Patents

Literature

681 results about "Dry cell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A dry cell is a type of electric battery, commonly used for portable electrical devices. It was developed in 1886 by the German scientist Carl Gassner, after development of wet zinc-carbon batteries by Georges Leclanché in 1866. The modern version was developed by Japanese Yai Sakizo in 1887.

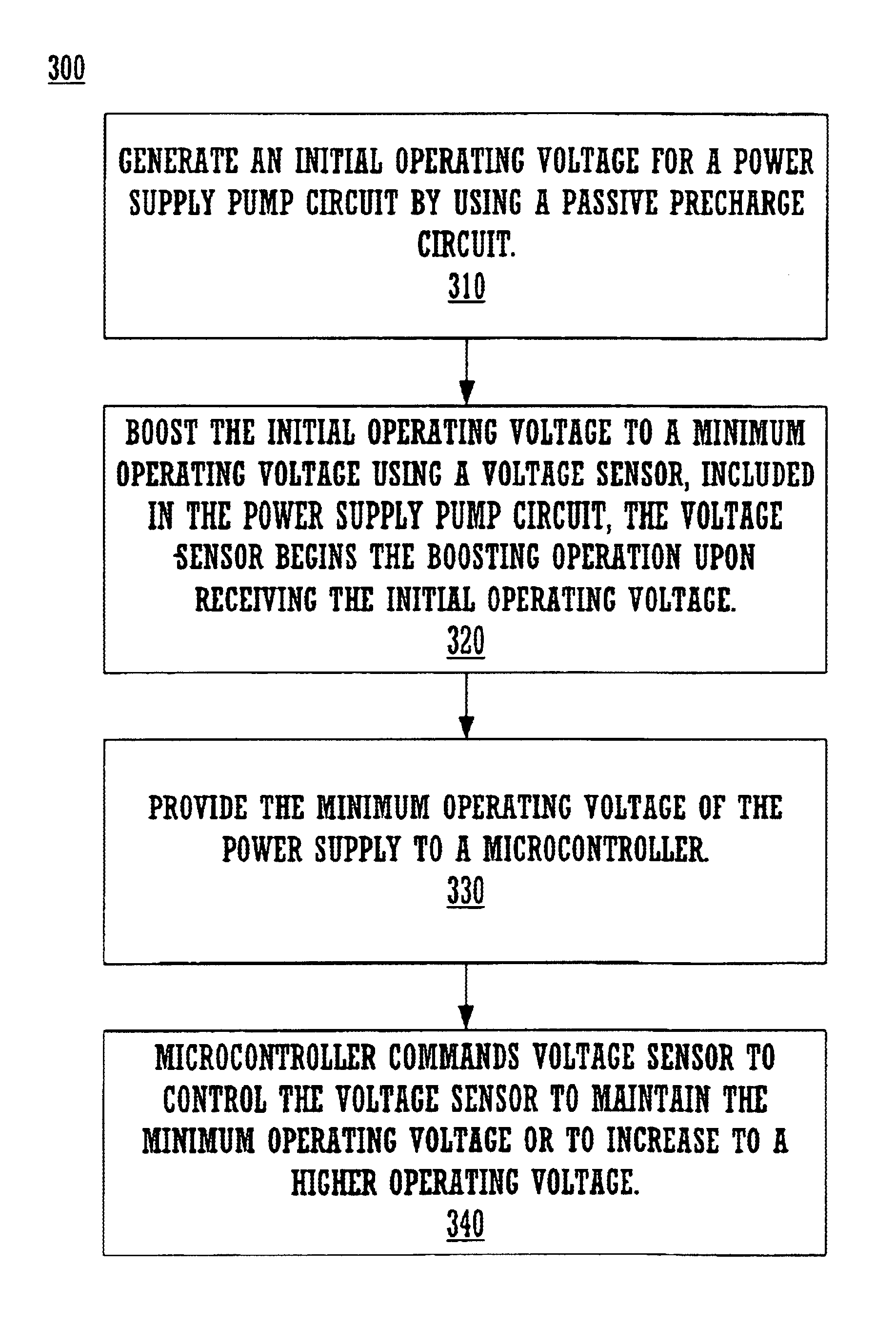

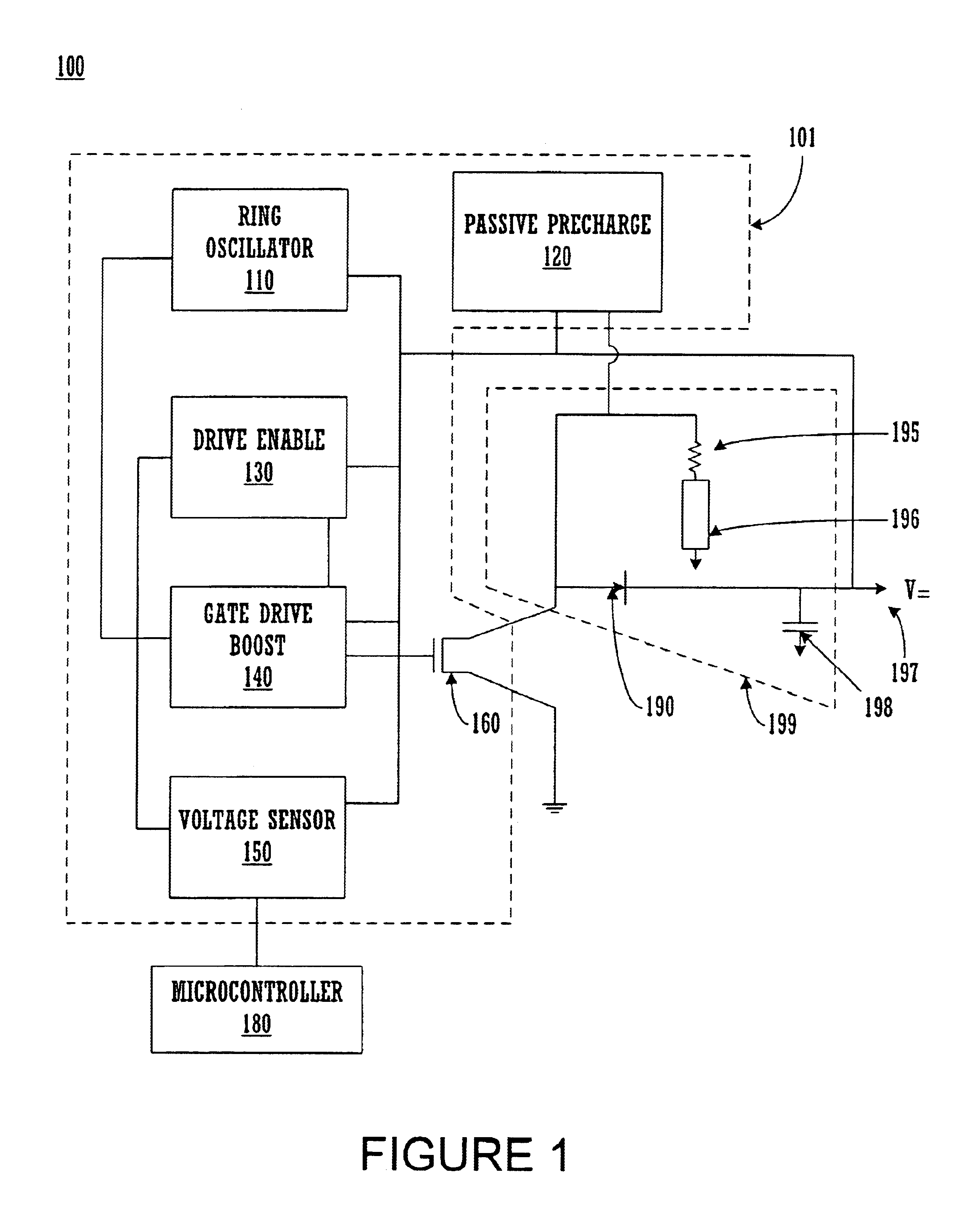

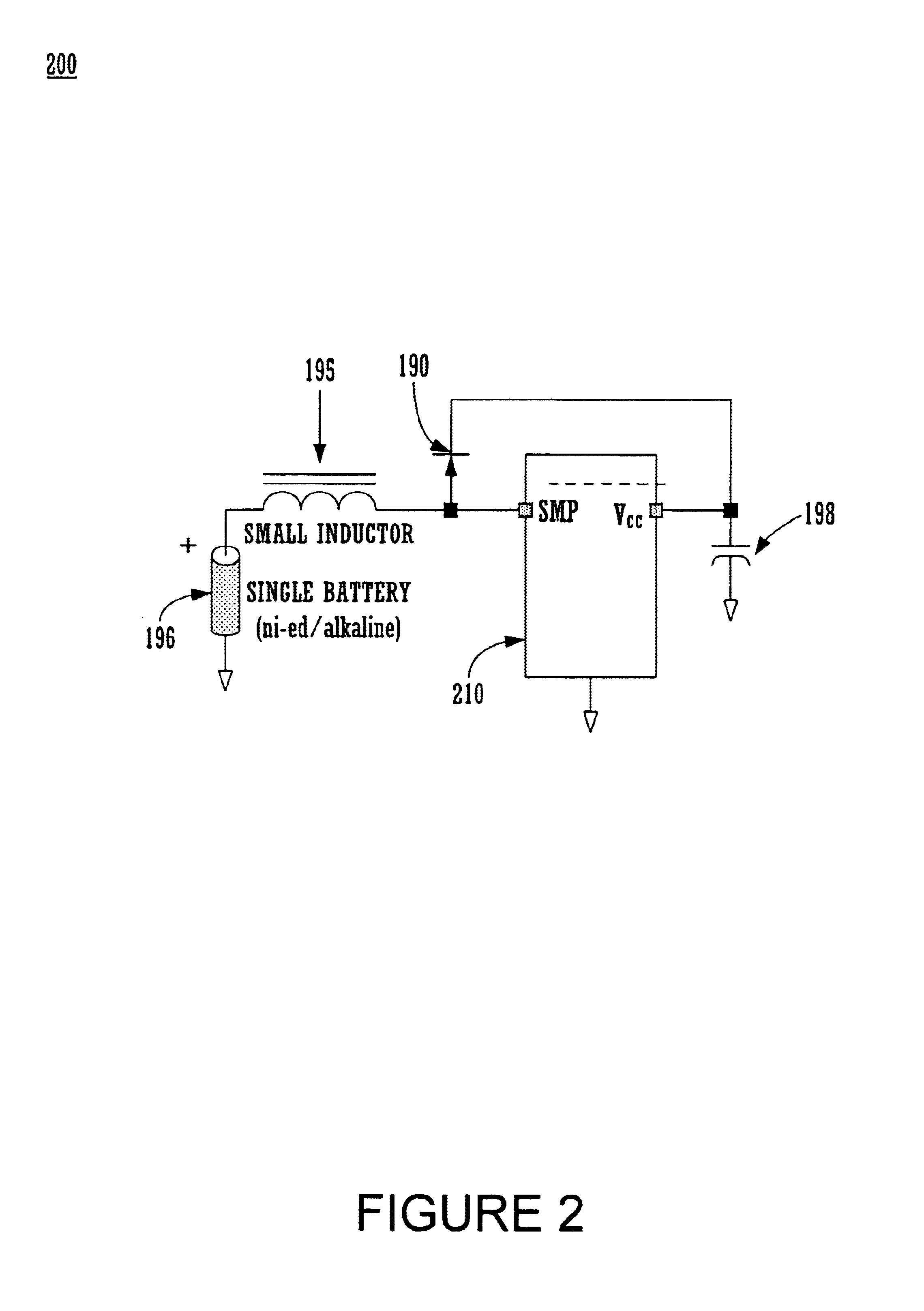

Method for efficient supply of power to a microcontroller

InactiveUS6892310B1Space minimizationImprove communication efficiencyDigital data processing detailsGain controlMicrocontrollerElectrical battery

A method and a system for supplying power to a microcontroller with a single cell. One embodiment of the present invention discloses incorporation of a power supply pump circuit with the microcontroller and their dynamic interaction. The microcontroller sends its power requirements to the power supply pump circuit and in response, the power supply pump circuit controls the operating voltage with optimal efficiency. The dynamic update of power supply pump circuit results in an efficient use of the power supply pump circuit and thus results in a reduction of the number of dry cell batteries to only a single cell. Incorporation of the microcontroller and power supply pump circuit onto a single chip reduces the pin number requirements as well as the space required on the printed circuit board.

Owner:NVIDIA CORP

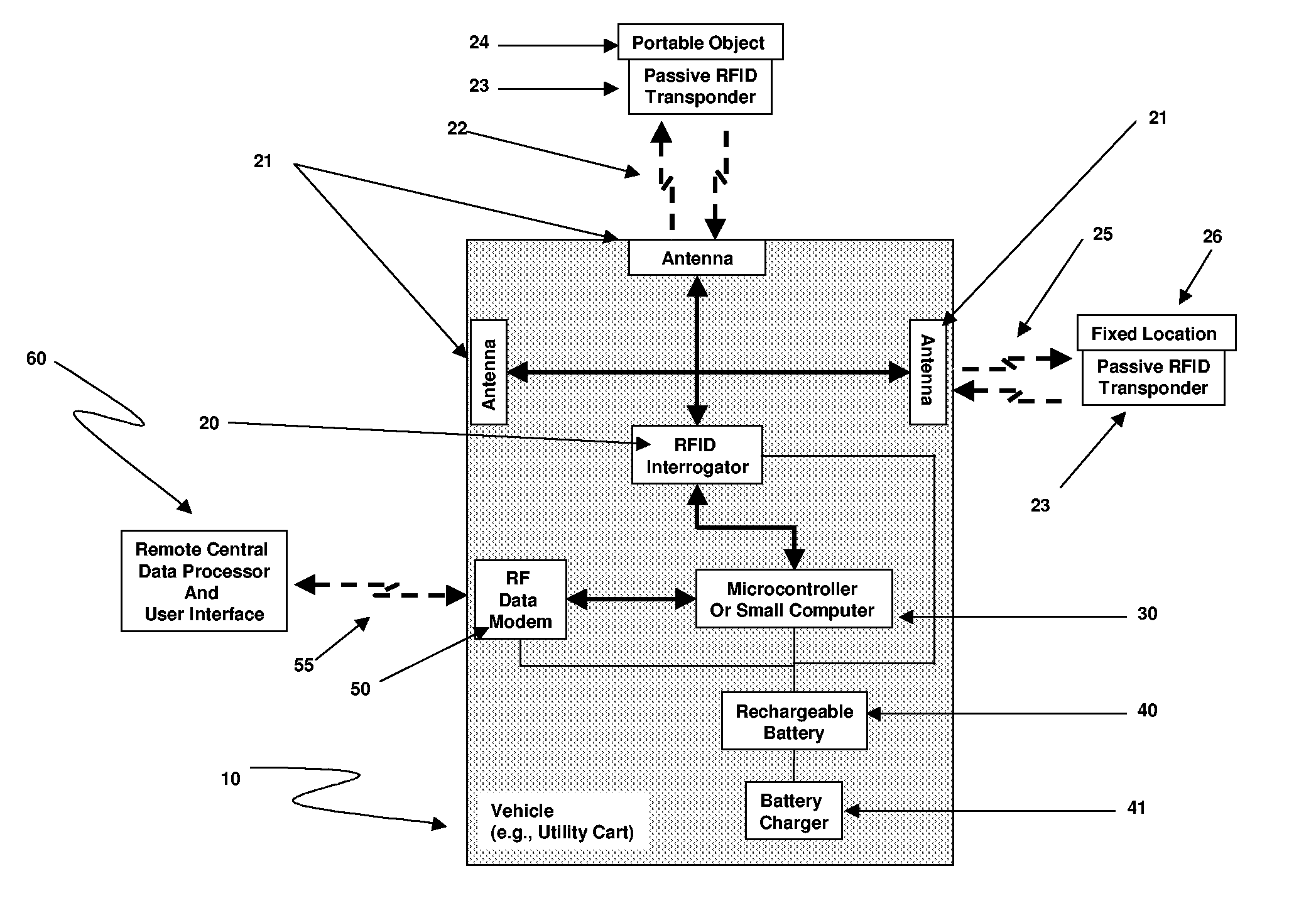

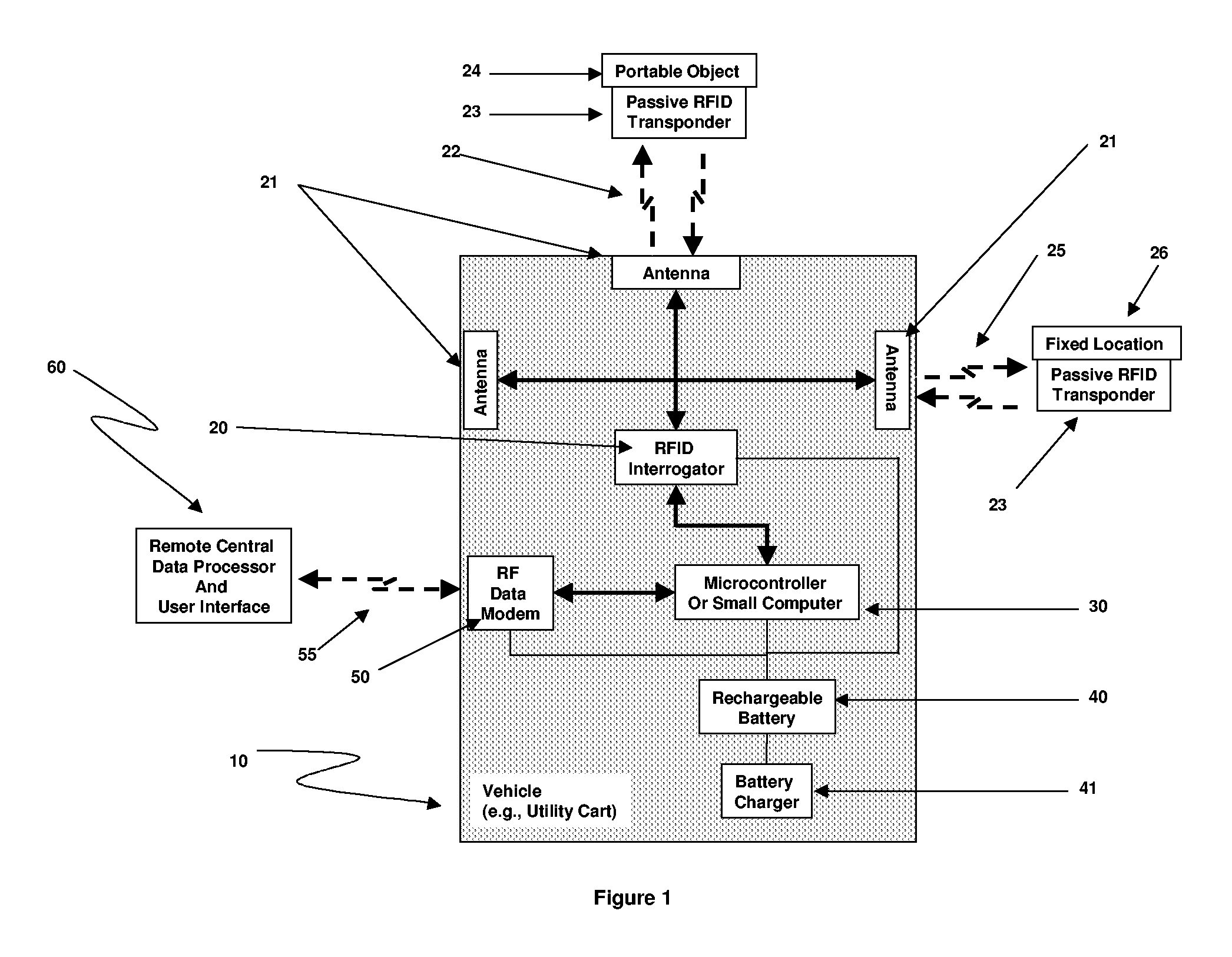

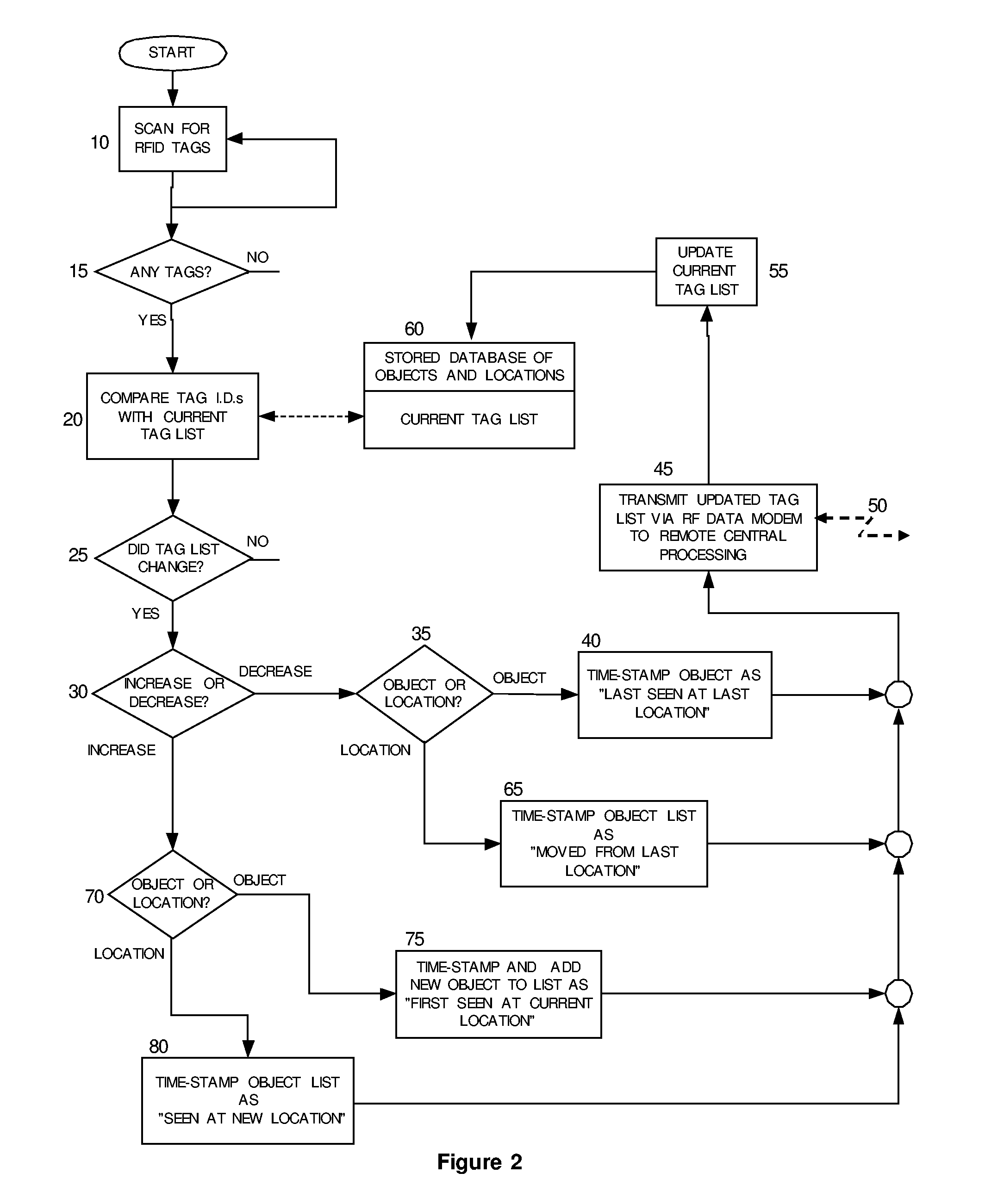

Wireless mobile asset tracking vehicle

InactiveUS20050246092A1Instruments for road network navigationMemory record carrier reading problemsModem deviceMedical equipment

A vehicle designed to detect, identify, and establish the location of portable objects in a building or structural space, such as portable medical equipment in a hospital environment, that move from place to place as they are used. The vehicle system provides for automatic detection and correlation of the objects' locations, while the vehicle is propelled within the structural environment, using passive radio frequency transponder technology to detect the presence of tagged objects and tagged fixed locations, basic identification of the object or spatial location replying to the interrogation, and time-stamped correlation of objects and spatial locations. The transmitters and antennae are mounted in the vehicle and are protected from environmental hazards such as pressure washing. An integrated microprocessor performs the requisite algorithms needed to process the reply from one or more Radio Frequency IDentification (RFID) tags, correlates the data and transmits the data, via a wireless RF modem mounted to the vehicle, to a central modem for storage and processing. Rechargeable dry cell or gel batteries power the vehicle's electronics for 24 hours or more, and the vehicle is equipped with an onboard battery charger that can be plugged into a standard AC power socket.

Owner:MOSCATIELLO RICHARD WILLIAM

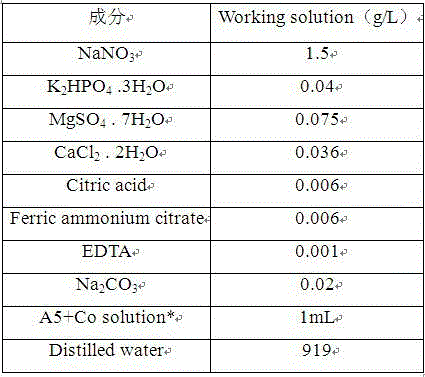

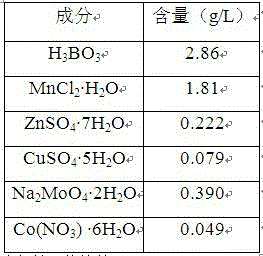

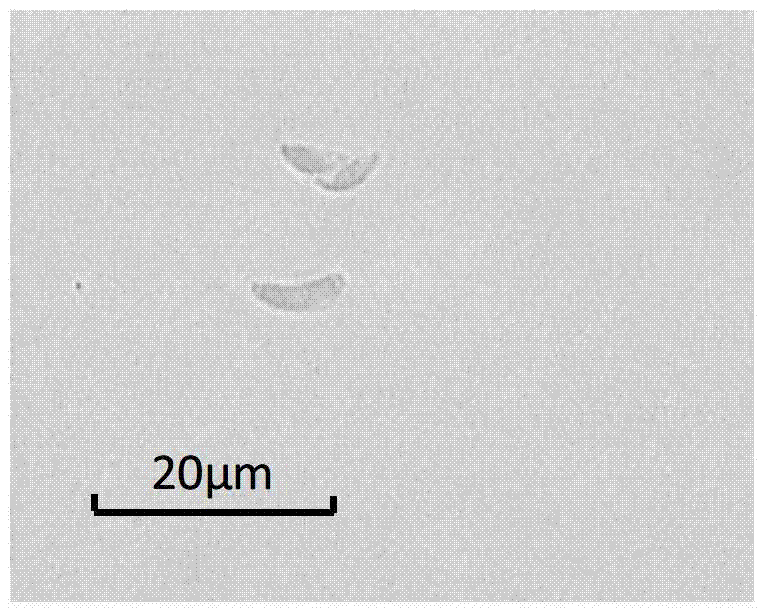

Highly oil-containing monoraphidium and culture and application thereof

The invention provides a highly oil-containing monoraphidium and culture and application thereof, the monoraphidium strain is SS-B1, the classification and nomenclature of the monoraphidium is monoraphidium sp, the monoraphidium is preserved in CGMCC (China General Microbiological Culture Collection Center) on April 15, 2013, and the preservation number is CGMCC No.7479. The monoraphidium strain is able to tolerate high concentrations of CO2 and SO2, highly oil-containing biological matters can be obtained by light autotrophic growth by use of CO2 and SO2 containing waste gas or flue gas, the carbon fixation efficiency is high, cell total lipid content accounts for more than 40% of dry cell weight, and biodiesel can be produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

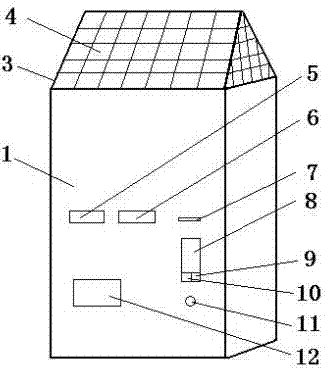

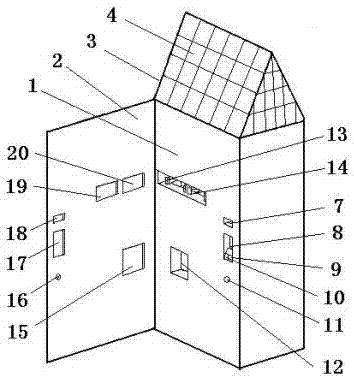

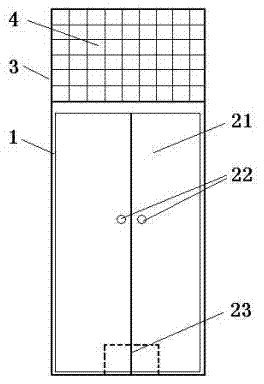

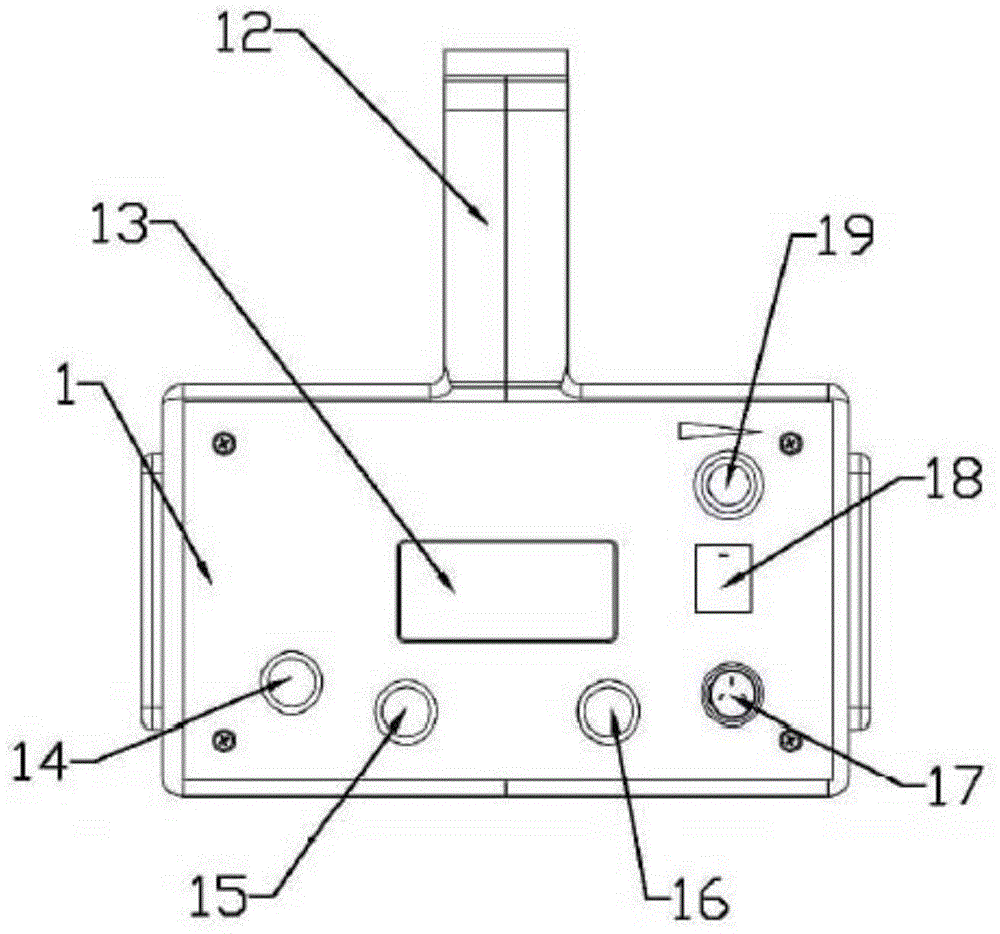

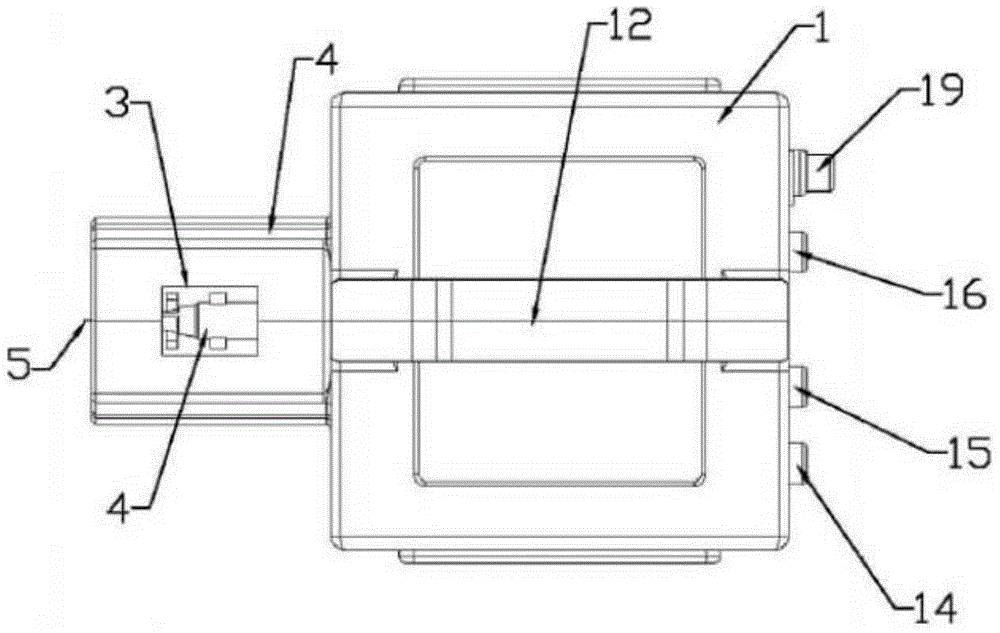

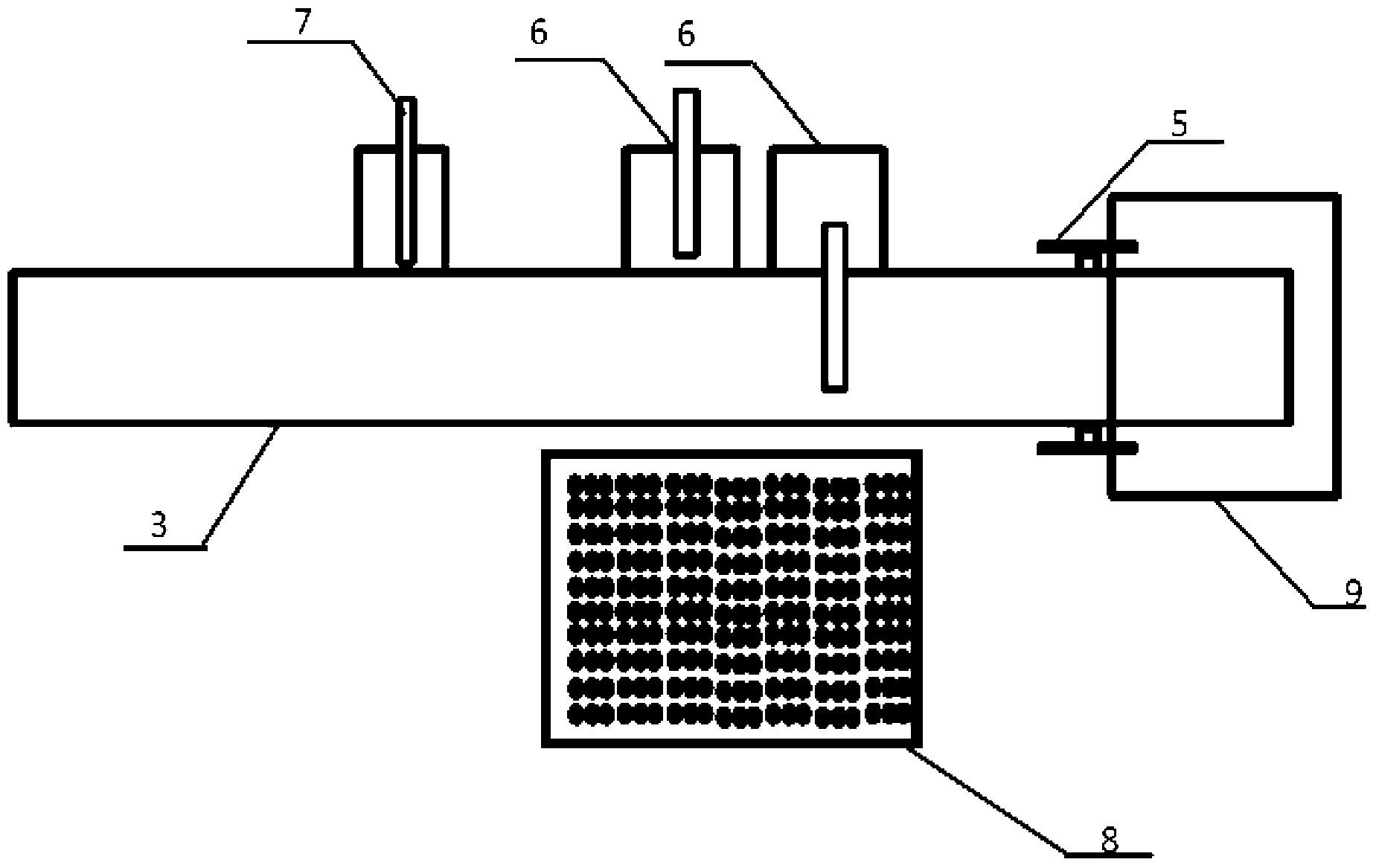

Solar-powered device for paid recycling of waste cells

InactiveCN102654927AAdapt to the needs of different applicationsActively Promote Recycling EffortsReturnable containers actuationLithiumEngineering

The invention relates to a solar-powered device for paid recycling of waste cells, containing a box body, a box door and a box top, wherein a dry cell and lithium cell inlet and an environmental bag providing opening are arranged on one side of the front surface of the box body, the inner end of the dry cell and lithium cell inlet is connected with a waste cell storage cavity, and the inner end of the environmental bag providing opening is connected with an environmental bag storage cavity; the other side of the front surface of the box body is provided with a card inserting opening, a display screen, an associated button and a locking eye; the back surface of the box body is provided with a back box locking eye and an accumulation cell; and the box door is provided with various opening holes consistent to a structure and a position of the front surface of the box body, a solar cell panel is arranged on the box top, the solar cell panel provides electric power for each component, the information of each working component is integrally processed and controlled by a control chip, and the processed information is displayed on a display screen. The invention provides the device for paid recycling of the waste cells, which uses the modes of rewarding with a real object, or calculating integrals for uniform award, thus positively developing a recycle operation of the waste cells.

Owner:SHANGHAI DIANJI UNIV

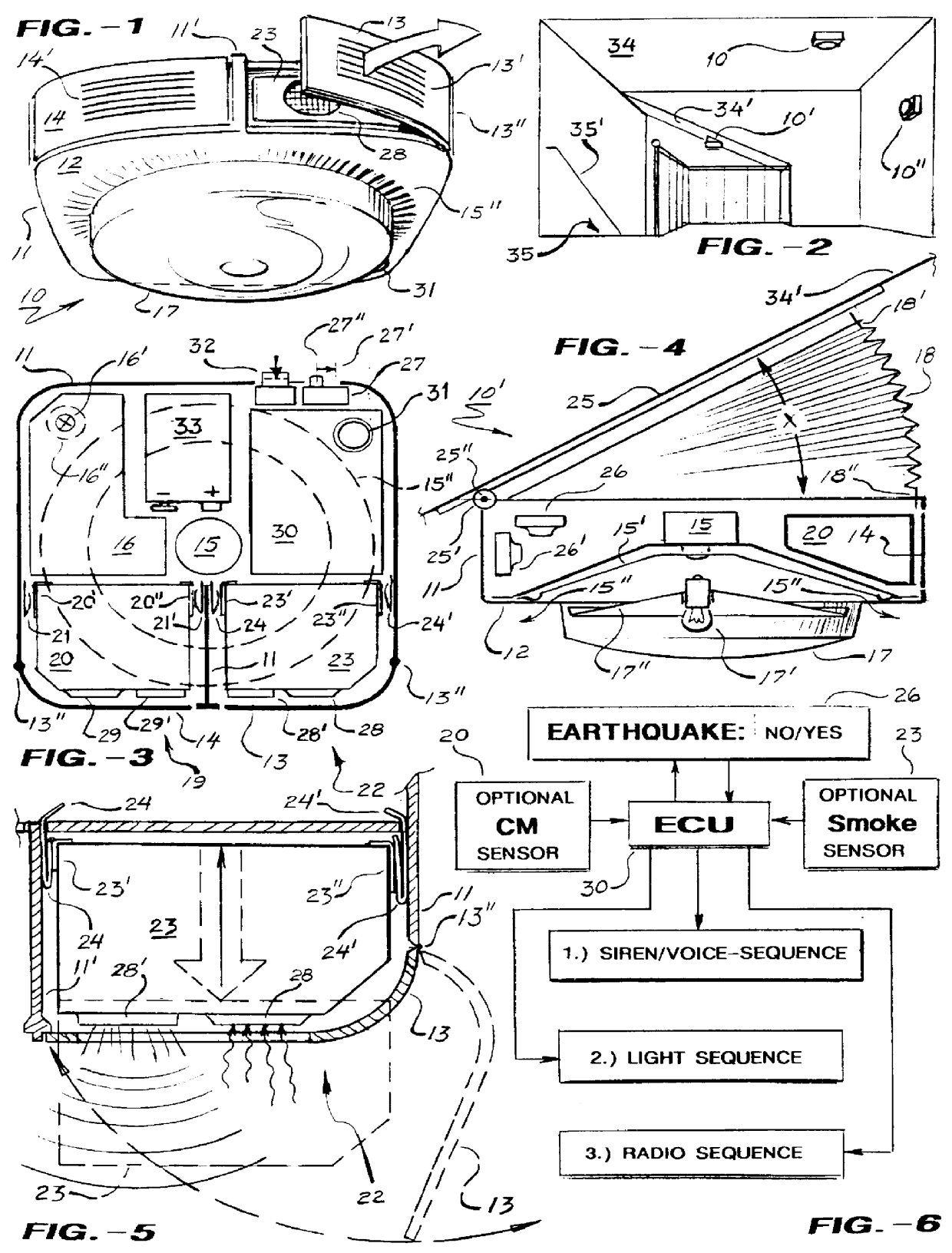

Quaker-alerter w/radio-advisory and modular options

An improved safety related compact hand-portable apparatus for home or office use, EQ-Alert TM is ceiling or shelf mountable, activating upon sensing a minimum-threshold earthquake preferably of about 3.25 / Rictor-scale intensity, instantly emitting a series of approximate 110-decibel level siren-alarms;-preferably along with activation of a safety-lamp to illuminate an immediate floor-area in event of community power-outage. A preferably dry-cell powered dc / electronic IC-chip timer-circuit, limits duration of the audible-alarm, triggered by sufficient movement of an internal omni-directional mercury n.o. / jiggle-switch. Upon completion of the timed audible-alarm and optional voice-chip announcement, the timer-circuit sequences a conventional integral superheterodyne-AM / radio user has preset to a local Conelrad / news-station, for ongoing notification of any earthquake rescue procedures. Optional provision for plug-in circuit-modules, facilitates adding of allied safety-units, such as substantially conventional smoke-alarm, and carbonmonoxide-alarm detectors, sharing the audio-transducer and IC-microprocessor; to issue forth separate short programed voice-announcements as to the detected hazards.

Owner:YOUSIF MARVIN J

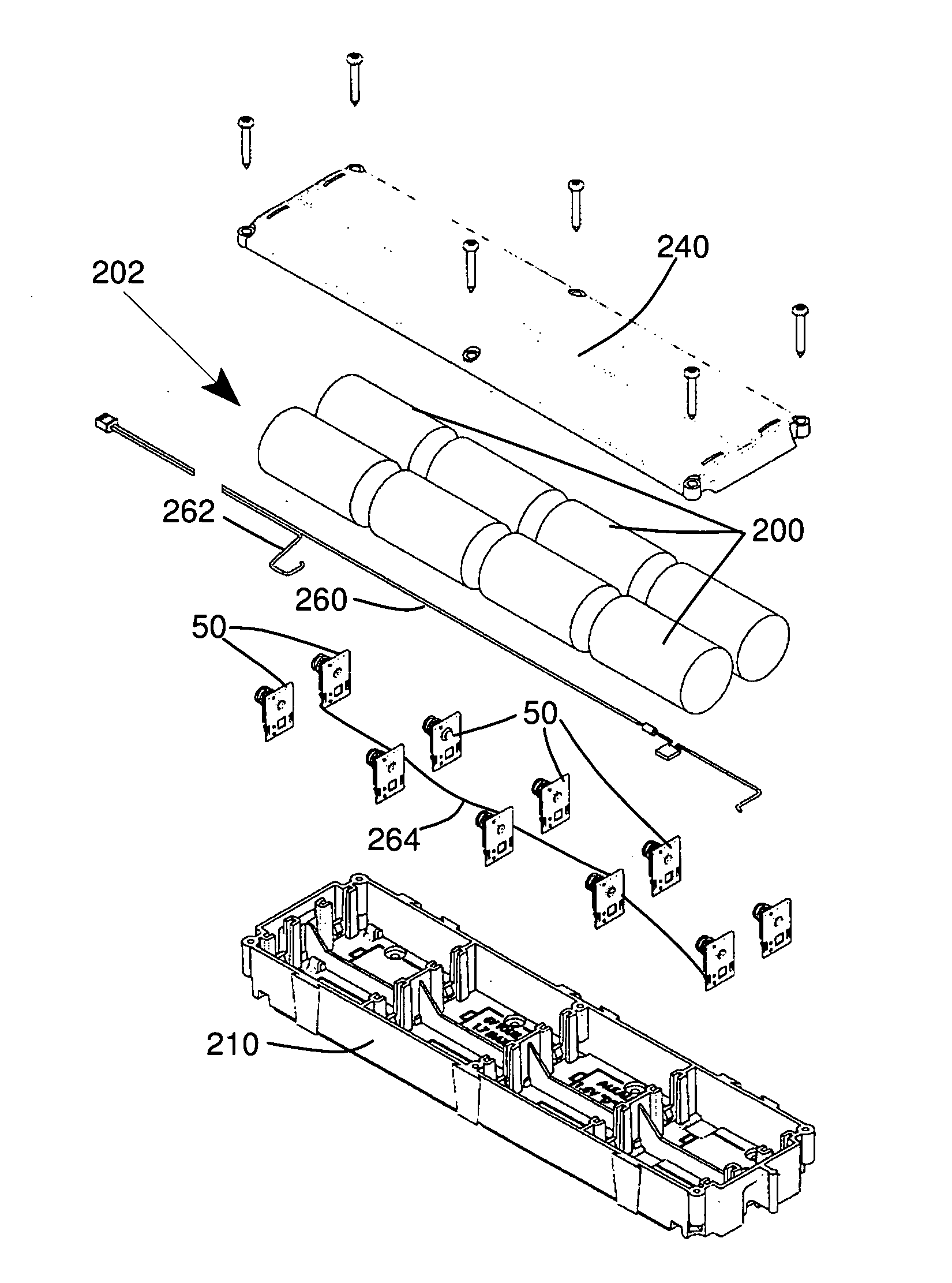

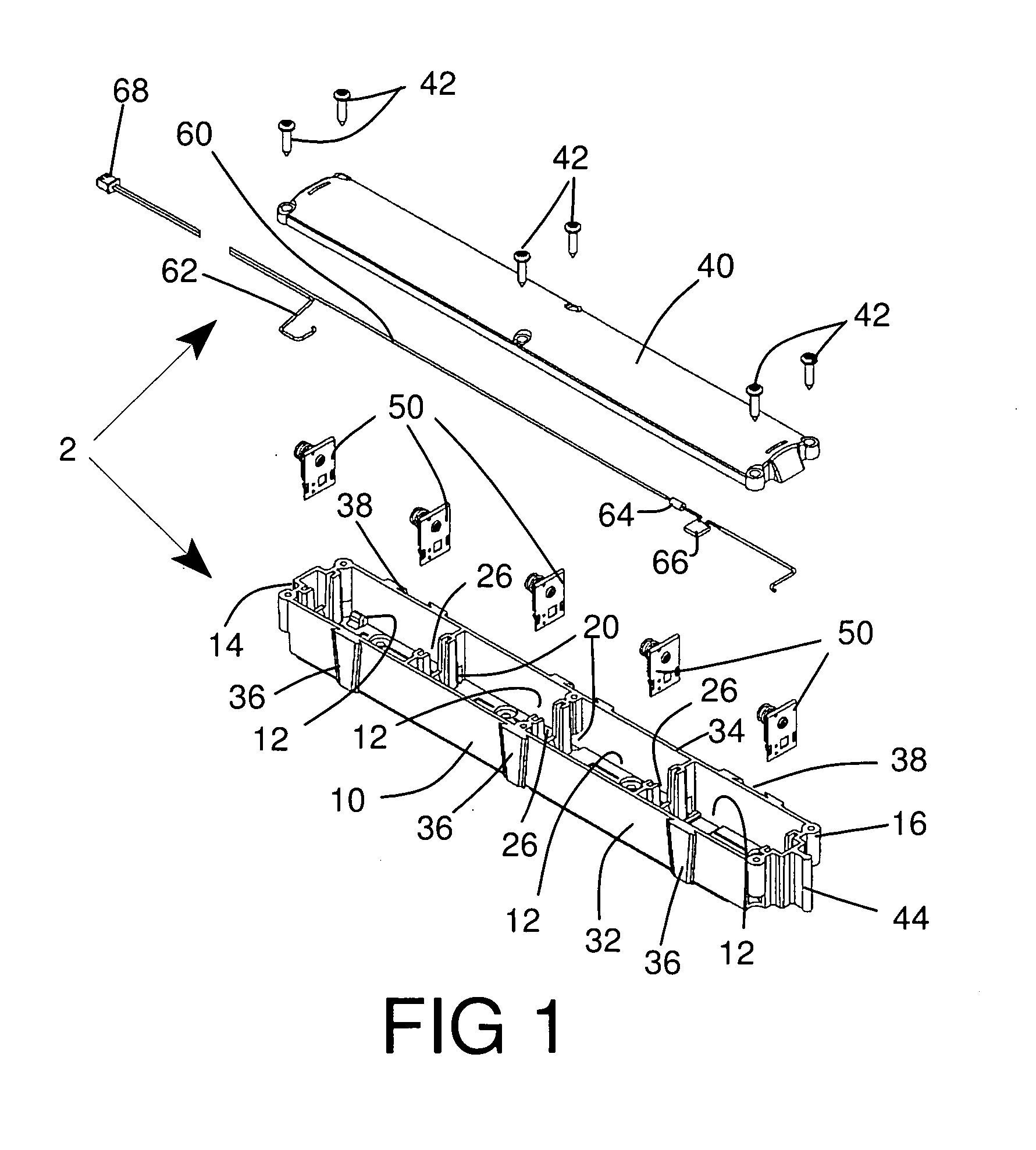

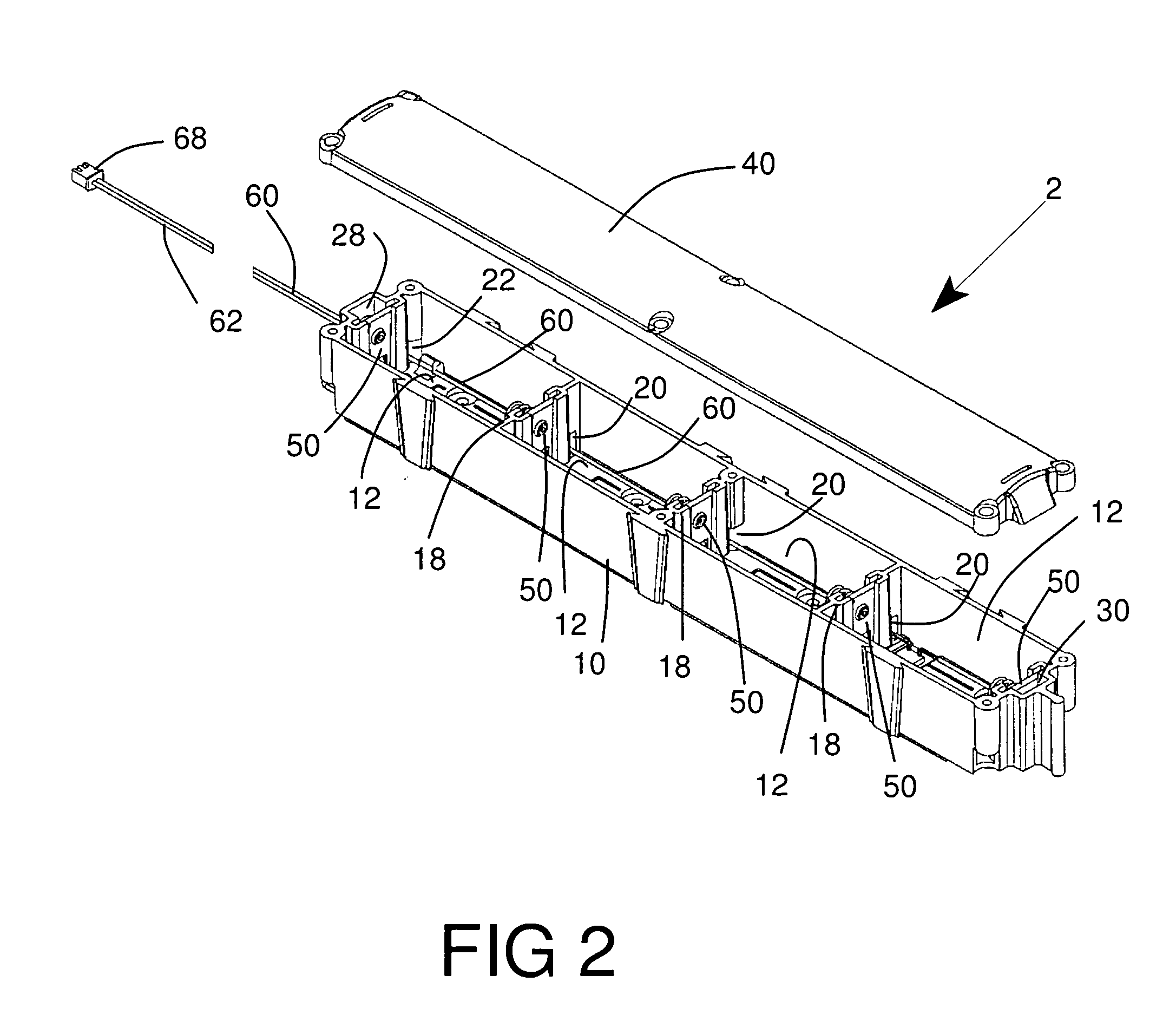

Modular dry cell battery pack

A battery pack or receptacle includes a battery housing having end to end battery compartments. Contacts are located at each end and between battery compartments so electrical continuity is possible only if the batteries are properly oriented. Contacts can be wired so that the batteries are wired in series and the batteries in different housings can be wired in parallel so that multiple battery receptacles can be ganged to provide prescribed DC voltage levels and amperage levels for many different applications. The battery receptacles and its components thus form a modular assembly suitable for use in electronic point of sale displays and in other applications where stand alone, portable or field assembled devices would be employed.

Owner:IMAGEWORKS DISPLAY & MARKETING GROUP

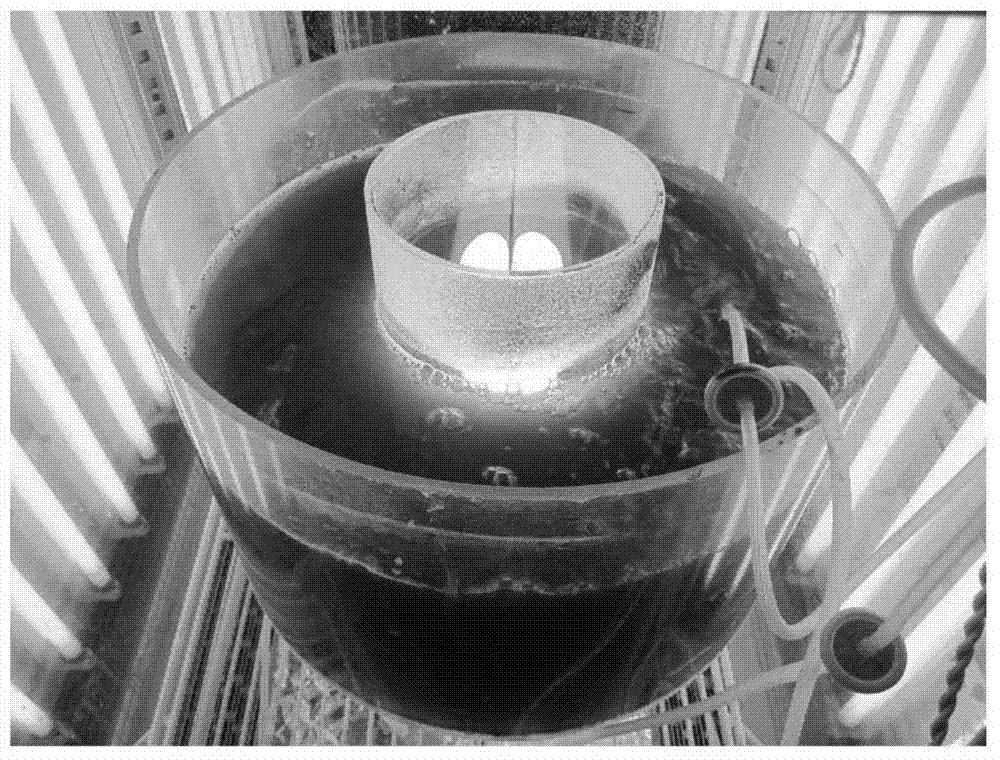

Portable electrostatic spinning equipment and using method thereof

ActiveCN104790049AAchieve directional depositionLight in massSpinning head liquid feederFilament/thread formingElectrical batteryVoltage regulation

The invention discloses portable electrostatic spinning equipment and a using method thereof. The equipment comprises a dry battery power source, a high-voltage electrostatic generator, a gas generator and a spinning ejection device. According to the equipment, a dry battery arranged in a battery bin is used as the power source, the high-voltage electrostatic generator comprises a DC-high voltage DC inverter and a voltage regulation circuit. The voltage provided by the dry battery is increased by the DC-high voltage DC inverter to be used as spinning voltage, the airflow auxiliary spinning technology is used, a spinning nozzle is sleeved with an airflow guide pipe connected with the gas generator, and the flow direction of airflow guided into the airflow guide pipe by the gas generator is the same as the spinning jet injection direction. The equipment is low in mass, small in size and convenient to carry, can be used with no external power source, is not limited by using environment, can precisely control and adjust spinning parameters, is convenient to use and wide in application range and can better achieve orientated fiber deposition.

Owner:QINGDAO KANGYUAN JULI BIOTECH CO LTD

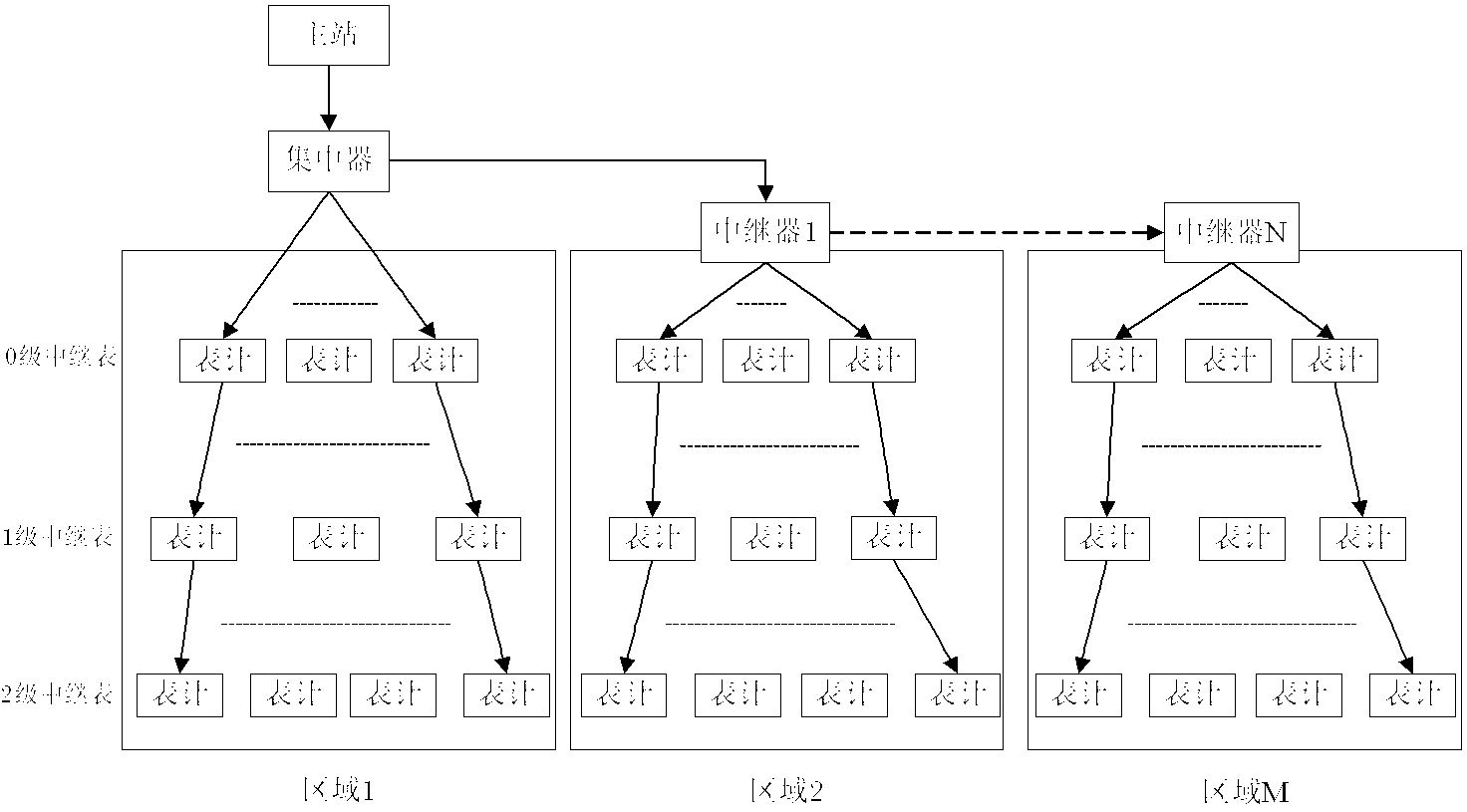

Method and system for networking wireless water meters or wireless gas meters

InactiveCN103280089AReduce power consumptionImprove networking efficiencyTransmission systemsResidenceEngineering

The invention discloses a method and a system for networking wireless water meters or wireless gas meters. The method comprises the following steps: carrying out regional division on wireless water meters or wireless gas meters in some residence community; reading all meters in one region by a concentrator, recording wireless signal intensity information of all levels of relay meters capable of directly reading; finding out all levels of stably reading relay meters through the wireless signal intensity analysis, and sequencing according to the priority sequence from the weak signal intensity to the strong signal intensity; finding out the reading ranges of all levels of relay meters according to the sequence; and finishing the regional networking by the concentrator, networking the meters regionally by the concentrator, finally finishing the networking in the residence community, and managing the meters according to routing information. The method is completely opposite to a conventional meter end self-networking mode, the concentrator is adopted to help the wireless water meters or the wireless gas meters to network, and the power consumption required by networking is reduced greatly, so that the requirement that the wireless water meters or the wireless gas meters supplied with power by batteries are used for more than 7 years is met.

Owner:HUNAN WEIMING ENERGY TECH CO LTD

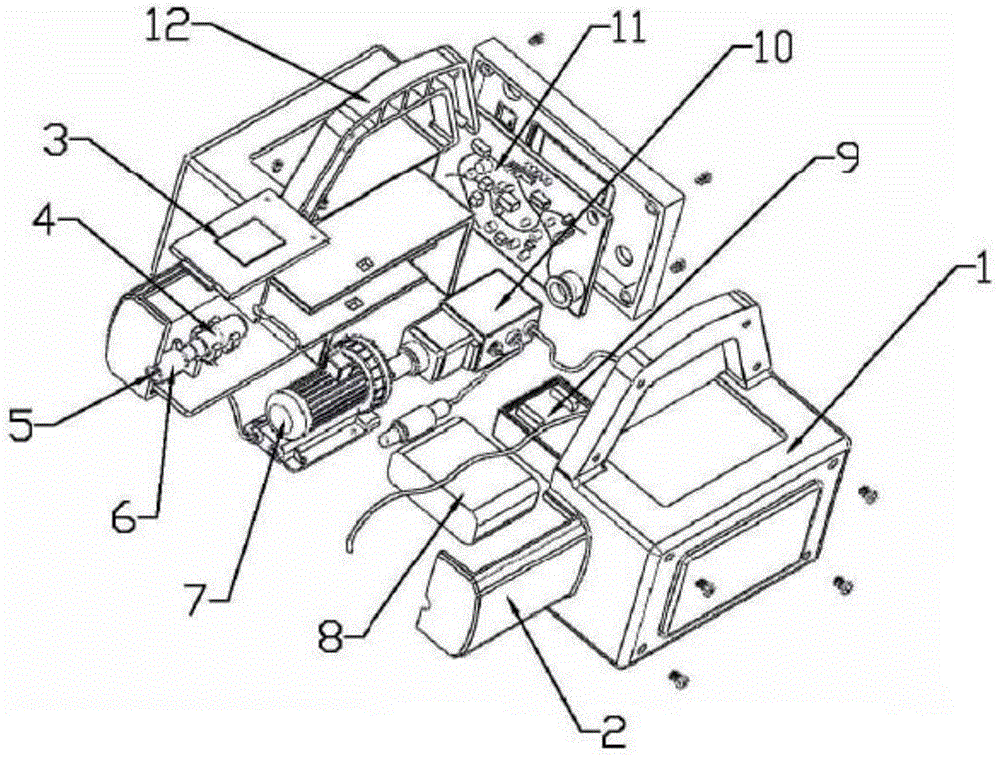

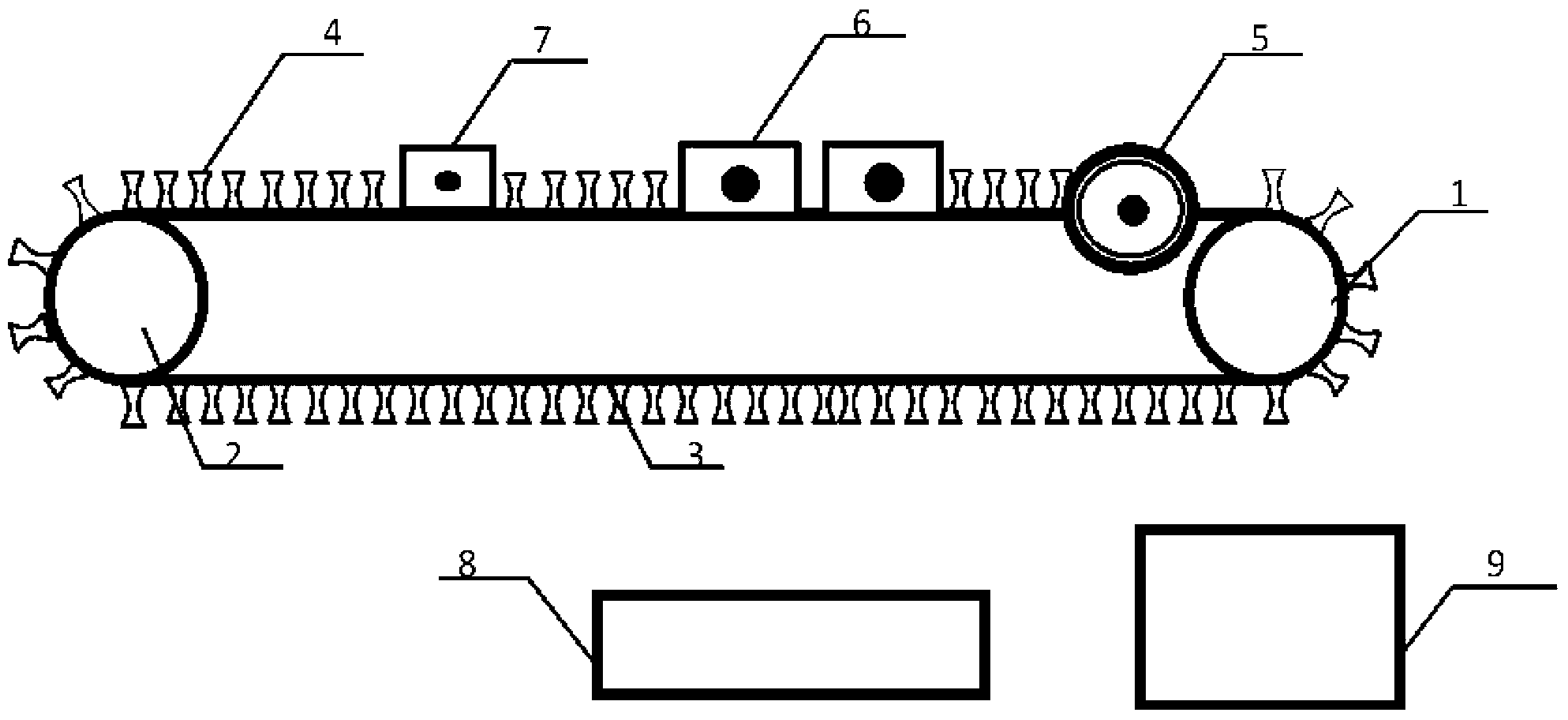

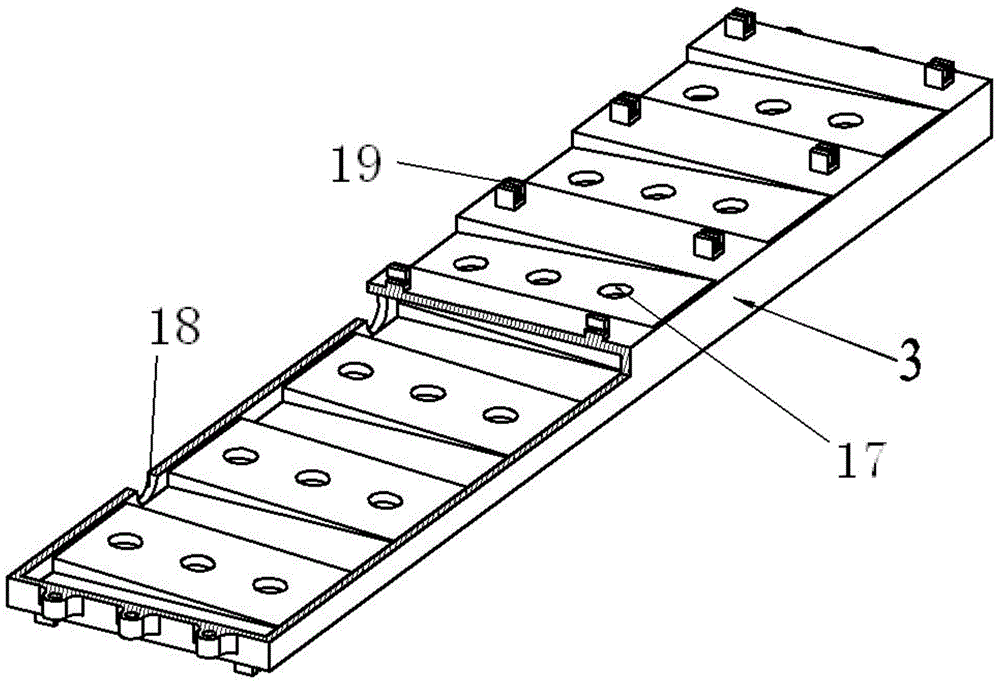

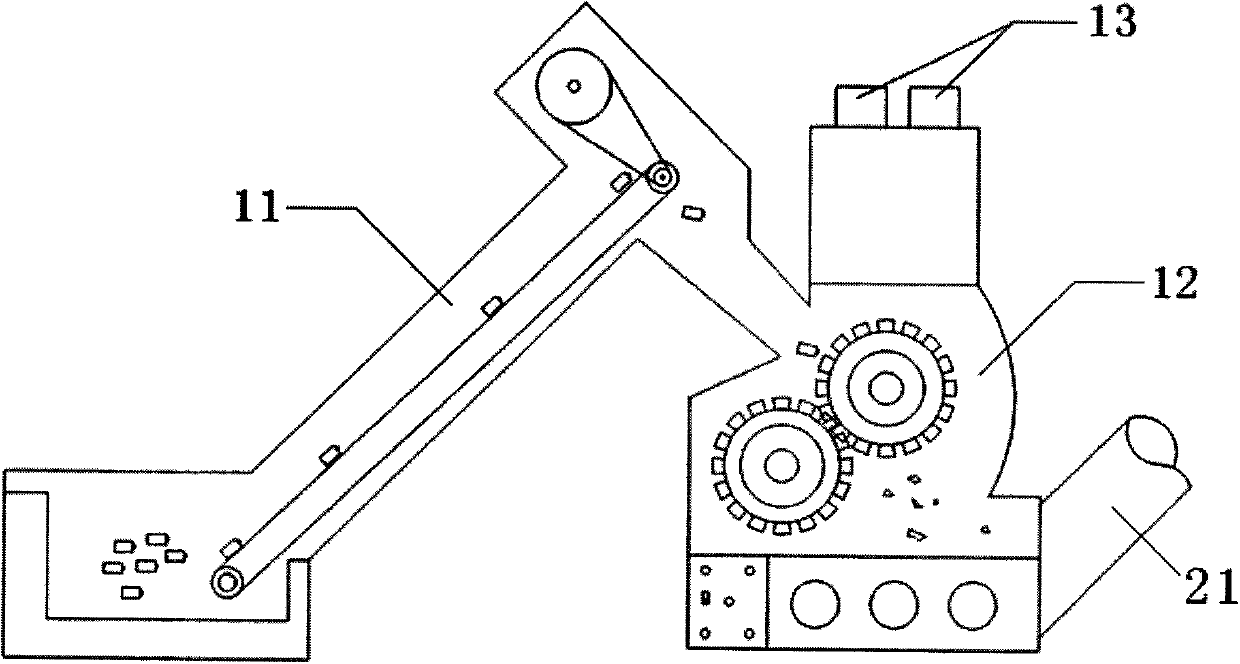

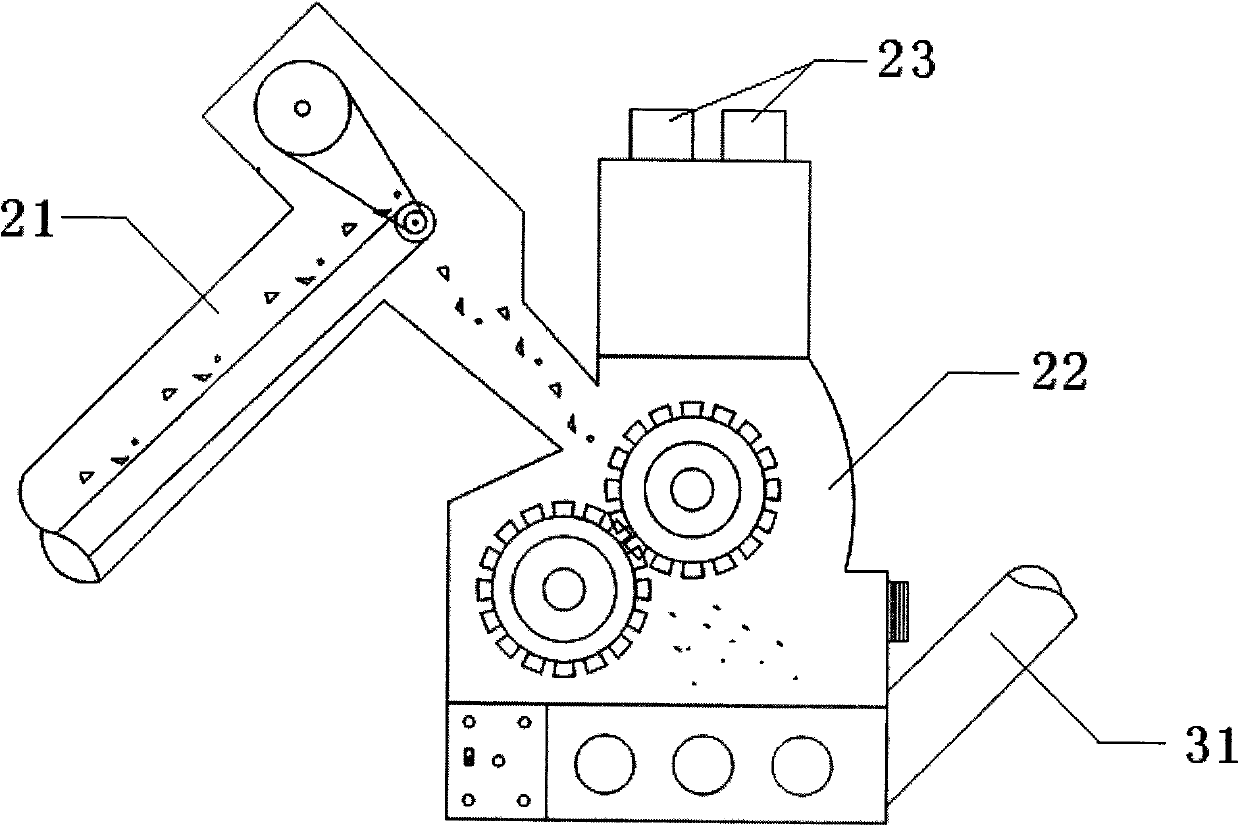

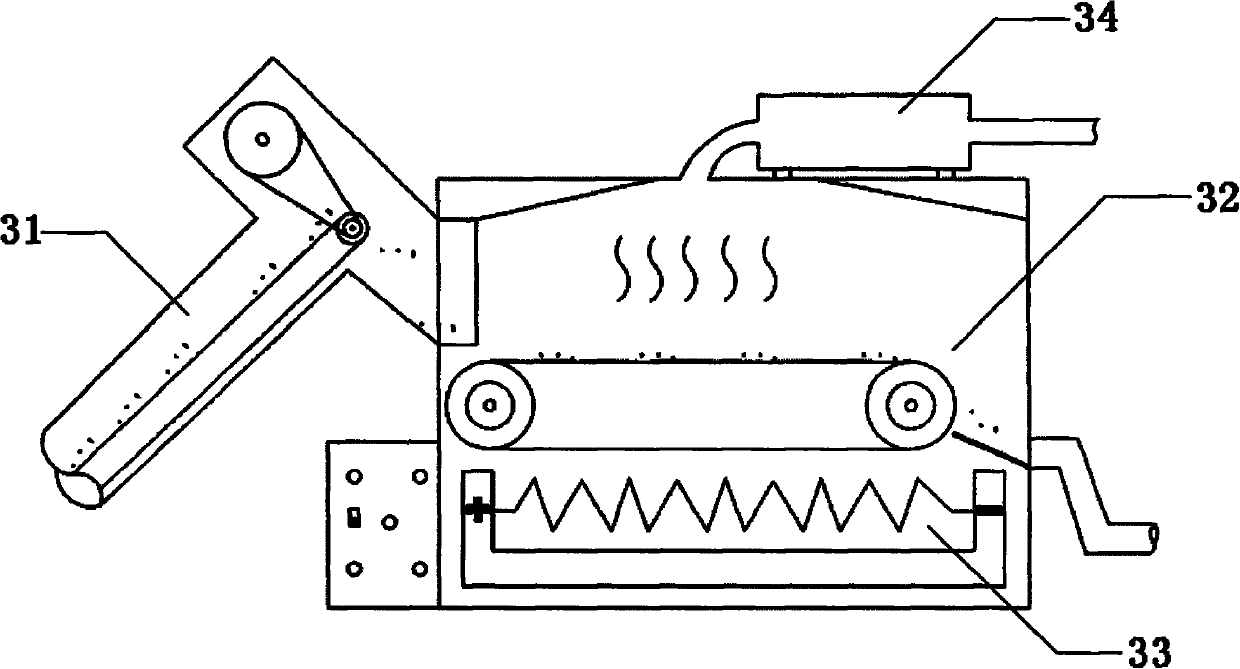

Automatic dismantling and separating device for waste dry cell and dismantling and separating method

InactiveCN103296294AAvoid processing inefficienciesSolve follow-up processing difficultiesSolid waste disposalReclaiming serviceable partsProcess engineeringConveyor belt

The invention discloses an automatic dismantling and separating device for a waste dry cell and a dismantling and separating method, The automatic dismantling and separating device comprises a roller, a belt, a grinding wheel group, a firing pin, a cutter and a vibrating screen, wherein the conveyor belt is provided with a plurality of rubber partition plates; the grinding wheel group is arranged on the conveyor belt; the first side of the conveyor belt is provided with the cutter and the firing pin; the second side of the conveyor belt is provided with the vibrating screen. A first roller, a grinding wheel, the cutter and the firing pin are powered on; the waste dry cells are fixedly arranged between two adjacent partition plates of the belt one by one. Along with the movement of the belt, two ends of each waste dry cell are cut off by the grinding wheel rotating at high speed, paste and a carbon bar of the dry cell are pushed out of a shell of the dry cell through the firing pin, and a zinc skin is separated from a plastic skin through the cutter. The automatic dismantling and separating device and dismantling and separating method for the waste dry cell have the advantages that a paste electrolyte, a zinc drum and the carbon bar can be comprehensively recycled, and the processing working efficiency and a separation effect of the waste dry cell can be improved.

Owner:ANHUI UNIV OF SCI & TECH

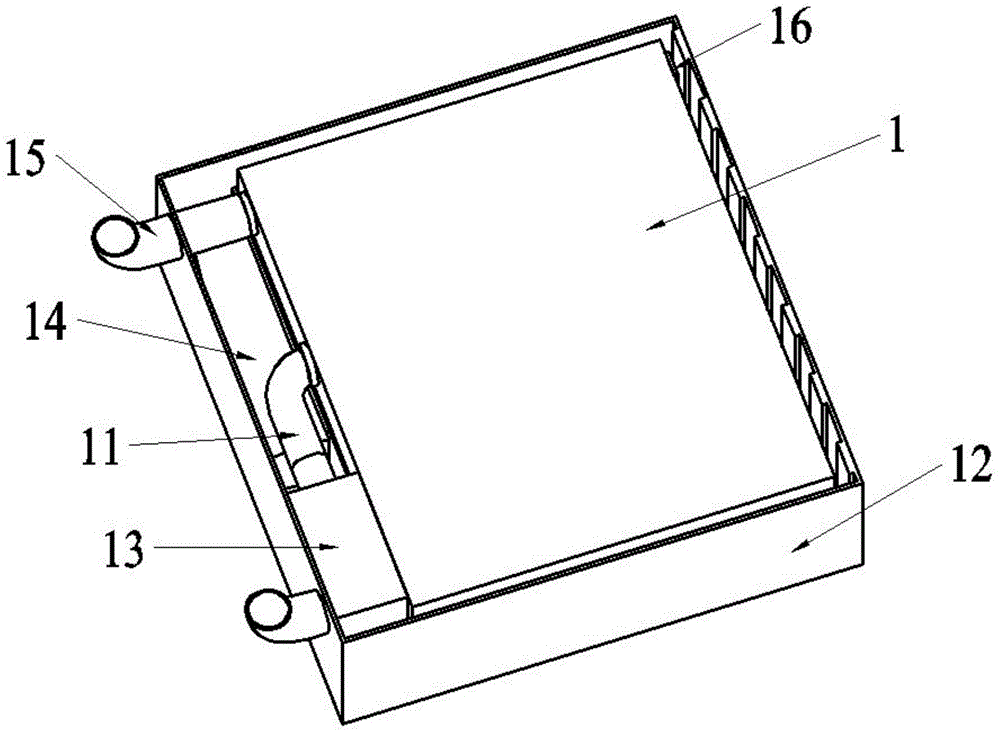

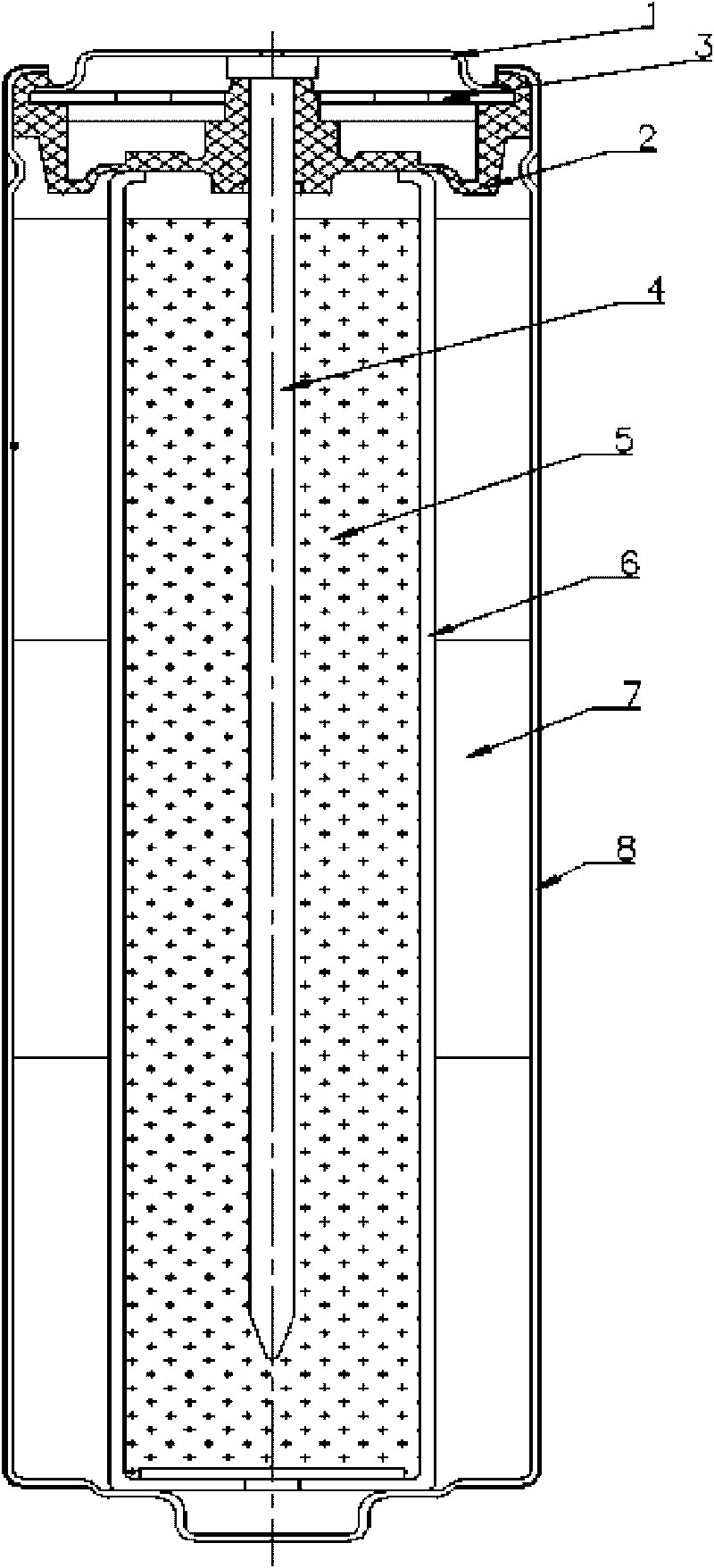

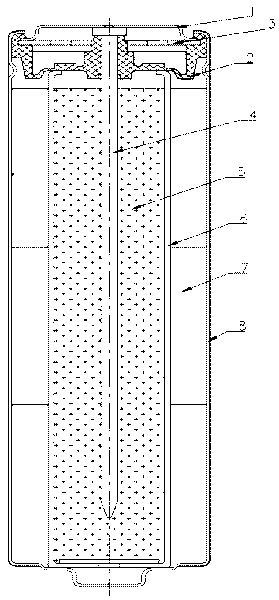

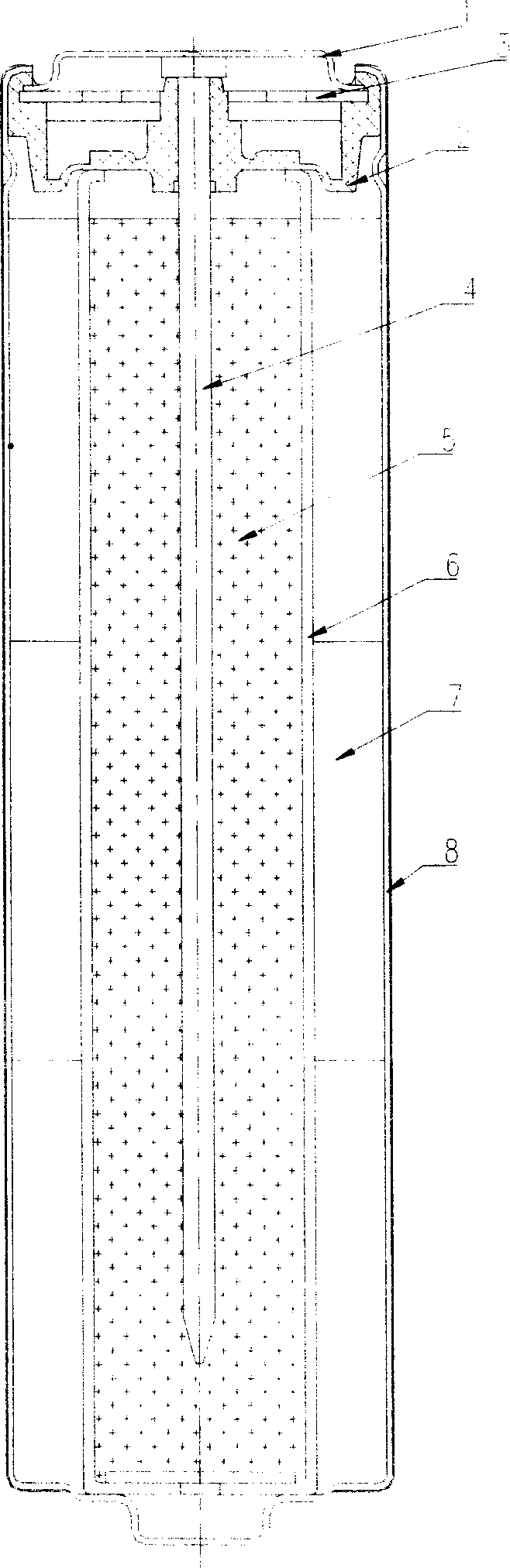

High water-resistant thermal-insulation battery box for electric automobile

ActiveCN103985922AEven heat dissipationGuaranteed temperature uniformitySecondary cellsCell component detailsHeat conservationBattery cell

The invention relates to the technical field of batteries of electric automobiles, specifically to a high water-resistant thermal-insulation battery box for an electric automobile. The battery box comprises a sealed box, a plurality of battery cells in the box and a radiator arranged in the box and connected with the plurality of battery cells, wherein each battery cell is provided with a heating device, and a battery box controller connected with the heating devices through a control circuit is arranged in the box. According to the invention, hollow heating radiating panels are arranged for heat radiation of each battery cell module, so uniform heat radiation of the battery cell modules is guaranteed, and heat radiation efficiency is improved. The heating devices are used for electric heating of the battery box when the battery box is in a low temperature state so as to guarantee reliable operation of a power lithium battery; through real time monitoring of heating plates, temperature homogeneity of a battery pack is guaranteed; the problems of heat radiation during working of batteries of an electric passenger car, heating during cold start-up and the like are overcome; and the battery box is safe and reliable and can be conveniently and rapidly dismounted.

Owner:STATE GRID CORP OF CHINA +2

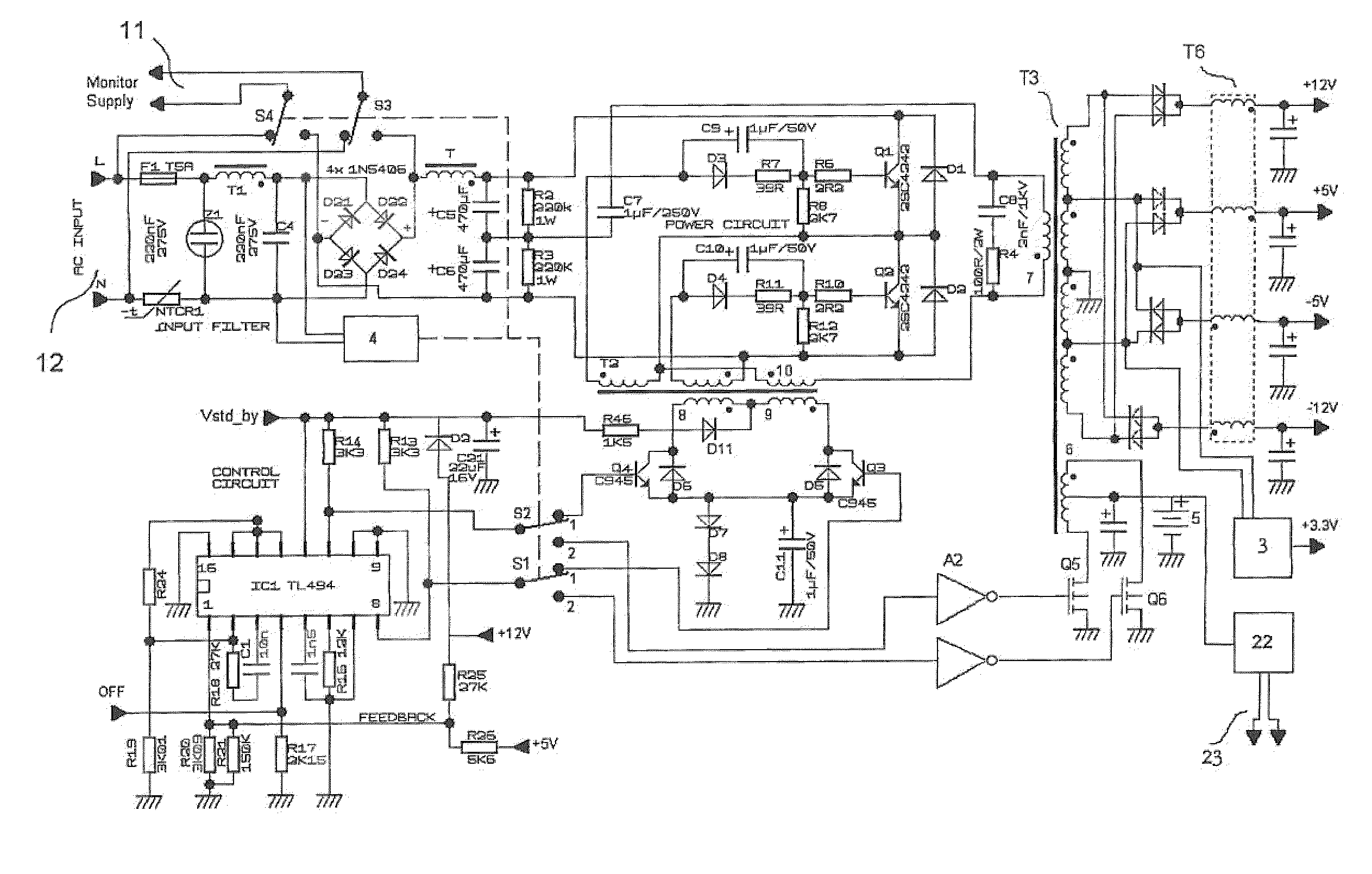

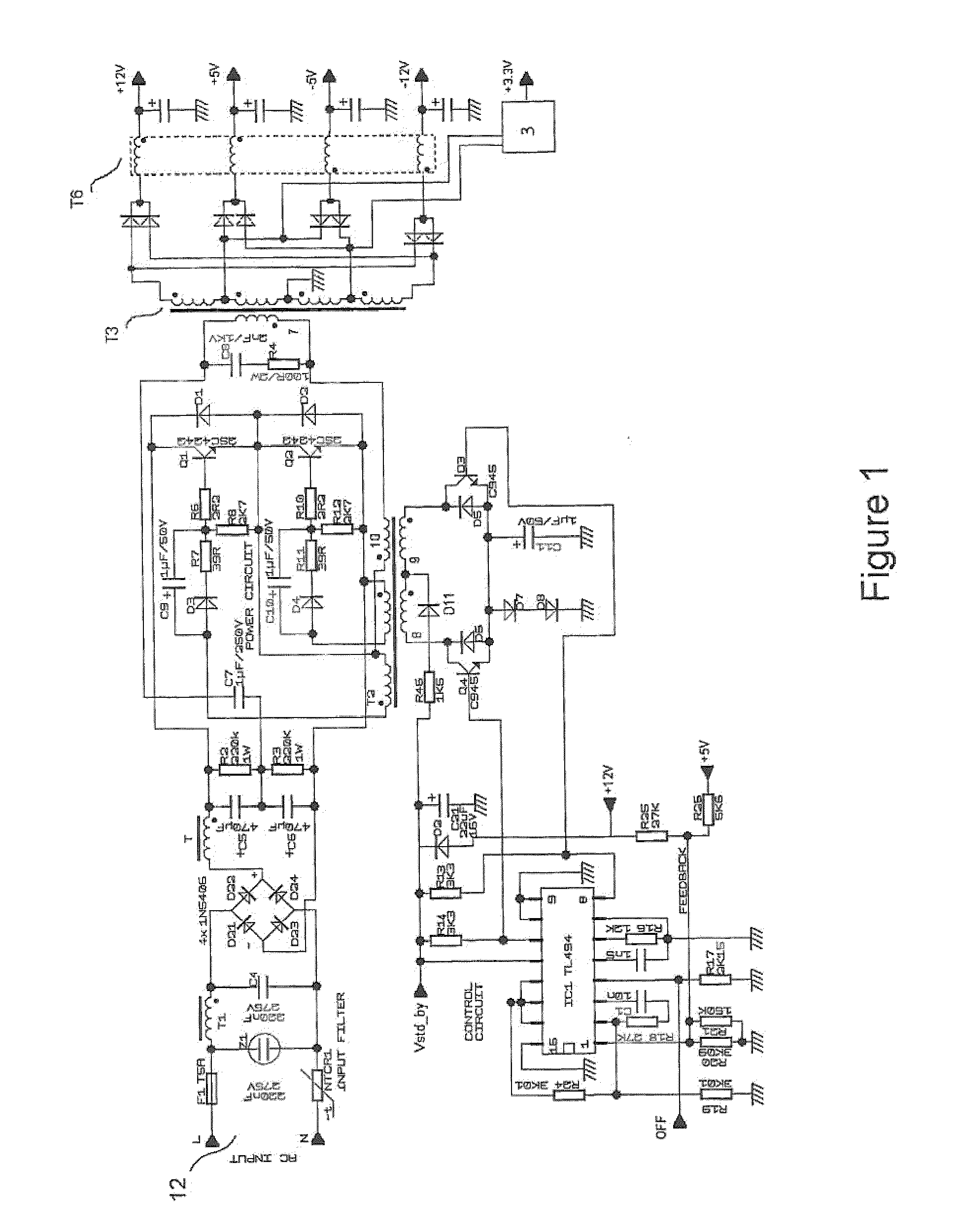

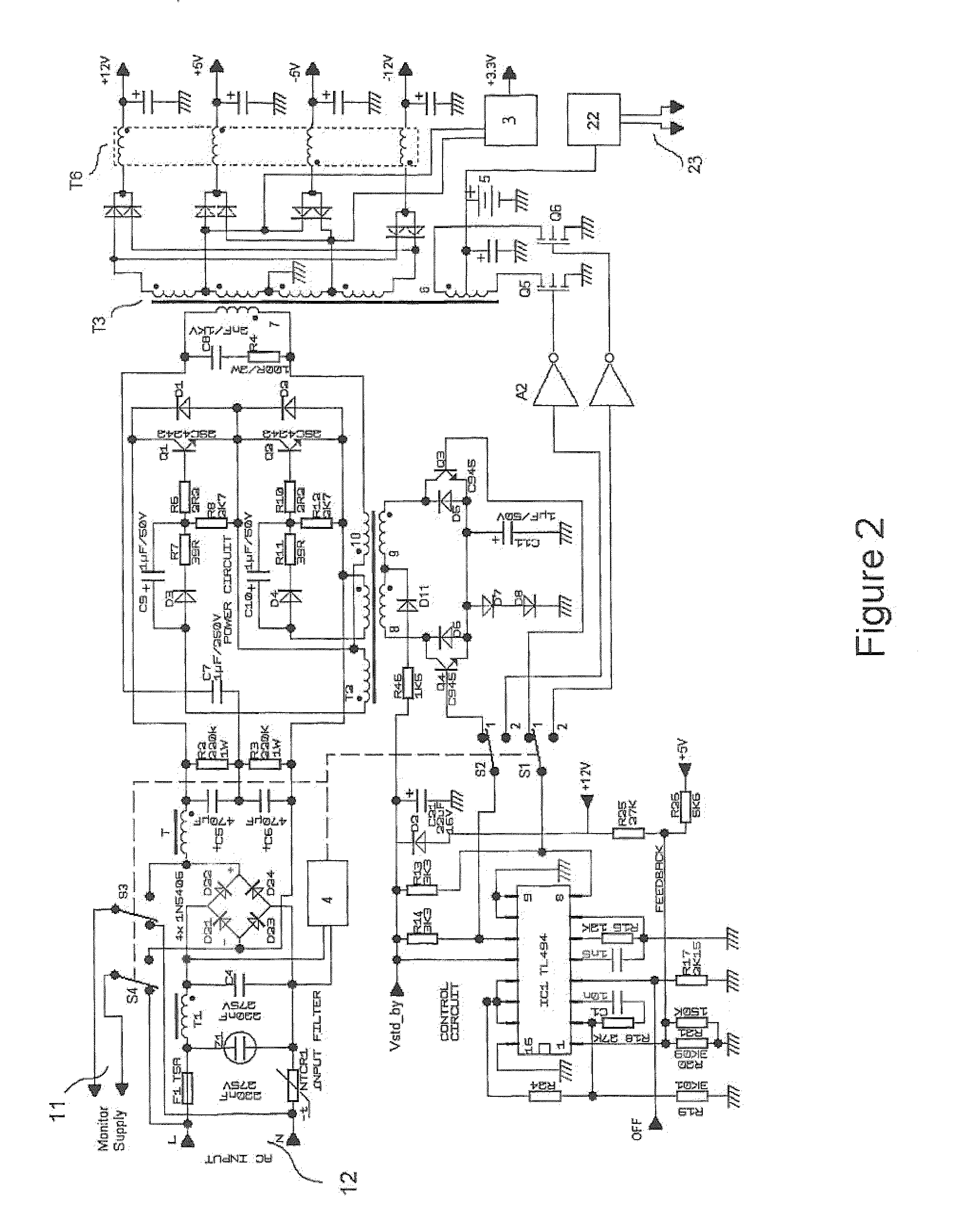

Smps circuit with multiple ac/dc inputs and application of such circuit to computer power supplies or laptop adapters

InactiveUS20100122096A1Cheap and practicalHigh voltageVolume/mass flow measurementDc-dc conversionTransformerHemt circuits

The invention relates to a switch mode power supply (SMPS—Switching Mode Power Supply) which provides the output voltages generated in the AC-network-input switch mode power supply (SMPS—Switching Mode Power Supply) circuits also with battery and similar supply inputs when necessary by using a shared power transformer (T3) having separate power input windings (7, 6) appropriate for the particular input voltage for each input supply and the power switching transistors (Q1, Q2, Q5, Q6) connected to this windings in accordance with the topology used and, which other remaining control, feedback, output rectifying and filtering circuits and other windings of the transformer are single and shared without using a second independent power supply or regulator circuit in addition to the network-input power supply. By the addition of a small dry battery, this concept is applied to the computer power supplies in order to develop an economical Uninterruptible Computer Power Supply (UCPS), which could be installed to the power supply housing in the computer case and which could power the monitor as well. It has also been applied to the laptop computer adaptors and a two-supply-input laptop computer adaptor, which works either from the automobile lighter outlet or from the network with a single adaptor, has been developed.

Owner:OZENC SERGIN

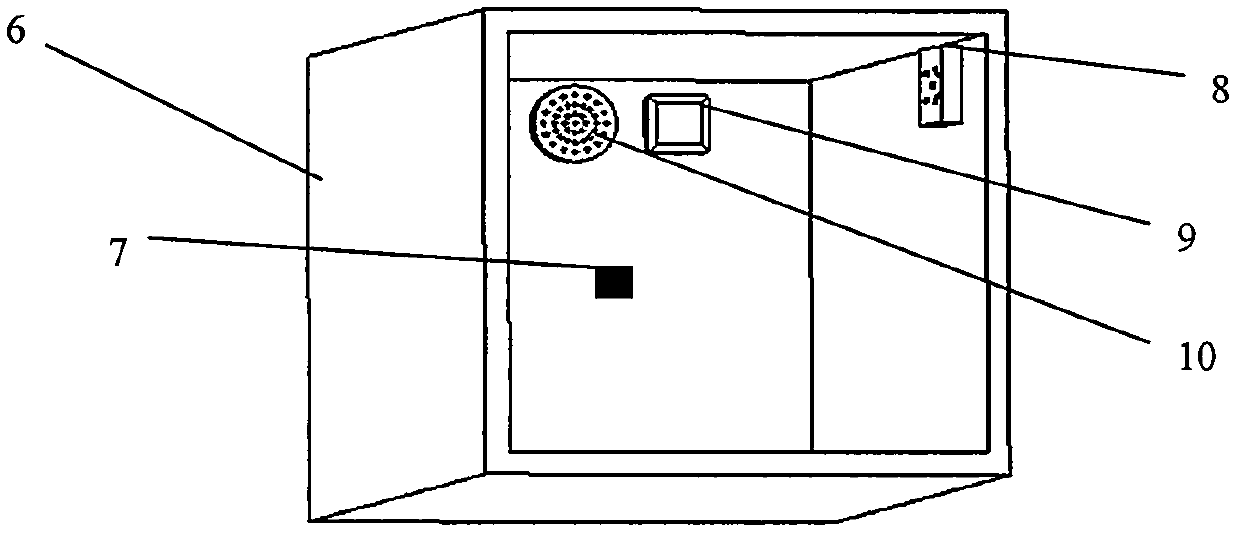

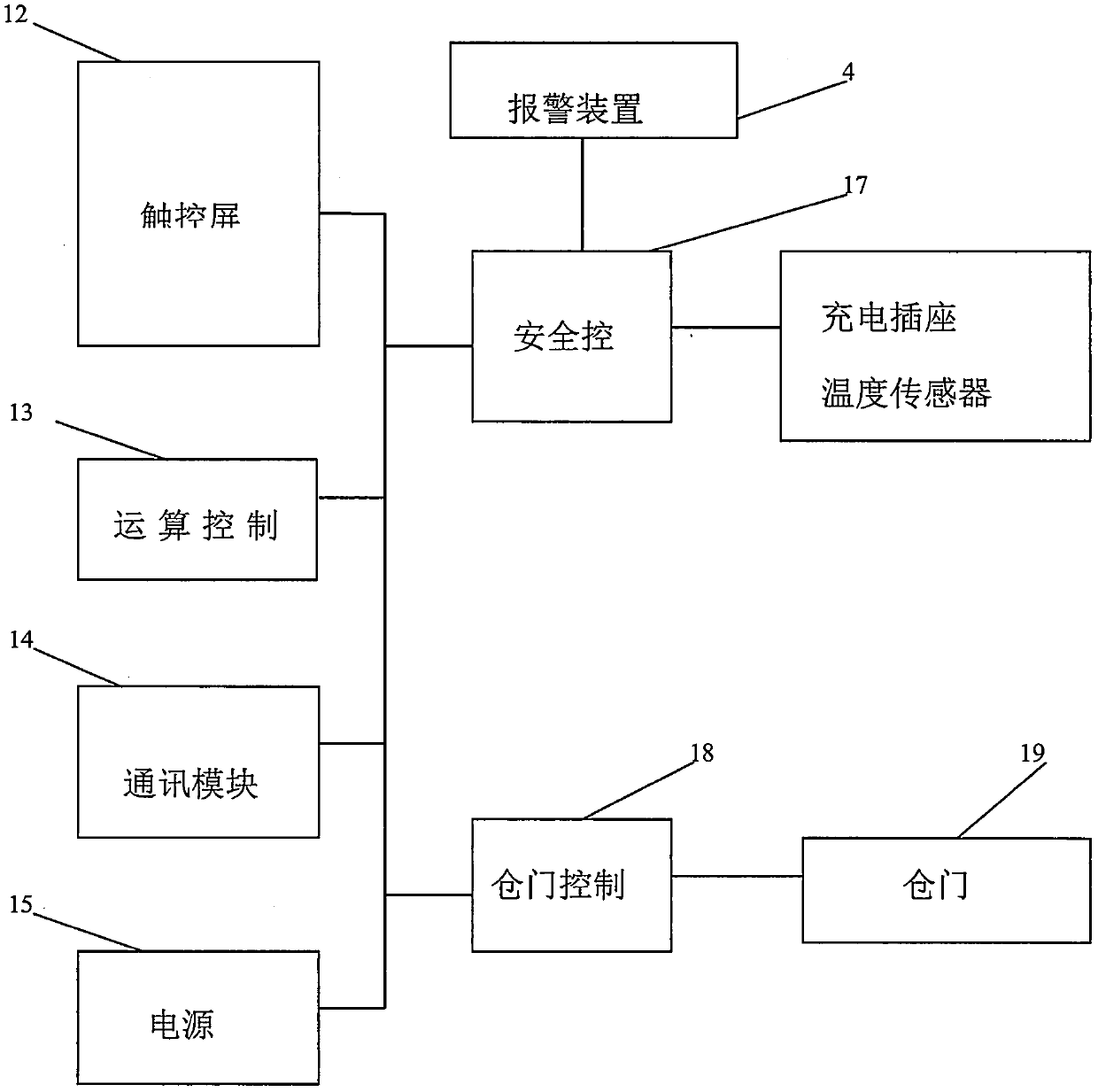

Battery safety charging storage cabinet and self-service charging method thereof

InactiveCN107856554AEasy to useRest assuredCharging stationsMobile unit charging stationsElectrical batteryDisplay device

The invention aims at providing a battery safety charging storage cabinet and a self-service charging method of the battery safety charging storage cabinet. The cabinet and the method aim at achievingthe purposes of battery charging storage safety, antitheft and charging convenience. The battery safety charging storage cabinet comprises a cabinet body, a control system and multiple battery charging storage bins, wherein the control system and the battery charging storage bins are arranged in the cabinet body. The control system comprises an operation and display device, a computing control device, a safety control device, a communication device, a bin door control device, an alarm device, a power source and the like. In addition, the battery safety charging storage cabinet has a fireproofand fire extinguishing function. By the adoption of the provided method, a self-service charging effect can be achieved, the cabinet is convenient and quick to use, a user charges a battery conveniently, meanwhile battery safety can be effectively guaranteed, and fire accidents caused by battery failure can be effectively avoided.

Owner:陈伊涵

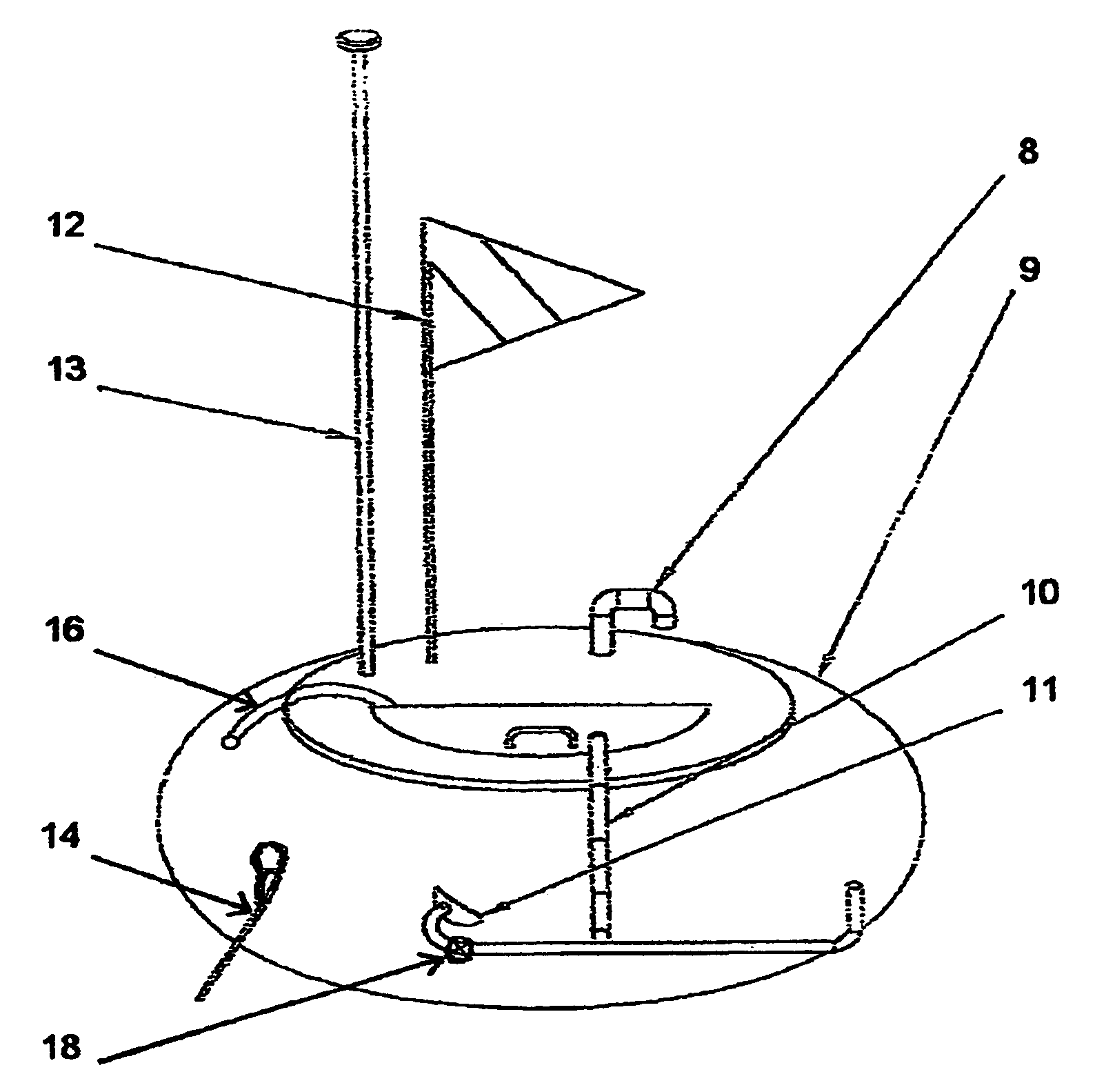

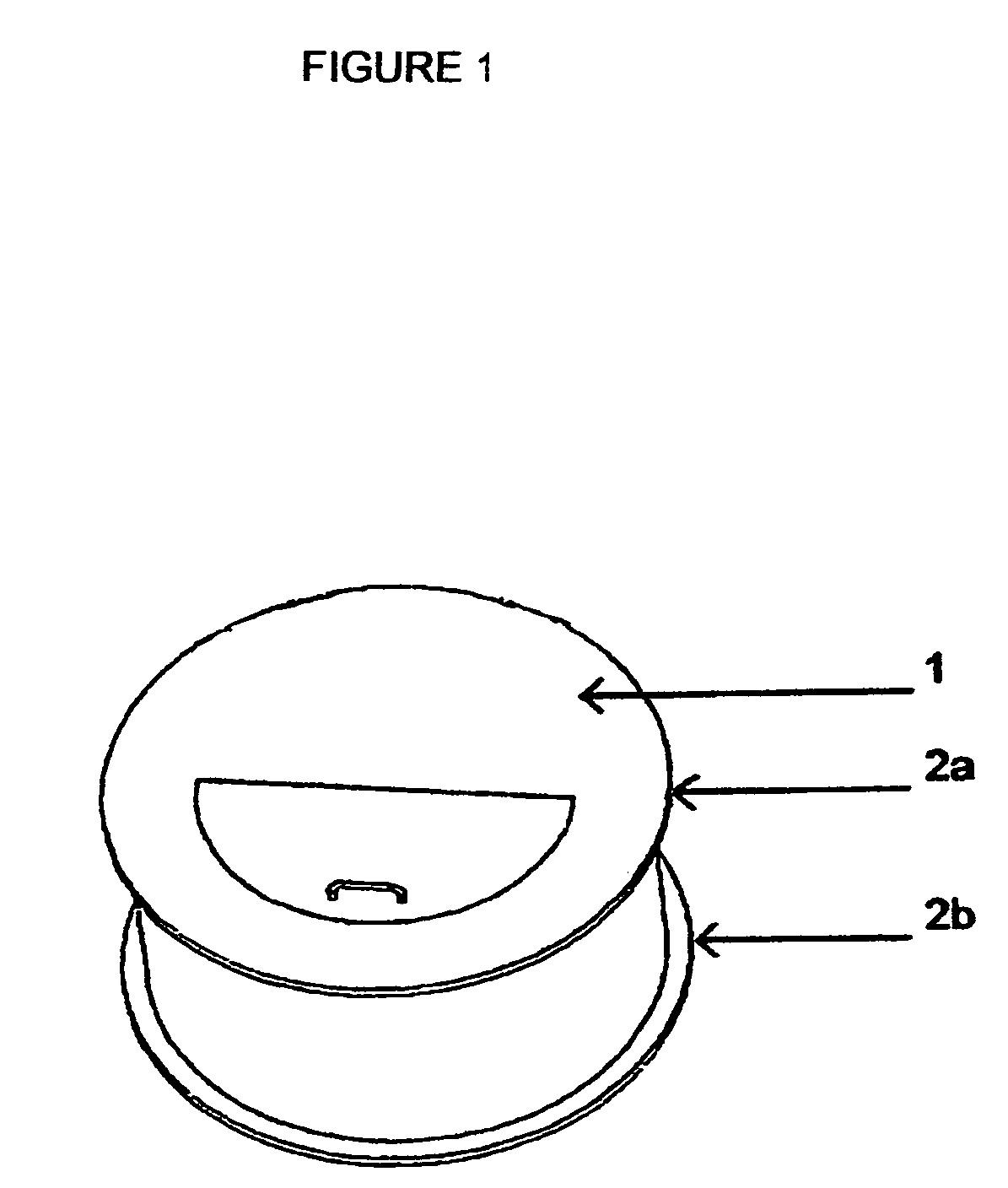

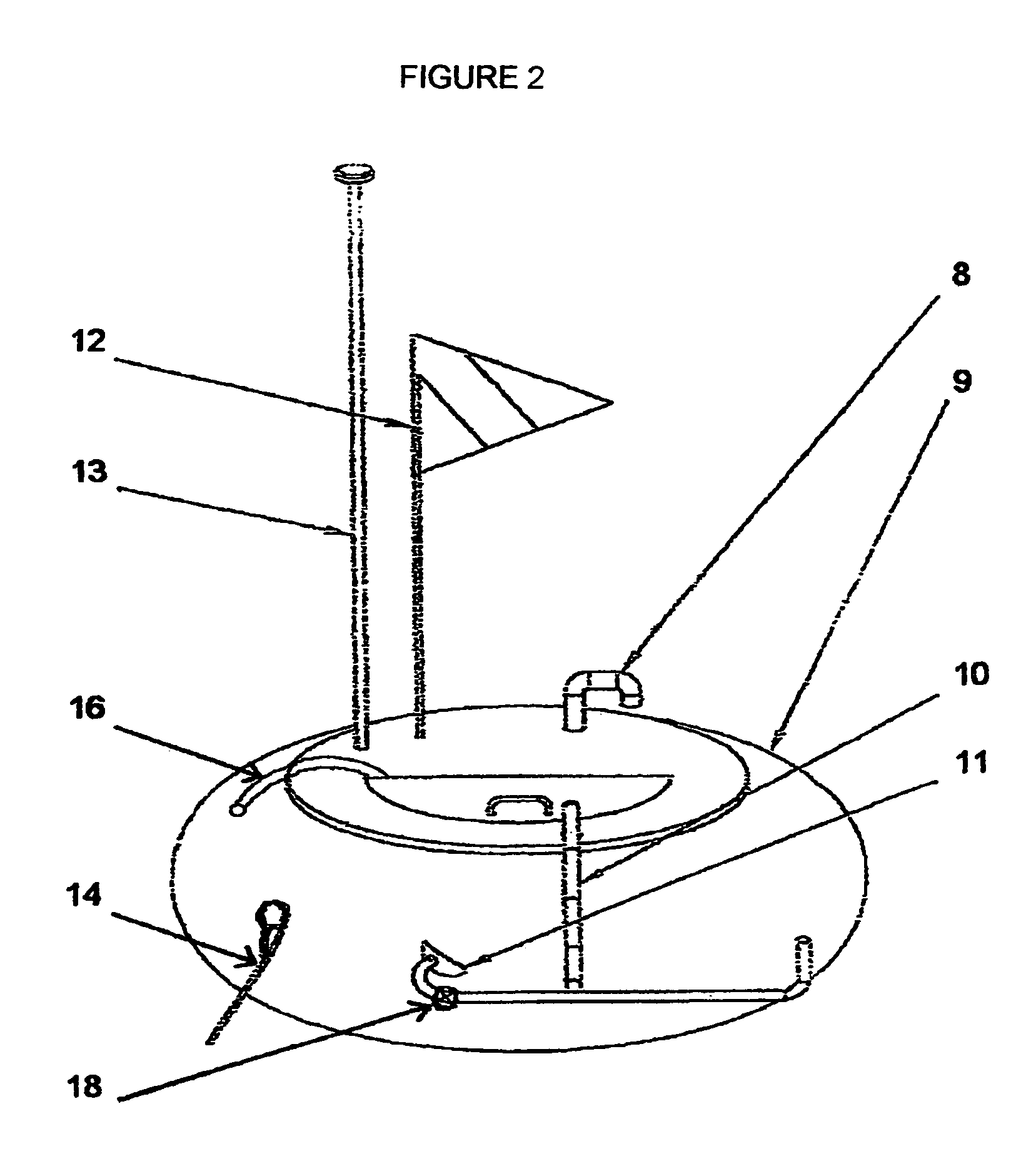

Snorkel apparatus and methods of use

InactiveUS7159528B1Relieving userSafe and simultaneous supplyUnderwater equipmentMouth pieceLine tubing

Disclosed is an apparatus and methods for a plurality of users to work and / or play underwater with a supply of breathable air. The breathable air is taken from the atmosphere above the surface of the water. The air is sent to one or two submerged users. The apparatus and its components are enclosed in a water resistant enclosure encapsulated by an inner tube which floats on the surface of the water. The apparatus provides breathable air to one or two users from a flexible air supply line, which runs from the apparatus to each submerged user. The air pumps of the apparatus push a constant flow of breathable air to each user. Each user inhales air from the apparatus with a mouth piece that is connected to the air supply line which is connected to the air pumps. Equipment such as regulators, tanks or reservoirs are not needed. The apparatus is powered by a dry cell battery and does not require fuel to operate.

Owner:HILLIKER WESLEY L

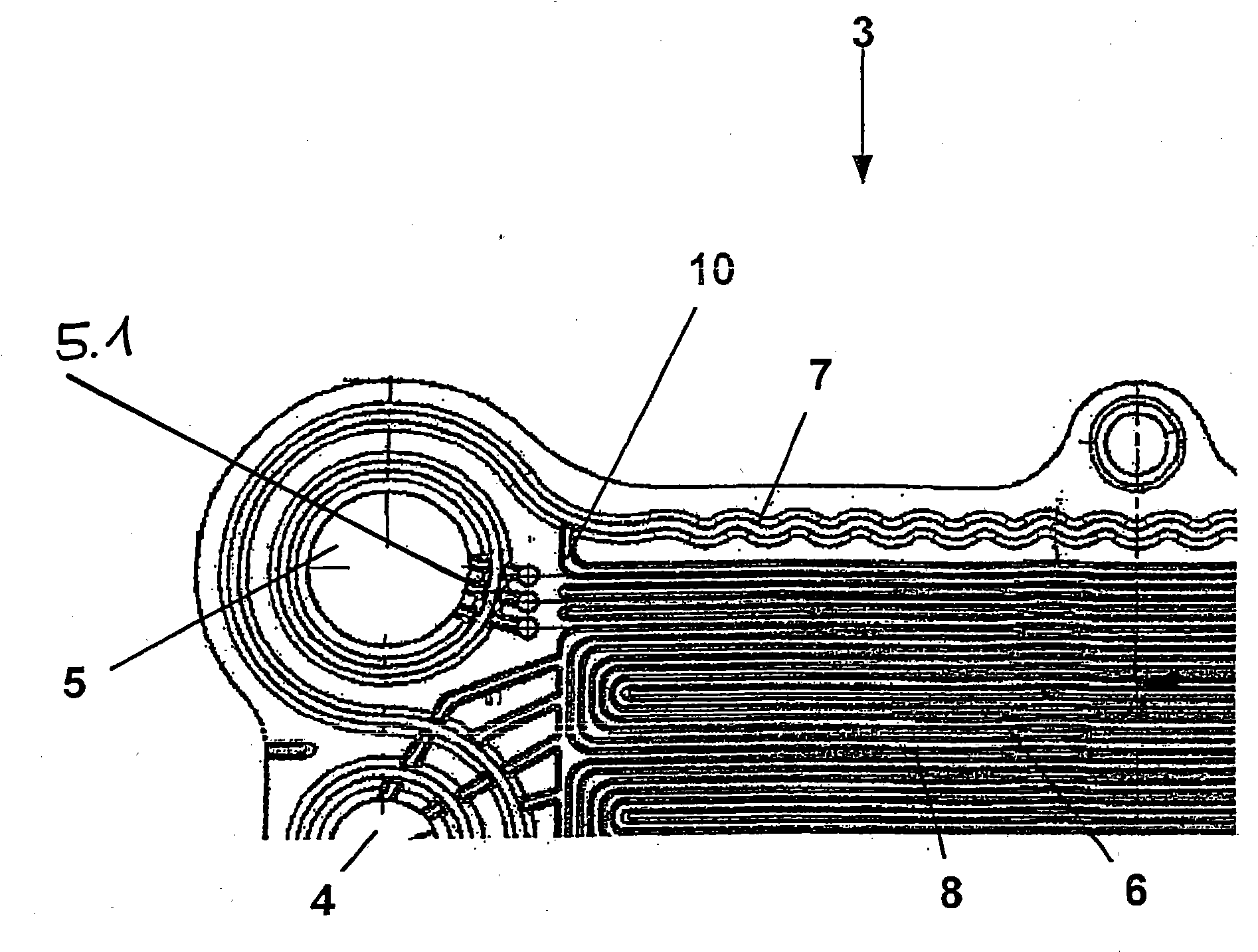

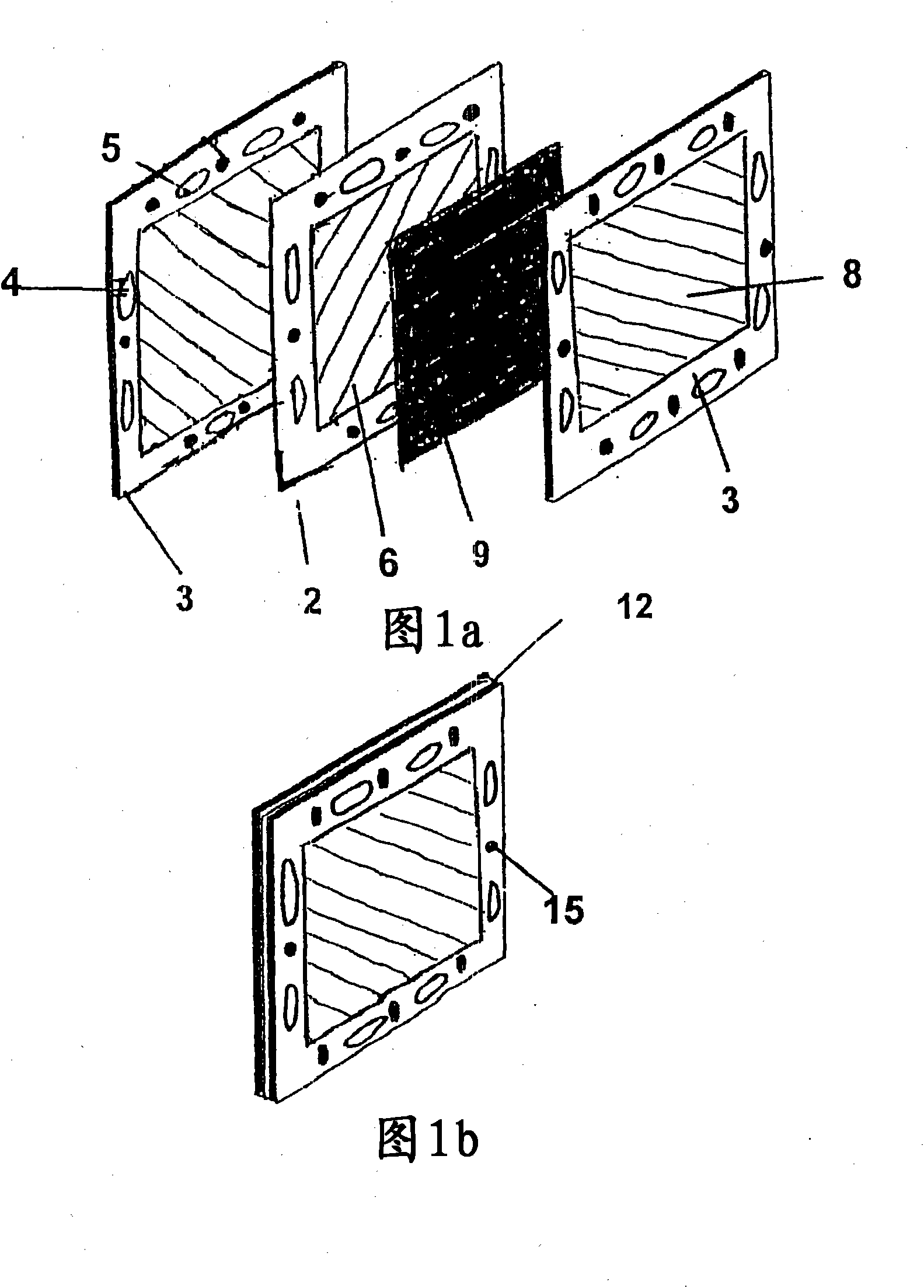

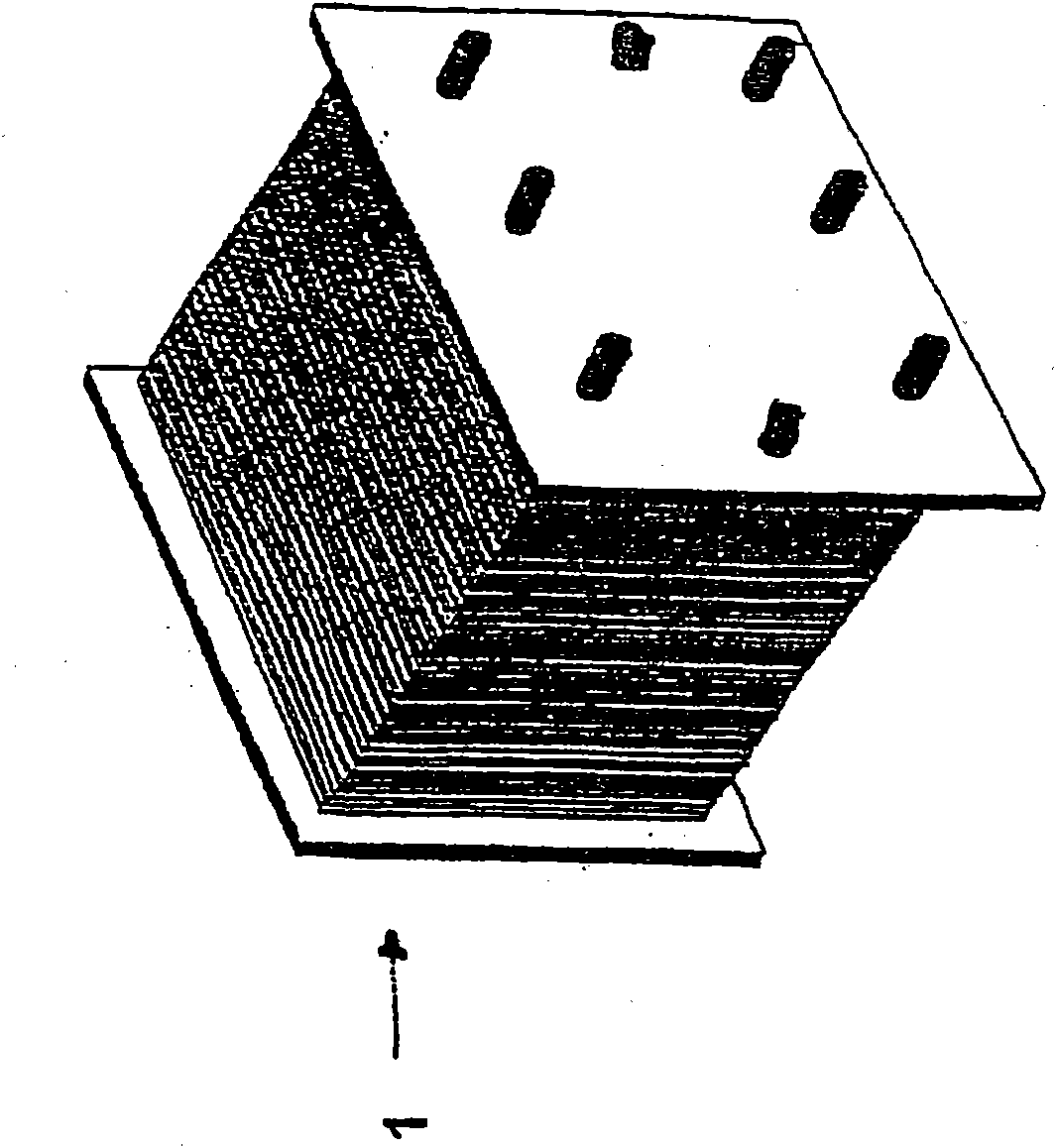

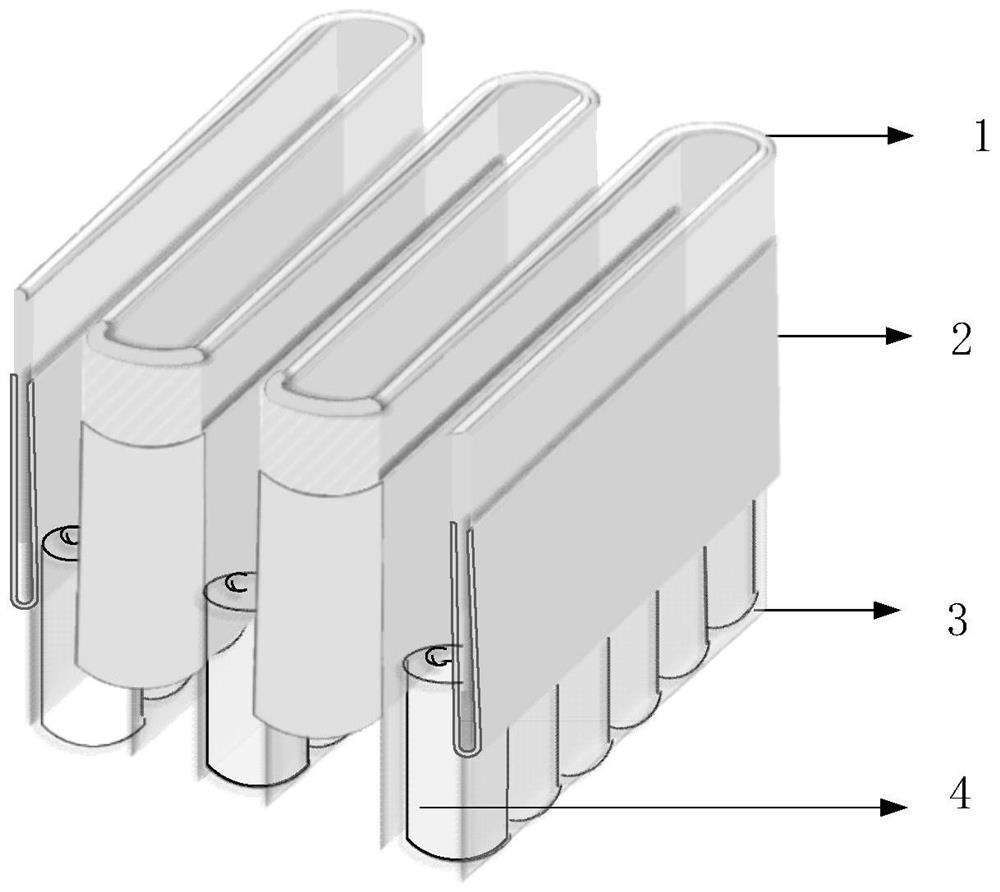

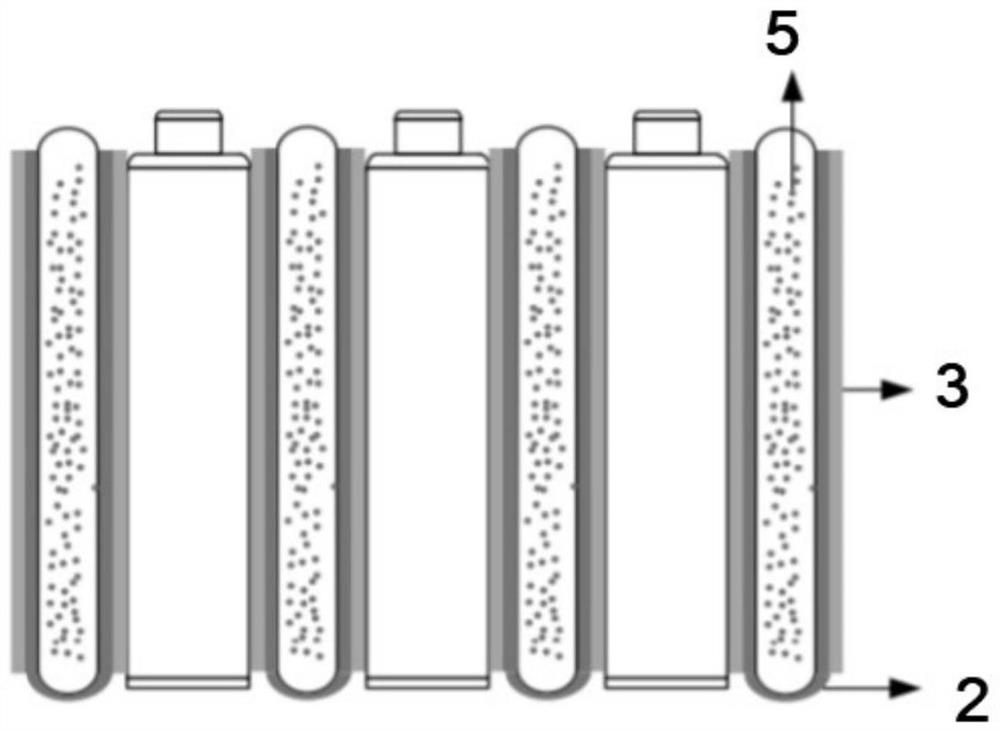

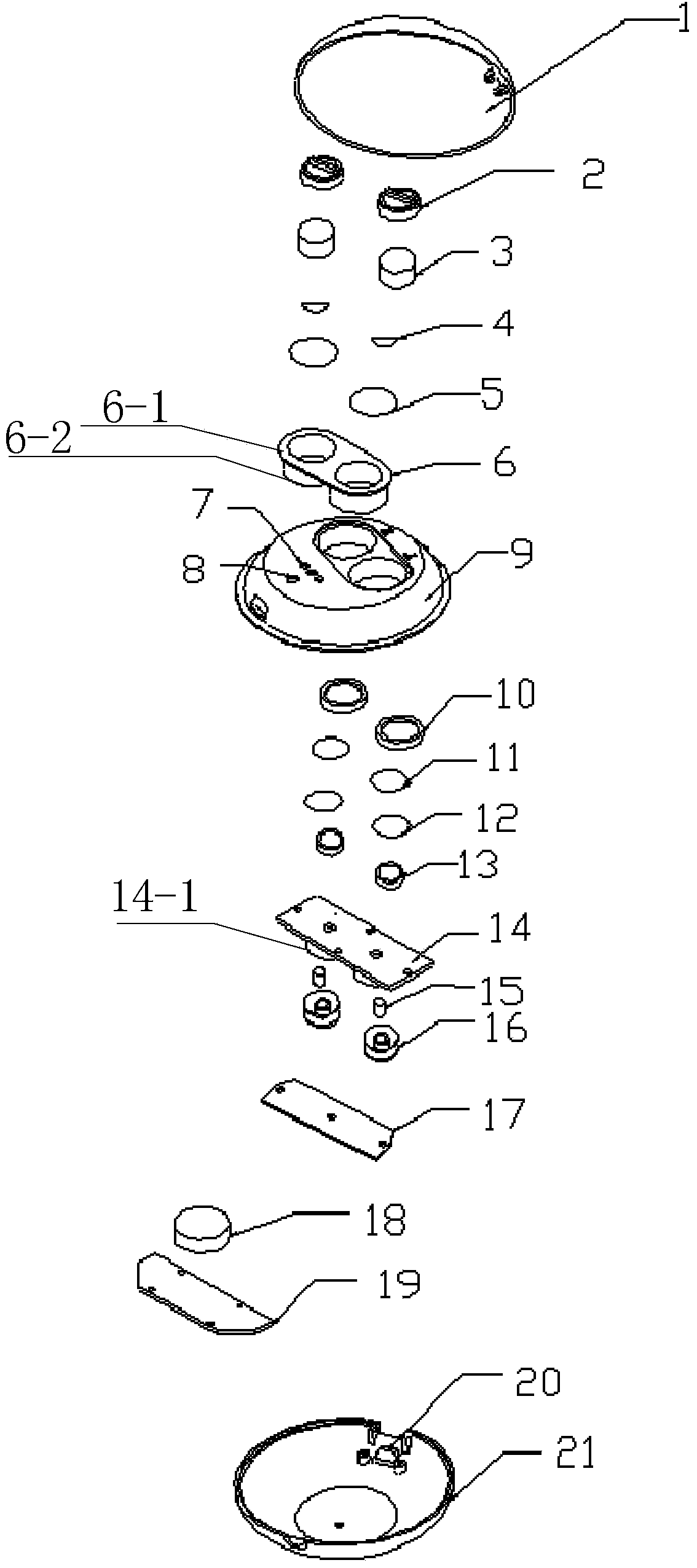

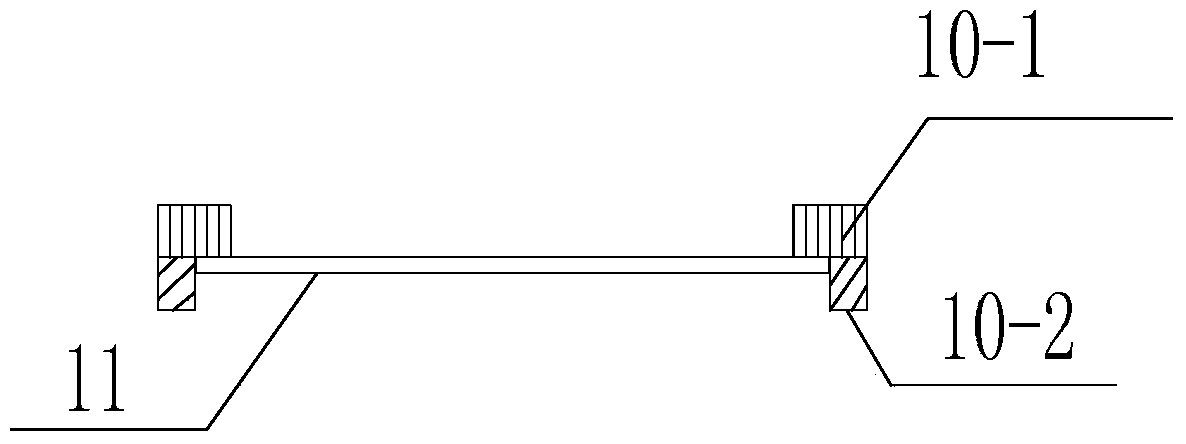

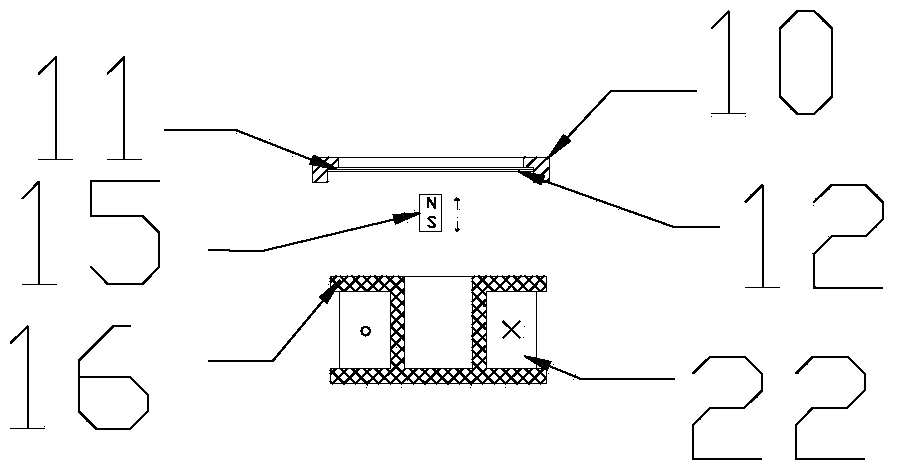

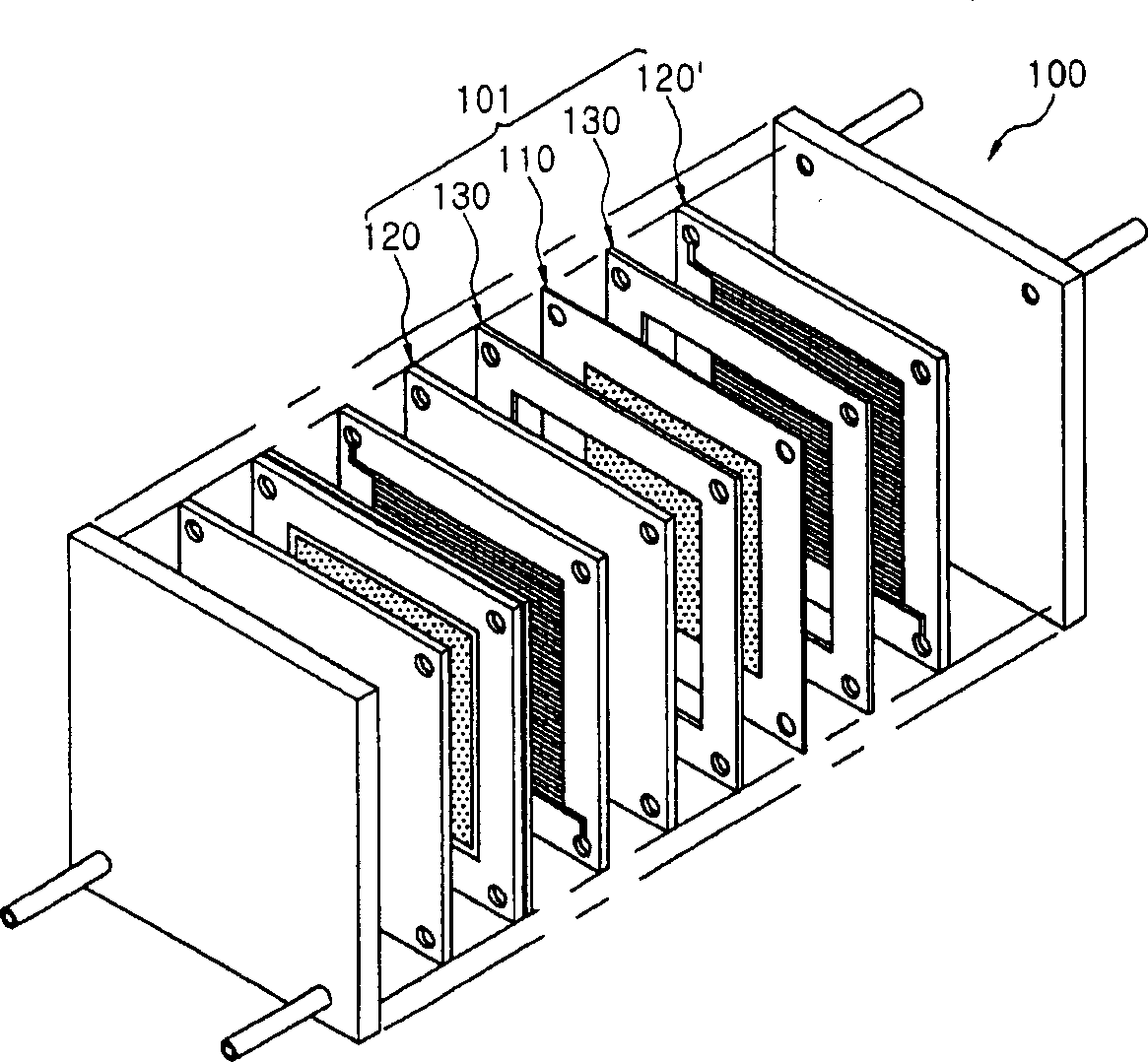

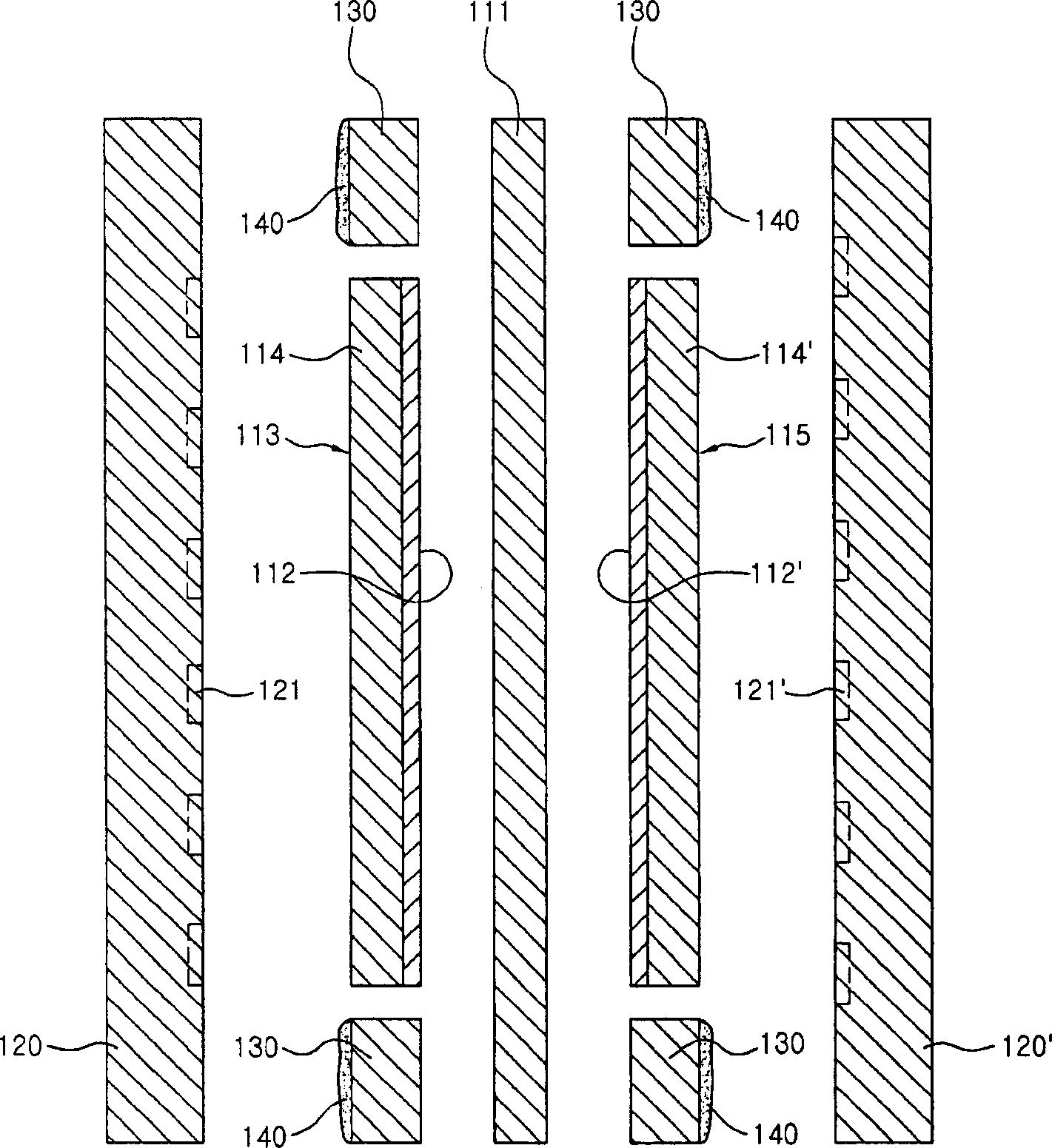

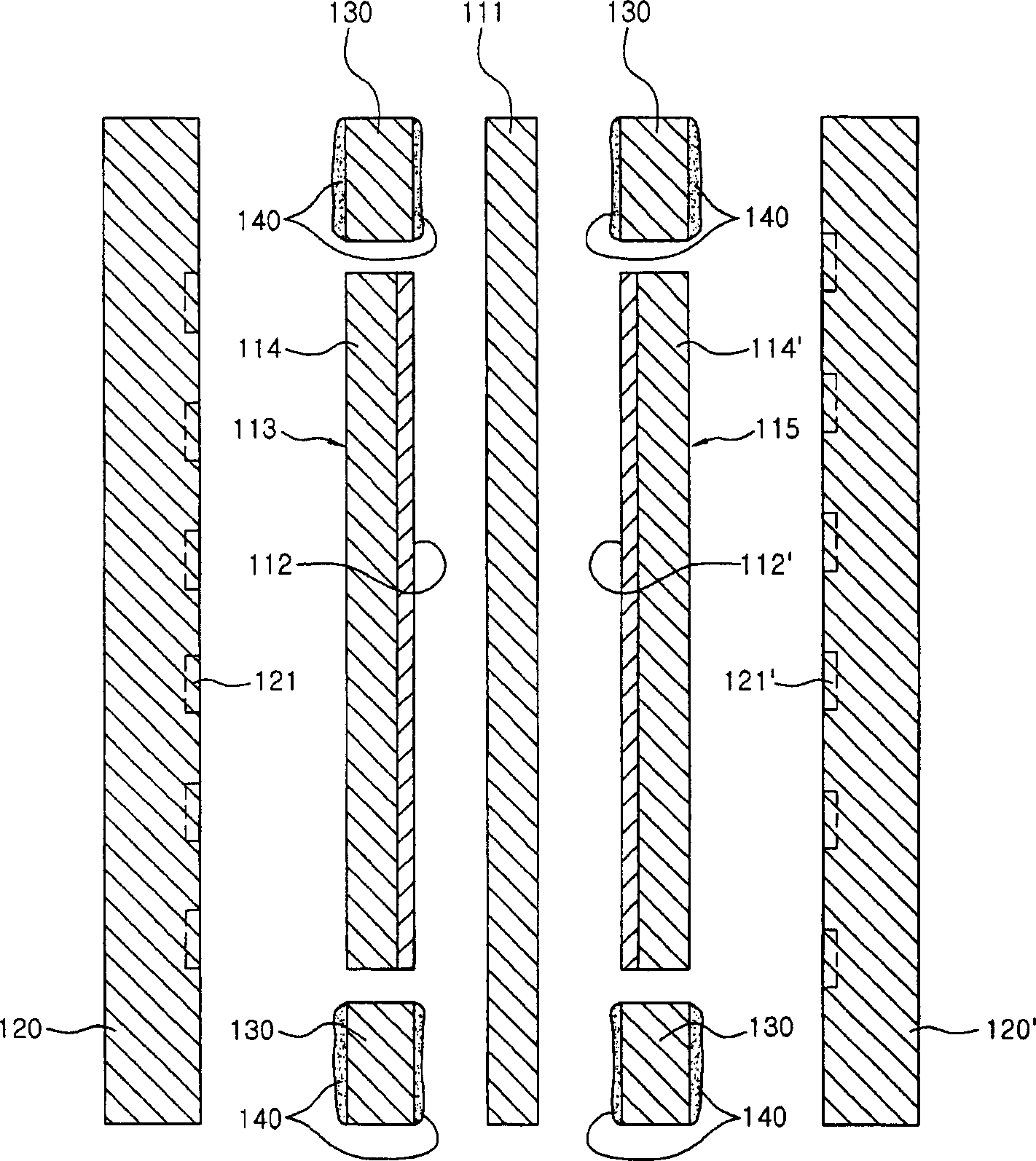

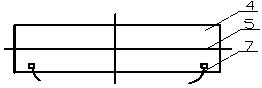

Electrochemical system

ActiveCN101816089AAvoid bypassEvenly distributedCellsFuel cells groupingChemical physicsElectrical battery

The present invention describes an electrochemical system as well as a bipolar plate for use in an electrochemical system. The electrochemical system (1), consists of a layering of several cells (2), which in each case are separated from one another by bipolar plates (3), wherein the bipolar plates comprise openings for the cooling (4) or for the removal and supply of operating media (5) to the cells, and the layering may be set under mechanical compressive stress, wherein at least one cell comprises an electrochemically active region (6) which is surrounded by a boundary wall (7) of the bipolar plate, and a channel structure (8) of the bipolar plate is provided within the electrochemically active region, for the uniform media distribution, wherein at least one gas diffusion layer (9) is provided for the micro-distribution of media. Limitation elements (10) are provided in the border region between the channel structure as well as the boundary wall, for avoiding fluid from bypassing between the channel structure and the boundary wall, wherein the gas diffusion layer covers the channel structure and / or at least parts of the limitation elements. The reliability and the efficiency of electrochemical systems are decisively increased by way of preventing the bypass in the border region of the electrochemically active field.

Owner:REINZ DICHTUNGS

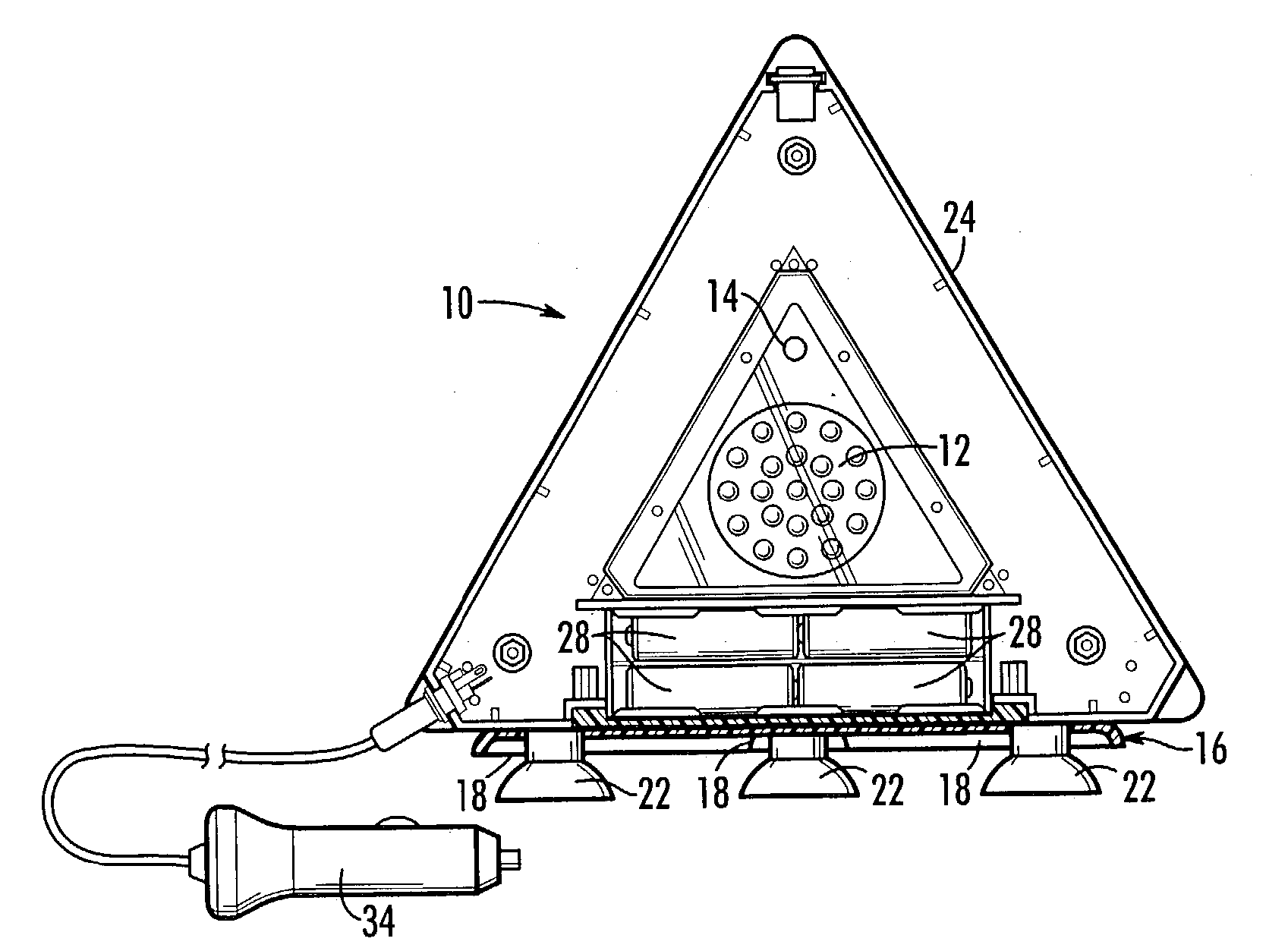

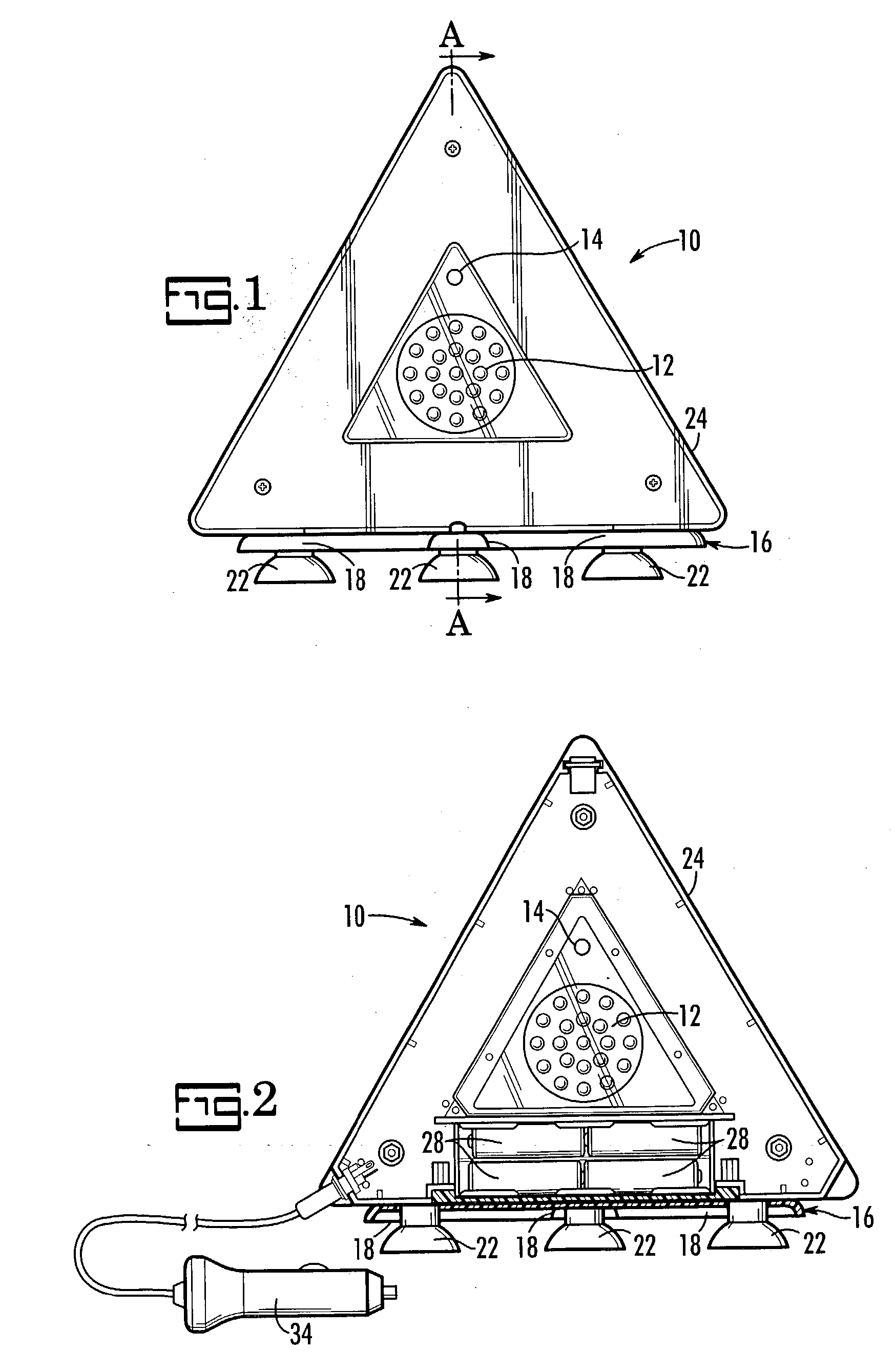

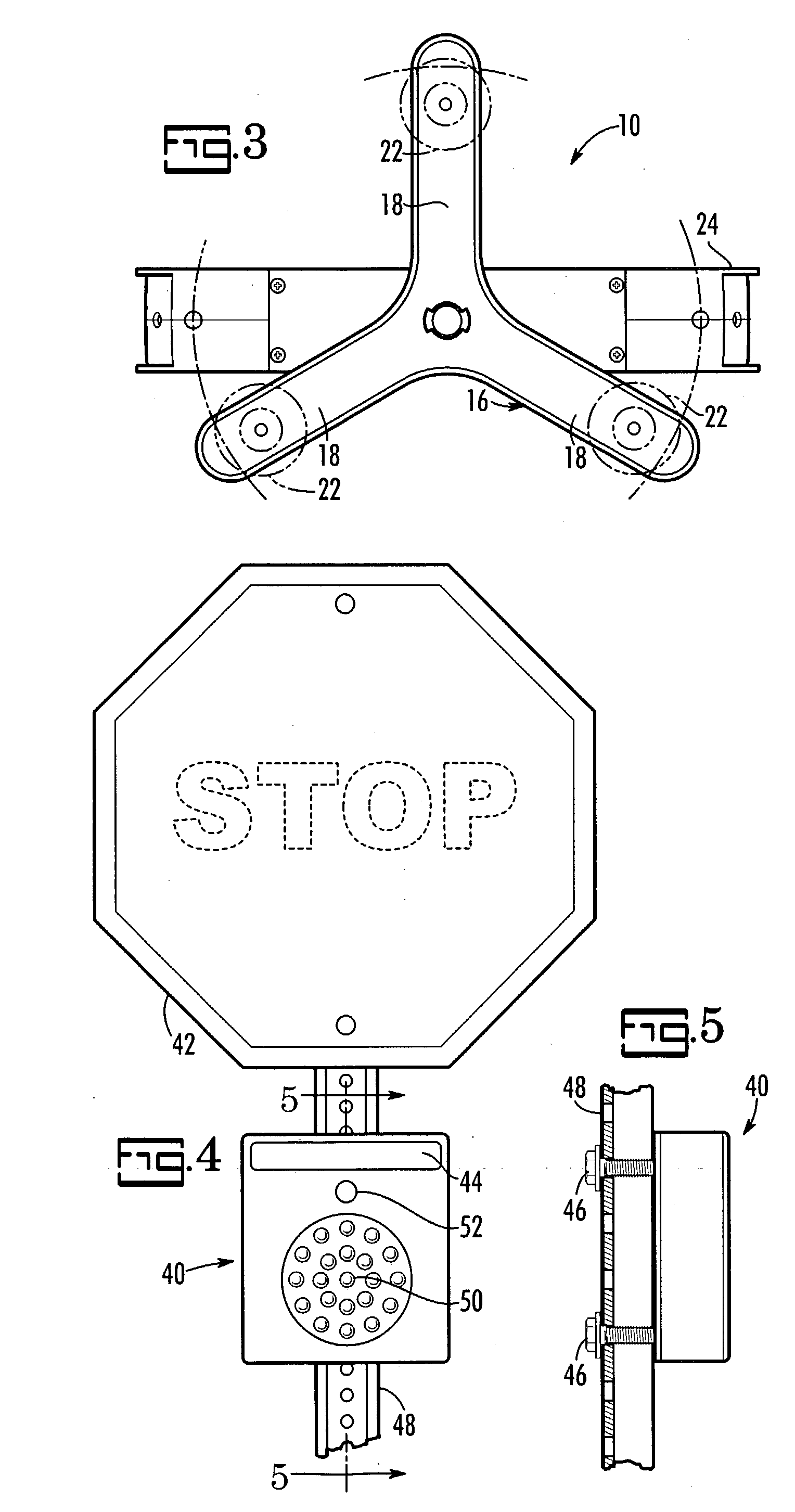

Portable warning light apparatus

InactiveUS20030222791A1Conserving chargePortable emergency signal deviceRoad vehicles traffic controlDriver/operatorAutomotive battery

A flashing warning light apparatus (10) for warning motorists in oncoming traffic that an object such as a car is stopped near the highway ahead. The apparatus (10) includes a housing (24) with an array of lights (12) on the front and possibly also the rear faces. Sensors (14) front and back sense oncoming traffic. A switch (36) allows the user to cause the arrays of lights (12) to flash continuously or only when oncoming traffic is sensed. The device may be powered by the car battery through a cigarette lighter adapter (34), dry cell batteries (28) or a solar cell (44).

Owner:NU TECH INNOVATIVE PRODS

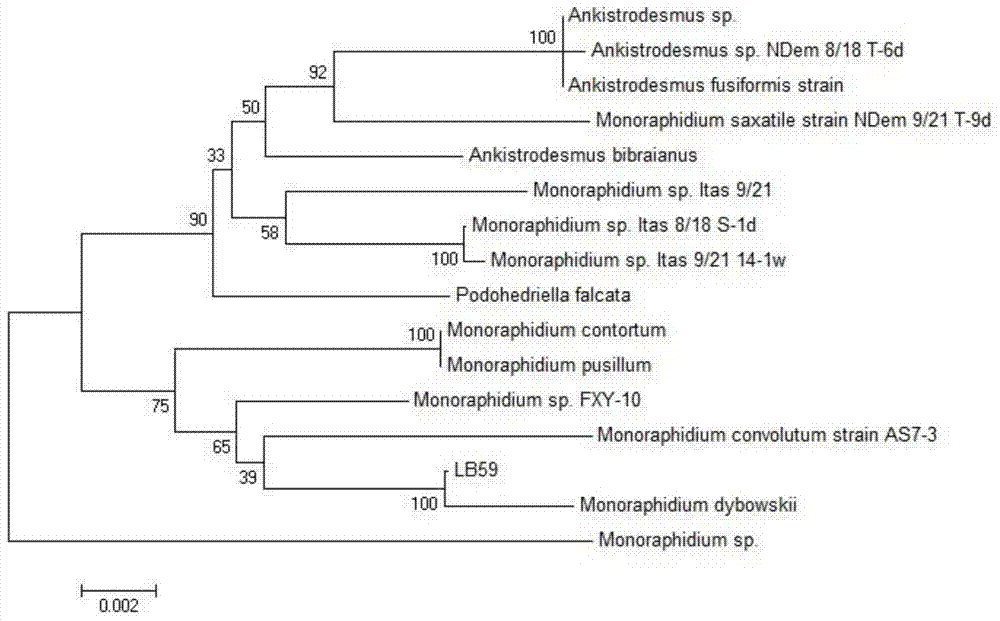

Obtaining and application of oil-producing monoraphidium LB59

ActiveCN103540533AAvoid infringementAvoid pollutionUnicellular algaeMicroorganism based processesBiotechnologySodium bicarbonate

The invention discloses an obtaining and an application of an oil-producing monoraphidium LB59, and relates to a screening and culturing technology of an oil-producing micro-alga. Through subjecting alga seeds separated from a field environment to 18SrDNA sequence analysis and morphological identification, the alga is determined to be a member of Monoraphidium, and the sequence is SEQ ID No.1. The oil-producing monoraphidium LB59 disclosed by the invention can tolerate high-concentrate sodium bicarbonate, is suitable for open type culture, is rich in grease, the grease content can reach 30.2% of dry cell weight under the condition that a growth and collection rate of 23.6g / m<2>d is held, and the fatty acid contains more than 20% of C-18 3-olefine acid and C-18 4-olefine acid.

Owner:INST OF AQUATIC LIFE ACAD SINICA +1

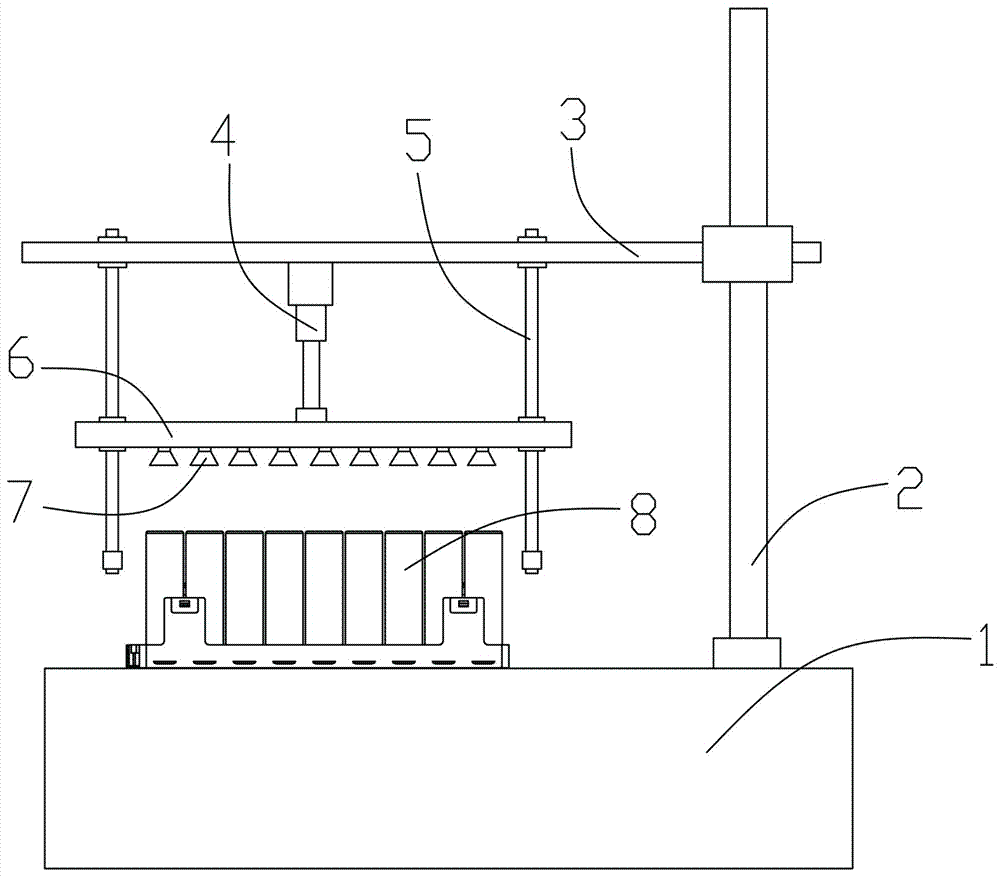

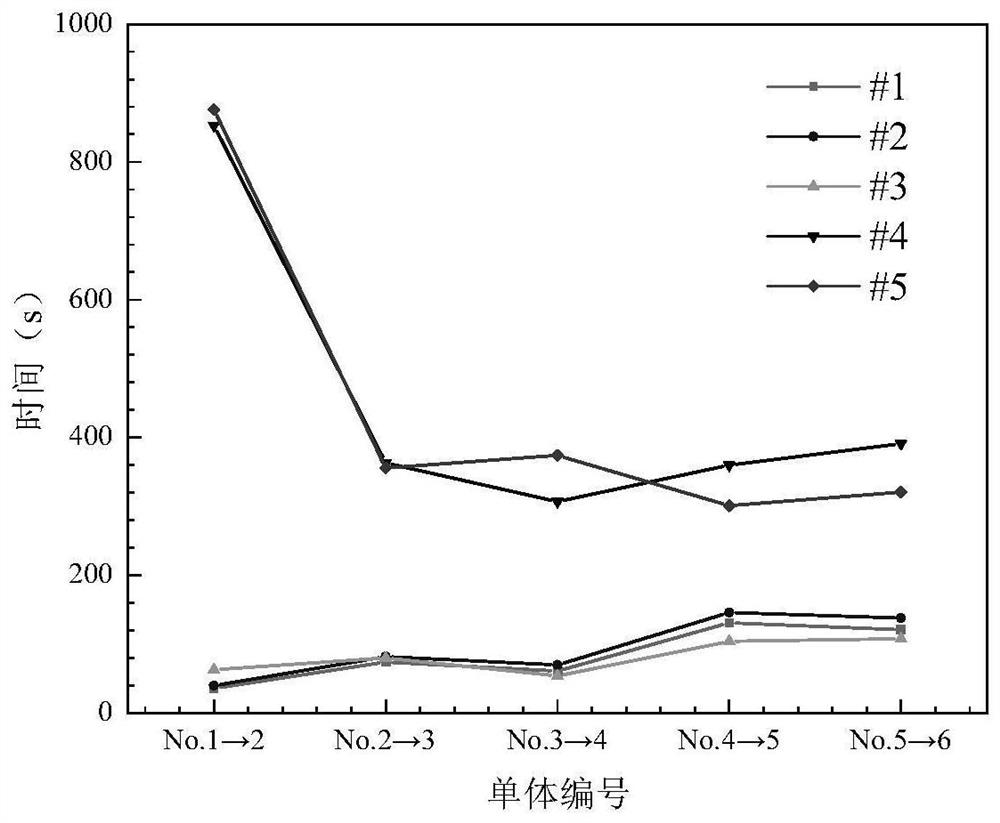

Battery welding intensity detecting method and device

PendingCN107515157ASo as not to damageEasy to detectMaterial strength using tensile/compressive forcesElectrical batteryEngineering

The invention relates to a battery welding intensity detecting method and device. The device comprises an adsorption moving device and suction nozzles, wherein the suction nozzles are arranged on the moving end of the adsorption moving device; a conducting sheet is welded at one end of a battery pack; an electrode arranged on the conducting sheet is welded with one end of a battery in the battery pack; the other end of the battery is sucked by the suction nozzle; the adsorption moving device pulls the battery towards the direction far away from the conducting sheet under the effect of constant tensile force; if one end of the battery is not separated from the electrode, the condition proves that the battery welding intensity meets the welding standard; otherwise, the condition proves that the battery welding intensity does not meet the welding standard. The adsorption moving device and the suction nozzles are used, and the suction nozzles are arranged on the moving end of the adsorption moving device, so that compared with the prior art, the device has the advantages that the tensile force is constant; the number of the suction nozzles can be the same as the number of the batteries. The detecting device can detect the welding intensity of a plurality of batteries and the electrode in one step, and has the advantages that the detection is convenient; the detection efficiency is high; the electrode cannot be damaged, and the like.

Owner:深圳市泰霸电源系统有限公司

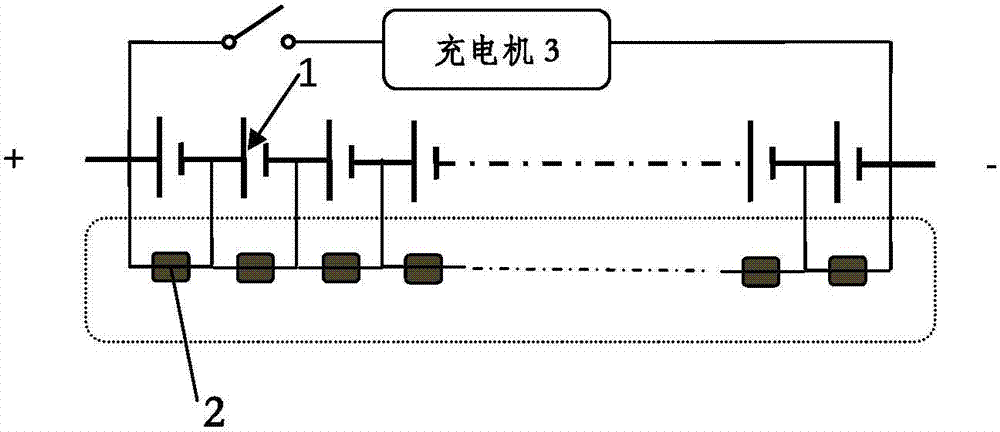

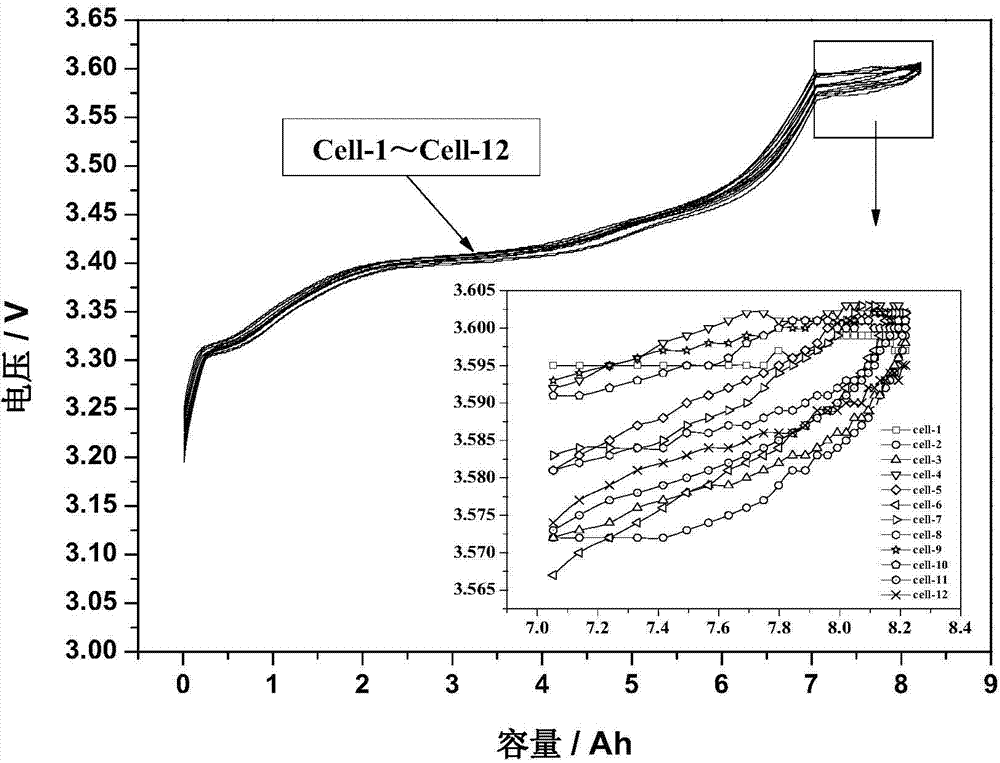

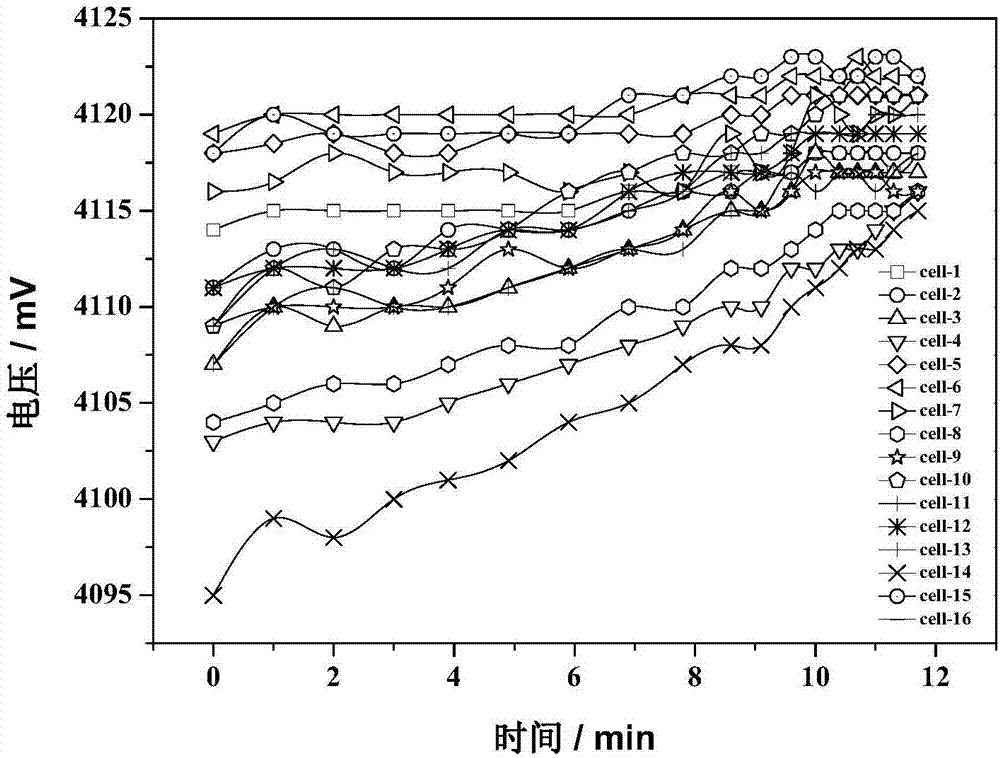

Power battery equalizing charge method and system

InactiveCN104734260AConsistent battery performanceExtended service lifeBatteries circuit arrangementsSecondary cells charging/dischargingPower batteryElectrical battery

The invention discloses a power battery equalizing charge method and system. When a battery system formed by connecting a plurality of battery modules in series is charged till voltage of any battery module reaches charge cut-off voltage or the battery system reaches upper limit charge voltage, a battery management system or an external detection control circuit automatically opens an external charge circuit, equalizing charge units start to play an equalizing charge role, each charge equalizing module starts to execute a unified constant-voltage charge process until all the battery modules reach output voltage values of the equalizing modules, and equalizing charge is completed. By the adoption of the equalizing charge method, even after long-time use, single batteries can still keep good consistency, and the overall service life of the battery system is prolonged. Through the method, a mutually parallel equalizing charge mode of the battery modules or the single batteries in the battery system is achieved; in the equalizing charge mode, no energy exchange or loss is generated in the battery system, and the method is simple and easy to implement.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

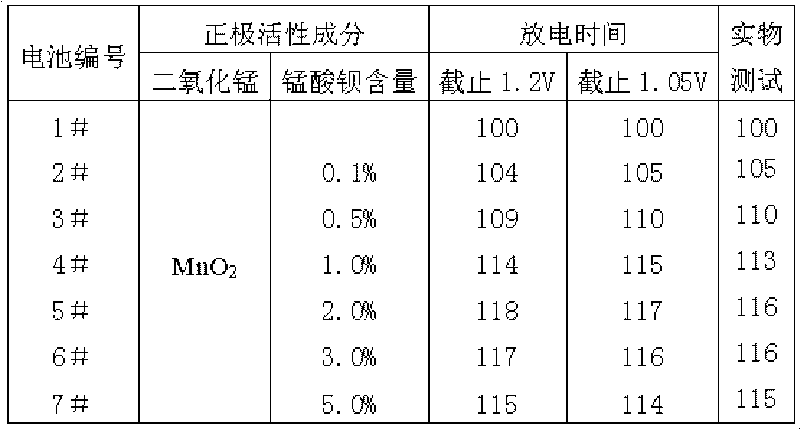

Positive electrode material of alkali dry battery and preparation method thereof and alkali dry battery

ActiveCN101719547AImprove high current constant power discharge performanceMeet power supply requirementsPrimary cell electrodesEngineeringCalcium

The invention relates to a positive electrode material of the alkali dry battery and a preparation method thereof and an alkali dry battery, belonging to the battery field. The technical problem to be solved by the invention is to provide a positive electrode material with low cost of the alkali dry battery and an alkali dry battery. The positive electrode material of the alkali dry battery comprises a positive electrode active ingredient, wherein the positive electrode active ingredient is a mixture of manganese dioxide and a compound with barium or calcium, and the content of the compound with barium or calcium is 0.1-5wt% of the positive electrode active ingredient. The positive electrode material of the invention can increase the high power discharge performance of the alkali dry battery, have low cost and easy promotion and application, provide a new choice for the field and have wide application prospects.

Owner:SICHUAN CHANGHONG NEWENERGY TECH

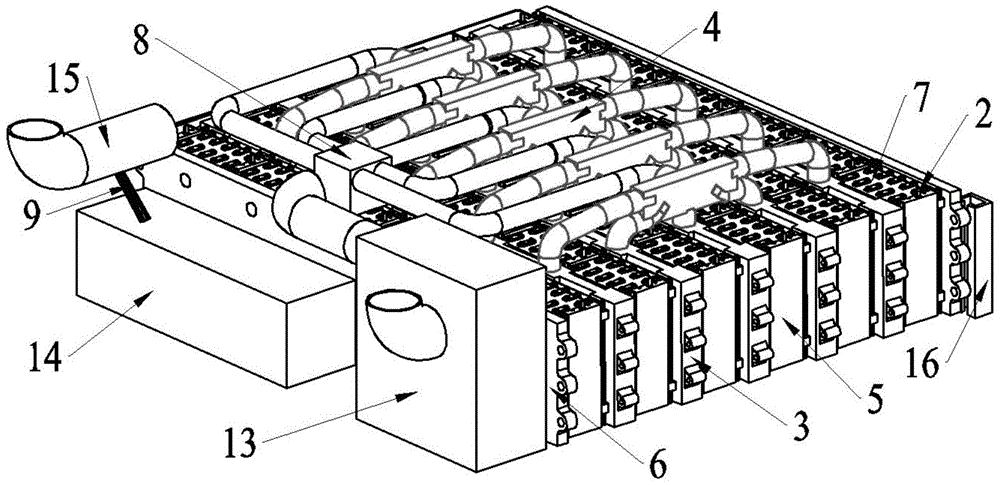

Energy storage power station battery thermal runaway protection system

InactiveCN112133980AImprove thermal conductivityImprove cooling effectSecondary cellsFire rescueElectrical batteryProcess engineering

The invention discloses an energy storage power station battery thermal runaway protection system which comprises solid-solid composite phase change material heat dissipation plates tightly attached to the two sides of battery modules. The battery modules are formed by connecting a plurality of single batteries in series, and the batteries are attached to the solid-solid composite phase change material heat dissipation plates through heat conduction and insulating double-faced adhesive tapes. Cold liquid plates are arranged between the adjacent battery module bodies, and the cold liquid platesare arranged between the battery modules in an S shape. Heat conduction silica gel layers are arranged between the solid-solid composite phase change material heat dissipation plates and the cold liquid plates, and the solid-solid composite phase change material heat dissipation plates are made of a paraffin / expanded graphite solid-solid composite phase change material. Al2O3 / H2O nano sol coolingliquid is adopted as cooling liquid in the cold liquid plates. Through combination of the solid-solid phase change material and the liquid cooling plates, efficient heat dissipation of a faulted thermal runaway battery is realized, and chain fire accidents caused by thermal runaway propagation of the battery are avoided.

Owner:国网陕西省电力公司汉中供电公司 +3

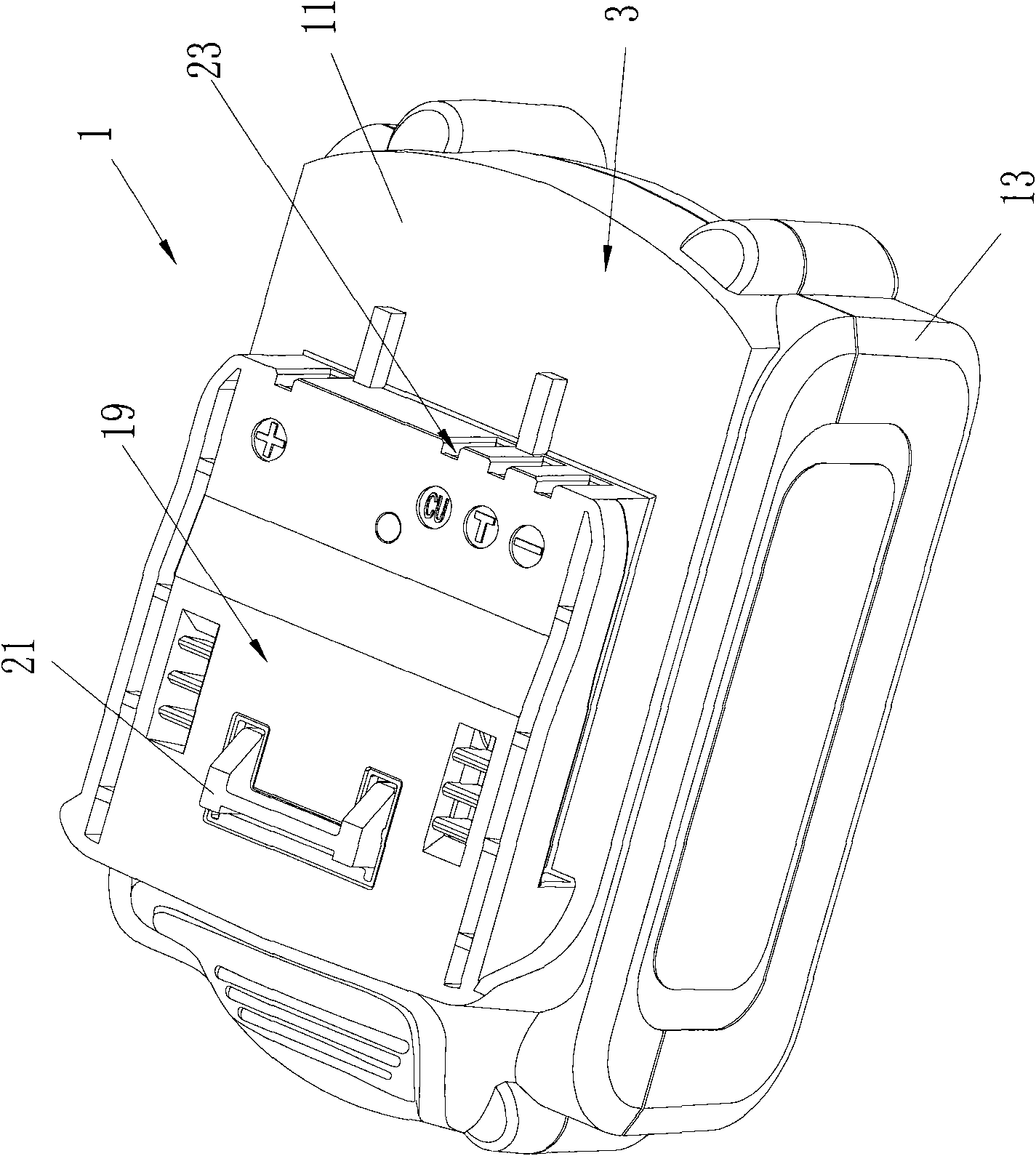

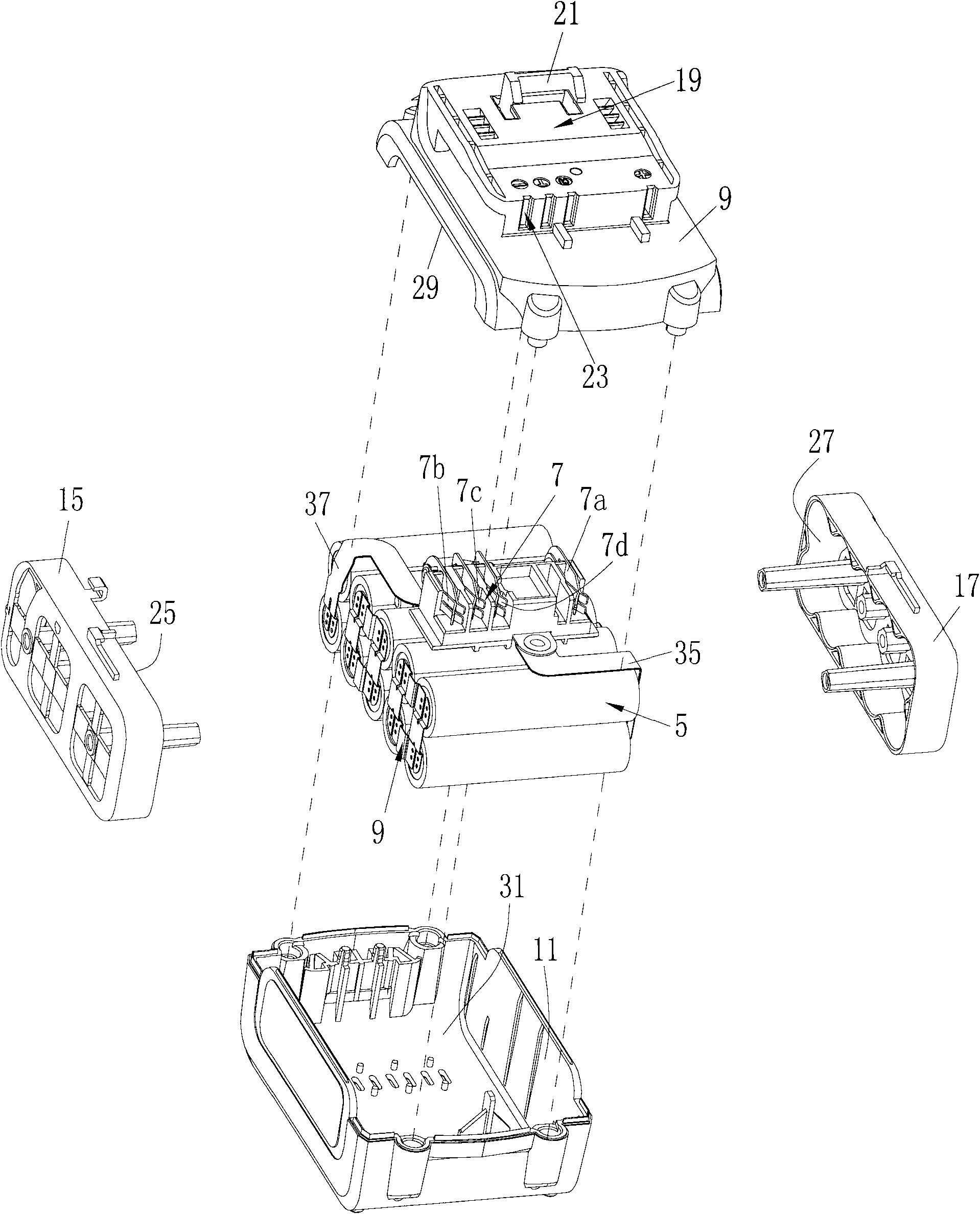

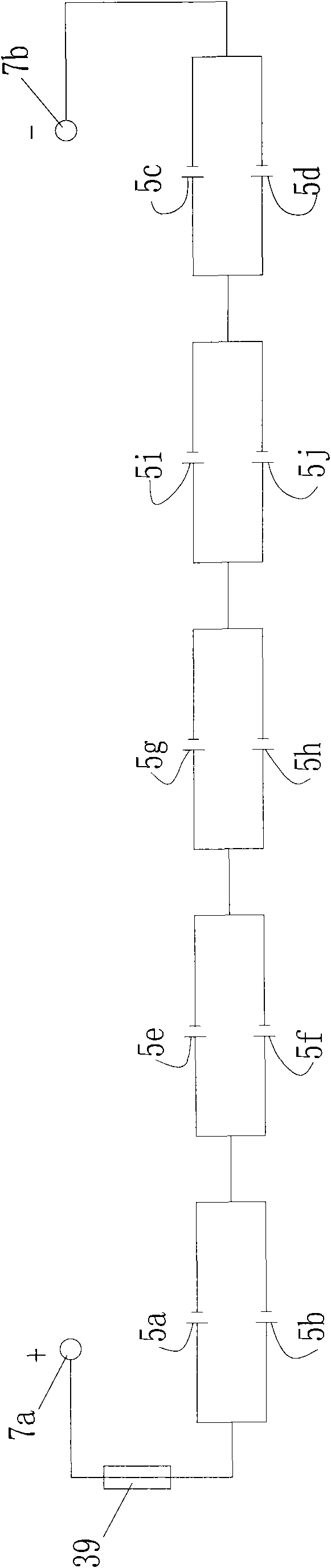

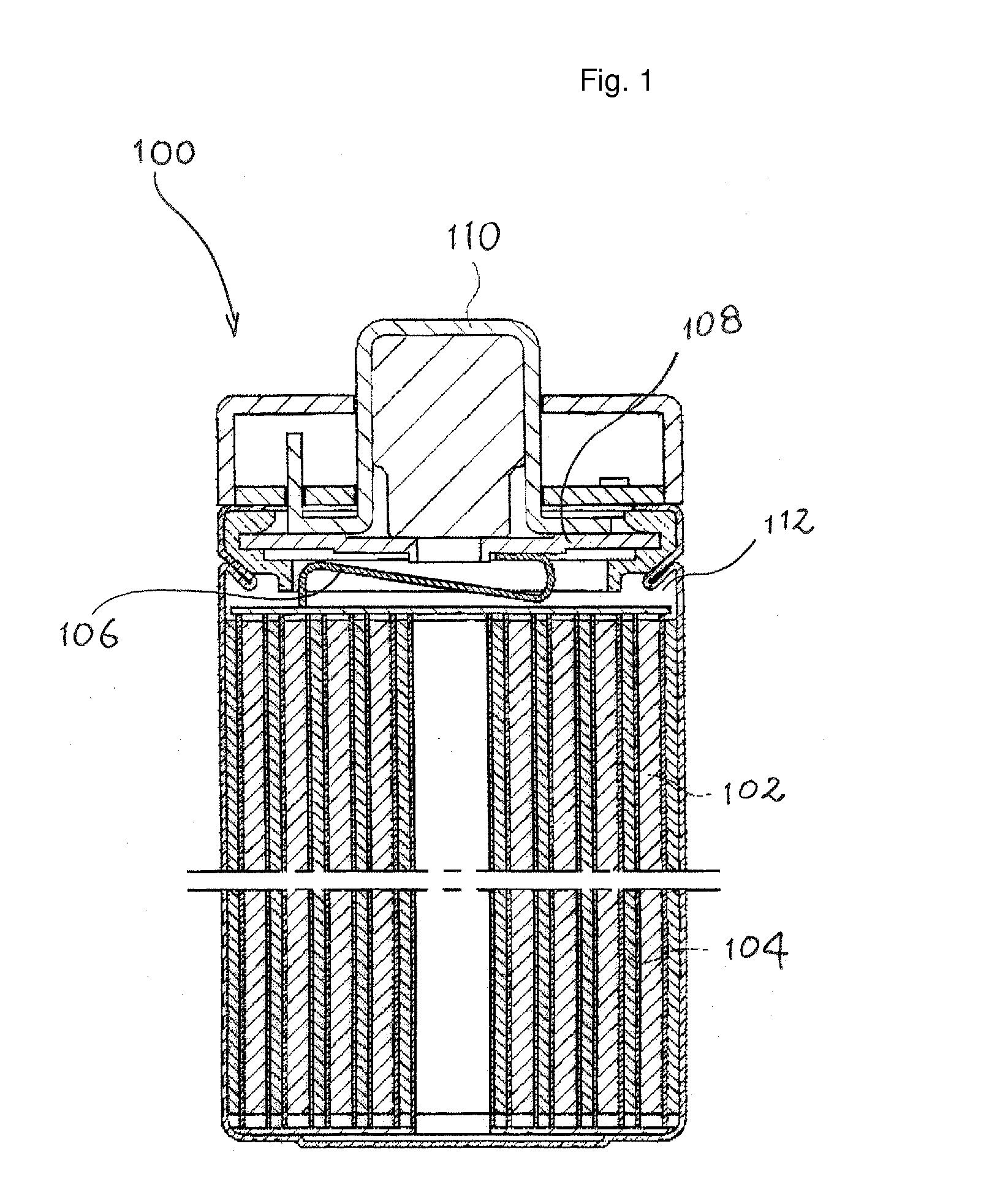

Battery pack

ActiveCN101651189AExtended service lifeSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsMetal sheetBattery pack

The invention provides a battery pack, which comprises a shell, an anode terminal, a cathode terminal, a plurality of battery units, a battery connecting sheet, an anode leading-out terminal connecting sheet and a cathode leading-out terminal connecting sheet, wherein the plurality of battery units are accommodated in the shell; the battery connecting sheet is used for electrically connecting theplurality of battery units; the anode leading-out terminal connecting sheet is used for connecting at least one of the plurality of battery units with the anode terminal; the cathode leading-out terminal connecting sheet is used for connecting at least one of the plurality of battery units with the cathode terminal; and at least one of the anode leading-out terminal connecting sheet and the cathode leading-out terminal connecting sheet comprises a plurality of metal sheets.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Waste battery recycling system and recycling method

ActiveCN104183855AEffective Environmental RecyclingEffective resource recyclingReclaiming serviceable partsBattery recyclingEddy current separatorProcess engineering

The invention discloses a waste battery recycling system and a recycling method. The system and method are as below: the waste dry batteries are subjected to two crushing to obtain components of powdered carbon, paper, film, plastics, carbon rods, iron, zinc and copper; the components are dried and have mercury removed, and sent into a vibration sieve to separate powdered carbon; the remaining components are sent into a vibration sieve in a next device; at the same time a blower and a suction fan are arranged on both sides of the vibration sieve in a line, so that lighter components containing paper, film and plastics are blown into a storage barrel and a space bag, and remaining iron, carbon rods, zinc and copper are sent into a conveyor belt of a magnetic separation device to isolate the iron; the remaining carbon rods, zinc and copper are crushed by a biaxial crusher; the carbon rods are crushed into powdered carbon, which is separated and sent into the space bag; and the remaining zinc and copper are sent into an eddy current separator for separation. The invention can carry out effective and environment-friendly recycling, harmless treatment and recycling on waste batteries, and realizes a self existence and continuously fixed recycling mode of resources.

Owner:深圳市泰力废旧电池回收技术有限公司

Plastic mask nose bridge batten

The invention relates to a plastic mask nose bridge batten which comprises the following material components in percentage by weight: 75-85% of polypropylene, 14-22% of polyvinyl chloride (PVC) and 1-3% of setting agent. The plastic mask nose bridge batten is formed by utilizing a screw extruder to carrying out pulling and winding. The plastic mask nose bridge batten of the invention replaces the original metallic nose bridge batten and is especially suitable for being used in dry battery plants, coal mining fields and other occasions capable of generating strong static electricity easily.

Owner:SHANGHAI DASHENG HEALTH PRODS MFG

Special automatic cleaning instrument for low-voltage direct current electromagnetic pulse-type contact lenses

ActiveCN103433234AGuaranteed cleaning effectQuality improvementCleaning using liquidsButton batteryElectromagnetic pulse

The invention relates to a special automatic cleaning instrument for low-voltage direct current electromagnetic pulse-type contact lenses. The cleaning instrument comprises a movable upper cover and a shell, wherein the movable upper cover is movably connected with the shell; the shell comprises a fixing plate and a lower bottom cover; the fixing plate is fixedly connected with the lower bottom cover; a control circuit, a power part and a cleaning part are arranged in the shell; and a USB charging port is formed on the lower bottom cover. The special automatic cleaning instrument is smaller in size and more convenient to carry, and the cleaning instrument avoids a problem of a No.7 dry battery which is frequently changed and is more environment-friendly; the cleaning instrument is stronger in dirt-removing power, and is specifically suitable for cleaning various contact lenses; and the cleaning instrument can guarantee perfect combination of damping variable frequency ultrasonic and button battery, a USB charger and sharp vibrating energy irreproachably.

Owner:杭州视亨光电有限公司

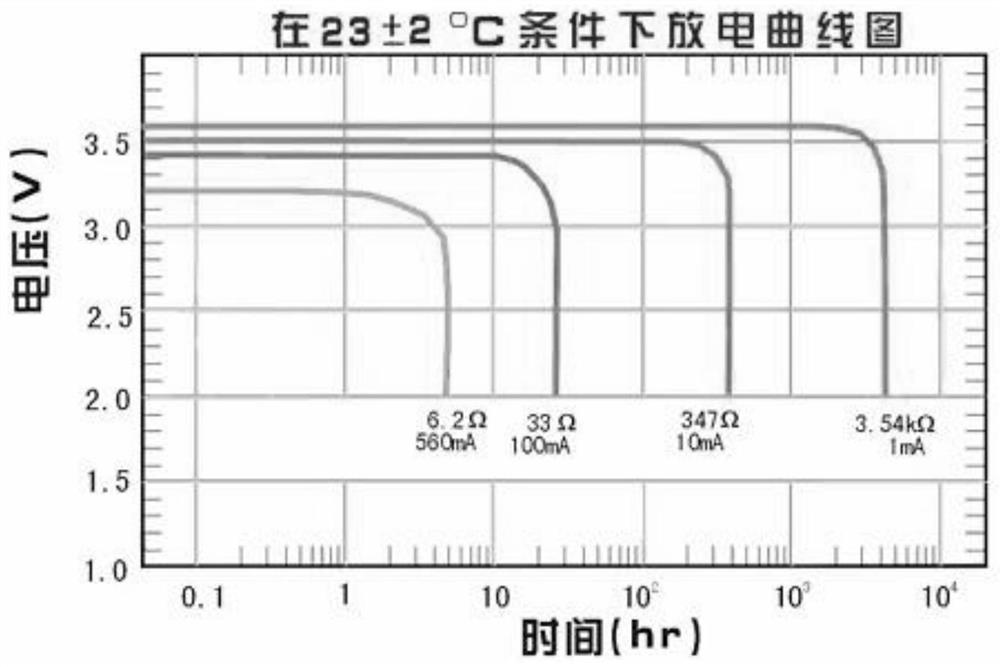

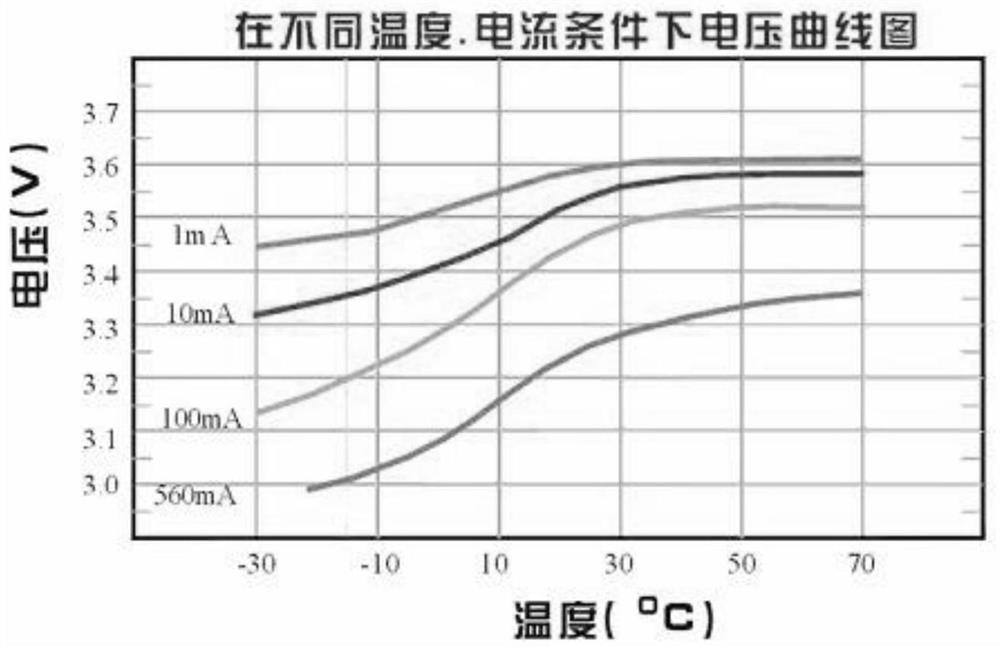

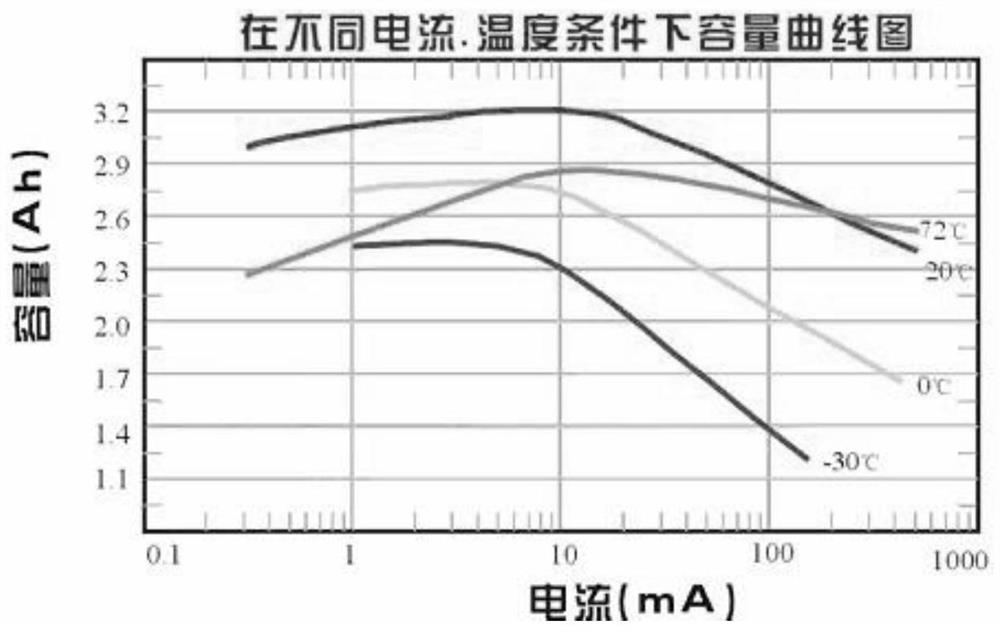

Internet of Things battery electric quantity measurement method, device, system and equipment and storage medium

InactiveCN112269136AAccurate remaining power valueElectrical testingTime informationElectrical battery

The invention is suitable for the technical field of the Internet of Things, and provides an Internet of Things battery electric quantity measurement method, device, system and equipment and a storagemedium, and the method comprises the steps: obtaining the electric quantity parameter information of a to-be-measured Internet of Things battery, and the electric quantity parameter information comprising voltage information, current information, temperature information and continuous working time information; according to the electric quantity parameter information and a preset battery electricquantity measurement model, determining the residual electric quantity of the Internet of Things battery; wherein the preset battery electric quantity measurement model is generated by training a plurality of pre-collected battery discharge samples carrying electric quantity parameter information through a deep learning neural network. According to the method, the electric quantity influence factors are fully considered, the battery electric quantity measurement model established according to the deep neural network and a large amount of sample data is utilized, the accurate battery remainingelectric quantity value can be obtained directly through the battery electric quantity parameters in the using process, and the method can be suitable for a scene with sudden large current.

Owner:深圳市智达百川科技有限公司

Positive pole material of alkaline dry cell and high power alkaline dry cell, and preparation method

InactiveCN1697213AReduce deterioration rateImprove performancePrimary cell electrodesDry cellsManganateNickel zinc

The material of positive pole includes compound of containing 0.l%- 20% of barium or calcium according to weight ration. Barium manganate or calcium manganate is optimal. The invention also discloses method for preparing alkaline cell in high power. Admixture from barium manganate or calcium manganate and hydroxy nickel oxide or admixture from hydroxy nickel oxide and manganese dioxide is as active material of positive pole so as to obtain new type alkaline dry battery with long service time and good storage quality. Comparing with nickel zinc cell in current market, the disclosed cell raises current capability more than 30%, and storage quality more than 50%.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

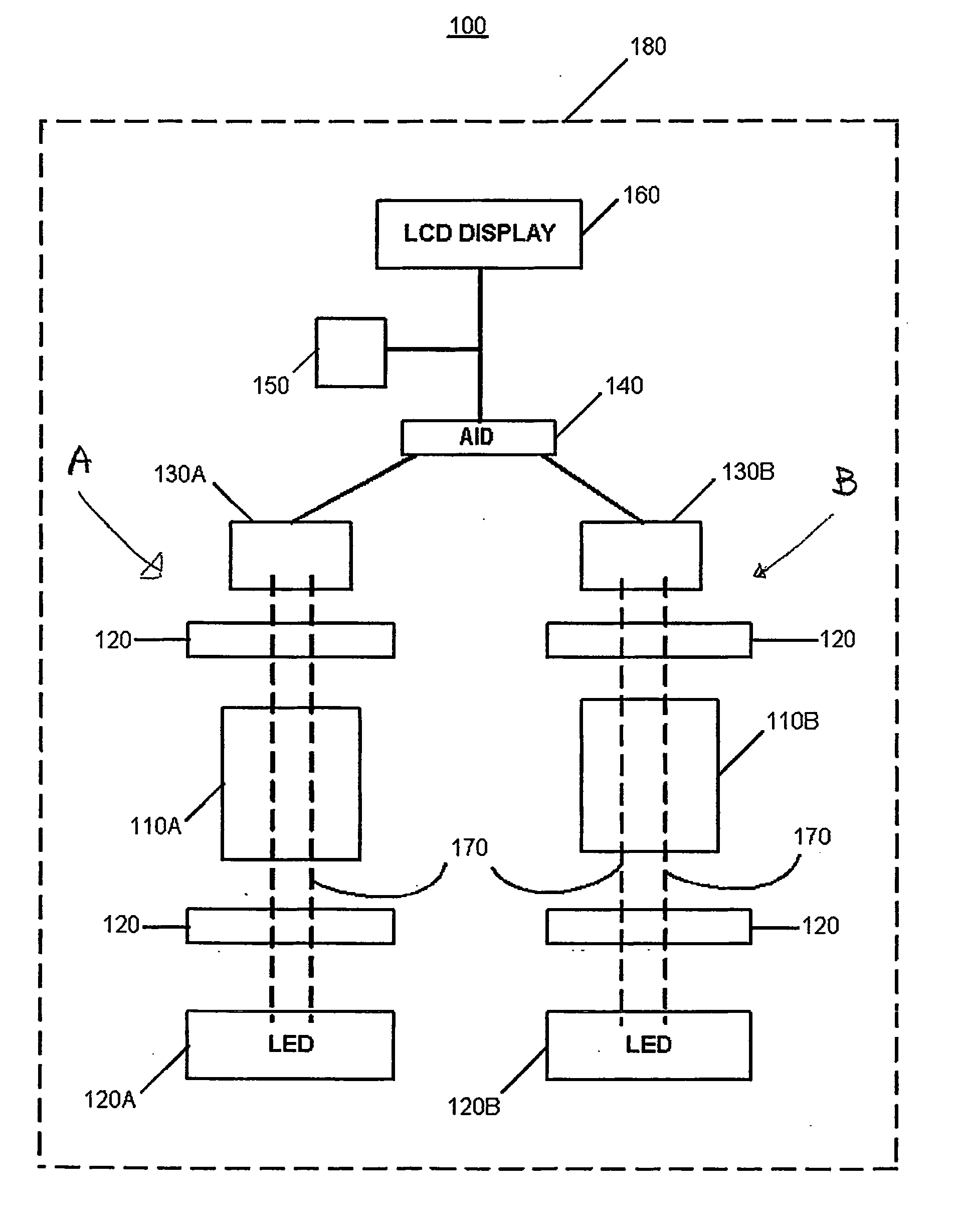

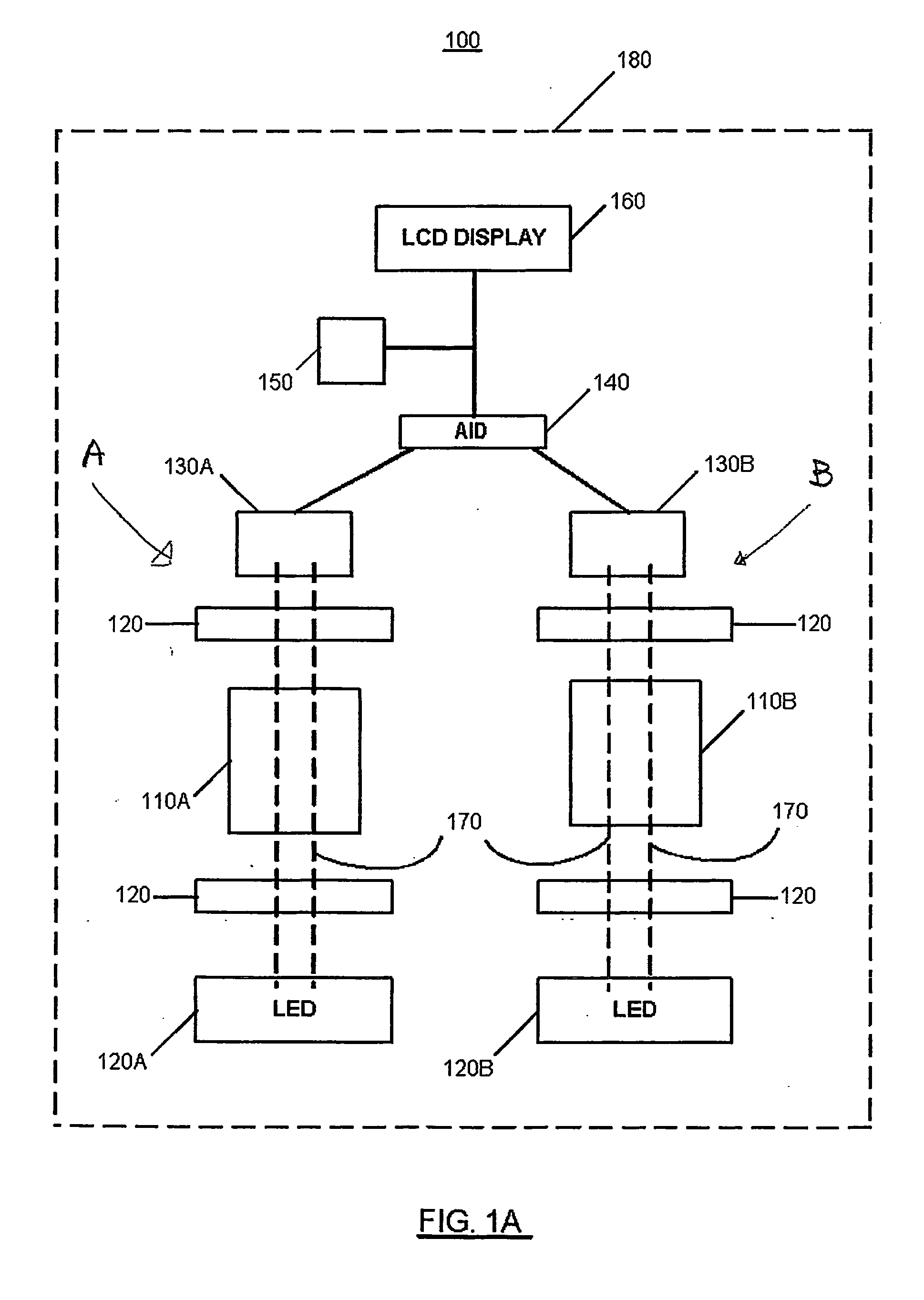

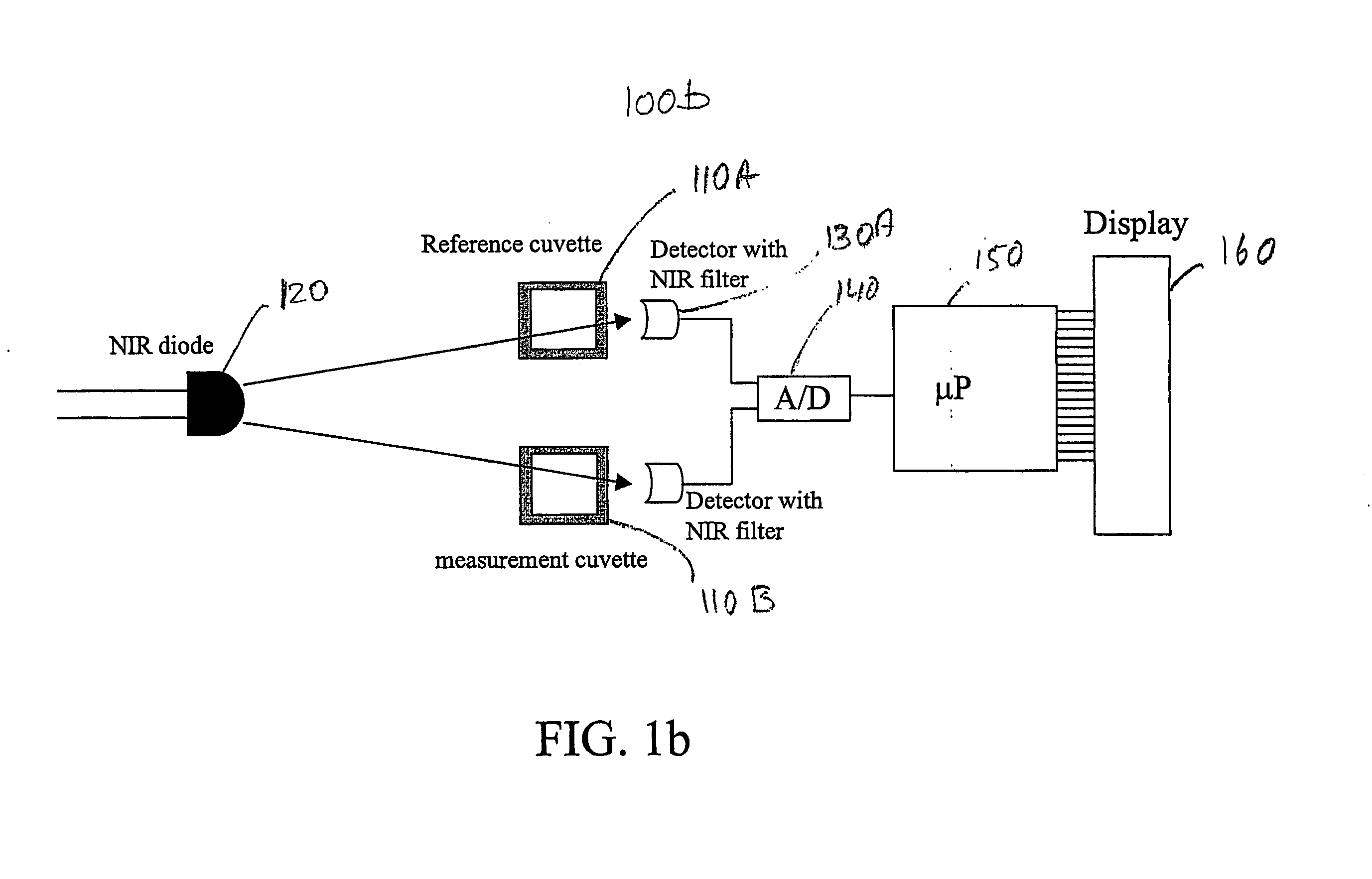

Arsenic meter

InactiveUS20060007445A1Radiation pyrometryMaterial analysis by observing effect on chemical indicatorMolybdenum blueField tests

A field test-kit for analyzing arsenic concentration in water samples is provided. The kit includes a portable infrared beam photometer for measuring light absorbance in aqueous specimens. An infrared light emitting diode is configured to direct a beam of light through a specimen. A photodetector diode measures the intensity of light passing through the specimen. The photodetector output voltages relate to the light absorbed in the specimen and are displayed on a liquid crystal display screen. The kit is assembled using off-the-shelf electronic and opto-electronic components that have low power requirements. Dry cell batteries or solar cells power the kit. To test for arsenic, molybdenum based chemistries are used to selectively bind and convert arsenates and phosphates in the specimen into molybdenum-blue color complexes. The light absorbance of a specimen with both arsenates and phosphates bound in molybdenum-blue color complexes is compared to that of a reference specimen in which phosphates but not arsenates are bound and converted. The differential light absorbance of the two specimens is used to arrive at a quantitative value for the arsenic concentration in the water sample.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Fuel cell, and a method for preparing the same

The invention discloses a fuel cell and a preparation method thereof. The fuel cell includes dry cells each having a membrane electrode assembly, a separator disposed on either side of the membrane electrode assembly, a separator between the membrane electrode assembly and the separator and on the edges of both, wherein an adhesive Adhesives are used to bond each separator to the separator, or to the membrane electrode assembly and the separator. The use of a separator with adhesive in a fuel cell according to the present invention provides an excellent airtight seal of the fuel and oxidant gases of the fuel cell.

Owner:SAMSUNG SDI CO LTD

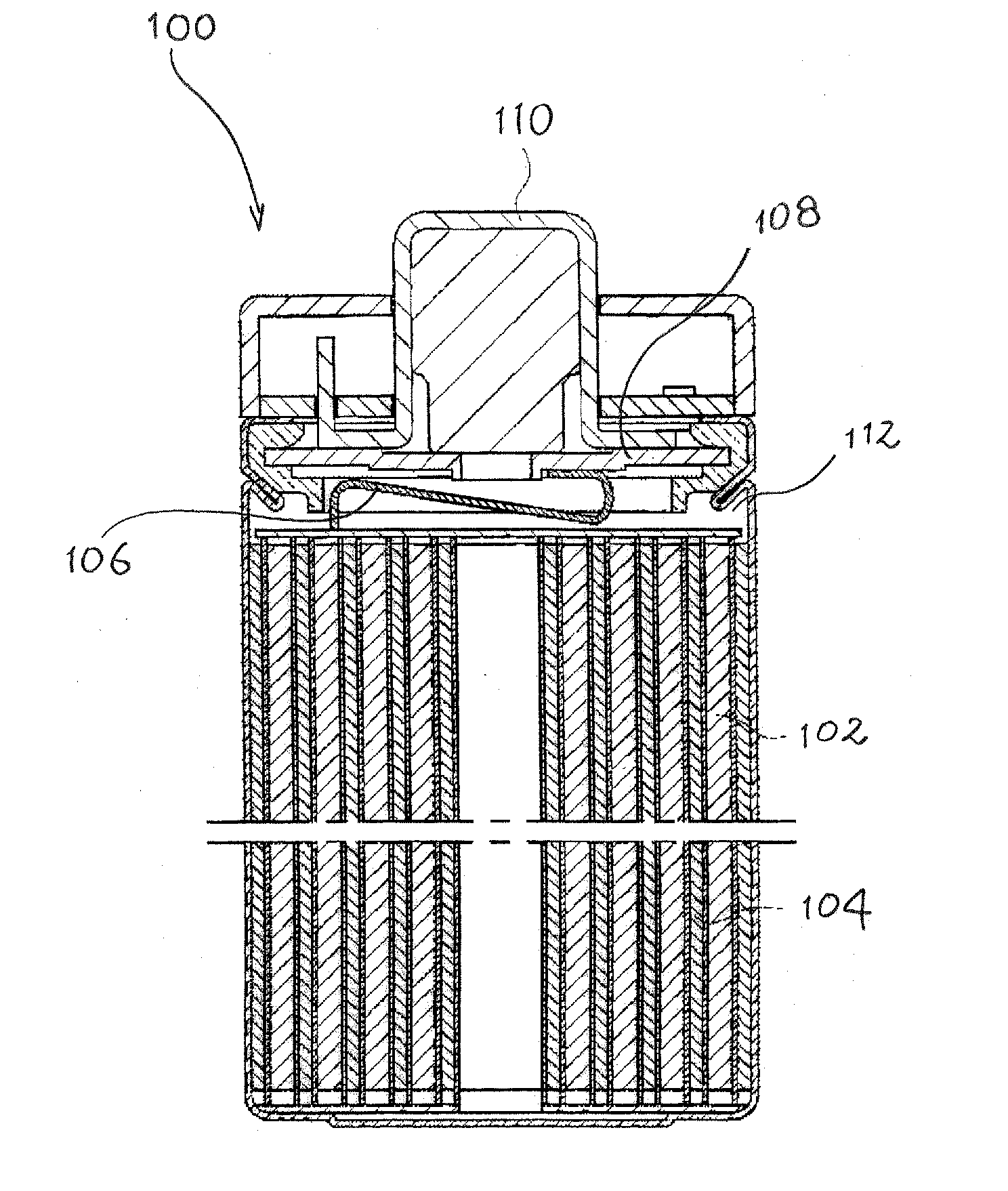

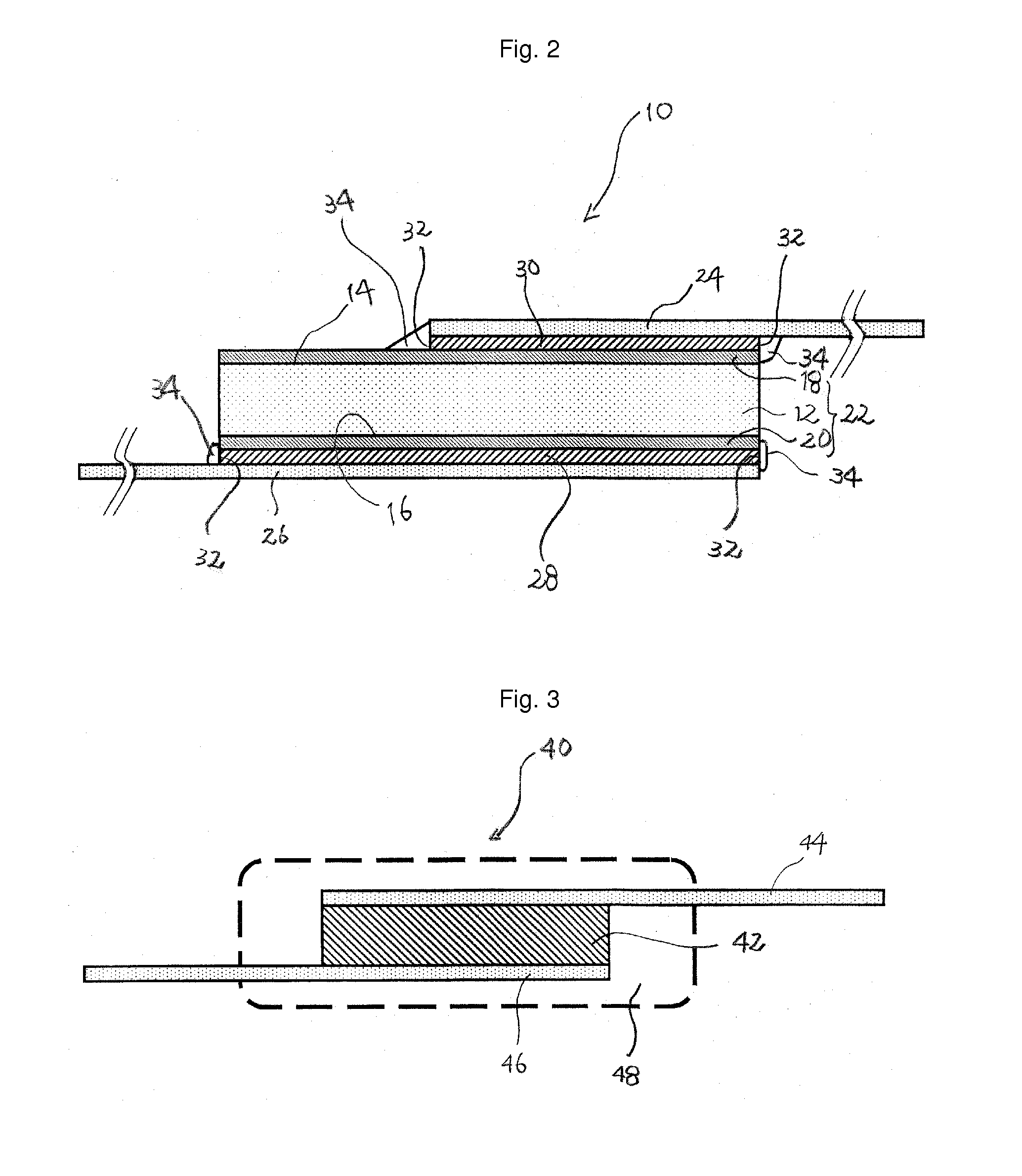

PTC Device and Secondary Battery Having the Same

InactiveUS20130196182A1Eliminate the effects ofSave spaceCurrent responsive resistorsCells structural combinationEpoxyConductive materials

A PTC device as well as an electrical device such as a battery pack or a dry-cell type secondary cell containing a PTC device and a secondary cell is made more compact. The PTC device includes (1) a PTC component including a laminar polymer PTC element having an electrically conductive filler and a polymer material, and a metal electrode disposed on a surface of each side of the polymer PTC element; and (2) a lead positioned at least in part on the metal electrode of the PTC component, and connected to the metal electrode by an electrically conductive material. An exposed part of the electrically conductive material is covered by a protective member including a polypropylene resin, a nylon resin or an epoxy resin.

Owner:LITTELFUSE JAPAN GK

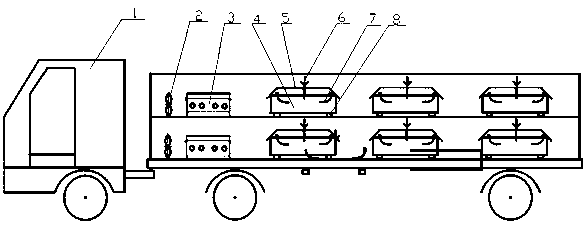

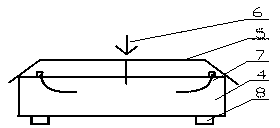

Mobile battery charging/changing station for electric vehicle

InactiveCN103010176APlace stableEasy to charge and replaceElectric propulsion mountingItem transportation vehiclesBattery chargeElectrical battery

The invention discloses a mobile battery charging / changing station for an electric vehicle. The mobile battery charging / changing station comprises a trailer, wherein a plurality of batteries are placed on a deck in a trailer carriage and are respectively connected with a charging machine arranged in the carriage, and the charging machine is connected with a controller arranged in the carriage; and the connections between the batteries and the charging machine as well as electric appliances on the electric vehicle and between the batteries are realized through battery leads in a slipknot manner or a threaded manner. According to the invention, the functions of the traditional fixed type battery charging / changing station are mobilized through the trailer; the batteries can be placed on the trailer conveniently and firmly only by slightly changing the trailer; and the batteries can be charged in any places capable of supplying electric energy as long as the charging machine and other accessory equipment are arranged in the trailer carriage, and the trailer can also be driven to any places in need so as to change the batteries for the electric vehicles. The mobile battery charging / changing station disclosed by the invention does not occupy fixed places, is flexible and convenient for battery charging and changing and low in investment, and has very good economic and social benefits.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com