Patents

Literature

142results about How to "Reduce the number of handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

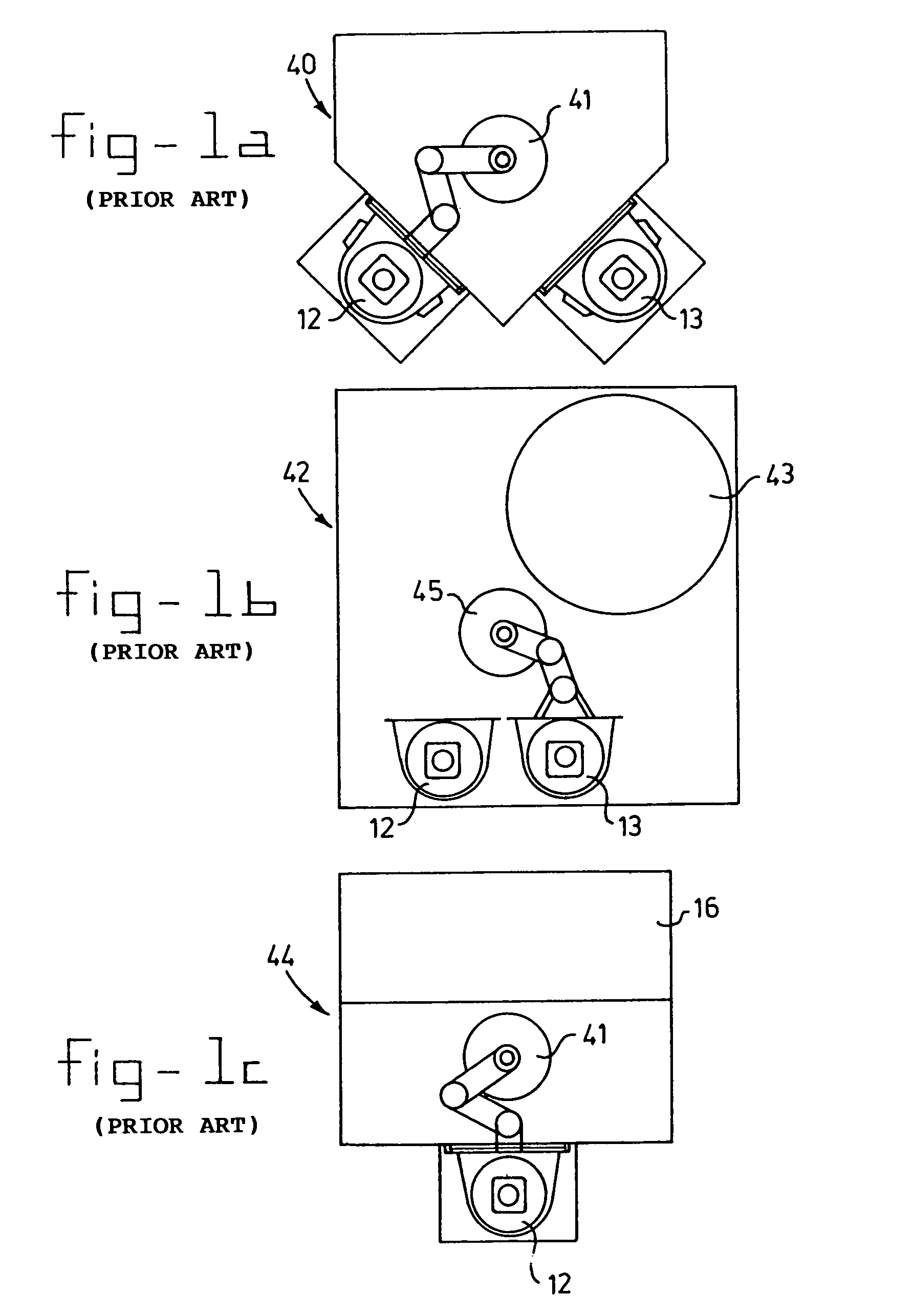

Sorting/storage device for wafers and method for handling thereof

InactiveUS7077614B1Easy and less-expensive to produceReducing throughout capacitySemiconductor/solid-state device manufacturingCharge manipulationMeasurement stationBiomedical engineering

Sorting / storage device for wafers. A sorting device is provided in which at least two cassettes containing wafers may be present and the wafers are moved from one cassette to the other cassette or vice versa. If appropriate, a measuring station may be present in the sorting device. In the immediate vicinity of the sorting device, the cassettes are stored in a magazine which is designed for this purpose and the cassettes are moved using a handling device for cassettes.

Owner:ASM INTERNATIONAL

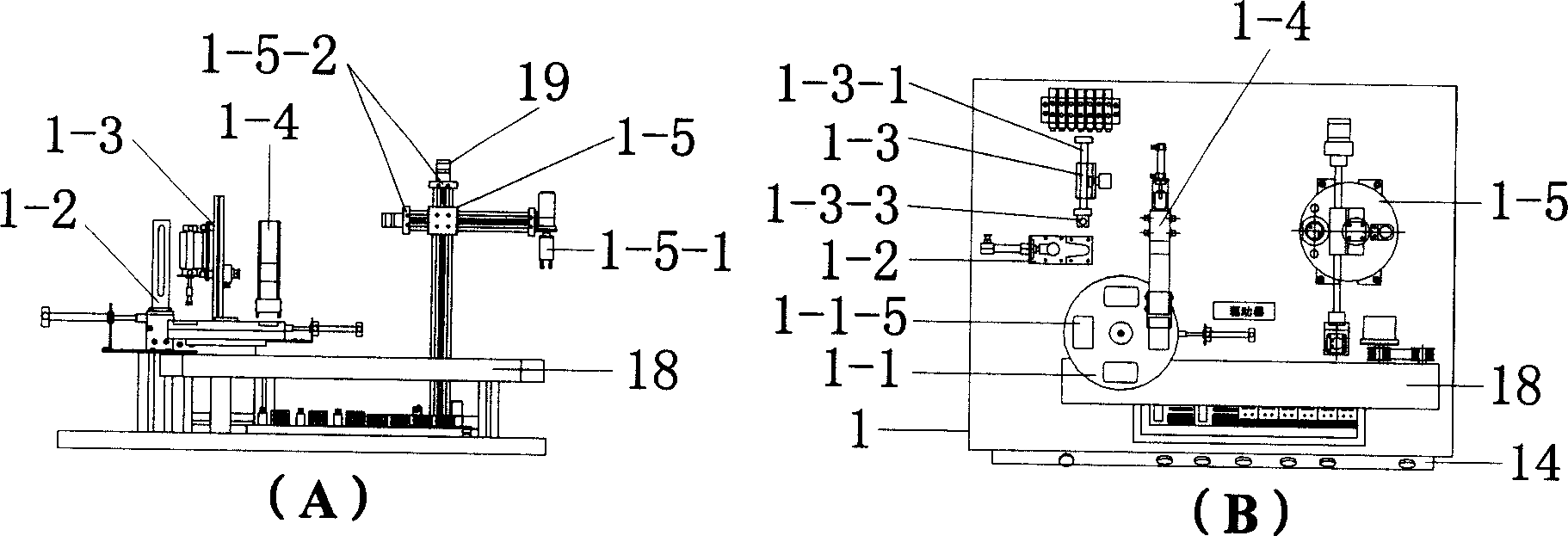

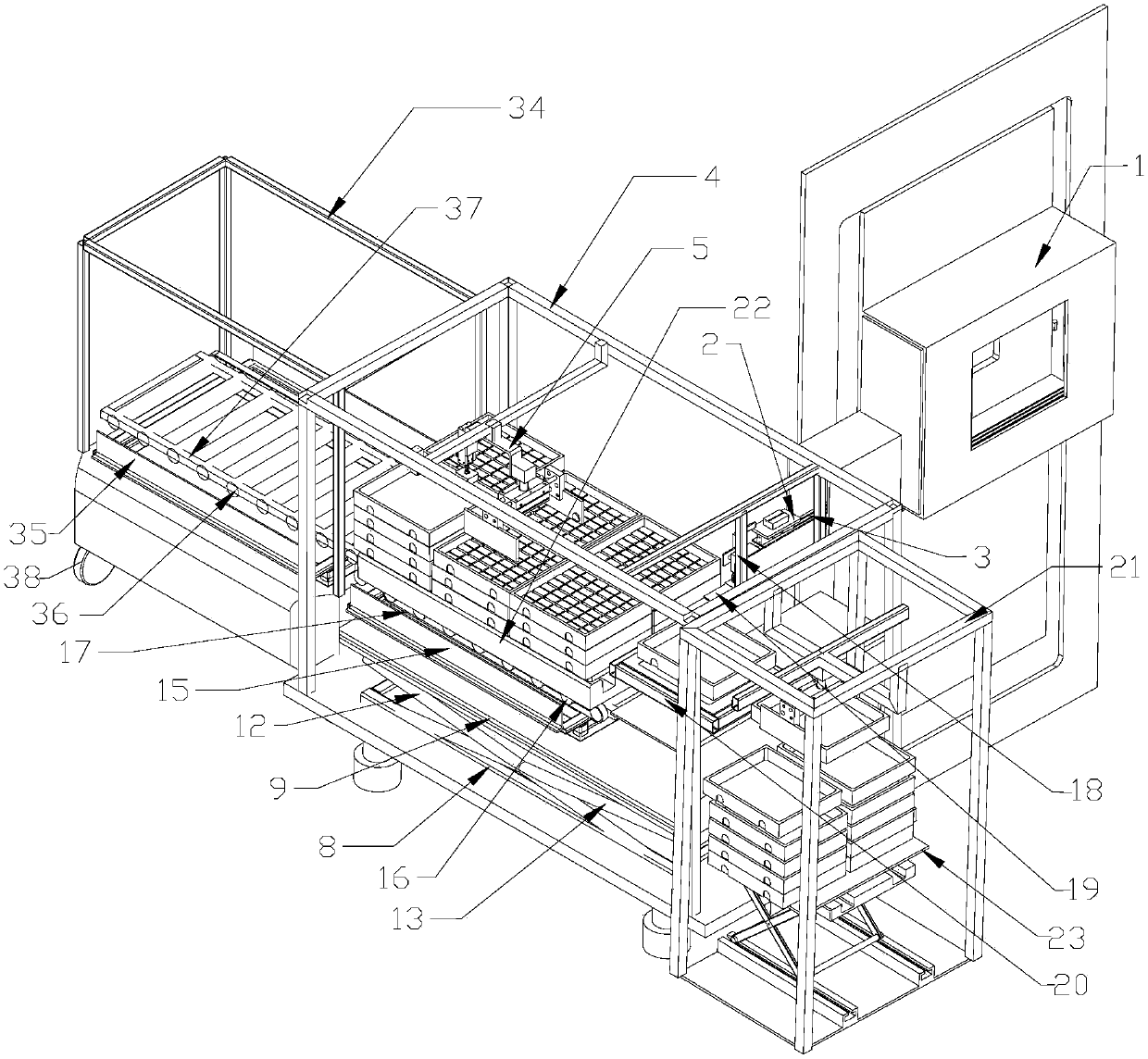

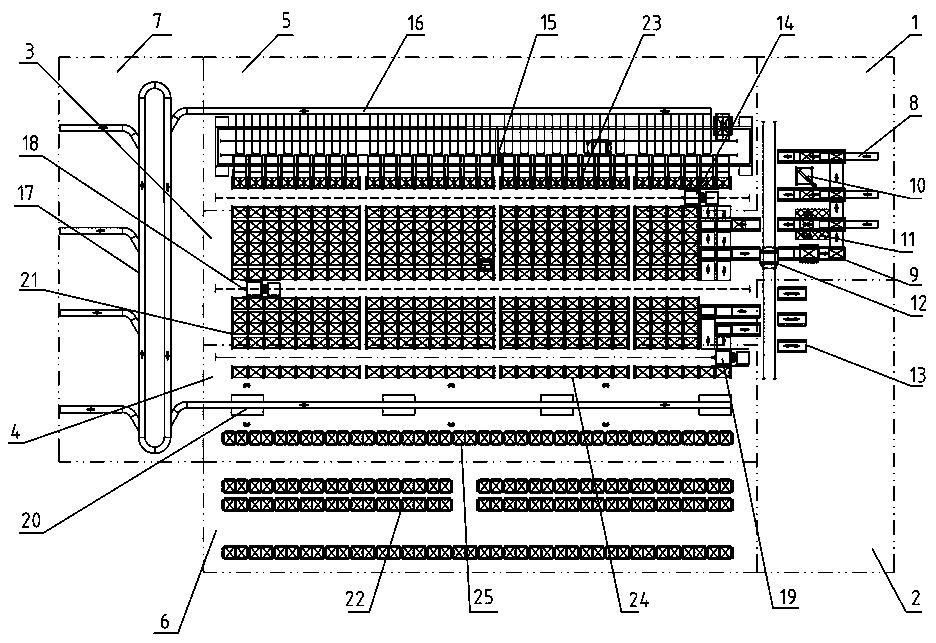

Logistics operation training system and making method

InactiveCN1716342AIncrease isolation protection functionEasy to set upEducational modelsMicrocontrollerLogistics management

The logistics operation training system includes manipulator assembling and conveying operation unit, automatic cargo distinguishing and buffering operation unit, stacking operation unit, automatic warehouse operation unit, visual detection operation unit, stacking operation unit, cargo flow direction controlling operation unit and container packing operation unit. Each of the operation units is provided with monolithic computer circuit and logic circuit with modular electric interface, and different units may be selected to form stepped configuration. The present invention is suitable for different teaching and training modes.

Owner:TIANJIN YUANFENG TECH DEV

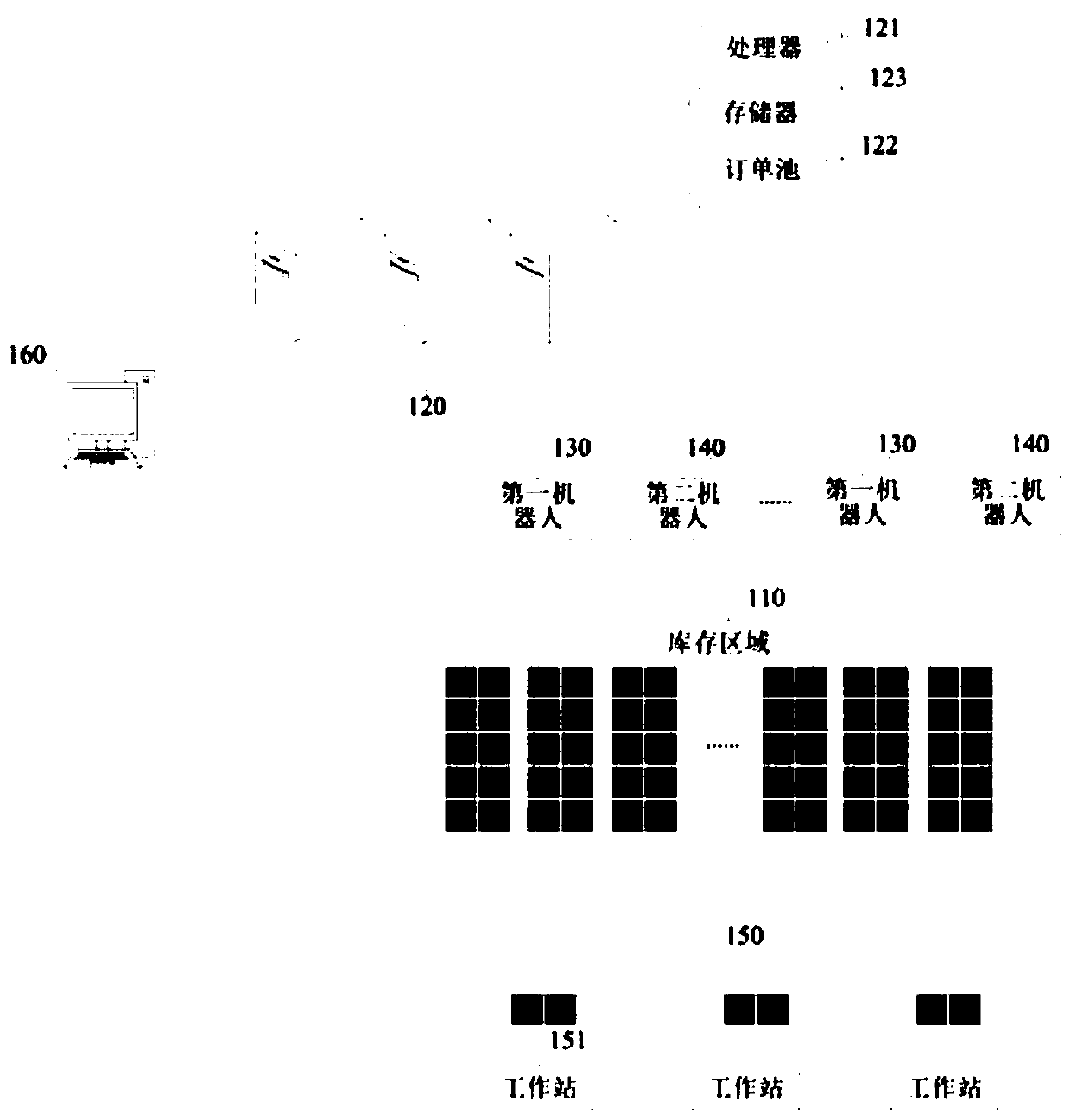

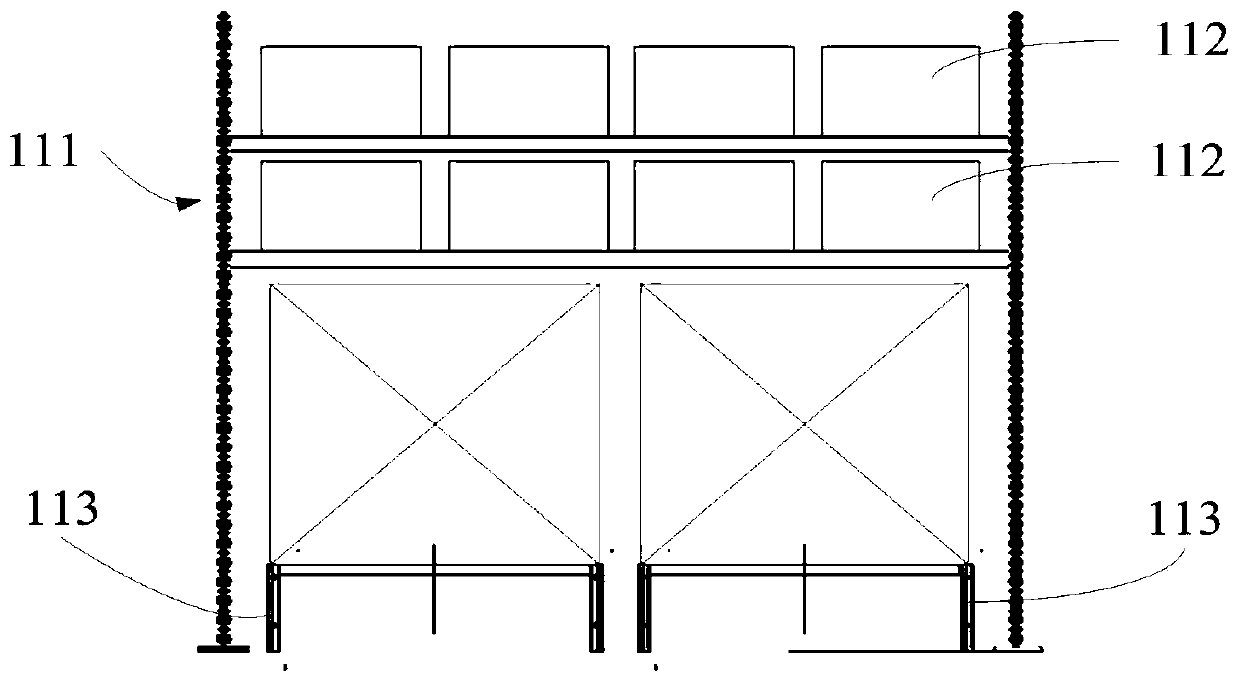

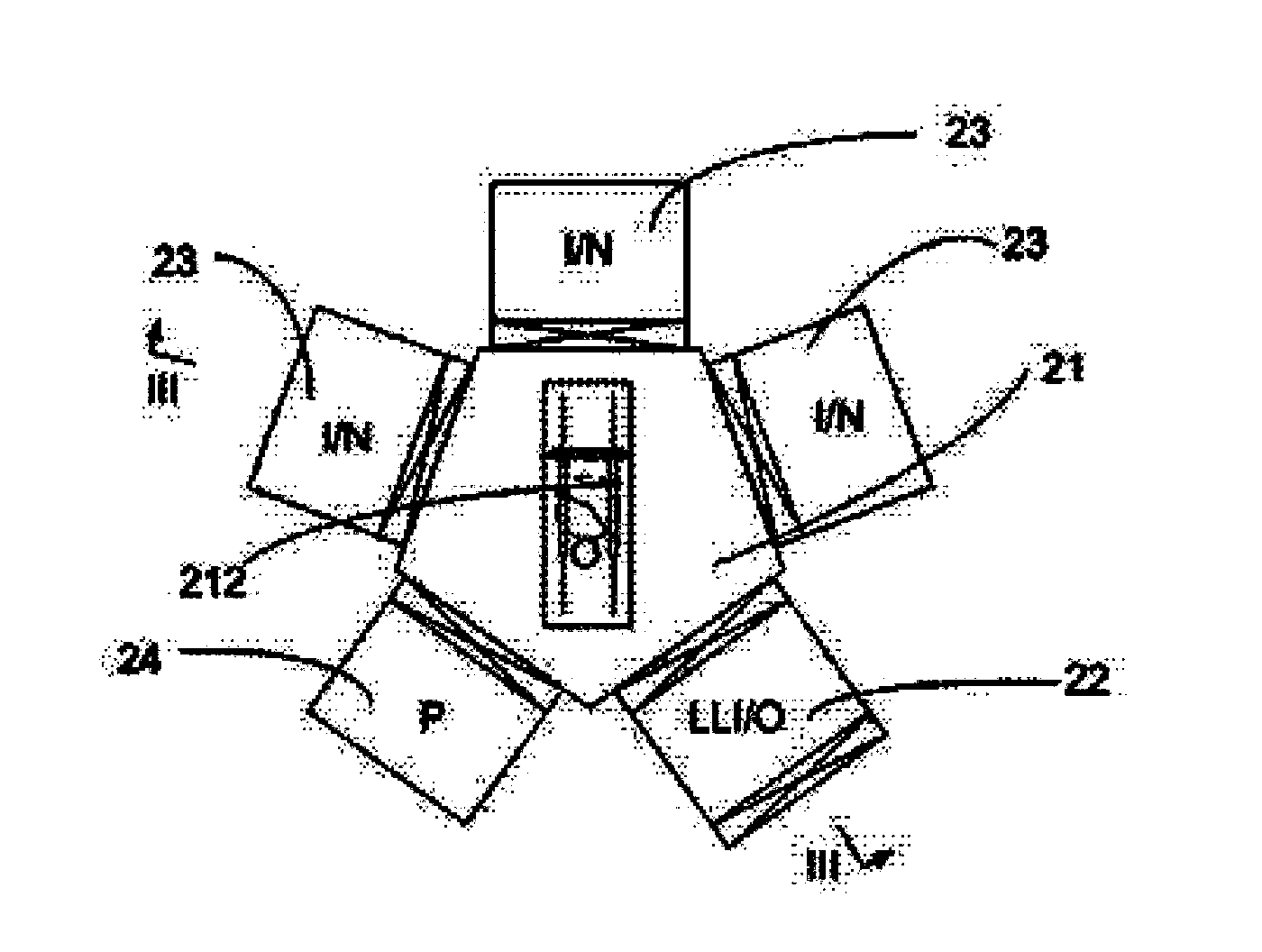

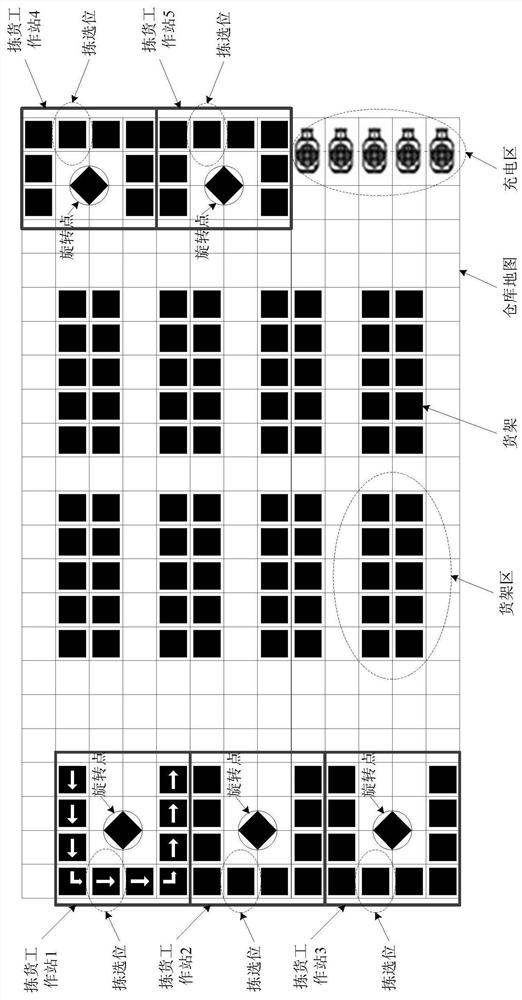

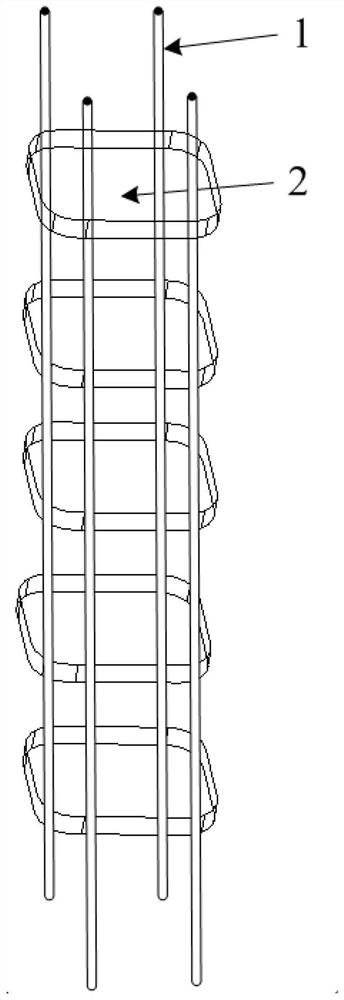

Stock rack set, storage system, robot control method, and robot

ActiveCN110949923AReduce the number of handlingReduce in quantityStorage devicesSimulationRobot control

The invention provides a stock rack set, a storage system, a robot control method, and a robot. The storage system includes a stock area, a control server, a first robot, a second robot, and a workstation, the first robot and the second robot are in wireless communication with the control server respectively; the stock area includes a plurality of stock racks, the layers other than bottom layers of the stock racks are for the placement of first storage containers capable of being transported, scattered goods are placed in the first storage containers, second storage containers capable of beingtransported are placed at bottom layers of the stock racks, full container loads are placed on the second storage containers, through a mix running method of two types of robots, carrying of target storage containers is achieved for sorting the full container loads and the scattered, the number of carrying times of the robot is significantly decreased, the number of robots is decreased, and thusthe sorting efficiency is improved.

Owner:BEIJING JIZHIJIA TECH CO LTD

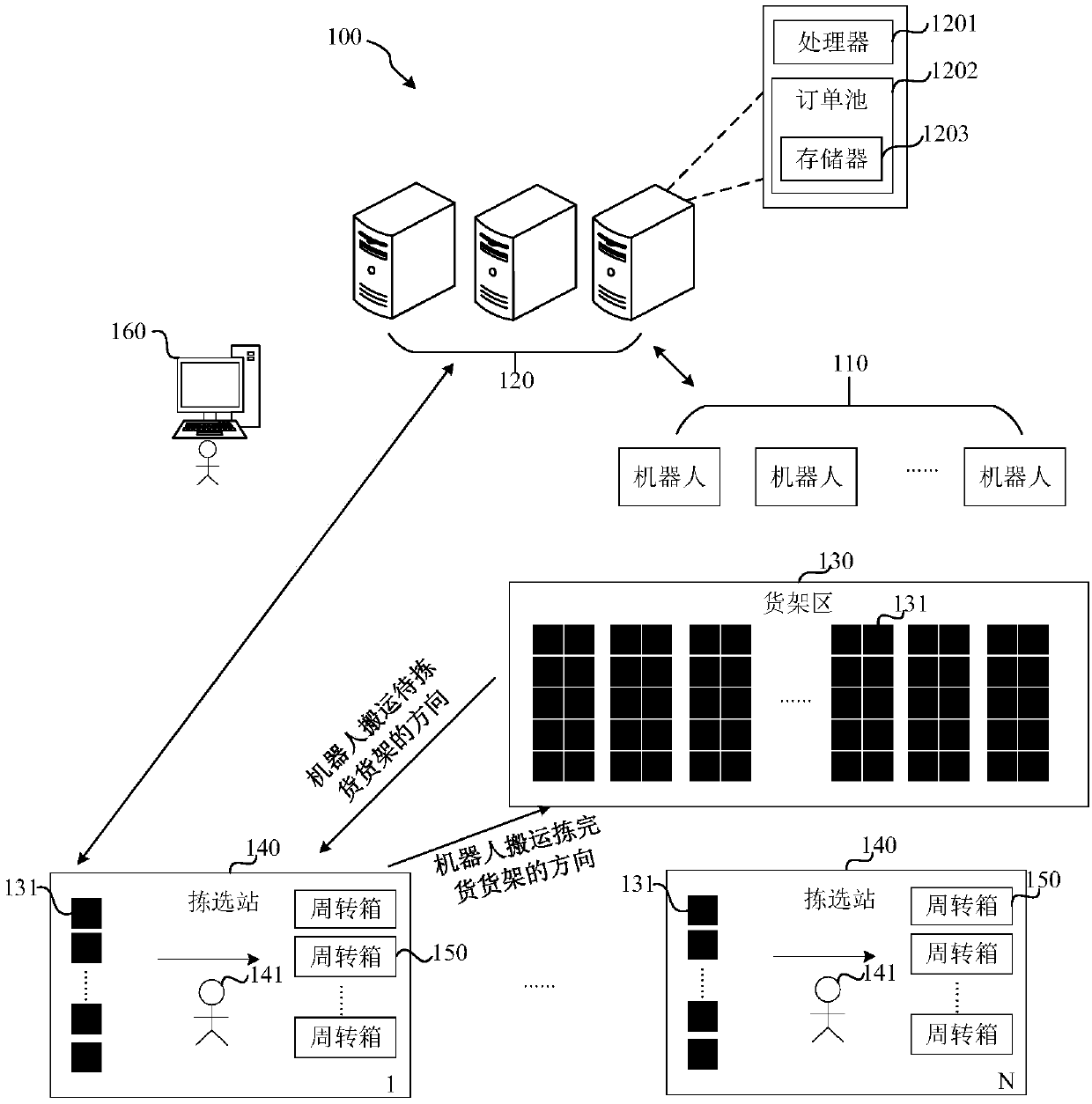

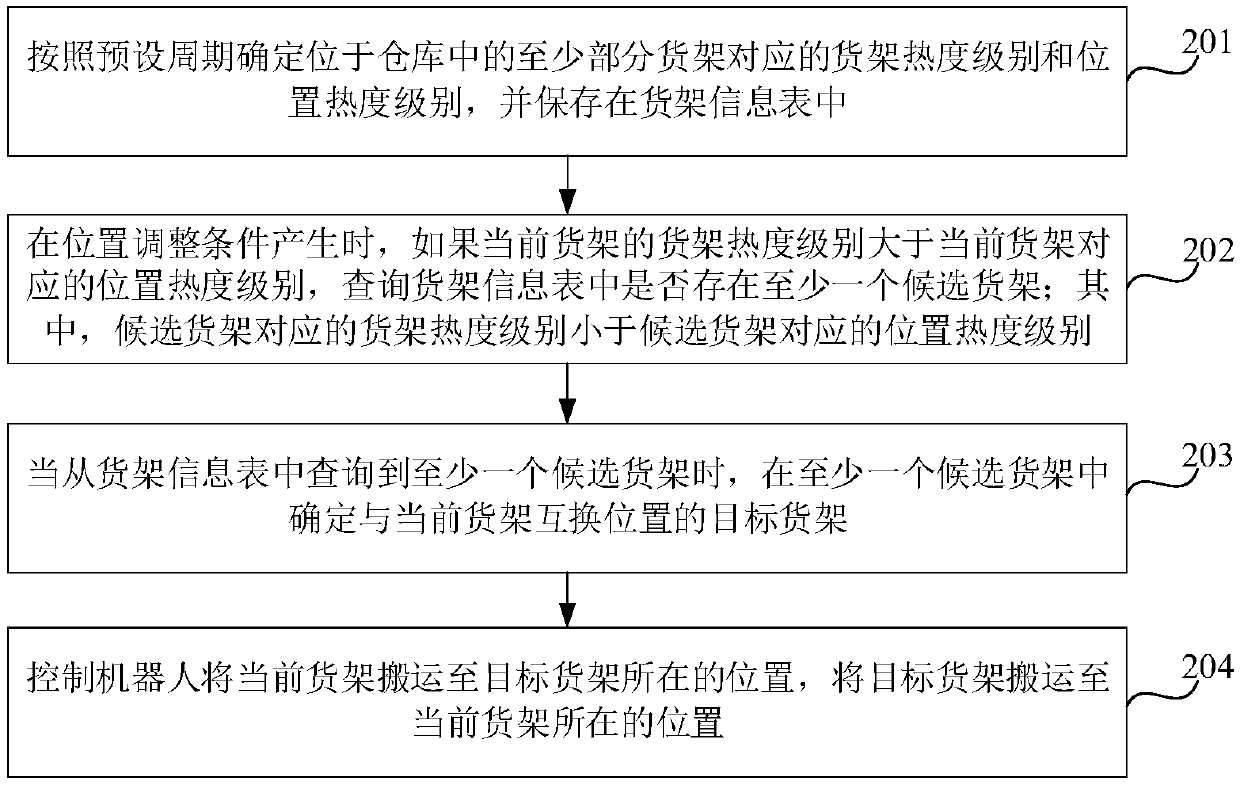

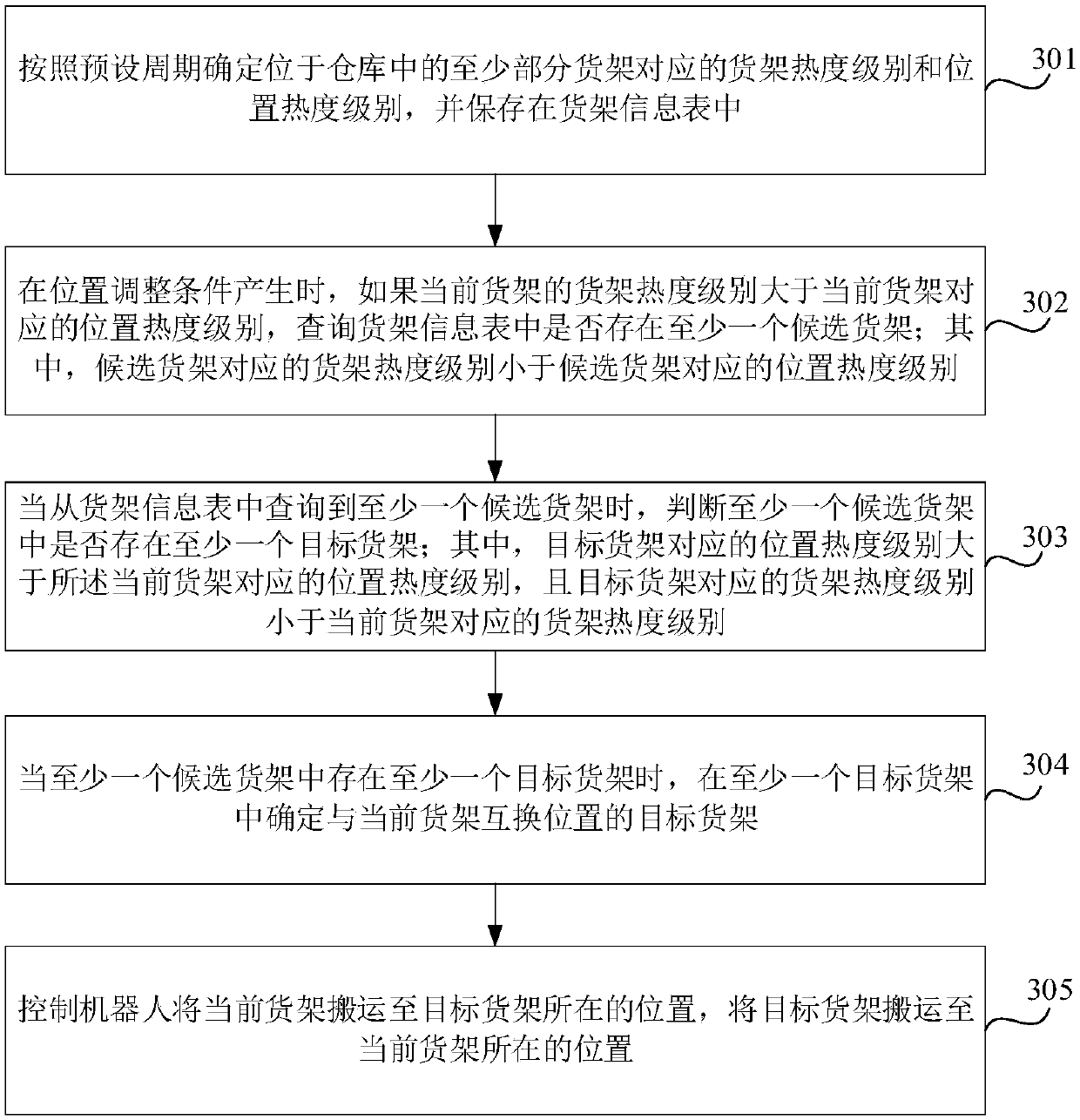

Shelf position adjusting method, device, computer device and storage medium

ActiveCN109086921AReduce the number of handlingShorten exercise distanceForecastingLogisticsComputer engineeringComputer device

The embodiments of the present invention disclose a shelf position adjusting method, a device, a computer device and a storage medium, The method comprises: determining a shelf heat level and a position heat level corresponding to at least a portion of shelves located in the warehouse according to a preset period, and stored in the shelf information table, as the position adjustment condition occur, if the shelf heat level of the current shelf is greater than the corresponding position heat level of the current shelf, querying whether at least one candidate shelf exists in the shelf information table, wherein the shelf heat level corresponding to the candidate shelf is smaller than the position heat level corresponding to the candidate shelf, and when the at least one candidate shelf is queried from the shelf information table, determining a target shelf in the at least one candidate shelf that is interchangeable with the current shelf; controlling the robot to move the current shelf to the location of the target shelf. The embodiment of the invention can reduce the moving distance of the shelf conveying robot, reduce the shelf conveying times, shorten the conveying time, and improve the picking efficiency.

Owner:BEIJING JIZHIJIA TECH CO LTD

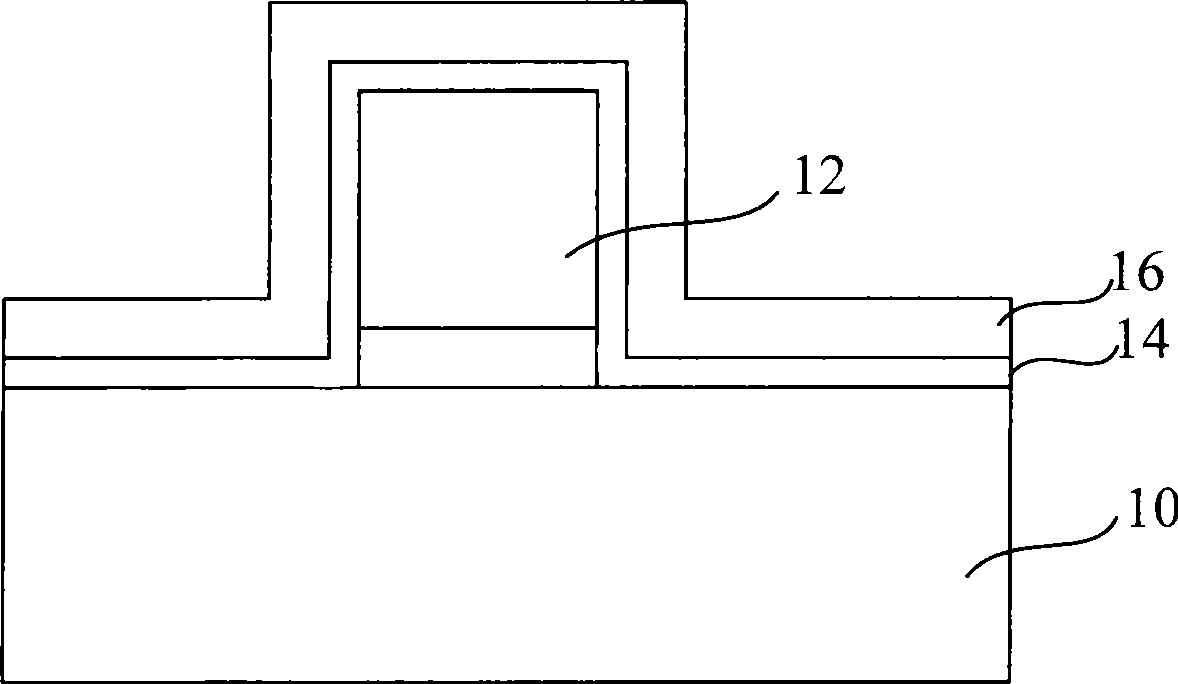

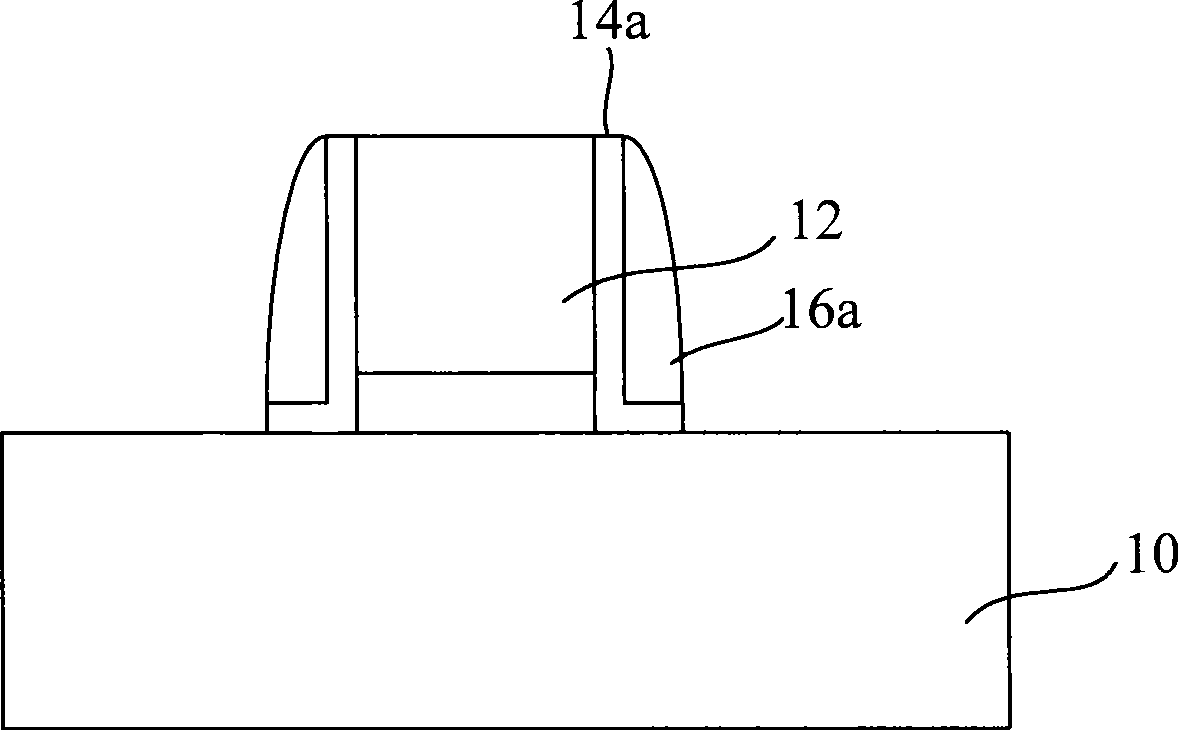

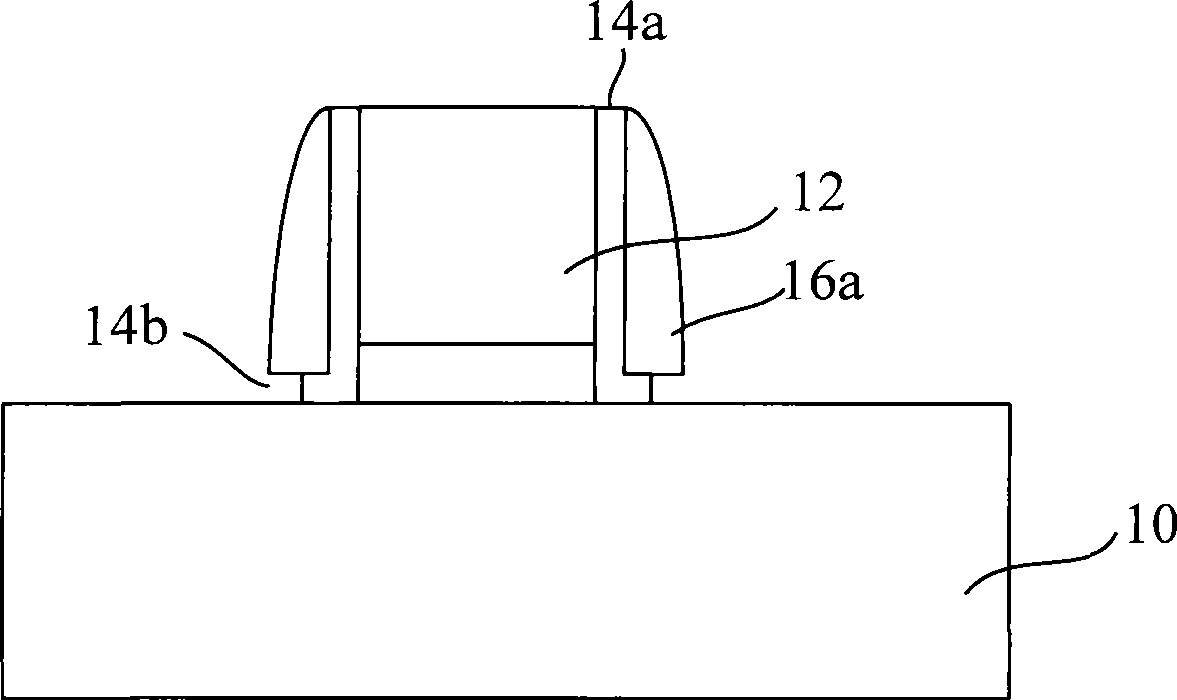

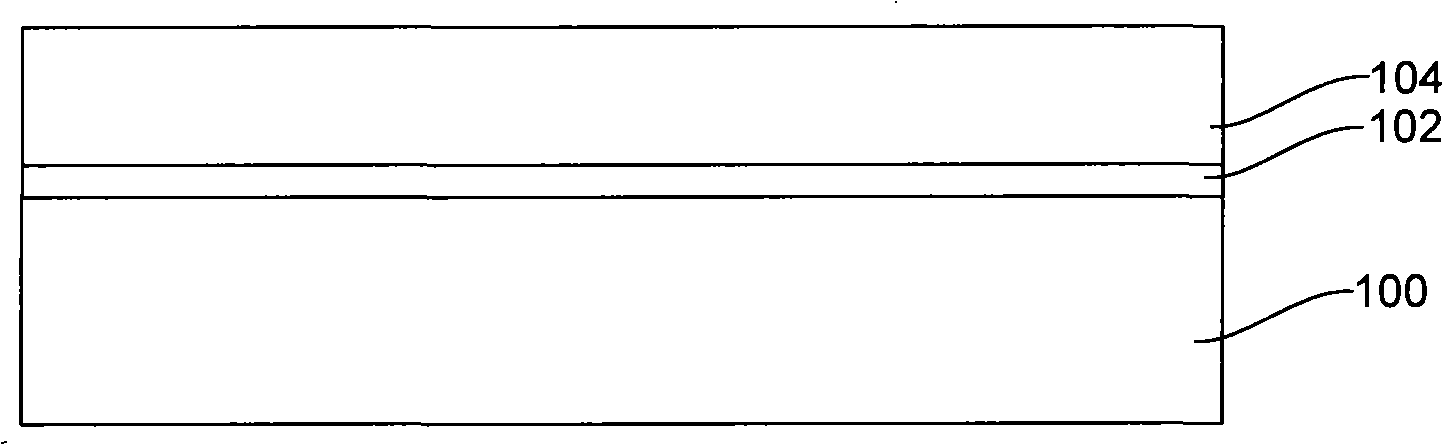

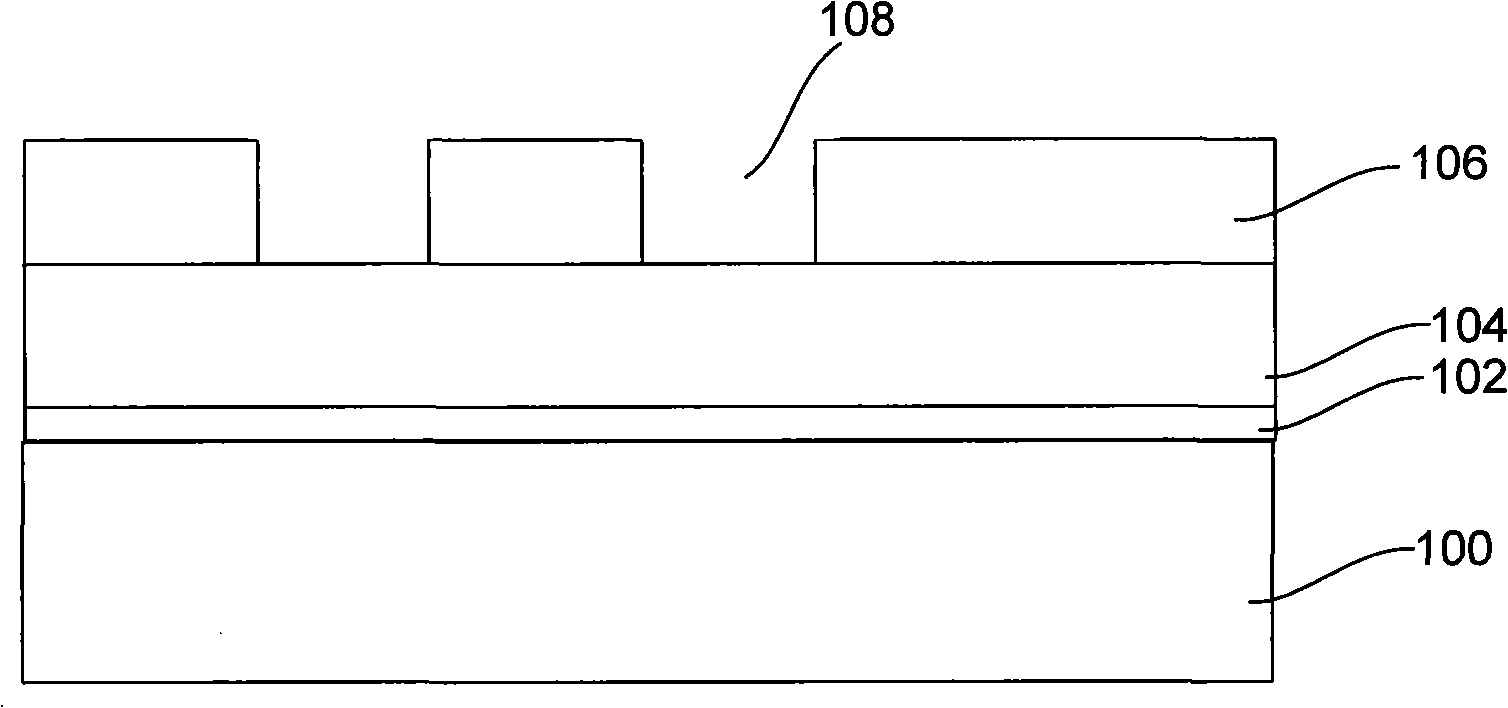

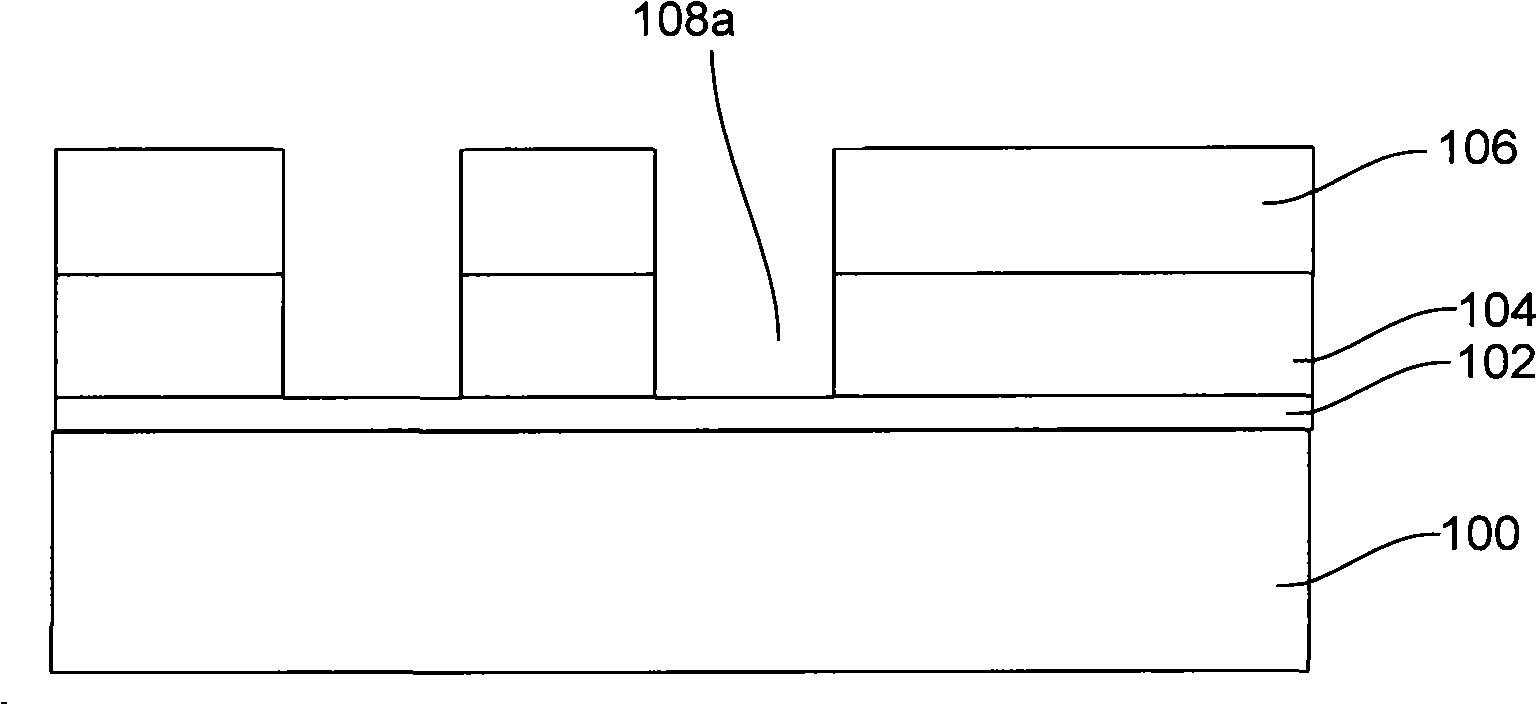

Manufacturing method for gate lateral wall layer and semi-conductor device

InactiveCN101393862AReduce the number of handlingThe process steps are simpleSemiconductor/solid-state device manufacturingSemiconductor devicesSilanesSemiconductor

A method for forming a side wall layer on a grid electrode comprises the following steps: a semi-conductor substrate provided with the grid electrode is provided; a first silica layer is formed on the surfaces of the semi-conductor substrate and the grid electrode; with hexa-chloro silane as a precursor, a first silicon nitride layer is formed on top of the first silica layer; and parts of the first silica layer and the first silicon nitride layer are removed in a selective manner so as to preserve the first silica layer and the first silicon nitride layer already formed on the side wall of the grid electrode. The invention further provides a method for manufacturing a semiconductor device. The invention can solve the problem that the bottom part of the side wall layer on the grid electrode is susceptible to depression.

Owner:SEMICON MFG INT (SHANGHAI) CORP

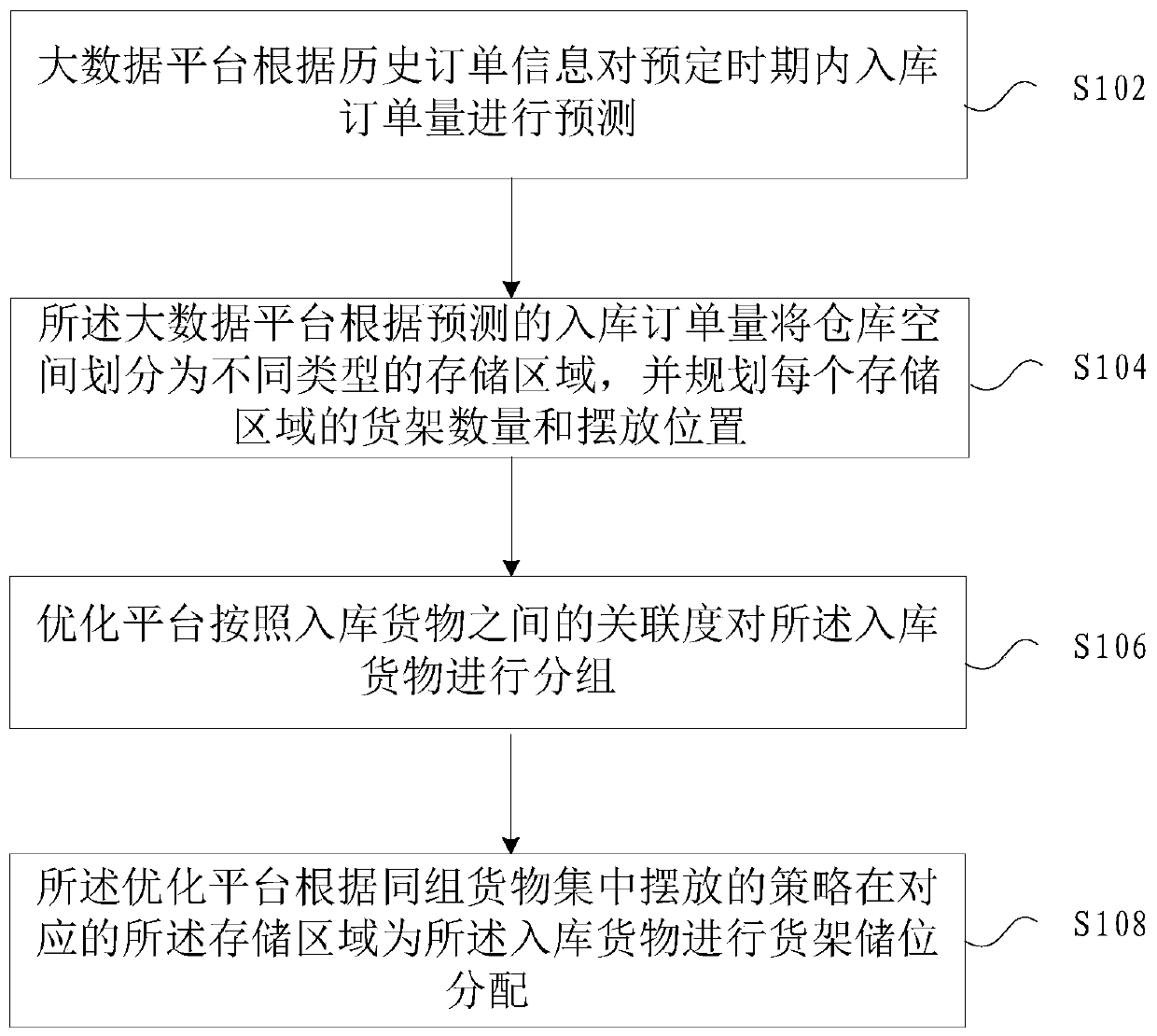

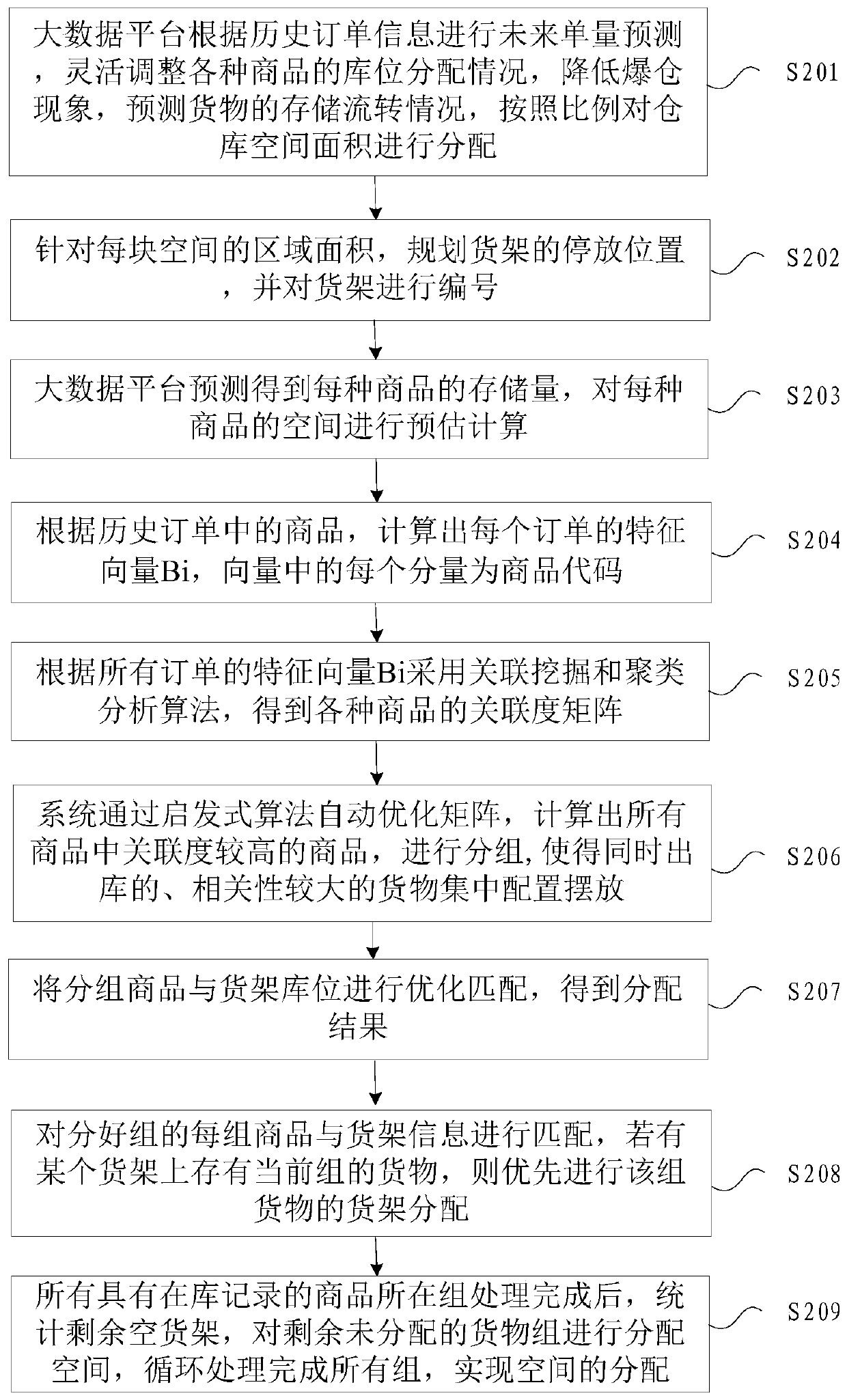

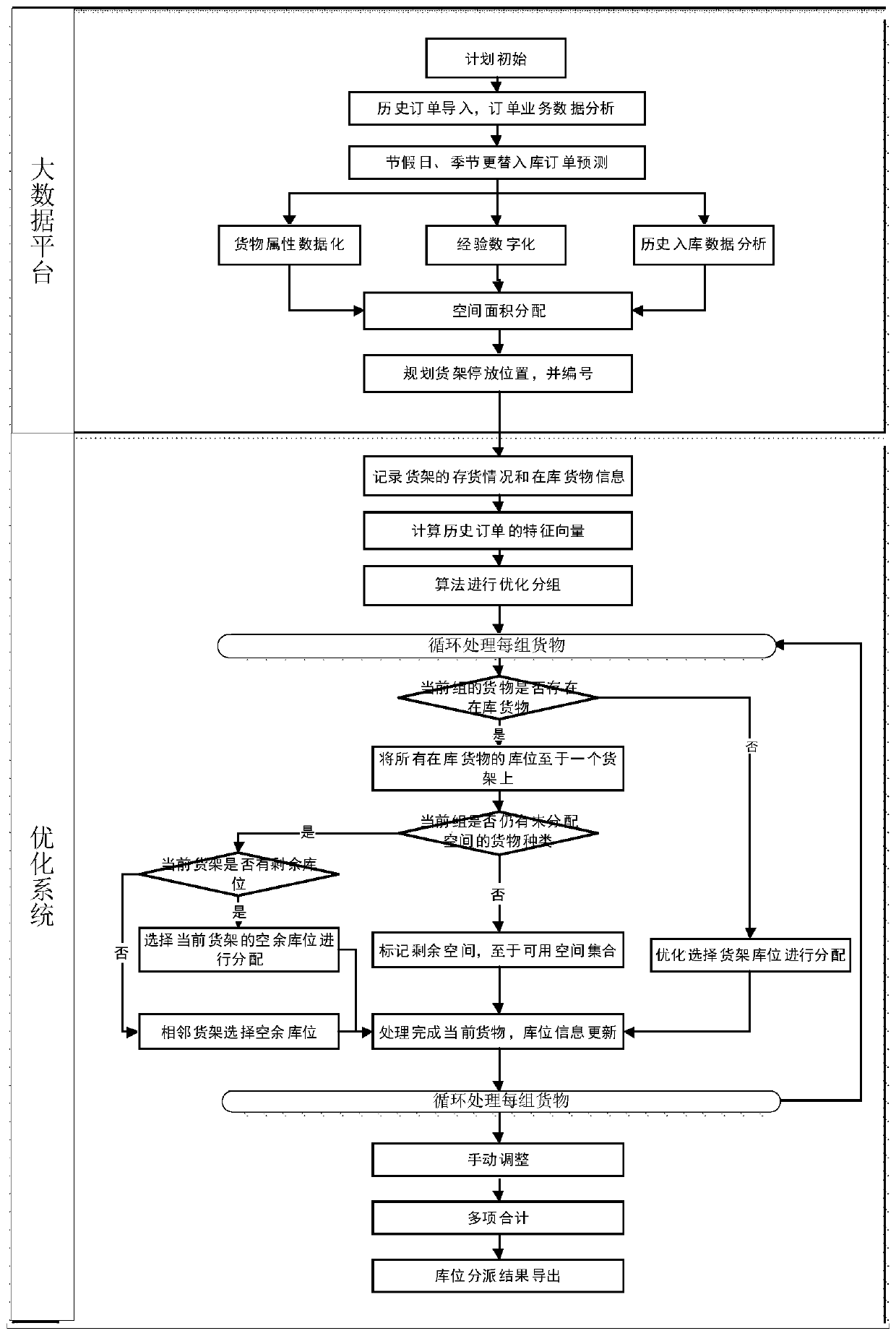

Warehouse storage location allocation method and system based on big data

The invention provides a warehouse storage location allocation method based on big data. The method comprises the steps that a big data platform predicts the warehousing order quantity in a predetermined period according to historical order information; the big data platform divides the warehouse space into different types of storage areas according to the predicted warehousing order quantity, andplans the shelf number and the placement position of each storage area; an optimization platform groups the warehoused goods according to the association degree between the warehoused goods; and theoptimization platform performs shelf storage location allocation on the warehoused goods in the corresponding storage areas according to the strategy of centralized placement of the goods in the samegroup. According to the invention, the big data platform is adopted to predict the warehousing order quantity in the predetermined period so as to carry out warehouse storage location allocation, at least the problem of unreasonable warehouse storage location allocation in the related technology is solved, and thus the order picking efficiency and the warehouse utilization rate are improved.

Owner:SHANGHAI MININGLAMP ARTIFICIAL INTELLIGENCE GRP CO LTD

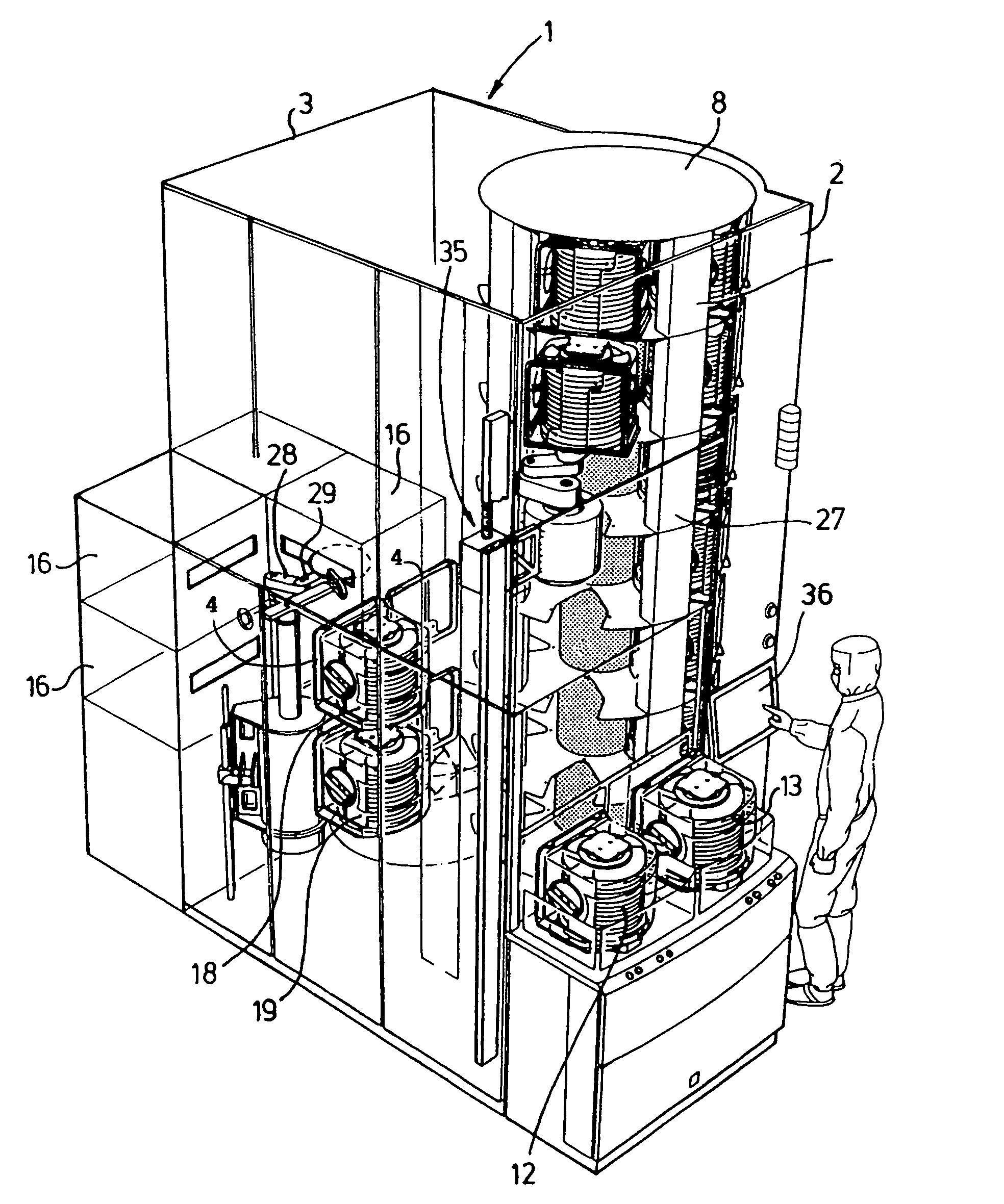

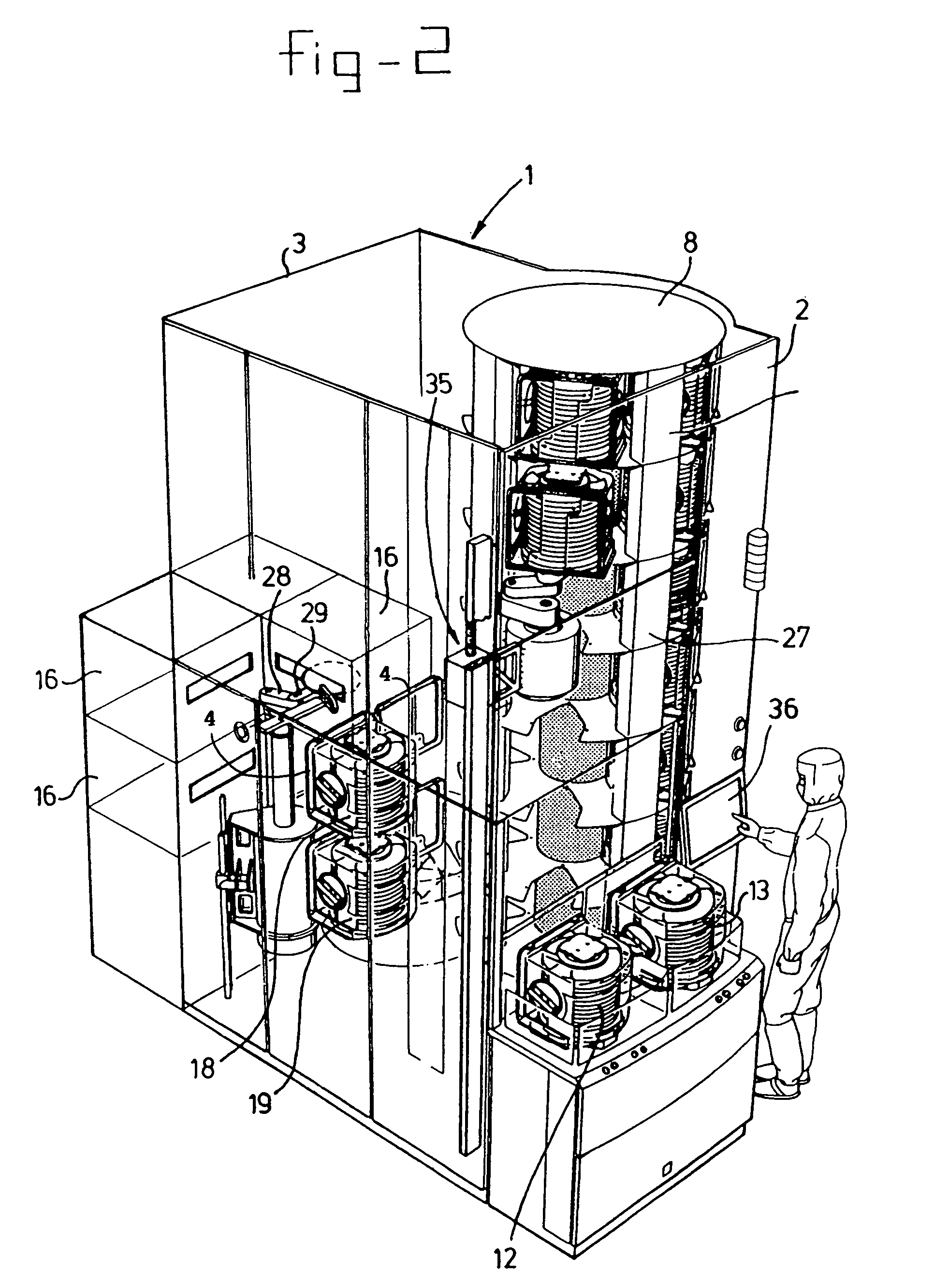

In-line type multicavity laminated parallel processing vacuum equipment and use method thereof

InactiveCN104164661AReduce the number of handlingReduce waiting timeChemical vapor deposition coatingThin membraneParallel processing

The invention relates to in-line type multicavity laminated parallel processing vacuum equipment, which includes: a sheet feed chamber, a reaction chamber and a sheet discharge chamber that are connected in order linearly. The equipment is characterized in that: a first transmission unit and a second transmission unit for substrate transmission are respectively disposed in the sheet feed chamber and the sheet discharge chamber. At least two sub-reaction chambers for preparation a needed film are vertically stacked inside the reaction chamber, and each of the sub-reaction chambers is provided with an open-close device respectively on a side facing the sheet feed chamber and on a side facing the sheet discharge chamber. The equipment can reduce the number of substrate carrying times, and improve the equipment productivity and production efficiency.

Owner:IDEAL ENERGY EQUIP (SHANGHAI) LTD

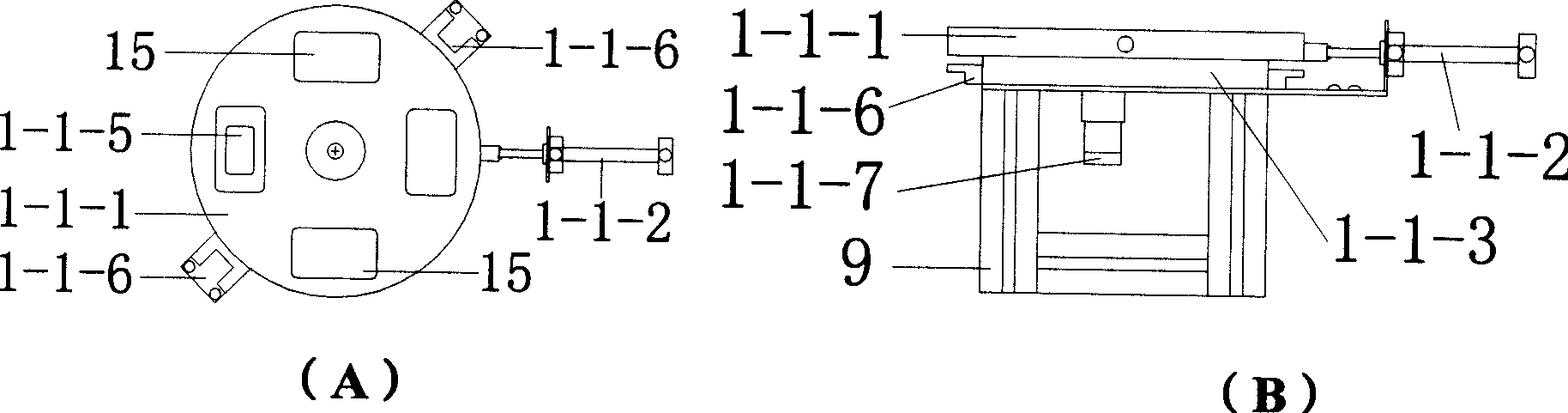

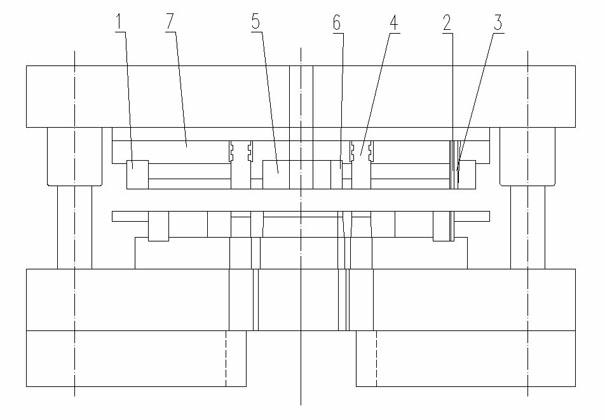

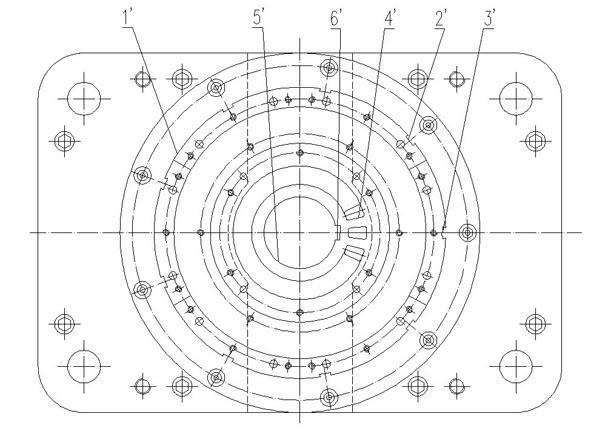

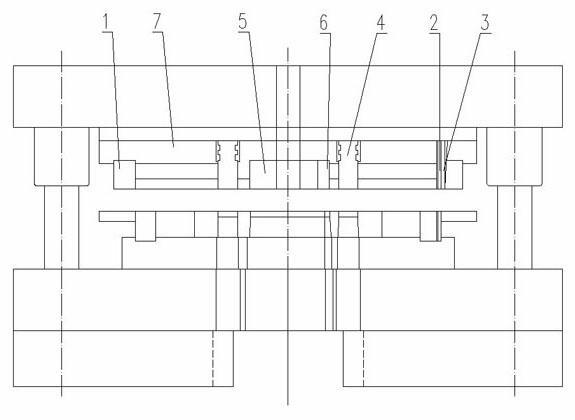

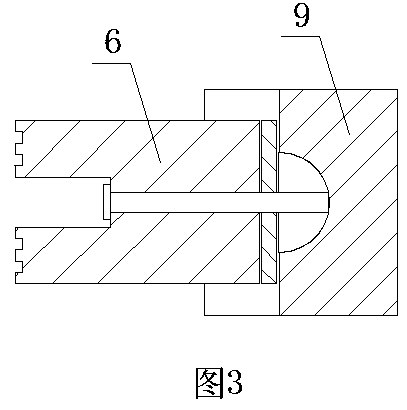

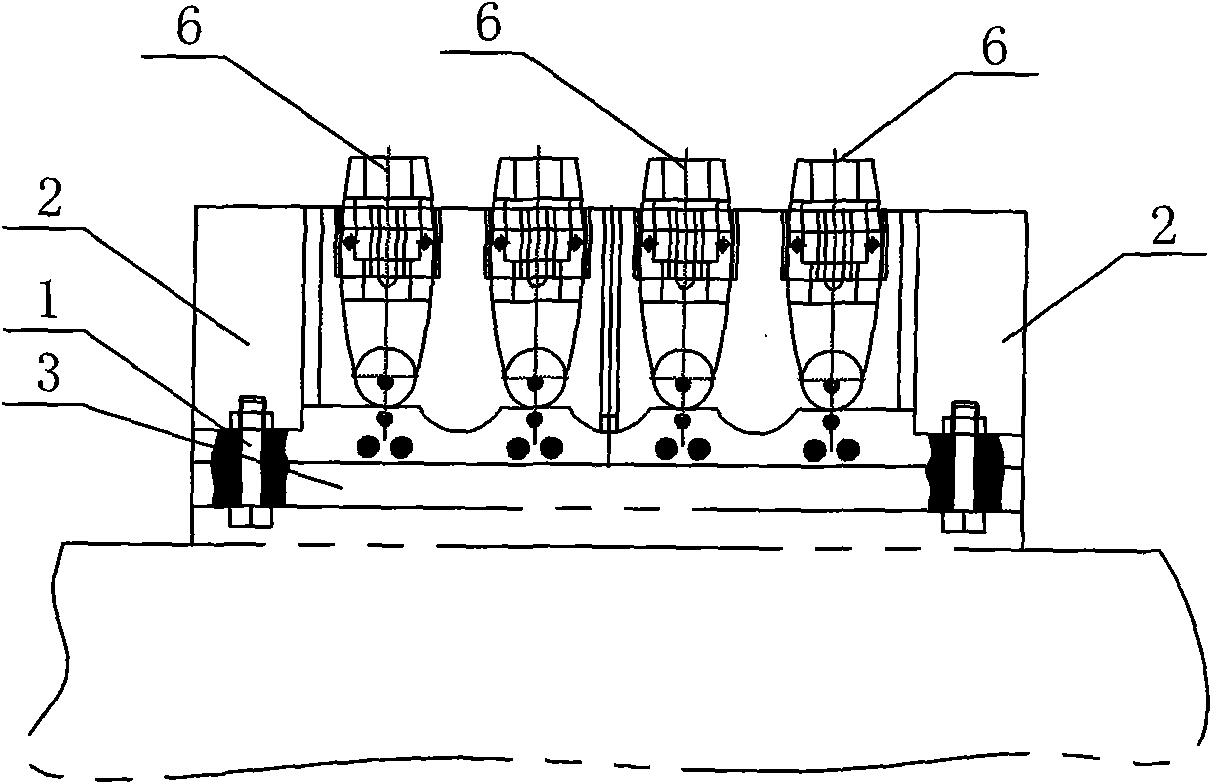

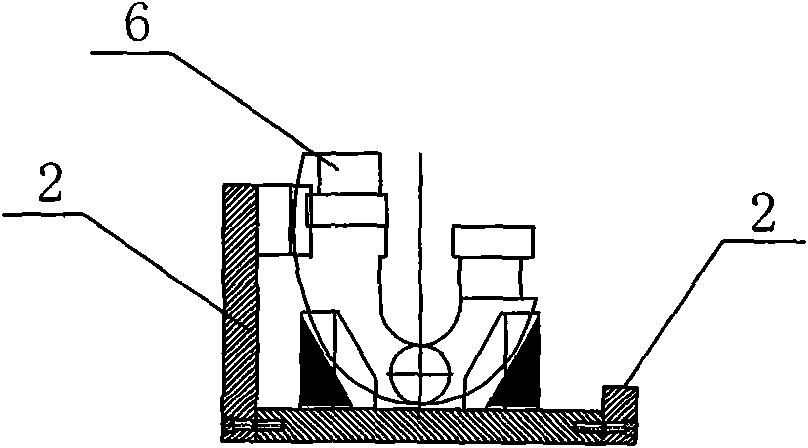

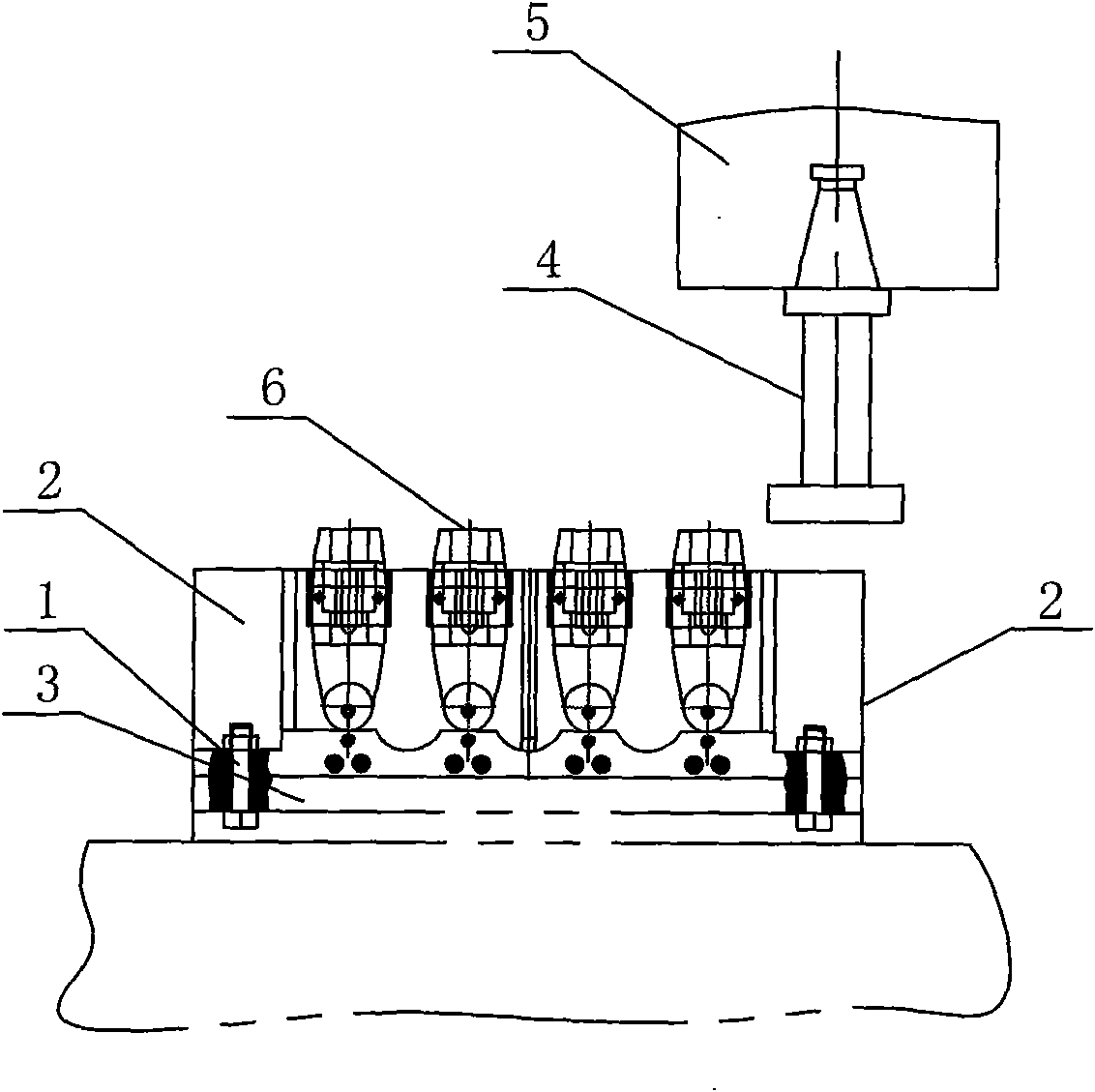

Process for blanking and stamping motor stator piece and rotor piece with air hole and key die thereof

ActiveCN102142743AAvoid uneven groovesAvoid wavinessManufacturing stator/rotor bodiesElectric machineStructural engineering

The invention provides a process for blanking and stamping a motor stator piece and a rotor piece with an air hole and a key die thereof. The process comprises the following technical stamping steps: (1) stamping a stator excircle, a rotor axle hole and an air hole again; (2) singly stamping a stator slot; and (3) singly stamping a rotor slot and separating the stator piece from the rotor piece. The key die comprises a top die part, a bottom die part and a guiding part, wherein the top die part comprises a stator excircle cavity die, a cramp slot punch, an external labeling slot punch, a rotor air hole punch, an axle hole terrace die and the upper cutting edge of a key slot punch; the upper cutting edge is fixed on an upper fixed plate; the position and the size of the upper cutting edge correspond to those of the stator excircle which needs to be stamped, the cramp slot, the external labeling edge, the rotor air hole, the axle hole and the key slot; and the bottom die part comprises a lower cutting edge corresponding to the upper cutting edge. In the process, two stamping steps are omitted, labor intensity is lowered, and stamping efficiency is improved. The phenomenon of the irregular shape of the stator sheet slot is avoided, the rotor sheet wave degree can be prevented, and stamping effect is good.

Owner:LANZHOU ELECTRIC CORP

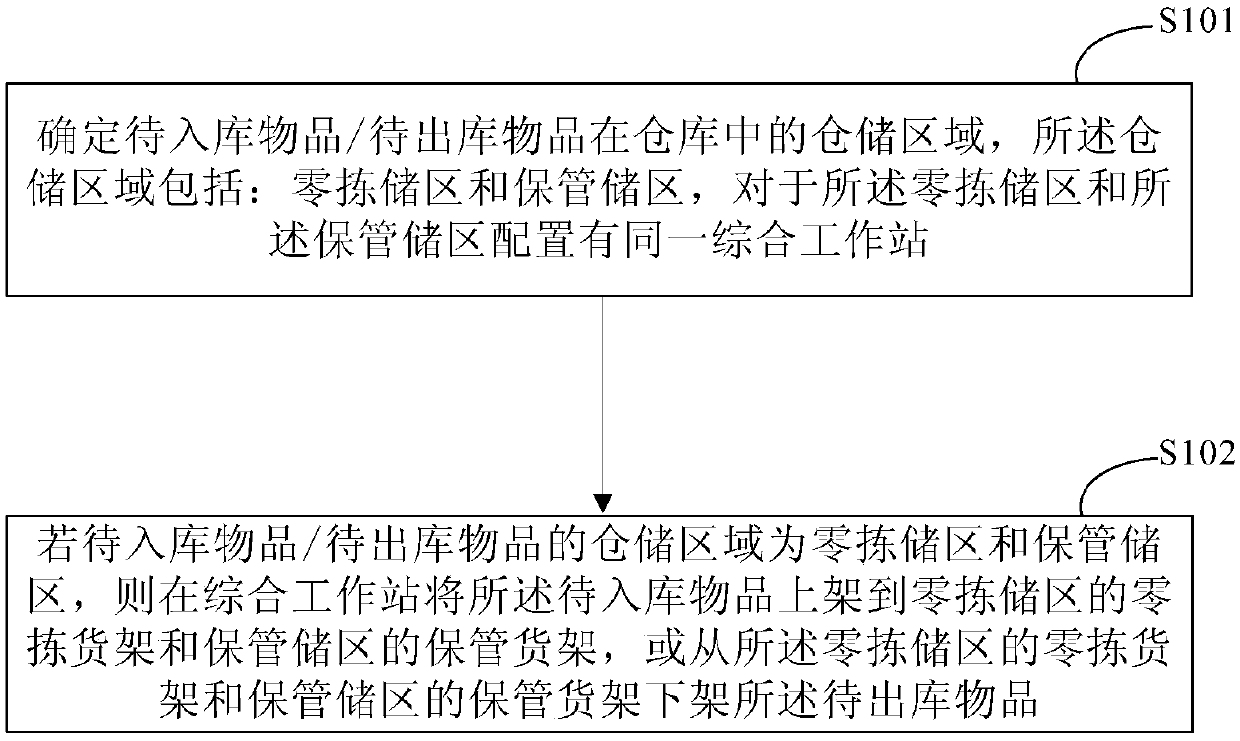

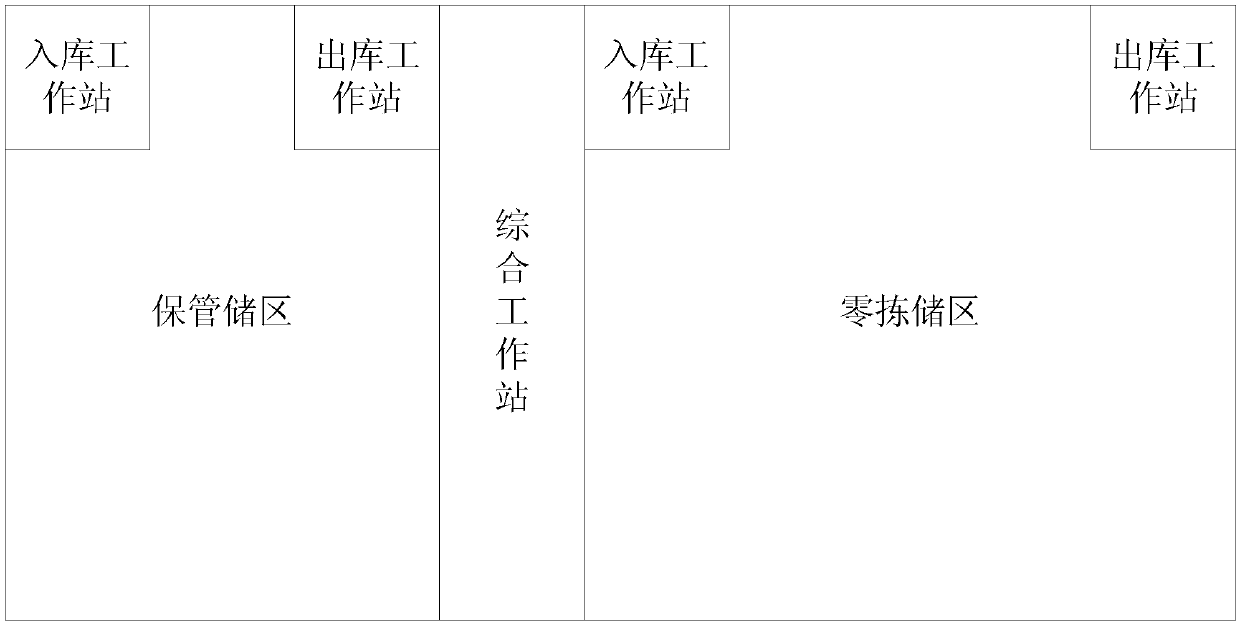

Warehouse management method and device

The invention discloses a warehouse management method and a warehouse management device, and relates to the technical field of computers. One specific embodiment of the method comprises the steps thata storage area of to-be-warehoused articles / to-be-delivered articles in a warehouse is determined, the storage area comprises a zero-sorting storage area and a storage area, and the zero-sorting storage area and the storage area are configured with the same comprehensive workstation; and if the storage areas of the to-be-warehoused articles / the to-be-warehoused articles are the zero-sorting storage area and the storage area, the to-be-warehoused articles are put on the zero-sorting shelves of the zero-sorting storage area and the storage shelves of the storage area or the to-be-warehoused articles are put off the zero-sorting shelves of the zero-sorting storage area and the storage shelves of the storage area. According to the embodiment, the article storage capacity of the warehouse canbe improved, and the article warehousing and racking efficiency and the warehouse-out sorting efficiency of the warehouse are improved.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

Cordyceps militaris plastic bag cultivation method

InactiveCN101245316AReduce the number of handlingReduce labor intensityFungiVaccinationGrowth management

The invention relates to a cultivation technology of edible medicinal fungi, in particular to a plastic bag cultivation method of the North cordyceps sinensis. The cultivation method includes the preparation of a plastic bag, the pretreatment of a culture medium, vaccination, fungi cultivation, the color change by seeing the light, grass growth management and collection; the culture medium of the cultivation method of the invention can maintain good gap and permeability, thus the hyphae on the culture medium can be grown rapidly; the method has big sunlight area, no dead ends, fast color change, fast cordyceps sinensis growth, high yield, simple operation and low labor intensity.

Owner:郑伟

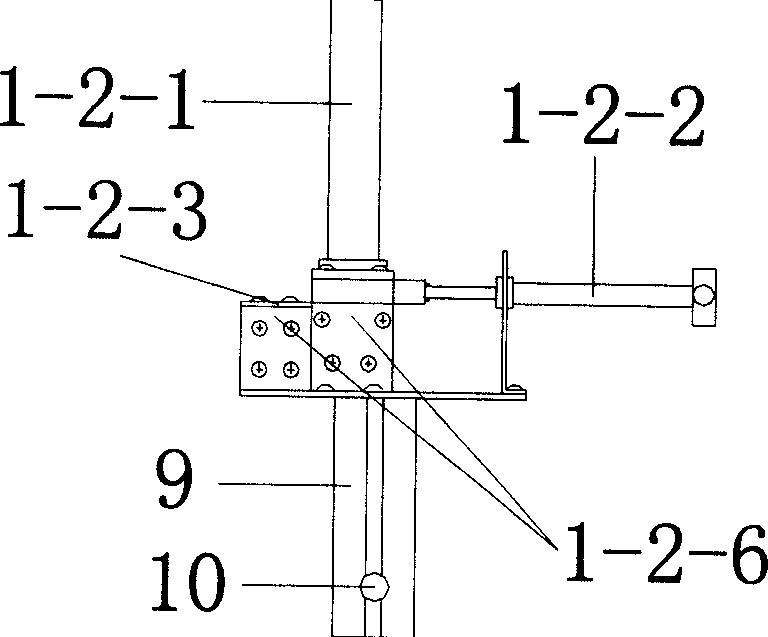

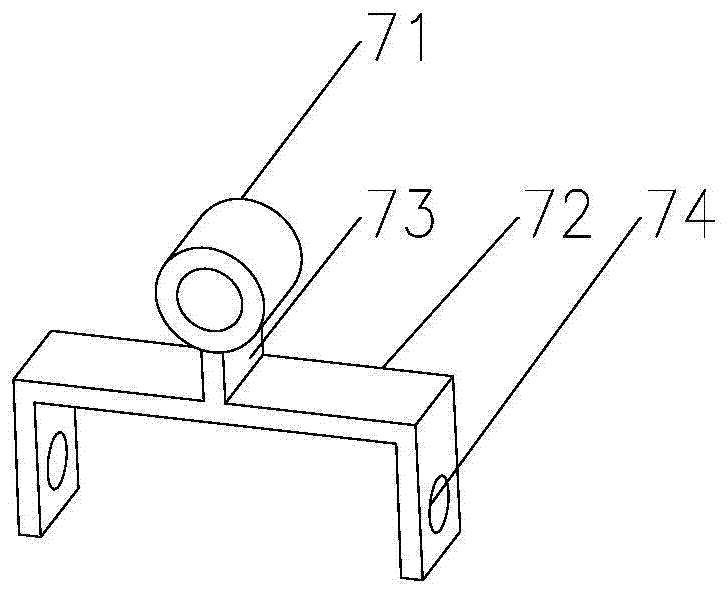

Warp knitting machine creel

InactiveCN103696117AImprove continuous working timeIncreased durabilityWarp knittingGlass fiberPolyether ether ketone

The invention relates to a warp knitting machine creel, comprising supports, wherein a plurality of groups of yarn guide plates are fixed between the supports; a plurality of yarn guide holes are formed in the yarn guide plates; cylindrical tension adjusting cross beams are arranged above cross beams; each group of yarn guide plates correspond to one tension adjusting cross beam; a tension adjuster is arranged on each tension adjusting cross beam in a sliding way and can rotate around the corresponding cross beam. According to the warp knitting machine creel, a whole glass fiber yarn drum is placed under the creel in a supporting way, the continuous working duration of a warp knitting machine is increased, the carry times of the yarn drum are greatly reduced, the labor intensity is greatly reduced, the yarn guide is stable, the production efficiency is improved, a wear-proof casing which is made of polyether-ether-ketone resin is adopted, the condition that the intensity of yarns is reduced due to the friction is prevented, the fuzzing of the yarns is effectively prevented, and the durability of the creel is improved.

Owner:JIANGSU CTC TECHN FABRICS

Method for removing photoresist and method for manufacturing mosaic structure

InactiveCN101329519ASmall bombardment capabilityAvoid damageSemiconductor/solid-state device manufacturingPhotosensitive material processingResistSemiconductor structure

The invention relates to a removing method of photosensitive resist which comprises the following steps of: providing semiconductor structure with a photosensitive resist layer, arranging the semiconductor structure into the oxygen plasma environment and removing the photosensitive resist layer by the incineration of the oxygen plasma, wherein, the generated power of an excitation source of the oxygen plasma is less than or equal to 400W; the invention also provides a method for applying the removing method of photosensitive resist to manufacture mosaic structure; the invention causes less damage to a dielectric layer of the lower layer of the photosensitive resist layer in the technique of removing the photosensitive resist.

Owner:SEMICON MFG INT (SHANGHAI) CORP

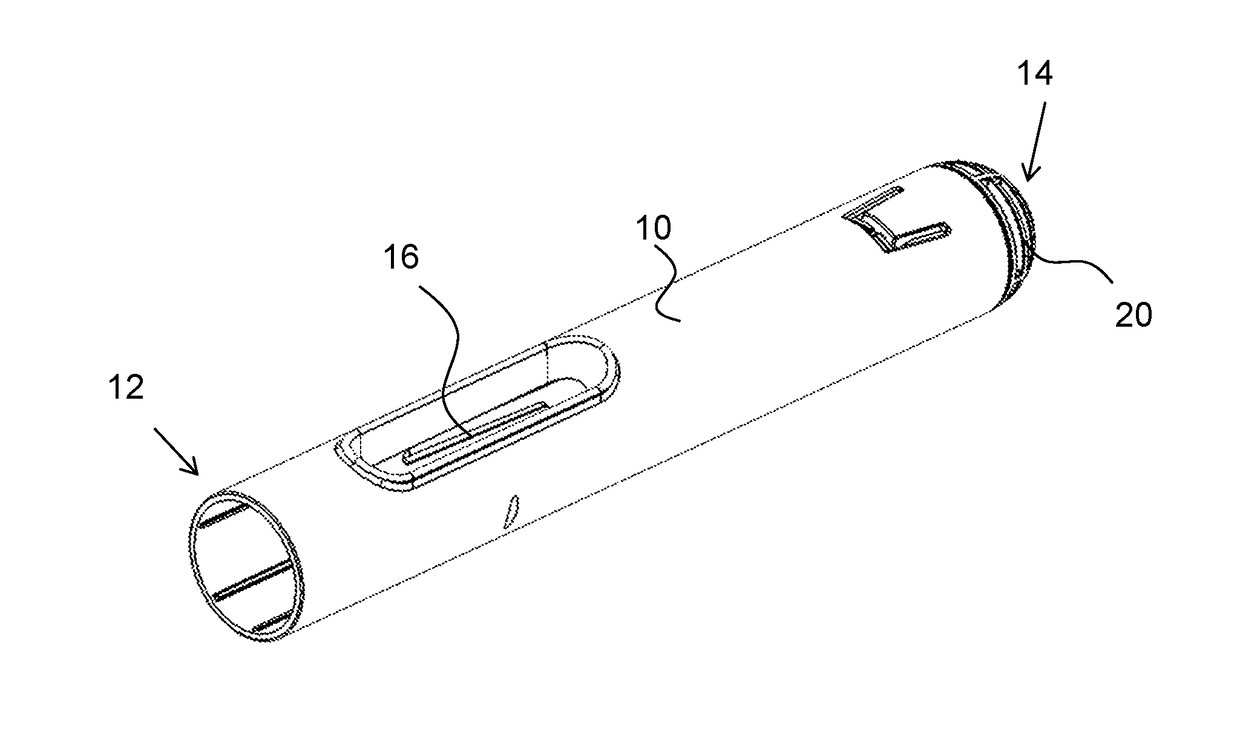

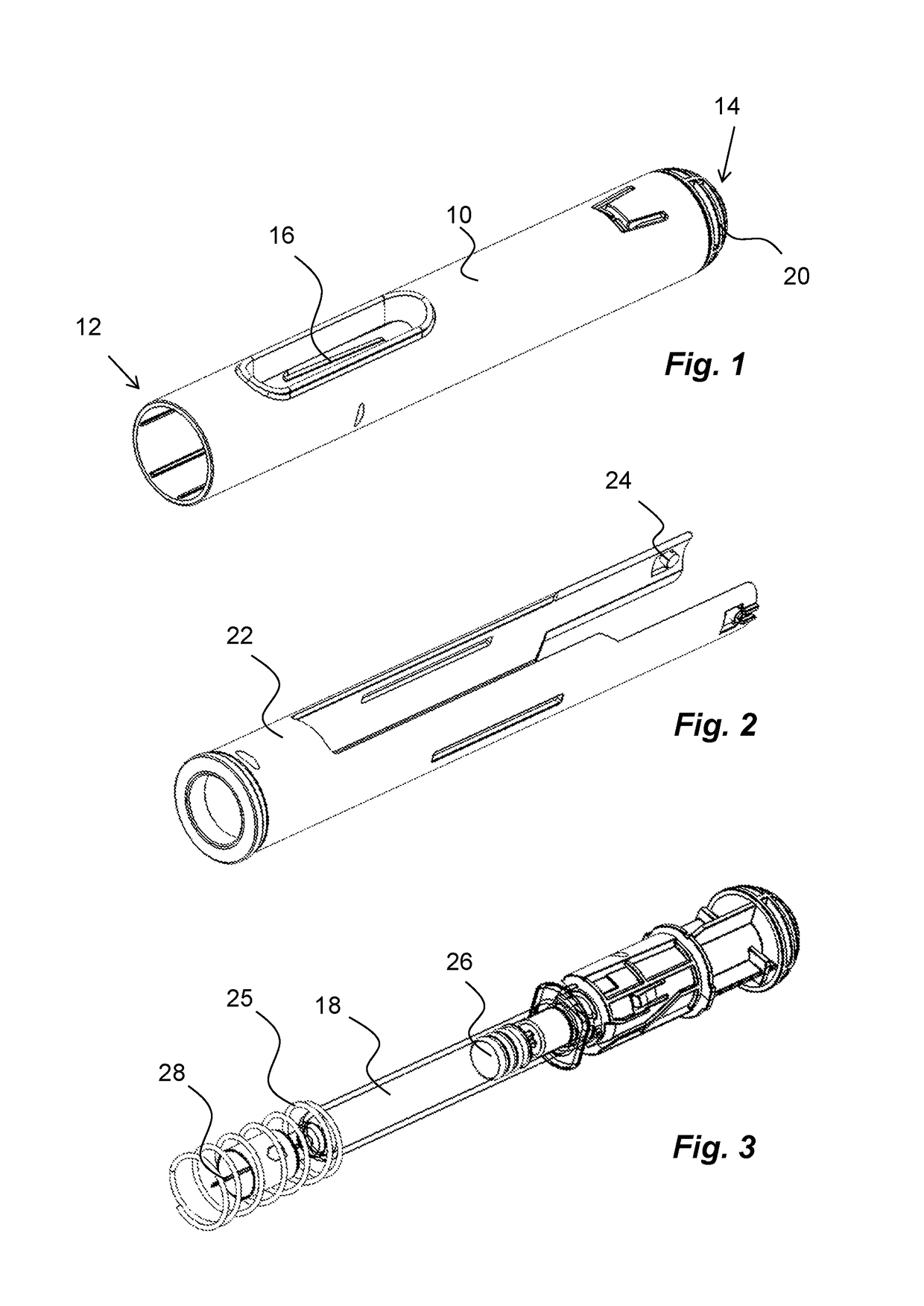

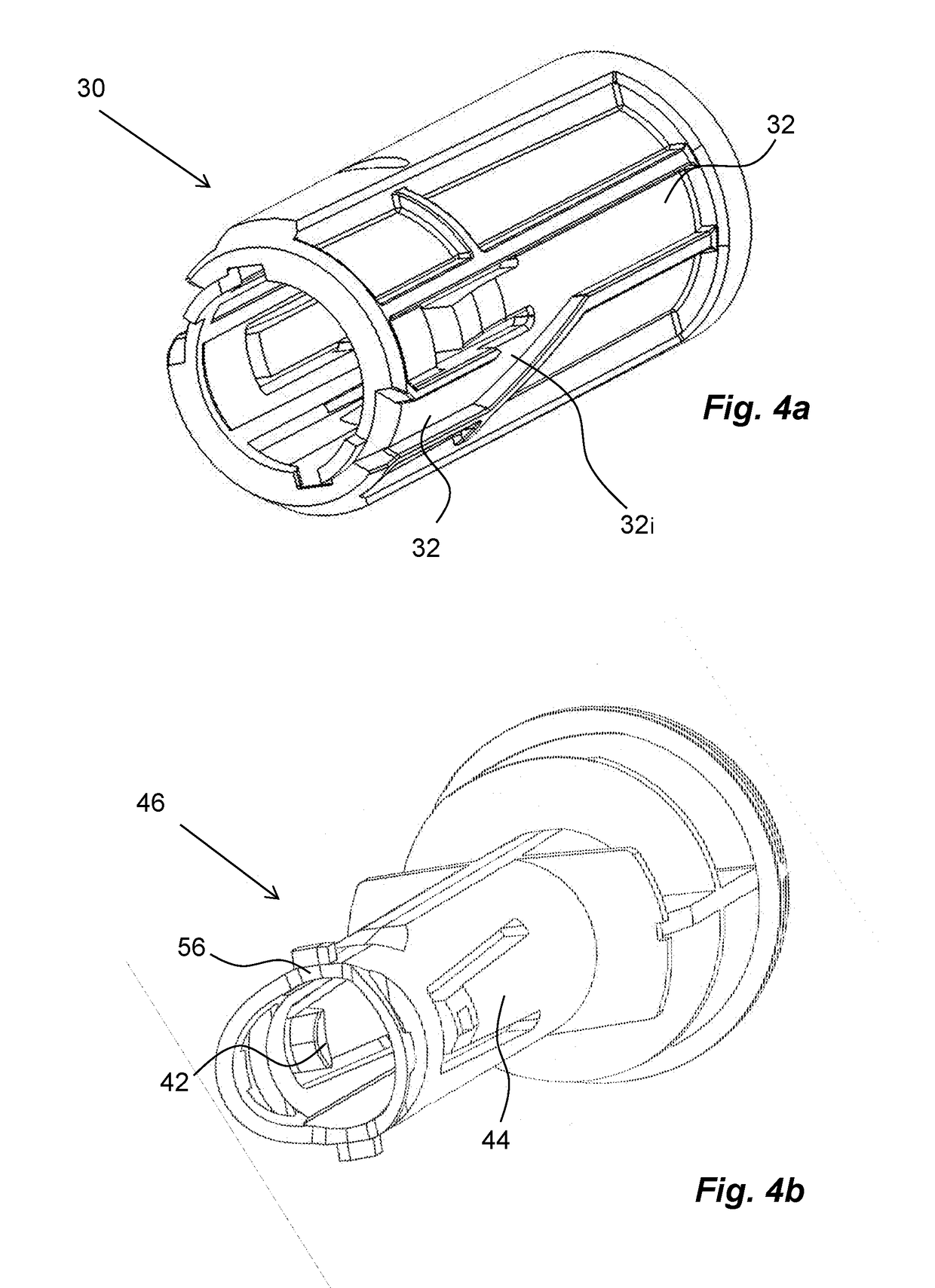

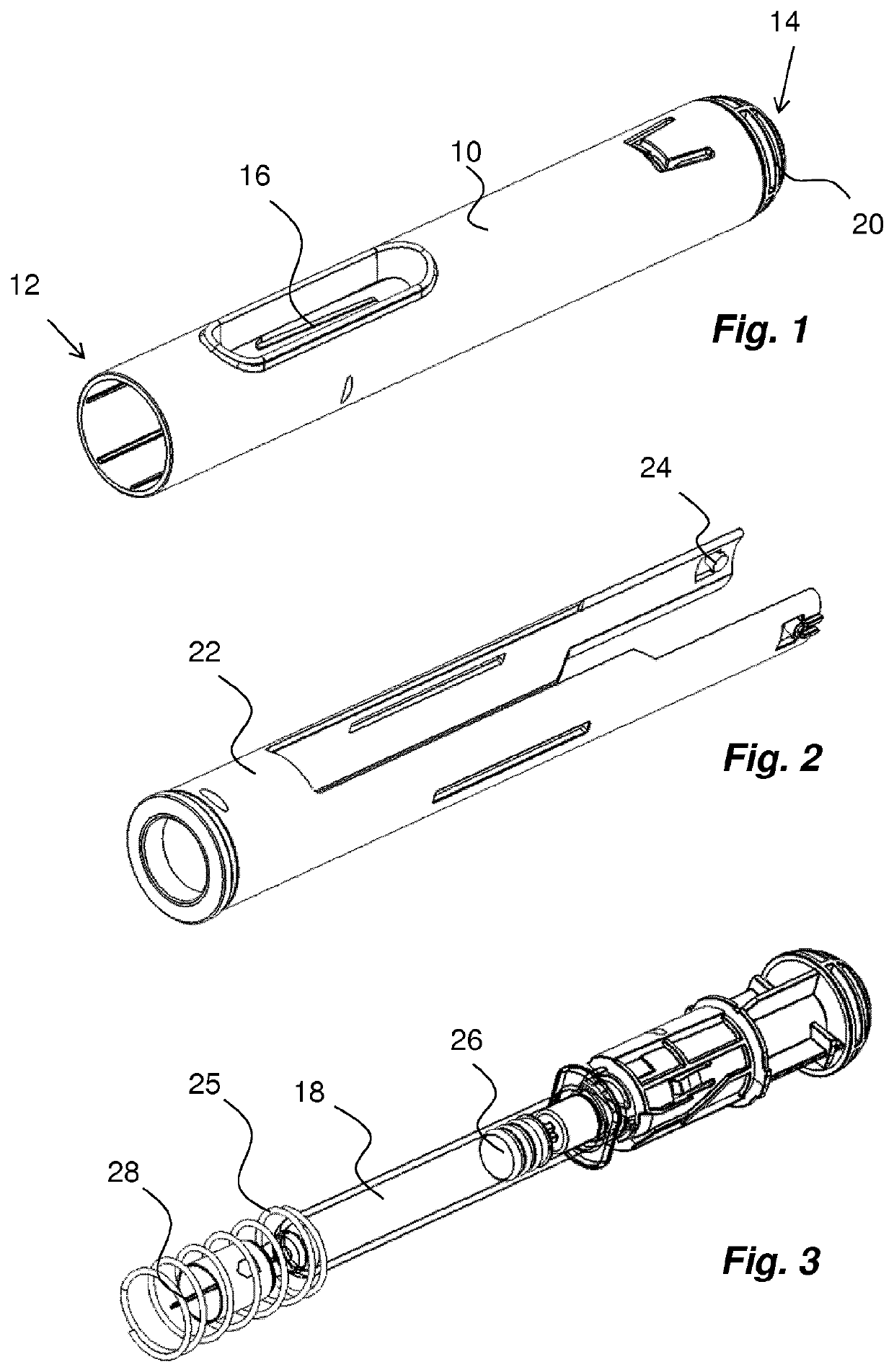

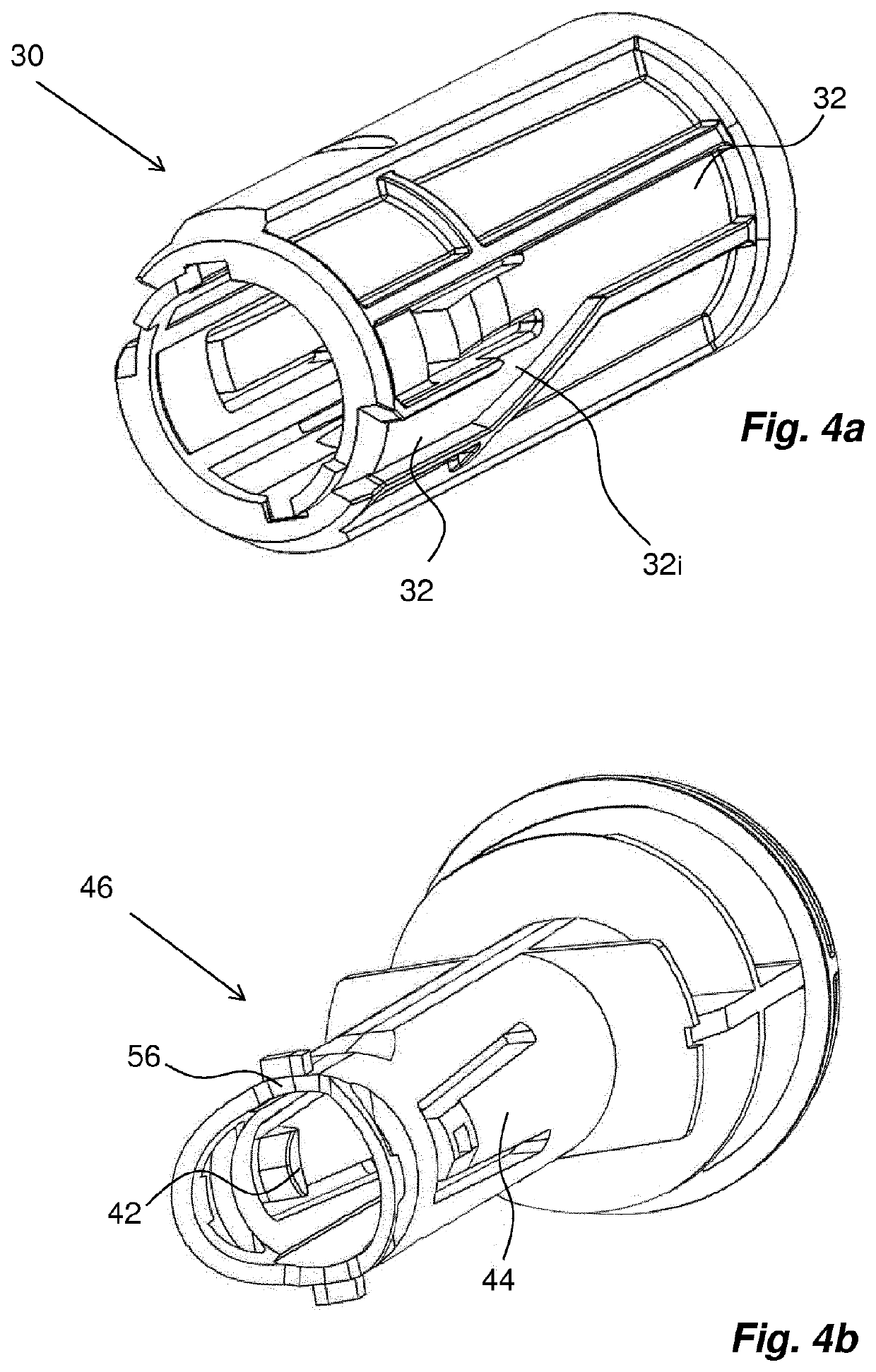

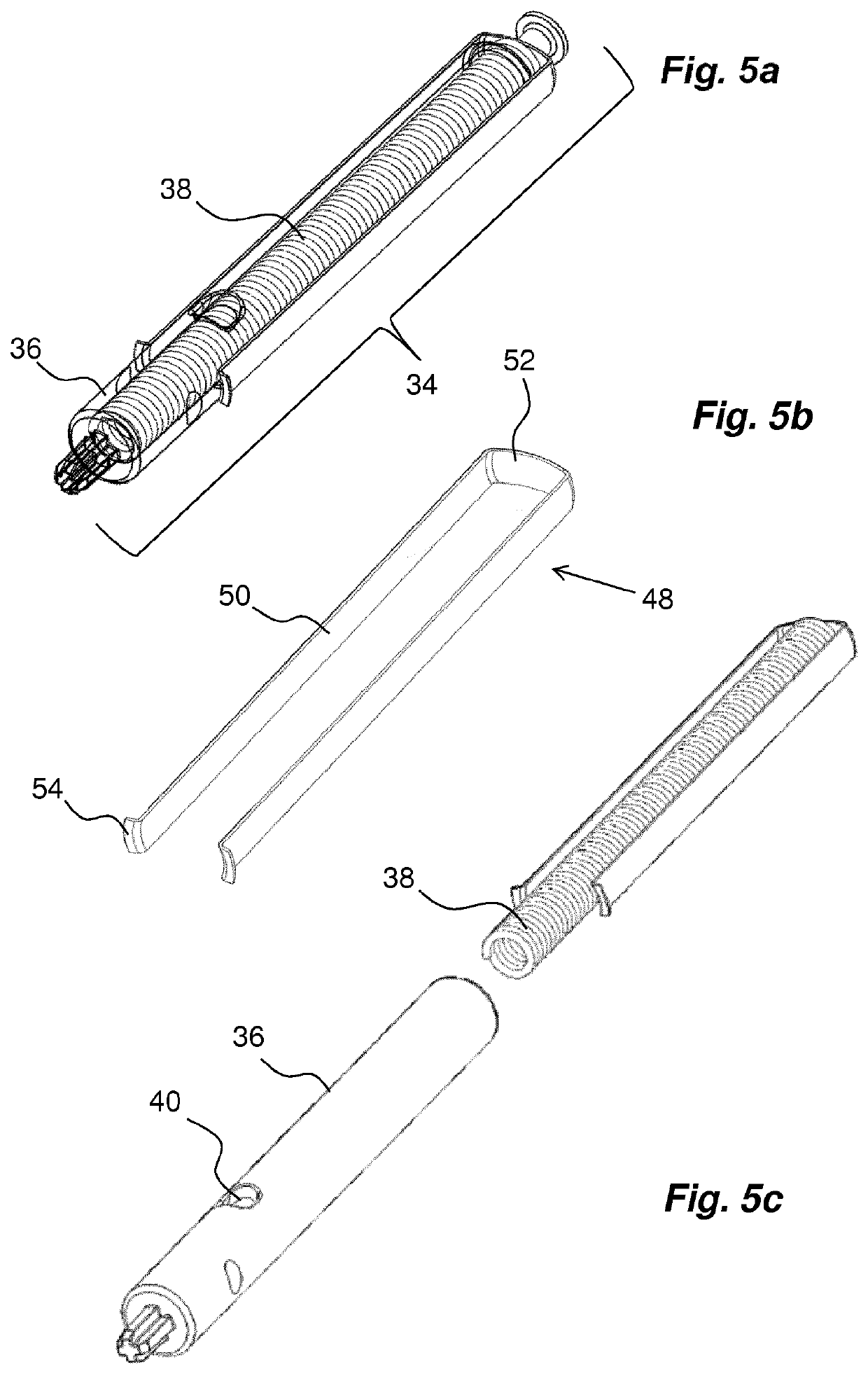

Medicament delivery device

ActiveUS20170304538A1Reduce the number of handlingReduce energy consumptionAutomatic syringesDrug and medicationsCommunication unitDose delivery

A medicament delivery device is presented having a housing that is arranged to accommodate a medicament container, a drive mechanism capable of, upon activation, act on said medicament container, a communication unit arranged in the housing, a switch operably connectable to the drive mechanism and connected to the communication unit for activating the communication unit when the switch is operated, wherein the switch is operated by the drive mechanism at the end of a dose delivery sequence.

Owner:SHL MEDICAL AG

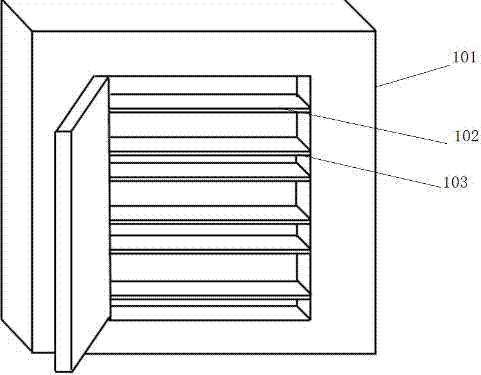

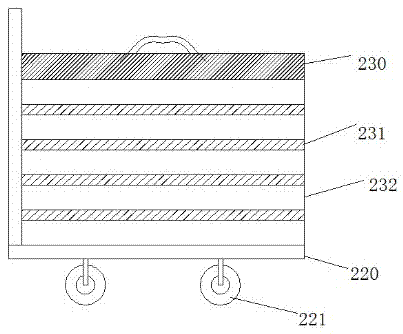

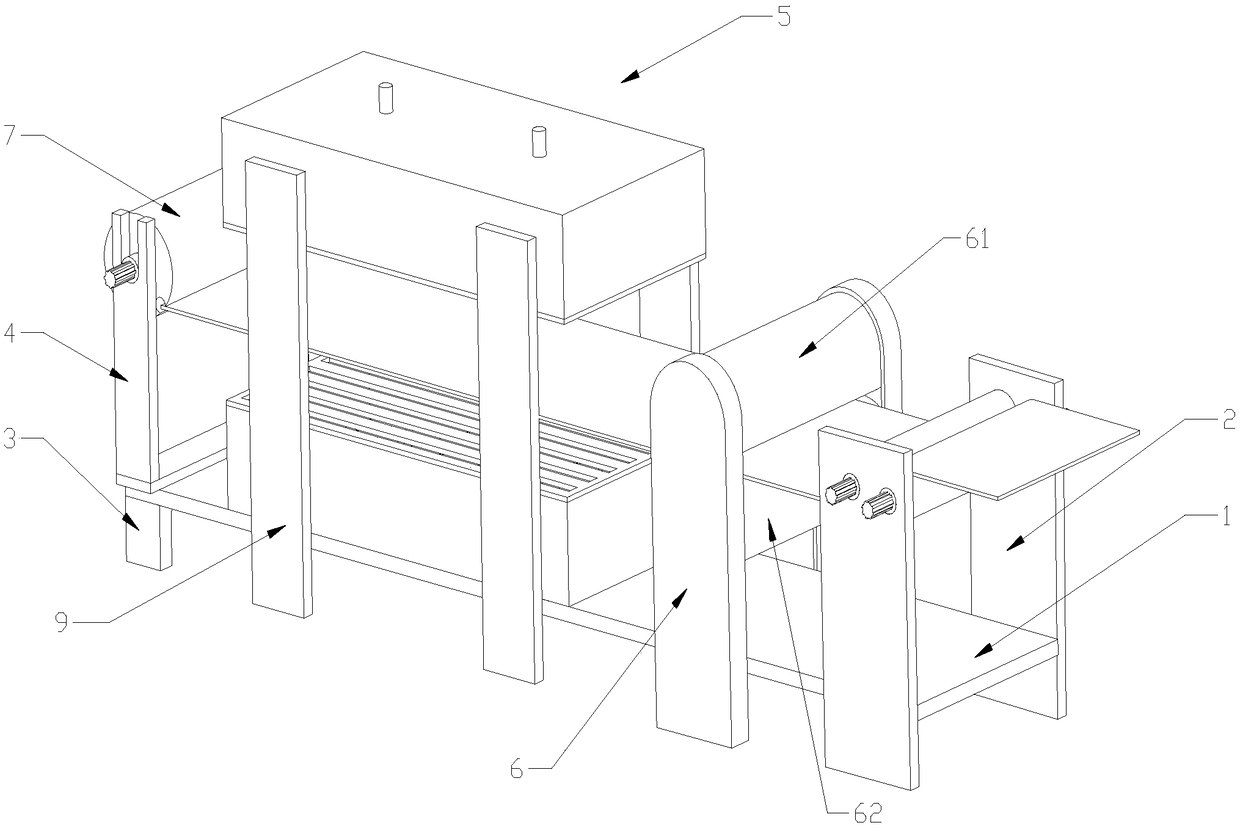

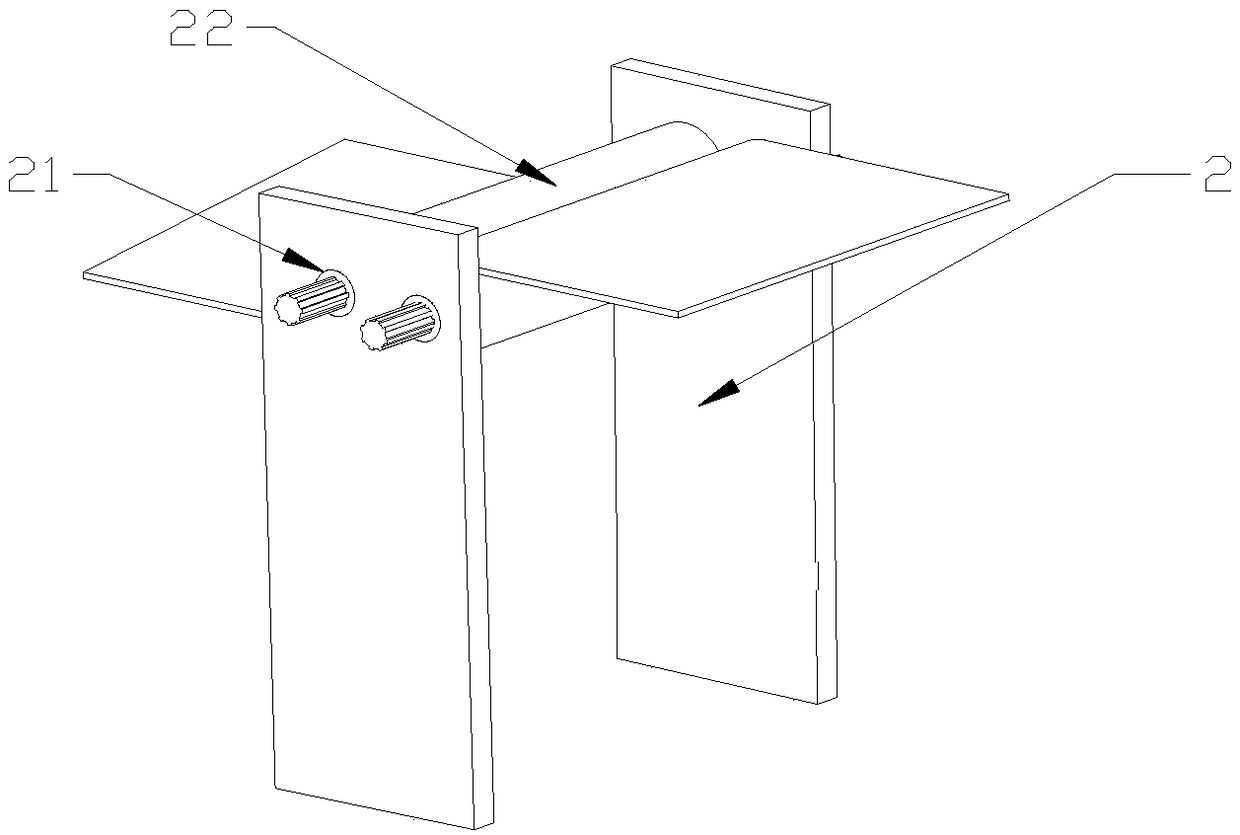

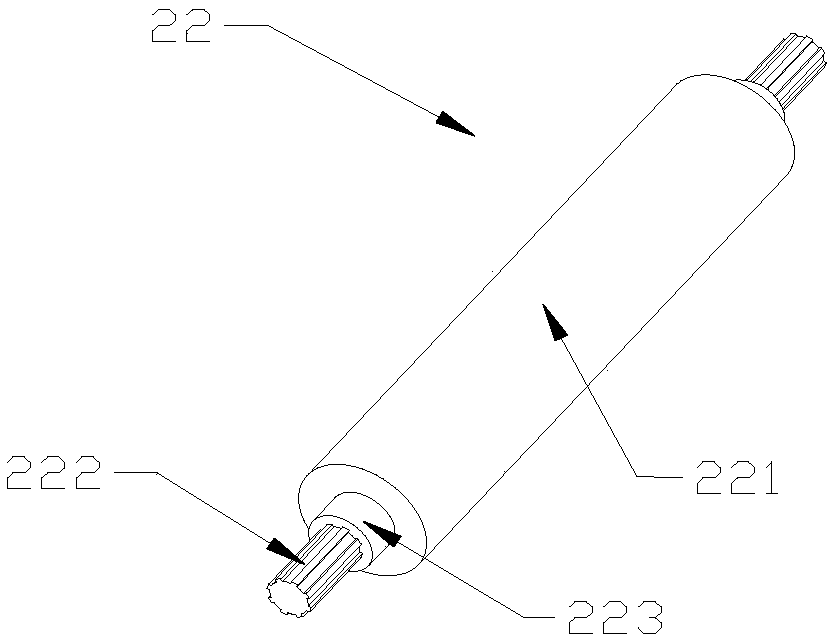

Material stacking and transferring system for sintered Nd-Fe-B formed blanks

ActiveCN107857129AReduce the number of handlingReduce weightStacking articlesStorage devicesMetallurgyMaterials science

The invention discloses a material stacking and transferring system for sintered Nd-Fe-B formed blanks. The material stacking and transferring system comprises a controller, a feeding device, a material and pot stacking device, a pot storage device and a transferring trolley. The feeding device is used for conveying the sintered Nd-Fe-B formed blanks output by a forming press into the material andpot stacking device, the pot storage device is used for storing to-be-used sintering pots, and the material and pot stacking device is used for transferring the sintering pots in the pot storage device into the material and pot stacking device, then arranging the sintering pots in sequence, stacking the sintered Nd-Fe-B formed blanks into the sintering pots in sequence and conveying the sinteringpots in which the sintered Nd-Fe-B formed blanks are stacked into the feeding trolley, and the feeding trolley is used for receiving the sintering pots in which the sintered Nd-Fe-B formed blanks arestacked and conveying the sintering pots to the position of a sintering furnace. The material stacking and transferring system has the beneficial effects that the oxidization risks are small, the transferring efficiency is high, the labor intensity is low, the labor cost is low, meanwhile, the transferring damage rate can be reduced, material waste is avoided, and environment pollution is reduced.

Owner:NINGBO YUNSHENG +2

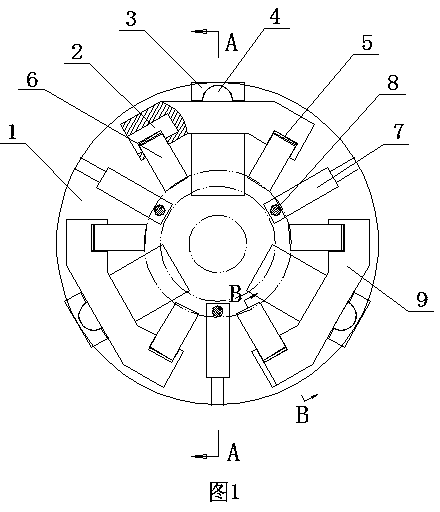

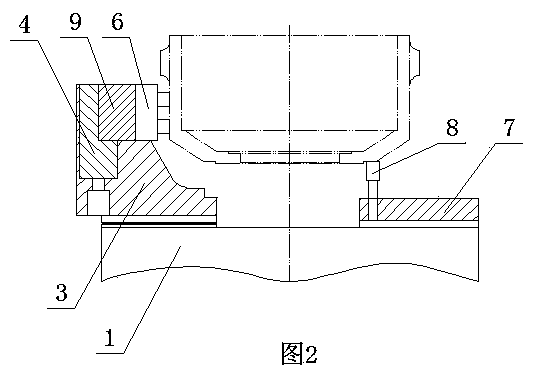

Hydraulic chuck clamp used for machining drum brake

The invention relates to a hydraulic chuck clamp used for machining a drum brake, and belongs to the technical field of clamps for machining the drum brake. The hydraulic chuck clamp is composed of a chunk body, base point blocks and automatic centering clamping bases, and the six base point blocks and the six automatic centering clamping bases are alternately installed on the chunk body. A base point screw rod is installed on every base point block; every automatic centering clamping base is composed of a substrate, a rotating beam, a beam rotating shaft, two clamping jaw rotating shafts, two gaskets and two clamping jaws, wherein the rotating beam is connected with the substrate through the bean rotating shaft, and the clamping jaws and the gaskets are installed at the two ends of the rotating beam. The hydraulic chuck clamp can automatically capture the center point of a workpiece, ensure the coaxiality and levelness of workpiece clamping, finish rough and fine turning on a braking face, reinforcing ribs, a spigot of a dust-proof baffle, an assembly spigot and the two end faces of the drum brake in a one-off mode, improve machining efficiency and save time and labor, and the production benefits are improved by 2.5 times. The problems that when the drum brake is machined in a traditional mode, people need to replace clamping planes repeatedly, time and labor are wasted, and machining accuracy can not be ensured are solved.

Owner:HUBEI JINLIN MACHINERY MFG

Machining technique of anchor chain Kenter shackle

InactiveCN101927373AReduce cumulative errorReduce processing costsMilling equipment detailsNumerical controlWorking environment

The invention relates to a machining technique of an anchor chain Kenter shackle, which comprises the following steps: connecting a tooling with a working platform of a numerical control (NC) milling machine, and connecting a molding cutter with the main shaft of the NC milling machine, wherein the fixture is provided with four workpiece mounting positions. The NC milling machine enables the main shaft to rotate to move the working platform, so that the molding cutter machines a workpiece according to the following steps: machining the surfaces A and B of each workpiece; machining the surfaces C and D of each workpiece; machining the surfaces E and F of each workpiece; and machining the surfaces G and H of each workpiece. The four workpieces are clamped and machined within one time, thereby ensuring uniform size of the workpieces; the invention reduces the number of clamping and the number of transportations by the workers, and greatly reduces the labor intensity; the eight machining surfaces of each workpiece are completed on one device, thereby lowering the machining cost of the workpieces and enhancing the machining efficiency; and the invention ensures the machining size and quality of the workpiece, reduces the remilling in the workpiece assembling process, improves the working environment of the workers and ensures the lawful rights of workers for security and health.

Owner:莱芜钢铁集团淄博锚链有限公司

Medicament delivery device

ActiveUS10512724B2Reduce the number of handlingReduce energy consumptionDrug and medicationsAutomatic syringesCommunication unitDose delivery

A medicament delivery device is presented having a housing that is arranged to accommodate a medicament container, a drive mechanism capable of, upon activation, act on said medicament container, a communication unit arranged in the housing, a switch operably connectable to the drive mechanism and connected to the communication unit for activating the communication unit when the switch is operated, wherein the switch is operated by the drive mechanism at the end of a dose delivery sequence.

Owner:SHL MEDICAL AG

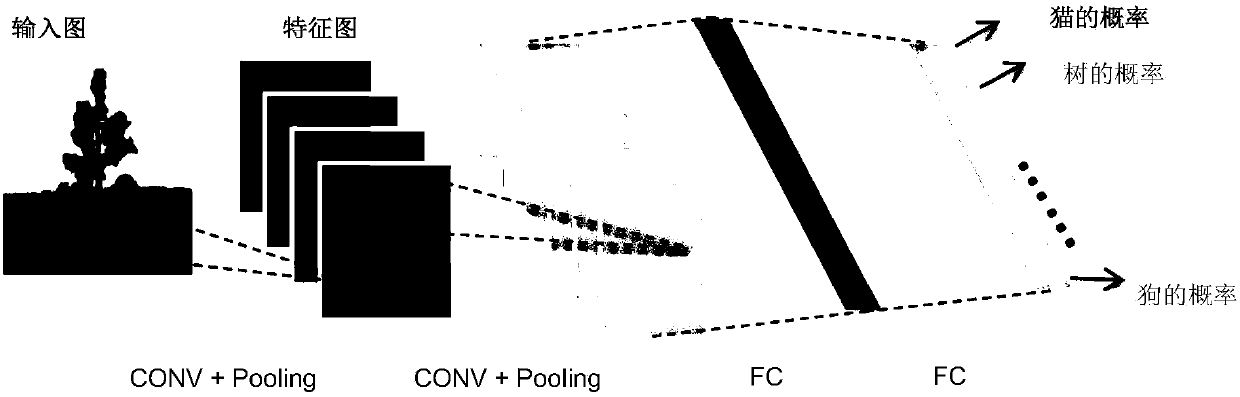

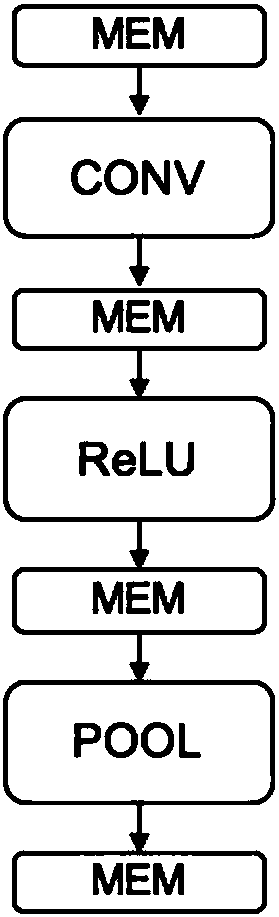

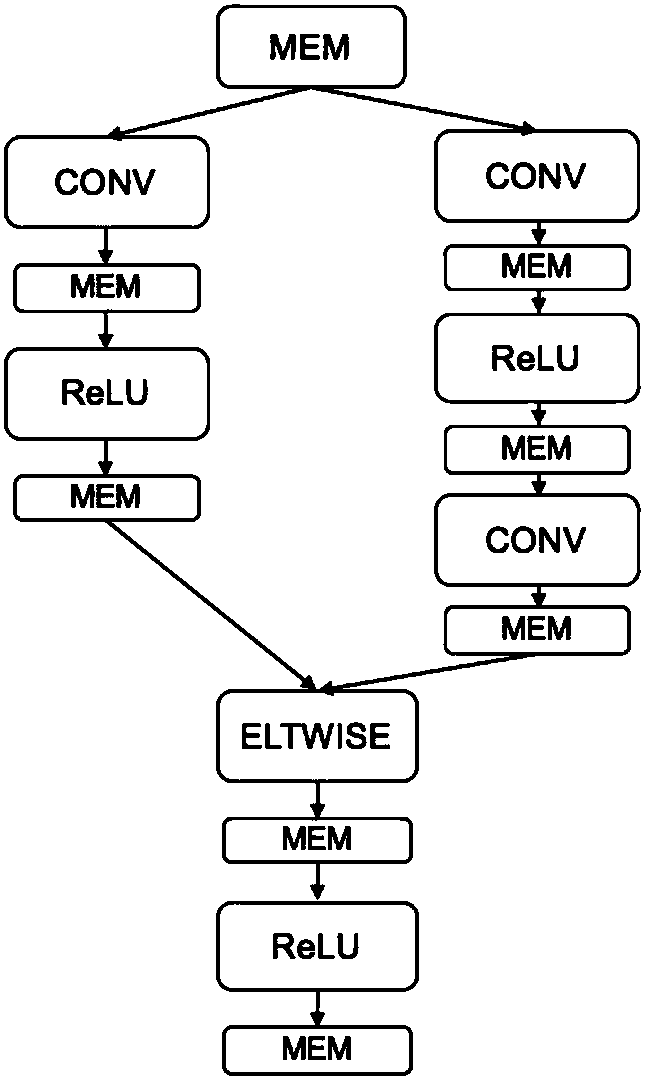

Computing platform implementation method and system for neural network

InactiveCN110321064AReduce the number of data transfersEliminate bottlenecksInput/output to record carriersNerve networkExternal storage

The invention discloses a computing platform implementation method for a neural network. The computing platform reads required data from an external memory, caches the read data and the intermediate calculation result of each operation in an on-chip cache; the method comprises the following steps: reading a first part of data of a feature map required by a first operation from the external memory,executing the first operation and at least one other operation for the first part of data, and storing an operation result for the first part of data back to the external memory; reading a second part of data of the feature map required by the first operation from the external memory, executing the reading operation from the external memory, the first operation and the at least one other operation for the second part of data, and storing the operations back to the external memory. By means of the scheme, the number of times of data carrying between off-chip storage and on-chip cache can be greatly reduced, and therefore the overall processing speed is increased.

Owner:XILINX TECH BEIJING LTD

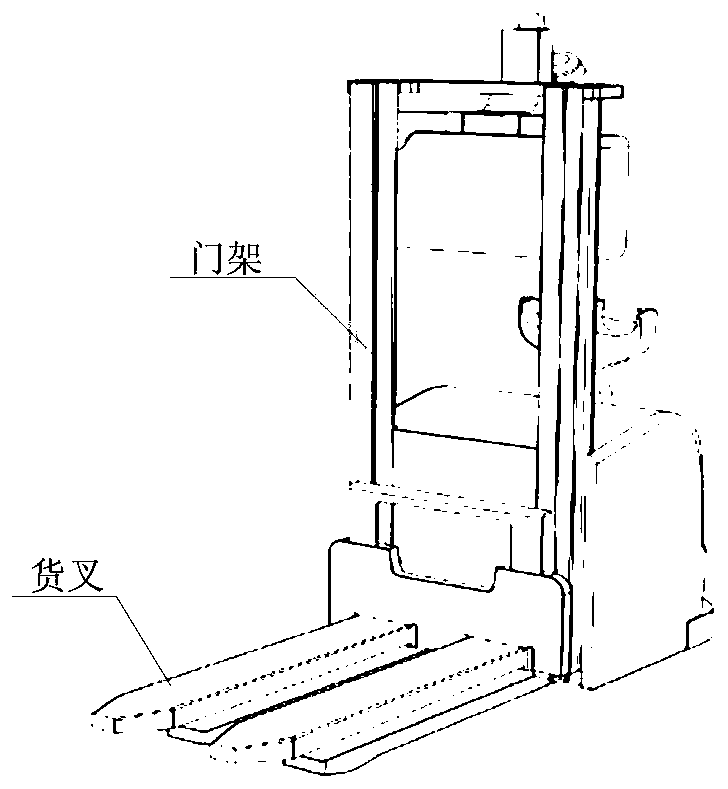

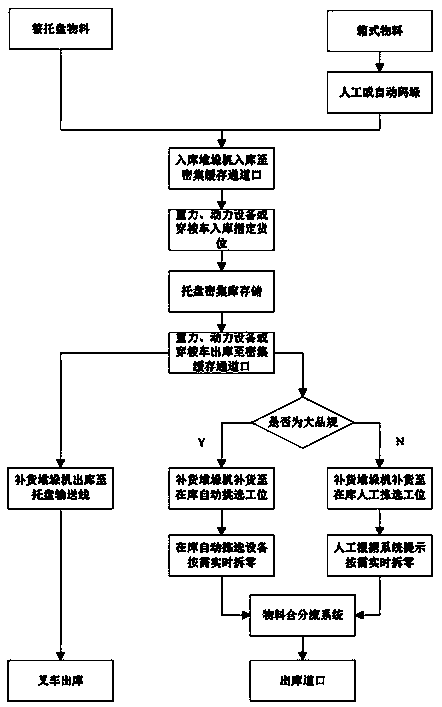

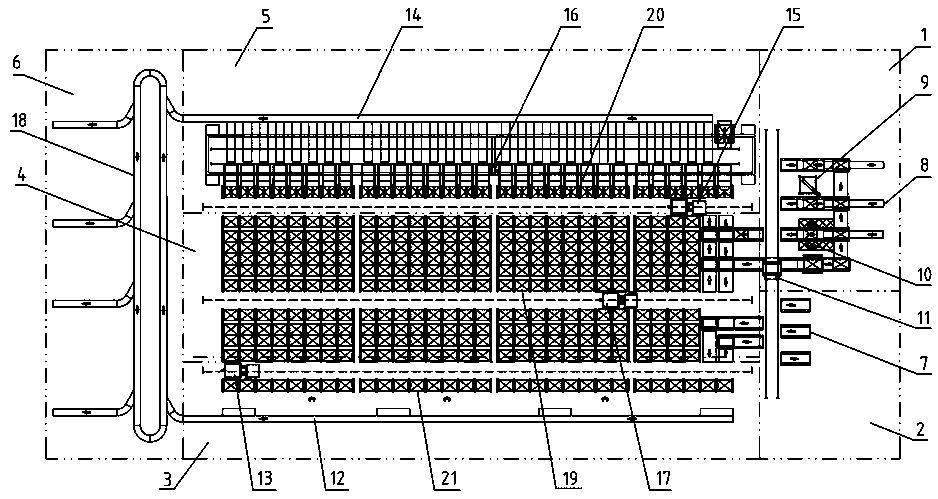

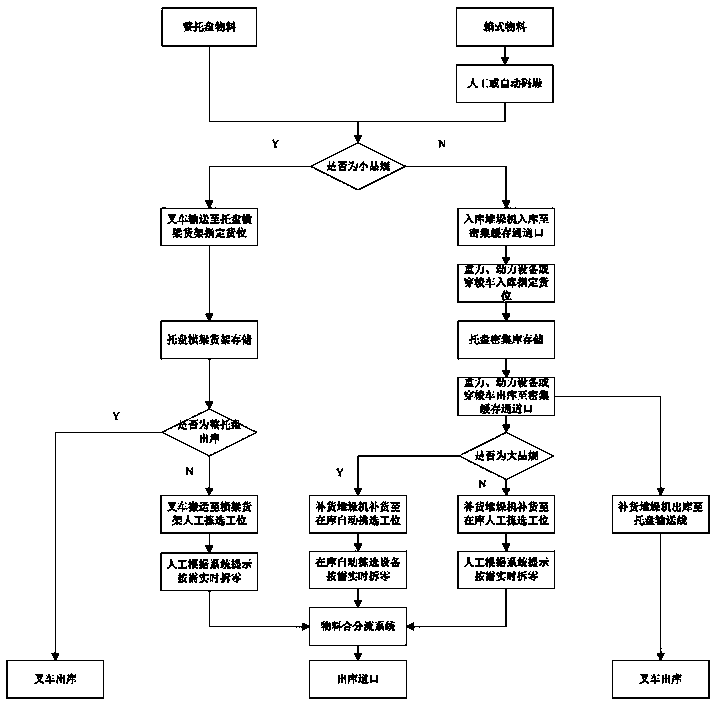

Tray dense warehouse in-warehouse sorting method and system

ActiveCN109625749ARealize direct dockingReduce the number of handlingStorage devicesEngineeringVolumetric Mass Density

The invention discloses a tray dense warehouse in-warehouse sorting method. 1, Box materials are transported to an automatic palletizing machine through a box material conveying line to be palletizedinto solid trays, and information is recorded to a WMS; 2, after whole-tray materials are subjected to code scanning, information is recorded to the WMS; 3, the WMS distributes goods positions according to the goods position distribution principle; 4, the WMS automatically arranges ex-warehouse dispatching after receiving a goods getting order of a sorting system; 5, whole tray warehouse exiting is carried out, wherein ex-warehouse trays are transported to whole-tray material in and out warehouse unit to be delivered out of the warehouse through a forklift; 6, the large-scale box materials aredelivered out of the warehouse, wherein the ex-warehouse trays are sent to an in-warehouse automatic sorting station to conduct detachment and replenishment of goods in sequence to a second materialex-warehouse conveying line; 7, small-scale box materials are delivered out of the warehouse, wherein the ex-warehouse trays are sent to a manual sorting station to conduct detachment and replenishment of the goods in sequence to an ex-warehouse conveying line; and 8, after being subjected to code scanning and being identified, the detached materials are delivered out of the warehouse through a material closing and splitting unit. The in-warehouse sorting method has the advantages of realizing direct docking of storage and detachment sorting and improving work efficiency. Meanwhile, the storage density is increased, and the workflow is optimized.

Owner:SIPPR ENG GROUP

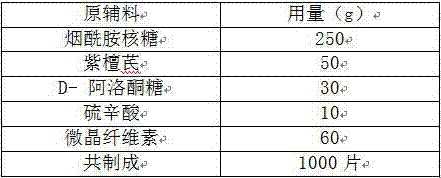

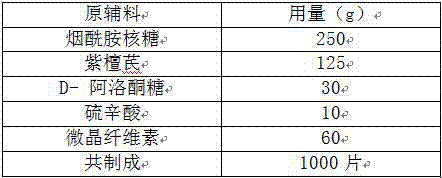

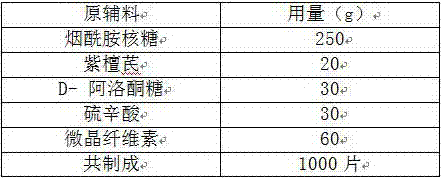

Composition for treating degenerative diseases and application of composition

InactiveCN106955290ARaw materials are easy to obtainReasonable ratioNervous disorderMetabolism disorderDegenerative DisorderPsicose

The invention relates to the technical field of medicines, foods and cosmetics and in particular relates to a composition containing nicotinamide ribose, pterostilbene, psicose and lipoic acid for treating degenerative diseases and application of the composition. The composition contains nicotinamide ribose, pterostilbene, psicose, lipoic acid and microcrystalline cellulose according to a mass ratio of (2-12.5):(1):(0.24-2.4):(0.08-1.5):(0.48-3). The composition containing the nicotinamide ribose, the pterostilbene, the psicose and the lipoic acid is first applied to treatment of the degenerative diseases, the raw materials are simple and readily available, the ratio is reasonable, the effects of reducing blood glucose and reducing blood fat are obvious, and the production cost is low.

Owner:南京顺昌医药科技有限公司

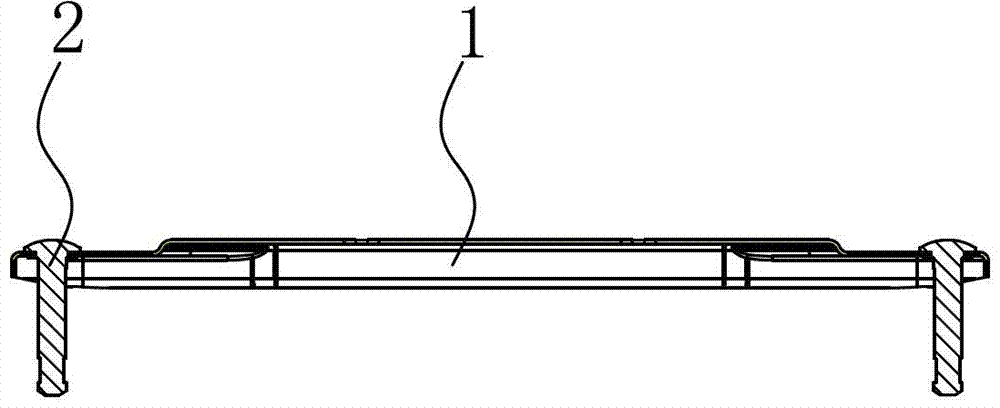

Machining technology and machining equipment for riveting base boards and caster axles of oil heaters

InactiveCN103394601AReduce the number of handlingReduce labor intensityMetal-working feeding devicesPositioning devicesAssembly lineEngineering

The invention discloses machining equipment for riveting base boards and caster axles of oil heaters. The machining equipment comprises an automatic riveting machine, a vibration disc and an automatic loading machine. The vibration disc is used for assembling caster axles and a base board body to form a base board combination, and the automatic loading machine is used for conveying the base board combination to the automatic riveting machine and penetrates the automatic riveting machine and the vibration disc. The machining equipment for riveting the base boards and the caster axles of the oil heaters has the advantages that the base board combination can be assembled, automatically loaded, riveted and unloaded under the matched actions of the vibration disc, the automatic loading machine and the automatic riveting machine, only the caster axles need to be placed into the vibration disc, and the base board body is placed into the automatic loading machine, so that the base board combination can be assembled, automatically loaded, riveted and unloaded without being repeatedly carried, the base board combination carrying frequency and the labor input are reduced, an assembly line is shortened, the production efficiency is improved for products, the yield of the products is increased, the labor intensity of workers is reduced, and the production cost is lowered.

Owner:NINGBO SINGFUN ELECTRIC APPLIANCE

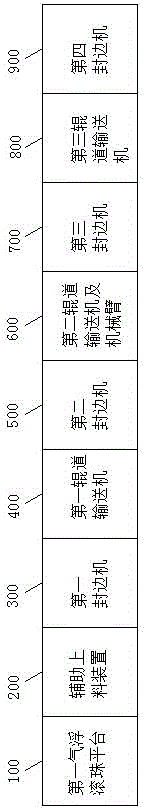

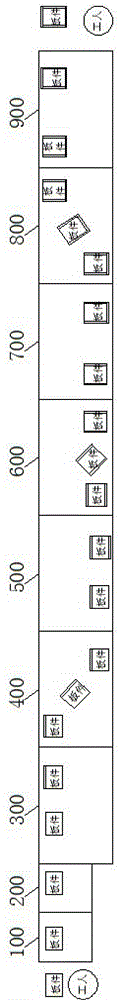

Novel continuous edge sealing system for kitchen cabinet plates and continuous edge sealing method for novel continuous edge sealing system

ActiveCN105479584AReduce collision damage rateReduce labor intensityWood working apparatusDomestic articlesEngineeringUltimate tensile strength

The invention relates to a novel continuous edge sealing system for kitchen cabinet plates and a continuous edge sealing method for the novel continuous edge sealing system. The novel continuous edge sealing system comprises a first gas-flotation rolling ball platform, an auxiliary loading device, a first edge sealer, a first roller conveyor, a second edge sealer, a second roller conveyor, a third edge sealer, a third roller conveyor and a fourth edge sealer which are sequentially arranged; a mechanical arm used for regulating a placement direction of plates is arranged above the second roller conveyor; the third edge sealer and the third edge sealer are positioned at the same side; and the second edge sealer and the fourth edge sealer are positioned at the other side opposite to the first edge sealer. According to the novel continuous edge sealing system for kitchen cabinet plates and the continuous edge sealing method for the novel continuous edge sealing system, the defects in the prior art are solved, continuous edge sealing for four ends of the same kitchen cabinet plate are realized, a collision damage rate of plates is reduced, labor intensity and production cost are reduced, and the edge sealing efficiency is improved.

Owner:合肥志邦家居有限公司

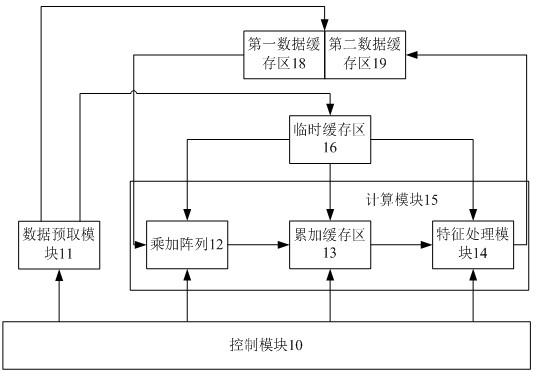

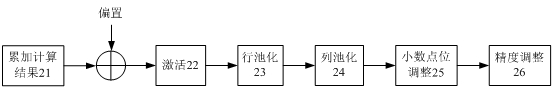

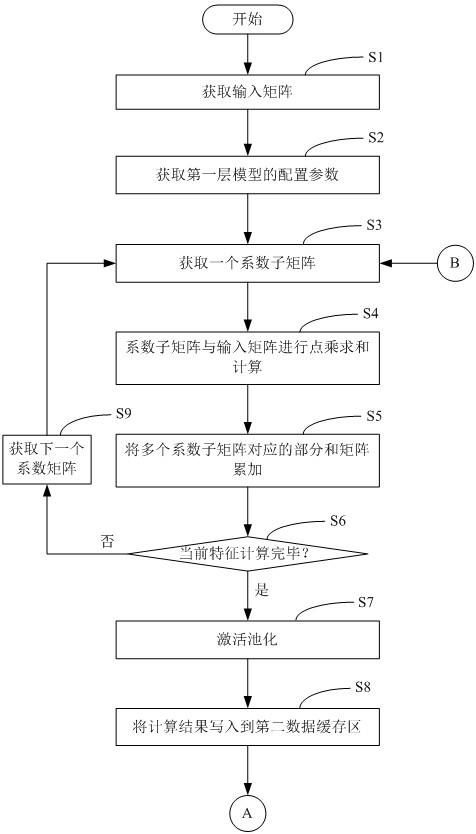

Acceleration calculation method of neural network, accelerator and computer readable storage medium

ActiveCN113947200AReduce the number of handlingImprove energy consumption ratioDigital data information retrievalDigital data processing detailsAlgorithmTheoretical computer science

The invention provides an acceleration calculation method of a neural network, an accelerator and a computer readable storage medium. The method comprises the following steps: storing an input matrix in a first data cache region; acquiring a coefficient matrix, decomposing the coefficient matrix into a plurality of coefficient sub-matrixes with a preset size, sliding the coefficient sub-matrixes relative to an input matrix at a preset step length, and performing point multiplication summation calculation on the coefficient sub-matrixes and the input matrix by applying at least one processing unit of a multiply-add array every time the coefficient sub-matrixes slide; obtaining a part and a matrix corresponding to each coefficient sub-matrix; and carrying out accumulation calculation on the corresponding parts of the plurality of coefficient sub-matrixes and the matrix to obtain an accumulation calculation result, carrying out feature calculation according to the accumulation calculation result, and storing a calculation result of the one-layer model in a second data cache region. The invention further provides a neural network accelerator for implementing the method and a computer readable storage medium. The method can reduce the number of data carrying times during neural network calculation, and improves the energy consumption ratio.

Owner:ZHUHAI SPACETOUCH LTD

PCB correction method and correction device

ActiveCN103249251AIncrease productivityReduce the number of handlingPrinted circuit manufactureHeat exchange apparatusProcess engineeringElectrical and Electronics engineering

The invention discloses a PCB correction method which comprises the steps as follows: a, stacking a plurality of pieces of PCBs into PCB groups, and stacking the PCB groups into a pile, wherein a heat transmission component is placed between every two PCB groups; b, applying pressure to the top of the whole pile of stacked PCB groups and heating for roasting; and c, performing cold pressing on the pile of PCBs. The invention further discloses a PCB correction device which comprises a roaster, and a carrier used for stacking and placing PCBs to be corrected; and the PCB correction device is characterized in that the carrier can be arranged in the roaster in an in-out manner, and is provided with a pressurizing component capable of applying pressure to the whole pile of PCBs simultaneously, and heat transmission components. According to the invention, pressure is applied to the top of the whole pile after the plurality of groups of PCBs to be corrected are stacked into the whole pile, so that the pile of PCBs can be corrected simultaneously, and production efficiency is improved; and compared with the traditional method, the PCB correction method and device for correcting the PCBs, disclosed by the invention, have the advantage that, double-area products can be processed every time.

Owner:南通胜宏科技有限公司

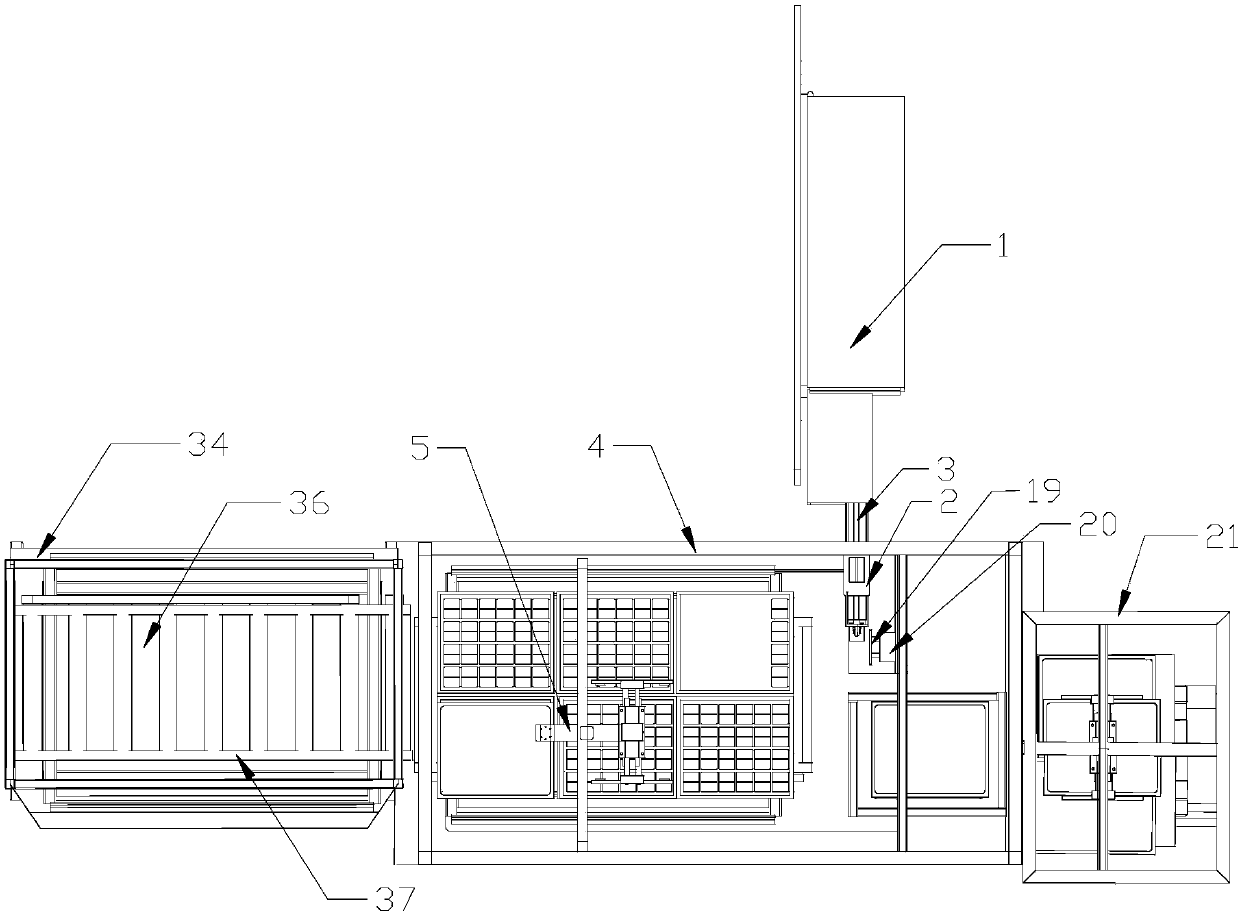

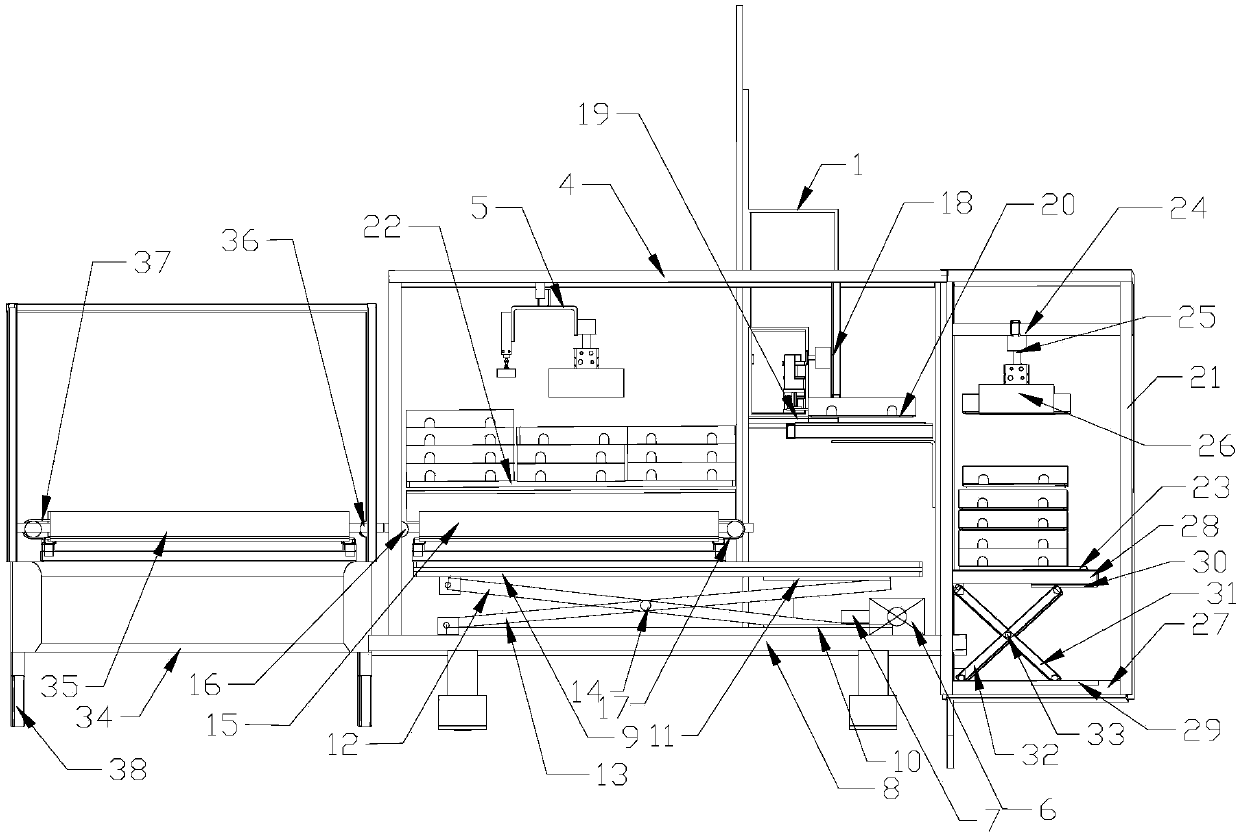

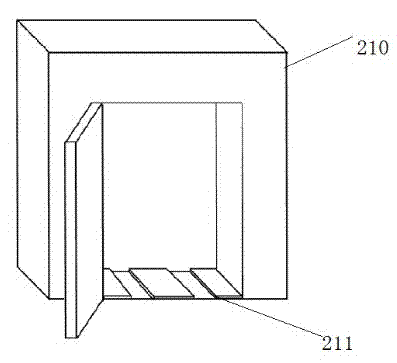

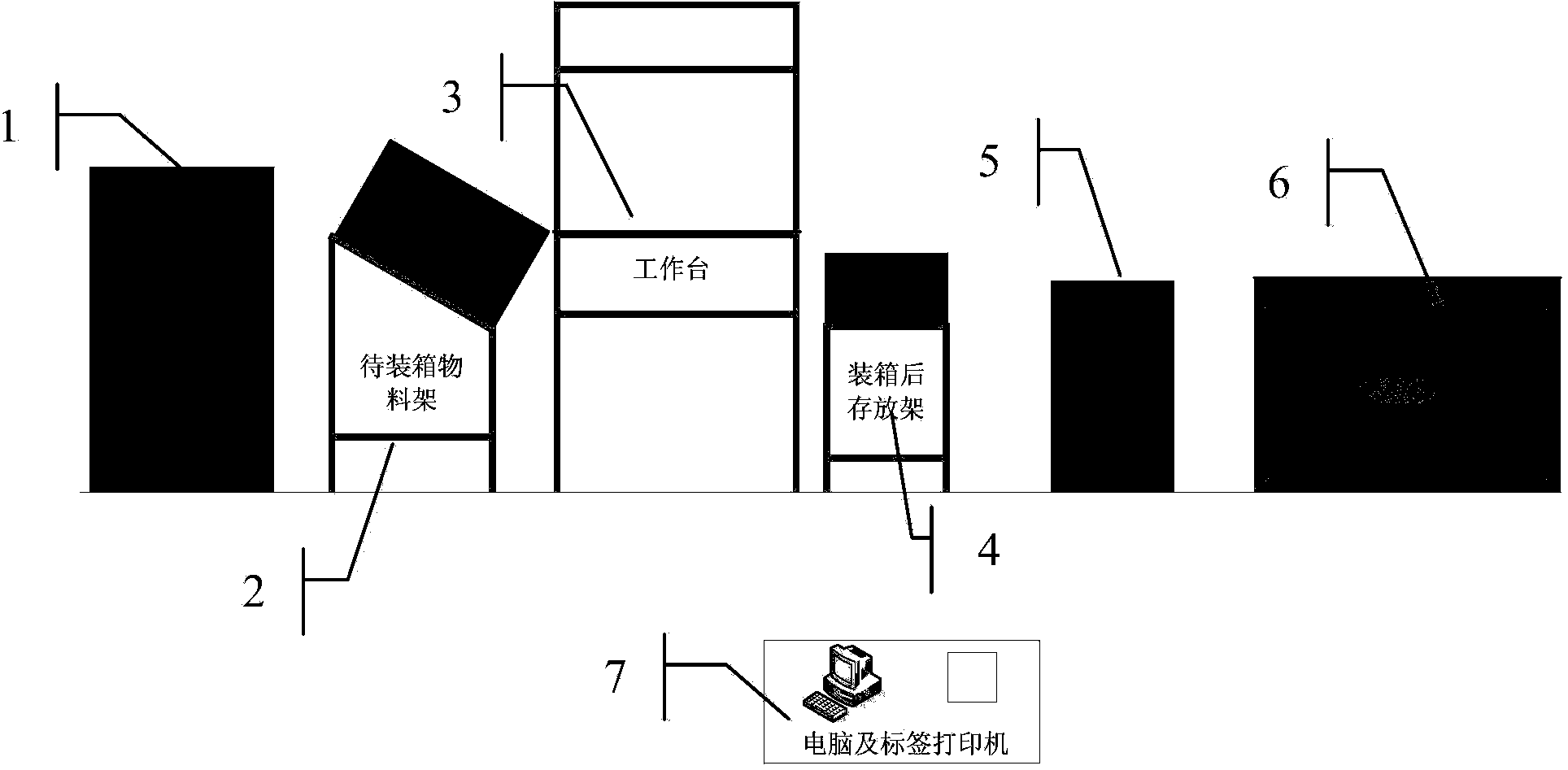

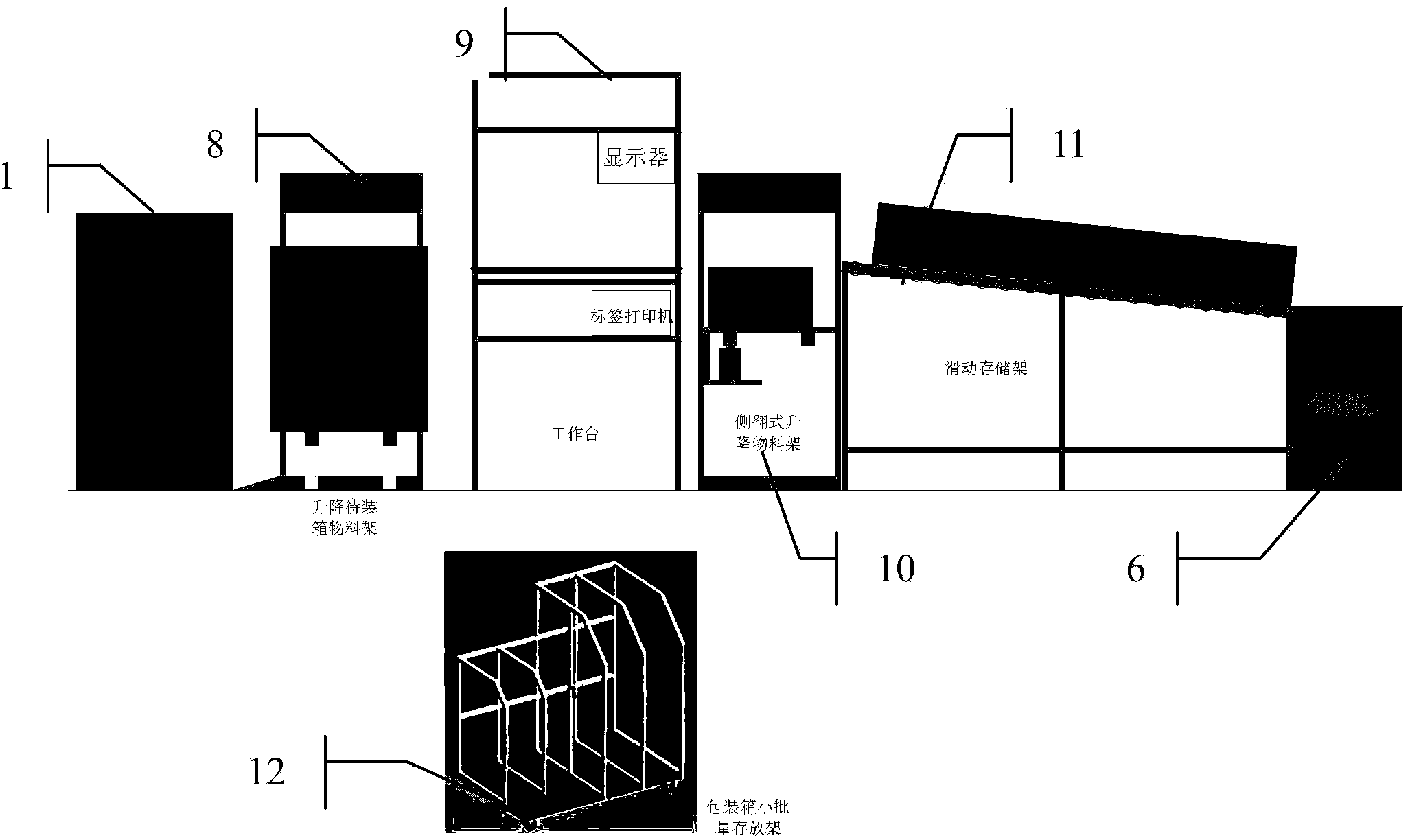

Packaging process production line equipment and operating method

ActiveCN103640742AAvoid wastingShorten the packaging cyclePackaging machinesProduction lineIdentification error

The invention relates to packaging process production line equipment and an operating method. According to the packaging process production line equipment, a to-be-cased product storage area, a lifting to-be-cased material shelf, a multifunctional workbench, a side-turning type lifting material shelf, a sliding storage rack and a packer are placed sequentially; a packaging case temporary storage rack belongs to a matched tool and is placed separately; and the side-turning type lifting material shelf, the sliding storage rack and the packer are connected through a conveying belt device of the sliding storage rack. Rubber tube packaging equipment and the operating method are studied and adjusted, so that packaging operations are streamlined, plenty of existing waste is eliminated, identification errors are prevented, and the labor intensity of workers is reduced.

Owner:TIANJIN PENGYI GRP CO LTD

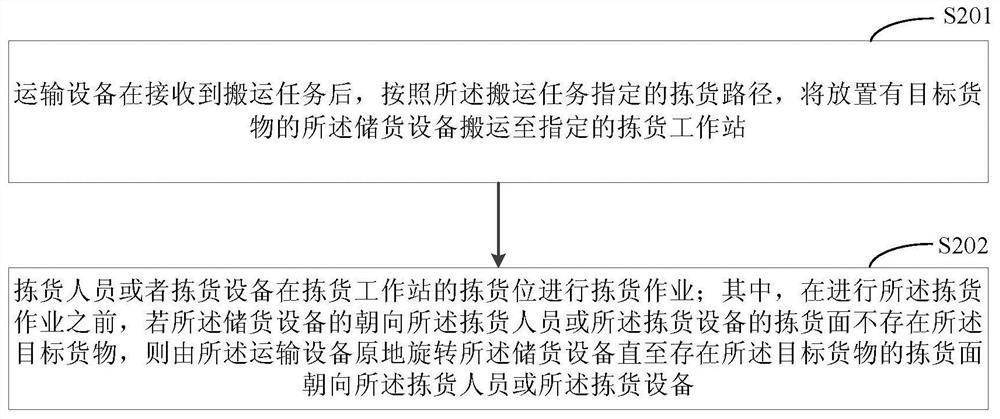

Goods picking method, goods picking device and goods picking system based on goods storage equipment

ActiveCN112239037AGuaranteed areaHigh densityStorage devicesLogistics managementMechanical engineering

The invention discloses a goods picking method, a goods picking device and a goods picking system based on goods storage equipment and relates to the technical field of warehouse logistics. One specific embodiment of the goods picking method comprises the points that the goods storage equipment comprises a main frame body and a storage layer installed on the main frame body, wherein a rotating track formed by the horizontal rotating storage layer is an inscribed circle of a warehouse map grid or is in the inscribed circle. When goods are picked based on the goods storage equipment, the goods picking method comprises the steps that transportation equipment carries the goods storage equipment where target goods are placed to a specified goods picking workstation according to a goods pickingpath specified by a carrying task, so that goods picking personnel or the goods picking equipment carries out goods picking operation; and before the goods picking operation is carried out, the goodsstorage equipment is rotated in situ until a goods picking surface where the target goods exist faces the goods picking personnel or the goods picking equipment. According to the goods picking method,the rotation track of the storage layer of the goods storage equipment is limited in the inscribed circle of the warehouse map grid, so that the goods storage equipment can rotate in situ, and the carrying efficiency and the picking efficiency are improved.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

Automatic drying and rolling-up perfecting press

InactiveCN109291636AFinish quicklyIncrease productivityPrinting press partsWebs handlingEngineeringPrinting press

The invention discloses an automatic drying and rolling-up perfecting press. The automatic drying and rolling-up perfecting press comprises a horizontal base; tightening supporting plates are disposedon the two sides of one end of the horizontal base correspondingly; a tightening rod is disposed between the two tightening supporting plates; a rolling-up device is disposed at the other end of thehorizontal base and comprises a rolling-up device base, and rolling-up barrel supports are disposed at the two ends of the base correspondingly; U-shaped grooves are formed in one ends of the rolling-up barrel supports; a second gear bearing is disposed in the U-shaped grooves; second gear rods penetrate through the center of the second gear bearing; the second gear rods penetrate through the center of a rolling-up roller; a dryer is disposed on the right side of the rolling-up device; a printing system is disposed on the left sides of the tightening supporting plates and comprises printer supports; and a first roller printer and a second roller printer are disposed between the printer supports. By means of the automatic drying and rolling-up perfecting press, the problems that existing printers do not have the automatic drying and rolling-up functions, and many devices occupy a large floor area are solved, the utilization ratio of a workshop is increased, the production takt is accelerated, and the labor intensity of operating staff is relieved.

Owner:JIESHOU CITY CHANGXING PRINTING PACKAGING CO LTD

Storage splitting method with tray compact warehouse combined with tray transverse beam goods shelves and system

ActiveCN109775214ASolve the problem of poor dismantling abilityImprove work efficiencyStorage devicesEngineeringStorage cell

The invention discloses a storage splitting method with a tray compact warehouse combined with tray transverse beam goods shelves. The storage splitting method comprises the steps that 1, incoming materials are judged; 2, large-medium-specification whole tray-type materials are conveyed to a warehouse inlet of a tray compact storage unit; 3, large-medium-specification box-type materials are conveyed to the warehouse inlet of the tray compact storage unit; 4, a warehouse management system (WMS) conducts goods allocation according to the goods allocation principle; 5, small-specification box-type materials are carried to tray transverse beam goods shelf stations; 6, small-specification whole tray-type materials are carried to the tray transverse beam goods shelf stations; 7, the WMS automatically arranges material discharge dispatching; 8, the large-medium-specification whole tray-type materials are discharged out of the warehouse through forklifts; 9, the small-specification whole tray-type materials are discharged out of the warehouse after code scanning; 10, large-specification box-type materials are split and supplemented to a large-specification material discharging conveying line; 11, medium-specification box-type materials are split and supplemented to a medium-small-specification material discharging conveying line; 12, the small-specification box-type materials are splitand supplemented to the medium-small-specification material discharging conveying line; and 13, the split materials are discharged out of the warehouse through a material combining and splitting unit. Through the storage splitting method, the problem that a tray compact warehouse is poor in splitting capacity is solved.

Owner:SIPPR ENG GROUP

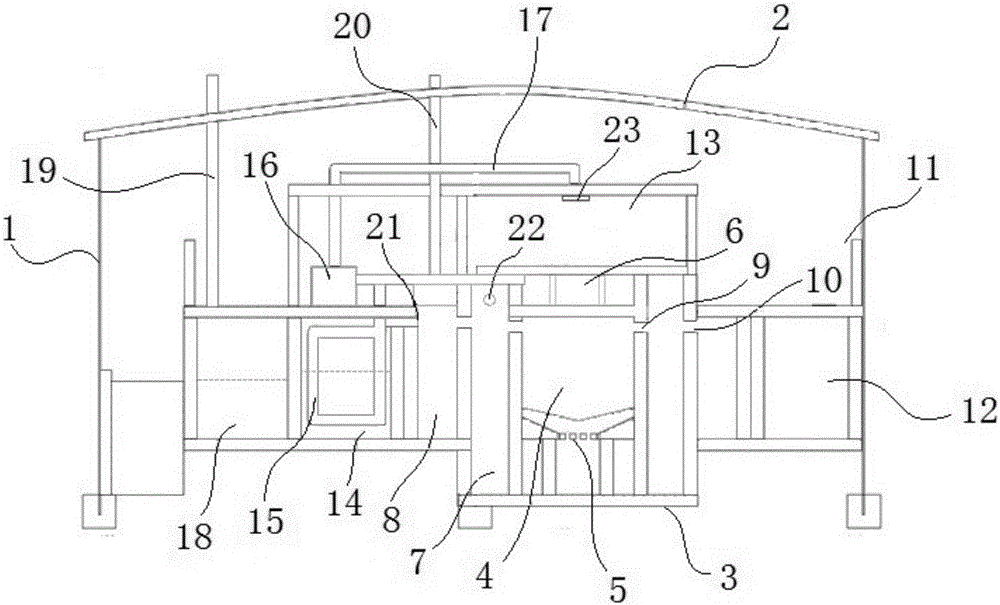

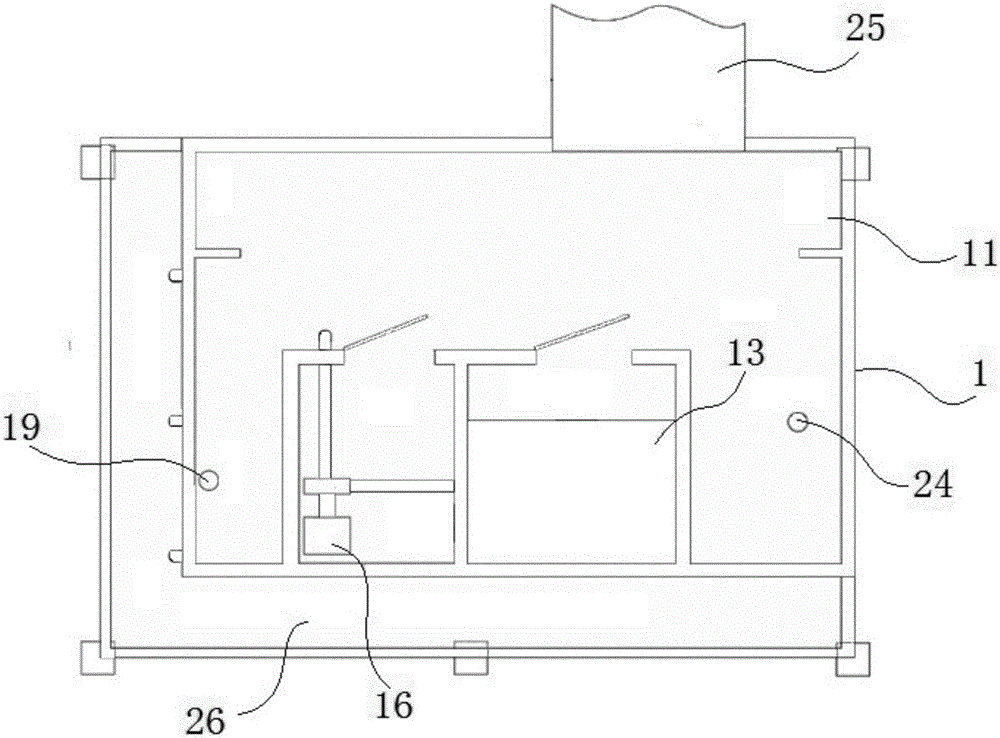

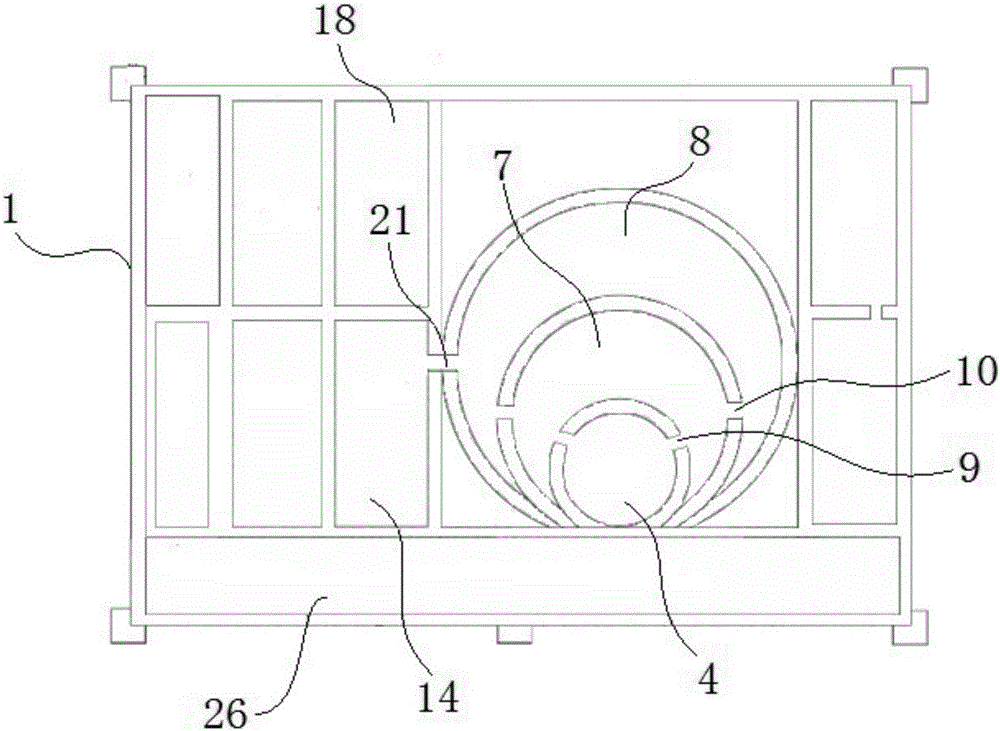

Household garbage incinerator

The invention discloses a household garbage incinerator. The household garbage incinerator comprises a house body, an incinerator body, a smoke exhausting system, a sorting tank, a septic tank and a drying chamber, wherein the house body is divided into an upper storey and a lower storey; the incinerator body is arranged at the lower storey of the house body and comprises a combustion chamber, a primary smoke chamber and a secondary smoke chamber, an incinerator opening and a feed port are formed in the combustion chamber, the primary smoke chamber and the combustion chamber are internally tangent to the side where the incinerator opening is formed, a first smoke port communicated with the primary smoke chamber is formed in the combustion chamber, the secondary smoke chamber and the primary smoke chamber are internally tangent to the side where the incinerator opening is formed, a second smoke port communicated with the secondary smoke chamber is formed in the primary smoke chamber, and a first smoke exhaust outlet is formed in the secondary smoke chamber; the smoke exhausting system is connected with the first smoke exhaust outlet; the sorting tank is arranged at the upper storey of the house body; the septic tank is arranged at the lower storey of the house body, and a feed inlet of the septic tank is located at the upper storey of the house body; the drying chamber is arranged at the upper storey of the house body and above the incinerator body. With the adoption of the household garbage incinerator, household garbage can be classified, dried, composted and combusted, the smoke treatment effect is good, the land utilization rate is high, and the treatment cost can be reduced.

Owner:泰安泰山产业发展有限公司

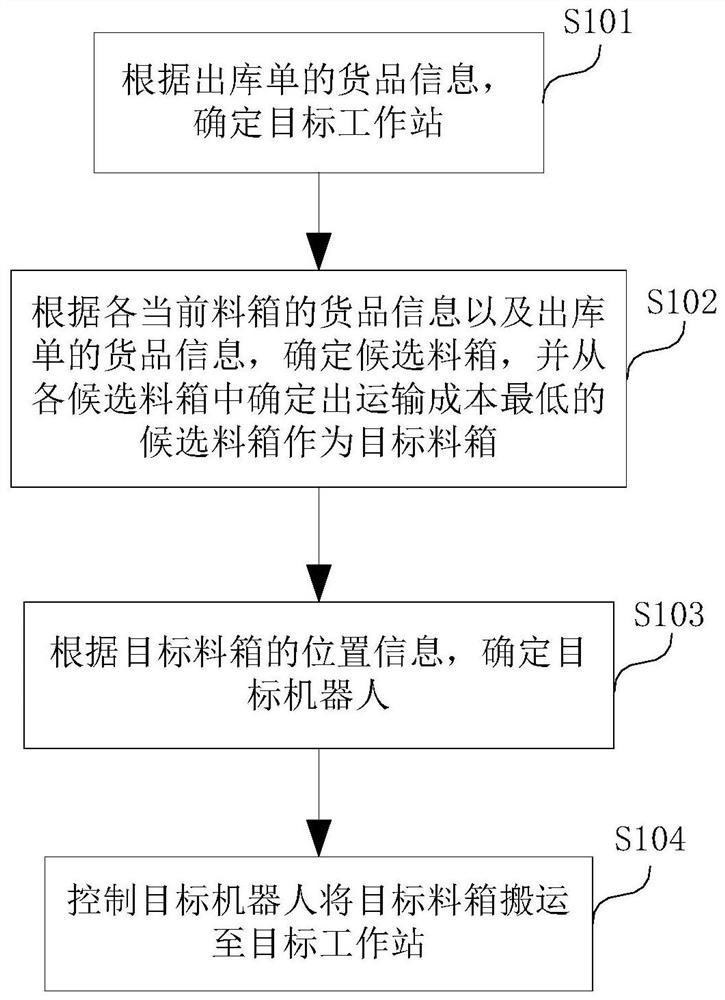

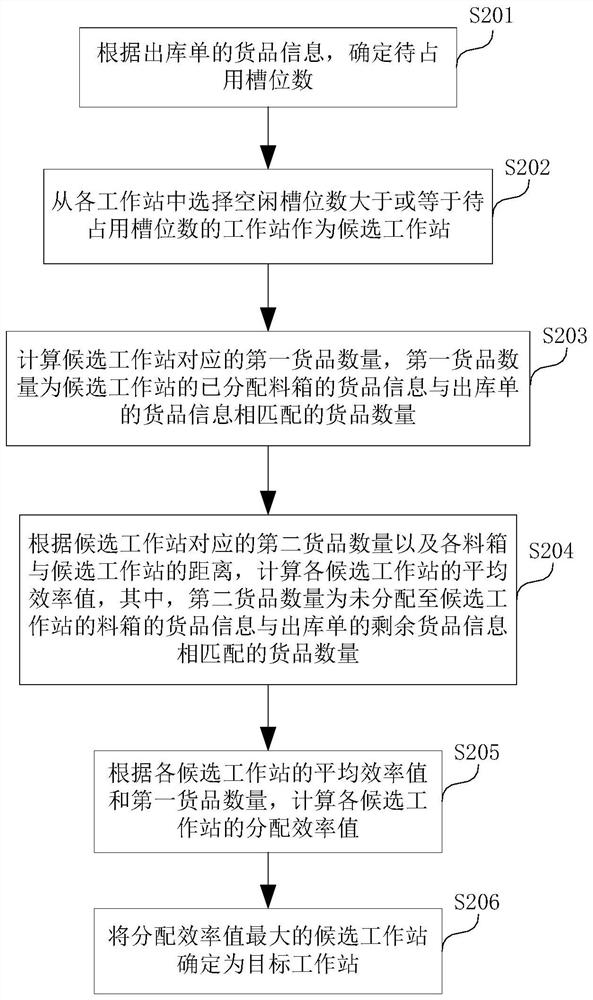

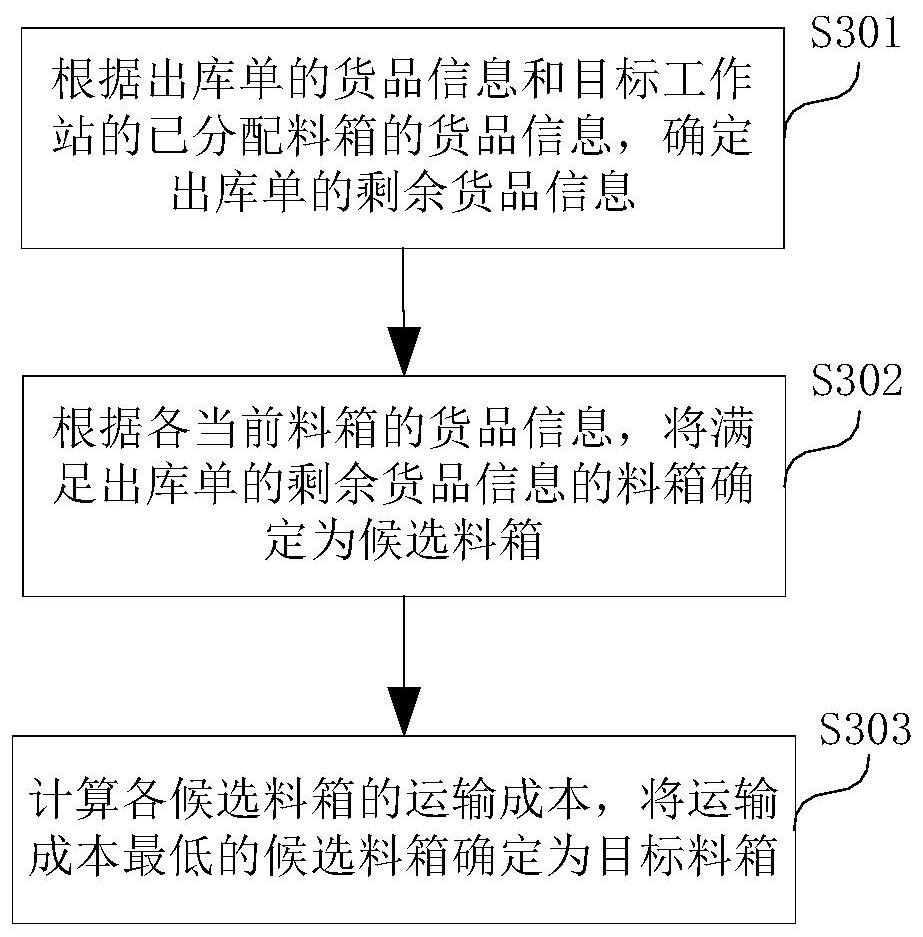

Goods delivery control method, device and equipment and computer readable storage medium

The invention provides a goods ex-warehouse control method, device and equipment and a computer readable storage medium, and the method comprises the steps: determining a target work station according to the goods information of an ex-warehouse list; candidate material boxes are determined according to the goods information of the current material boxes and the goods information of the ex-warehouse list, and the candidate material box with the lowest transportation cost is determined from the candidate material boxes to serve as a target material box; determining a target robot according to the position information of the target material box; and the target robot is controlled to carry the target material box to the target workstation. By adopting the scheme, the material box which is carried from the storage shelf to the target work station and has the highest carrying efficiency can be selected from the plurality of candidate material boxes to serve as the target material box, so that the conveying time of the target robot for conveying the target material box to the target work station is shortened or the carrying frequency of the target robot is reduced; and the delivery efficiency of the goods is improved.

Owner:SHANGHAI QUICKTRON INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com