Patents

Literature

3950results about How to "Improve installation accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

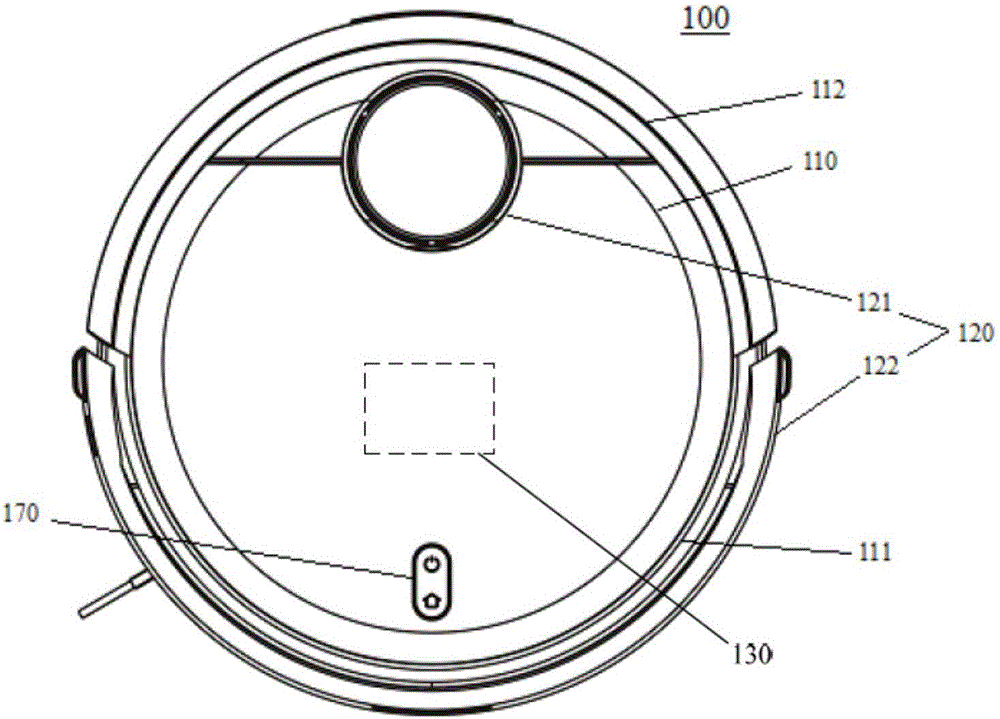

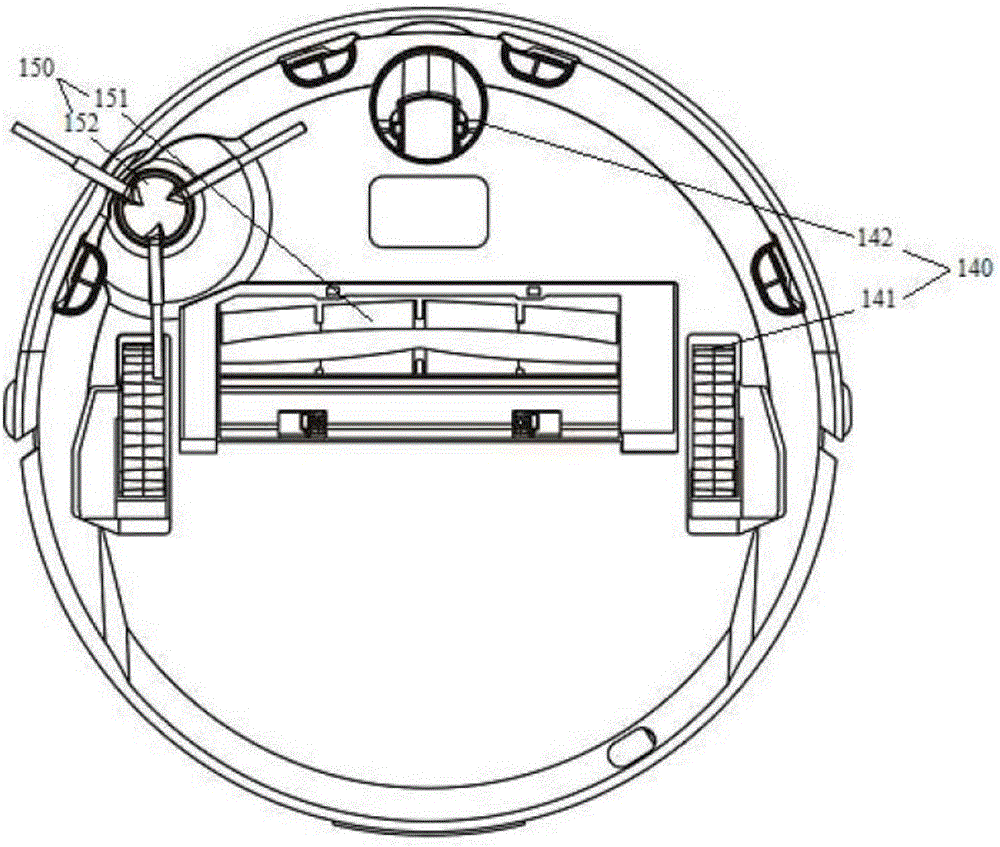

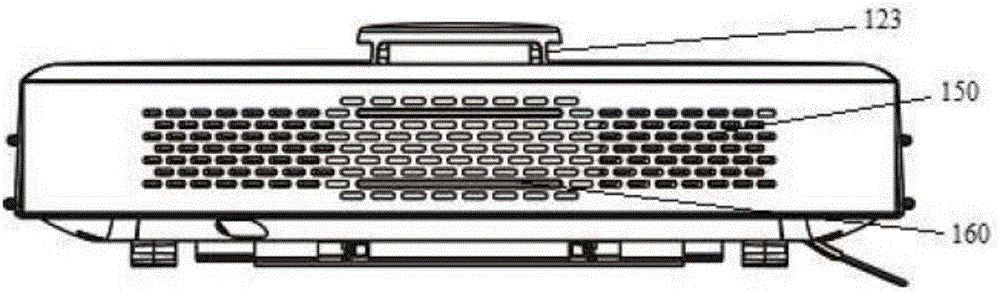

Self-cleaning device

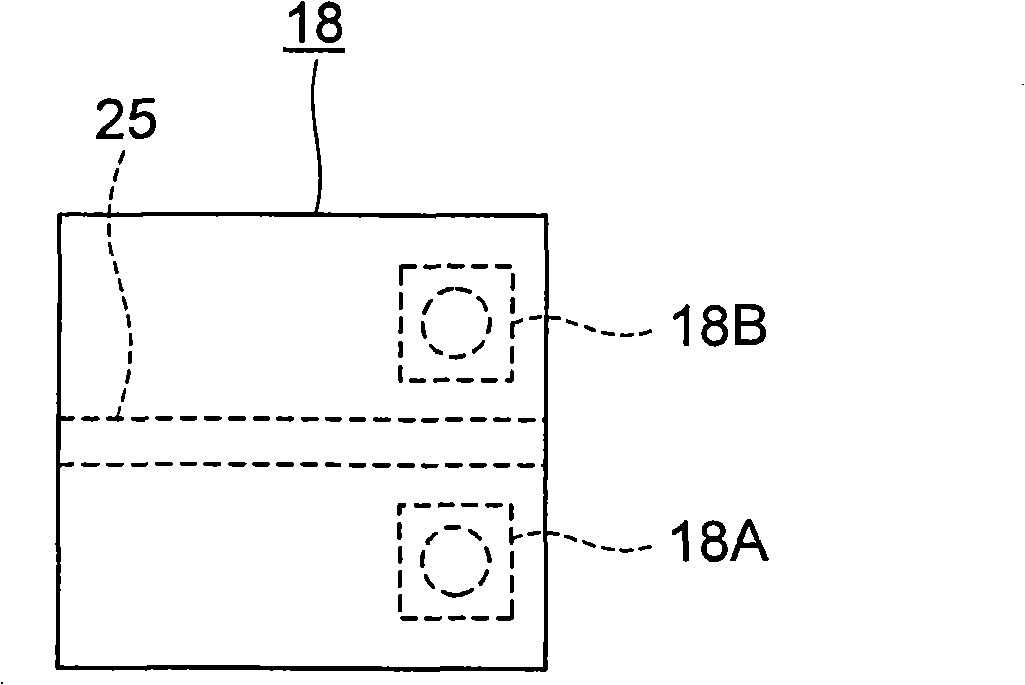

InactiveCN105982611AImprove maintenance efficiencyEasy to disassembleAutomatic obstacle detectionAutonomous decision making processEngineeringChassis

The invention relates to a self-cleaning device which comprises a device main body, a driving module, a cleaning module and a sensing module, wherein the device main body comprises a chassis and an upper shell fixed on the chassis; the driving module is connected with the chassis and is used for driving the self-cleaning device to advance according to a preset line; the cleaning module is distributed in the device main body; the sensing module is assembled on a preset position of the upper shell and is used for acquiring the condition of barriers at the periphery of the self-cleaning device; the driving module, the cleaning module and the sensing module are respectively assembled on the device main body in a detachable way. All the function modules in the self-cleaning device provided by the invention are respectively mounted in accommodating space reserved on the device main body and can be independently detached from the device main body, so that the damaged function modules can be independently detached for conveniently repairing or replacing new function modules and the repairing efficiency of the self-cleaning device is greatly increased.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD +1

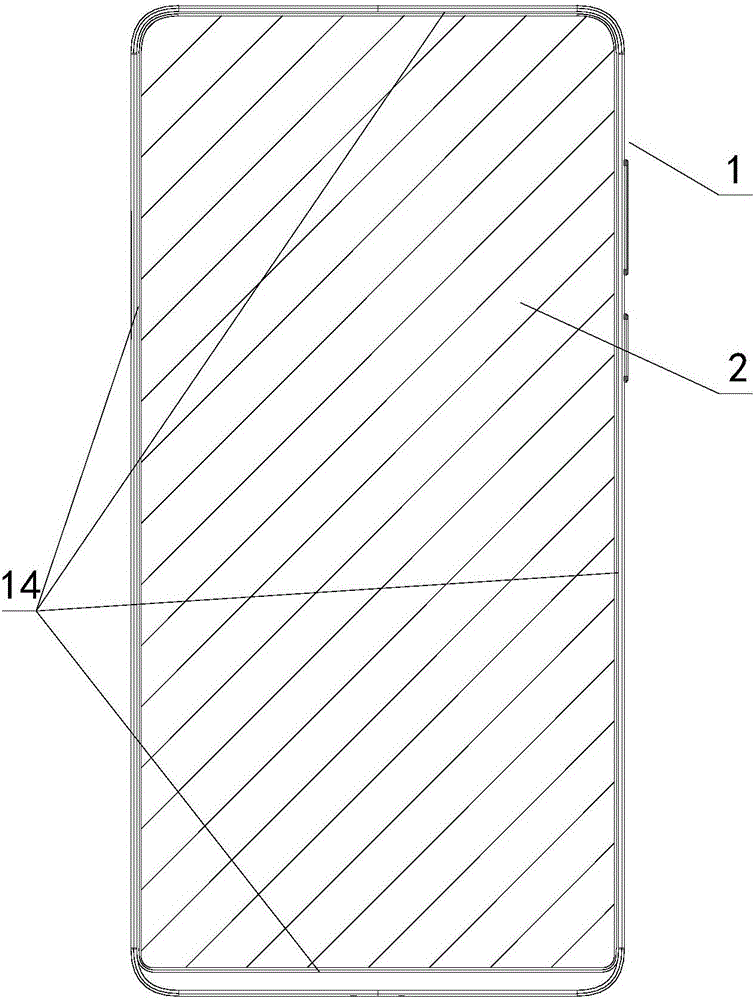

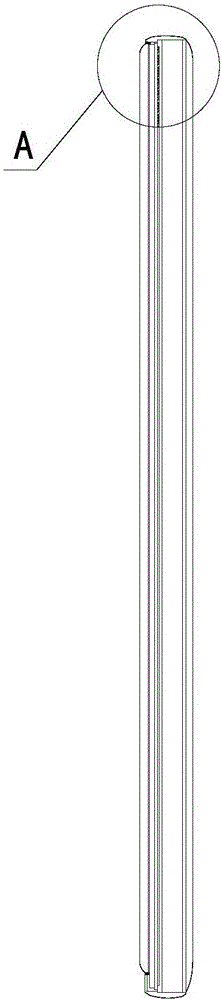

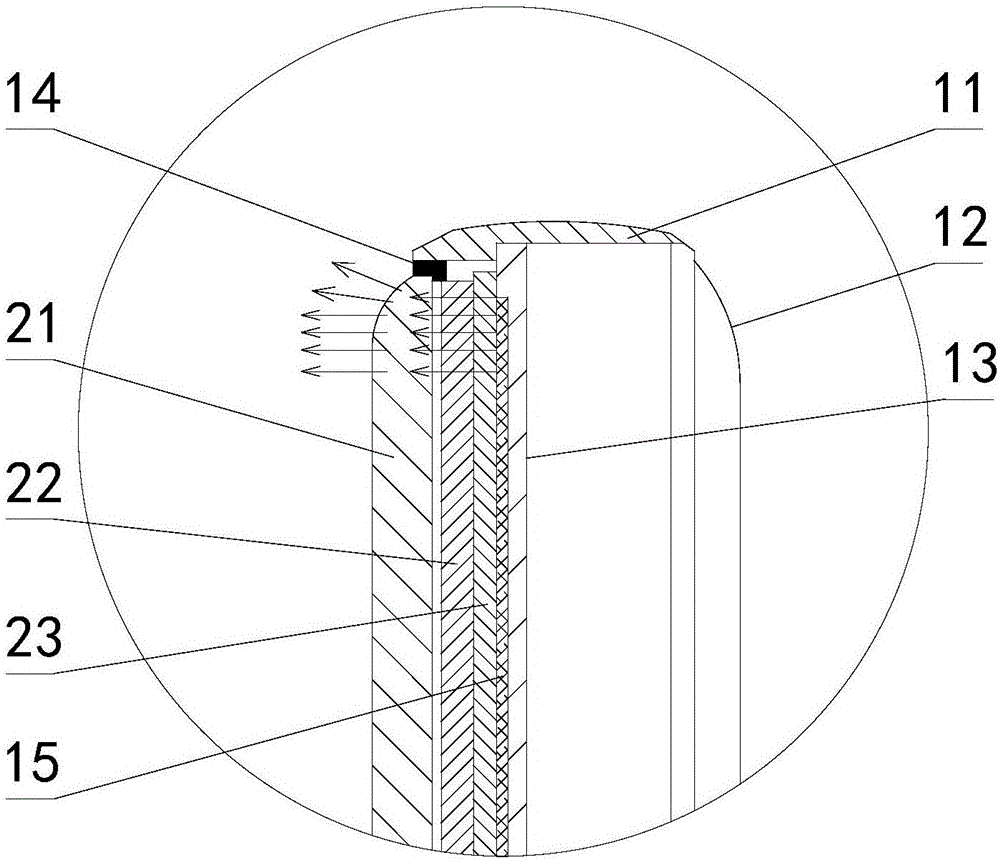

Mobile terminal (MT)

PendingCN106850894AImprove connection reliabilityRealize borderless displayTelephone set constructionsComputer hardwareScreen design

The invention discloses a mobile terminal (MT) including a bottom case, a display module, a middle frame shell and a mounting support. The display module is fixed on the mounting support. One side of the middle frame shell is provided with an installation channel in which the display module and the mounting support are fixed. The other side of the middle frame shell is provided with a connector by which the bottom case is buckled on the middle frame shell. The MT is applicable to the technical field of communication electronics and improves the structural stability; and moreover, a full screen design of the MT can be achieved, creating a better visual effect.

Owner:NUBIA TECHNOLOGY CO LTD

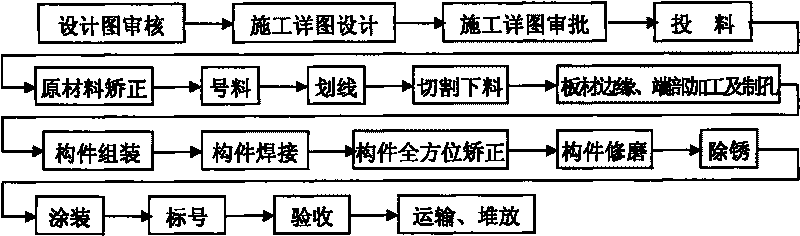

Segmental slipping and assembling process of overhead large-span steel structure

InactiveCN101725255AImprove installation accuracyFast constructionBuilding material handlingSpandrelSteel structures

The invention relates to a segmental slipping and assembling process of an overhead large-span steel structure, which is characterized by comprising the following steps of: firstly building a temporary track beam support, then arranging a slipping track beam and an assembling jig frame on the temporary track beam support, assembling a steel structure truss element on the jig frame according to drawing requirements, dismantling the assembling jig frame after the assembly is finished, pushing and slipping the steel structure truss element forwards along the a slipping track, moving the steel structure truss element to the expected position of the steel structure, then carrying out next span area steel structure truss element assembly on the emptied-out assembling jig frame, carrying out welding connection between the next span steel structure truss element and the previous element, slipping and pushing the steel structure truss elements to the expected position in sequence, analogizing the process in sequence till all steel structure slipping and assembly are finished, and finally unloading, landing and fixing to finish the whole installation work of the steel structure.

Owner:高申甫

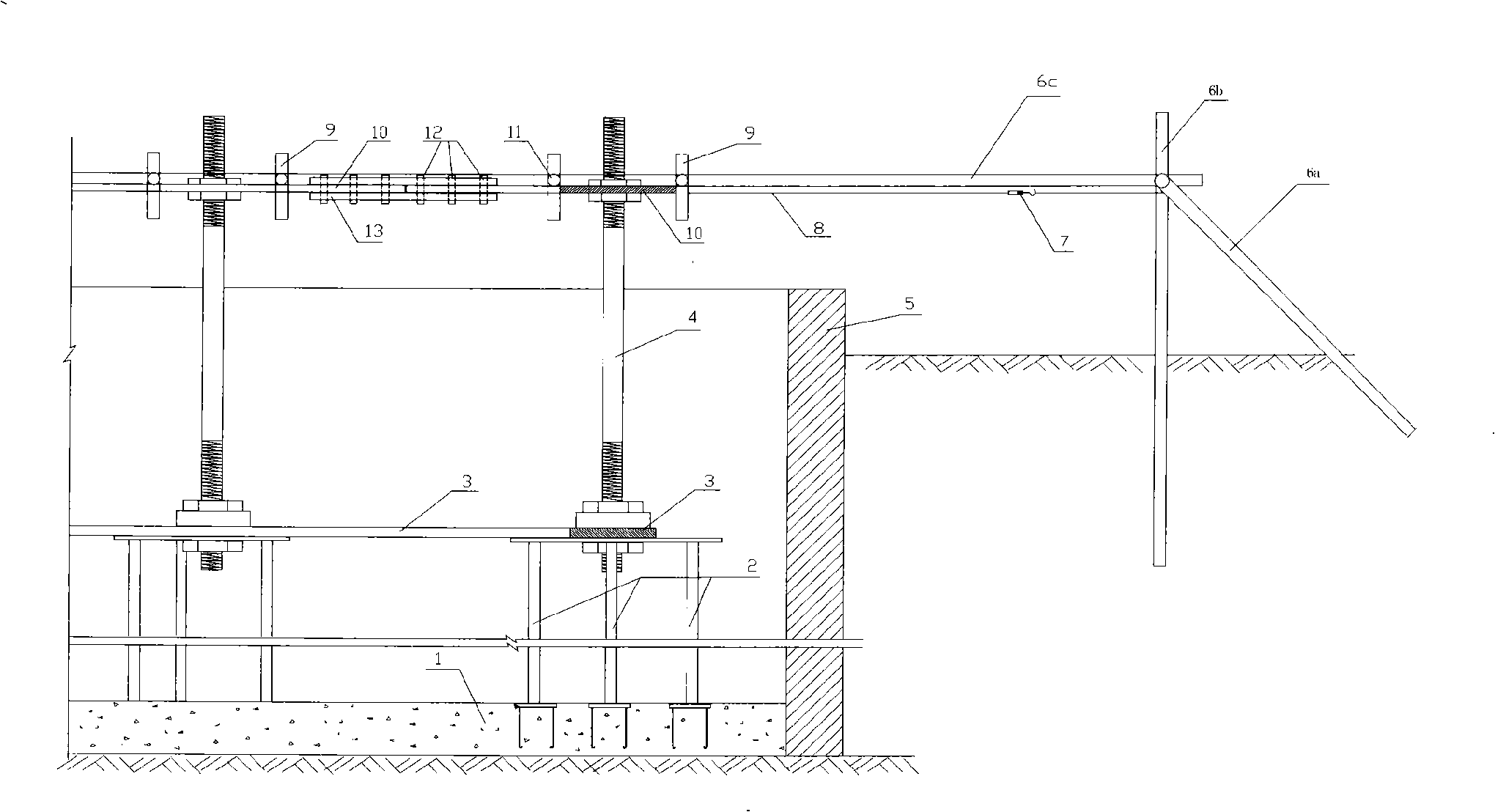

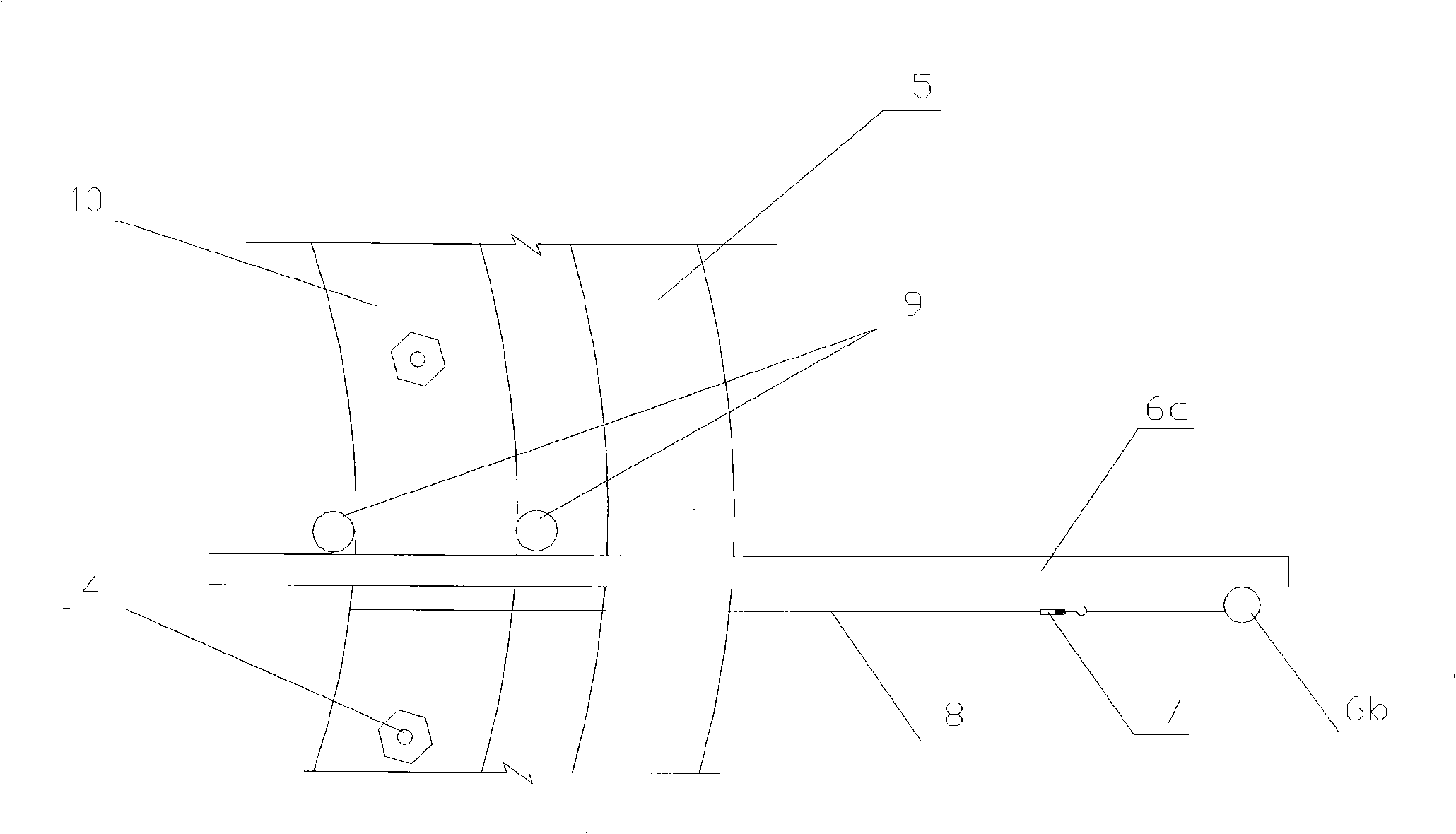

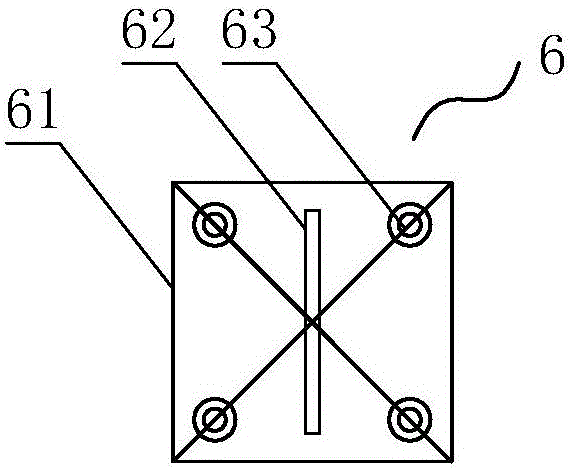

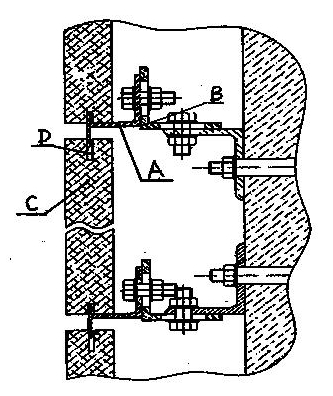

Integral built-in process for groups of anchor bolts

ActiveCN101338566AAdjustable deviationTimely correctionRail fastenersFoundation engineeringEngineeringWrench

The invention discloses an integral embedded method for a group of anchor bolts. The method comprises the following steps: after assembled lower positioning plates are fixed on a steel bracket in a foundation trench, the lower ends of the embedded bolts are fixedly connected with the lower positioning plates, and upper positioning plates are correspondingly installed on the embedded anchor bolts; steel pipe cat anchors are arranged on the periphery of the foundation trench to adjust the axial line positions of the embedded bolts, concrete is poured into the foundation trench, and after the concrete pouring is accomplished, the axial line positions of the embedded anchor bolts are adjusted. By adopting the method, the bracket and the ring-shaped positioning steel plate can be processed in a plant in advance, few construction site and little operational sequence time are occupied, the on-site splicing can be accomplished by only a spanner tool, the operational sequence is simple, the conventional on-site splicing time is saved, not only the construction speed is greatly accelerated, simultaneously the installation precision is enhanced, the engineering embedded bolt detection indicates that the permissible accuracy error for the embedded bolt installation is above the requirement of the national regulation, and the qualification rate of the engineering large-scale embedded anchor bolt can be up to 100 percent.

Owner:河北省第四建筑工程有限公司

BIM-based pre-assembling method for double-curved glass curtain wall

ActiveCN106013535AEliminate biasImprove installation accuracyWallsBuilding material handlingSolid componentPoint cloud

The invention relates to a BIM-based pre-assembling method for a double-curved glass curtain wall. The method includes the following steps that three-dimensional models of glass curtain wall components are established according to a modeling standard; detailed glass curtain wall component drawings are guided out and numbered, and then processing and production are carried out; three-dimensional scanning is carried out on the processed glass curtain wall components, point cloud data are obtained, and three-dimensional point cloud models are established through the point cloud data; the three-dimensional point cloud models and the three-dimensional models are compared to obtain deviation values of glass curtain wall component solid bodies, and glass curtain wall component information is adjusted till the deviation values meet glass curtain wall standard requirements; and overall pre-assembling of the three-dimensional point cloud models meeting the requirements is simulated in Revit, accumulative errors in the assembling process are eliminated till the pre-assembled three-dimensional point cloud models are completely matched with the three-dimensional models, and then the glass curtain wall components are delivered out of a factory and delivered to a construction site for solid component installation. By means of the method, the problems that the double-curved glass curtain wall is large in field installation difficulty, low in installation efficiency and low in precision are solved.

Owner:SHANGHAI BAOYE GRP CORP

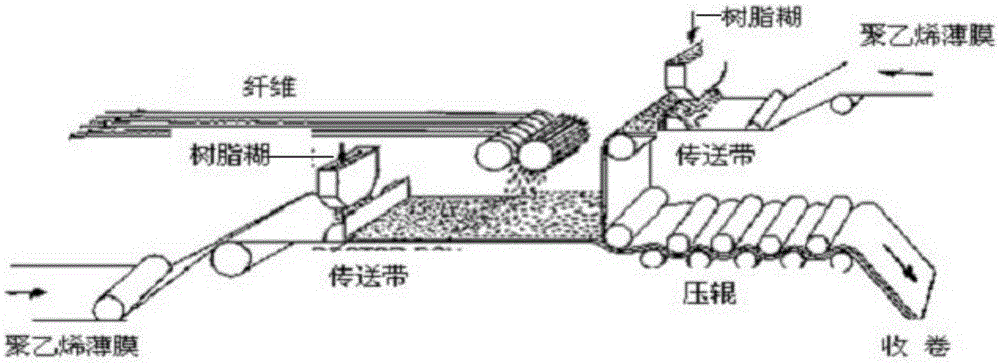

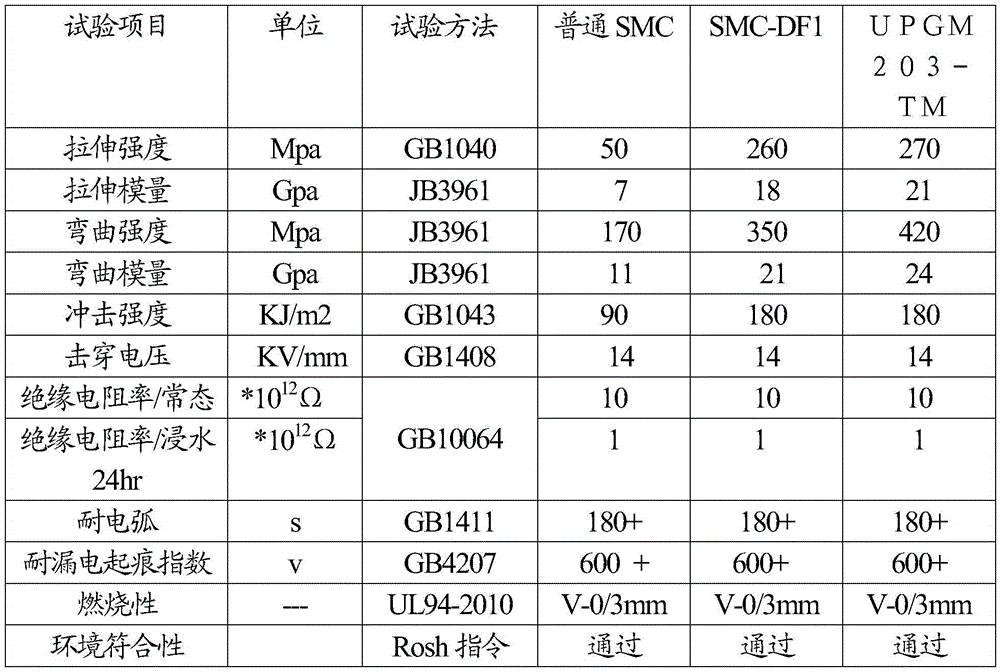

Unsaturated polyester resin fiber reinforced sheet-shape molding compound and preparation method thereof

The invention discloses an unsaturated polyester resin fiber reinforced sheet-shape molding compound, comprising unsaturated polyester resin, a low shrinkage agent, a filler, a curing agent, a thickener, a mold release agent, a reinforcing material, a colorant and an additive. The unsaturated polyester resin is characterized by comprising one or more of o-phenylene resin, m-phenylene resin and vinyl ester resin in mixing; the filler is modified aluminium hydroxide; the reinforcing material is made of one or more selected from the group containing alkali-free chopped glass fiber, alkali-free untwisted continuous glass fiber rove, high silica glass fiber and Kevlar fiber. The molding compound combines light weight, high strength, retardance, corrosion resistance and insulation, has the advantages of high weight percentage of reinforced material, good electrical properties, significantly improved mechanical properties, tensile strength of not less than 100Mpa, bending strength of not less than 300Mpa, impact strength not less than 260 KJ / m<2>, dielectric strength of not less than 12KV / mm, flame retardance of UL94V-0 and product thickness of up to 60mm, and can be used for compression molding of electrical insulation structural parts.

Owner:SICHUAN D&F ELECTRICAL TECH

Method for manufacturing and installing guide rail in container ship cargo hold

InactiveCN101885368AImprove installation accuracyAvoid welding deformationVessel partsEngineeringSlipway

The invention discloses a method for manufacturing and installing a guide rail in a container ship cargo hold, which comprises the following steps of: (a) manufacturing the guide rail; (b) two-dimensional preassembly: assembling and welding a processed guide plate and the guide rail on a platform by using a doubling plate as a basal plane; (c) hoisting and boarding: installing an eye ring of the guide rail on the guide rail a quarter away from the upper end, respectively installing one eye ring at the left side and the right side of the guide plate, correspondingly reinforcing the eye rings from the back side, and hoisting the whole guide rail to a slipway; adding a toggle plate behind the doubling plate to reinforce the guide rail with low intensity; and after manufacturing the guide rail of a following ship in two segments, connecting the two segments into one guide rail after correction, and hoisting the assembled guide rail; (d) slipway installation: marking, and installing the guide rail; and (e) packaging and testing. In the method, the guide rail is firstly preassembled on the platform by using the doubling plate as the basal plane, and then, the whole guide rail is hoistedonto the slipway and installed. The invention has simple and reasonable method, convenient construction and high guide rail installation accuracy. The upward and downward hoisting and the reasonable arrangement of containers in the cargo hold can be ensured, and thus, the working efficiency and the ship manufacturing quality are increased.

Owner:YANGFAN GROUP

Large valve and large-diameter pipeline pre-assembly pup joint manufacturing and hoisting method

ActiveCN106624639ANo depressionNo damageWelding/cutting auxillary devicesPipeline systemsButt jointEconomic benefits

The invention discloses a large valve and large-diameter pipeline pre-assembly pup joint manufacturing and hoisting method. The manufacturing and hoisting method is characterized in that a prefabricated segment and a pre-assembly entirety are manufactured in a ground machining field, and the pre-assembly entirety is hoisted in place with a vertical transportation machine to be connected with an installed overhead large-diameter pipeline in a butt-joint welding mode; the method comprises the technological processes of construction preparing, prefabricated segment manufacturing, pre-assembly entirety manufacturing, pre-assembly entirety hoisting, butt-joint welding of the pre-assembly entirety and the installed overhead pipeline and checking and accepting. The hoisting method has the advantages that the tedious and high-difficulty high-altitude operation process is simplified and completed in the ground machining field, and therefore the problems that in traditional construction, the construction processes are tedious, the construction period is long, the high-altitude operation construction operation surface requirement is high, and the welding and installing quality is difficult to guarantee are solved; the whole construction process is in a safe, stable and controllable state, the installation precision is high, the construction period can be shortened, the construction efficiency is improved, the labor and material cost is reduced, and the economic benefit is significant.

Owner:广西建工第五建筑工程集团有限公司

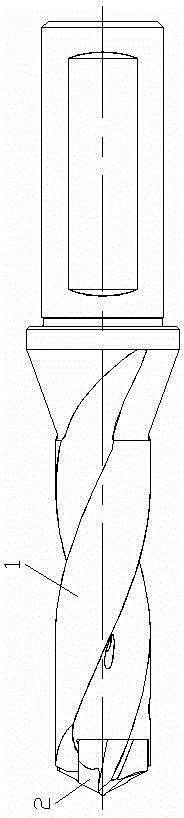

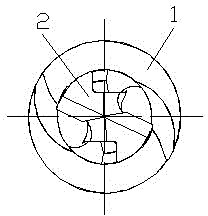

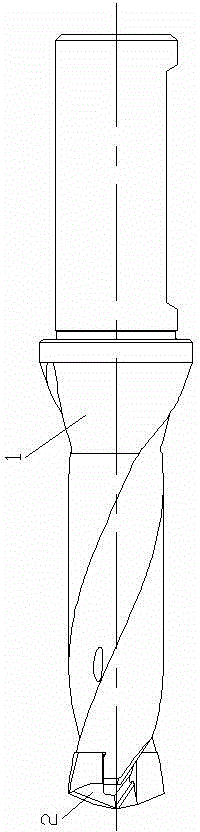

Drill bit of replaceable cutter head type structure

ActiveCN104907612AImprove installation accuracyGuaranteed stabilityTransportation and packagingCutting insertsEngineeringDrill bit

The invention discloses a drill bit of a replaceable cutter head type structure. Currently, a drill bit of a replaceable cutter head type structure high in machining accuracy, high in mounting accuracy and stable in rotating does not exist. The drill bit comprises a cutter rod, a cutter head and a fixing screw. The cutter rod comprises a cutter rod body. The drill bit is characterized in that a cutter head locating groove is formed in the front end of the cutter rod body, two supporting planes are arranged on the cutter head locating groove, after one supporting plane rotate around the axis of the cutter rod by 180 degrees, the supporting plane and the other supporting plane are overlapped, a locking groove is formed in a fixing column, the fixing column is arranged in a cutter head locating hole in a sleeved mode, a cutter head body is placed in the cutter head locating groove, the two supporting faces on the cutter head are tightly attached to the two supporting planes on the cutter rod respectively, the locating bottom face on the cutter head is tightly attached to the bottom of the cutter head locating groove, the fixing screw is in thread connection into a cutter head fixing hole, and the front end of the fixing screw abuts against the locking groove in the cutter head. The drill bit is high in machining accuracy, high in mounting accuracy, stable in rotating and stable in cutting, the cutter head can be abandoned, and service life is long.

Owner:ZHEJIANG XINXING TOOLS CO LTD

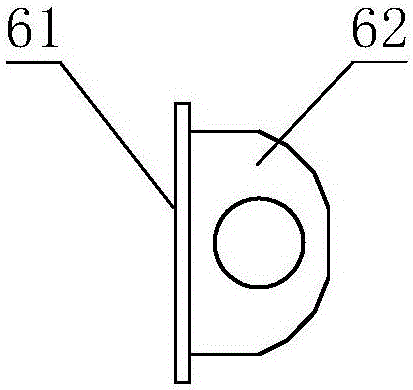

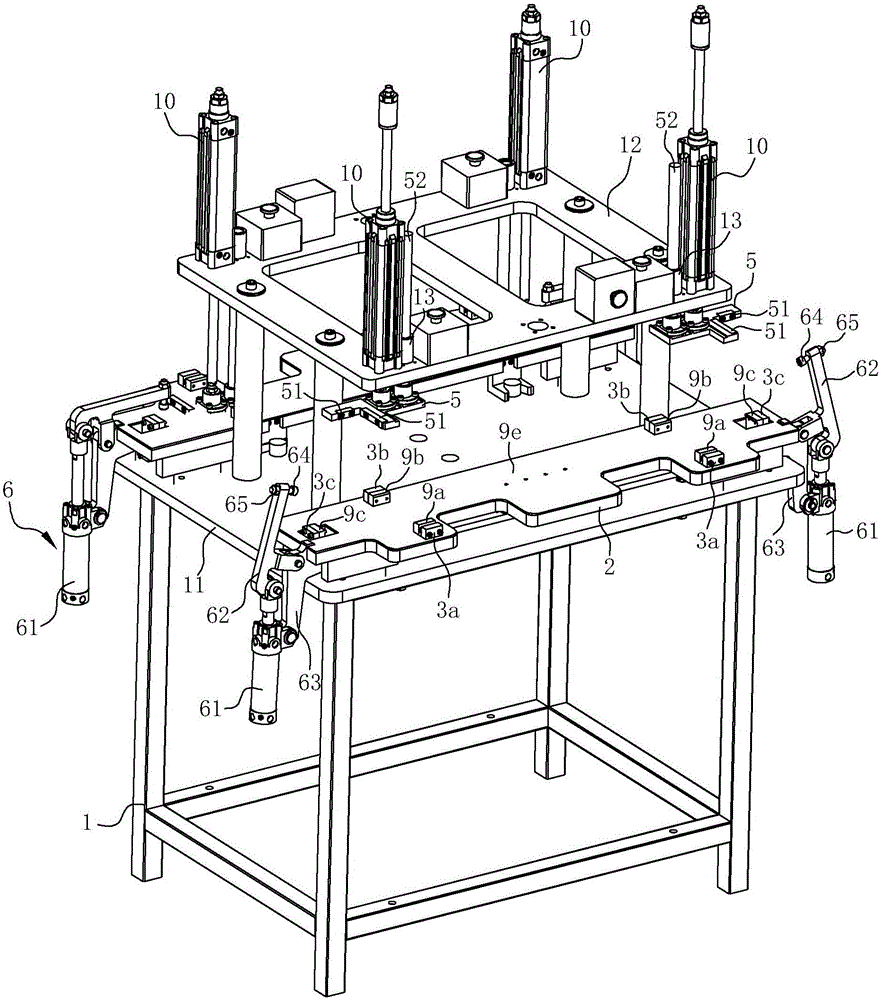

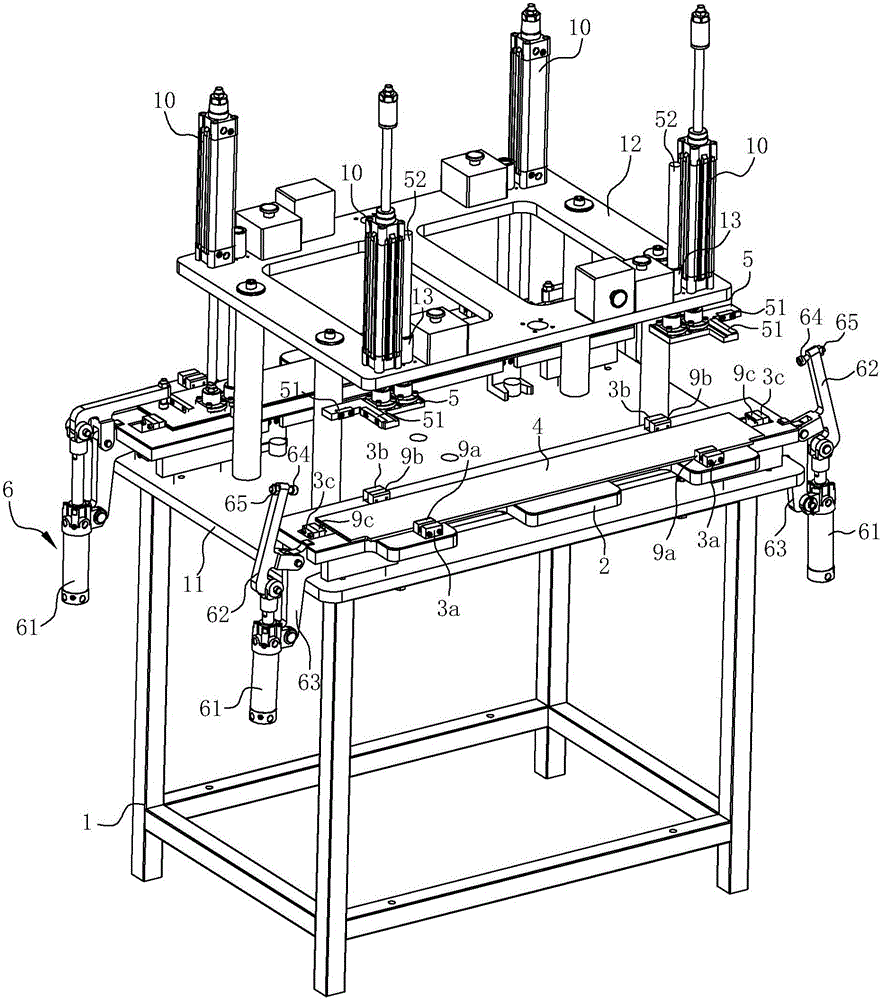

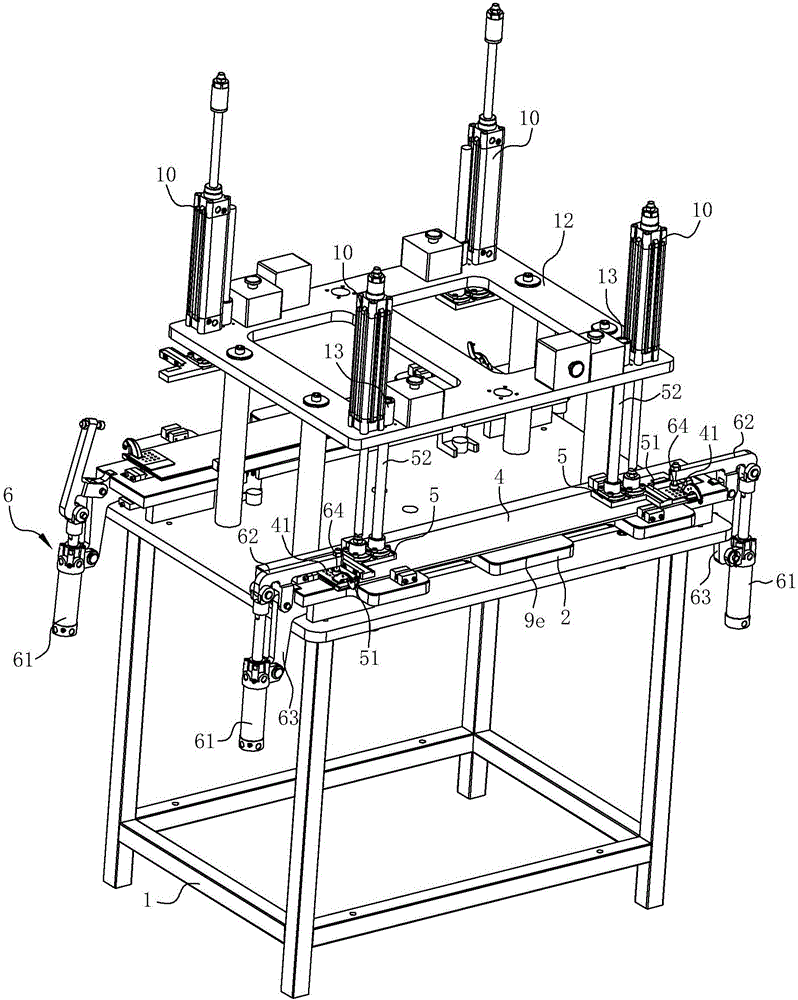

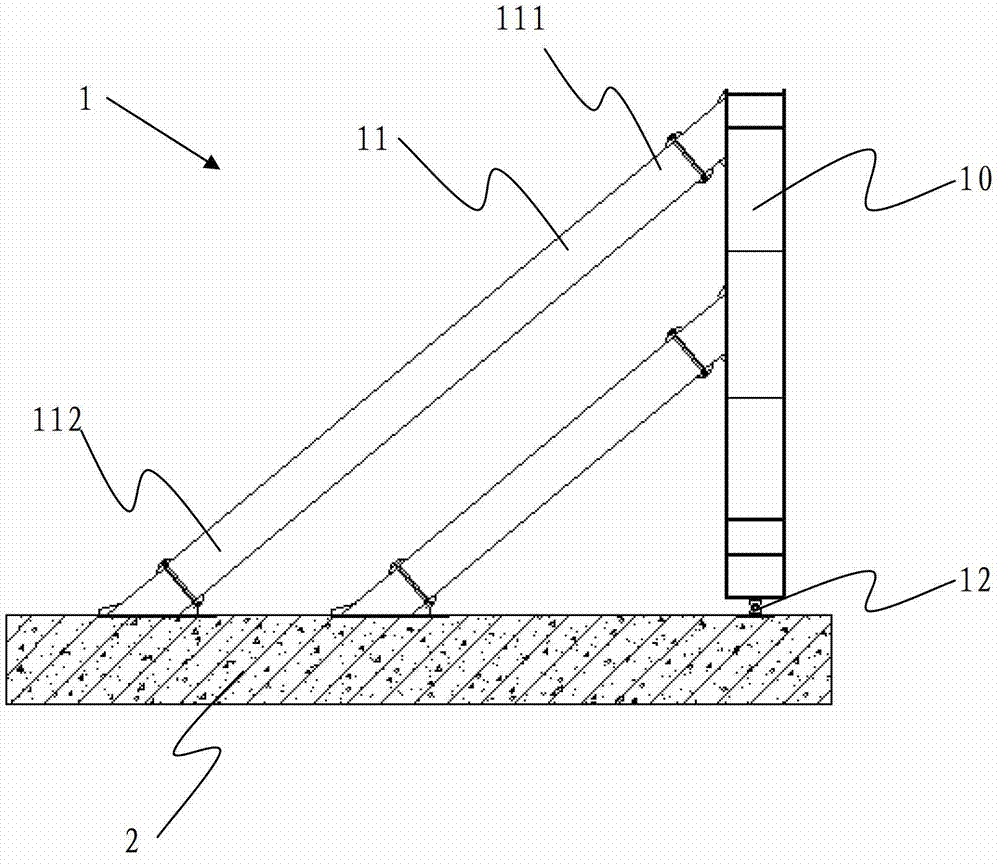

Adhesion clamp for smoke baffle

ActiveCN105818020AEasy to operateGood adhesionMaterial gluingWork holdersMechanical engineeringSmoke

The invention relates to an adhesion clamp for a smoke baffle. The adhesion clamp for the smoke baffle comprises a frame. The frame is provided with a table top, an upper mounting plate and at least one set of adhesion structure. The adhesion clamp for the smoke baffle is characterized in that the adhesion structure comprises a shelf, a circumferential limiting structure, two L-shaped limiting blocks and two pressing mechanisms; the circumferential limiting structure is used for restraining the smoke baffle in the circumferential direction, and comprises a front positioning block, a rear positioning block, a left positioning block and a right positioning block; the front positioning block and the rear positioning block are fixed to the shelf; the left positioning block and the right positioning block are restrained on the shelf and can slide left and right synchronously; the two L-shaped limiting blocks are used for limiting rotary shaft components, and can move vertically under driving of an air cylinder mounted on the upper mounting plate; and the two pressing mechanisms can press the rotary shaft components onto the upper end face of the smoke baffle to maintain the pressure for adhesion. By means of the adhesion clamp, the rotary shaft components can be accurately and firmly mounted onto the smoke baffle, the dimensions of the rotary shaft components at the two ends of the smoke baffle can be accurate, the both sides are balanced in error, and the situation that errors are lumped at one end is avoided.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

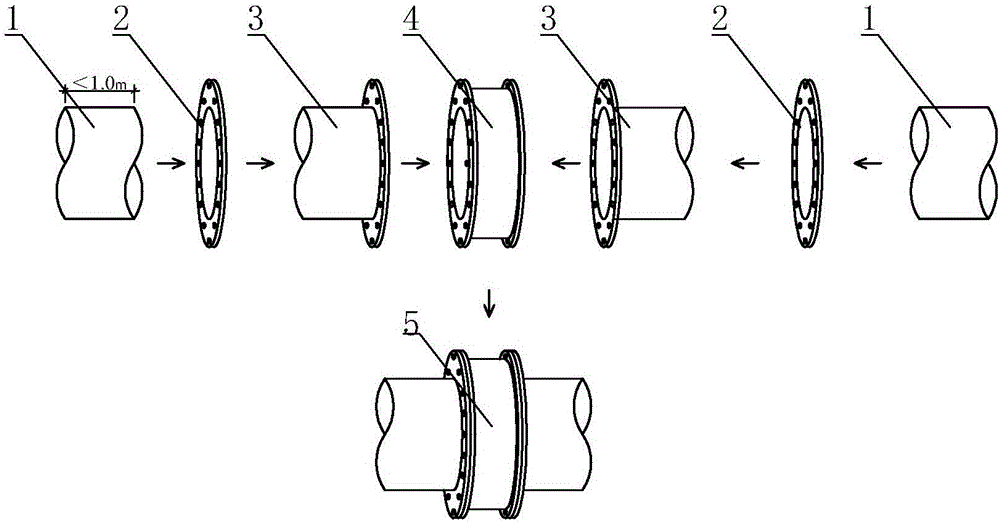

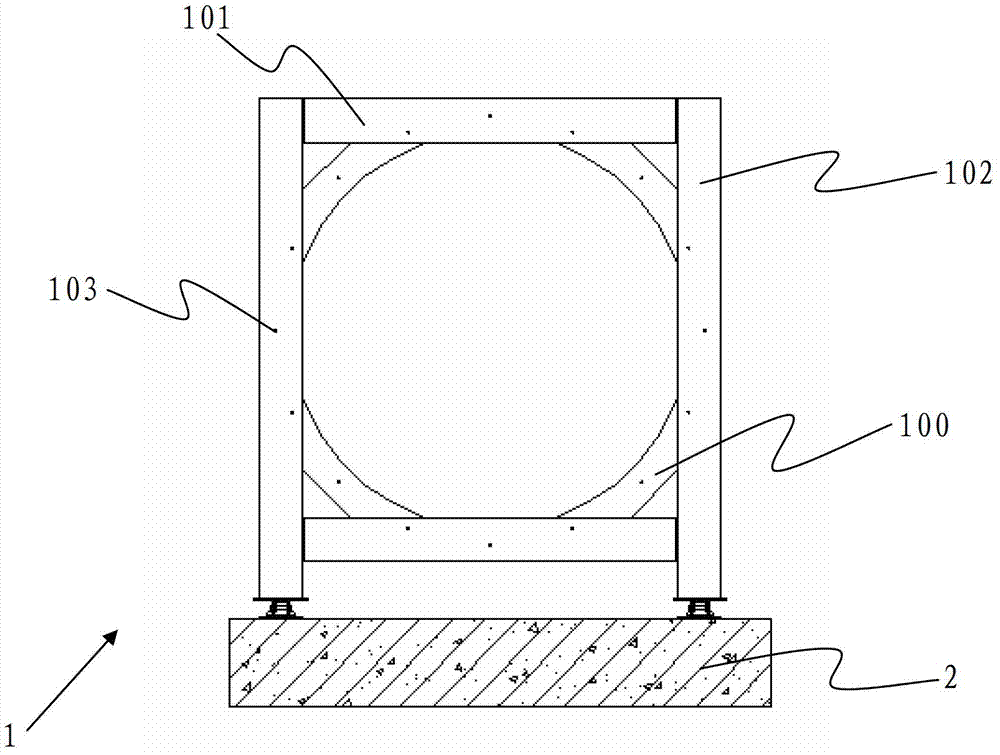

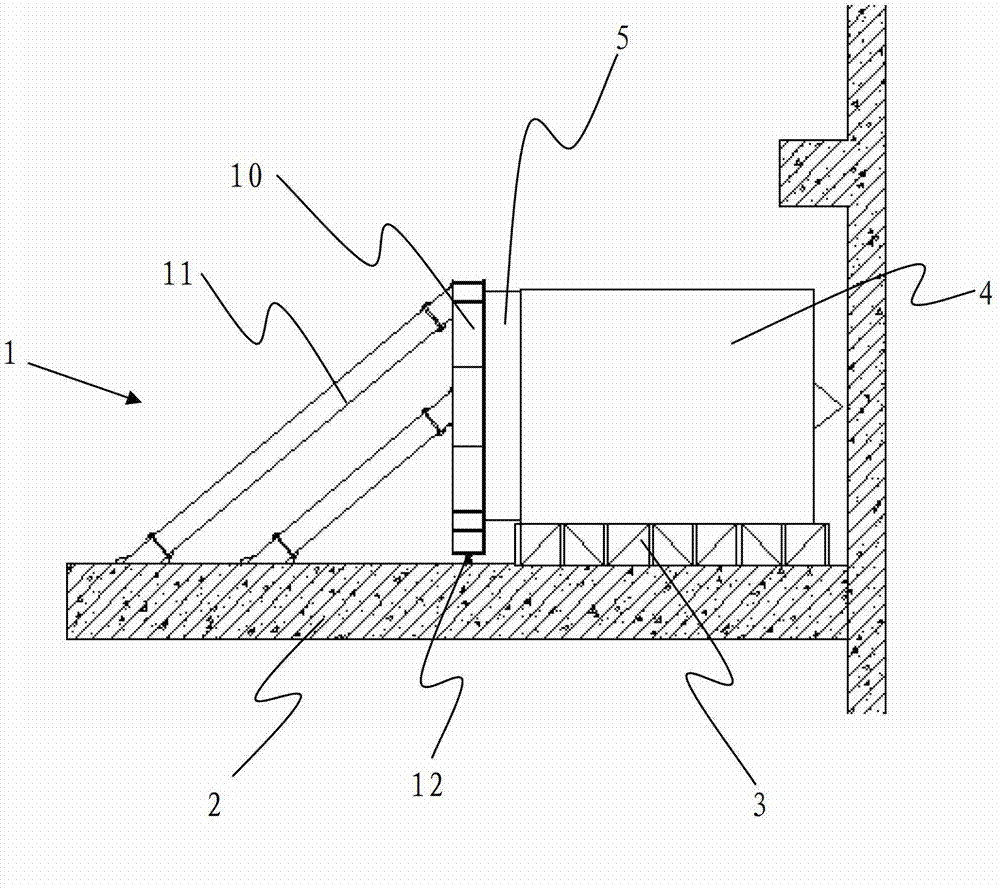

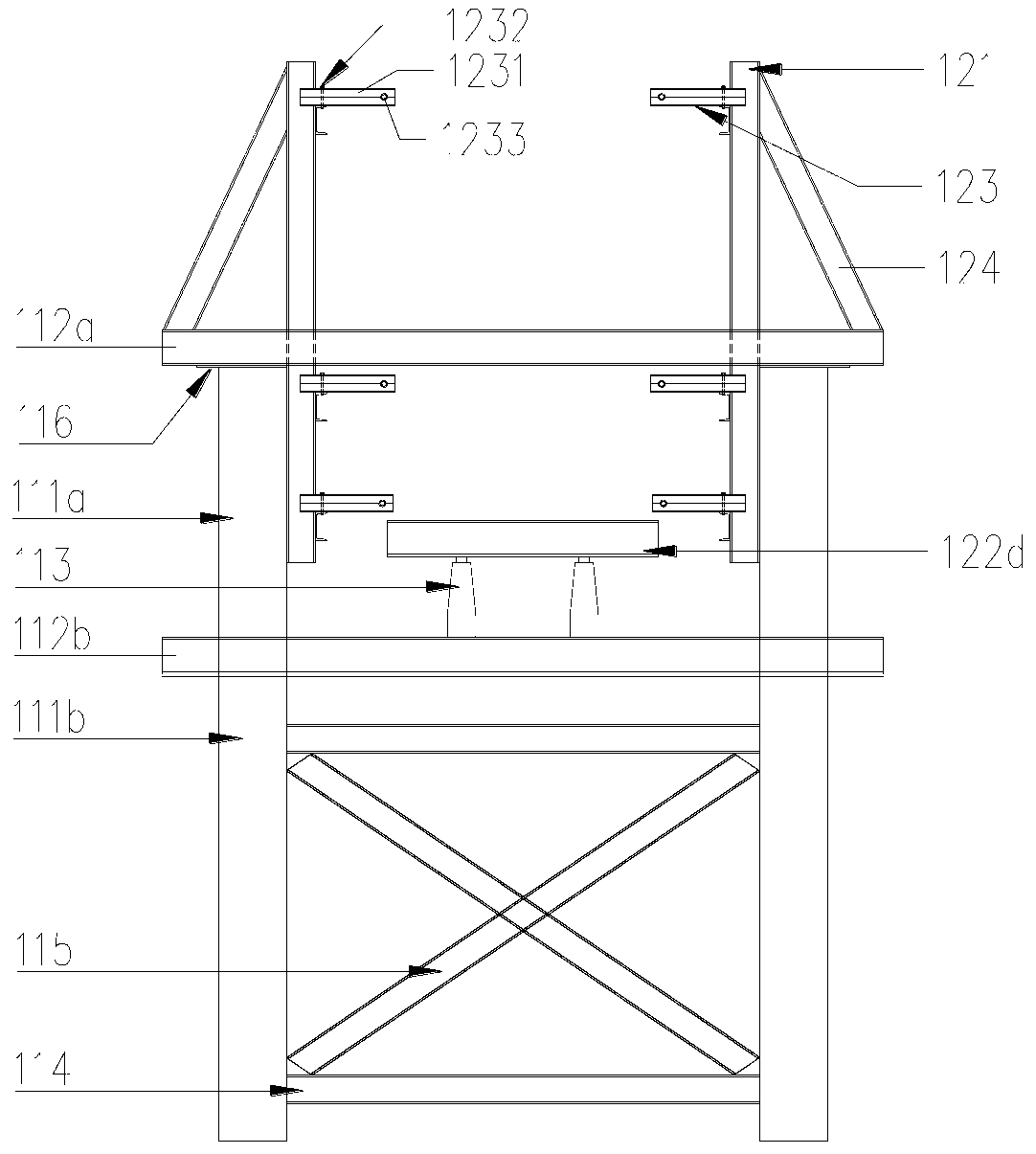

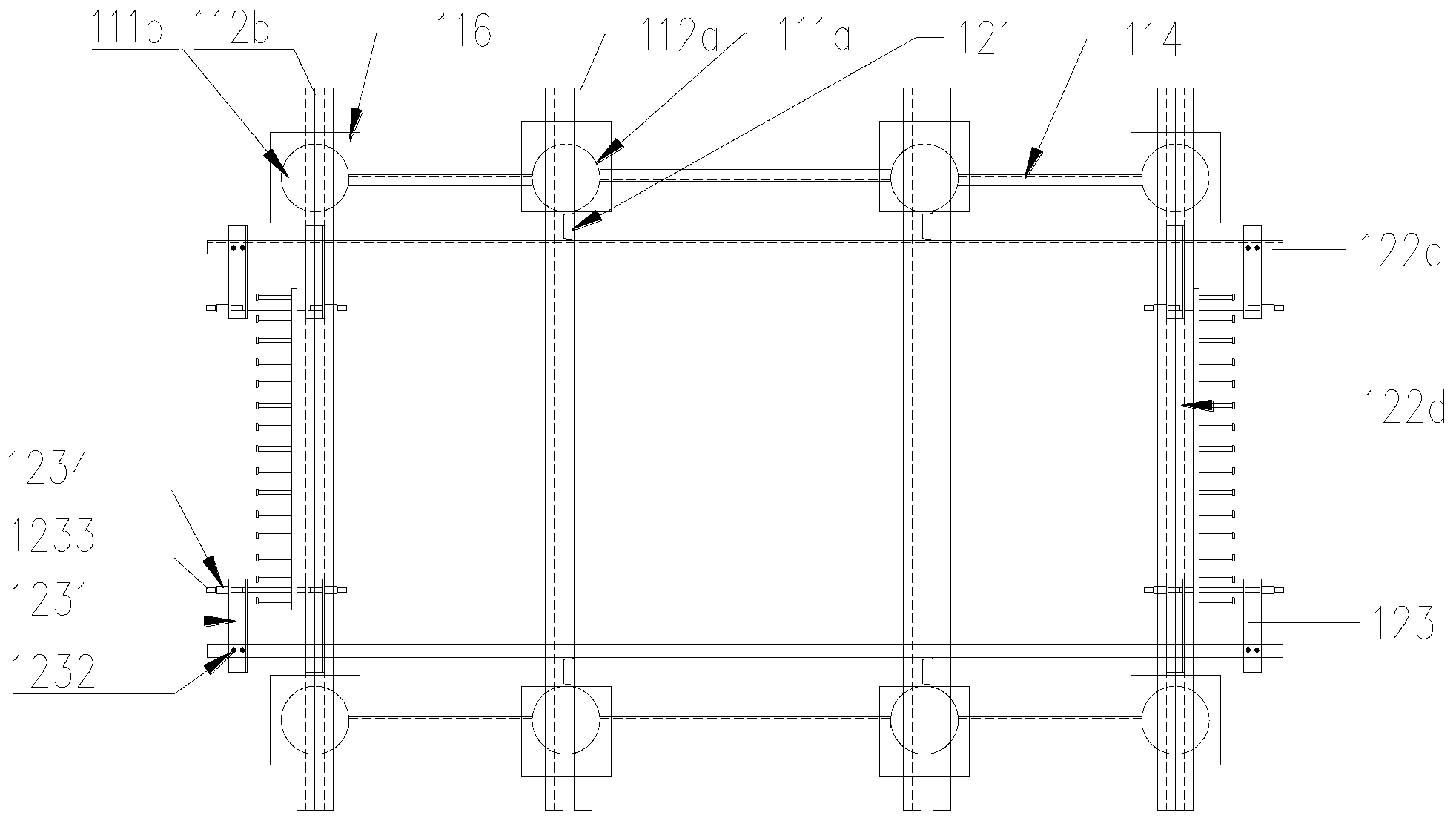

Assembling type reaction frame device for shield launching and propulsion

InactiveCN102758634AEasy to controlGuarantee smooth implementationUnderground chambersTunnel liningEngineeringHinge angle

The invention discloses an assembling type reaction frame device for shield launching and propulsion, and the device is arranged on a bottom plate of a work shaft, wherein the reaction frame device comprises a frame and a plurality of supporting rods; the frame is connected to the bottom plate of the work shaft by a hinge; the first ends of the supporting rods are connected with the frame; the second ends of the supporting rods are connected with the bottom plate of the work shaft; the frame is coaxial to a tunnel portal; the frame further comprises two cross beams and two vertical beams which are mutually connected to form a rectangular frame; the frame also comprises a plurality of reaction ring assembling beams and a plurality of bolt holes; the reaction ring assembling beams are arc-shaped and are respectively connected at the four corners in the rectangular frame; the surfaces of the reaction ring assembling beams and the surface of the rectangular frame form a plane; and the bolt holes are distributed on the surface of the frame and are corresponding to the positions of longitudinal bolt holes of pipe pieces. Since the whole assembling structure can be repeatedly utilized and the position can be freely adjusted, the assembling type reaction frame device is applicable to different types of work shafts.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD. +1

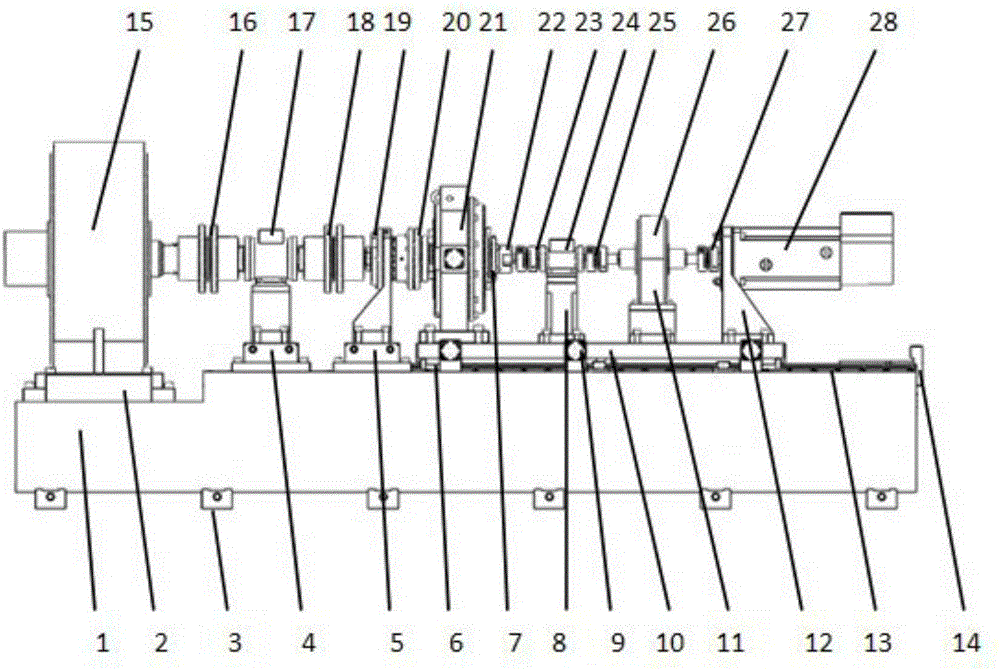

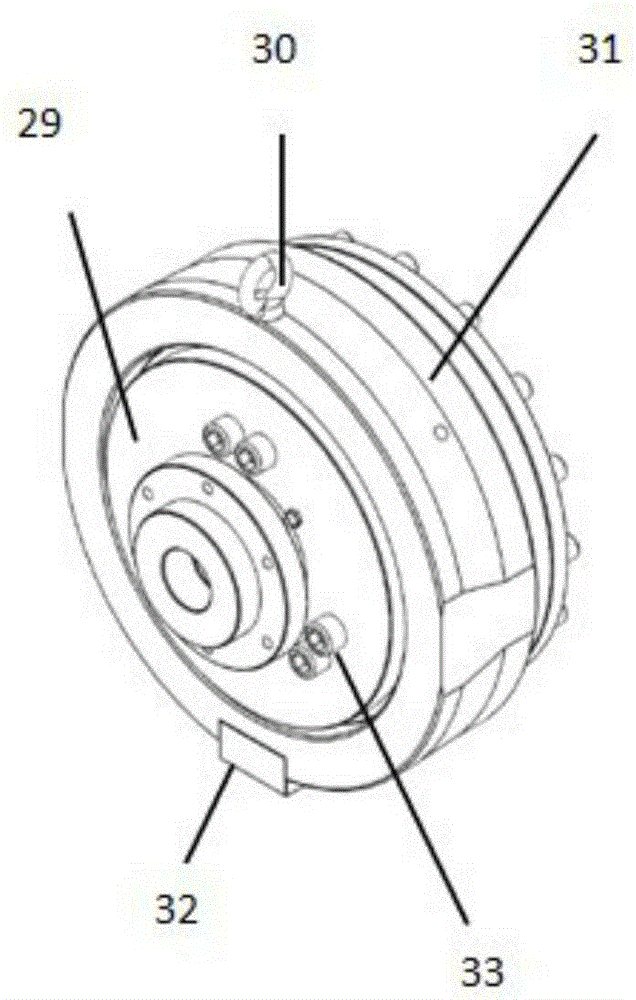

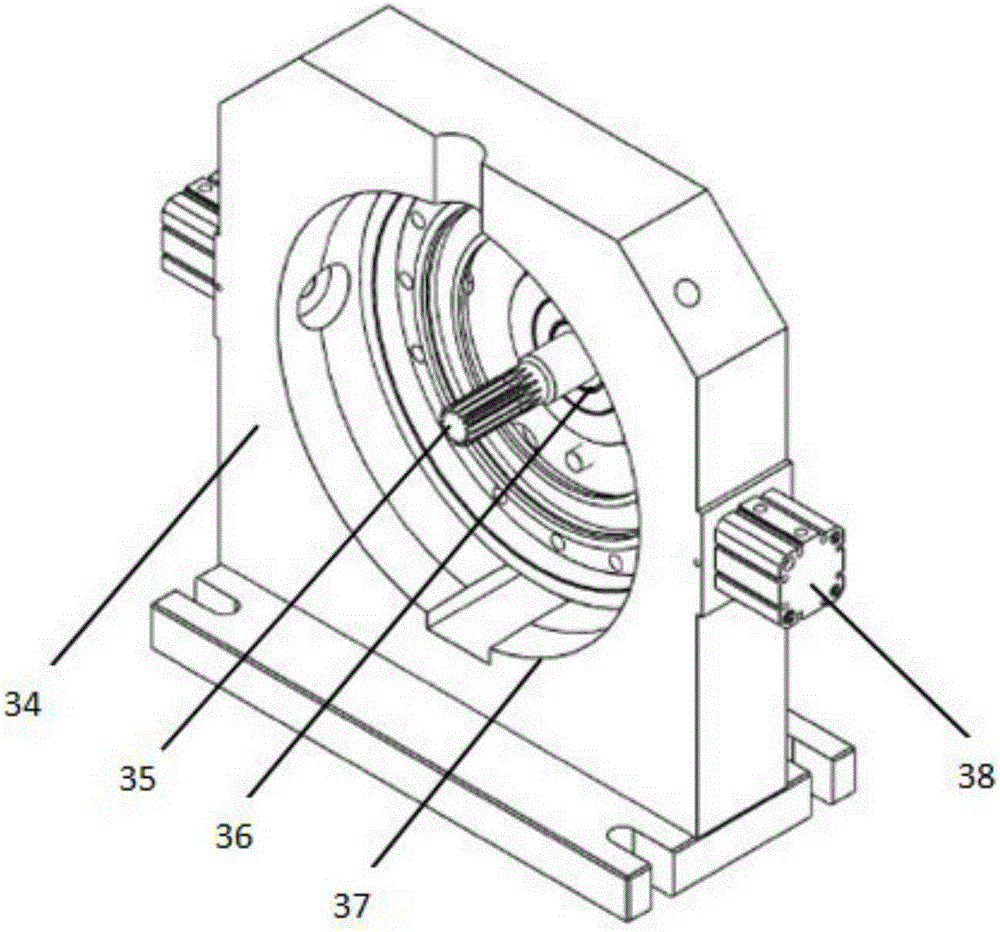

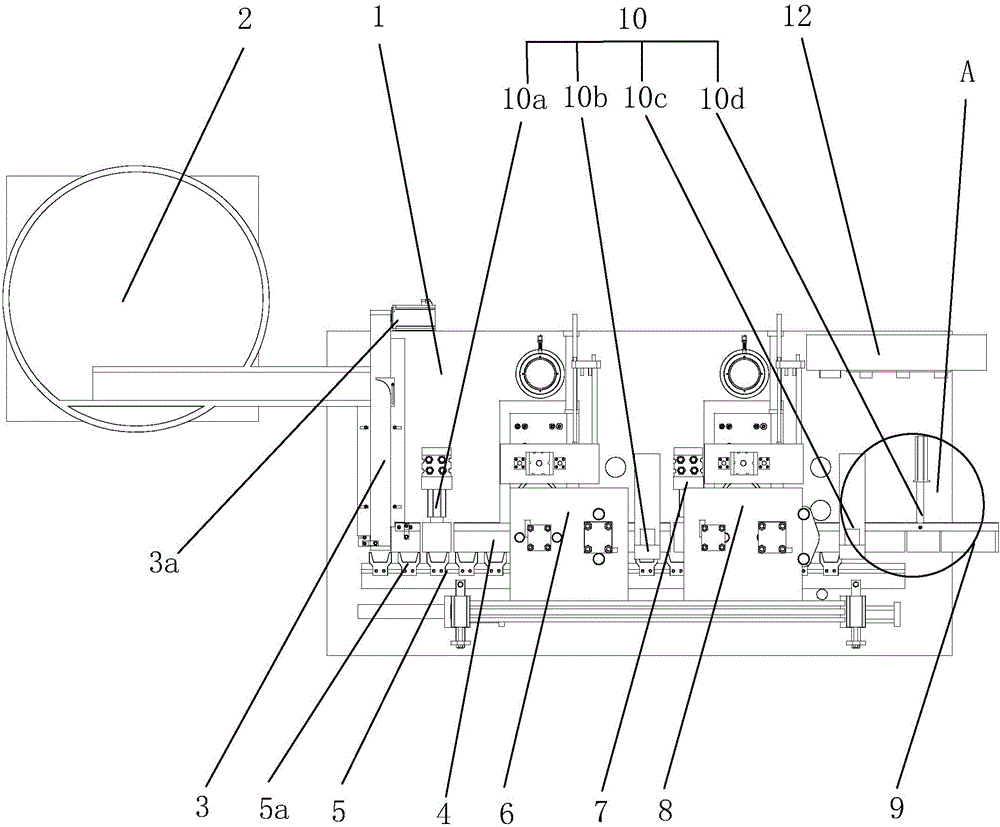

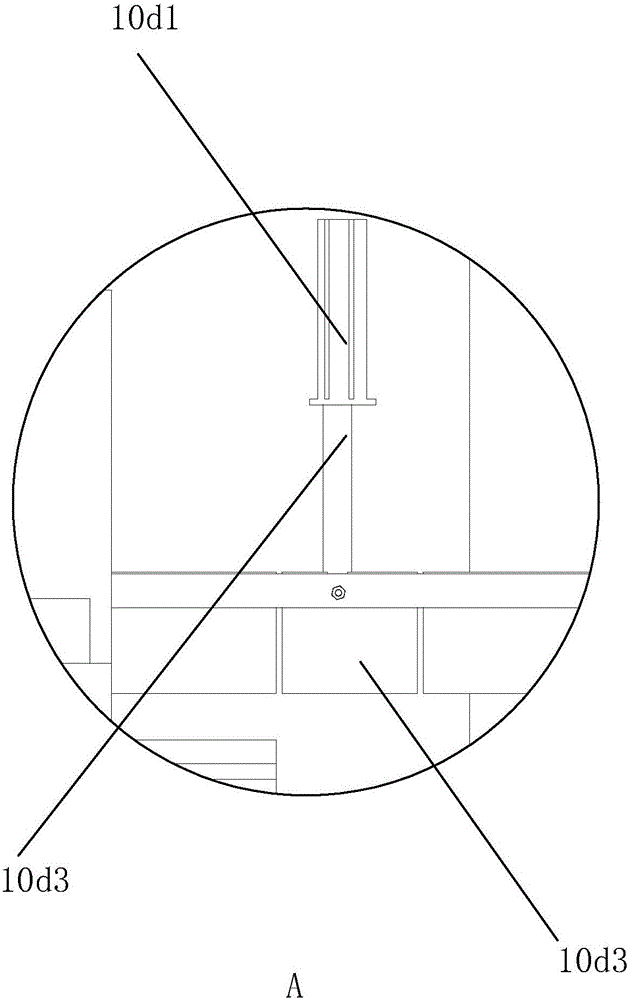

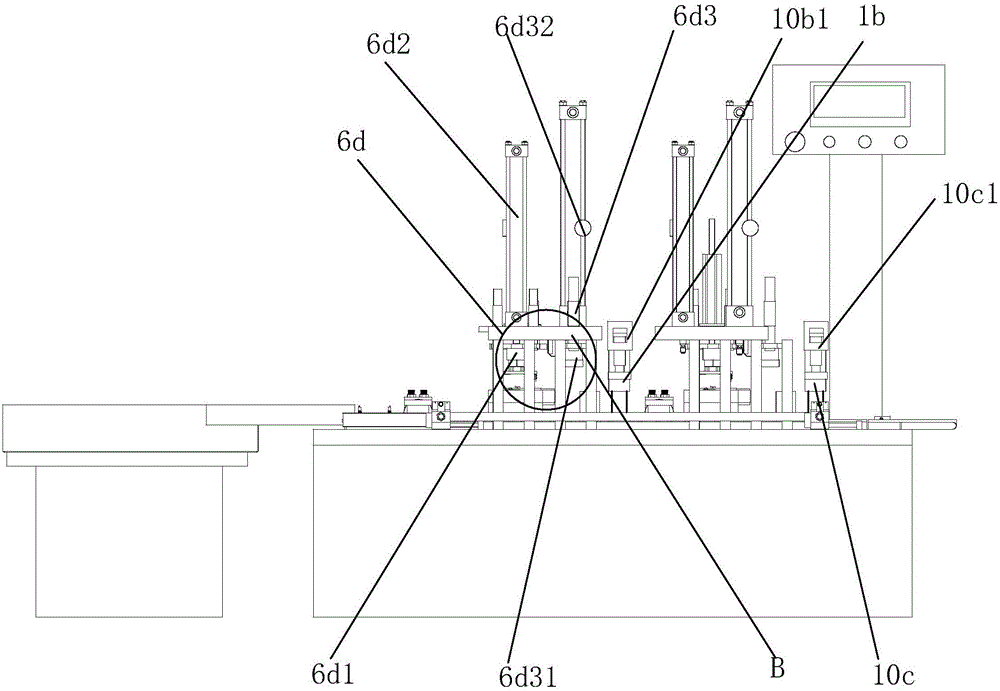

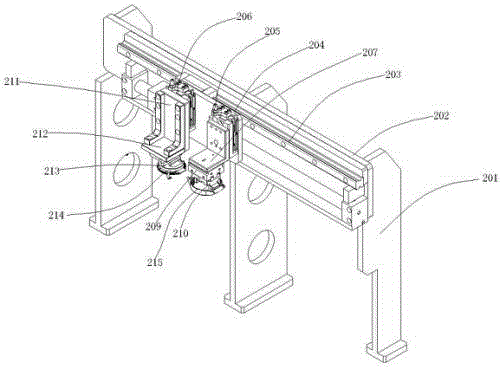

Comprehensive test platform for industrial robot joint reducer

InactiveCN105181329AReduce the impactImprove test efficiencyMachine gearing/transmission testingTest efficiencyReduction drive

A comprehensive test platform for an industrial robot joint reducer includes a bed body, a linear guide rail is laid on the right half part of the bed body, a magnetic powder brake connected with a left side end of the bed body is connected with a first torque sensor through a coupling, the first torque sensor is connected with a first angle encoder through a coupling, the first angle encoder is connected through an end-toothed disc with an output disc of a tested joint reducer installed in a special jig, the special jig is fixed on a movable platform, and the movable platform is mounted on the linear guide rail through sliding blocks; and a second angle encoder is mounted on an input shaft of the tested joint reducer, the input shaft of the tested joint reducer is connected with a second torque sensor through a coupling, the second torque sensor is connected with an output of a magnetic powder clutch through a coupling, and the magnetic powder clutch is fixed on the movable platform, and is connected with a spindle motor fixed on the movable platform through a coupling. The comprehensive test platform for the industrial robot joint reducer can realize testing of multiple parameters, and substantially improves testing efficiency.

Owner:XI AN JIAOTONG UNIV

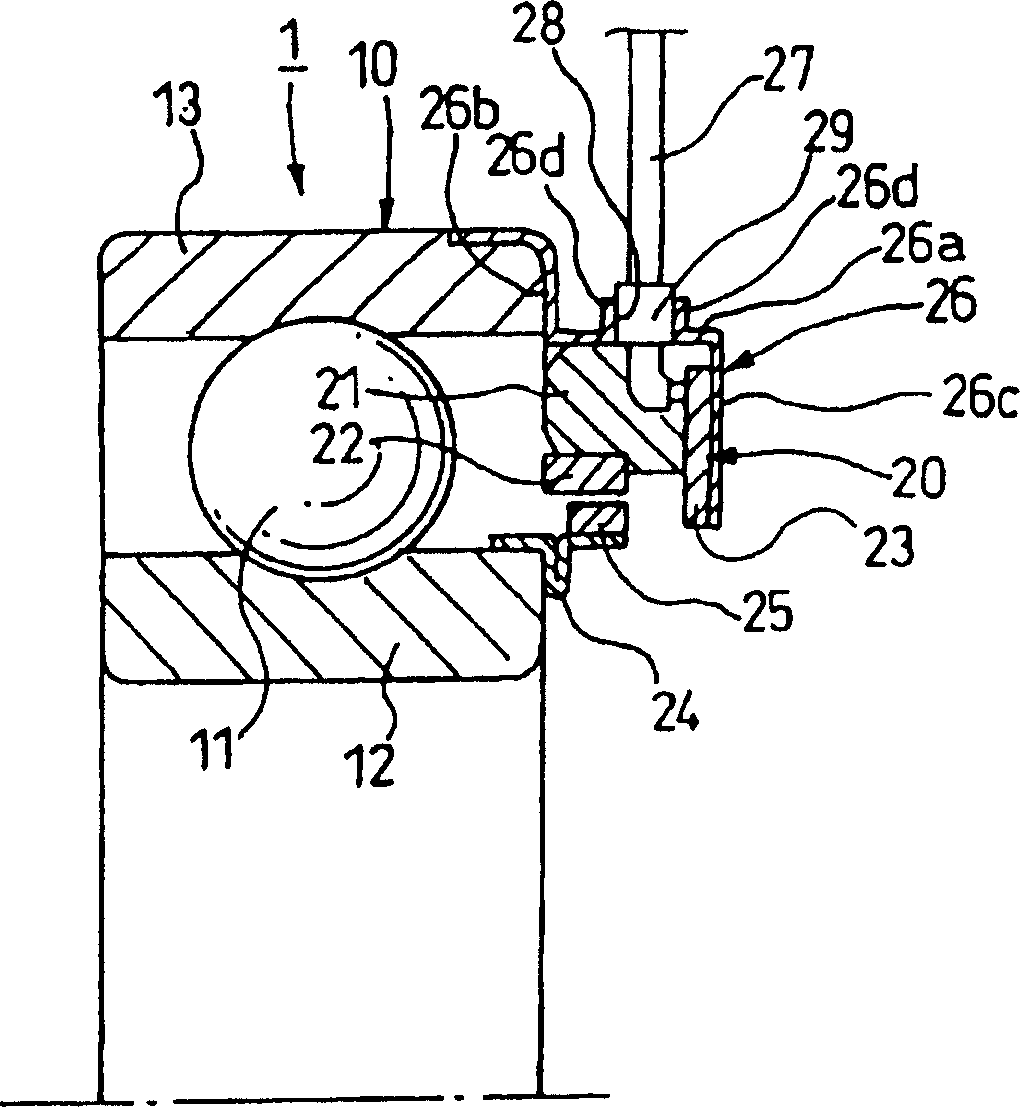

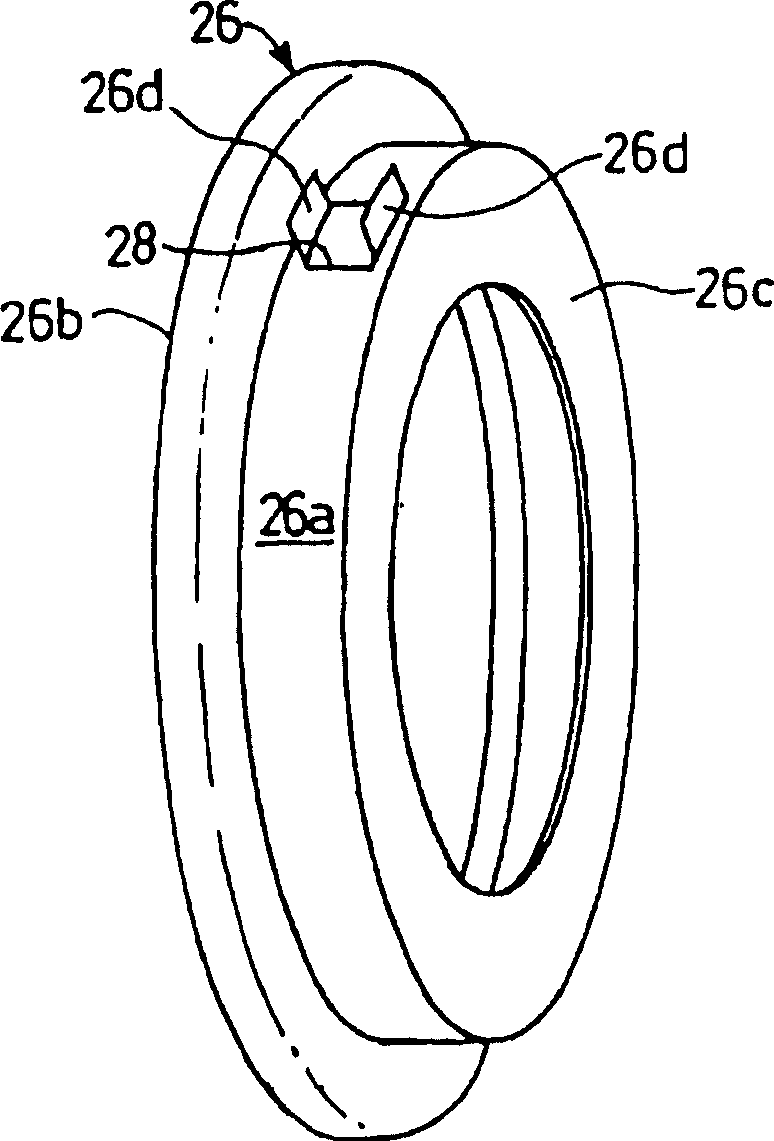

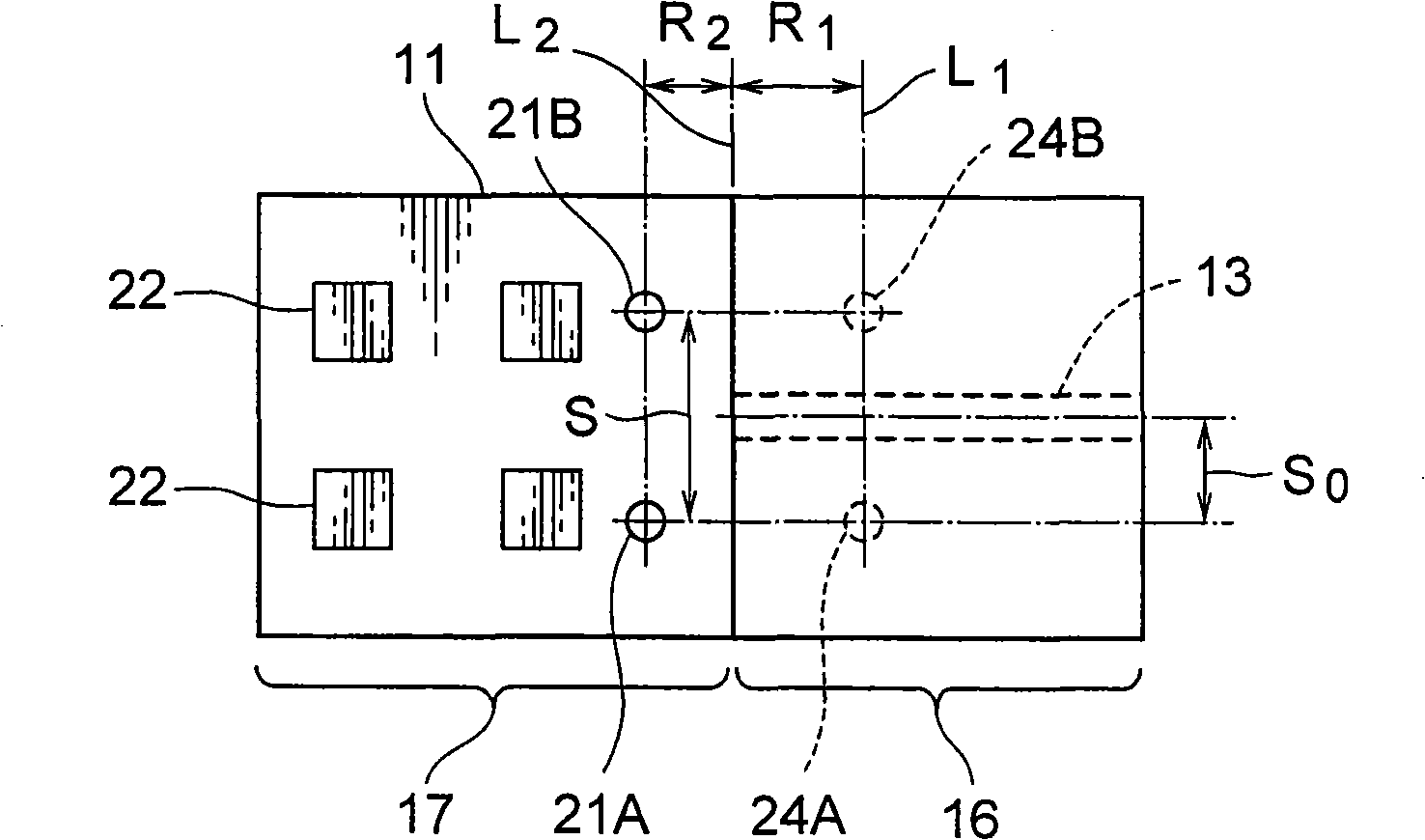

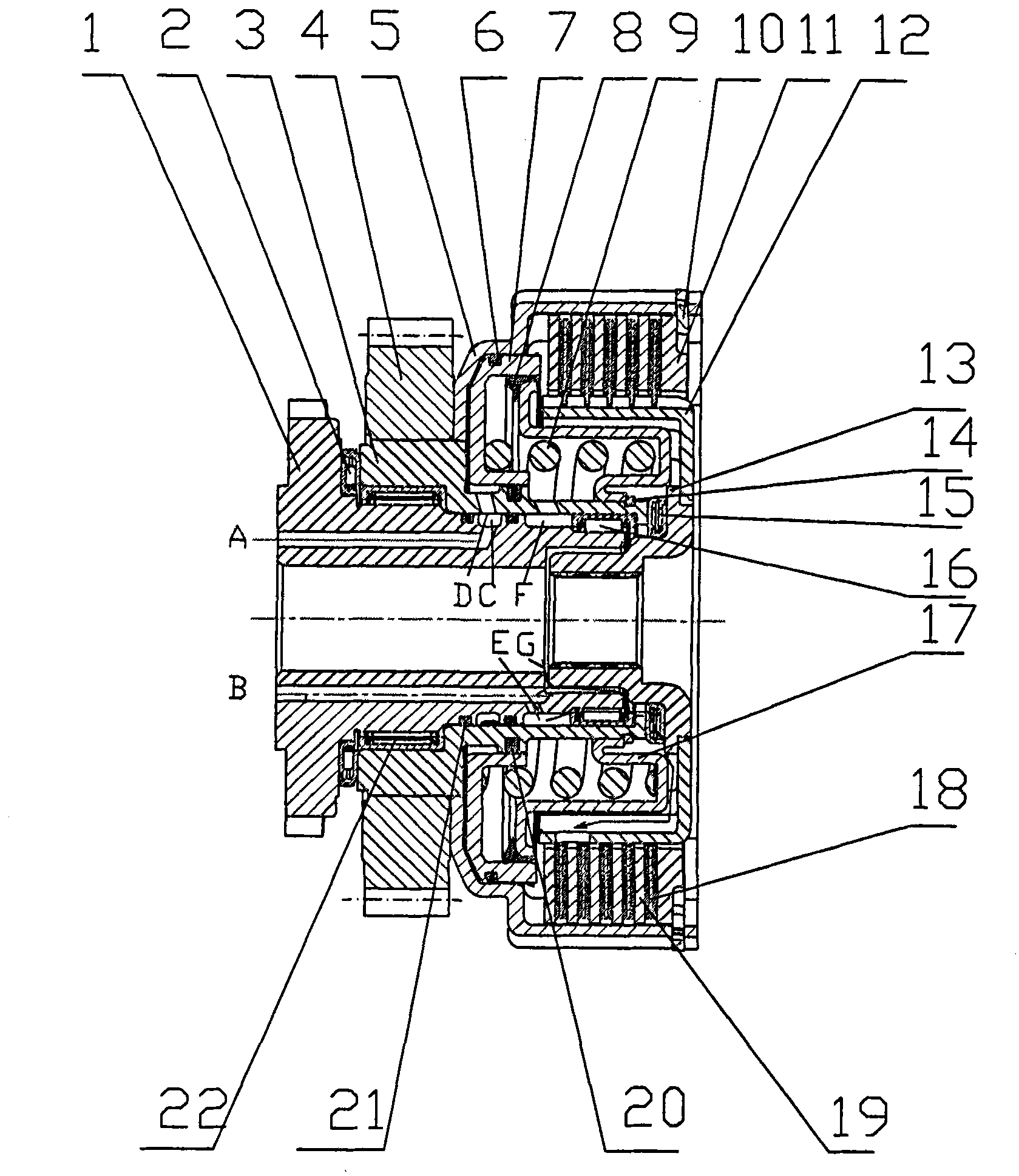

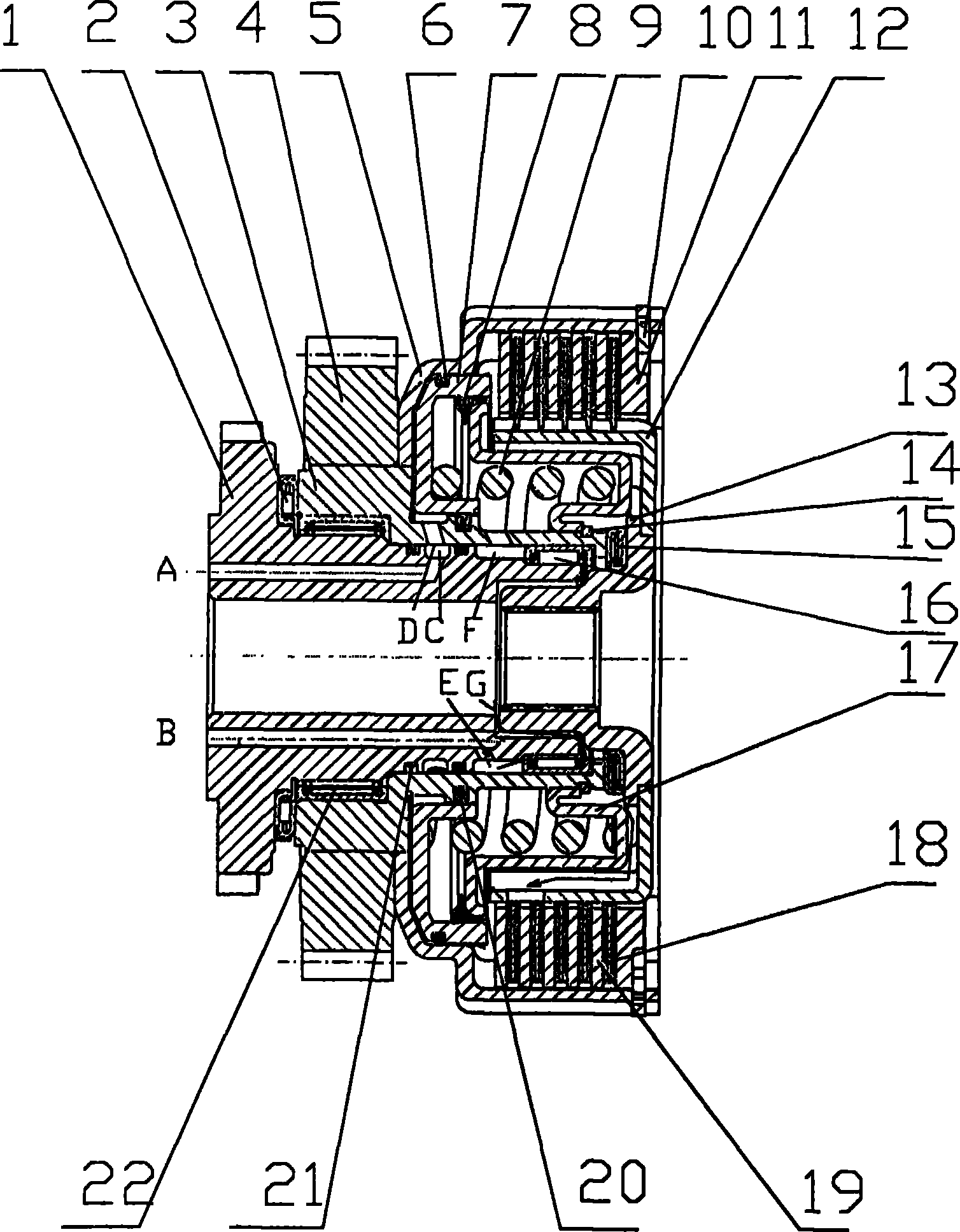

Bearing device with sensor and rolling bearing with sensor

InactiveCN1708692APrevent rotationSimple structureBearing assemblyLinear/angular speed measurementRolling-element bearingEngineering

Owner:NSK LTD

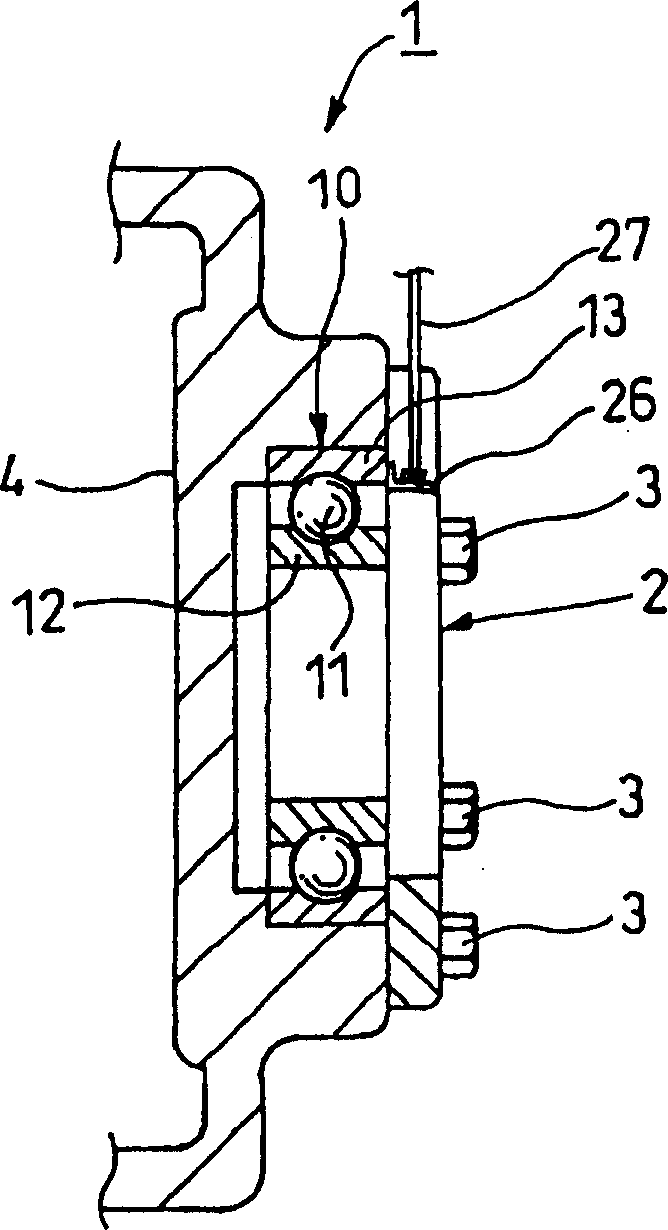

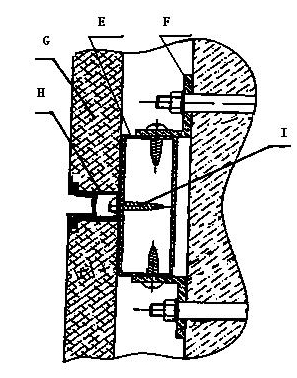

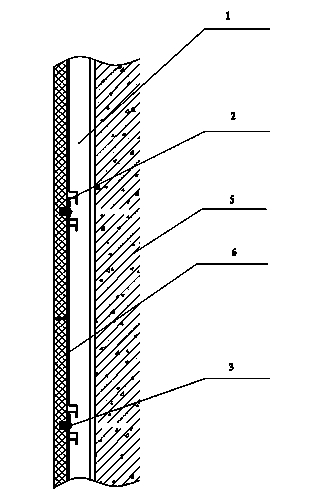

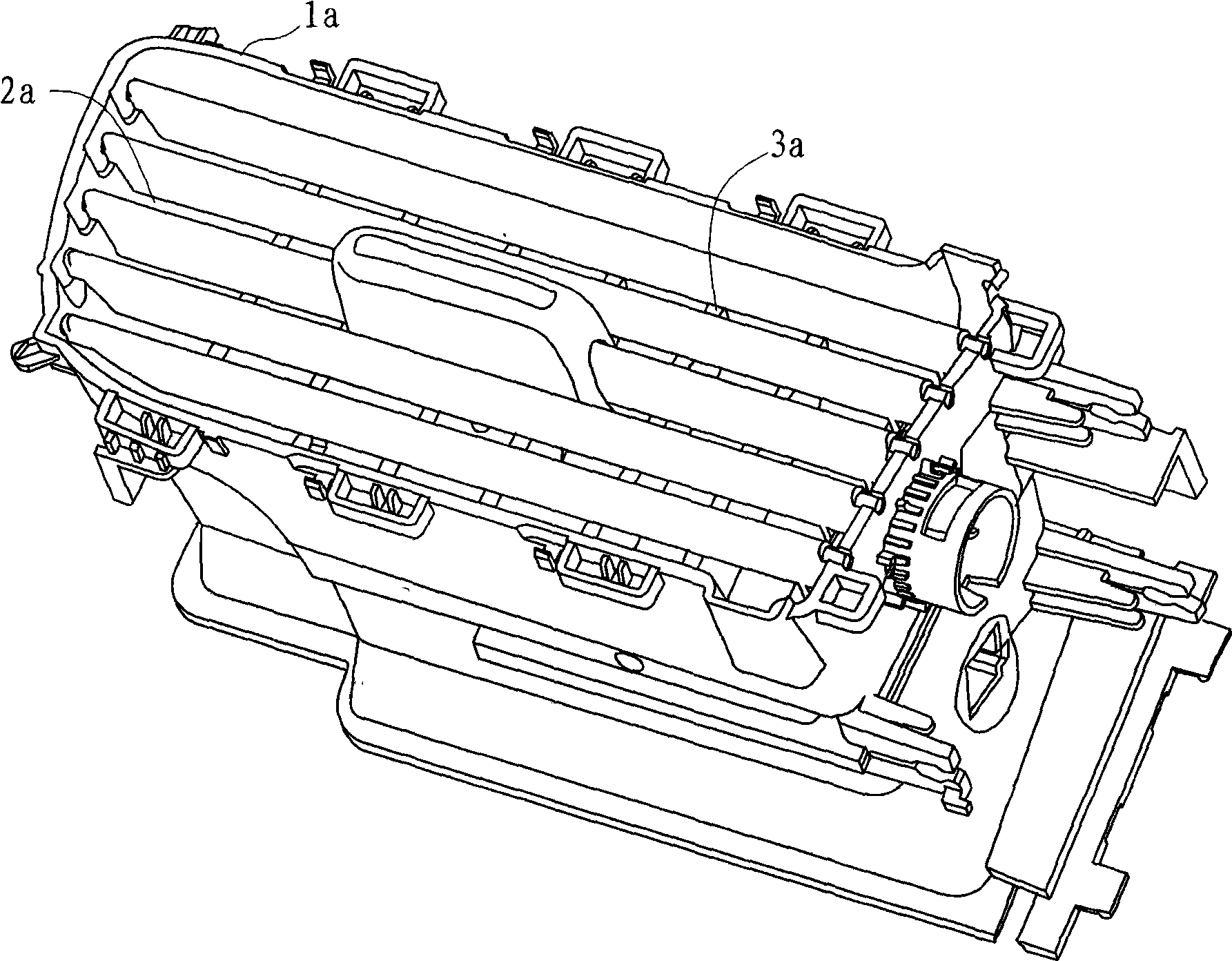

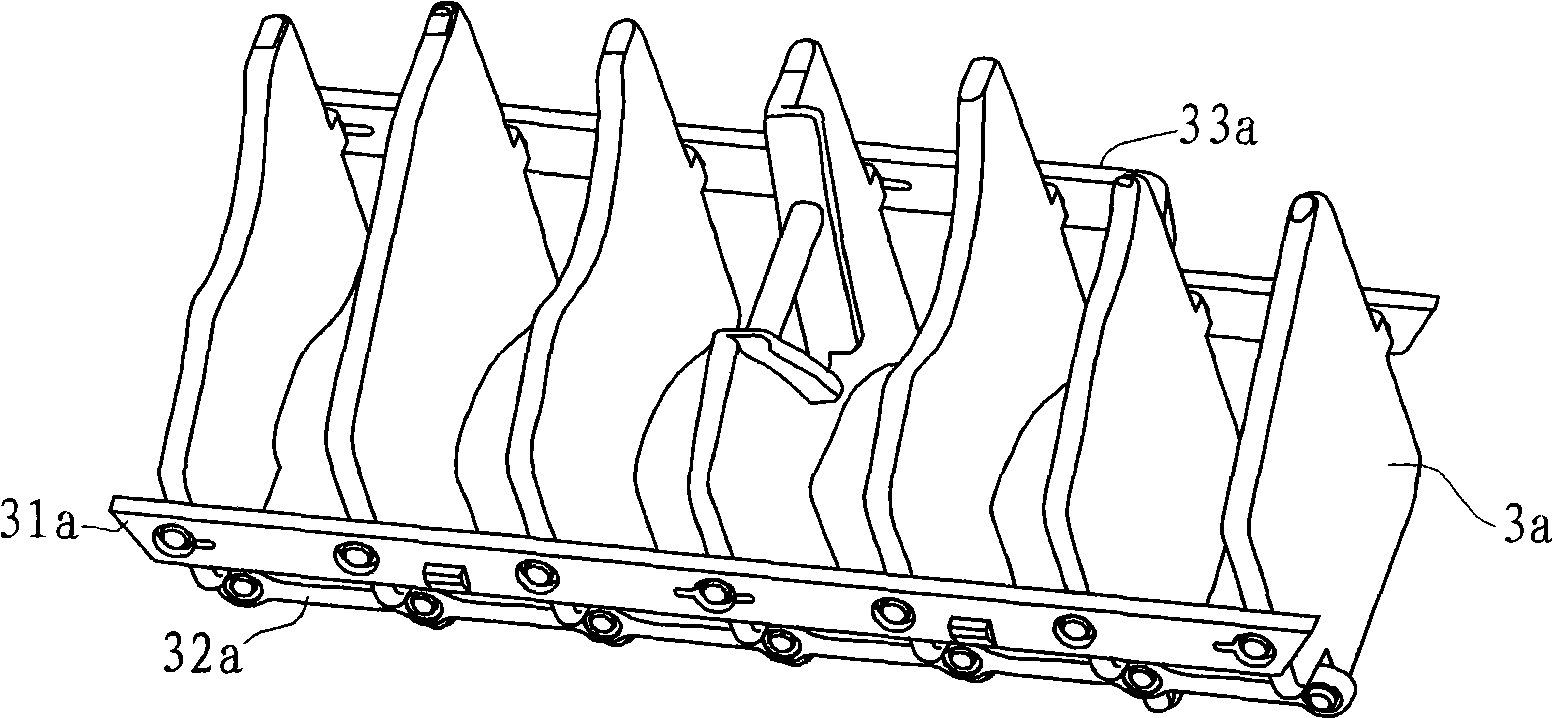

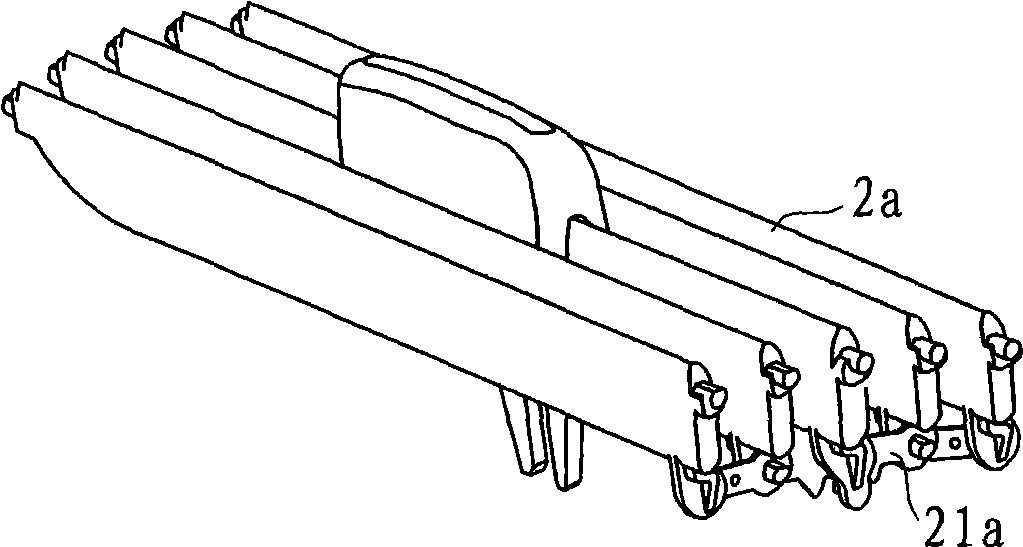

Wallboard installing component and method for installing decorative wallboard by using same

The invention relates to a wallboard installing component which comprises a main keel (1) and an auxiliary keel (2), wherein the main keel (1) is vertically arranged, and the auxiliary keel (2) is horizontally arranged; the main keel is a rectangular pipe with an opening at the back, and paired grooves (1a, 1a'), which are concave and are downwards extended, are continuously arranged on the front surface of the main keel, thereby paired upward fasteners (1b, 1b') are formed on the main keel; the auxiliary keel is a trough type keel which is provided with downward folding edges at the bottom ends of the upper side wall and the lower side wall; the two downward folding edges form a pair of buckling strip sides (2a, 2a'); the pair of buckling strip sides (2a, 2a') of the auxiliary keel are blocked and arranged in the paired grooves (1a, 1a') of the main keel to form a movable fitting device; a raised fixed point sleeve component (3) is arranged on the front surface (2d) of the auxiliary keel; and a lower buckling strip side of the auxiliary keel is provided with continuously paired limiting wedge openings (2c) which are arranged on left and right side walls of the main keel. The installing component provided by the invention can form a keel structure in which the main keel bears an integral force-bearing point, and the auxiliary keel bears a single row force-bearing point; the decorative wallboard is arranged on the auxiliary keel through the fixed point sleeve component, thereby the balanced load bearing of the keel structure can be realized; and the wallboard installing component is not only easy to install, dismantle and maintain, but also has high installation accuracy.

Owner:湖北格林森绿色环保材料股份有限公司

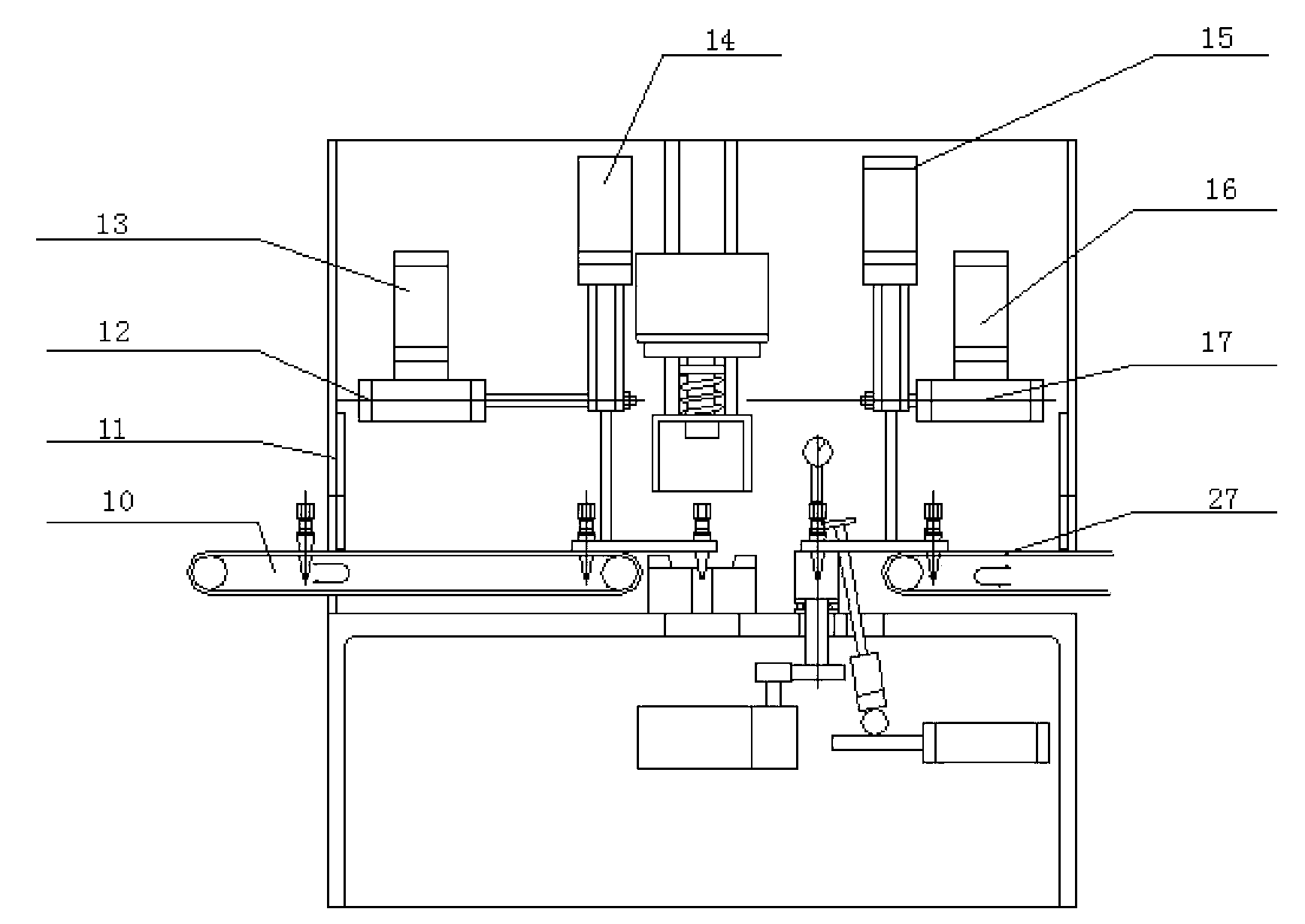

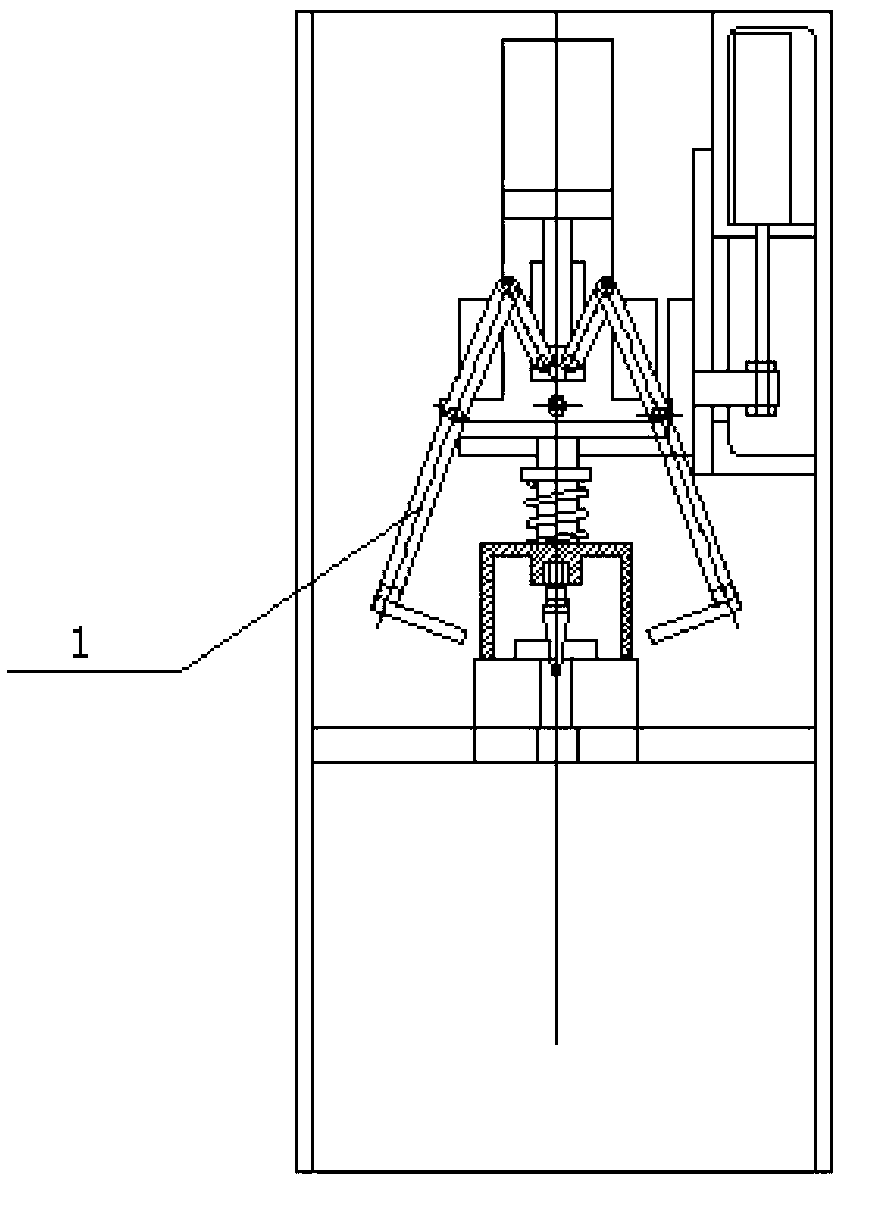

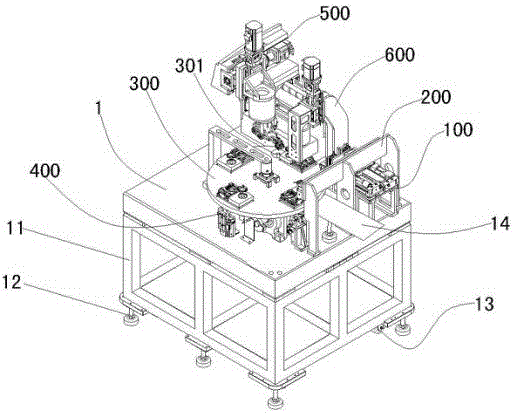

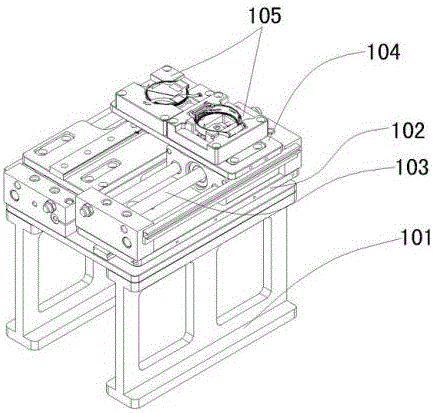

Automatic assembling tightening machine for special glass bottle and bottle cap

InactiveCN103317333AImprove installation efficiencyImprove installation accuracyMetal working apparatusAutomatic controlProgrammable logic controller

Owner:NORTHWESTERN POLYTECHNICAL UNIV

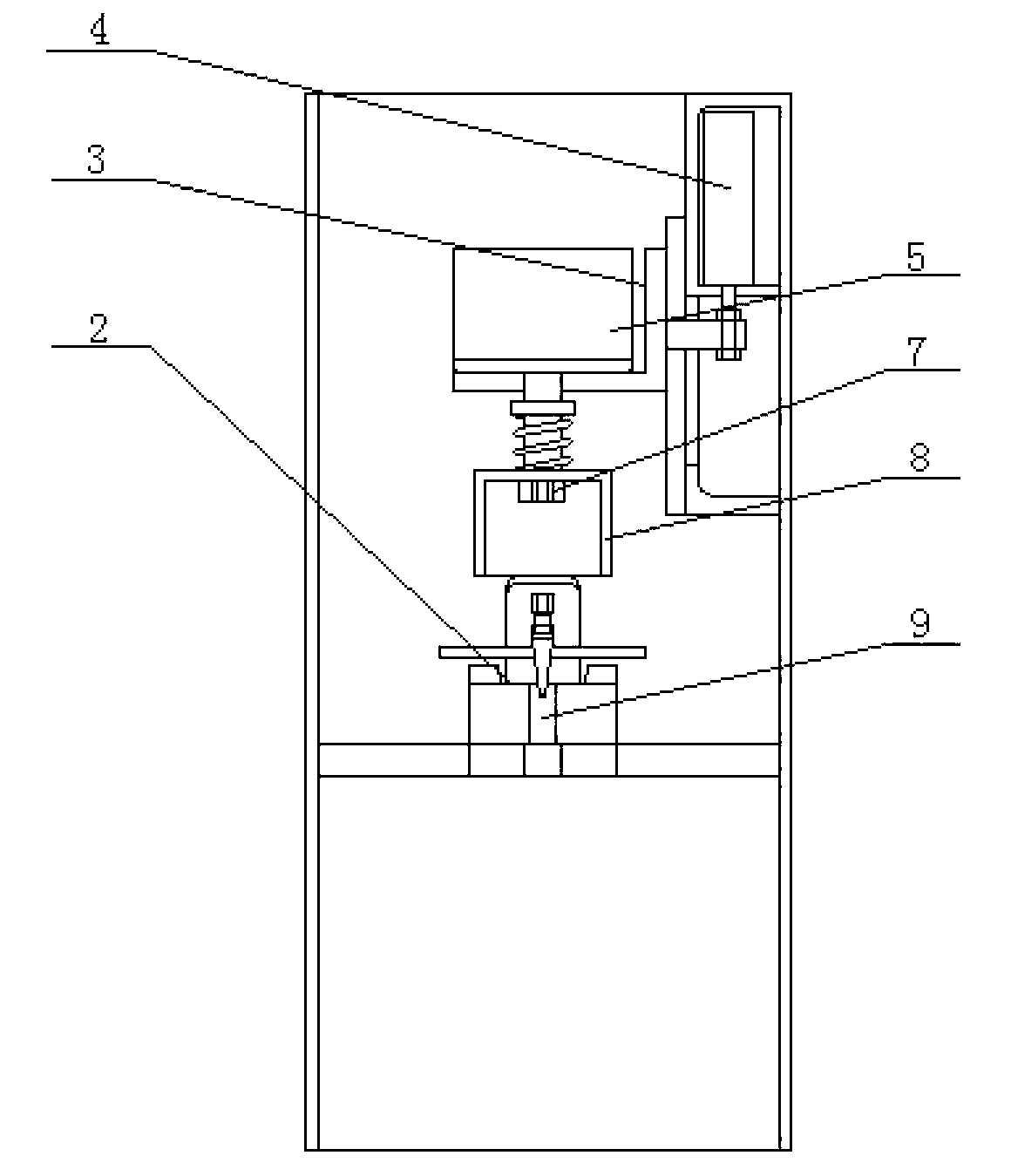

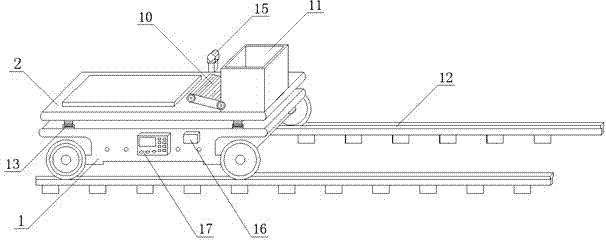

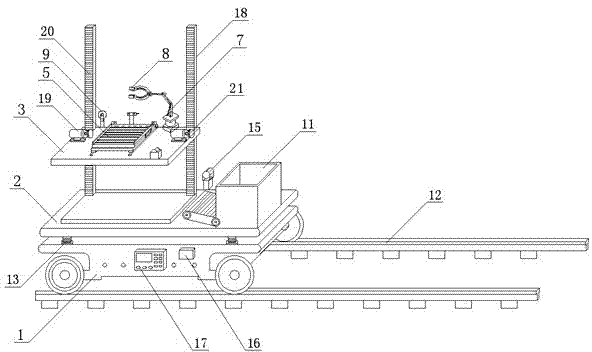

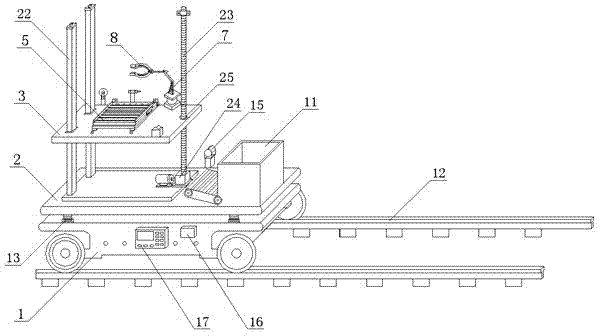

Full-automatic installation device for building outer wall stones

InactiveCN103790367APrecise positioningImprove installation efficiencyBuilding constructionsCeramic tilesBuilding construction

A full-automatic installation device for building outer wall stones comprises a walking device (1) and is characterized in that an adjustable platform (2) is installed on the upper surface of the walking device (1) through horizontal adjusters (13), a lifting device (4) is arranged on one side of the upper surface of the adjustable platform (2), a lifting platform (3) is installed on the lifting device (4), and a positioning panel turning mechanism (5) is arranged on the lifting platform (3). One or more mechanical arms (8) are installed on one side, close to the panel turning mechanism (5), of the lifting platform (3), the problem that in the traditional process that the stones or ceramic tile panels are constructed on a wall space, an automatic device can not be adopted for installation and construction is effectively solved, the stones or the ceramic tile panels can be fully automatically installed for a building outer wall in the whole process, installation efficiency and precision are high, construction safety is good, and the full-automatic installation device has incomparable superiority compared with traditional manual installation and has good using prospects in the future.

Owner:湖北远大建设集团有限公司

Device for combining and assembling air conditioner discharge set

ActiveCN101518870AIncrease productivityImprove installation accuracyAssembly machinesMetal working apparatusControl theory

A device for combining and assembling air conditioner discharge sets is characterized by comprising a base, a blade installing mechanism, a shell installing mechanism, a sliding cylinder and a controller, wherein the blade installing mechanism is arranged on the base and comprises a base cylinder; the shell installing mechanism is used for installing a shell and is arranged on the base; the sliding cylinder drives the fastened base to move towards the shell installing mechanism; and the controller is used for controlling each cylinder to work. Compared with the prior art, the invention adopts a series of actions of the controller controlling the cylinders to replace the hand assembling work, has high production efficiency, can avoid the missing package and the error package caused by human factors, and has high installing accuracy, firm connection and durability.

Owner:NINGBO FUERDA SMARTECH CO LTD

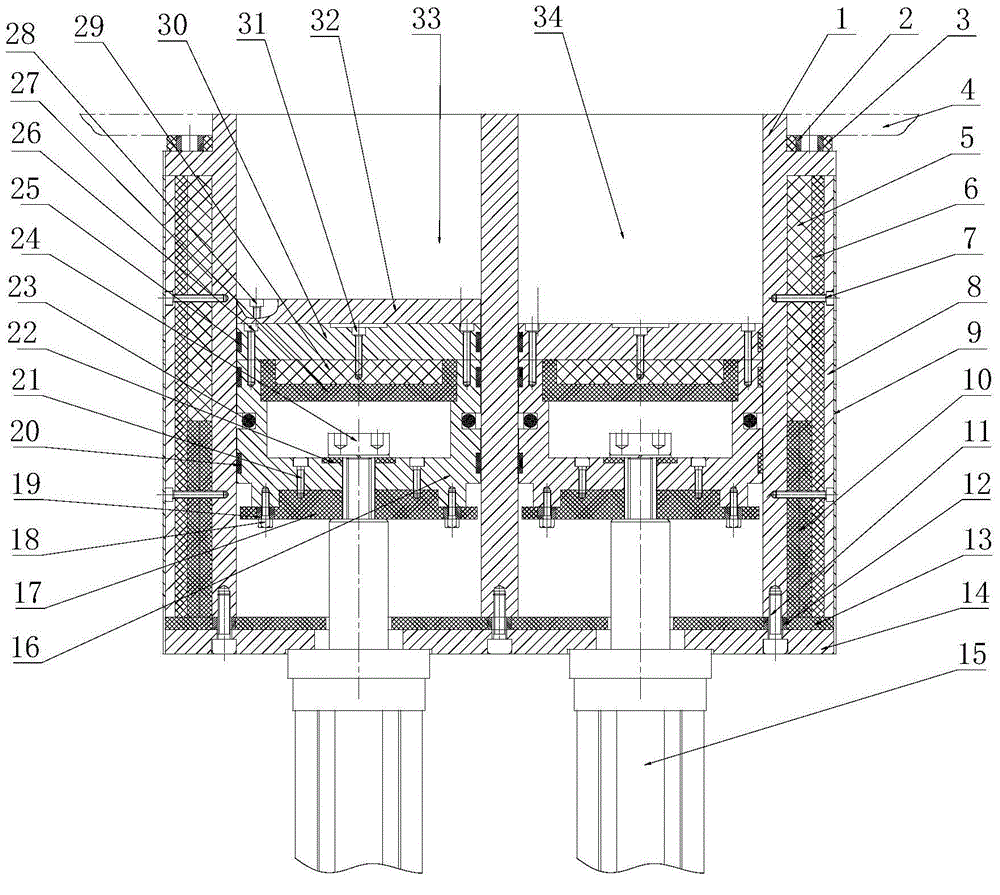

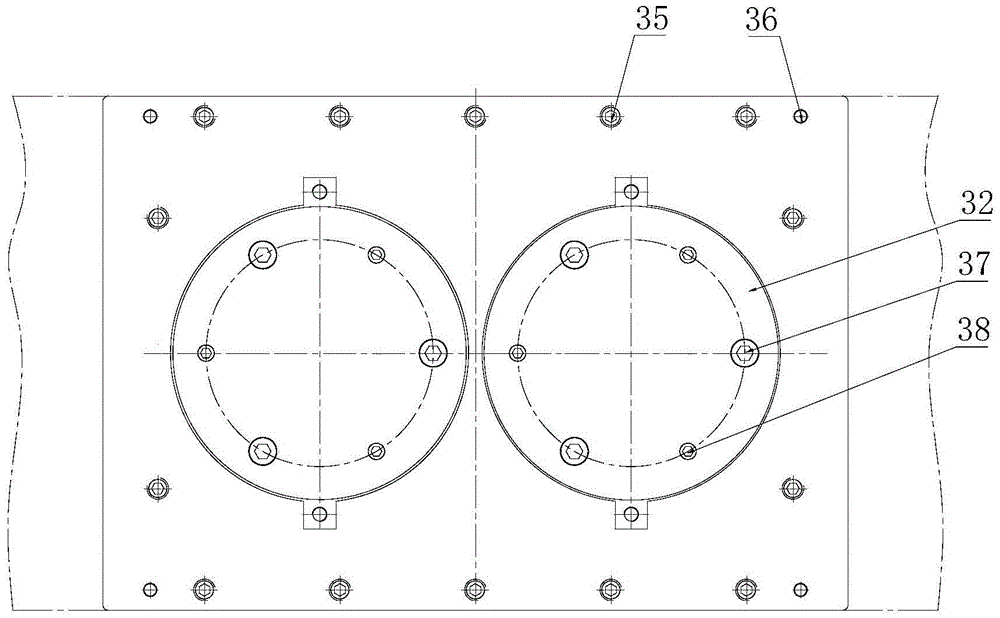

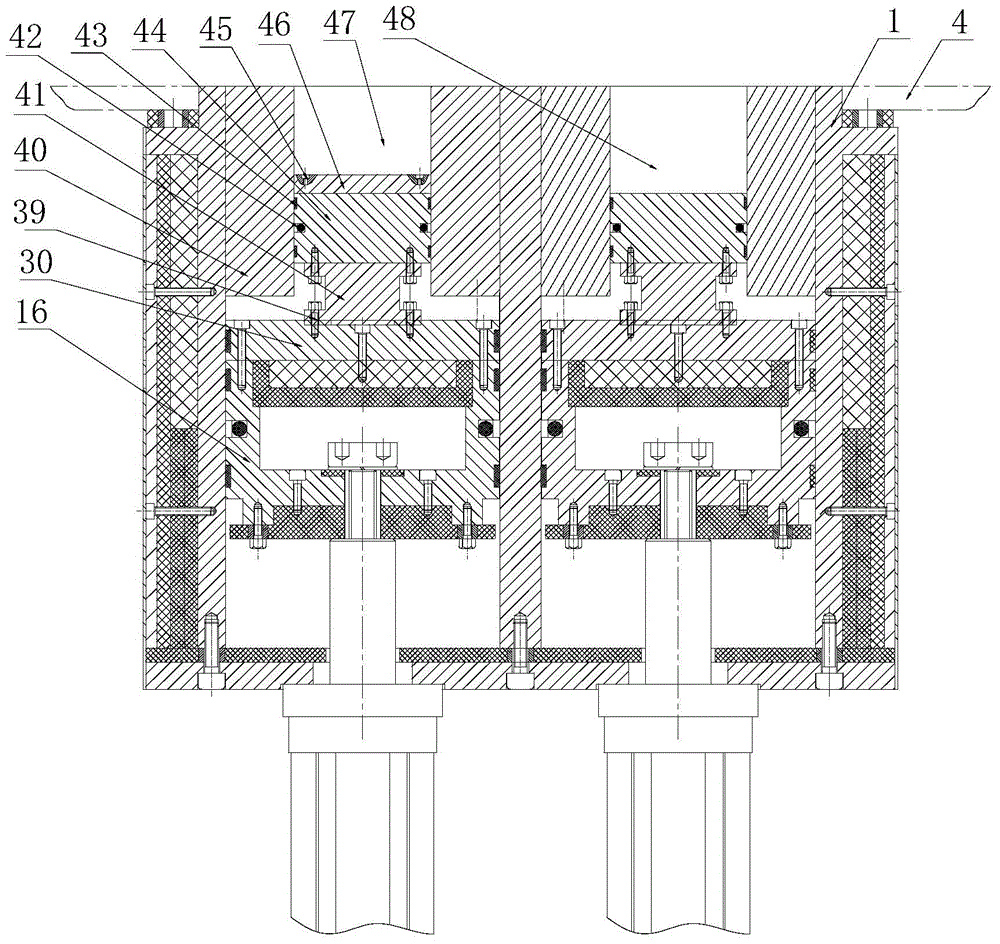

Metal laser selective melting forming double-piston controllable preheating powder cylinder

ActiveCN105014071AAvoid wastingAvoid errorsAdditive manufacturing apparatusCylinder blockMetal powder

The invention discloses a metal laser selective melting forming double-piston controllable preheating powder cylinder capable of respectively working in two states of single piston and double pistons. When the powder cylinder works in the state of single piston, firstly, a large piston basal plate in a forming cylinder is leveled; and then, the periphery of a cylinder body is heated by using a cylinder body heating ring, and a piston heating plate is used for heating a piston cover plate to realize indirect heating of a forming cylinder and metal powder in a powder feeding cylinder. When the powder cylinder works in the state of double pistons, firstly, a small piston basal plate is leveled; and then, powder in a small piston forming cylinder and a small piston powder feeding cylinder is uniformly heated by using the cylinder body heating ring and the piston heating plate. The powder cylinder adopts an integrated double-piston design; a small piston can be replaced and disassembled to realize the laser forming of metal components with different sizes; powder is saved; and meanwhile, the powder cylinder can be heated in all directions, so that the controllable powder preheating is realized, the powder heating is uniform, the temperature gradient is improved, and the deformation and the split of the components are reduced.

Owner:XI AN JIAOTONG UNIV

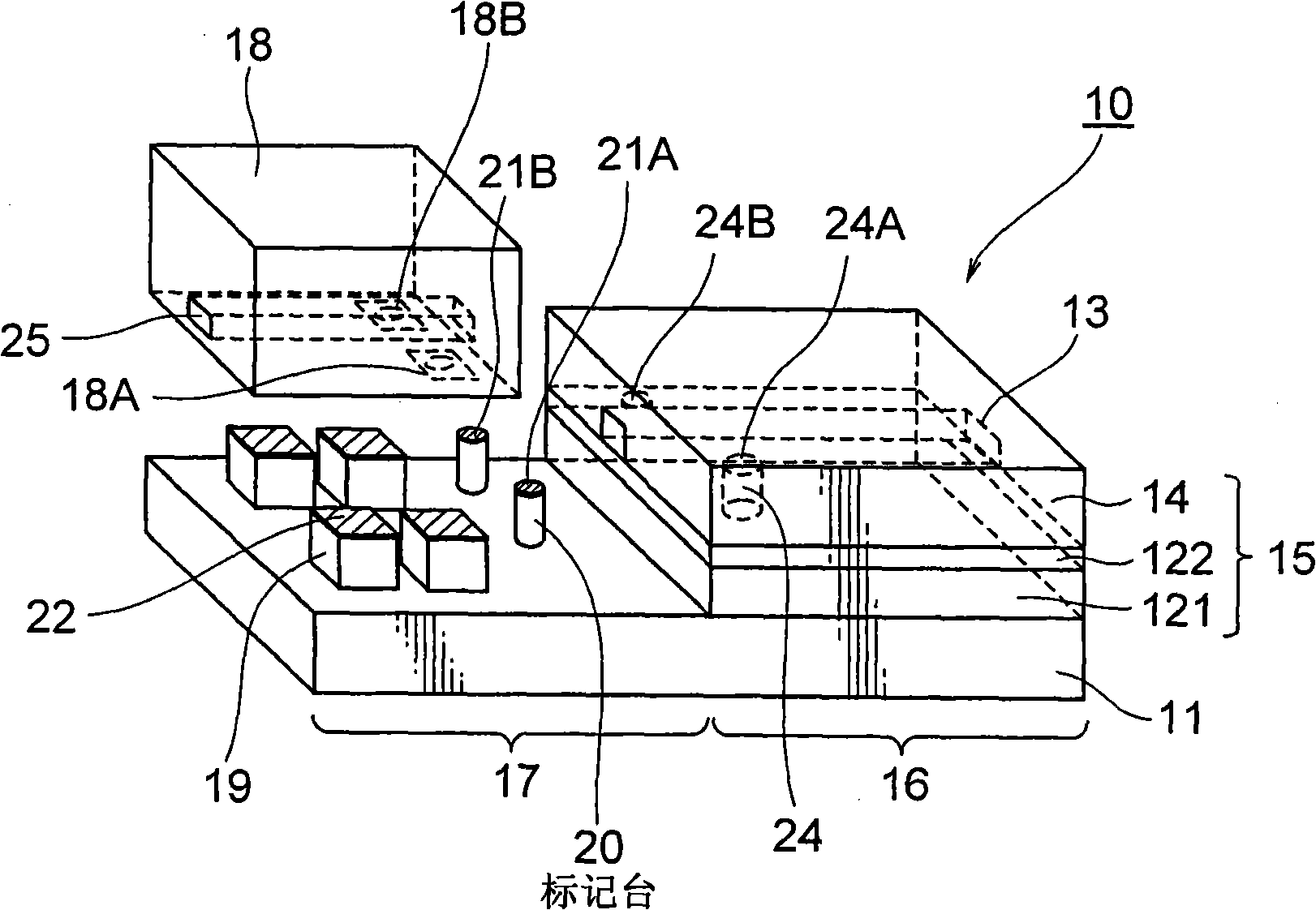

Optical waveguide device and manufacturing method for the same

InactiveCN101271175ASecurity arrangementImprove installation accuracyCoupling light guidesOptical waveguide light guideWaveguideDistortion

To obtain an optical waveguide device capable of improving mounting accuracy and productivity for correcting misalignment of alignment marker caused by distortion due to a substrate stressed and distorted. An optical waveguide device includes an optical waveguide section, including a waveguide core formed on a substrate, and an optical device (LD) mounted on the substrate to correspond the optical waveguide section, both of which are coupled at a light end face and mounted by hybrid mounting. LD side alignment markers are provided in both sides of an active line in the optical device. Substrate side alignment markers are provided at positions where centers thereof and those of the optical device side markers are matched when the optical device is mounted on the corresponding substrate. Fiducial markers are formed during the formation of the core so that the relative positional relationship with the waveguide core on the substrate becomes stable. Thus, a misalignment amount is detected.

Owner:NEC CORP

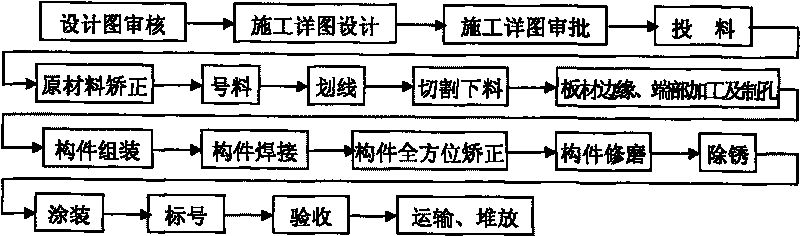

Converse construction process for middle-high steel structure building

ActiveCN101691787AAvoid welding deformationGuaranteed stiffnessBuilding material handlingFloor slabSystem construction

The invention relates to a converse construction process for the middle-high steel structure building, belonging to the steel structure system construction field and aiming at solving the problems that the construction surfaces are less, the construction efficiency is low, the construction period is long and the manufacturing of the steel structure components can not meet the integral mounting quality standard requirements because the steel floorslabs and the steel structure frameworks are constructed synchronously during the construction of the prior steel structure building. The converse construction process for the middle-high steel structure building comprises the following steps: refining and enlarging the connection nodes of the steel structure frameworks; processing and assembling the steel structure components according to the enlarged construction drawing; transporting and stacking the steel structure components; mounting the steel structure frameworks; and moungin the steel floorslabs. Because the converse construction process of mouting the main structures of all the steel structure frameworks before the mouting the steel floorslabs is adopted, the steel structure frameworks and the steel floorslabs can be constructed on the same plane and can be constructed in a vertical and cross way without mutual influence, the construction speed can be accelerated, and the construction efficiency can be improved. The converse construction process is simple, convenient, economical, reasonable, safe and reliable, ensures high mounting precision and can be applied to the construction of various middle-high steel structure buildings.

Owner:BUILDING & MOUNTING ENG CO LTD NO 12 BUREAU MINIST OF RAILWAYS +1

Bearing retainer ring installation device and bearing retainer ring thereof

InactiveCN105081742AImprove installation efficiencyReduce manual operation costsBearing componentsMetal working apparatusControl systemMechanical engineering

The invention discloses a bearing retainer ring installation device. The bearing retainer ring installation device comprises a machine frame and a control system. The machine frame sequentially comprises a conveying disc, a conveying station, a shifting fork transferring station, a bearing containing station, a first assembly station, a turning station, a second assembly station and a discharging station. The bearing retainer ring installation device has the advantages that the installation device is suitable for installing retainer rings of irregular structures, installation is accurate and firm, and two end faces of a bearing can be assembled at the same time.

Owner:CIXI CTZ BEARING

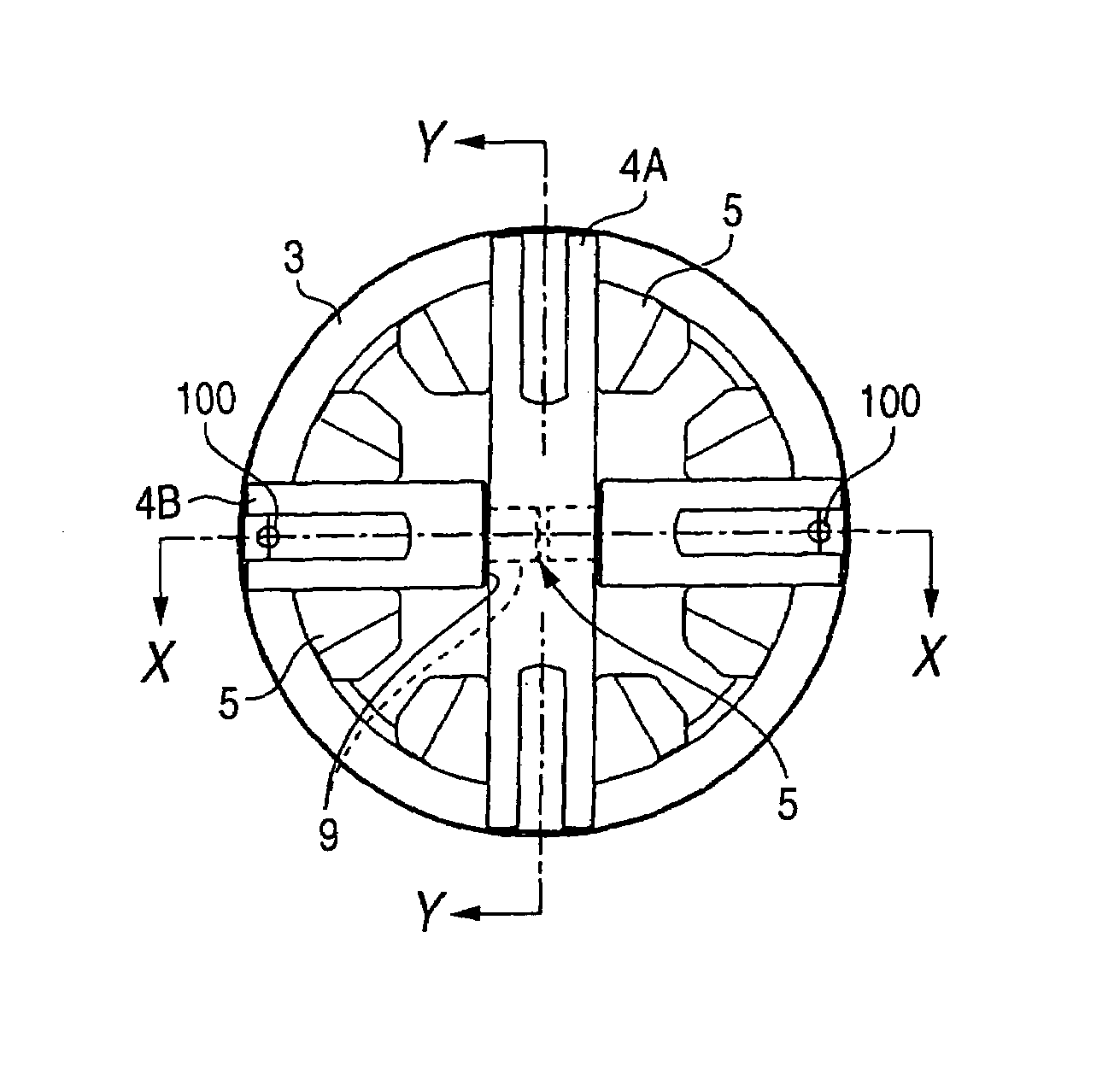

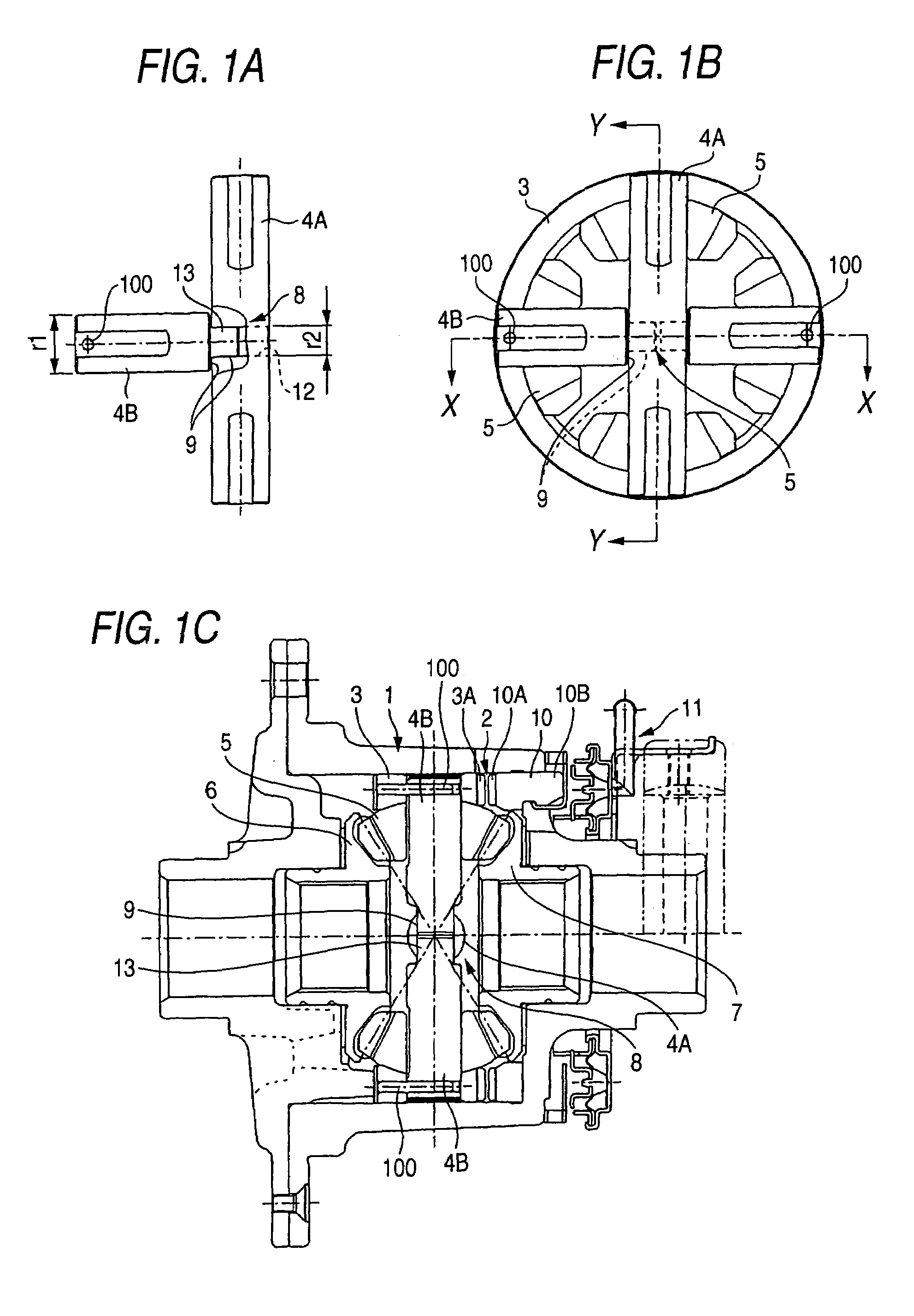

Differential apparatus

ActiveUS7081065B2Reduce in quantityIncreased durabilityTransmission elementsDifferential gearingsRotational axisEngineering

A junction at which the pinion shafts are connected to each other by themselves is formed in a portion of the rotational axis of an outer rotary member where the pinion shafts meet each other. Therefore, the positional relation of the pinion shafts without any substantial error is reliably secured and maintained, and the uniform transmission of power to the pinion shafts becomes possible. Accordingly, the number of parts is reduced, and it is not necessary to give any heat treatment to the clutch tooth or select any material of high strength therefor.

Owner:TOCHIGI FUJI IND CO LTD

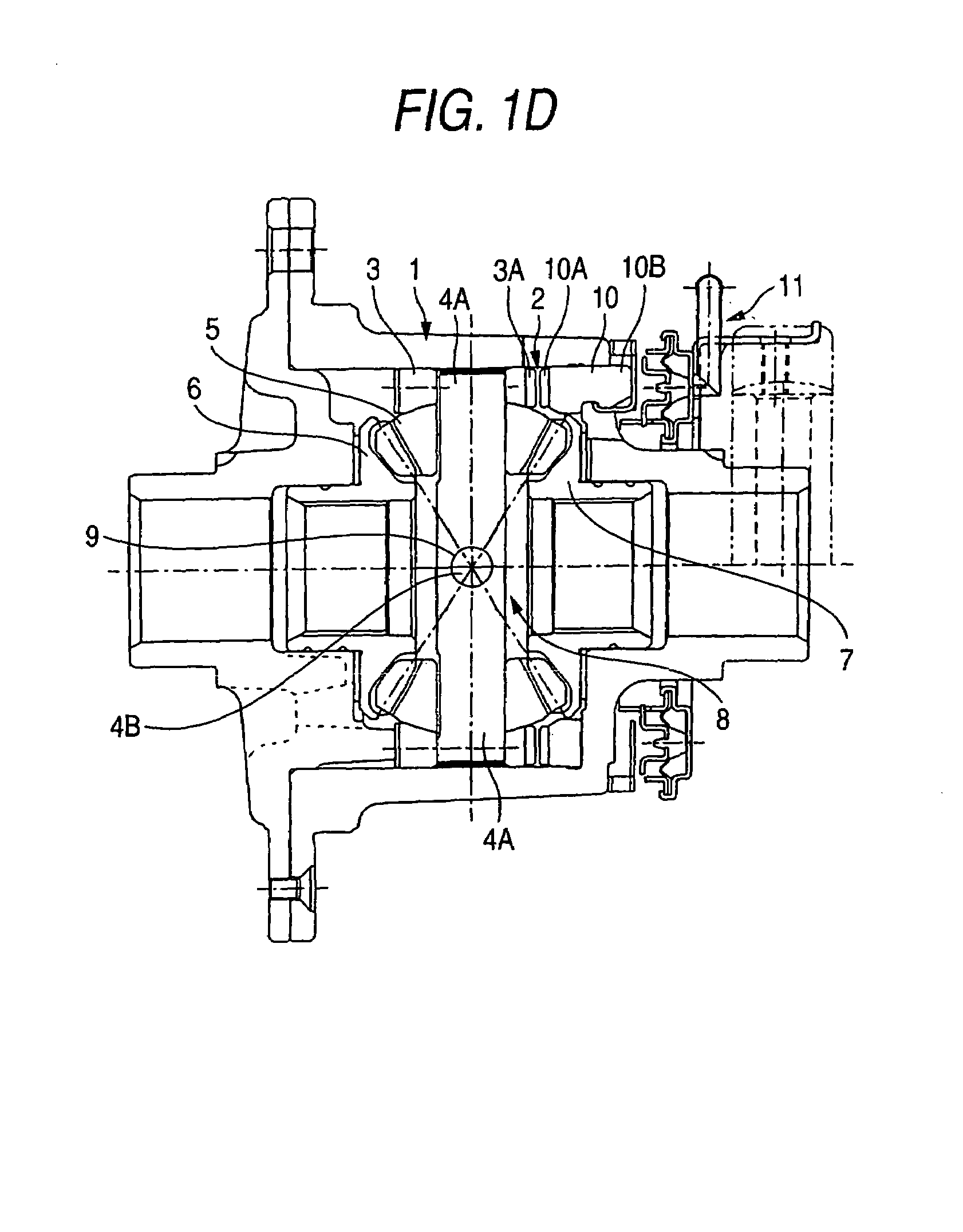

Rear shell positioning assembly device of watch and processing technology thereof

ActiveCN106773605ARealize automatic photo detectionIncrease temperatureClock support devicesEngineeringMechanical engineering

The invention discloses a rear shell positioning assembly device of watch and processing technology thereof. The assembly device comprises a working bench and a turntable assembly of the working bench. The turntable assembly is provided with a charging component, a gripping component, a contraposition component and a CCD component. The rear shell positioning assembly device of watch has the advantages of CCD automatic camera detection, accurate positioning and assembly, high temperature equipment, high installation accuracy, high production efficiency, good quality.

Owner:SHENZHEN RUIHUI BELL & WATCH

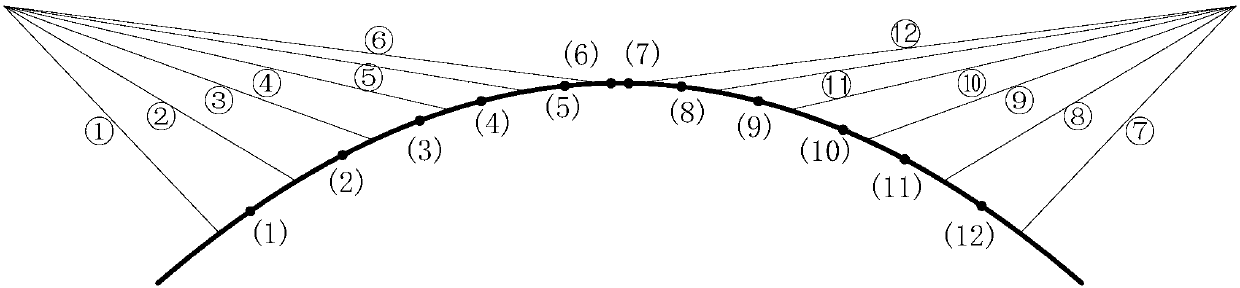

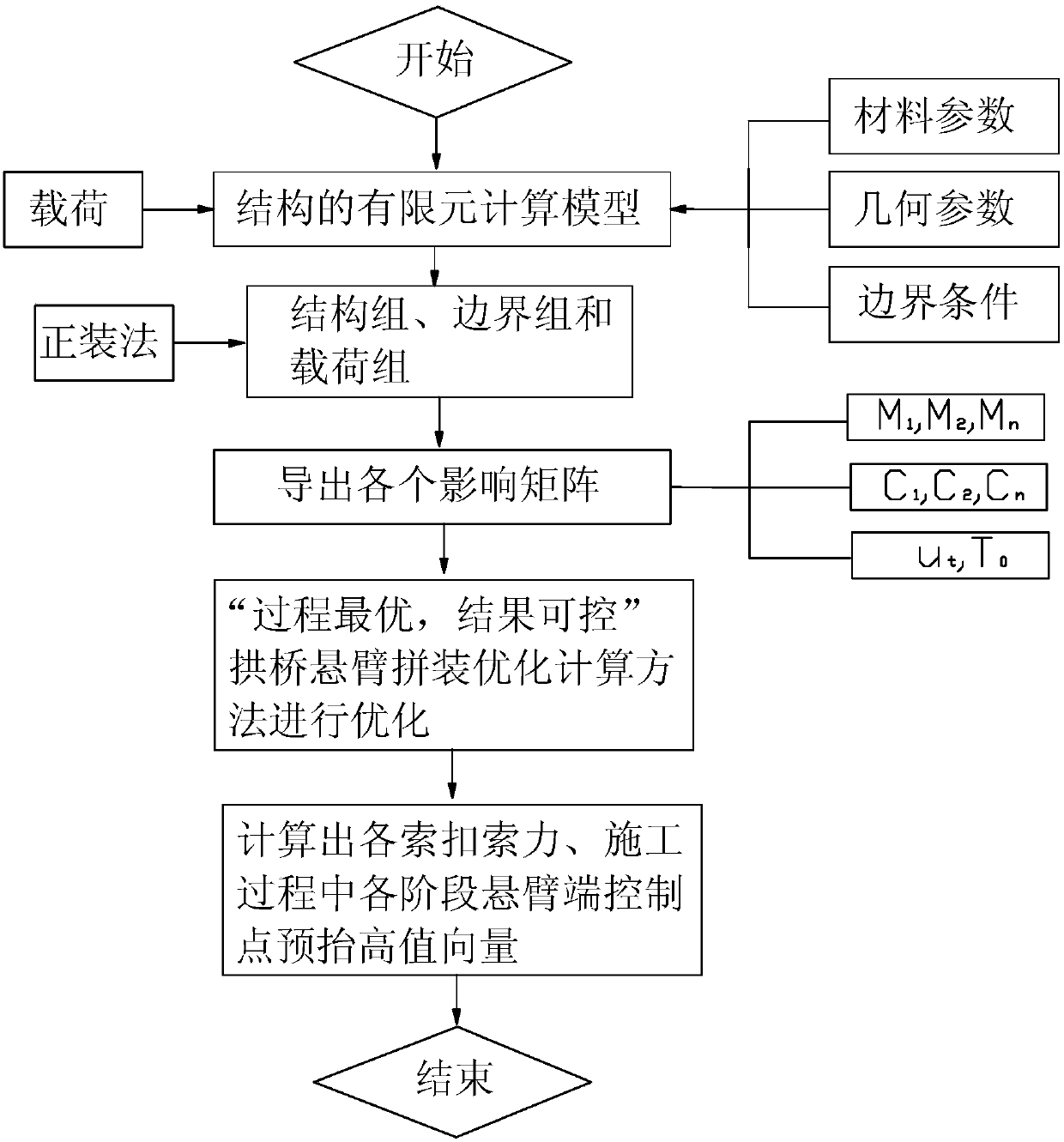

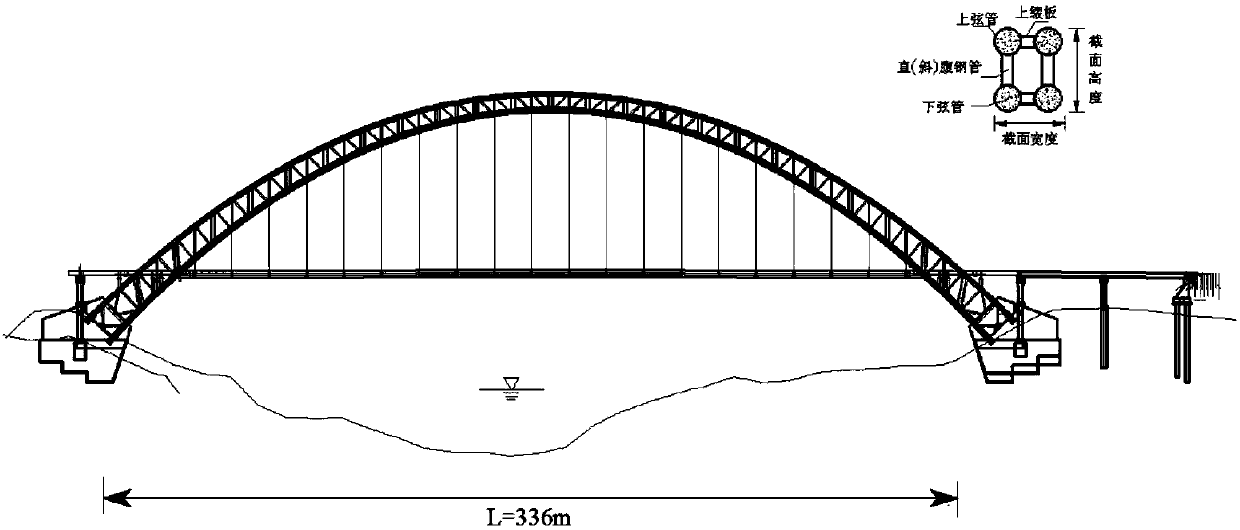

Arch bridge cantilever assembling construction optimization model and optimization calculation method

ActiveCN108038326ASmooth changeNo stress concentrationGeometric CADDesign optimisation/simulationStress concentrationConstraint control

The invention provides an arch bridge cantilever assembling construction optimization calculation method. An actual line shape and a target line shape in each construction lifting stage are strictly controlled, so that the preraised height value of each control node is changed mildly, the cable force uniformity is good, and the stress concentration phenomenon of a material in a construction process does not occur. An arch bridge cantilever assembling construction optimization model has the advantage of relatively few constraint conditions; the constraint condition that a deviation between theline shape after cable tightening and release, and the target line shape is in an allowed range mainly achieves a constraint control effect; and the problems of large buckling cable force gradient, poor uniformity and the like during adoption of a conventional method for performing construction optimization calculation are solved.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

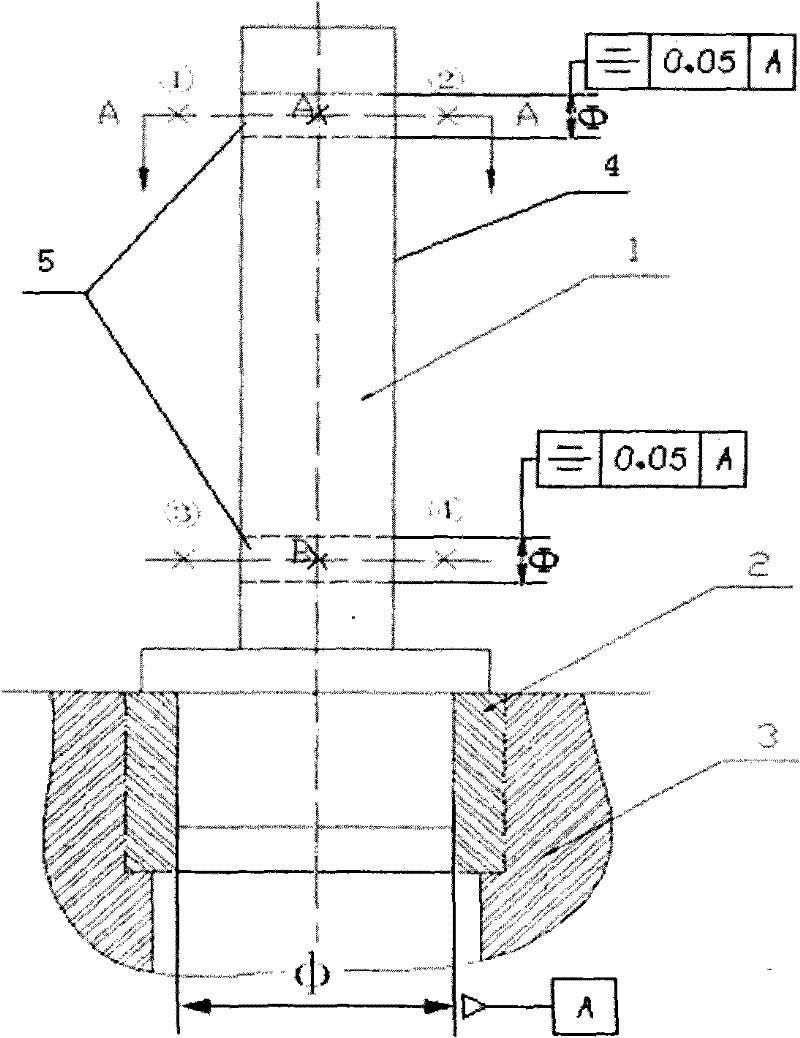

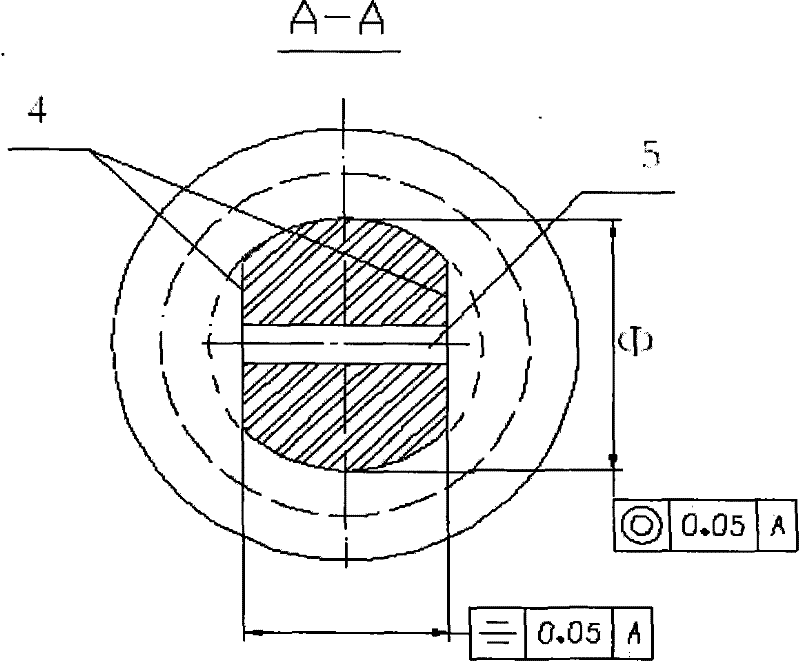

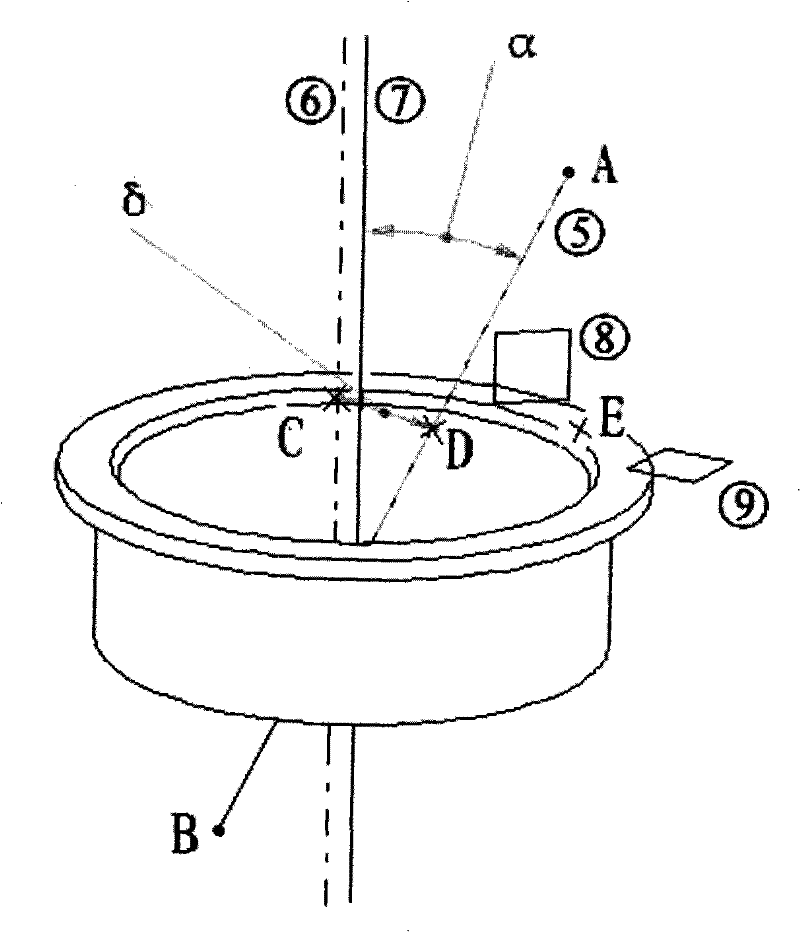

Hole axis detection tool and detection method thereof

InactiveCN102494641AImprove installation accuracyReduce assembly errorsUsing optical meansEngineeringAirplane

The invention belongs to the airplane assembly technology, relates to a tool and a method for detecting assembly error of center points of end faces of joint holes and assembly error of joint hole axes during airplane assembly, and particularly relates to a hole axis detection tool and a detection method thereof. The hole axis detection tool is a shaft, the lower end of the shaft is matched with an assembling join hole, the upper portion of the shaft is provided with two planes machined by utilizing the plane of the axis as a symmetry plane, two through holes are manufactured on the two planes vertically, and center lines of the through holes are intersected with the axis of the shaft. The method includes steps of mounting the shaft in a joint bushing hole of an assembled product during use; measuring coordinates of points 1, 2, 3 and 4 respectively; computing coordinates of center points A and B according to the coordinates of points 1,2,3 and 4; drawing the actual axis, running through the center points A and B, of the joint hole; comparing and analyzing the actual axis of the joint hole and the theoretical axis; accurately analyzing assembly error of the center point of the end face of the joint hole and the hole axis after assembling; and finally taking measures to guarantee assembly accuracy of joints so that quality of products is guaranteed.

Owner:HARBIN

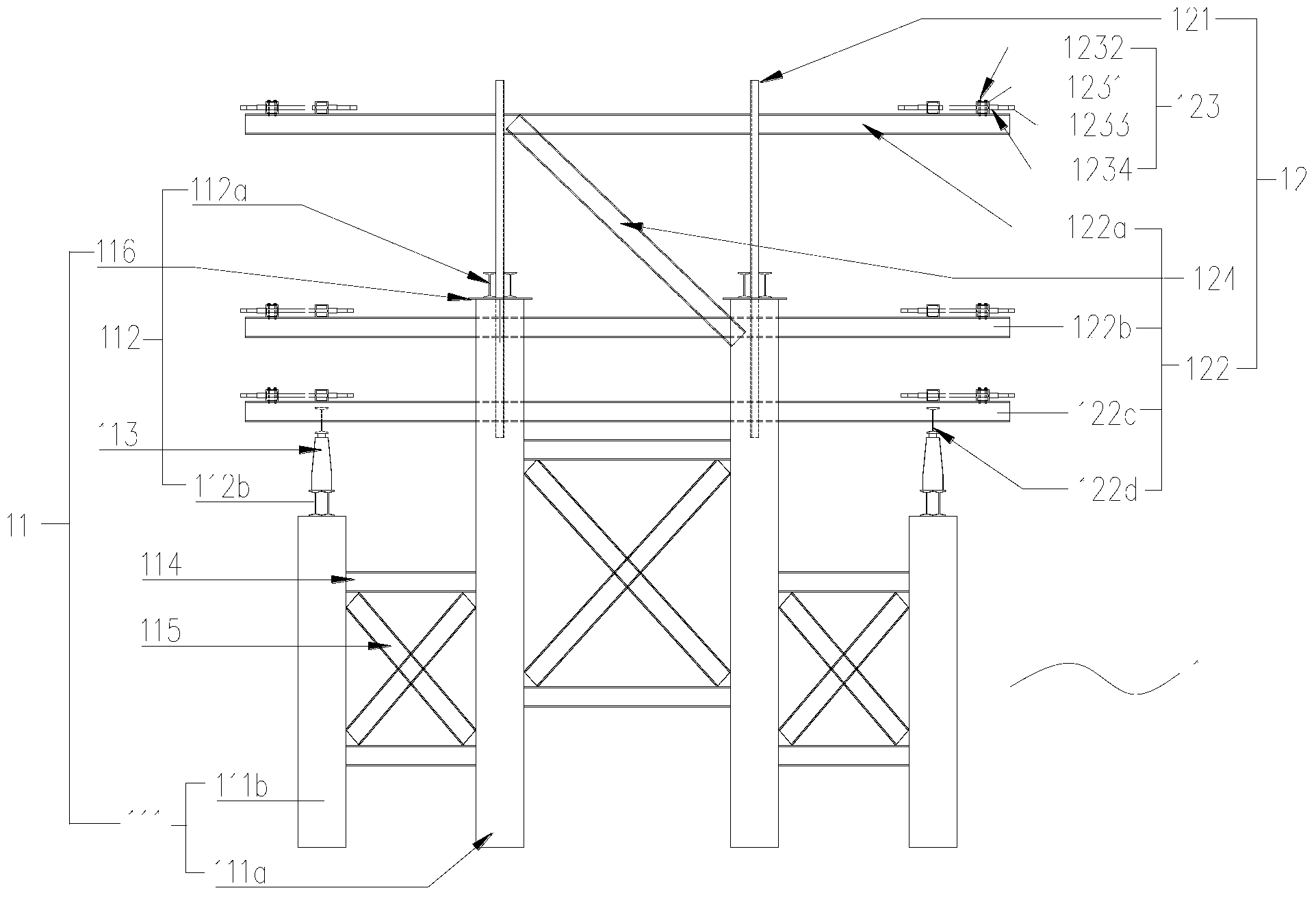

Mounting method for steel anchor beam of cable-stayed bridge and assembly jig and cable bent tower mounting platform used in method

ActiveCN103243654AImprove installation accuracyFast installationBridge erection/assemblyAssembly lineCable stayed

The invention discloses a mounting method for a steel anchor beam of a cable-stayed bridge and an assembly jig and a cable bent tower mounting platform used in the method. The steel anchor beam and steel corbels are preassembled on the steel anchor beam assembly jig, a hoist is used for replacing the steel anchor beam to hoist the steel corbels and the assembly jig integrally, the steel corbels are positioned and mounted through the steel anchor beam cable bent tower mounting platform on a cable bent tower, and the steel anchor beam is assembled. According to the mounting method for the steel anchor beam of the cable-stayed bridge and the assembly jig and the cable bent tower mounting platform used in the method, construction costs are saved, construction processes are simple and convenient, and accurate adjustment and positioning is facilitated.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

BIM technology-based curtain wall mounting design method

InactiveCN108460189AEliminate biasImprove installation accuracyGeometric CADDesign optimisation/simulationPoint cloudEngineering

The invention discloses a BIM technology-based curtain wall mounting design method. The method comprises the following steps of (1) importing a two-dimensional drawing of a curtain wall to BIM software Revit, and building three-dimensional models of to-be-mounted curtain wall unit members according to modeling specifications; (2) exporting detail drawings according to the three-dimensional modelsof the to-be-mounted curtain wall unit members, and performing processing production according to the detail drawings of the curtain wall unit members by a factory; (3) building three-dimensional point cloud models of the curtain wall unit members by utilizing fixed point cloud information; (4) adjusting information of the curtain wall unit members by using a processing device; and (5) simulatingwhole pre-mounting of the curtain wall in the Revit according to the three-dimensional point cloud models of the curtain wall unit members meeting specification requirements, and according to a pre-mounting process, performing entity member mounting. The BIM technology-based curtain wall mounting design method solves the problems of high field mounting difficulty, low mounting efficiency and low precision of the curtain wall.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

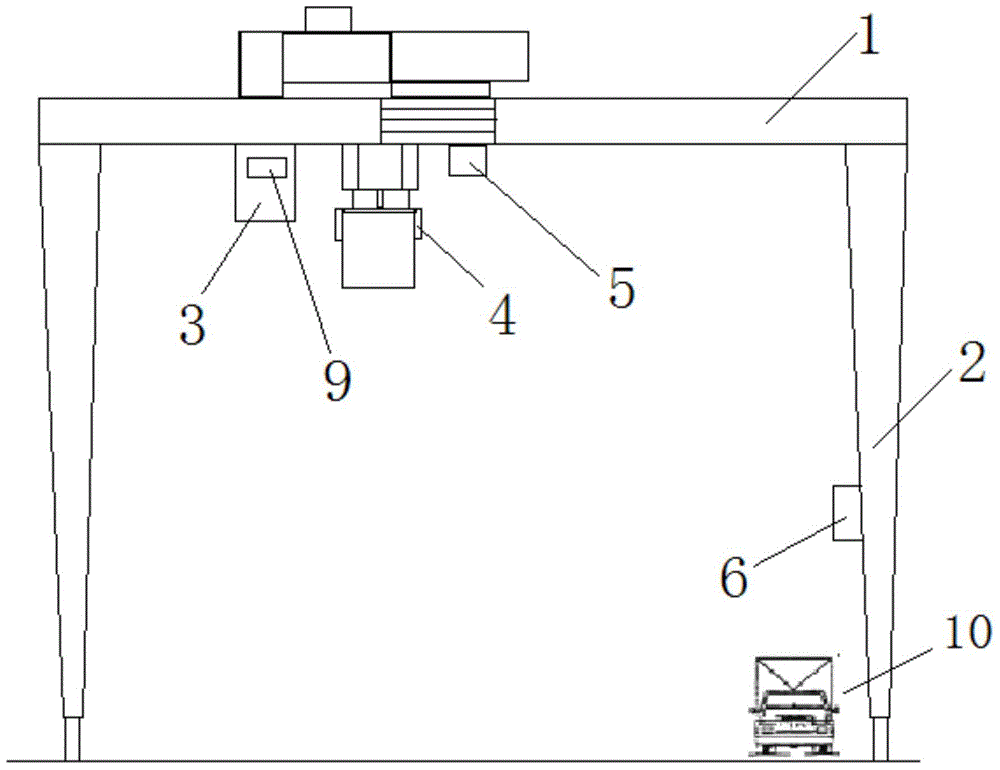

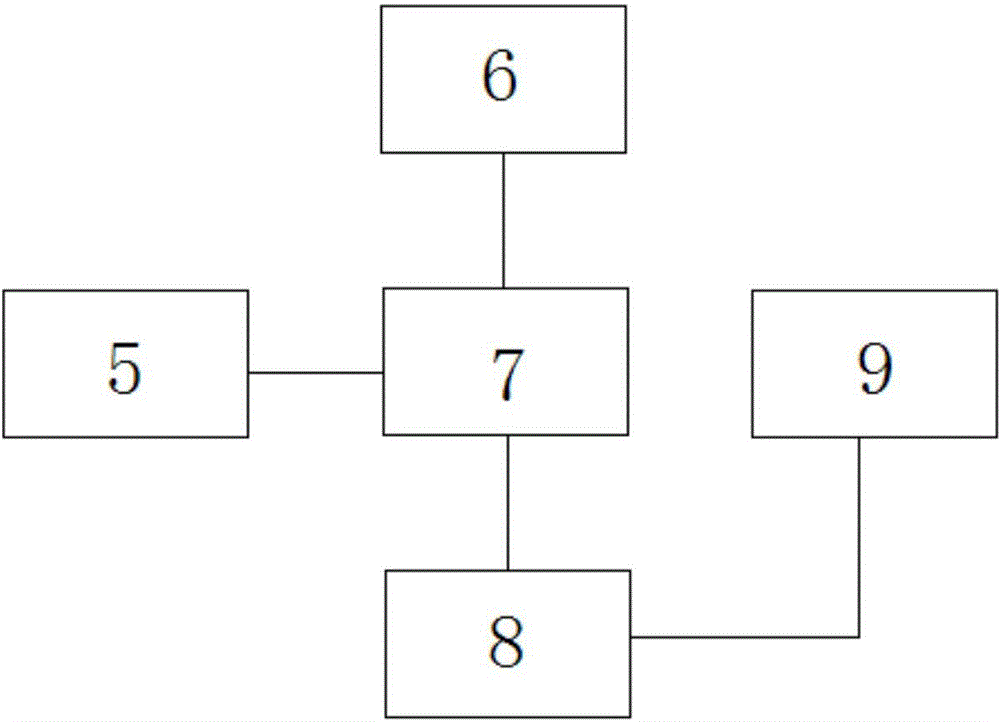

Container wharf RTG and RMG lower container truck alignment guide system and method

The invention discloses a container wharf RTG and RMG lower container truck alignment guide system and method. A laser scanning rangefinder, an LED display screen, a loudspeaker, a high-speed embedded controller and other components are adopted, and automatic precise guide of alignment of an RTG / RMG lower container truck is achieved. The high-speed embedded controller carries out conversion, calculation and contour recognition on measured data obtained through two-dimensional scanning on a container truck frame or a container on the frame through the laser scanning rangefinder in the direction parallel to the central line of a container lane, the position of the container truck and the deviation distance between the container truck and the benchmark hoisting point of a gantry crane are accordingly judged, meanwhile, the hoisting direction and distance information of the container truck deviating the hoisting point are displayed on the LED display screen, and a driver of the container truck is prompted to adjust the parking position of the container truck in advance.

Owner:CATHAY NEBULA SCI & TECH CO LTD

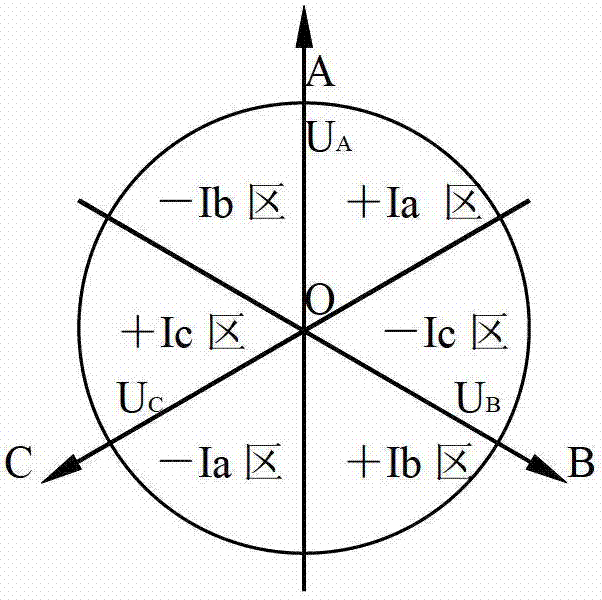

Method for rapidly judging wiring error of power distribution transformer monitoring terminal

ActiveCN102735986ARealize automatic operationAutomatically judge wiring errorsDirection of current indicationVoltage polarity indicationElectricityDistribution transformer

The invention discloses a method for rapidly judging a wiring error of a power distribution transformer monitoring terminal. The method is characterized by comprising two steps of voltage detection and current return accuracy detection, wherein the intelligent judgment on the wiring error of the power distribution transformer monitoring terminal is realized according to the phase relationship between a three-phase voltage and a current. According to the method, the method is embedded into the terminal in mode of embedded software directly; the automatic operation can be realized when the terminal is powered on, and then the wiring error of the terminal is judged automatically; and the installation personnel are prompted through a liquid crystal interface and a buzzer; the accuracy rate of the installation is improved; and the labor waste caused by secondary construction is avoided.

Owner:安徽中鑫继远信息技术股份有限公司

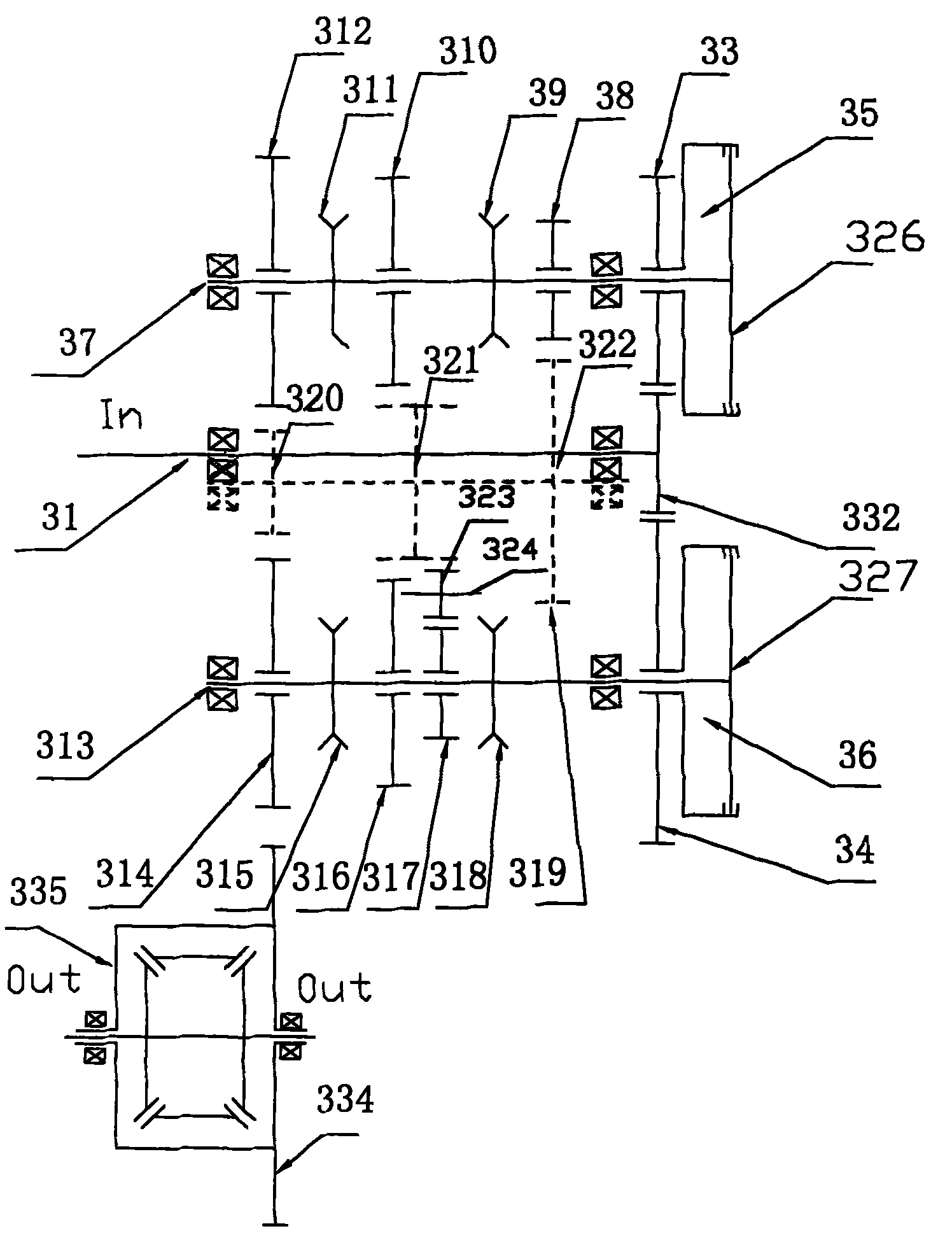

Dual-clutch automated transmission

ActiveCN101979898ASimplify the difficulty of production and processingLow costFluid actuated clutchesToothed gearingsAutomatic transmissionLayshaft

The invention relates to a dual-clutch automated transmission. An input shaft gear is arranged on an input shaft of an engine. The dual-clutch automated transmission comprises two independent monomer clutches, wherein the driving gear of the odd-gear clutch and the driving gear of the even-gear clutch are meshed with the input shaft gear in different transmission ratios respectively; the driving gear of the odd-gear clutch is fixed on a first secondary shaft; the driving gear of the even-gear clutch is fixed on a second secondary shaft; and the first secondary shaft and the second secondary shaft are arranged on two sides of the input shaft respectively and are parallel to the input shaft. In the dual-clutch automated transmission, an integrated dual-clutch is separated into two monomer clutches and the coaxial structure of the traditional dual-clutch transmission is transformed into a parallel structure, so that the manufacturing and processing difficulty of the dual-clutch transmission is simplified and the cost is reduced.

Owner:HEFEI CHANGAN AUTOMOBILE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com