Suspension arm attachment structure

A technology for mounting structures and suspension arms, which is applied to suspensions, substructures, and cantilevers mounted on pivots, etc., to achieve the effects of increased strength and rigidity, and improved installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

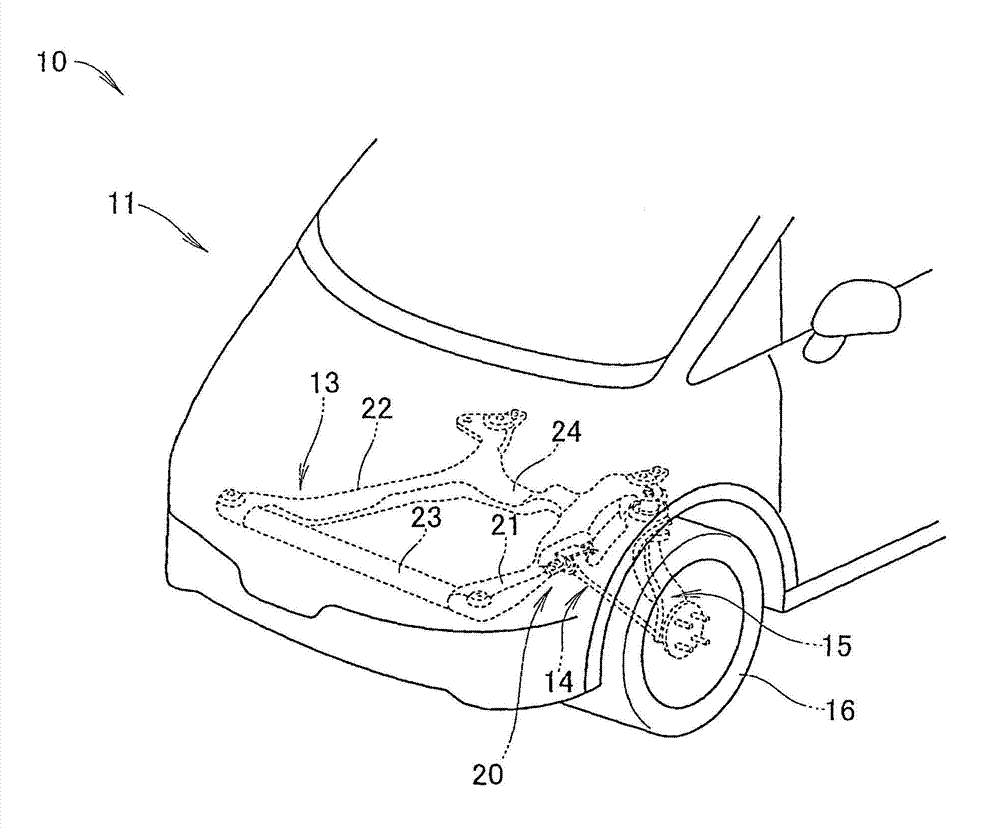

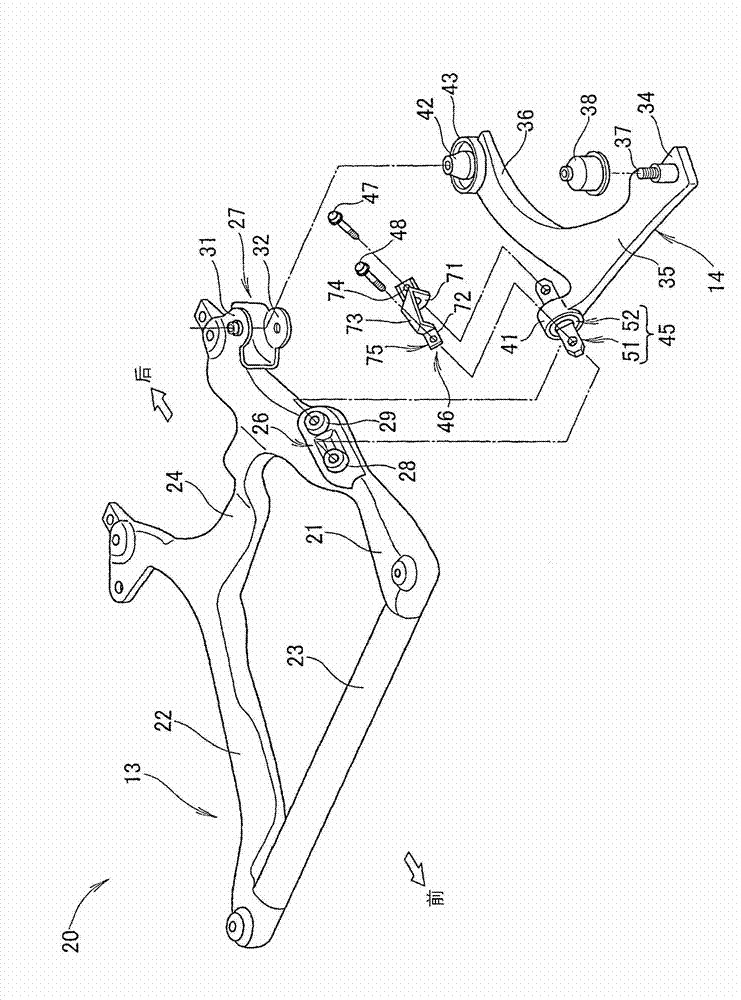

[0040] Reference figure 1 and figure 2 , The vehicle 10 includes: a front sub-chassis 13, which is mounted on the vehicle body 11, and supports an engine (not shown), a gear box (not shown), etc.; a suspension arm 14 that is swingably supported on the front sub-chassis 13; steering knuckle 15, which is supported by the suspension arm 14; wheels 16, which are mounted on the steering knuckle 15.

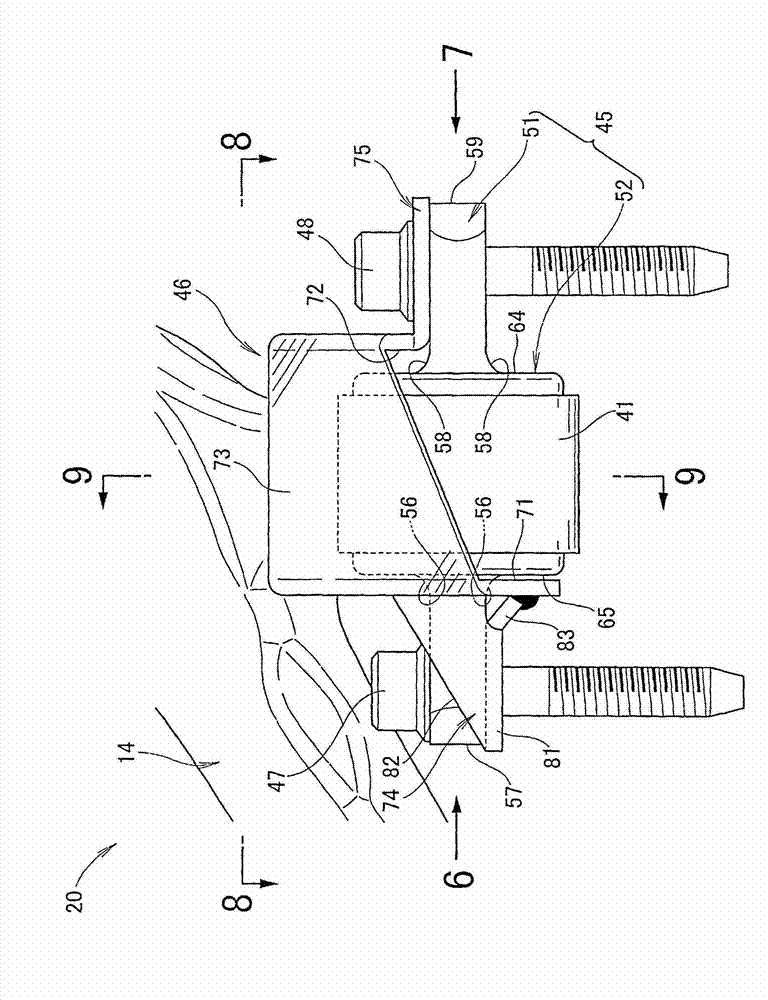

[0041] The suspension arm mounting structure 20 includes: a suspension arm 14 which is mounted on the vehicle body 11 and connected to the steering knuckle 15 supporting the wheels 16; and a mounting tube portion 41 which is provided on the suspension arm 14 and swingably supported on the vehicle body 11; Cylindrical anti-vibration bushing 52, which is fitted into the mounting tube portion 41, and is mounted to the vehicle body 11 via the core member 51; a stop member 46, which restricts the axial movement of the mounting tube portion 41.

[0042] The core member 51 is attached to the fron...

Embodiment 2

[0072] Next, combine Figure 13 ~ Figure 15 The suspension arm mounting structure 100 of the second embodiment will be described. For the suspension arm mounting structure 20 ( Figure 1 ~ Figure 12 For the common components used in ), the symbols are misappropriated and the detailed description is omitted.

[0073] Reference Figure 13 ~ Figure 15 , The suspension arm mounting structure 100 includes a front sub-chassis 13 ( figure 2 ), the forearm support portion 26, the suspension arm 14, the mounting cylinder portion 41 of the suspension arm 14, the vibration-proof bushing 52, the anti-drop member 106, and the bolts 47 and 48. The anti-vibration bush assembly 45 includes a core member (shaft) 51, an anti-vibration bush 52, and an outer tube 53.

[0074] The anti-drop member 106 has: the other side opposed wall 112 and the one side opposed wall 111 respectively corresponding to the end surfaces 64 and 65 of the anti-vibration bush 52; and the above-mentioned one side opposed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com