Method for producing metal nanoparticles

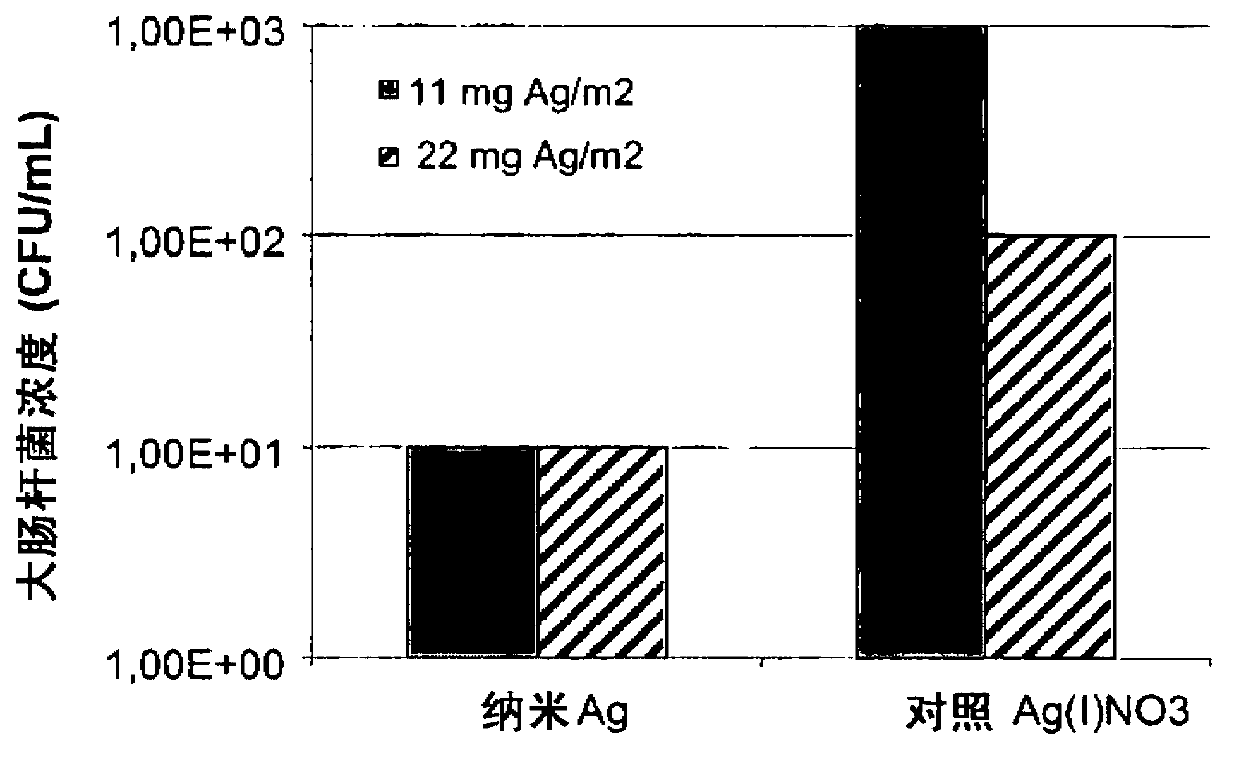

A metal and colloidal metal technology, applied in the field of preparation of silver or gold nanoparticles, disinfection products, silver or gold nanoparticles to improve their antimicrobial efficiency, can solve the problems of insufficient bactericidal activity of silver nanoparticles, long incubation time, etc., to achieve Reproducible controllable size and distribution, reduced demand, cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0061] According to another embodiment of the present invention, the method comprises the step of incubating the probiotic bacteria (as defined hereinbefore) with an aqueous solution containing at least 4 mM gold salt, which aqueous solution may also contain a suitable amount of alkali metal hydroxide, such as but Not limited to sodium hydroxide or potassium hydroxide in the absence of ammonia and / or ammonium salts.

[0062] A suitable alkali metal hydroxide such as, but not limited to, sodium hydroxide or potassium hydroxide, may be added to the aqueous incubation solution to a concentration of up to about 1M. Preferably, the incubation is performed at a pH of at least 8, such as in the range of about 8 to about 12, or in a more specific embodiment from about 8.5 to about 11.

[0063]According to one embodiment of the present invention, the ratio of the weight of silver or gold to the dry cell weight of probiotic bacteria (hereinafter abbreviated as CDW) is at least about 0.0...

Embodiment 1

[0101] Embodiment 1--the preparation of nano silver

[0102] A culture of Lactobacillus fermentum Beijerinck 1901AL (ATCC 11976, LMG 8900, from the intestinal tract of 8-day-old breastfed infants) was prepared in MRS broth (purchased from Oxoid, Basingstoke, United Kingdom). ) and cultured at 37°C for 15 hours under moderate and microaerobic conditions. Collect cells from MRS by centrifugation at 3,000 g at 15°C for 10 minutes, wash twice with milliQ water, and then resuspend in milliQ water to obtain a final optical density at 600 nm (OD 600 ) is 1.5. Add 1N sodium hydroxide mother solution to the cell suspension, such as the final concentration of 0.05N NaOH and 0.10N NaOH.

[0103] Prepare 425mg AgNO in 50mL milliQ water 3 and 225mg NH 4 Cl in Ag(I) mother liquor. 1 volume of this Ag(I) stock solution was added to 10 volumes of cell suspension containing 0.05 and 0.10 N NaOH, respectively. These mixtures were incubated under visible light at 25°C with gentle agitati...

Embodiment 2

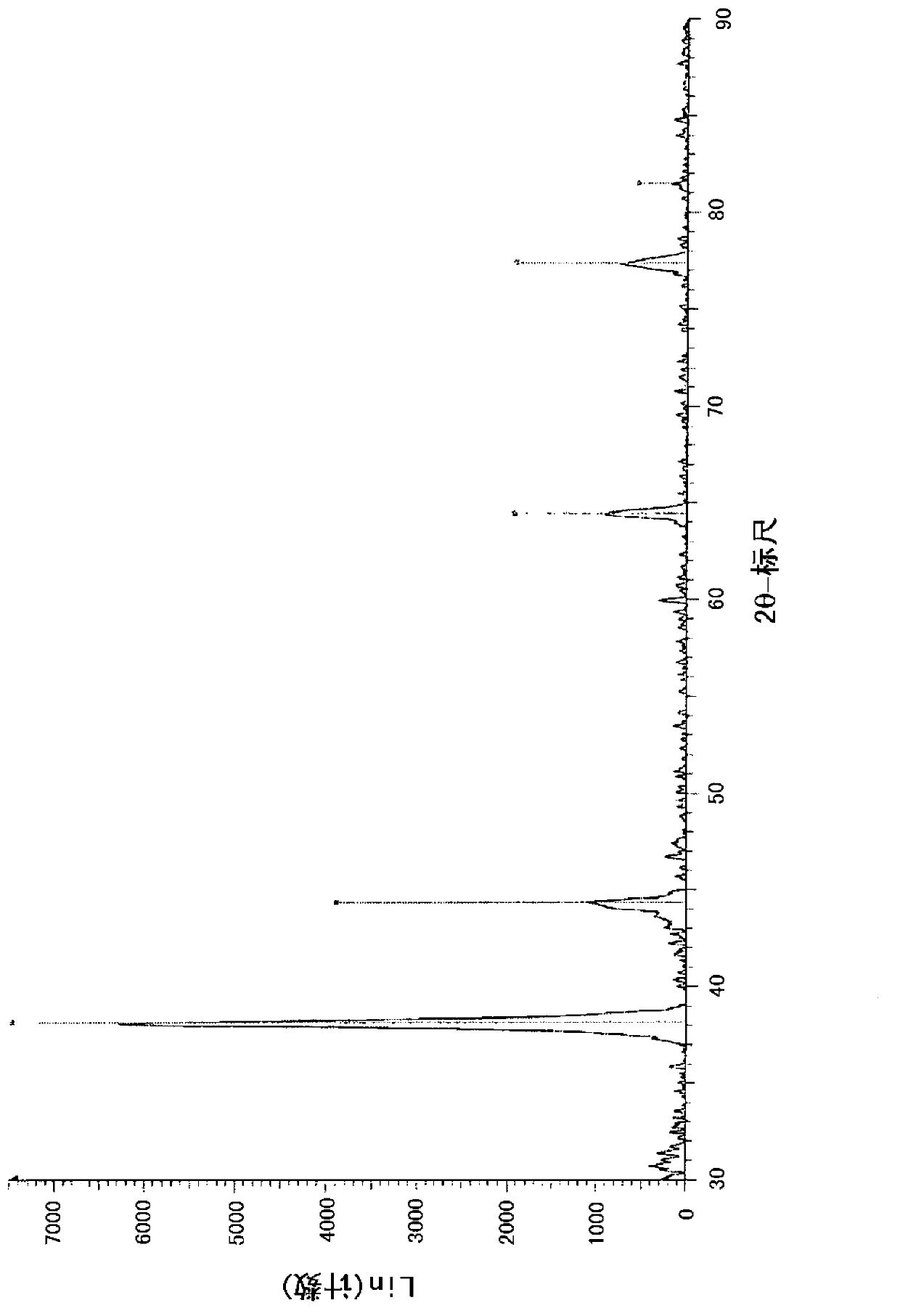

[0104] Embodiment 2-nano silver XRD analysis

[0105] After the biological substance with silver particles obtained in Example 1 was further dried at 30°C, X- Ray Diffraction (XRD). X-rays were generated by a copper X-ray tube with a power of 1.6kW (40kV, 40mA). Measurements were made between 25-90 degrees 2Θ with a "tep time" of 1.6 seconds in steps of 0.02 degrees. The resulting spectrum (not shown) indicated the presence of metallic silver and sodium oxide X-ray diffraction patterns. The latter is the residue of sodium hydroxide used to make nanosilver.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com