Molecular distillation separation method for grease chemical product and equipment

A molecular distillation and oleochemical technology, applied in molecular distillation, fat oil/fat refining, fat production, etc., can solve the problem that the heat conduction oil chamber is easy to protrude and break into the oil chamber, the distillation and evaporation effect is not good, and the main equipment is not scientific and other issues, to achieve the effects of saving power resources, good sealing effect, low equipment manufacturing and operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A molecular distillation and separation device for oleochemical products, which includes a molecular distillation device body 1 and a vacuum tube 6, and the cross section of the molecular distillation device body 1 is a semicircular or semielliptical hollow cylinder.

[0054] The material heating panel of the molecular distillation equipment body 1 is a rectangular side plane of a hollow cylinder, and a heating medium coil is welded close to the back; there is a material distribution pipe 15 on the top of the heating surface, and the material distribution is composed of a material distribution groove plate 8 There is a material redistribution tank composed of a material redistribution tank plate 7 in the middle of the tank; the bottom end of the arc surface of the molecular distillation equipment body 1 is connected to the vacuum tube 6, and the molecular distillation equipment body 1 has a material feeding tube 2 on it, and a material outlet tube 3 on the bottom ; Molec...

Embodiment 2

[0058] A molecular distillation and separation device for oleochemical products, which includes a molecular distillation device body 1 and a vacuum tube 6, and the cross section of the molecular distillation device body 1 is a semicircular or semielliptical hollow cylinder.

[0059] The material heating panel of the molecular distillation equipment body 1 is a rectangular side plane of a hollow cylinder, and a heating medium coil is welded close to the back; there is a material distribution pipe 15 on the top of the heating surface, and there is a material distribution groove composed of a material distribution groove plate 8. The middle part has a material redistribution tank composed of a material redistribution tank plate 7; the bottom end of the arc surface of the molecular distillation equipment body 1 is connected to the vacuum tube 6, and the molecular distillation equipment body 1 has a material feeding tube 2 and a material outlet tube 3 under it.

[0060] The inner ca...

Embodiment 3

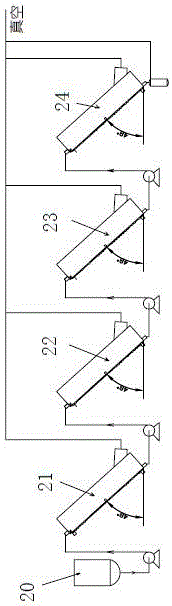

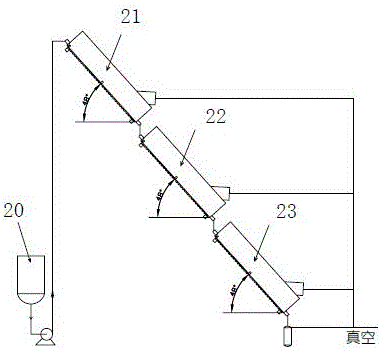

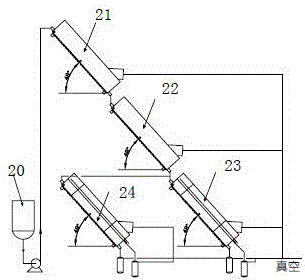

[0066] The molecular distillation and separation equipment for oleochemical products can be used individually, or multiple devices can be used in series and / or in parallel, and the separation and purification effect is better.

[0067] Such as figure 1 As shown in -3, the oily product in the oily product storage tank 20 passes through the first stage 21 of the molecular still. , evenly distributed on the heating surface, forming a uniform film that flows from top to bottom, flows to the middle material redistribution channel plate 7, and distributes evenly again, and the low boiling point oily product evaporates under the action of heating and vacuum Take away in vacuum, the remaining high-boiling point oily products are collected into the material outlet pipe 3, flow out of the first stage 21 of the molecular still, enter the second stage 22 of the molecular still, and so on, enter the third stage 23 of the molecular still, and the fourth stage of the molecular still twenty ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com