Patents

Literature

376results about How to "High material strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

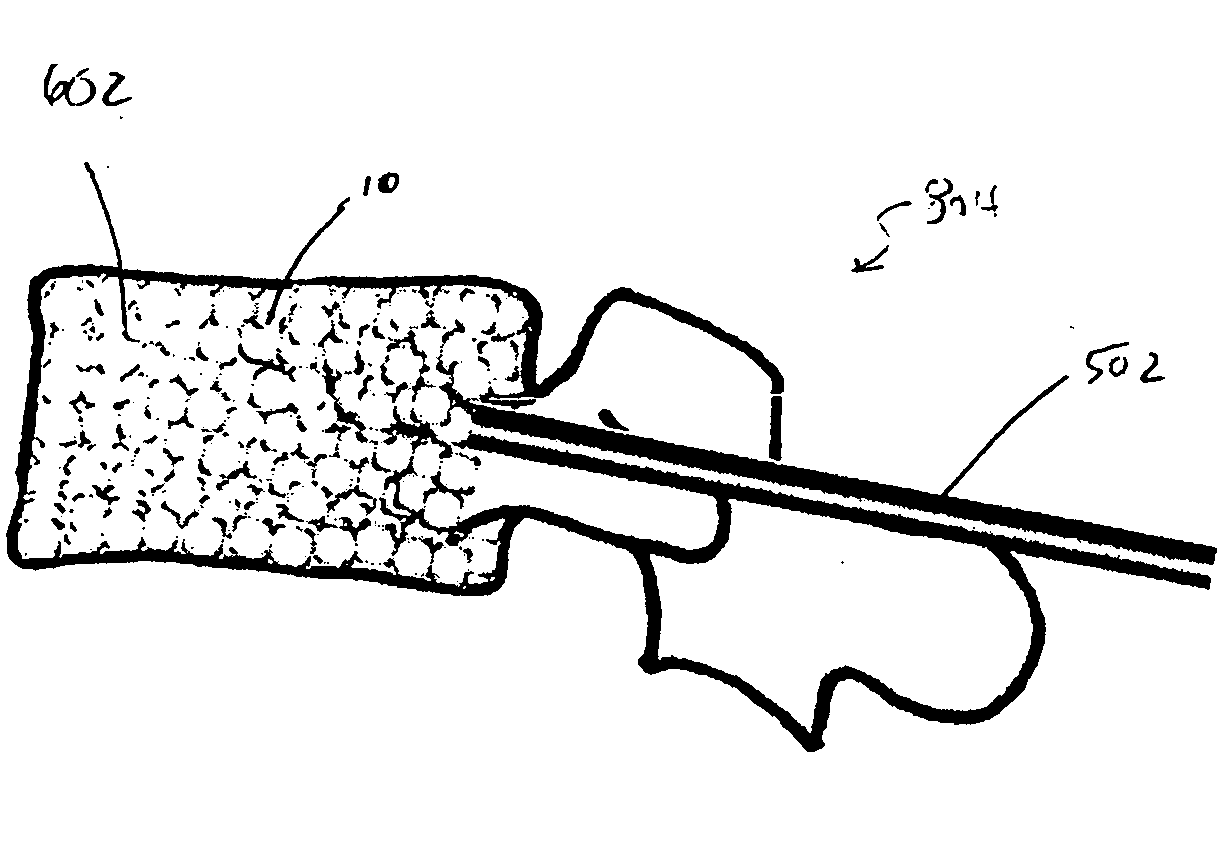

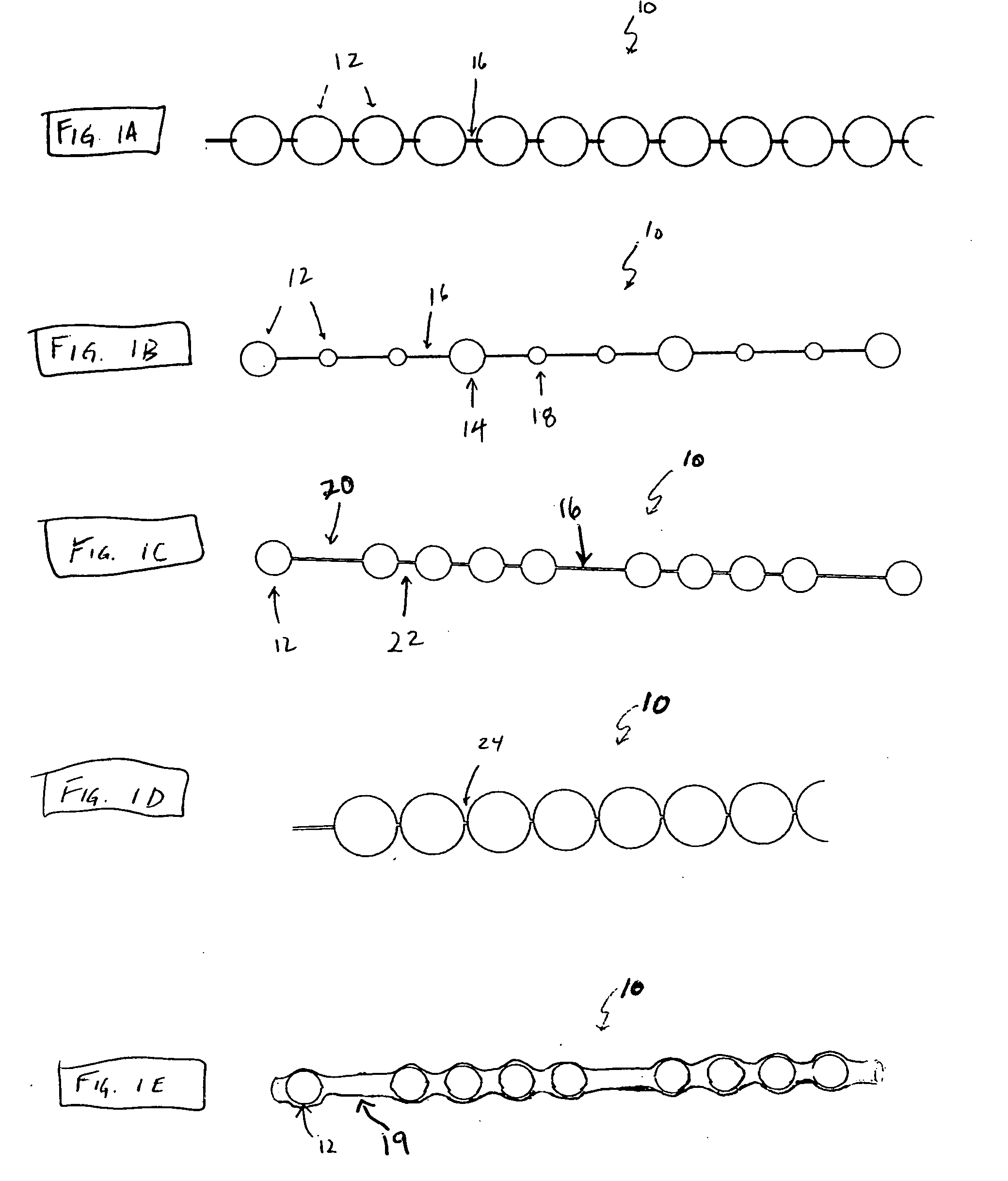

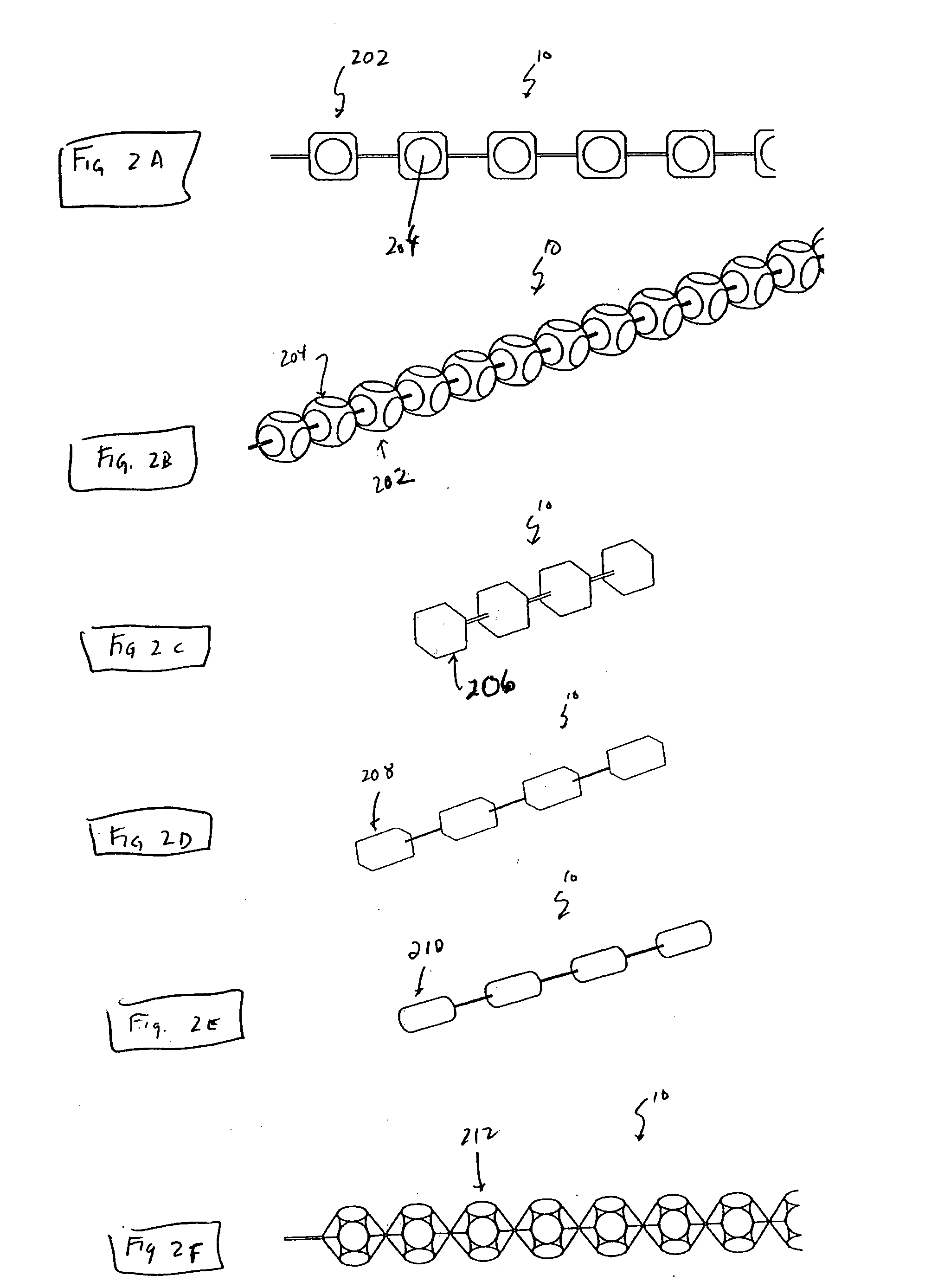

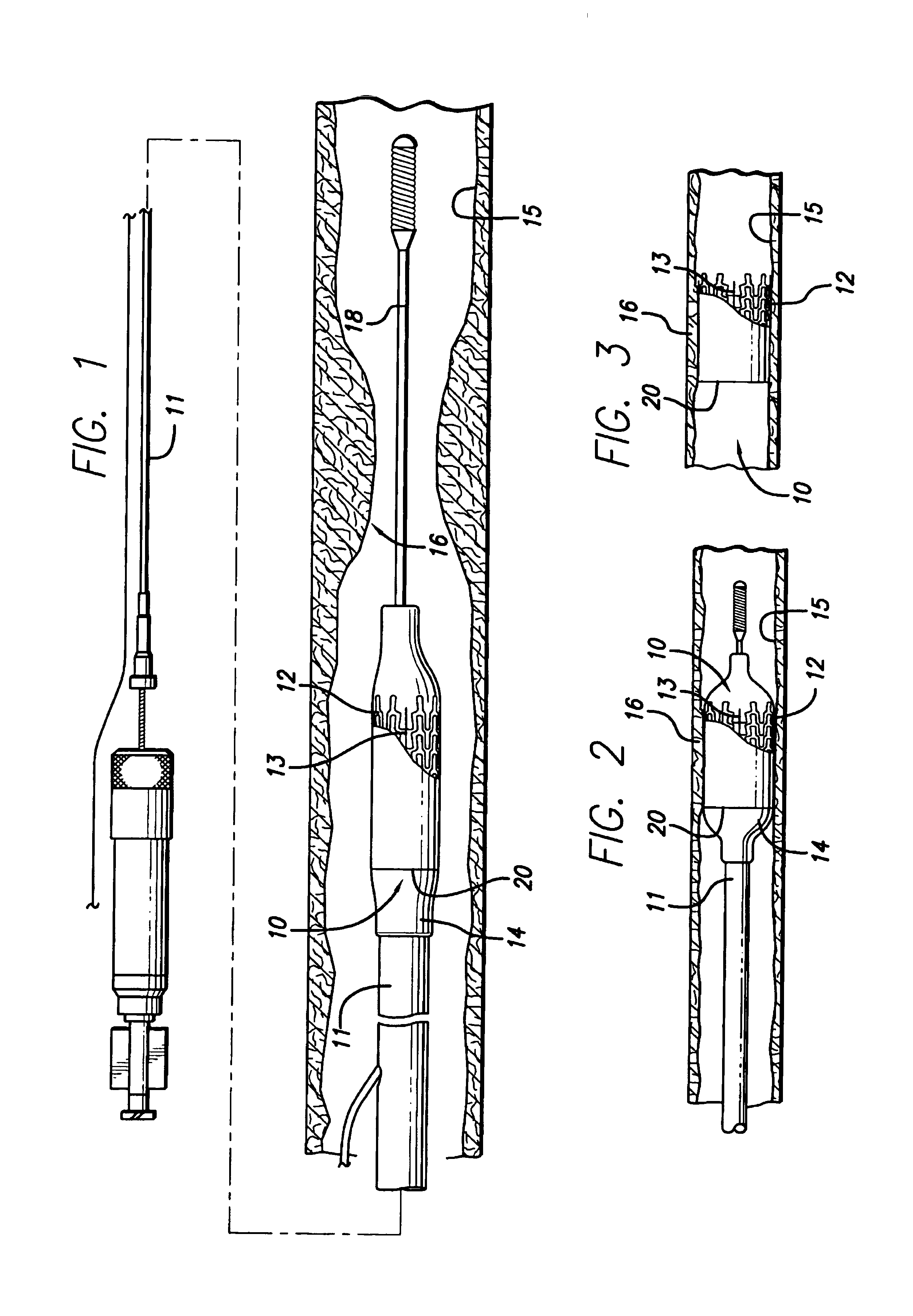

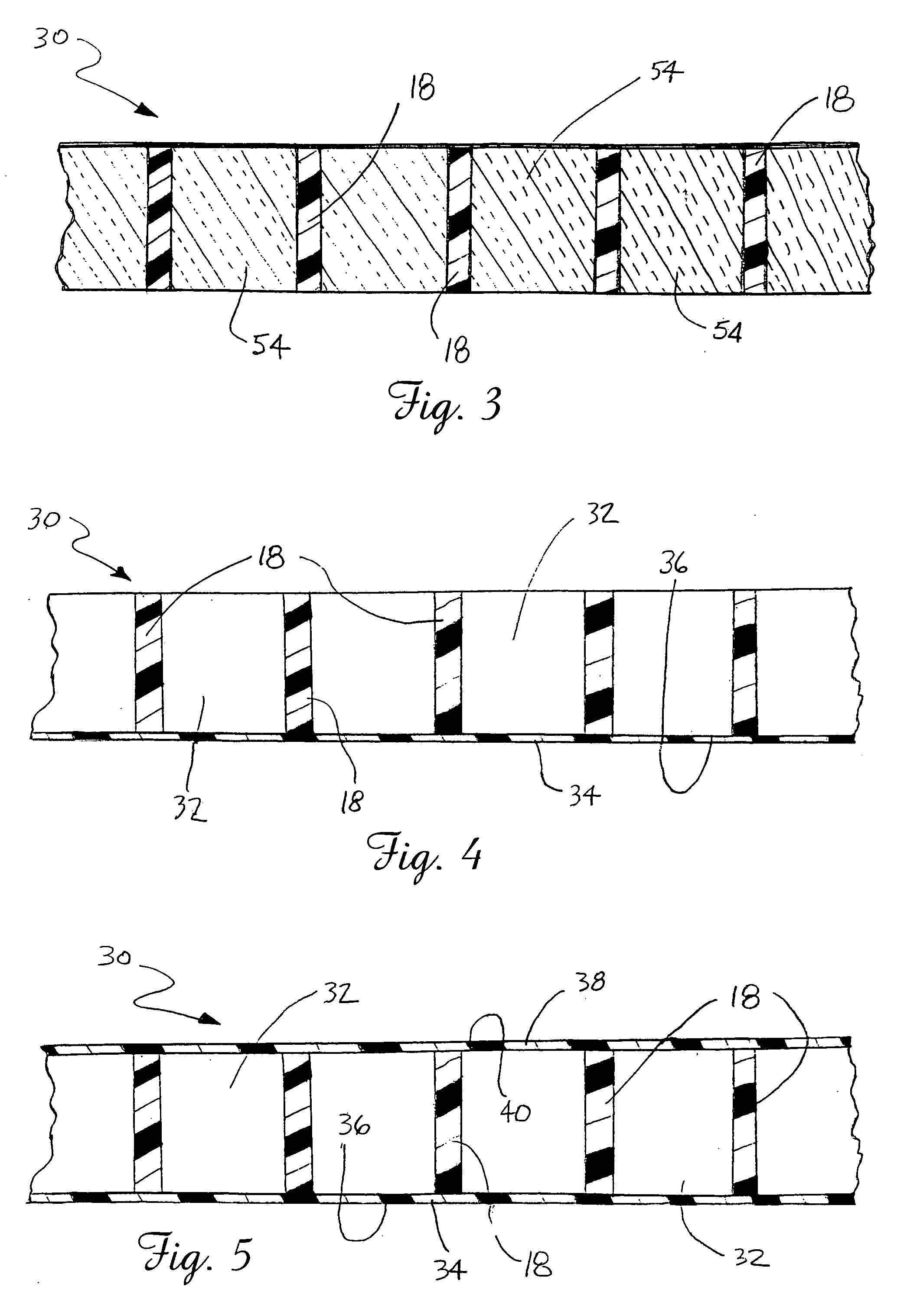

Method and apparatus for filling a cavity

InactiveUS20050278023A1High material strengthHigh compressive strengthInternal osteosythesisBone implantUltimate tensile strengthBiomedical engineering

An implant for filling and / or distracting a body region, particularly a non-soft tissue cavity, has a plurality of segments wherein at least two of the segments are flexibly connected. The segments have a crush-strength sufficient to create and / or maintain the distraction of two or more non-soft tissue body surfaces, and to maintain the stability of the body region. The implant may be inserted into a cavity by an applicator having a cannula with a distal opening, and a rotary driver for applying force to move the implant within the cannula.

Owner:SPINAL VENTURES

Ultraviolet light cured transfer printing film and preparation method and application thereof

InactiveCN101941339AHigh material strengthGood weather resistanceDecorative surface effectsOrnamental structuresLacquerPrinting ink

The invention belongs to the field of decorative materials, and particularly relates to an ultraviolet light cured transfer printing film and a preparation method and application thereof. The preparation method comprises the following steps of: uniformly coating or printing a mold release agent on a base load film, and performing infrared curing; uniformly coating or printing an ultraviolet light cured printing ink with a patterning function on a mold release agent layer, and performing curing through ultraviolet irradiation; or uniformly coating or printing an ultraviolet cured protective layer coating with anti-scratching and wear-resistant functions on the mold release agent layer first, then uniformly coating or printing the ultraviolet light cured printing ink with the patterning function on the mold release agent layer after the curing through the ultraviolet irradiation, and performing the curing through the ultraviolet irradiation; and uniformly coating or printing an ultraviolet light cured bottom color coating on an ultraviolet light cured printing ink decorative pattern layer, and performing the curing through the ultraviolet irradiation to obtain the ultraviolet light cured transfer printing film which can be used for producing an ultraviolet light cured transfer printing film decorative board. The ultraviolet light cured transfer printing film has high material strength, and has the advantages of high weathering resistance, high environmental protection, rich colors and patterns, full lacquer film, high hardness, scratch resistance, easy cleaning, noninflammability and the like.

Owner:ZHUHAI DONGCHENG UV MATERIALS

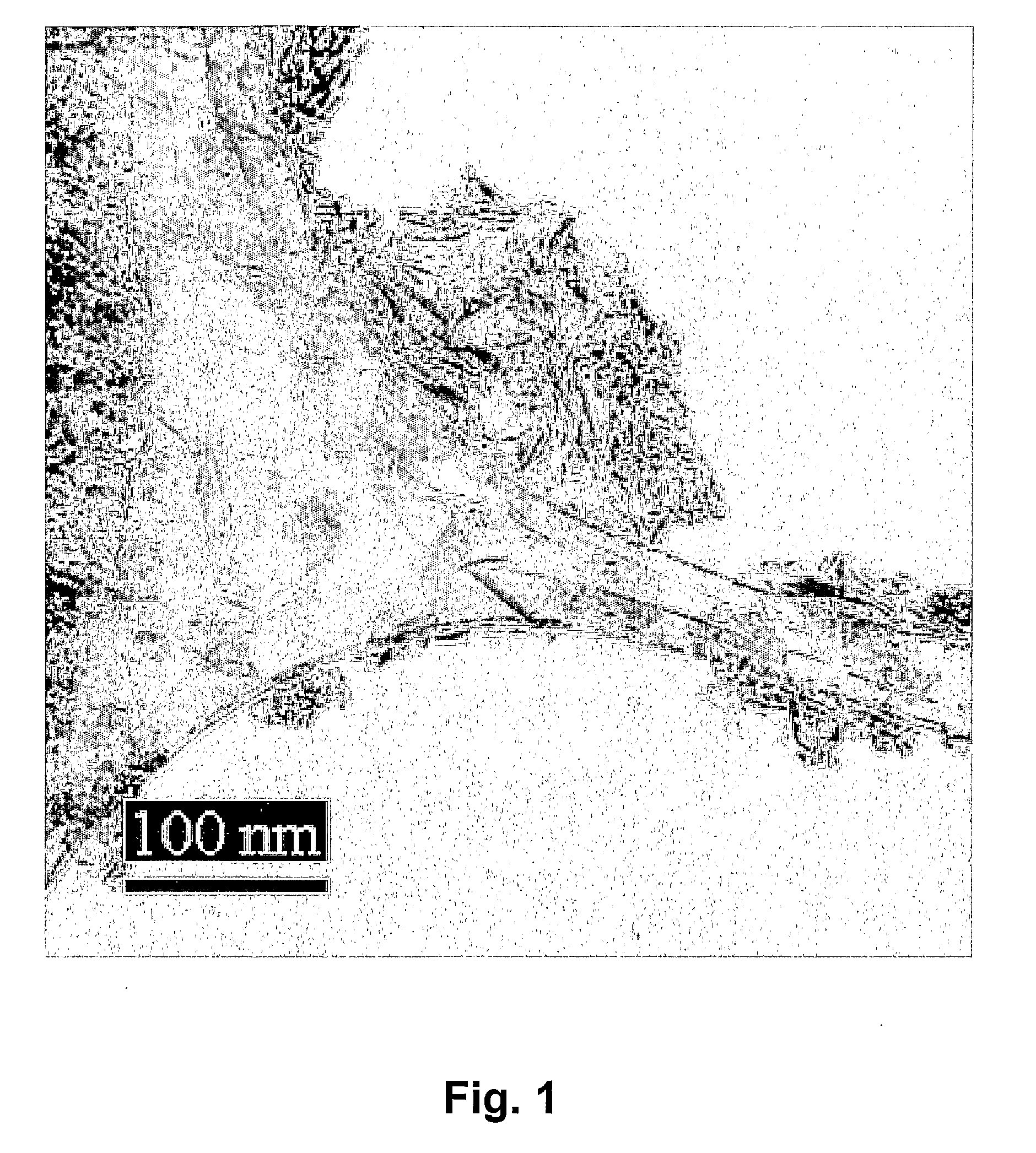

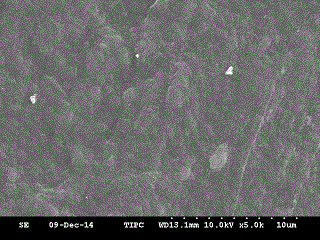

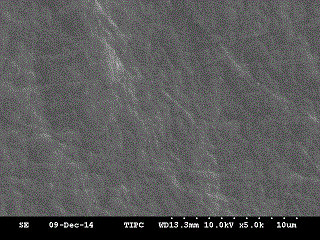

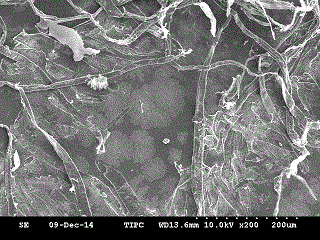

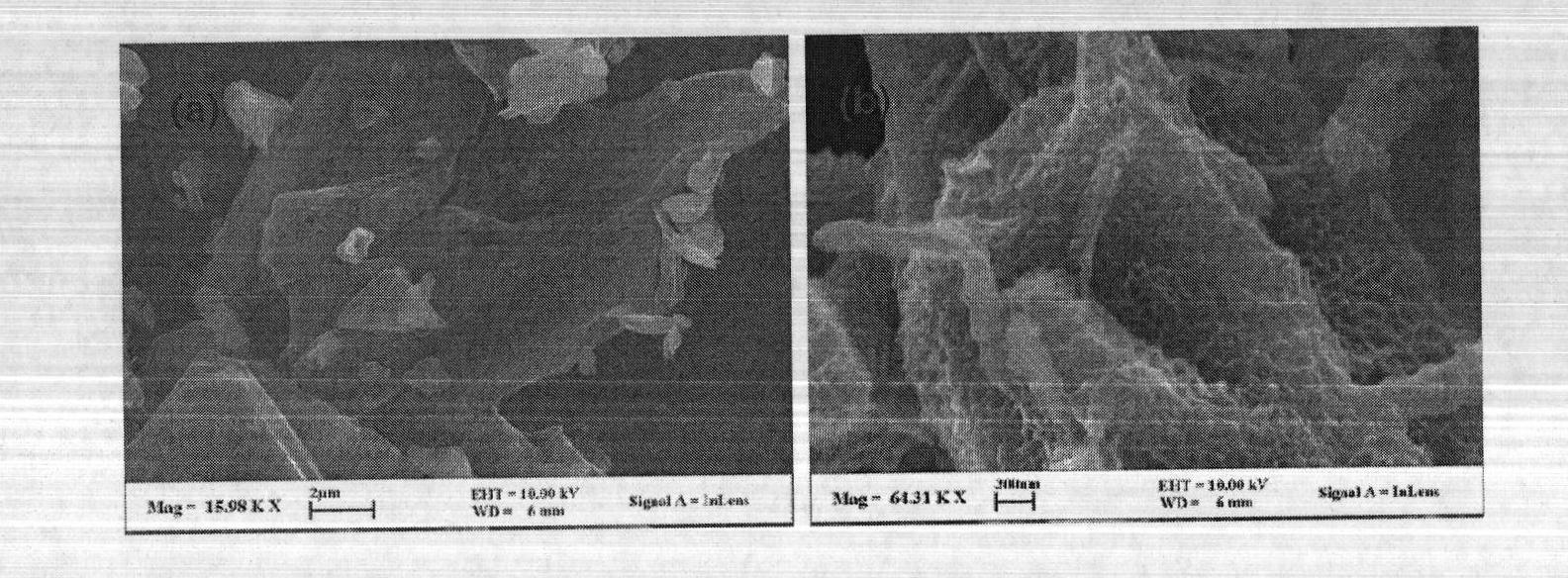

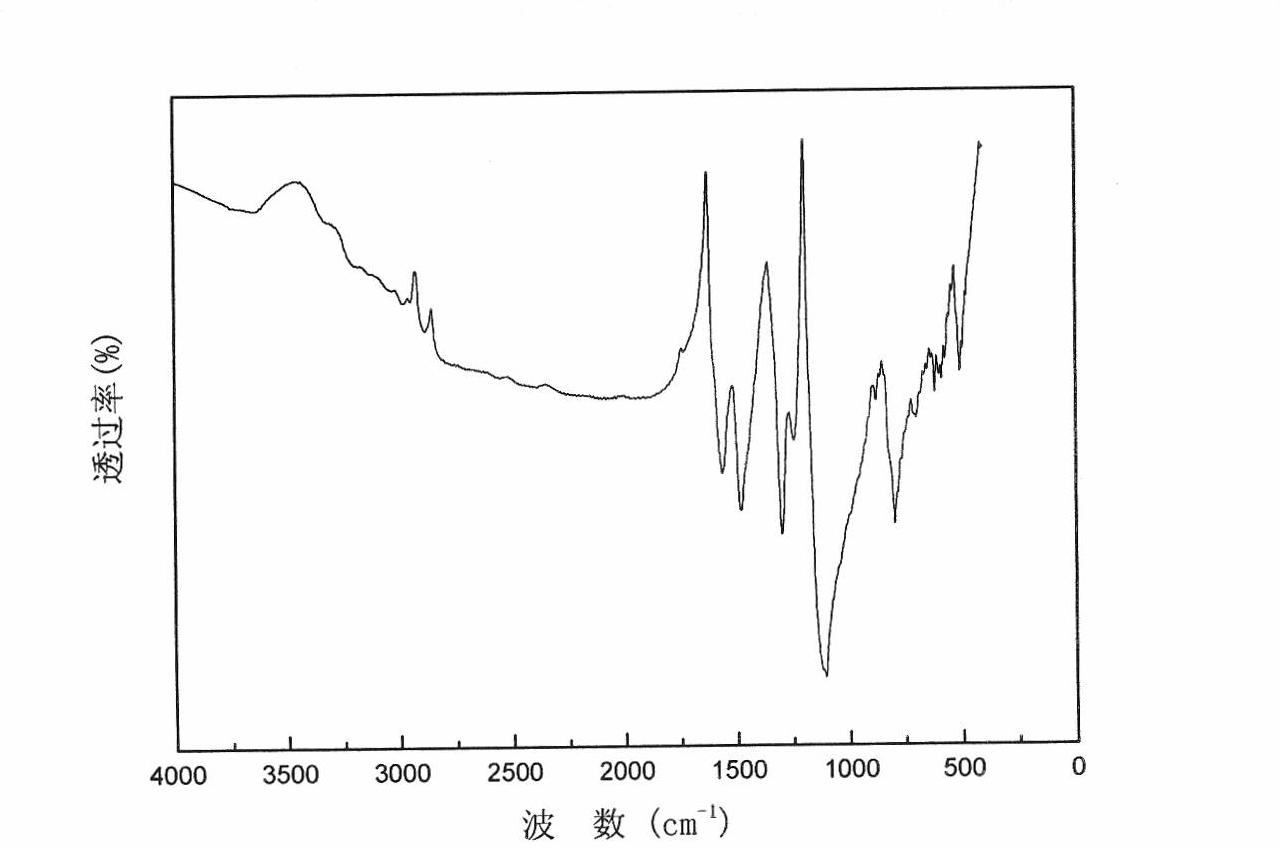

Reinforced carbon nanotubes

InactiveUS6911260B2Improve mechanical propertiesHigh strengthMaterial nanotechnologyLiquid surface applicatorsCarbon nanotubeBoron carbide

The present invention relates generally to reinforced carbon nanotubes, and more particularly to reinforced carbon nanotubes having a plurality of microparticulate carbide or oxide materials formed substantially on the surface of such reinforced carbon nanotubes composite materials. In particular, the present invention provides reinforced carbon nanotubes (CNTs) having a plurality of boron carbide nanolumps formed substantially on a surface of the reinforced CNTs that provide a reinforcing effect on CNTs, enabling their use as effective reinforcing fillers for matrix materials to give high-strength composites. The present invention also provides methods for producing such carbide reinforced CNTs.

Owner:BOSTON COLLEGE

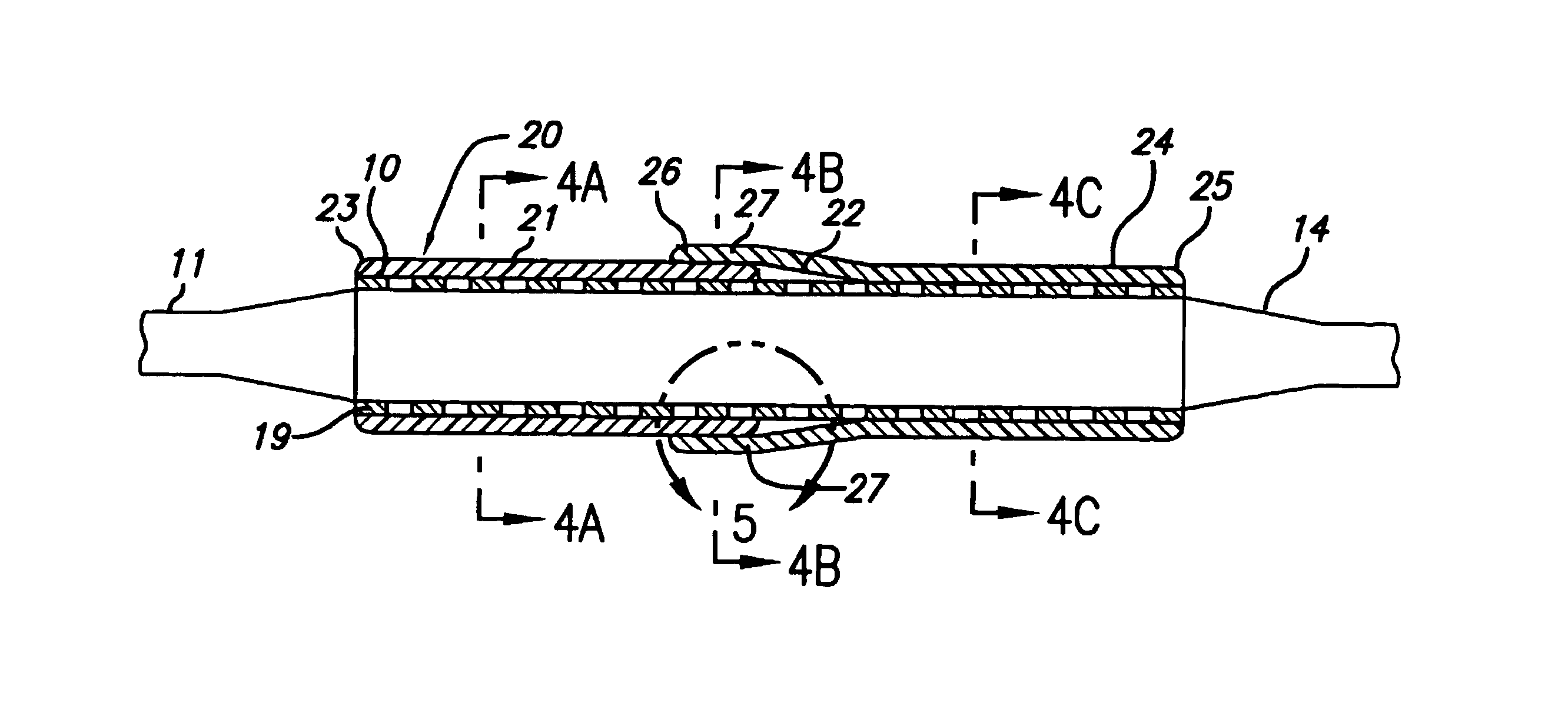

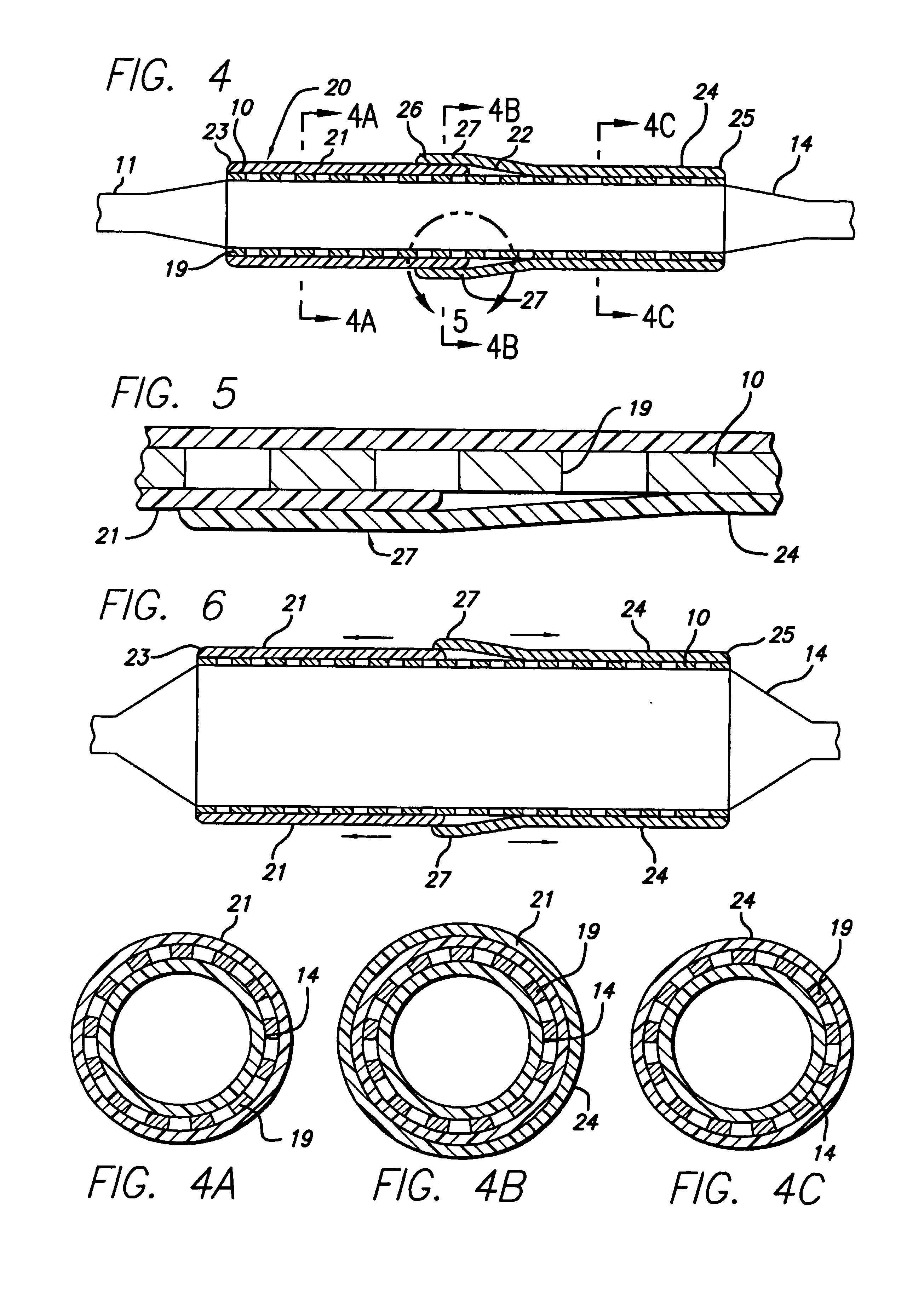

Covered stent assembly for reduced-shortening during stent expansion

InactiveUS7118592B1SpeedMinimize covered stent shrinkageStentsSurgeryInsertion stentIntravascular stent

A polymeric material such as polyurethane, PET, or ePTFE is used to cover an intravascular stent. The cover material has an overlapping portion which is slidable upon itself so that when the stent is expanded, the cover material does not contribute to stent foreshortening, if any. The cover material can be provided with holes to permit endothelialization and can be drug loaded to facilitate repair of a damaged vessel.

Owner:ABBOTT CARDIOVASCULAR

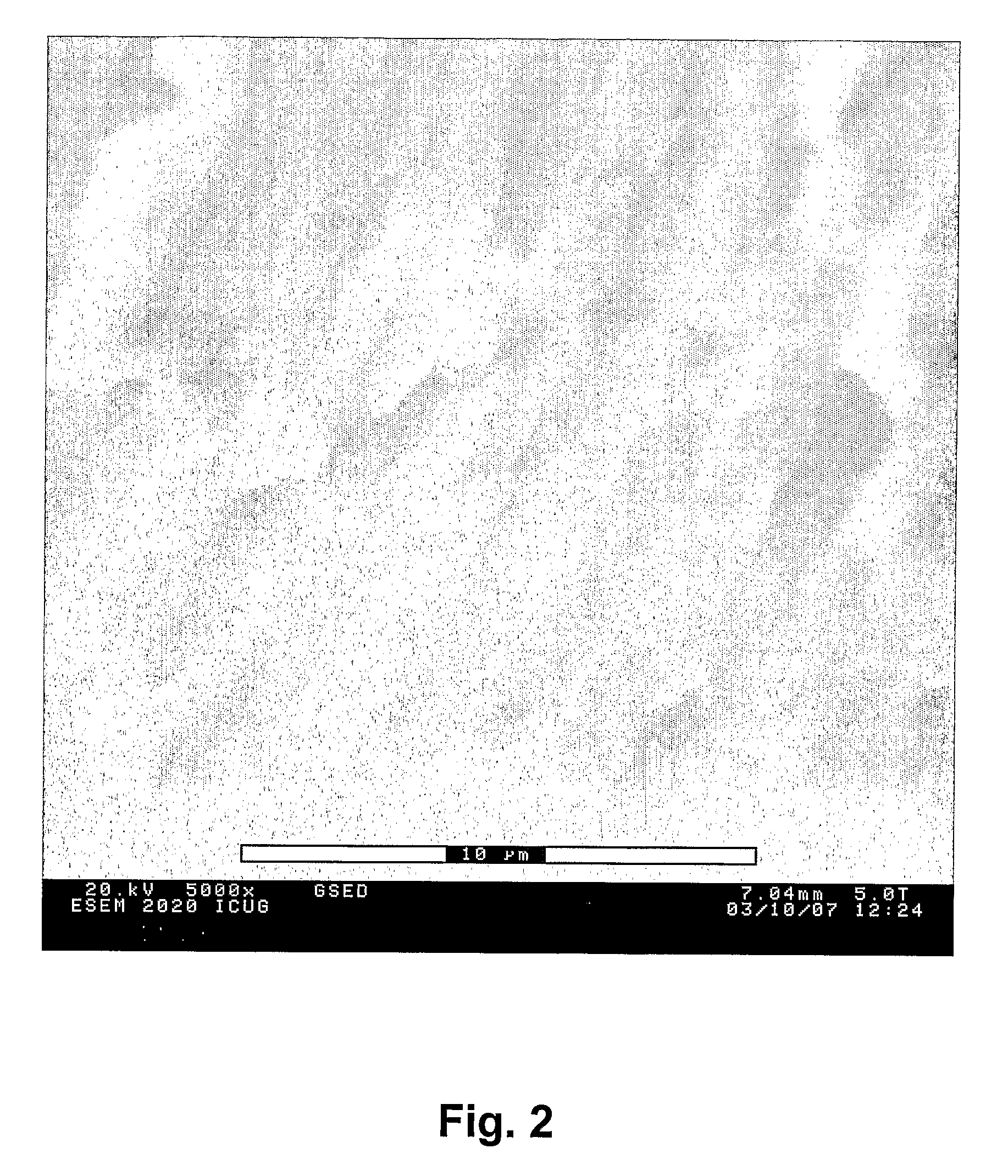

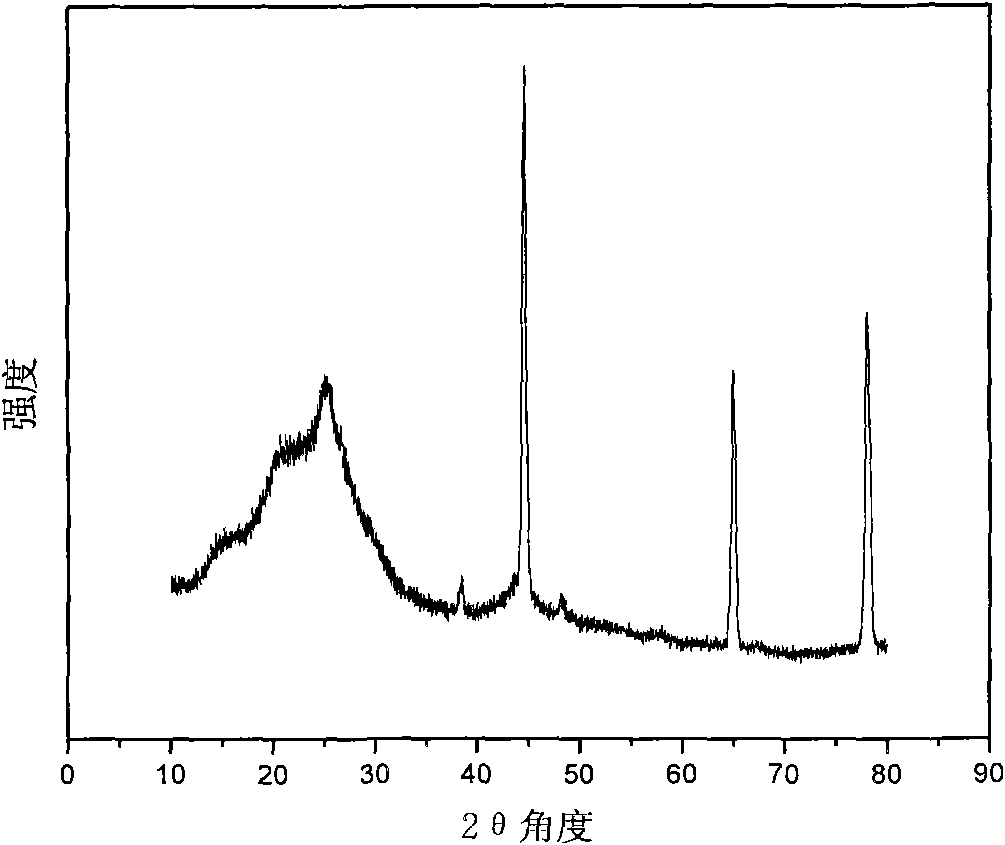

Synthetic Nano-Sized Crystalline Calcium Phosphate and Method of Production

ActiveUS20080220233A1Easy to depositMaximize adherence to surfaceMaterial nanotechnologyNanostructure manufactureLiquid crystallineSolvent

Synthetic nano-sized crystalline calcium phosphate, particularly hydroxyapatite, having a specific surface area in the range of 150 m2 / g to 300 m2 / g, is described. The nano-sized crystalline calcium phosphate may be in the form of a powder or in the form of a coating on a surface. A method of producing a nano-sized crystalline calcium phosphate powder or coating is also described. The method comprises formation of a liquid crystalline phase in a water solution of calcium, phosphor and a surfactant, placing the phase in an ammonia atmosphere so that nano-sized crystals are formed, followed by either removal of the surfactant with a solvent and recovering the nano-sized crystals to obtain the powder, or diluting the ammonia-treated liquid crystalline phase with a hydrophobic organic solvent to create a microemulsion of the nano-sized crystals in water, dipping an oxide layer-coated surface of an object into the microemulsion, or alternatively saving the step of ammonia treatment of the liquid crystalline phase until after the dipping of the surface of an object into the microemulsion, followed by removal of the organic solvent and the surfactant from the surface to obtain the coating.

Owner:PROMIMIC

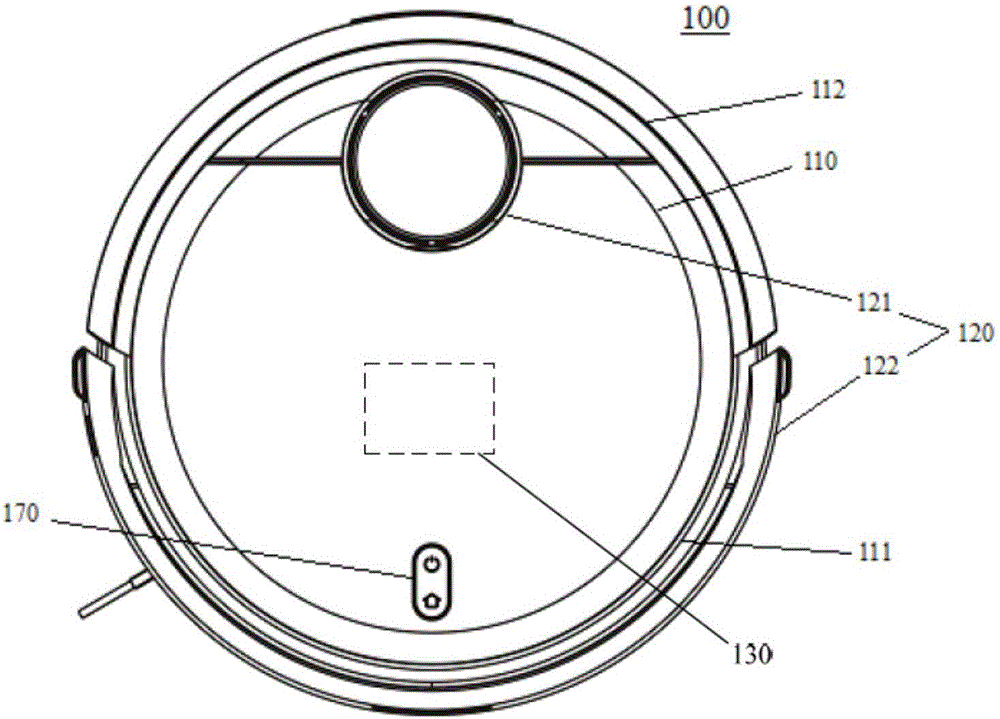

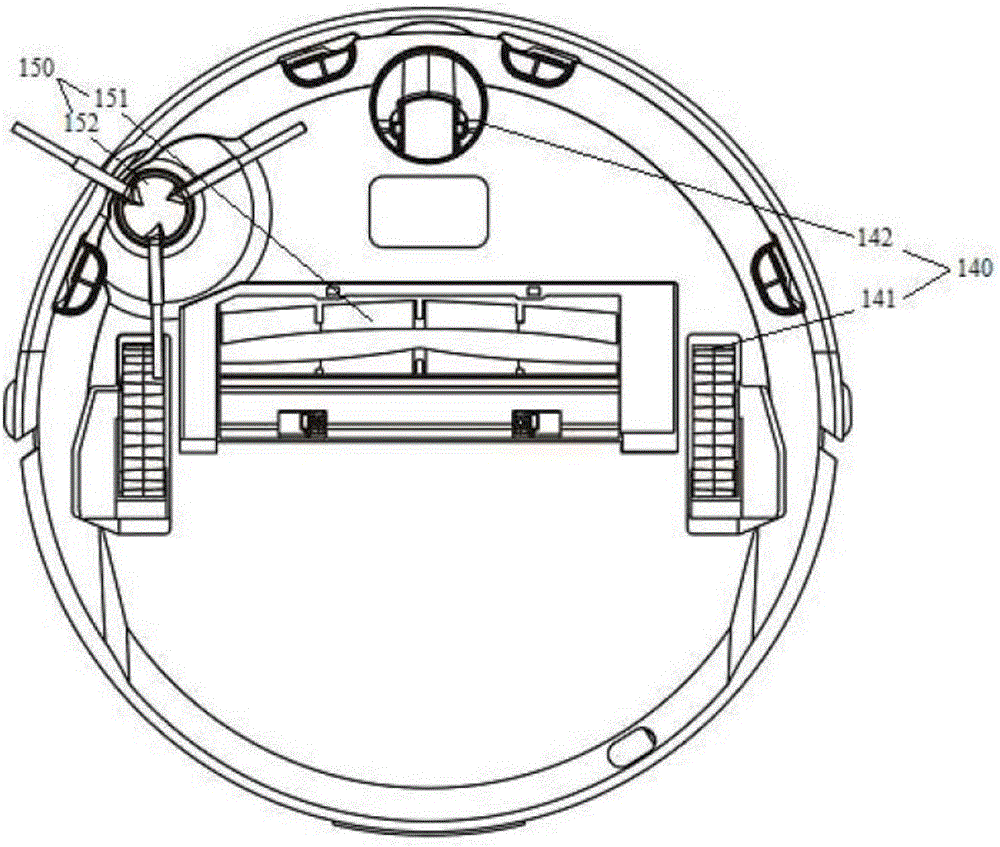

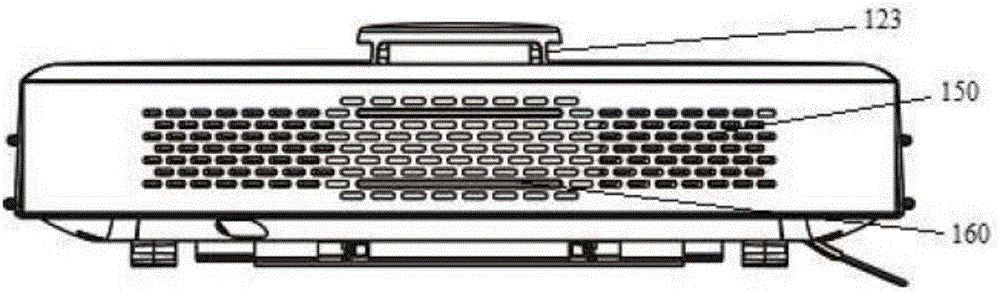

Self-cleaning device

InactiveCN105982611AImprove maintenance efficiencyEasy to disassembleAutomatic obstacle detectionAutonomous decision making processEngineeringChassis

The invention relates to a self-cleaning device which comprises a device main body, a driving module, a cleaning module and a sensing module, wherein the device main body comprises a chassis and an upper shell fixed on the chassis; the driving module is connected with the chassis and is used for driving the self-cleaning device to advance according to a preset line; the cleaning module is distributed in the device main body; the sensing module is assembled on a preset position of the upper shell and is used for acquiring the condition of barriers at the periphery of the self-cleaning device; the driving module, the cleaning module and the sensing module are respectively assembled on the device main body in a detachable way. All the function modules in the self-cleaning device provided by the invention are respectively mounted in accommodating space reserved on the device main body and can be independently detached from the device main body, so that the damaged function modules can be independently detached for conveniently repairing or replacing new function modules and the repairing efficiency of the self-cleaning device is greatly increased.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD +1

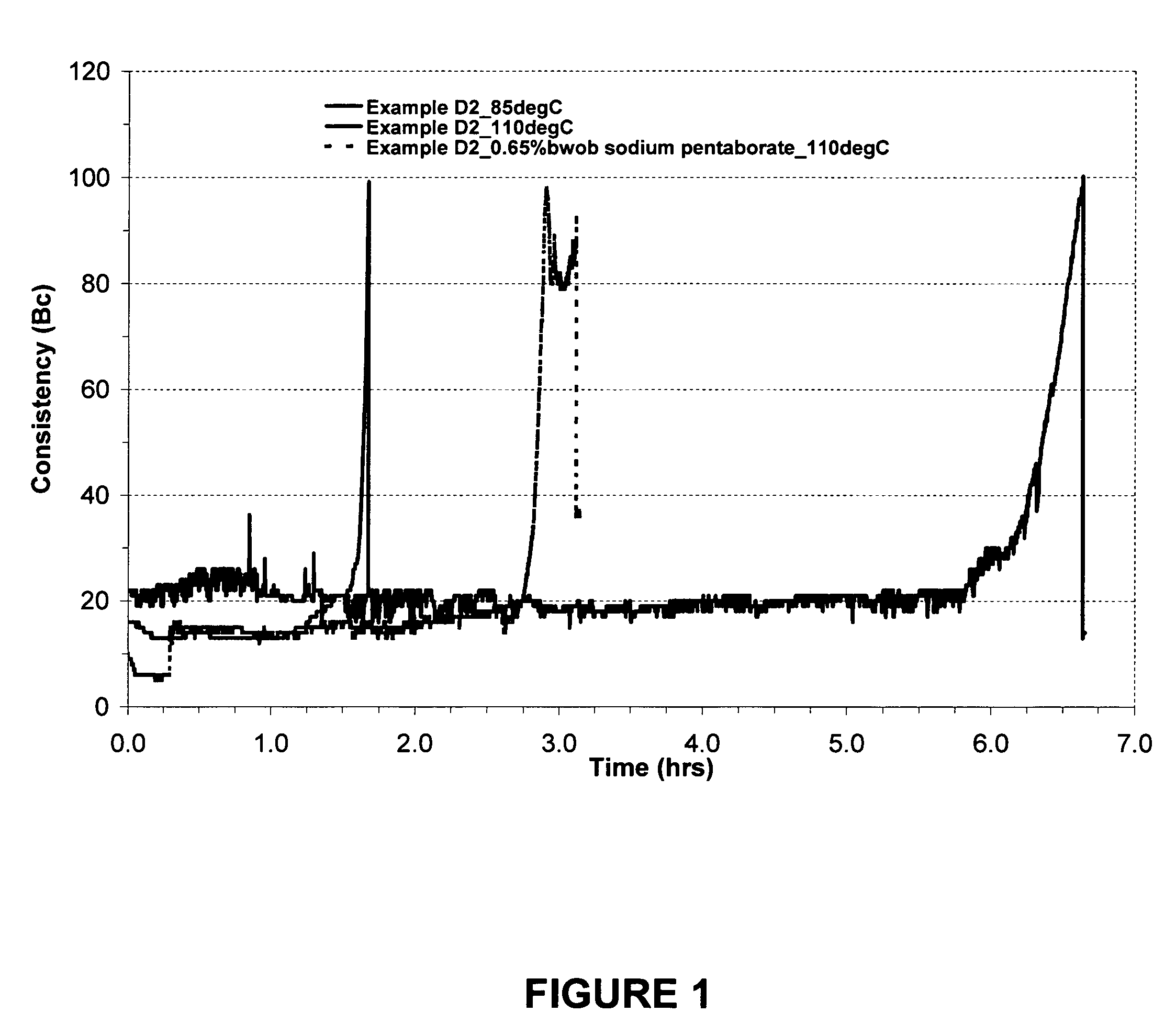

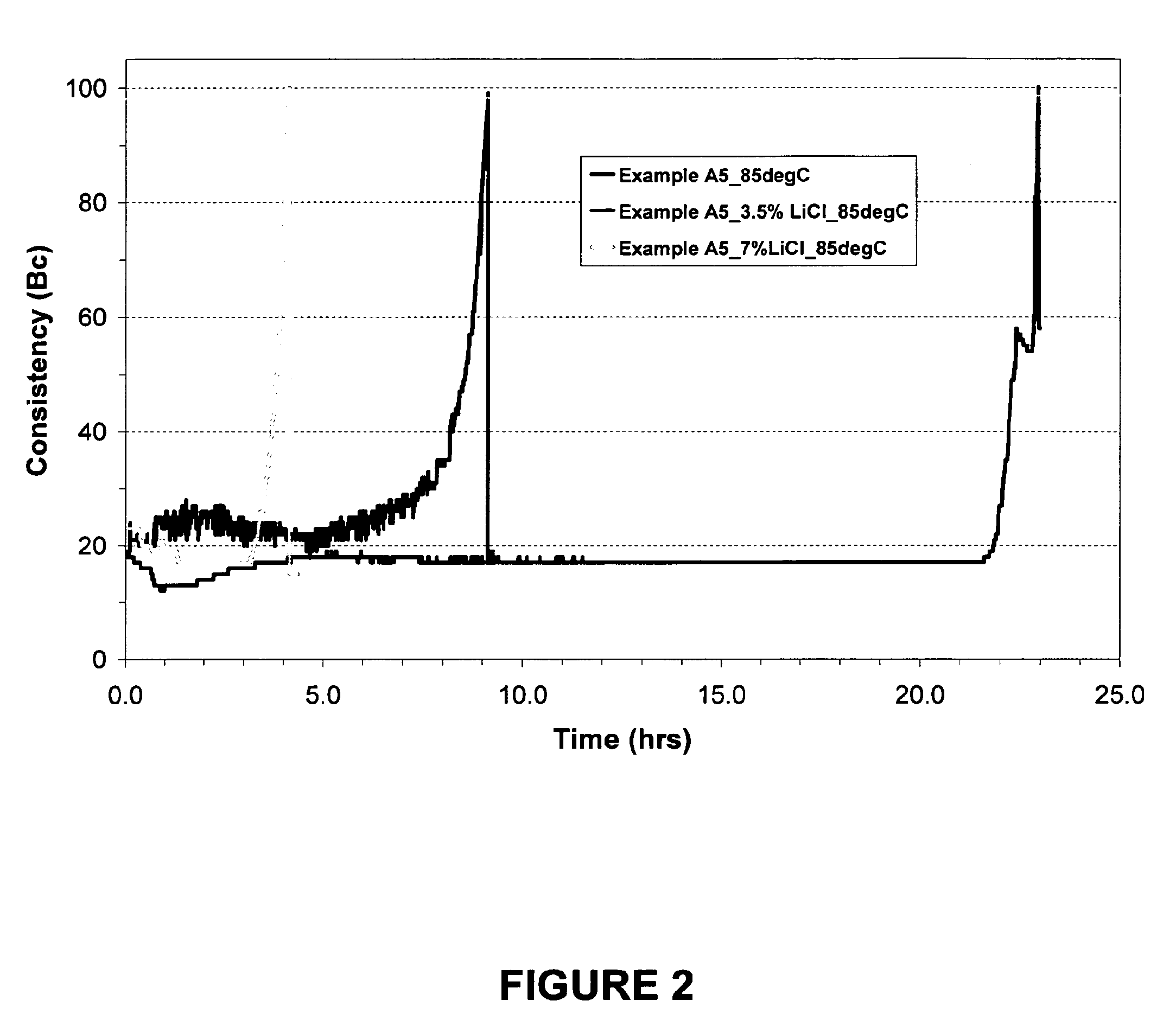

Pumpable geopolymer formulation for oilfield application

InactiveUS20110073311A1Enhanced pumpabilityImprove stabilityFluid removalCement productionAluminateCarrier fluid

The invention provides geopolymeric compositions, which have controllable thickening and setting times for a wide range of temperatures and a large range of geopolymer slurry densities. The geopolymer slurry compositions have good mixability and pumpability, whilst the set materials develop good compressive strength and permeability. The invention discloses a method for preparing geopolymer for oilfield cementing applications. The geopolymeric compositions according to the invention comprises a suspension made of an aluminosilicate source, a carrier fluid, an activator taken from the list constituted by: a metal silicate, a metal aluminate, an alkali activator, or a combination thereof, and an aluminum containing compound taken in the list constituted of bauxite, aluminum oxide and aluminum salt and the suspension is a pumpable composition in oilfield industry and the suspension is able to set under well downhole conditions.

Owner:SCHLUMBERGER TECH CORP

Multi-element heat-resistant aluminum alloy material with high strength and preparation method thereof

ActiveUS20120152414A1Improve mechanical propertiesImprove corrosion resistanceTransportation and packagingMetal-working apparatusHeat resistanceUltimate tensile strength

A heat-resistant aluminum alloy material with high strength and preparation method thereof are provided. The aluminum alloy material comprises (by weight %): Cu: 1.0˜10.0, Mn: 0.05˜1.5, Cd: 0.01˜0.5, Ti: 0.01˜0.5%, B: 0.01˜0.2 or C: 0.0001˜0.15, Zr: 0.01˜1.0, R: 0.001˜3 or (R1+R2): 0.001˜3, RE: 0.05˜5, and balance Al:, wherein, R, R1, and R2 include Be, Co, Cr, Li, Mo, Nb, Ni, W. The Al alloy has the advantages of narrow quasi-solid phases temperature range of alloys, low hot cracking liability during casting improved high temperature strength and high heat resistance.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

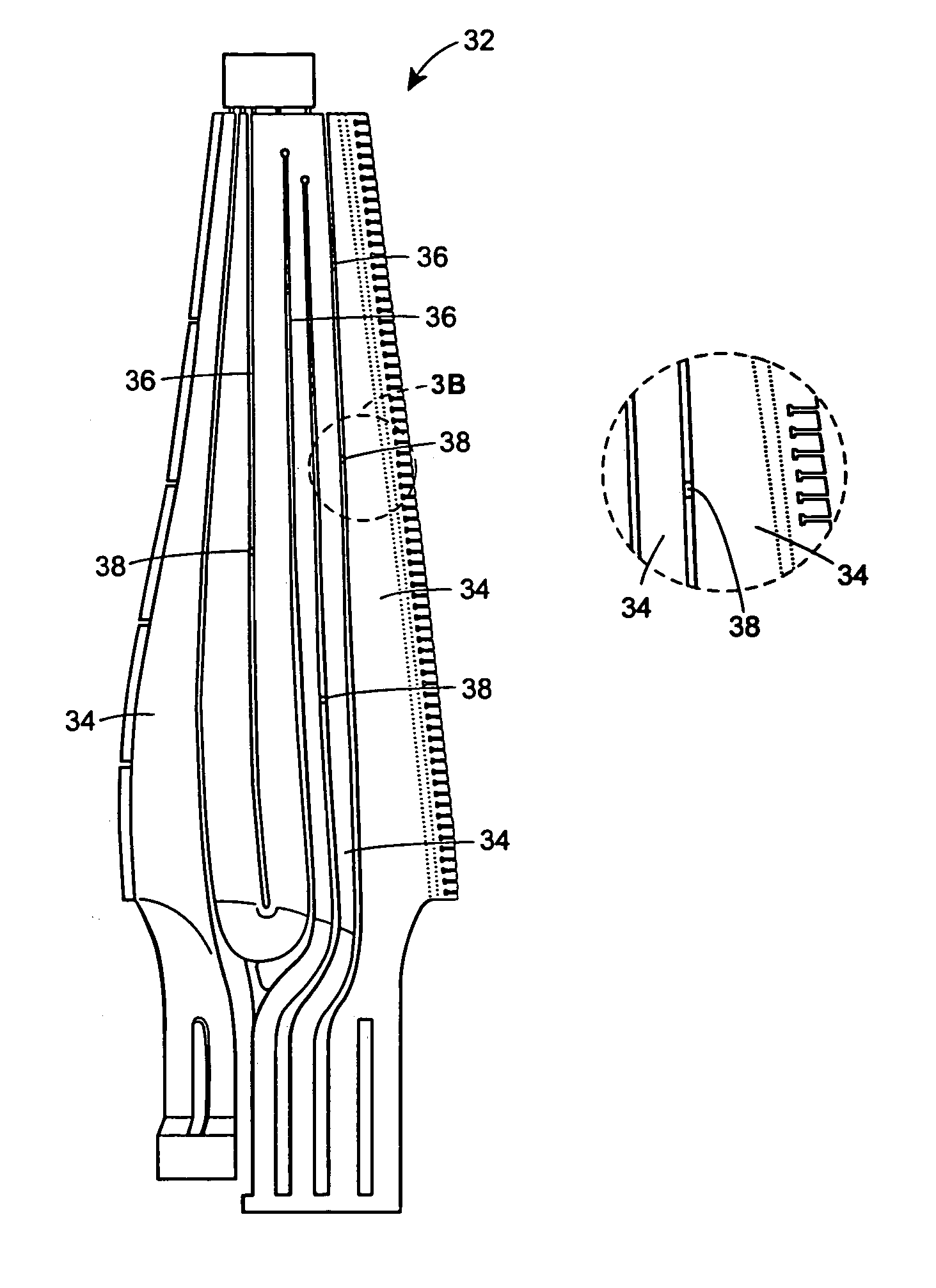

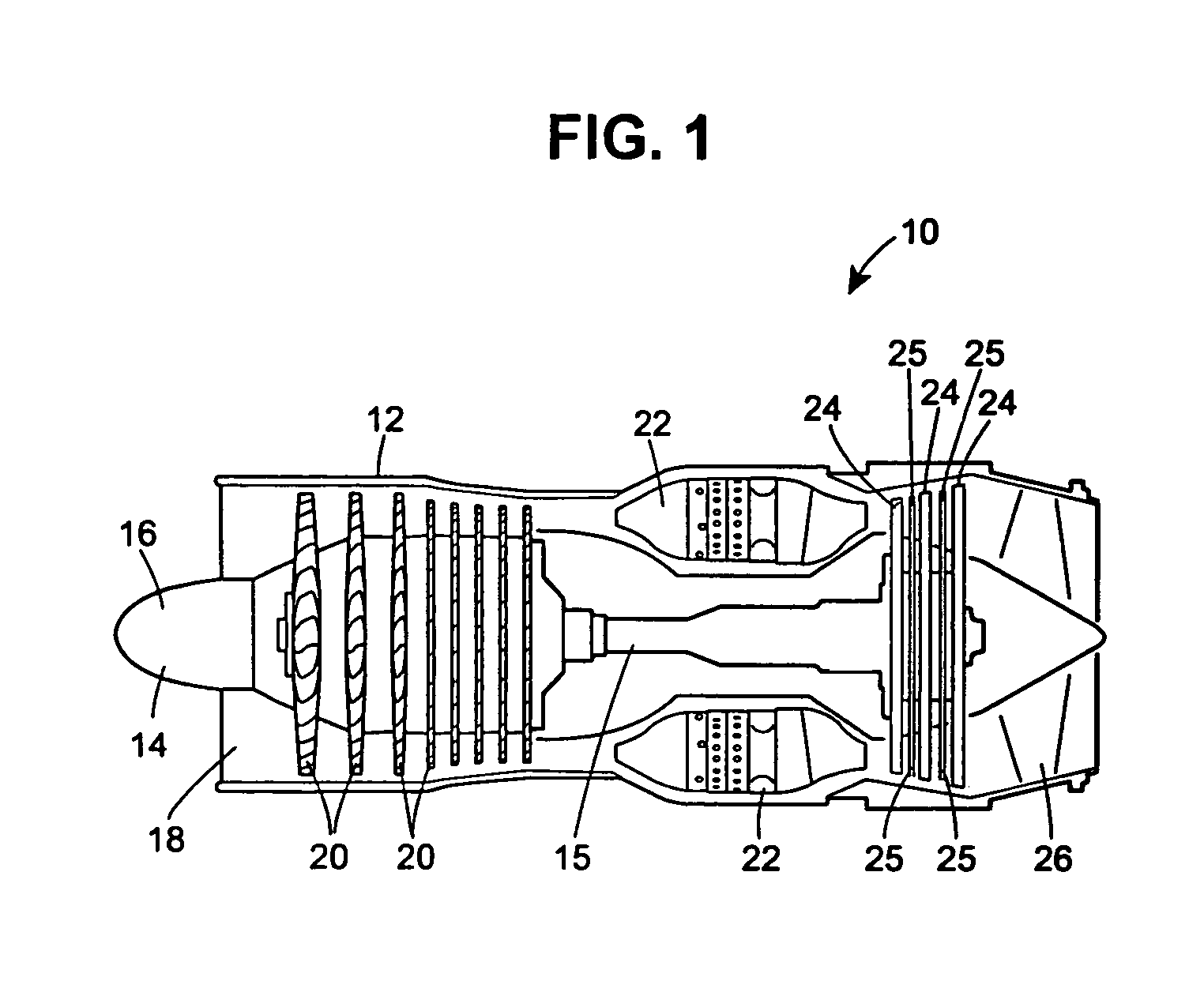

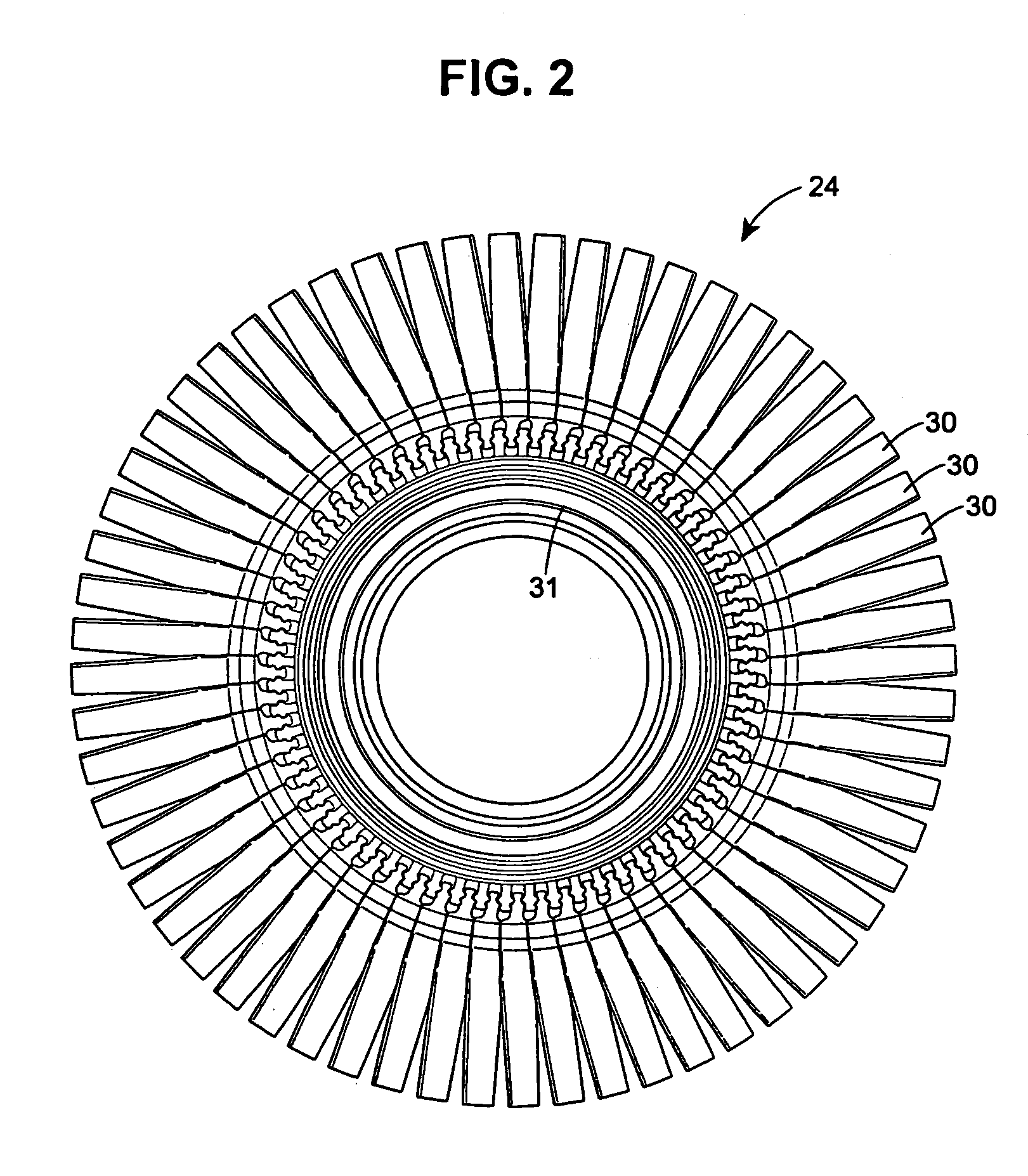

Apparatus and method for reducing operating stress in a turbine blade and the like

ActiveUS7216694B2Minimize operating mechanical stressRelieve pressureBlade accessoriesFoundry mouldsTurbine bladeMaterials science

A core for casting a metal part having a body with solid portions spaced apart by hollow portions. The body includes at least one support element extending between adjacent solid portions. The support element provides stiffness and strength for the casting core during the casting process. The support element has an optimized shape to prevent the core from fracturing during the casting process and to minimize operating stress in the metal part around the area formed by the support element.

Owner:RTX CORP

Synthesis of boron carbide nanoparticles

InactiveUS20060057050A1Improve mechanical propertiesHigh strengthMaterial nanotechnologyMulti-walled nanotubesNanoparticleCarbide

The present invention relates generally to reinforced carbon nanotubes, and more particularly to reinforced carbon nanotubes having a plurality of microparticulate carbide or oxide materials formed substantially on the surface of such reinforced carbon nanotubes composite materials. In particular, the present invention provides reinforced carbon nanotubes (CNTs) having a plurality of boron carbide nanolumps formed substantially on a surface of the reinforced CNTs to reinforce the CNTs, enabling their use as effective reinforcing fillers for matrix materials to give high-strength composites. The present invention also provides methods for producing carbide reinforced CNTs.

Owner:TRUSTEES OF BOSTON COLLEGE THE

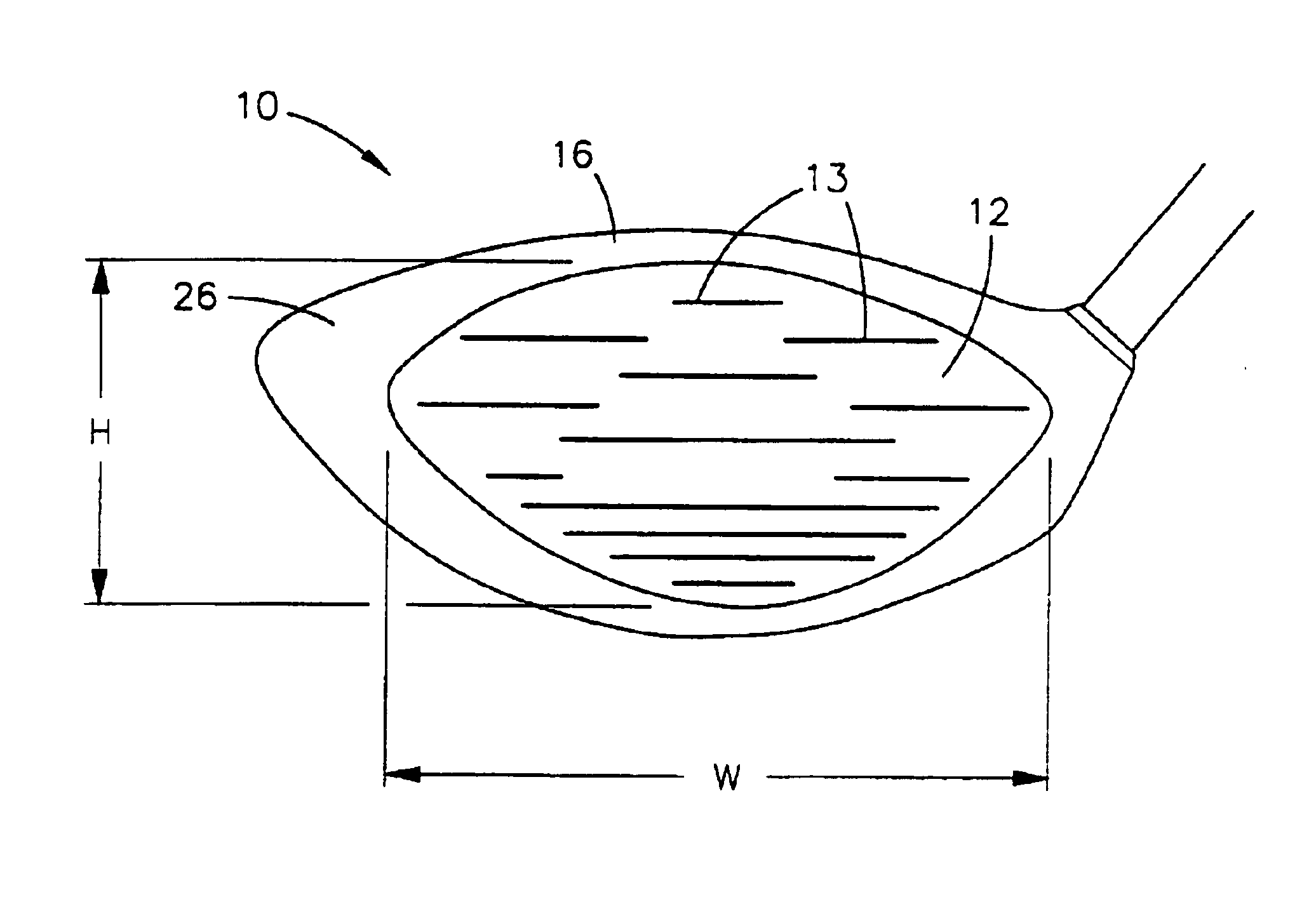

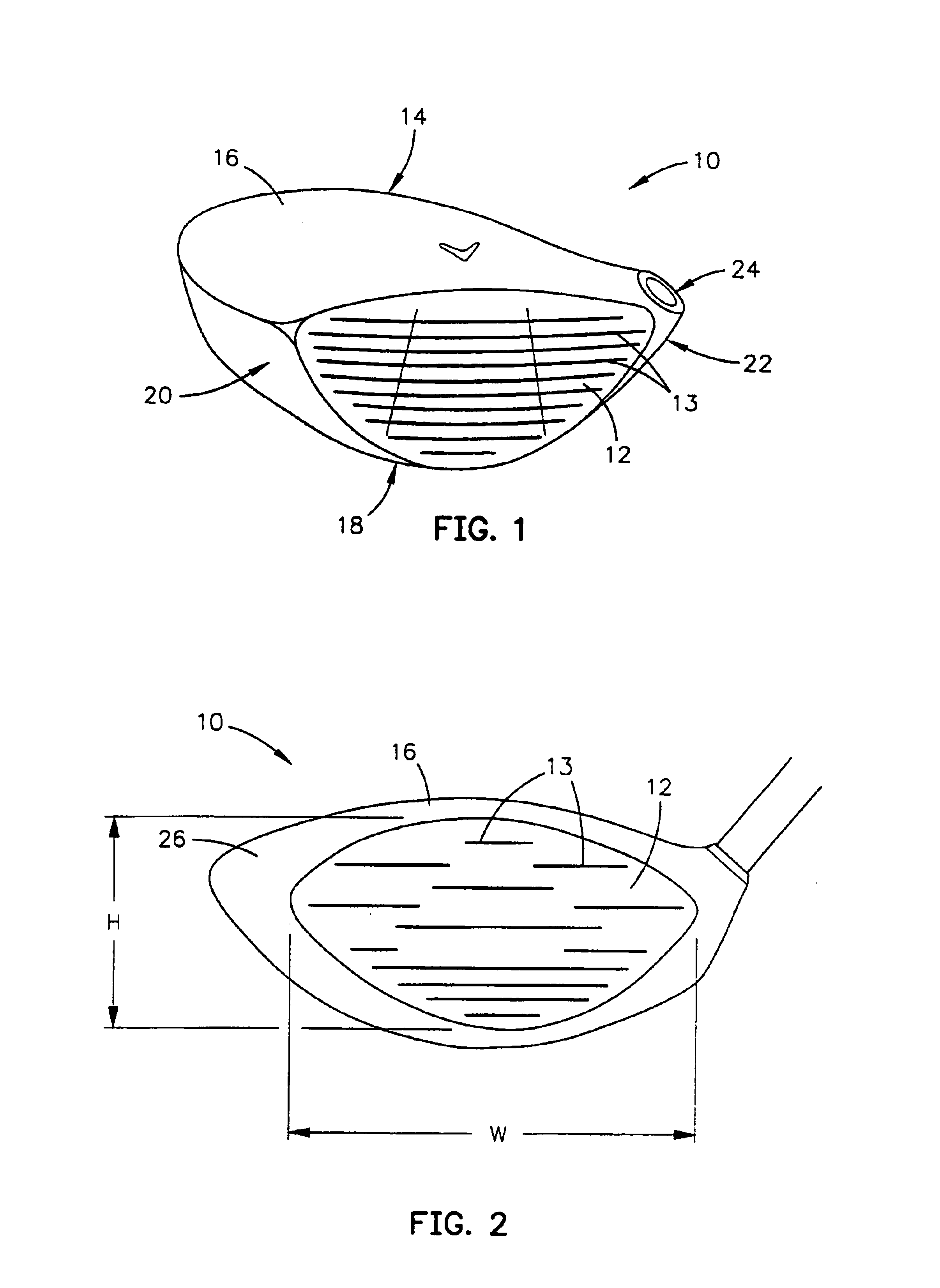

Golf club head having a striking face with improved impact efficiency

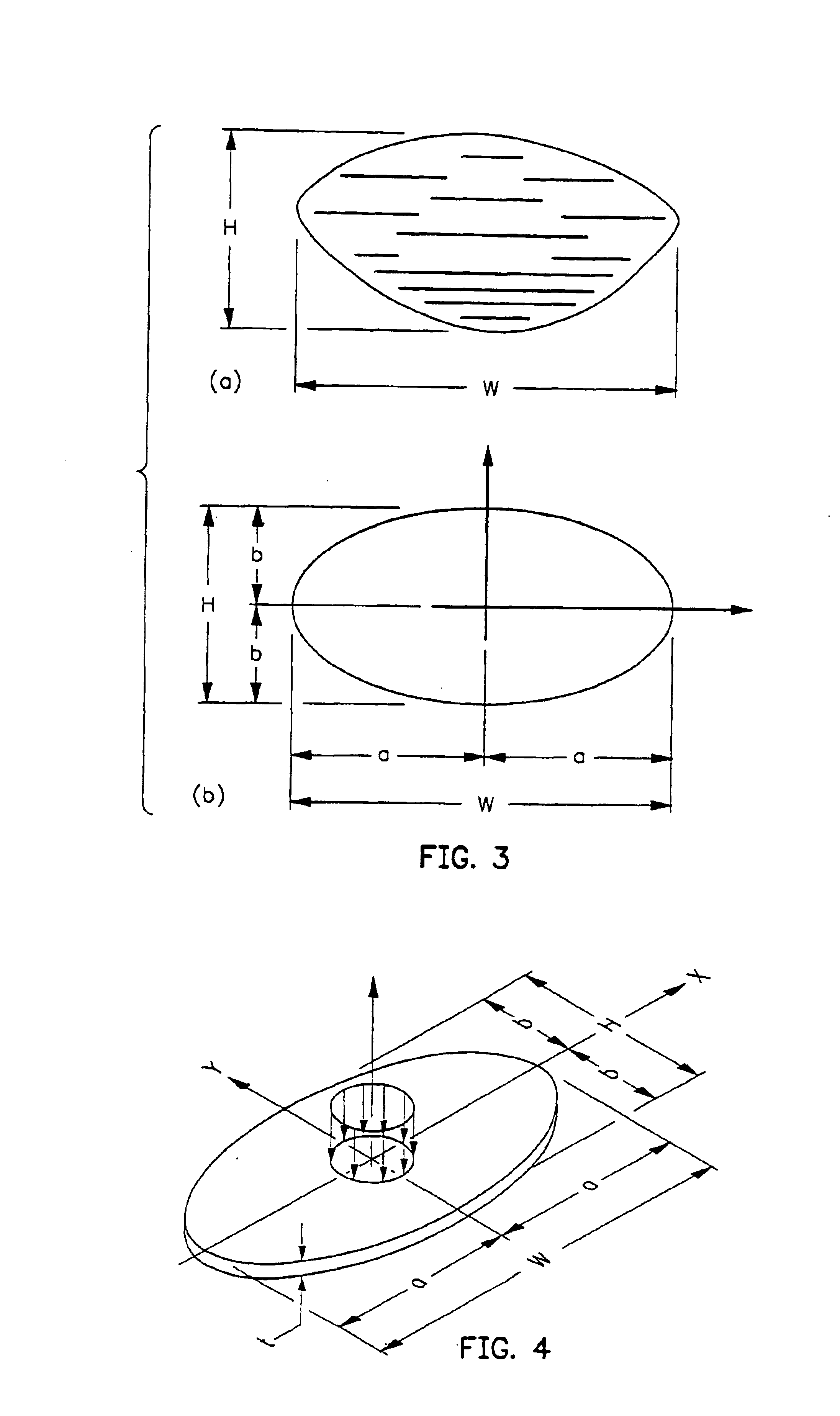

InactiveUS6949032B2Improve energy efficiencyReduced magnitudeGolf clubsRacket sportsStrain rateEnergy loss

A compliant golf club head permits a more efficient impact between a golf ball and the golf club head. Material and geometry constraints of a striking plate of the golf club head can reduce energy losses caused by large strain and strain rate values of the golf ball, these constraints on the striking plate yield a measure of the impact efficiency of the golf club head. Designating a required natural frequency range of the striking plate provides improved impact efficiency between the golf ball the golf club head.

Owner:CALLAWAY GOLF CO

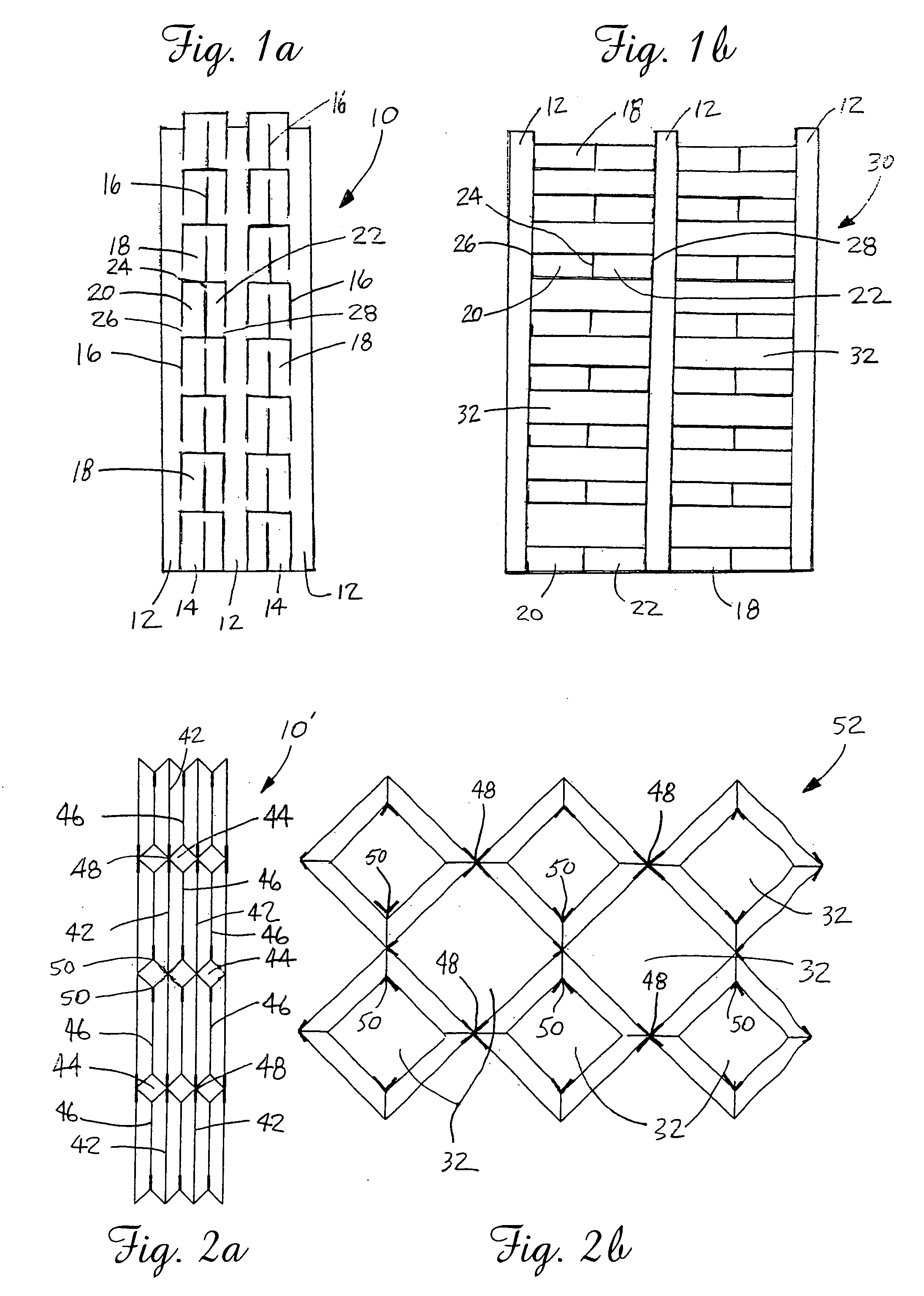

Die cut mesh material from polymer fiber

InactiveUS20060008614A1High material strengthFriability is minimizedPaper/cardboard articlesLayered productsHoneycomb structureEngineering

A honeycomb web precursor includes a body of polymer material having a series of branched slits. The body is capable of expanding into a web of honeycomb construction. Various panels and partitions are also disclosed. A method is also provided for producing a honeycomb web of polymer material. That method includes the making of a series of branched slits in a body of polymer material so as to define multiple expansion ribs and the expanding of the body and erecting of the expansion ribs by folding so as to form the honeycomb web.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Shoulder pads

Owner:RIDDELL

High-strength bionic collagen membrane and preparation method thereof

The present invention provides a preparation method of high-strength bionic collagen membrane. The preparation method is by conducting gradient dialysis process on collagen to rearrange collagen molecules into an ordered structure, and endow the molecules with more consistent and more extensive collagen fiber orientation, thus improving the mechanical properties of the material. The collagen membrane prepared by using the method has similar appearance, structure and performance to natural dura and amnion of mammals, and good rehydration, and is free to bend and fold after water absorption; the bionic collagen membrane with high tensile strength can be stitched by using suture and can be used in clinical guided tissue regeneration or repair of various tissues.

Owner:BEIJING PAISHENG BIOTECH CO LTD

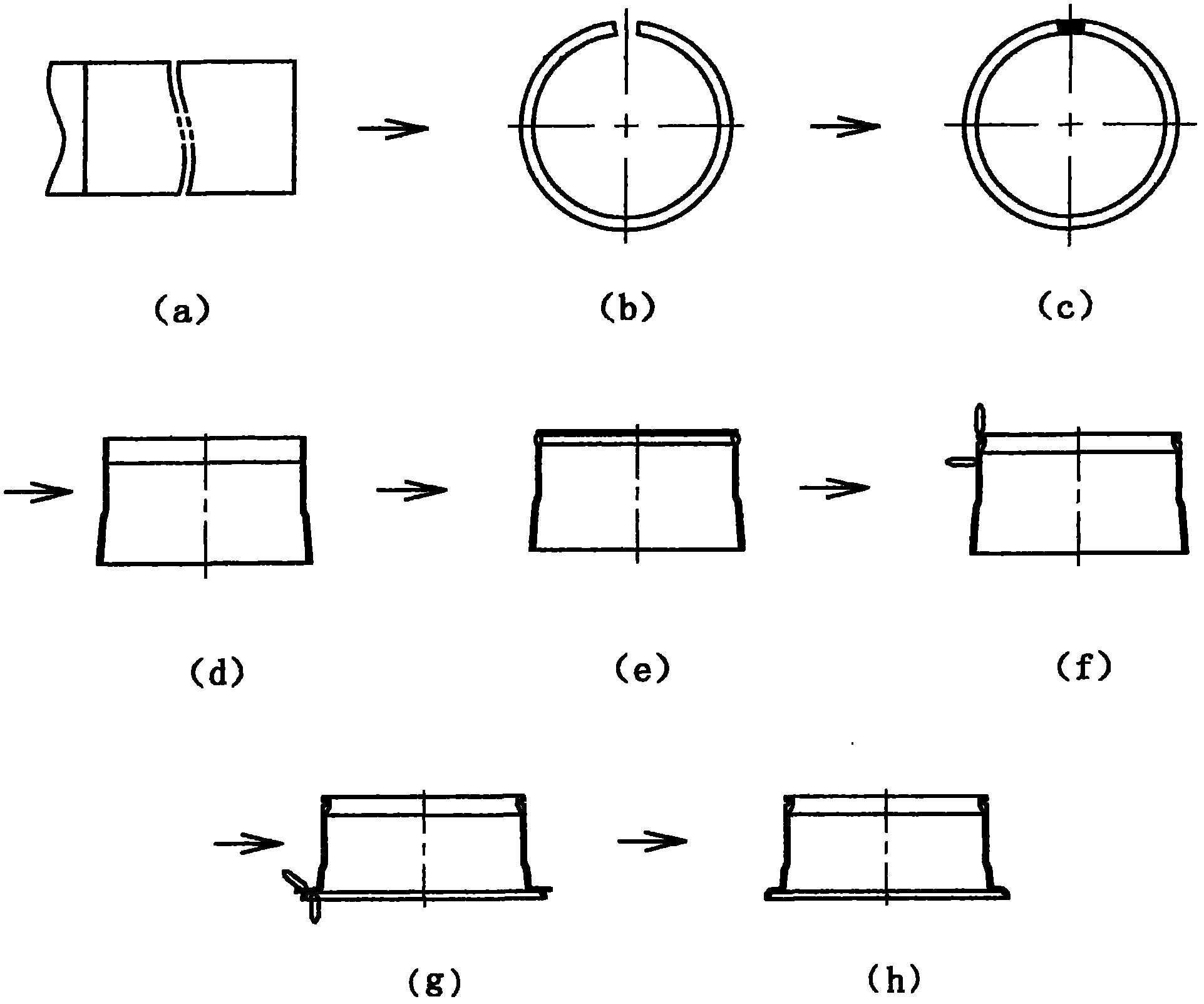

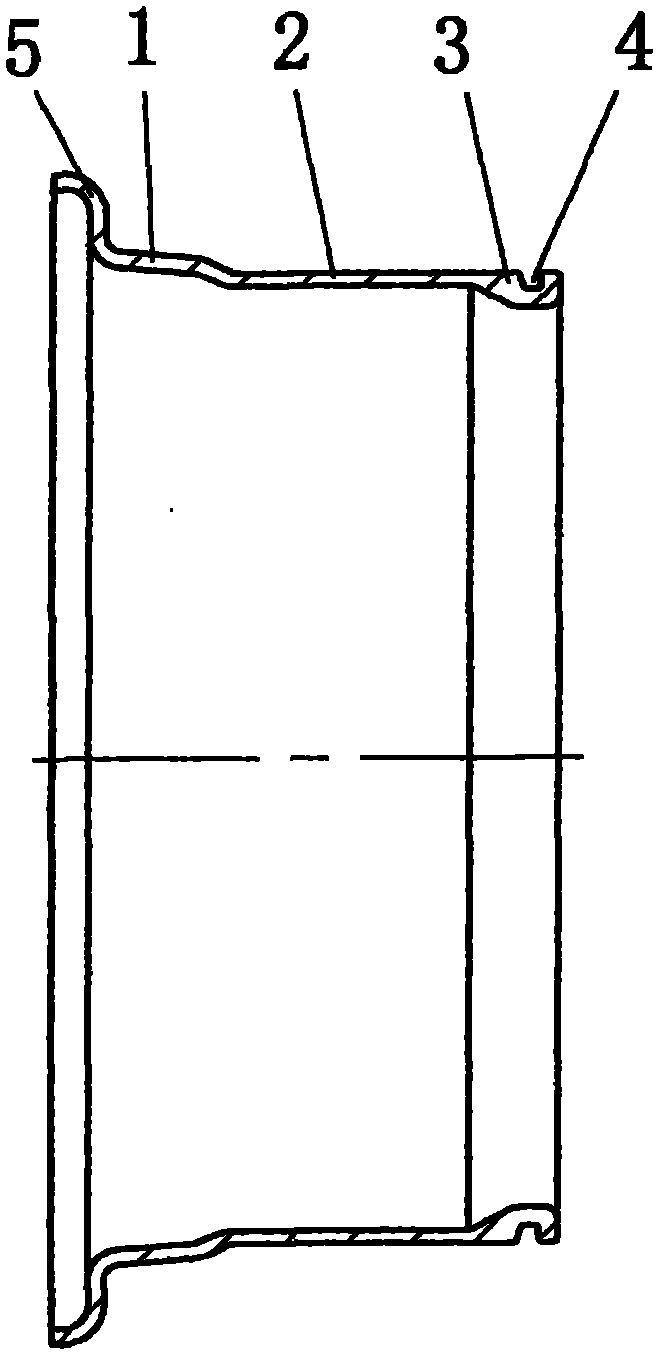

Method for manufacturing wheels of engineering vehicle

The invention provides a method for manufacturing wheels of an engineering vehicle, which comprises the steps of respectively manufacturing rims and spokes and then welding the rims and spokes together, wherein the method for manufacturing the rims comprises the following steps: (a) unloading a flat steel strip; (b) circling; (c) welding; (d) flaring a big-opening end; (e) rotatably hot-upsetting a small-opening end; (f) spinning and shaping a small-opening section, a linear section and a bead seat; (g) spinning and shaping wheel edges; and (h) turning the two opening-ends. The method sets conditions for spinning and shaping the small-opening section by rotatably hot-upsetting the small-opening end before the step (f) of spinning and shaping so that the method can adopt the flat steel strip with less thickness as raw materials, thereby greatly reducing work load of cold spinning in the following process; in addition, in the process of spinning and shaping of the step (f), the method can change the thickness according to the exerted situations of various parts of the rims to process the rims into the rims with identical intensity; and the method can improve material intensity and processing precision of the wheels by cold spinning.

Owner:JIAXING STONE WHEEL

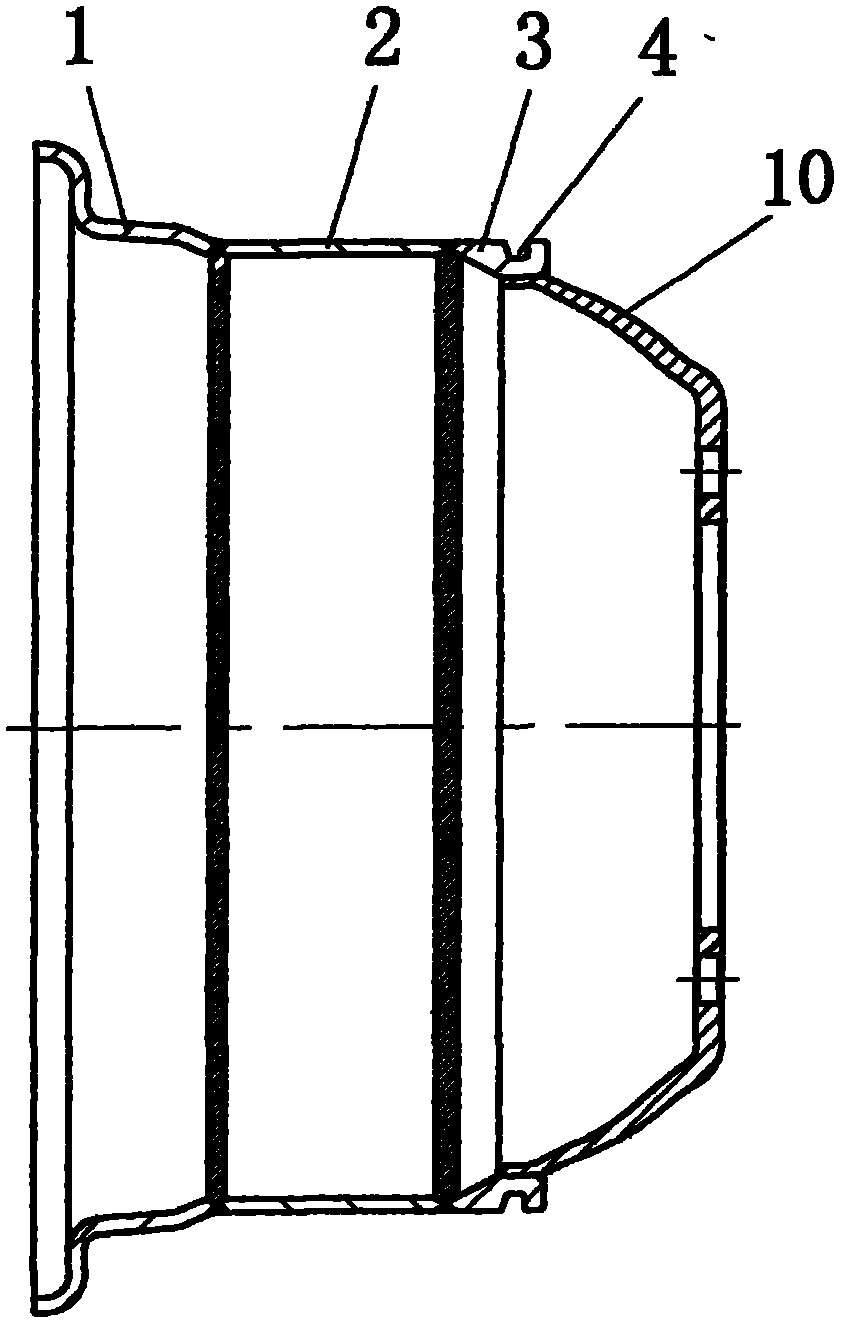

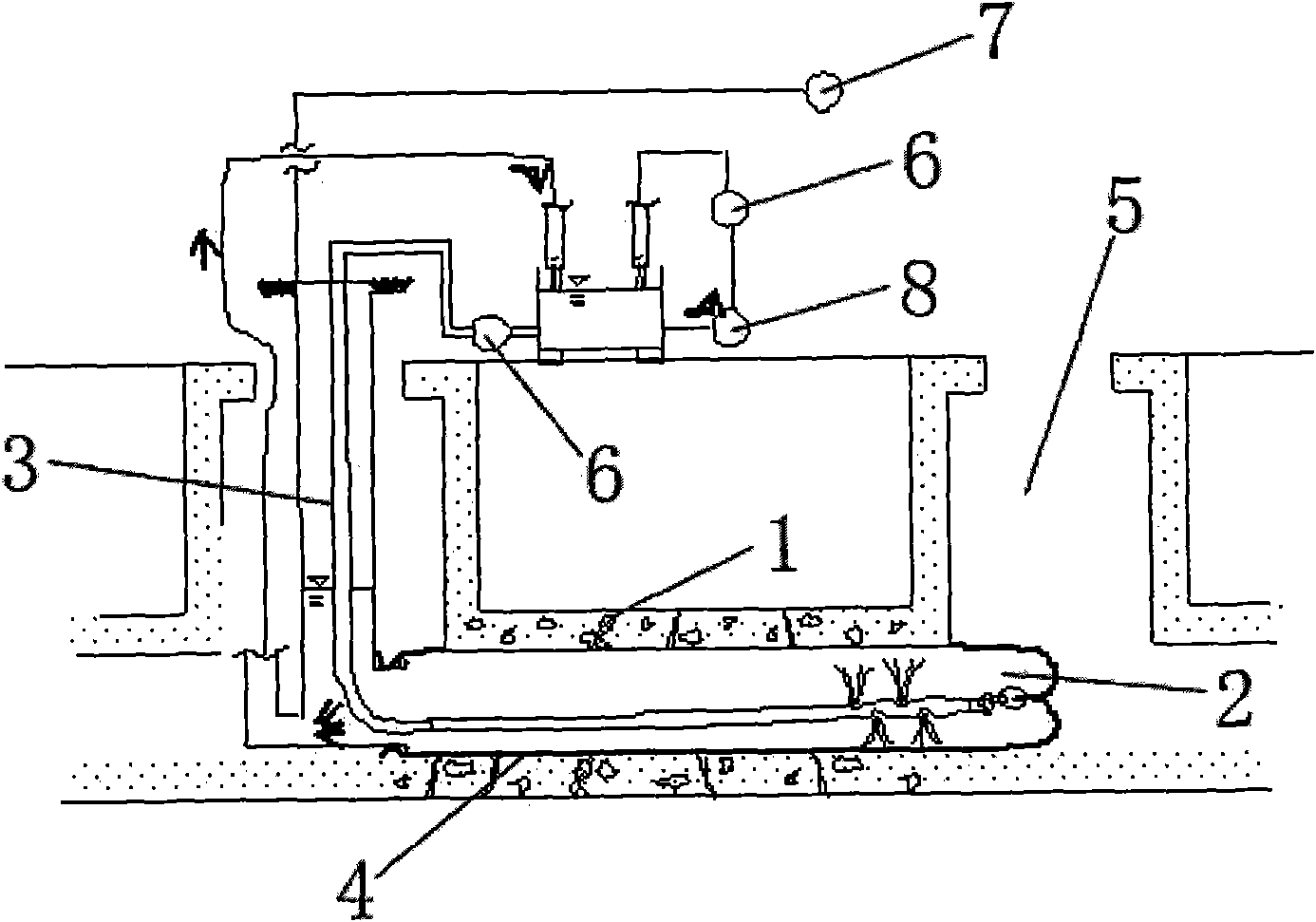

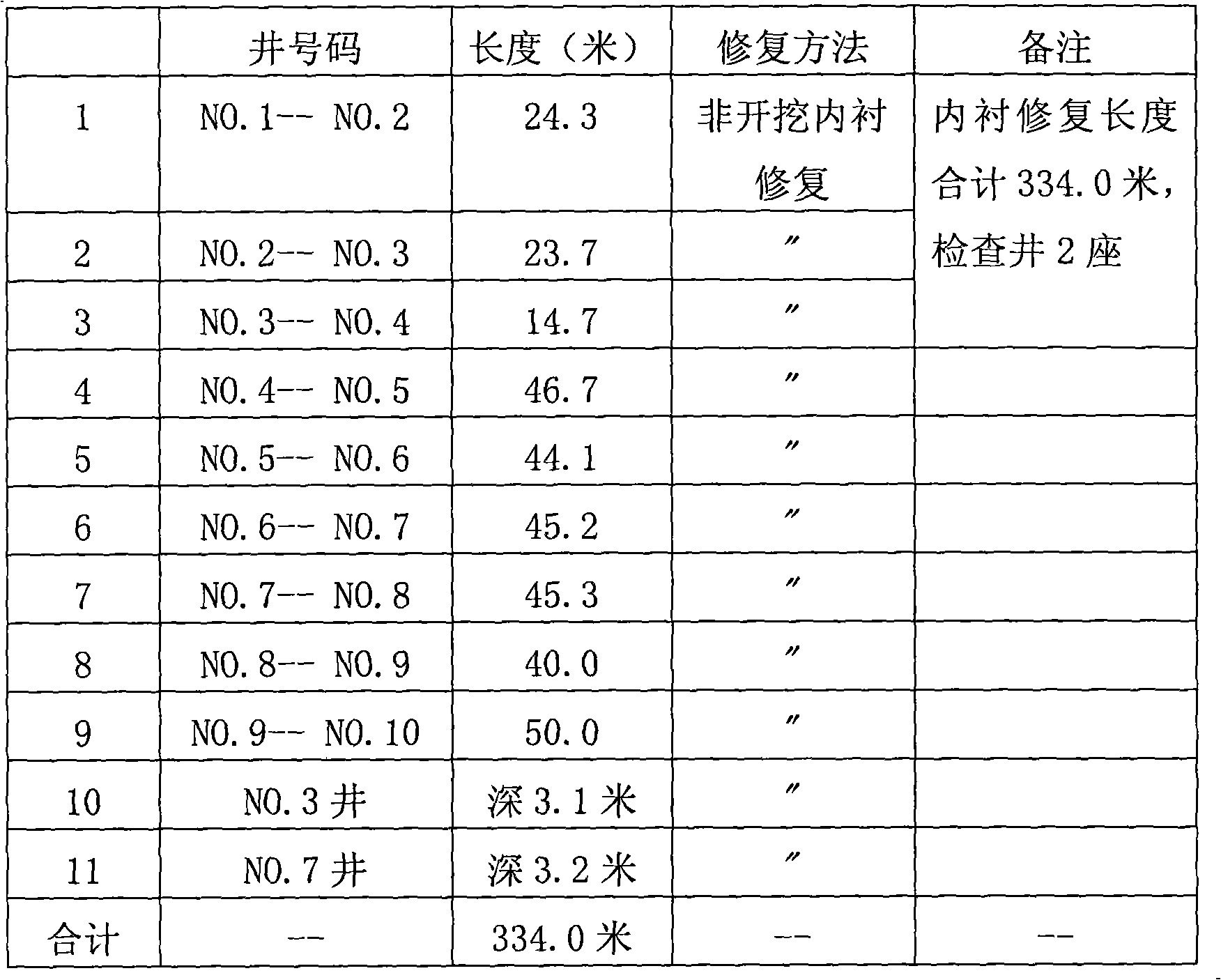

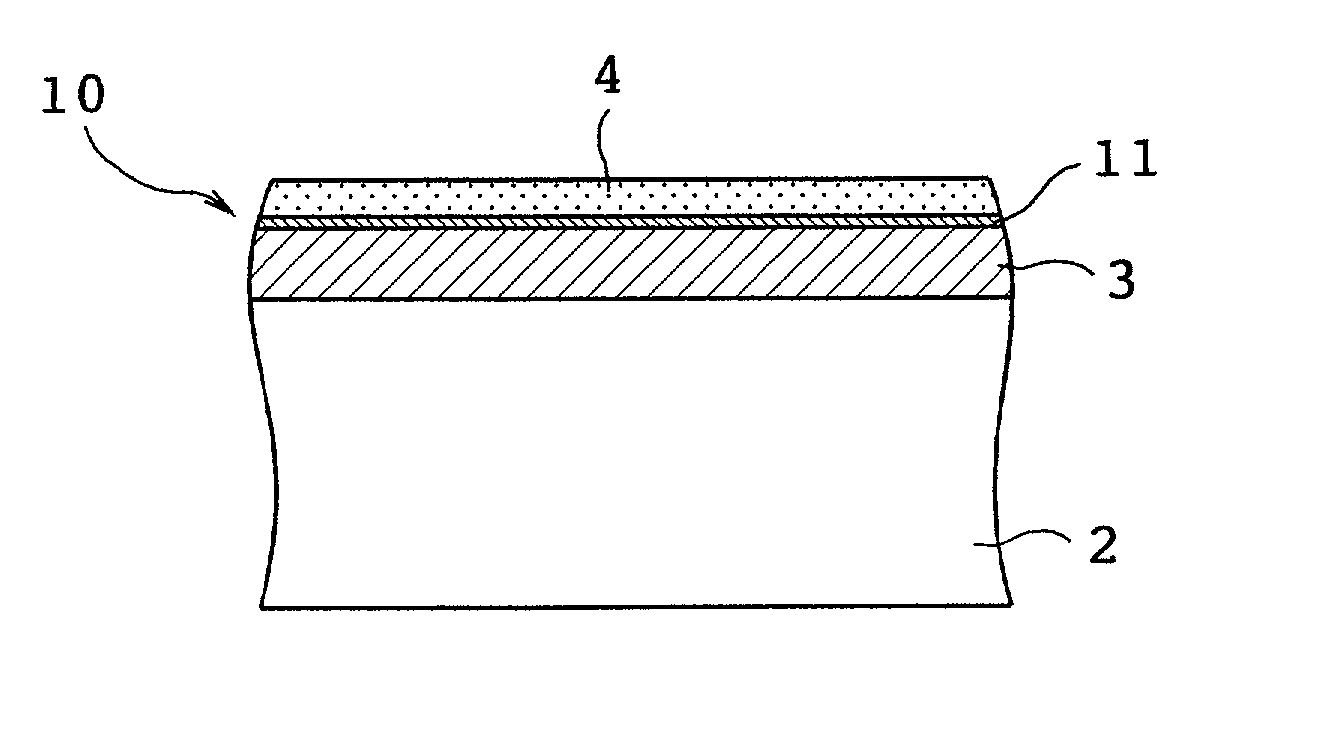

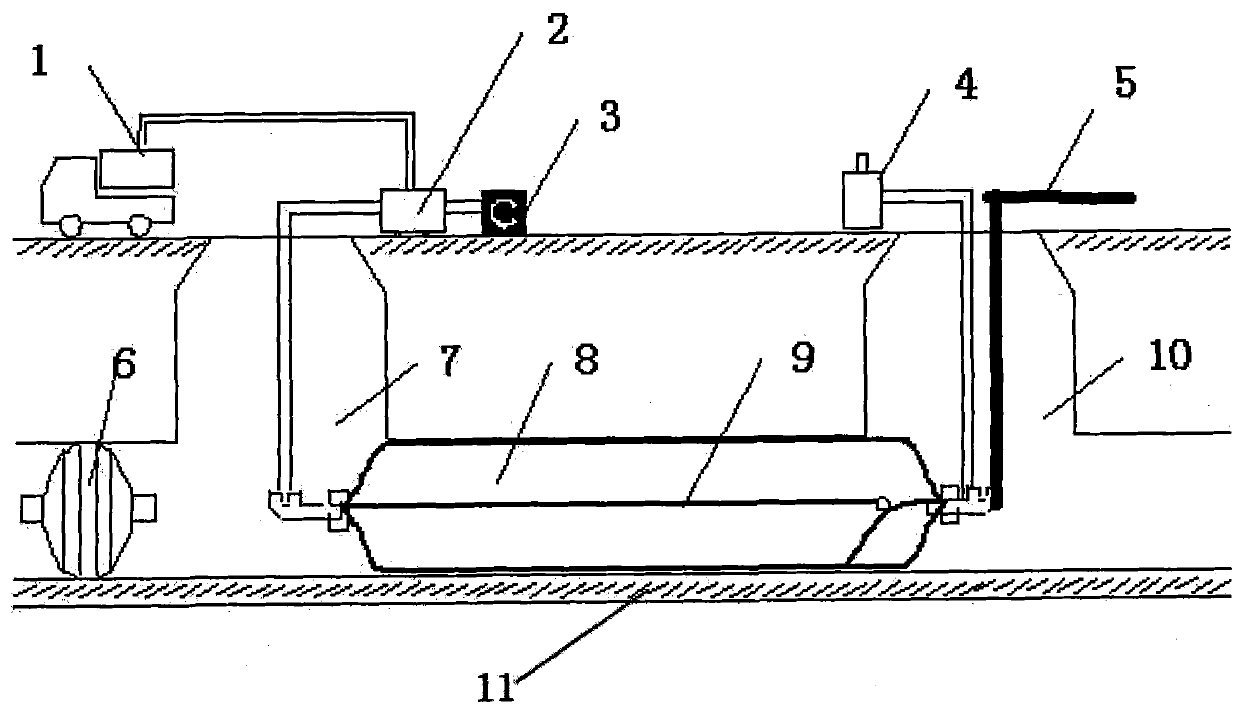

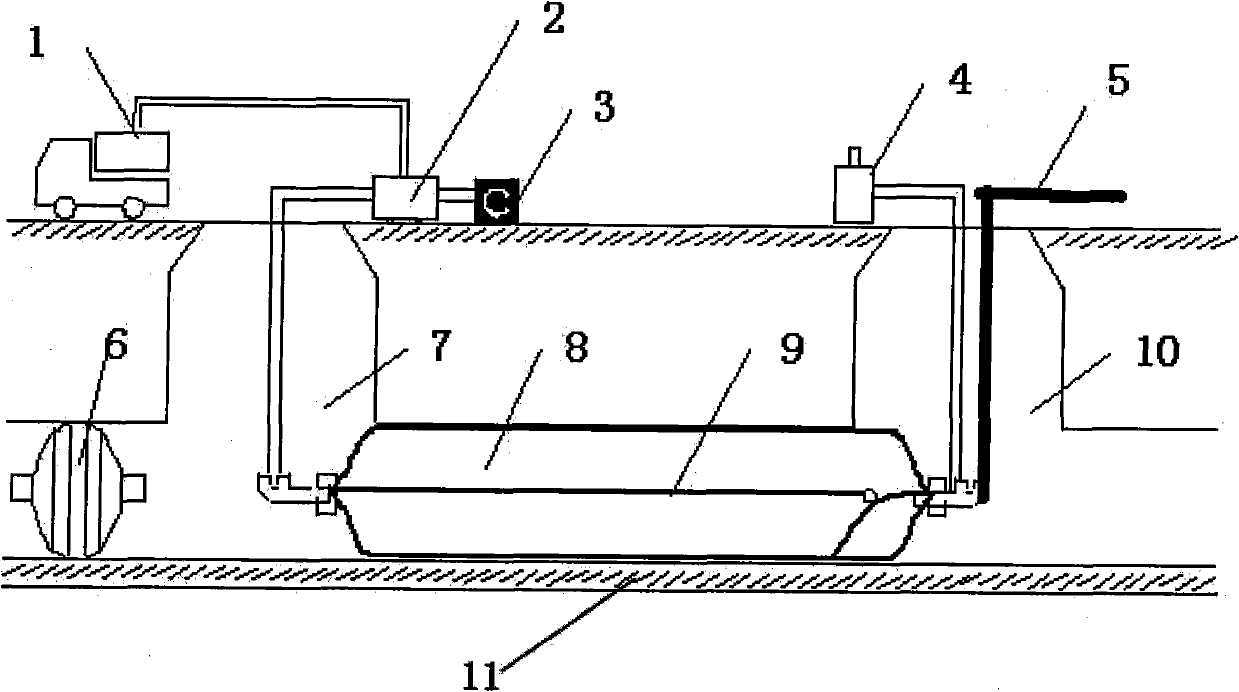

Method for repairing underground pipeline without digging

InactiveCN101649944AShort construction timeSolving Temporary Drainage ProblemsPipe elementsWarm waterSewage

The invention relates to a method for repairing an underground pipeline without digging, which comprises the following steps: (1) blocking and cleaning an old sewage pipeline needing repair and usingclosed circuit TV system (CCTV) equipment to detect the inner part of the pipeline; (2) delivering a waterproof barrel-shaped auxiliary lining hose pipe into the pipeline and injecting thermosetting resin to form a resin hose pipe; (3) turning over and inserting the resin hose pipe and a warm water delivery pipe for heating into the waterproof barrel-shaped auxiliary lining hose pipe; (4) expanding the resin hose pipe with water and compressed air so that the resin hose pipe is tightly attached to the inner wall of an old pipe, circularly heating by warm water and hardening and molding the thermosetting resin hose pipe so that the inner wall of the old pipe forms a new lining pipe with high strength; (5) opening pipe openings at both ends of the new lining pipe by cutting to smooth the pipeline; and (6) cutting at the extending positions of the pipe openings of the new lining pipe, which are positioned in the well wall of a check well. The method can prevent leakage, protect the pipe openings, prevent the thermosetting resin injected into the lining hose pipe from being mixed with underground water and prevent a poor phenomenon of lining material part hardening.

Owner:管丽环境技术(上海)有限公司 +1

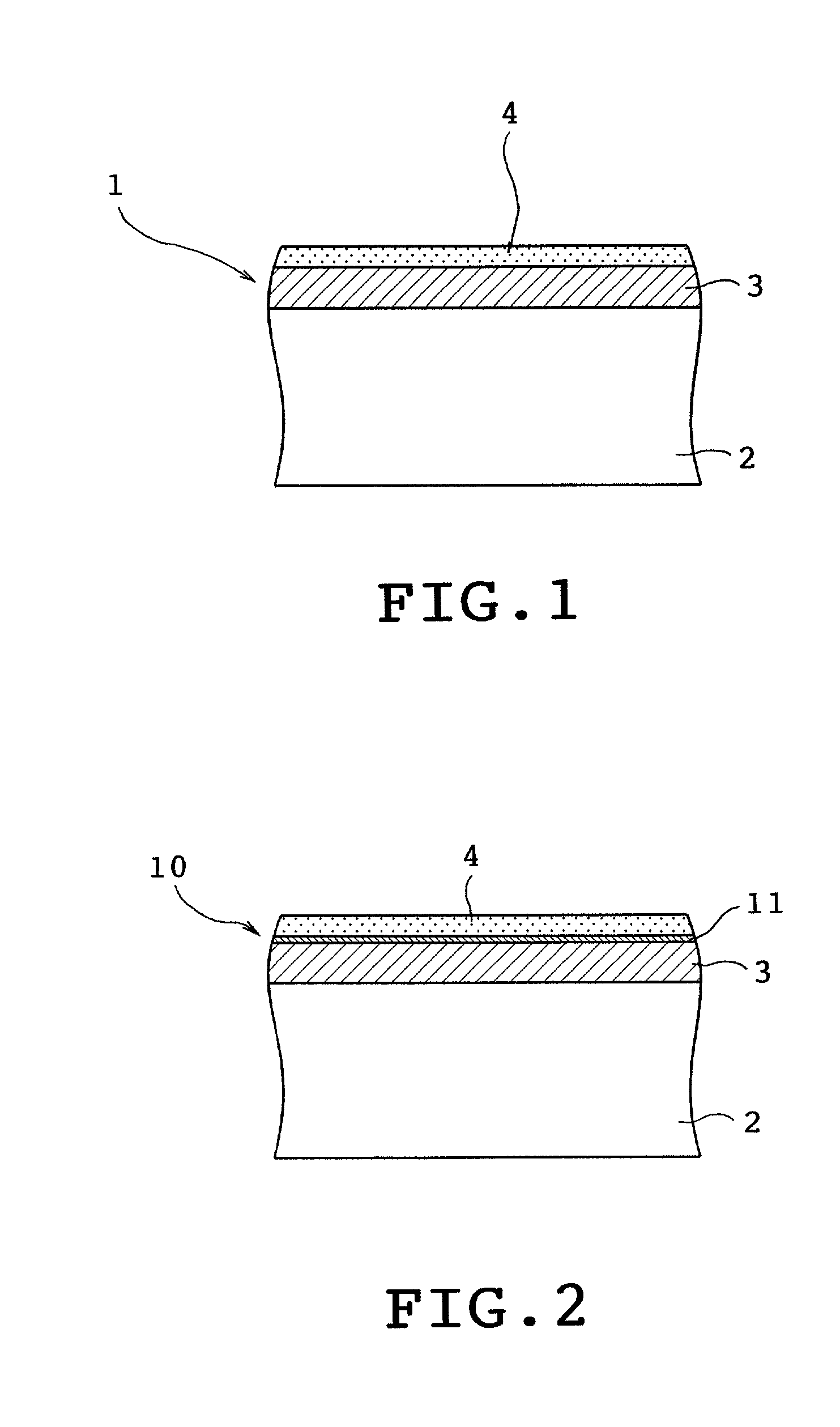

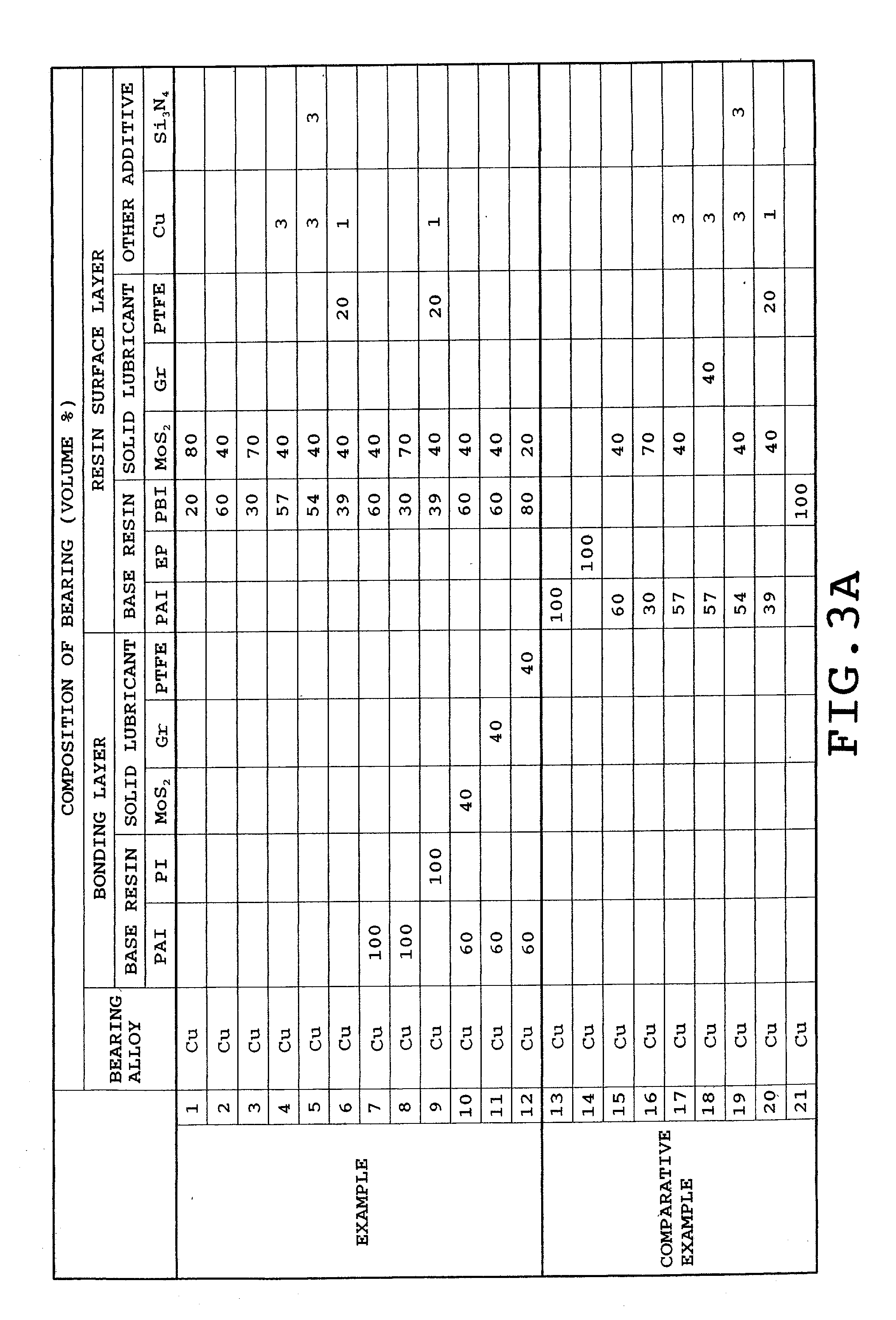

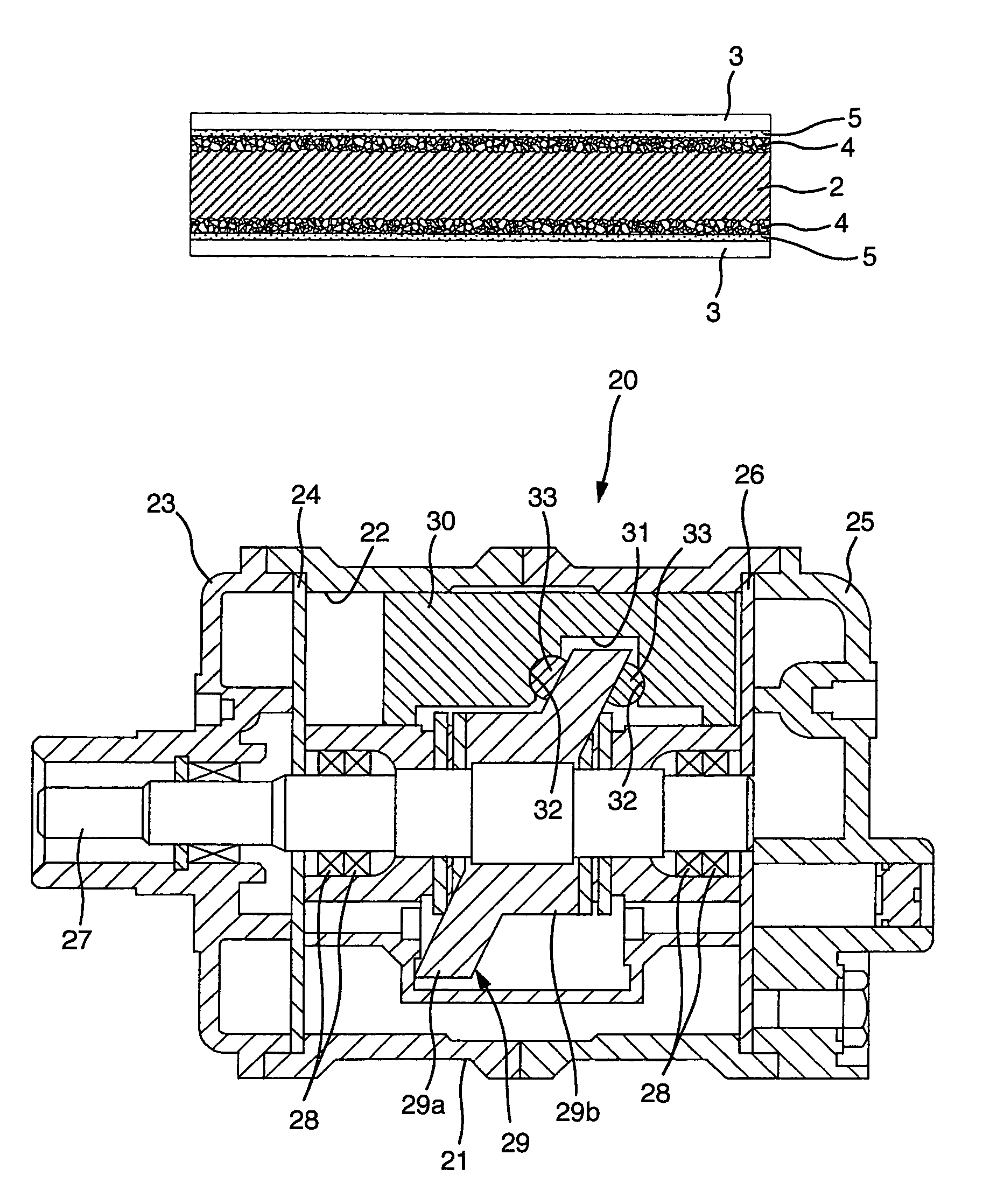

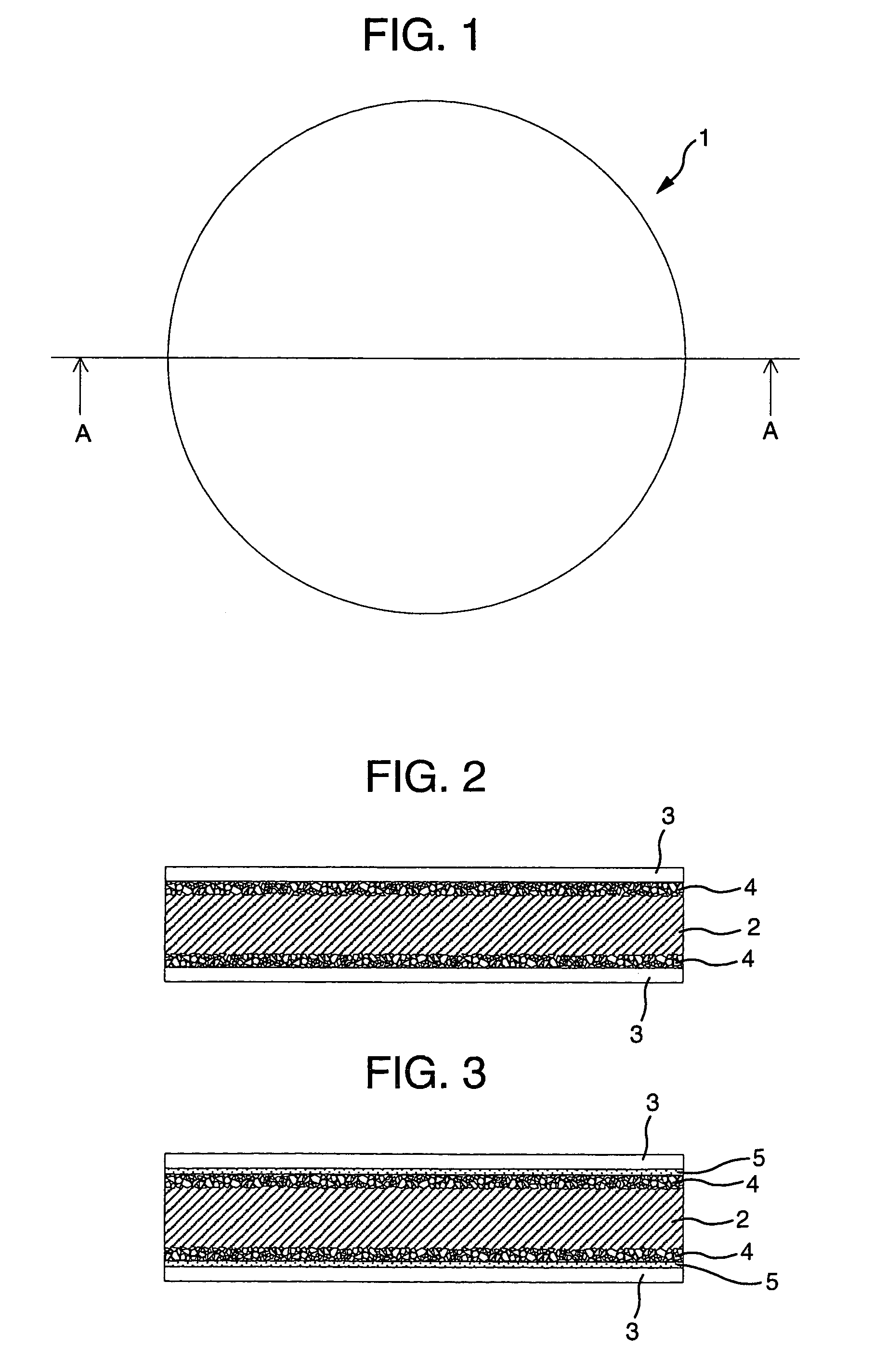

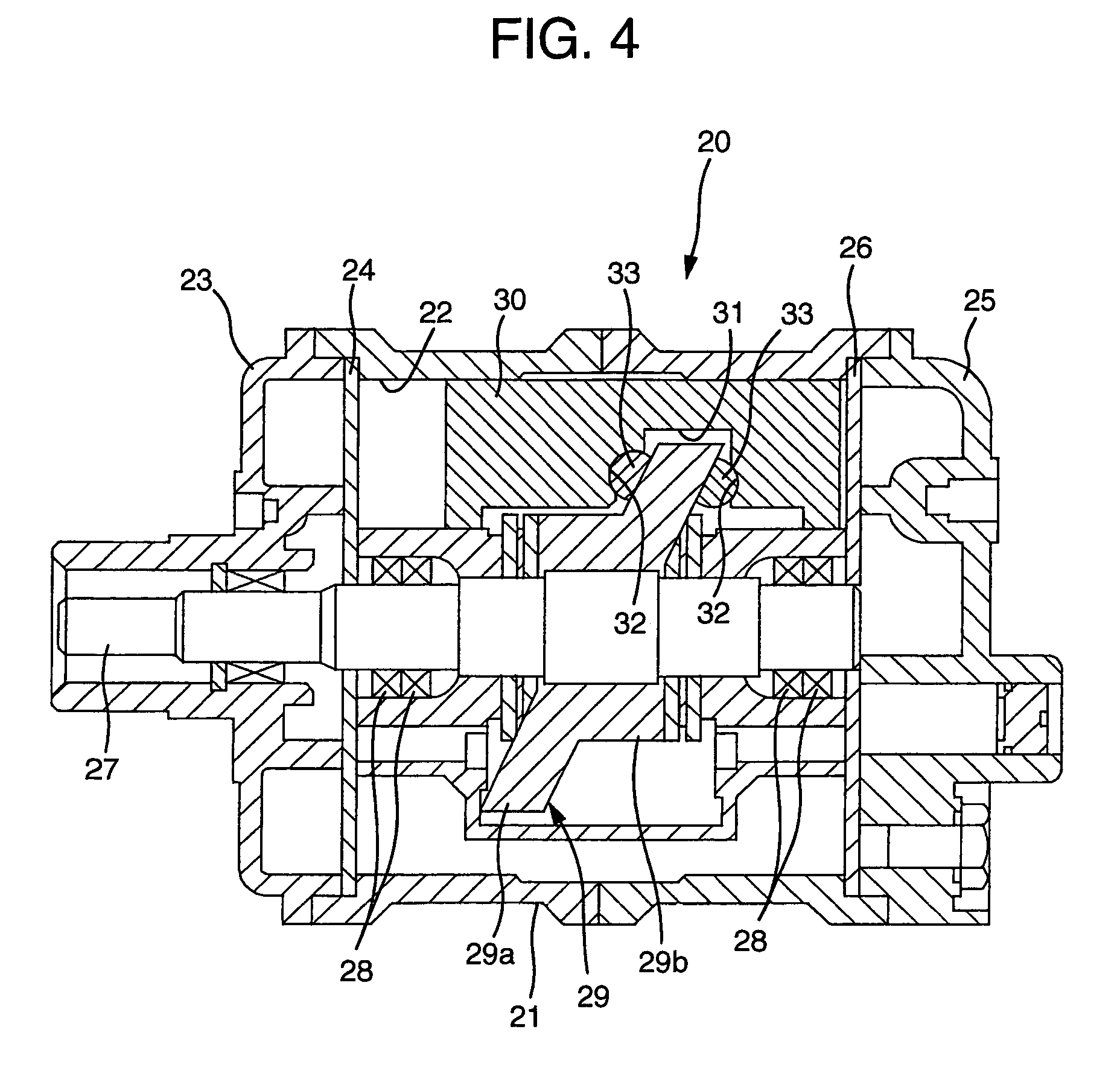

Sliding bearing and method of manufacturing the same

InactiveUS20020155304A1Increase resistanceHigh strengthRolling contact bearingsShaftsSurface layerAlloy

A sliding bearing includes a bearing alloy layer having a sliding surface and a resin surface layer formed on the sliding surface of the bearing alloy layer and containing polybenzimidazole and a solid lubricant. In manufacturing the sliding bearing, a resin surface layer composition is applied to a roughened surface of a bearing alloy layer. The resin surface layer composition contains polybenzimidazole and a solid lubricant. The resin surface layer composition is heated so as to be hardened to be formed into a resin surface layer.

Owner:DAIDO METAL CO LTD

Trenchless repairing method of underground pipeline with drawing-type liner pipe

InactiveCN101907213AShort construction timeSolving Temporary Drainage ProblemsPipe elementsWarm waterSewage

The invention relates to a trenchless repairing method of an underground pipeline with a drawing-type liner pipe. The method comprises the following steps of: (1) blocking and cleaning a worn sewage pipeline and detecting the interior of the pipeline; (2) drawing a watertight cylindrical auxiliary liner hose in the worn pipeline, preliminarily impregnating thermosetting resin in a non-woven hose to form a resin hose and well turning the resin hose; (3) drawing the well-turned resin hose and a warm water conveying pipe for heating in the watertight cylindrical auxiliary liner hose which is already arranged in the worn pipeline; and (4) expanding the resin hose by adopting compression air to tightly attach to the worn pipe, directly adding hot water to the resin hose to harden and form the thermosetting resin hose in the worn pipe and forming a new high-strength liner pipe on the inner wall of the worn pipe. The invention solves limitation caused by a construction site when repairing an underground pipeline through liner by using a turning method, solves the problem of uneven resin curing strength, simplifies the process flows of on-site construction and has the advantages of easy and simple operation, time saving and damage resistance.

Owner:管丽环境技术(上海)有限公司 +1

Lead-free and preferably arsenic-free lanthanum heavy flint glass

ActiveUS7091145B2Good chemical resistanceSufficient crystallization resistanceOptical elementsAlkali metal oxideRefractive index

The lead-free and arsenic-free optical glass has a refractive index nd of 1.84≦nd≦1.96 and an Abbé number νd of 27≦νd≦36, with good chemical resistance, excellent crystallization resistance and the following composition (in % by weight based on oxide): SiO2, 1 to 8, B2O3, 13 to 19.5, La2O3, 34 to 50; MgO, 0 to 6, CaO, 0 to 6, BaO, 0 to 6, ZnO, 0 to 9 with ΣMO, 1 to 10; and TiO2, 4 to 15, ZrO2, 0 to 11, Nb2O5, 6 to 14.5. In addition, the glass according to the invention, as well as having a maximum alkali metal oxide content of 10% by weight, may also contain standard refining agents other than arsenic. The glass according to the invention is used in imaging, projection, telecommunications, optical communication and / or laser technology.

Owner:SCHOTT AG

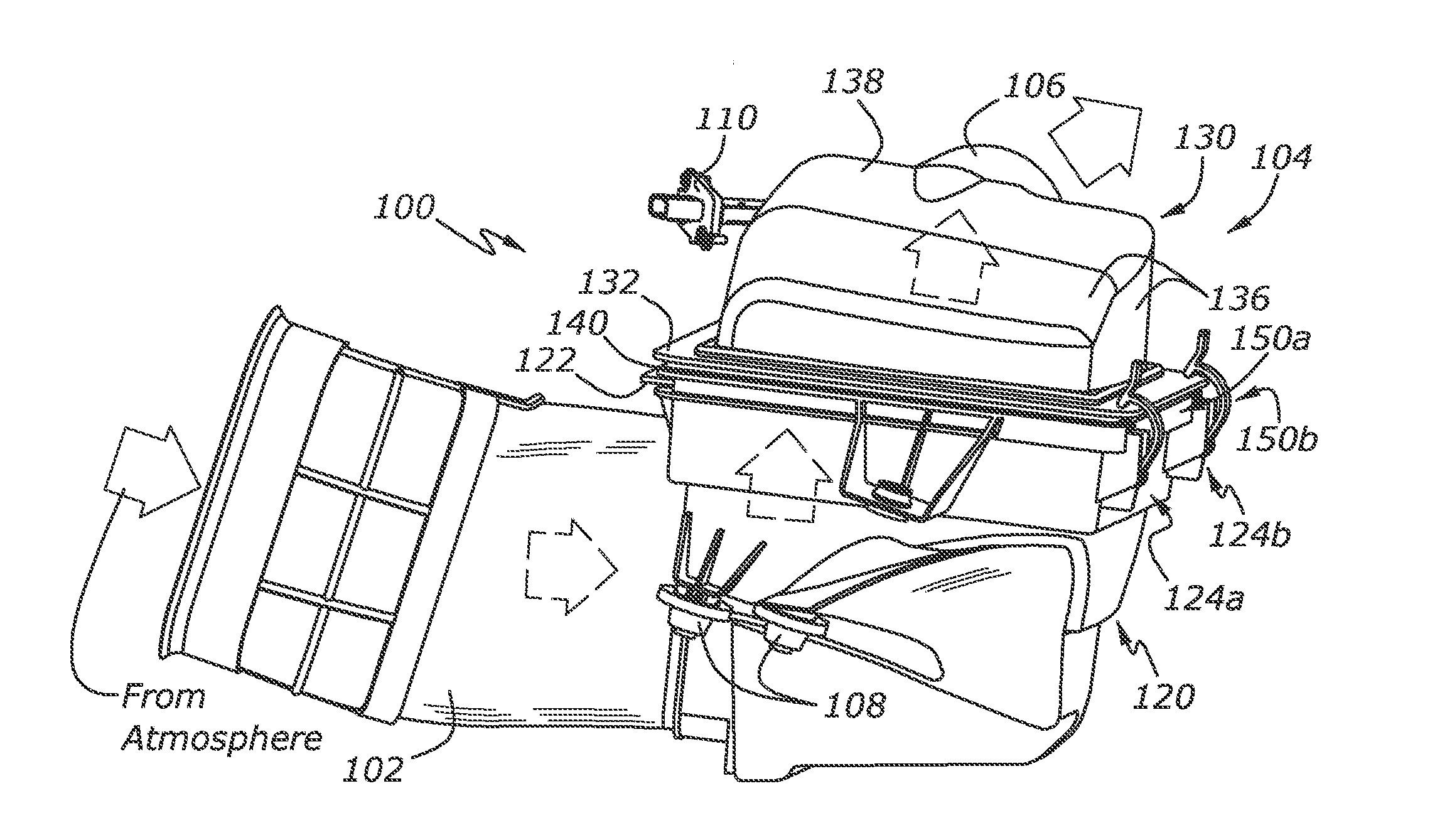

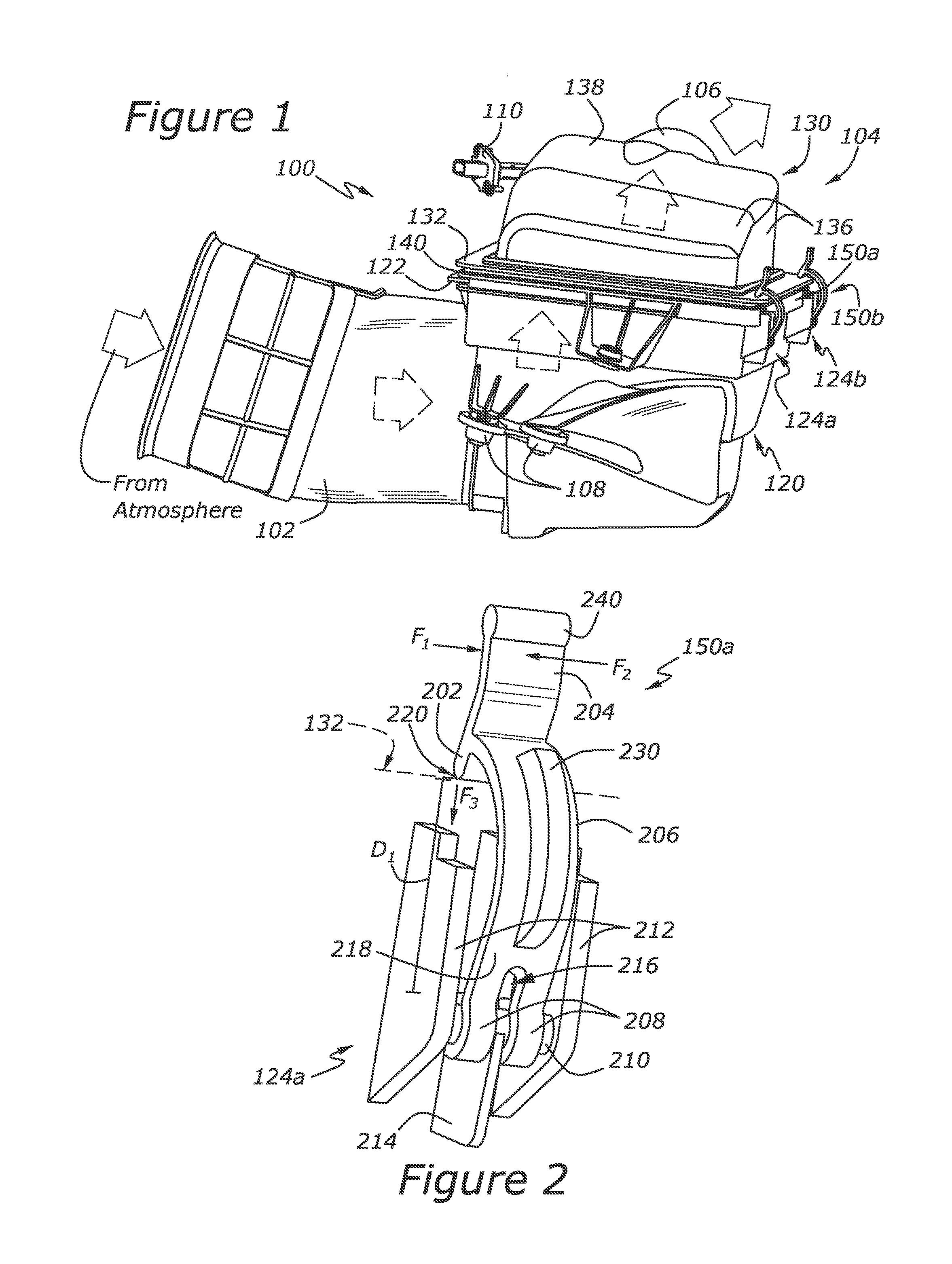

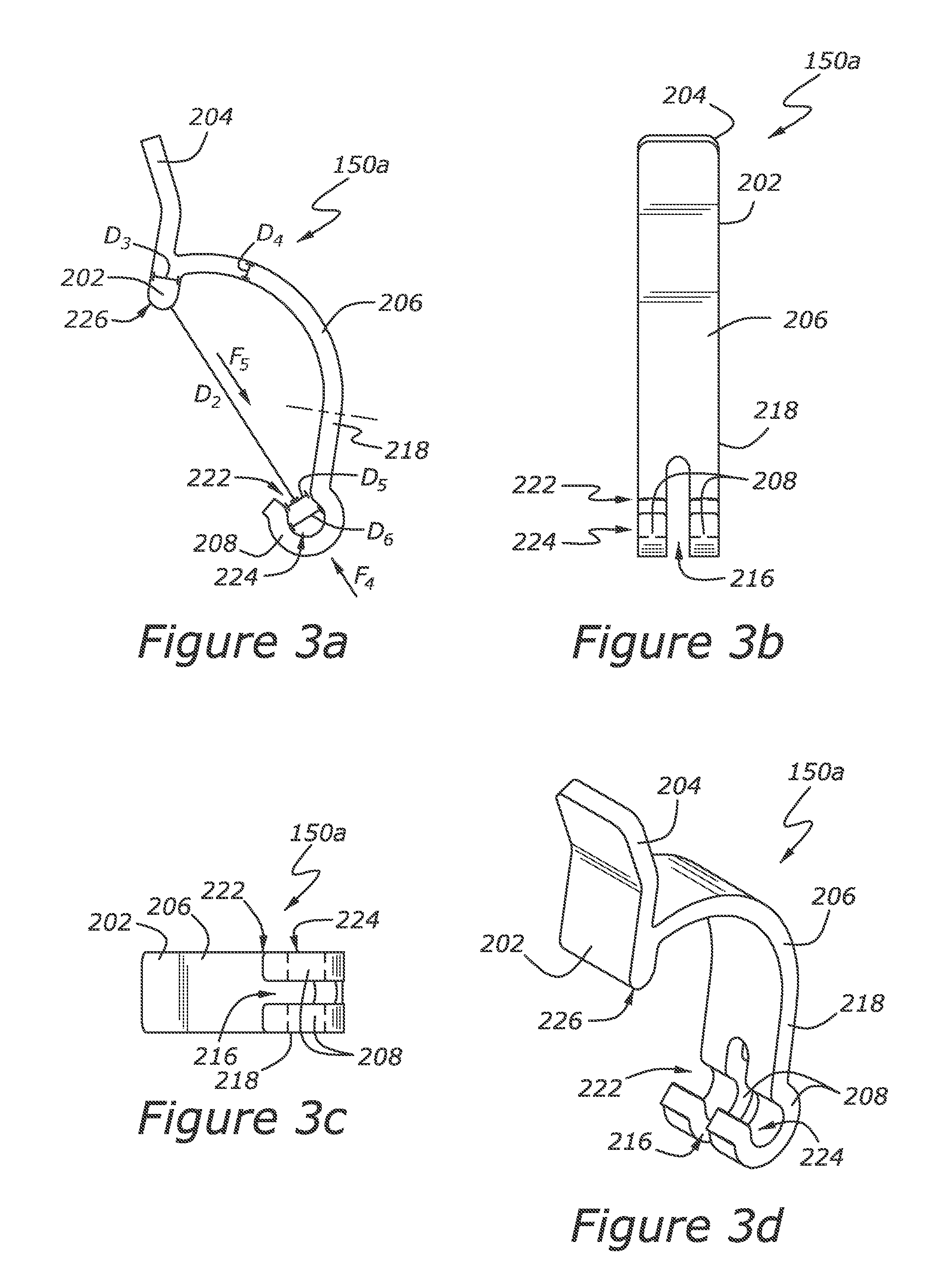

Spring clamp for an air filter housing

ActiveUS20120047856A1Limit compressive loadAvoid compressionCombination devicesDispersed particle filtrationAir filtrationAir filter

A spring clamp for providing a compressive load to a compression seal in an air filtration system for a vehicle. The spring clamp may be comprised of plastic composite and includes an arch-like arm wherein elastic deformation is distributed throughout the arch while providing a compressive load. The spring clamp may include a head piece with a greater thickness than the other parts of the spring clamp to provide greater material strength at a point of contact between the spring clamp and an air filter housing.

Owner:FORD GLOBAL TECH LLC

Carbon-based ternary composite electrode material for super capacitor and preparation method for carbon-based ternary composite electrode material

ActiveCN102585496AGood growth aggregationImprove conversion rateElectrolytic capacitorsCapacitanceIn situ polymerization

The invention discloses a carbon-based ternary composite electrode material for a super capacitor and a preparation method for the carbon-based ternary composite electrode material. The preparation method for the carbon-based ternary composite electrode material comprises the following steps of: firstly, performing ultrasonic dispersion on reactivated active carbon and a nanometer metallic oxide to prepare an active carbon / nanometer metallic oxide composite material; controlling the molar ratio of the active carbon / nanometer metallic oxide composite material to aniline monomer to be (3:1)-(10:1) through an in-situ polymerization method, and performing stirring reaction for 5-25h to obtain the carbon-based ternary composite electrode material for the super capacitor. According to the material, electric double-layer capacitance is provided for the super capacitor by effectively utilizing high-specific surface area active carbon. By combining with Faraday pseudocapacitance provided by conductive polyaniline, and meanwhile, by utilizing the high mechanical strength and a nanometer synergistic effect of the nanometer metallic oxide, the initial specific capacitance of the material in an organic electrolyte can reach 178F / g, and if the material is circulated for 2000 times, the specific capacitance can still be kept to be 148F / g.

Owner:河北中芯凤华科技发展有限公司

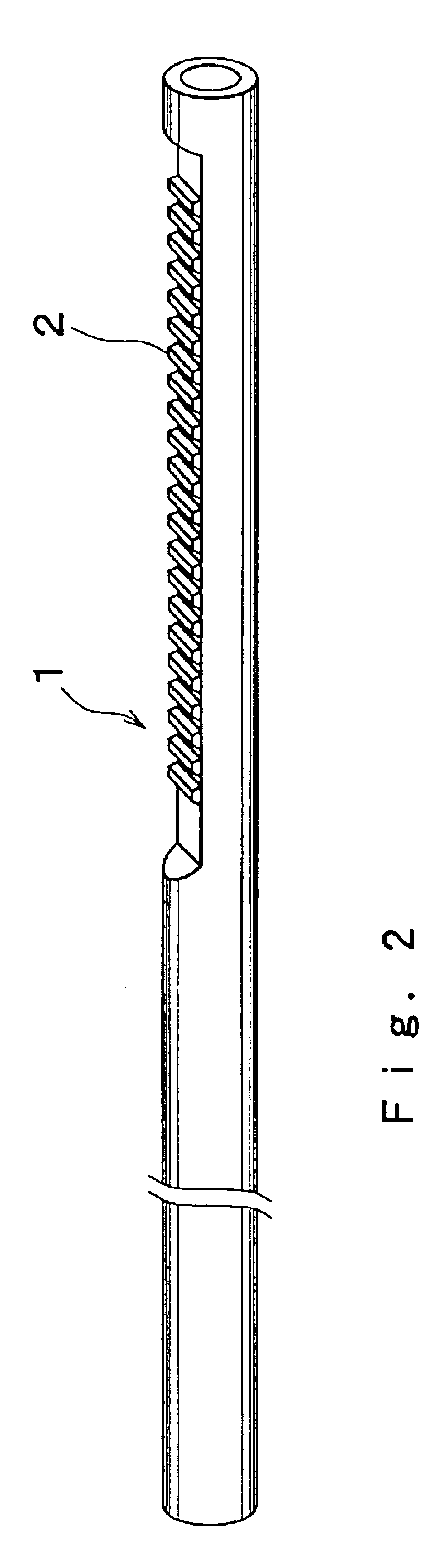

Hollow steering rack bar and its manufacturing method

ActiveUS6925899B2High costHigh material strengthPortable liftingToothed gearingsSteel tubeEngineering

Described is a steering rack bar which is low in costs, which is hollowed in overall length, and for use in steering equipment for automobiles. A rack is formed on a first steel tube by plastic working, wherein the first steel tube has good plastic workability by low carbon content, and has high strength after hardening. The above first steel tube and a second steel tube are joined to complete a hollow steering rack bar, wherein the second steel tube has a higher carbon content and is lower in cost than the first steel tube. Moreover, the second steel tube which has a margin of the strength can be thinner than the first steel tube for reduction of weight.

Owner:NETUREN CO LTD

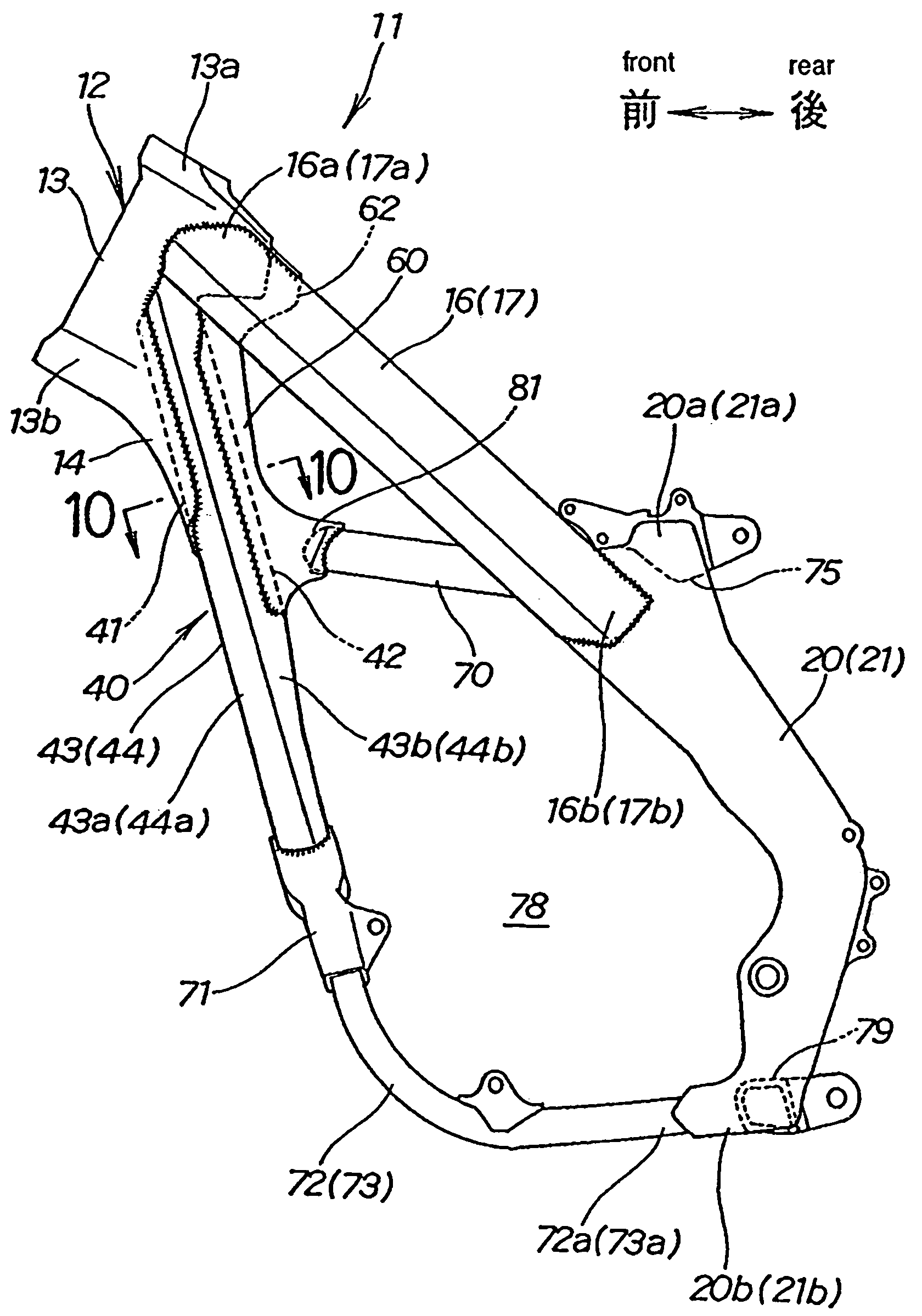

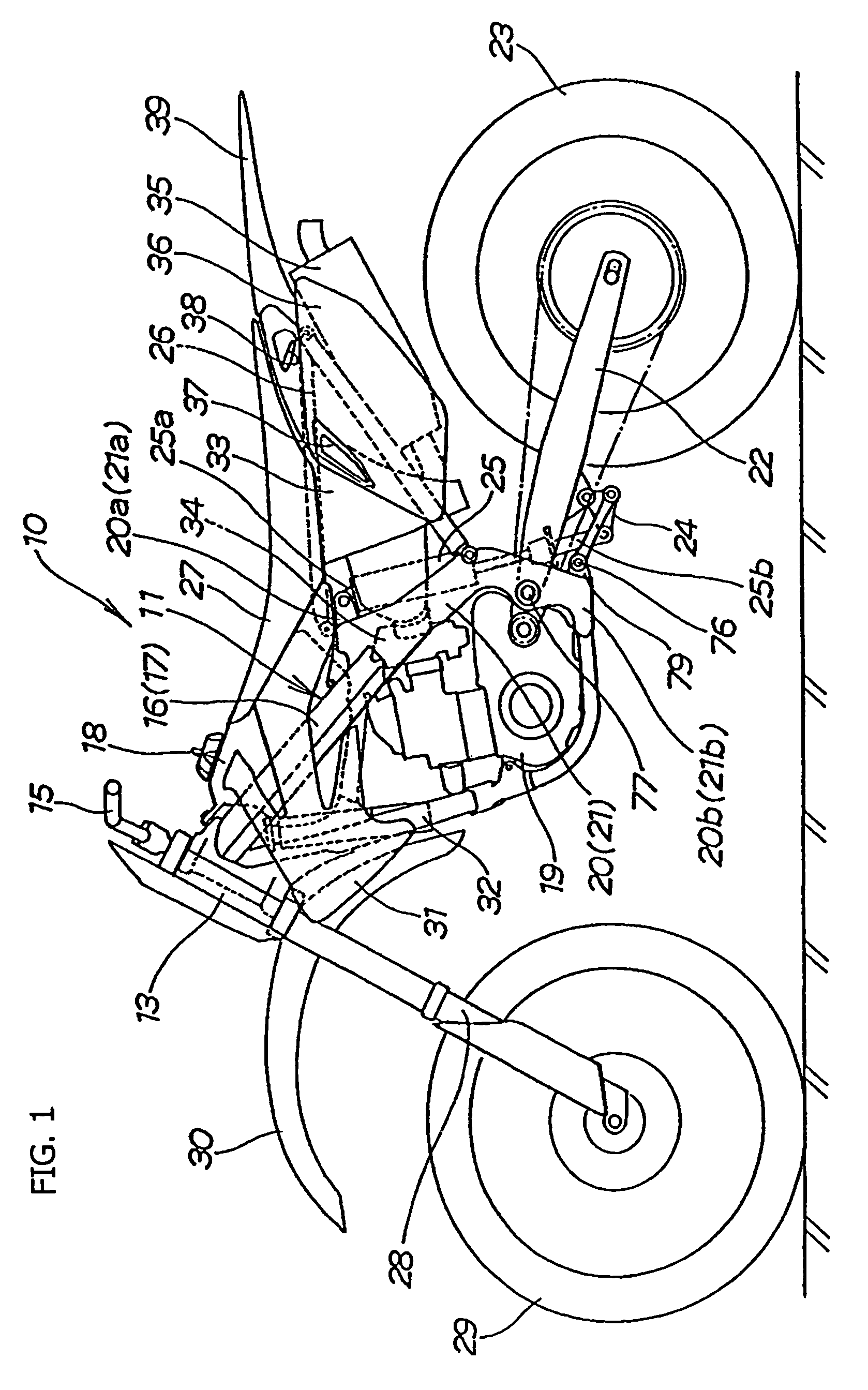

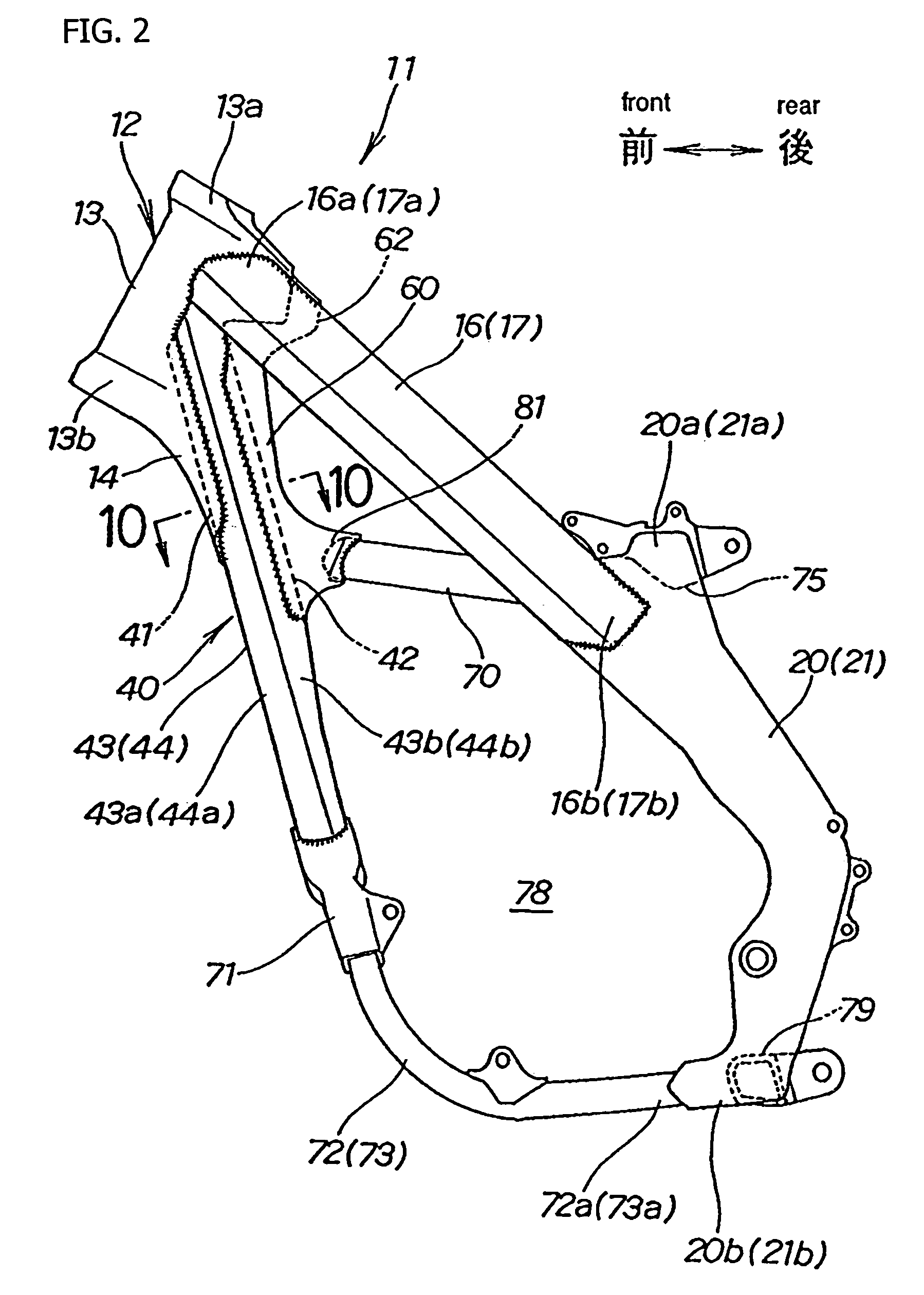

Motorcycle frame structure

ActiveUS7360619B2Improve rigidityIncreased durabilityPassenger cyclesChildren cyclesGusset plateVehicle frame

A frame structure of a motorcycle includes a head pipe gusset forged integrally with a head pipe, and a front fitting recess to which a front wall and front-half parts of right and left side walls of a down pipe are fit is provided with the head pipe gusset. The structure also includes a forged stiffener pipe gusset, and a rear fitting recess to which a rear wall and rear-half parts of right and left side walls of the down pipe can be fit is provided with the stiffener pipe gusset. The right and left front-half parts of the down pipe are inclined in accordance with a draft angle of the front fitting recess, and the right and left rear-half parts are inclined in accordance with a draft angle of the rear fitting recess.

Owner:HONDA MOTOR CO LTD

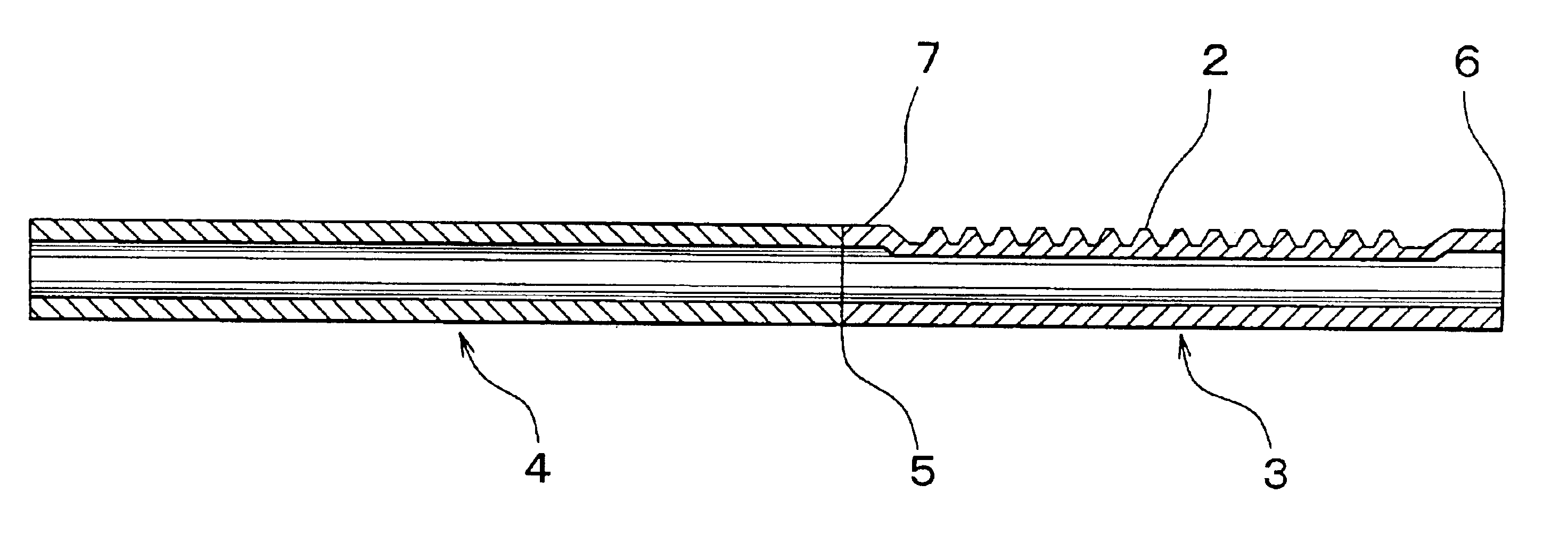

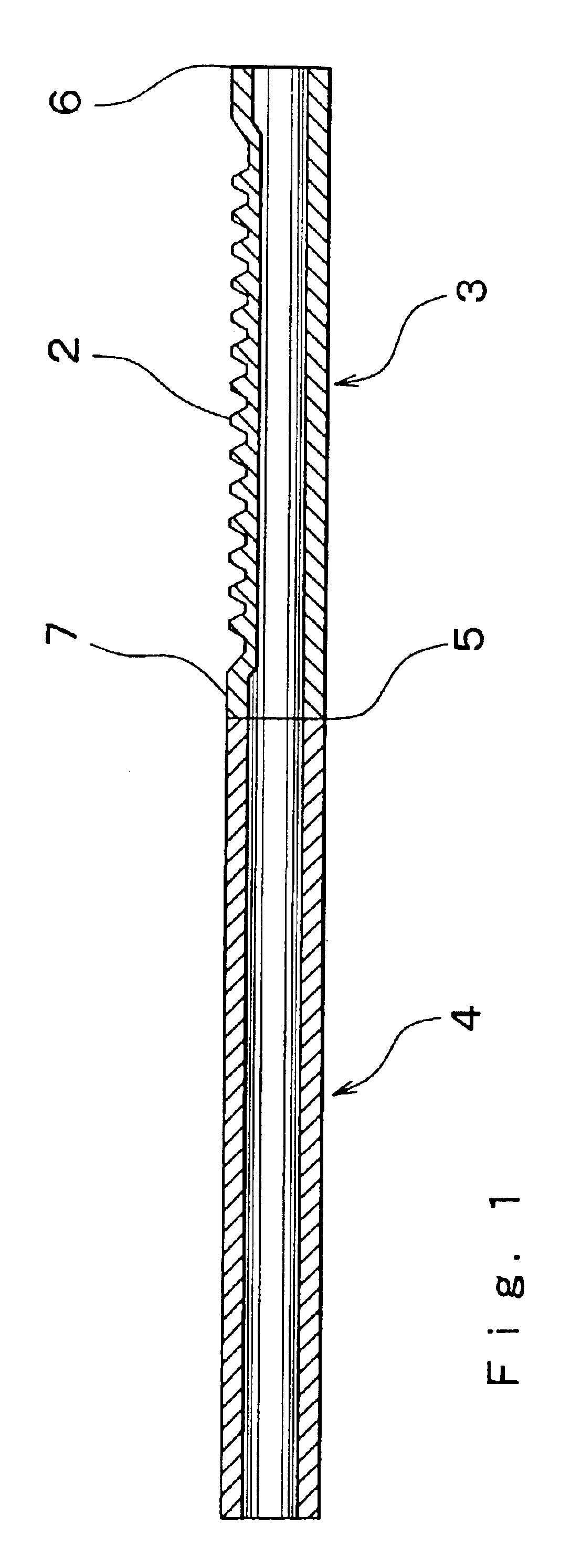

Sliding member

InactiveUS6983681B2Improved seizure resistanceSufficient frictional abrasion propertyShaftsSynthetic resin layered productsHigh resistanceHeat resistance

An object of the present invention is to provide a sliding member which can slide for a longer period of time even in a dry state. In the present invention, sliding layers 3 are provided on the surfaces of a base material 2, and the sliding layer 3 contains polybenzimidazole (PBI) and 1 to 70 vol % of a solid lubricant. Since PBI, which is a thermoplastic resin, has higher heat resistance and also has higher material strength than PAI, PI, and EP, which are the conventionally used thermosetting resins, the wear resistance and the anti-seizure property can be improved and a decrease in material strength caused by high-temperature atmosphere, heat generation at the time of sliding, etc. can be restrained. Furthermore, the initial conformability can be improved because of high elongation percentage. Also, since the sliding layer contains the solid lubricant, the coefficient of friction can be decreased, and hence the anti-seizure property can be enhanced.

Owner:DAIDO METAL CO LTD

Method for producing bevel gear with ratchet on end face through powder metallurgy warm forming

InactiveCN102672183AHigh material strengthHigh gear precisionSolid state diffusion coatingFurnace typesPowder metallurgyNitrogen atmosphere

The invention discloses a method for producing a bevel gear with ratchets on an end face through powder metallurgy warm forming. The method comprises the following steps of: preparing iron powder, copper powder, nickel powder, molybdenum powder, graphite powder and a warm forming special lubricant into a mixer to mix according to a proportion; filling in a heated mould; preparing a compact under the condition of unit pressing pressure of 6.5-7.5 T / cm<2> and density of reaching 7.2-7.3 g / cm<3>; placing the compact in a sintering furnace and sintering in a protective atmosphere of mixed gas of hydrogen and nitrogen at 1,120 DEG C for 40 minutes; nitrocarburizing the sintered compact in a carbon and nitrogen atmosphere of 850 DEG C in a controllable atmosphere thermal treatment furnace for 60 minutes; quenching at 850 DEG C; oil-cooling at a cooling speed of 110 DEG C / 10 minutes; tempering at 180 DEG C for 1 hour to machine an inner hole on a precision numerical control lathe to dimensional requirements through tooth shape positioning; finishing; removing thermal treatment oil stain and surface burrs; cleaning; drying; and soaking anti-rust oil to prepare a finished product. The method has the advantages of high product consistency, capability of meeting requirements of large-scale stable production, particular suitability for producing the bevel gear of high accuracy, high strength and high difficulty.

Owner:马鞍山市华东粉末冶金厂

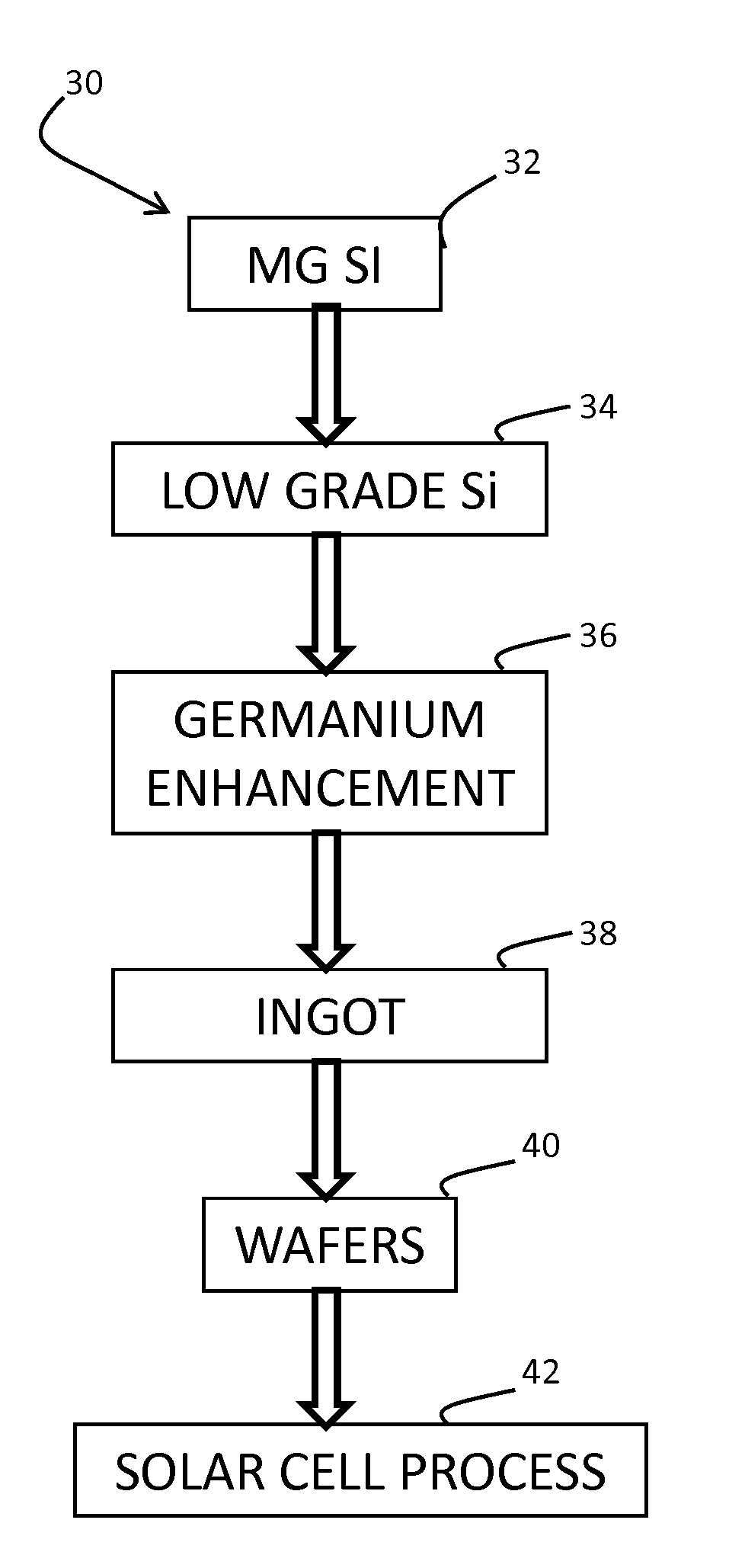

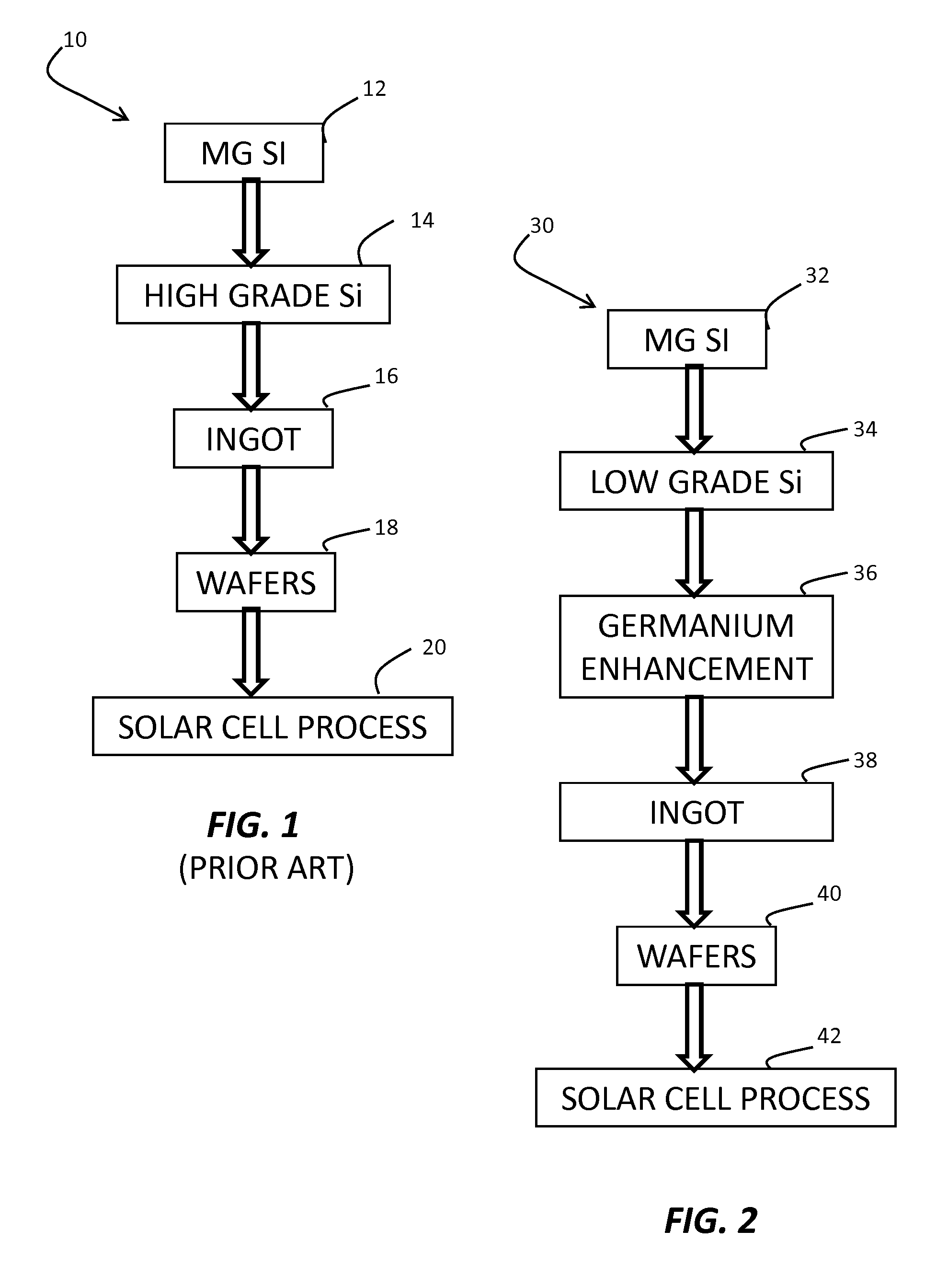

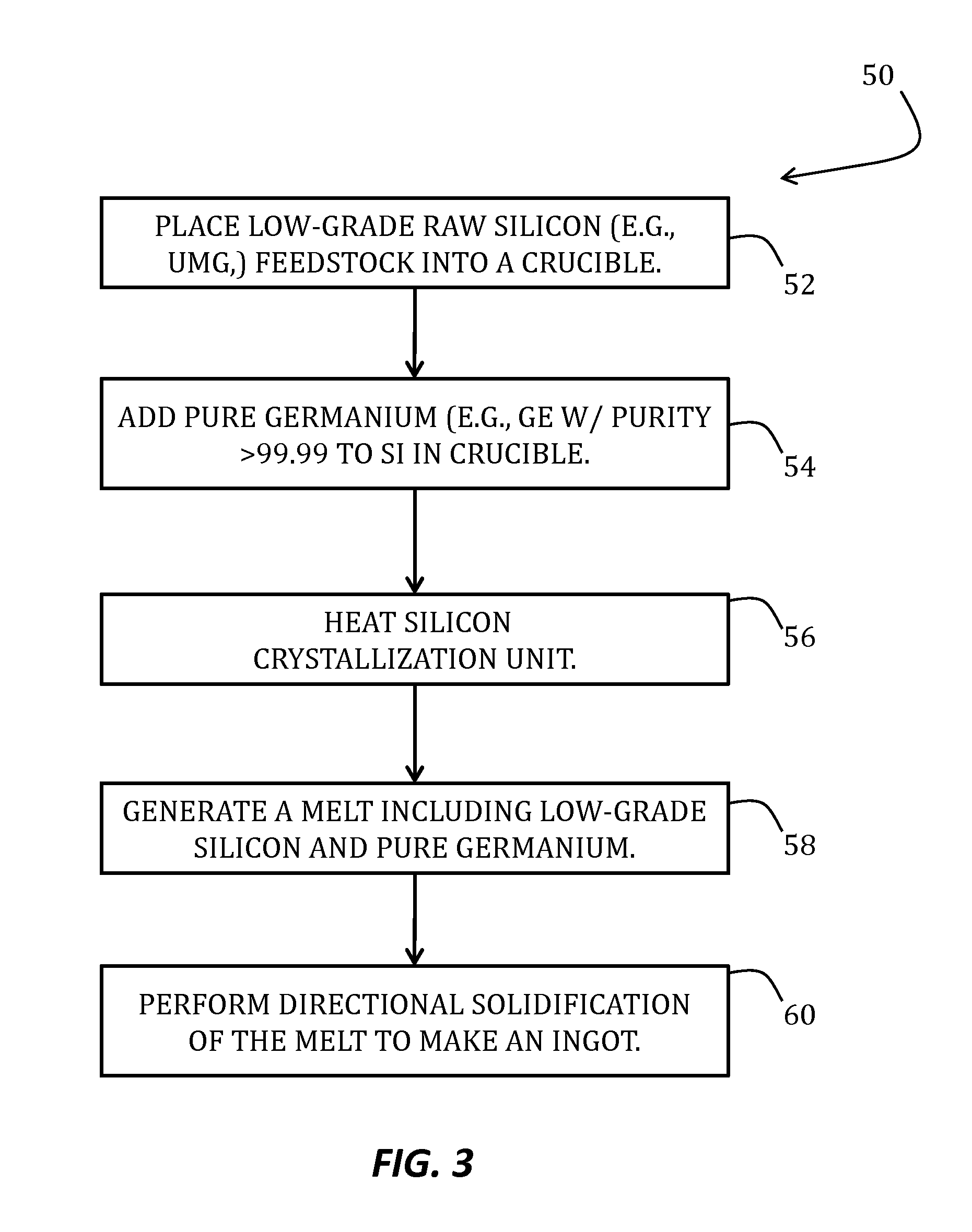

Germanium-enriched silicon material for making solar cells

InactiveUS20090308455A1Increased compressive lattice strainEasy to controlPolycrystalline material growthBy zone-melting liquidsComputer moduleIngot

Techniques for the formation of silicon ingots and crystals using silicon feedstock of various grades are described. Common feature is adding a predetermined amount of germanium to the melt and performing a crystallization to incorporate germanium into the silicon lattice of respective crystalline silicon materials. Such incorporated germanium results in improvements of respective silicon material characteristics, mainly increased material strength. This leads to positive effects at applying such materials in solar cell manufacturing and at making modules from those solar cells. A silicon material with a germanium concentration in the range (50-200) ppmw demonstrates an increased material strength, where best practical ranges depend on the material quality generated.

Owner:HIGHLAND MATERIALS INC

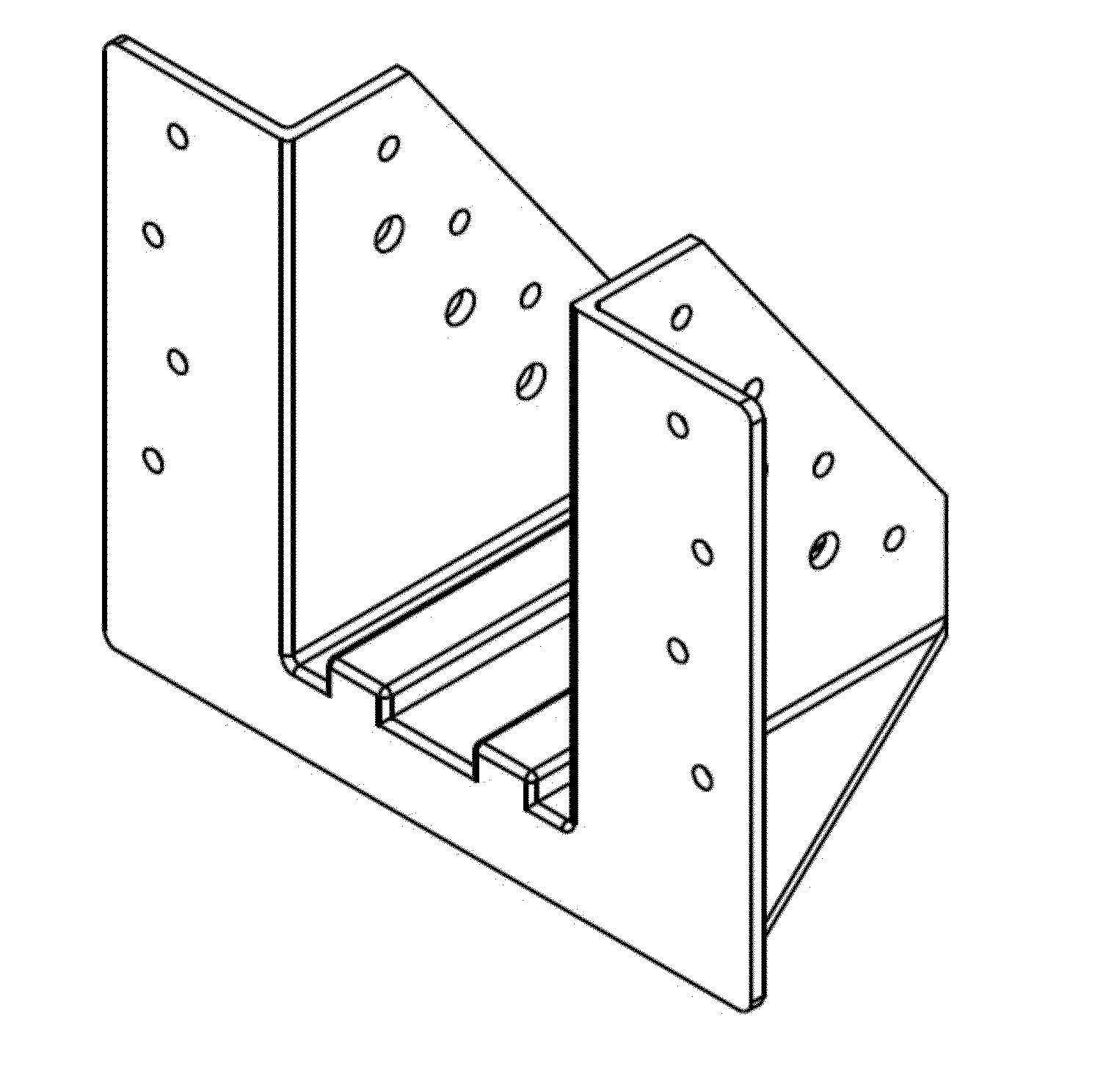

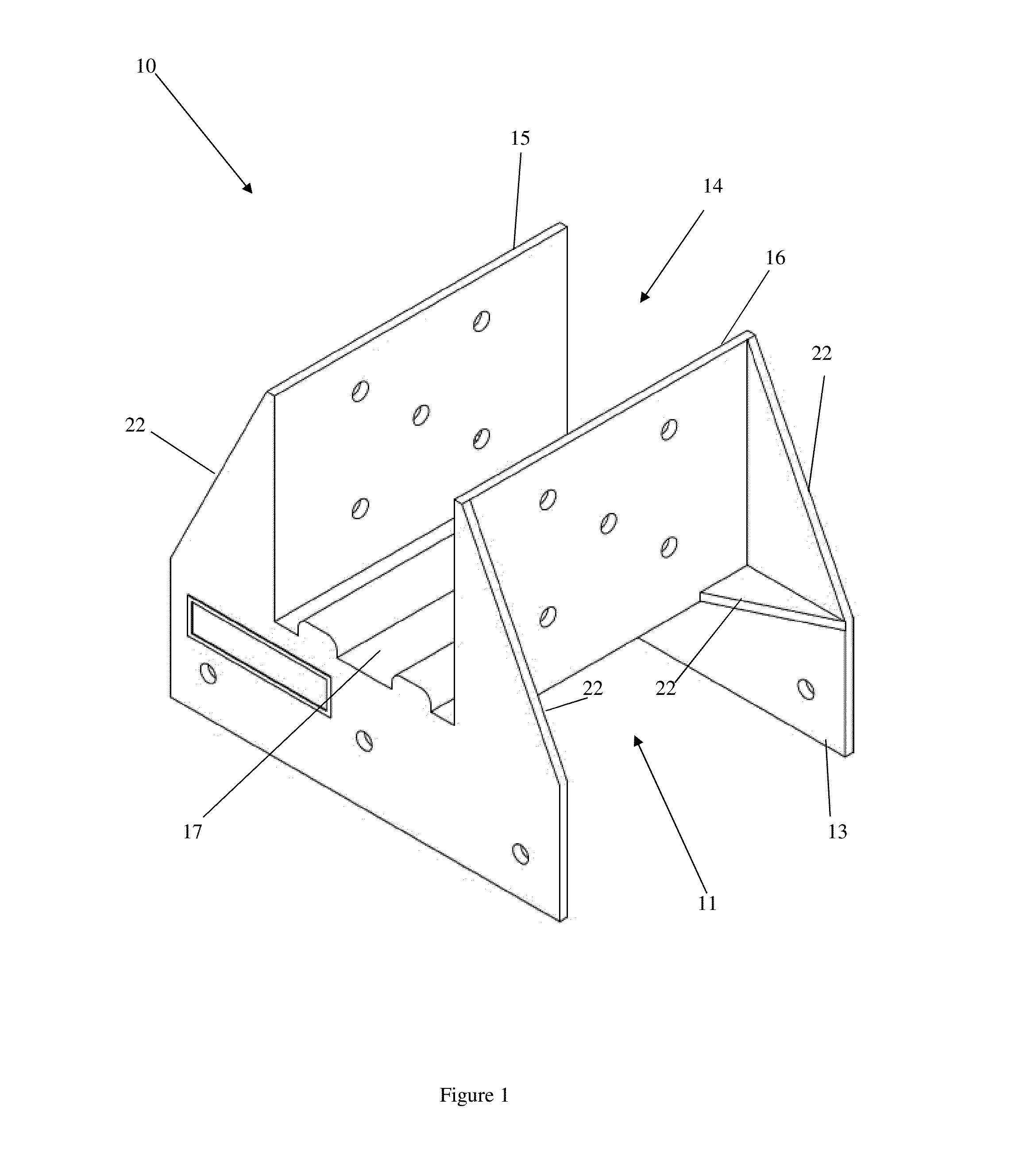

Joist connector

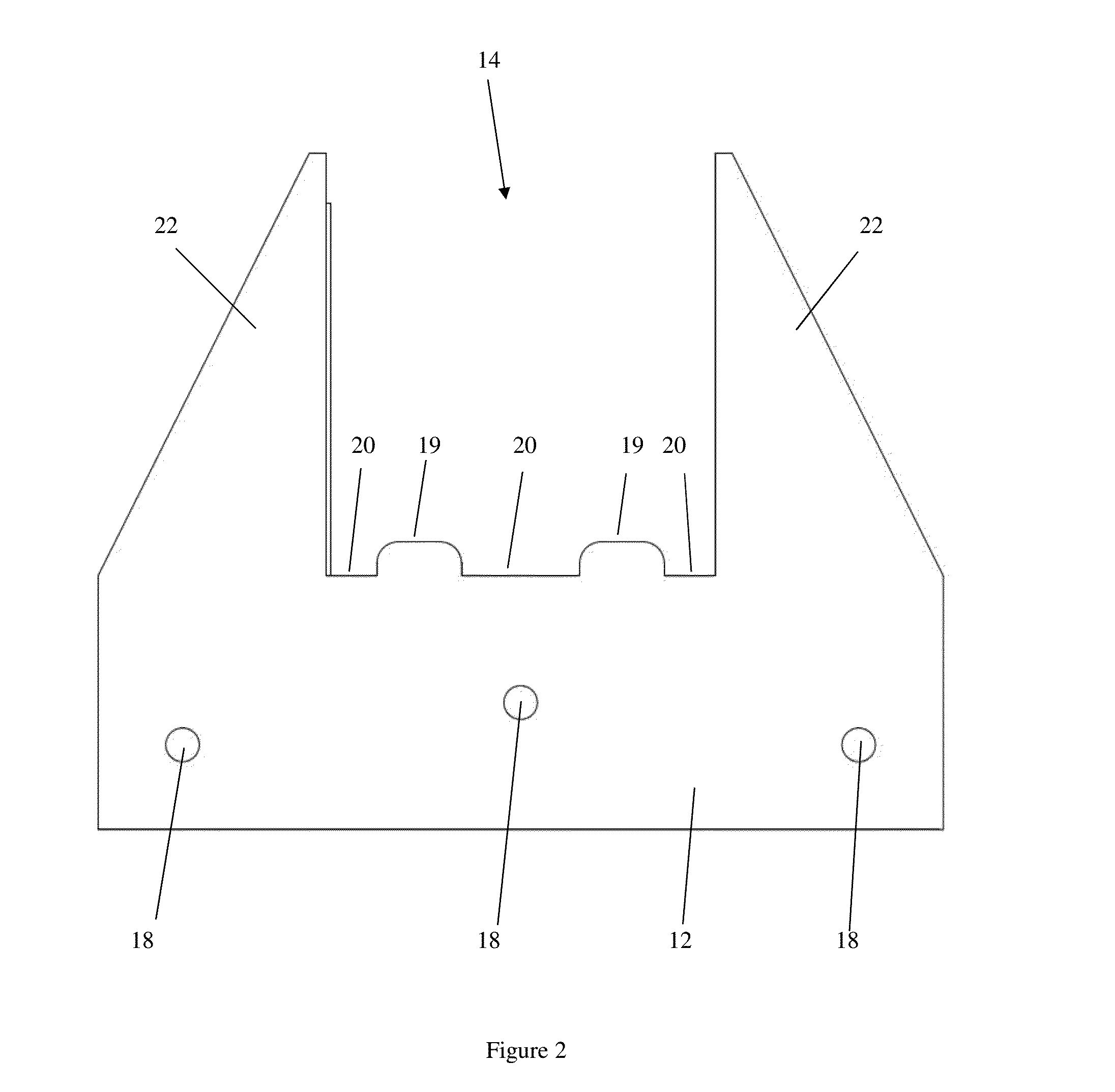

ActiveUS20160002912A1Overcome disadvantagesHigh degreeConstruction materialBuilding reinforcementsStructural engineeringMechanical engineering

A joist connector including a unitary body with a first channel defined by at least two spaced apart flanges and a second channel defined by at least two spaced apart flanges and offset from the first channel.

Owner:KLEVAKLIP SYST

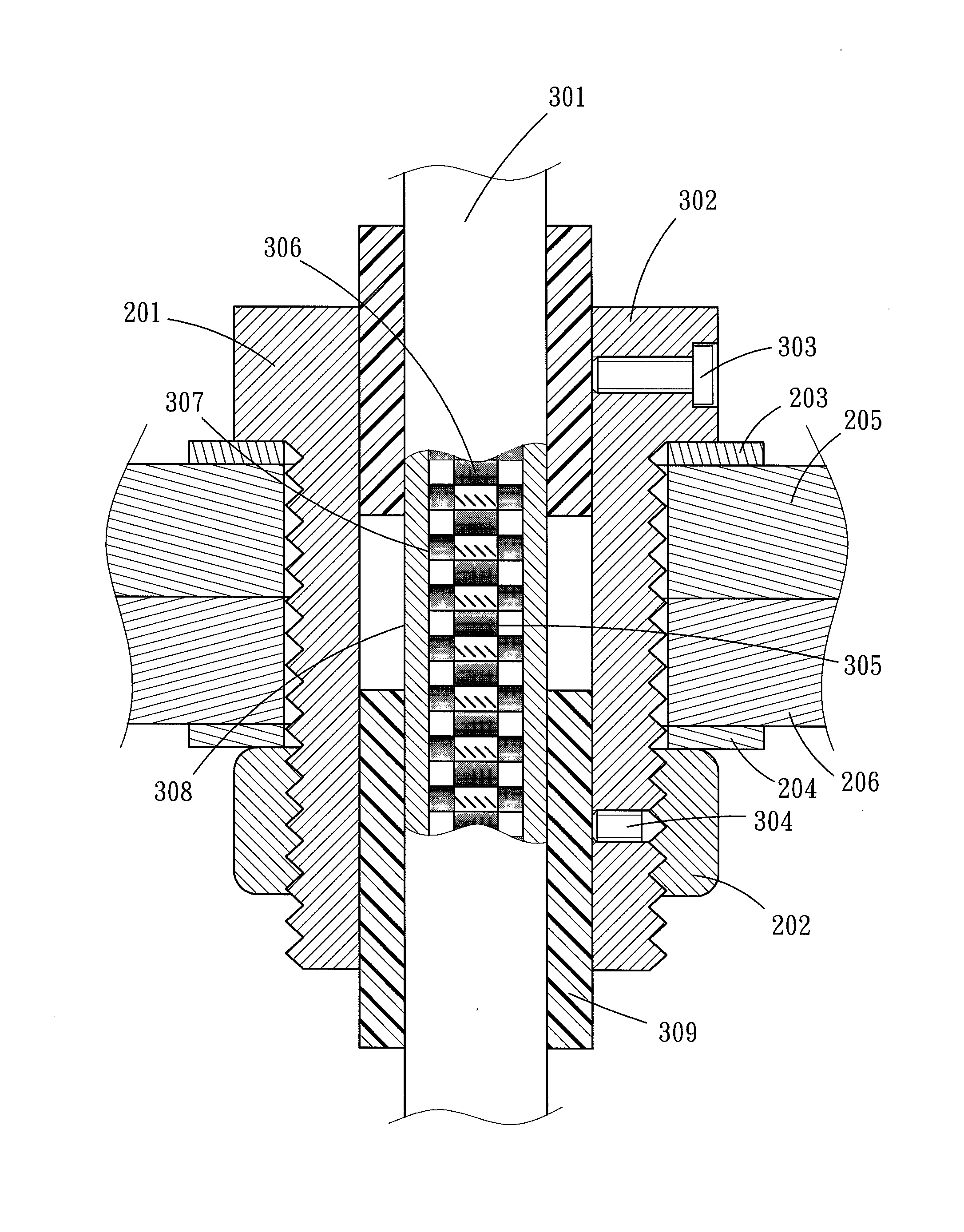

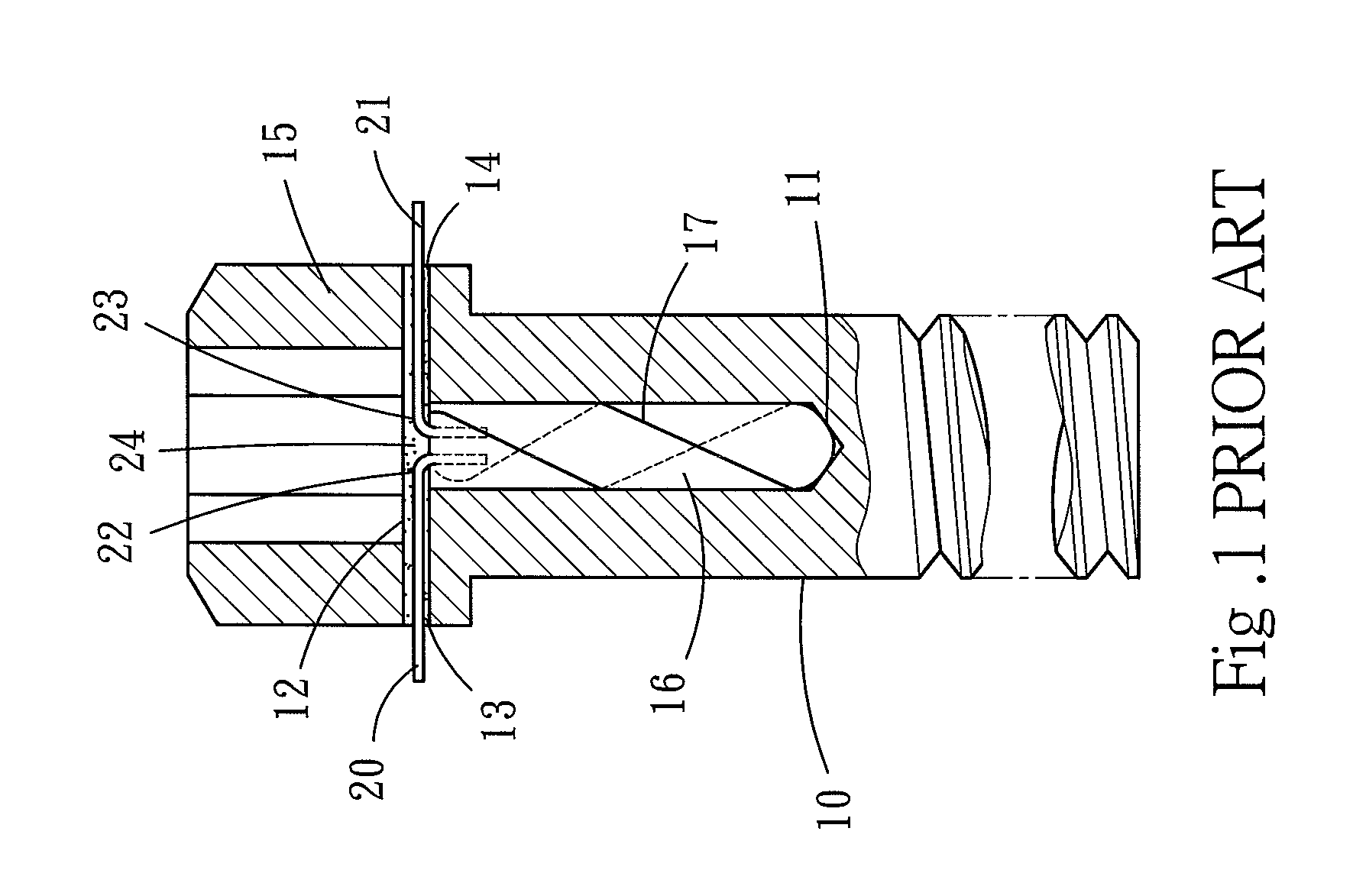

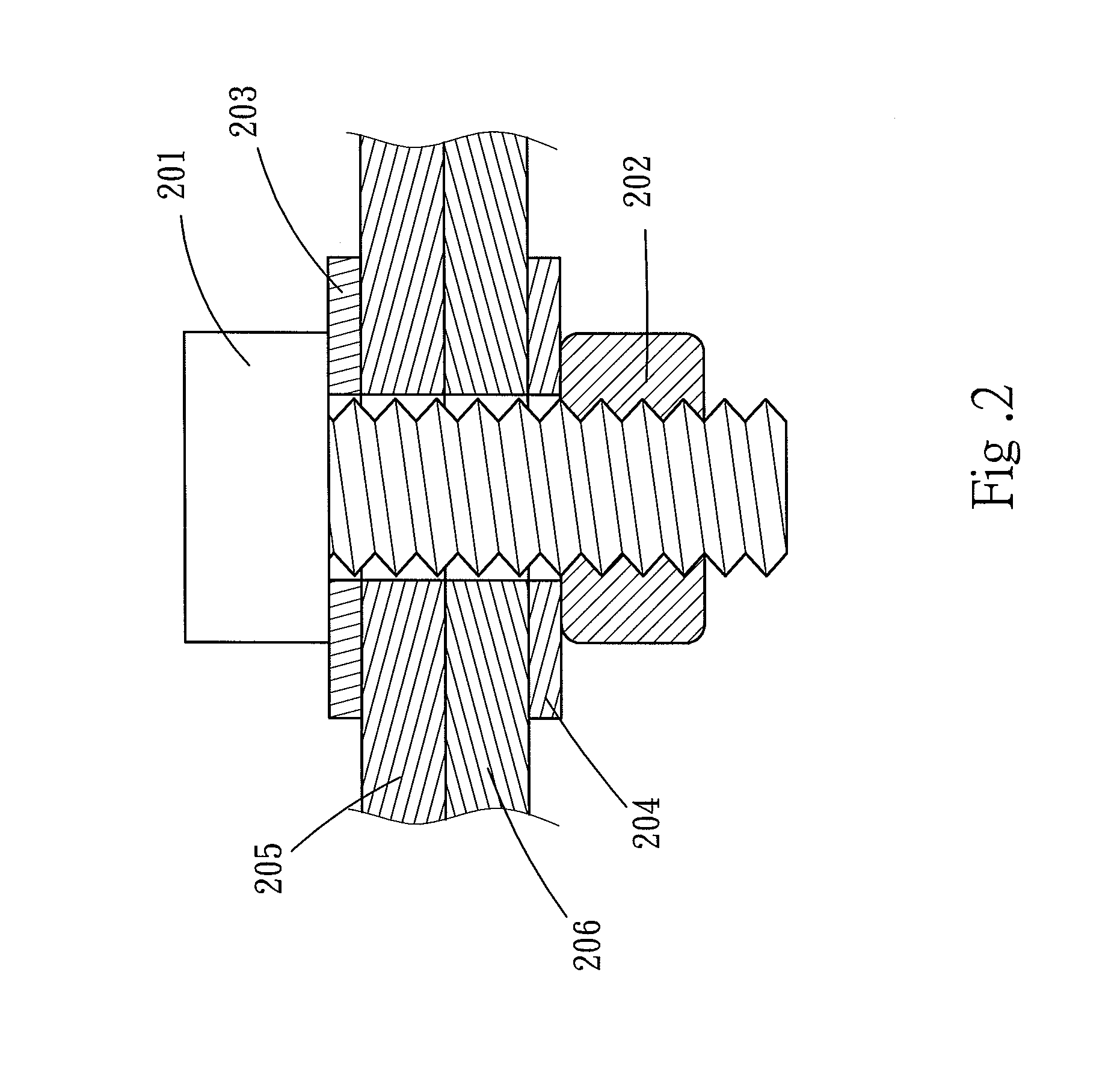

Synchronous pre-tensionable sensing screw with fiber bragg grating devices

ActiveUS20140373636A1Overcome inaccuraciesSmall sizeMeasurement of torque/twisting force while tighteningLoad modified fastenersGratingFiber Bragg grating

An apparatus includes a sensing screw capable of providing synchronous both pre-drawing of fiber Bragg grating and pre-tightening of bolt with induced characteristics to detect feedback control of large scale public engineering structures or precise equipments to facilitate fabrication of precise elements to achieve more precise control and record fabrication processes. Through the sensing screw apparatus a precision system structure can be formed to meet expectation of improved product quality and comprehensive recording of complete production process and physical characteristics at important points of the production process. The invention can provide instant onsite status and accumulate data or make parameter pre-action to avoid error accumulation, thereby improve production yield or safety of large scale structures.

Owner:CHUN CHU YANG +1

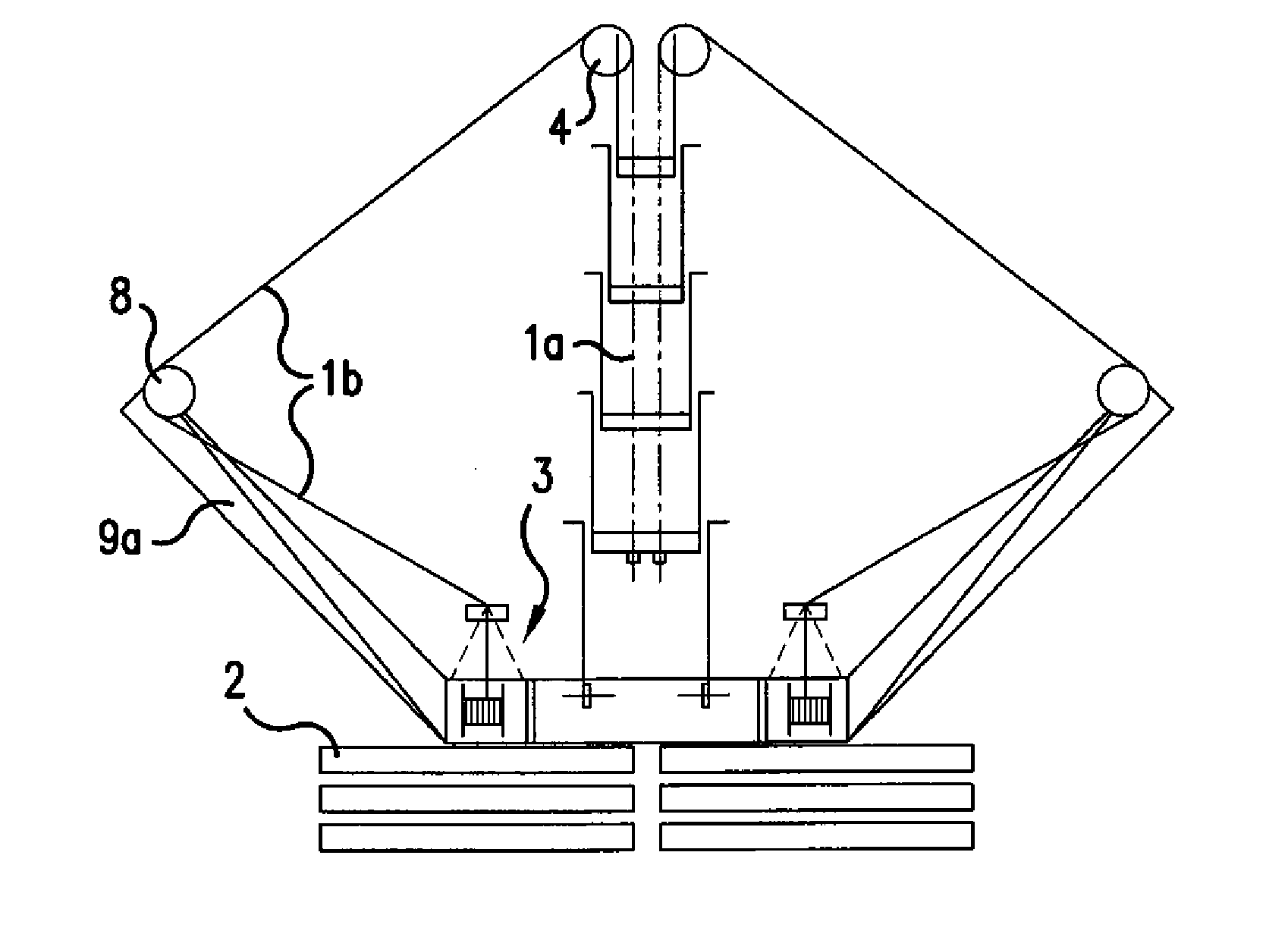

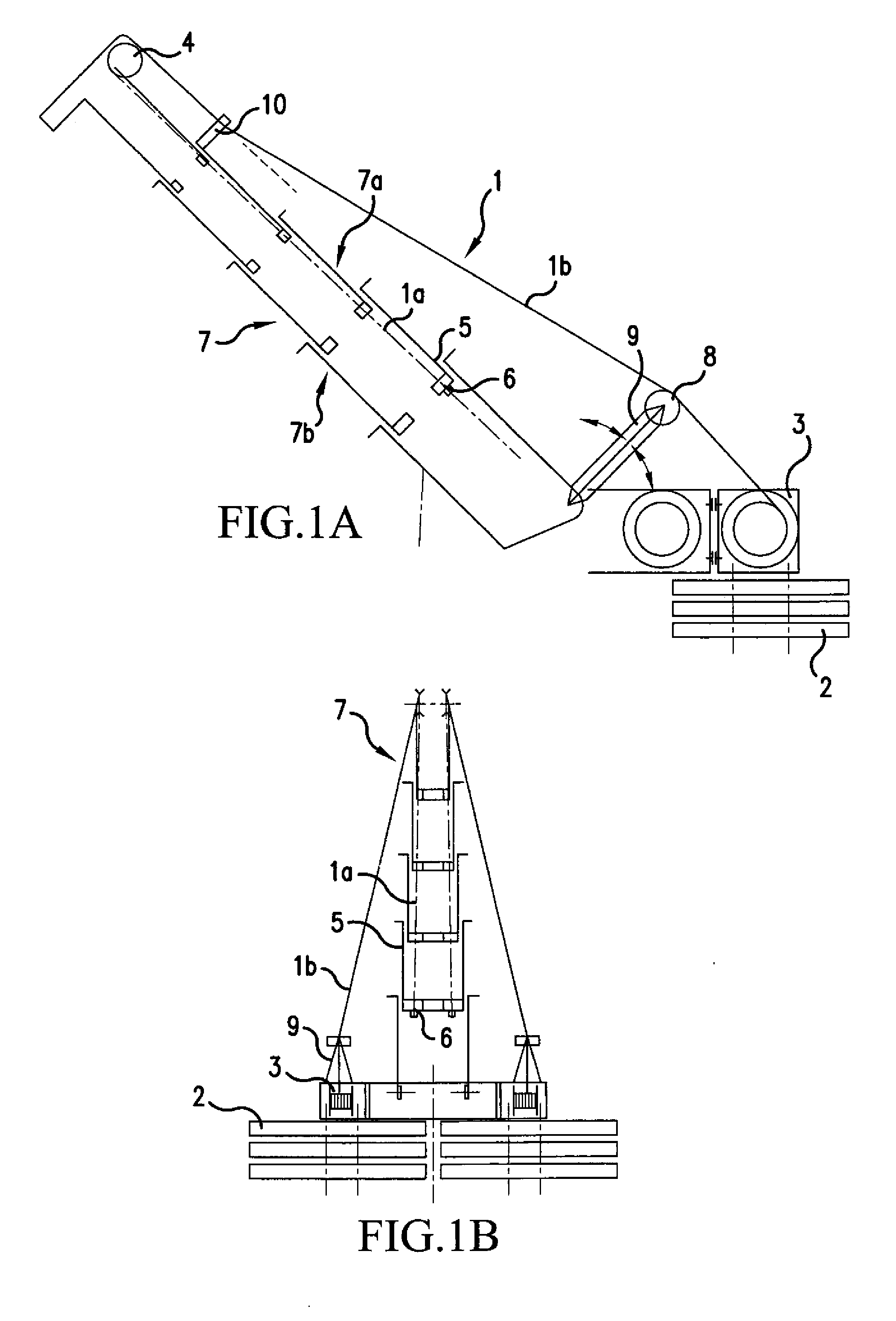

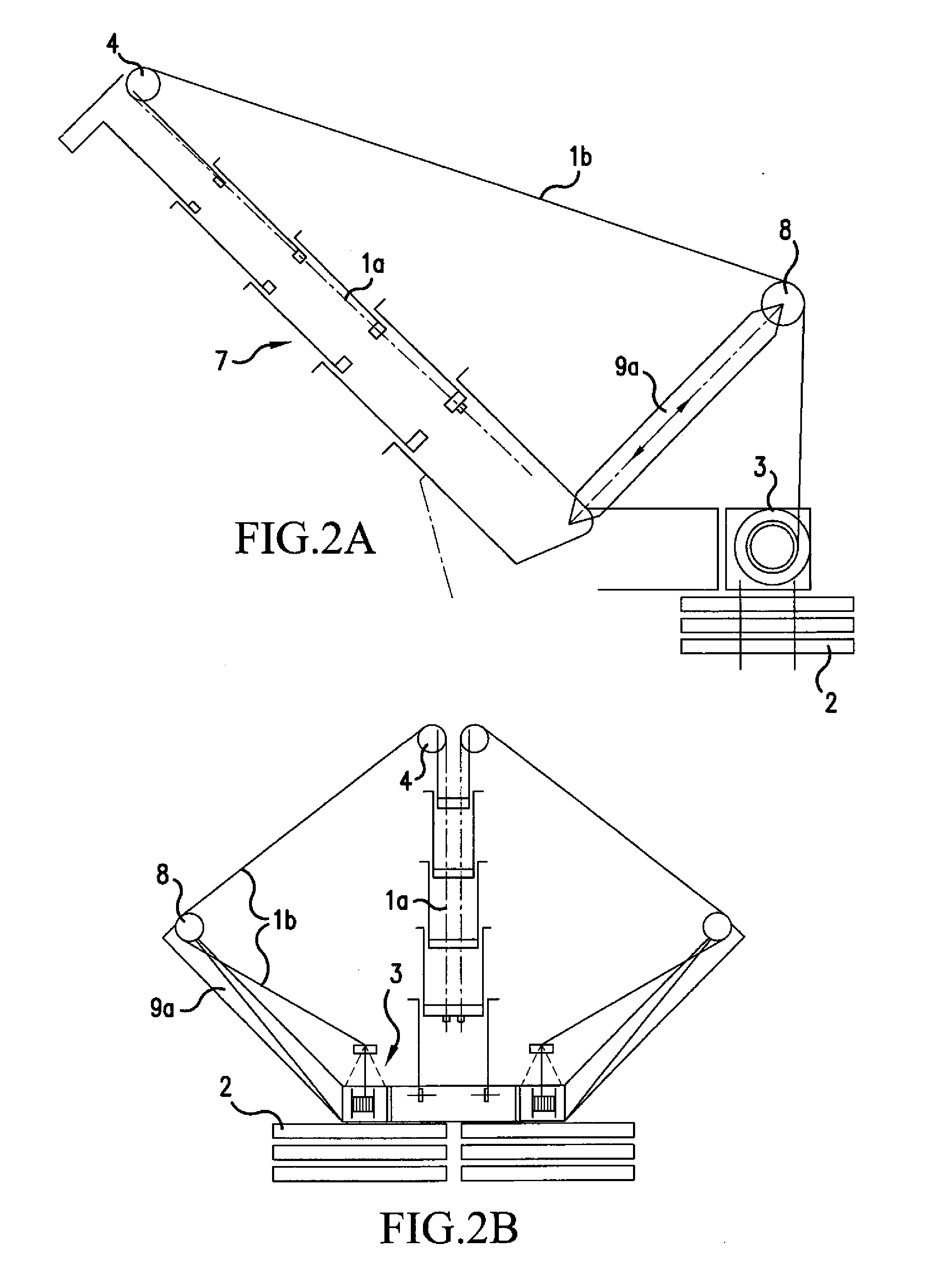

Tensioning System for a Mobile Telescopic Crane

InactiveUS20080023432A1Point becomes highHigh material strengthCargo handling apparatusPassenger handling apparatusEngineeringWinch

A tensioning system for a mobile telescopic crane having a telescopic mast includes at least one tensioning cable for bracing the telescopic mast and at least one tensioning winch mounted on the crane superstructure for tensioning the cable. The tension in the cable creates a pressure bias within the mast. The winch is movable with respect to said superstructure of the crane and movement of the winch relative to the superstructure also imposes tension on the tensioning cable.

Owner:GROVE US LLC

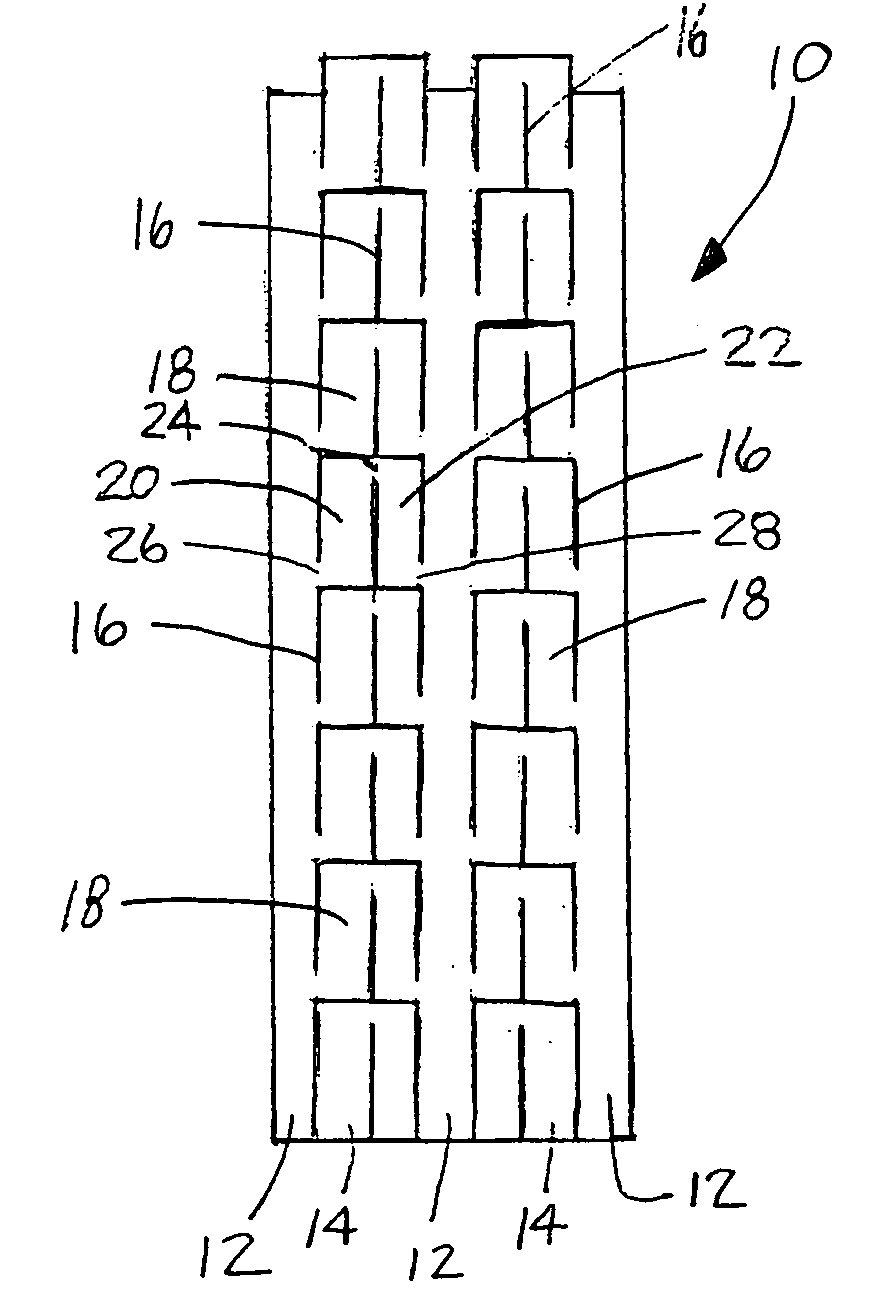

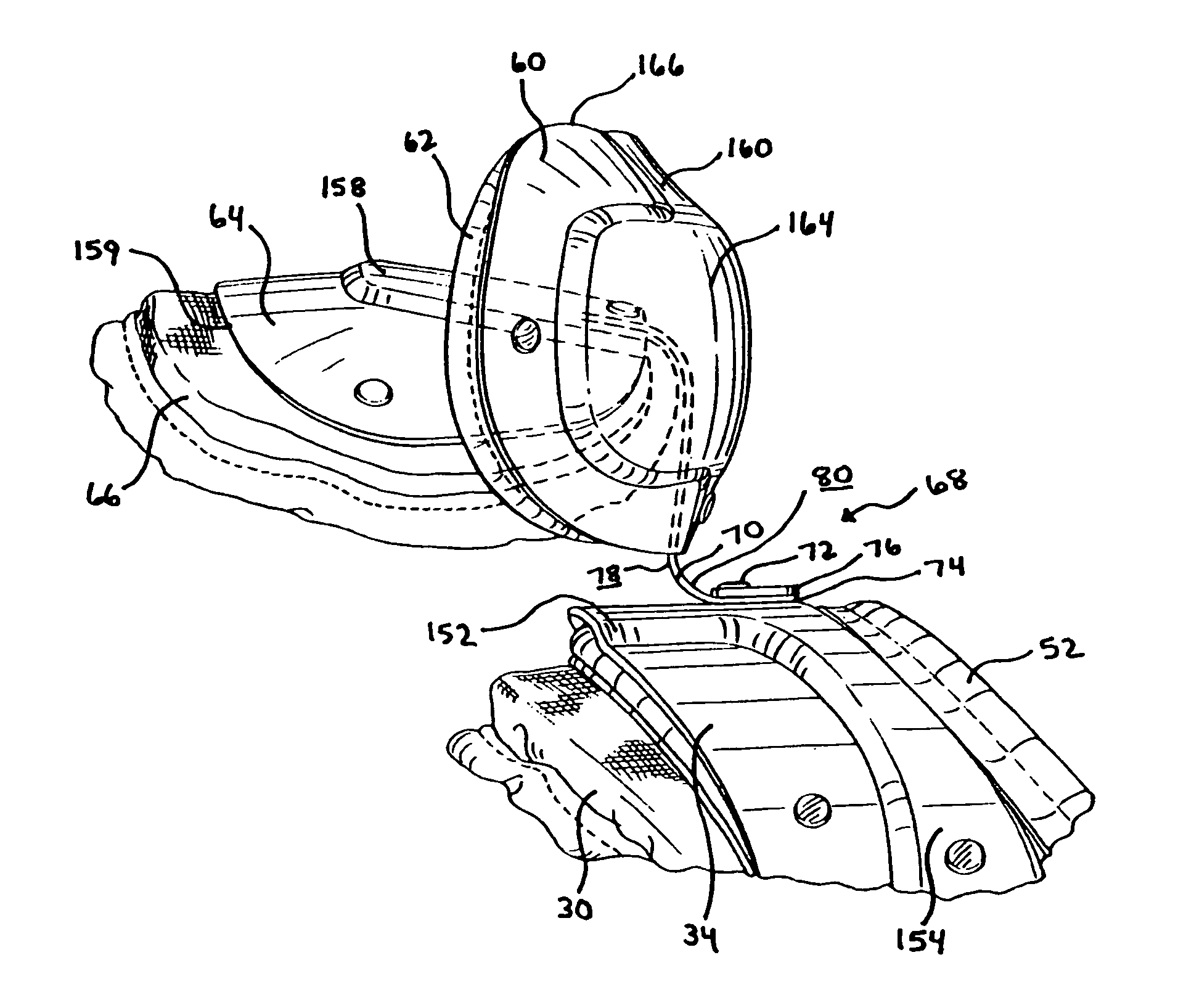

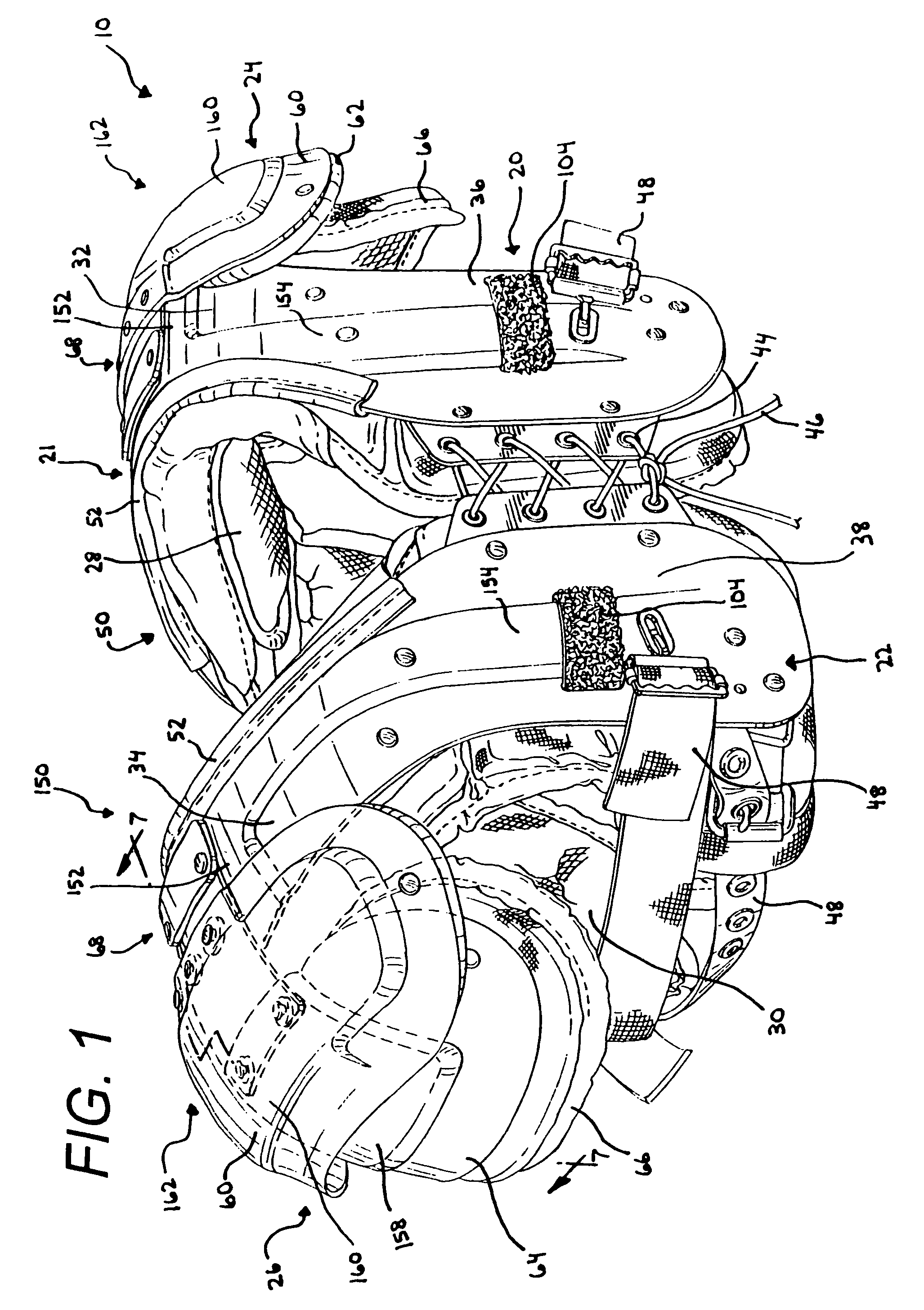

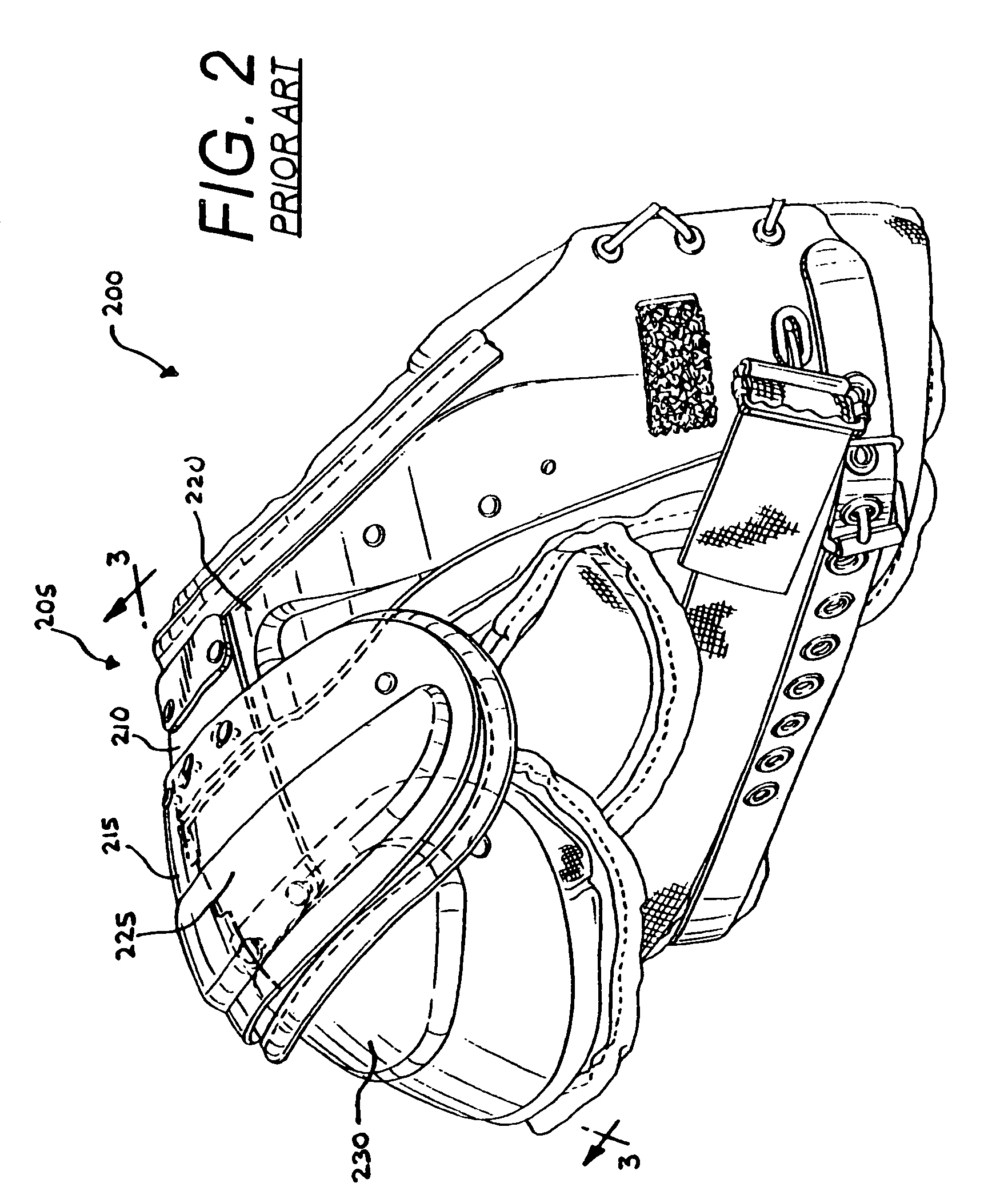

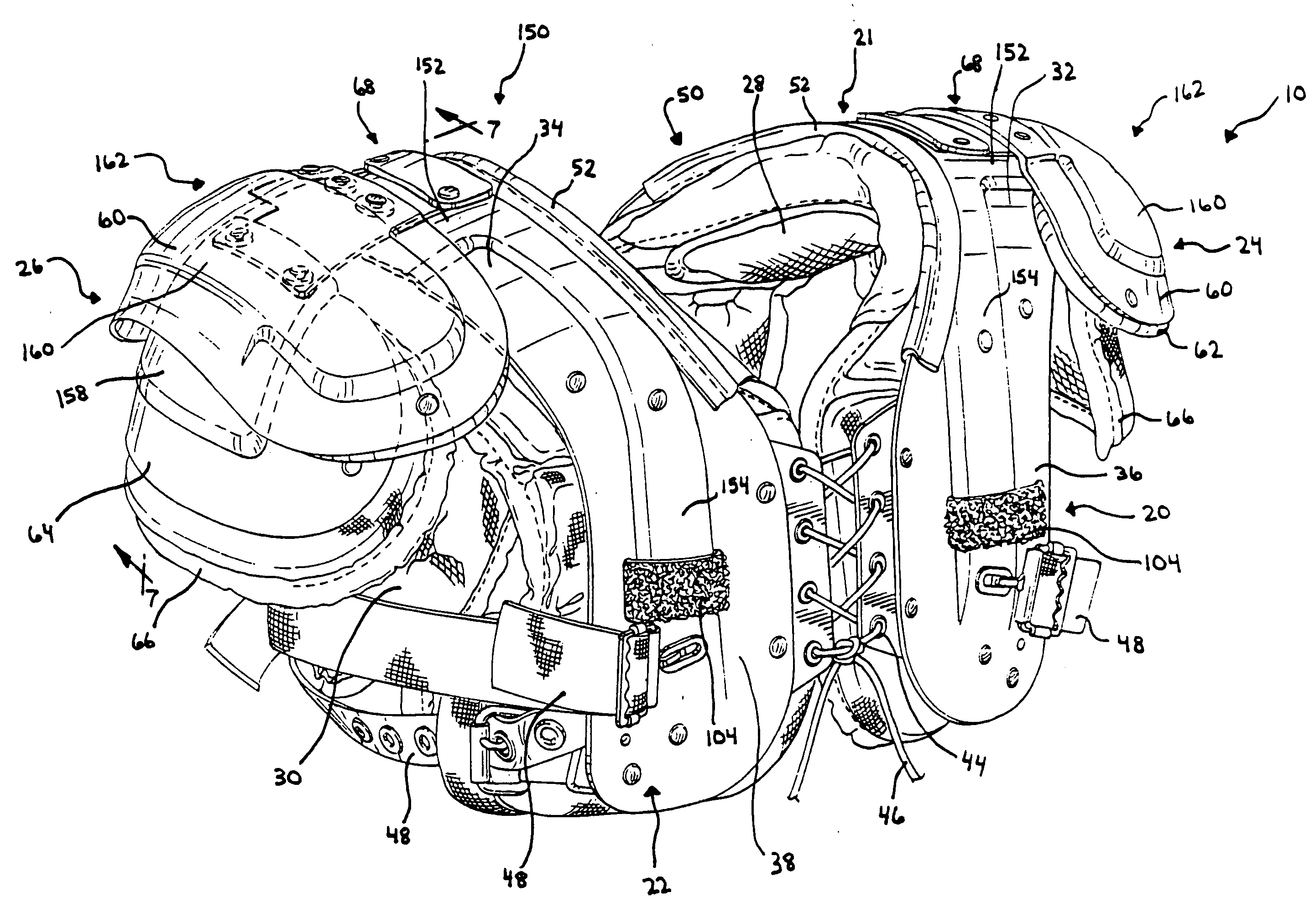

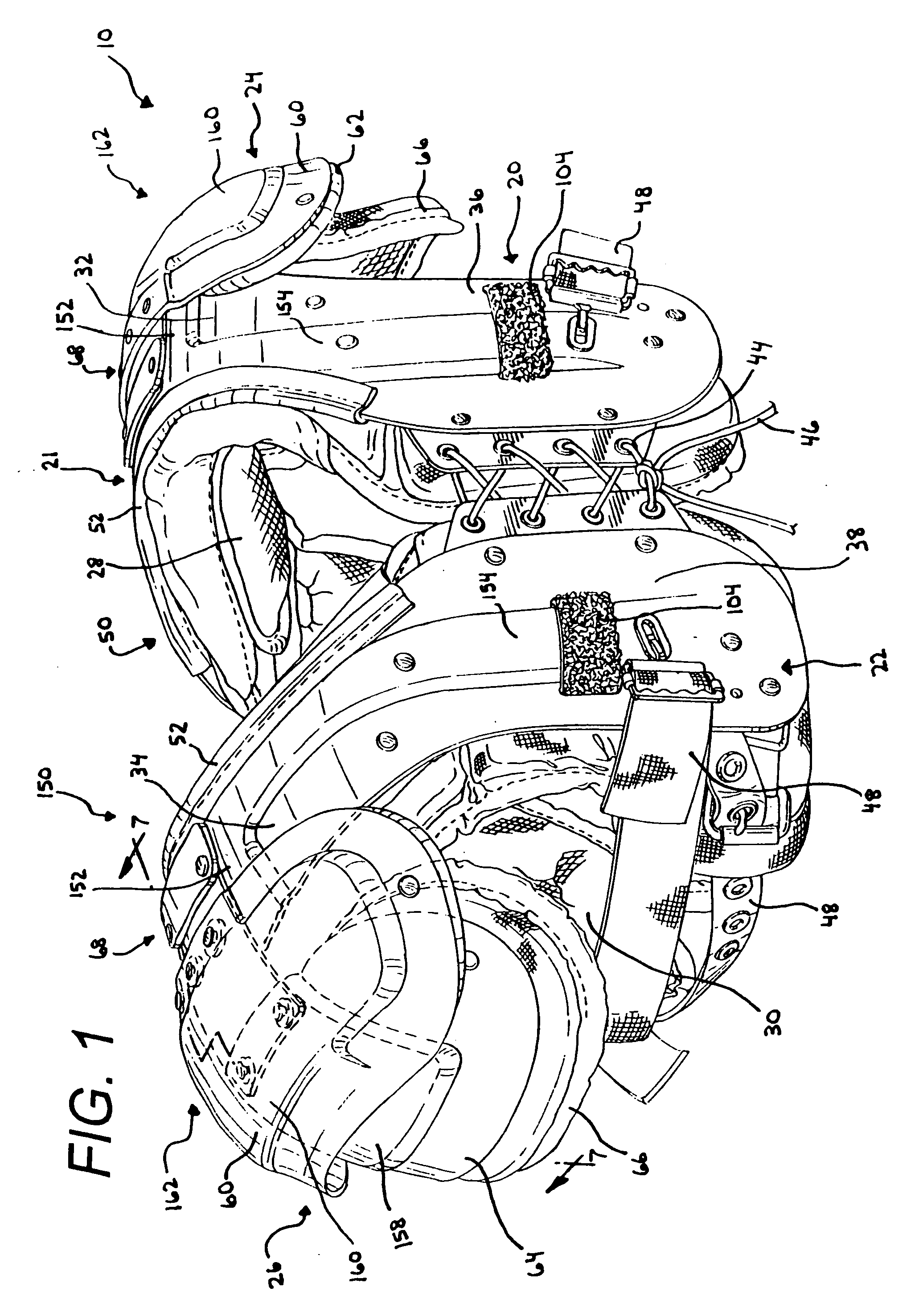

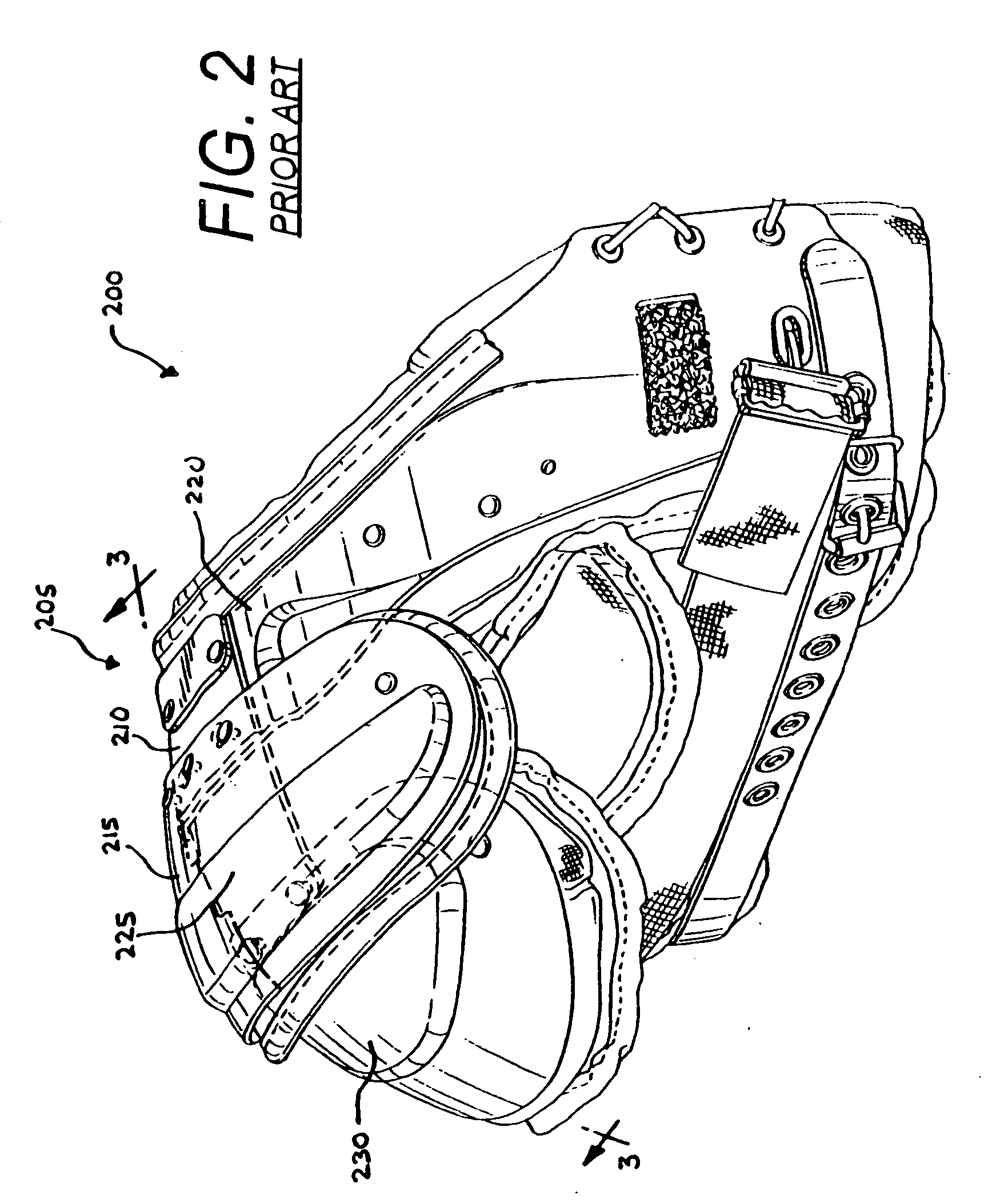

Shoulder pads

InactiveUS20100192287A1Increased material strength characteristicReduce weightBall sportsProtective garmentYarnAir management

The present invention provides a shoulder pad for use in a contact sport, such as football, hockey or lacrosse, that is formed from a consolidated polymer fiber composite material, such as polypropylene tape yarn that reduces the overall weight of the shoulder pad. The shoulder pad includes a pair of arch members, each having an upper portion, a front portion depending from the upper portion, and a rear portion depending from the upper portion. The shoulder pad further includes at least one side pad assembly having an epaulet and a shoulder cap, wherein the shoulder cap overlies the wearer's shoulder region and the epaulet overlies both the arch member and the shoulder cap. The side pad assembly is operably secured to the body arch member by a fastening assembly that includes a flexible single band. Unlike conventional designs, the single band secures both the epaulet and the shoulder cap to the upper portion of the arch member. The shoulder pad further includes a pair of interior pad assemblies wherein each interior pad assembly is removably connected to an arch member. The interior pad assembly is an integrated unit formed from a front pad, an intermediate pad, and a rear pad joined together to form distinct air management chambers.

Owner:RIDDELL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com