Patents

Literature

274results about How to "Guaranteed area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

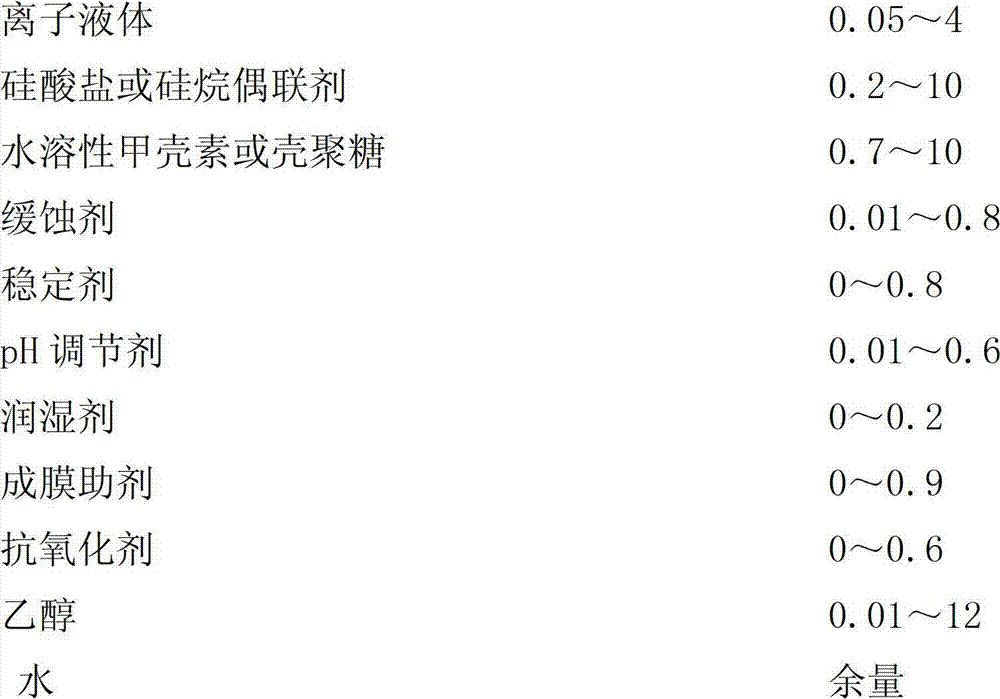

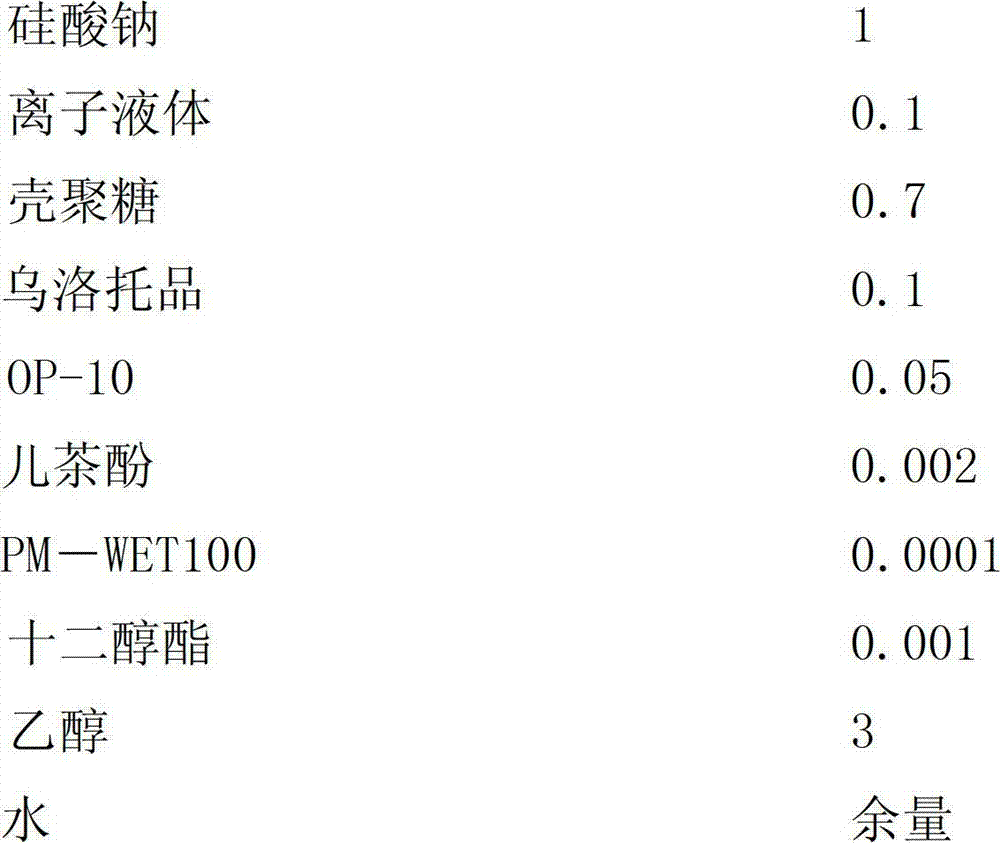

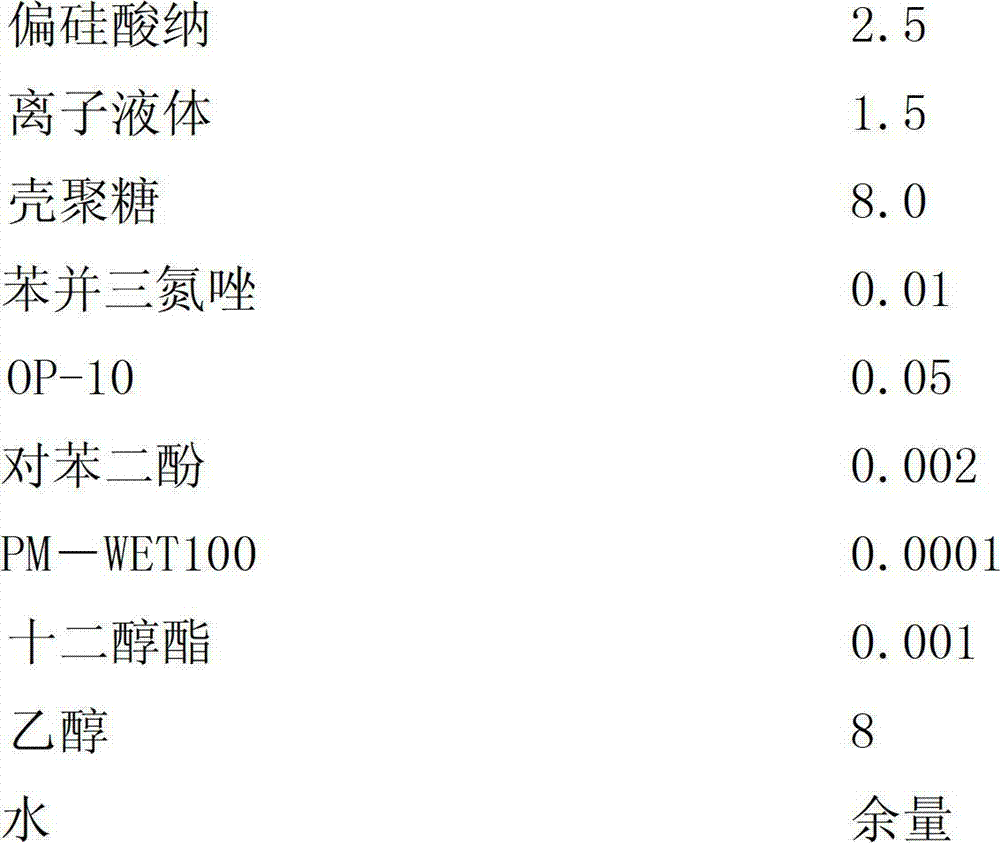

Metal surface treatment agent

InactiveCN102787310AReduce corrosion rateReduce surface tensionMetallic material coating processesNitrogenous heterocyclic compoundIonic liquid

The invention provides a metal surface treatment agent composed of aqueous solution or aqueous emulsion containing ionic liquid. The metal surface treatment agent comprises the ionic liquid, silicate or silane coupling agent, water-soluble chitin or chitosan, corrosion inhibitor, stabilizer, pH modifier, wetter, coalescing agent, antioxidant, ethanol and water, the ionic liquid is room-temperature ionic liquid consisting of nitrogenous heterocyclic compound cations and inorganic or organic anions, one or more of nanoscale titanium dioxide, zirconium oxide or zirconium fluoride is uniformly mixed into the silicate or silane coupling agent by the weight equivalently accounting for 3%-25% of that of the silicate or silane coupling agent. A chemical conversion coating is formed on a metal surface by the metal surface treatment agent, can inhibit corrosion of the metal surface, and has a fine coating performance. The metal surface treatment agent is used for treating cold-rolled plates, galvanized plates and aluminum plates, and the metal surface treated by the metal surface treatment agent has the coating adhesion force equivalent to that of a metal surface treated by a phosphorus-containing metal surface treatment agent.

Owner:DALIAN POLYTECHNIC UNIVERSITY

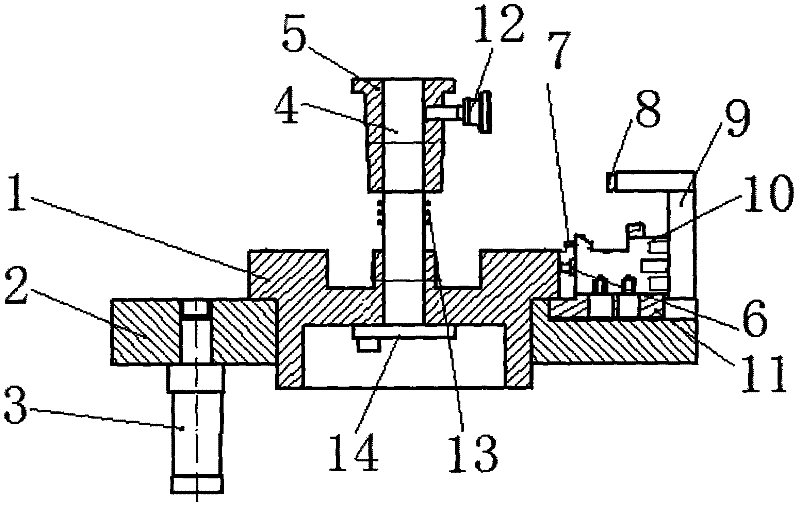

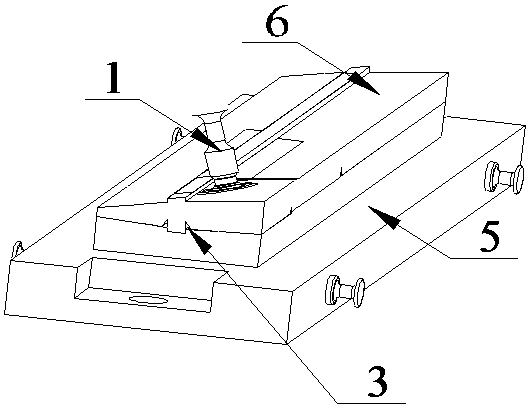

Manufacturing method and fixture of integral bladed-disk wax mold

ActiveCN102363199AImprove consistencyHigh dimensional accuracyFoundry moulding apparatusWaxPrimary standard

The invention discloses a manufacturing method and a fixture of an integral bladed-disk wax mold. According to the invention, an integral bladed-disk wax pattern is divided into single blades and a disk shaft. Processes of separated pressing, precise fixture positioning and wax mold welding assembling are adopted. The integral wax pattern is precisely cast. According to the invention, the disk shaft is fixed on an assembling fixture; the blades are sequentially positioned on positioning points on the fixture, and are welded onto the disk shaft. Blade bodies and channel inner walls with high precisions are adopted in the positioning of the blades, such that good consistency is provided for the blades. When the wax pattern is assembled, positioning points are positioned on the blade bodies;blade body positioning points are consistent with processing positioning points, primary standards of cold and hot processing are consistent, such that blade dimensional precision of the whole cast is optimally improved, throat areas between blades are ensured, and flow rate homogeneity is ensured. Positioning parts of the fixture can be adjusted according to measured dimensions of parts, such that the volume of flow rate can be changed according to directional positions of angles of the blades. Therefore, repairing or even rejecting risks caused by unqualified integral mold dimensions are avoided, production period is saved, and production cost is reduced. With the method provided by the invention, hard processes are turned easy, product precision is improved, and production efficiency is improved.

Owner:AECC AVIATION POWER CO LTD

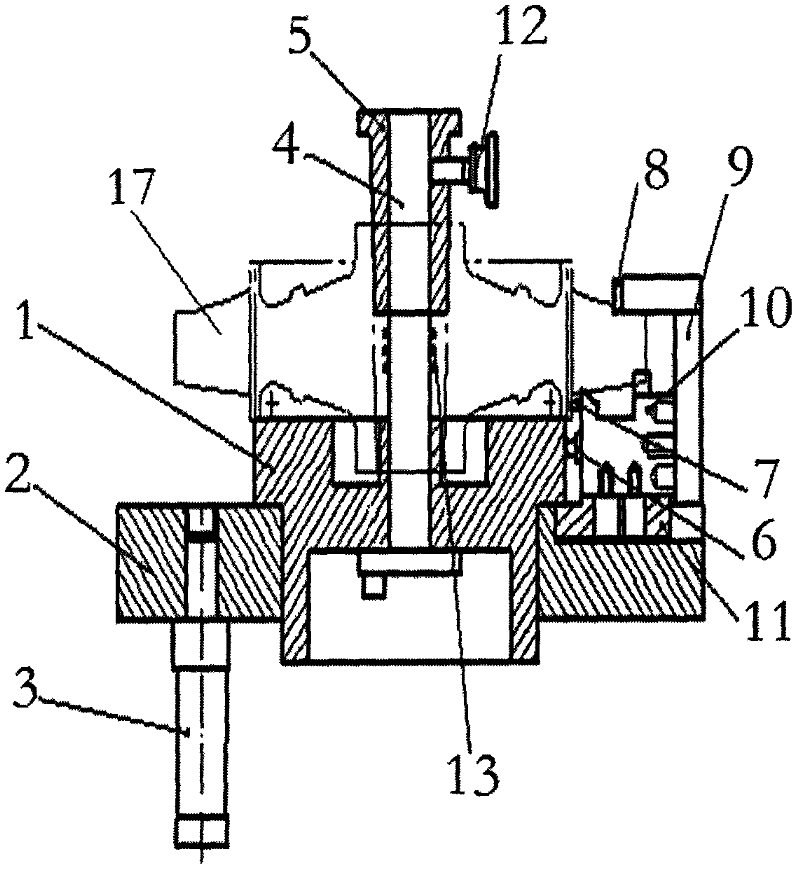

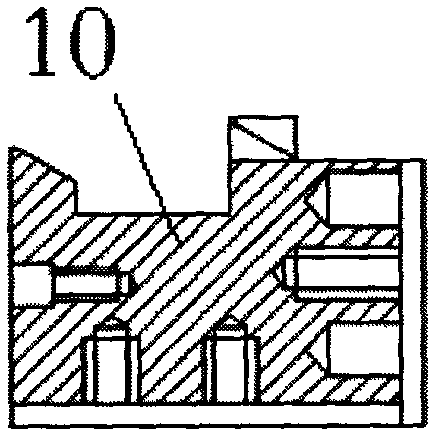

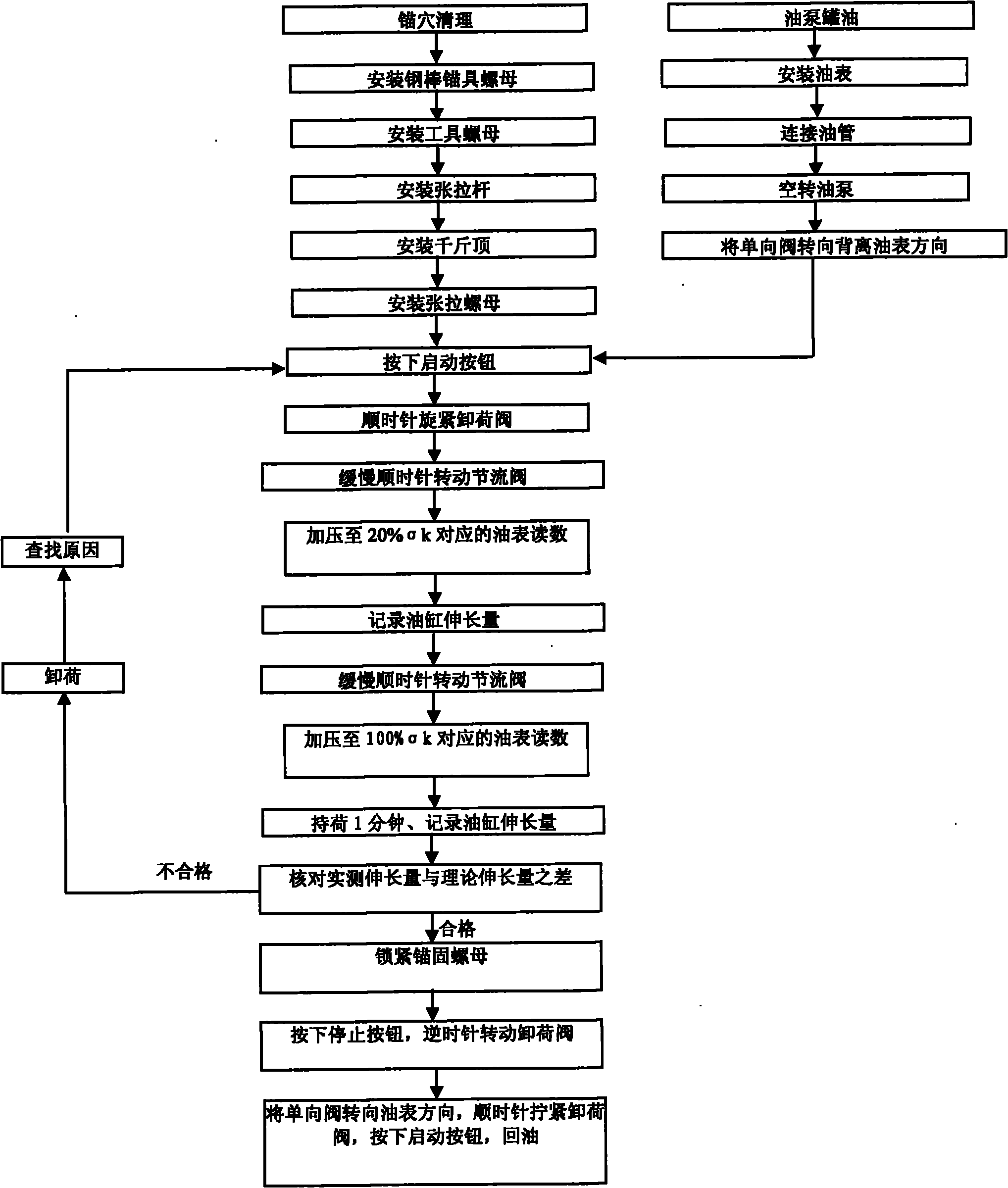

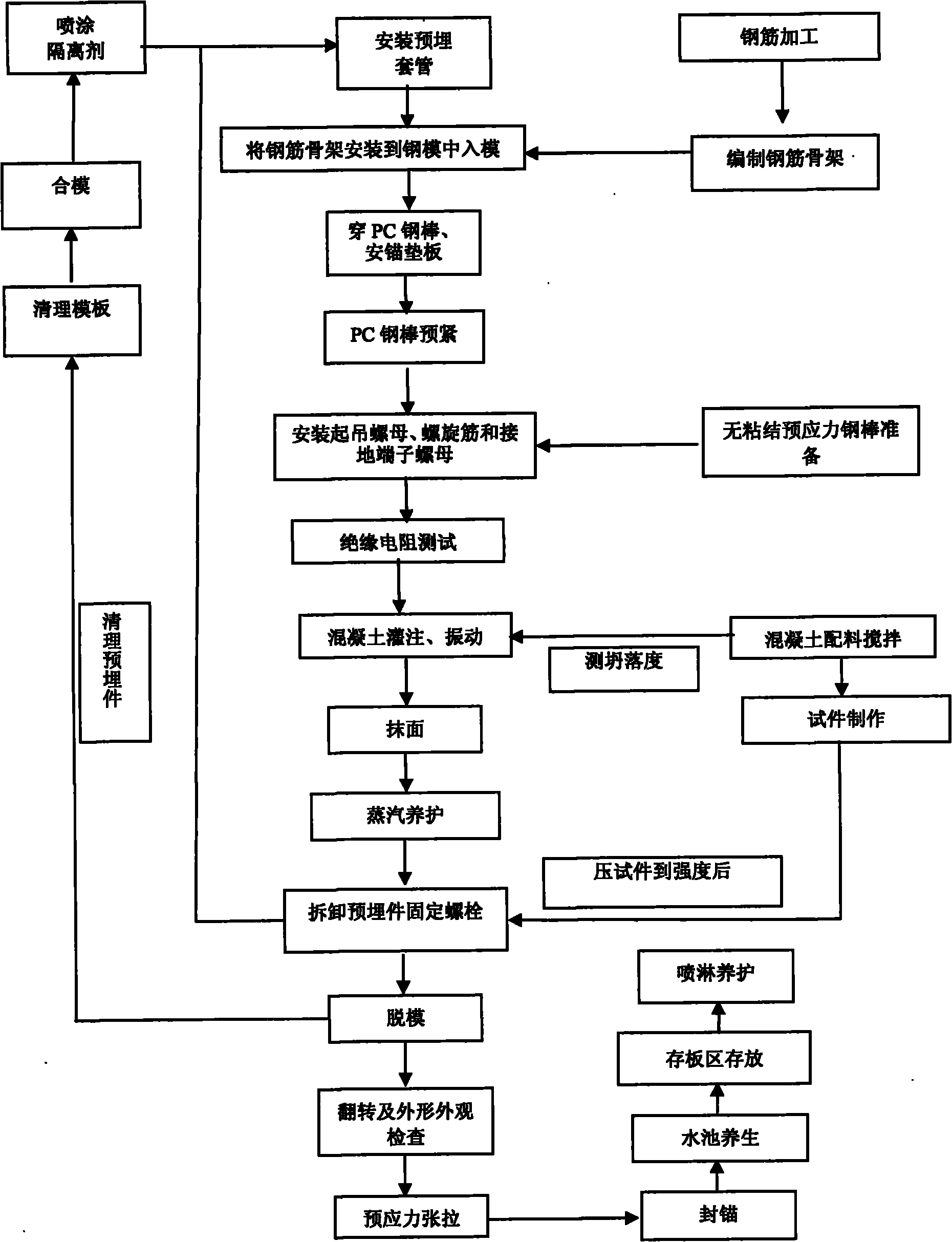

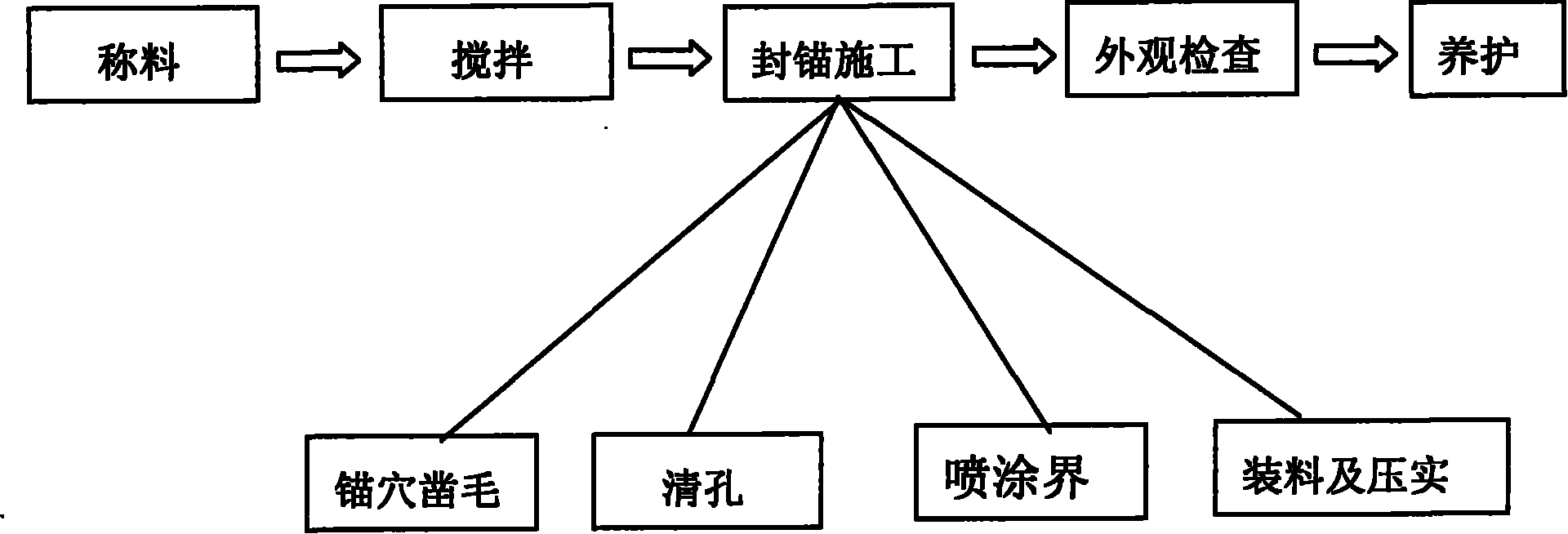

Concrete track slab prefabricating construction method of CRTS I type slab ballastless track

InactiveCN101830036AImprove cutting efficiencyUniform clothCeramic shaping apparatusRebarInsulation resistance

The invention relates to a concrete track slab prefabricating construction method of a CRTS I type slab ballastless track. The method comprises the following steps of: (1) weaving a steel reinforcement framework; (2) mounting the steel reinforcement framework in a steel mould, wherein the steel mould is internally sprayed with a separant and provided with a pre-embedded sleeve; (3) penetrating a PC (Prestressed Concrete) steel rod and mounting an anchor backing slab; (4) pre-tightening the PC steel rod; (5) mounting a hoisting nut, a spiral bar and a grounding terminal nut; (6) testing an insulation resistor; (7) pouring concrete and vibrating; (8) plastering the surface; (9) maintaining by using steam; (10) dismounting fixing bolts of a pre-embedded piece; (11) demoulding: cleaning the pre-embedded piece and a template, closing the mould, spraying the separant in the steel mould and mounting the pre-embedded sleeve for later use; (12) overturning and examining shape: turning over the CRTS I type slab ballastless track contrete track slab obtained in the step (11) and examining the shape and the appearance; (13) stretching by prestress; (14) sealing the anchor; (15) maintaining in a water pool; and (16) storing in a slab storage area.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

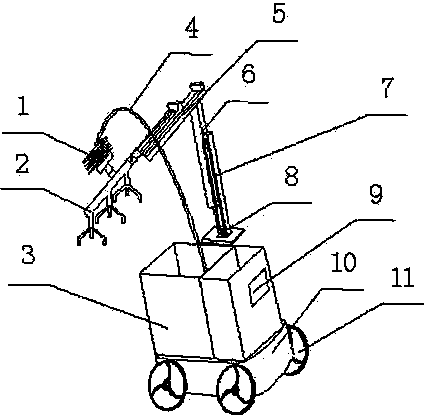

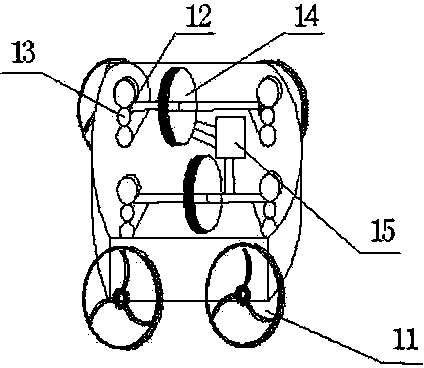

Full-automatic watering vehicle

InactiveCN105248256ALow energy consumptionReduce labor intensityWatering devicesCultivating equipmentsElectric machineryPiping

The invention discloses a full-automatic watering vehicle. The full-automatic watering vehicle is characterized in that a water storing tank and a storage cabinet are arranged over a lower vehicle body; a vertical telescopic assembly is arranged beside the water storage tank; a telescopic rod of the vertical telescopic assembly is provided with a chain; the chain is driven by a motor; a horizontal driving slide block of a horizontal telescopic assembly is engaged with a horizontal driving screw rod; the end part of the horizontal driving screw rod is provided with a pressing device; the pressing device is installed over a supporting water pipe; a water spraying head is installed under the supporting water pipe; the lower vehicle body is provided with a worm gear rod and a damping wheels; the worm gear rod is engaged with a turning gear via a driving motor; the turning gear is engaged with a wheel driving shaft; and the worm gear rod and the turning gear transmit power to damping wheels, so the damping wheels can rotate and drive the lower vehicle body to move forward, backward and steer. Watering load can be reduced for workers, so less labor and time can be achieved for flower planting workers; and the full-automatic watering vehicle benefits people.

Owner:QINGDAO LANNONGGU AGRI PROD RES & DEV

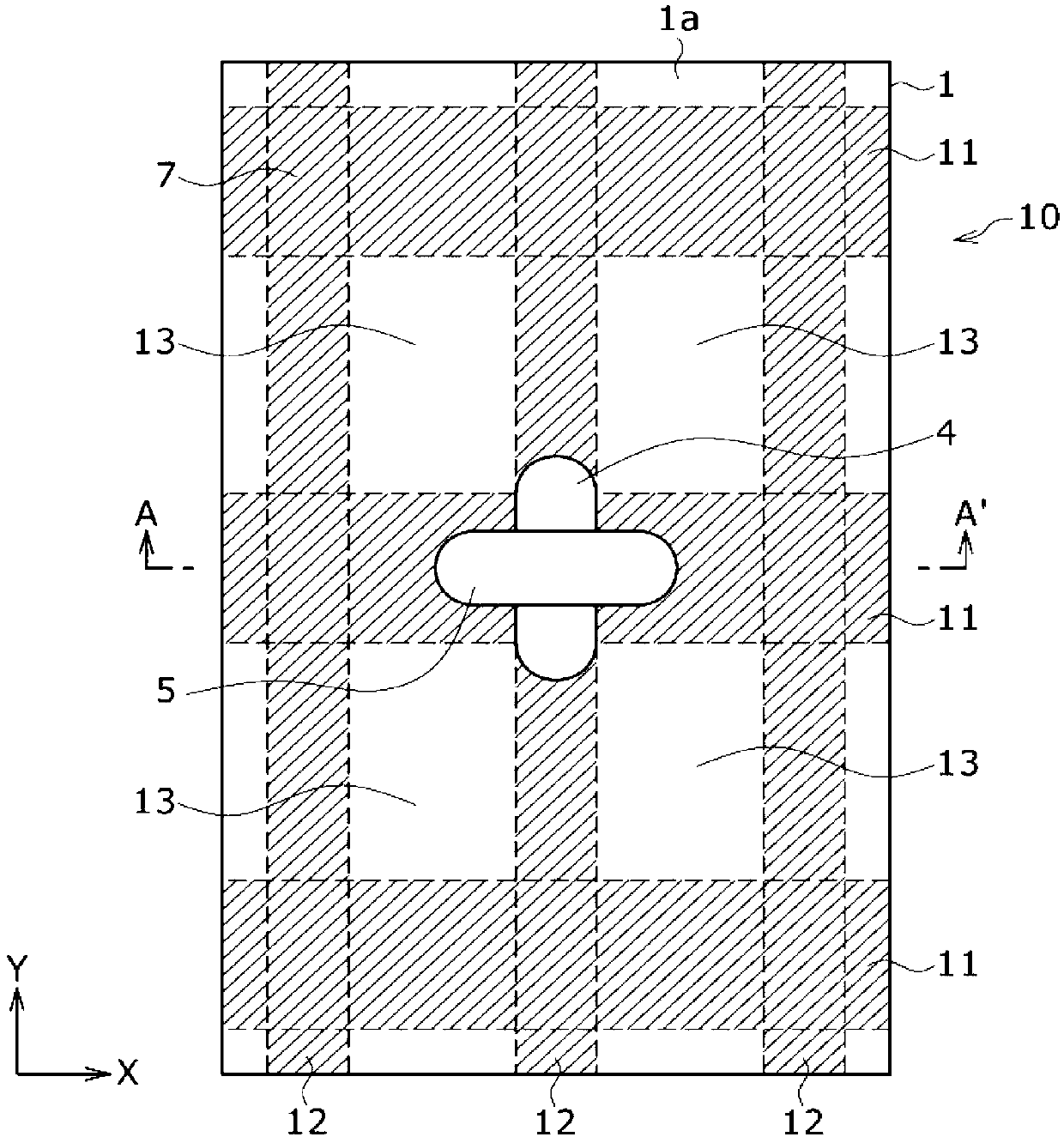

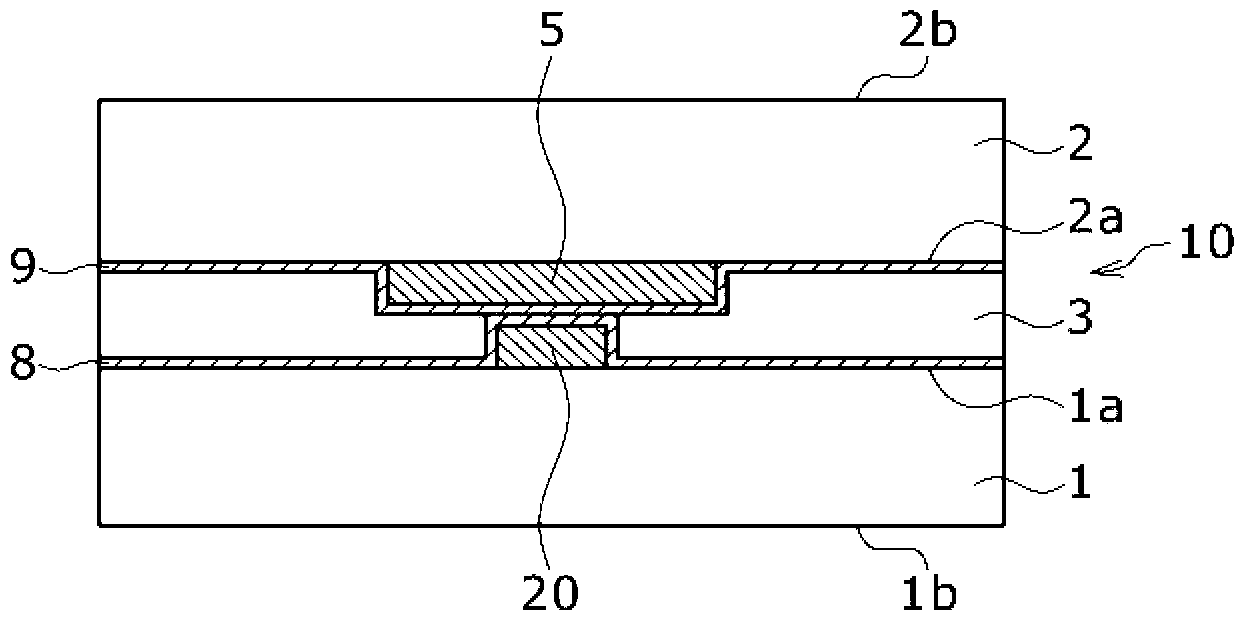

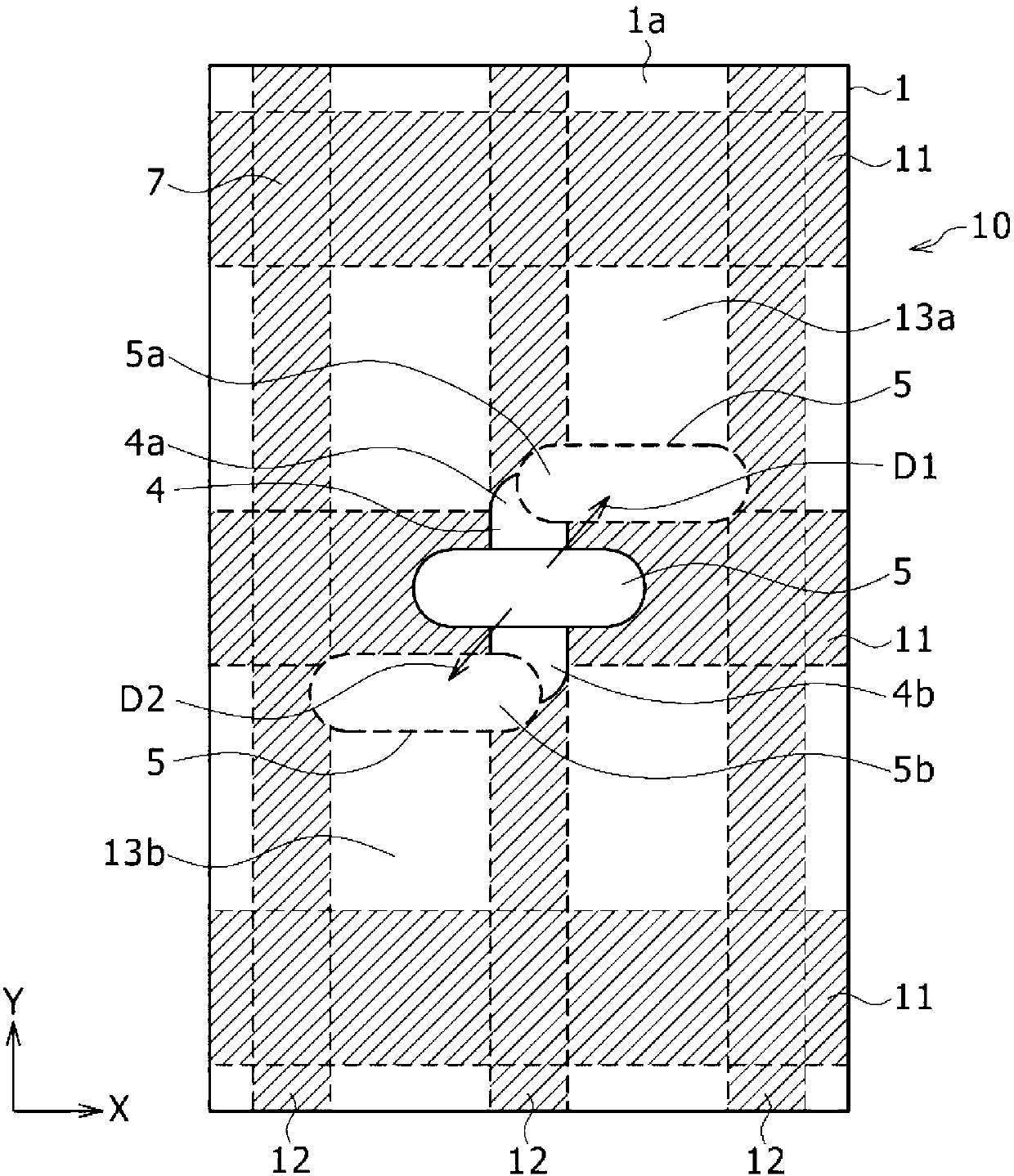

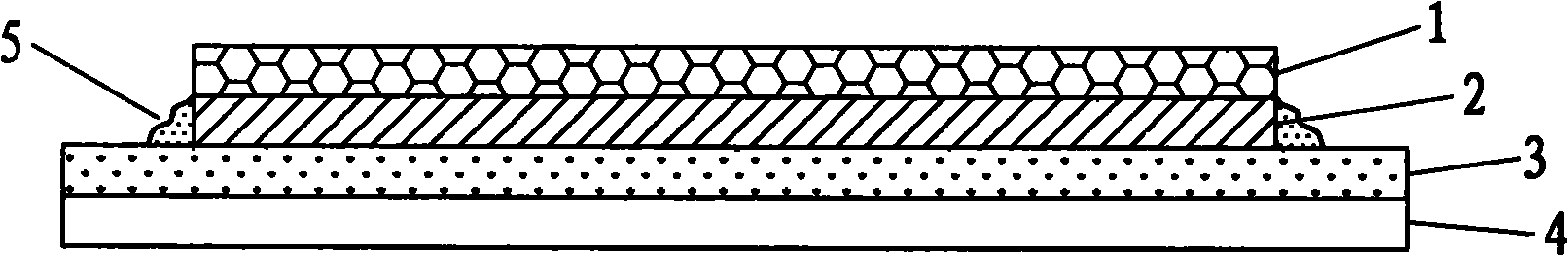

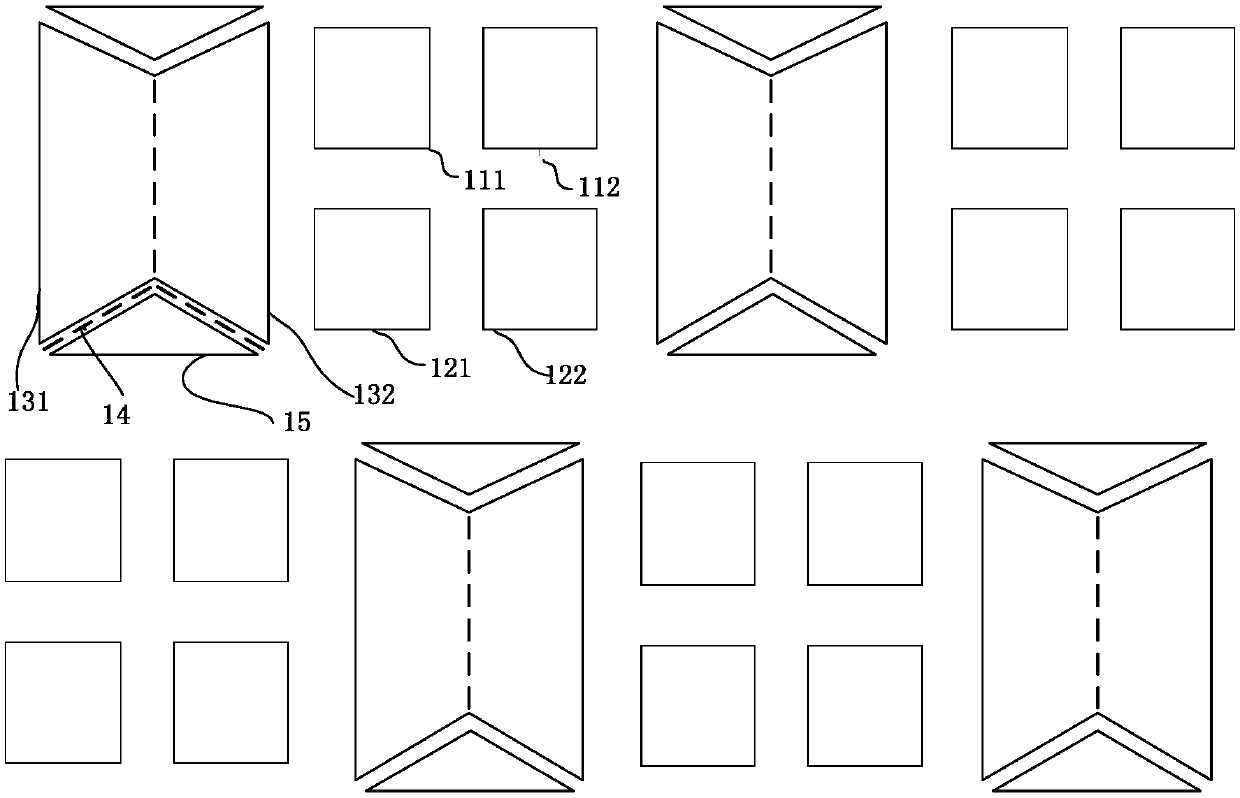

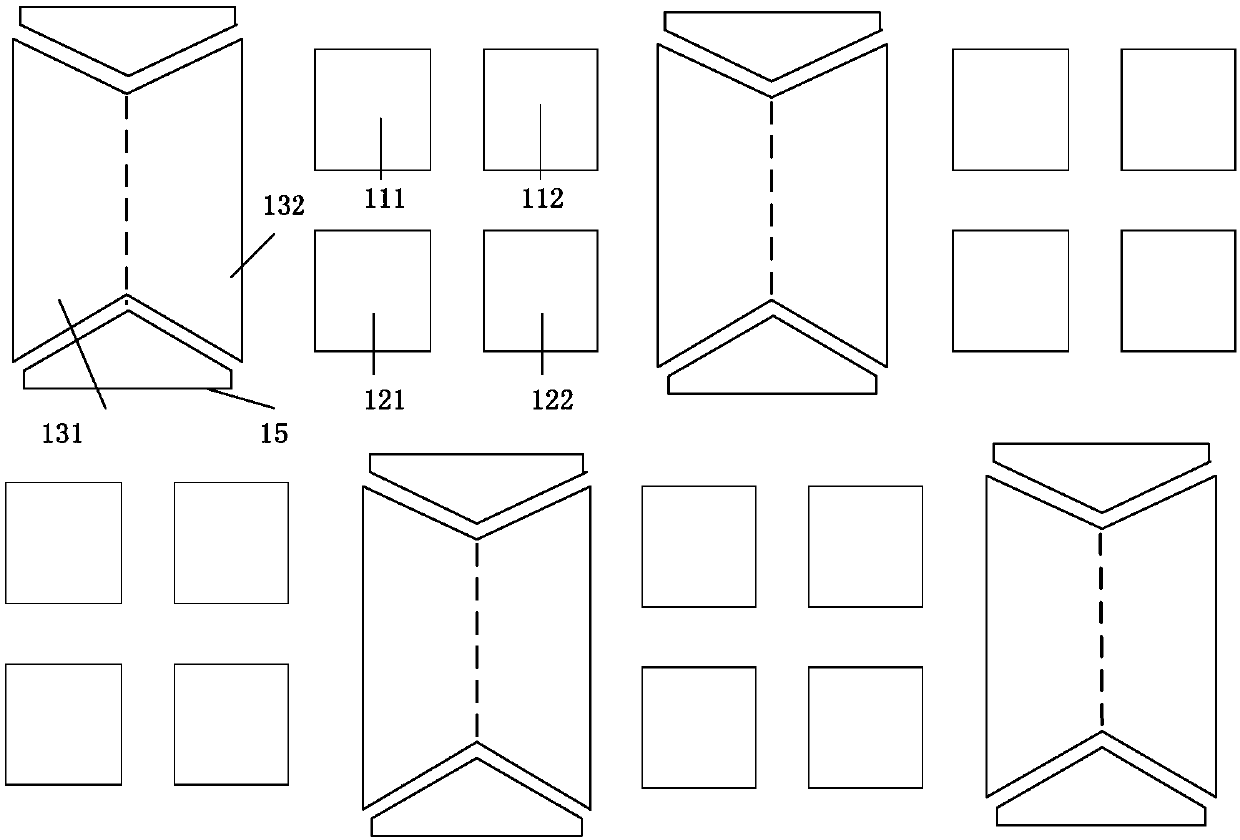

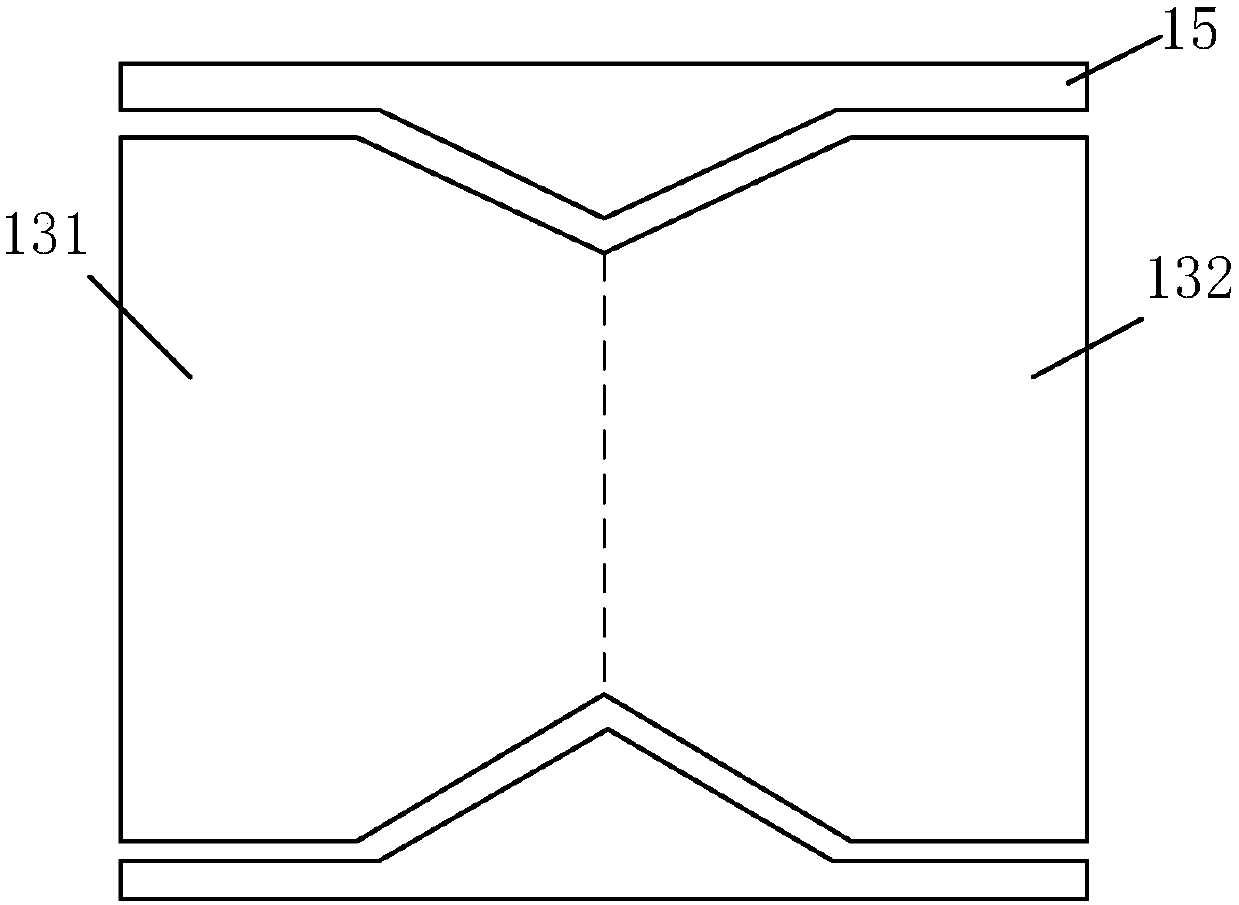

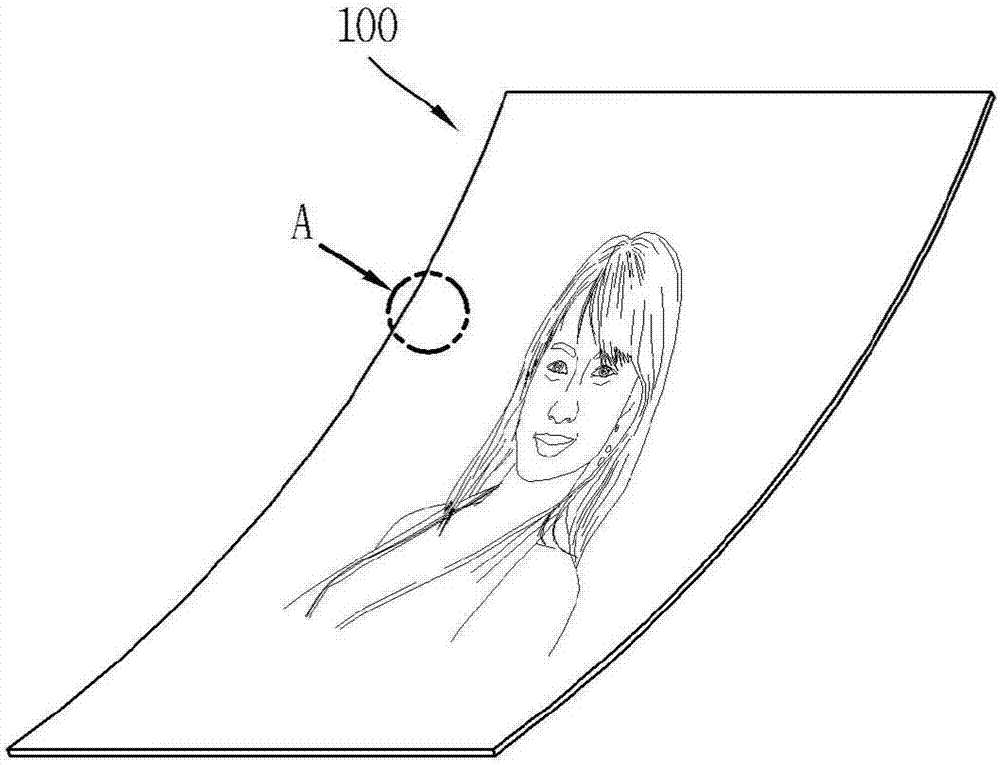

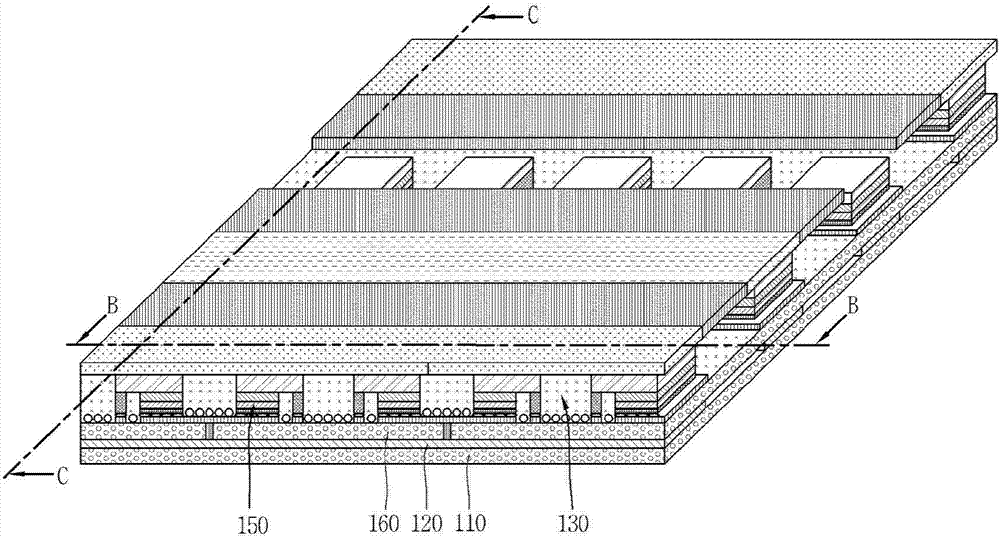

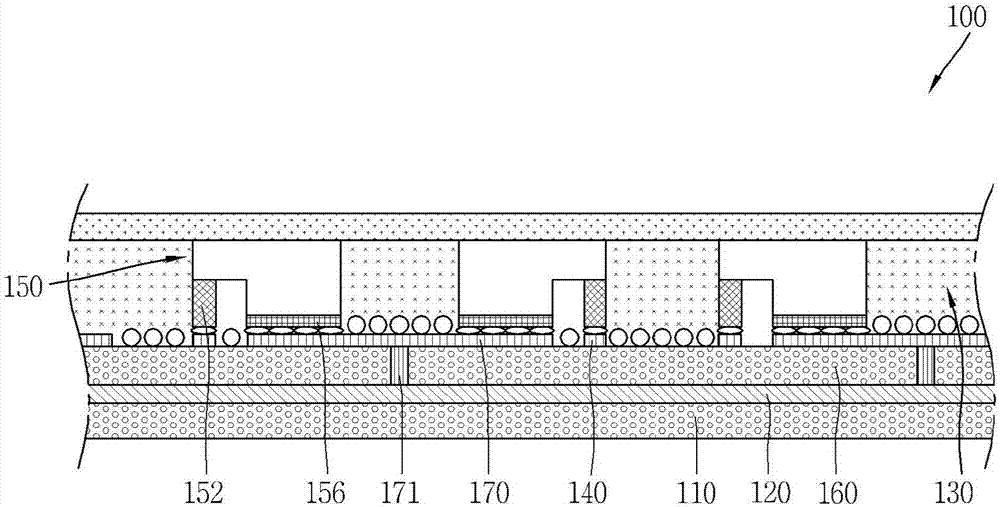

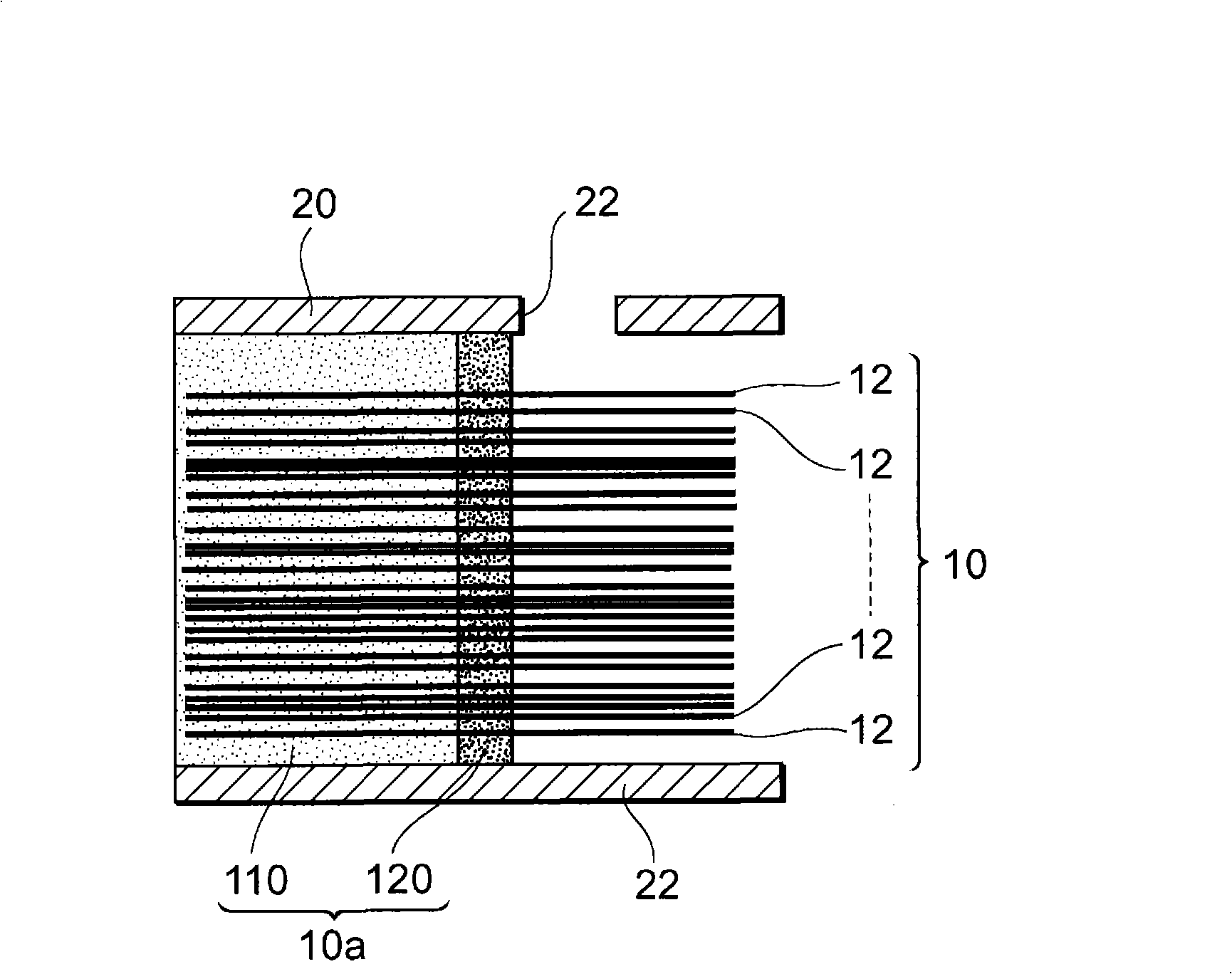

Liquid crystal display device, manufacturing method of the same and electronic equipment

ActiveCN103309091AGuaranteed areaTransportation and packagingMixer accessoriesLiquid-crystal displayEngineering

Provided are a liquid crystal display device, a manufacturing method of the same and electronic equipment. The liquid crystal display device includes first and second substrates, liquid crystal layer, and first and second spacer sections. The first substrate has a first surface including a light-shielding region in a lattice form and a plurality of opening regions surrounded by the light-shielding region. The light-shielding region includes a plurality of first extended portions extending in a first direction and a plurality of second extended portions extending in a second direction that intersects the first direction. The first substrate has a plurality of transistors formed thereon. The second substrate has a second surface that is opposed to and spaced from the first surface. The liquid crystal layer is arranged between the first and second surfaces. The first spacer section has long sides oriented in the second direction, and the second spacer section has long sides oriented in the first direction. The spacer sections protrude into the liquid crystal layer.

Owner:JAPAN DISPLAY INC

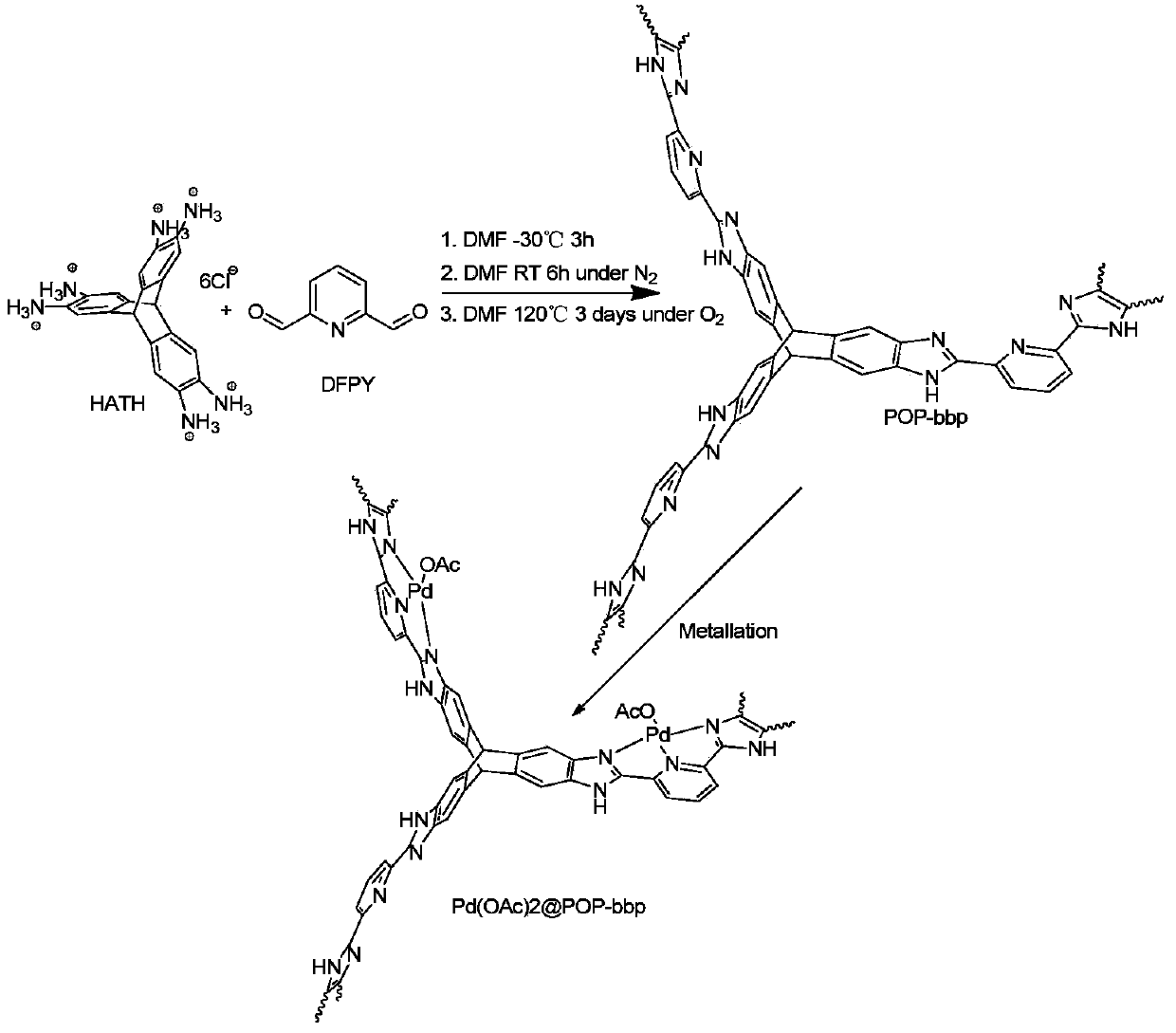

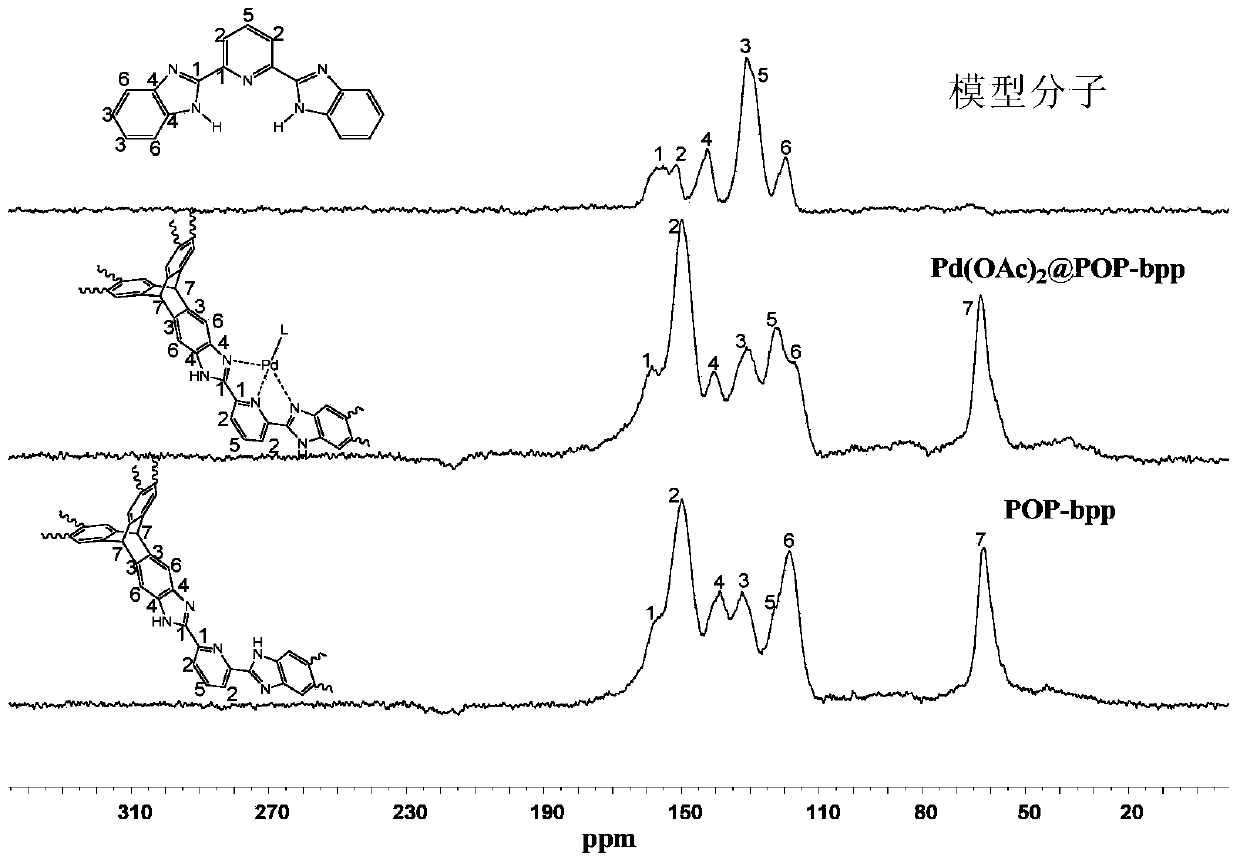

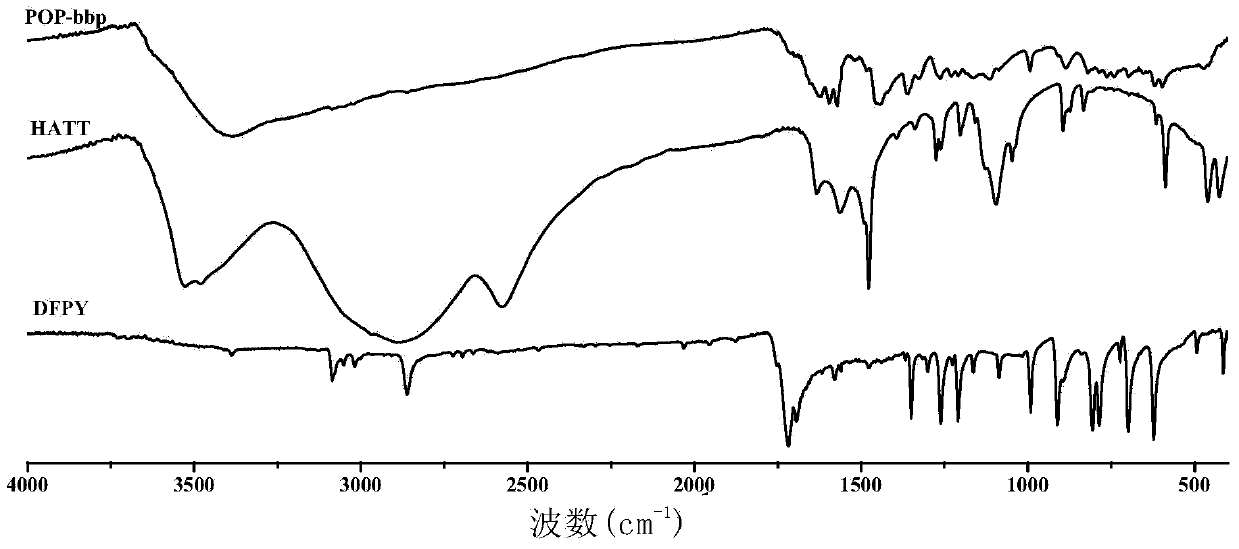

Nitrogen-containing tridentate ligand organic microporous polymer material as well as preparation and application thereof

ActiveCN104211928AEasy to prepareEasy to operateCatalyst carriersOrganic compound preparationBenzimidazoleTriptycene

The invention provides a nitrogen-containing tridentate ligand organic microporous polymer material as well as preparation and an application thereof and particularly provides an organic porous polymer which has a triptycene structural unit and a 2, 6-di(2-benzimidazolyl) structural unit. The triptycene structural unit and the 2, 6-di(2-benzimidazolyl) structural unit have the arrangement mode shown in a formula I. The organic porous polymer provided by the invention is a good adsorbing material and catalyst-loading material and has a good application prospect in metal catalyst loading, particularly noble metal loading.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

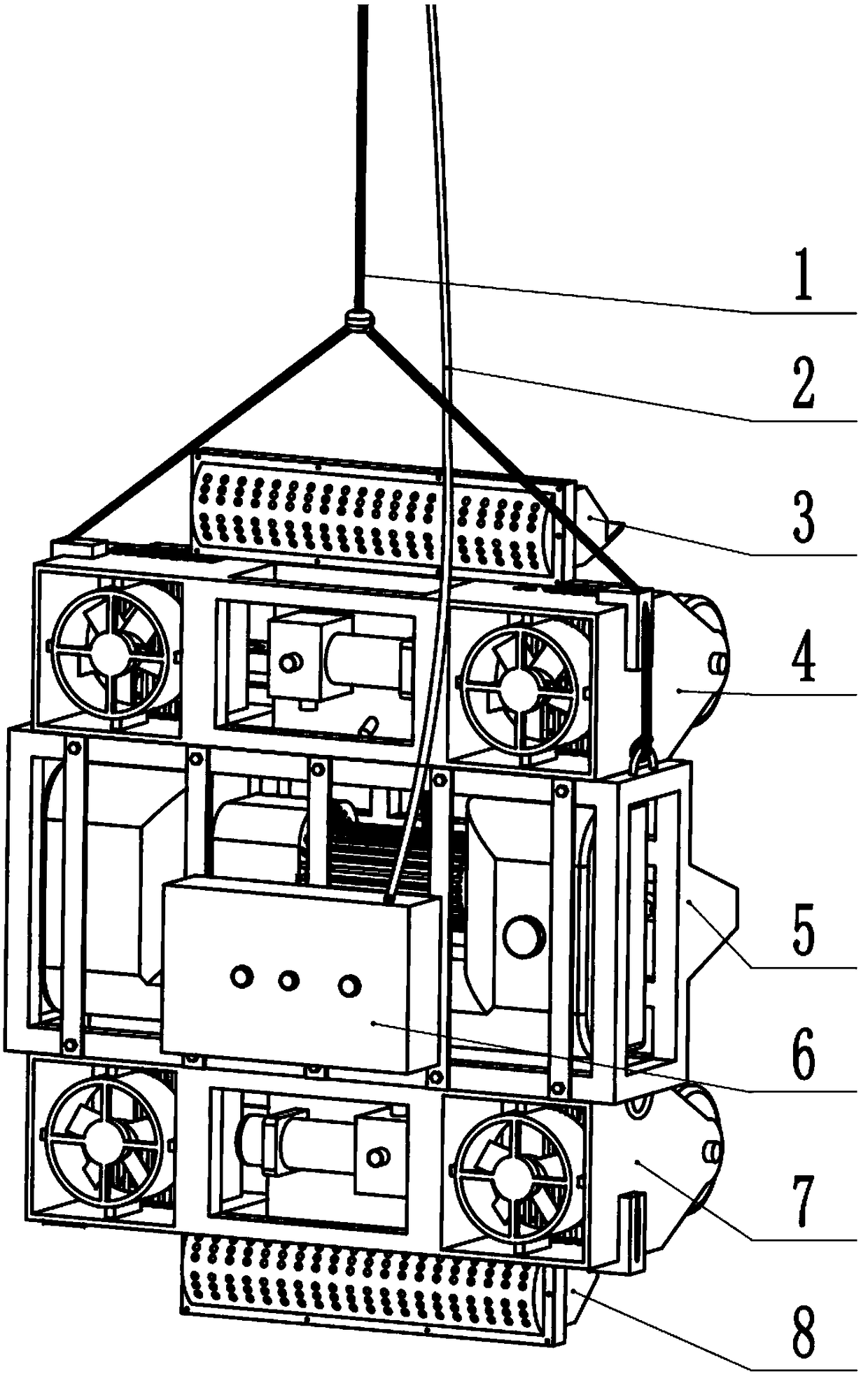

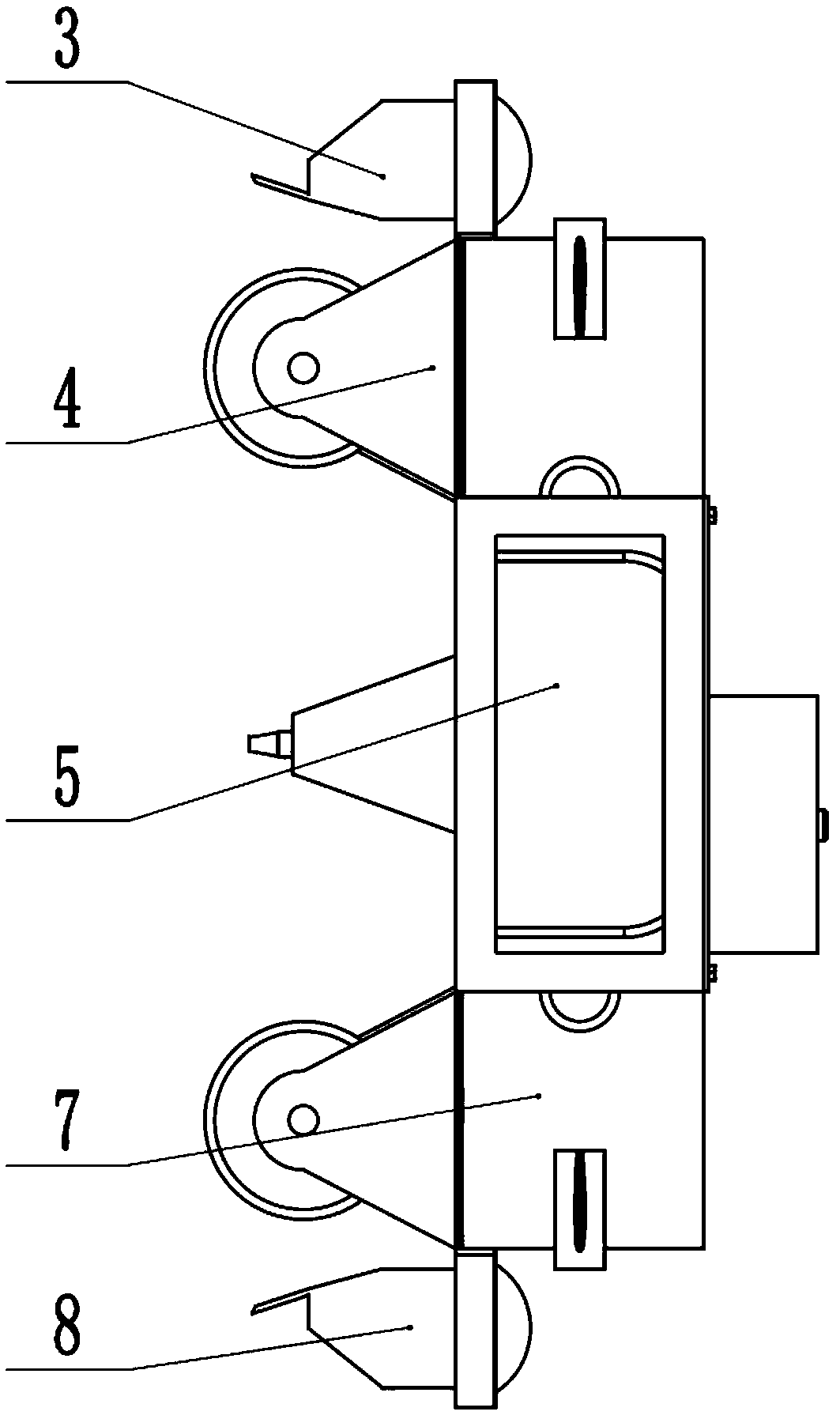

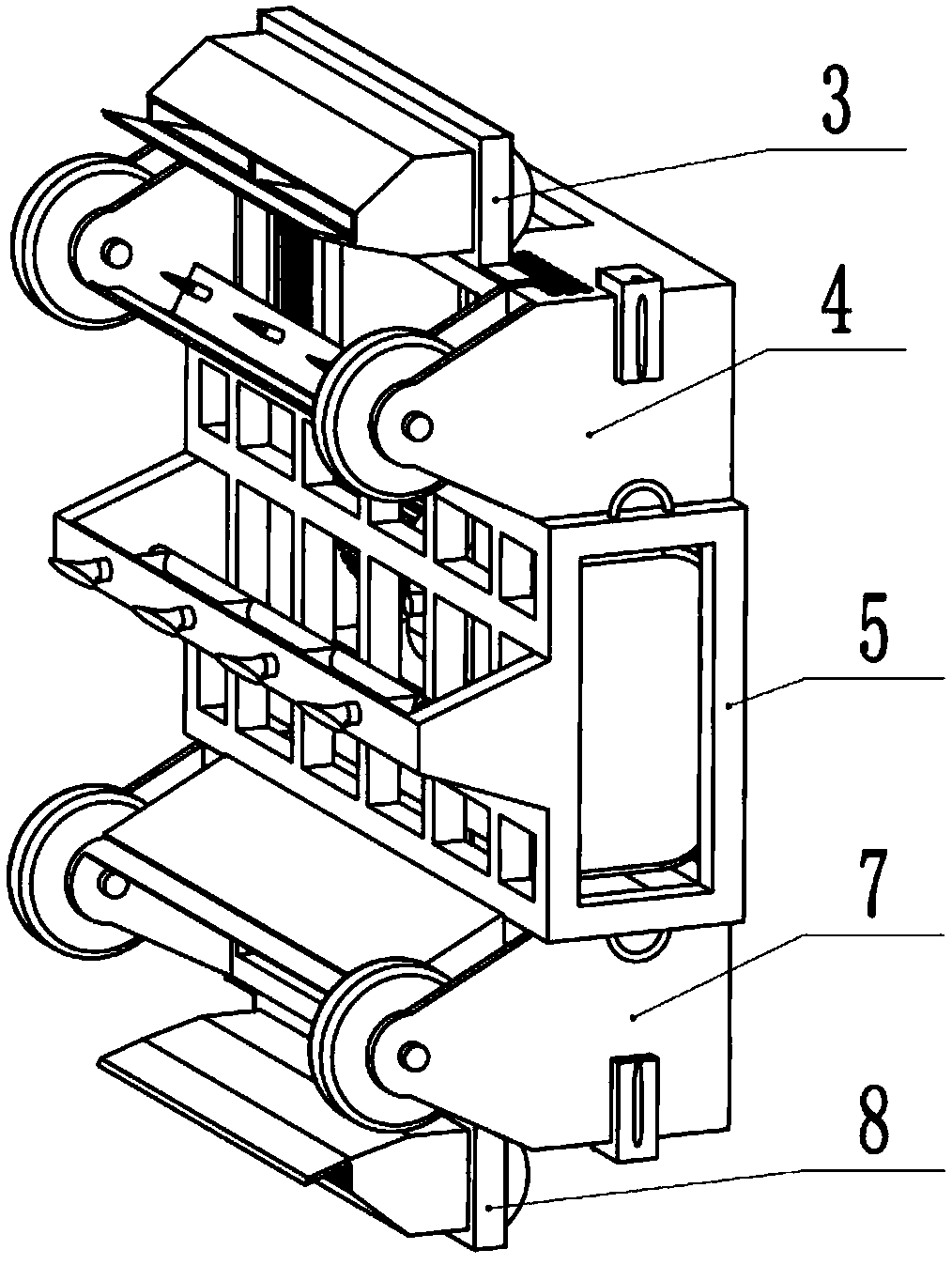

High-rise wall spraying robot

ActiveCN109162431AFully automatedGuaranteed uniformityBuilding constructionsRemote controlControl system

The invention discloses a high-rise wall spraying robot and relates to the technical field of high-rise wall surface spraying. The high-rise wall spraying robot comprises a hoist, an electric cable pay-off and take-up device, a roof moving crane, a panoramic camera, an anemometer, a remote control device, a steel wire rope and a cable line. The roof moving crane is parked on a side close to a wallto be painted. The high-rise wall spraying robot also includes a hot air drying device I, a dust cleaning device I, a spraying device, a control system device, a dust cleaning device II, and a hot air drying device II. The anemometer is also arranged on the mobile crane. The hoist is connected to the spraying device through the steel wire rope. The spraying device is provided with the control system device and the panoramic camera. An upper side of the spraying device is sequentially connected to the dust cleaning device I and the hot air drying device I, and a lower side of the spraying device is sequentially connected to the dust cleaning device II and the hot air drying device II. According to the invention, the automation of the wall surface spraying is realized, the spraying efficiency is improved, the uniformity of the spraying density is ensured, the labor cost is reduced, an artificial high-altitude operation is substituted, and the danger is reduced.

Owner:冠品机具(深圳)流体科技有限公司

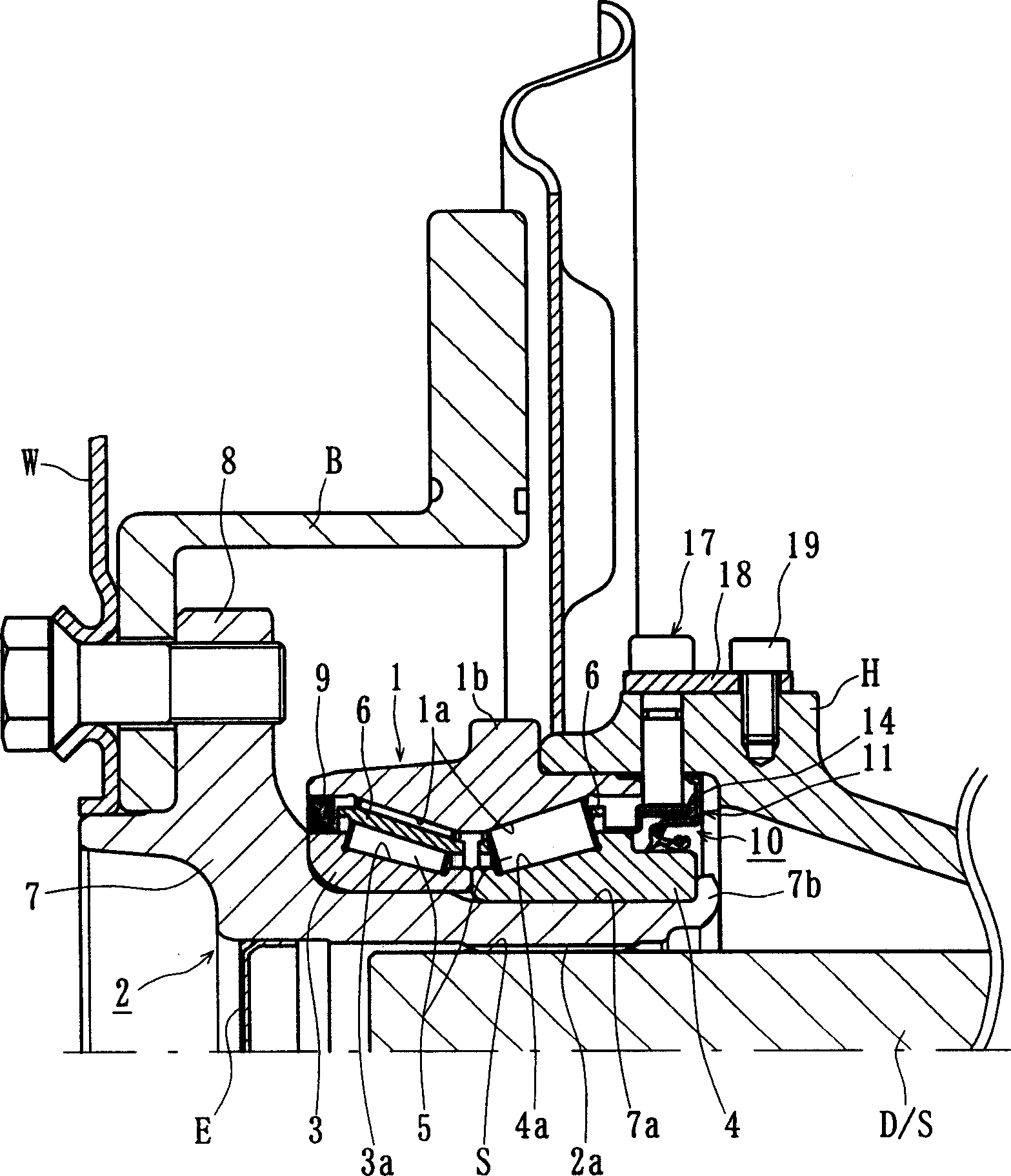

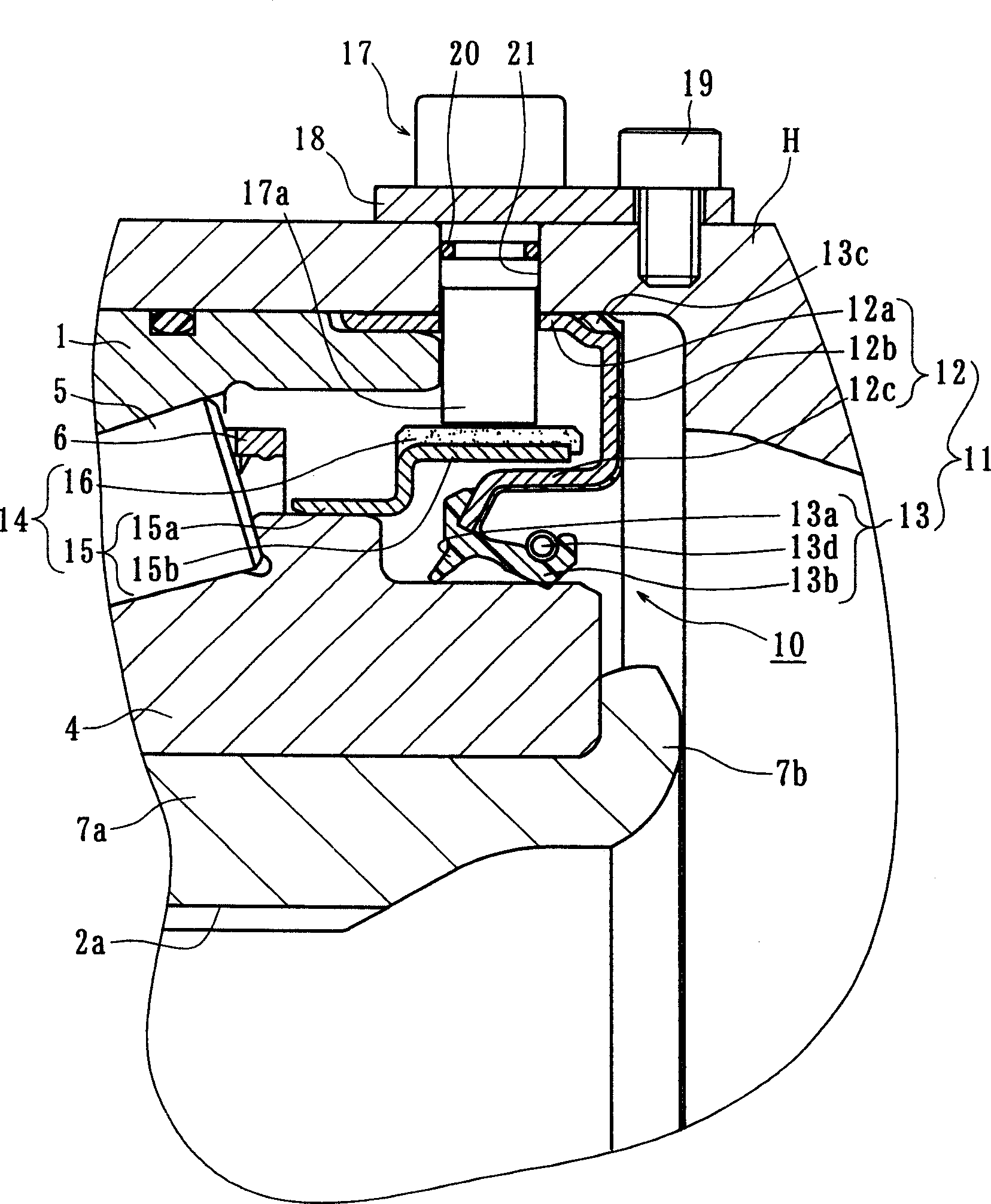

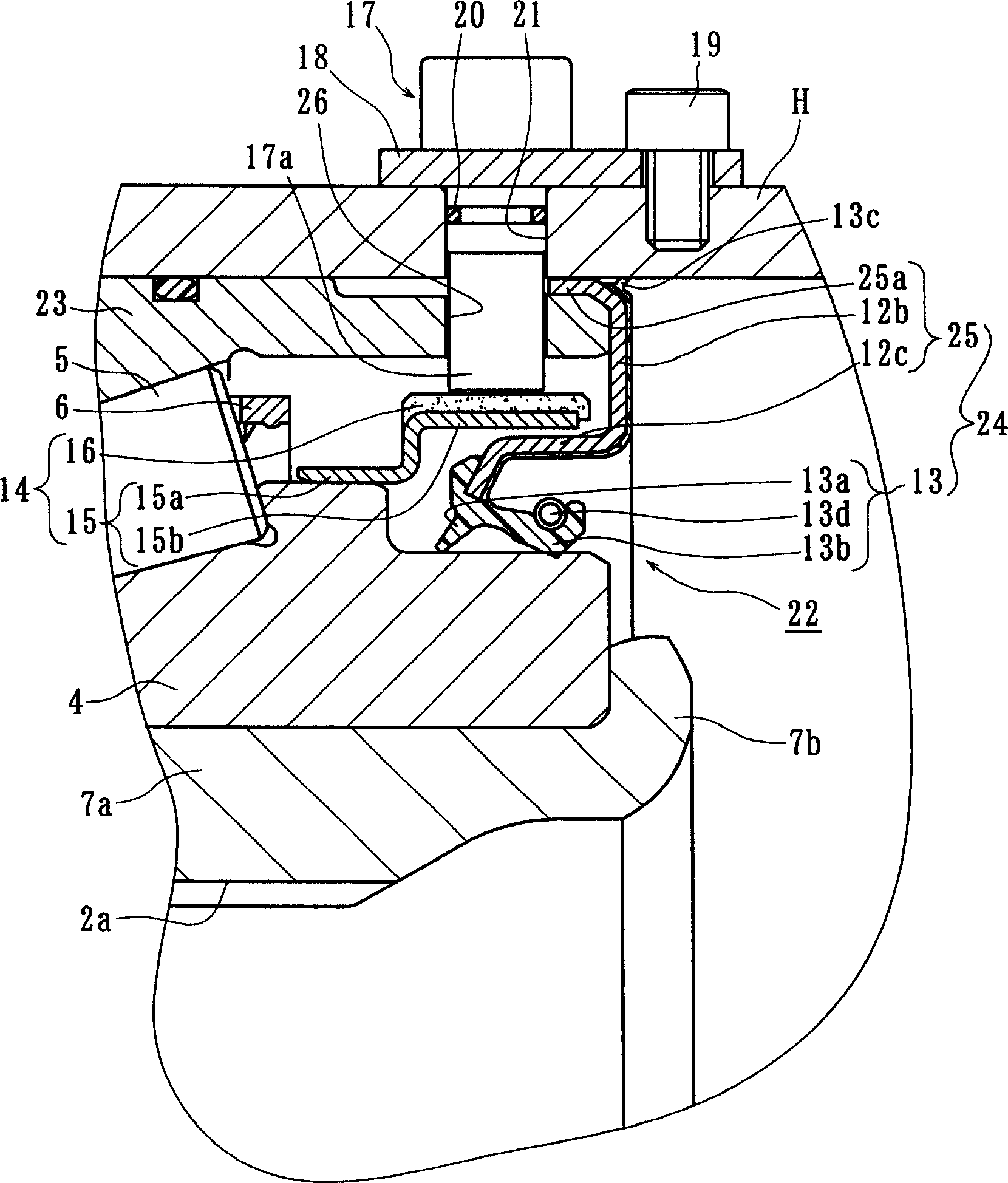

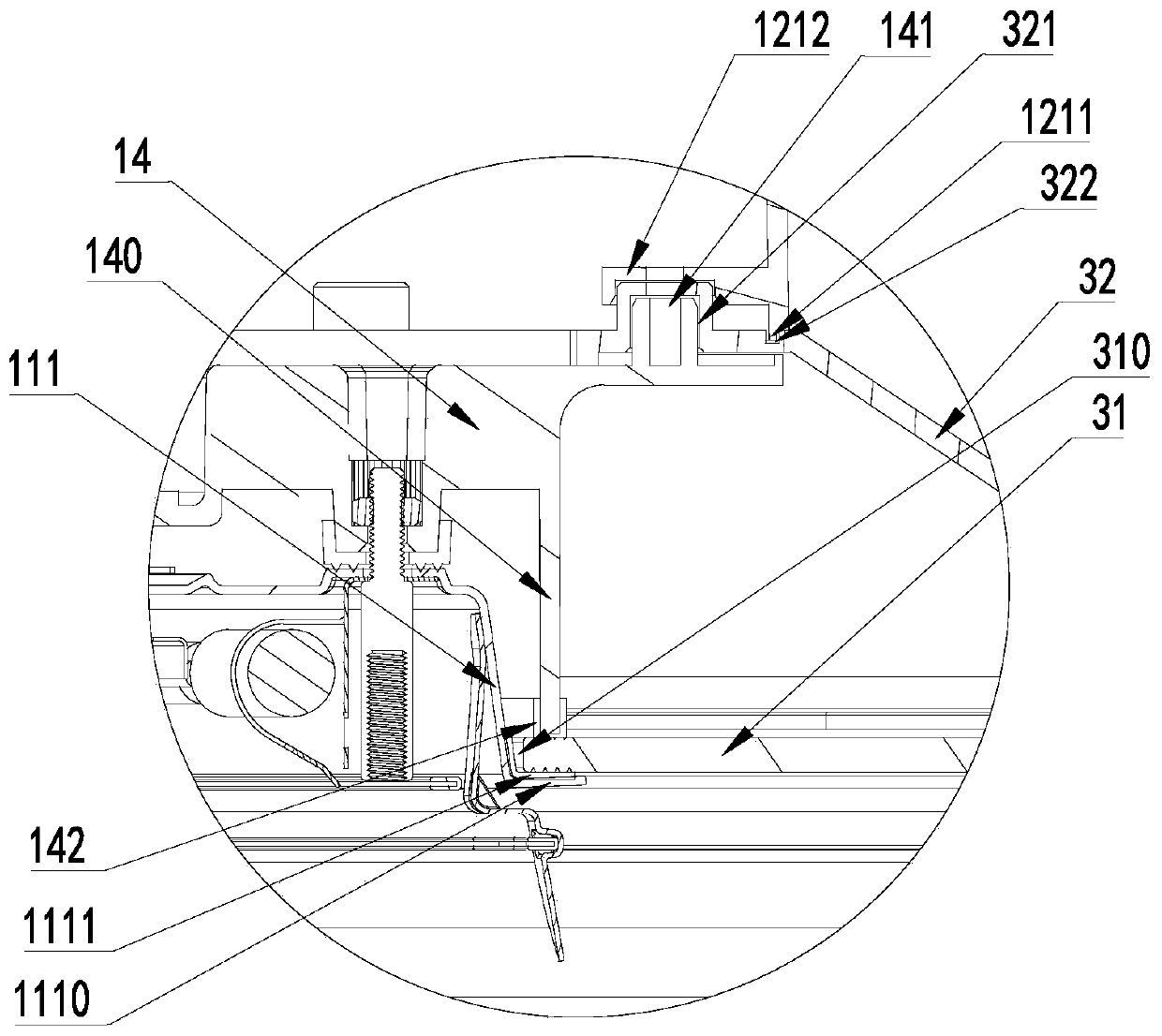

Rolling bearing for a wheel of vehicle and a semi-float type bearing apparatus having it

ActiveCN1573150AGuaranteed areaAvoid enteringEngine sealsRoller bearingsPulsarRolling-element bearing

A vehicle wheel rolling bearing has a sealing device integrated with a magnetic encoder. A semi-float type bearing apparatus has said rolling bearing which can protect a magnetic encoder and improve the sensing ability of the detecting sensor. The rolling bearing has an inner member with a wheel hub having a wheel mounting flange and an inner ring formed with inner raceway surfaces. An outer member is formed with double row outer raceway surfaces opposite the inner raceway surfaces. Double row rolling elements are between the raceway surfaces. Sealing devices include an inboard sealing device with an annular seal fitted on the outer member. A pulsar ring is mounted on the inner member and has an encoder mounted on a cylindrical holding portion. The encoder is arranged opposite to the annular seal. The encoder includes magnetic poles formed by magnetic powder with alternating polarity along its circumferential direction. A detecting sensor passes through the cylindrical portion of the seal and opposes the encoder. A predetermined air gap is kept between the encoder and detecting sensor.

Owner:NTN CORP

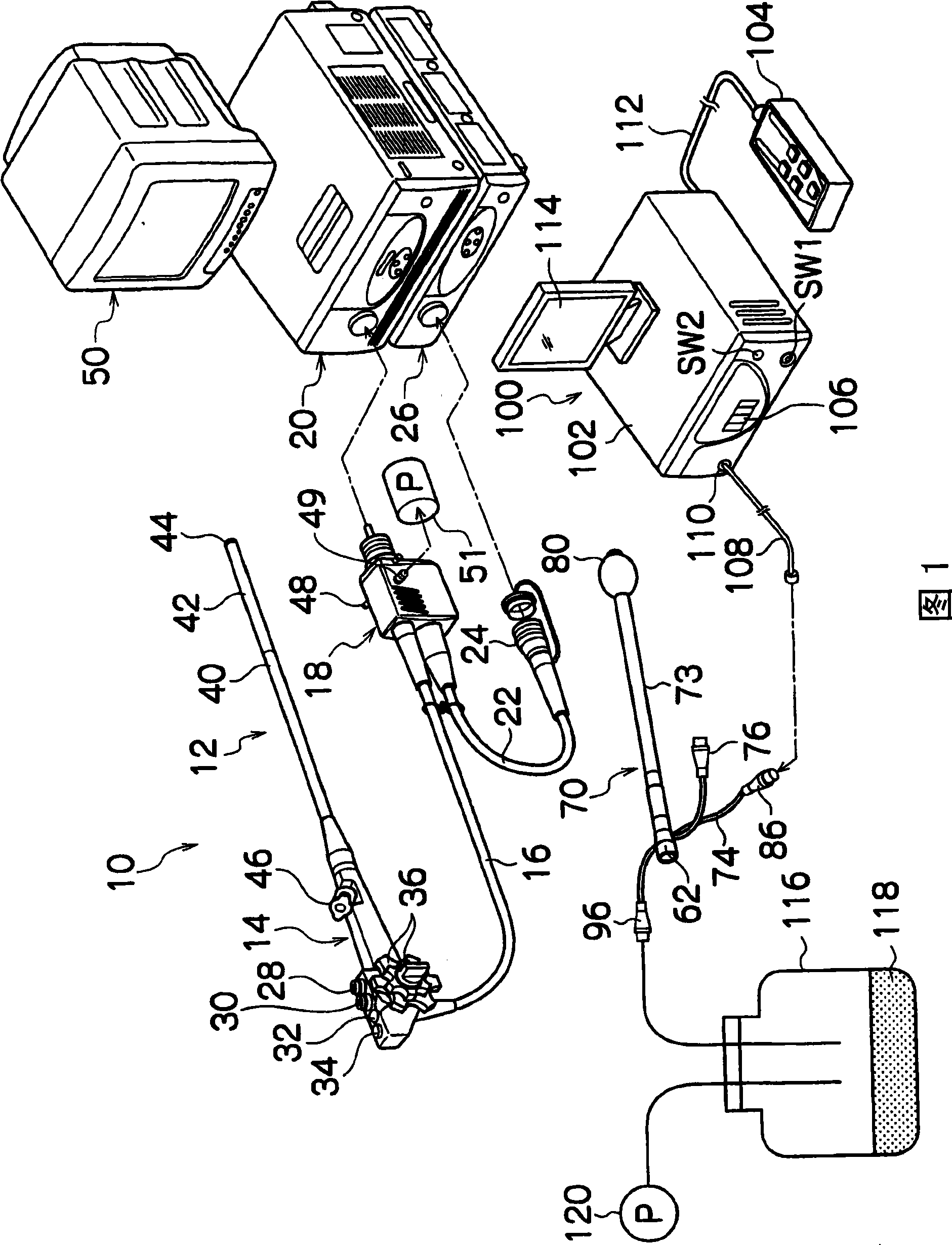

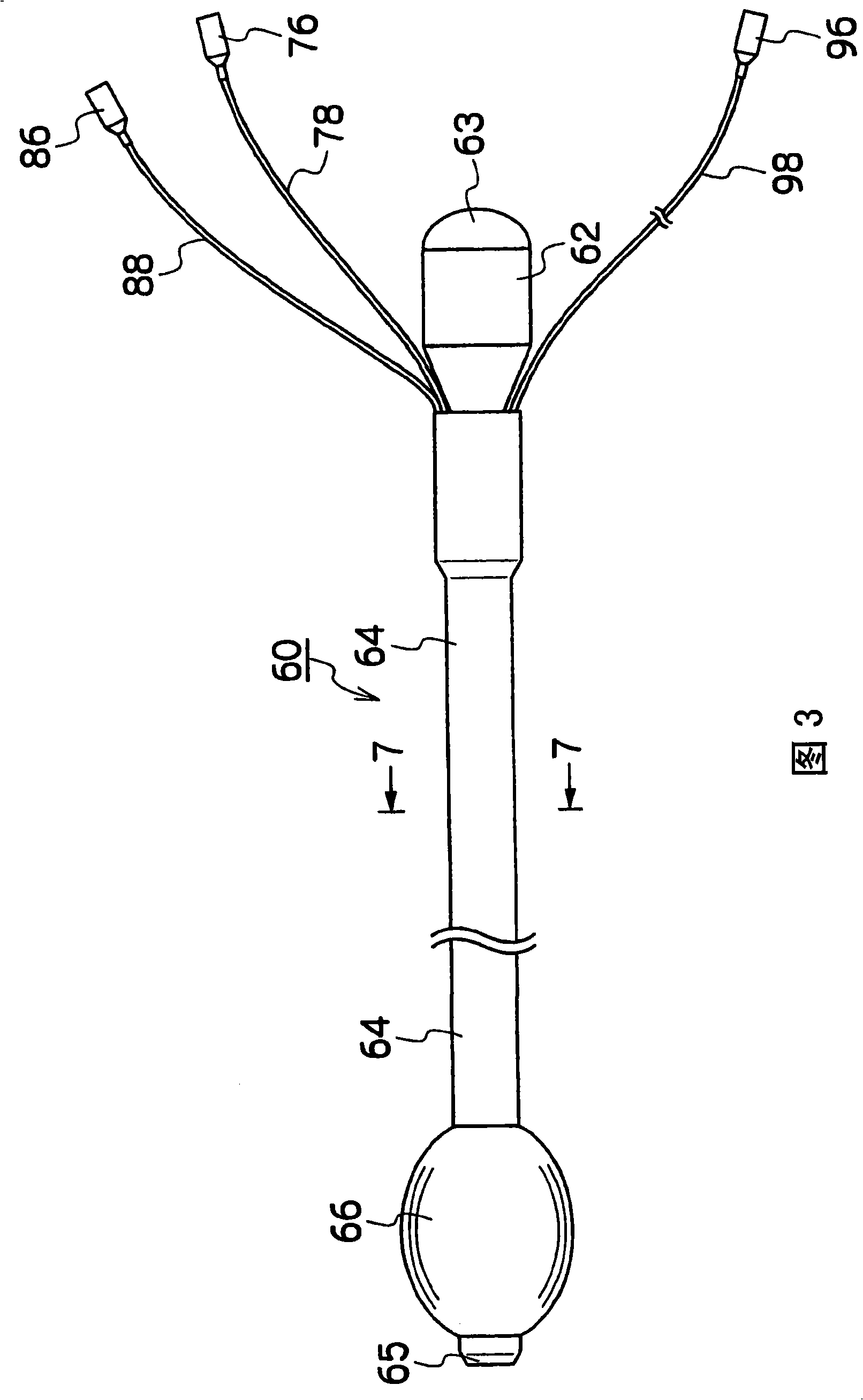

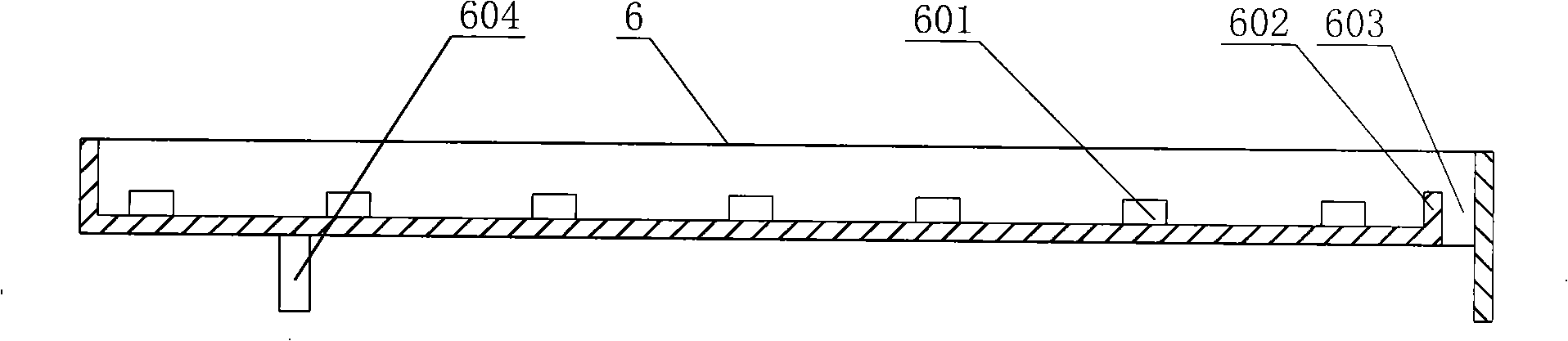

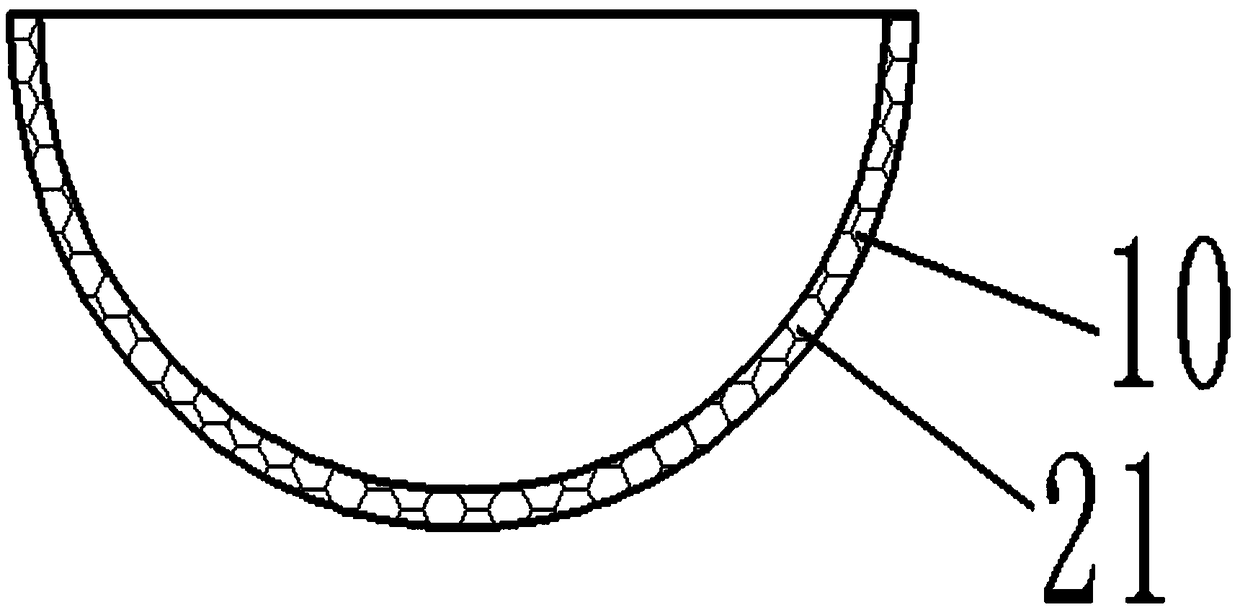

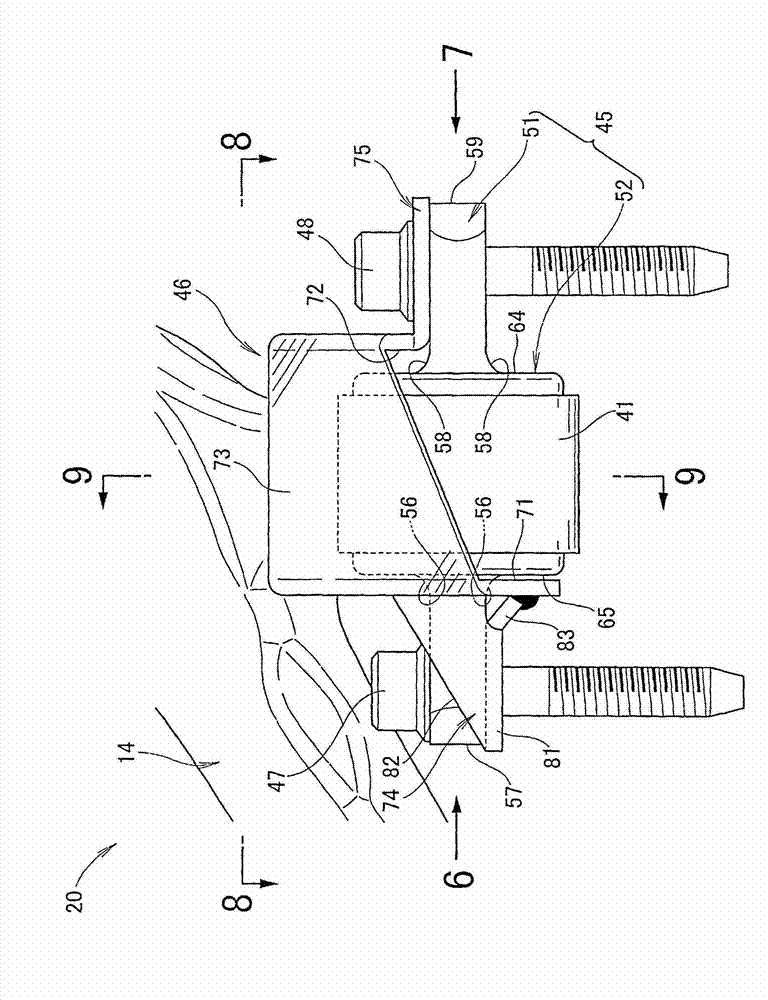

Insertion assisted tool

An insertion assisting tool (60) is provided and includes an insertion path (70) in which the insertion portion of an endoscope is inserted and a tube for fluid (72,74) which is formed along the axial direction at the tubular wall portion of the insertion path. The insertion path has a circular shape in its section orthogonal to the axial direction. The tube is configured in a manner that the sectional shape thereof along the axial direction is longer in the circumferential direction than the radial direction.

Owner:FUJI PHOTO OPTICAL CO LTD

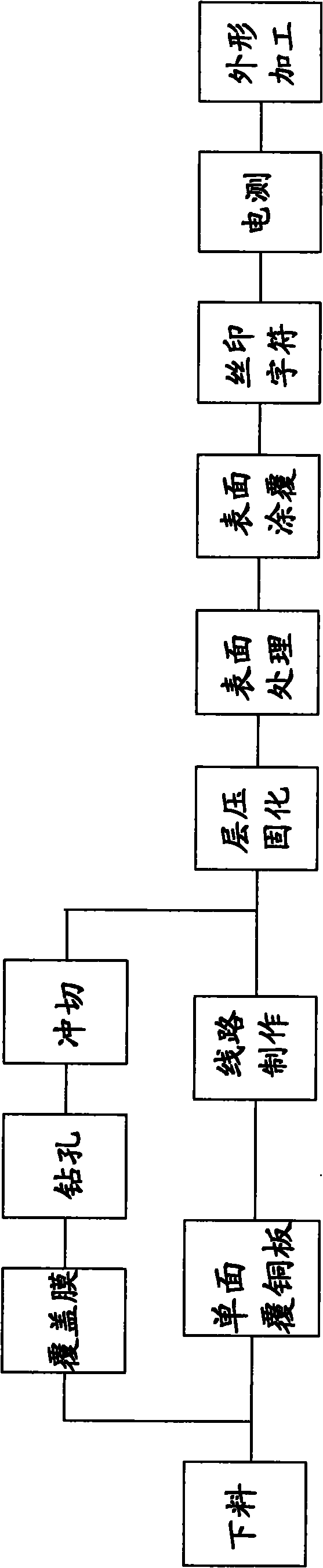

Manufacture method of single-sided flexible circuit board

ActiveCN101917824ASimple structureGuaranteed weldingPrinted circuit secondary treatmentPunchingFlexible circuits

The invention relates to a manufacture method of a single-sided flexible circuit board. The method comprises the following steps of: baiting; then, making a circuit and a laser alignment cross target on a copper foil layer of an S-CCL (Single-sided Copper Clad Laminate); attaching a cover film drilled with cover film alignment holes and other auxiliary holes onto the circuit surface to laminate and solidify; adopting laser to cut a bottom substrate opening at a copper-exposed part on a substrate layer of the S-CCL; then, removing residues of the copper-exposed part through plasma treatment; and finally obtaining a single-sided flexible circuit board through the processes of surface treatment, surface coating, electrical measurement, punching and molding. The finger region substrate can be fully removed through laser cutting to avoid the influence of an overflowing adhesive of the cover film on golden fingers; since the accuracy of laser cutting and alignment is high, the accuracy of the opening size of the bottom substrate is improved so as to ensure the welding and splicing areas of the golden fingers; in addition, since the golden fingers ar protected by the surrounding substrate, the antistripping strength of the golden fingers is improved so as to improve the manufacture yield rate of the single-sided flexible circuit board product.

Owner:厦门弘信智能科技有限公司

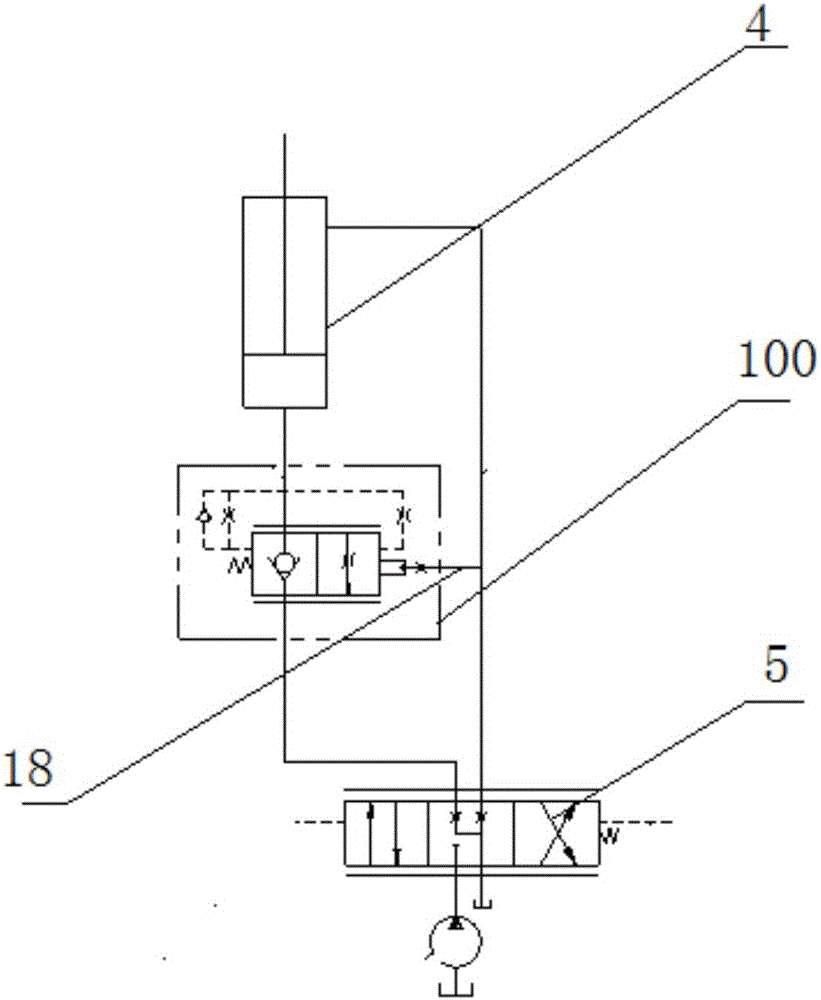

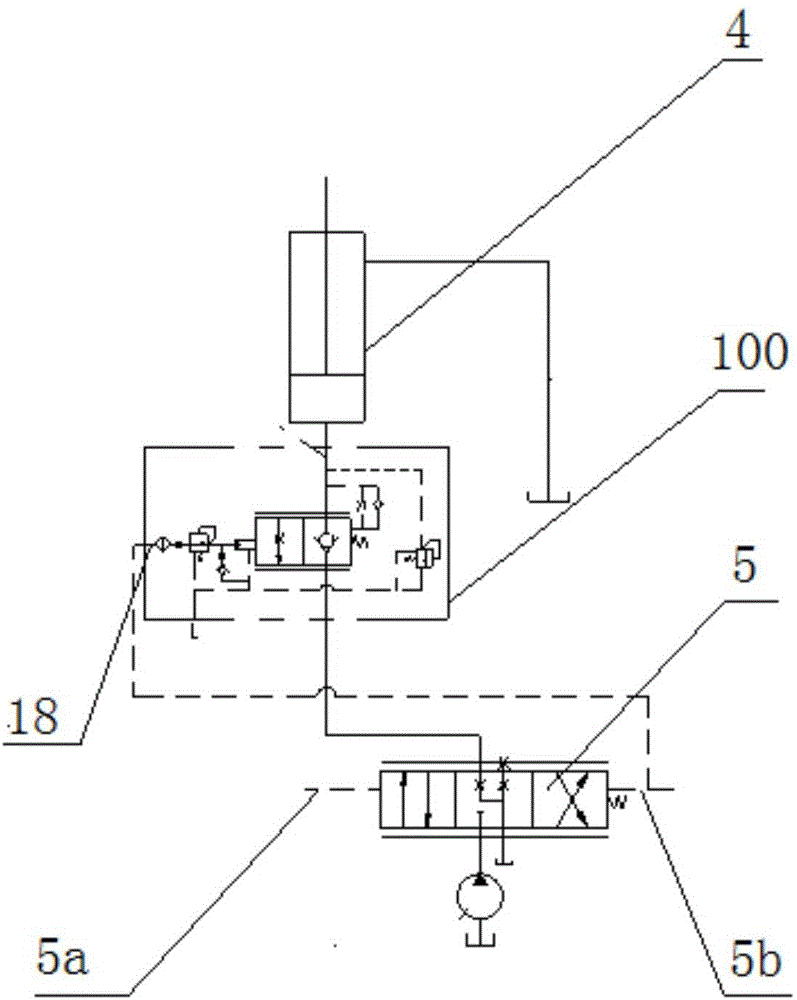

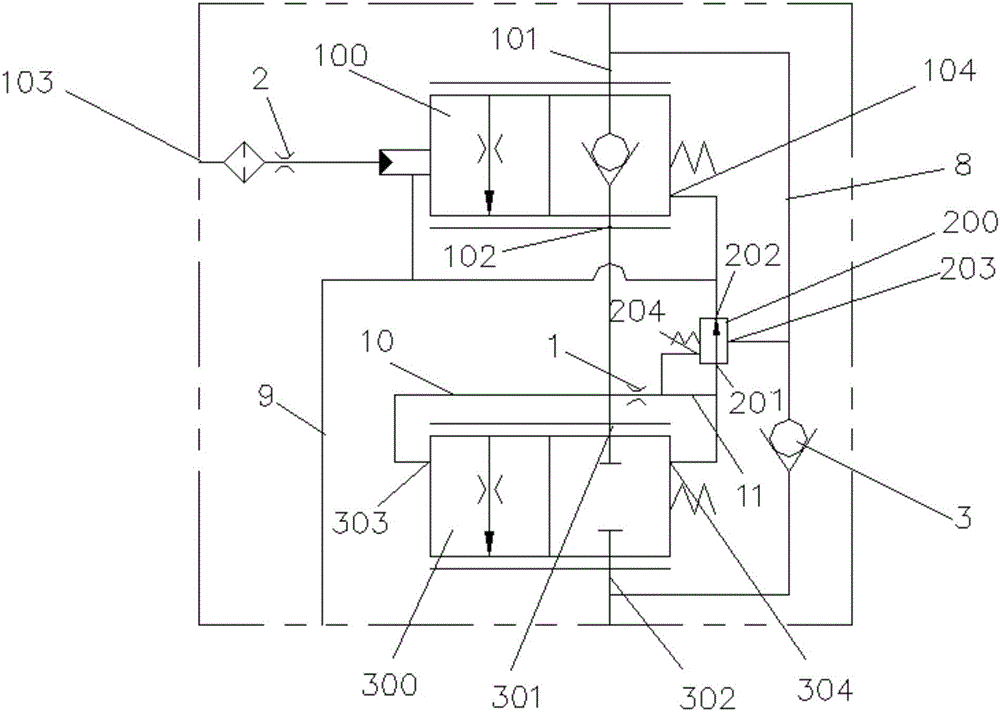

Balance valve group and hydraulic system

The invention discloses a balance valve group and a hydraulic system. The balance valve group comprises a balance valve (100), wherein the balance valve (100) is provided with a first balance valve working port (101) leading to loads, a second balance valve work oil opening (102) leading to an oil source or an oil tank, a balance valve hydraulic control cavity (103) and a balance valve spring cavity (104), and the balance valve hydraulic control cavity (103) and the balance valve spring cavity (104) are located at the two ends of a valve element of the balance valve (100). The balance valve group further comprises a pressure compensation device connected with the balance valve (100). Therefore, when hydraulic oil sequentially passes through the first balance valve work oil opening (101) and the second balance valve work oil opening (102) from the loads and flows back to the oil tank, the pressure difference between the first balance valve work oil opening (101) and the second balance valve work oil opening (102) keeps constant, and the flow amount of the hydraulic oil passing through the balance valve (100) depends on the position of the valve element of the balance valve instead of the pressure of the loads.

Owner:CHANGDE ZHONGLIAN ZHONGKE HYDRAULIC +1

Display panel and display device therefor

ActiveCN107871775AReduce manufacturing difficultyGuaranteed areaSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceComputer science

The invention discloses a display panel and a display device therefor. The display panel comprises an array substrate and a package substrate, wherein the array substrate comprises a substrate, a plurality of subpixels located on the substrate and arranged in an array, and spacer columns; the plurality of subpixels include a plurality of first pixels of a first color, a plurality of second pixelsof a second color and a plurality of third pixels of a third color, wherein each third pixel comprises at least two third subpixels; the edge of each third pixel is provided with recesses toward the inside of the pixel at the adjacent sides of two third subpixels; and at least one part of each spacer column is located in the corresponding recess.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Low nitrogen oxide burner of fuel gas heating water heater

ActiveCN106642109AImprove fire stabilityThe overall thickness is thinGaseous fuel burnerCombustorLow nitrogen

The invention discloses a low nitrogen oxide burner of a fuel gas heating water heater. When the low nitrogen oxide burner is applied, fuel gas and air mixed gas directly rushes upwards through a fuel gas mixing inlet injection pipe; when the fuel gas and air mixed gas collides a fuel gas guide concave bag, due to blocking of the fuel gas guide concave bag, a part of fuel gas and air mixed gas flows to the two sides, the other part of fuel gas and air mixed gas is directly upwards to enter a mixed gas groove, part of fuel gas and air mixed gas is straightly upwards to burn at the top of a fire dividing hole, the other small part of fuel gas and air mixed gas is blocked by a fire receiving hole separating plate to generate positive pressure, and under the influence of the positive pressure, part of gas enter an outer side fuel gas mixing gas dividing groove from a transverse fuel gas and air mixing air flow outlet hole and burns in an outer side burning hole; and the top of a burner shell cover is provided with a plurality of flame burning holes through a plurality of transverse plates in a mesh dividing manner, and the fire power of fire behaviors generated by burning is strong; meanwhile, the flame area is greatly increased, and burning is more sufficient.

Owner:黄婉平

Preparation method of graphene for heater

InactiveCN106276874AHigh degree of oxidationIncrease layer spacingSingle layer grapheneAfter treatmentHydrogen

The invention relates to the technical field of graphene, in particular to a preparation method of graphene for a heater. The method is characterized in that the graphene is prepared by adopting an oxidation-reduction method and specifically comprises the following steps: firstly, peroxidation of the graphene; secondly, oxidization of graphite, wherein oxidation treatment comprises four stages, namely low-temperature reaction, medium-temperature reaction, high-temperature reaction and after treatment; in the low-temperature reaction and the medium-temperature reaction, an ultrasonic and mechanical stirring combined action is adopted, and hydrogen is introduced into a reaction system; thirdly, preparation of the graphene, wherein a drying mode in the preparation process adopts freeze drying. According to the preparation method of the graphene for the heater, provided by the invention, a production process is controllable, and large-scale production can be realized; nano ions are not easy to agglomerate in the preparation process; a prepared graphene crystal is complete in structure and excellent in conductivity.

Owner:ANHUI NINGGUO TIANCHENG ELECTRICAL APPLIANCES

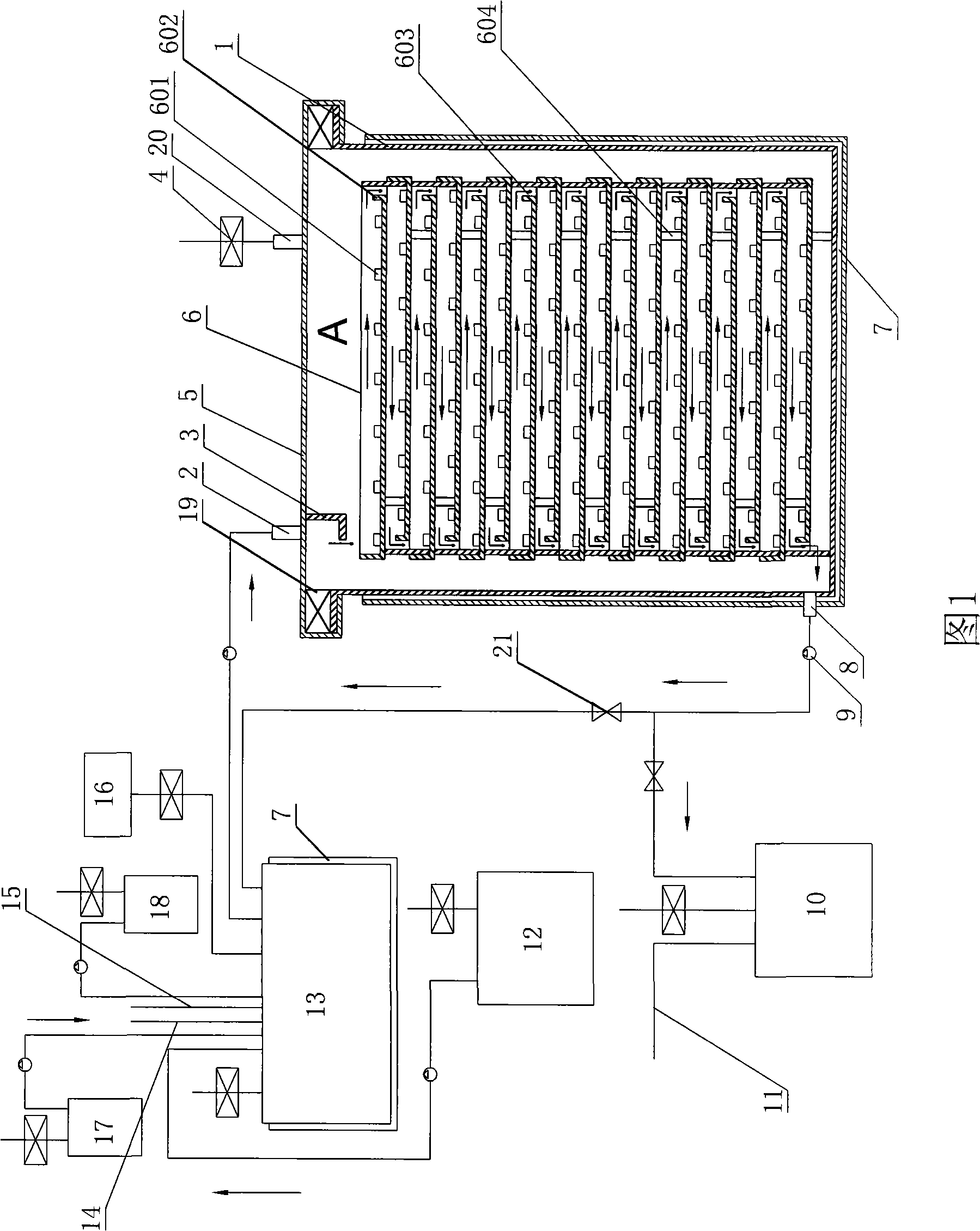

Bioreactor for producing tissue engineering products

ActiveCN101402917AGood scalabilitySimple structureBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid interfaceCartilage

The invention relates to a bioreactor for producing tissue engineering products, which comprises a waste liquid bottle, a fluid replacement bottle, a liquid storage bottle, a four-nature mixer, an acid liquor bottle, an alkali liquor bottle and a bioreaction box assembled by a reaction box body, a reaction box cover, layer boxes, a constant temperature jacket and a sealing gasket. The layer boxes are superposed from bottom to top in an alternate manner of forward direction and backward direction in the reaction box; the overflow gutter of the pan of the upper layer is over the opposite end of the overflow gutter of the pan of the lower layer, and one end of the overflow gutter of the pan at the lowest layer is close to the liquid outlet of the reaction box body and one end of the positioning pin of the pan at the uppermost layer is arranged below a liquid baffle. Compared with the prior art, the bioreactor has good expansibility, simple structure, small volume, few pipes, high universal property and wide application range, is suitable for mass production, not only applicable for the culture of tissue engineering skin at gas-liquid interfaces to produce tissue engineering skin but also for the systemization and production of scaffold tissue engineering products (such as bones, cartilage, muscle tendon and the like).

Owner:威力保生物技术(成都)有限公司

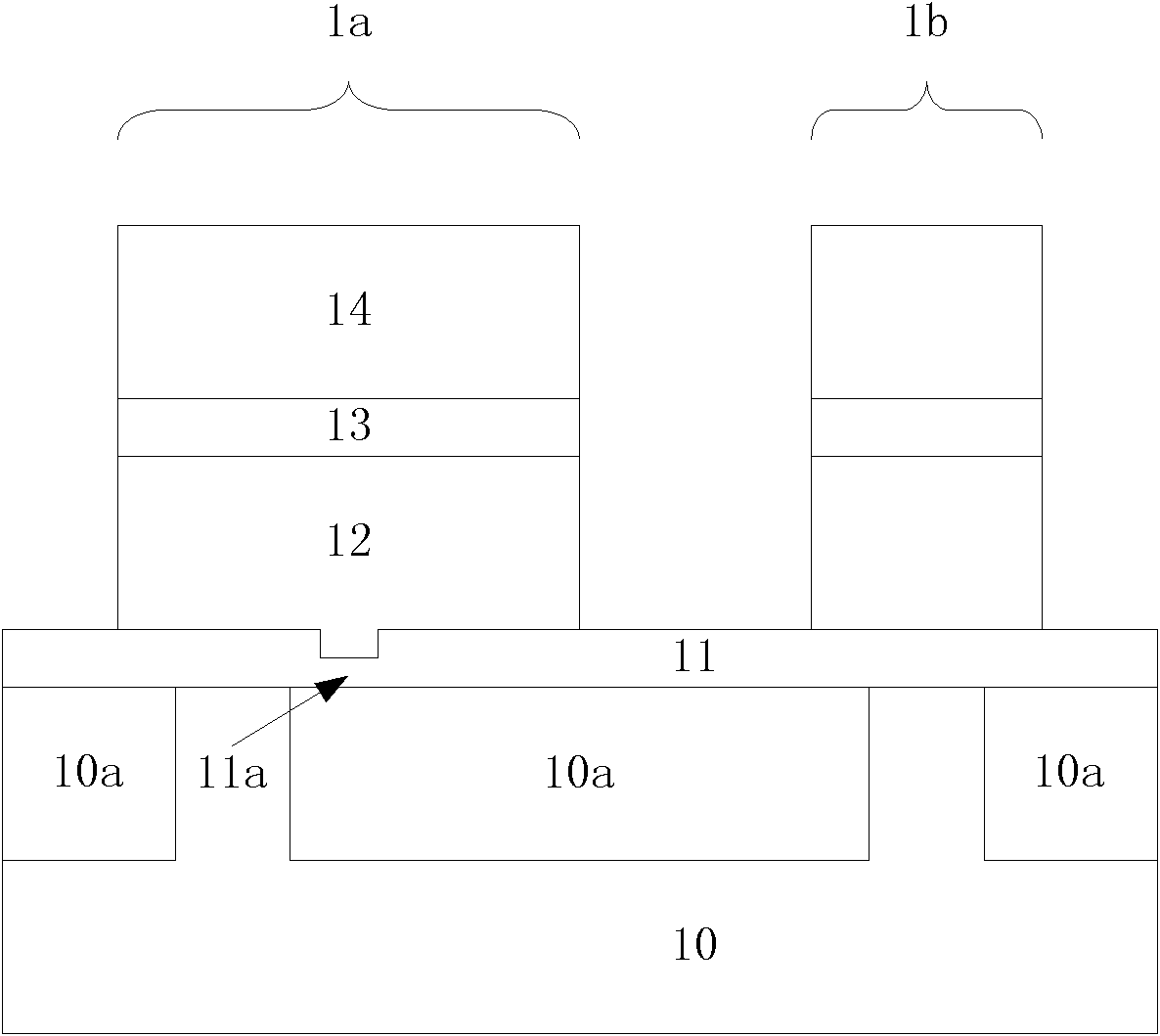

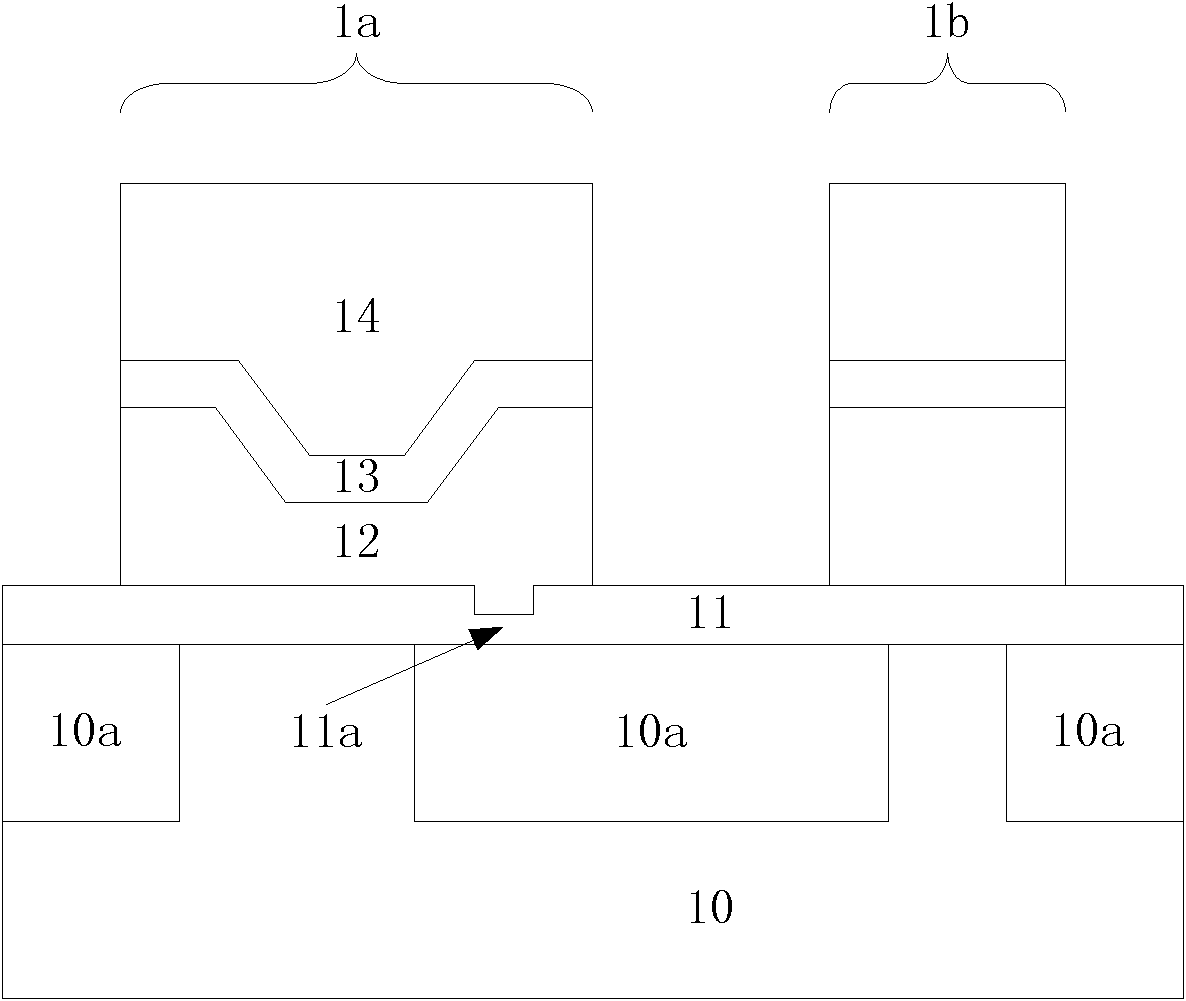

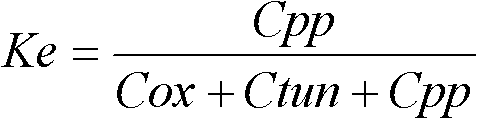

Floating gate type EEPROM (Electrically Erasable Programmable Read Only Memory) device and manufacturing method thereof

InactiveCN102760737AIncrease capacitor areaIncreased Voltage Coupling EfficiencyTransistorSolid-state devicesCoupling efficiencyEtching

The invention discloses a floating gate type EEPROM (Electrically Erasable Programmable Read Only Memory) device. A memory cell of the EEPROM device comprises a memory transistor and a selection transistor, wherein the memory transistor comprises a floating gate positioned at the lower part and a control gate positioned at the upper part; and a dielectric layer is arranged between the floating gate and the control gate, and is in a curved surface shape. The invention further discloses a manufacturing method of the device, which mainly comprises the step that the floating gate is subjected to shallow trench etching, so that the dielectric layer is in the concave curved surface shape. Compared with the traditional flat dielectric layer, the capacitance area is increased; and the increased capacitance is proportional to the depth of a shallow trench, so that the voltage coupling efficiency and the coupled voltage are increased, and the area of the existing device can be kept or even reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

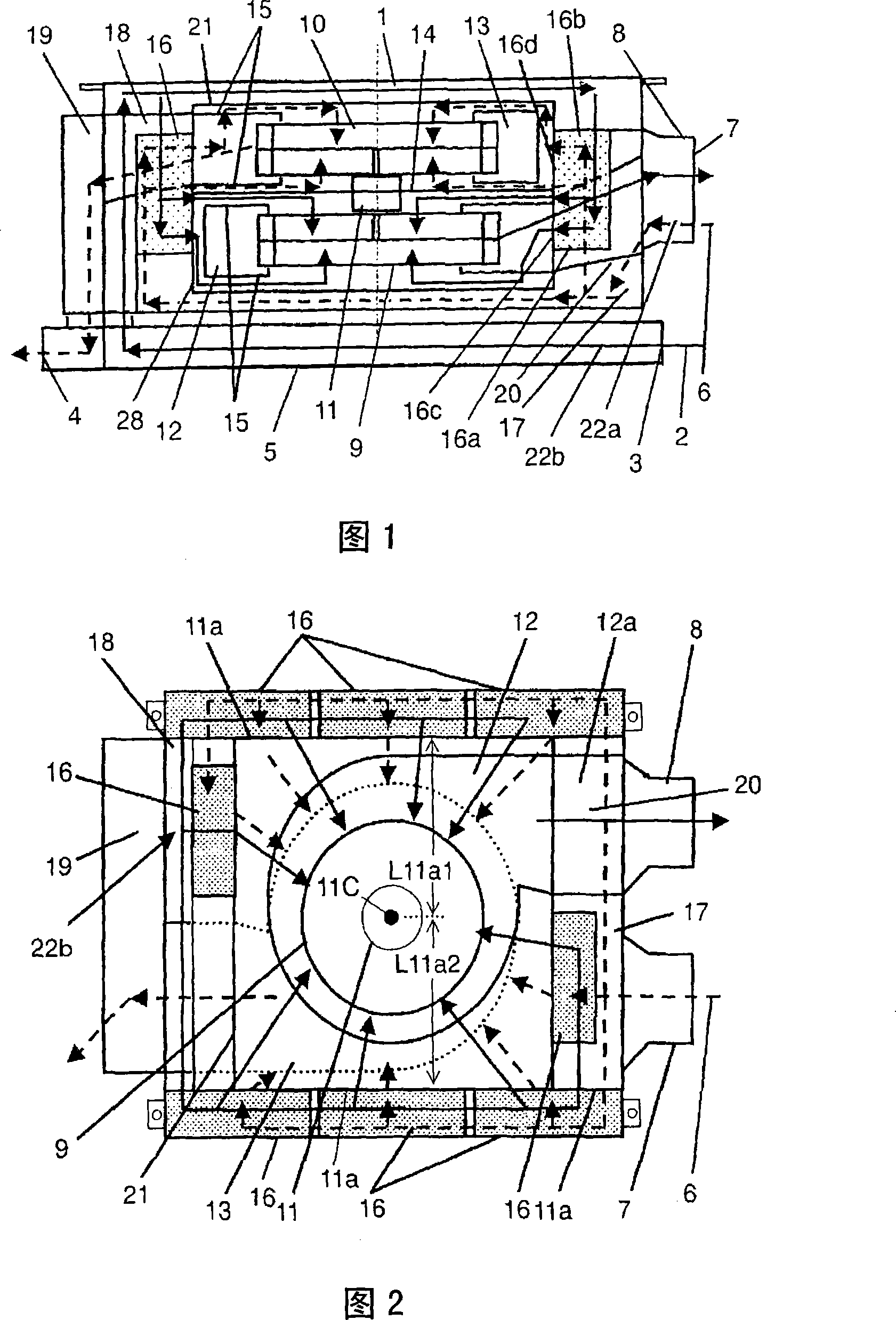

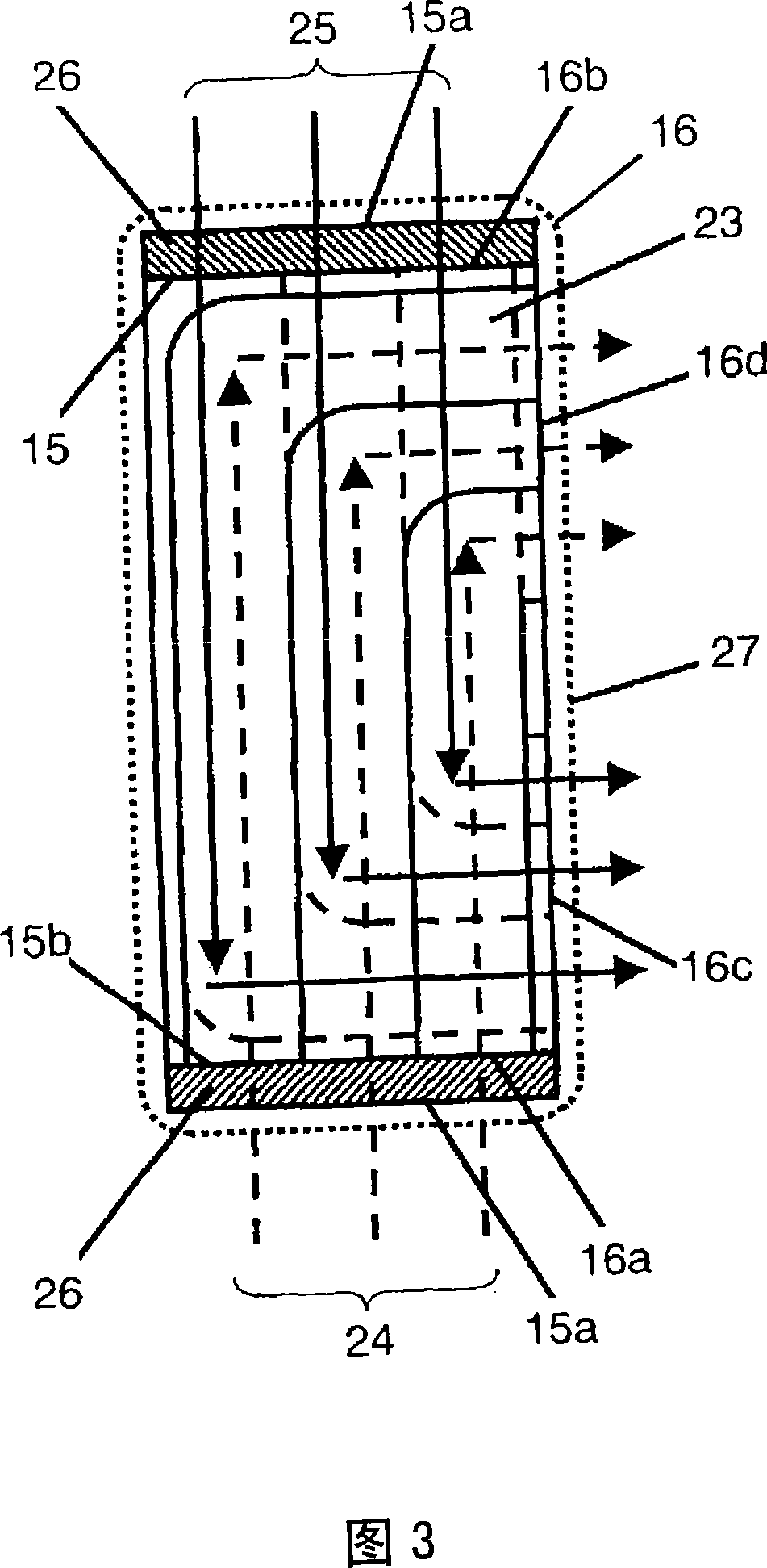

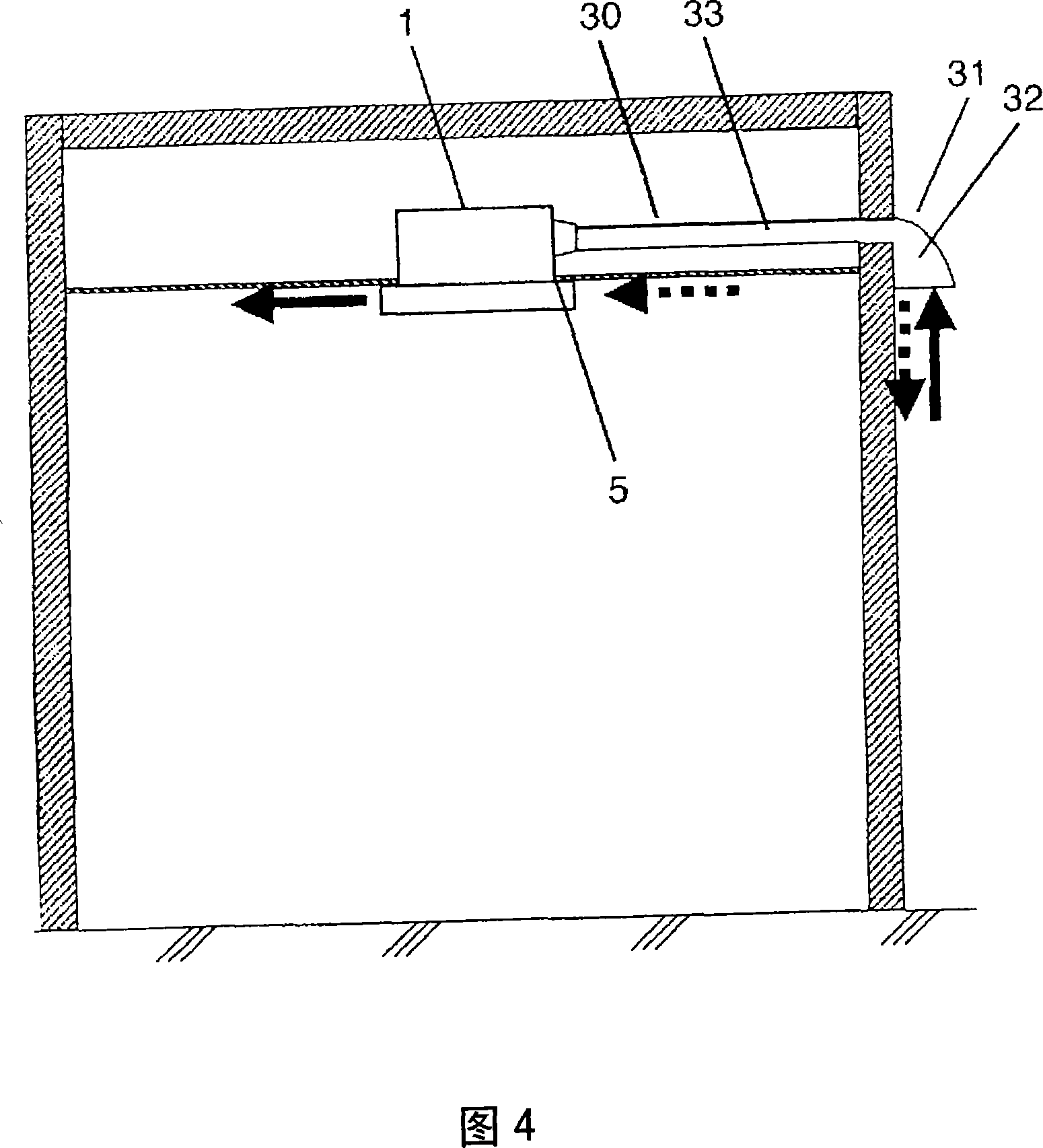

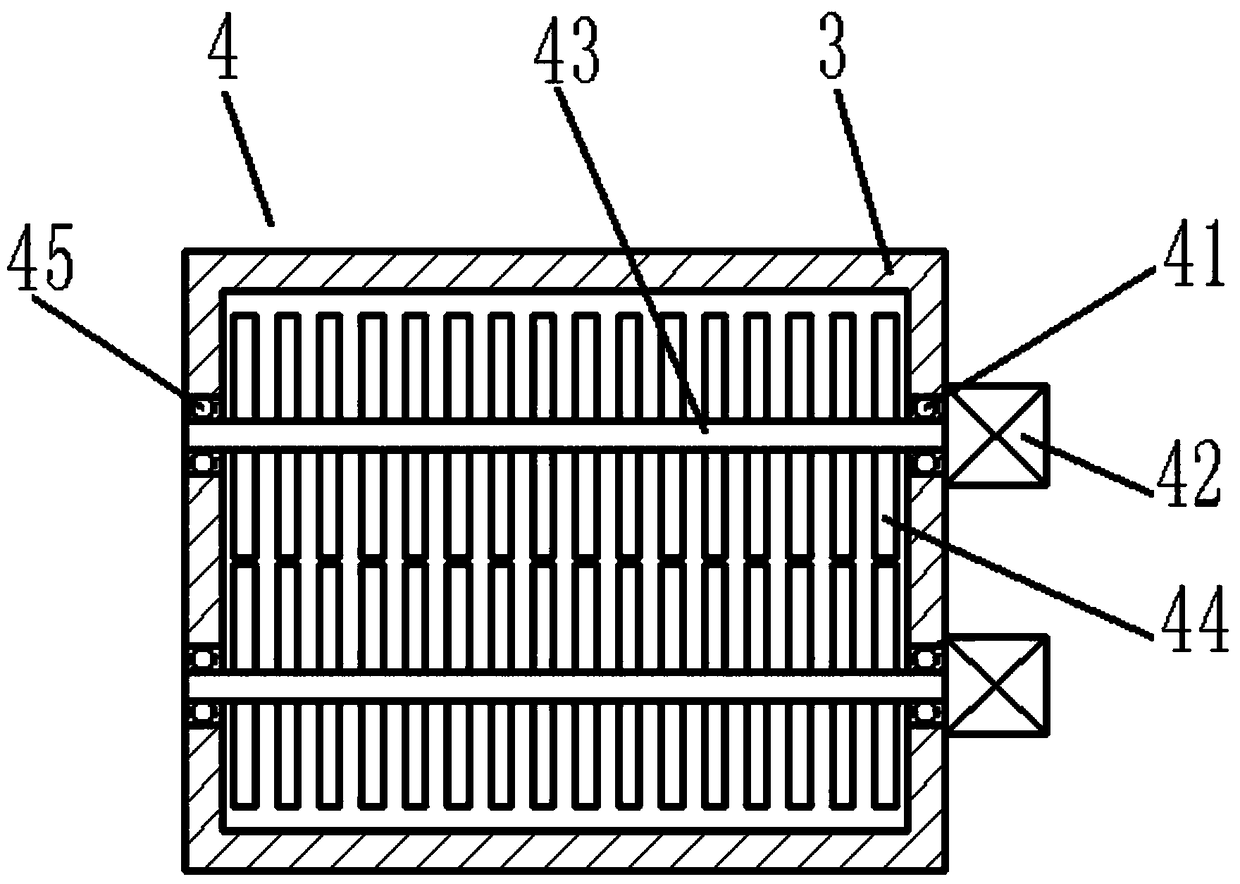

Heat exchanger

InactiveCN101198825AImprove heat exchange performanceSmall pressure lossEnergy recovery in ventilation and heatingHeat recovery systemsIndoor airEngineering

A heat exchanger of small size and thin type is provided. It includes a machine body (1), an indoor suction port (3) for sucking indoor air (2), an indoor diffuser (4), an outdoor suction port (7) for sucking in outdoor air (6), an outdoor diffuser (8), a motor (11) provided inside the machine body (1), an exhaust blade (9) and an intake blade (10) disposed at the motor (11), an exhaust fan casing (12) provided around the exhaust blade (9), an intake fan casing (13) provided around the intake blade (10), and a plurality of heat exchange elements (16) disposed around the exhaust fan casing (12) and intake fan casing (13).

Owner:PANASONIC CORP

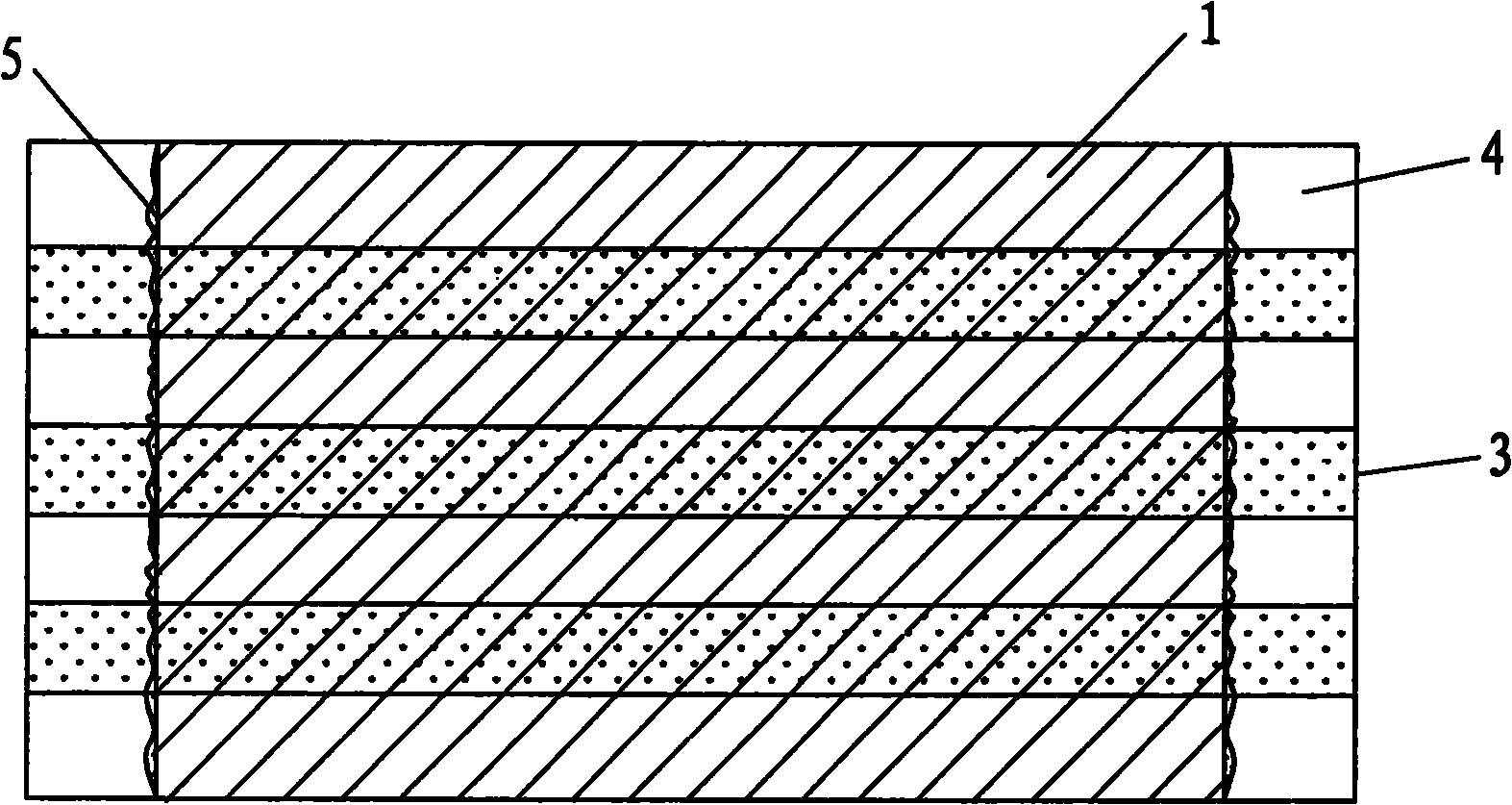

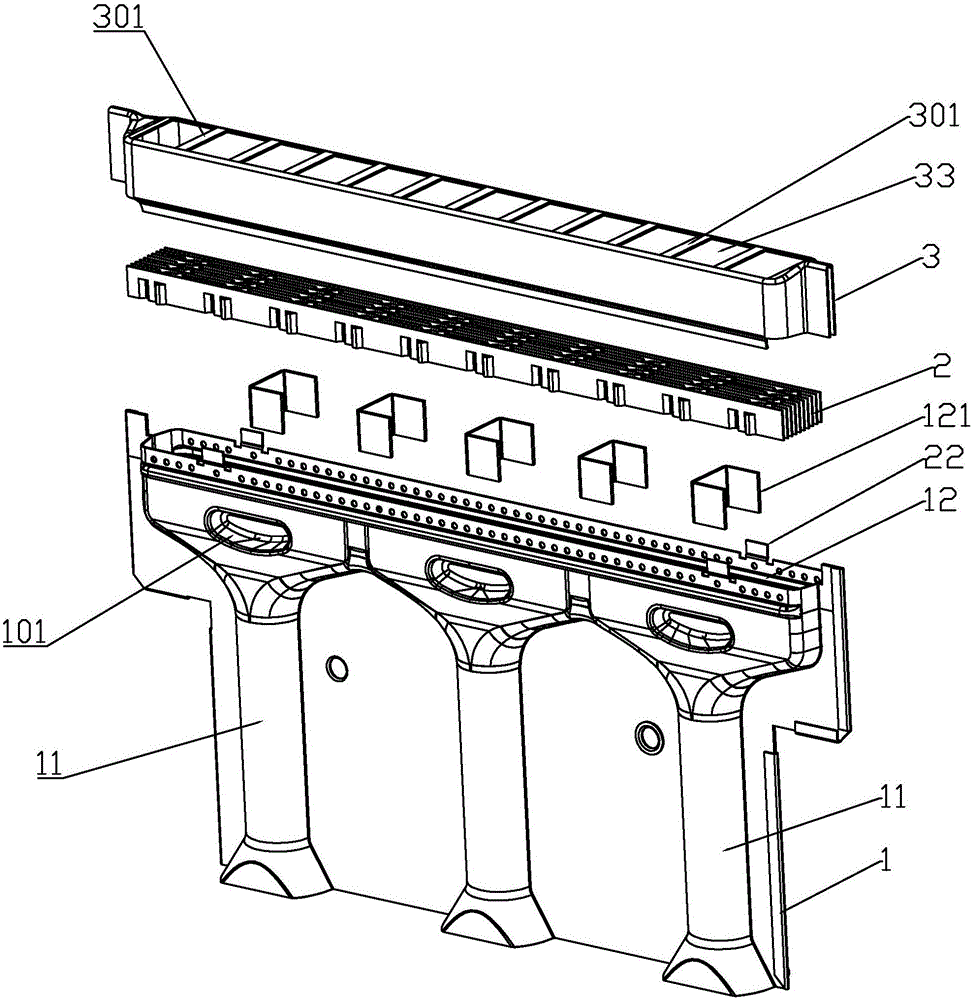

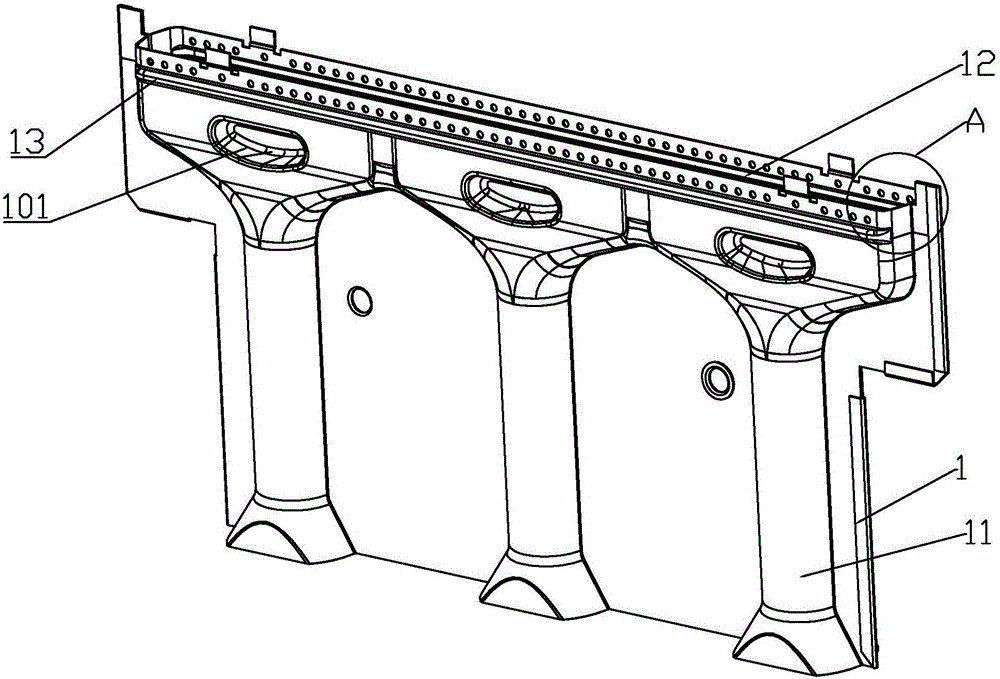

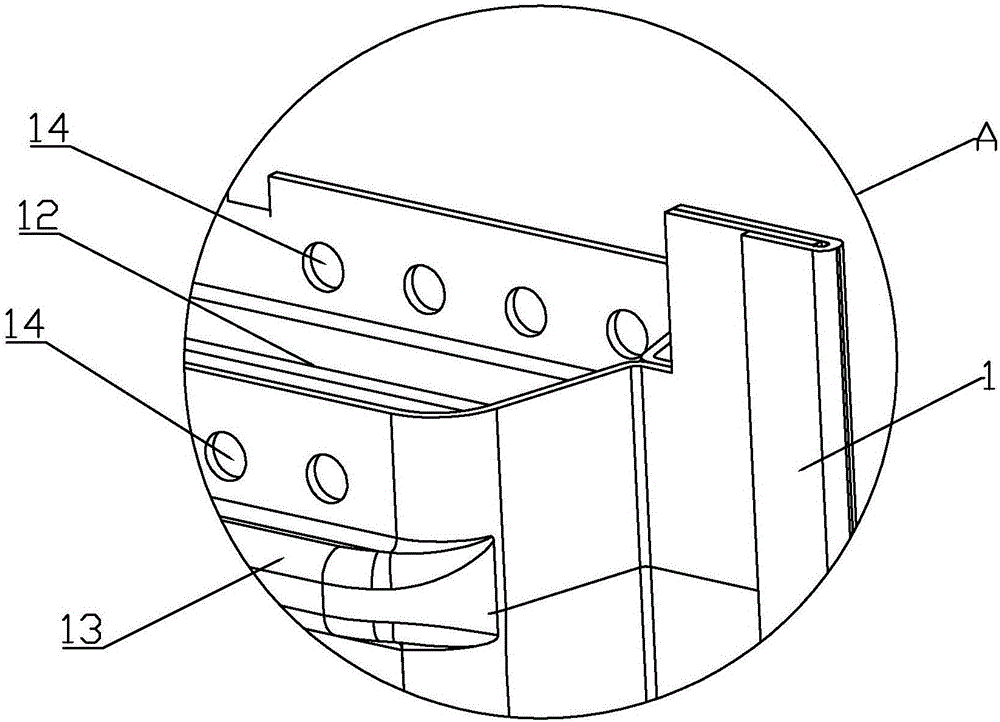

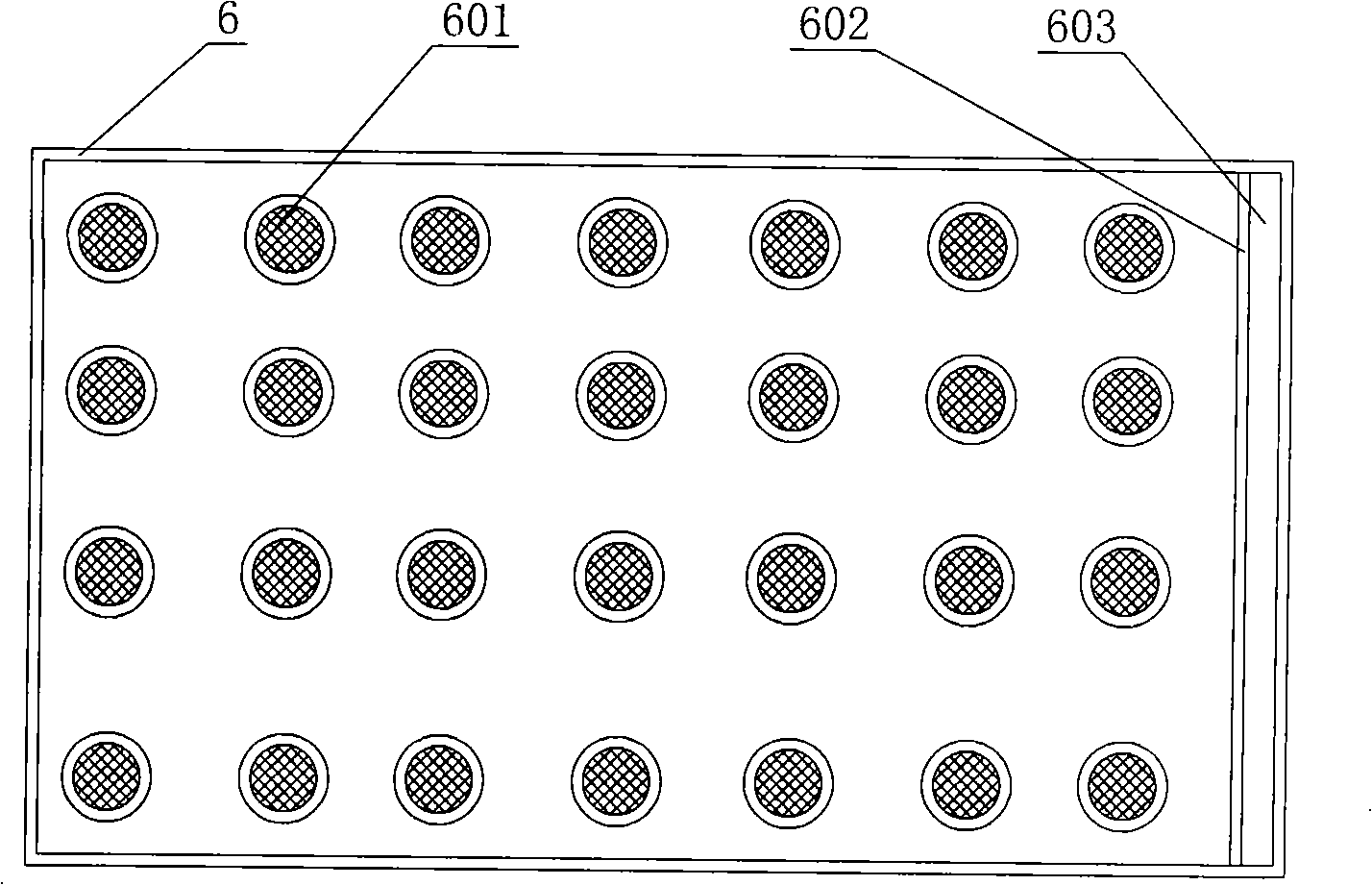

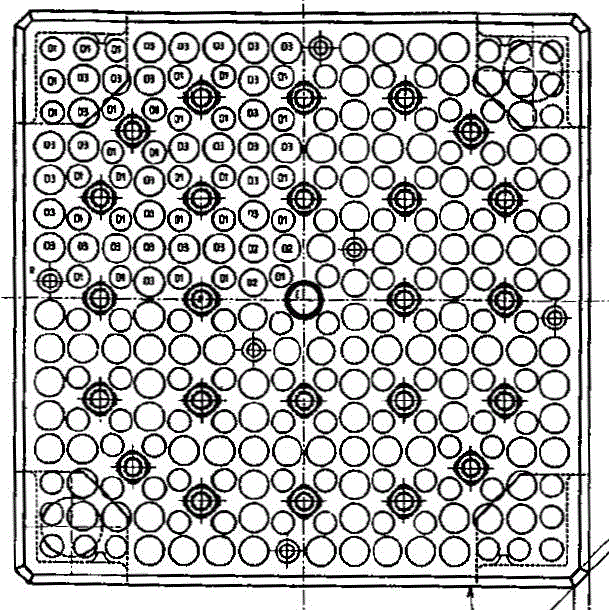

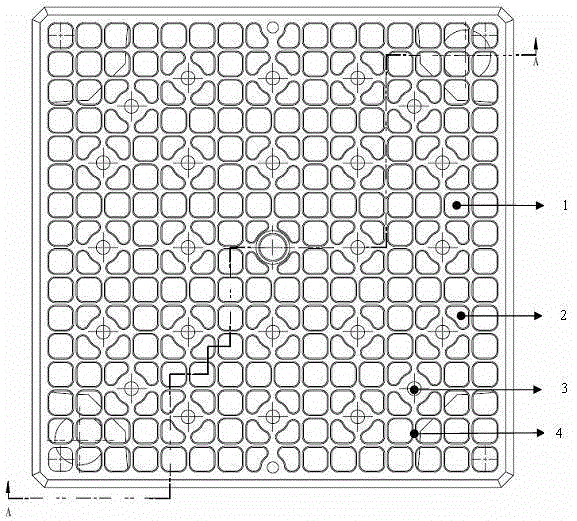

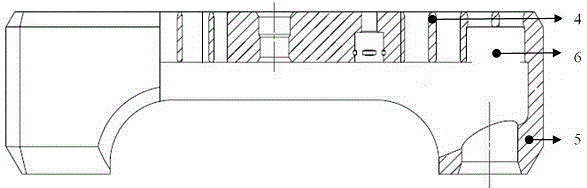

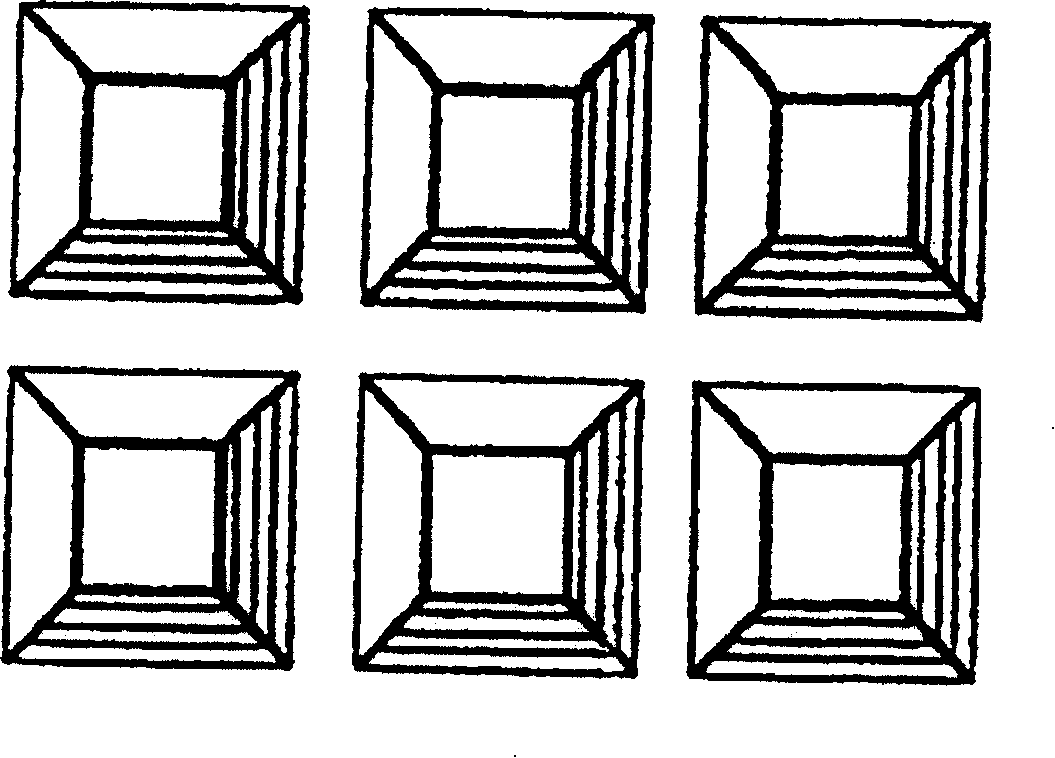

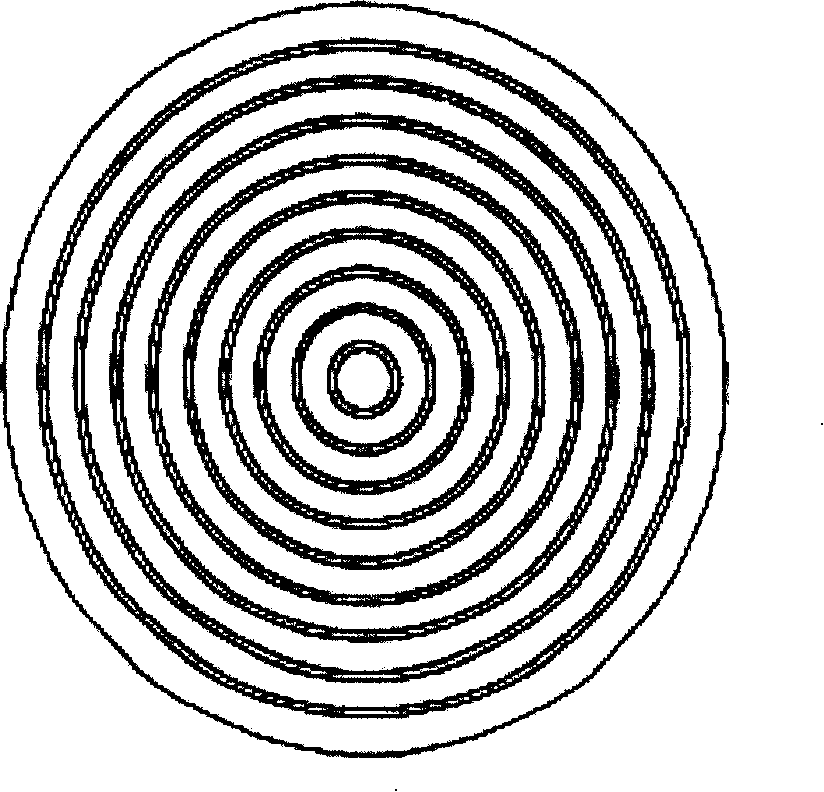

Nuclear fuel component lower pipe seat with filter plate and filter plate processing technology of nuclear fuel component lower pipe seat

ActiveCN102750991AIncrease the share of circulation areaSmall pressure dropNuclear energy generationFuel element assembliesEngineeringNuclear fuel

The invention discloses a nuclear fuel component lower pipe seat with a filter plate. The nuclear fuel component lower pipe seat with the filter plate mainly consists of a square connecting plate (4) and supporting legs (5) on the lower portion of the square connecting plate (4). The square connecting plate (4) is penetratingly provided with connecting holes (3) and triangular drain holes (2) around the connecting holes (3) which are used for mounting of fuel component guide pipes, and other positions of the connecting plate (4) is uniformly provided with square drain holes (1). The invention further discloses a processing technology for the filter plate of the nuclear fuel component lower pipe seat. Coolant is high in circulation share and uniform in flow distribution.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Polishing pad and chemico-mechanical polishing method

InactiveCN101190507AOptimize the extraction processOvercome the defect of low flatness of the wafer surfacePolishing machinesSemiconductor/solid-state device manufacturingWaferPolishing

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

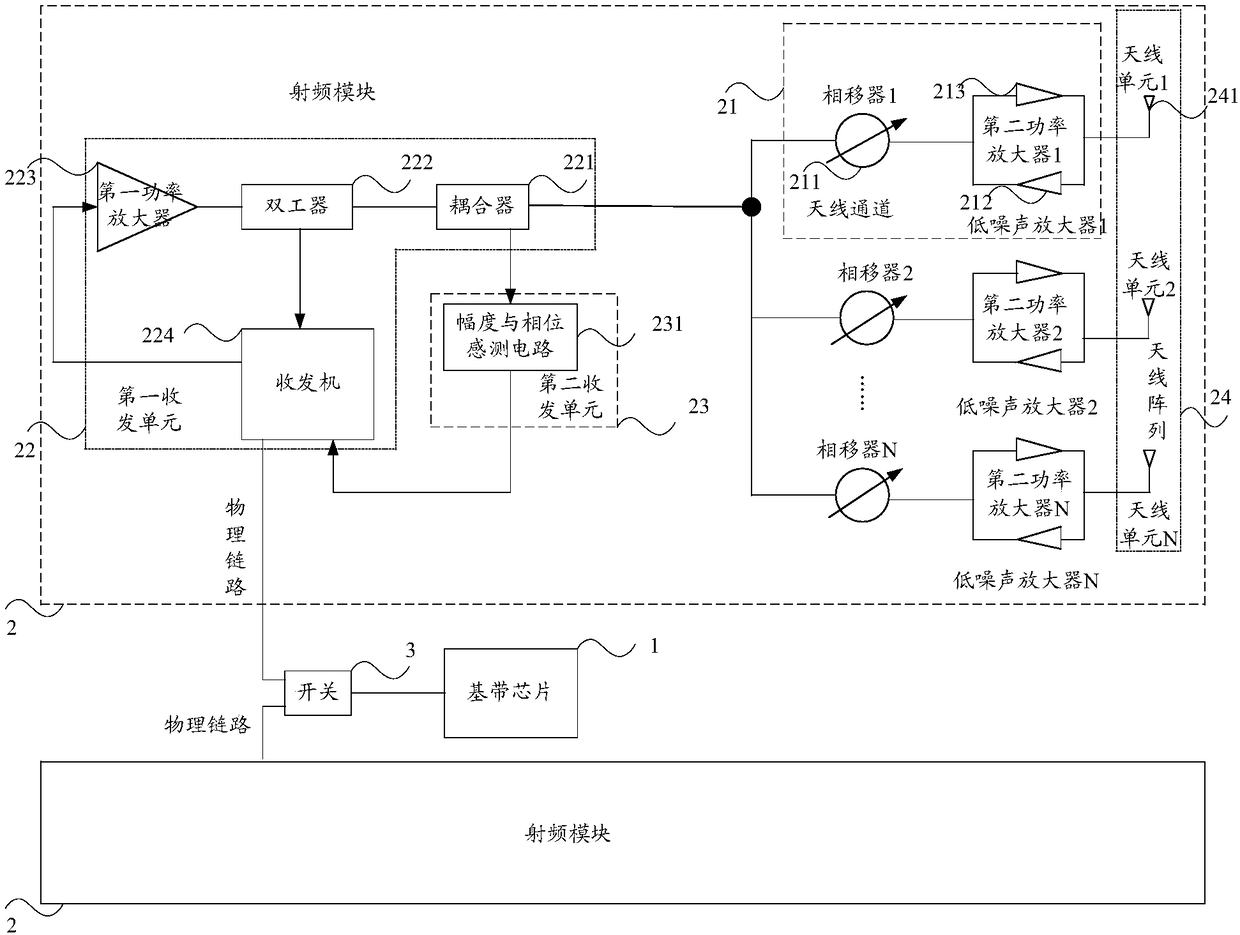

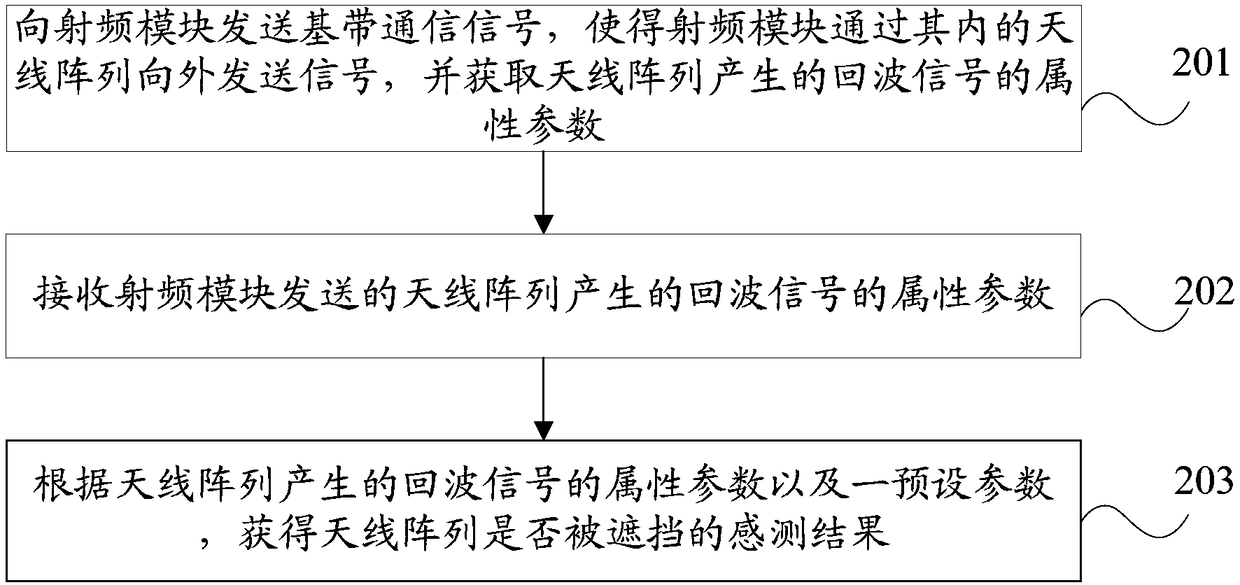

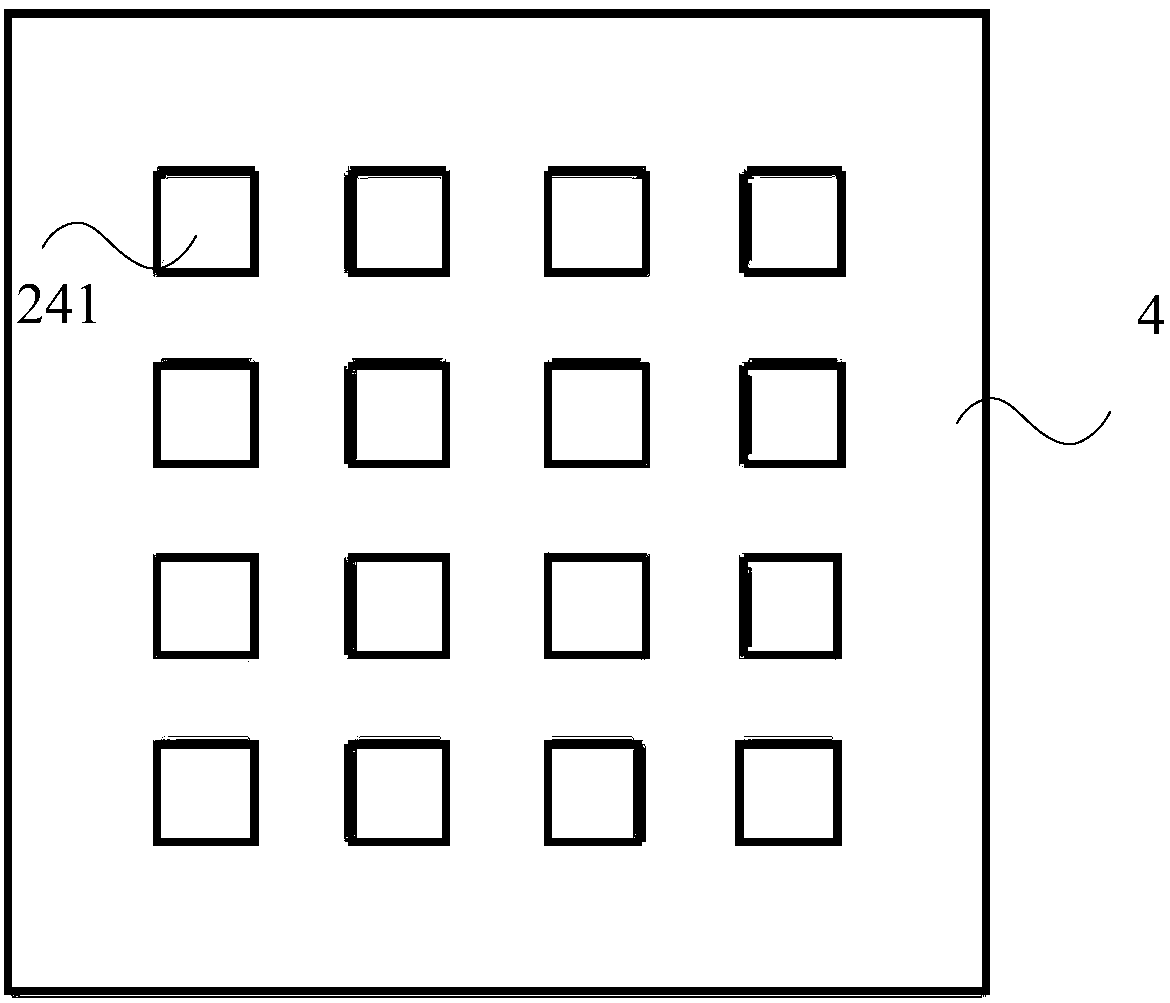

Antenna beam switching sensing system and method and mobile terminal

ActiveCN109391308AShorten the sensing timeAssurance of Accuracy and CompletenessSpatial transmit diversityAntenna detailsRadio frequencyBeam switching

Owner:VIVO MOBILE COMM CO LTD

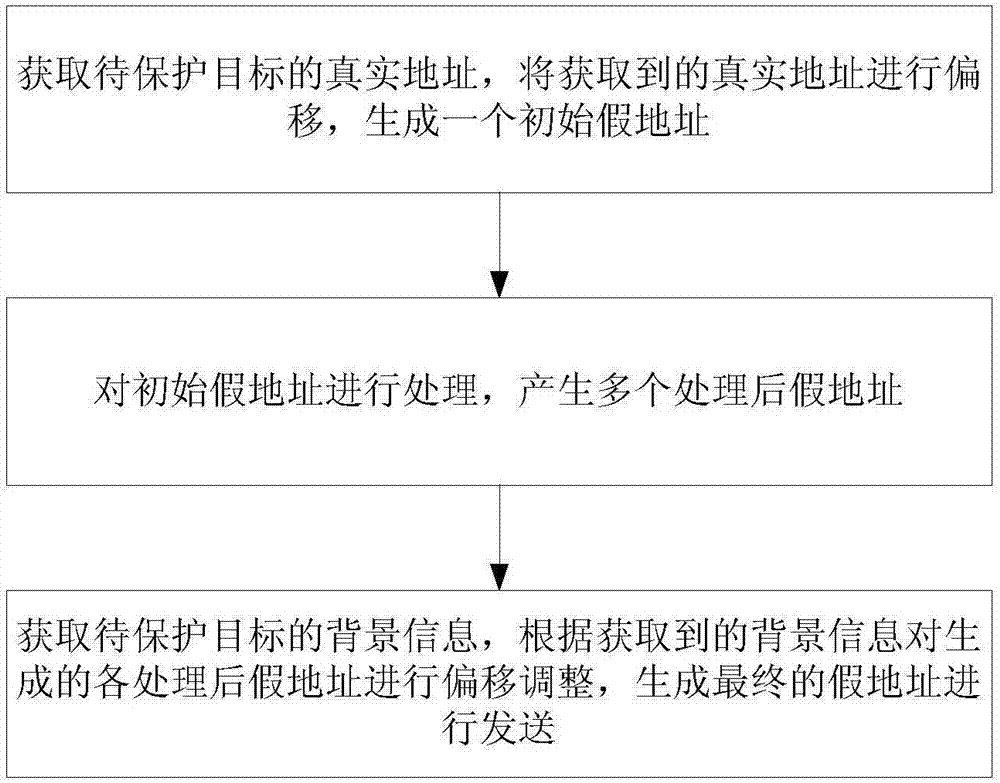

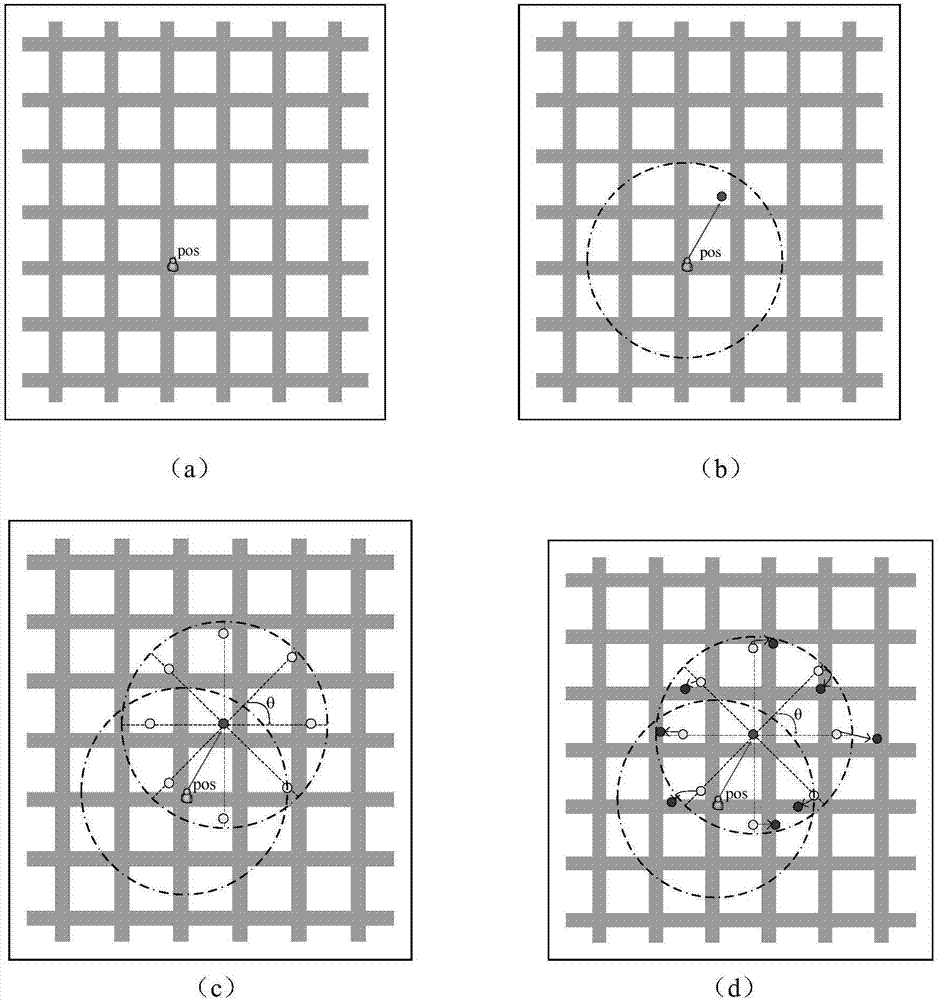

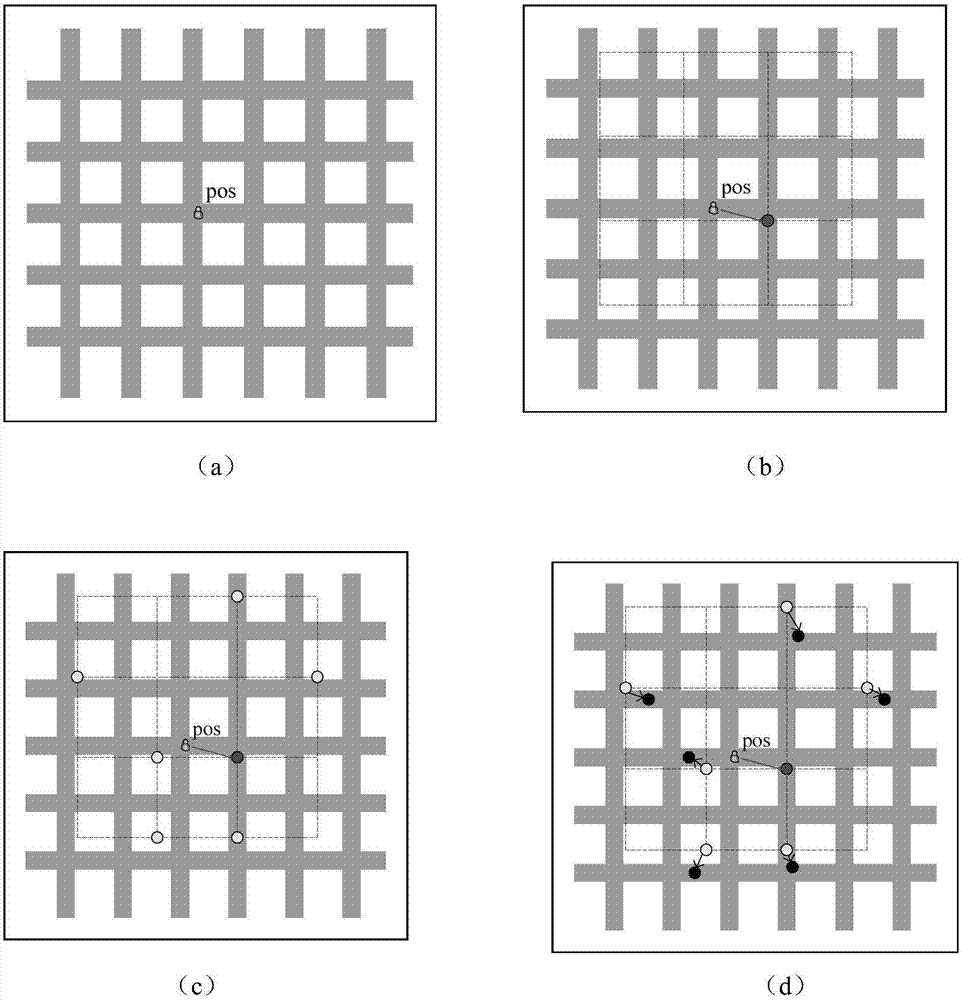

Location privacy protection method based on background information

InactiveCN107368751AGuaranteed areaImprove the performance of location privacy protectionDigital data protectionTransmissionEmail addressBackground information

The invention discloses a location privacy protection method based on background information. The method includes the steps that S1, the real address of a target to be protected is acquired, and the acquired real address is deflected to generate a false address; S2, multiple false addresses are generated according to the false address generated in S1; S3, the background information of the target to be protected is acquired, deflection adjustment is conducted on the false addresses generated in S2 according to the acquired background information, and a final false address is generated to protect the location privacy of the target to be protected. By means of the method, location privacy protection can be achieved by using the background information; the implementation method has the advantages of being simple, low in cost, good in privacy protection effect, high in efficiency and the like.

Owner:HUNAN UNIV

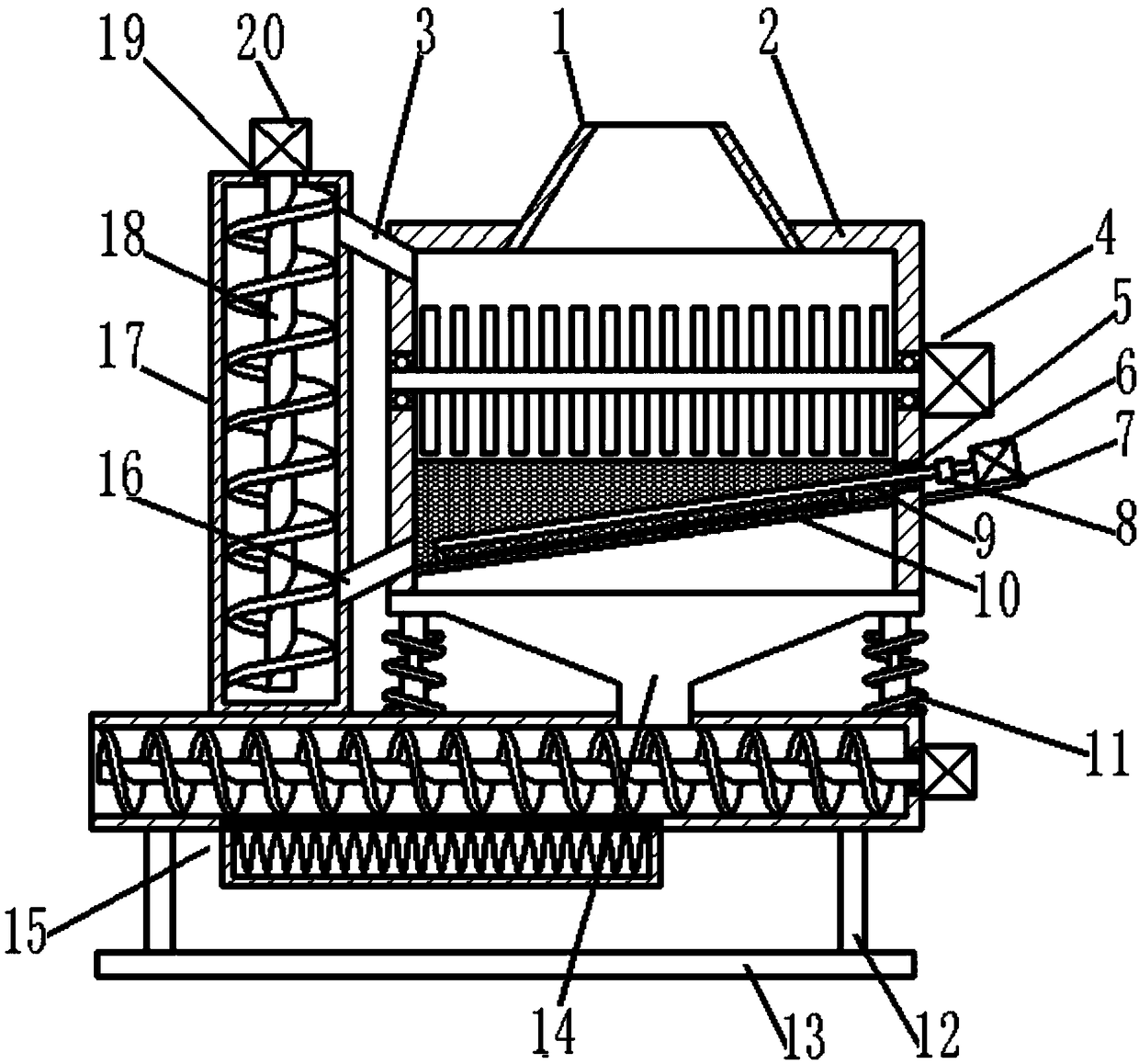

Agricultural straw crushing, screening and drying device

The invention relates to an agricultural straw crushing, screening and drying device which comprises a feeding cylinder, a crushing box, a straw crushing device, a screening and scraping device, a semicircular screening cylinder, a damping and supporting device and a discharging and drying device. The feeding cylinder is welded at the center of the upper end wall of the crushing box, the crushingbox is welded at the upper end of a guide cover, a crushing device is arranged on the side wall of the crushing box, the semicircular screening cylinder is obliquely welded on the inner wall of the crushing box and arranged at the left end of the screening and scraping device, the right end of the screening and scraping device is connected with a coupler through a third bearing, the damping and supporting device is welded at the upper end of the discharging and drying device, and the discharging and drying device is welded on a supporting frame. According to the device, crushing and drying areintegrated, straws are crushed, screened and crushed again, the crushing effect of the straws is ensured, drying is performed in the overturning and discharging process, the heated area of the strawsis ensured, and the drying efficiency is improved.

Owner:原起科技(杭州)有限公司

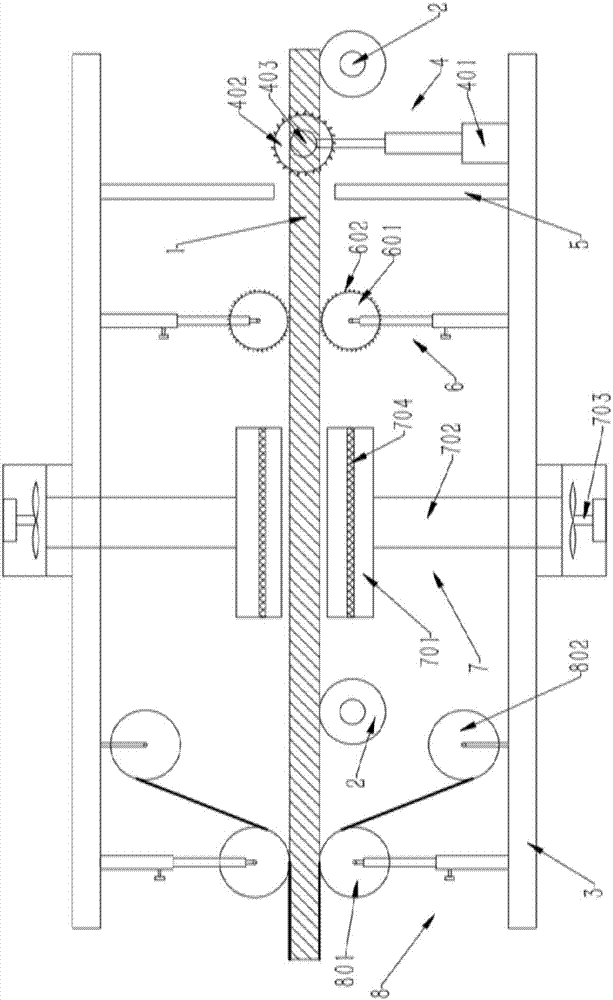

Double-side membrane coating device for wall surface decoration plate

InactiveCN107253389AGuaranteed areaImprove efficiencyLamination ancillary operationsLaminationMembrane configurationMembrane coat

The invention relates to the technical field of wall surface decoration plate manufacturing equipment, in particular to a double-side membrane coating device for a wall surface decoration plate. The double-side membrane coating device comprises conveying roller shafts, cutting components, support plates, retaining plates, cleaning roller shafts, dust collecting components and membrane coating components, wherein the conveying roller shafts are arranged on the lower side of the wall surface decoration plate, the cutting components are arranged on the left and right sides of the wall surface decoration plate, the support plates are symmetrically arranged on the upper and lower sides of the wall surface decoration plate, the retaining plates are symmetrically arranged on the upper and lower sides of the wall surface decoration plate, the cleaning roller shafts are symmetrically arranged on the upper and lower sides of the wall surface decoration plate, the dust collecting components are symmetrically arranged on the upper and lower sides of the wall surface decoration plate, and the membrane coating components are symmetrically arranged on the upper and lower sides of the wall surface decoration plate. The double-side membrane coating device has the advantages that limit cutting is performed to guarantee the area of plate membrane-coating regions, the cleaning rollers shafts are used to perform primary processing on the plate, the dust collecting components are used to perform secondary processing on the plate, and symmetrical membrane coating rollers matched with compression rollers are used to perform double-side membrane coating on the plate, and high efficiency and a good effect are achieved.

Owner:ANHUI TIANRUN PLASTIC IND

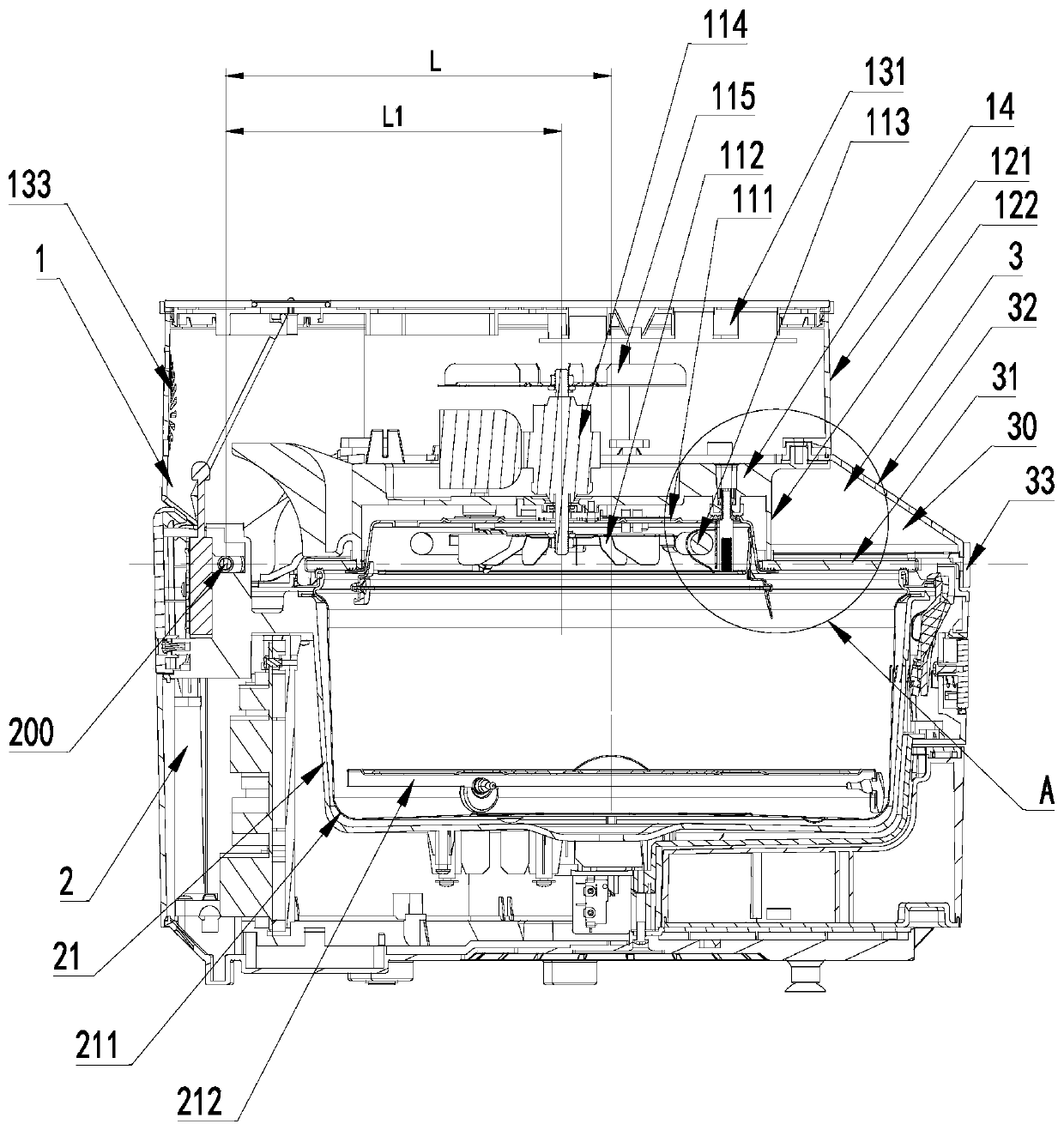

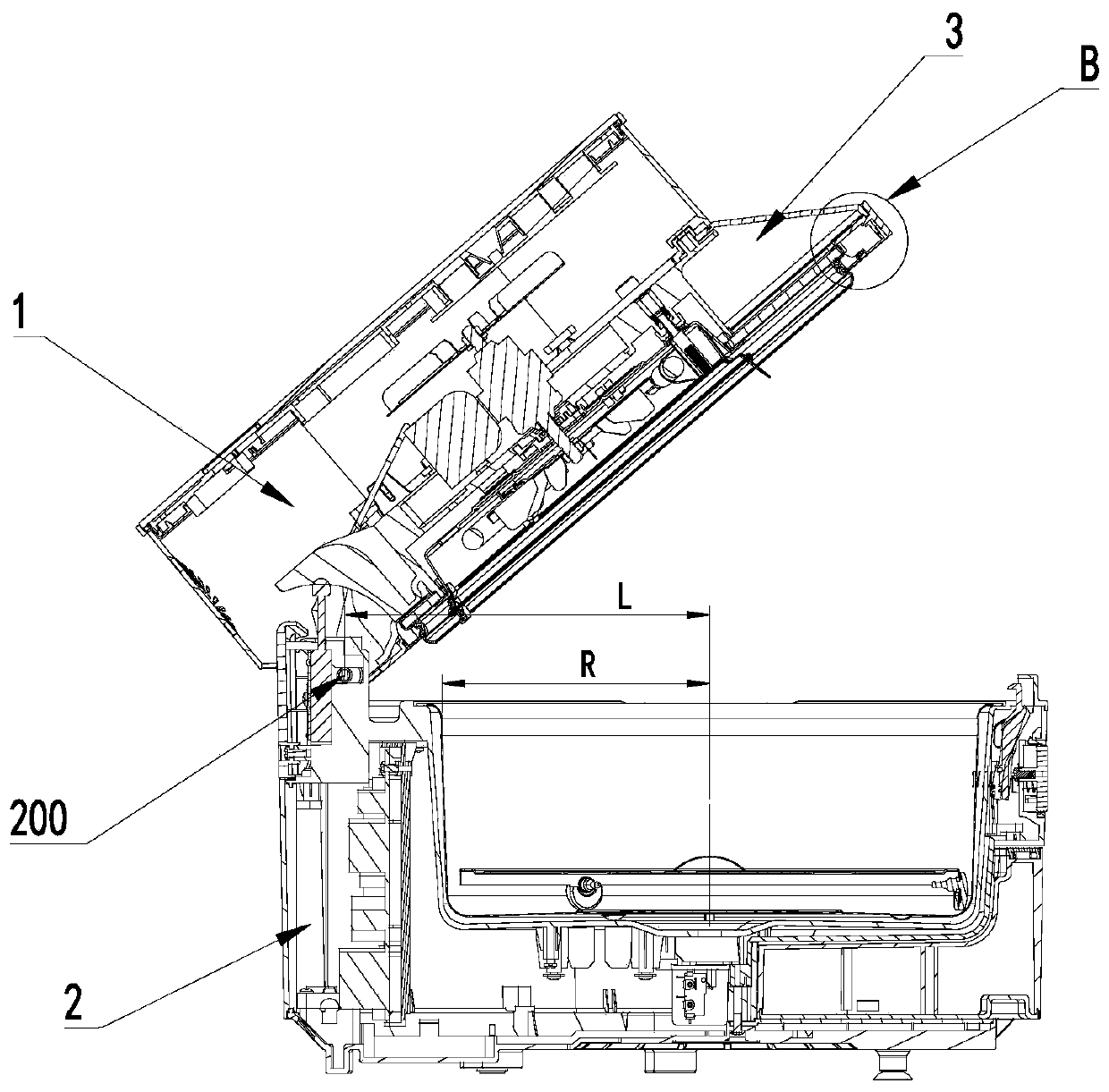

Air fryer reliable in control

ActiveCN110876567AGuaranteed effective use of the areaGuaranteed Proportional DemandCooking-vessel lids/coversLighting elementsEngineeringGravity center

The invention relates to an air fryer stable in control. The air fryer comprises a base and a cover body hinged to the base. A fyer assembly is arranged in the machine base. The fryer assembly comprises an inner pot. A hot air assembly is arranged in the cover body, the hot air assembly comprises an air guide plate, a fan and a heating piece. The fan and the heating piece are positioned below theair guide plate; a transparent visual window is arranged on the cover body, the center of the hot air assembly deviates from the center of the fryer assembly, the distance between the center of the hot air assembly and the hinge center is smaller than the distance between the center of the fryer assembly and the hinge center, and the visual window surrounds the hot air assembly and is located above the inner pot. The hot air assembly is far away from a user relative to the fryer assembly, the area of the visual window located on one side of the user is enlarged, and therefore the user can visually observe the interior of the fryer assembly through the visual window. Meanwhile, the heights of the cover body and the whole air fryer can be effectively reduced, the gravity centers of the coverbody and the whole air fryer are reduced, and when the cover body is opened or closed, the whole air fryer is stably operated.

Owner:JOYOUNG CO LTD

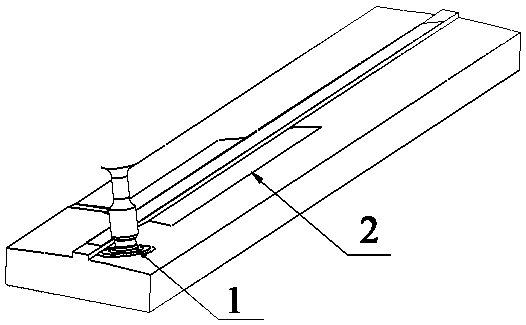

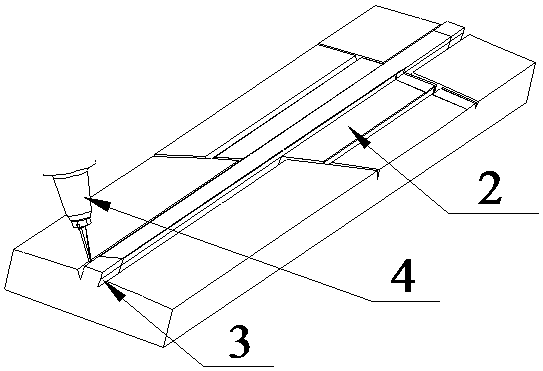

Long and narrow girder honeycomb core part machining method

The invention discloses a long and narrow girder honeycomb core part machining method. The method comprises the steps that an ultrasonic machine tool is adopted, a honeycomb core blank is fixedly clamped to a vacuum platform, the upper profile of the part is subjected to rough machining and fine machining through a cutter disk, and the machined surface of the part is expanded to the boundary of the blank; and a wedge groove is formed in the edge of the outline of the upper profile by adopting a dagger through cutting, the part is turned over so that the lower profile of the part can be machined, and the outline of the honeycomb core part is obtained axially through cutting by adopting the dagger along the outline line of the part at a time with the nose of the dagger only exceeding the topof the wedge. According to the long and narrow girder honeycomb core part machining method, rough machining and fine machining are directly conducted on the upper profile and the lower profile of thepart, the machined surface of the part is expanded to the boundary of the blank, the turning positioning area is ensured, and the fixed clamping strength is improved; the wedge groove is formed in the upper profile of the part through cutting, part turning positioning is facilitated, machining interference is prevented, the fixed clamping risk is reduced, pulling up and overcut of the part are avoided, and the machining quality is ensured; and one-time cutting machining is conducted on the outline of the part through the ultrasonic dagger, the material removal rate is high, part deformation is low, and the part machining efficiency is improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

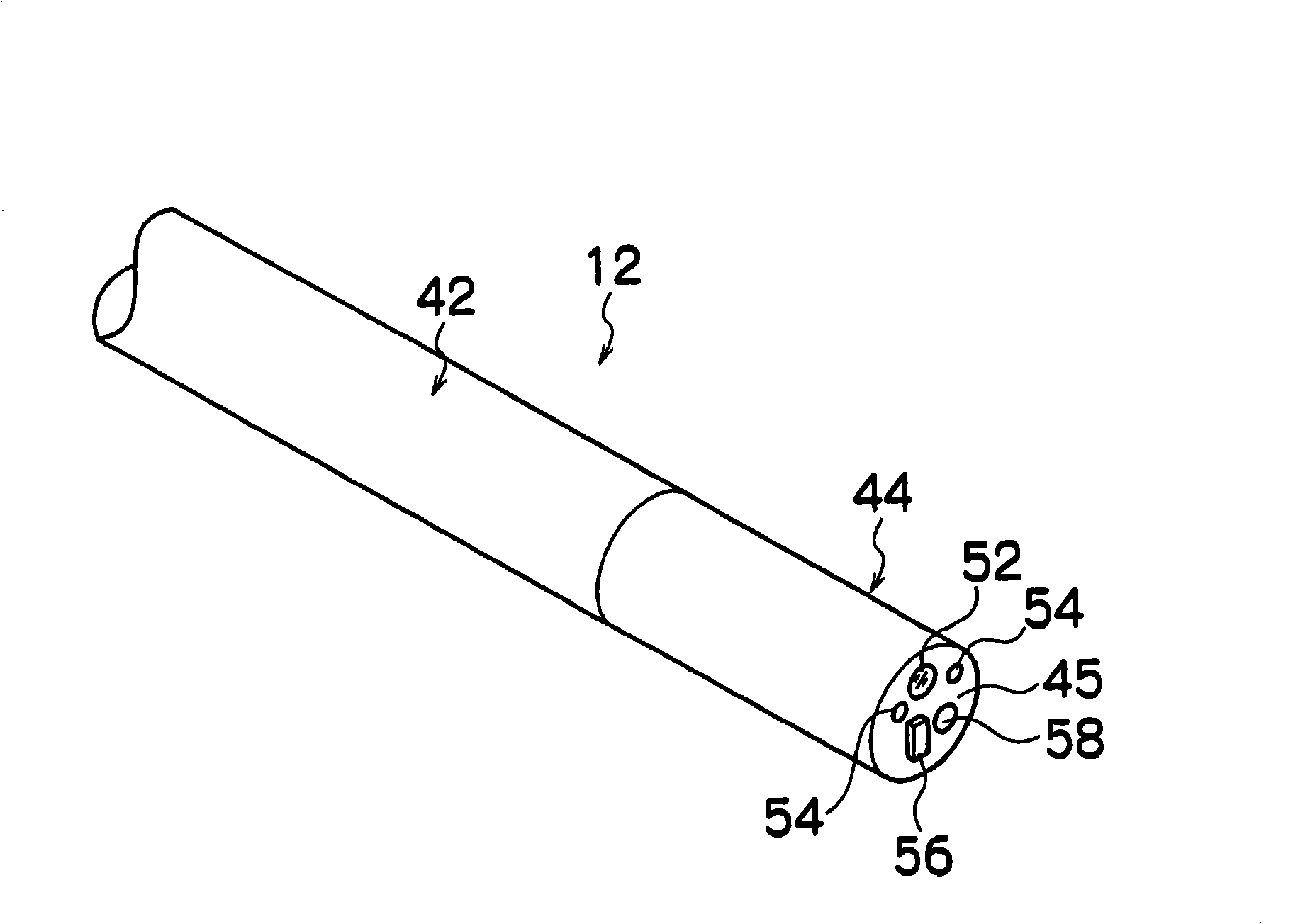

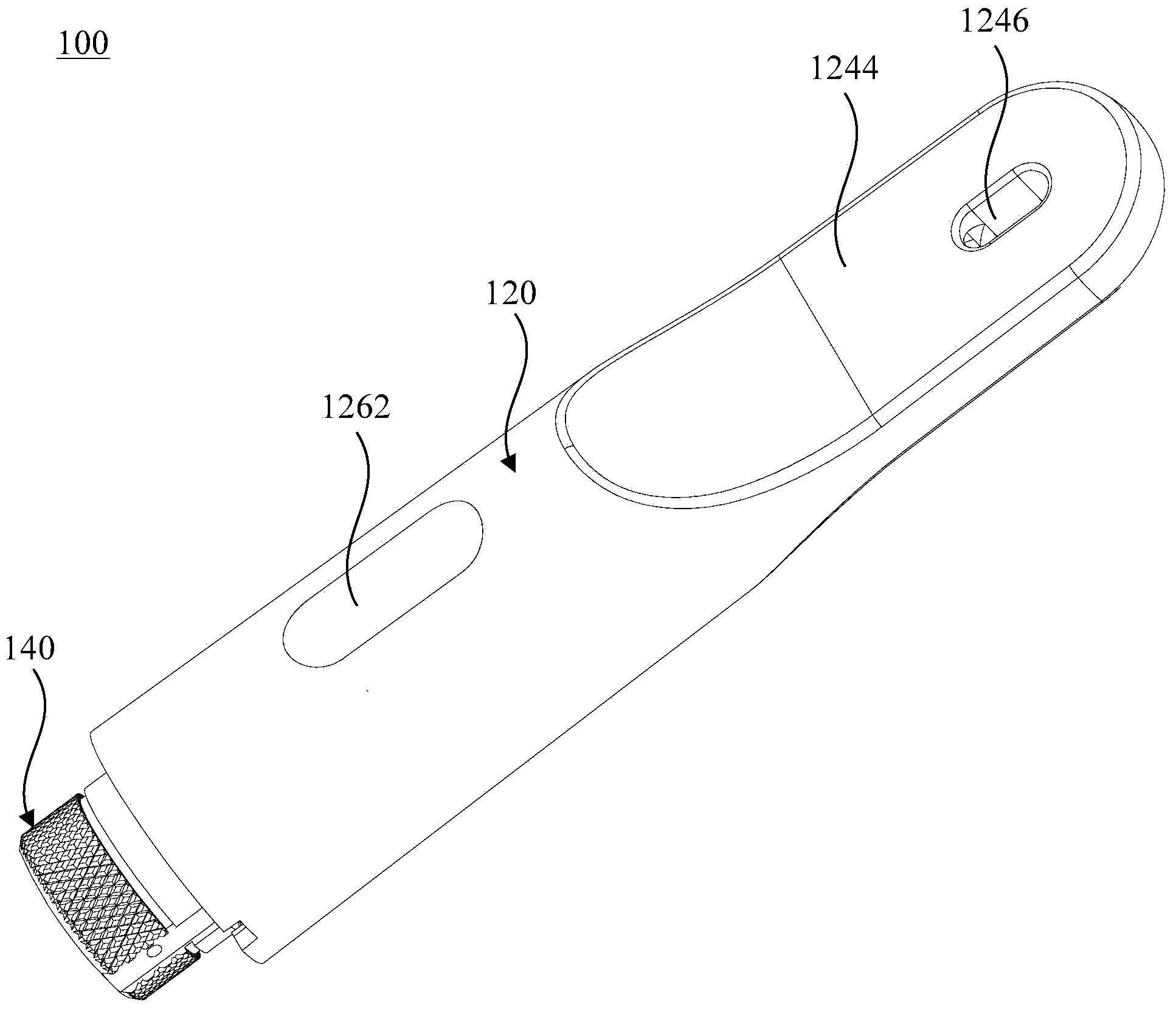

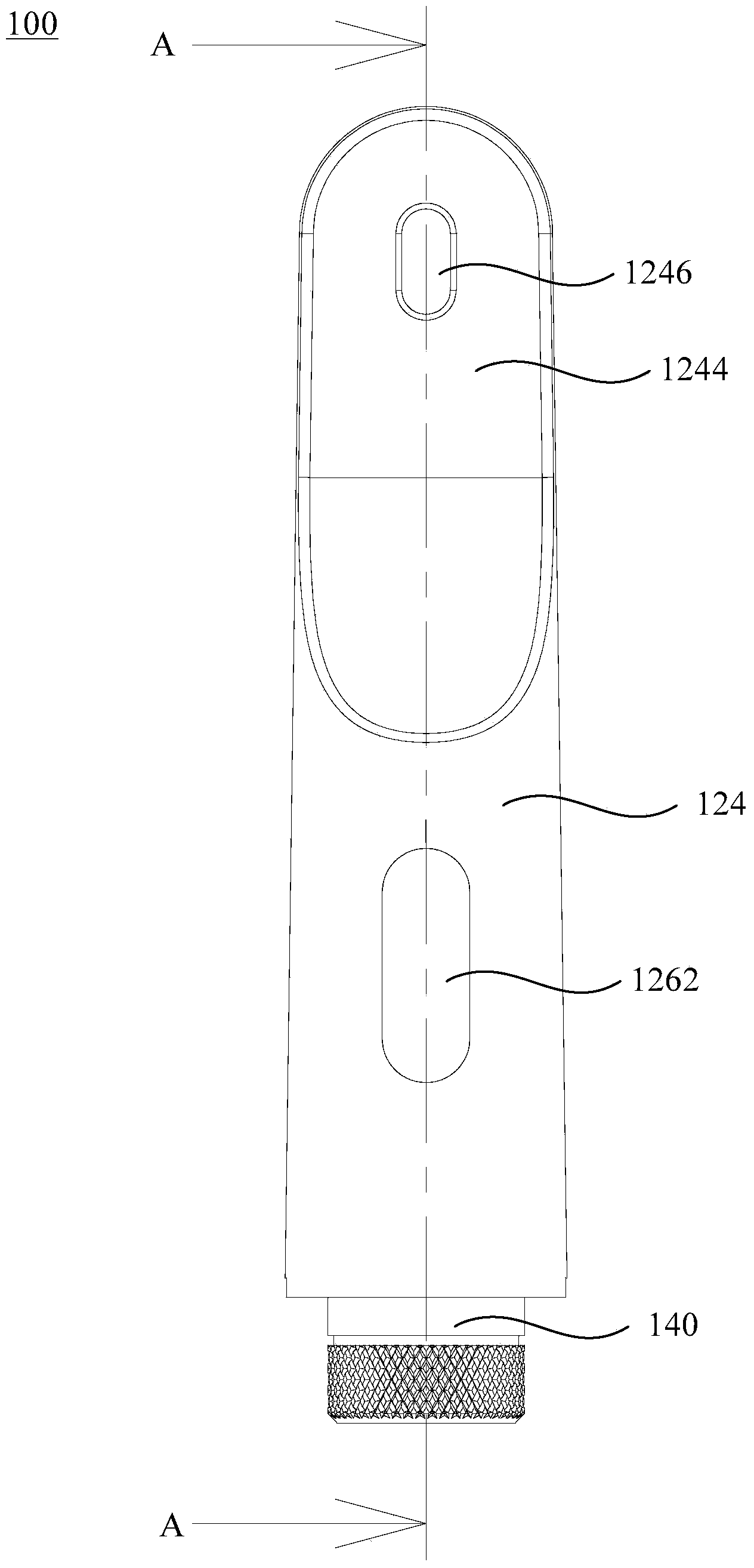

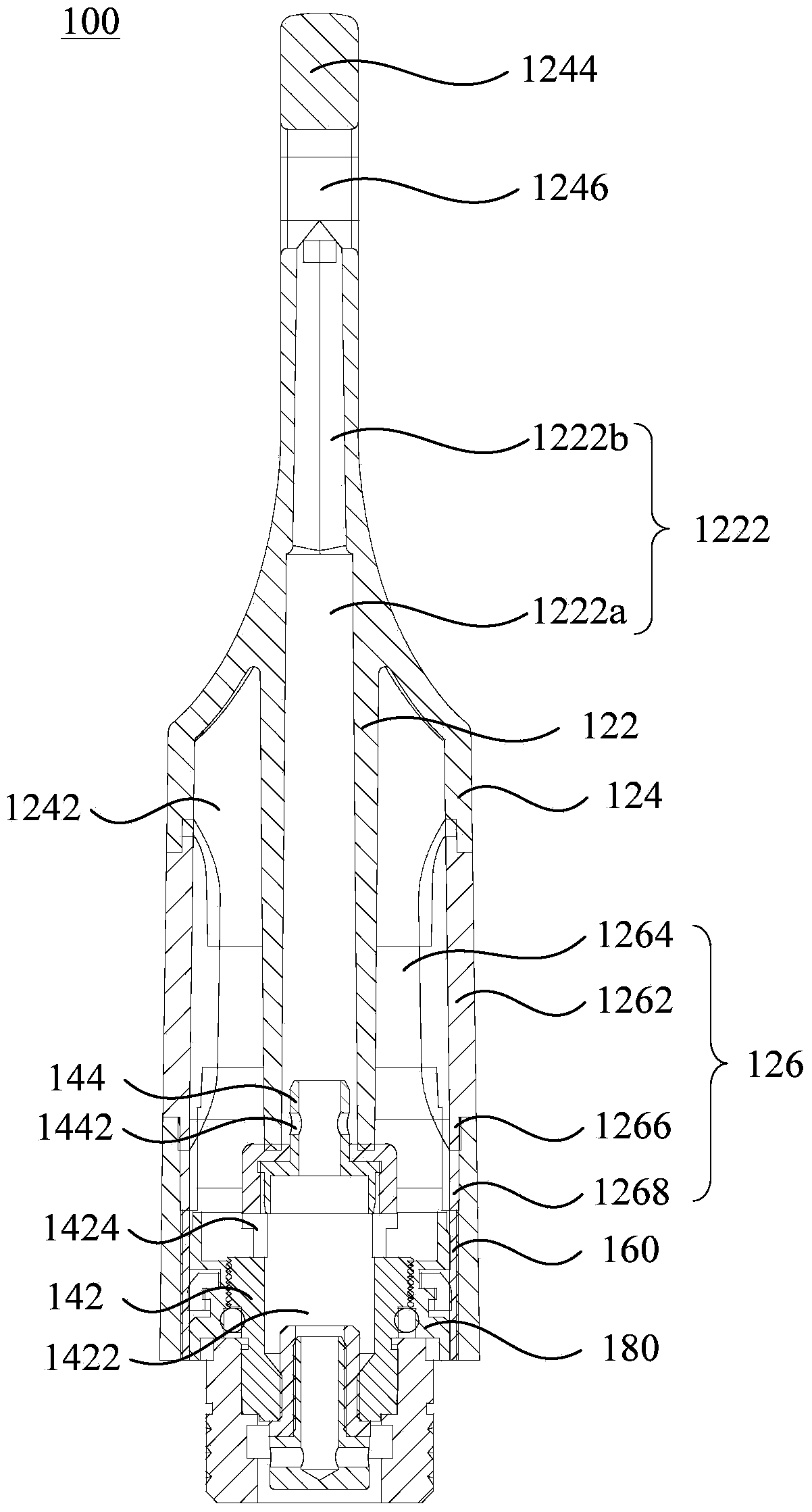

Inhaler and atomization assembly thereof

The invention relates to an inhaler and an atomization assembly of the inhaler. The atomization assembly of the inhaler comprises a shell and an atomization core arranged to be combined with the shell. The shell comprises an outer shell and a breather pipe, a liquid storing cavity used for storing liquid is formed in the outer shell, a flat suction nozzle is formed at one end of the outer shell, and an inhaling hole is formed in the suction nozzle; an airflow channel is formed in the breather pipe, the breather pipe is located in the liquid storing cavity, one end of the breather pipe is connected with the atomization core, the other end of the breather pipe is connected with the outer shell, and the airflow channel is communicated with the inhaling hole. The cross section of at least part of the airflow channel is flat, the part, with the flat cross section, of the airflow channel is close to the inhaling hole, and the shape of the airflow channel is matched with that of the suction nozzle. The cross section of the at least part of the airflow channel is flat to be matched with the flat suction nozzle, it is ensured that the outer shell and the breather pipe are thick enough, the product qualified rate is increased, the area of the cross section of the airflow channel is ensured, and therefore a user can suck the atomized liquid into the mouth easily.

Owner:SHENZHEN SMOORE TECH LTD

Display device using semiconductor light emitting device and method for manufacturing the same

ActiveCN107211504ASecure spaceSmall sizeElectroluminescent light sourcesSolid-state devicesPhosphorDisplay device

A display device include a substrate including a wiring electrode; an adhesive layer disposed on the substrate; a plurality of semiconductor light emitting devices adhered to the adhesive layer, and electrically connected to the wiring electrode; and a phosphor layer disposed to cover the plurality of semiconductor light emitting devices. Further, the phosphor layer includes a plurality of phosphor portions for converting a wavelength of light, and a plurality of partition wall portions formed between the plurality of phosphor portions. The plurality of partition wall portions are sequentially disposed between the phosphor portions along a first direction and a second direction crossing each other, respectively, and at least one of the sequentially disposed partition wall portions overlaps with at least one of the plurality of semiconductor light emitting devices.

Owner:LG ELECTRONICS INC

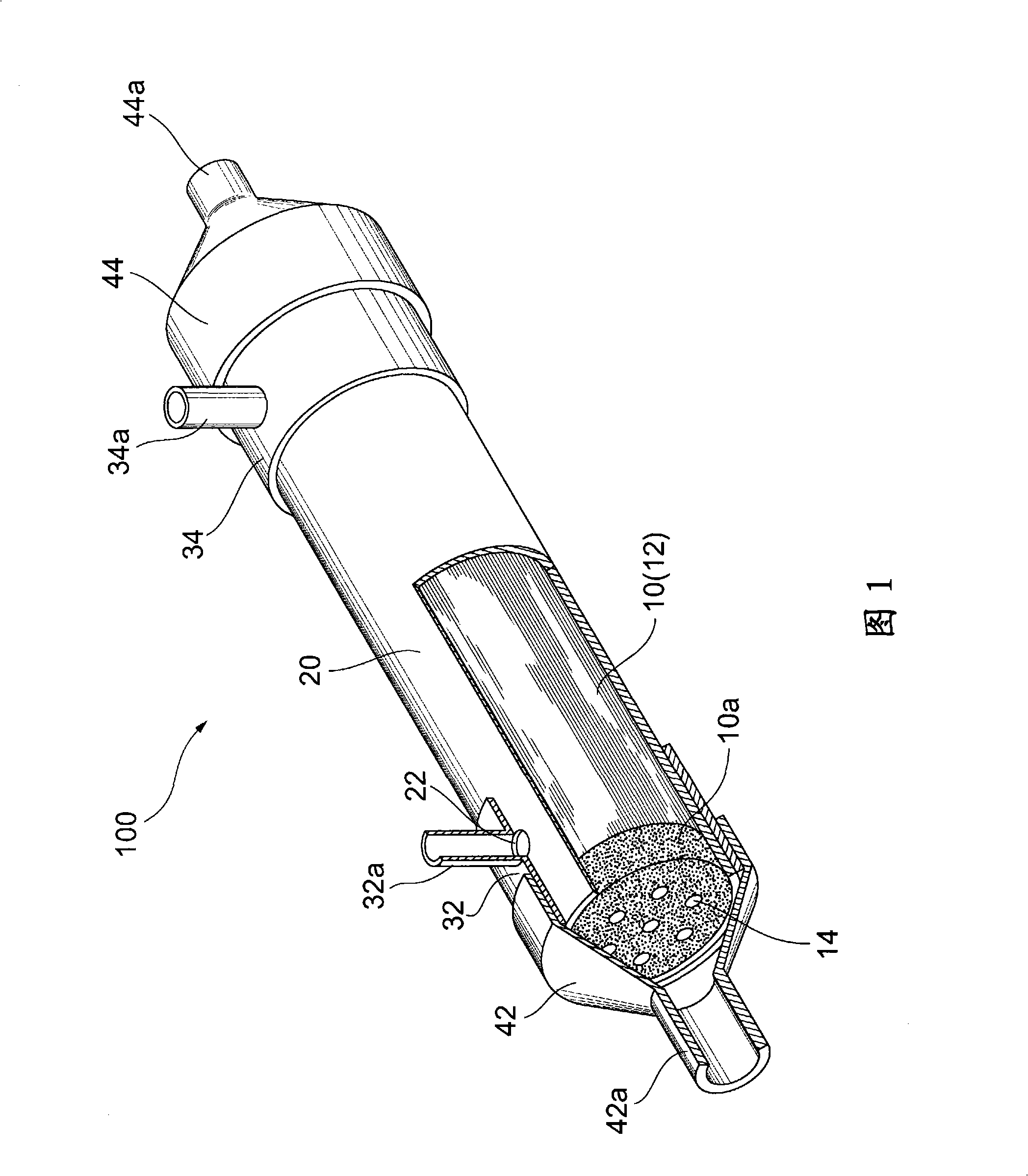

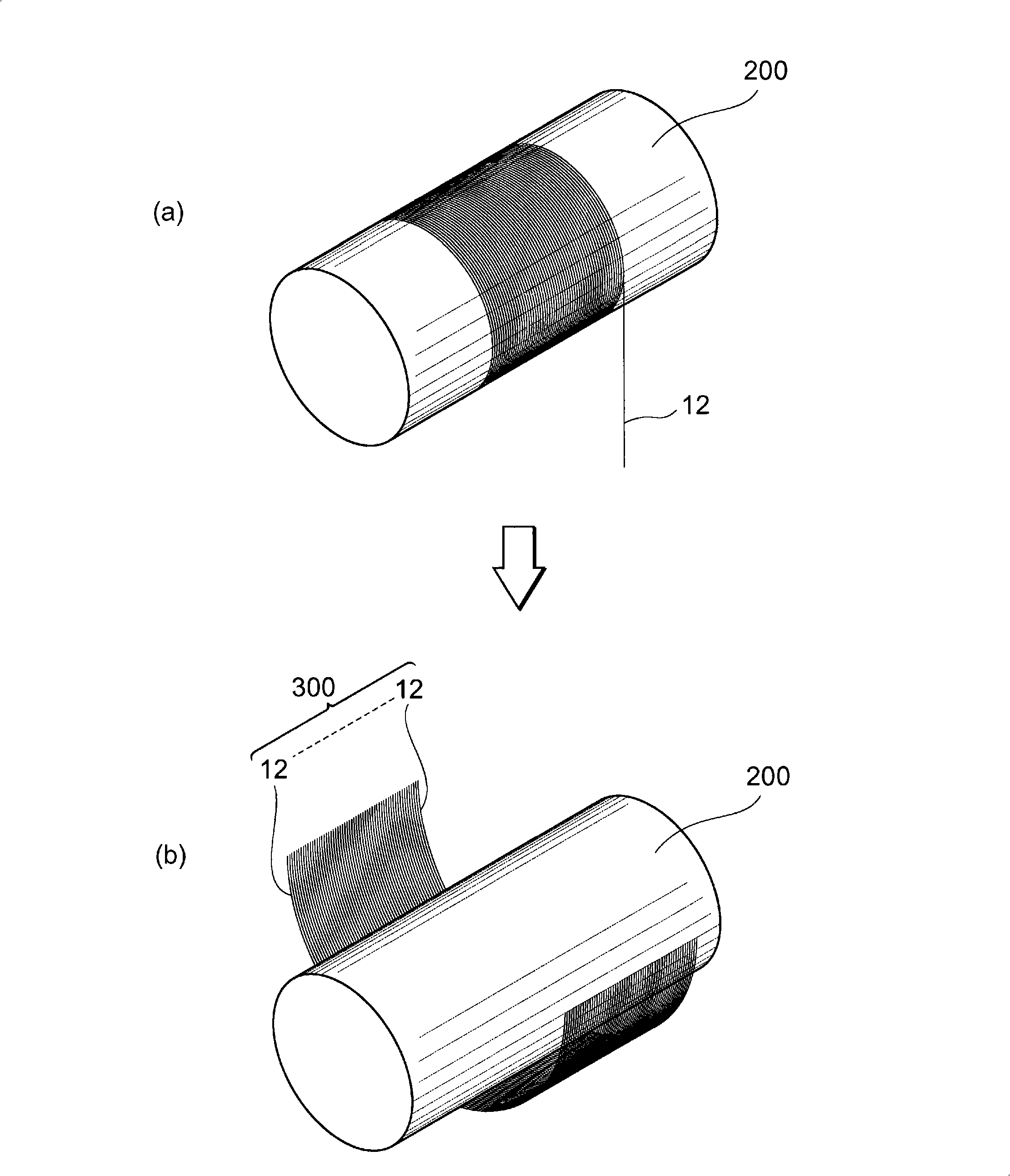

Potting material, hollow-fiber module, and process for producing the same

InactiveCN101351261AEnsure the membrane areaGuaranteed areaMembranesSemi-permeable membranesFiberViscosity

A potting material which, when used in stationary potting, is less apt to scramble up and can sufficiently penetrate into the spaces among porous hollow fibers. The potting material is one for fixing an end part of a group of porous hollow fibers. It comprises a resin material and a filler, wherein the content of the filler is up to the filler content corresponding to a rising point in a curve showing changes in viscosity of the potting material with changing filler content.

Owner:KUREHA KAGAKU KOGYO KK

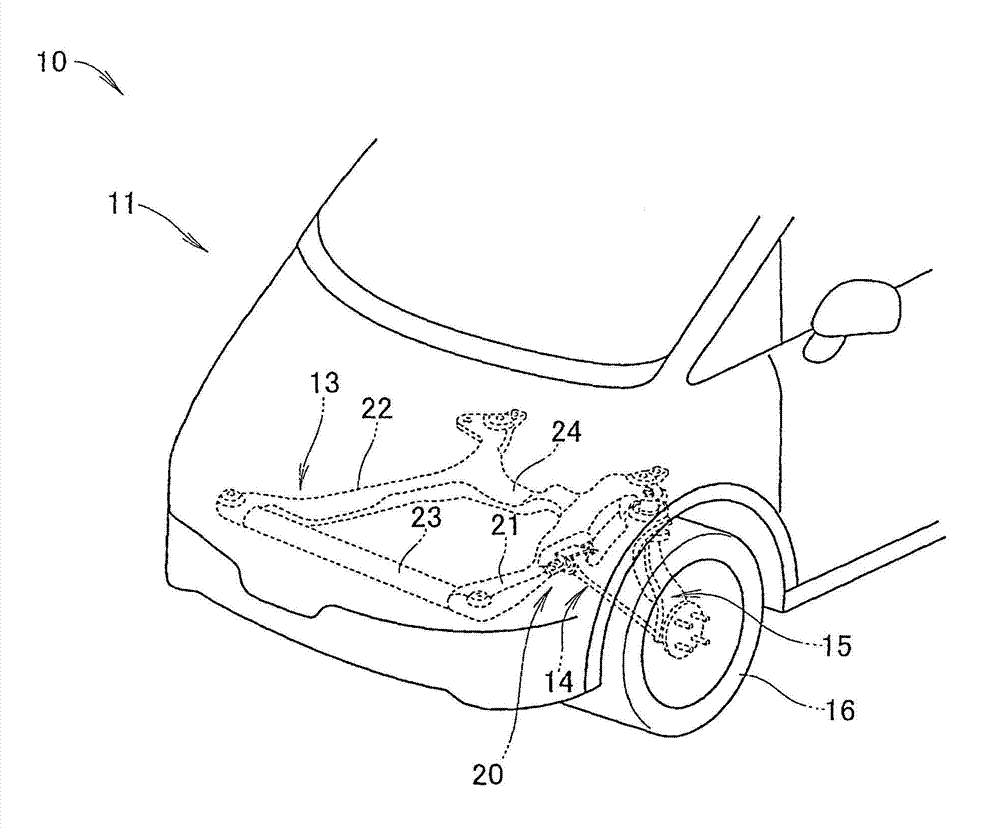

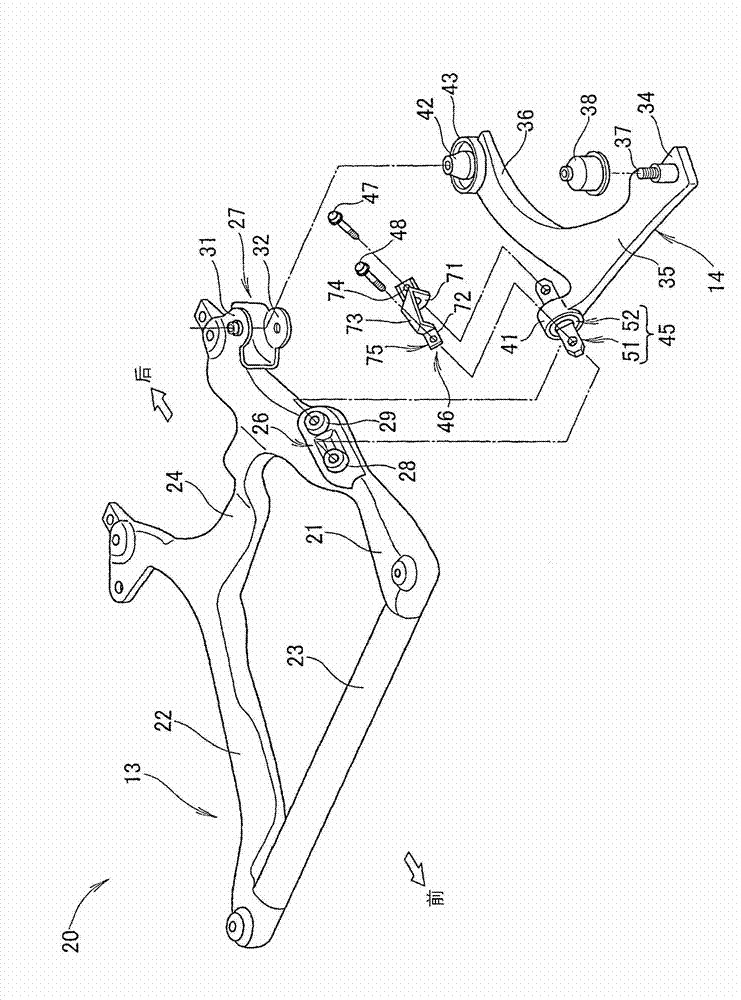

Suspension arm attachment structure

ActiveCN102781689AAvoid exposureHigh precisionUnderstructuresPivoted suspension armsBiomedical engineering

Owner:HONDA MOTOR CO LTD

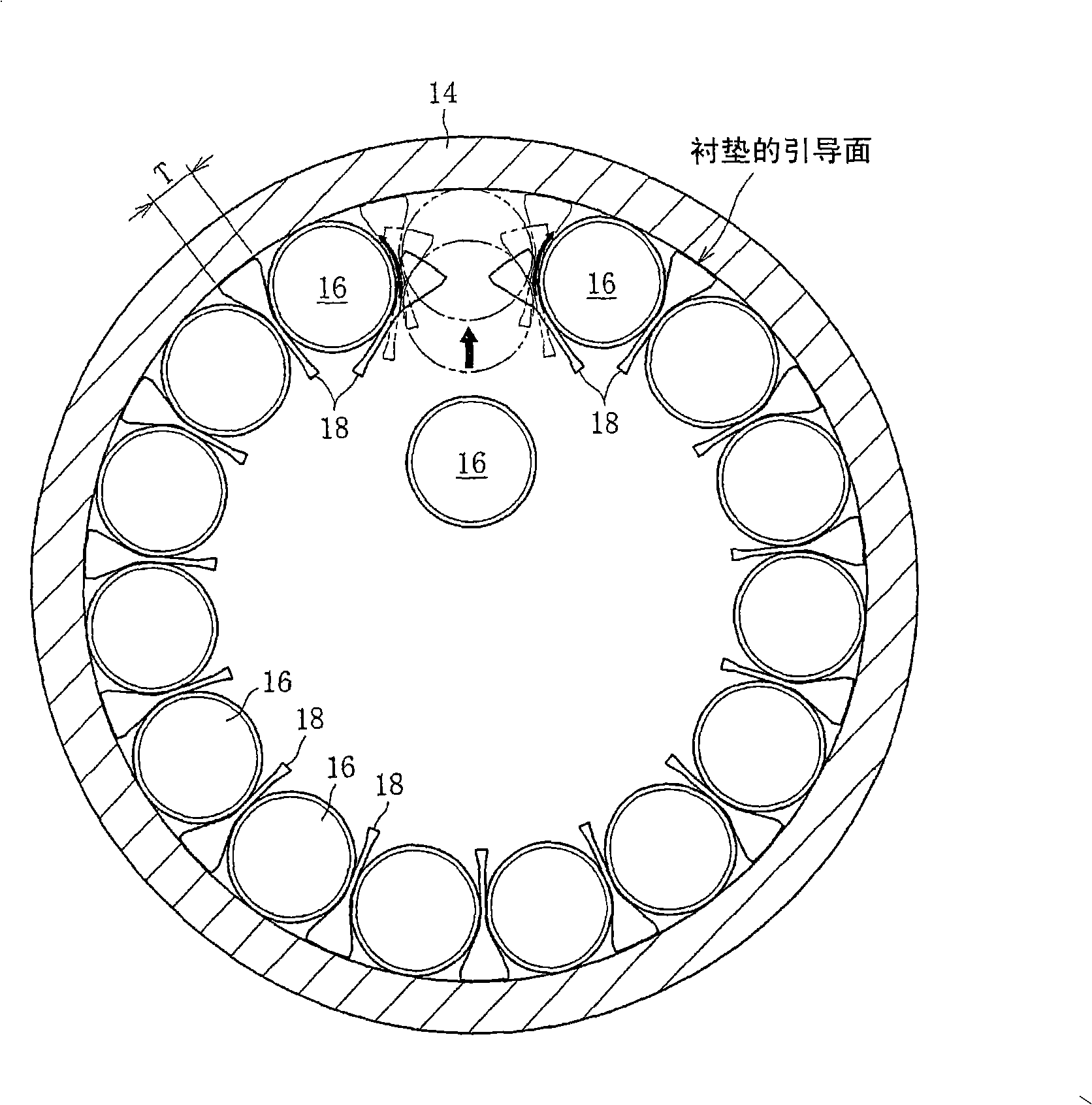

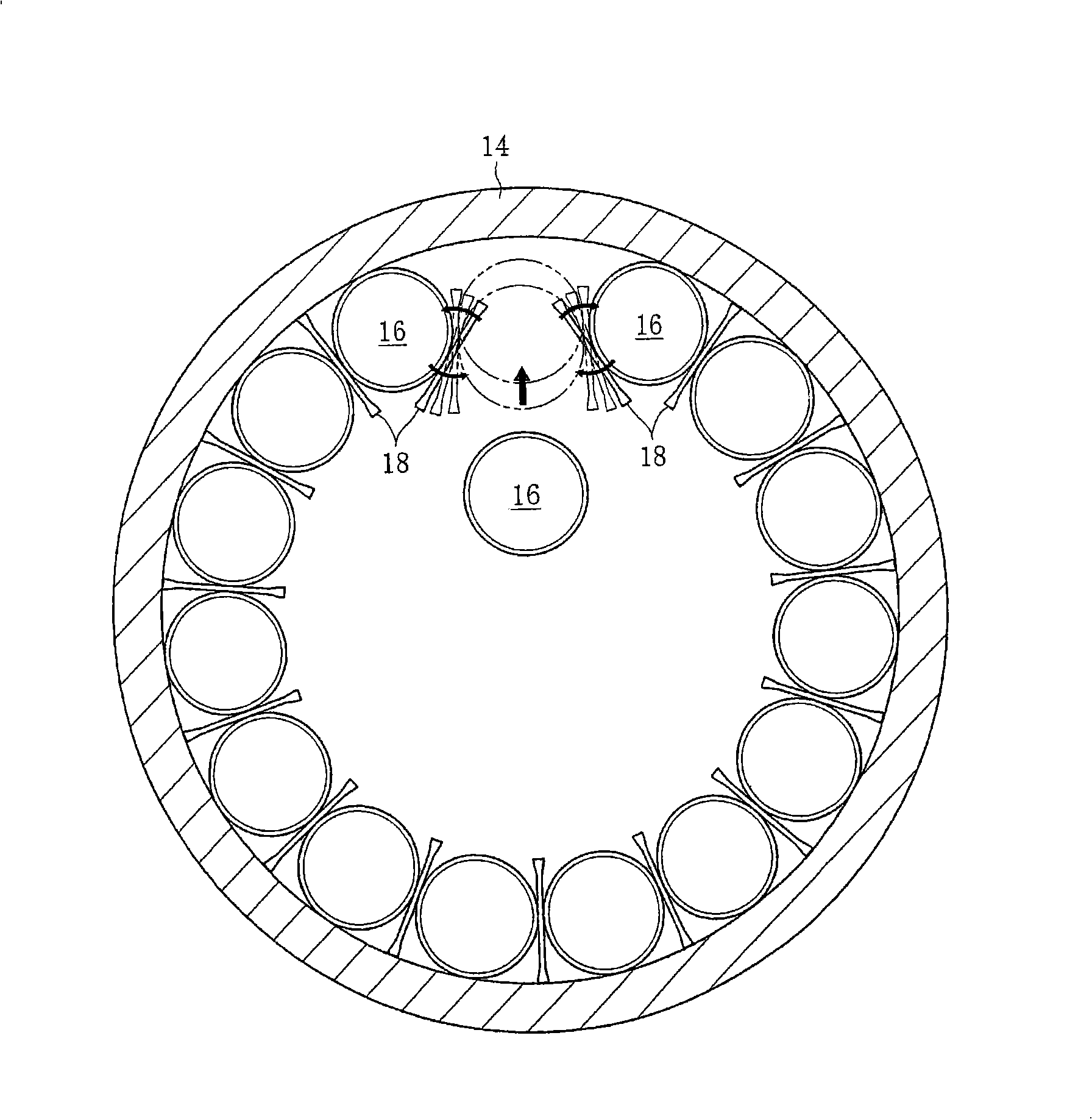

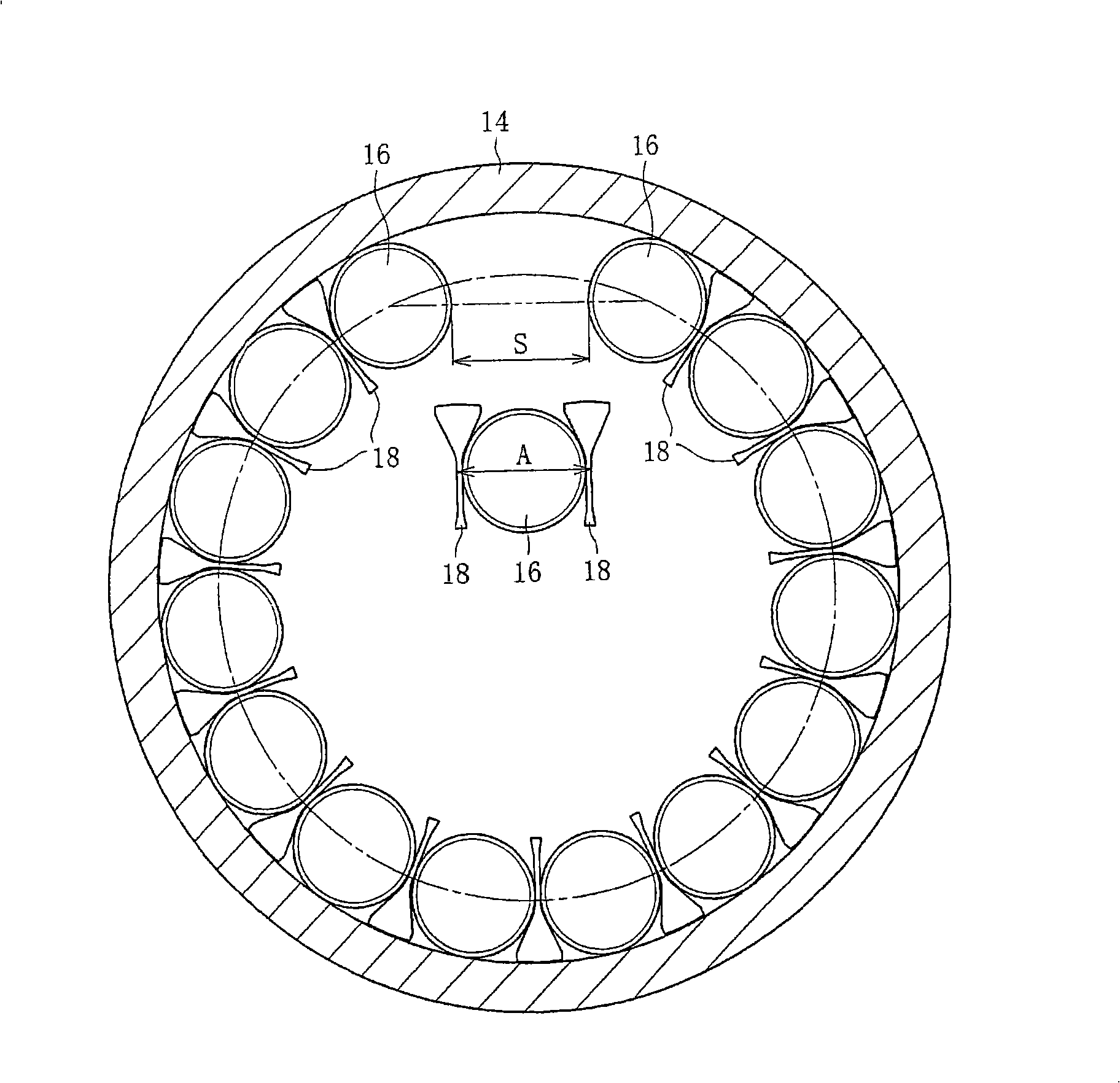

Assembling method of roller bearing

A method of assembling a roller bearing having intermediate members placed between rollers, with which method the bearing can be assembled without elastic deformation of the intermediate members or with a minimum necessary amount of elastic deformation. Rollers (16) and intermediate members (18) are alternately arranged on the inner circumference of the outer ring (14). Then, a roller (16) to be assembled into place at the end of the bearing assembly is inserted toward the outer ring (14). This causes the rollers (16) having been arranged to be assembled into the inner circumference of the outer ring (14) while the intermediate members (18) located at both sides of the roller (16) are allowed to slide. In this process, the intermediate member (18) positioned on both sides of the roller (16) to be assembled at the end are kept set along the bearing bore side of the rolling surfaces on which the rollers (16) having been arranged roll.

Owner:NTN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com