Patents

Literature

71 results about "Ion pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An ion pump (also referred to as a sputter ion pump) is a type of vacuum pump which operates by sputtering a metal getter. Under ideal conditions, ion pumps are capable of reaching pressures as low as 10⁻¹¹ mbar. An ion pump first ionizes gas within the vessel it is attached to and employs a strong electrical potential, typically 3–7 kV, which accelerates the ions to into the a solid electrode. Small bits of the electrode are sputtered into the chamber. Gasses are trapped by a combination of chemical reactions with the surface of the highly-reactive sputtered material, and being physically trapped underneath that material.

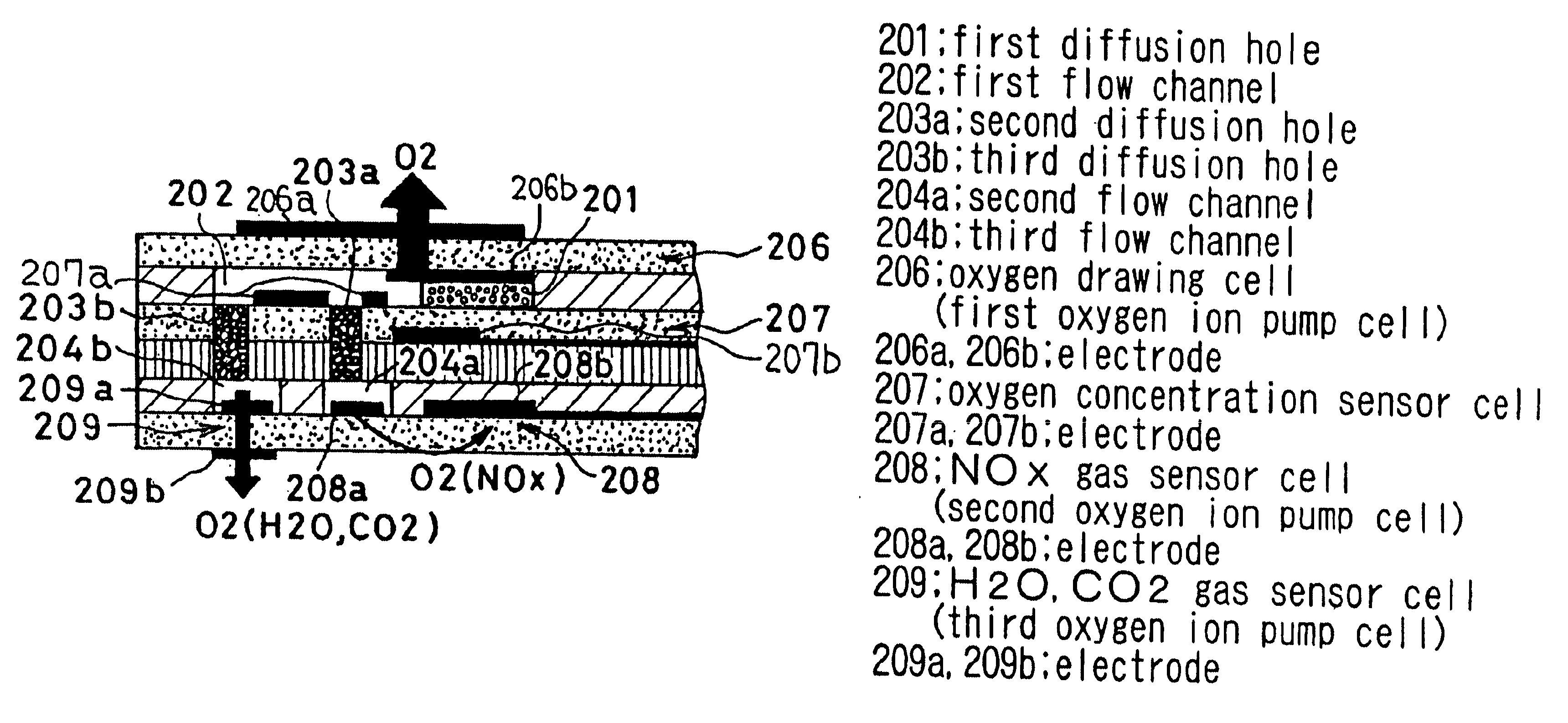

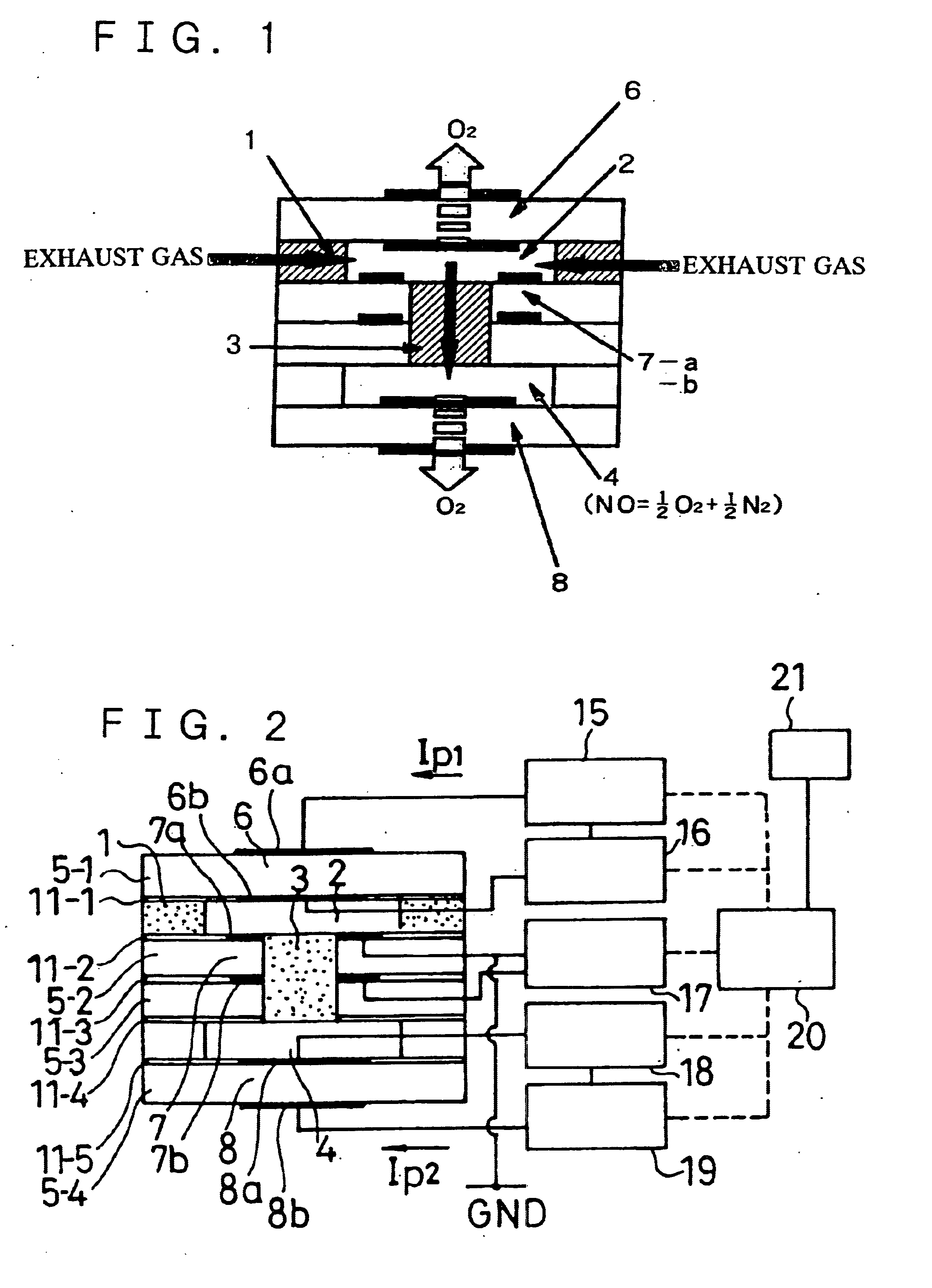

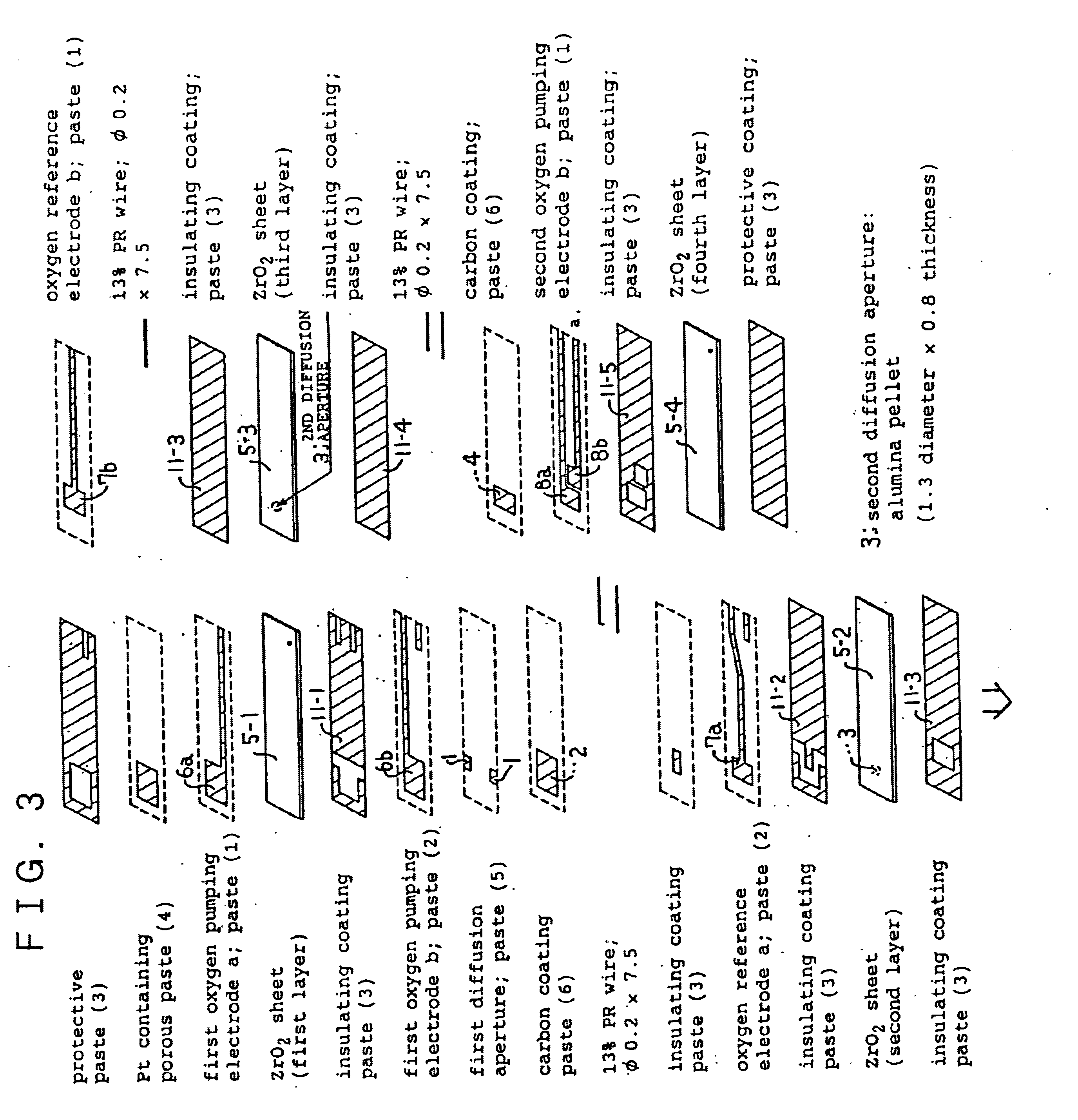

Method and apparatus for measuring NOx gas concentration

InactiveUS6695964B1Accurate measurementAvoid dissociationWeather/light/corrosion resistanceVolume/mass flow measurementDiffusion resistanceOxygen ions

Method and sensor for measuring accurate measurement of NOx concentration in an exhaust gas containing O2,H2O, CO2 and NOx and a NOx gas concentration sensor. A first oxygen pump cell sufficiently pumps out oxygen in a measurement gas such as not to decompose NOx. A pair of electrodes is provided on an inner side and an outer side of a second measurement chamber into which the gas is introduced from a first measurement chamber via a diffusion resistance. A voltage is impressed across the paired electrodes for decomposing NOx in the second measurement chamber to dissociate oxygen which causes the current to flow in a second oxygen ion pump cell. The NOx gas concentration is measured for this current. The voltage impressed across the paired electrodes of the second oxygen ion pump cell is set so as not to dissociate H2O and CO2 present in the second measurement chamber.

Owner:NGK SPARK PLUG CO LTD

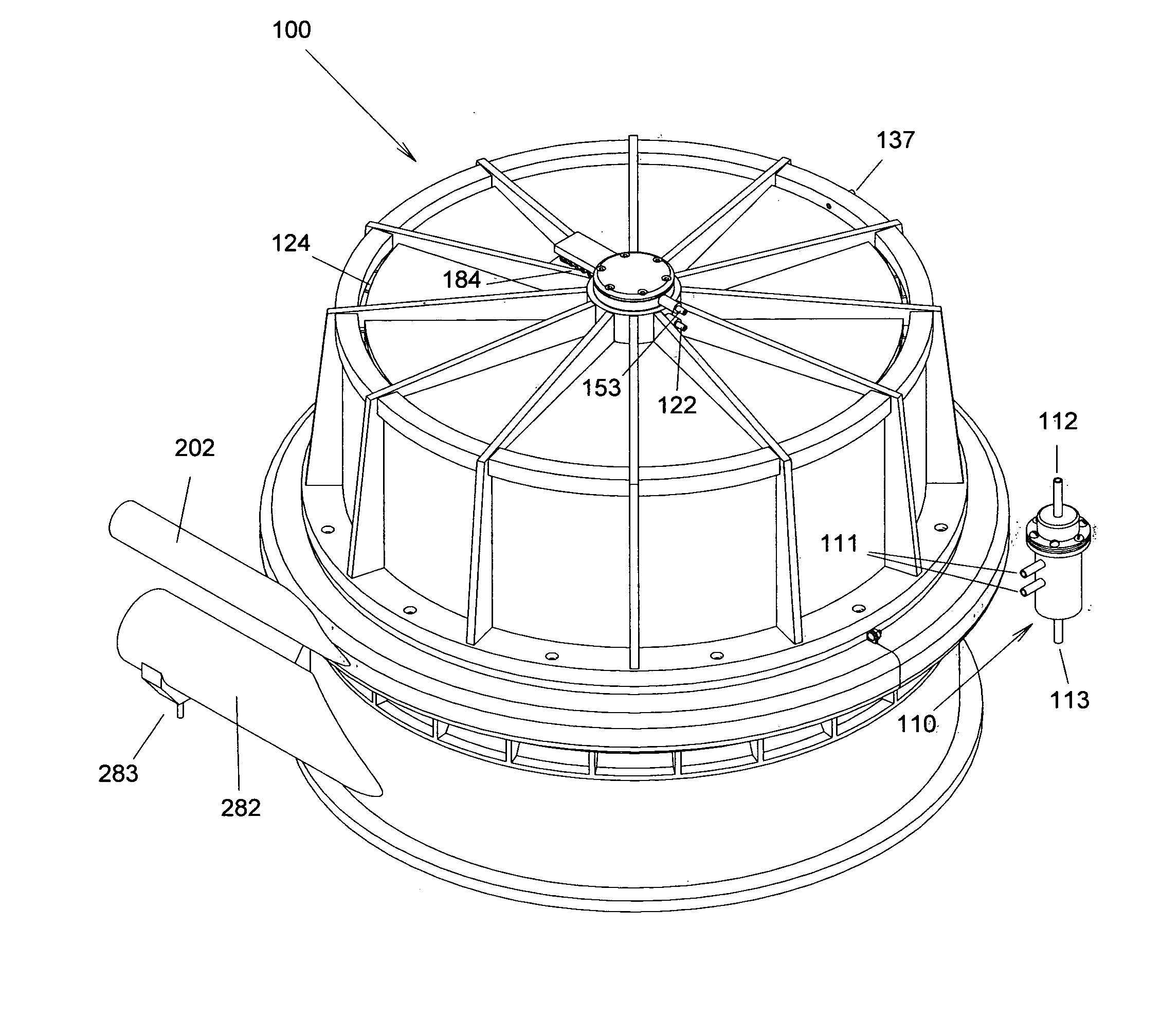

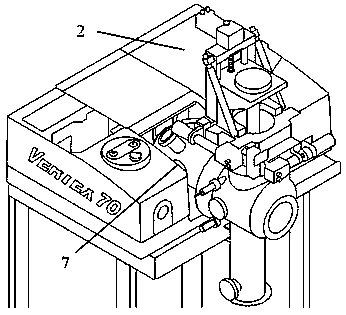

Ion pump and an electrochemical engine using same

InactiveUS20090038315A1Increases activity of ion pumpHigh activitySludge treatmentVolume/mass flow measurementElectrochemistryUltrasonic generator

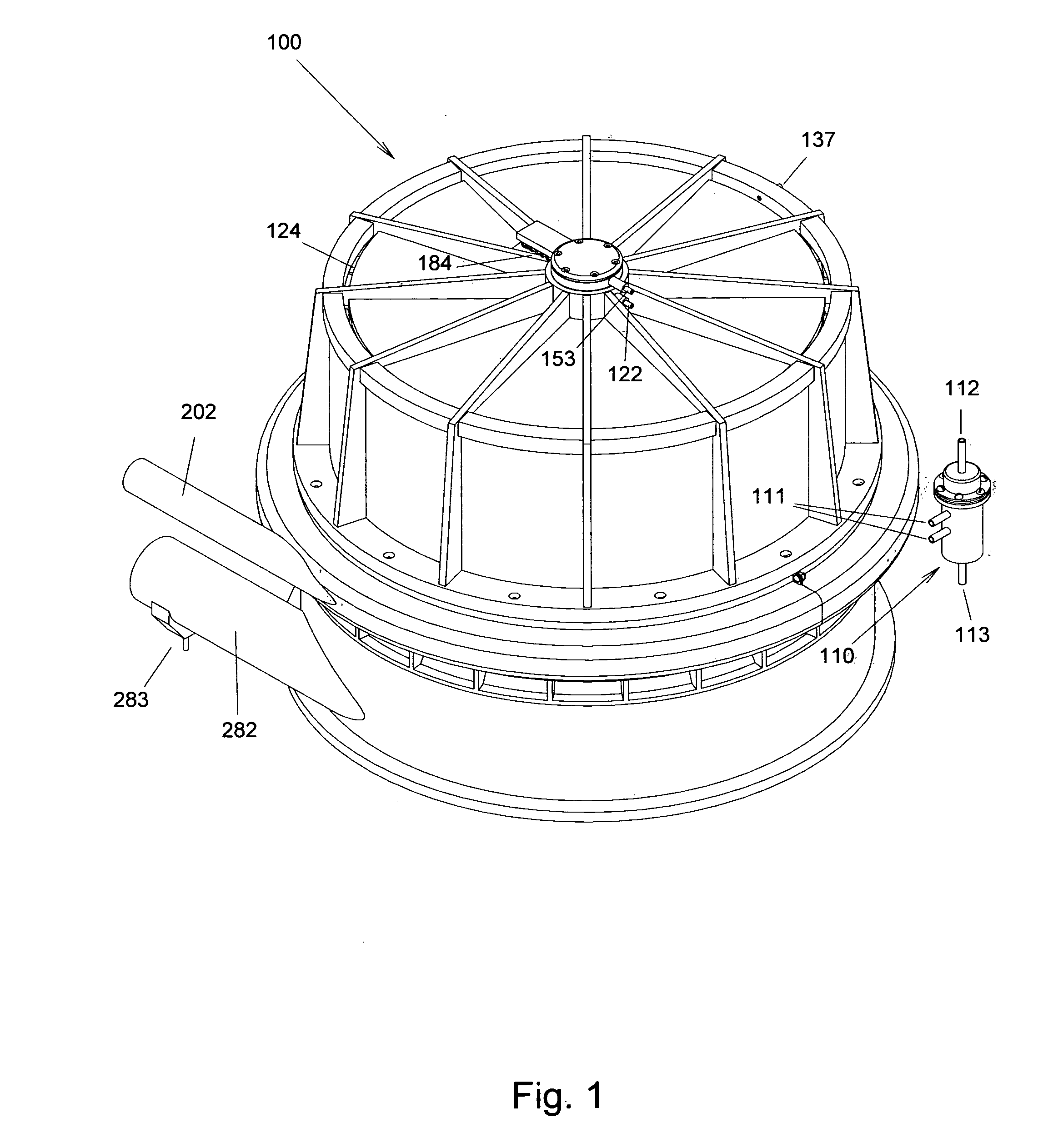

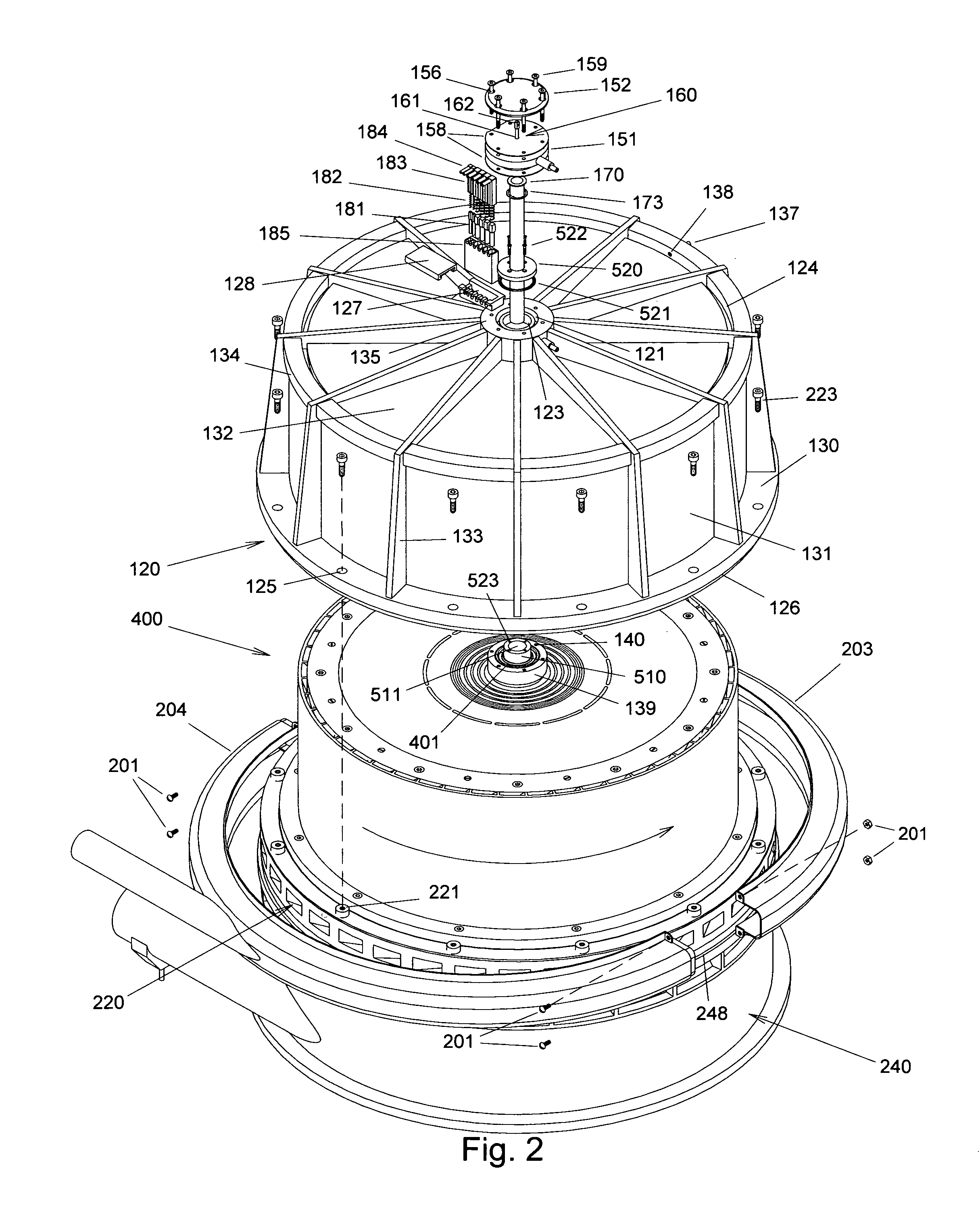

An ion pump that generates a stream of unbalanced aqueous anions that transit from a cathode surface to a region adjacent to an anode surface. The ion pump works in conjunction with an ultrasound generator that produces standing waves having the intensity to dehydrogenate liquid hydrocarbons at the catalytic anode surface. Current density of the ion pump and frequency of the ultrasound transducer are synchronized according to the rate hydrogen permeates through a membrane. An electrochemical engine uses ion pumps and ultrasound generators to convert liquid hydrocarbon fuel to useful work while recovering hydrogen-depleted carbon from the fuel for recycling, including production of renewable fuel. When carbon is recovered, carbon dioxide is not produced. Tensile stress applied to the ion-pump membranes by rotation, high-frequency pressure waves, and radial acceleration of the interstitial hydrogen are applied in a collective manner that facilitates hydrogen permeation through the ion pump membranes.

Owner:JOHNSON ROBERT PAUL

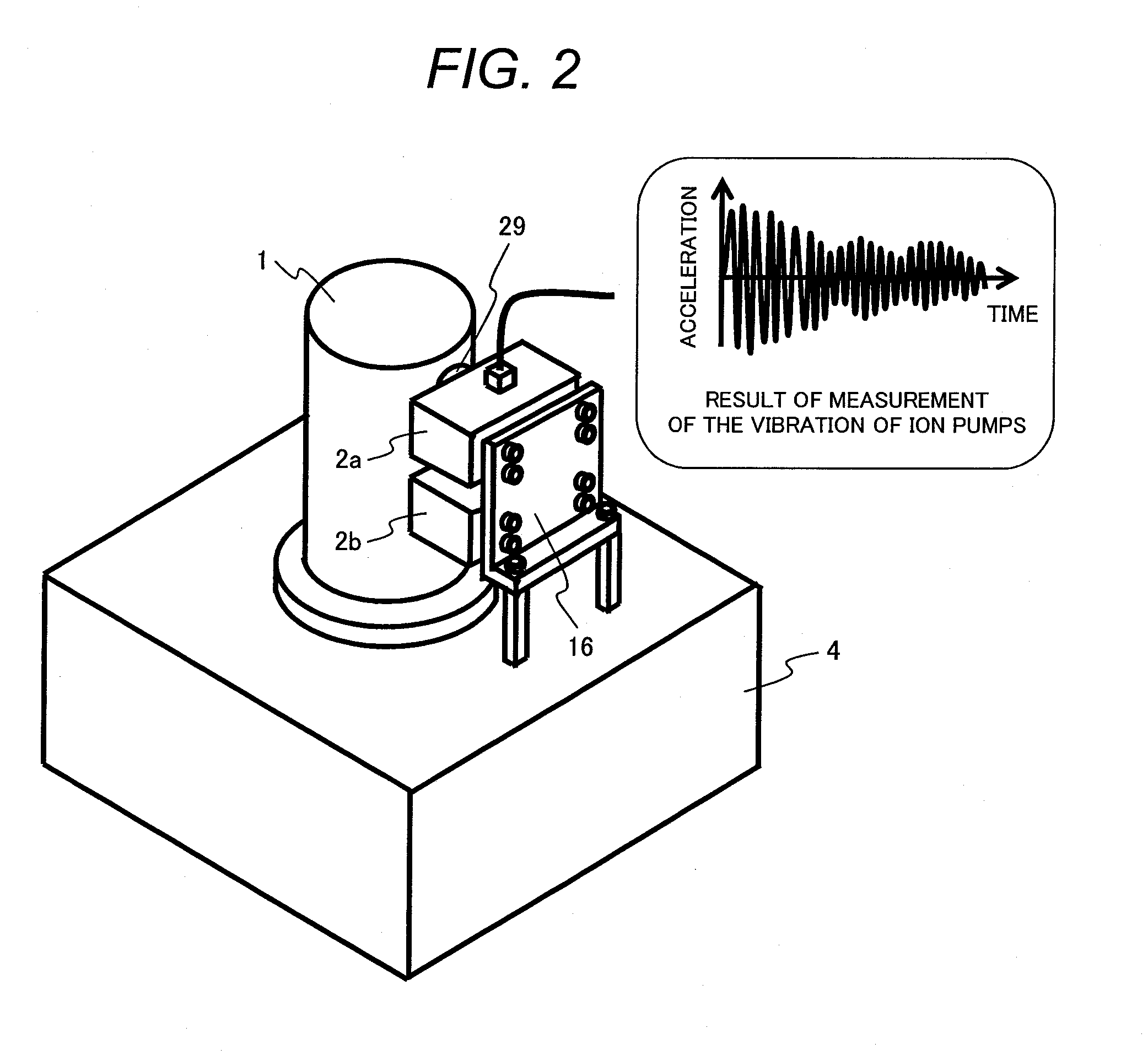

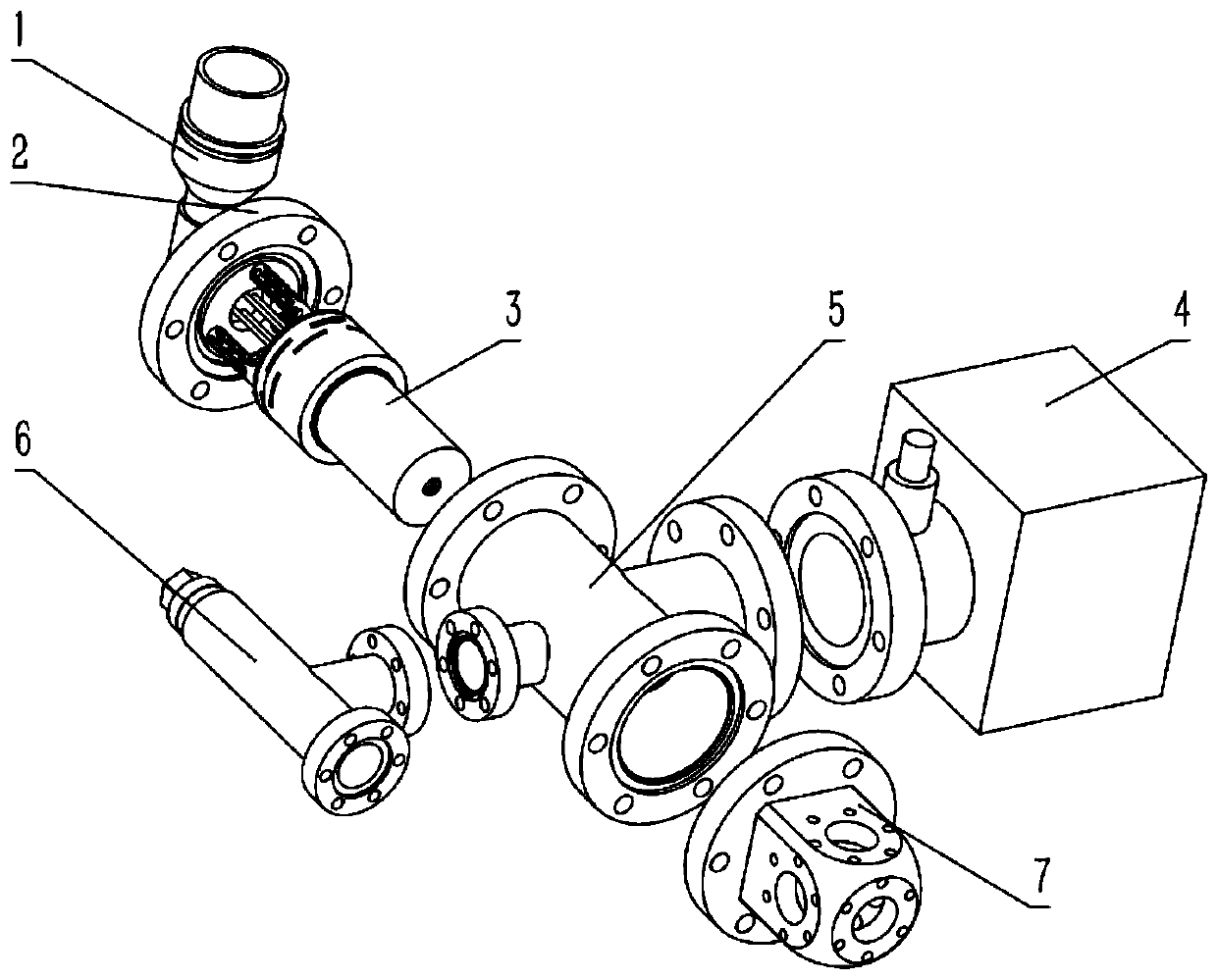

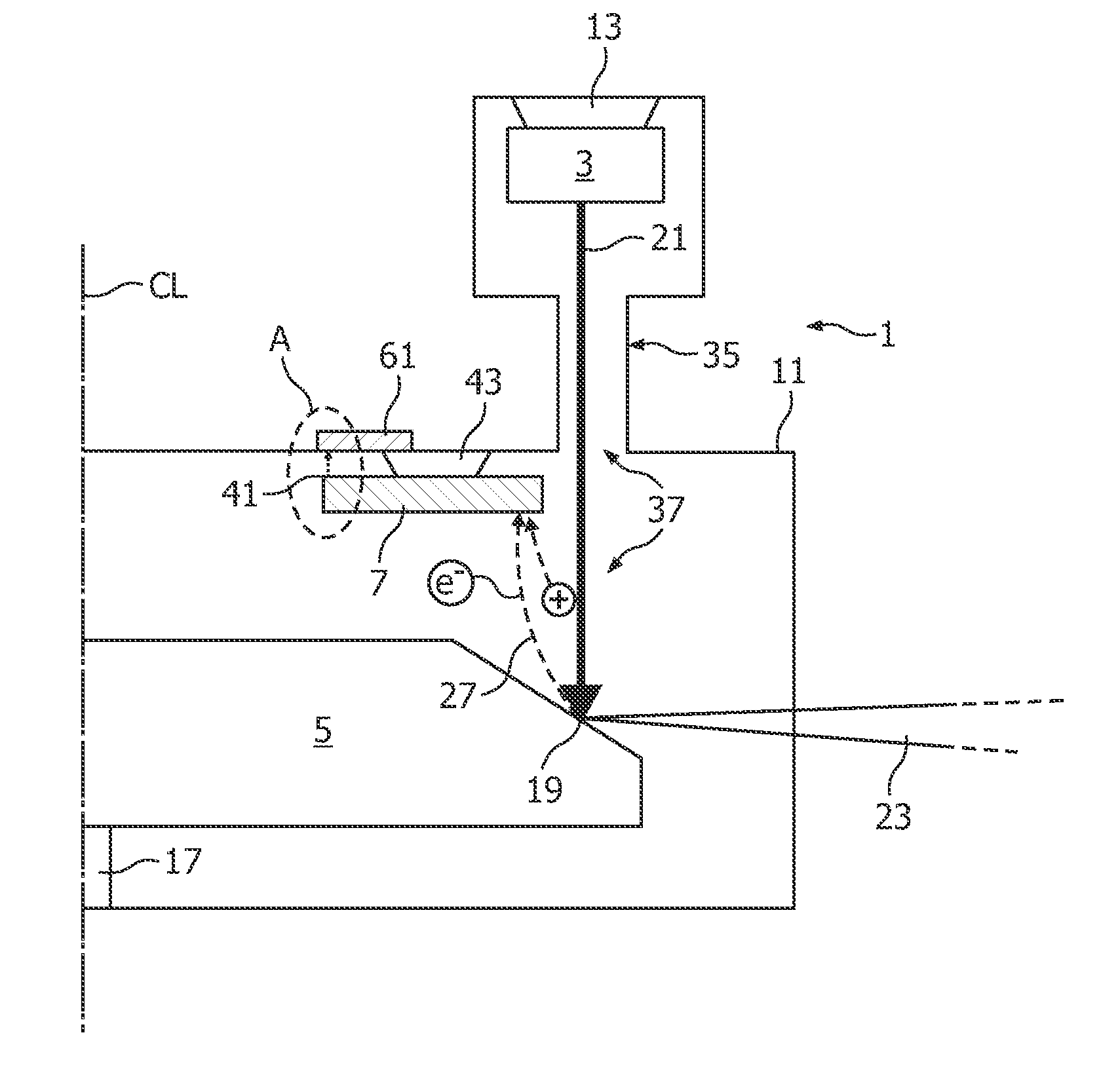

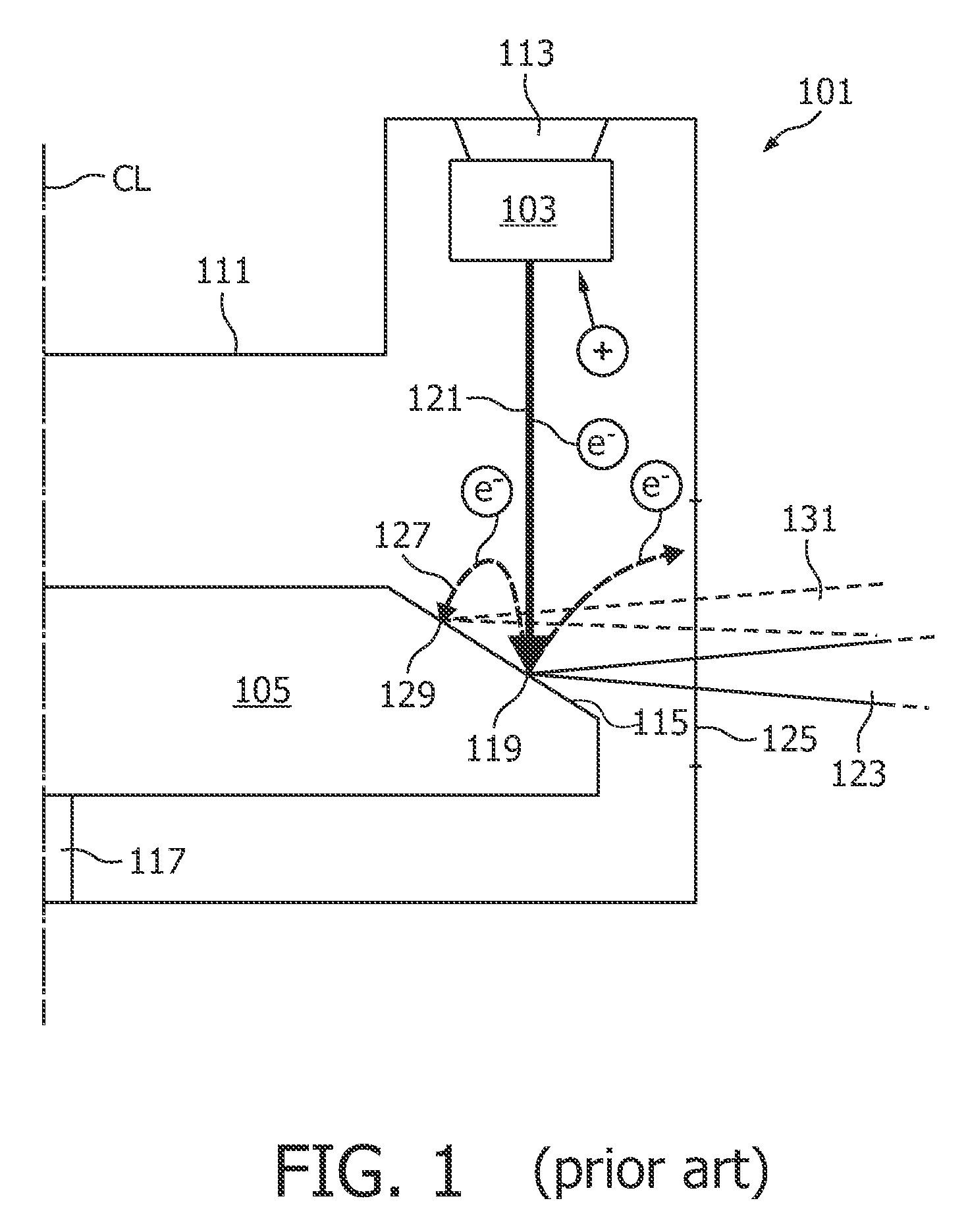

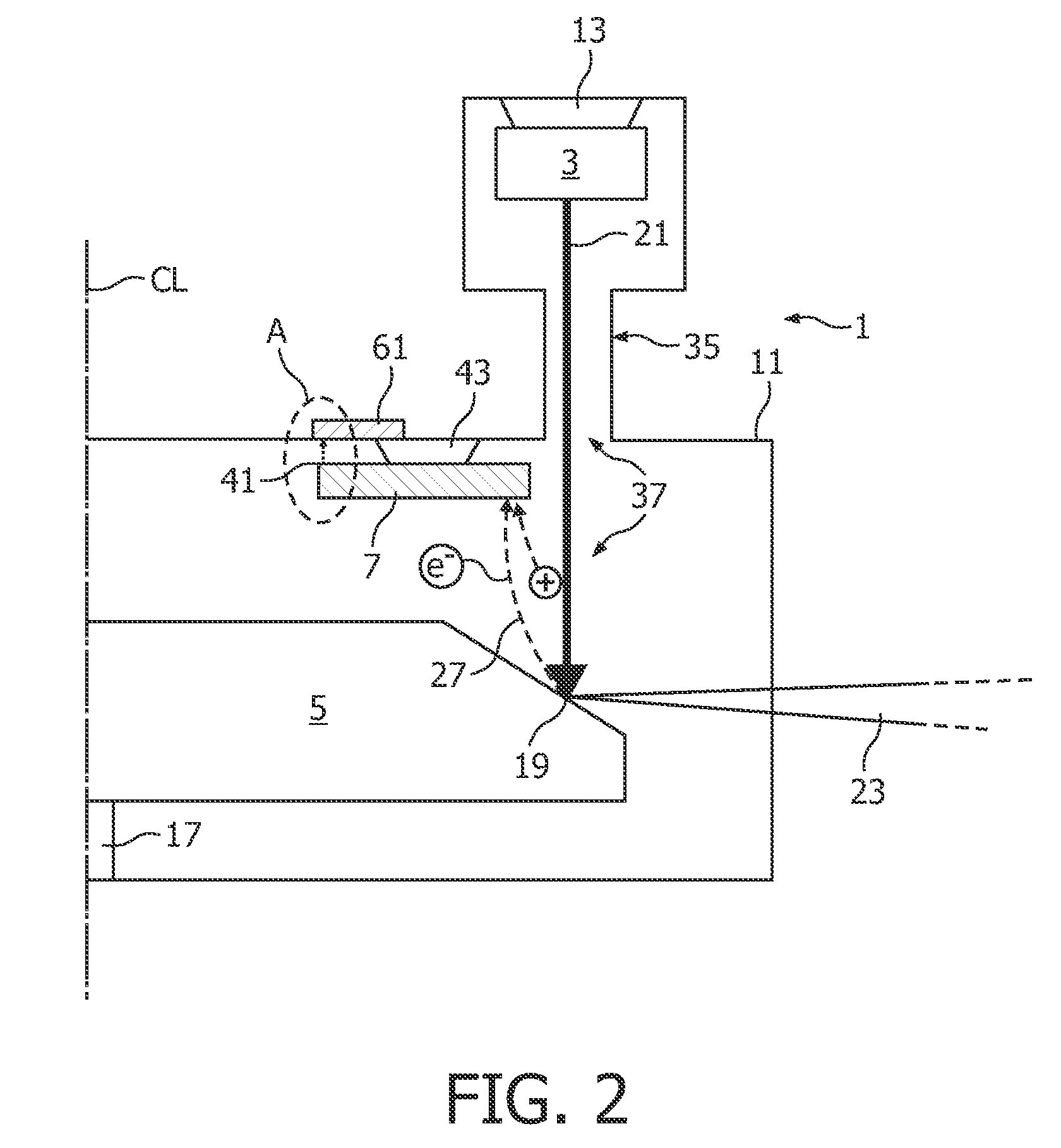

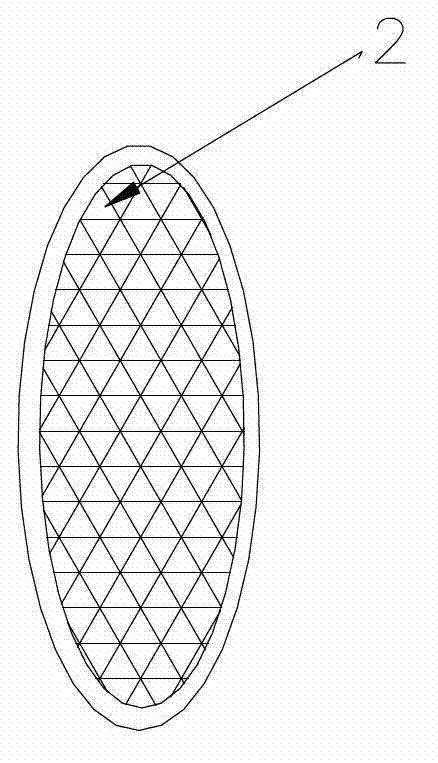

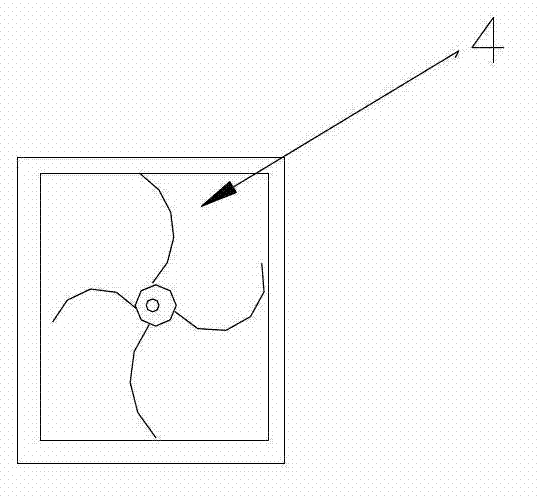

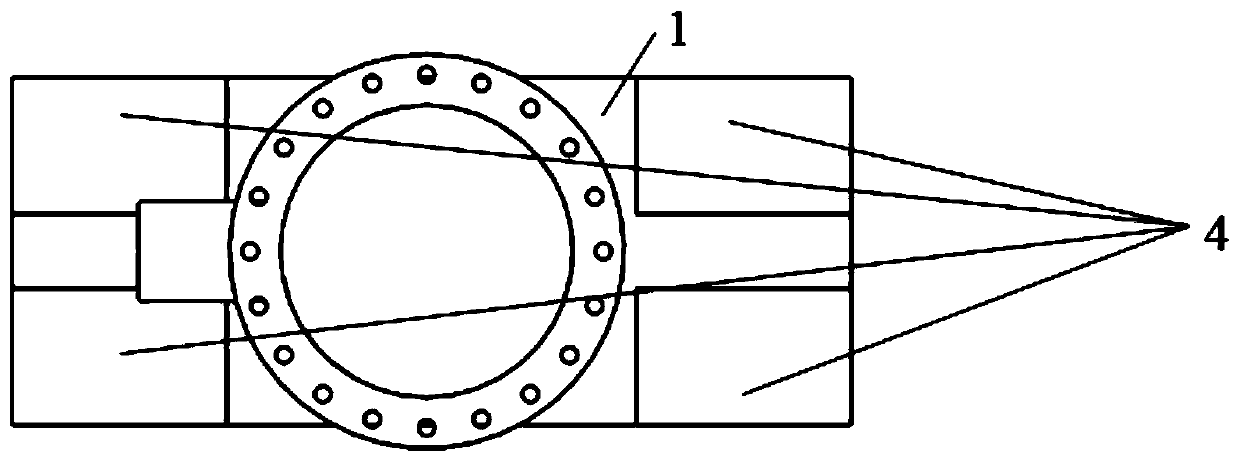

Charged particle radiation device

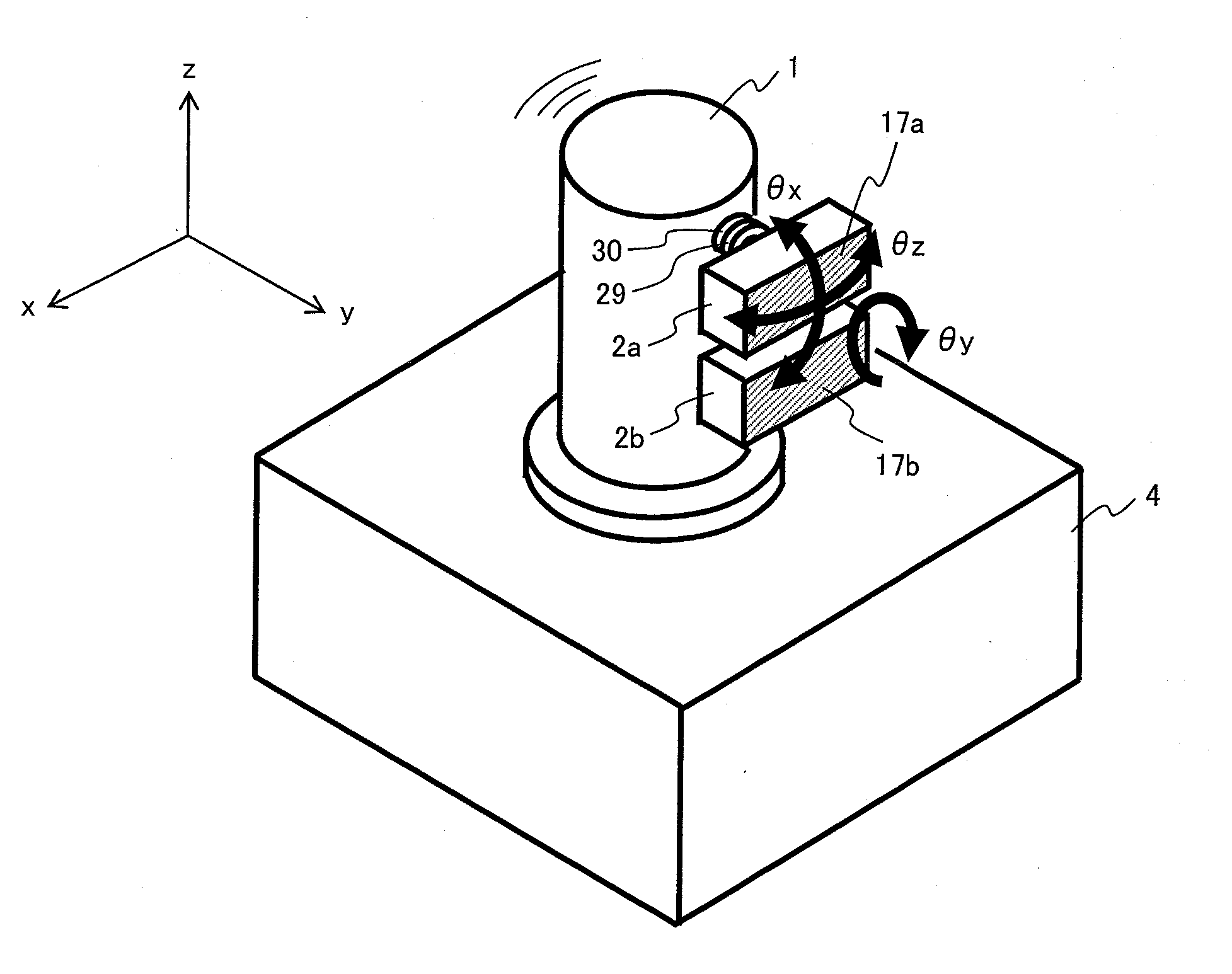

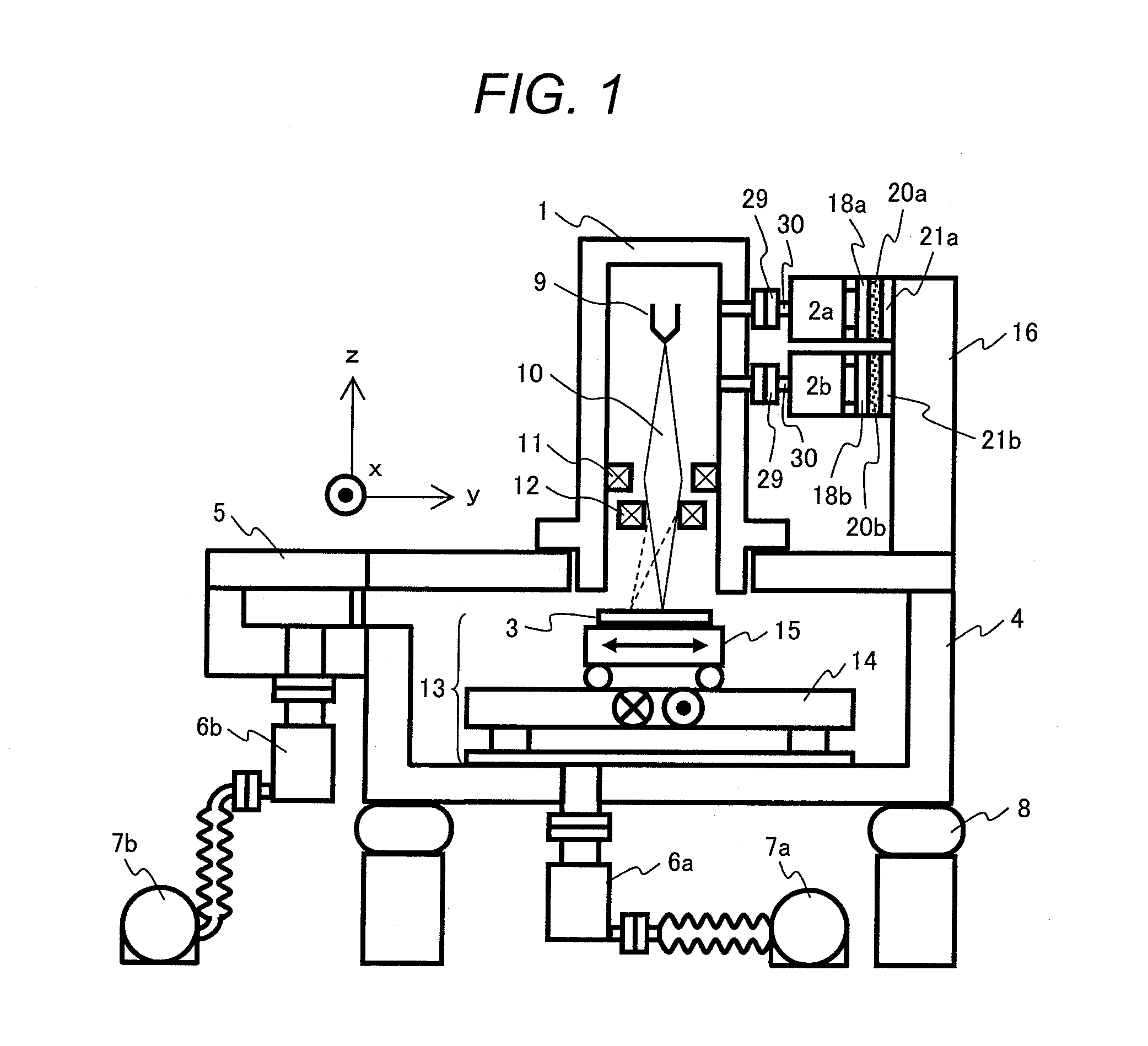

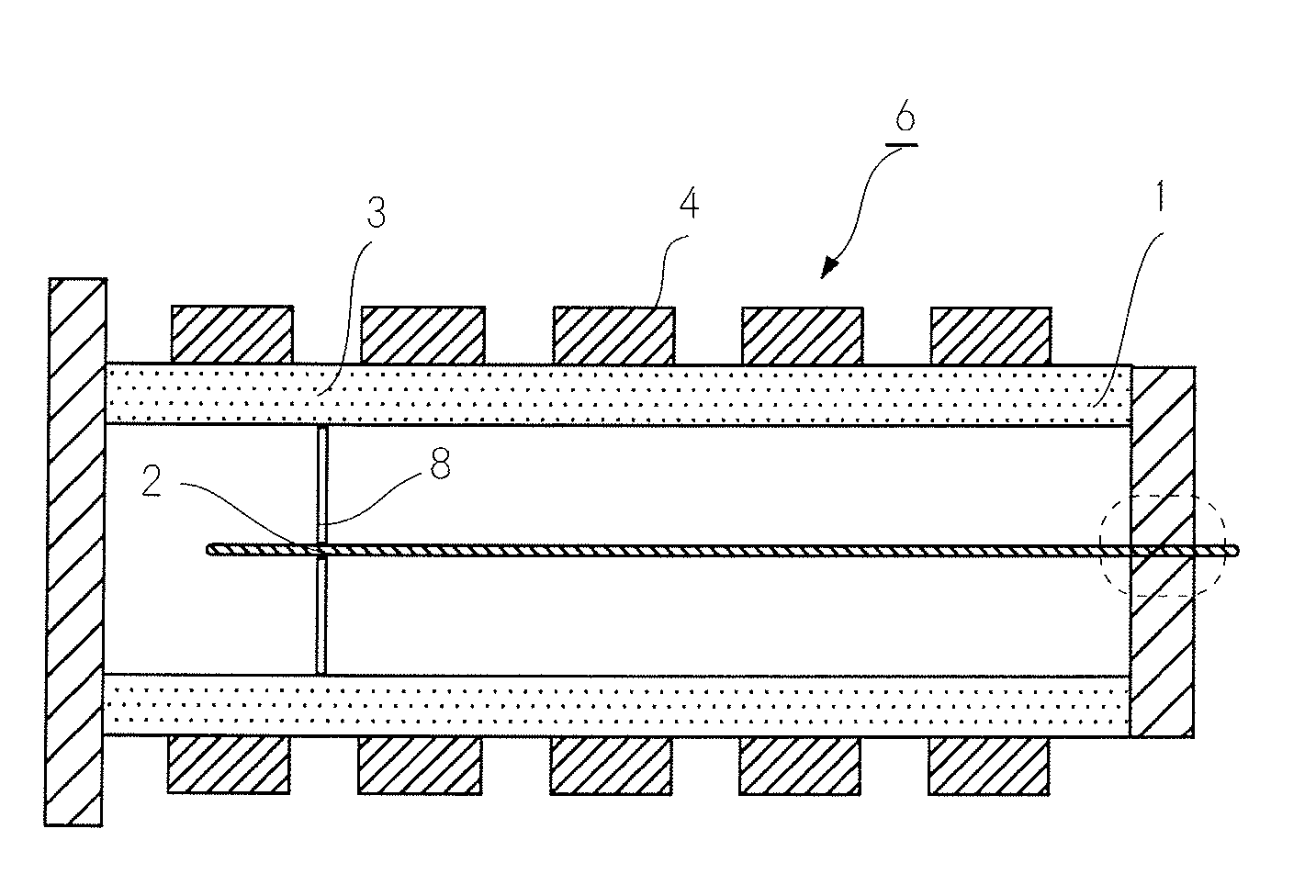

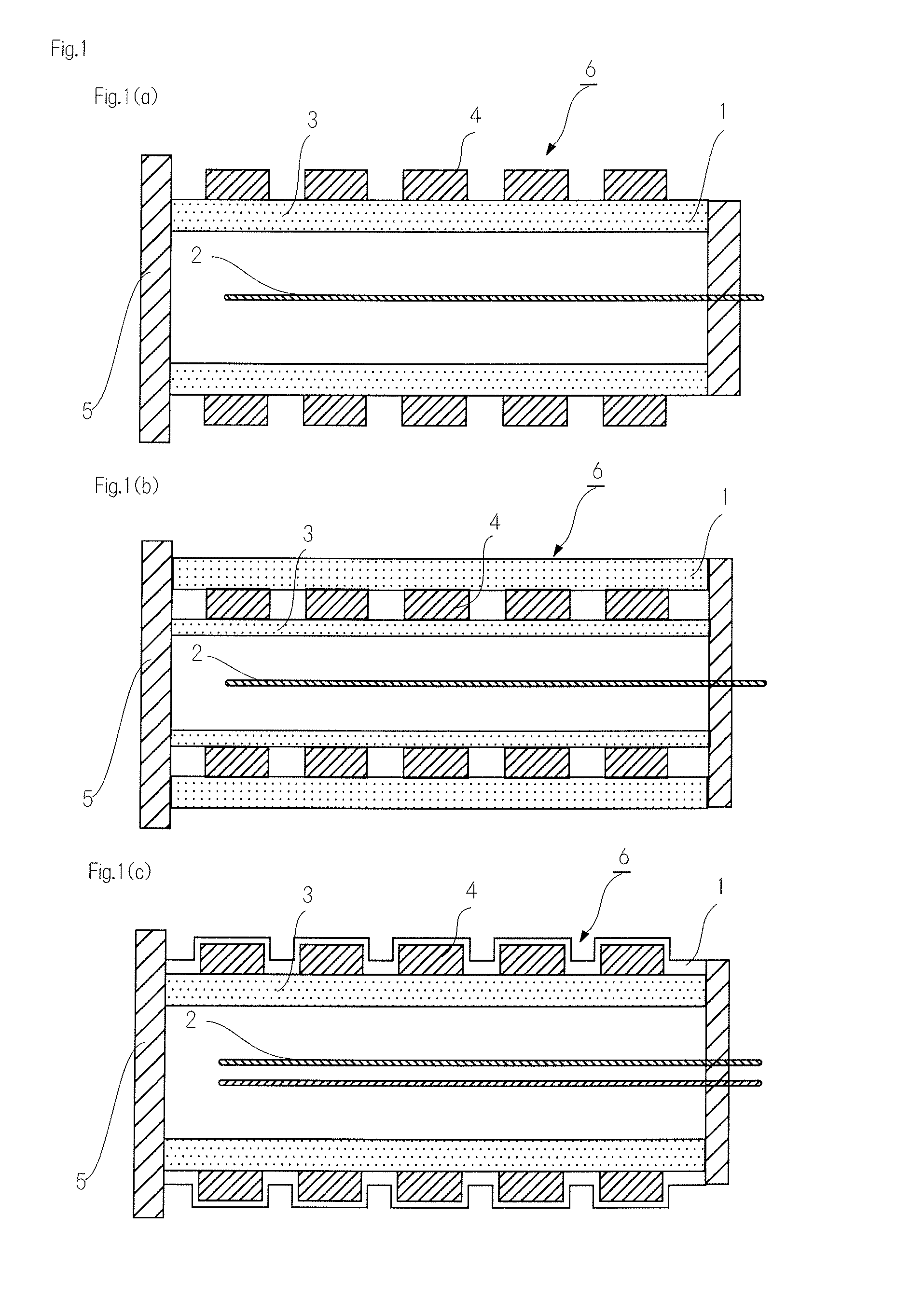

ActiveUS20120091362A1Reduce natural vibrationAvoid it happening againSpringsElectric discharge tubesParticle physicsSample chamber

Disclosed is a high resolution and high throughput charged particle radiation device that attenuates the natural vibration of an ion pump in a short time, excited by a reaction force at the time of driving the stage, and prevents occurrence of a loop of force and a loop of current. The charged particle radiation device includes a sample chamber (4) for disposing a sample (3) therein, a charged particle radiation optical lens tube (1) for irradiating the sample (3) with charged particle radiation (10), ion pumps (2a, 2b) for evacuating the charged particle radiation optical lens tube (1), a frame (16) fixedly attached to the sample chamber (4), the frame (16) facing one end of each of the ion pumps (2a, 2b), and vibration absorbers provided between the frame (16) and the one end of each of the ion pumps (2a, 2b), each of the vibration absorbers including a layered structure which includes a viscoelastic sheet (20a, 20b) sandwiched between metal plates (18a, 18b, 21a, 21b).

Owner:HITACHI HIGH-TECH CORP

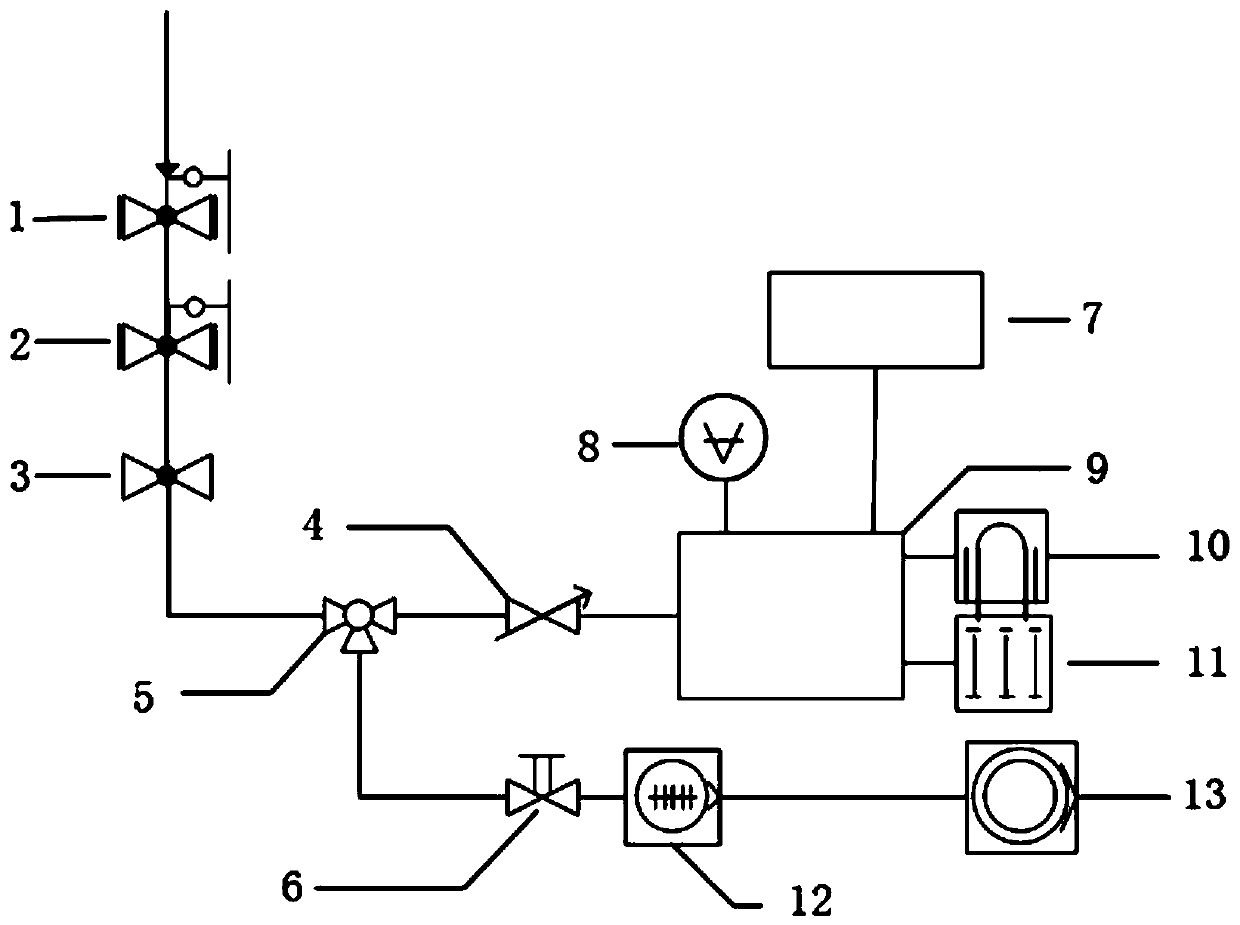

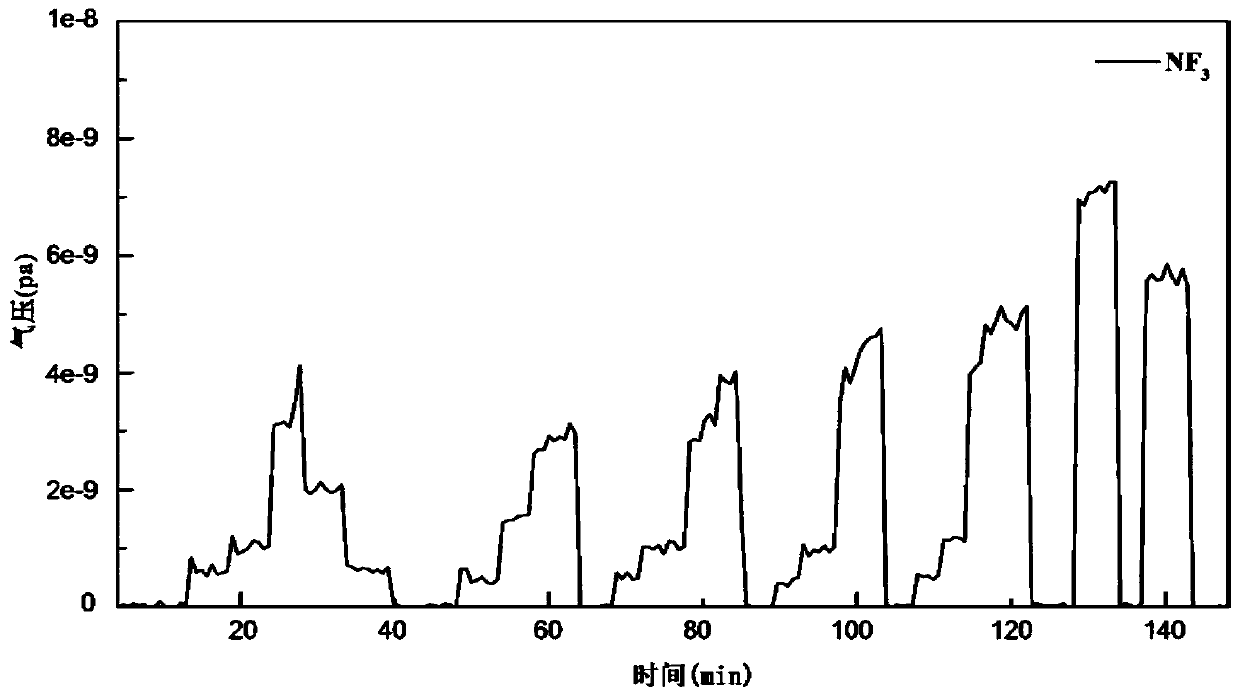

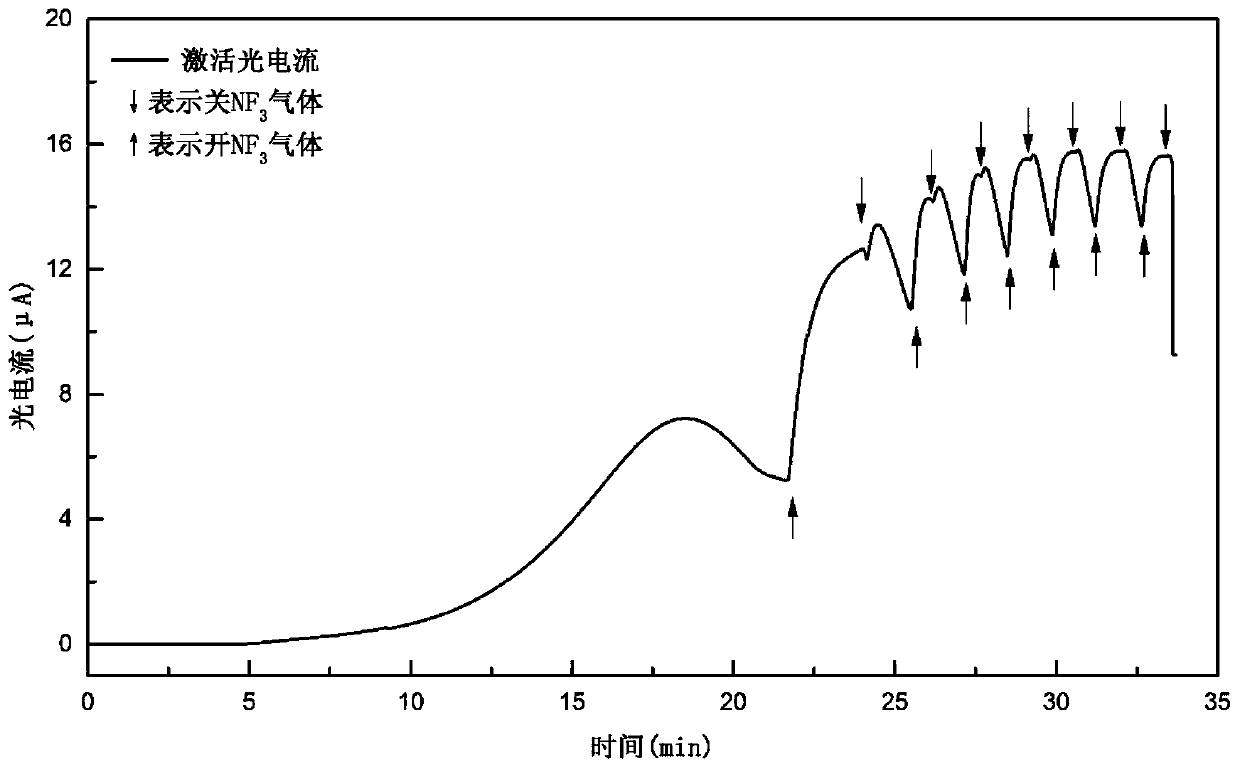

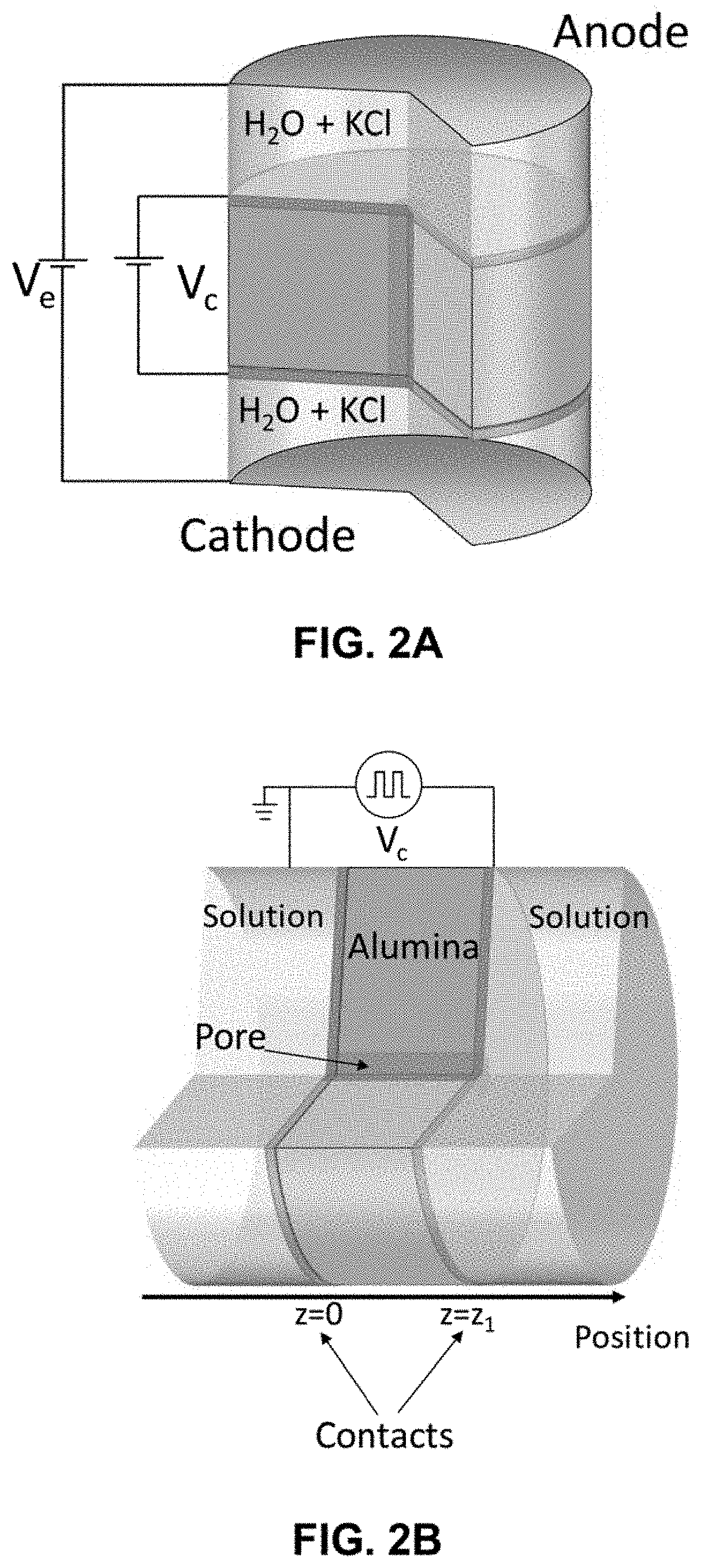

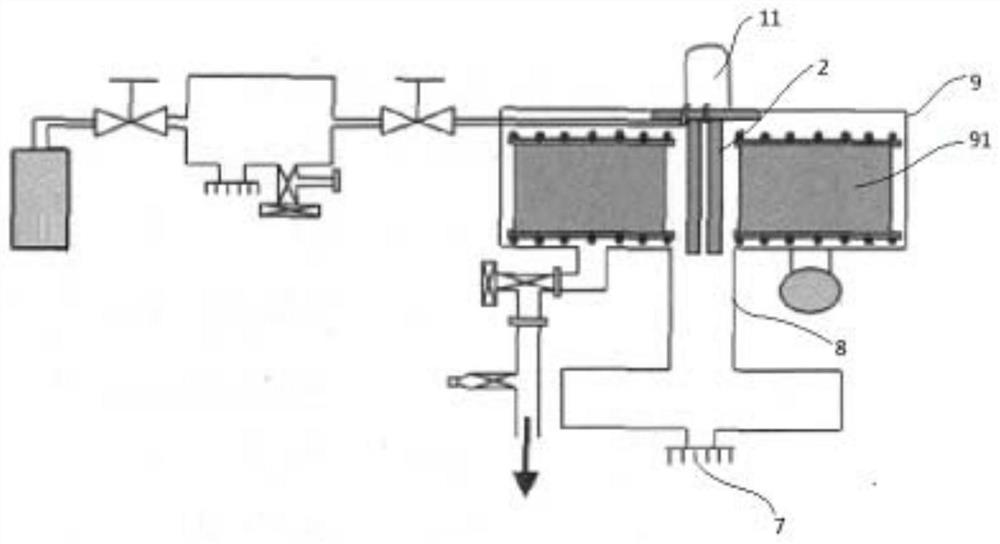

High-purity NF3 intake control device and method of ultra-high vacuum system

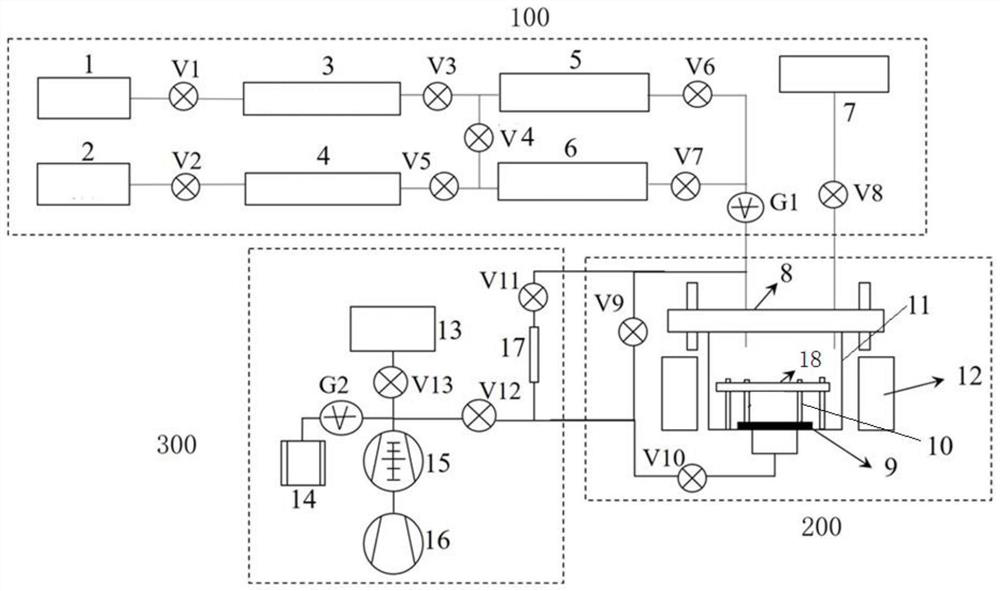

InactiveCN110927240AEasy to operateMeet the photocathode activation experimental requirementsMaterial analysis by electric/magnetic meansMass spectrometersUltra-high vacuumInlet valve

The invention discloses a high-purity NF3 air inlet control device and method of an ultrahigh vacuum system. The device comprises a primary pressure reducing valve, a secondary pressure reducing valve, a ball valve, an adjustable trace air inlet valve, a tee joint, a turbo molecular pump angle valve, a quadrupole mass spectrometer, a vacuum gauge, an ultrahigh vacuum activation chamber, a titaniumsublimation pump, a sputtering ion pump, a turbo molecular pump and a mechanical pump. The method comprises the following steps: firstly, closing the trace air inlet valve, and opening the first-stage pressure reducing valve, the second-stage pressure reducing valve and the ball valve, so that the pipeline is filled with NF3 gas; then closing the ball valve, opening an angle valve of the turbo molecular pump, and extracting residual gas in the gas inlet pipeline; then closing the angle valve, opening the ball valve, and flushing the air inlet pipeline with NF3; and finally, controlling the NF3 gas entering the ultrahigh vacuum system through an adjustable trace gas inlet valve, and respectively detecting the partial pressure of the NF3 and the vacuum degree of the system by using a quadrupole mass spectrometer and a vacuum gauge. Residual air in the air inlet pipeline can be removed, and the air inflow of NF3 can be slightly and accurately controlled.

Owner:NANJING UNIV OF SCI & TECH

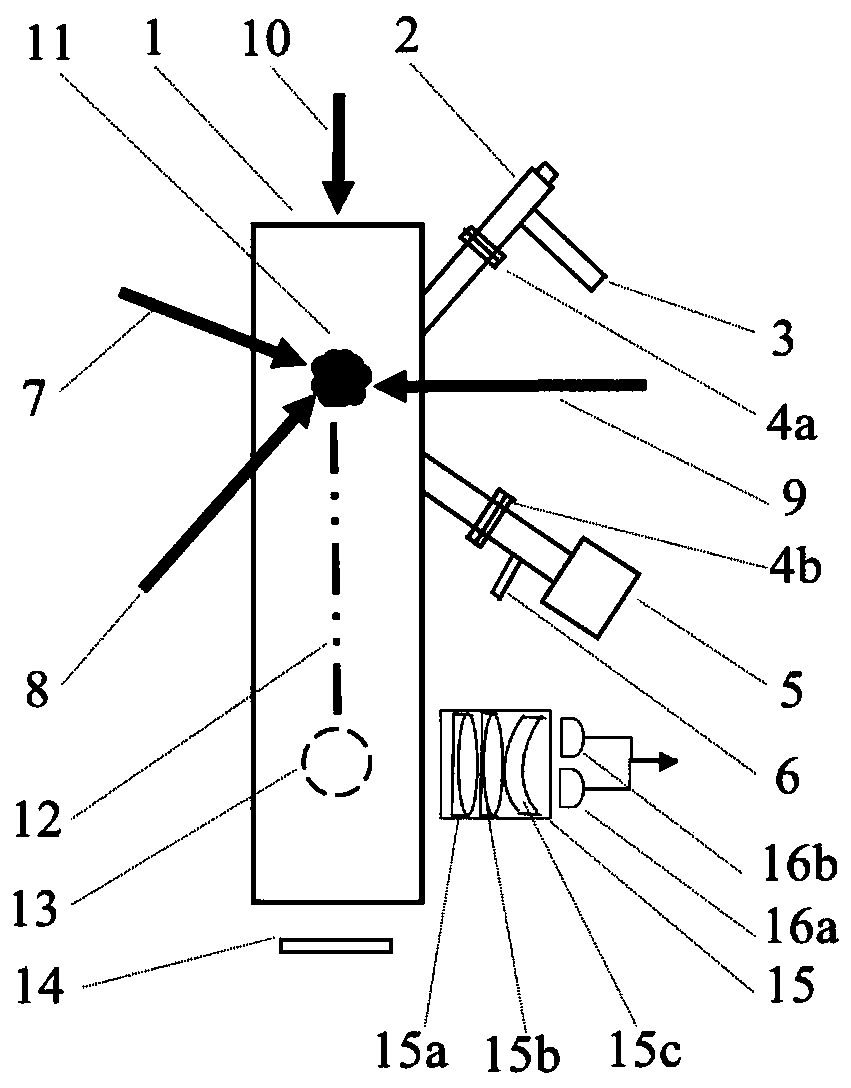

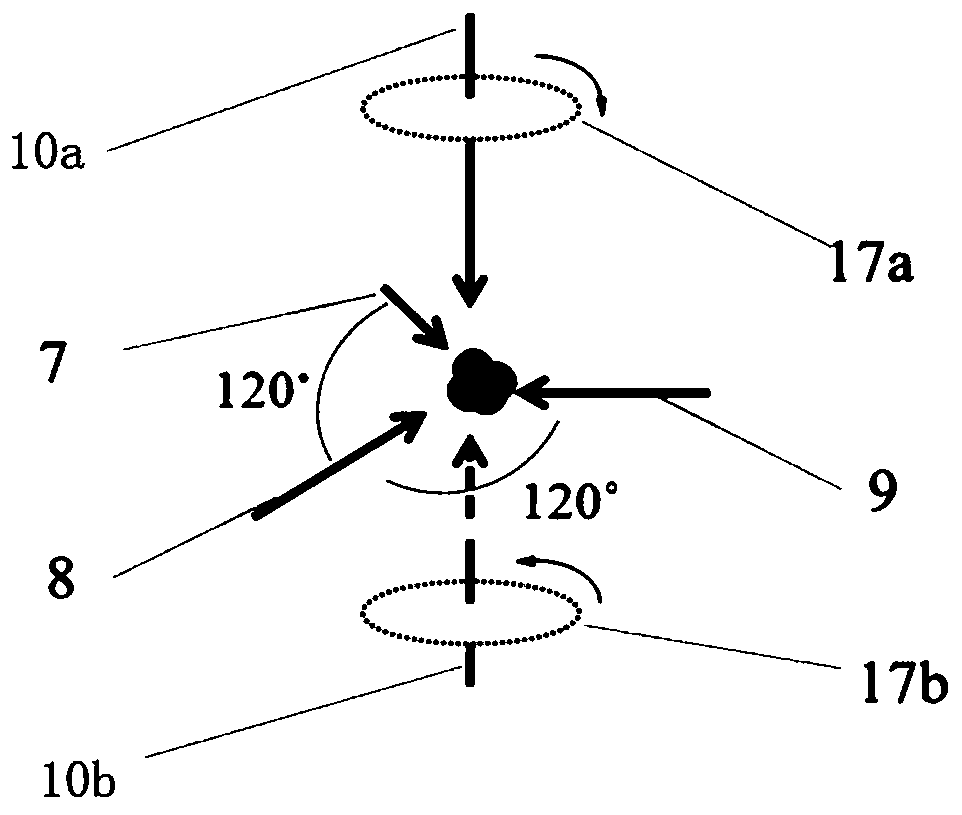

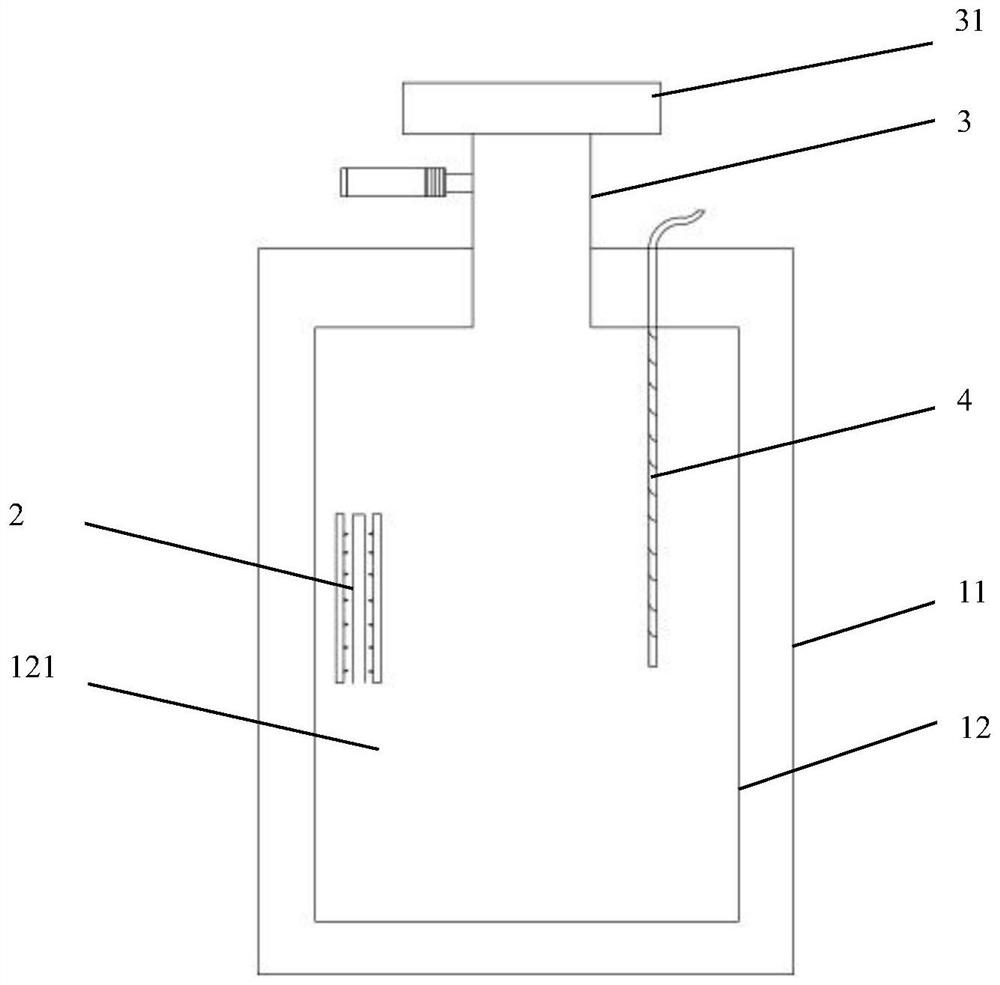

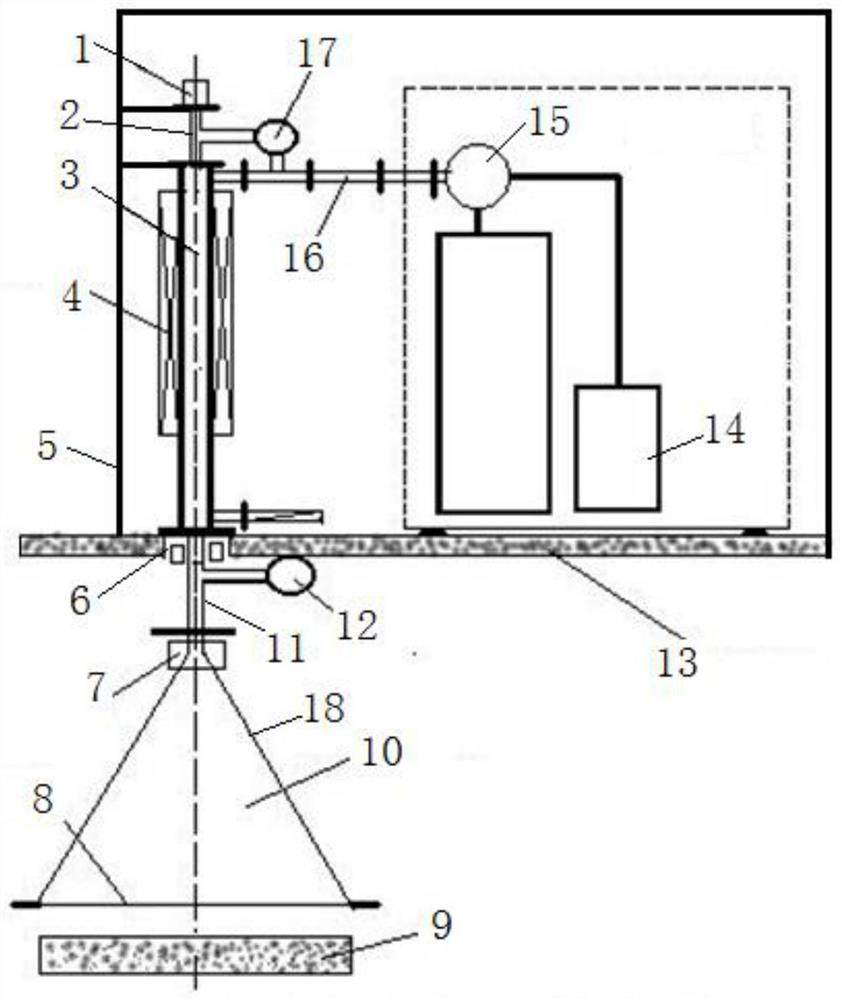

Magneto-optical trap device for gravity measurement

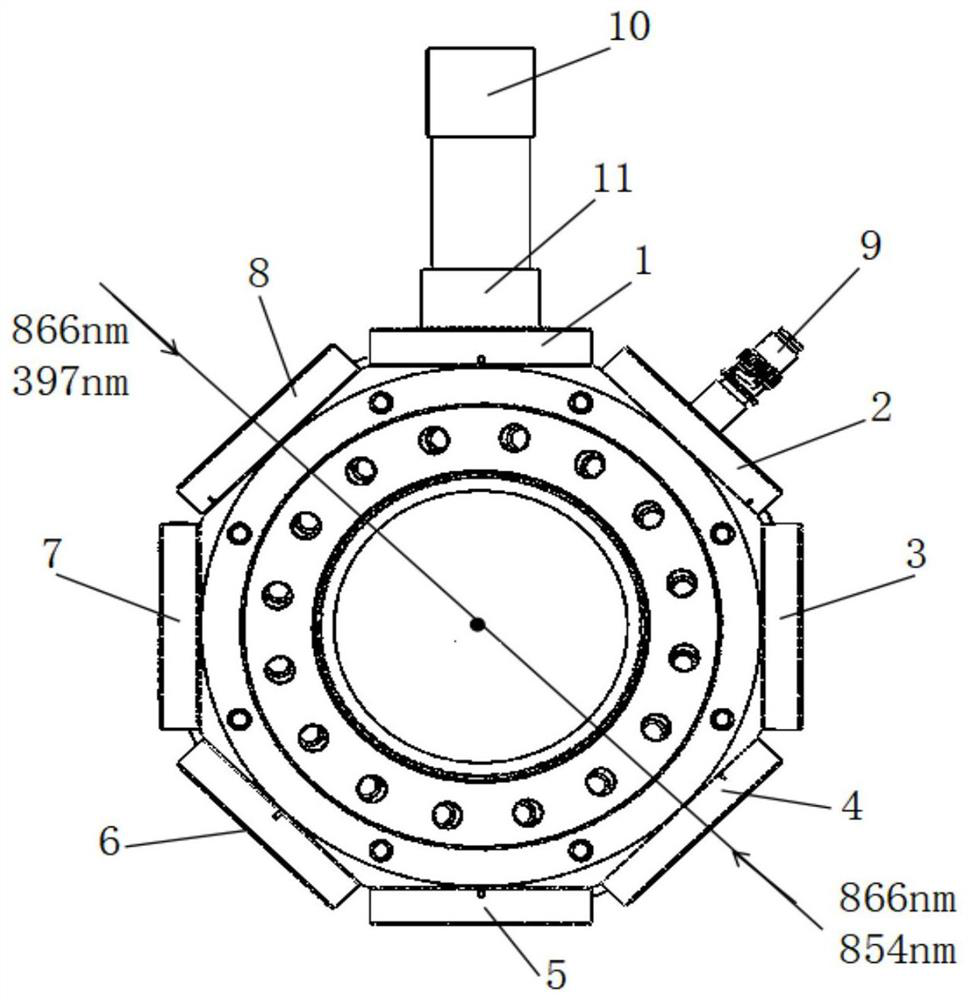

The invention relates to a magneto-optical trap device for gravity measurement, wherein a magneto-optical trap capture area is provided on the upper part in a vacuum cavity, and an interference area and a detection area are provided on the lower part in order; a rubidium source is connected to a rubidium source angle valve, and the rubidium source angle valve and an ion pump are respectively connected by means of sealing to two obliquely arranged glass pipelines outside the vacuum cavity; a Raman mirror is set directly below the vacuum cavity; a fluorescence collection device is set at a horizontal position corresponding to the detection area outside the vacuum cavity, and two photodetectors are set at the outer side of the fluorescence collection device; first, second and third capture light are at an angle of 120 degrees in the same horizontal plane and are irradiated at the magneto-optical trap capture area in the horizontal direction; a composite beam is respectively composed of the lights at four frequencies including the capture light, detection light, Raman light and stop light in the vertical direction, wherein the capture light is reflected by the Raman mirror to form fourth and fifth capture lights, and five capture lights and a pair of reverse Helmholtz coils form a magneto-optical trap. The device can make the gravity head sensitive head compact in structure and reduced in size.

Owner:TIANJIN NAVIGATION INSTR RES INST

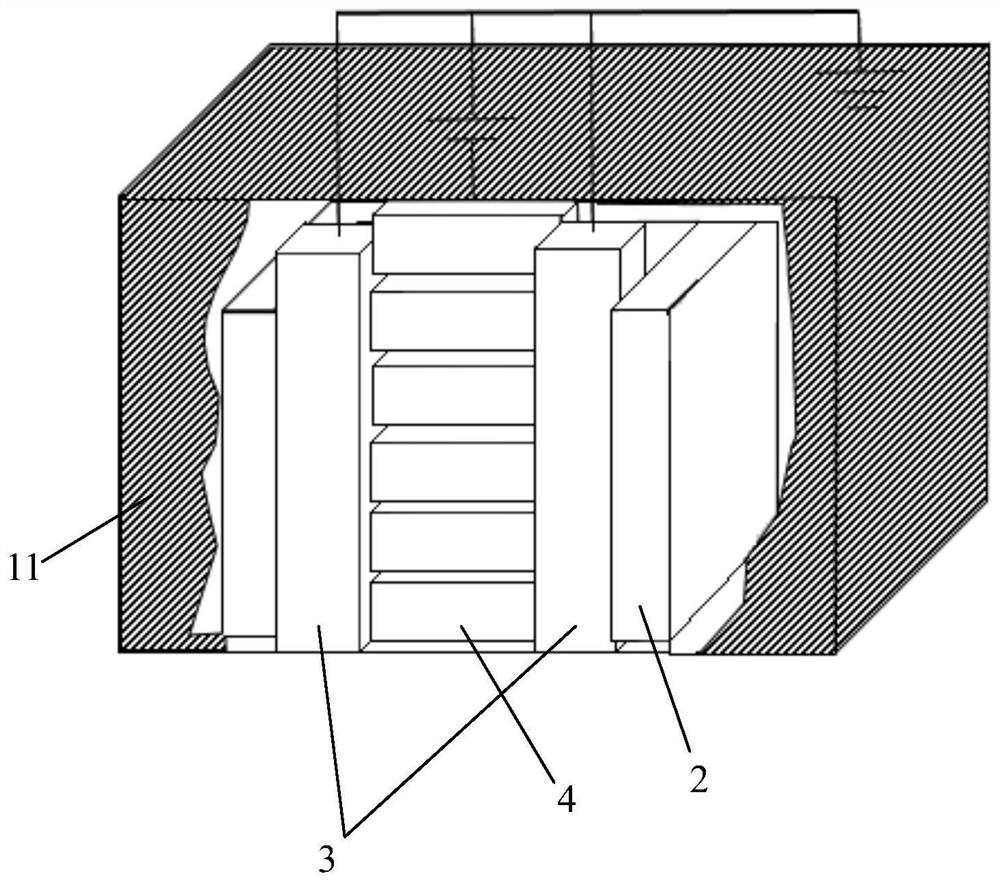

Ionizing pump stage

The invention relates to an ionizing pump stage, in particular for a vacuum pump, comprising an inlet for gas entering into the pump stage; an ionizing section communicating with the inlet in a gas-conductive manner and an ionizing device for ionizing the gas entered into the ionizing section; an acceleration device for accelerating the ionized gas present in the ionizing section in the conveying direction; and a neutralizing section following the ionizing section in the conveying direction and communicating with the ionizing section in a gas-conductive manner and a neutralizing device for the electrical neutralizing of the ionized gas entering into the neutralizing section.

Owner:PFEIFFER VACUUM GMBH

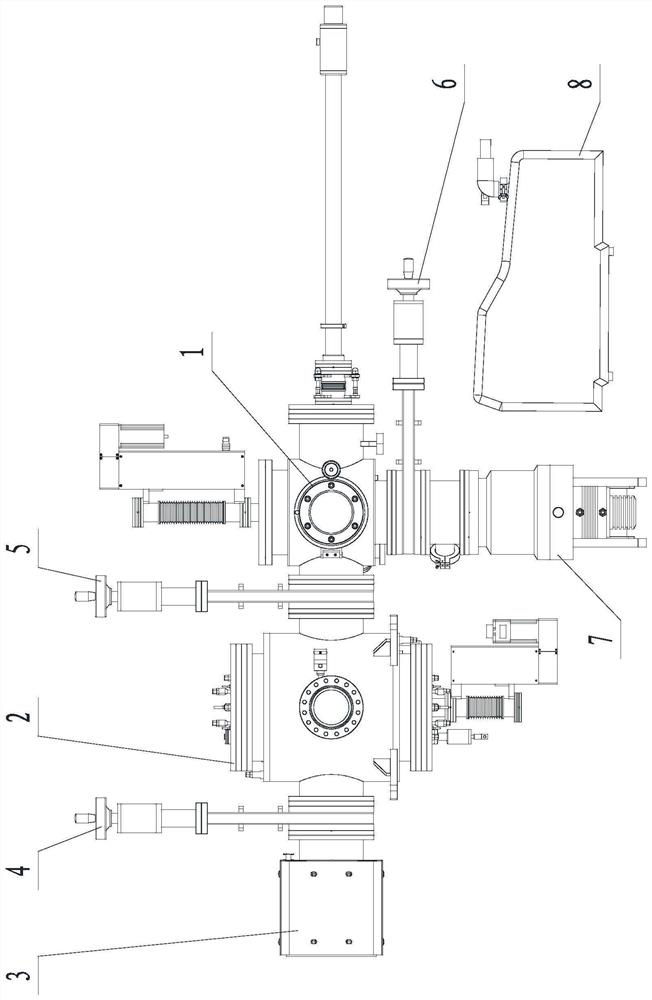

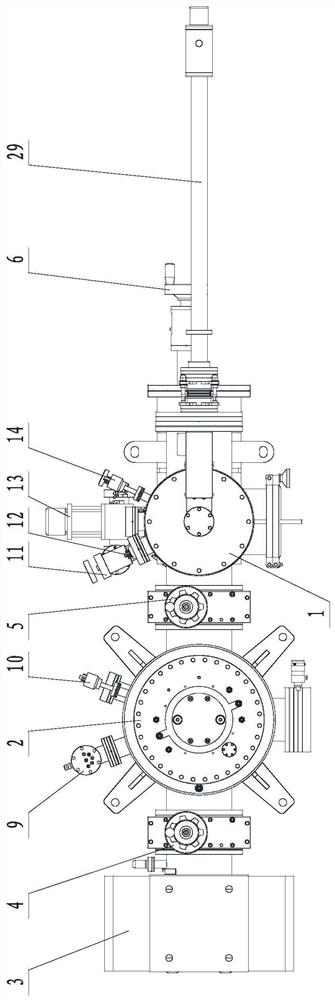

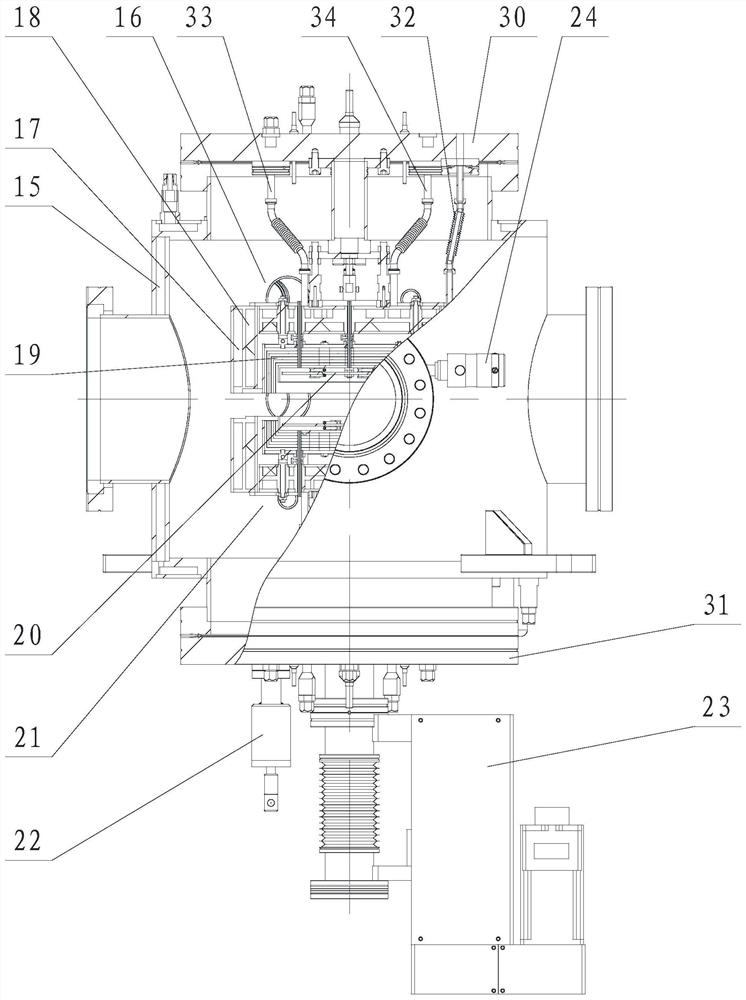

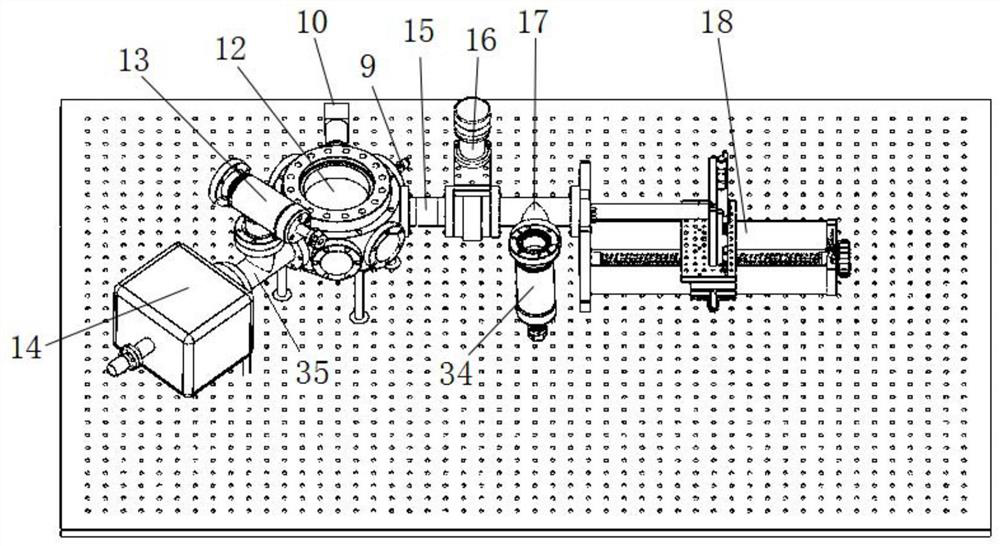

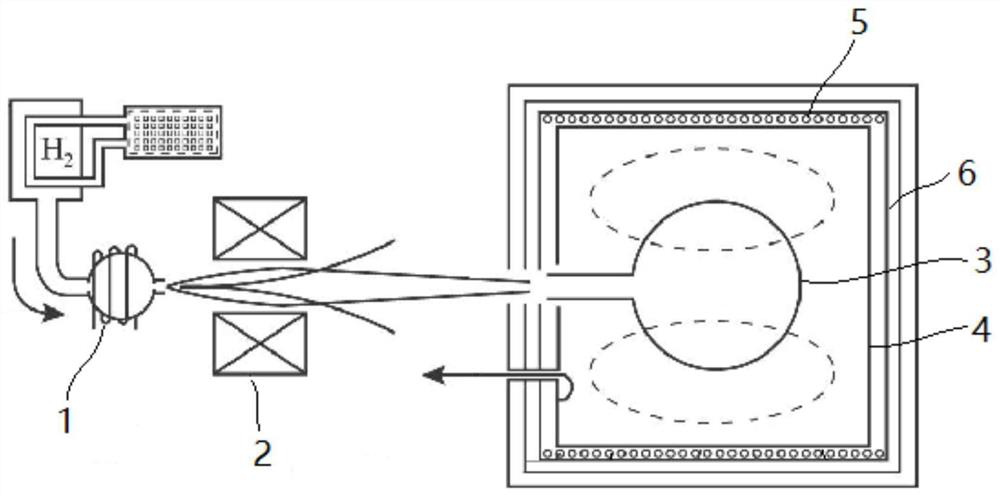

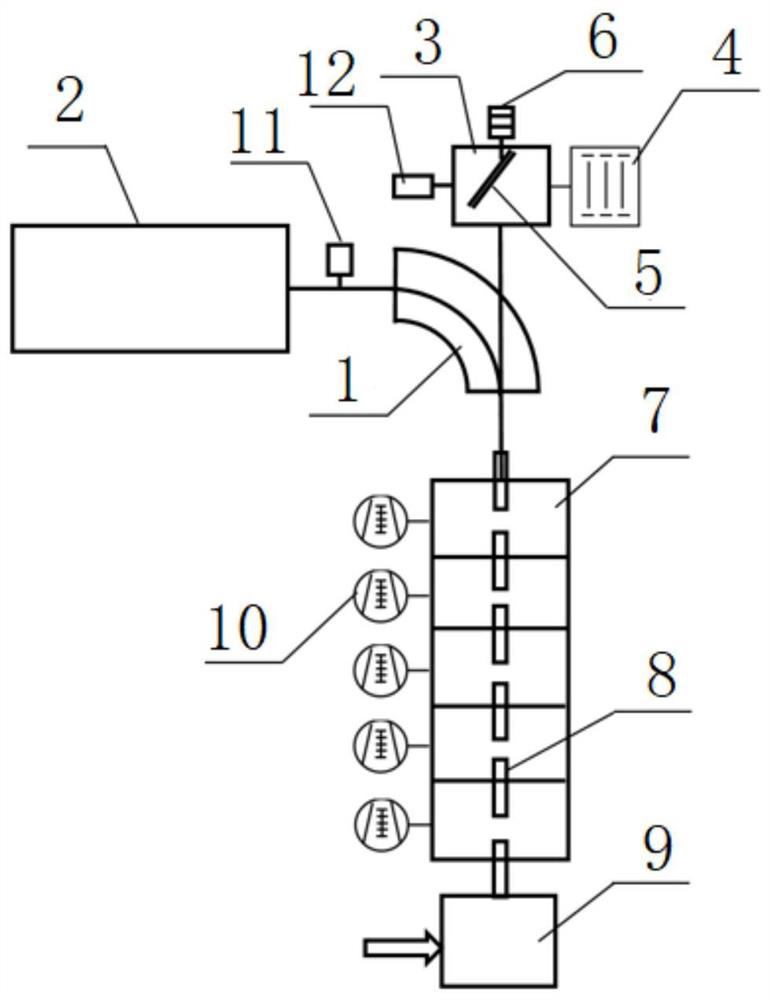

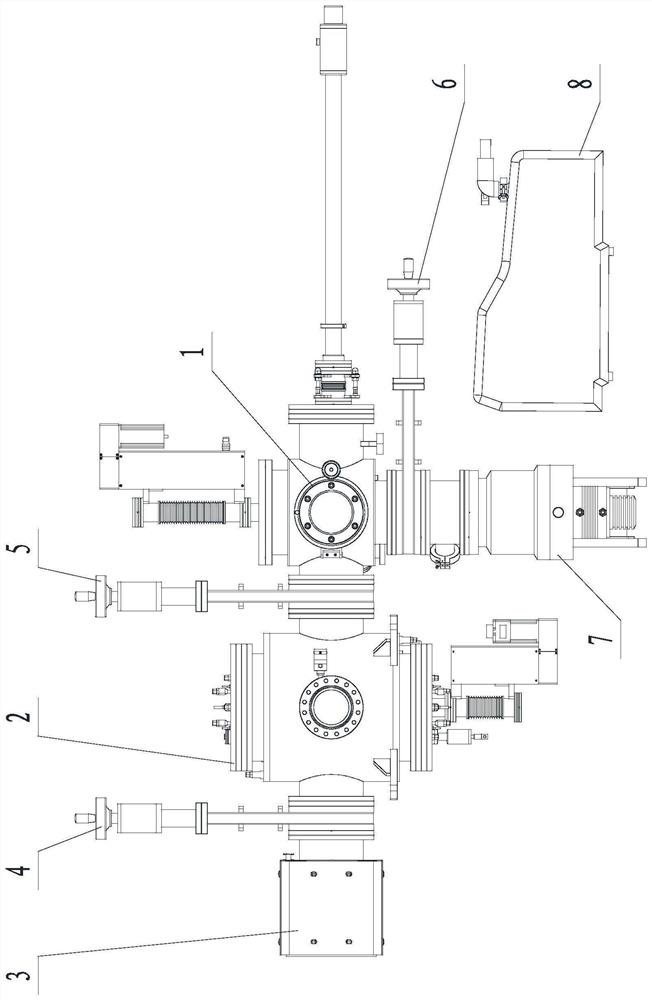

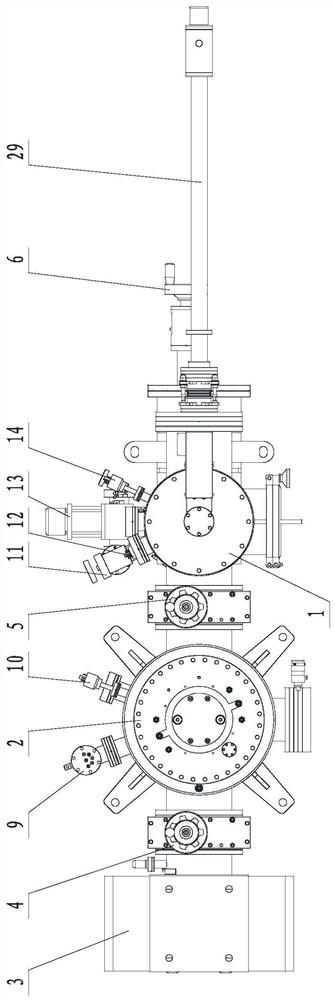

Ultrahigh vacuum acquisition system and method for experimental preparation of ultra-cold atoms and molecules

ActiveCN111441029AExtend your lifeIncrease vacuumVacuum evaporation coatingSputtering coatingUltra-high vacuumParticle physics

The invention relates to an ultrahigh vacuum system, in particular to an ultrahigh vacuum acquisition system and method for experimental preparation of ultra-cold atoms and molecules, and solves a problem that the vacuum degree of an existing ultrahigh vacuum system is not high enough. The ultrahigh vacuum acquisition system for experimental preparation of the ultra-cold atoms and molecules comprises a first vacuum chamber, a second vacuum chamber, a third vacuum chamber, a fourth vacuum chamber, a first titanium sublimation pump, a second titanium sublimation pump, a first sputtering ion pump, a second sputtering ion pump, a third sputtering ion pump, a first angle valve, a second angle valve, a first turbo molecular pump, a second turbo molecular pump, a first ion gauge, a second ion gauge, a third ion gauge, an inflation valve, a nitrogen source, an alkali metal source, a first gate valve, a second gate valve, a Zeeman slower and a three-way pipe. The system and the method are applicable to experimental preparation of the ultra-cold atoms and molecules.

Owner:SHANXI UNIV

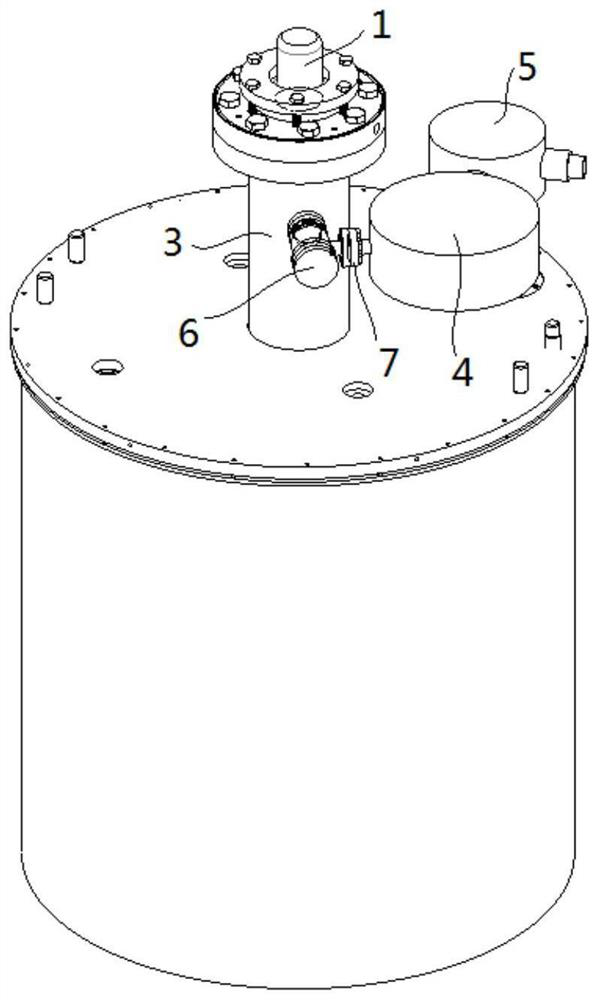

Space strontium optical clock built-in vacuum high-temperature evaporation source device

PendingCN111076543AImprove performanceReduce energy consumptionFurnace typesElectric heating for furnacesCrucibleElectrical connection

The invention discloses a space strontium optical clock built-in vacuum high-temperature evaporation source device. A vacuum electrode is electrically connected with a heating device through a flange,the exterior of the heating device is provided with a vacuum cavity, and the vacuum cavity is connected with an ion pump, a collimation cavity and an angle valve; heating wire bare wires in the heating device are evenly arranged through machinable ceramic and mounted around a crucible connected with a collimator, a thermocouple mounting hole is preserved in the bottom of the crucible, a thermocouple and heating wires are connected with an external temperature controller through a flange integrated electrode, the whole crucible is arranged at a heat-insulation base and a heat-insulation hood an connected with a supporting column of the flange through a general bolt, and the flange is connected with the vacuum cavity through a bolt. The space strontium optical clock built-in vacuum high-temperature evaporation source device has the advantages that a built-in vacuum is achieved, the size is small, heat insulation performance is good, energy consumption is small, and disassembly and assembly are convenient, and the space strontium optical clock built-in vacuum high-temperature evaporation source device can be generalized and applied to the technical field of quantum evaluation.

Owner:NAT TIME SERVICE CENT CHINESE ACAD OF SCI

Small cold atomic clock device and method for time keeping system

PendingCN111856917AMiniaturizationShorten the working cycleApparatus using atomic clocksPulse automatic controlMicrowave cavityMagneto-optical trap

The invention discloses a small cold atomic clock device and method for a time keeping system. A two-dimensional magneto-optical trap is arranged in the atomic beam emitting direction of an atomic furnace; an atomic beam emitted from the two-dimensional magneto-optical trap enters a three-dimensional magneto-optical trap through a collimating device; a magnetron microwave cavity is placed in the three-dimensional magneto-optical trap; after cold atom preparation, atomic groups enter the magnetron microwave cavity under the action of gravity; atomic groups pass through the magnetron microwave cavity and then enter an annular microwave cavity; atoms passing through the annular microwave cavity enter a population detection device; the population detection device is connected with an ion pump,the ion pump maintains the vacuum environment of the whole system, three layers of magnetic shielding cylinders made of permalloy materials are sequentially arranged outside the system, an optical shutter is further arranged between the three-dimensional magneto-optical trap and the annular microwave cavity, and cold atom loading and microwave excitation processes are allowed to be implemented inparallel. The cold atomic clock device has the advantages of compact structure, short working period and the like, and the cost and size of the cold atomic clock can be remarkably reduced.

Owner:NAT TIME SERVICE CENT CHINESE ACAD OF SCI

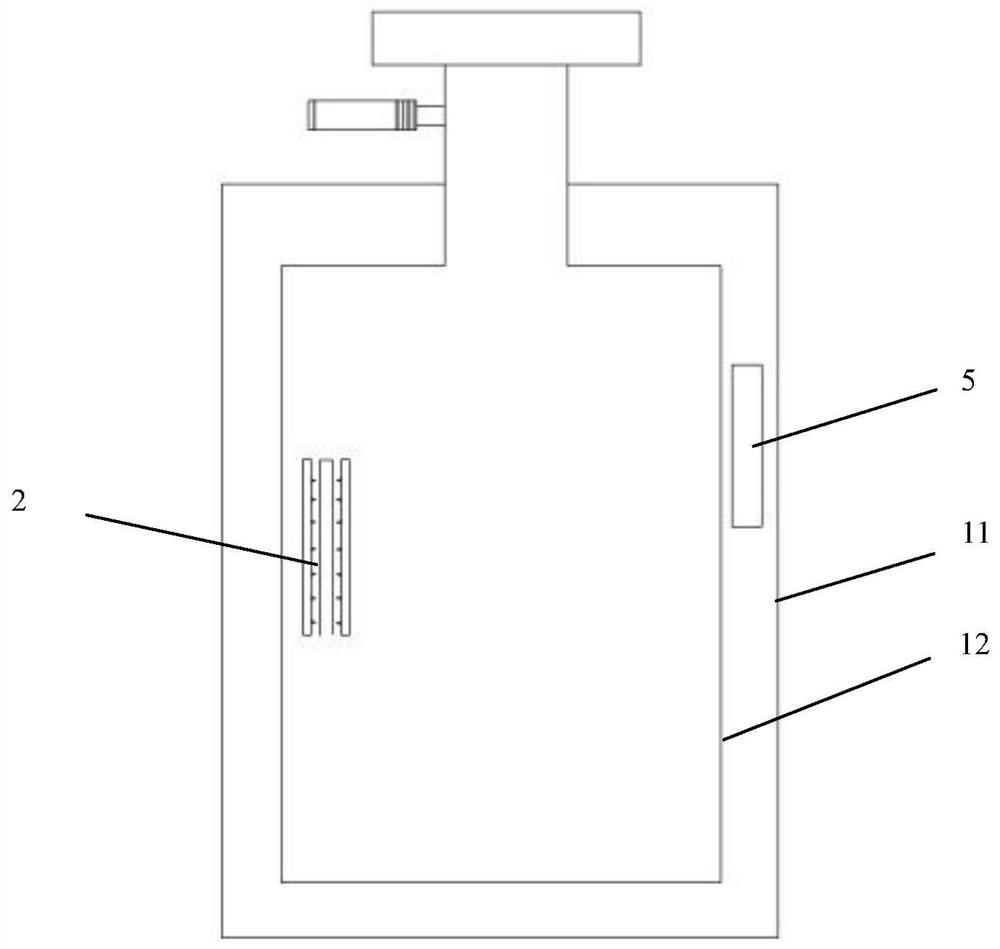

High-temperature and high-vacuum annealing furnace

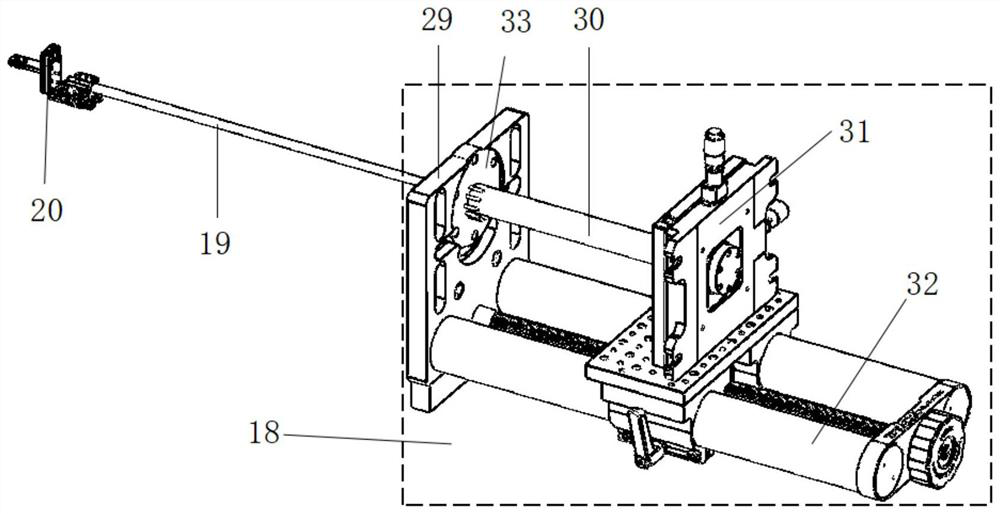

ActiveCN113493904AAvoid getting lostIncrease usageVacuum evaporation coatingSputtering coatingUltra-high vacuumIon pump

The invention relates to vacuum coating experimental equipment, in particular to a high-temperature and high-vacuum annealing furnace. The furnace is characterized in that an ion pump, an annealing chamber cavity, a sample introduction chamber cavity and a molecular pump are sequentially connected, and the molecular pump is connected with a mechanical pump through a pipeline; gate valves are arranged between the ion pump and the annealing chamber cavity, between the annealing chamber cavity and the sample introduction chamber cavity and between the sample introduction chamber cavity and the molecular pump; and a fixed upper heater and a lower heater capable of lifting up and down are arranged in the annealing chamber cavity, a multi-layer sample library capable of lifting up and down is arranged in the sample introduction chamber cavity, and a manual transfer rod manipulator is mounted at one side of the sample introduction chamber cavity. Sample exchange with an annealing chamber can be rapidly completed through the high-temperature and high-vacuum annealing furnace under the vacuum condition, and it is guaranteed that the annealing chamber is in a high-vacuum state all the time. According to the high-temperature and high-vacuum annealing furnace, the cold-state limit vacuum degree of the annealing chamber can reach 10<-8> Pa ultrahigh vacuum, the hot-state vacuum degree can reach 10<-6> Pa when the annealing chamber is heated to 1600 DEG C, and long-time heat preservation annealing of a sample at the temperature not higher than 1600 DEG C can be achieved.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

Ion pump device

ActiveUS20100143159A1Simple structurePositive displacement pump componentsPumpsElectrical polarityEngineering

Owner:NAT INST OF INFORMATION & COMM TECH

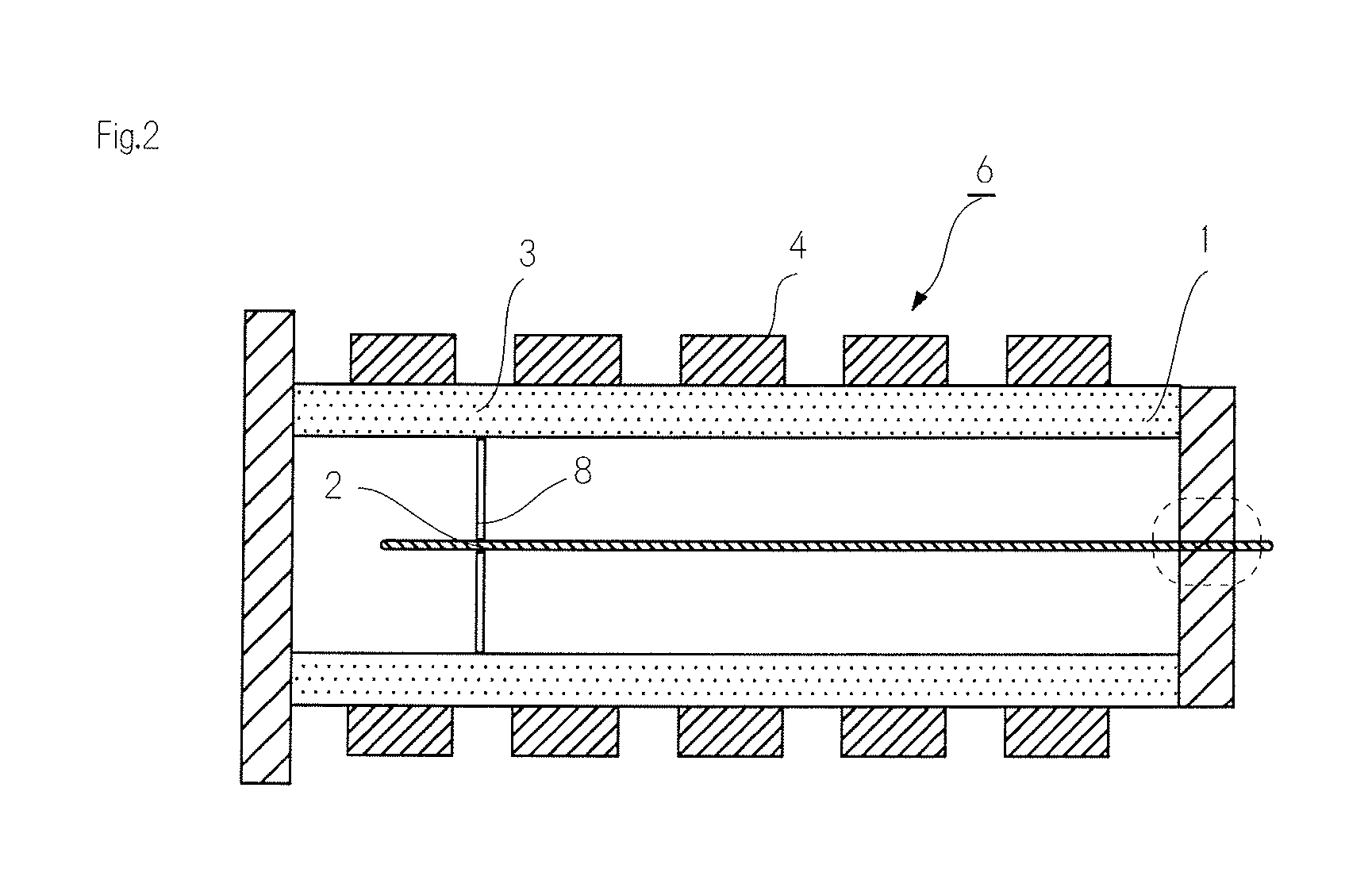

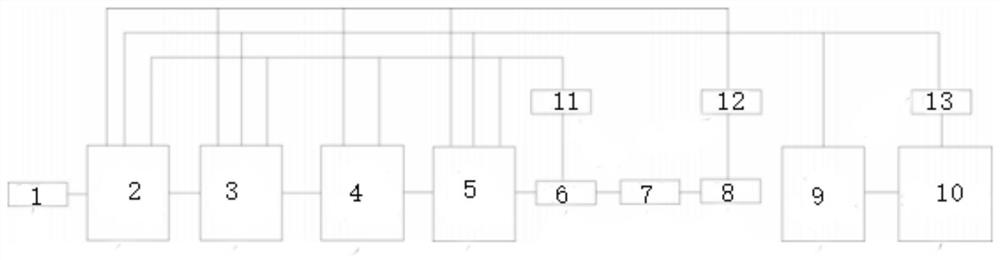

Ganoderan tripeptide filtering system process device

ActiveCN104788534AHigh and low temperature process purificationHigh purityPeptide preparation methodsBulk chemical productionFilter systemEngineering

The invention discloses a ganoderan tripeptide filtering system process device. The ganoderan tripeptide filtering system process device is composed of a transporting pump, a stock solution tank, a stop valve, a control valve, a high-pressure pump, a pressure generator, a four-way diverter valve, a series tube, a second four-way diverter valve, a shunt tube, an ultrahigh pressure reaction tank, a polysaccharide peptide storage, a degradation reactor, a refluxing separator, a vacuum pump, a beta-reactor, a protein separator, an ion separator, an ion pump, a homogeneous purifier, a draft tube and a return tube. The ganoderan tripeptide filtering system process device is characterized in that the high-pressure pump and the pressure generator are connected with one end of the refluxing separator through a return tube screw and the other end of the refluxing separator is connected with the screw double-head connector of the high pressure reaction tank through a draft tube screw; a higher pressure than that of the supercritical fluid extracting method is adopted, an ultrahigh pressure is adopted to substitute the supercritical fluid needed temperature cooperation and the damage of the partial substances under high temperature can be avoided; the device is a pure physical extracting process device, the temperature is not higher than 20 DEG C when the ultrahigh pressure is 600 MPa, the low temperature process purifying degree is higher than that of the supercritical fluid extracting method, and the device is an innovative process device for producing the ganoderan peptide injection.

Owner:FEATURE-TEC (WUXI) FILTRATION TECH CO LTD

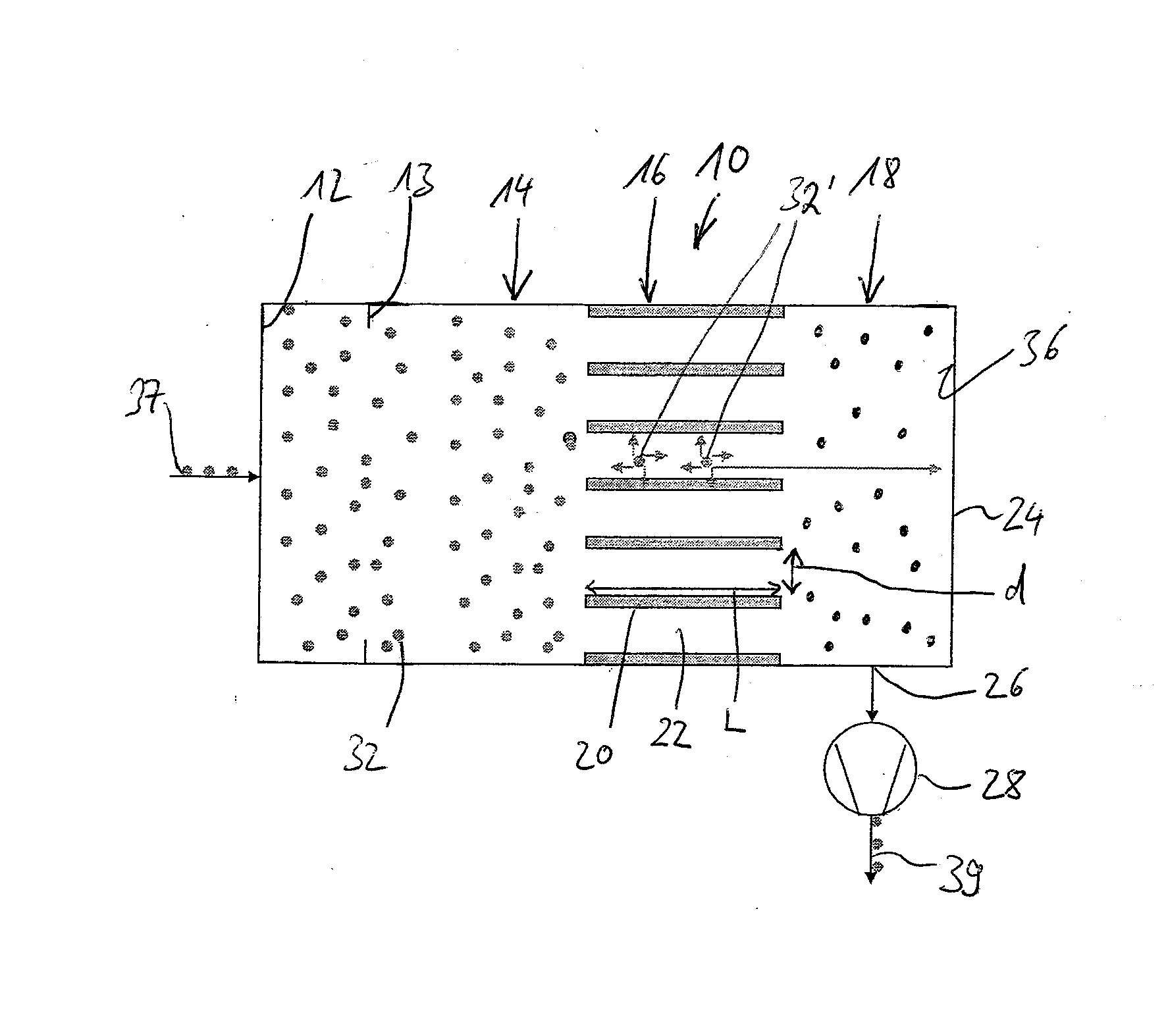

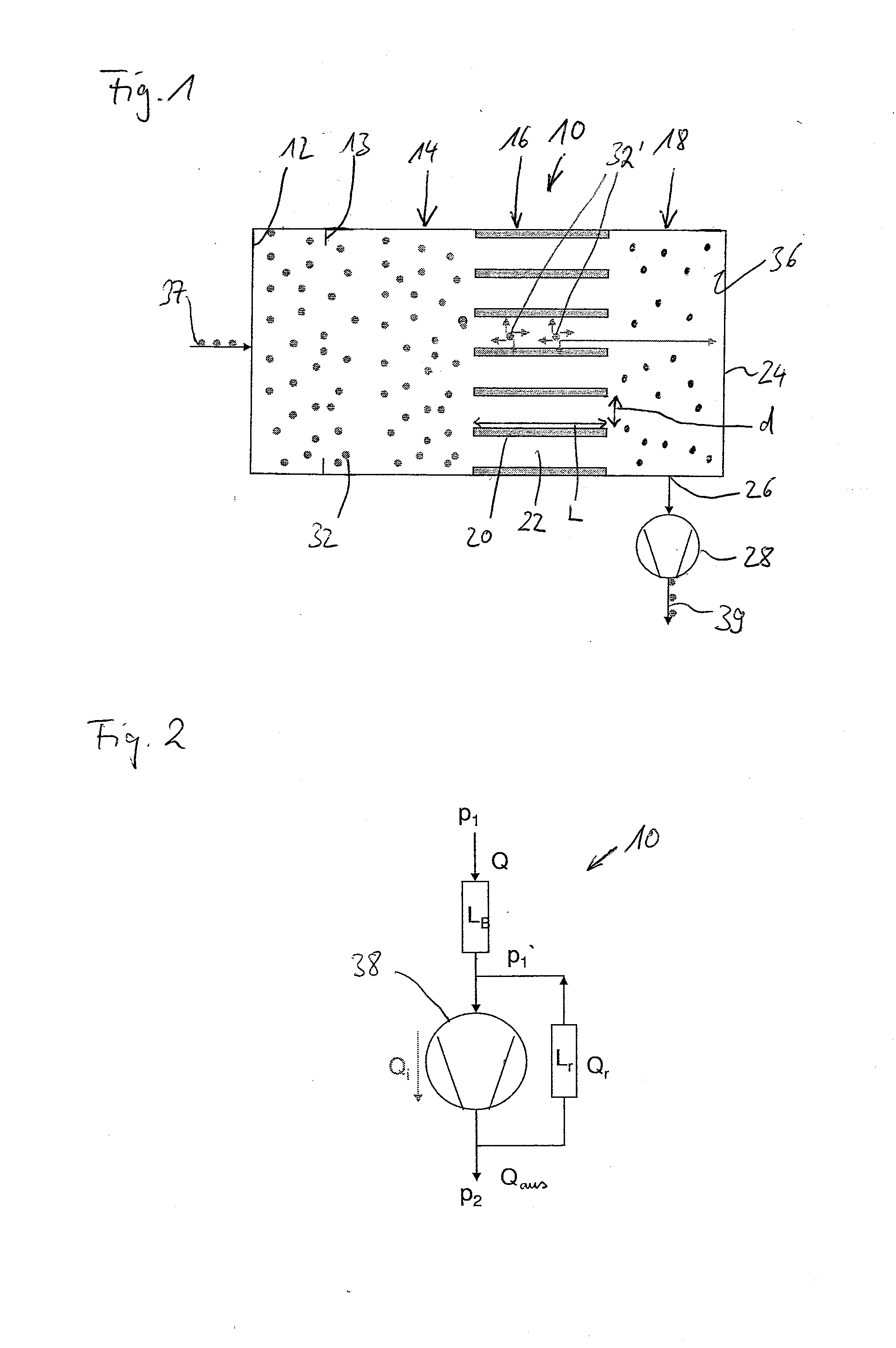

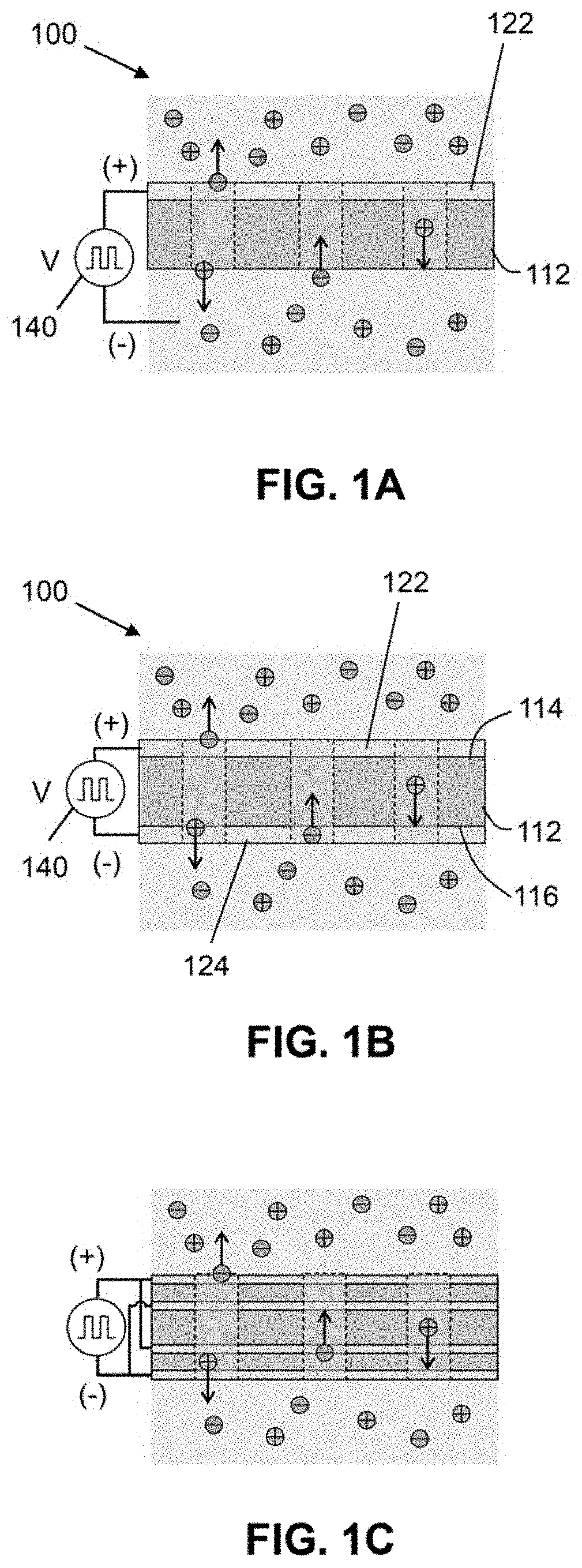

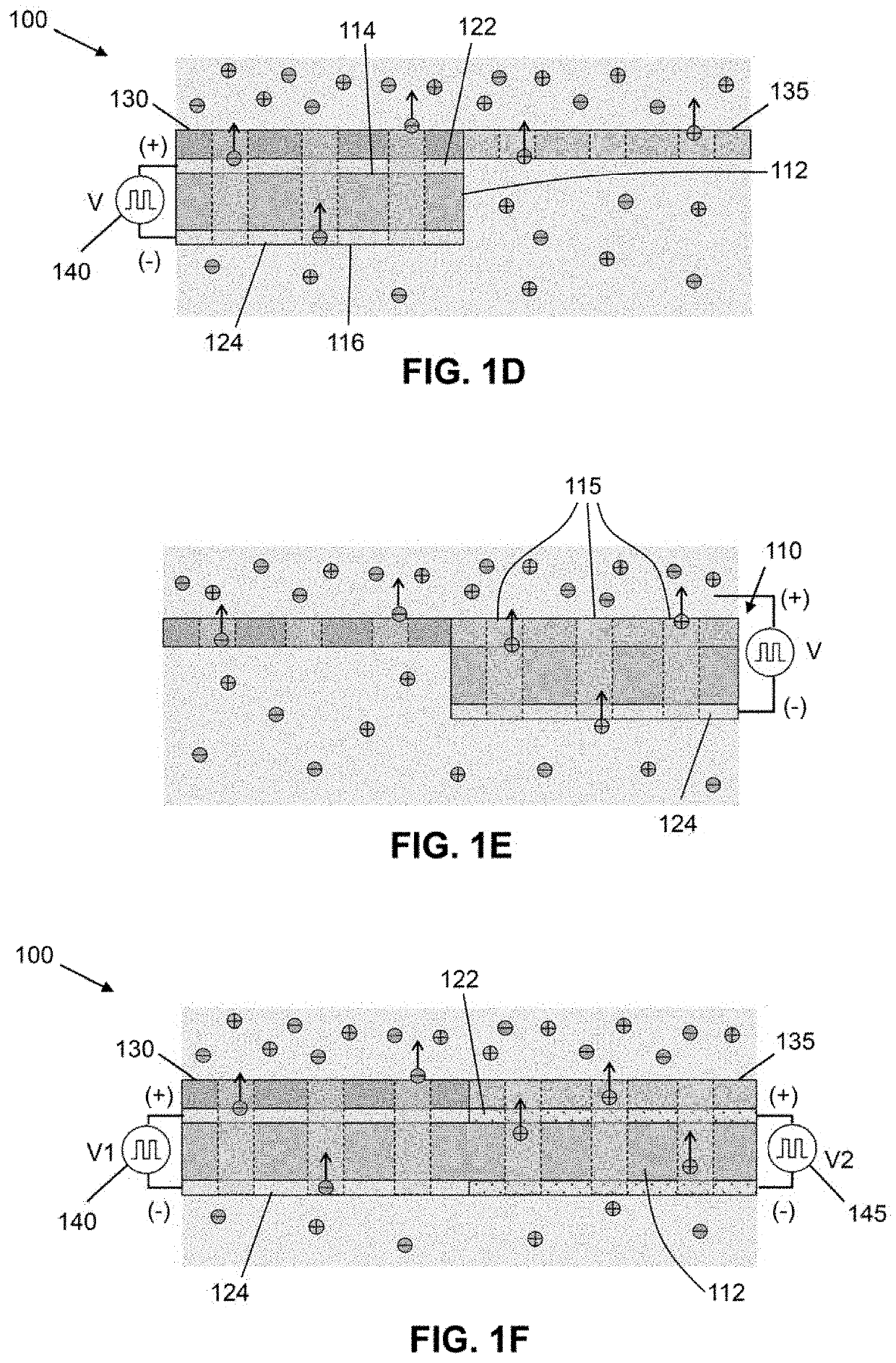

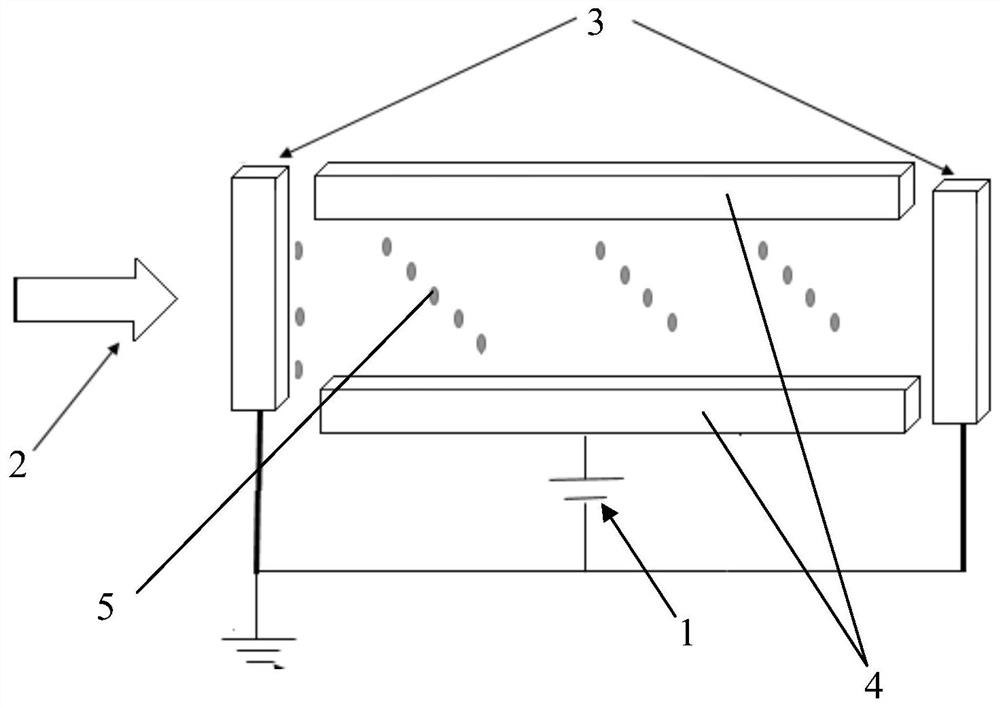

Ratchet-based ion pumping membrane systems

PendingUS20200402782A1Energy efficiencyMembranesGeneral water supply conservationIon currentIon pump

Described herein is an ion pump system implementing an electronic ratchet mechanism produced by modulating a spatially varying electric potential distribution that can result in a net ionic current and voltage. The ion pumping membrane system includes an ion-permeable layer integrated with ion-selective membranes. The electric potential distribution within the ion-permeable layer is modulated through external stimuli. When immersed in solution, ions within the ion-permeable layer experience a time varying, spatially asymmetric electric field distribution resulting in ratchet-driven direction pumping, which can be used in applications such as desalination.

Owner:RGT UNIV OF CALIFORNIA

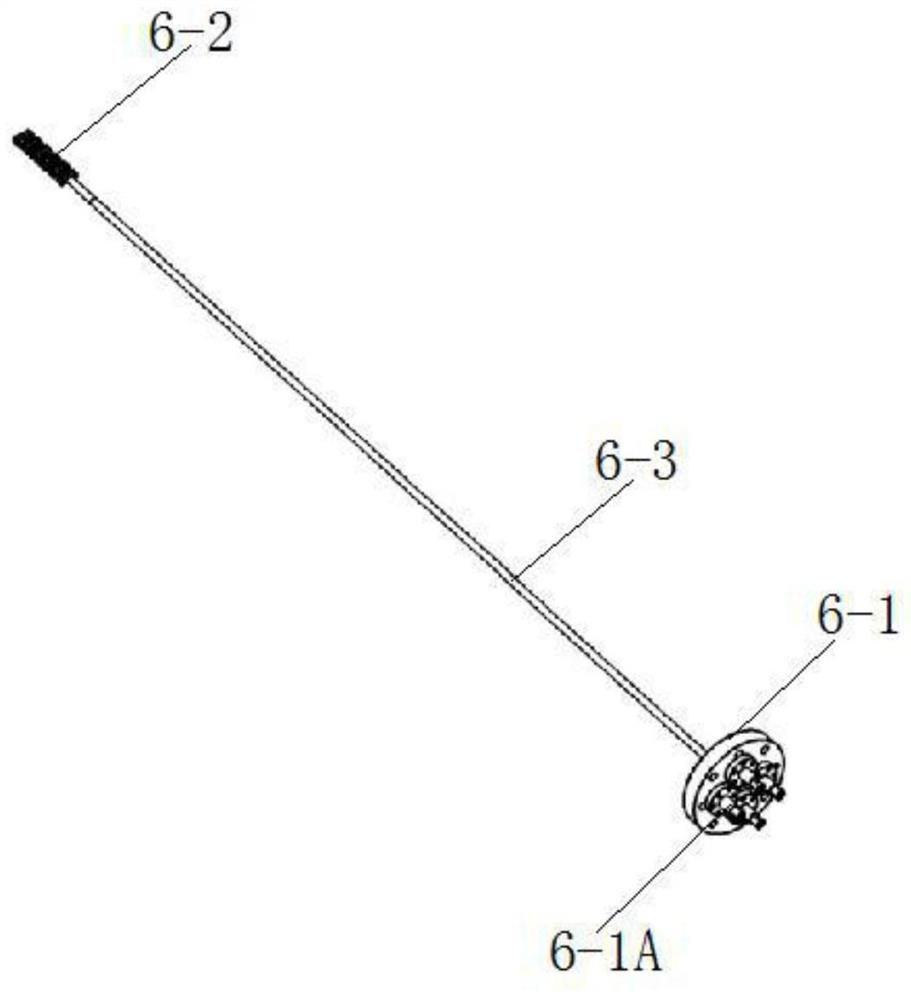

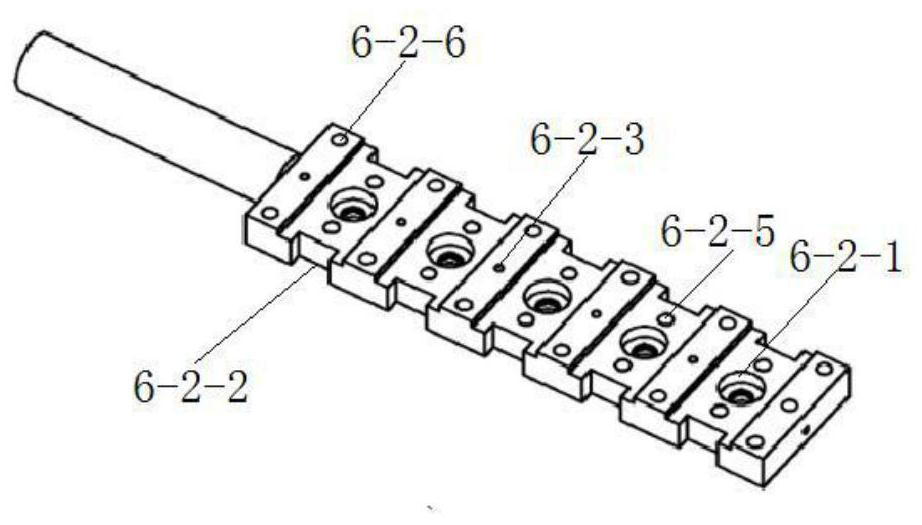

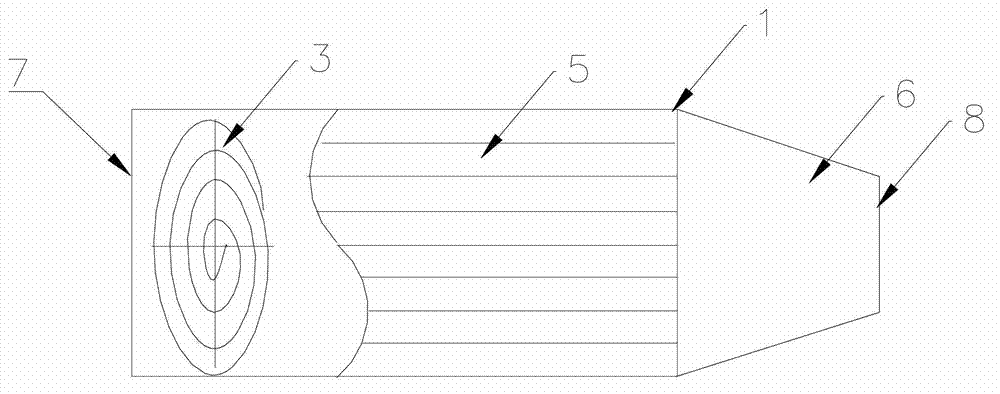

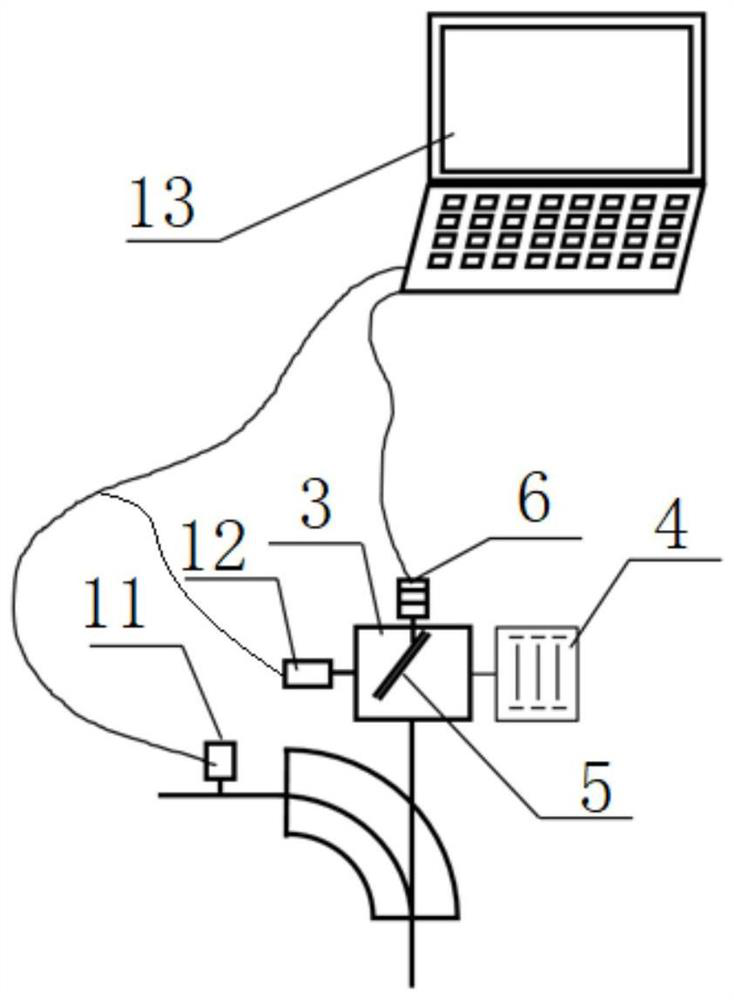

Hundred-kilovolt ultrafast electron diffraction device

InactiveCN112485276AReduce distanceReduce complexityMaterial analysis using wave/particle radiationPhotocathodeParticle physics

The invention discloses a flexible and compact hundred-kilovolt ultrafast electron diffraction device which comprises an electron gun body, and the electron gun body comprises an electron gun chamber,and a direct-current photocathode electron gun body, a magnetic lens, a sample chamber, a pump light back incidence unit, a Faraday cup chamber and an imaging device arranged in the electron gun chamber, a sample displacement table is fixedly installed on the side face of the sample chamber, a sample fixing device is fixedly arranged in the sample displacement table, and a titanium sublimation pump, an ion pump, a molecular pump and a vacuum measuring device are fixedly arranged at the bottom of the sample chamber. According to the flexible and compact hundred-kilovolt ultrafast electron diffraction device, the direct-current photocathode electron gun body and the sample holder are flexible and multifunctional, so that the whole device can carry out various experimental detection, the sample holder is detachable and replaceable, and some devices needing to be connected in series between the electron gun body and the sample chamber can be connected to the sample rod; the complexity ofthe system is reduced, and the distance between the cathode and the sample is further shortened.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

X-ray tube with passive ion collecting electrode

InactiveUS8351576B2Easy constructionLow costX-ray tube vessels/containerX-ray tube shielding arrangementsParticle physicsVoltage source

Owner:KONINK PHILIPS ELECTRONICS NV

Instant heating type ion pump maintenance device

PendingCN111654928AReduce maintenance costsEasy to makeHeater elementsIon diffusion discharge tubesThermodynamicsIon pump

The invention discloses an instant heating type ion pump maintenance device. The device comprises two thermistor aluminum shell heaters, wherein the two thermistor aluminum shell heaters are fixed ontwo opposite side surfaces of the ion pump through two aluminum shell fixators, the two aluminum shell fixators are connected and fixed through bolts and nuts, the two thermistor aluminum shell heaters are connected with a power supply through conducting wires, and the aluminum shell fixators are provided with wire passing holes for the conducting wires to pass through. According to the invention,the thermistor aluminum shell heater is fixed on the ion pump by adopting the two aluminum shell fixators, the two bolts and the two nuts, and is connected with the power supply through two high-temperature heat-resistant insulating rubber wires, the air attached to the interior of the ion pump is exhausted through high-temperature baking, and therefore the functions of the ion pump are rapidly recovered, the device is easy to manufacture, convenient to use and reusable, the maintenance cost of the ion pump is greatly saved, and large-scale application and popularization are facilitated.

Owner:INTEGRA TED SERVICE TECH SHANGHAI CO LTD

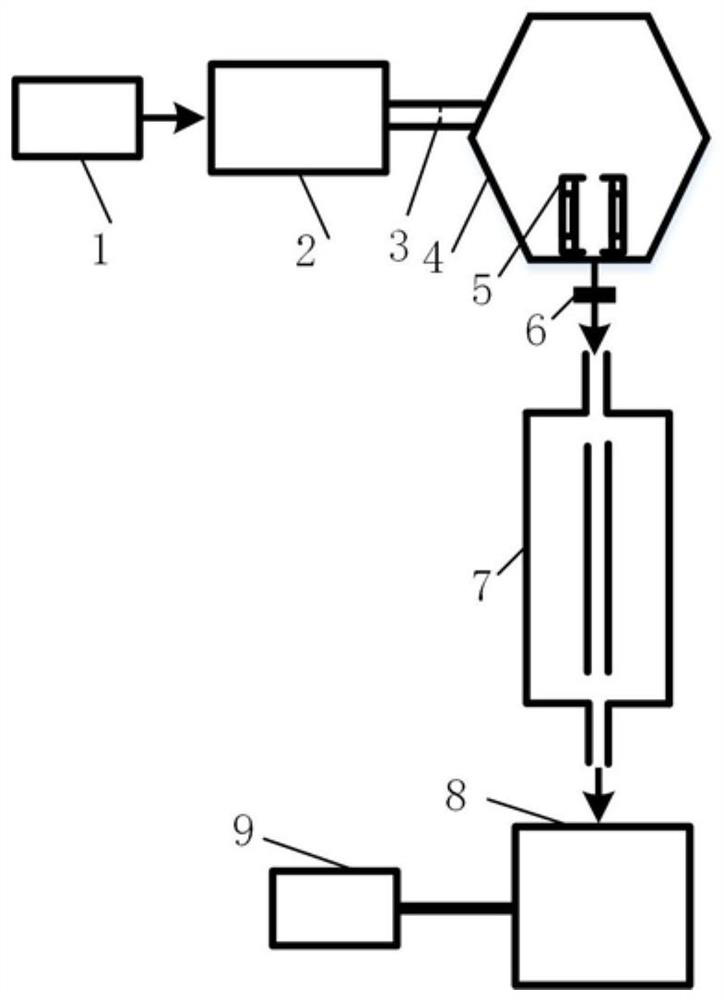

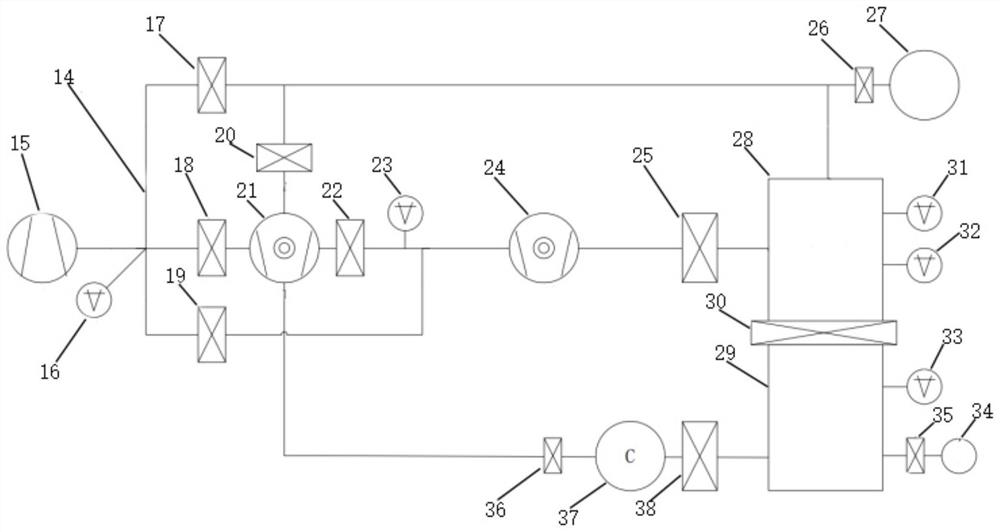

Device and method for testing permeation of hydrogen and isotopes thereof under corrosion synergy

PendingCN114414462AEfficient removalEasy to controlWeather/light/corrosion resistancePreparing sample for investigationMass analyzerAnion Pumps

The invention relates to a fusion reactor fuel technology, in particular to a hydrogen and isotope penetration test device and method under corrosion synergy, and the device comprises a gas treatment system, a corrosion system and a penetration detection system; the gas treatment system comprises a gas source, a mass flow meter and a 5A molecular sieve bed, the corrosion system comprises a heating unit and a corrosion kettle unit, the penetration test system comprises a hydrogen isotope standard leak hole, a quadrupole mass spectrometer, an ion pump, a molecular pump and a mechanical pump, and the method comprises the steps of sample pretreatment, sample loading, ventilation and vacuumizing, verification, gas replacement and data analysis. According to the device, impurity components in hydrogen isotope gas can be effectively removed, experimental conditions are more accurately controlled, experimental data are more effective, real-time online monitoring of the hydrogen isotope permeation flux in the corrosion process can be achieved, the obtained data are closer to the real service environment of materials, and more accurate data are provided for fusion reactor tritium breeding cladding design.

Owner:SOUTHWESTERN INST OF PHYSICS

Vacuum system and method for obtaining ultrahigh vacuum

PendingCN111394711AIncrease vacuumImprove the experimental effectVacuum evaporation coatingSputtering coatingUltra-high vacuumEngineering

Owner:SHANXI UNIV

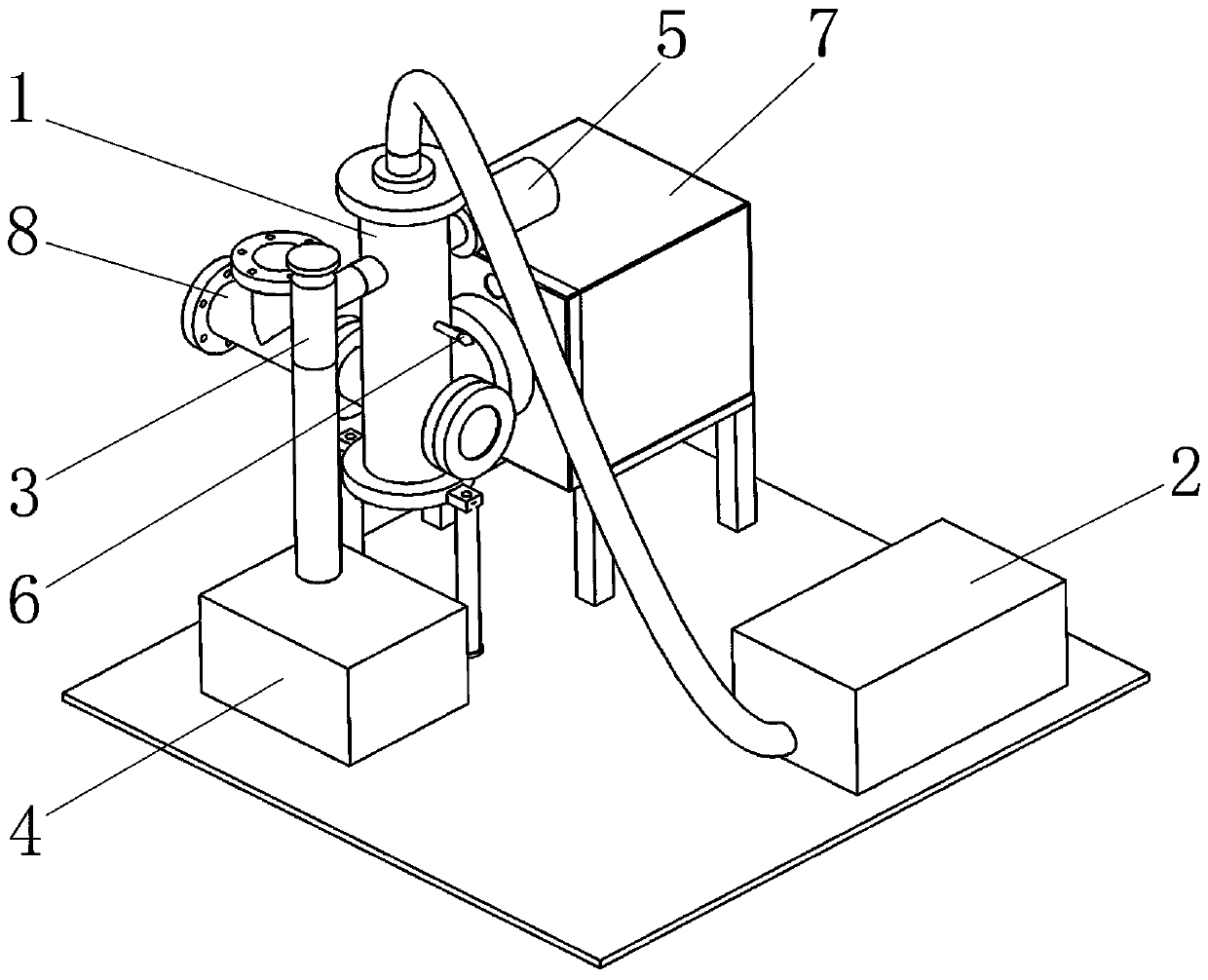

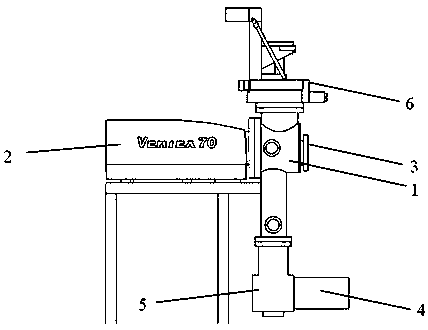

Sputter ion pump baking device

PendingCN112815630ANot easy to demagnetize at high temperatureStrong magnetismDrying solid materials without heatDrying chambers/containersEngineeringIon pump

The invention discloses a sputter ion pump baking device which comprises an ion pump body, wherein a pump cavity of the ion pump body is a vacuum cavity, an air exhaust unit is arranged in the vacuum cavity, an air exhaust channel is fixedly installed in the middle part of the upper end of the ion pump body and communicates with the interior of the vacuum cavity, a vacuum flange is fixedly connected to the upper end of the air exhaust channel, and a baking heater is arranged in the vacuum cavity of the ion pump body. For the sputter ion pump baking device disclosed by the invention, the baking heater is arranged in the pump cavity of the ion pump body and directly bakes and heats the inner wall of the inner pump body, so that the baking efficiency is high; in addition, the baking heater is far away from a magnet, and the magnet is not prone to high-temperature demagnetization, so that the magnet which is higher in magnetism and slightly low in temperature resistance can be selected; the baking heater of the sputter ion pump is located in the pump cavity of the ion pump body, and the baking heating effect on the air exhaust unit is remarkably improved.

Owner:SHANGHAI MITSUI GUANGZHONG VACUUM EQUIP CO LTD

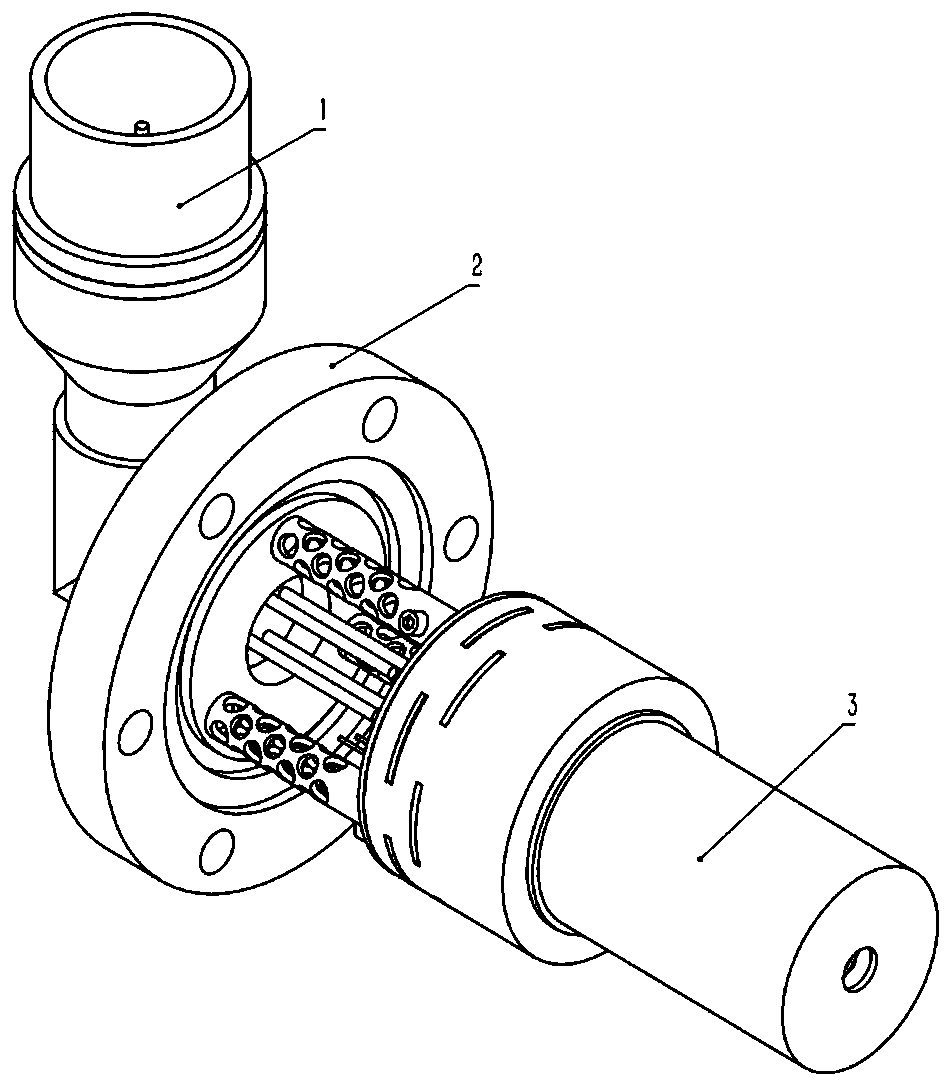

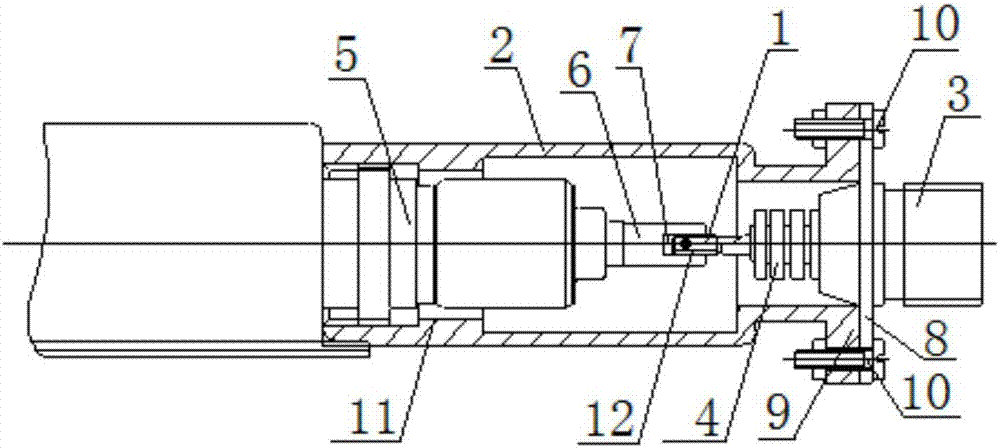

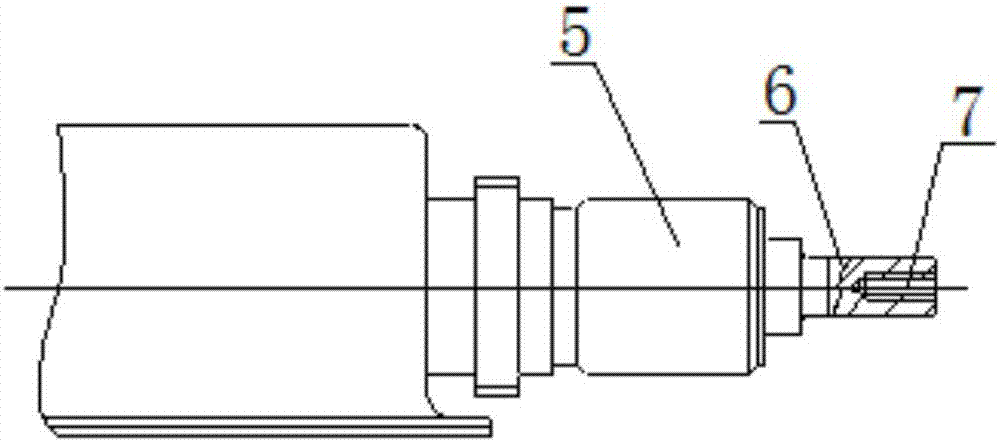

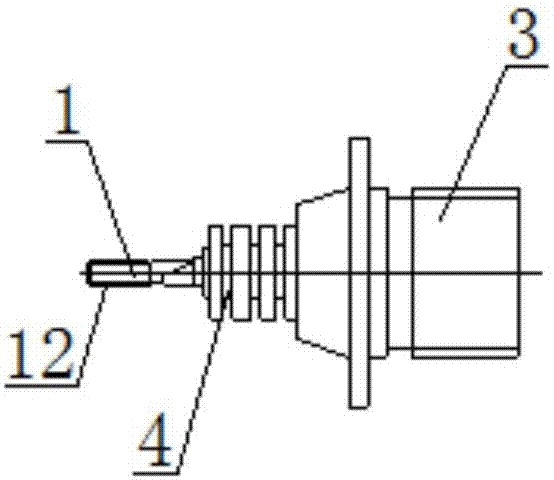

High-voltage electrode structure used for ionic pump

PendingCN107293899AFirmly connectedImprove securityCoupling device detailsSoldered/welded conductive connectionsElectrical conductorEngineering

The invention relates to the field of ultrahigh frequency vacuum electron devices, and discloses a high-voltage electrode structure used for an ionic pump. The high-voltage electrode structure comprises a grounding connecting cylinder and a standard high-voltage joint. The inner wall of one end of the grounding connecting cylinder is provided with internal threads cooperated with an ionic pump screwed joint. A connecting conductor end of the standard high-voltage joint is welded with a high-voltage terminal inner conductor. The outer periphery of the end of the high-voltage terminal inner conductor is provided with external threads cooperated with a binding post screw hole on the end of the ionic pump screwed joint. The standard high-voltage joint and the other end of the grounding connecting cylinder are in interference fit. The high-voltage electrode structure used for an ionic pump is firm in connection, good in security, simple in structure, and easy in processing and assembling.

Owner:湖北汉光科技股份有限公司

Portable air negative ion pump

The present invention belongs to the field of health care appliances, wherein a purpose of the present invention is to provide a portable air negative ion pump so as to meet requirements of people having high requirements on air quality. The technical scheme comprises that: the portable air negative ion pump comprises a shell, a honeycomb ceramic air negative ion generator, a screw rod air negative ion generator and a fan, wherein the honeycomb ceramic air negative ion generator and the screw rod air negative ion generator are installed inside the shell, the shell is provided with a fan air inlet and an air negative ion outlet, and air negative ions generated by the honeycomb ceramic air negative ion generator and the screw rod air negative ion generator can be output to air outside the shell through the air negative ion outlet with the fan. The portable air negative ion pump has the following advantages that: the portable air negative ion pump adopts the double air negative ion generators, and is suitable for people having high requirements on air quality; and the pump volume can further become small, carrying is convenient, and a problem of static electricity generated by metals or plastics can be avoided.

Owner:WUXI XINYUE ENVIRONMENTAL SCI DEV

Device and method for rapidly measuring surface electric field noise of metal

ActiveCN111856165AQuick changeReduce the difficulty of measurement manipulationNoise figure or signal-to-noise ratio measurementElectrical testingEngineeringCcd camera

The invention discloses a device for rapidly measuring the surface electric field noise of metal. The device comprises a vacuum cavity, a CCD (Charge Coupled Device) camera, a first vacuum angle valve, an ion pump, a vacuum baffle valve, a three-way vacuum connector, a second vacuum angle valve, a three-dimensional driver, a three-dimensional nano moving table and a to-be-measured sample holder. The device further comprises a chip supporting frame arranged in the vacuum cavity, a calcium atom furnace and a filter circuit board are arranged on the chip supporting frame, and an ion trap chip isarranged in a chip containing hole of the filter circuit board. The invention further discloses a method for rapidly measuring the surface electric field noise of metal. The method comprises the stepsof ion trapping and laser cooling, ion quantum state control, ion imaging through the CCD camera and data processing. According to the invention, a metal sample to be measured can be rapidly replacedwithout destroying the vacuum degree of the ion trap; and meanwhile, under the condition that the measurement operation difficulty is reduced, a simpler and faster method is provided for detecting the surface electric field noise of the metal sample to be measured through ion imaging based on the CCD camera.

Owner:INNOVATION ACAD FOR PRECISION MEASUREMENT SCI & TECH CAS

Vacuum maintaining device for hydrogen atom maser and hydrogen atom maser

The invention discloses a vacuum maintaining device for a hydrogen atom laser, which comprises a neck channel arranged between an ionization bubble and an atom storage bubble, at least one adsorption pump and an ion pump, the ion pump is communicated with the adsorption pump, and the vacuum maintaining device is characterized in that the number of the adsorption pump is at least one; and each adsorption pump is arranged on the side edge of the neck channel and is independently communicated with the neck channel. According to the technical scheme, when the adsorbent is baked, activated and heated, a very complex cooling circulation system is not needed to cool the ionization bubble, the state selection magnet and the nearby shell, a large amount of heat energy is prevented from being transmitted to the ionization bubble, the state selection magnet and other components, and the vacuum failure of the hydrogen atom laser or the magnetic loss of the state selection magnet is avoided. And the adsorption pump is not sleeved on the neck channel any more, so that the volume structure is more compact, and the volume and the weight of the adsorption pump are greatly reduced. And after the valve and the flange are additionally arranged on the adsorption pump, the adsorption pump can be conveniently backed up, disassembled and assembled under the condition that the vacuum environment of the hydrogen atom laser is not damaged, and the service life of the hydrogen atom laser is effectively prolonged.

Owner:SHANGHAI PHOTONLINK ELECTRONIC TECH CO LTD

Device and method for inhibiting differential system inflation airflow effect

PendingCN113301704ASolve Airborne ProblemsSolving Vacuum Span ProblemsLinear acceleratorsNuclear energy generationEngineeringSuperconducting accelerator

The invention relates to a device for inhibiting an inflation airflow effect of a differential system. The output end of a differential vacuum system is connected with one end of a deflection magnet and one end of a vacuum chamber through a transmission pipeline; the other ends of the deflection magnet and the vacuum chamber are connected with the output end of the superconducting accelerator through a transmission pipeline; a the superconducting accelerator is used for outputting charged particle beams; and an extraction system is arranged above the deflection magnet and the vacuum chamber, and the input end of the extraction system is communicated with the deflection magnet and the upper portion of the middle of the vacuum chamber through a transmission pipeline. The invention further relates to a method for restraining the inflation airflow effect of the differential system, and the method comprises the steps that the inclination angle of the spoiler is set to be the optimal restraining angle; a beam output by a superconducting accelerator is deflected by a deflection magnet and a vacuum chamber and then enters a differential vacuum system, and He gas output by a differential pipeline enters a collection vacuum chamber through the deflection magnet and the vacuum chamber; and the He gas flow collected in the collection vacuum chamber is disturbed by a spoiler and then is pumped out by a three-pole sputtering ion pump.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

Ultrahigh vacuum infrared spectrum in-situ analysis system

PendingCN110857912AEnables in situ analysisSolve matching problemsMaterial analysis by optical meansFt ir spectraUltra-high vacuum

The invention discloses an ultrahigh vacuum infrared spectrum in-situ analysis system. The system comprises an infrared spectrometer. The system further comprises a sample control device and an ultrahigh vacuum obtaining device which are connected with an ultrahigh vacuum sample chamber; ultrahigh vacuum KBr infrared windows are formed at two sides of the ultrahigh vacuum sample chamber; the ultrahigh vacuum obtaining device comprises an oil-free mechanical pump, a turbo molecular pump and a sputtering ion pump; the sample control device controls a sample holder below the sample control devicethrough a micrometer head and by means of a shaft and a rod; the sample control device is in sealed connection with the ultrahigh vacuum sample chamber through metal; and the sample control device transmits forces and motion through a corrugated pipe. With the ultrahigh vacuum infrared spectrum in-situ analysis system of the invention adopted, the infrared spectrum in-situ analysis of a materialsurface in a simulated space environment is realized.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Compact low-energy irradiation accelerator

PendingCN112863730AReduce volumeLow priceLinear acceleratorsIrradiation devicesNuclear engineeringWaveguide

The invention discloses a compact low-energy irradiation accelerator, and belongs to the technical field of particle accelerators, the compact low-energy irradiation accelerator comprises an electron gun, a standing wave edge coupling accelerating tube, a scanning magnet and a scanning box which are sequentially arranged from top to bottom, the electron gun is connected with the standing wave edge coupling accelerating tube through a first waveguide, and the standing wave edge coupling accelerating tube is connected with the scanning magnet through a second waveguide; a focusing coil is arranged on the outer side of the standing wave edge coupling accelerating tube, and the accelerating tube is connected with a magnetron through a third waveguide; the first waveguide, the second waveguide and the third waveguide are all connected with an air exhaust port of the ion pump; and the scanning box is equipped with a scanning vacuum chamber,and a titanium window is fixedly arranged at the bottom end of the scanning box. The compact low-energy irradiation accelerator is small in size and relatively low in price.

Owner:ANDESON SUPERCONDUCTING RF ACCELERATOR TECHCO +1

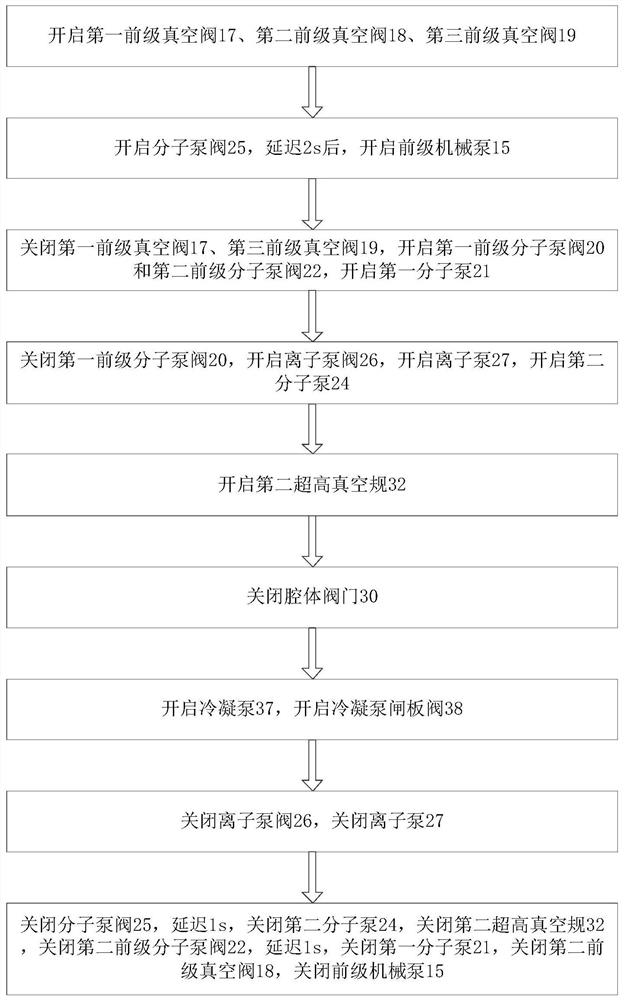

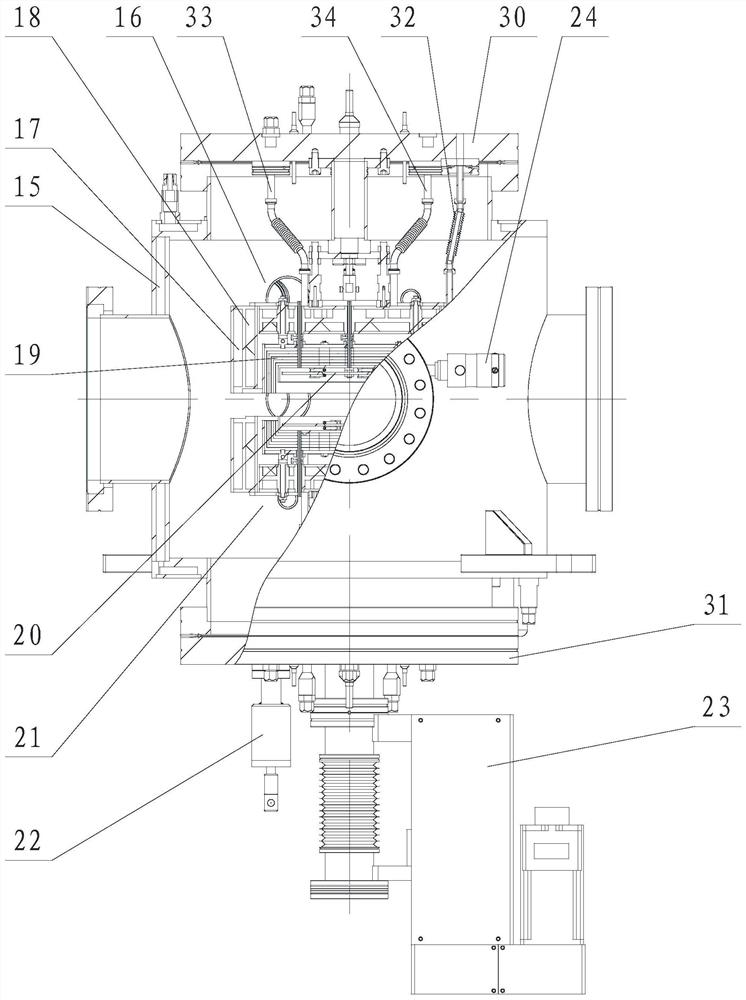

arpes vacuum system, vacuum safety interlock system and vacuum safety interlock method

ActiveCN108196502BImprove protectionProgramme control in sequence/logic controllersAngle-resolved photoemission spectroscopyEngineering

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

A high temperature and high vacuum annealing furnace

ActiveCN113493904BAvoid getting lostIncrease usageVacuum evaporation coatingSputtering coatingUltra-high vacuumIon pump

The invention relates to vacuum coating experimental equipment, specifically a high-temperature and high-vacuum annealing furnace, in which an ion pump, an annealing chamber cavity, a sampling chamber cavity, and a molecular pump are connected in sequence, and the molecular pump is connected to a mechanical pump through a pipeline. Between the pump and the cavity of the annealing chamber, between the cavity of the annealing chamber and the cavity of the sampling chamber, and between the cavity of the sampling chamber and the molecular pump, there are flap valves; the cavity of the annealing chamber is equipped with a fixed upper heater And the lower heater that can be lifted up and down, the cavity of the sampling chamber is equipped with a multi-layer sample library that can be lifted up and down, and a manual transfer rod manipulator is installed on one side of the cavity of the sampling chamber. The invention can quickly complete the sample exchange with the annealing chamber under vacuum conditions, ensuring that the annealing chamber is always in a high vacuum state. In the high-temperature and high-vacuum annealing furnace of the present invention, the cold-state ultimate vacuum degree of the annealing chamber can reach 10 ‑8 Pa ultra-high vacuum, when heated at 1600°C, the thermal vacuum degree can reach 10 ‑ 6 Pa, and it can realize the long-term heat preservation annealing of the sample not higher than 1600 °C.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

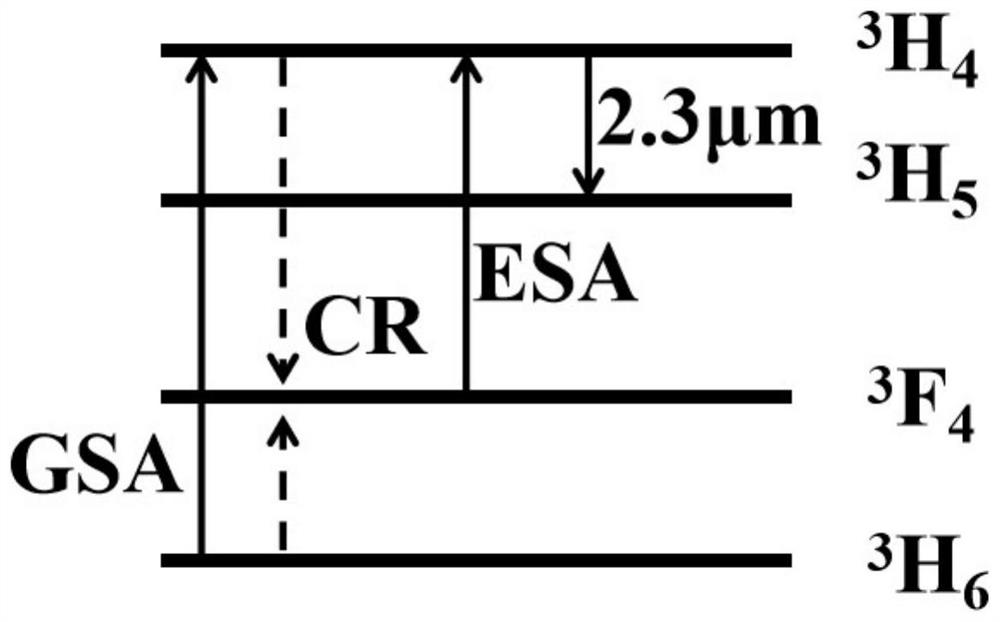

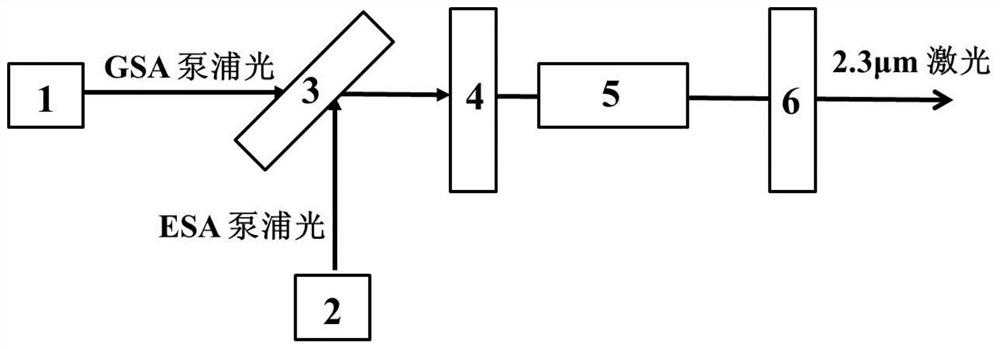

A dual-wavelength pumped thulium-doped laser based on gsa and esa

The invention discloses a GSA and ESA dual-wavelength pumped thulium-doped laser, which is composed of a GSA pump source, an ESA pump source, a pump light beam combiner, an input mirror, a thulium-doped laser medium and an output mirror. GSA is the ground state absorption, corresponding to the thulium-doped laser medium 3 h 6 → 3 h 4 transition, ESA is excited state absorption, corresponding to 3 f 4 → 3 h 4 transition. Pumped by a GSA pump source, based on 3 h 6 → 3 h 4 The ground state absorption caused by the transition will change the Tm in the thulium-doped laser medium 3+ ion pumping to 3 h 4 Energy level, realize the first layout of the number of particles in this energy level. At the same time, the cross-relaxation process between thulium ions will further realize the metastable state 3 f 4 The particle population layout of the energy levels. Pumped by the ESA pump source, using 3 f 4 → 3 h 4 The excited state absorption caused by the transition will 3 f 4 The number of particles accumulated on the energy level is precisely pumped to 3 h 4 energy level, achieve 3 h 4 The second layout of the number of energy level particles. The scheme of pumping thulium-doped laser medium by GSA and ESA dual-wavelength that the present invention proposes can effectively improve 3 h 4 → 3 h 5 The layout of the number of particles on the energy level of the transition increases the laser output power in the 2.3-2.5μm band.

Owner:XUZHOU NORMAL UNIVERSITY

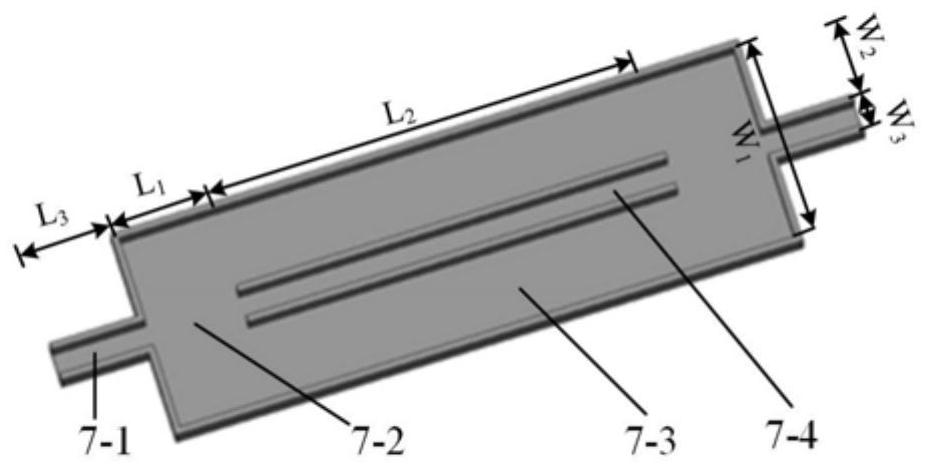

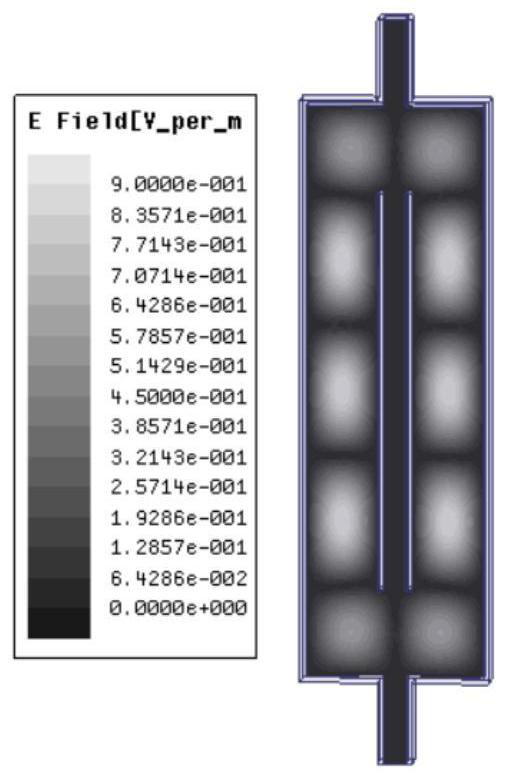

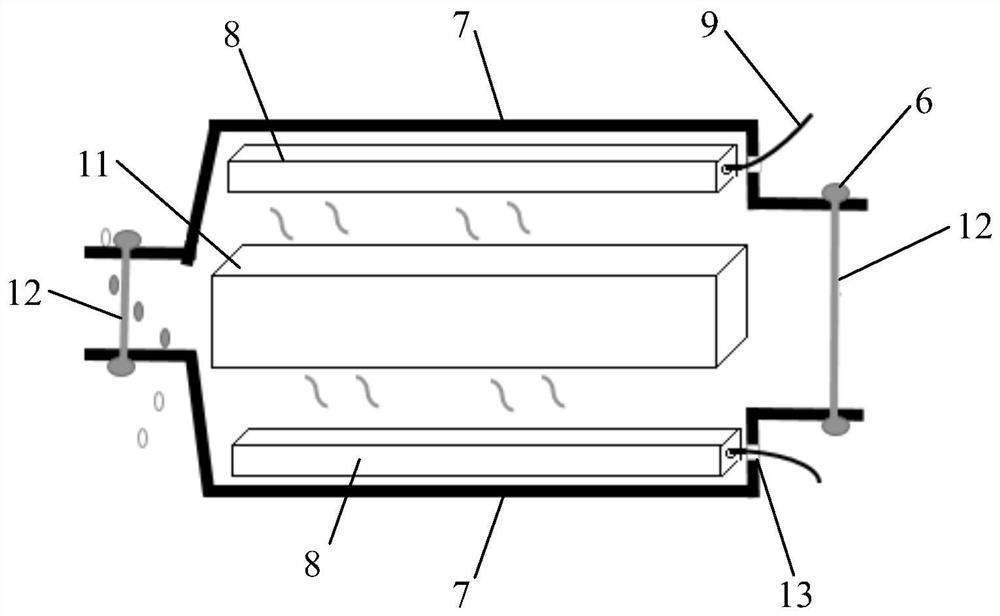

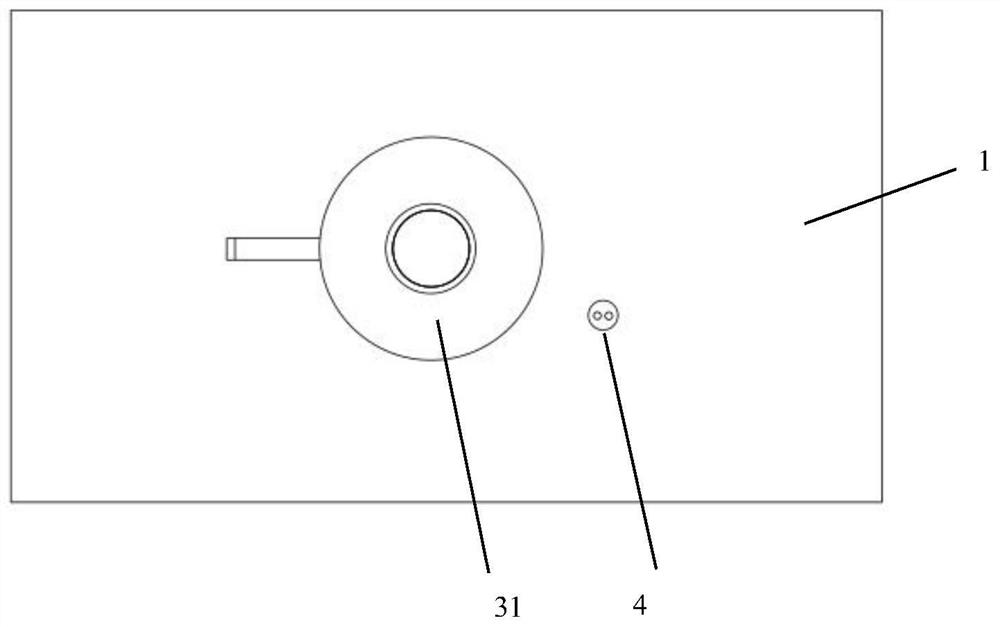

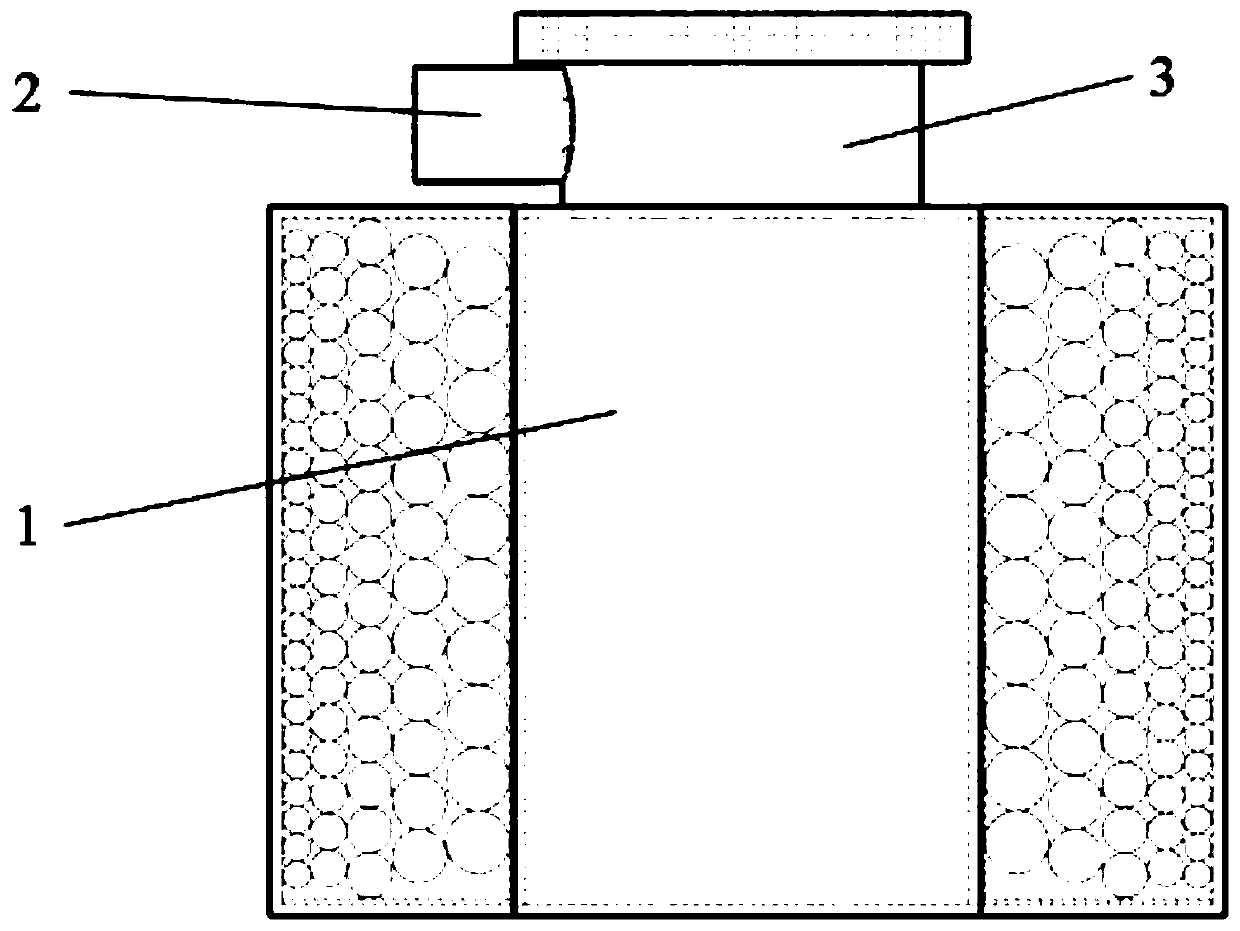

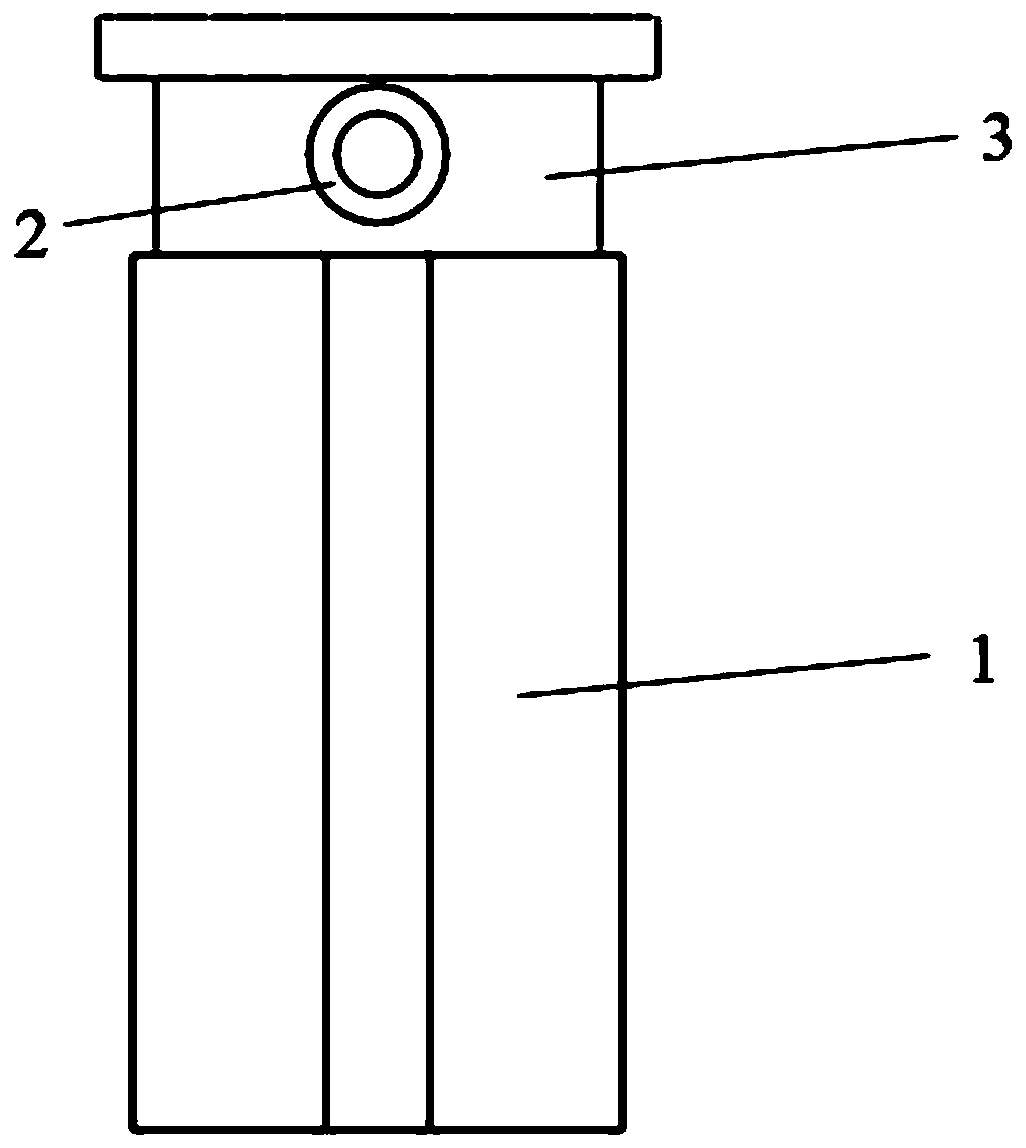

A Novel Sputtering Ion Pump for Anode Barrel Array

ActiveCN109360780BIncrease pumping rateIncrease pumping speedIon diffusion discharge tubesUltra-high vacuumEngineering

A new type of sputtering ion pump with an anode cylinder array, which is characterized in that it includes a casing, an air inlet is provided on the top of the casing, magnets are installed on the left and right sides of the casing, and the anode cylinder array is insulated and installed inside the casing. , and there are cathode plates on both sides of the anode cylinder array. The high-voltage electrode is fixedly assembled with the air inlet. Its positive potential is connected to the anode cylinder array, and its zero potential is connected to the two cathode plates respectively. The cathode plate and the anode cylinder array form a A chamber used to extract gas. The anode cylinder array is composed of multiple groups of anode cylinders. The closer the anode cylinder is to the air inlet, the larger the radius, the lower the height, and the larger the gap between the upper and lower surfaces of the anode cylinder and the cathode plate. , the farther the anode cylinder is from the air inlet, the smaller the radius, the higher the height, and the smaller the gap between the upper and lower surfaces of the anode cylinder and the cathode plate; the present invention can greatly improve the air pumping per unit volume in the sputtering ion pump speed, and can maintain a high pumping speed even in ultra-high vacuum environments.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com