Patents

Literature

255results about "Molecular distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

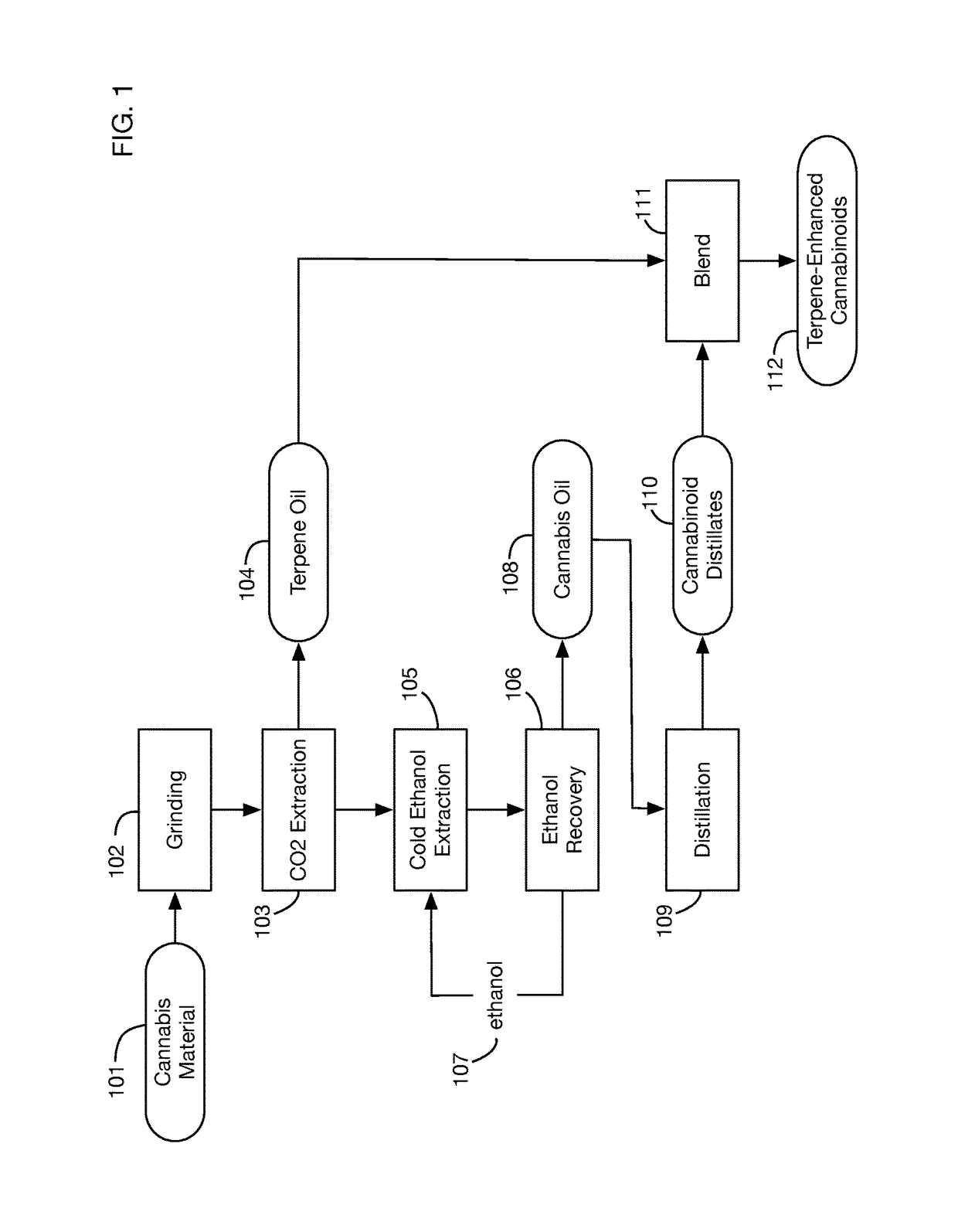

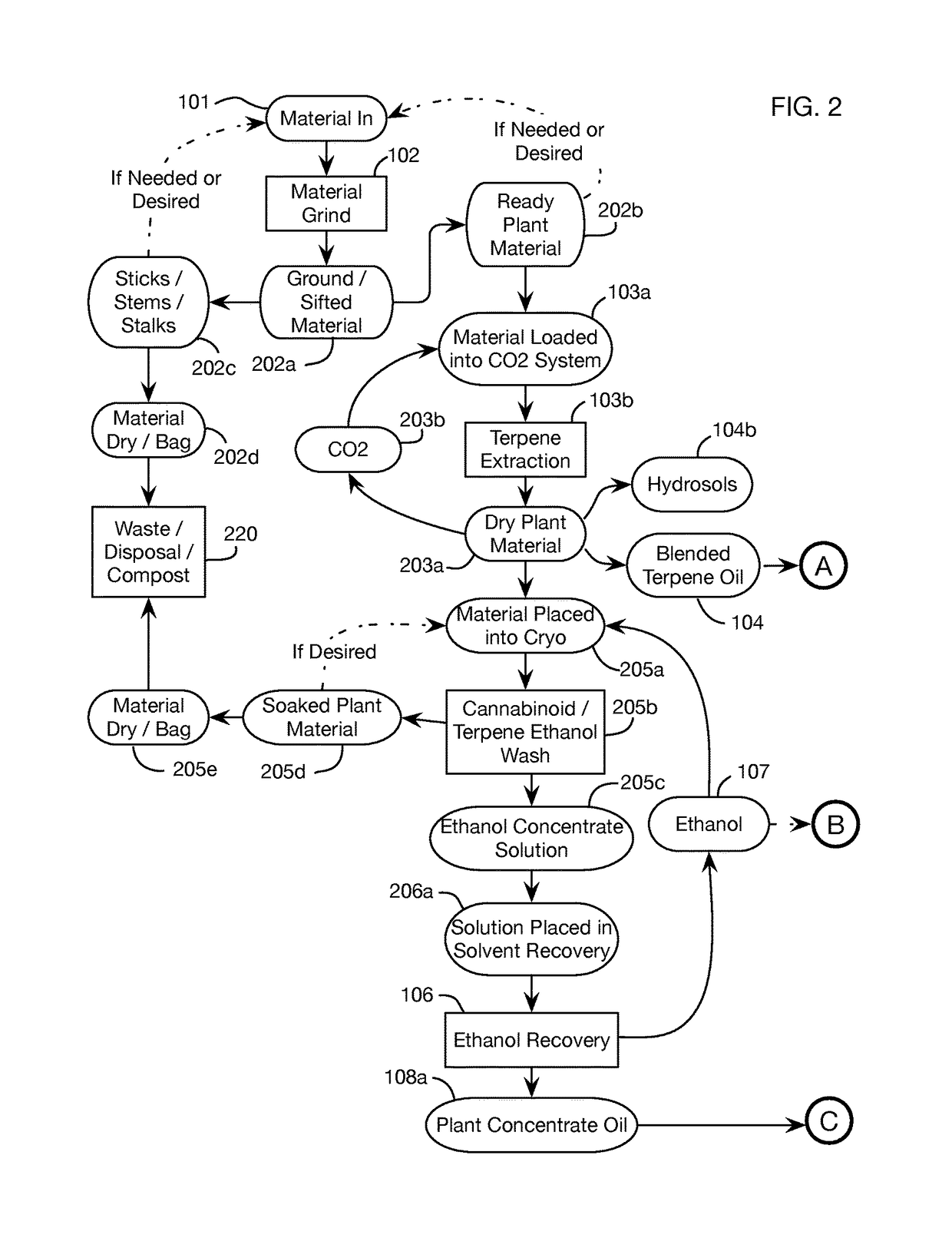

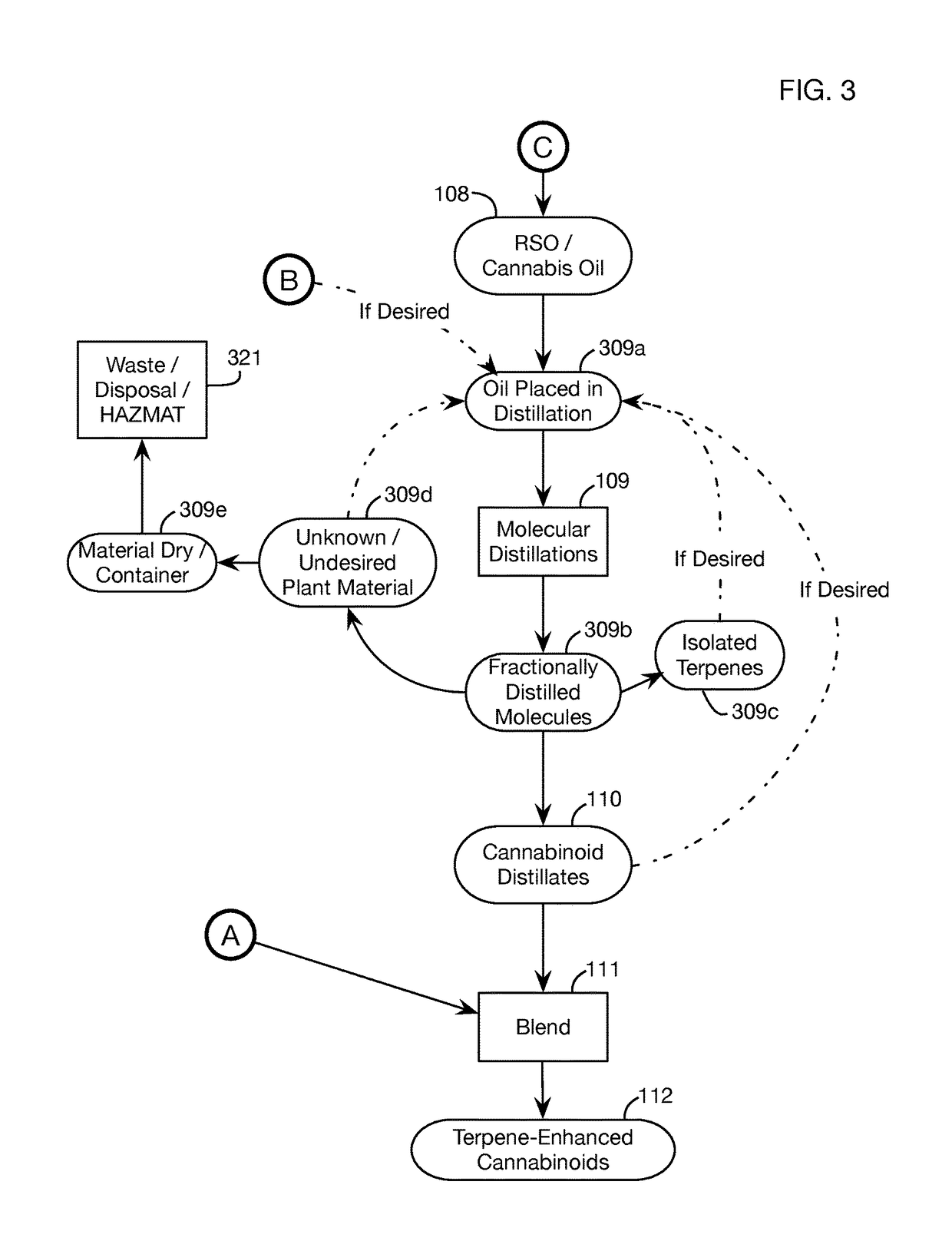

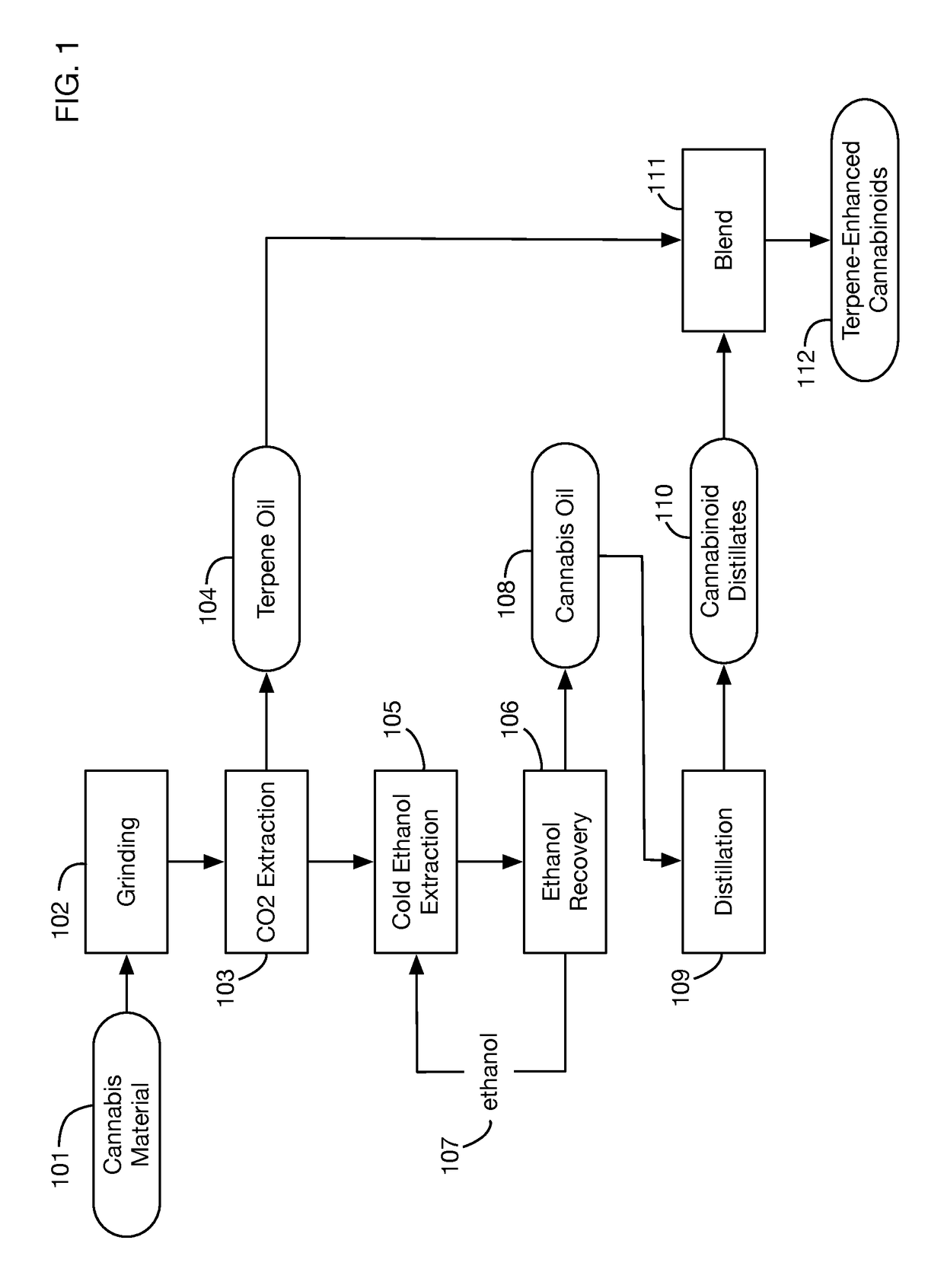

System and method for producing a terpene-enhanced cannibinoid concentrate

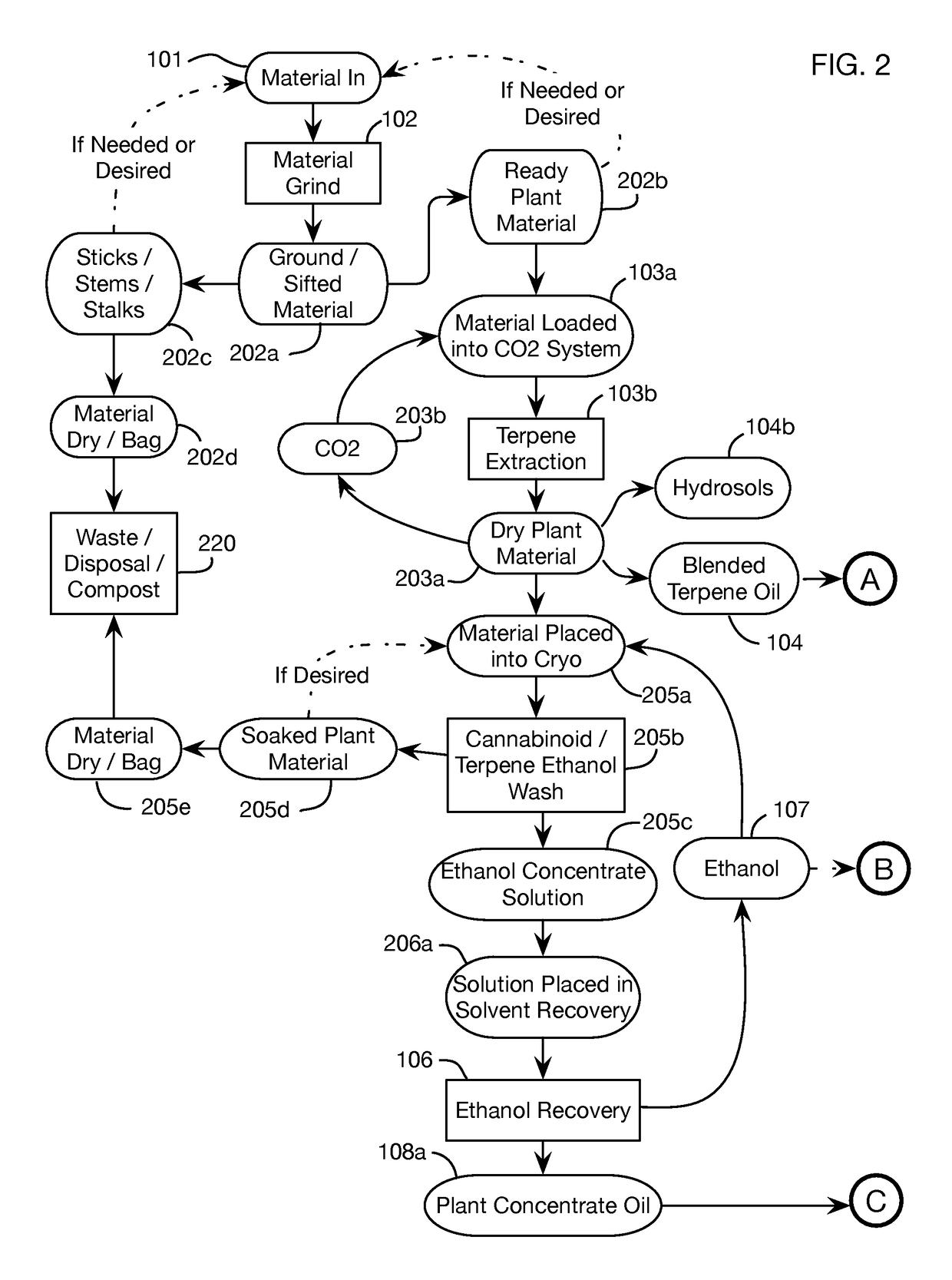

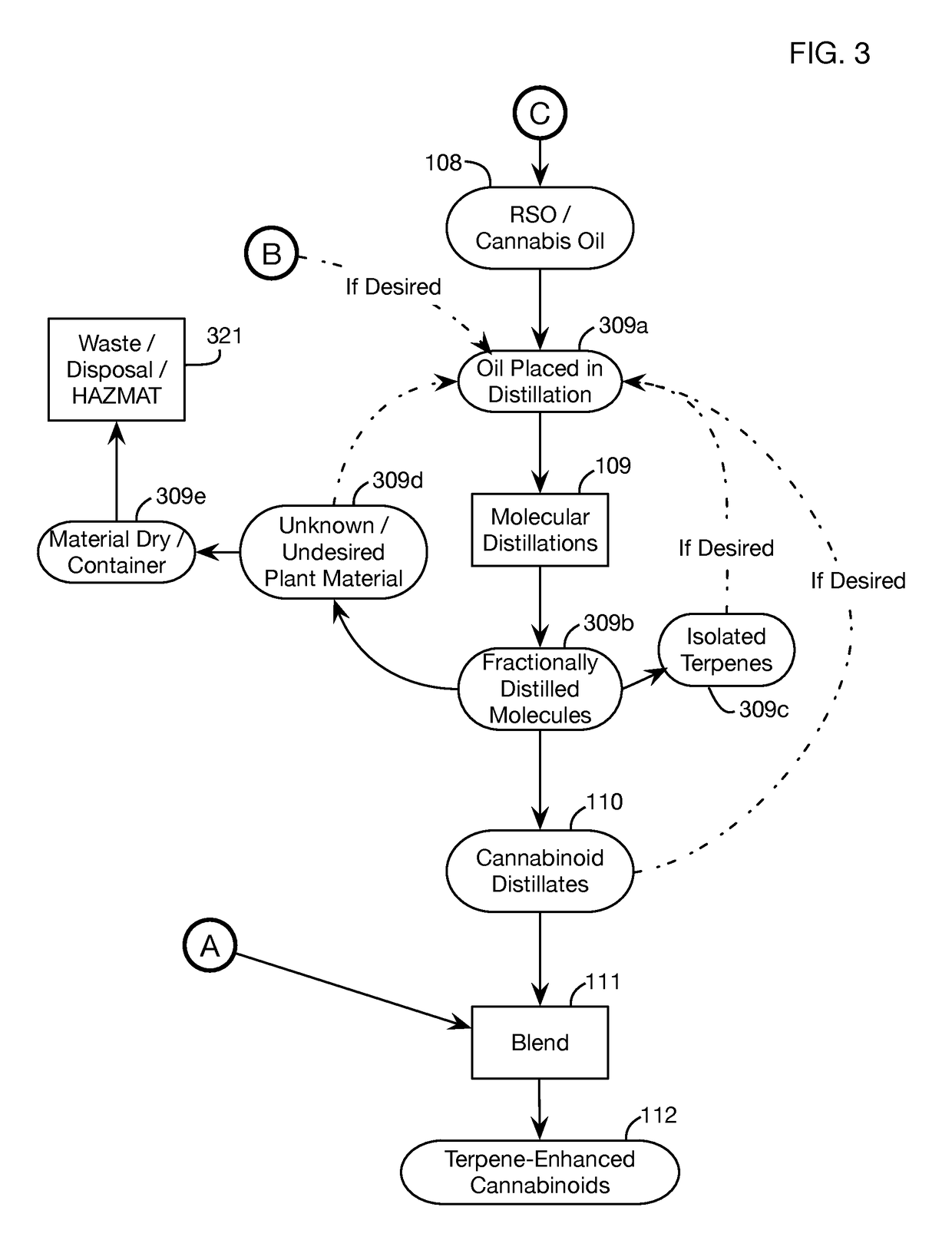

A system and method of producing a blended extract of cannabinoids and terpenes, which extracts terpenes using supercritical CO2, and extracts a cannabinoid concentrate from the residual material using a cold ethanol flush followed by distillation; the CO2-extracted terpenes are then added back to the cannabinoid concentrate in a final blending step. Blending terpenes at the end of extraction may enhance the flavor and effectiveness of the cannabinoid concentrate. By separately extracting terpenes and cannabinoids, optimal processes and parameters may be used for each step. Blending may combine terpenes and cannabinoids in any desired ratio; for example, a terpene-to-cannabinoid ratio of approximately 1:10 may be used. The ethanol used in the cold ethanol extraction of cannabinoids may be recovered and reused for subsequent batches. Cannabinoid concentrates may be redistilled multiple times to enhance their concentration, followed by terpene blending.

Owner:THE HOUSE OF GREEN

System for producing a terpene-enhanced cannabinoid concentrate

A system for producing a blended extract of cannabinoids and terpenes, which extracts terpenes using supercritical CO2, and extracts a cannabinoid concentrate from the residual material using a cold ethanol flush followed by distillation; the CO2-extracted terpenes are then added back to the cannabinoid concentrate in a final blending step. Blending terpenes at the end of extraction may enhance the flavor and effectiveness of the cannabinoid concentrate. By separately extracting terpenes and cannabinoids, optimal processes and parameters may be used for each step. Blending may combine terpenes and cannabinoids in any desired ratio; for example, a terpene-to-cannabinoid ratio of approximately 1:10 may be used. The ethanol used in the cold ethanol extraction of cannabinoids may be recovered and reused for subsequent batches. Cannabinoid concentrates may be redistilled multiple times to enhance their concentration, followed by terpene blending.

Owner:OAK & CRANE LLC

Multiple application purification and recycling device

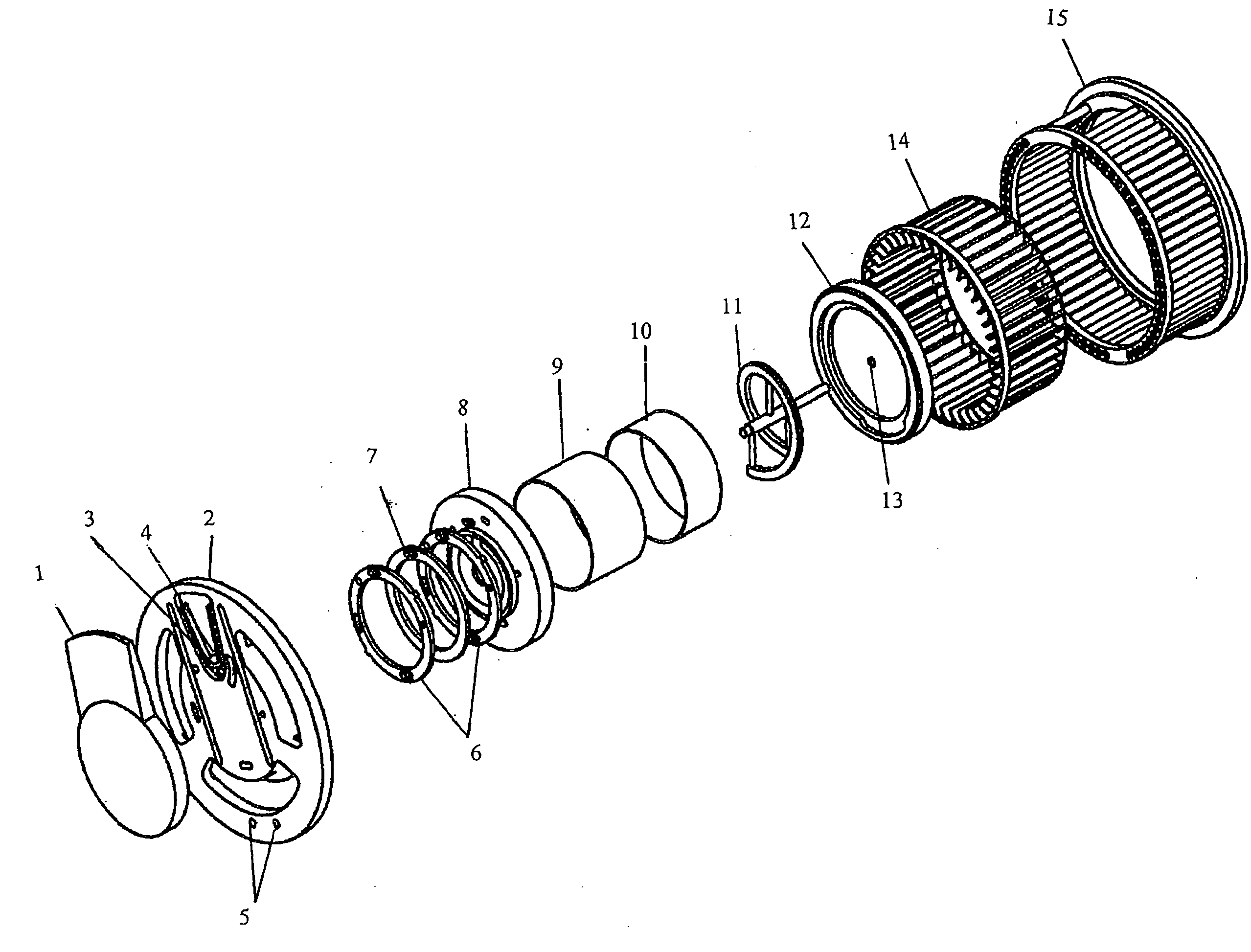

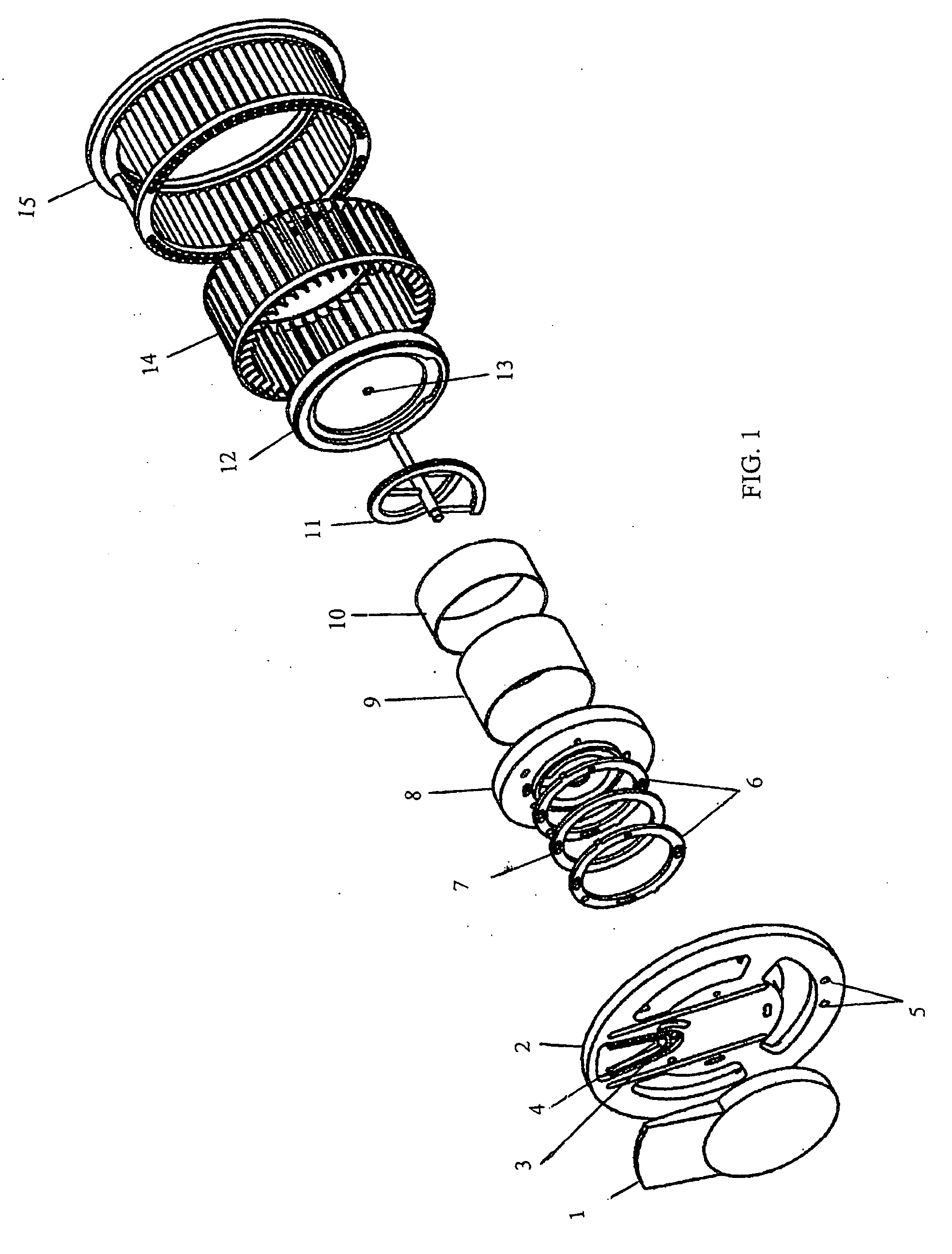

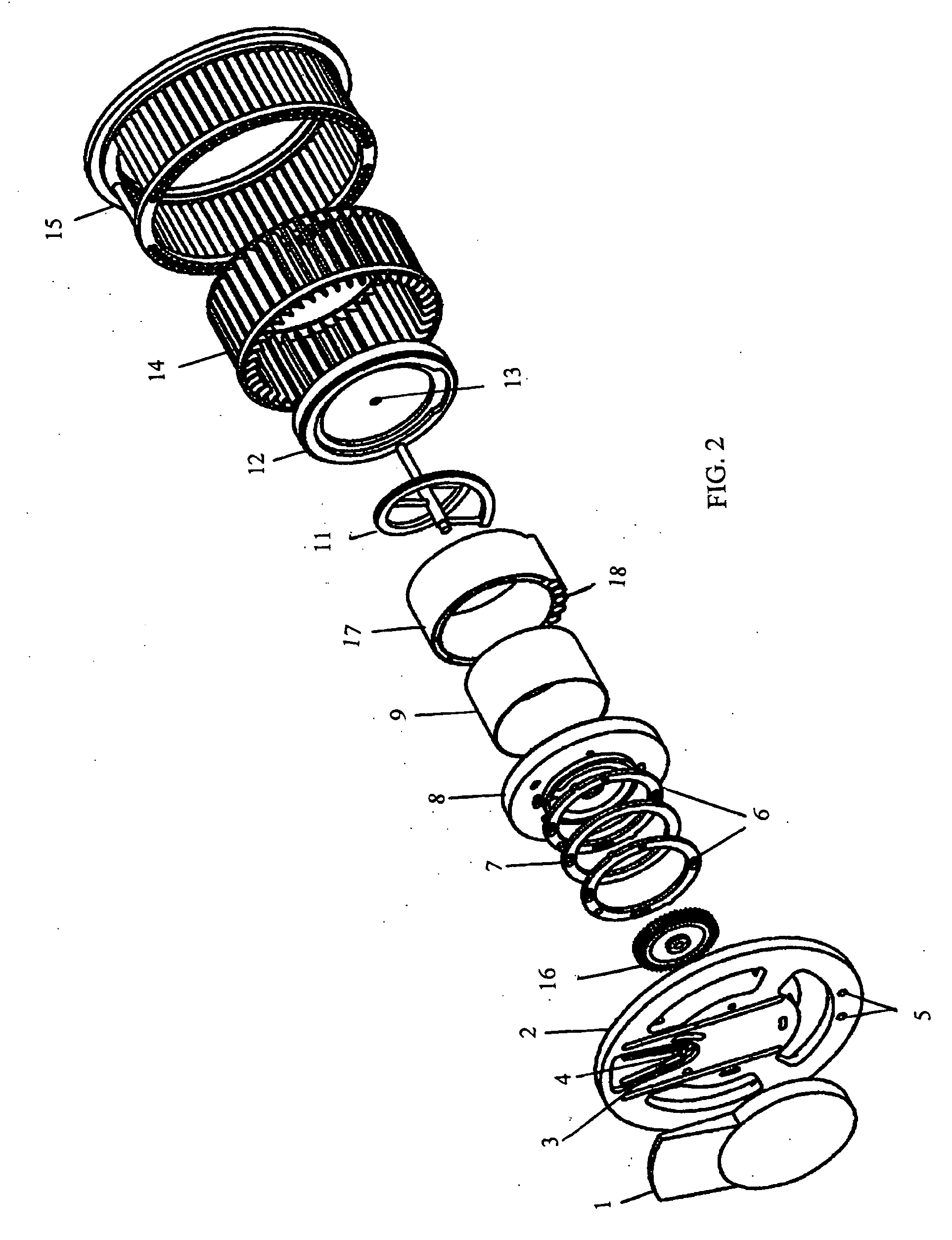

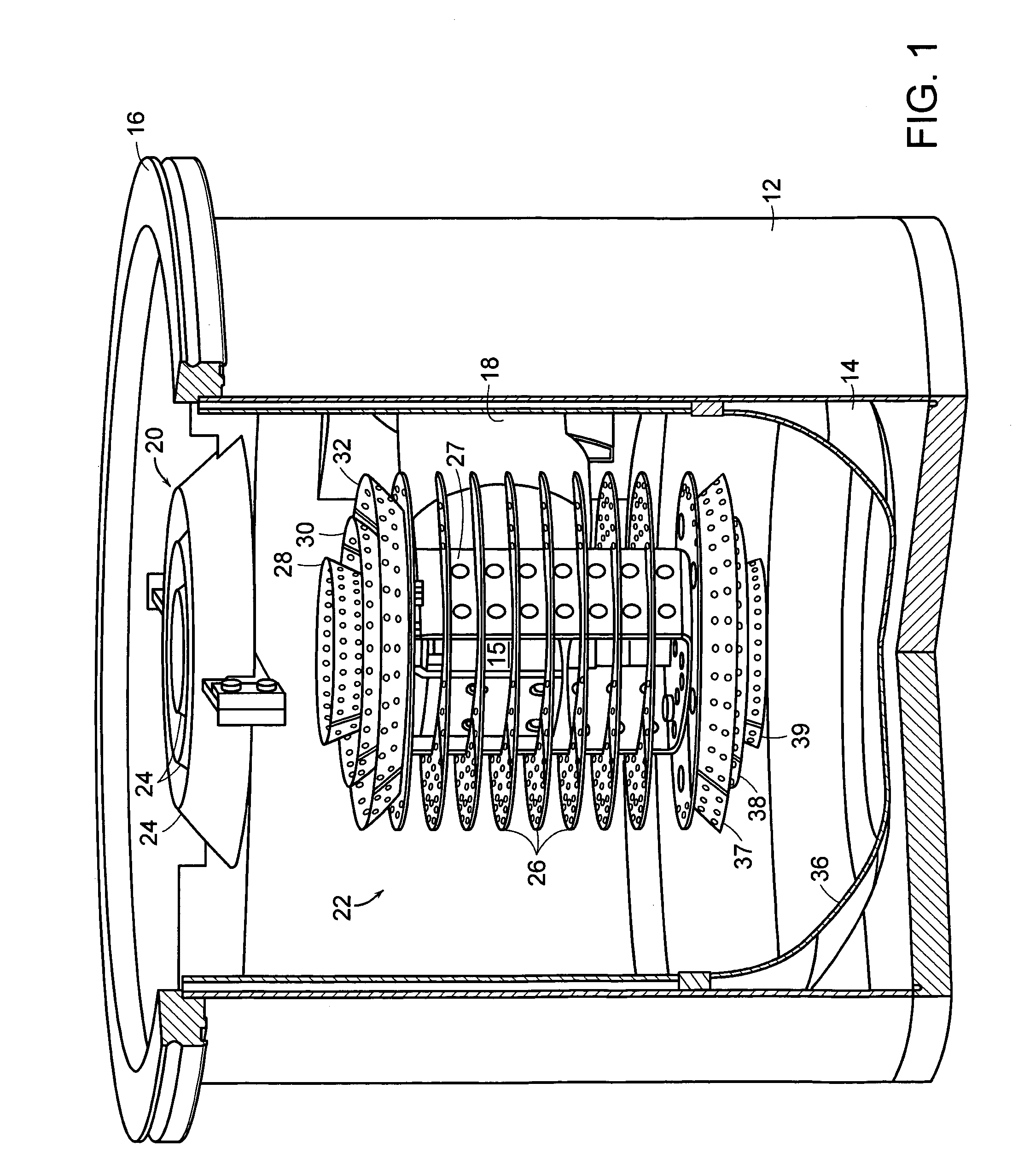

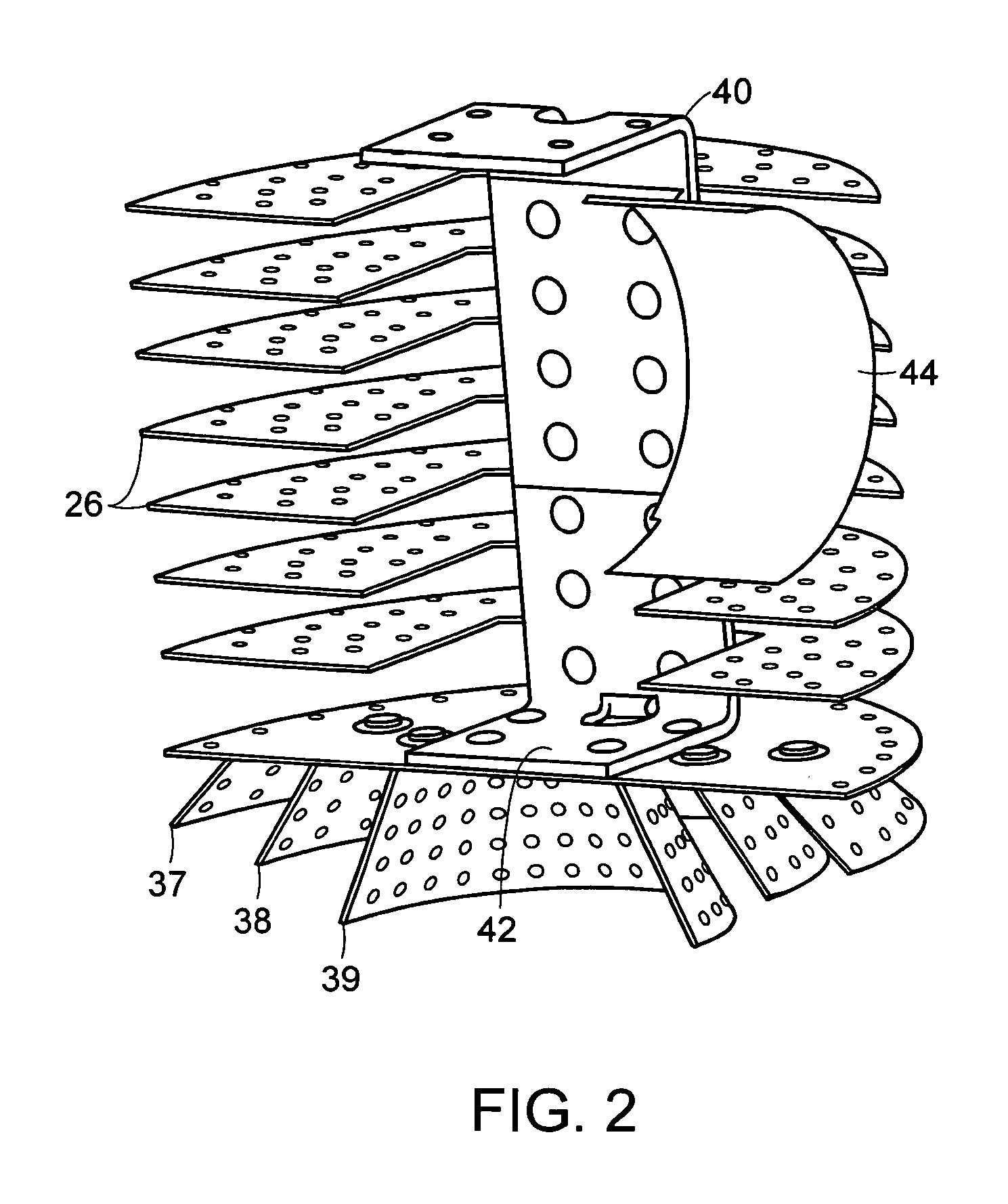

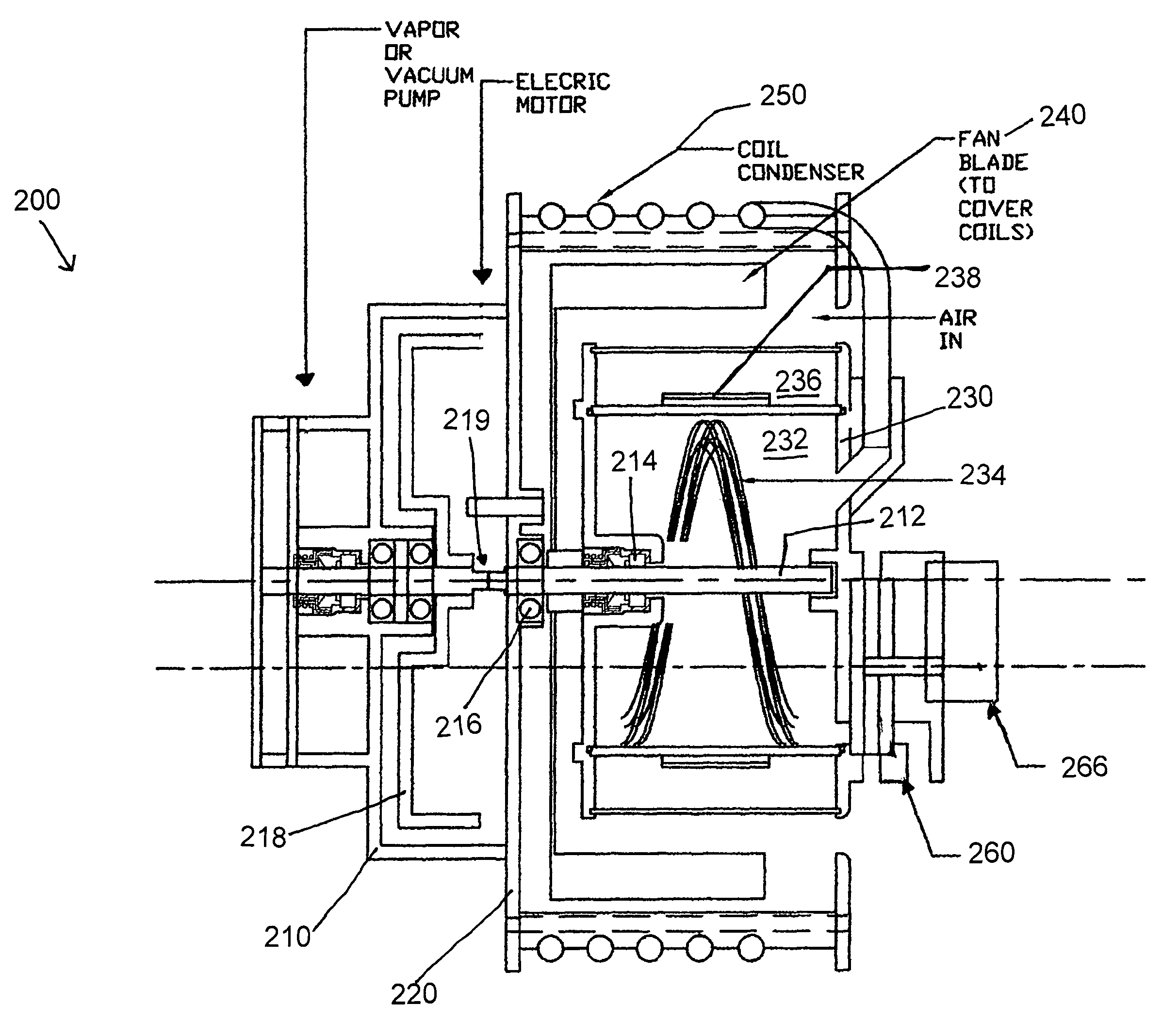

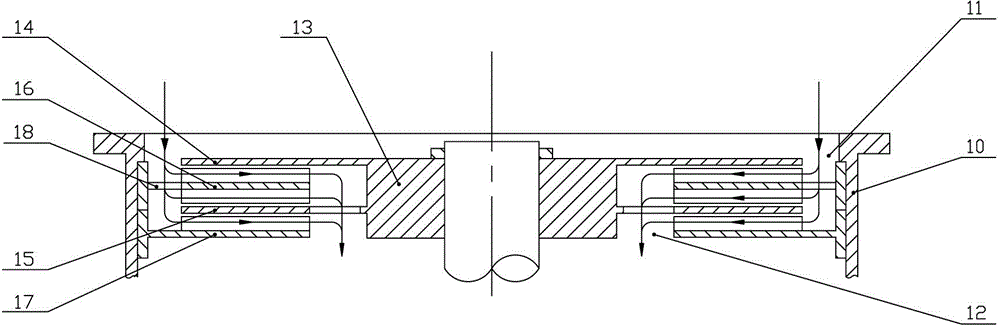

InactiveUS20070170049A1Easy constructionFlexible operationDistillation regulation/controlEvaporation with vapour compressionDistillationMultiple applications

A multiple application recycling and purification device has a coaxial core that is horizontally oriented, non-rotating, cylindrical distillation chamber. The enhanced, completely coaxial configuration continuously cleans the entire distillation chamber and spreads a thin film of liquid to enhance distillation and positively aid in the removal of remaining contaminants. Through a timed and positioned valve, the device removes and purges lower-temperature contaminants. Timed valves and sensors control all phases of the distillation to provide a coaxially integrated, stand-alone, adaptable, scalable and maintenance free distillation unit that self-monitors, self-cleans and economically functions to produce the pure distilled liquid, e.g., water. This device can be modified to purify any numerous array of liquids and can be scaled to produce any amount of purified liquids for either household, commercial, or industrial applications.

Owner:MANSUR CORP

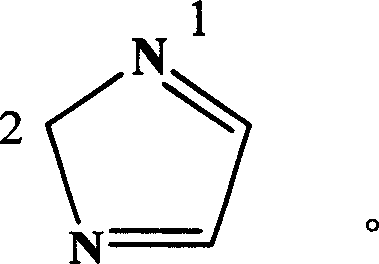

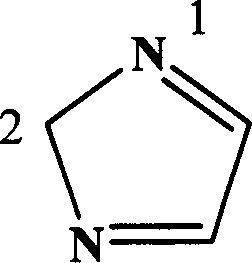

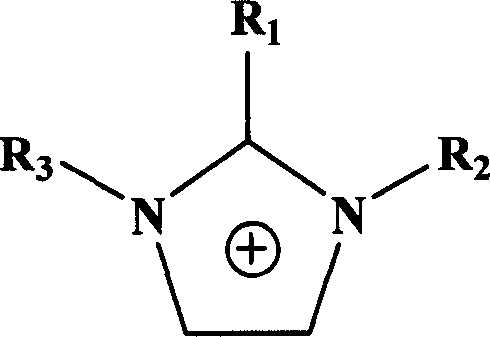

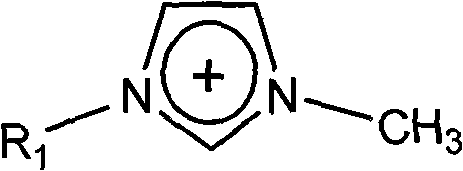

Purification method of ion liquid

InactiveCN101003510AEfficient removalOrganic chemistryMolecular distillationPurification methodsDistillation

This invention discloses a method for purifying ionic liquid by molecular distillation. The method comprises: preheating crude ionic liquid, adding into a molecular distillation apparatus, adjusting the pressure, performing molecular distillation at an appropriate temperature, and collecting the heavy component to obtain purified ionic liquid. The method can efficiently remove residual volatile organic reactants, and the purity of purified ionic liquid is higher than 99%. Since the light component can be recovered for recycling, the method is thus environmentally friendly.

Owner:GUANGDONG UNIV OF TECH

Molecular distillation apparatus

The invention relates to a molecular distillation apparatus, comprising a motor, a cylinder body, sleeves around the cylinder body, a feed inlet, a rotary shaft, a running wheel device, a condensation pipe assembly, and a light oil collecting flute, wherein the condensation pipe assembly is a cylindrical device formed by enclosing of a plurality of condensation pipes; and the motor is connected with the rotary shaft via a reducing gear, and the rotary shaft penetrates through the end cover of the cylinder body to be fixedly connected with the running wheel device. The molecular distillation apparatus is characterized in that the radial distance between the outer side pipe wall and the inner wall of the cylinder body of the condensation pipe is set to be 3.6-4.2cm. The invention has simple structure and convenient operation.

Owner:朱文冲

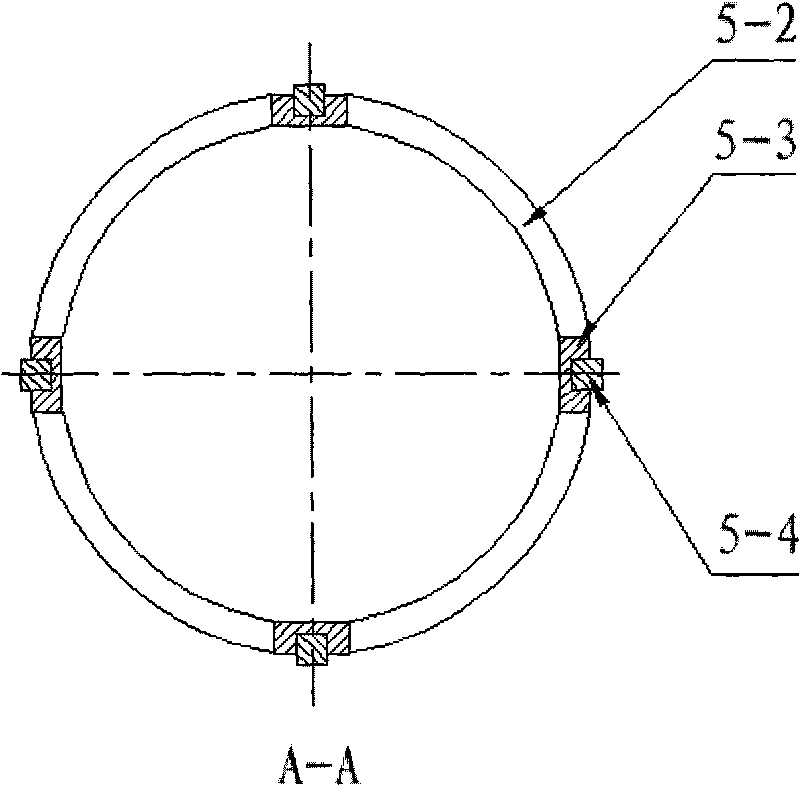

High conductance cryopump for type III gas pumping

A cryopump provides for high pumping speed of Type III gases. An open configuration of a frontal array provides high conductance of gases into a radiation shield which is shaped to focus gases toward a second stage array. The second stage array has an open configuration of baffles coated with adsorbent. Substantially all of the adsorbent has a direct line of sight to the radiation shield or to the opening in the radiation shield, and substantially all of the baffles are coated with adsorbent. In one form, the second stage cryopump array comprises an array of discs fanned to define a generally ball shaped envelope.

Owner:EDWARDS VACUUM LLC

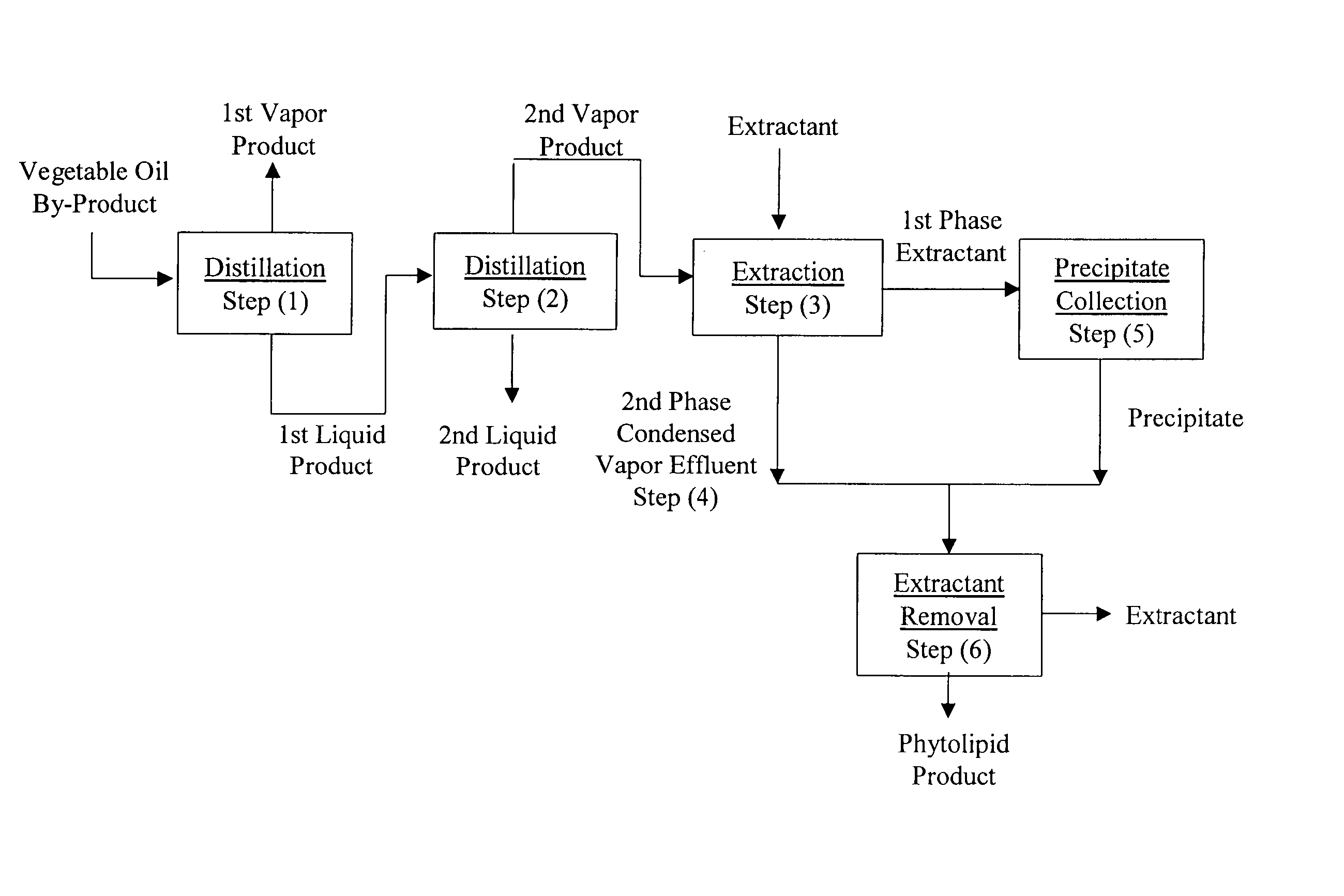

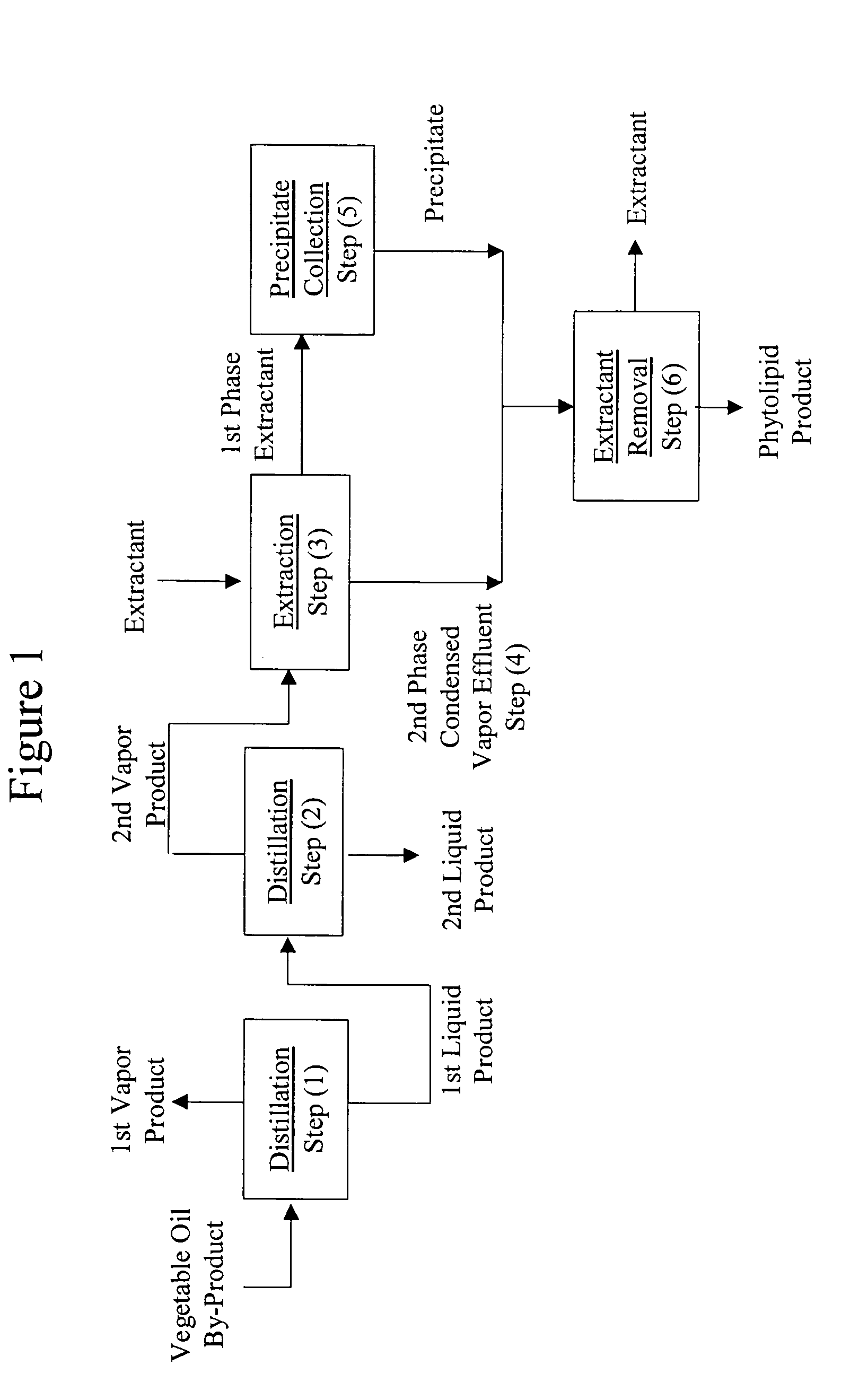

Process for the recovery of a phytolipid composition

InactiveUS20050051419A1Easy to prepareLow viscosityFatty oils/acids recovery from wasteEdible oils/fats ingredientsVegetable oilMedicine

Disclosed is a process for the recovery of a phytolipid composition from a vegetable oil by-product. The phytolipid composition produced comprises squalene, phytosterols, mixed tocopherols and tocotrieneols, and vegetable wax and is useful as an emollient. The phytochemical composition may be applied directly to the skin to provide emolliency. Alternatively, the phytolipid composition may be formulated in various aqueous or anhydrous cosmetic compositions such as creams, lotions, gels, ointments, lip balms, sticks, or pencils for treatment of the skin and lips. The phytolipid composition also may be incorporated into foods, beverages, and nutraceuticals to provide health benefits.

Owner:EASTMAN CHEM CO

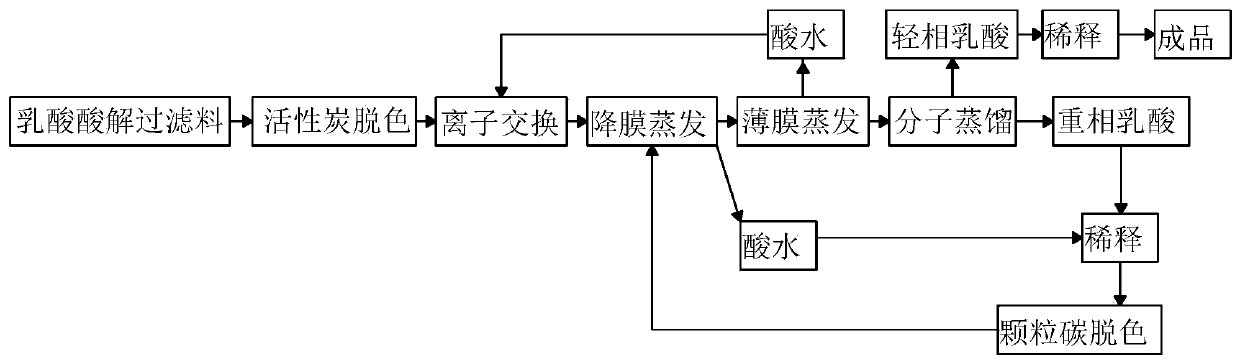

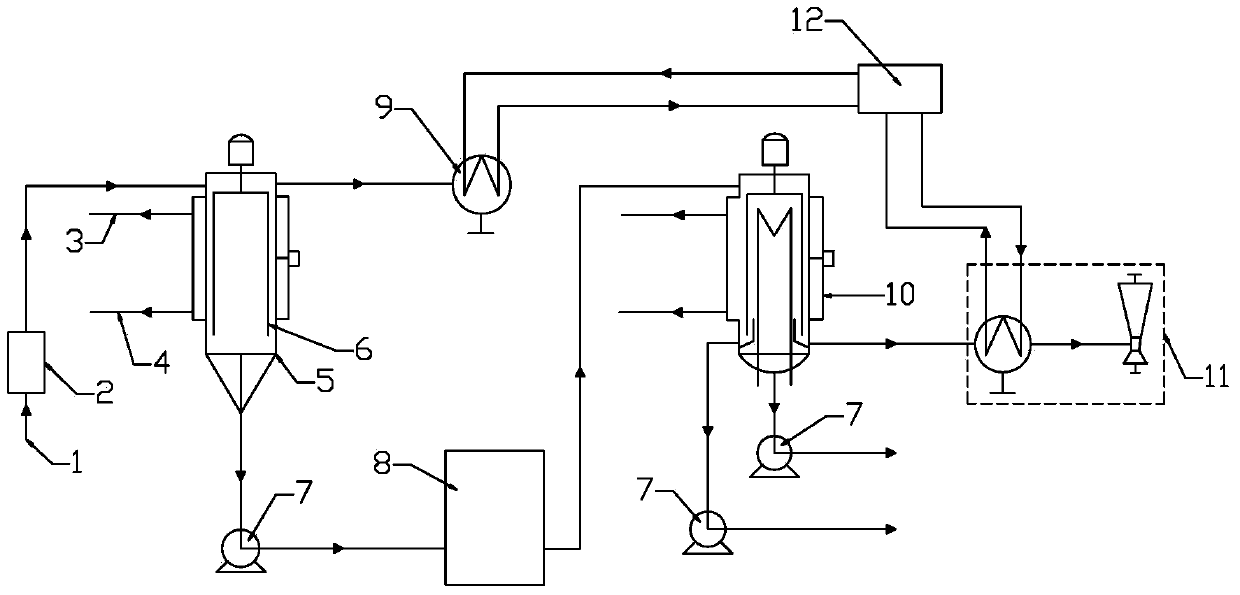

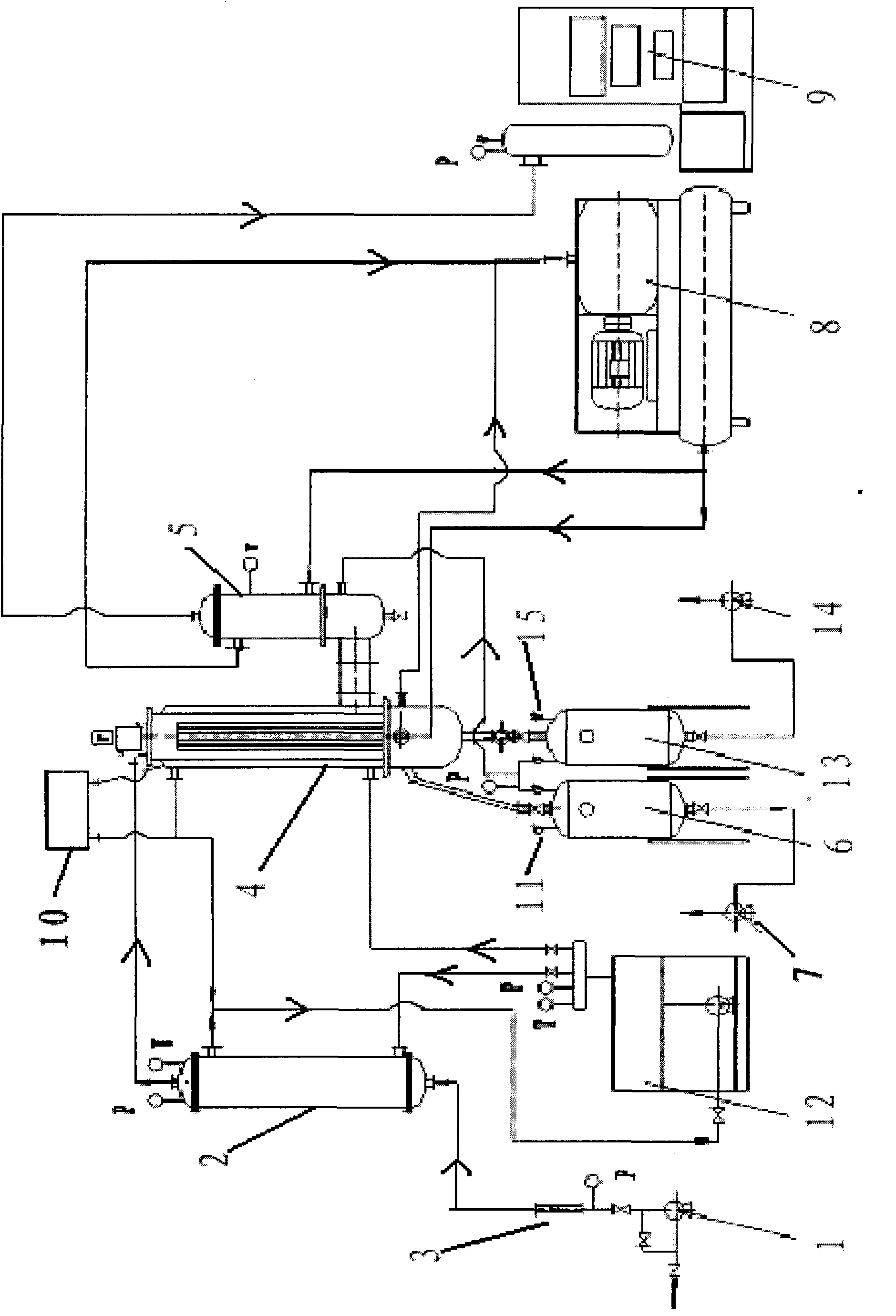

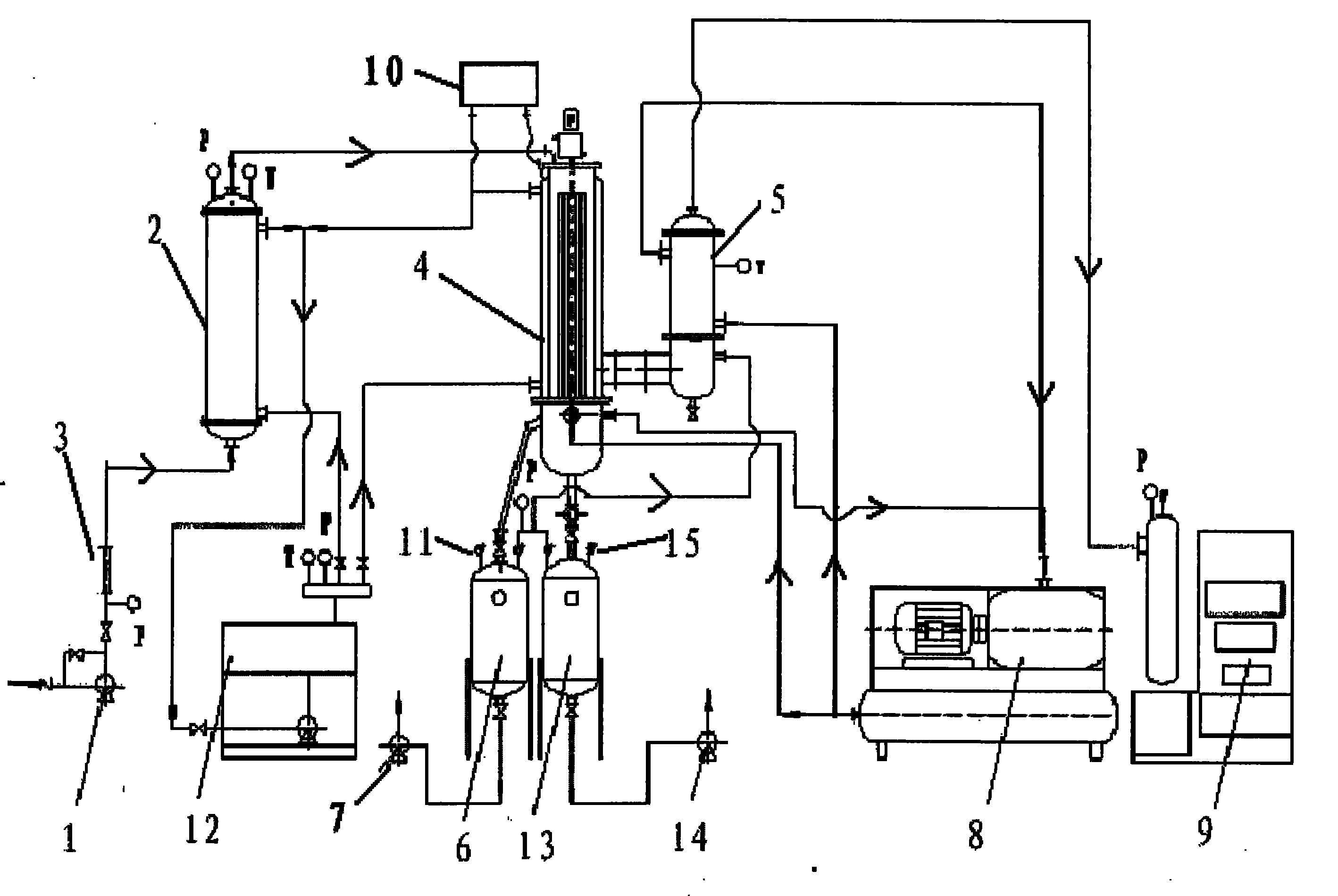

Method of industrial production of lactic acid by employing molecular distillation technology

ActiveCN103724183AReduce chromaIron salt reductionMolecular distillationCarboxylic compound separation/purificationActivated carbonDistillation

The invention discloses a method of industrial production of lactic acid by employing a molecular distillation technology. The method comprises the following steps of: (A) decoloring material liquid obtained after acidolysis filtration of lactic acid fermentation liquid with active carbon, (B) performing ion exchange on the decolored material liquid, (C) performing falling film evaporation on the material liquid after the ion exchange, (D) performing thin film evaporation on a lactic acid material obtained after the falling film evaporation to allow the mass fraction of water in the material to be less than or equal 2%, and (E) performing molecular distillation on the lactic acid material obtained after the thin film evaporation to form fine lactic acid, namely the target product. Lactic acid produced by the method meets the high-purity requirements and can be directly used for preparing polylactic acid.

Owner:河南金丹乳酸科技股份有限公司

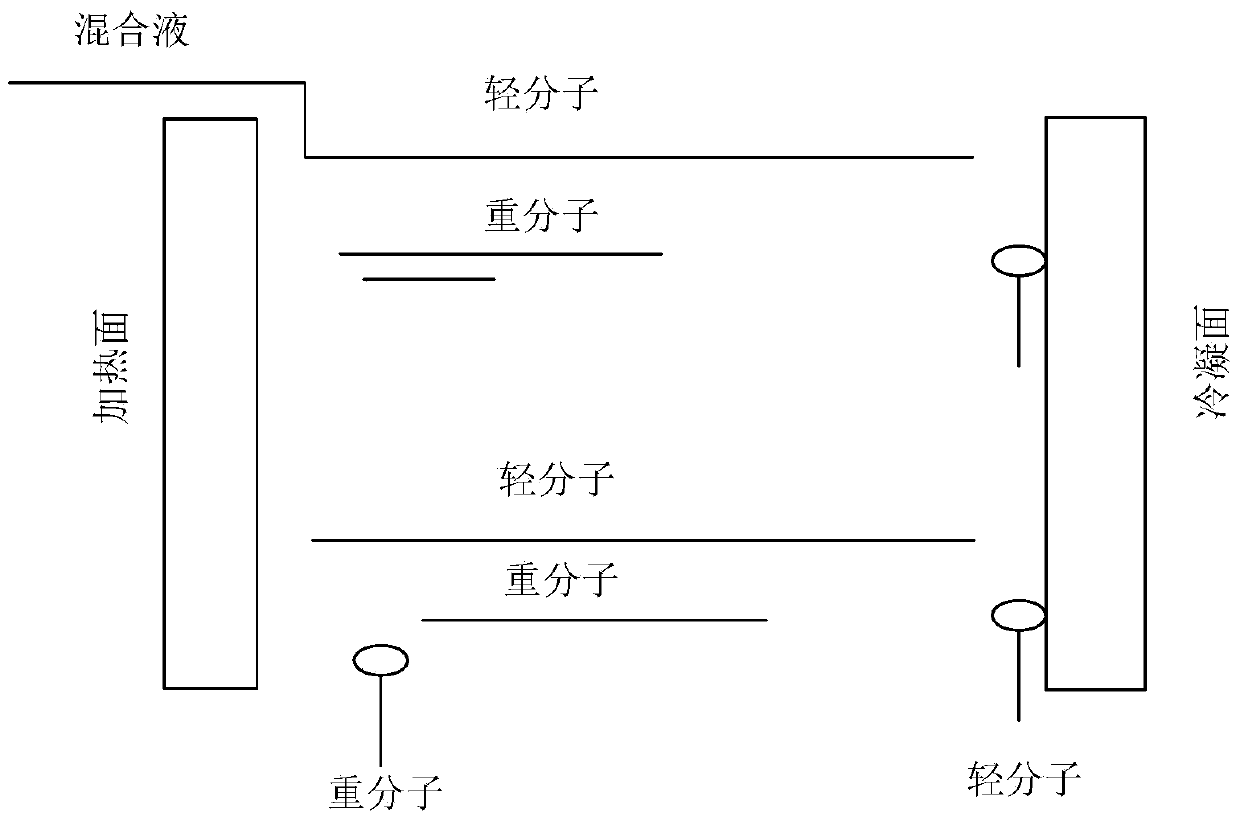

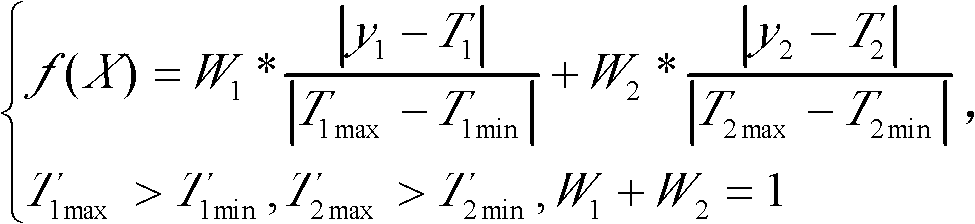

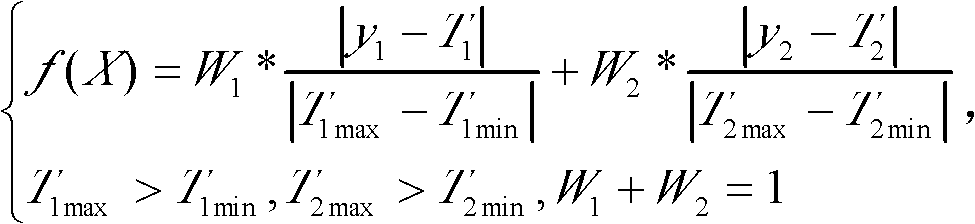

Molecular distillation process parameter optimizing method based on GA-BP (Genetic Algorithm-Back Propagation) algorithm

InactiveCN102626557AIncrease productivityReduce manufacturing costDistillation regulation/controlMolecular distillationDistillationGenetic algorithm

The invention discloses a molecular distillation process parameter optimizing method based on a GA-BP (Genetic Algorithm-Back Propagation) algorithm, which relates to the field of molecular distillation optimization. The method comprises the following steps of: optimizing the weight value and threshold value of a BP neural network by using a GA algorithm; forecasting the purity and yield of a distillate through three process control parameters, i.e., the evaporating surface temperature, the vacuum degree in an evaporator and feeding speed in a molecular distillation process by using the BP neural network; and realizing a process of acquiring optimized process control parameter input value by using the expected purity and yield in molecular distrilling process by using GA algorithm. Due tothe adoption of the method, the purity and yield of the distillate can be comprehended immediately, accurate forecasting can be performed, adjusting measures can be adopted immediately, key factors influencing the product quality of the distillate are controlled reasonably, the purity and yield of the product are kept in a specified range, the production efficiency of an enterprise is effectivelyincreased, energy is saved, and the production cost of the enterprise is lowered.

Owner:CHANGCHUN UNIV OF TECH

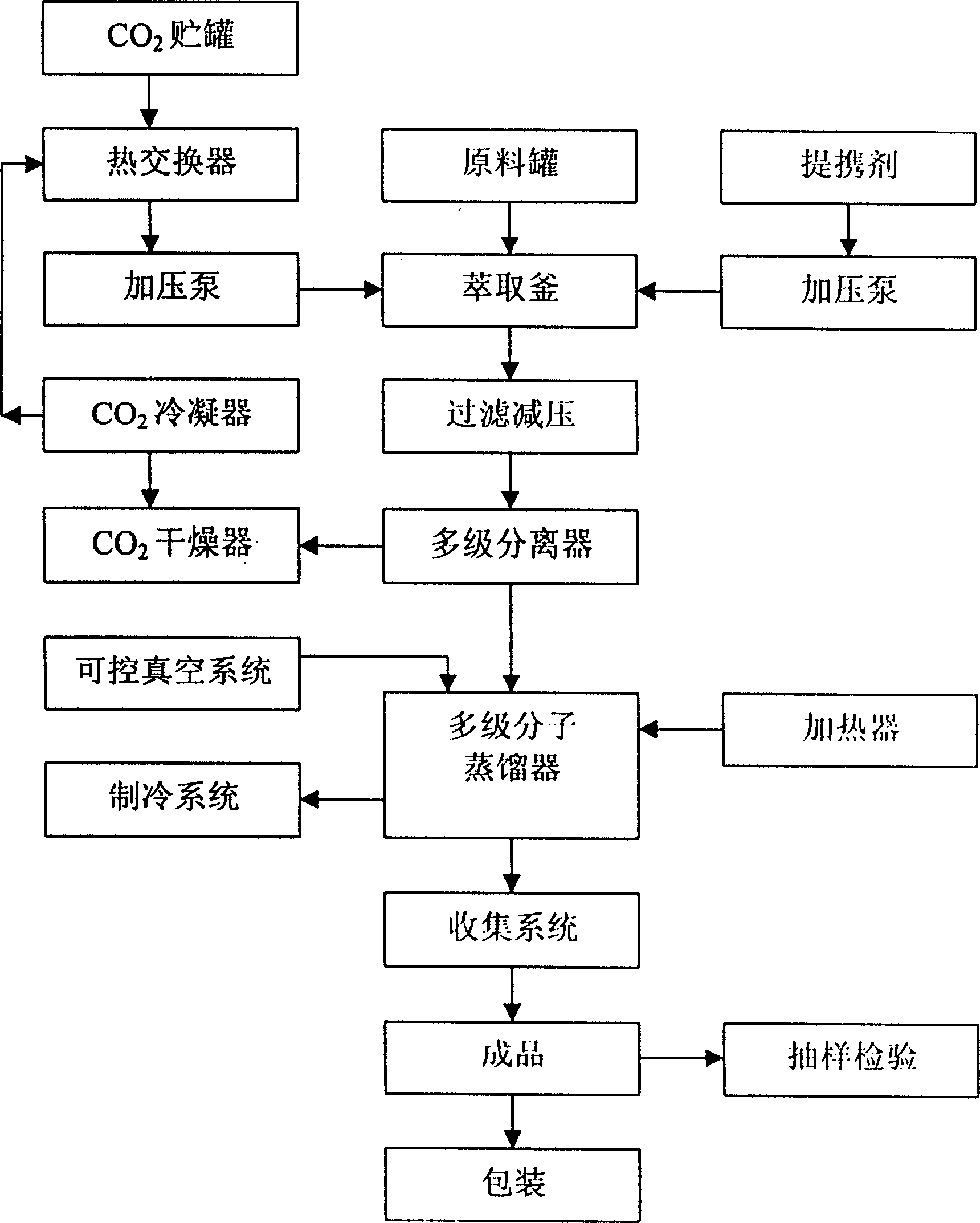

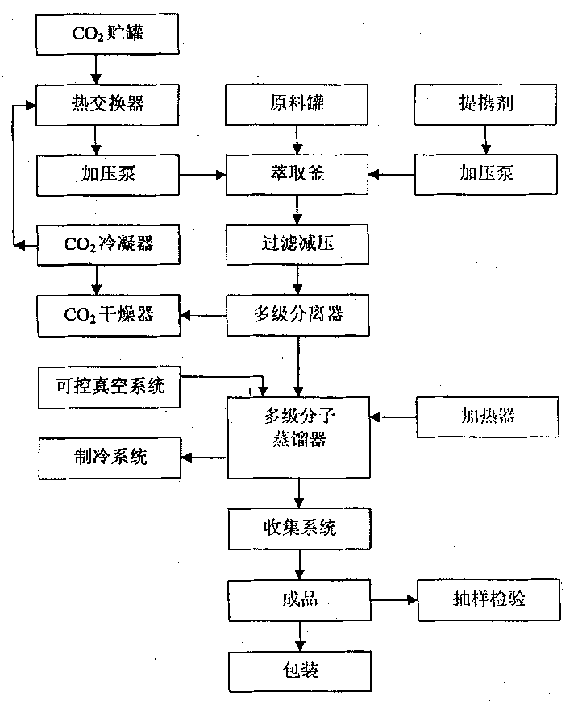

Method for extracting effective components from natural materials

A process for extracting the active component from natural product features that the supercritical CO2 fluid extraction and the molecular distillation are combined for fully playing their roles.

Owner:李绍光 +1

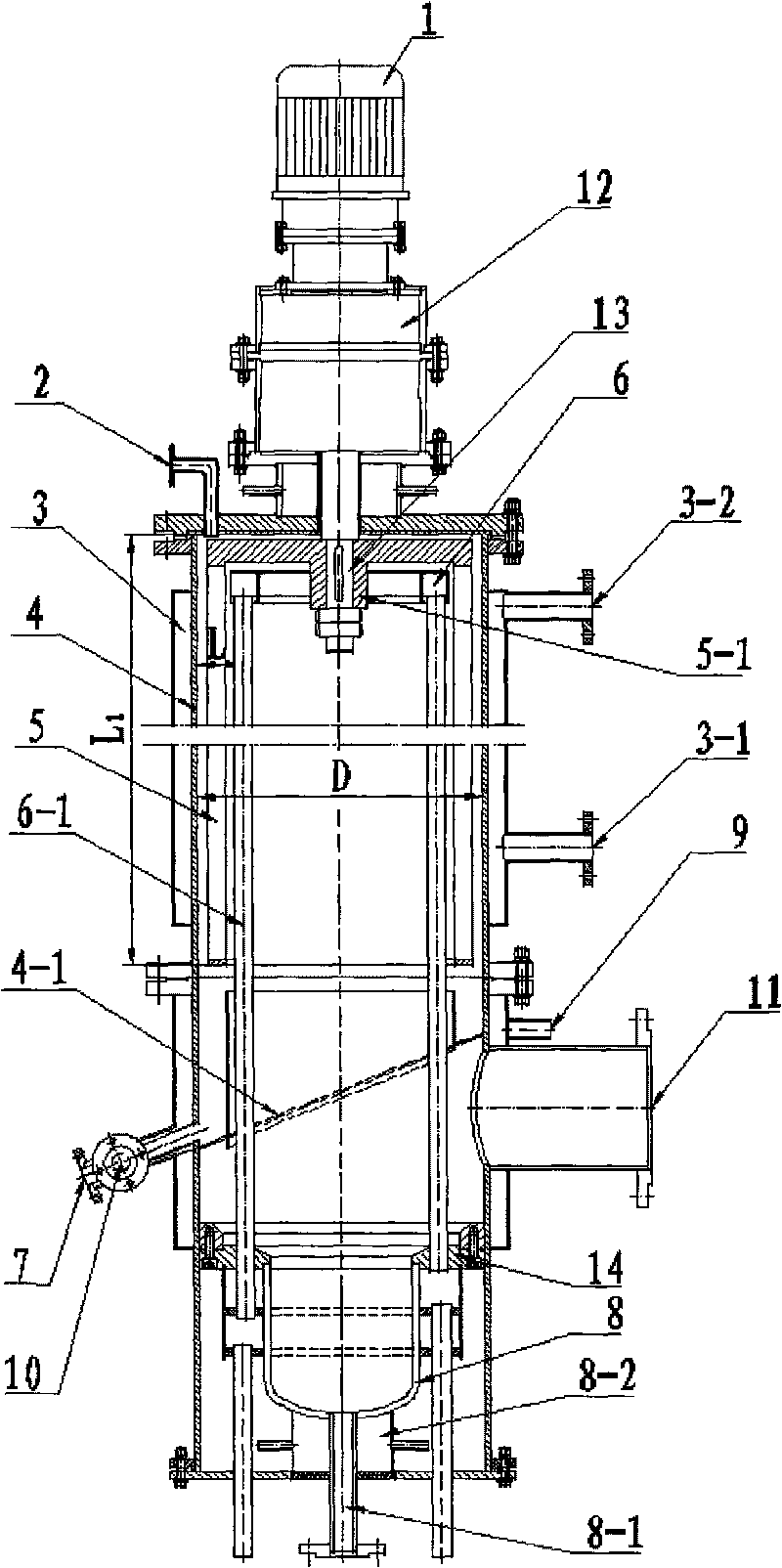

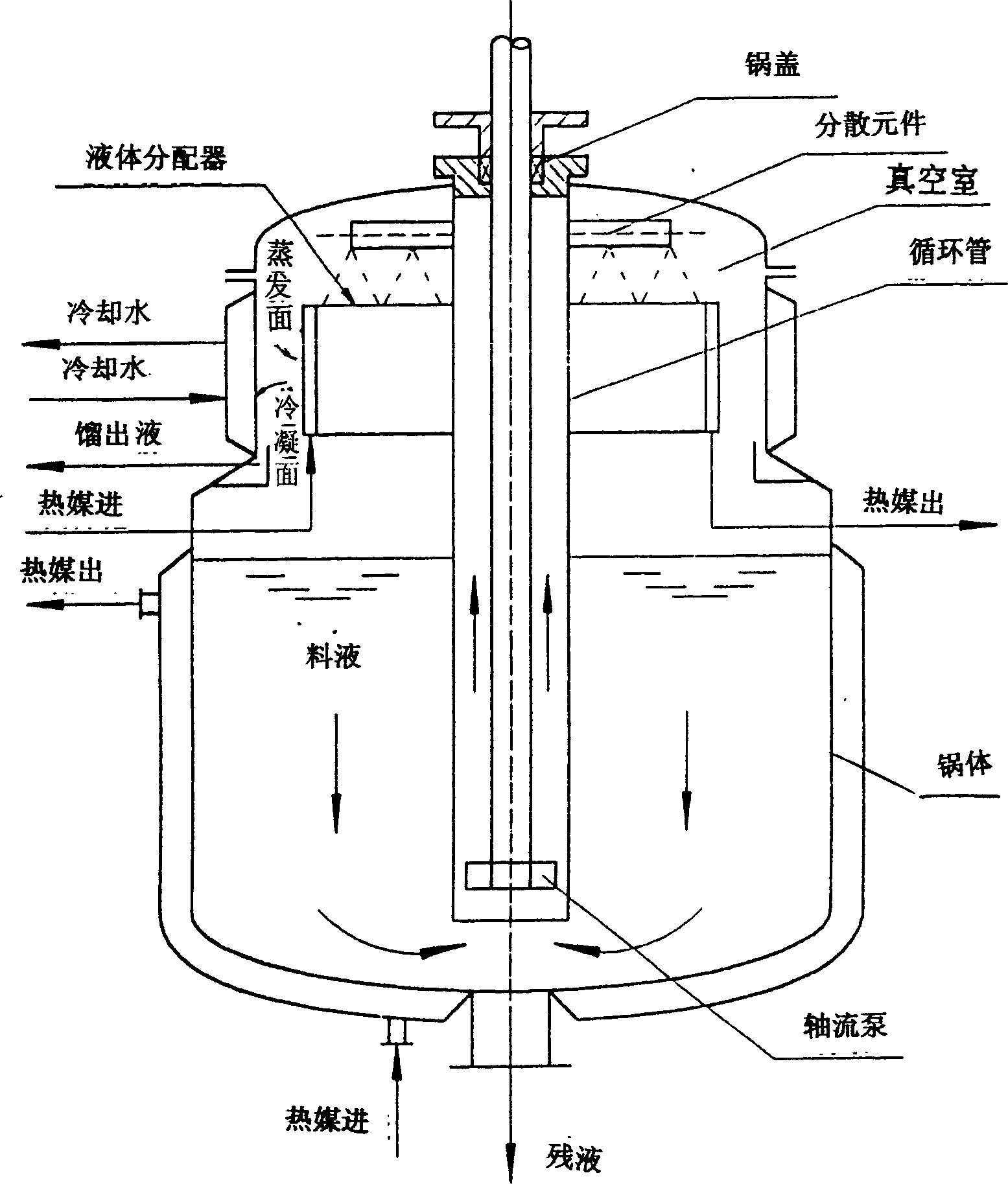

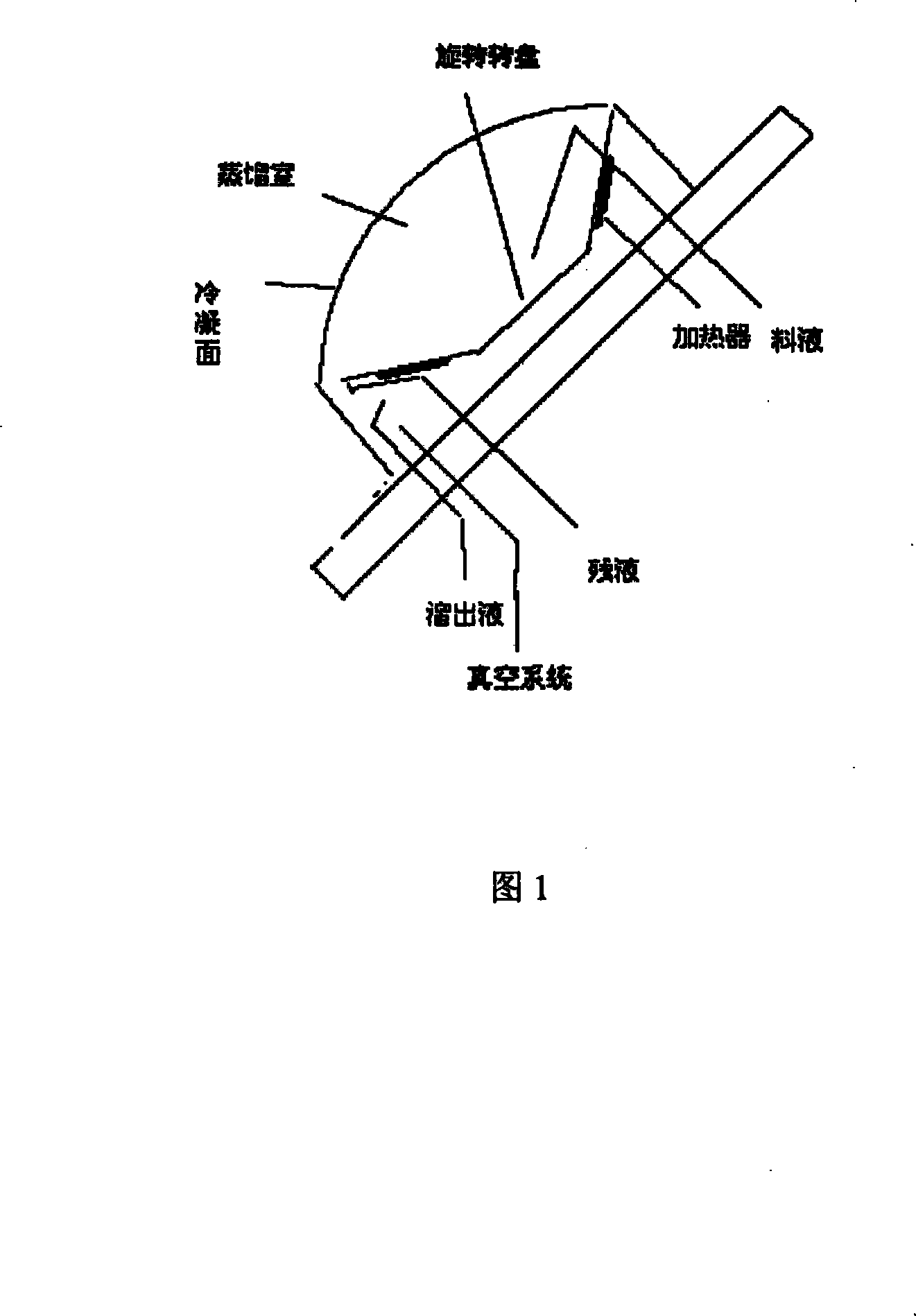

Internally circulating falling-film molecular distillator

InactiveCN1583207AReduce equipment costsReduce maintenance costsMolecular distillationAxial-flow pumpLow voltage

A falling-film molecular distilling apparatus with internal circulation is disclosed. The raw liquid is sucked in it from its bottom by an axial-flow pump, then lifted in vacuum chamber via circulating tube, and then dispersed into liquid film or liquid column or liquid drops to drop down by the dispersing element and finally redistributed by liquid distributor. The low voltage component in heated raw liquid is pumped from the top of vacuum chamber to condenser or carried downward by raw liquid for next cycle, so the raw liquid is continuously concentrated by evaporation.

Owner:钱德康

Preparation method for tobacco extract of dark sun-cured tobacco

ActiveCN105533793AIncrease the fragranceImprove the shortcomings of the lack of satisfactionTobacco treatmentMolecular distillationDistillationMass ratio

The invention relates to a preparation method for a tobacco extract of dark sun-cured tobacco. The method comprises the following steps: dark sun-cured tobacco leaves are dried, ground and sieved; tobacco powder is mixed with an alcoholic solution with the mass fraction of 65%-75% in a mass ratio of the tobacco powder to the alcoholic solution being 1:8-14, the mixture is subjected to extraction at the temperature of 55-65 DEG C for 1-2 h, solid-liquid separation is performed after extraction, and a product is concentrated; a primary extract is subjected to molecular distillation, second-level molecular distillation light components and fourth-level molecular distillation light components are assembled in the ratio being 1:0.8-2.4, and the final tobacco extract of the dark sun-cured tobacco is obtained. The prepared tobacco extract of the dark sun-cured tobacco can improve aroma of a low-tar blank cigarette, improve the smoke concentration, improve the aftertaste and reduce stimulation, an aroma enhancing purpose is achieved, and novel thought is provided for aroma enhancement of low-tar cigarettes.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

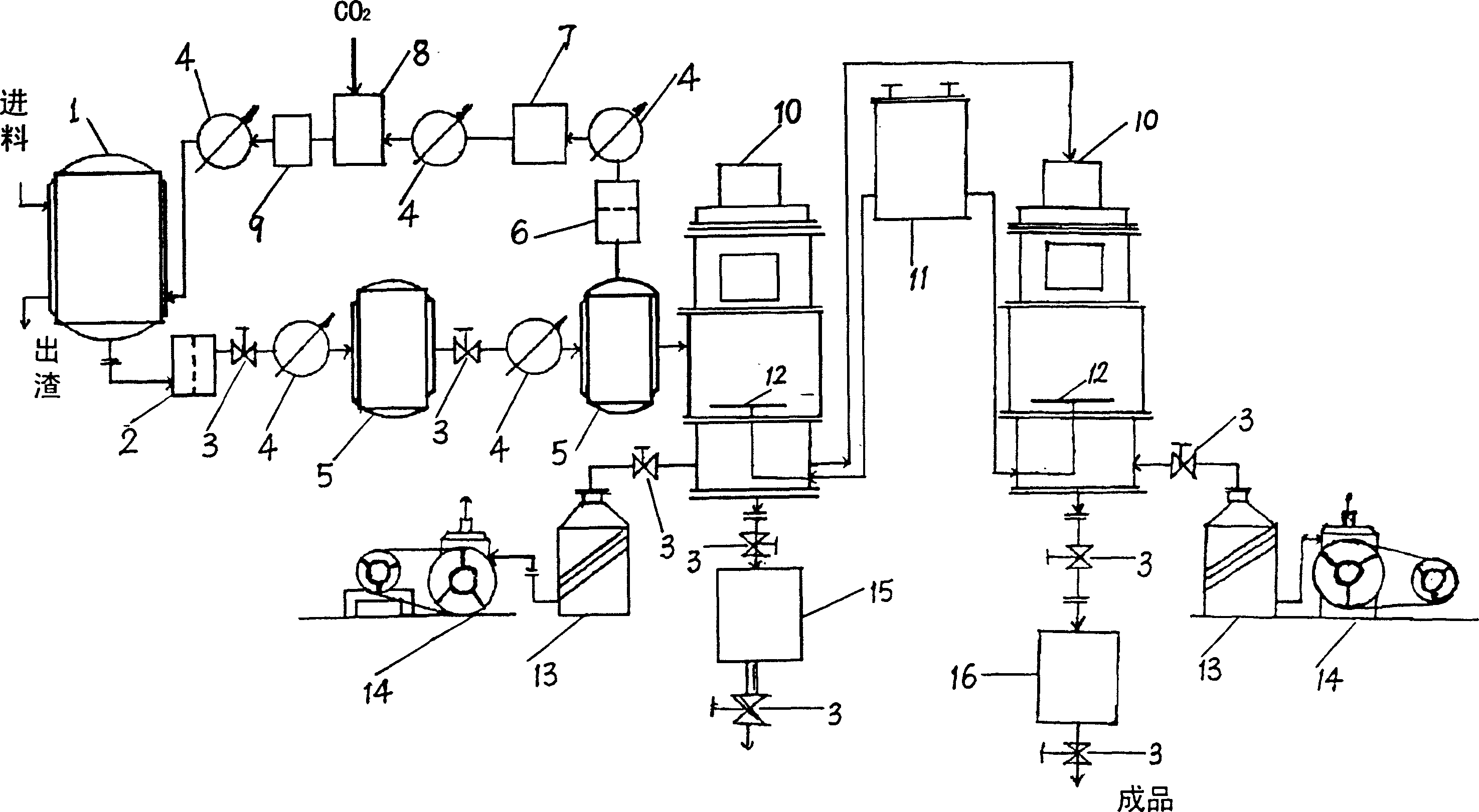

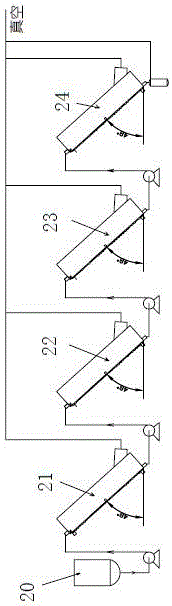

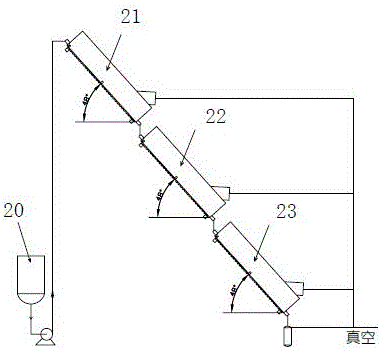

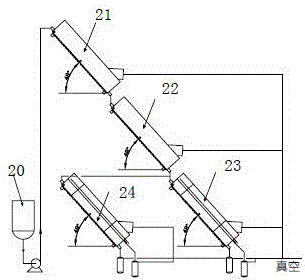

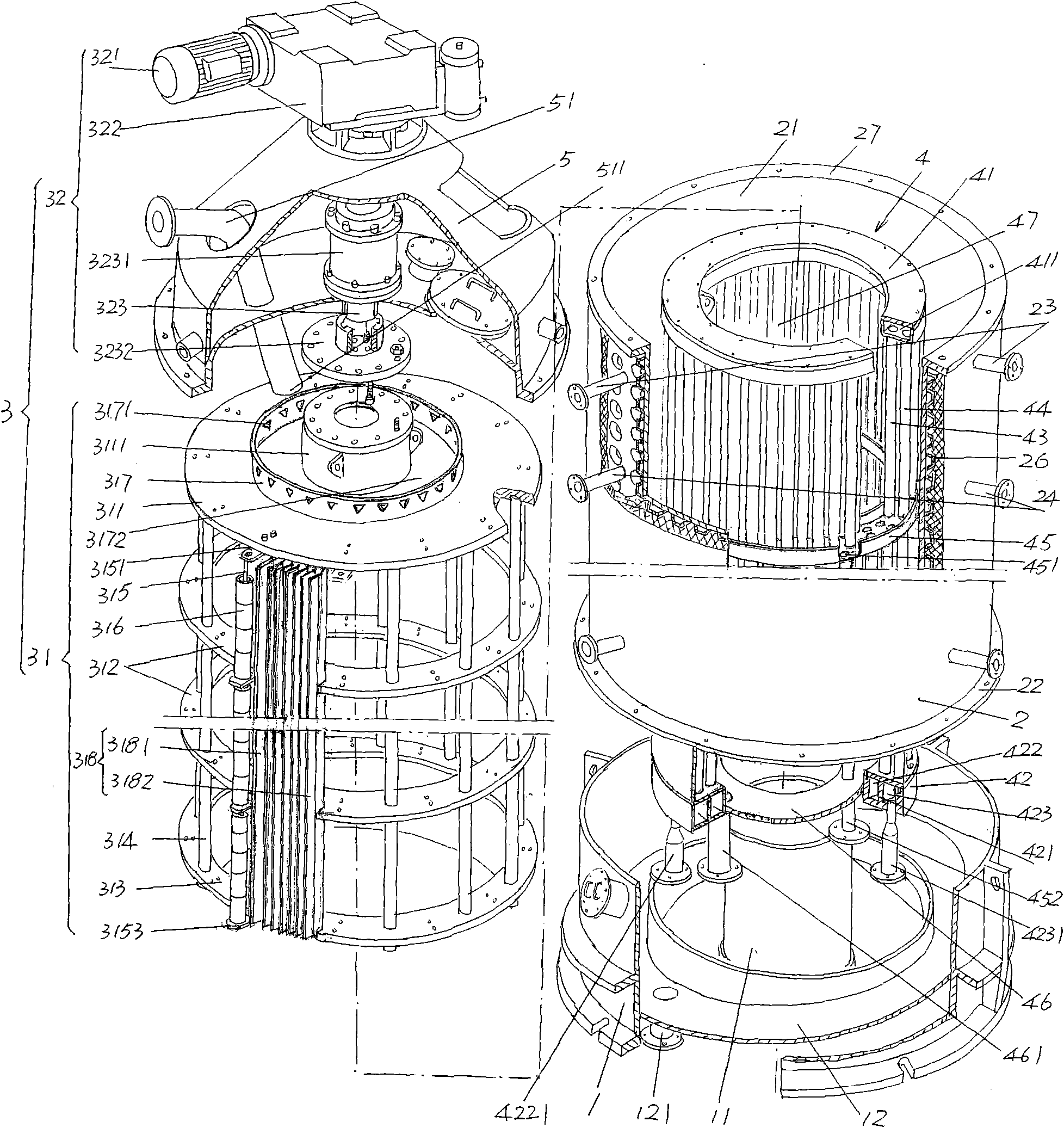

Molecular distillation separation method for grease chemical product and equipment

InactiveCN106811291AImprove sealingReduce productionFatty-oils/fats refiningMolecular distillationOil and greaseBoiling point

The invention discloses a molecular distillation separation method for a grease chemical product and equipment. A molecular distillation system consists of single molecular distillation equipment or multi-stage molecular distillation equipment in manners of serial connection, parallel connection or combination of serial connection and parallel connection; the multi-stage molecular distillation equipment is arranged in horizontal positions, up and down positions or combined way of horizontal positions and up and down positions; a product to be distilled is fed into the molecular distillation equipment from the top, is uniformly allocated for a first time through allocation tube holes or / and groove plates, is uniformly distributed to the upper part of a heating surface of the equipment to form a uniform film flowing from top to bottom, and is at least uniformly allocated further for a second time through an allocation groove plate or screening holes, and is uniformly distributed to the bottom from the heating surface of the equipment; under the action of heating and vacuum, a low-melting point oil chemical product is evaporated and recycled as a product of a first-class type; a high-melting point oil chemical product is fed to a next stage of molecular distillation; temperature and vacuum degrees of different stages of the molecular distillation equipment are determined according to low-melting point oil chemical products to be removed in equipment of a same stage, and various types of high-quality products can be prepared finally.

Owner:饶攀

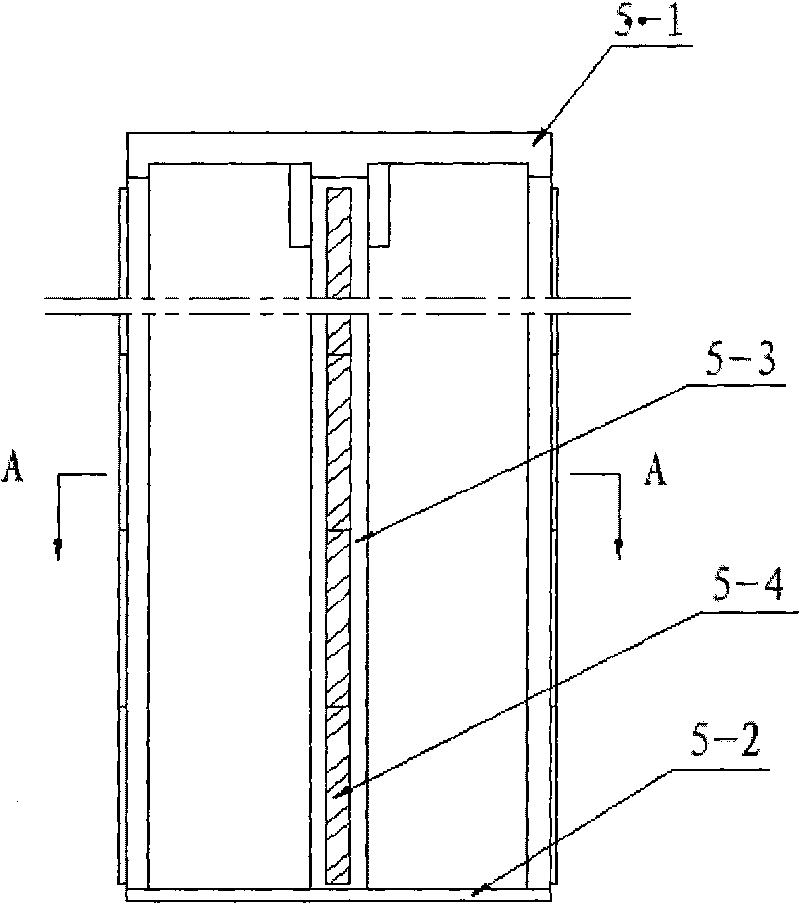

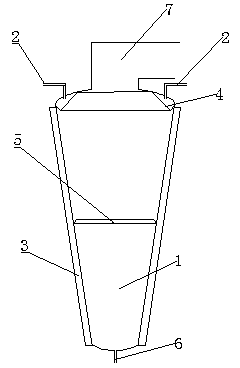

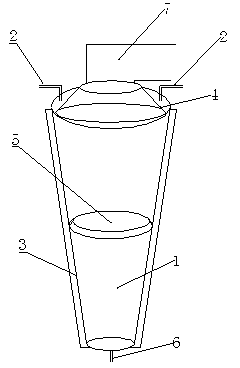

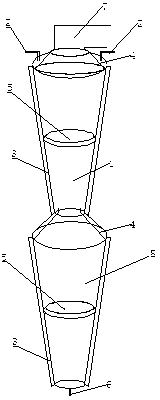

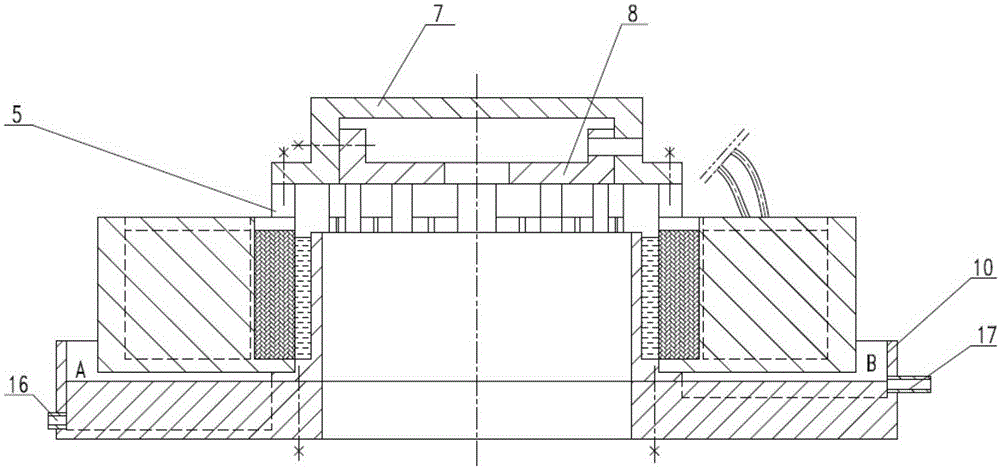

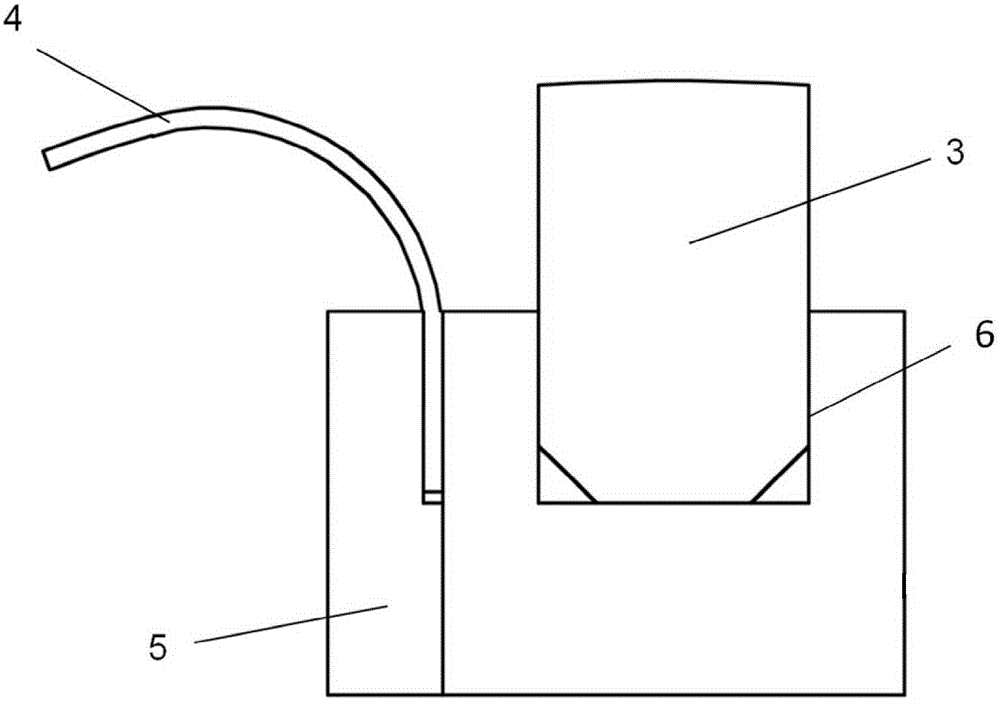

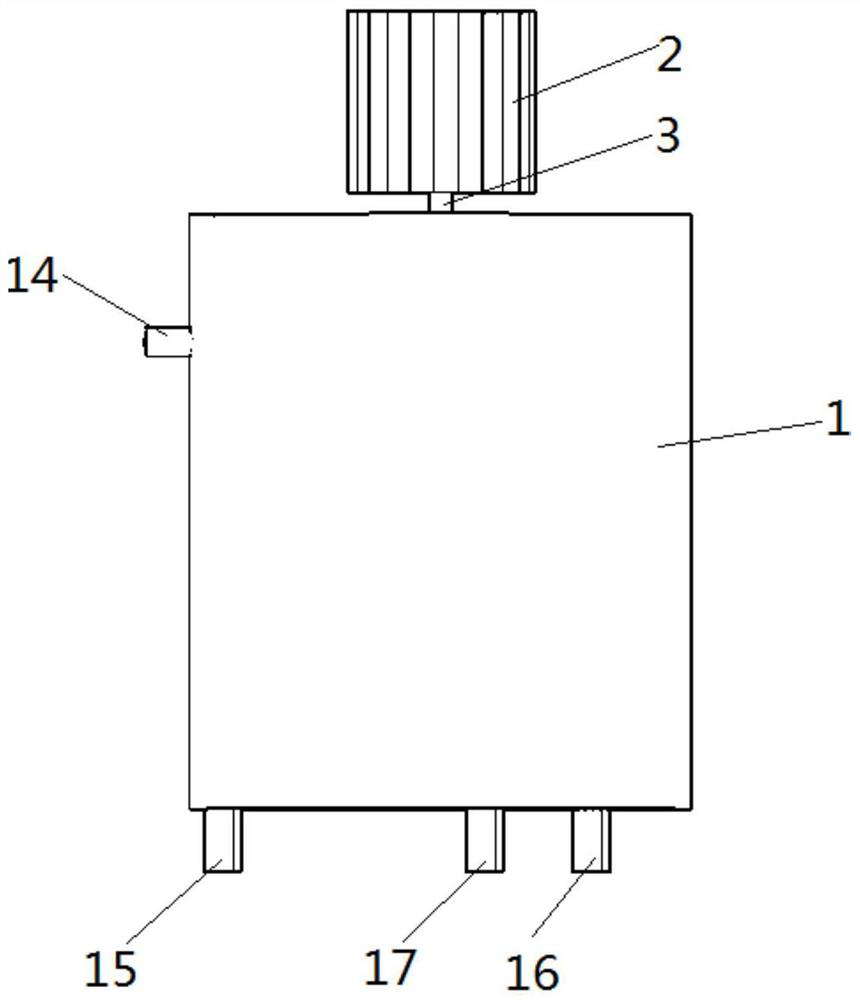

Molecular distillation device

The invention discloses a molecular distillation device which comprises a molecular distillation device body (1) and a vacuum pipe (7) and is characterized in that the molecular distillation device body (1) is an inversion body annular round table with the upper ring larger than the lower ring. The included angle formed by intersection of two opposite generatrixes of the inversion body annular round table ranges from 45 degrees to 85 degrees. The body is connected with a top end sealing head connected with a material adding pipe (2), and the inner wall of the top end sealing head is connected with the upper end side of a distribution annular round table formed by material distribution groove plates (4). An annular gap is retained between the lower end side of the distribution annular round table formed by the material distribution groove plates (4) and the lateral wall of the body, and an outlet of the material adding pipe (2) is arranged in a distribution groove. The middle of the lateral wall of the body is connected with the lower end side of a redistribution annular round table formed by material redistribution groove plates (5). An upper body and a lower body of the device body are connected in series when necessary, and a condensation system is arranged in an inner cavity of the body. The molecular distillation device is good in sealing effect, and a film is automatically formed from top to bottom along the table face by materials. The molecular distillation device does not require stirring and has the advantages of saving electricity, improving heat energy utilization ratio, reducing production cost and the like.

Owner:饶攀

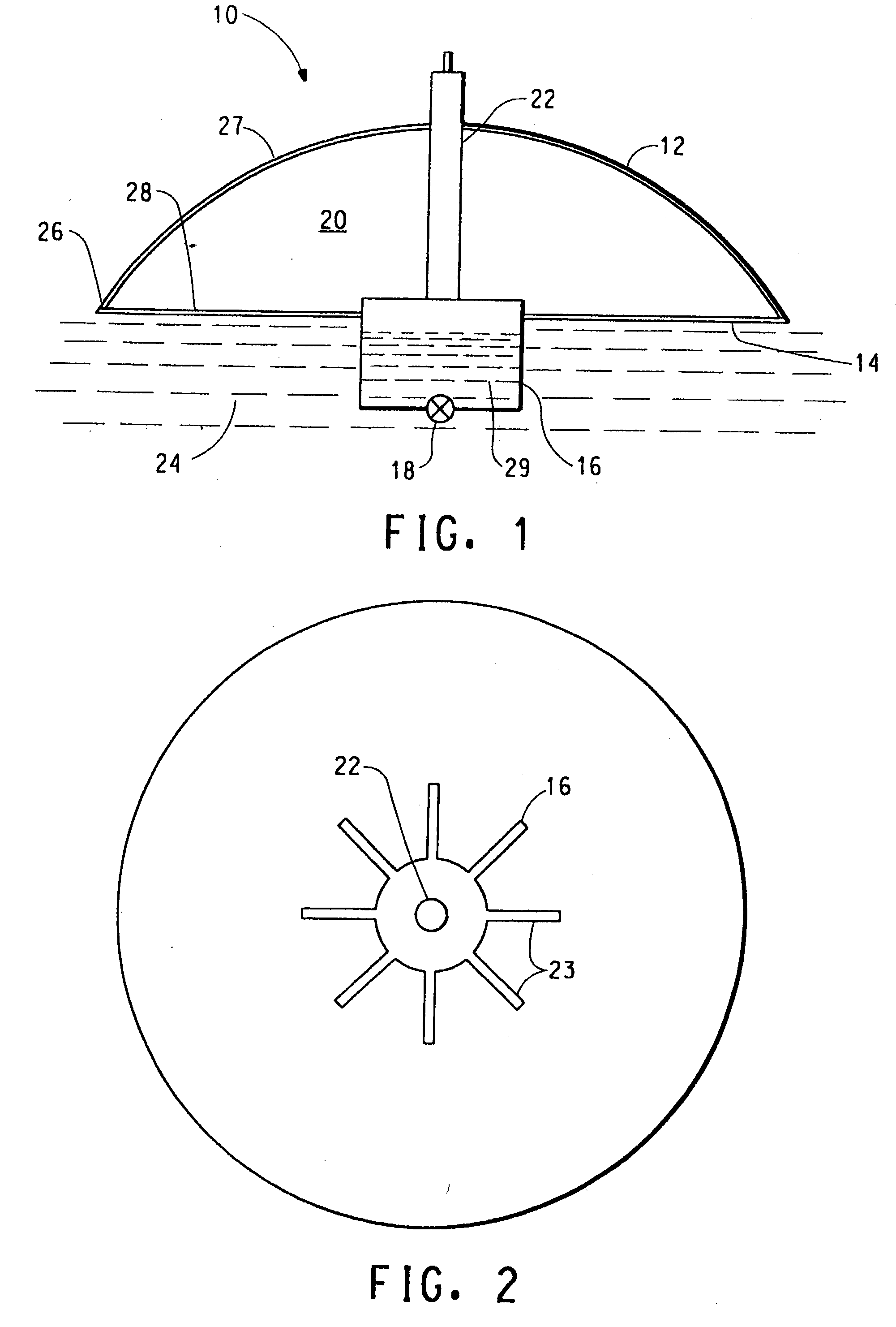

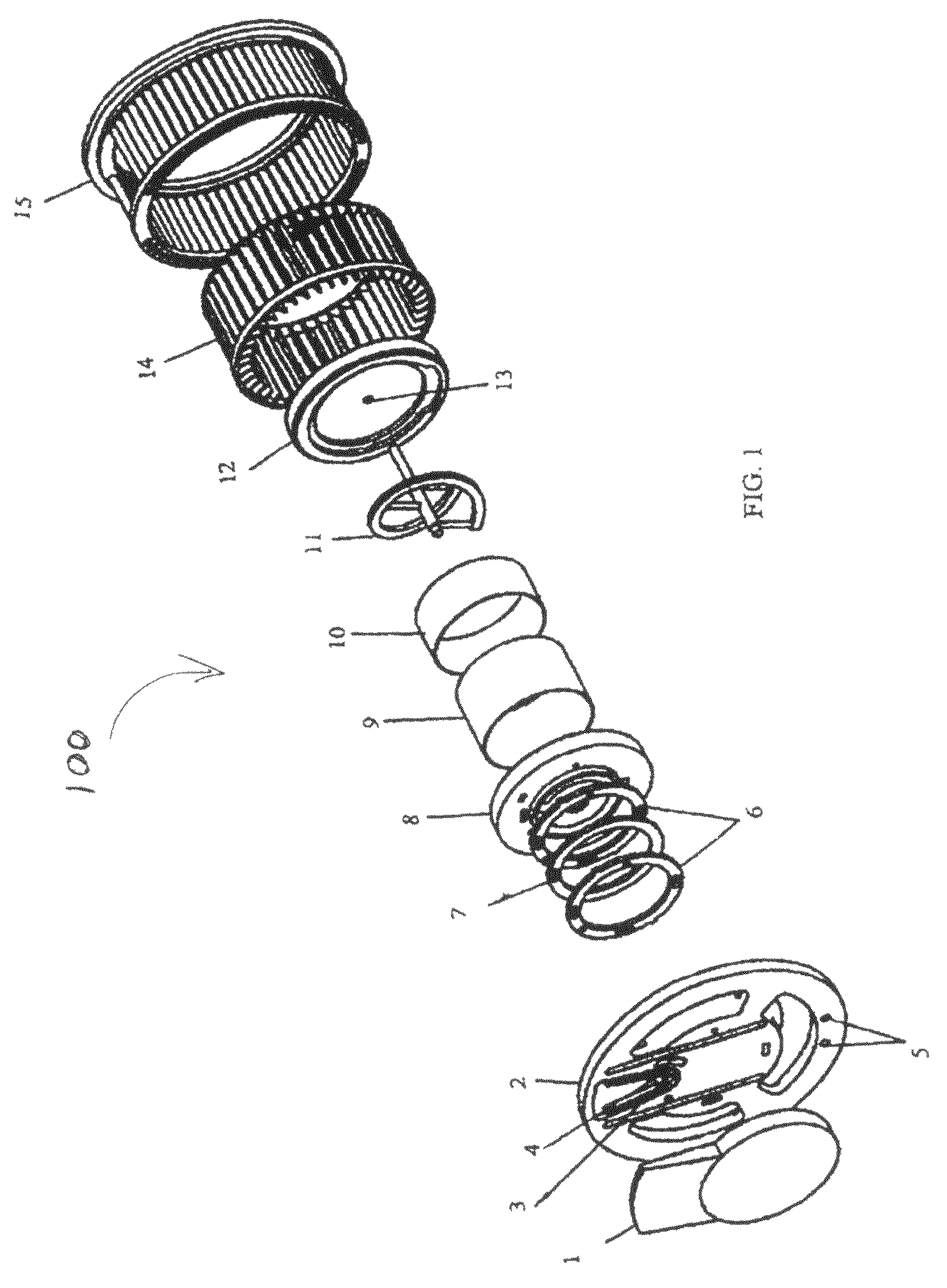

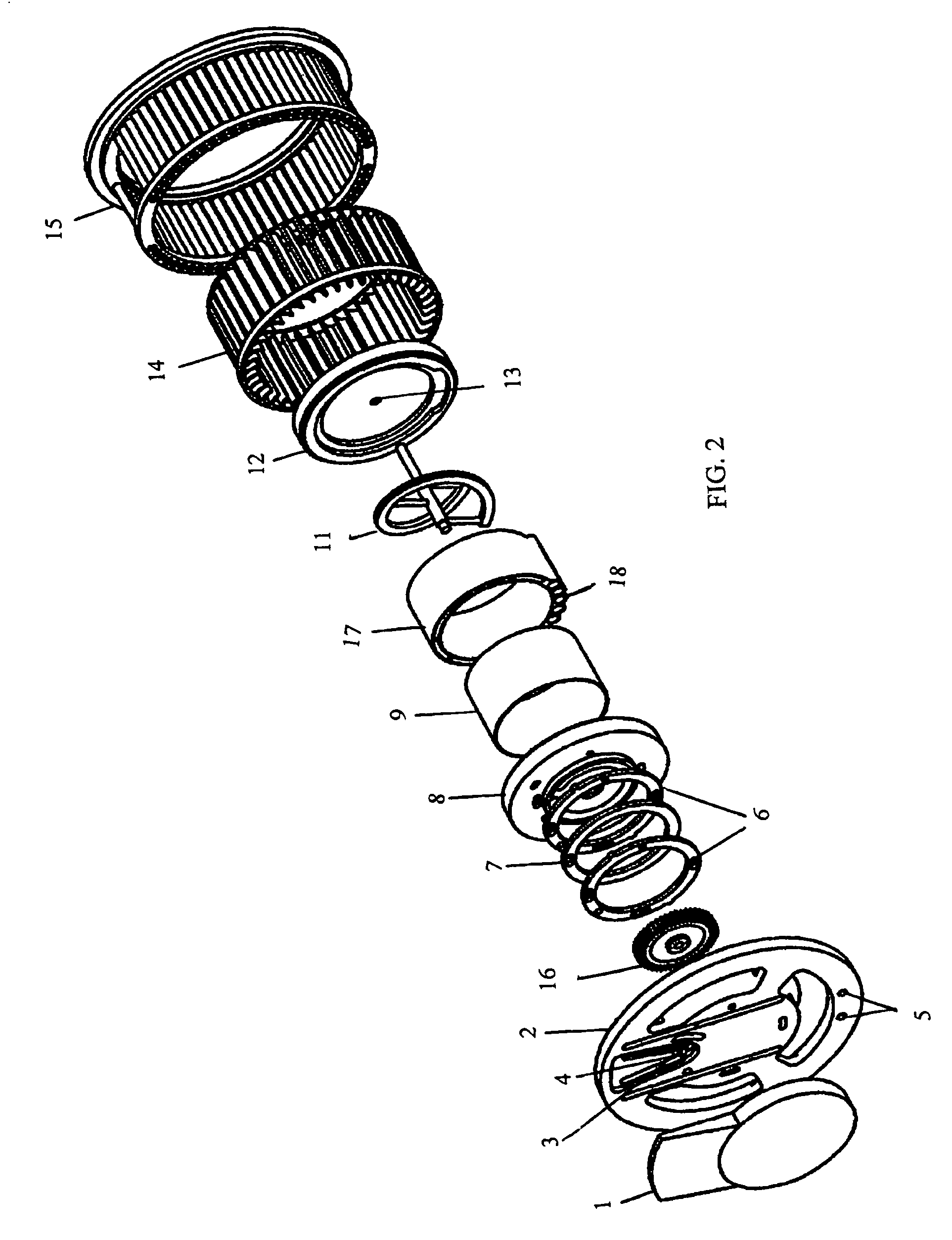

Water still and method of operation thereof

InactiveUS20030209419A1Simple mechanical structureEasy to assembleGeneral water supply conservationAuxillariesWater sourcePervaporation

A mechanical water still (10) includes an impervious dome-like upper surface (12) and a membrane base (14) that is coupled (26) to the impervious dome-like structure (12) to form, when inflated, a chamber (20). The membrane base (14) supports a water pervaporation process therethrough. A water collection well (16) has an opening into which water droplets condensed from the water pervaporation process collect. The water collection well (16) is sited within the membrane base (14) and generally extends outwardly and downwardly from the membrane base (14), as shown in FIG. 1. In use, a contaminated water source (24) is brought into, ideally, complete contact with the membrane base (14), with the water collection well (16) arranged both to act as a heat sink into the water source (24) and to provide stability to the water still (10) when floating and immersed in the water source (24).

Owner:DESIGN TECH & INNOVATION

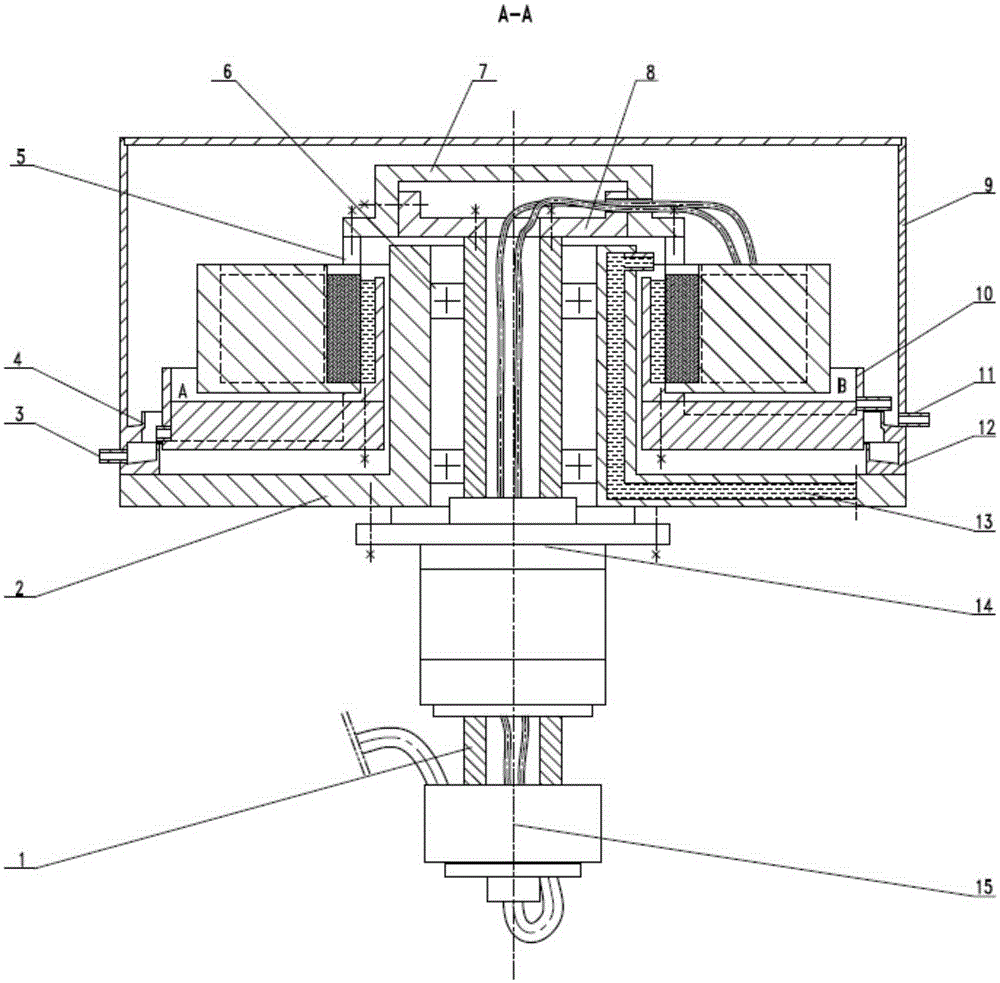

Semiconductor cooler-type centrifugal molecular distillation device

ActiveCN105169735AEasy to assemble and disassembleEasy to install and maintainMolecular distillationDistillationAuxiliary memory

A semiconductor cooler-type centrifugal molecular distillation device belongs to the field of a distillation technology. The semiconductor cooler-type centrifugal molecular distillation device mainly comprises a hollow power transmission shaft, a liquid inlet pedestal, a first collecting tank, a centrifugal distillation rotor, a bearing, an outer cover, a second collecting tank and a hollow-shaft torque motor. The centrifugal distillation rotor adopts a semiconductor cooler and simultaneously is used as a heat source and a cold source. The whole device has no auxiliary medium system such that there exists no oxidation or leakage problem of an auxiliary medium. The device has a compact structure and occupies little area.

Owner:BEIJING UNIV OF CHEM TECH

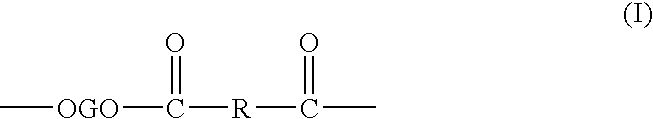

Technology for synthesizing polyester of cane sugar acids with high degree of esterification

A process for synthesizing the polyester of glycofatty acid from methyl ester (or ethyl ester) of fatty acid features that the film evaporator or molecular distiller is used for cyclic distilling multiple times for increasing the reaction efficiency and esterifying degree while excessive methylester (or ethyl ester) can be distilled out.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Method for preparing high-pure lactic acid by using centrifugal molecular distillation technique

InactiveCN101234960AShort stayNo pollution in the processMolecular distillationCarboxylic compound separation/purificationHeat resistanceDistillation

The invention discloses a method for preparing high-purity lactic acid with molecular distillation technology. The method comprises the following procedures: after pre-treatment, lactic acid fermentation broth is transmitted to a falling-film evaporator for condensation by dehydration and deaeration so that the weight percent of lactic acid rises to 40-70 percent; condensed lactic acid is transmitted by a pump with uniform speed into a centrifugal molecular distillation apparatus; at a distillation temperature of 60-100 degrees centigrade, under a vacuity of 0.1-10Pa and at a rotation speed of 500-5,000r / min, the lactic acid is transformed into an exceedingly thin evaporating liquid film on the rotation surface under the effect of centrifugal force, and thereby high-purity lactic acid is yielded. Lactic acid produced with the method of the invention has good thermostability, high purity, high yield and low cost. In addition, the technology of the invention is environment-friendly and can be industrialized easily.

Owner:江苏道森生物化学有限公司

Waste rolling oil regeneration device

InactiveCN101775330AReasonable structural designImprove regeneration efficiencyMolecular distillationLubricant compositionHeat conductingFuel oil

The invention relates to a waste rolling oil regeneration device belonging to the technical field of regeneration device structures. The waste rolling oil regeneration device comprises an oil feeding pump which is connected with a heat exchanger; a flowmeter for metering waste rolling oil is arranged between the oil feeding pump and the heat exchanger; the output end of the heat exchanger is communicated with a thin film distiller for separating rolling oil from heavy oil; the input ends of the heat exchanger and the thin film distiller are circularly communicated with a heat conducting oil furnace; the thin film distiller is connected with a condenser for collecting gas rolling oil; the condenser is connected with a vacuum unit for meeting the vacuum degree required by the thin film distiller and evaporating the rolling oil below a flash point; and the lower end of the thin film distiller is connected with a heavy oil tank for collecting heavy oil which is not evaporated and a finished product oil tank for collecting finished oil. The invention has reasonable structural design and fully protects base oil components of the rolling oil and addictive components from being damaged; and meanwhile, the regeneration efficiency of the waste rolling oil is excessively high and the purity of the regenerated rolling oil is excessively high.

Owner:王树波 +1

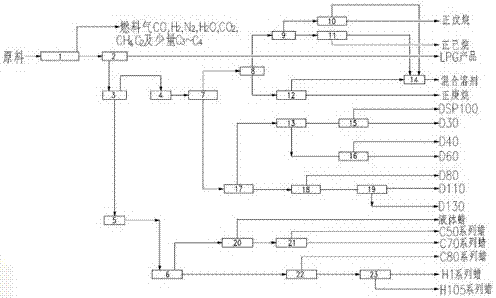

Separation method of Fischer-tropsch synthesized crude product

ActiveCN107325838AEfficient removalMeet different market needsTreatment with plural serial refining stagesMolecular distillationAlkaneWax

The invention relates to a separation method of a Fischer-tropsch synthesized crude product. The method comprises a plurality of technological steps: crude separation of products, oil hydrogenation, alkane refining, solvent oil refining, wax hydrogenation, wax refining and the like, and according to different synthesis temperatures of the Fischer-tropsch synthesized crude product, different quantities of various high-added-value products such as naphtha, n-pentane, n-heptane, DSP100, DSP40, DSP80 or DSP110 solvent oil, C50, C70 or C80 series wax, H1 and H105 series wax and the like can be obtained. The separation method has the advantages of improving the added value of the Fischer-tropsch synthesized crude product, and being simple in technological flow, and easy for industrial production.

Owner:SEDIN ENG

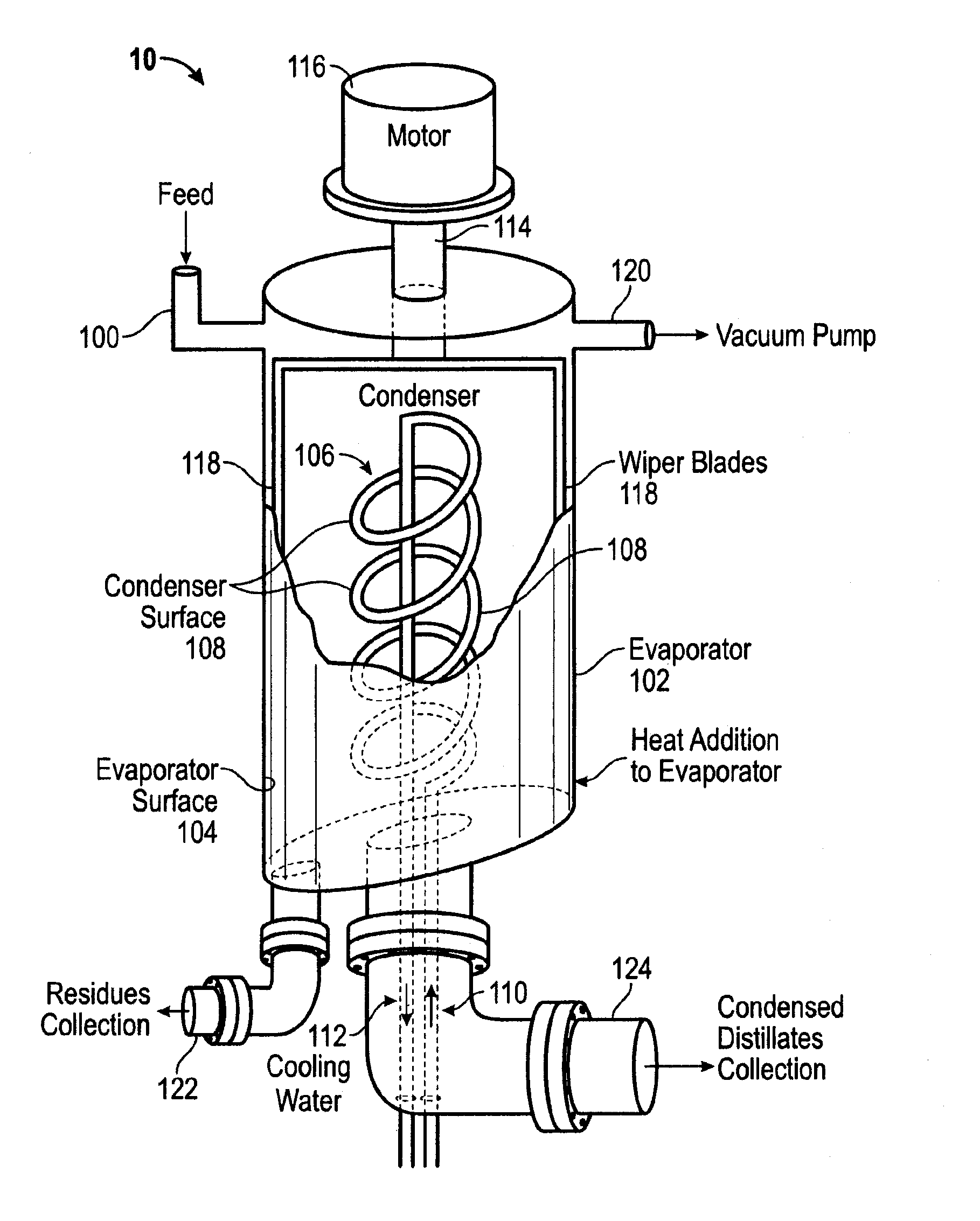

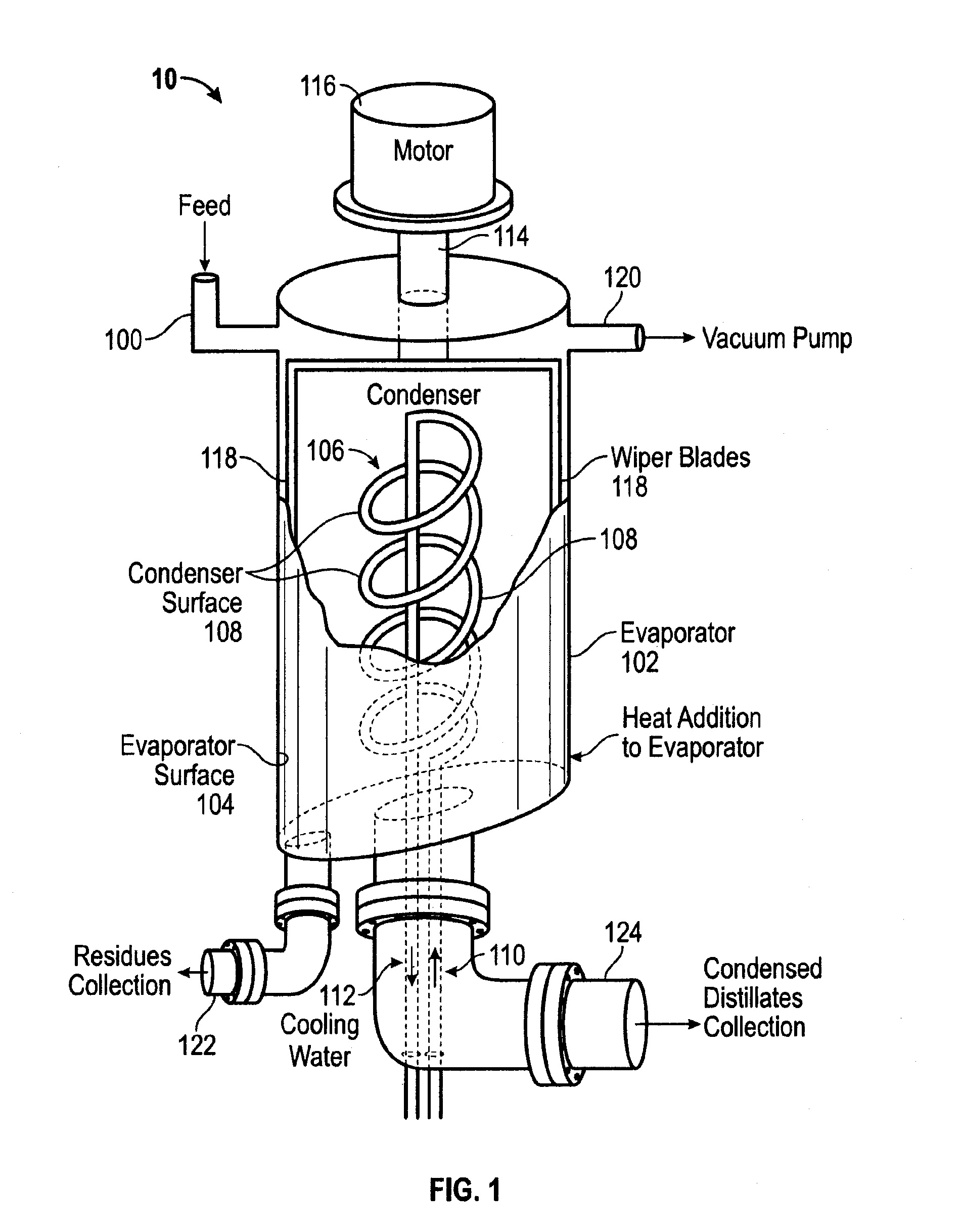

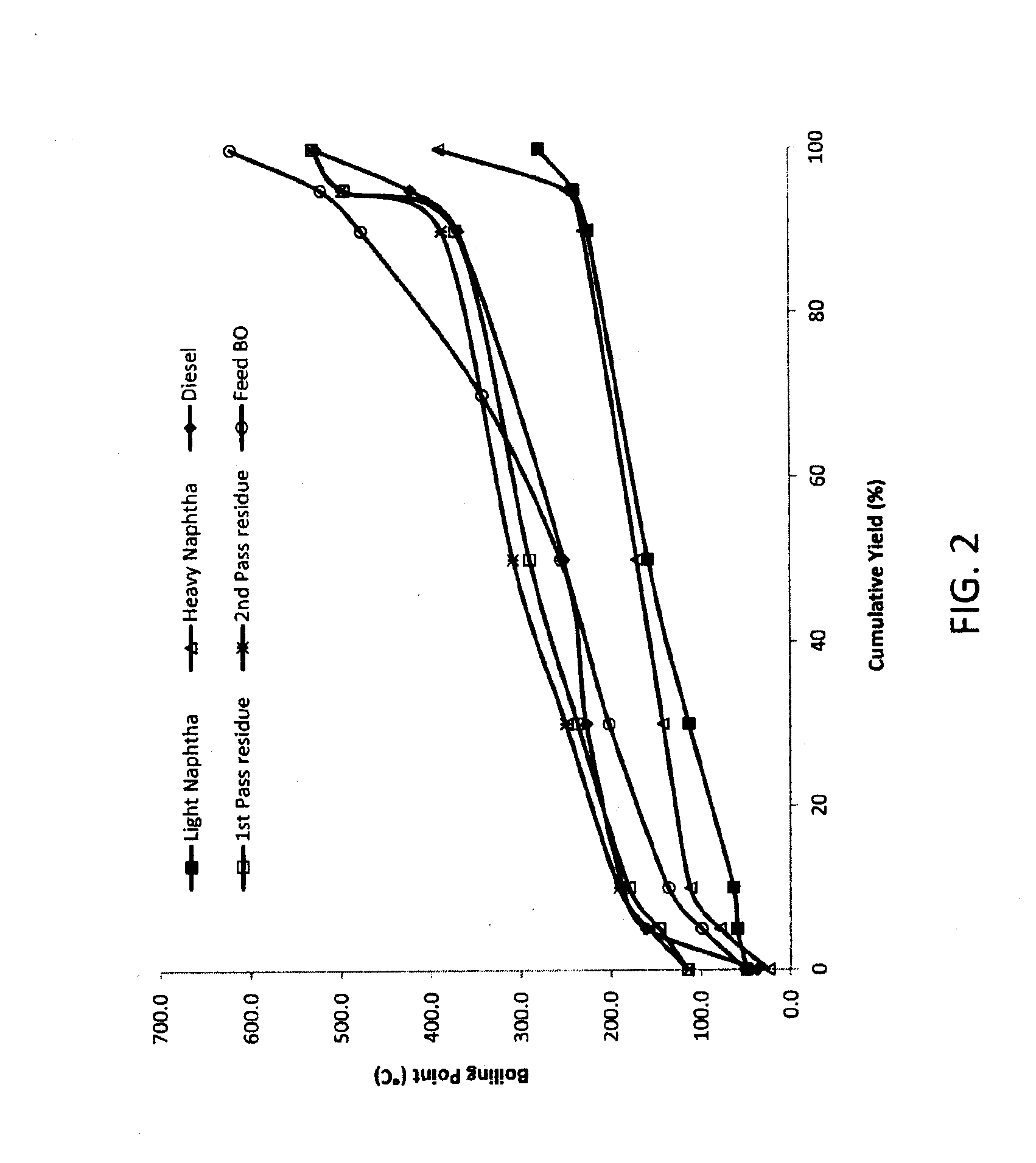

Bio-Oil Fractionation

Disclosed is a process / system for the fractionation of bio-oil, produced from the thermo-catalytic conversion of biomass, into boiling point fractions. The fractionation of the bio-oil is performed using molecular distillation under conditions which minimize the thermal stress to the bio-oil and fractions obtained therefrom.

Owner:MARD INC

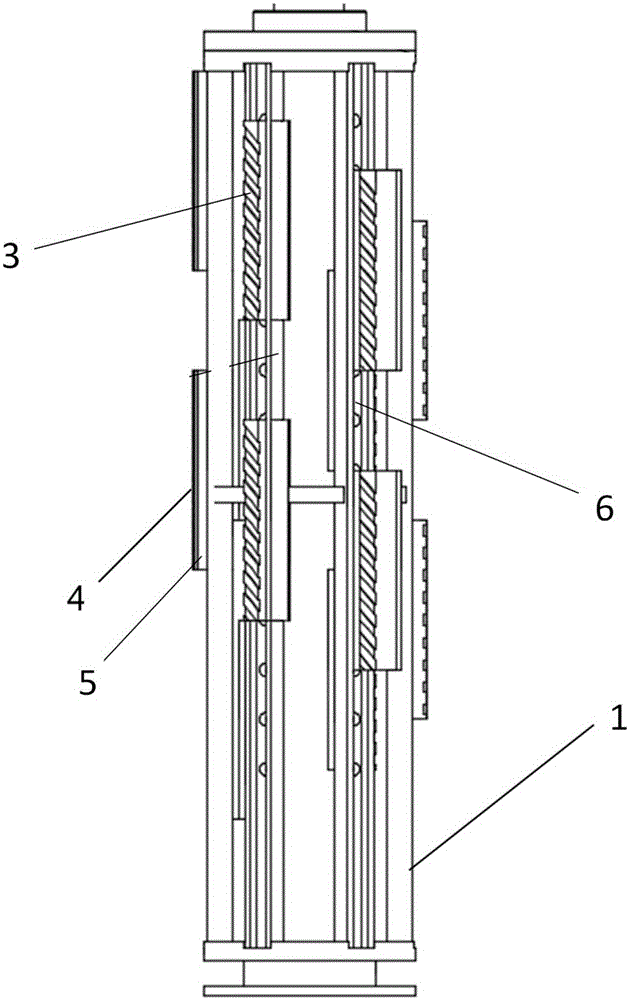

Molecular distiller

ActiveCN106552438AReduce the chance of thermal decompositionIncreased chance of thermal decompositionMolecular distillationDistillationEvaporation

The invention relates to the technical field of molecular distillation and discloses a molecular distiller. The molecular distiller comprises a motor, a distillation cylinder, a heating jacket located outside the distillation cylinder, and a condenser and a membrane scraper located in the middle of the distillation cylinder. The membrane scraper is driven by the motor and is arranged in the distillation cylinder and close to the inner wall of the distillation cylinder. The membrane scraper comprises several membrane scraper groups. The membrane scraper group at least comprises a scraper plate and a flexible scraper blade, the flexible scraper blade is arranged at the rear end of the scraper plate, and the scraper plate and the flexible scraper blade slide along a rotation direction of the membrane scraper. The scraper plate and the distillation cylinder inner wall form an appropriate space and do not contact with each other. A part of the flexible scraper blade fits to the inner wall of the distillation cylinder. The molecular distiller utilizes a combined structure of the rigid scraper plate and the flexible scraper blade, forms a uniform liquid material membrane, prevents mechanical friction between the membrane scraper and the evaporation surface, and is particularly suitable for molecular distillation of the heat-sensitive material and / or the mechanical friction sensitive material.

Owner:YASHENTECH CORP

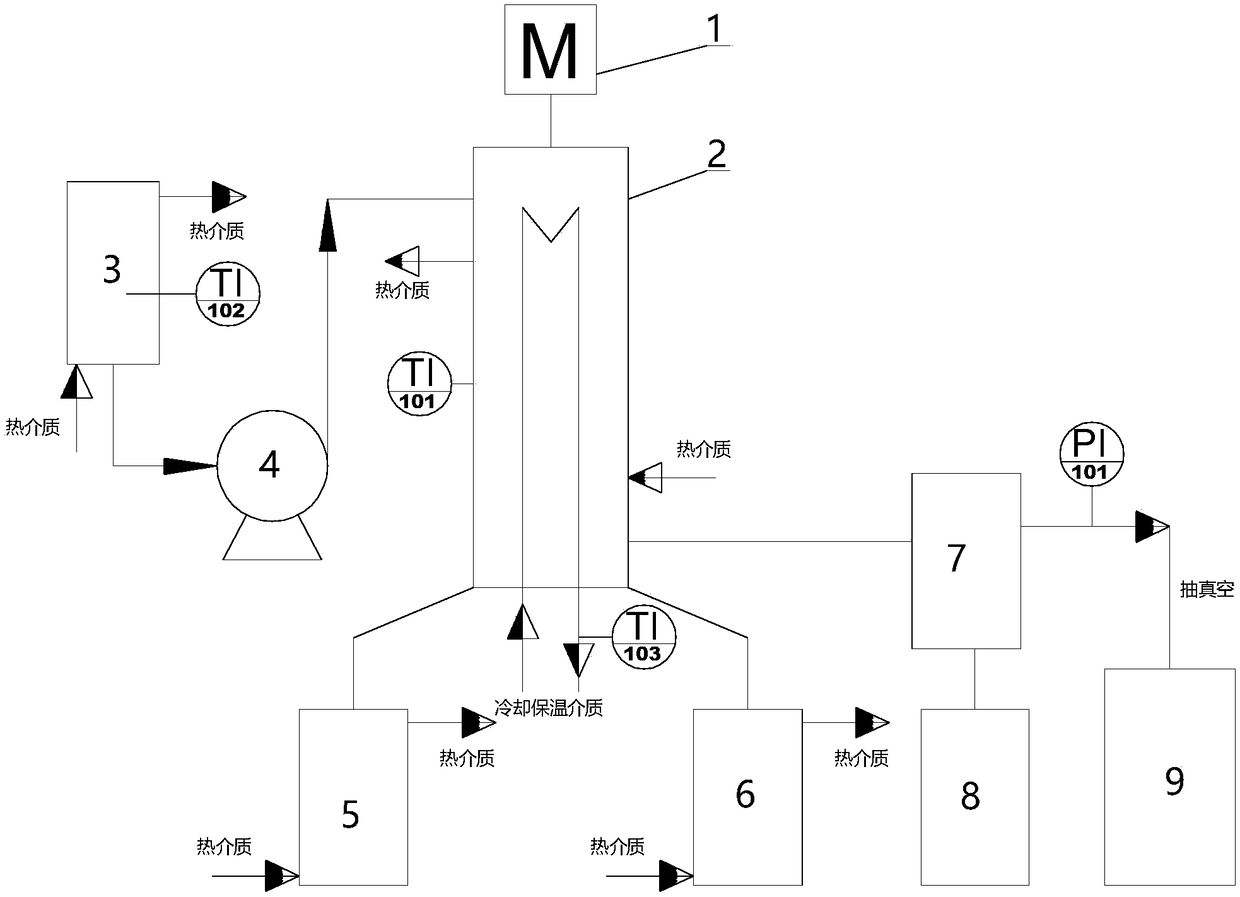

Application method of molecular short-range distiller for extracting cannabidiol from medical marijuana

InactiveCN108479098AEfficient distillationPromote crystallizationOrganic chemistryOrganic compound preparationMedicineSolvent

The invention discloses an application method of a molecular (short-range) distiller for extracting cannabidiol in medical marijuana, which comprises the following steps of: 1, selecting medical marijuana extract for later use; 2, the extract is put into a feeding tank for heating, and extract solution is pumped into a molecular short-range distiller by a feeding pump when the extract melts and can freely flow, and the extract solution is distilled by a molecular (short-range) distiller. Vacuumizing the molecular short-range distiller through a vacuum pump, controlling the stirring speed, andsimultaneously introducing cooling / heating medium into the condenser in the molecular short-range distiller; 3, collecting the cannabidiol in the material collecting tank 2, collecting the extract residue in the material collecting tank 1, and simultaneously introducing heat medium into the material collecting tank 1 and the jacket of the material collecting tank 2 to carry out heating and heat preservation; 4, heating the freezing medium in a cold well, and obtaining a small amount of tetrahydrocannabinol and a solvent in the material collecting tank 3; 5, when the extract in the feeding tankis almost finished, adding extract into the feeding tank until the extract is finished, and ending the experiment / production.

Owner:上海弗华机电设备有限公司

Multiple application purification and recycling device

InactiveUS7955476B2Flexible operationEasy constructionEvaporation with vapour compressionDistillation regulation/controlDistillationMultiple applications

A multiple application recycling and purification device has a coaxial core that is horizontally oriented, non-rotating, cylindrical distillation chamber. The enhanced, completely coaxial configuration continuously cleans the entire distillation chamber and spreads a thin film of liquid to enhance distillation and positively aid in the removal of remaining contaminants. Through a timed and positioned valve, the device removes and purges lower-temperature contaminants. Timed valves and sensors control all phases of the distillation to provide a coaxially integrated, stand-alone, adaptable, scalable and maintenance free distillation unit that self-monitors, self-cleans and economically functions to produce the pure distilled liquid, e.g., water. This device can be modified to purify any numerous array of liquids and can be scaled to produce any amount of purified liquids for either household, commercial, or industrial applications.

Owner:MANSUR CORP

Method for extracting high-content lutein by utilizing molecular distillation technology and simulated moving bed technology

ActiveCN101712643AReduce pollutionWill not bring inOrganic chemistrySolid sorbent liquid separationDistillationSimulated moving bed

The invention discloses a method for extracting high-content lutein by utilizing a molecular distillation technology and a simulated moving bed technology. The method comprises the following steps of: adding an organic solvent to a marigold extract and then extracting to obtain a condensate; carrying out primary molecular distillation and secondary molecular distillation on the condensate; dissolving distillates with petroleum ether, extracting with ethanol water and merging ethanol water layers; concentrating by decompression and drying to obtain orange red oily lutein the lutein content of which is higher than or equal to 50 percent; and then purifying the lutein with the simulated moving bed technology to obtain the high-content lutein the quality content of which is 85-95 percent. Themethod can save a great quantity of solvent, lowers the requirements on equipment, reduces the pollution to the environment and can not bring new impurities and toxic substances, thereby being suitable for industrial big production. The lutein obtained by the method has high purity and high yield.

Owner:天津市尖峰天然产物研究开发有限公司

Rotary polymer distiller

ActiveCN112316466APrevent splashReduce separation efficiencyMolecular distillationDistillationThin membrane

The invention belongs to the field of molecular distillation equipment, and particularly relates to a rotary macromolecular distiller which comprises a distillation cylinder, a motor is mounted at thetop of the distillation cylinder, the output end of the motor is connected with a rotating rod rotationally connected to the interior of the distillation cylinder, and a transmission device is arranged on the outer side of the rotating rod. The transmission device comprises a horizontally-arranged rotating plate, the middle of the rotating plate is movably connected to the outer portion of the rotating rod in a sleeving mode through a first one-way bearing, cylindrical holes are formed in the periphery of the rotating plate, and movable rods are arranged in the cylindrical holes. The belts ina film scraping device are arranged at equal intervals along the center of the distillation cylinder, a uniform thin film is formed when the belts rotate, and when redundant liquid which is not subjected to film forming splashes towards the middle, the liquid is continuously brought to the other side of the inner wall of the distillation cylinder by the non-film-scraping ends of the belts to be subjected to the film forming process; and a plurality of belts form a redundant liquid to continuously participate in the film forming operation, so that the unseparated liquid is prevented from splashing onto the condensation plate.

Owner:ANHUI JINGHE IND

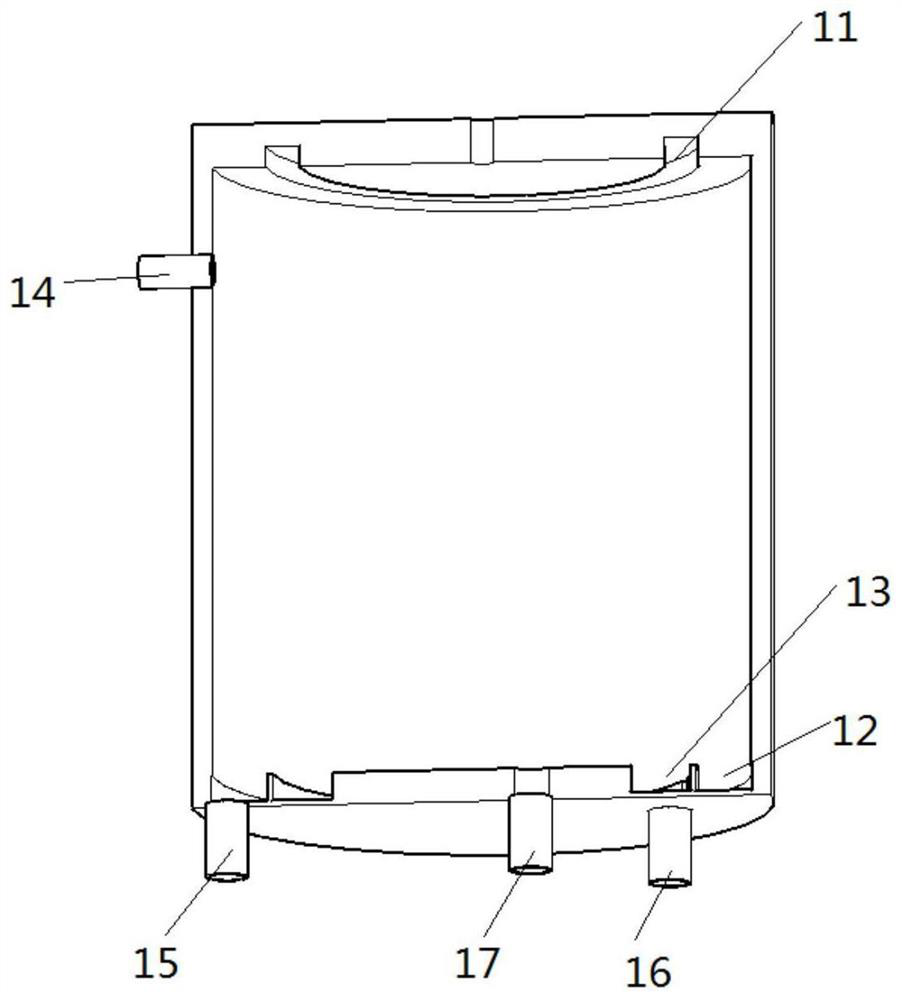

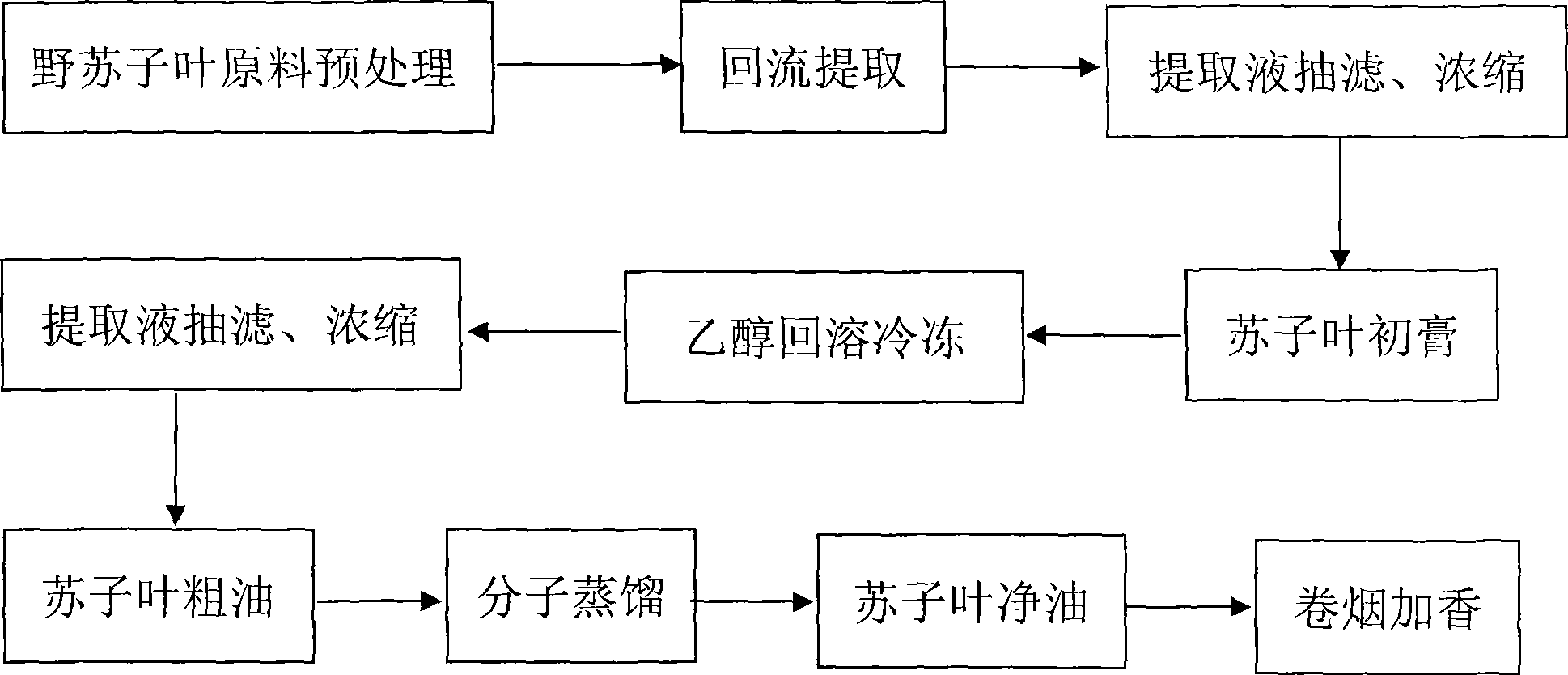

Preparation of Perilla leaf clean oil

ActiveCN101486950AKeep active ingredientsAvoid destructionTobacco treatmentFatty-oils/fats refiningOrganic solventDistillation

The invention discloses a preparation method of folium perillae neat oil, which consists of preparing folium perillae powder, organic solvent reflowing, extracting and concentrating, re-suspending, freezing, sucking filtrating and concentrating, and molecular distillation separating and purifying to obtain the folium perillae neat oil. The obtained su cotyledon neat oil is used in the cigarette flavoring, can improve the fragrance and increase the smoothness and fine degree of the smoke, and reveals unique delicate fragrance.

Owner:JILIN TOBACCO IND

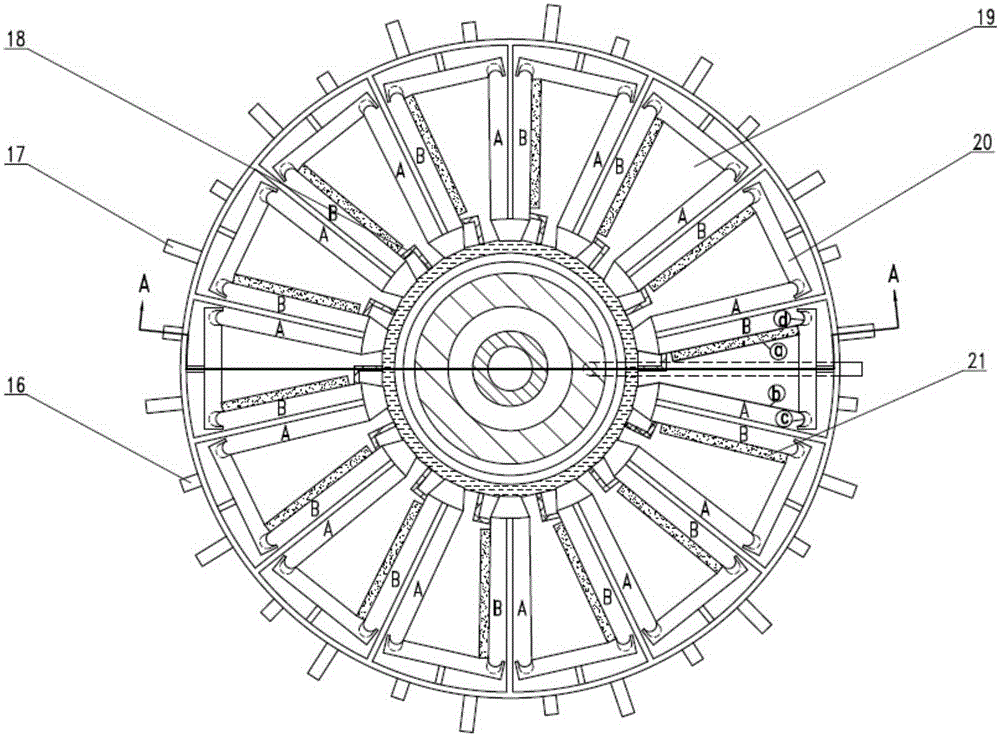

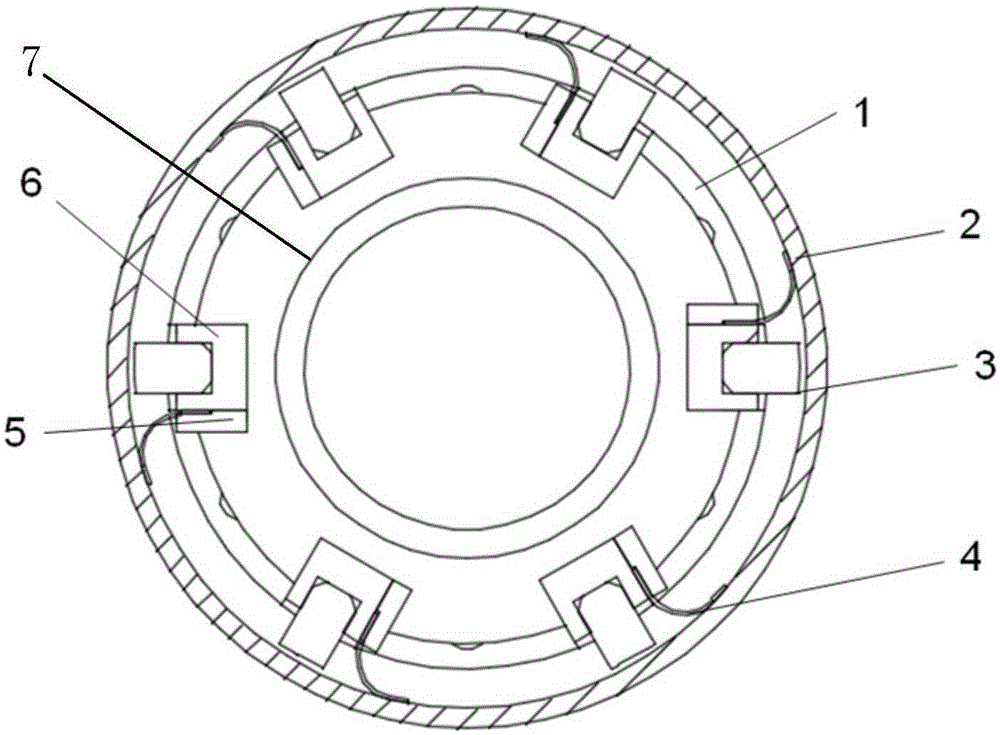

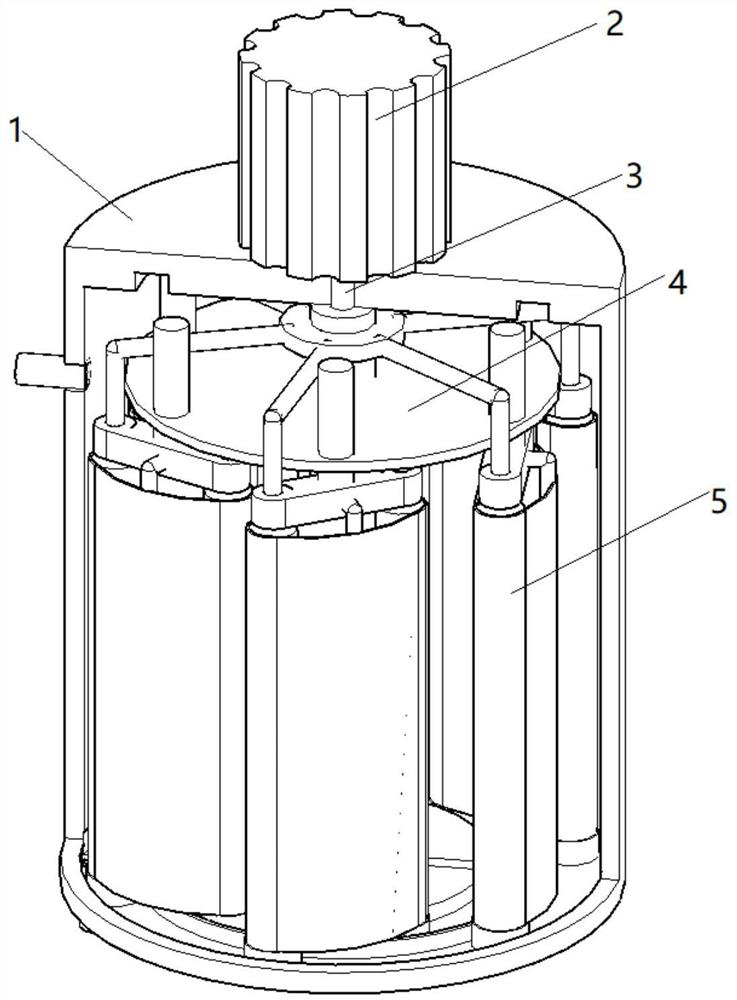

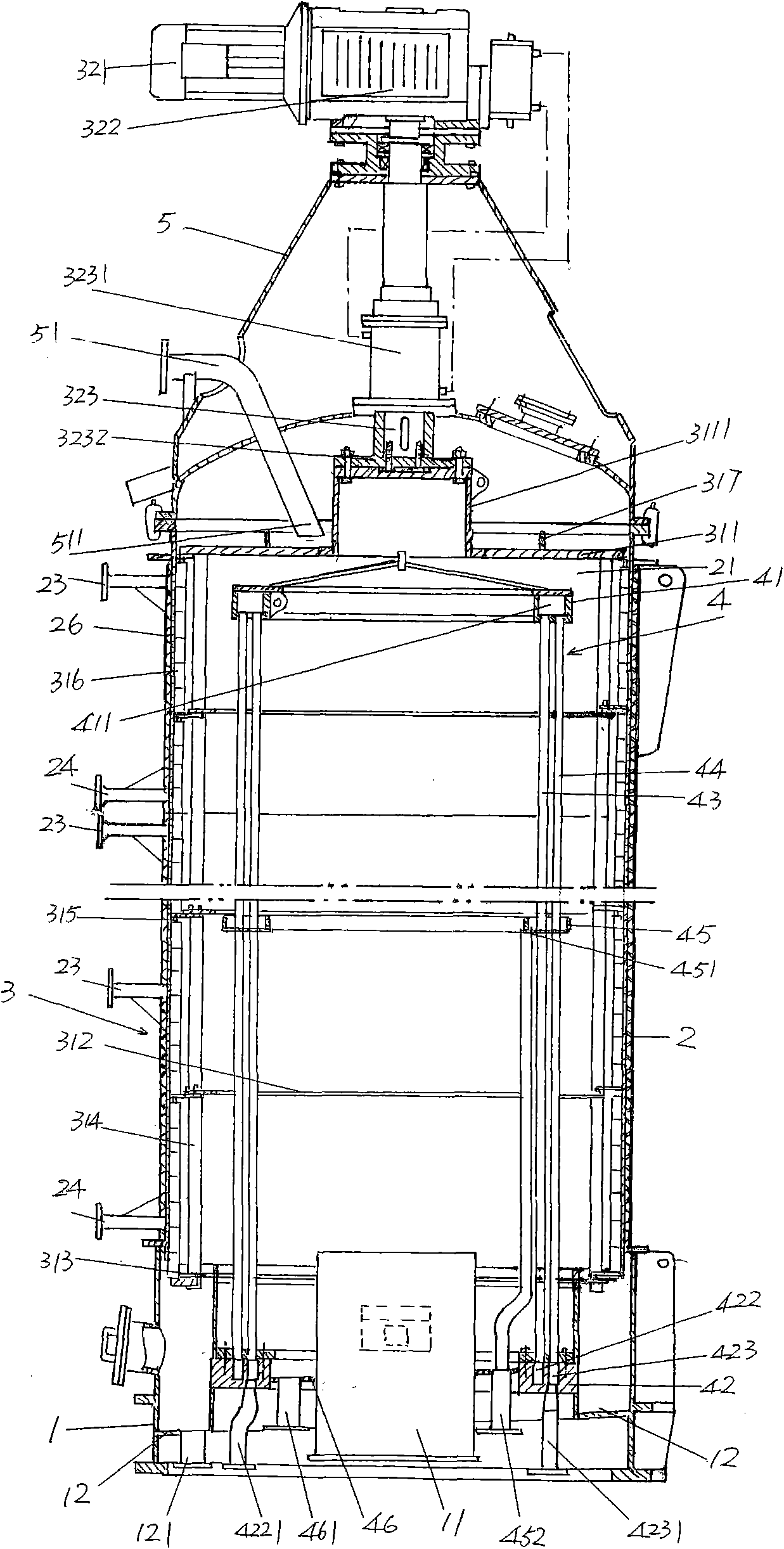

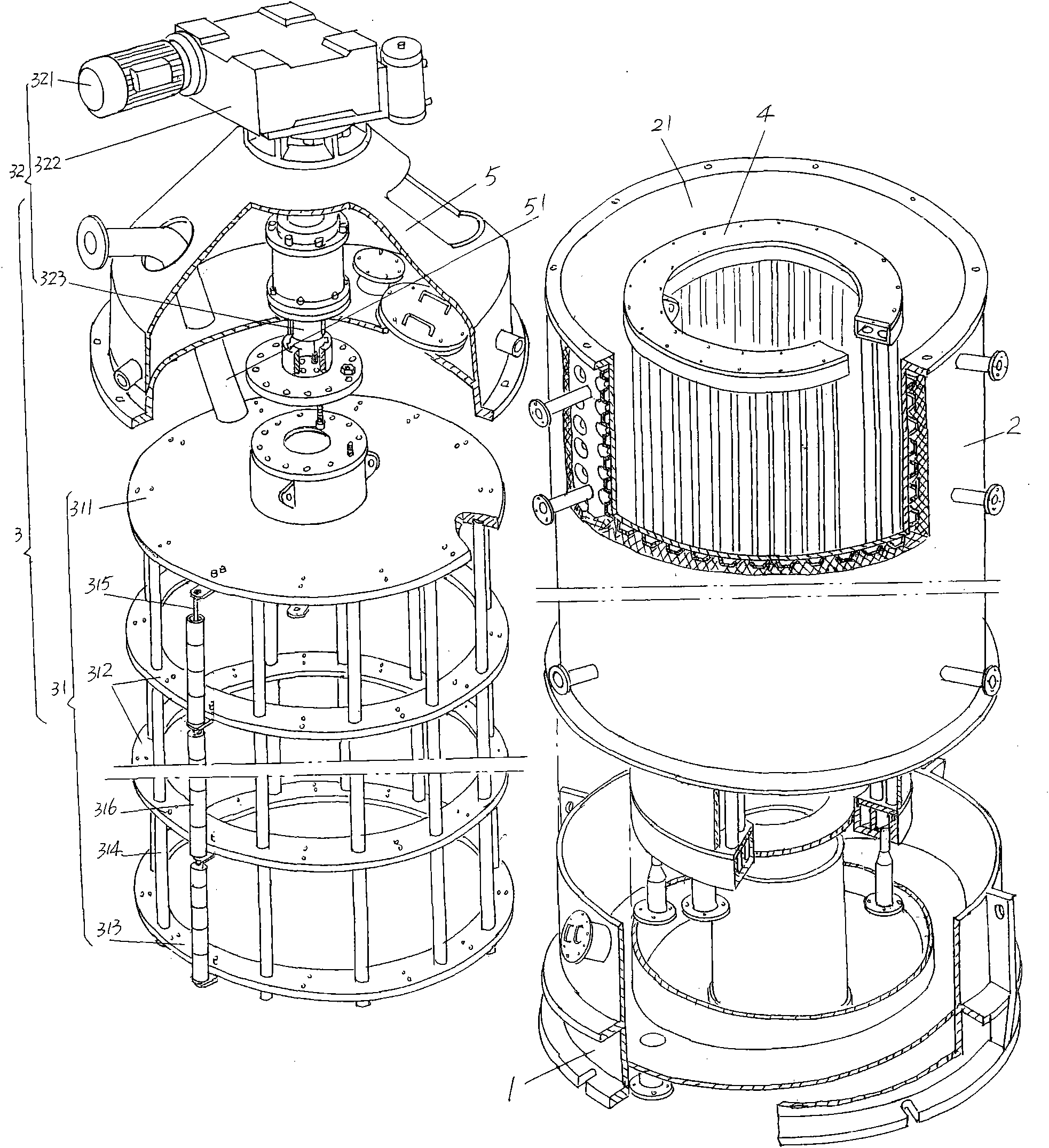

Molecular distillation device

ActiveCN101537261AImprove separation efficiencySave energyMolecular distillationDistillationAgricultural engineering

The invention discloses a molecular distillation device, belonging to the technical field of medicine biochemical engineering equipment. The molecular distillation device comprises a base, an evaporator, a condenser, a cover and a film scraping device, wherein the evaporator and the condenser are arranged on the base, the cover is arranged at the upper part of the evaporator and is provided with a feed pipe, and the film scraping device is connected to the cover and comprises a rotating cage and a rotating cage drive mechanism being in transmission connection with the rotating cage. The rotating cage is arranged in a cavity between the evaporator and the condenser, and comprises a material receiving disc, a set of middle fixed rings, a bottom rotating disc, a set of fixed rods, a set of film scraping roller shafts and a set of film scraping rollers. The set of fixed rods are arranged at intervals, the upper end of each fixed rod is fixed with the material receiving disc, the middle part of each fixed rod is fixed on the set of middle fixed rings in a penetrating way, the lower end of each fixed rod is fixed with the bottom rotating disc, the set of film scraping roller shafts are arranged at intervals to be fixed with the material receiving disc, the middle fixed rings and the bottom rotating disc, and each film scraping roller is sleeved on each film scraping roller shaft. The invention is characterized in that a liquid surrounding weir is arranged on the material receiving disc, and material distributing holes are arranged on the liquid surrounding weir at intervals. The invention improves the separation efficiency, and saves the energy.

Owner:JIANGSU SHAJIABANG CHEM EQUIP

Recovery method for ionic liquid solvent generated from homogeneous acylation reaction of cellulose

The present invention relates to a recovery method for an ionic liquid solvent generated from a homogeneous acylation reaction of cellulose. According to the method, the ionic liquid waste solution generated from the homogeneous acylation reaction of the cellulose is decolorized and filtered; the filtered ionic liquid waste solution is subjected to vacuum distillation; the resulting ionic liquid waste solution is added to a molecular distillation device; appropriate conditions of a feeding temperature, a feeding speed, an evaporation temperature, an evaporation pressure, a wiped film rotationspeed and a condensation temperature are selected to carry out molecular distillation, the collected heavy components are the recovered ionic liquid. With the method of the present invention, the vacuum distillation technology and the molecular distillation technology are combined, such that organic residues and water in the ionic liquid waste solution generated from the homogeneous acylation reaction of the cellulose can be efficiently removed, the purity of the resulting ionic liquid is more than 99%. The method has advantages of lower energy consumption, simple process and high efficiency.The recovered ionic liquid can be recycled.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

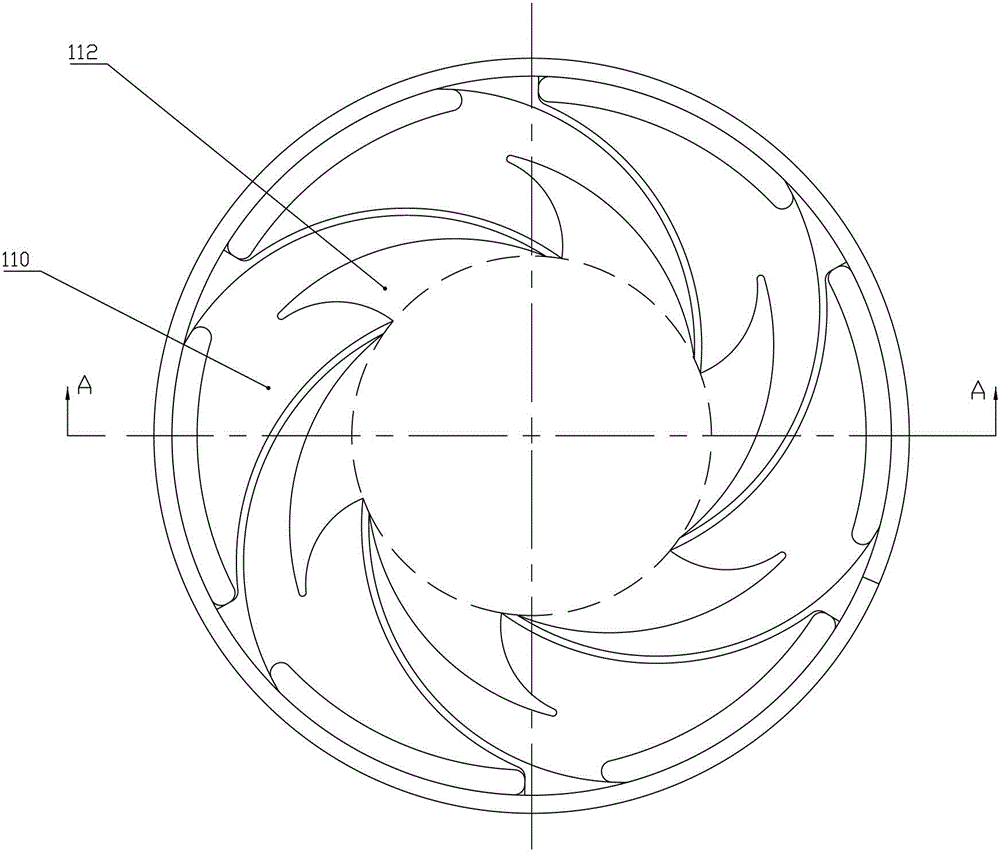

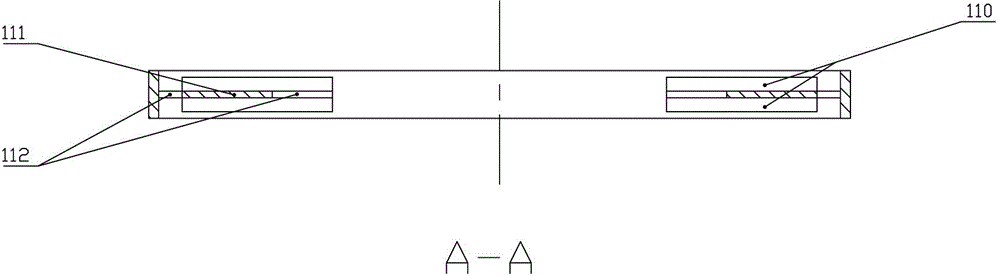

Complex radial flow pump, combined radial flow pump and air extraction system

ActiveCN104806535AEliminate pollutionReduce energy consumption of pumpingPump componentsMolecular distillationEngineeringMechanical engineering

Owner:储继国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com