High-strength bionic collagen membrane and preparation method thereof

A bionic glue and high-strength technology, applied in medical science, prosthesis, surgery, etc., can solve the problems of long production process, reduce medical costs, and high production costs, achieve high mechanical properties, facilitate large-scale production, and reduce production costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

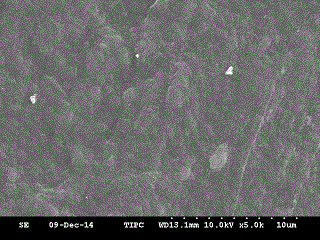

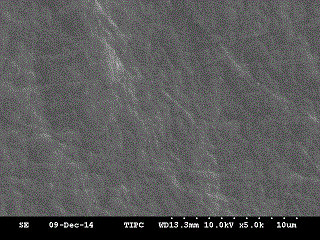

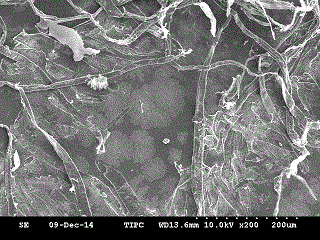

Image

Examples

Embodiment 1

[0058] Step 1, take the pigskin, remove the hair, add delipase and rinse in purified water for 24 hours to remove the fat;

[0059] Step 2, after slicing, add acetic acid solution with a pH value of 1.0, then add pepsin, and enzymatically hydrolyze at 4°C for 90 hours;

[0060] Step 3, after enzymolysis, use a centrifuge to centrifuge the enzymolysis solution to take the supernatant, use an alkaline solution to adjust the pH value to 7, and then use a sodium chloride salt solution to salt out the collagen;

[0061] Step 4: Take the collagen, put it into a dialysis bag, and use the method of gradient dialysis to dissolve it in acetic acid solution for dialysis, including the following steps;

[0062] S1-1: Put 20g of collagen into a dialysis bag with a diameter of 6cm and a length of 50cm, and seal the port of the dialysis bag;

[0063] S1-2: The first gradient dialysis, using pH=2 acetic acid solution for 7 days, the temperature is 4°C, and the dialysate is changed twice a da...

Embodiment 2

[0069] Step 1, take the beef Achilles tendon, add methyl chloride, soak for 24 hours, and remove the fat;

[0070] Step 2, after slicing, add a citric acid solution with a pH value of 2.0, add papain, and enzymolyze at 10°C for 36 hours;

[0071] Step 3, after enzymolysis, use a centrifuge to centrifuge the enzymolysis solution to take the supernatant, use an alkaline solution to adjust the pH value to 6, and then use a potassium chloride salt solution to salt out the collagen;

[0072] Step 4: Take the collagen, put it into a dialysis bag, and use the method of gradient dialysis to dissolve it in acetic acid solution for dialysis, including the following steps;

[0073] S1-1: Put 10g of collagen into a dialysis bag with a diameter of 6cm and a length of 40cm, and seal the port of the dialysis bag;

[0074] S1-2: The first gradient dialysis, using pH = 1.5 acetic acid solution for 3 days, the temperature is 10°C, and the dialysate is changed once a day;

[0075] S1-3: The se...

Embodiment 3

[0080] Step 1: Purchase commercially available soluble collagen, put it into a dialysis bag, and use gradient dialysis to dissolve and dialysis in acetic acid solution, including the following steps;

[0081] S1-1: Put 8g of collagen into a dialysis bag with a diameter of 5cm and a length of 45cm, and seal the port of the dialysis bag;

[0082] S1-2: The first gradient dialysis, use pH=2.5 acetic acid solution for 7 days, the temperature is 15°C, change the dialysate twice a day;

[0083] S1-3: The second gradient dialysis, use pH=4 acetic acid solution for 5 days, the temperature is 15°C, and the dialysate is changed twice a day;

[0084] S1-4: The third gradient dialysis, use neutral purified water for 2 days, the temperature is 15 ℃, change the dialysate twice a day.

[0085] Step 2, take a circular stainless steel mesh tank mold with a diameter of 20cm, spread a layer of silk on the bottom surface, and then inject the collagen solution obtained from dialysis into the mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com