Patents

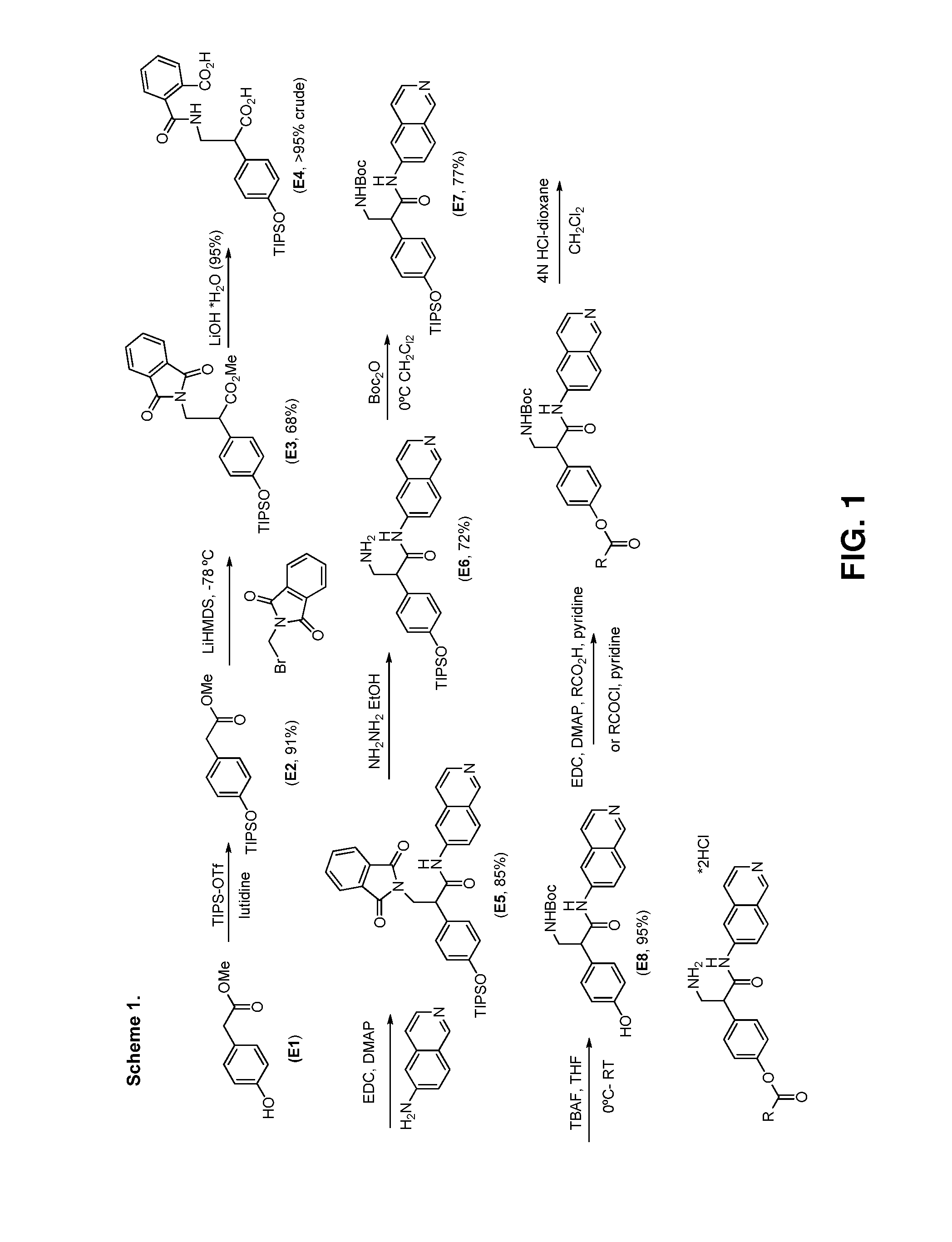

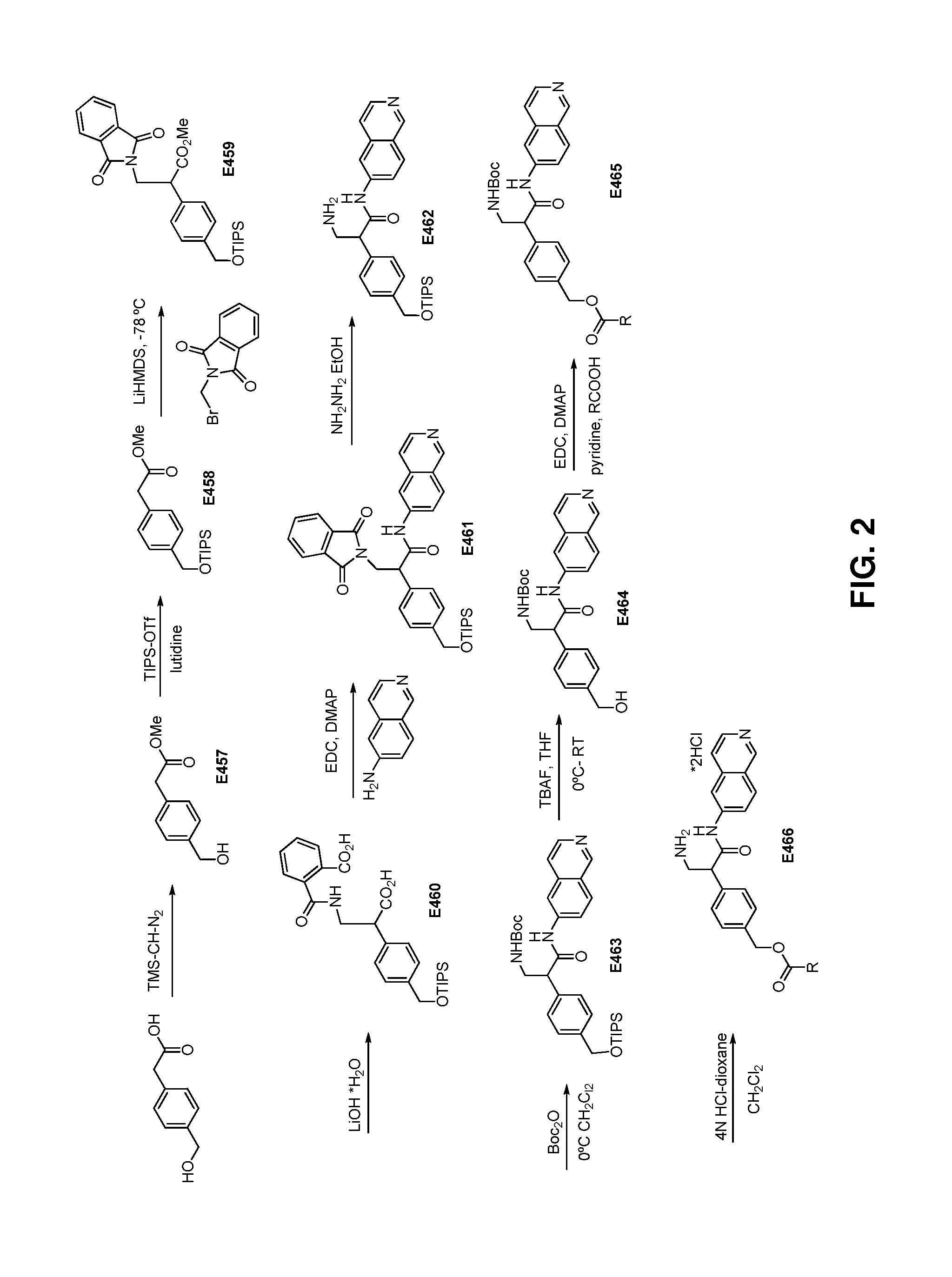

Literature

1070 results about "Dual action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dual Action polishers are characterized by the motion of the head. It spins on a central spindle, and this spindle rotates around an eccentric offset. A good metaphor for a dual action polisher is the earth's orbit. The earth itself spins and it also orbits around the sun. Dual action polishers are also called orbital polishers for this reason.

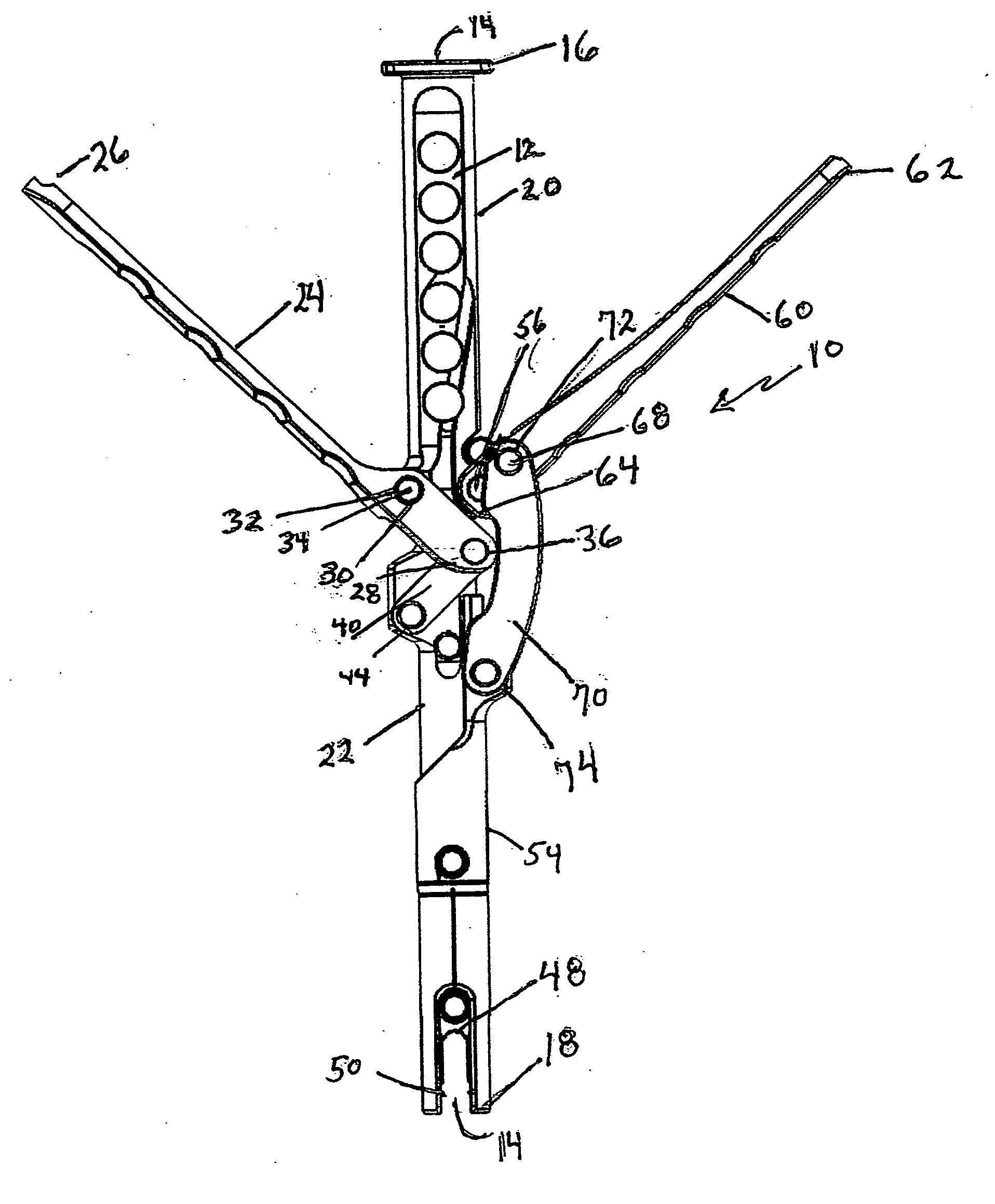

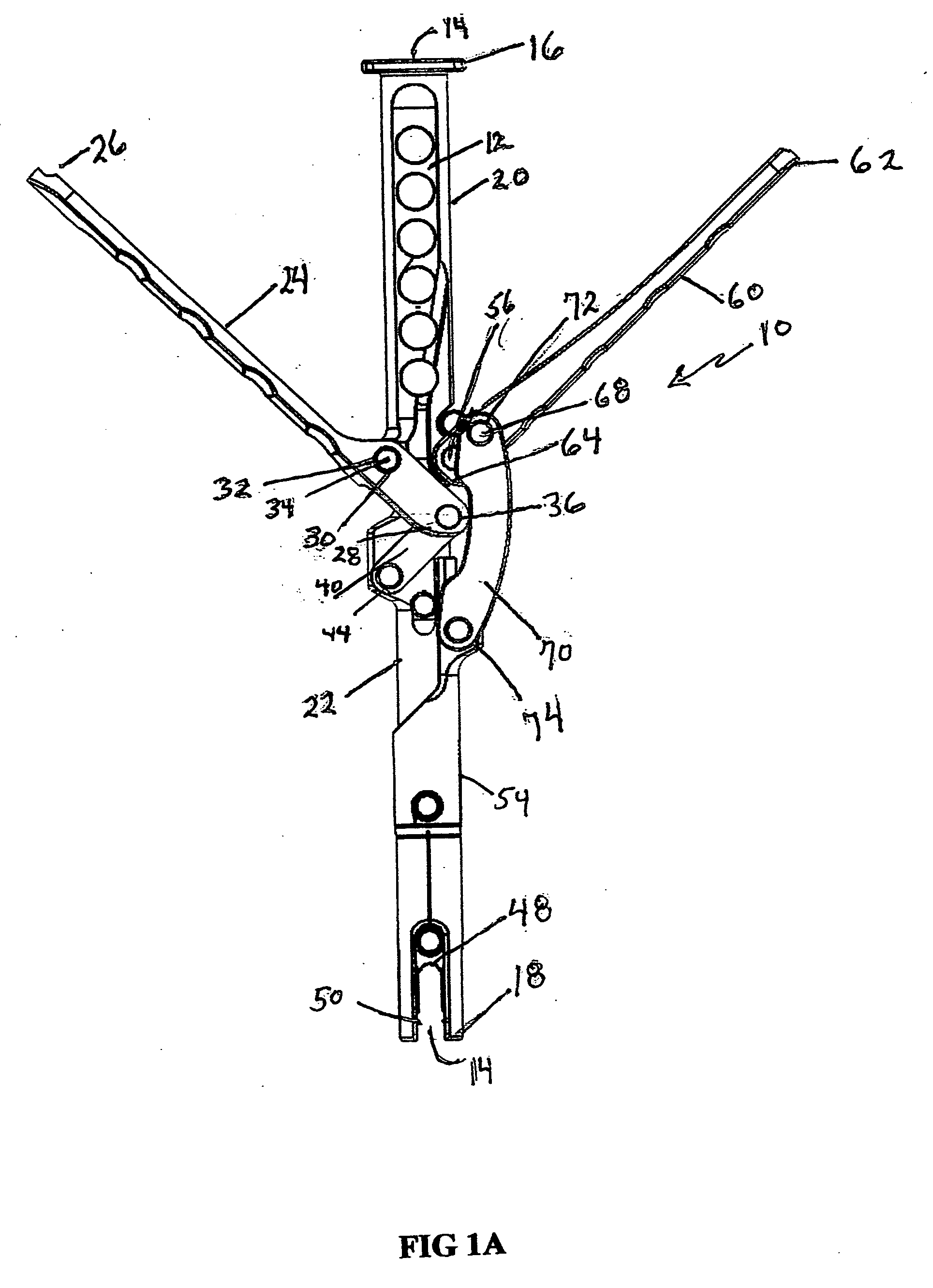

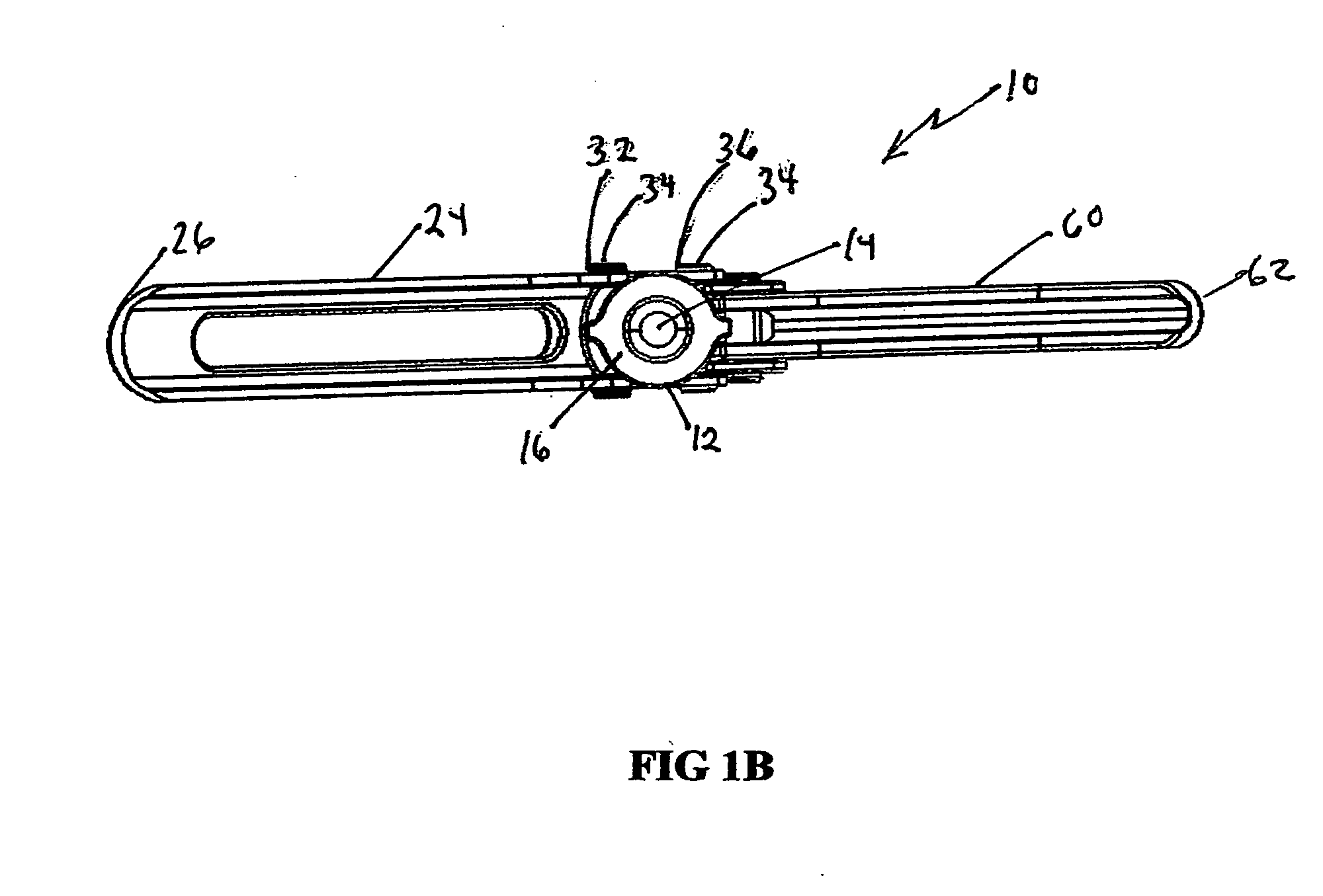

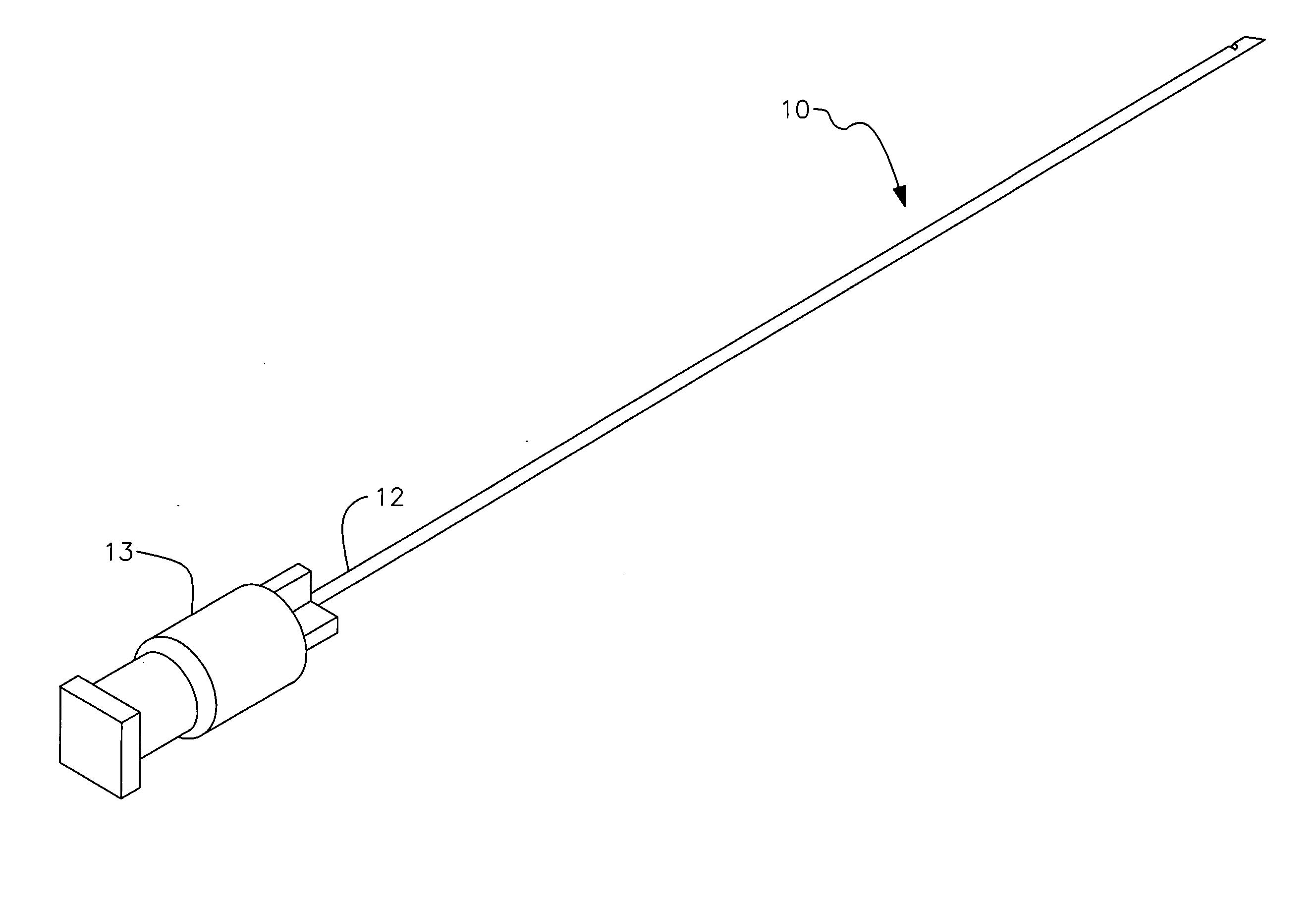

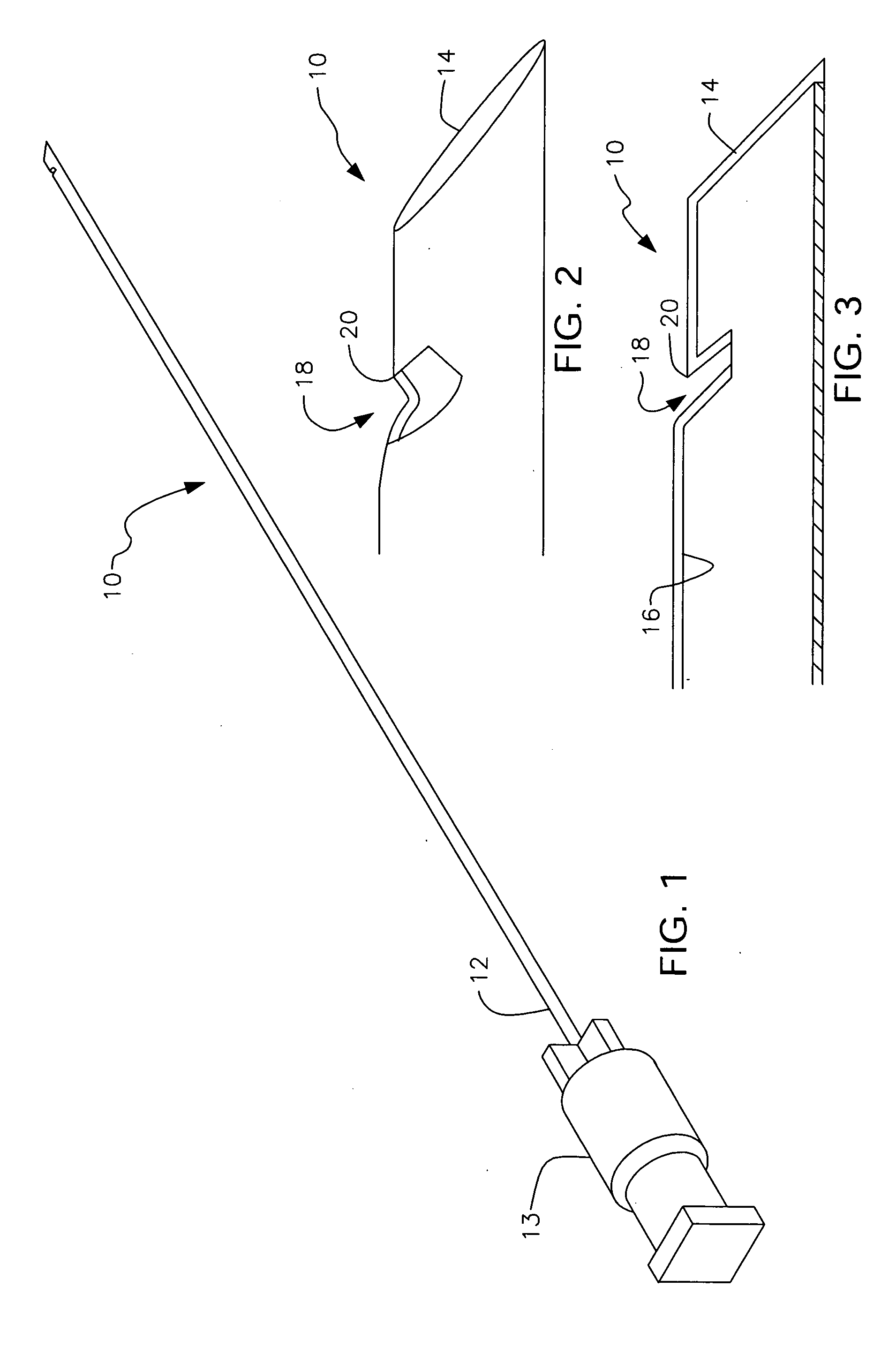

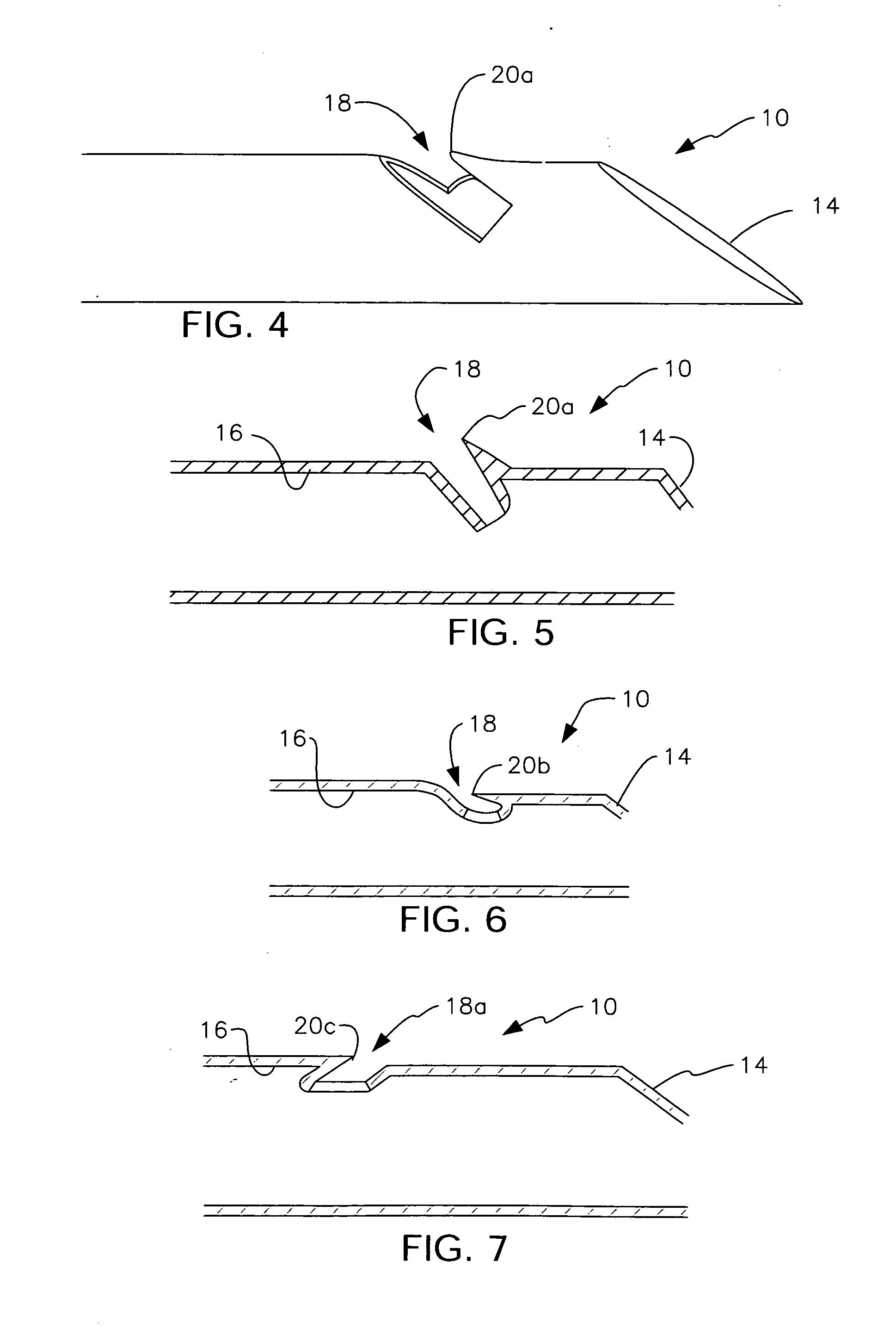

Dual action rod reducing and locking device and method

Provided is a dual action surgical instrument for use in orthopedic surgical procedures that is capable of reducing a rod into position in a rod receiving notch in the head of a bone screw with a first action and subsequently locking the rod into the receiving notch by a second action of the same instrument. A method of using the device is also provided.

Owner:K2M

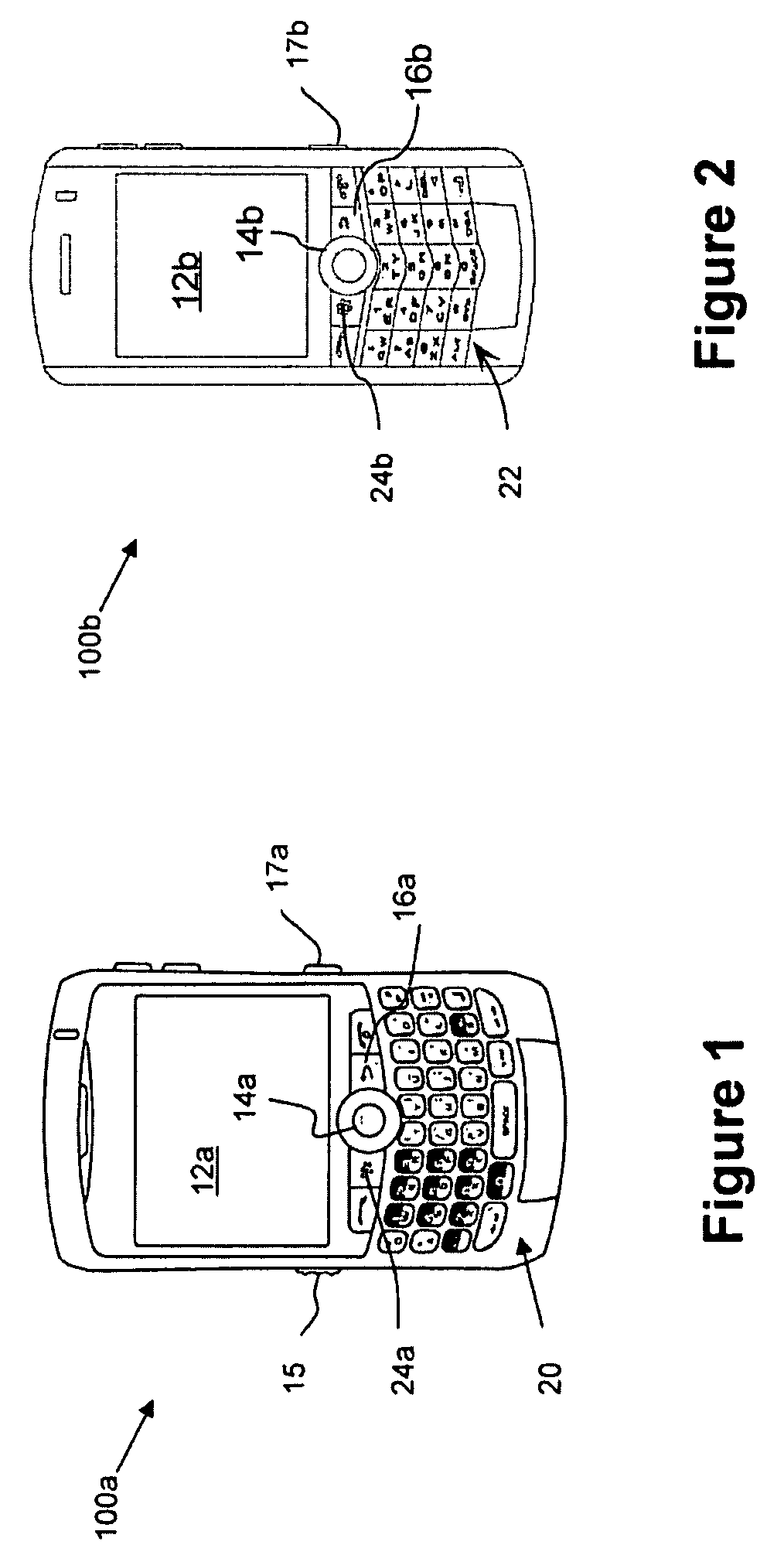

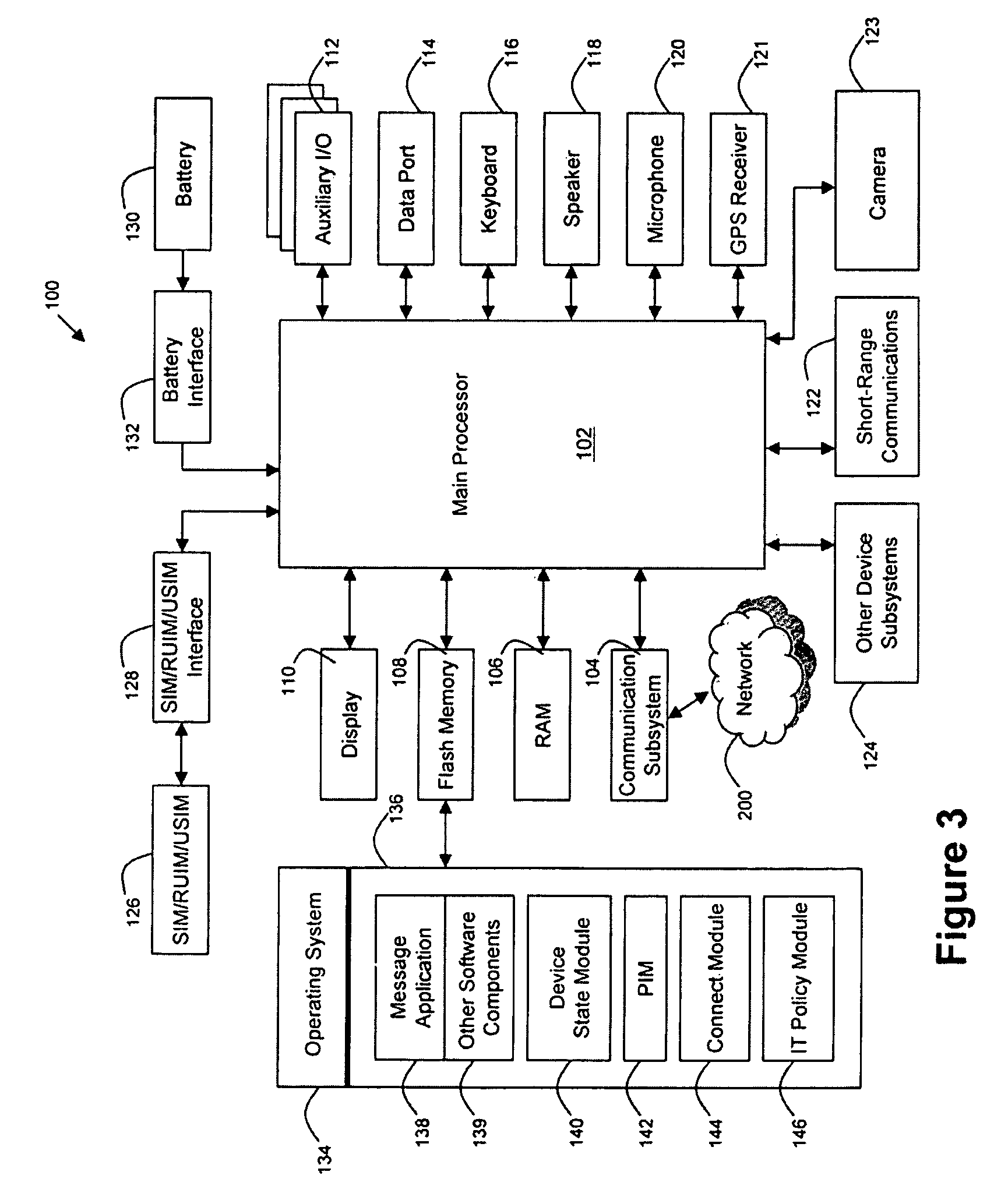

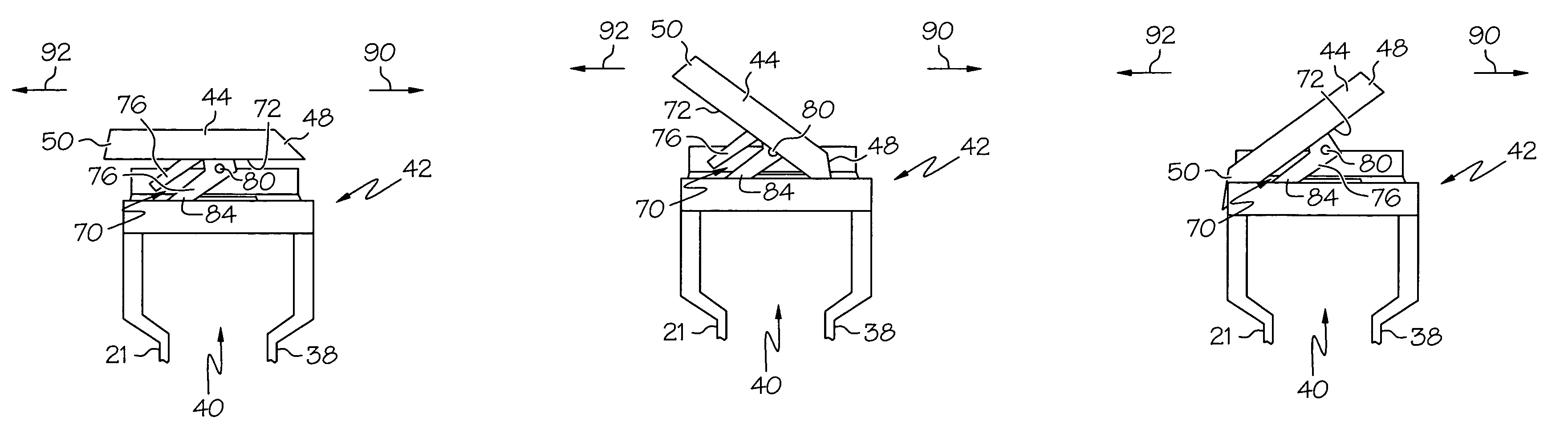

Dual-action single-key mechanism

A switch assembly is provided to actuate a pair of switches using a single key cap, e.g. for a camera that utilizes a first switch to activate an image focusing function and a second switch to activate a camera shutter. The switch assembly comprises an inner switch and an outer switch, wherein the outer switch partially or completely surrounds the perimeter of the inner switch. The outer switch comprises an upper conductive surface and a lower conductive surface that, when in contact, electrically couples two terminals for closing a circuit. The inner switch comprises an actuator and a dome switch. When the key cap receives a first downward force, only the outer switch becomes activated and a first electric circuit is completed. When the key cap receives a second downward force that is greater than the first force, the dome switch collapses and a second electric circuit is completed.

Owner:MALIKIE INNOVATIONS LTD

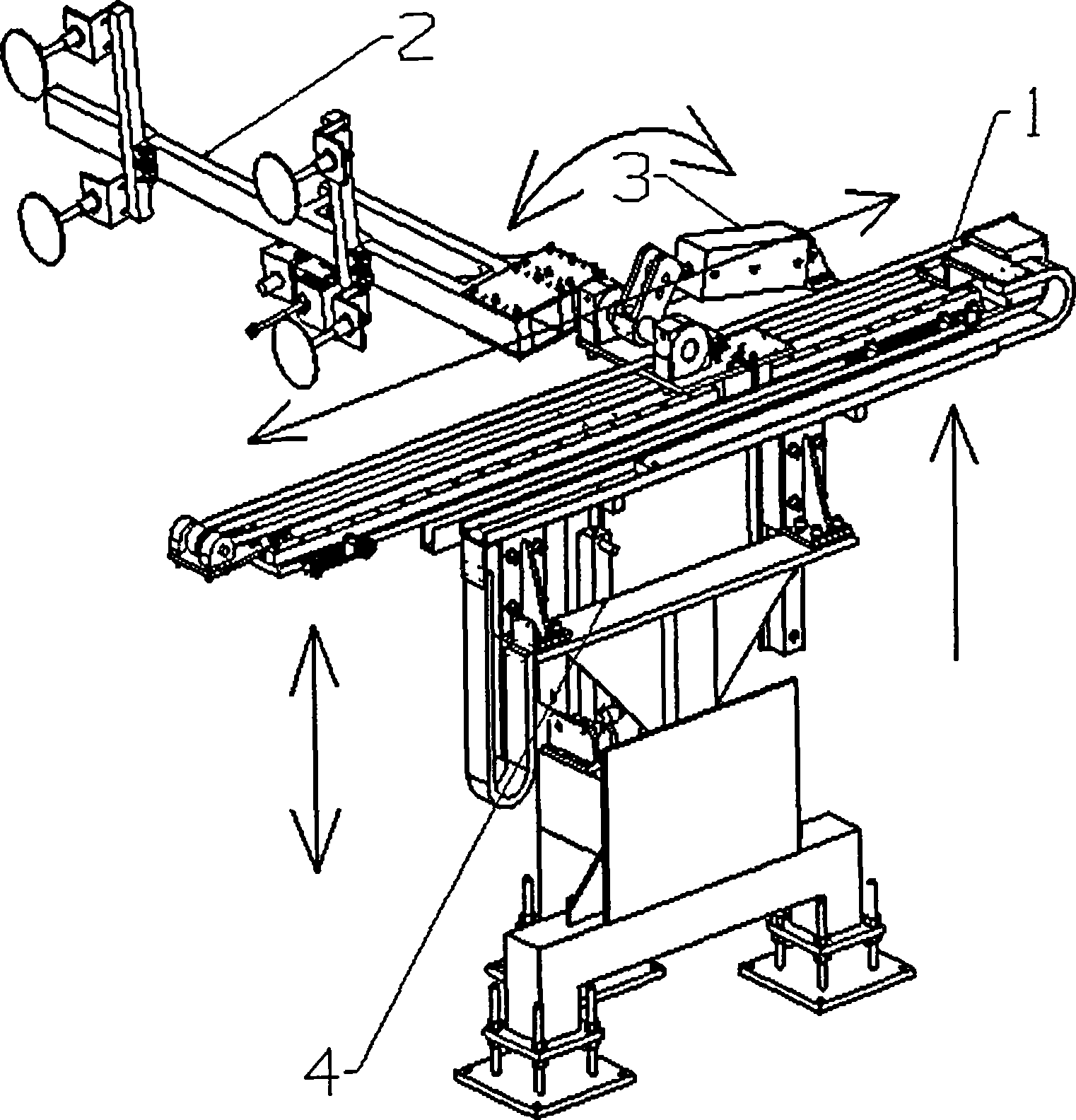

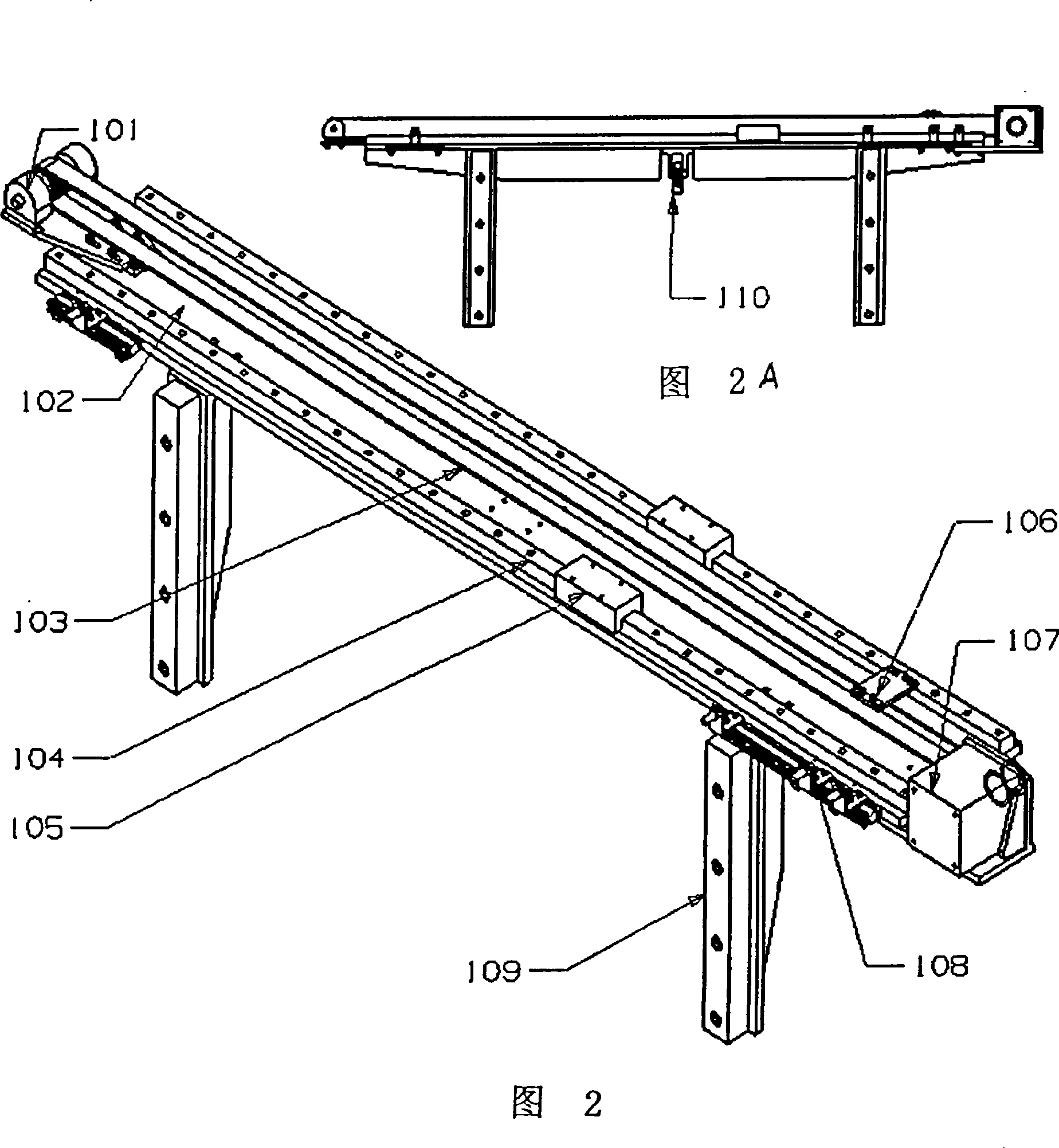

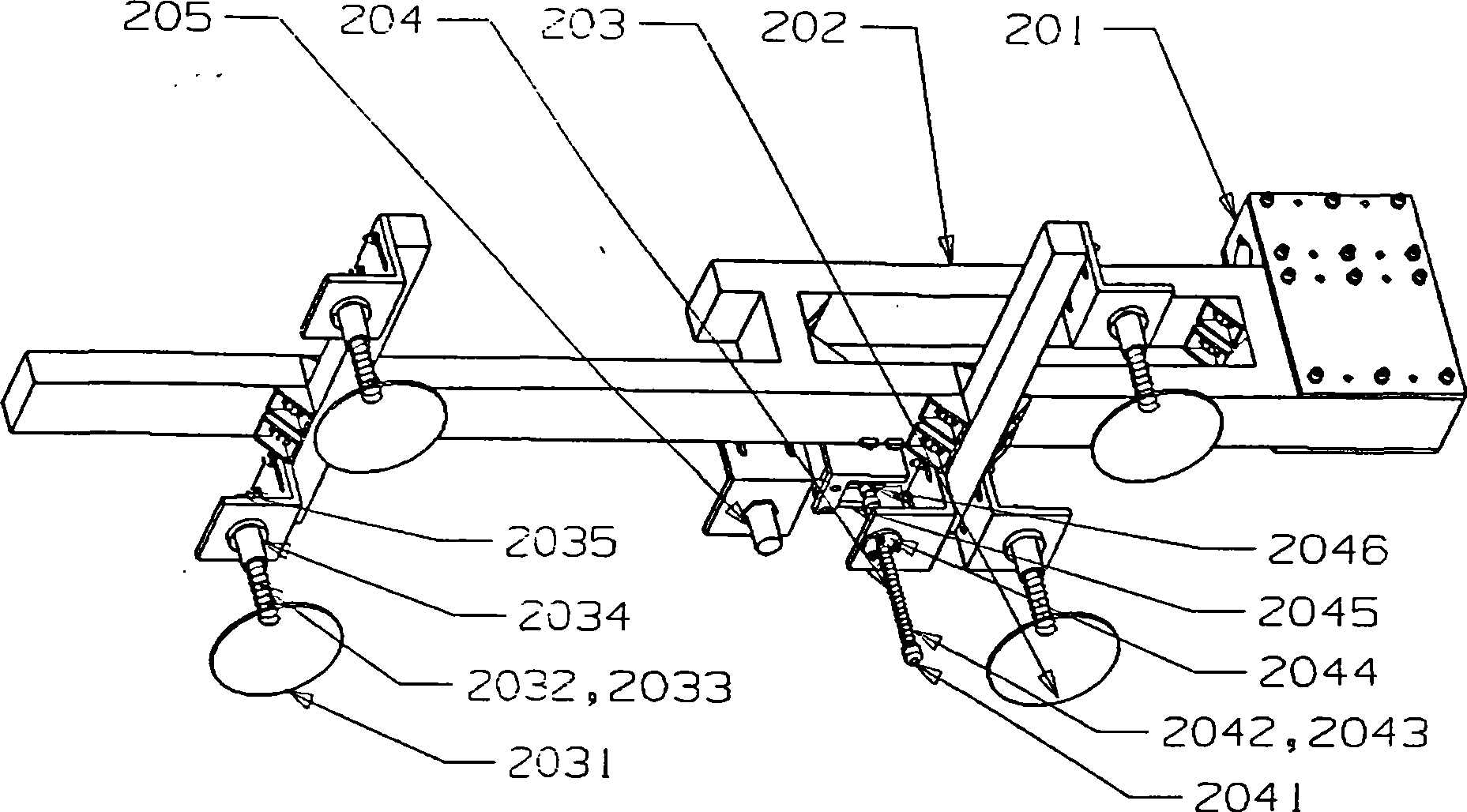

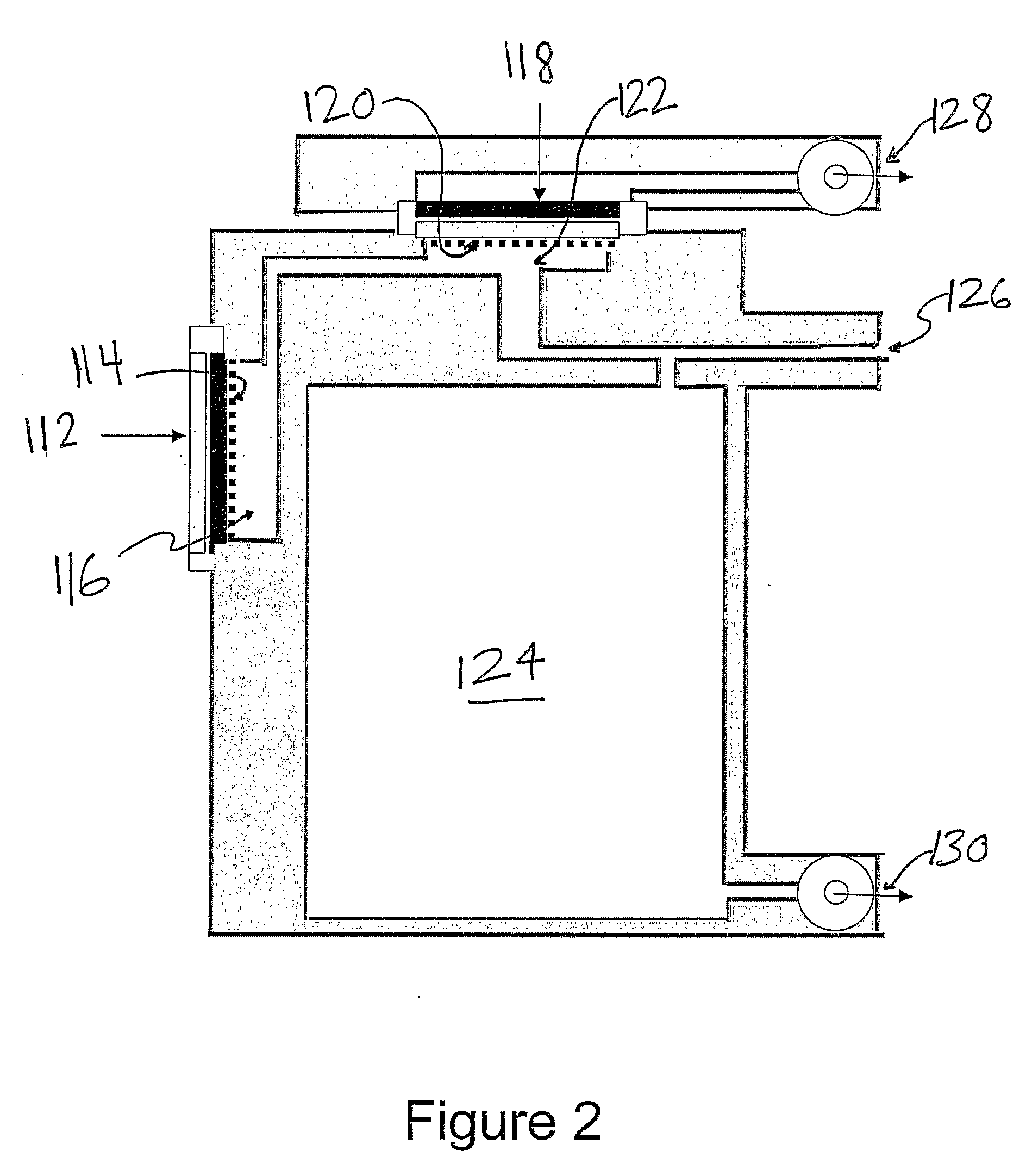

Automatic original-glass fetching manipulator of automobile glass pre-treatment production line

InactiveCN101417422ADecrease productivityExtended duty cycleProgramme-controlled manipulatorJointsRotational axisProduction line

The invention relates to an automatic loading machine hand of car glass pre-treatment production lines, comprising a driving mechanism platform, a grabbing arm and a sense touch mechanism, an arm rotary mechanism and a rising and falling buffering mechanism; wherein, the driving mechanism platform is arranged on the rising and falling buffering mechanism which consists of 3 three-foot single-leg frames; the grabbing arm and the sense touch mechanism are connected with a rotation axis of the arm rotary mechanism. The invention has the advantages that the rising and falling movements along a Z shaft direction are carried out by using a dual action cylinder to drive the driving mechanism platform to move from left to right along an X shaft direction, when rising, the grabbing glass is lifted by 300mm so as to separate glass on a stacking frame and avoid a ledge on the stacking frame; when falling, the grabbing glass is led to fall by 300mm to put the glass on a conveyer moving in a Y shaft direction; the device is delicate and aesthetic in shape, and small in occupation space; the design concept is innovative, novel, practical and prospective; the structure is simple; therefore, the machine hand can be easily made, assembled, and programmed and the manufacturing price is low.

Owner:上海耀皮康桥汽车玻璃有限公司

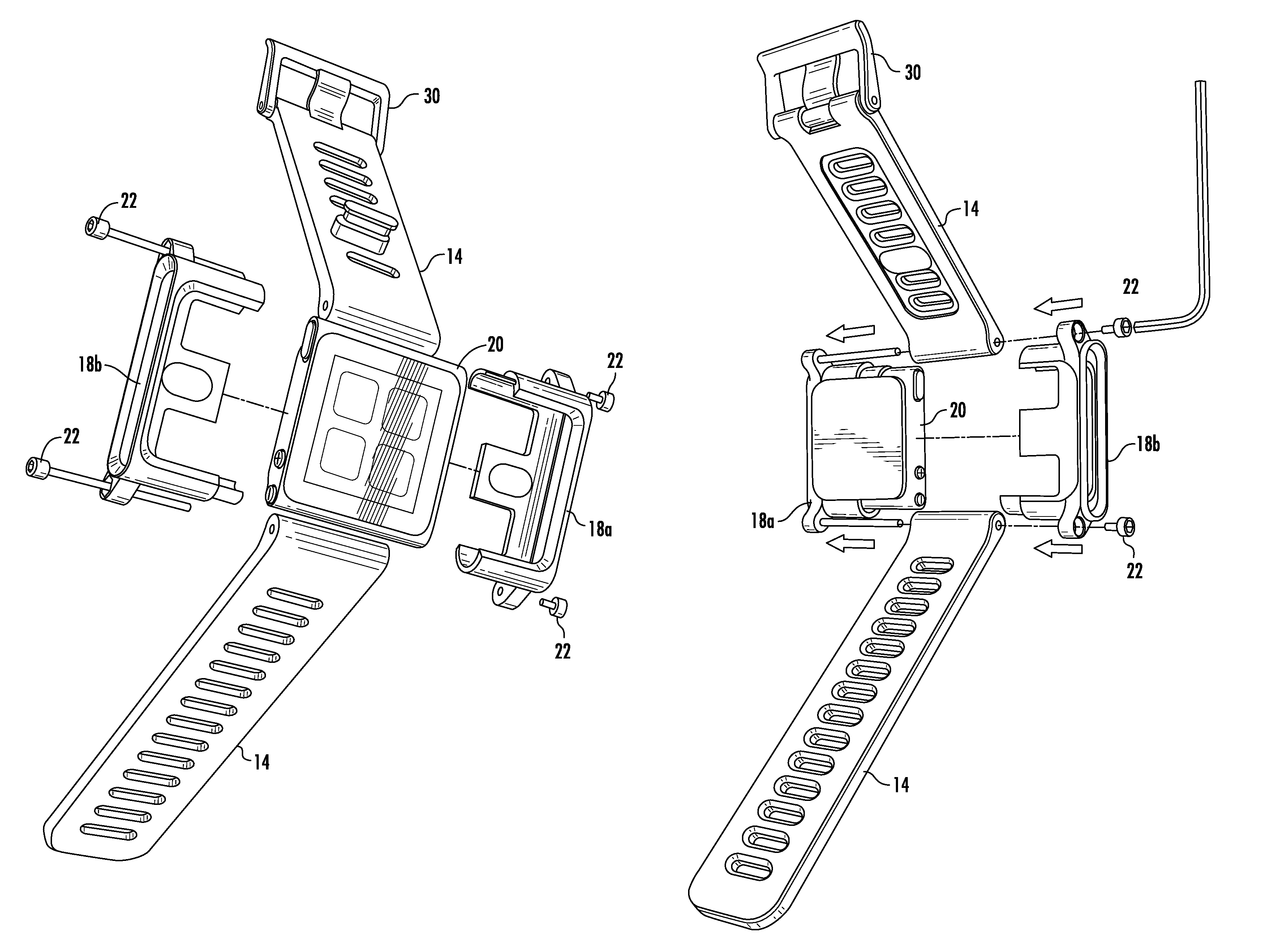

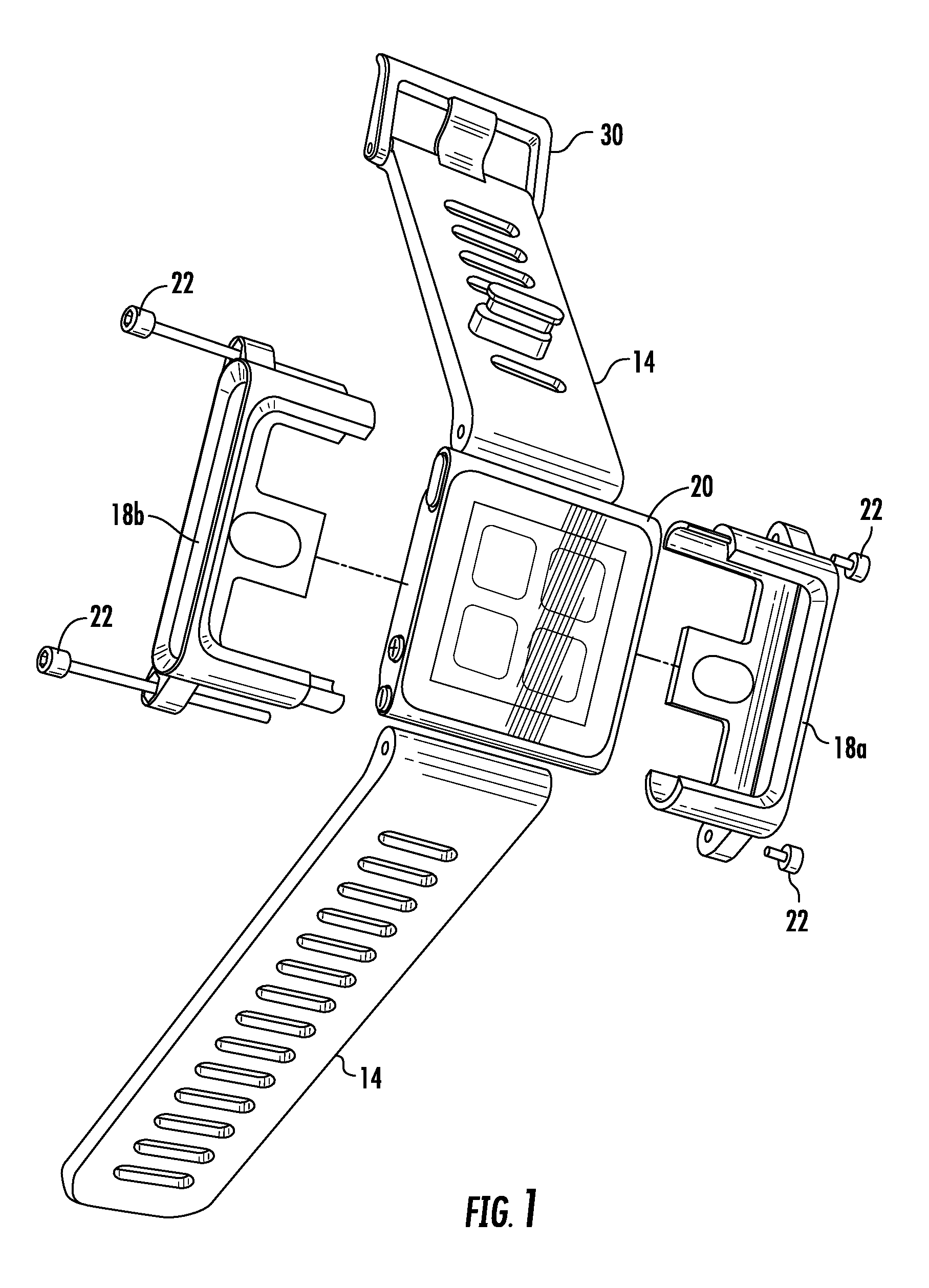

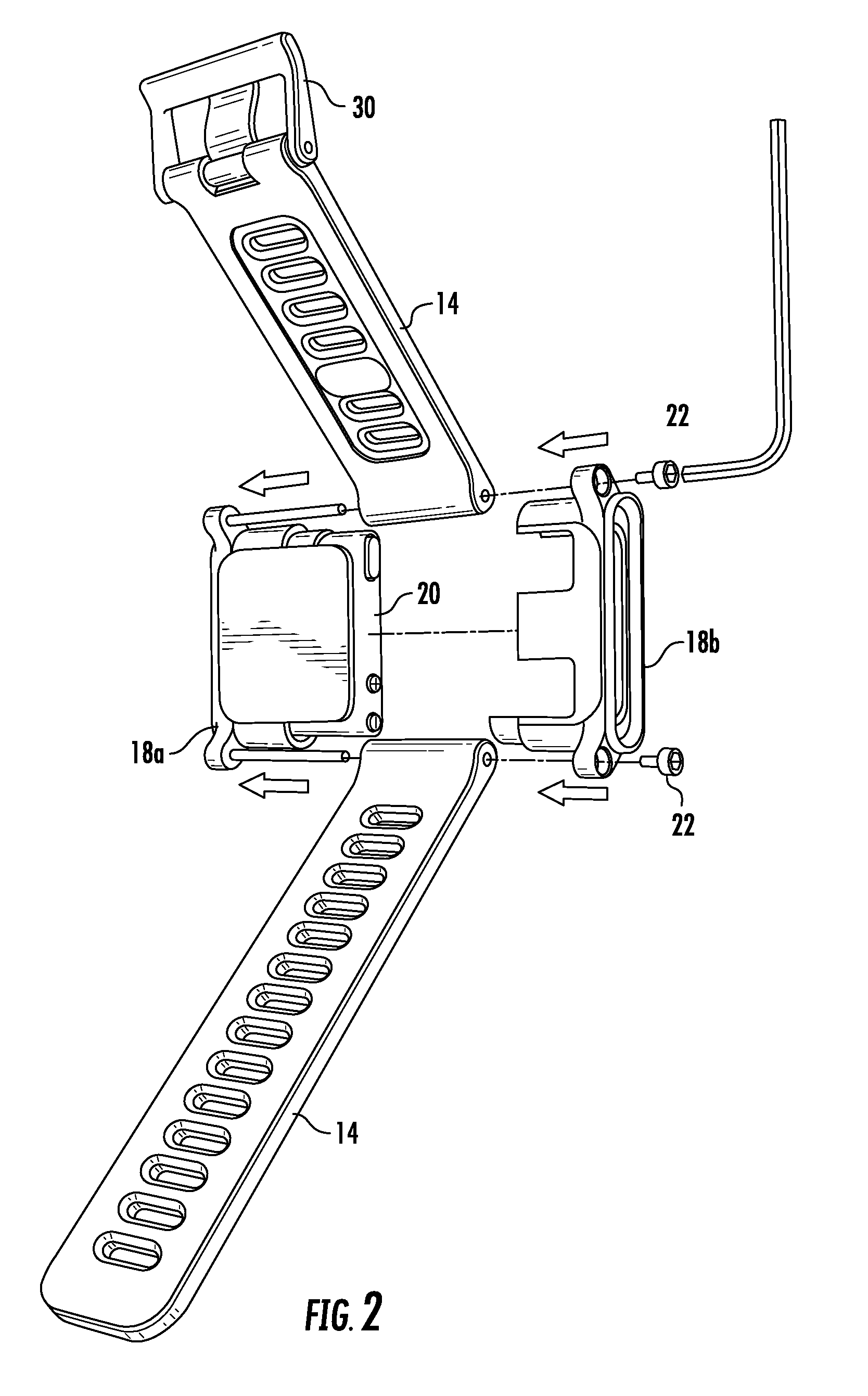

Electronic device casing

InactiveUS9101184B2Enhanced advantageAvoid disadvantagesTravelling carriersHoldersDual actionEngineering

A wearable electronic device holder having a retention member for retaining an electronic device, such as a smartwatch or an MP3 player, and a wrist strap attached to the retention member is disclosed. The retention member includes a protective frame comprising one or more covers or openings for receiving and allowing interaction with one or more buttons, knobs, and / or ports of the electronic device. At least one of the covers is configured to enable the dual-action functionality of a knob of the electronic device. The protective frame may also include an opening adapted to receive sound-permeable, waterproof inserts for an audio port of the electronic device. The protective frame further includes fastening holes for attachment to the wrist strap. The protective frame may be a two-piece frame that partially encloses the electronic device.

Owner:WIMO LABS

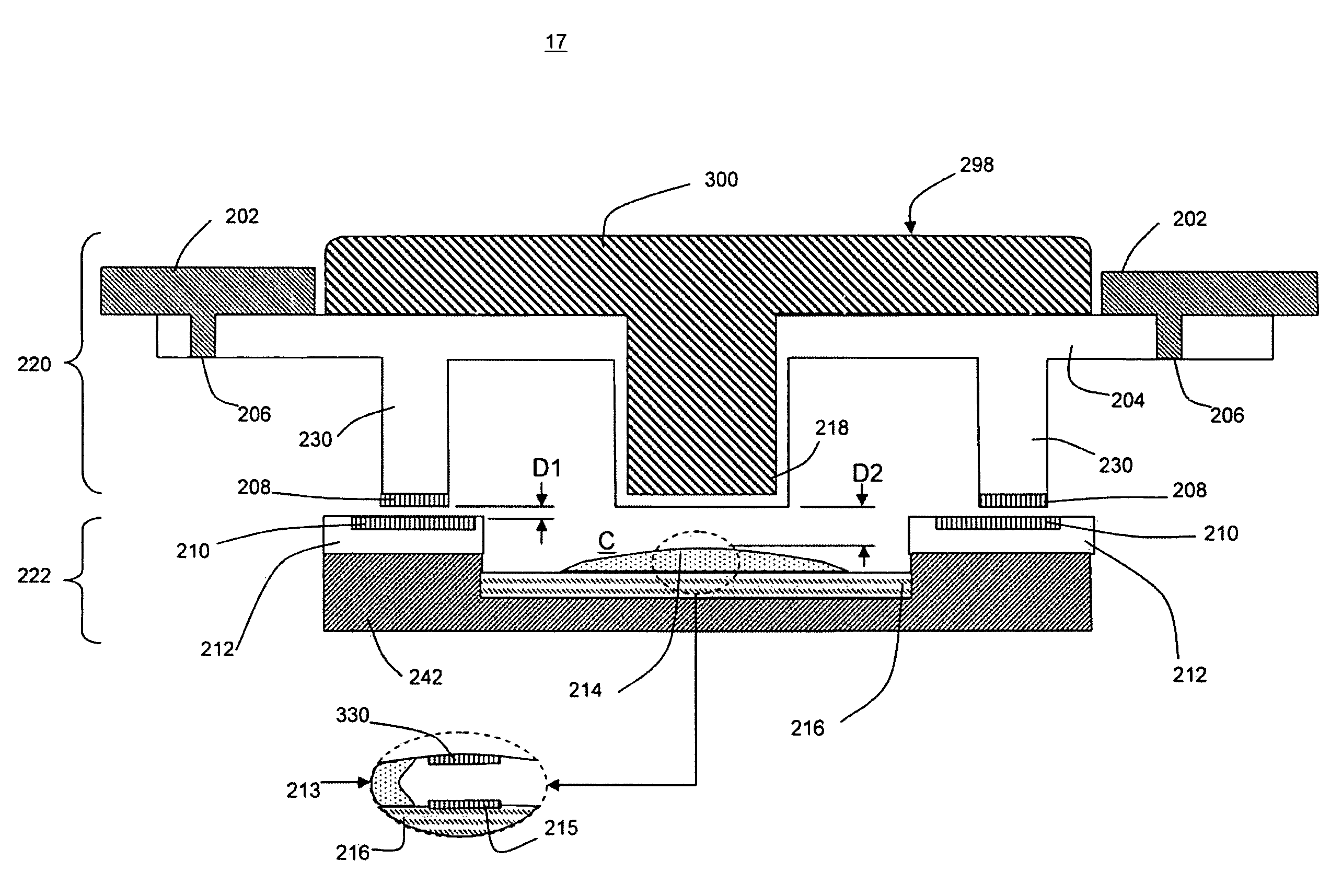

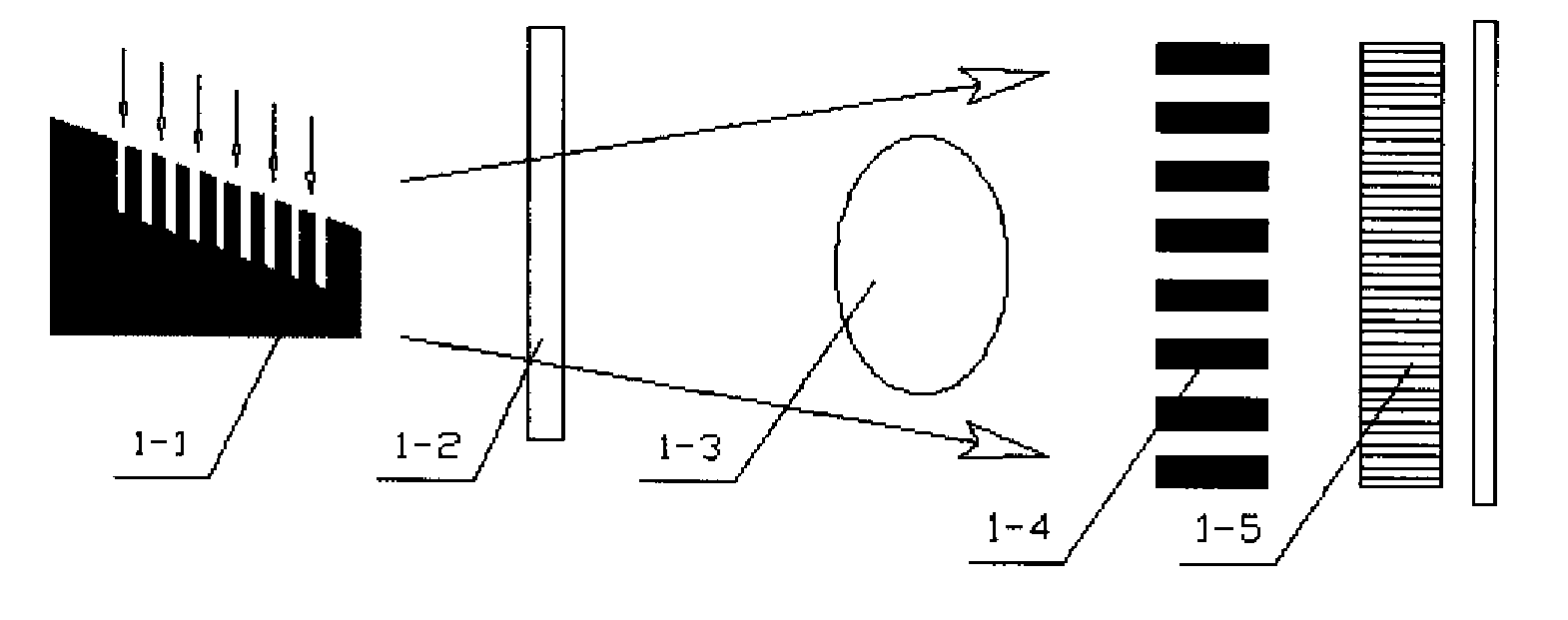

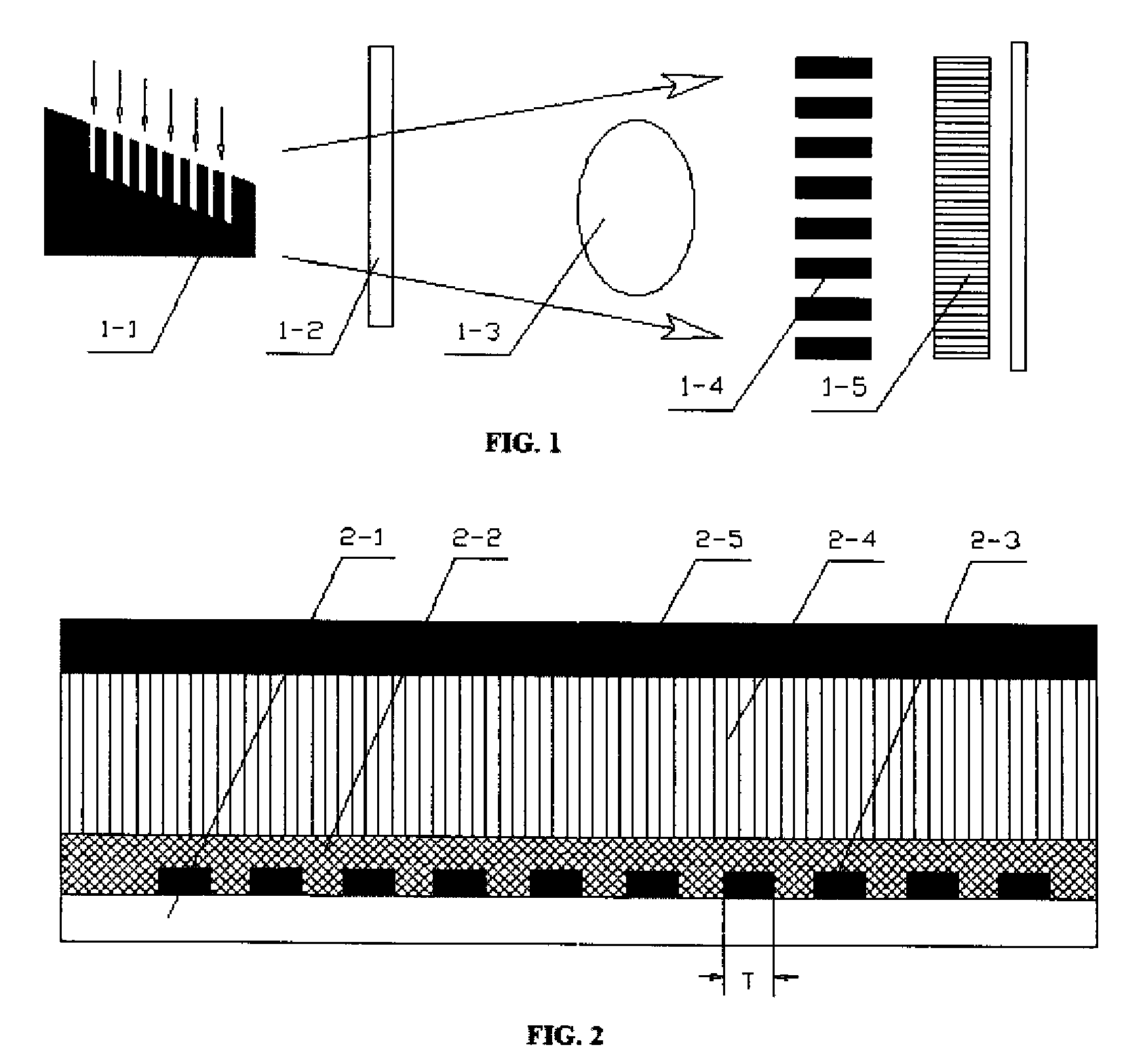

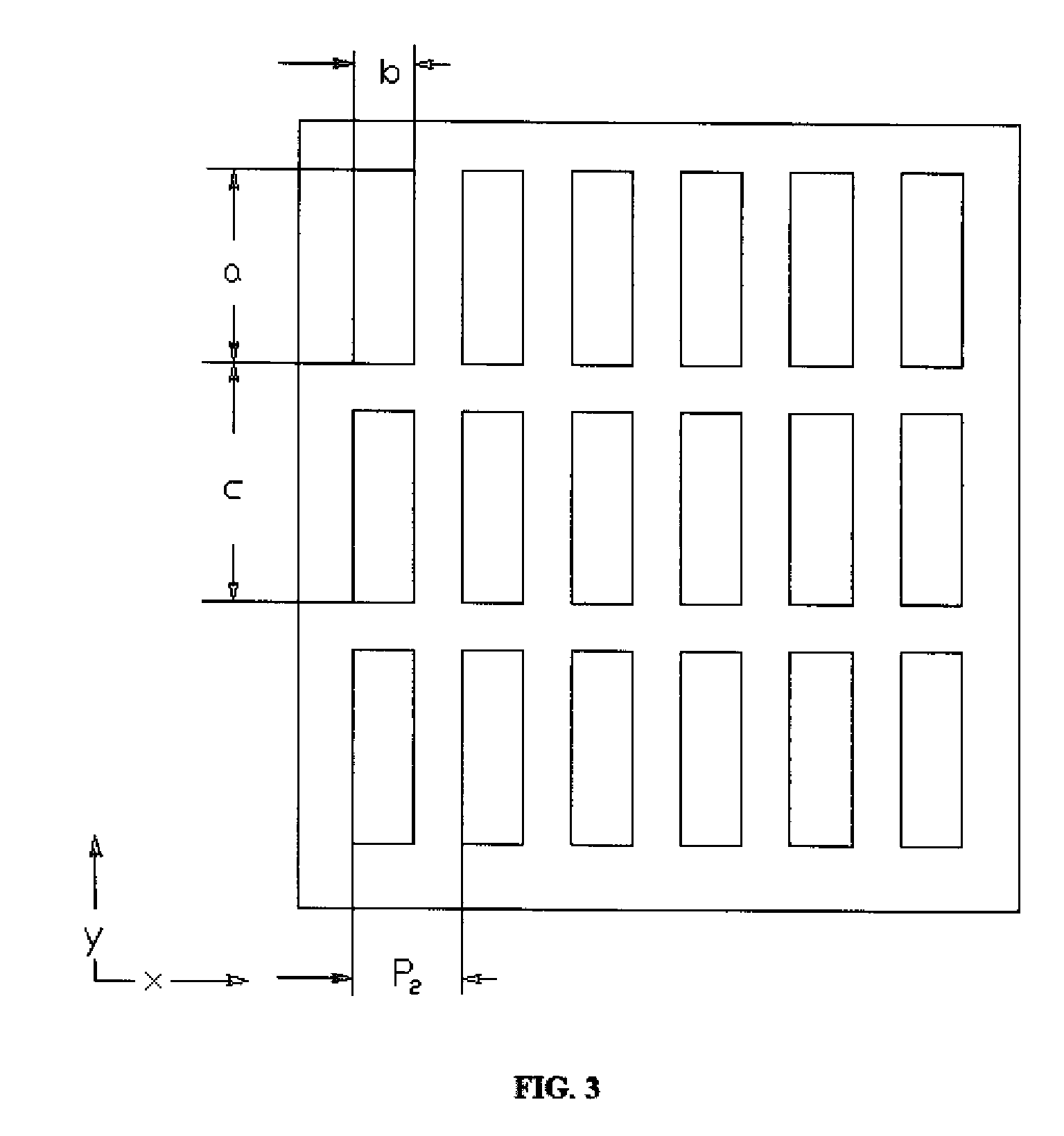

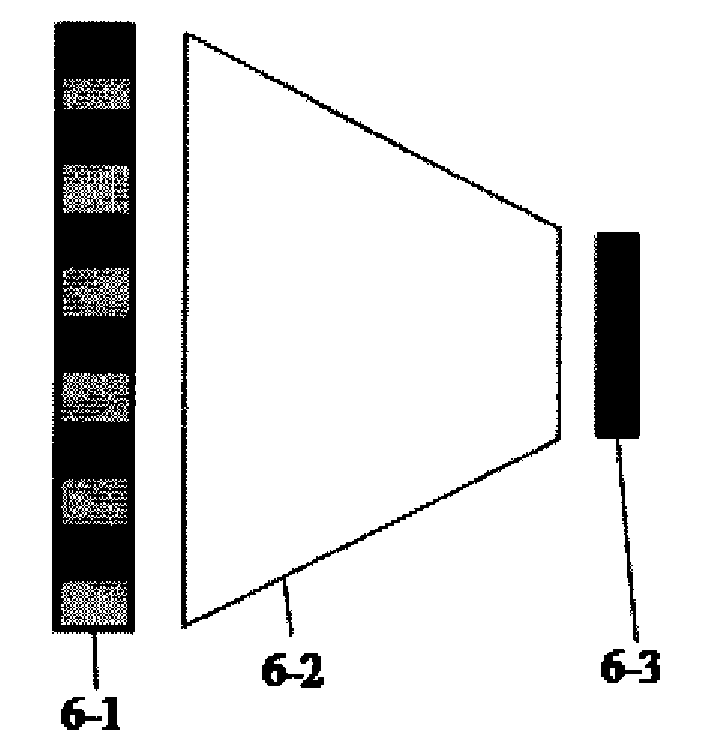

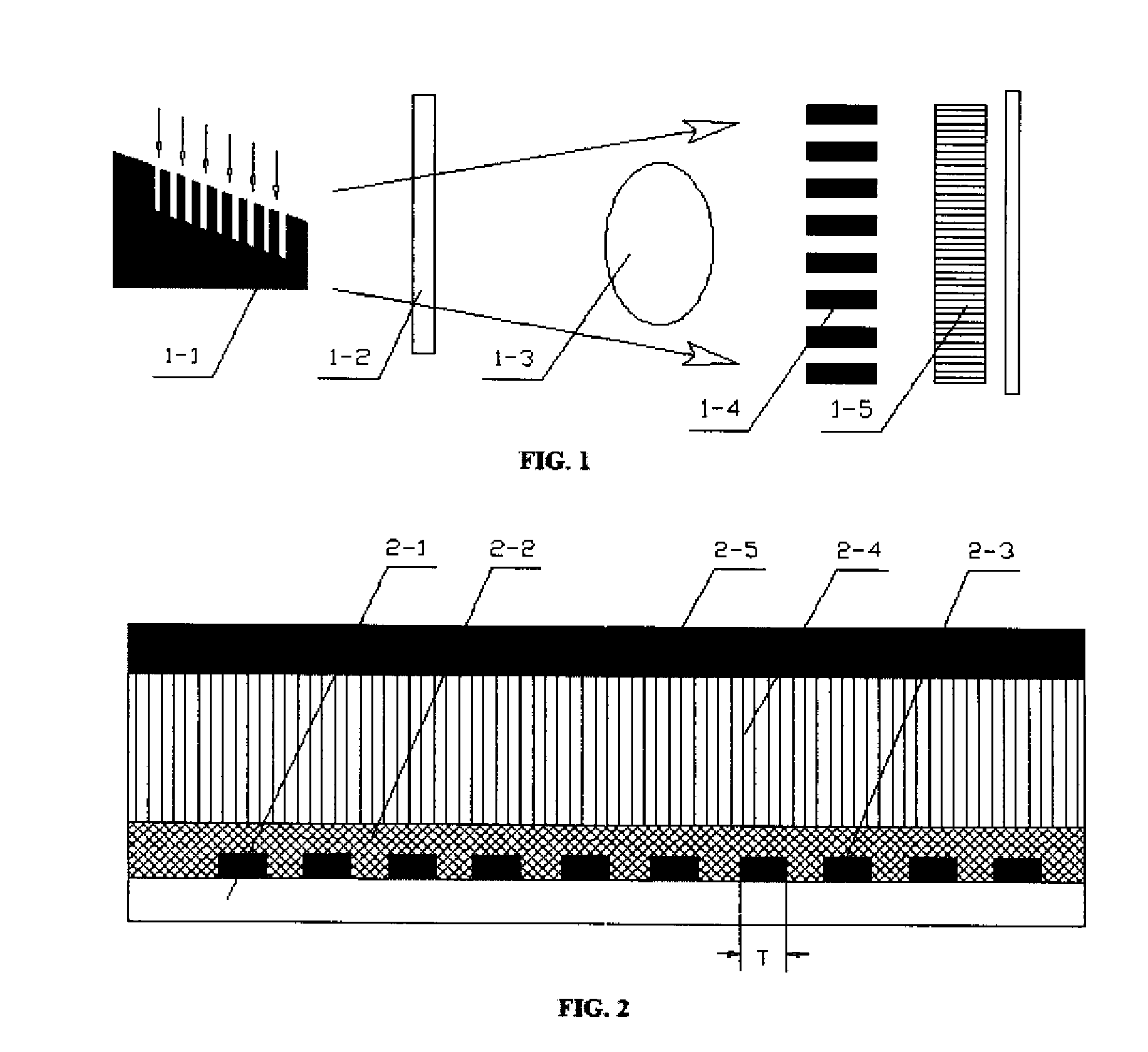

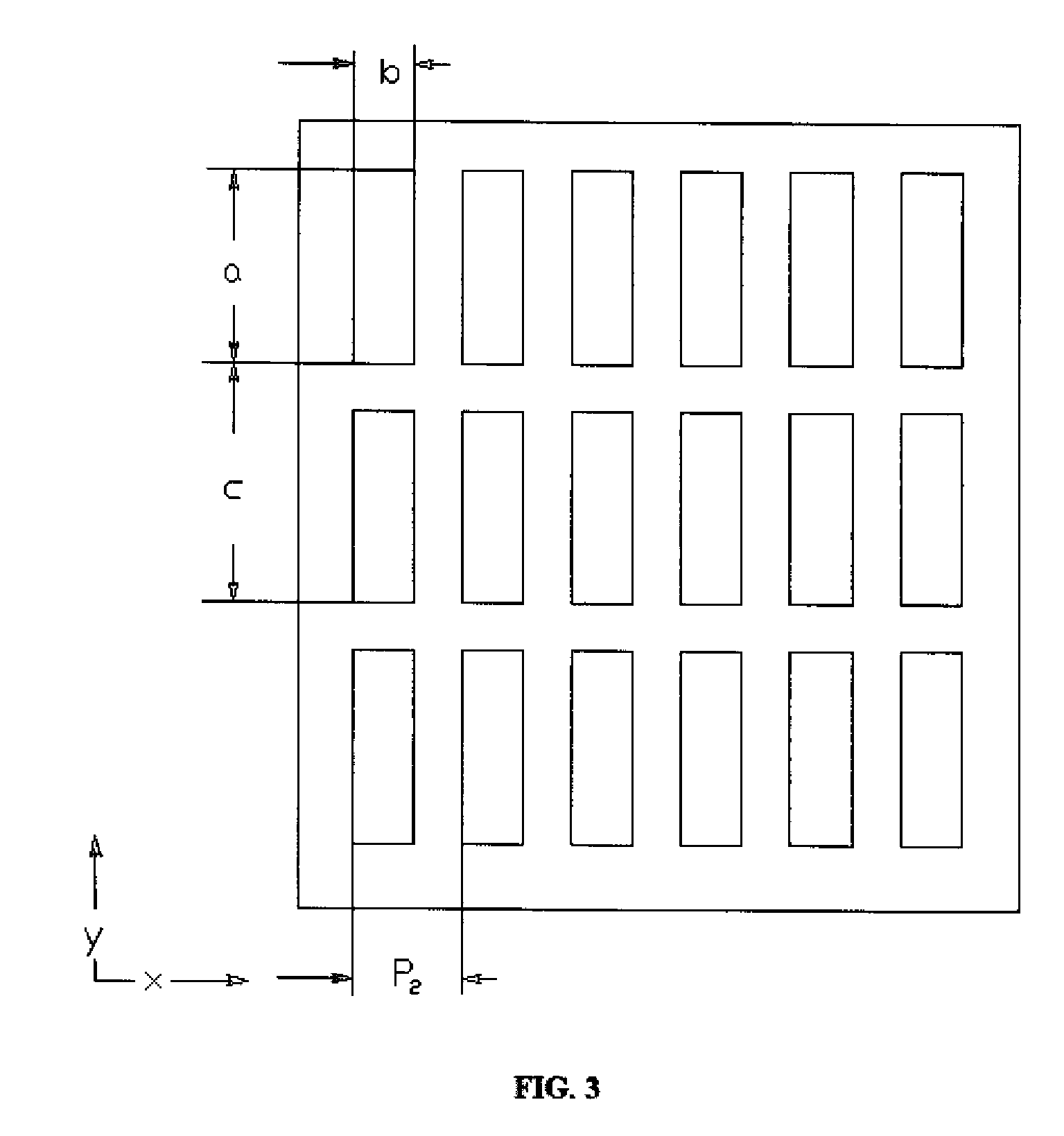

Differential interference phase contrast X-ray imaging system

InactiveUS8073099B2High radiant fluxPhoton energy is highImaging devicesX-ray tube electrodesHigh energyPhotoconductive detector

A differential phase-contrast X-ray imaging system is provided. Along the direction of X-ray propagation, the basic components are X-ray tube, filter, object platform, X-ray phase grating, and X-ray detector. The system provides: 1) X-ray beam from parallel-arranged source array with good coherence, high energy, and wider angles of divergence with 30-50 degree. 2) The novel X-ray detector adopted in present invention plays dual roles of conventional analyzer grating and conventional detector. The basic structure of the detector includes a set of parallel-arranged linear array X-ray scintillator screens, optical coupling system, an area array detector or parallel-arranged linear array X-ray photoconductive detector. In this case, relative parameters for scintillator screens or photoconductive detector correspond to phase grating and parallel-arranged line source array, which can provide the coherent X-rays with high energy.

Owner:SHENZHEN UNIV

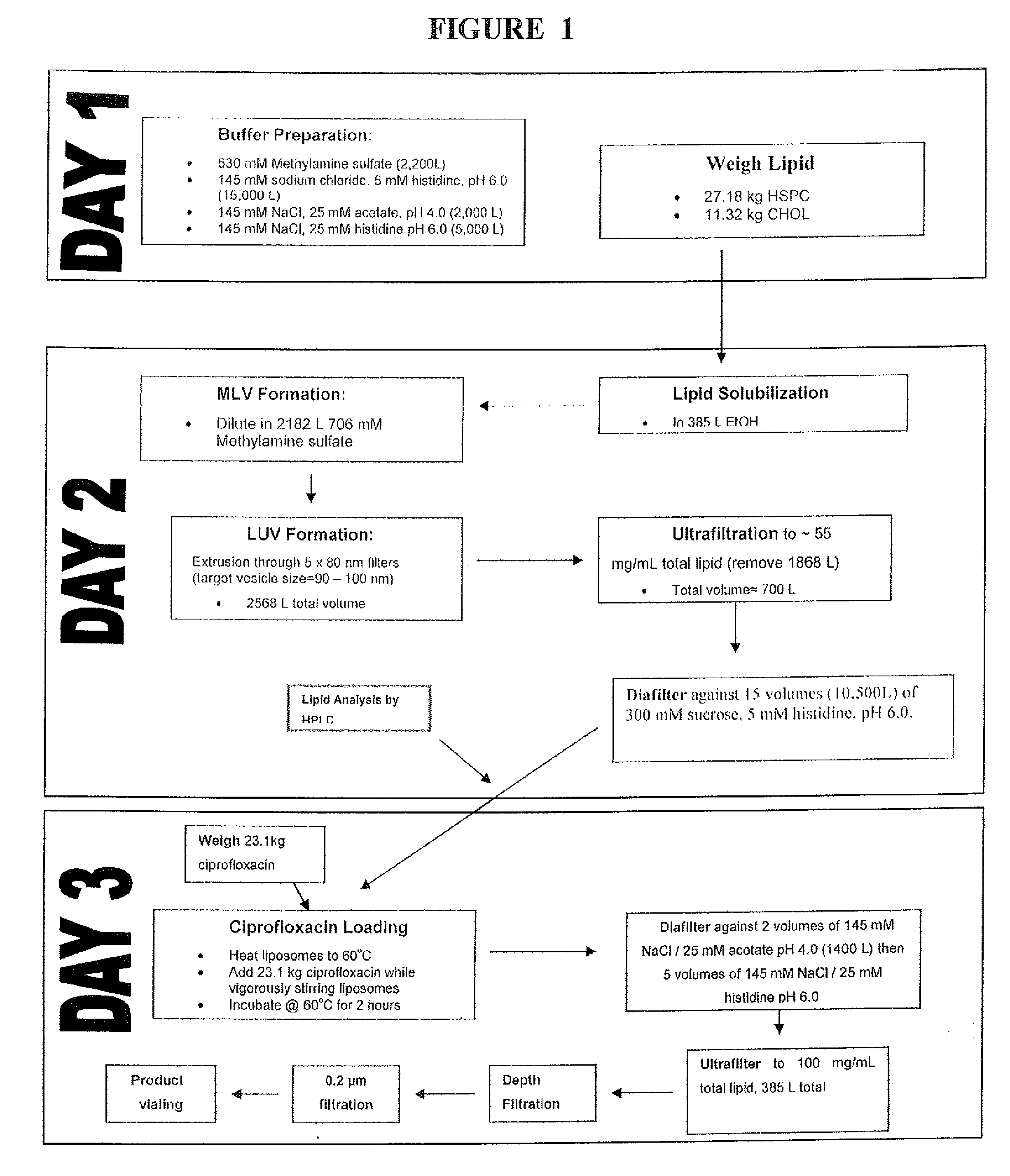

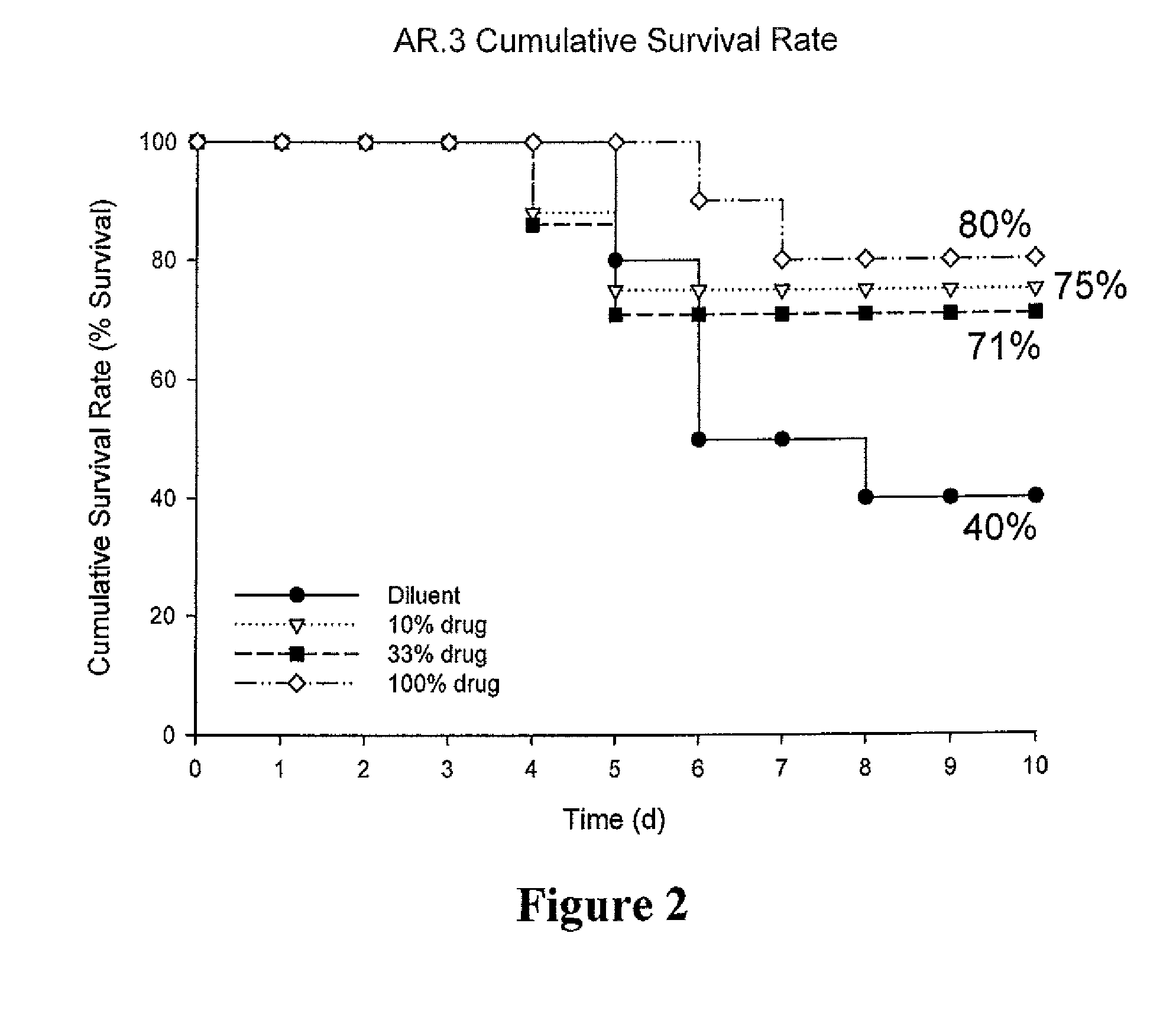

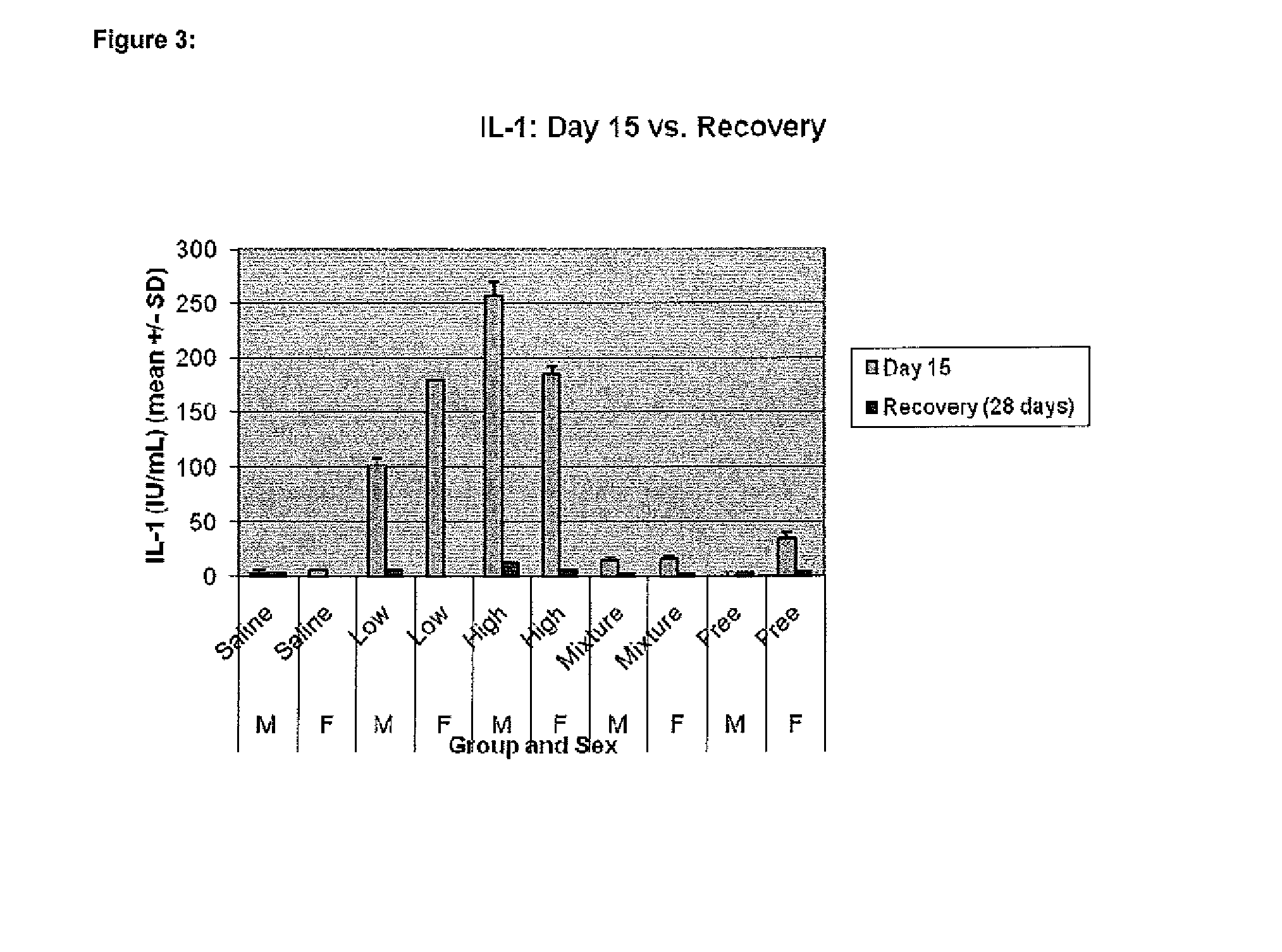

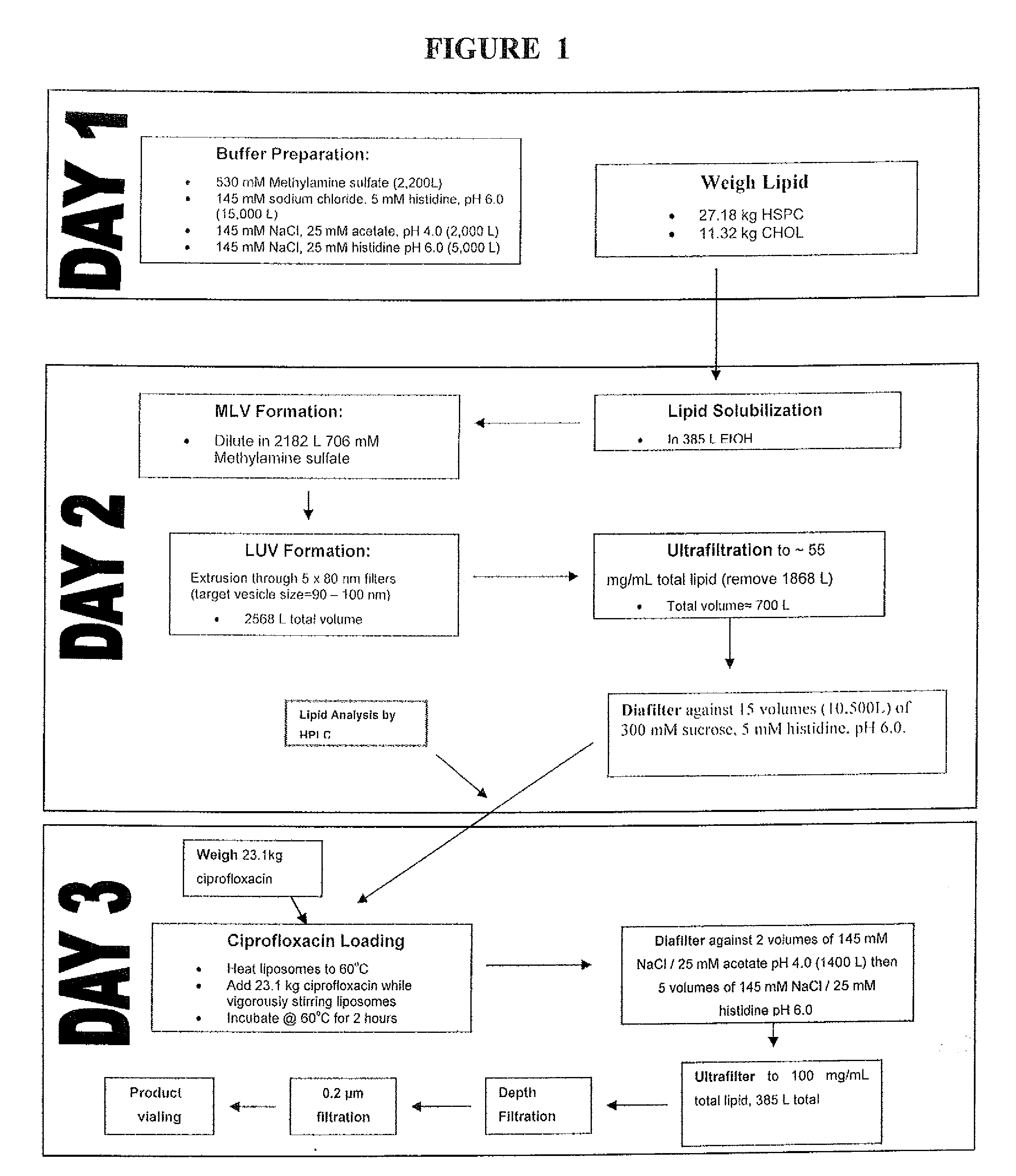

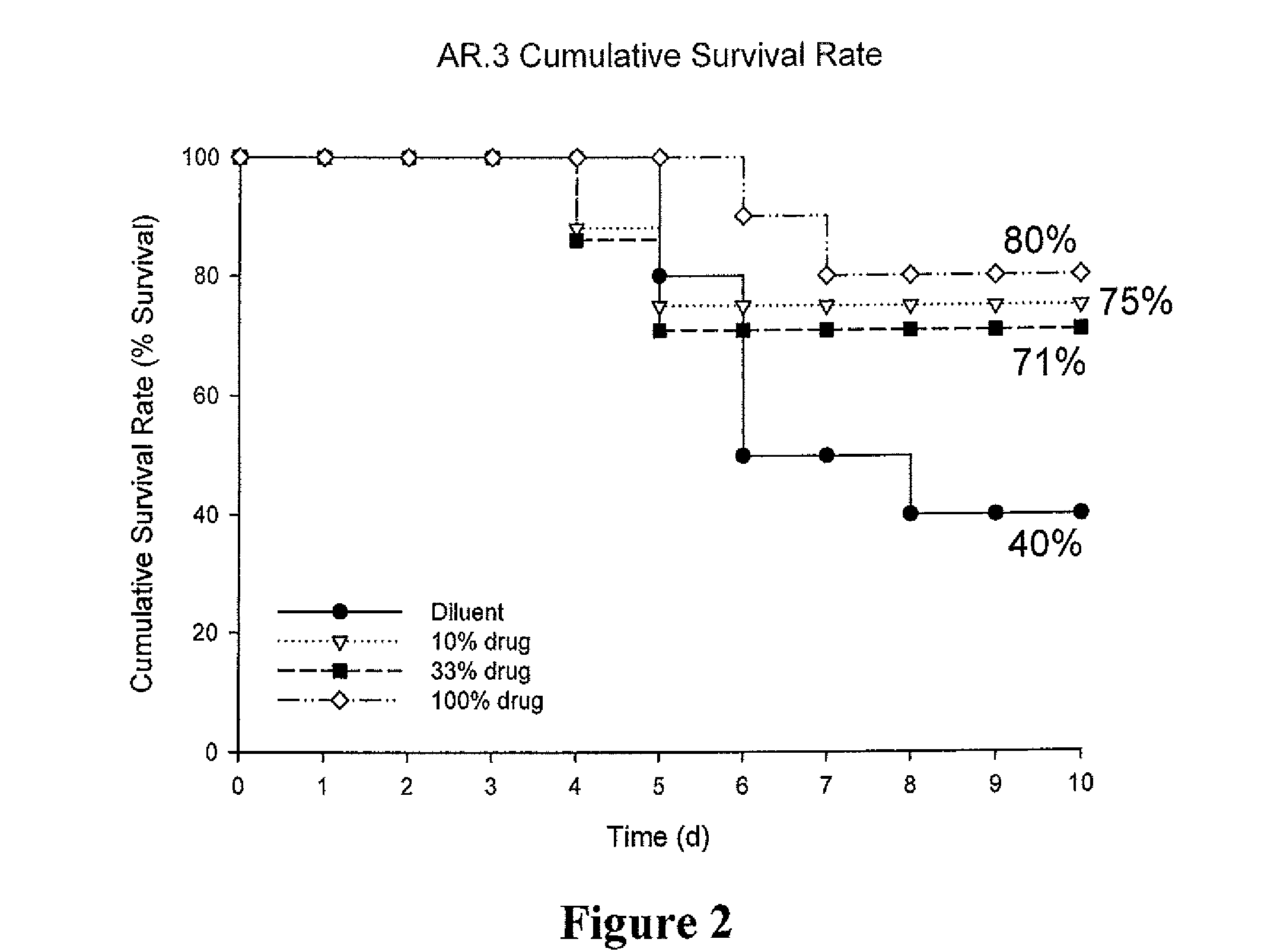

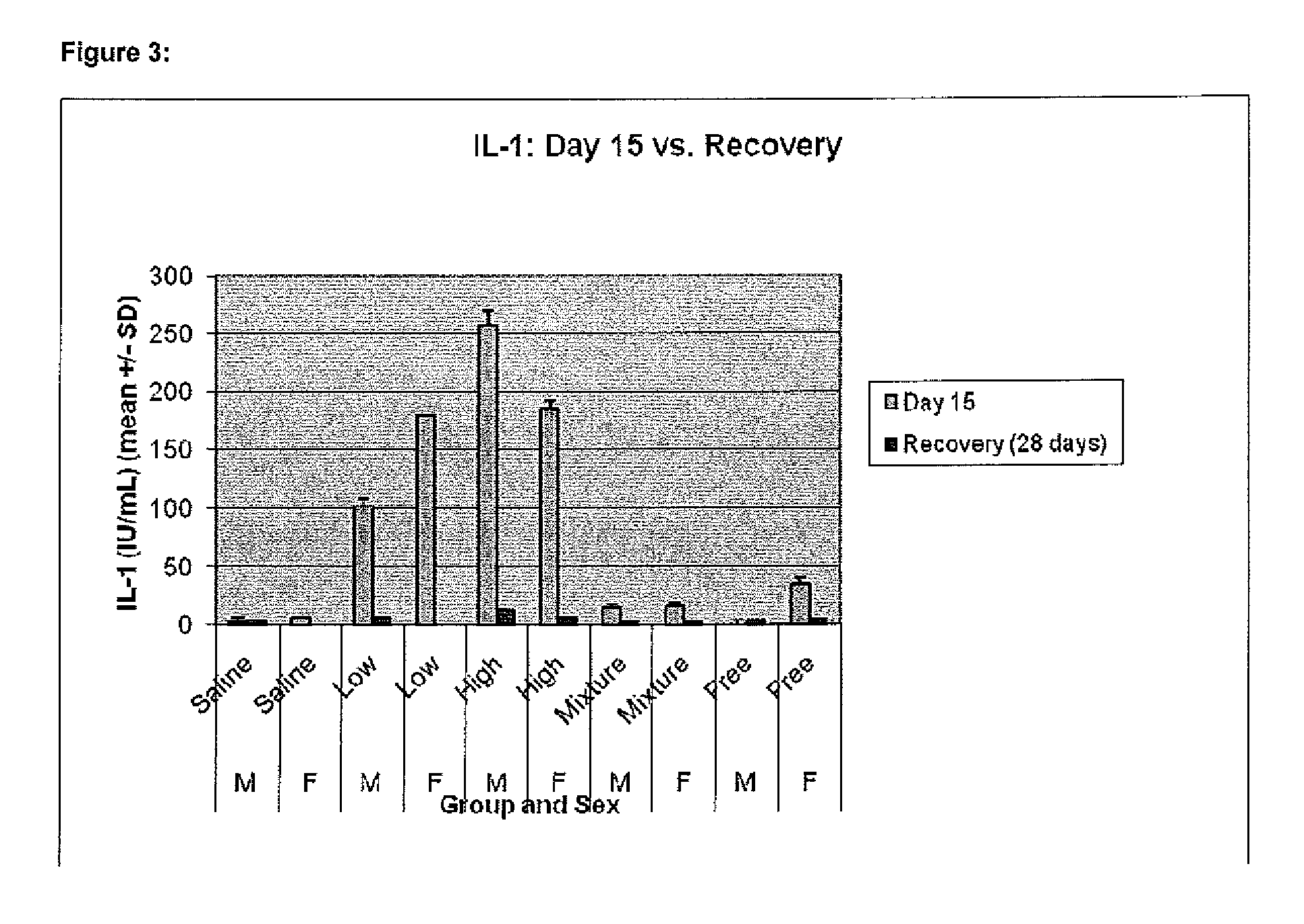

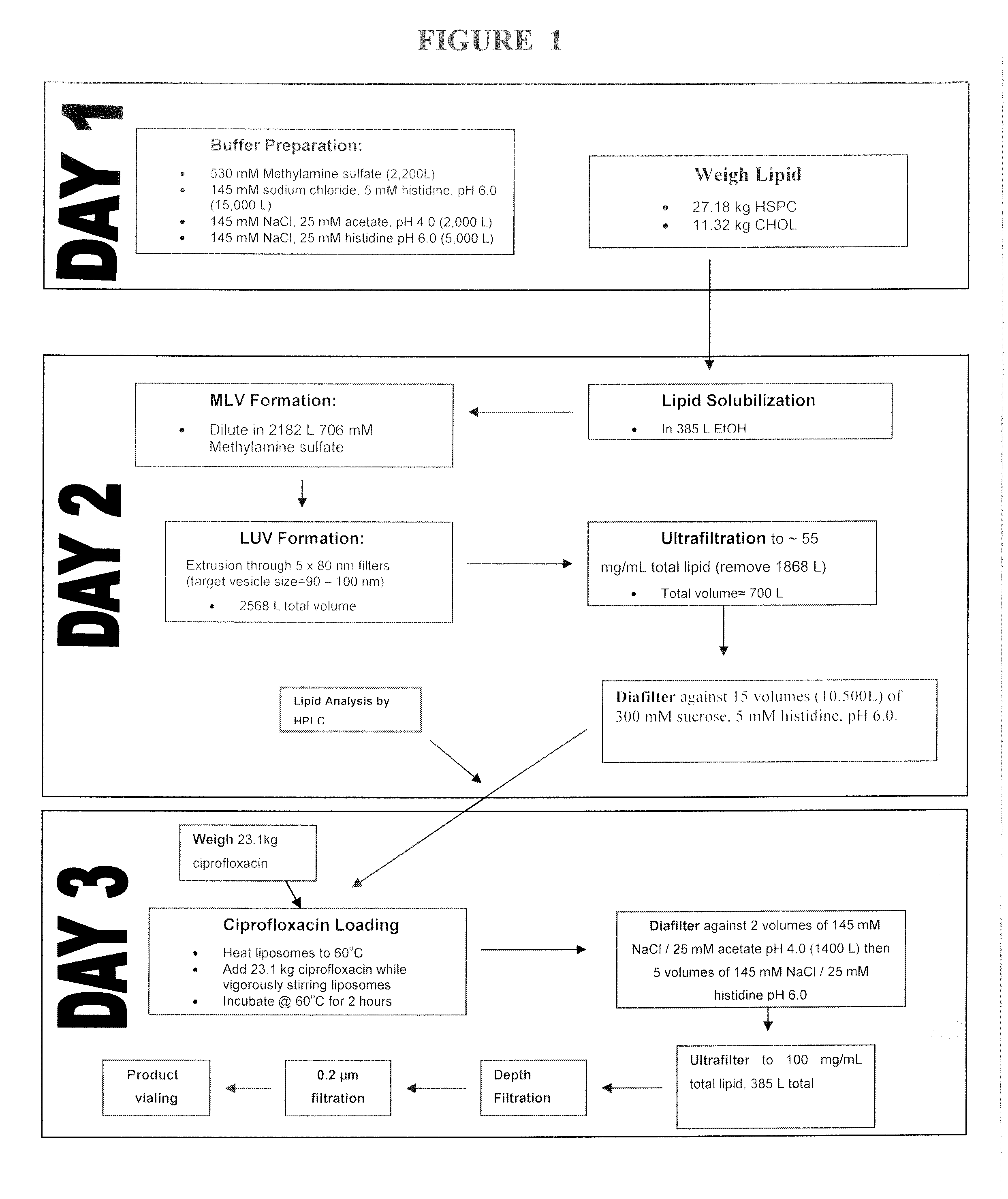

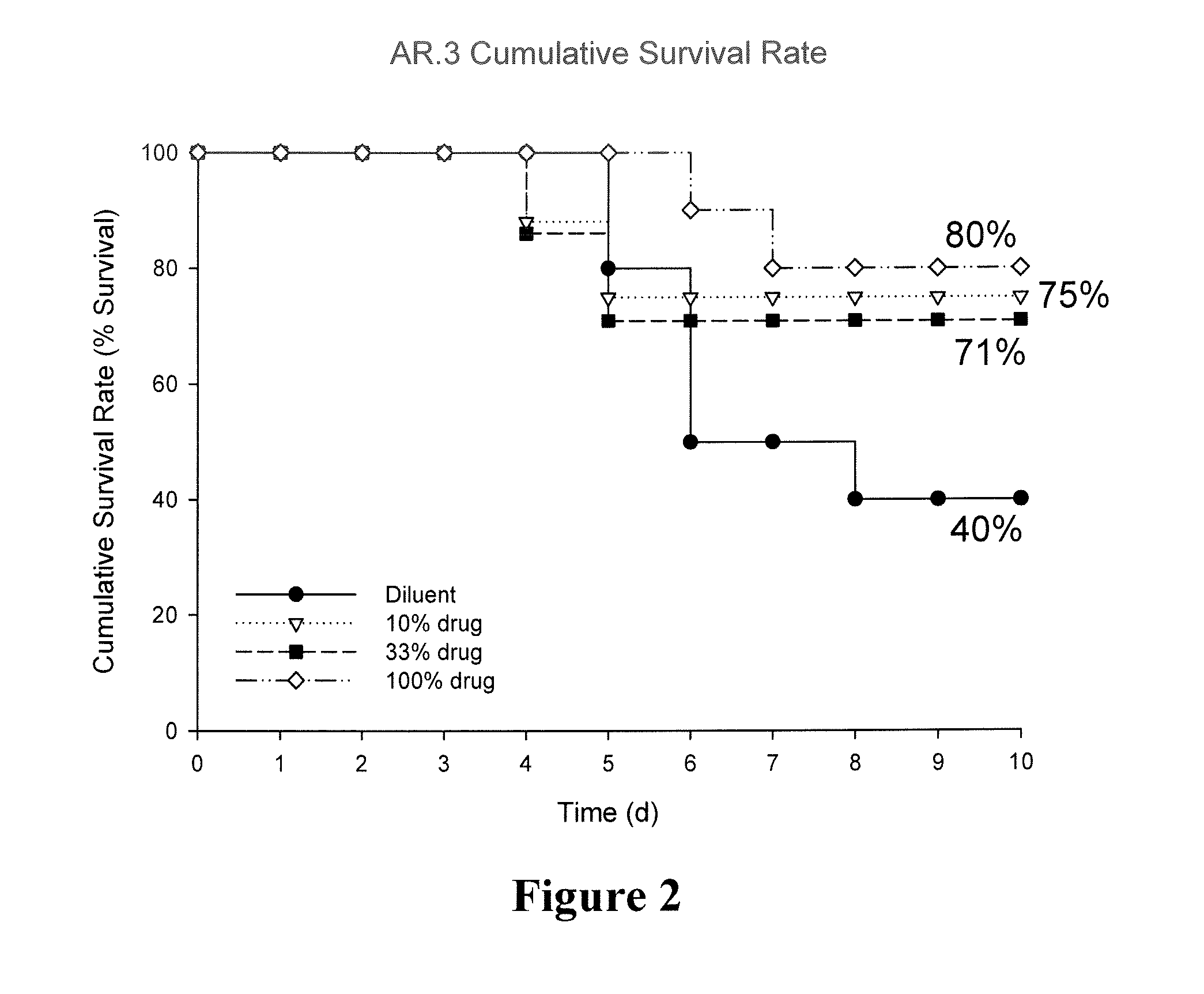

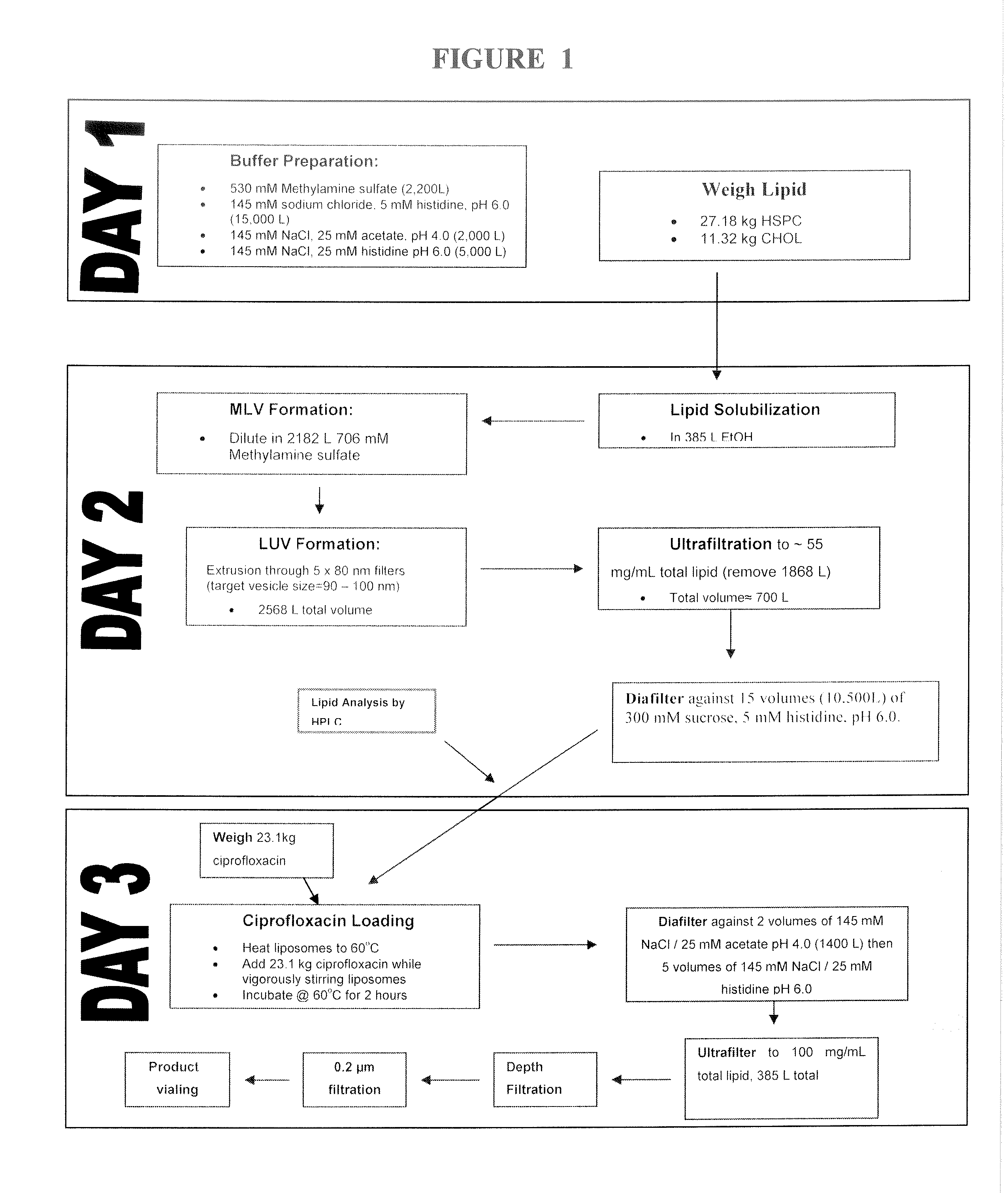

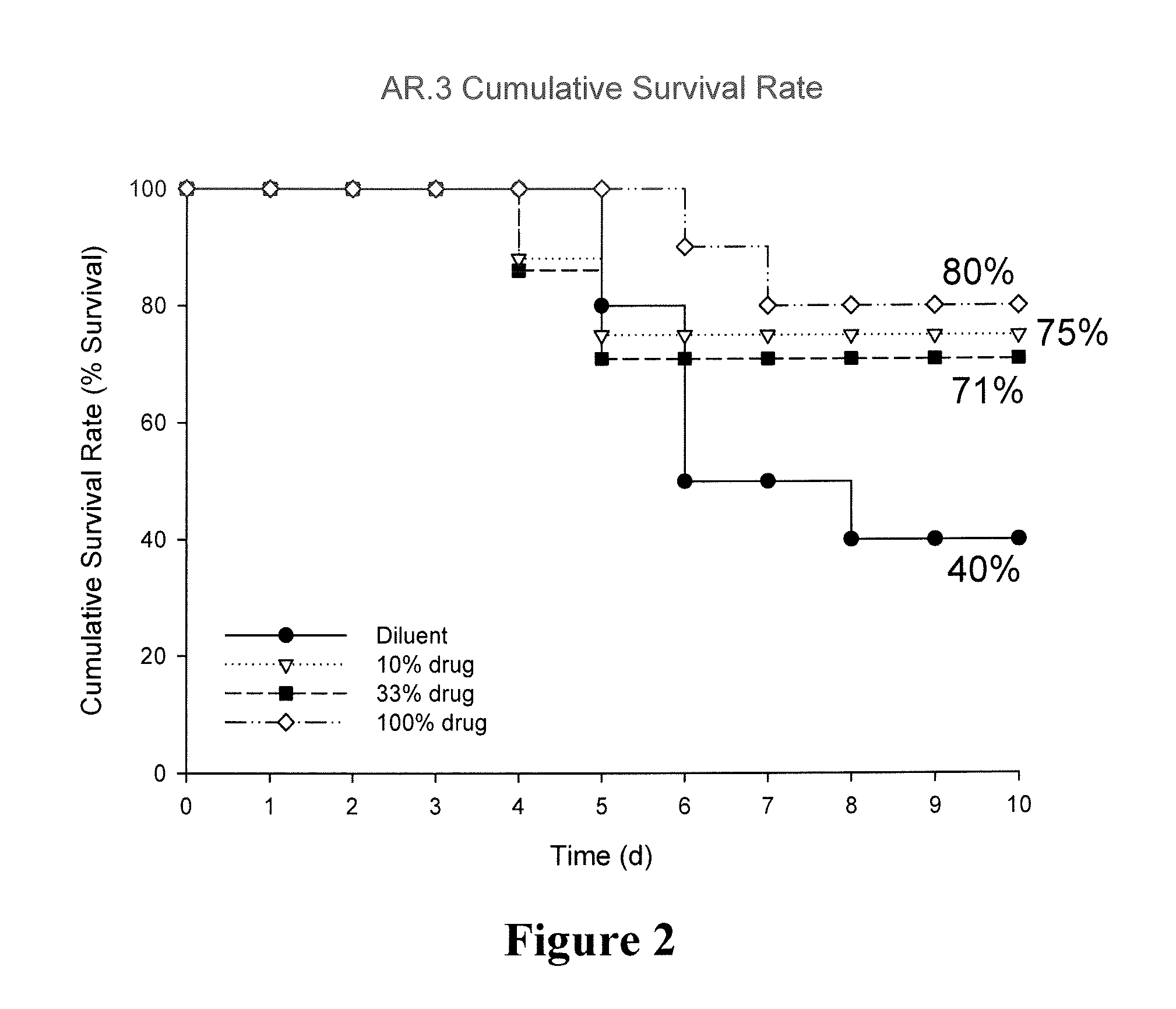

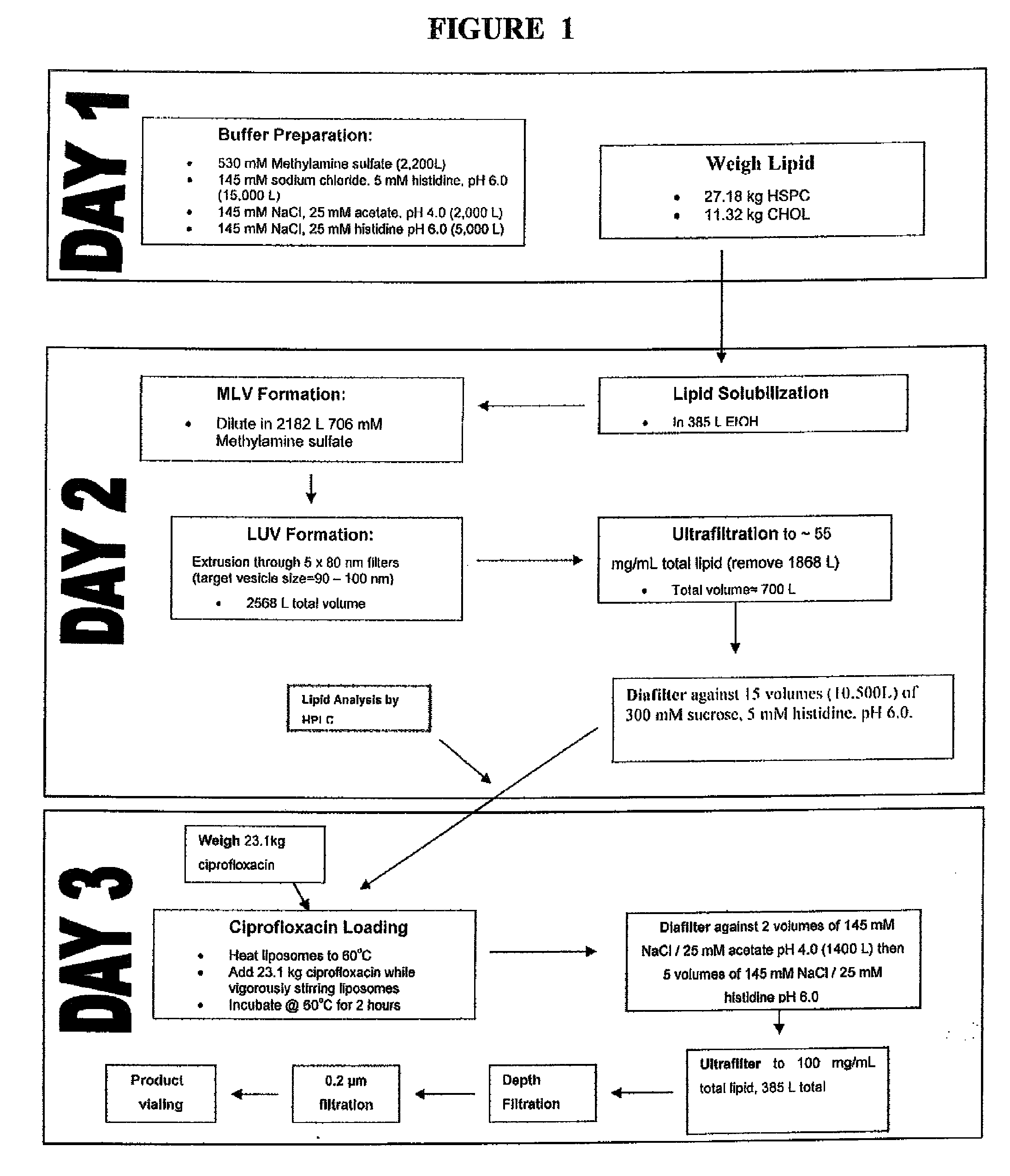

Dual action, inhaled formulations providing both an immediate and sustained release profile

ActiveUS20090269396A1Improve treatmentSustained release of anti-infective over timePowder deliveryBiocideDual actionAnesthesia

Methods for formulating immediate and sustained release anti-infectives and delivery of such for treatment of respiratory tract infections and other medical conditions, and devices and formulations used in connection with such are described.

Owner:GRIFOLS

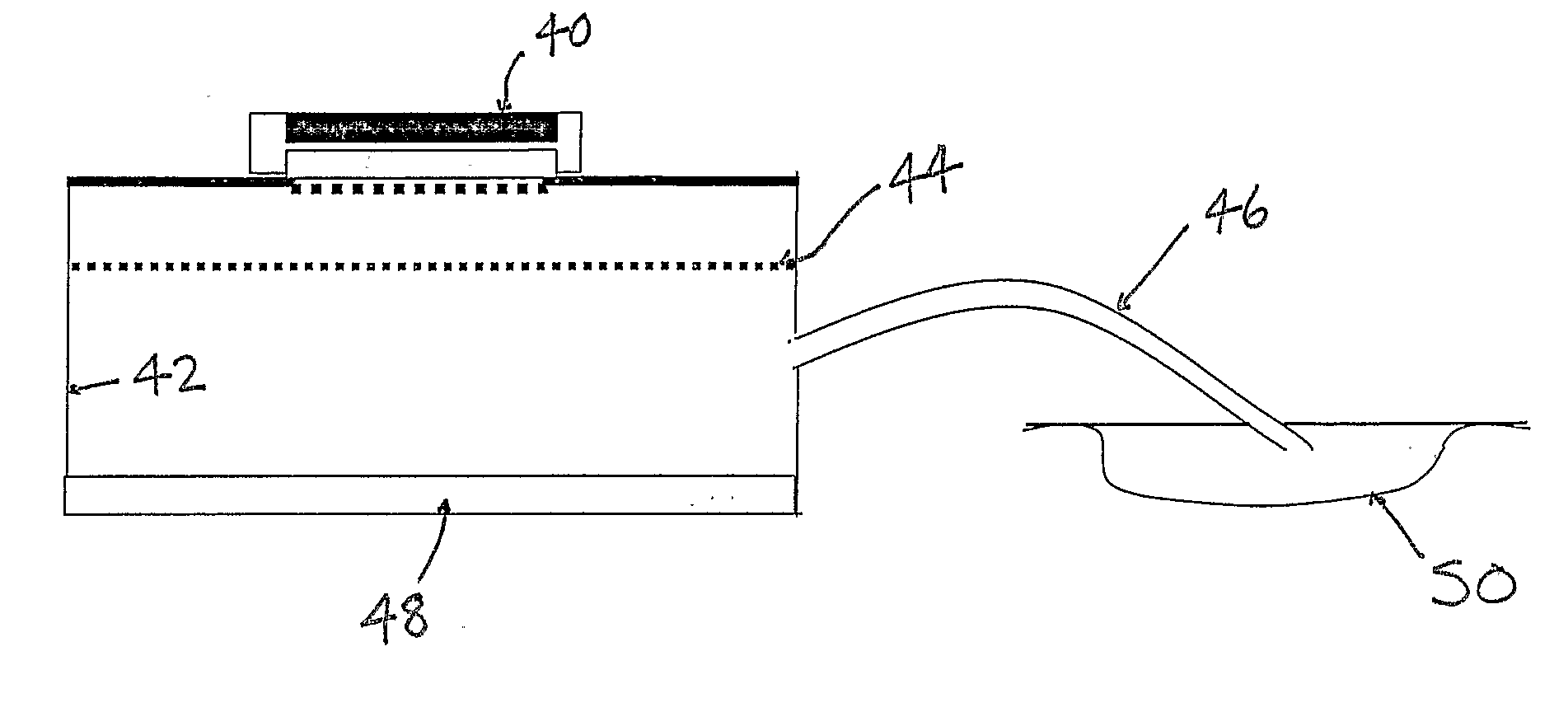

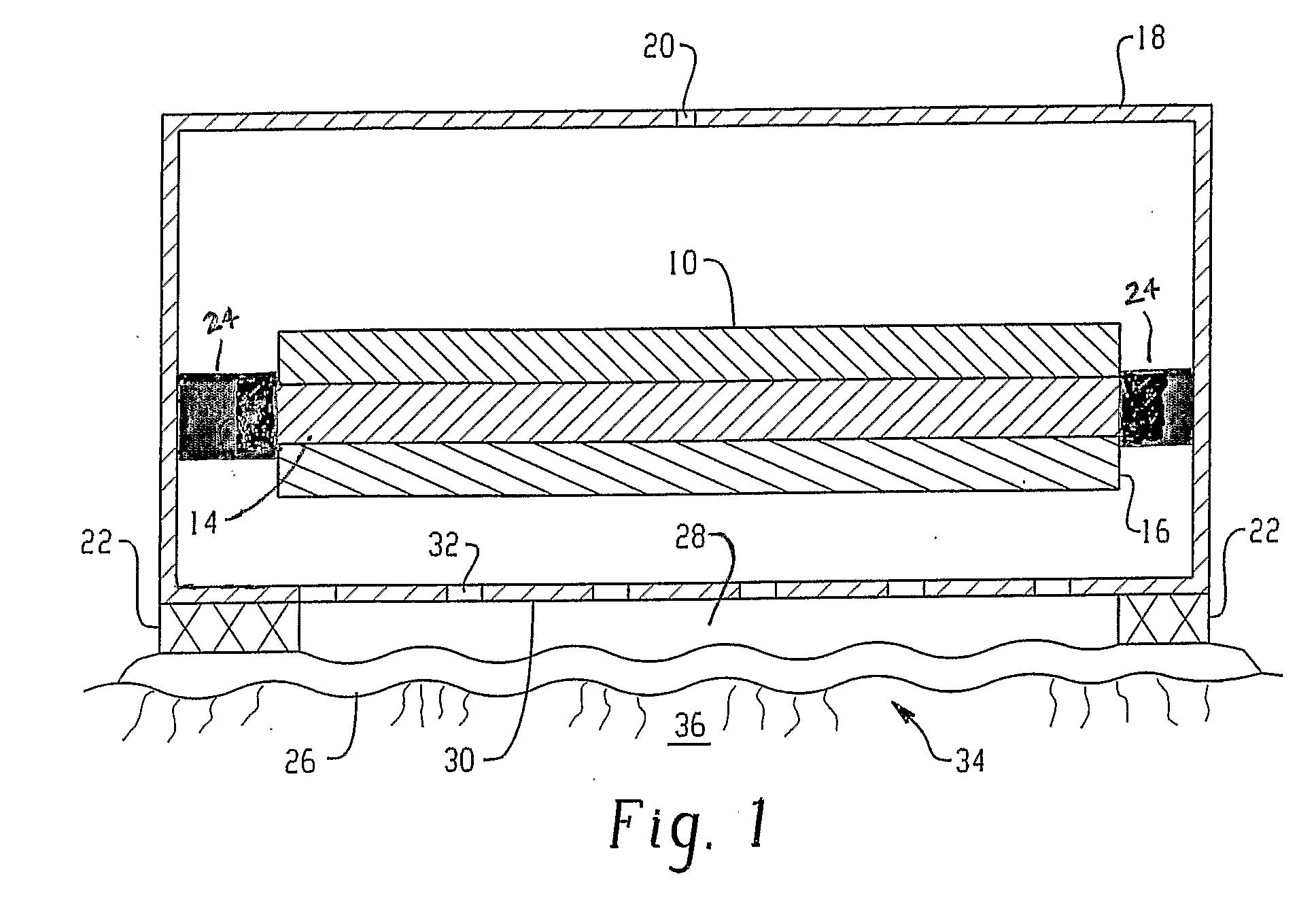

Novel portable electrochemical devices for dual action wound healing

ActiveUS20090149821A1Reduce pressureElectrotherapyMedical applicatorsHigh concentrationWound dressing

A portable, self-contained device is described for the topical application of oxygen and the removal of wound exudates to promote the healing of skin wounds. The device includes a wound dressing that incorporates at least one electrochemical cell for generating oxygen. The device can regulate the supply of oxygen to the wound at various concentrations, pressures and dosages and is used to produce a high concentration of oxygen at the wound site. By reversing the polarity of the power source a reduced pressure can be created in a reservoir attached to our device. The reduced pressure in the reservoir draws naturally flowing exudates away from the wound. Alternately, two reverse polarity cells are used to alternately supply oxygen and draw away exudates.

Owner:NEOGENIX LLC

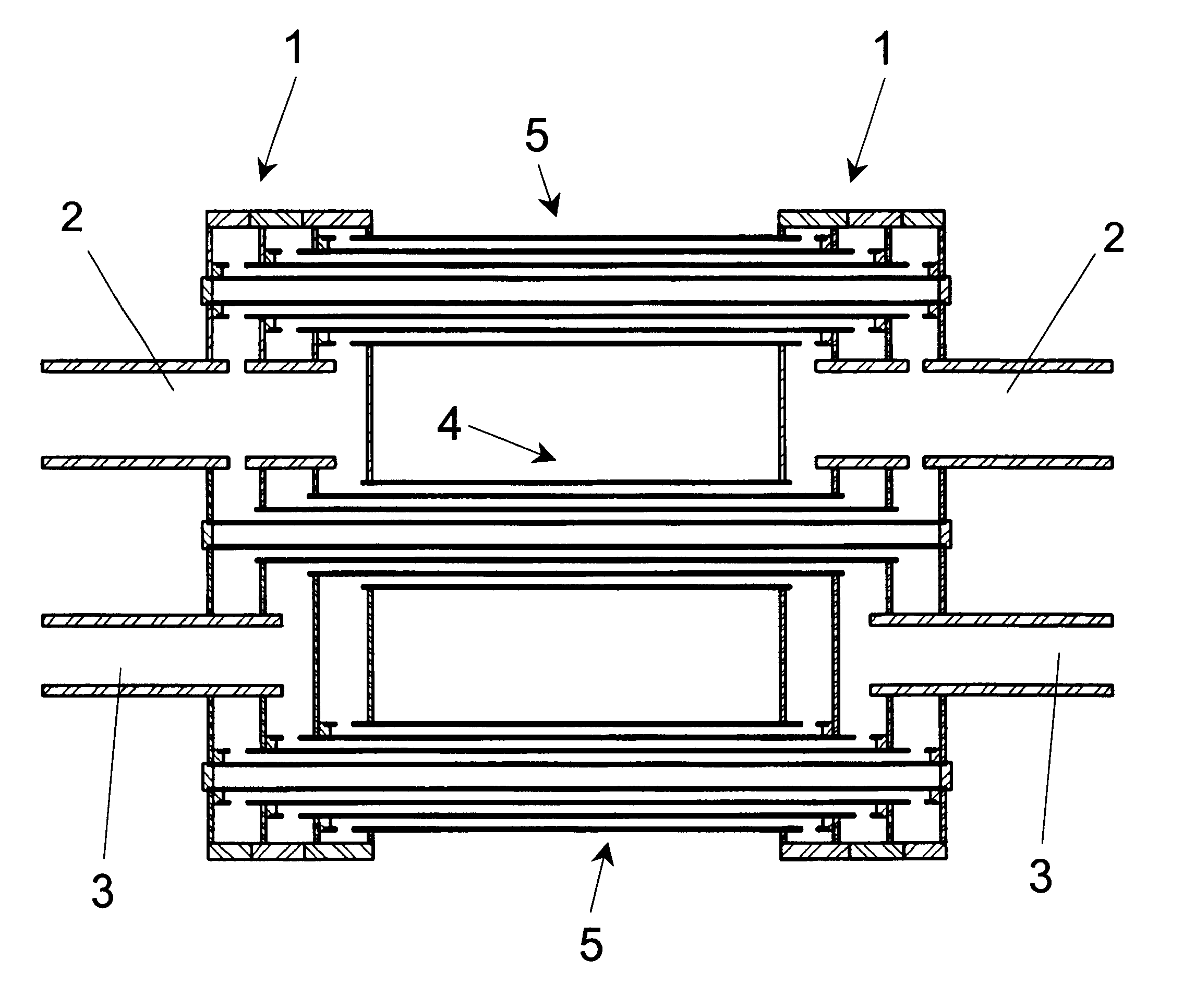

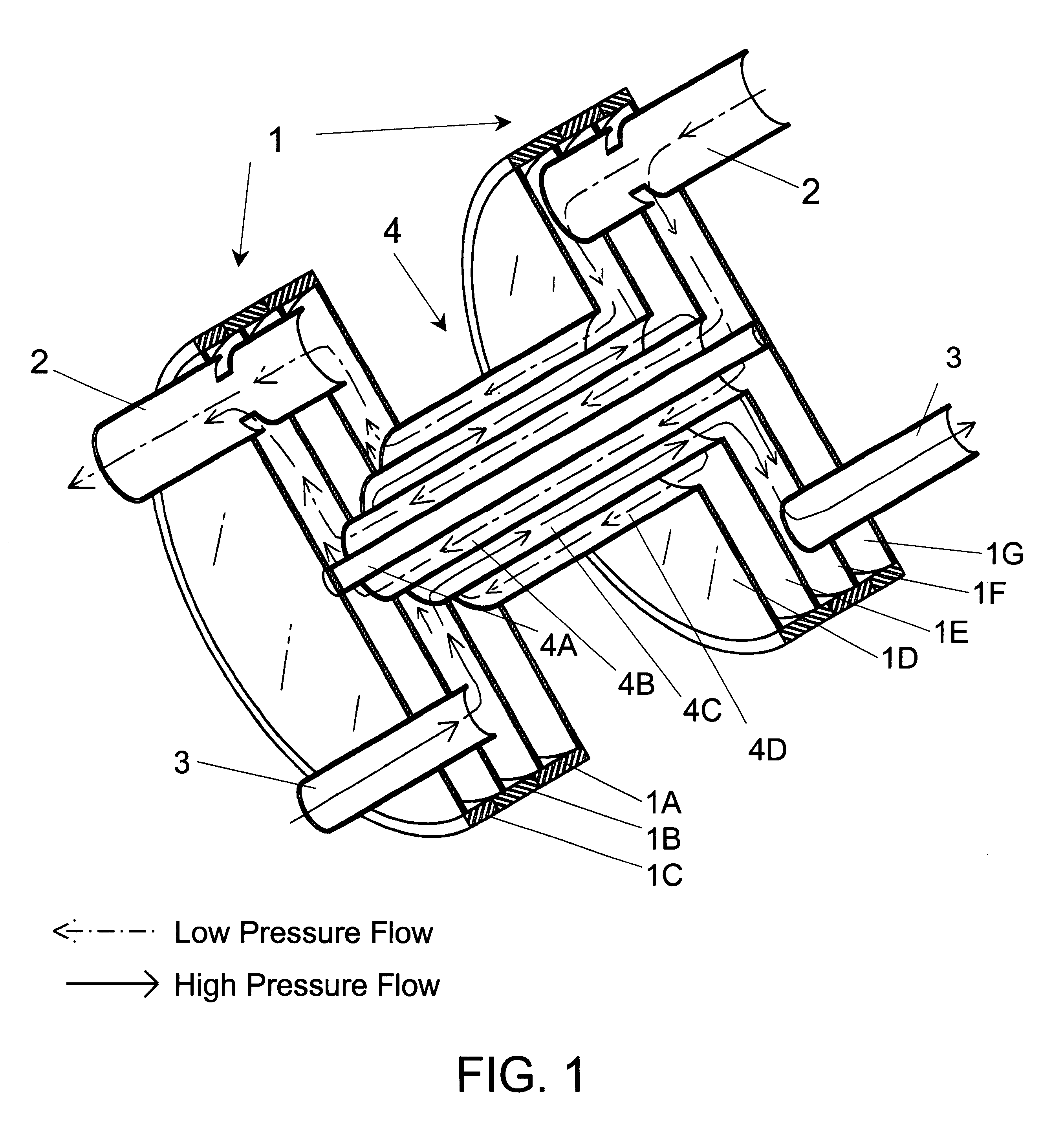

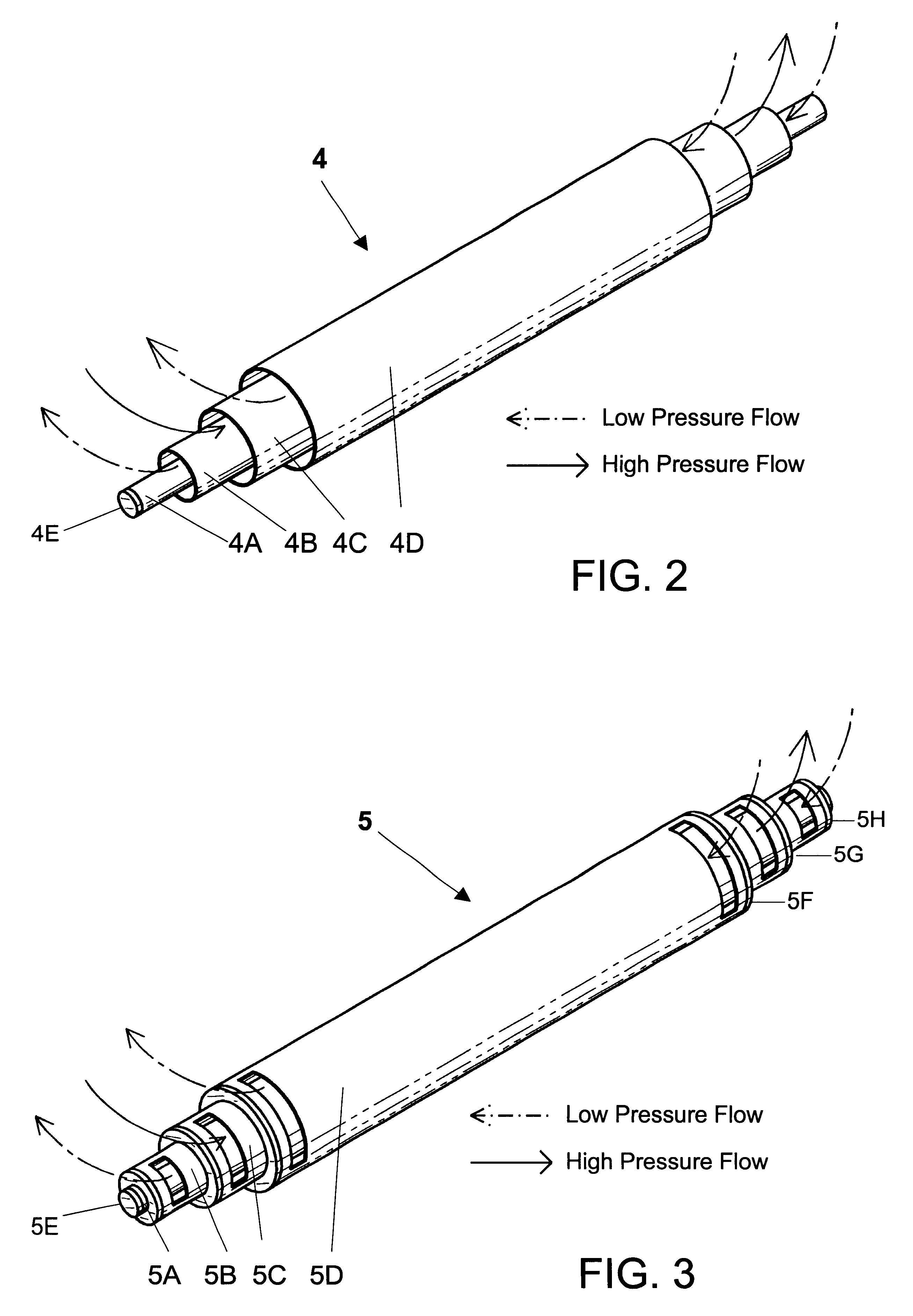

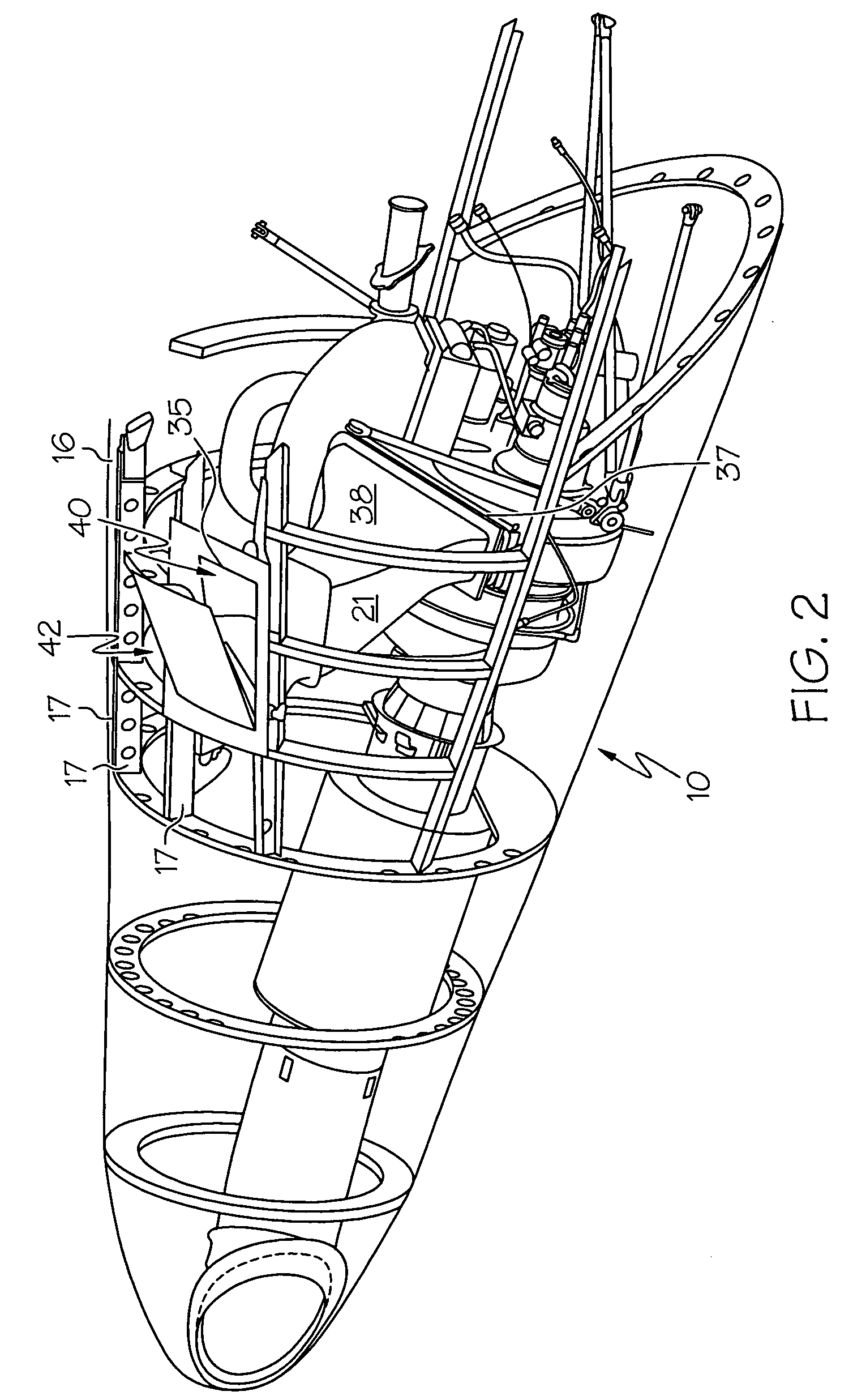

Annular flow concentric tube recuperator

InactiveUS6390185B1Minimal effectivenessNegligible reduction in effectivenessRecuperative heat exchangersStationary tubular conduit assembliesCounter flowVolumetric Mass Density

An annular flow concentric tube heat exchanger for heating two counter flowing fluid streams has been devised. Although capable of heating gases or liquids, the primary purpose of the invention is to function as an improved recuperator for recovering exhaust heat from a Brayton Cycle gas turbine engine, Ericsson Cycle engine or similar recuperated engine. The basic element of the recuperator is a concentric tube assembly that, in the preferred embodiment, is comprised of four concentric tubes that enclose three concentric annular flow passages. The low pressure exhaust flows through the inner and outer annular passages while the high pressure compressor exit air flows through the annular passage that is between the two low pressure passages. The high and low pressure flows are in opposite directions to achieve the high effectiveness that is only available with a counterflow heat exchanger. Heat is transferred from the exhaust gas to the compressor air though the tube walls on each side of the high pressure passage. Two low pressure passages are provided for each high pressure air passage to compensate for the lower pressure (and therefore lower density) of the exhaust gas. Multiple concentric tube assemblies are used to make a recuperator. The tube assemblies terminate in header assemblies located at each end of the concentric tube assemblies. The headers are made of simple plates and rings that serve the dual function of structurally locating the concentric tube assemblies and directing the flow to the proper passage in the concentric tube assemblies. High and low pressure flow tubes provide flow passages connecting the recuperator to the engine compressor air and exhaust tubing respectively. The annular flow concentric tube recuperator can be easily made from commercial tubing with minimal special tooling and is capable of very high effectiveness with very low pressure drop.

Owner:PROE POWER SYST

Deep Acting Topically Working Facial Care Appliance

InactiveUS20100222719A1Easy to useEasy accessChiropractic devicesBathroom accessoriesCuticleDual action

A deep acting topically working facial care appliance includes a dual action facial puck having a rotating and counter rotatable facial implement that is dually effective both to clean, massage, apply compositions and otherwise topically work the skin and to deeply act to penetrate below the epidermis and into the dermis massaging and deeply passivating and enervating the dermis and dermal collagen.

Owner:HEADWATERS RES & DEV

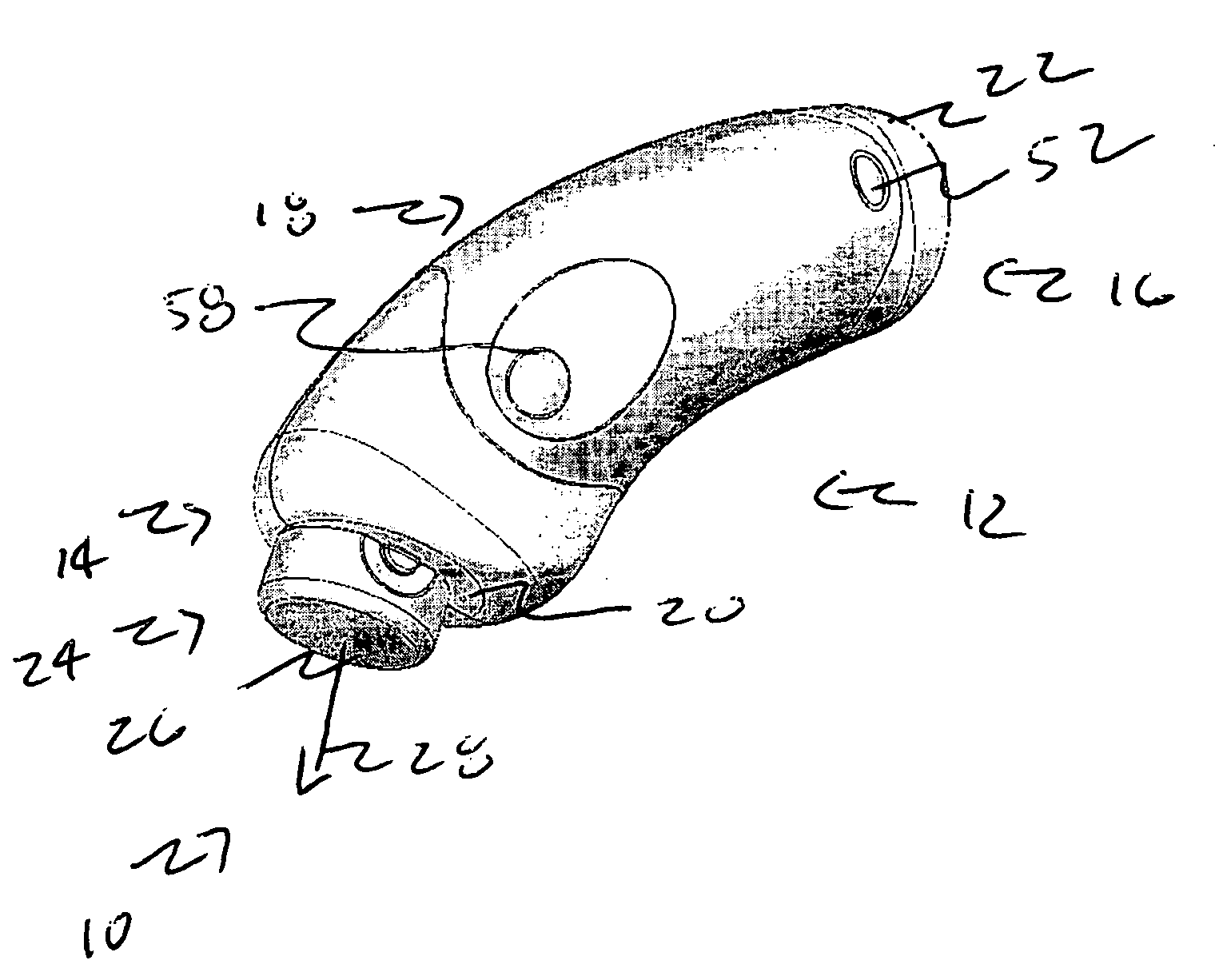

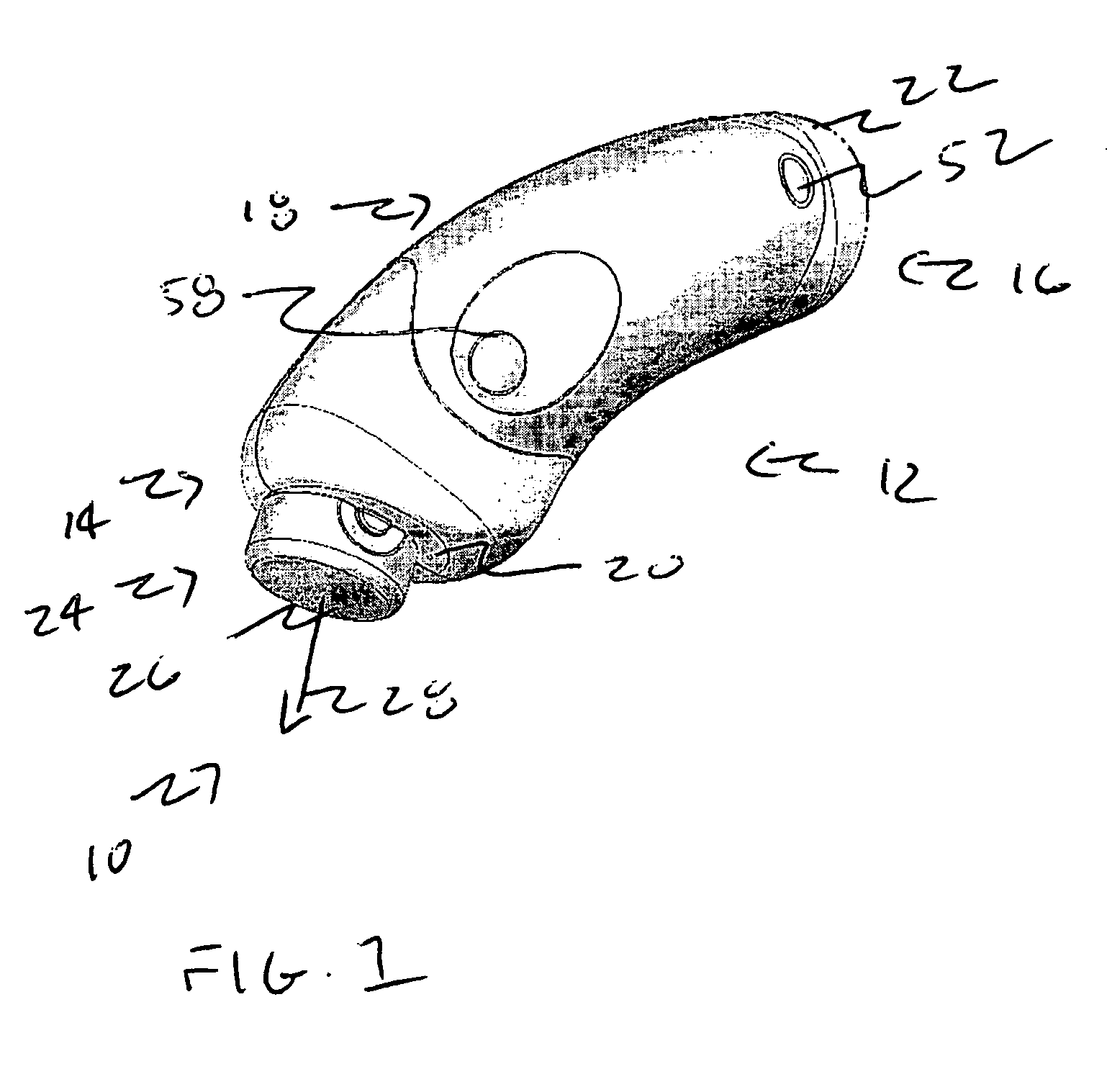

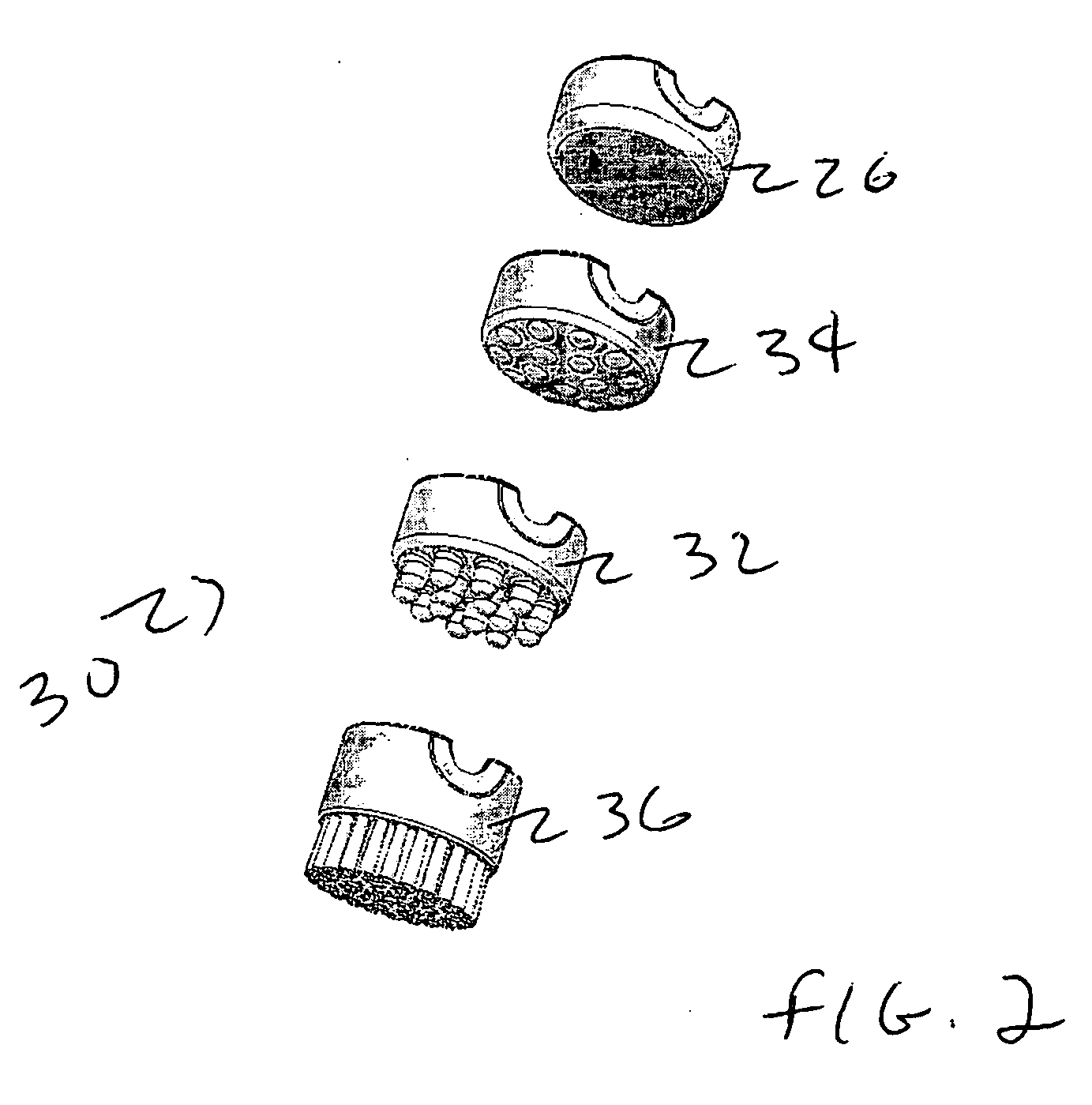

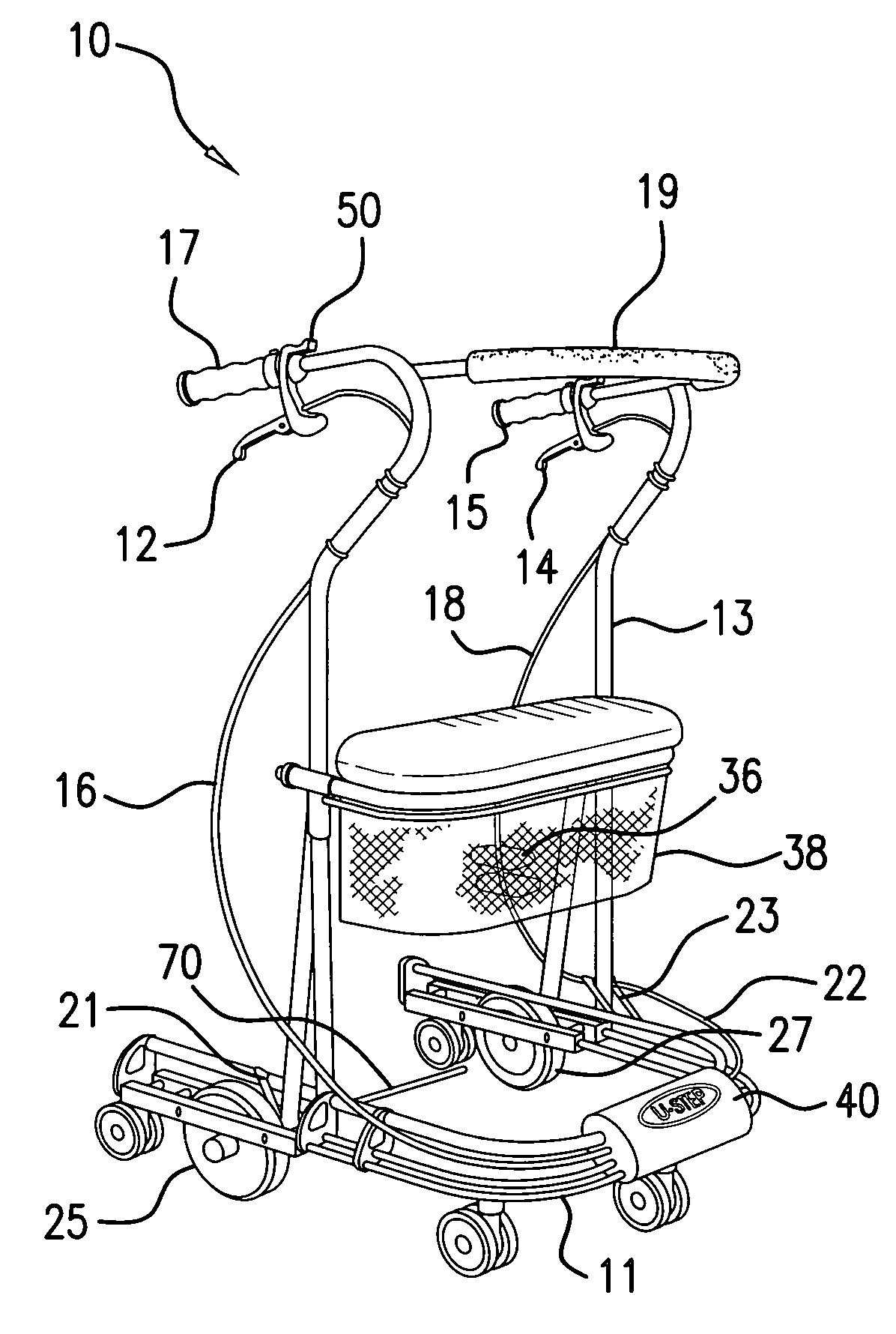

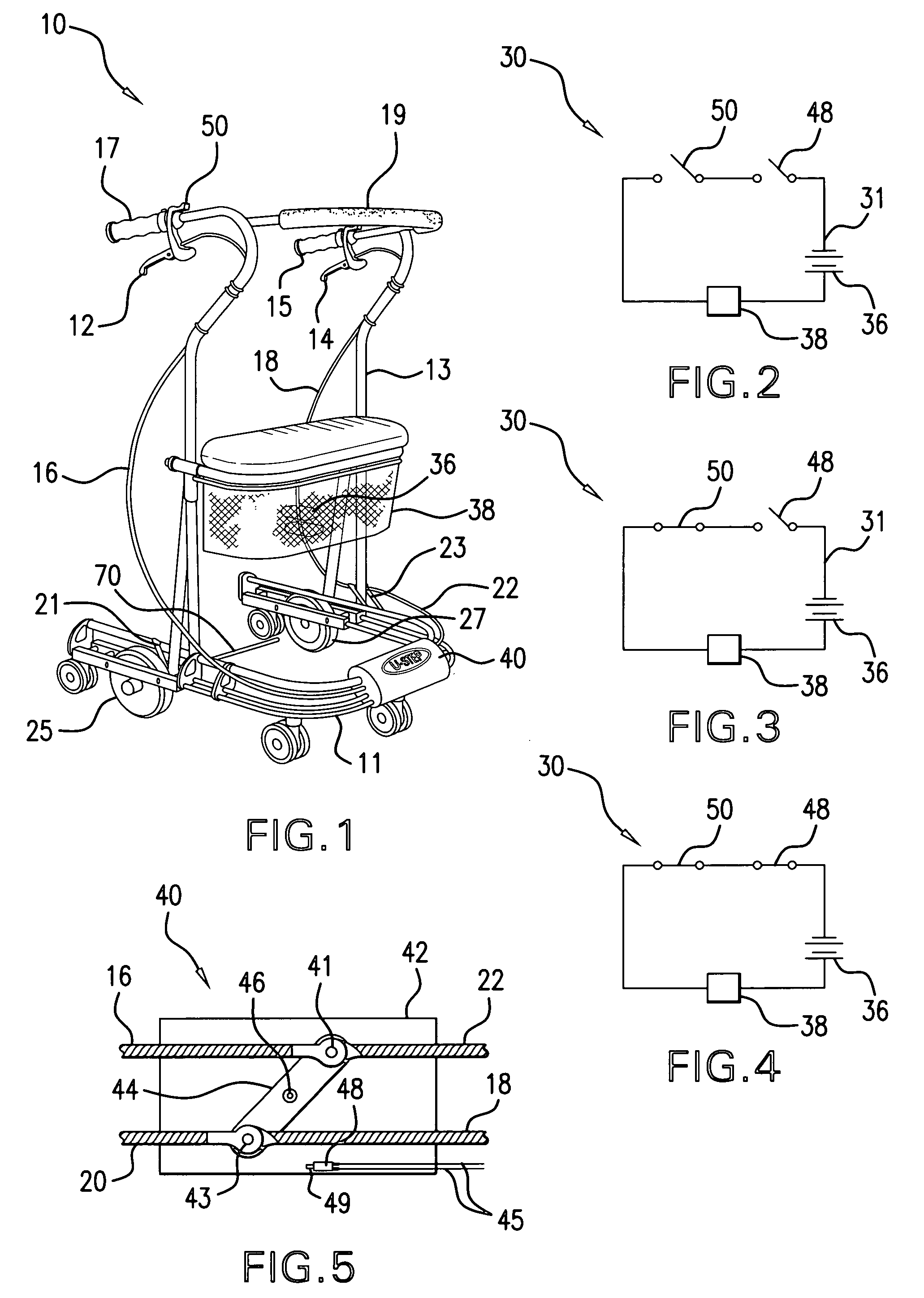

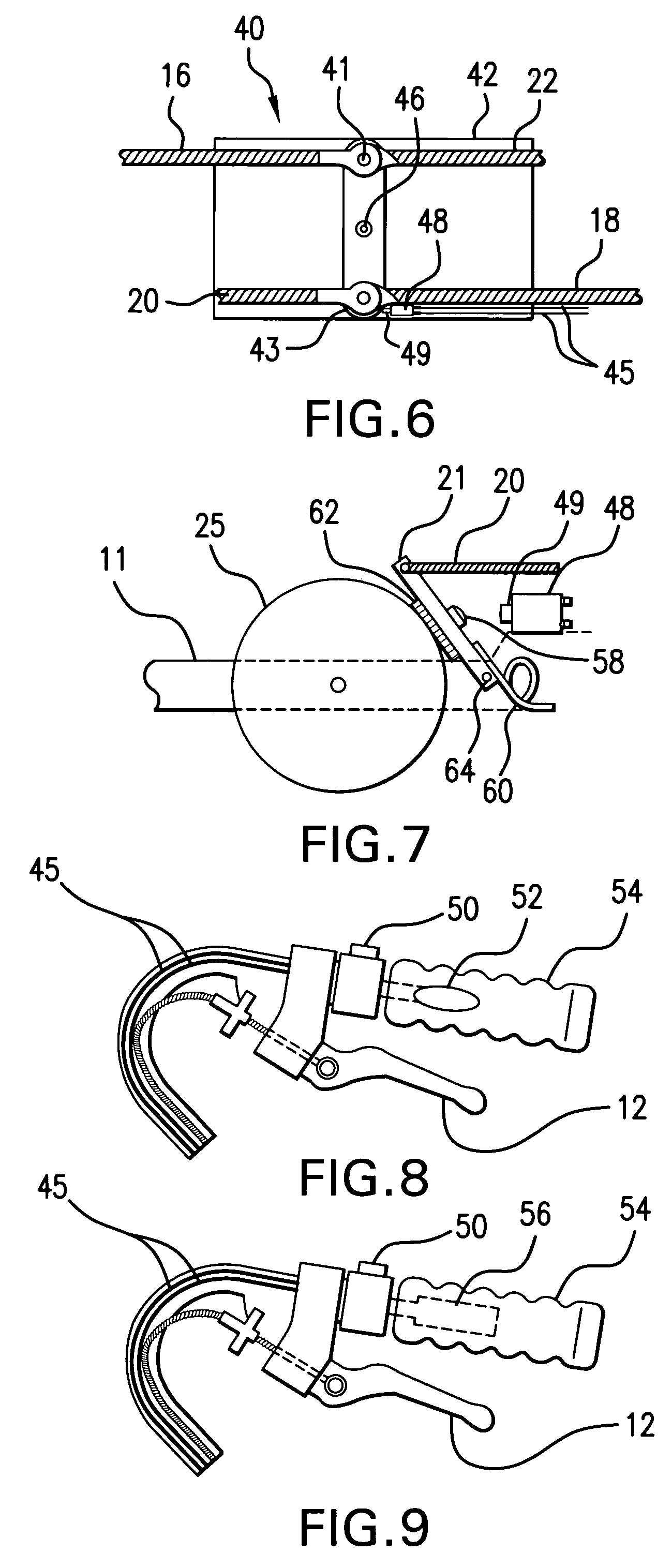

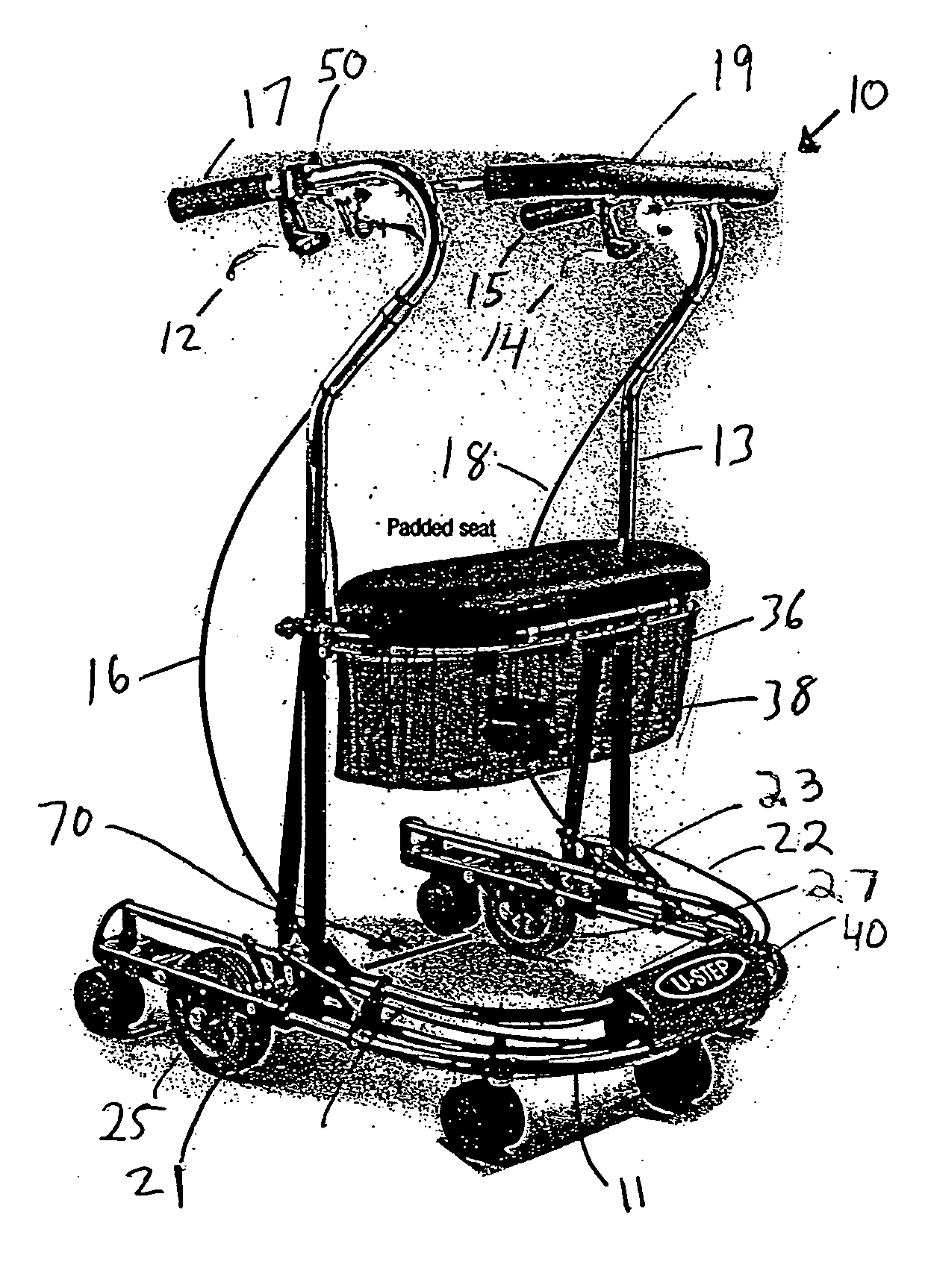

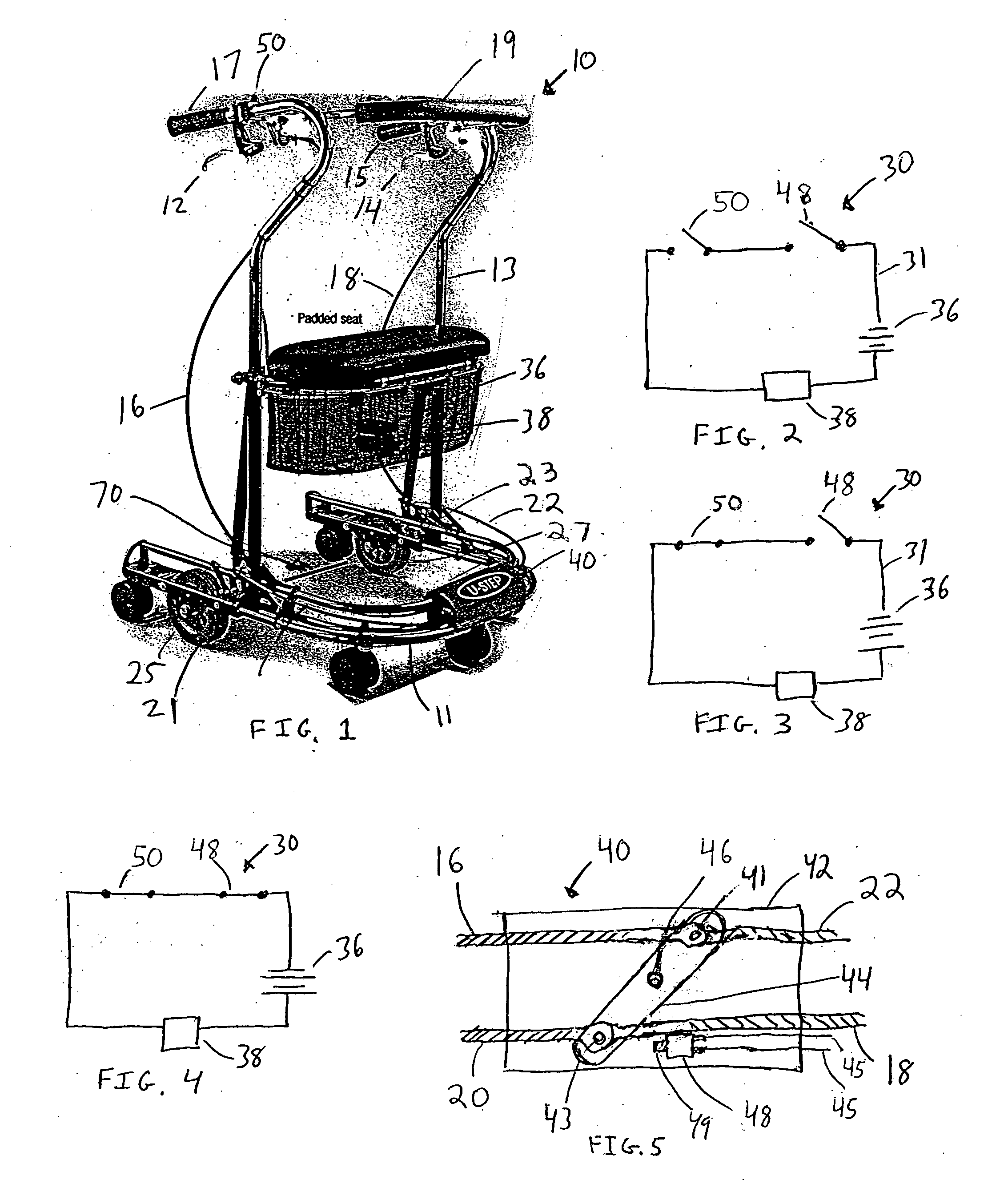

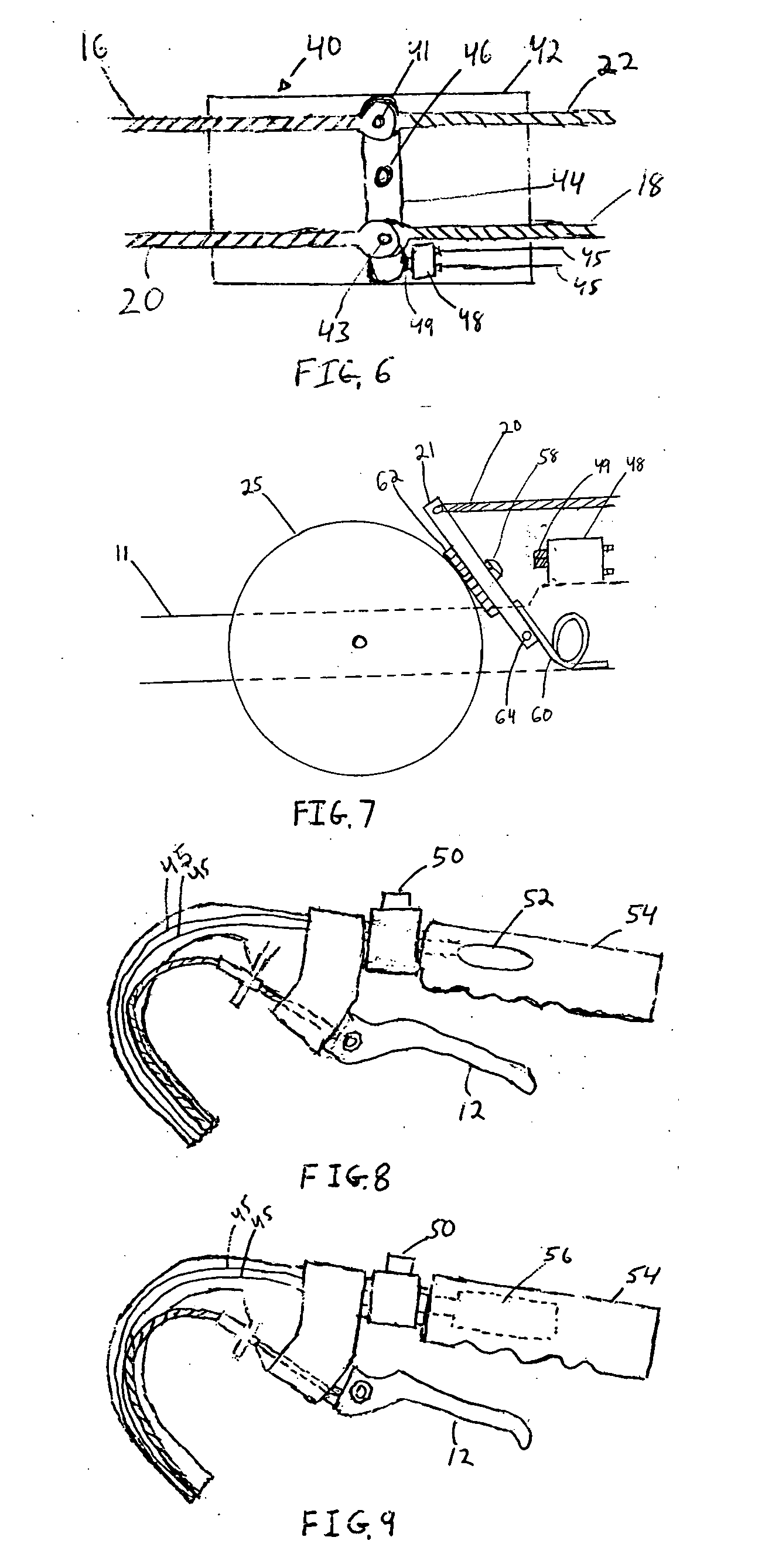

Projection and actuation device for a walking stabilizer

A walking stabilizer equipped to combat the effects of akinesia paradoxica by employing a novel method and device to regulate and actuate a projection instrument which generates a pattern perpendicular to the user's direction of travel. The regulating and actuating device comprises a two pole series switch circuit configuration in tandem with the walking stabilizer's novel dual action braking mechanism. The projection device is only operable when the user concurrently selects its use and when the walker stabilizer is free for movement or in contact with the patient.

Owner:MILLER JONATHAN JAY

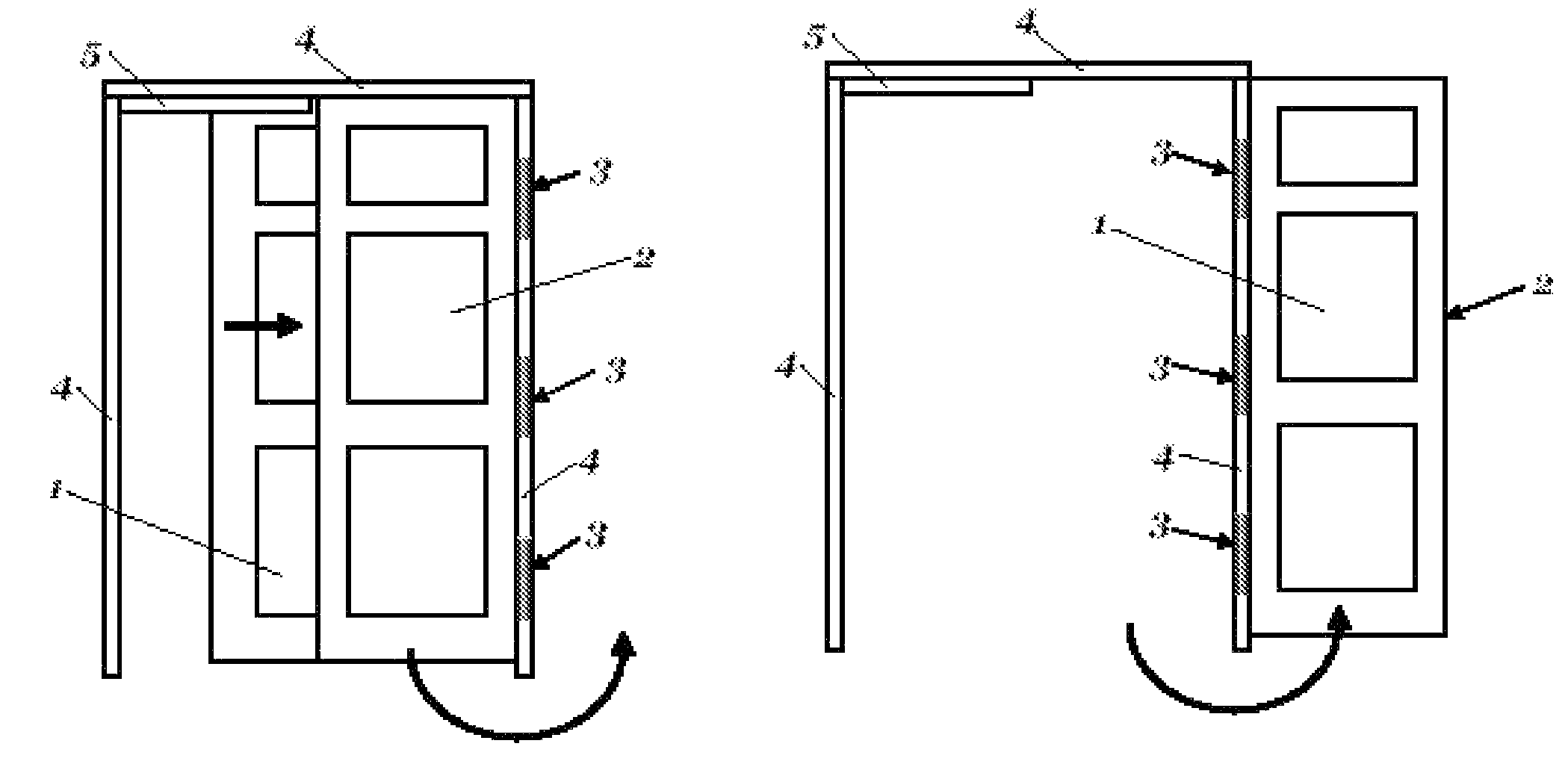

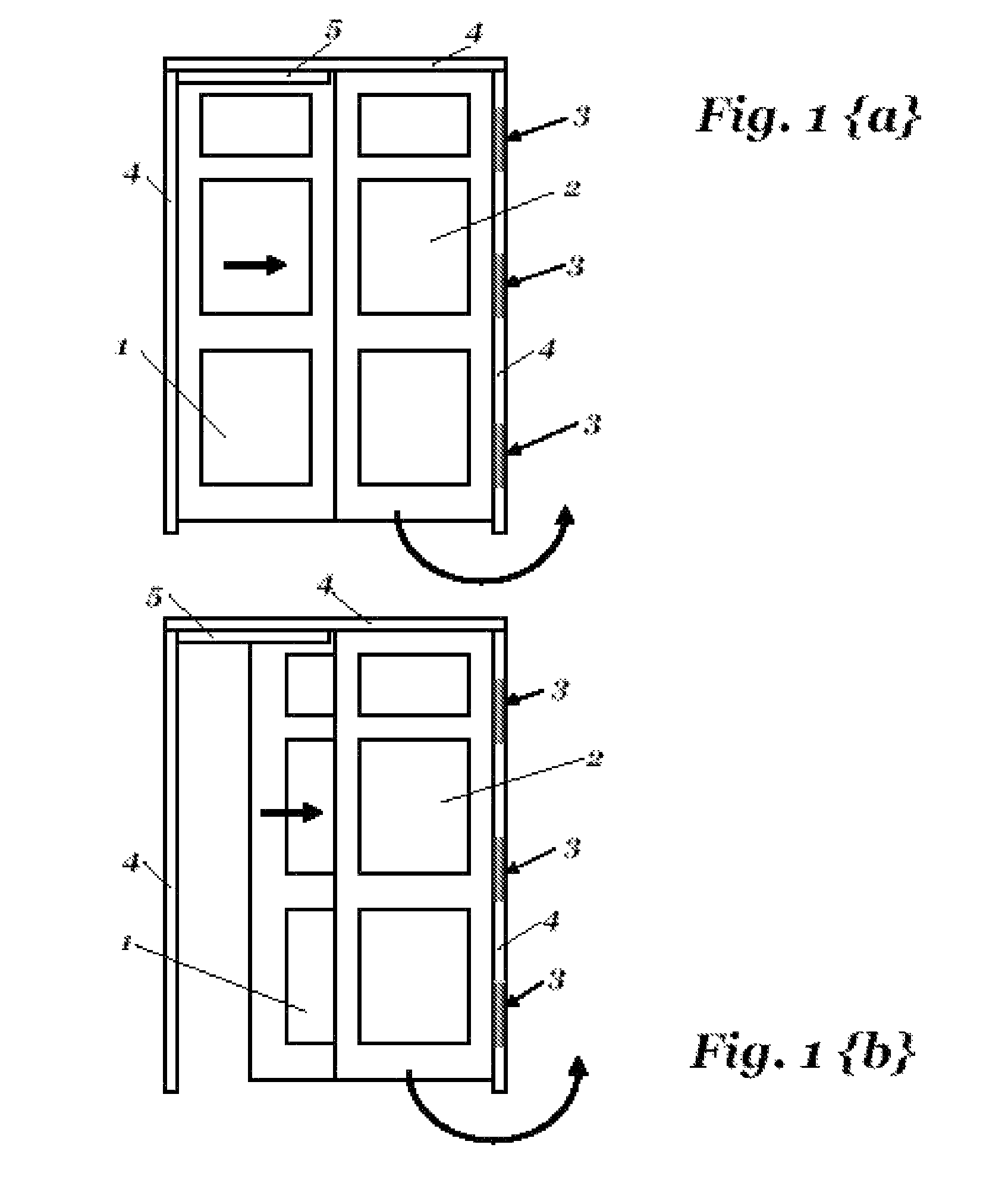

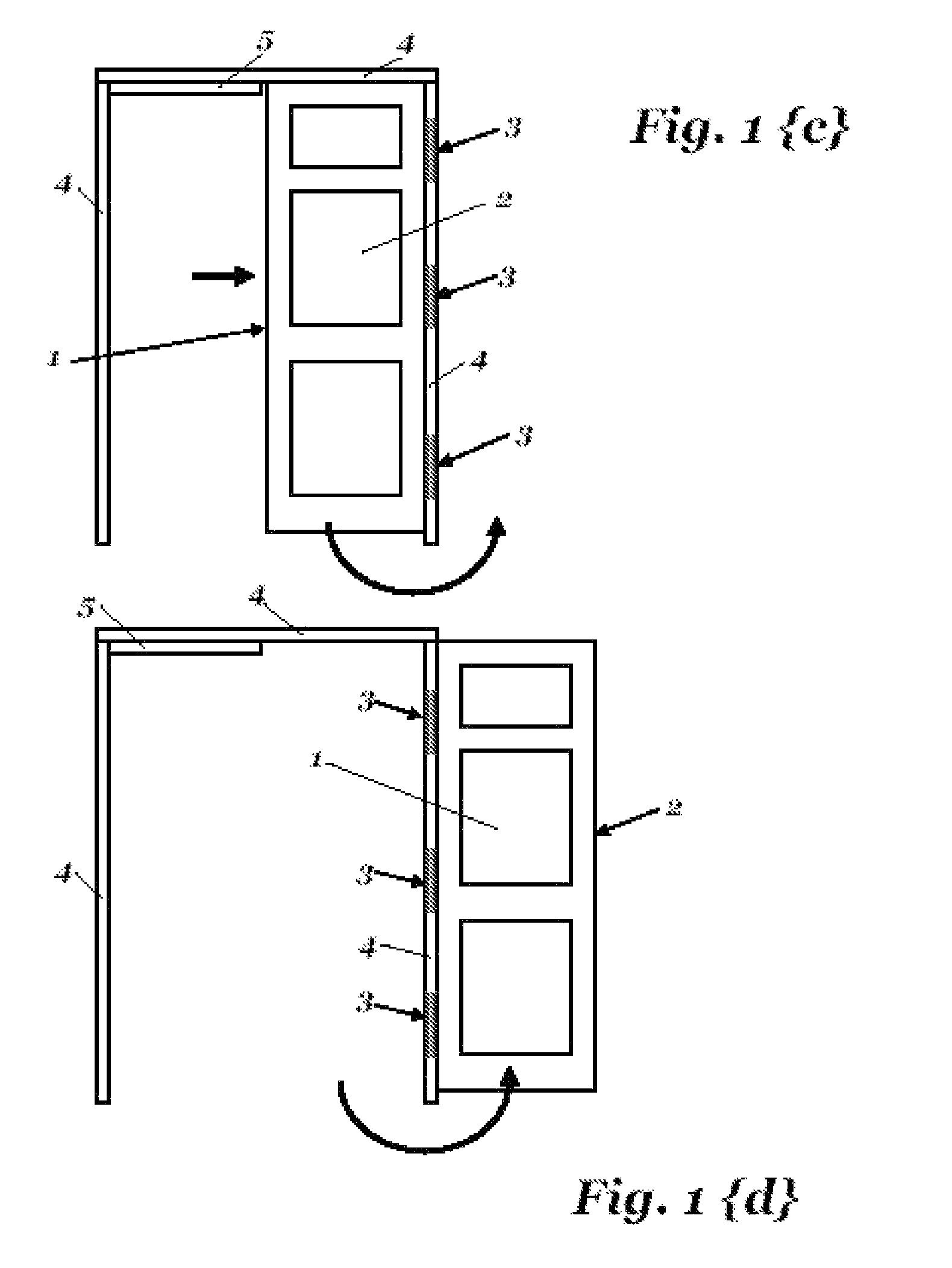

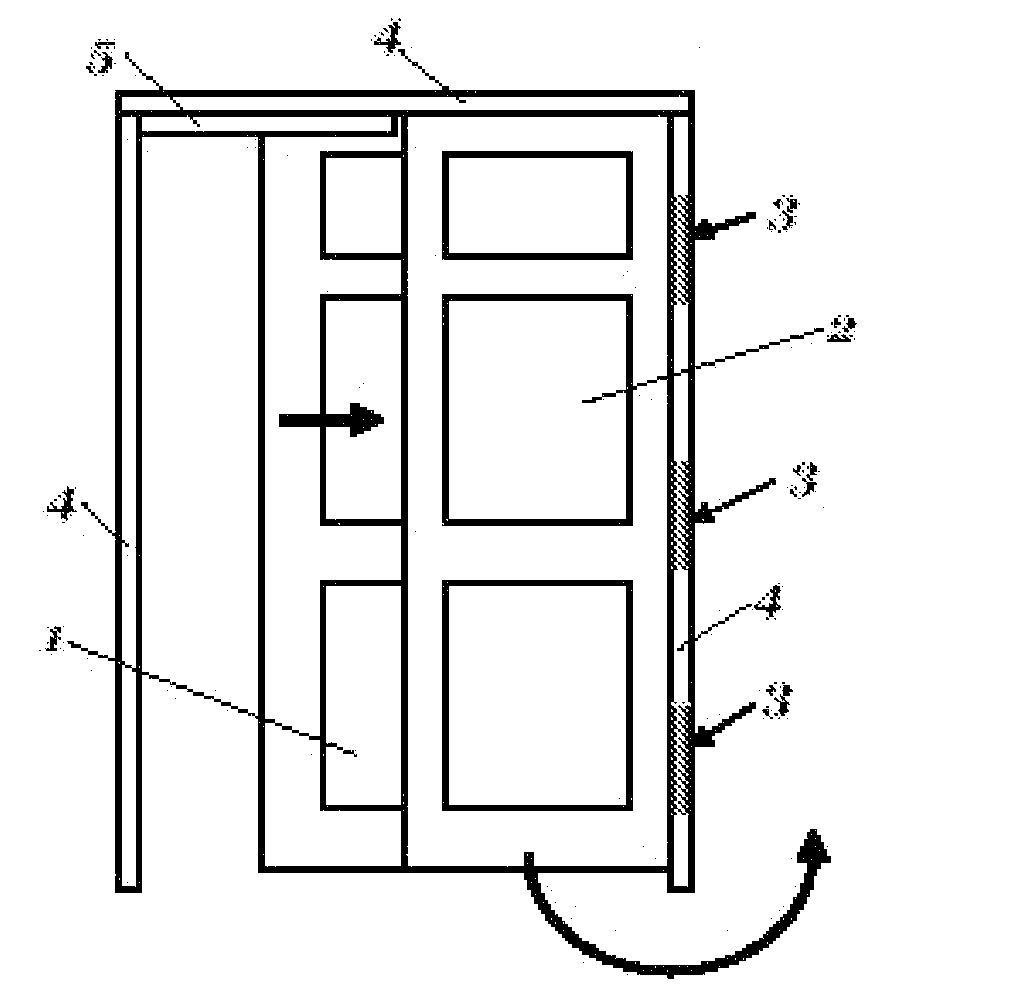

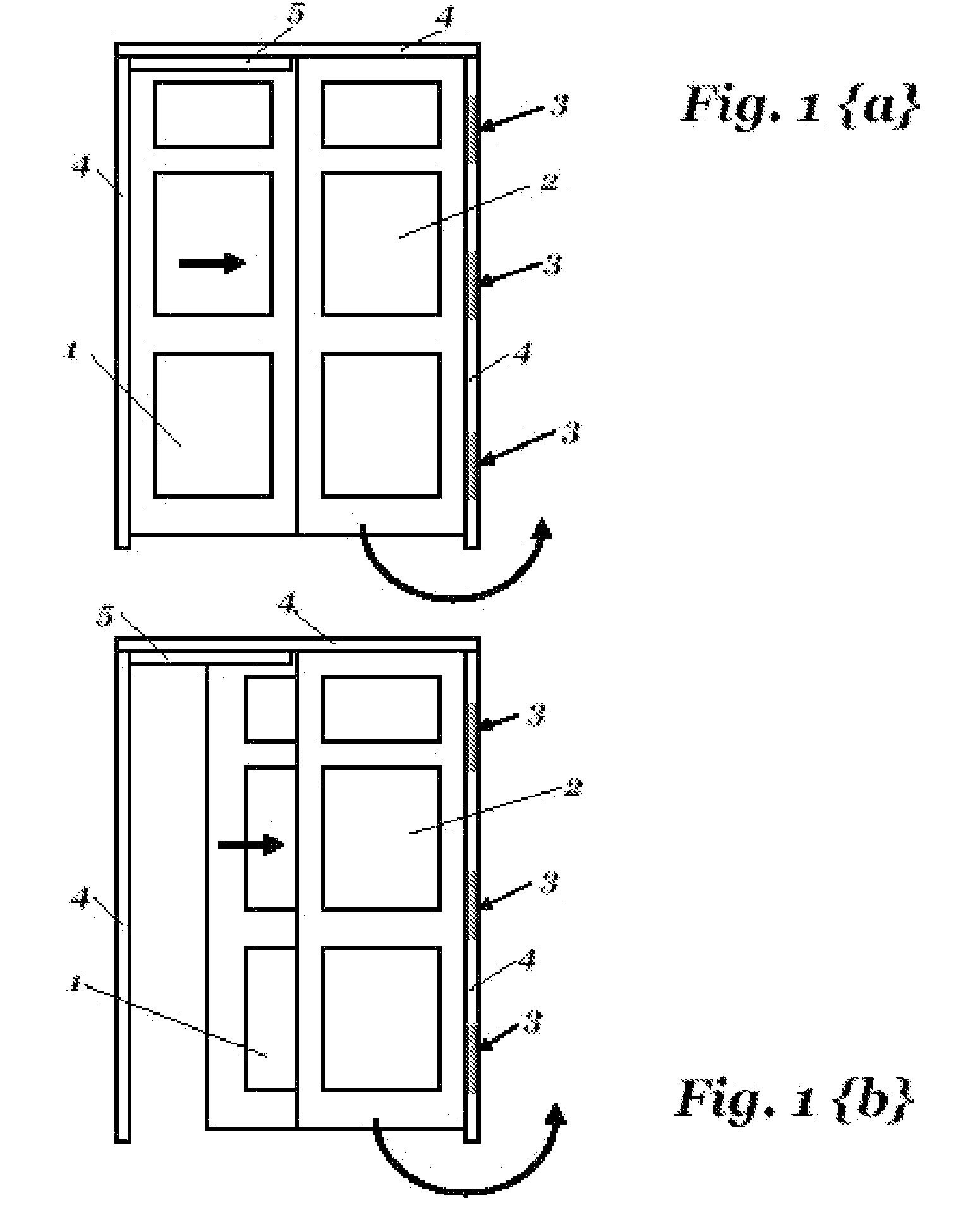

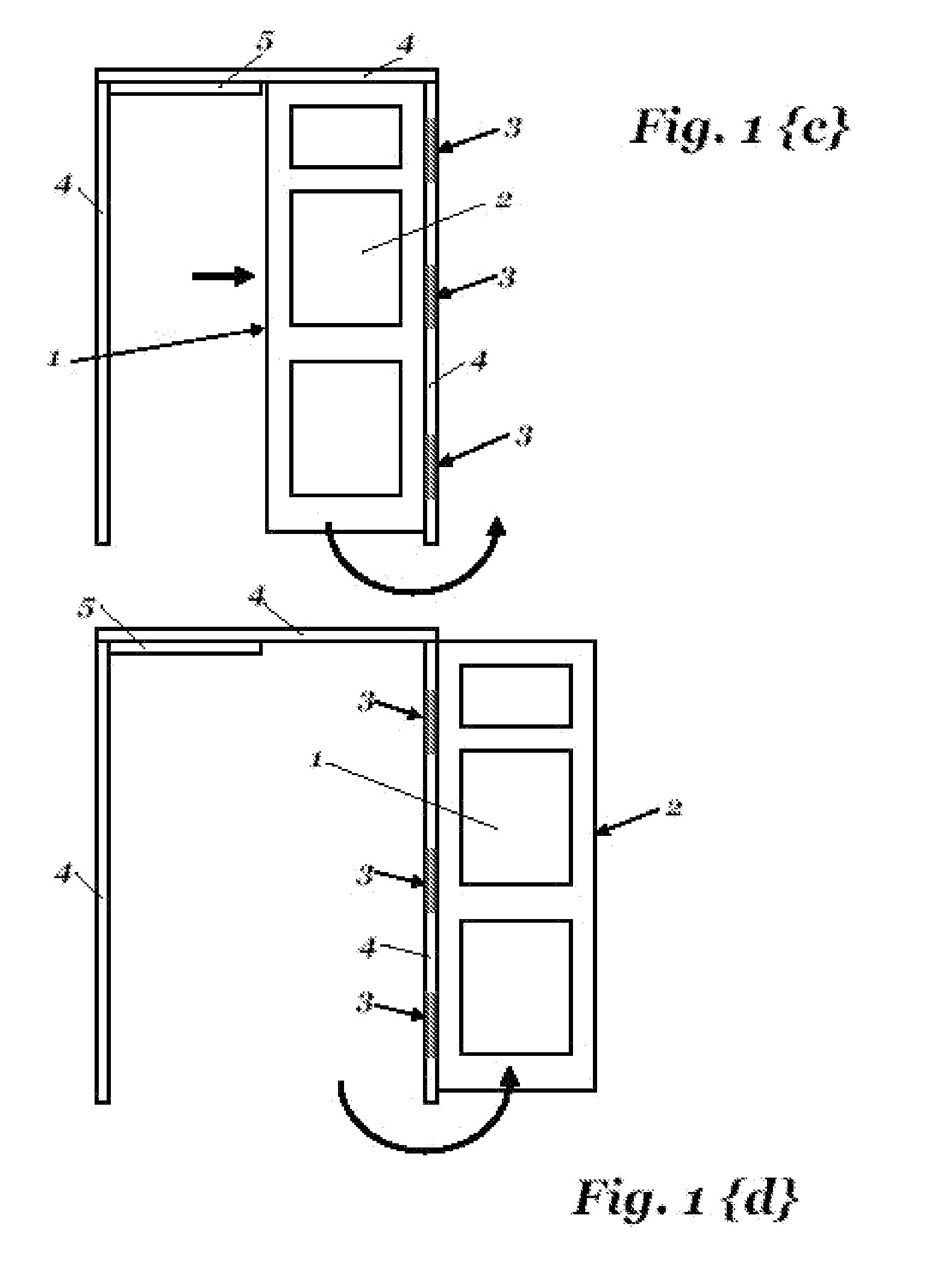

Combination-action slide and hinge swinging door

By providing a door wherein the components forming a multi-panel unit assembly, a support & alignment mechanism, an automatic actuating panel action locking and release mechanism, sliding mechanism and hinges, a dual action door assembly is achieved which assures component engagement that allows the door assembly to operate within controlled confines combining first a sliding action and then a swing action to open the door for full unobstructed access of a range of doorway widths from narrow to ultra-wide while overcoming the support problems, full open access problems and wide swing radii problems consistent with conventional doors.

Owner:ANDERSON LINDA LEE

Differential Interference Phase Contrast X-ray Imaging System

InactiveUS20100091947A1Photon energy is highWide emission angleImaging devicesX-ray tube electrodesPhotoconductive detectorHigh energy

A differential phase-contrast X-ray imaging system is provided. Along the direction of X-ray propagation, the basic components are X-ray tube, filter, object platform, X-ray phase grating, and X-ray detector. The system provides: 1) X-ray beam from parallel-arranged source array with good coherence, high energy, and wider angles of divergence with 30-50 degree. 2) The novel X-ray detector adopted in present invention plays dual roles of conventional analyzer grating and conventional detector. The basic structure of the detector includes a set of parallel-arranged linear array X-ray scintillator screens, optical coupling system, an area array detector or parallel-arranged linear array X-ray photoconductive detector. In this case, relative parameters for scintillator screens or photoconductive detector correspond to phase grating and parallel-arranged line source array, which can provide the coherent X-rays with high energy.

Owner:SHENZHEN UNIV

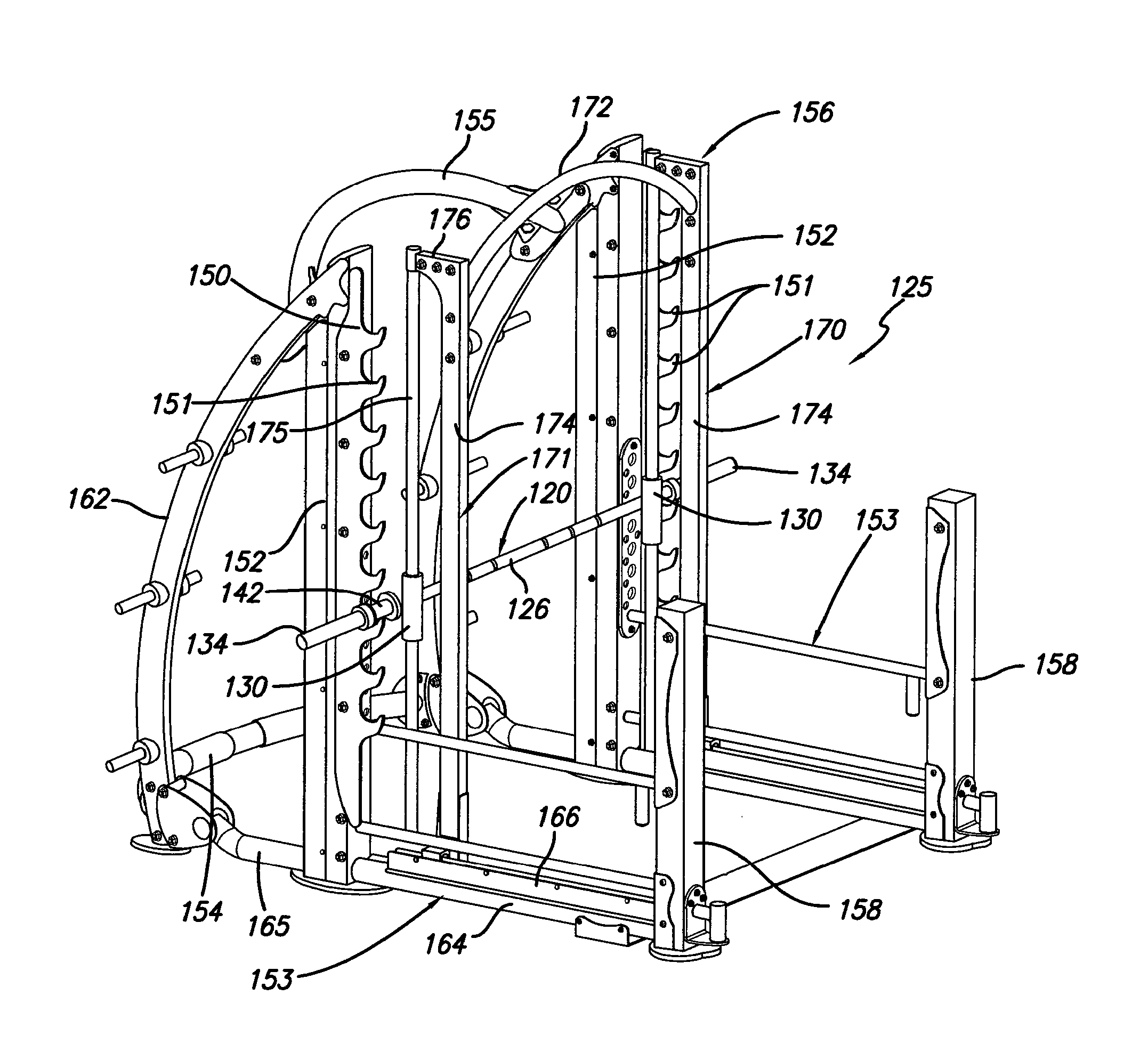

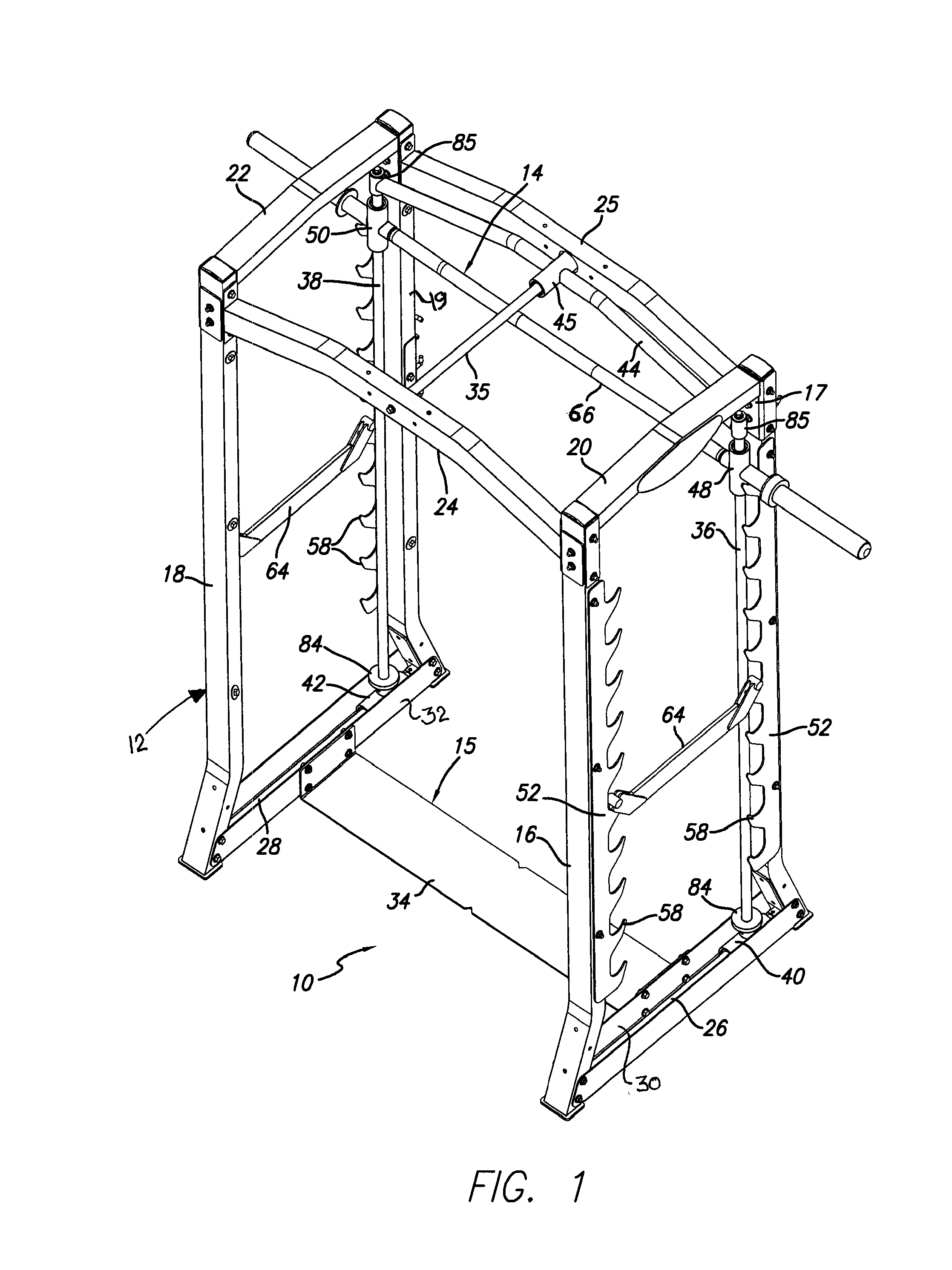

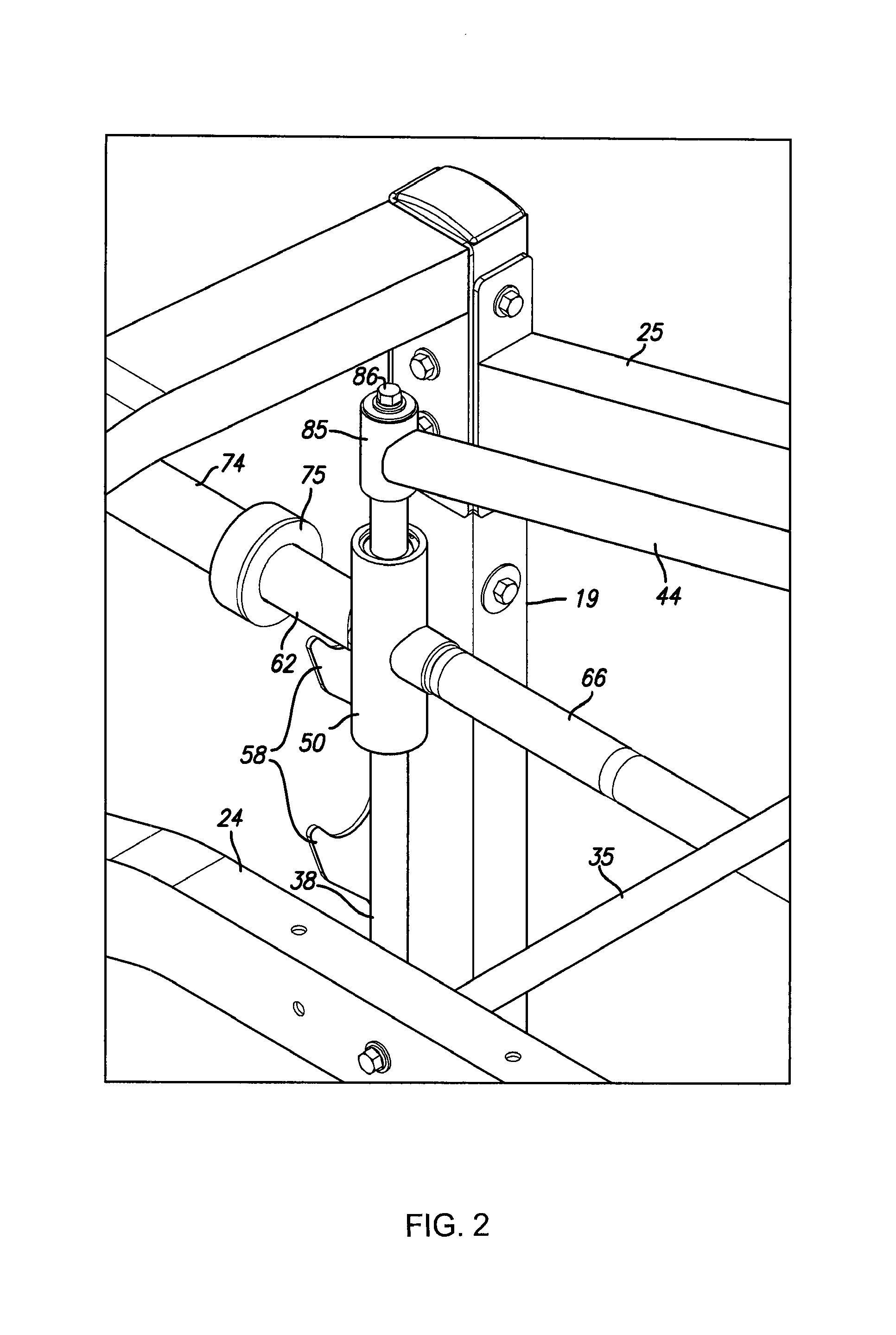

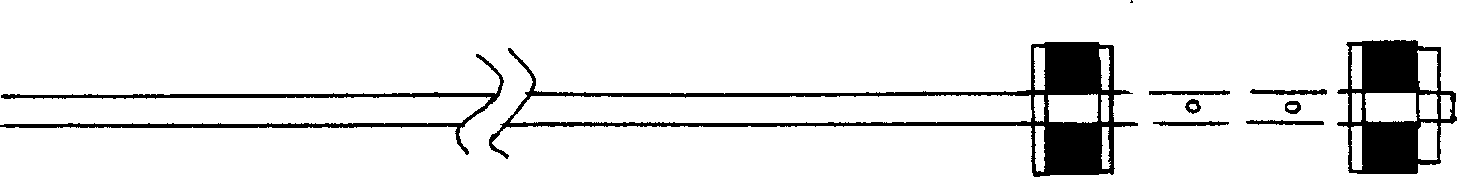

Exercise bar assembly for dual action weightlifting machine

A dual action weightlifting machine has a stationary frame including a racking portion and spaced vertical guides slidably mounted on opposite sides of the frame for horizontal movement relative to the frame. A horizontally extending exercise bar assembly has spaced first and second vertical slides slidably mounted on the vertical guides, at least one rotatable user engaging portion for gripping by a user, at least one rack engaging portion comprising a rotatable wear sleeve which rotates independently from the user engaging portion, and opposite first and second end portions for receiving one or more selected weights. The user engaging portion is located between the opposite sides of the frame and has a central longitudinal axis which is coaxial with the cylindrical surfaces of the wear sleeves.

Owner:HOIST FITNESS SYST

Dual Action Aspiration Biopsy Needle

InactiveUS20050090765A1Reduce intrusionExpensive to performCannulasSurgical needlesAxis of symmetryAspiration biopsy

Owner:MEDICAL DEVICE TECH

Dual action, inhaled formulations providing both an immediate and sustained release profile

ActiveUS20090274754A1Improve treatmentReduce the probability of spreadingOrganic active ingredientsBiocideDual actionAnesthesia

Methods for formulating immediate and sustained release anti-infectives and delivery of such for treatment of respiratory tract infections and other medical conditions, and devices and formulations used in connection with such are described.

Owner:GRIFOLS

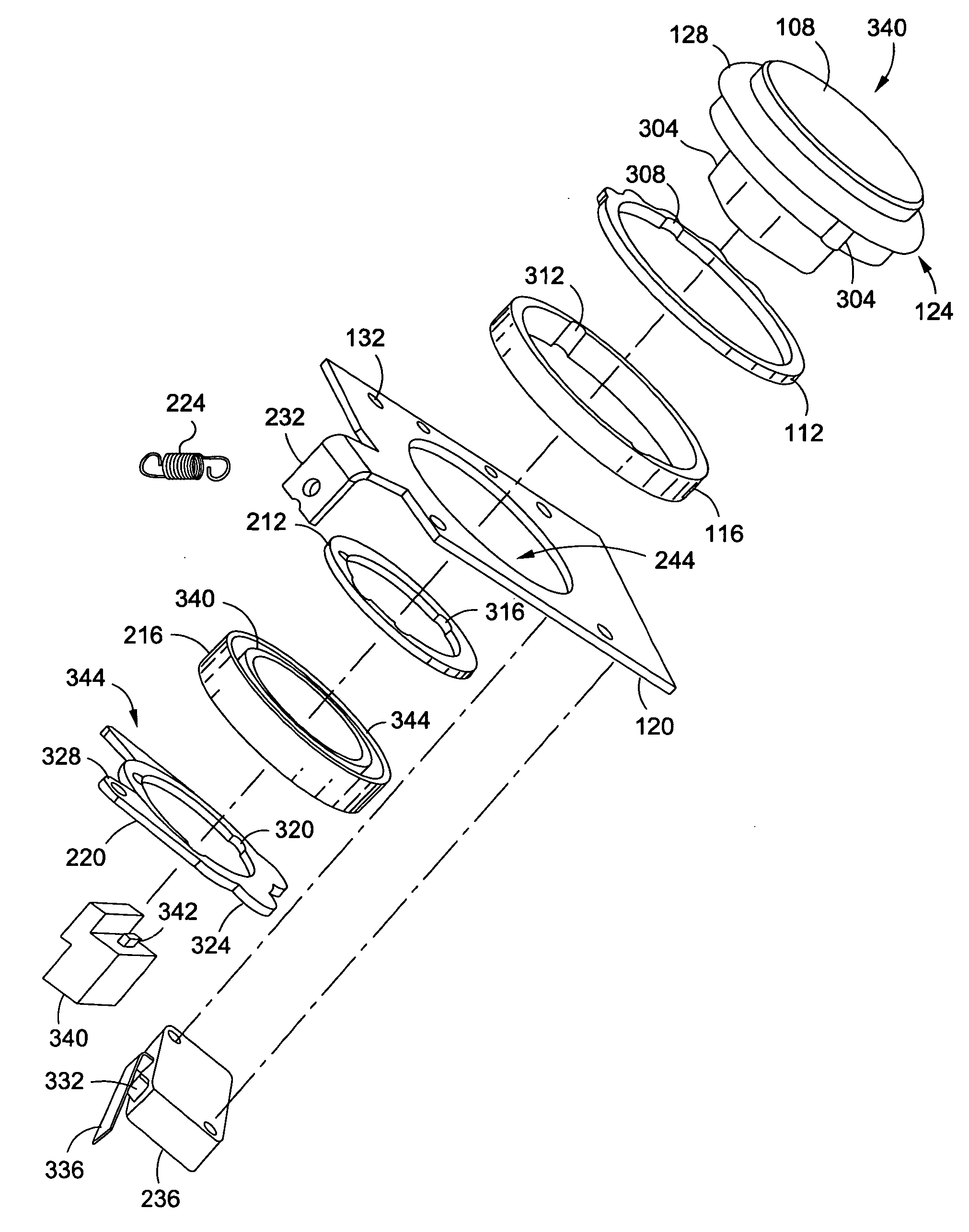

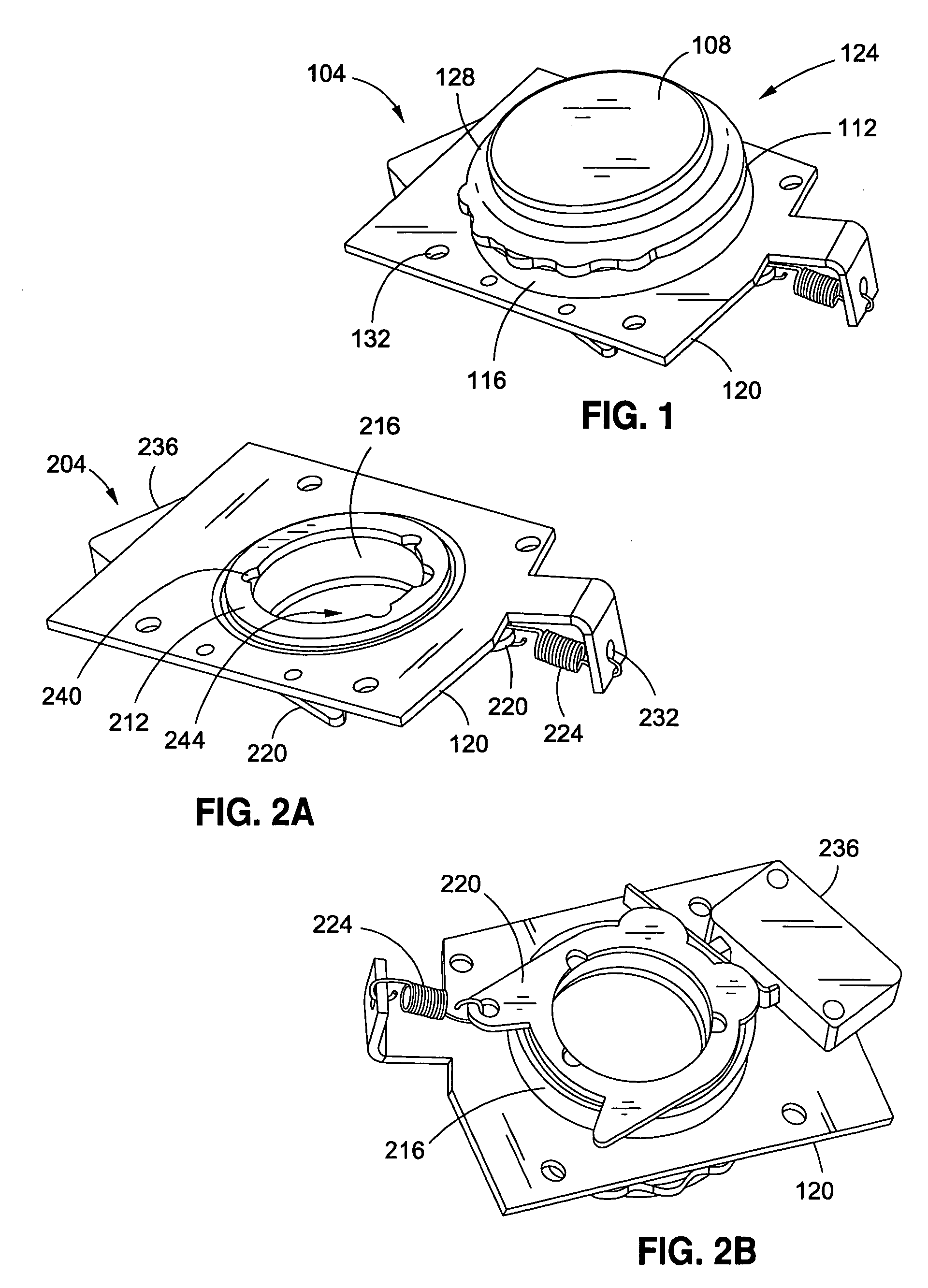

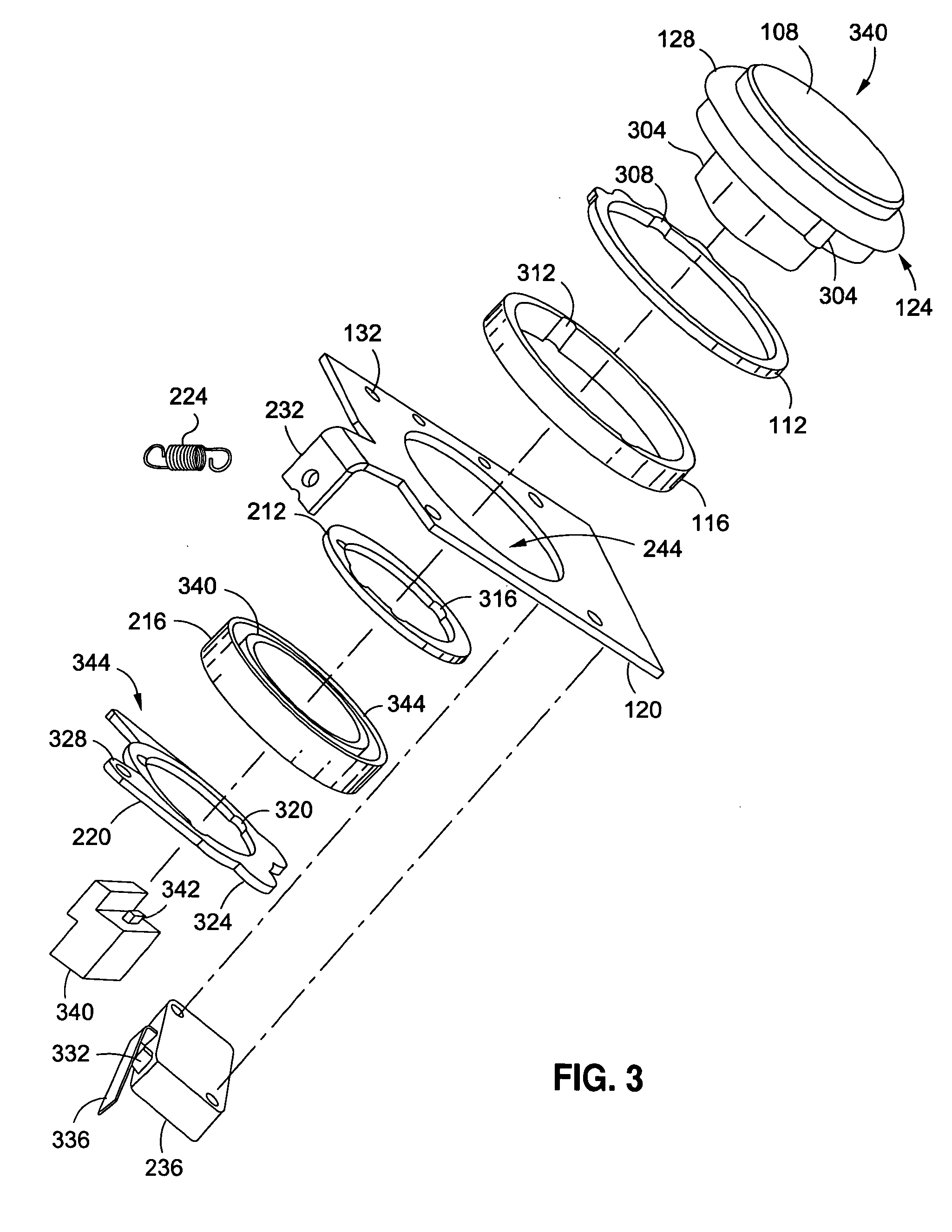

Dual action push-type button

A dual action button assembly permits a user to depress a portion of a push button or to rotate the push button to provide input. The dual action button assembly comprises a push button having a plunger which is moveable relative to a housing to actuate a first electrical switch. The push button is rotatably mounted to a button support. Rotation of the push button causes an actuator to actuate a second electrical switch. The dual action button assembly may be custom configured with a push button or be configured as an attachment for use with an existing single-action push button to retro-fit such a button to a dual action button. The dual action button has particular utility to wagering type gaming machines.

Owner:CASINO TECH

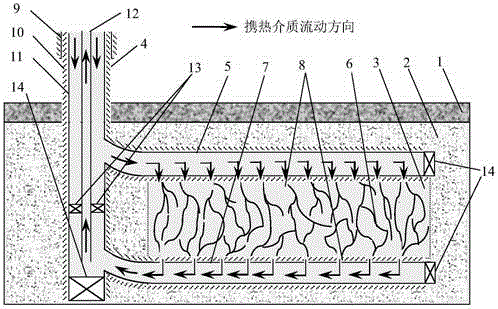

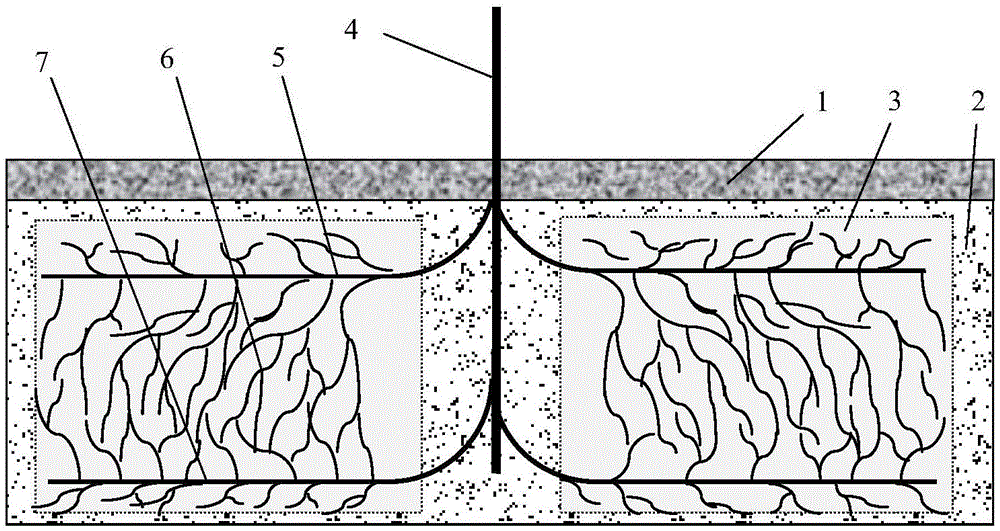

Method for self-circulation exploitation of geothermal energy of hot dry rock with multilateral well and volume fracturing technologies

InactiveCN105840146AAvoid the problem of not being able to connect efficientlyIncrease temperatureOther heat production devicesGeothermal energy generationInjection pressureDual action

The invention relates to the field of geothermal exploitation and provides a method for self-circulation exploitation of geothermal energy of hot dry rock with multilateral well and volume fracturing technologies. According to the method, firstly, multilateral well holes are drilled in different depths of a reservoir of the hot dry rock, the reservoir between upper and lower multilateral well holes is fractured with the volume fracturing technology, a high-permeability hot dry rock reservoir is constructed, and finally, thermal-carrying media are injected and exploited for geothermal exploitation. Annularly-injected low-temperature thermal-carrying media flow to the fractured reservoir of the hot dry rock along the multilateral well holes in the upper part of the reservoir, flow to the multilateral well holes in the lower part under the double actions of injection pressure and potential-energy difference and finally flow back to the ground along an oil pipe. According to the method, the multilateral well and fracturing technologies are sufficiently utilized, the reservoirs of the hot dry rock are effectively communicated, the problem about crack communication during conventional double-well fracturing for injection and exploitation is solved, the potential-energy difference in different depths can be further effectively utilized, and the flowing capability of the thermal-carrying media is greatly improved. With the use of the thermal insulation oil pipe, the thermal loss in the exploitation process of the thermal-carrying media is further reduced, and the exploitation efficiency of geothermal energy is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

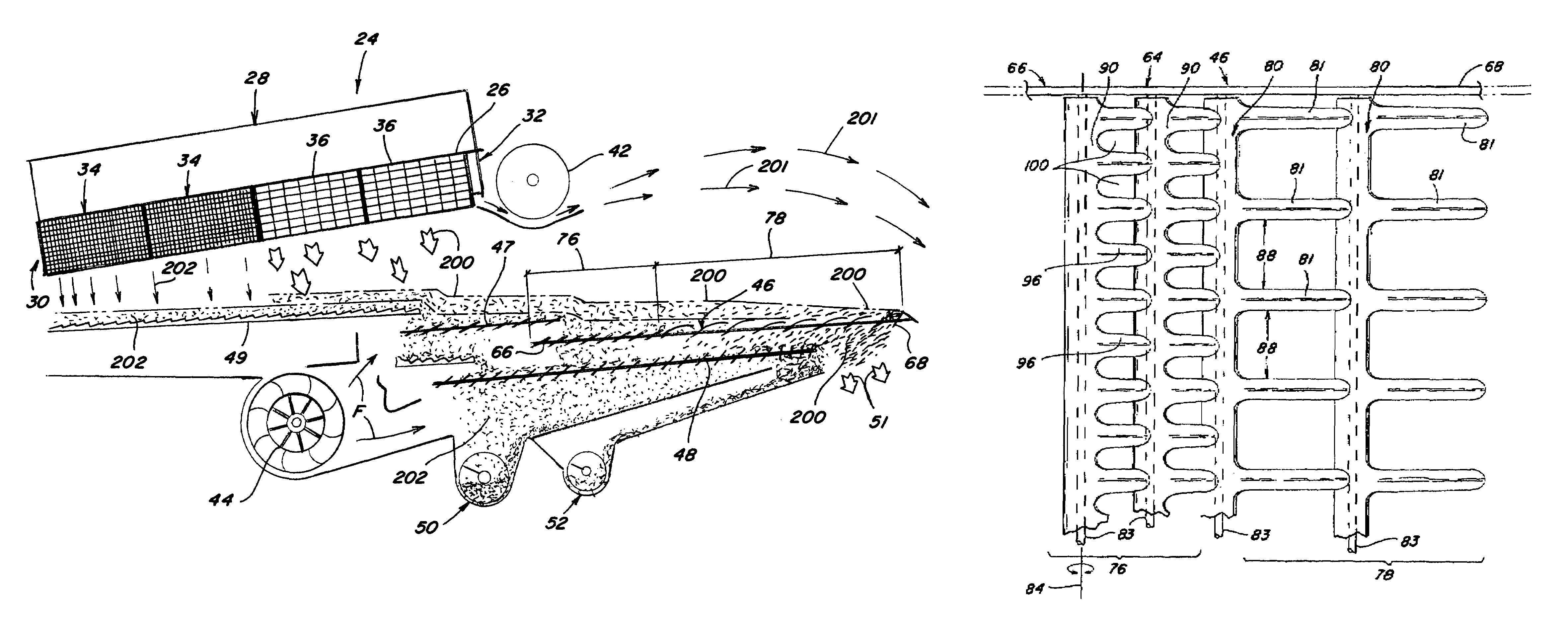

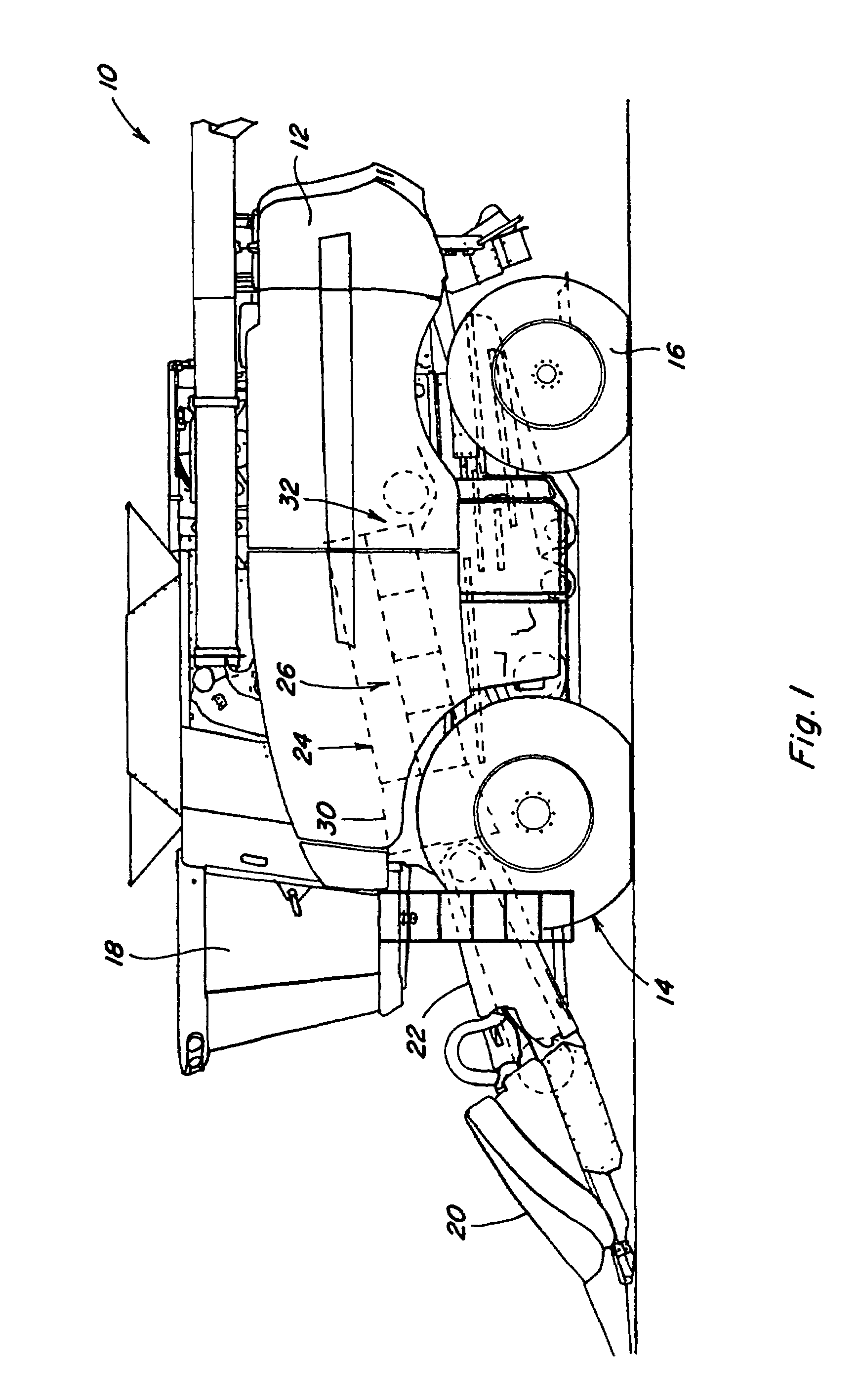

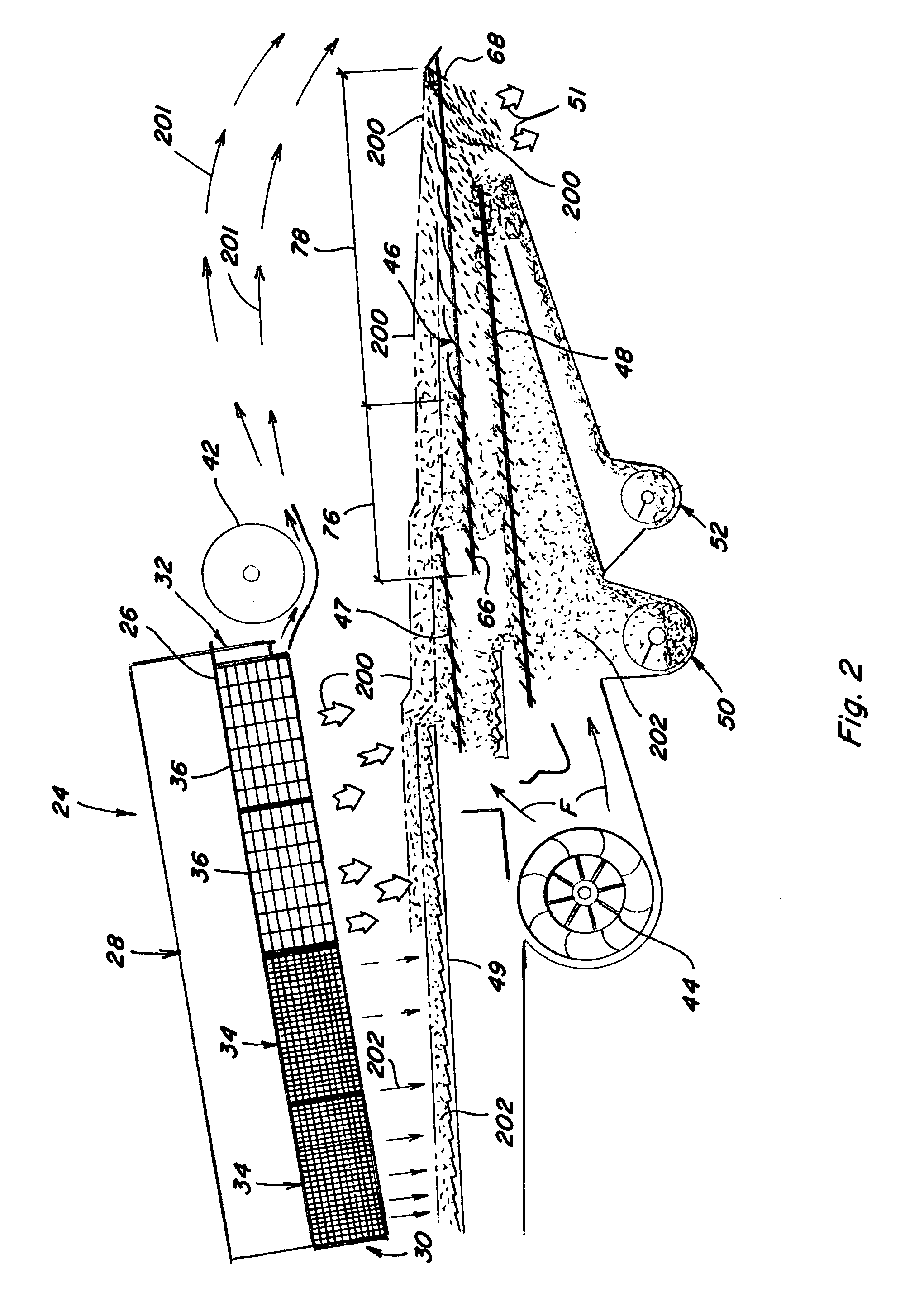

Dual action corn cob separation and improved chaffer for whole corn cobs

InactiveUS7566266B1Ensure efficient flowEasy to separateSievingScreeningDual actionSeparation system

A dual action corn cob cleaning separation system having a whole corn cob sieve with elongated and rounded finger extensions for reorienting corn cobs traveling widthwise to instead travel lengthwise.

Owner:BLUE LEAF I P INC

Combination-action slide and hinge swinging door

By providing a door wherein the components forming a multi-panel unit assembly, a support & alignment mechanism, an automatic actuating panel action locking and release mechanism, sliding mechanism and hinges, a dual action door assembly is achieved which assures component engagement that allows the door assembly to operate within controlled confines combining first a sliding action and then a swing action to open the door for full unobstructed access of a range of doorway widths from narrow to ultra-wide while overcoming the support problems, full open access problems and wide swing radii problems consistent with conventional doors

Owner:ANDERSON LINDA LEE

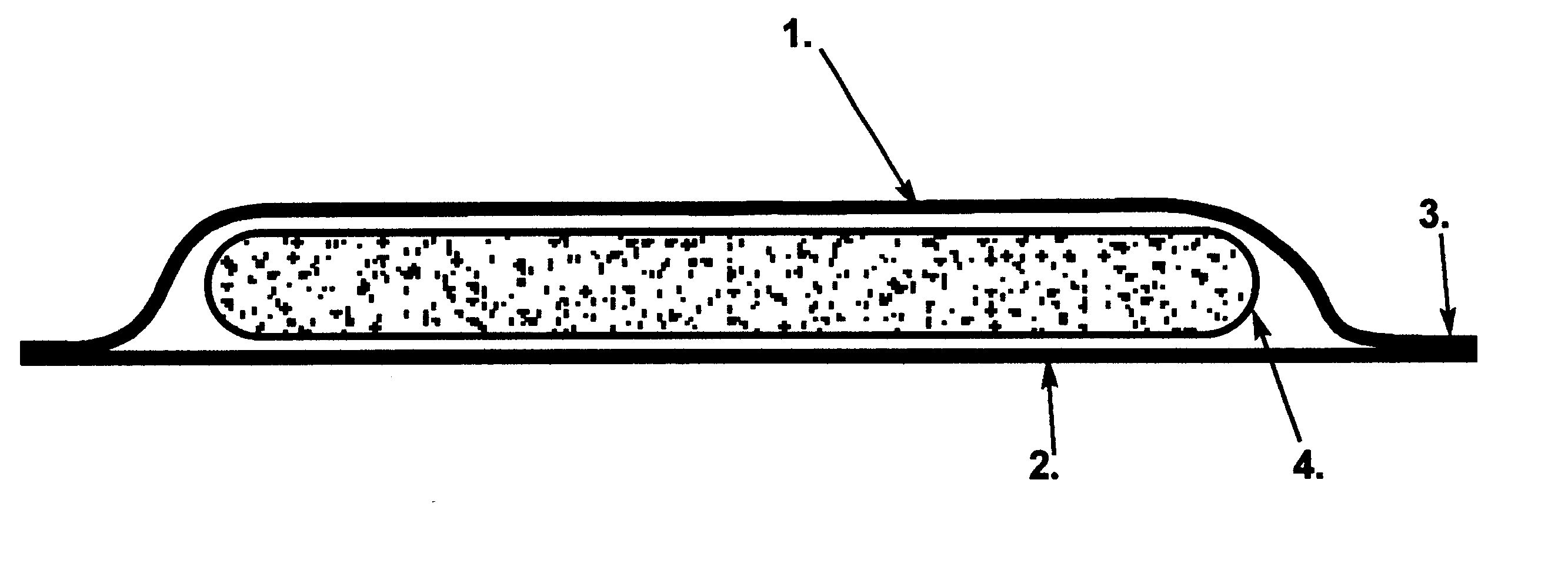

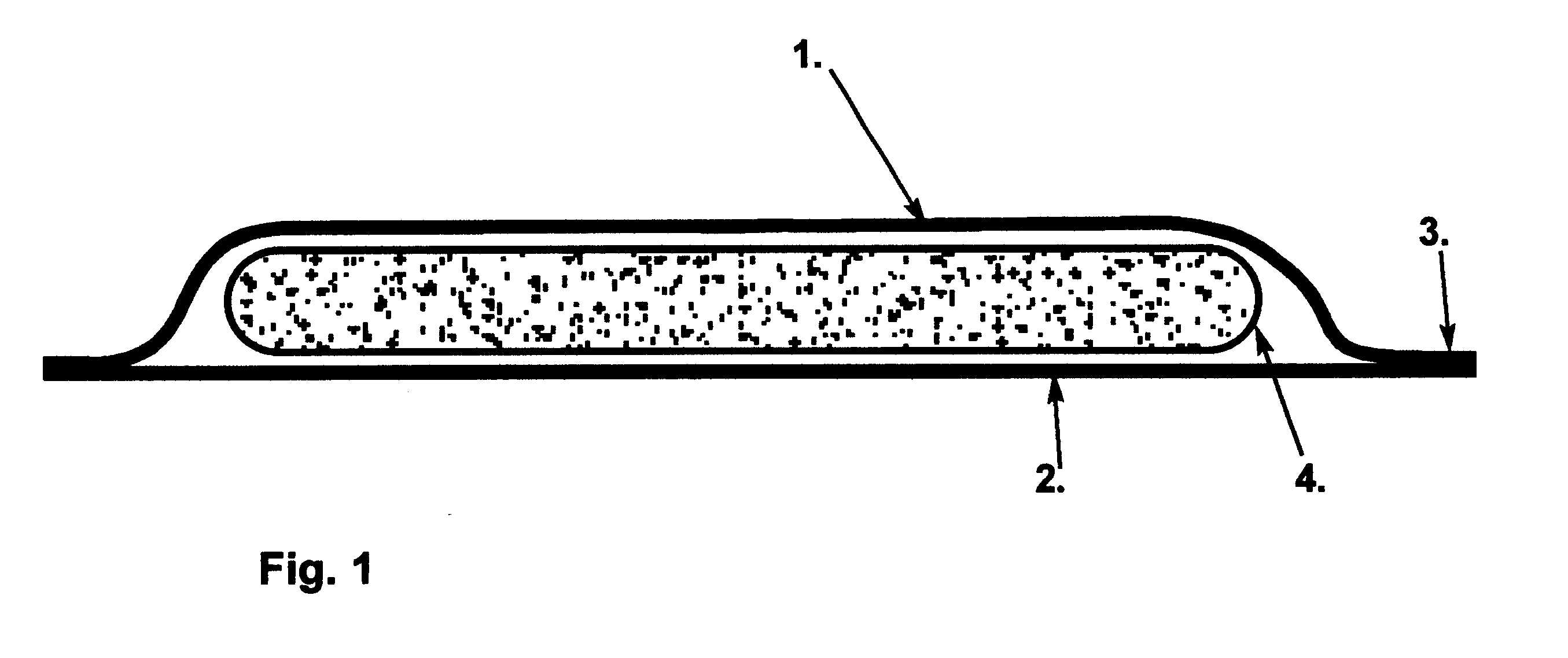

Air-holding protective foam pad construction

An air-holding protective foam pad construction where open cell foam is enveloped in an air-holding cavity formed by top and bottom air-holding sheets. The foam is not attached to the top and bottom air-holding sheets and the sheets are totally and continuously sealed together around a narrow common perimeter. Upon potentially destructive impact, the open cell foam first absorbs some of the impact force, and secondly the air expelled from the foam bloats the air-holding cavity. The result of the latter is a redistribution of impact forces over a larger surface area, reducing the intensity of force at the site of initial impact. The pad construction thereby has a dual action attenuation of both absorbing and redistributing the intensity of an initial localized impact force.

Owner:GOODWIN EDWARD L

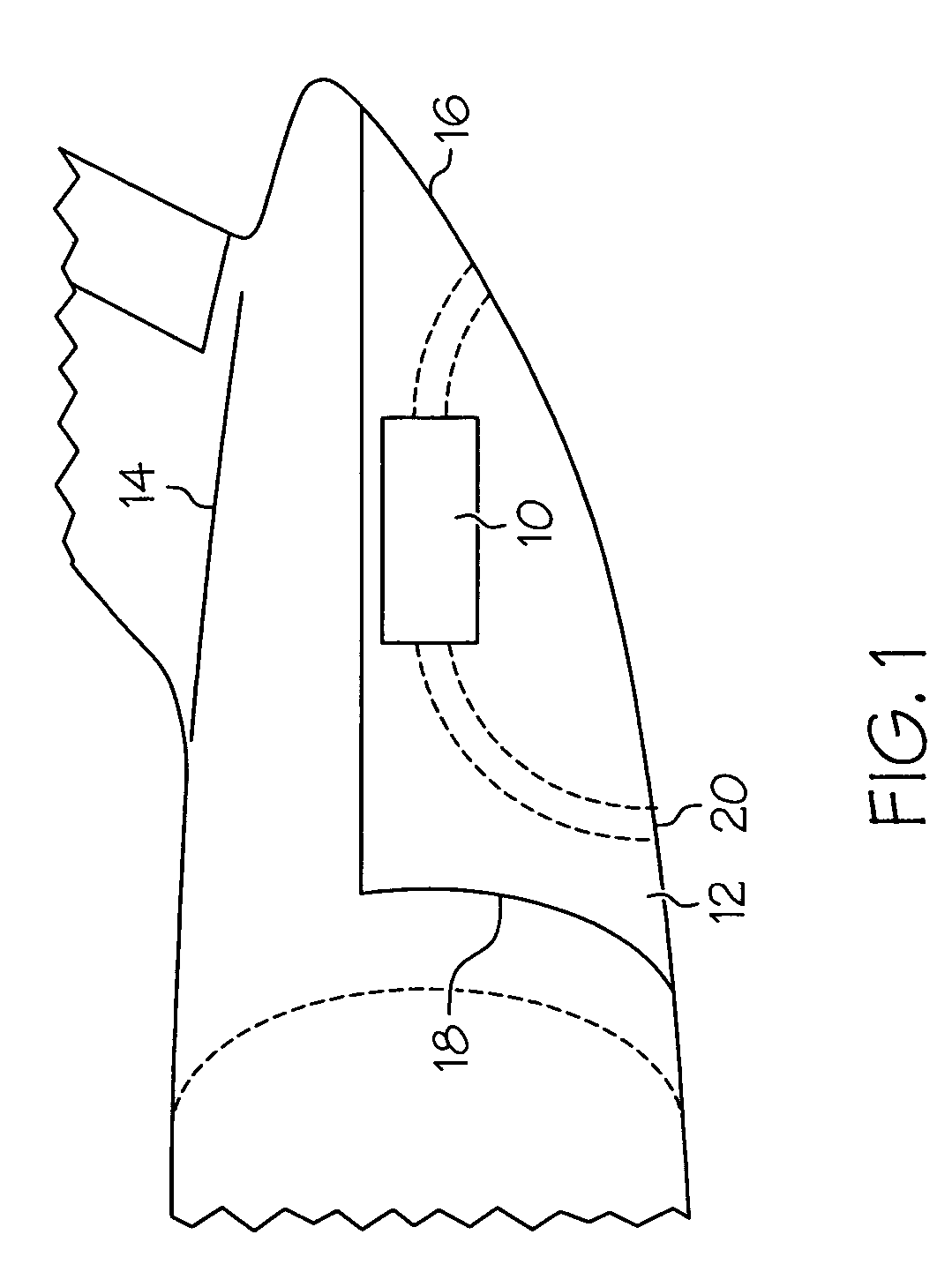

Dual action inlet door and method for use thereof

InactiveUS7014144B2Reduce noiseReducing APU noisePower installationsEngine fuctionsDual actionEngineering

An inlet door assembly and method for reducing noise from an auxiliary power unit (APU) contained within an aircraft housing is provided. The inlet assembly includes an inlet duct, an actuator, and a door. The inlet duct is configured to extend from the auxiliary power unit to the aircraft housing and has a sidewall that defines a flow passage through which APU noise propagates. The actuator is disposed at least partially within the inlet duct. The door coupled to the actuator. The actuator is also configured to selectively rotate the door between at least a first position, in which at least a portion of the door deflects APU noise in a first direction, and a second position, in which at least a portion of the door deflects the APU noise in a second direction.

Owner:HONEYWELL INT INC

Projection and actuation device for a walking stabilizer

ActiveUS20070034243A1Save battery powerReduce frequencyCarriage/perambulator accessoriesWalking sticksDual actionEngineering

A walking stabilizer equipped to combat the effects of akinesia paradoxica by employing a novel method and device to regulate and actuate a projection instrument which generates a pattern perpendicular to the user's direction of travel. The regulating and actuating device comprises a two pole series switch circuit configuration in tandem with the walking stabilizer's novel dual action braking mechanism. The projection device is only operable when the user concurrently selects its use and when the walker stabilizer is free for movement or in contact with the patient.

Owner:MILLER JONATHAN JAY

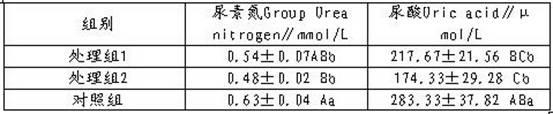

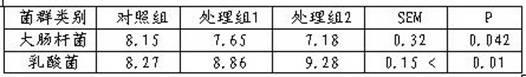

Feed for meat ducks and traditional Chinese medicine additive thereof

ActiveCN102450523AIncrease production capacityBoth non-specific antibacterial effectAnimal feeding stuffBaical Skullcap RootHouttuynia

The invention relates to a feed for meat ducks, and the feed comprises corn flour, soybean flour, wheat bran, fish meal, yeast powder, shell powder, pulverized lime, iodized salt, beef tallow, a premix of vitamins, a premix of minerals and a traditional Chinese medicine additive. The traditional Chinese medicine additive comprises dwarf lilyturf tuber, spreading hedyotis herb, glossy privet fruit, sessile stemona root, common selfheal fruit-spike, heartleaf houttuynia herb, baical skullcap root, indigowoad leaf, largehead atractylodes rhizome, pilose Asiabell root, membranous milkvetch root, Chinese angelica, maifanite, Chinese magnoliavine fruit, south dodder seed, barbed skullcap herb, lotus leaf, rhizoma corydalis and fructus forsythiae. The feed additive disclosed by the invention combines the dual actions of being medicinal and nutritive, and can be used for preventing diseases, improving the production performance, and further regulating the immune functions of organisms; and the feed additive has a non-specific antibacterial effect, and can be used for fundamentally protecting and coordinating the overall health of livestock and poultry, preventing the diseases, fully playing and improving the potential ability of the organisms, improving the digestion rate and utilization rate of nutrient substances, enhancing the metabolism of the livestock and the poultry, promoting blood circulation and increasing the growth rate.

Owner:SHANDONG NEW HOPE LIUHE GROUP

Dual action, inhaled formulations providing both an immediate and sustained release profile

ActiveUS20120244206A1Improve treatmentSustained release of anti-infective over timeAntibacterial agentsBiocideDual actionAnesthesia

Methods for formulating immediate and sustained release anti-infectives and delivery of such for treatment of respiratory tract infections and other medical conditions, and devices and formulations used in connection with such are described.

Owner:GRIFOLS

Dual action, inhaled formulations providing both an immediate and sustained release profile

ActiveUS8268347B1Improve treatmentReduce the probability of spreadingAntibacterial agentsOrganic active ingredientsDual actionAnesthesia

Methods for formulating immediate and sustained release anti-infectives and delivery of such for treatment of respiratory tract infections and other medical conditions, and devices and formulations used in connection with such are described.

Owner:GRIFOLS

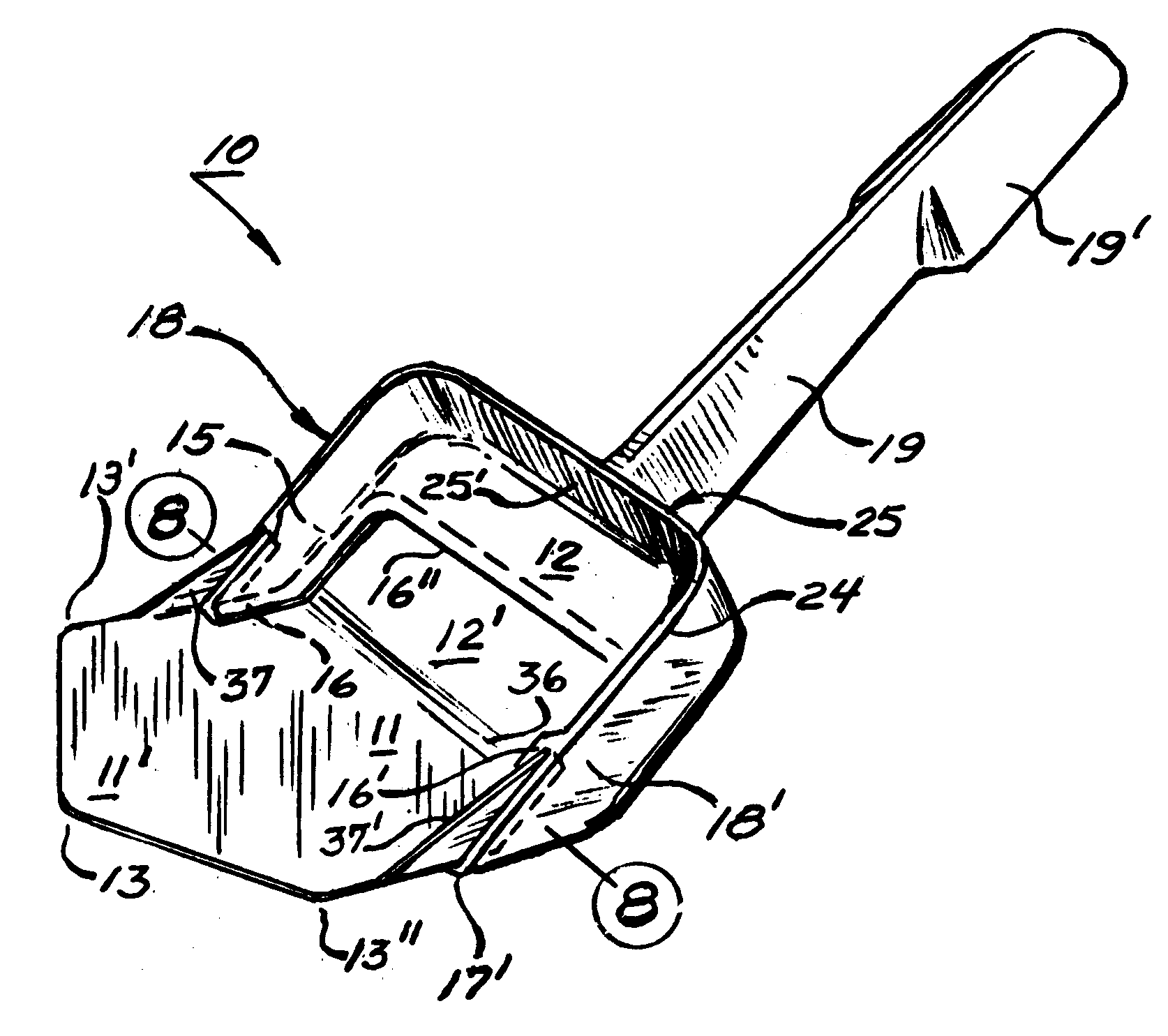

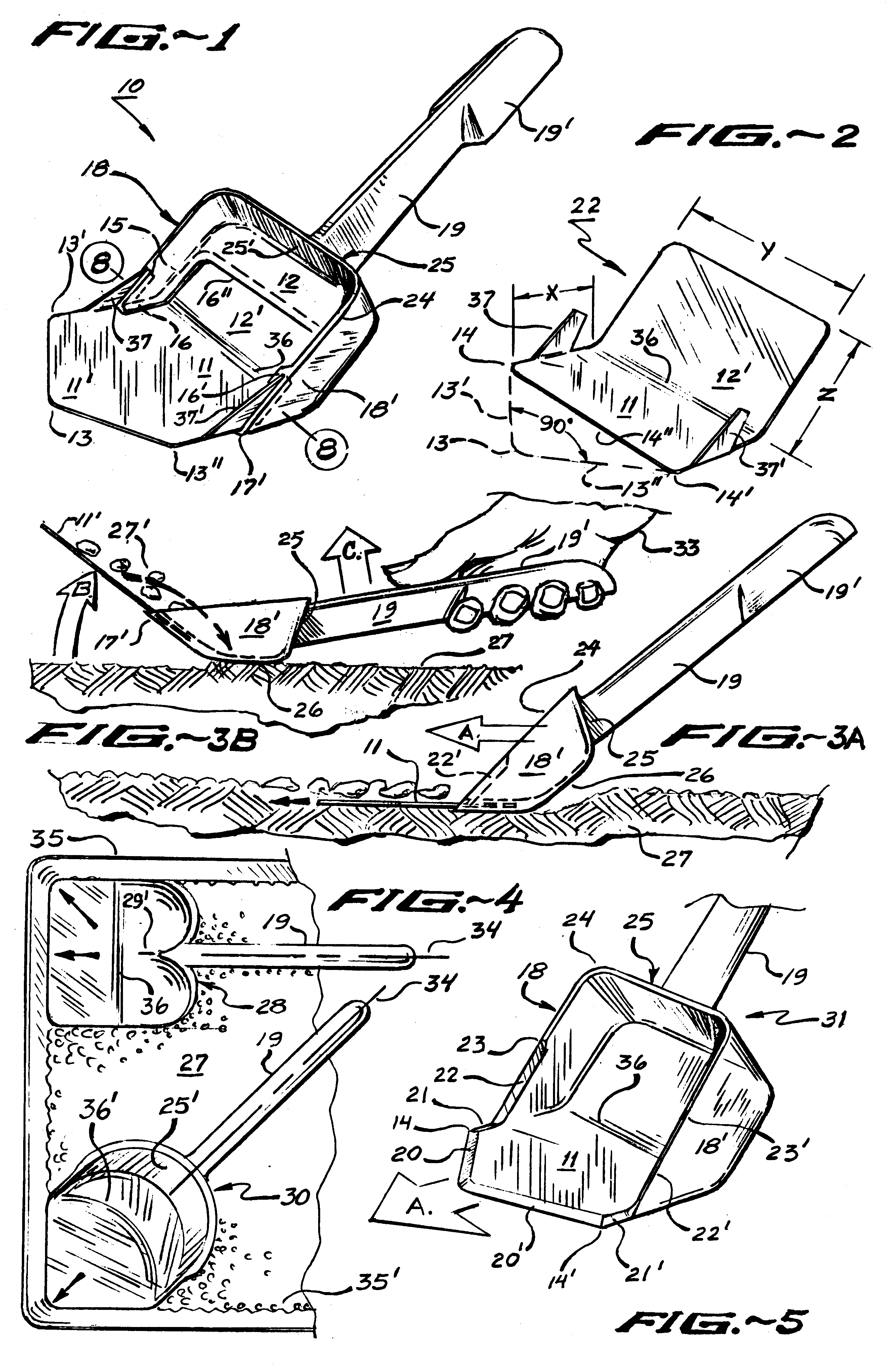

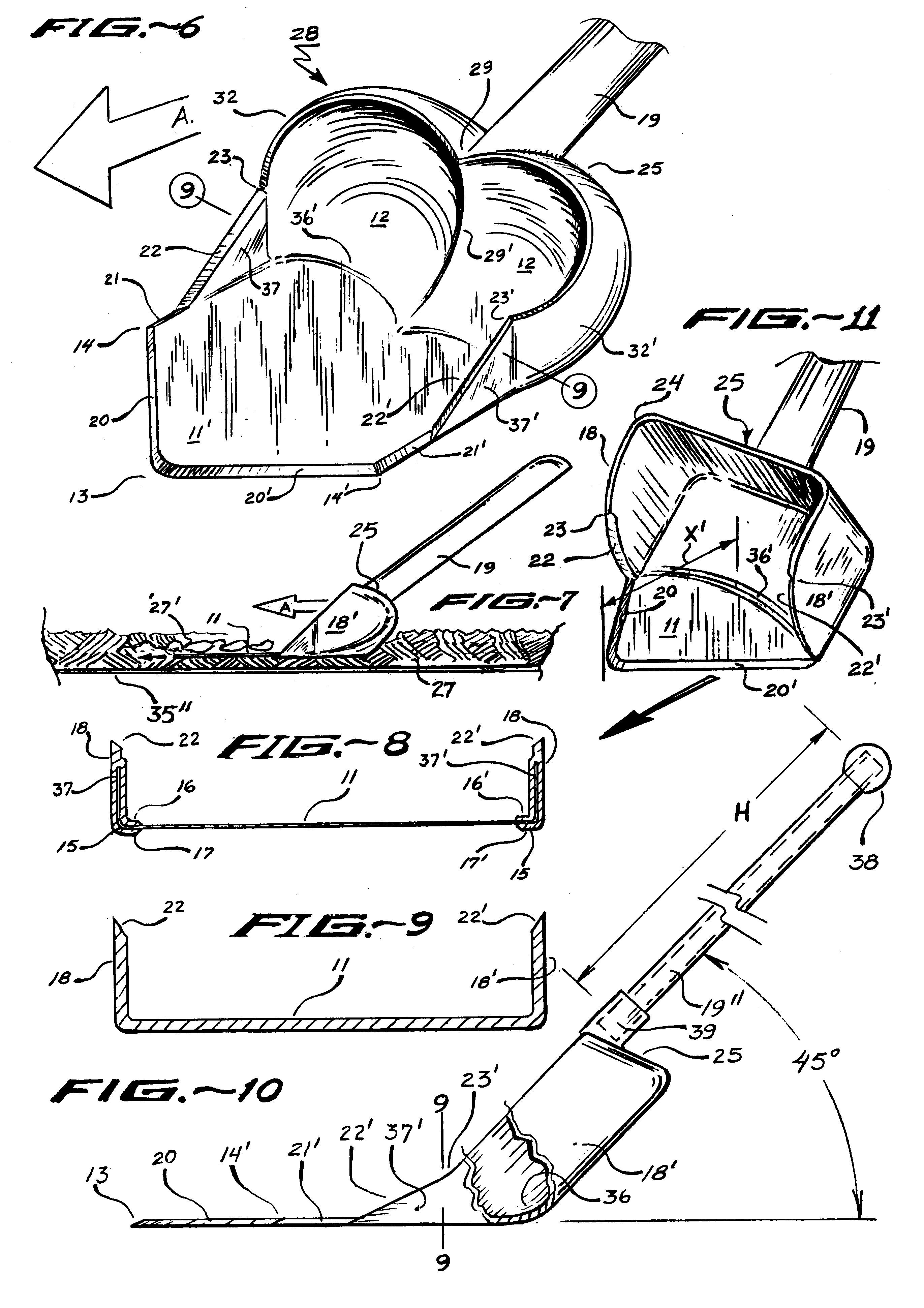

Dual Action Scooper for clumping and non-clumping cat litter

InactiveUS6234549B1Effectively segregateEfficient removalAnimal housingShop accessoriesLeading edgeDual action

An improved hand-held two-stage cat-litter scooper tool critically configured to more effectively segregate and lift-away wet cat-litter, without causing migration into, or disturbing clean dry areas. The planar leading-edge of the scooping-blade portion, is formed to either a 90-degree triangular, or transversely-square, plan-view shape; either shape thus able to project closely into the corners of a conventional cat-litter box. The rear portion of either scooping-blade includes an approximate 40-degree transverse-bend, creating an aftward containment-bowl area, effectively holding wet cat-litter when the rearward projecting handle is tilted down (the scooping-blade thus tilting upward) after a horizontal forward scooping motion. The handle is arranged along the medial longitudinal-axis of the tool, angling upward at approximately 45-degrees relative to the plane of the scooping-blade, facilitating the special "tilt-loading action" without dragging of one's hand into the cat-litter. A further aid to performance of the tool being shoved through soiled cat-litter, includes acutely up-turned blade sides; both set slightly back from the actual frontal-sides of the scooping-blade. This particular formation being discovered to function most effectively, providing minimal disturbance to surrounding cat-litter, while very precisely shaving away waste cat-litter. Generic-variations include a preferred 2-piece construction, embodying a stainless-steel blade portion, permanently locking into a retention-groove formed into the aftward injection-molded plastic-body forming the side-walls of the essential containment-bowl; including an integral handle member thereto.

Owner:SPENCER LOUIS E

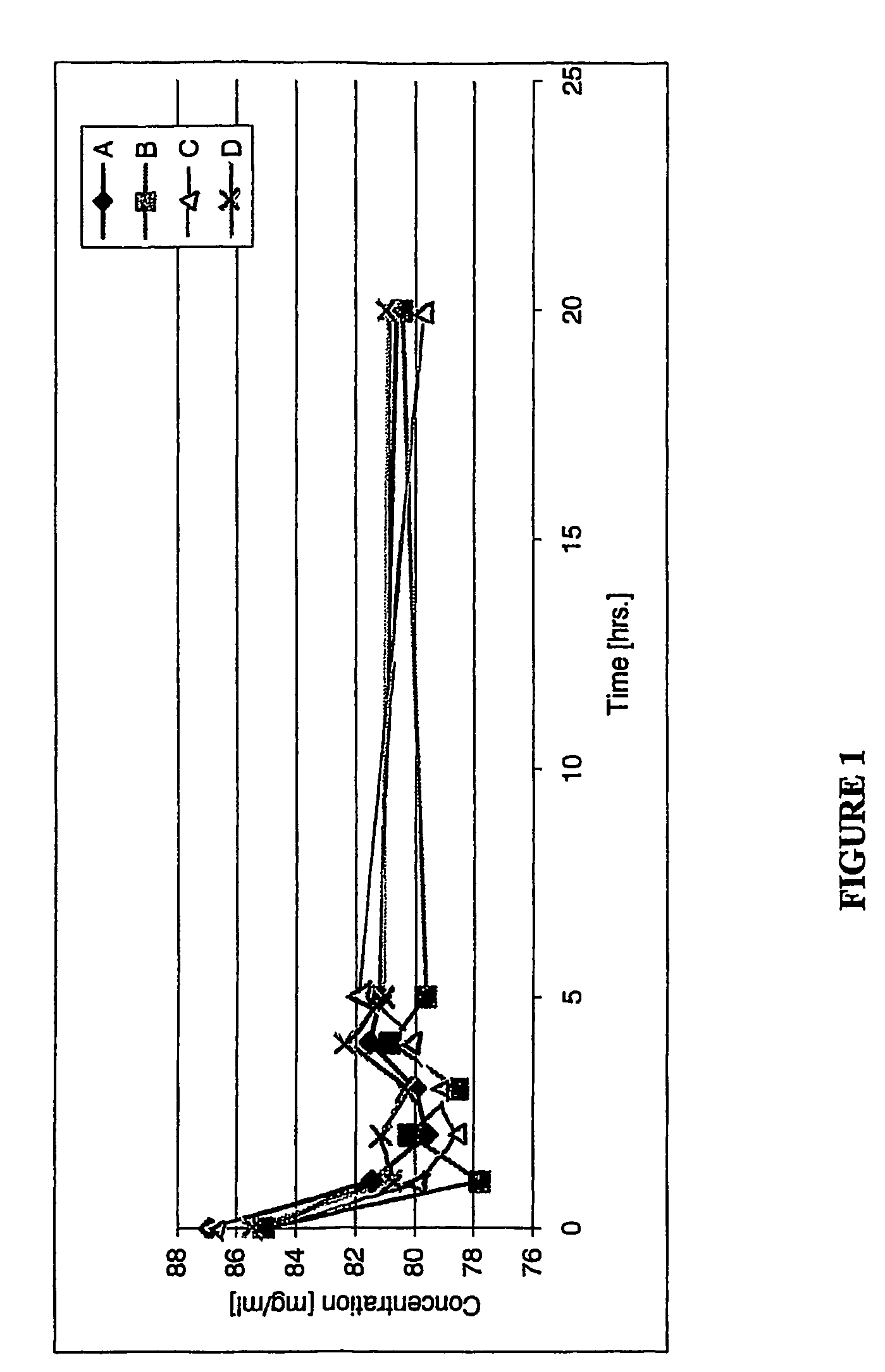

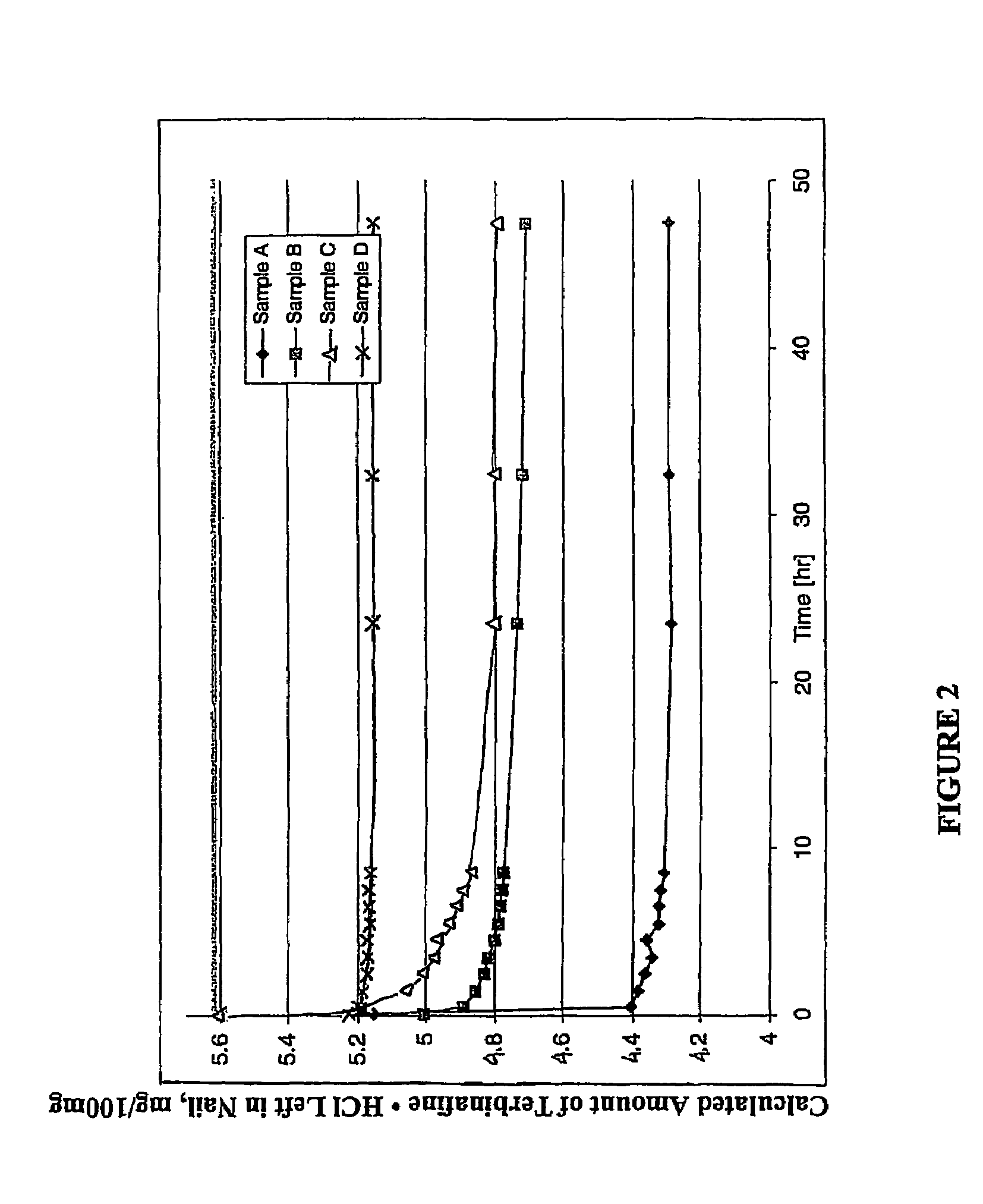

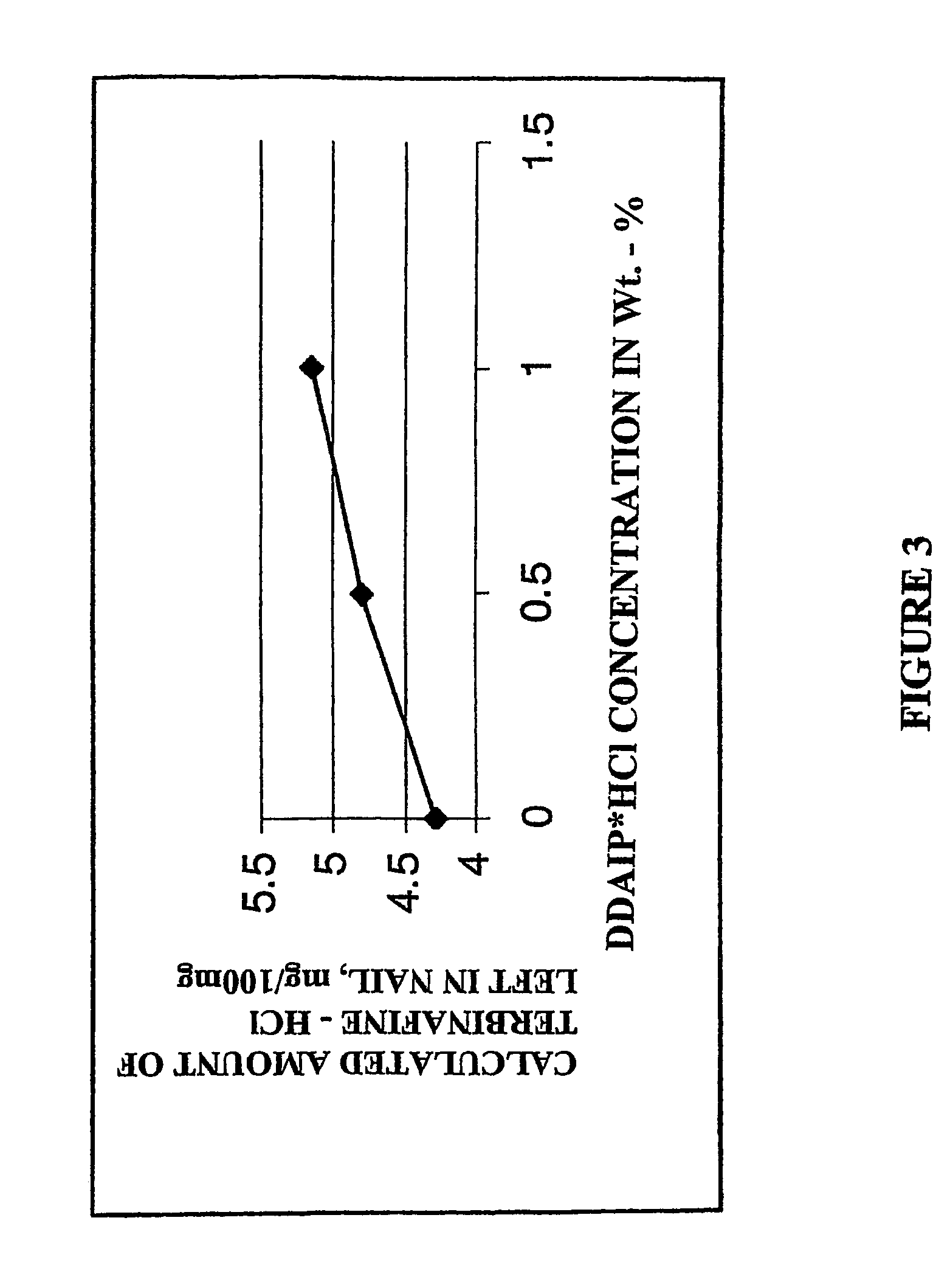

Antifungal nail coat and method of use

InactiveUS7462362B2Maintain sustained releaseImprove topical bioavailabilityCosmetic preparationsAntimycoticsAntifungalRegimen

A dual action antifungal nail coat composition and method of use for ameliorating or preventing fungal infection of the nails, and onychomycosis, in particular, is disclosed. Composition embodiments in the form of one-coat type and two-coat type suitable for daily fungicidal regimens are disclosed. A preferred antifungal nail coat composition comprises an effective fungicidal amount of antifungal agent, a permeation enhancing amount of a substantially non-volatile, permeation enhancer, a film-forming amount of a hydrophilic polymer, and a pharmaceutically acceptable, volatile carrier. The composition provides a substantially water-soluble fungicidal coating on contacting a fungally susceptible or infected nail.

Owner:NEXMED HLDG INC

Dual action, inhaled formulations providing both an immediate and sustained release profile

ActiveUS8071127B2Improve treatmentSustained release of anti-infective over timePowder deliveryBiocideDual actionAnesthesia

Methods for formulating immediate and sustained release anti-infectives and delivery of such for treatment of respiratory tract infections and other medical conditions, and devices and formulations used in connection with such are described.

Owner:GRIFOLS

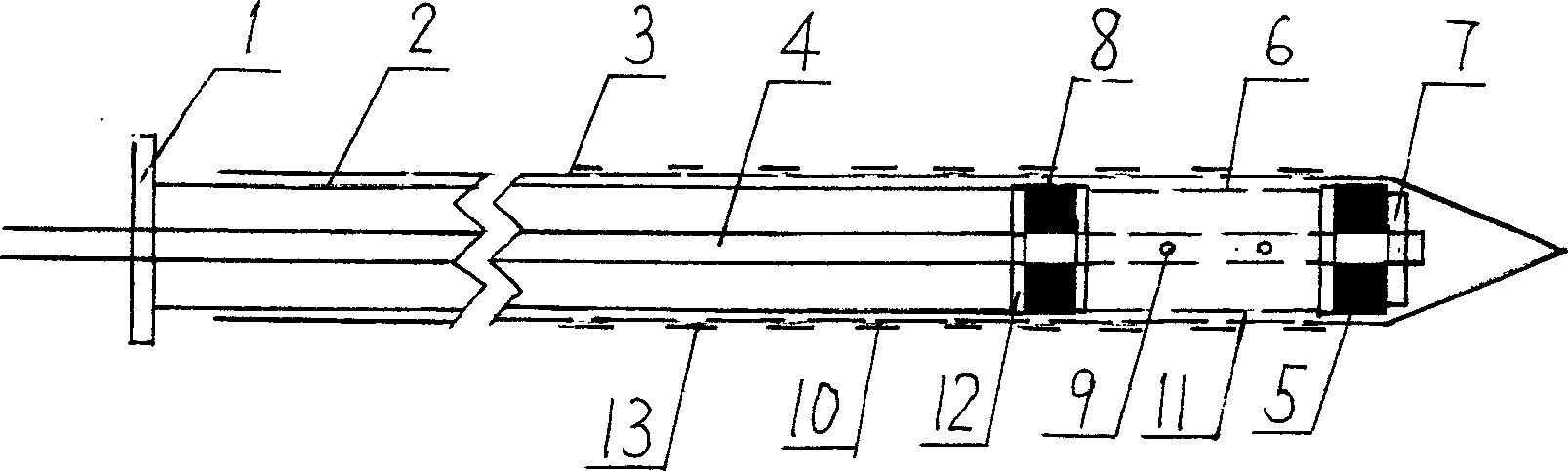

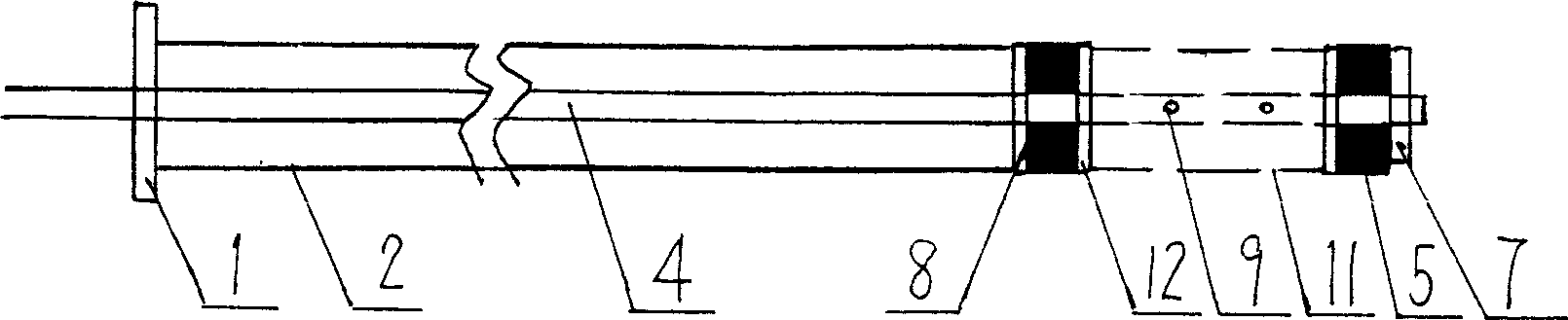

Slip casting lattice pipe with double plug and construction process

InactiveCN1485505AGuaranteed StrengthAct as reinforcementBulkheads/pilesSoil preservationDual actionMetallurgy

A double plug slip casting flower tube and construction process thereof, wherein the tube body of the slip casting flower tube is in cylindrical shape, the tube tip is conical, a slip casting hole isarranged on the tube wall,an one-way valve is arranged on the slip casting hole, a slip casting combination core member is inserted concentrically into the flower tube member, which mainly comprises slip casting core tube, front and rear rubber grout stopping plug, washer, connection pipe, top pipe and top pipe screw cap. The invention solves the problems existed in the conventional slip casting devices, such as, only backward type slip casting processes can be used, the slip casting scope control is not flexible, and the slip casting stress is not centralized.

Owner:北京市城市建设工程研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com