Patents

Literature

165results about How to "Increase pumping speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

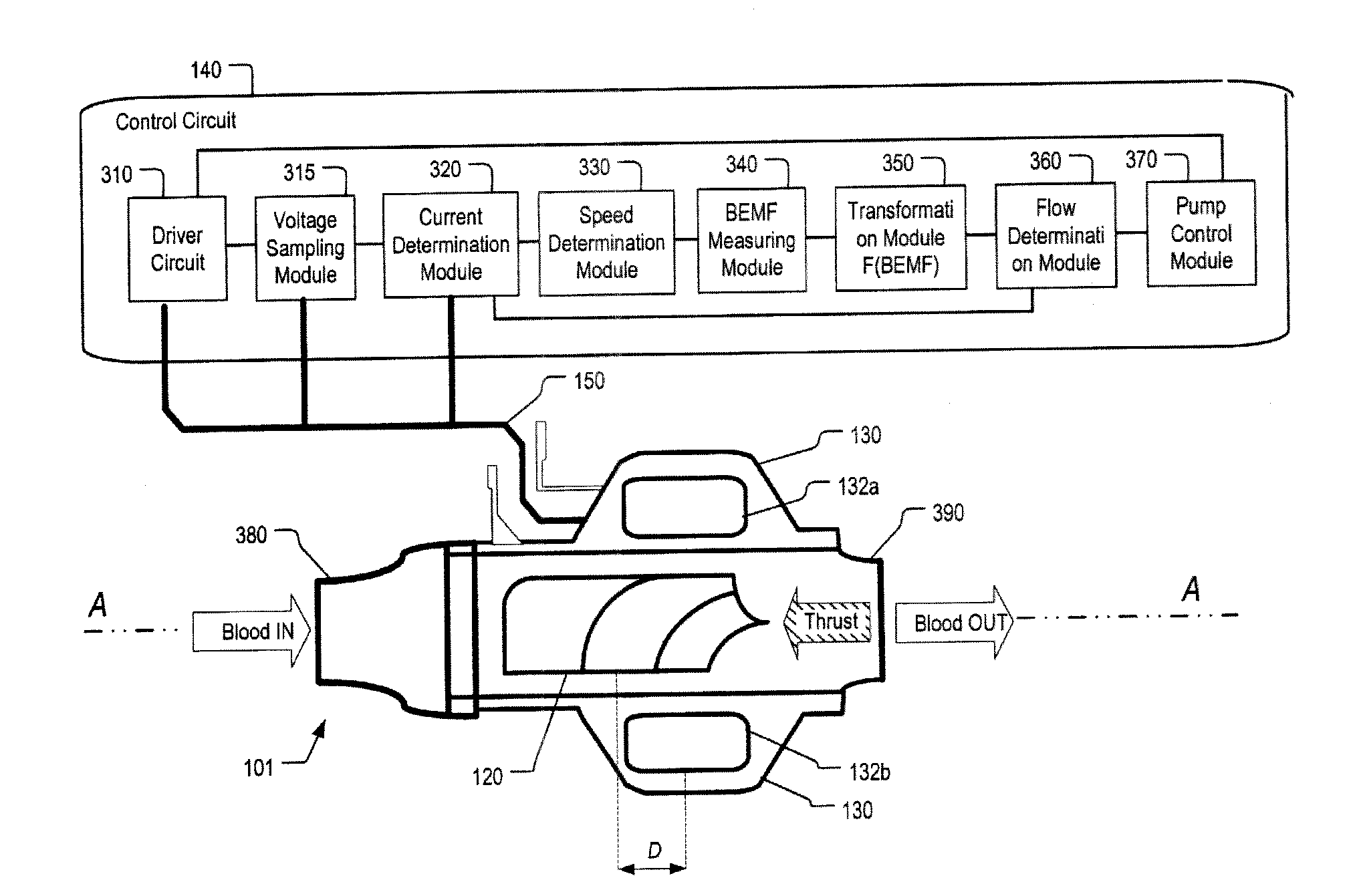

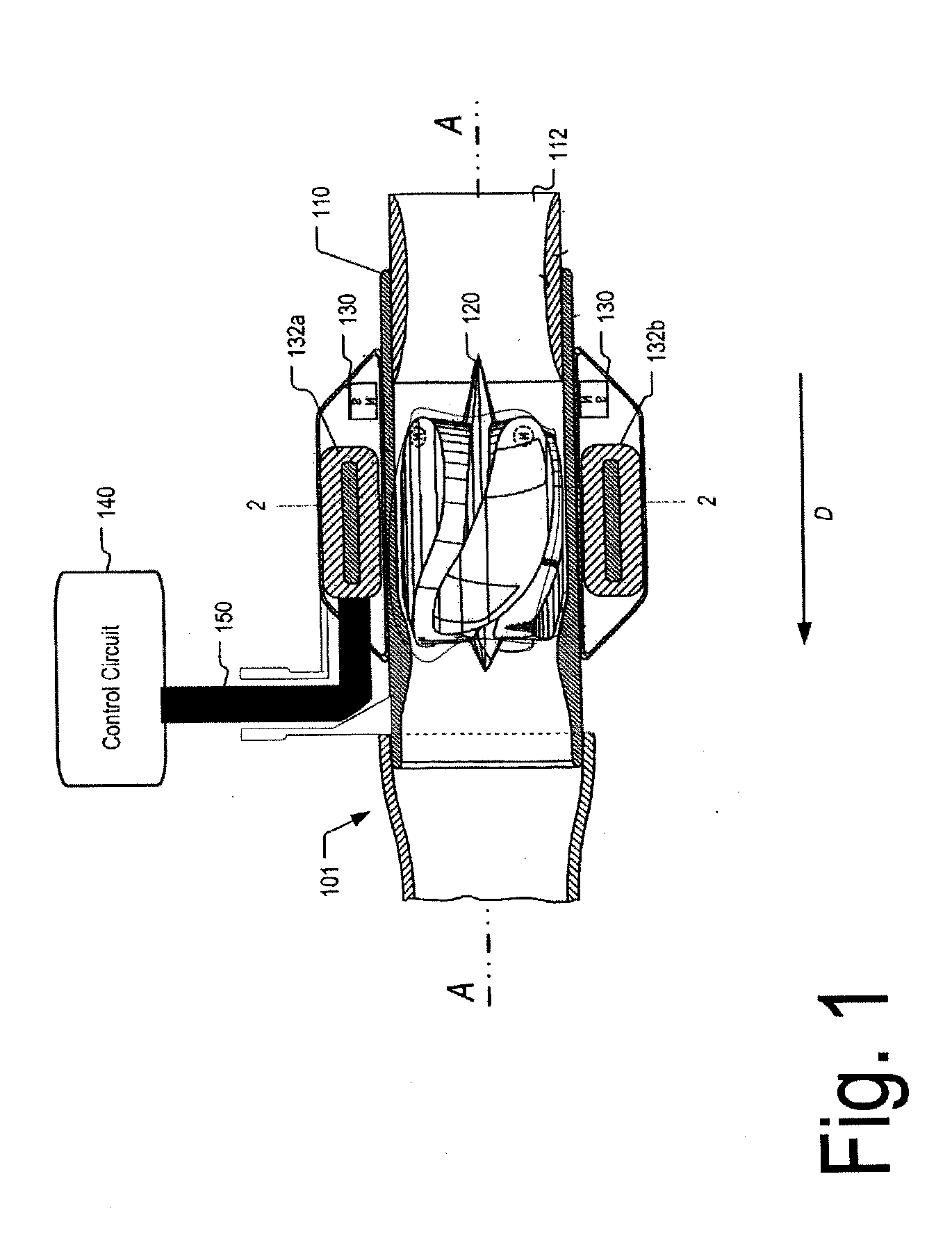

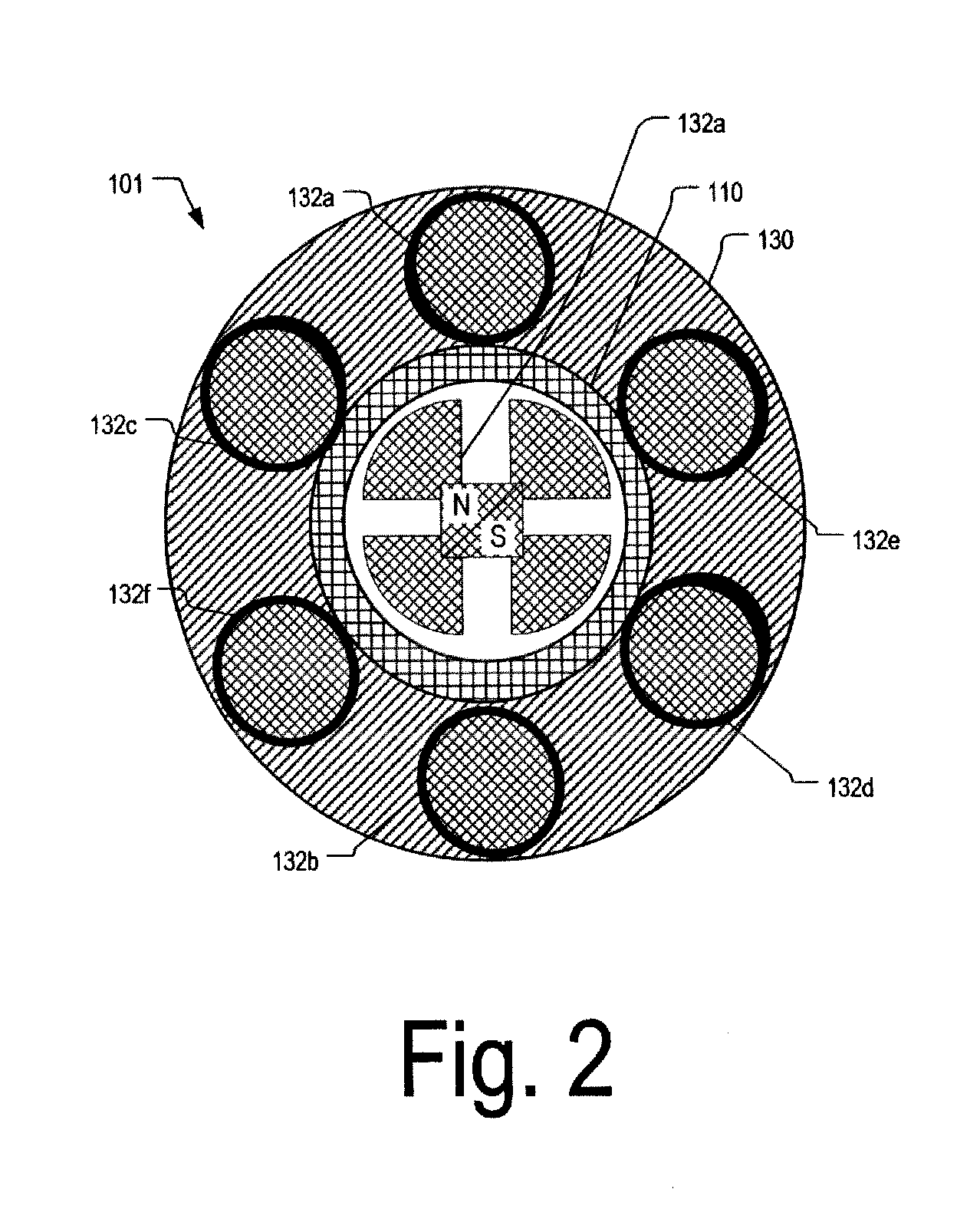

Suction detection on an axial blood pump using bemf data

ActiveUS20140100413A1Increase pumping speedShorten speedControl devicesBlood pumpsPR intervalBlood pump

The presence or absence of a suction condition in an implantable blood pump is determined at least in part based on a parameter related to flow, such as a parameter related to thrust on the rotor of the pump. A local extreme of the parameter representing the minimum flow during ventricular diastole in an earlier interval is used to establish a threshold value. A value of the parameter representing the minimum flow during ventricular diastole in a later interval is compared to this threshold. If the comparison indicates a substantial decline in the minimum flow between the earlier and later intervals is associated with a suction condition. During the absence of a suction condition, the threshold is continually updated, so that the system does not indicate presence of a suction condition if the flow decreases gradually.

Owner:HEARTWARE INC

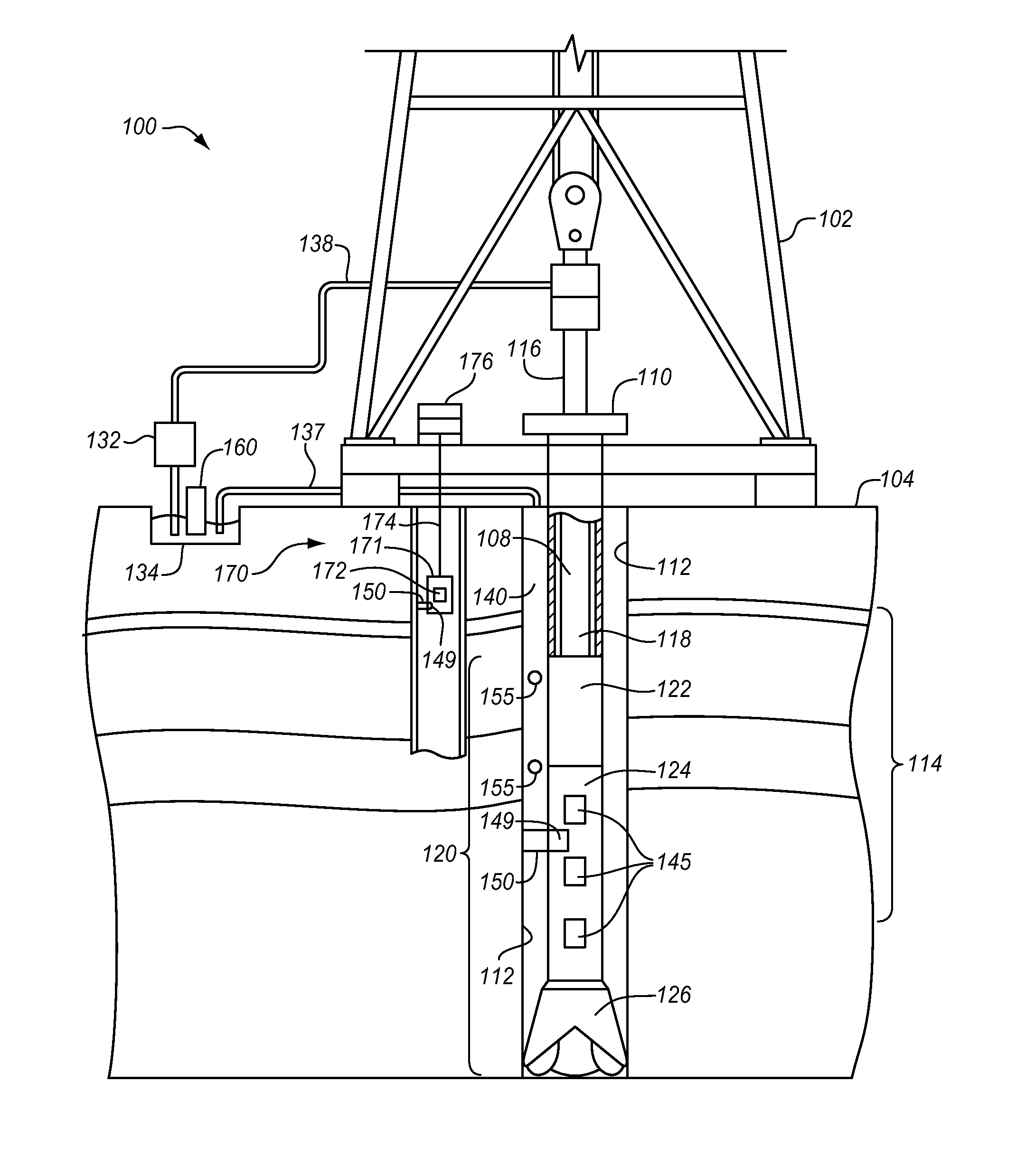

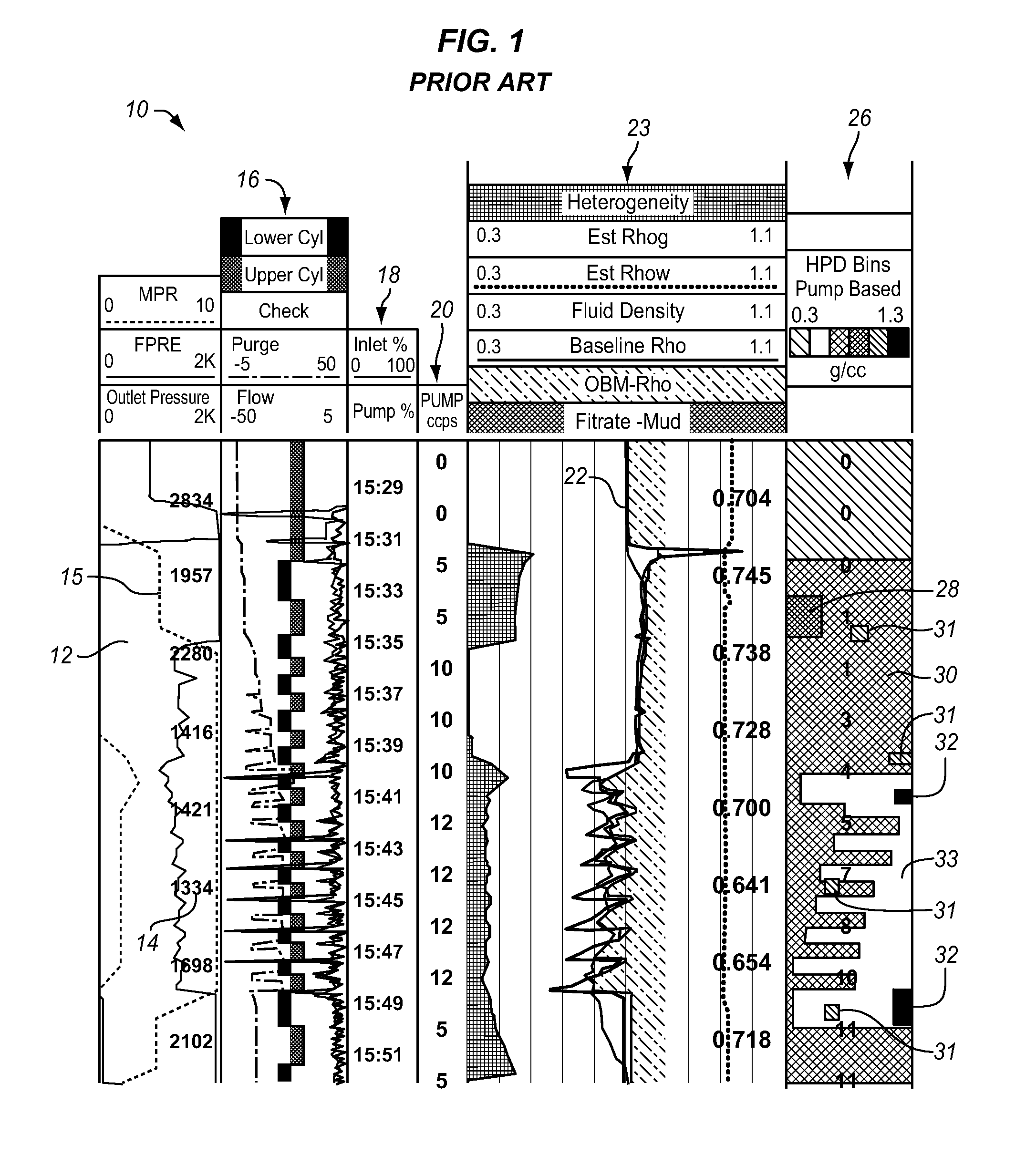

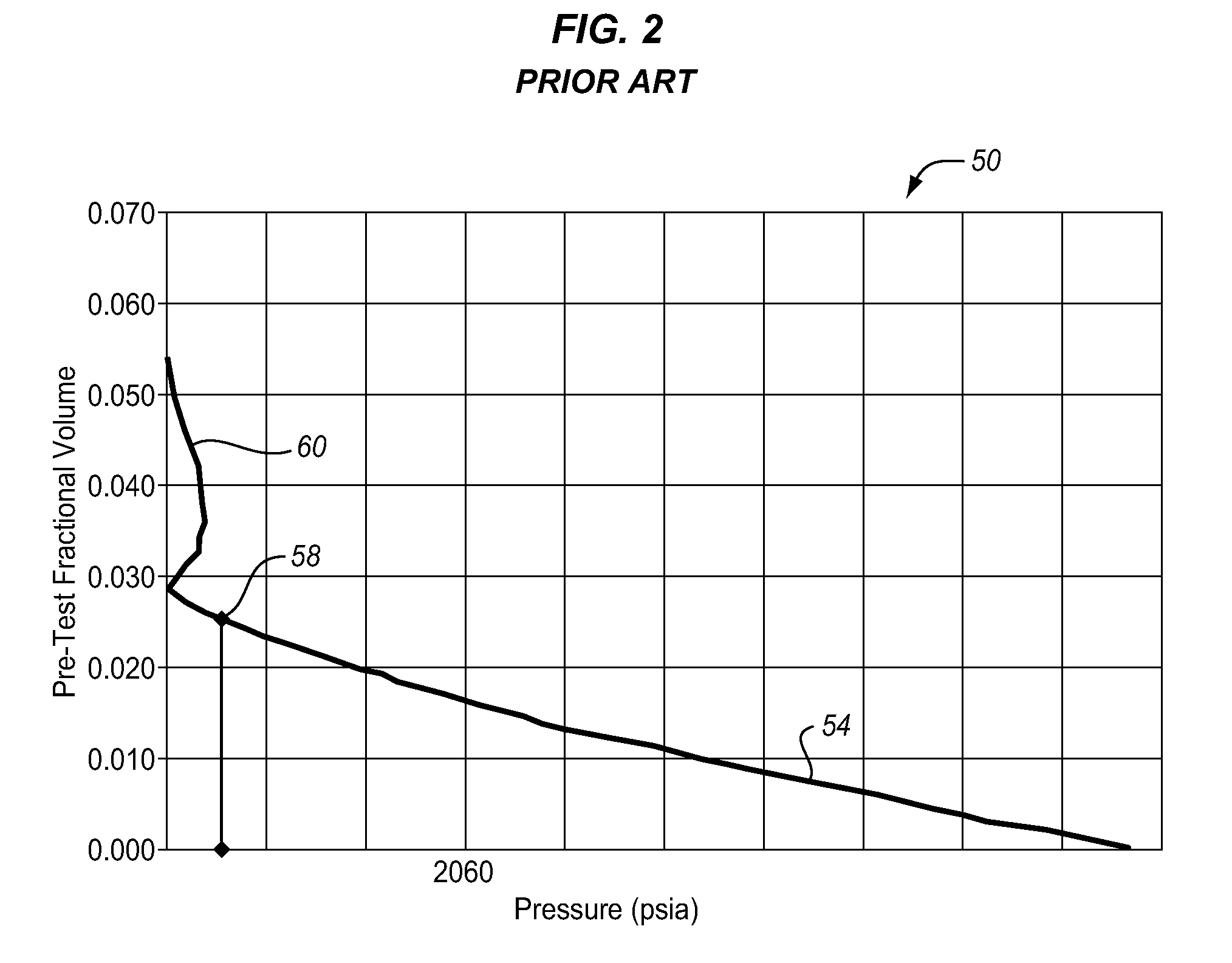

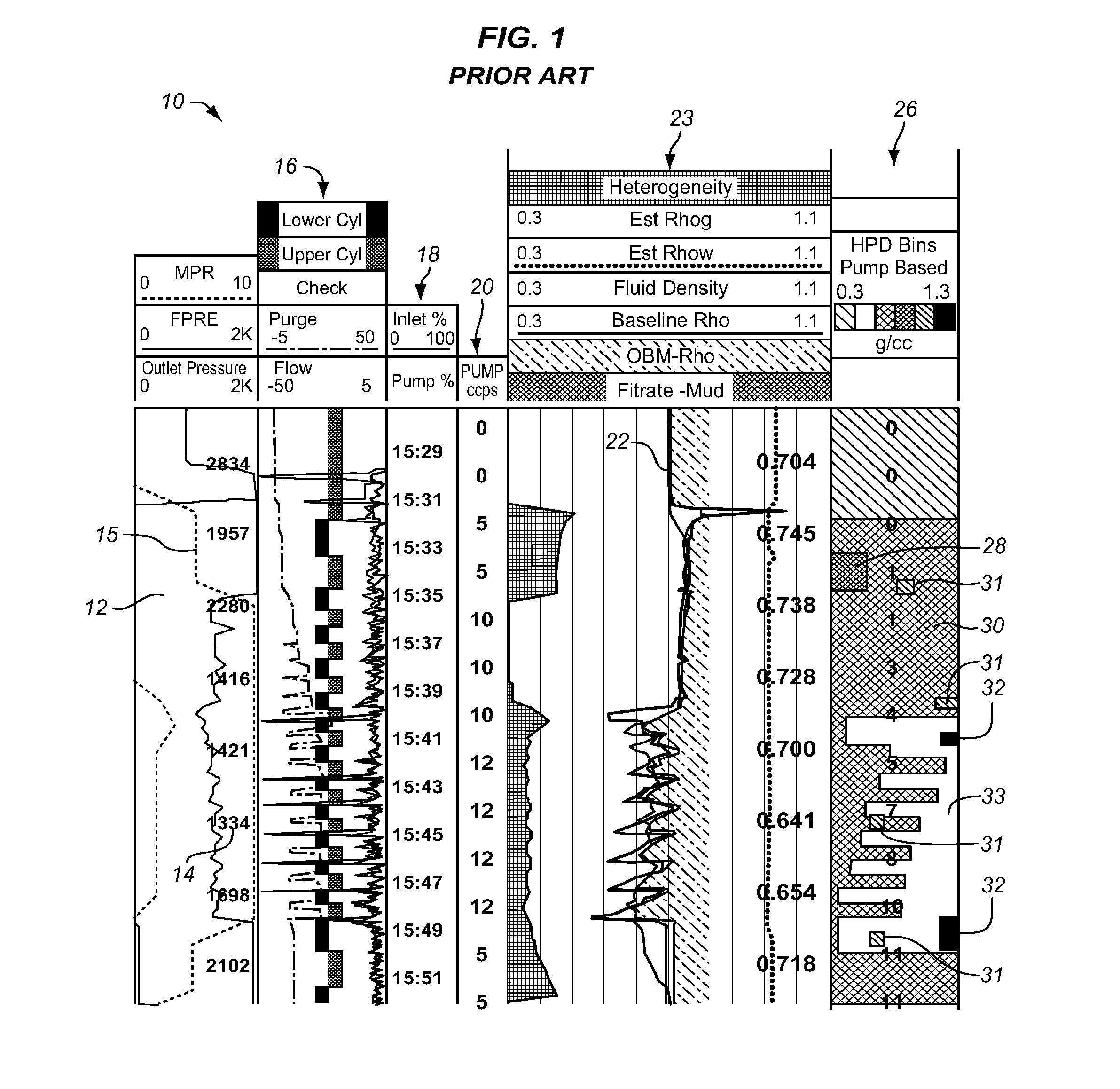

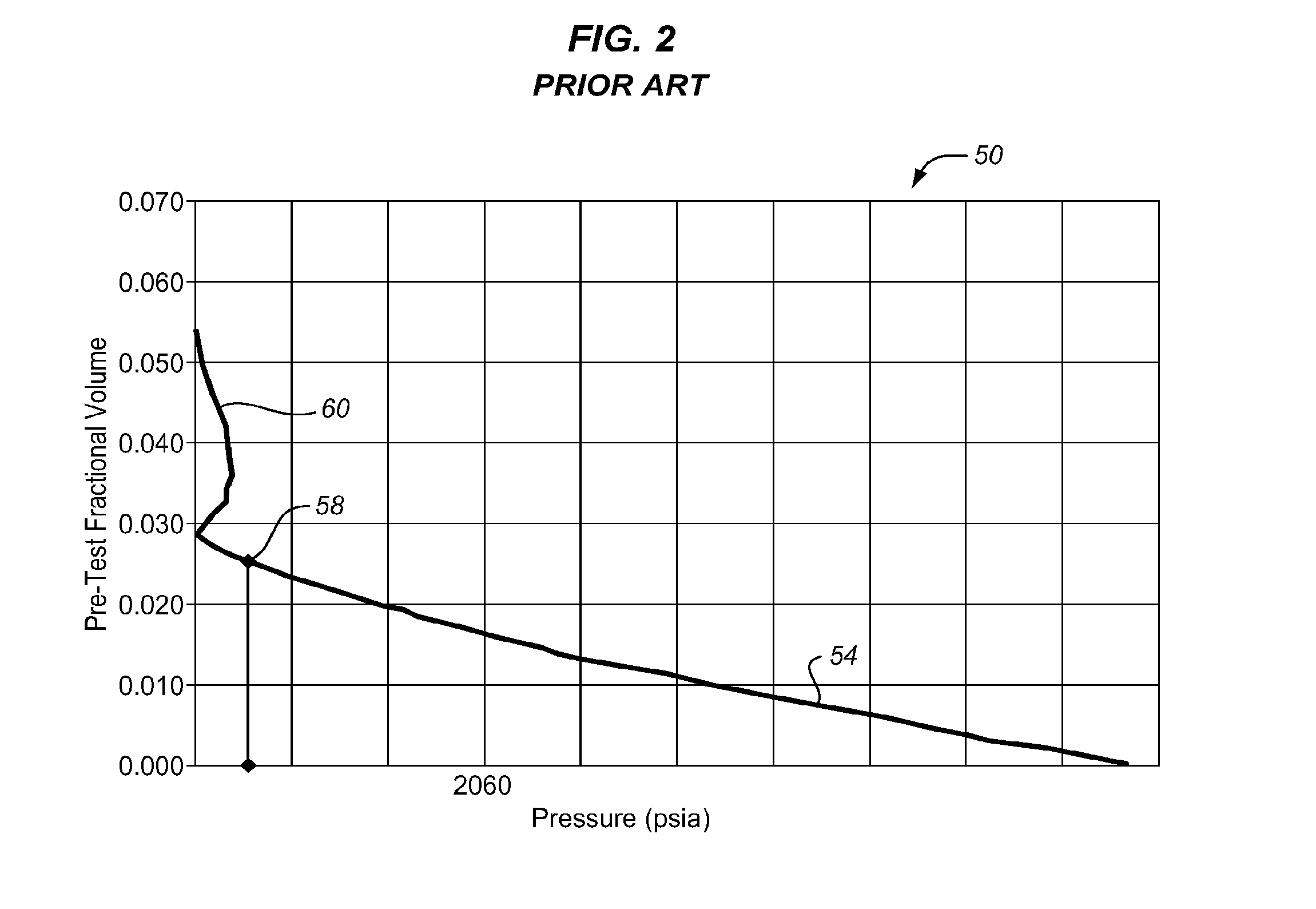

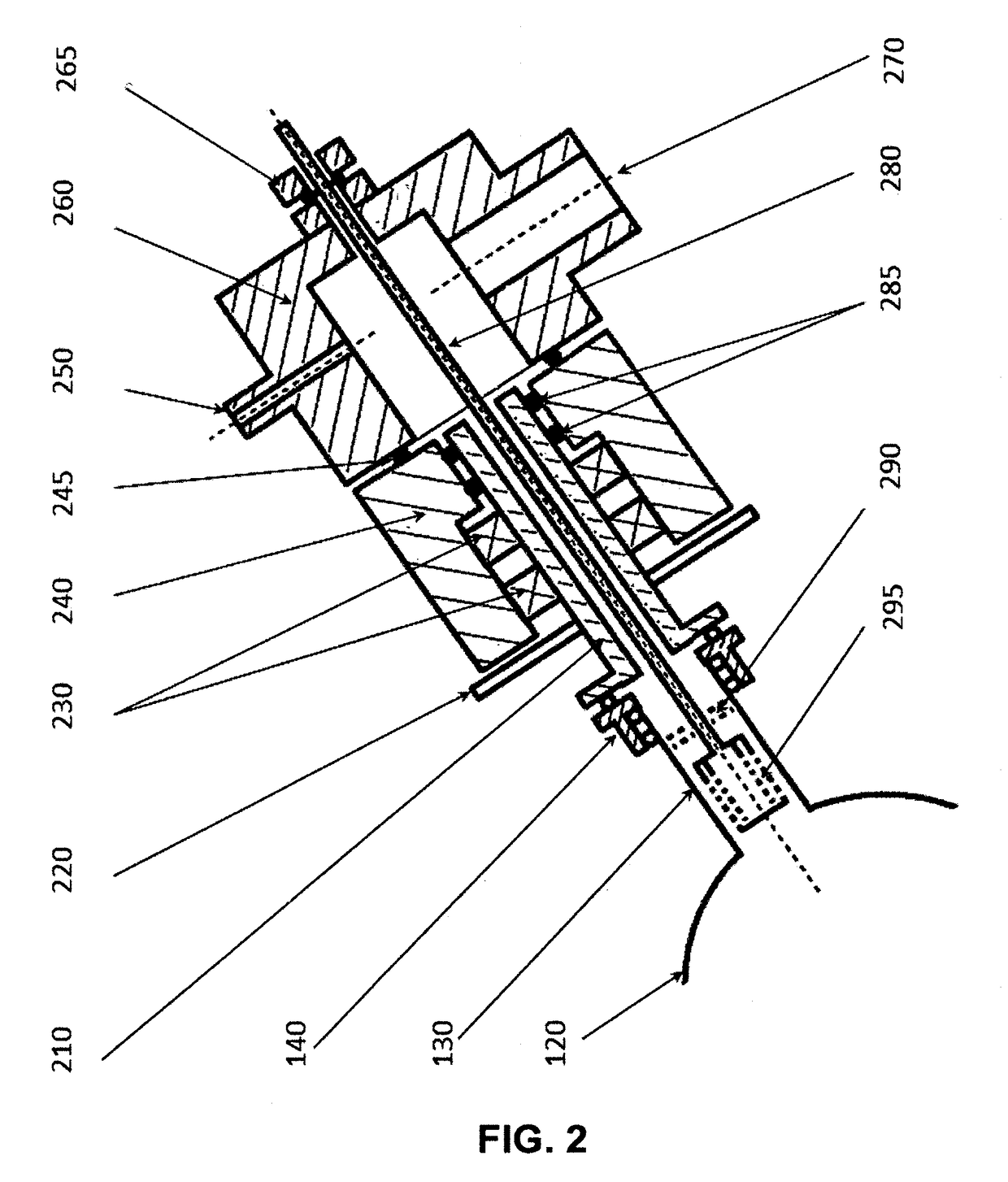

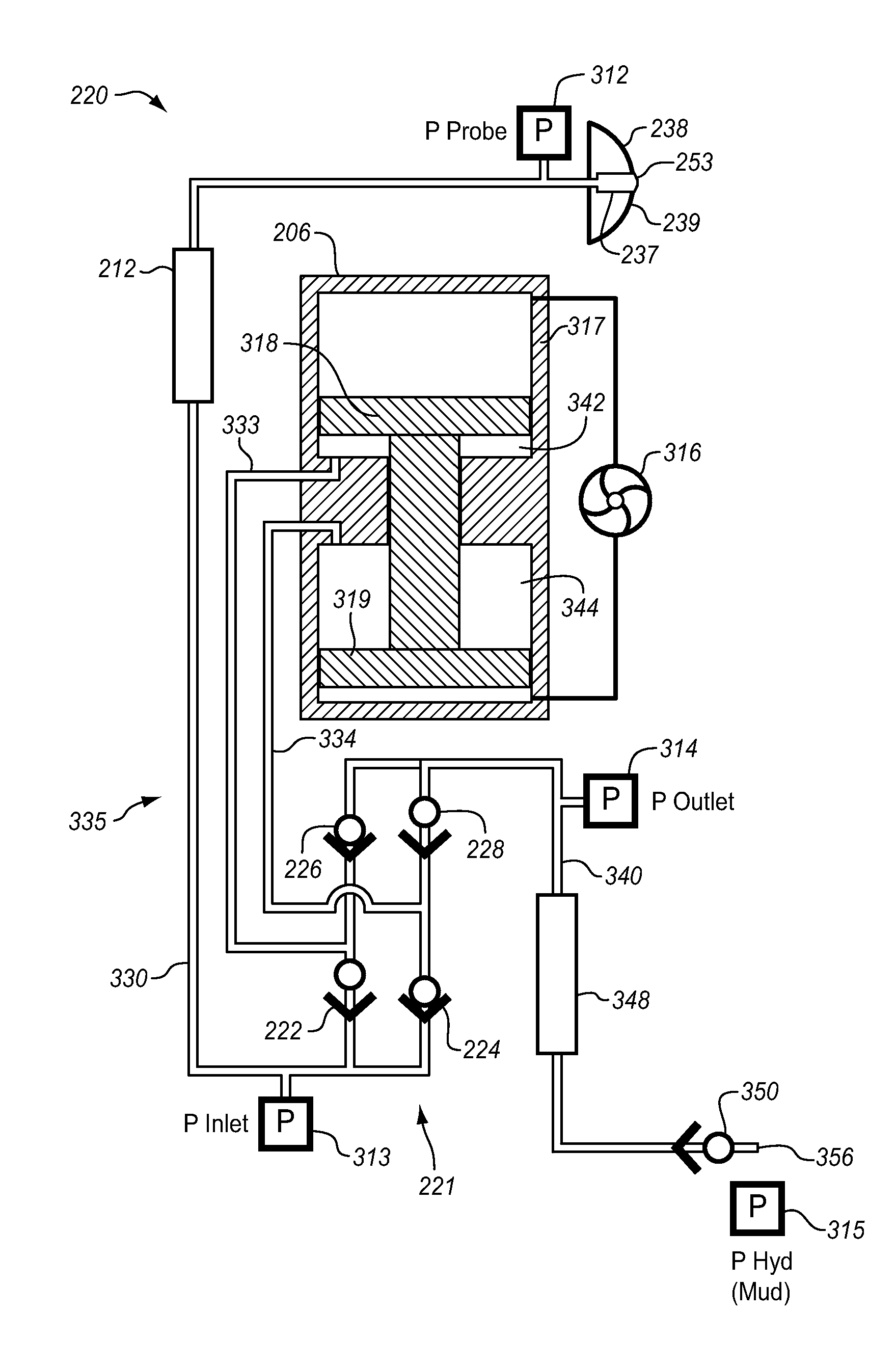

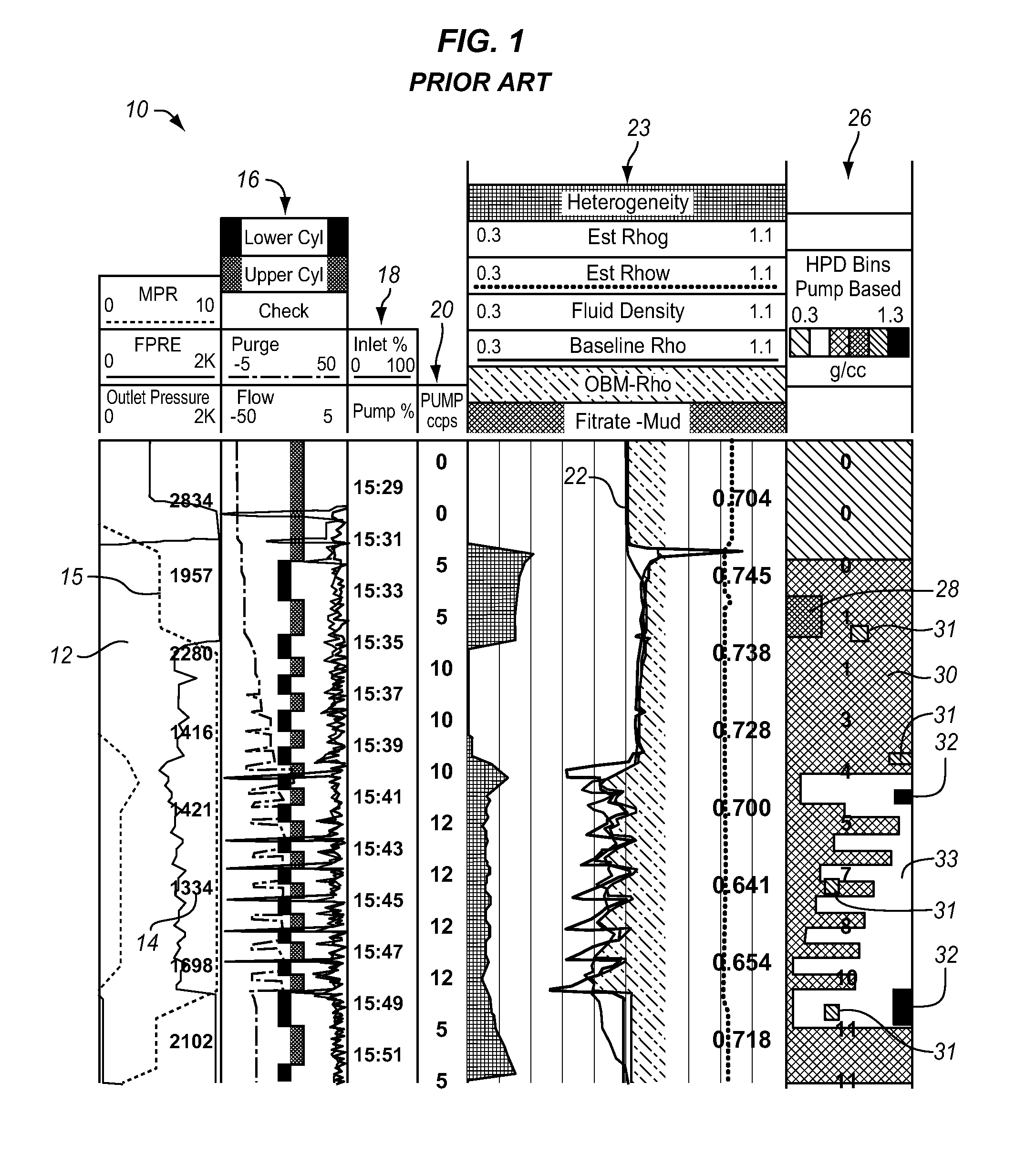

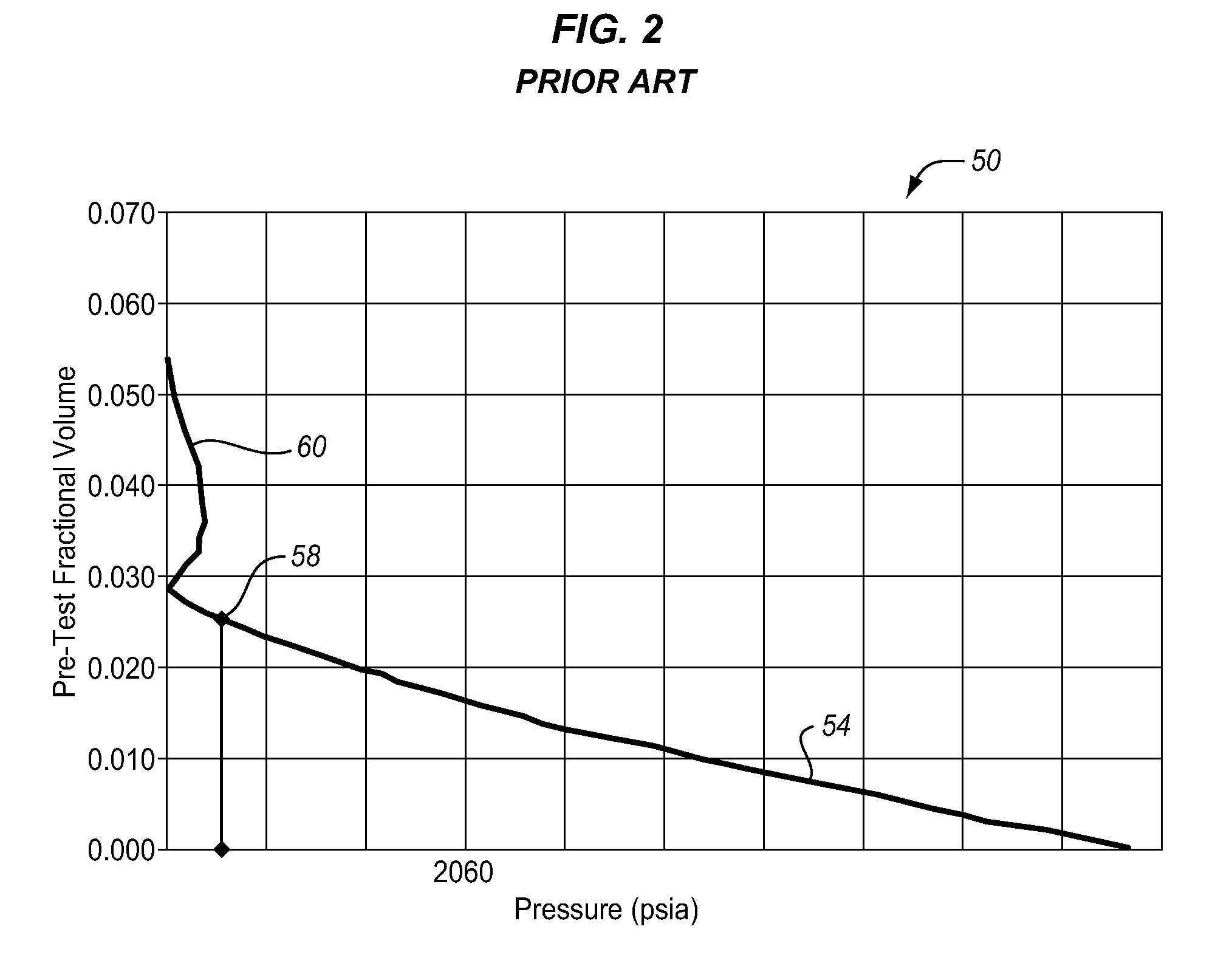

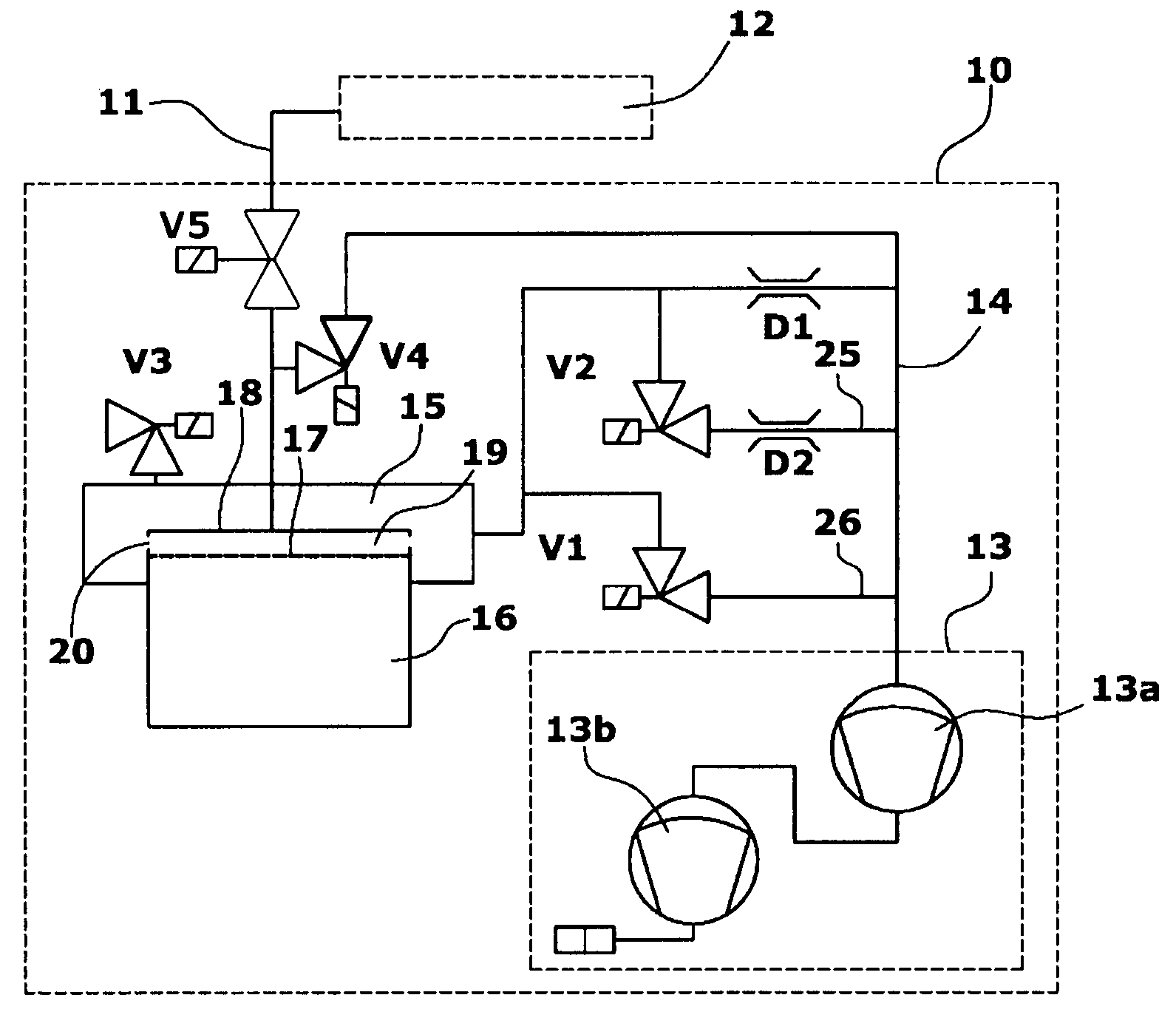

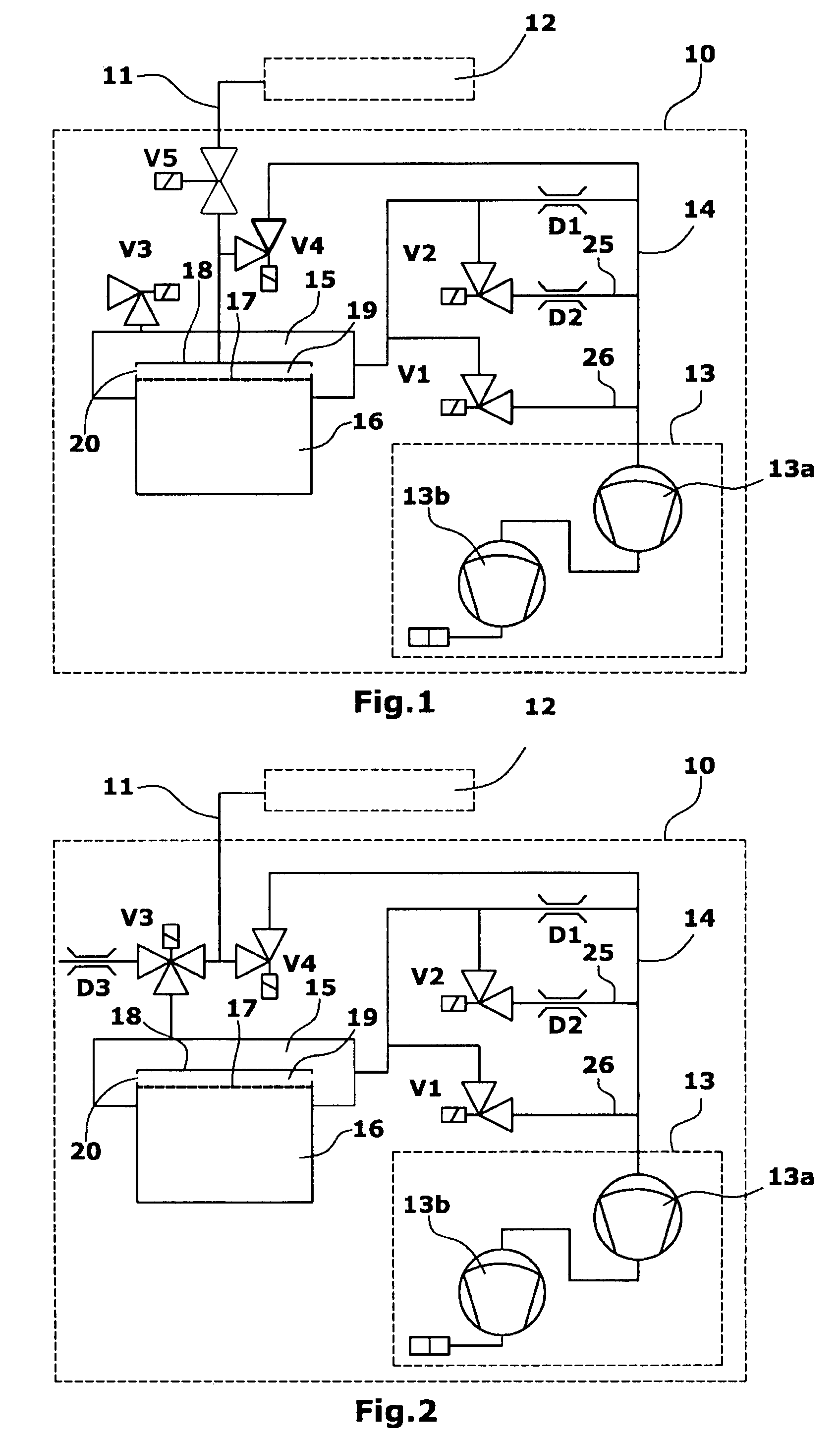

Fluid control in reservior fluid sampling tools

ActiveUS20120018152A1Easy to controlIncrease pumping speedSurveyFluid removalFluid controlReservoir fluid

A pumping system comprising: a probe to suction a fluid from a fluid reservoir; a pump in fluid communication with said probe; a sensor for detecting phase changes in said pumping system, said sensor in fluid communication with said probe or pump, said sensor generating a sensor signal; a fluid exit from said pumping system, said fluid exit being in fluid communication with said pump; and a variable force check valve located between said probe and said fluid exit.

Owner:HALLIBURTON ENERGY SERVICES INC

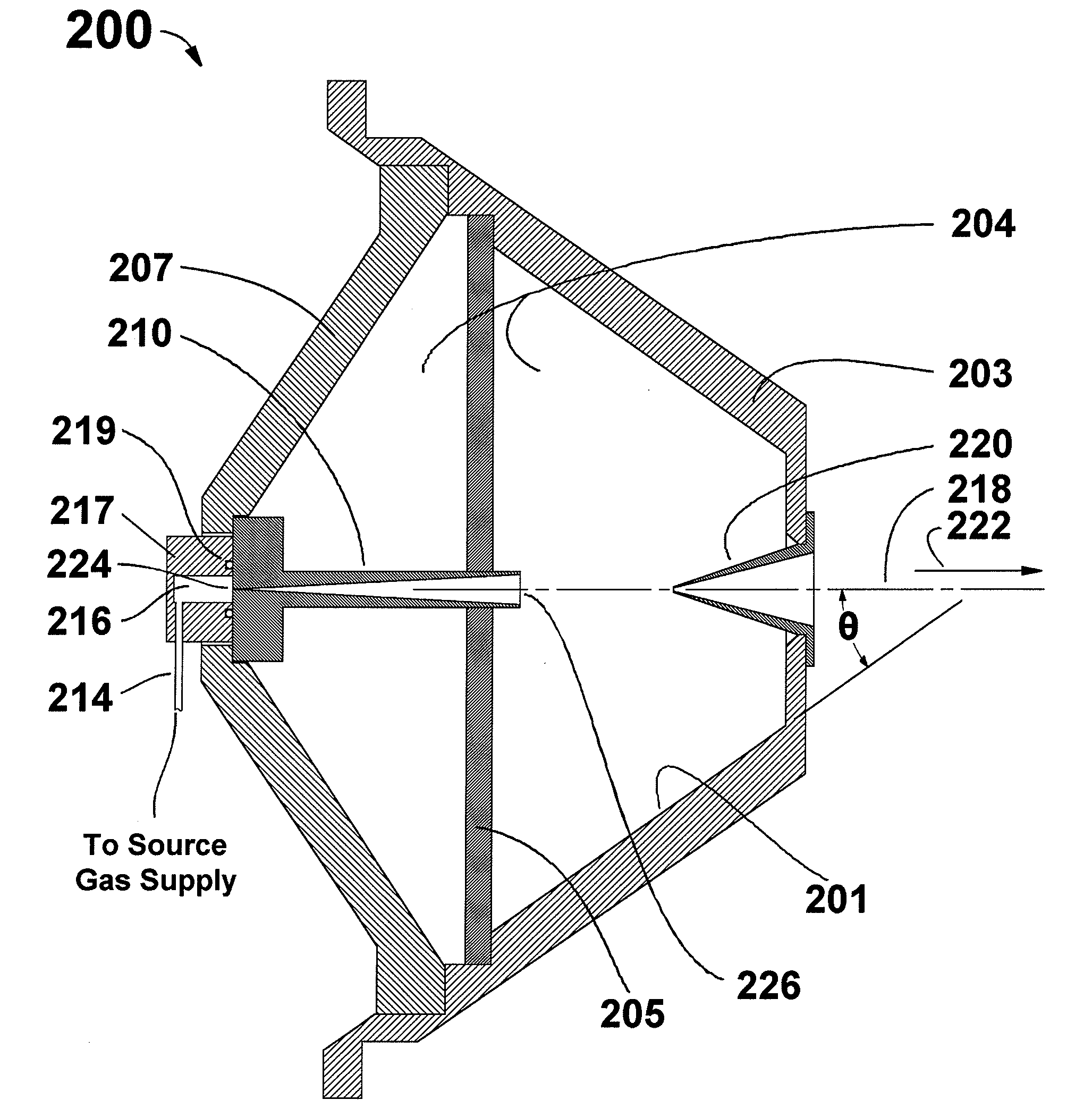

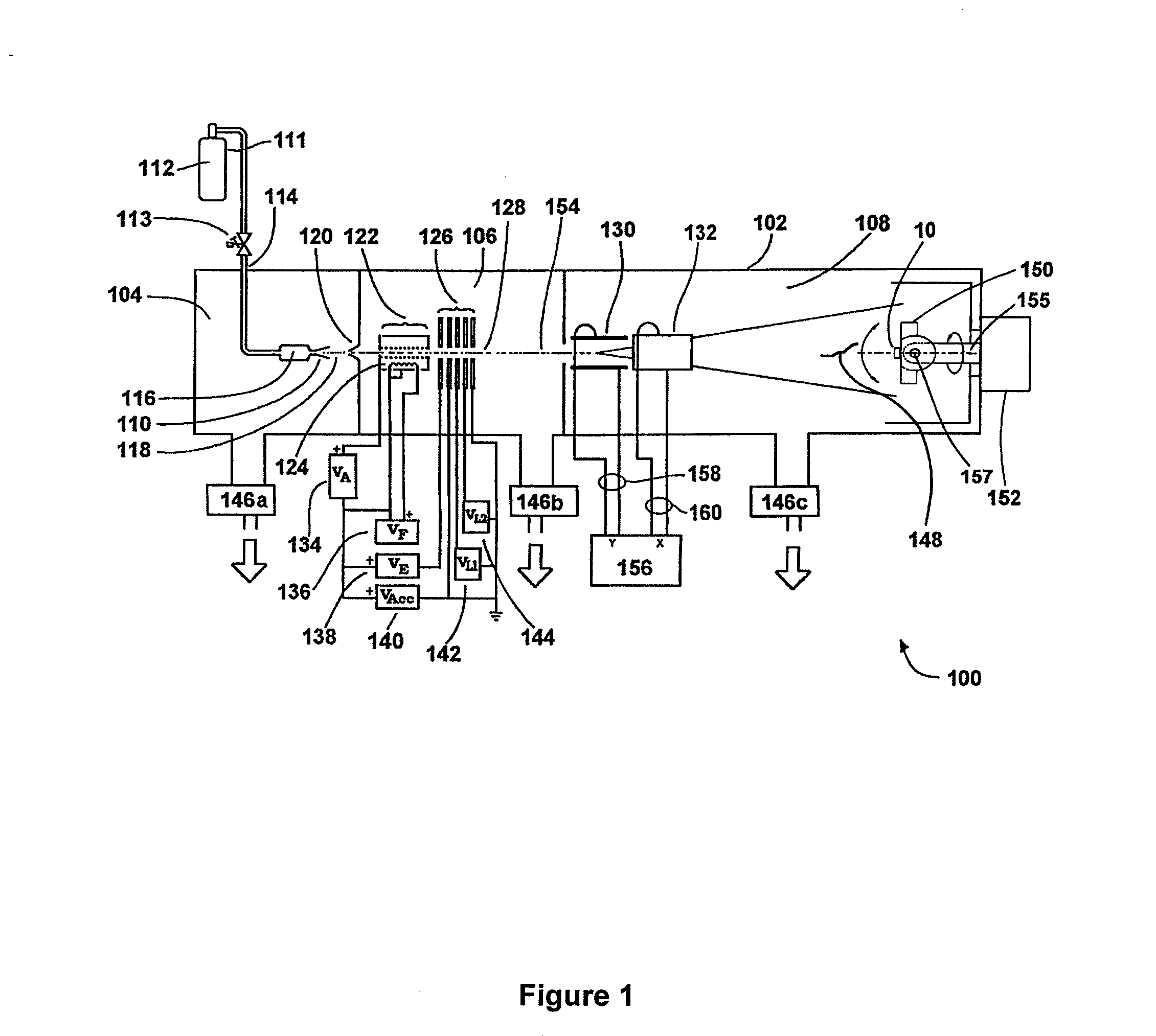

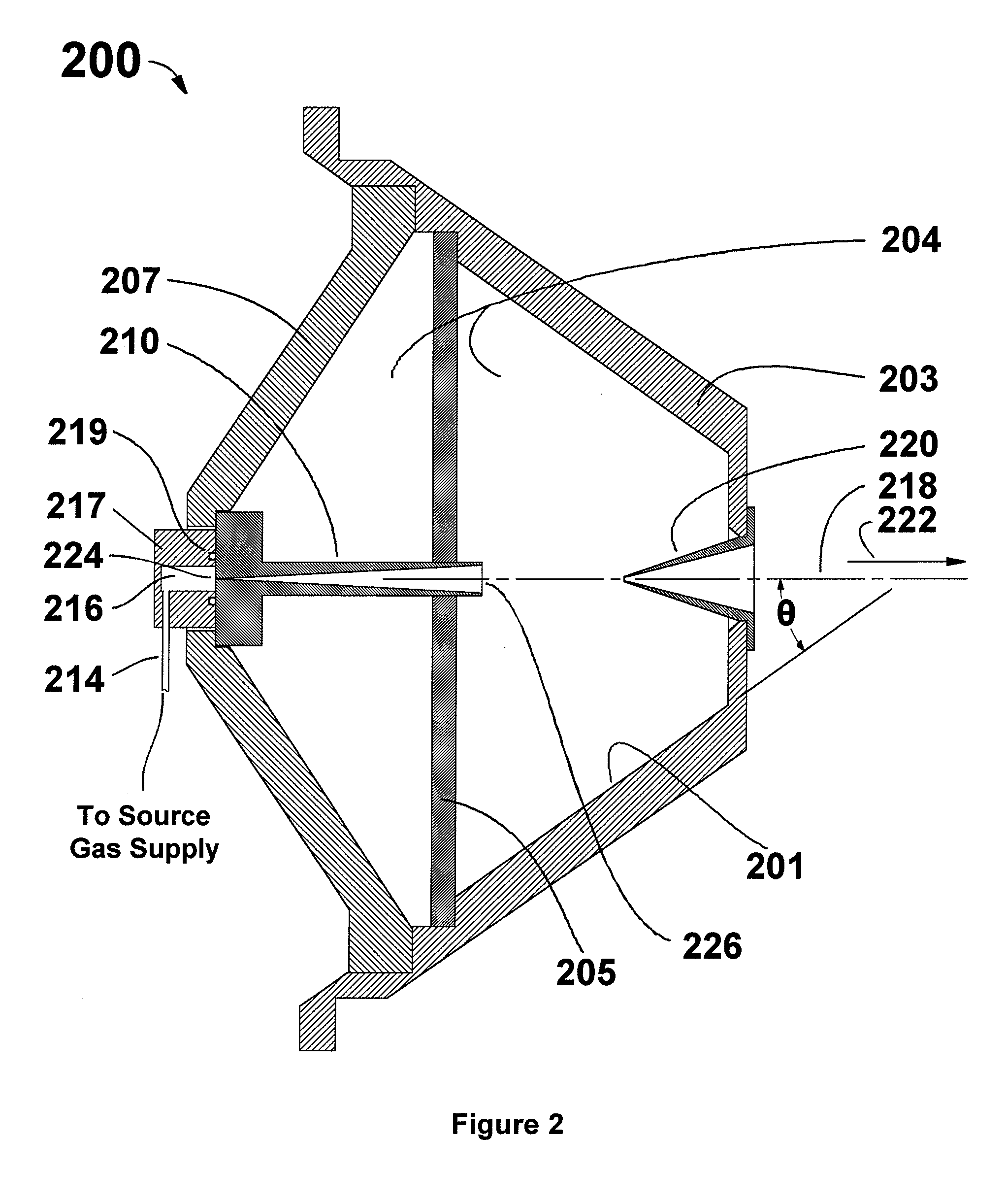

Gas-cluster-jet generator and gas-cluster ion-beam apparatus utilizing an improved gas-cluster-jet generator

ActiveUS20110155897A1Improved vacuum management technique and apparatusImprove conductivityLaser detailsParticle separator tubesGas cluster ion beamSpray nozzle

A gas-cluster-jet generator with improved vacuum management techniques and apparatus is disclosed. The gas-cluster-jet generator comprises a substantially conically shaped vacuum chamber for housing the nozzle and jet exit portions of the gas-cluster-jet generator. A skimmer may be located at the narrow end of the conical chamber and a close-coupled vacuum pump is located at the wide end of the conical chamber. Support members for the nozzle are high conductivity “spider” supports that provide support rigidity while minimizing gas flow obstruction for high pumping speed. The conically shaped vacuum chamber redirects un-clustered gas in a direction opposite the direction of the gas-cluster-jet for efficient evacuation of the un-clustered gas. The nozzle and a skimmer may have fixed precision relative alignment, or may optionally have a nozzle aiming adjustment feature for aligning the gas-cluster-jet with the skimmer and downstream beamline components. Also disclosed are various configurations of gas-cluster ion-beam processing tools employing the improved gas-cluster-jet generator.

Owner:EXOGENESIS CORP

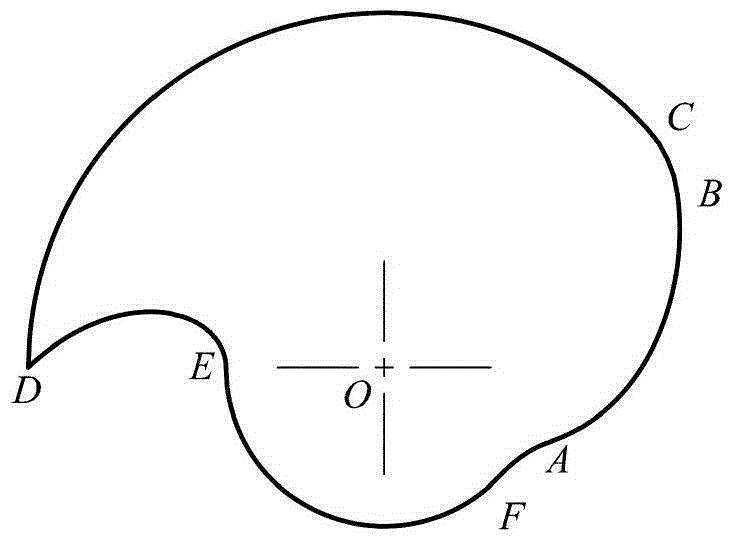

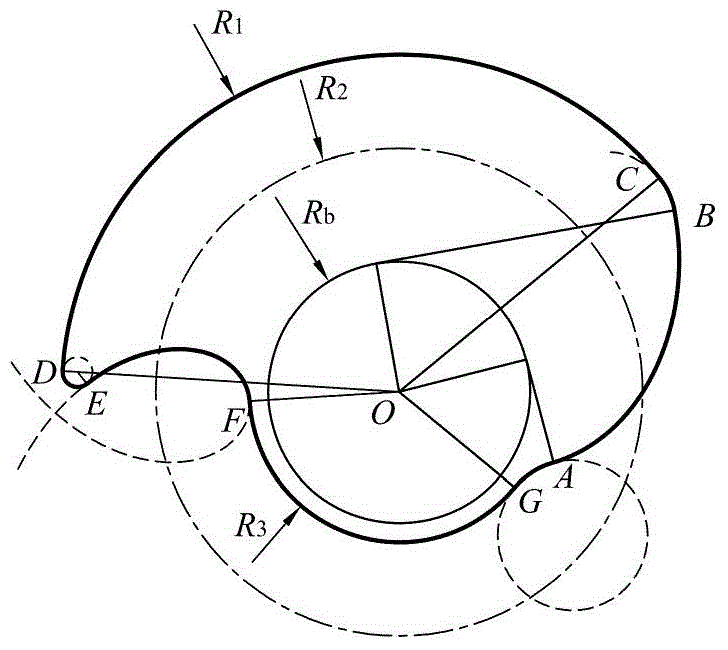

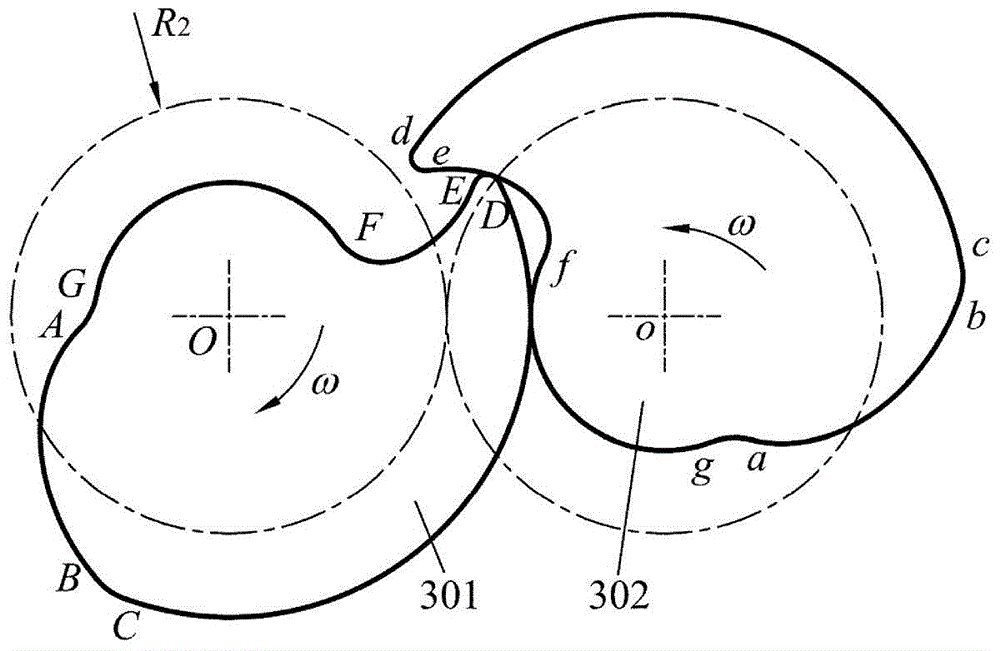

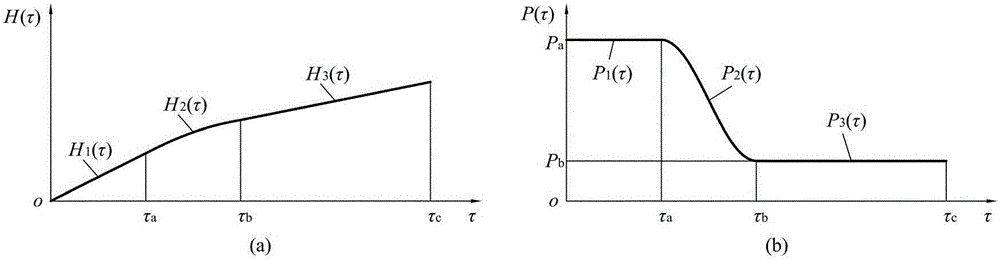

Fully-smooth screw rotor of twin-screw vacuum pump

InactiveCN105240277AImprove sealingImprove mechanical propertiesRotary piston pumpsRotary piston liquid enginesStress concentrationEngineering

The invention discloses a fully-smooth screw rotor of a twin-screw vacuum pump, and belongs to the technical field of dry-process twin-screw vacuum pumps. An end surface molded line of the screw rotor consists of 7 sections of curves which are smoothly connected without cuspidal points; a circular-arc DE and an equidistant curve EF of a cycloid are used for smoothly connecting a tooth-crest circular arc CD with a tooth-root circular arc FG; a circular arc GA is adopted for smoothly connecting the tooth-root circular arc FG with a circle involute AB; an equidistant curve BC of the cycloid is used for smoothly connecting the circle involute AB with the tooth-crest circular arc CD; and two screw rotor end surface molded lines which are conjugated and engaged with each other are the same, so that correct engagement can be realized in work; and the screw rotor generated by the screw rotor end surface molded lines consists of 7 tooth surfaces, and all tooth surfaces of the screw rotor are in smooth transition for eliminating an area which easily generates stress focus. The screw rotor has the advantages of high strength, good tightness, small abrasion and a long service life.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

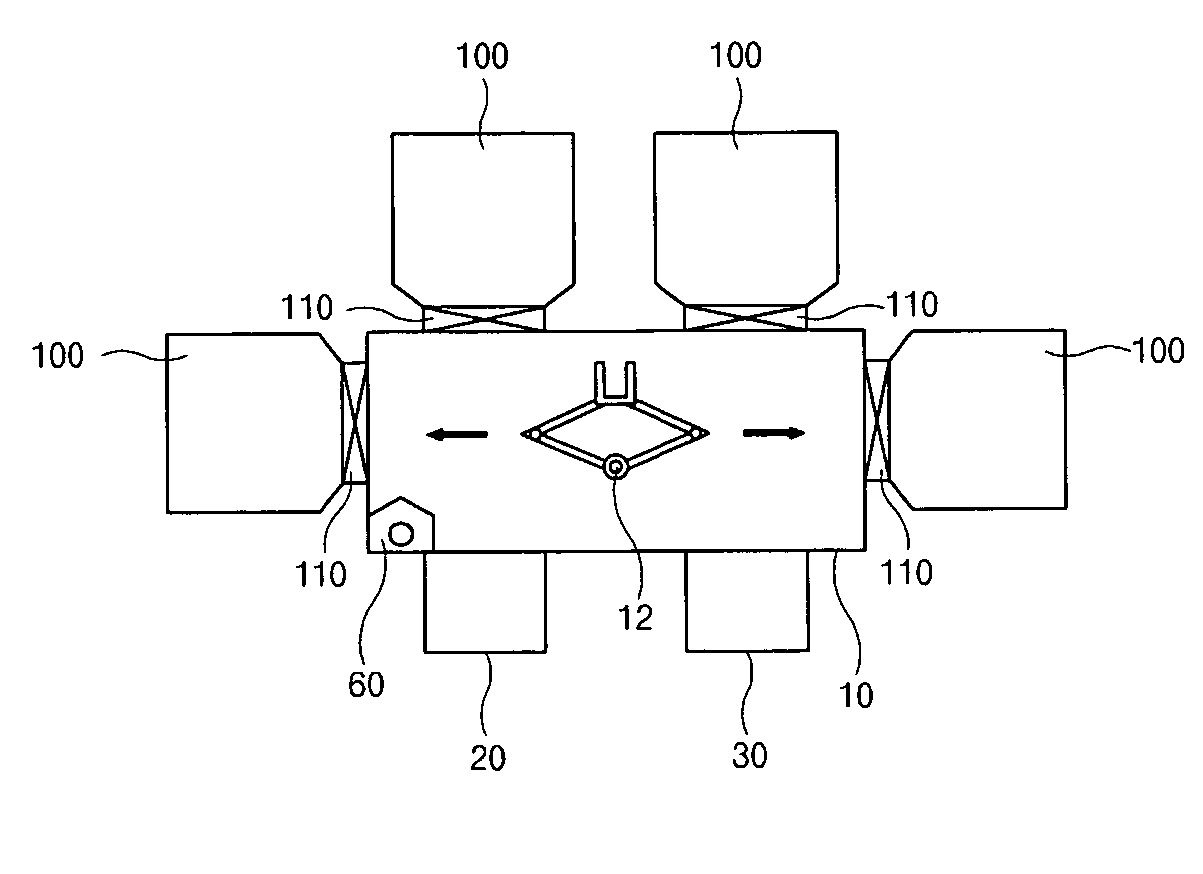

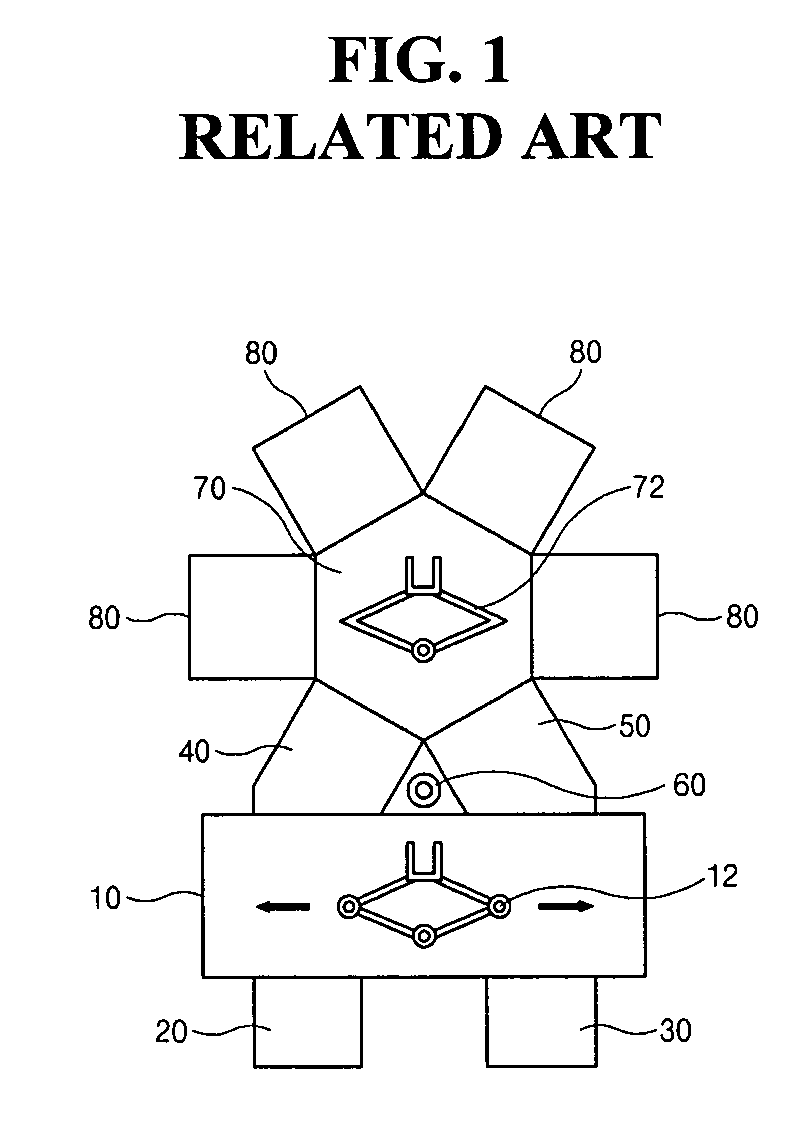

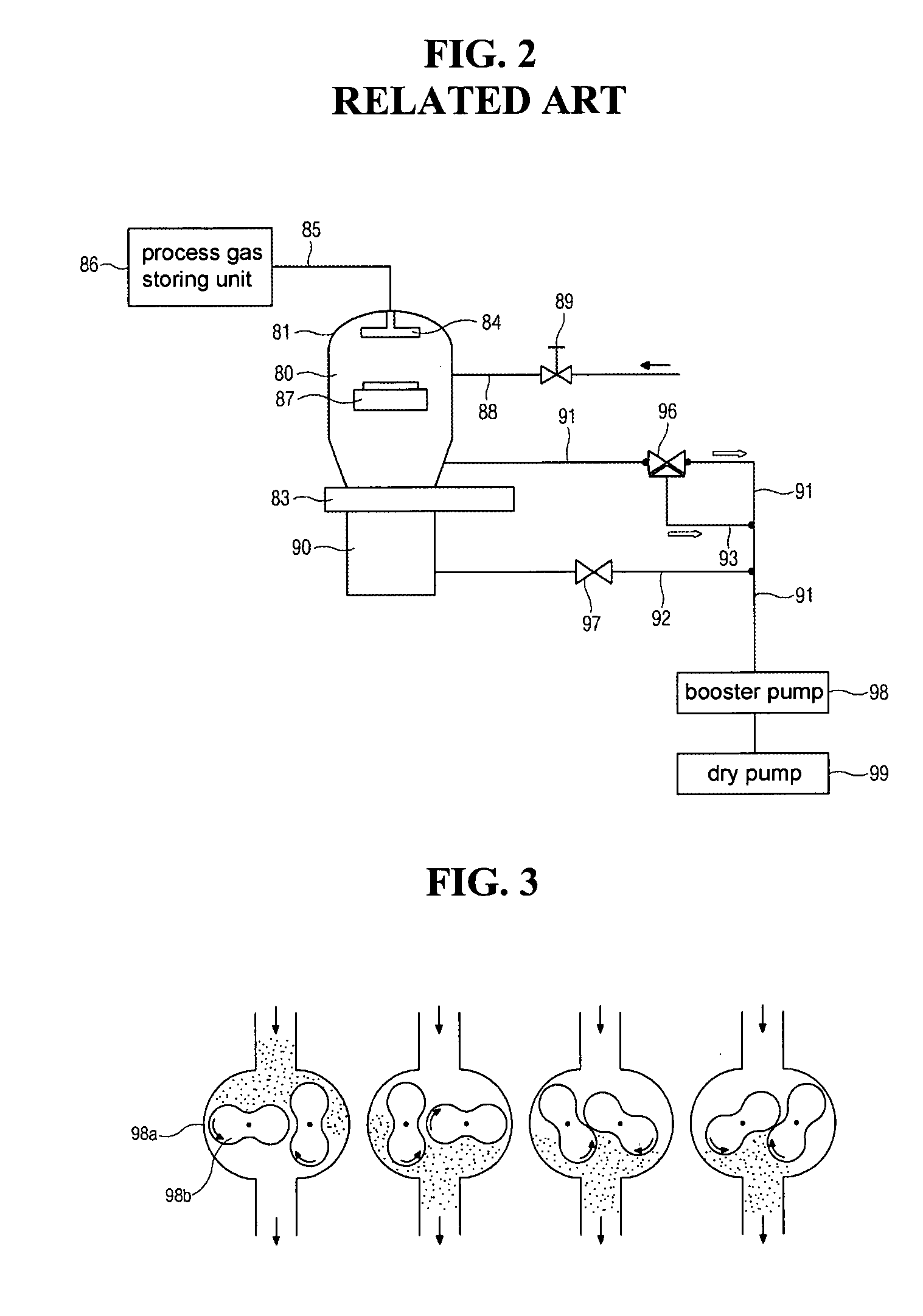

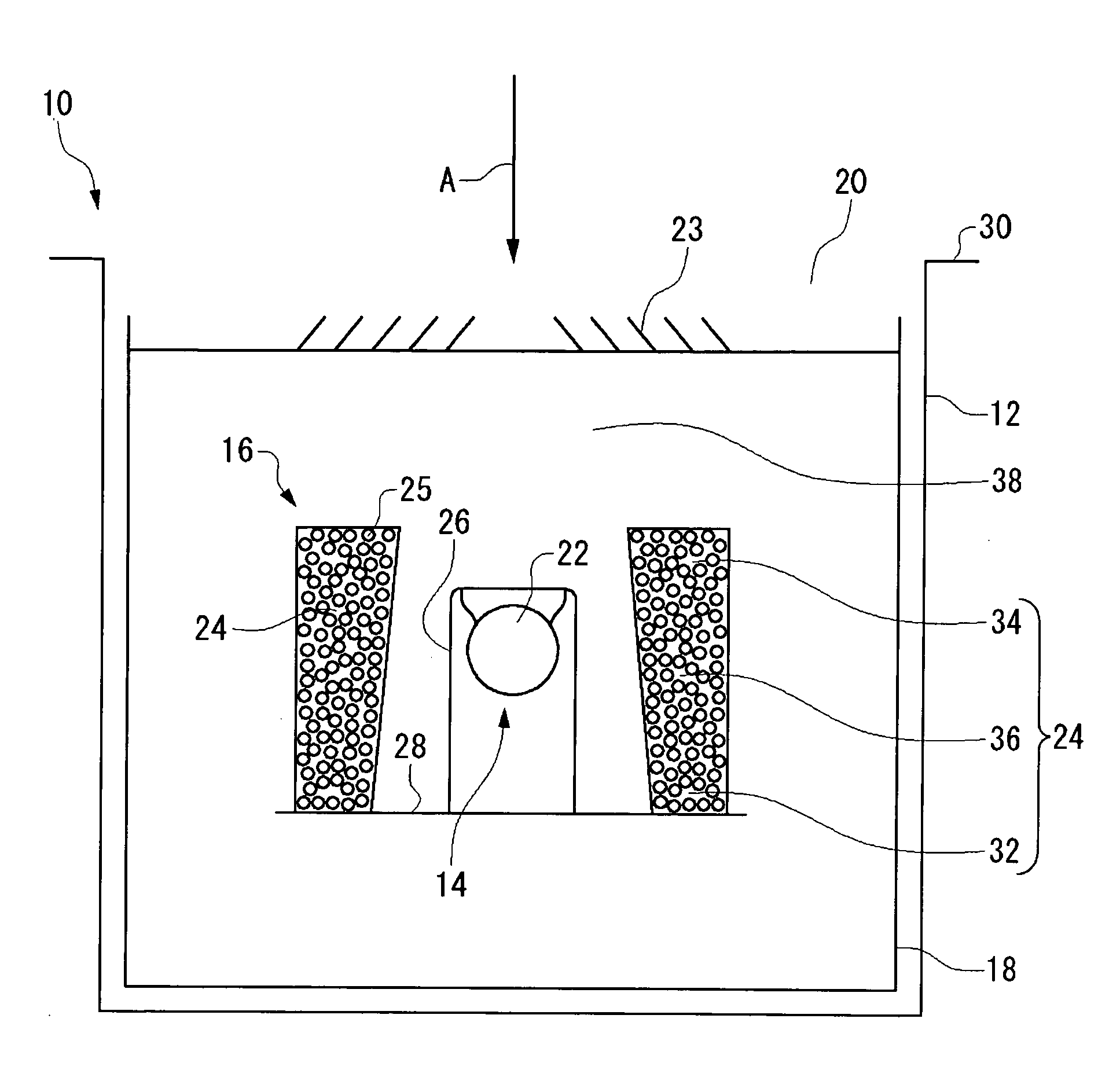

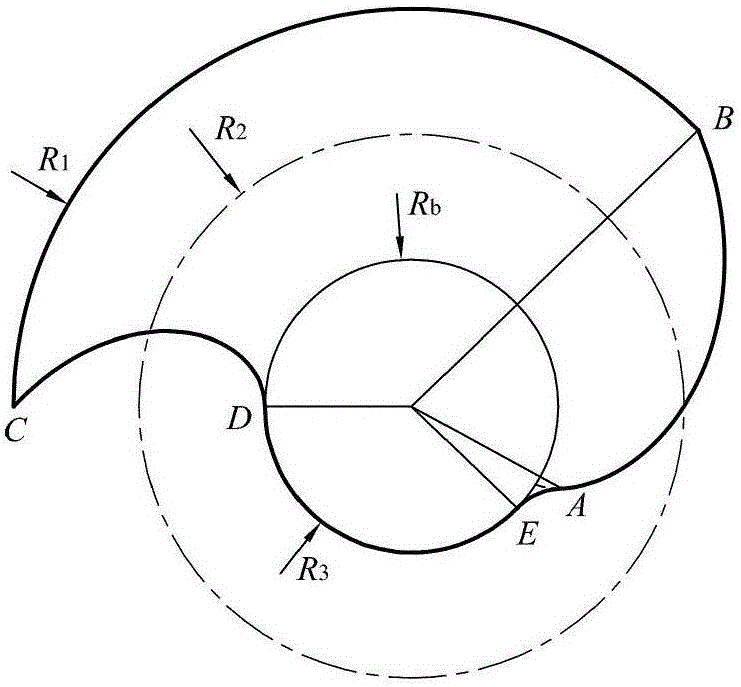

Vacuum pumping system, driving method thereof, apparatus having the same, and method of transferring substrate using the same

InactiveUS20050196254A1Efficient use ofReduced footprintStatic indicating devicesVacuum evaporation coatingVacuum pumpingEngineering

An apparatus includes a transfer unit under an atmospheric condition and having a robot therein; and at least one process chamber connected to one side of the transfer unit with a slot valve there between, and being alternately under a vacuum condition and under an atmospheric condition.

Owner:JUSUNG ENG

Cryopump and evacuation method

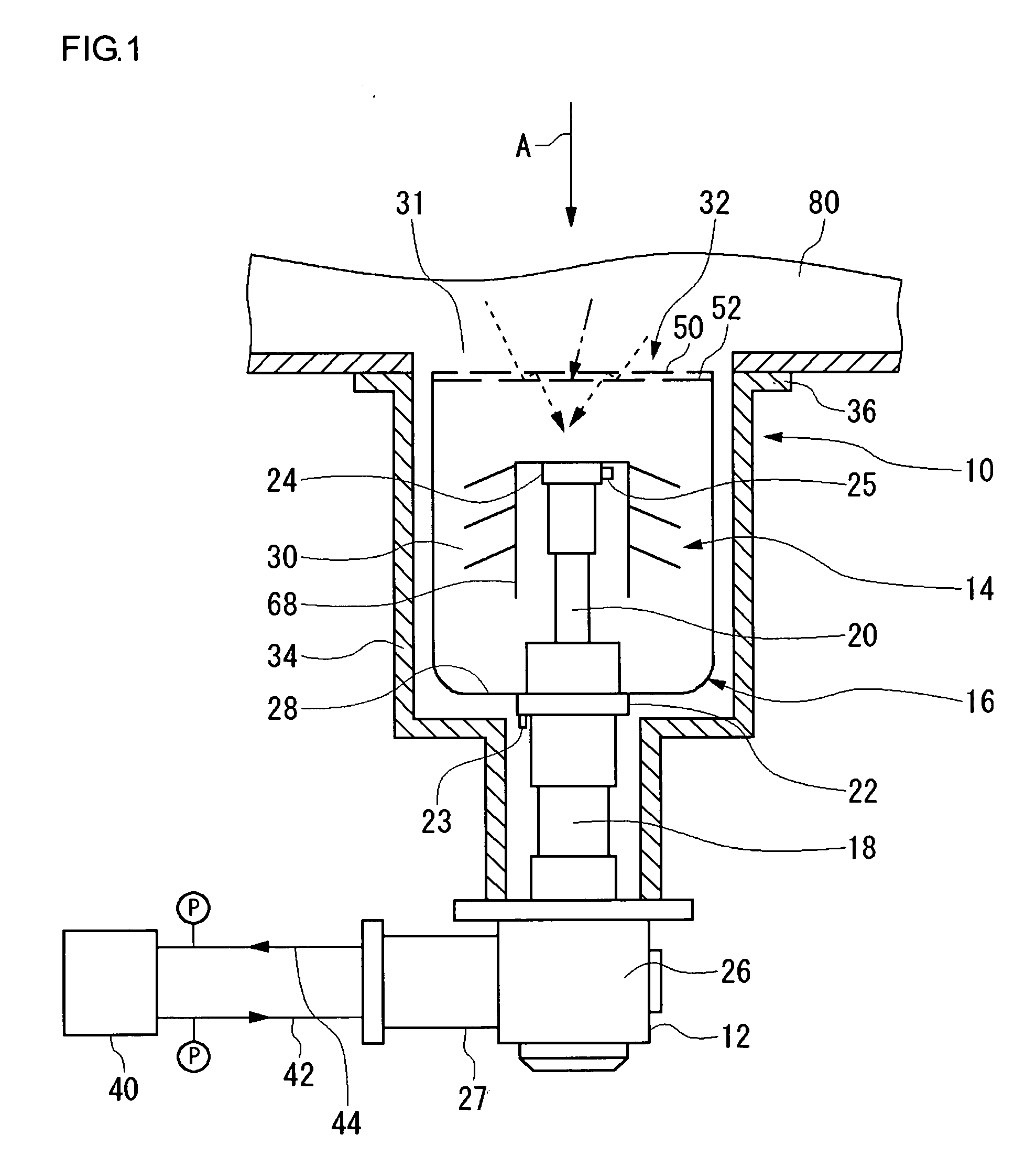

ActiveUS20090165469A1Improve pump performanceEliminate the effects ofSolidificationLiquefactionPump chamberEngineering

A cryopump includes: a cryopump chamber having an inlet port through which a gas to be pumped is introduced; a refrigerator provided with a second cooling stage provided in the cryopump chamber; an intermediate member thermally coupled to the second cooling stage; and a cryopanel having a connecting part connected to the intermediate member at a position farther from the inlet port in the direction in which the gas is introduced than the second cooling stage, and extending from the connecting part toward the inlet port. For example, a cryopump having a suspended panel structure is provided.

Owner:SUMITOMO HEAVY IND LTD

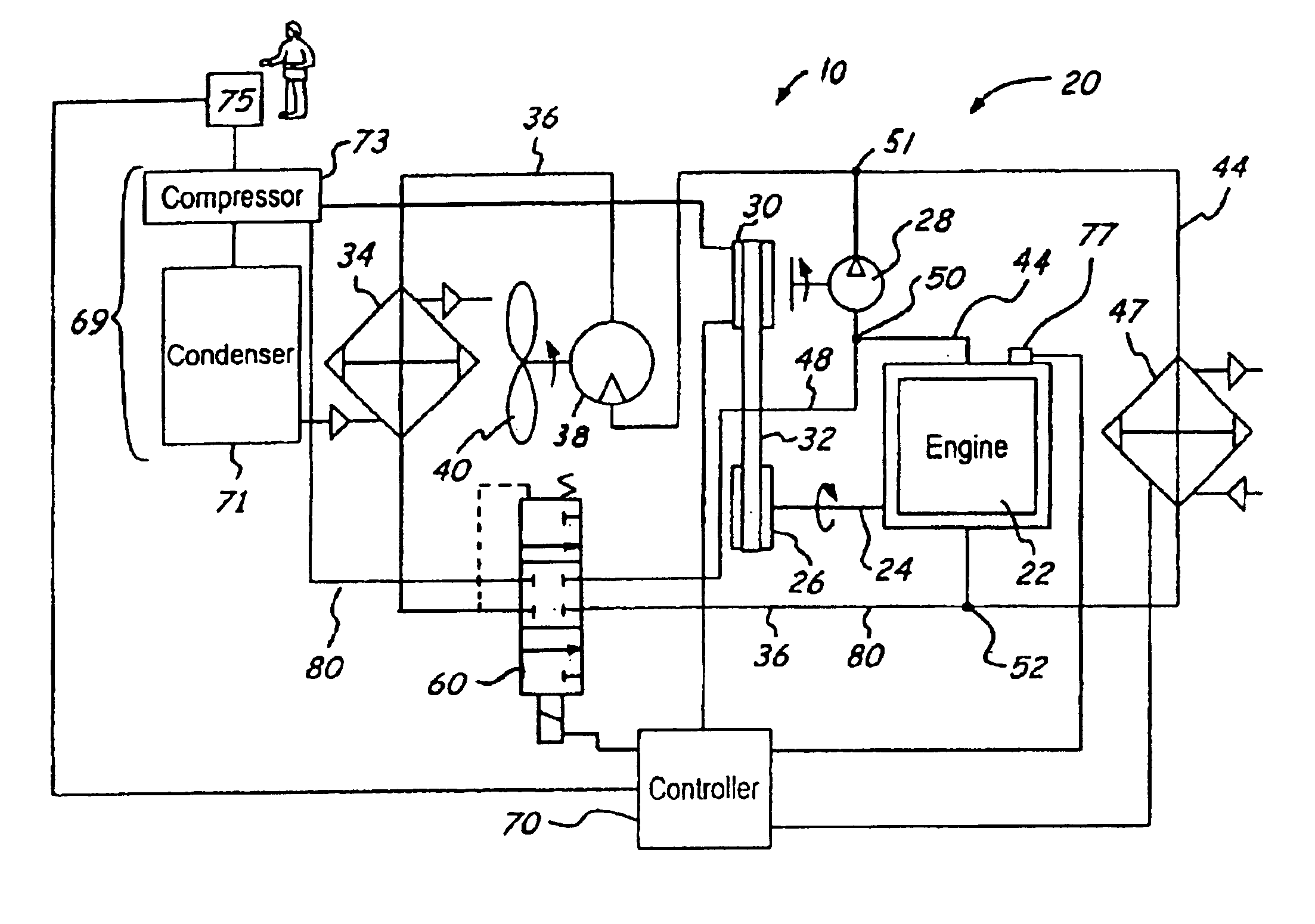

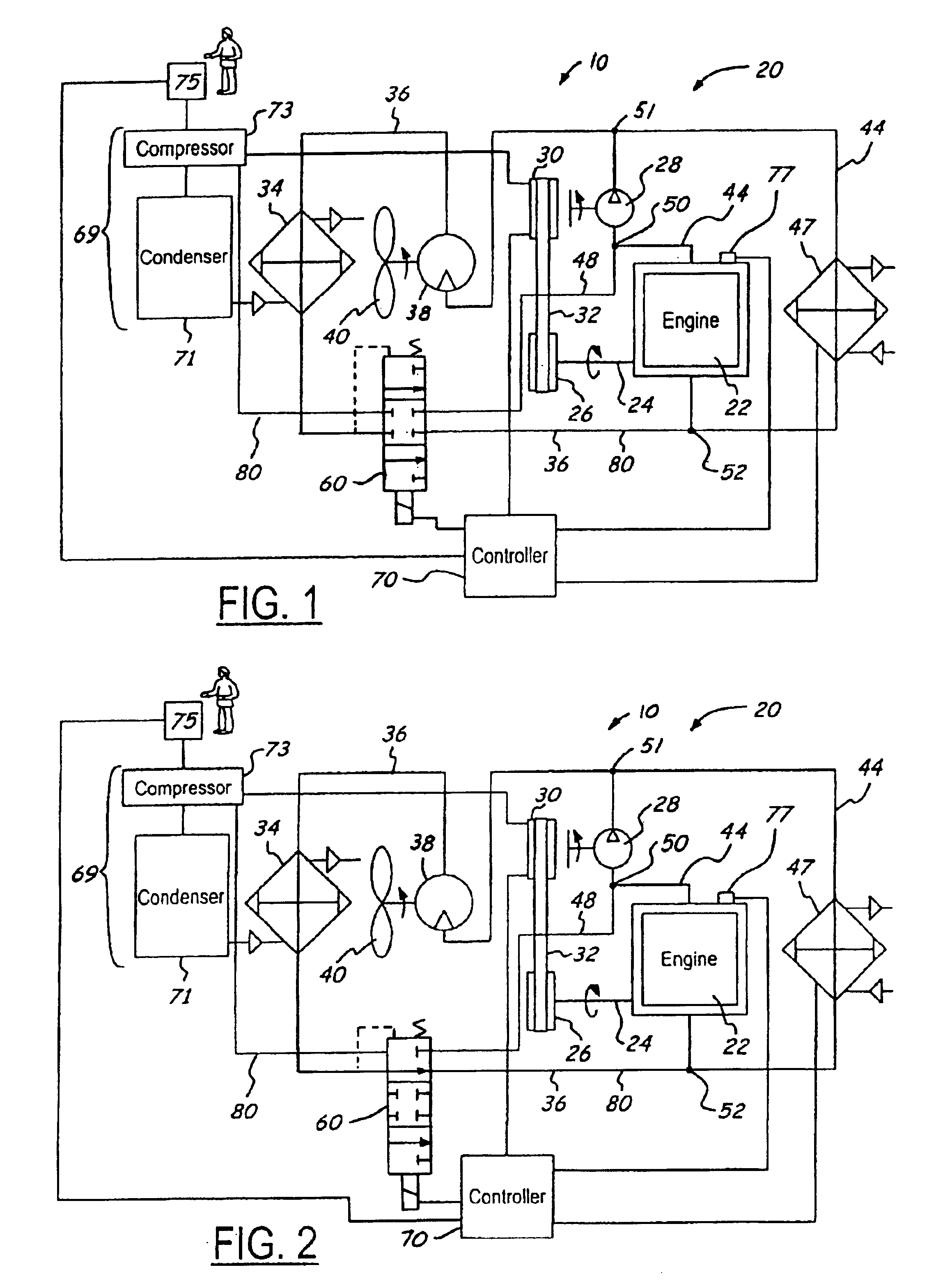

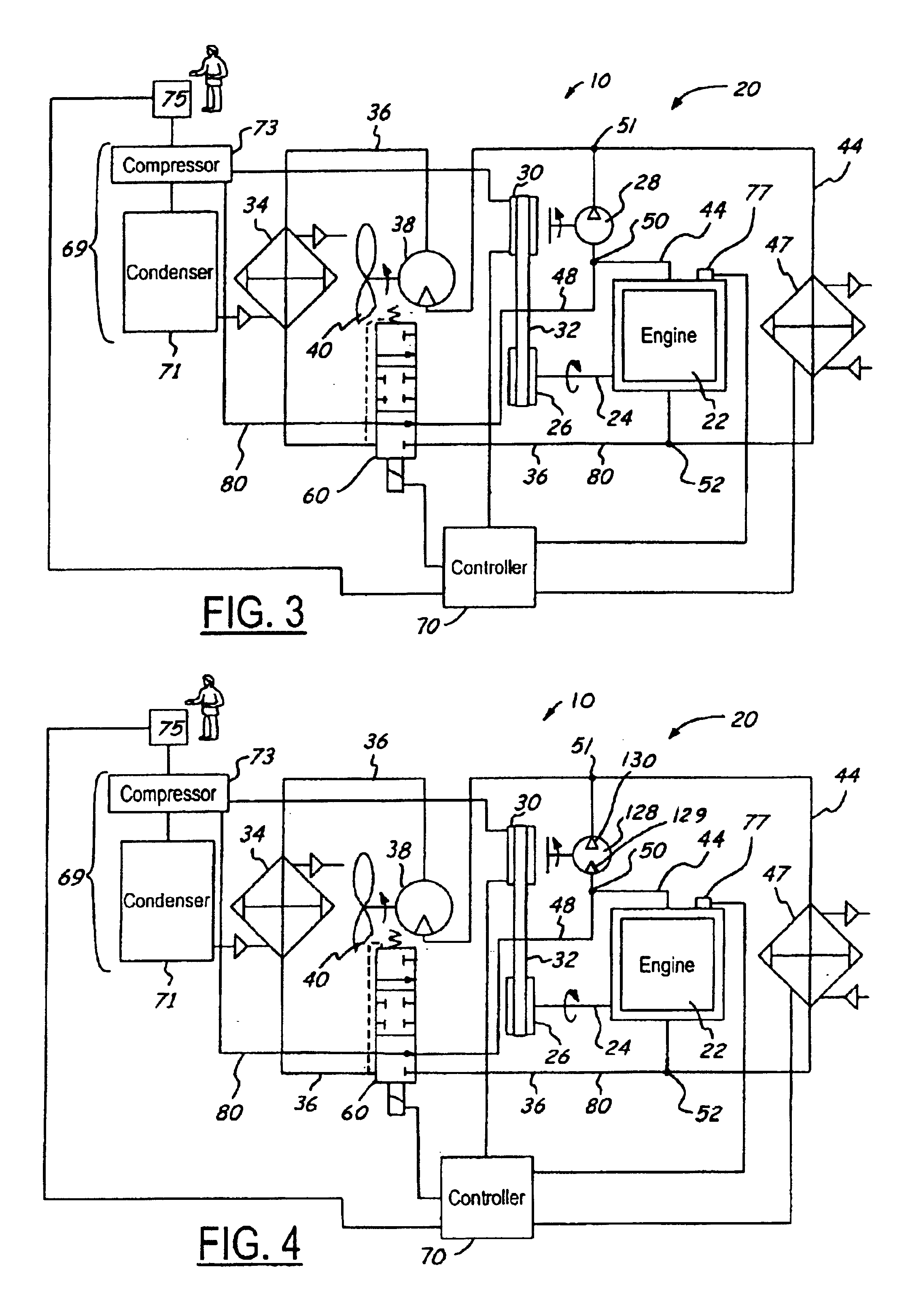

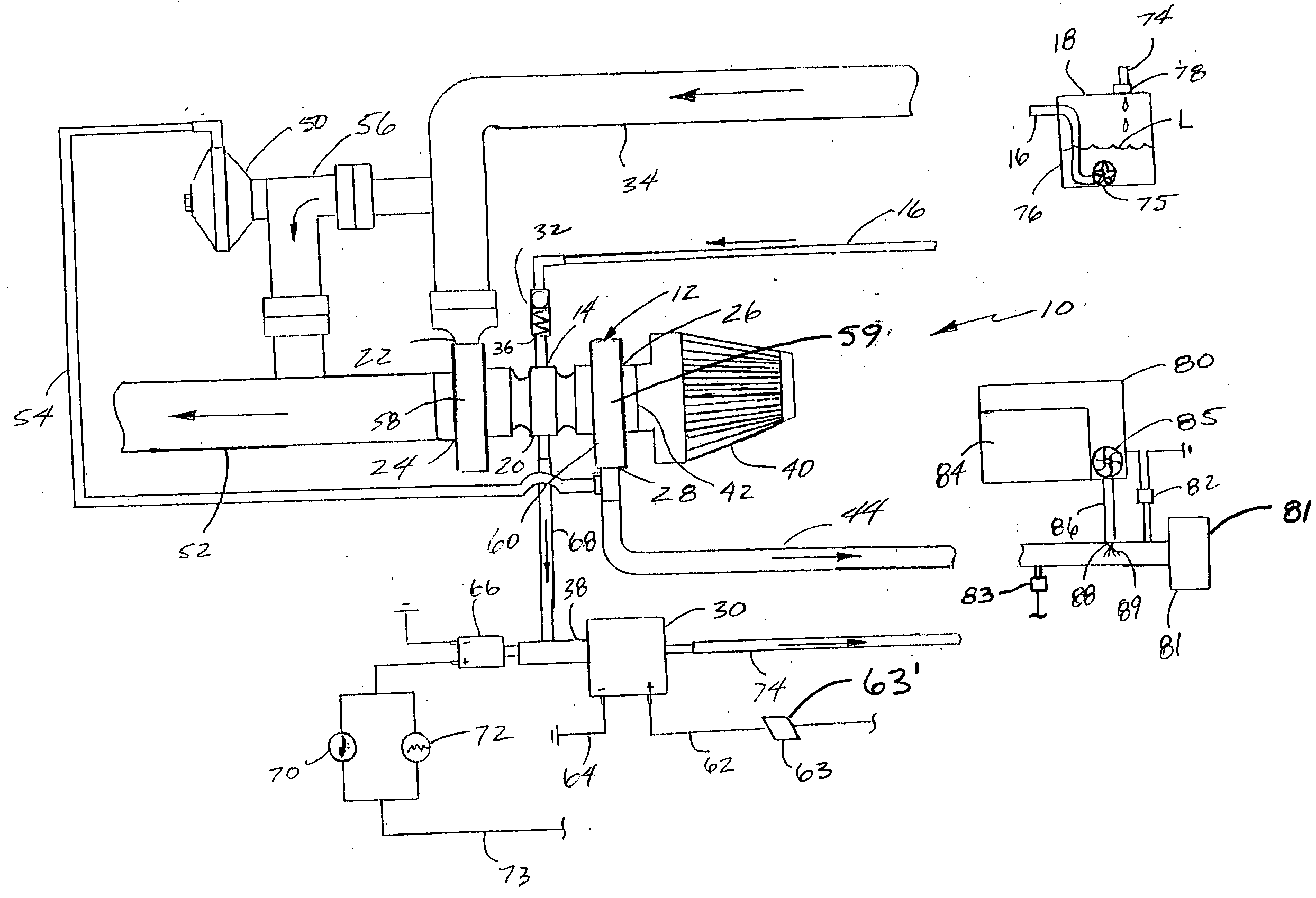

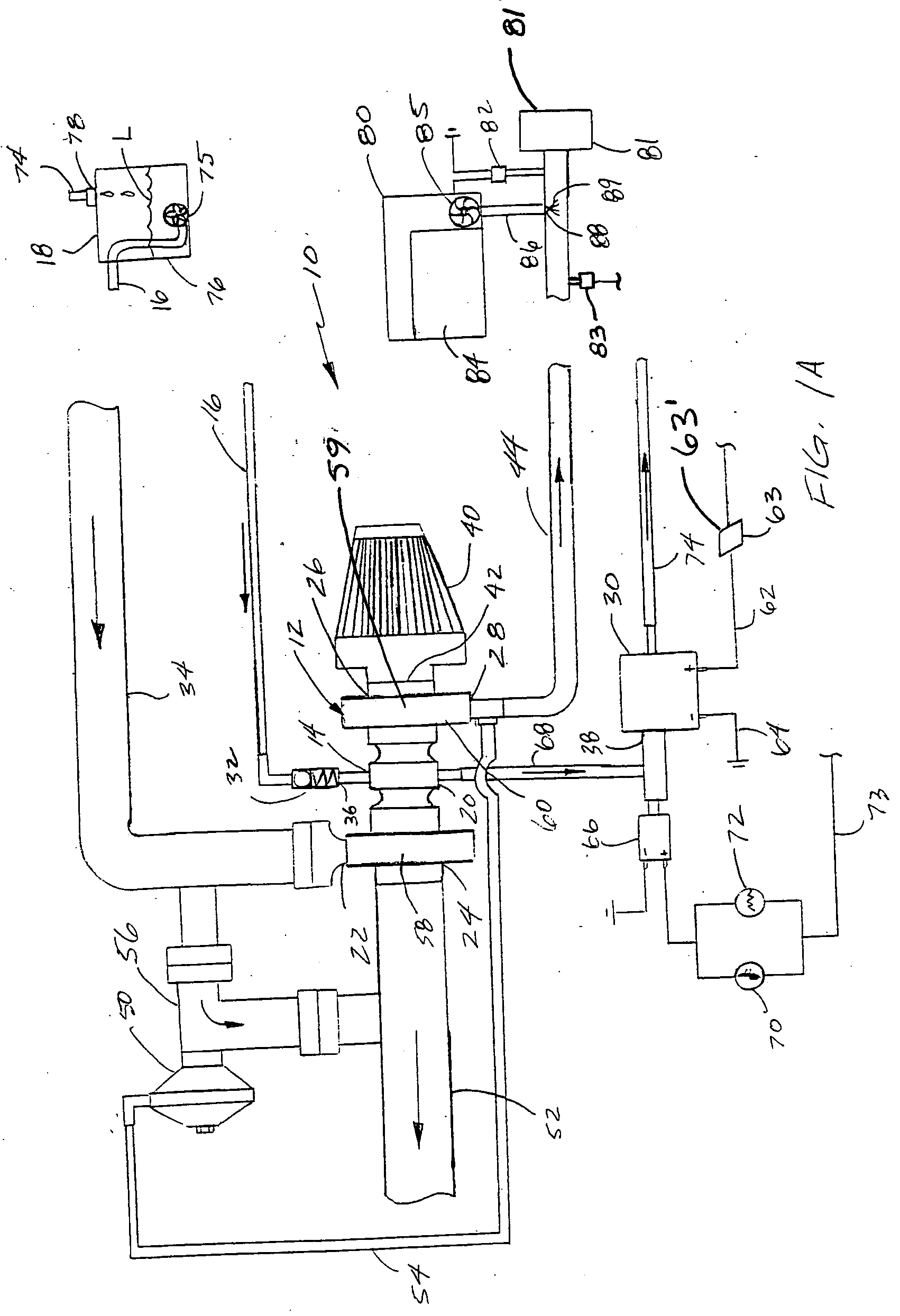

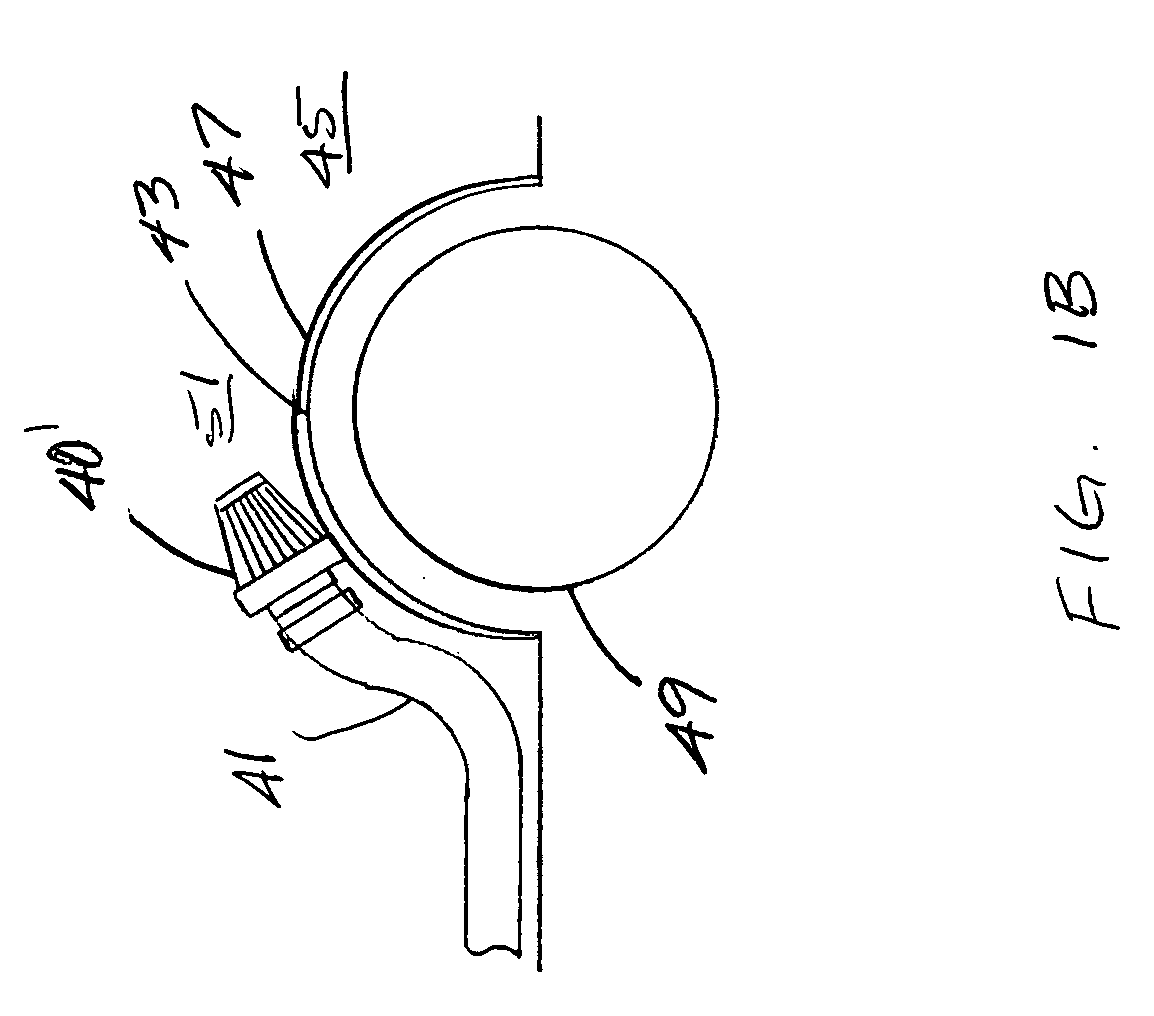

Coolant motor fan drive

ActiveUS6868809B1Vary responseSave energyAir-treating devicesCoolant flow controlCoolant flowCoupling

The control of the coolant flow is accomplished through valving or by adjusting the pumping speed of a water pump and a water motor, or a combination of all three elements. During normal operation, where engine cooling is not required, the speed control coupling maintains a slow and constant water pump speed at all engine-operating speeds. The valve is maintained to stop coolant flow from entering the radiator while allowing coolant to flow through a heater. If engine cooling is required, the valve is actuated such that coolant is circulated to the engine and through the radiator. If air conditioning is required, the speed control coupling simply increases the water pump speed and the fan speed while the valve is set to bypass coolant flow to the engine. If air conditioning and engine cooling are required, the valve is actuated to allow coolant flow to the engine.

Owner:BORGWARNER INC

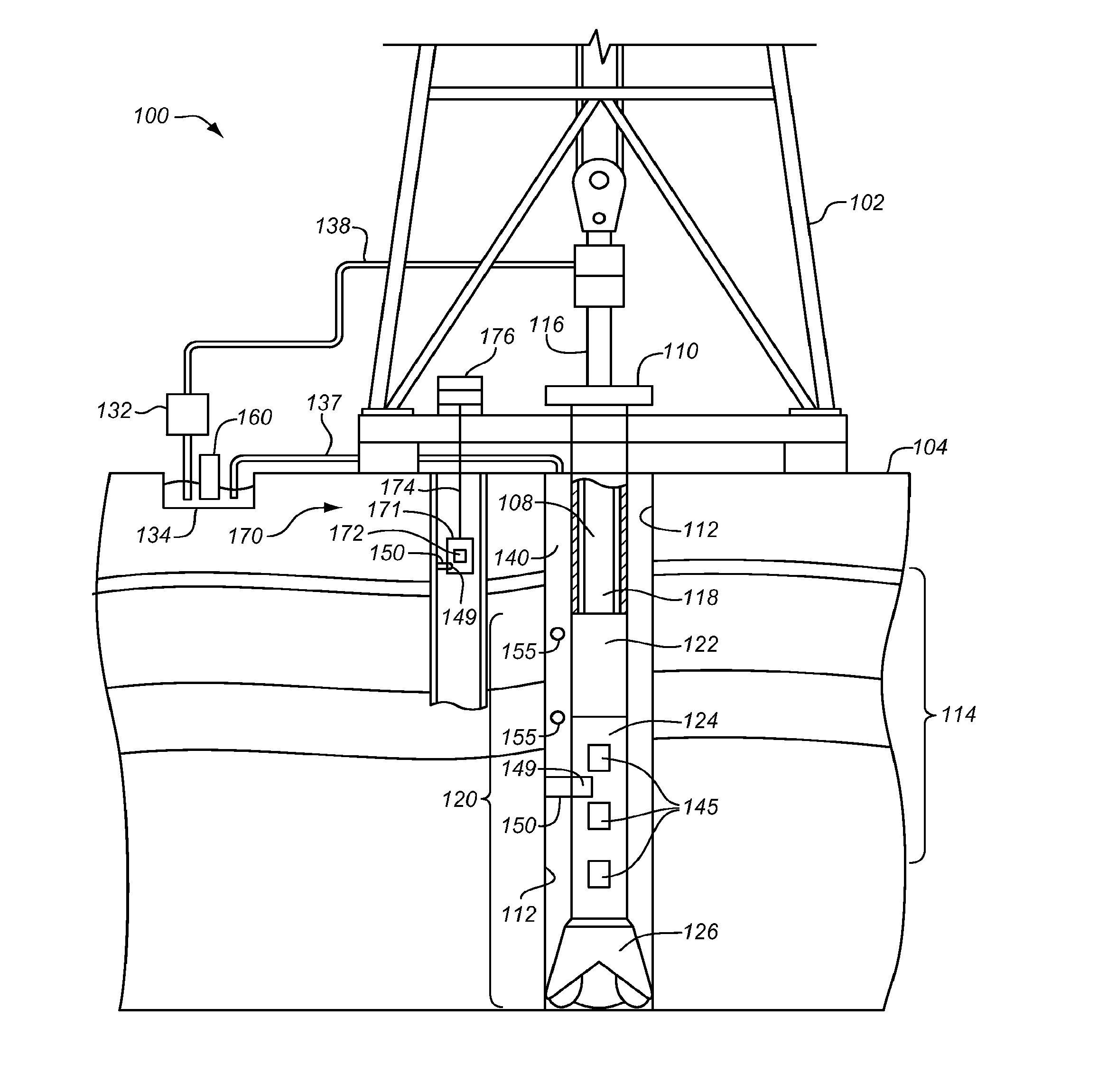

Fluid control in reservoir fluid samplilng tools

InactiveUS20140096957A1Increase pumping speedMaximum pumping speedSurveyFluid removalFluid controlReservoir fluid

A pumping system includes a probe to suction a fluid from a fluid reservoir, a pump in fluid communication with the probe, and a sensor for detecting phase changes in said pumping system. The sensor is in fluid communication with the probe or pump and is operable to generate a sensor signal. The pumping system also includes a fluid exit from the pumping system that is in fluid communication with said pump, and a variable force check valve that is located between the probe and fluid exit.

Owner:HALLIBURTON ENERGY SERVICES INC

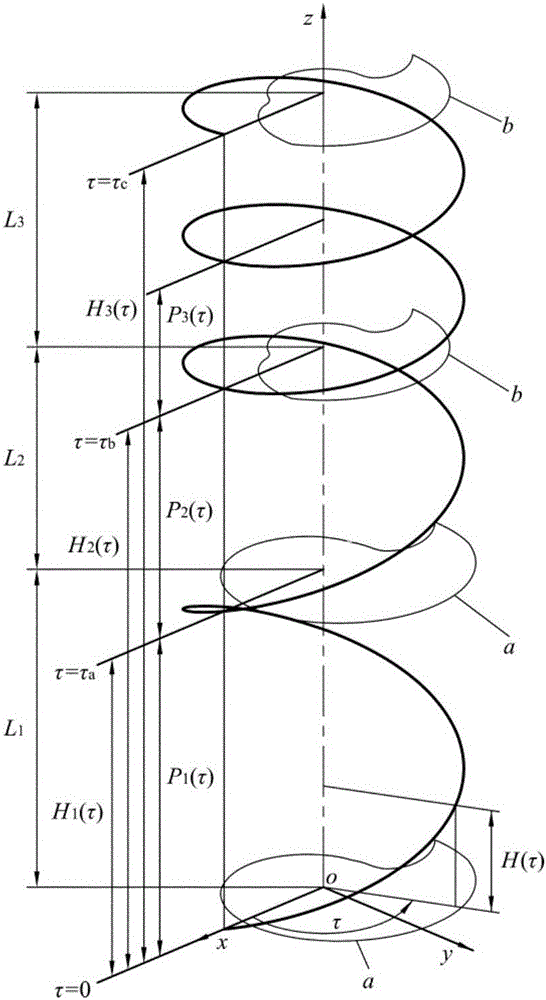

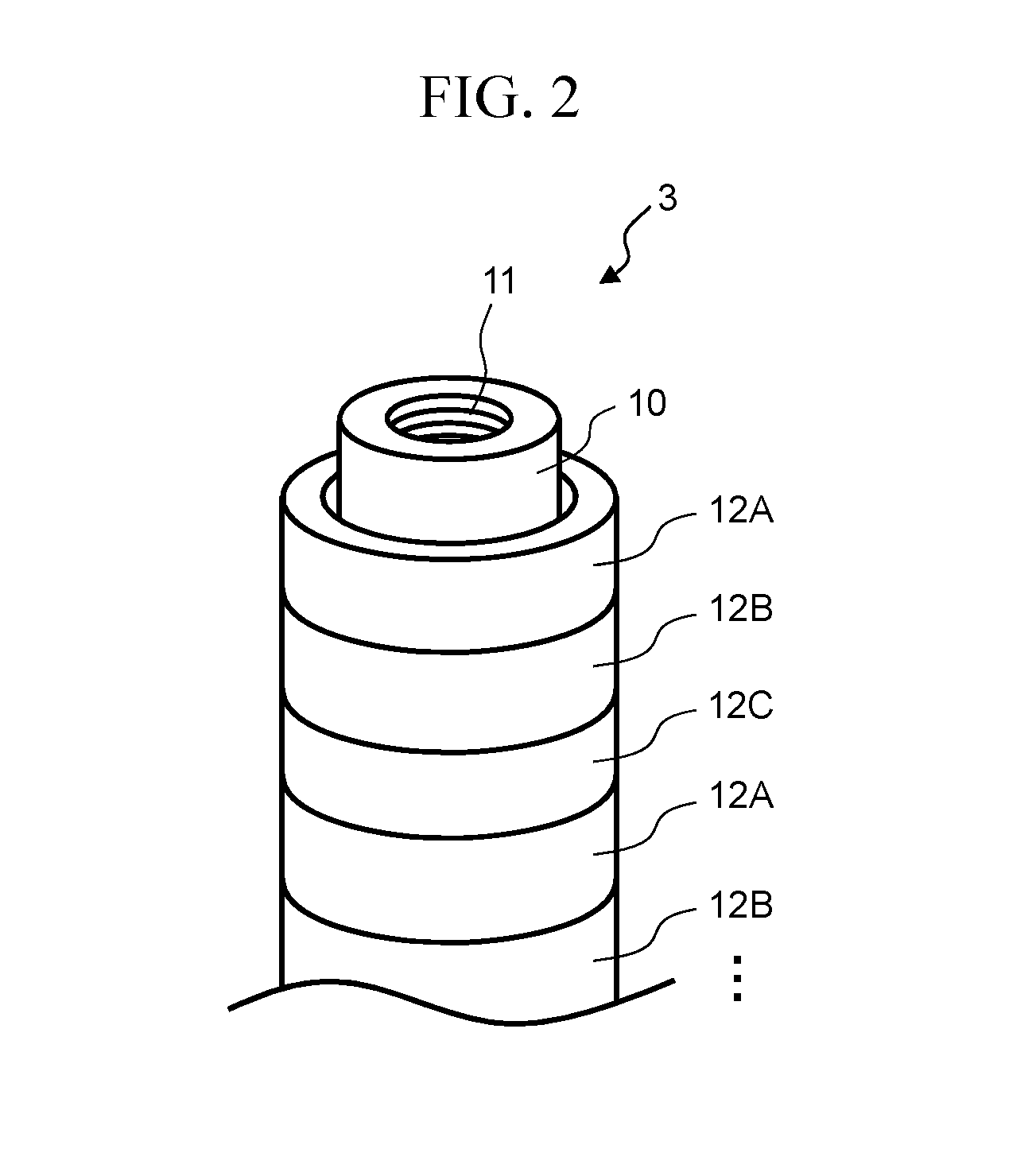

Conical screw rotor and double-screw vacuum pump thereof

InactiveCN105971877AIncrease the internal volume ratioIncrease inspiratory volumePump componentsRotary piston pumpsVacuum pump

The invention discloses a conical screw rotor and a double-screw vacuum pump thereof and belongs to the field of dry double-screw vacuum pumps. The conical screw rotor comprises a suction section, a compression section and an exhaust section, wherein molded lines of cross sections of the suction section, the compression section and the exhaust section change continuously along spiral spread angles; the molded lines with uniform pitches and uniform cross sections are adopted in the suction section and the exhaust section of the conical screw rotor, the molded lines with variable pitches and variable cross sections are adopted in the compression section of the conical screw rotor; spiral spread directions of a main screw rotor I and an auxiliary screw rotor II are opposite; the main screw rotor I and the auxiliary screw rotor II can be meshed correctly at work; the screw rotor can form a big suction volume and a small exhaust volume in a short axial dimension, thus the inner volume ratio of the screw rotor is improved to the maximum degree. The screw rotor has the advantages of high inner volume ratio, compact structure, short axial dimension and low processing difficulty, and improves the limit vacuum degree and the pumping speed of the double-screw vacuum pump.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Ion pump and charged particle beam device using the same

An ion pump and a charged particle beam device each includes two opposite flat-plate cathodes, an anode with a cylindrical shape having openings that face the respective flat-plate cathodes, a voltage application unit configured to apply a potential higher than potentials of the flat-plate cathodes to the anode, a magnetic field application unit configured to apply a magnetic field along an axial direction of the cylindrical shape of the anode, and a cathode bar arranged within the anode. The surface of the cathode bar is formed with a material that forms a non-evaporative getter alloy film on the anode or the flat-plate cathodes.

Owner:HITACHI LTD

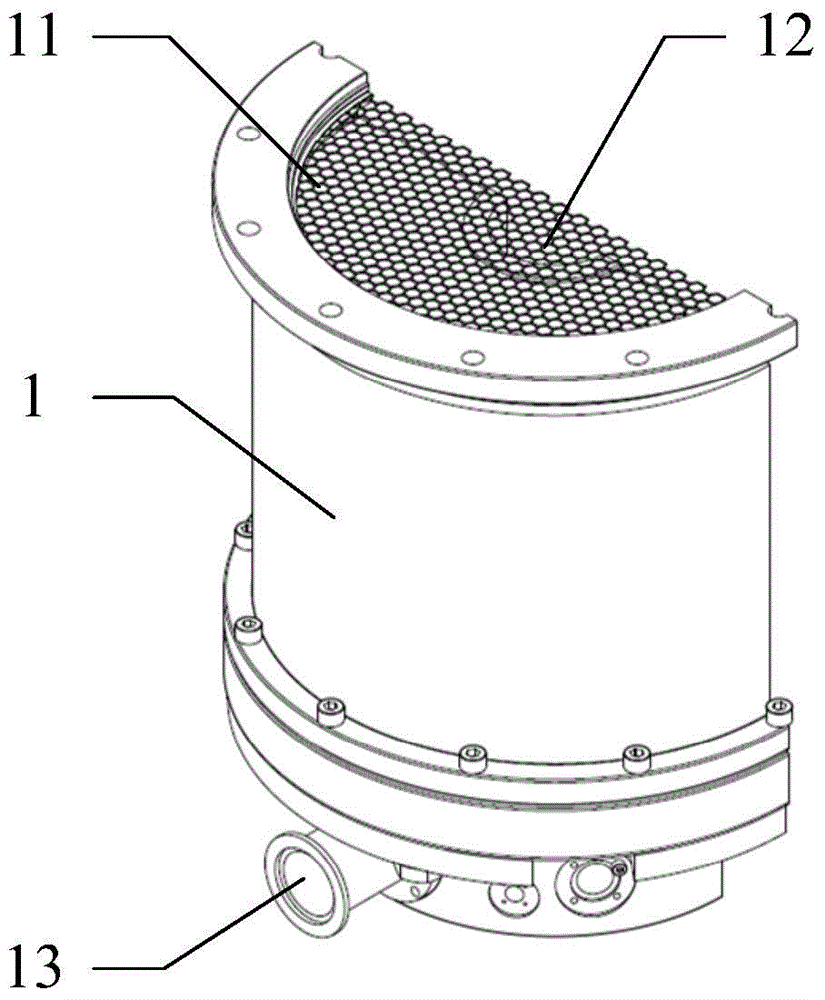

Composite vacuum pump

InactiveCN101852199AIncrease ultimate vacuumReduce energy consumptionRotary piston pumpsRotary piston liquid enginesVacuum pumpingProcess engineering

The invention belongs to the field of vacuum-pumping equipment and provides a composite vacuum pump which comprises a pump shell, a gas inlet and a gas outlet, wherein the gas inlet and the gas outlet are formed on the pump shell; a plurality of levels of molecular drag pumps and Roots pumps, which are installed coaxially, are arranged in the pump shell; the molecular drag pumps are combined in parallel or series and are arranged at the part near the gas inlet; the Roots pumps are combined in series and are arranged at the part near the gas outlet; and the molecular drag pumps and the Roots pumps are combined in series. The composite vacuum pump provided by the invention has the advantages of high pumping speed, high ultimate vacuum, low energy consumption, small size and light weight and can also acquire clean medium vacuum and high vacuum.

Owner:储继国

Roots vacuum pump

ActiveCN103104489AReduce volumeExtended maintenance cycleSealing arrangement for pumpsRotary piston pumpsDrive motorEngineering

The invention relates to the technical field of vacuum pumps, and in particular relates to a roots vacuum pump. The vacuum pump comprises a motor, front and back bearing cavities, a roots cavity and a gear cavity, wherein the front and back bearing cavities are located at the both sides of the roots cavity, and the gear cavity is connected with the back bearing cavity; the roots cavity is provided with an air inlet and an air outlet and is internally provided with a driving rotor shaft and a driven rotor shaft; the driving rotor shaft and the driven rotor shaft are respectively and correspondingly provided with a roots driving rotor and a roots driven rotor; one end of the driving rotor shaft is connected with the motor, and the other end of the driving rotor shaft is provided with a driving gear; one end of the driven motor shaft is provided with a driven gear which is in transmission connection with the driving gear and accommodated in a gear box; and the front bearing cavity and the back bearing cavity are internally provided with bearings and bearing support rings which are sleeved and fixed at the both ends of the driving rotor shaft and the driven rotor shaft. The roots vacuum pump has the advantages of being small in size, high in pumping speed, energy-saving, space-saving, and applicable to IC equipment.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

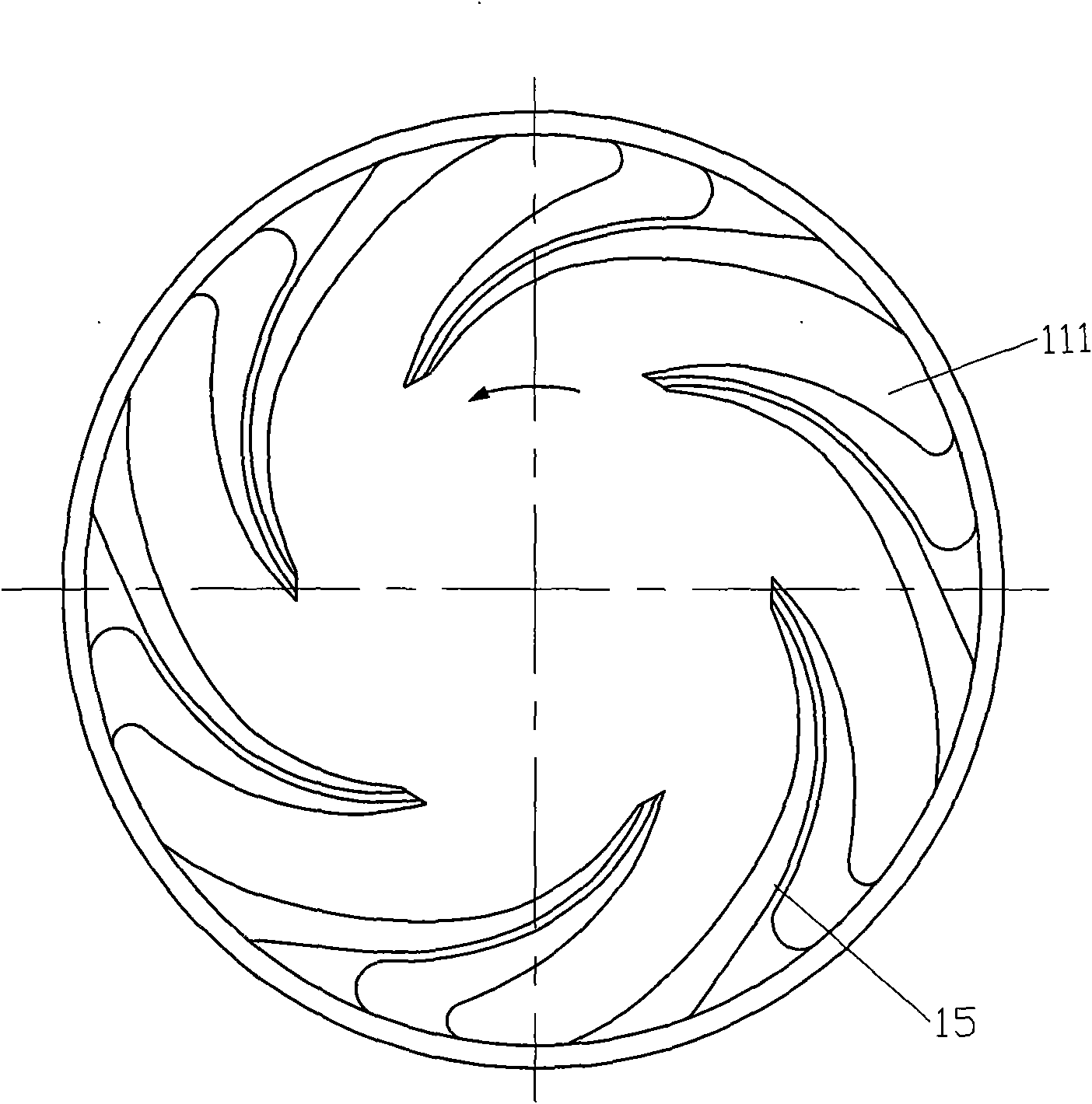

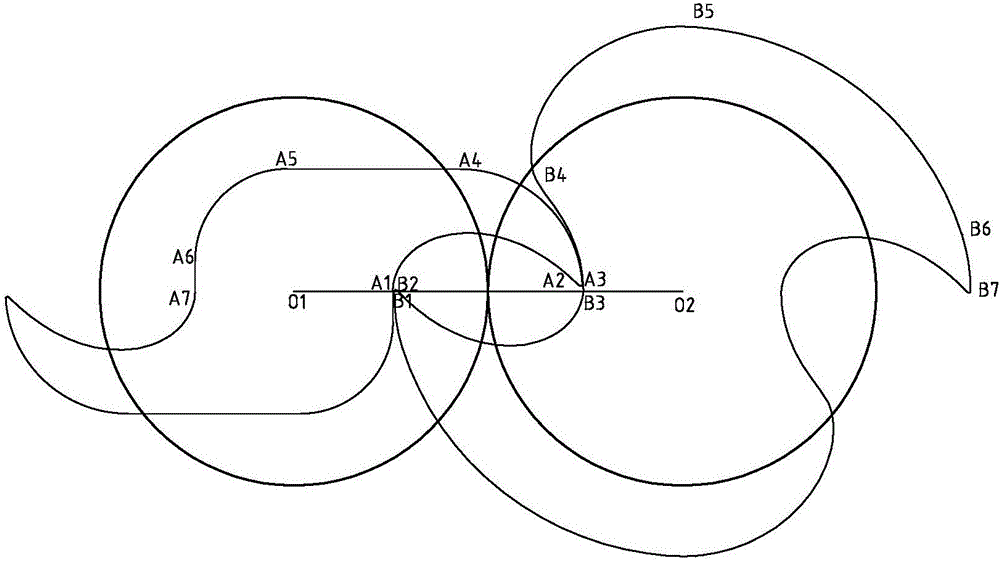

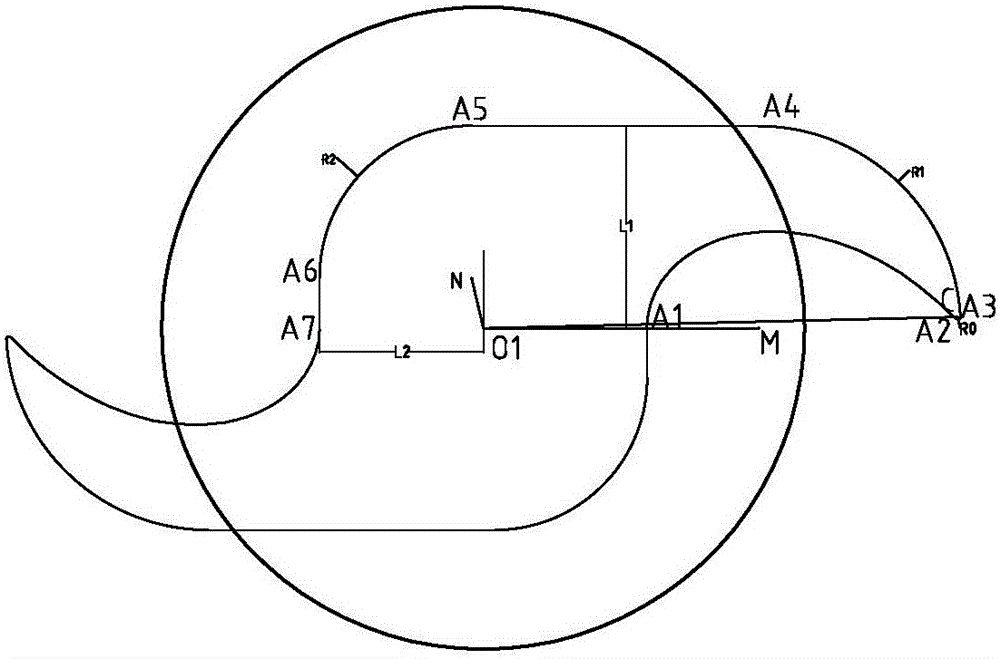

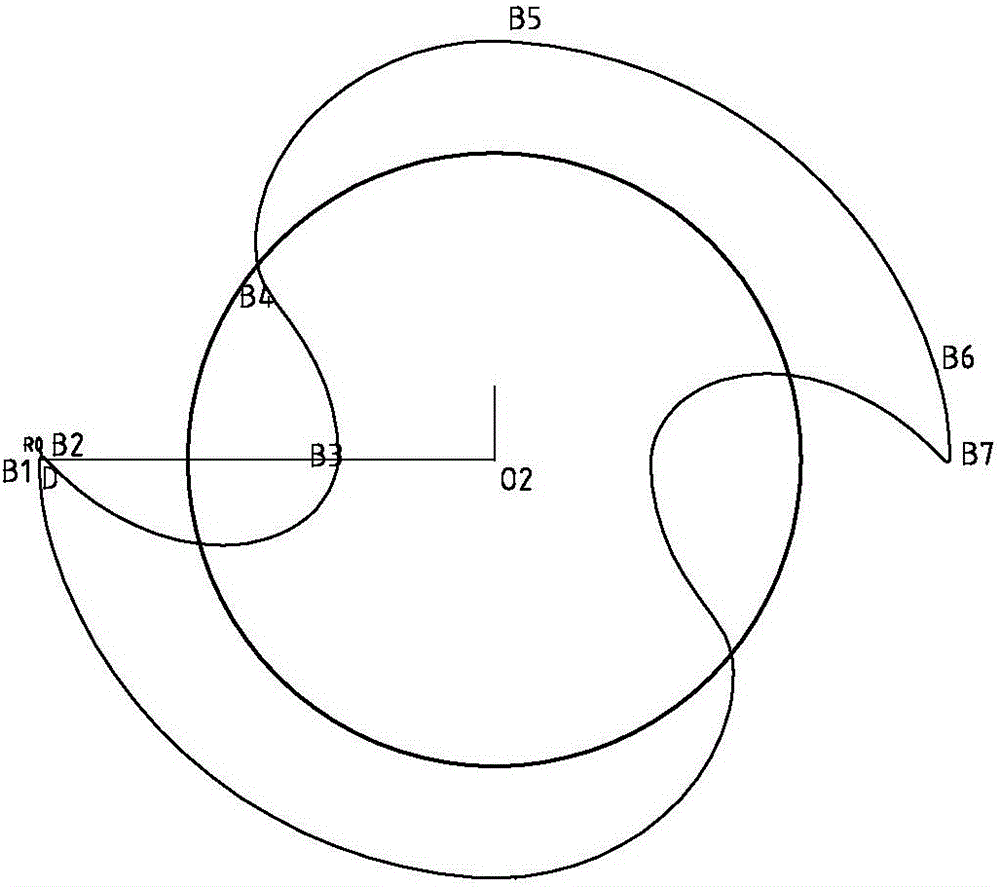

Special claw type rotor profile

ActiveCN105756929ASimple structureReasonable designRotary piston pumpsRotary piston liquid enginesPhysicsCentral symmetry

The invention relates to a special claw type rotor profile, and belongs to the technical field of claw type vacuum pumps.The special claw type rotor profile comprises a special claw type rotor A and a special claw type rotor B which are meshed with each other and are both of a central symmetry structure; the special claw type rotor A is composed of an arc R0 curve conjugate curve A1A2, a first arc A2A3, a second arc A3A4, a first straight line A4A5, a third arc A5A6 and a second straight line A6A7, and the special claw type rotor B is composed of an arc R0 curve B1B2, a first arc conjugate curve B2B3, a second arc conjugate curve B3B4, a first straight line conjugate curve B4B5, a third arc conjugate curve B5B6 and a straight line conjugate curve B6B7.Compared with an existing single-claw rotor, on the premise that the exradius Rm is equal to the pitch radius R of the rotor, the coefficient of utilization of capacity of a pump is greatly improved by 30-50%, high pumping speed can be realized, and the special claw type rotor profile is high in practicability.

Owner:伯仲(山东)工业设备有限公司

TiZrVHf quaternary getter thin film and preparation method thereof

ActiveCN108531877AStrong adhesionExtended service lifeVacuum evaporation coatingSputtering coatingCrystalliteGetter

The invention discloses a TiZrVHf quaternary getter thin film. The TiZrVHf quaternary getter thin film comprises four elements, namely, Ti, Zr, V and Hf, and the atomic number ratio is (0.9-1.1): (0.9-1.1): (0.9-1.1): (0.9-1.1): (0.9-1.1). The TiZrVHf quaternary getter thin film comprises a compact layer and a prismatic layer, wherein the compact layer and the prismatic layer sequentially grow inthe inner wall of a substrate pipe. The compact layer is a thin film, has a flat surface, and has no obvious grain structure under an electron microscope. The prismatic layer is a thin film has a rough surface, and has a obvious grain structure under the electron microscope. The prismatic layer has a large surface area and a large suction area, so that the suction rate per unit area of the substrate pipeline increases significantly. The TiZrVHf quaternary getter thin film belongs to the technical field of getter thin films. The TiZrVHf quaternary getter film can be activated at low temperature, strong adhesion and long service life are achieved, the vacuum degree of a particle accelerator is effectively improved, and the secondary electron emission coefficient is reduced.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

Cryopump

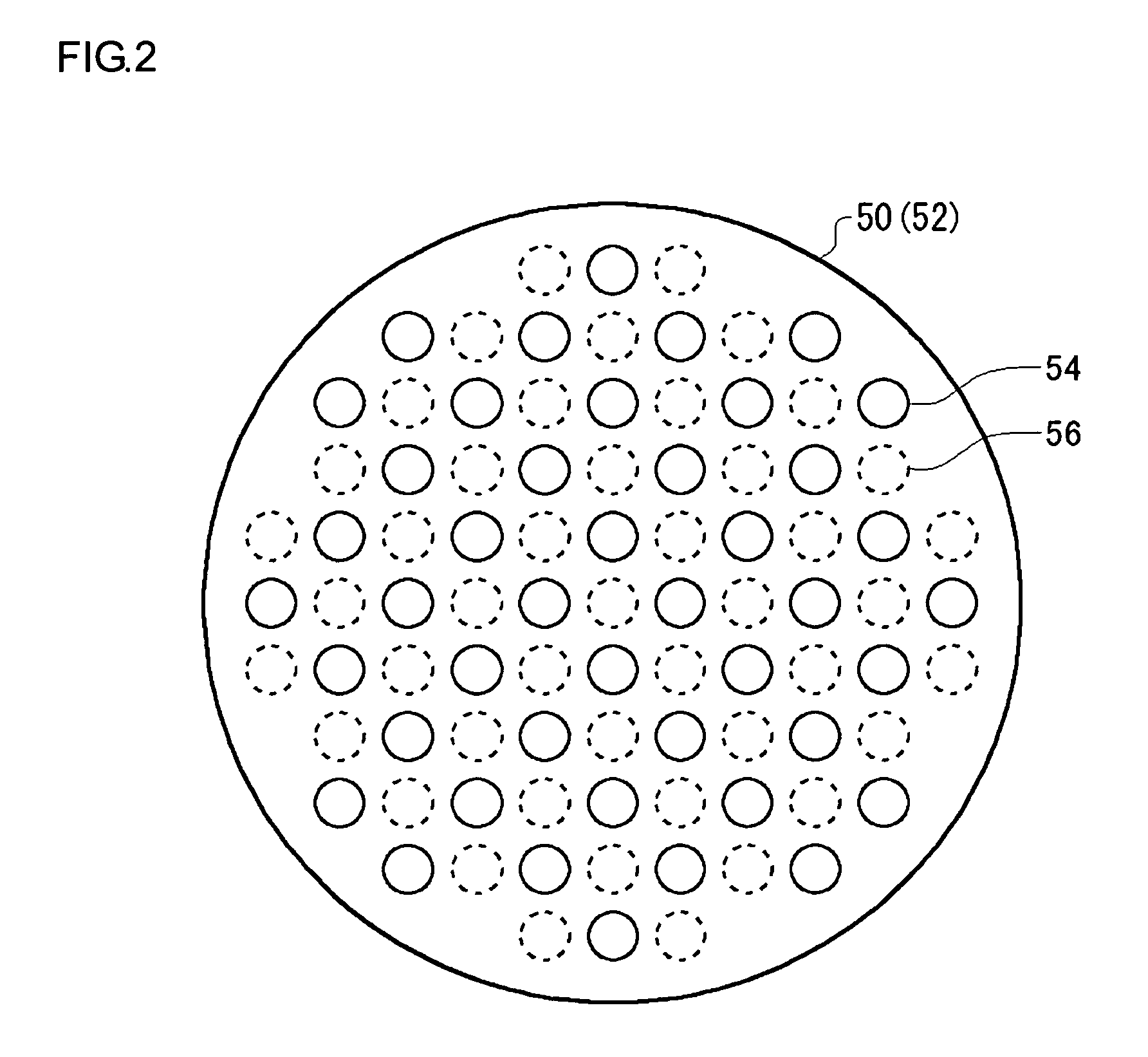

ActiveUS20100077771A1Reduce influenceIncrease pumping speedSolidificationLiquefactionElectrical and Electronics engineeringCryopump

A cryopump includes a second-stage cryopanel, a radiation shield that surrounds the second-stage cryopanel and has a shield opening, and a first-stage cryopanel provided in the shield opening. The first-stage cryopanel includes a first panel provided with opening regions thereon in a first distribution, and a second panel arranged closer to the second-stage cryopanel than the first panel and provided with opening regions thereon in a second distribution different from the first distribution when viewed in an arrangement direction of the first and second panels.

Owner:SUMITOMO HEAVY IND LTD

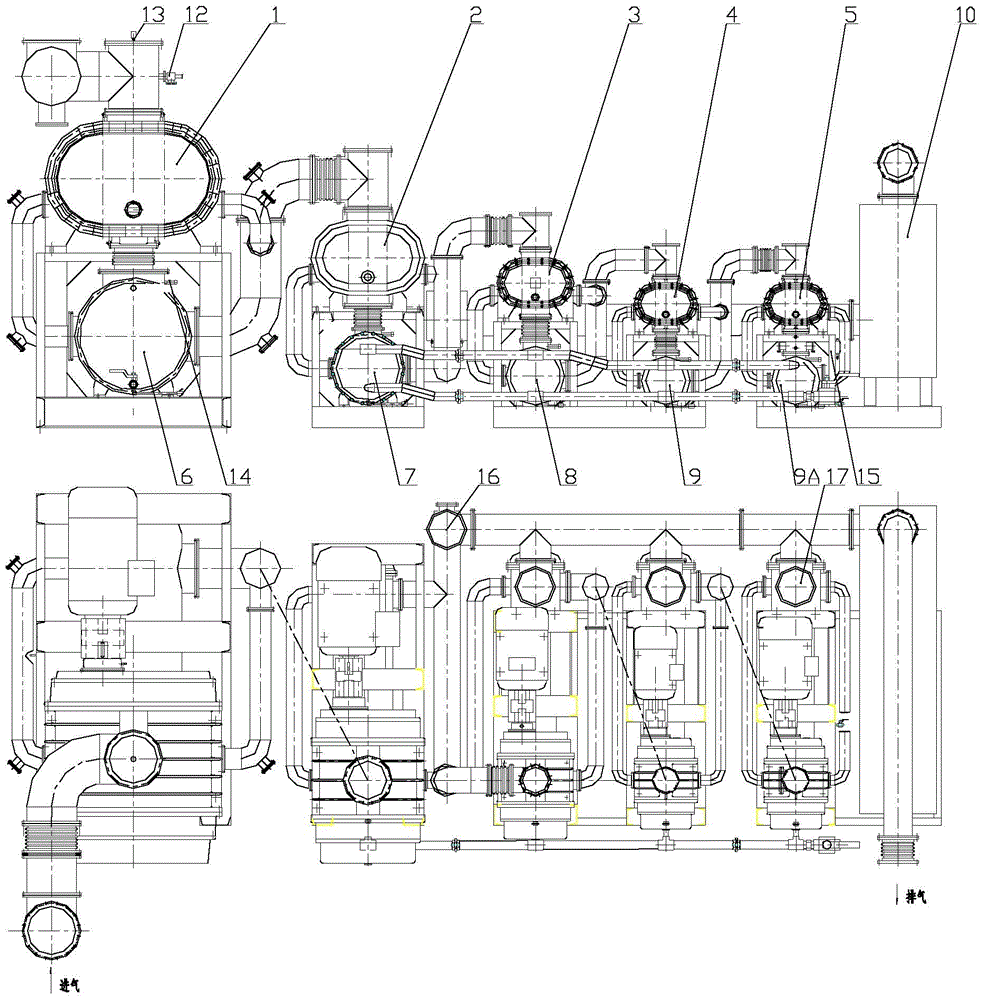

Vacuum-pumping system for wind tunnel body

ActiveCN105222980AImprove the noise reduction effectSimple structureAerodynamic testingVacuum pumpingReflux valve

The invention relates to a vacuum-pumping system for a wind tunnel body. The vacuum-pumping system includes a multi-level air cooled lobe pump assembly, a set of heat exchangers, a silencer, an overflow valve, and a check valve; the upper part of each air cooled lobe pump is provided with an air inlet, and the lower part of each air cooled lobe pump is provided with an air outlet; two sides of each air cooled lobe pump are provided with a cool air returning opening respectively, so that heat balance of a pump body can be maintained when the pump operates under a high pressure difference; when the pressure of an air inlet connected to the back end of the lobe pump system is greater than the discharge pressure of the lobe pump assembly, a part of pumped air can be directly discharged into the silencer via the overflow valve, and then is discharged into the atmosphere via the silencer; the other part of the pumped air is discharged into the atmosphere via the overflow valve and the silencer. Each vacuum heat exchanger of the system mainly includes a housing, heat exchanger tubes, and an anti-reflux valve. A PLC control technology and a frequency converter technology are adopted by the system, so that the vacuum-pumping system can automatically adjust the pumping speed according to the pressure of an entrance.

Owner:ZHEJIANG VACUUM EQUIP GROUP

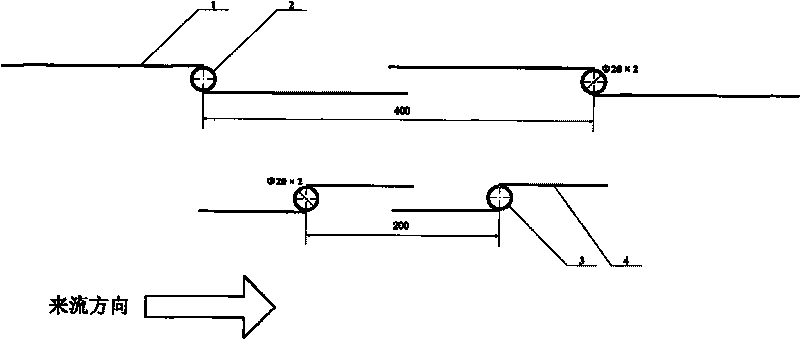

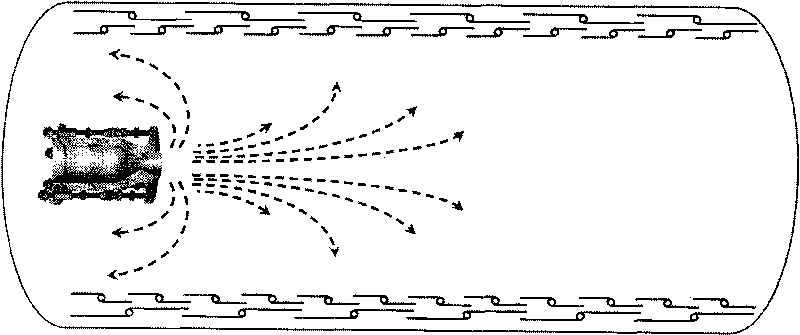

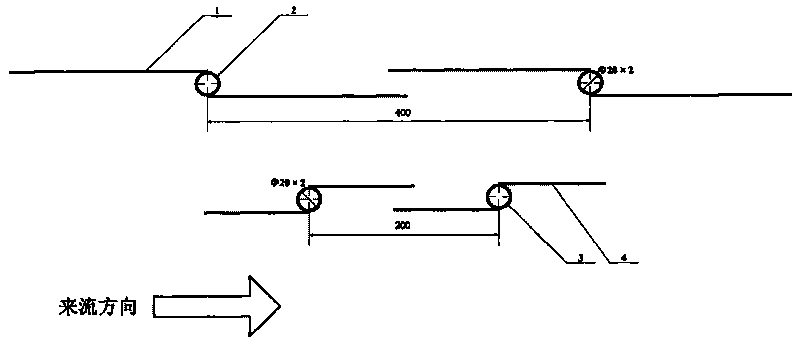

Heat sink wall panel structure arrangement for increasing absorption of plume gas

The invention relates to a heat sink wall panel for plume test, mainly consisting of a liquid nitrogen heat sink fin (1), a liquid nitrogen heat sink branch pipe (2), a liquid nitrogen heat sink branch pipe (3) and a liquid nitrogen heat sink fin (4). The liquid nitrogen heat sink is located inside the liquid nitrogen heat sink to reduce the heat load of a vacuum container to the liquid nitrogen heat sink; the liquid nitrogen heat sink directly faces to the gas in plume test ensuring high pumping speed and high plume absorption efficiency; the opening direction of the liquid nitrogen heat sink wall panel is opposite to the direction of the plume, and the plume gas can rapidly enter into the liquid nitrogen heat sink and the liquid nitrogen heat sink interlayer to reduce the plume ejection sped and improve the absorption efficiency via multiple bounce; the opening direction of the liquid nitrogen heat sink wall panel is in the plume direction and is in geometric symmetry with the opening direction of the liquid nitrogen heat sink wall panel so that the plume gas is easy to enter and difficult to come out, the capturing rate of gas is increased; gap is left between the fins so that both sides of the heat sink can absorb flume gas, thereby effectively increasing the plume absorption area; and the materials adopt stainless steel branch pipes and copper fins, thereby effectively improving the static and dynamic vacuum degree inside the vacuum container.

Owner:BEIHANG UNIV

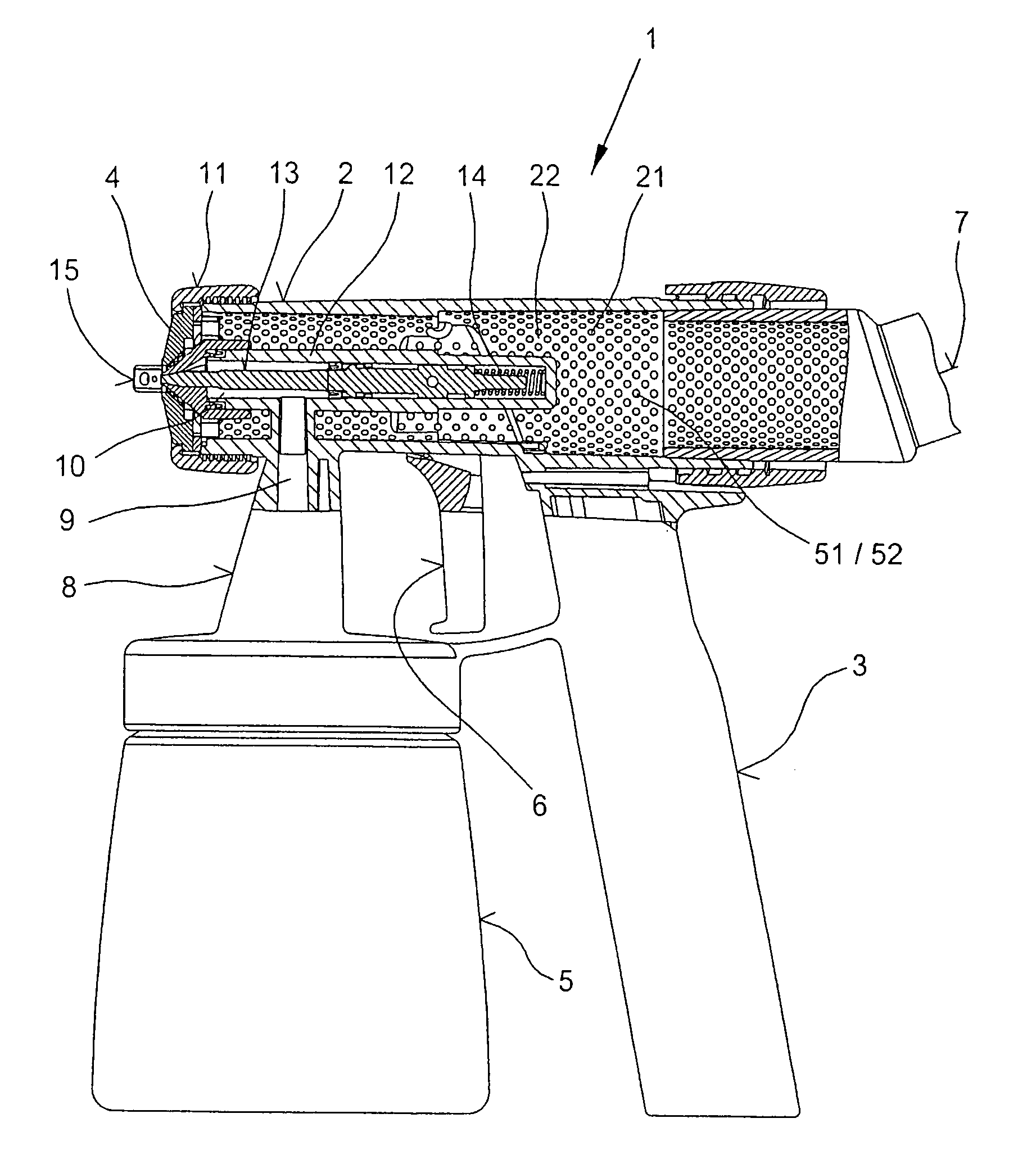

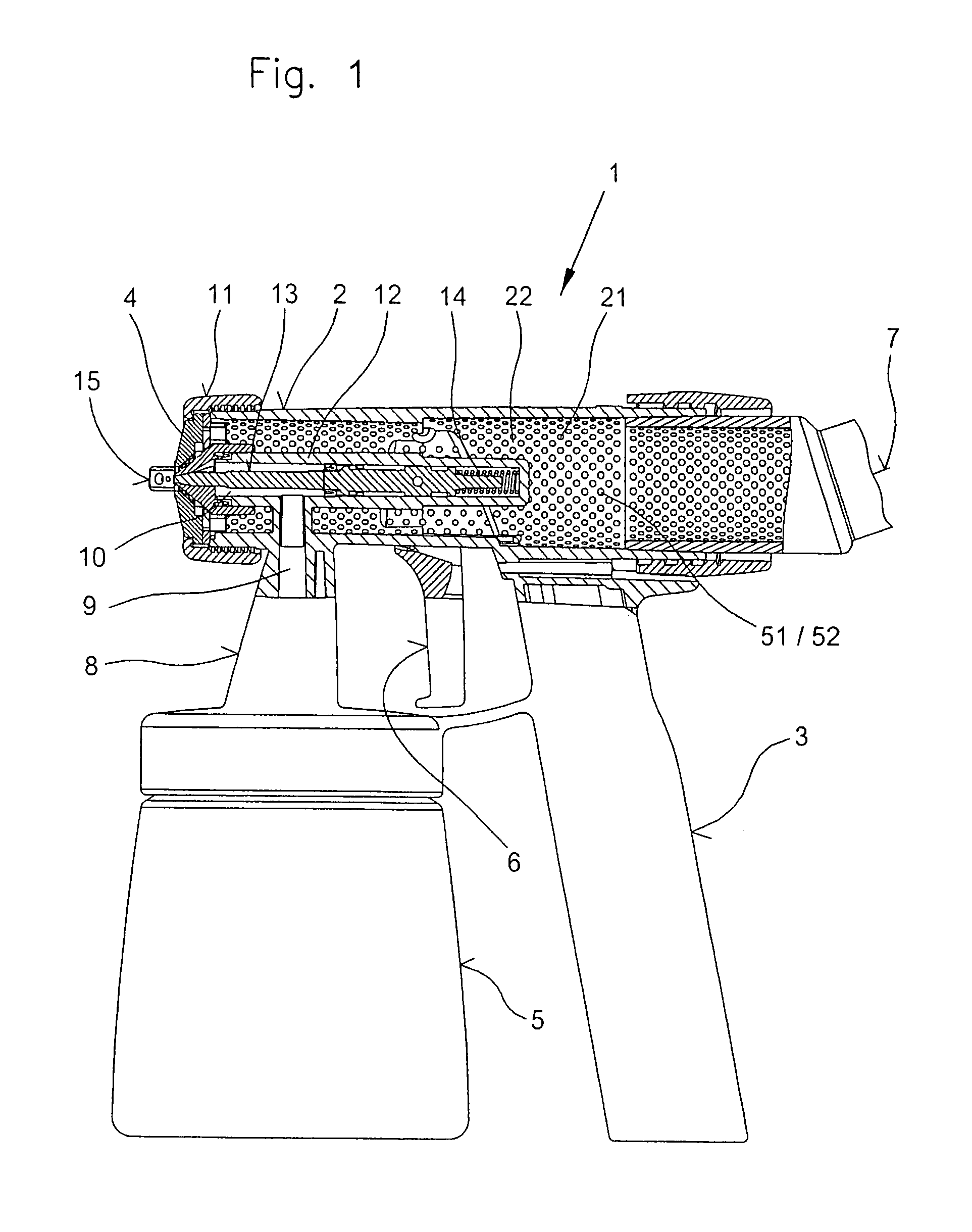

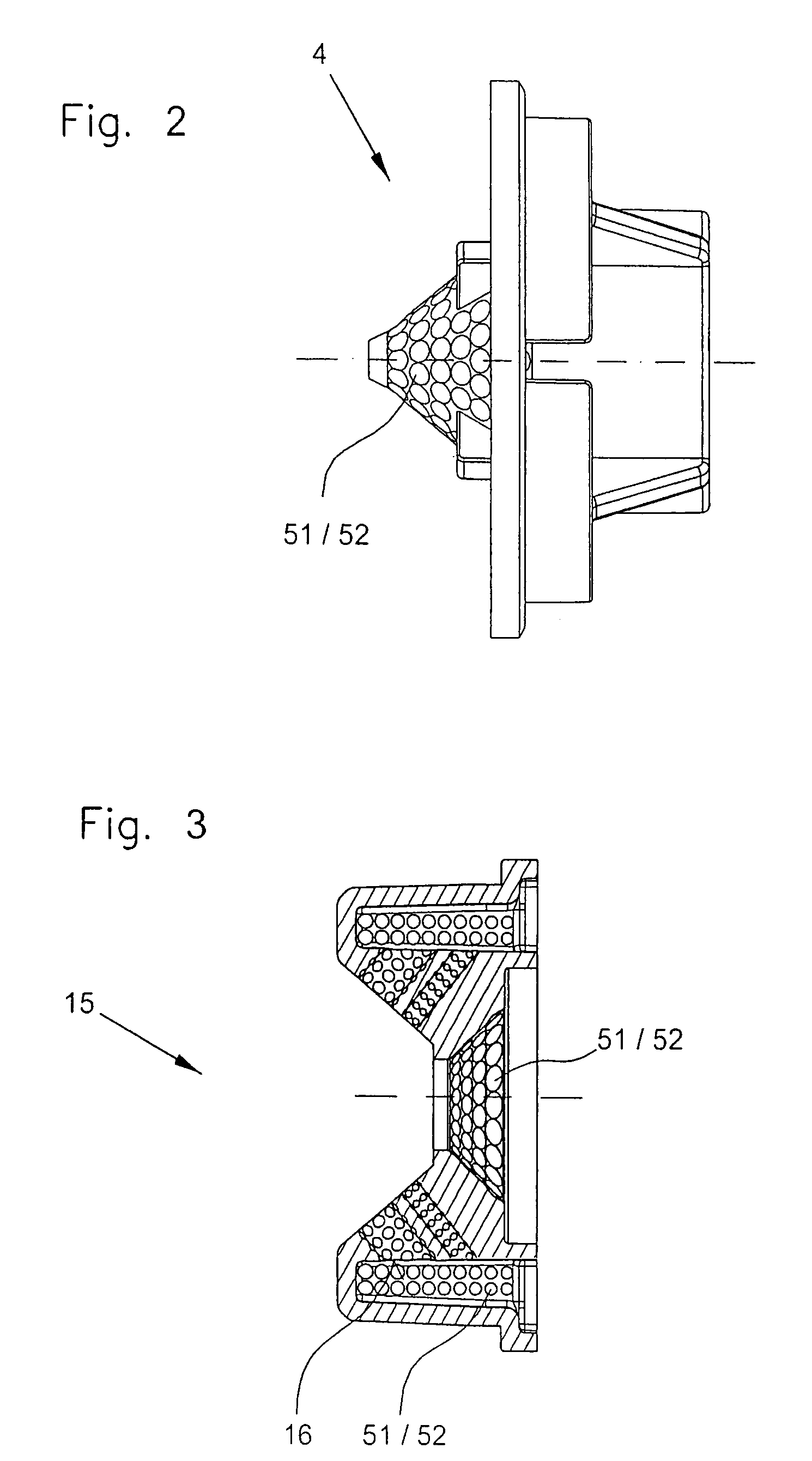

Spray gun

ActiveUS7431223B2Increased rate of transportationIncrease pump speedSpray nozzlesFluid dynamicsEngineeringViscous medium

A spray gun for spraying paints and similar viscous media that can be propelled pneumatically, comprising a gun housing for accommodating components of the spray gun that effect propulsion, mixture and / or metering, a handle projecting from the gun housing, and a reservoir tank removably attached to the gun housing for holding the medium to be processed, with the housing of the spray gun provided with an air guidance duct through which the compressed air responsible for atomization flows to an atomizer nozzle, wherein surfaces of the air guidance duct and / or atomizer nozzle, and / or an air cap, which come into contact with the stream of compressed air, or are wetted, are provided wholly or in part with a structured surface in the form of indentations and / or protrusions worked into the surfaces.

Owner:J WAGNER GMBH

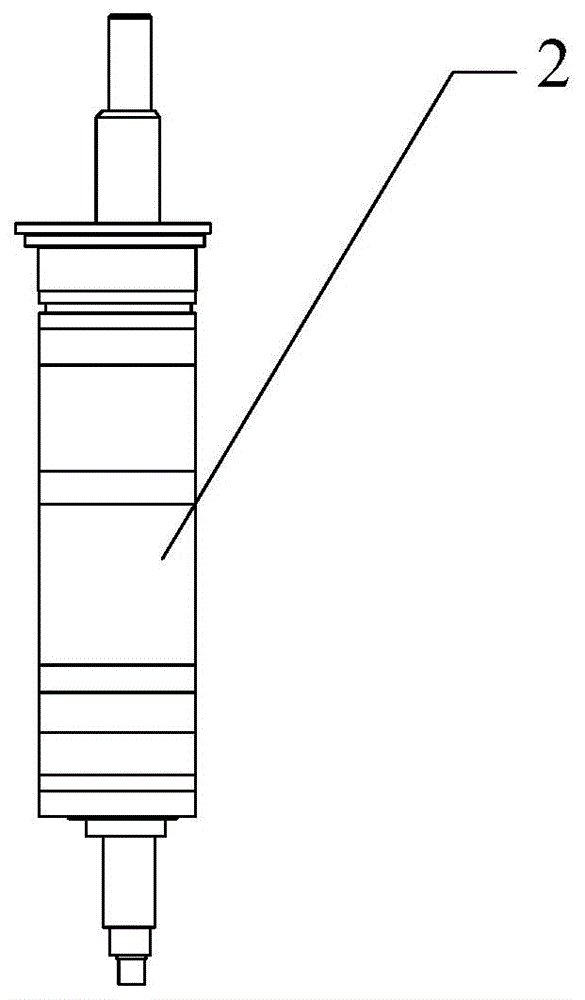

Compound molecular pump

ActiveCN104895808AIncrease pumping speedCompact structurePump componentsPump controlMagnetic bearingEngineering

The invention provides a compound molecular pump. A plurality of layers of stator blades are sequentially and fixedly mounted on the inner wall of a pump shell in the axial direction, and a main shaft is vertically arranged in the pump shell; rotors comprise a turbine stage rotor and a traction stage rotor; a plurality of layers of rotor blades are sequentially distributed and arranged on the periphery of the turbine stage rotor in the axial direction, and the rotor blades and the stator blades are alternatively arranged in the axial direction and are opposite in the inclined direction; compound spiral groove stators comprise horizontal type spiral groove stators and vertical type spiral groove stators, wherein the horizontal type spiral groove stators and the vertical type spiral groove stators are connected into a whole; and the rotor blades on the bottommost layer match the horizontal type spiral groove stators. Sensors and heating devices are arranged in material sedimentary areas in molded line spiral flow guide grooves, and the lower end of the main shaft is sleeved with a radial magnetic bearing. The compound molecular pump is compact in structure, and under the premise of the large pumping speed and the high compression ratio, rotating speed sudden increasing, high temperature resisting and corrosion resisting of the rotors in the short time can be achieved; material sedimentation can be effectively reduced; and the health state of the molecular pump can be monitored in real time, and the molecular pump can be prevented from losing efficacy in time.

Owner:SHANGHAI FUYAO VACUUM TECH CO LTD

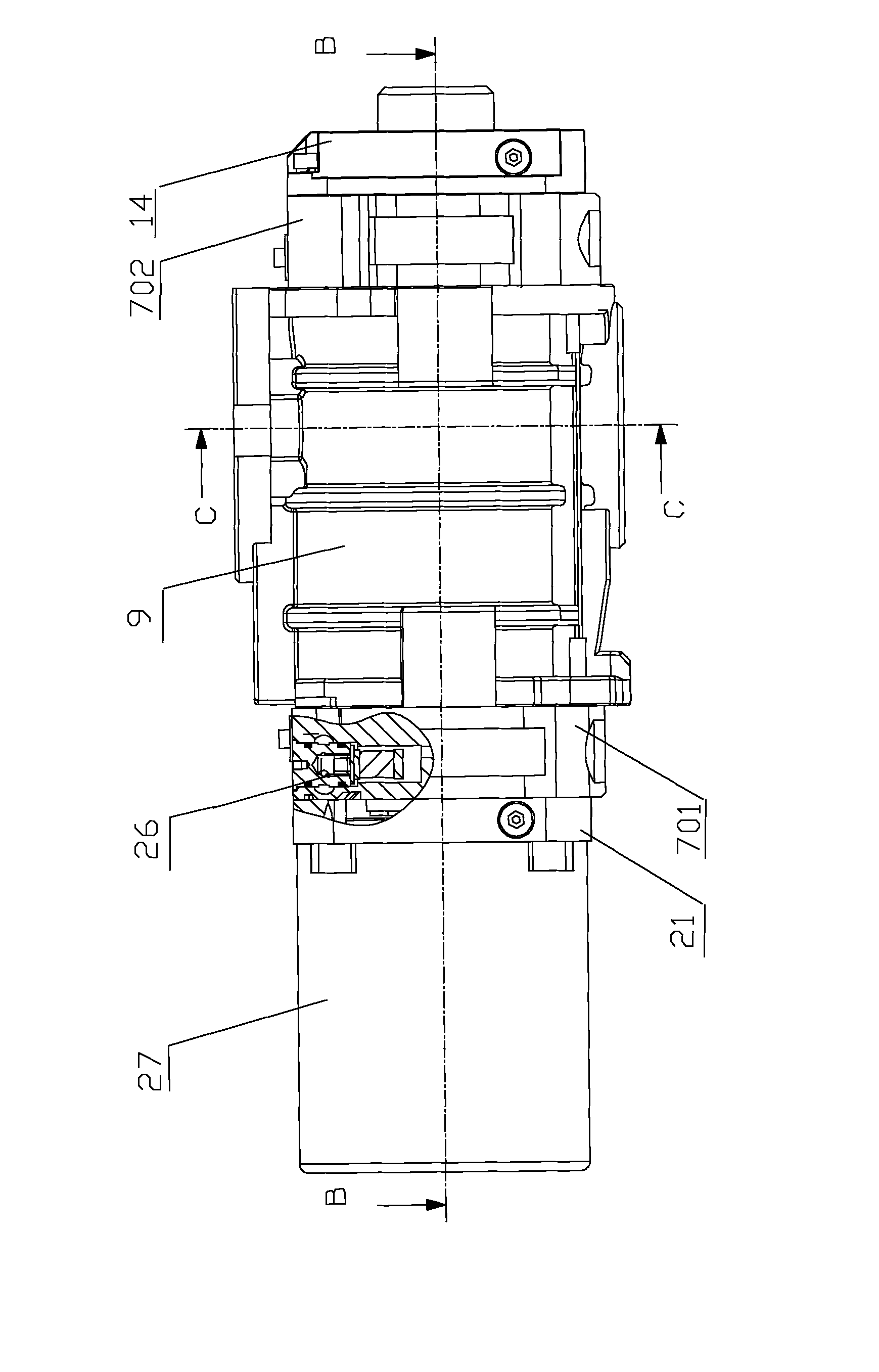

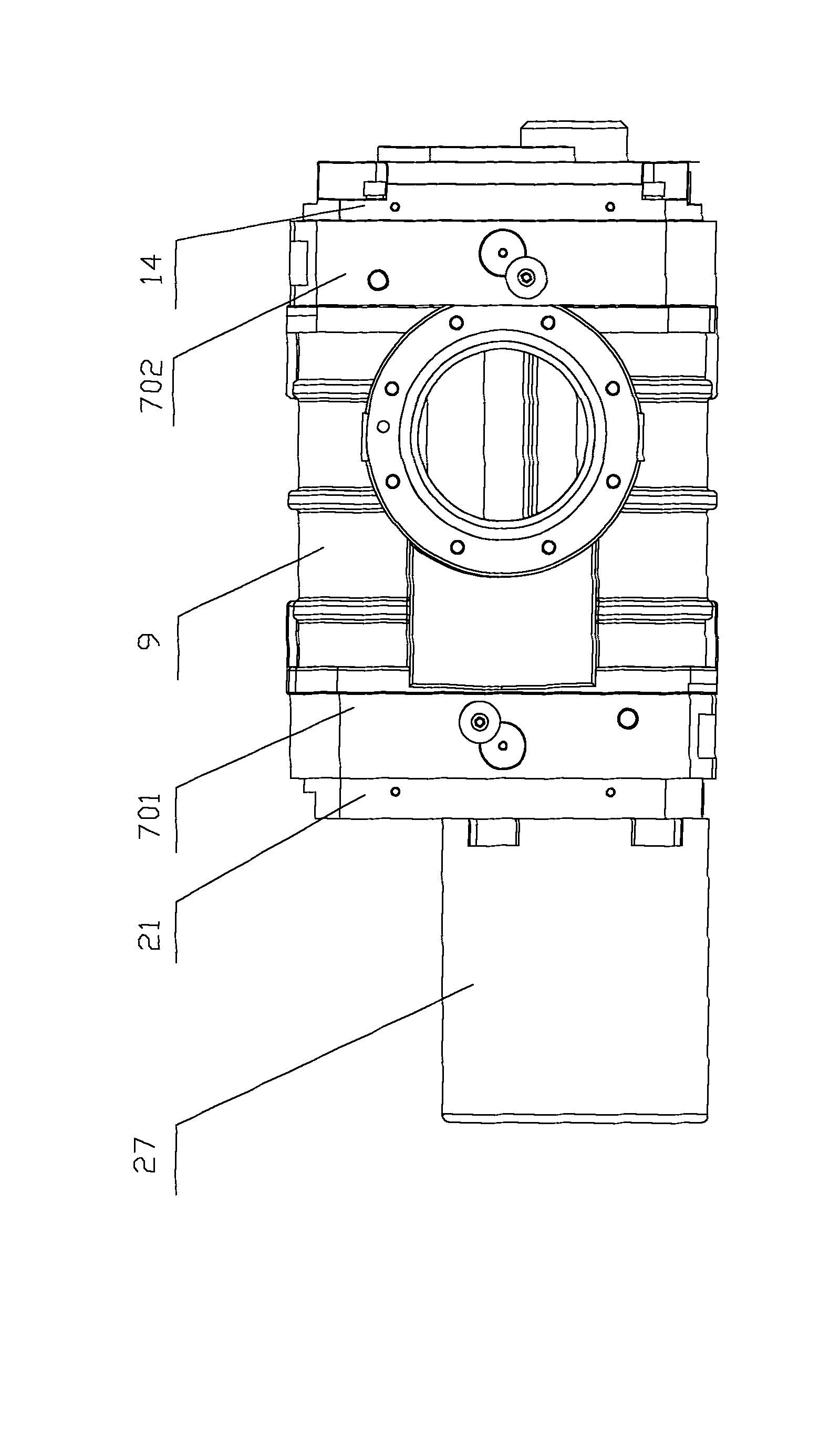

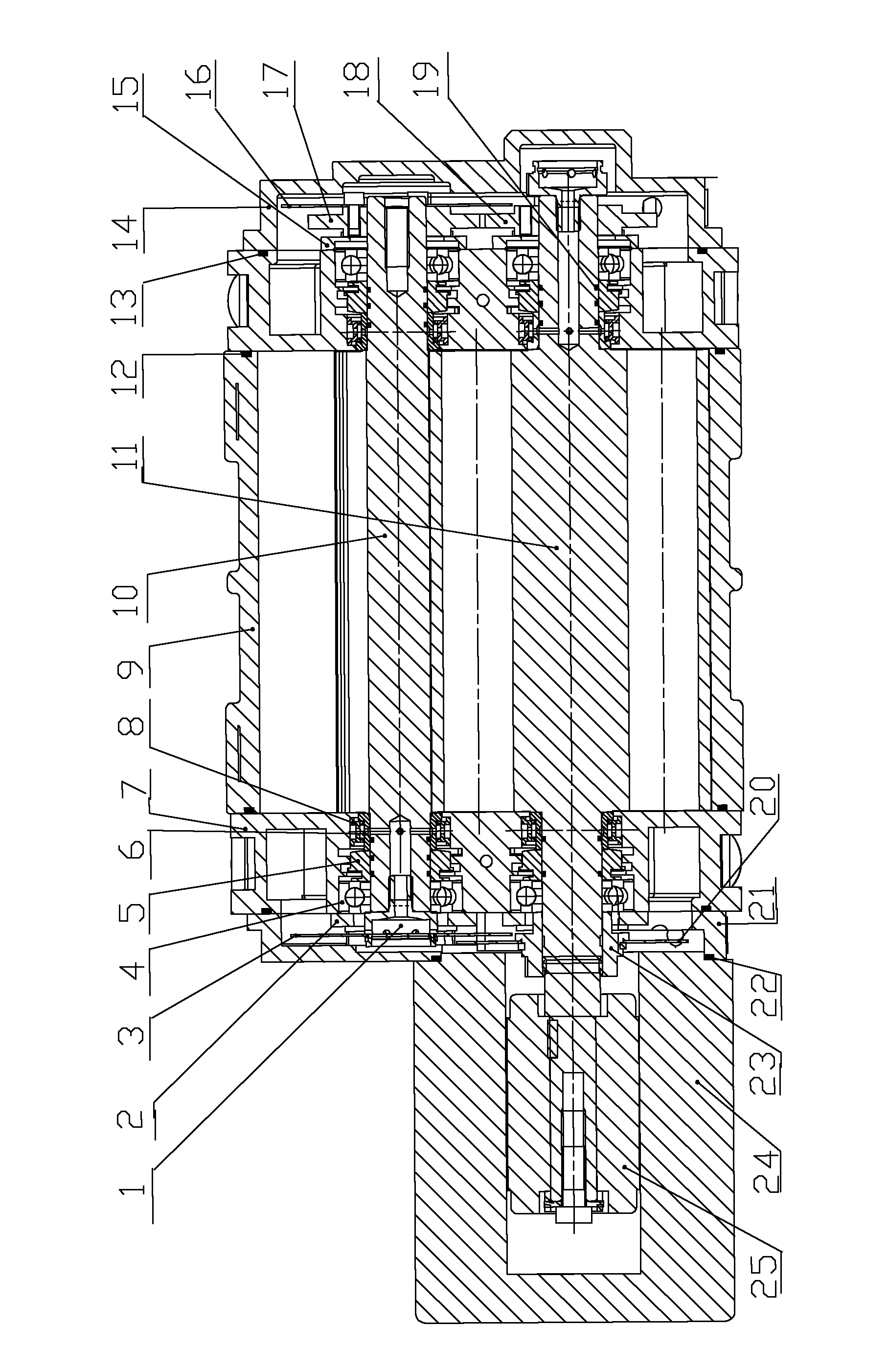

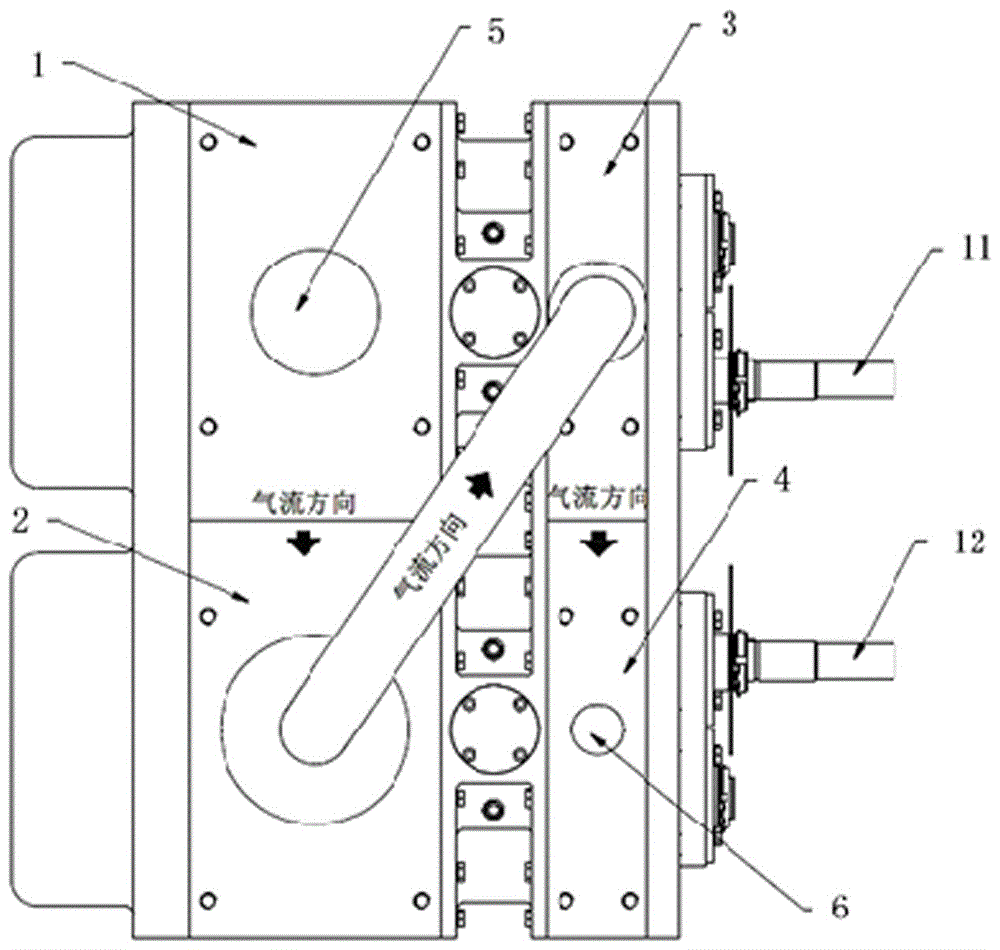

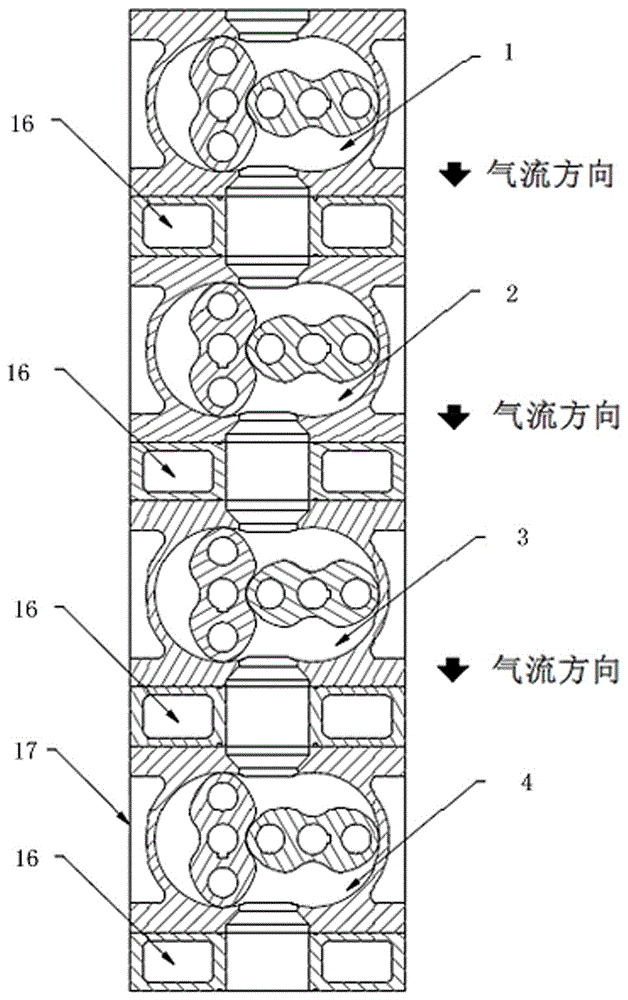

Modular integrated multi-stage and multi-drive chamber partially non-coaxial dry type vacuum single pump

InactiveCN106438365AIncrease mass flowHigh calorific valueRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsDrive shaftAtmospheric air

The present invention discloses a modular integrated multi-stage and multi-drive chamber partially non-coaxial dry type vacuum single pump, which comprises a plurality of modular vacuum drive chambers. The dry type vacuum single pump is characterized in that the plurality of modular vacuum drive chambers are integrated as an overall single pump. The plurality of modular vacuum drive chambers are connected in series to form a multi-stage vacuum single pump. At least two vacuum drive chambers, among the above plurality of modular vacuum drive chambers, are associated in the two non-coaxial manner, wherein the gas mainstream direction is perpendicular to the drive shaft of a rotor. The inlet of a first-stage vacuum chamber is directly introduced to the atmosphere. According to the technical scheme of the invention, the plurality of modular vacuum drive chambers are non-coaxial, so that the compression ratio of each vacuum drive chamber is adjustable. In this way, in the high-vacuum environment, the compression ratio is large. In the rough vacuum environment, the compression ratio is small. Therefore, both the safety and the efficiency are given consideration to, and the optimized control is enabled. The differential pressure sharing and the heat sharing at each stage are more uniform.

Owner:ELIVAC CO LTD +2

Turbo system and method of installing

InactiveUS20070107429A1Minimize debris entering the compressorReduce removalNon-fuel substance addition to fuelInternal combustion piston enginesCombustionTurbocharger

A turbocharger system for a combustion engine and method of installing a turbocharger system includes a turbocharger having an oil inlet configured for being coupled to a pressure side of an oiling system and an oil outlet, an exhaust inlet and outlet and an air charge inlet and outlet. An oil pump is connected to the oil outlet of the turbocharger and is further connected to the oiling system. A pressure driven check valve is coupled to the oil inlet of the turbocharger to prevent oil from flowing into the turbocharger when the pressure on the pressure side of the oiling system drops below a predetermined level. The turbocharger system also includes mounting hardware for mounting the turbocharger to an exhaust pipe and away from the engine and at or below the oil level of the oiling system. In one embodiment, the method of installing the turbocharger system includes removing an existing muffler from the vehicle and mounting the turbocharger in the location of the existing muffler.

Owner:STS TURBO

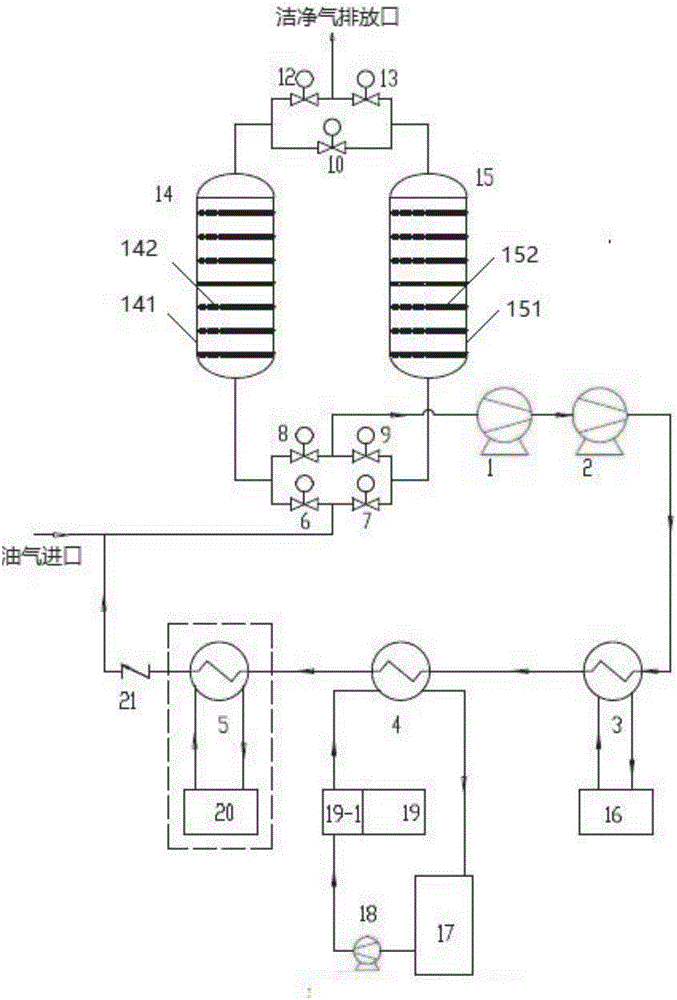

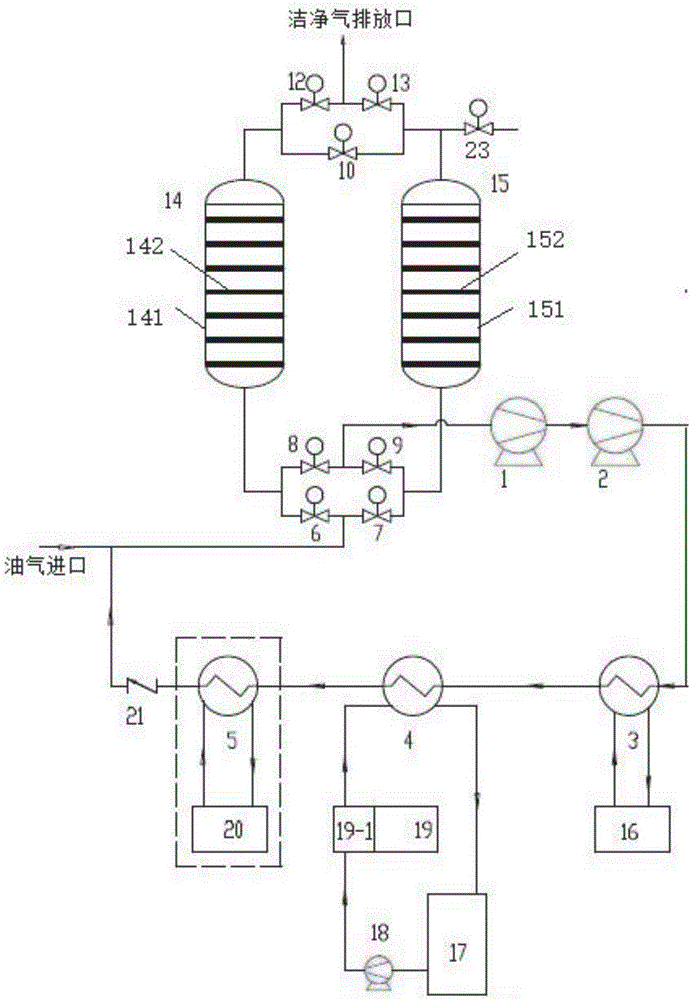

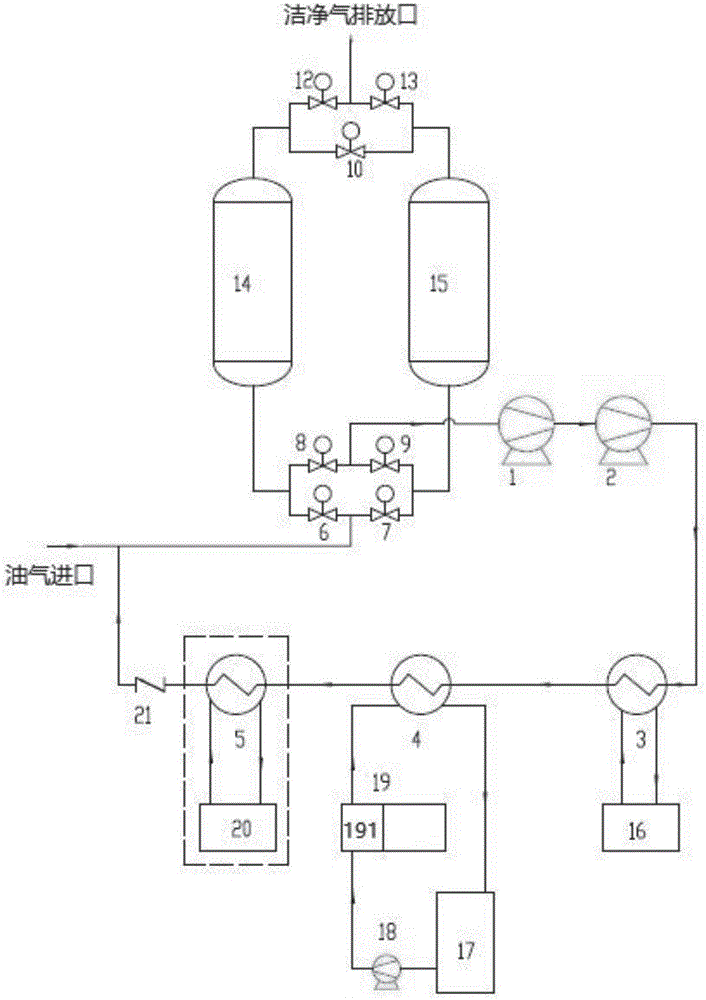

Adsorbing condensing type oil vapor recovery device for effectively preventing adsorption temperature rise and oil vapor recovery method

ActiveCN106731445ALess investmentReduce energy consumptionGas treatmentMultiple-effect/fractional condensationRecovery methodExhaust valve

The invention discloses an adsorbing condensing type oil vapor recovery device for effectively preventing adsorption temperature rise and an oil vapor recovery method. The device comprises an oil vapor inlet, a first valve set, an adsorption tank set, a second valve set, a clean gas exhaust port, a vacuum pump set, a first-level oil vapor condenser, a second-level oil vapor condenser, a third-level oil vapor condenser and a check valve, wherein the first valve set is composed of a gas inlet valve set under the adsorption tank set and a vacuum valve set in parallel connection with each other; the second valve set is composed of an exhaust valve set above the adsorption tank set and a blow-down valve set in parallel connection with each other; the blow-down valve set, the adsorption tank set, the vacuum valve set, the vacuum pump set, the first-level oil vapor condenser, the second-level oil vapor condenser, the third-level oil vapor condenser and the check valve are connected in turn; the check valve is connected with the oil vapor inlet; the oil vapor inlet is connected with the gas inlet valve set, the adsorption tank set, the exhaust valve set and the clean gas exhaust port in turn; a solid-liquid phase variable energy storage substance is filled into the adsorption tank set.

Owner:上海聚宸新能源科技有限公司

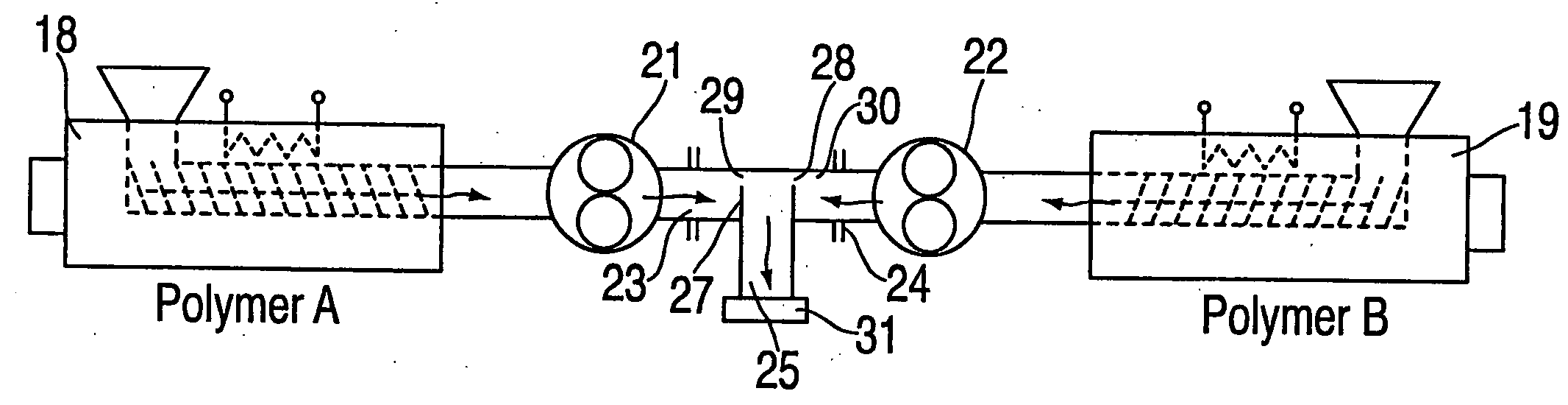

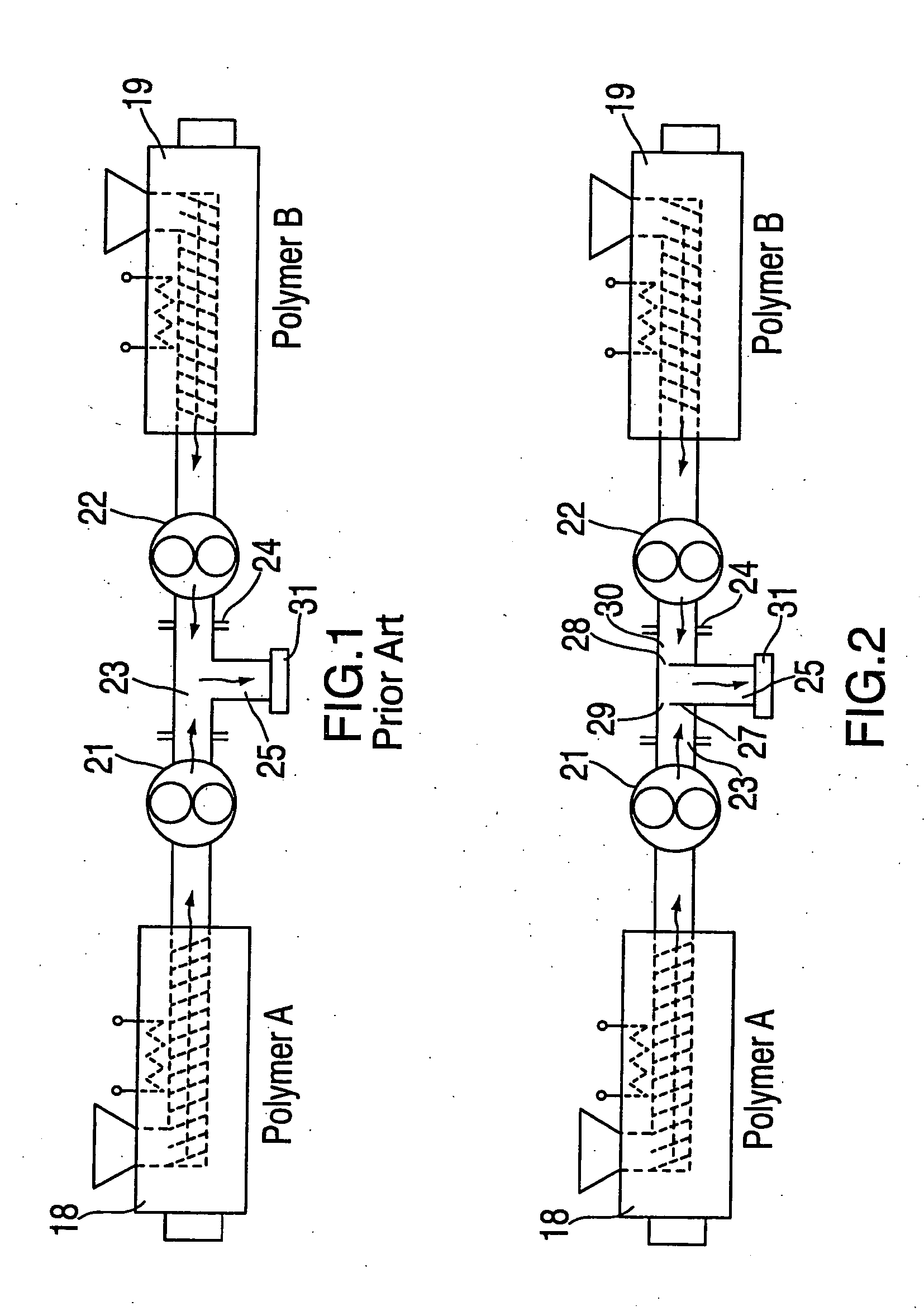

Alternate polymer extrusion method with reduced drool

InactiveUS20050017387A1Increase pressureIncrease pumping speedConfectioneryFilament/thread formingMulti materialPolymer

An alternate polymer extrusion method and system reduces “drool” effects that detract from precise control over the content of two or more materials in an extrudate along its length. In the system, two or more extruders direct melt to two or more gear pumps. Control of the speed of the gear pumps controls the amount of each material emergent from the pumps, proceeding to a convergence in the paths from the pumps and thence to a die. Melt in each path between each pump and the convergence tends to expand and drool into the convergence as its associated pump is slowed and stopped. To prevent this, in the die, a constriction in each path just upstream of the convergence greatly reduces drool past that point by requiring a much greater pressure to force the melt past the constriction. The increased pressure required increases compression and expansion of the melt between the pump and the construction as a pump starts or increases in speed, on one hand, and stop or decreases in speed, on the other hand. Compensatory pump speed changes are made to counter this effect.

Owner:DAVIS STANDARD

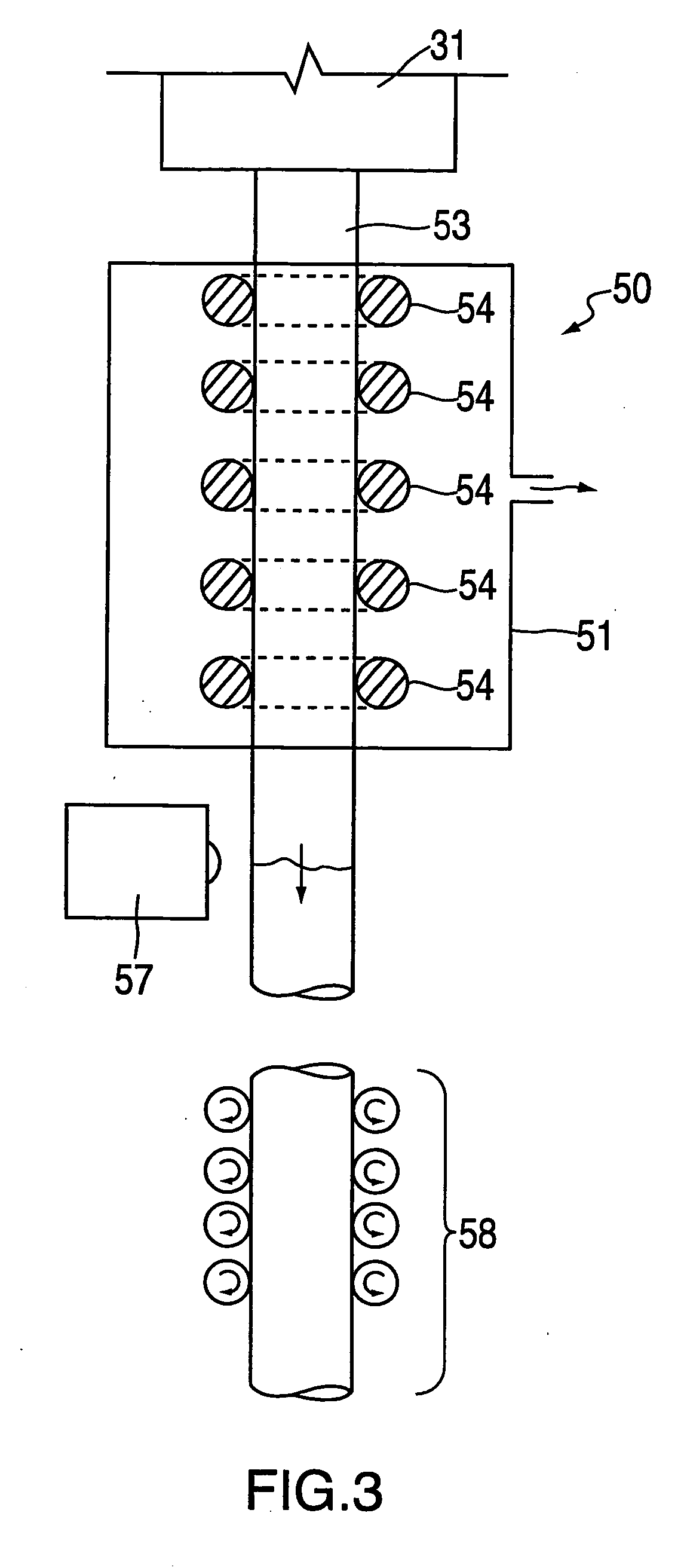

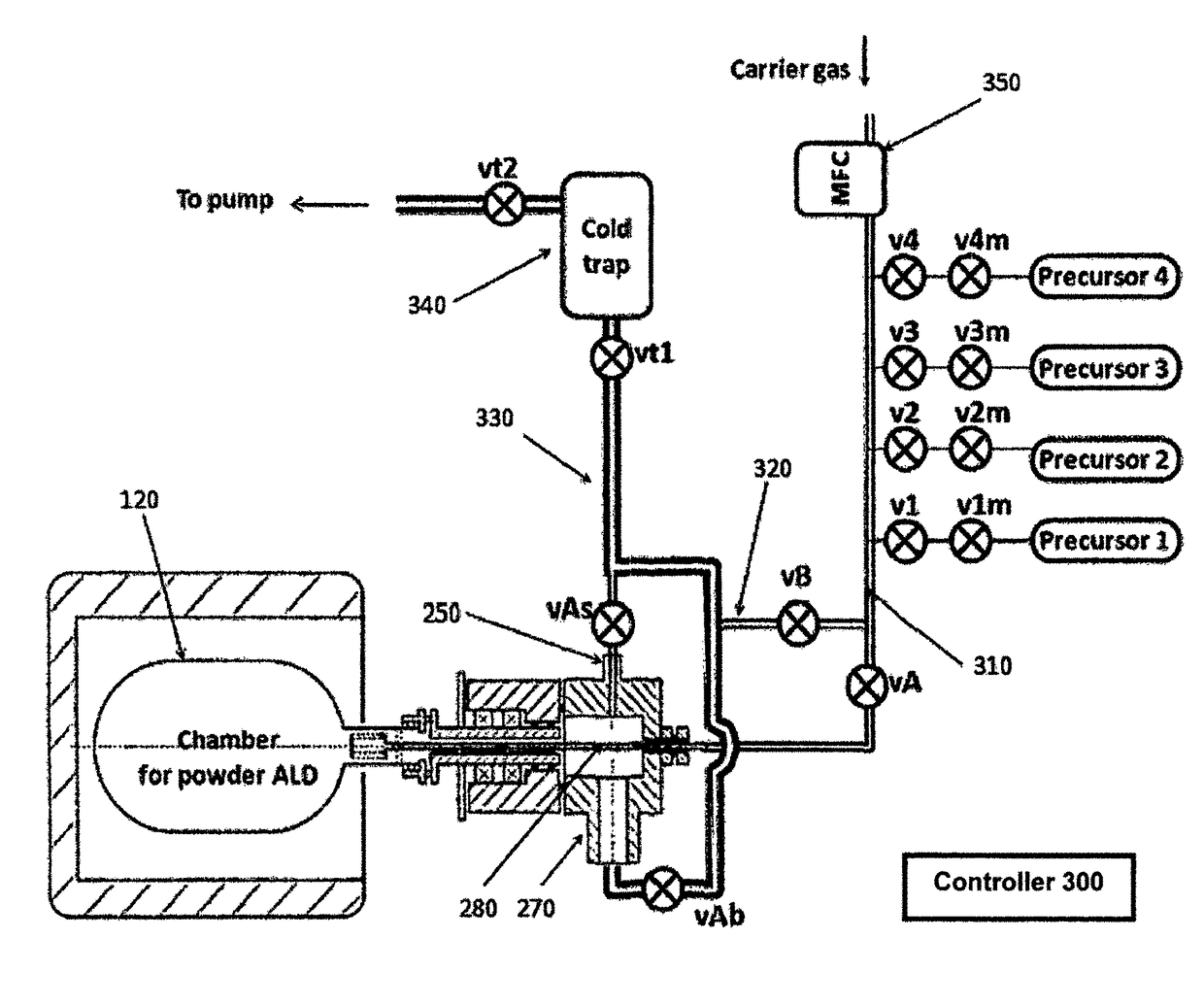

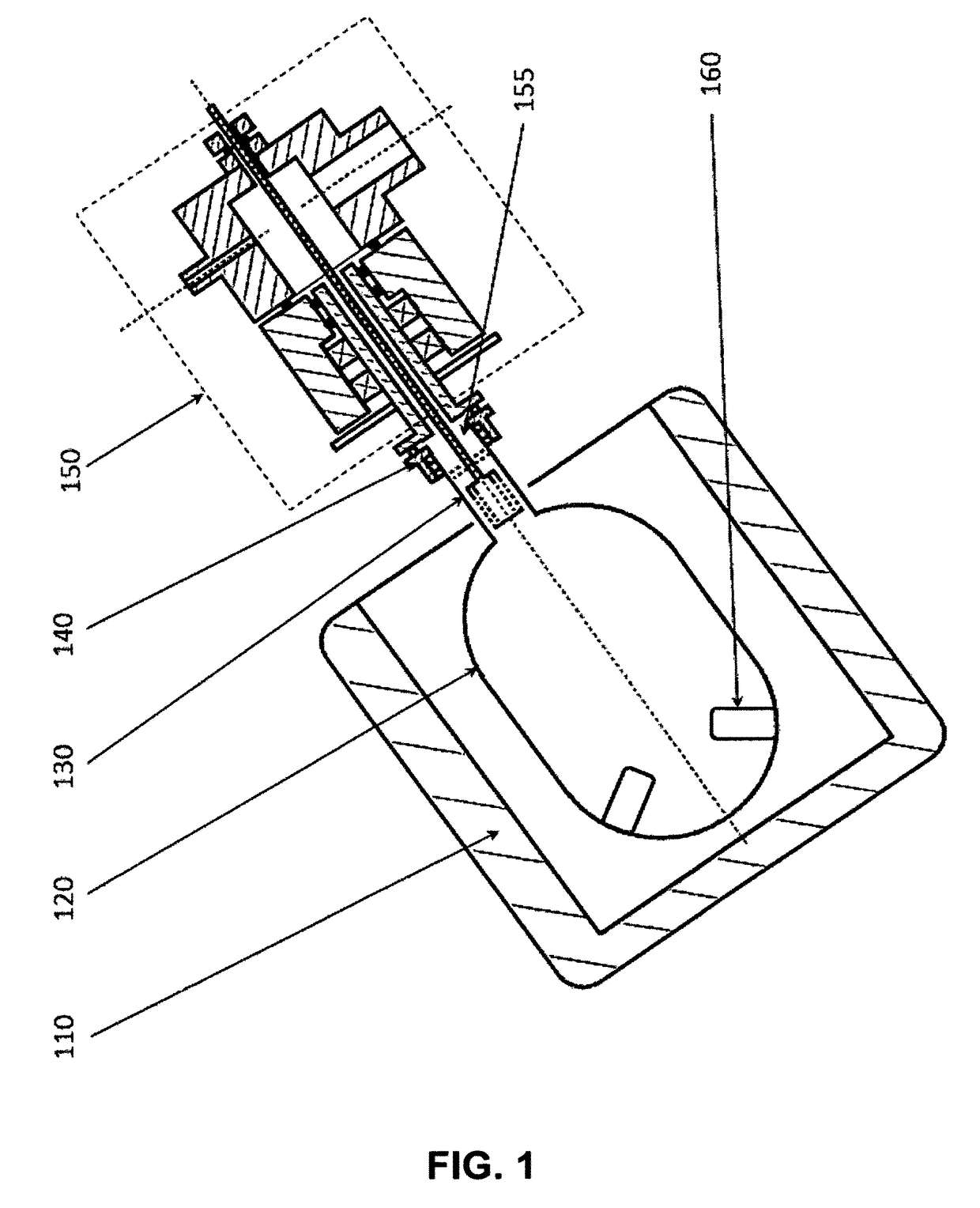

Apparatus and method for making atomic layer deposition on fine powders

InactiveUS9951419B2Good curative effect“purge” stepsLiquid surface applicatorsChemical vapor deposition coatingEngineeringAtomic layer deposition

Method and apparatus for making atomic layer deposition on powdered materials are provided. A rotary vessel with tilted rotation axis can be used as the deposition chamber. The rotary vessel can be directly used as the deposition chamber, or the rotary vessel is positioned inside a vacuum chamber that serves as the deposition chamber. A hallow shaft can be used to deliver rotary motion and facilitate pumping. A tube can be inserted into the hollow shaft or the rotary vessel to introduce precursors. Gas diffuser and slowly increased pumping speed can be used to reduce the agitation caused by gas flow. Intermittent rotation, variable rotary speed, extruding structures on inner surface of the rotary vessel, and the addition of easy-to-agitate powder or beads of other materials can be used to enhance the powder agitation caused by rotation.

Owner:JIANG YING BING +1

Fluid control in reservoir fluid sampling tools

ActiveUS8672026B2Increase pumping speedMaximum pumping speedSurveyPositive displacement pump componentsFluid controlReservoir fluid

A pumping system comprising: a probe to suction a fluid from a fluid reservoir; a pump in fluid communication with said probe; a sensor for detecting phase changes in said pumping system, said sensor in fluid communication with said probe or pump, said sensor generating a sensor signal; a fluid exit from said pumping system, said fluid exit being in fluid communication with said pump; and a variable force check valve located between said probe and said fluid exit.

Owner:HALLIBURTON ENERGY SERVICES INC

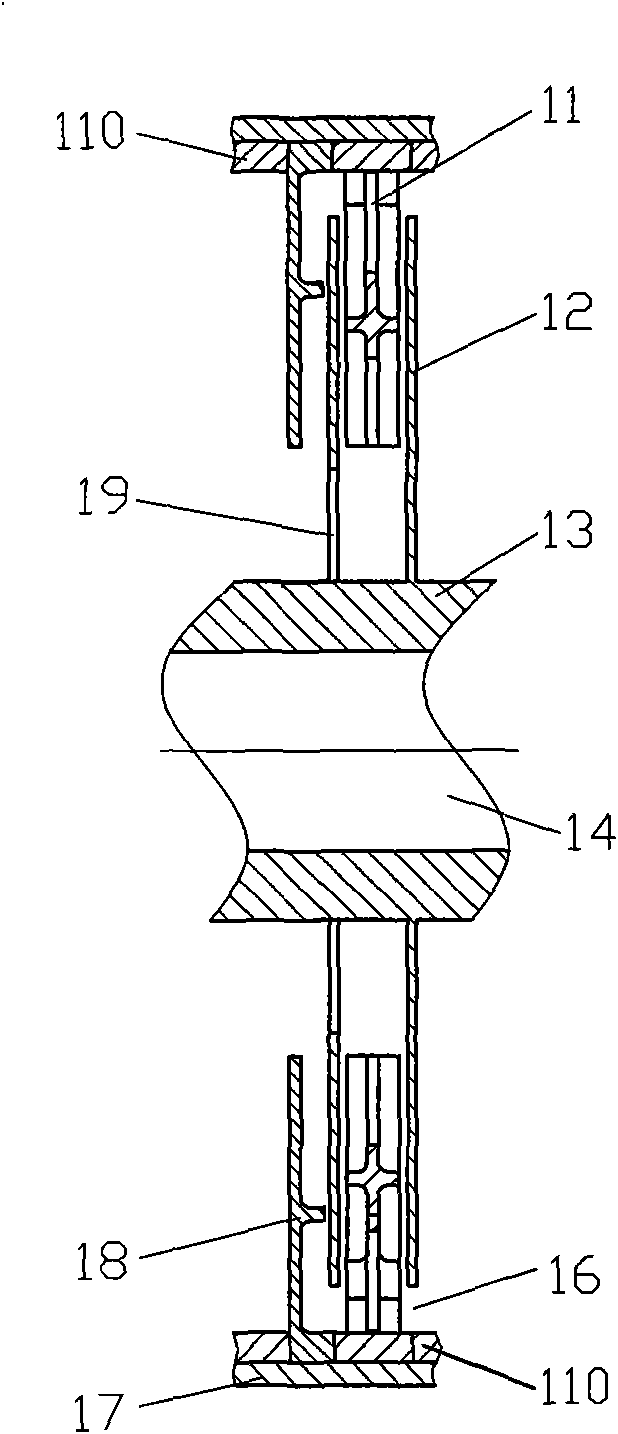

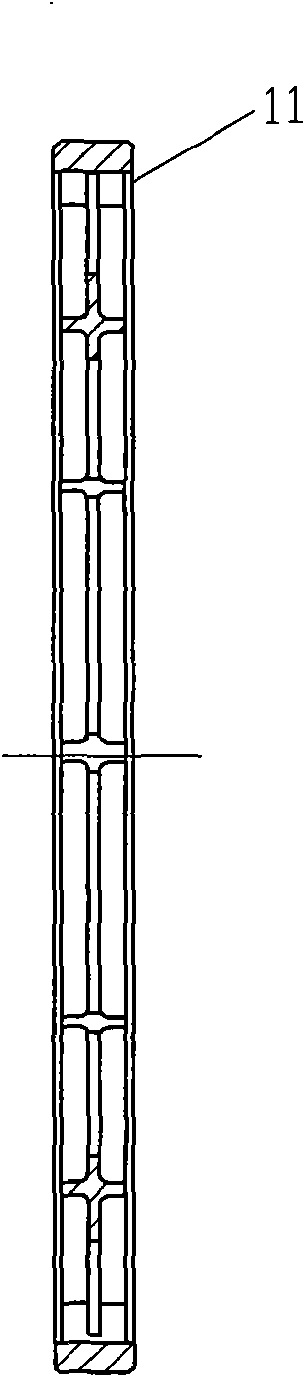

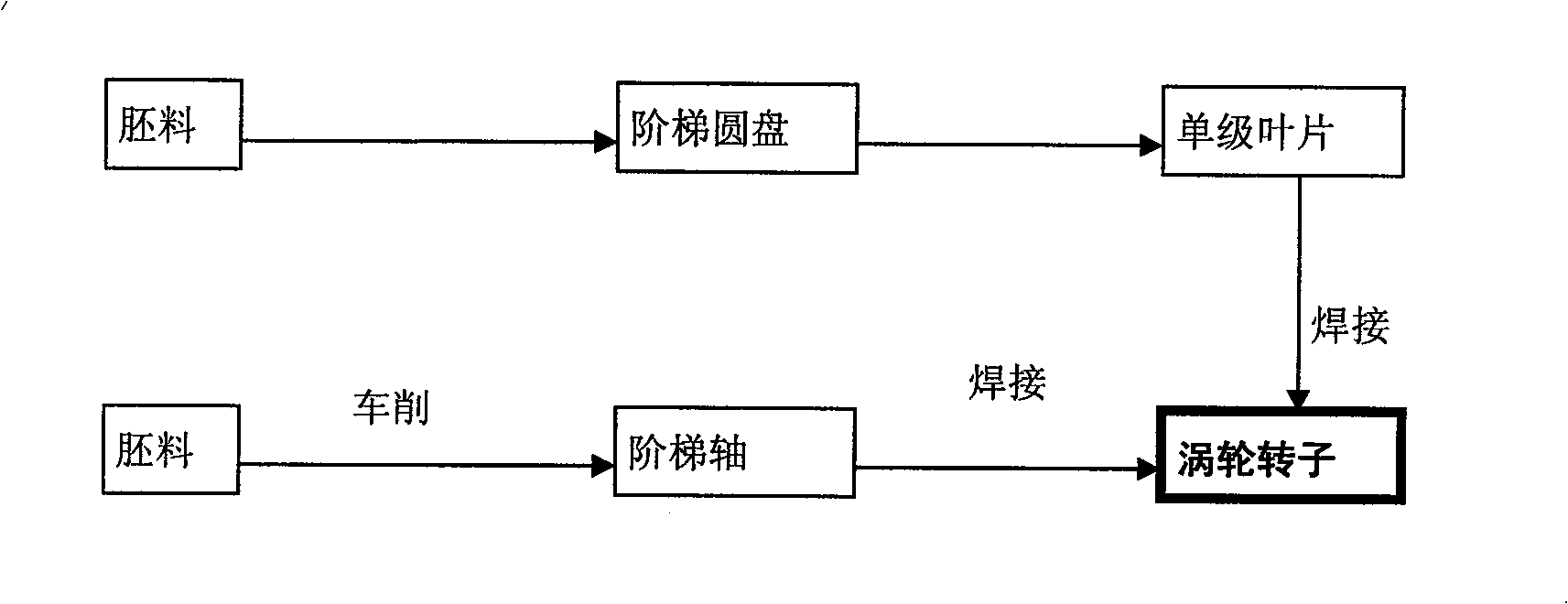

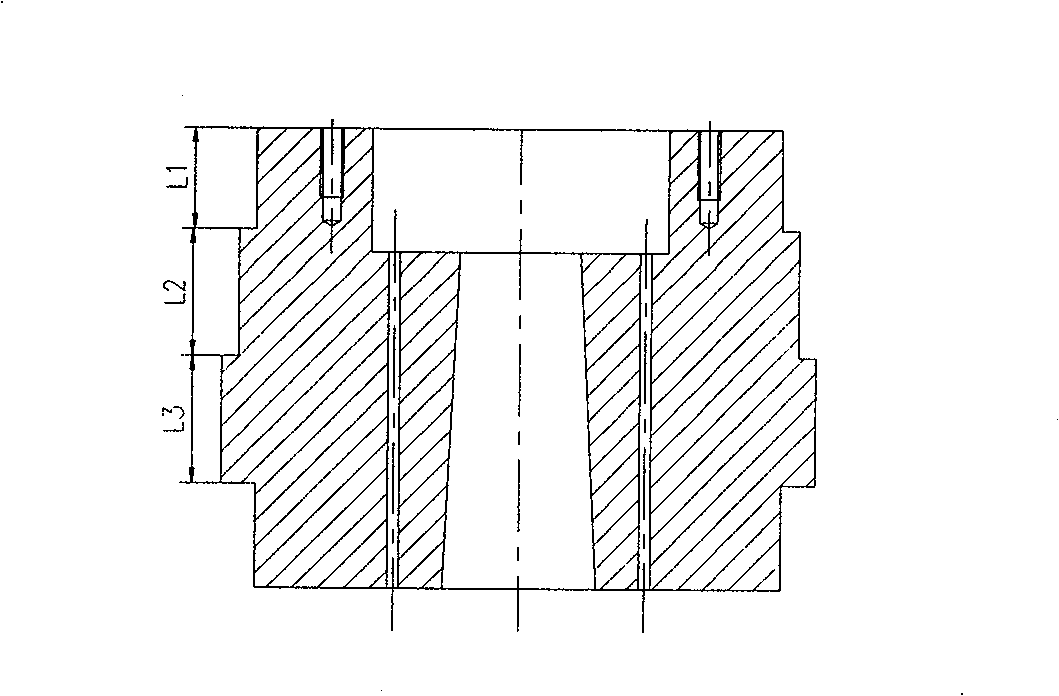

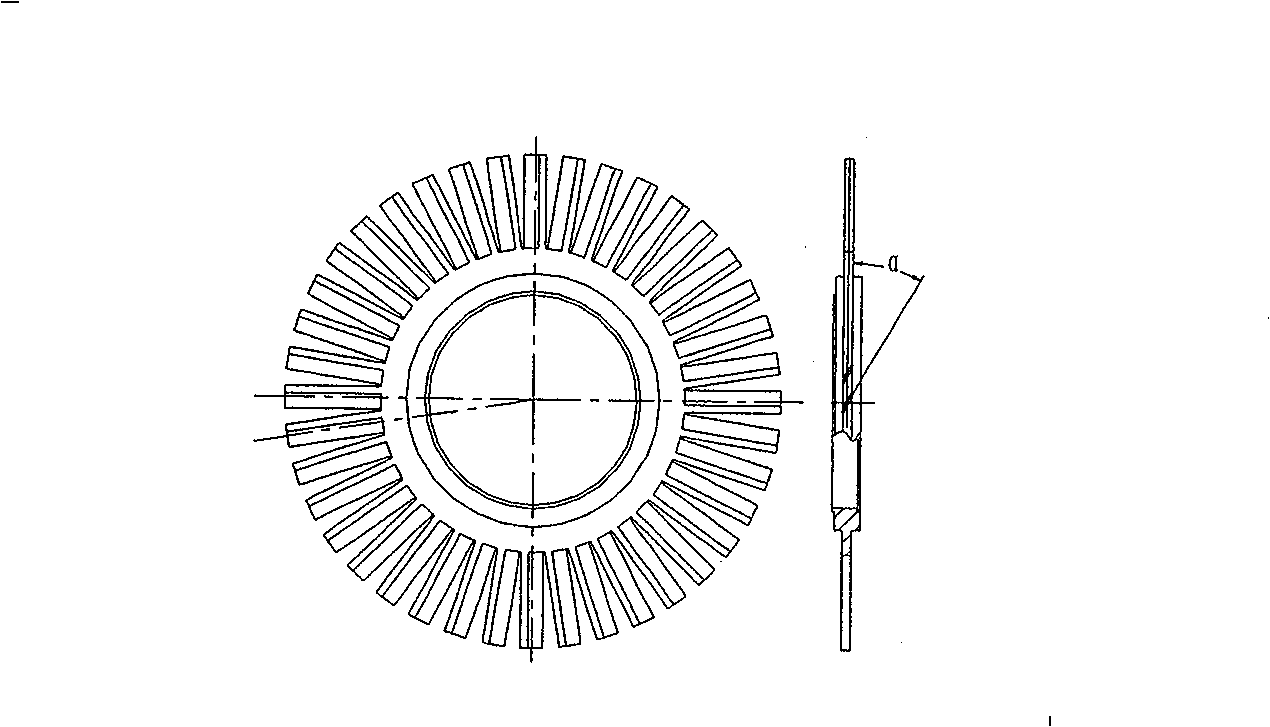

Manufacturing method of turbine rotor of large-sized turbine molecular pump

A manufacture method of turbine rotor for large turbomolecular pump comprises the following steps: (1) processing single-stage blades and inner core connectors by lathe and milling machine, cleaning the single-stage blades and the inner core connector, and arranging each single-stage blade on an inner core; and (2) welding by a vacuum electron beam to form an entire turbine rotor, wherein the welding depth of the vacuum electron beam is 3 to 18 mm.

Owner:KYKY TECH

Sniffer lead detector comprising a detector with a quartz window

ActiveUS20090193876A1High measurement accuracyReduce pressureDetection of fluid at leakage pointEngineeringVacuum pump

A sniffer leak detector comprising a detector with a quartz window, the window being selectively permeable to a tracer gas. The quartz window is located in a suction chamber that is connected to a vacuum pump. To reduce the response time, a gas guidance plate is situated in the suction chamber, the guidance plate and quartz window together delimiting a narrow gas guidance chamber.

Owner:INFICON GMBH

Multi-refrigerator high speed cryopump

ActiveUS20130205805A1Improved refrigeration capabilityImprove efficiencySolidificationLiquefactionEngineeringTemperature difference

A refrigerator system or cryopump includes a first refrigerator having at least first and second stages, and a second refrigerator. A thermal coupling between the first stage of the first refrigerator and a cold end of the second refrigerator is restricted to maintain a temperature difference between the cold end of the second refrigerator and the first stage of the first refrigerator. The refrigerator system or cryopump also includes a radiation shield in thermal contact with the cold end of the second refrigerator, and a condensing surface, spaced from and surrounded by the radiation shield, and in thermal contact with a second stage, e.g., coldest stage, of the first refrigerator. The restricted thermal coupling can be configured to balance the cooling load on the two refrigerators.

Owner:EDWARDS VACUUM LLC

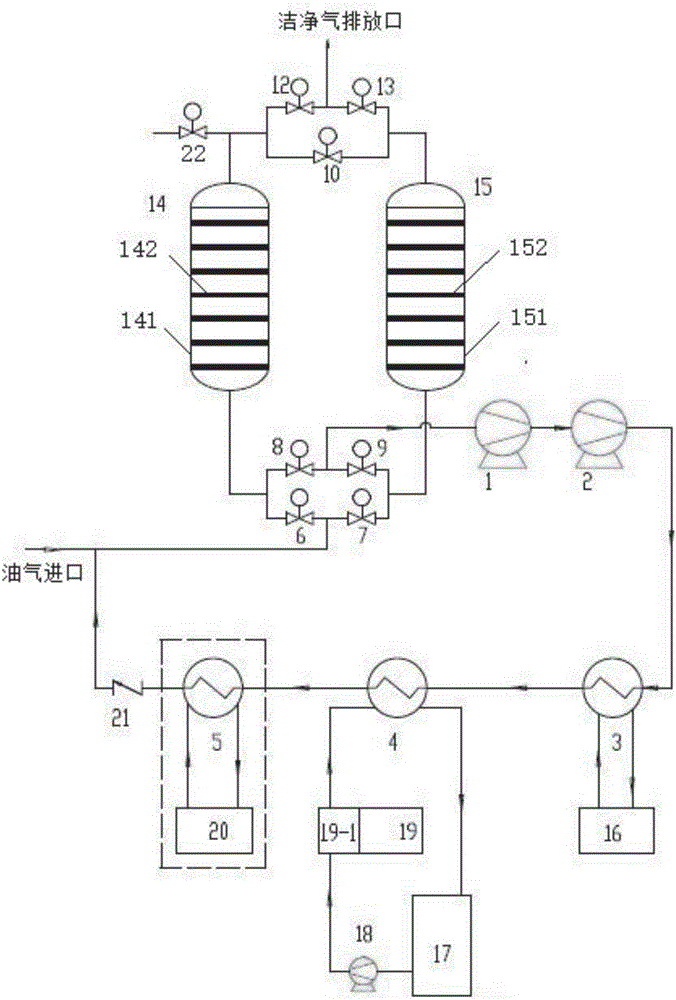

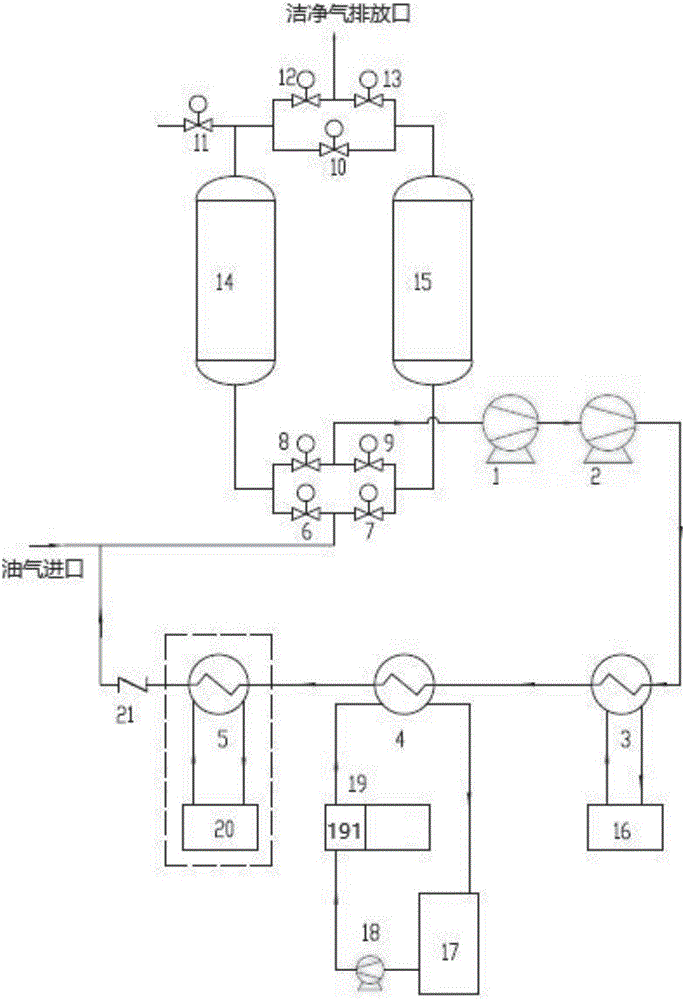

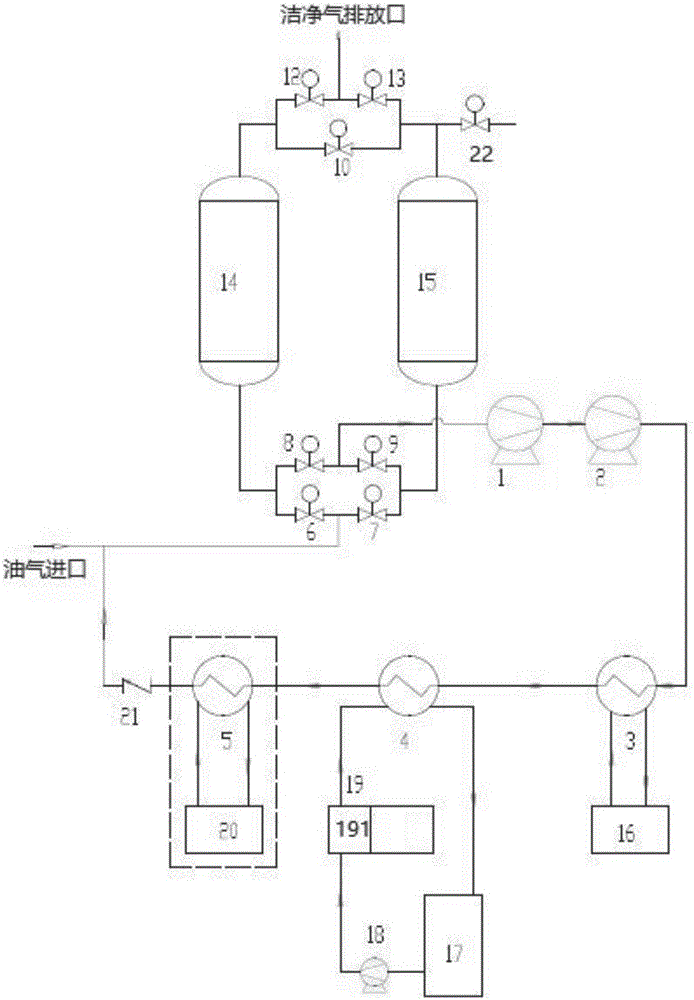

Adsorption and condensation type oil gas recovery device and adsorption and condensation type oil gas recovery process by self-adsorptive heat regeneration

ActiveCN106807179ALess investmentReduce energy consumptionGas treatmentMultiple-effect/fractional condensationInlet valveCheck valve

The invention discloses an adsorption and condensation type oil gas recovery device and an adsorption and condensation type oil gas recovery process by self-adsorptive heat regeneration. The adsorption and condensation type oil gas recovery device by the self-adsorptive heat regeneration comprises an oil gas inlet, a first valve group, a Roots vacuum pump, a dry vacuum pump, a primary oil gas condenser, a secondary oil gas condenser, a tertiary oil gas condenser, a check valve, an adsorption tank group, a second valve group and a clean gas discharge outlet. The first valve group comprises a gas inlet valve group and a vacuum valve group, wherein the gas inlet valve group and the vacuum valve group which are in parallel connection are arranged below the adsorption tank group. The second valve group comprises a gas discharge valve group and a balanced purge valve, wherein the gas discharge valve group and the balanced purge valve are in parallel connection and arranged over the adsorption tank group. The balanced purge valve, the adsorption tank group, the vacuum valve group, the Roots vacuum pump, the dry vacuum pump, the primary oil gas condenser, the secondary oil gas condenser, the tertiary oil gas condenser and the check valve are connected in sequence, and then the check valve is connected with the oil gas inlet. The oil gas inlet is sequentially connected with the gas inlet valve group, the adsorption tank group, the gas discharge valve group and the clean gas discharge outlet.

Owner:上海聚宸新能源科技有限公司

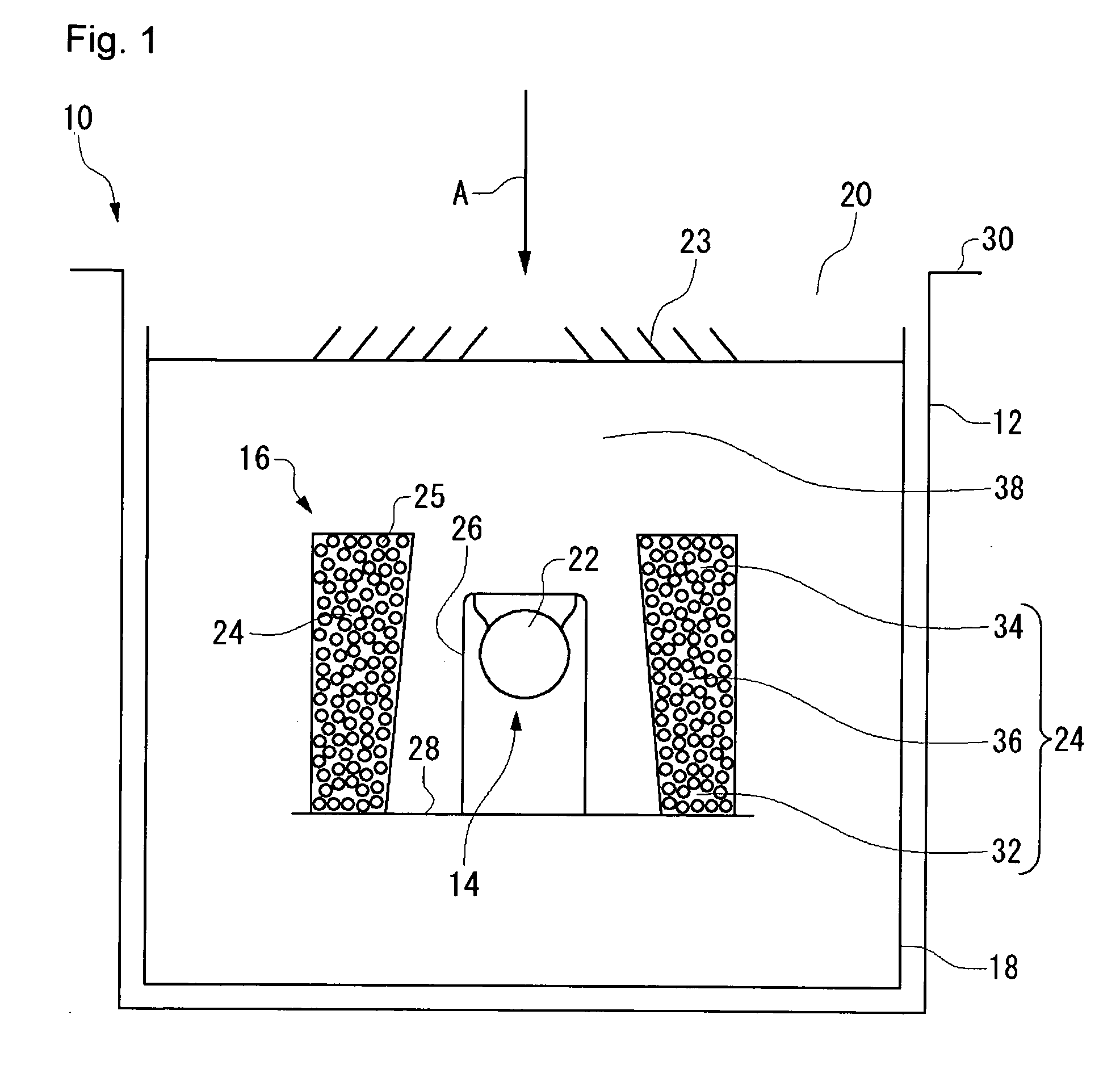

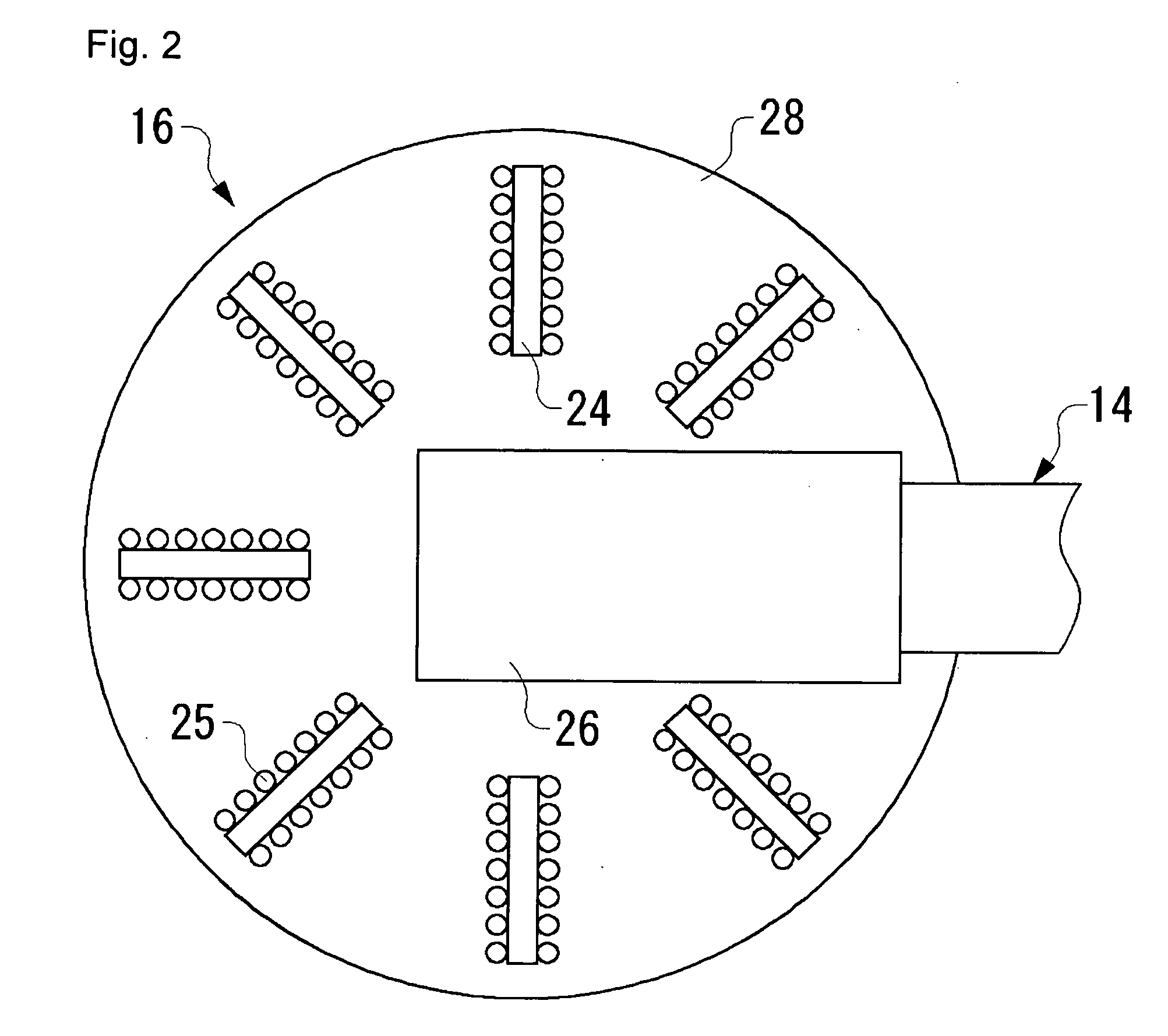

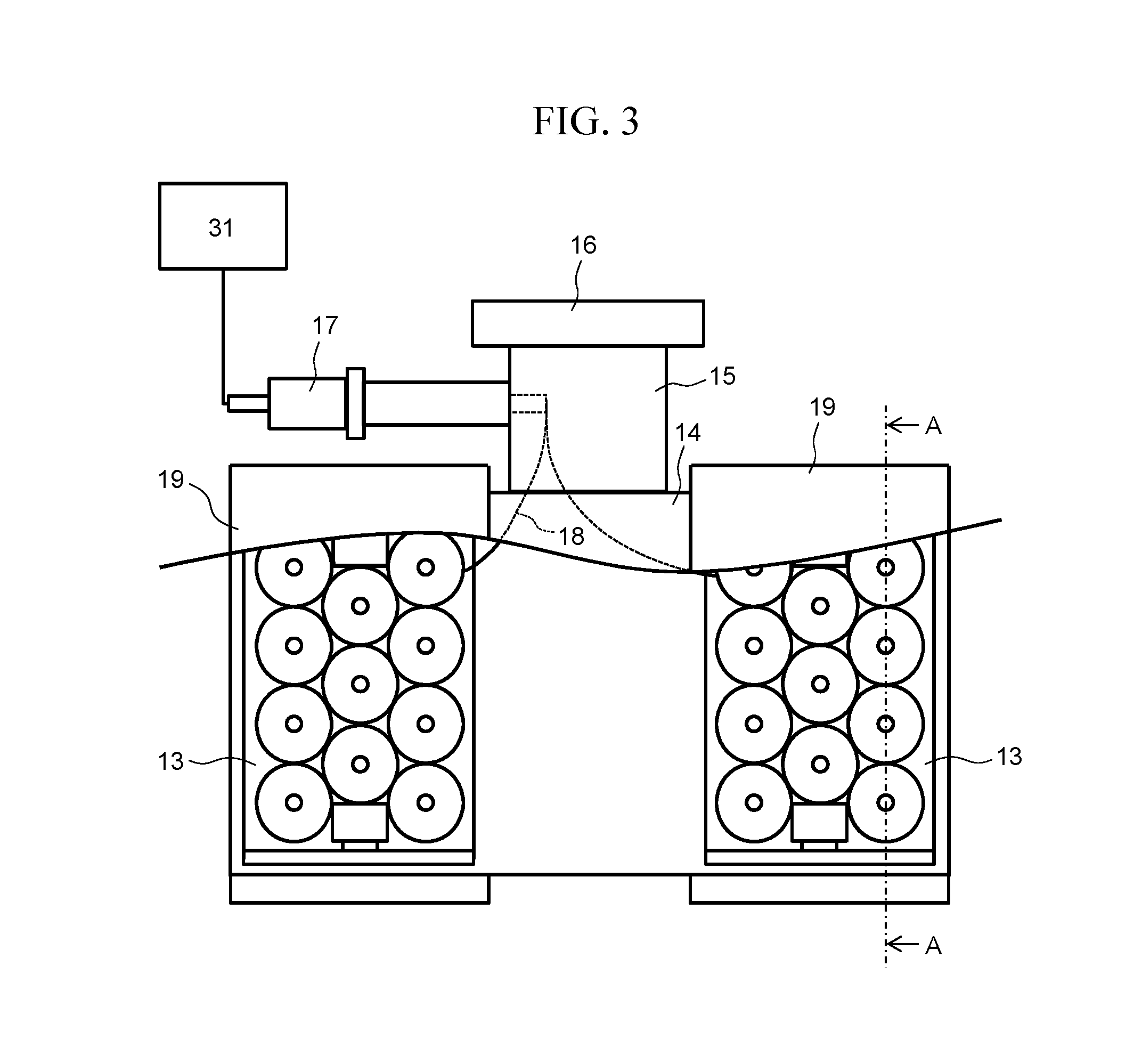

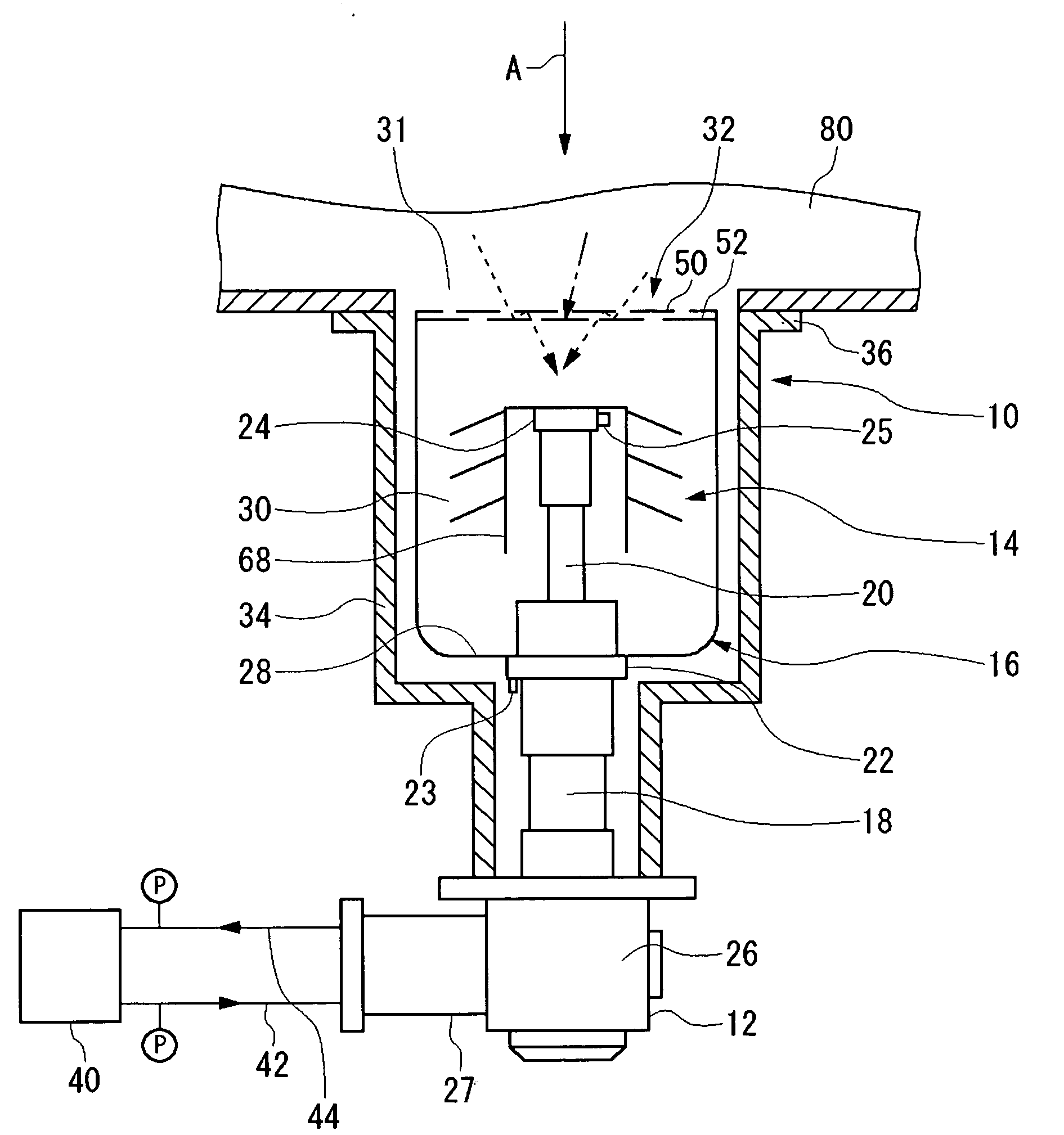

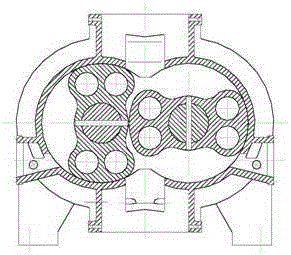

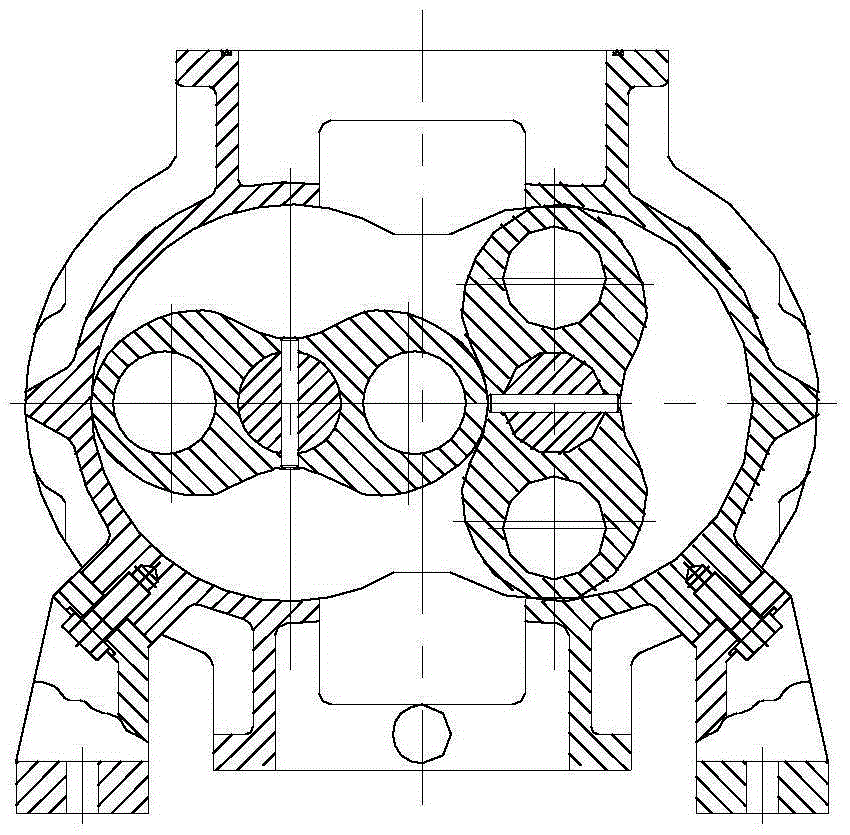

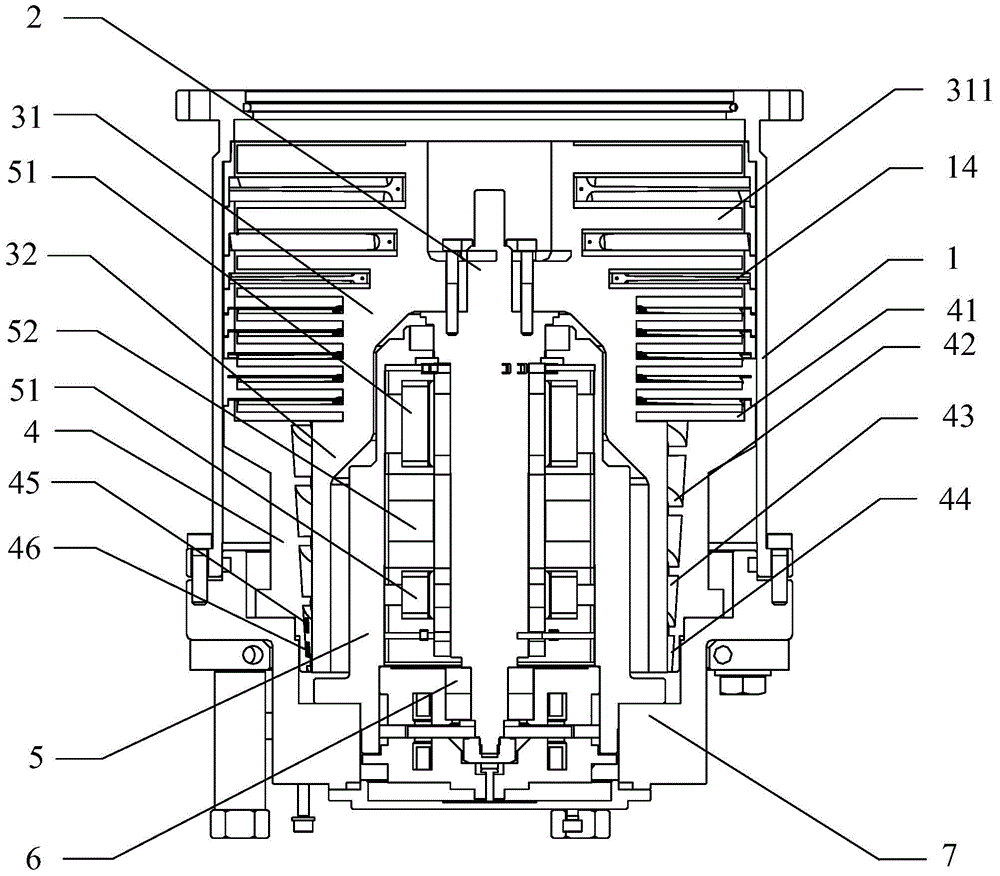

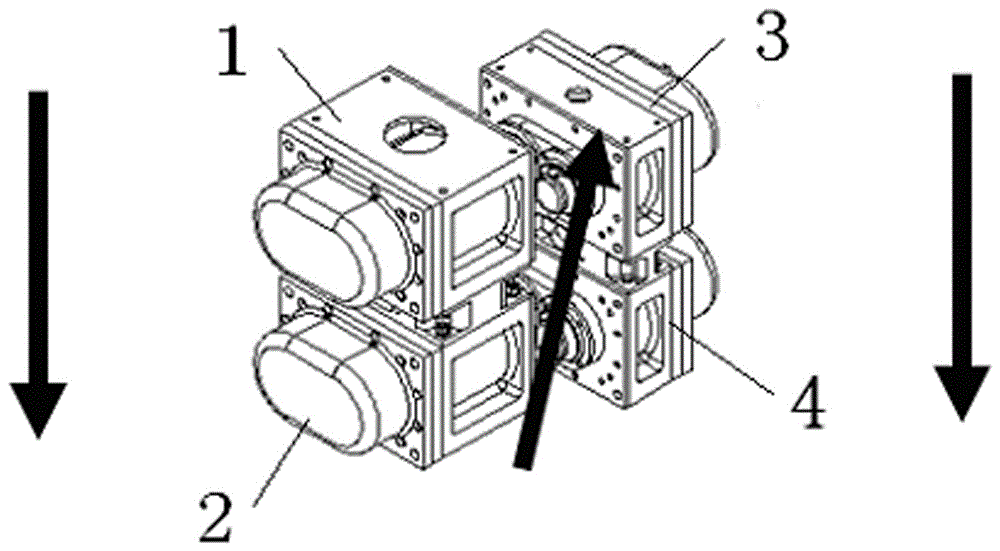

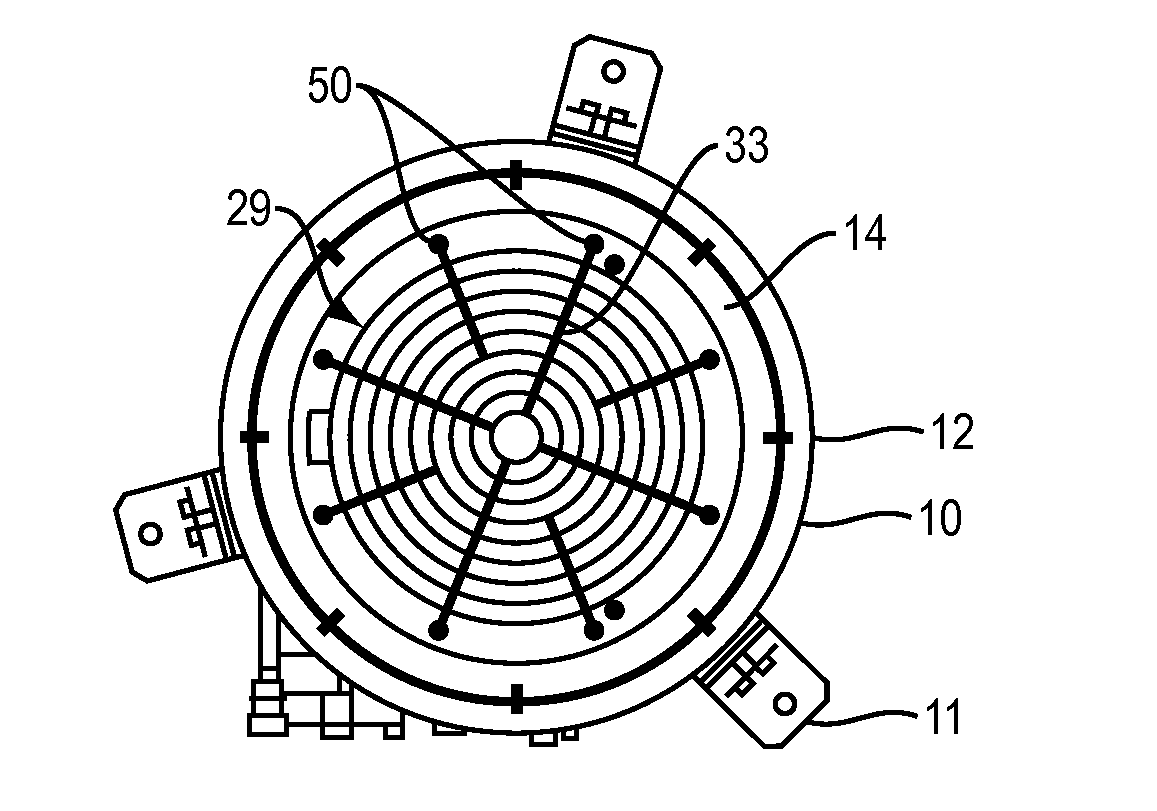

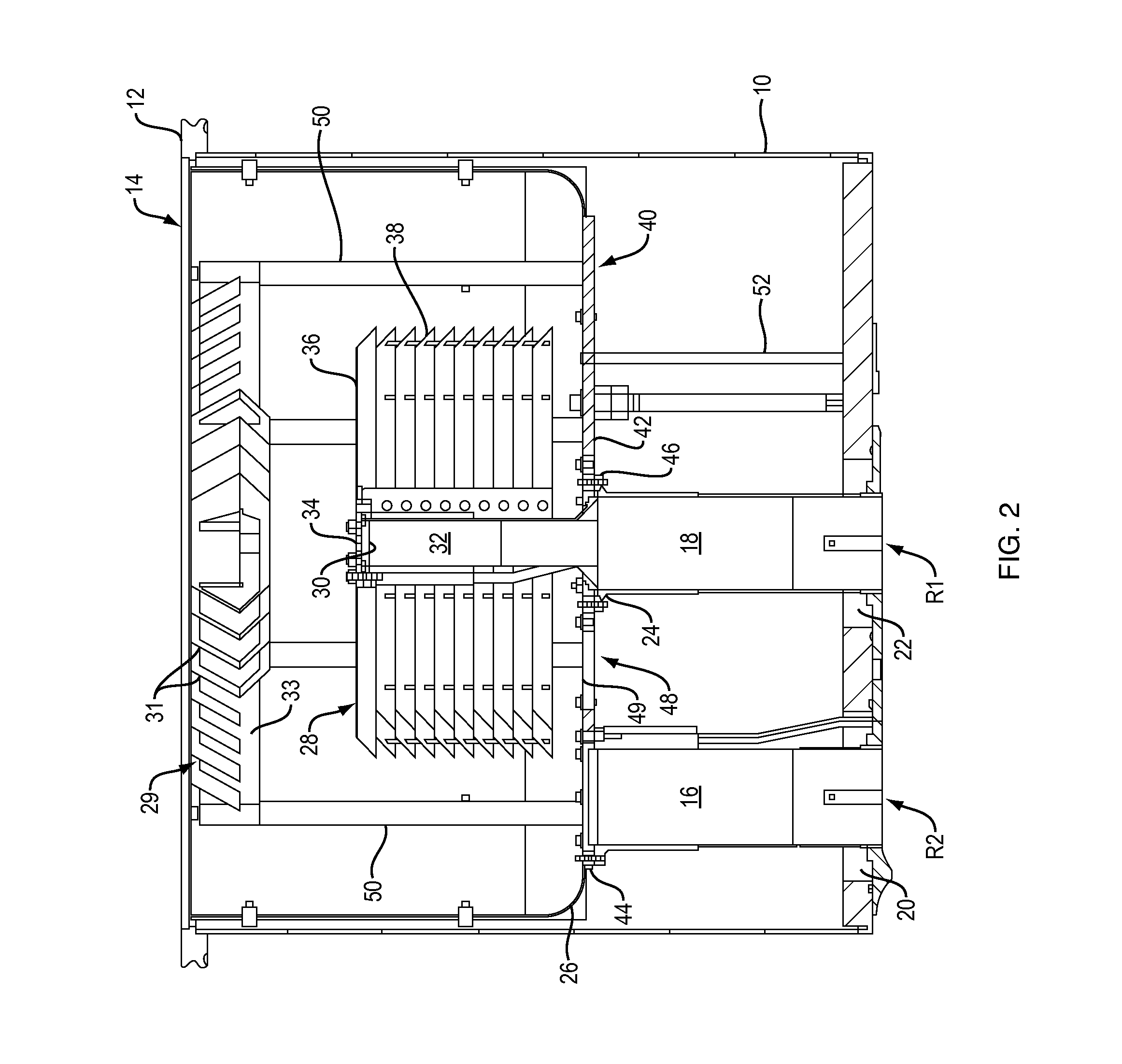

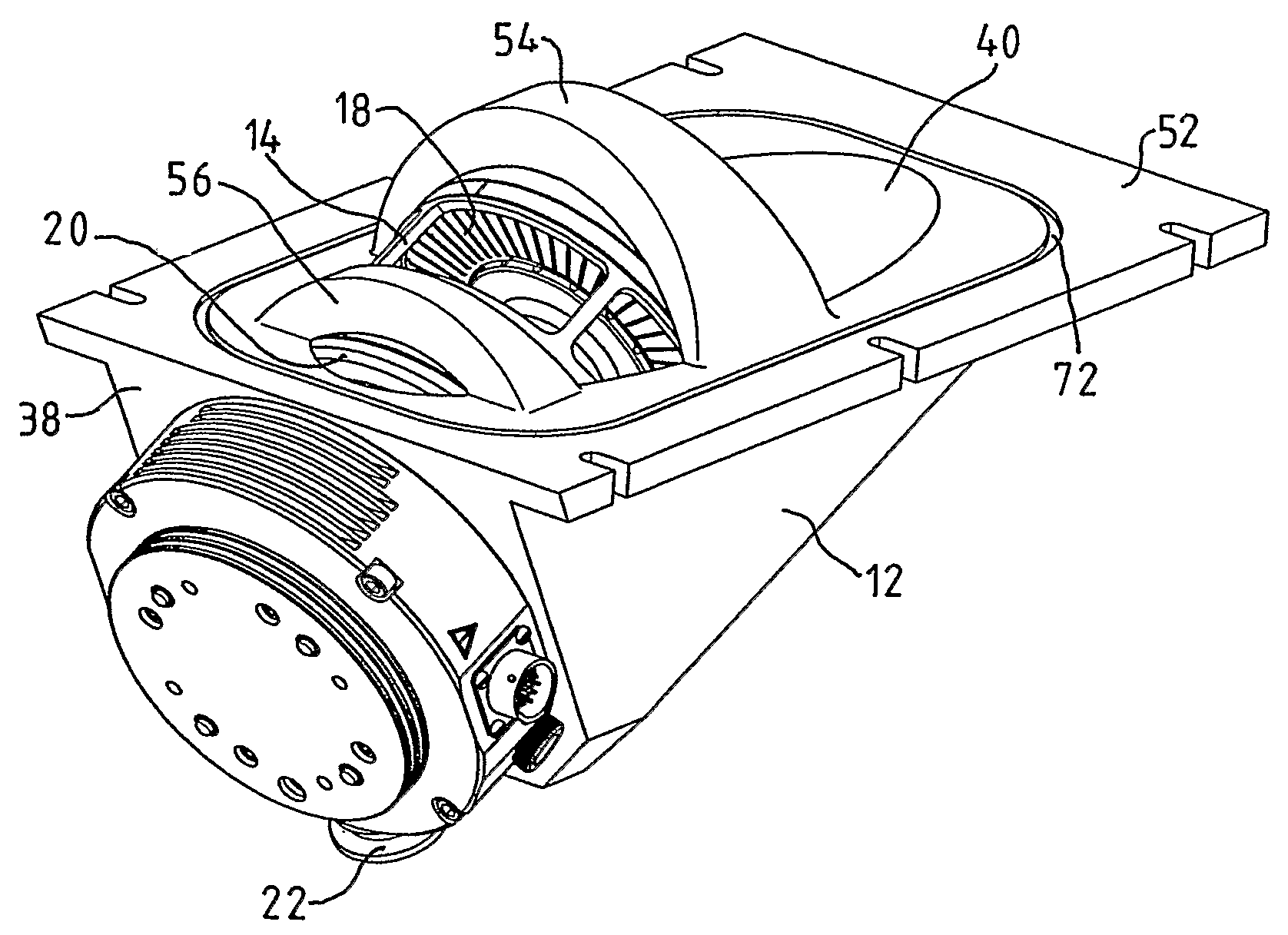

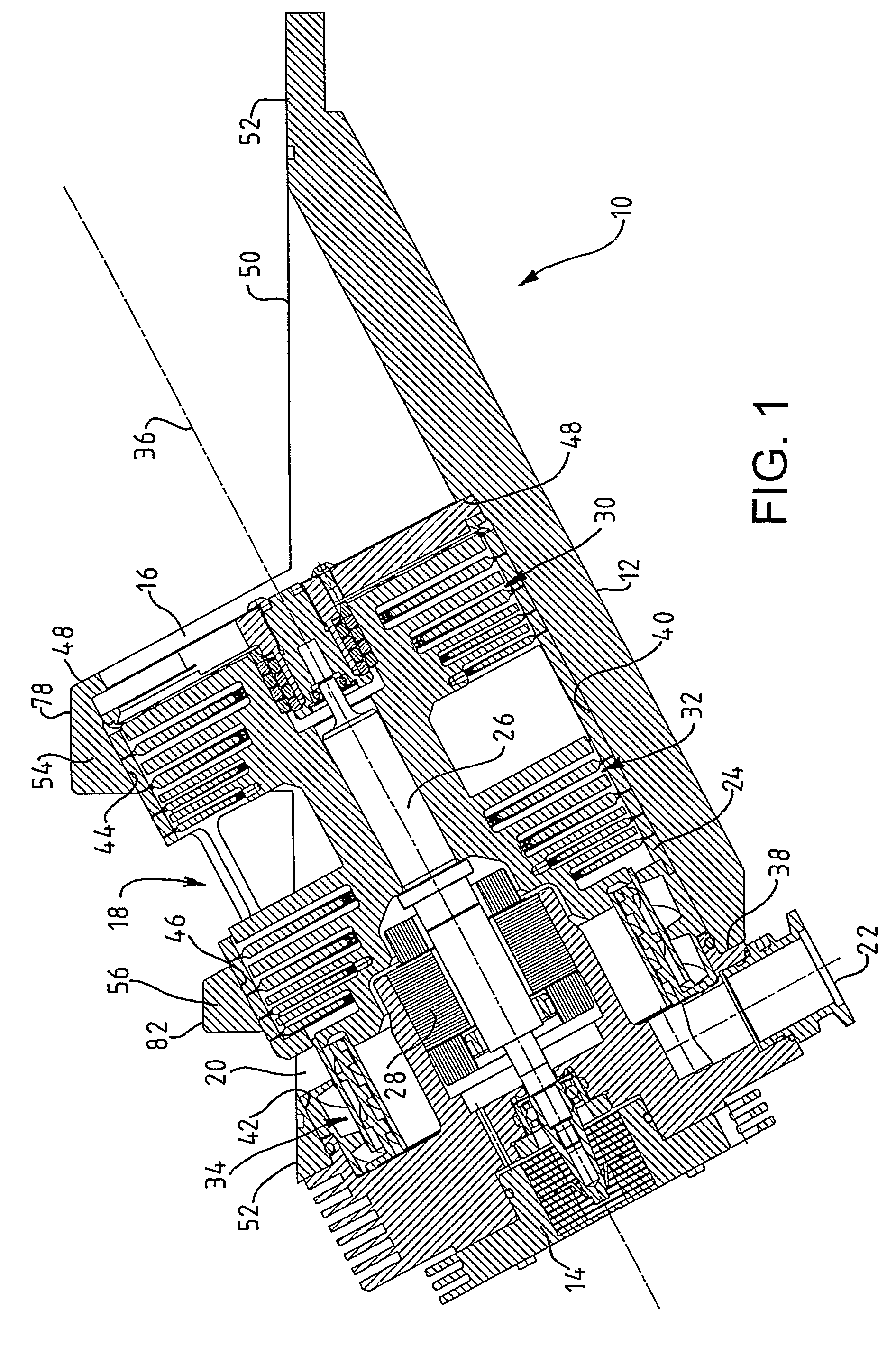

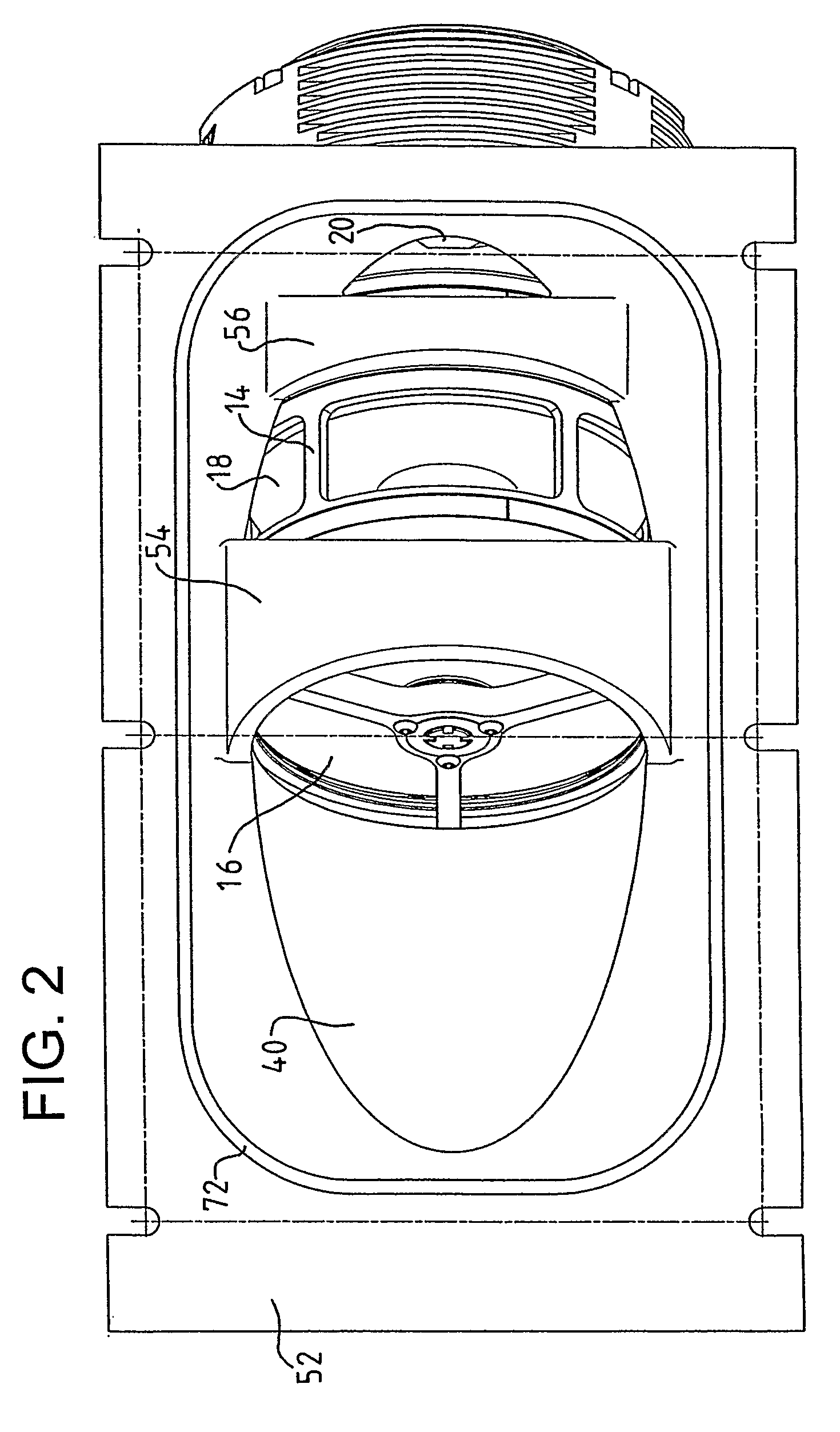

Vacuum pump for differential pumping multiple chambers

ActiveUS7811065B2Increase pumping speedOverall volume occupied by the chambers and pump is minimisedDetection of fluid at leakage pointPump componentsVacuum pumpSpectrometer

A differentially pumped mass spectrometer system comprises a mass spectrometer having first and second pressure chambers through which, during use, ions are conveyed along a path. A pump assembly (10) for differentially evacuating the chambers (62, 66, 68) is attached to the mass spectrometer. The pump assembly comprises a housing (12) attached to the mass spectrometer and a cartridge (14) inserted into the housing. The cartridge has a plurality of inlets (16, 18, 20) each for receiving fluid from a respective pressure chamber (62, 68, 66) and a pumping mechanism (30, 32, 34) for differentially pumping fluid from the chambers. The cartridge is inserted into the housing such that the pumping mechanism (10) is inclined relative to the ion path (76), but with the cartridge protruding into the mass spectrometer to such an extent that at least one of the inlets (16, 18) at least partially protrudes into its respective chamber (62, 68) without crossing the ion path.

Owner:EDWARDS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com