Patents

Literature

41 results about "Dermal collagen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

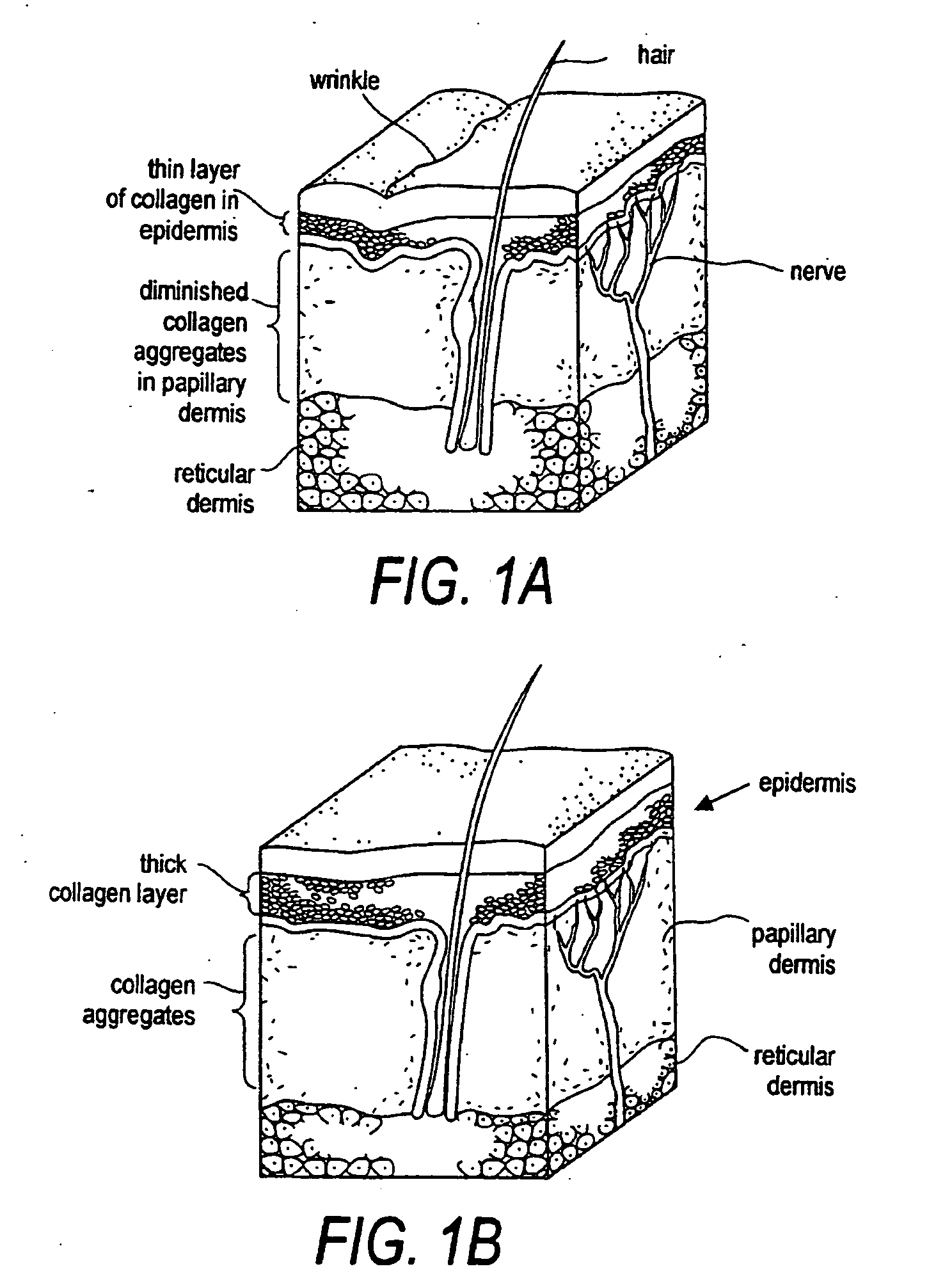

The dermis is made up mostly of collagen and about 4% elastin fibers. Collagen provides the strength of the skin, while elastin allows it to stretch and snap back. Collagen and elastin fibers are held together in a pool of very complex sugars and proteins. Hyaluronic acid is one of the sugars of the skin.

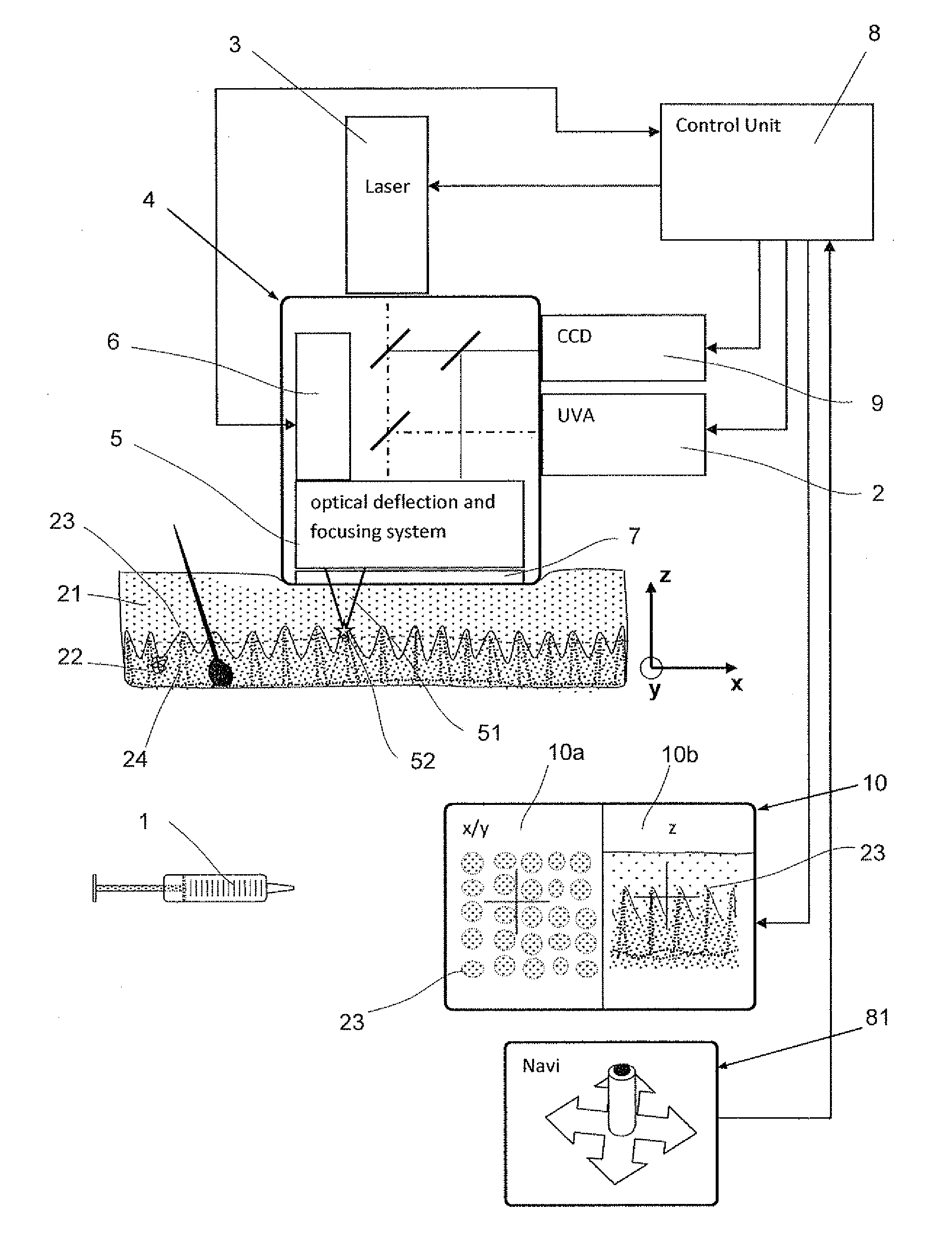

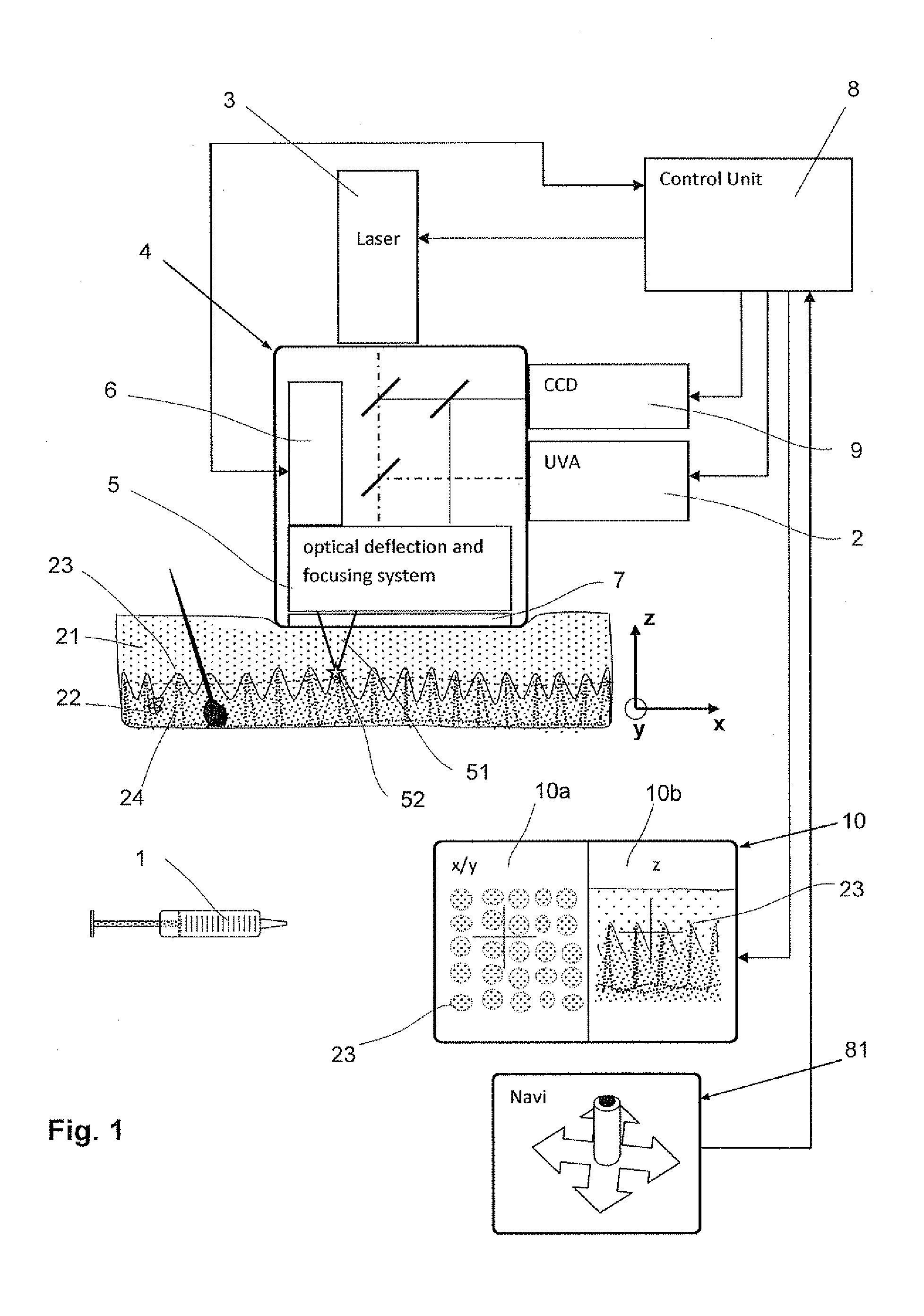

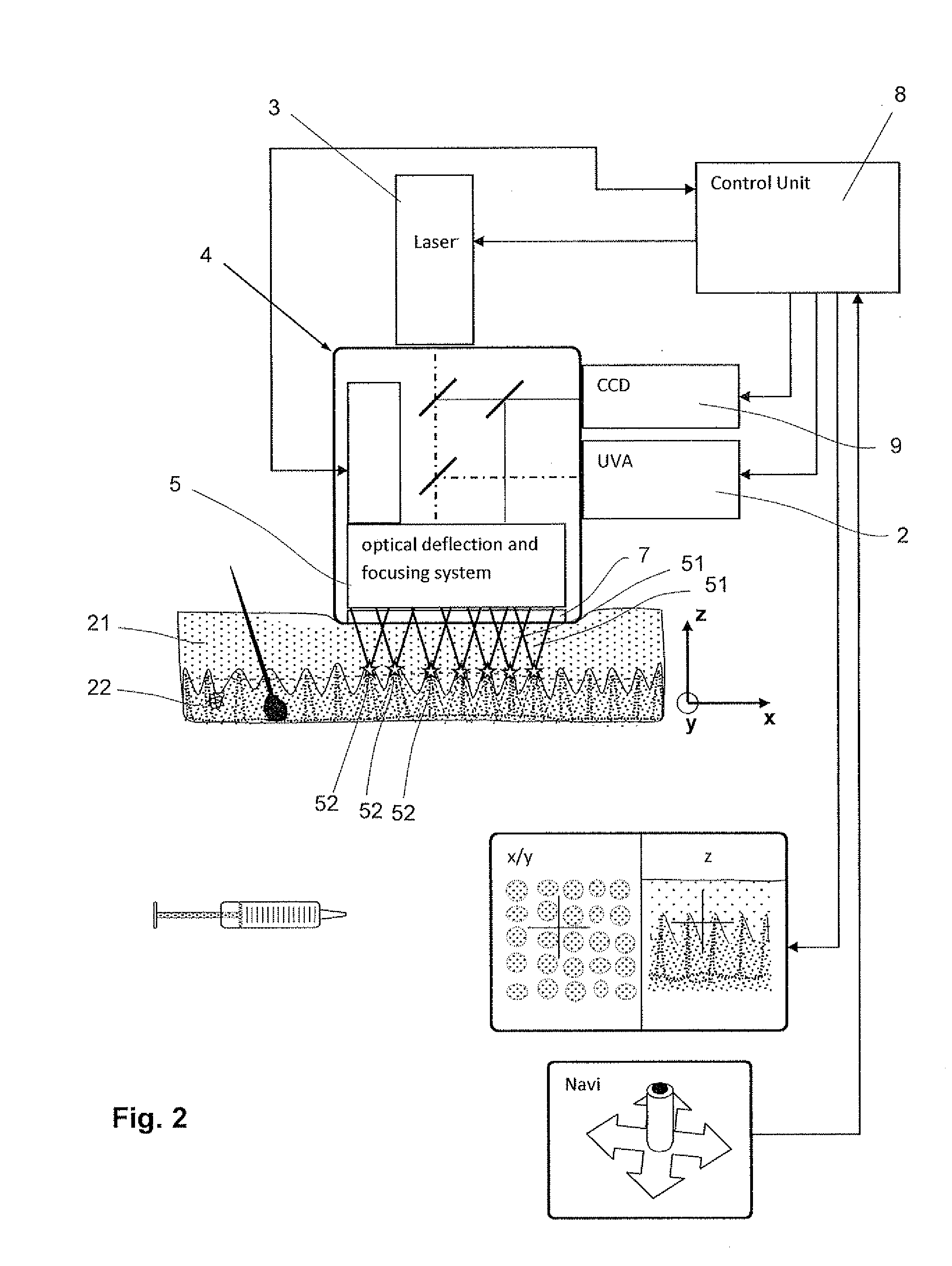

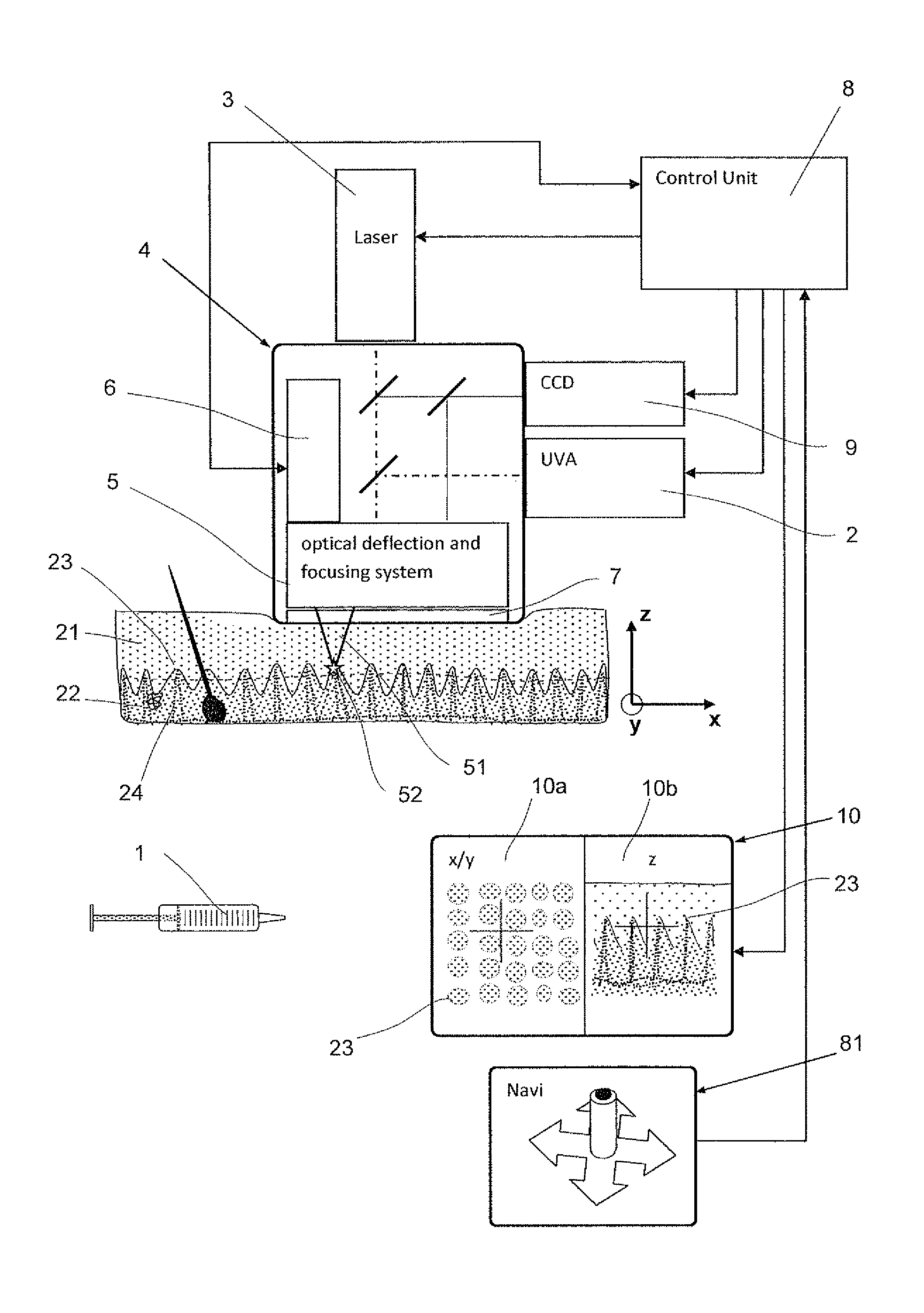

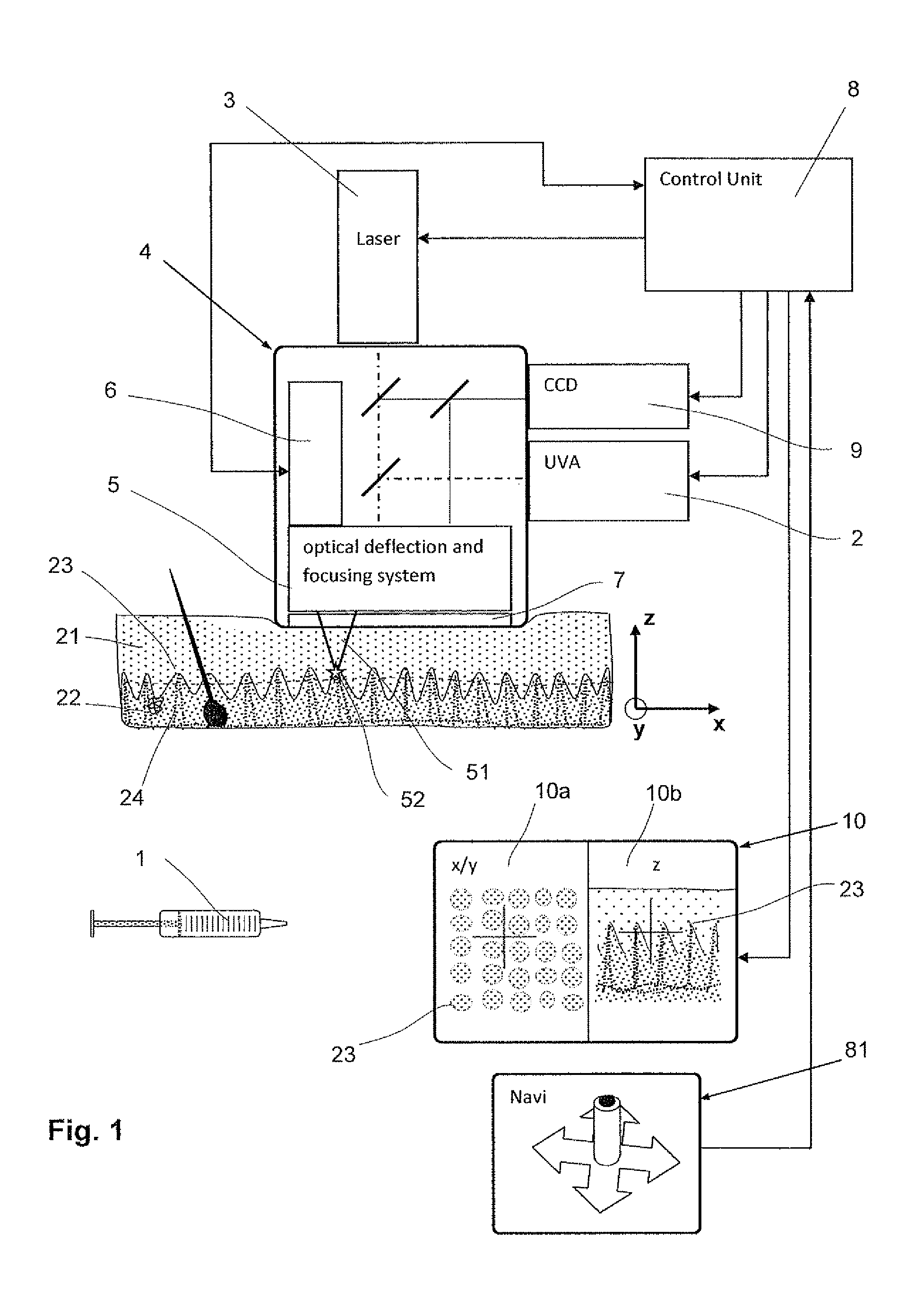

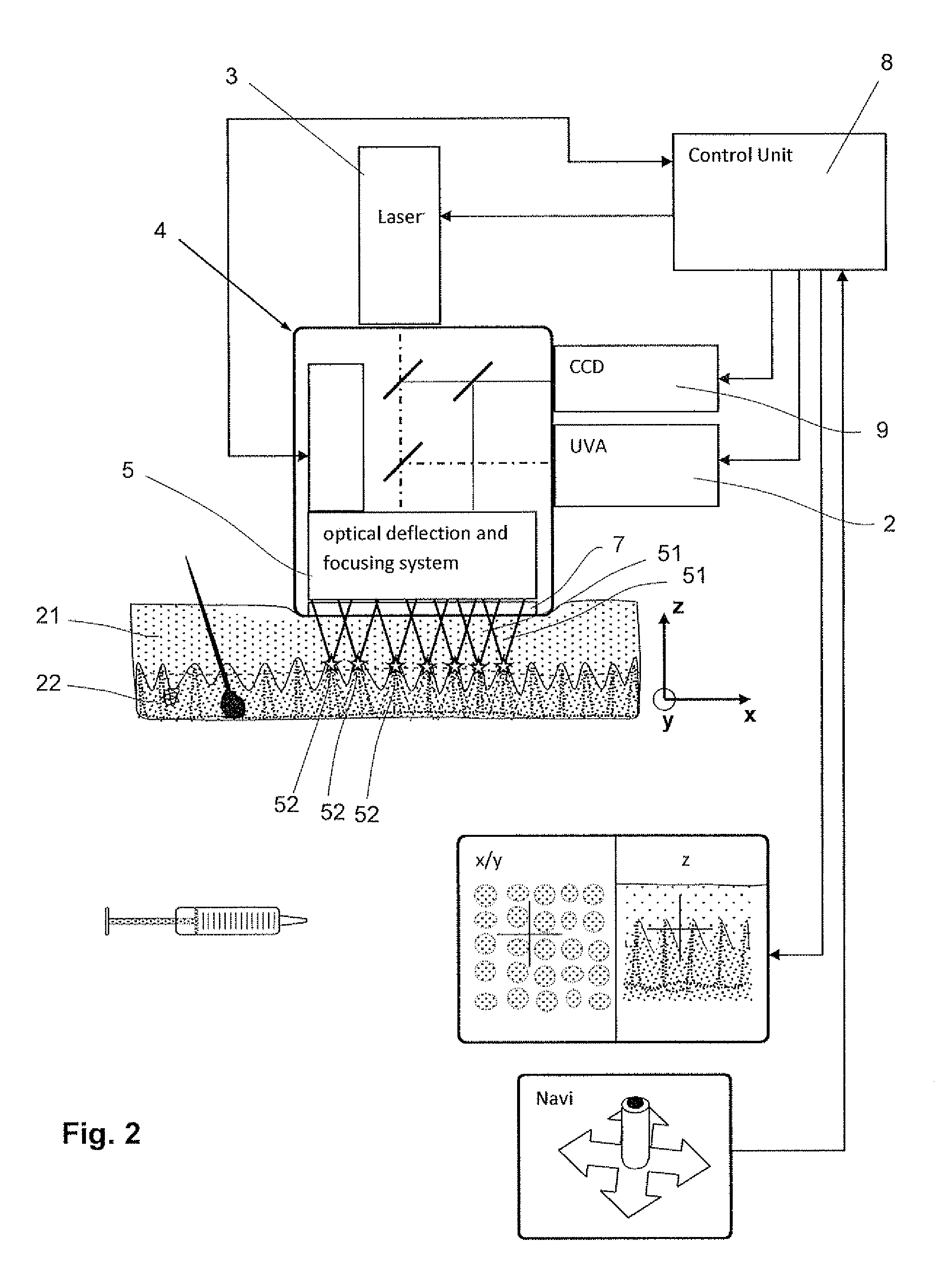

Laser therapy system with UVA and IR laser light for directional generation of a dermal collagen matrix

ActiveUS20130023966A1Eliminate disadvantagesSurgical instrument detailsLight therapySkin treatmentsPhotosensitizer

The present invention refers to a Laser therapy system and a method for skin treatment, comprising:a unit for dispensing a Photosensitizer containing agent;a first light source which generates at least one first light with a first wavelength;a second light source as a Laser light source which generates at least a second light with a second wavelength;an optical system which is connected to the first and to the second light source, comprising an electromechanical displacement device with an optical deflection and focusing system such that the first and second light gets focused and a respective focus point can be controllably positioned in the skin; anda control unit for controlling the electromechanical displacement device and the first and the second light source such that the respective light spot with a controlled energy and position in the skin is produced.

Owner:TELESTO SP ZOO

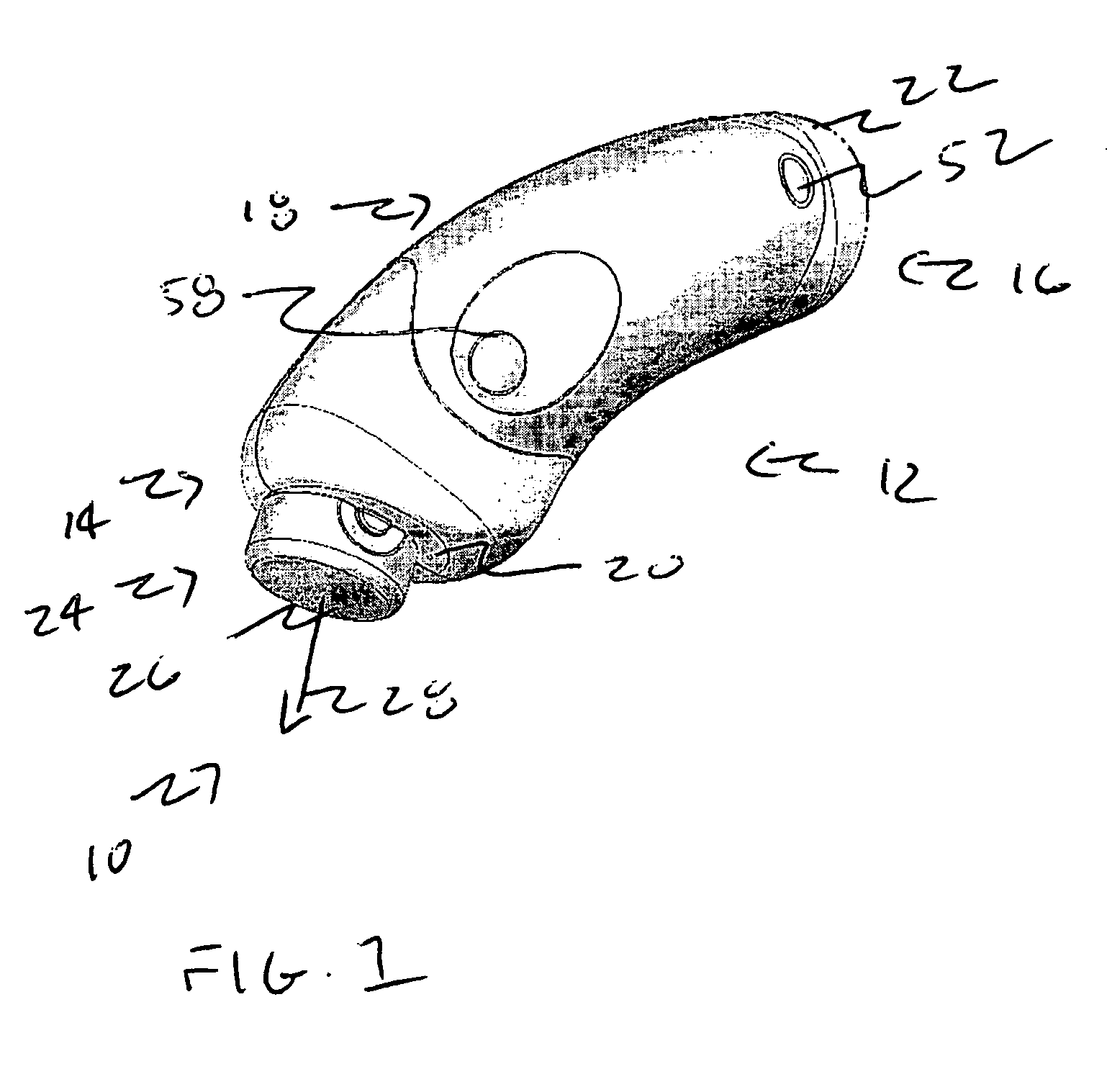

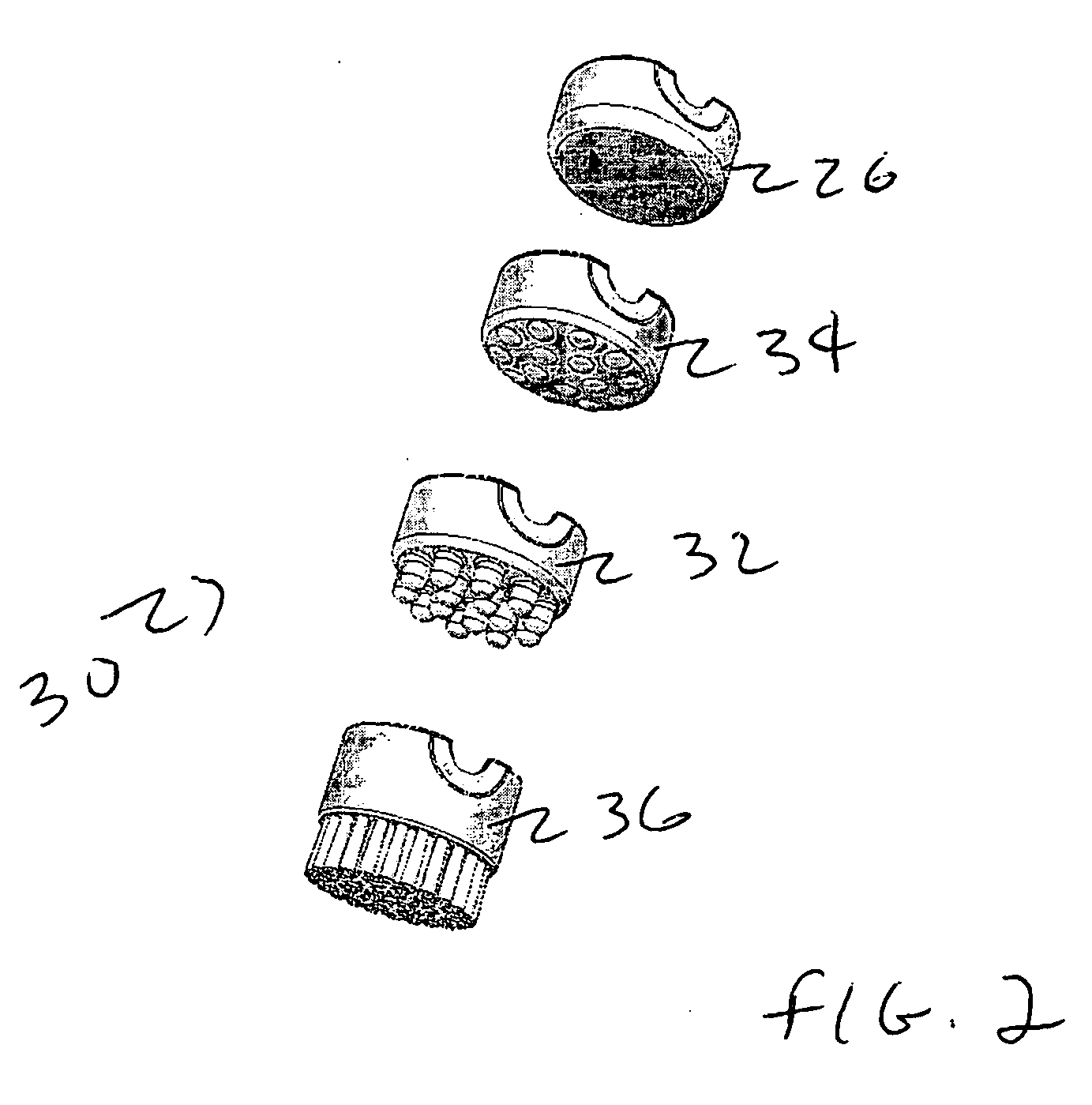

Deep Acting Topically Working Facial Care Appliance

InactiveUS20100222719A1Easy to useEasy accessChiropractic devicesBathroom accessoriesCuticleDual action

A deep acting topically working facial care appliance includes a dual action facial puck having a rotating and counter rotatable facial implement that is dually effective both to clean, massage, apply compositions and otherwise topically work the skin and to deeply act to penetrate below the epidermis and into the dermis massaging and deeply passivating and enervating the dermis and dermal collagen.

Owner:HEADWATERS RES & DEV

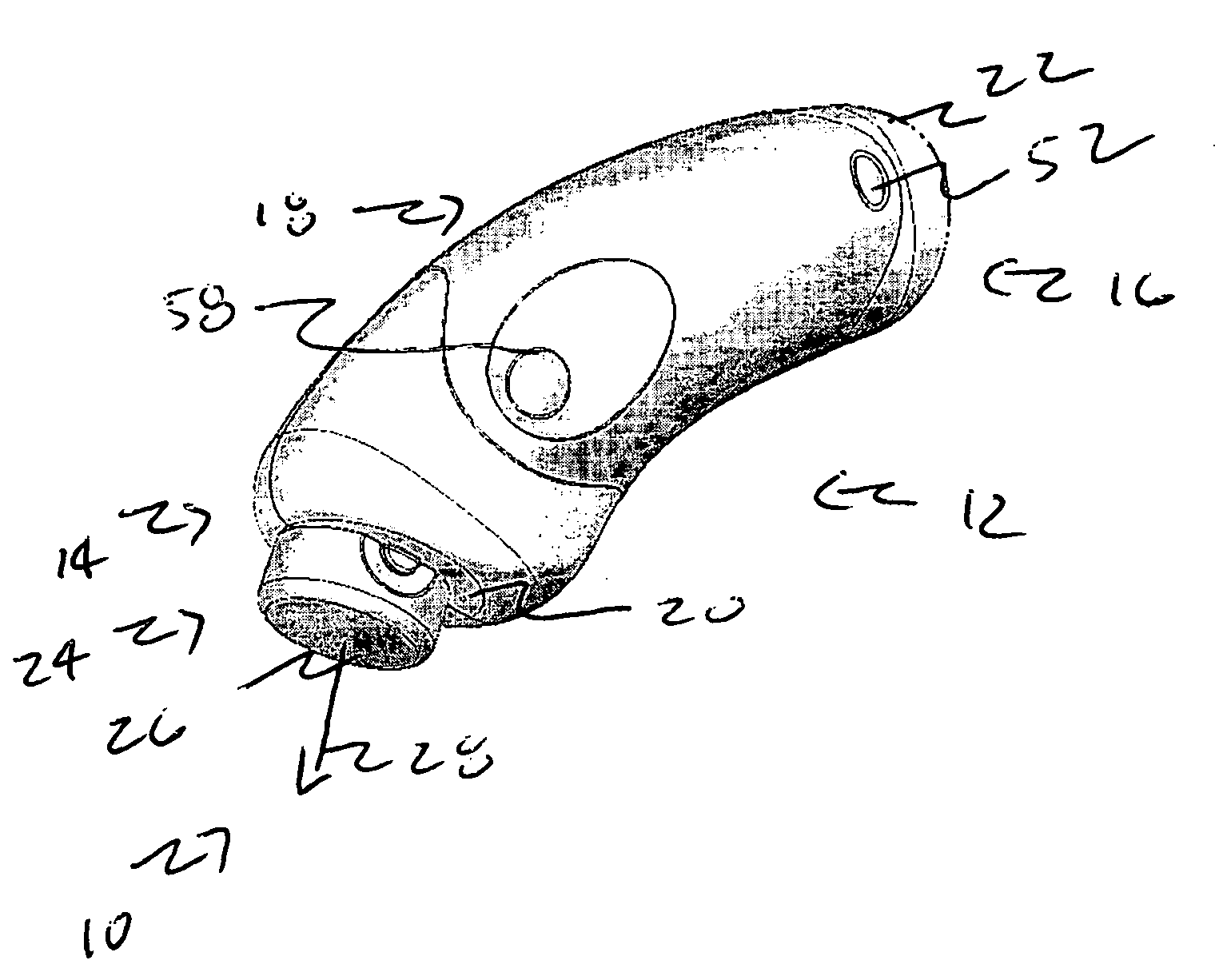

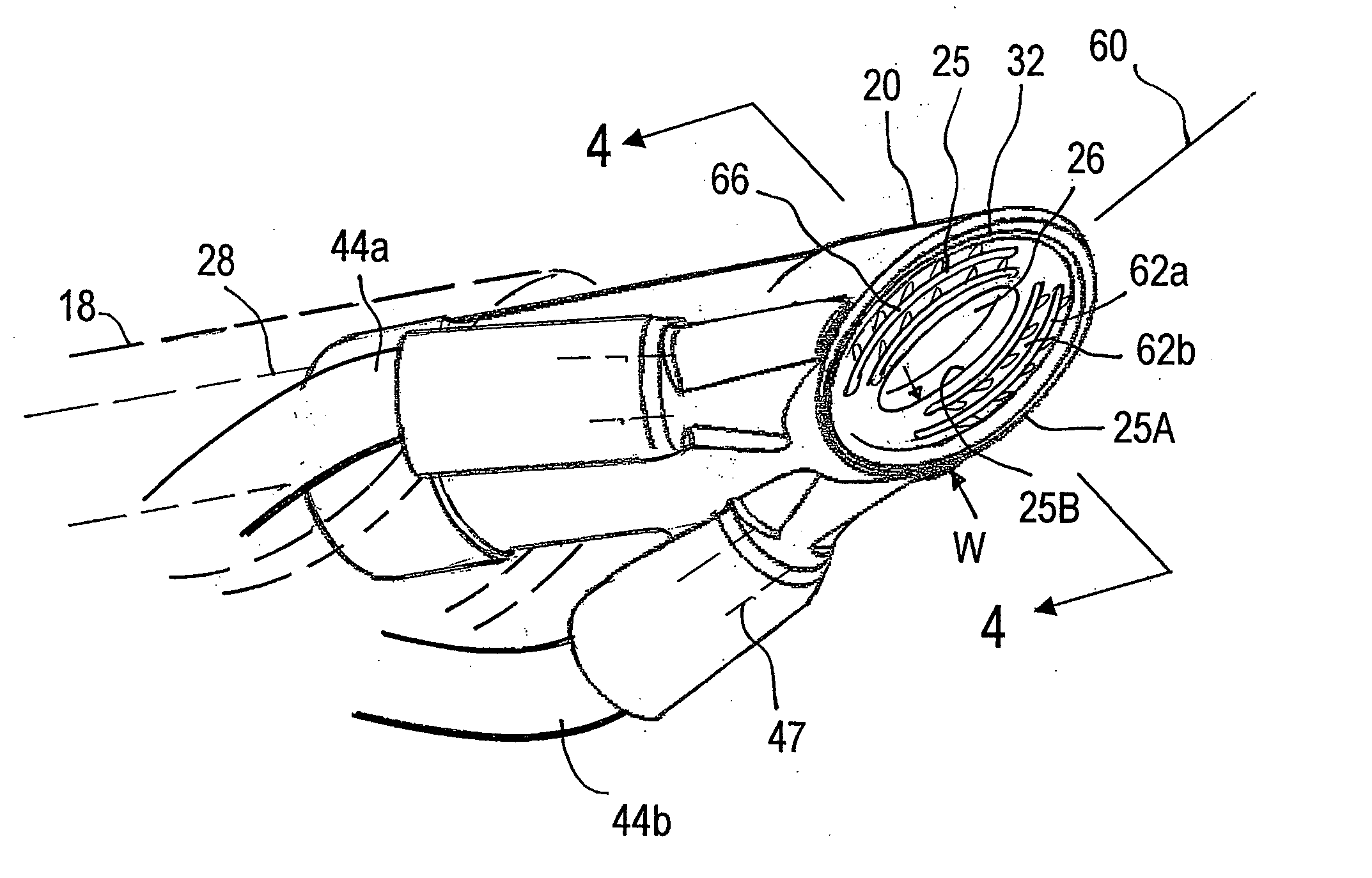

Instruments and techniques for controlled removal of epidermal layers

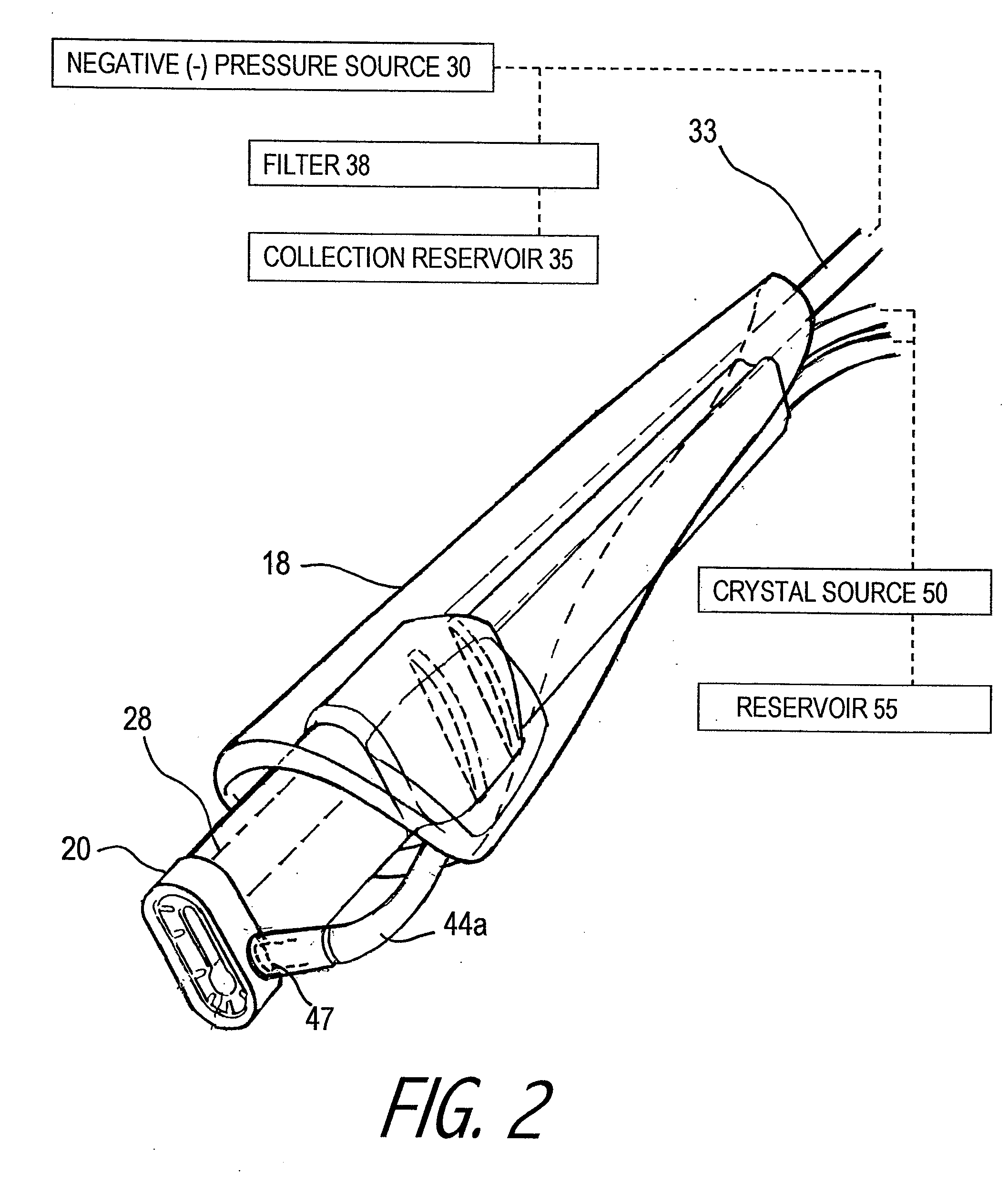

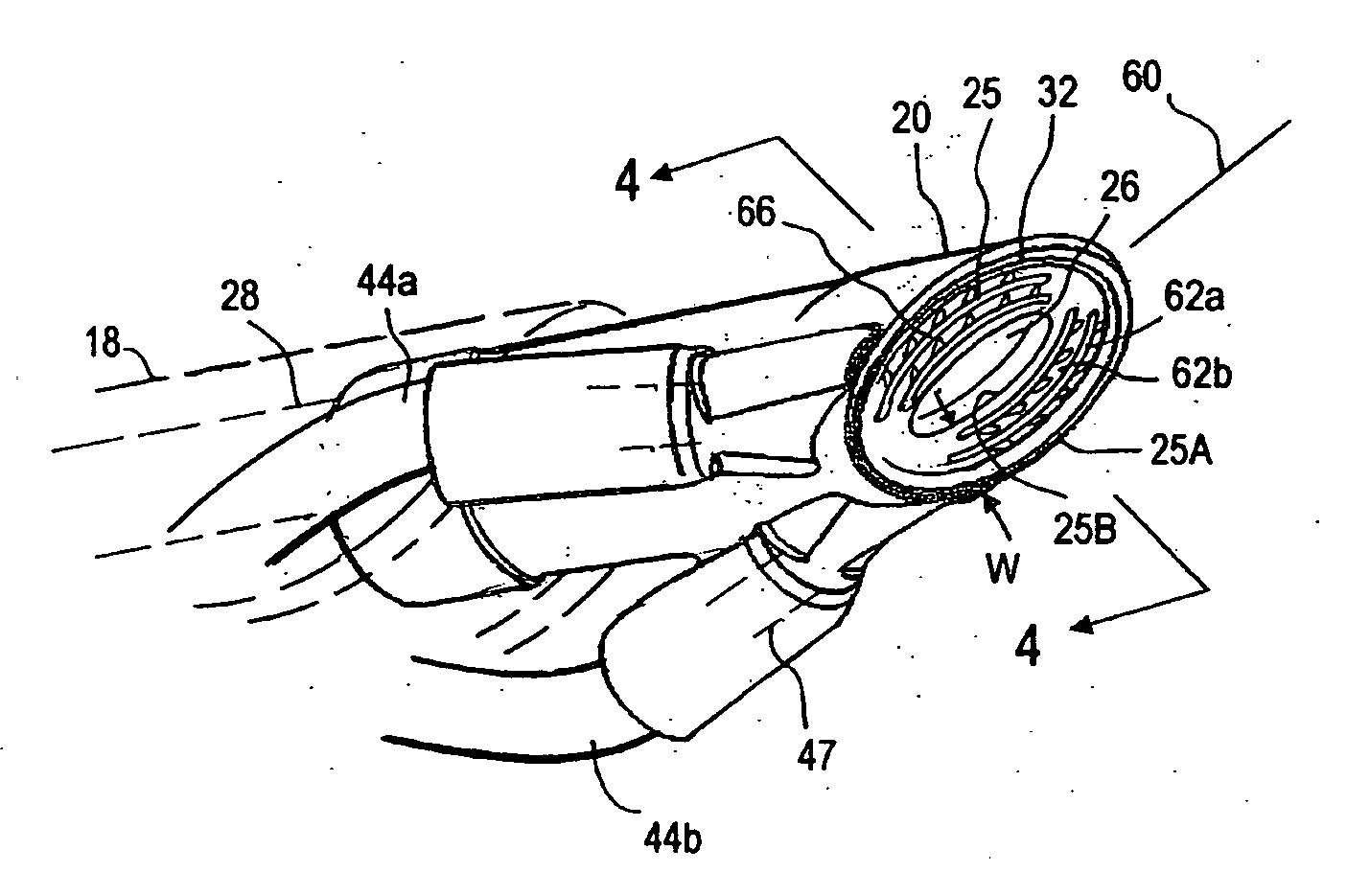

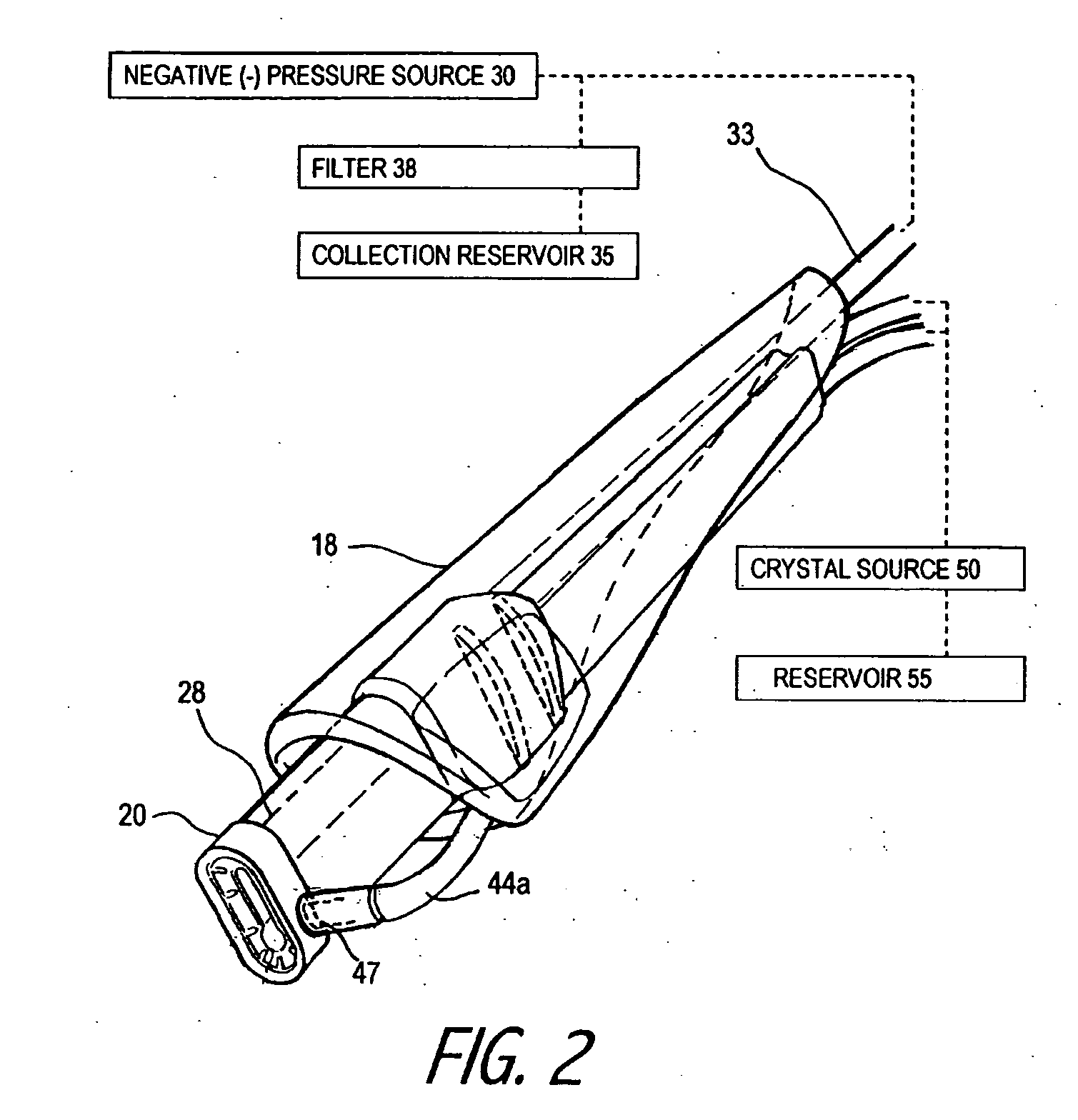

An instrument and technique for the removal of epidermal layers in a controlled manner utilizing a hand-held instrument with a working end that (i) a vacuum aspiration system, (ii) a source for delivery of a sterile fluids or pharmacological agents to the skin; and (iii) a skin interface surface in the working end that has specially shape structure for abrading surface layers of the patient's epidermis as the working end is moved over the patient's skin while at the same time causing rapid penetration of the fluids into the skin for therapeutic purposes. Movement of the working end across the skin causes abrasion of the surface layers in a path over the patient's skin. The method of the invention may be used in a periodic treatment for the removal of superficial skin layers that enhances the synthesis of dermal collagen aggregates by inducing the body's natural wound healing response. The method of the invention creates more normal dermal architectures in skin with limited depths of skin removal by the series of superficial treatments that may be comparable to the extent of neocollagenesis caused by a deep skin removal treatment (e.g., CO2 laser skin removal).

Owner:EDGE SYST CORP

Instruments and techniques for controlled removal of epidermal layers

An instrument and technique for the removal of epidermal layers in a controlled manner utilizing a hand-held instrument with a working end that (i) a vacuum aspiration system, (ii) a source for delivery of a sterile fluids or pharmacological agents to the skin; and (iii) a skin interface surface in the working end that has specially shape structure for abrading surface layers of the patient's epidermis as the working end is moved over the patient's skin while at the same time causing rapid penetration of the fluids into the skin for therapeutic purposes. Movement of the working end across the skin causes abrasion of the surface layers in a path over the patient's skin. The method of the invention may be used in a periodic treatment for the removal of superficial skin layers that enhances the synthesis of dermal collagen aggregates by inducing the body's natural wound healing response. The method of the invention creates more normal dermal architectures in skin with limited depths of skin removal by the series of superficial treatments that may be comparable to the extent of neocollagenesis caused by a deep skin removal treatment (e.g., CO2 laser skin removal).

Owner:EDGE SYST CORP

Moisturizing facial mask solution, preparation method of moisturizing facial mask solution and moisturizing facial mask

InactiveCN104814918AEasy to prepareGood moisturizing effectCosmetic preparationsToilet preparationsSodium hyaluronatePolymer

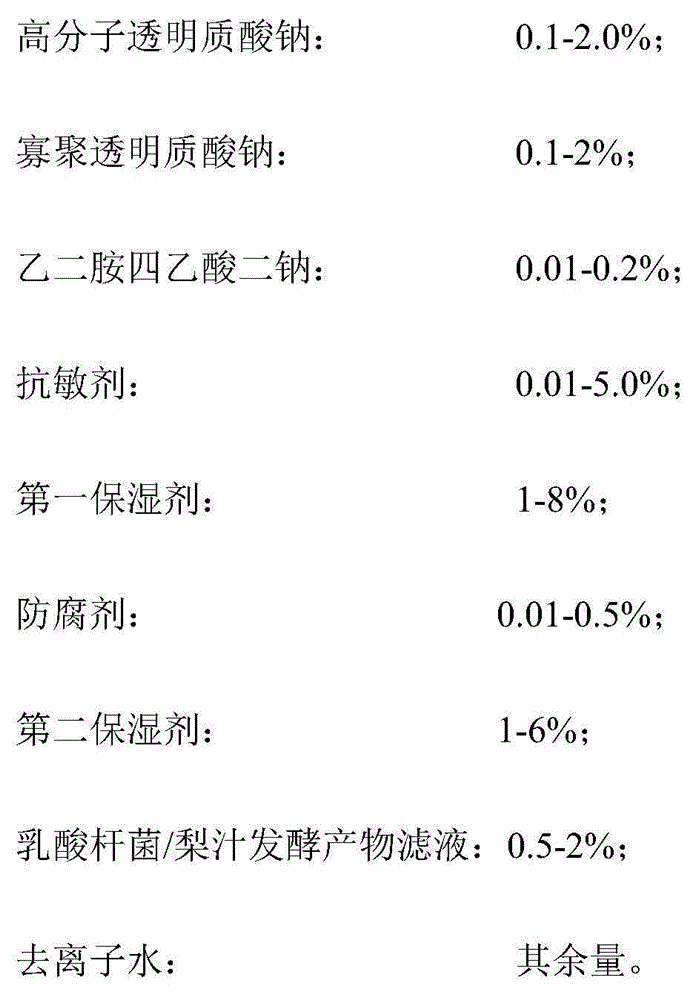

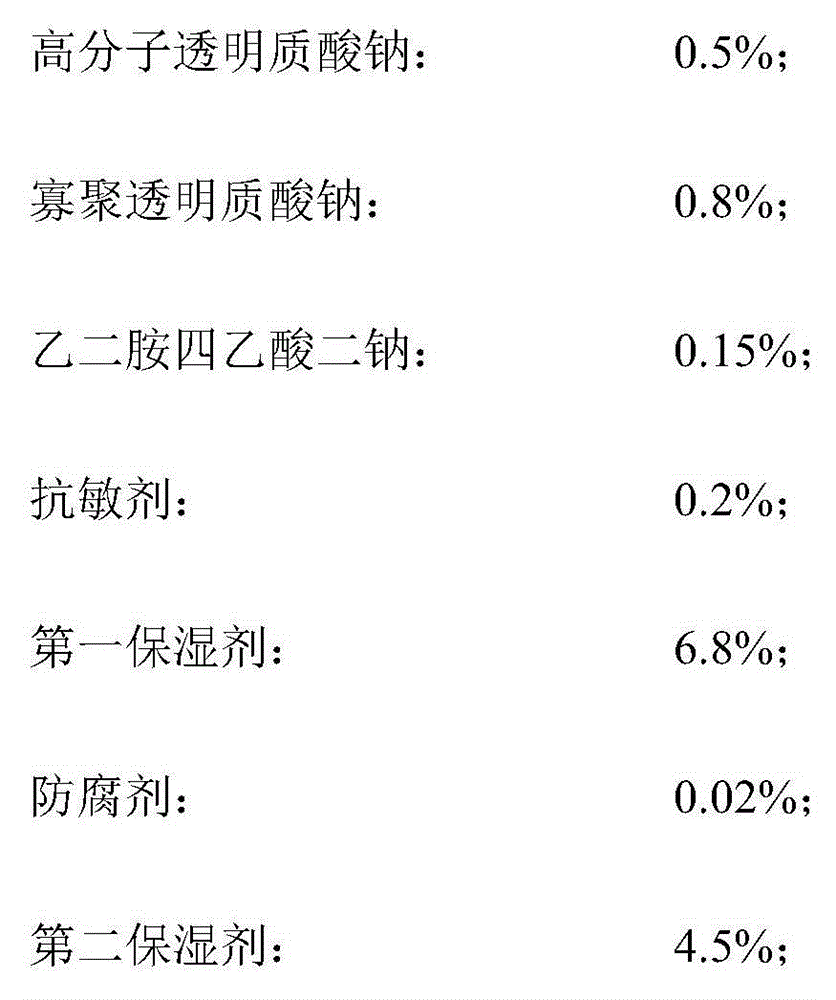

The invention discloses a moisturizing facial mask solution and a preparation method thereof. The moisturizing facial mask solution is composed of the following components in percentage by weight: 0.1-2.0% of polymer sodium hyaluronate, 0.1-2% of oligomeric sodium hyaluronate, 0.01-0.2% of EDTA-2Na, 0.01-5.0% of an anti-allergy agent, 1-8% of a first moisturizing agent, 0.01-0.5% of preservatives, 1-6% of a second moisturizing agent, 0.5-2% of lactobacillus / pear juice ferment filtrate and the balance of deionized water. According to the moisturizing facial mask solution, the preparation method is simple; under the joint functions of double moisturizing factors (polymer sodium hyaluronate and oligomeric sodium hyaluronate) and a biotic factor (lactobacillus / pear juice ferment filtrate), the moisturizing facial mask solution achieves the functions of improving skin growth conditions, providing an excellent external environment for synthesizing dermal collagen and elastic fibers, reinforcing the supply of nutrients and finally reaching the efficient moisturizing effect.

Owner:广州致美化妆品有限公司

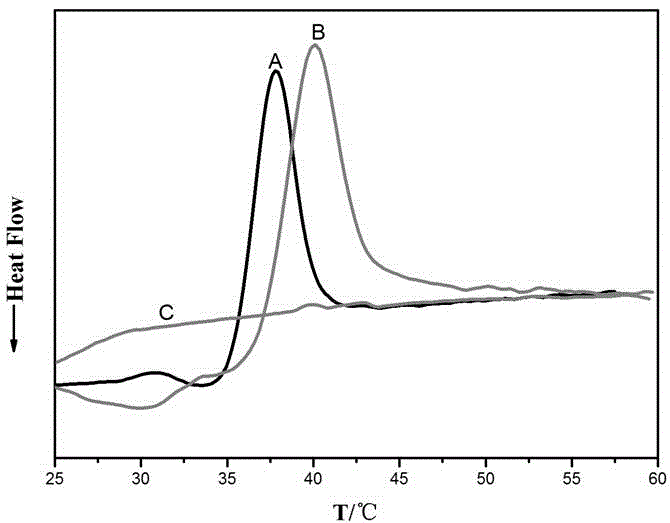

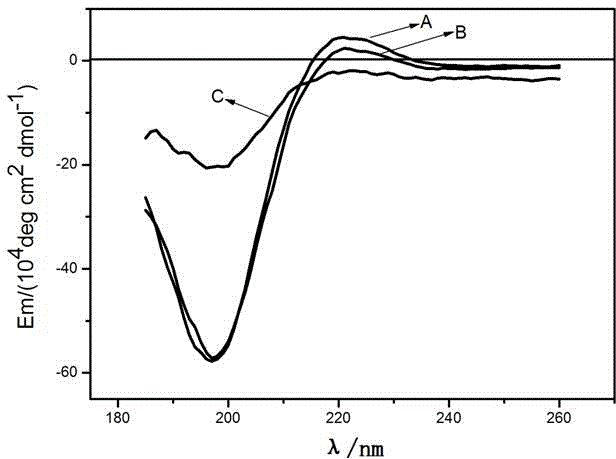

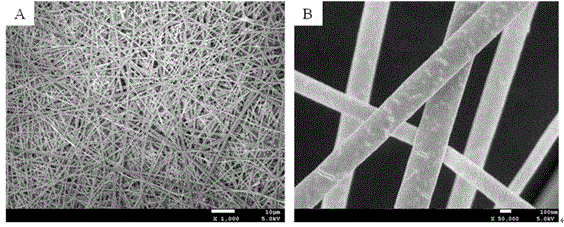

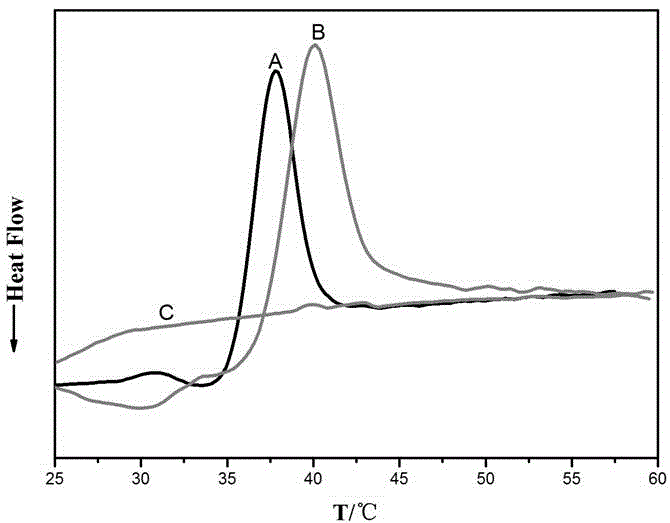

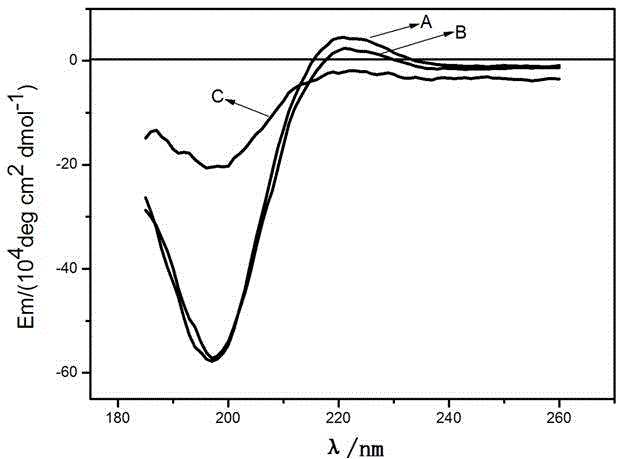

Oxidation chitosan graft modified porcine dermal collagen micro-nano fiber membrane and preparation method thereof

ActiveCN104013995AMaintain biological activityImprove mechanical propertiesFibre treatmentAbsorbent padsMicro nanoFiber

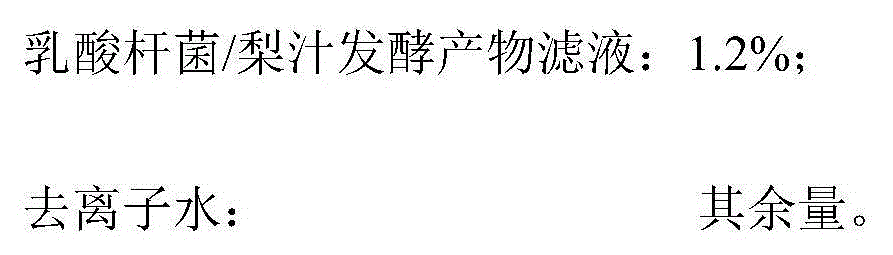

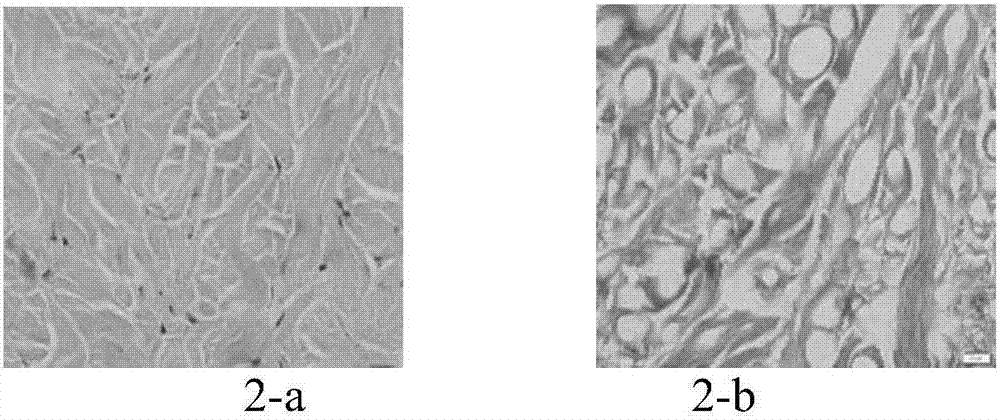

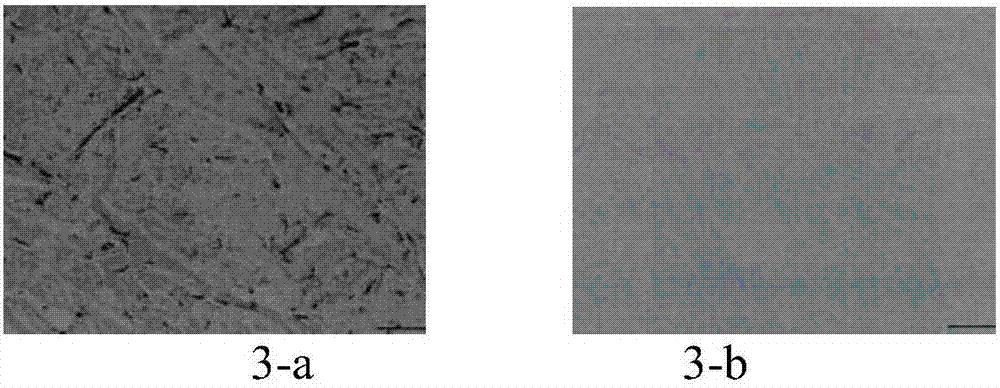

The invention discloses an oxidation chitosan graft modified porcine dermal collagen micro-nano fiber membrane and a preparation method thereof. The oxidation chitosan graft modified porcine dermal collagen micro-nano fiber membrane is characterized in that the preparation method comprises the steps: by applying an electrostatic spinning technology and using traceable purified porcine dermis as a raw material and hexafluoroisopropanol as a solvent, stirring at 4-10 DEG C until the mixture is transparent, formulating to obtain electrostatic spinning mother liquor with concentration of 0.5-10%, and directly spinning to obtain the porcine dermal collagen micro-nano fiber membrane; then performing graft modification on the porcine dermal collagen micro-nano fiber membrane by using oxidation chitosan, thereby finally obtaining the oxidation chitosan graft modified porcine dermal collagen micro-nano fiber membrane. A membrane material not only has good bio-compatibility, biodegradability and mechanical properties, but also has anti-oxidation effects, antibacterial activities, anti-inflammation / wound healing promotion effects, anti-cancer / anti-tumor effects and antiviral effects of chitosan, is significantly better than a collagen composite membrane material prepared by using collagen as the raw material, and can be widely applied to the preparation of biomedical materials such as hemostatic materials, tissue engineering scaffold materials, biological dressings and the like.

Owner:SICHUAN UNIV

Antigen-free porcine dermal collagen fibers

ActiveCN102121133AGood biocompatibilityGood mechanical propertiesSuture equipmentsAnimal materialAntigenCarding

The invention discloses antigen-free porcine dermal collagen fibers and a preparation method thereof. The antigen-free porcine dermal collagen fibers with excellent performance and wide application are prepared by using purified porcine skin as a raw material and adopting a method of combining physics, chemistry and biochemistry to perform a series of treatment such as fluffing, fiber decomposition, fiber separation, carding and the like on the purified porcine skin on the premise of ensuring good mechanical property of the purified porcine skin unchangeable. The antigen-free porcine dermal collagen fibers have good biocompatibility, good mechanical property and proper degradability, and can be widely applied to preparation of medicinal biological materials such as tissue engineering scaffold materials, hemostatic materials, medicinal operation stitches and the like.

Owner:SICHUAN UNIV

Laser therapy system with UVA and IR laser light for directional generation of a dermal collagen matrix

ActiveUS9486284B2Eliminate disadvantagesSurgical instrument detailsLight therapySkin treatmentsPhotosensitizer

The present invention refers to a Laser therapy system and a method for skin treatment, comprising:a unit for dispensing a Photosensitizer containing agent;a first light source which generates at least one first light with a first wavelength;a second light source as a Laser light source which generates at least a second light with a second wavelength;an optical system which is connected to the first and to the second light source, comprising an electromechanical displacement device with an optical deflection and focusing system such that the first and second light gets focused and a respective focus point can be controllably positioned in the skin; anda control unit for controlling the electromechanical displacement device and the first and the second light source such that the respective light spot with a controlled energy and position in the skin is produced.

Owner:TELESTO SP ZOO

Preparation method of xenogenic acellular dermal matrix

ActiveCN105727367AEasy to drainPromote regenerationTissue regenerationProsthesisSocial benefitsMedicine

The invention discloses a preparation method of a xenogenic acellular dermal matrix. The method specifically includes the following steps of taking dermis, removing epidermal layers, conducting acellular disposal, punching holes through lasers, and conducting sterilizing. By means of the method, cell components are removed thoroughly, antigenicity is low, the dermal collagen structure is kept, histocompatibility is high, the time of the whole preparation process is only about 60 hours, disposal time is short, disposal cost is low, and good social benefits and economic benefits are achieved.

Owner:王忠新

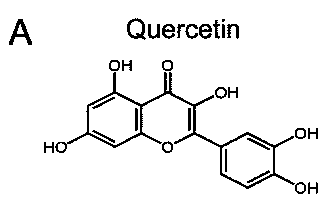

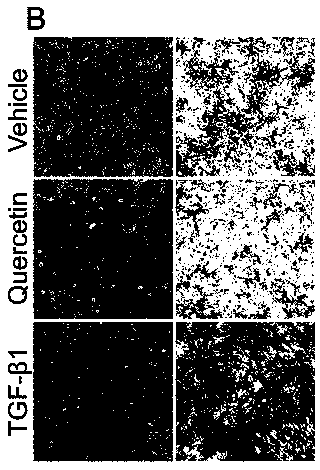

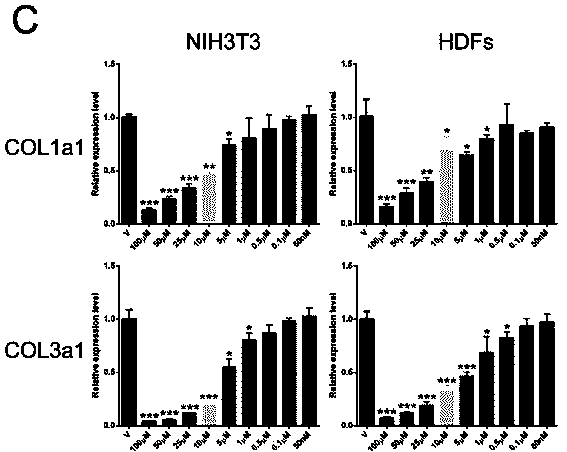

Application of flavonoid quercetin in inhibition of skin scar formation and skin fibration

InactiveCN104127403ASmall molecular weightIncrease fat solubilityCosmetic preparationsOrganic active ingredientsSKIN SCARRINGQuercitrin

The invention relates to an application of flavonoid quercetin in inhibition of skin scar formation and skin fibration. The application verifies that quercetin has no toxicity to fibroblast, human dermal fibroblast I / III-type collagen mRNA expression and protein synthesis can be inhibited by inhibiting a TGF beta1 signal pathway in cells, fibroblast can be inhibited to myofibroblast differentiation, so that skin scar formation or dermal collagen deposition (fibration) can be inhibited, Animal in-vitro experiment confirms that quercetin is effected on mice skin, bleomycin-induced mice skin fibration and tension force-induced mice skin scar formation can be inhibited. Because that quercetin has the characteristics of small molecular weight, high lipid solubility and good transdermal absorption capability, the molecules can be used for preparing the medicine for resisting skin scar formation and skin fibration, and have wide application prospect in medical, shaping and cosmetic fields.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Preparation method of heterogeneous acellular dermal matrix

ActiveCN107412867AGood biocompatibilityImprove antibacterial propertiesTissue regenerationProsthesisFiberMedicine

The invention relates to a preparation method of heterogeneous acellular dermal matrix. The preparation method comprises the following steps: taking bama miniature pig skin as a skin source, reversely taking split-thickness skin by adopting a skin drum, carrying out the steps of removing epidermis and extracting cells, thus obtaining acellular dermis, enabling the acellular dermis to react with carboxymethyl chitosan, thus obtaining acellular dermal matrix, finally, treating the acellular dermal matrix by adopting a softening agent and a humectant, so that the prepared acellular dermal matrix is closer to the natural state of the skin of the human body, and thus the use compliance of the acellular dermal matrix is improved. The heterogeneous acellular dermal matrix prepared by adopting the method disclosed by the invention is low in immunogenicity, meanwhile, the heterogeneous acellular dermal matrix keeps the three-dimensional stereoscopic structure of dermal collagen fibers, improves the stability of the three-dimensional structure of the dermal collagen fibers, and has the excellent biocompatibility.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

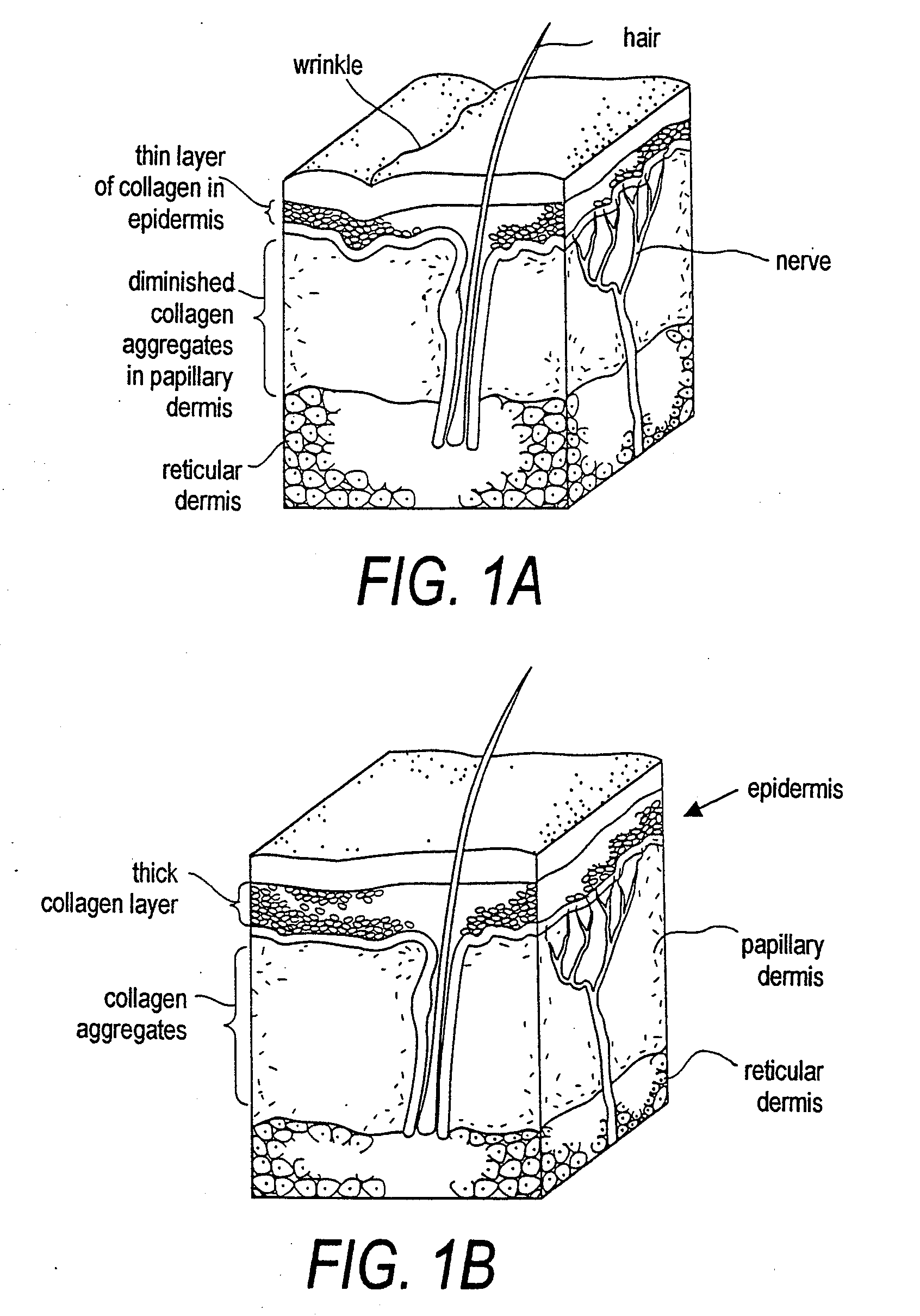

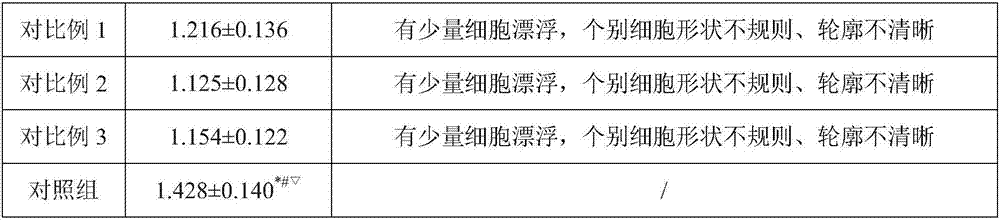

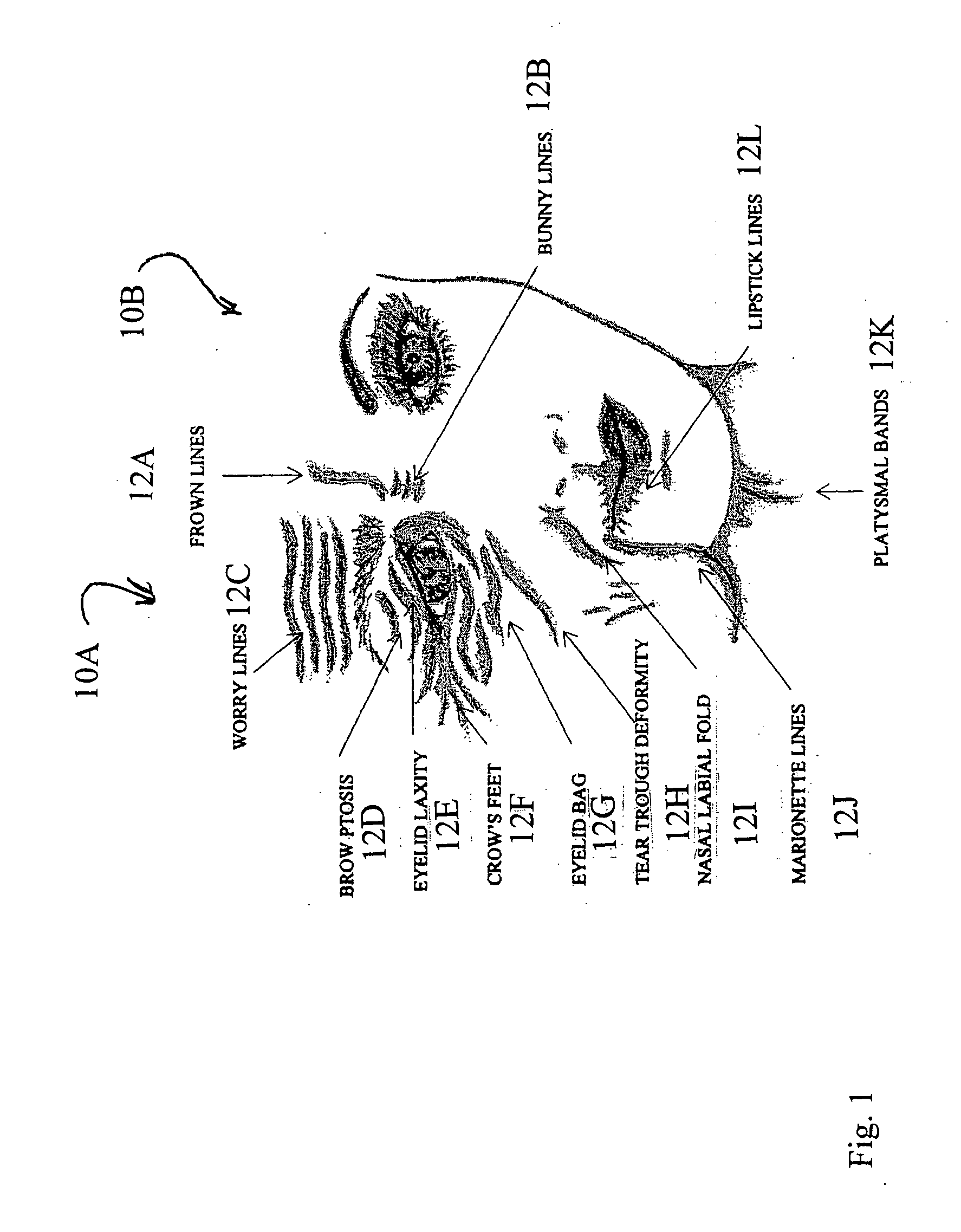

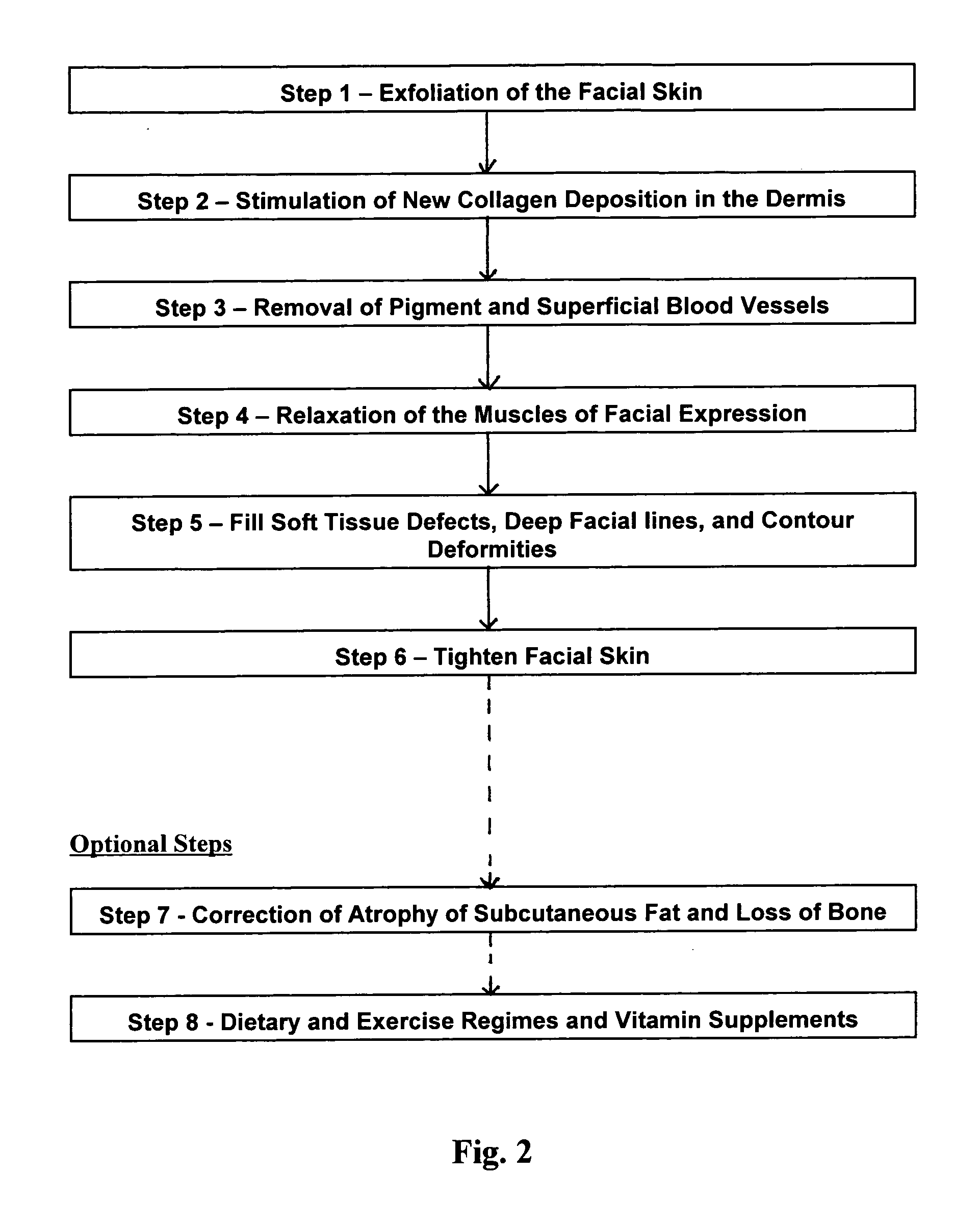

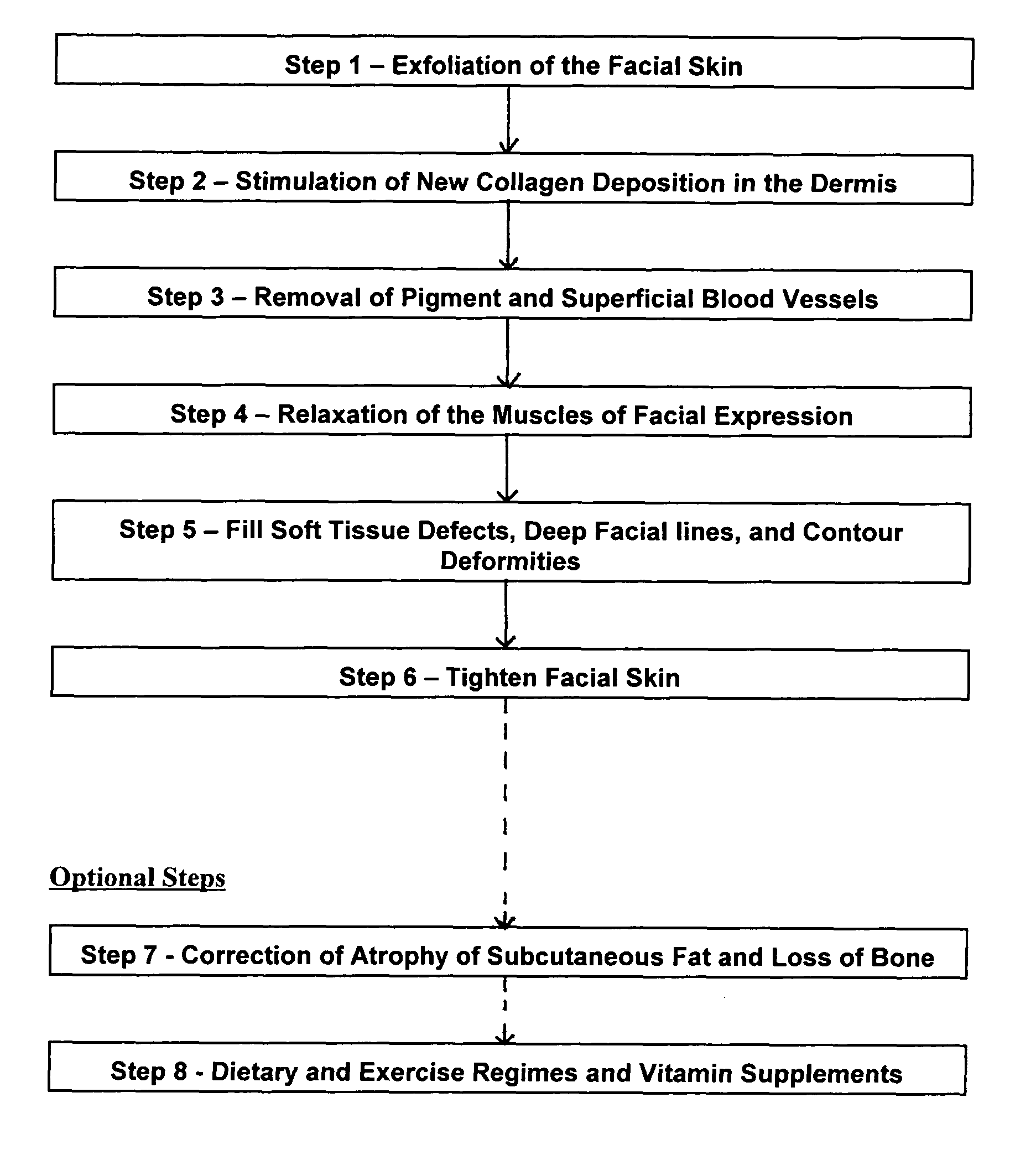

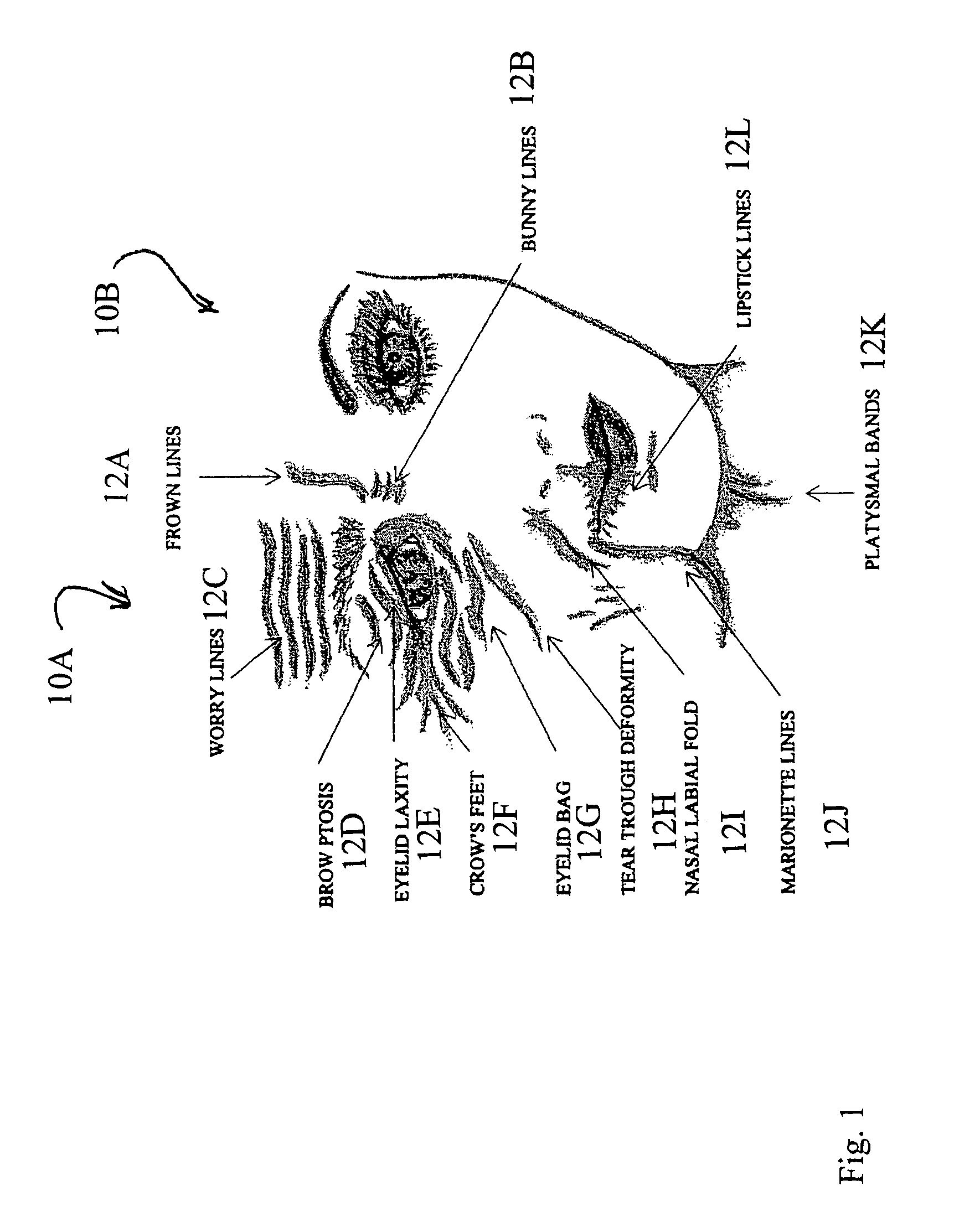

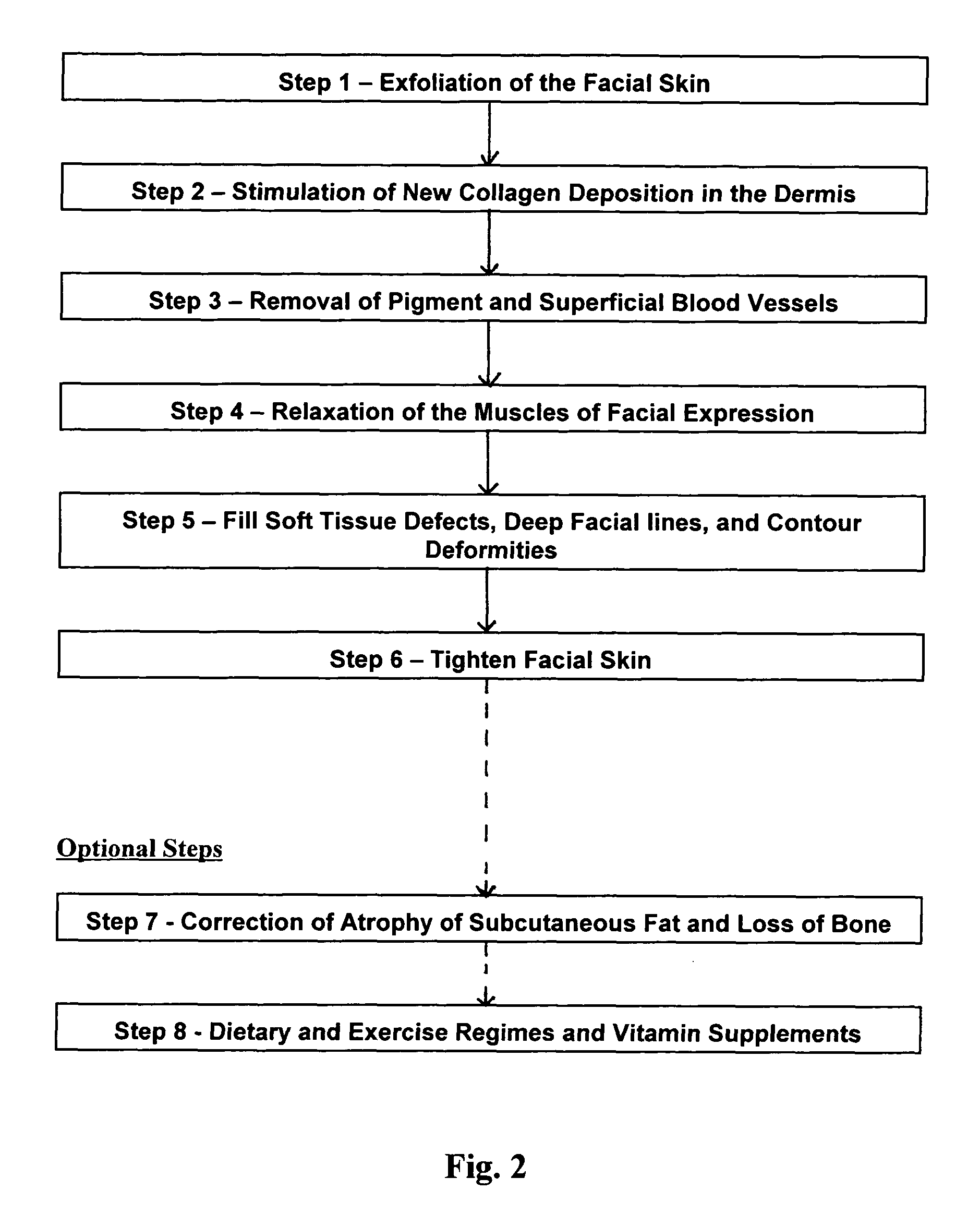

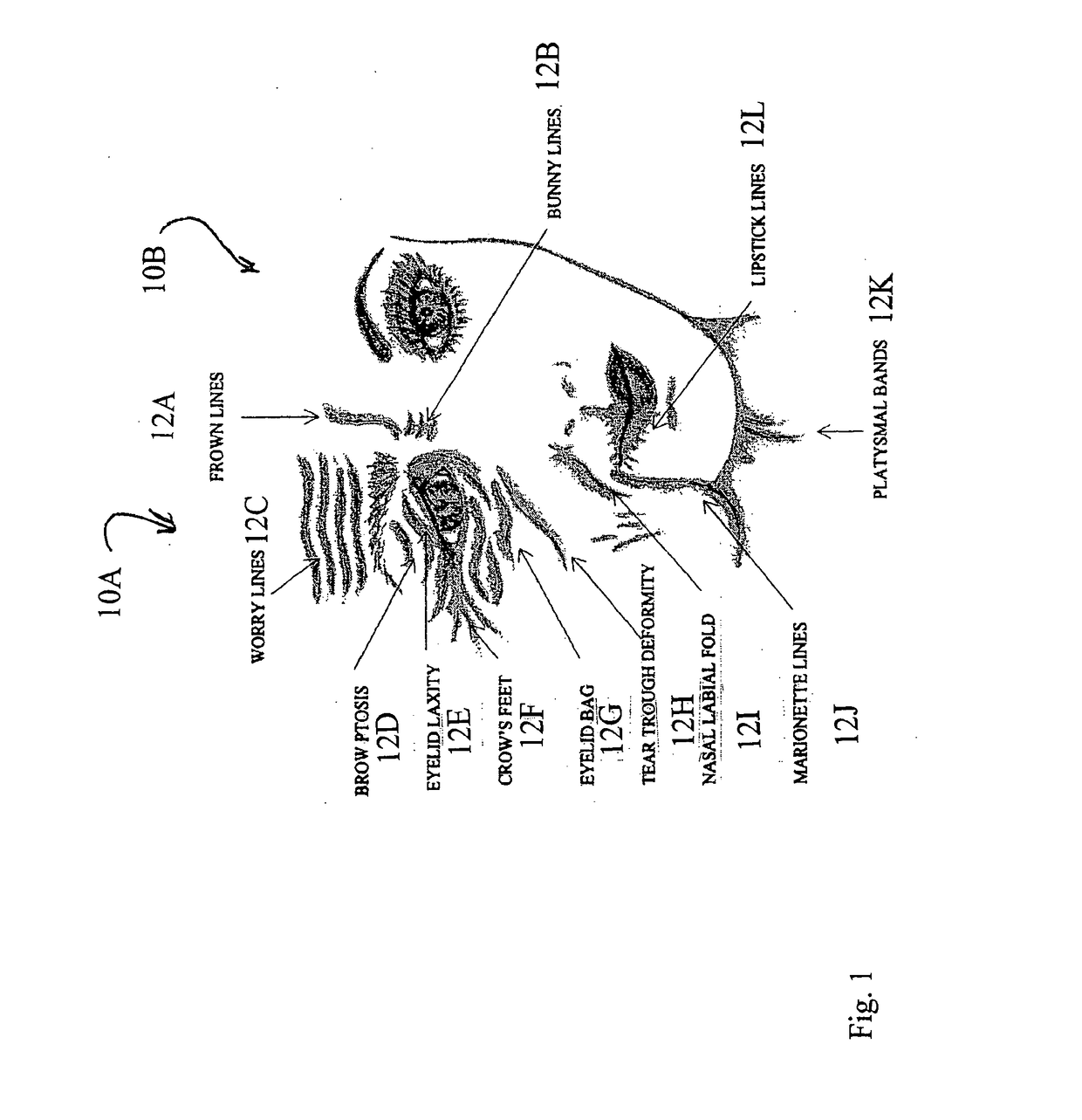

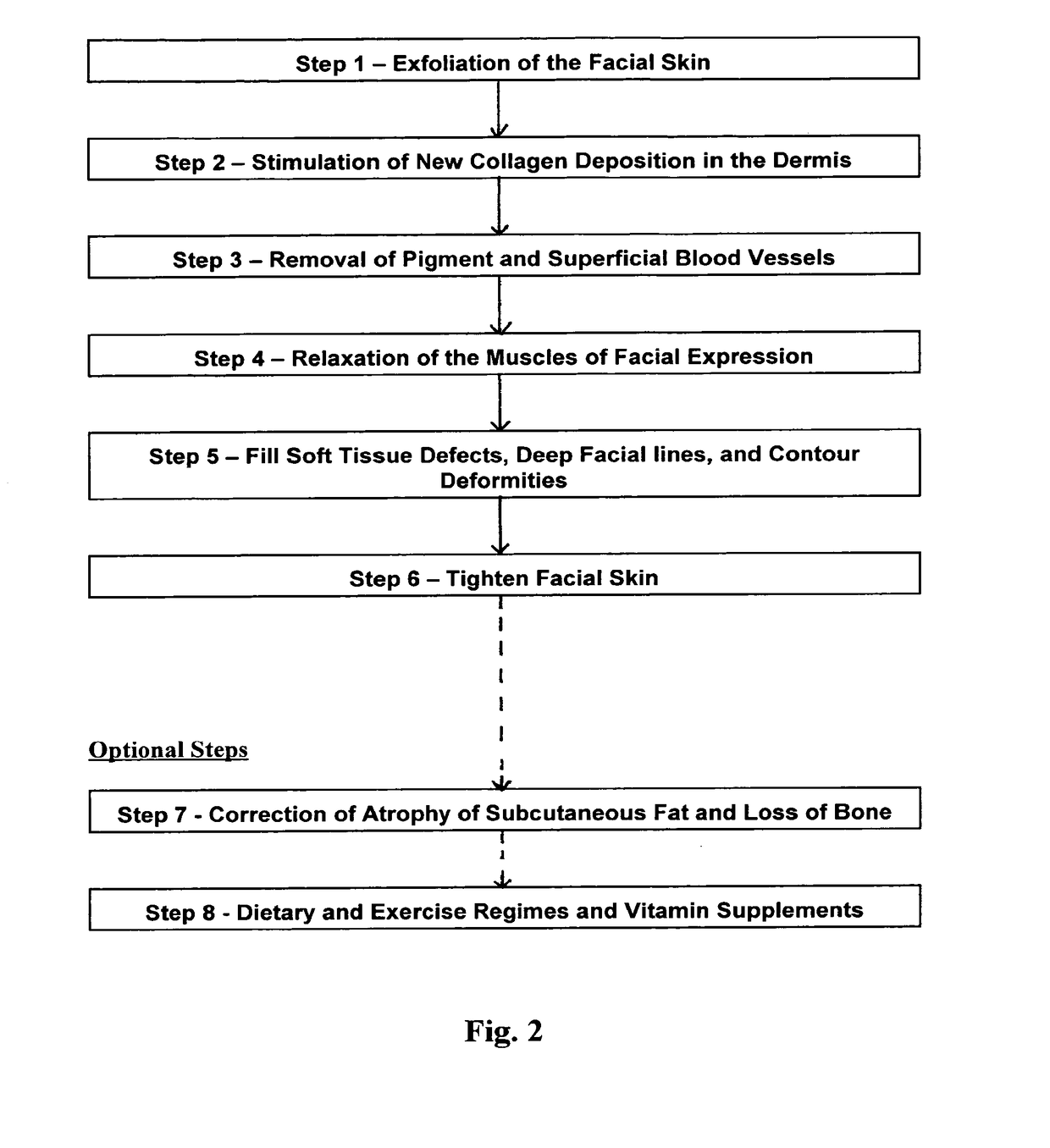

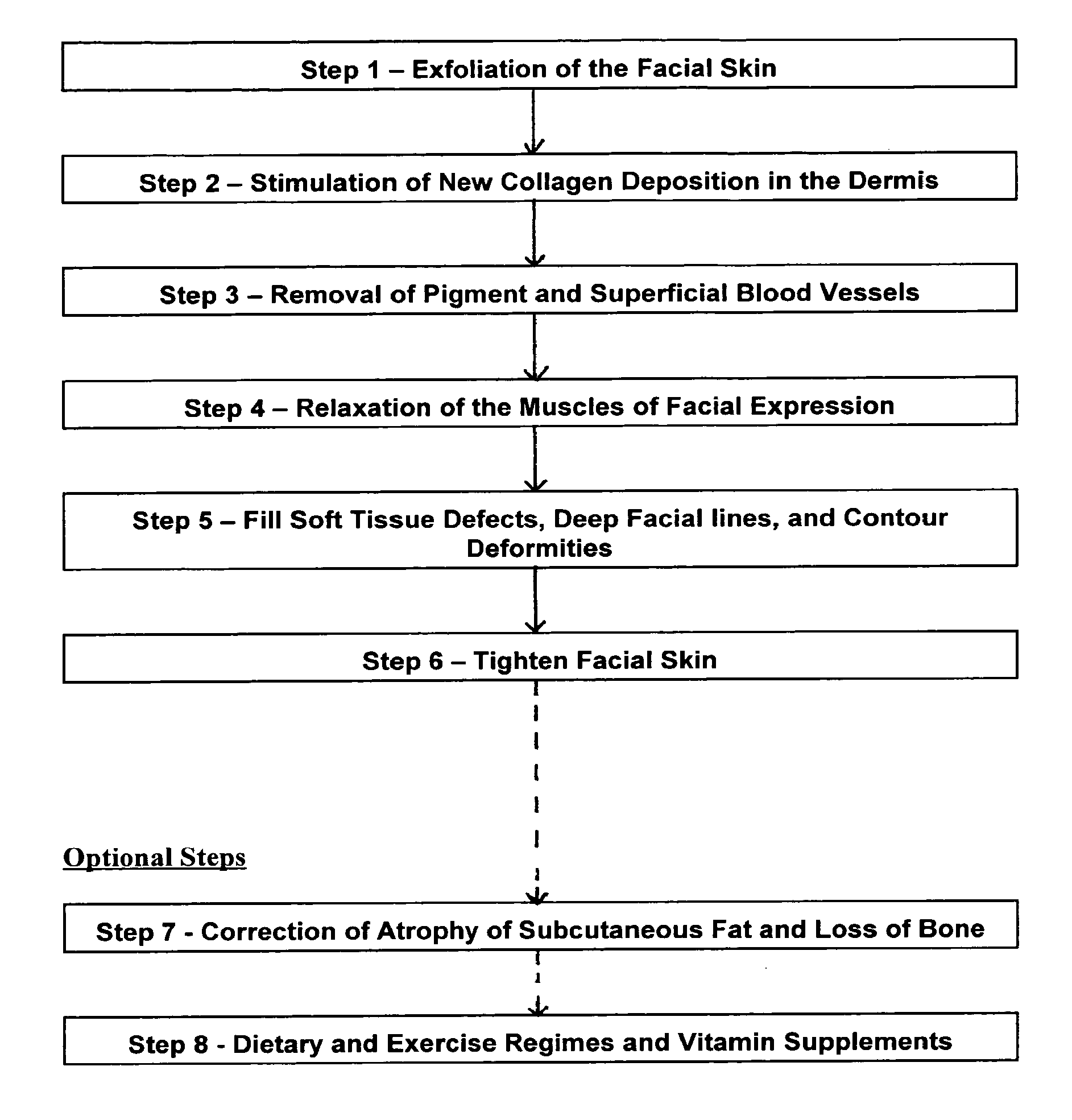

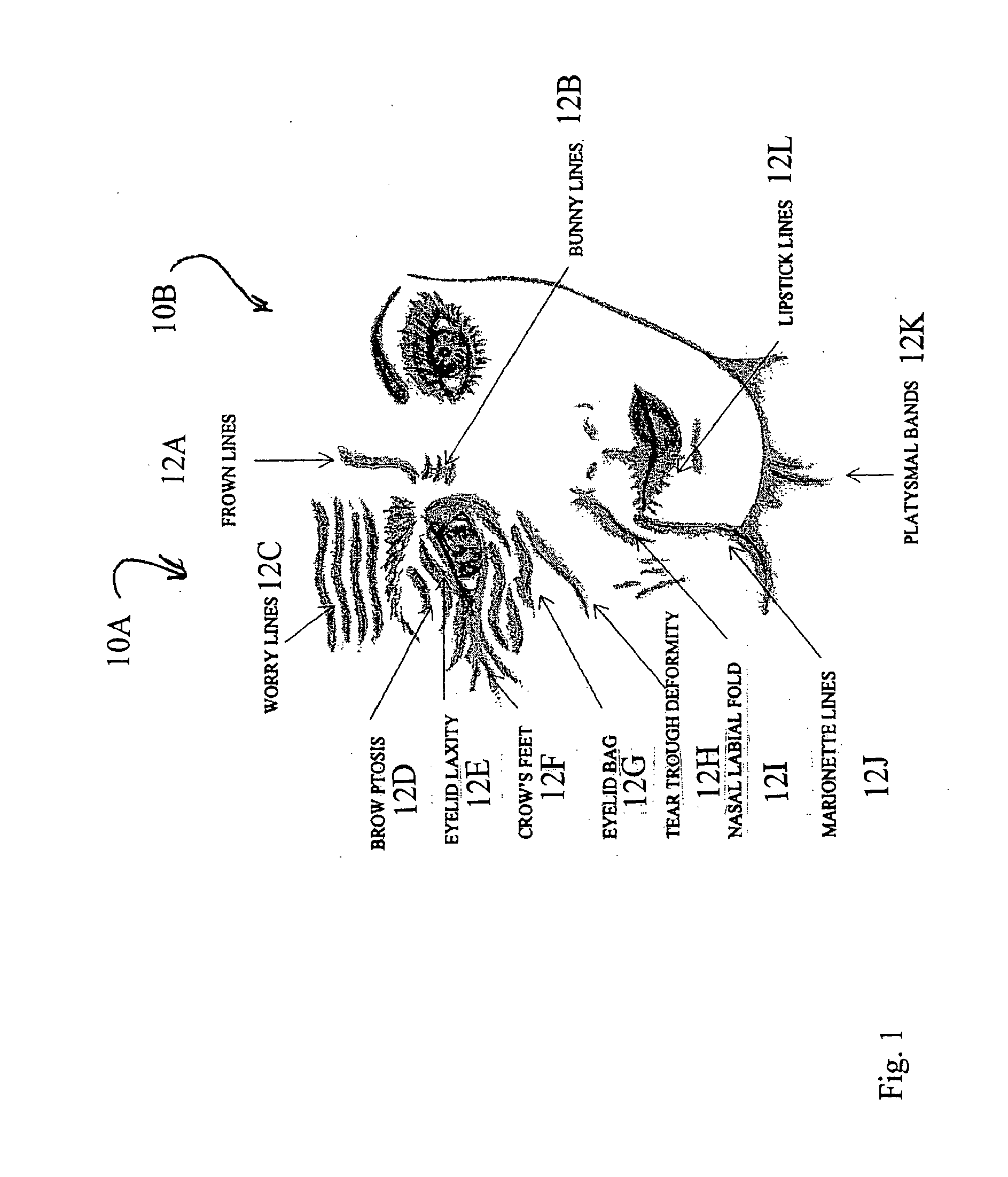

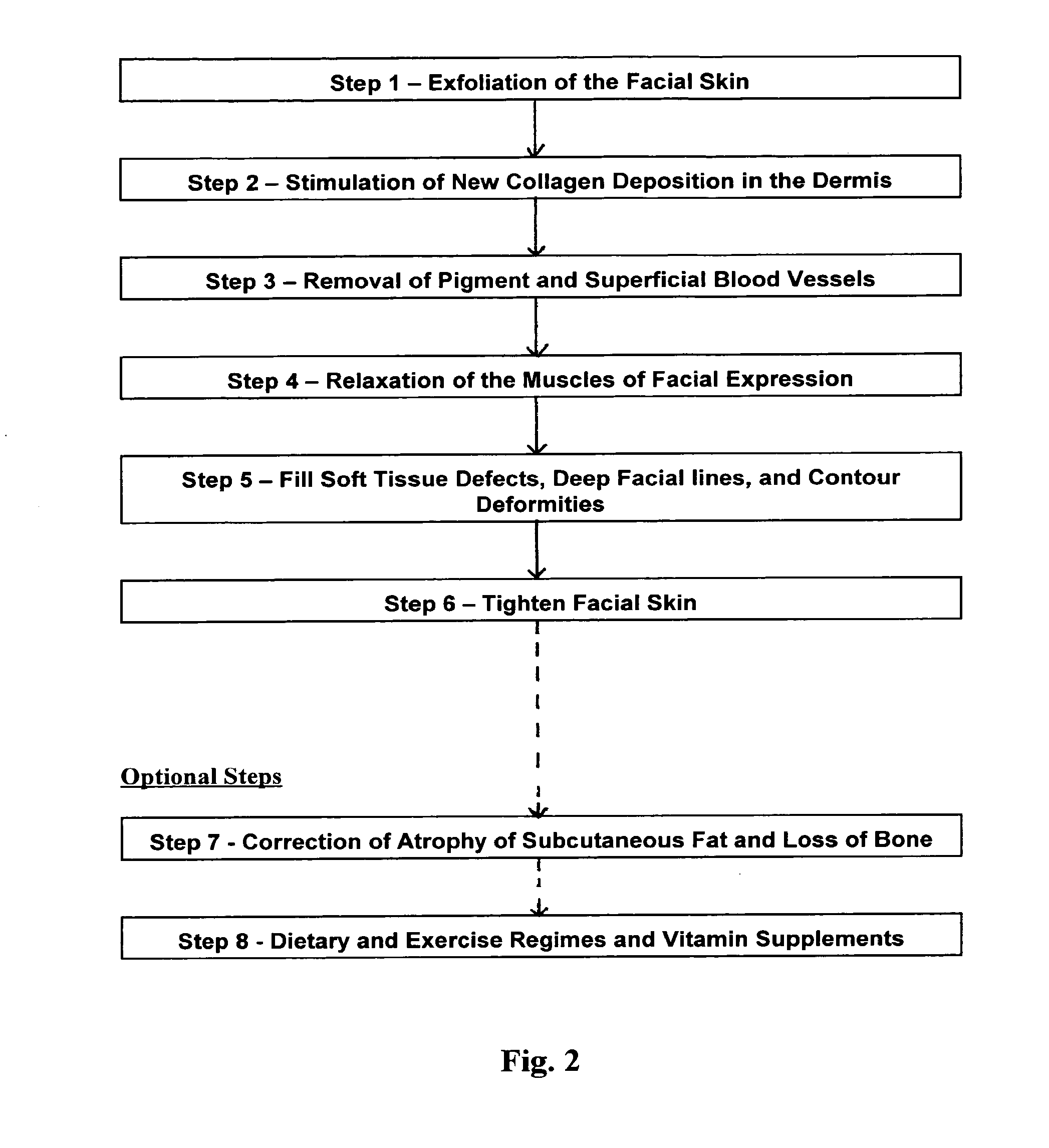

Method for non-surgical facial rejuvenation

A method for non-surgical rejuvenation of facial skin to correct both Type a aging changes in the epidermis layer of the skin causing visual changes in the skin and Type 2 aging changes in the dermis layer of the skin causing damage to supportive elements of the skin. The method includes the steps of exfoliation of the facial skin, stimulation of new dermal collagen deposition, removal of at least one of pigment and superficial blood vessels, relaxation of facial expression muscles, filling of soft tissue defects including at least one of deep facial lines and contour deformities, and tightening of the facial skin, and the steps of the method are applied according to a selected one of a plurality of age determined regimens.

Owner:SECKEL BROOKE R

Dermal collagen fiber prepared from tanning chromium-containing subsidiary waste

InactiveCN102425018AAchieving a circular economyWide variety of sourcesTextile disintegration and recoveryAnimal materialCardingMoisture regain

The invention discloses a dermal collagen fiber prepared from tanning chromium-containing subsidiary waste and a preparation method thereof. In the preparation method, the tanning chromium-containing subsidiary waste is used as a raw material, is subjected to processing of puffing, separating fibers, splitting fibers and carding and the like by a physical, chemical and biochemical combination method on the premise of ensuring unchanged good physical and mechanical conditions of collagen fibers, and is prepared into the dermal collagen fiber with good performance and wide application ranges. The dermal collagen fiber reaches the following technical indexes: (1) the outer surface is provided with light blue fiber materials and does not have visible impurities; (2) the moisture content is between 18 and 25 percent; (3) the linear density is between 1.2 and 2.0 dtex; (4) the fiber length is between 20 and 30mm; (5) the breaking strength is more than or equal to 3.5 cN / tex; (6) the elongation at break is between 10 and 30 percent; and (7) the moisture regain is between 6 and 10 percent. The dermal collagen fiber can be used as raw materials of high-simulation leather (automobile seat leather, furniture leather, instep leather, garment leather, shoe lining leather, belt leather, luggage leather and the like), natural leather base cloth, senior carpets, senior wall paper, dermal fiber bedding and the like.

Owner:SICHUAN UNIV

Method for non-surgical facial rejuvenation

A method for non-surgical rejuvenation of facial skin to correct both Type 1 aging changes in the epidermis layer of the skin causing visual changes in the skin and Type 2 aging changes in the dermis layer of the skin causing damage to supportive elements of the skin. The method includes the steps of exfoliation of the facial skin, stimulation of new dermal collagen deposition, removal of at least one of pigment and superficial blood vessels, relaxation of facial expression muscles, filling of soft tissue defects including at least one of deep facial lines and contour deformities, and tightening of the facial skin, and the steps of the method are applied according to a selected one of a plurality of age determined regimens.

Owner:SECKEL BROOKE R

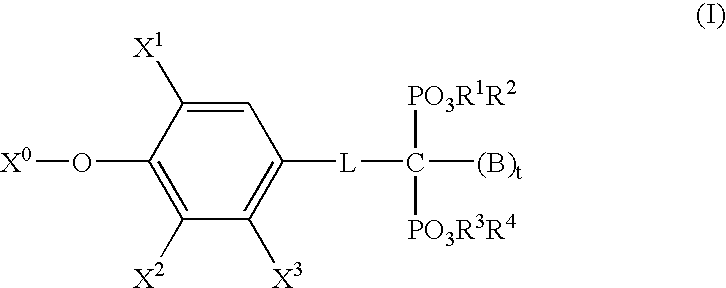

Methods of treating skin with diphosphonate derivatives

The present invention provides for the administration of aryl-substituted 1,1-diphosphonate compounds to increase the dermal collagen content of skin and effect improvement in photoaged skin, chronologically aged skin and in skin of postmenopusal women and patients suffering from osteoporosis.

Owner:ILEX PRODUCTS INC

Protein beverage formula for cosmetic whitening and preparation method thereof

InactiveCN108902622AEasy to manufactureEasy to carryFood ingredient functionsVitamin COligosaccharide

The invention discloses a protein beverage formula for cosmetic whitening and a preparation method thereof. The protein beverage comprises the following raw materials in parts by weight: 100 parts ofwater, 5 to 10 parts of ocean fish oligopeptide powder, 6 to 12 parts of honey peach fruit powder, 8 to 15 parts of fructose-oligosaccharide, 5 to 10 parts of mulberry, 2 to 8 parts of soy peptide powder, 5 to 10 parts of acerola cherry powder, 2 to 5 parts of bird's-nest, 0.5 to 1 part of gamma-aminobutyric acid and 1 to 3 parts of vitamin C. The protein beverage disclosed by the invention has the advantages that excessive secretion of black poison is inhibited, deposited pigment and stains are metabolized, the skin metabolism is promoted, a dermal collagen network is repaired, and blood circulation of skin is promoted; the collagen supplementing structure is firmly fixed through elastin to form a tight and meticulous structure with filling and no collapse while collagen can be effectively supplemented for people; wrinkles are reduced and the elasticity is enhanced; the protein beverage is conductive to skin health and has a good beauty whitening effect.

Owner:广东美栖文化传播有限公司

Preparation method of acellular dermal matrix and prepared acellular dermal matrix

InactiveCN107412868ALow antigenicityLow heterologous DNA contentTissue regenerationProsthesisMedicineDecellularization

The invention relates to the technical field of tissue engineering, in particular to a preparation method of an acellular dermal matrix and the prepared acellular dermal matrix. By means of the provided preparation method of the acellular dermal matrix, cell ingredients can be cleanly removed, the antigenicity is low, the dermal collagen structures are reserved, the heterologous DNA content is very low, and good mechanical performance is obtained.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

Method for non-surgical facial rejuvenation

A method for non-surgical rejuvenation of facial skin to correct both Type 1 aging changes in the epidermis layer of the skin causing visual changes in the skin and Type 2 aging changes in the dermis layer of the skin causing damage to supportive elements of the skin. The method includes the steps of exfoliation of the facial skin, stimulation of new dermal collagen deposition, removal of at least one of pigment and superficial blood vessels, relaxation of facial expression muscles, filling of soft tissue defects including at least one of deep facial lines and contour deformities, and tightening of the facial skin, and the steps of the method are applied according to a selected one of a plurality of age determined regimens.

Owner:SECKEL BROOKE R

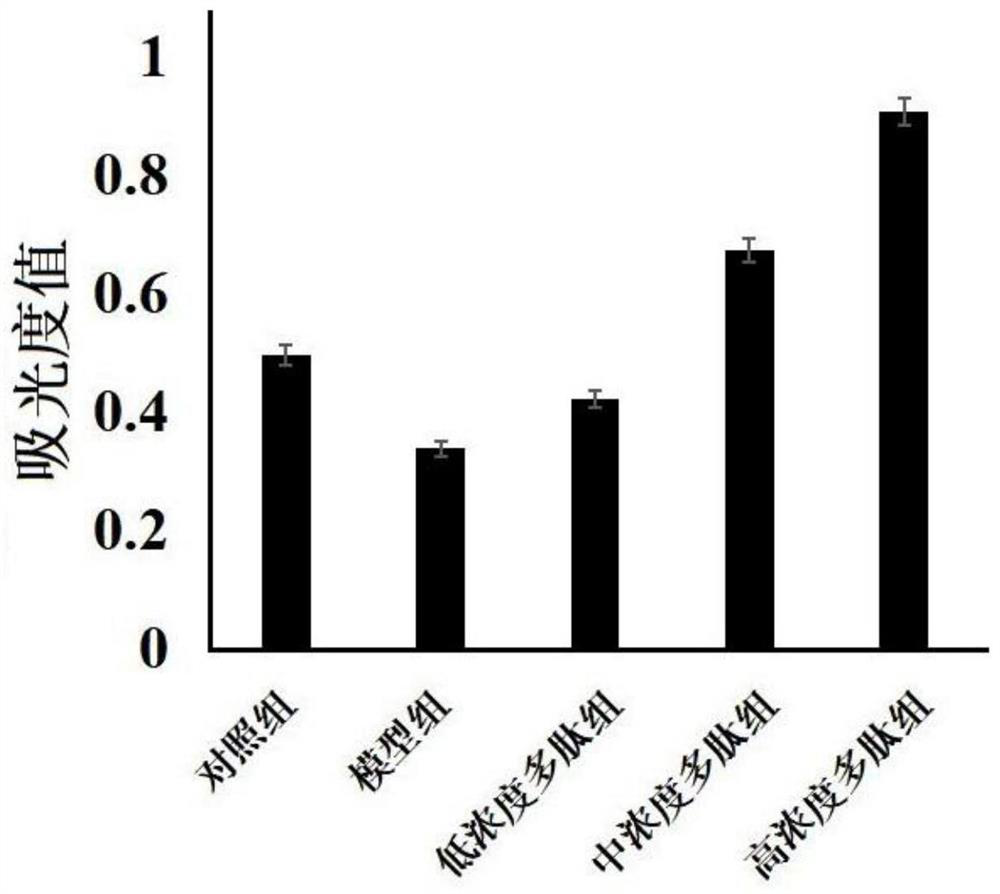

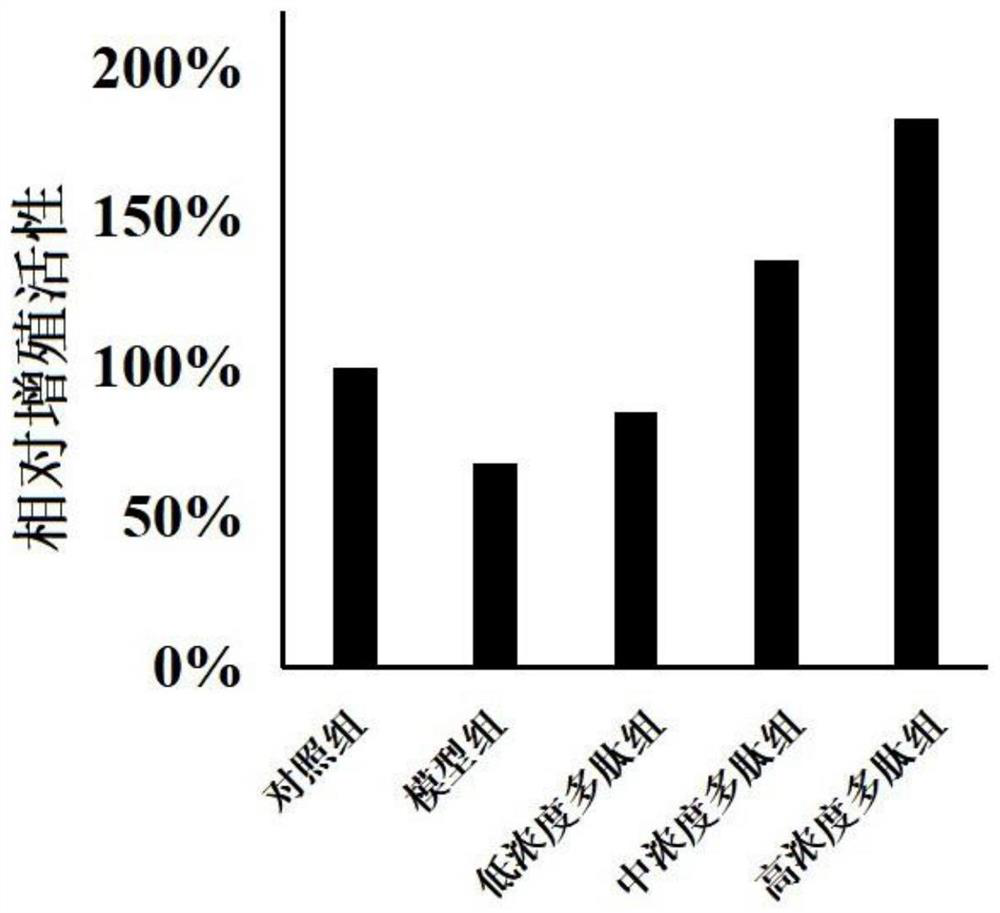

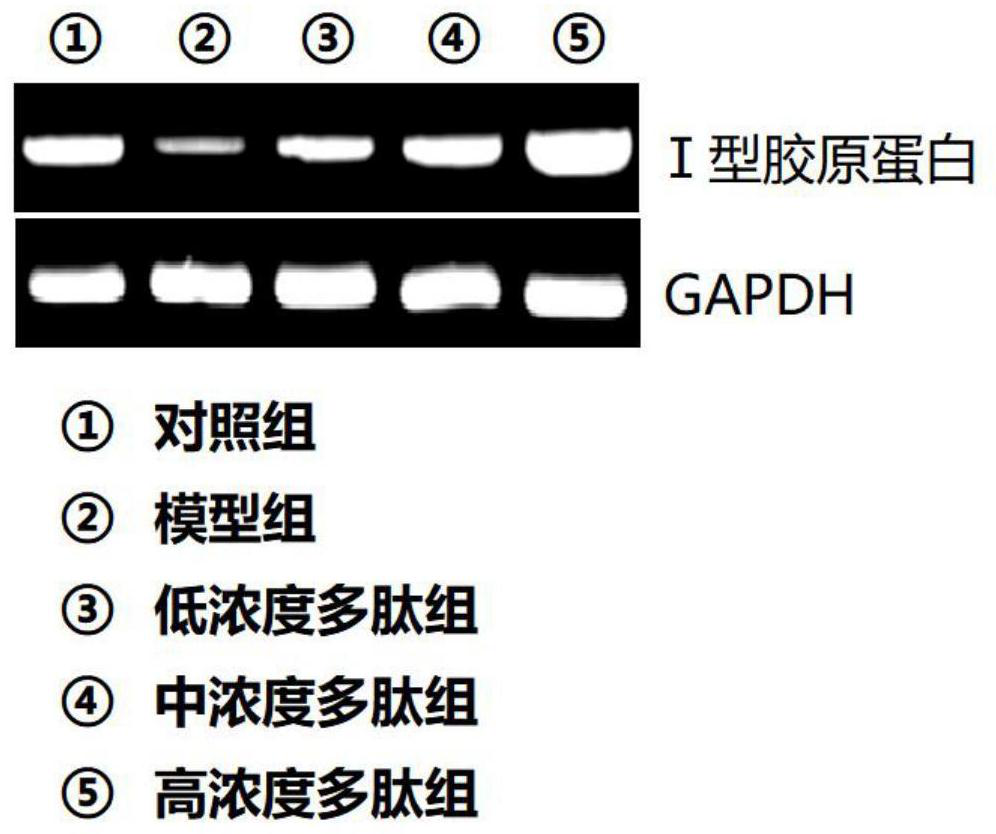

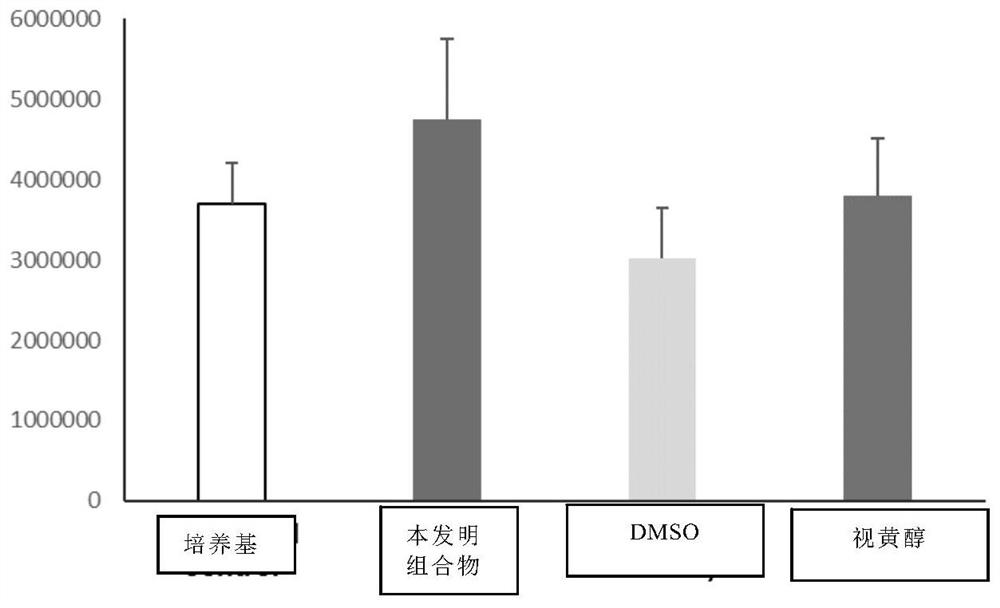

Plant-derived polypeptide with anti-aging effect, face cream containing plant-derived polypeptide and preparation method of face cream

PendingCN112080543AStay youngPromote proliferationCosmetic preparationsToilet preparationsFacial creamWrinkle

The invention discloses a plant-derived polypeptide with an anti-aging effect, face cream containing the plant-derived polypeptide and a preparation method of the face cream. The plant-derived polypeptide is a sage seed polypeptide. Skin aging is a part of body aging, is shown as skin relaxation and thinning, and is one of the most intuitive external expressions of body aging due to wrinkle formation and gradual increase and deepening. Researches show that skin aging is related to the proliferation ability of skin fibroblasts and the decrease of the content of dermal collagen. Therefore, the promotion of the proliferation of human skin fibroblasts and the synthesis of collagen is an important aspect for keeping skin young and resisting aging. The test results show that the sage seed polypeptide can promote the proliferation of human skin fibroblasts and the synthesis of collagen by human skin fibroblasts, has an anti-skin aging effect, and can be used for preparing anti-skin aging cosmetics.

Owner:张超科

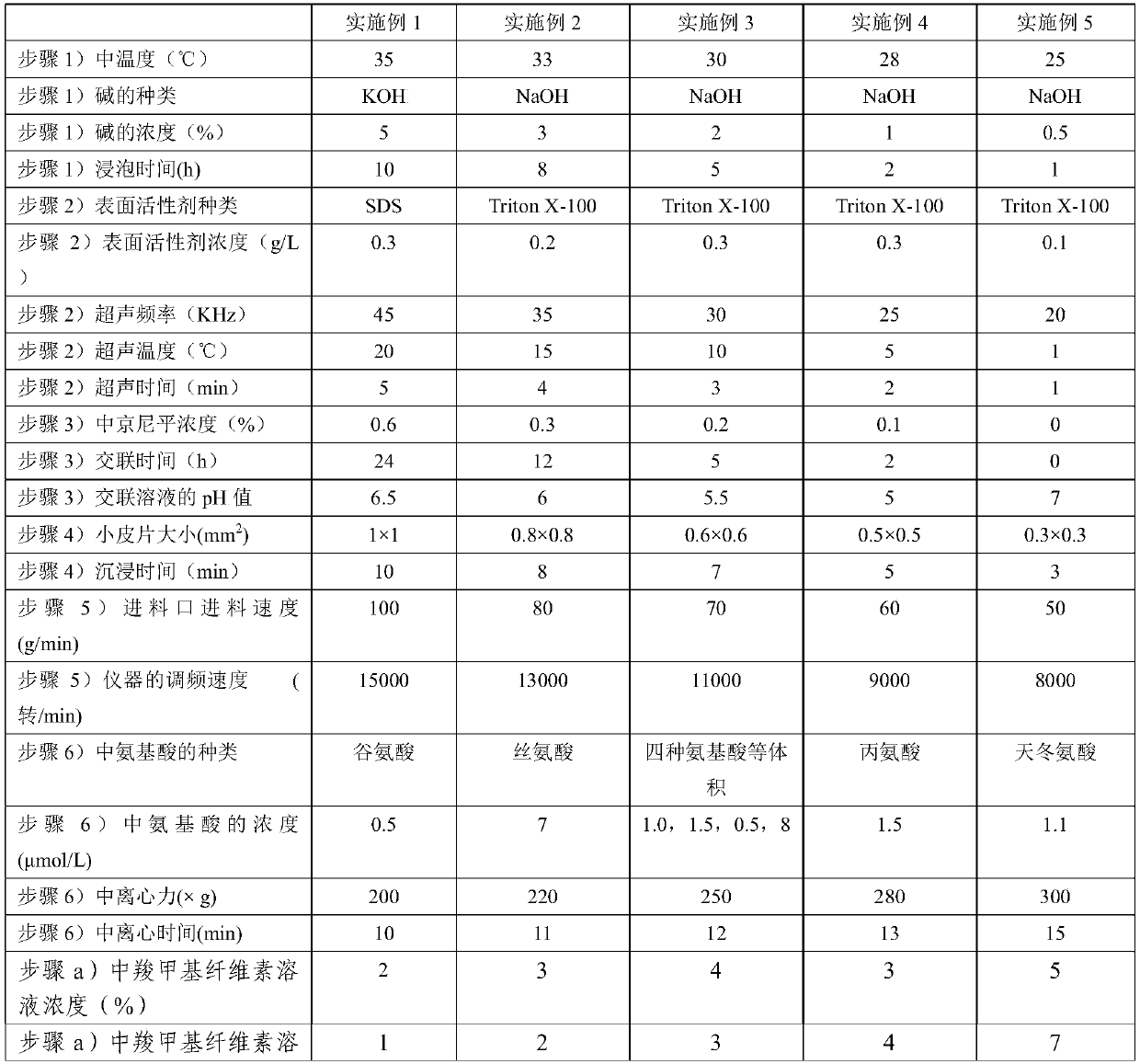

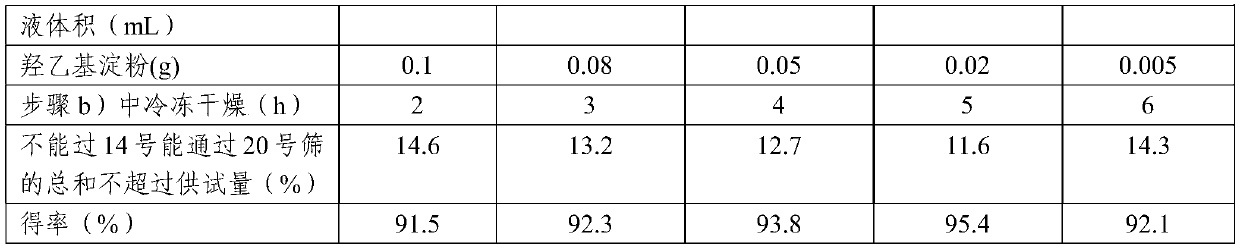

Regenerated tissue matrix composition for micro-surgery, preparation and application

ActiveCN109646718APreserve the 3D frame structureImprove adhesionPharmaceutical delivery mechanismProsthesisWrinkle skinFiber

The invention provides a regenerated tissue matrix composition for micro-surgery, preparation and application. The reconstituted tissue matrix composition comprises regenerated tissue matrix microparticles, hydroxyethyl starch and carboxymethylcellulose; the regenerated tissue matrix microparticles contain an extracellular matrix in a microparticle state, and can pass through a 100-mesh screen, but cannot pass through a 400-mesh sieve. The regenerated tissue matrix composition has a three-dimensional structure and good biocompatibility, thereby being capable of serving as a stent for tissue supporting and cell growth and serving as a filler for facial micro-surgery. A minimally invasive injection product comprising the composition causes no immunological rejection in clinical use, is suitable for being injected into the dermis layer to repair facial wrinkles caused by the reduction of dermal collagen and elastic fiber or modify defective skin, and has a good tissue repair effect.

Owner:北京颢美细胞基因生物技术有限公司

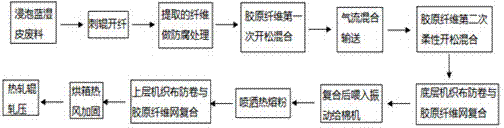

Method for producing artificial leather base material by compounding collagen fibers by utilizing spun-laced water jetting

ActiveCN102182015BStrong skin feelingImprove the simulation effectNon-woven fabricsPolymer sciencePolymer chemistry

At present, the synthetic leathers are made of artificial fibers, and due to the performance difference between the artificial fibers and real leather collagen fibers, the performances of the artificial leathers are greatly different from the performances of the real leathers. The existing reclaimed leathers have harder handfeel and the environment is polluted in the production processes of the reclaimed leathers. The invention provides a method for producing an artificial leather base material by compounding collagen fibers by utilizing spun-laced water jetting. The method comprises the following steps: 1) firstly preparing the collagen fibers into a collagen fiber sheet for compounding by utilizing spun-laced water jetting; and 2) opening and entangling the collagen fiber sheet by utilizing spun-laced water jetting in a spun-laced nonwoven process, at the same time, compounding the collagen fiber sheet with an opened and carded synthetic fiber sheet, and after compounding, implanting the synthetic fibers in the collagen fibers so that the two different fiber sheets are firmly bonded as a whole. The method has the following beneficial effects: after undergoing the subsequent coating processing, the obtained base material has stronger leather feel and better simulation than the traditional synthetic leathers and softer handfeel than the reclaimed leathers; and the method is more environment-friendly than the traditional production methods of the reclaimed leathers.

Owner:浙江弘扬无纺新材料有限公司

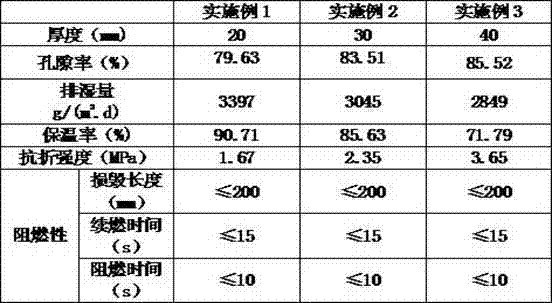

Environment-friendly building material and preparation method thereof

ActiveCN104760348AGram weight highIncreasing the thicknessLamination ancillary operationsSynthetic resin layered productsFiberThermal insulation

Owner:JIAXING UNIV

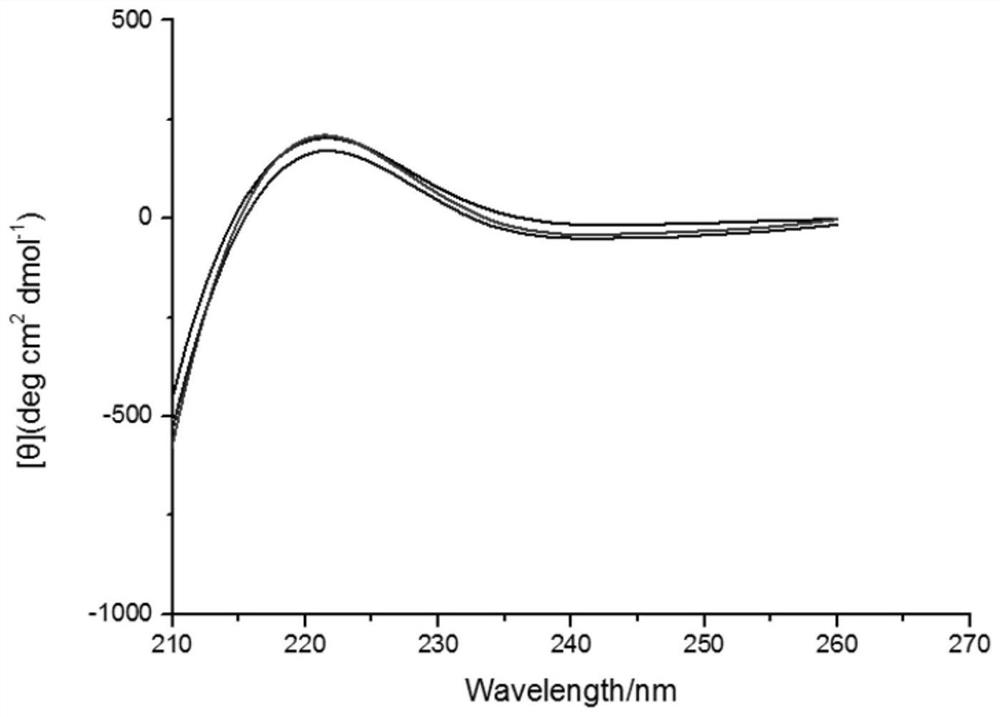

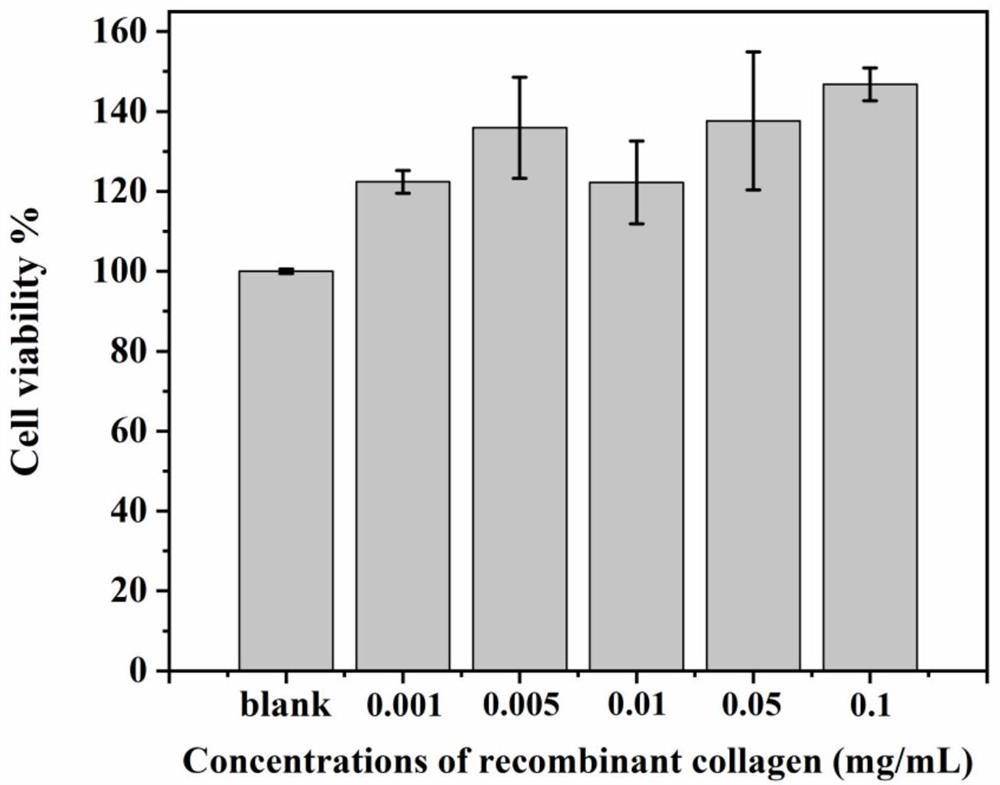

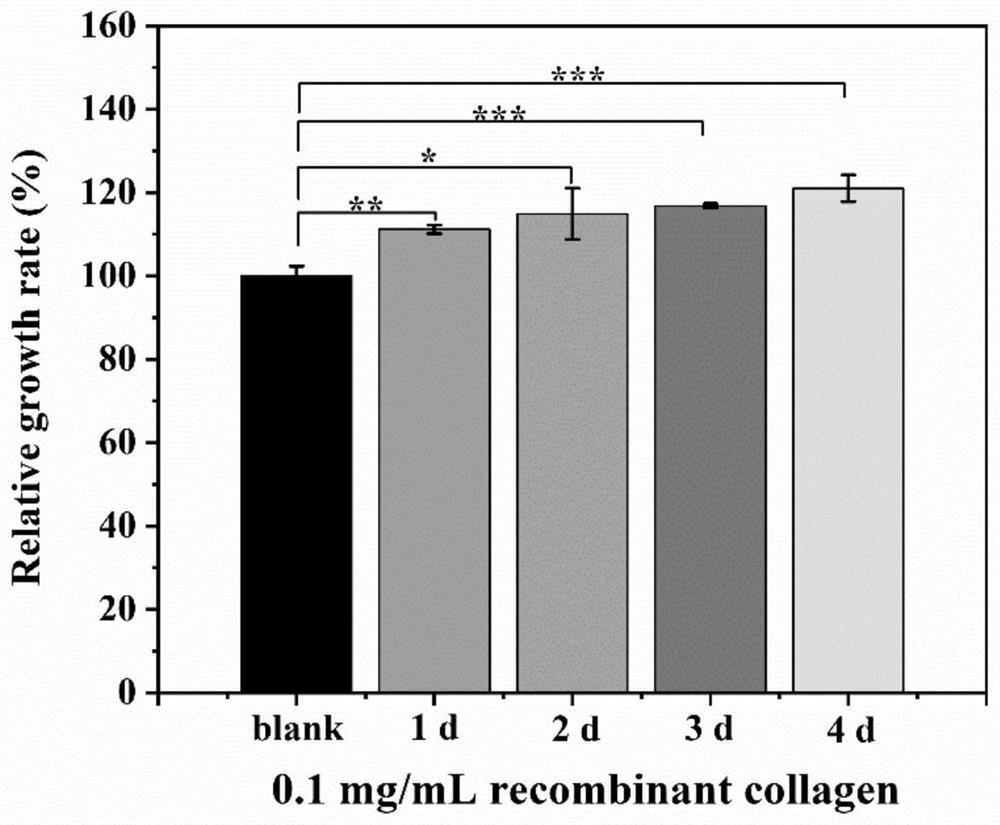

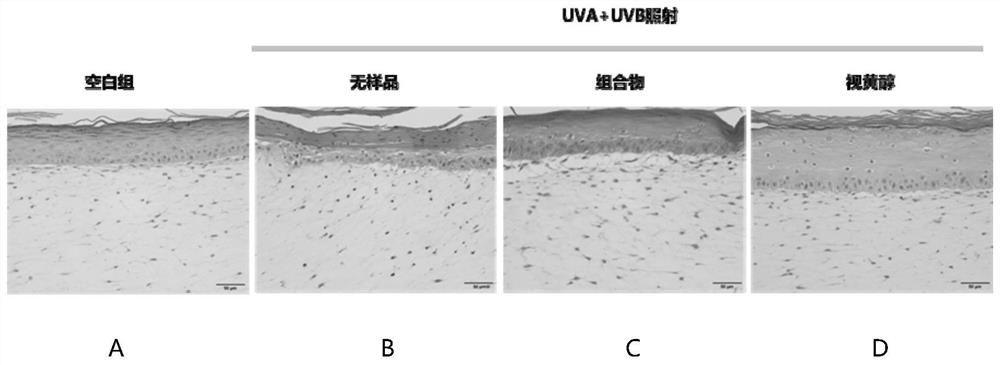

A recombinant collagen product for skin photodamage repair

ActiveCN113520899BImprove securityImprove adhesionCosmetic preparationsPeptide/protein ingredientsBiologyCollagen fibres

The invention belongs to the field of dermatology, and in particular relates to a recombinant collagen product used for repairing skin ultraviolet damage. The invention provides a recombinant collagen, which has a good repair effect on the skin damaged by ultraviolet rays, has a good adhesion effect on fibroblasts, can promote the proliferation of skin fibroblasts, and has no effect on the skin. Stimulating effect, good safety; at the same time, the recombinant collagen can significantly improve the inflammatory symptoms after skin damage, maintain the moisture of the epidermis, induce the growth of skin epidermal cells, and help repair the collagen fibers of the dermis, repair the skin damaged by light, and can be used for Preparation of cosmetic or medical cosmetic products.

Owner:胶原蛋白(武汉)生物科技有限公司

Method for non-surgical facial rejuvenation

A method for non-surgical rejuvenation of facial skin to correct both Type 1 aging changes in the epidermis layer of the skin causing visual changes in the skin and Type 2 aging changes in the dermis layer of the skin causing damage to supportive elements of the skin. The method includes the steps of exfoliation of the facial skin, stimulation of new dermal collagen deposition, removal of at least one of pigment and superficial blood vessels, relaxation of facial expression muscles, filling of soft tissue defects including at least one of deep facial lines and contour deformities, and tightening of the facial skin, and the steps of the method are applied according to a selected one of a plurality of age determined regimens.

Owner:SECKEL BROOKE R

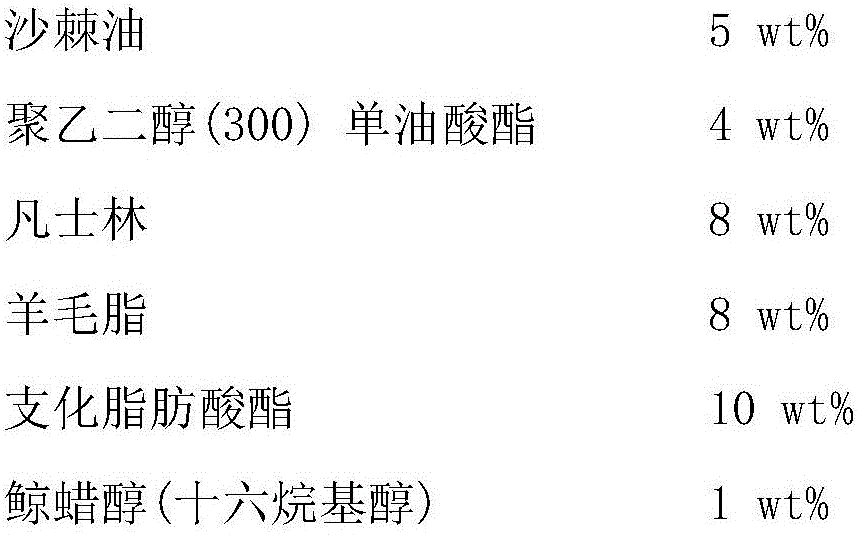

Seabuckthorn oil body lotion containing hydrolyzed pearl powder flexible nano liposome

InactiveCN105796460AImprove the immunityImprove textureCosmetic preparationsToilet preparationsCutinLotion

The invention provides seabuckthorn oil body lotion containing hydrolyzed pearl powder flexible nano liposome. The seabuckthorn oil body lotion is prepared by conducting emulsification and homogenizing on the hydrolyzed pearl powder flexible nano liposome, seabuckthorn oil, emulgator, a moisturizing agent, stablizer and deionized water. Multiple nutrition substances including amino acid, microelements, polypeptide and the like contained in the hydrolyzed pearl powder are utilized, and metabolism of skin epithelial cells and dermal fibroblasts is effectively enhanced; the flexible nano liposome can penetrate through the skin surface of the human body easily to combine with cells, so that pearl powder plays a better functions, in cooperation with seabuckthorn oil which deeply moistens skin cutin to form cells and enhance the hydration of the dermal skin, the flexible nano liposome and the seabuckthorn oil jointly act, regeneration of a skin barrier and dermal collagen can be better promoted, skin texture is improved, health of the skin can be guaranteed, and skin resistance is enhanced. The seabuckthorn oil body lotion is natural, mild, nearly free of stimulation and capable of being used for moistening skin and preserving moisture for a long time, has good water supplementation and moisture preservation effects on dry skin, sensitive skin and the like and effectively whitens the skin.

Owner:ZHEJIANG UNIV

Preparation method for moisturizing cream for breast skin

InactiveCN109646317AIncrease elasticityReduce pigmentCosmetic preparationsToilet preparationsWrinkle skinMonoglyceride

The invention discloses a preparation method for a moisturizing cream for breast skin. The method comprises the steps that S1, liquid paraffin, stearic acid, IPP, acetylated lanolin, vaseline and monoglyceride are mixed to obtain an A mixture; S2, glycerol, gropylene glycol, konjac gum, (C16-C18) alkyl alcohol ethoxylate, methyl paraben, ethylenediaminetetraacetic acid disodium salt and water aremixed to obtain a B mixture; absolute alcohol, piperine, piperic acid, quercetin, ferulic acid and hyaluronic acid are fully mixed to obtain a C mixture. The moisturizing cream has the advantages of heat preserving, ultraviolet ray resisting and oxidation resisting, the skin elasticity can be improved, pigments can be reduced, wrinkles are lightened, ageing is slowed down, the skin is allowed to be tender and smooth, the absorption of other active components and nutritious substance can be promoted to improve the nutritious metabolism of skin, and a better environment is provided for the synthesis of dermal collagen and elastic fibers.

Owner:肇庆巧巧日用化工有限公司

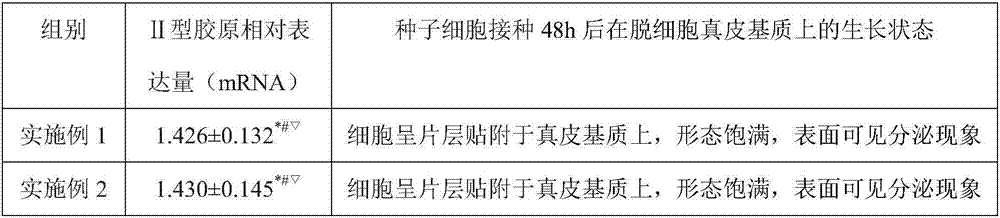

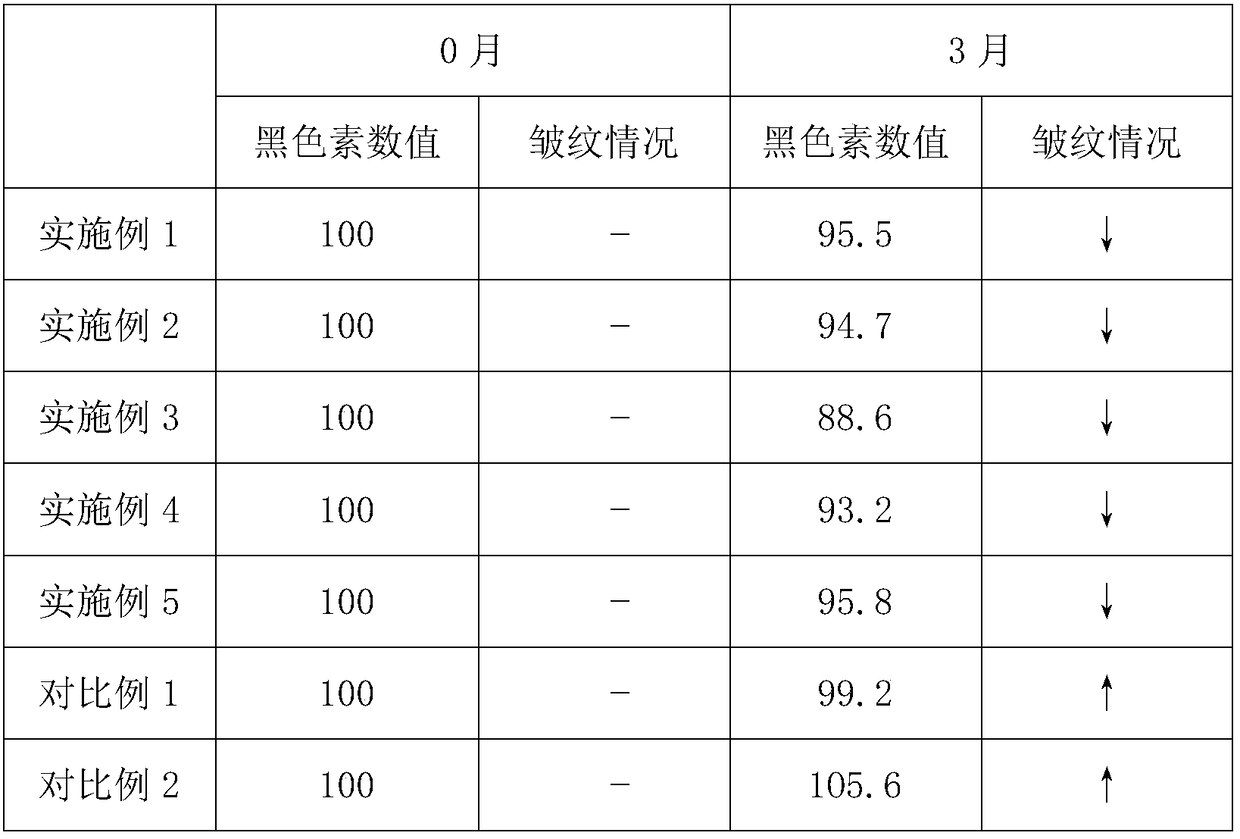

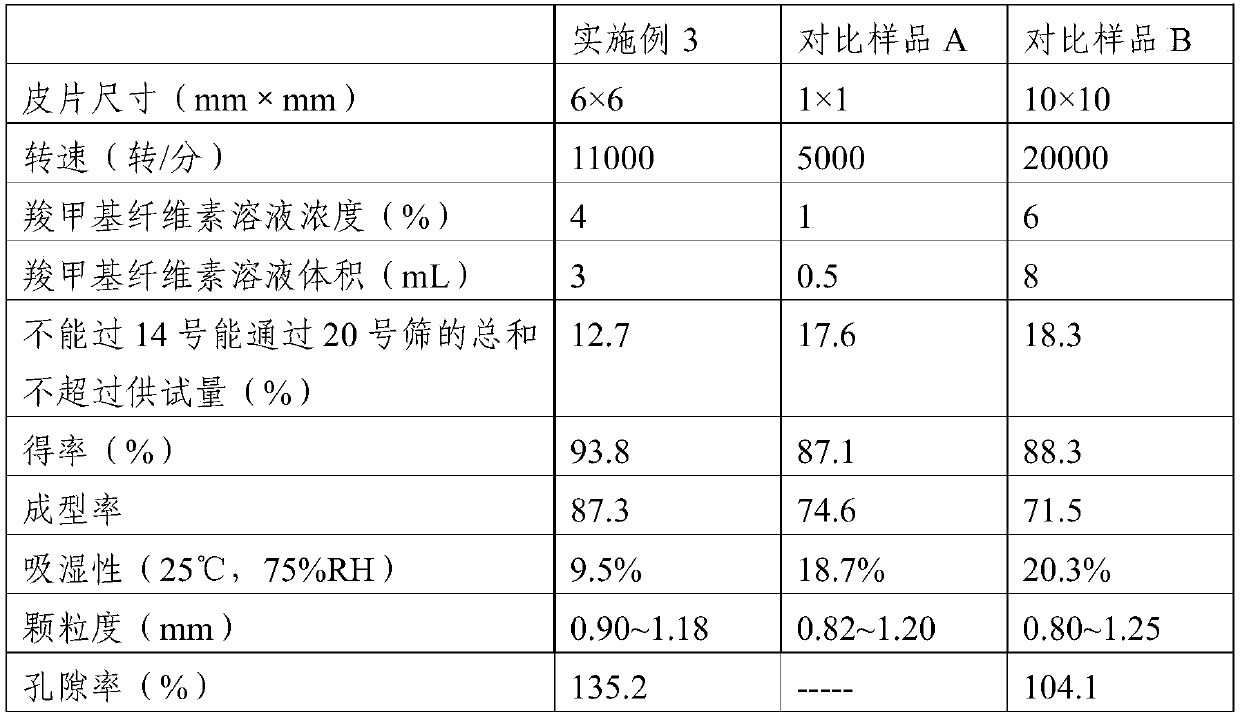

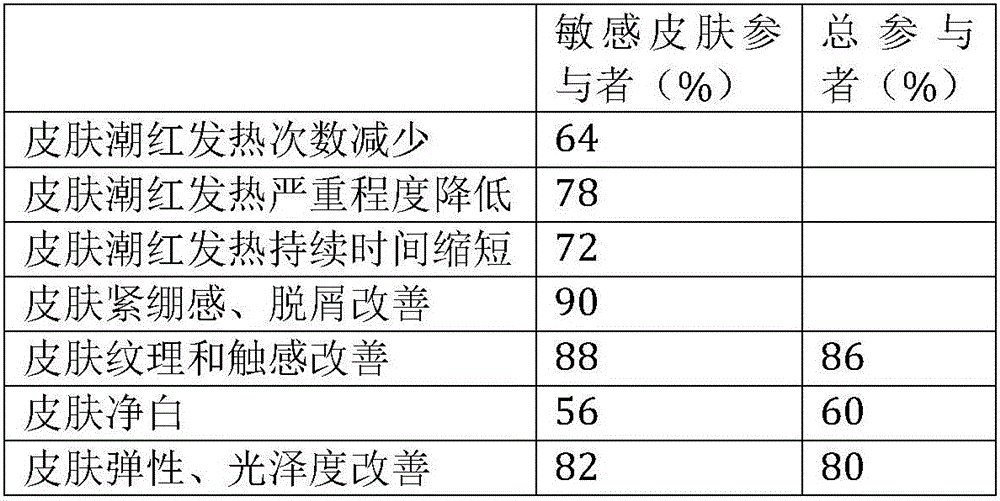

Anti-aging composition for increasing dermal collagen protein mass and maintaining fibroblast morphology and application of anti-aging composition

PendingCN114224803AHigh densityEasy to shapeCosmetic preparationsToilet preparationsBiotechnologyTree root

The invention discloses a composition as well as a preparation method and application thereof. The composition comprises a component (a), a component (b), a component (c) and a component (d), the component (a) is a soybean hydrolysate, the component (b) is a rambutan leaf extract, the component (c) is a kangaroo claw extract, and the component (d) contains a false leaf root extract and escin.

Owner:SHANGHAI PECHOIN BIOTECH CO LTD

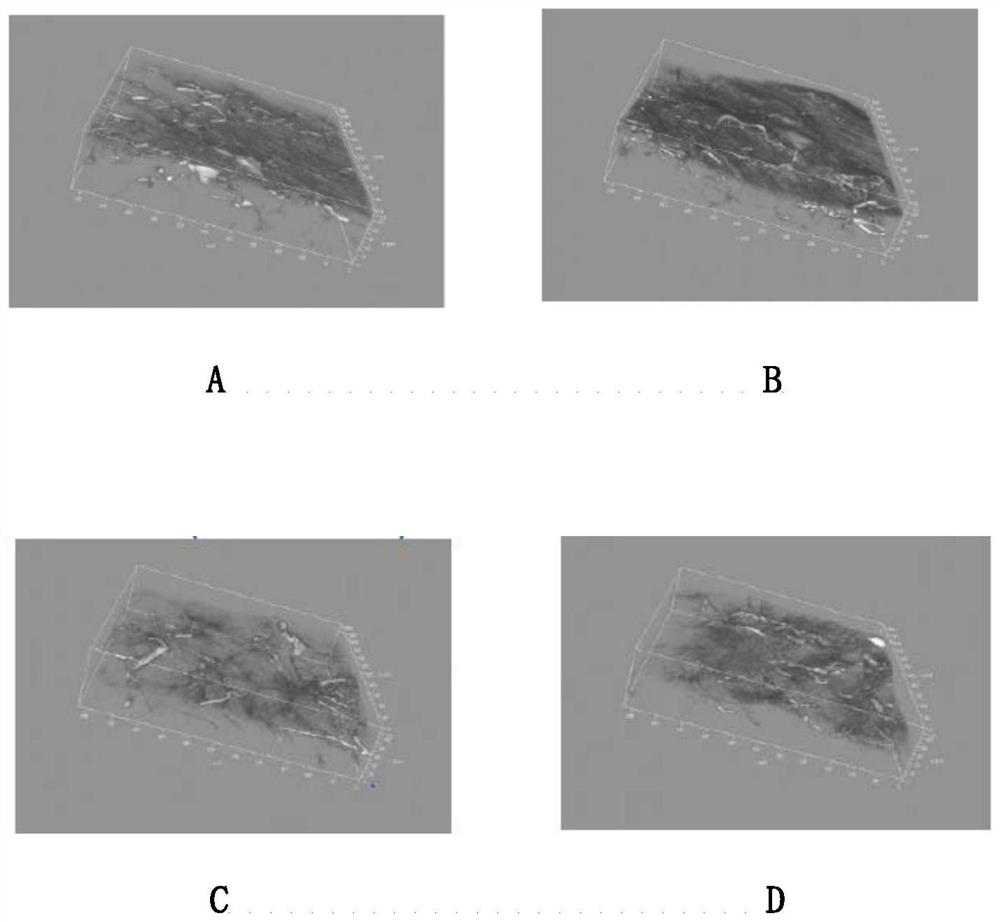

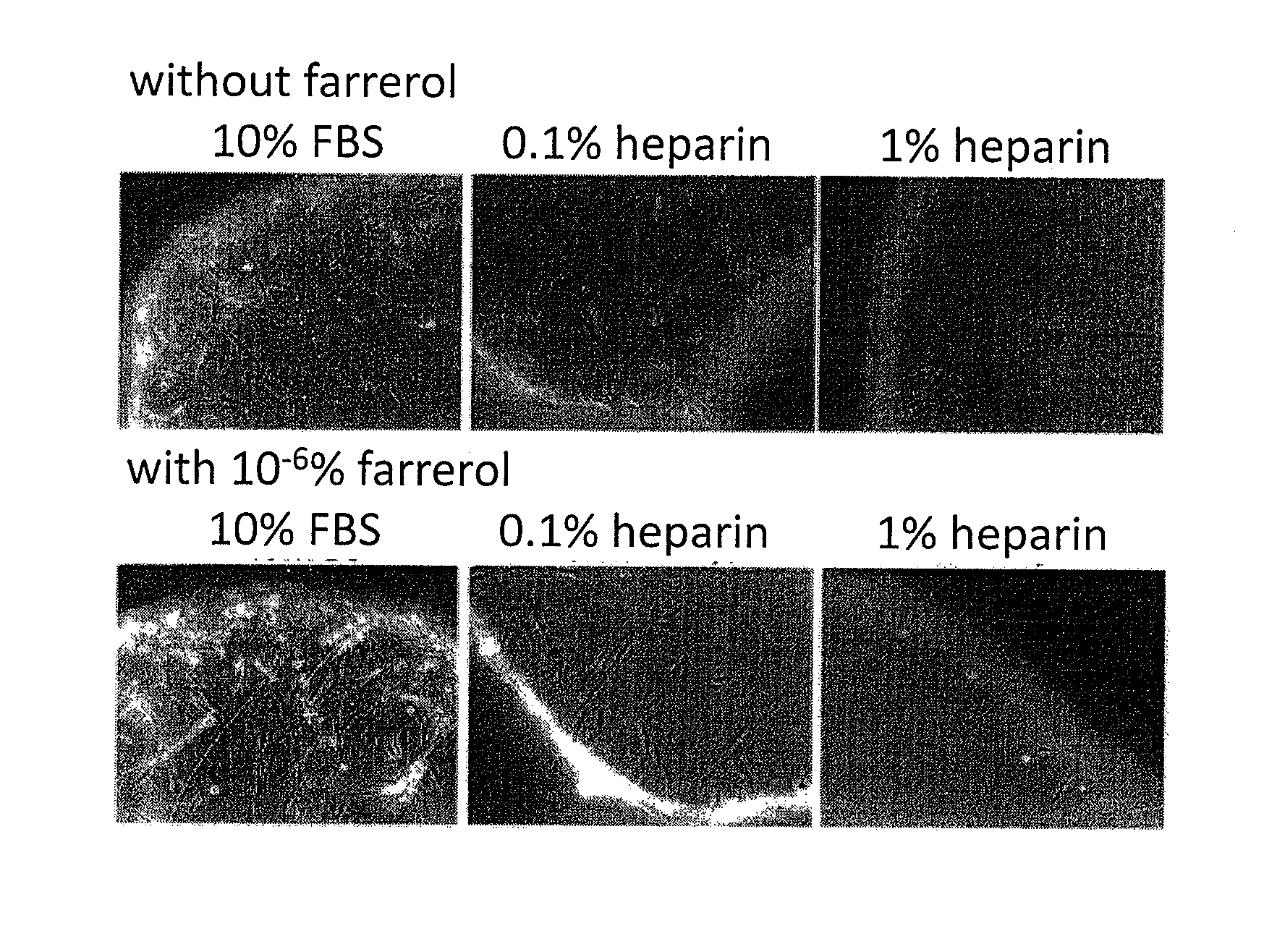

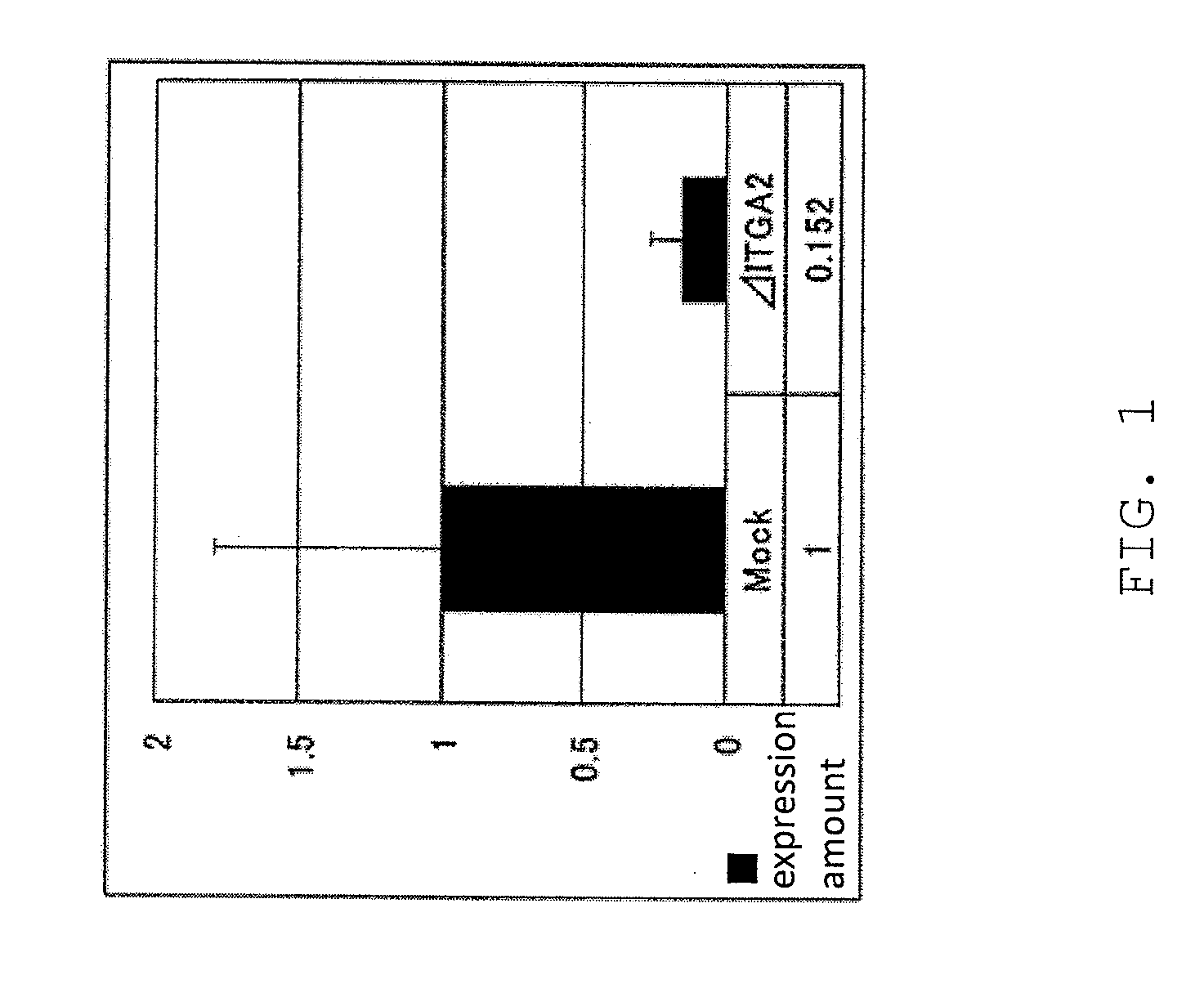

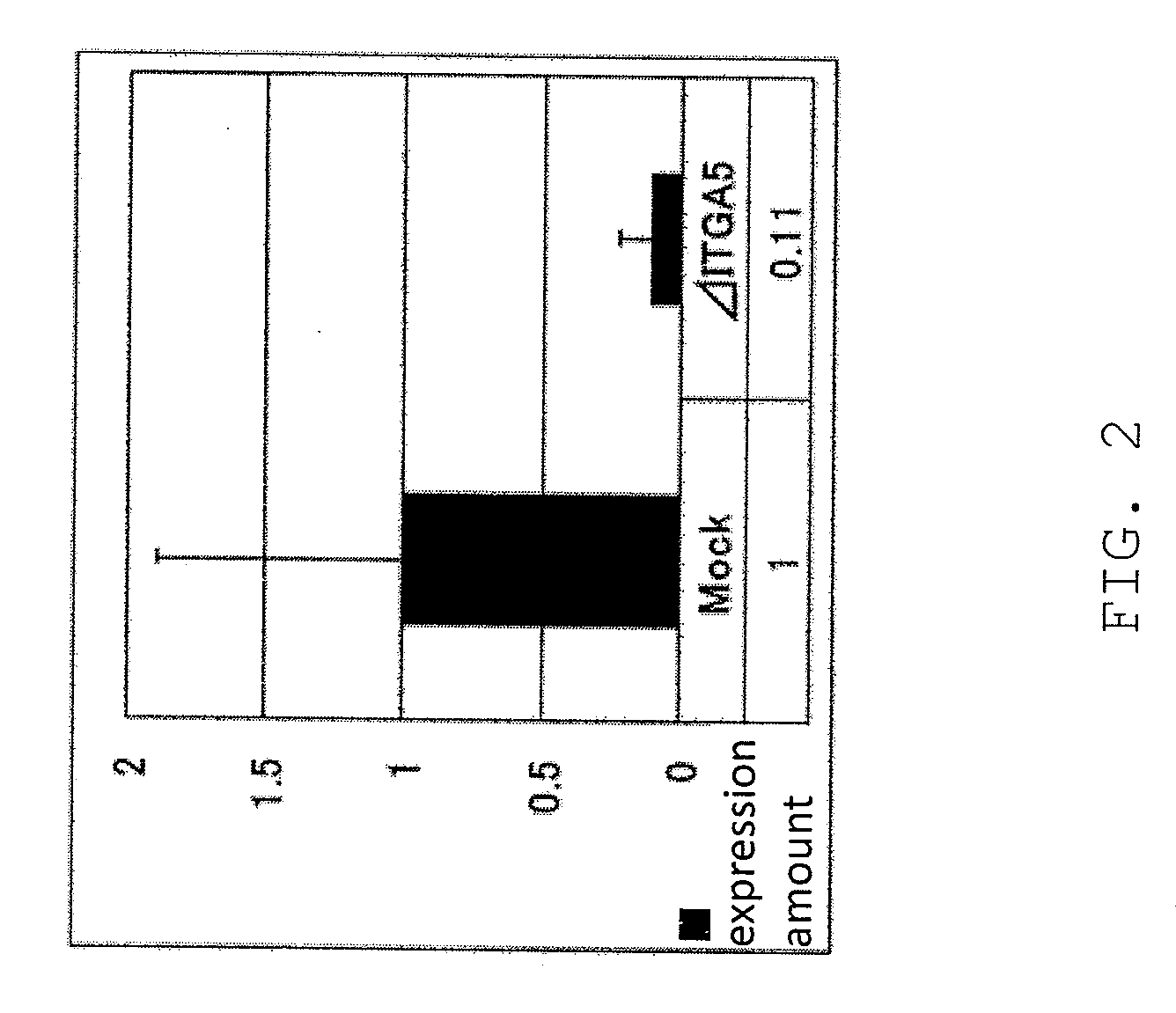

Method of evaluating antiwrinkle substance and method of assessing the skin

InactiveUS20100081162A1Large wrinkle-improvement effectSignificant differenceOrganic chemistryMicrobiological testing/measurementWrinkle skinFiber bundle

It is intended to provide a method whereby the skin conditions (for example, loss in the skin elasticity, wrinkle formation possibility, insufficient tightness in dermal collagen fiber bundles, or the like) can be exactly and conveniently assessed. It is also intended to provide a method whereby the wrinkle-improvement effect of a test substance can be exactly and conveniently evaluated. The skin conditions are assessed by using the expression amount of an adhesion factor in skin cells as an indication. The wrinkle reducing effect of a test substance is evaluated by using the expression amount of an adhesion factor in skin cells in the presence of the test substance as an indication.

Owner:POLA CHEM INDS

Oxidized chitosan grafted modified porcine dermis collagen micro-nanofibrous membrane and preparation method thereof

ActiveCN104013995BMaintain biological activityImprove mechanical propertiesFibre treatmentAbsorbent padsMicro nanoFiber

The invention discloses an oxidation chitosan graft modified porcine dermal collagen micro-nano fiber membrane and a preparation method thereof. The oxidation chitosan graft modified porcine dermal collagen micro-nano fiber membrane is characterized in that the preparation method comprises the steps: by applying an electrostatic spinning technology and using traceable purified porcine dermis as a raw material and hexafluoroisopropanol as a solvent, stirring at 4-10 DEG C until the mixture is transparent, formulating to obtain electrostatic spinning mother liquor with concentration of 0.5-10%, and directly spinning to obtain the porcine dermal collagen micro-nano fiber membrane; then performing graft modification on the porcine dermal collagen micro-nano fiber membrane by using oxidation chitosan, thereby finally obtaining the oxidation chitosan graft modified porcine dermal collagen micro-nano fiber membrane. A membrane material not only has good bio-compatibility, biodegradability and mechanical properties, but also has anti-oxidation effects, antibacterial activities, anti-inflammation / wound healing promotion effects, anti-cancer / anti-tumor effects and antiviral effects of chitosan, is significantly better than a collagen composite membrane material prepared by using collagen as the raw material, and can be widely applied to the preparation of biomedical materials such as hemostatic materials, tissue engineering scaffold materials, biological dressings and the like.

Owner:SICHUAN UNIV

Dermal collagen fiber prepared from tanning chromium-containing subsidiary waste

InactiveCN102425018BAchieving a circular economyWide variety of sourcesTextile disintegration and recoveryFibre disintegrationCardingMoisture regain

The invention discloses a dermal collagen fiber prepared from tanning chromium-containing subsidiary waste and a preparation method thereof. In the preparation method, the tanning chromium-containing subsidiary waste is used as a raw material, is subjected to processing of puffing, separating fibers, splitting fibers and carding and the like by a physical, chemical and biochemical combination method on the premise of ensuring unchanged good physical and mechanical conditions of collagen fibers, and is prepared into the dermal collagen fiber with good performance and wide application ranges. The dermal collagen fiber reaches the following technical indexes: (1) the outer surface is provided with light blue fiber materials and does not have visible impurities; (2) the moisture content is between 18 and 25 percent; (3) the linear density is between 1.2 and 2.0 dtex; (4) the fiber length is between 20 and 30mm; (5) the breaking strength is more than or equal to 3.5 cN / tex; (6) the elongation at break is between 10 and 30 percent; and (7) the moisture regain is between 6 and 10 percent. The dermal collagen fiber can be used as raw materials of high-simulation leather (automobile seat leather, furniture leather, instep leather, garment leather, shoe lining leather, belt leather, luggage leather and the like), natural leather base cloth, senior carpets, senior wall paper, dermal fiber bedding and the like.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com