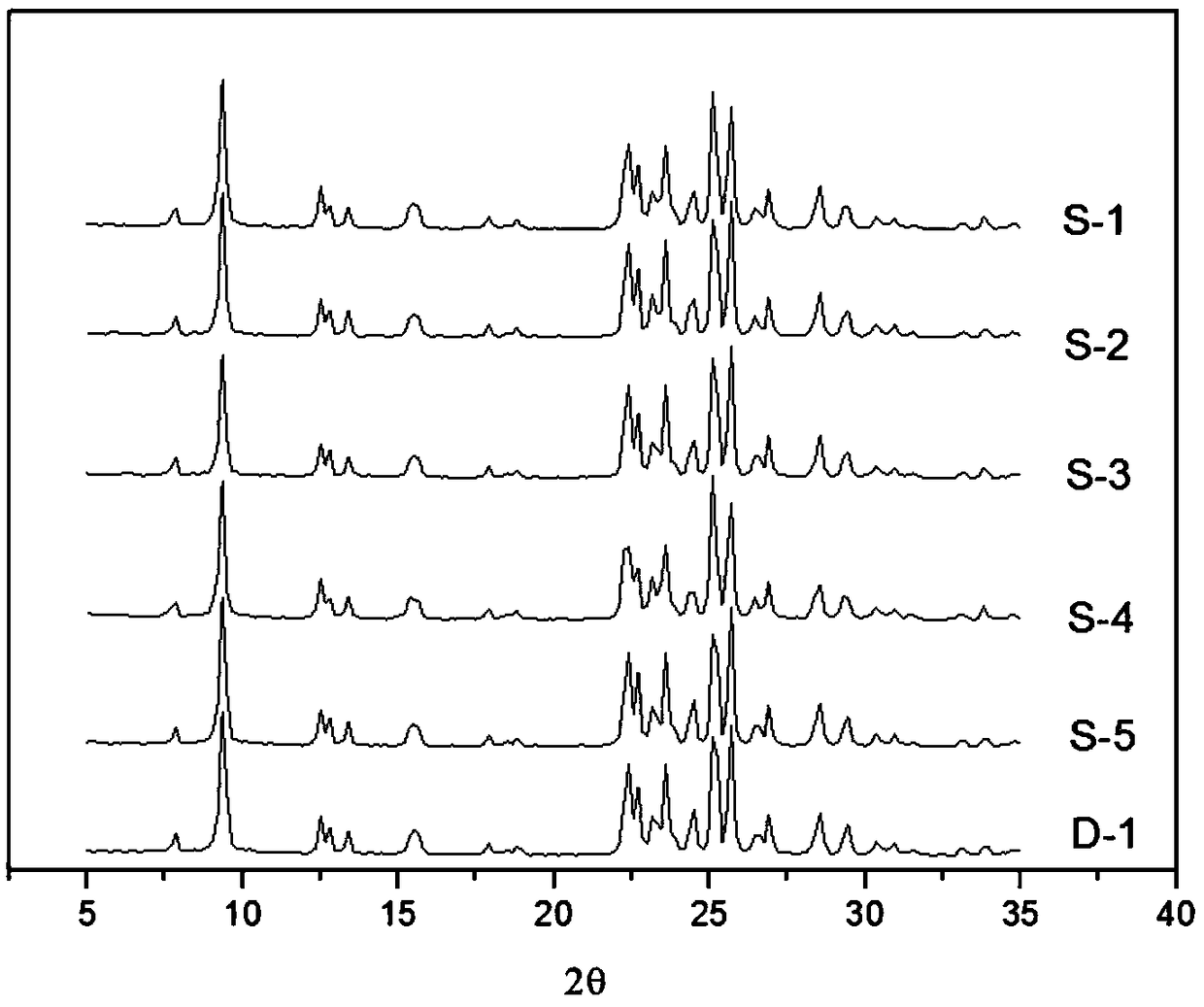

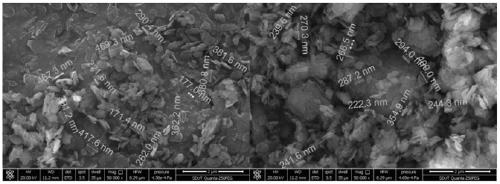

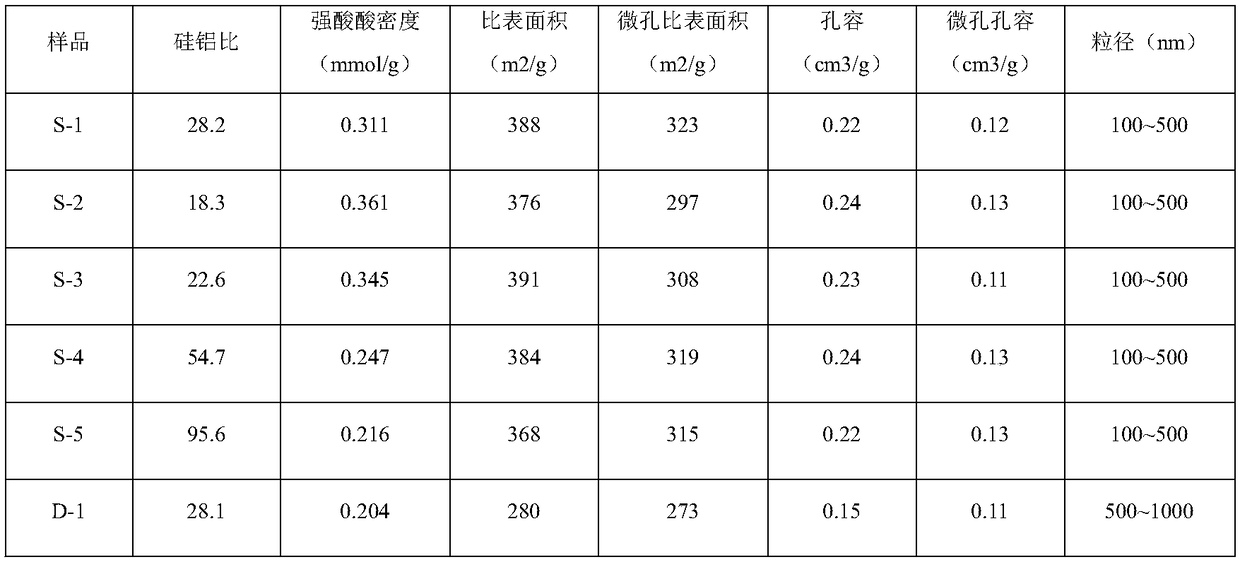

Preparation method of ZSM-35 molecular sieve

ActiveCN109502606ALarge specific surface areaSmall specific surface areaFerrierite aluminosilicate zeoliteMolecular sieveSilicon

The invention relates to a preparation method of a ZSM-35 molecular sieve, and belongs to the field of preparation of molecular sieves. The preparation method comprises the following steps: (a) preparing an aluminum source, a complexing agent and water into a solution a and aging the solution a at 10 to 100 DEG C for 1 to 48 hours to obtain aging liquid, wherein the aging condition in the preferred scheme that aging is performed for 6 to 24 hours at 30 to 70 DEG C; (b) uniformly mixing a silicon source, the aluminum source, an alkali source, a template agent, water and a ZSM-35 molecular sievecrystal seed to obtain gel b; (c) transferring the gel b into a crystallization kettle and crystallizing at 50 to 150 DEG C for 12 to 72 hours; (d) replenishing the aging liquid obtained in the step(a) into the crystallization kettle in the step (c), and crystallizing at 150 to 180 DEG C for 12 to 72 hours; (e) after the reaction ends, separating mother liquid, washing, exchanging, drying and calcining to obtain the ZSM-35 molecular sieve. The preparation method for preparing the ZSM-35 molecular sieve which has controllable silicon aluminum distribution, a mesoporous structure, small grainand high specific surface area is of great significance.

Owner:SHANDONG QILU HUAXIN HIGH TECH

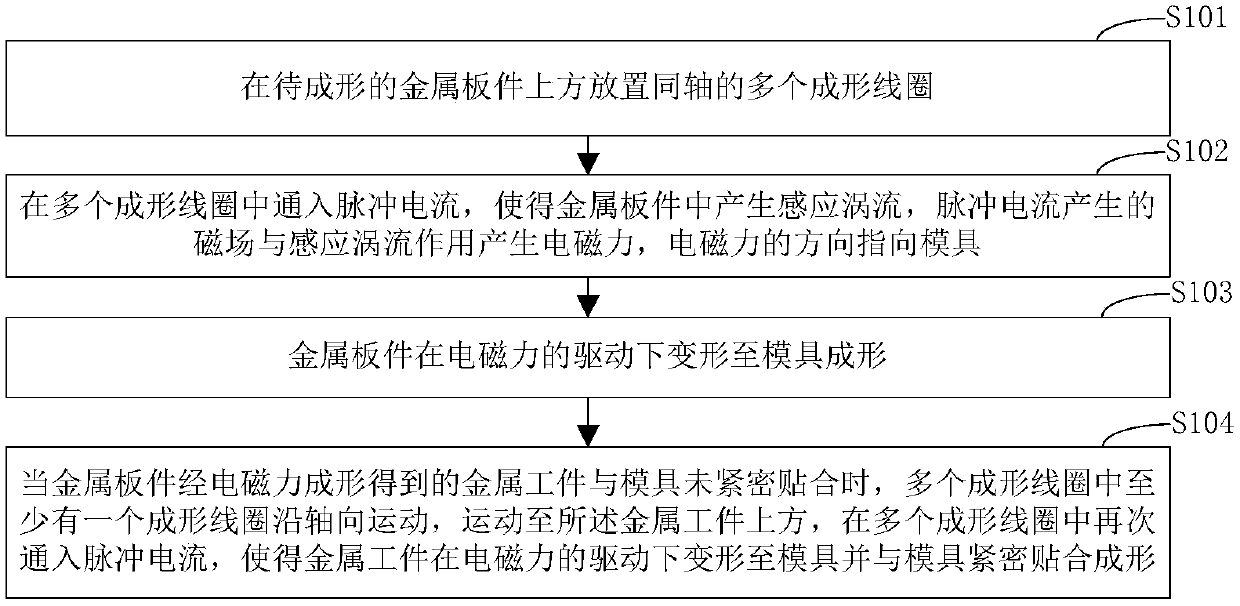

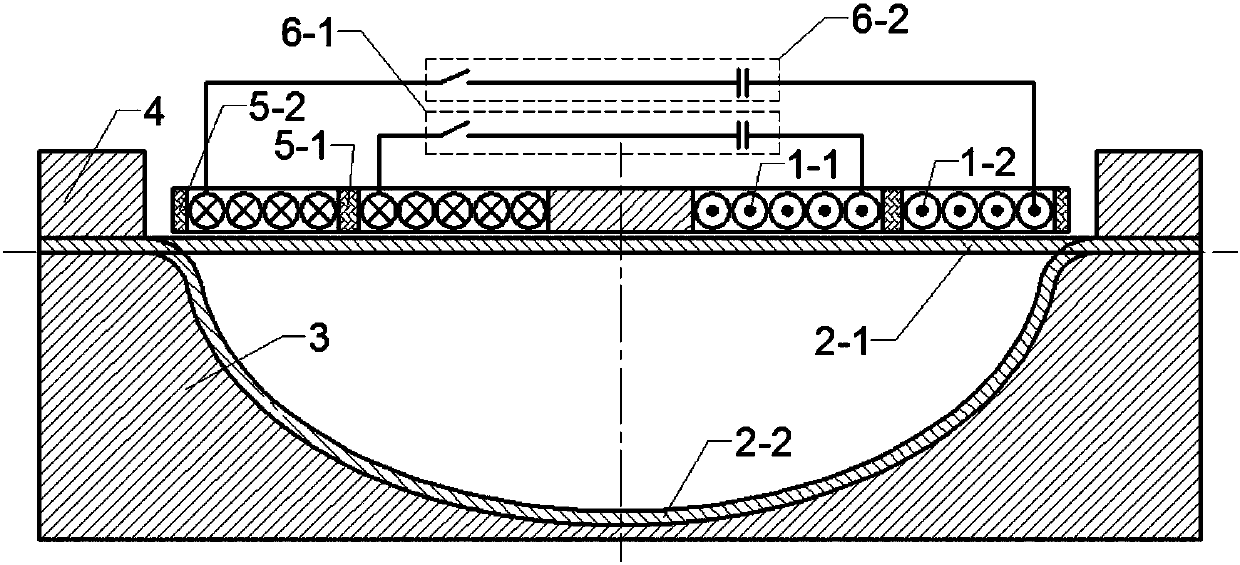

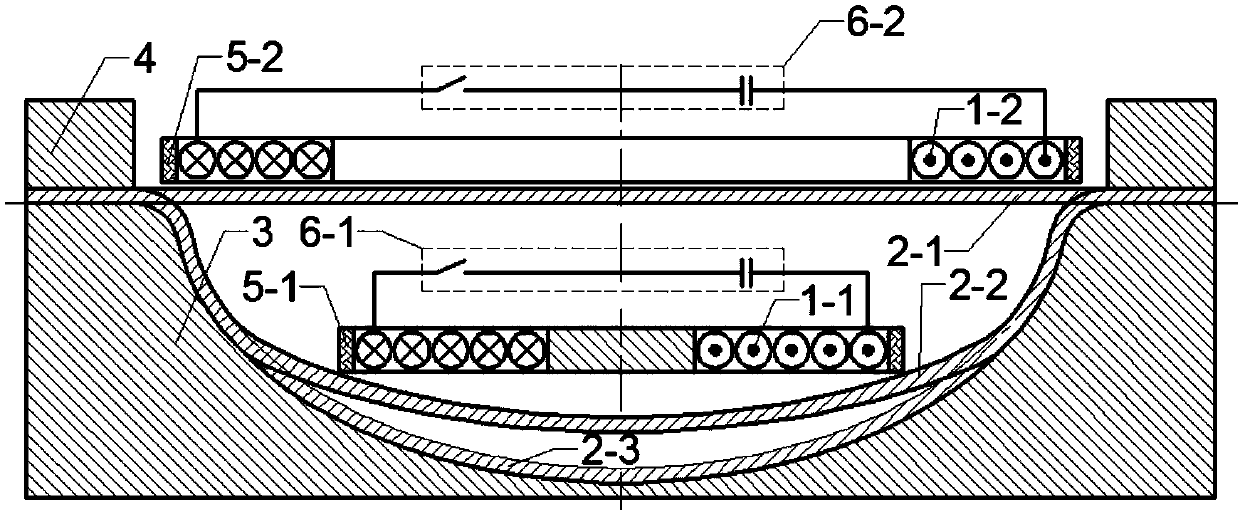

Electromagnetic forming method and device of metal plate

ActiveCN107584001AReasonable distributionControllable distributionIncreasing energy efficiencyMagnetic tension forceElectricity

The invention discloses an electromagnetic forming method and device of a metal plate. The method comprises the steps that a plurality of coaxial forming coils are placed above the to-be-formed metalplate; pulse currents are introduced into the forming coils, induced eddy currents are generated in the metal plate, a magnetic field generated by the pulse currents and the induced eddy currents actto generate electromagnetic force, and the electromagnetic force points to a die; the metal plate is deformed to the die to be formed under the driving of the electromagnetic force; when a metal workpiece obtained by forming the metal plate through the electromagnetic force is not closely attached to the die, at least one forming coil in the forming coils moves axially to the upper portion of themetal workpiece, and then pulse currents are introduced into the forming coils again, so that the metal workpiece is deformed to the die under the driving of the electromagnetic force and is closely attached to the die to be formed. A single coil is divided into a plurality of independent or mutually-correlated coaxial single coils, so that the energy utilization rate in the discharging process isincreased, the structural strength of the coils is improved, and the controllability of electromagnetic field distribution is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Self-supporting oxygen reduction/oxygen evolution double-effect oxygen electrode catalyst and preparation method therefor

InactiveCN106602086ASimple incorporation methodSimple and fast operationCell electrodesOxygen evolutionOxygen reduction

The invention discloses a self-supporting oxygen reduction / oxygen evolution double-effect oxygen electrode catalyst and a preparation method therefor, and belongs to the fields of catalysis and materials. A certain amount of nitrogen source, sulfur source and transitional metal salt are dissolved in a water solution; and meanwhile, carbon paper is added to further synthesize a nitrogen, sulfur and transitional metal co-doped self-supporting oxygen reduction / oxygen evolution double-effect oxygen electrode through a hydrothermal reaction in one step. The method is simple and convenient to operate; the reaction is completed in one step; the adopted raw materials are common reagents used in laboratories, so that low manufacturing cost, short reaction period and high repeatability are realized; and the electrode represents high oxygen reduction and oxygen evolution double-effect property in electro-catalysis, is long in cycling life, and can be applied to many fields of a metal air cell, an integrated regenerative fuel cell, a zinc air flow cell and the like.

Owner:BEIJING UNIV OF CHEM TECH

Microneedle capable of extracting skin tissue fluid and preparation method thereof

ActiveCN110664439AFlexible adjustment of porosityFlexible adjustment of apertureSurgeryVaccination/ovulation diagnosticsFoaming agentTissue fluid

The invention discloses a microneedle capable of extracting skin tissue fluid and a preparation method thereof. The microneedle comprises porous network frameworks and hydrophilic polymer layers modified at the internal and external surfaces of the framework, wherein the porous network frameworks penetrate through each other. The preparation method specifically comprises the following steps: preparing a mixed solution of a polymer and a pore-foaming agent, filling the mixed solution into a microneedle mold, removing the pore-foaming agent to obtain the porous network framework with interpenetration, and finally modifying hydrophilic polymer layers on the inner surface and the outer surface of the porous network framework. The microneedle capable of extracting the skin tissue fluid is obtained by improving the thickness of the hydrophilic polymer layer adopted by the microneedle, the porosity and the aperture of the microneedle and the overall process flow design of the corresponding preparation method. The microneedle provided by the invention is good in biocompatibility and high in skin tissue fluid extraction speed, does not need an additional negative pressure device, does not cause obvious pain and skin infection, and does not need to be operated by professionals.

Owner:HUAZHONG UNIV OF SCI & TECH +1

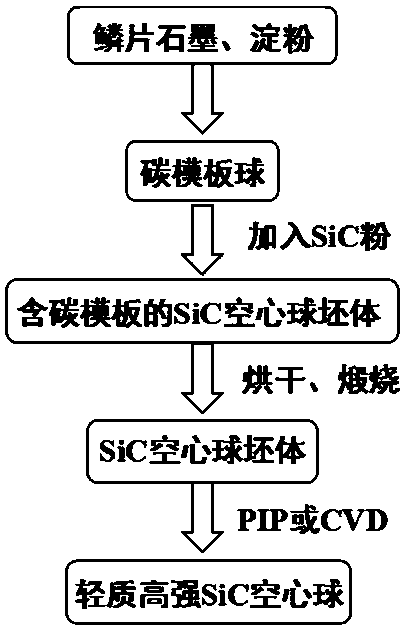

SiC hollow sphere and preparation method of same

The invention discloses a SiC hollow sphere and a preparation method of same. The preparation method includes the steps of: 1) mixing raw materials, including flake graphite, starch and water, and forming carbon template spheres in a pelletizing machine, placing the carbon template spheres in a roll-forming machine, adding SiC powder, in several batches, into the roll-forming machine to form a SiChollow sphere green body internally coated with the carbon template sphere, and drying and calcining the green body to remove the carbon template sphere to obtain a SiC hollow sphere green body; 2) compacting the surfaces of the SiC hollow sphere green body in the step 1) through a precursor vacuum impregnation pyrolysis process or a chemical vapor deposition process. The light-weight and high-strength SiC hollow sphere has high density and high compression resistance, has uniform and controllable size and smooth and compact surface, can reach 10-50 MPa in compression resistance, and can be widely applied to light packing, catalysis materials, heat preservation and insulation materials, fire-proofing and water-proofing materials, anti-radiation materials, etc.

Owner:NAT UNIV OF DEFENSE TECH

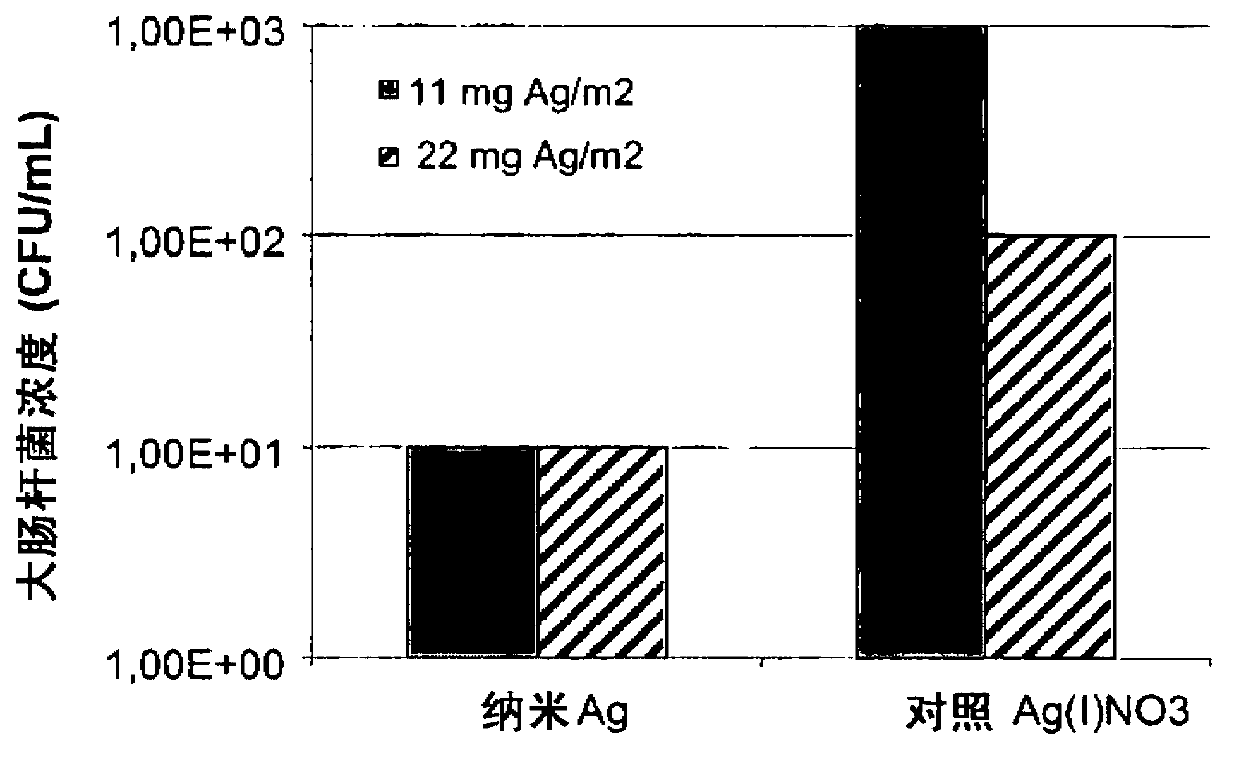

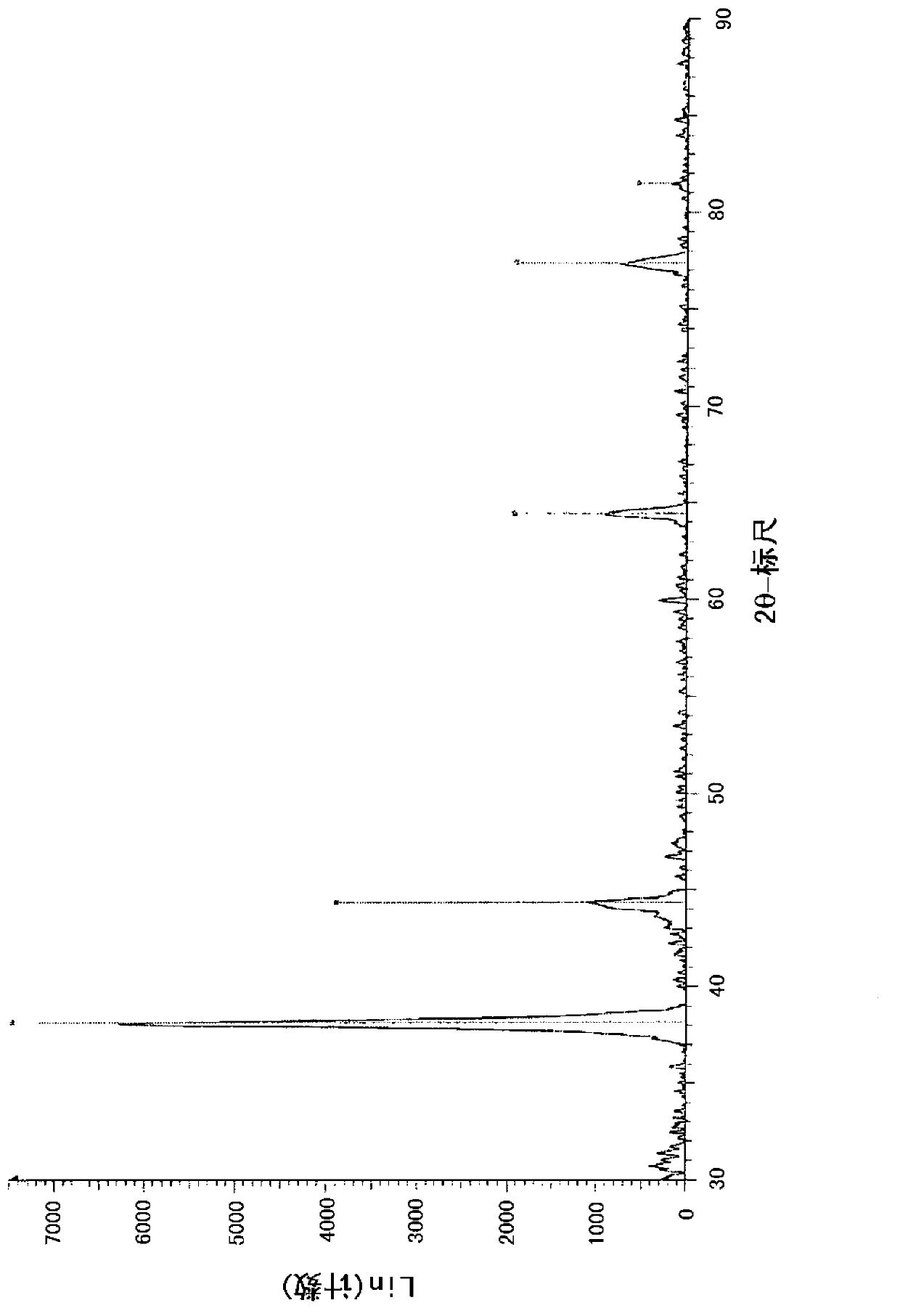

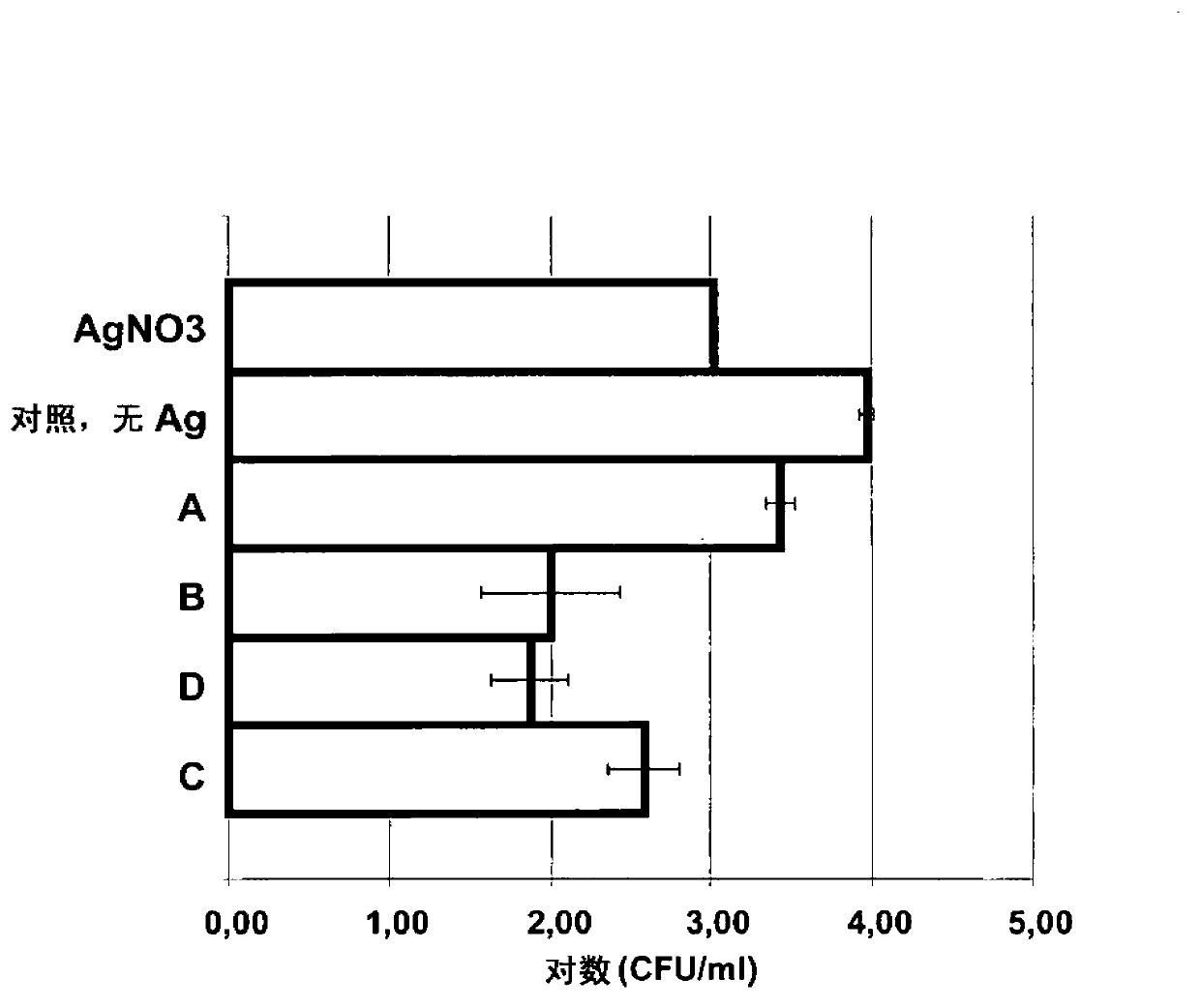

Method for producing metal nanoparticles

InactiveCN102978241AGood size controlControllable distributionMicroorganism based processesFermentationPlatinumColloidal nanoparticles

This invention provides a method for producing a composition comprising colloidal nanoparticles of metals including silver, gold, zinc, mercury, copper, palladium, platinum, or bismuth, by contacting a metal or metal compound with bacteria. An embodiment of the method comprises a step of incubating probiotic bacteria with an aqueous solution comprising at least 4 mM of a silver or gold salt. A resulting nanosilver-containing composition is useful as a highly efficient antimicrobial agent, for instance when impregnated onto a carrier, or an algicide agent or a herbicide agent.

Owner:JANSSEN PHARMA NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com