Material stacking and transferring system for sintered Nd-Fe-B formed blanks

A technology of forming blanks, NdFeB, applied in the stacking, transportation and packaging of objects, storage devices and other directions, can solve the problems of falling corners, high transfer damage rate, environmental pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

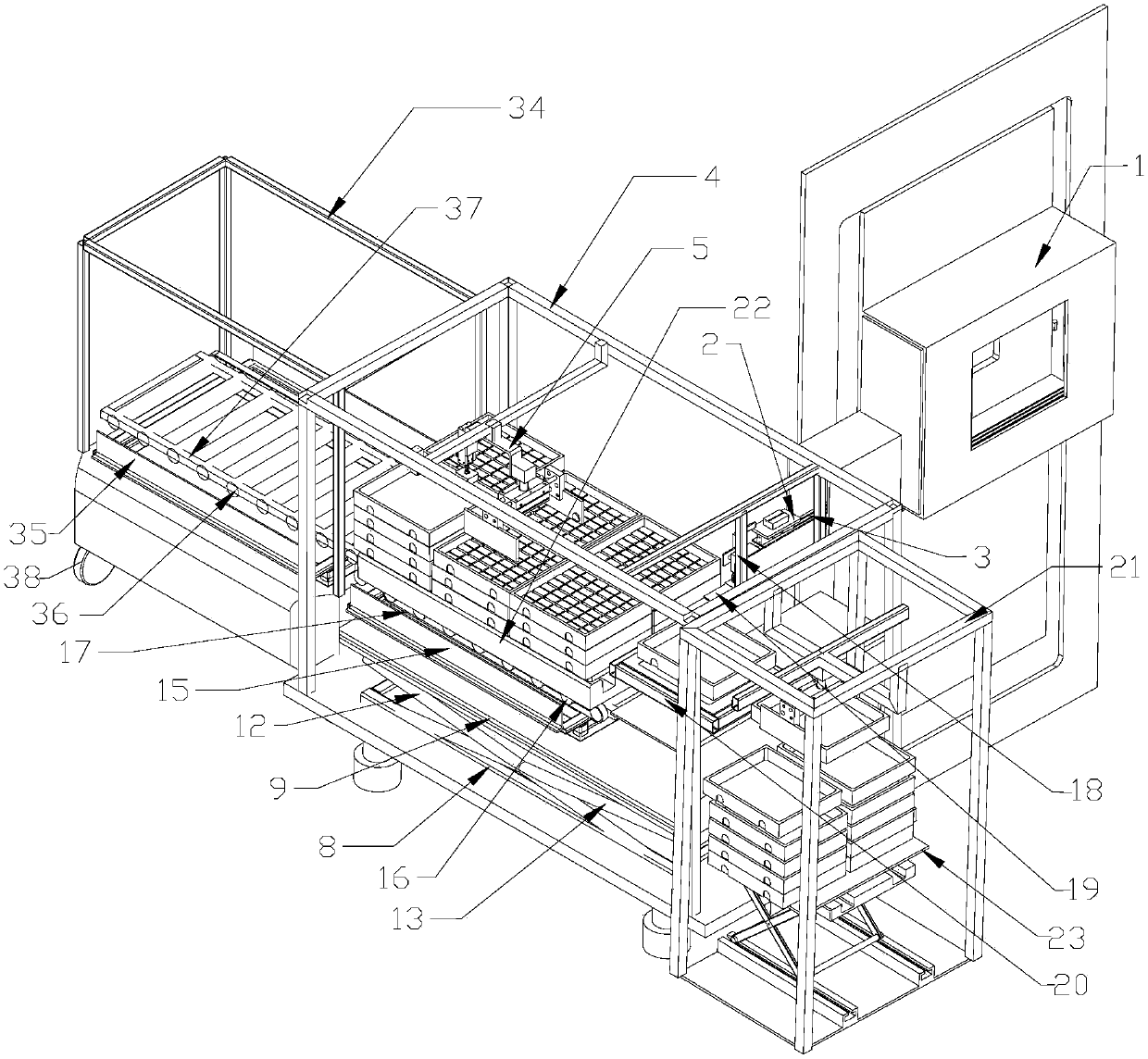

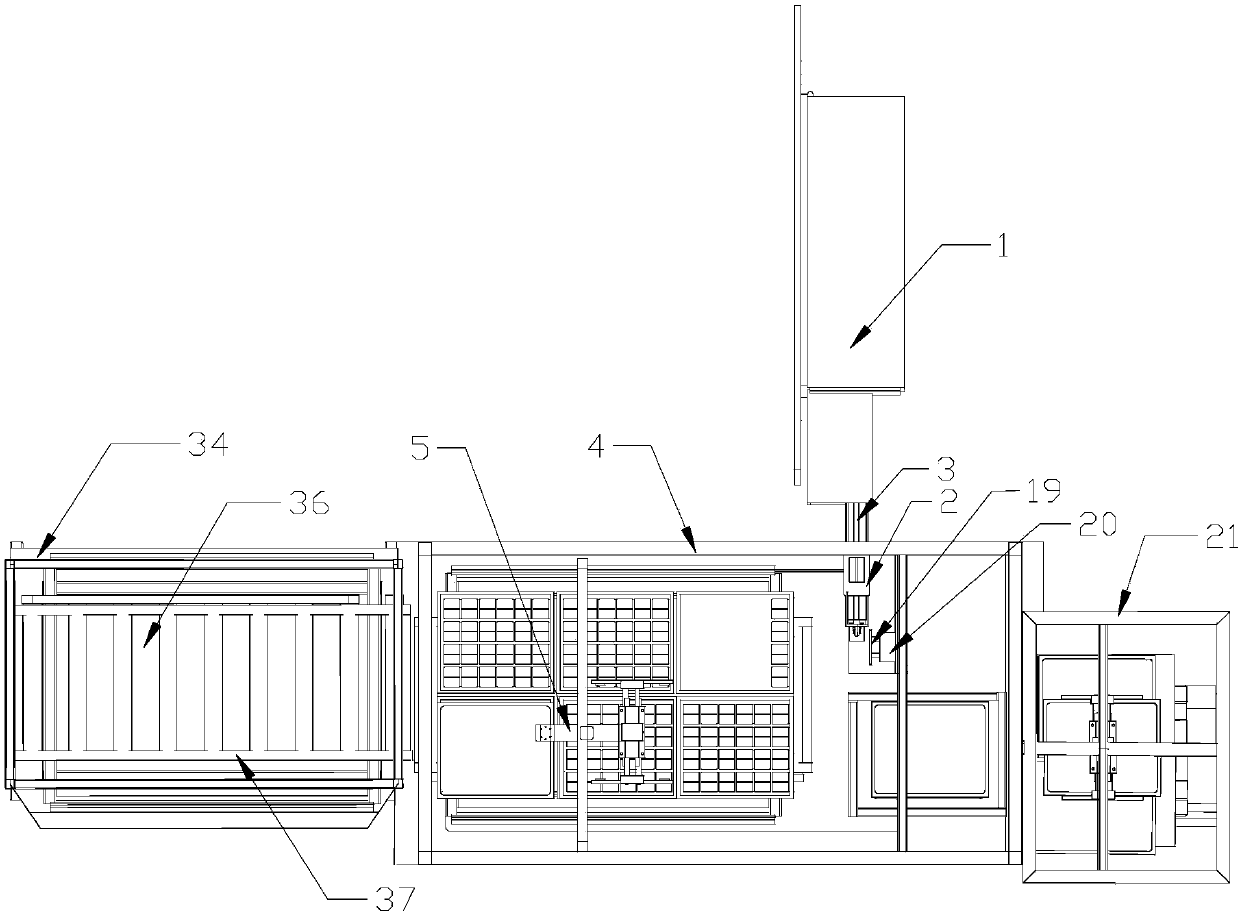

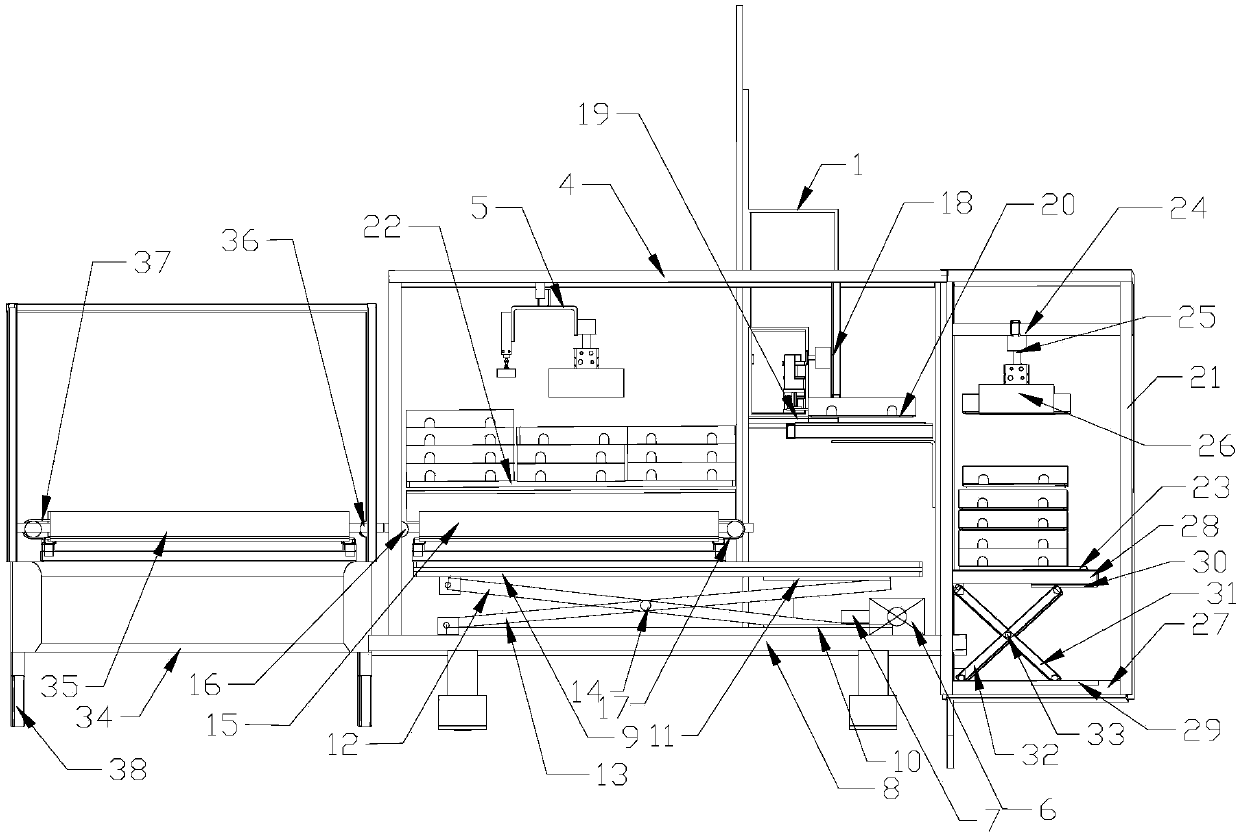

[0023] Embodiment 1: As shown in the figure, a code material and transfer system for sintered NdFeB molding blanks, including a controller, a feeding device, a code material basin device, a storage basin device and a transfer car; the feeding device is located in the code material basin On the front side of the device, the storage basin device is located on the right side of the code basin device, the transfer car is located on the left side of the code basin device, and the feeding device is used to feed the sintered NdFeB molding blank output by the forming press into the code material In the stacking pot device, the storage pot device is used to store the sintering pots to be used, and the material coding pot device is used to transfer the sintering pots in the storage pot device into it, and then arrange the sintering pots in sequence, and place the sintered NdFe The boron molding blanks are coded into the sintering basin in sequence and the sintering basins of the coded si...

Embodiment 2

[0024] Embodiment 2: As shown in the figure, a code material and transfer system for sintered NdFeB molding blanks, including a controller, a feeding device, a code material basin device, a storage basin device and a transfer car; the feeding device is located in the code material basin On the front side of the device, the storage basin device is located on the right side of the code basin device, the transfer car is located on the left side of the code basin device, and the feeding device is used to feed the sintered NdFeB molding blank output by the forming press into the code material In the stacking pot device, the storage pot device is used to store the sintering pots to be used, and the material coding pot device is used to transfer the sintering pots in the storage pot device into it, and then arrange the sintering pots in sequence, and place the sintered NdFe The boron molding blanks are coded into the sintering basin in sequence and the sintering basins of the coded si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com