Patents

Literature

49 results about "Roughing pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A roughing pump is any vacuum pump (typically mechanical) used to initially evacuate a vacuum system, as a first stage towards achieving high vacuum or ultra high vacuum. The term "roughing pump" derives from the vacuum range it works in, "rough vacuum", above 1x10⁻³ torr (0.1 Pa). Pumps that operate in the high vacuum ranges typically don't operate, or only operate inefficiently, at atmospheric pressures, whereas pumps that work efficiently at atmospheric pressure usually cannot produce a vacuum lower than approximately 1x10⁻³ torr.

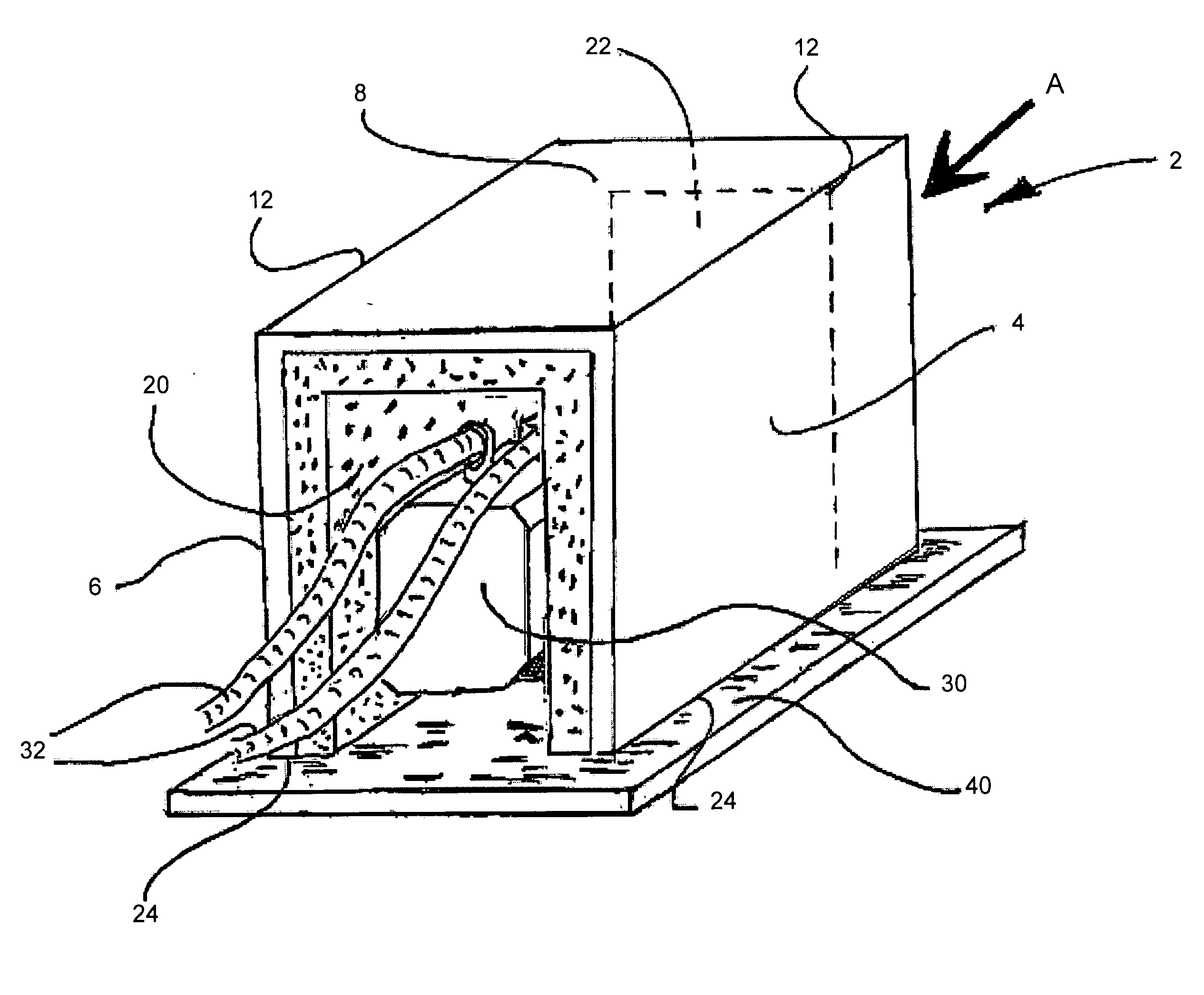

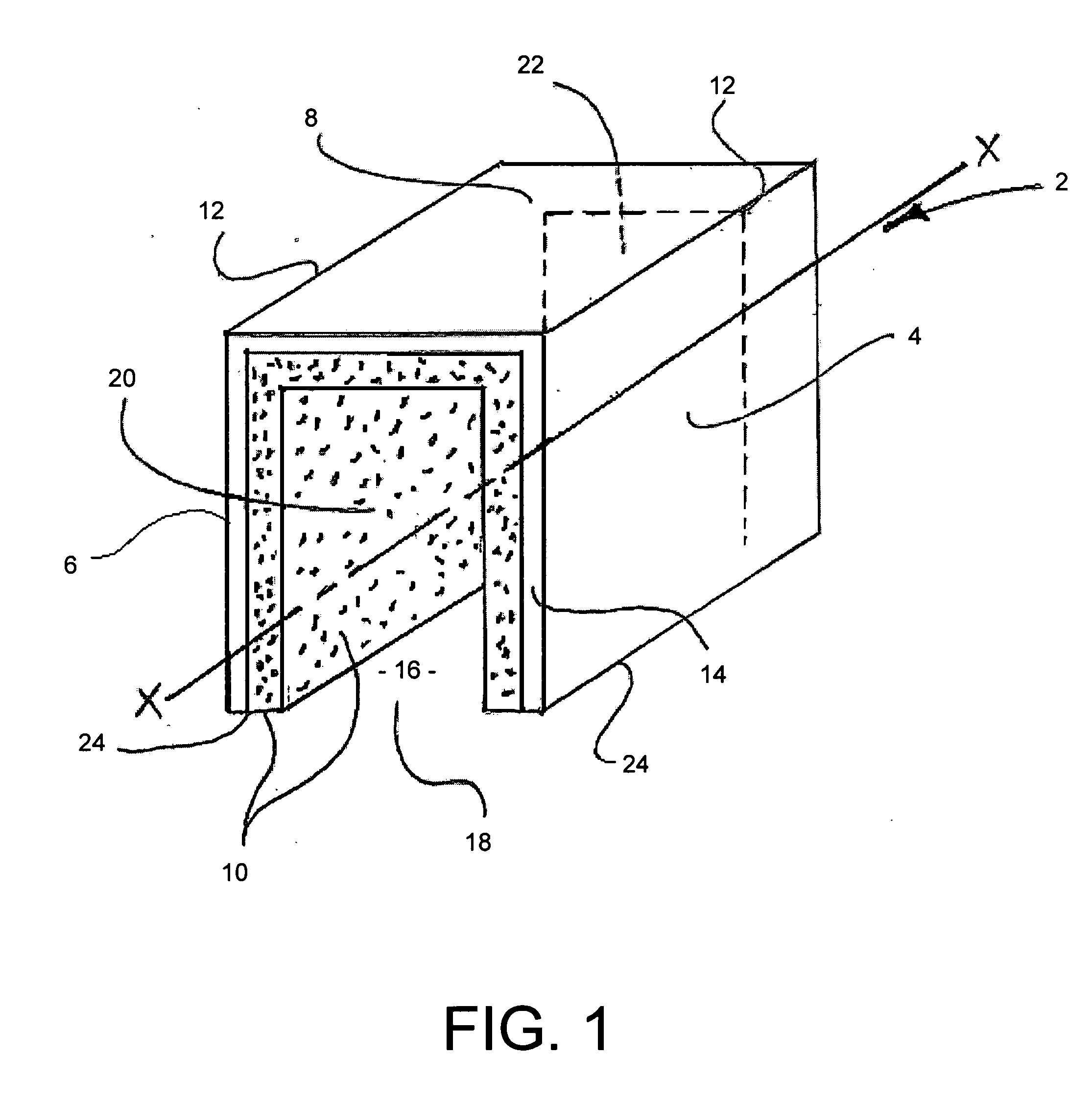

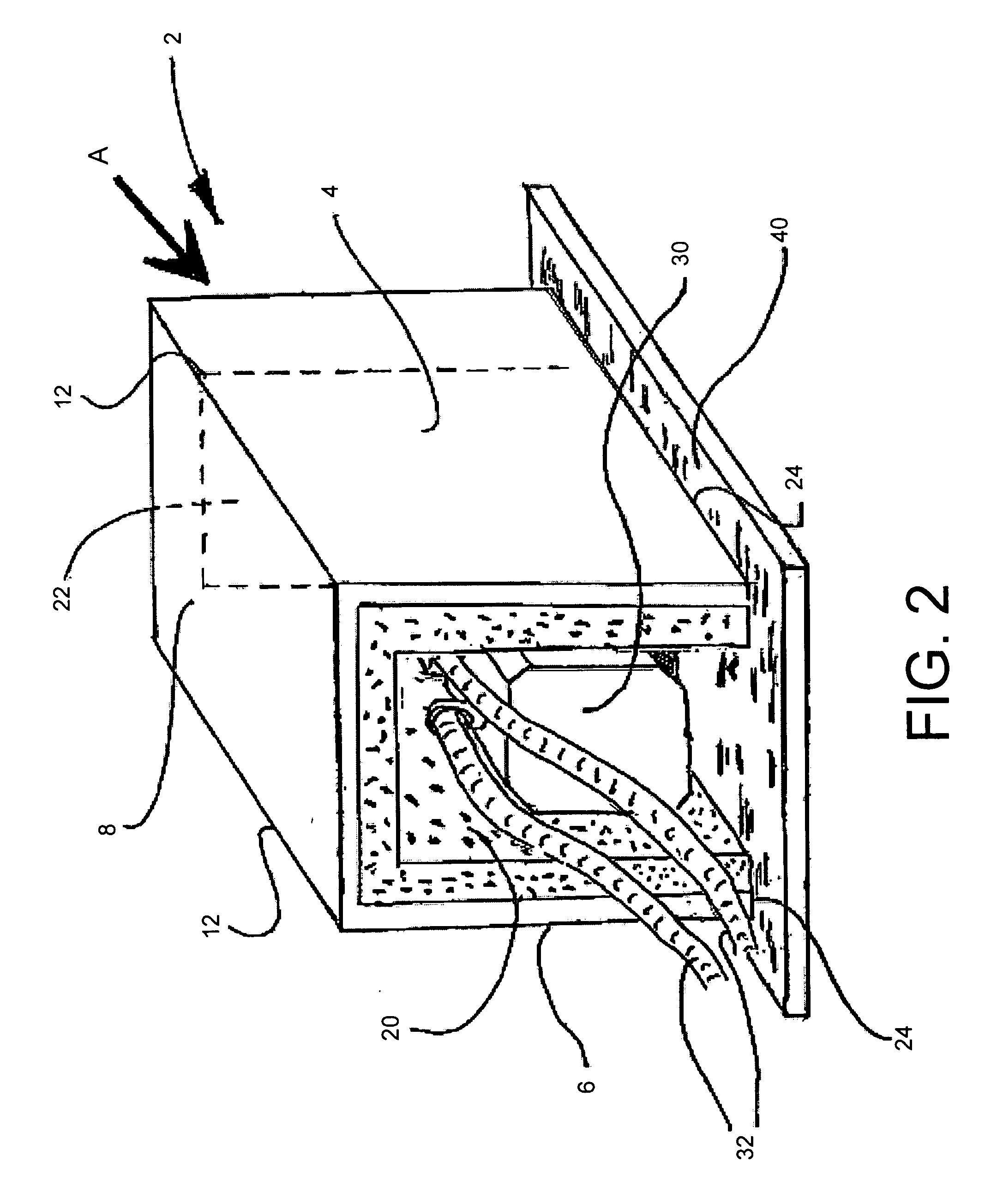

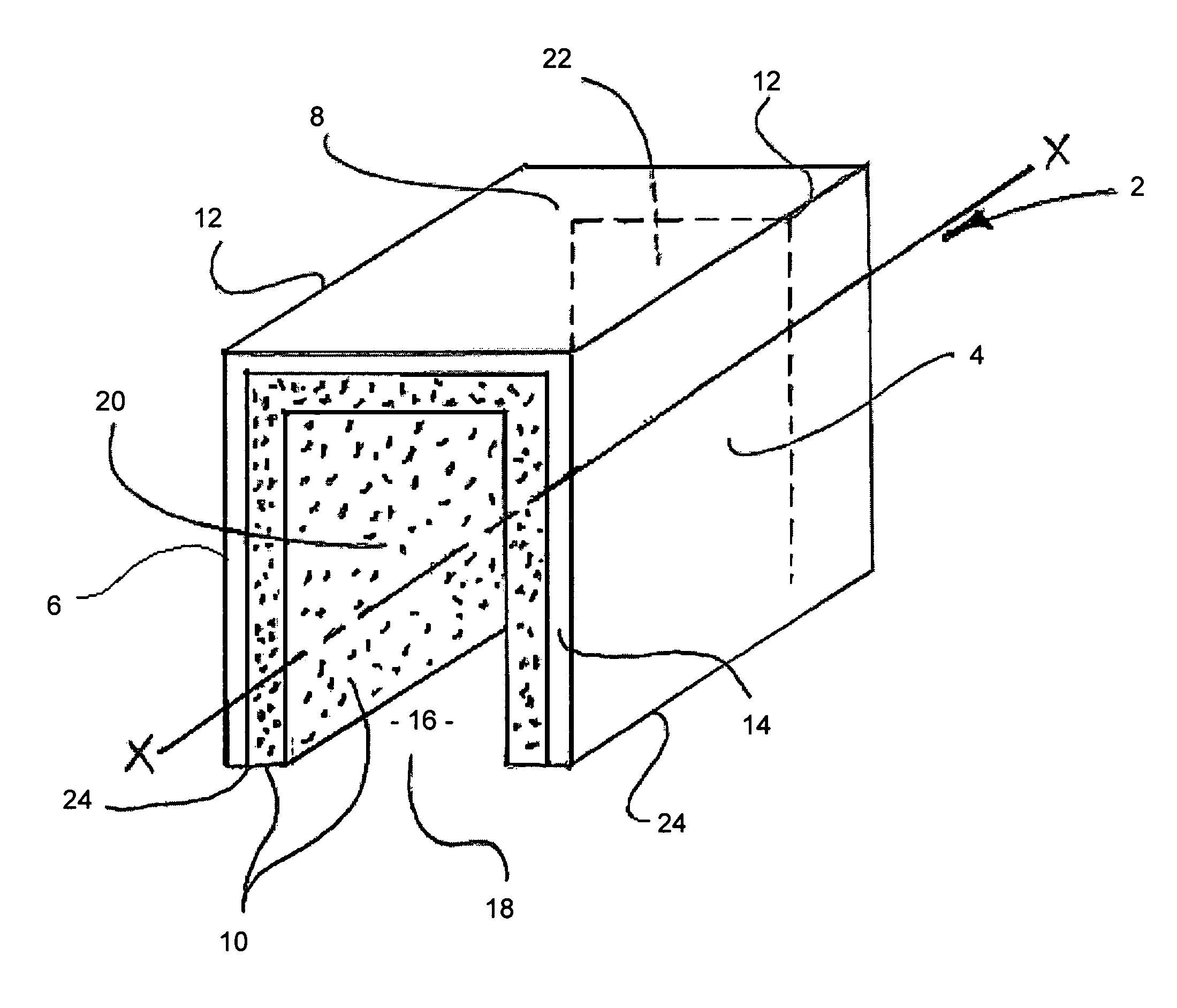

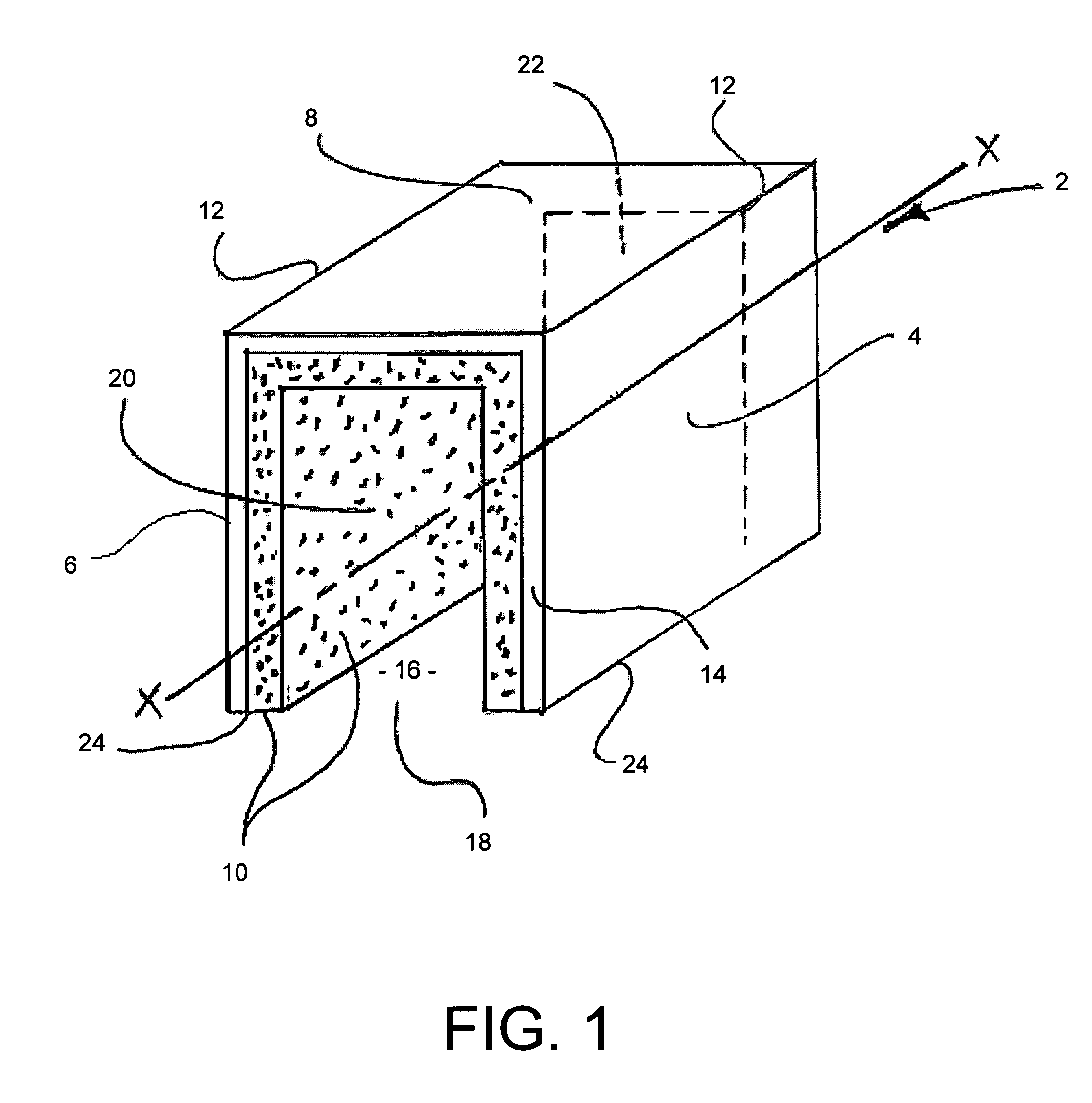

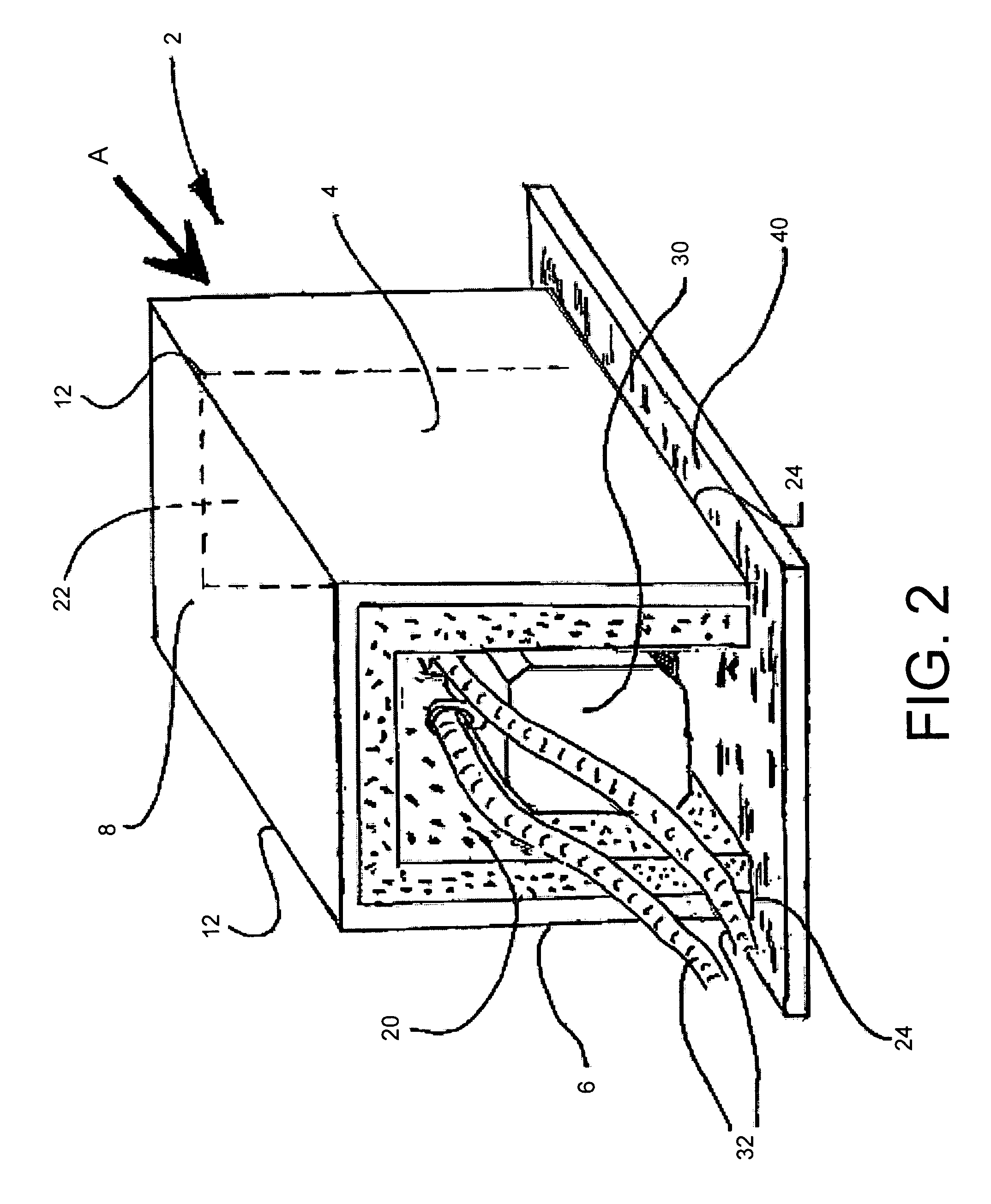

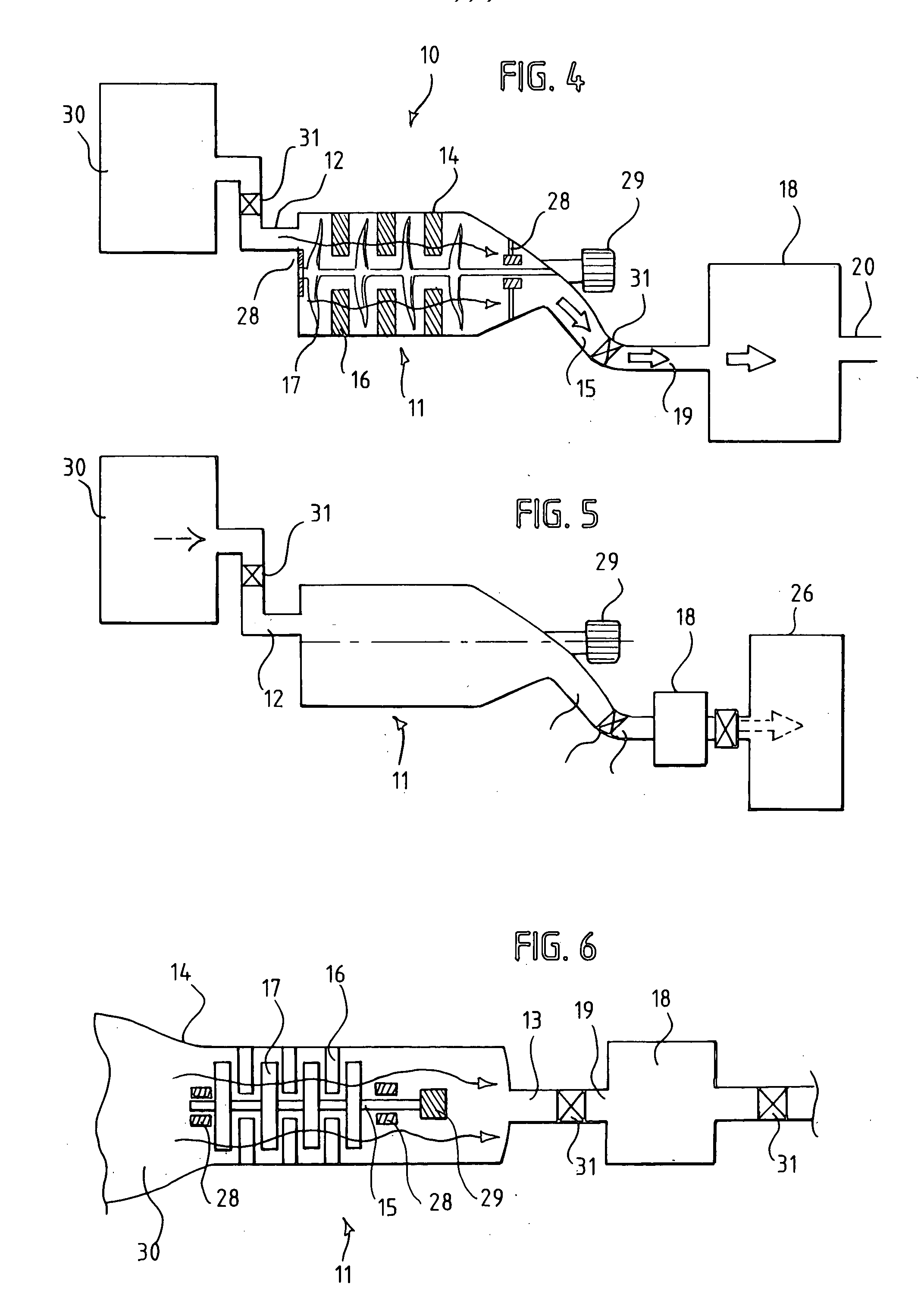

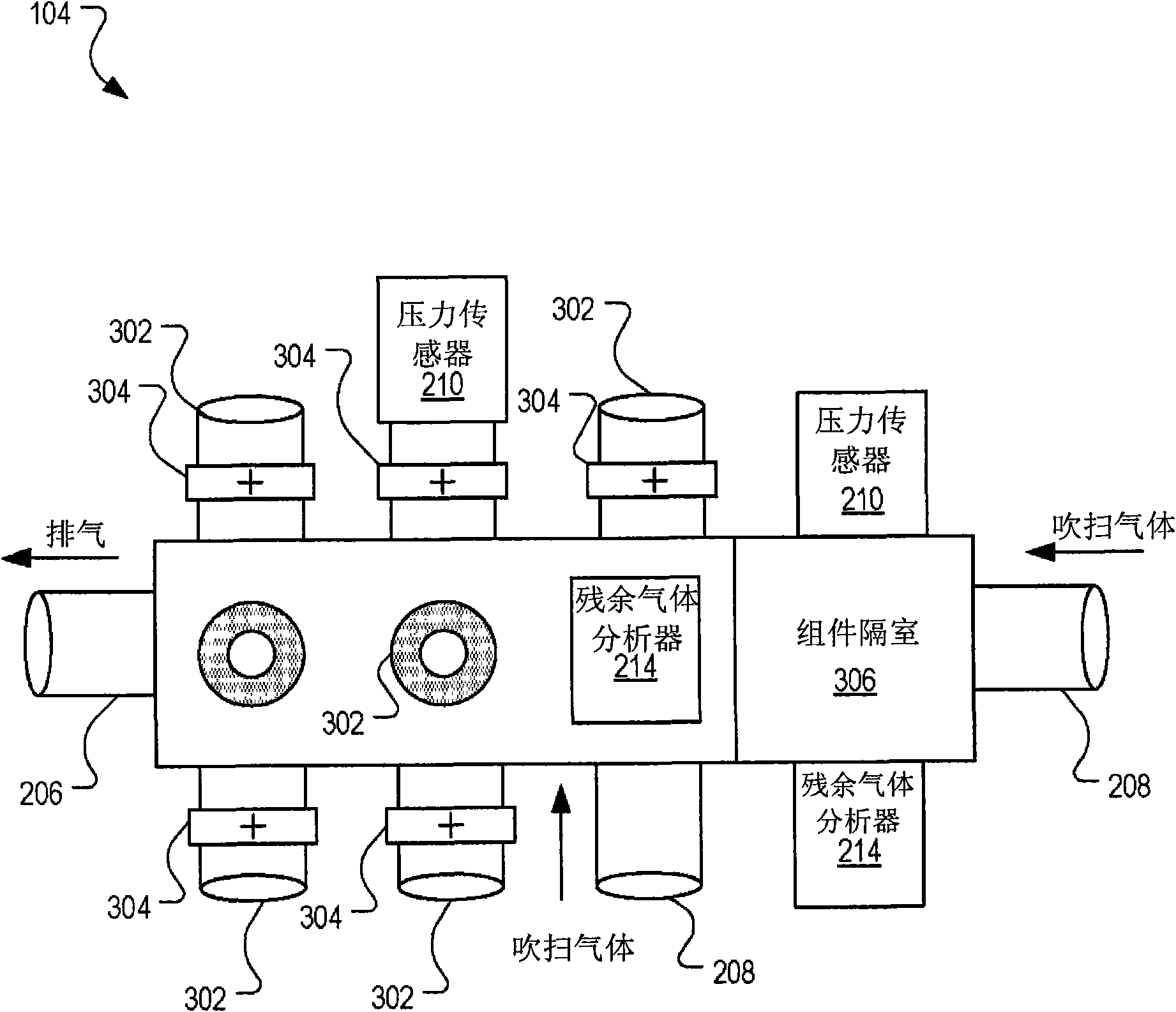

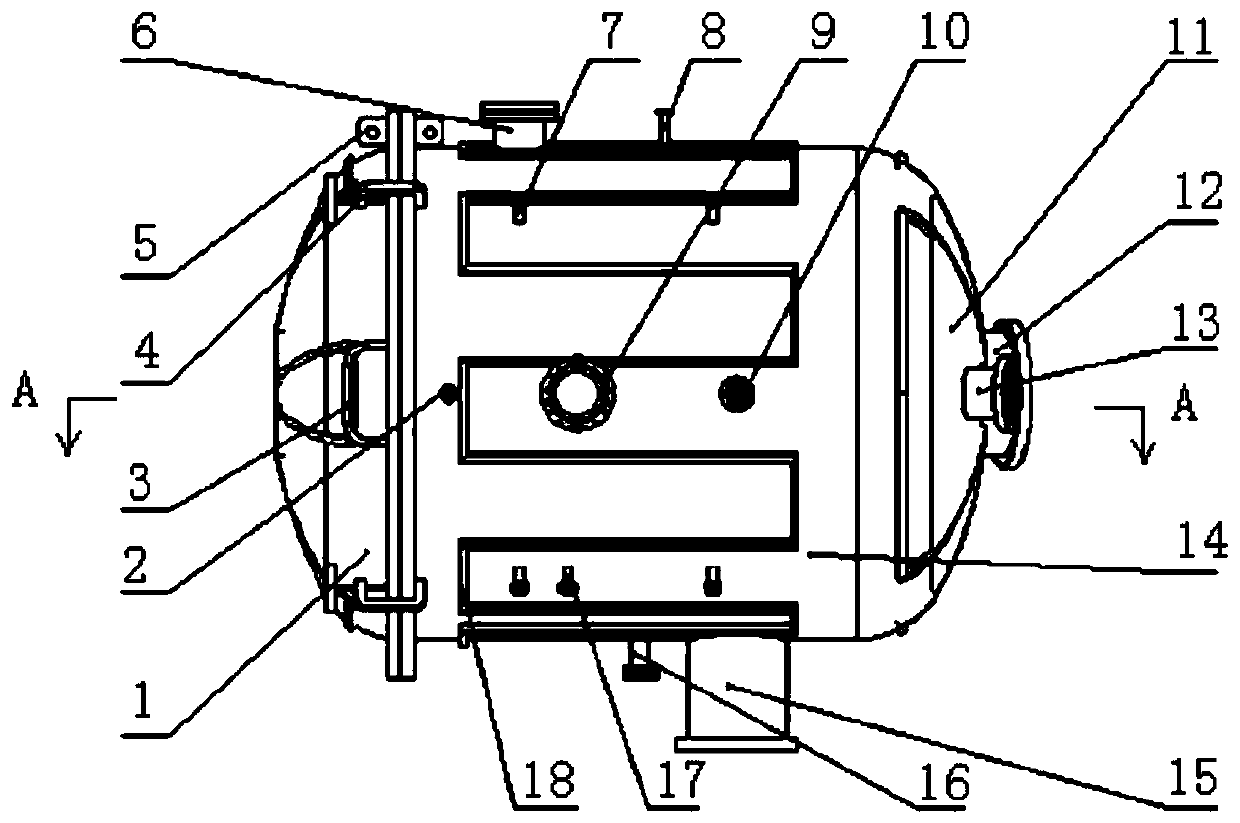

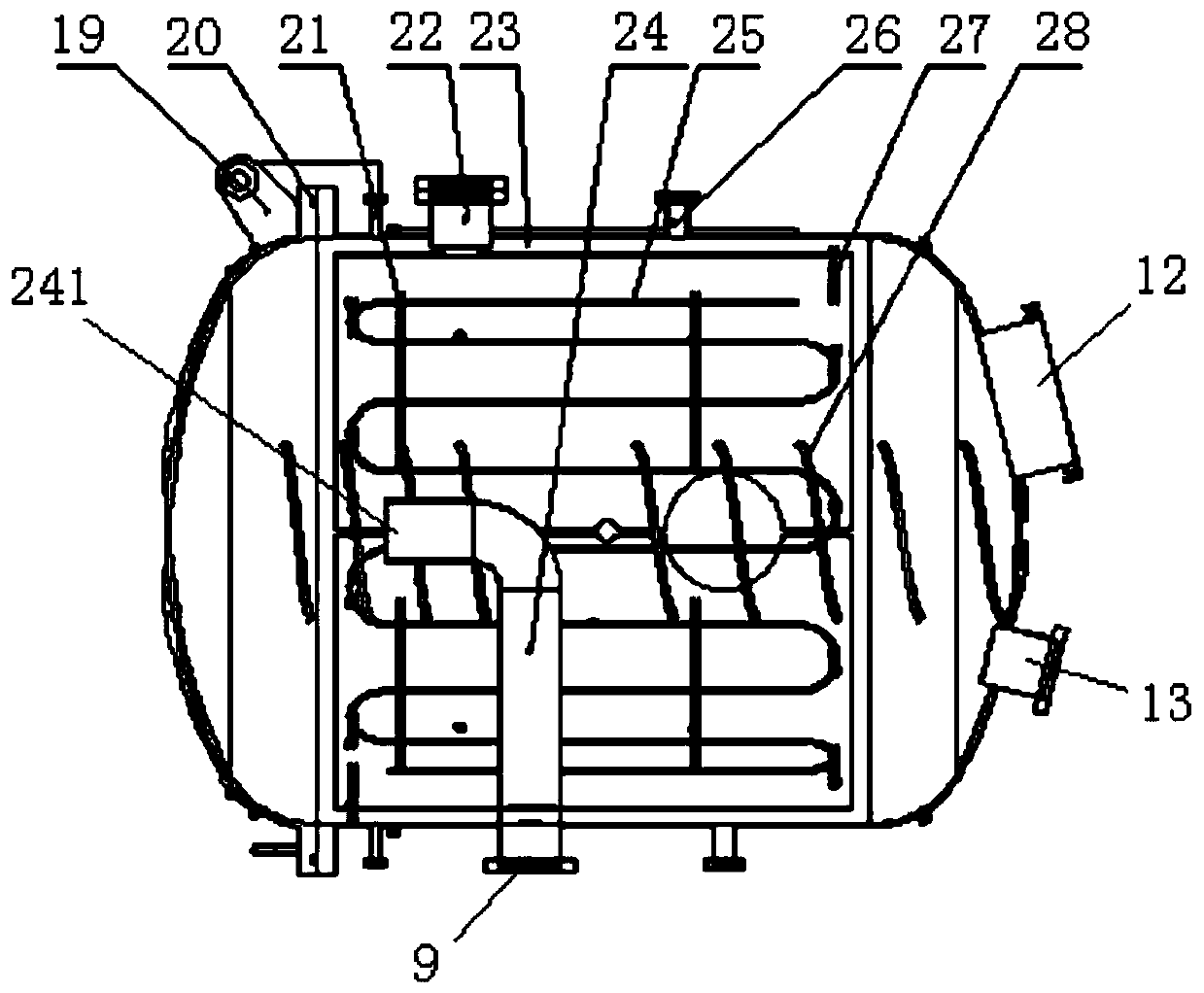

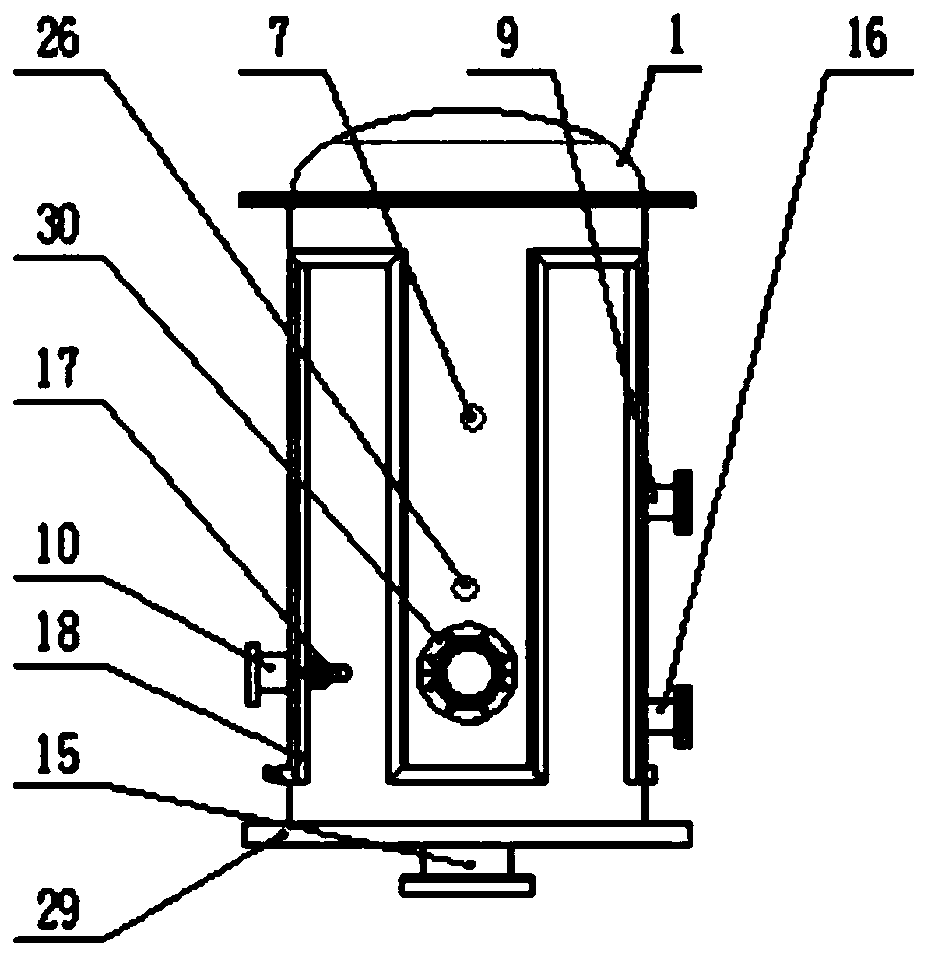

Enclosure,assembly and method for reducing noise from a pump and mass spectrometry system

InactiveUS20100116583A1Easy to viewReduce noiseMachine framesParticle separator tubesRoughing pumpVacuum pumping

The invention provides a noise reducing enclosure for reducing the noise from a vacuum pump, e.g. a roughing pump of a high vacuum system, the vacuum pump having a long axis and the enclosure comprising a noise dampening material and being shaped to radially enclose the vacuum pump along its long axis and being axially open at each end. Airflow is permitted through the enclosure in use and optional integrated cooling means on the pump may assist cooling of the pump. The invention also provides an assembly of the pump and enclosure, a method for reducing the noise from a vacuum pump using the enclosure and a mass spectrometry system comprising: a mass spectrometer having one or more chambers therein which in operation are held under vacuum; and a vacuum pumping system for producing said vacuum, the vacuum pumping system comprising at least one vacuum pump which has a long axis and wherein the mass spectrometry system further comprises a noise reducing enclosure for radially enclosing the vacuum pump along its long axis, wherein the enclosure is axially open at each end.

Owner:THERMO FISHER SCI BREMEN

Large high-vacuum air pumping set

InactiveCN101776063AEliminate pollutionQuality improvementPump installationsPositive-displacement liquid enginesRoughing pumpVacuum extractor

The invention relates to a novel air pumping set which is applicable to the evacuating field. The novel air pumping set comprises a traction molecular pump, an arc titanium pump, a roughing pump and a fore pump, complements each other's advantages, and achieves the purpose of replacing the traditional air pumping set comprising a diffusion pump, a Roots pump and a roughing pump. Compared with the traditional air pumping set, the invention can save the air-pumping energy by 60-90%, eliminate the oil steam pollution in a vacuum chamber, and obviously improve the quality of vacuum products. The cost performance of the air pumping set is approximately 2-3 times better than that of the traditional high-vacuum air pumping set. Besides, the transpiration rate of the titanium materials of the air pumping set can be accurately controlled, and the titanium materials have a high use ratio and can be recycled. The roughing pump of the invention works in a very short time, and one roughing pump can be shared by multiple high-vacuum air pumping sets, thereby saving the device cost and the occupied space.

Owner:SHENZHEN MOL VACUUM TECH CO LTD

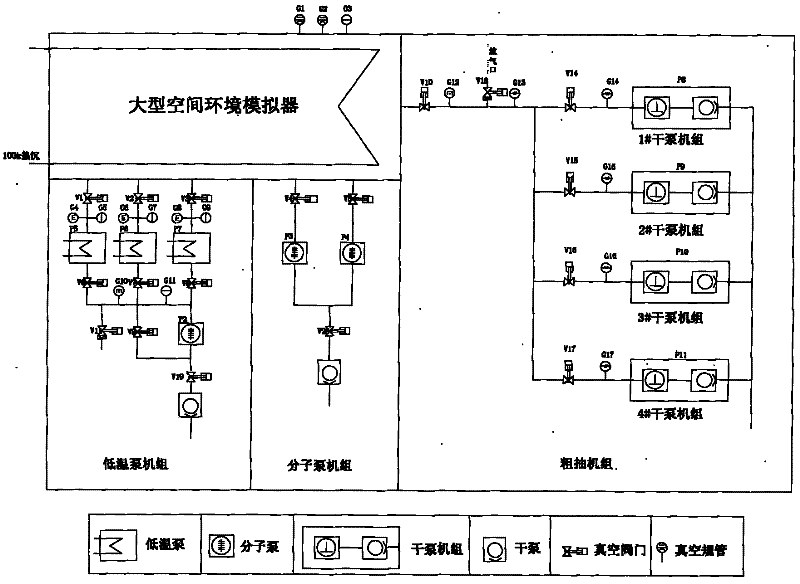

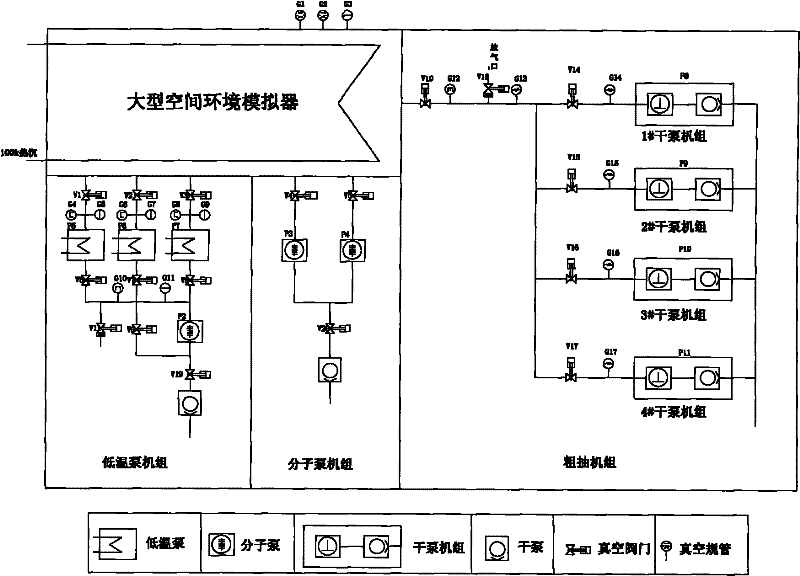

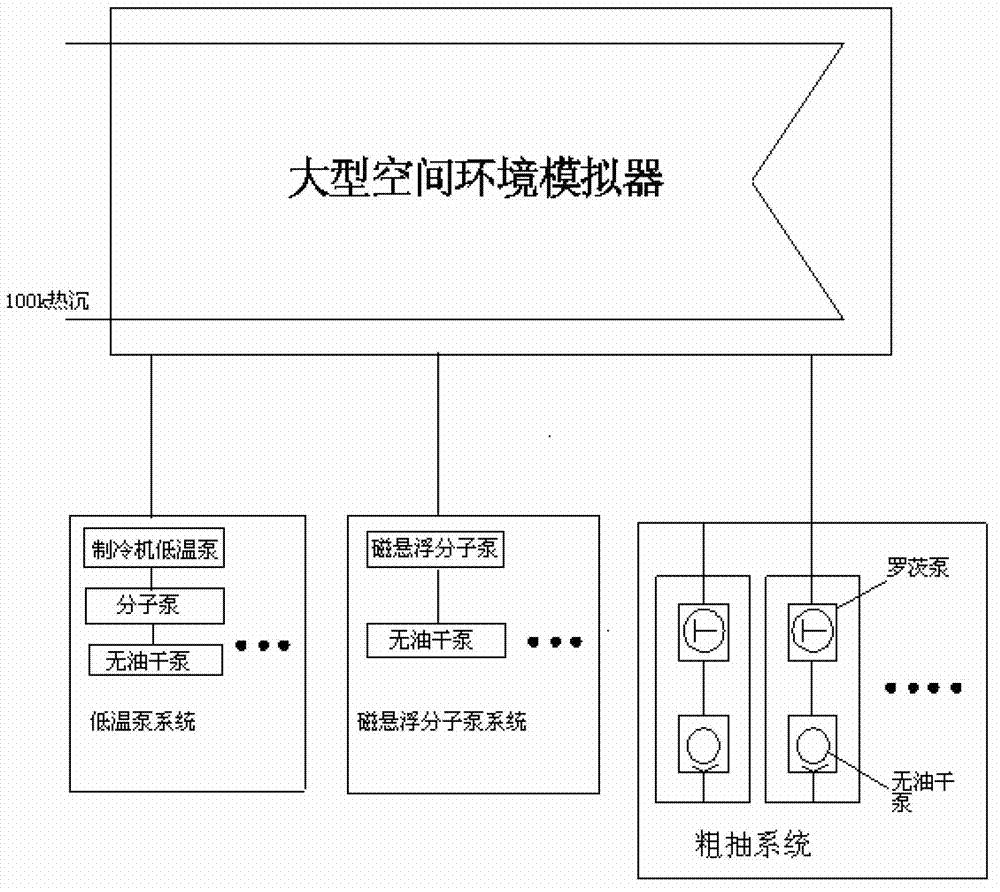

Cleaning vacuum air exhaust technology for large-sized space environmental simulator

The invention relates to cleaning vacuum air exhaust technology for a large-sized space environmental simulator, which is mainly applied to research of large-sized space environmental simulators, and provides high vacuum test conditions for tests of spacecrafts. In order to obtain high vacuum of the large-sized space simulator, at first, a novel oilless rough pumping unit of a vacuum system exhausts air in a vacuum container in a vacuum manner so that the pressure in the vacuum container is lower than 10Pa, then a turbo molecular pump is utilized to exhaust air in a transitional manner until start vacuum degree of a main pump is achieved, finally, a low-temperature pump is utilized as the main pump for realizing high vacuum air exhaust, so that working vacuum degree of equipment is higher to 1.3X10-3Pa, and the working vacuum degree is maintained until a test is finished. The high vacuum air exhaust technology realizes that cleaning high vacuum for the large-sized space environmental simulator is obtained by the aid of completely oilless vacuum air exhaust equipment.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

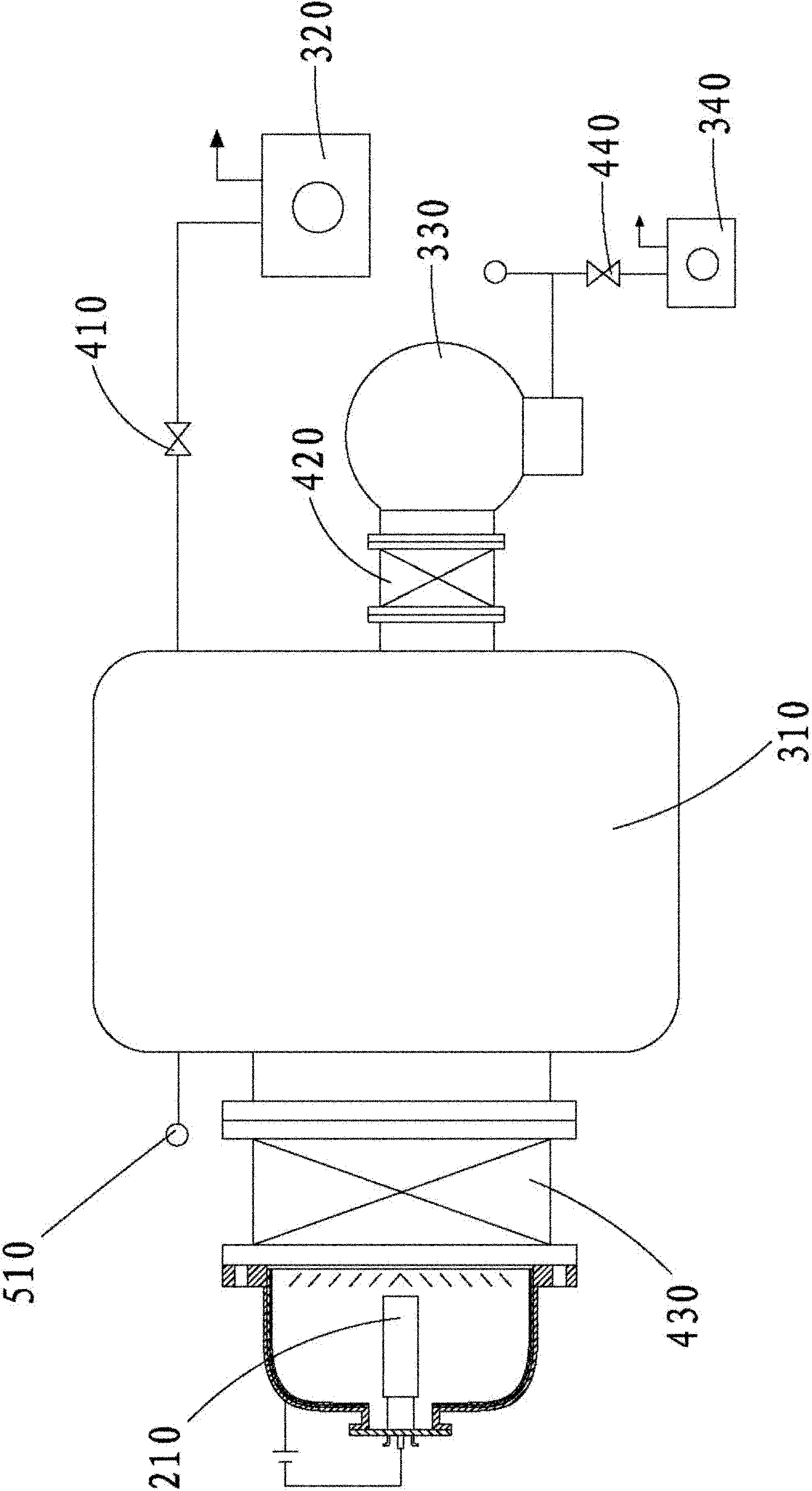

Clean vacuum pumping system and pumping method for large space environment simulator

InactiveCN102966518AReduce pollutionImprove reliabilityPump controlPump installationsVacuum pumpingRoughing pump

The invention discloses a clean vacuum pumping system and pumping method for a large space environment simulator. The clean vacuum pumping system comprises a rough pumping system, a magnetic suspension molecular pump system and a cryopump system, wherein the rough pumping system comprises a plurality of rough pumping units that are connected in parallel; each rough pumping unit consists of an oil-free dry pump and roots pump unit that is applied to an semiconductor industry; a PLC (programmable logic controller) and a host computer are adopted to automatically control and measure the overall process of vacuum pumping, so as to obtain and maintain high vacuum of the large space environment simulator; the magnetic suspension molecular pump system consists of magnetic suspension molecular pump, and oil-free dry pump and roots pump units that are applied to the semiconductor industry; the cryopump system adopts a cooling machine cryopump; and a preceding stage of the cryopump system adopts a unit consisting of a molecular pump and an oil-free dry pump and roots pump unit. The invention also discloses a corresponding pumping technology. As the oil-free vacuum pumping system and the reasonable pumping technology are adopted, the cleanness and high vacuum of the large space simulator are achieved.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

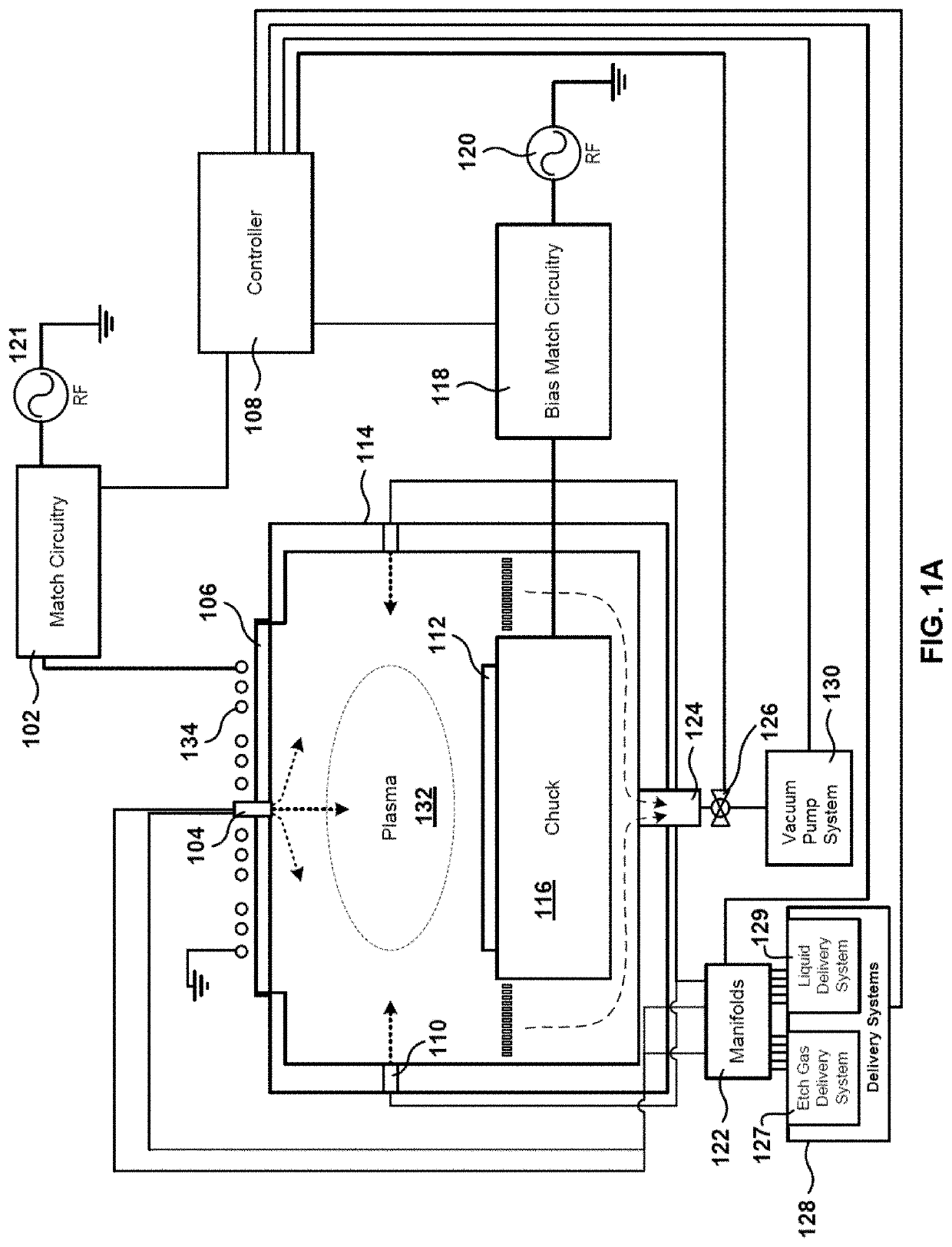

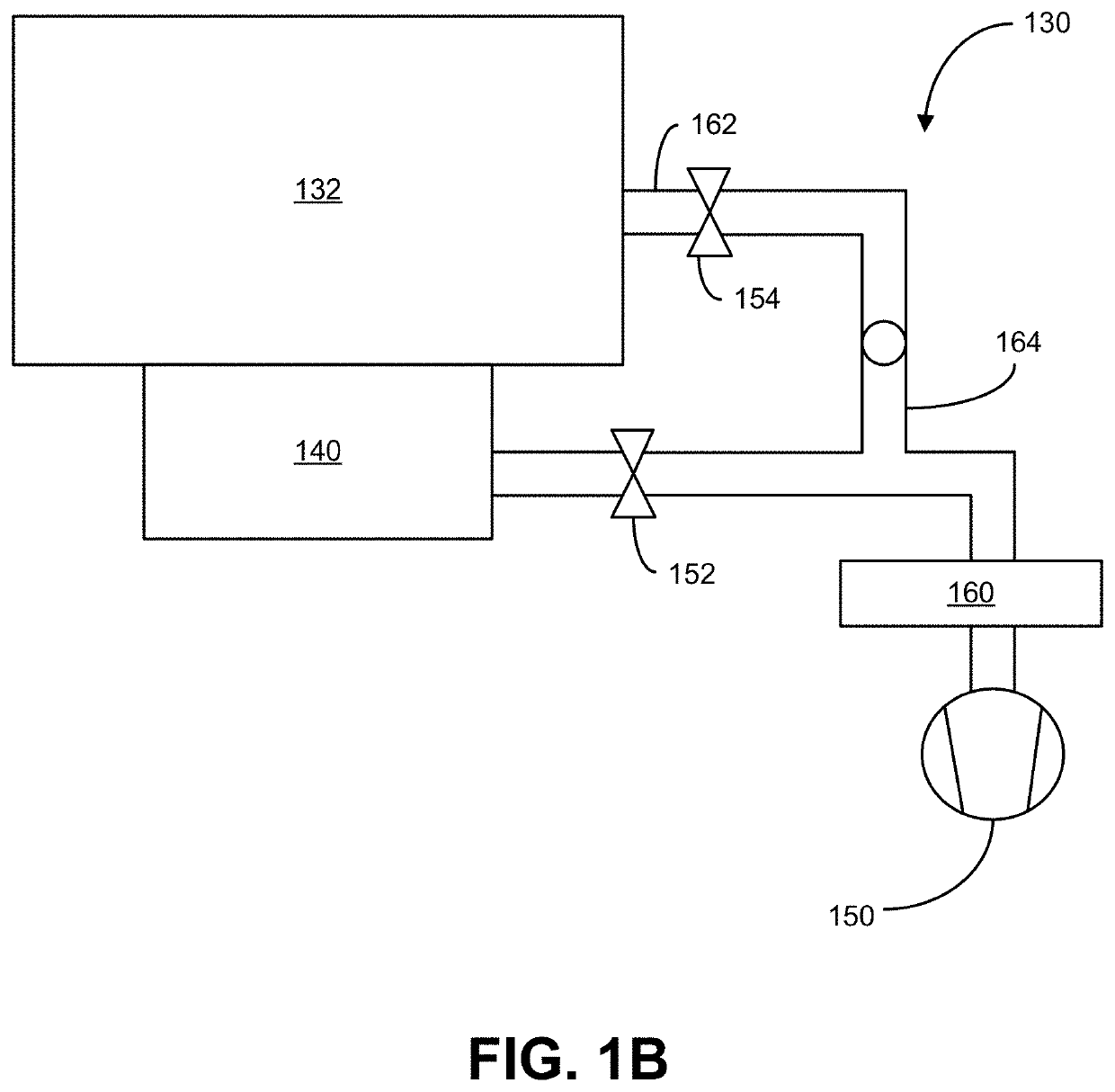

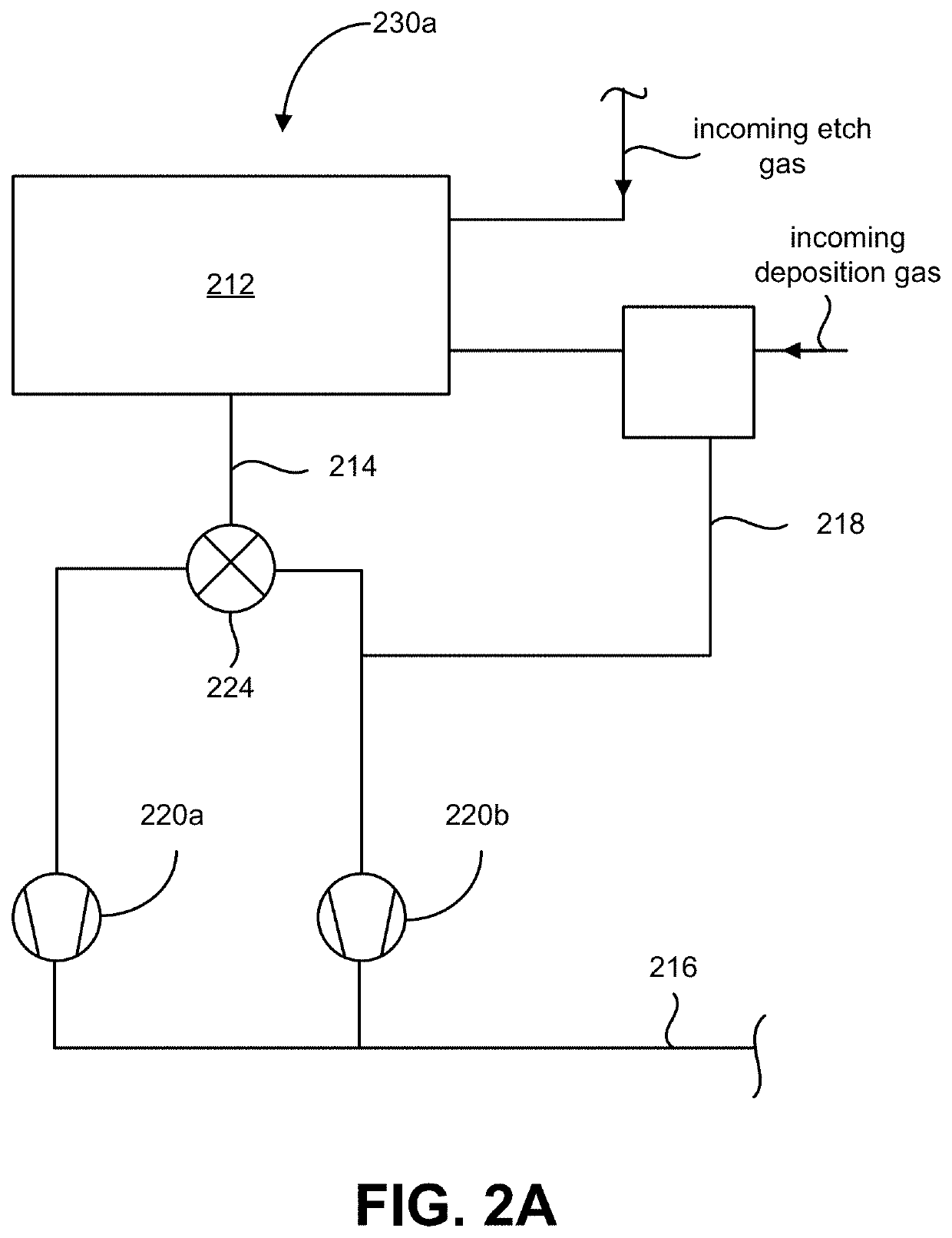

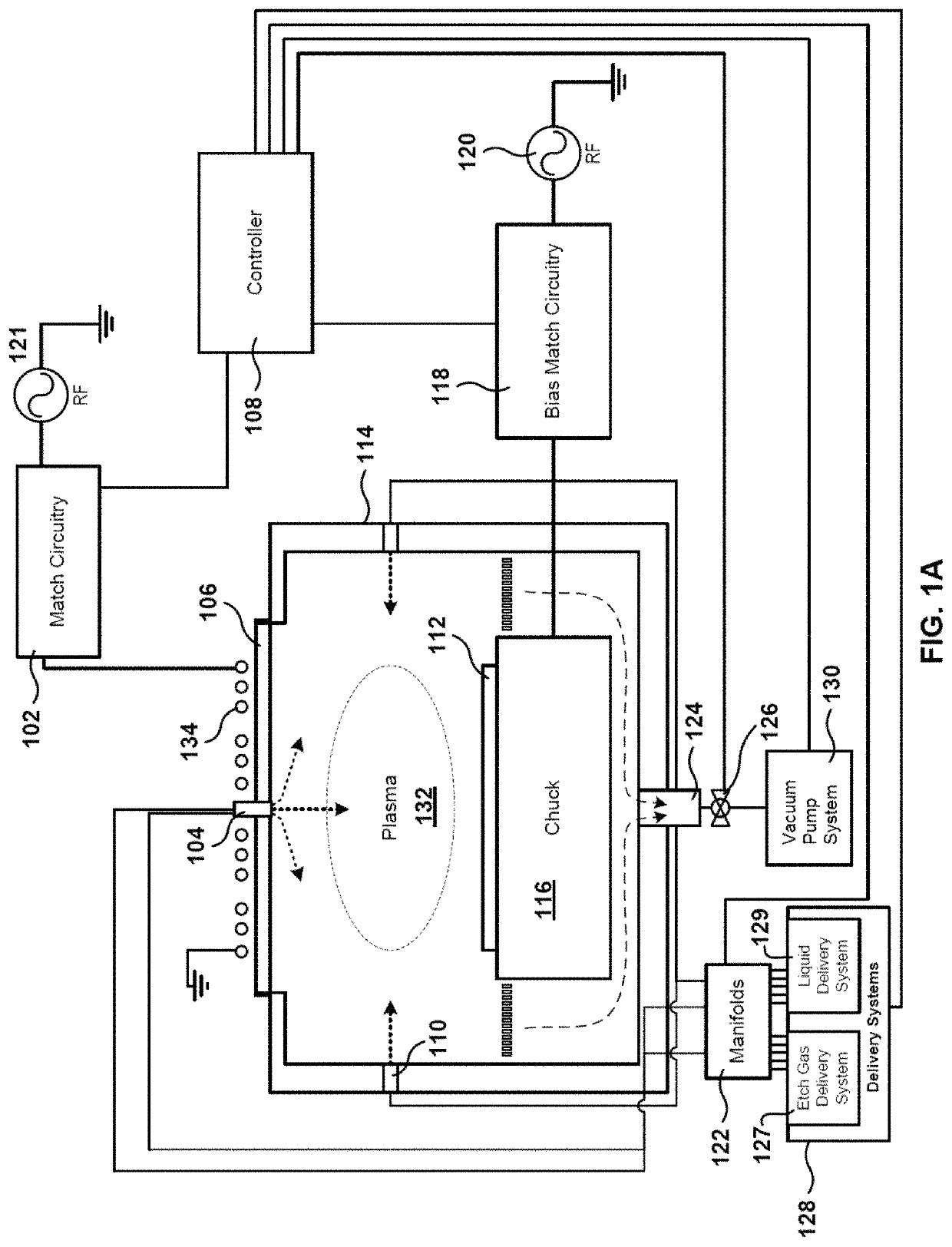

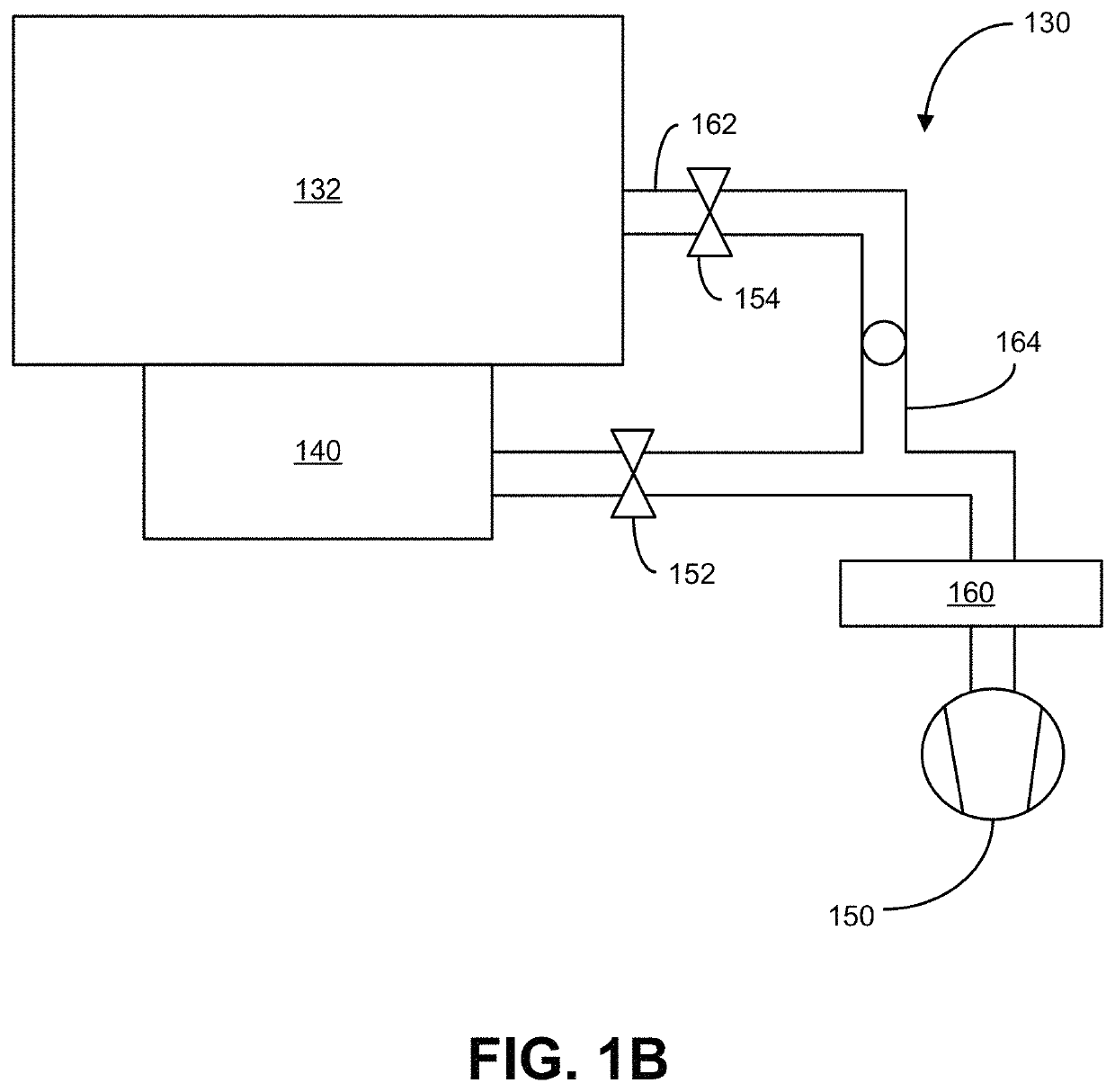

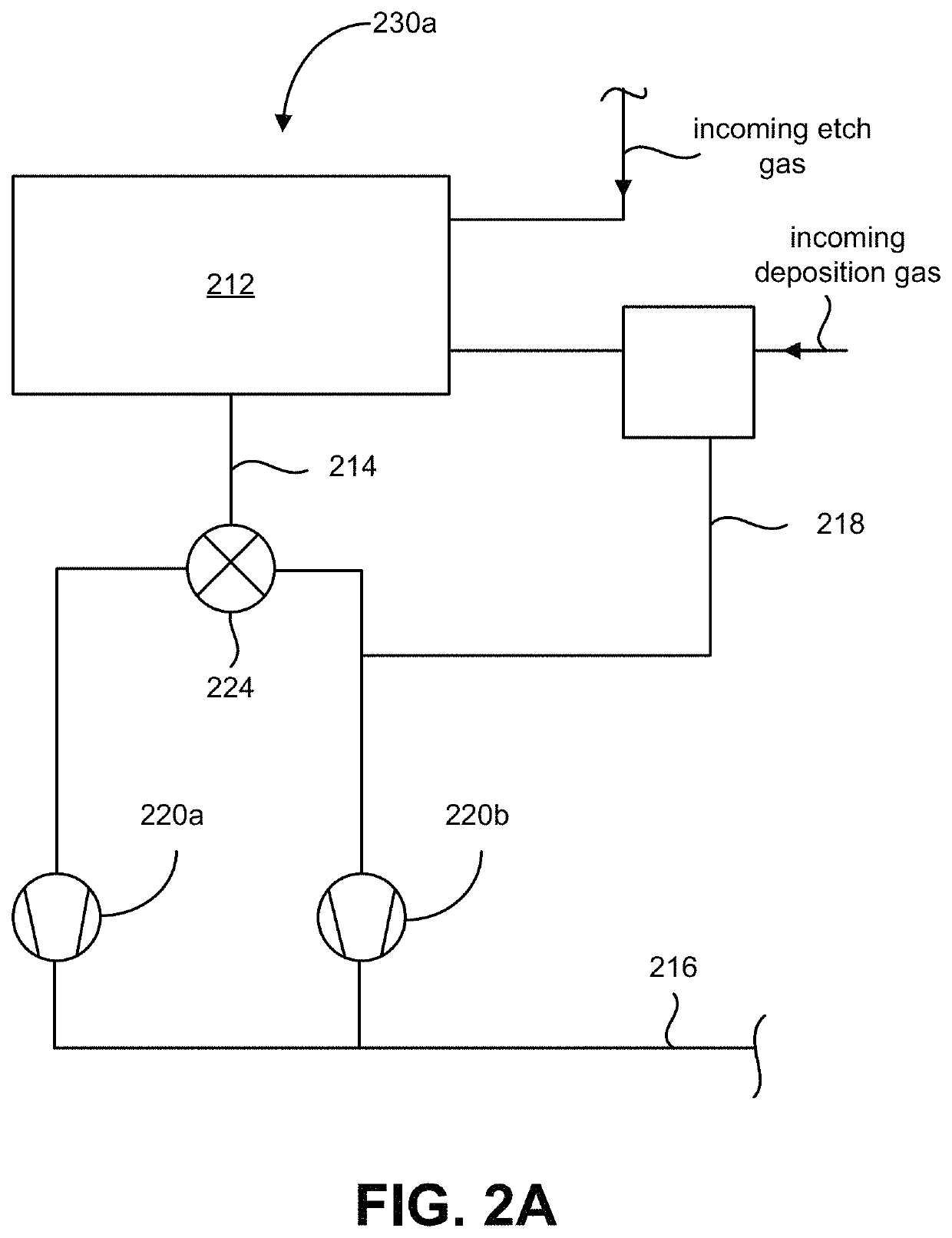

Vacuum pump protection against deposition byproduct buildup

ActiveUS20200105509A1Electric discharge tubesSemiconductor/solid-state device manufacturingRoughing pumpEngineering

A processing chamber such as a plasma etch chamber can perform deposition and etch operations, where byproducts of the deposition and etch operations can build up in a vacuum pump system fluidly coupled to the processing chamber. A vacuum pump system may have multiple roughing pumps so that etch gases can be diverted a roughing pump and deposition precursors can be diverted to another roughing pump. A divert line may route unused deposition precursors through a separate roughing pump. Deposition byproducts can be prevented from forming by incorporating one or more gas ejectors or venturi pumps at an outlet of a primary pump in a vacuum pump system. Cleaning operations, such as waferless automated cleaning operations, using certain clean chemistries may remove deposition byproducts before or after etch operations.

Owner:LAM RES CORP

Electric arc titanium pump and vacuum air pump group comprising same

InactiveCN101936278AIncreases chances of adsorbing gasOvercome the disadvantage of uneven thicknessPumpsPositive-displacement liquid enginesRoughing pumpHigh energy

The invention is applies to the technical field of vacuum acquisition and discloses an electric arc titanium pump and a vacuum air pumping group comprising the same. The electric arc titanium pump comprises a pump shell, a trapping plate, a cathode arc source member and a power supply, wherein the trapping plate is arranged on the inside wall of the pump shell, the cathode arc source member is fixedly arranged in the pump shell, and the pump shell and the cathode arc source member are in cylindrical shapes and are coaxially arranged; and the vacuum air pumping group comprises a vacuum chamber, wherein a molecular pump, a prepump, a roughing pump and the electric arc titanium pump are connected to the vacuum chamber. The electric arc titanium pump can be used for leading atoms steamed by the cathode arc source member to form an active film with even thickness and increasing the utilization rate of the cathode arc source member, thereby increasing pumping speed and air-pumping flow rate and reducing energy consumption and operation cost. The vacuum air pumping group can be used for replacing the current large-size diffusion pump with high energy consumption and high oil-vapor pollution and a Lobed pump air-pumping group in order to clean vacuum, save pumping energy consumption and reduce operation cost.

Owner:储继国

Experiment system for space lower earth orbit plasma environment simulation

The invention provides an experiment system for space lower earth orbit plasma environment simulation. The experiment system comprises a microwave plasma source a, a source module a, a gate valve a, an experiment module door, an experiment module, a gate valve b, a source module b, a microwave plasma source b, a vacuum roughing pump set, a cryogenic pump b, a mobile platform, a cryogenic pump c, a cryogenic pump d and a cryogenic pump a, wherein one end of the experiment module is connected with the source module a through the gate valve a; the other end of the experiment module is connected with the source module b through the gate valve b; the microwave plasma source a is installed on the end surface of the source module a; the microwave plasma source b is installed on the end surface of the source module b; the cryogenic pump a and the cryogenic pump b are installed in the middle of the experiment module; the cryogenic pump c and the cryogenic pump d are installed at the lower part of the experiment module; the experiment module door is installed at one end of the interior of the experiment module; the vacuum roughing pump set is installed on the lower side of the other end of the experiment module; the mobile platform used for placement of testing equipment and instruments is installed at the lower part of the interior of the experiment module.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Vacuum furnace air-pumping system and air-pumping technology thereof

InactiveCN103291586AQuick extractionReduce energy consumption of pumpingPump installationsPositive-displacement liquid enginesRoughing pumpAir pump

The invention discloses a vacuum furnace air-pumping system and an air-pumping technology of the vacuum furnace air-pumping system. An electric arc titanium pump, traction molecular pump and backing pump unit conducting air-pumping and arranged in parallel connection is adopted, so that a high-vacuum diffusion pump, medium-vacuum roots pump machine and roughing pump unit conducting air-pumping and arranged in parallel connection in the prior art is replaced. An electric arc titanium pump is used for rapidly pumping high-vacuum active gases and a traction molecular pump and a backing pump are used for rapidly pumping medium-vacuum gases and high-vacuum inert gases. Due to the fact that the electric arc titanium pump and the traction molecular pump are both low-energy pumps, the electric arc titanium pump mainly operates at an accurate pumping stage, and the operation time usually occupies about 70% of the whole air-pumping time, the air-pumping energy consumption can be obviously reduced, In addition, the electric arc titanium pump, traction molecular pump and backing pump unit is free of oil vapor contamination, so that the oil vapor contamination of a traditional vacuum furnace air-pumping system is eliminated.

Owner:苏州摩星真空科技有限公司

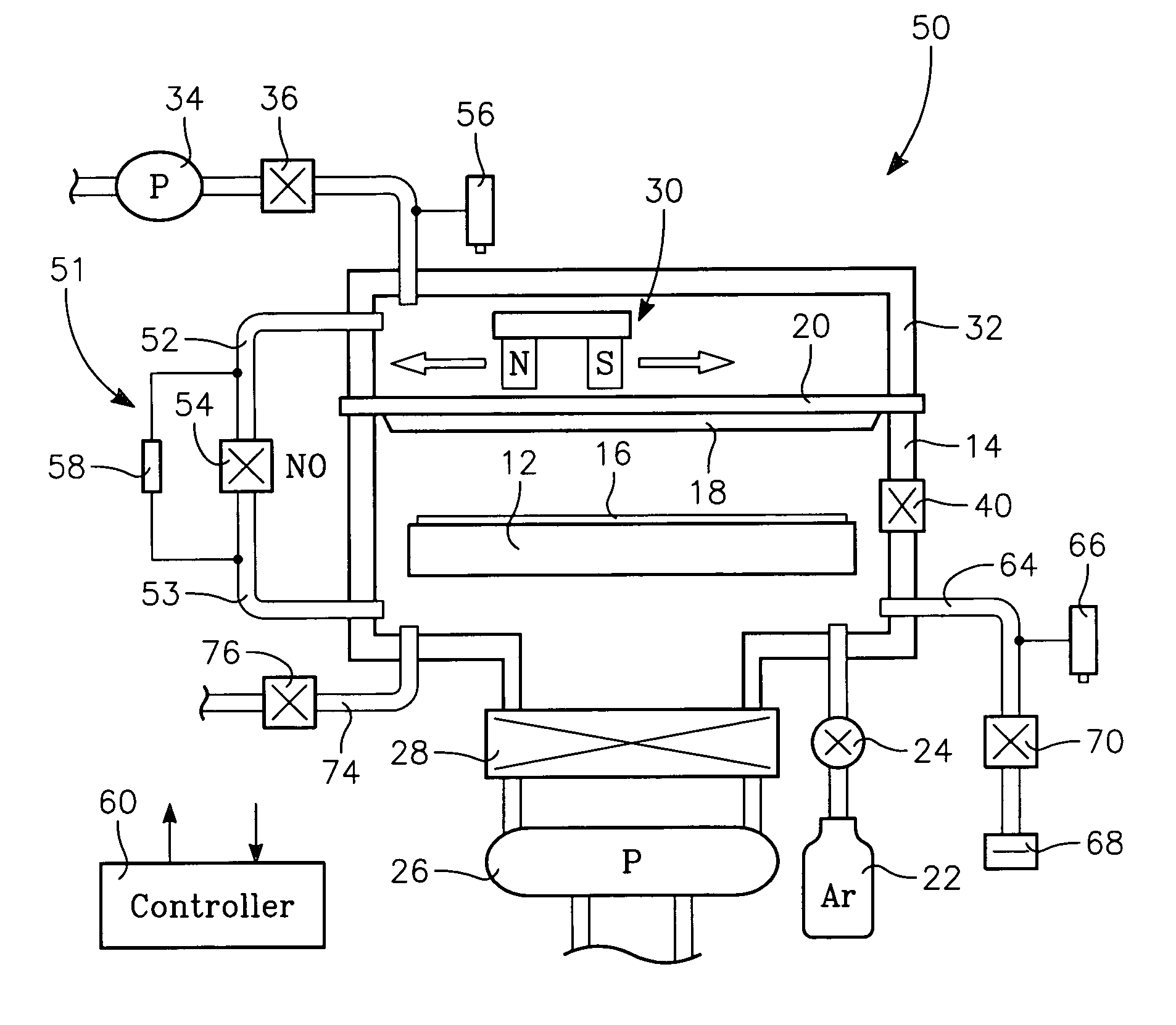

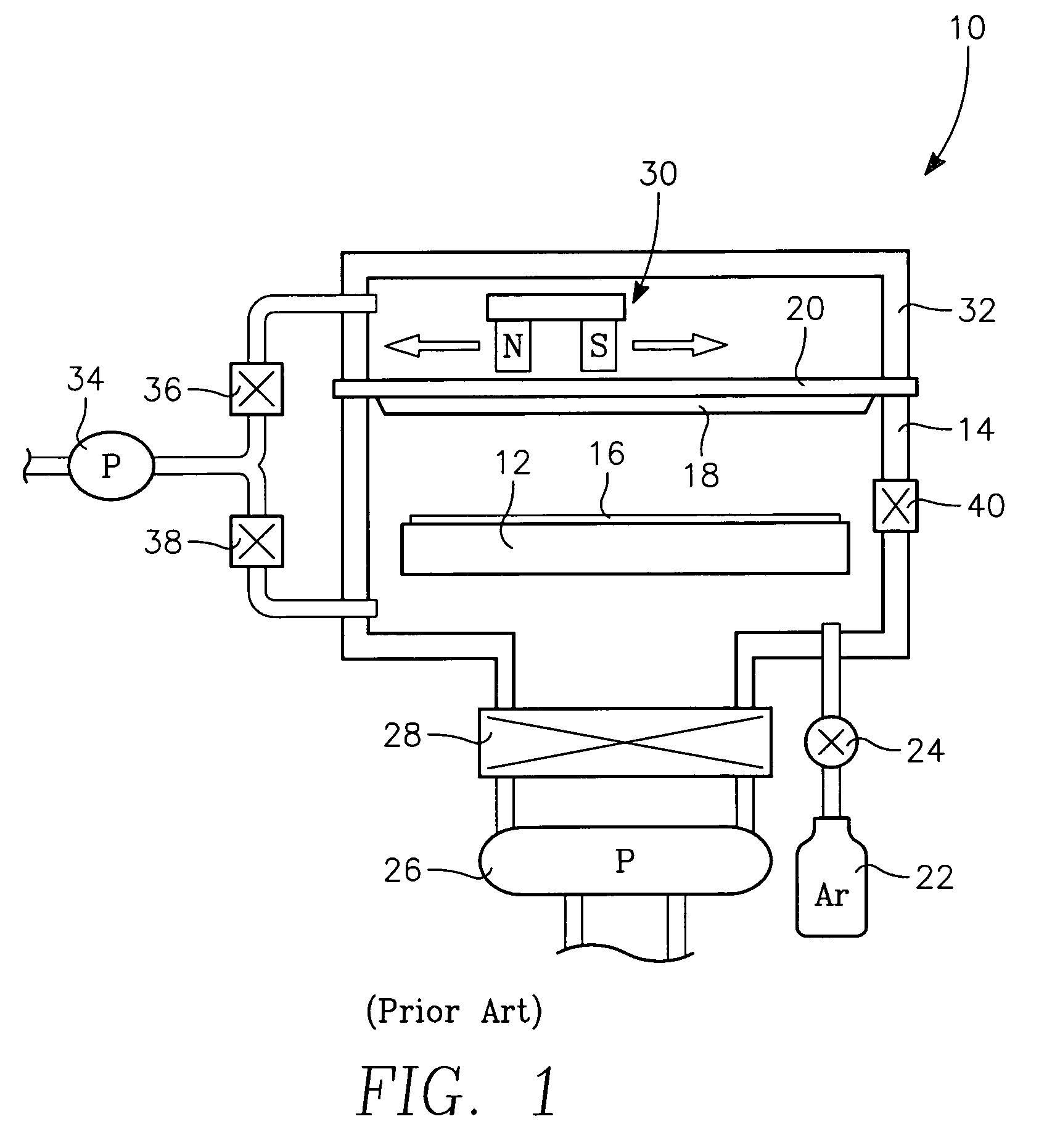

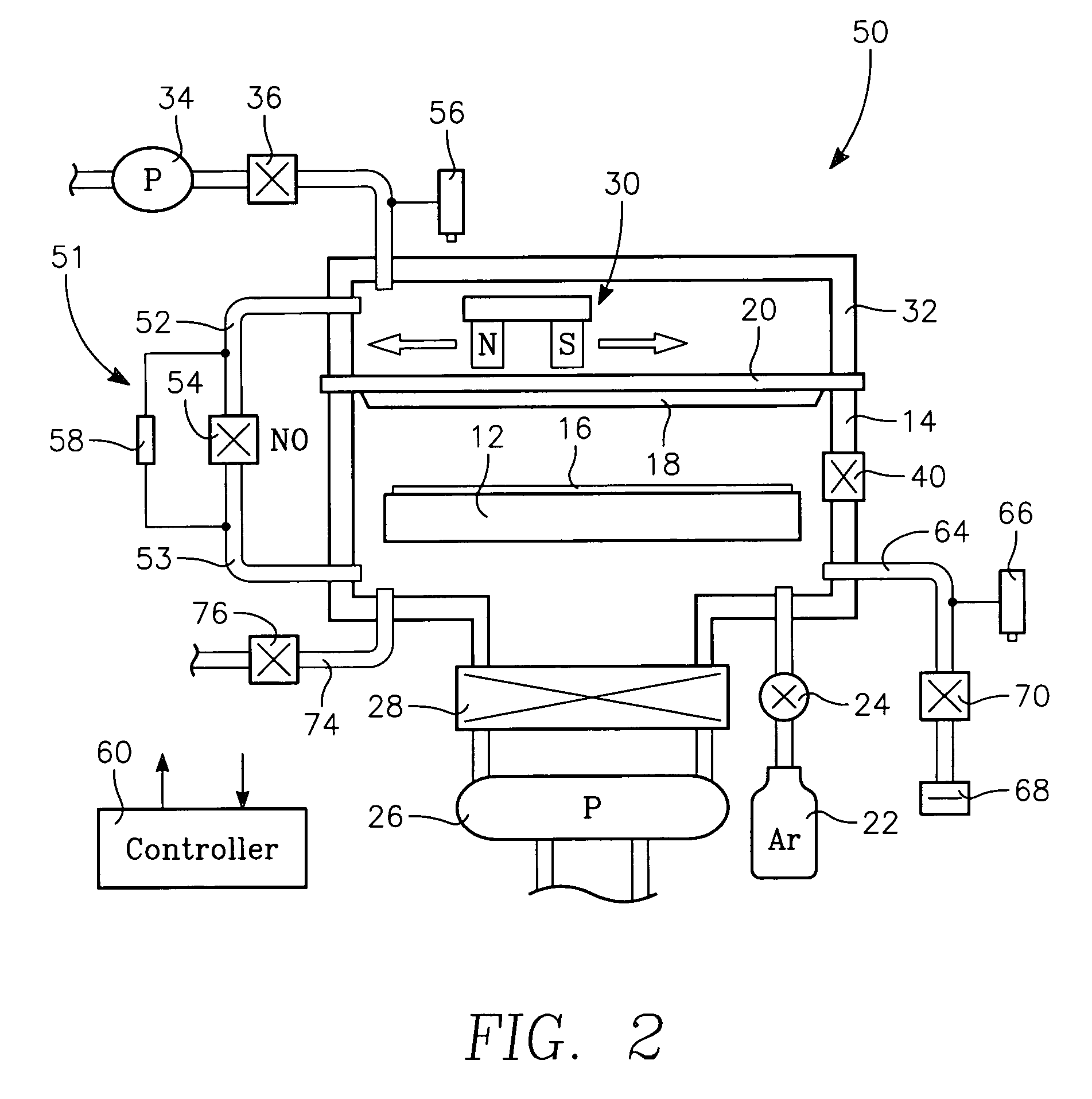

Evacuable magnetron chamber

A vacuum pumping system and method in conjunction with a sputter reactor having a vacuum-pumped magnetron chamber sealed to the target backing plate. A main sputter chamber is vacuum sealed to the target front and cryo pumped. A bypass conduit and valve connect the magnetron and main chambers. A mechanical roughing pump connected to the magnetron chamber pumps the main chamber through the bypass conduit to less than 1 Torr before the bypass valve is closed and the cryo pump is opened and thereafter continues to pump the magnetron chamber to reduce the pressure differential across the target. A pressure differential switch connected across the bypass valve immediately open it whenever the pressure differential exceeds a limit, such as 20 Torr, for example when there is a leak or an electrical failure. The bypass conduit is also used in a venting procedure.

Owner:APPLIED MATERIALS INC

Enclosure, assembly and method for reducing noise from a pump and mass spectrometry system

The invention provides a noise reducing enclosure for reducing the noise from a vacuum pump, e.g. a roughing pump of a high vacuum system, the vacuum pump having a long axis and the enclosure comprising a noise dampening material and being shaped to radially enclose the vacuum pump along its long axis and being axially open at each end. Airflow is permitted through the enclosure in use and optional integrated cooling means on the pump may assist cooling of the pump. The invention also provides an assembly of the pump and enclosure, a method for reducing the noise from a vacuum pump using the enclosure and a mass spectrometry system comprising: a mass spectrometer having one or more chambers therein which in operation are held under vacuum; and a vacuum pumping system for producing said vacuum, the vacuum pumping system comprising at least one vacuum pump which has a long axis and wherein the mass spectrometry system further comprises a noise reducing enclosure for radially enclosing the vacuum pump along its long axis, wherein the enclosure is axially open at each end.

Owner:THERMO FISHER SCI BREMEN

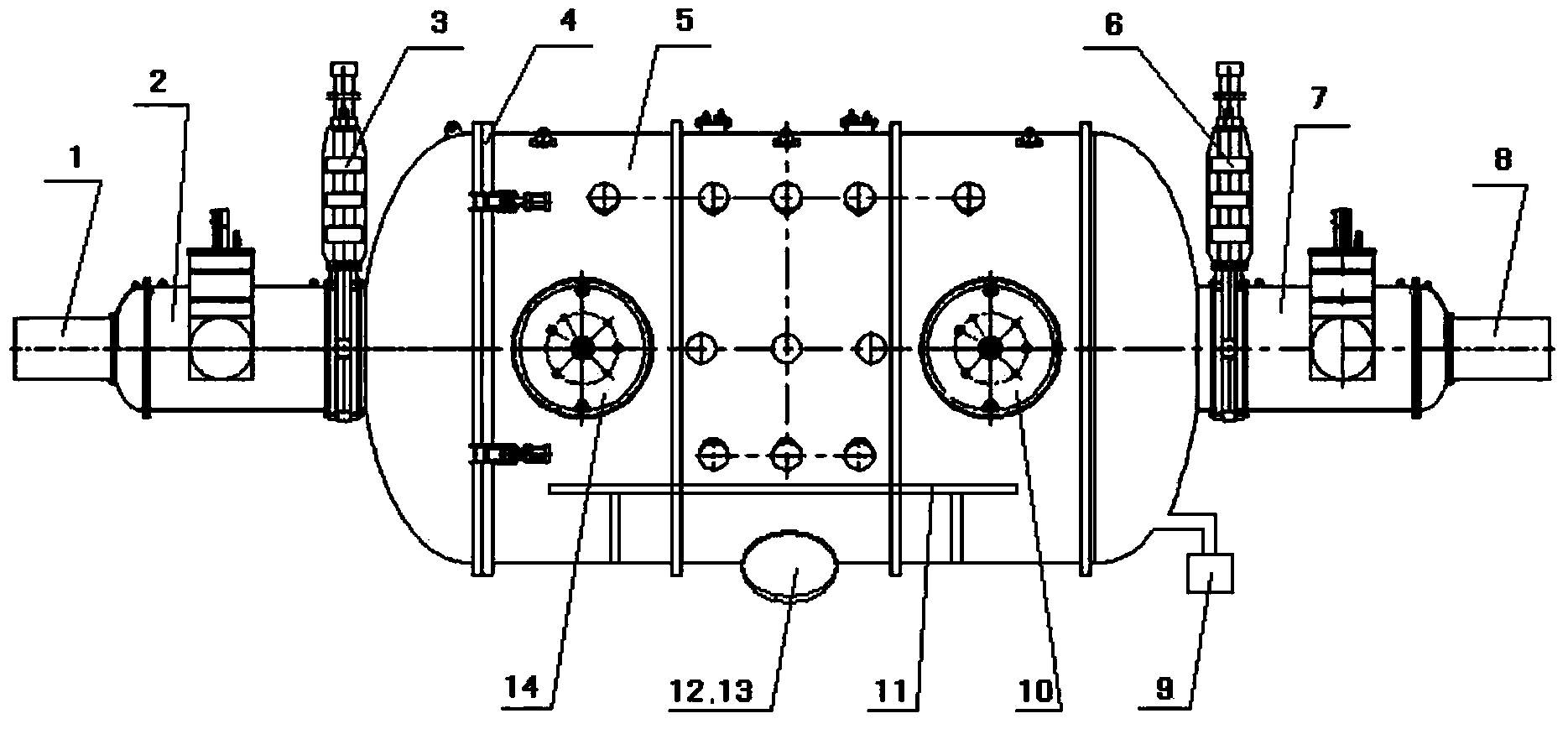

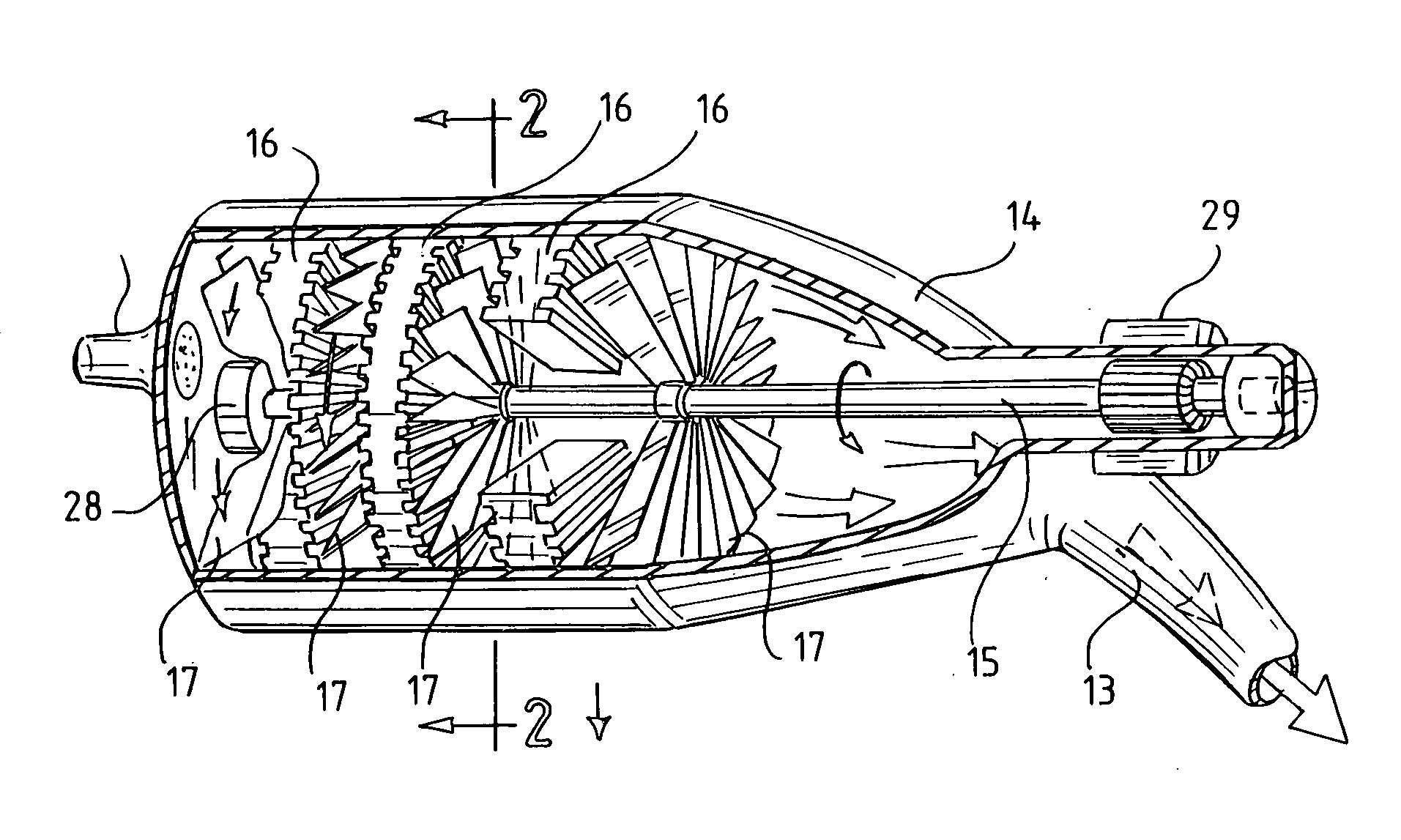

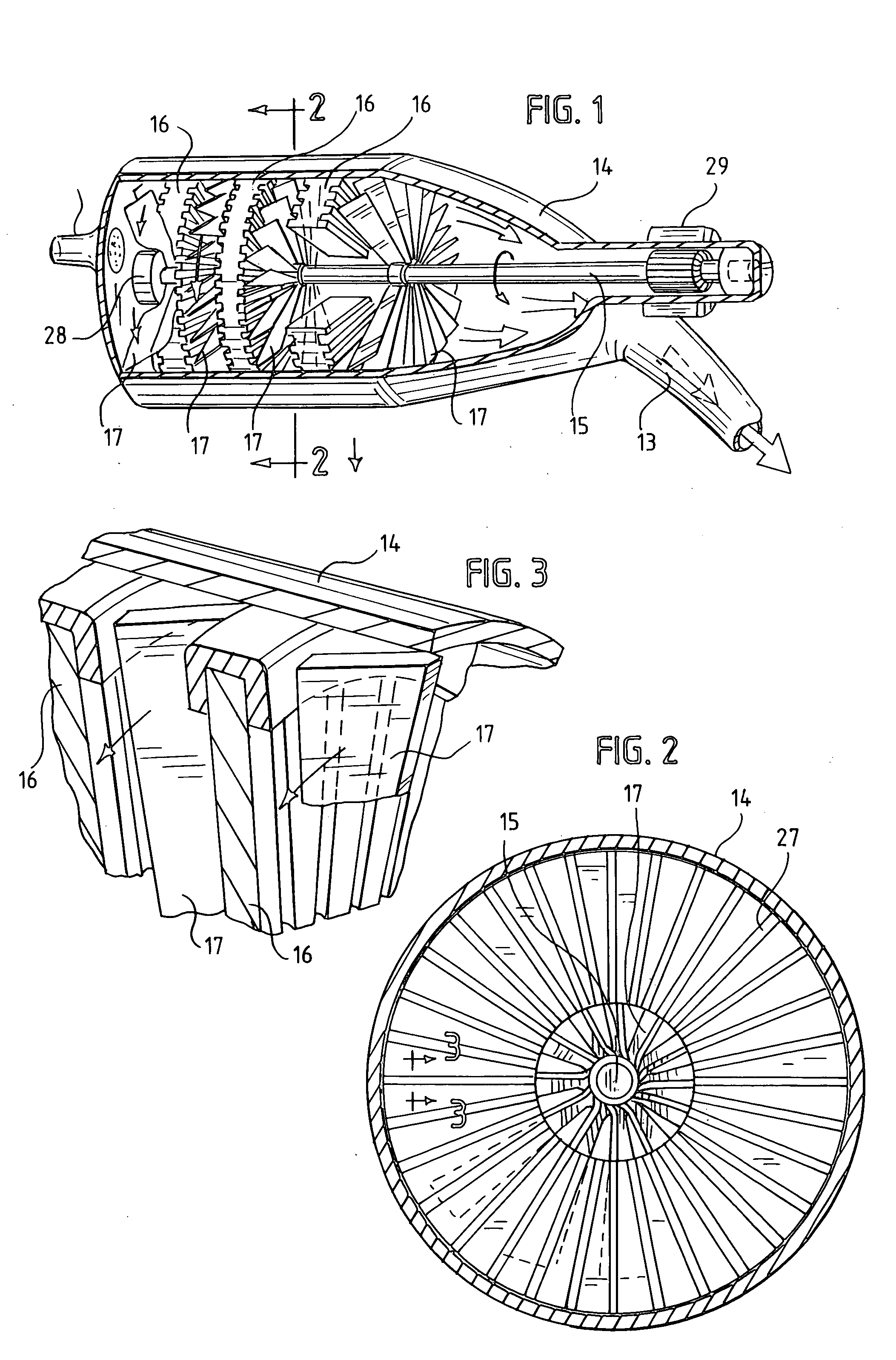

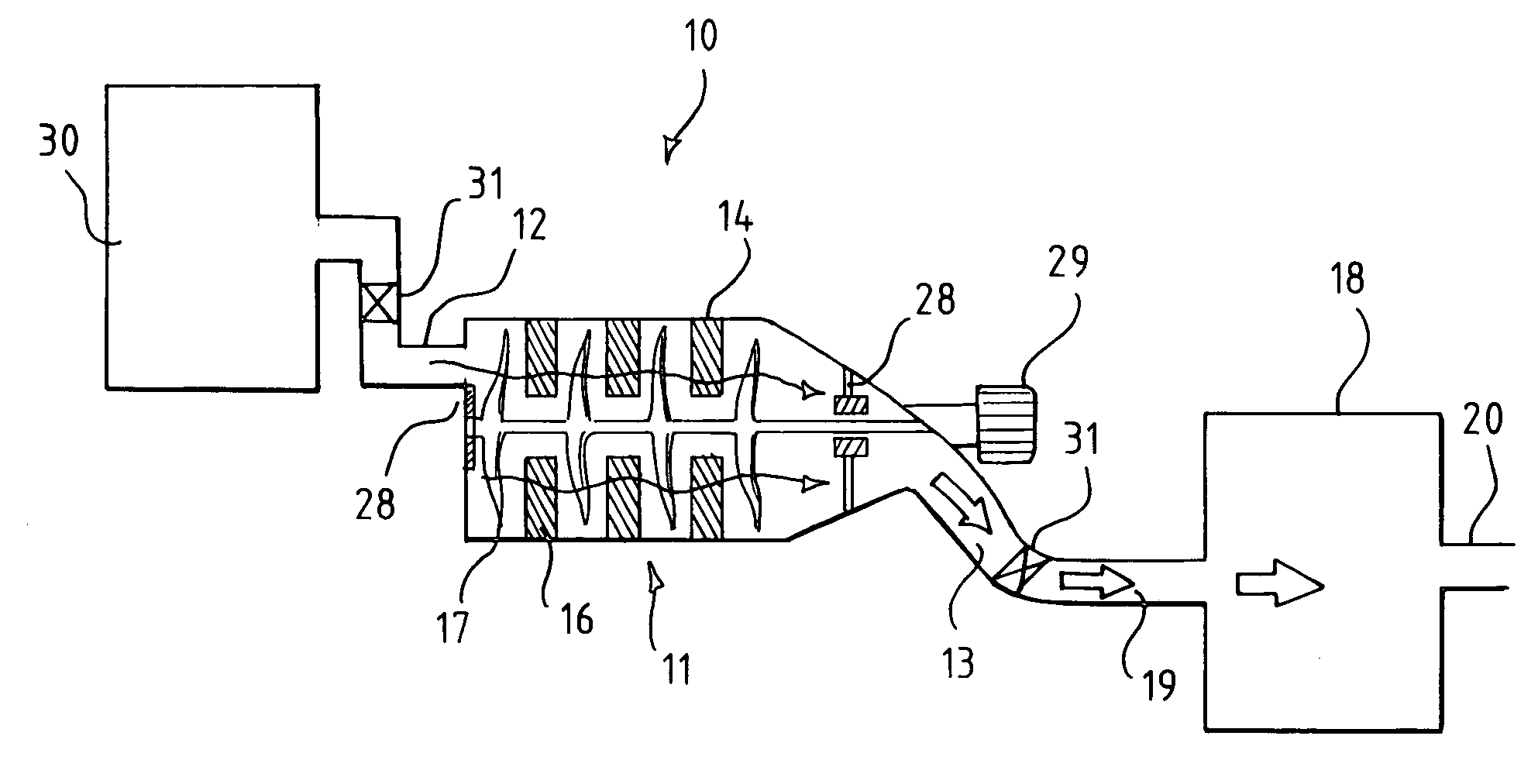

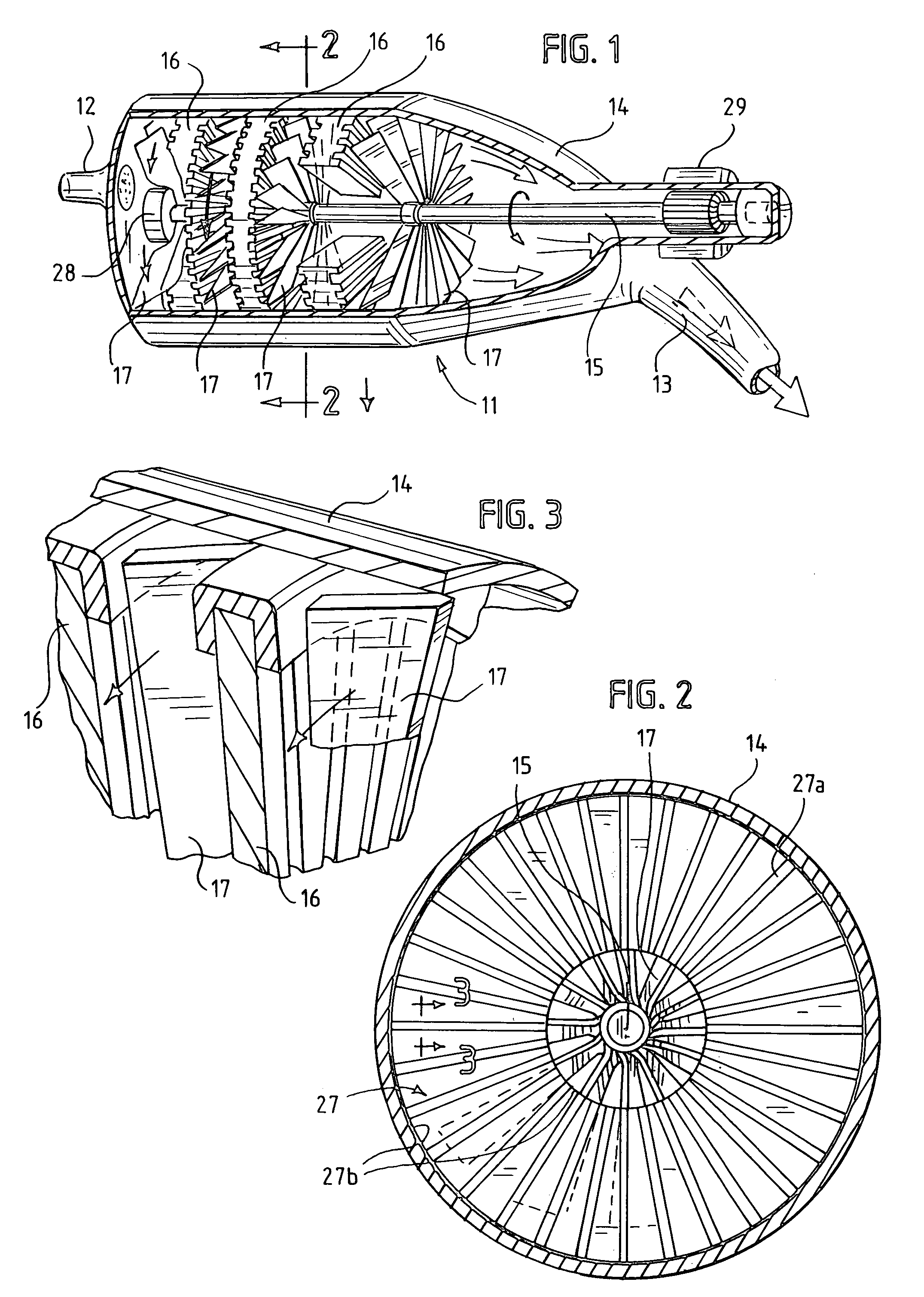

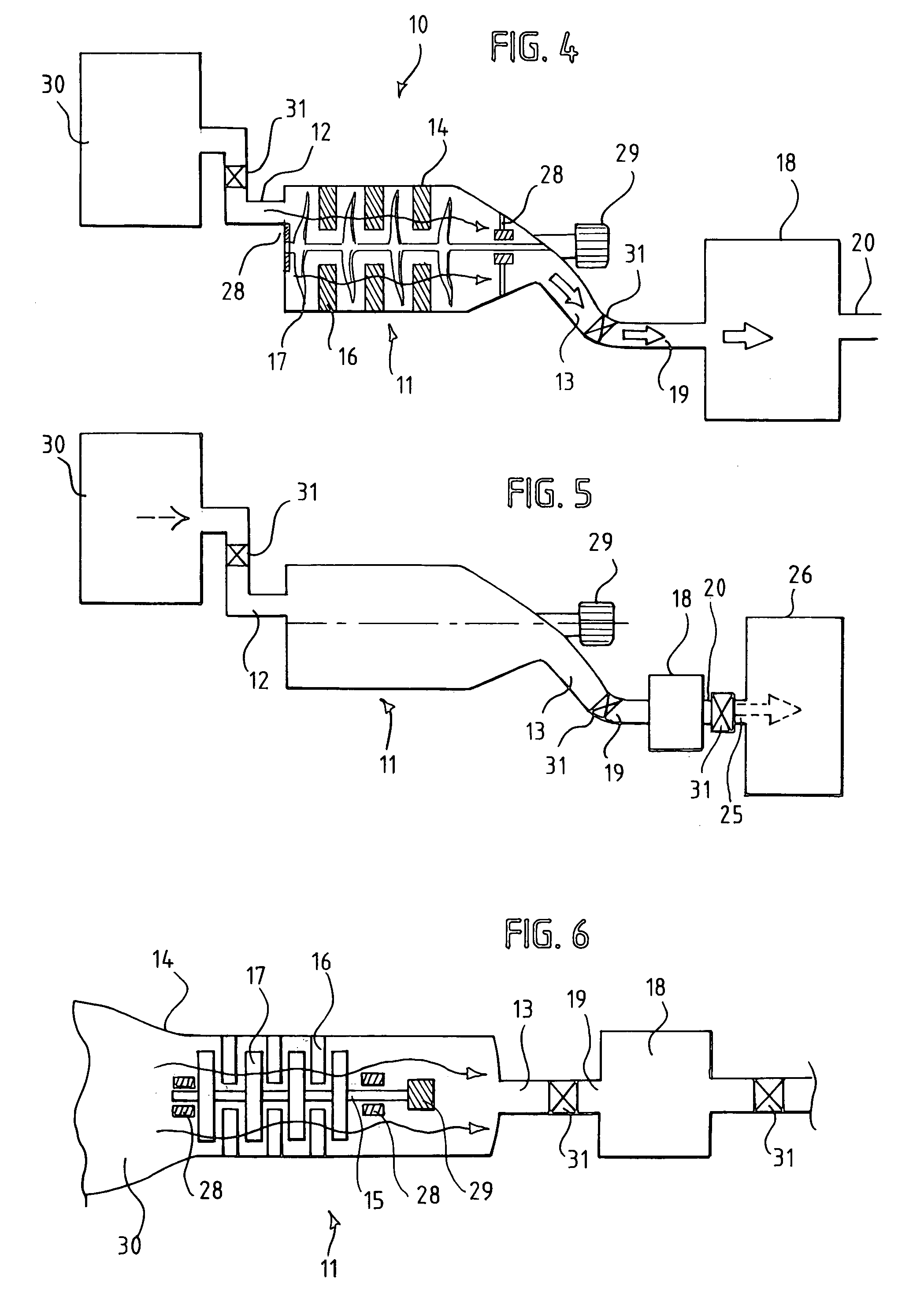

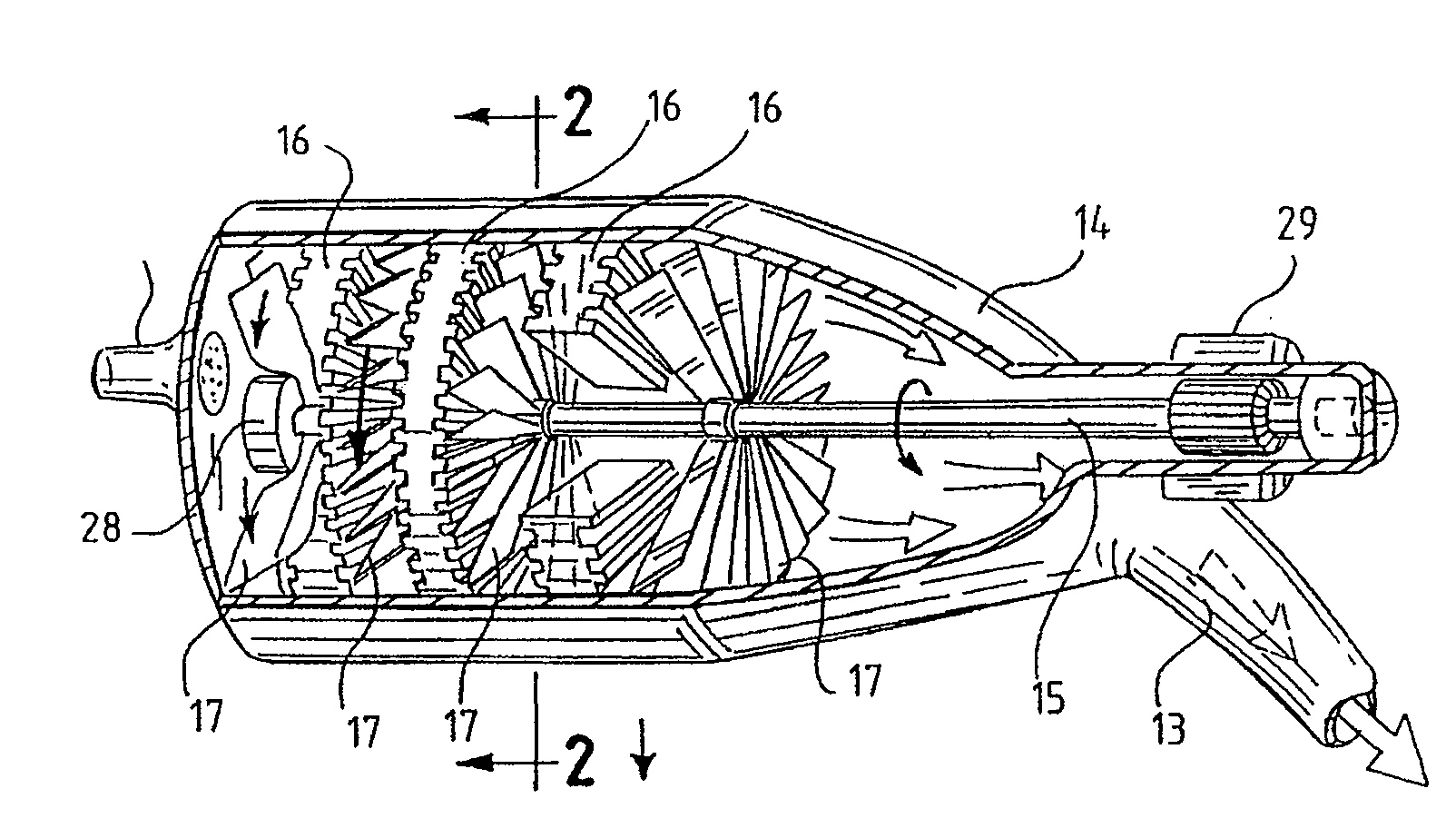

Ultra-high speed vacuum pump system with first stage turbofan and second stage turbomolecular pump

InactiveUS20050129509A1Increase pumping speedSimple componentsPump componentsCombination enginesRoughing pumpUltra high speed

An ultra-high speed vacuum pump evacuation system includes a first stage ultra-high speed turbofan and a second stage conventional turbomolecular pump. The turbofan is either connected in series to a chamber to be evacuated, or is optionally disposed entirely within the chamber. The turbofan employs large diameter rotor blades operating at high linear blade velocity to impart an ultra-high pumping speed to a fluid. The second stage turbomolecular pump is fluidly connected downstream from the first stage turbofan. In operation, the first stage turbofan operates in a pre-existing vacuum, with the fluid asserting only small axial forces upon the rotor blades. The turbofan imparts a velocity to fluid particles towards an outlet at a high volume rate, but moderate compression ratio. The second stage conventional turbomolecular pump then compresses the fluid to pressures for evacuation by a roughing pump.

Owner:FERMI RESEARCH ALLIANCE LLC

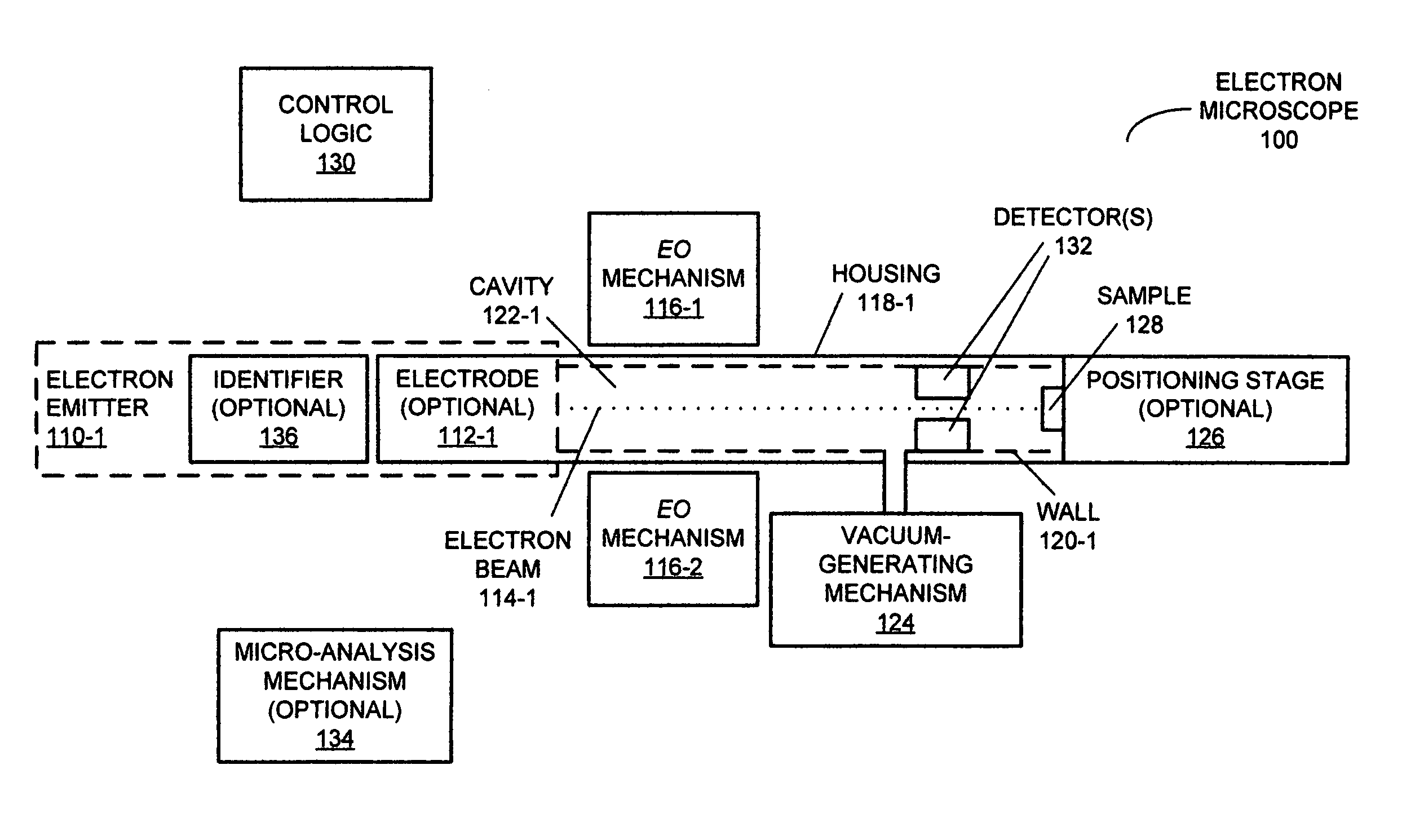

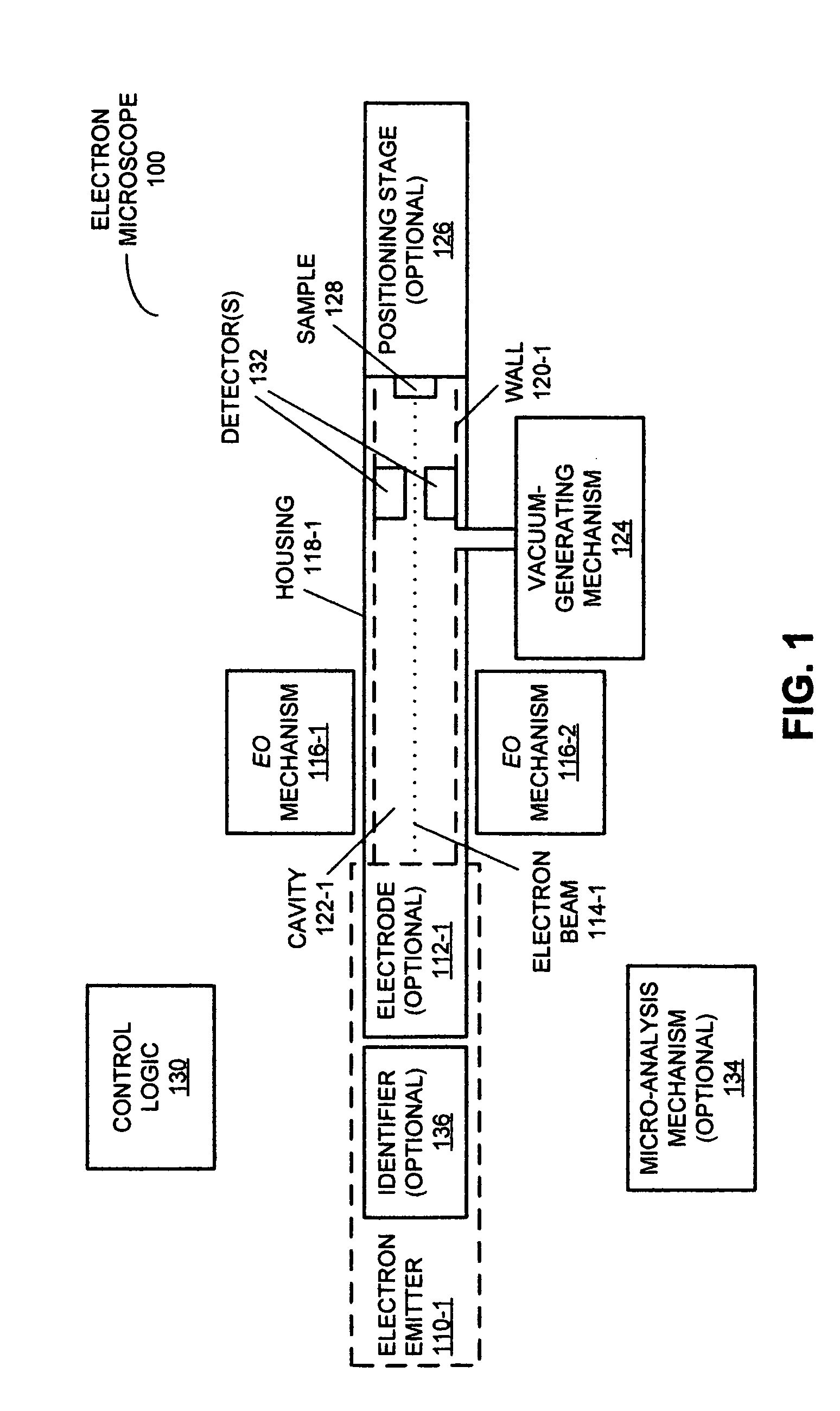

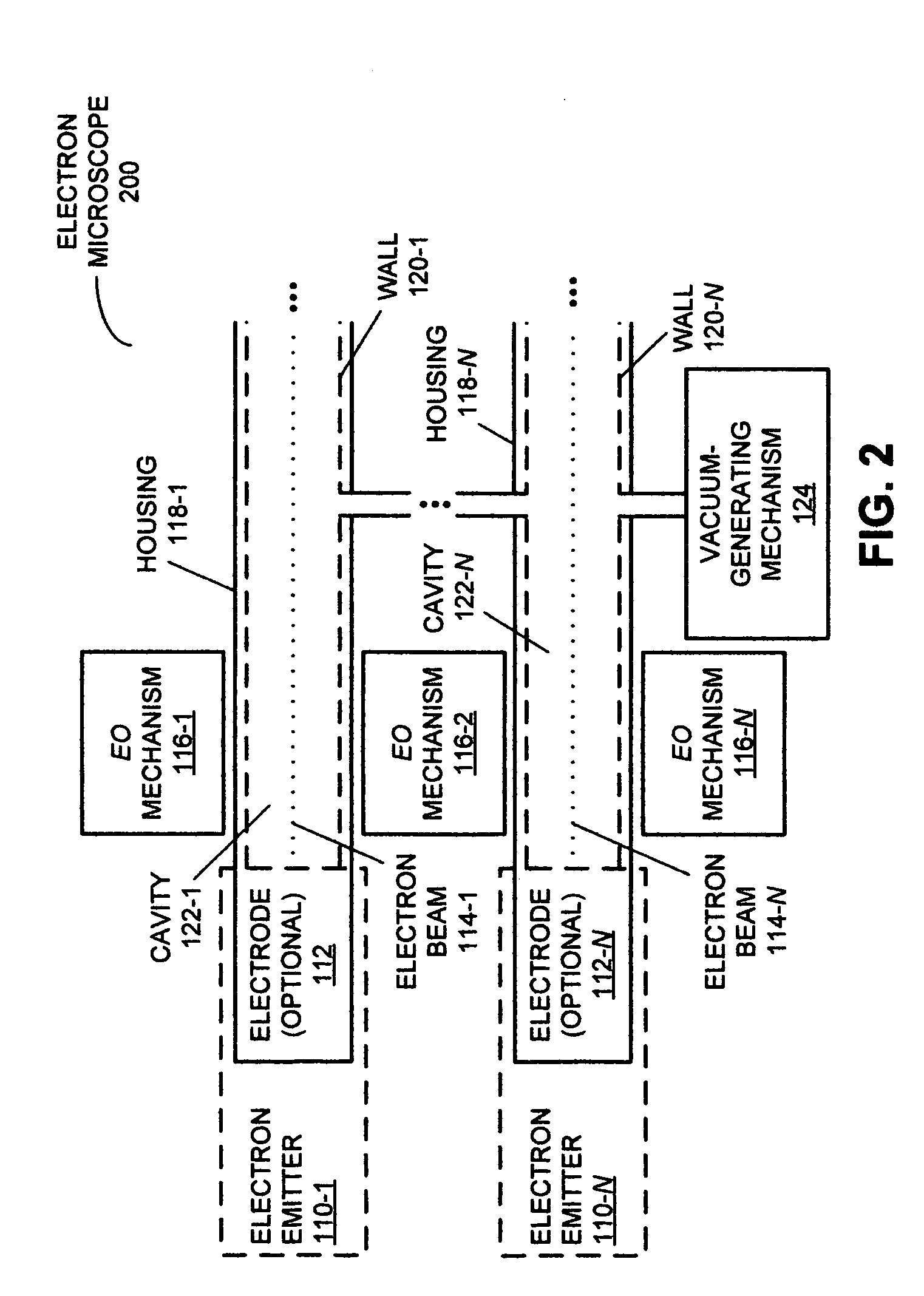

Electron microscope with an emitter operating in medium vacuum

InactiveUS8729470B2Stimulate displacementFast imagingMaterial analysis using wave/particle radiationElectric discharge tubesRoughing pumpHand held

An electron microscope is described. This electron microscope includes an electron emitter that has an evaporation or sublimation rate that is significantly less than that of tungsten at the reduced pressures around the electron emitter during operation of the electron microscope. As a consequence, the electron microscope may be able to operate at reduced pressures that are much larger than those in existing electron microscopes. For example, at least during the operation the reduced pressure in the electron microscope may be greater than or equal to a medium vacuum. This capability may allow the electron microscope to use a roughing pump to provide the reduced pressure, thereby reducing the cost and complexity of the electron microscope, and improving its reliability. In addition, the size of the electron microscope may be reduced, which may enable a hand-held or portable version of the electron microscope.

Owner:DLA INSTR

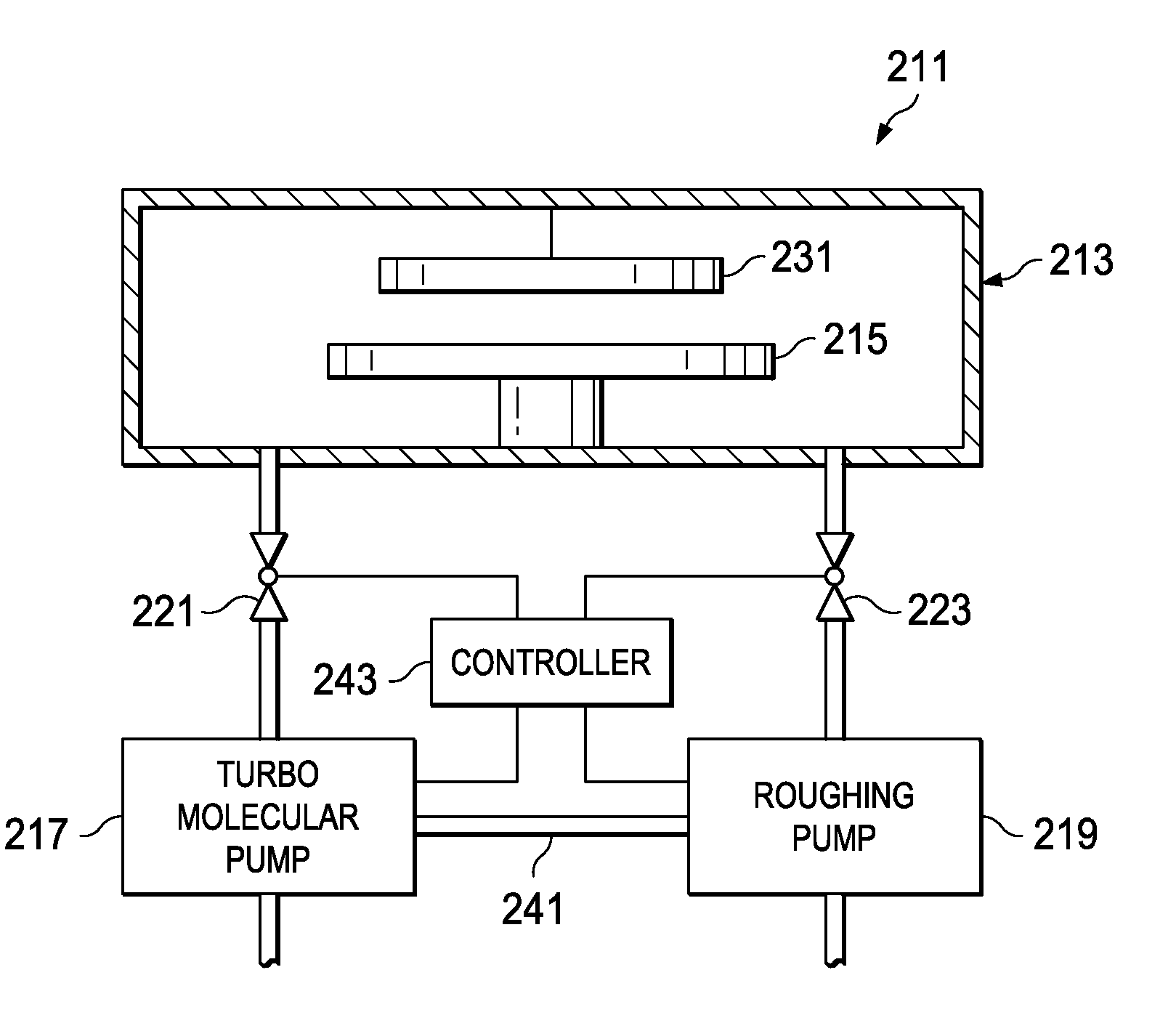

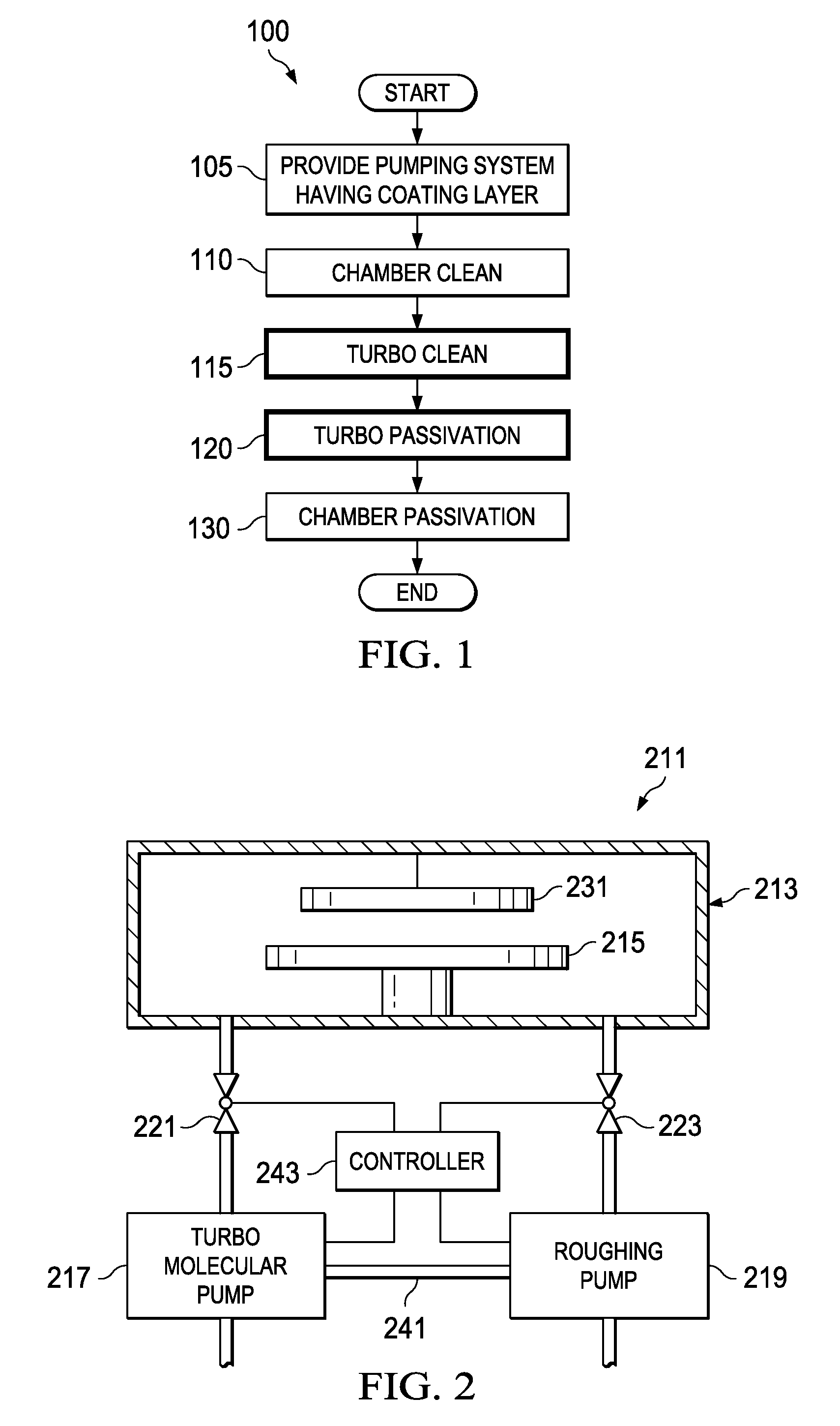

Automatic insitu post process cleaning for processing systems having turbo pumps

An automatic method (100) of in-situ cleaning a processing system (211) including a process chamber (213) pumped by a roughing pump (219) and a turbomolecular pump (217) includes the steps of automatically performing a first RF plasma clean (110) (referred to herein as a chamber clean) to clean the process chamber, wherein the turbomolecular pump (217) is isolated and the roughing pump (219) pumps the processing chamber (213). The turbomolecular pump (217) is automatically switched on to pump the processing chamber (213). While the turbomolecular pump is pumping the processing chamber (213), a second RF plasma clean (115) (referred to herein as an automatic turbo clean) is performed clean the turbomolecular pump (217). In embodiments of the invention the turbo clean (115) automatically sets at least one gas flow, an RF power, and a pressure in the chamber (213).

Owner:TEXAS INSTR INC

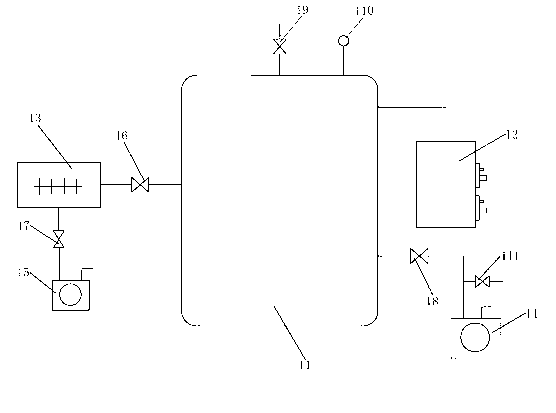

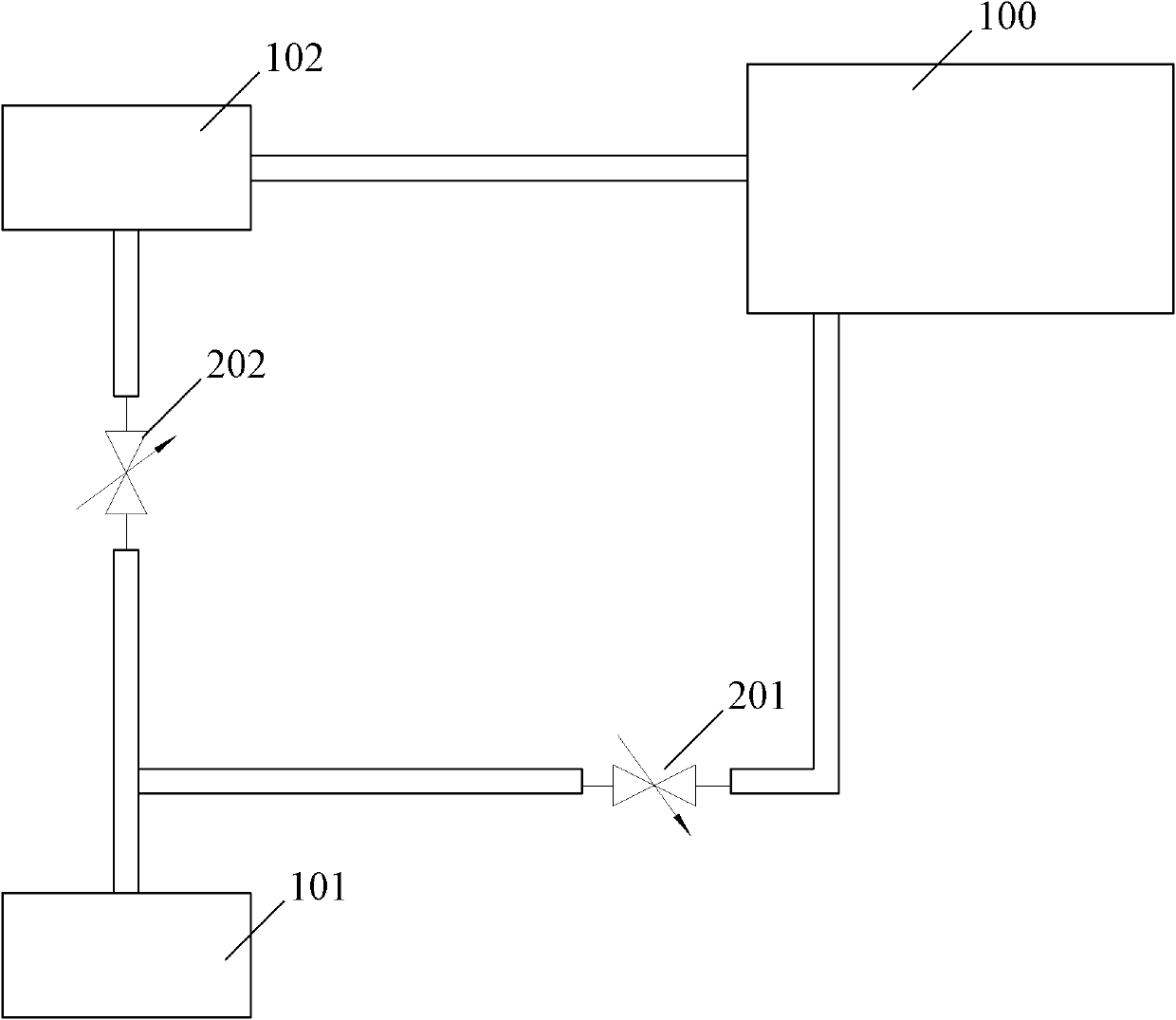

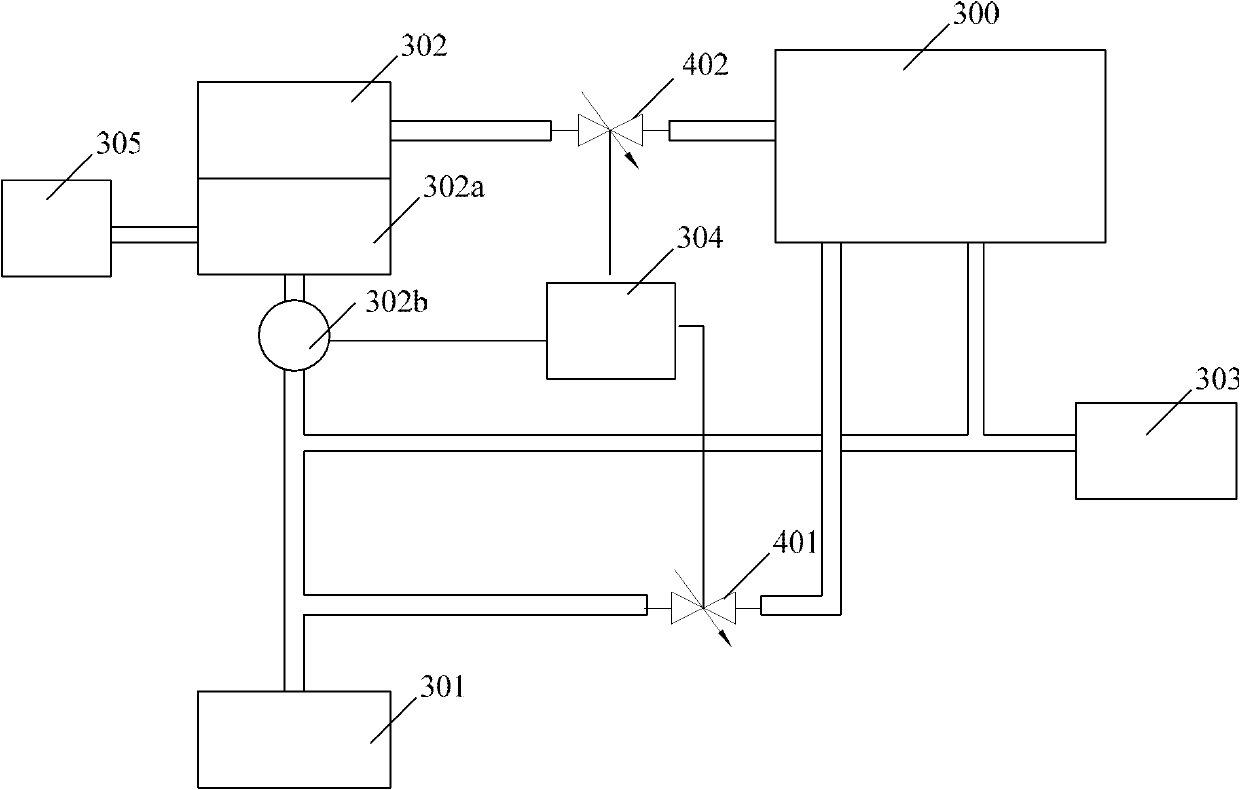

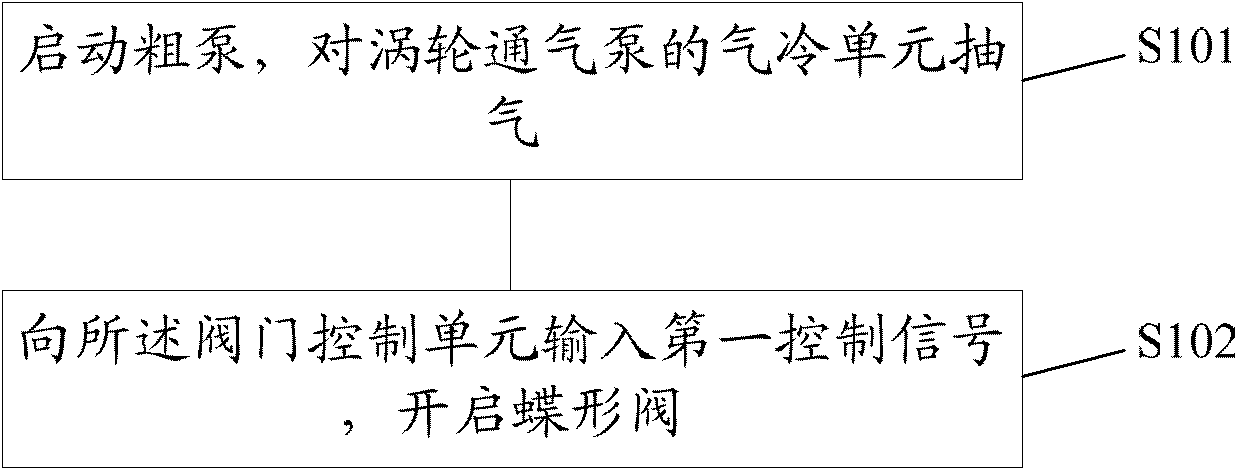

Gas pipeline system of reaction chamber and control method of gas pipeline system

ActiveCN102568991AReduce air pressurePrevent reverse chargingElectric discharge tubesExhaust gasRoughing pump

The invention provides a gas pipeline system of a reaction chamber and a control method of the gas pipeline system. The gas pipeline system comprises a roughing pump connected with a reaction chamber by a butterfly damper for exhausting gas in the reaction chamber; a turbine aerating pump connected with the reaction chamber for aerating the reaction chamber, wherein a gas cooling unit of the turbine aerating pump is communicated with the roughing pump; and a valve control unit for comparing the gas pressure in the gas cooling unit with gas pressure in the reaction chamber and closing a butterfly valve when the gas pressure in the gas cooling unit is more than that of the reaction chamber. In the invention, the roughing pump always exhausts gas in the gas cooling unit when working, can reduce gas pressure in the gas cooling unit and enable the gas pressure to keep balance with the gas pressure of the reaction chamber; the valve control unit compares the gas pressures, controls opening or closing of the butterfly valve, thereby effectively preventing the cooling gas from being reversely filled to the reaction chamber.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Ultra-high speed vacuum pump system with first stage turbofan and second stage turbomolecular pump

InactiveUS7021888B2Rotor designLower resistancePump componentsCombination enginesRoughing pumpUltra high speed

An ultra-high speed vacuum pump evacuation system includes a first stage ultra-high speed turbofan and a second stage conventional turbomolecular pump. The turbofan is either connected in series to a chamber to be evacuated, or is optionally disposed entirely within the chamber. The turbofan employs large diameter rotor blades operating at high linear blade velocity to impart an ultra-high pumping speed to a fluid. The second stage turbomolecular pump is fluidly connected downstream from the first stage turbofan. In operation, the first stage turbofan operates in a pre-existing vacuum, with the fluid asserting only small axial forces upon the rotor blades. The turbofan imparts a velocity to fluid particles towards an outlet at a high volume rate, but moderate compression ratio. The second stage conventional turbomolecular pump then compresses the fluid to pressures for evacuation by a roughing pump.

Owner:FERMI RESEARCH ALLIANCE LLC

Automatic vacuum evaporation method

InactiveCN112831756AReduce pressureVacuum evaporation coatingSputtering coatingRoughing pumpCrucible

The invention provides an automatic vacuum evaporation method which adopts a vacuum evaporator to perform vacuum evaporation in a full-automatic manner, and comprises the following steps: S1, adopting a rough suction pump to vacuumize the interior of a cavity of the vacuum evaporator; S2, turning off the rough suction pump, and continuing to vacuumize by adopting a fine suction pump; S3, during vacuumizing in the step S2, adopting a heating lamp in a cavity of the vacuum evaporator to begin to preheat so as to remove moisture on the surface of the workpiece product; S4, preheating the evaporation coating material in a crucible while the heating lamp in the step S3 starts to heat, so that the granular evaporation coating material is fused into a whole; S5, starting an ion source device, and performing physical bombardment on the surface of the workpiece product; and S6, for the evaporation coating material fused into a whole in the crucible, changing the evaporation coating material into a liquid state from a solid state and then into a gas state by utilizing the electron beam or thermal resistance evaporation principle, enabling gas molecules of the evaporation coating material to reach the surface of the workpiece, and forming a coating film on the surface of the workpiece after solidification nodules.

Owner:苏州佑伦真空设备科技有限公司

Vacuum pumping pipeline device for spacecraft environmental simulation test equipment

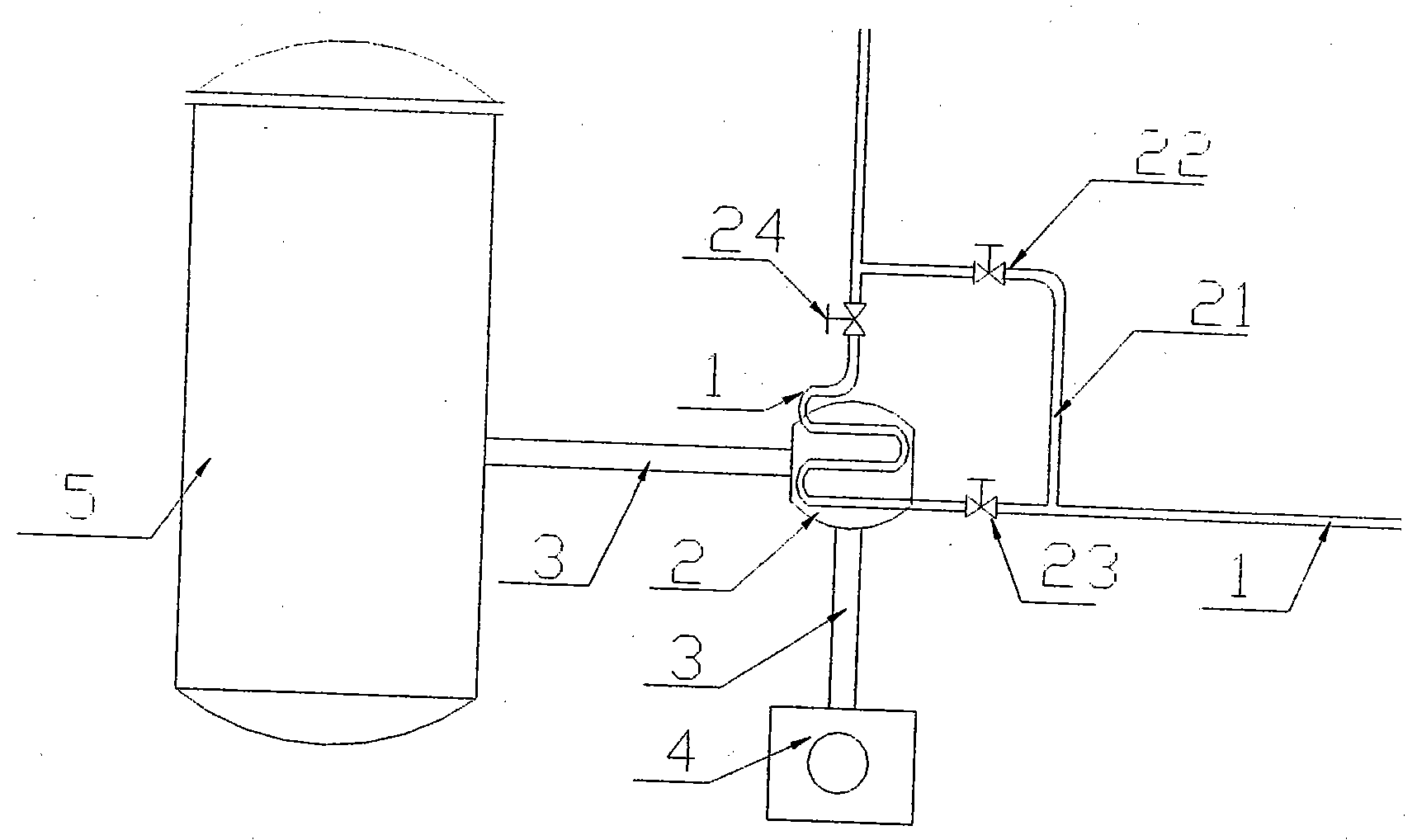

ActiveCN105493656BSolve the problem of oil returnReduced oil returnCosmonautic condition simulationsPipeline systemsRoughing pumpVacuum pumping

The invention discloses a vacuum pumping pipeline device of a spacecraft environment simulation test equipment, comprising: a vacuum rough pumping pipeline [3] of a spacecraft space environment simulator [5] connected in series with a liquid nitrogen oil retaining cold trap [2] ]; there is a liquid nitrogen pipeline [1] in the liquid nitrogen oil-retaining cold trap [2]; according to the present invention, on the liquid nitrogen pipeline [1] in the liquid nitrogen oil-retaining cold trap [2], a roadside The liquid nitrogen pipeline [21] is connected in series with the low temperature shut-off valve [22]; the low temperature shut-off valve [24], [twenty three]. The invention solves the problem of oil return from the mechanical vacuum pump of the rough vacuuming pipeline of the spacecraft environmental simulation test equipment, and achieves the beneficial effects of improving test reliability and effectively preventing the vacuum pump oil from polluting the spacecraft.

Owner:SHANGHAI INST OF SATELLITE EQUIP

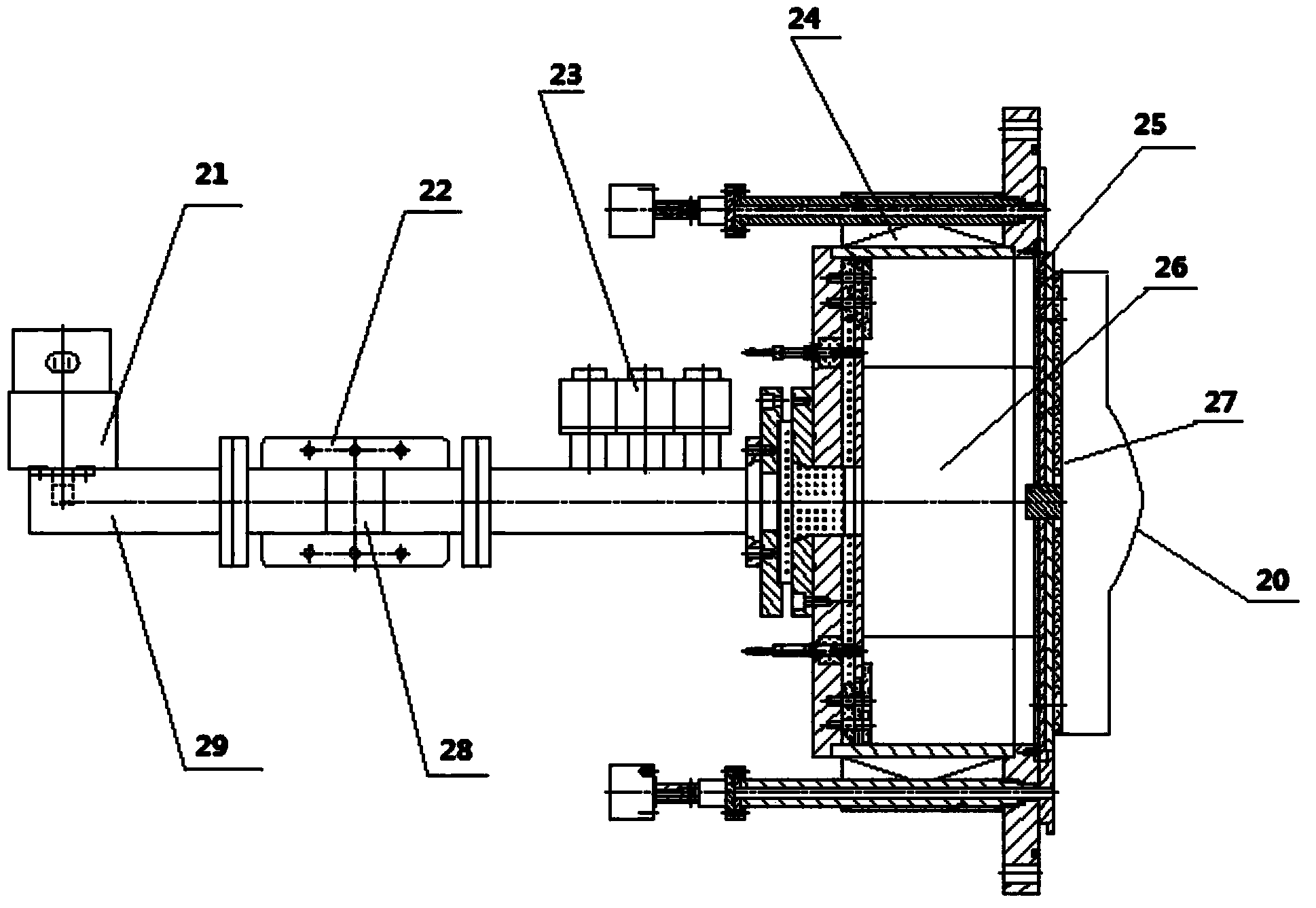

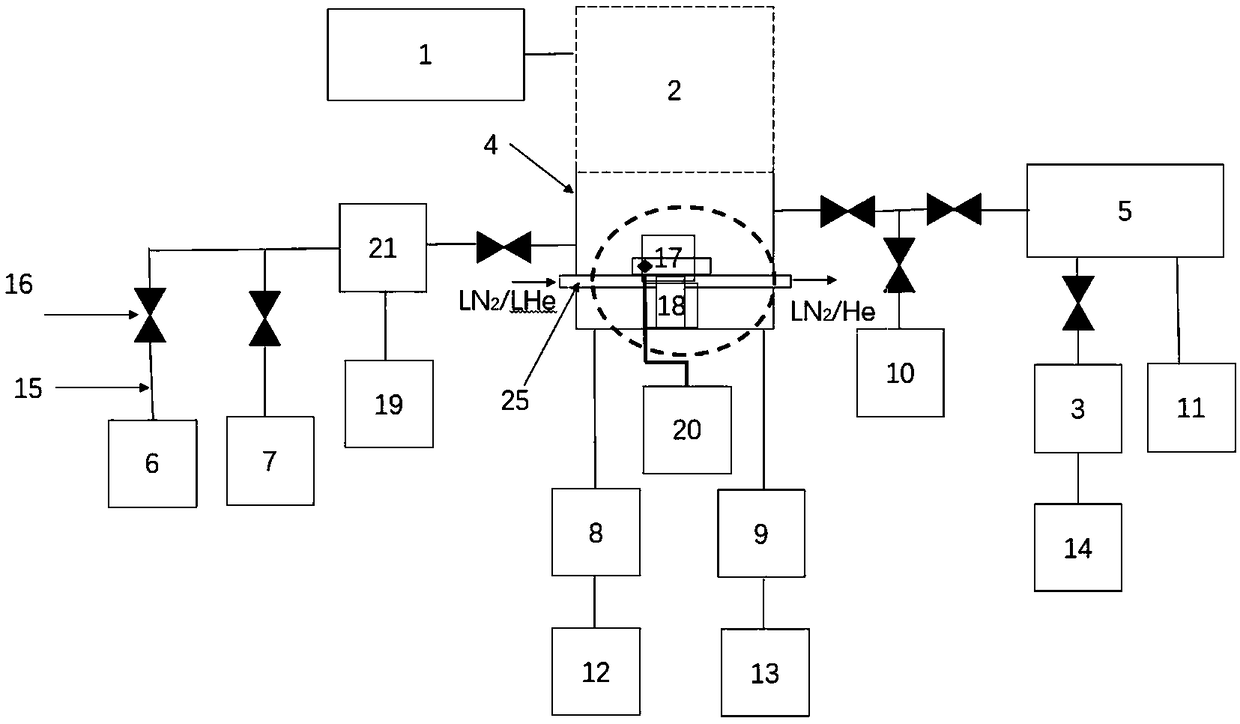

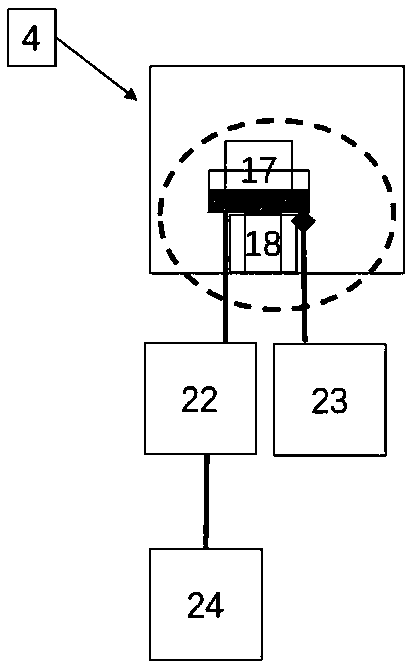

Electronic/ion induced desorption yield integral test device and method

InactiveCN108760566AImplement testRaise the test temperature zoneMaterial analysisRoughing pumpDesorption

The invention discloses an electronic / ion induced desorption yield integral test device and method. The device comprises a standard vacuum chamber, a vacuum test cavity, an electronic source / ion source, an ion pump, a roughing pump, a second turbine molecular pump, a first turbine molecular pump, a high-purity standard gas input pipeline, a pressure intensity test system, a diaphragm type vacuum gauge, a temperature sensor, a refrigerating system and a heating disc; the second turbine molecular pump and the high-purity standard gas source input pipeline are communicated with an inlet of the standard vacuum chamber; an outlet of the standard vacuum chamber is communicated with the vacuum test cavity; a sample support frame for placing samples is arranged in the vacuum test cavity; the electronic source / ion source directly faces to the samples on the sample support frame; the ion pump, the roughing pump and the first turbine molecular pump are respectively communicated with the vacuum test cavity. The device and the method have the advantages that the electronic induced desorption yield test and ion induced desorption yield test can be realized; the test temperature region range is wide.

Owner:XI AN JIAOTONG UNIV +1

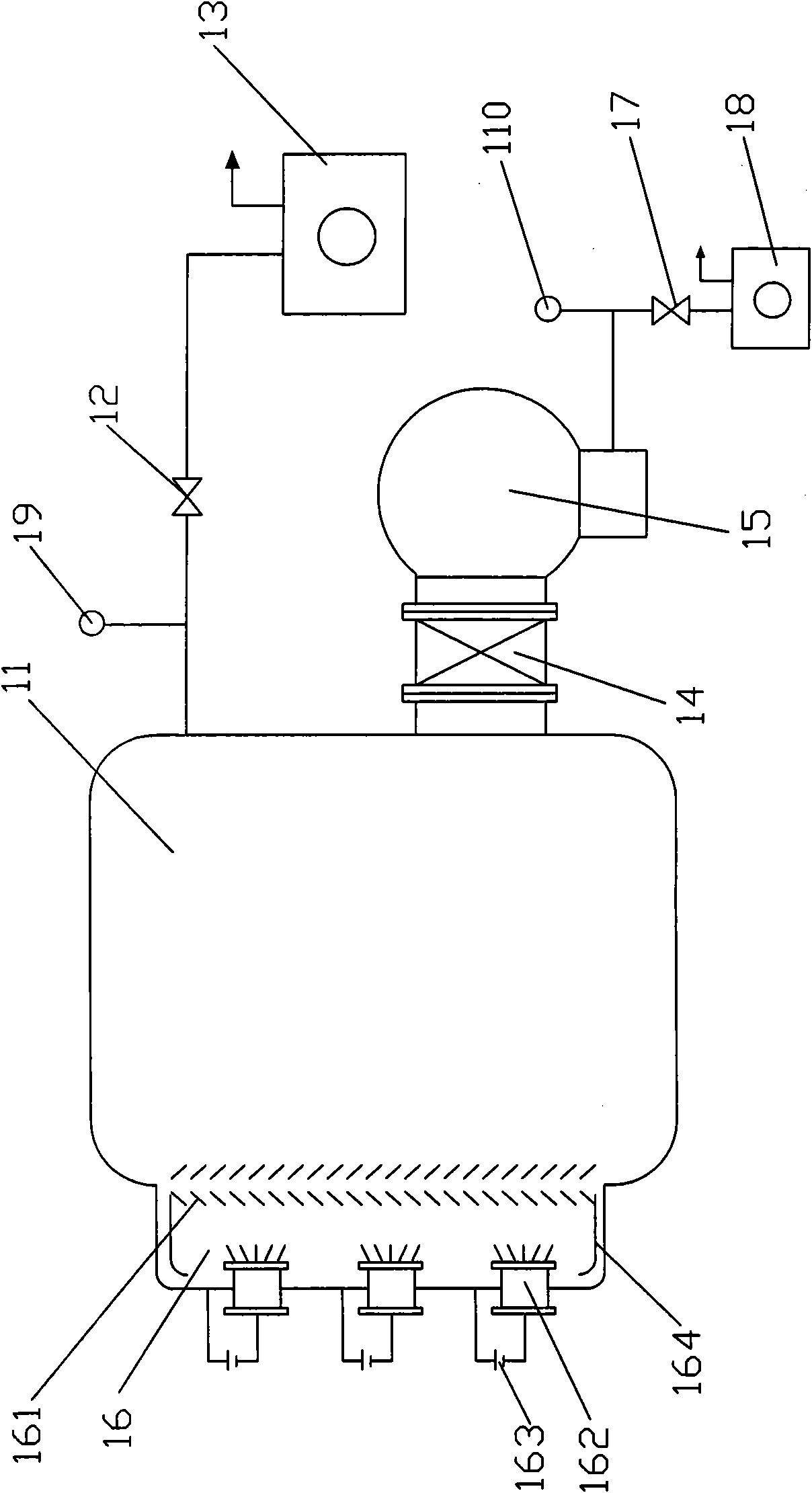

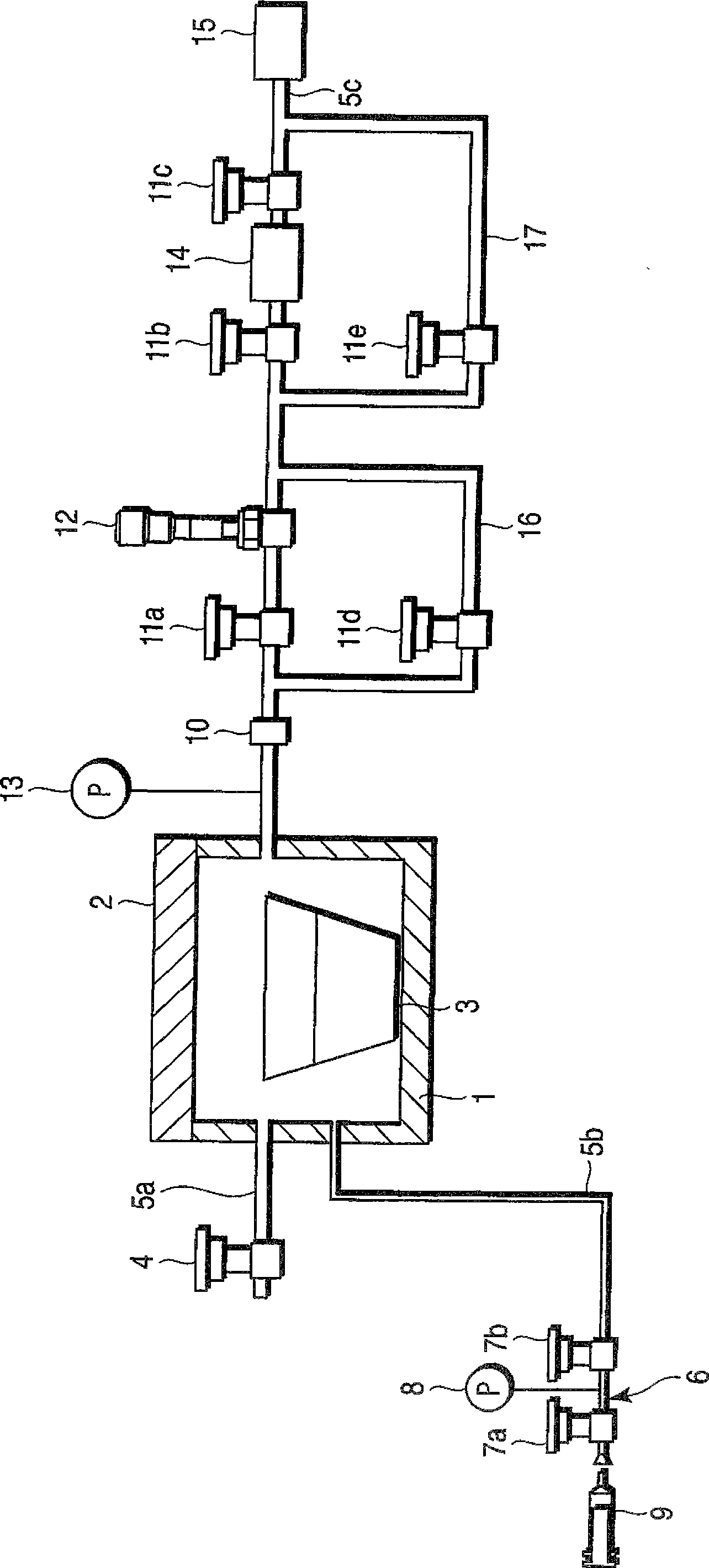

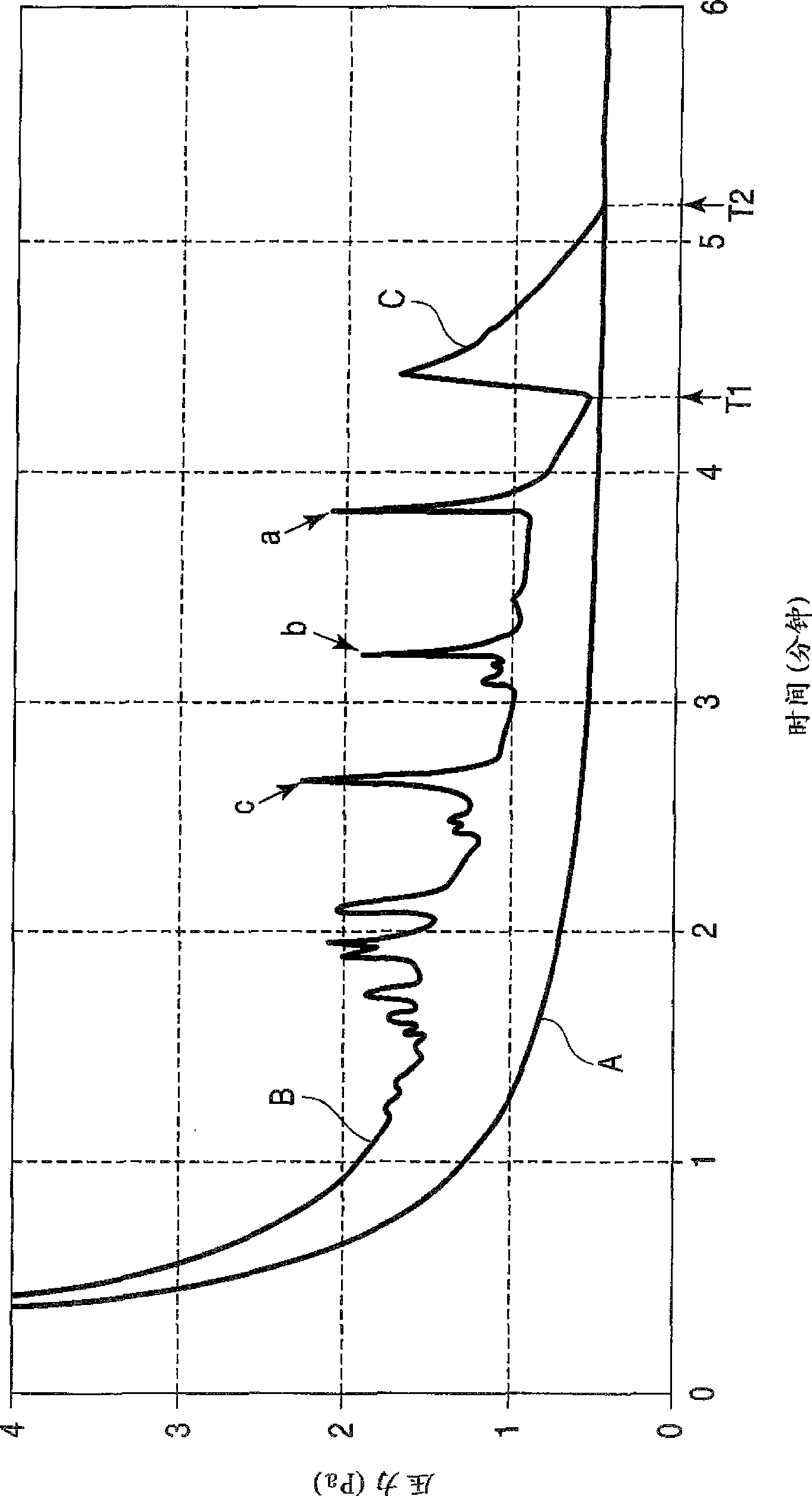

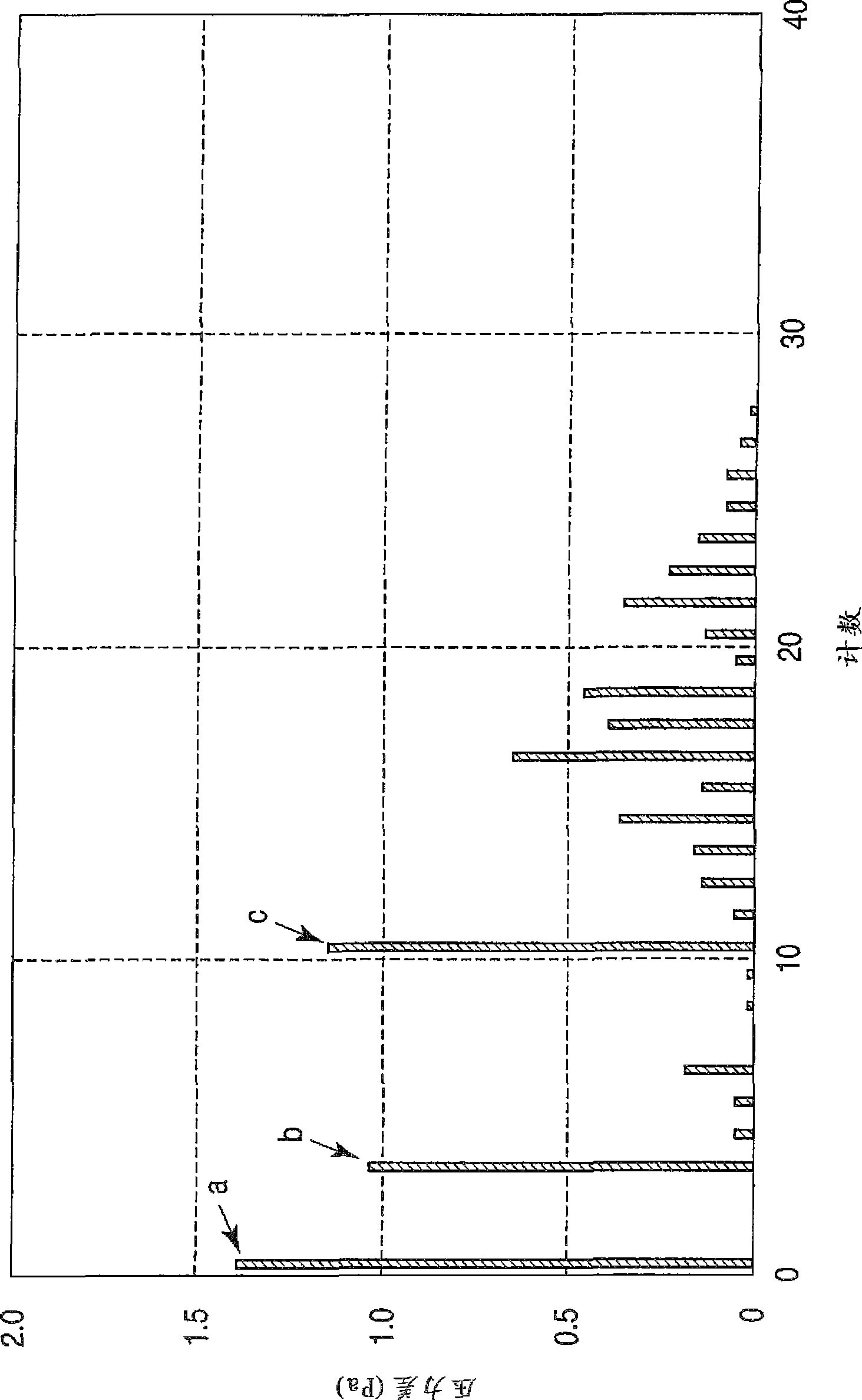

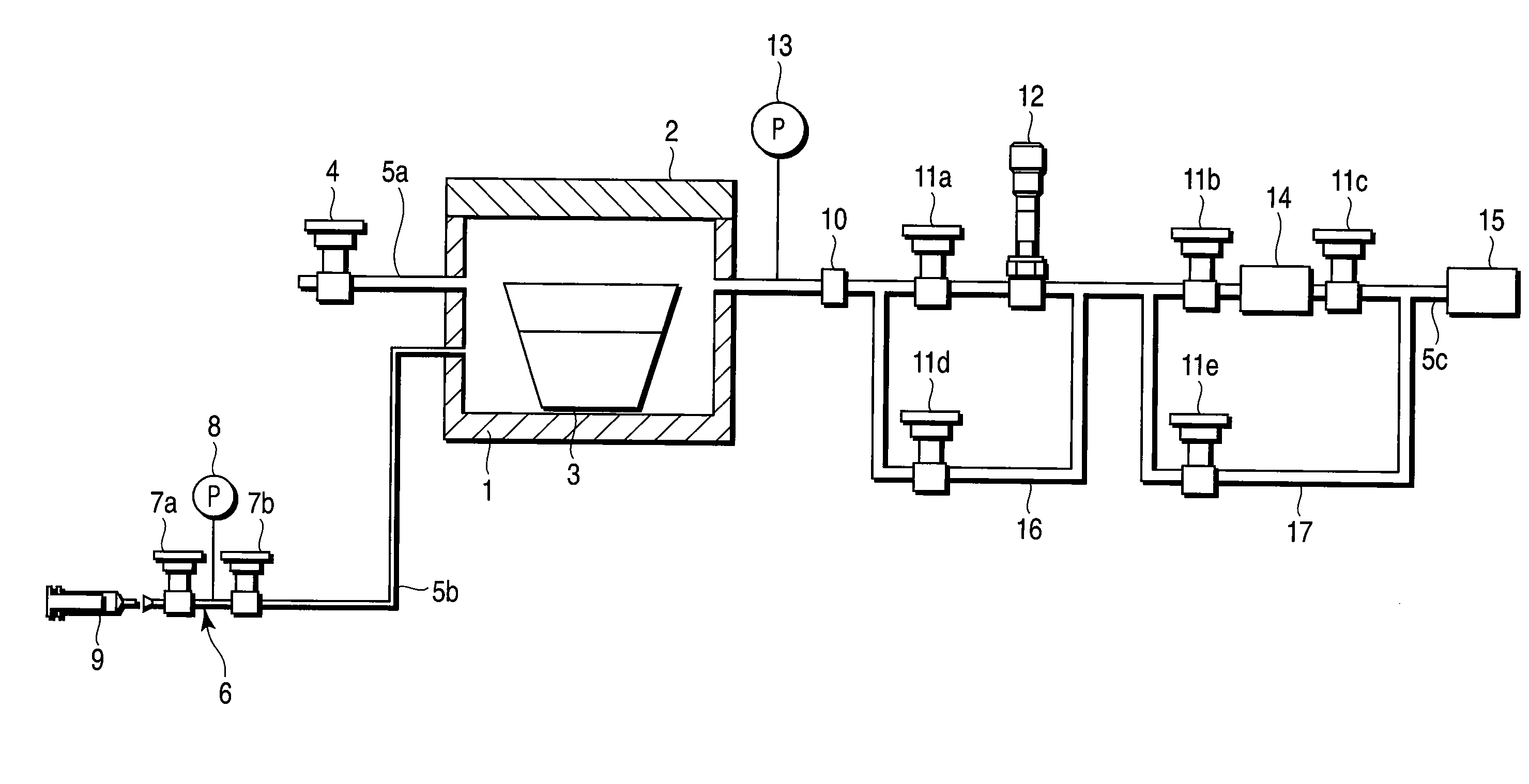

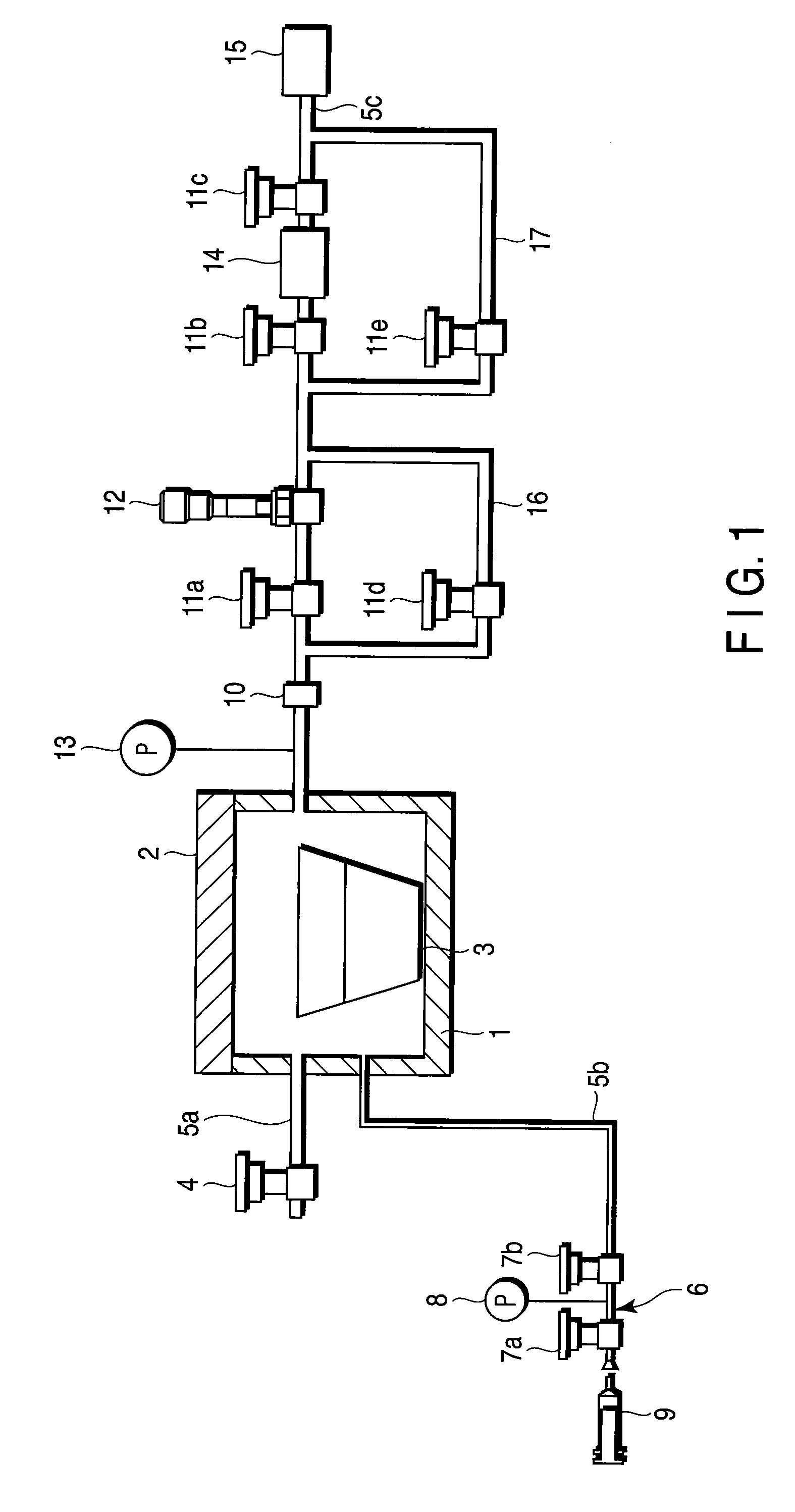

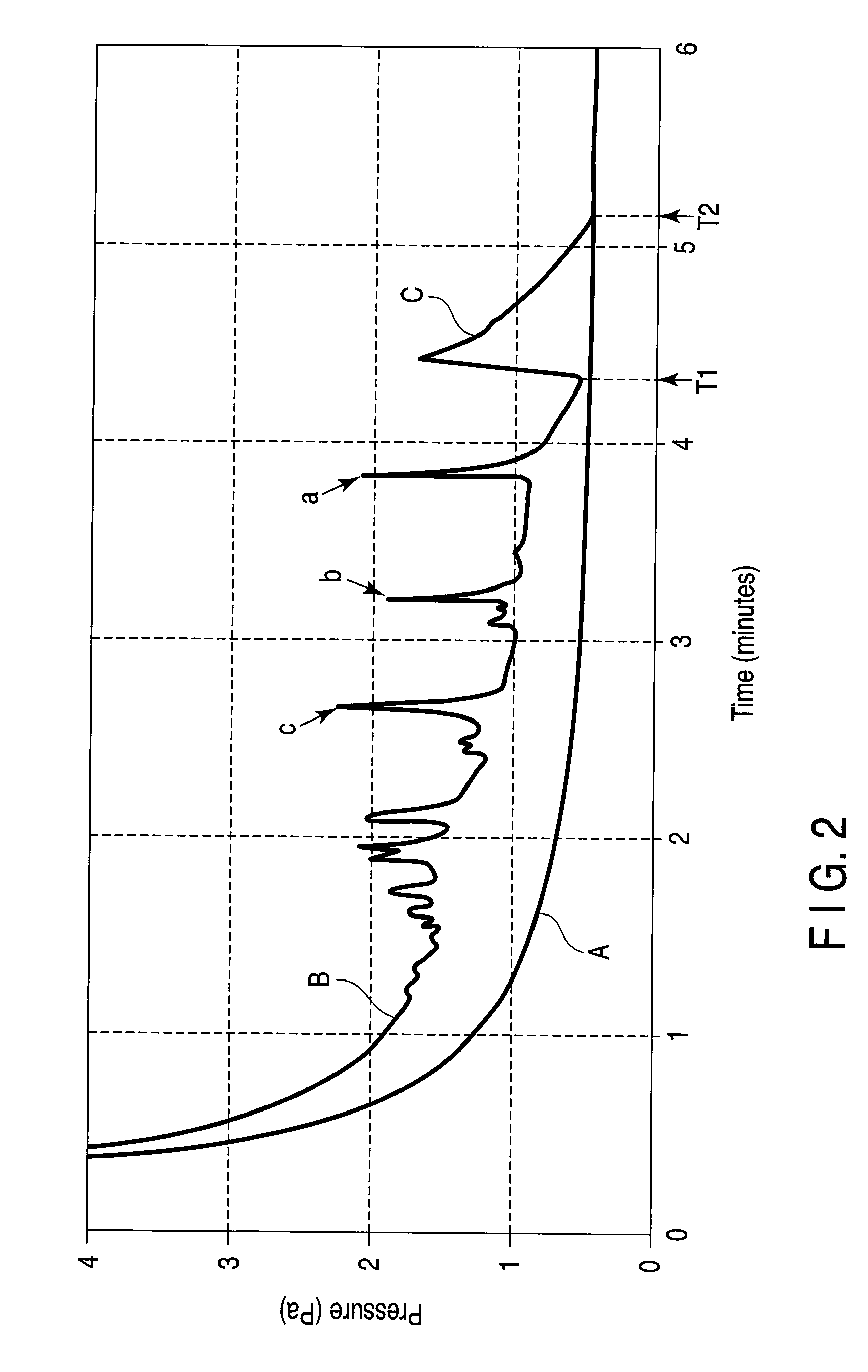

Gas amount measurement device

A gas amount measuring device includes a vacuum container (1) filled with a molten metal, a first pipe (5a) being attached to the vacuum container (1), an air release valve (4) being attached to the first pipe (5a), a second pipe (5b) being attached to the vacuum container (1), a calibration gas generator (6) being attached to the second pipe (5b), a third pipe (5c) being attached to the vacuum container (1), a vacuum gauge (13), a first valve (11a), a leak valve (12), a second valve (11b), a turbomolecular pump (14), a third valve (11c), and a roughing pump (15) being attached to the third pipe (5c) in order from a vacuum container (1) side, a first bypass pipe (16) connecting the third pipe (5c) between the vacuum container (1) and the first valve (11a) to the third pipe (5c) between the leak valve (12) and the second valve (11b), a fourth valve (11d) being attached to the first bypass pipe (16), and a second bypass pipe (17) connecting the third pipe (5c) between the leak valve (12) and the second valve (11b) to the third pipe (5c) between the third valve (11c) and the roughing pump (15), a fifth valve (11e) being attached to the second bypass pipe (17).

Owner:NIPPON KINZOKU KAGAKU

Vacuum pump protection against deposition byproduct buildup

ActiveUS11031215B2Electric discharge tubesSemiconductor/solid-state device manufacturingRoughing pumpEngineering

A processing chamber such as a plasma etch chamber can perform deposition and etch operations, where byproducts of the deposition and etch operations can build up in a vacuum pump system fluidly coupled to the processing chamber. A vacuum pump system may have multiple roughing pumps so that etch gases can be diverted a roughing pump and deposition precursors can be diverted to another roughing pump. A divert line may route unused deposition precursors through a separate roughing pump. Deposition byproducts can be prevented from forming by incorporating one or more gas ejectors or venturi pumps at an outlet of a primary pump in a vacuum pump system. Cleaning operations, such as waferless automated cleaning operations, using certain clean chemistries may remove deposition byproducts before or after etch operations.

Owner:LAM RES CORP

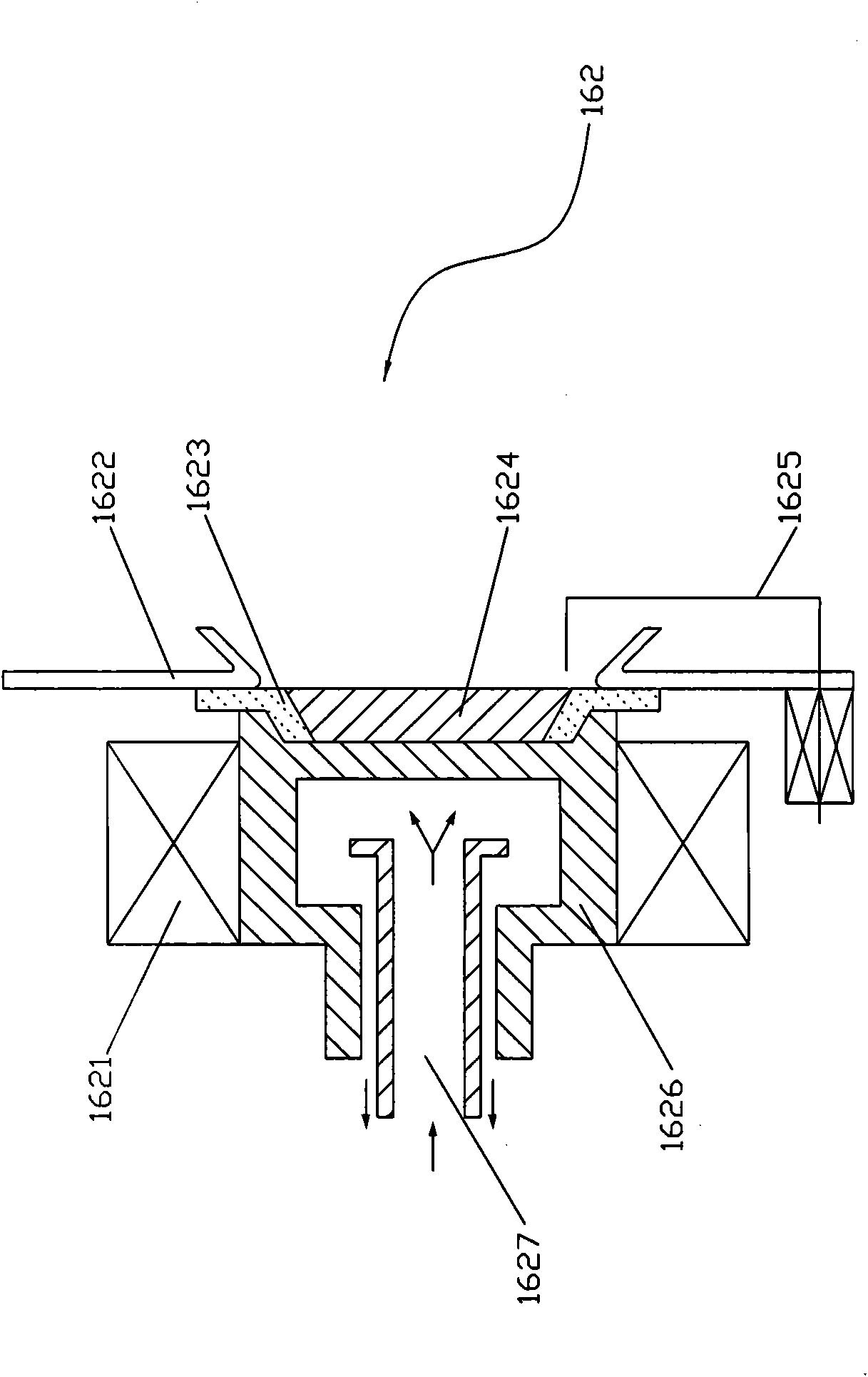

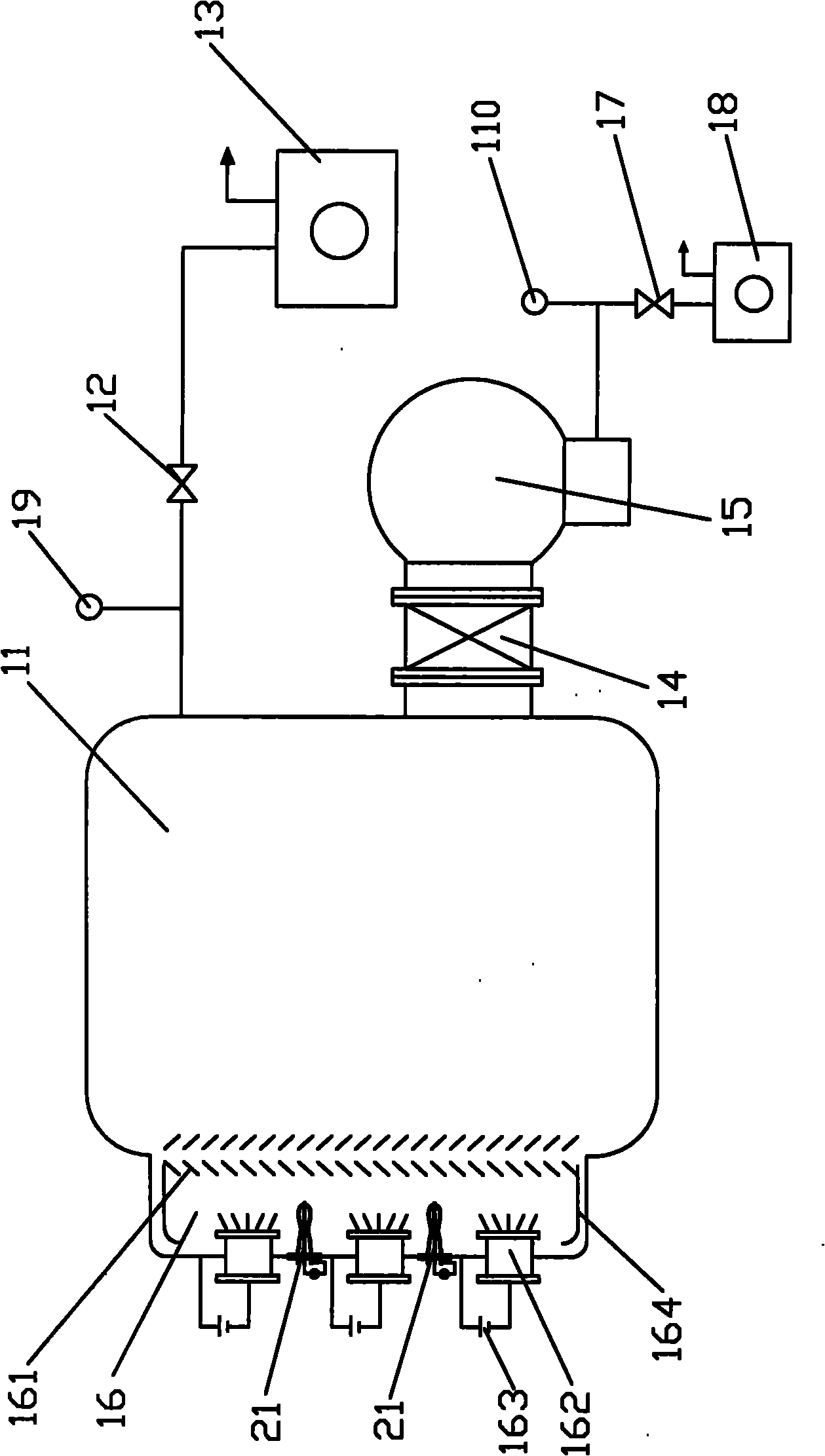

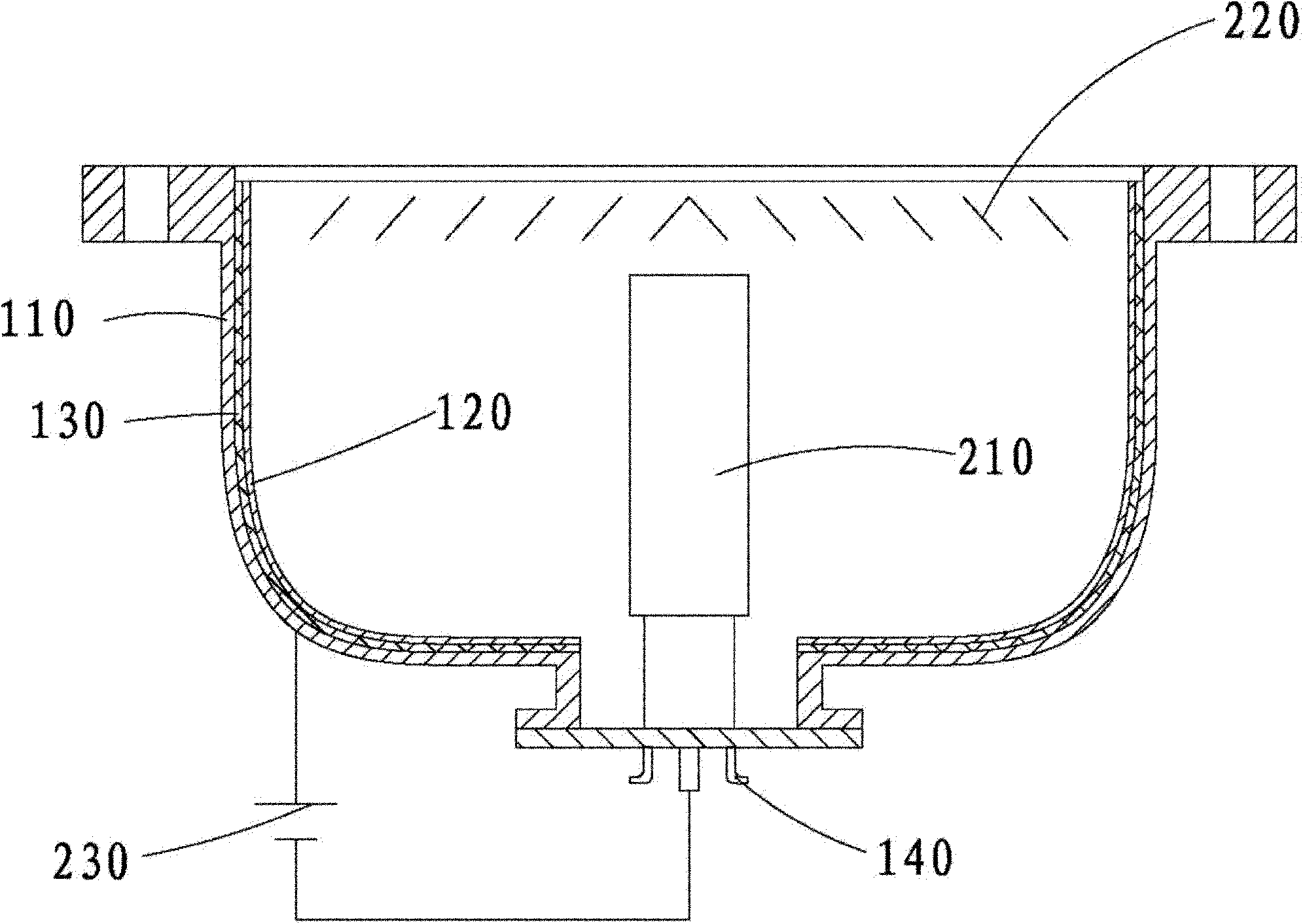

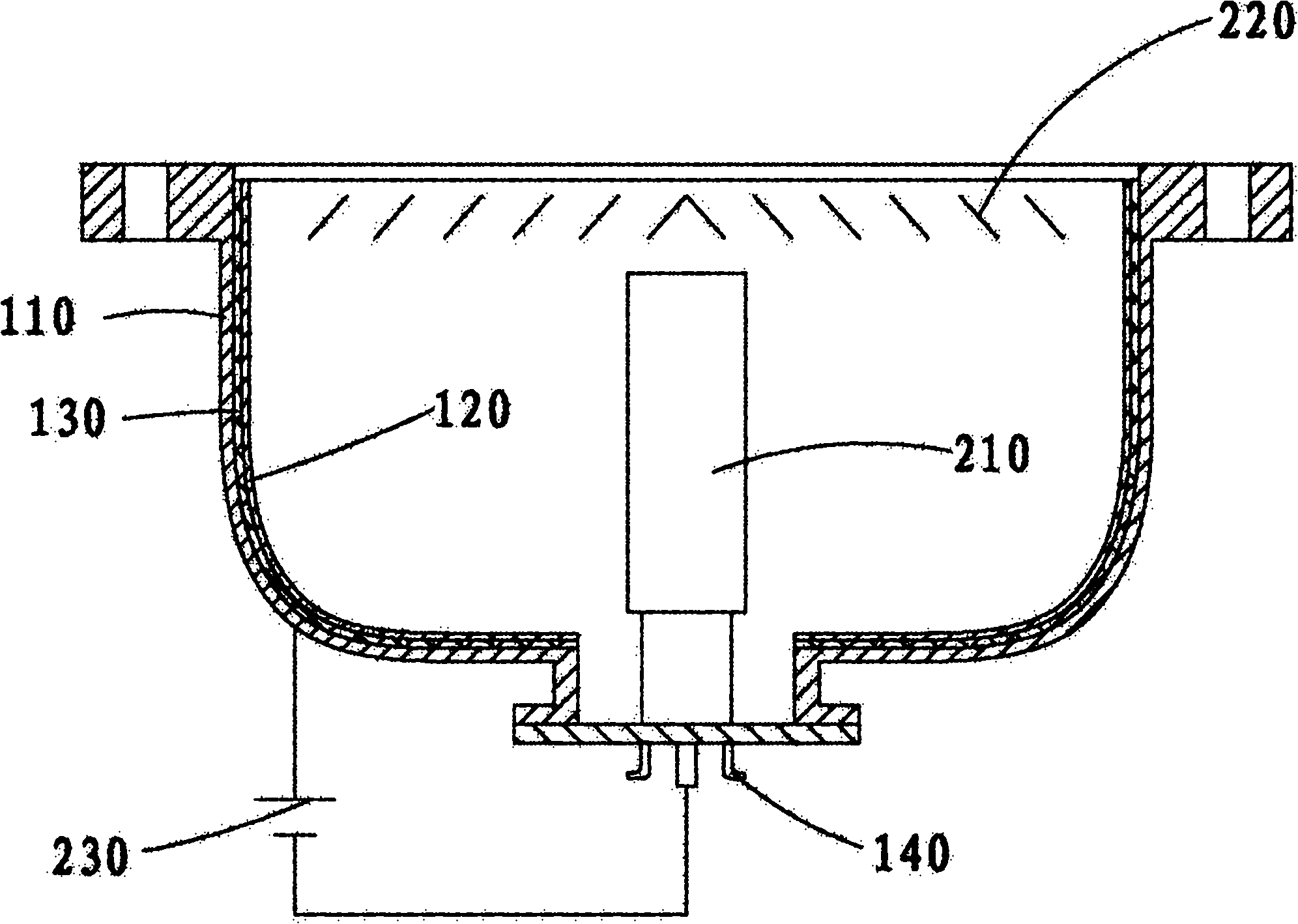

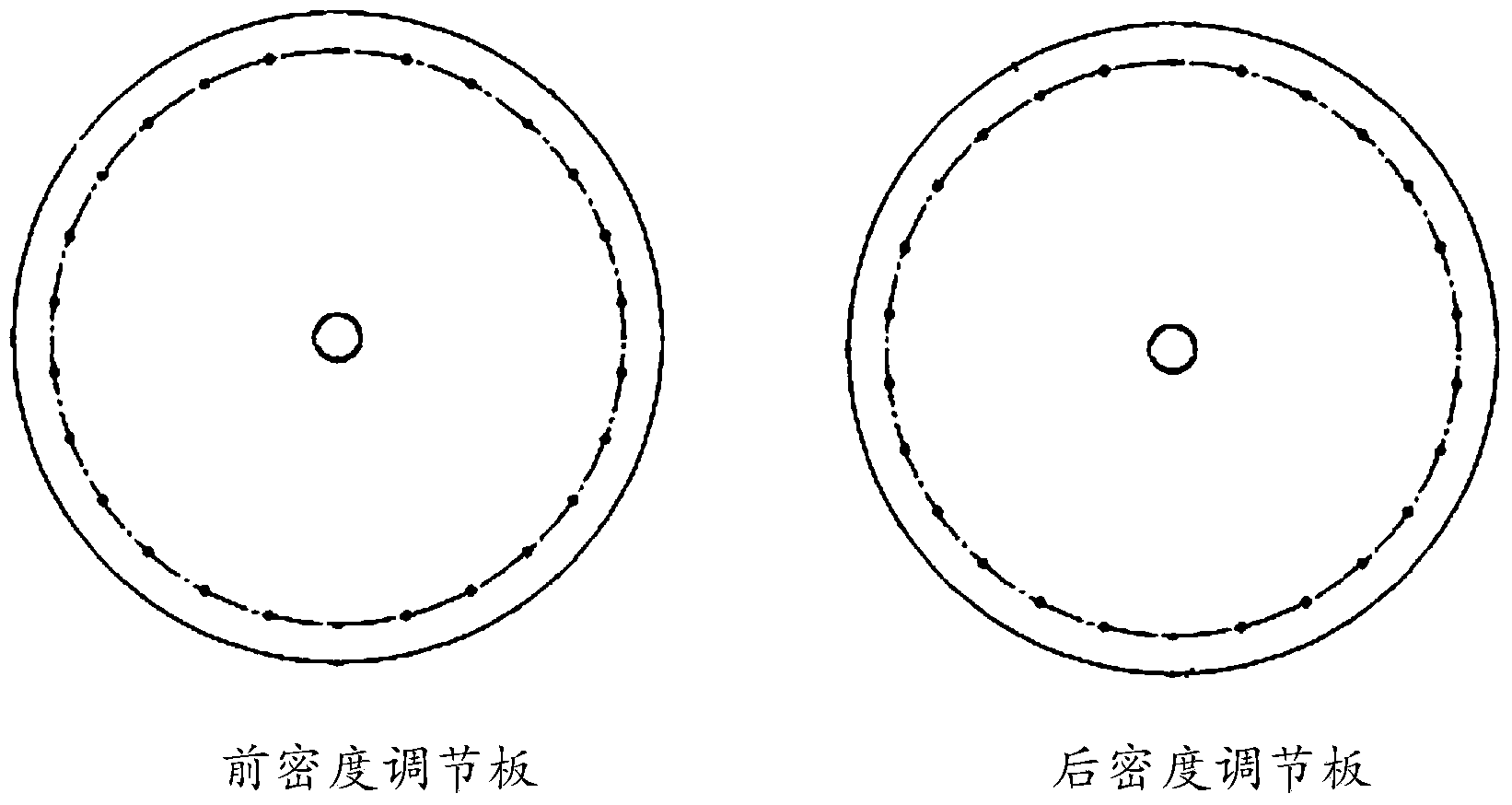

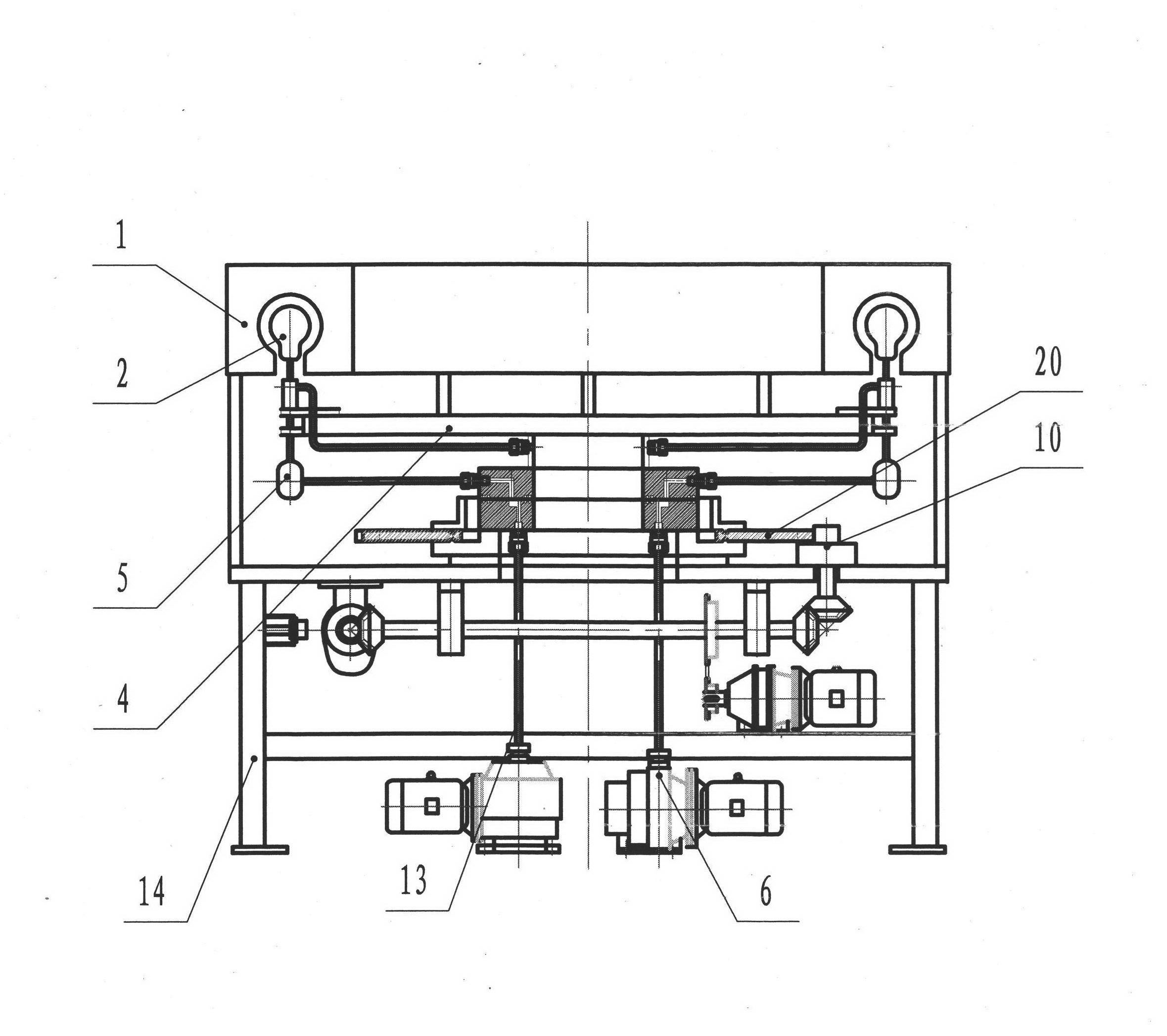

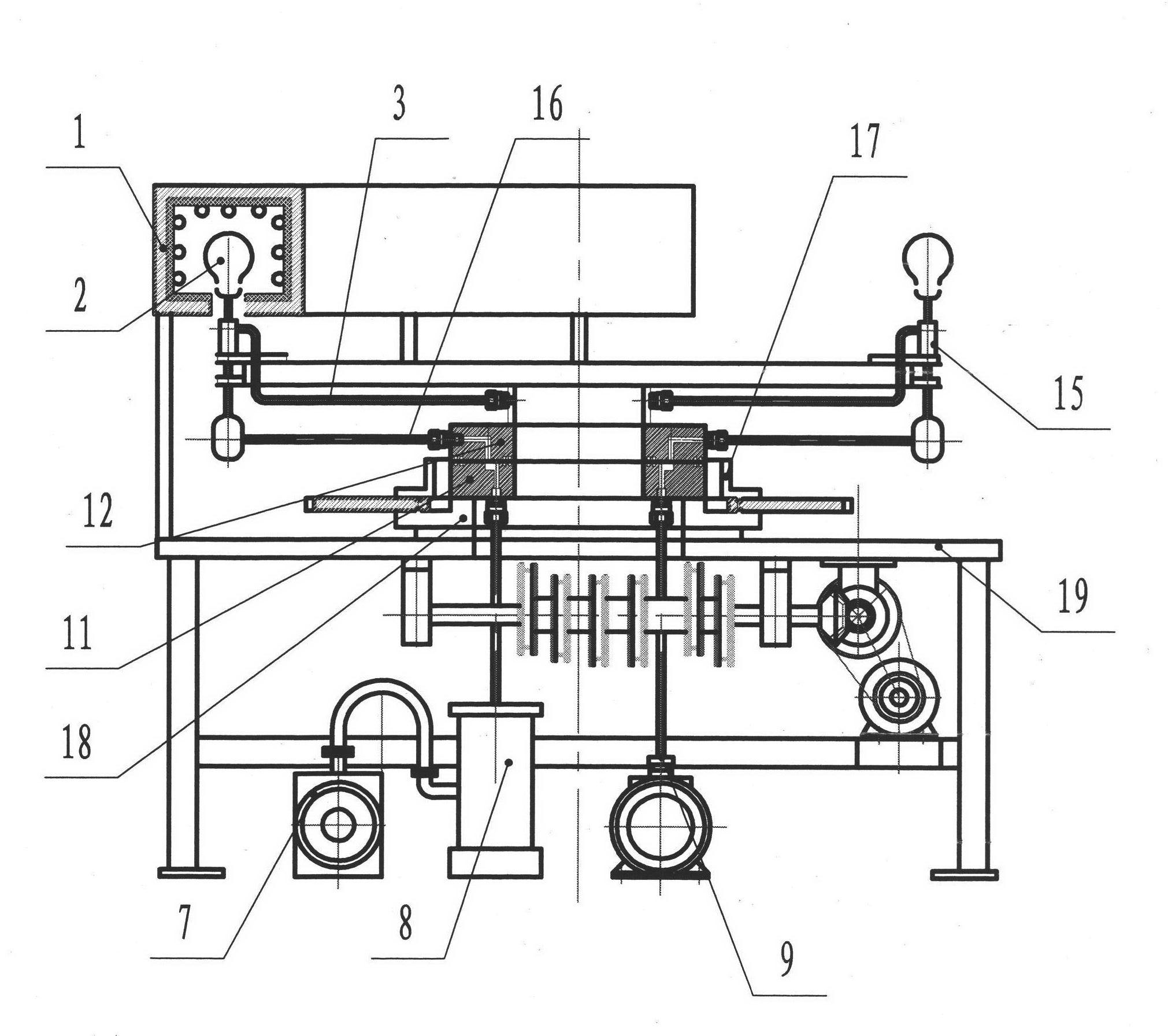

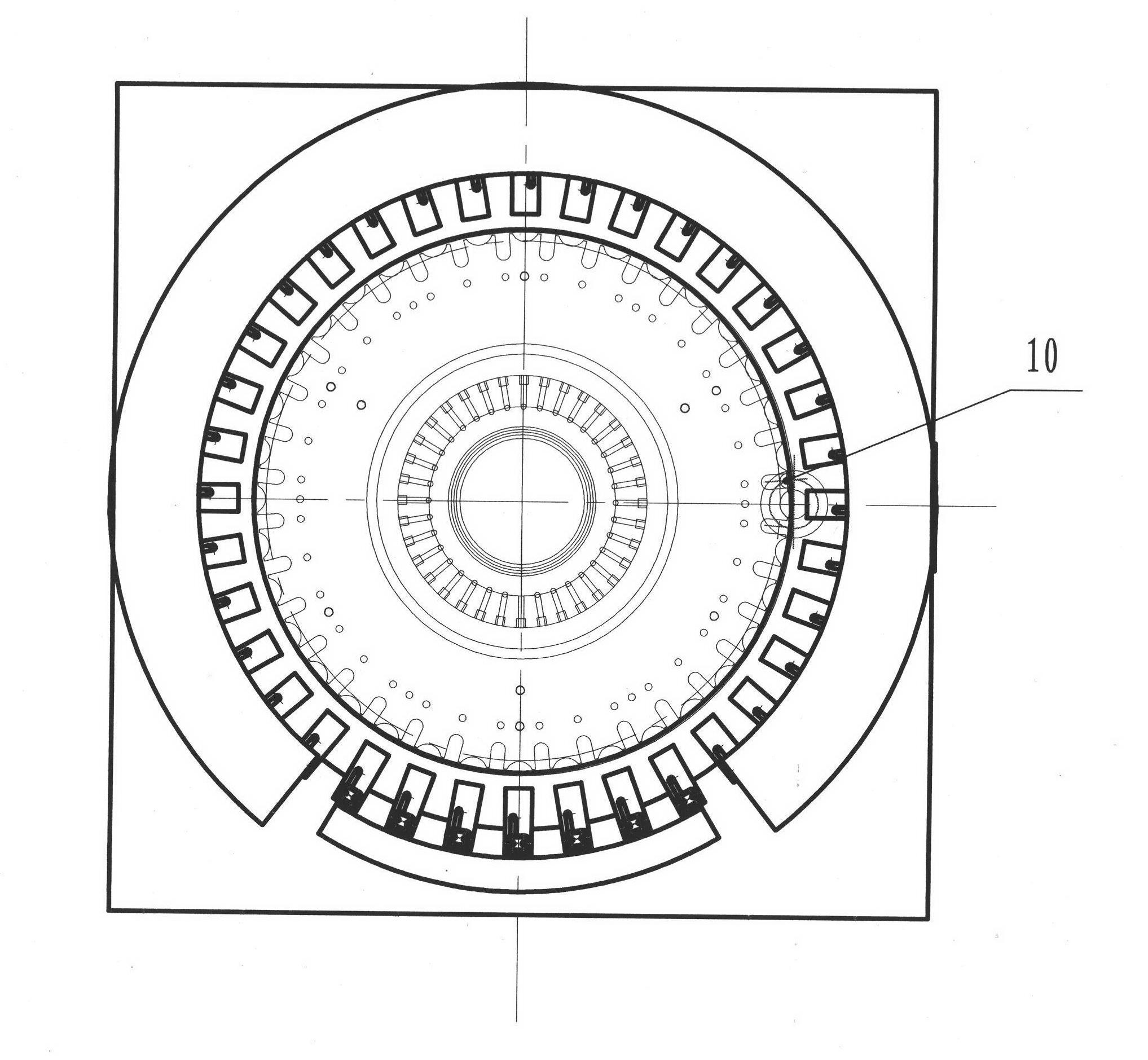

Automatic exhausting machine of electrodeless lamp

InactiveCN102427013AReduce large content spaceImprove degassing effectTube/lamp vessels exhaustionRoughing pumpEngineering

An automatic exhausting machine of an electrodeless lamp comprises: a rack, a center disc installed on the rack, an oven and an air pump. Several automatic sealed devices are uniformly distributed on a circle edge of the center disc. A lower end is connected with a collector. A bottom of the collector is communicated with an air hole in an upper sealed plate body through an air tube. The periphery bottom of the upper sealed plate body is connected with a support. A lower part of the support is connected with a dial position plate. Shifting forks are distributed on a circle of the dial position plate. Pins are arranged on the rack and are matched with the shifting forks. The lower part of the upper sealed plate body is provided with a lower sealed plate body. The air holes, which are matched in the positions, are arranged on a contact surface between the upper sealed plate body and the lower sealed plate body. A gas seal structure is arranged between the upper sealed plate body and the lower sealed plate body. The lower sealed plate body is fixedly installed on a support platform. The air holes of the lower sealed plate body are communicated with a roughing pump, a molecular pump or a diffusion pump, and an argon gas pipe. The molecular pump or the diffusion pump is connected with a fine drawing pump through a pipeline. The machine is high efficient and energy saving. A production speed is fast. The machine has an active role in development of the electrodeless lamp.

Owner:HEBEI XIAOXUANFENG LIGHTING TECH DEV

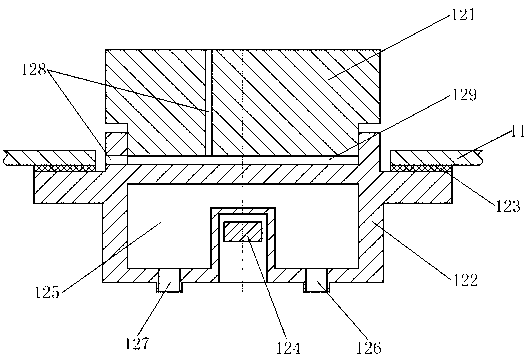

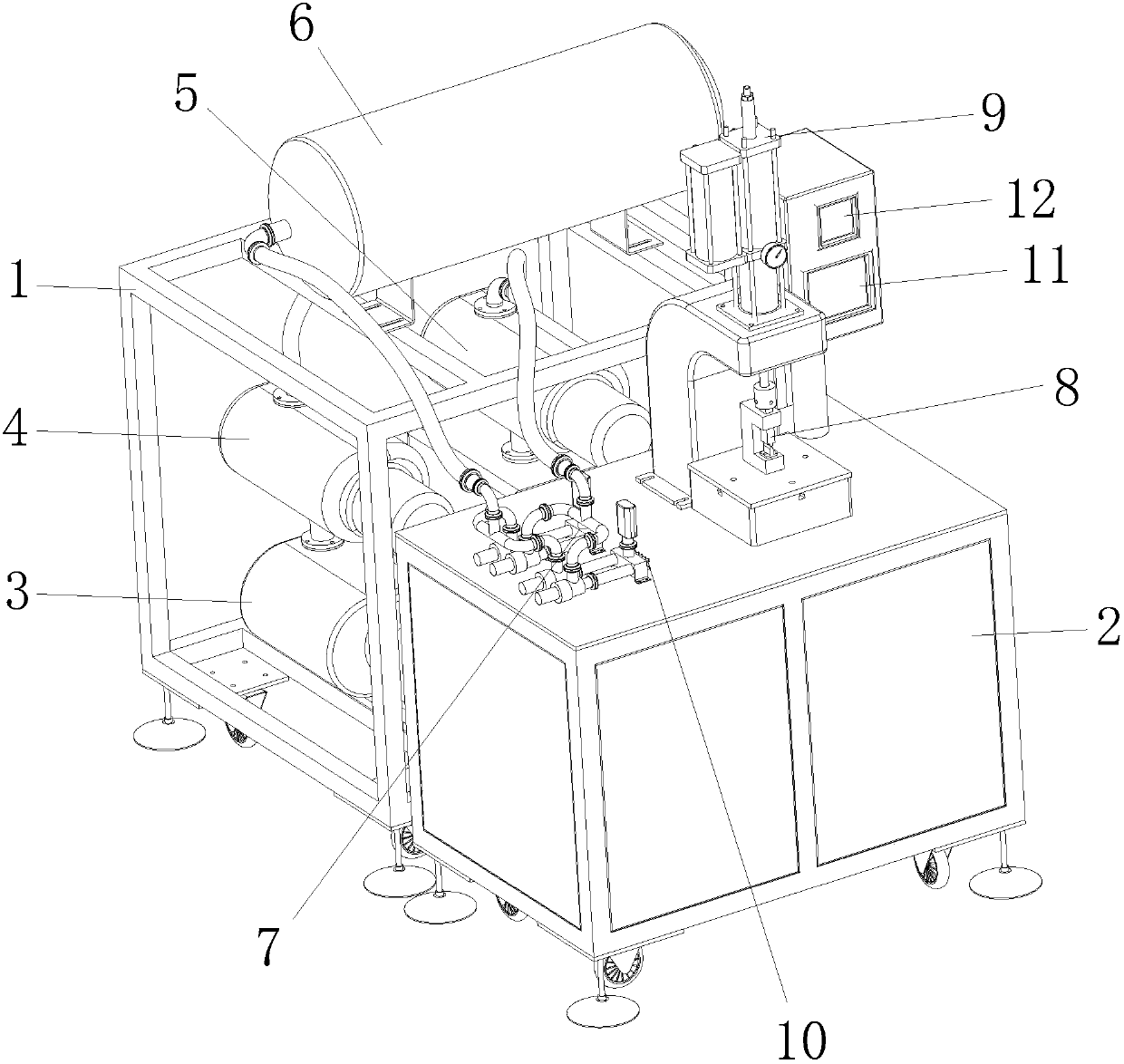

Twenty-four-station vacuum degassing machine

PendingCN107939641AGuaranteed vacuuming effectPump controlPump installationsRoughing pumpMachine control

The invention discloses a twenty-four-station vacuum degassing machine. The twenty-four-station vacuum degassing machine comprises a pumping frame and an equipment console; the pumping frame is mounted at the side end of the equipment console in parallel; a pump before rough vacuumizing, a rough vacuumizing pump and a finish vacuumizing pump are arranged on the inner side of the pumping frame; a vacuum buffer tank is arranged at the upper end of the pumping frame; and the equipment console is provided with a vacuum control valve bank, a riveting module and a gas-liquid pressure table. The twenty-four-station vacuum degassing machine uses a human-computer control screen for controlling and detecting vacuumizing states in the vacuum buffer tank, and uses a vacuum display screen for displaying an internal state; after a vacuum state is reached, the gas-liquid pressure table is controlled to work through the human-computer control screen, and the riveting module is pushed to work; and thepump before rough vacuumizing, the rough vacuumizing pump and the finish vacuumizing pump are totally adopted to perform three grades of vacuumizing, so that the vacuumizing effect is guaranteed.

Owner:东莞市晋旭机电设备有限公司

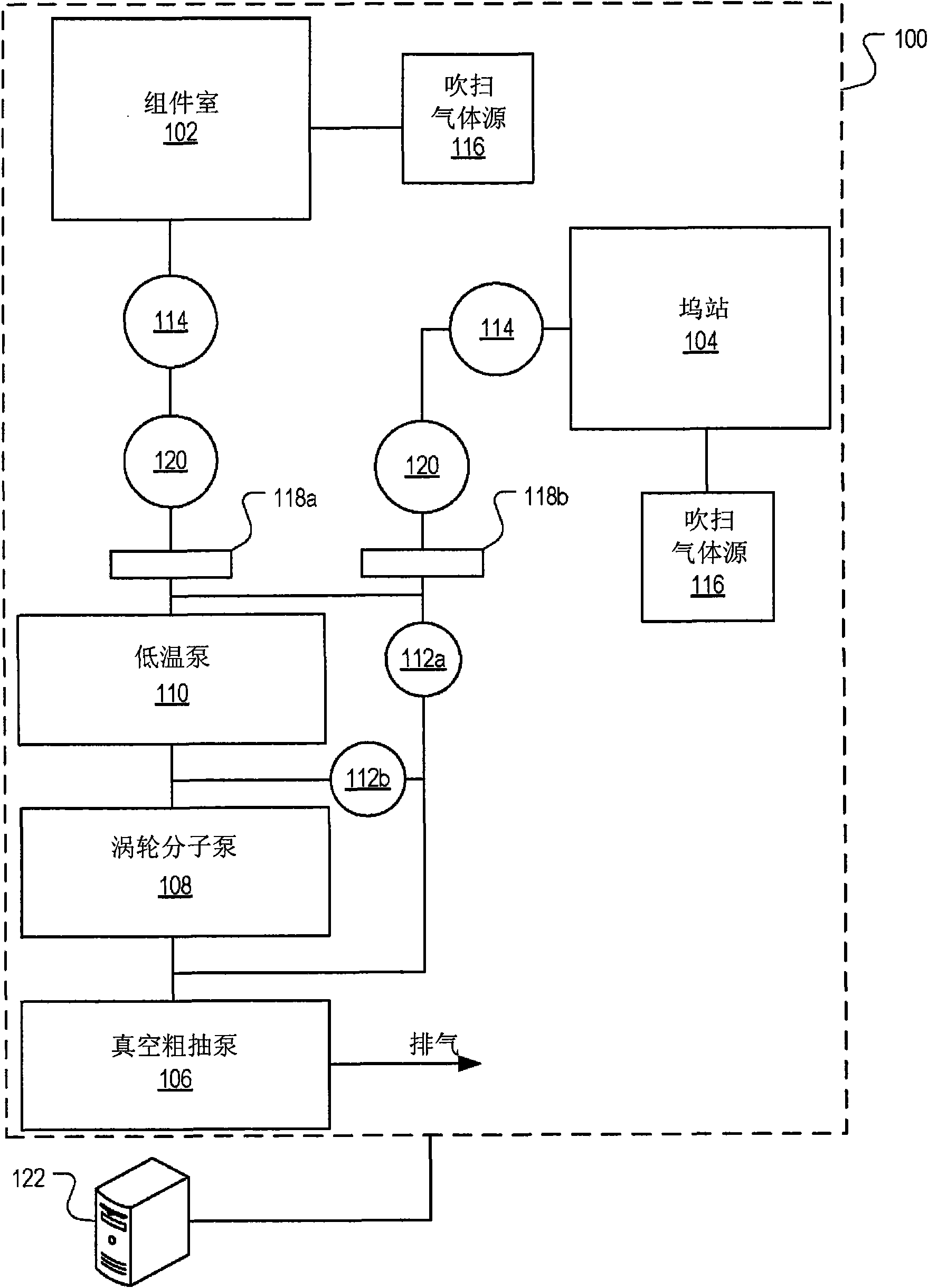

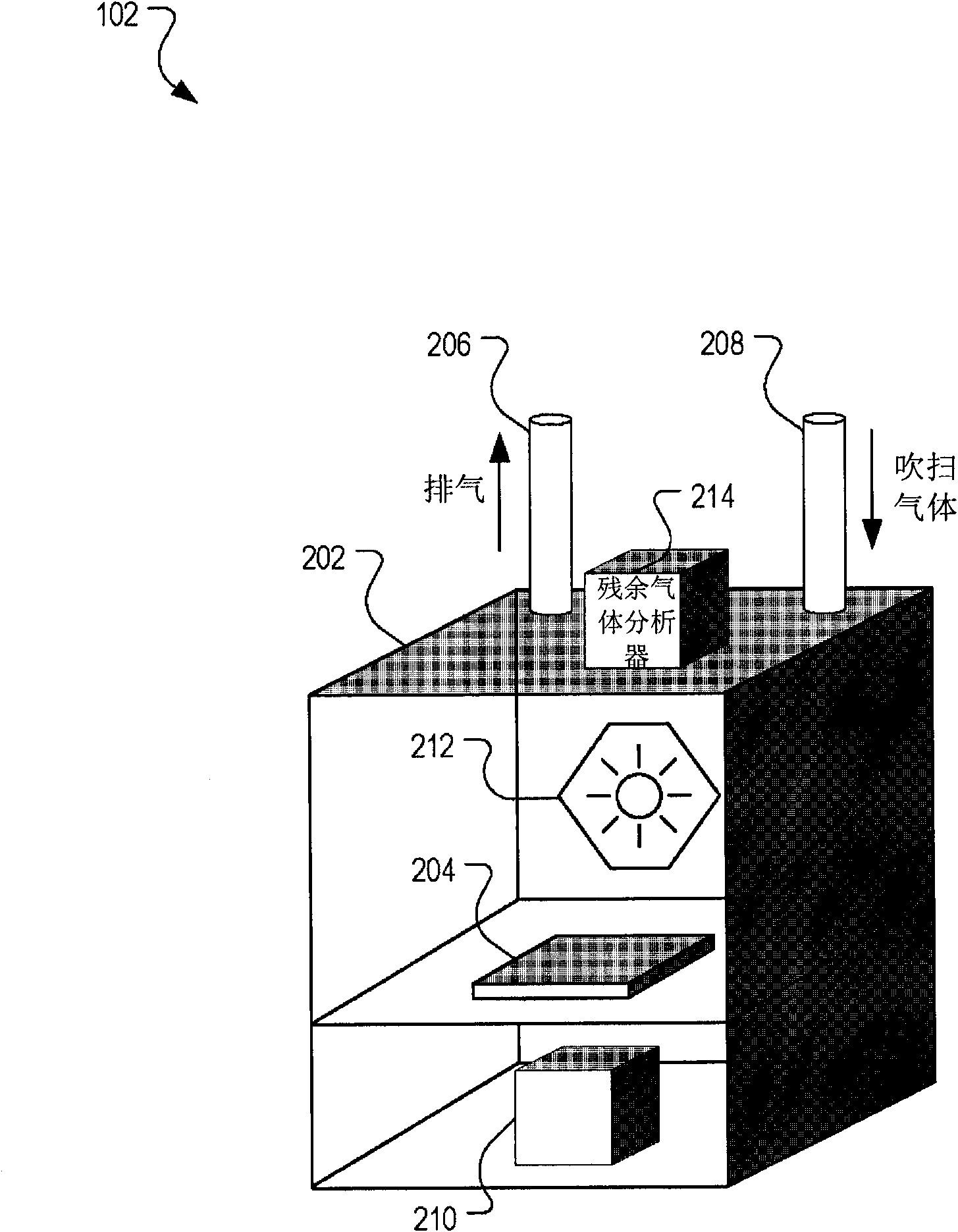

Ex-situ component recovery

InactiveCN101635254AReduce downtimeEasy to troubleshootSemiconductor/solid-state device manufacturingThin material handlingRoughing pumpDocking station

Disclosed herein are devices, methods and systems for ex-situ component recovery. The ex-situ recovery can be performed by desorbing or outgassing components of a processing system in a recovery system, rather than in the processing system itself. The recovery system can include a docking station and / or a heated vacuum chamber. The heated vacuum chamber can be used to desorb or outgas components that will be located inside the processing system, while the docking station can be used to desorb or outgas components that will be connected to the processing system. The processing system components can be placed under pressure by the recovery system to desorb or outgas contaminants and remove virtual leaks. The recovery system pressure can include a vacuum roughing pump, a turbomolecular pump, and / or a cryogenic pump to apply a pressure necessary to desorb or outgas the components.

Owner:ATMEL CORP

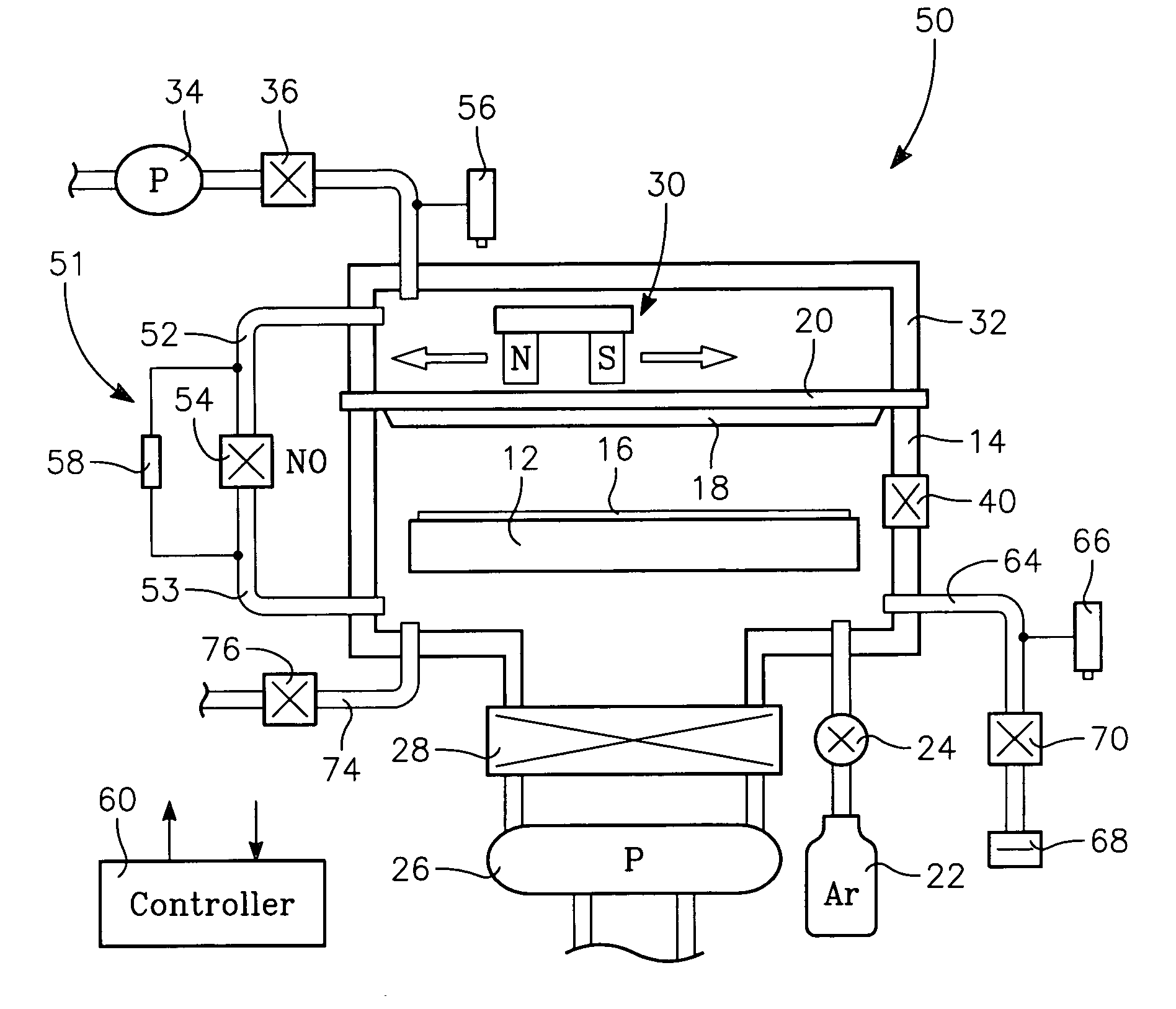

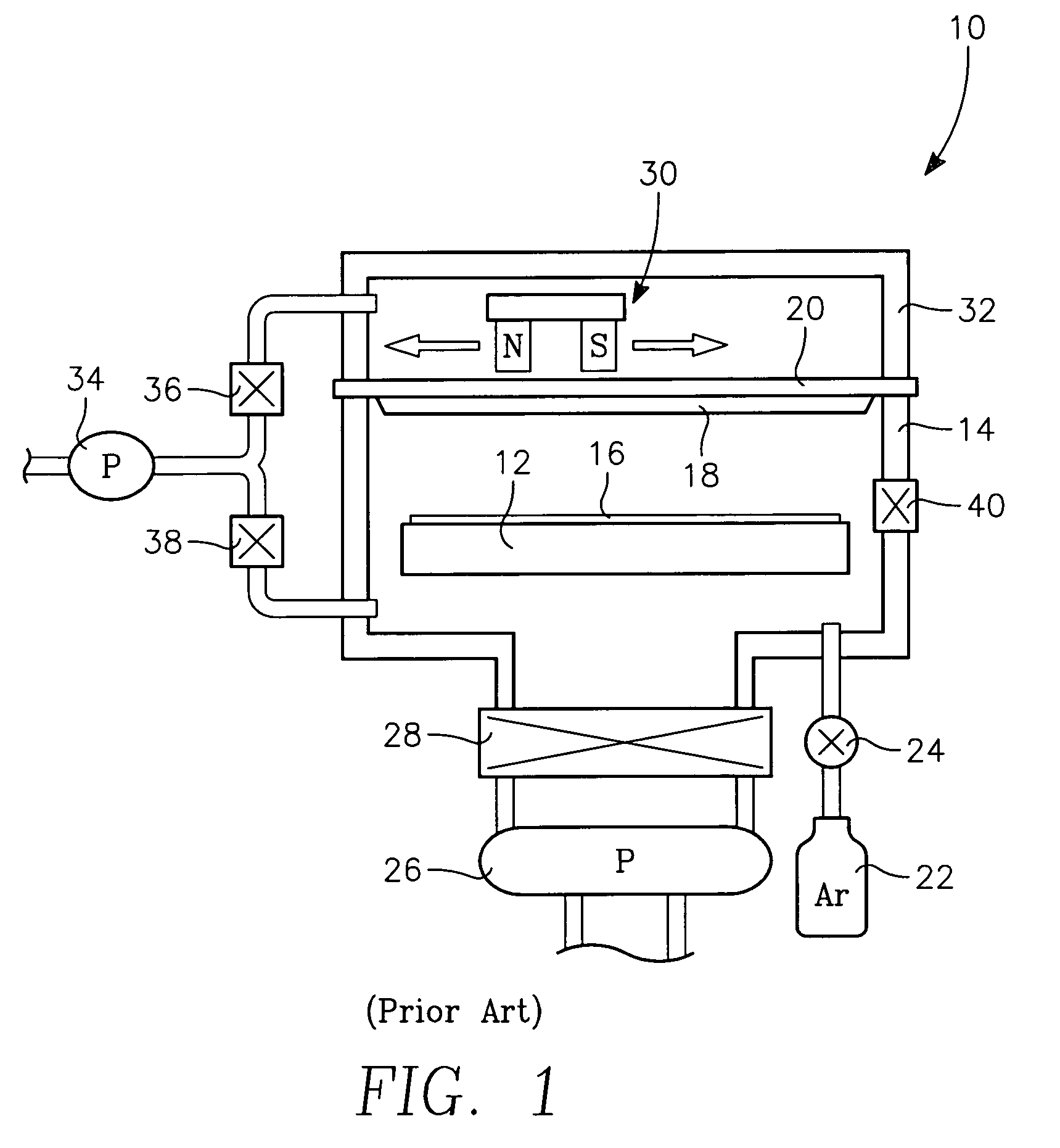

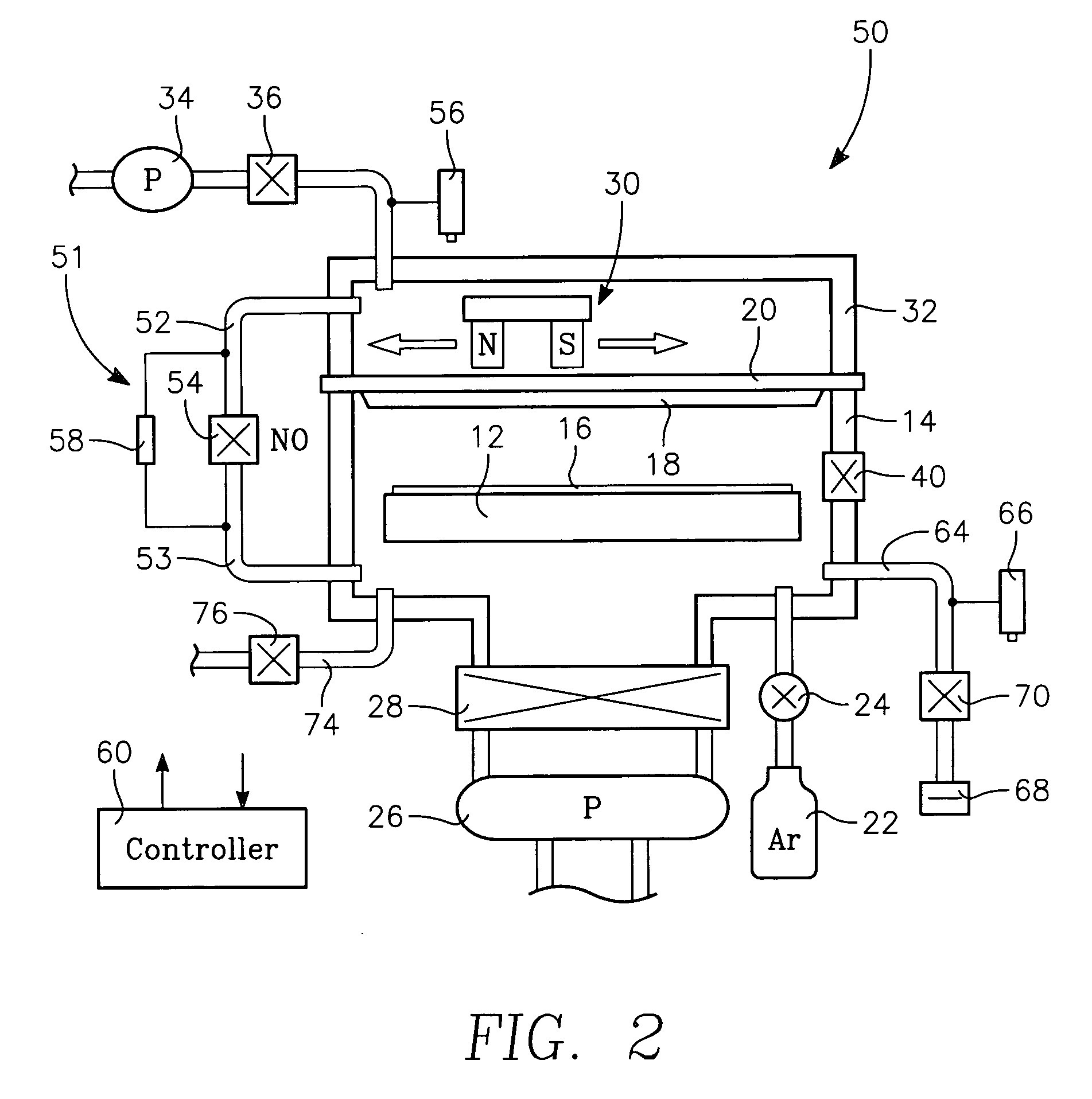

Evacuable magnetron chamber

A vacuum pumping system and method in conjunction with a sputter reactor having a vacuum-pumped magnetron chamber sealed to the target backing plate. A main sputter chamber is vacuum sealed to the target front and cryo pumped. A bypass conduit and valve connect the magnetron and main chambers. A mechanical roughing pump connected to the magnetron chamber pumps the main chamber through the bypass conduit to less than 1 Torr before the bypass valve is closed and the cryo pump is opened and thereafter continues to pump the magnetron chamber to reduce the pressure differential across the target. A pressure differential switch connected across the bypass valve immediately open it whenever the pressure differential exceeds a limit, such as 20 Torr, for example when there is a leak or an electrical failure. The bypass conduit is also used in a venting procedure.

Owner:APPLIED MATERIALS INC

Gas amount measurement device

ActiveUS20090178460A1Accurately grasping characteristicAccurate representationMaterial analysis by electric/magnetic meansMaterial analysis by optical meansRoughing pumpMeasurement device

A gas amount measuring device including a vacuum container, a first pipe, an air release valve being attached to the first pipe, a second pipe, a calibration gas generator being attached to the first pipe, a third pipe, a vacuum gauge, a first valve, a leak valve, a second valve, a turbomolecular pump, a third valve, and a roughing pump being attached to the third pipe in order from a vacuum container side, a first bypass pipe connecting the third pipe between the vacuum container and the first valve to the third pipe between the leak valve and the second valve, a fourth valve being attached to the first bypass pipe, and a second bypass pipe connecting the third pipe between the leak valve and the second valve to the third pipe between the third valve and the roughing pump, a fifth valve being attached to the second bypass pipe.

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP +1

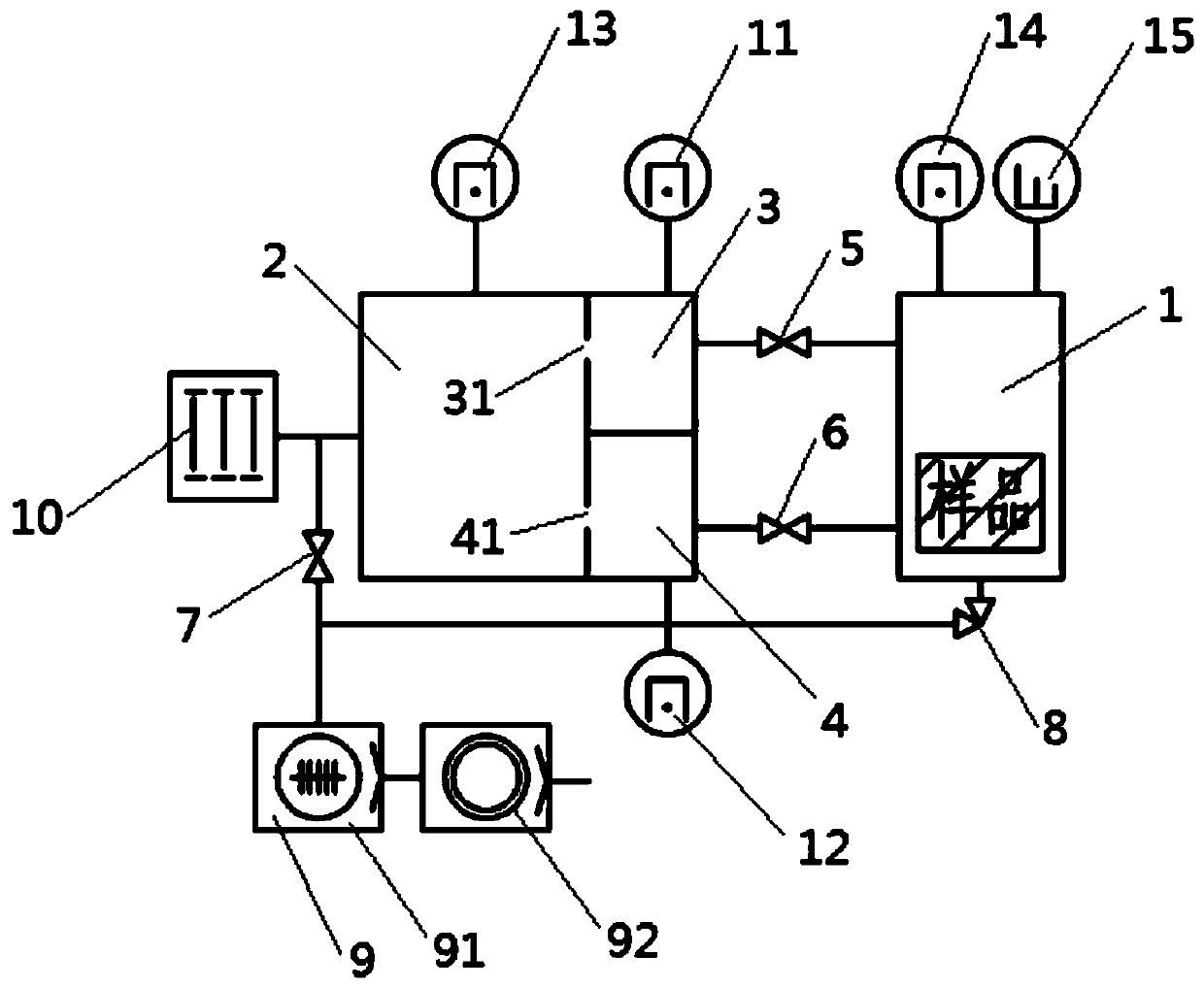

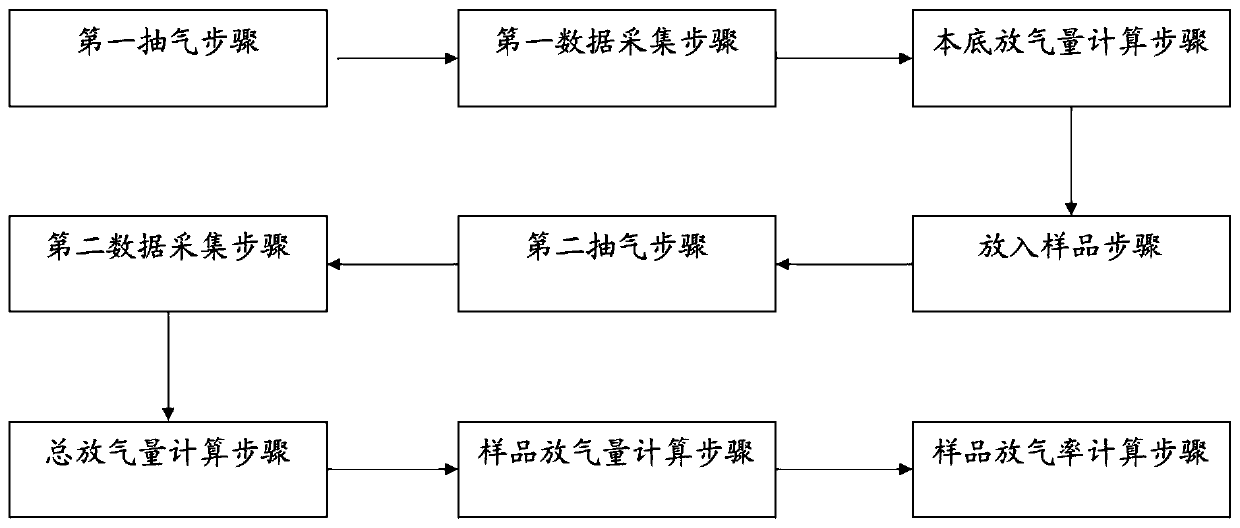

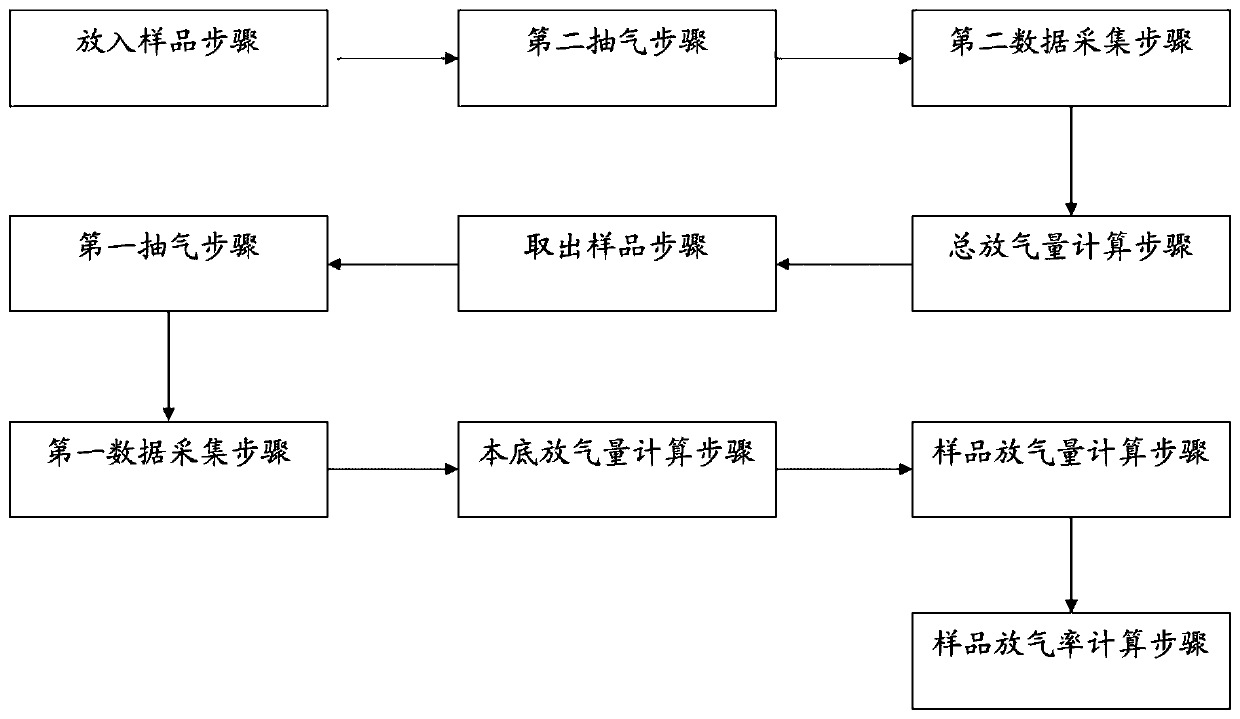

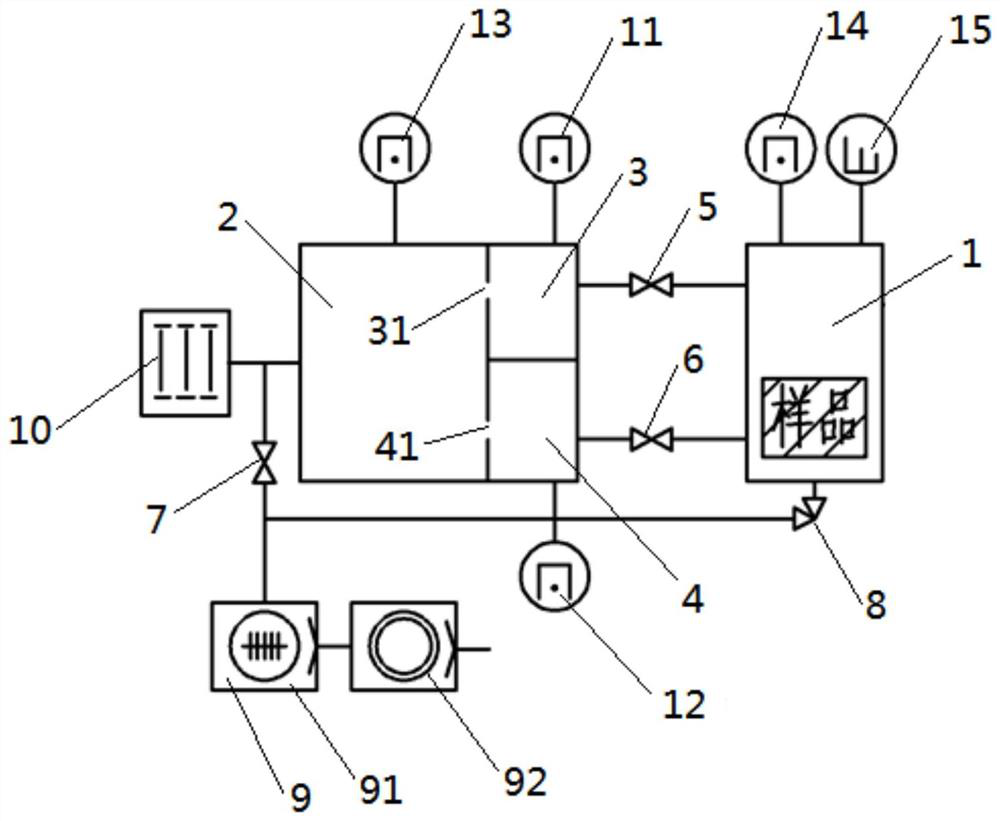

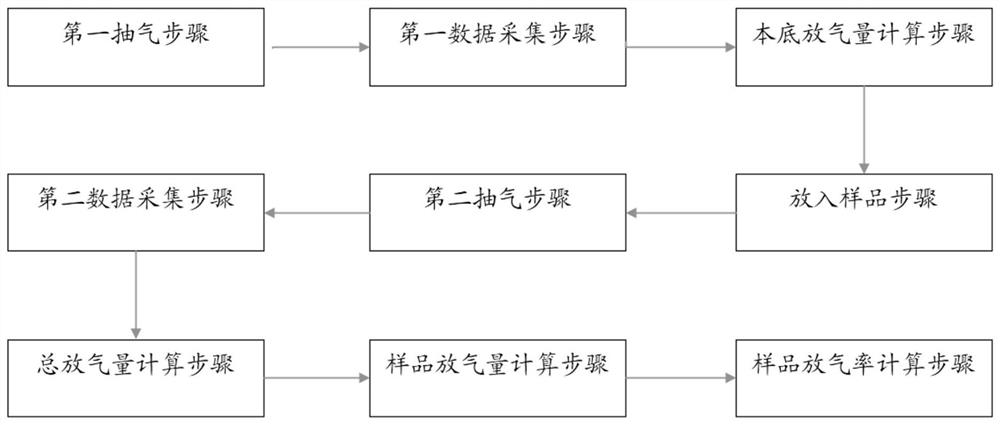

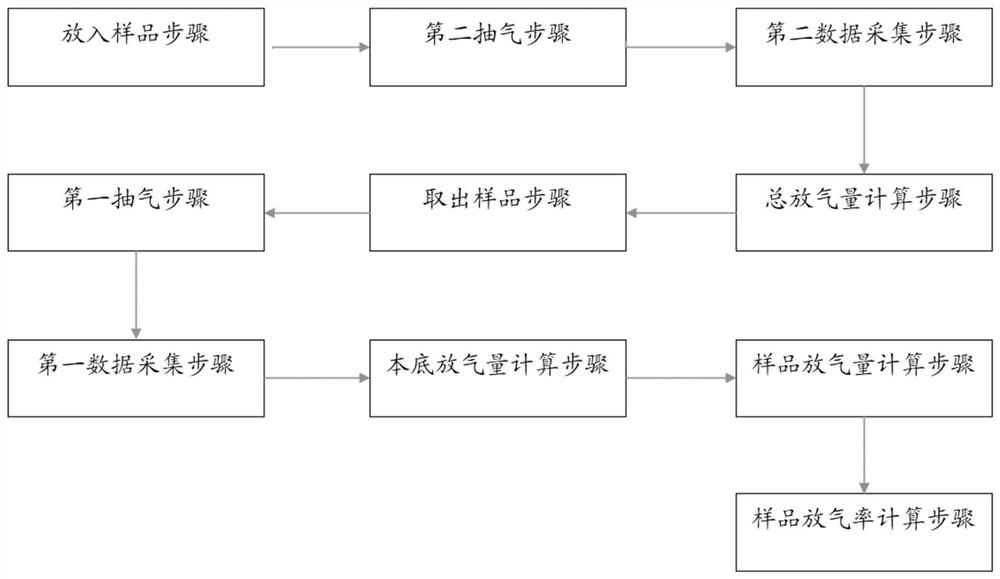

Device and method for measuring material outgassing rate in dual test chambers

ActiveCN110501257AAvoid approximate equalityEliminate errorsMaterial analysisRoughing pumpUltra-high vacuum

The invention discloses a device and a method for measuring the material outgassing rate in dual test chambers. The device comprises a high vacuum chamber, a first test chamber, a first valve, a second test chamber, a second valve, an ultra high vacuum chamber, a roughing pump unit, a precision pump, a first vacuum gauge, a second vacuum gauge and a third vacuum gauge. Due to the addition of the second vacuum gauge, when the first valve or the second valve is opened, the pressure in the first test chamber and the second test chamber can be measured at the same time. Time-induced errors are eliminated. The mechanical action of changing a gas circuit during actual measurement is not needed, which avoids the disturbance of the valve switching on vacuum readings, and improves the measurement efficiency.

Owner:CHINA SPALLATION NEUTRON SOURCE SCI CENT +1

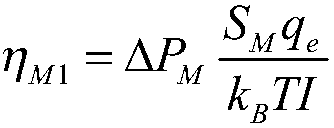

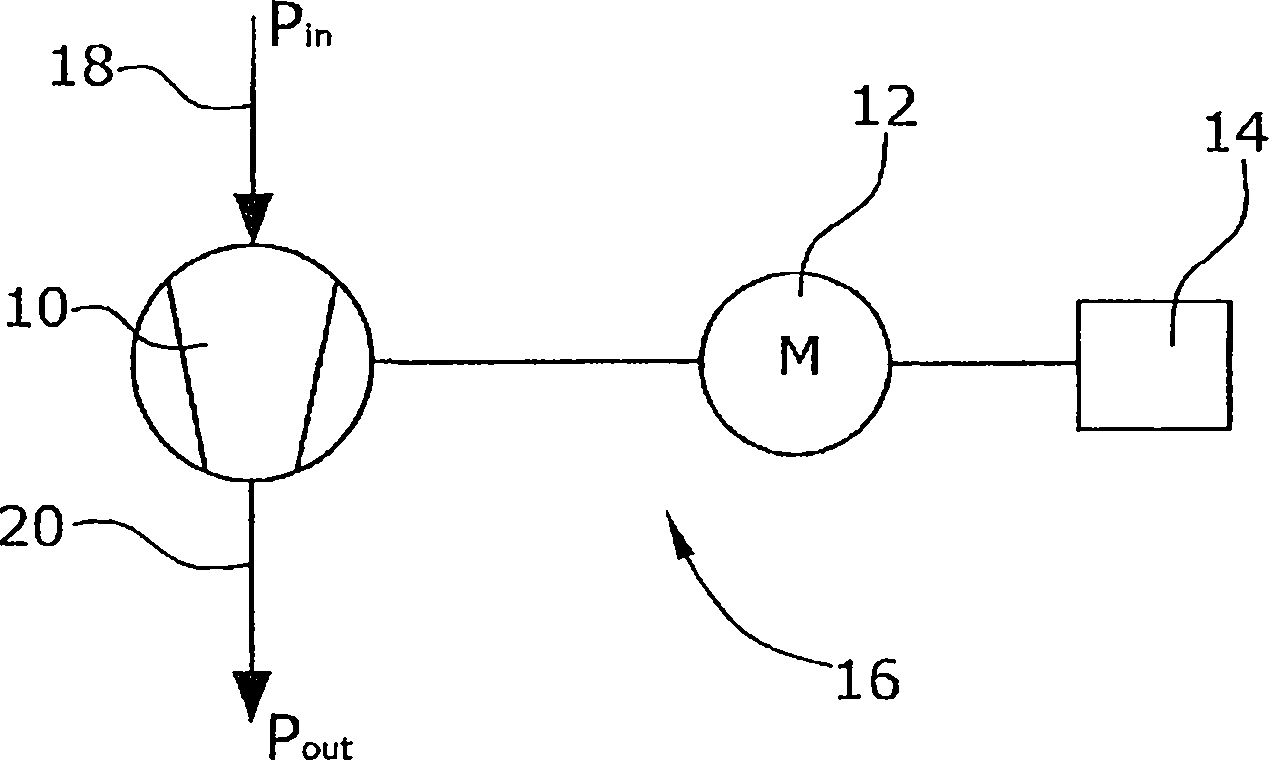

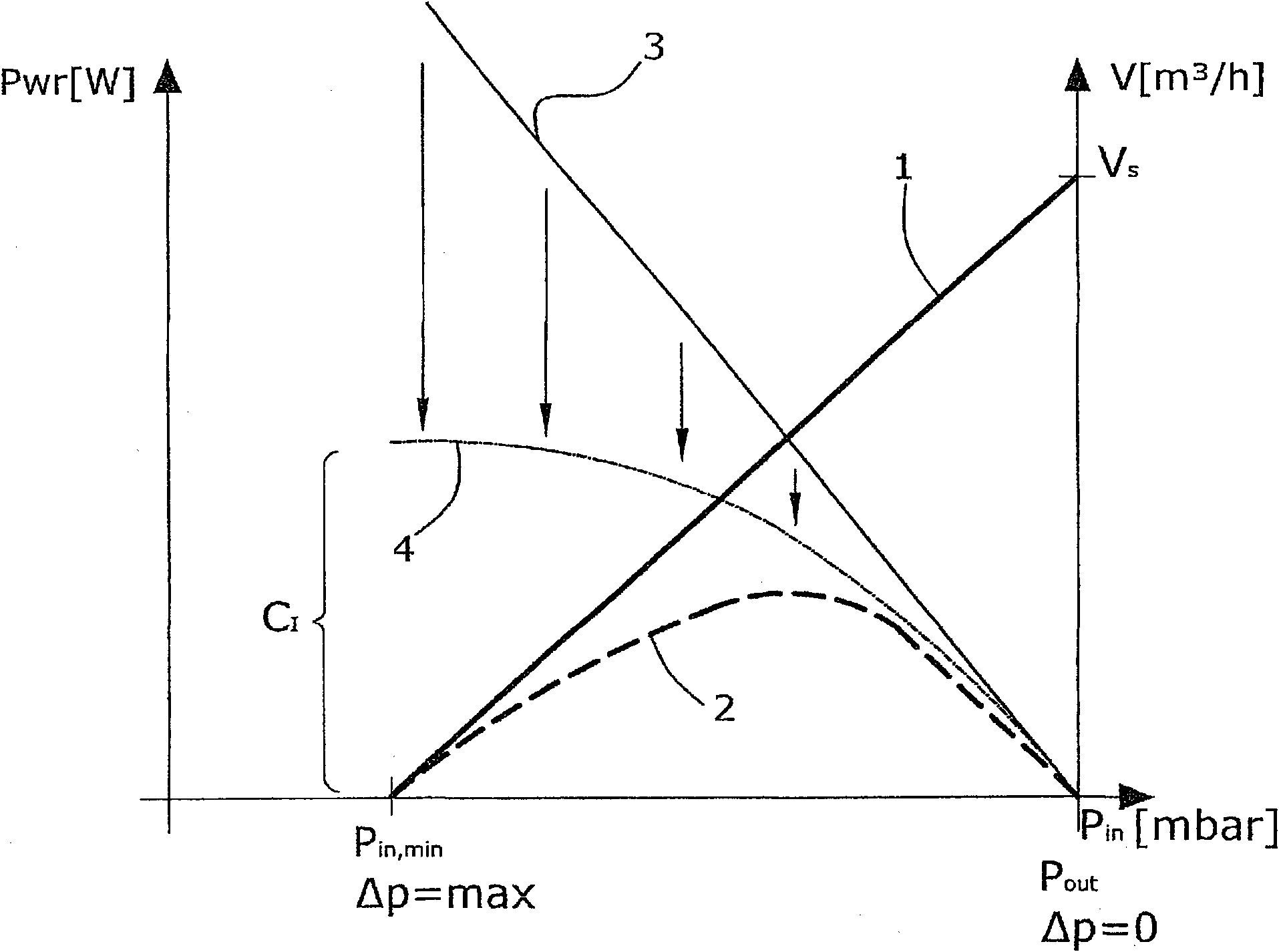

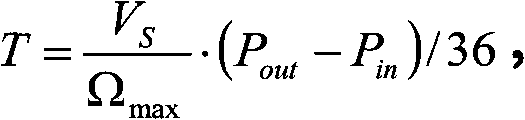

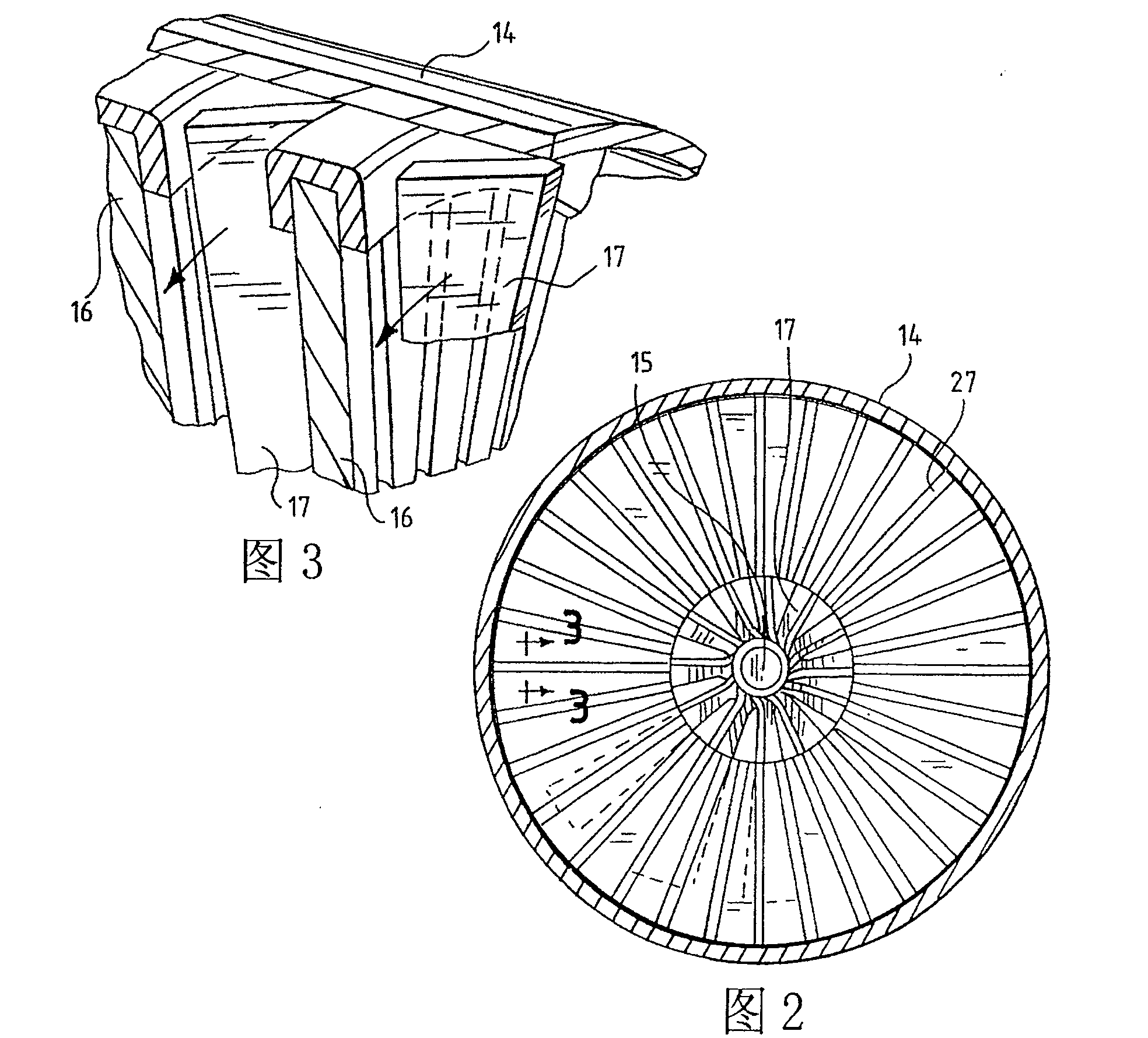

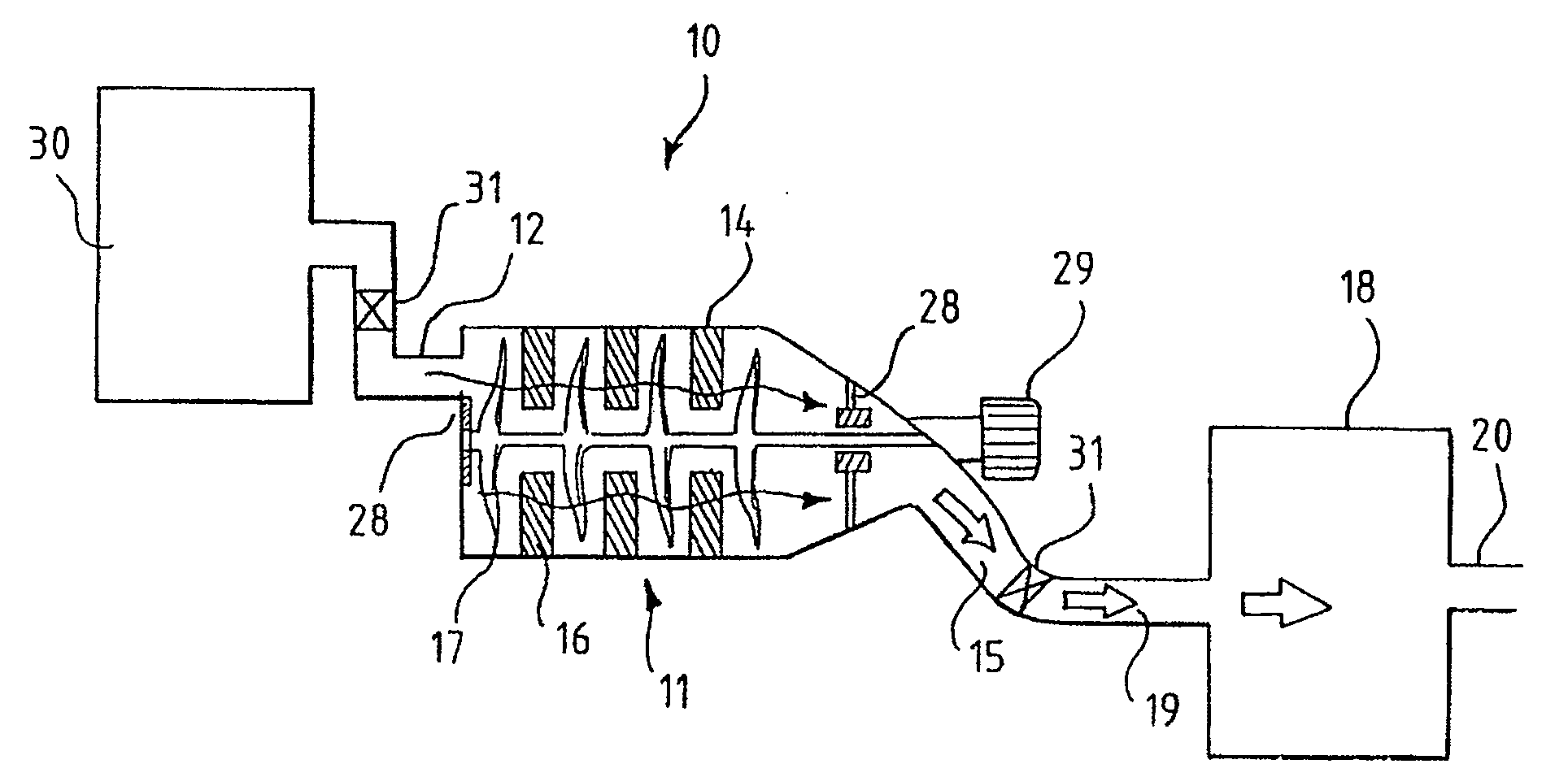

Roughing pump method for a positive displacement pump

InactiveCN102395792BSimple and energy-efficient roughing methodPump componentsRotary piston pumpsRoughing pumpDifferential pressure

In order to provide a simple and energy-efficient rough pumping method for a displacement pump (10), intended to generate a maximum differential pressure (ΔPmax) between the inlet (18) and the outlet (20) of the displacement pump (10), the rotational speed (Ω) of the displacement pump (10) is adjusted such that the maximum differential pressure (ΔPmax) to be generated that the power input (3, 4) of the displacement pump (10) approximates the minimum power (2) physically required for compressing the gas in order to establish the maximum differential pressure (ΔPmax).

Owner:OERLIKON LEYBOLD VACUUM

Device and method for measuring outgassing rate of materials with double test chambers

The application discloses a device and method for measuring the outgassing rate of a material with a double test chamber, the device includes a high vacuum chamber, a first test chamber, a first valve, a second test chamber, a second valve, an ultra-high vacuum chamber, a rough Pumping unit, fine pump, first vacuum gauge, second vacuum gauge and third vacuum gauge. Due to the addition of the second vacuum gauge, when the first valve or the second valve is opened, the pressure in the first test chamber and the second test chamber can be measured at the same time, which eliminates the error caused by time and does not need to be converted during the actual measurement process The mechanical action of the gas circuit not only avoids the disturbance of the vacuum reading due to the opening and closing of the valve, but also improves the measurement efficiency.

Owner:CHINA SPALLATION NEUTRON SOURCE SCI CENT +1

Multifunctional vacuum pump testing cover

ActiveCN111365219AGuaranteed stabilityGuaranteed accuracyPump testingPositive-displacement liquid enginesRoughing pumpAir pump

The invention relates to the field of vacuum pump testing, in particular to a multifunctional vacuum pump testing cover comprising a shell, a water cooling pipe, a heating wire and a reflecting cover;the water cooling pipe is arranged outside the shell, the reflecting cover and the heating wire are arranged inside the shell, an openable first sealing cover is arranged at one end of the shell, andthe other end of the shell is closed and is provided with a to-be-tested pump port; and the shell is provided with an air inlet, a temperature measuring port, a pressure measuring port, a PIV observation port and a plurality of air pumping ports, wherein the air pumping ports comprise a main air pumping port connected with a main pump and a rough pumping port connected with a rough pumping pump.The multifunctional vacuum pump testing cover integrates a series of functions of heating, cooling, air exhaust, air intake, pressure measurement, temperature measurement and PIV observation and can enable the gas environment in the vacuum pump testing cover to meet the requirement for the performance test of the vacuum pump; and simultaneously, the stability and the accuracy of the test result are improved.

Owner:NORTHEASTERN UNIV +1

Ultra-high speed vacuum pump system with first stage turbofan and second stage turbomolecular pump

InactiveCN100590318CSpeed up the flowGuaranteed uptimePump componentsAxial flow pumpsRoughing pumpUltra high speed

An ultra-high speed vacuum pump evacuation system includes a first stage ultra-high speed turbofan and a second stage conventional turbomolecular pump. The turbofan is either connected in series to achamber to be evacuated, or is optionally disposed entirely within the chamber. The turbofan employs large diameter rotor blades operating at high linear blade velocity to impart an ultra-high pumpingspeed to a fluid. The second stage turbomolecular pump is fluidly connected downstream from the first stage turbofan. In operation, the first stage turbofan operates in a pre-existing vacuum, with the fluid asserting only small axial forces upon the rotor blades. The turbofan imparts a velocity to fluid particles towards an outlet at a high volume rate, but moderate compression ratio. The secondstage conventional turbomolecular pump then compresses the fluid to pressures for evacuation by a roughing pump.

Owner:FERMI RESEARCH ALLIANCE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com