Patents

Literature

326results about How to "Guaranteed temperature uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

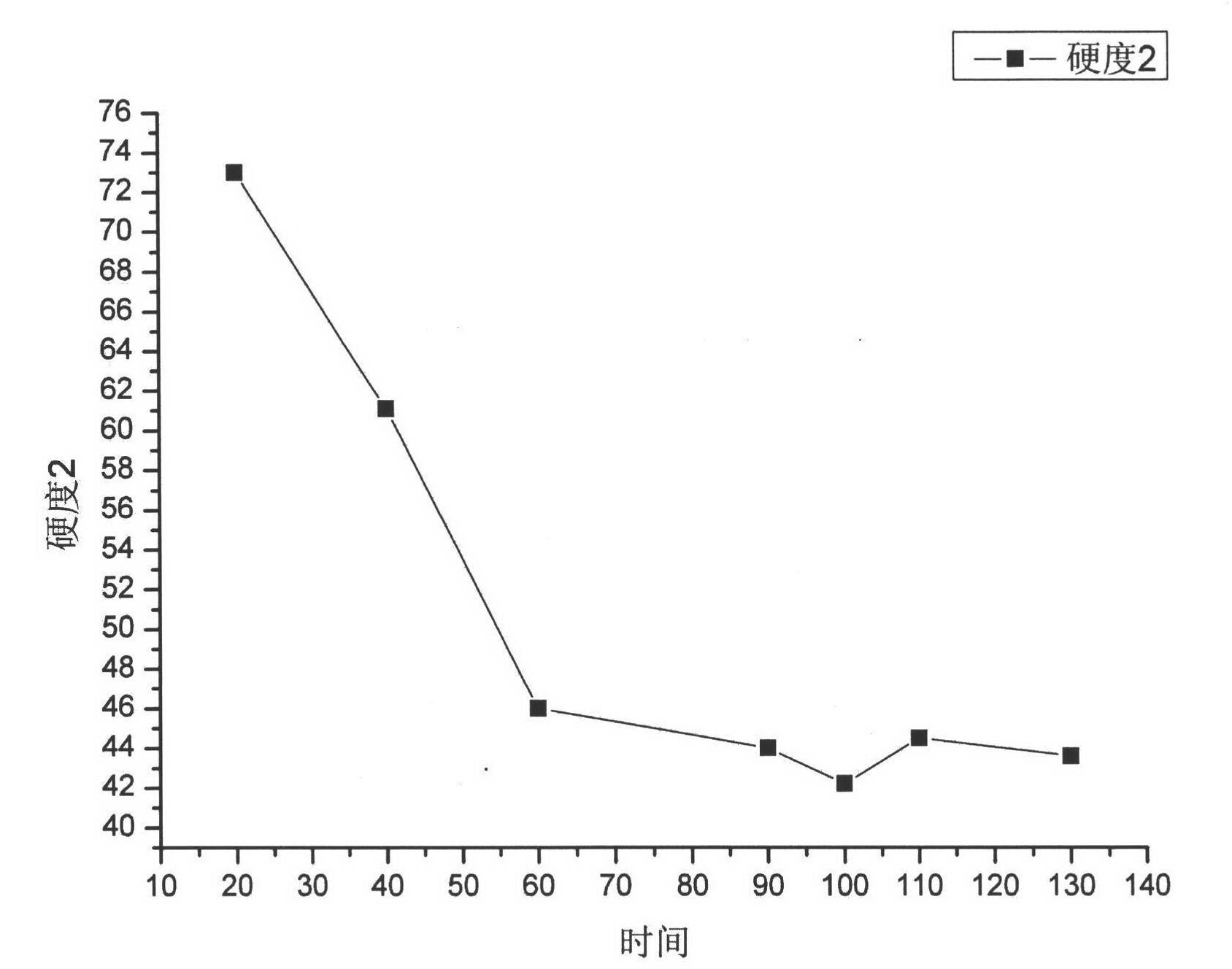

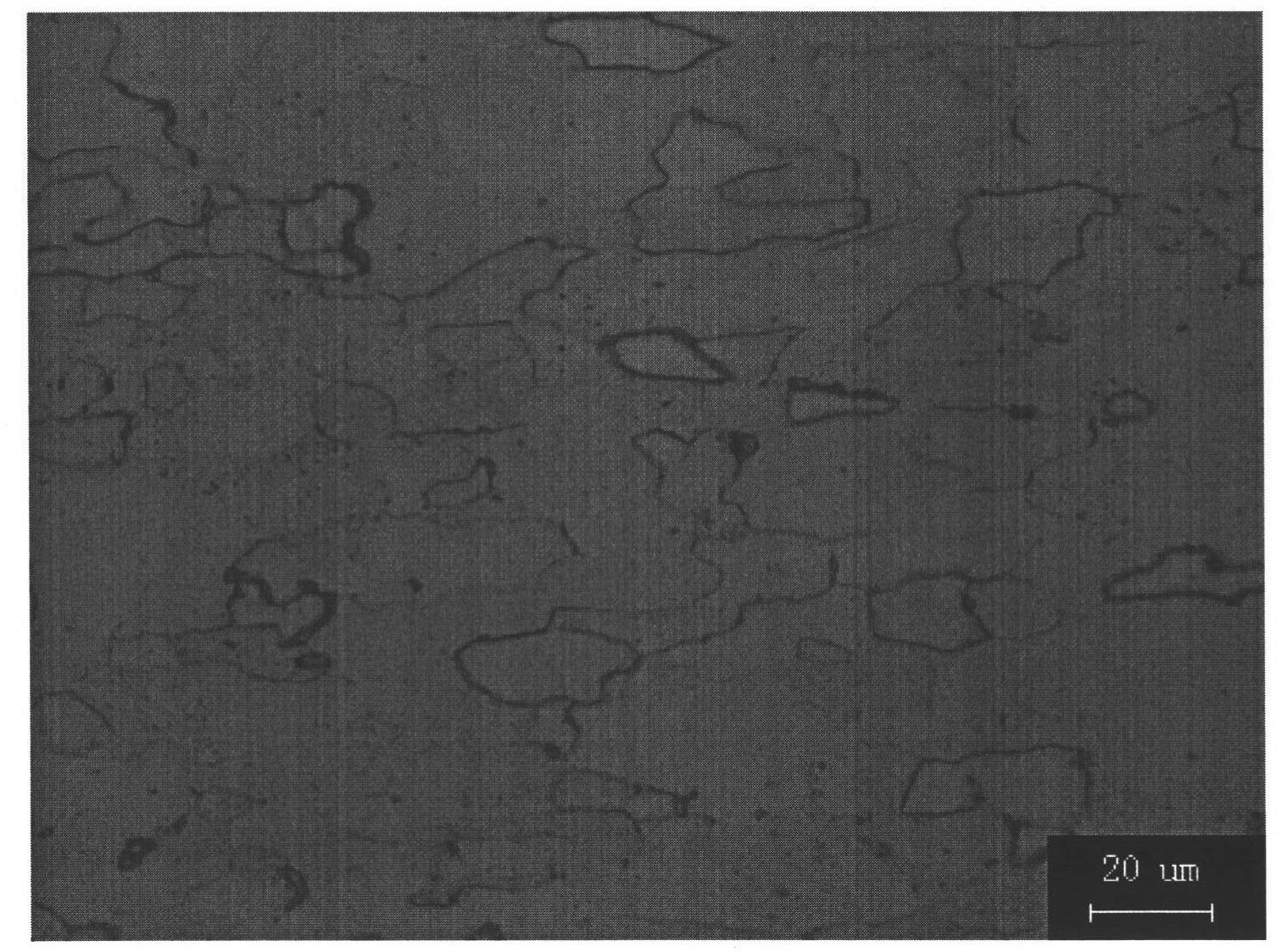

Low-temperature continuous-annealing interstitial-free atom cold-rolled steel plate and production method thereof

ActiveCN102653839ALower recrystallization temperatureRealize the structureChemical compositionReduction ratio

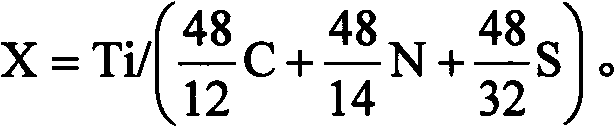

The invention relates to a low-temperature continuous-annealing interstitial-free atom cold-rolled steel plate and a production method thereof and belongs to the technical field of iron-based alloys. The production method of the cold-rolled steel plate comprises the following steps of: controlling the components of the cold-rolled steel plate in percentage by mass: 0.0005-0.0025% of C, less than or equal to 0.03% of Si, 0.05-0.15% of Mn, less than or equal to 0.015% of P, less than or equal to 0.01% of S, less than or equal to 0.0025% of O, less than or equal to 0.0025% of N, 0.015-0.050% of Al, 0.03-0.07% of Ti, and the balance of Fe and inevitable mixed elements; and meanwhile, controlling the continuous-annealing temperature of the cold-rolled steel plate to be 710-740 DEG C, and controlling the cold-rolling reduction ratio to be not less than 80%. According to the cold-rolled steel plate and the production method thereof, the reasonable chemical components and the suitable control of cold-rolling reduction are adopted, the recrystallization temperature is lowered, full-old-rolled microstructures are formed, and a lower continuous-annealing temperature can be adapted, so that the equipment cost and energy consumption are reduced, the control difficulty of a production process is reduced, the product defects and production accidents are avoided.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

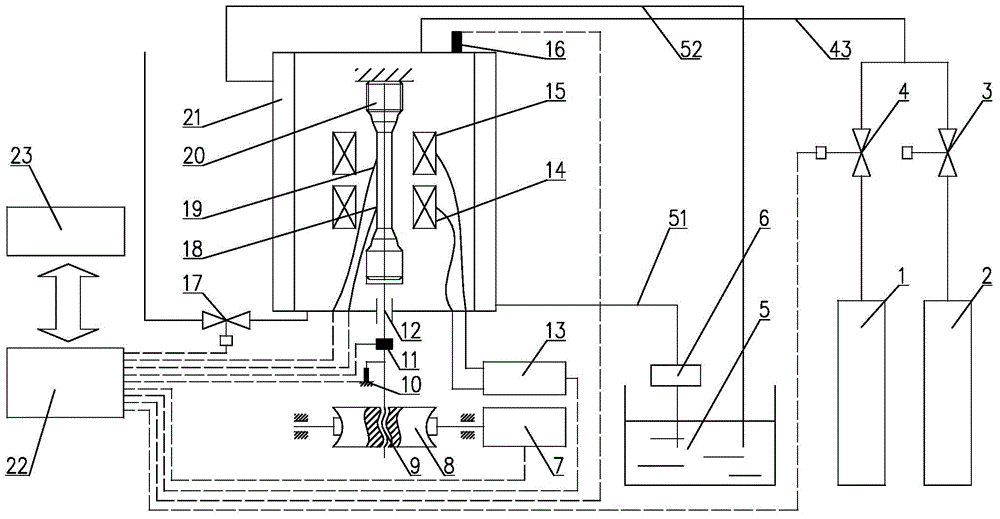

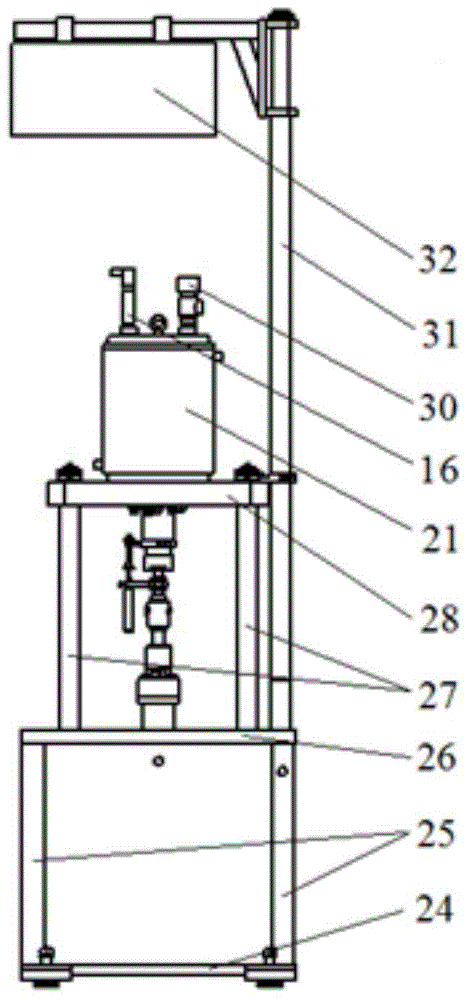

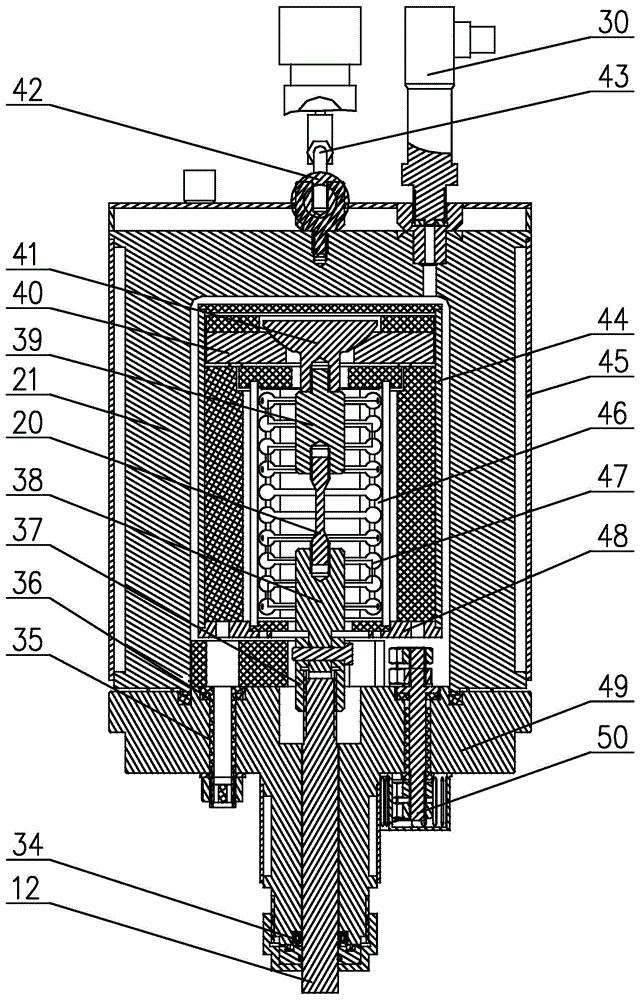

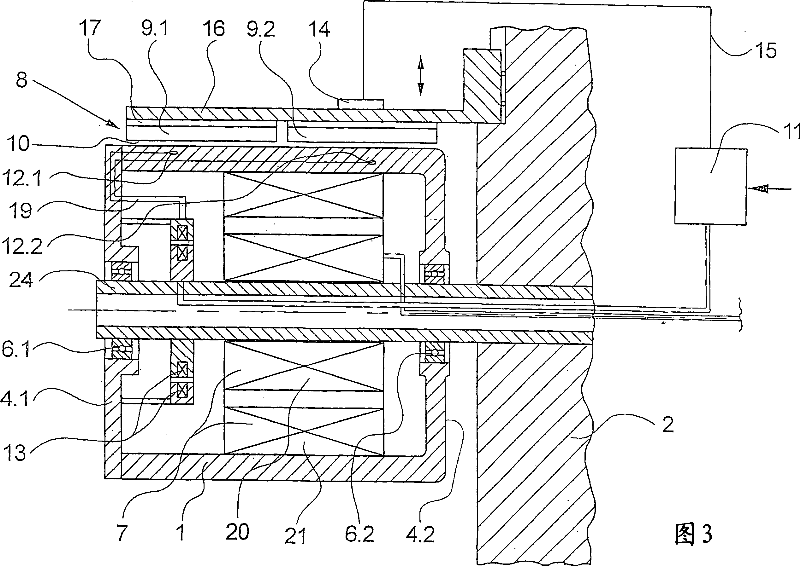

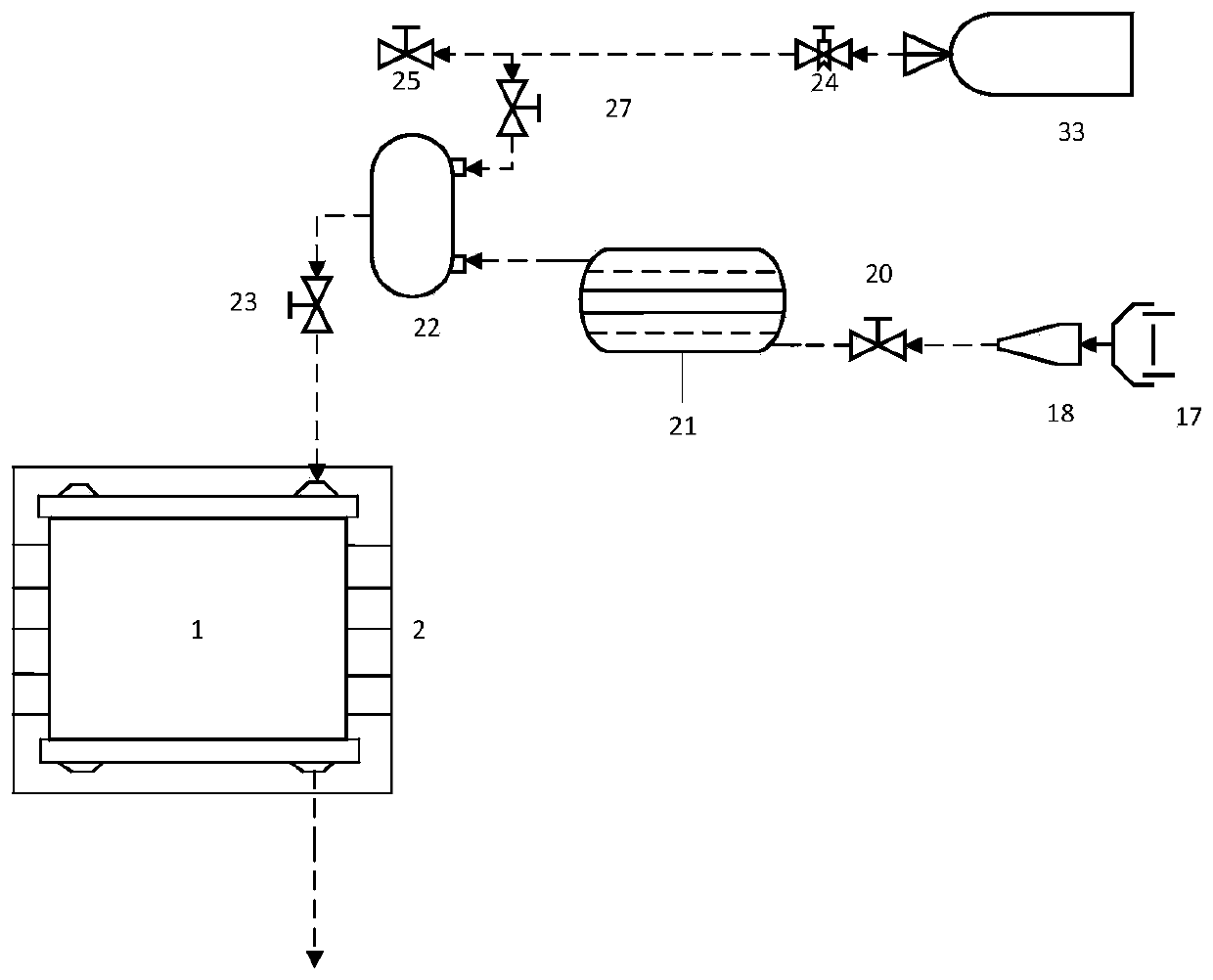

Device for testing material properties in high-temperature hydrogen environment

ActiveCN104897476AReasonable and reliable device structureShort heat transfer chainWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesProcess engineeringHydrogen supply

The invention relates to a device for testing material properties in a high-temperature hydrogen environment. The device comprises a hydrogen environment box and a host machine loading framework, wherein a test sample is arranged in the hydrogen environment box; a pull rod is mounted on the host machine loading framework; the hydrogen environment box is arranged on the host machine loading framework; an upper clamping part, a lower clamping part and an electrical heating component are arranged in the hydrogen environment box; the pull rod penetrates through the hydrogen environment box and is fixedly connected with the lower clamping part; the hydrogen environment box is connected with a hydrogen supply pipe; an air-relief solenoid valve is arranged on the hydrogen environment box. The device further comprises sensors and a control component, wherein the sensors are used for monitoring test sample stress load, test sample deformation, test sample environment temperature and test sample ambient hydrogen pressure; the control component is used for monitoring and processing the information collected by the sensors. The device can be used for testing the creep property, stress rupture property and tension-tension alternating load fatigue property of a metal material in the hydrogen environment, can ensure the accuracy of testing results, works reliably and stably and has high efficiency.

Owner:HEFEI GENERAL MACHINERY RES INST +1

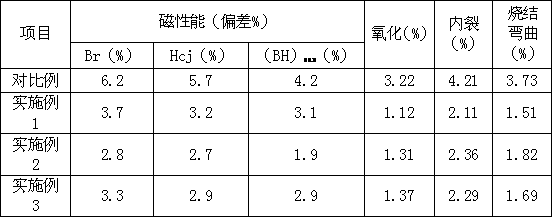

Partial pressure sintering method for sintering neodymium-iron-boron magnet

ActiveCN103000363AEnsure consistencyGuaranteed uniformityInductances/transformers/magnets manufactureMagnetic materialsMetallurgyVacuum pump

The invention relates to a partial pressure sintering method for sintering a neodymium-iron-boron magnet. Certain inert gases Ar are filled into various deflation sections in the sintering process, the pressure of the Ar gases inside a furnace is regulated according to blank deflation velocity and vacuum pump system exhaust velocity through vacuum degree control, so that heating sintering is carried out by uniformly deflating under different partial pressures of the Ar gases, and negative pressure is still kept. The partial pressure sintering method disclosed by the invention ensures the consistency and uniformity of magnetic property and saves the sintering time.

Owner:宁波永久磁业有限公司

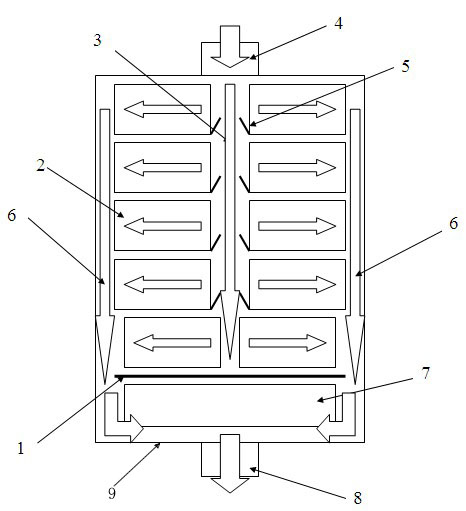

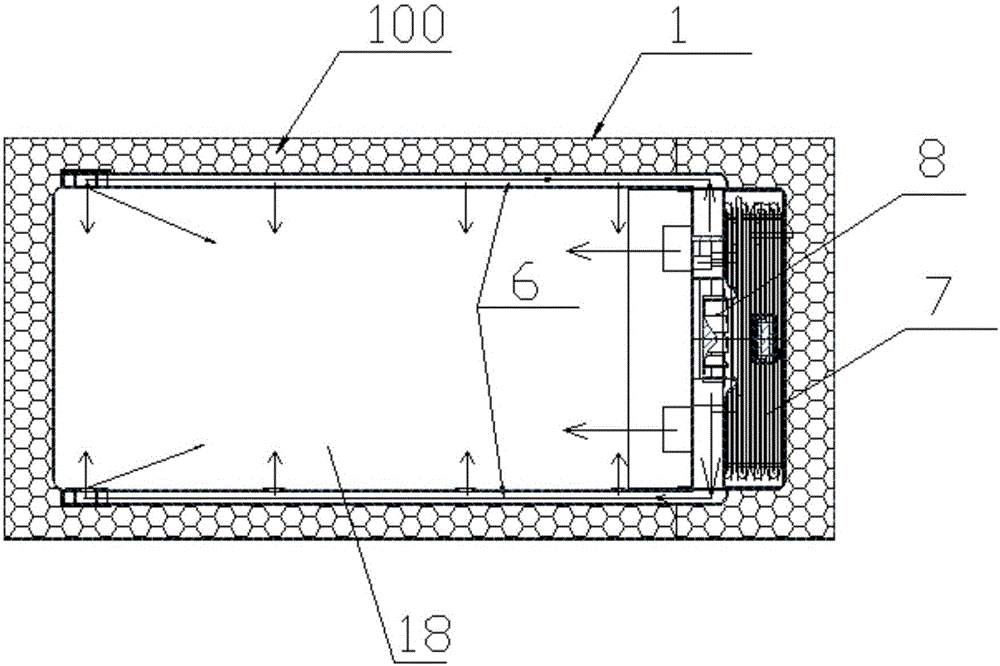

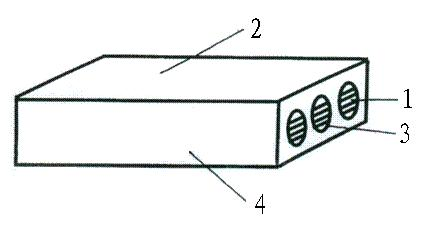

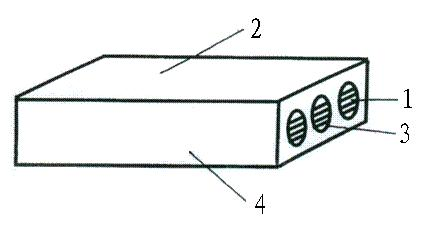

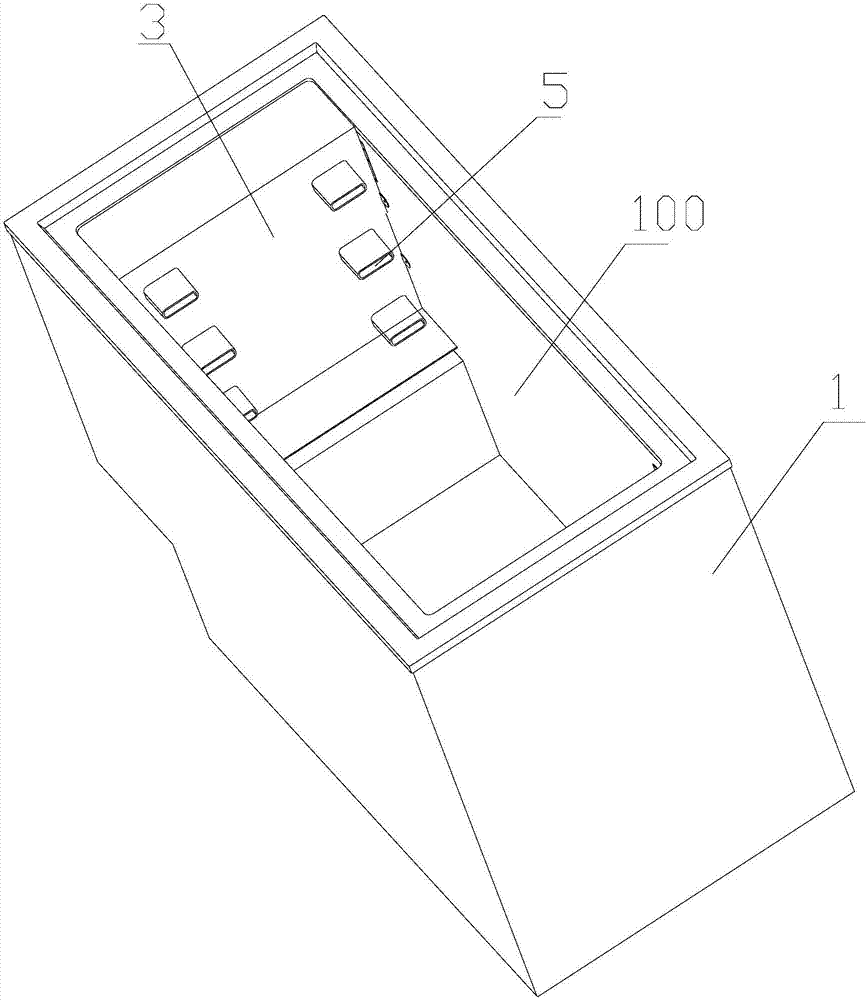

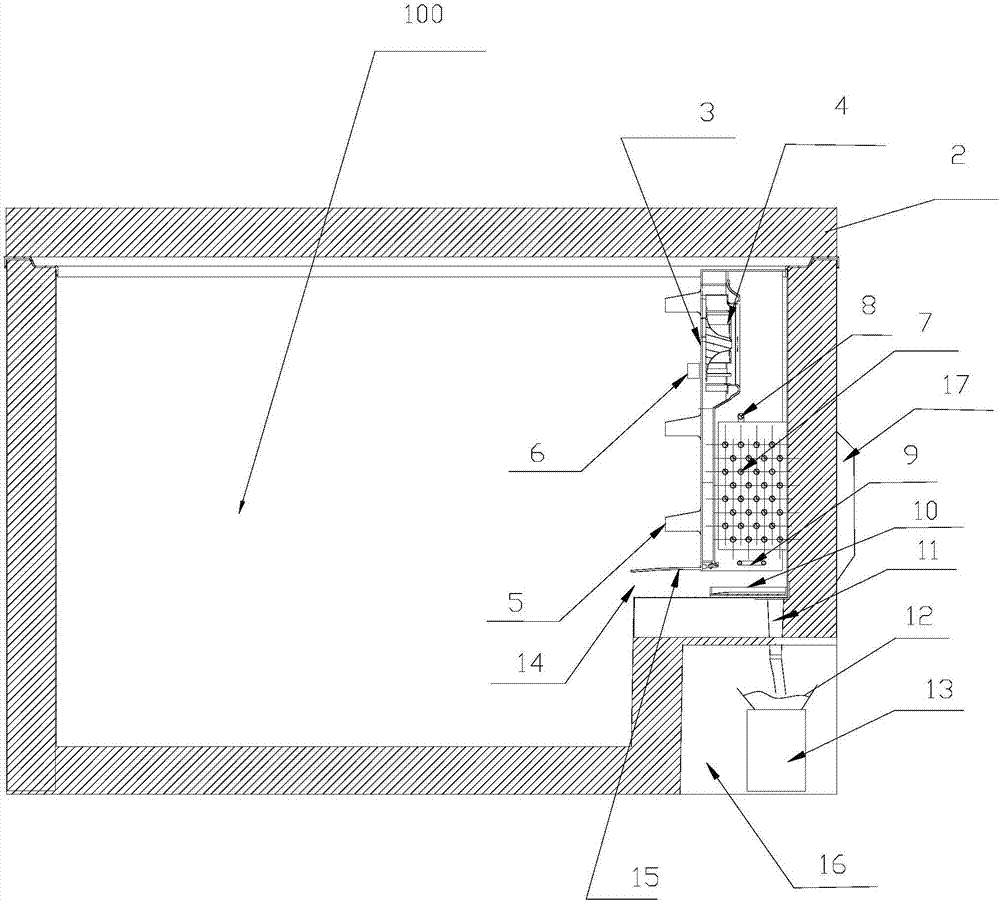

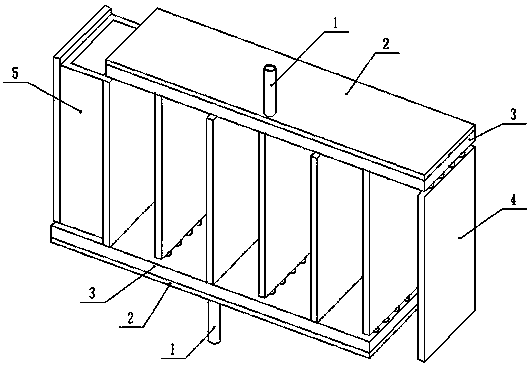

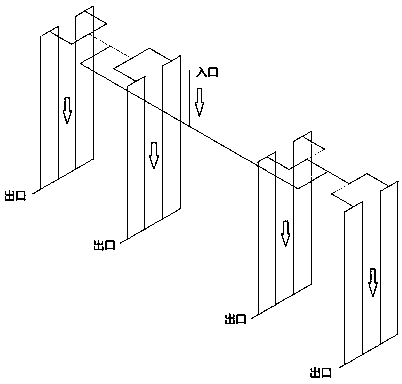

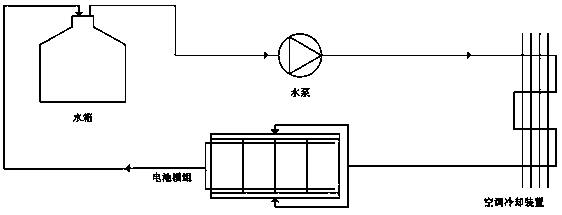

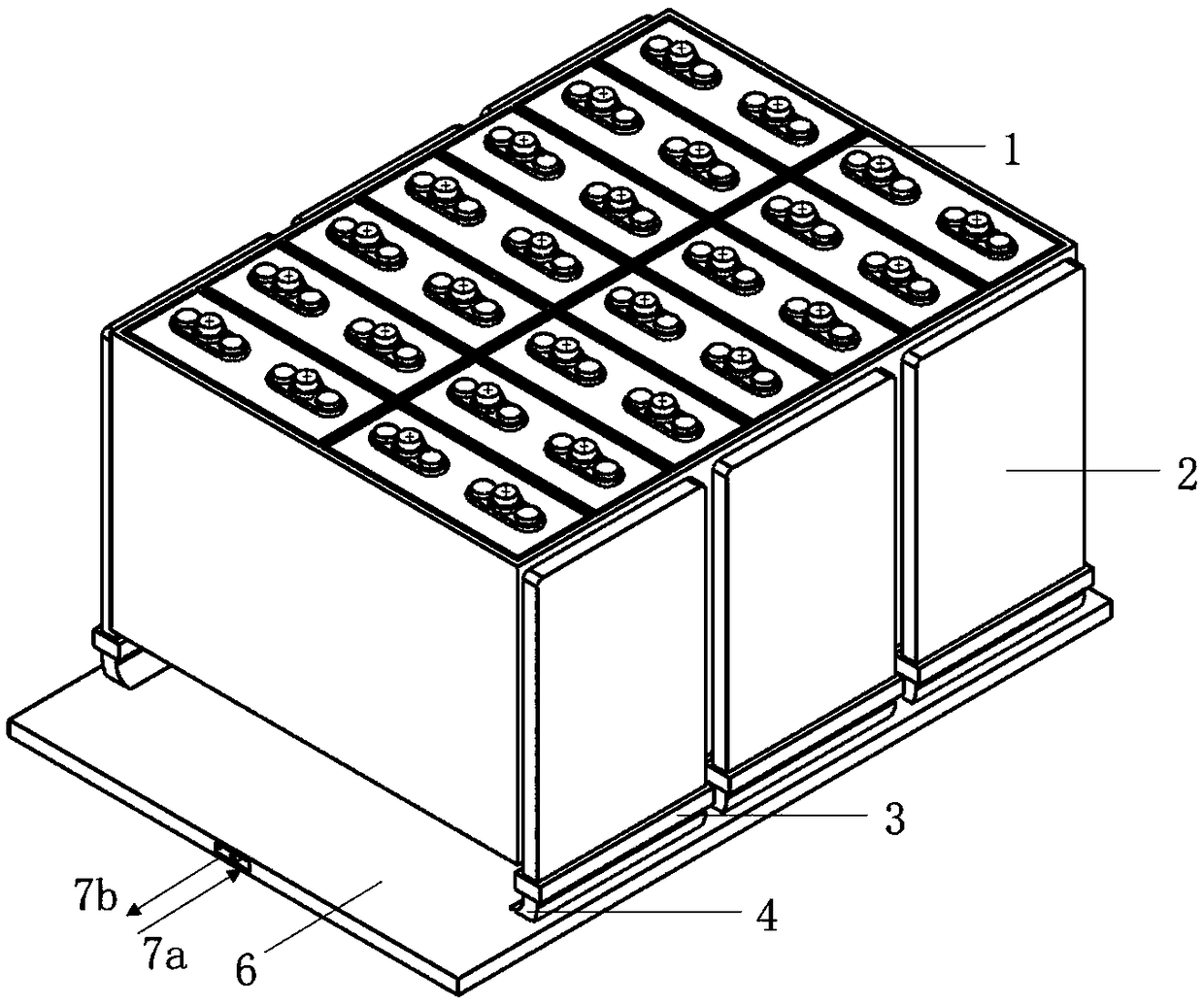

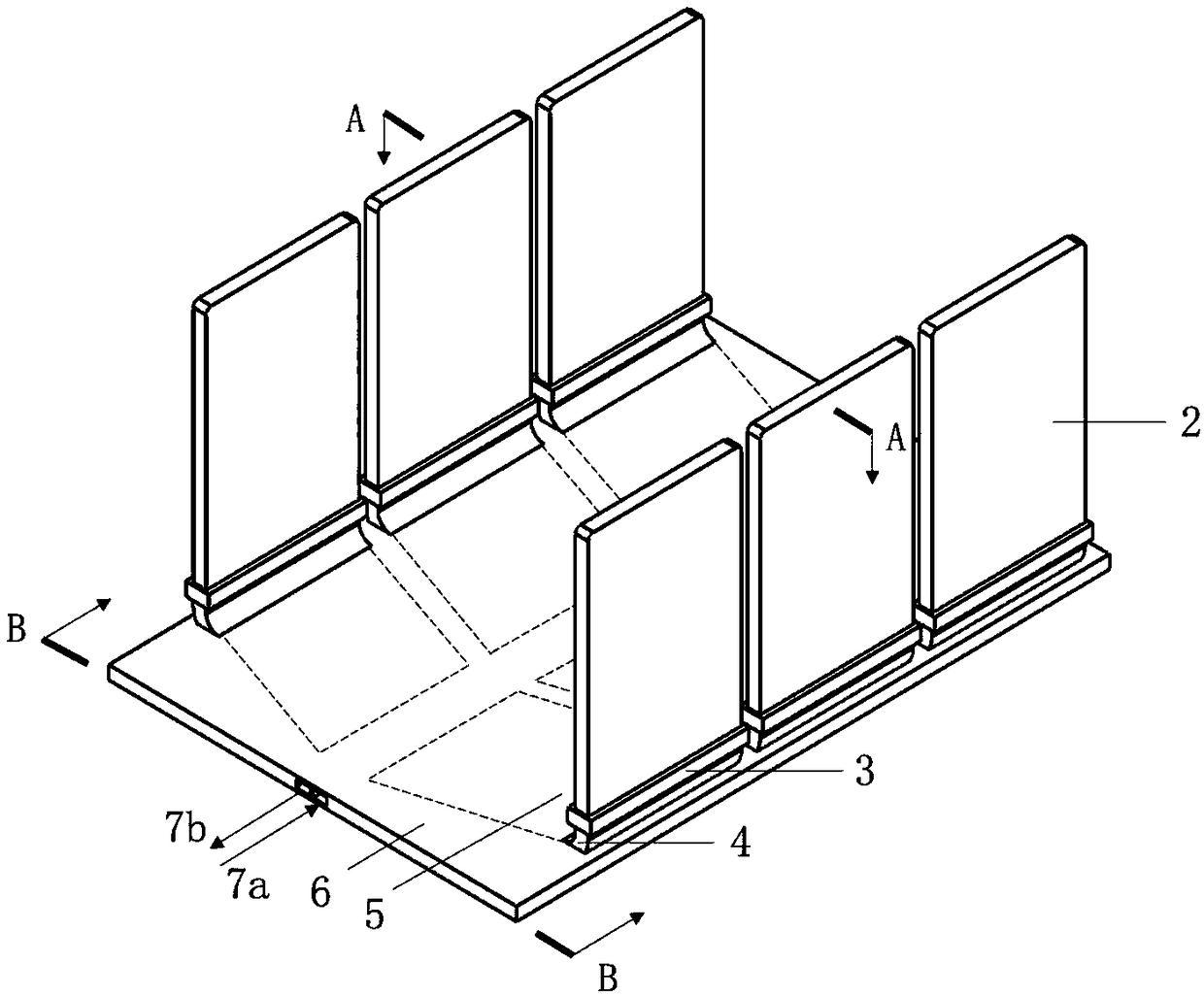

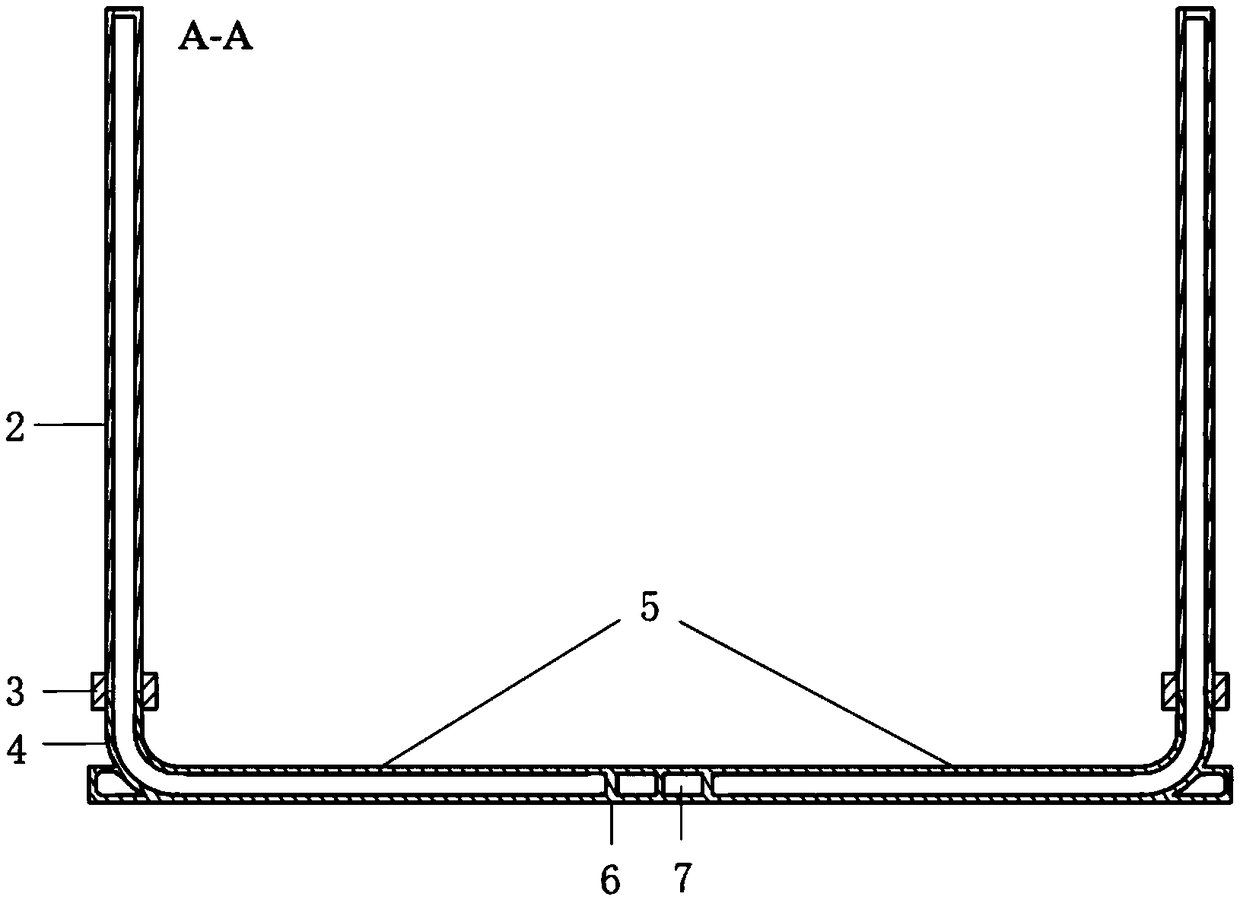

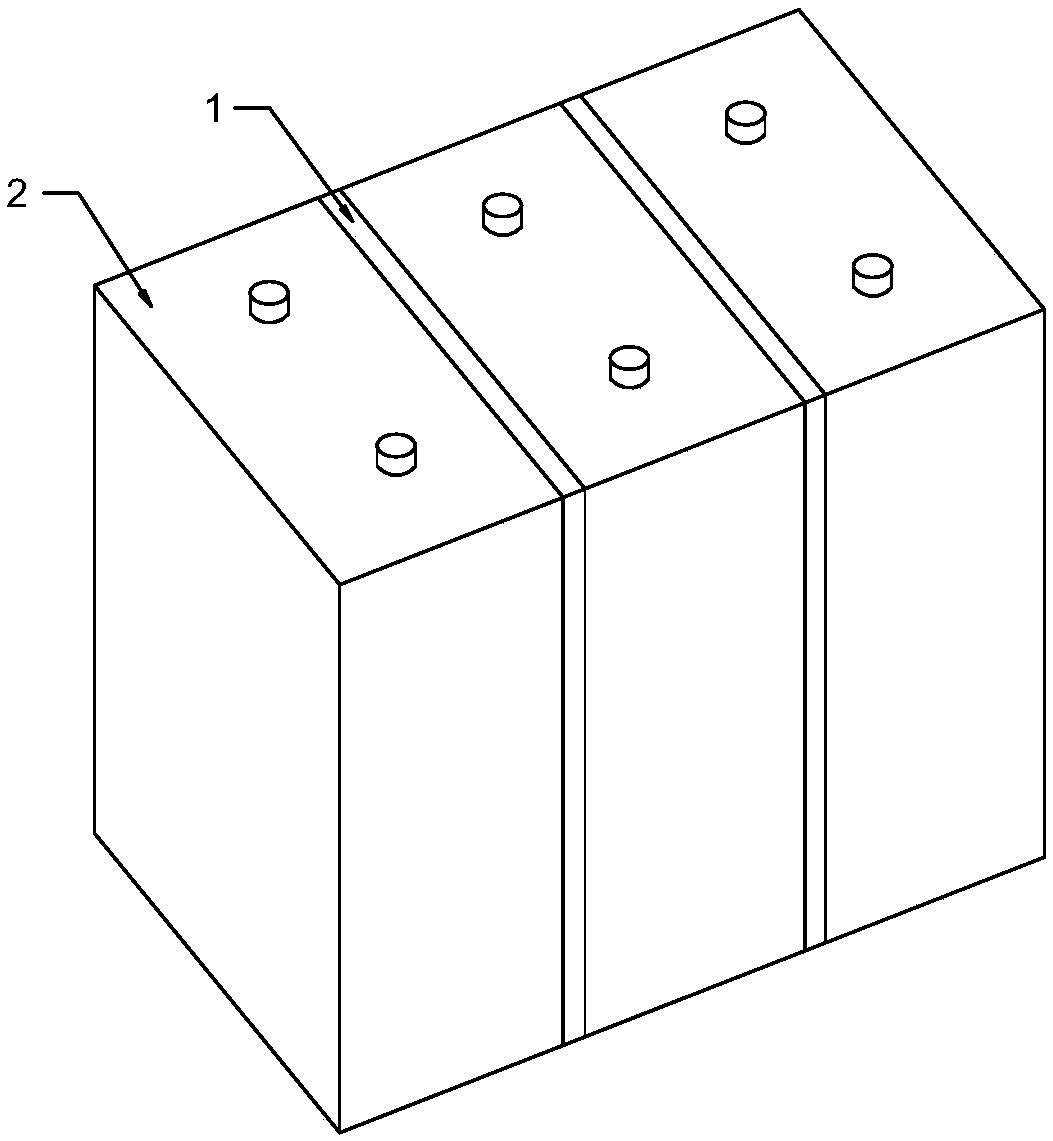

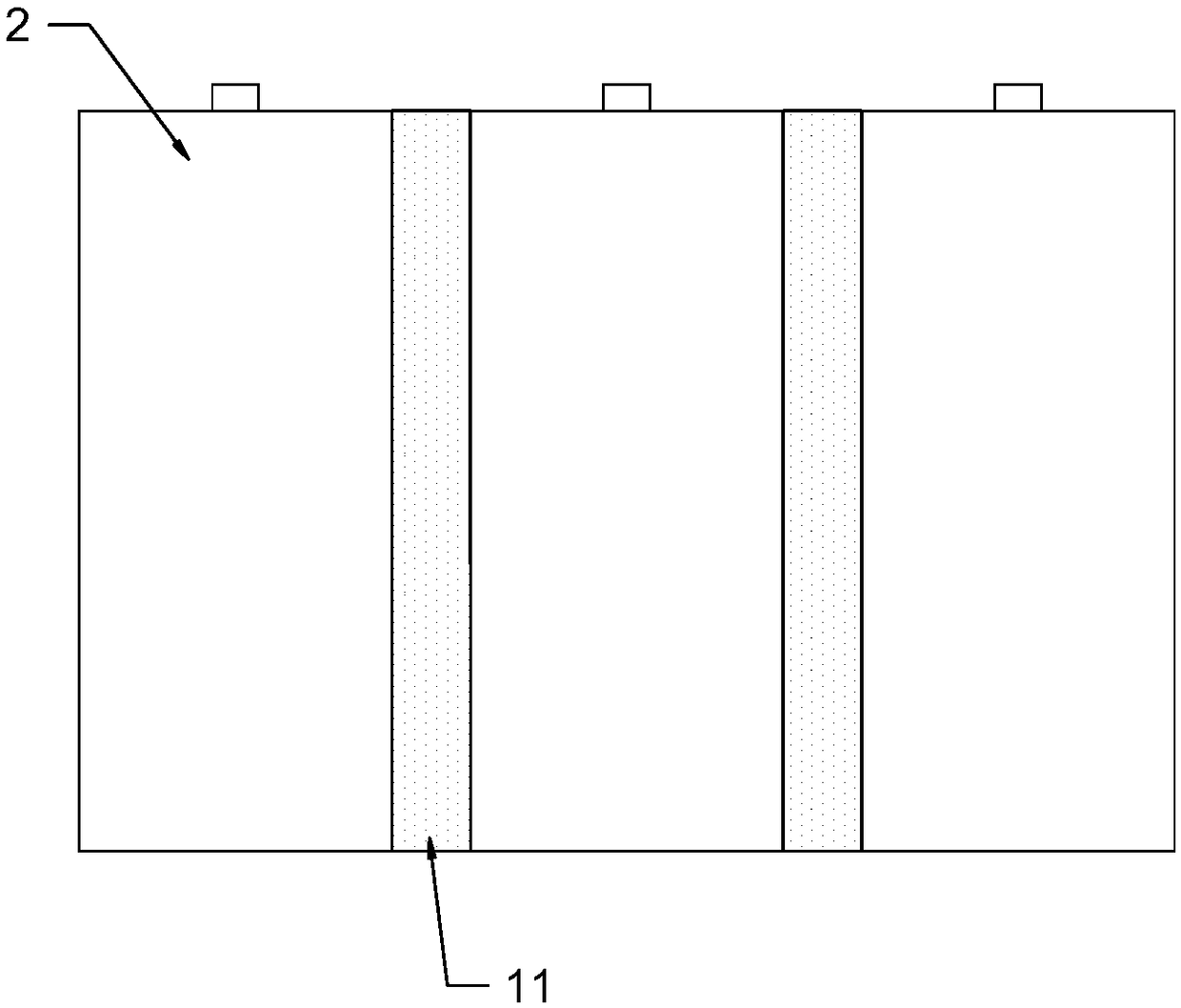

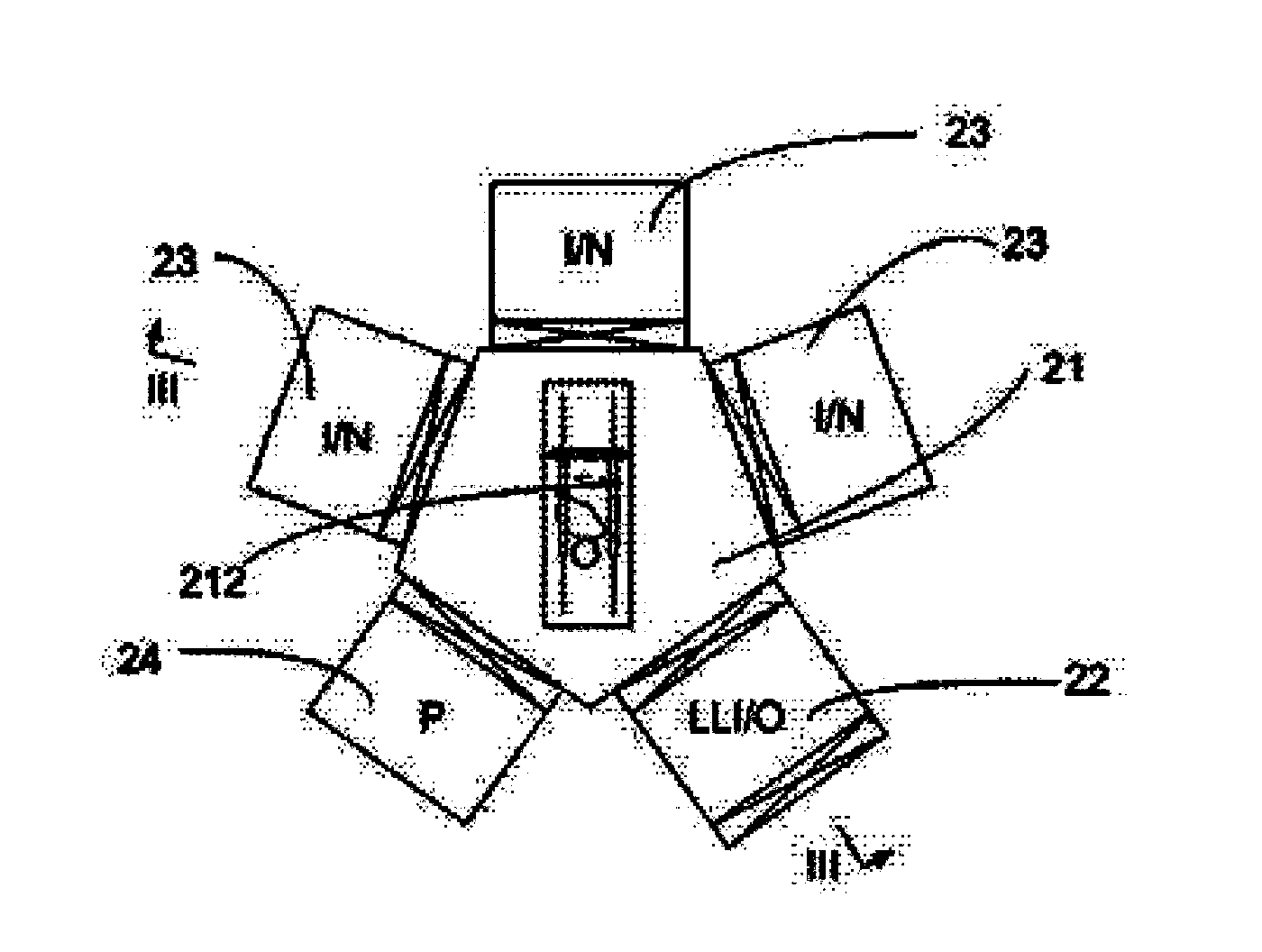

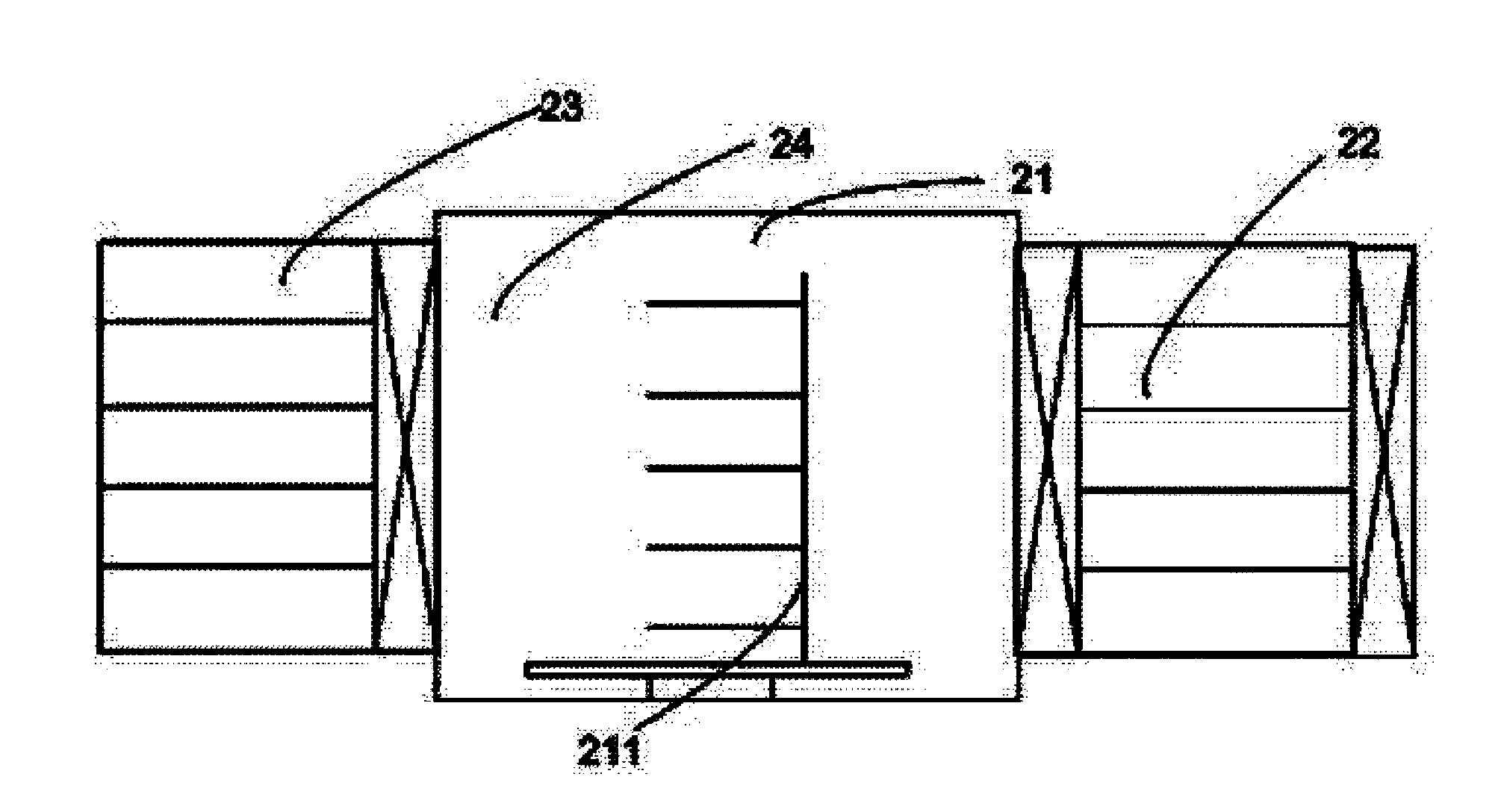

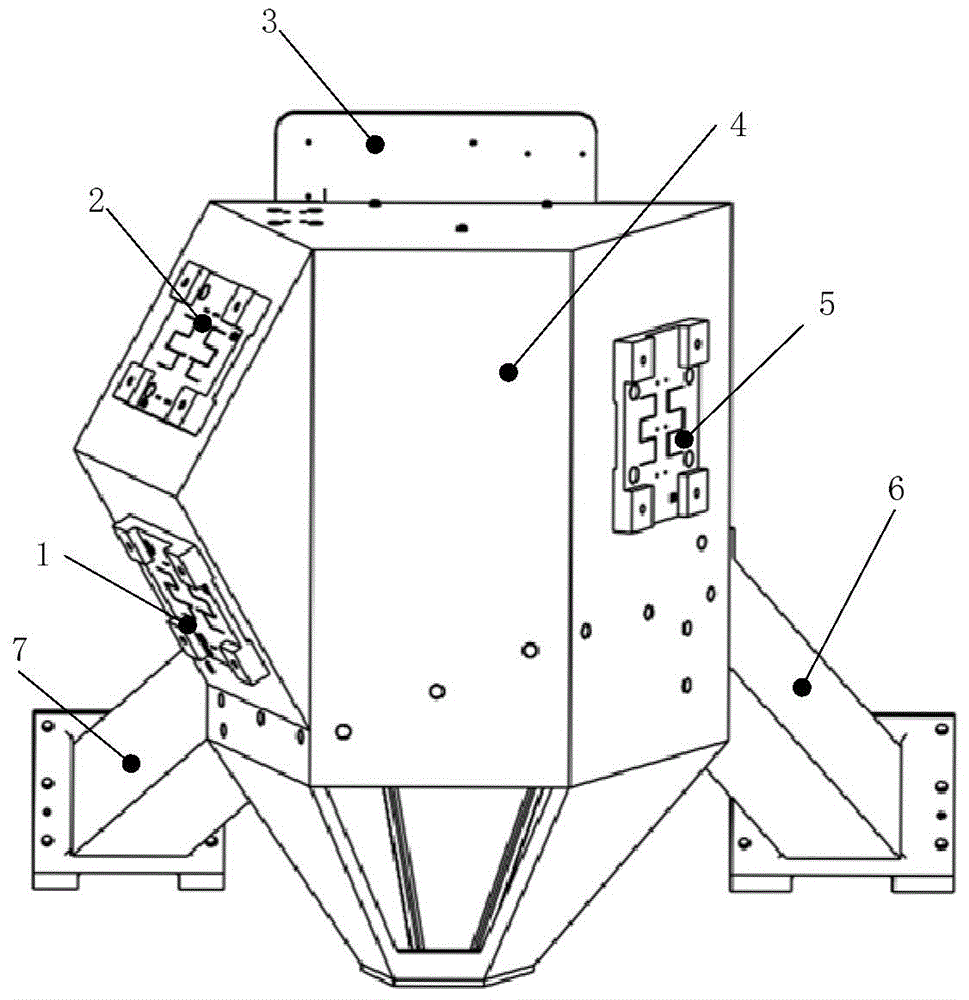

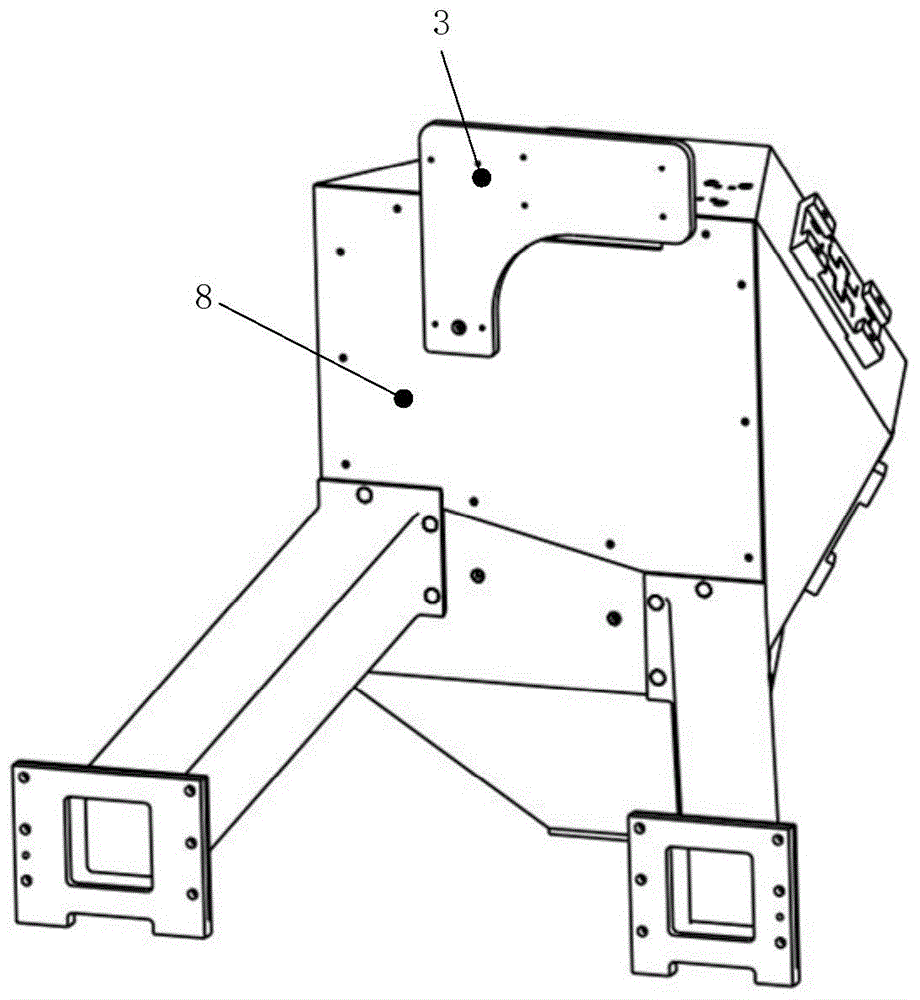

Lithium ion battery system for hybrid electric vehicle (HEV)

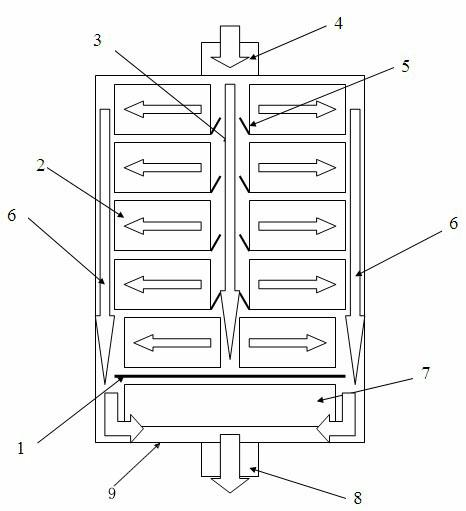

ActiveCN102074749AGuaranteed temperature uniformityOvercome heat dissipationCell component detailsSecondary cells servicing/maintenanceCooling effectEngineering

The invention provides a lithium ion battery system for a hybrid electric vehicle (HEV), comprising a battery box body, battery module groups in the battery box body, a battery management system and a high-voltage device, wherein the battery management system is arranged in the battery box body and is close to one end of a forward engine room in the HEV; the battery box body is provided with an air inlet and an air outlet; the battery module groups are symmetrically arranged at the left and the right in two rows along an air-in / air-out direction; an air-in wedge-shaped channel is reserved between the two rows of the battery module groups; an air-out channel is reserved between the outside of the left and the right battery module groups and the battery box body; the air-out channel is communicated with the air outlet of the battery box body; and a diffuser grid plate is arranged in the air-in wedge-shaped channel so as to strengthen wind resistance to evenly disperse the air at the two sides of a battery pack. Air channels are arranged in a gap between the battery module groups, thus solving the problems of long air flow, unconspicuous cooling effect, and larger temperature difference between the air inlet and the air outlet, and ensuring that the single battery inside the battery pack is even in temperature, simple in structure, and easy to manufacture.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD +1

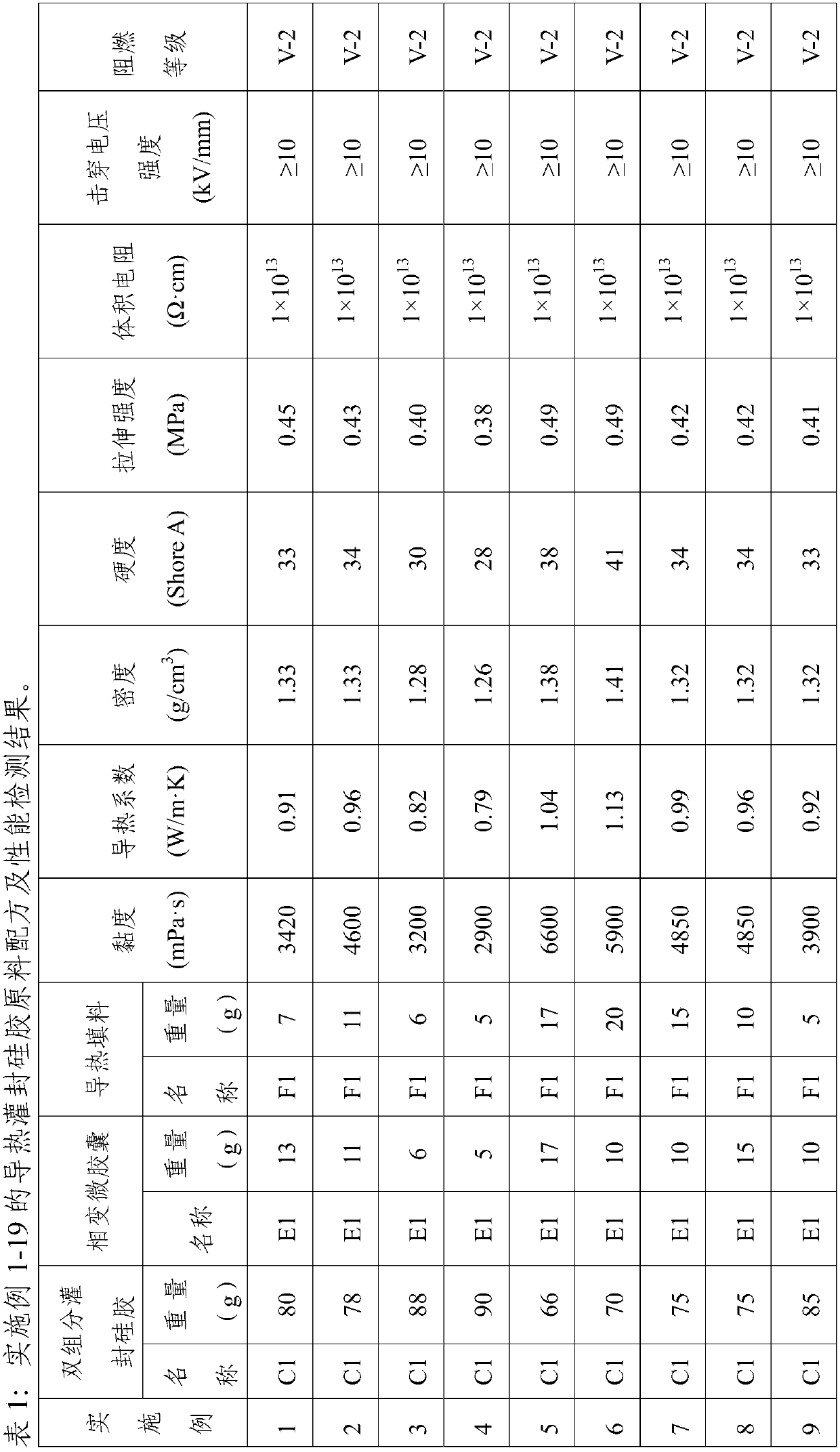

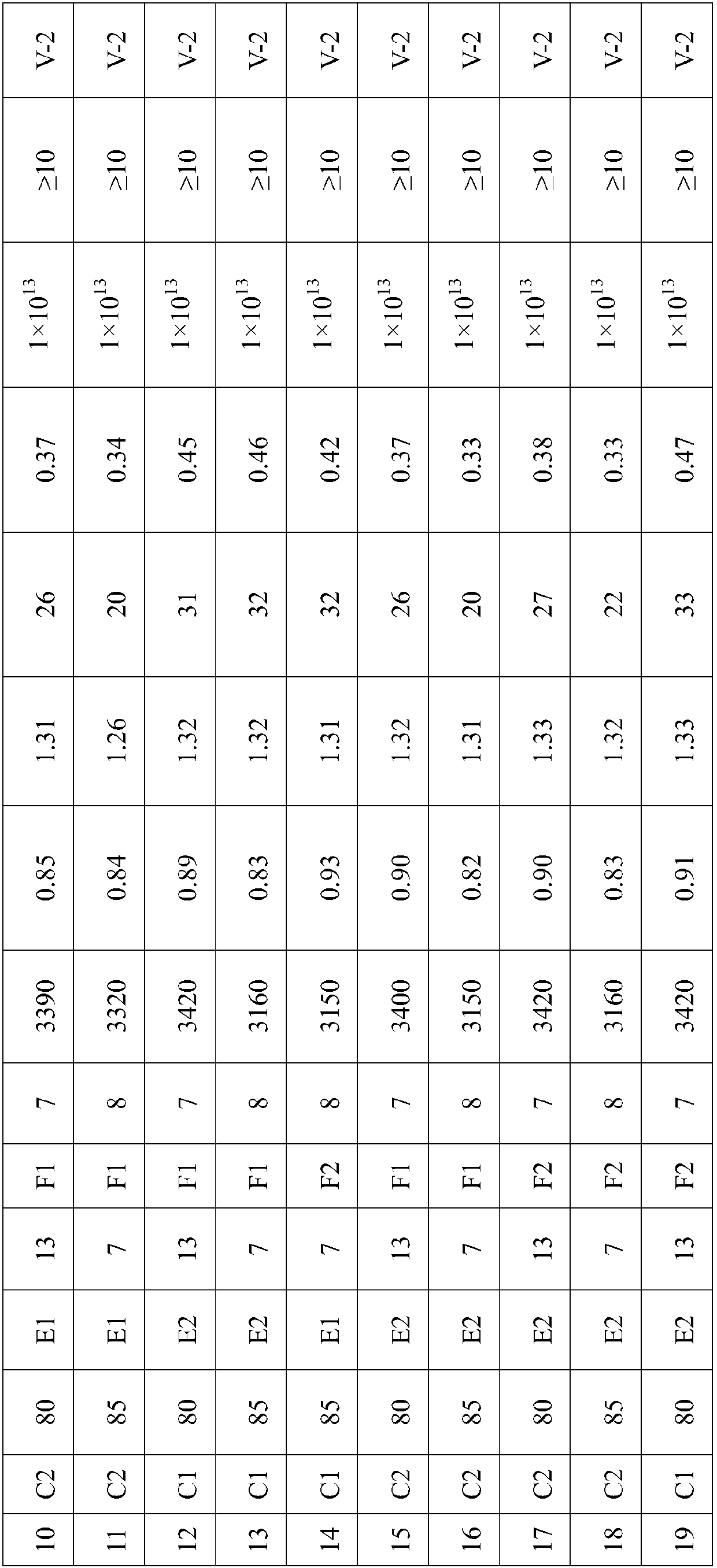

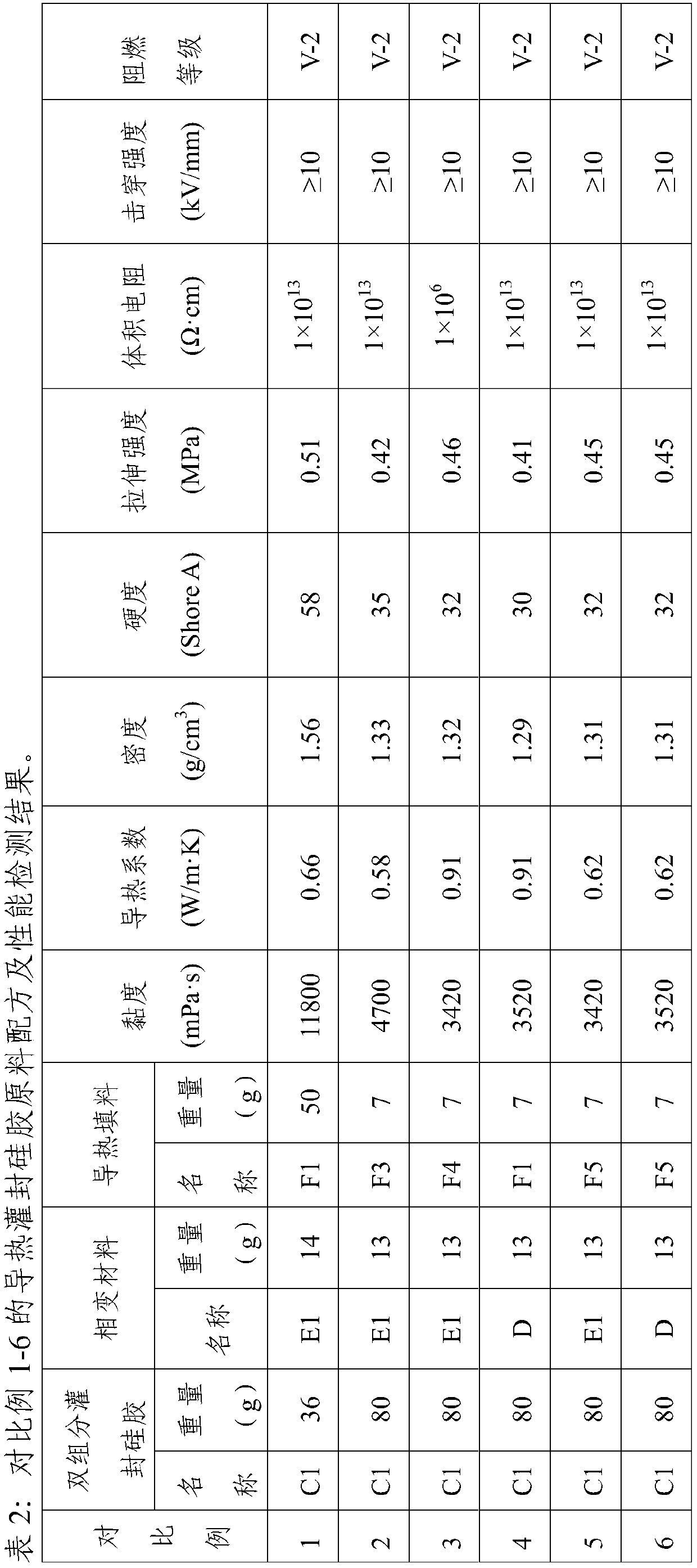

Thermal conduction potting silica gel based on phase-changing microcapsule and preparation method of thermal conduction potting silica gel

ActiveCN107815286AGood dispersionIncrease the amount addedNon-macromolecular adhesive additivesSecondary cellsDispersityTemperature control

The invention relates to thermal conduction potting silica gel based on a phase-changing microcapsule and a preparation method of the thermal conduction potting silica gel. The thermal conduction potting silica gel is prepared from the following components by mass percent: 50 to 90 percent of dual-component potting silica gel, 5 to 25 percent of phase-changing microcapsules and 5 to 25 percent ofsurface-treated thermal conduction filler. The preparation method comprises the following steps: treating the surface of the thermal conduction filler; preparing the thermal conduction composite filler; preparing a component A and a component B in the dual-component potting silica gel; preparing a component A1 and a component B1 in the thermal conduction potting silica gel; and preparing the thermal conduction potting silica gel. According to the preparation method, the surface treatment is performed on the thermal conduction filler in the preparation process, so that the dispersity of the thermal conduction filler in a silica gel matrix is improved, and the thermal conduction performance of the thermal conduction potting silica gel is improved; and by adding the phase-changing microcapsule, the thermal conduction potting silica gel has the heat-storage temperature control performance. The thermal conduction potting silica gel has good thermal conduction performance and heat-storage temperature control performance.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

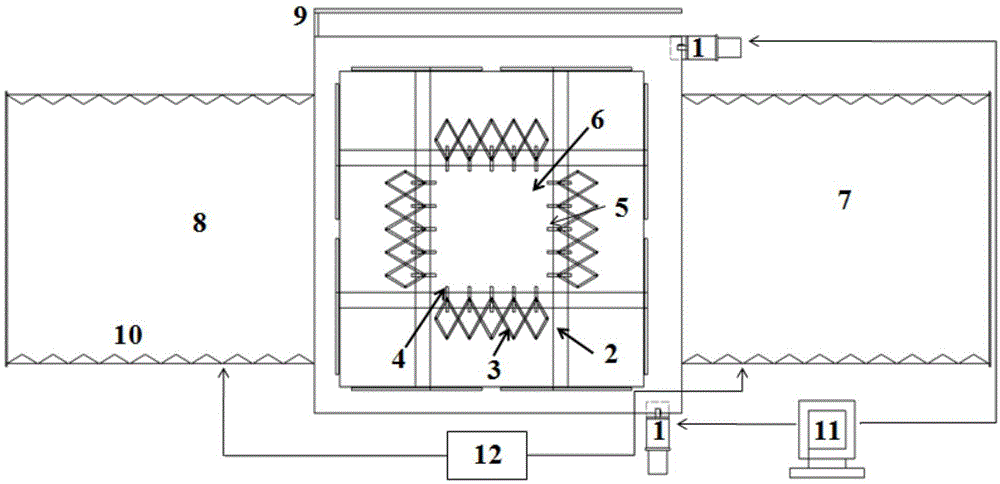

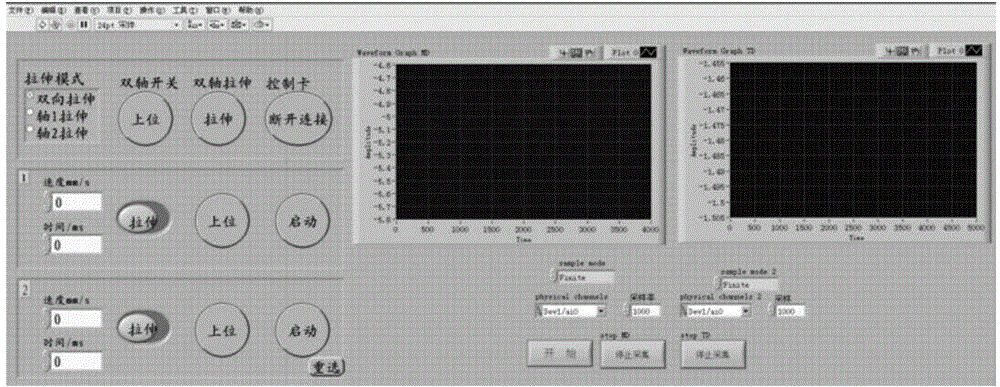

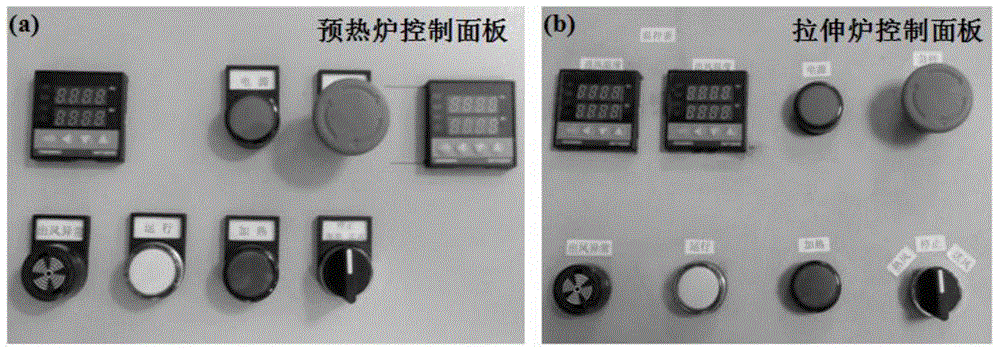

Temperature-control high-speed large-strain membrane two-way stretching device and experimental method thereof

InactiveCN104132853AAchieve stretchPlay the role of sealing cavityMaterial strength using tensile/compressive forcesTemperature controlMembrane stretch

The invention provides a temperature-control high-speed large-strain membrane two-way stretching device and an experimental method thereof. A servo motor drives four #-shaped guide rails to move, and a membrane sample is stretched through a scissors mechanism. A high-pressure pneumatic clamp quickly clamps the sample and can realize pressure compensation. Two independent temperature control furnaces are respectively used for preheating the device and stretching the sample. A hot air circulating system can be adopted to realize rapid temperature rise of the control furnaces and also can ensure the temperature uniformity of cavities. Tension sensors are respectively mounted in two stretch directions and used for collecting stress-strain information in the membrane stretching process. The servo motor drives a ball screw so as to enable a stretch part to be switched among different stations. The temperature-control high-speed large-strain membrane two-way stretching device can realize two-way synchronous stretching, two-way asynchronous stretching, limited one-way stretching and unlimited one-way stretching, thus being a good device for simulating industrial membrane stretching processing and establishing the relationship between processing parameters and the membrane structure performance.

Owner:UNIV OF SCI & TECH OF CHINA

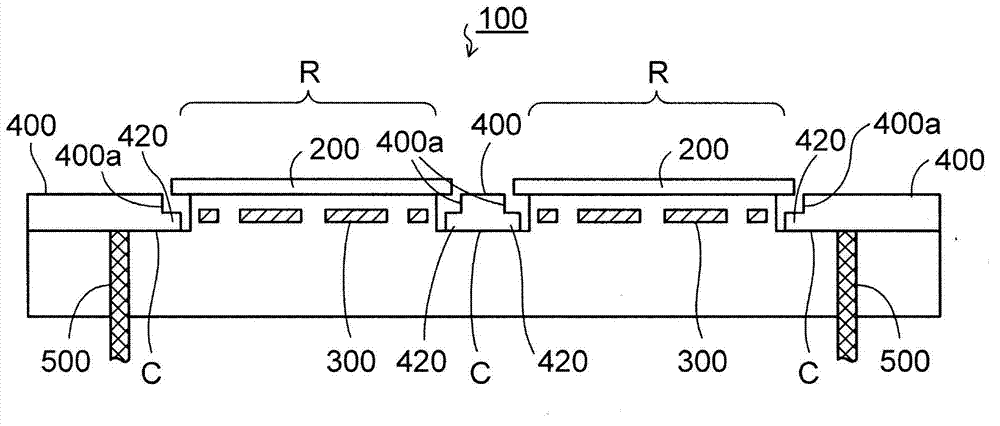

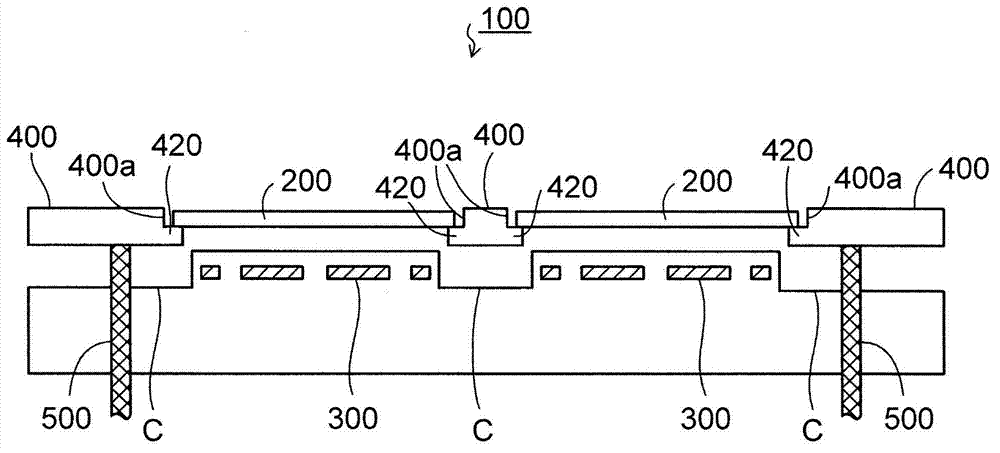

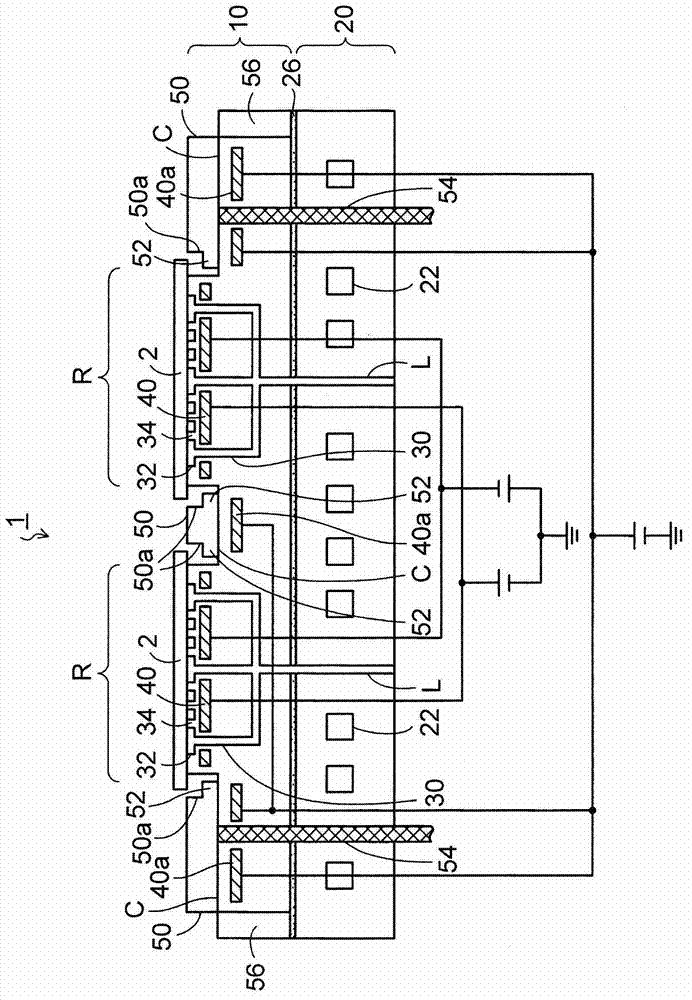

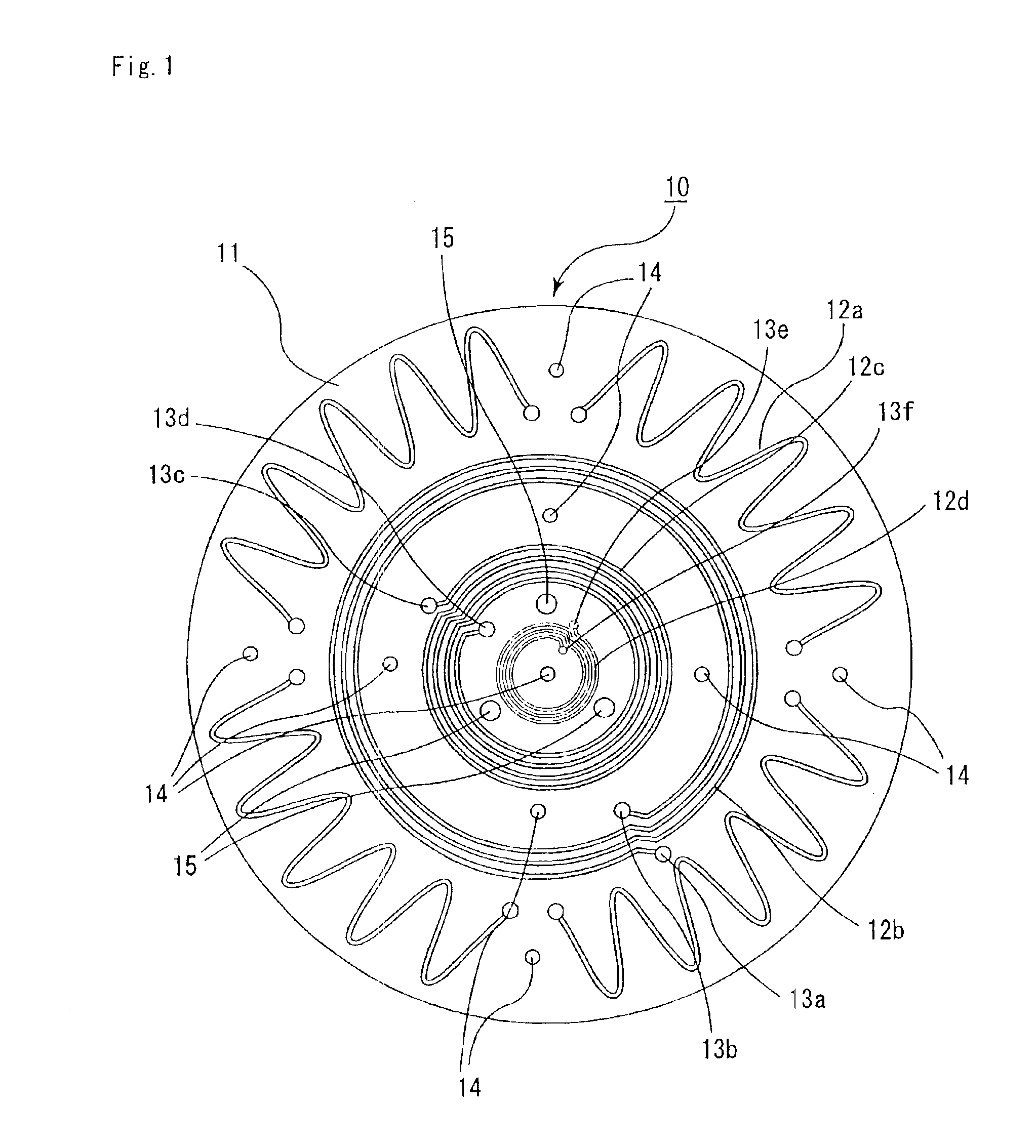

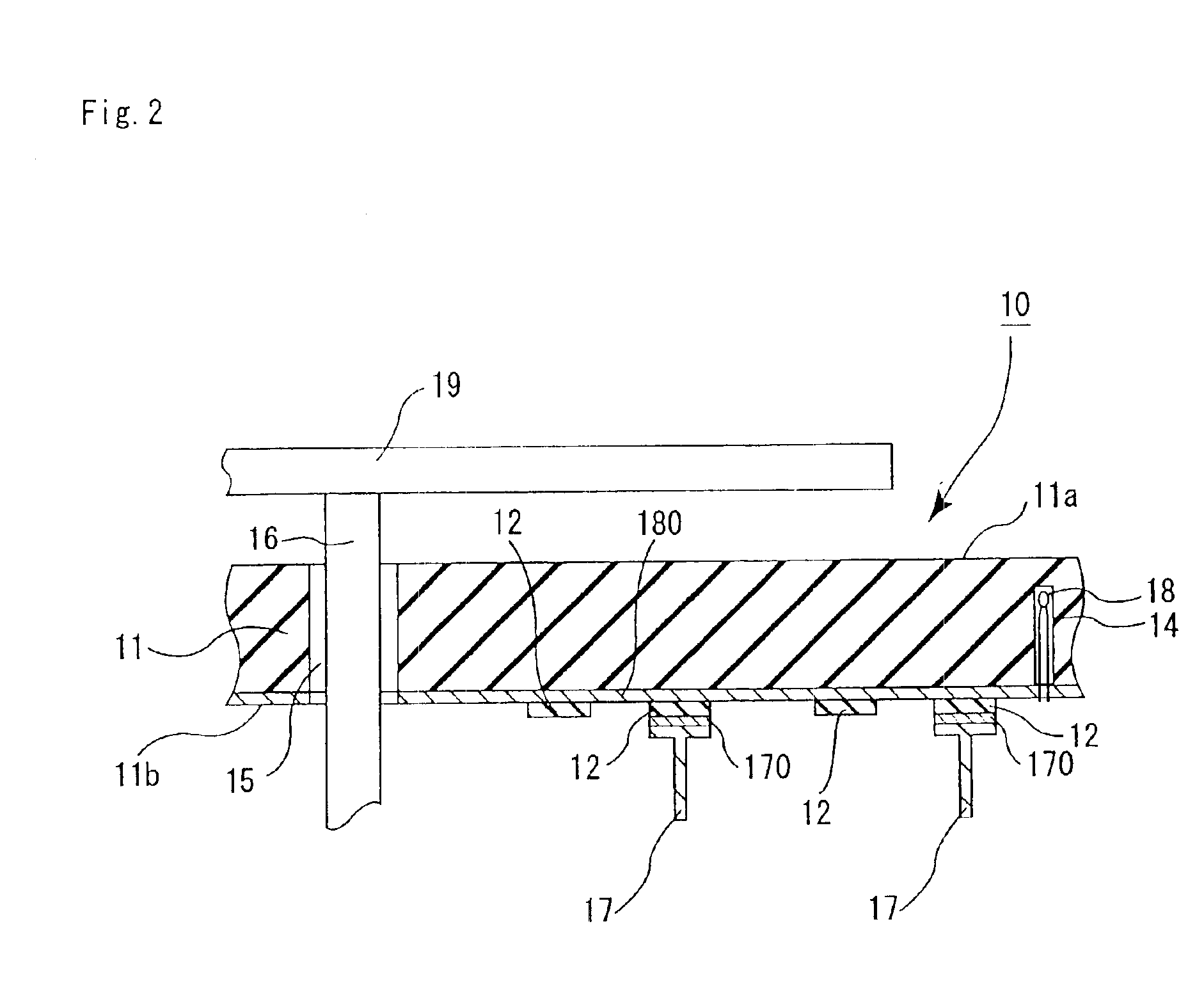

Electrostatic chuck and semiconductor/liquid crystal manufacturing equipment

ActiveCN102956533AGuaranteed temperature uniformityImprove pass rateElectric discharge tubesSemiconductor/solid-state device manufacturingLiquid crystalConcave surface

The invention provides an electrostatic chuck and semiconductor / liquid crystal manufacturing equipment. The subject of the invention is to raise reliability by configuring an electrostatic chuck for transporting chip trays in a plurality of chuck regions and in a concave surface portion arranged in an outside area. An electrostatic chuck includes, a chuck function portion including a plurality of chuck regions (10) on which an attractable object is placed respectively, and a concave surface portion (C) provided in an outer region of the chuck regions (R), and electrodes (40, 40a) arranged in an inner part of the chuck function portion corresponding to the chuck regions (R) and an inner part of the chuck function portion (10) corresponding to the concave surface portion (C), respectively.

Owner:SHINKO ELECTRIC IND CO LTD

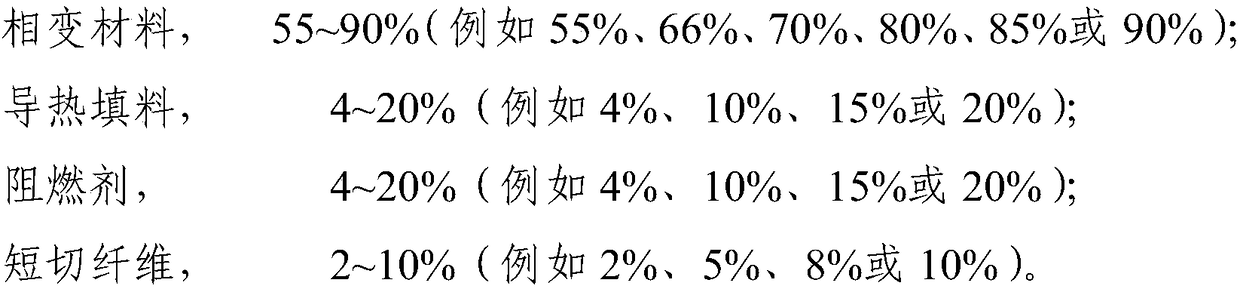

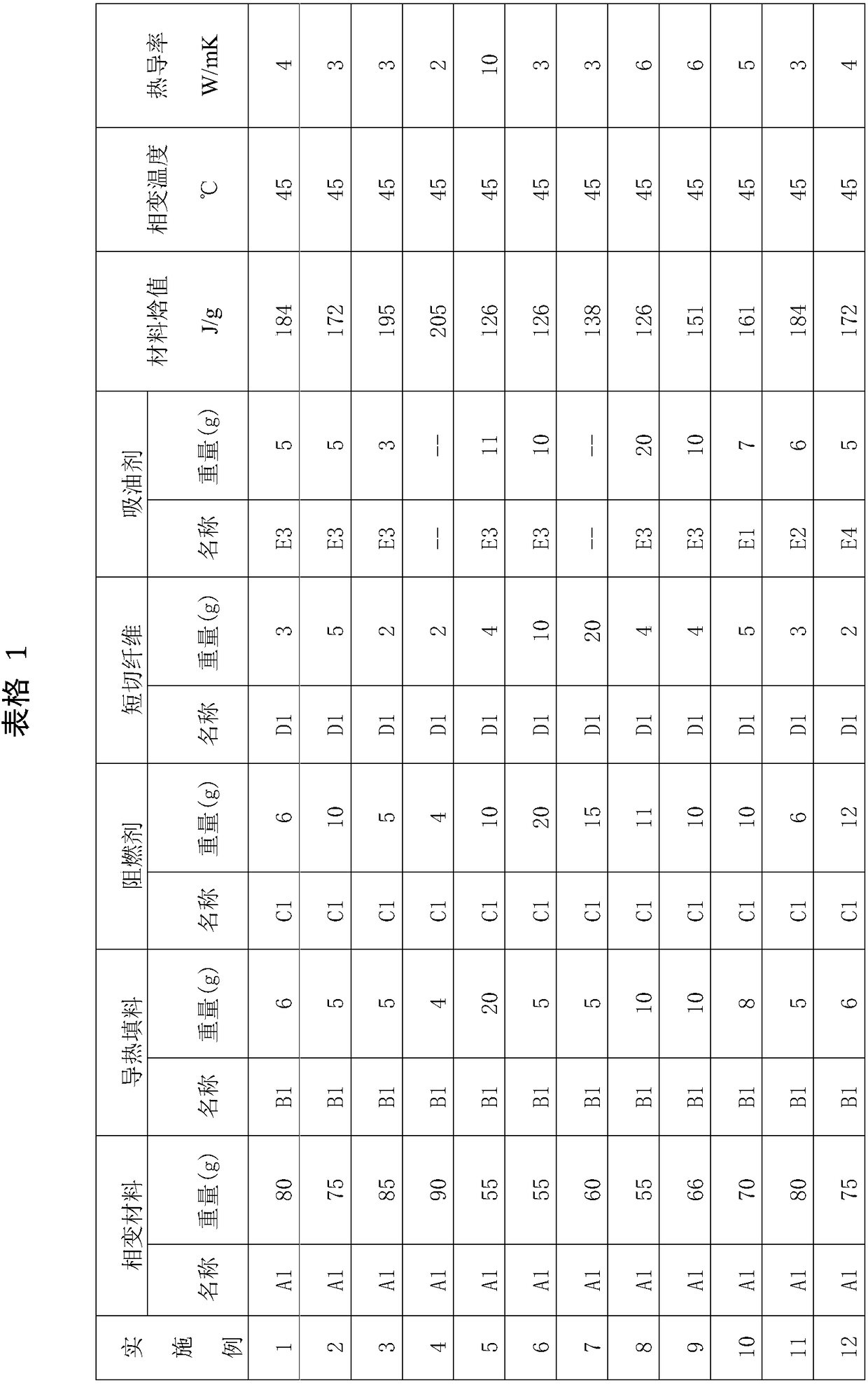

Phase-change-material-based thermal management material, preparation method and applications thereof

ActiveCN108199113AImprove thermal conductivityGood temperature control functionSecondary cellsHeat-exchange elementsFiberPhase-change material

The invention relates to a phase-change-material-based thermal management material, a preparation method and applications thereof, wherein the thermal management material comprises, by mass, 55-90% ofa phase change material, 4-20% of a thermal conduction filler, 4-20% of a flame retardant, and 2-10% of chopped fiber. According to the present invention, by adding an appropriate amount of the chopped fibers, the deformation of the phase change material due to volume expansion or contraction can be effectively prevented, such that the content of the phase change material in the thermal management material can be substantially increased so as to improve the heat storage capacity of the thermal management material and stably regulate and control the temperature.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

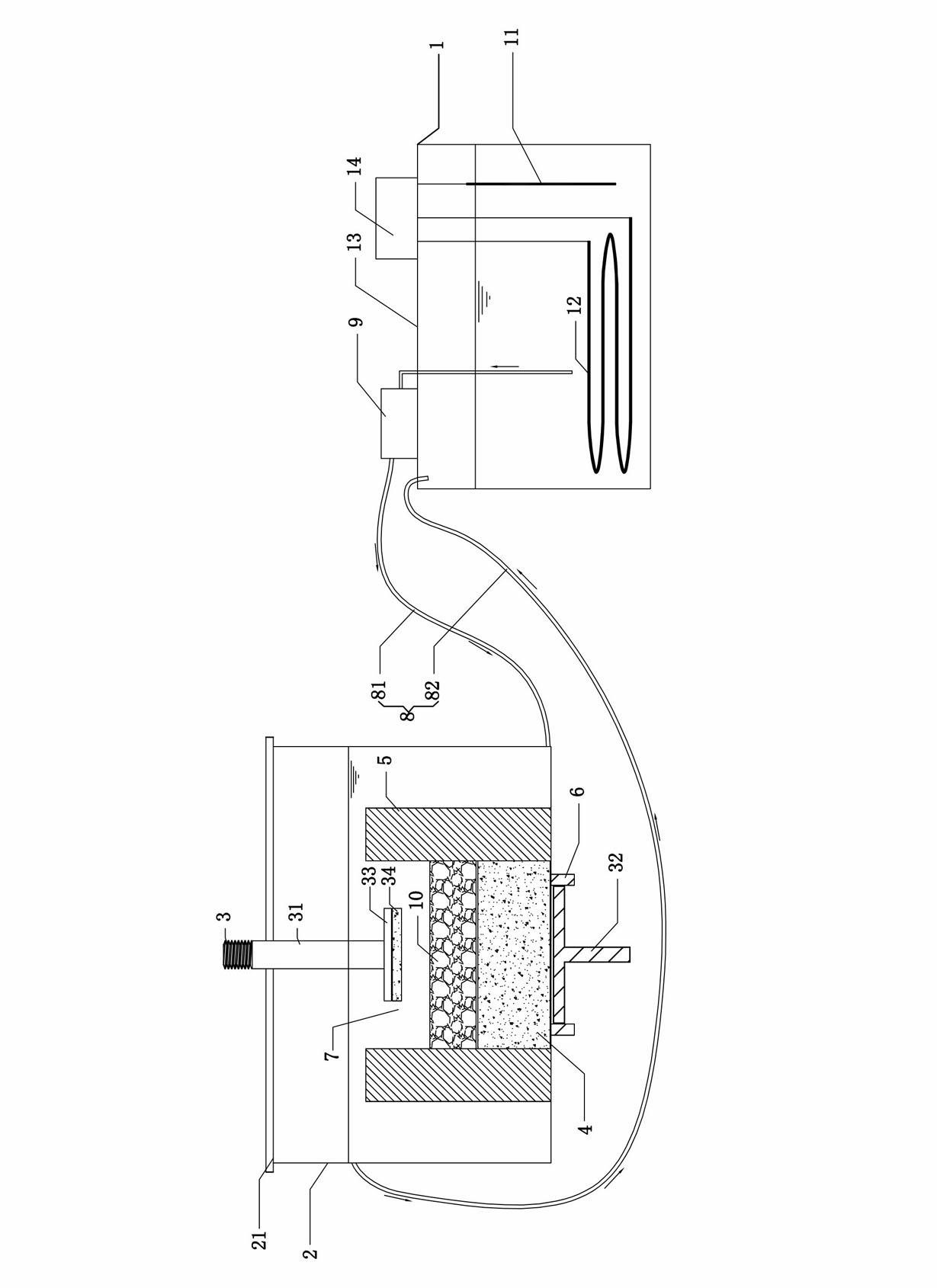

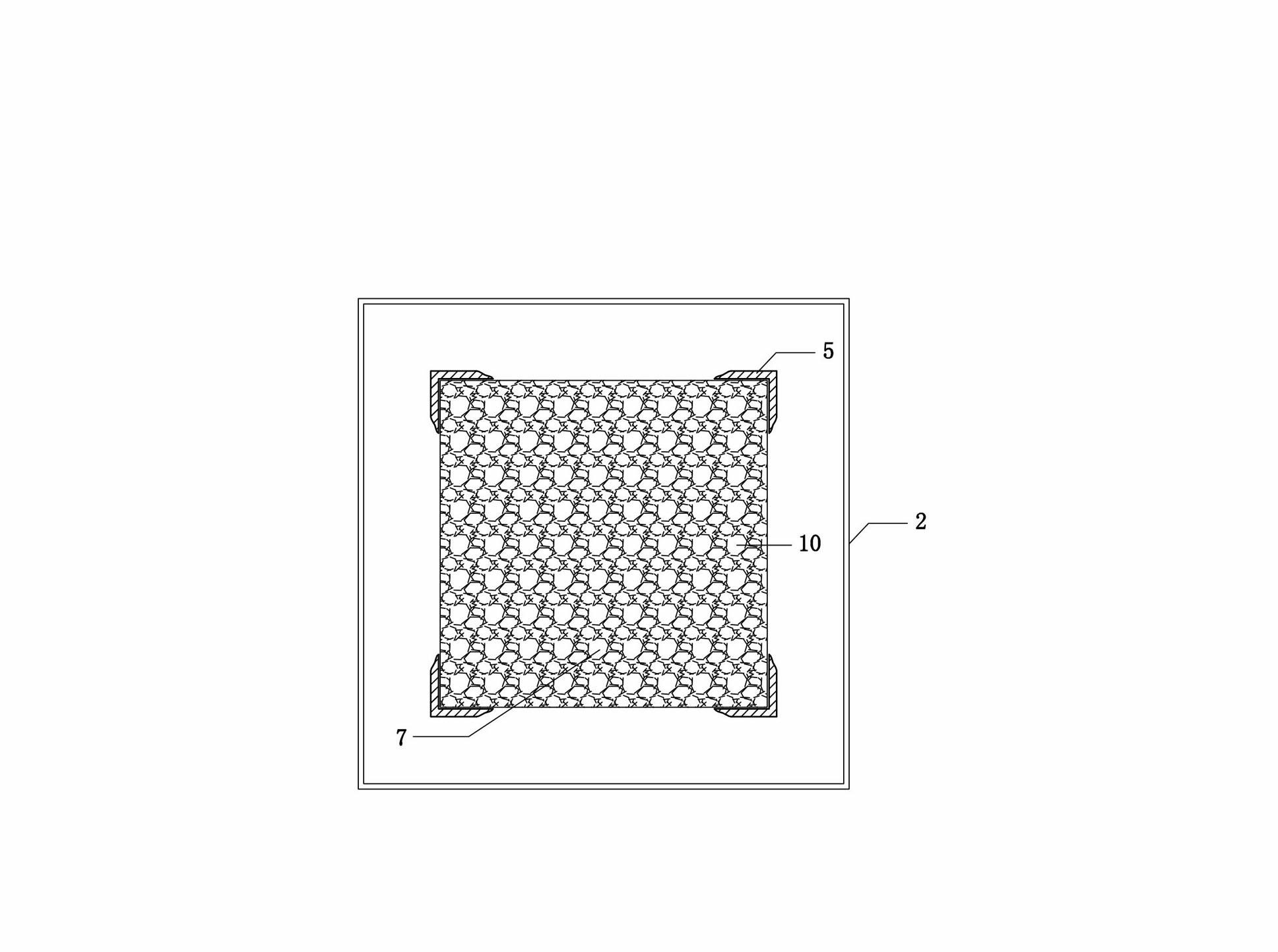

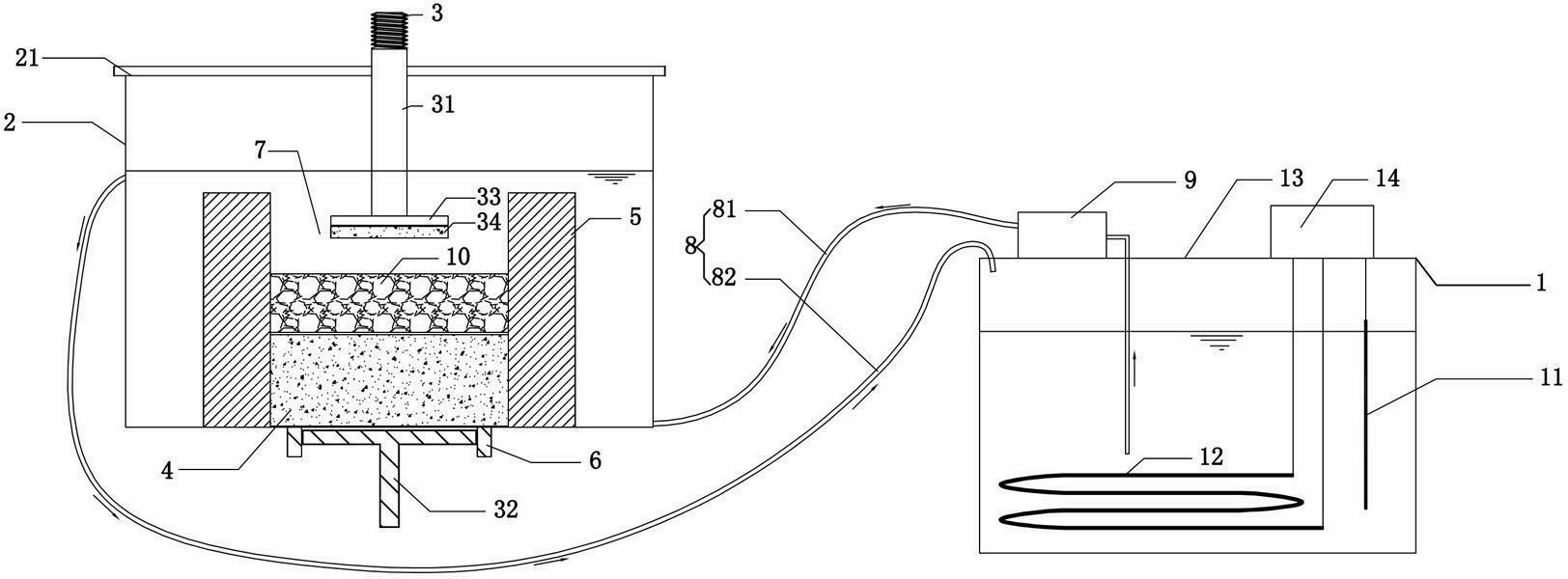

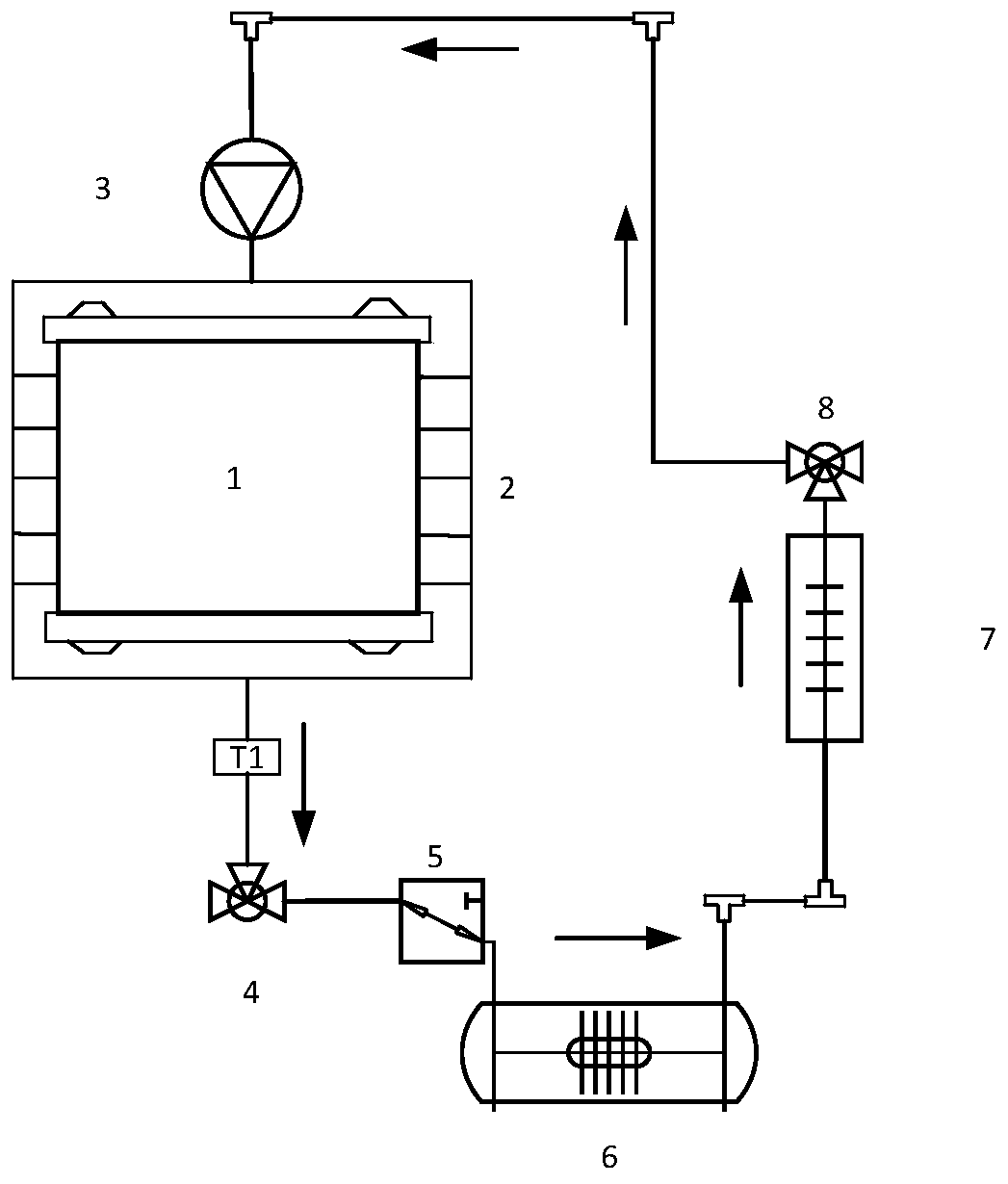

Testing device and evaluating method for water stability of water-permeable bituminous mixture

InactiveCN102636401AEffective simulation of damageGuaranteed temperature uniformityWeighing by removing componentMaterial strength using repeated/pulsating forcesTemperature controlWater baths

The invention discloses a testing device and an evaluating method for water stability of a water-permeable bituminous mixture. The testing device comprises a testing container, a loading system and a water-bath constant temperature control device connected with the testing container; a to-be-tested piece accommodating area is arranged in the testing container; and the loading system comprises a loading rod and a loading base which are connected with a servo loading testing machine. The evaluating method provided by the invention comprises the steps of: firstly, assembling the testing device; weighting the to-be-tested piece and recording the weight G1 of the to-be-tested piece; starting the water-bath constant temperature control device and forming water bath in the testing container, and keeping constant temperature after reaching a preset temperature; starting the servo loading testing machine to dynamically load the to-be-tested piece back and forth; if the to-be-tested piece is loosened after loading, confirming as being unqualified; otherwise, washing and drying, and then weighting and marking as G2; and calculating a stripping rate according to a formula. The bigger the stripping rate value is, the worse the water stability is. The testing device provided by the invention has the advantages of simple structure, low cost, convenience in assembling, high testing precision, and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

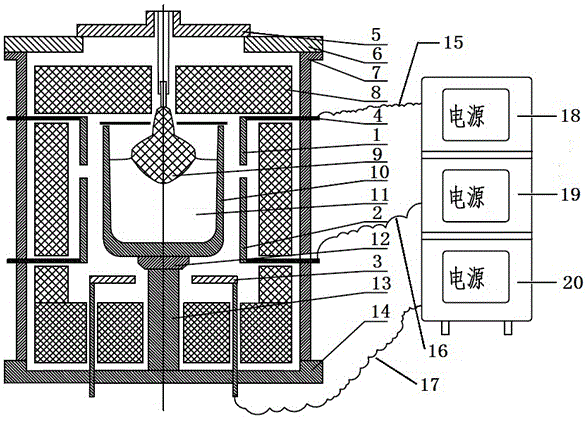

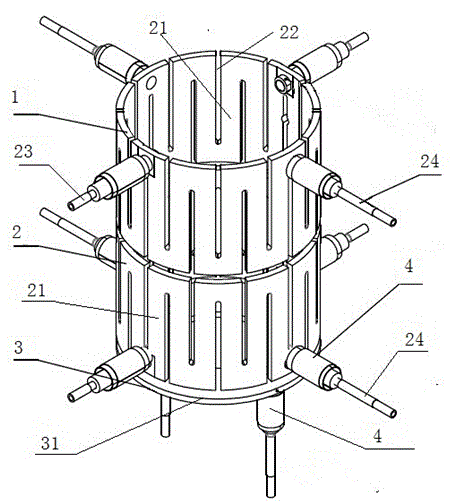

Multistage graphite heating system of sapphire crystal growth equipment and using method of multistage graphite heating system

InactiveCN104451892AImprove product qualityChange the temperature distributionAfter-treatment apparatusPolycrystalline material growthGraphite electrodeControl power

The invention belongs to the technical field of sapphire crystal growth furnace equipment, and provides a multistage graphite heating system of the sapphire crystal growth equipment and a using method of the multistage graphite heating system. The multistage graphite heating system comprises an upper heater, a middle heater, a bottom heater, three power supply devices, a growth furnace cavity, a crucible device and a heat preservation layer, wherein the growth furnace cavity comprises a small furnace cover, a large furnace cover, a furnace cylinder and a furnace base plate; the crucible device comprises a crucible, a crucible tray and a crucible supporting column; each of the upper heater and the middle heater comprise a continuous S-shaped fence-shaped graphite cylinder, four graphite round columns, two long water cooling copper electrodes and two short water cooling copper columns; the bottom heater comprises an S-shaped fence-shaped graphite disc, two graphite electrodes and a water cooling copper electrode; the three individually controlled power supplies are connected with water cooling cables of the upper heater, the middle heater and the bottom heater. The multistage graphite heating system of the sapphire crystal growth equipment and the using method of the multistage graphite heating system have the advantages that the temperature gradient requirement for the growth of large-sized sapphire crystals at each stage can be met, the cost can be reduced, and the quality can be improved.

Owner:SHANGHAI HUICUI OPTICAL TECH

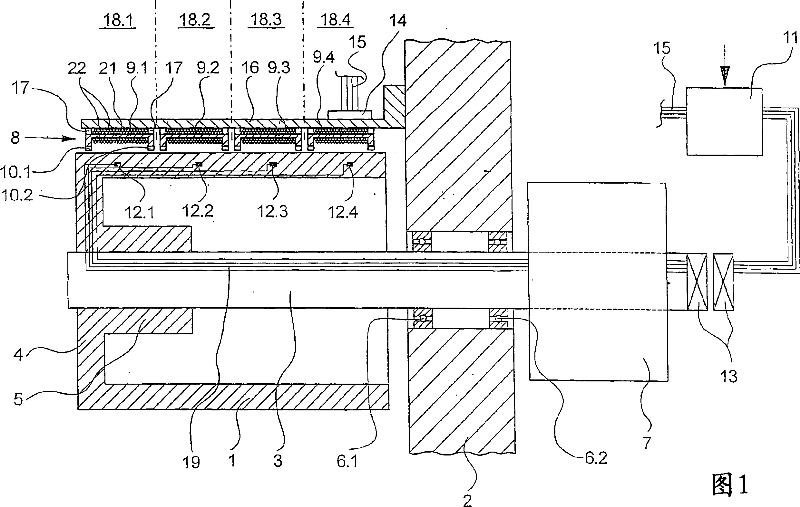

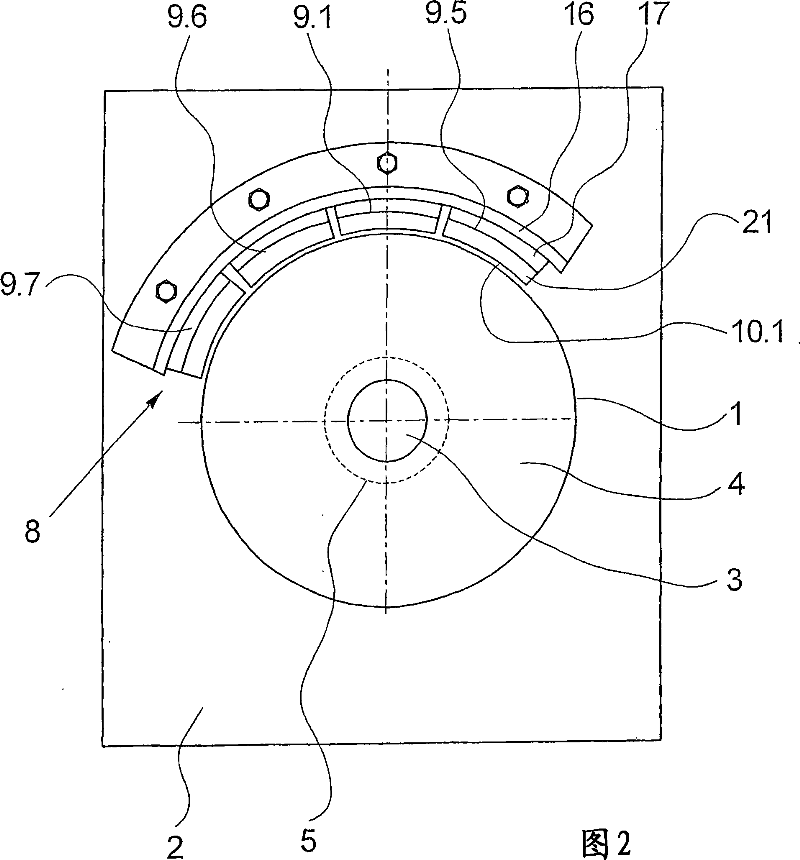

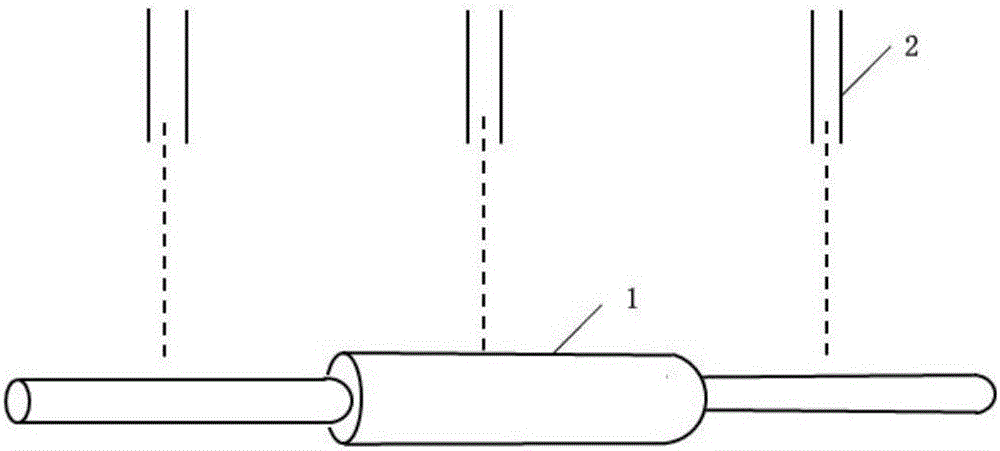

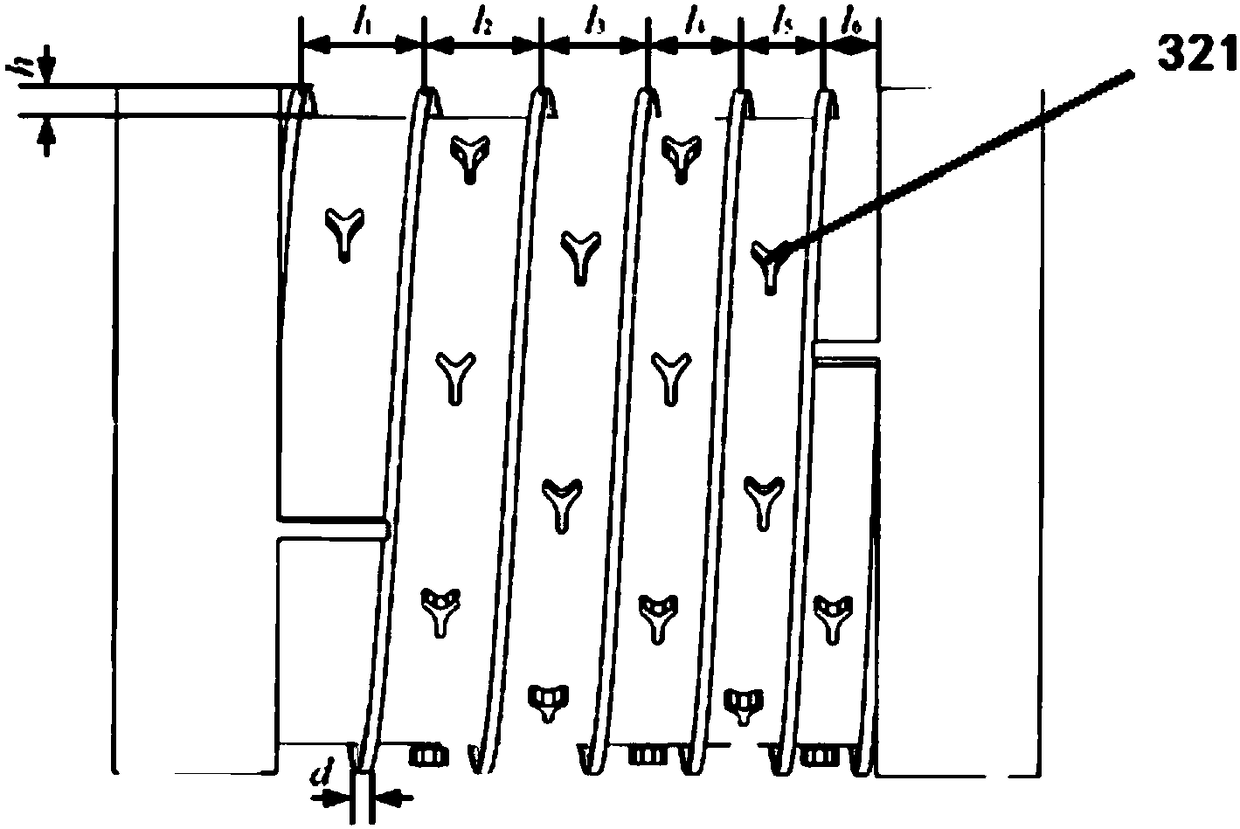

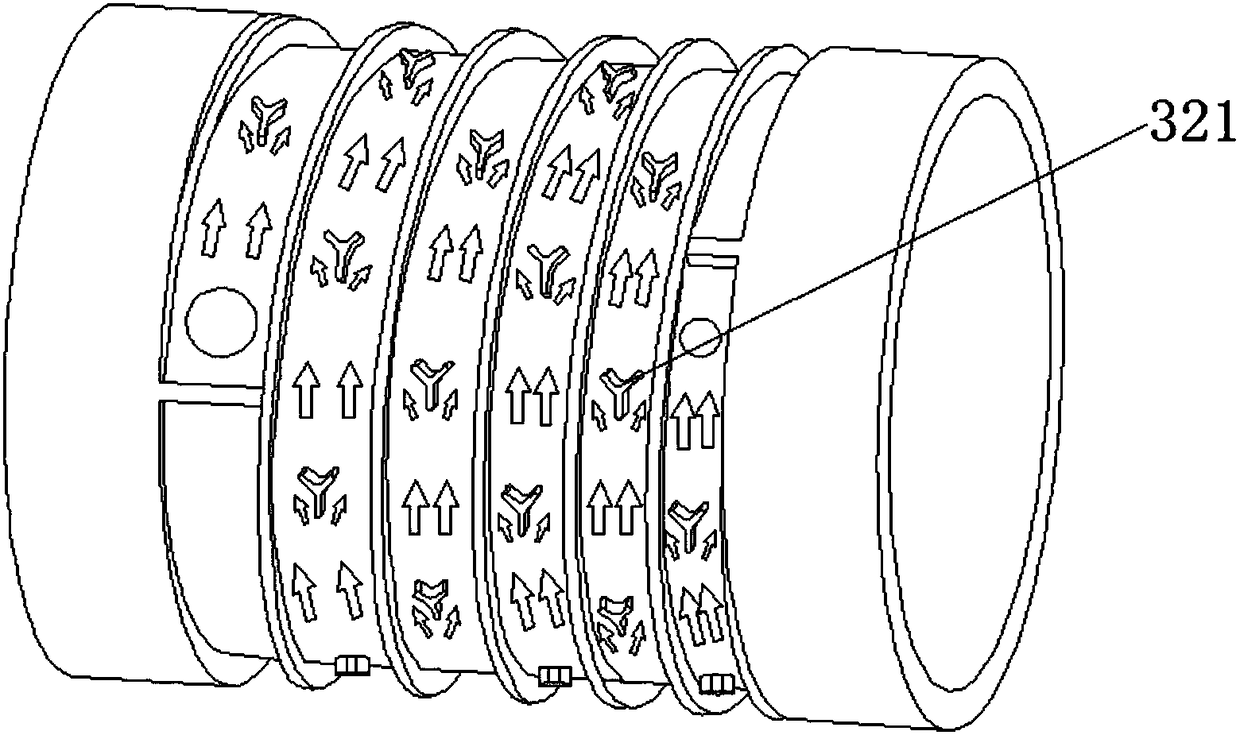

Galette for guiding, heating and transporting a thread

InactiveCN101040074AGuaranteed temperature uniformityKeep strongFilament handlingTextiles and paperElectrical and Electronics engineeringInduction coil

The invention relates to a galette for guiding, heating and transporting a thread, said galette comprising a rotating, driveable, hollow cylindrical galette jacket. An induction heating device is provided for heating the galette jacket, said device comprising a plurality of induction coils arranged at a distance from the galette jacket. The aim of the invention is to influence the heating of the galette jacket as directly and instantaneously as possible. To this end, the induction device is arranged outside the galette jacket (1).

Owner:SAURER GMBH & CO KG

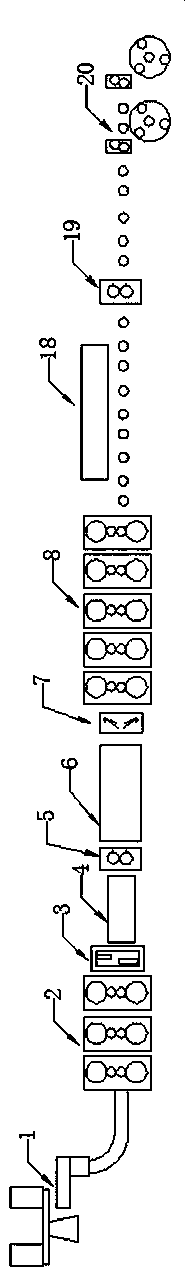

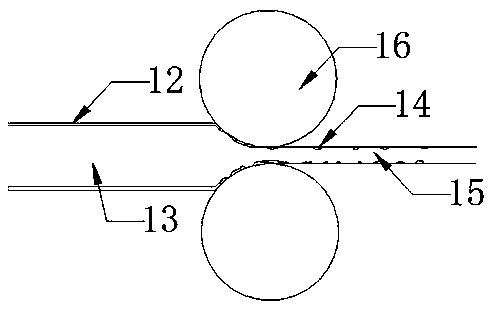

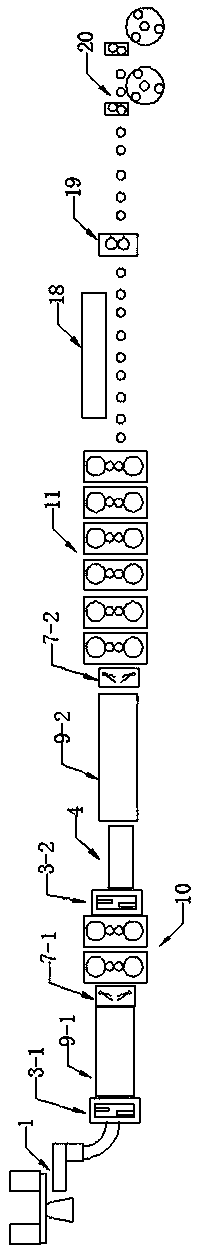

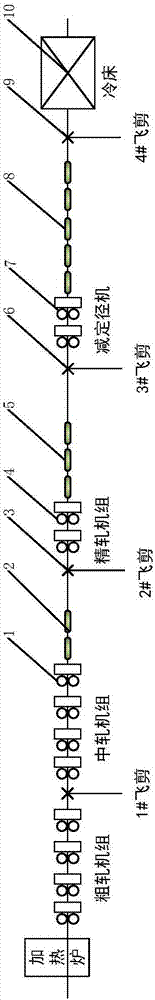

Sheet billet continuous casting and rolling production line and production process thereof

ActiveCN109013701AAvoid major production accidentsPromote warmingMetal rolling arrangementsProduction lineLaminar cooling

The invention relates to a sheet billet continuous casting and rolling production line and a production process thereof, and belongs to the technical field of sheet billet continuous casting and rolling. According to the technical scheme, the sheet billet continuous casting and rolling production line comprises a continuous casting machine (1), a 1#pendulum shear (3-1), a 1#tunnel type heating furnace (9-1), a 1#descaler (7-1), a roughing mill group (10), a 2#pendulum shear (3-2), a billet picking device (4), a 2#tunnel type heating furnace (9-2), a 2#descaler (7-2), a finishing mill group (11), a laminar cooling (18), a flying shear (19) and a reeling-up machine set (20) which are arranged in sequence according to a rolling sequence. When the continuous casting speed of the continuous casting machine (1) is less than 5m / min, single block rolling or semi-endless rolling is adopted; and when the continuous casting speed of the continuous casting machine (1) is greater than or equal to 5m / min, endless rolling is adopted. The sheet billet continuous casting and rolling production line and the production process thereof have the beneficial effects that the temperature uniformity and the surface quality of a casting blank can be ensured, and different rolling modes can be adopted according to the continuous casting speed of the continuous casting machine.

Owner:唐山全丰薄板有限公司

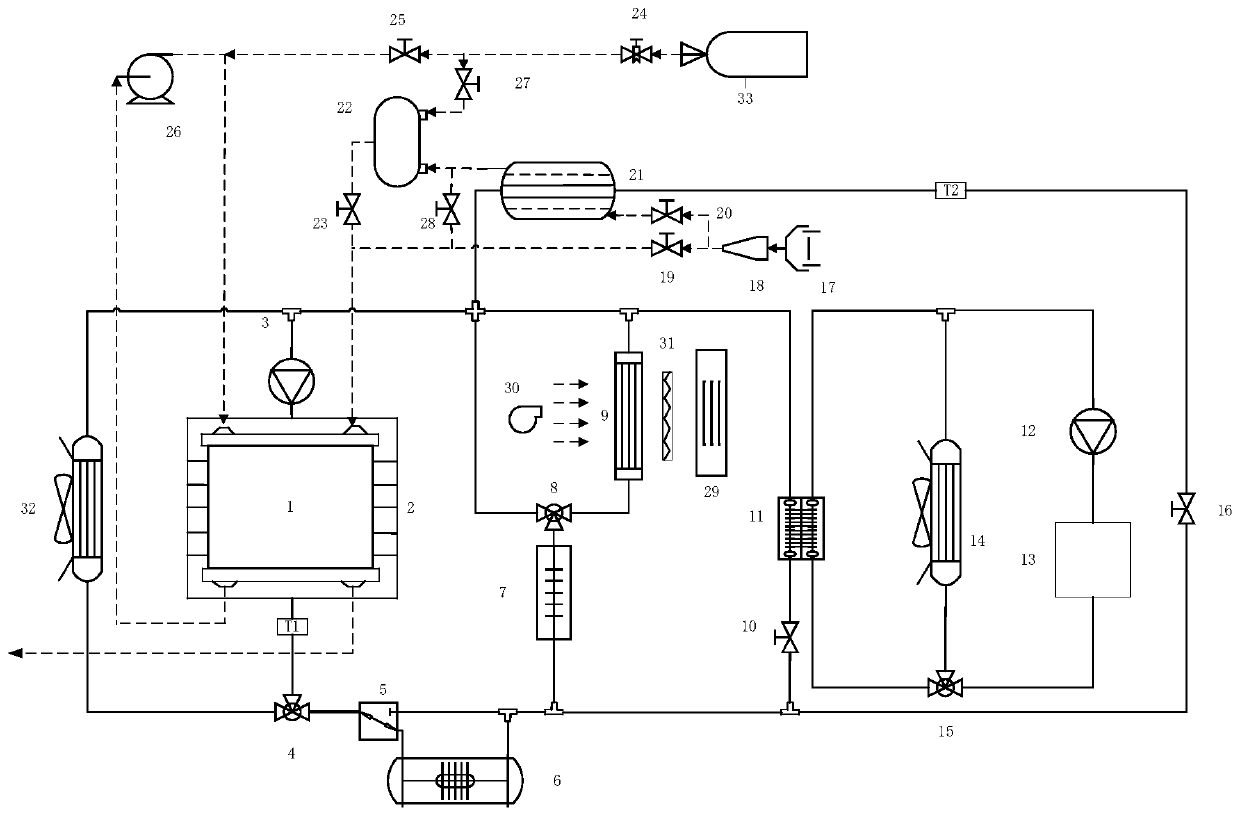

Fuel cell thermal management system with phase change heat storage and preheating functions

ActiveCN111463453AImprove cold start speedReduce consumptionFuel cell heat exchangeMotive system fuel cellsFuel cellsEngineering

The invention discloses a fuel cell thermal management system with phase change heat storage and preheating functions. The fuel cell thermal management system comprises a heat pipe heat exchange part,a liquid path preheating loop, a liquid path heating loop, a gas path preheating loop and a gas path heating loop, wherein the heat pipe heat exchange part is embedded into a heat pipe in a polar plate to exchange heat with an external liquid path, a first phase-change heat exchanger is connected with a liquid path, a second phase-change heat exchanger is simultaneously connected with a gas pathand the liquid path, the liquid path preheating loop heats the liquid path through the first phase change heat exchanger, the gas path preheating loop heats the gas path through the second phase change heat exchanger to jointly preheat a fuel cell, waste heat of a fuel cell in the liquid path heating loop accumulates heat for the phase change heat exchanger or heats a lithium battery and a passenger compartment, the gas path heating loop indirectly heats inlet gas through cooling liquid. The fuel cell thermal management system is advantaged in that the waste heat of the fuel cell can be storedin the phase change heat exchanger and used for preheating the fuel cell through a liquid path and a gas path or for heat preservation of the fuel cell, in addition, the waste heat of the fuel cell can heat intake air, a lithium battery or a passenger compartment, and the energy utilization rate is increased.

Owner:JILIN UNIV

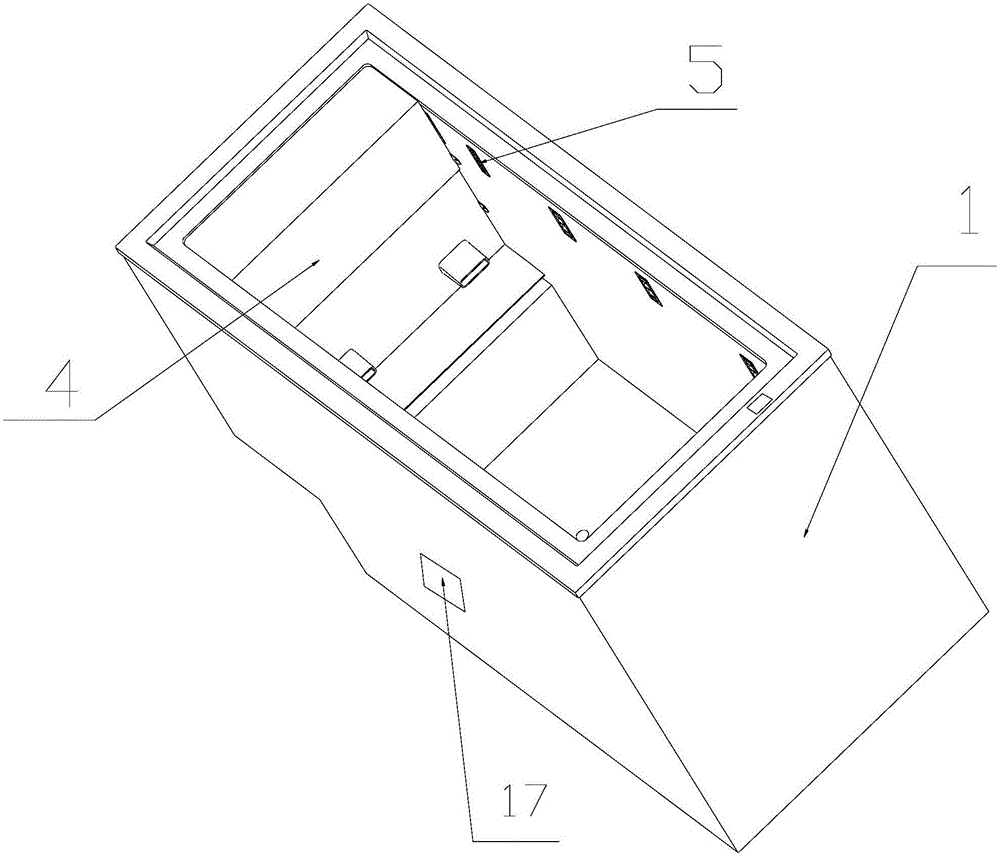

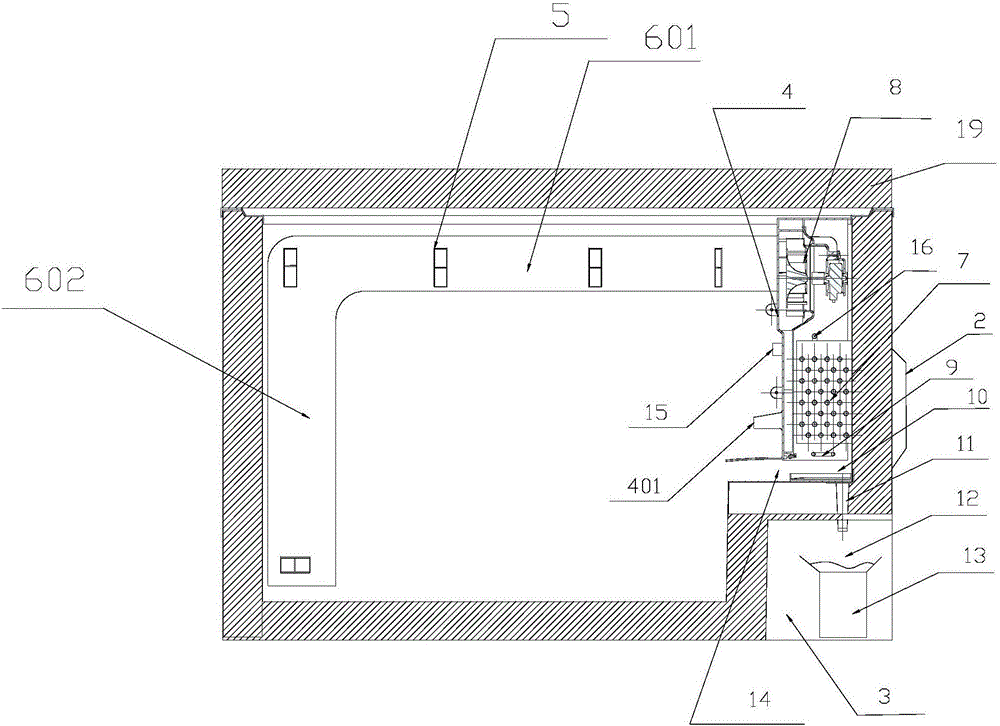

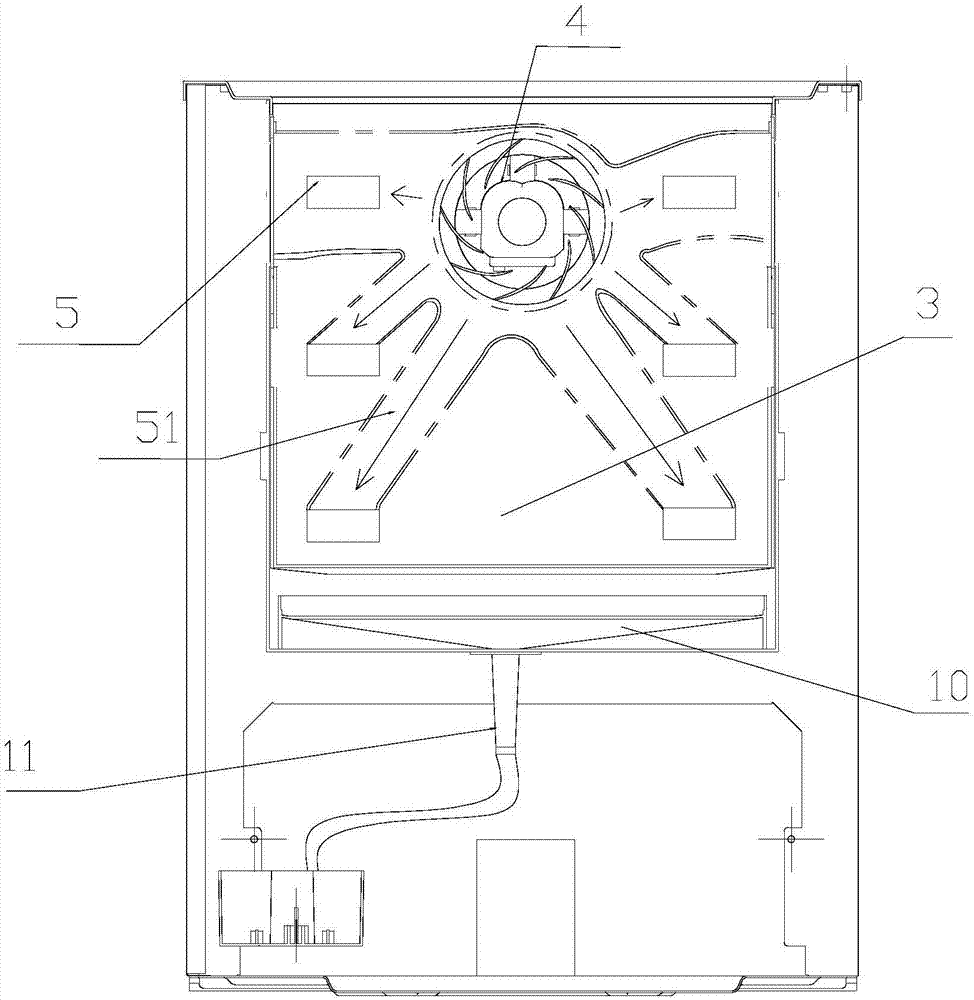

Horizontal type frost-free refrigerator

PendingCN106642905AReasonable structural designCompact layoutLighting and heating apparatusDomestic refrigeratorsFrostEngineering

The invention discloses a horizontal type frost-free refrigerator which comprises a box body and a door body. A chamber is arranged in the box body. An air flue system is arranged in the box body and comprises an evaporator, an air supply fan, an air inlet flue and an air return flue. The evaporator is located in an evaporator cavity. The evaporator cavity is located at the end in the length direction of the box body. The air supply fan is located above the evaporator. The evaporator is provided with an evaporator temperature sensor, a defrosting heater and a defrosting protector. An evaporator water receiving tray is arranged below the evaporator. The air inlet flue comprises two sub air inlet flues arranged on the two sides of the chamber correspondingly. Each sub air inlet flue is composed of a horizontal section and a vertical section and is in an L shape. The horizontal section of each sub air inlet flue extends in the length direction of the box body, the vertical section of each sub air inlet flue is vertically arranged at the end, away from the evaporator cavity, of the box body, and the bottom end of the vertical section of each sub air inlet flue extends to the bottom of the chamber. The horizontal type frost-free refrigerator has the advantages that regular and automatic defrosting action can be completed, the whole defrosting process is safe and efficient, and great convenience is brought to users.

Owner:CHANGHONG MEILING CO LTD

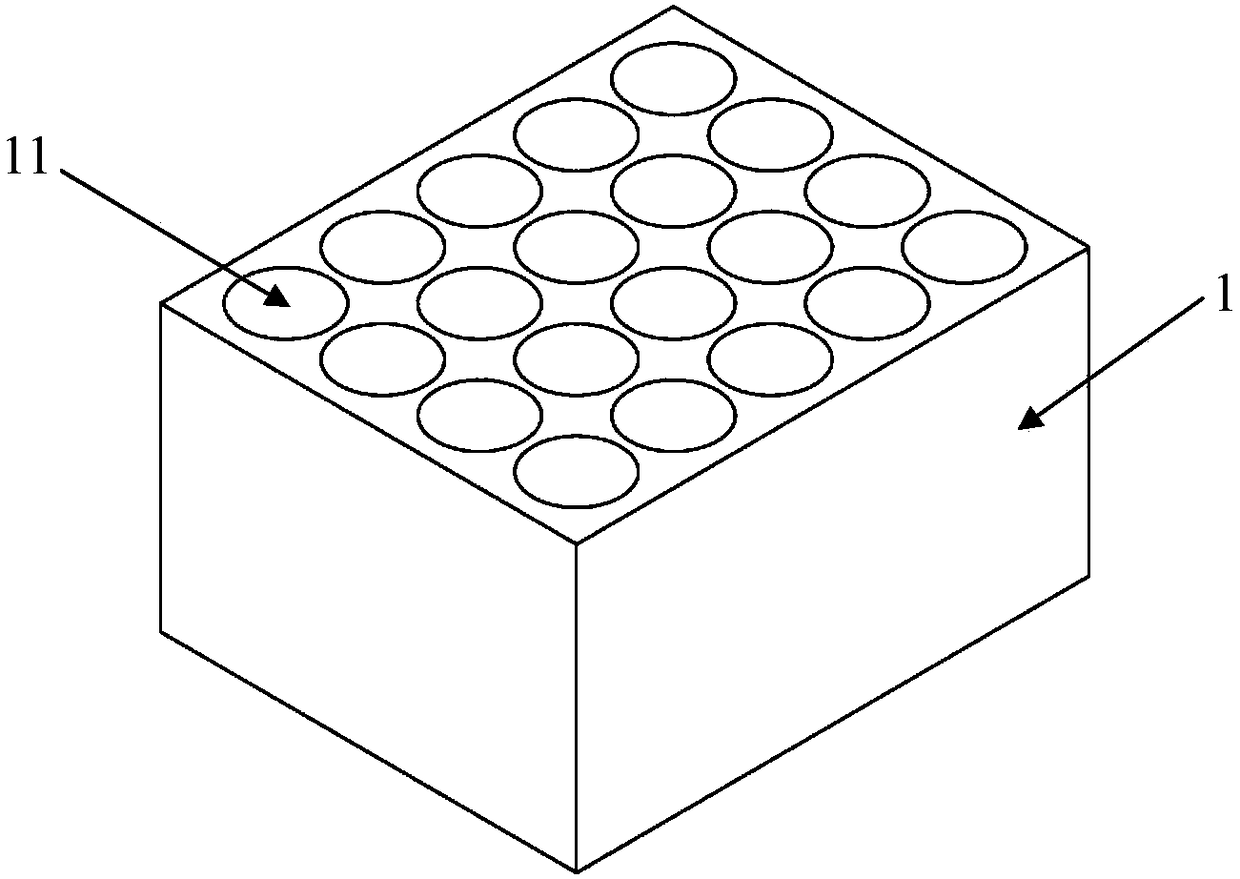

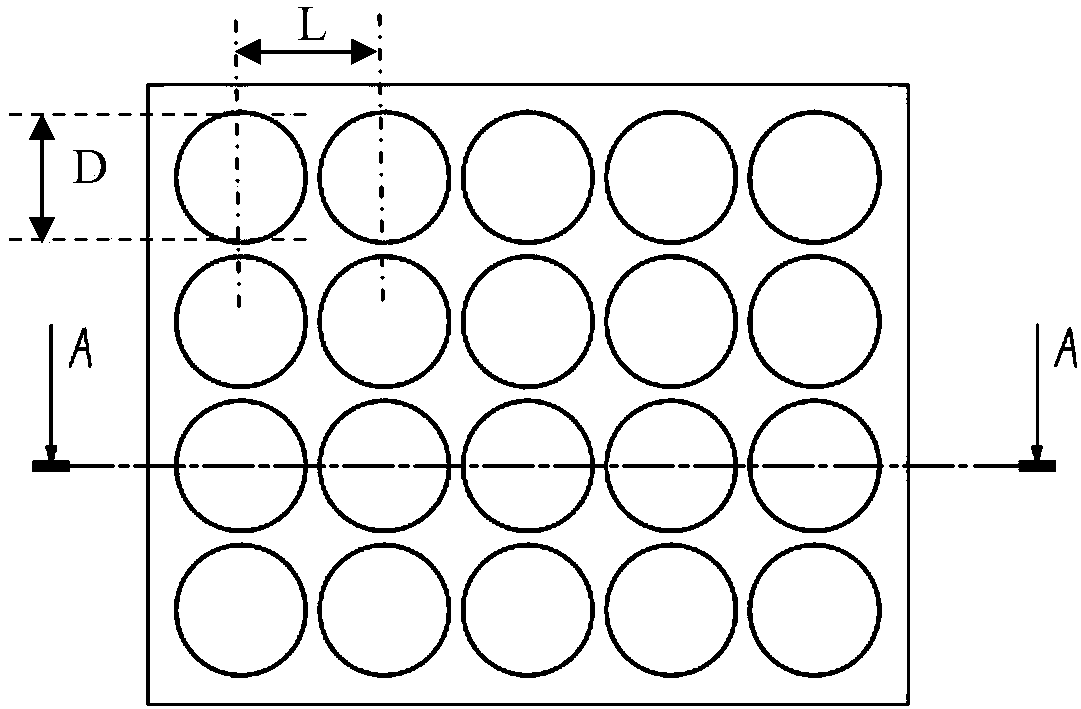

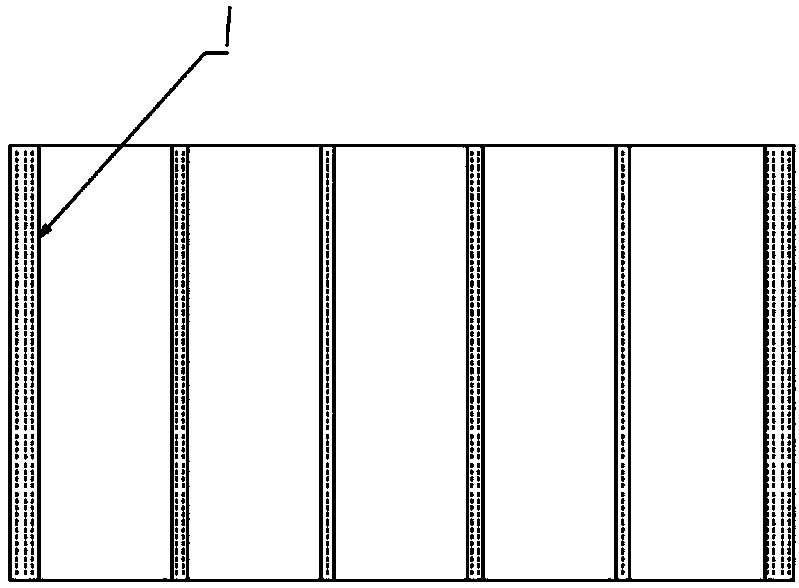

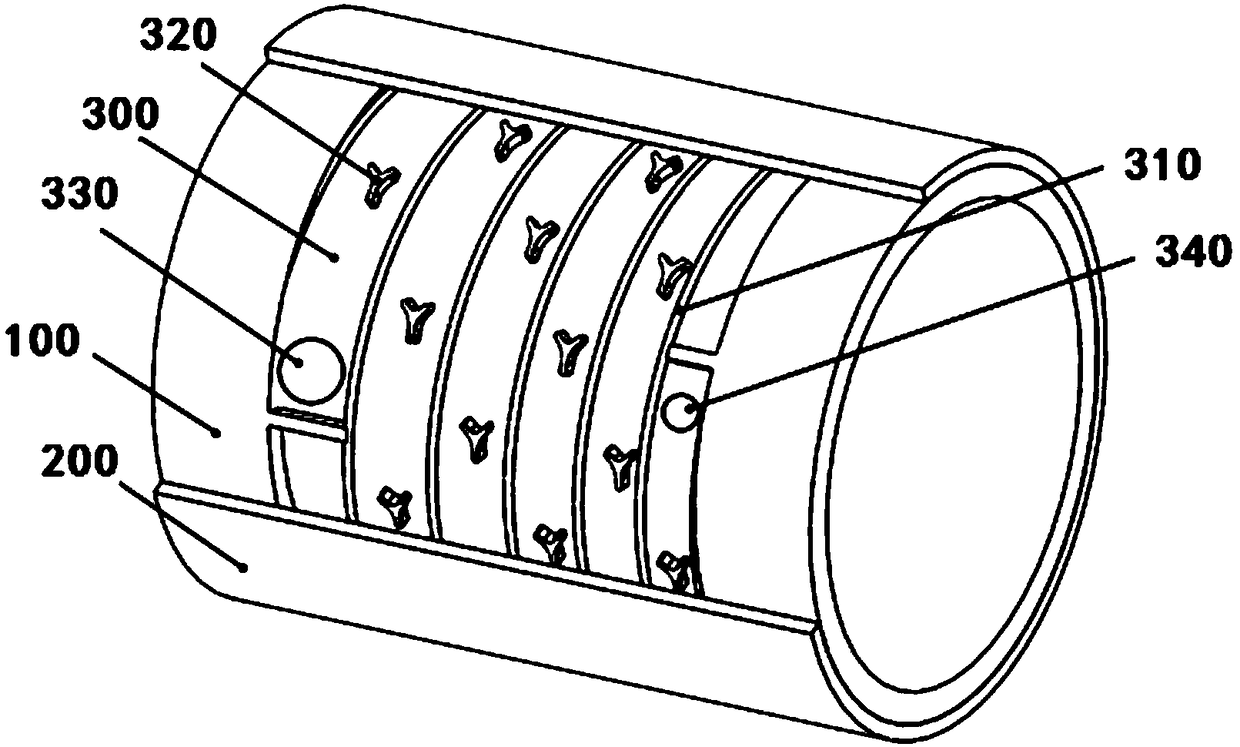

Heat management module for cylindrical batteries and preparation method thereof and battery pack

ActiveCN108288739AImprove thermal conductivityGuaranteed temperature uniformityBattery isolationSecondary cellsFiberHeat management

The invention relates to a heat management module for cylindrical batteries and a preparation method thereof and a battery pack. The heat management module comprises a heat management material mouldedbody; a plurality of cylindrical holes for accommodating the cylindrical batteries are formed in the heat management material moulded body; the heat management material moulded body is prepared froma heat management material by a moulding method; and the heat management material comprises the following components in percent by mass: 55-90% of a phase change material, 4-20% of a heat-conducting filler, 4-20% of a flame retardant and 2-10% of chopped fiber. Through addition of the chopped fiber into the heat management module, an effective enhancing effect can be achieved; the content of the phase change material in the heat management material can be increased to a relatively large extent, and thus the heat storage capacity of the heat management module is improved, so that the heat management module regulates and controls the temperature more stably.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Ply-rolling pack for pack ply-rolling of titanium alloy sheet

InactiveCN102107225AAvoid local flow asynchronyAvoid pitting and other defectsAuxillary arrangementsMetal rolling arrangementsTitanium alloyComposite material

The invention discloses a ply-rolling pack for pack ply-rolling of a titanium alloy sheet, and relates to the ply-rolling pack which is used in the production process of rolling the titanium alloy sheet by a ply-rolling method. The ply-rolling pack is characterized by comprising a ply-rolling pack core block and a ply-rolling pack cover, wherein the ply-rolling pack core block is a square core block which is formed by directly laminating titanium alloy sheets; the ply-rolling pack cover comprises surface covering steel sheets and lateral sealing steel sheets; the surface covering steel sheets are attached to the outside the uppermost layer of titanium alloy sheet and the lowermost layer of titanium alloy sheet of the ply-rolling pack core block; the lateral sealing steel sheets are attached to the side faces of the ply-rolling pack core block; the steel sheets are mutually welded to form a square pack cover; and a pair of opposite lateral sealing steel sheets are provided with through holes. Through the ply-rolling pack, the problems of pack breaking, cracking, moving and folding of a core sheet, piling and the like in the hot rolling process can be solved, and finally the titanium alloy sheet with uniform size and high performance is machined.

Owner:BAOJI TITANIUM IND

Small-volume horizontal frostless refrigerator

PendingCN106958973AReasonable structural designSimple structureLighting and heating apparatusDomestic refrigeratorsEngineeringWater collection

The invention discloses a small-volume horizontal frostless refrigerator which comprises a refrigerator body and a door body, wherein the refrigerator body is internally provided with an air duct system; the air duct system comprises an evaporator, a supply fan, an air intake duct and an air return duct; the evaporator is located in a cavity of the evaporator; a fan cover covers in a chamber; an evaporator temperature sensor, a defrosting heater and a defrosting protector are arranged on the evaporator; an evaporator water collection disk is arranged below the evaporator; the air intake duct comprises a plurality of air intake sub-ducts arranged in an interlayer of the fan cover; the air intake sub-ducts are dispersed and distributed at the periphery by taking the supply fan as a center; an inlet end of each air intake sub-duct is communicated with the supply fan; an outlet end of each air intake sub-duct is connected with an air outlet; the air outlets are distributed at the upper part, the middle part and the lower part of the front side of the fan cover. The refrigerator has the advantages that the purpose of automatic defrosting can be achieved on the premise of low cost.

Owner:CHANGHONG MEILING CO LTD

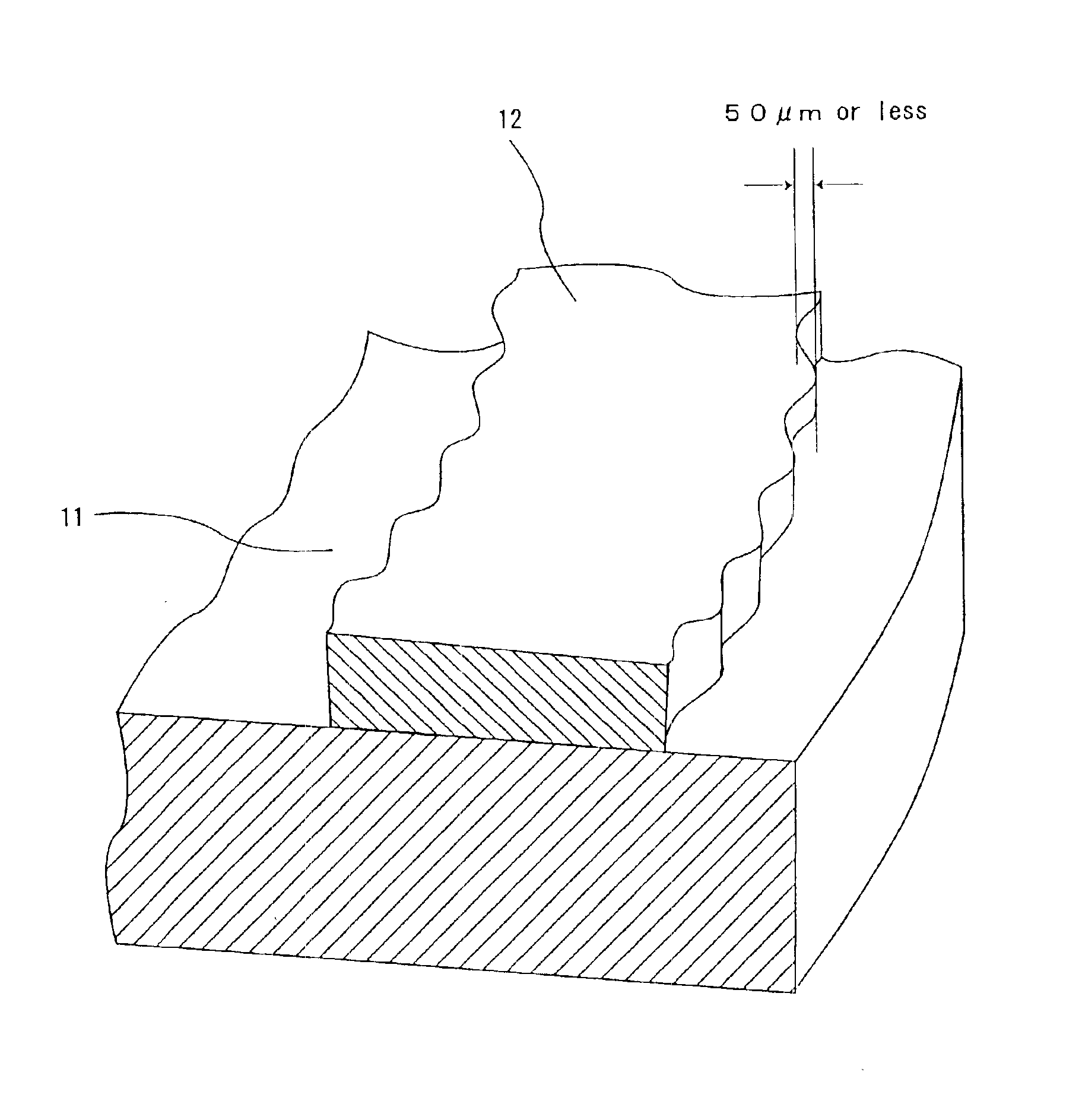

Ceramic heater for semiconductor manufacturing/testing apparatus

InactiveUS6897414B2Guaranteed temperature uniformityDifficult problemSemiconductor/solid-state device manufacturingHot plates heating arrangementsMetallurgySemiconductor

A ceramic beater for a semiconductor producing / examining device having a resistance heating element superior in adhesion to a substrate. The ceramic heater includes a ceramic substrate and a resistance heating element formed on the surface of the ceramic substrate. Further, irregularities are formed on the side face of the resistance heating element.

Owner:IBIDEN CO LTD

Novel heat management system for vehicle-mounted lithium ion batteries

ActiveCN108520991AReduce the temperatureCompact structureSecondary cellsVehicular energy storagePower batteryHeat management

The invention relates to a novel heat management system for vehicle-mounted lithium ion batteries. The system comprises square lithium iron phosphate battery modules, heat dissipation cold plates, tree branch type upper-layer fluid distribution pipeline plates and distribution pipeline cover plates, wherein upper-layer fluid distribution pipelines and the cover plates are combined vertically, outlets of the distribution pipelines are connected with the heat dissipation cold plates respectively, and the heat dissipation cold plates and the batteries are arranged alternately. Each set of the system comprises the upper pipeline and the lower pipeline, fluids in the pipelines in the cold plates adjacent to the batteries are opposite in flow direction, and the upper cover plate and the lower cover plate are both provided with an inlet. Cooling liquid is distributed in the cold plates through tree branch type manifolds in the distribution pipelines, each cold plate is internally provided with three heat dissipation pipelines, and the cooling liquid flows out together from side outlets of the cold plates. By means of the system, the temperature of the vehicle-mounted power batteries can be effectively reduced, the problem that the internal temperature difference is large when the battery modules discharge is solved, the temperature uniformity in the battery modules can be guaranteed,and meanwhile, the system is compact in structure and suitable for automobiles with limited space and the like.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

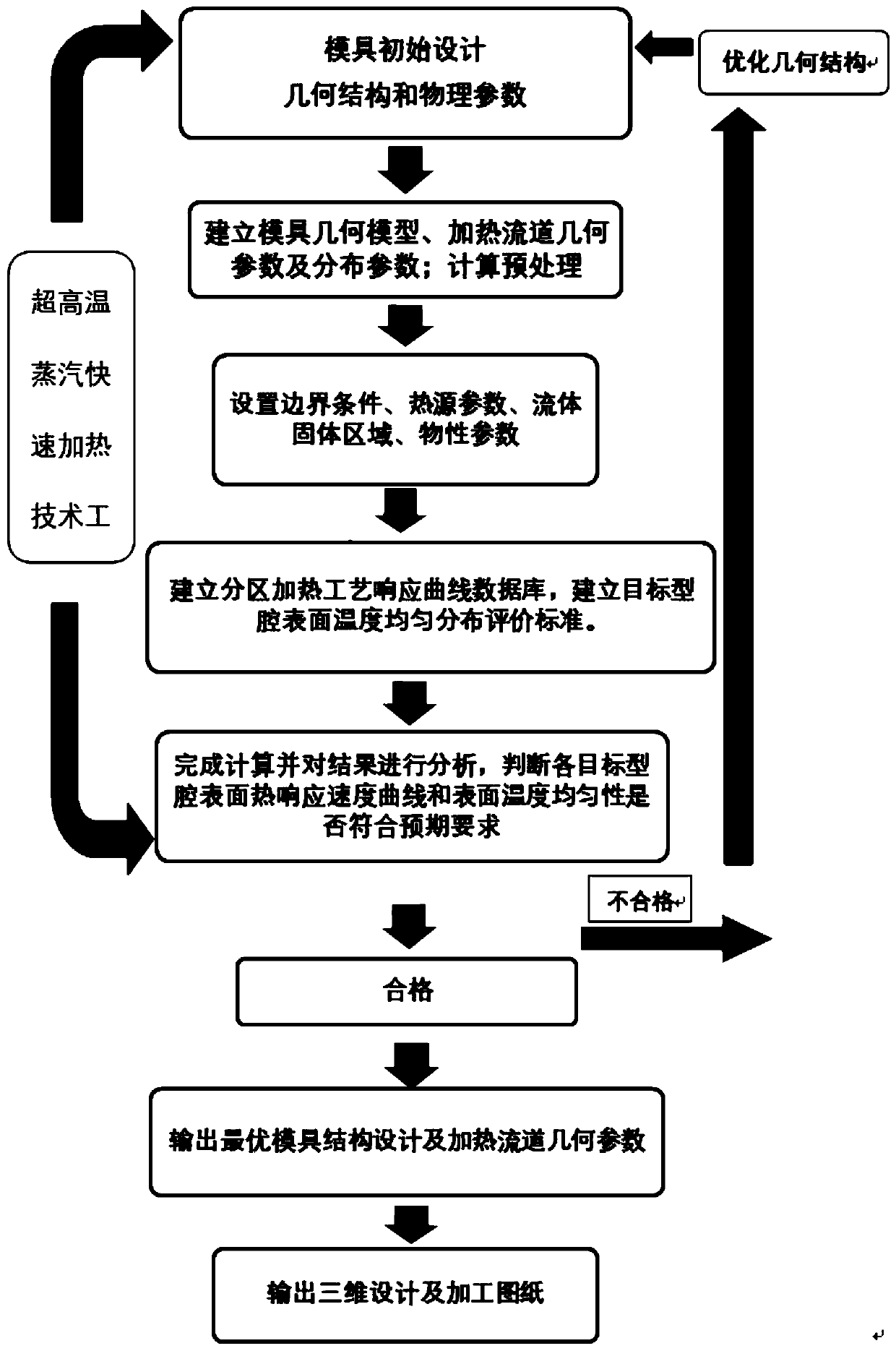

Mould preparation method, mould, mould heating system and heating controlling method

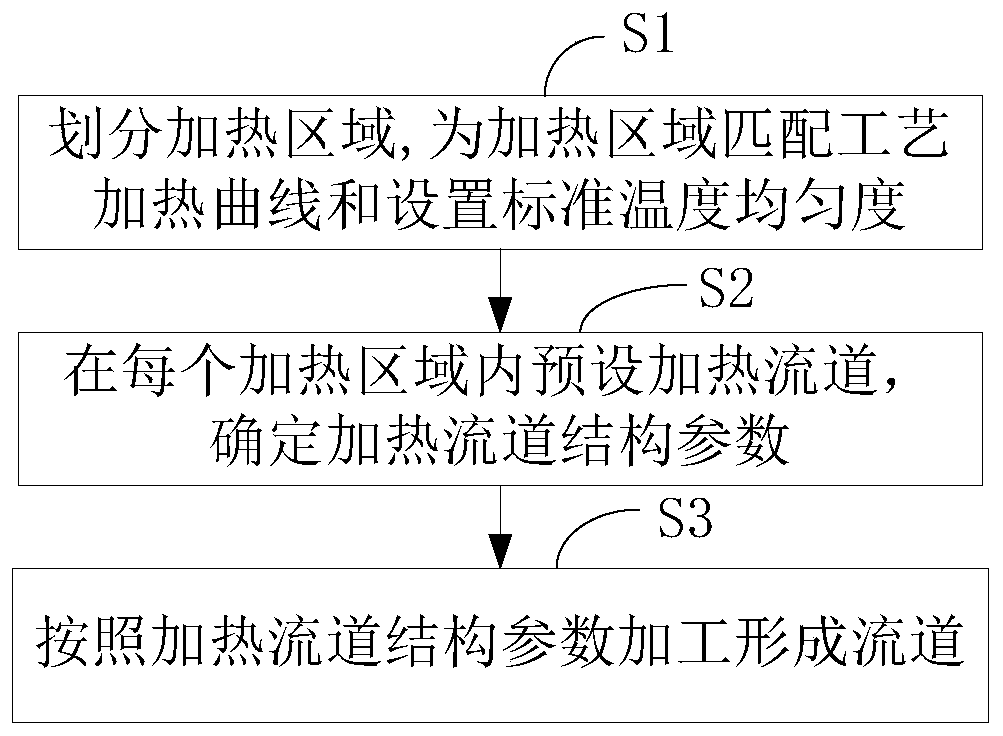

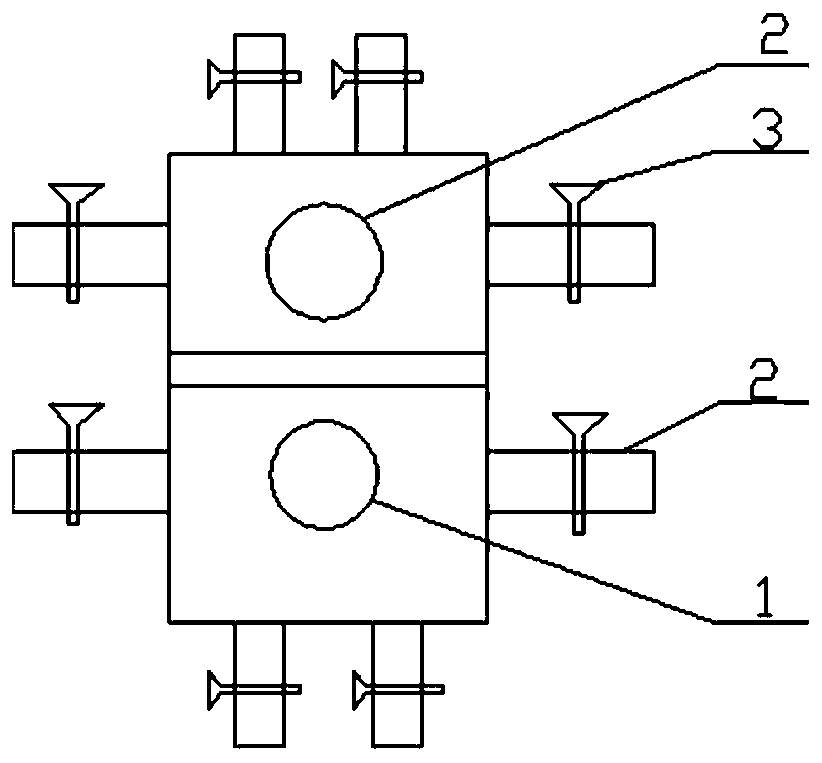

ActiveCN110027139AUniform temperatureMeet the needs of fast-changing mold temperatureThermometers using electric/magnetic elementsUsing electrical meansHot runnerModular unit

The invention discloses a mould preparation method, a mould, a mould heating system and a heating controlling method. The method comprises the following steps: S1, dividing heating areas; S2, pre-setting at least one heating flow channel in each of the heating areas, and the method for determining structural parameters of the heating flow channels comprises the following steps: S21, pre-setting the structural parameters of the heating flow channels; S22, obtaining an actual heating curve of each of the heating areas and actual temperature of each of position points of a mold cavity surface; S23, carrying out deviation analysis and adjusting the structural parameters of the heating flow channels according to a deviation analysis result; S24, repeatedly carrying out the steps S22 and S23; and S3, carrying out processing according to the structural parameters of the heating flow channels to form flow channels. The mould is heated in subareas, and the structural parameters of the flow channels are determined separately in each of the heating areas, so that the phenomena that the overall heat response speed of the mould and the temperature uniformity of the whole mold cavity can meet the requirement can be ensured, and by adopting the method, the requirement on quick change of the mould temperatures of complicated modular unit structures can be met, and subarea heating can be conveniently carried out.

Owner:宁波柚贝儿童用品有限公司

Battery module-based integrated heat exchange structure

Disclosed is a battery module-based integrated heat exchange structure. The integrated heat exchange structure comprises a cold plate and at least one separated flat plate heat pipe; the cold plate isarranged below the battery module; heat pipe evaporation sections are tightly attached to the two sides of the battery module, and are connected with heat pipe condensation sections through heat pipebending sections and heat pipe connecting pieces; a plane is formed by enabling the parallelogram heat pipe condensation sections to be arranged in the cold plate, so that a double-flow-direction leaf vein flow channel is formed between the adjacent heat pipe condensation sections and between the heat pipe condensation sections and the side wall surface of the cold plate; and the flow directionsof fluids on the two sides of the center line are opposite, and a micro turbulent flow piece or a micro groove is additionally arranged in the flow channel. According to the integrated heat exchange structure, the structural design of combining the flat heat pipes and the cold plate technology is adopted, so that the heat pipe condensation sections and the cold plate are integrated, so that efficient heat dissipation can be achieved, the working temperature of the battery can be reduced, and the temperature uniformity of the battery module is improved; and in addition, the size is small, and the structure is compact, so that the technical defect that the temperature uniformity of the battery is poor due to the fact that the heat dissipation capacity of the heat pipes in the traditional heat pipe cooling mode is inconsistent is effectively overcome.

Owner:TSINGHUA UNIV

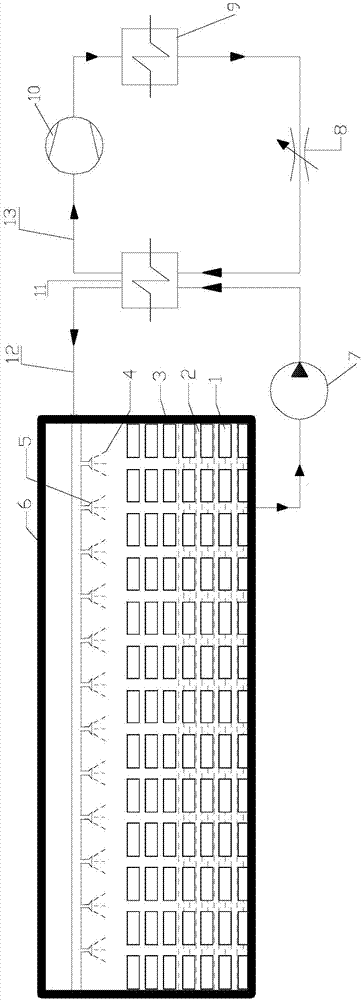

Spraying type heating and refrigerating integrated safety battery pack

PendingCN106876823AReduce dosageGuaranteed temperature uniformitySecondary cellsBatteriesSprayerTemperature difference

The invention discloses a spraying type heating and refrigerating integrated safety battery pack. The battery pack comprises a battery box and batteries accommodated in the battery box; and the battery pack also comprises a spraying liquid loaded in the battery box, a sprayer fixed in the battery box, a spraying liquid circulation pipe, a liquid pump connected with the spraying liquid circulation pipe, and a heat exchange system connected with the spraying liquid circulation pipe, wherein the head and tail ends of the spraying liquid circulation pipe are connected with the spraying liquid and the sprayer respectively. On one hand, the battery pack is in a proper use environment, so that a huge amount of heat generated in the operating process of the battery pack can be taken away in time; on the other hand, uniform temperature between the single batteries in the battery pack can be maintained, so that battery pressure difference caused by overhigh temperature difference can be avoided; and therefore, the electrochemical performance and the service life of the battery can be improved and prolonged, and the hidden danger of thermal runaway caused by partial overheating also can be avoided.

Owner:SUZHOU ANKAO ENERGY

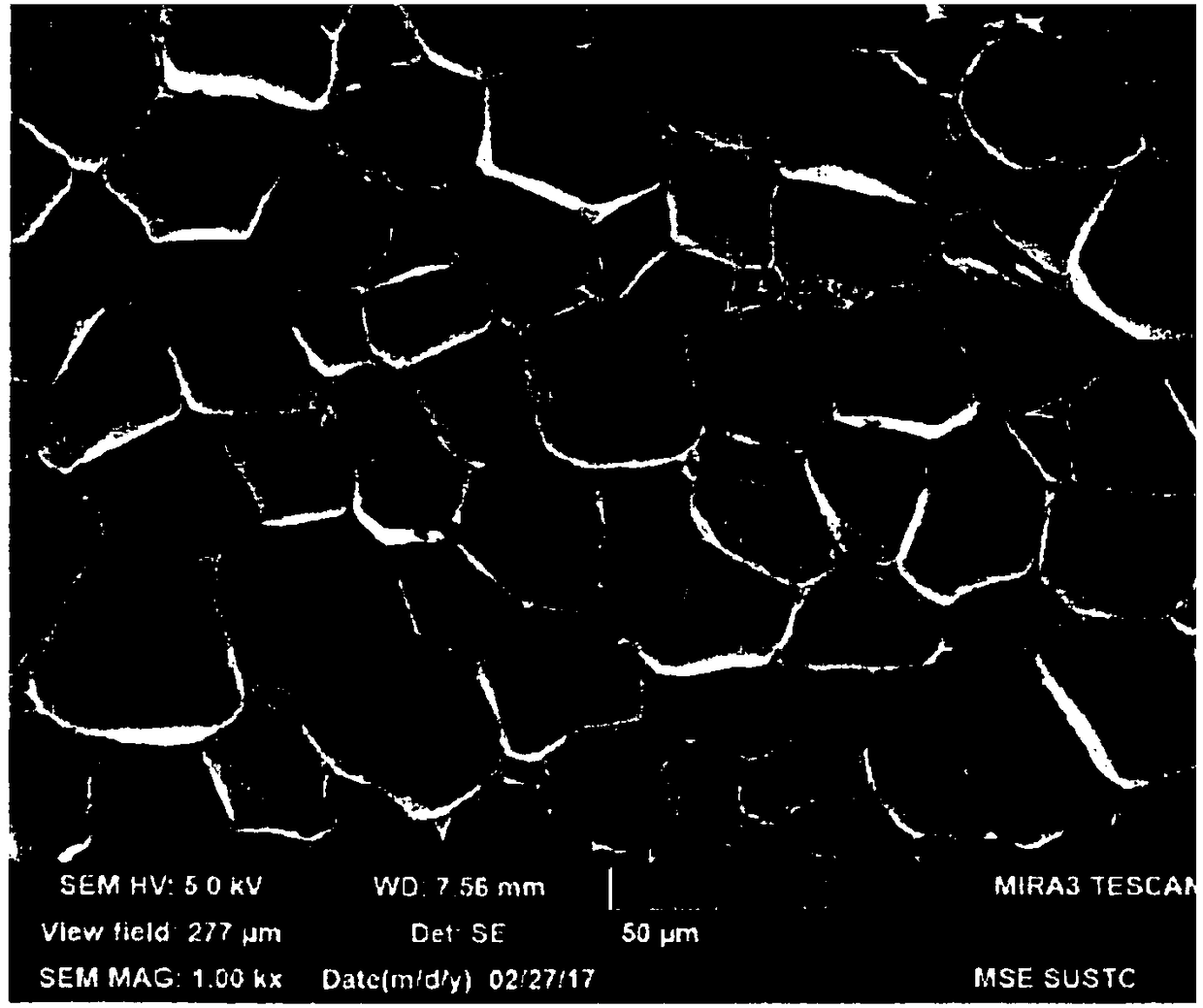

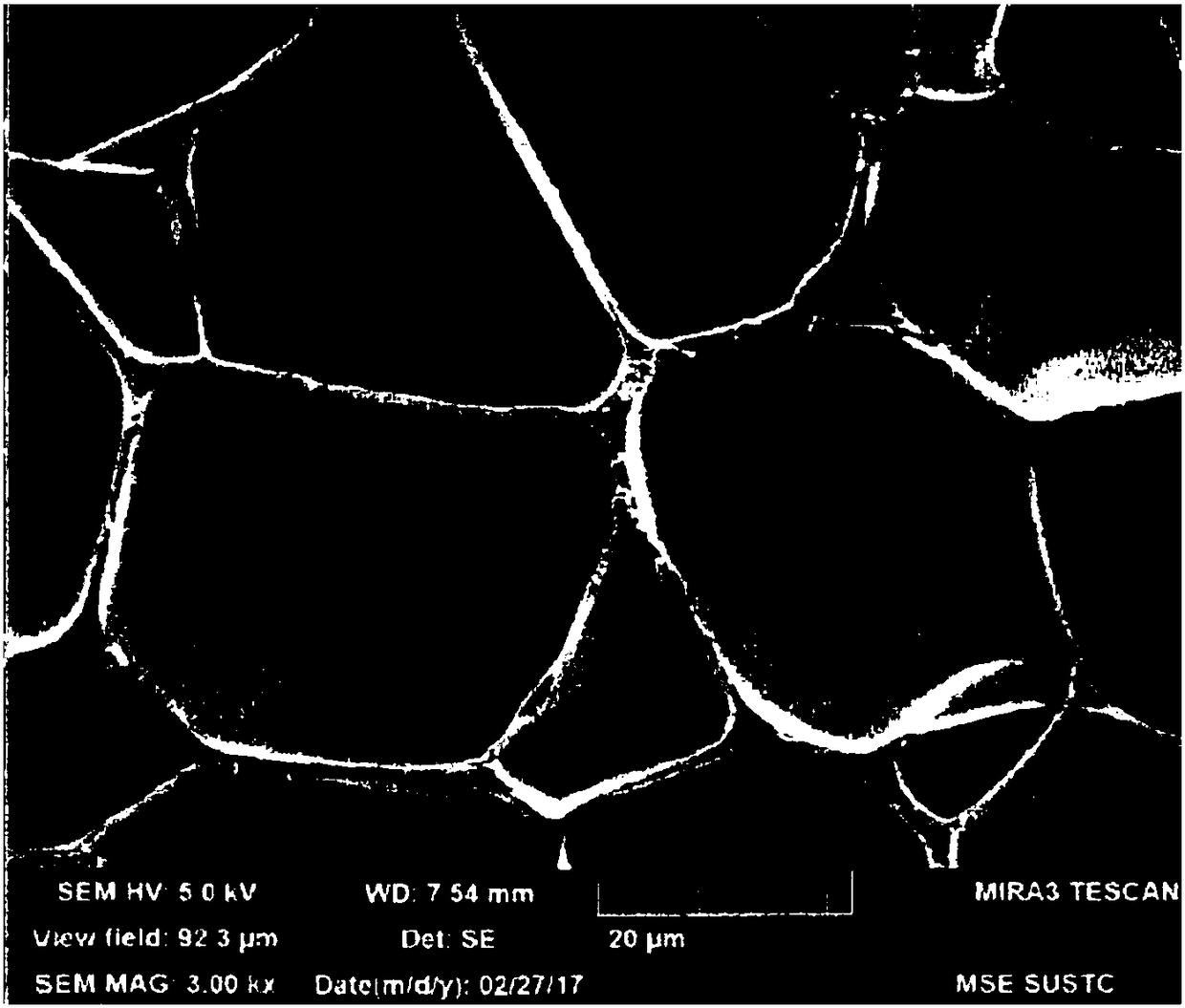

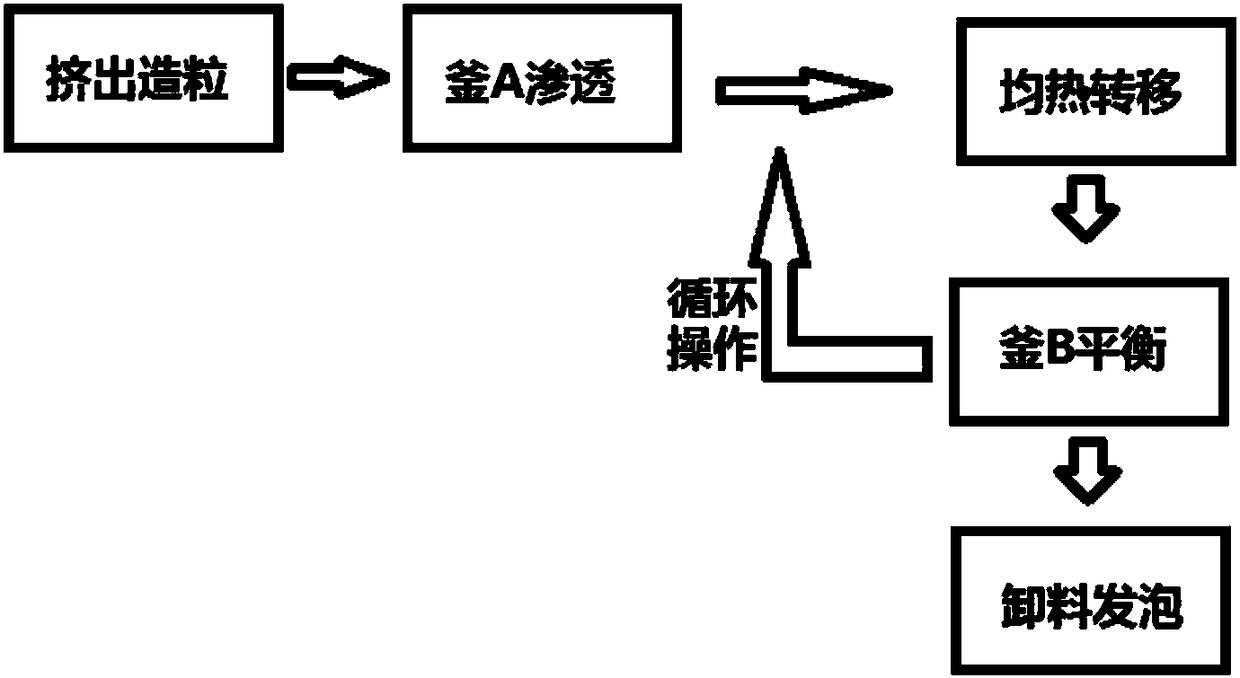

Thermoplastic polymer foam bead and method for preparing same

InactiveCN108410061AGuaranteed temperature uniformityGuaranteed uniformityChemical industryPelletizingBall valve

The invention discloses a thermoplastic polymer foam bead and a method for preparing the same. The method includes 1), extruding and granulating foam-grade thermoplastic polymer resin compositions toobtain to-be-foamed particles; 2), placing the to-be-foamed particles constant-temperature high-pressure reaction kettles A, filling the constant-temperature high-pressure reaction kettles A with supercritical fluid and carrying out permeating and swelling to reach diffusion balance so as to form polymer-supercritical fluid homogenous systems; 3), transferring balanced to-be-foamed particles intohigh-pressure reaction kettles B by the aid of magnetic sealed stirring devices under the constant pressures; 4), unloading materials in the high-pressure reaction kettles B by the aid of quick opening ball valves under the pressures and foaming and expanding polymer particles to obtain the thermoplastic polymer foam bead. The pore diameters of the thermoplastic polymer foam bead range from 30 micrometers to 50 micrometers, and the rate of the thermoplastic polymer foam bead ranges from 10 times to 60 times.

Owner:常州晟润新材料科技有限公司

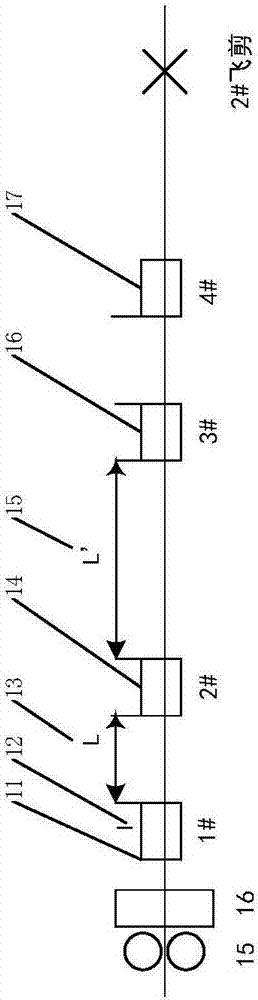

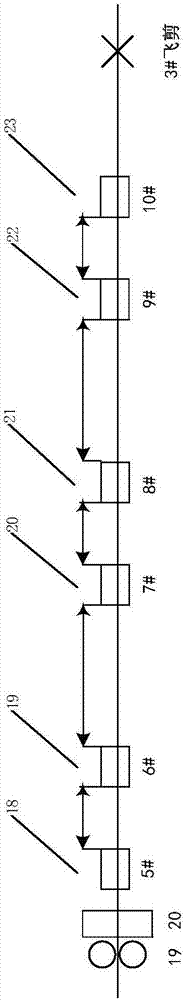

Excellent-quality steel bar controlled rolling and cooling method

ActiveCN107185968AAvoid Surface QuenchesGuaranteed surface recovery temperatureTemperature control deviceWork cooling devicesSurface layerMetallurgy

The invention provides an excellent-quality steel bar controlled rolling and cooling method and belongs to the technical field of rolled steel production controlled rolling and cooling. The specific technological process comprises the step that controlled rolling and cooling of bars with the specification of the diameter being 12-70 mm adopts short cooling, I section short temperature resetting, short cooling, II section long temperature resetting, short cooling, interrupt cooling and temperature resetting circular control technology. Short cooling adopts a water cooling manner, I section controlled cooling, II section controlled cooling and III section controlled cooling adopt the short cooling manner, and the length of a cooler ranges from 500 mm to 1000 mm. Pressure of cooling water ranges from 0.5 MPa to 1.5 MPa, temperature resetting adopts an air cooling manner, the I section short temperature resetting length is 1000-1800 mm, and the II section long temperature resetting length is 2400-3600 mm. According to the method, on the basis of meeting mechanical performance of bars, the problem that in the traditional controlled rolling and cooling technology, a deeper quenched layer is generated on the surface layer is solved, generation of the quenched martensitic structure of the surface layer is effectively avoided, control over organization types is achieved, meanwhile, better uniformity of the surface layer and heart temperature is ensured, and the surface layer and heart temperature difference is smaller than or equal to 50 DEG C.

Owner:UNIV OF SCI & TECH BEIJING

Thermal management module for square battery, and preparation method thereof, and battery pack

ActiveCN108199112AImprove thermal conductivityGuaranteed temperature uniformitySecondary cellsFiberComputer module

The invention relates to a thermal management module for a square battery, and a preparation method thereof, and a battery pack. The thermal management module comprises a thermal management material molding body, which is prepared from a thermal management material through a molding method, wherein the thermal management material contains, by mass, 55-90% of a phase change material, 4-20% of a thermal conduction filler, 4-20% of a flame retardant, and 2-10% of chopped fiber. According to the present invention, by adding the chopped fiber, the thermal management module can provide the effectiveenhancing effect, and can greatly increase the phase change material content in the thermal management material so as to improve the heat storage capacity of the thermal management module and stablyregulate and control the temperature.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

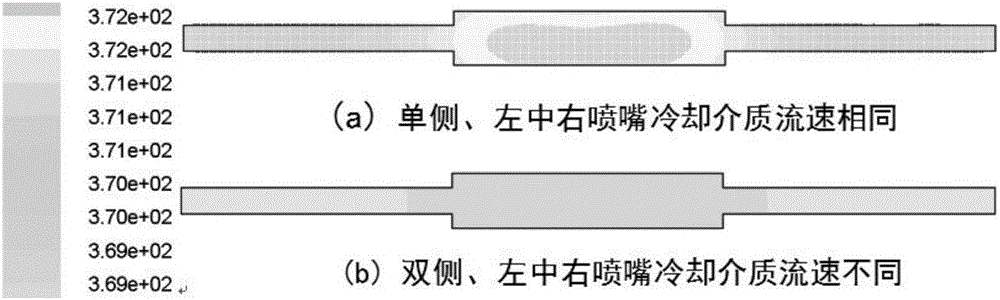

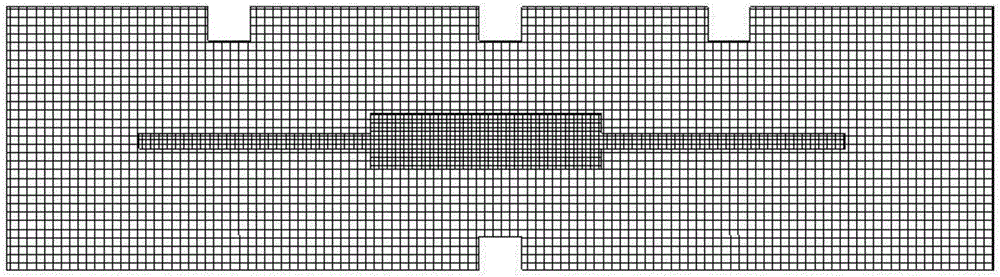

Method for optimizing complicated member gas-quenching system based on CFD software

InactiveCN106682346AGuaranteed temperature uniformityReduce lossesDesign optimisation/simulationSpecial data processing applicationsInternal temperatureSoftware

The invention discloses a method for optimizing complicated member gas-quenching system based on CFD software. The method comprises the steps that a member gas-quenching system solid computation domain and a fluid computation domain geometric model are established; grid partition is conducted on a geometric model; the geometric model is imported to the CFD software, and a temperature field is set and solved; the steps are repeated by modifying relevant parameters to perform multiple times of numerical simulation; temperature field data corresponding to the multiple times of numerical simulation are organized, a database is established, the minimum internal temperature difference of a member is regarded as a target, automatic optimizing is performed through the database, and an optimum process parameter combination is selected to ensure the uniformity of the internal temperature of the member. The temperature field inside the member is predicted under various gas-quenching working conditions by adopting a computer analog technology, the minimum internal temperature difference of the member is regarded as the optimizing target so as to ensure uniformity of the internal temperature of the member, and a rapid way is provided for optimization of the complicated member gas-quenching system.

Owner:CENT SOUTH UNIV

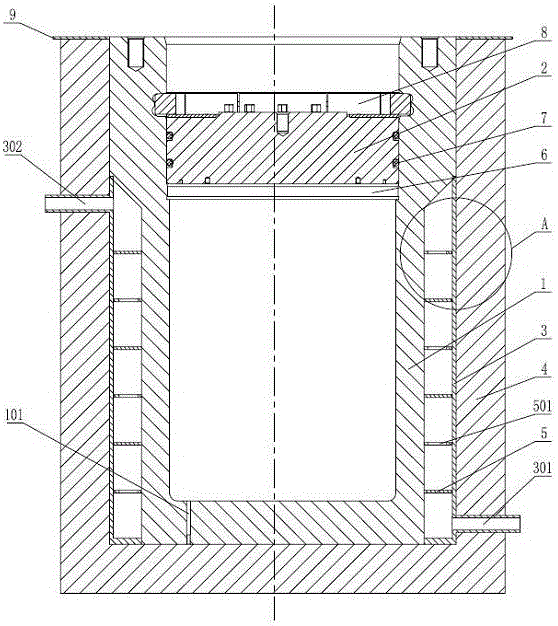

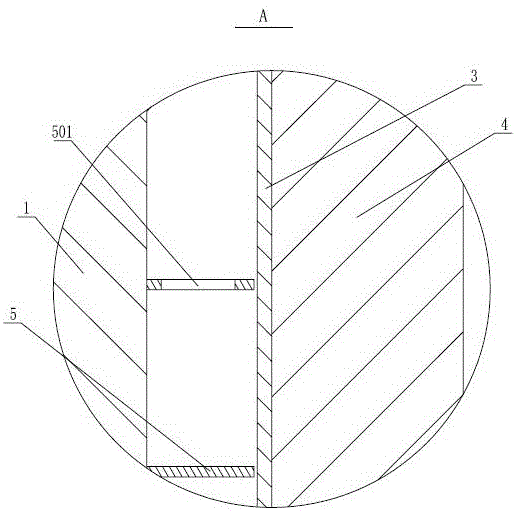

Deep sea high-temperature high-pressure environment simulator

ActiveCN106111218AEffective simulationRegulating pressureAir-pressure/air-lock chambersEngineeringHigh pressure

The invention relates to a deep sea high-temperature high-pressure environment simulator. The deep sea high-temperature high-pressure environment simulator comprises a barrel body with an opening in an upper end, the opening of the upper end of the barrel body is covered with a plug cover, and the plug cover and the barrel body are sealed to form a sealed cavity; a pressurizing opening is formed in the barrel body, a jacket is arranged outside the barrel body, the jacket coats the periphery of the sealed cavity, an inlet for temperature adjusting mediums and an outlet for the temperature adjusting mediums are formed in the jacket, and heat preservation cotton is jointed to the outer wall surface of the jacket and the outer wall surface which is not coated with the jacket on the barrel body; and a plurality of partition boards are fixedly connected to the outer wall surface of the sealed cavity, and are distributed at intervals in the height direction of the sealed cavity, and a diversion hole is formed in each partition board. The deep sea high-temperature high-pressure environment simulator disclosed by the invention can effectively simulate the high-temperature high-pressure environment of deep sea, pressure and temperature can be adjusted, and besides, the deep sea high-temperature high-pressure environment simulator is simple in structure and reliable to work.

Owner:中国船舶重工集团公司第七〇二研究所

In-line type multicavity laminated parallel processing vacuum equipment and use method thereof

InactiveCN104164661AReduce the number of handlingReduce waiting timeChemical vapor deposition coatingThin membraneParallel processing

The invention relates to in-line type multicavity laminated parallel processing vacuum equipment, which includes: a sheet feed chamber, a reaction chamber and a sheet discharge chamber that are connected in order linearly. The equipment is characterized in that: a first transmission unit and a second transmission unit for substrate transmission are respectively disposed in the sheet feed chamber and the sheet discharge chamber. At least two sub-reaction chambers for preparation a needed film are vertically stacked inside the reaction chamber, and each of the sub-reaction chambers is provided with an open-close device respectively on a side facing the sheet feed chamber and on a side facing the sheet discharge chamber. The equipment can reduce the number of substrate carrying times, and improve the equipment productivity and production efficiency.

Owner:IDEAL ENERGY EQUIP (SHANGHAI) LTD

Motor machine shell water channel structure and motor

PendingCN108306444AGuaranteed temperature uniformityEnhanced convective heat transferCooling/ventillation arrangementSupports/enclosures/casingsTemperature controlNew energy

The invention provides a motor machine shell water channel structure and a motor, and relates to the technical field of heat dissipation of a new energy automobile motor. The motor machine shell waterchannel structure comprises an inner machine shell and an outer machine shell; the outer machine shell is mounted on the exterior of the inner machine shell; a hollow cavity for allowing a cooling medium to pass through is formed between the inner machine shell and the outer machine shell; a water channel is formed in the outer surface of the inner machine shell; and the width of the water channel is gradually reduced from the water inlet to the water outlet so as to improve the convection and heat transfer capability of the cooling medium in the water outlet and ensure the thermal homogeneity of the motor, thereby solving the technical problem of disadvantage in uniform temperature control of the motor.

Owner:ZHONGSHAN POLYTECHNIC

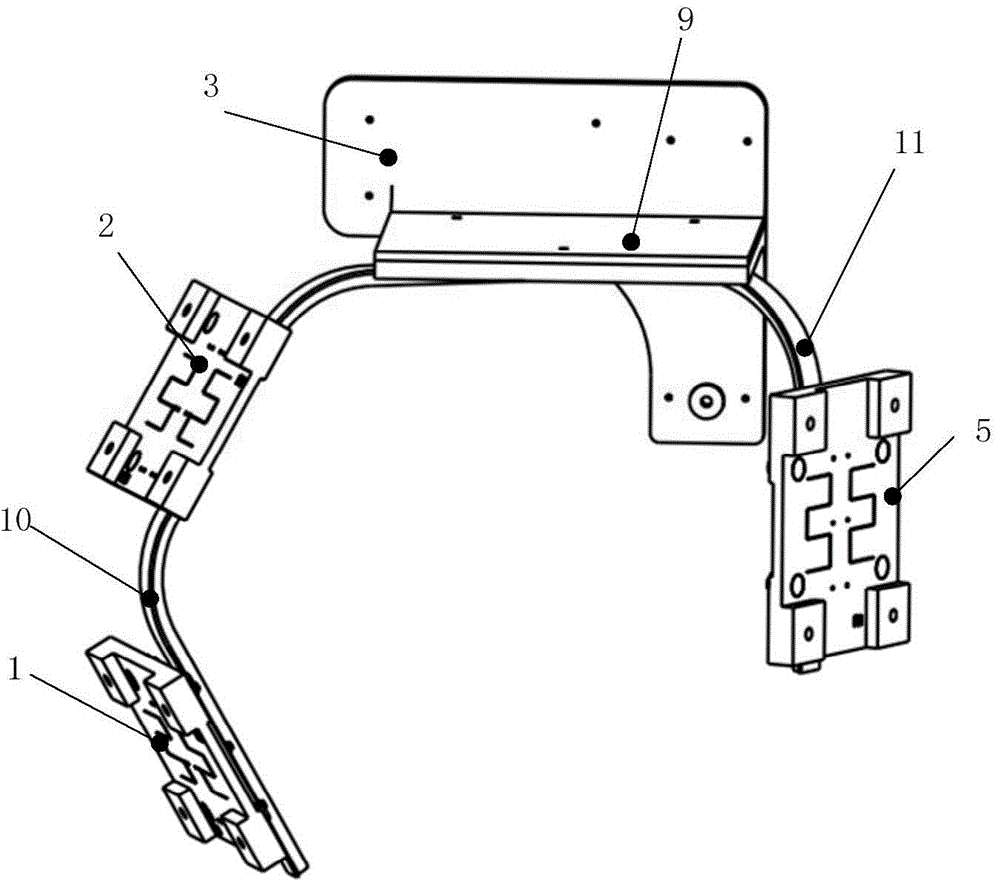

High-accuracy micro deformation star sensor mounting bracket

ActiveCN104691790AAccuracy meetsFulfil requirementsCosmonautic vehiclesCosmonautic partsThermal deformationEngineering

The invention discloses a high-accuracy micro deformation star sensor mounting bracket. A star sensor mounting plate is connected to the outer surface of a thin-wall shell structure; a heat pipe is positioned inside the thin-wall shell structure; one end of the heat pipe is connected to the star sensor mounting plate; the other end of the heat pipe is connected with a heat collecting plate; the heat collecting plate is connected to the inner side of the top of the thin-wall shell structure and partially extends out of the top of the thin-wall shell structure; a first insulation mat is mounted between the heat collecting plate and the thin-wall shell structure; a rear cover board is connected to the back of the thin-wall shell structure so as to form a mounting bracket head; one end of a strut assembly is connected with the mounting bracket head; the other end of the strut assembly is used for mounting a spacecraft optical imaging effective load structure body. The high-accuracy micro deformation star sensor mounting bracket solves the technical difficult problem of harsh thermal deformation of a high-orbit spacecraft star sensor mounting bracket so as to meet the requirements on high-accuracy attitude determination of a spacecraft and image navigation registration, and meanwhile, has the advantages of novel structural form, light weight and the like.

Owner:SHANGHAI SATELLITE ENG INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com