Complex radial flow pump, combined radial flow pump and air extraction system

A technology of radial flow and air extraction grooves, which is applied to radial flow pumps, parts of pumping devices for elastic fluids, pumps, etc., which can solve the problem of low linear velocity inside the rotor flat plate, reduced air extraction performance of radial flow pumps, and reduced Radial flow molecular pump pumping performance and other issues, to achieve the effect of saving pumping energy consumption, saving equipment, and improving the quality of vacuum products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment one composite radial flow pump

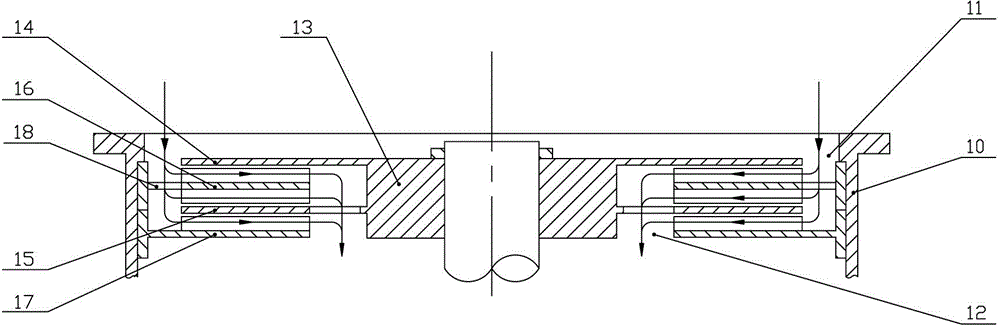

[0034] Such as Picture 1-1 As shown, Embodiment 1 of the present invention provides a composite radial flow pump, including a housing 10, the housing 10 is provided with an air inlet 11 and an exhaust port 12, and the housing 10 is provided with a rotor 13, a static wheel 16 and a dynamic seal 17, The rotor 13 is fixedly provided with two flat disc moving wheels 14, 15, and the stationary wheel 16 is arranged between the two moving wheels 14, 15, and the outer side of the stationary wheel 16 is provided with communicating air holes 18.

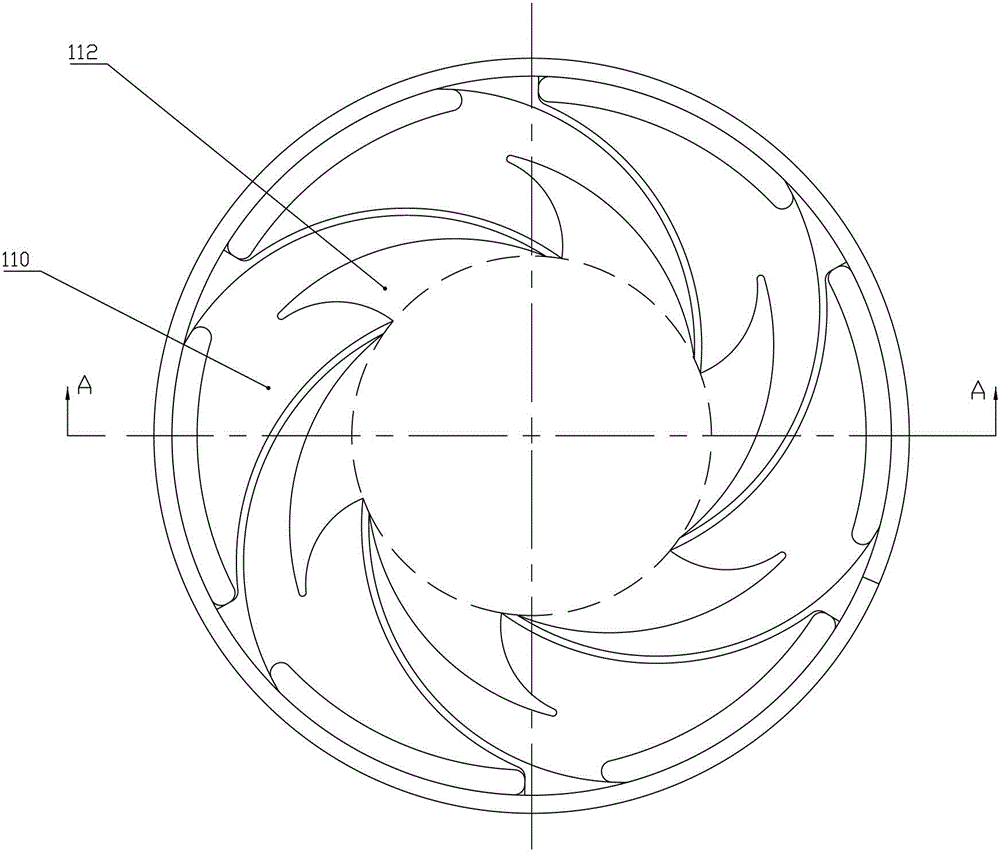

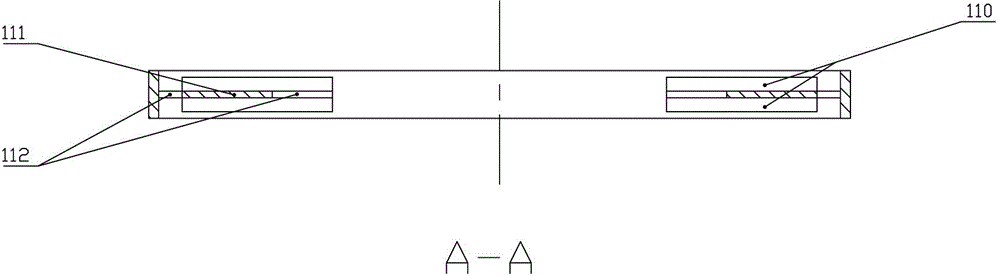

[0035] Such as Figure 1-2 and Figure 1-3 As shown, the upper and lower sides of the static wheel 16 are respectively provided with a number of spiral air suction grooves 110 of the same shape, and the air suction grooves 110 on the upper and lower sides of the static wheel 16 share a groove bottom 111, and the groove bottom 111 is provided with an opening 112. The opening 112 is used to...

Embodiment 2

[0039] Embodiment two combined radial flow pump

[0040] Such as figure 2 As shown, a combined radial flow pump provided by Embodiment 2 of the present invention includes a pump casing 20, an air inlet 21 and an exhaust port 22 are provided on the pump casing 20, a rotor 23 is arranged inside the pump casing 20, and the pump casing 20 The middle part is provided with a first air pumping stage 24, and the first air pumping stage 24 adopts 6 groups of parallel compound radial flow pumps as described in Embodiment 1, and the first air pumping stage 24 pumps air from the outside to the inside;

[0041] The two sides of the first pumping stage 24 are respectively provided with dynamic seals 25, and the outer sides of each dynamic seal 25 are respectively provided with a second pumping stage 26, and the second pumping stages 26 adopt two sets of parallel connection as described in the first embodiment. compound radial flow pump, the second pumping stage 26 pumps air from the ins...

Embodiment 3

[0045] Embodiment 3 The exhaust system of the compound radial flow pump low-pressure plasma discharge device

[0046] Such as image 3 As shown, the third embodiment provides an air pumping system for a compound radial pump low-pressure plasma discharge device, including a discharge chamber 30, which is connected to a roughing pump 32 through a first vacuum valve 31, and the discharge chamber is also connected to a roughing pump 32 through a first vacuum valve 31. Two vacuum valves 36 are connected with the radial flow pump 35, the composite radial flow pump 35 is connected with the backing pump 33 through the third vacuum valve 34, the discharge chamber 31 is also connected with the working gas container 39 through the fourth vacuum valve 38, and the discharge chamber 31 is also connected with the working gas container 39 respectively. The vacuum gauge 37 is connected to the purge valve 310 .

[0047] Wherein, the rough pump 32 is only used for the pumping of the rough pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com