Patents

Literature

527 results about "Collagen fibres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Collagenous fiber. [kəlaj′ənəs] any one of the tough, white protein fibers that constitute much of the intercellular substance and the connective tissue of the body. Collagenous fibers contain collagen. They are often arranged in bundles that strengthen the tissues in which they are imbedded.

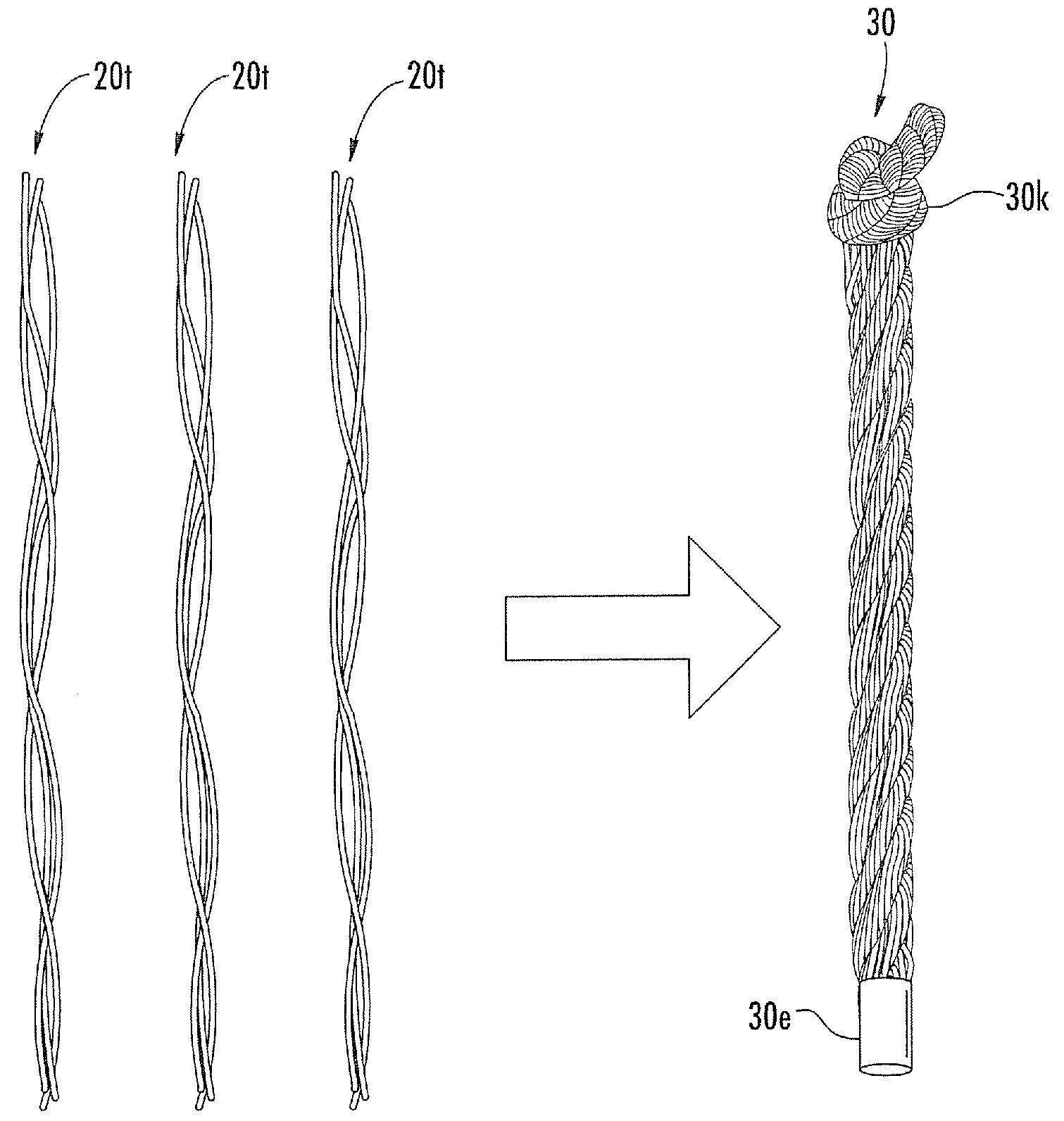

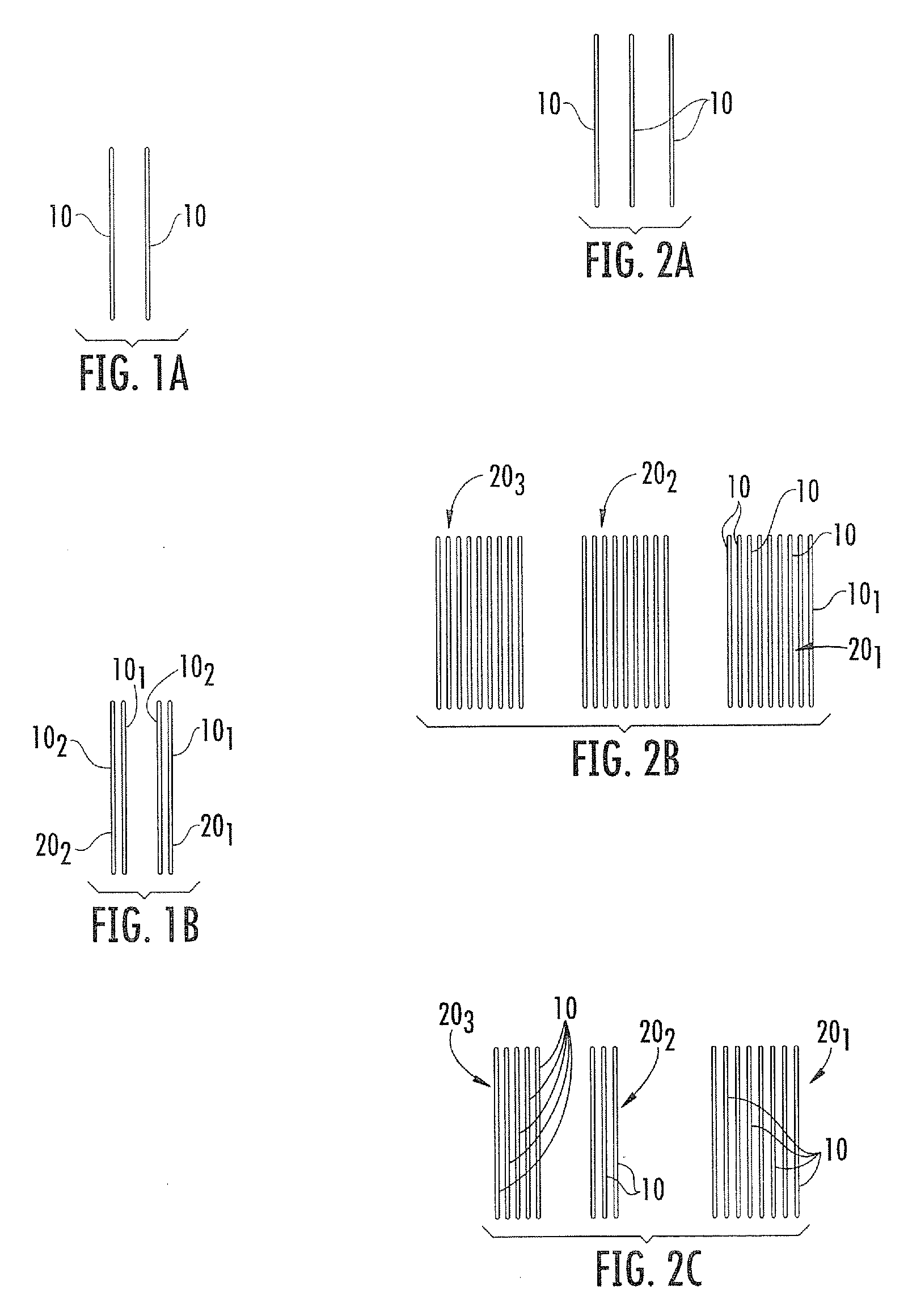

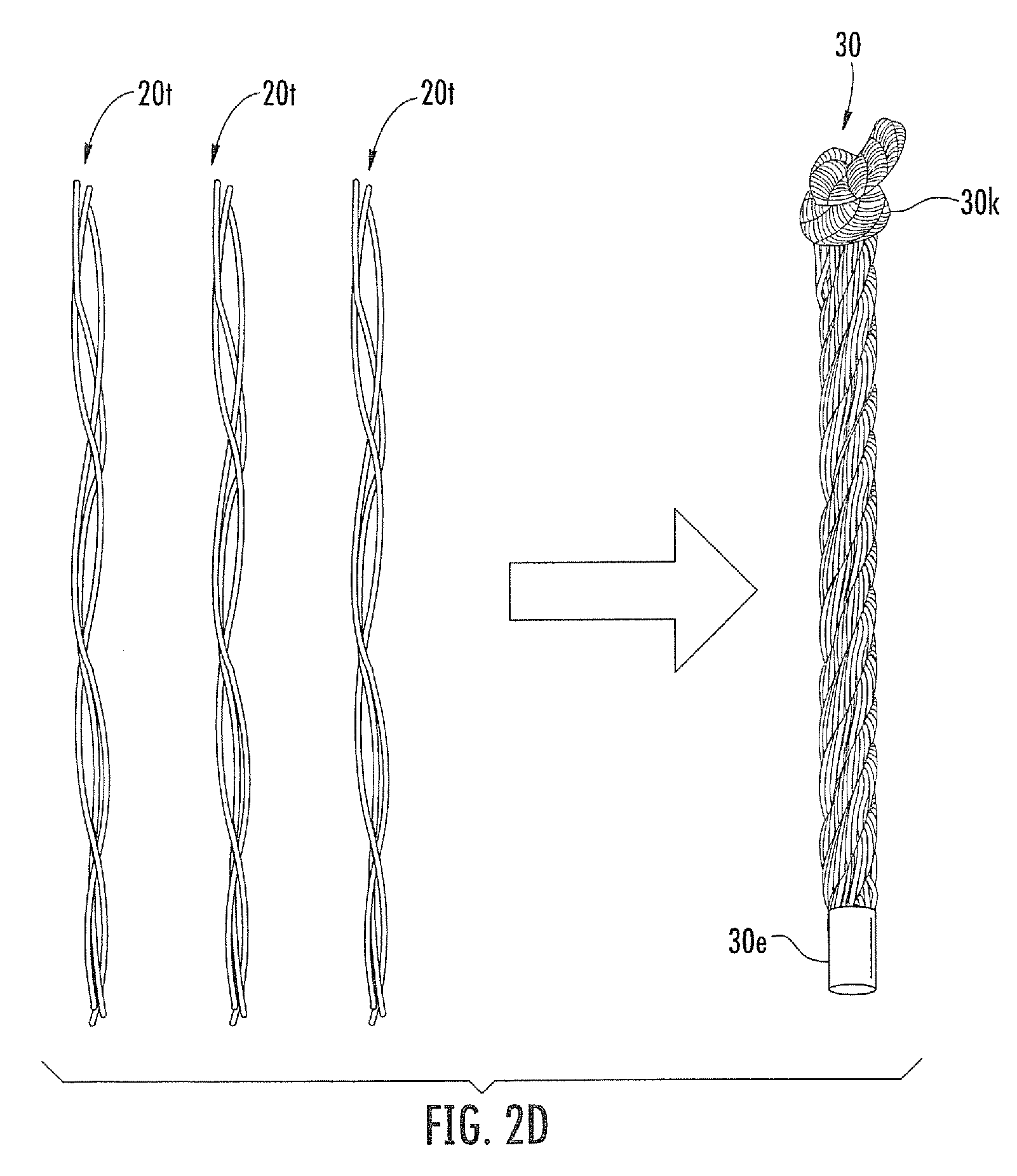

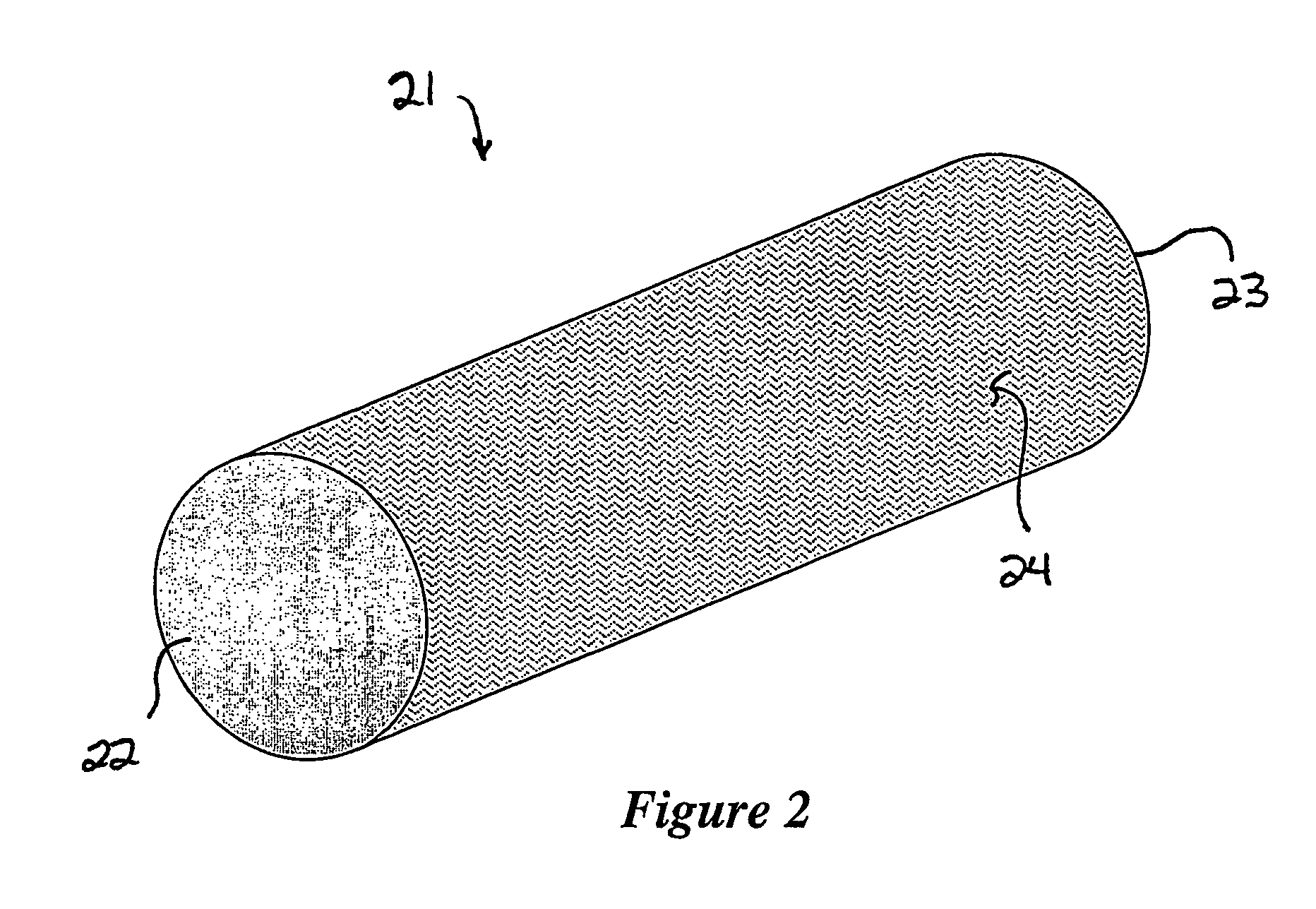

Medical constructs of twisted lengths of collagen fibers and methods of making same

Owner:MIMEDX GROUP

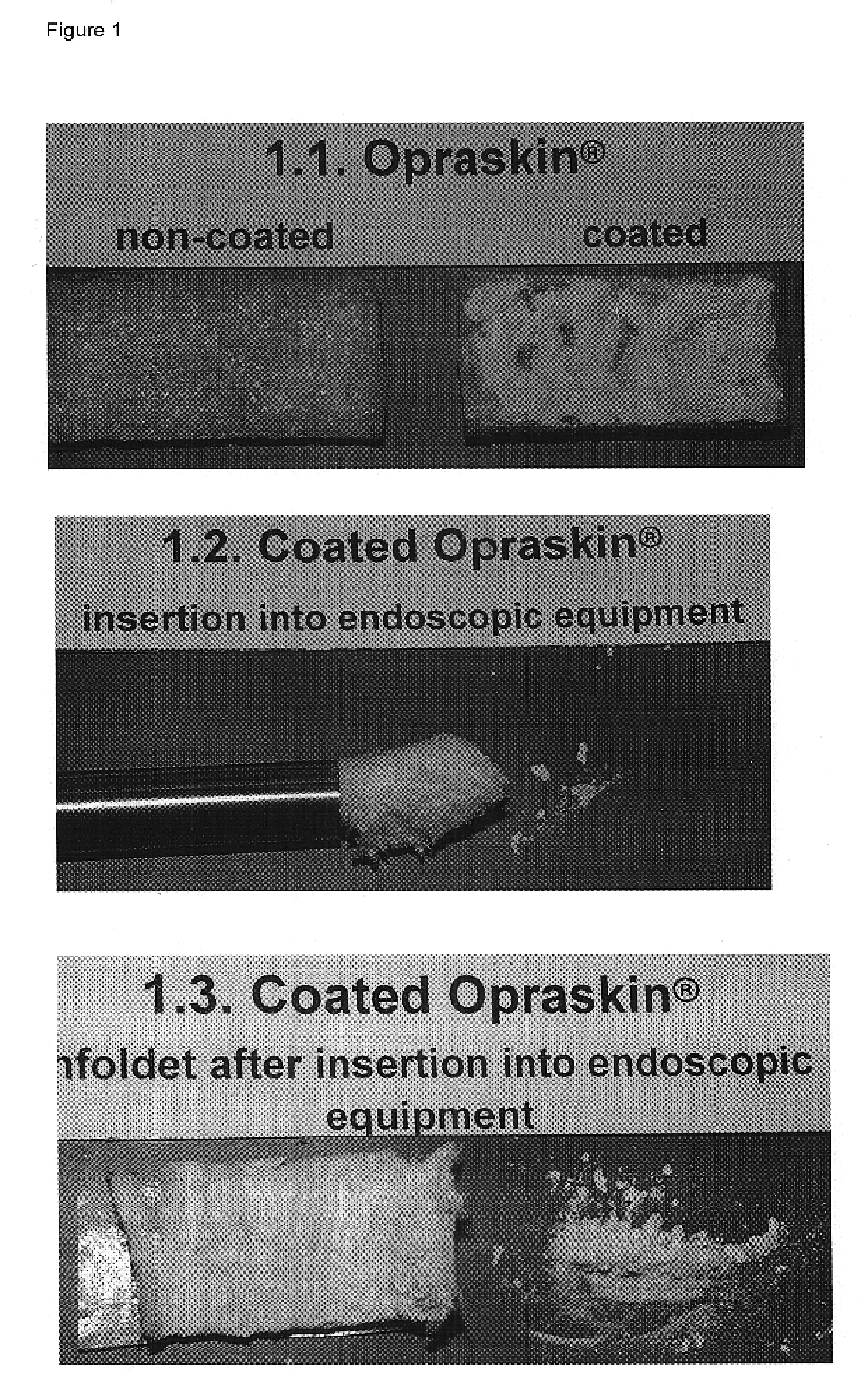

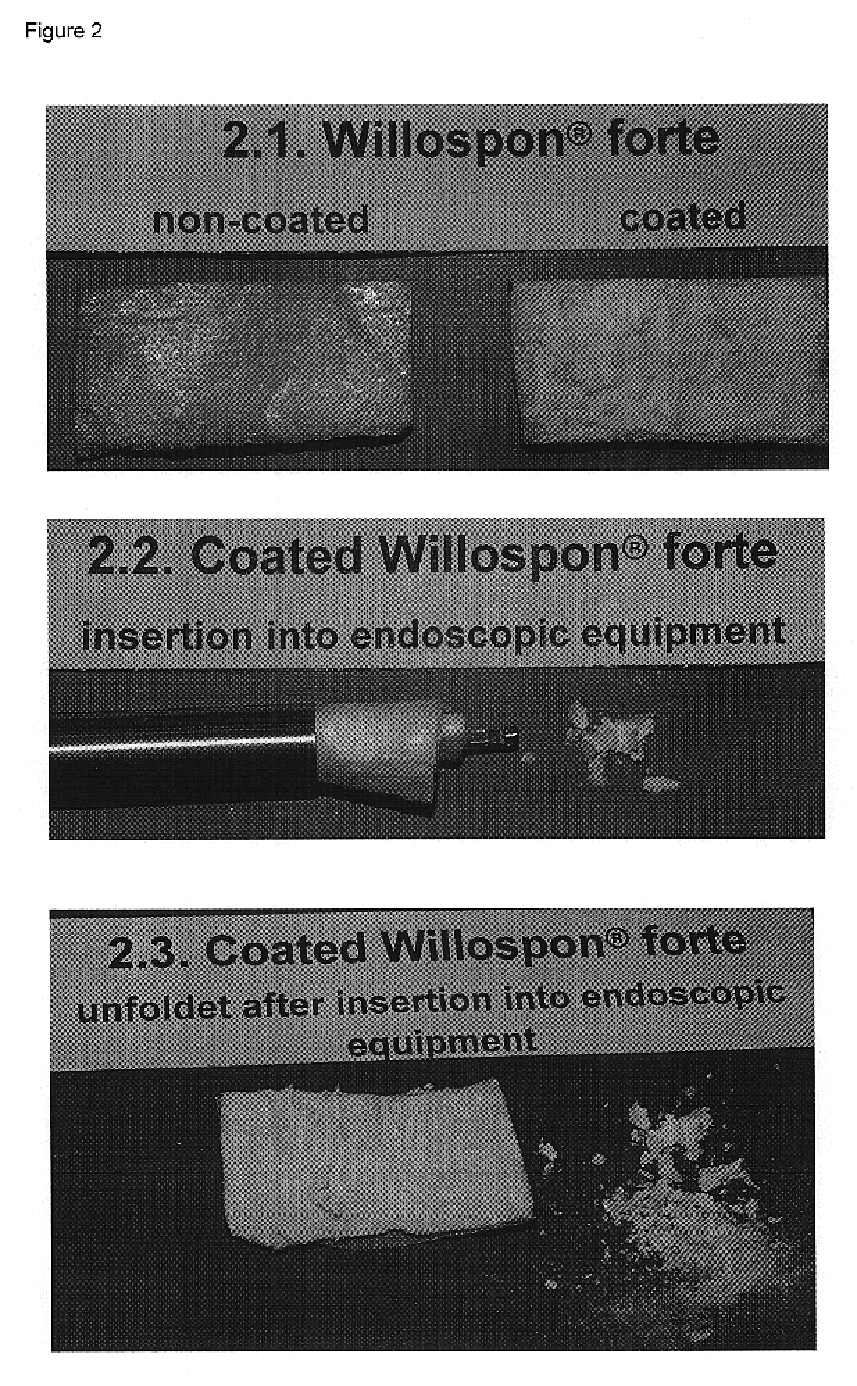

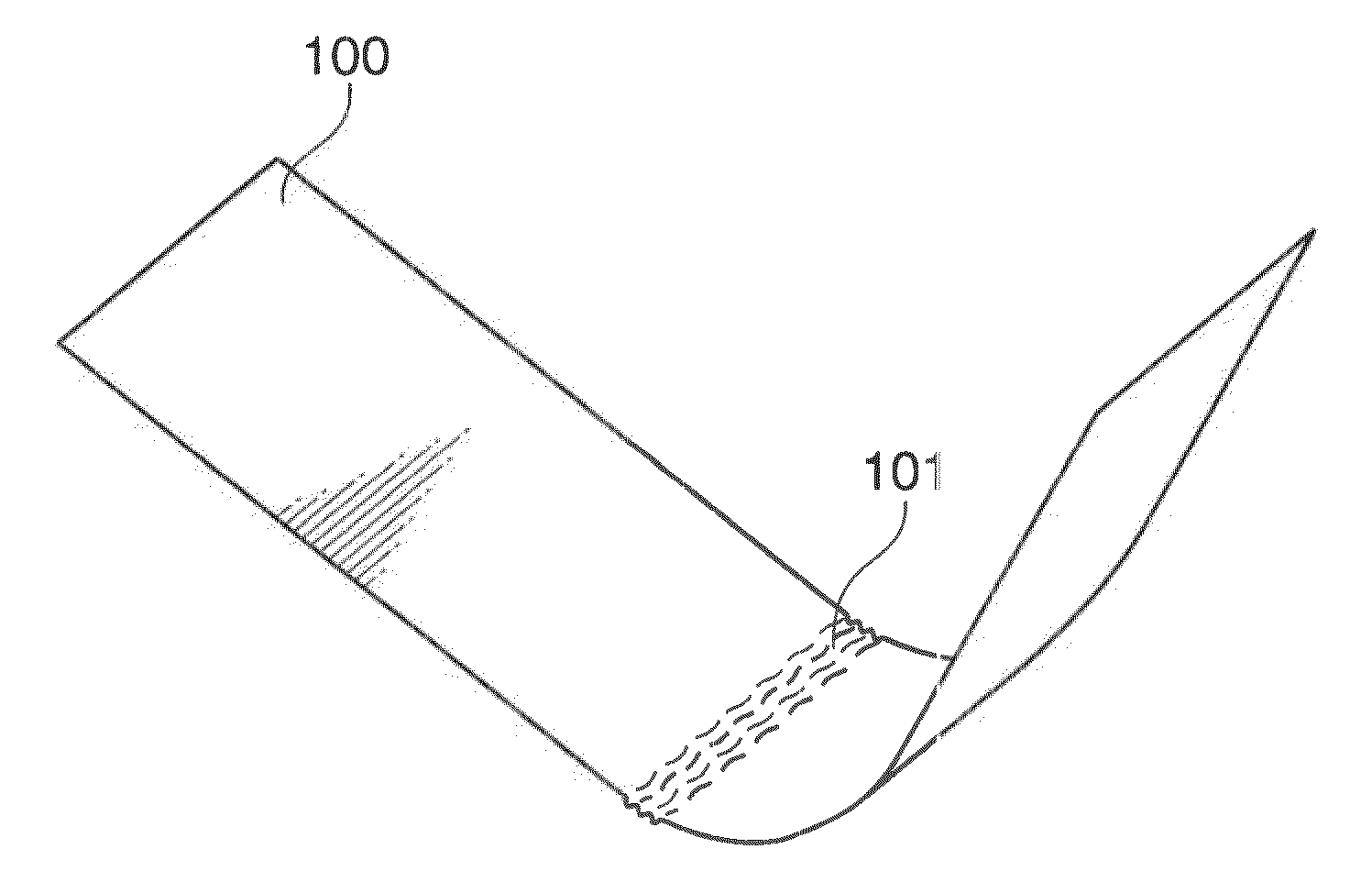

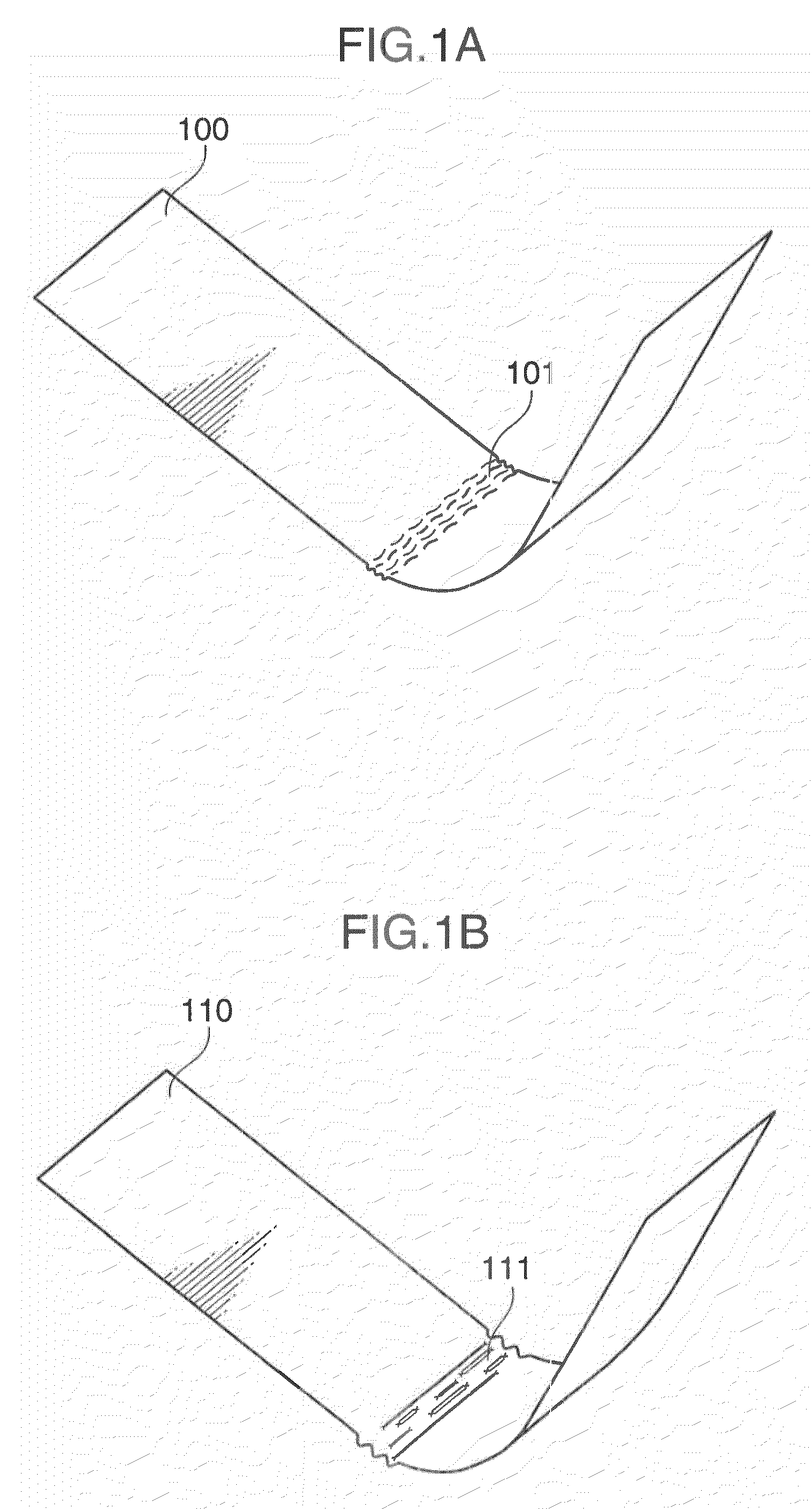

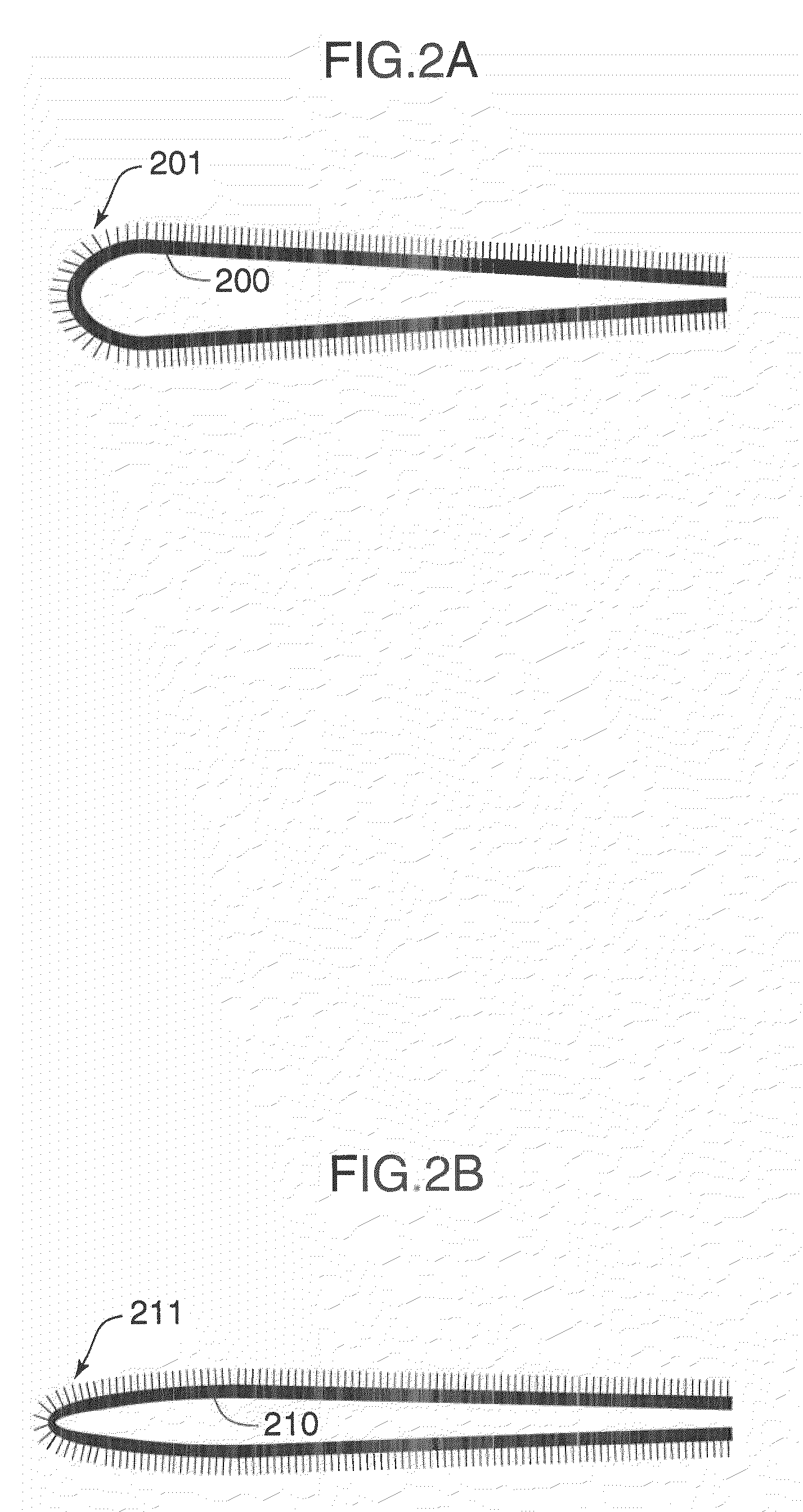

Carrier with solid fibrinogen and solid thrombin

The present invention relates to a solid composition useful for tissue gluing, tissue sealing and haemostasis consisting essentially of a) a carrier which has at least one of the following physical properties: elasticity module in the range of 5-100 N / cm, density of 1-10 mg / cm<3>, chamber diameter of more than 0.75 mm and less than 4 mm and / or having a chamber diameter average below 3 mm and evenly distributed and fixed upon said carrier, b) solid fibrinogen, and c) solid thrombin.The carrier is a biodegradable polymer such as a polyhyaluronic acid, polyhydroxy acid, e.g. lactic acid, glucolic acid, hydroxybutanoic acid, a cellulose, gelatine or collagen, such as a collagen sponge, e.g. a collagen sponge consisting essentially of collagen type I fibres. The fibrinogen and thrombin are preferably human, purified from a natural source, or transgenic or recombinant human fibrinogen and / or thrombin. In a preferred embodiment the composition does not comprise any antifibronolytic agent such as aprotinin, epsilon-aminocaproic acid or alpha2-antiplasmin,

Owner:TOPAZ INVESTMENT AS

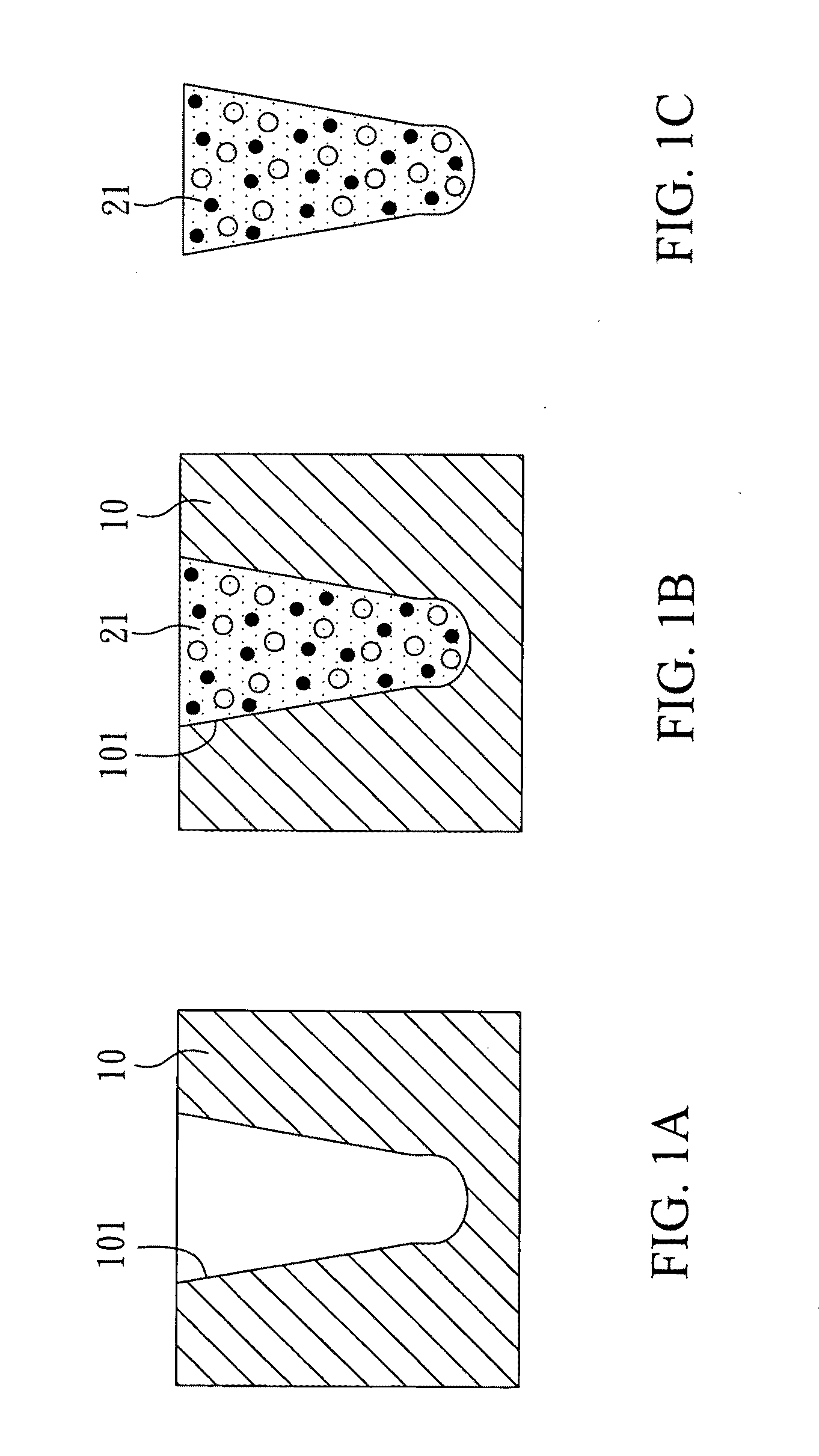

Split leather product and manufacturing method therefor

InactiveUS20110020590A1Increase physical strengthComposite leathersFurniture partsElastomerWrinkle skin

An aspect of the invention is a split leather product provided with a base material comprising split leather, and a skin layer laminated on a surface of the base material. The skin layer comprises a composite body of an entangled nonwoven fabric formed from microfine fibers, and a polymeric elastomer that impregnates the gaps in the entangled nonwoven fabric. The entangled nonwoven fabric in such a split leather product has the effect of increasing physical strength without detracting from a leather-like texture, in the same way as the longitudinally and transversally crisscrossing collagen fibers in the reticular layer. It is thus possible to obtain a split leather product that resembles leather not only in outward appearance but also in the feel derived from wrinkles and the like resulting when the leather is bent.

Owner:KURARAY CO LTD

Carrier with solid fibrinogen and solid thrombin

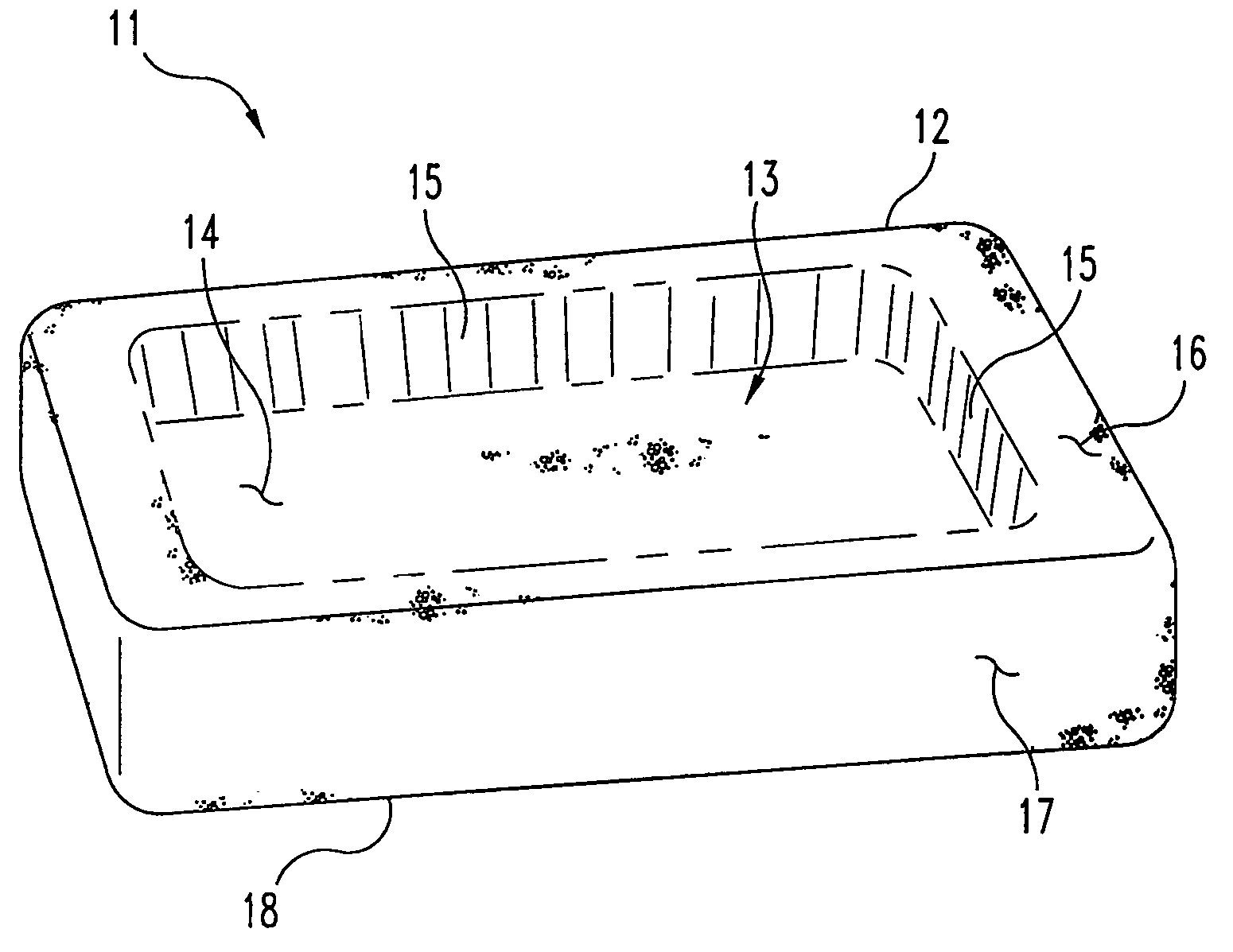

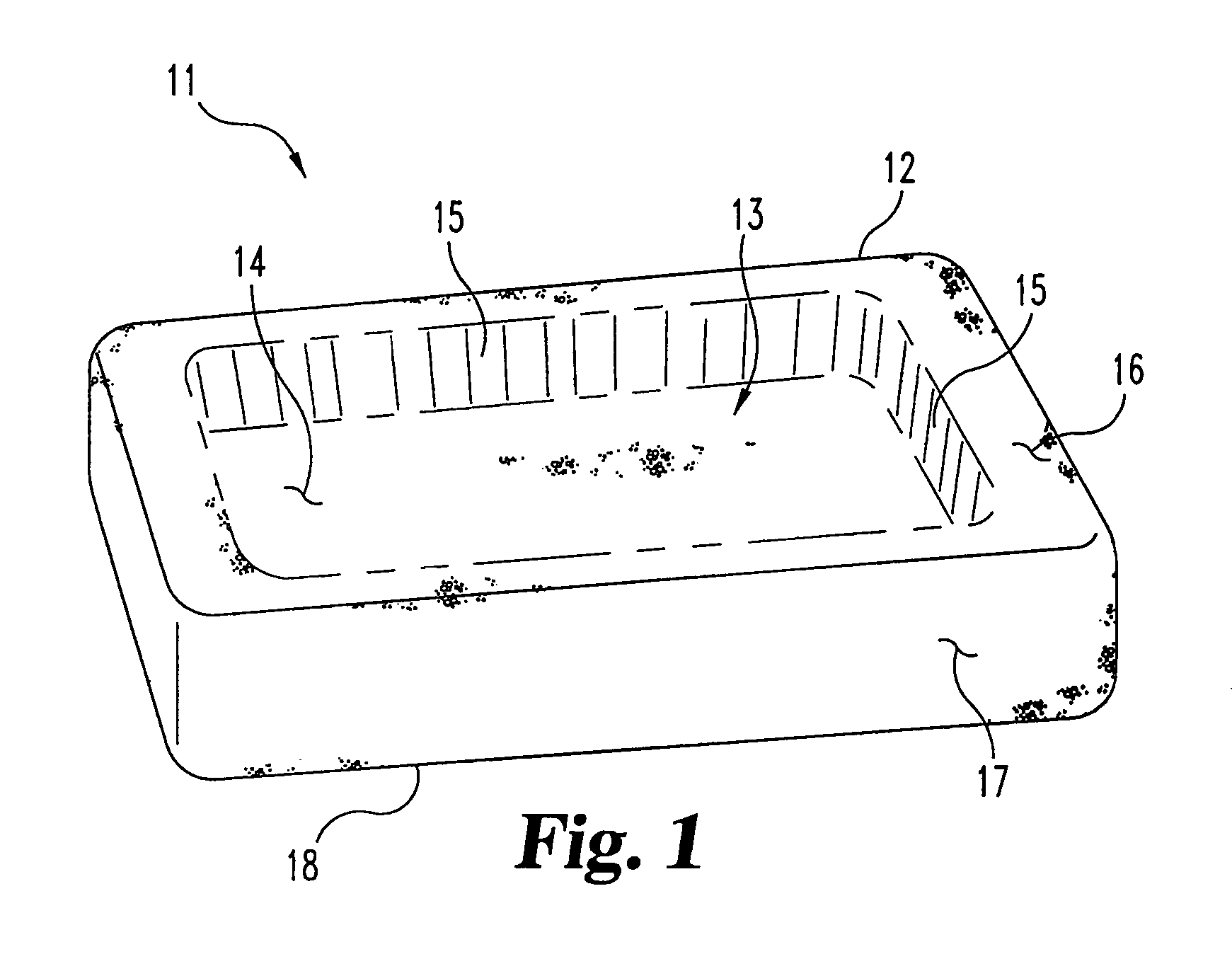

InactiveUS7052713B2Safety and efficacyShorten hemostasis timePowder deliverySurgical adhesivesNatural sourceFiber

The present invention relates to a solid composition useful for tissue gluing, tissue sealing and hemostasis consisting essentially of a) a carrier which has at least one of the following physical properties: elasticity module in the range of 5-100 N / cm, density of 1-10 mg / cm3, chamber diameter of more than 0.75 mm and less than 4 mm and / or having a chamber diameter average below 3 mm and evenly distributed and fixed upon said carrier, b) solid fibrinogen, and c) solid thrombin.The carrier is a biodegradable polymer such as a polyhyaluronic acid, polyhydroxy acid, e.g. lactic acid, glucolic acid, hydroxybutanoic acid, a cellulose, gelatine or collagen, such as a collagen sponge, e.g. a collagen sponge consisting essentially of collagen type I fibers. The fibrinogen and thrombin are preferably human, purified from a natural source, or transgenic or recombinant human fibrinogen and / or thrombin. In a preferred embodiment the composition does not comprise any antifibronolytic agent such as aprotinin, ε-aminocaproic acid or α2-antiplasmin,

Owner:TOPAZ INVESTMENT AS

Cohesive osteogenic putty and materials therefor

Described is an implantable medical material comprising a malleable, cohesive, shape-retaining putty including mineral particles, insoluble collagen fibers and soluble collagen. The medical material can be used in conjunction with biologically active factors such as osteogenic proteins to treat bone or other tissue defects in patients.

Owner:WARSAW ORTHOPEDIC INC

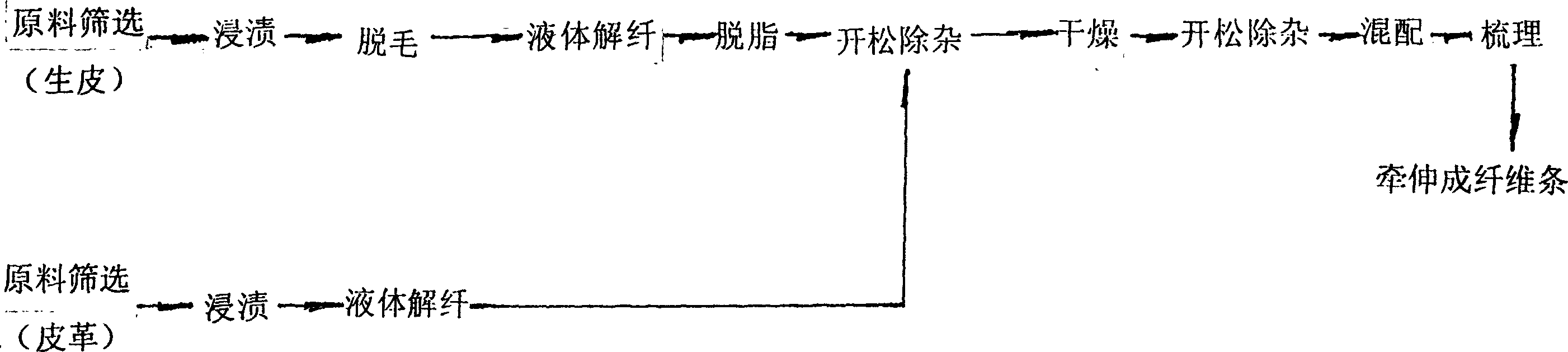

Fabric strip for spinning and its processing method

The invnetion relates to a spinning fiber rod comprised of 5-100% collagen fiber and residual textile fiber. Wherein, the process method comprises: screening material, dipping, defibering, degreasing, cleaning, dewatering, drying, opening to remove impurity, mixing, carding, and drafting. This invention can obtain material from wide source, has well applicability, high tensile strength, well moisture / oil absorption properties, and fit to spread in textile industry.

Owner:张立文

Human umbilical cord mesenchymal stem cell exosome type external cream and preparation method thereof

InactiveCN107854418AEasy to get materialsA large amountCosmetic preparationsToilet preparationsFiberBase cream

The invention provides human umbilical cord mesenchymal stem cell exosome type external cream and a preparation method thereof, and aims at the solving the problem in effectively inducing human umbilical cord mesenchymal stem cells to massively synthesize and secrete mesenchymal stem cell exosome capable of specifically promoting epidermis cell and hypodermal cell to proliferate, divide and differentiate, promoting the formation of collagenous fibers, reticular fibers and elastic fibers, and adjusting the secreting functions of collagen and mucopolysaccharide. The cream comprises human umbilical cord mesenchymal stem cell exosome extracting liquid and a base cream formula based on the mass ratio ranging from (1:20) to (3:10), wherein the human umbilical cord mesenchymal stem cell exosome extracting liquid is prepared by performing hungry culture on P2-P5 generations of human umbilical cord mesenchymal stem cells and stimulating through epidermal growth factors. The prepared cream has the effects of improving the skin quality, resisting the aging of skin cells, recovering the normal structure and physiological function of the skin, reducing the skin atrophy exsiccosis, and moisturizing the skin tissue.

Owner:南京九圣生物医学科技股份有限公司

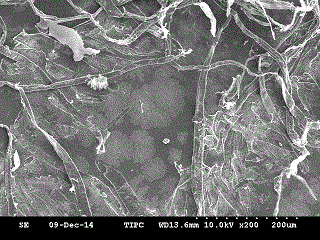

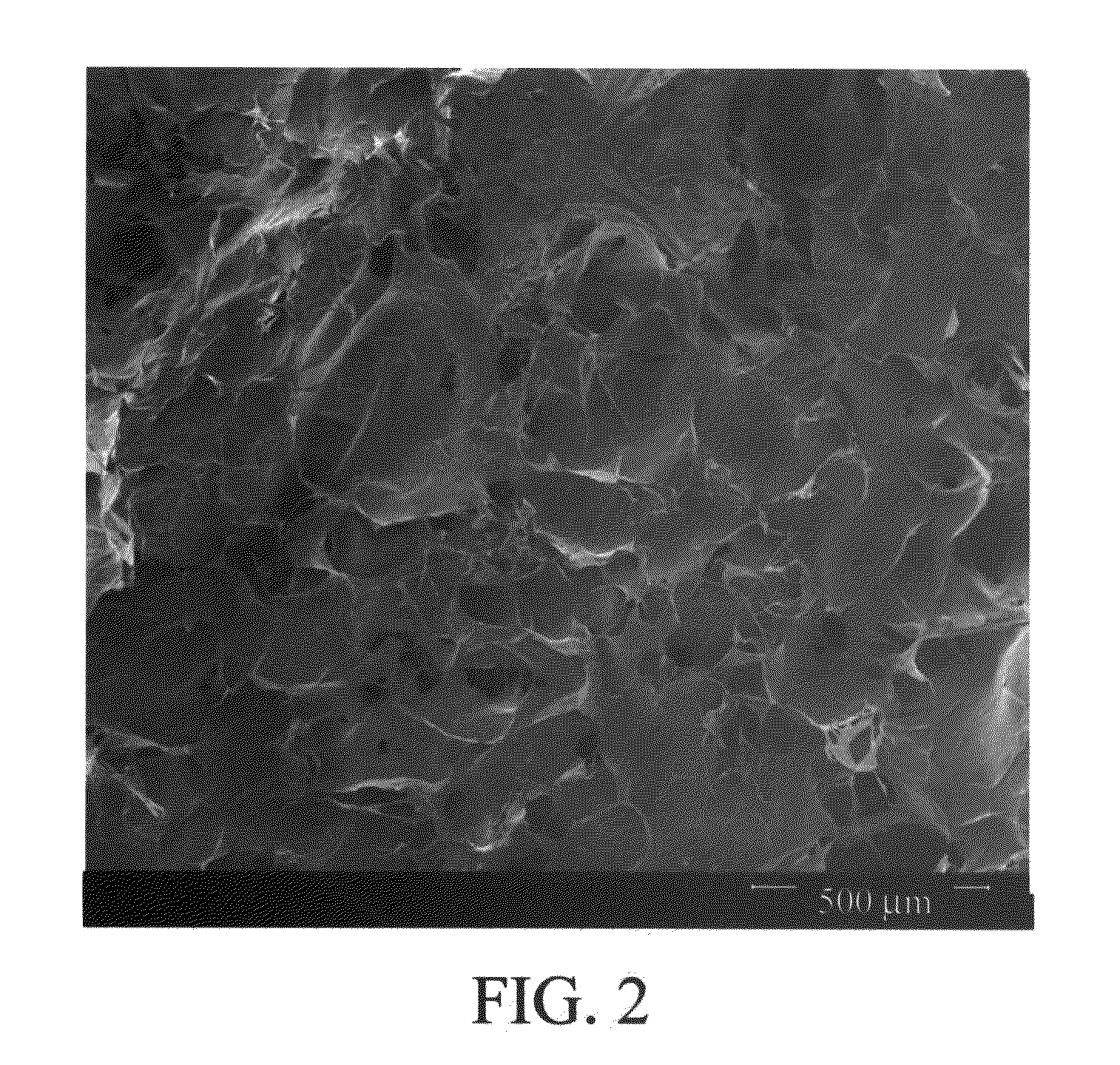

Antigen-free collagen aggregate and preparation method thereof

The invention discloses an antigen-free collagen aggregate and a preparation method thereof. The preparation method is characterized by comprising the following steps: with traceable animal skin or tendo calcaneus as a raw material, performing operations by the process such as fleshing, stripping fascia, degreasing, removing foreign protein and decellularizing; performing fine purification on the animal skin or tendo calcaneus, and then carrying out separation and purification on the collagen aggregate by the methods of acid fluffing, homogenizing, salting out for a plurality of times, centrifuging for a plurality of times and the like, thereby finally obtaining the antigen-free collagen aggregate. The collagen aggregate is a mixture of a collagen fiber and a collagen bundle, and has a periodic light and shade horizontal grain structure; and the space between the horizontal grains is about 67nm. The material has good biocompatibility, biodegradability, mechanical property and hemostatic performance, also has the characteristics of low antigenicity, biological activity and the like, and can be widely applied to preparation of biomedical materials such as a hemostatic material, a tissue engineering material, a biological dressing, a biodegradable medical suture and a plastic material.

Owner:SICHUAN UNIV

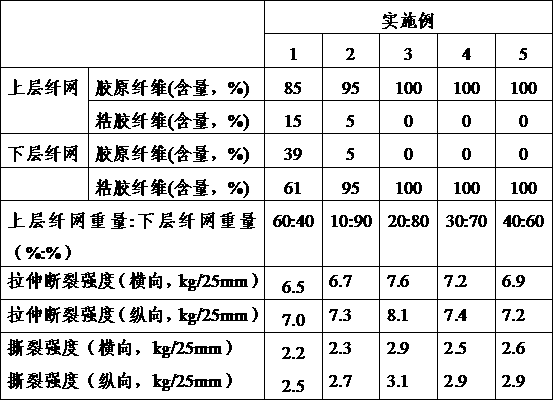

Environment-friendly collagen fiber leather substrate and production method thereof

ActiveCN102115955AIncrease profitNo pollution in the processFilament/thread formingNon-woven fabricsFiberPolymer science

At present, researchers do the research of reasonable utilization of chrome-containing leather shavings all the time; however, the leather shavings of leather making enterprises are difficult to treat in batch. The invention provides an environment-friendly collagen fiber leather substrate which is characterized by comprising an intermediate-layer fiber web, a surface-layer fiber web tightly connected on the upper surface of the intermediate-layer fiber web, and a bottom-layer fiber web tightly connected on the lower surface of the intermediate-layer fiber web, wherein the surface-layer fiber web and the bottom-layer fiber web respectively comprise the components by mass percentage of: 90 to 97 percent of collagen fibers, 3 to 10 percent of polylactic acid bi-component fibers; the intermediate-layer fiber web is made of polylactic acid bi-component fibers; the weight of the surface-layer fiber web and the weight of the bottom-layer fiber web are both 30 to 150 grams per square meter; and the weight of the intermediate-layer fiber web is 10 to 30 grams per square meter. The non-woven synthetic leather substrate prepared by using collagen fiber extracted from leather leftovers has good simulation performance, avoids secondary pollution to the environment, and is beneficial to the follow-up coating of PU (polyurethane).

Owner:GUANGZHOU CANUDILO FASHION & ACCESSORIES CO LTD

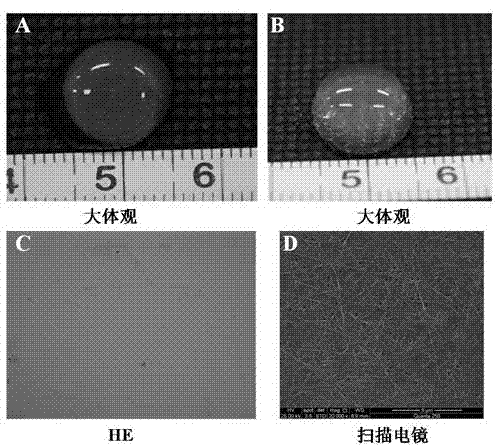

Lamellar corneal stroma bracket as well as preparation method and application thereof

The invention discloses a lamellar corneal stroma bracket as well as a preparation method and application thereof. The method comprises the following steps: carrying out low-permeability swelling, repetitive freeze-thawing, enzyme digesting, drying and sterilizing treatment on a corneal stroma sheet of a fresh animal eyeball cut down under a sterile condition, wherein the enzyme digesting adopts buffer liquor containing DNA (deoxyribonucleic acid) enzyme and RNA (ribonucleic acid) enzyme to treat, ultrasonic treatment is carried out after the enzyme digestion treatment, and then drying and sterilizing treatment is carried out. The invention further provides application of the lamellar corneal stroma bracket as a corneal stroma substrate. The method disclosed by the invention can be used for reducing damages on a corneal stroma collagen structure to the greatest extent; collagenous fiber arrangement is orderly, holes are uniform and regular, cell residues are avoided, the lamellar structure is kept complete, and the biocompatibility of the bracket material is improved.

Owner:QINGDAO CHUNGHAO TISSUE ENG

Collagen fiber solidified tannin adsorptive material and its preparation method and its adsorption and separation of metallic ion

InactiveCN1410157AEliminate solubilityEliminate strengthOther chemical processesWater/sewage treatment by sorptionFiberTannin

An adsorbing collagen fibre-solidified tannin material for adsorbing and separating metallic ions (Pb, Cd, Hg, Cr and Cu) is prepared from animal skin through preparing collagen fibre membrane or granules, adding the said collagen fibres along with the aqueous solution of tannin to a reactor, reacting at 10-45 deg.c for 6-24 hr, laying aside for 12-24 hr, filtering, washing to remove excessive tannin, adding cross-linking agent, reacting at 20-70 deg.c for 2-8 hr, filtering, washing and drying at 60 deg.c for 12-24 hr. It has very high adsorption selectivity.

Owner:SICHUAN UNIV

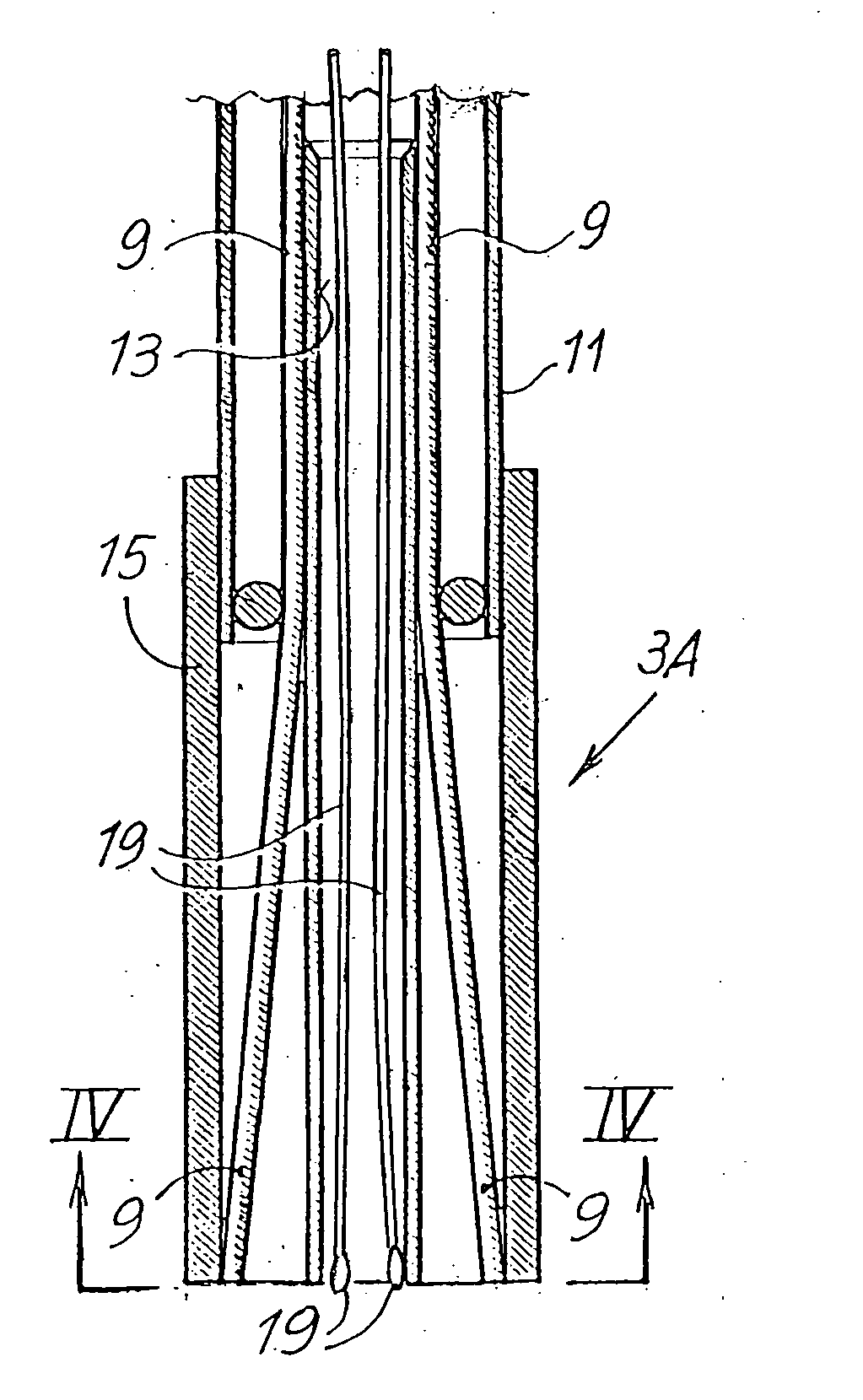

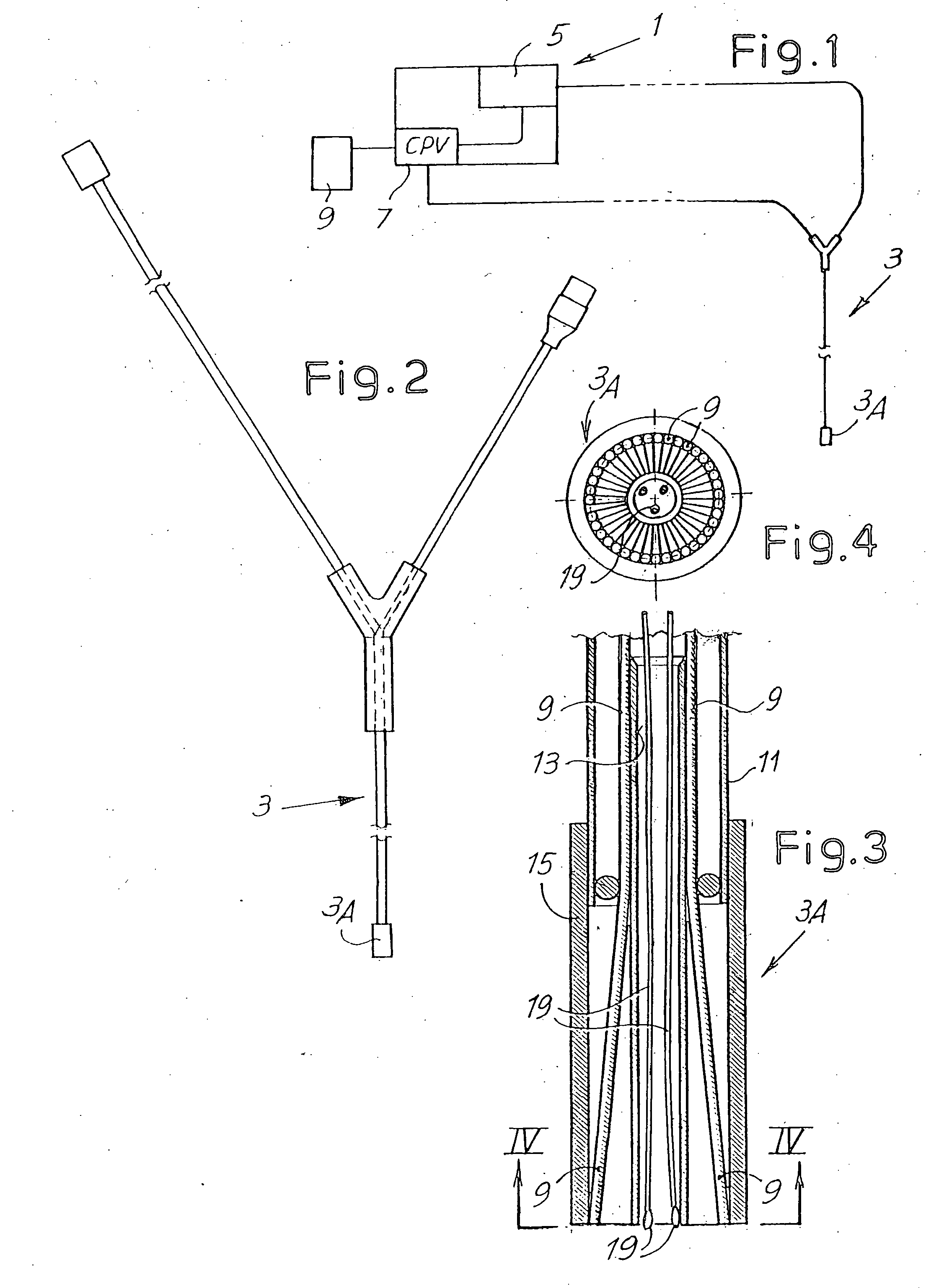

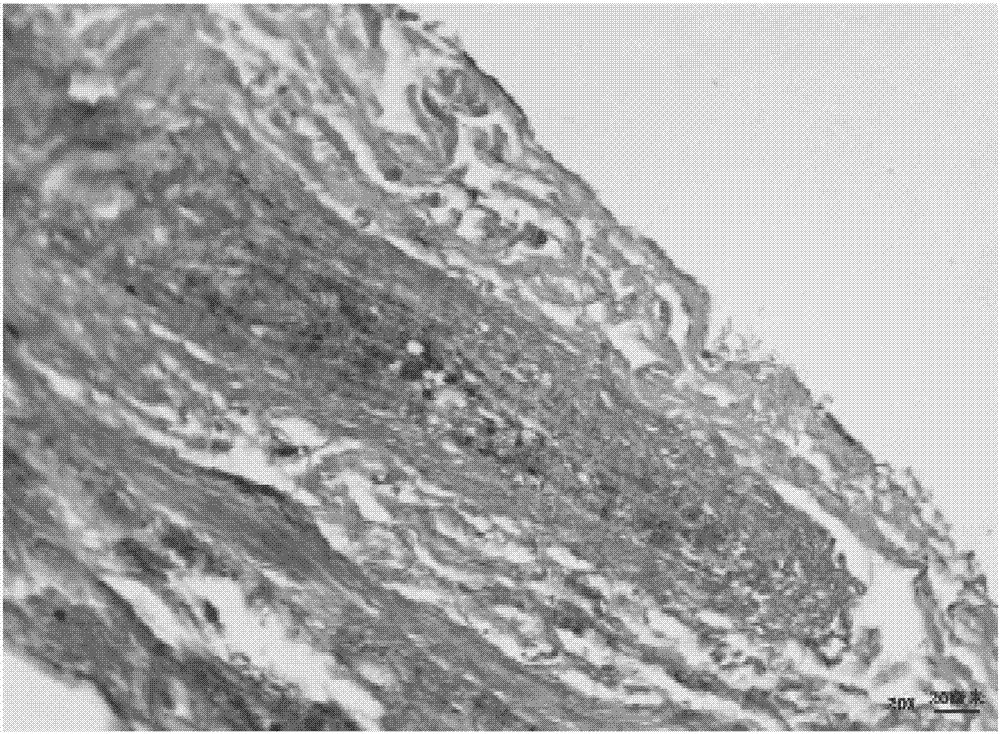

Device, a catheter, and a method for the curative treatment of varicose veins

InactiveUS20060189967A1Increase supplyReduce intrusionCatheterSurgical instrument detailsTunica mediaFiber

Described herein are a device and a method for the treatment of varicose veins via laser radiation, and in particular using a holmium laser. The radiation of a laser source (5) is injected in a fiber (3) that can be inserted in the vessel to be treated. The laser source emits a radiation such as to cause a hyalinizing sclerosis with structural modifications both to the fibers of the collagen (shrinkage) and to the extracellular matrix of the median coat of the vein by the photothermal effect, substantially without thermal stress of the morphological component of the tunica media and of the tunica intima.

Owner:EL EN SPA

Ply tissue engineering corneal frame and manufacturing method and application thereof

ActiveCN101947144AThe production process is simple and reliableShorten the timeEye implantsDiseaseFiber

The invention discloses a ply tissue engineering corneal frame and a manufacturing method and an application thereof, relating to a ply tissue engineering corneal frame of the biomedicine. Compared with the existing materials, the invention provides a ply tissue engineering corneal frame and a manufacturing method and an application thereof, which has abundant resources, high transparency, good biocompatibility, thorough decellularization and strong safety, and the performance approaches to that of a fresh cornea, so that the ply tissue engineering corneal frame can be accepted by majority of patients and applied clinically for a long term. The ply tissue engineering corneal frame is an animal derived decellularized ply corneal stroma sheet and does not contain cellular constituents; collagenous fibers are tidily arranged, and gaps are regular; corneal light transmittance is 80-95%, and tensile strength is 2-5N / mm<2>. The ply tissue engineering corneal frame can be served as the substitute for various donor materials for corneal transplantation and can be used for treating a series of diseases of corneal trauma and chemical burn, corneal tumor and a series of hyperplastic diseases, a series of diseases of corneal neovascularisation and scar, corneal immune diseases, a series of diseases caused by corneal transplantation exclusive reaction and other keratopathy.

Owner:XIAMEN DAKAI BIOTECH CO LTD

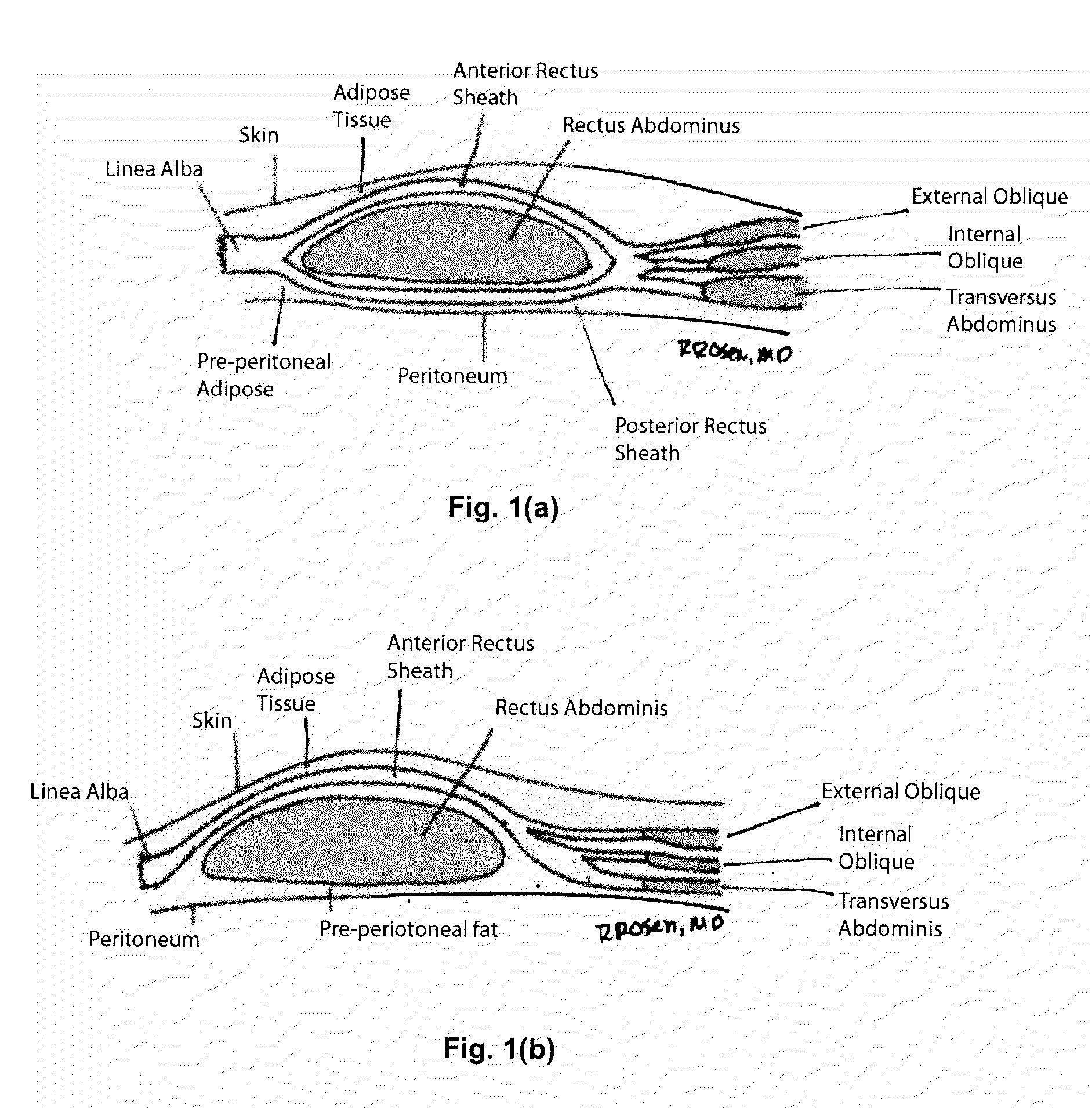

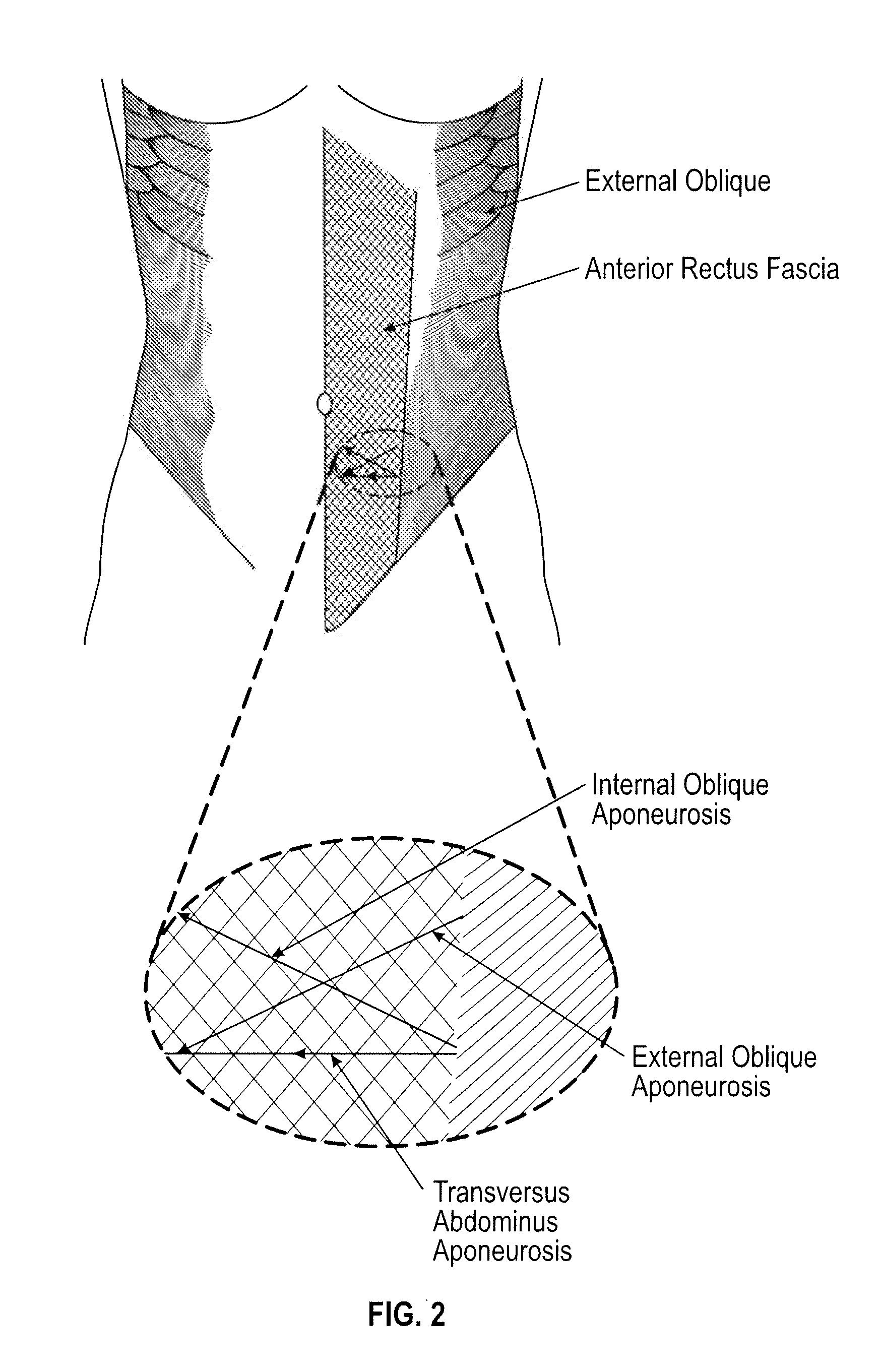

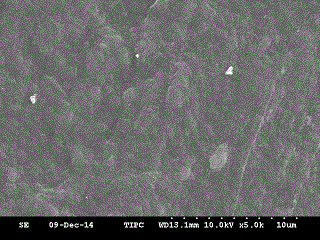

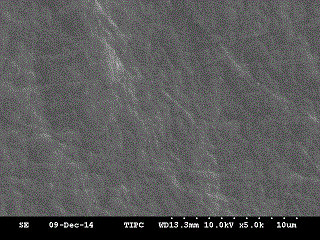

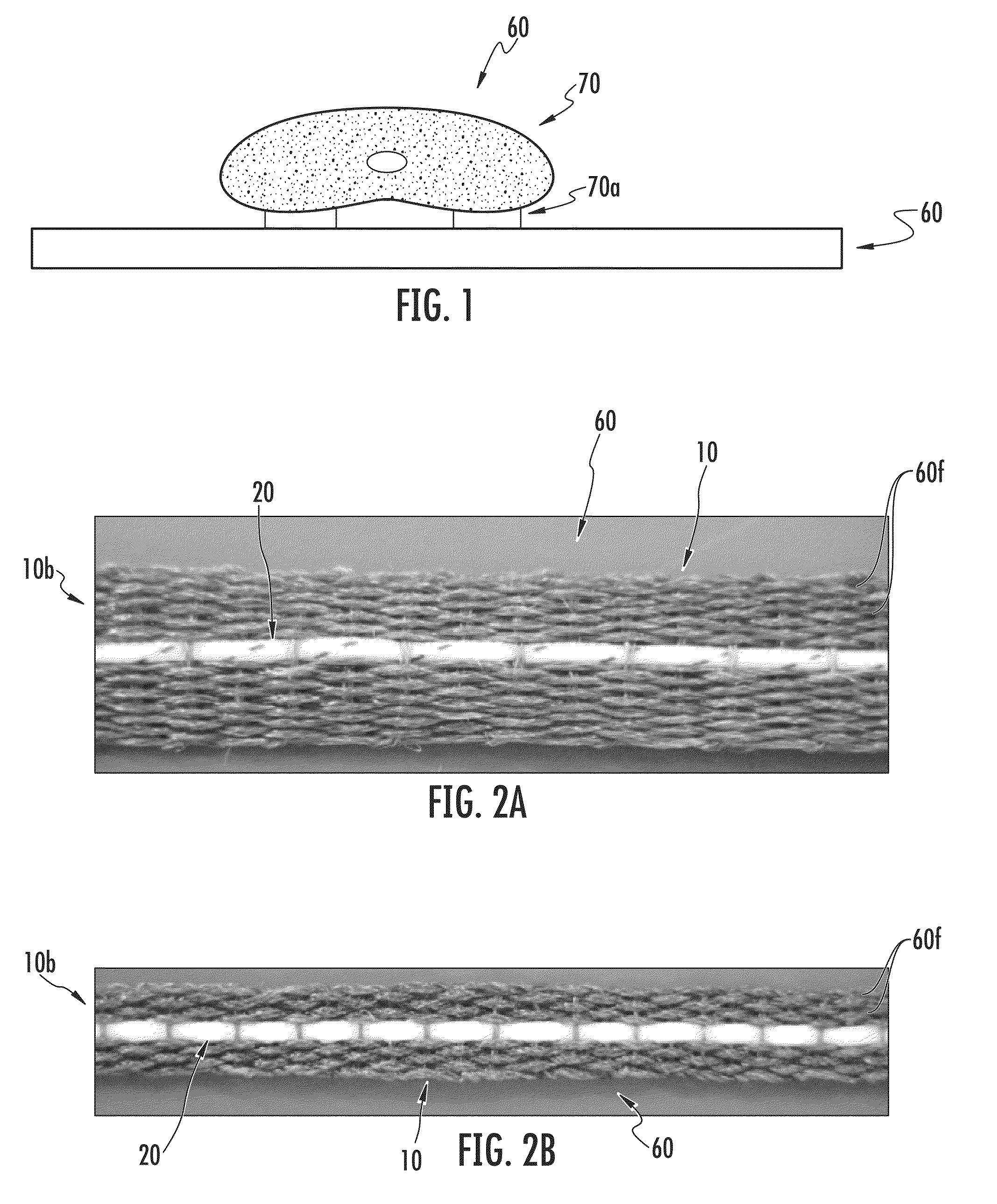

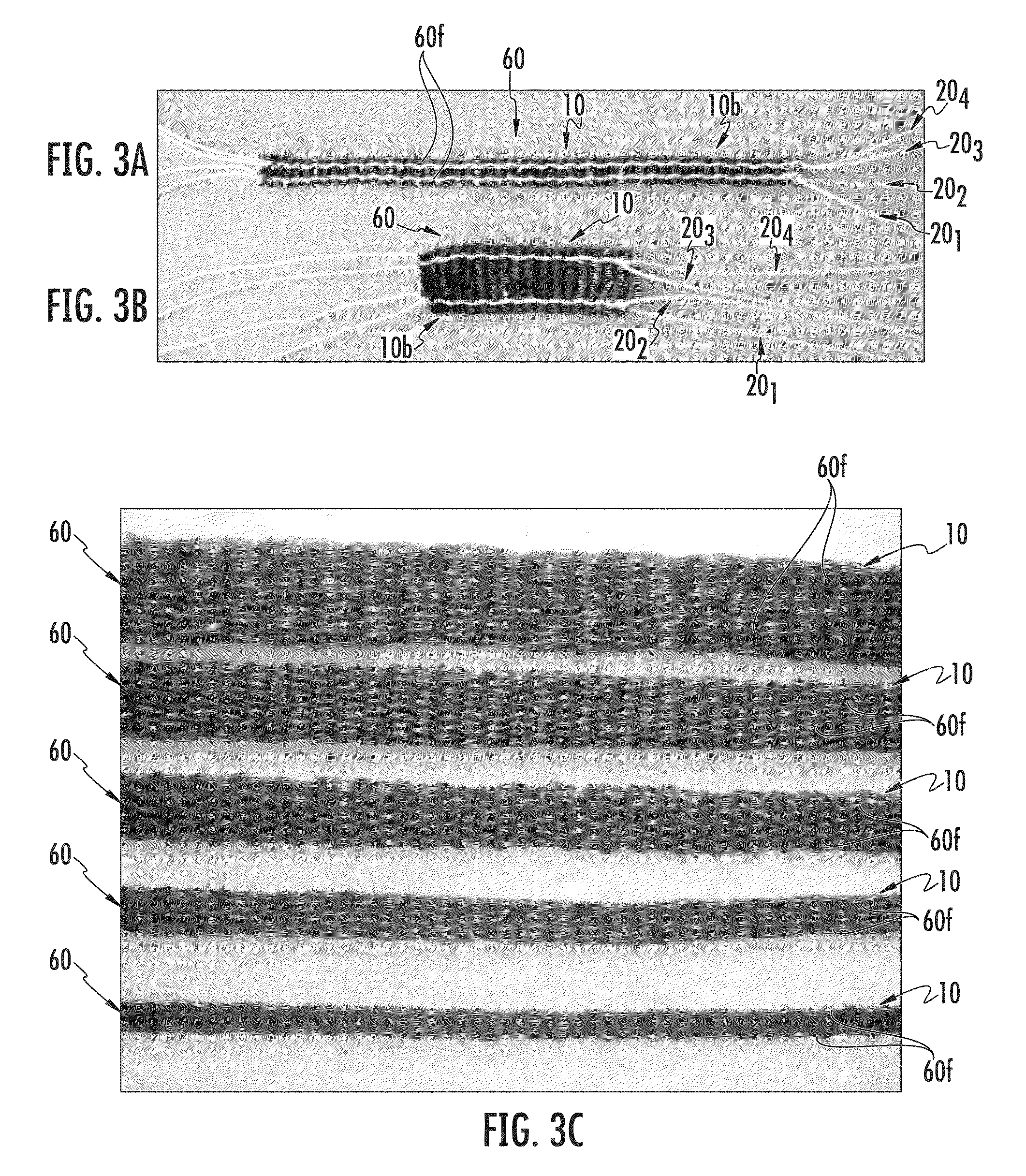

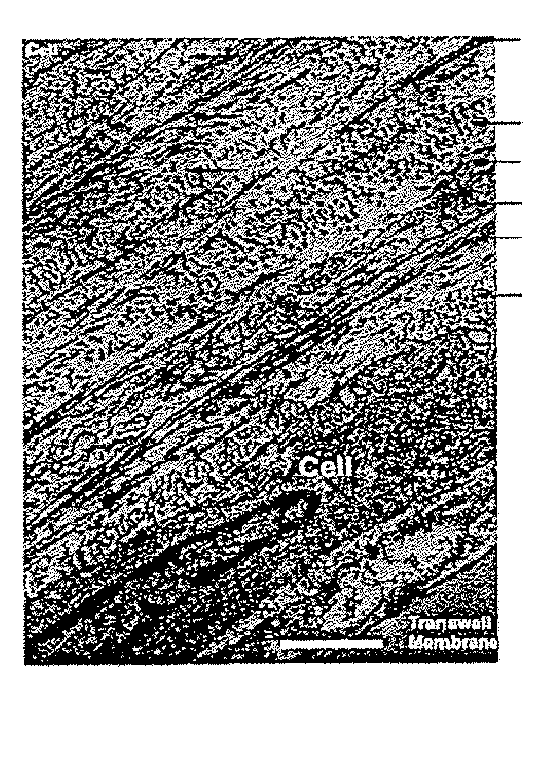

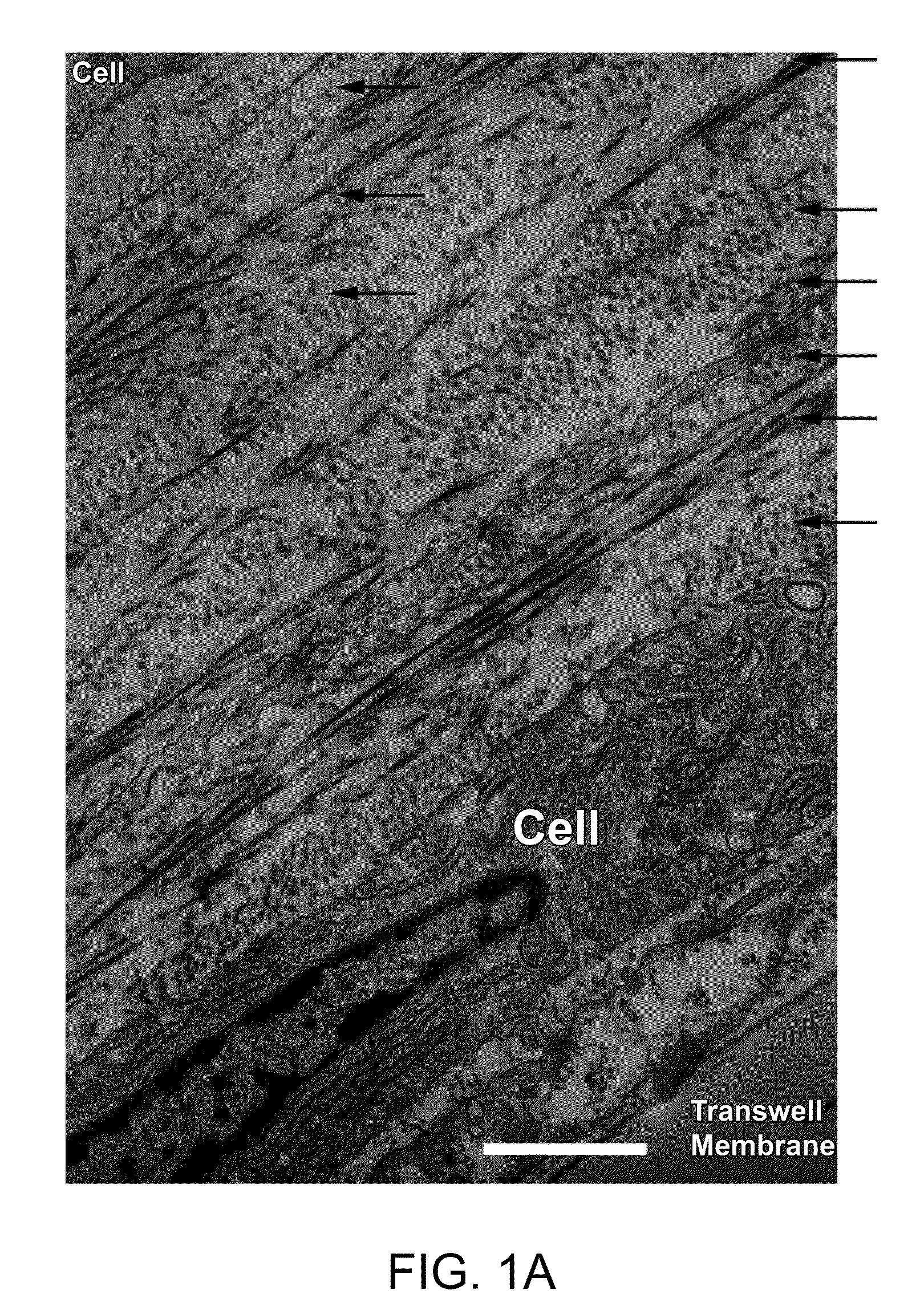

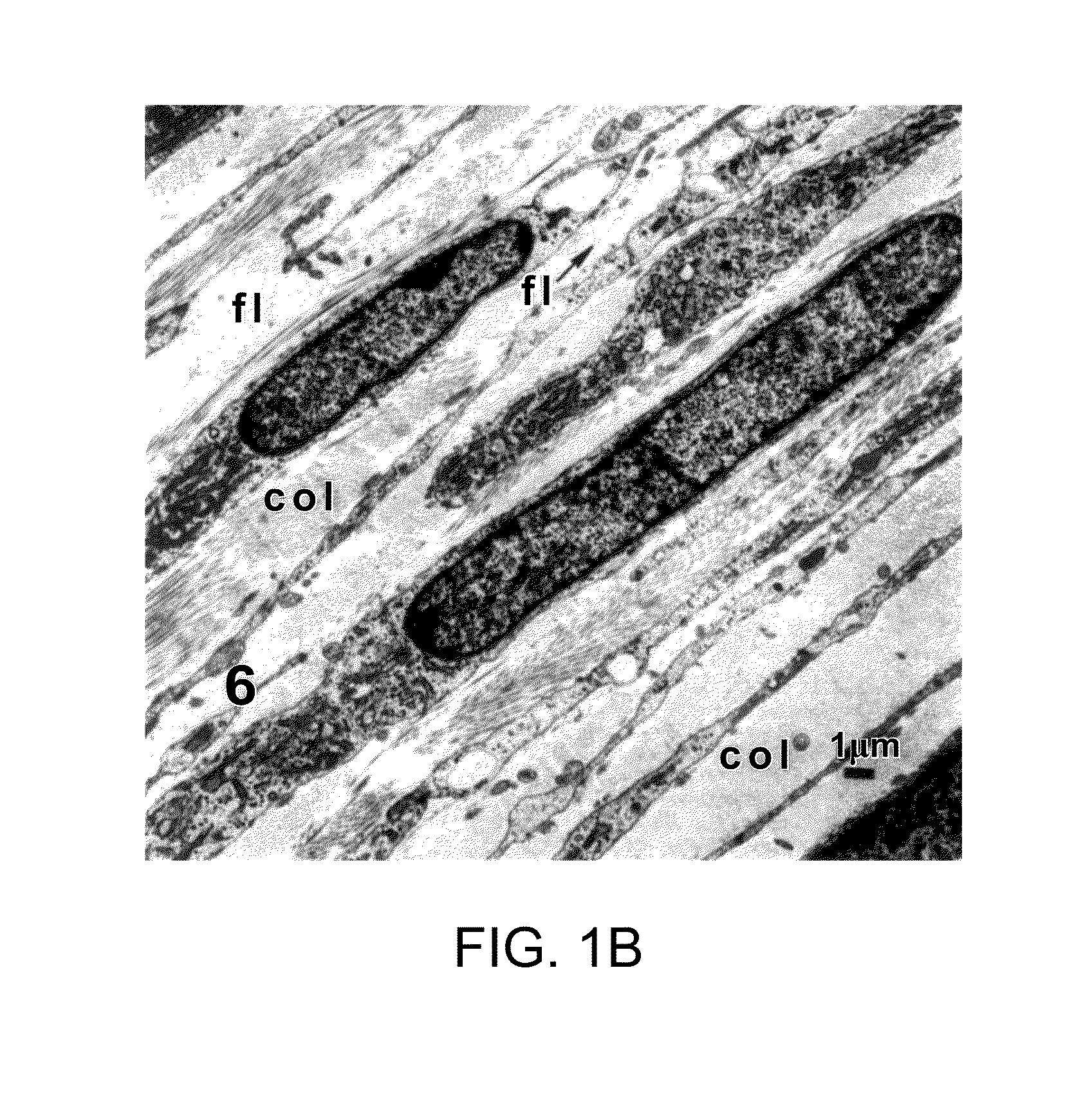

Materials for soft and hard tissue repair

Biomaterials and methods and uses for repair or augmentation of tissues are provided. In particular, the invention provides a multi-layered, naturally occurring multi-axial oriented biomaterial comprising predominately type I collagen fibers. The invention further provides methods and uses for repair or augmentation of tissues using biomaterials of the invention.

Owner:OBI BIOLOGICS

High-strength bionic collagen membrane and preparation method thereof

The present invention provides a preparation method of high-strength bionic collagen membrane. The preparation method is by conducting gradient dialysis process on collagen to rearrange collagen molecules into an ordered structure, and endow the molecules with more consistent and more extensive collagen fiber orientation, thus improving the mechanical properties of the material. The collagen membrane prepared by using the method has similar appearance, structure and performance to natural dura and amnion of mammals, and good rehydration, and is free to bend and fold after water absorption; the bionic collagen membrane with high tensile strength can be stitched by using suture and can be used in clinical guided tissue regeneration or repair of various tissues.

Owner:BEIJING PAISHENG BIOTECH CO LTD

Biological tissue matrix material, and preparation method and purpose thereof

ActiveCN107007886AImprove processing efficiencyHigh bonding strengthTissue regenerationProsthesisFiberCell-Extracellular Matrix

The invention provides a biological tissue matrix material, and a preparation method and a purpose thereof. The biological tissue matrix material is characterized by comprising an extracellular matrix, wherein the extracellular matrix comprises collagenous fiber, growth factors and fibronectin. The biological tissue matrix material is prepared from small intestinal submucosa matrix materials. The preparation method is characterized by comprising the following steps that decellularization is performed: decellularized liquid contains trypsin and PBS solution, and also contains EDTA, EDTA-2Na or EDTA-4Na; the decellularized liquid is used for treatment in multi-frequency ultrasonic environment for decellularization; the dual-frequency ultrasound at least contains two ultrasonic frequencies with different frequencies. The decellularization process technology is improved; the DNA residual quantity of the obtained product is lower; the immunogenicity is lower; the anti-infection capability is higher; the restoration capability is higher.

Owner:BEIJING BIOSIS HEALING BIOLOGICAL TECH

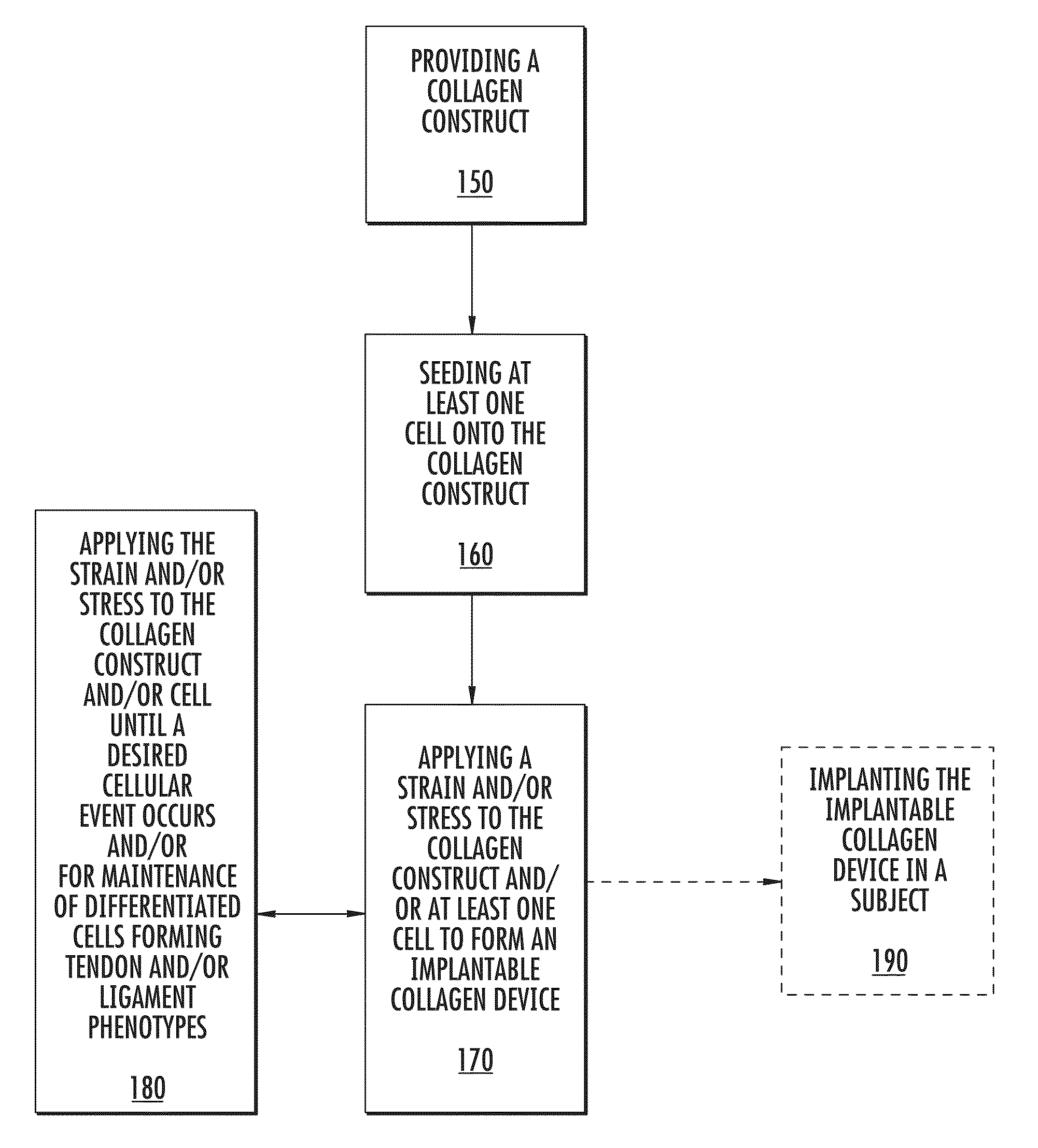

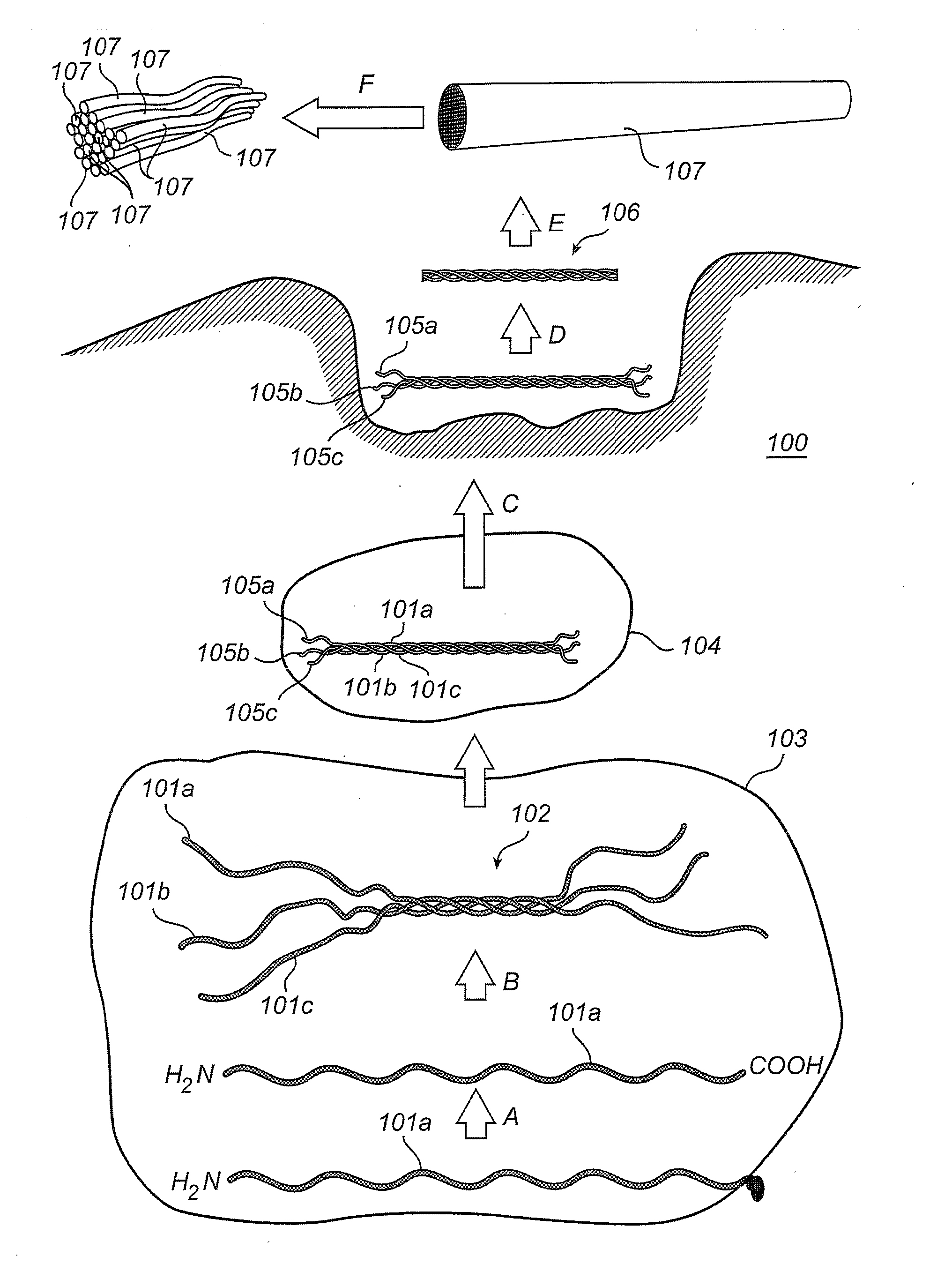

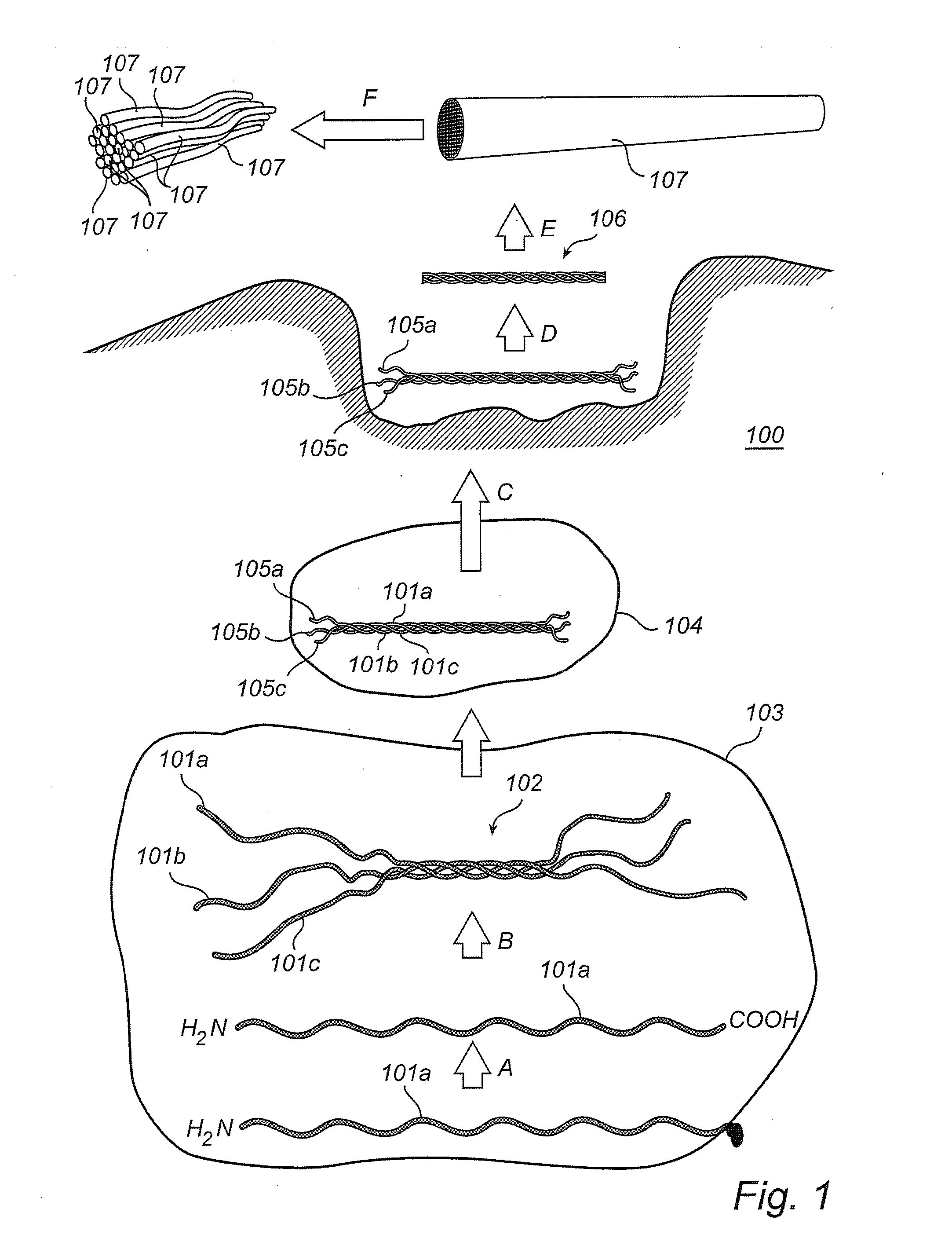

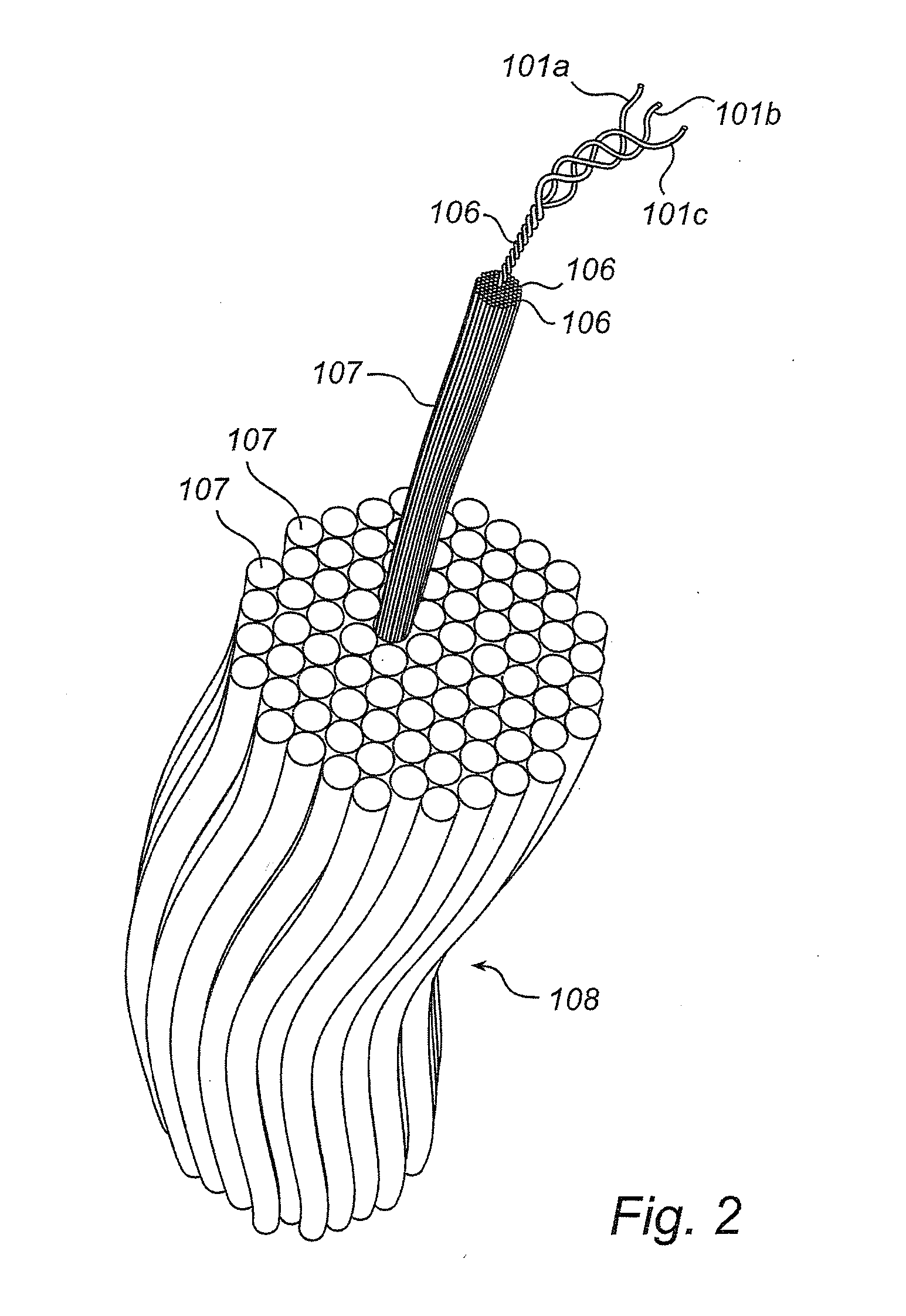

Implantable collagen devices and related methods and systems of making same

The invention relates to implantable collagen devices made by seeding at least one elongate collagen construct, e.g., comprising at least one elongate synthetic collagen fiber with a plurality of cells and applying a strain and / or stress to the at least one elongate collagen fiber to induce the cells to differentiate into target phenotypes, e.g., tendon or ligament phenotype cells (and / or fibroblasts), typically with an extracellular matrix of collagen to organize into a tissue on the at least one collagen fiber.

Owner:MIMEDX GROUP

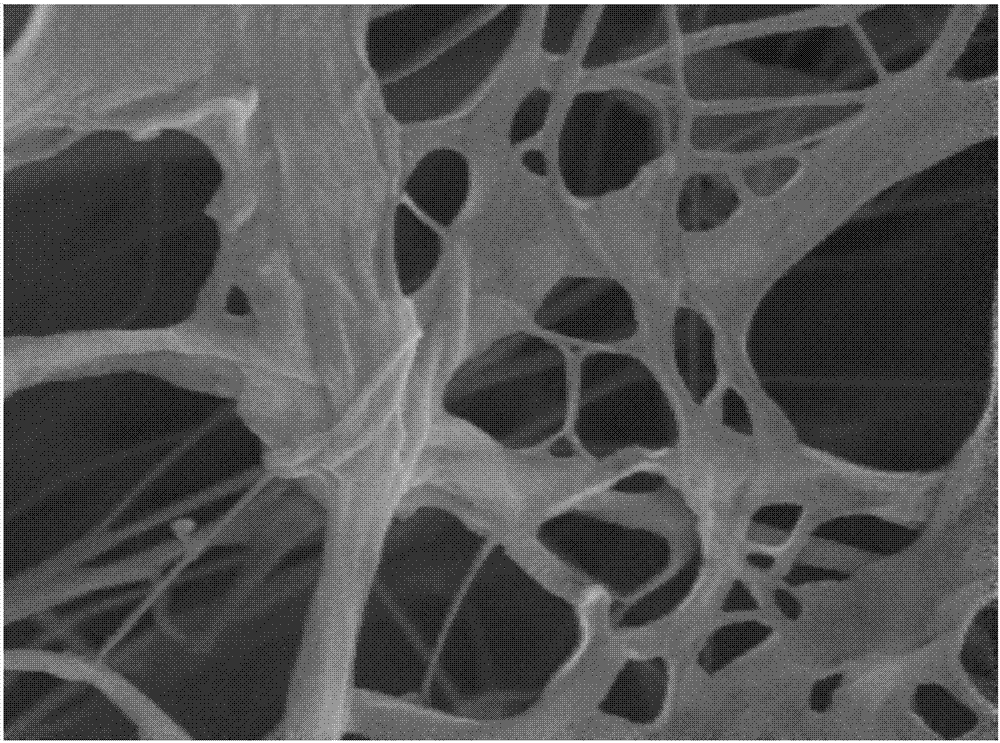

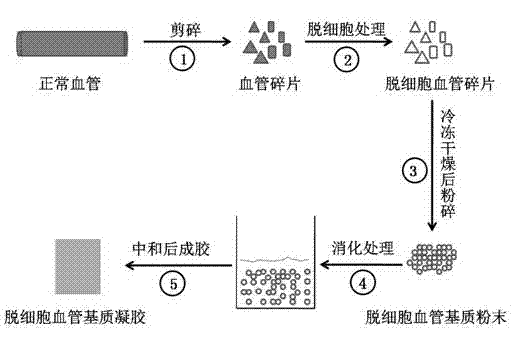

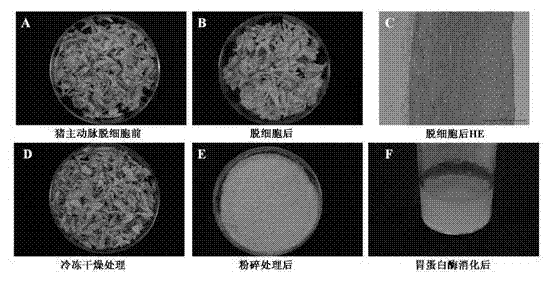

Decellularized blood vessel matrix gel, preparation method therefor and applications thereof

InactiveCN103705542AGood shaping effectGuaranteed uniformityAerosol deliveryOintment deliveryDigestionBlood vessel

The invention relates to a kind of decellularized blood vessel matrix gel, a preparation method therefor and applications thereof. The preparation method is as follows: first, after blood vessel outer membranes and anadesma are removed, the blood vessels are cut into blood vessel pieces, the blood vessel pieces are subjected to decellularized treatment in a TritonX-100 solution, then subjected to freeze drying, smashed into powder, and filtered with a 60-mesh screen, and decellularized blood vessel matrix powder is obtained; second, the decellularized blood vessel matrix powder is placed in a hydrochloric acid solution containing pepsin with a concentration of 0.09-0.11%, and subjected to digestion for 66-78h, a sodium hydroxide solution is added to neutralize hydrochloric acid, then PBS is added to balance ion concentration, finally, the gel solution is placed in an incubator with a temperature of 37 DEG C for gel forming. The decellularized blood vessel matrix gel has good molding capability and mechanical properties, the interior is loose, the gel has certain poriness, and the collagen fiber has appropriate diameters and good stability. The gel can meet requirements of preparation of medicines treating ischemic diseases, support materials of tissue engineering and / or cell culture.

Owner:SHANGHAI CHILDRENS MEDICAL CENT AFFILIATED TO SHANGHAI JIAOTONG UNIV SCHOOL OF MEDICINE

Method for producing artificial leather base material by compounding collagen fibers by utilizing spun-laced water jetting

At present, the synthetic leathers are made of artificial fibers, and due to the performance difference between the artificial fibers and real leather collagen fibers, the performances of the artificial leathers are greatly different from the performances of the real leathers. The existing reclaimed leathers have harder handfeel and the environment is polluted in the production processes of the reclaimed leathers. The invention provides a method for producing an artificial leather base material by compounding collagen fibers by utilizing spun-laced water jetting. The method comprises the following steps: 1) firstly preparing the collagen fibers into a collagen fiber sheet for compounding by utilizing spun-laced water jetting; and 2) opening and entangling the collagen fiber sheet by utilizing spun-laced water jetting in a spun-laced nonwoven process, at the same time, compounding the collagen fiber sheet with an opened and carded synthetic fiber sheet, and after compounding, implanting the synthetic fibers in the collagen fibers so that the two different fiber sheets are firmly bonded as a whole. The method has the following beneficial effects: after undergoing the subsequent coating processing, the obtained base material has stronger leather feel and better simulation than the traditional synthetic leathers and softer handfeel than the reclaimed leathers; and the method is more environment-friendly than the traditional production methods of the reclaimed leathers.

Owner:浙江弘扬无纺新材料有限公司

Production method of collagen casing

The invention relates to a casing of meat sausage product, and especially discloses a production method of collagen casing. The production method comprises following steps of washing the leather materials to be used, softening the leather materials by liming, water washing, cutting, removing calcium salt, puffing, extracting collagen, stirring, extruding and moulding, pre-solidifying, water washing, drying and fixing, folding and packaging. The invention is aimed to provide a collagen casing, which is produced by a special technology. The technology takes animal skins such as pigs or cows as the raw materials and soybean protein as the auxiliary material. The collagen casing has the advantages of natural flavor and color, unique taste and safe edibility. The preparation method overcomes the shortage of overlarge contraction by adopting part skins with relative large protein denaturation and adding a certain amount of short fiber protein such as soybean protein; through adding a great amount of water, the collagen solid is less, so that viscosity is low, treatment is convenient, and errors of product indexes are correspondingly reduced.

Owner:SHANDONG STANDARD DETECTION TECH CO LTD

Antigen-free porcine dermal collagen fibers

ActiveCN102121133AGood biocompatibilityGood mechanical propertiesSuture equipmentsAnimal materialAntigenCarding

The invention discloses antigen-free porcine dermal collagen fibers and a preparation method thereof. The antigen-free porcine dermal collagen fibers with excellent performance and wide application are prepared by using purified porcine skin as a raw material and adopting a method of combining physics, chemistry and biochemistry to perform a series of treatment such as fluffing, fiber decomposition, fiber separation, carding and the like on the purified porcine skin on the premise of ensuring good mechanical property of the purified porcine skin unchangeable. The antigen-free porcine dermal collagen fibers have good biocompatibility, good mechanical property and proper degradability, and can be widely applied to preparation of medicinal biological materials such as tissue engineering scaffold materials, hemostatic materials, medicinal operation stitches and the like.

Owner:SICHUAN UNIV

Collagen fibrillar construction

Methods and compositions are described for organizing collagen into fibrillar networks, e.g, short and long-range organization. Collagen produced by the disclosed methods can be used for tissue engineering.

Owner:NORTHEASTERN UNIV

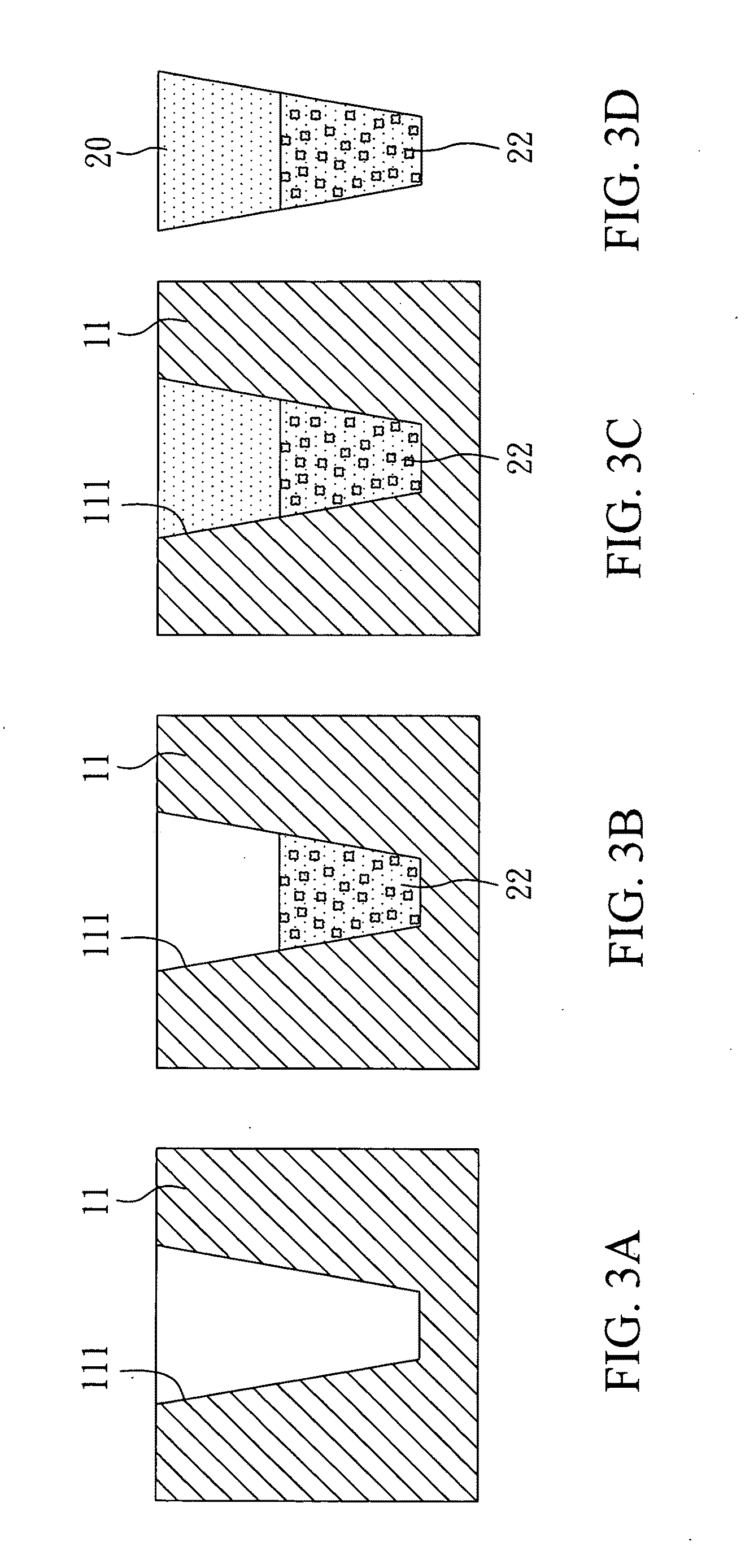

Biodegradable filler for restoration of alveolar bones

A biodegradable filler for restoration of alveolar bones is disclosed, which includes: first cross-linked collagen fibers prepared from reacting Non-crosslinked collagen fibers with a cross-linking agent; and supporting particles which are biomedical ceramic particles, bioactive glass, or a combination thereof, and distributed among the first cross-linked collagen fibers.

Owner:SUNMAX BIOTECH

Collagen coated article

ActiveUS20120316646A1Promote tissue regenerationImproves tissue integrationDental implantsPeptide/protein ingredientsChemistryCollagen fibres

The invention provides a biocompatible article having a surface comprising collagen fibrils attached to said surface via one or more linker molecules, wherein each of said collagen fibrils is attached to at least one of said one or more linker molecules at a proximal end of the fibril, and wherein each of said collagen fibril has a proximal portion extending from said proximal end to a point P along said fibril, wherein, for a majority of said fibrils, each fibril at said point P is oriented so as to form an angle αP in the range of 0° to 45° to the surface normal N at the point of attachment of said fibril to said surface. The collagen fibril-coated surface has improved biocompatibility and is useful in a medical implant intended for implantation into soft tissue or bone tissue.

Owner:DENTSPLY SIRONA INC

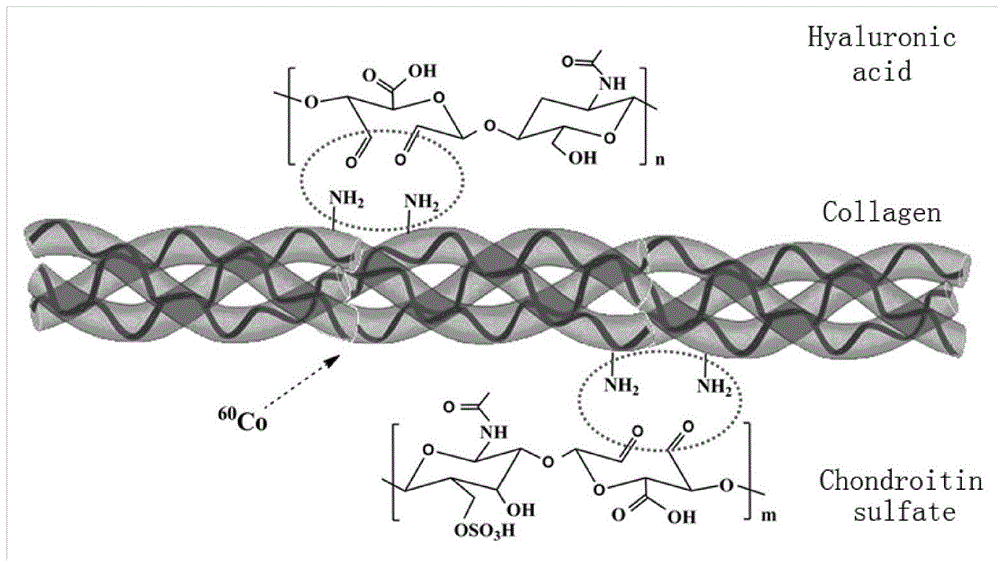

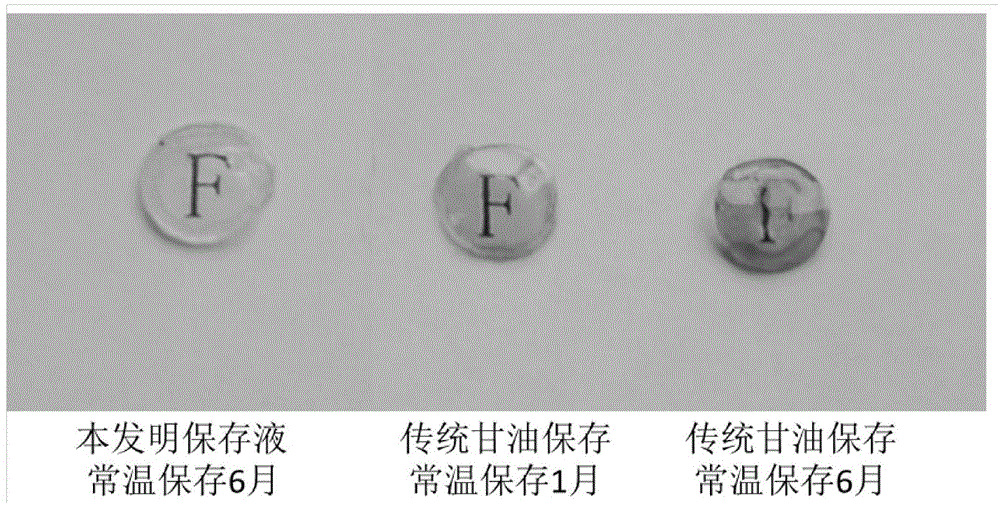

Lamellar corneal preserving solution

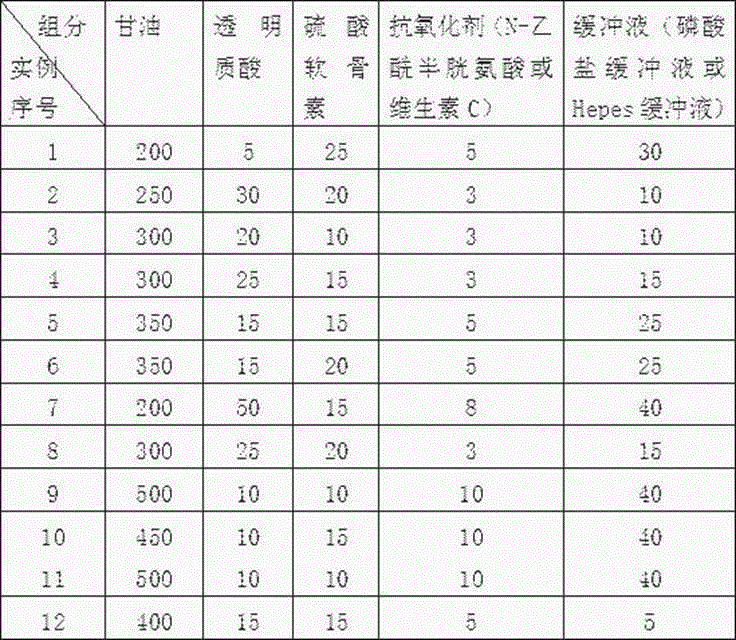

ActiveCN104094925AAvoid damageEfficient removalSenses disorderHydroxy compound active ingredientsOphthalmologyGlycerol

The invention discloses a lamellar corneal preserving solution which is characterized by comprising components as follows: glycerol with the concentration of 200-500g / L, hyaluronic acid with the concentration of 5-50g / L, chondroitin sulfate with the concentration of 10-25 g / L, antioxidant with the concentration of 1-10g / L and buffer salt solution with the concentration of 10-40 mmol / L and PH of 6.0-8.0. The lamellar corneal preserving solution is suitable for storage of a lamellar corneal material, can maintain original collagenous fiber structure and transparency of the cornea, and prevents the collagenous fiber of the cornea from being damaged due to irradiation sterilization treatment.

Owner:GUANGZHOU YOUDEQING BIOTECH

Carrier with solid fibrinogen and solid thrombin

The present invention relates to a solid composition useful for tissue gluing, tissue sealing and haemostasis consisting essentially of a) a carrier which has at least one of the following physical properties: elasticity module in the range of 5-100 N / cm, density of 1-10 mg / cm3, chamber diameter of more than 0.75 mm and less than 4 mm and / or having a chamber diameter average below 3 mm and evenly distributed and fixed upon said carrier, b) solid fibrinogen, and c) solid thrombin. The carrier is a biodegradable polymer such as a polyhyaluronic acid, polyhydroxy acid, e.g. lactic acid, glucolic acid, hydroxybutanoic acid, a cellulose, gelatine or collagen, such as a collagen sponge, e.g. a collagen sponge consisting essentially of collagen type I fibres. The fibrinogen and thrombin are preferably human, purified from a natural source, or transgenic or recombinant human fibrinogen and / or thrombin. In a preferred embodiment the composition does not comprise any antifibronolytic agent such as aprotinin, epsi-aminocaproic acid or alpha2-antiplasmin,

Owner:TOPAZ INVESTMENT AS

Collagenous fiber regenerated leather low in production cost and manufacturing method thereof

The invention relates to a collagenous fiber regenerated leather low in production cost and a manufacturing method thereof. The regenerated leather is composed of double-layer fiber nets, wherein the double-layer fiber nets on one side contain low-cost viscose fibers which achieve 100% in weight, and the double-layer fiber nets on the other side are collagenous fibers. During recombination, one side, containing a large number of the viscose fibers, of the regenerated leather and other cloth layers or leather layers are recombined, and therefore adulteration of the viscose fibers does not affect hand feeling of the regenerated leather. Meanwhile, as the regenerated leather contains a large number of the viscose fibers, the production cost of the regenerated leather is greatly reduced. The double-layer fiber nets on one side can contain the low-cost viscose fibers, besides, the viscose fibers achieving 15% to the maximum in weight can be adulterated in the double-layer fiber nets on the other side, and the cost of the regenerated leather is further reduced. According to the method of the collagenous fiber regenerated leather, effective winding between the upper fiber nets and the lower fiber nets is formed in a puncture fixing mode, and the strength of the regenerated leather is guaranteed. In addition, the species and the number of net laying devices of the collagenous fiber regenerated leather can be regulated according to the ratio of the upper fiber nets and the lower fiber nets so that high cloth passing speed and high production efficiency can be achieved.

Owner:JIANGYIN JUNHUA TEXTILE TECH

Method for extracting collagen fibers from offal produced during tanning process

InactiveCN102492998AHigh extraction rateNo pollution in the processAnimal materialMechanical treatmentChemical treatmentUltrasound device

The invention discloses a method for extracting collagen fibers from offal produced during a tanning process. At present, the offal produced during the tanning process is treated through a chemical treatment method which has the defects that though the product added value is higher, the treatment is complex, the cost is high, secondary pollution is generated, the offal utilization ratio is low, and a great quantity of leather waste cannot be effectively utilized all along. The method provided by the invention comprises the following steps: selecting blocky wet blue leather scrap, immersing the wet blue leather scrap in soda lye for 36 to 48 hours, treating the tumefied wet blue leather scrap with ultrasonic equipment for 20 to 30 min, passing the wet blue leather scrap through a high-pressure water jet device slowly, drying, and finally beating and opening through a cotton carding machine to ensure complete separation between the collagen fibers and obtain the collagen fibers. The invention mainly adopts the physical and mechanical method, so as to ensure that trivalent chromium cannot be converted into poisonous hexavalent chromium; environment pollution is avoided; and the extraction rate of collagen fiber approximately reaches 70 percent.

Owner:JIAXING UNIV

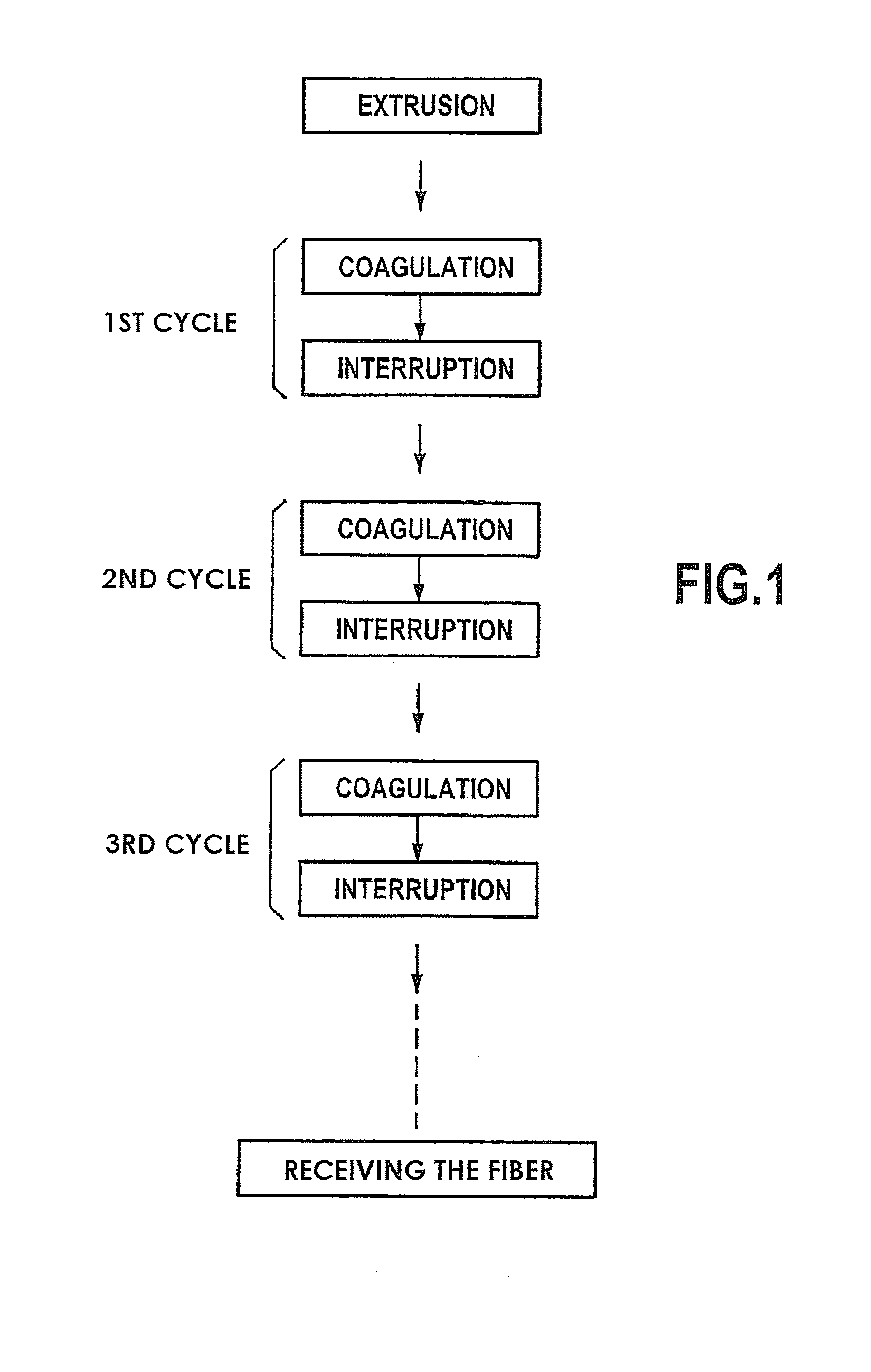

Hollow, notably multi-membrane fibers, method for preparation thereof by spinning and device for applying said method

InactiveUS20120040463A1Reduce moistureAnimal cellsMonocomponent protein artificial filamentFiberPolysaccharide

The present invention relates to a method for preparing fibers, notably of polysaccharide or collagen, by wet spinning under coagulation, said method notably comprising: a step for extruding a coagulable macromolecular assembly solution through a normal die; at least one partial coagulation cycle comprising a coagulation step on the one hand and a step for interrupting the coagulation on the other hand; and a step for receiving, notably by winding up, the obtained hollow fiber. The invention also relates to multi-membrane hollow fibers consisting of a same macromolecular assembly which may be spun by coagulation, notably a natural or modified natural polysaccharide in the physical hydrogel or partly dehydrated state. Said fibers including at least over their length two superposed coaxial membranes separated from each other by an inter-membrane space. The invention also relates to the spinning device for applying said method.

Owner:UNIV CLAUDE BERNARD LYON 1 +1

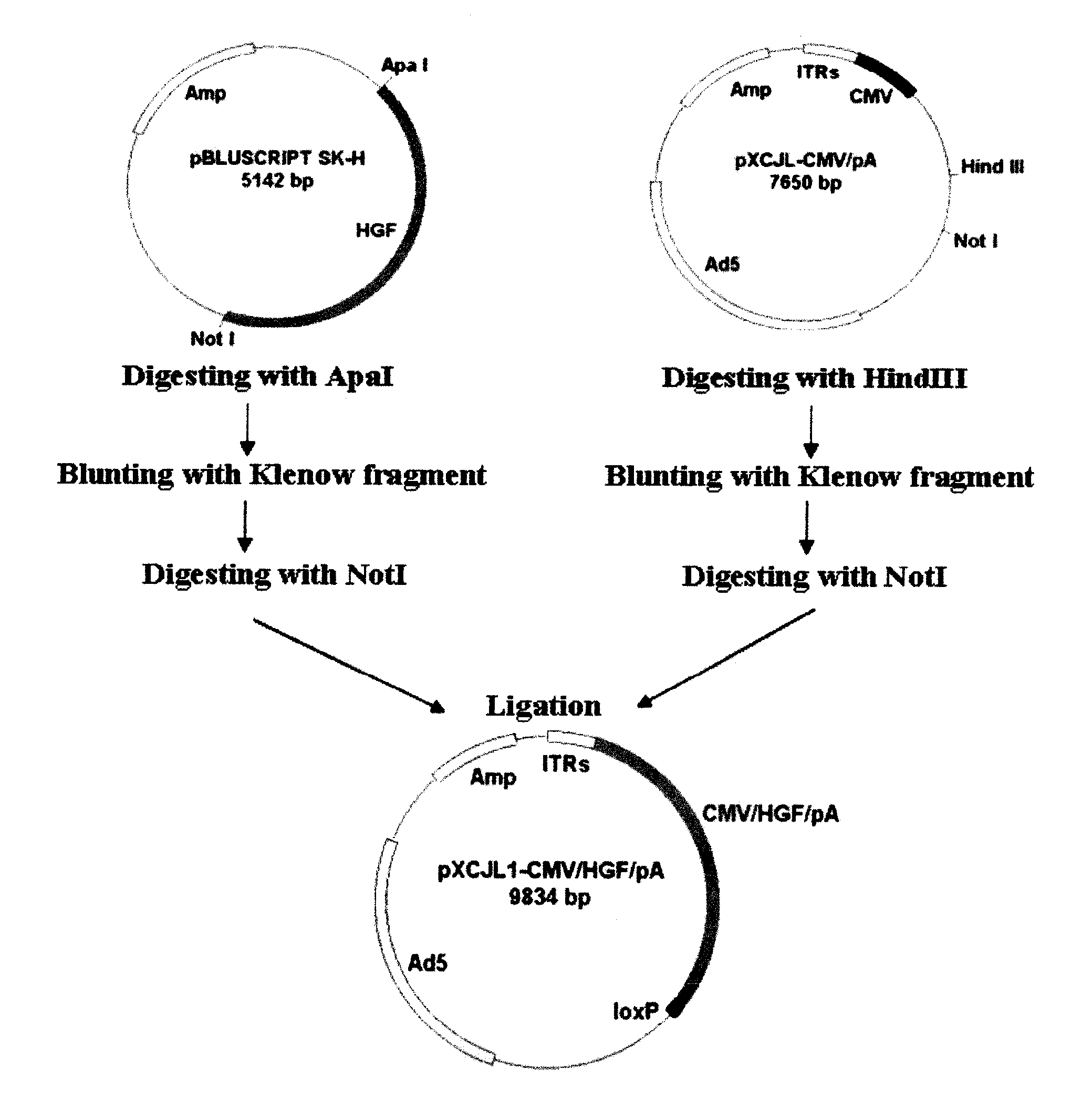

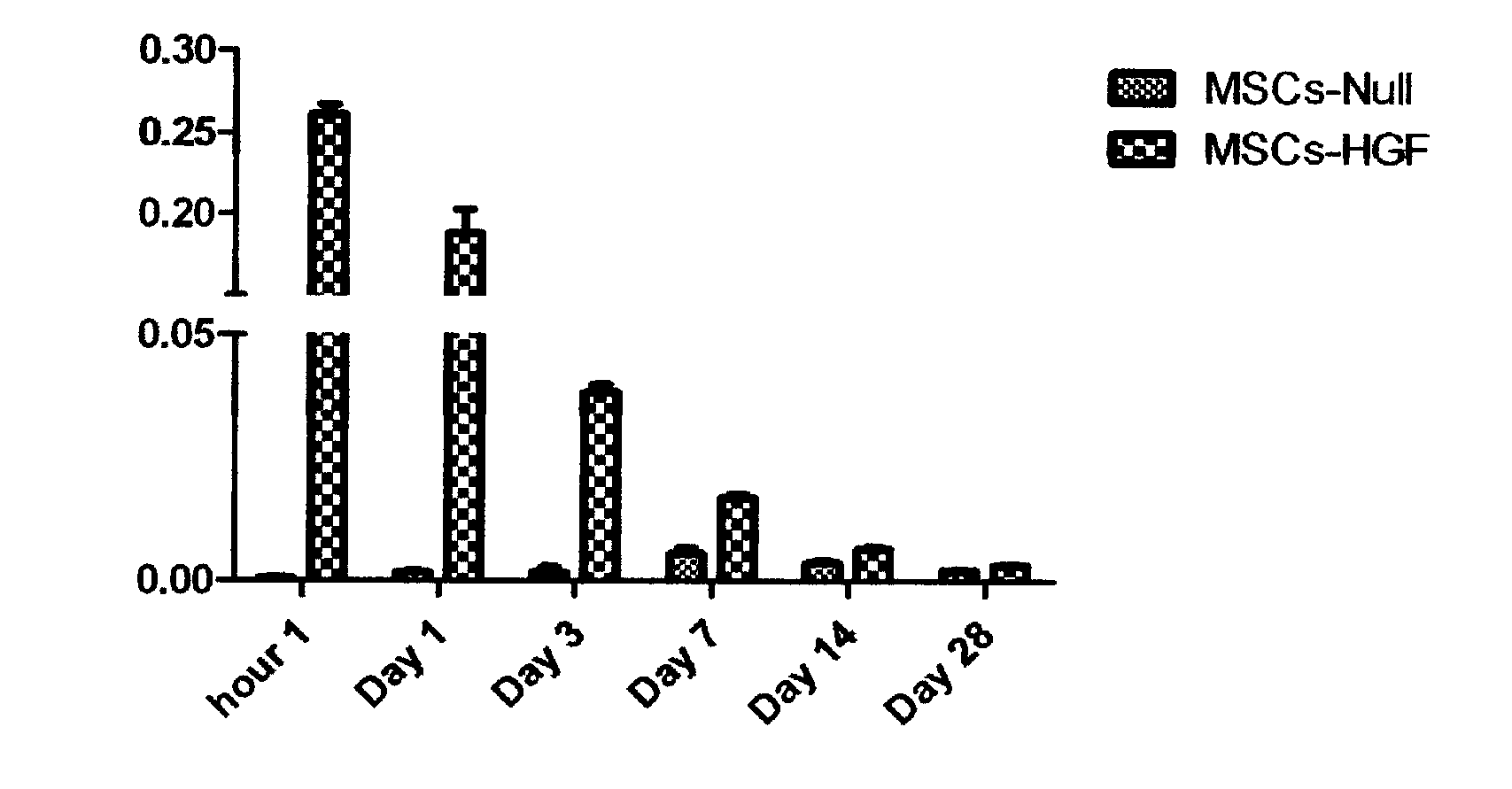

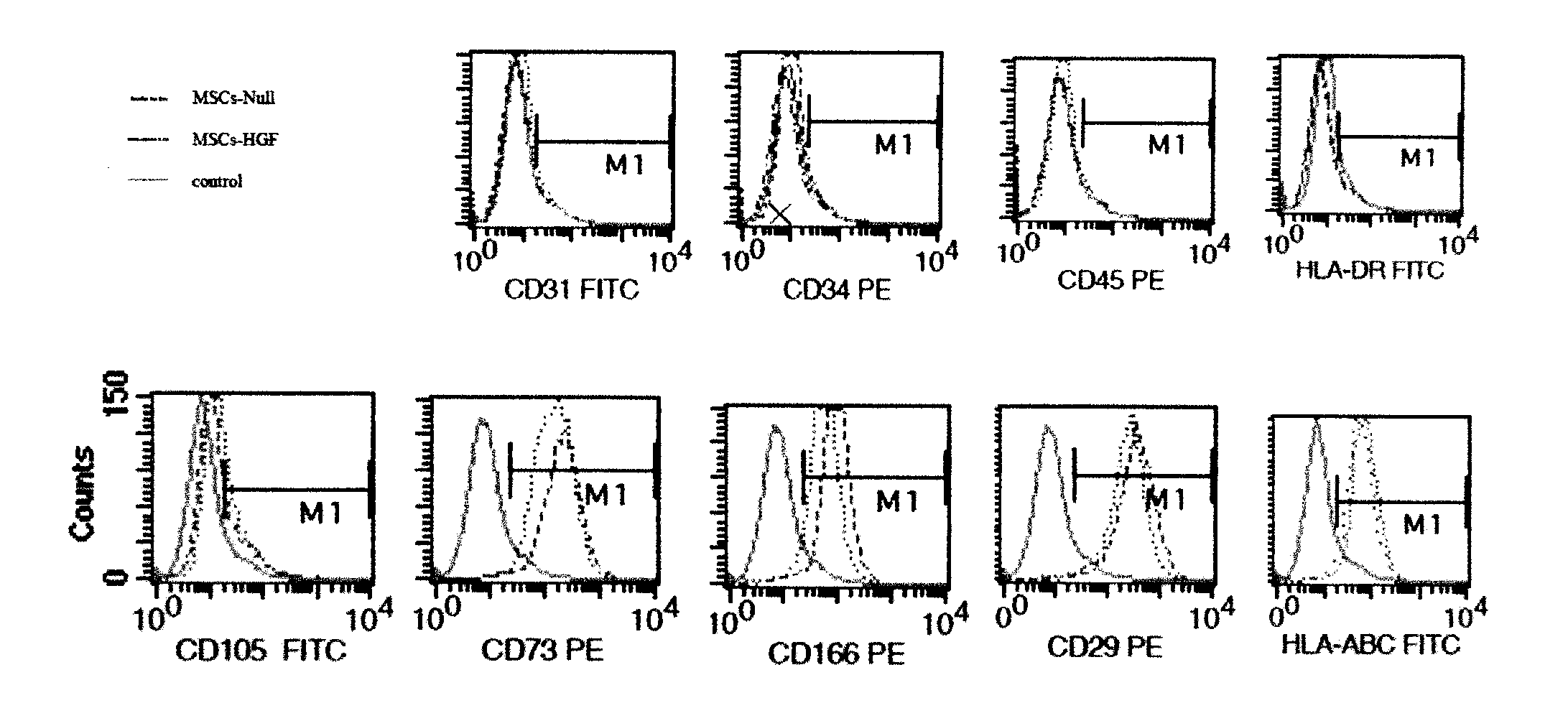

Application of gene modified mesenchymal stem cell in pulmonary fibrosis treatment

InactiveCN103203025AHigh activityPromote proliferationPeptide/protein ingredientsGenetic material ingredientsBone marrowFactor ii

Relating to the fields of biotechnologies and gene therapy, the invention provides application of a gene modified mesenchymal stem cell in pulmonary fibrosis treatment. The gene modified mesenchymal stem cells are obtained through: in-vitro isolated culture and amplification of a mesenchymal stem cell (MSC) deriving from bone marrow and an umbilical cord, and recombinant adenovirus Ad-HGF mediated in-vitro modification of the MSC by a hepatocyte growth factor (HGF). By transplanting the gene modified MSC to a C57 mouse to intervene in radiation induced lung injury and fibrosis, exudation of a plurality proteins including albumin, IgM and the like from an alveolar space can be reduced, local inflammatory responses of the lung can be alleviated, and expression of TNF-alpha, soluble ICAM-1 and multiple factors is inhibited, expression of the profibrotic factor TGF-beta, the collagen gene col1 alpha 1 and col 3 alpha 1 can be inhibited, and pulmonary tissue collagen fiber deposition is reduced. The expression results of endogenous HGF and its receptor cmet show that endogenous HGF expression can be induced and endogenous MSC can home to injured parts. Therefore, the employment of HGF modified MSC in treatment of lung injury and fibrosis brought by various pathogenic causes is of great significance.

Owner:INST OF RADIATION MEDICINE ACAD OF MILITARY MEDICAL SCI OF THE PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com