Patents

Literature

337results about How to "Act as reinforcement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

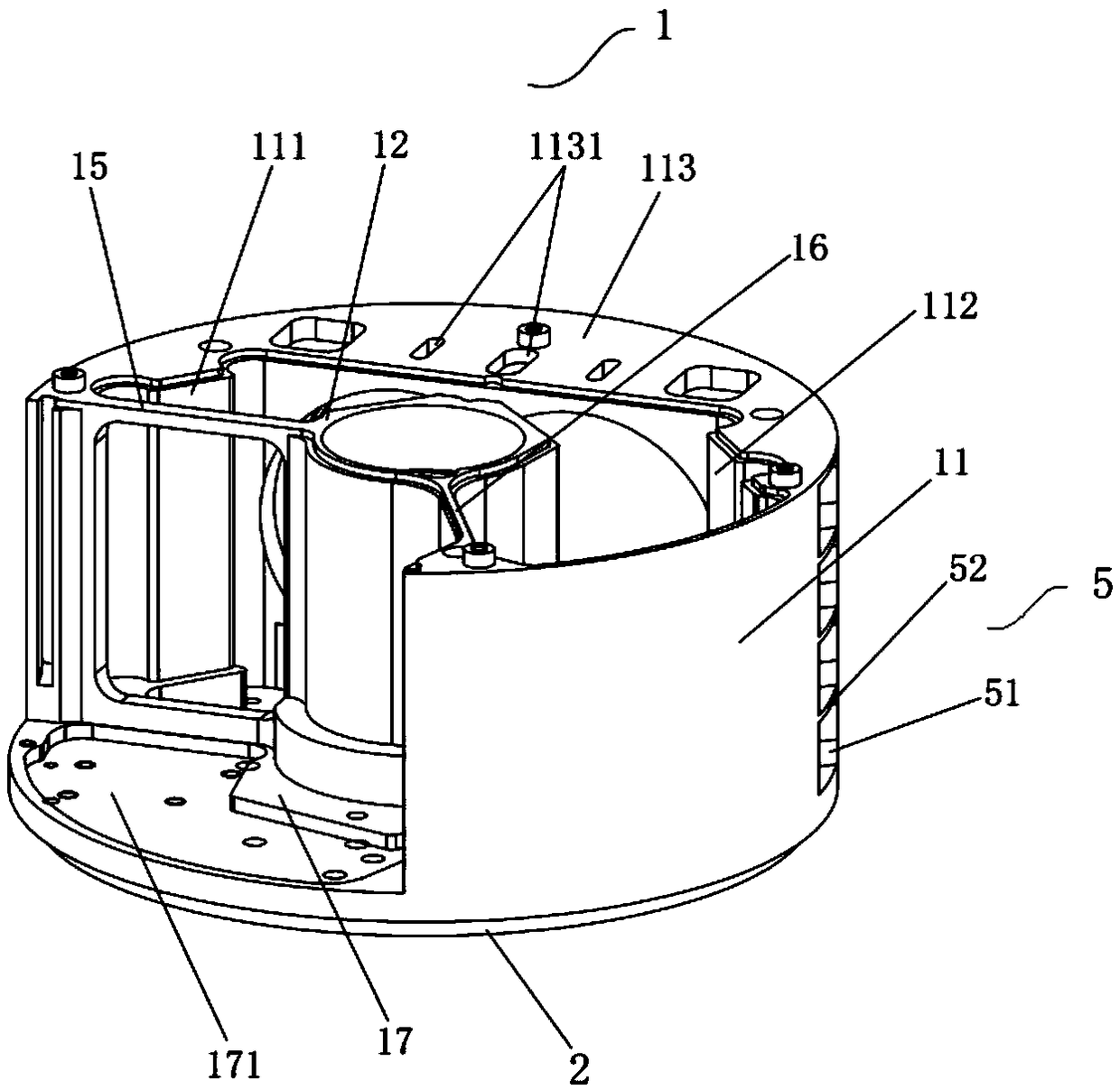

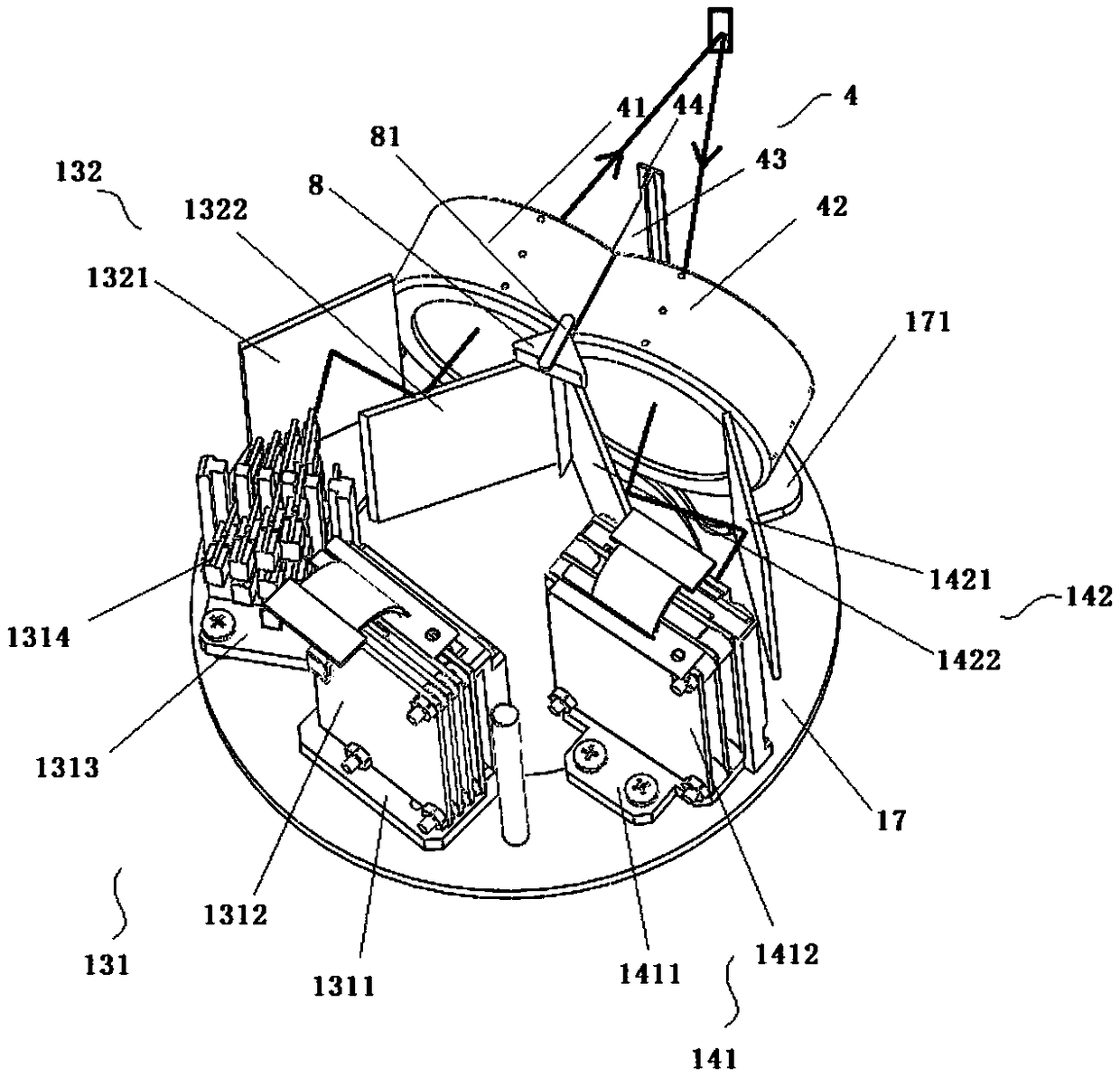

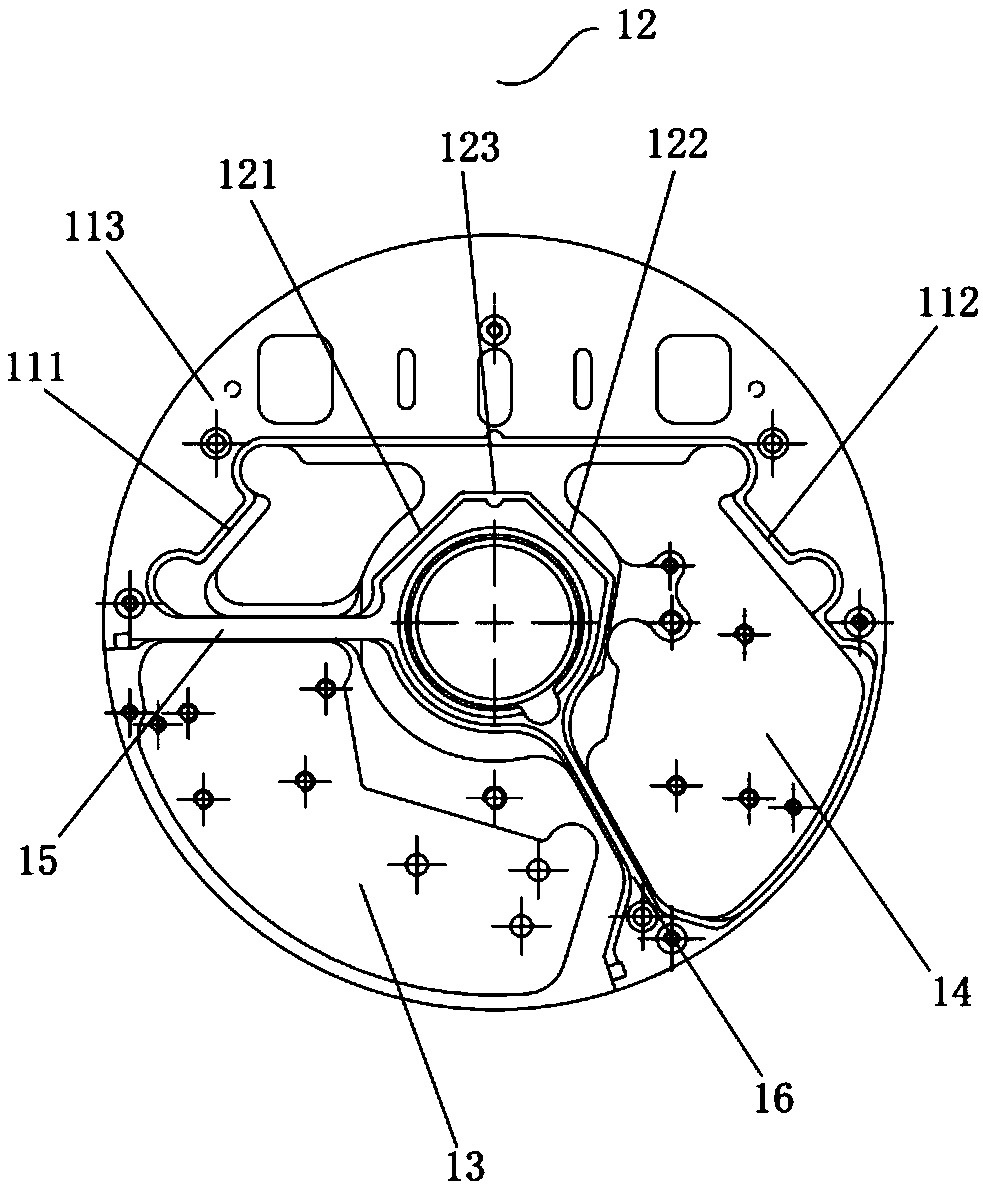

Laser radar

The invention provides a laser radar which comprises a rotor, a laser emission system and a reception system. The rotor comprises an emission chamber and a reception chamber isolated from the emissionchamber, the laser emission system is arranged in the emission chamber, and the reception system is arranged in the reception chamber. The laser emission system comprises a laser support which is used to fix at least one laser emission plate. A laser radar of higher wire harness can be realized via the arrangement manner of the laser emission plate on the laser support and the arrangement mannerof the laser emitters, a laser array is distributed in a non-uniform way so that low wire harness can realize high vertical angle resolution; and the rotor is provided with a third counterweight structure, so that counterweight is adjusted, heat radiation is more effective, and the laser radar can be light.

Owner:HESAI TECH CO LTD

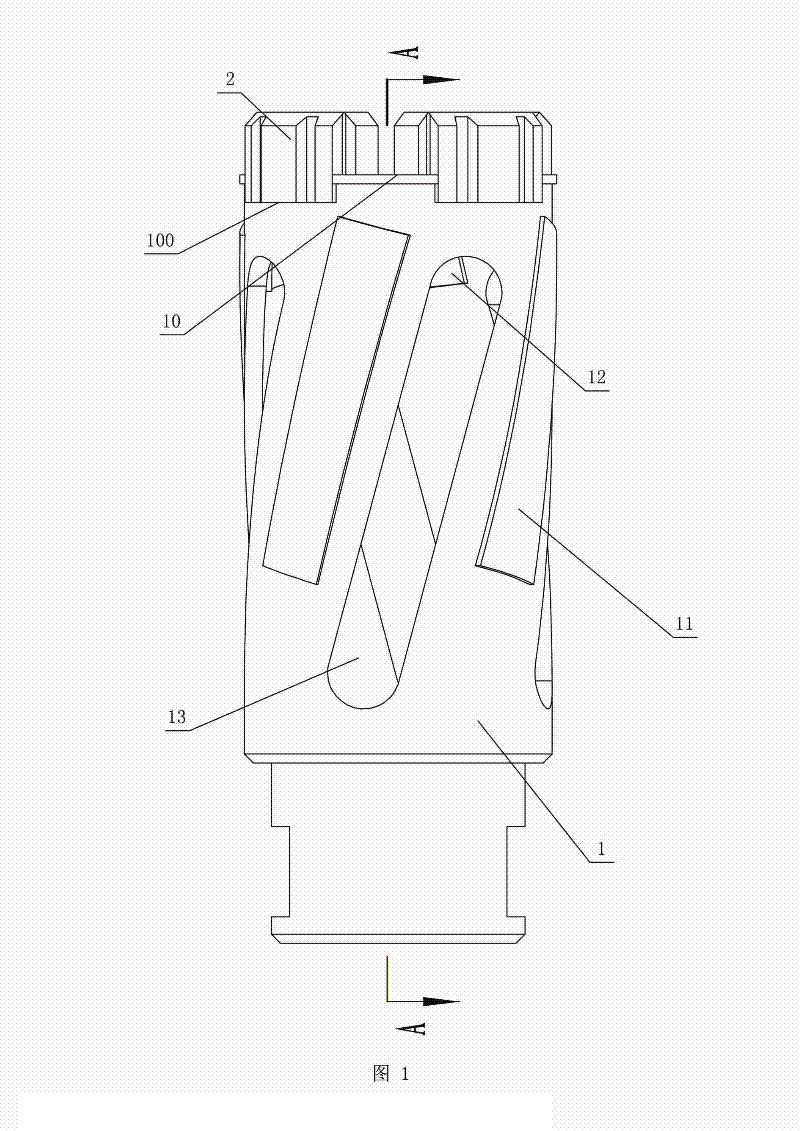

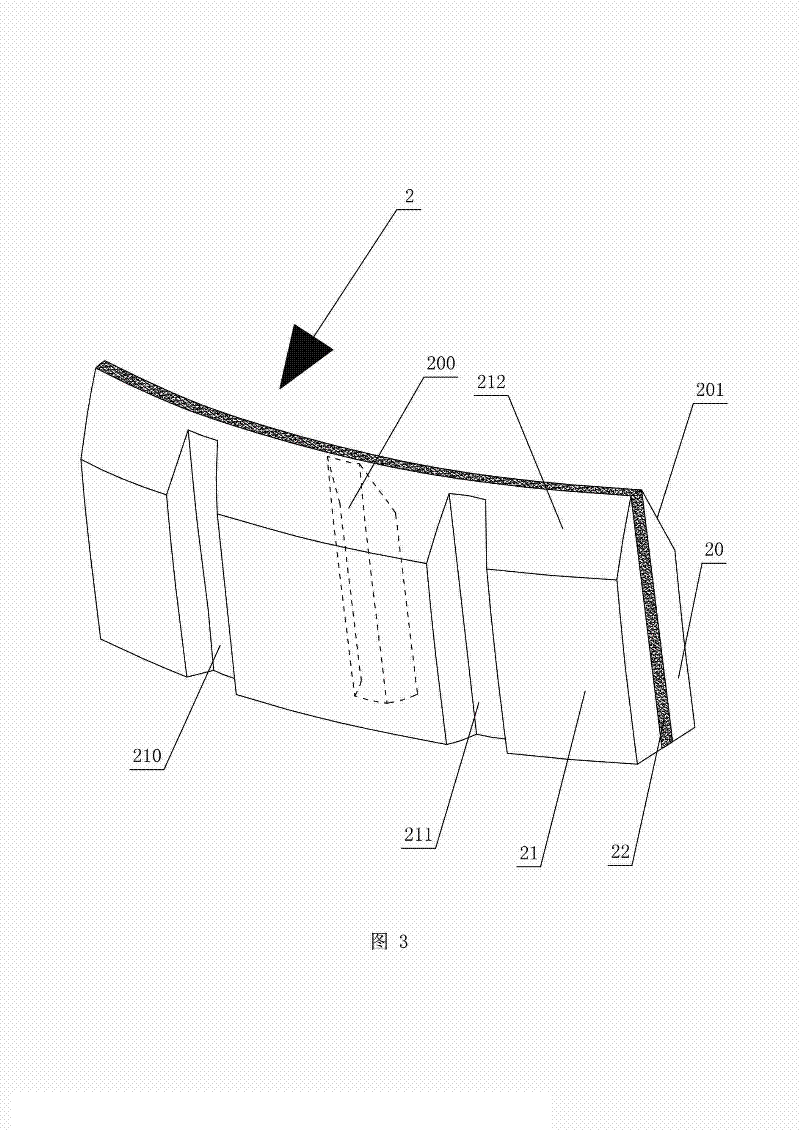

High-efficiency diamond bit and production process thereof

ActiveCN102528942ANot easy to fall offImprove performanceStone-like material working toolsWear resistantHardness

A high-efficiency diamond bit comprises a base and a tool bit fixedly disposed on the base. The tool bit consists of an inner sharp blank, an outer sharp blank and a wear-resistant hard blank sandwiched between the inner sharp blank and the outer sharp blank, and diamond particles and pre-alloyed powder are sintered after being mixed to form each of the inner sharp blank, the outer sharp blank and the wear-resistant hard blank. The tool bit is a sandwich type structure, namely, the wear-resistant hard blank is sandwiched between the inner sharp blank and the outer sharp blank, and excellent sharpness of the top of the tool bit is improved. In addition, when the tool bit grinds, the hardness of the inner sharp blank and the hardness of the outer sharp blank are lower than the hardness of the wear-resistant hard blank, accordingly, a triangular pointed edge can be constantly formed on the top of the tool bit, an excellent self-sharpening performance and excellent sharpness of the cutting head are constantly kept, and cutting force is high.

Owner:福建省泉州万龙石业有限公司

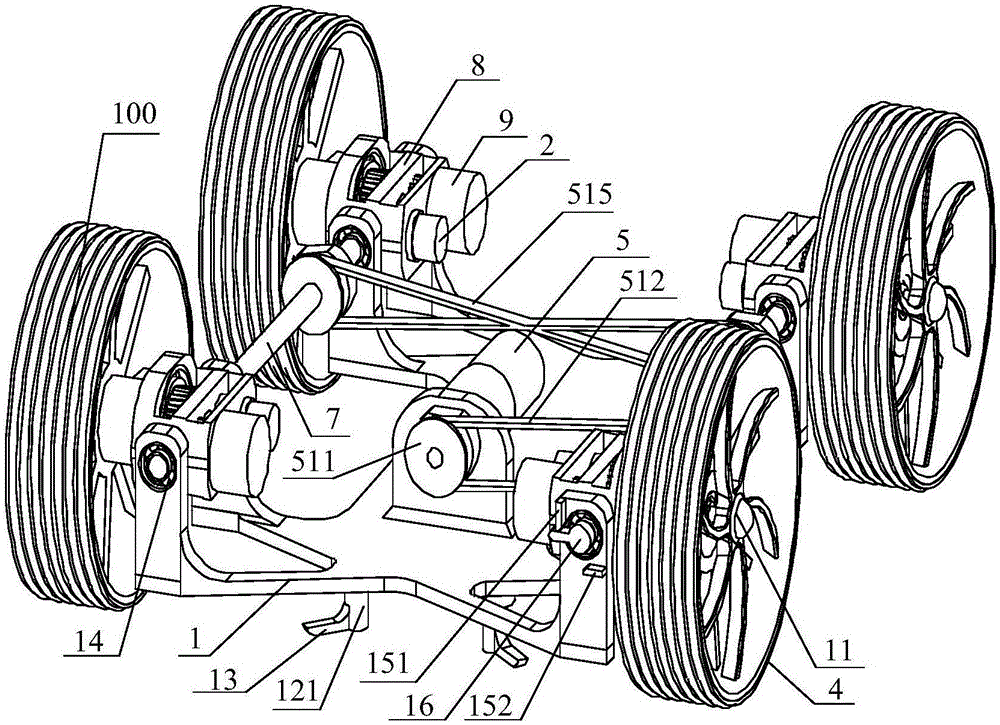

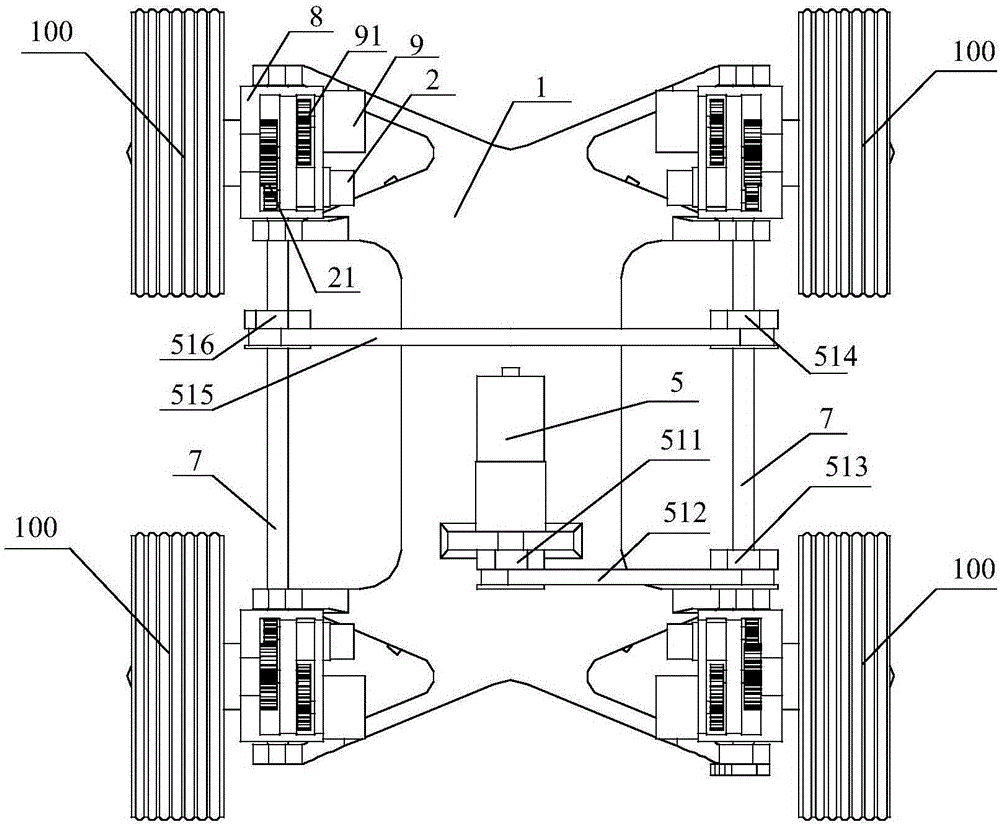

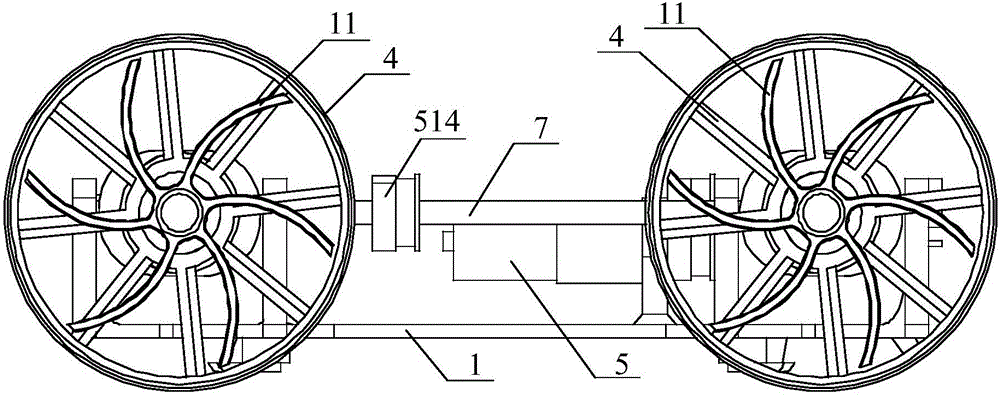

Wing wheel compound mobile flying amphibious robot device

ActiveCN106240262APlay hubAct as reinforcementAircraft convertible vehiclesCompound structureRoad surface

The invention provides a wing wheel compound mobile flying amphibious robot device and belongs to the technical field of robots. The wing wheel compound mobile flying amphibious robot device comprises a turning motor, a supporting assembly, a rotor assembly, a wheel assembly and a turning frame. Through the device, the amphibious robot with road surface moving and in-air flying functions is obtained. Wheels and rotors of the device are of a compound structure, power input is independent, the structure is compact, and mutual interference is avoided, the land moving and in-air flying functions are achieved, moving and flying can be switched according to requirements, switching is easy and feasible, and controlling is easy. According to the device, turning of a plurality of wing wheel compound units is achieved through one turning motor, and stable road surface and air mode switching is achieved through cooperation of extending and retracting of a supporting frame; shells of the wheels are designed into rotor ducts, the energy utilization rate of flying is increased, the power consumption of long-distance moving or flying is small, and the endurance capacity is high; and the functions of hubs and reinforcing ribs are achieved through rotors for the shells of the wheels, the size is small, and moving and flying can be conducted in a small space.

Owner:广州市轻工职业学校

Continuous spray lawn nursery method

The invention pertains to the environmental protection technical field, and in particular relates to a continuous silk spraying vegetation method. The continuous silk spraying vegetation method is applied to a high and steep rock slope for the construction of vegetation layers. The invention is characterized in that the vegetation layers are formed by the continuous and synchronous spraying on bacteria soil base materials and long woven silks under high-pressure air, and the bacteria soil vegetation layer is provided with mutually entangled fiber meshes. The overlaying of a fiber net and the bacteria soil layer enhances shearing strength and dynamic stress resistance, which can closely and firmly contact with rock surfaces and enhance the anti-erosion performance, thus effectively preventing the failure of slope protection caused by rainwater erosion. The base material is bacteria soil containing compound microbial bacterial fertilizer, wherein, the compound microbial bacteria can activate the soil, promote the growth and extension of roots, organically integrate with the fiber net and the bacteria soil, realize interception, promote precipitation, achieve water conservation and prevent water and soil erosion.

Owner:深圳市如茵生态环境建设有限公司

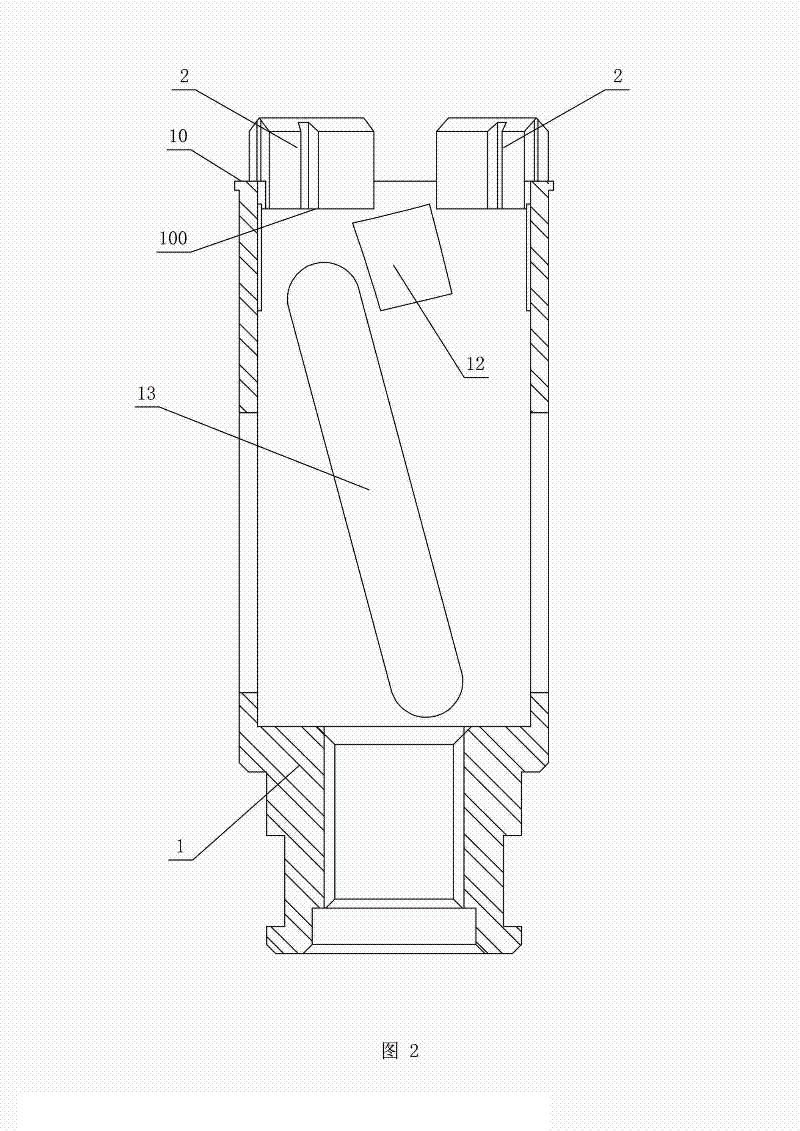

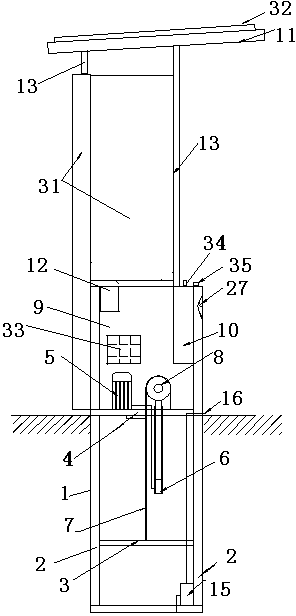

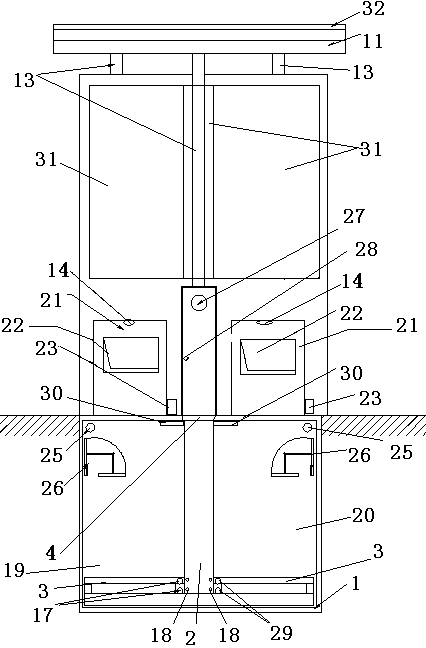

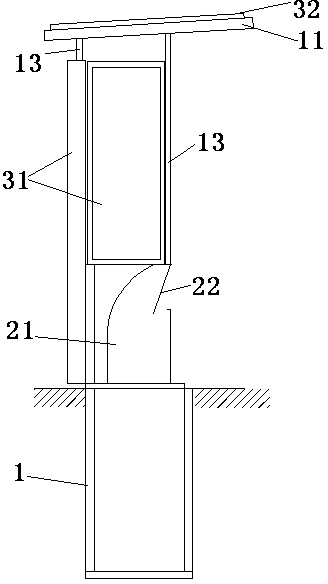

Buried elevating-type environmentally-friendly dustbin

ActiveCN104163302AEffortless positioningPull effortRefuse receptaclesIdler-wheelEnvironmentally friendly

The invention discloses a buried elevating-type environmentally-friendly dustbin which comprises an outer box body. The top of the outer box body is provided with a bracket, and an elevating mechanism is fixed to the bracket. Supporting protruding strips are arranged on two inner side walls opposite to the outer box body respectively, and the inner side faces of the supporting protruding strips are provided with grooves. An inner cavity of the outer box body further contains an elevating platform connected with the elevating mechanism. The side face, opposite to the supporting protruding strips, of the elevating platform is provided with a first idler wheel set and a second idler wheel set. The rolling surface of the first idler wheel set and the rolling surface of the second idler wheel set abut against the left side face and the right side face of each supporting protruding strip in an attached mode respectively. A plurality of adjustable roll balls are further arranged on the side face of the elevating platform between the first idler wheel set and the second idler wheel set, and the rolling surfaces of the adjustable roll balls abut against the bottom faces of the grooves. A first containing box and a second containing box are arranged on the elevating platform, and the top of the first containing box and the top of the second containing box are provided with rubbish throwing boxes respectively, wherein the rubbish throwing boxes are communicated with corresponding inner cavities of the first containing box and the second containing box. The buried elevating-type environmentally-friendly dustbin solves the technical problem of an existing buried elevating-type dustbin.

Owner:陈江

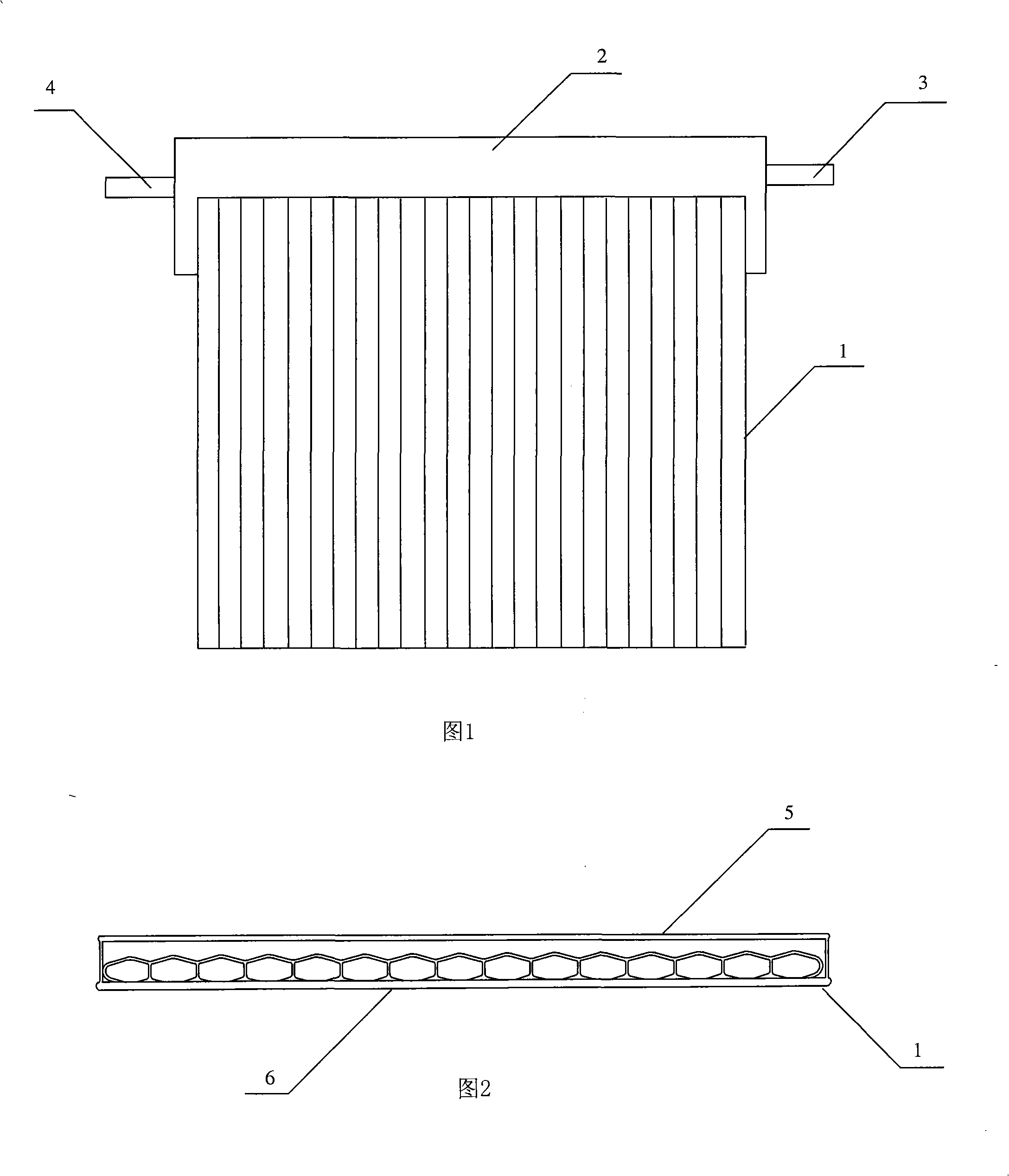

Plate-shaped heat pipe and its processing technique

InactiveCN101403578AImprove structural strengthWith ultra-thinSolar heating energySolar heat devicesEngineeringMechanical engineering

Owner:赵耀华

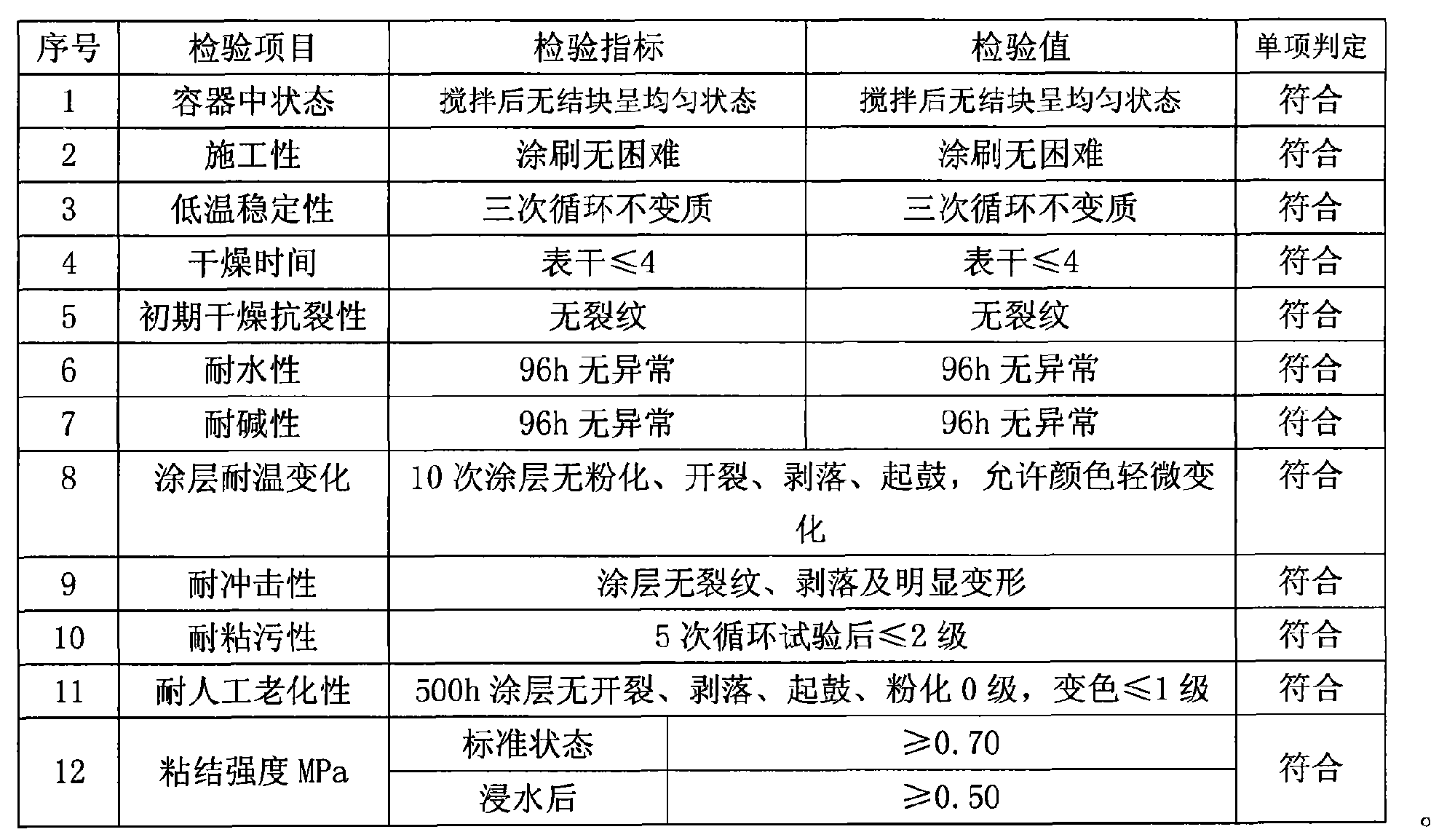

Anti-cracking environment-protection paint and method for preparing the same

The invention discloses an anti-cracking environmental-friendly coating, which is characterized in that the anti-cracking environmental-friendly coating is formed by components with the following percentage by weight, such as water 30-35%, promoter 5-10%, powder 20-30%, elastic pure acrylic emulsion and silicon dissolvent 20-30%, strong anti-cracking fiber 5-10% and colored stone sand 20-30%. The invention also discloses a process for preparing anti-cracking environmental-friendly coating. The anti-cracking environmental-friendly coating has the advantages of excellent anti-cracking effect, low production cost and the like.

Owner:刘春雨

Concrete brick with high water permeability

InactiveCN106673526AImprove water permeabilityImprove pore structureCeramicwareMetakaolinSilica fume

The invention discloses a concrete brick with high water permeability. The concrete brick is prepared from raw materials in parts by weight as follows: 120-200 parts of cement, 250-300 parts of gravel, 10-35 parts of ardealite, 10-50 parts of slag, 10-50 parts of steel slag, 200-350 parts of river sand, 20-50 parts of fly ash, 5-20 parts of silica fume, 10-35 parts of sintered magnesia, 2-15 parts of metakaolin, 10-40 parts of mixed fiber, 5-38 parts of straw powder, 3-8 parts of a water reducer, 0.1-0.5 parts of ethylene diamine tetra (methylene phosphonic acid) sodium and 20-50 parts of water. The concrete brick with high water permeability has very high compressive strength and excellent water permeability and can meet the use requirement of multiple fields.

Owner:安徽城洁环境科技有限公司

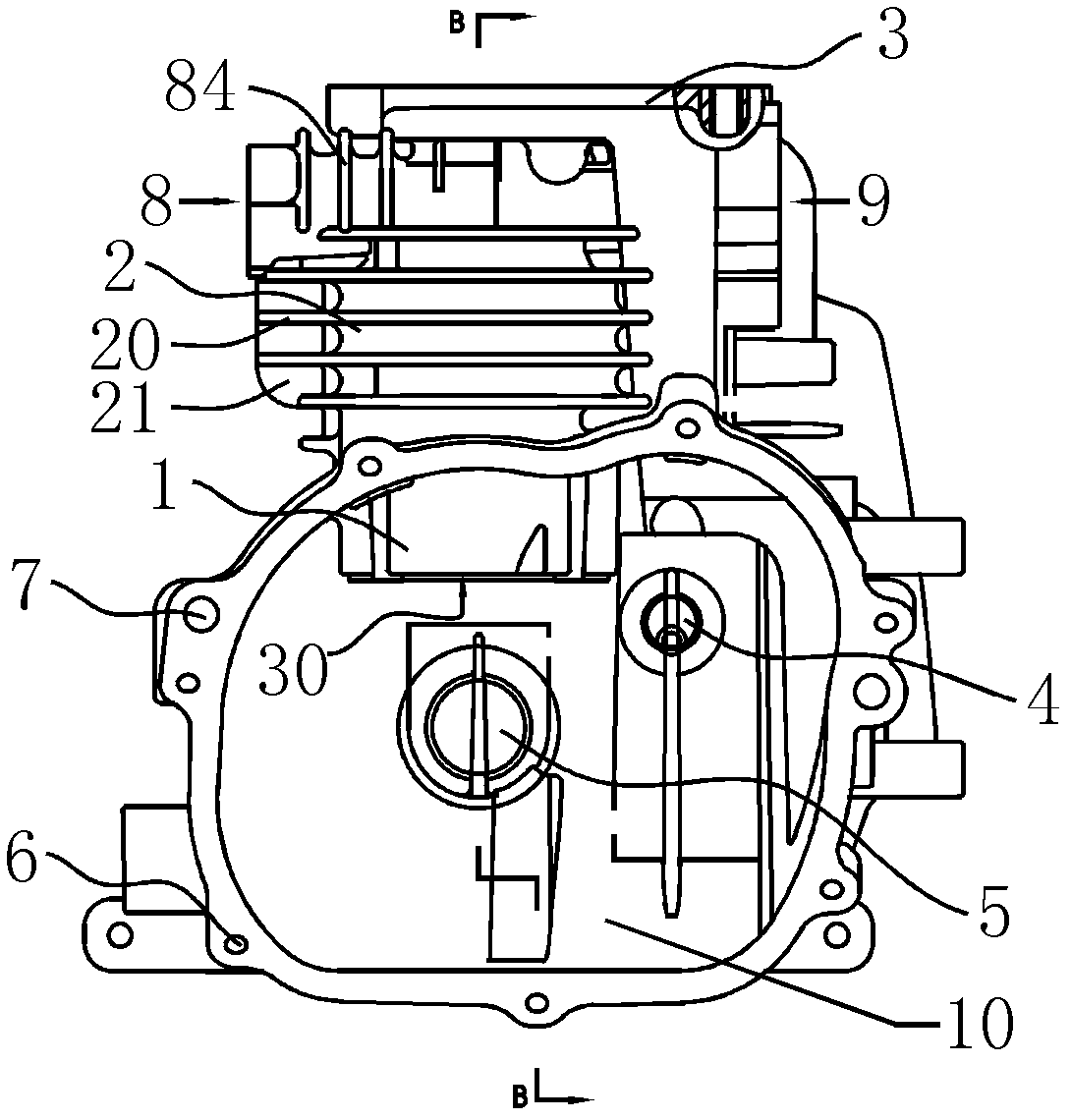

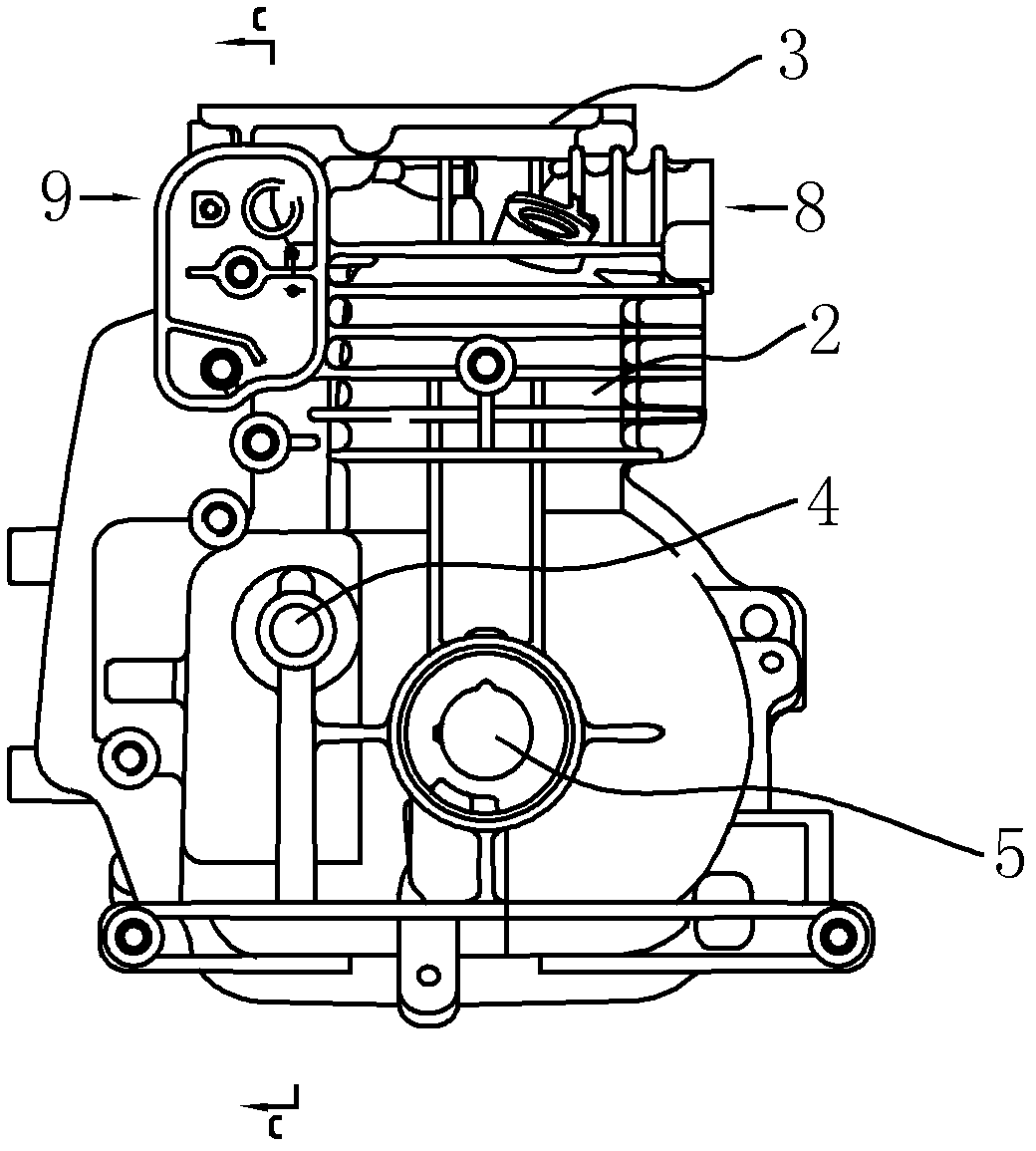

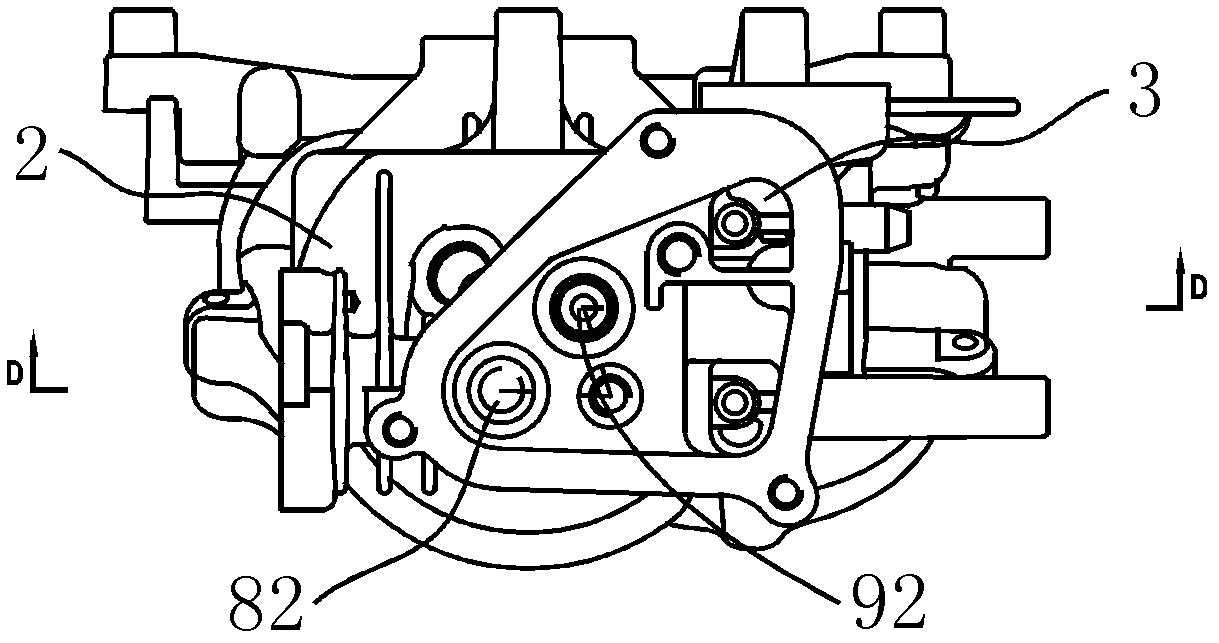

Integrated aluminum alloy tank

InactiveCN102562353AReduce intermediate connectorsLow costCasingsCylinder headsHeat sinkCylinder block

The invention relates to a general tank structure for a gasoline engine and a diesel engine, in particular to an integrated aluminum alloy tank. The integrated aluminum alloy tank comprises a cylinder body, a cylinder head, a cylinder cover and a crank chamber which are integrally formed by casting aluminum alloy materials; moreover, the cylinder head is provided with an air inlet and an air discharge port which are connected to a cylinder hole in the cylinder body respectively; the connection parts of the air inlet and the air discharge port on the cylinder hole are an inverted taper hole respectively; the large ends of the inverted taper holes are positioned on the end face of the cylinder hole; air valve push rod channels are arranged on the parts of the cylinder cover, which are opposite to the inverted taper holes; bushes are arranged in the air valve push rod channels; a stripped gating channel is formed on the outer wall of the cylinder hole and is intersected with a cooling fin on the outer wall of the cylinder hole; and a reinforcing rib is arranged on the outer wall of the air discharge port. The integrated aluminum alloy tank has novel design and a new structure, is manufactured by a new process, meets the requirements of energy saving and emission reduction and reduces manufacturing and assembly cost.

Owner:重庆三华工业有限公司

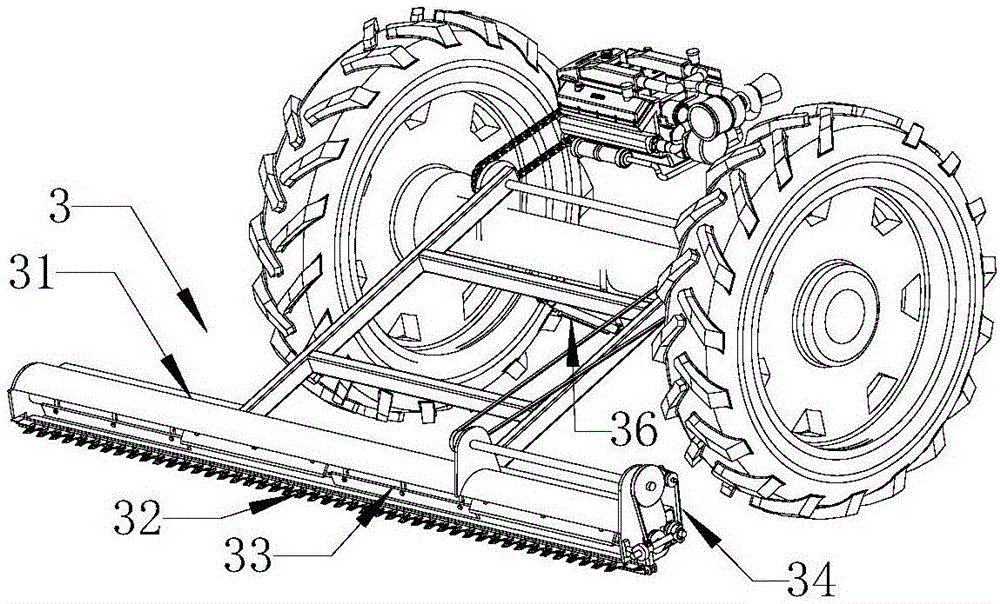

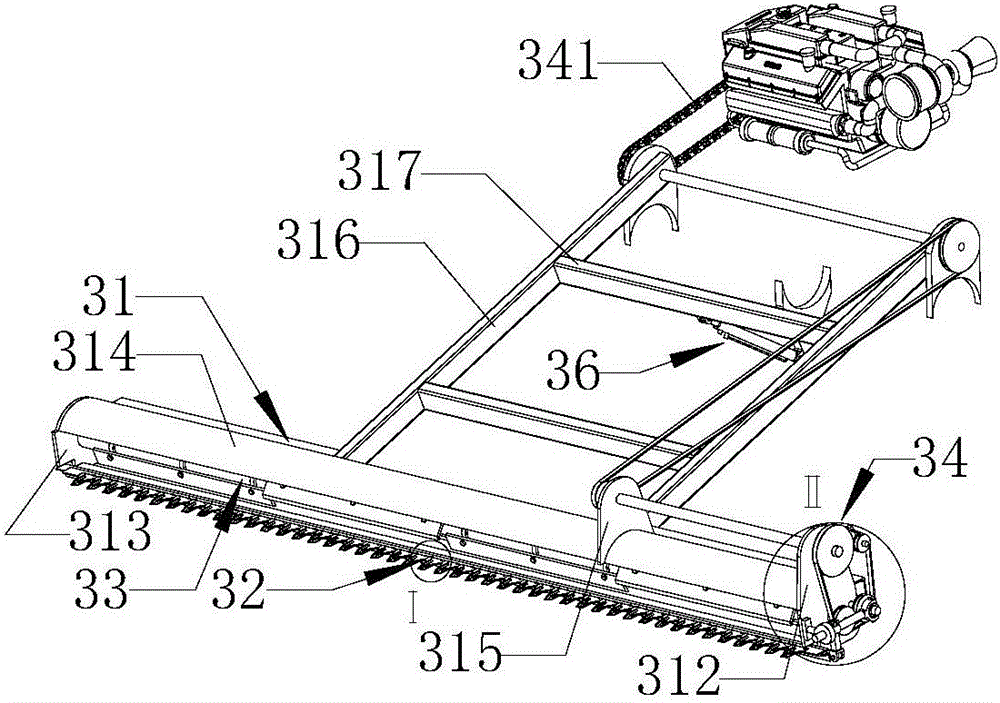

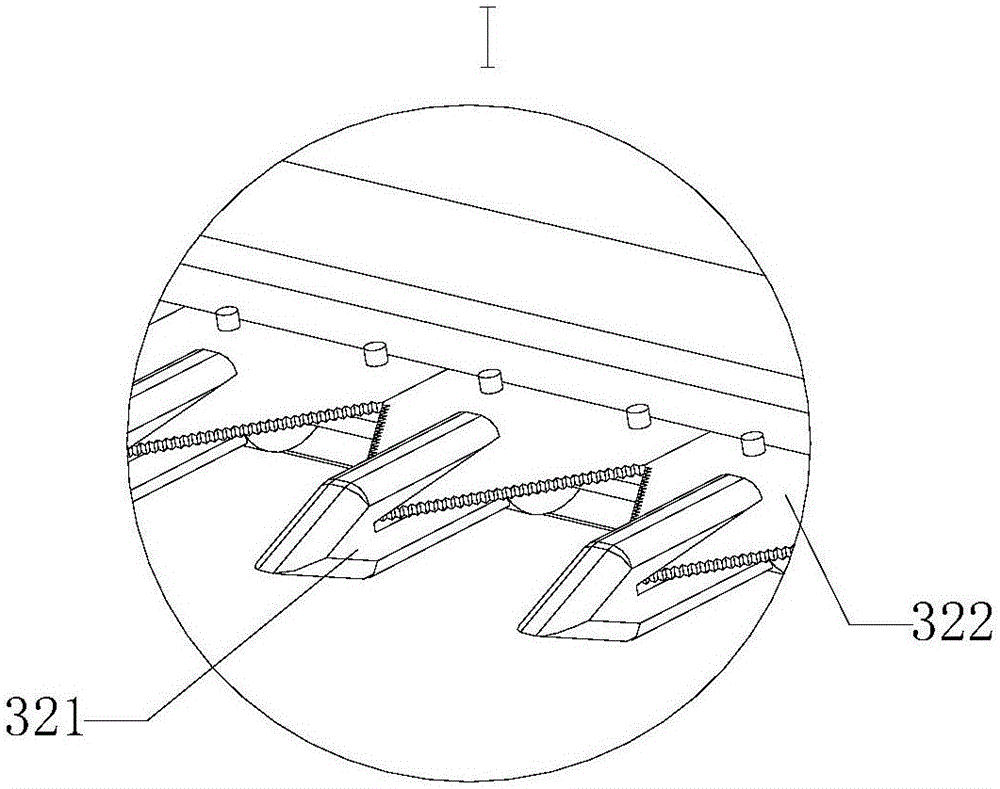

Harvester provided with protective ladder and lifting type lower header capable of smashing straw and preventing smashed straw from splashing

The invention discloses a harvester provided with a protective ladder and a lifting type lower header capable of smashing straw and preventing the smashed straw from splashing. The harvester comprises the lower header and the protective ladder, and the lower header is hinged to a front axle of the harvester. The lower header comprises a lower header main frame, a lower cutting mechanism, a straw smashing mechanism, a transmission mechanism and a lower header lifting mechanism. Blocking angle iron is further fixedly connected with the rear portion of a shield of the lower header main frame. The lower header lifting mechanism comprises a lower header lifting oil cylinder, a lower header lifting oil cylinder upper base and a lower header lifting oil cylinder lower base. The harvester provided with the protective ladder and the lifting type lower header capable of smashing straw and preventing the smashed straw from splashing can cut and smash straw left after grain harvesting, and the feed quantity of the harvester is reduced. Cutting stubbles are short and flat so that tillage can be convenient. The straw cutting and smashing efficiency is high, smashing is uniform, and the smashed straw cannot splash. The lower header can ascend and descend so as to control the height of the cutting stubbles and avoid obstacles to protect equipment safety. The arranged protective ladder makes people climb safely and conveniently, and can also be used as a safety guardrail.

Owner:纪小坤

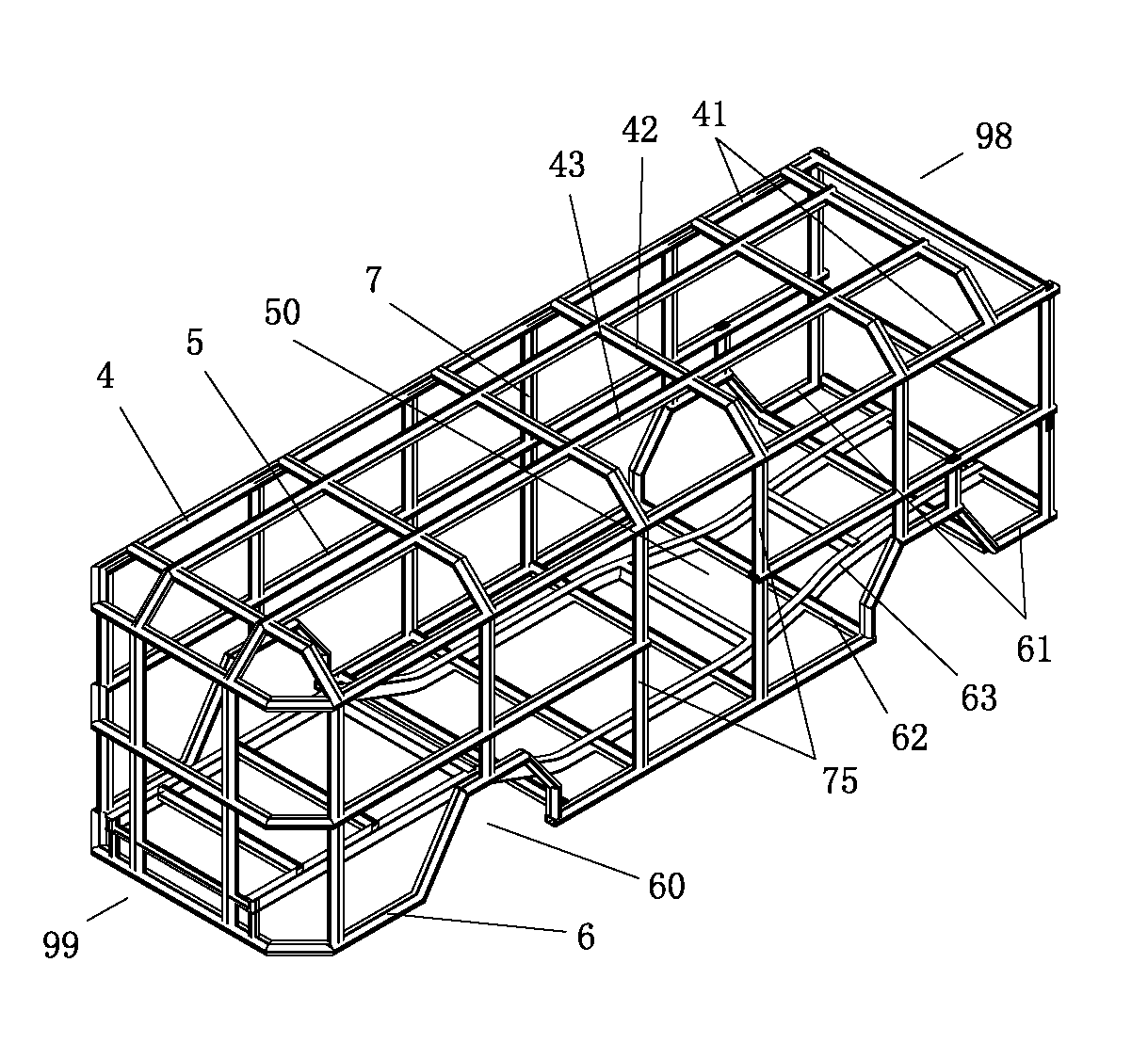

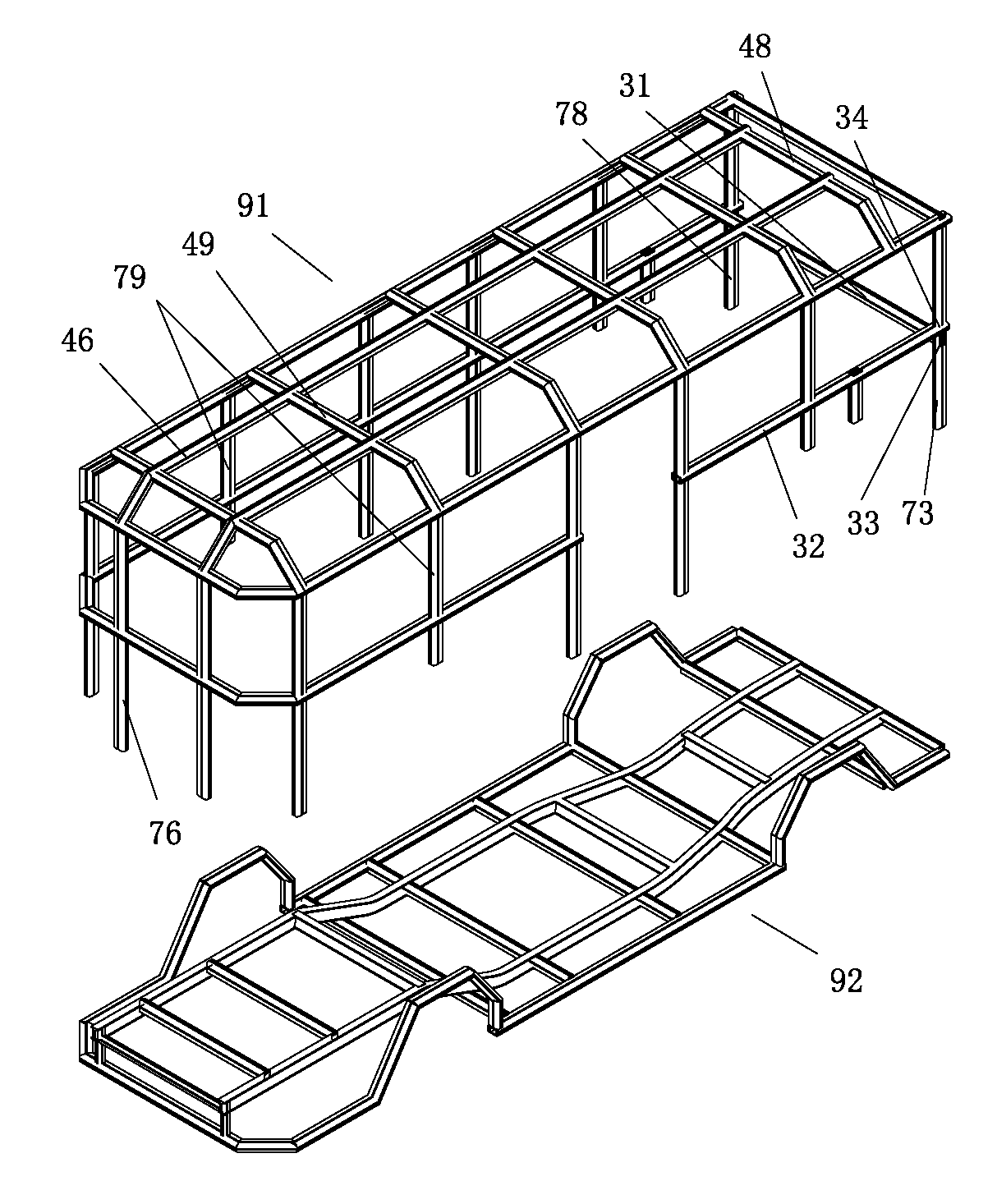

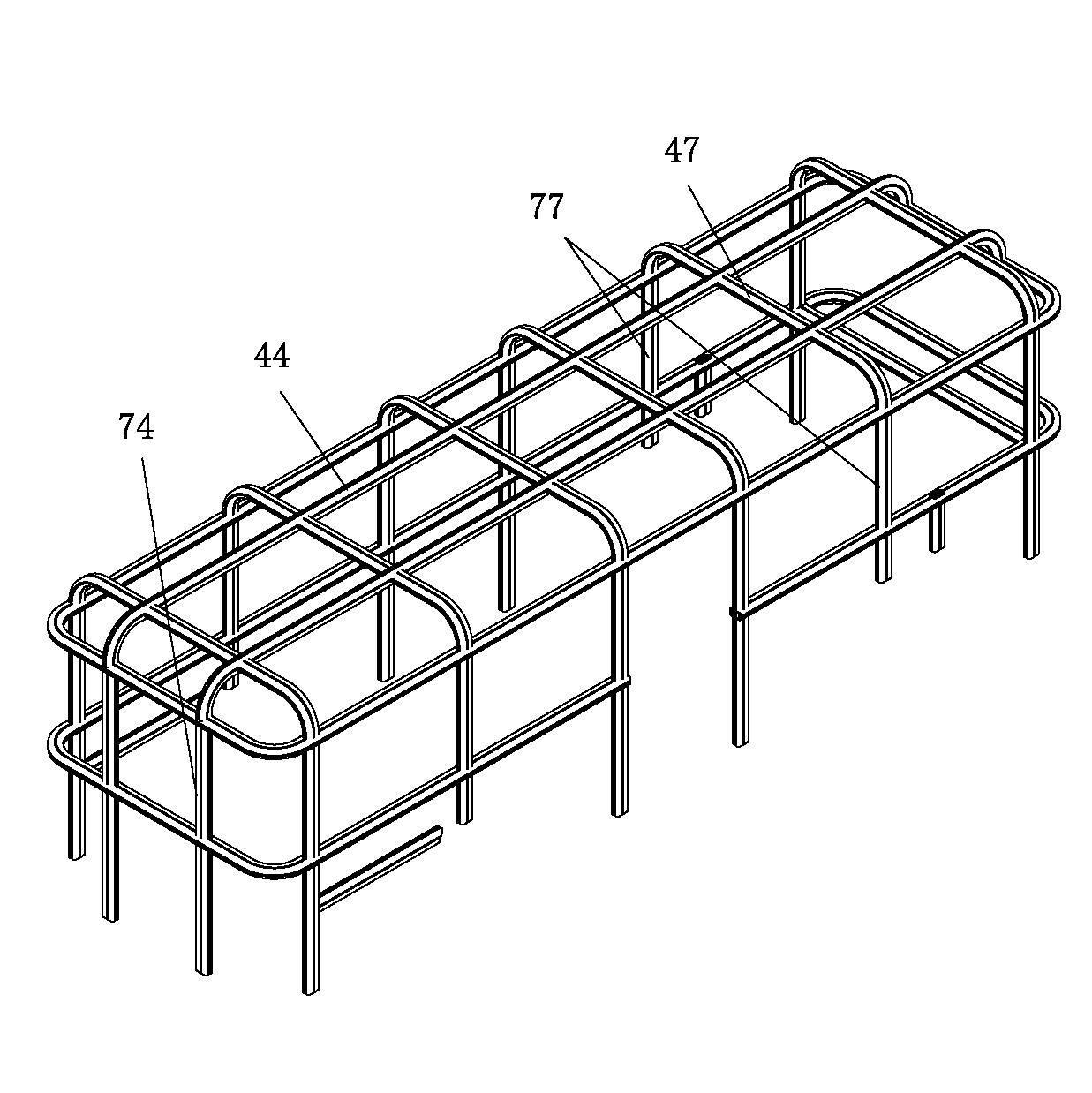

Light weight bus frame

InactiveCN103101574ASimple structureSimple topologyUnderstructuresSuperstructure subunitsVehicle frameEmbedded system

The invention relates to the technical field of an automobile, in particular to a light weight bus frame which comprises annular frames, wherein the annular frames encircle a bus head, two sides of a bus and a bus tail and include a bus top annular frame, a bus waist annular frame and a bus bottom annular frame. A gap exists at a position of the bus waist annular frame, wherein the position of the bus waist annular frame located at a bus door position. The bus bottom annular frame is placed at wheel position to hunch upwards to contain wheels. A plurality of beams which are in bridge joint with two side rims of the bus bottom annular frame are arranged on the bus bottom which is further provided with longitudinal beams which are in bridge joint with the beams. The bus head, the two sides of the bus and the bus tail are all provided with a plurality of vertical beams which are in bridge joint with the annular frames which are section bar beams, and the beams, the longitudinal beams and the vertical beams are the section bar beams. The light weight bus frame is firm in structure. The section bar beams are adopted, excessive connecting pieces are not needed, and at the same time, the light weight, simple and safe requirements can be met.

Owner:东莞三新电动汽车技术有限公司

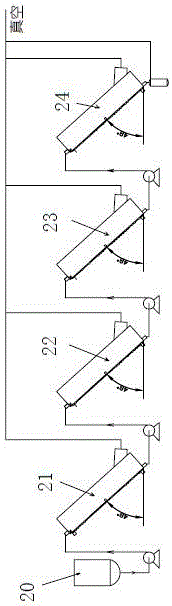

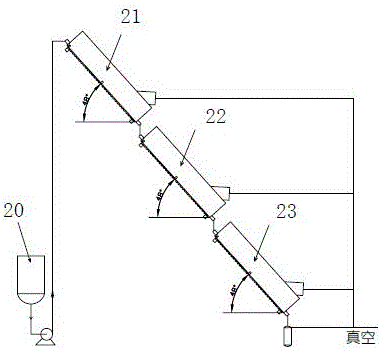

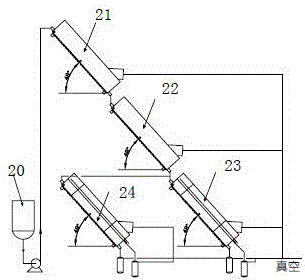

Molecular distillation separation method for grease chemical product and equipment

InactiveCN106811291AImprove sealingReduce productionFatty-oils/fats refiningMolecular distillationOil and greaseBoiling point

The invention discloses a molecular distillation separation method for a grease chemical product and equipment. A molecular distillation system consists of single molecular distillation equipment or multi-stage molecular distillation equipment in manners of serial connection, parallel connection or combination of serial connection and parallel connection; the multi-stage molecular distillation equipment is arranged in horizontal positions, up and down positions or combined way of horizontal positions and up and down positions; a product to be distilled is fed into the molecular distillation equipment from the top, is uniformly allocated for a first time through allocation tube holes or / and groove plates, is uniformly distributed to the upper part of a heating surface of the equipment to form a uniform film flowing from top to bottom, and is at least uniformly allocated further for a second time through an allocation groove plate or screening holes, and is uniformly distributed to the bottom from the heating surface of the equipment; under the action of heating and vacuum, a low-melting point oil chemical product is evaporated and recycled as a product of a first-class type; a high-melting point oil chemical product is fed to a next stage of molecular distillation; temperature and vacuum degrees of different stages of the molecular distillation equipment are determined according to low-melting point oil chemical products to be removed in equipment of a same stage, and various types of high-quality products can be prepared finally.

Owner:饶攀

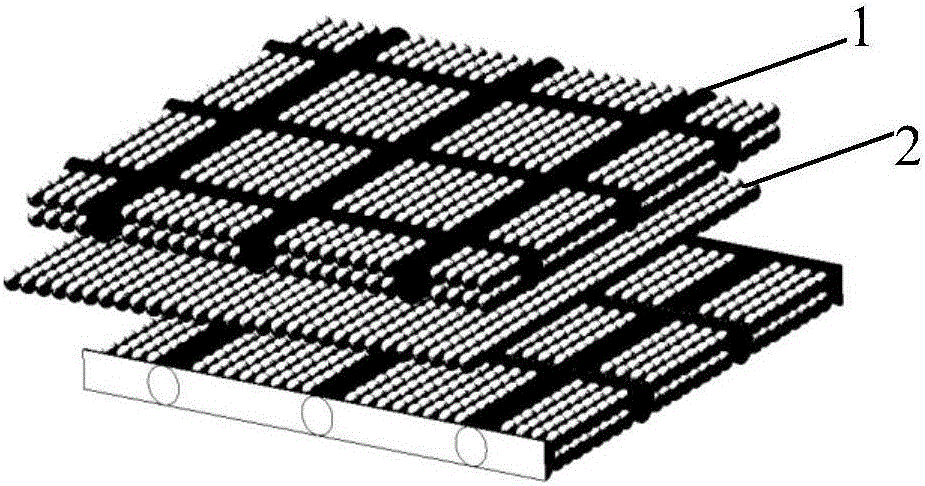

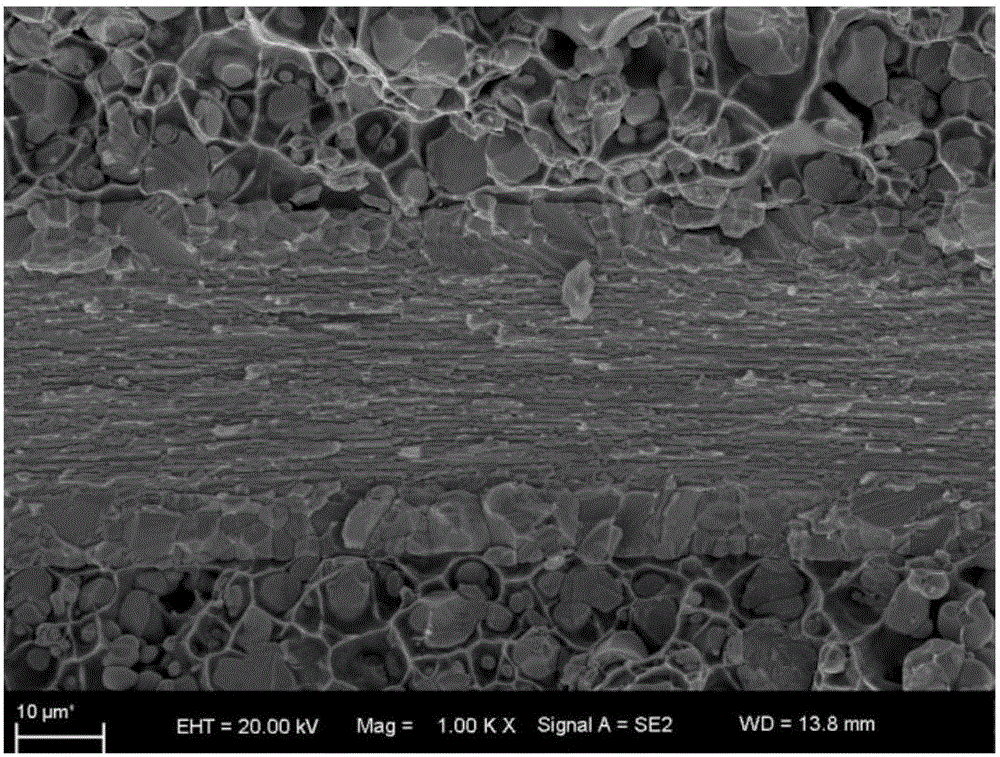

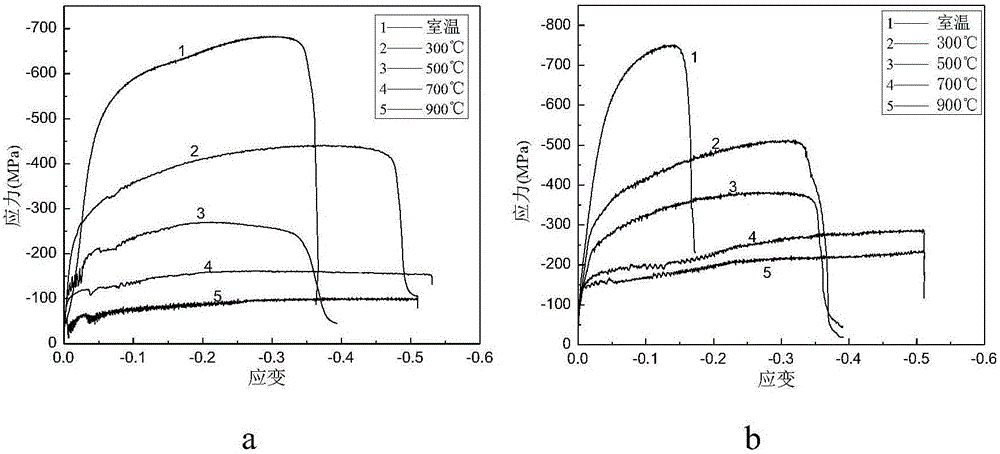

Preparation method for W-Cu composite materials of fiber and particle hybrid structure

The invention provides a preparation method for W-Cu composite materials of a fiber and particle hyrid structure. Particularly, W powder and Cu powder hyrid evenly and a W fiber net obtained after acid pickling are laid in a cold pressing mold in a layered mode and then subjected to pre-pressing and pressure maintenance to obtain a composite material green body; then the green body is put in to a mold capable of being pressurized and subjected to hot pressing in an atmosphere protection hot pressing furnace; and finally, the composite material green body obtained after hot pressing is subjected to copper cementation in a high-temperature atmosphere sintering furnace, so that the W-Cu composite materials of the fiber and particle hyrid structure are obtained. The two-dimensional W fiber net is added in the preparation process of a W-Cu pseudo alloy W framework. The two-dimensional W fiber net and the W-Cu pseudo alloy W framework form metallurgical bonding through processing of an interface of fibers and the W framework and reasonable technological parameters, the W fiber net has a function like reinforcing ribs for the W framework, and therefore the high-temperature strength of the composite materials is obviously improved.

Owner:XIAN UNIV OF TECH

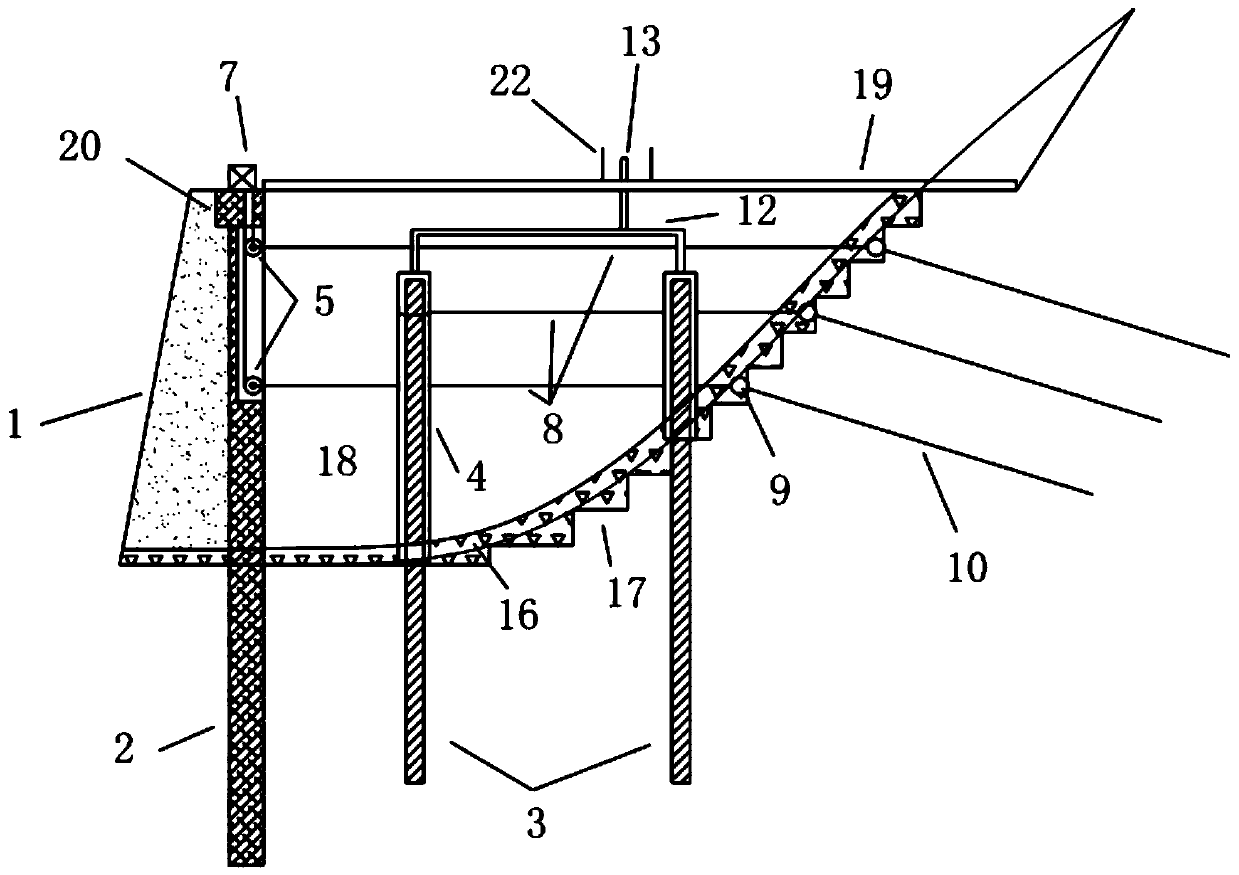

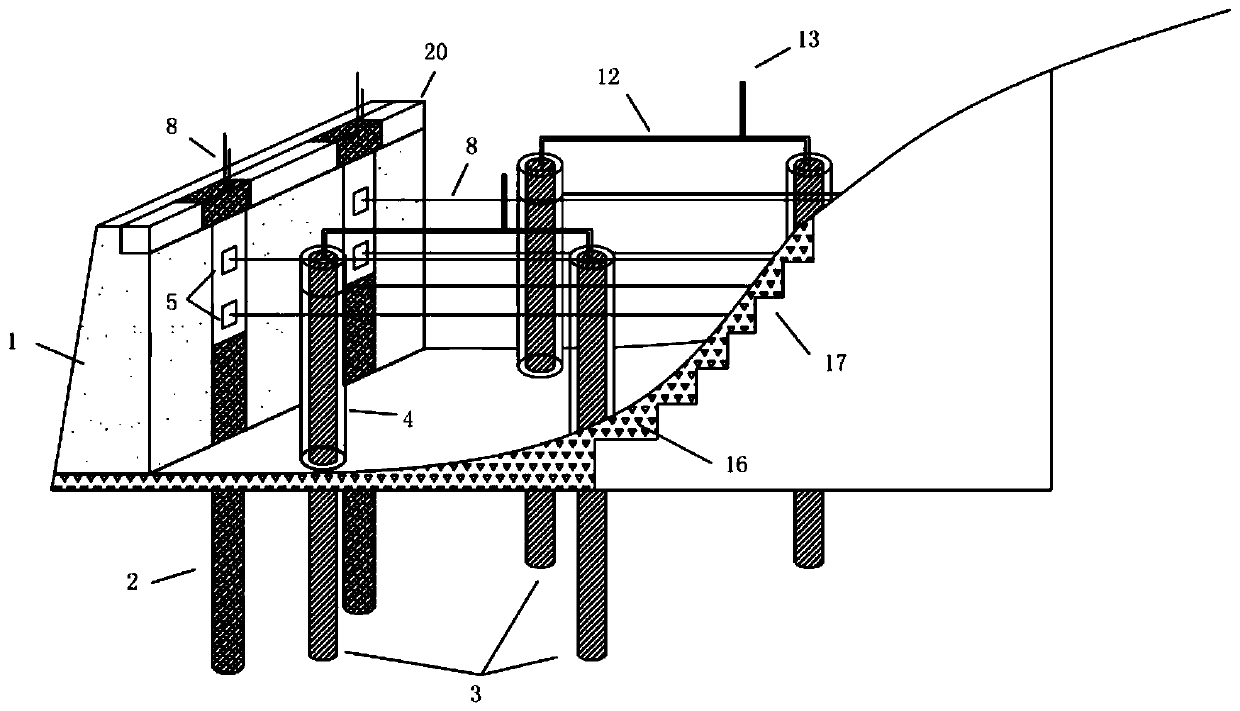

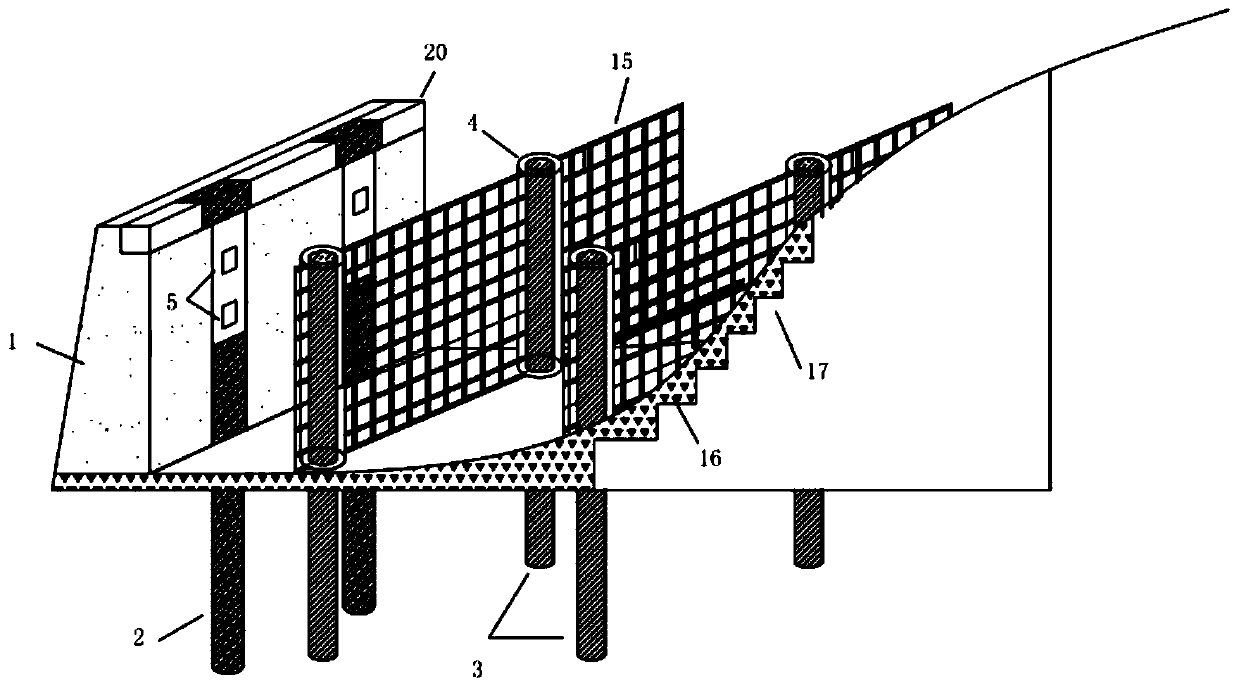

High embankment slope stabilizing structure and construction method thereof

ActiveCN111501796AReduce landslide riskPerfect drainage systemArtificial islandsRoadwaysSteel tubeRock bolt

The invention discloses a high embankment slope stabilizing structure. The high embankment slope stabilizing structure comprises a retaining wall, steel pipe piles and anchor rods; the retaining wallis arranged at the foot of a high embankment slope, concrete-filled steel pipe piles are arranged on the inner surface of the retaining wall, an excavation step and a gravel drainage zone are arrangedat a filling and excavation interface, the bottoms of the concrete-filled steel pipe piles and the steel pipe piles penetrate through the gravel drainage zone, and the upper sections of the steel tube piles are sleeved with grouting sleeves correspondingly; the lower end of the grouting sleeves extend to the gravel drainage zone, the upper end of each grouting sleeve is connected with a groutingopening through a grouting pipe, a fixed pulley and a pipeline channel are arranged inside each concrete-filled steel pipe pile, the anchor rods are is fixed in a rock stratum behind the excavation step, the exposed parts of the tops of the anchor rods are connected with steel strands, and the steel strands are connected to the fixed pulleys or the steel pipe piles at the same height; the steel strands connected to the fixed pulleys are led out of crown beam through the pipeline channel and connected with a steel strand tensioning device. The high embankment slope stabilizing structure is suitable for reinforcing and active control of embankment deformation in the embankment construction and operation process, and is particularly suitable for embankment projects with high requirements forembankment stability and later operation safety.

Owner:ZHEJIANG UNIV CITY COLLEGE

Asphalt mixture anti-rutting additive and preparation and use method thereof

ActiveCN101805470AEnhanced recovery from deformationImprove toughnessBuilding insulationsPolypropylenePitch blende

The invention relates to an asphalt mixture anti-rutting additive and a preparation and use method thereof. The anti-rutting additive which is in common use at present has insufficient toughness and poor deformation recovery capability under the condition of heavy load, or has poor adaptability and small application range because the existing anti-rutting additive needs to take chemical reaction with the asphalt. The invention provides the asphalt mixture anti-rutting additive, which is prepared from the following ingredients in weight parts: 25 to 75 percent of polyethylene, 5 to 35 percent of polypropylene, 5 to 25 percent of PVC, 3 to 5 percent of rubber, 5 to 10 percent of asphalt, 1 to 5 percent of tougheners and 1 to 3 percent of UV ageing resistant agents. The ingredients are mixed and uniformly stirred according to the ingredient mixture ratio, and are put into a screw extruder to be heated into 110 to 180 DEG C, the materials are extruded into granules after being fused and prepared into uniform substances, and the asphalt mixture anti-rutting additive can be directly mixed with the asphalt mixture in a dry mode when in use. The additive of the invention has the advantages of low asphalt cost and stable structure, the wear resistance and pressure resistance performance is improved by 15 to 30 percent, the elasticity recover performance index of the asphalt is improved by 10 to 25 percent, and the time limitation of the road surface antifatigue performance is prolonged by 10 to 25 percent.

Owner:CCCCRUITONG ROAD & BRIDGE MAINTENANCE TECH +1

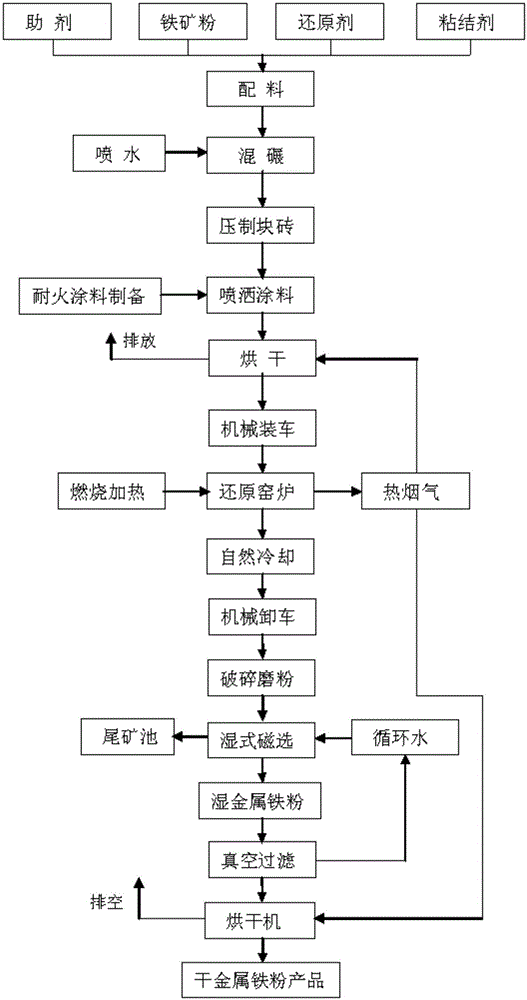

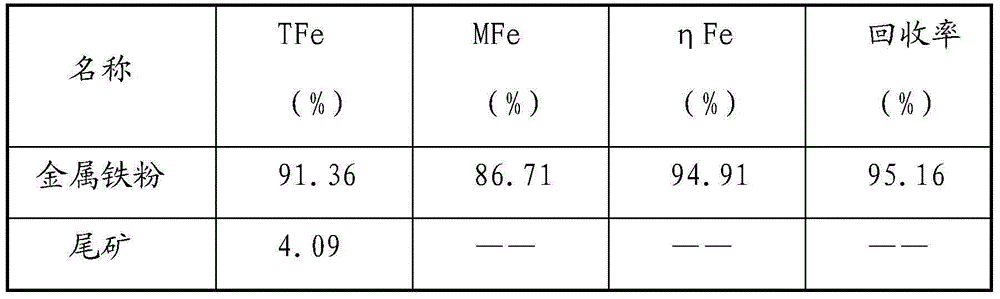

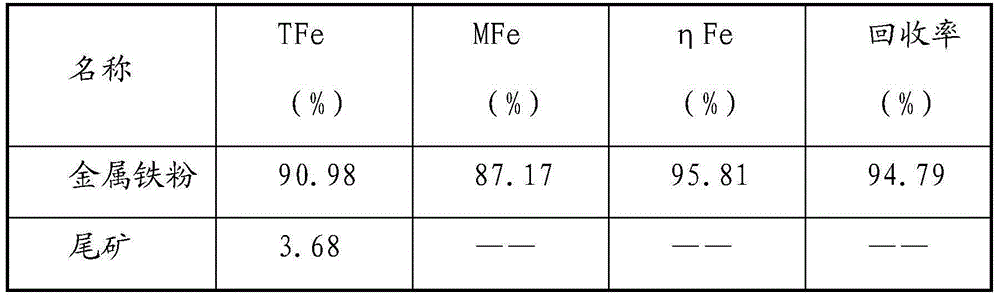

Method for separating and reducing iron powder from refractory mineral, complex ore and iron-containing waste materials

InactiveCN105018722APrevent burstDoes not affect the tasteMagnetic separationProcess efficiency improvementProduction lineSteelmaking

The invention belongs to the technical field of metallurgy, in particular to a method for separating and reducing iron powder from refractory mineral, complex ore and iron-containing waste materials. According to the method, the phase structure is converted into the easily-selected phase structure while the refractory mineral or the complex ore or the iron-containing waste materials are reduced and converted into metal iron; through simple magnetic separating, metal iron powder products high in recovery rate are obtained, considerable economic benefits are obtained, emission of a large amount of waste gas is reduced, and non-coking steelmaking is achieved; and meanwhile, the development of short-process steelmaking is promoted. By means of the method, capacity of a single production line is high, the production line can be in a concentric double-square shape, and the single production line can process 800,000 or more tons of various types of iron ore.

Owner:唐竹胜

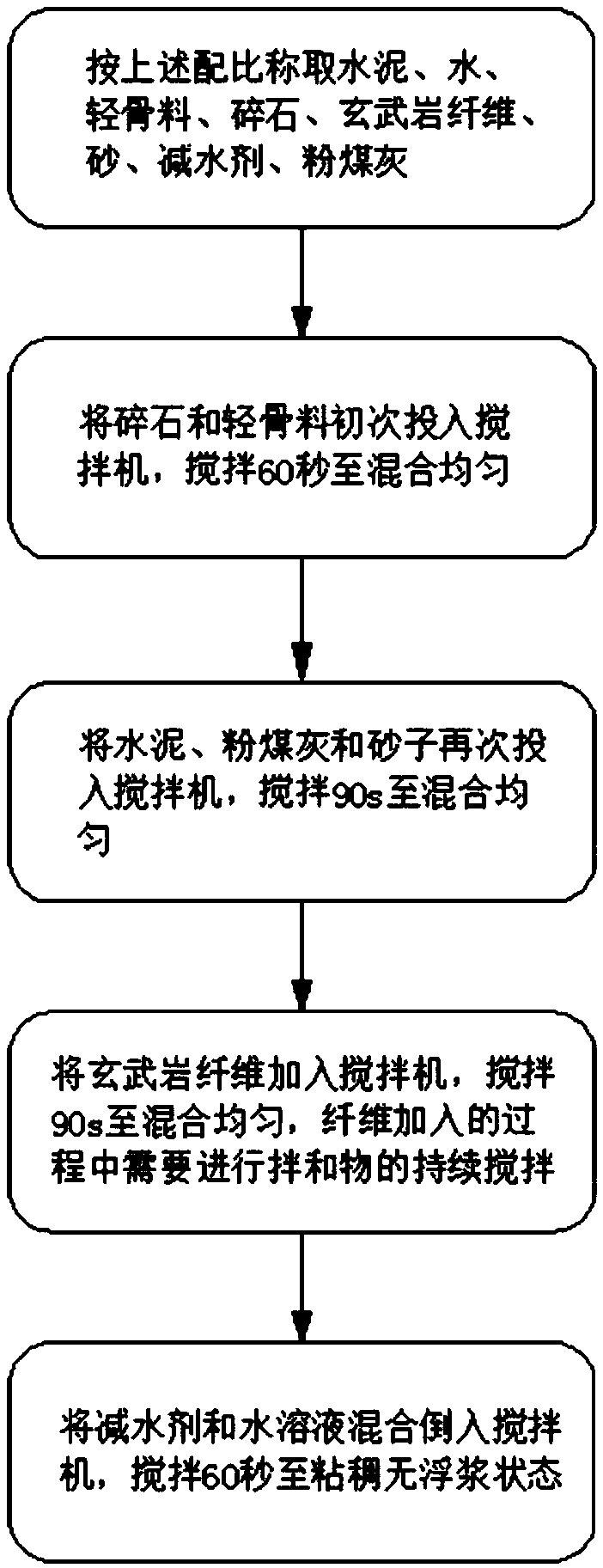

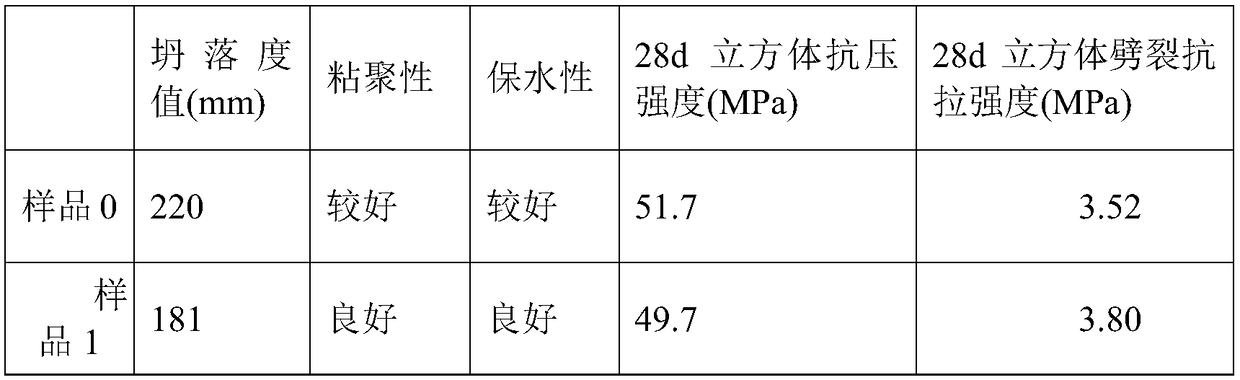

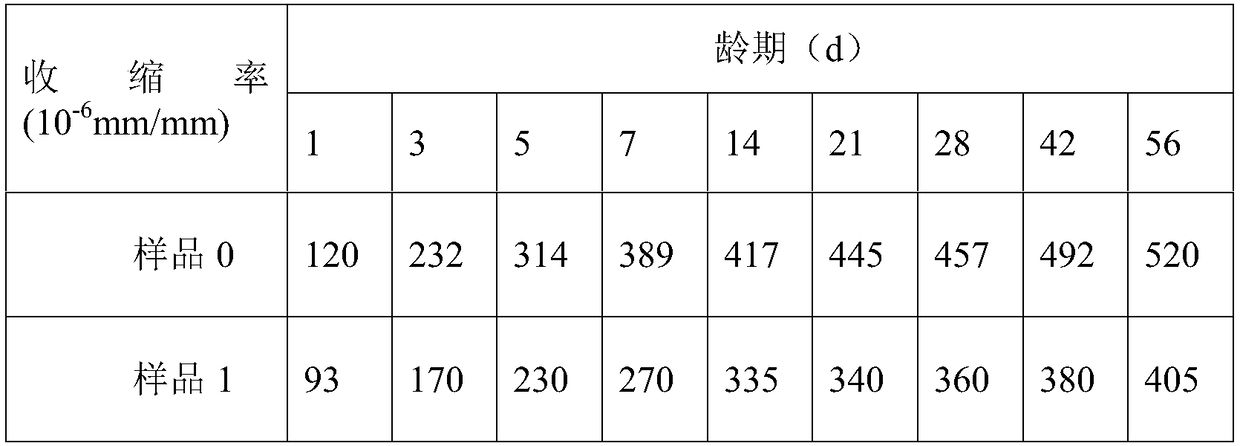

Shrinkage-reducing anti-cracking pavement cement concrete and preparing method thereof

Shrinkage-reducing anti-cracking pavement cement concrete and a preparing method thereof are disclosed. The cement concrete is prepared from water, cement, fly ash, basalt fibers, light aggregate, broken stone, sand and a water reducing agent in a mass ratio of (180-200):(400-410):(40-50):(2.65-5.3):(229-286):(465-559):(830-850):(4.1-4.5). The light aggregate is uniformly dispersed in the concrete, the concrete is not liable to crack, adhesive force between the fibers and cement slurry is high, microcrack development is slow, and the concrete has high fatigue resistance and tension resistance.

Owner:CHANGAN UNIV

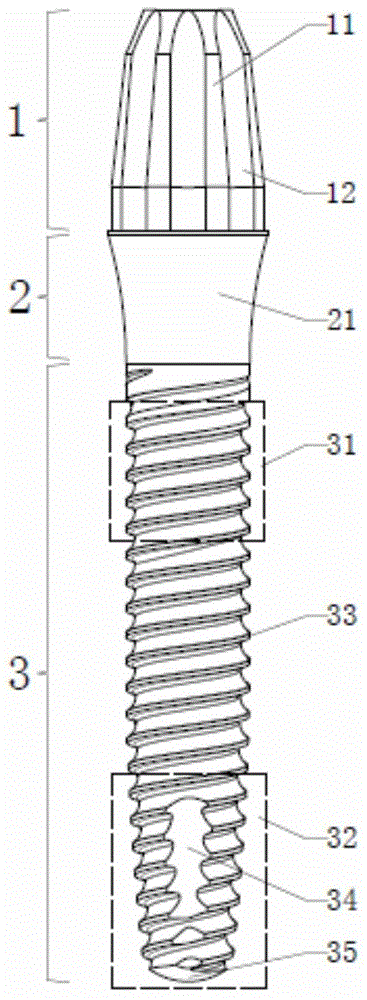

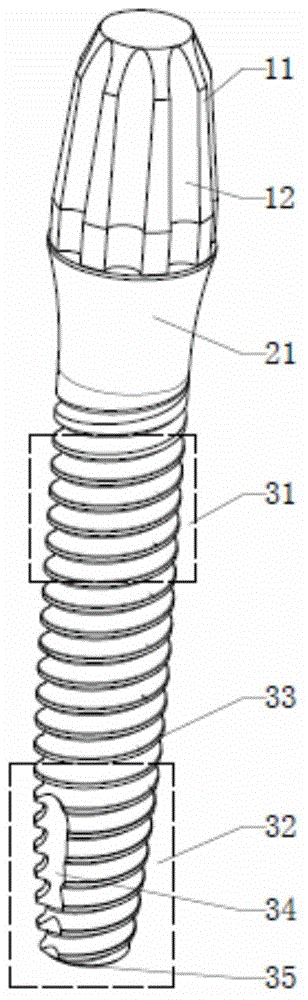

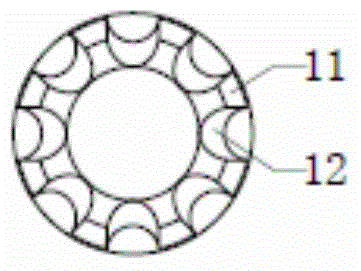

One-part form artificial dental implant and implanting method thereof

InactiveCN103550005AImprove self-tappingGuaranteed structural strengthDental implantsAbutmentScrew thread

The invention provides a one-part form artificial dental implant and an implanting method thereof. The one-part form artificial dental implant comprises an implanting section, a gingival penetration section and an abutment which are integrally, sequentially and coaxially connected, wherein a screwed thread is formed in the surface of the implanting section, a frustum is formed at one end, far from the gingival penetration section, of the implanting section, the small-diameter end of the frustum is an arc surface with the radius of R / 2 which is 1-2mm; a tapping slot is formed in the frustum, and is a vertical tapping slot or spiral tapping slot. The invention also discloses a method for implanting the one-part form artificial dental implant. According to the one-part form artificial dental implant and the implanting method thereof, multiple defects in the prior art can be overcome, and the tapping performance of the implant can be strengthened while the structure strength is guaranteed.

Owner:DALIAN SANSHENG SCI & TECH DEV

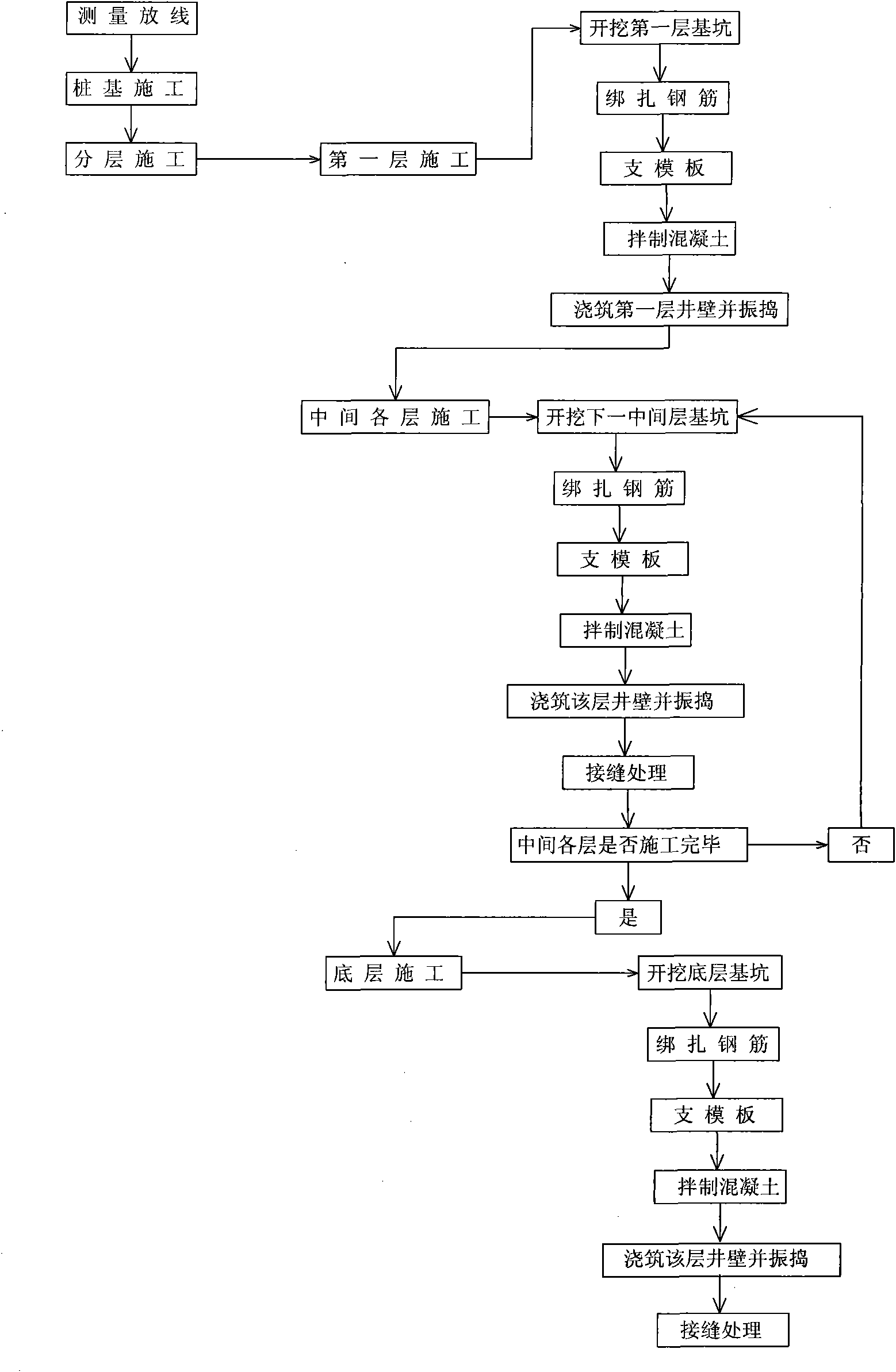

Suspension type construction method of top pipe shaft

InactiveCN101638898ASolve the problem of lateral deformationReduce the impactArtificial islandsUnderwater structuresEarthquake resistanceEngineering

The invention discloses a suspension type construction method of a top pipe shaft. The suspension type construction method is characterized by comprising the following construction steps: firstly, measuring and laying at the position of the shaft; secondly, pipe foundation construction: pressing at least four engineering piles into the ground and distributing the engineering piles along the periphery of the shaft; and thirdly, layered construction, namely excavating a foundation pit in a layering manner and casting the shaft wall in a layering manner, wherein the size and the position of the foundation pit are the same as the shaft; and the third step comprises three substeps in sequence: the first substep is the construction of a first layer, namely the uppermost layer, excavating the first layer and carrying out casting to the shaft wall of the uppermost layer; the second substep is the construction of all the layers in the middle, downward continuously excavating in a layer manner and carrying out casting to the shaft wall layer by layer; and the third substep is construction of the bottom layer, excavating the bottommost layer and casting the shaft wall and the shaft bottom ofthe layer. The suspension type construction method creates the construction method of inversely casting the shaft wall from top to bottom, shortens the construction period, does not need to arrange asupporting structure additionally in construction, solves the problem of lateral deformation of the original maintaining wall and improves the earthquake resistance of the shaft.

Owner:ZHENGZHOU MUNICIPAL ENG CORP +1

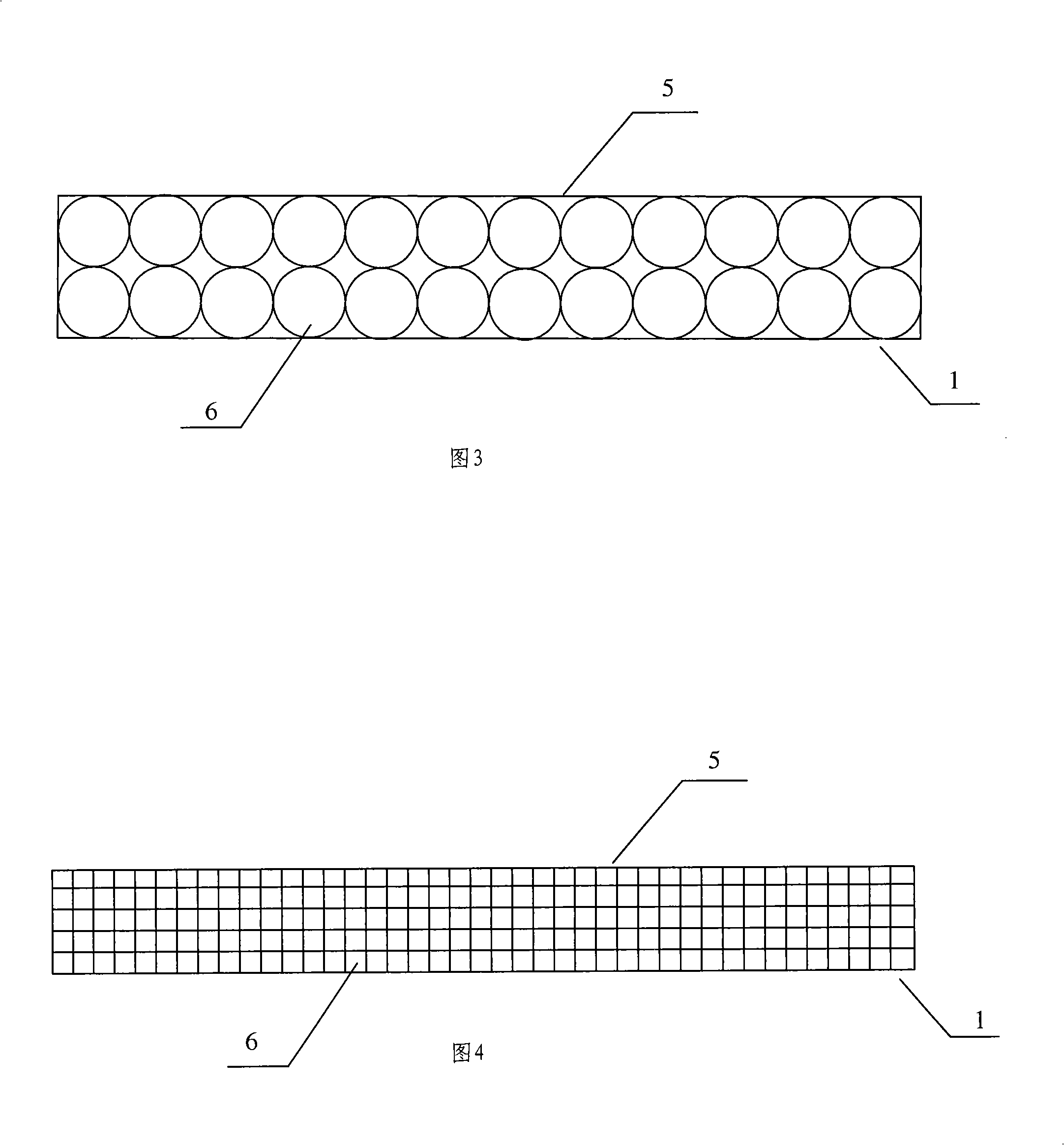

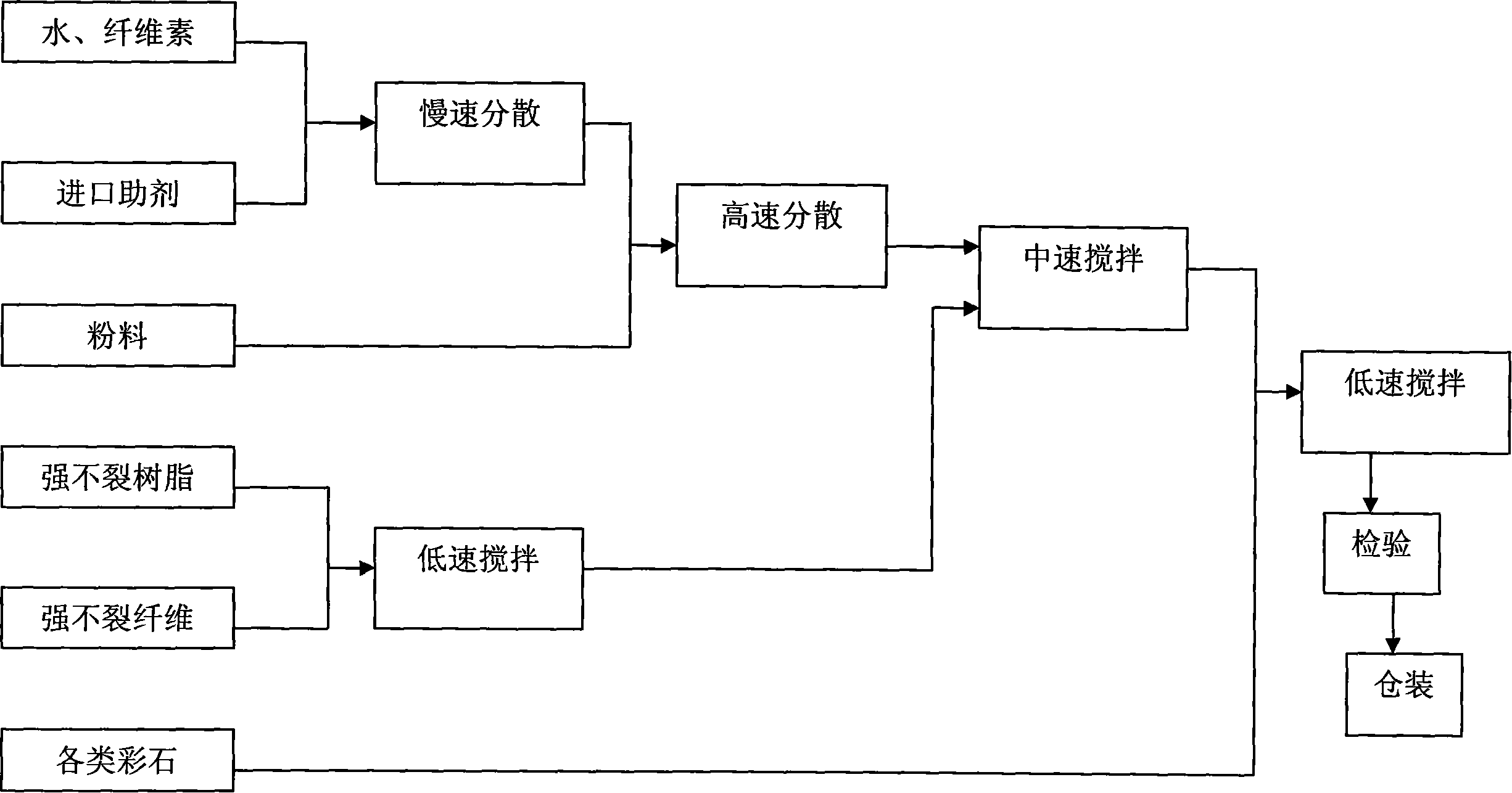

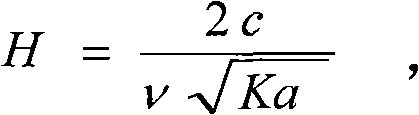

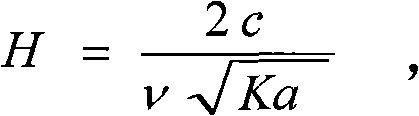

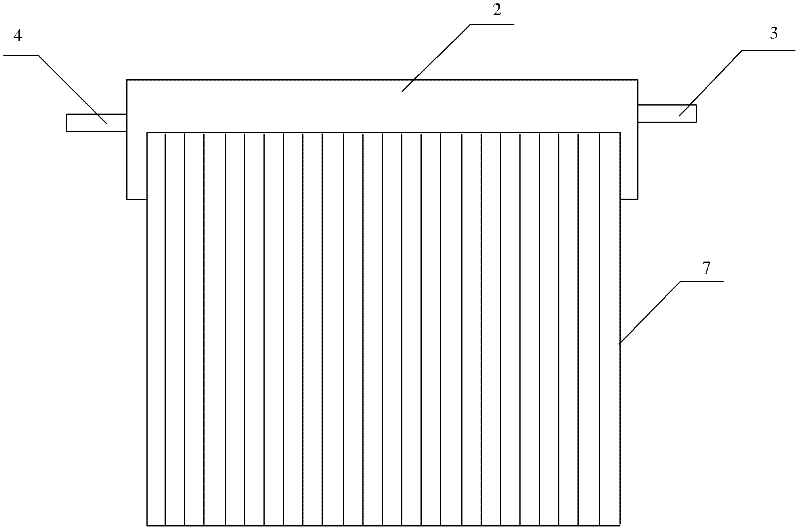

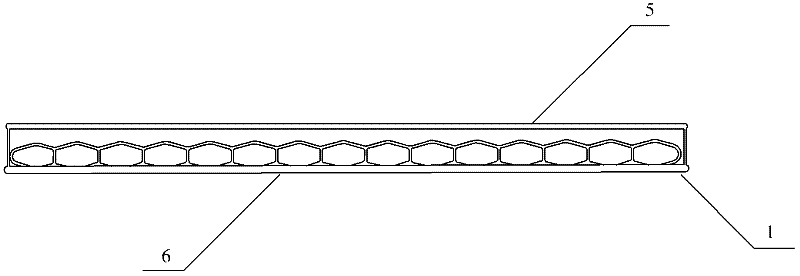

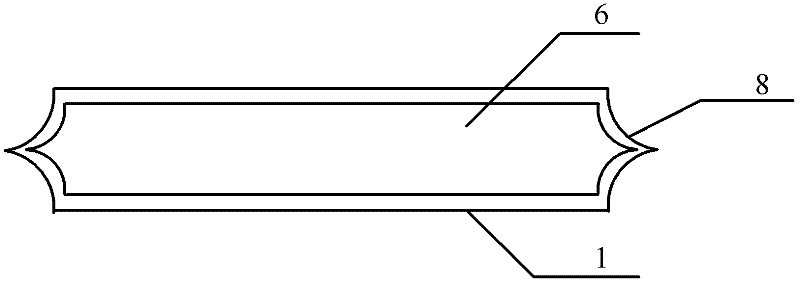

Platy heat pipe and processing technology thereof

InactiveCN102506597AImprove structural strengthWith ultra-thinSolar heating energyIndirect heat exchangersTrunk structureEngineering

The invention provides a platy heat pipe, comprising a platy heat pipe frame, wherein the platy heat pipe frame is internally provided with a microporous pipe trunk structure which is formed by a group of microporous pipes, side walls of the microporous pipes are connected to mutually enhance the strength of each microporous pipe, each microporous pipe is filled with a working medium with a phase inversion heat exchange effect, two ends of the platy heat pipe are sealed, and at least one end is provided with a gradually contractive sealing belt formed by cold welding. The platy heat pipe provided by the invention has the characteristics of high strength, super thinness, high efficiency and high heat transportation volume and can substitute an oscillation heat pipe and a common heat pipe.

Owner:赵耀华

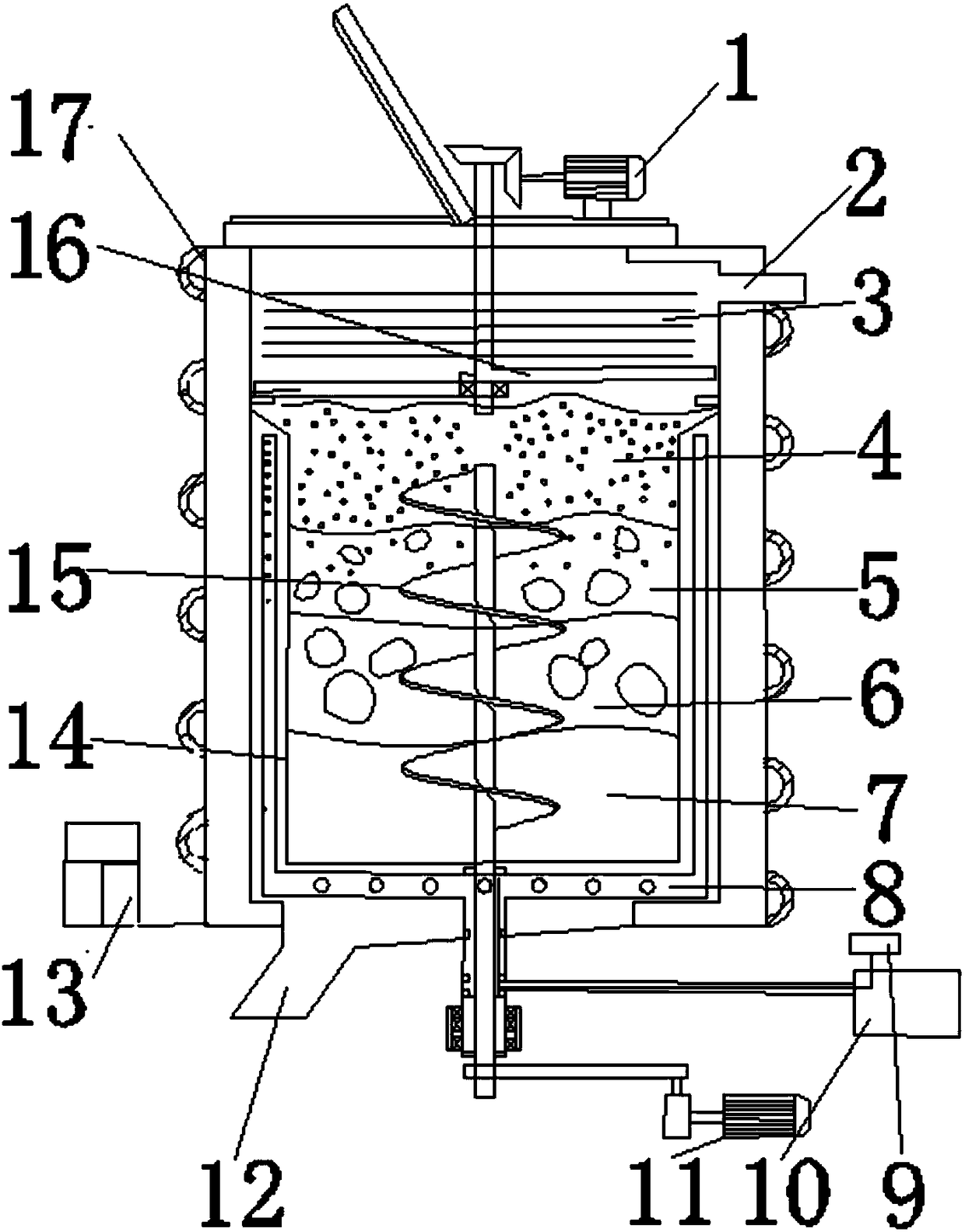

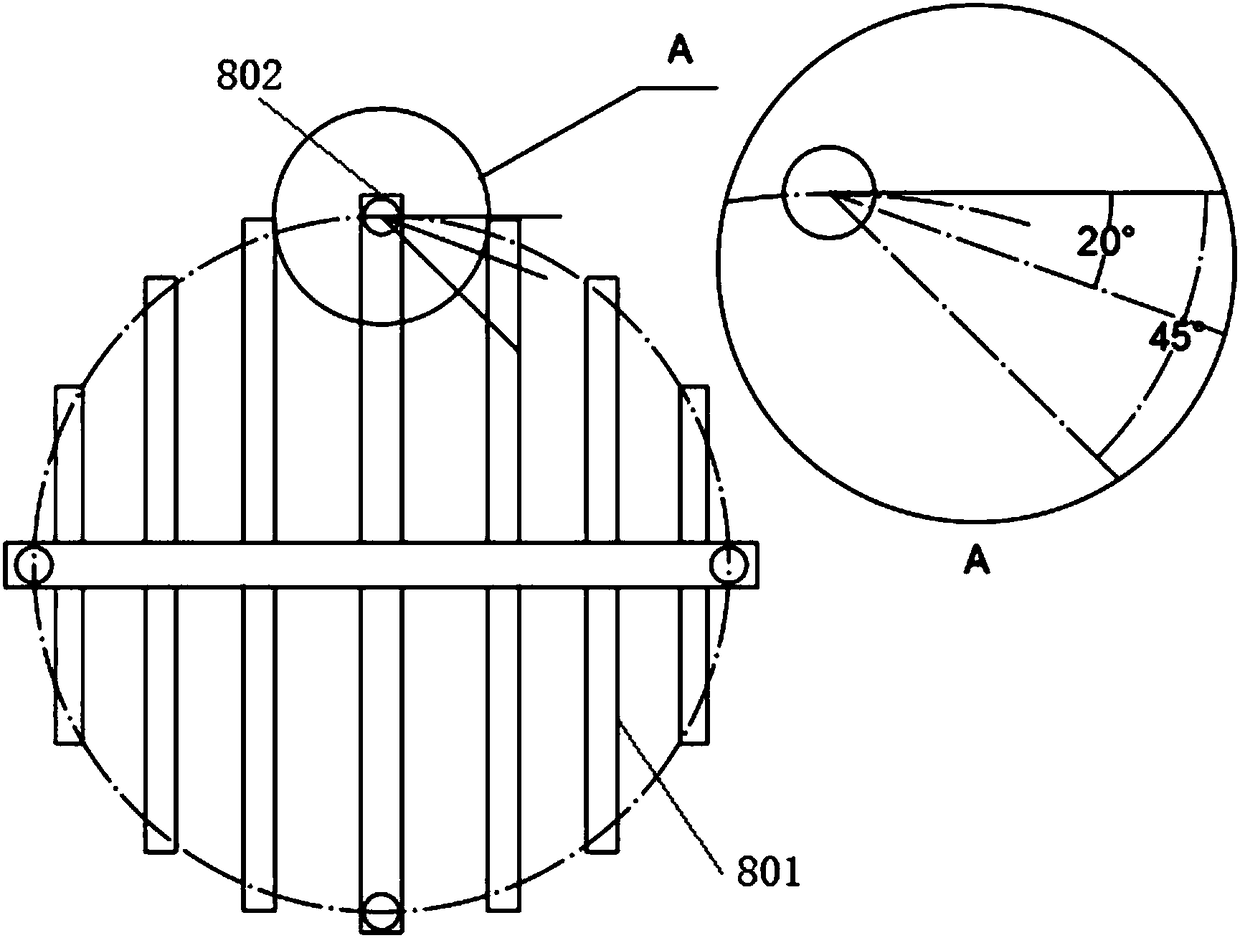

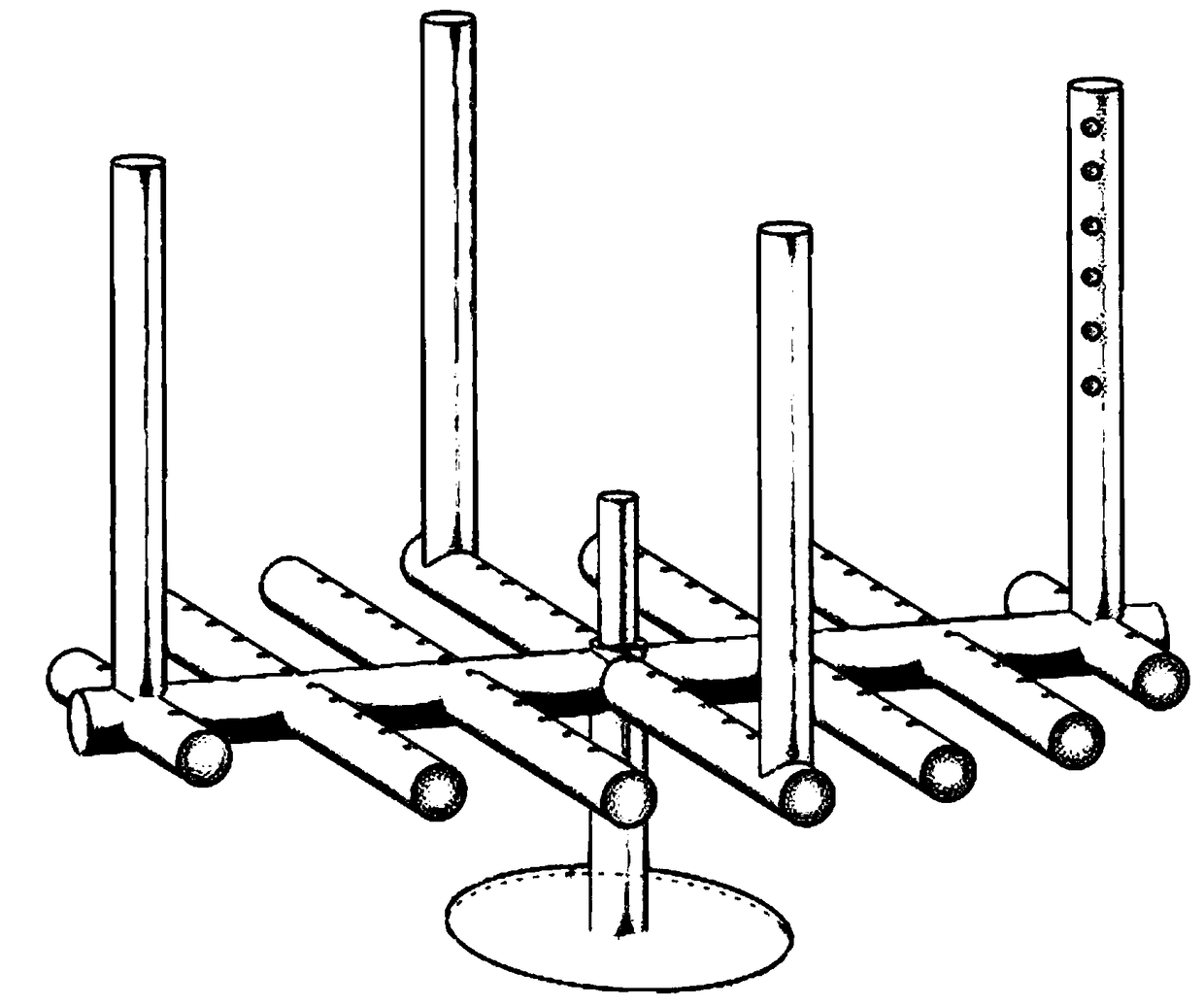

Wind power blade waste pyrolysis incinerator and control method thereof

The invention discloses a wind power blade waste pyrolysis incinerator and a control method thereof. The wind power blade waste pyrolysis incinerator comprises an incinerator body; a cooling pipe is arranged at the exterior of the incinerator body; an opening is formed in the top of the incinerator body; a smoke vent communicating with the outside is formed in the upper end of the incinerator body; an ash discharge chute furnace is arranged at the bottom of the incinerator body; a working cavity is formed in the incinerator body; an electric control feed door, a spiral agitator, a gas supply and distributing device and an isolation hood are arranged in the incinerator body; the electric control feed door and the spiral agitator are driven by motors correspondingly; the electric control feed door is arranged between a drying zone and a pyrolysis zone; a plurality of through holes are formed in the electric control feed door; the spiral agitator is located in the pyrolysis zone and the combustion zone; the gas supply and distributing device is arranged at the bottom of a combustion zone, is connected with a spiral bearing and can rotate in the incinerator body; and the isolation hoodis arranged on the inner side of the gas supply device and is used for isolating the gas supply device and a wind power blade material. Wind power blade waste can be pyrolyzed and burnt fully, and pollution is reduced.

Owner:上海博士高环保成套工程有限公司

High-performance building cement and preparation method thereof

InactiveCN106946480AImprove migration efficiencyEffect of improving long-term weather resistanceFiberSlag

The invention discloses high-performance building cement and a preparation method thereof, wherein the high-performance building cement is prepared from the following raw materials by weight: 20.4-33.6 parts of sulphoaluminate clinker, 3-5 parts of a bamboo phenol alcohol liquefaction resin, 3-8 parts of an AS resin, 0.5-1.5 parts of carboxymethyl cellulose, 23-47 parts of a core-shell acrylic elastic emulsion, 8-20 parts of waste paper pulp, 3-6 parts of a heat stabilizer, 0.9-4.9 parts of a chemical-resistant modifier, 15-20 parts of 4-hydroxy-3-methoxyphenylethyl alcohol, 10-25 parts of a heat conduction filler, 10-18 parts of slag micro-powder, 0.75-2.65 parts of infrared reflective titanium dioxide, 0.4-0.6 part of a light stabilizer, 0.1-0.8 part of a coupling agent, 0.7-4.3 parts of an accelerator, 4-8 parts of bamboo fiber, 2.5-8.5 parts of silicon nanoparticles, 7-13 parts of nanometer calcium carbonate, and the like. The high-performance building cement of the present invention has advantages of good durability, good weathering resistance, good thermal insulation, and good strength.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

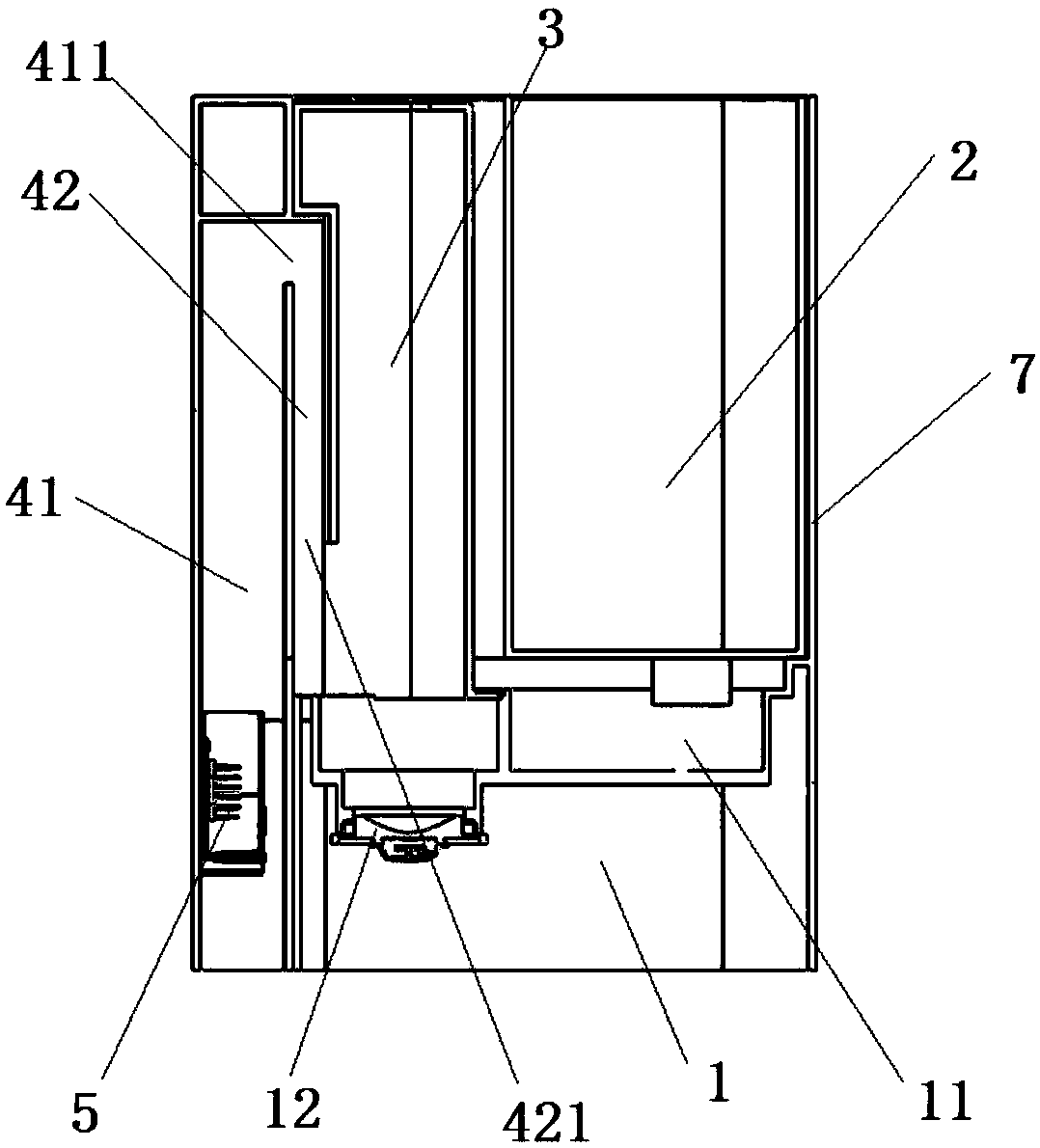

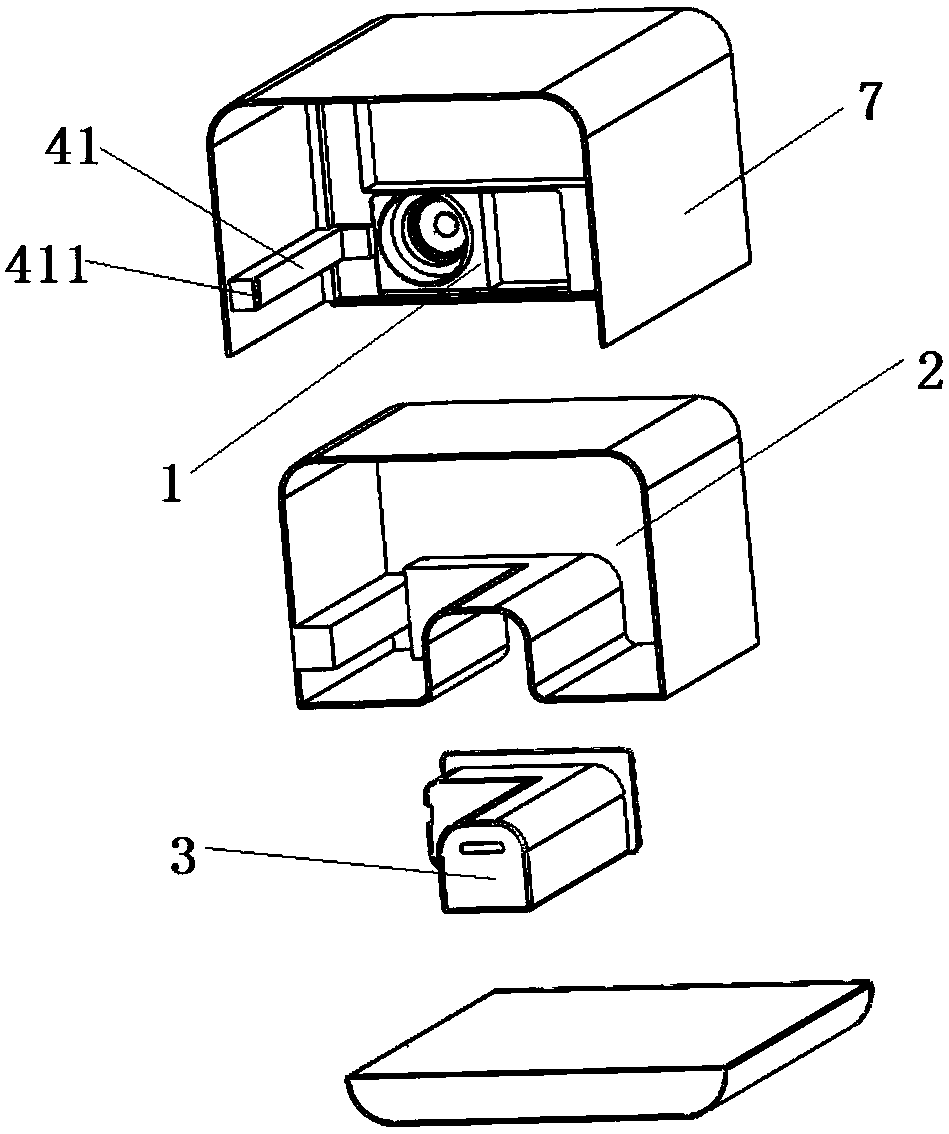

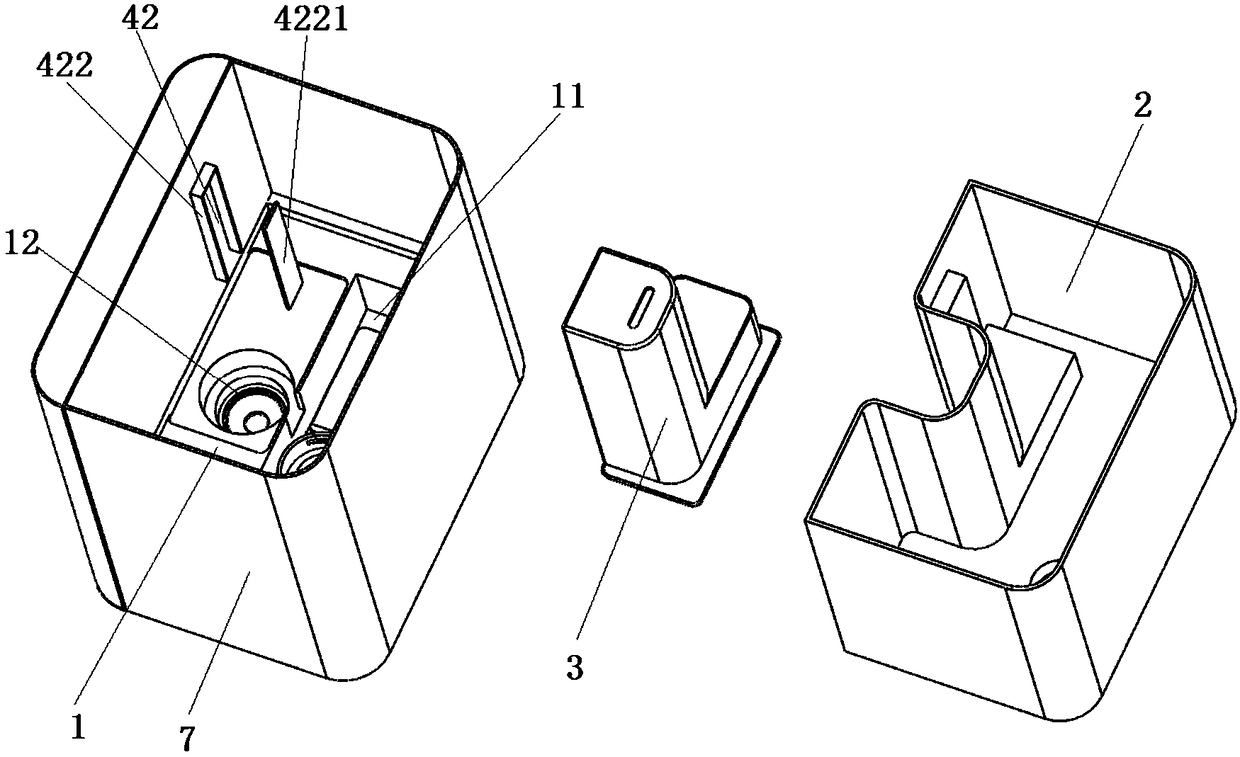

Humidifier

ActiveCN108413543APrevent leakageImprove securityLevel controlLighting and heating apparatusWater storageNebulizer

The invention provides a humidifier. The humidifier comprises a machine seat, a water tank, a water storage chamber, an atomizer, a mist-out channel and a water-out control device. The water tank is provided with a water outlet. The water storage chamber is arranged on the machine seat and is provided with the atomizer, and the mist-out channel discharges the mist generated by the atomizer out ofthe humidifier. The water-out control device is used for controlling opening and closing of the water outlet so that the water in the water tank can enter the water storage chamber. The humidifier further comprises an outer wrapping body, wherein the upper portion of the outer wrapping body is open to prevent the water from being leaked out, the water tank is separately arranged in the outer wrapping body, and the lowest point at the upper end of the outer wrapping body is higher than the highest water level of the water leaked out of the water tank. The humidifier has the following advantagesof being stable as a whole, being capable of preventing water leakage, convenient to detach and clean, high in fan efficiency, firm in structure, high in insurance, high in safety coefficient, convenient to operate, clean and tidy and high-end in appearance and optimal in performance.

Owner:FOSHAN JINXINGHUI ELECTRICAL APPLIANCE

Biological tendon repairing material and preparation method thereof

ActiveCN107854727APromote growthEasy to climbTissue regenerationProsthesisCell-Extracellular MatrixCellular infiltration

The invention provides a biological tendon repairing material and a preparation method thereof. The biological tendon repairing material comprises an extracellular matrix body subjected to immunogen removal, wherein the extracellular matrix body consists of one or more layers and comprises a first surface and a second surface; the first surface comprises a first area and a second area; the mechanical strength of the first area is lower than that the second area. During preparation of an extracellular matrix subjected to immunogen removal, layering is avoided. As the biological tendon repairingmaterial is provided with the surface which consists of the first area and the second area, cellular infiltration of defective tissues is facilitated, tissue repairing is accomplished, stress born bythe repairing material can be uniformly distributed, and local stress cannot be excessively large. Besides, the surface has a high suture retention force and can serve as the second surface of a suture area of the repairing material, and the strength of the repairing material can be guaranteed while repairing of the defective tissues is facilitated.

Owner:BEIJING BIOSIS HEALING BIOLOGICAL TECH

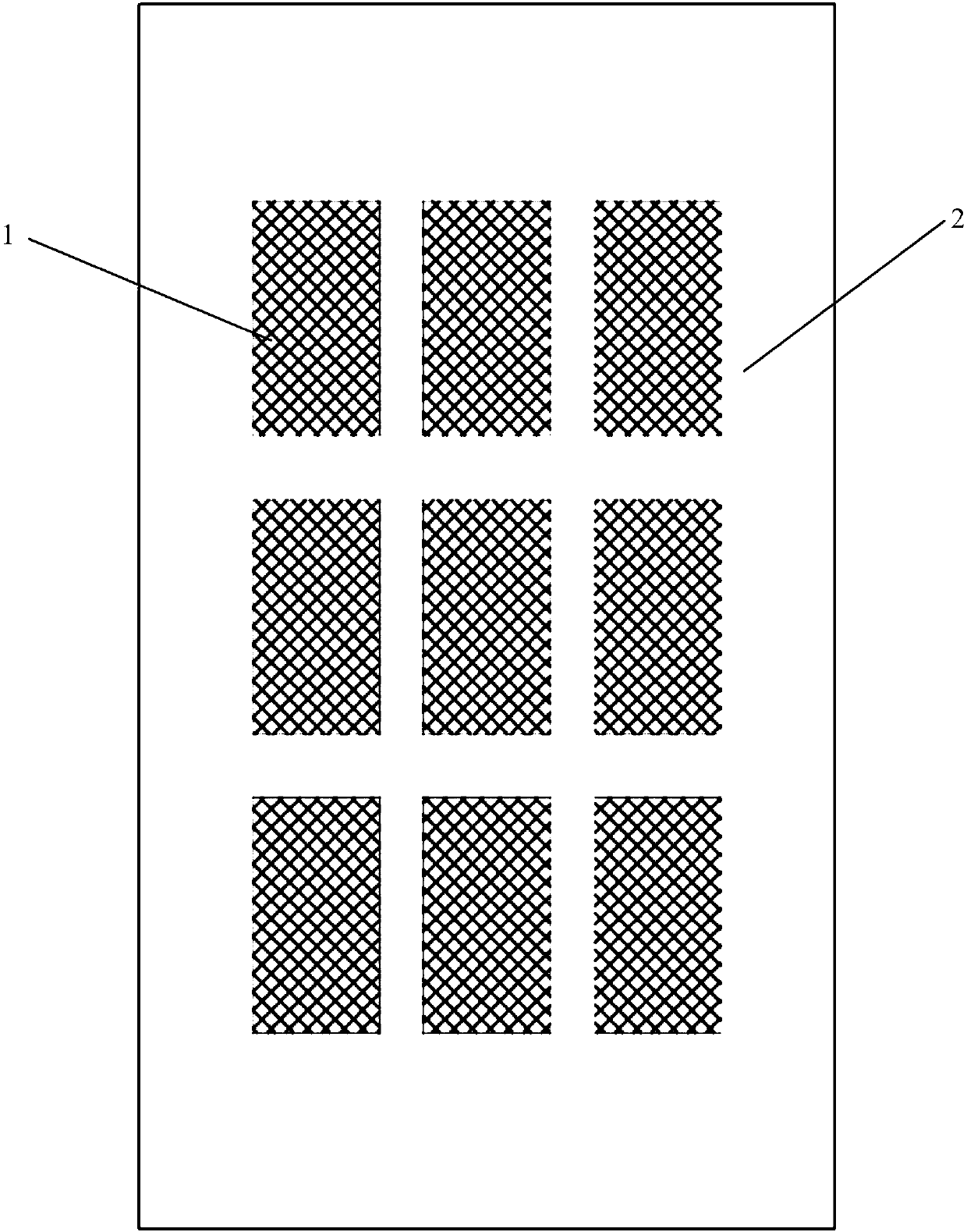

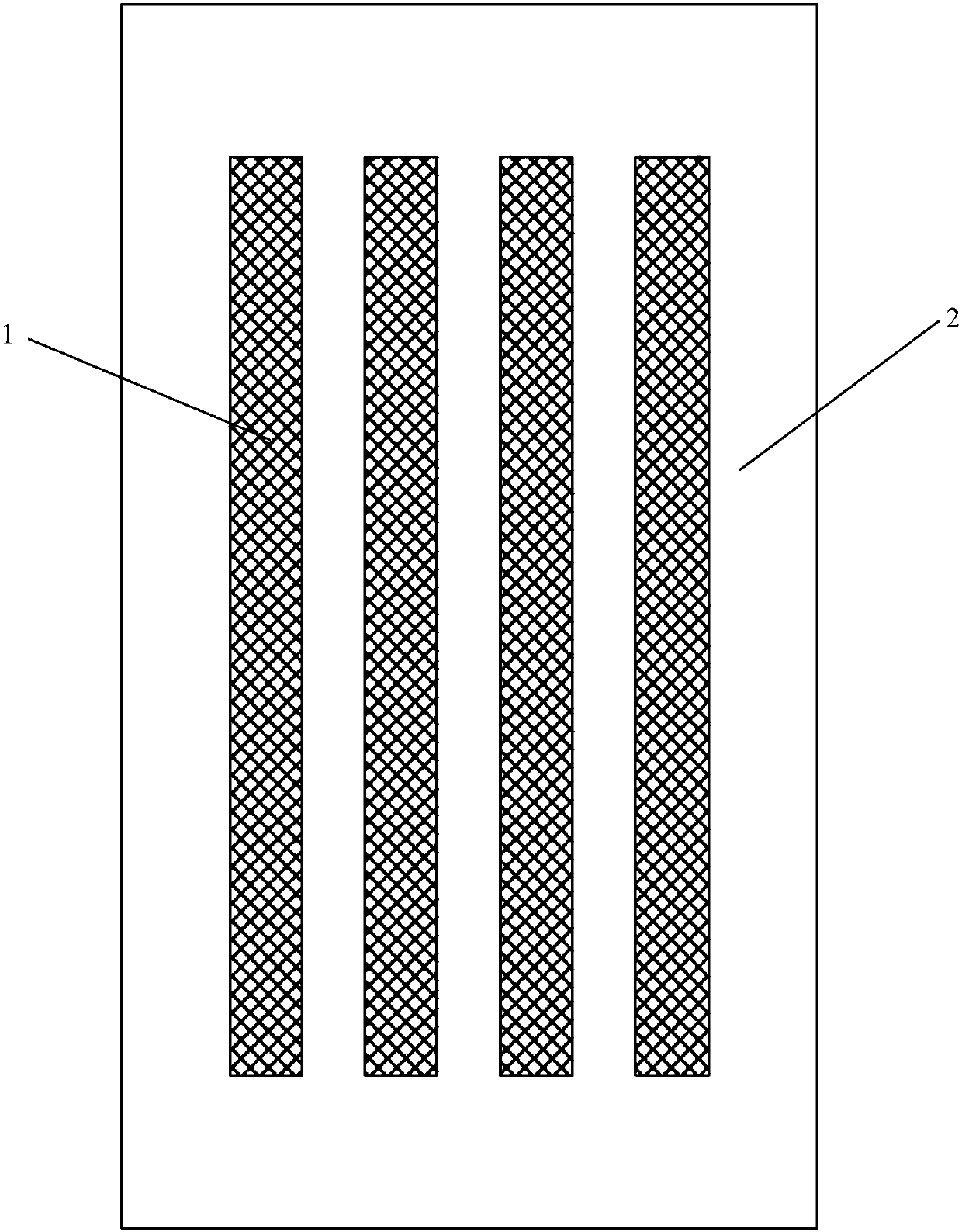

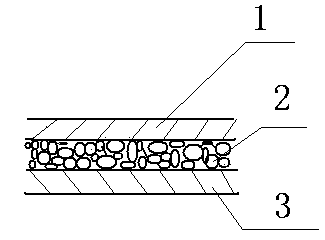

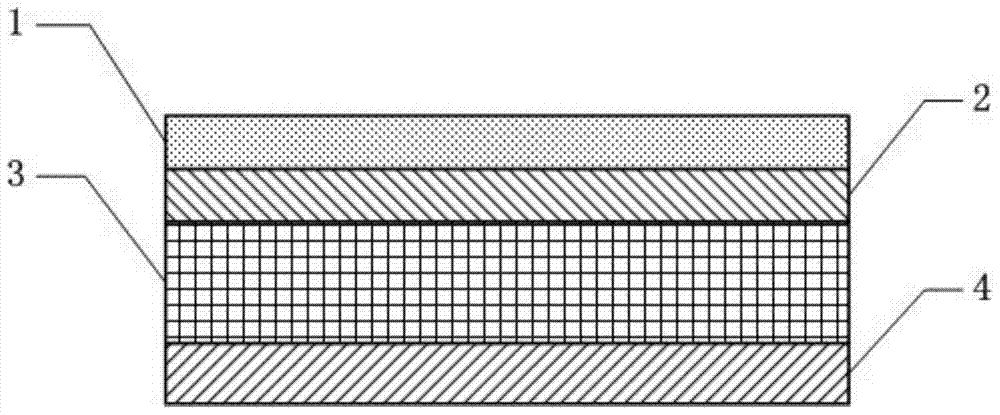

Geofabric used for ecological restoration

InactiveCN103568409AReduce absorptionDoes not affect respirationContaminated soil reclamationProtective foundationFiberEnvironmental resistance

The invention discloses a geofabric used for ecological restoration, and belongs to the field of textile geosynthetics used for industry. The geofabric is formed by a three-layer structure in a composite mode; the three-layer structure comprises an acupuncturing chopped fiber non-woven geofabric layer of 200 grams, a modified montmorillonite mineral powder layer, and a continuous fiber acupuncturing non-woven geofabric layer from top to bottom; and the three layers are connected together by acupuncturing technology in the composite mode. The geofabric is capable of absorbing heavy metals effectively, and have strong absorbability on heavy metals and low-molecule organic compounds. The content of formed complexes is extremely low in water solution. The geofabric is capable of effectively removing heavy metals and other toxic matters in surface water sources or air floating objects, further reducing soil and water pollution caused by heavy metals, and realizing water-saving and energy-saving, sustained release and environmental protection, prevention of water and soil loss via reinforcement, and the like. The geofabric can be used in projects such as farm field soil heavy metal treatment, garbage landfills and sewage processing plants. The geofabric is characterized in convenient construction, low cost, and the like, and is capable of solving problems of existing heavy metal processing that technical requirement is strict, and cost is high.

Owner:DEZHOU ORIENT GEOSYNTHETICS

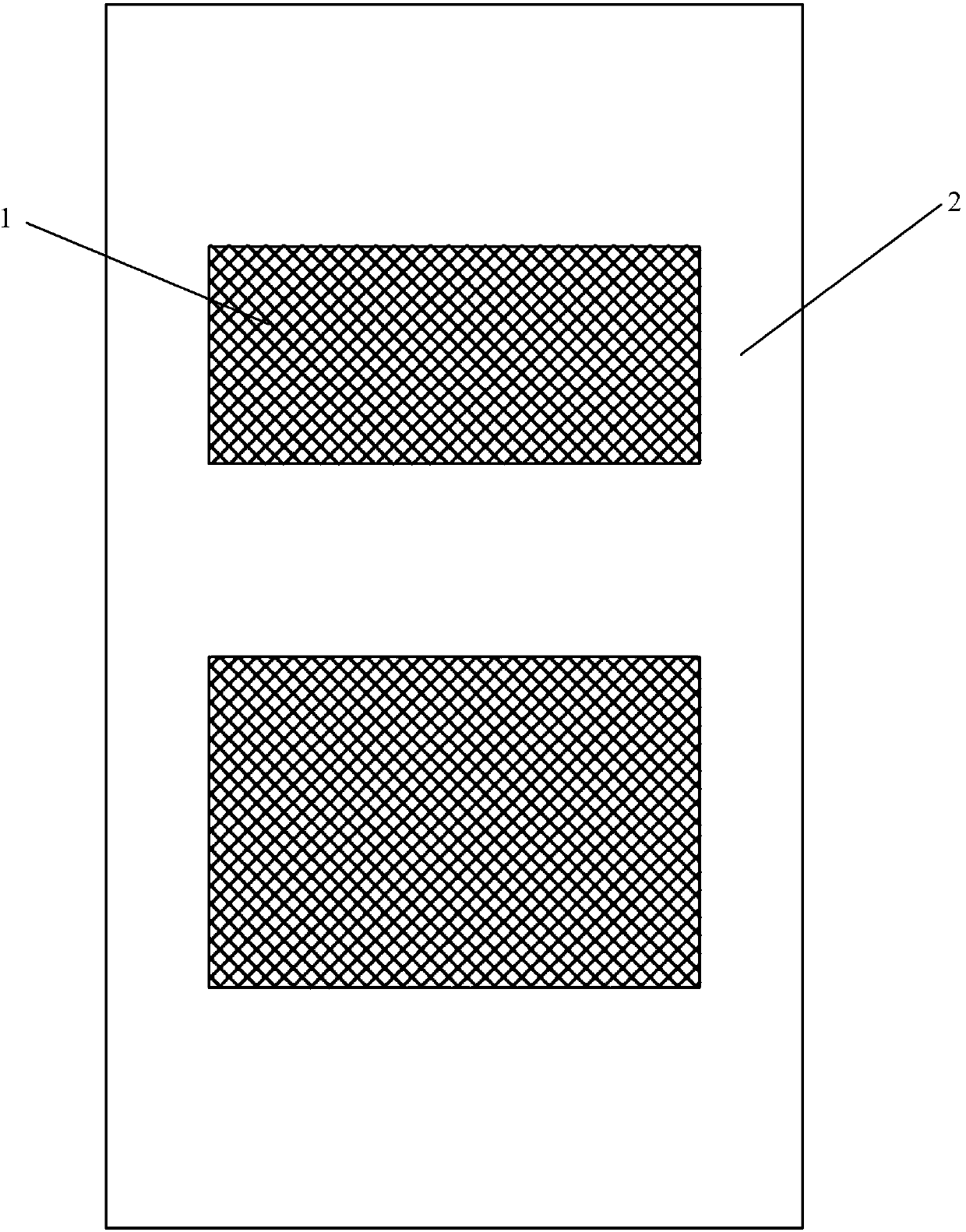

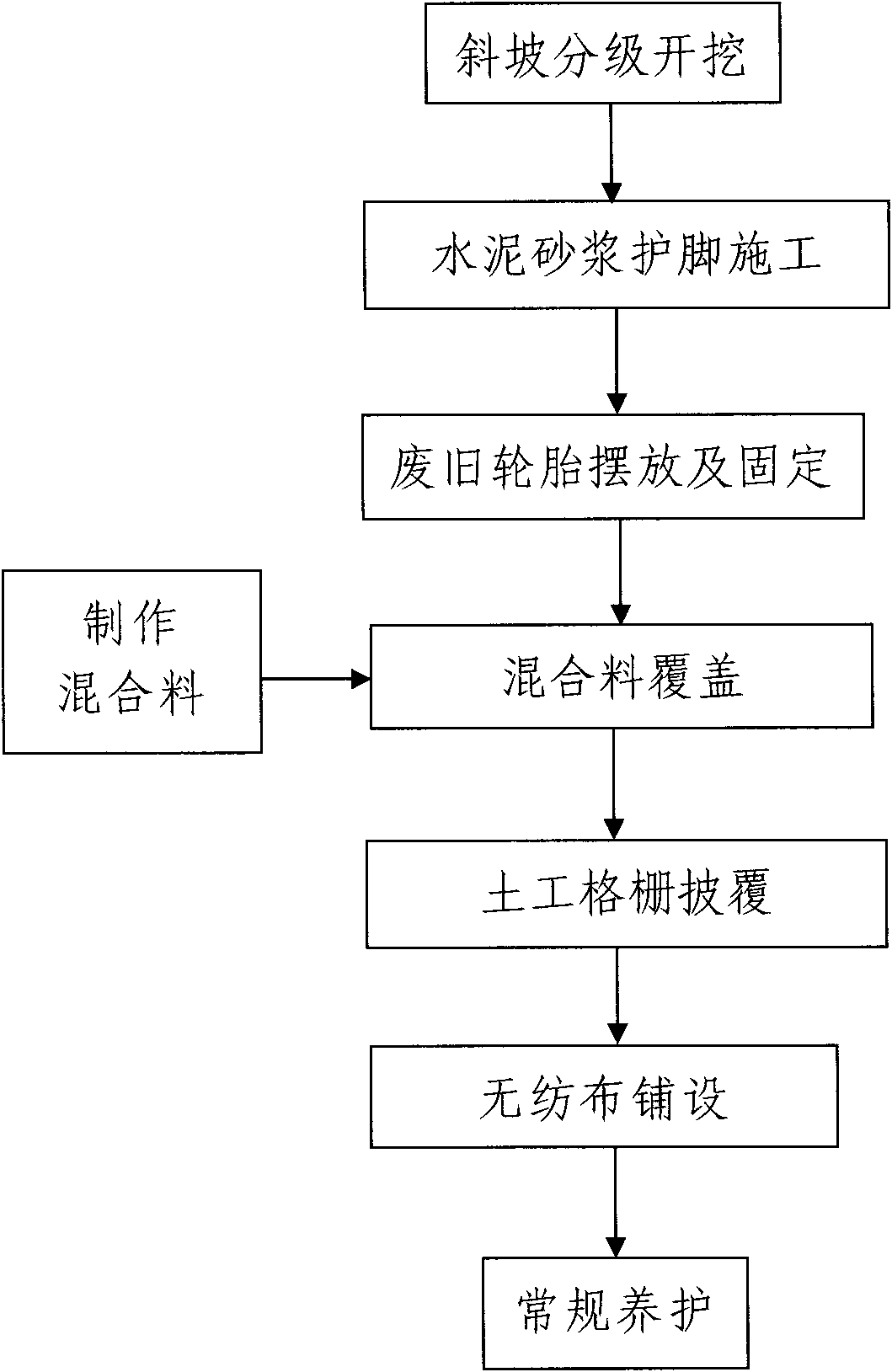

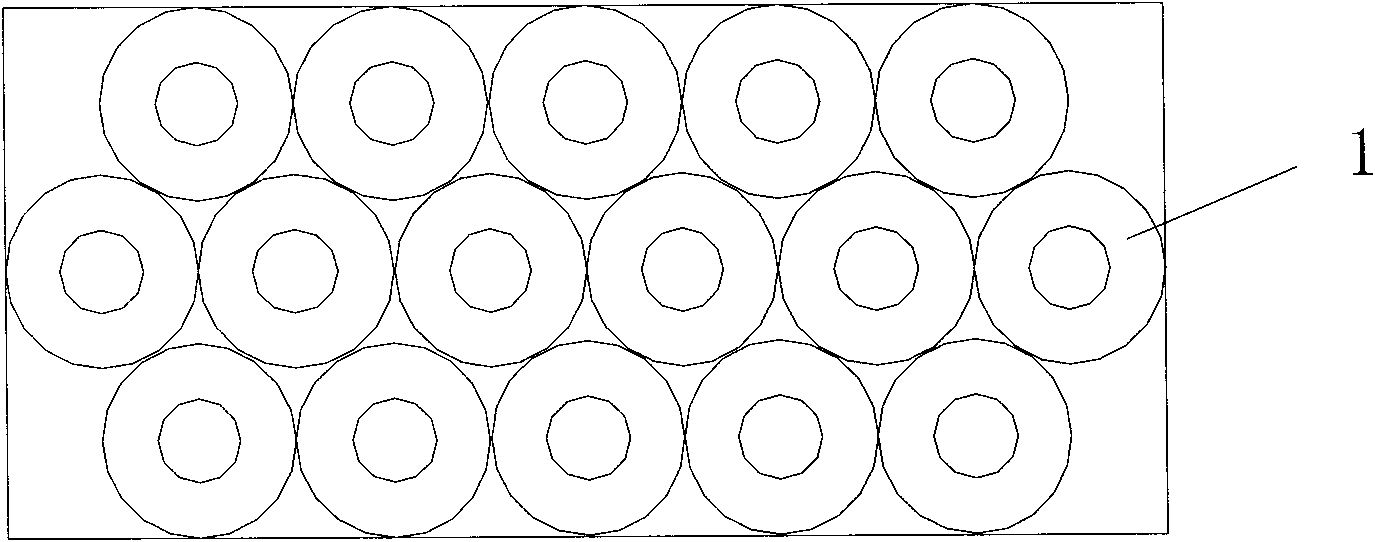

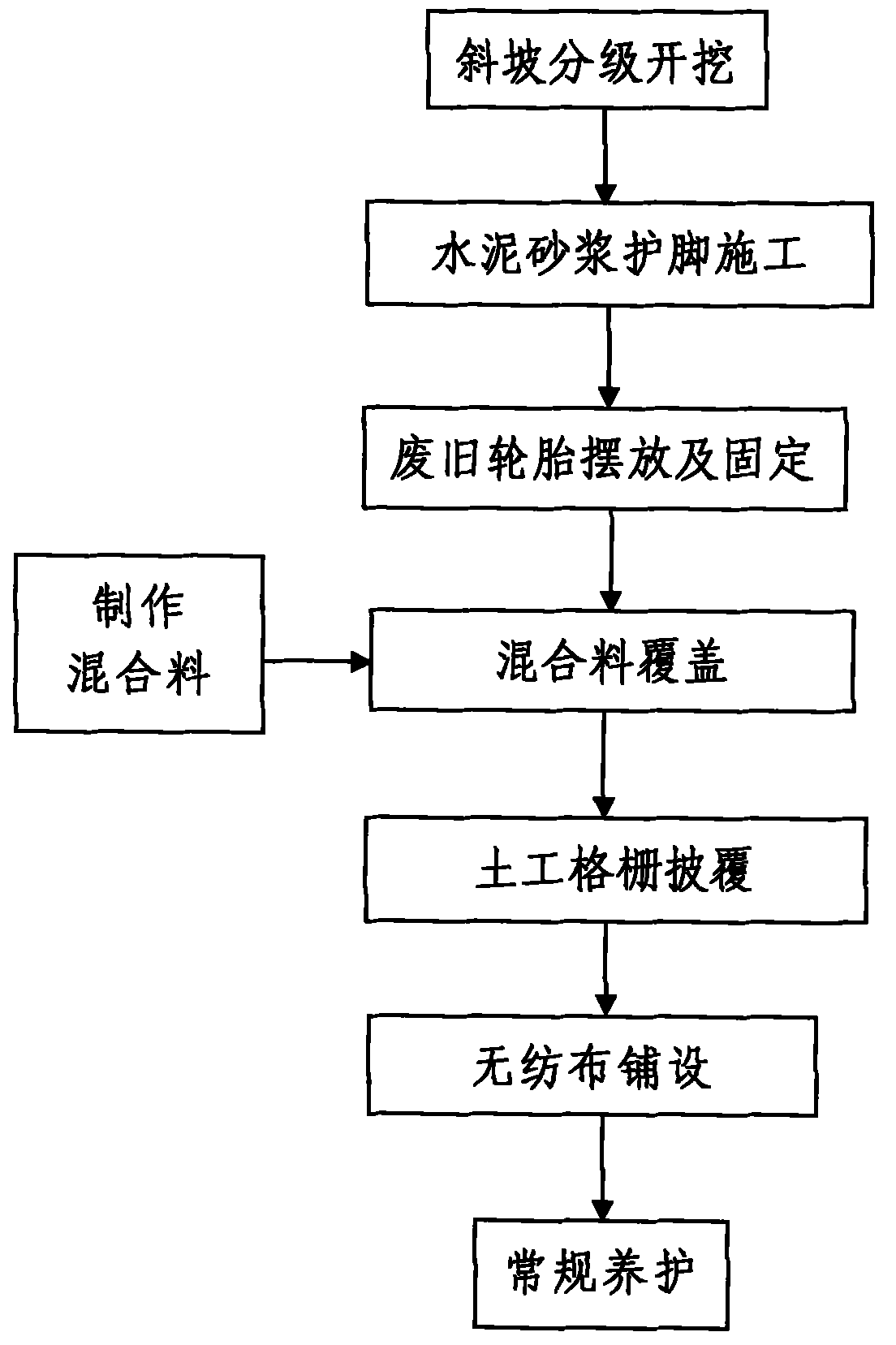

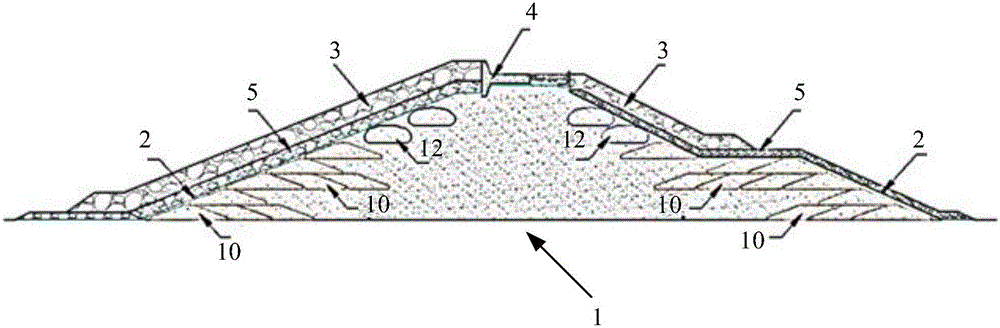

Method for treating shallow disease of expansive soil slope

The invention discloses a method for treating a shallow disease of an expansive soil slope. The method comprises the following steps of: 1, excavating the slope into different levels; 2, constructing a protection foundation by using cement mortar: uniformly painting a cement mortar layer on a slope base of each level of the excavated multi-level stepped slope to form a slope base protection foundation; 3, treating the slope level by level: treating the multi-level slope of the multi-level stepped slope level by level from top to bottom or from bottom to top, wherein for any level of the slope Ai, the treatment process comprises the following steps of: laying and fixing waste tires; overlaying a mixed material; covering geogrids; and paving non-woven fabrics; and 4, post-stage curing: curing the mixed material according to a conventional herbaceous plant curing method. The method for treating the shallow disease of the expansive soil slope has the advantages of novel and reasonable design, simple and practical operation, low cost, good treatment effect and capacity of effectively solving the problem of shallow diseases of the expansive soil slope.

Owner:XIAN UNIV OF SCI & TECH

Semi-permeable groyne and molding method thereof

The invention provides a semi-permeable groyne. The semi-permeable groyne is molded underground, and comprises a groyne body, an inverted filter layer, a protection surface structure and a wave wall, wherein the groyne body is a main body of the groyne; the inverted filter layer is laid on the groyne body; the protection surface structure is laid above the inverted filter layer to form a wave resisting structure; and the wave wall is mounted and laid at the top of the groyne body. Multiple sand bags are filled in the groyne body; gravels are filled in the sand bags; and the sand bags are constructed on water and built on the edge of the groyne body to form an underwater cofferdam so as to prevent the loss of backfill materials and reinforce the side edges of the backfill groyne body. The sand bags are covered with soil engineering pipe belts; the soil engineering pipe belts are built above the sand bags to form a land cofferdam; the tubular sand bags and the soil engineering pipe belts are respectively built on the edges of the groyne body to protect the backfill materials in the groyne center to prevent or reduce the permeable loss, so that the edges of the groyne body are reinforced, the antiskid stability of the groyne body is improved, the effect of reinforcing ribs is achieved, and the whole stability of the groyne is promoted; and the groyne center adopts the backfill materials to reduce such building materials as groyne center stones, so that the engineering cost is saved. The invention further provides a method for molding the semi-permeable groyne.

Owner:CCCC FHDI ENG +1

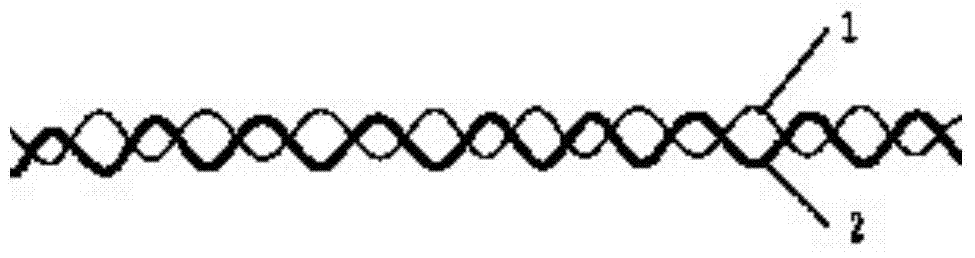

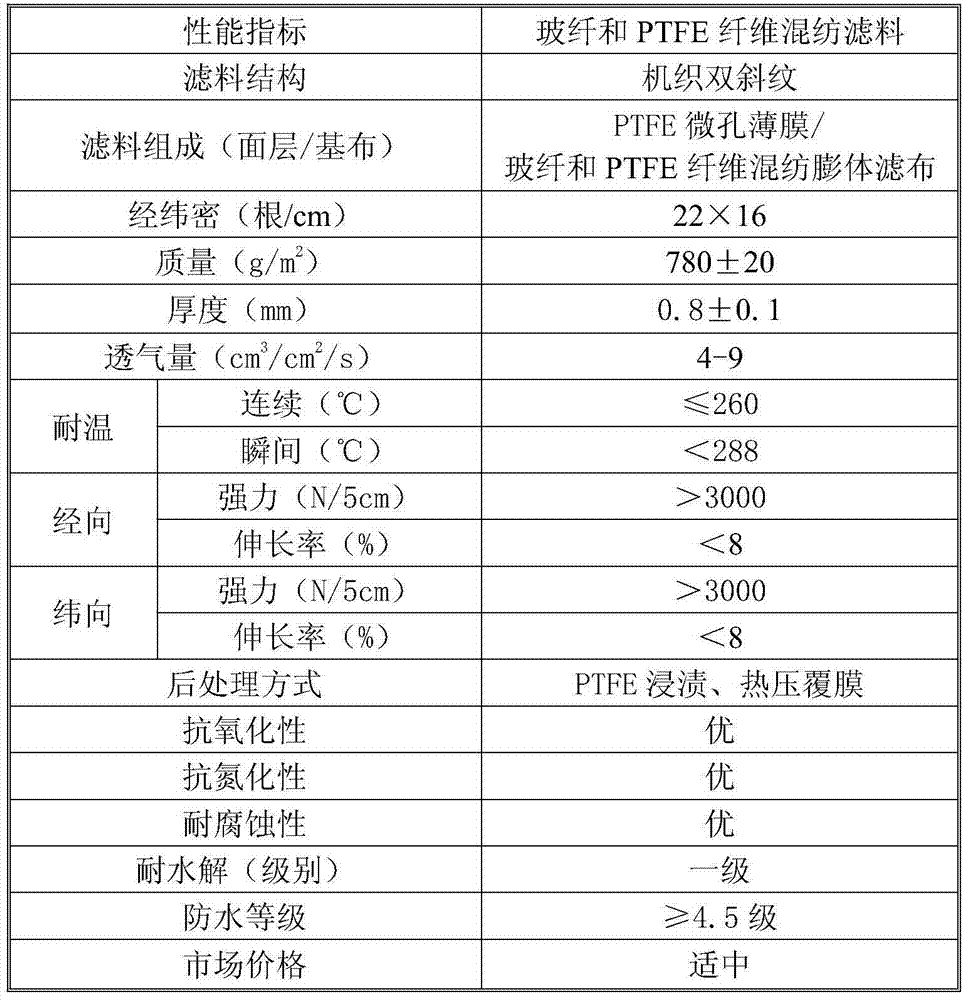

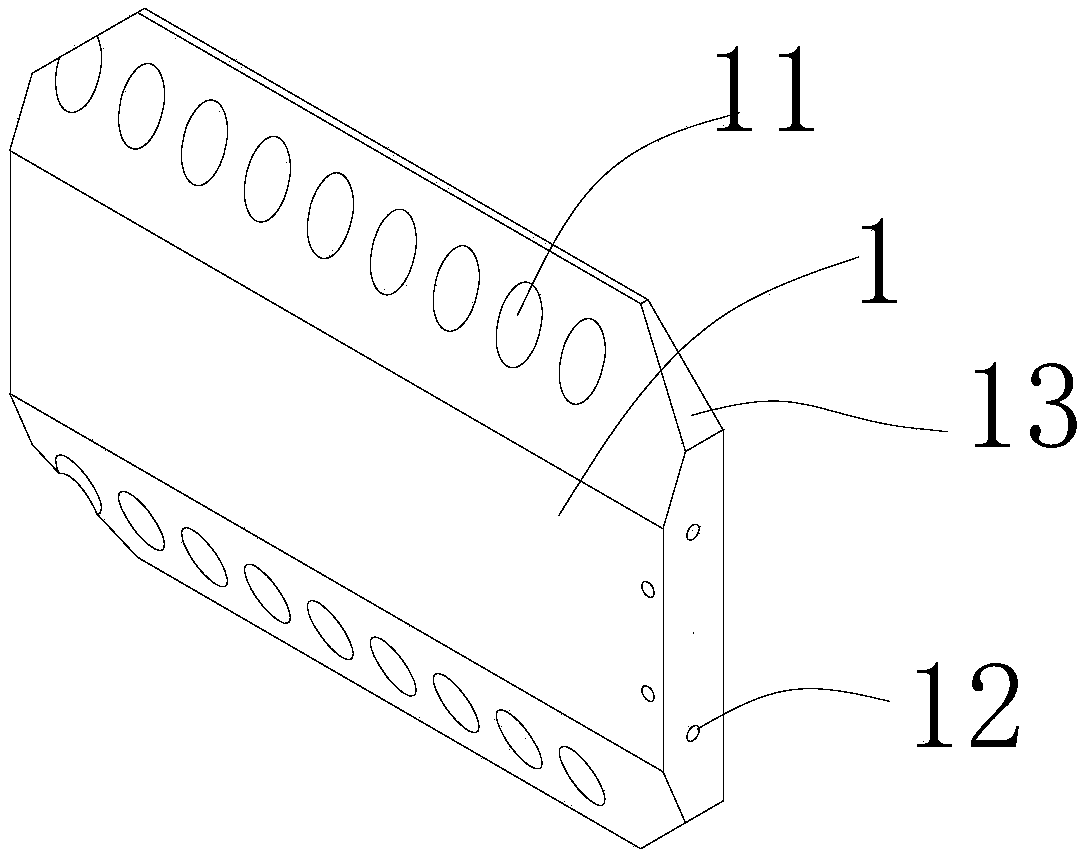

Glass fiber and PTFE (Polytetrafluoroethylene) fiber blended filter material and preparation method thereof

ActiveCN103785224AGood flexibilityImprove folding resistanceSynthetic resin layered productsGlass/slag layered productsMolten stateYarn

The invention provides a glass fiber and PTFE (Polytetrafluoroethylene) fiber blended filter material. The glass fiber and PTFE fiber blended filter material comprises a polytetrafluoroethylene microporous membrane layer, a polytetrafluoroethylene dipping treatment layer, and a glass fiber and fiber blended expanded fabric layer which are arranged in sequence from a dust surface and a clean air surface, wherein the polytetrafluoroethylene dipping treatment layer is characterized in that the dipping treatment temperature is higher than 300 DEG C, PTFE is in a half-molten state under the high temperature, and thus the glass fibers can be adhered with the PTFE fibers. According to the glass fiber and PTFE fiber blended filter material, both weft and warp yarns of the filter material are the glass fiber and PTFE blended yarns, the PTFE fiber content is controlled to be 55 to 60wt%, and thus the flexibility and folding resistance of the filter material are obviously improved, the coating fastness is high, the air permeability is outstanding, and the filtering precision is high; in addition, the filter material also shows a filtering effect, and is resistant to high temperature and corrosion, high in service life, low in cost, and applicable to working conditions with complex smoke components, high temperature and serious corrosion.

Owner:辽宁新洪源环保材料有限公司

Novel galvanometer for laser machining equipment

ActiveCN108161219AShort preparation timeImprove efficiencyLaser beam welding apparatusLaser processingGalvanometer

The invention provides a novel galvanometer for laser processing equipment. The galvanometer body is a flake-like structure, and the galvanometer is characterized in that the galvanometer body is madeof aluminum or aluminum alloy; one face of the galvanometer body is plated with a reflecting film formed as a reflecting surface; one end of the galvanometer body is connected to a rotating output end of a motor, and the rotation axis is located in the galvanometer body, and is parallel to the mirror surface; the galvanometer body is internally provided with a plurality of hollow holes arranged in parallel, and partition walls between adjacent hollow holes are formed as reinforcing ribs of the galvanometer; the hollow holes are formed opposite the rotation axis, parallel to the mirror surface, and penetrate from one end of the galvanometer body to the opposite end; The novel galvanometer has the advantages that the structure design is original, the production cost is low and the materialsare different, so that it is convenient for production and industrialization, and the service life is long.

Owner:GUANGZHOU NEW CKLASER CO LTD

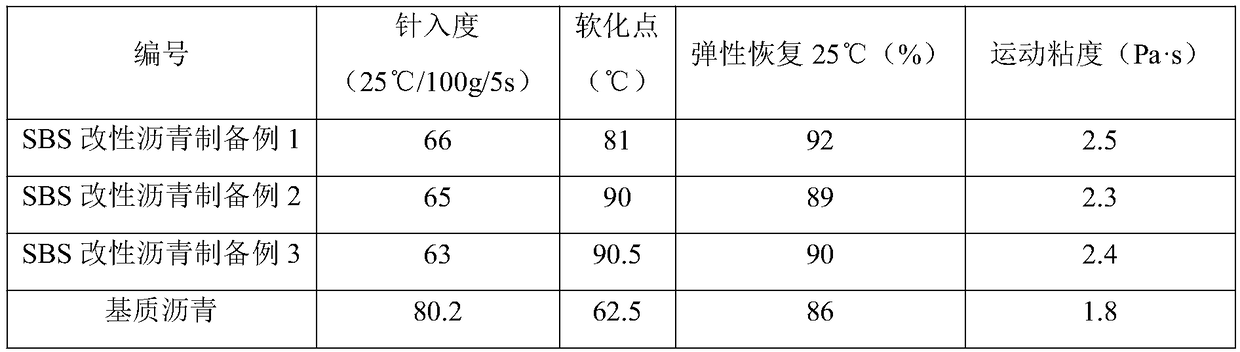

Asphalt mastic macadam mixture and preparation method thereof

InactiveCN109231890AImprove low temperature performanceImprove temperature sensitivityCrack resistanceRoad engineering

The invention discloses an asphalt mastic macadam mixture and a preparation method thereof and belongs to the field of road engineering materials. The asphalt mastic macadam mixture contains the following raw materials in parts by weight: 100 parts of aggregate, 5-7 parts of SBS (Styrene-Butadiene-Styrene) modified asphalt, 8-12 parts of mineral powder, 0.2-0.6 part of a fiber stabilizer, 2-7 parts of carbon black, 5-8 parts of phenolic resins and 2-3 parts of a curing agent. The asphalt mastic macadam mixture is capable of improving the strength and durability of the pavement, and can achievethe effects of enabling the pavement to achieve excellent cracking resistance and wear resistance and reducing risk of rut diseases on the asphalt pavement.

Owner:平湖市中建沥青混凝土工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com