Rolling bearing for a wheel of vehicle and a semi-float type bearing apparatus having it

A rolling bearing and wheel technology, which is applied to devices using electric/magnetic methods, rolling contact bearings, roller bearings, etc., can solve the problems of slow perception of rotational speed, enlarged air gap, and inability to perceive rotational speed sensitively enough. Achieve the effect of increased strength and simplified assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

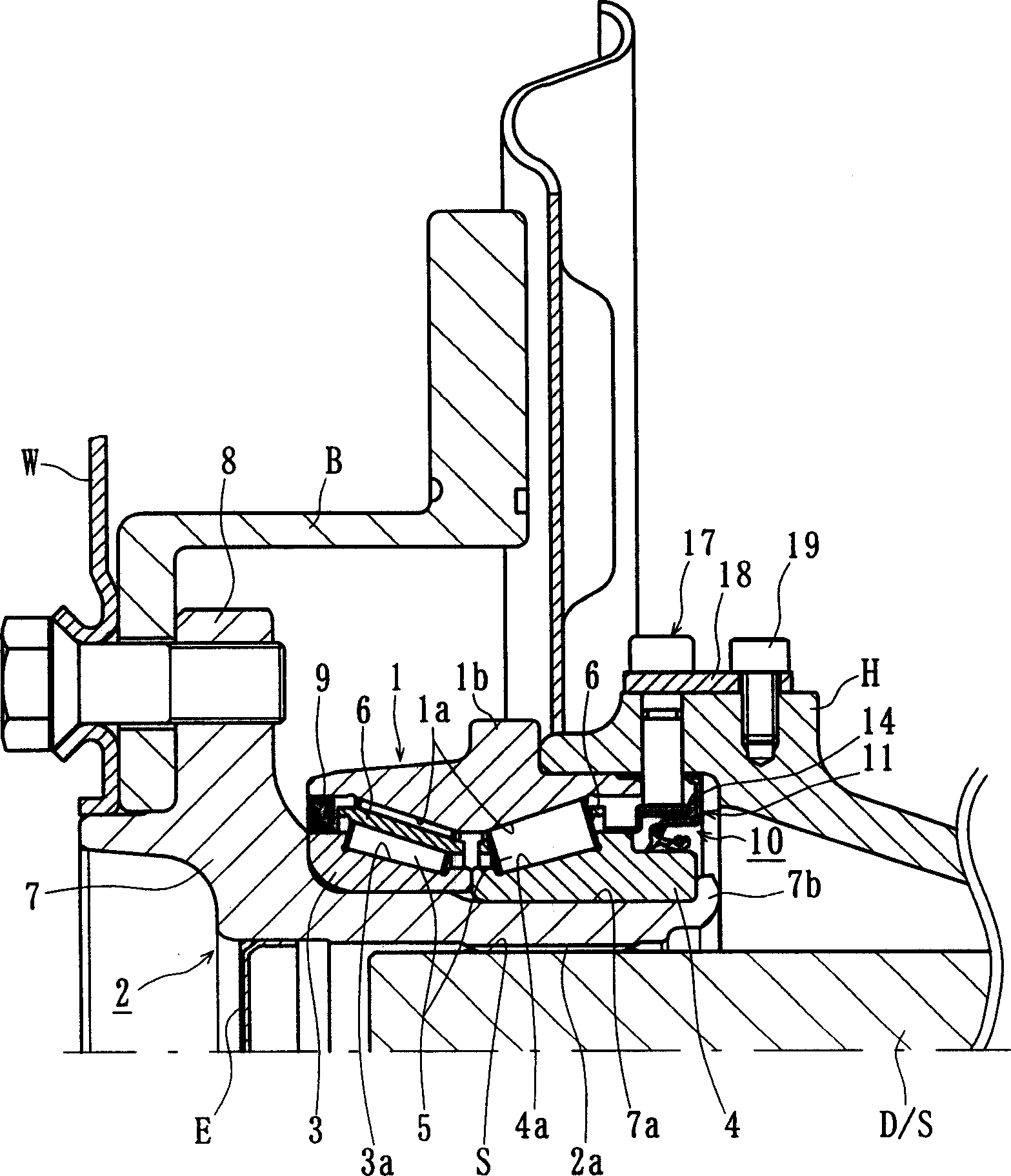

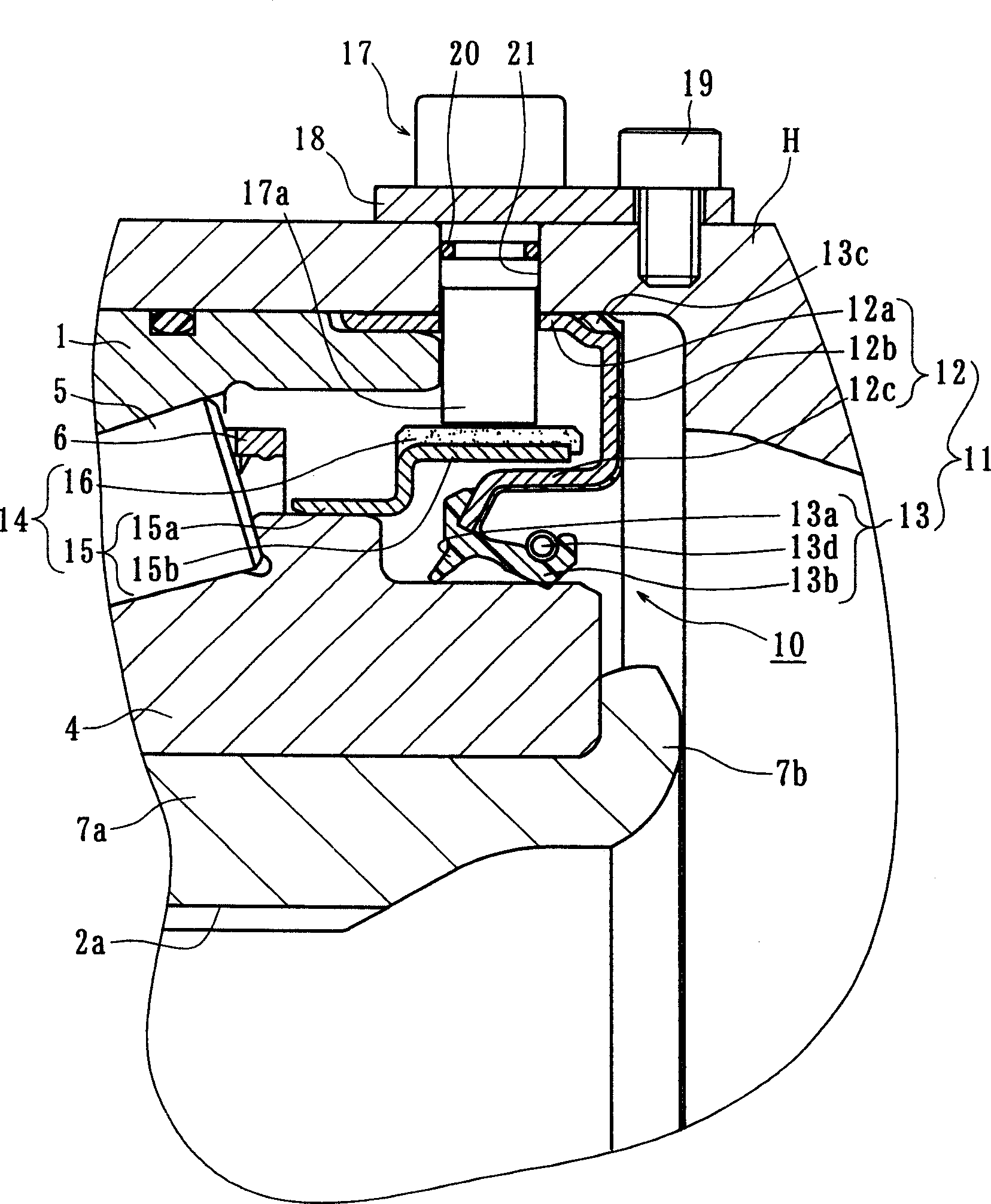

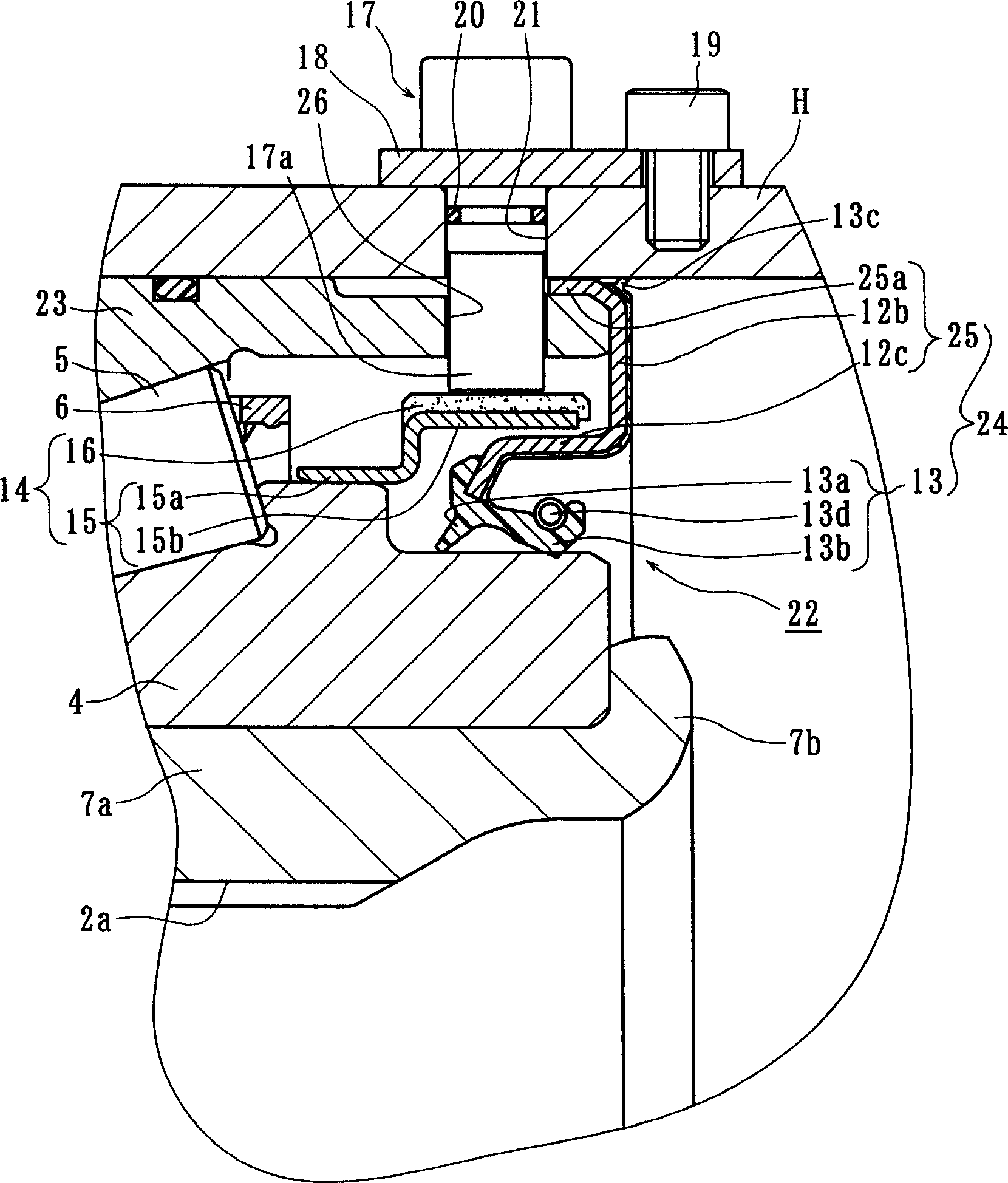

[0026] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is a longitudinal sectional view showing the first embodiment of the semi-floating wheel bearing device of the present invention, figure 2 Yes figure 1Enlarged view of important parts of . In the following description, the side closer to the vehicle outer side in the assembled state of the vehicle is referred to as the vehicle outer side (left side in the drawing), and the side closer to the center is called the vehicle inner side (right side in the drawing).

[0027] In the rolling bearing for a wheel of the present invention, a semi-floating drive shaft D / S is rotatably supported inside a housing (semi-shaft casing) H supported by springs under the chassis of an automobile body. That is, in the semi-floating type wheel bearing device having the wheel rolling bearing of the present invention, one end of the hub H is engaged with an unillustrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com