Patents

Literature

322 results about "Cryopump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cryopump or a "cryogenic pump" is a vacuum pump that traps gases and vapours by condensing them on a cold surface, but are only effective on some gases. The effectiveness depends on the freezing and boiling points of the gas relative to the cryopump's temperature. They are sometimes used to block particular contaminants, for example in front of a diffusion pump to trap backstreaming oil, or in front of a McLeod gauge to keep out water. In this function, they are called a cryotrap, waterpump or cold trap, even though the physical mechanism is the same as for a cryopump.

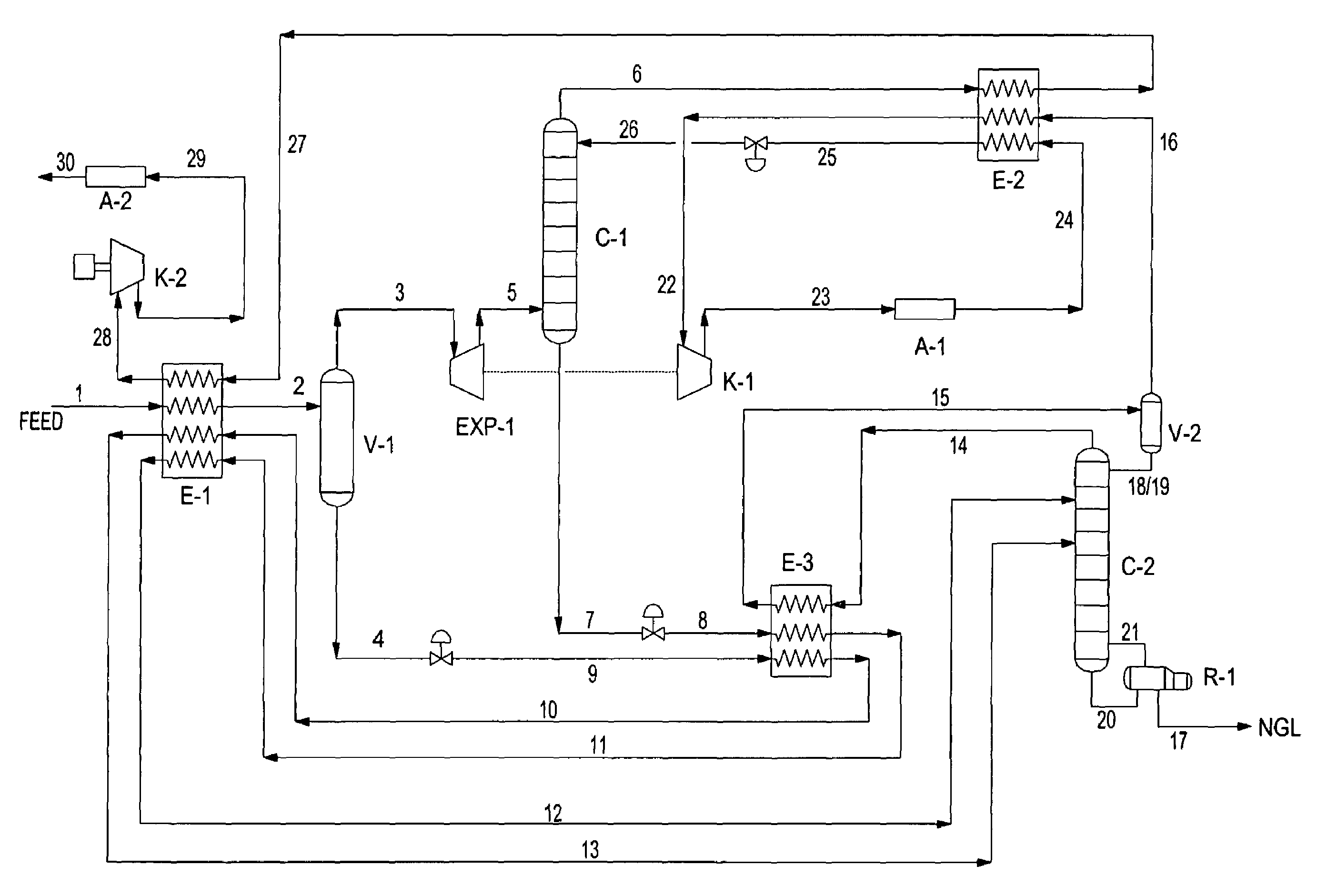

Ethane plus and HHH process for NGL recovery

InactiveUS7219513B1Good fractionation effectHeavy componentSolidificationLiquefactionFractionating columnPetrochemical

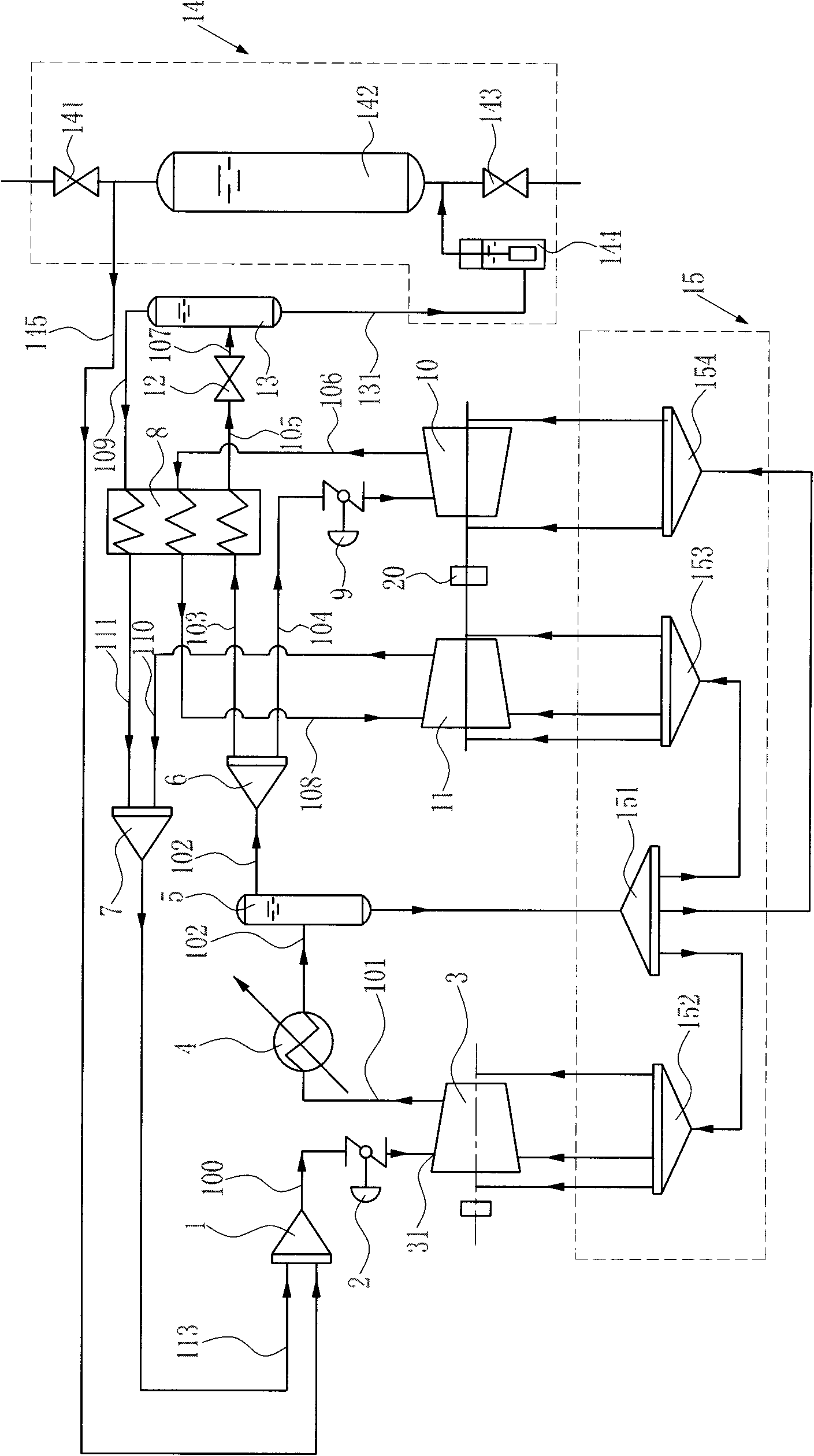

The present invention relates to methods for separating and recovering ethane, propane and heavier components from a feed gas, e.g. raw natural gas or a refinery or petroleum plant gas stream or a petrochemical plant gas stream. These methods employ a common new concept which is the use of the turbo-expander shaft compressor to generate the reflux requirement for the cryogenic absorber or distillation columns. The power of the turbo-expander which is absorbed by the shaft compressor is always high enough so that reflux generation by a specific gas compression through the expander shaft compressor and subsequent cooling, condensation and sub-cooling can always be easily maintained. The present invention allows for higher cryogenic absorber pressure and a lower demethanizer / de-ethanizer column pressure thus eliminating the common cryogenic pump at absorber bottom. The present invention ultimately results in a lower residue compression and utilities consumption. The present invention as such allows for a higher 99+% recovery of NGL from the feed gas stream.

Owner:MOSTAFA HUSSEIN MOHAMED ISMAIL

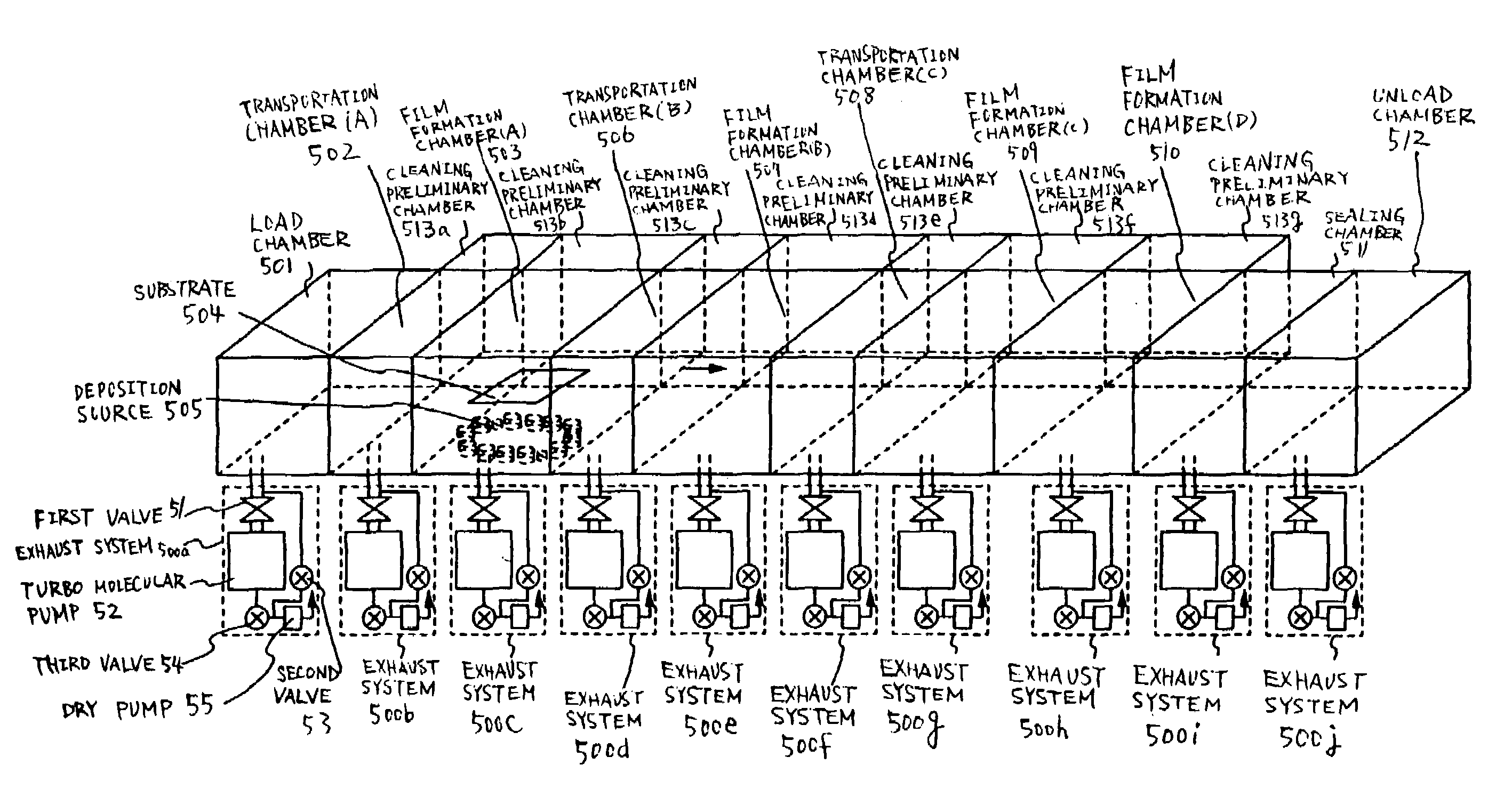

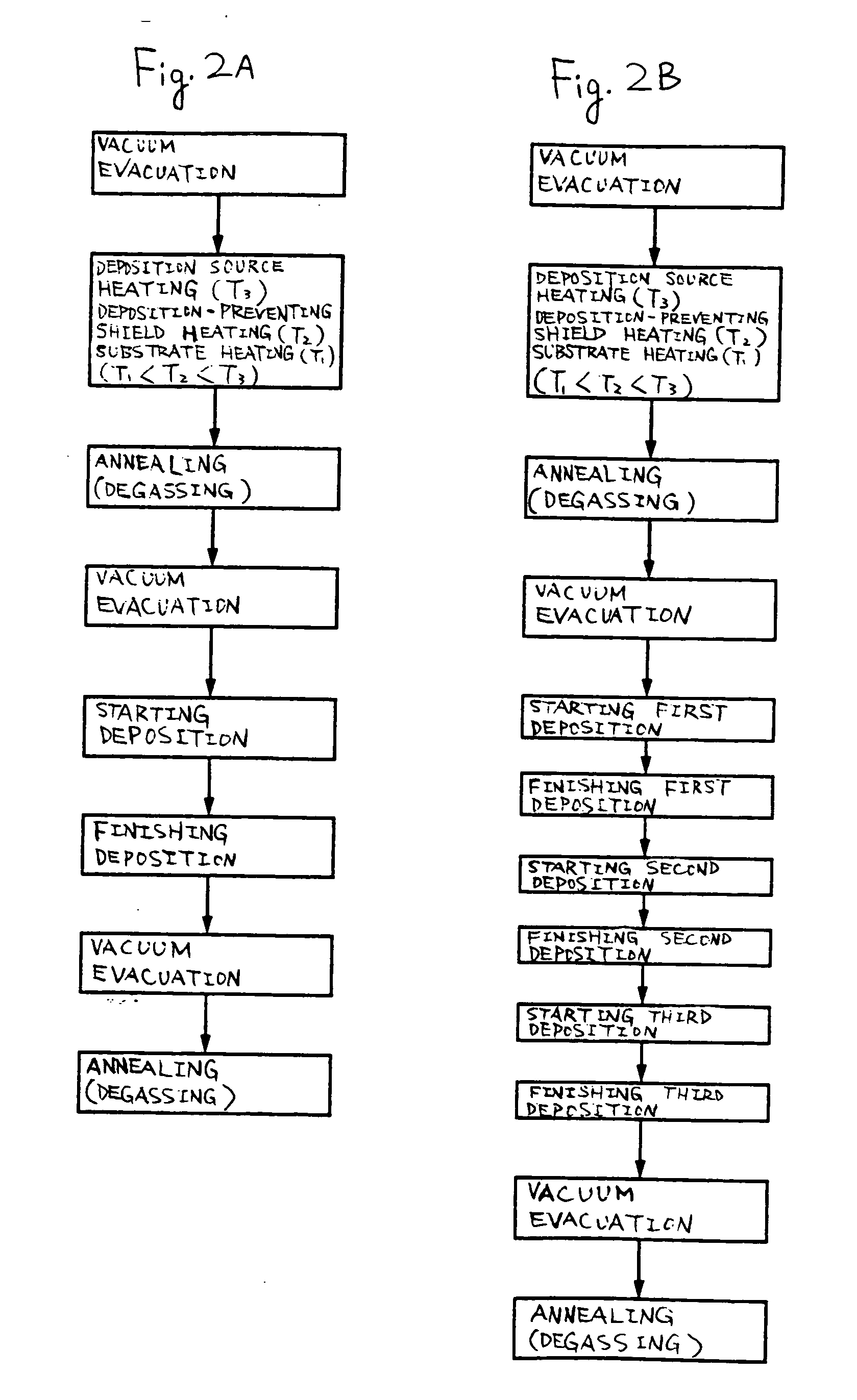

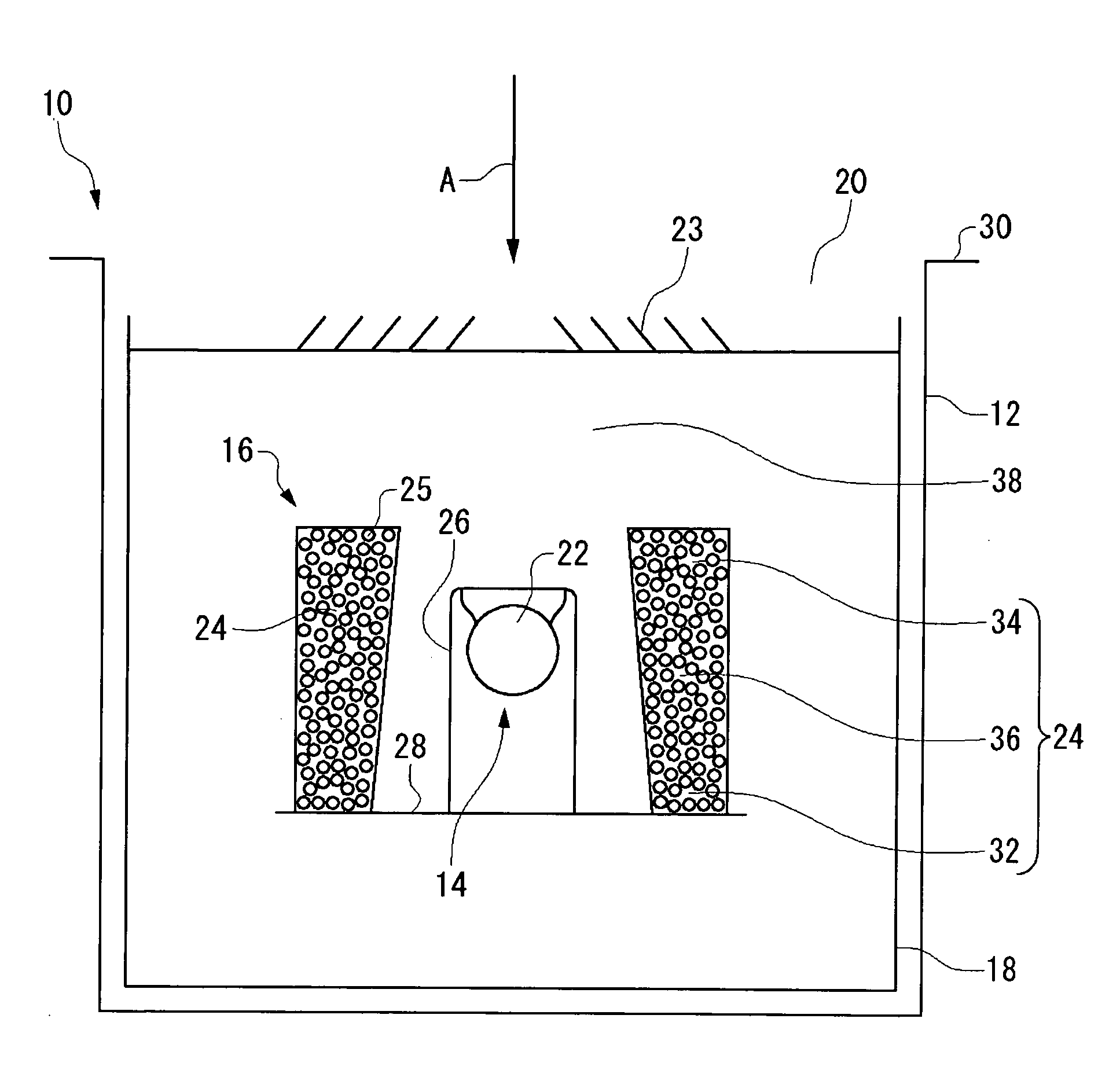

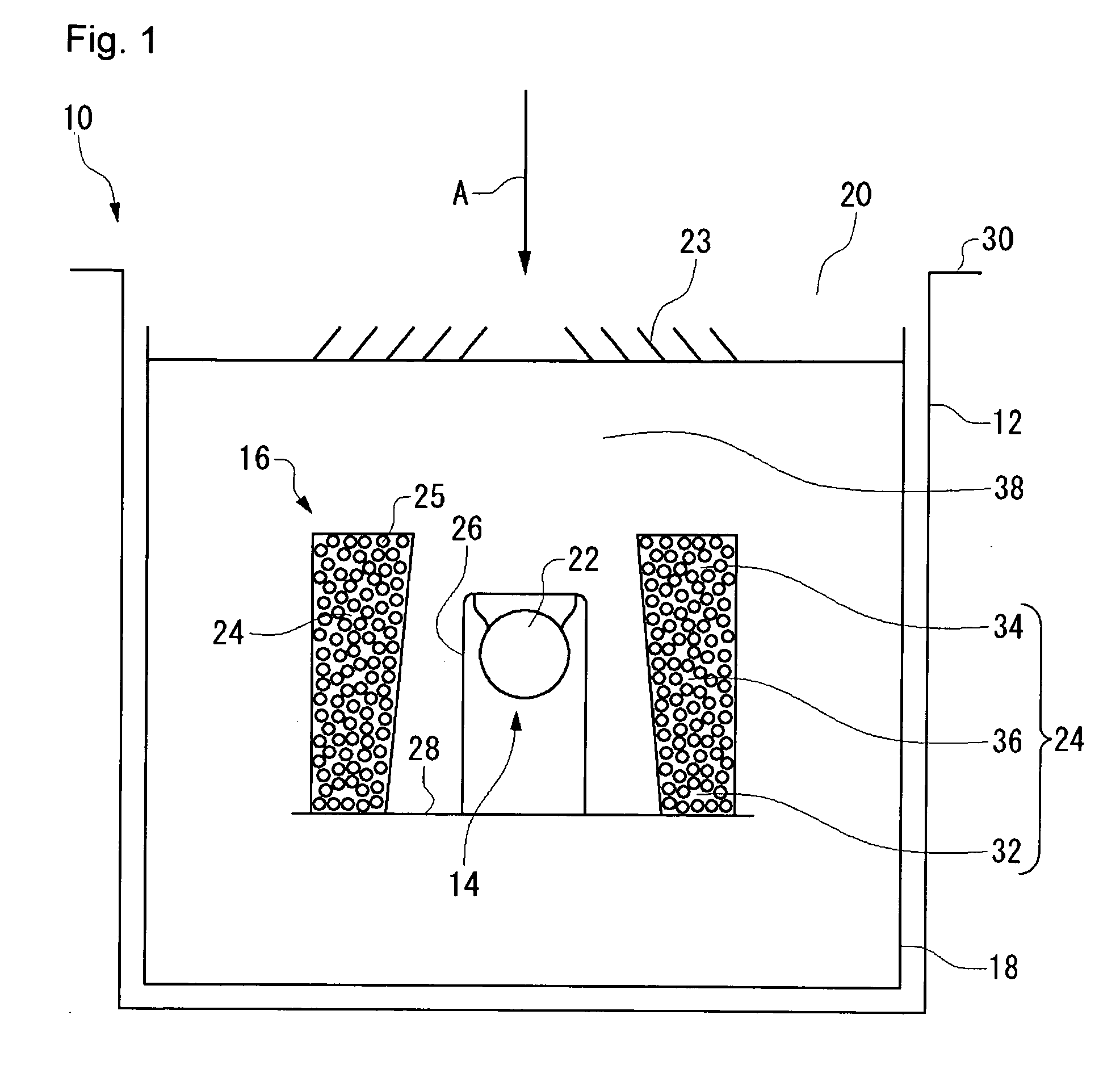

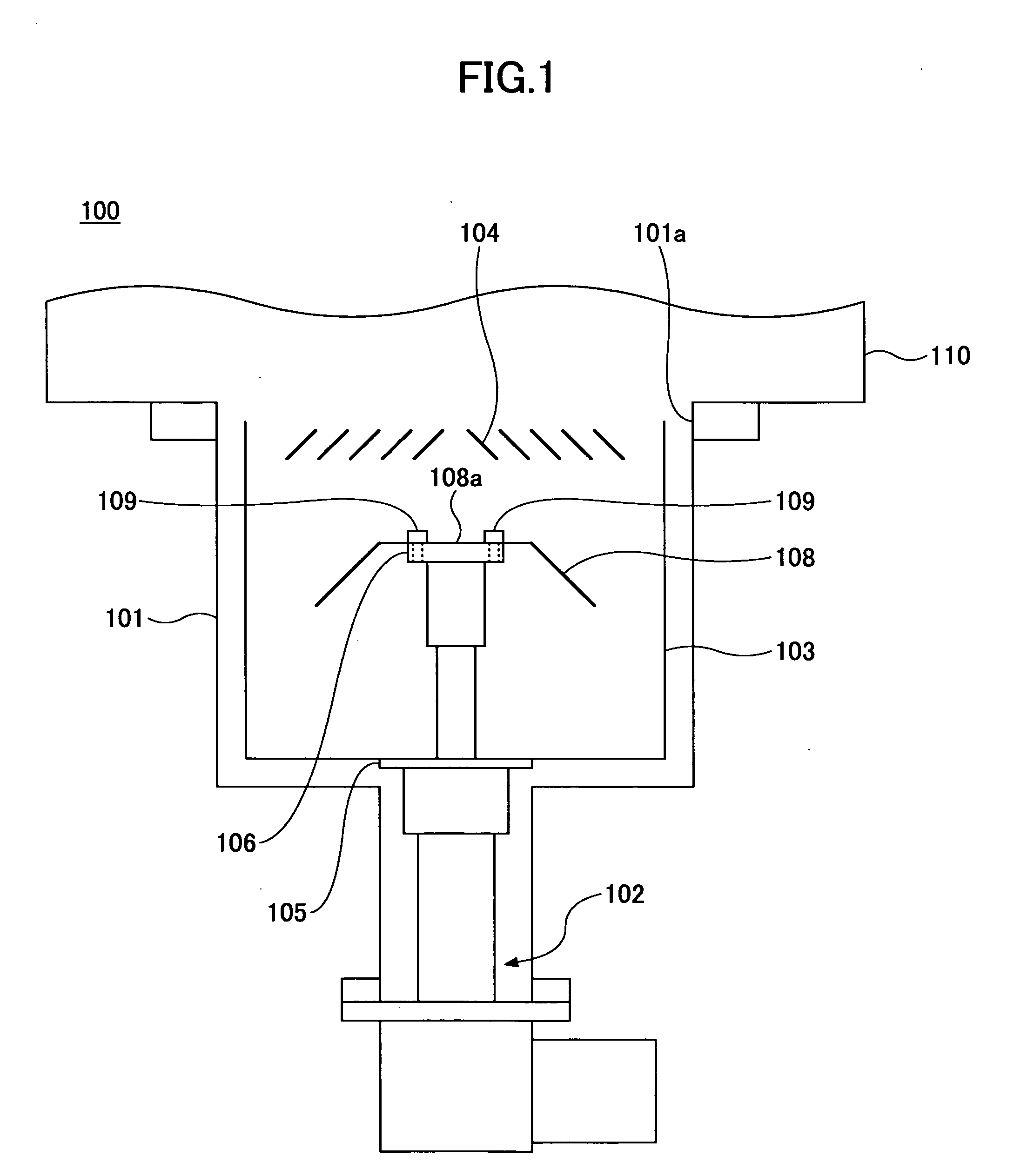

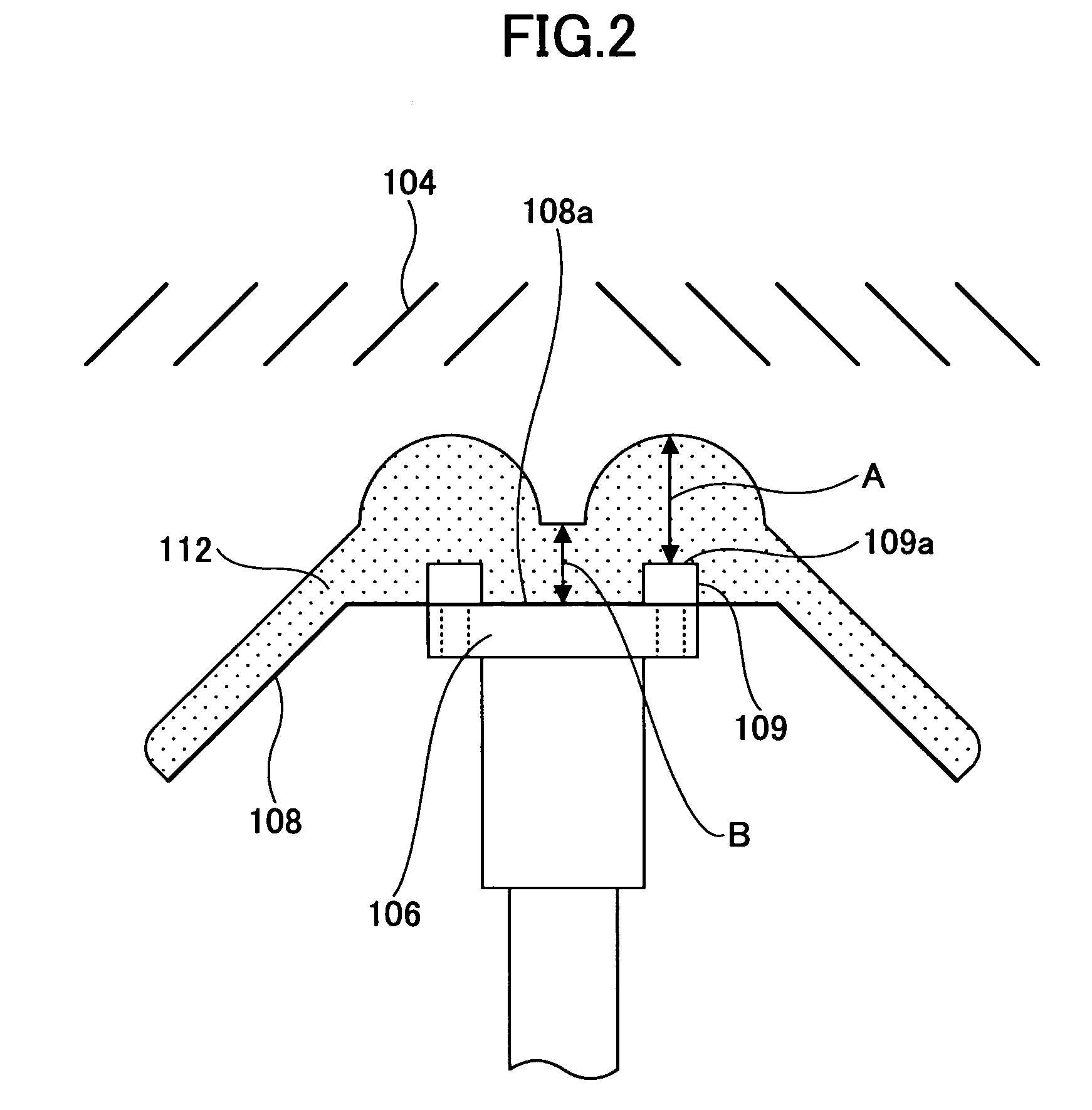

Film formation apparatus and film formation method and cleaning method

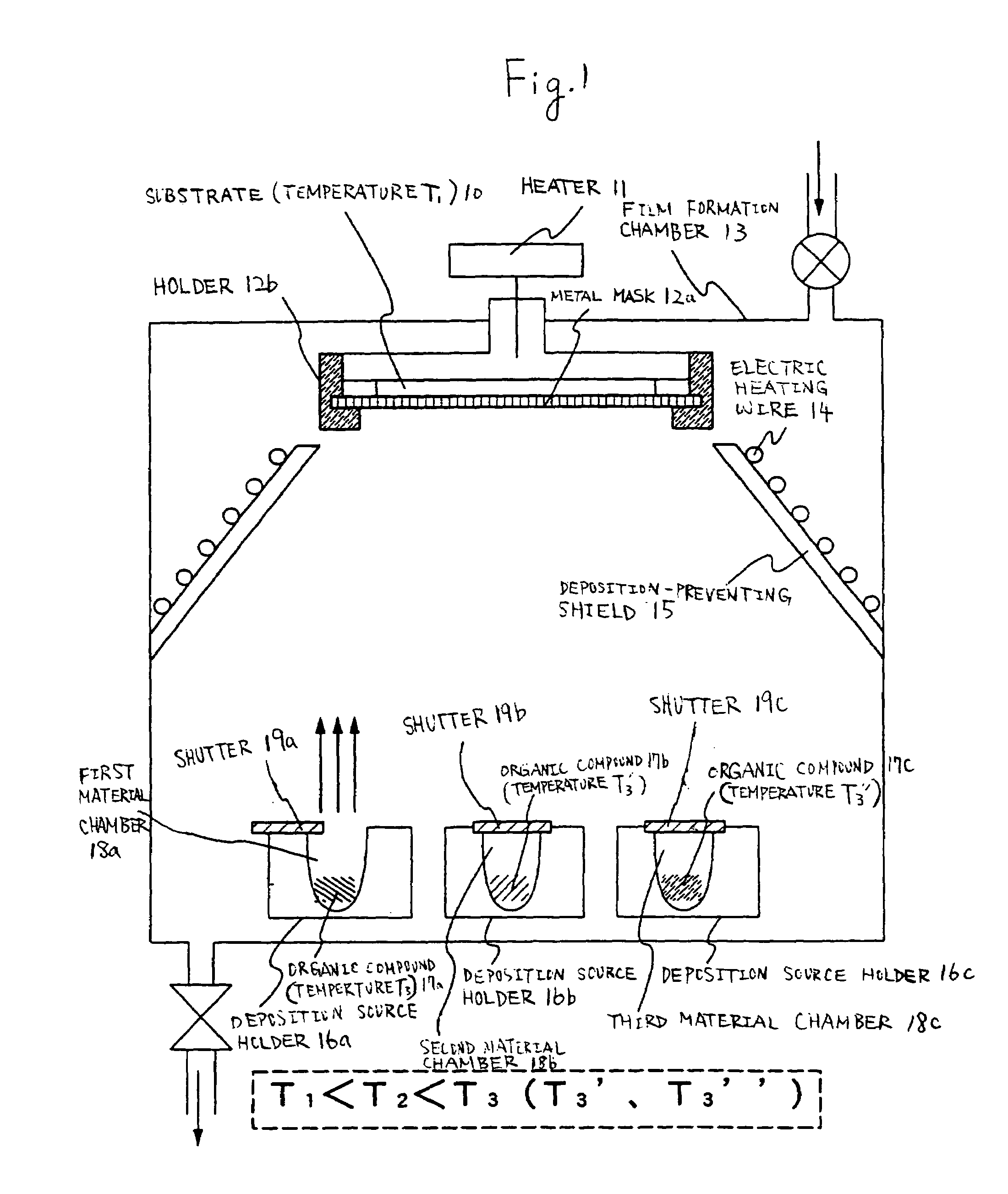

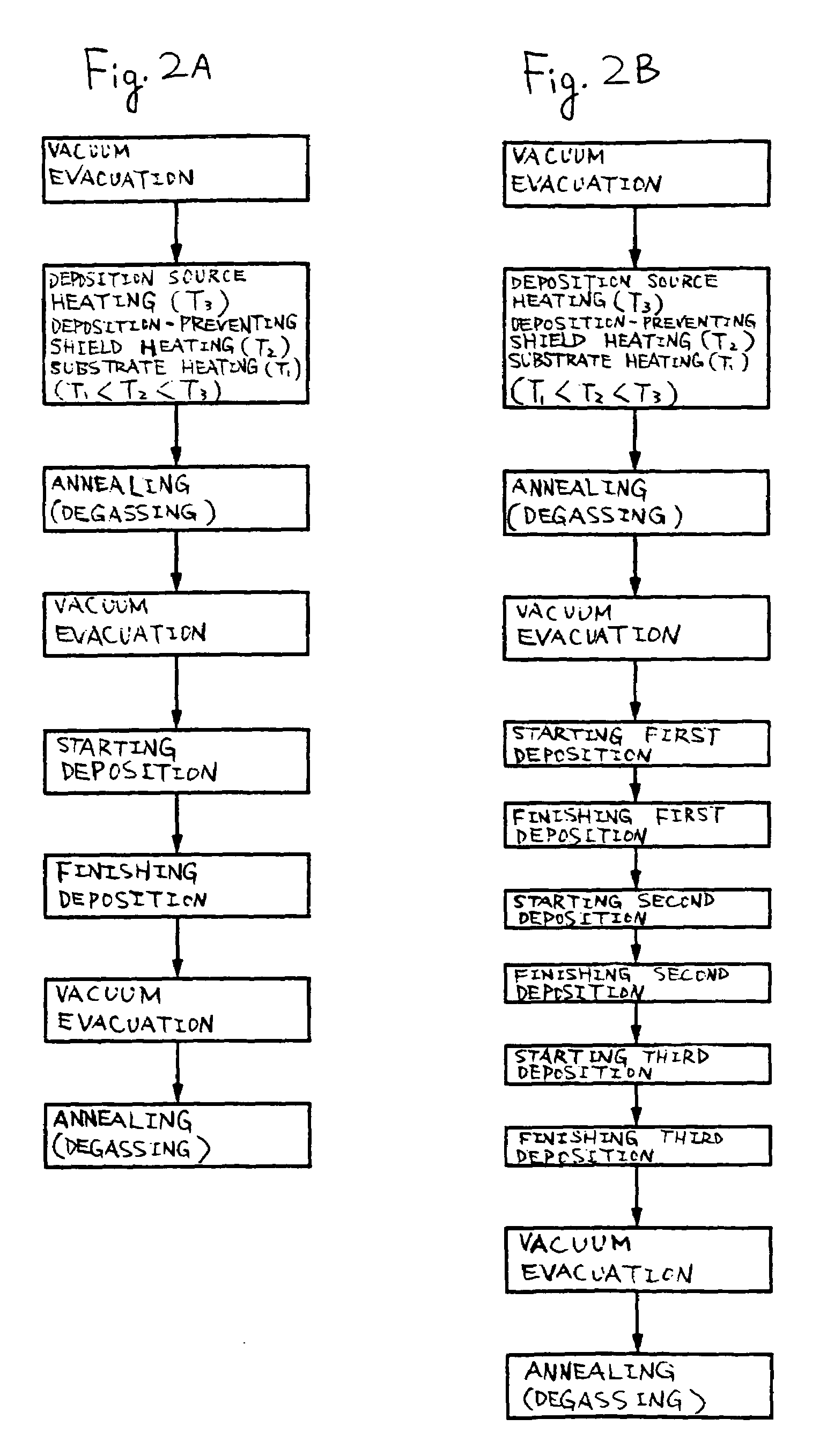

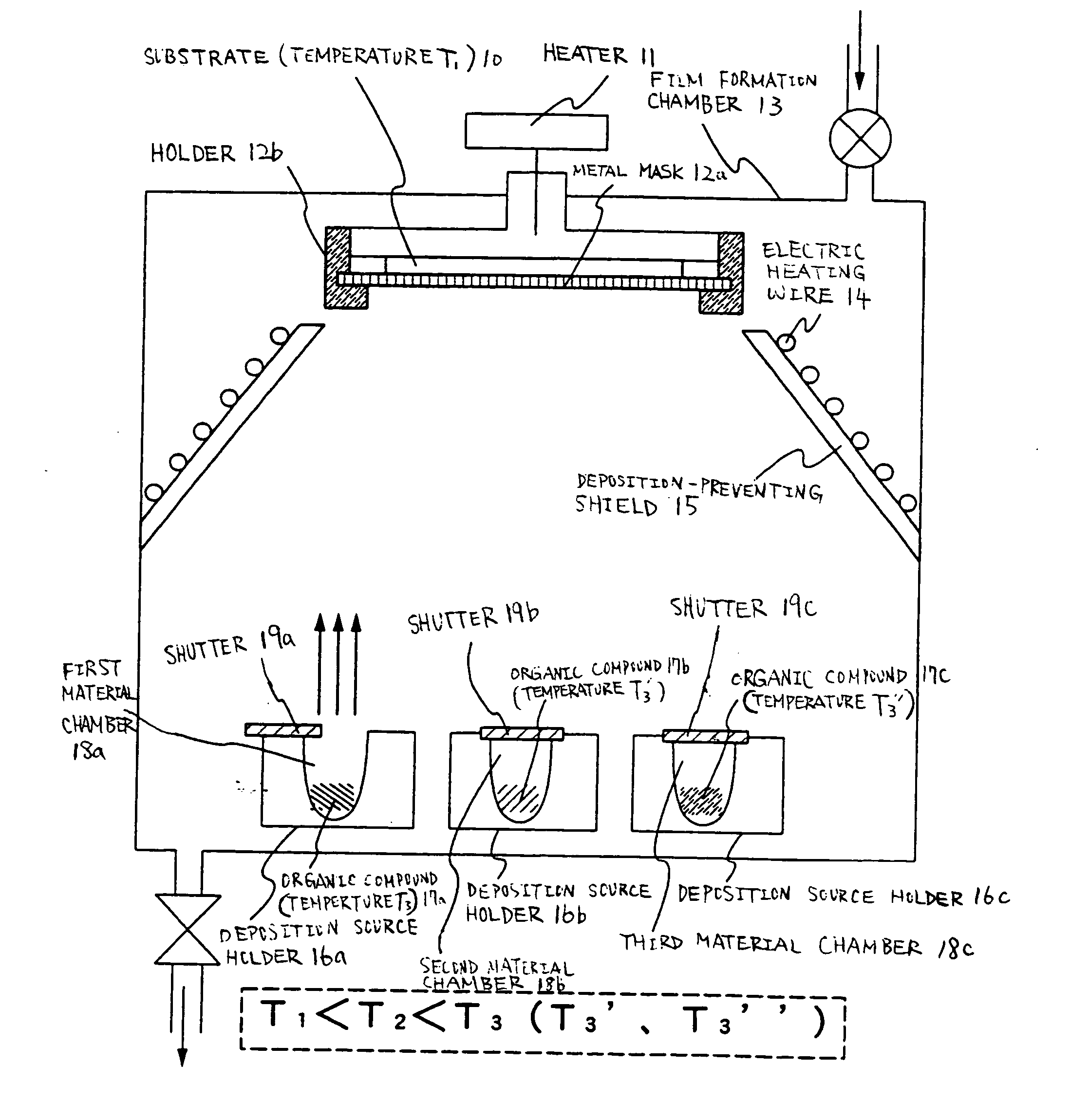

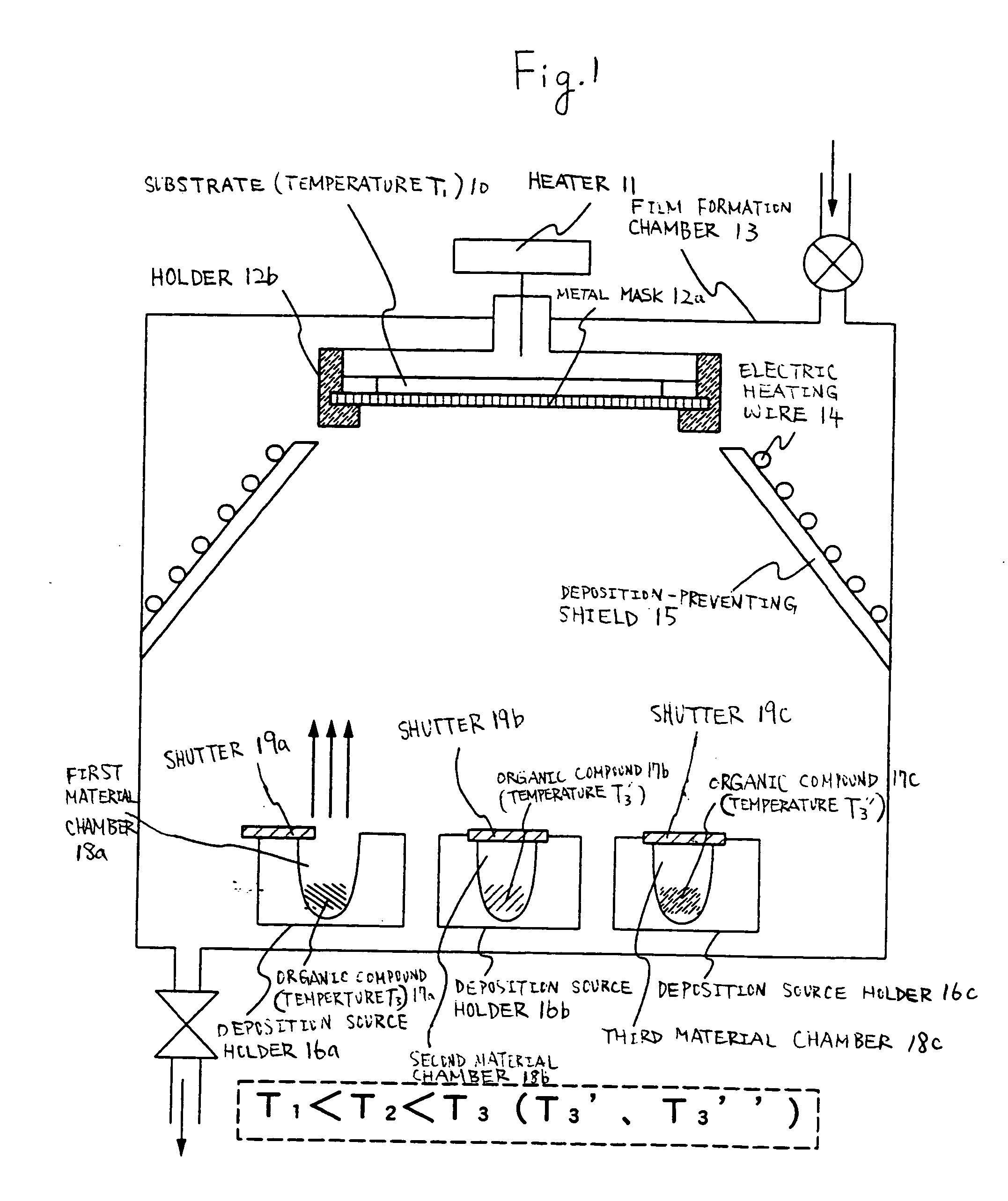

InactiveUS7316983B2Moderate energyReduce the driving voltageLiquid surface applicatorsVacuum evaporation coatingPressure decreaseHigh density

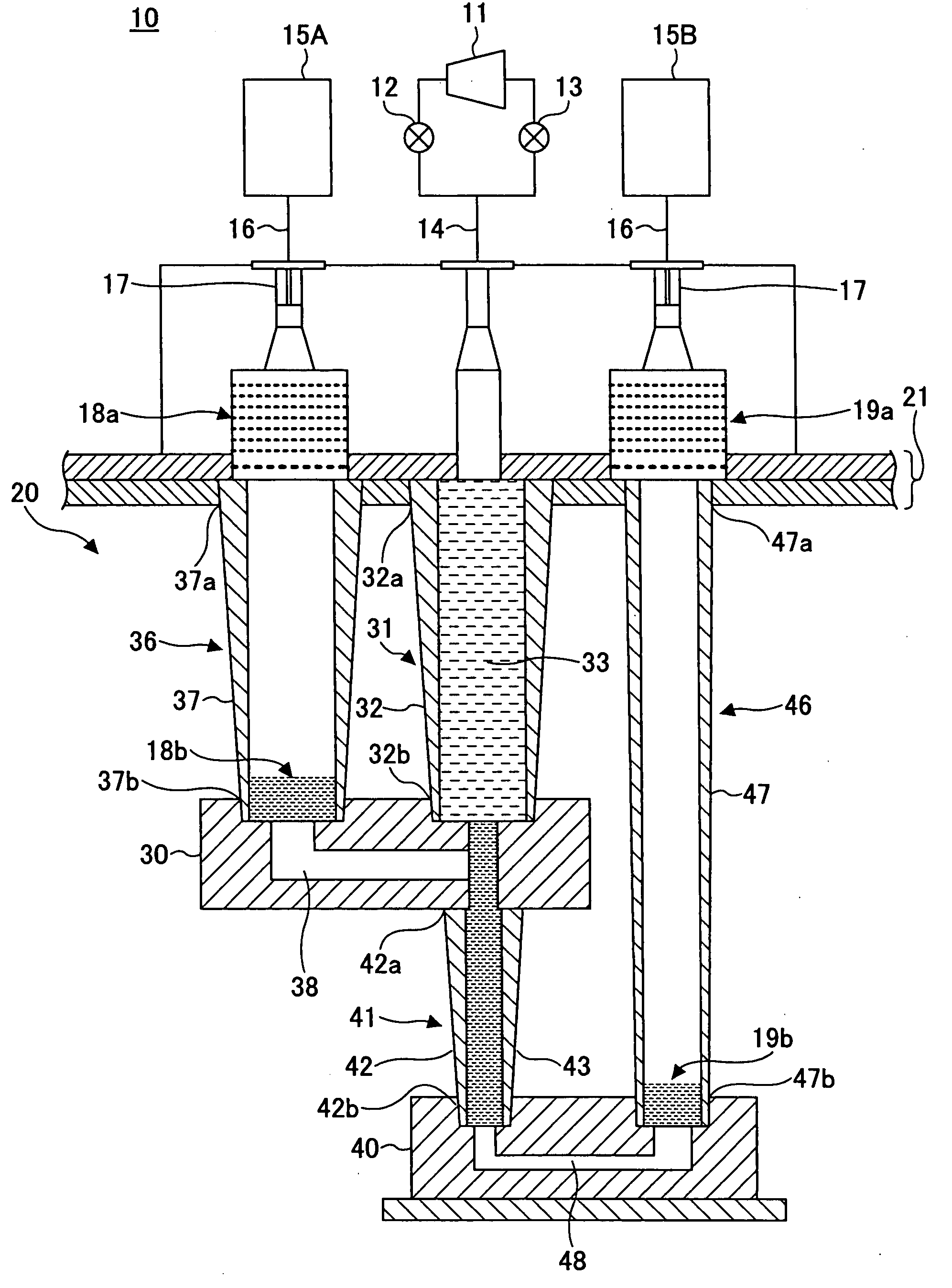

The purpose of the invention is to provide a film formation apparatus capable of forming an EL layer with a high purity and a high density, and a cleaning method. The invention is a formation of an EL layer with a high density by heating a substrate 10 by a heating means for heating a substrate, decreasing the pressure of a film formation chamber with a pressure decreasing means (a vacuum pump such as a turbo-molecular pump, a dry pump, or a cryopump) connected to the film formation chamber to 5×10−3 Torr (0.665 Pa) or lower, preferably 1×10−3 Torr (0.133 Pa) or lower, and carrying out film formation by depositing organic compound materials from deposition sources. In the film formation chamber, cleaning of deposition masks is carried out by plasma.

Owner:SEMICON ENERGY LAB CO LTD

Film formation apparatus and film formation method and cleaning method

InactiveUS20050106322A1Moderate energyReduce the driving voltageSolid-state devicesVacuum evaporation coatingPressure decreaseHigh density

The purpose of the invention is to provide a film formation apparatus capable of forming an EL layer with a high purity and a high density, and a cleaning method. The invention is a formation of an EL layer with a high density by heating a substrate 10 by a heating means for heating a substrate, decreasing the pressure of a film formation chamber with a pressure decreasing means (a vacuum pump such as a turbo-molecular pump, a dry pump, or a cryopump) connected to the film formation chamber to 5×10−3 Torr (0.665 Pa) or lower, preferably 1×10−3 Torr (0.133 Pa) or lower, and carrying out film formation by depositing organic compound materials from deposition sources. In the film formation chamber, cleaning of deposition masks is carried out by plasma.

Owner:SEMICON ENERGY LAB CO LTD

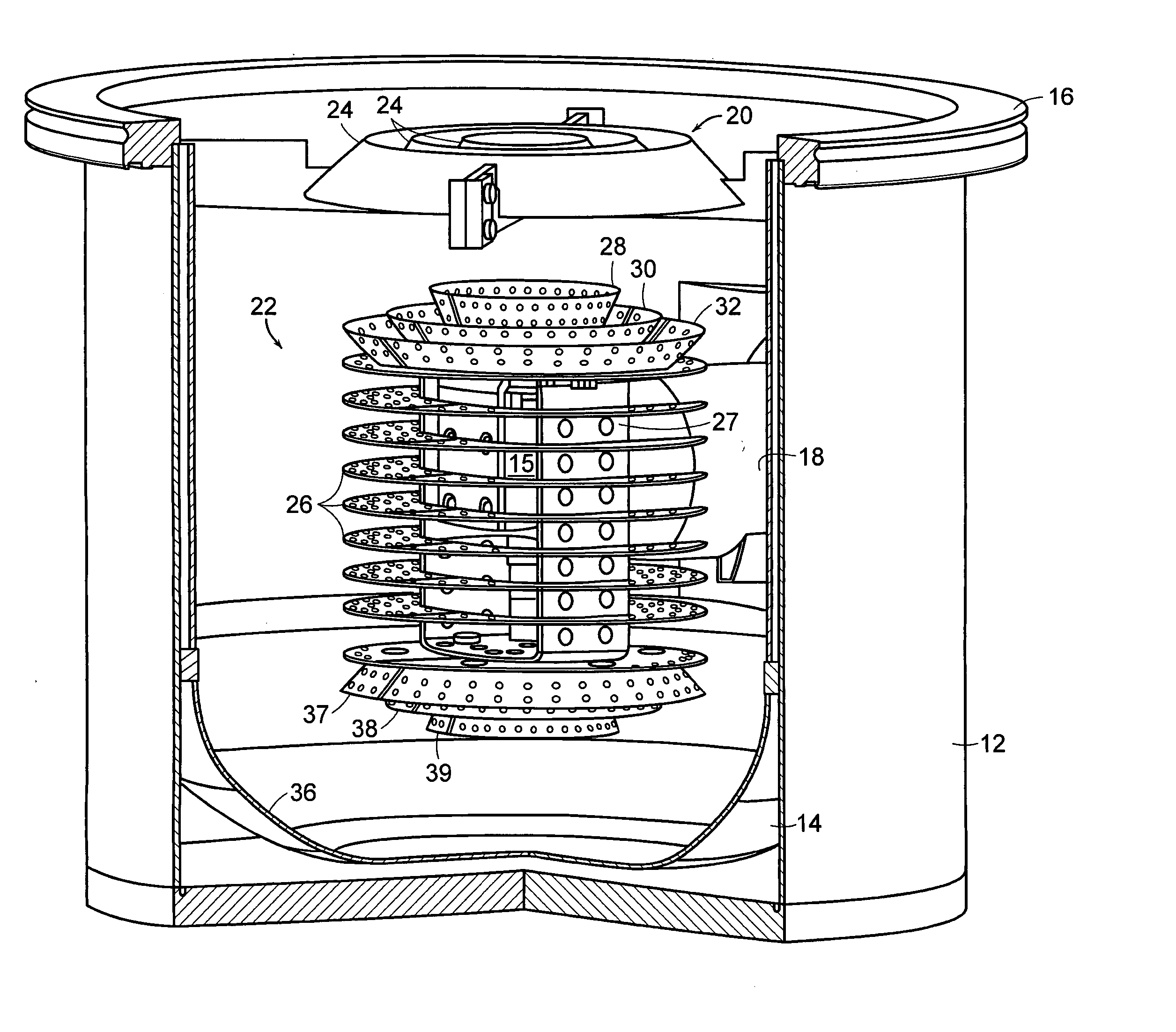

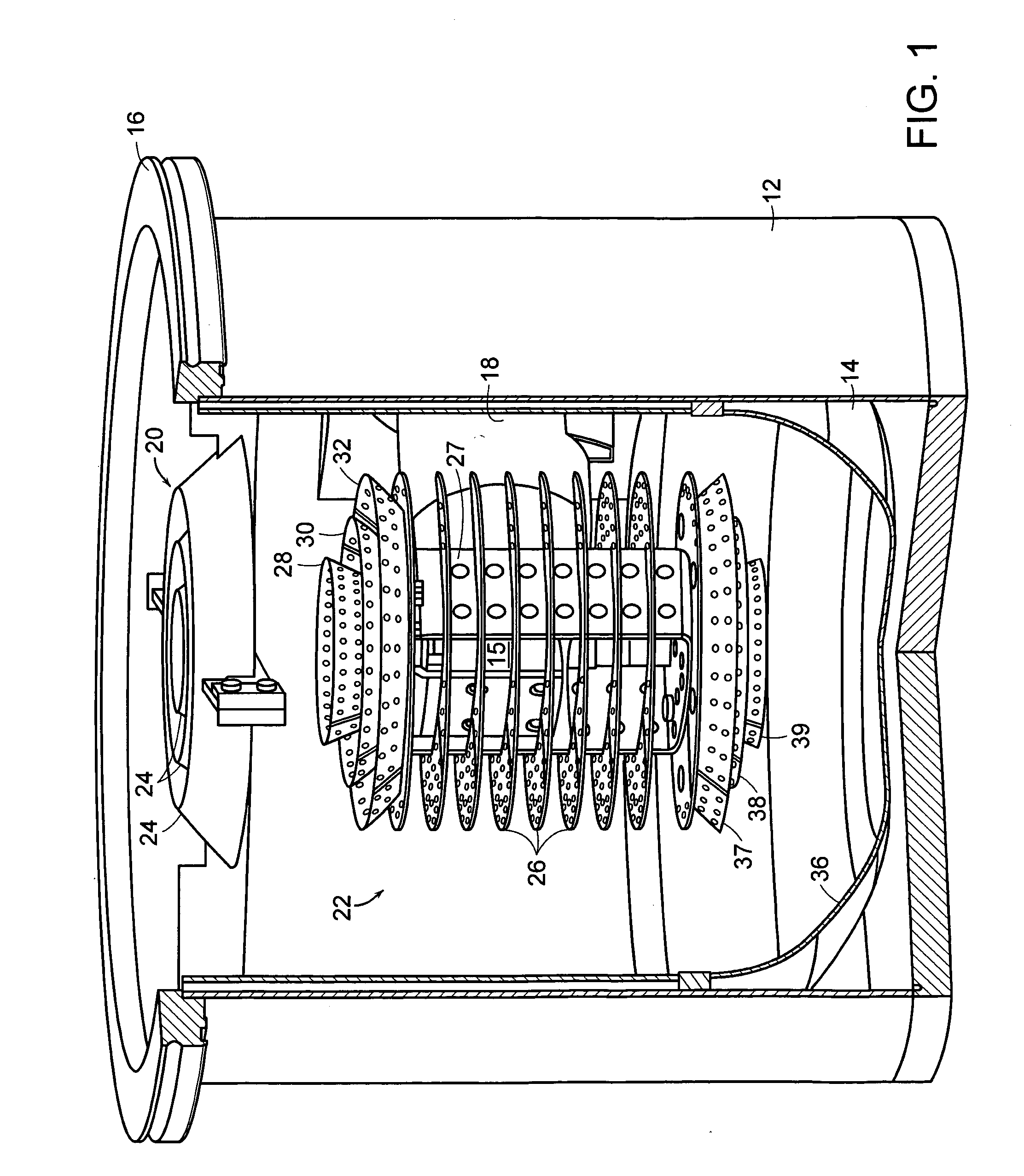

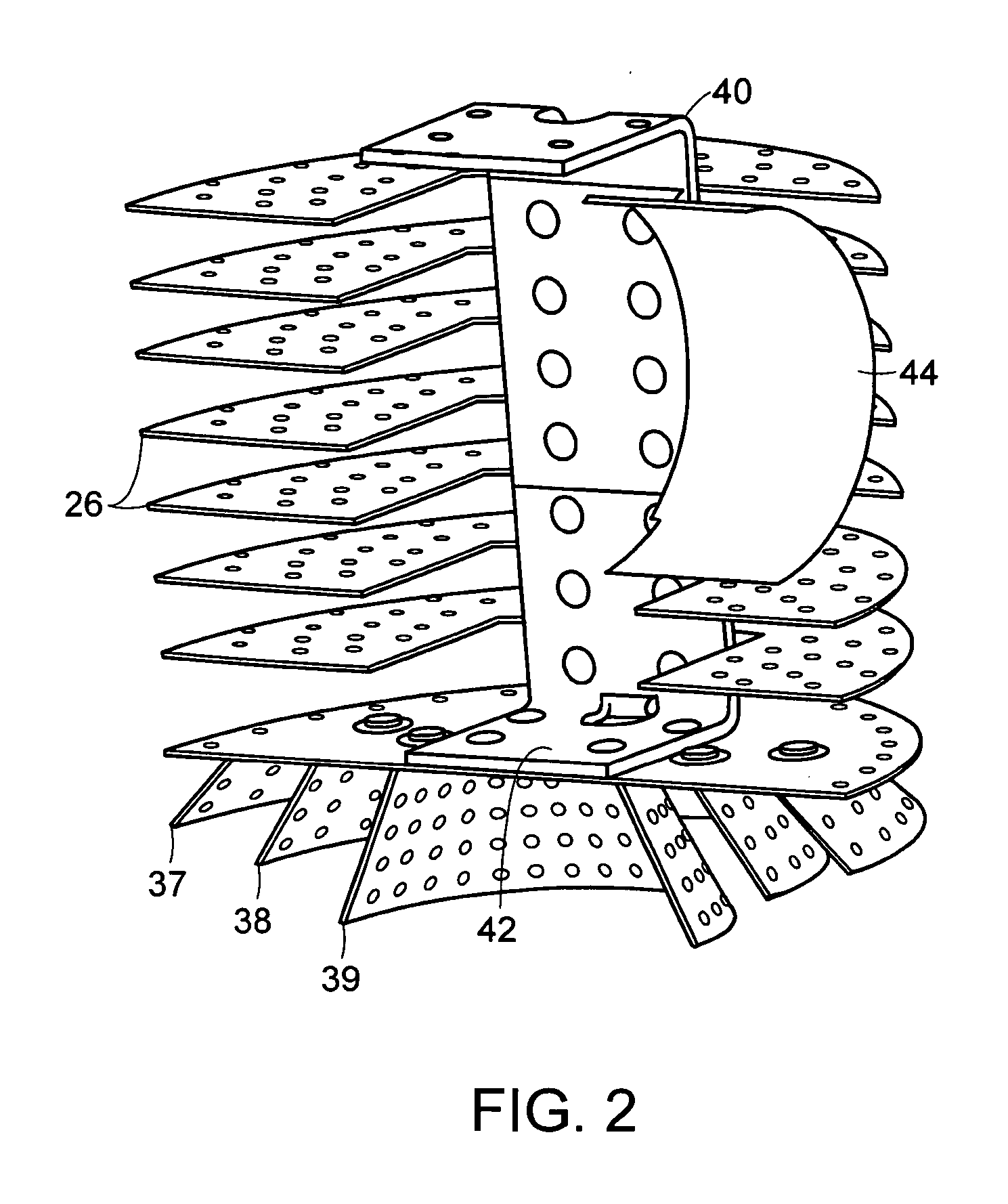

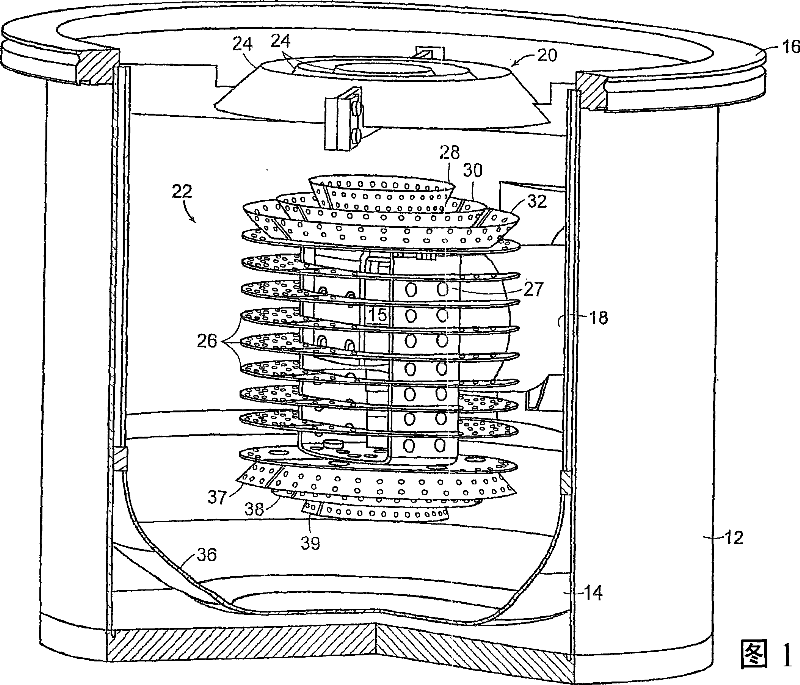

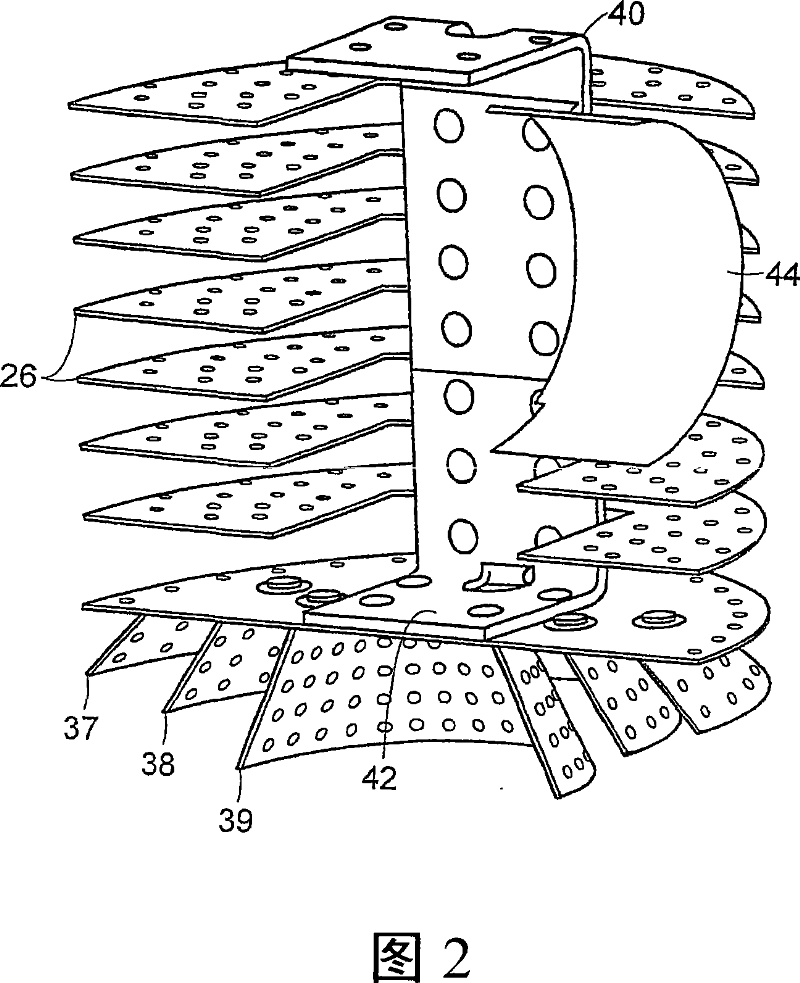

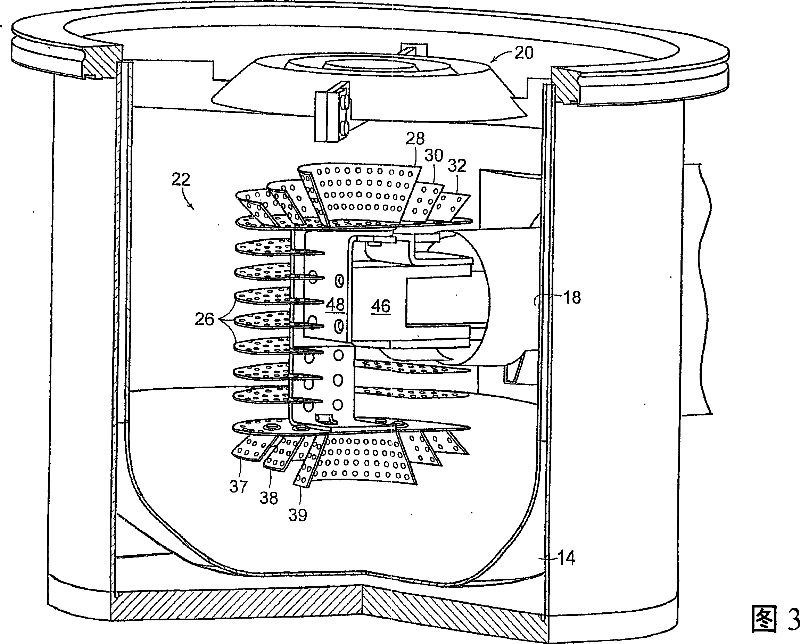

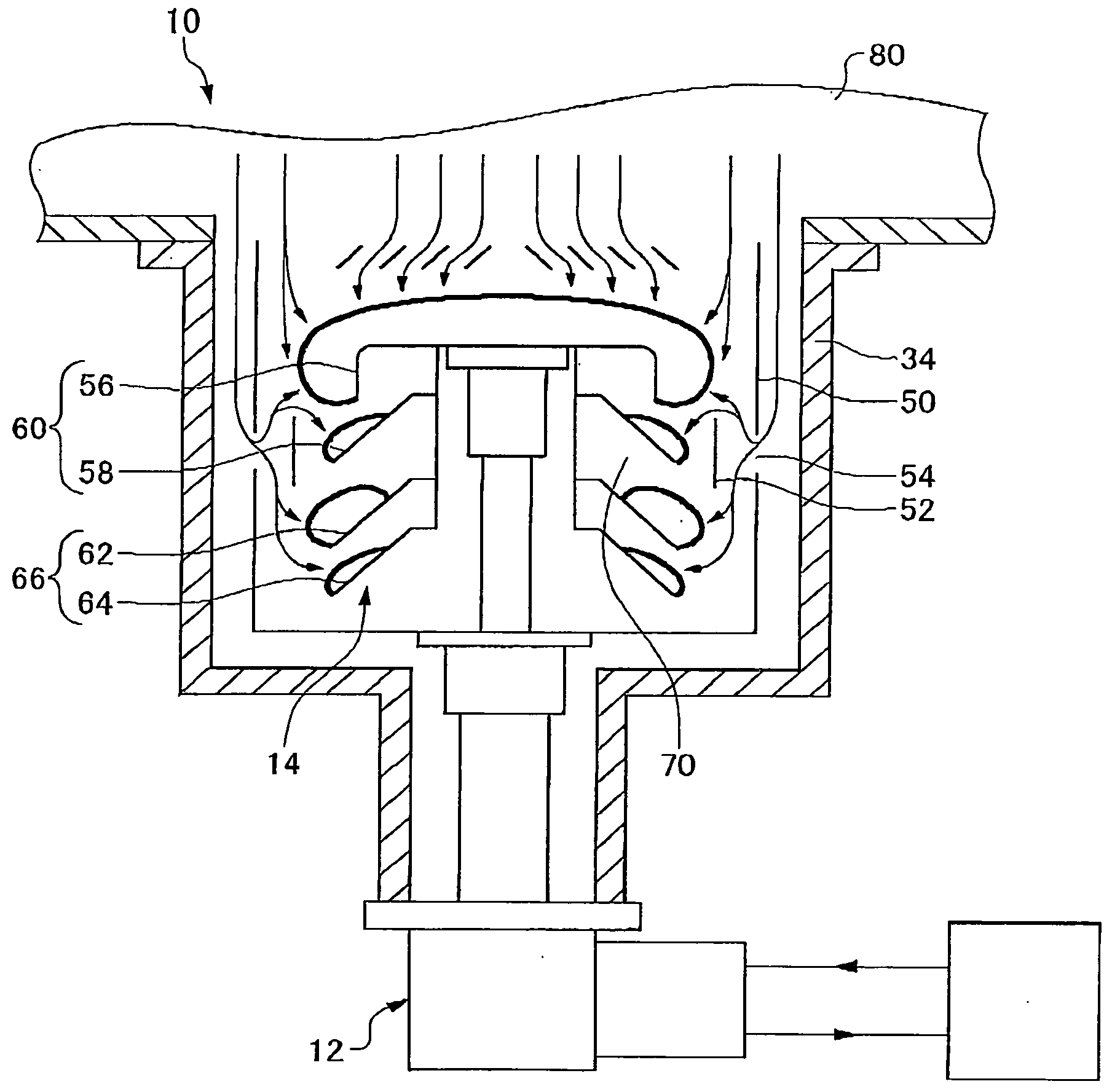

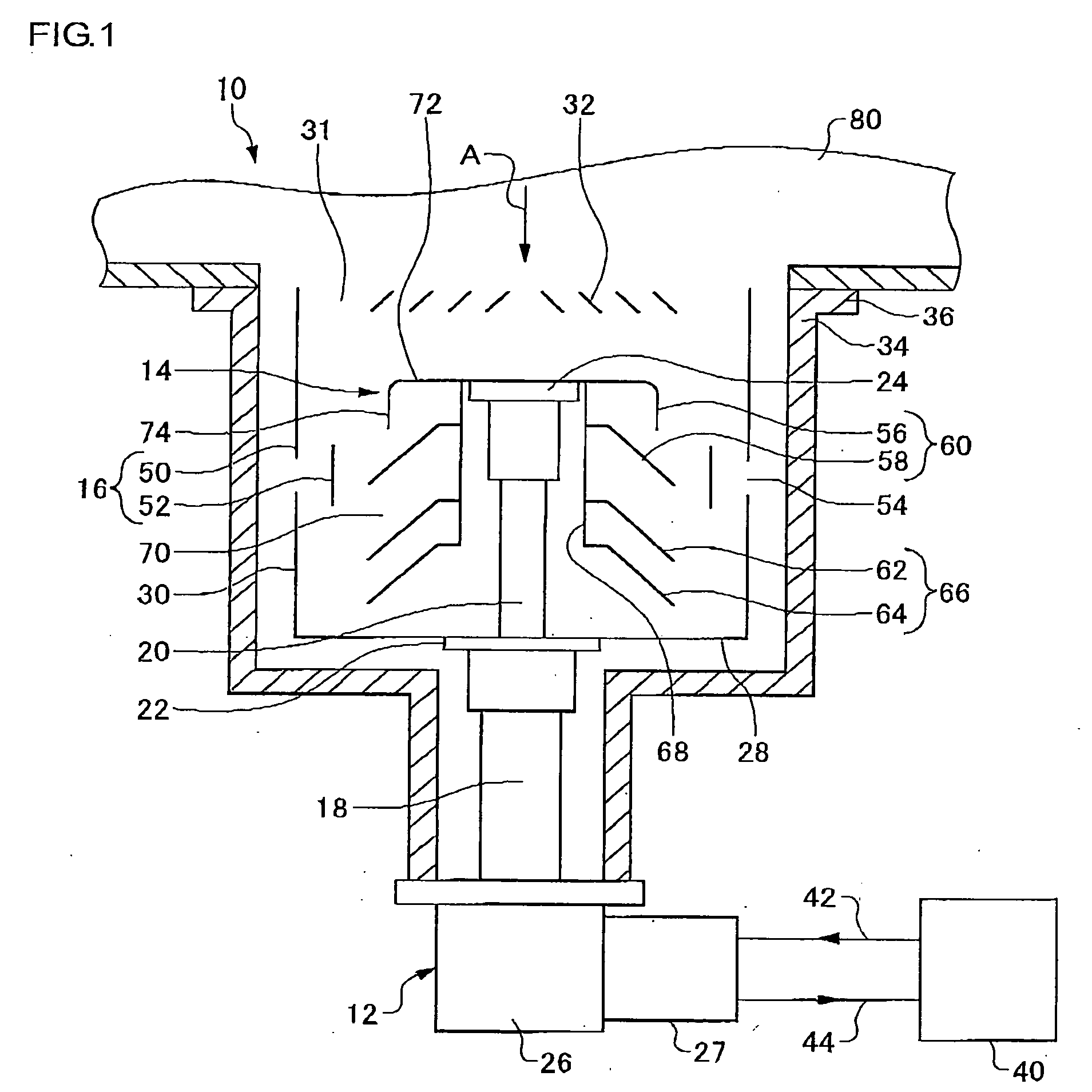

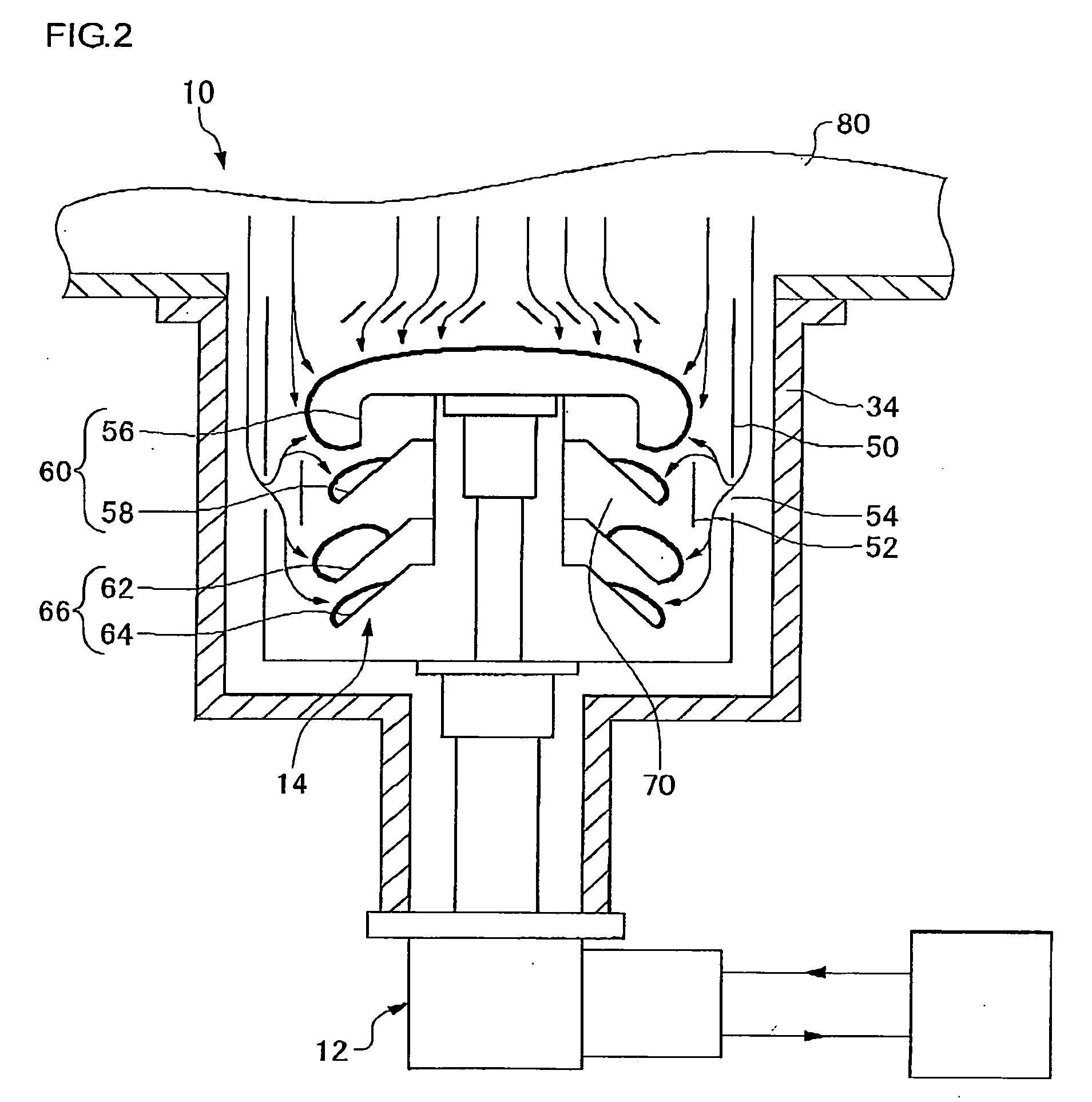

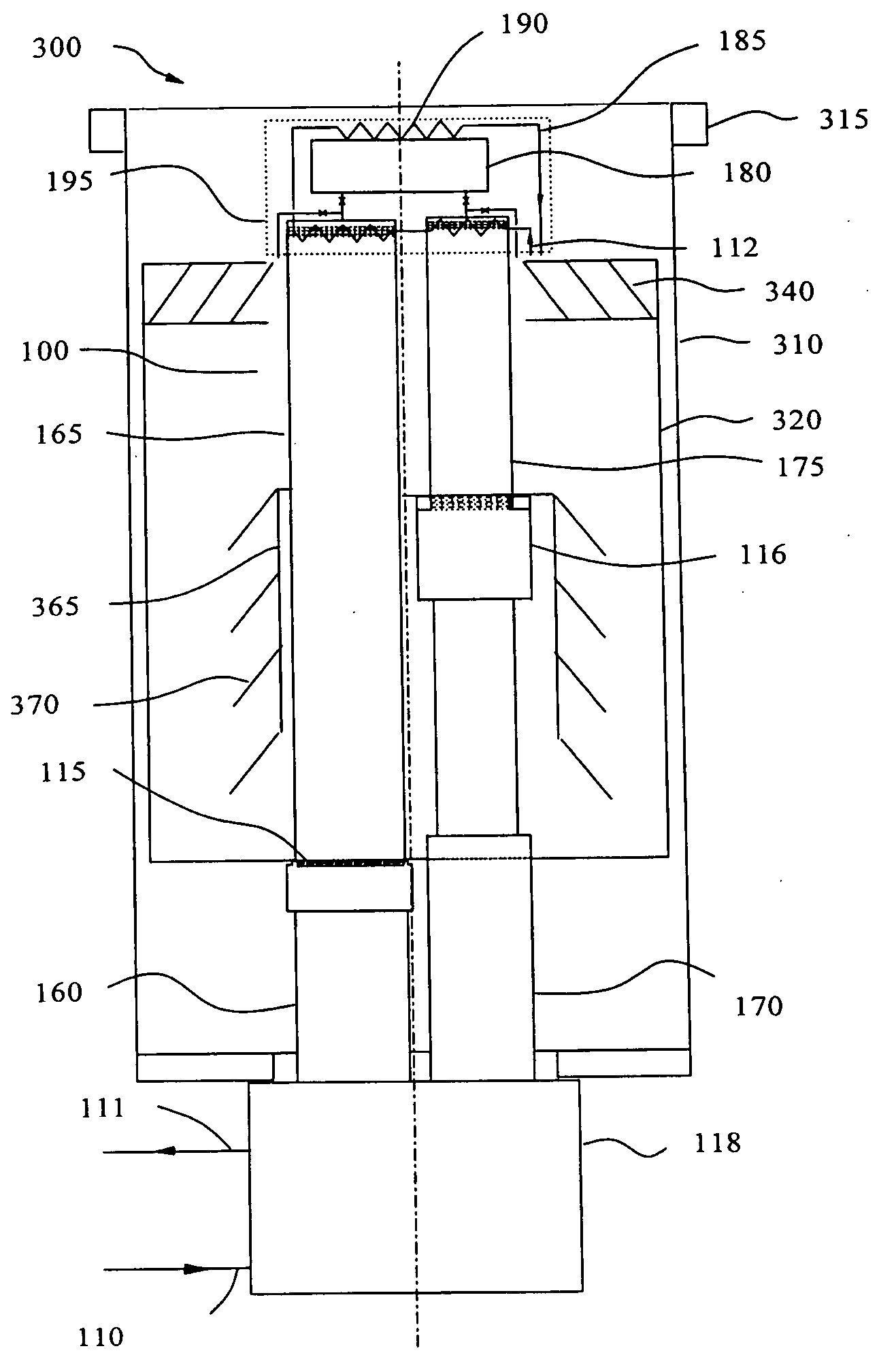

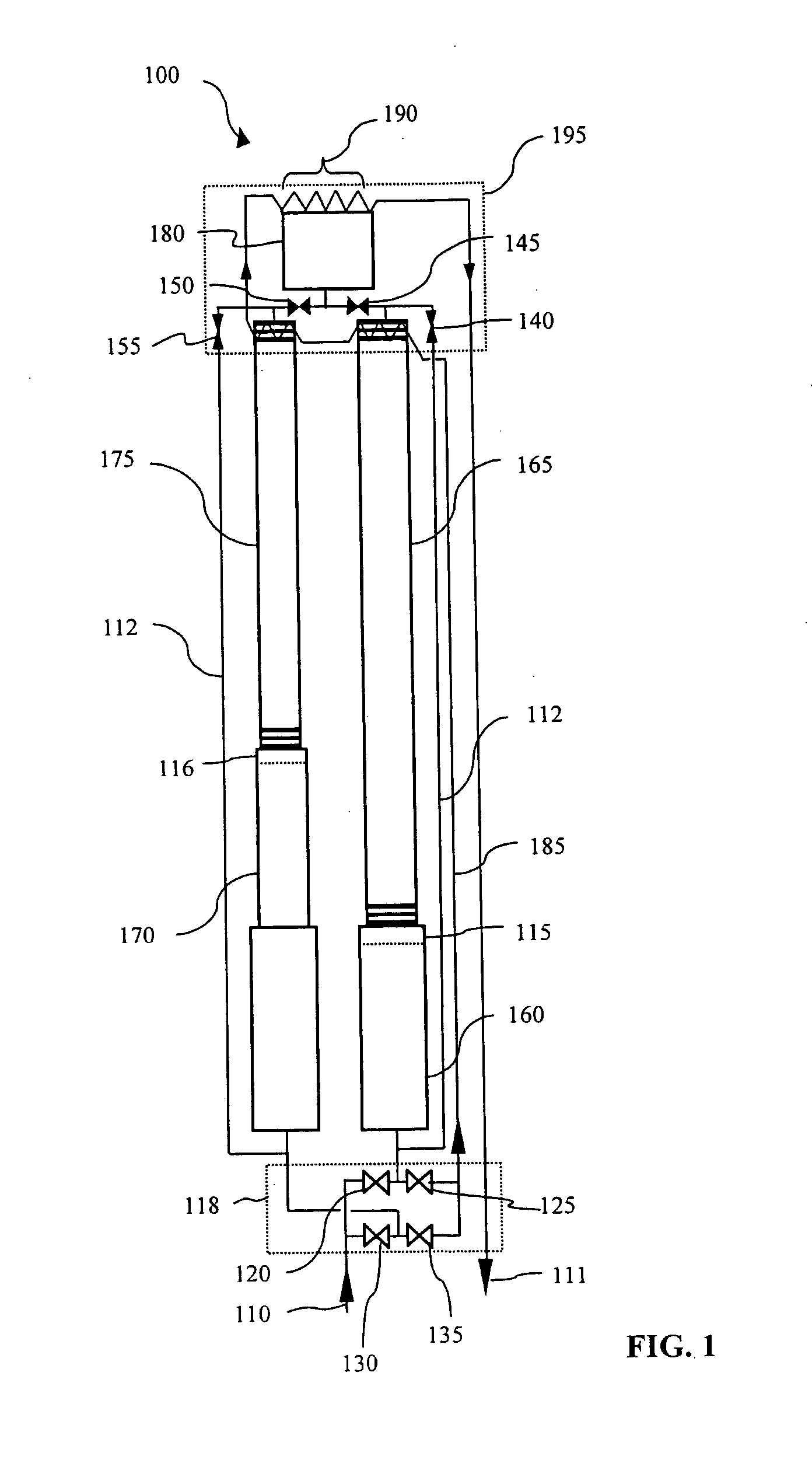

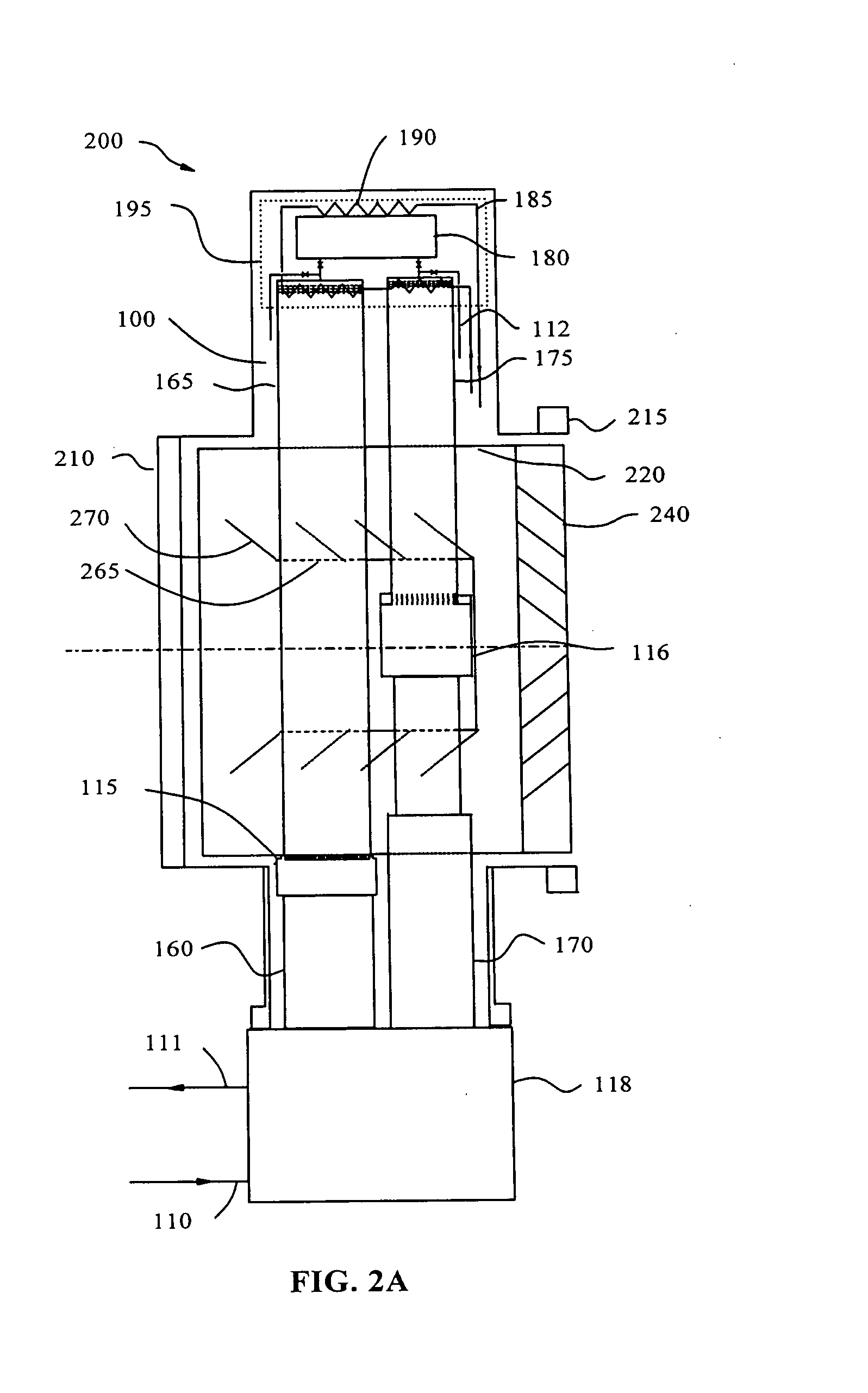

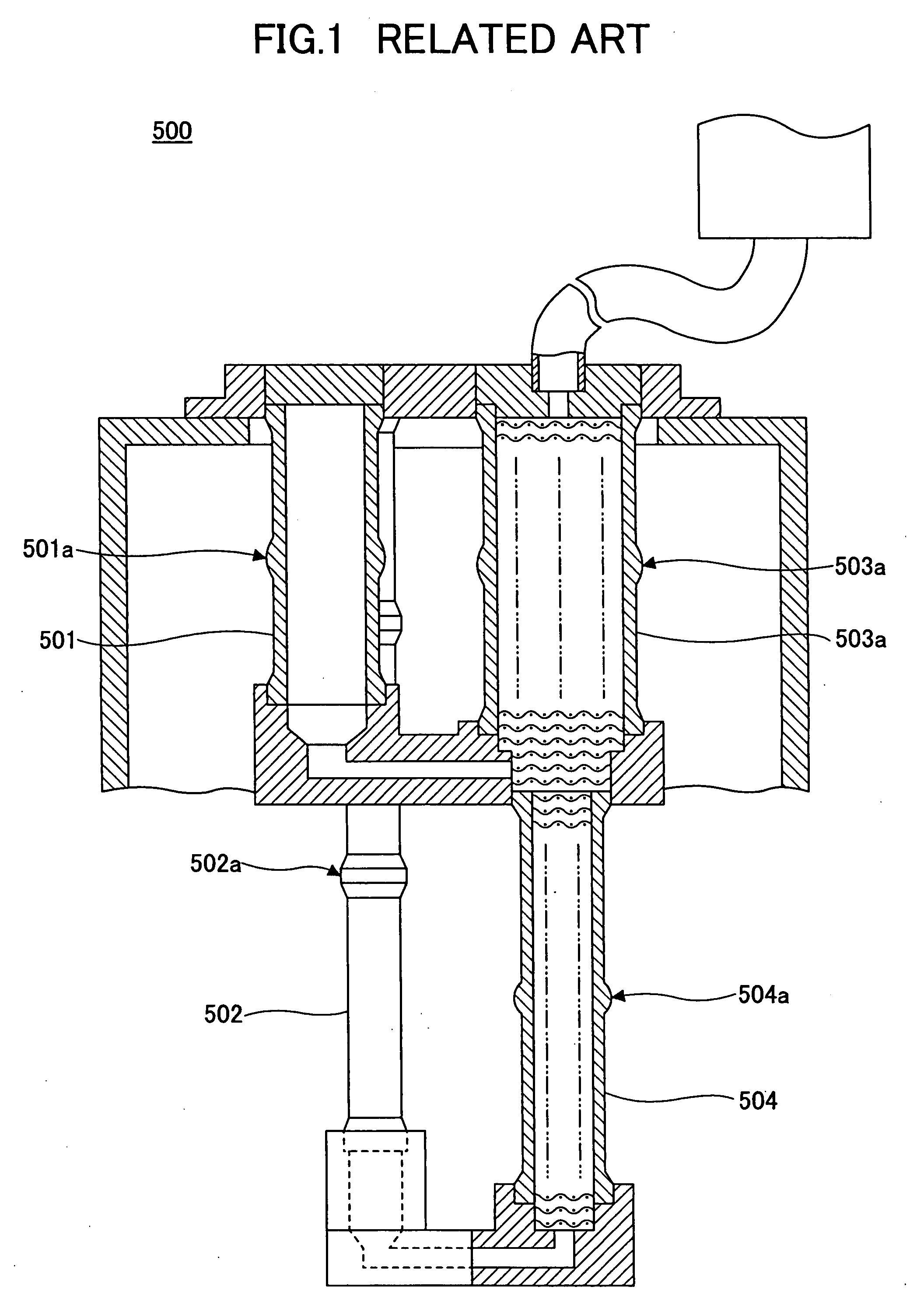

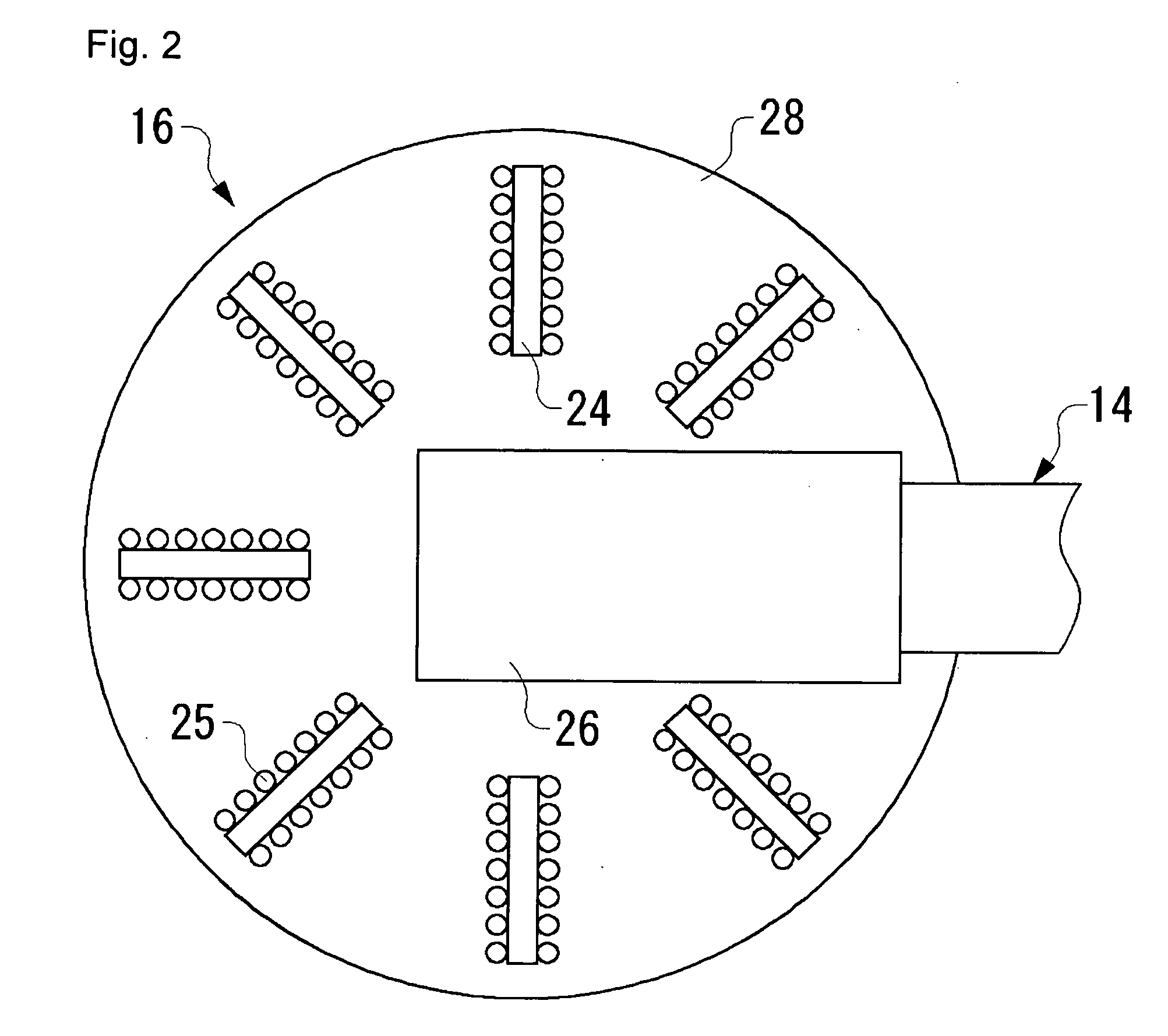

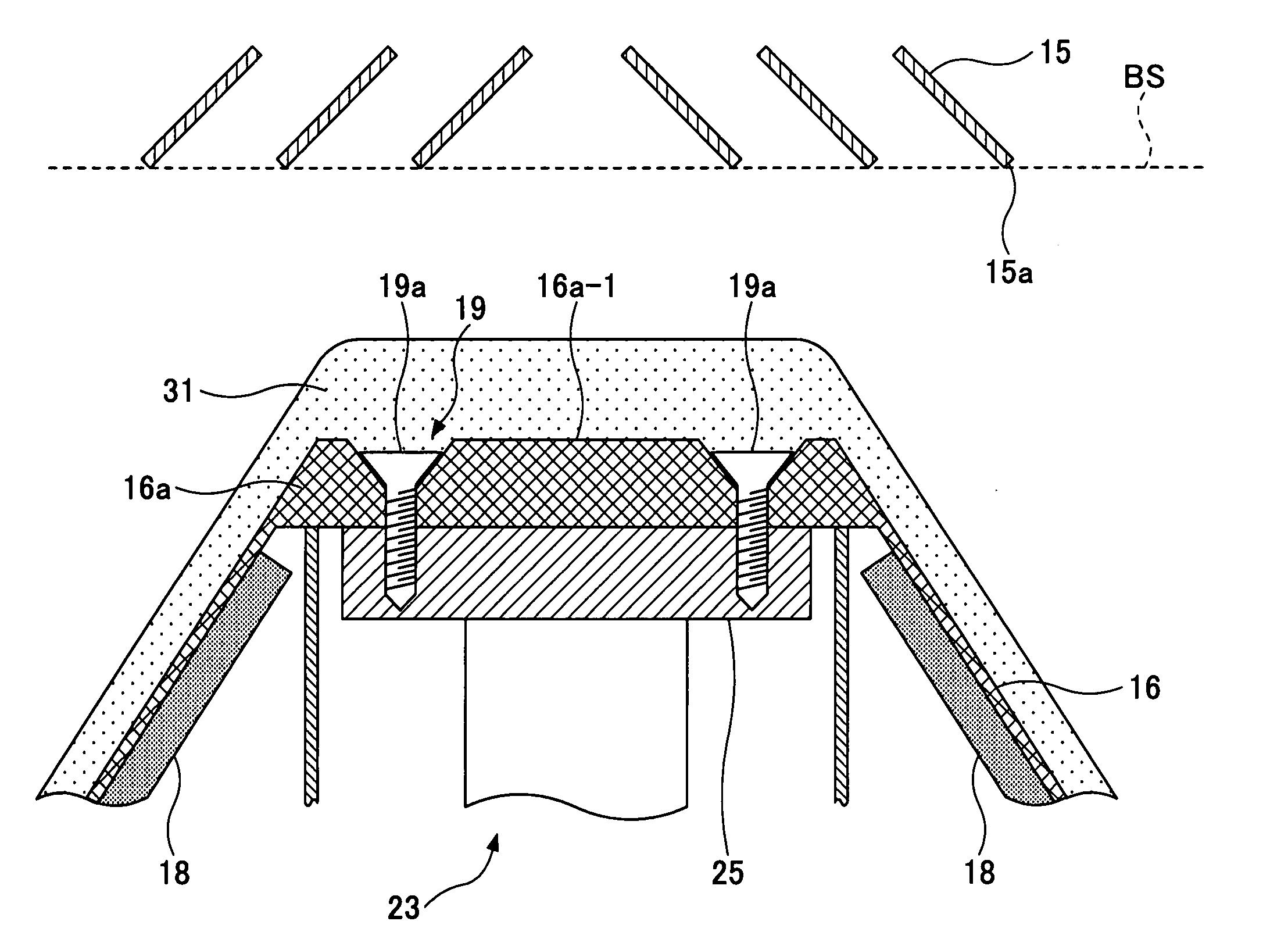

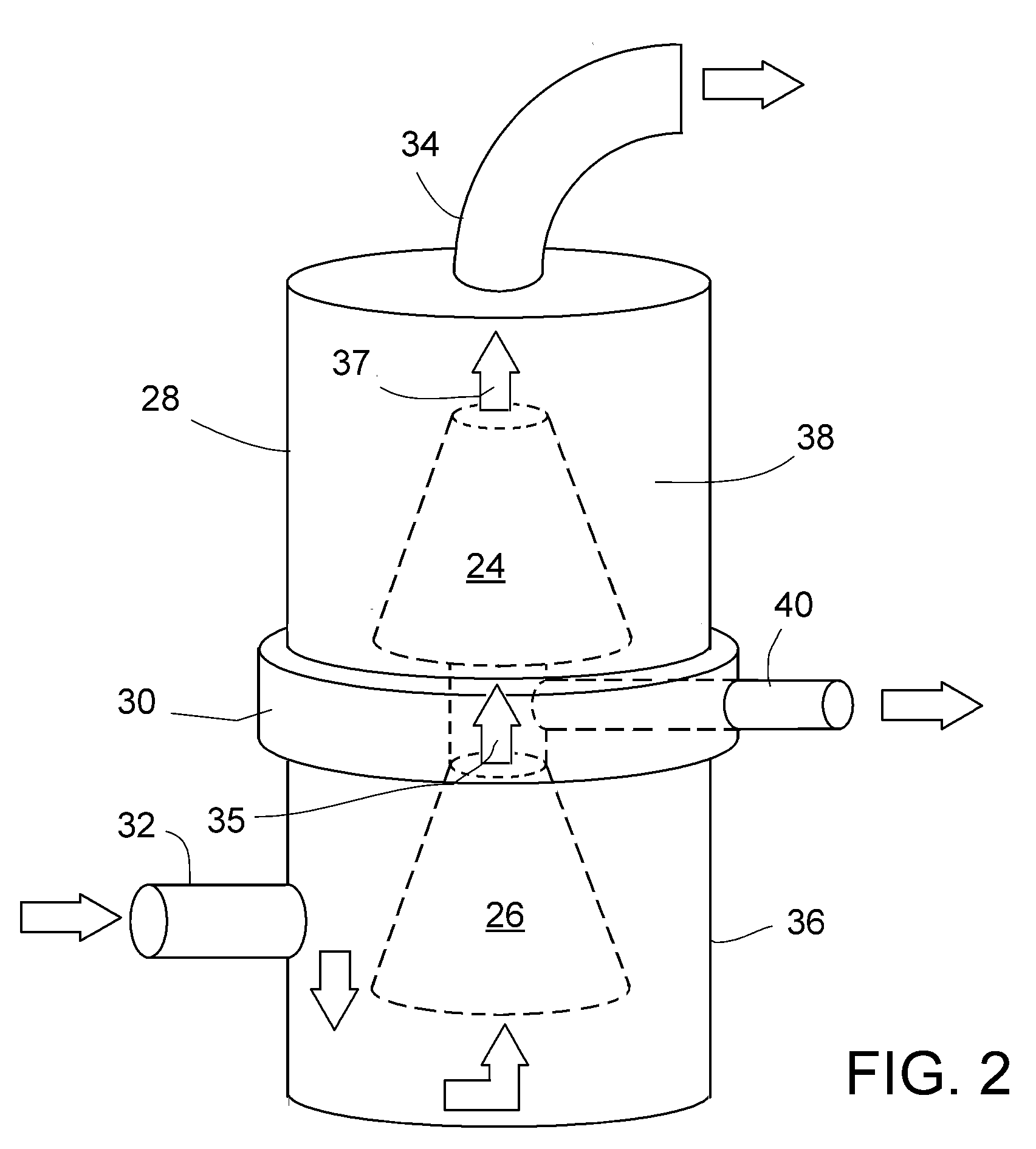

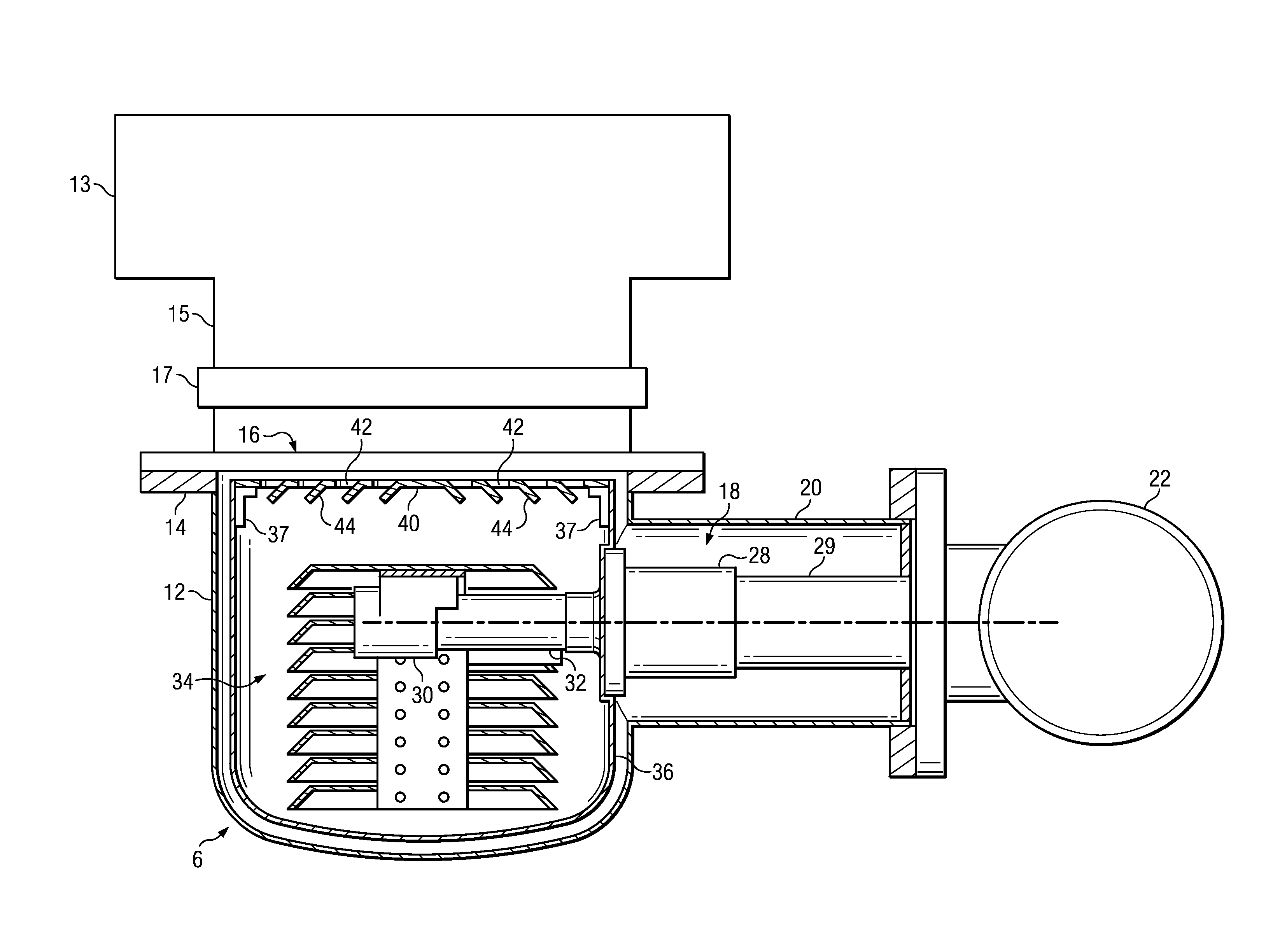

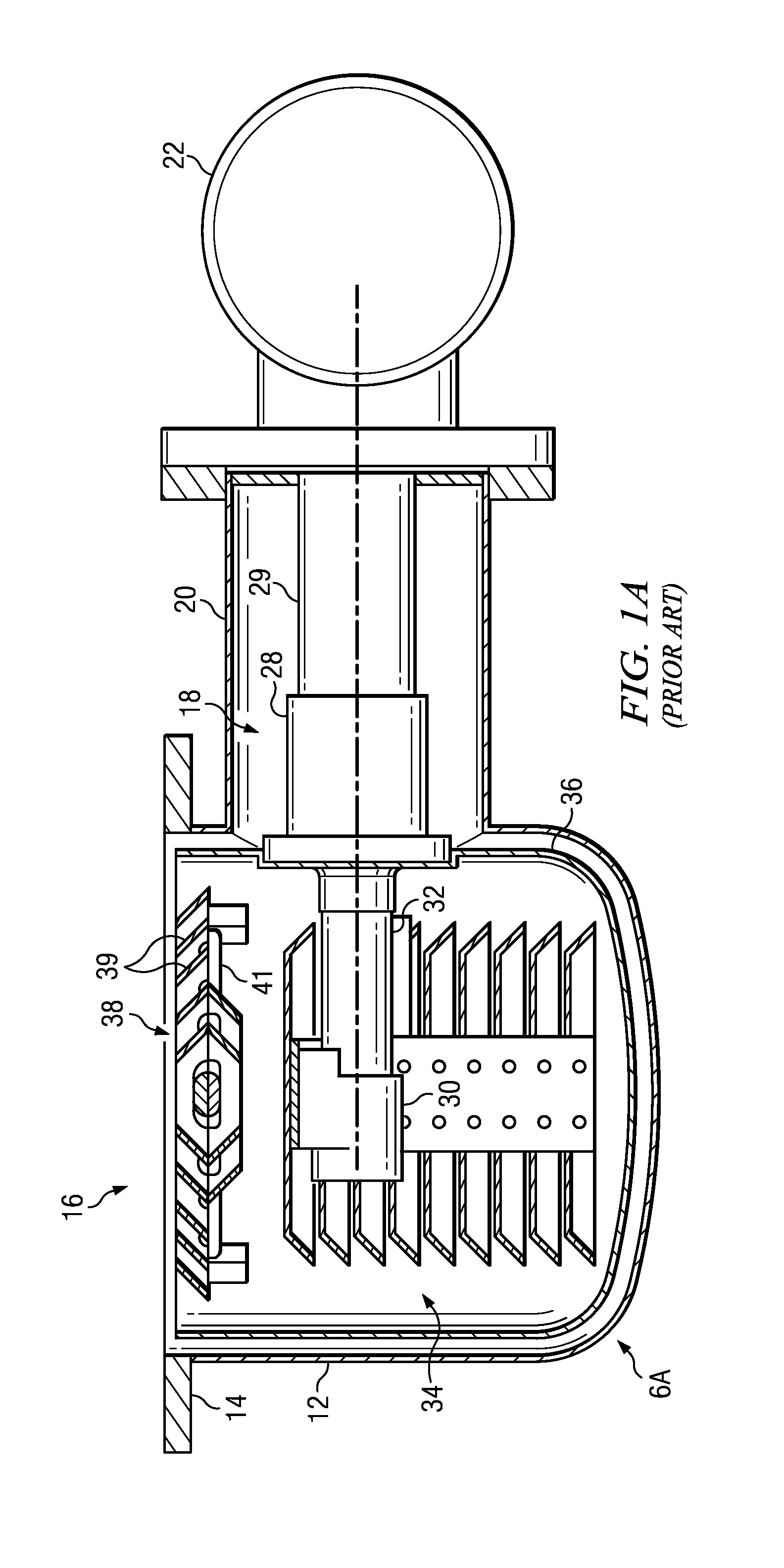

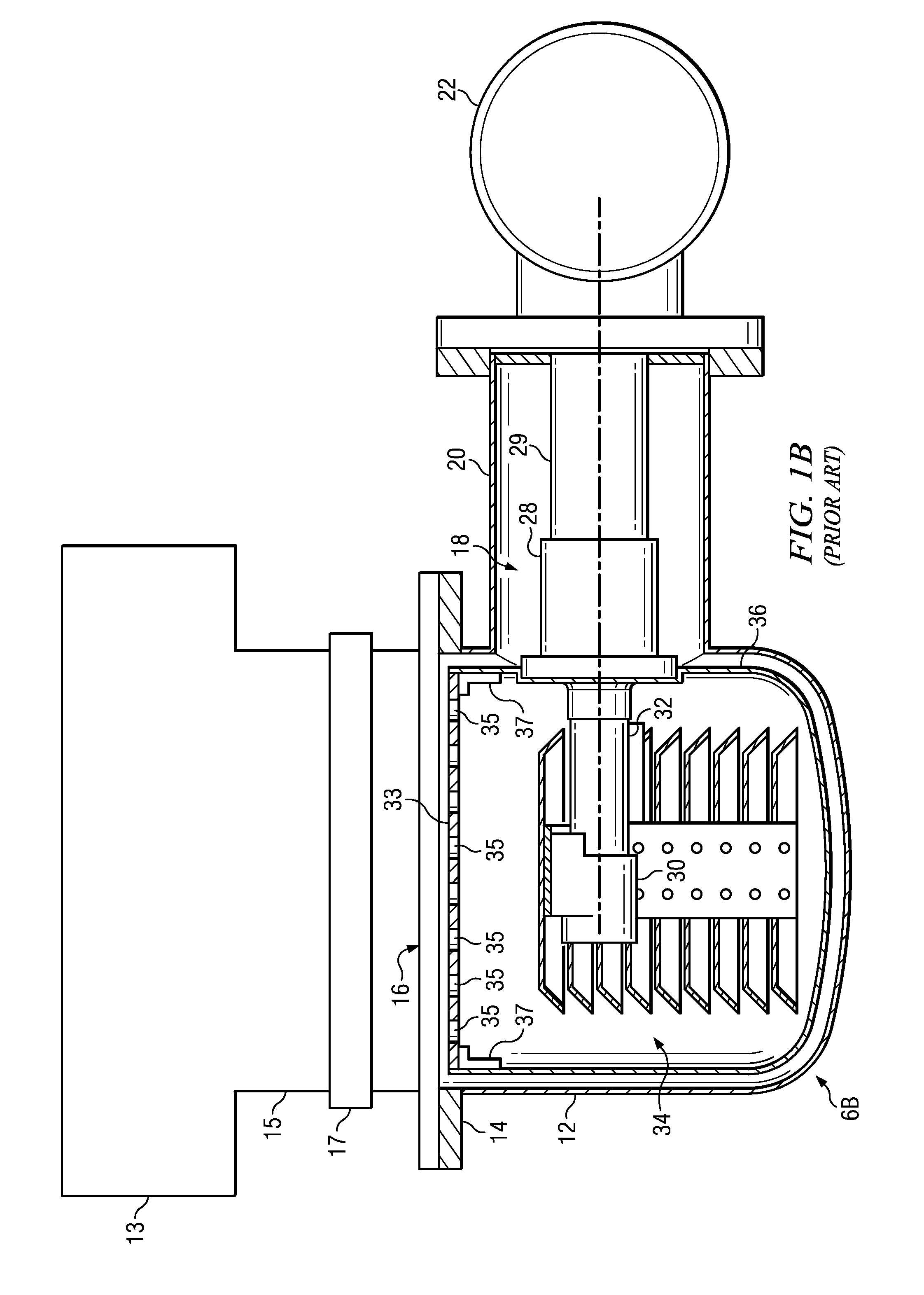

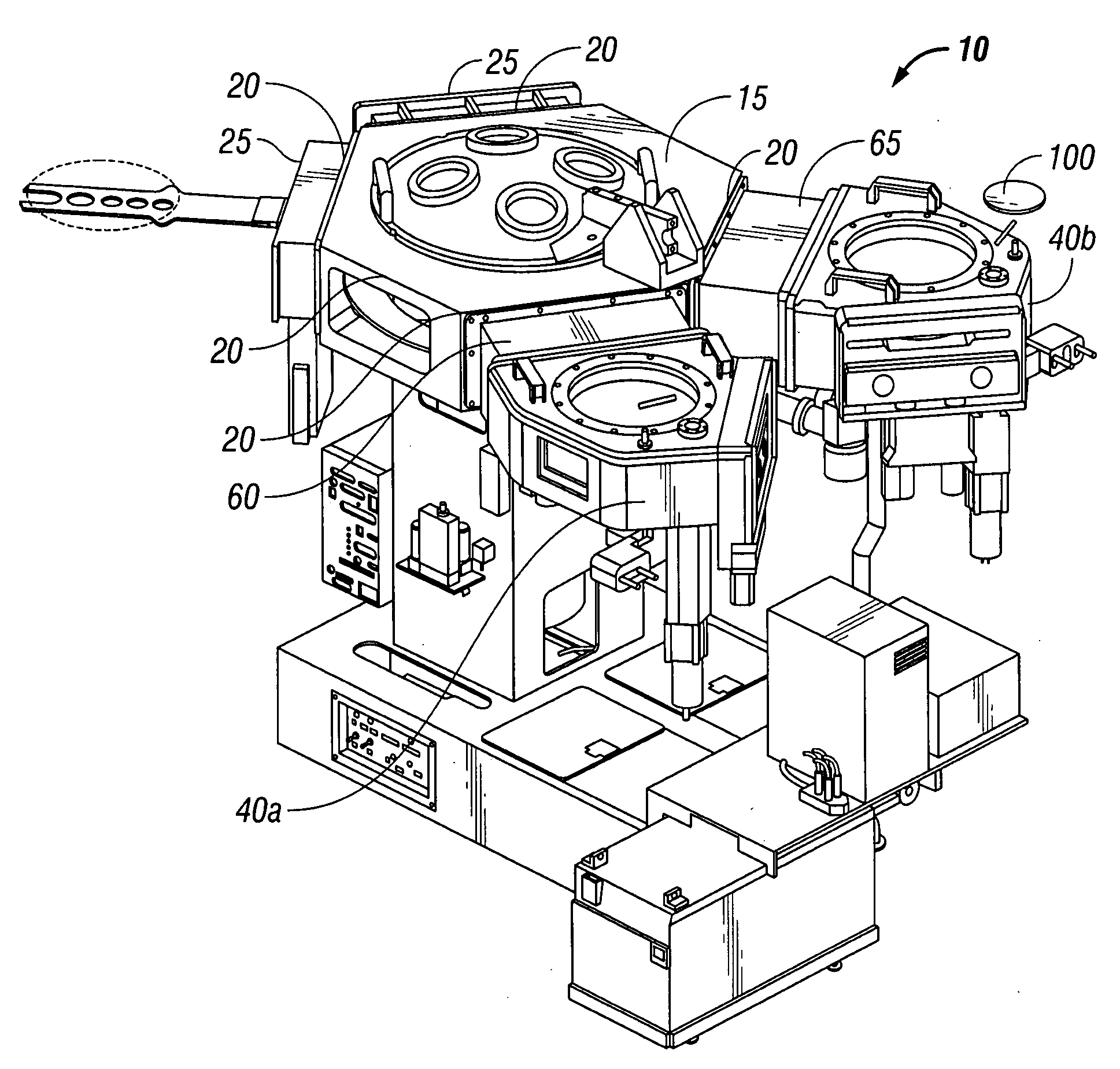

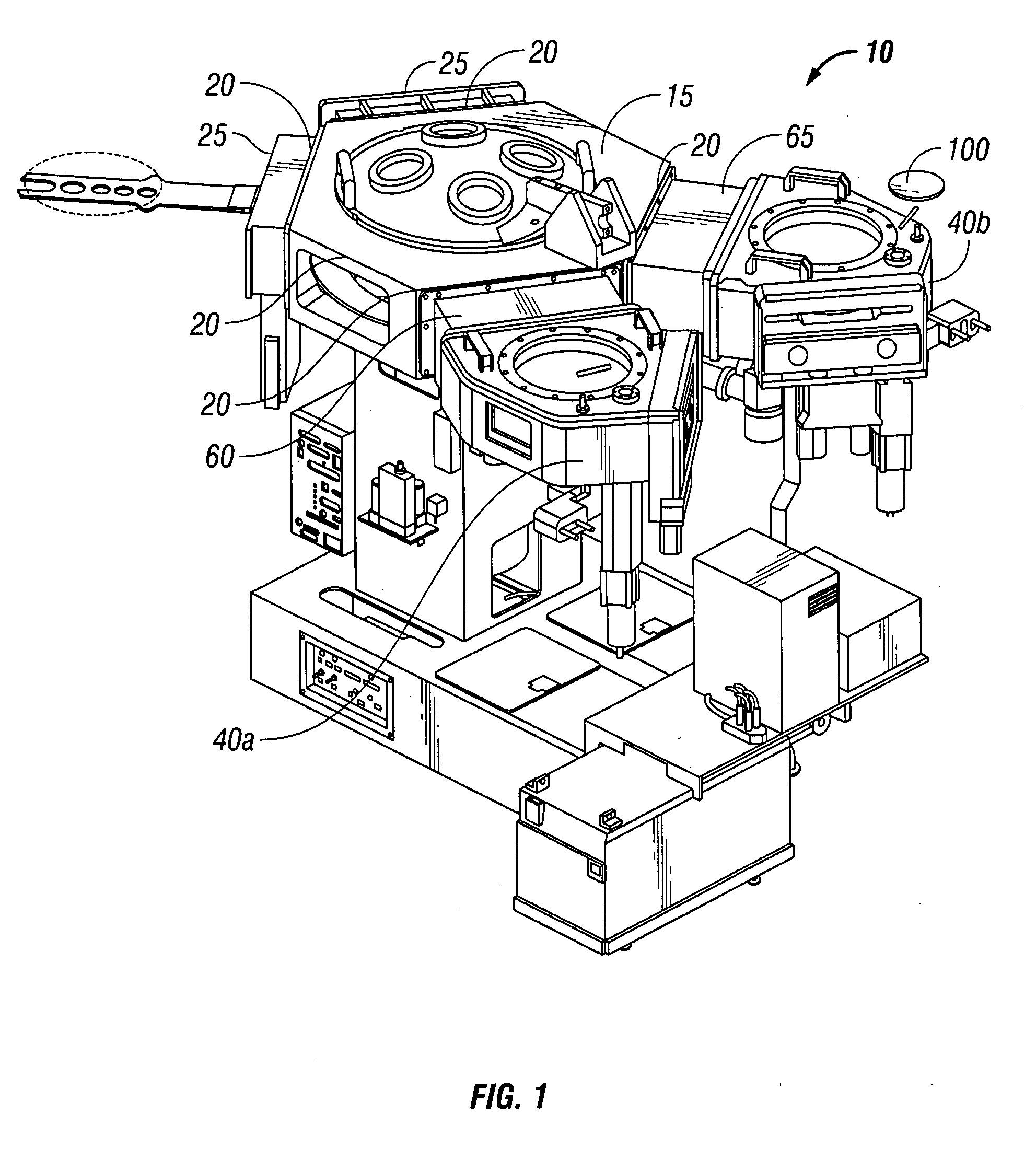

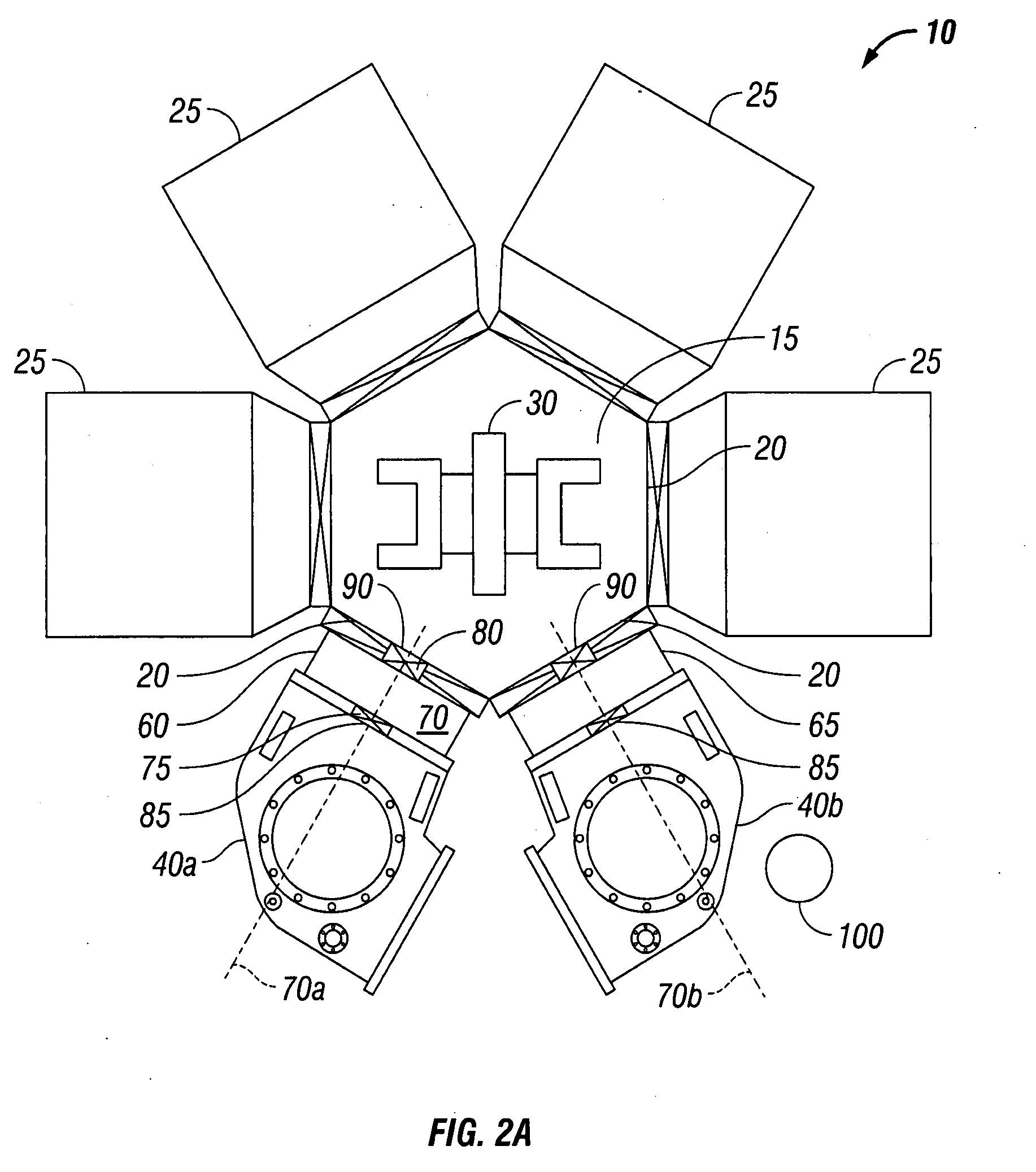

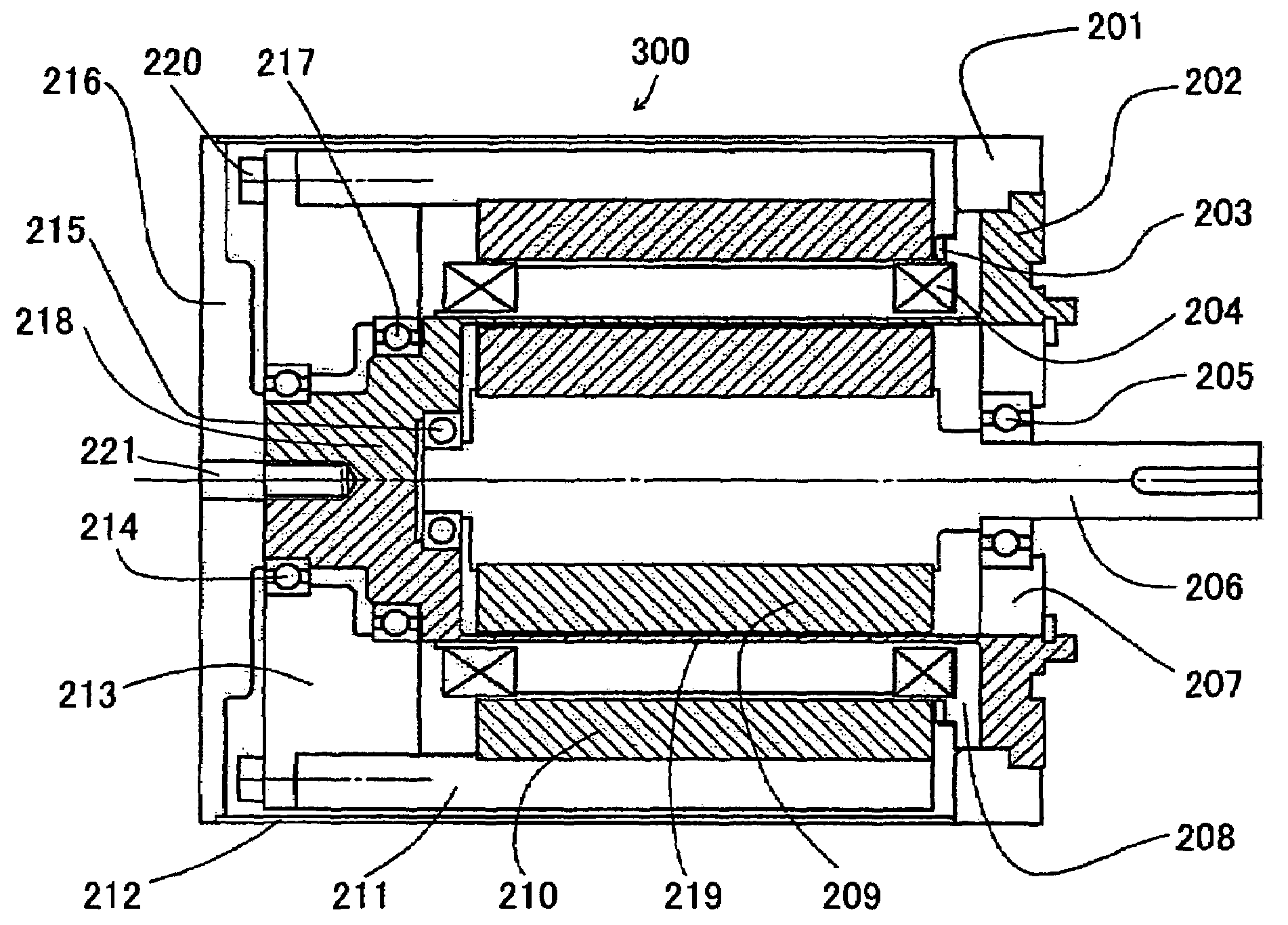

High conductance cryopump for type III gas pumping

ActiveUS20060064990A1High conductanceQuick collectionSolidificationLiquefactionEngineeringRadiation shield

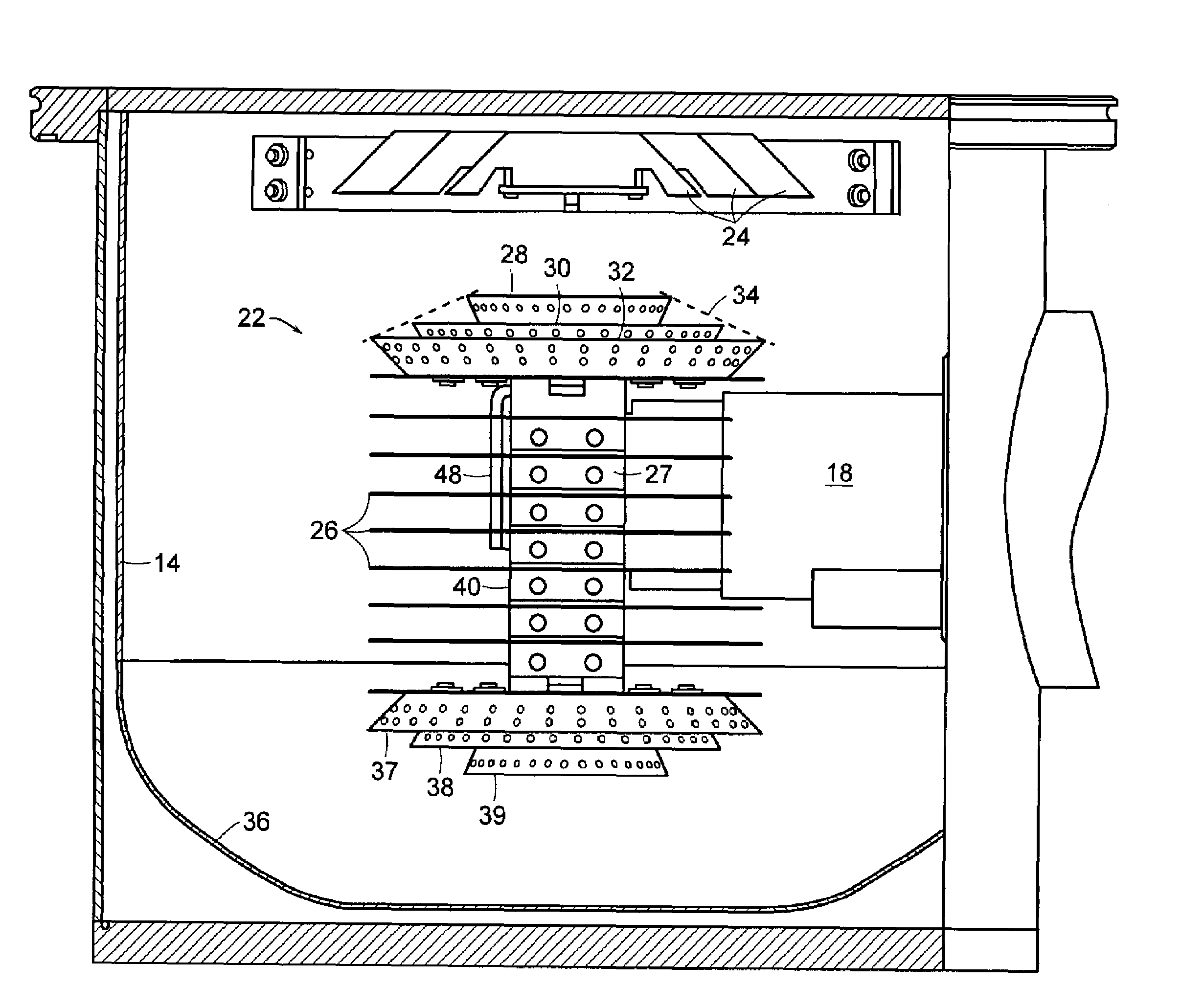

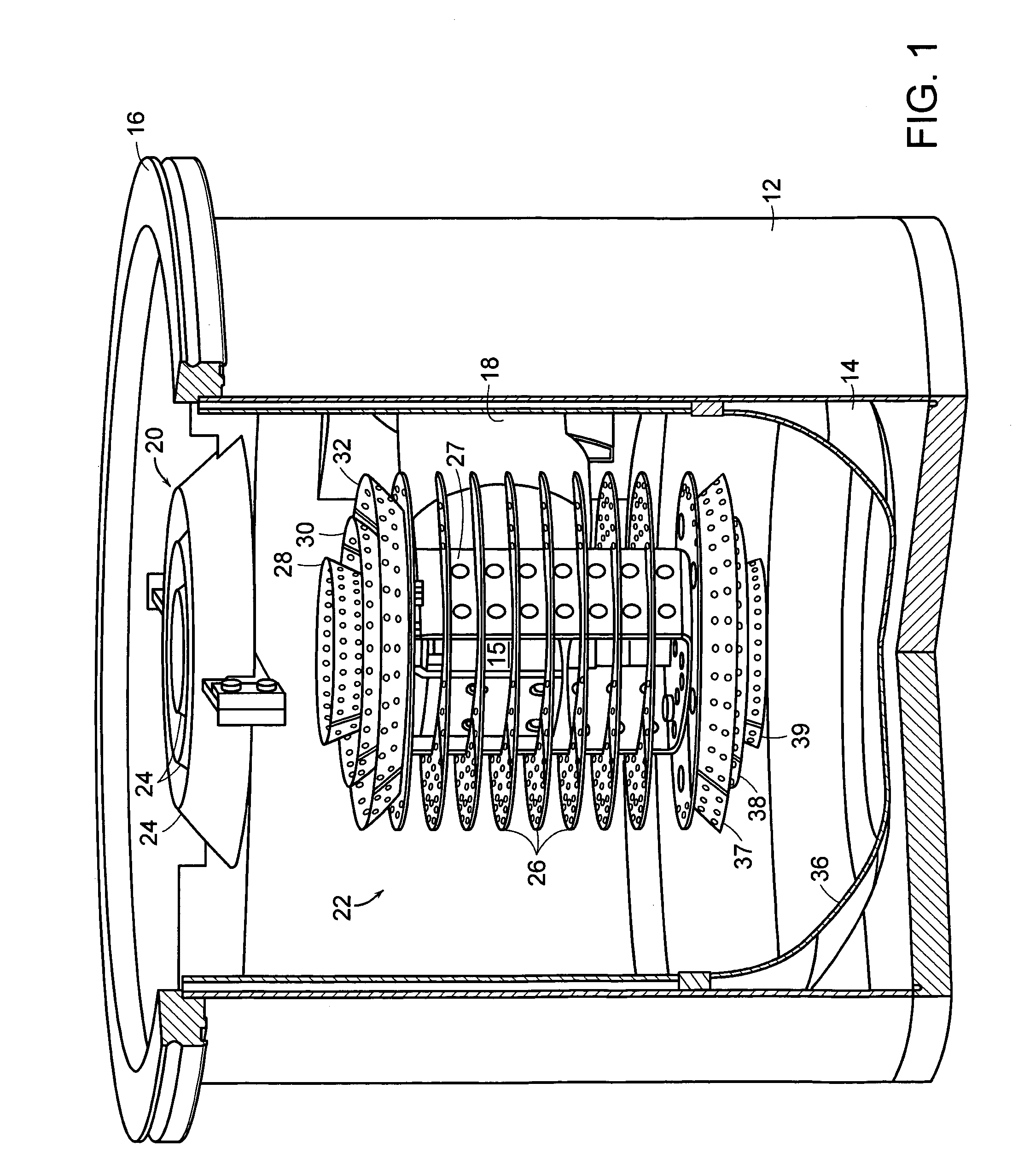

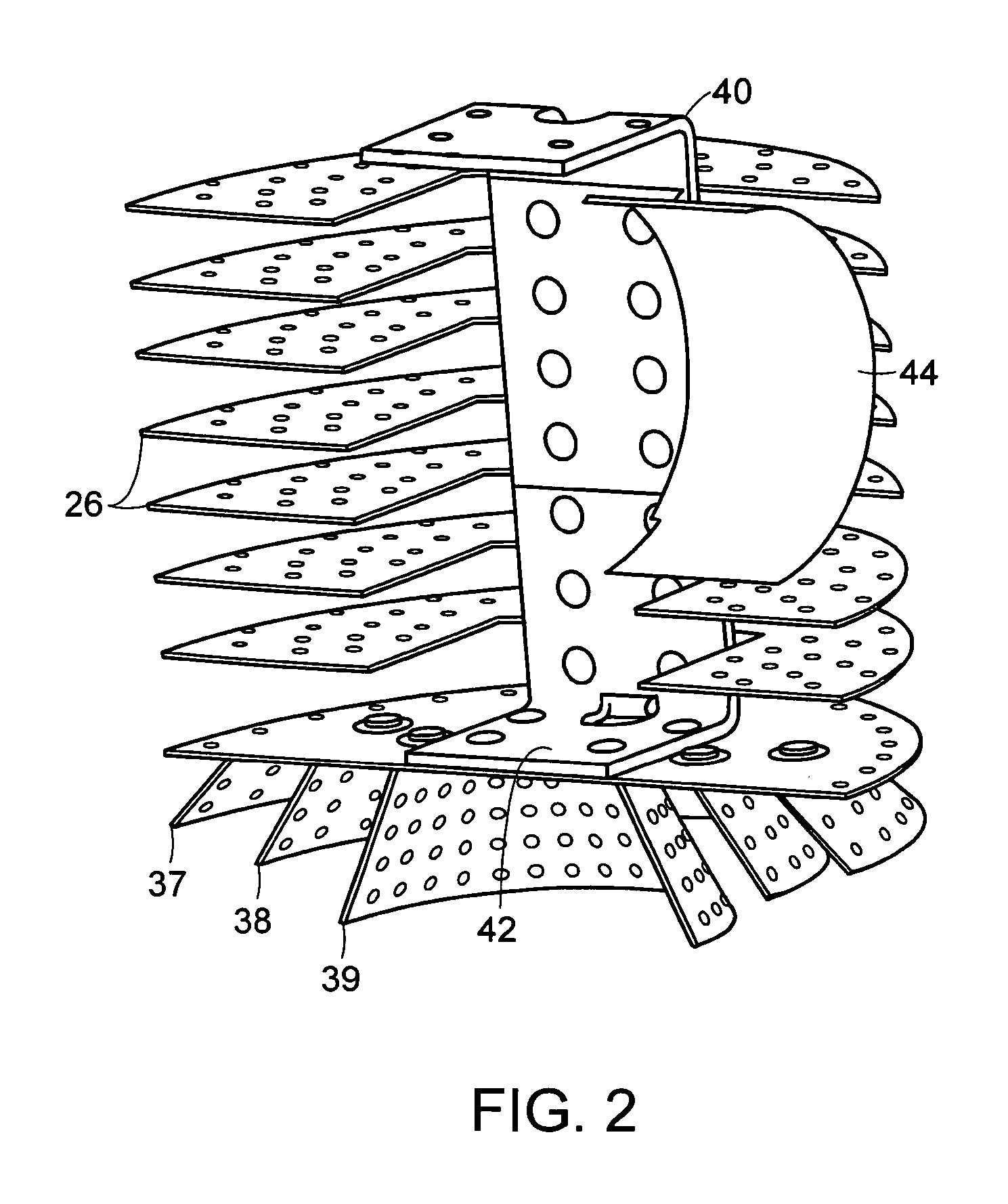

A cryopump provides for high pumping speed of Type III gases. An open configuration of a frontal array provides high conductance of gases into a radiation shield which is shaped to focus gases toward a second stage array. The second stage array has an open configuration of baffles coated with adsorbent. Substantially all of the adsorbent has a direct line of sight to the radiation shield or to the opening in the radiation shield, and substantially all of the baffles are coated with adsorbent. In one form, the second stage cryopump array comprises an array of discs fanned to define a generally ball shaped envelope.

Owner:EDWARDS VACUUM LLC

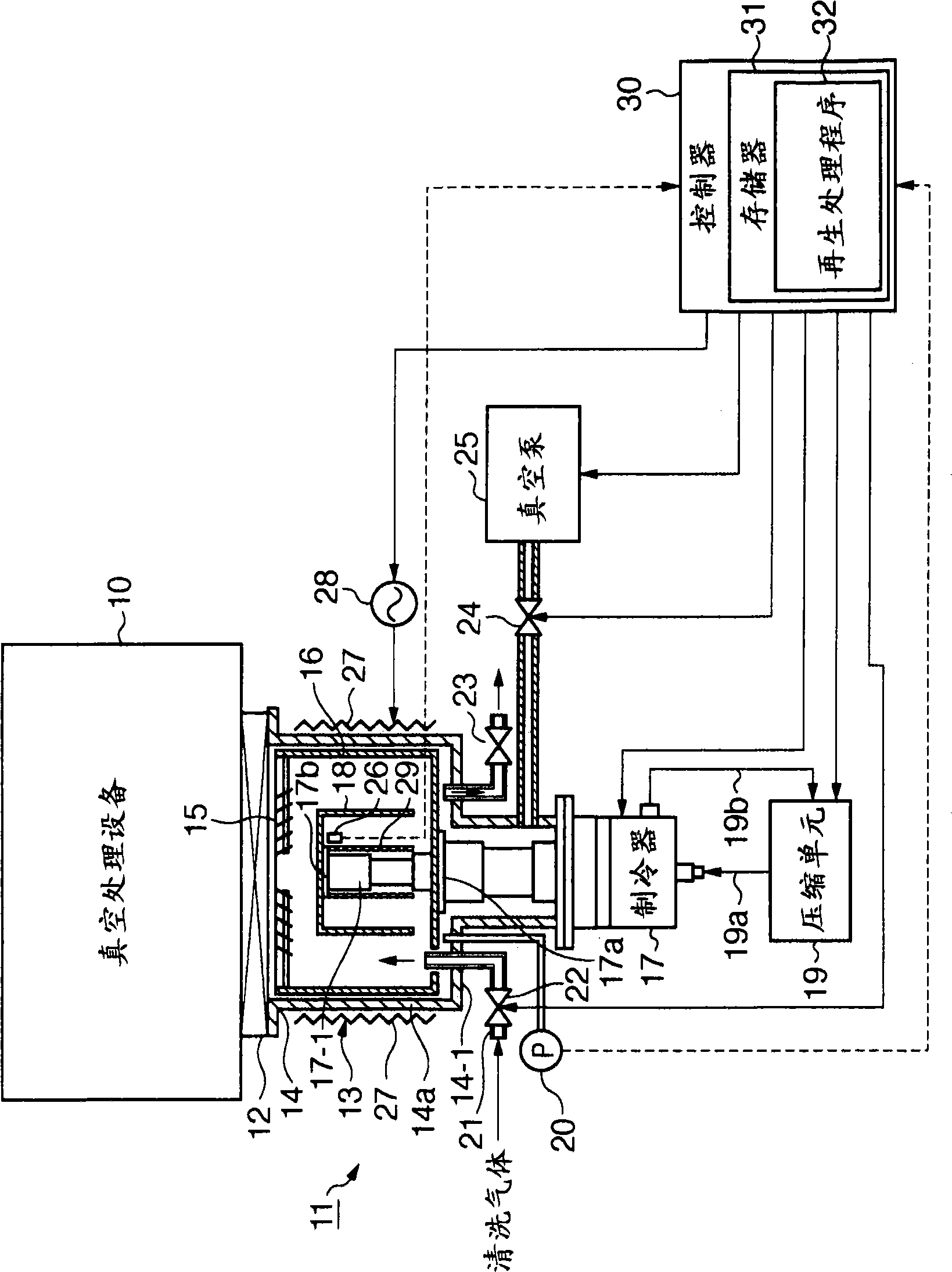

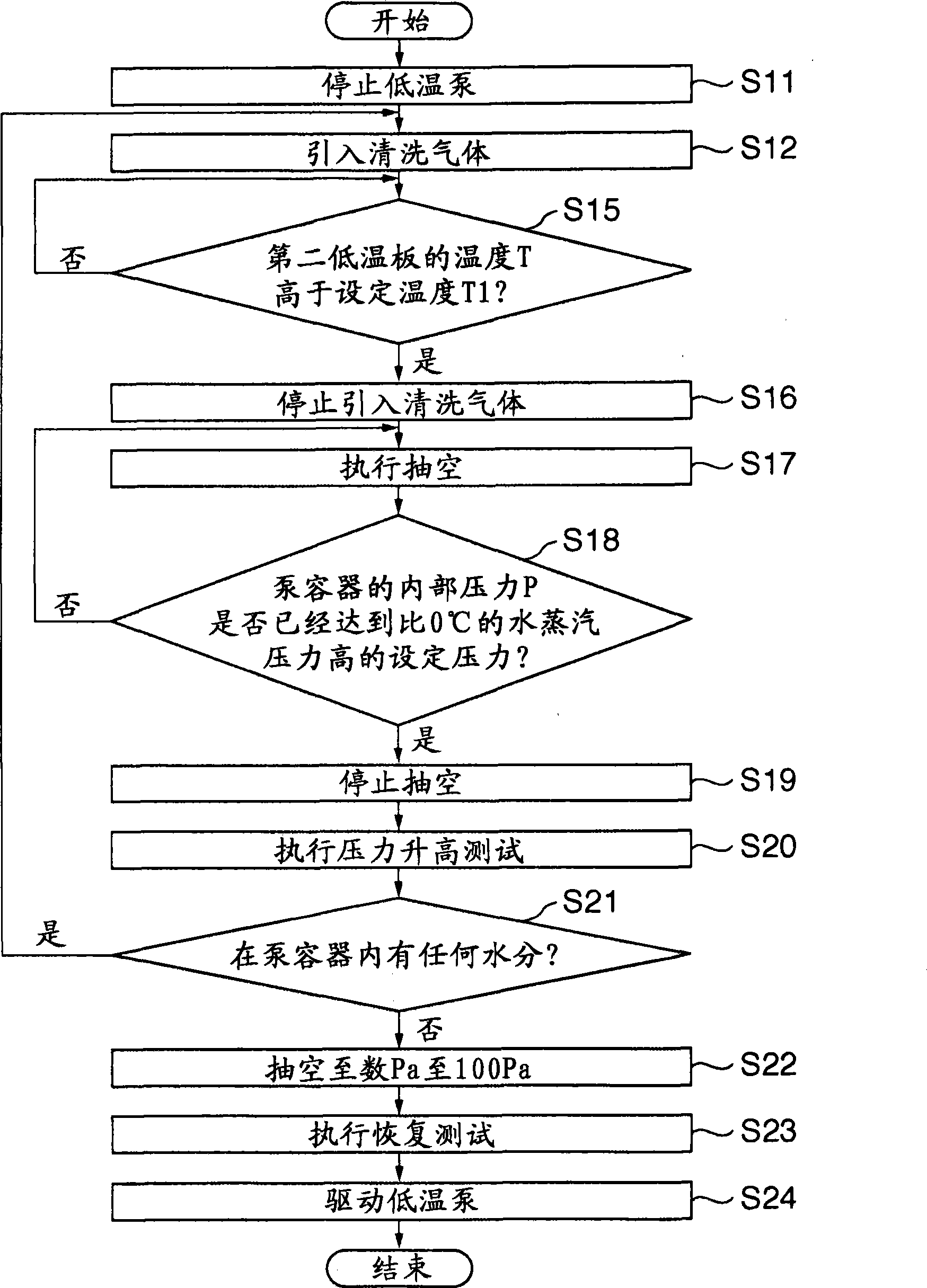

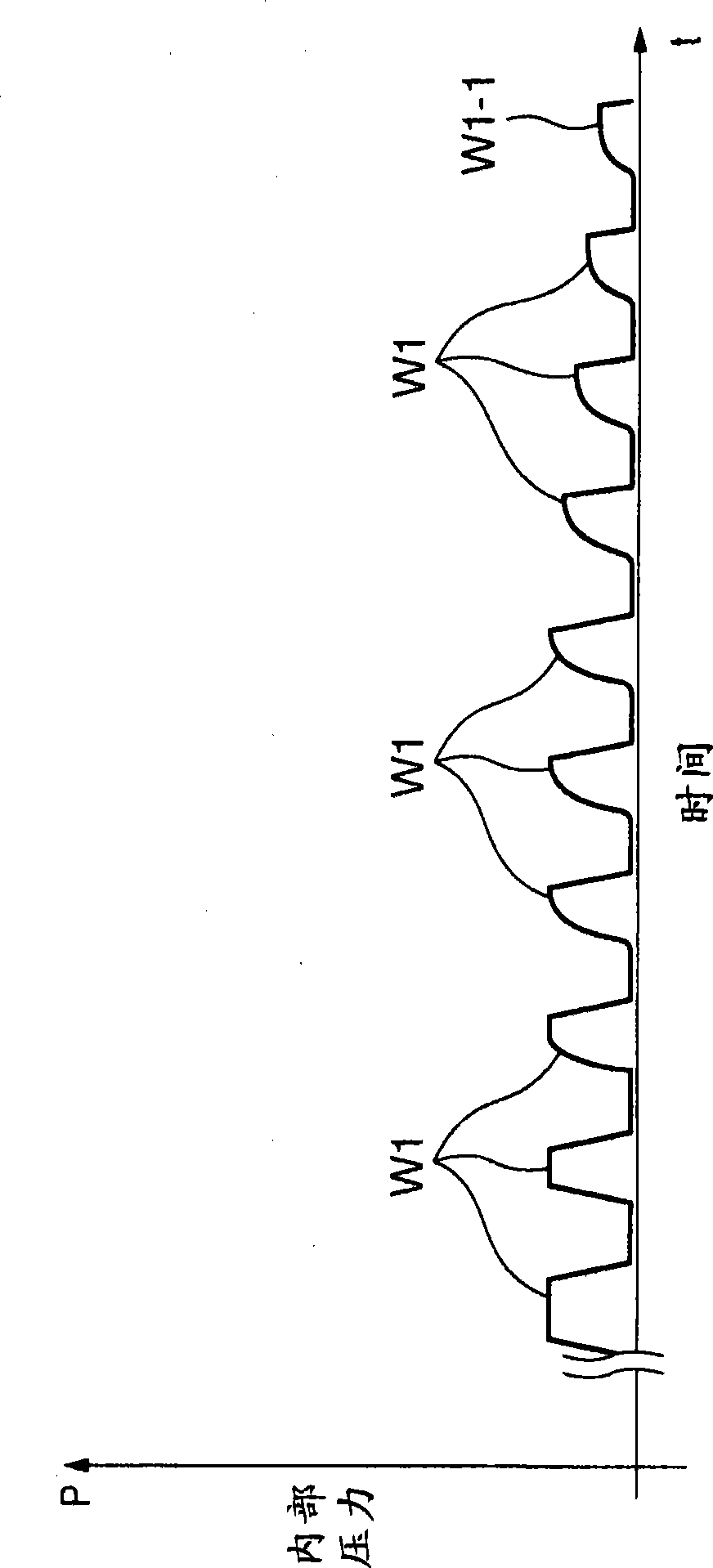

Cryopump, cryopump unit, vacuum processing apparatus including cryopump unit, and cryopump regeneration method

InactiveCN101469689AAccurate observationShort regeneration timePumpsPositive-displacement liquid enginesInternal pressurePressure rise

Owner:CANON ANELVA CORP

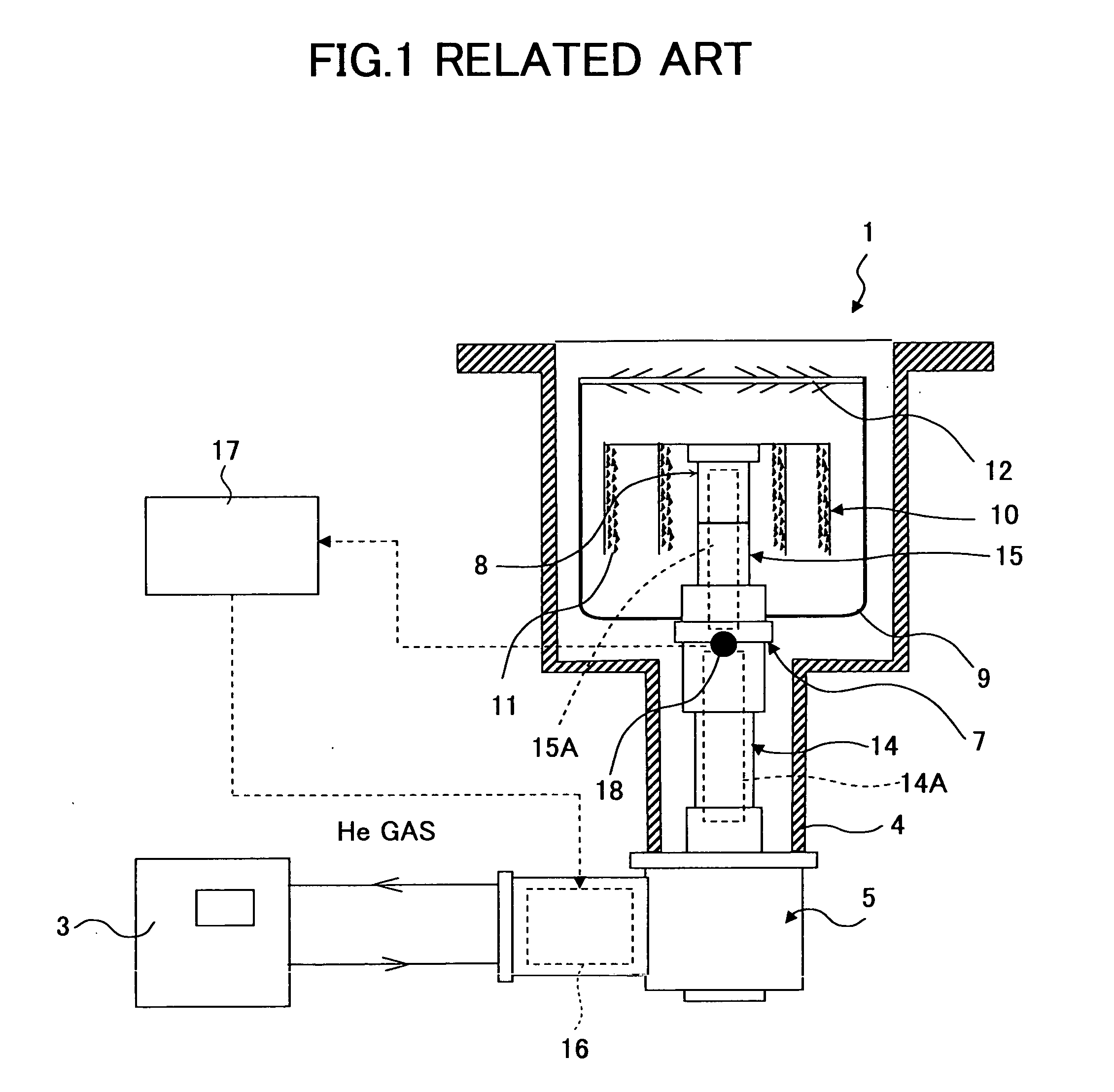

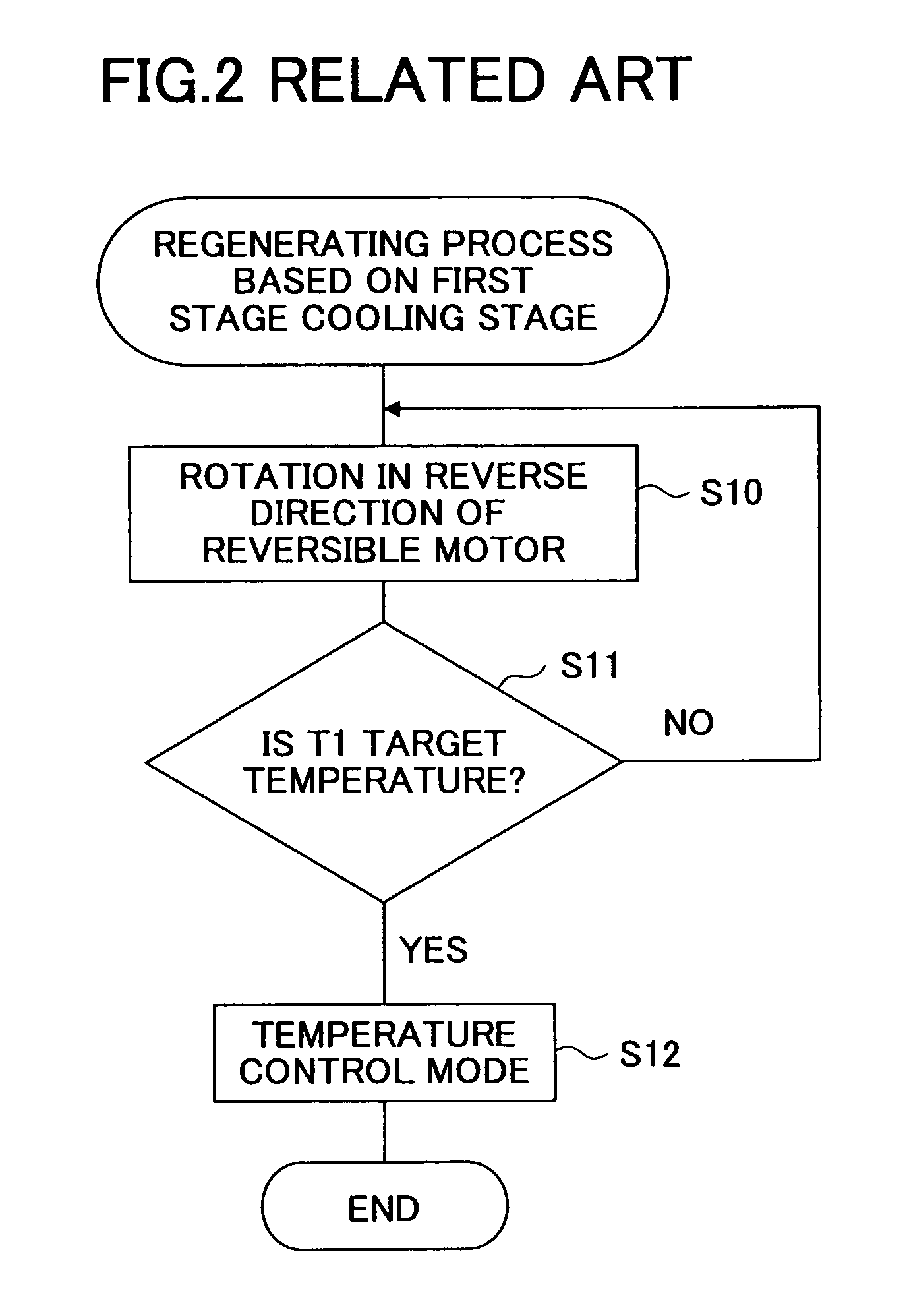

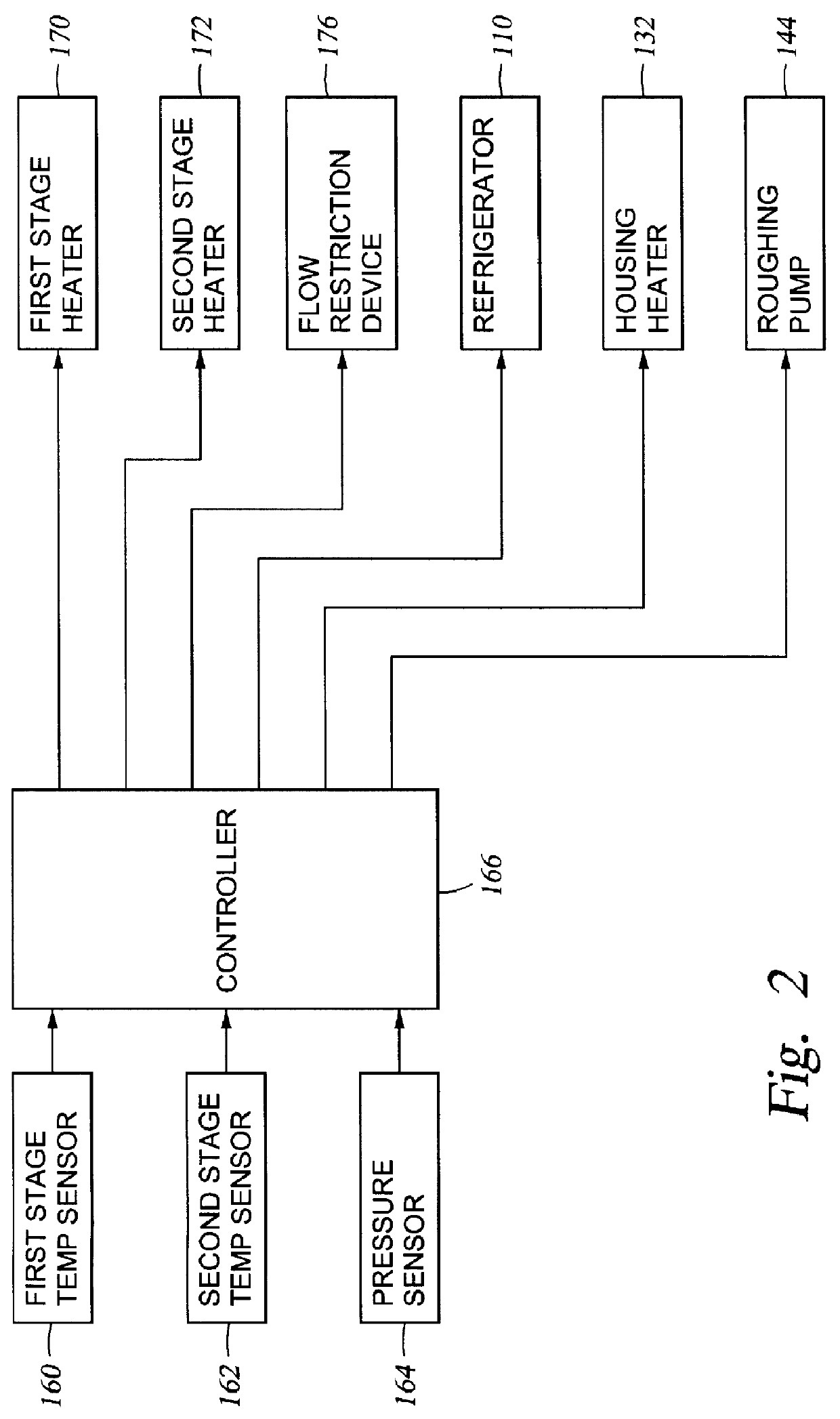

Cryopump and regenerating method of the cryopump

ActiveUS20070256429A1Shorten the timeIncrease temperatureSolidificationLiquefactionEngineeringCryopump

A cryopump and a regenerating method of the cryopump whereby temperatures of a first stage and a second stage can be securely increased to target temperatures and time required for regenerating can be shortened are provided. At the time of regenerating, the temperature of the second stage cooling stage is controlled based on the temperature detected by the second temperature detection part. In the case where the temperature of the first stage cooling stage reaches the limiting temperature, namely critical temperature, of the first stage displacer, the rotation in the reverse direction of the reversible motor is controlled or stopped and thereby the regenerating process is stopped for a while.

Owner:SUMITOMO HEAVY IND LTD

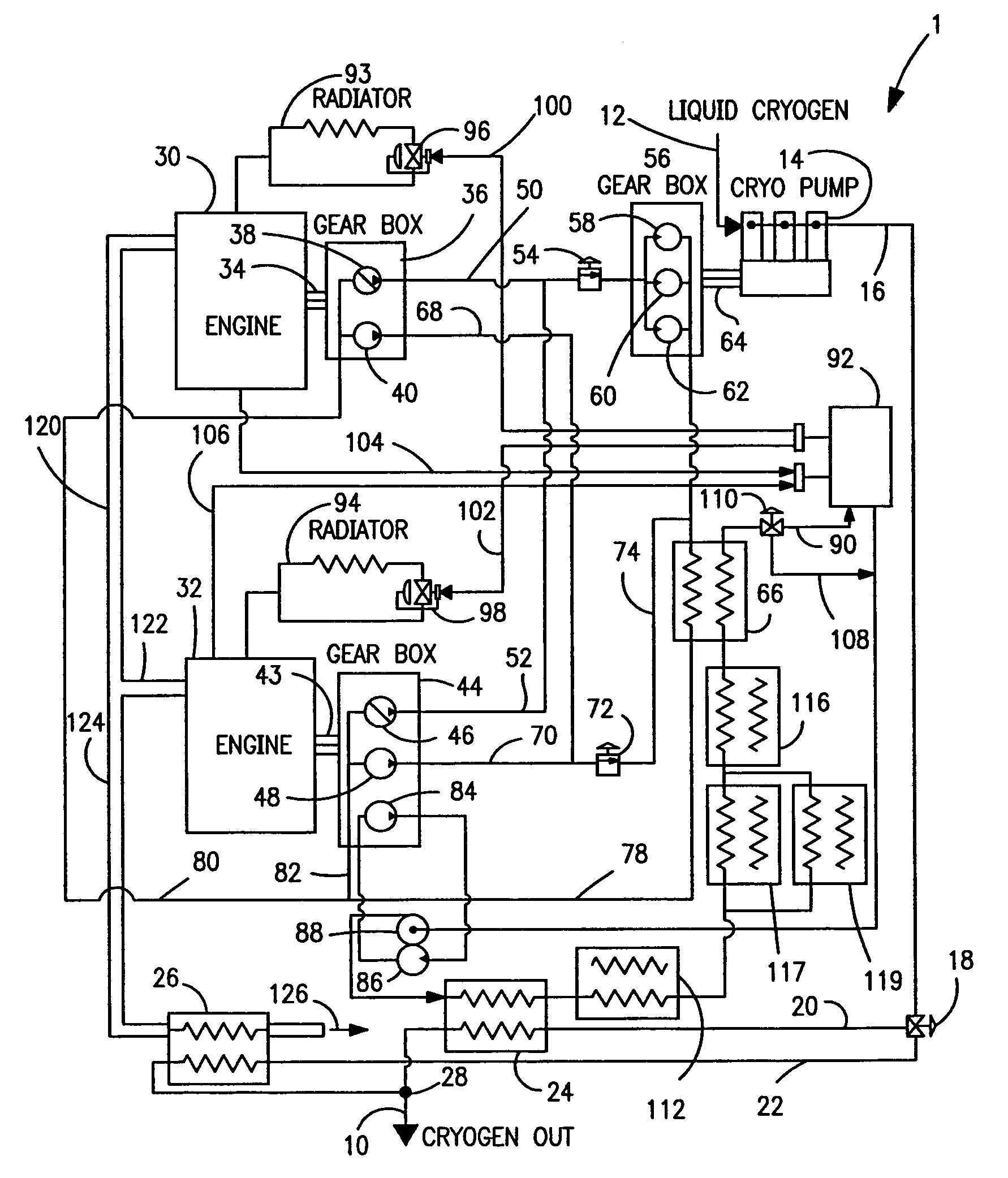

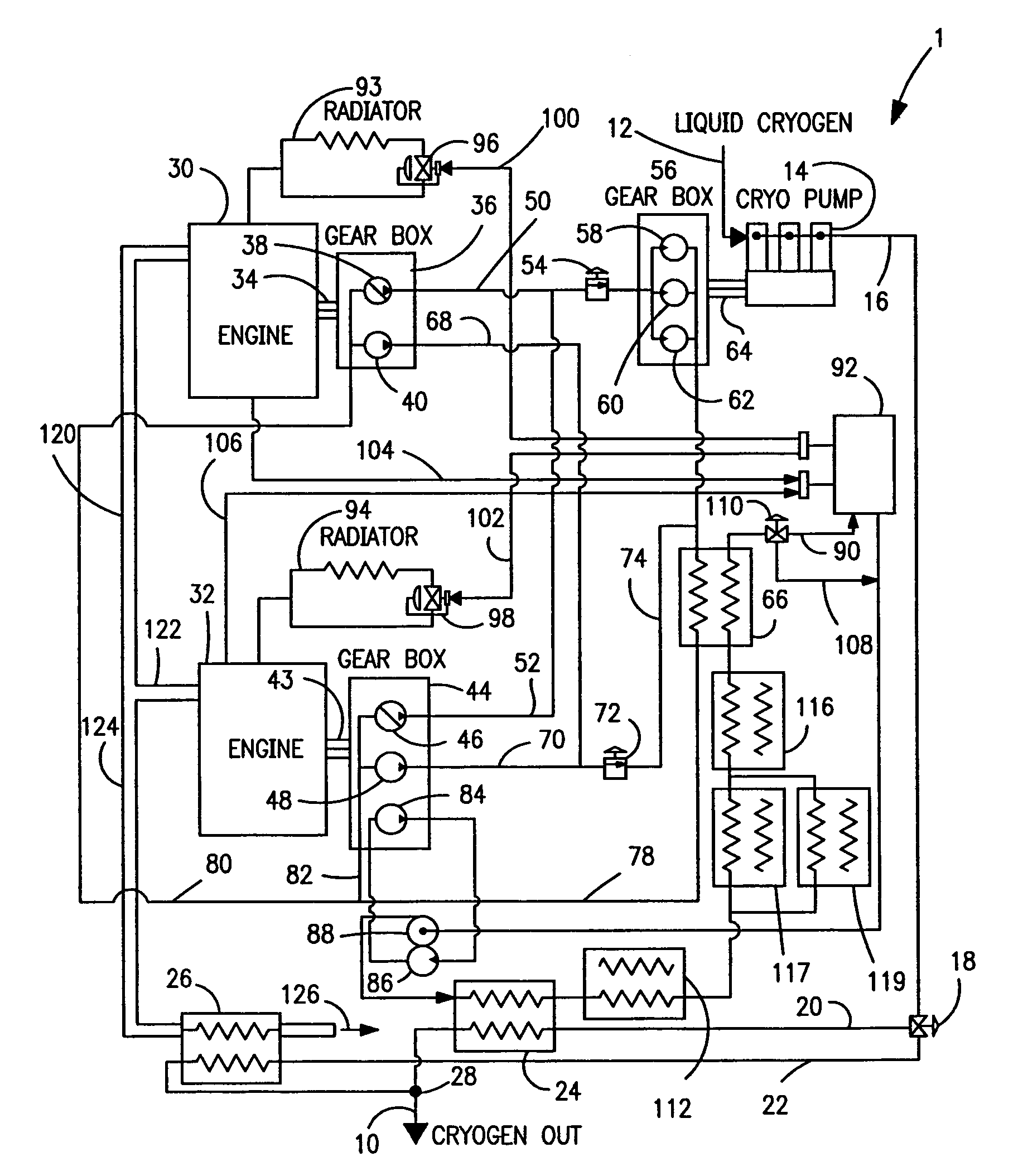

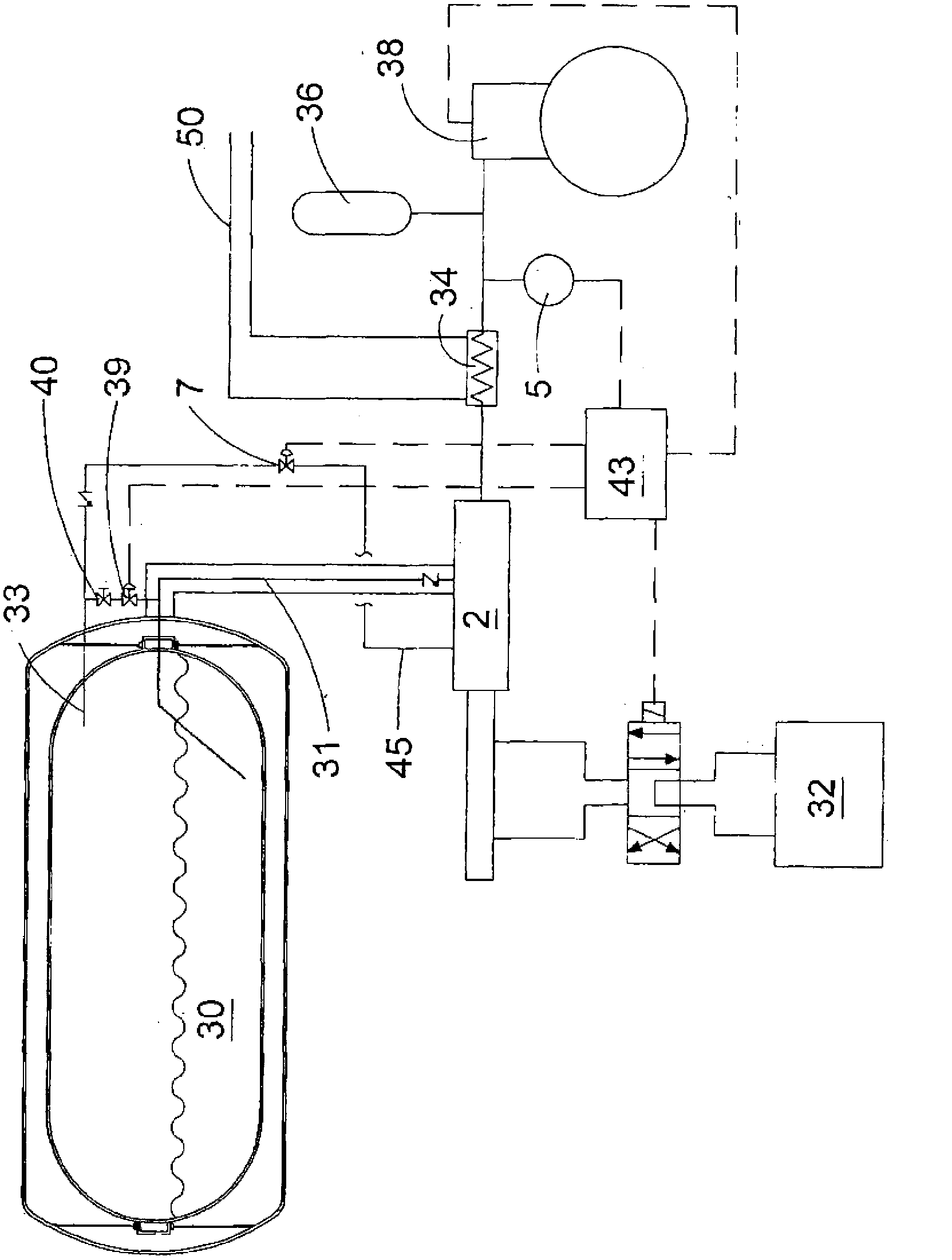

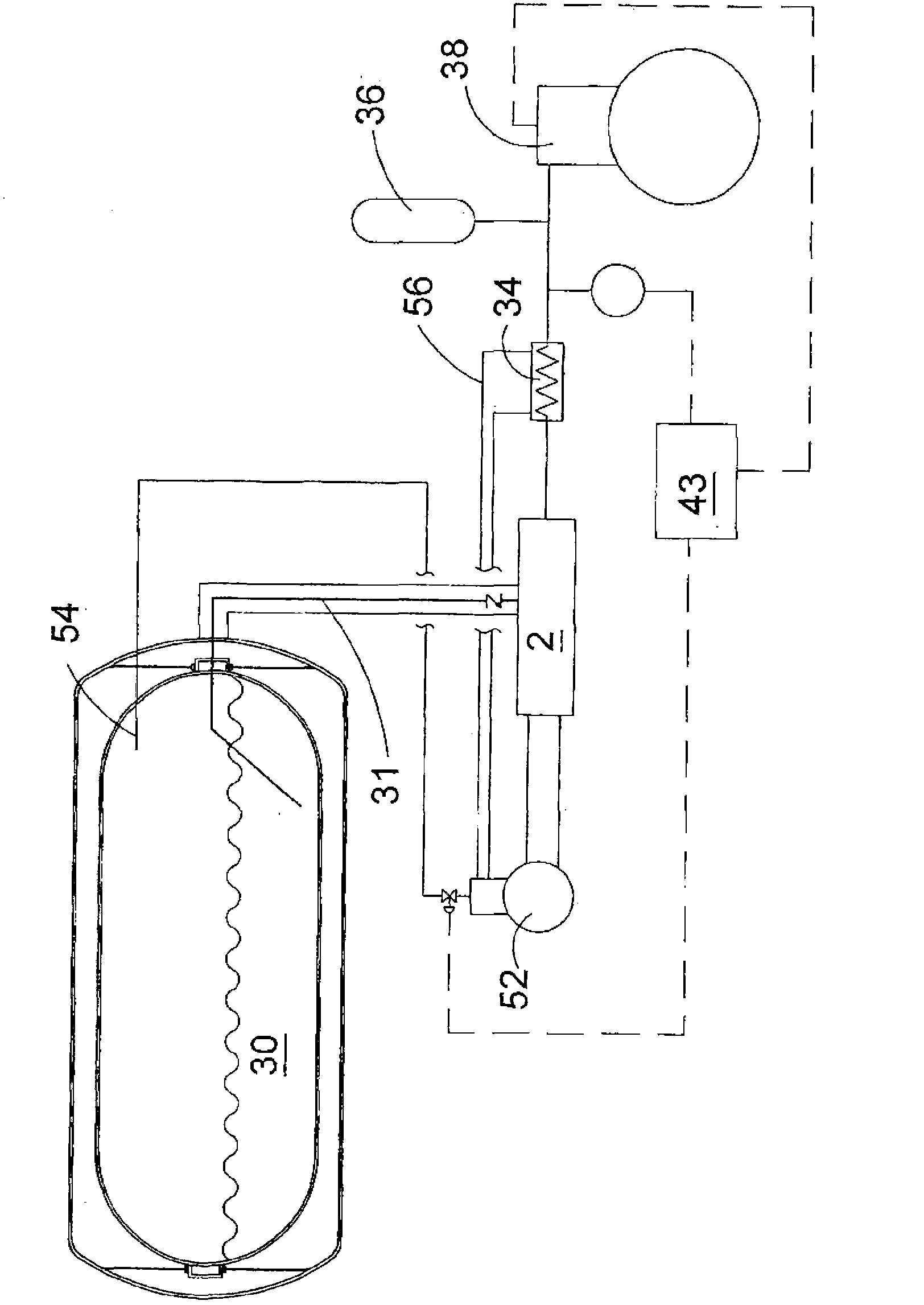

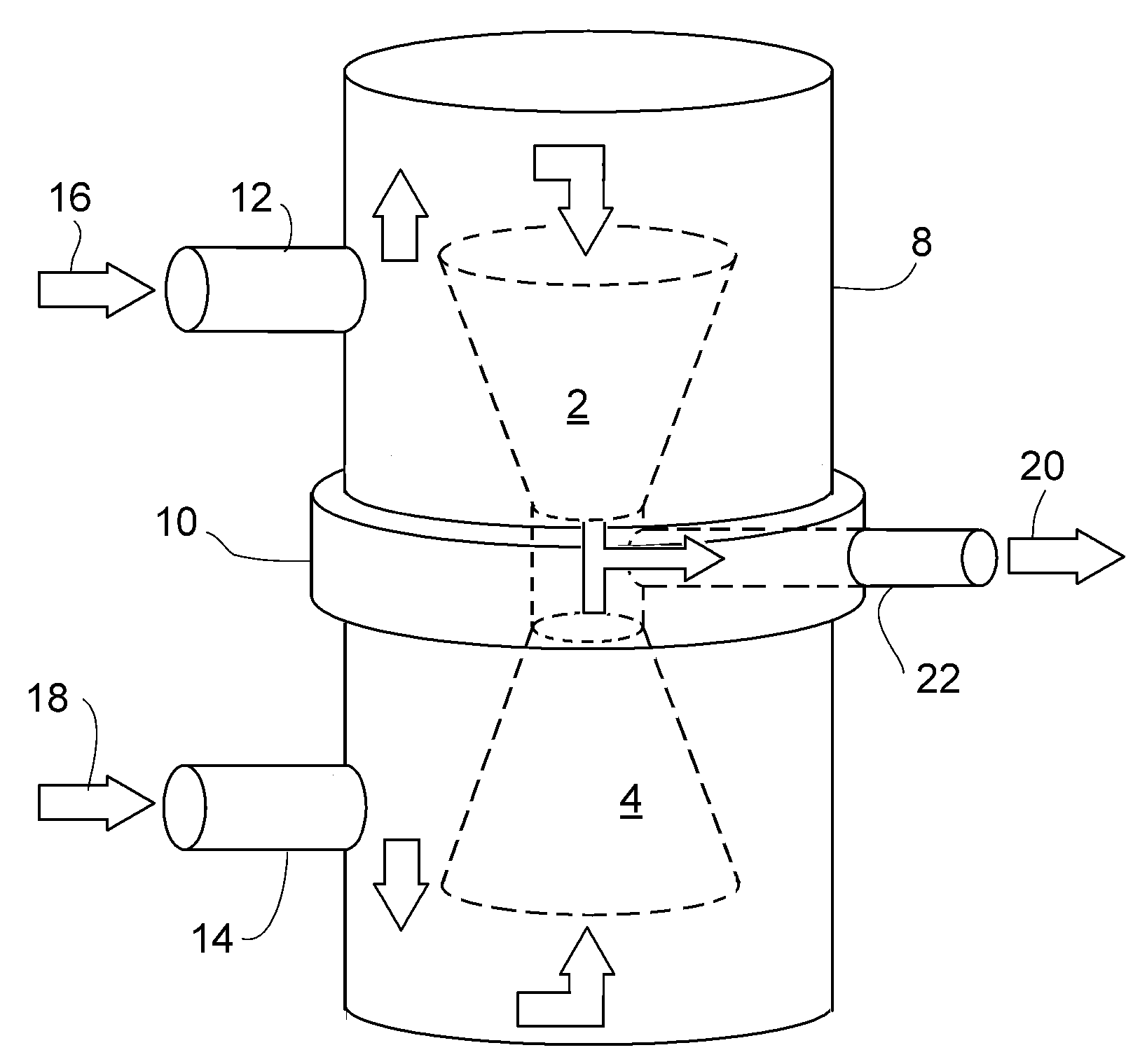

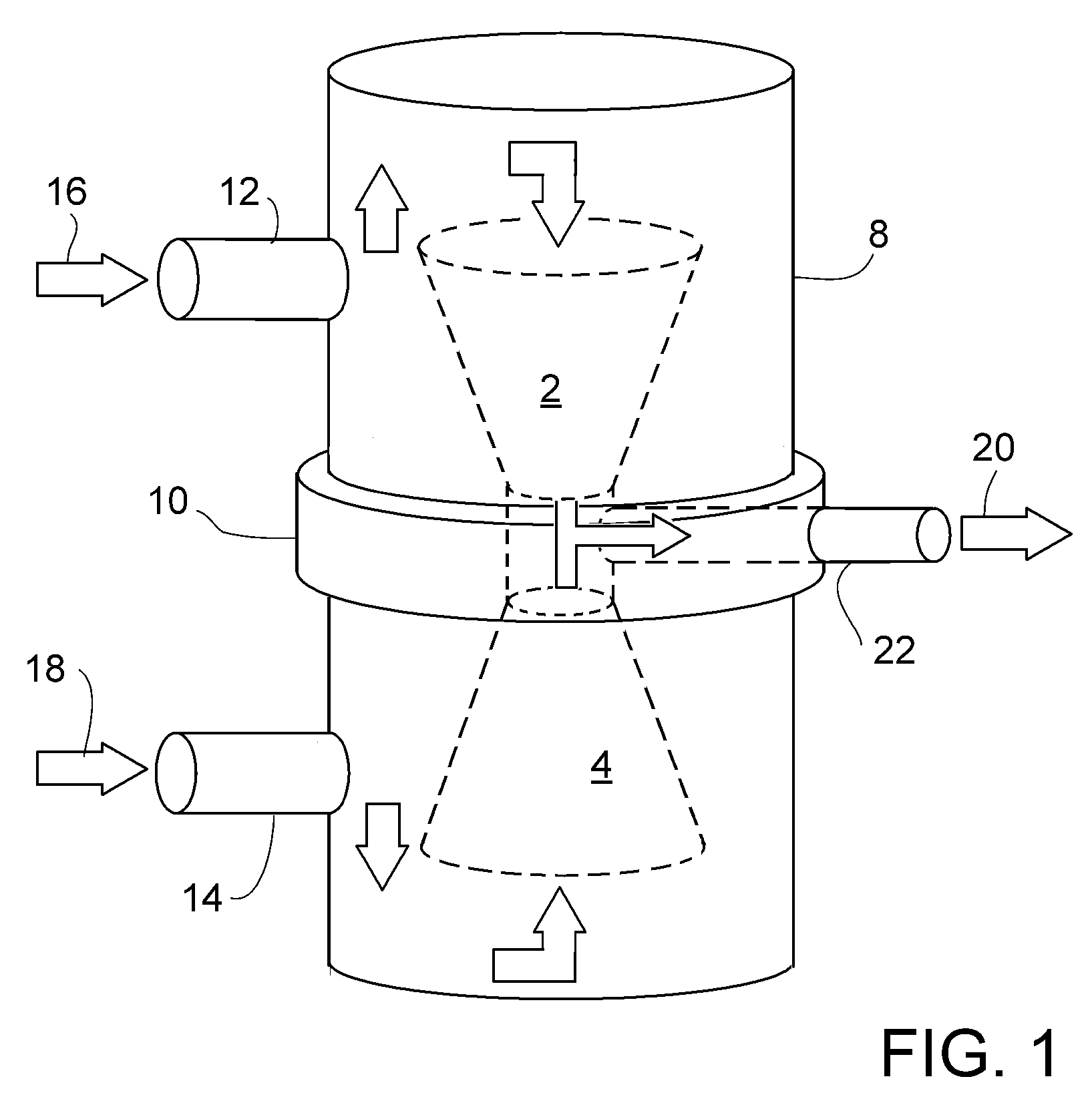

Apparatus and method for producing a pressurized vapor stream

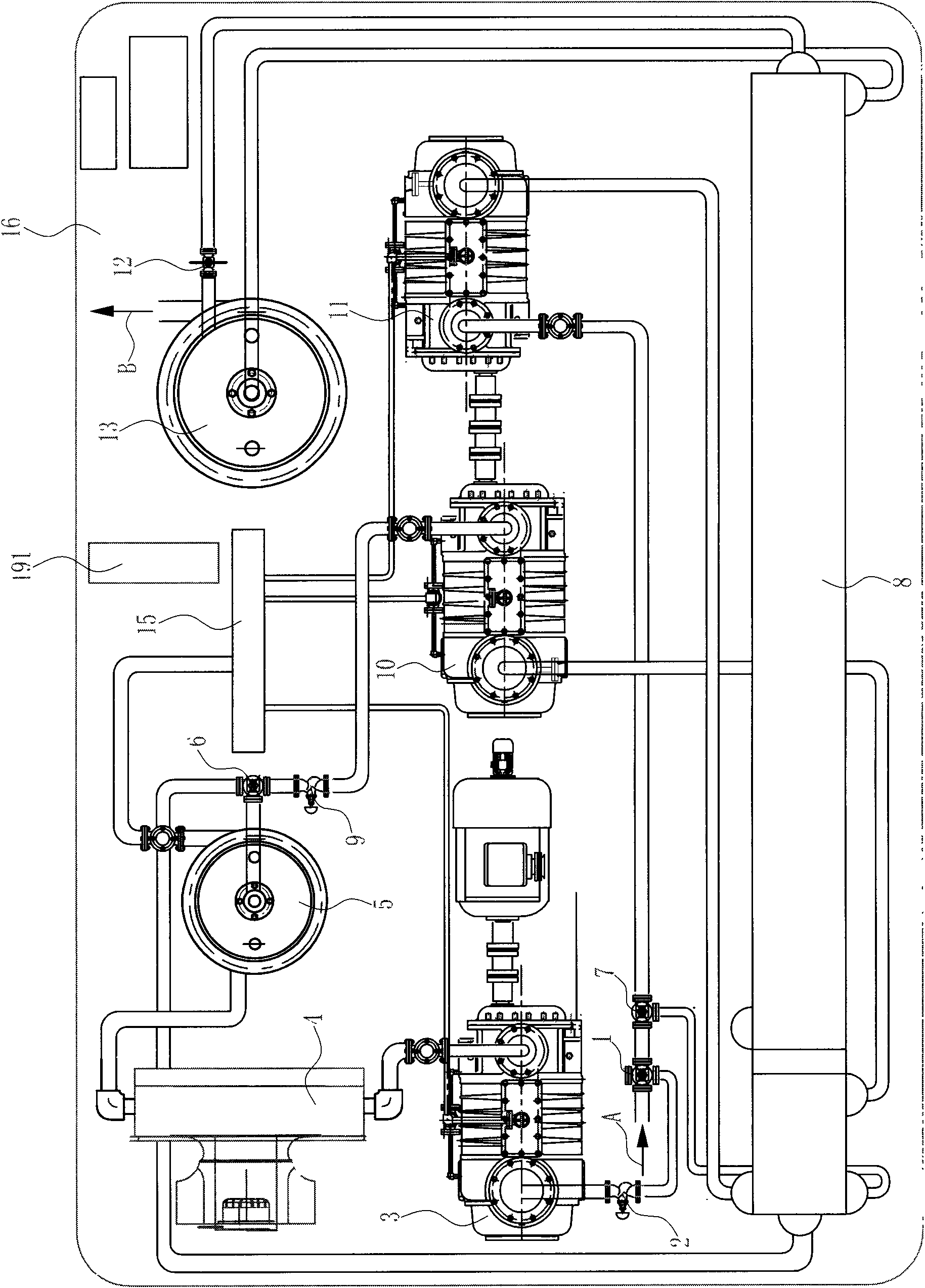

ActiveUS6981850B1Less complex and expensive devicesEasy to controlFluid couplingsContainer filling methodsHydraulic pumpEngineering

A cryogenic stream is pumped by a cryopump and then vaporized in a vaporizer to produce the pressurized vapor stream. The cryopump is driven by a transmission that is in turn driven by a hydraulic fluid. The hydraulic fluid flows within a hydraulic fluid circuit having first and second hydraulic fluid flow paths. The first of the flow paths is used to drive the hydraulic transmission. The second of the flow paths is dedicated to raising heat. Hydraulic fluid is circulated within the flow path by hydraulic fluid pumps and the amount of heat generated is controlled by adjustable back pressure valves. The adjustable back pressure valves in both fluid flow paths can be adjusted to control the degree to which heat is added to the vaporizer and therefore the pressurized vapor stream. The hydraulic fluid pumps can be driven by diesel engines. Heat may also be recovered from the diesel engines and gear oil used in pumps and the cryopump to also help vaporize the pressurized liquid stream. The aforesaid system of first and second pumps driven by an engine and first and second flow paths can be replicated to allow for expansion of pumping capacity.

Owner:PRAXAIR TECH INC +1

High conductance cryopump for type iii gas pumping

A cryopump provides for high pumping speed of Type III gases. An open configuration of a frontal array provides high conductance of gases into a radiation shield which is shaped to focus gases toward a second stage array. The second stage array has an open configuration of baffles coated with adsorbent. Substantially all of the adsorbent has a direct line of sight to the radiation shield or to the opening in the radiation shield, and substantially all of the baffles are coated with adsorbent. In one form, the second stage cryopump array comprises an array of discs fanned to define a generally ball shaped envelope.

Owner:EDWARDS VACUUM LLC

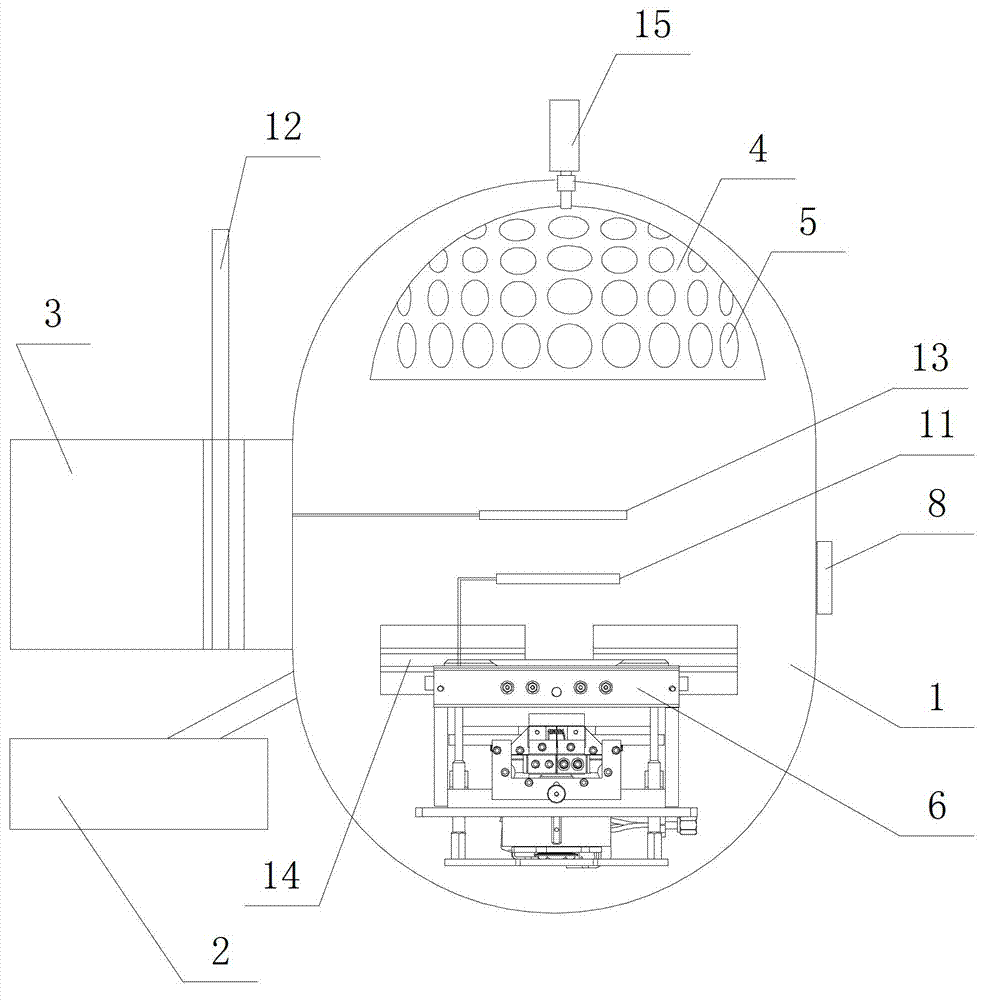

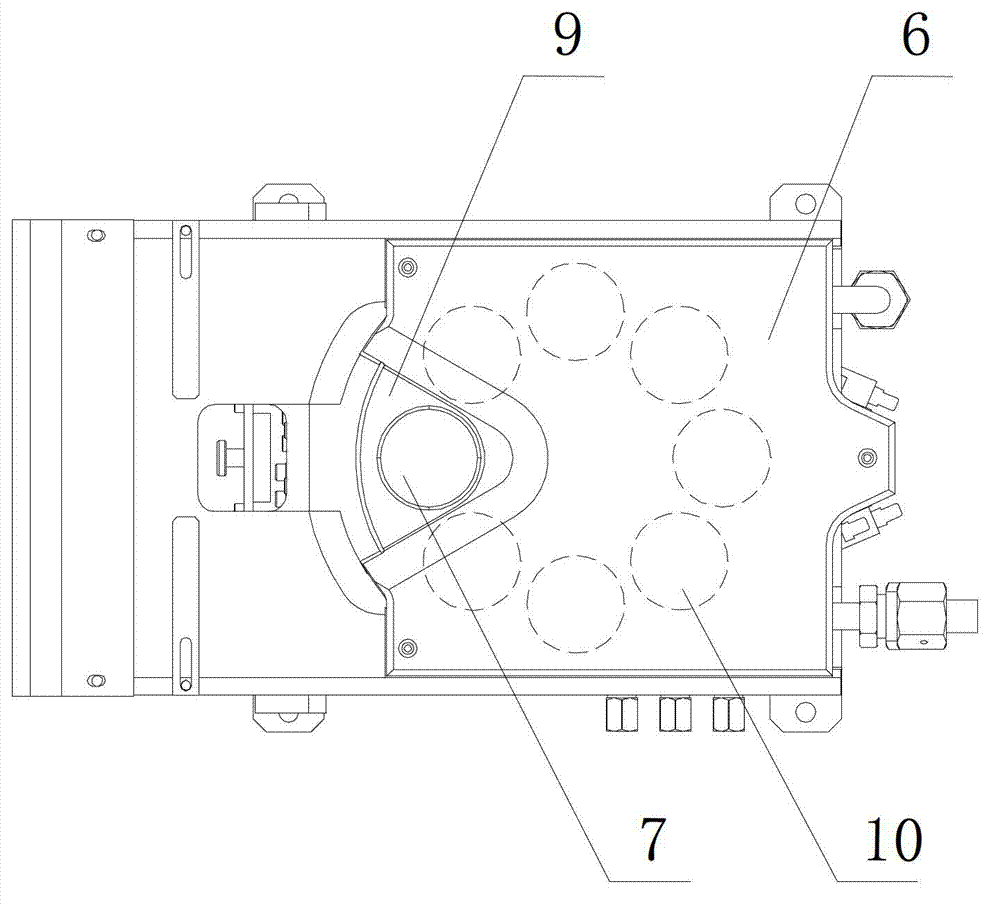

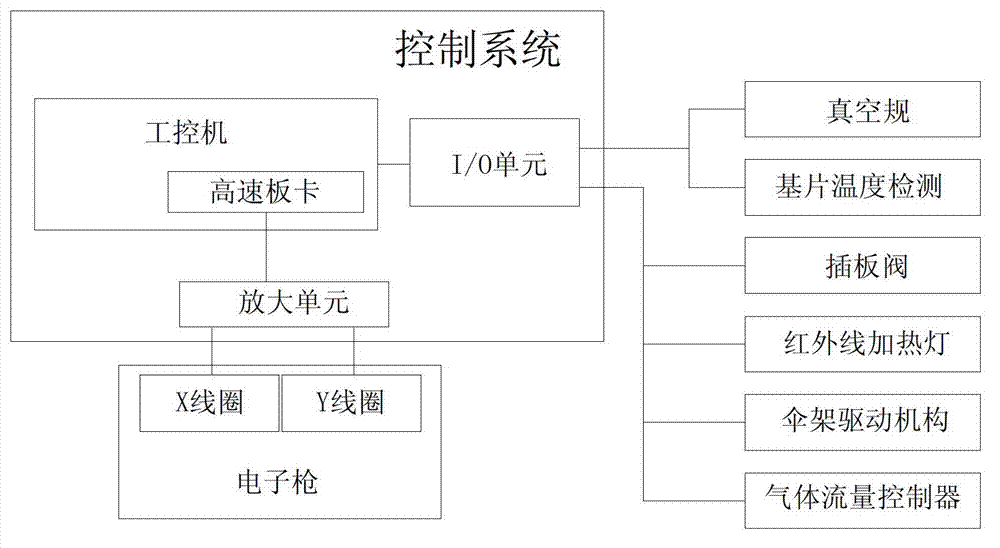

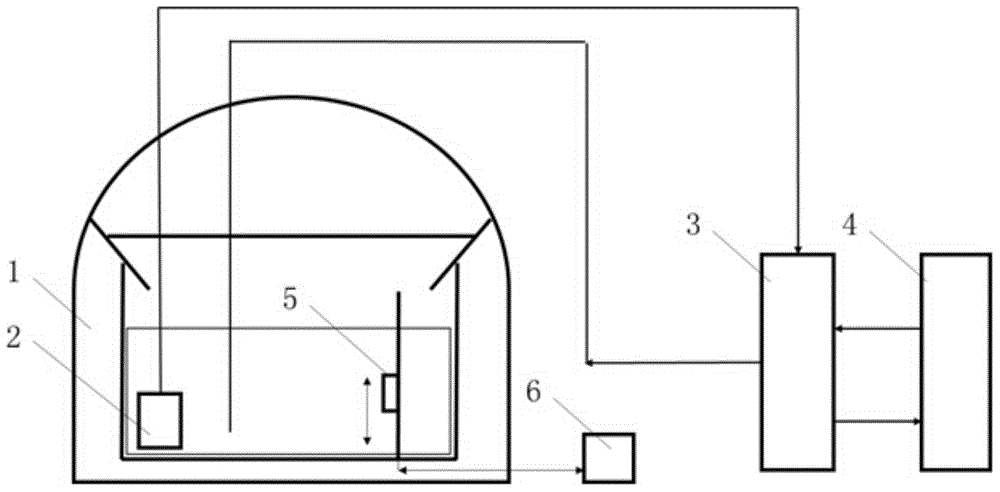

Vacuum coating device, vacuum coating control system and control method

ActiveCN102787299AAvoid damageAvoid scrappingVacuum evaporation coatingSputtering coatingEvaporationEngineering

The invention discloses a vacuum coating device, a vacuum coating control system and a control method. The vacuum coating device comprises a vacuum chamber, a vacuum pump and a cryogenic pump. The top of the vacuum cavity is provided with an umbrella frame, and a substrate to be coated is placed on the umbrella frame; the vacuum cavity is provided with an e-type electron gun, which is provided with crucibles in a circle and capable of rotating around the center of the circle; a crucible is provided with a coating material; a baffle is arranged above a crucible heating position; and a pipe connecting the cryogenic pump and the vacuum chamber is provided with a flapper valve. According to the invention, a zoning control principle is applied to trajectory control of electron beam from the electron gun; current frequencies of an X axis scanning coil and a Y axial scanning coil in each zone are respectively controlled, thereby further controlling scan time of the electron beam in each block on the surface of the coating material. The invention avoids pit phenomenon caused by uneven evaporation of an oxide material, and effectively prevents crucible damage or substrate scrapping.

Owner:HANGZHOU DAHE THERMO MAGNETICS CO LTD

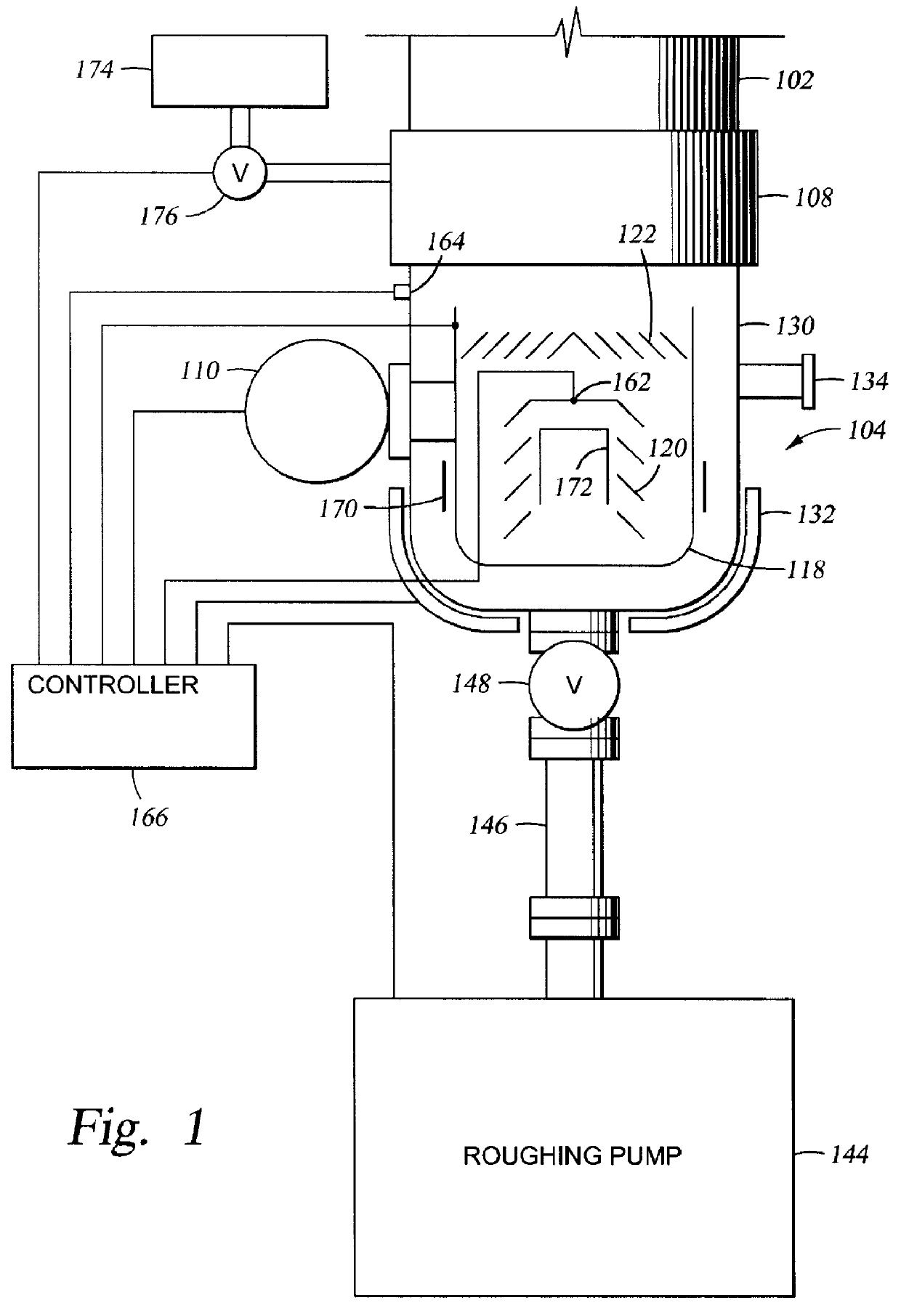

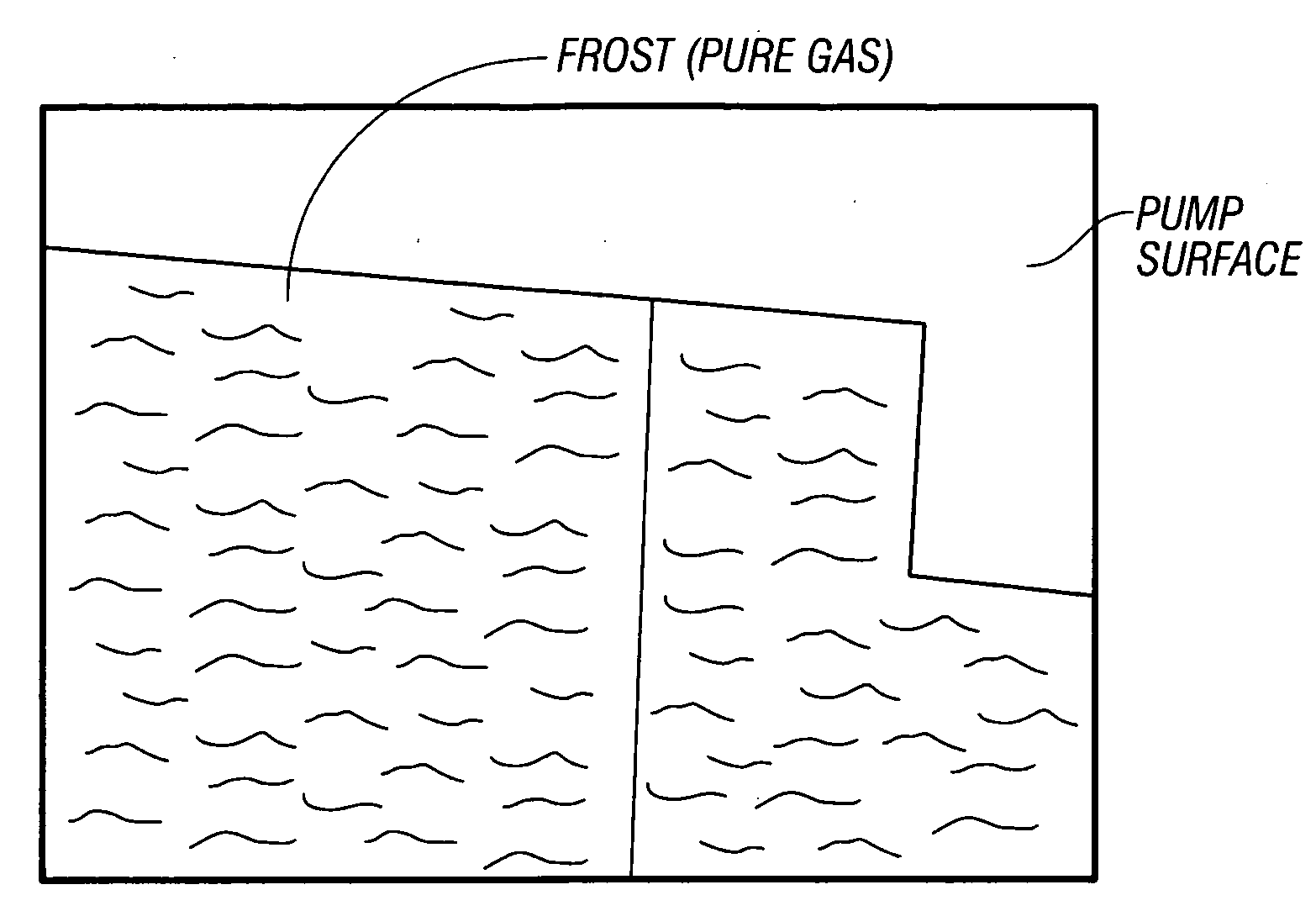

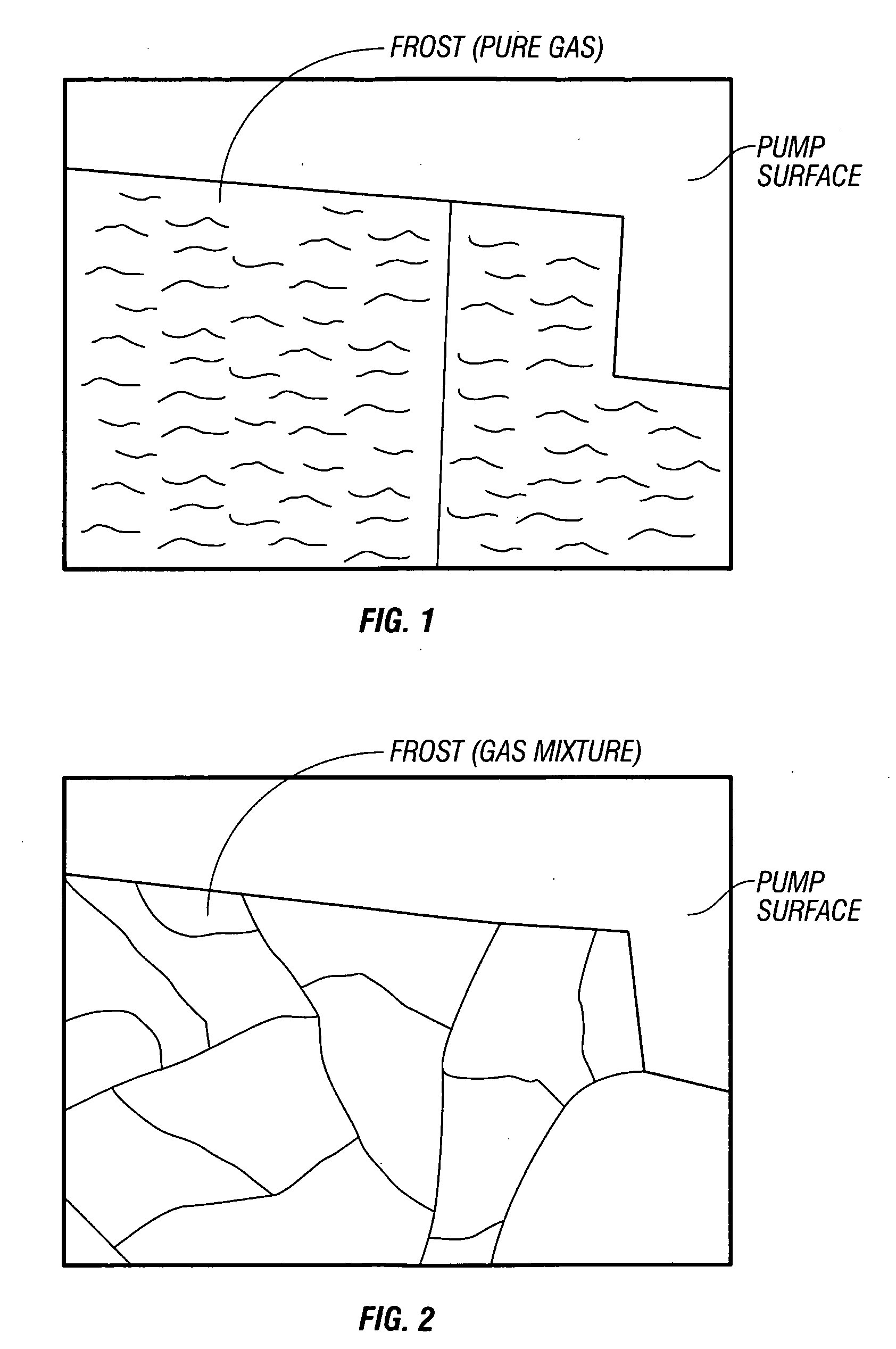

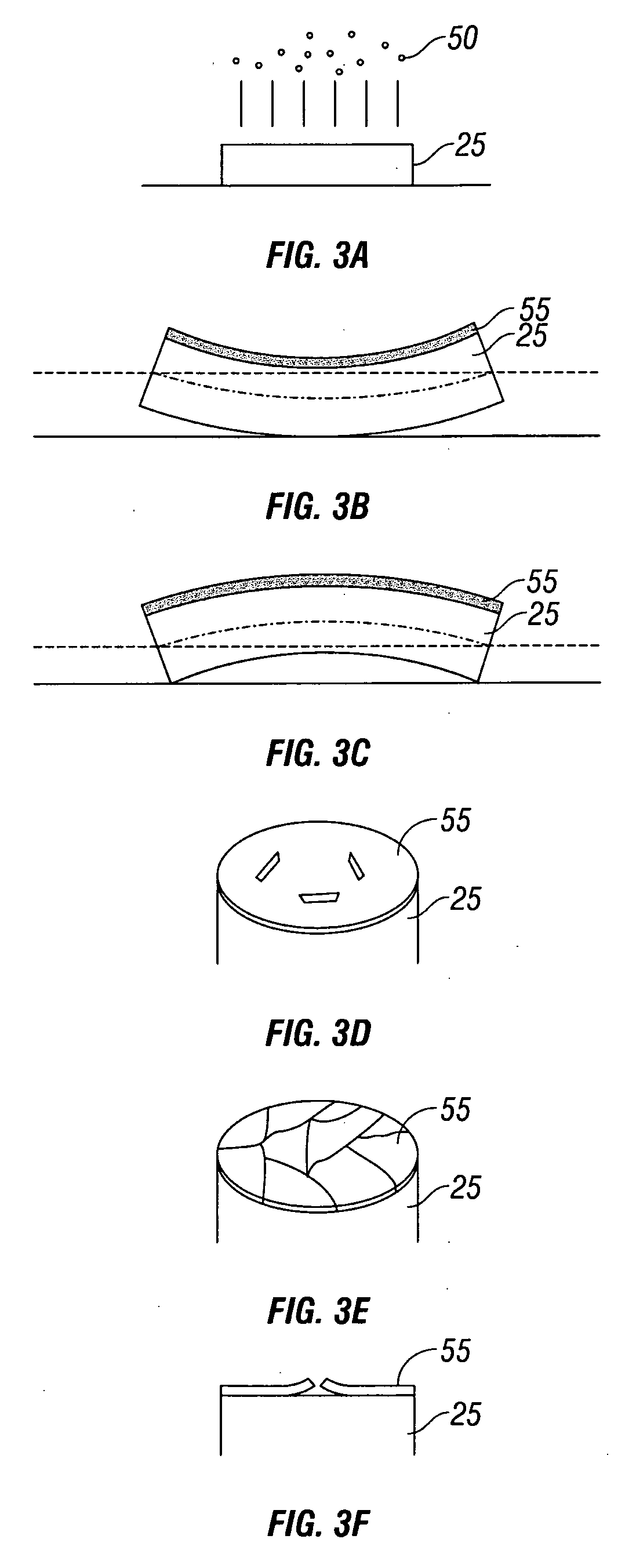

Method for reducing particulate generation from regeneration of cryogenic vacuum pumps

InactiveUS6116032AReduces the thermal and mechanical shockSolidificationLiquefactionParticulatesProcess engineering

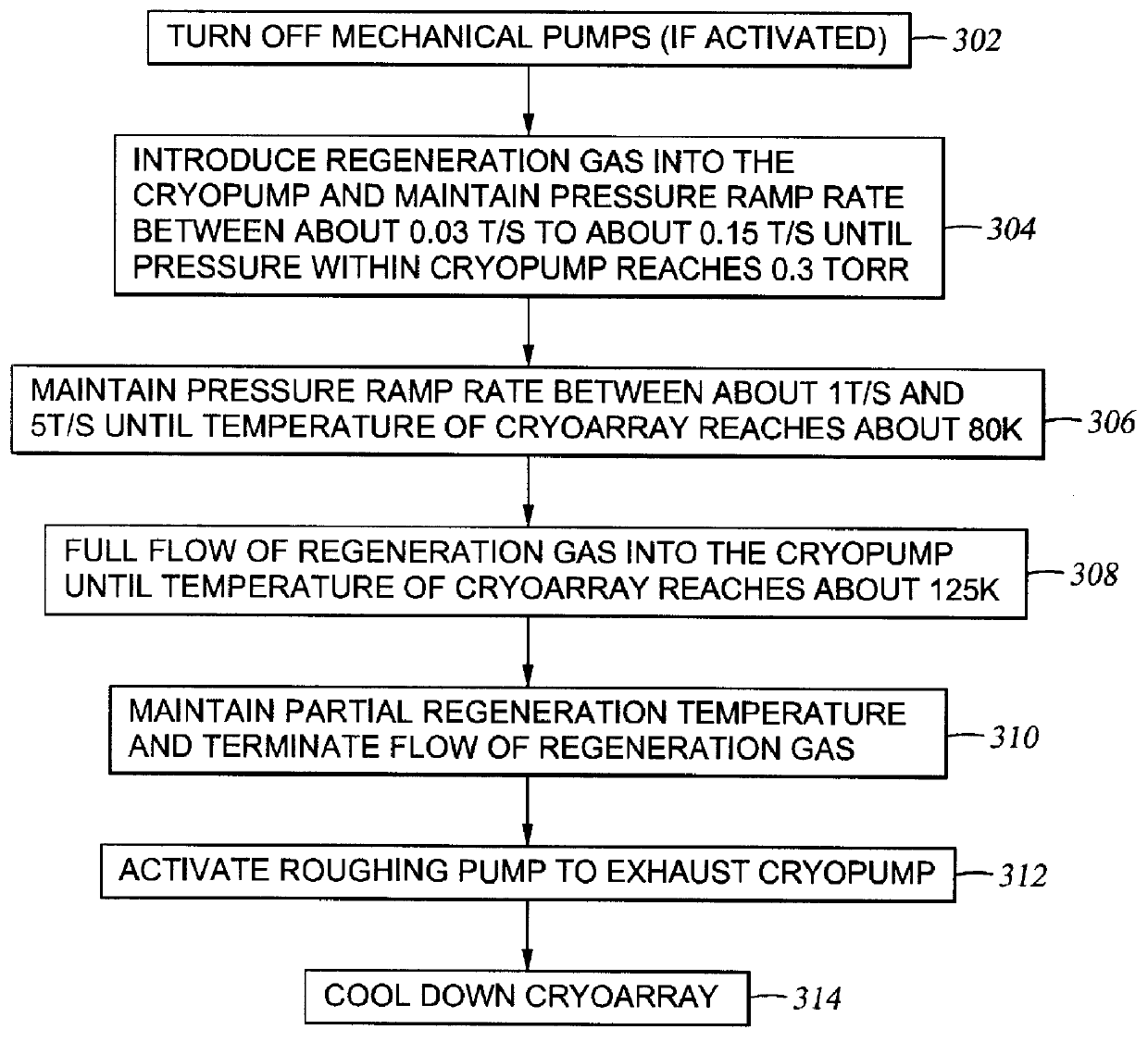

A method for reducing particulate generation from regeneration of cryogenic vacuum pumps. The method comprises controlling a pressure ramp rate inside the cryopump during an initial introduction of a regeneration gas into the cryopump. Preferably, the pressure ramp rate is controlled by maintaining a first pressure ramp rate, preferably between about 0.03 T / s and 0.15 T / s, until a first pressure of about 0.3 T is reached inside the cryopump and maintaining a second pressure ramp rate between about 1 T / s and 5 T / s until the surface in the cryopump reaches an intermediate temperature between about 40 K and 100 K. Preferably, the temperature ramp rate is also controlled by heating the surface at a temperature ramp rate between about 0.1 K / s and about 0.5 K / s until the intermediate temperature has been reached. Preferably, the temperature ramp rate is controlled by regulating the flow of an inert gas into the cryopump using a flow restriction device. Alternatively, the second stage cryoarray temperature is increased at the rate of between 0.1 K / s and 0.5 K / s using a PID controlled heater.

Owner:APPLIED MATERIALS INC

High conductance cryopump for type III gas pumping

A cryopump provides for high pumping speed of Type III gases. An open configuration of a frontal array provides high conductance of gases into a radiation shield which is shaped to focus gases toward a second stage array. The second stage array has an open configuration of baffles coated with adsorbent. Substantially all of the adsorbent has a direct line of sight to the radiation shield or to the opening in the radiation shield, and substantially all of the baffles are coated with adsorbent. In one form, the second stage cryopump array comprises an array of discs fanned to define a generally ball shaped envelope.

Owner:EDWARDS VACUUM LLC

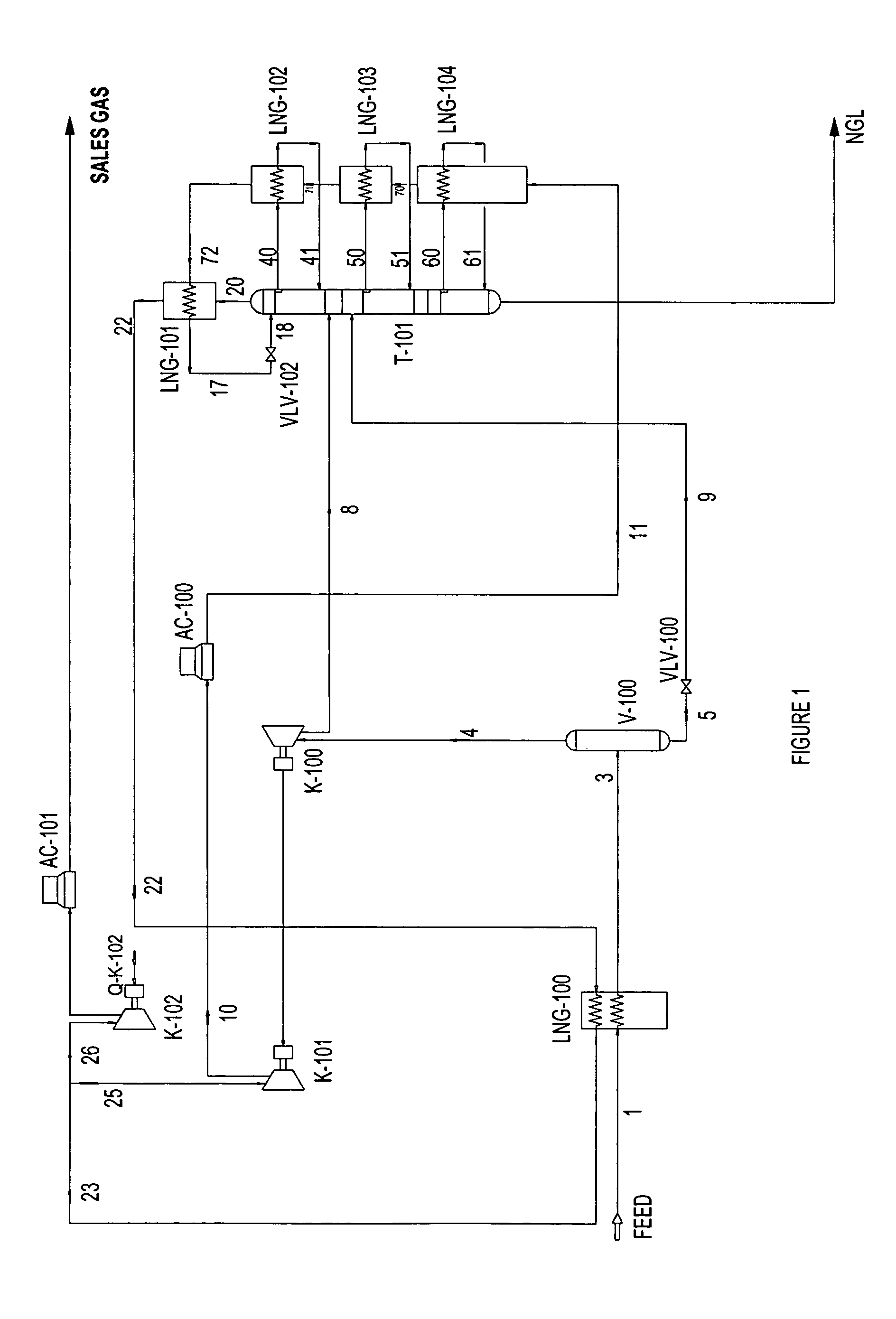

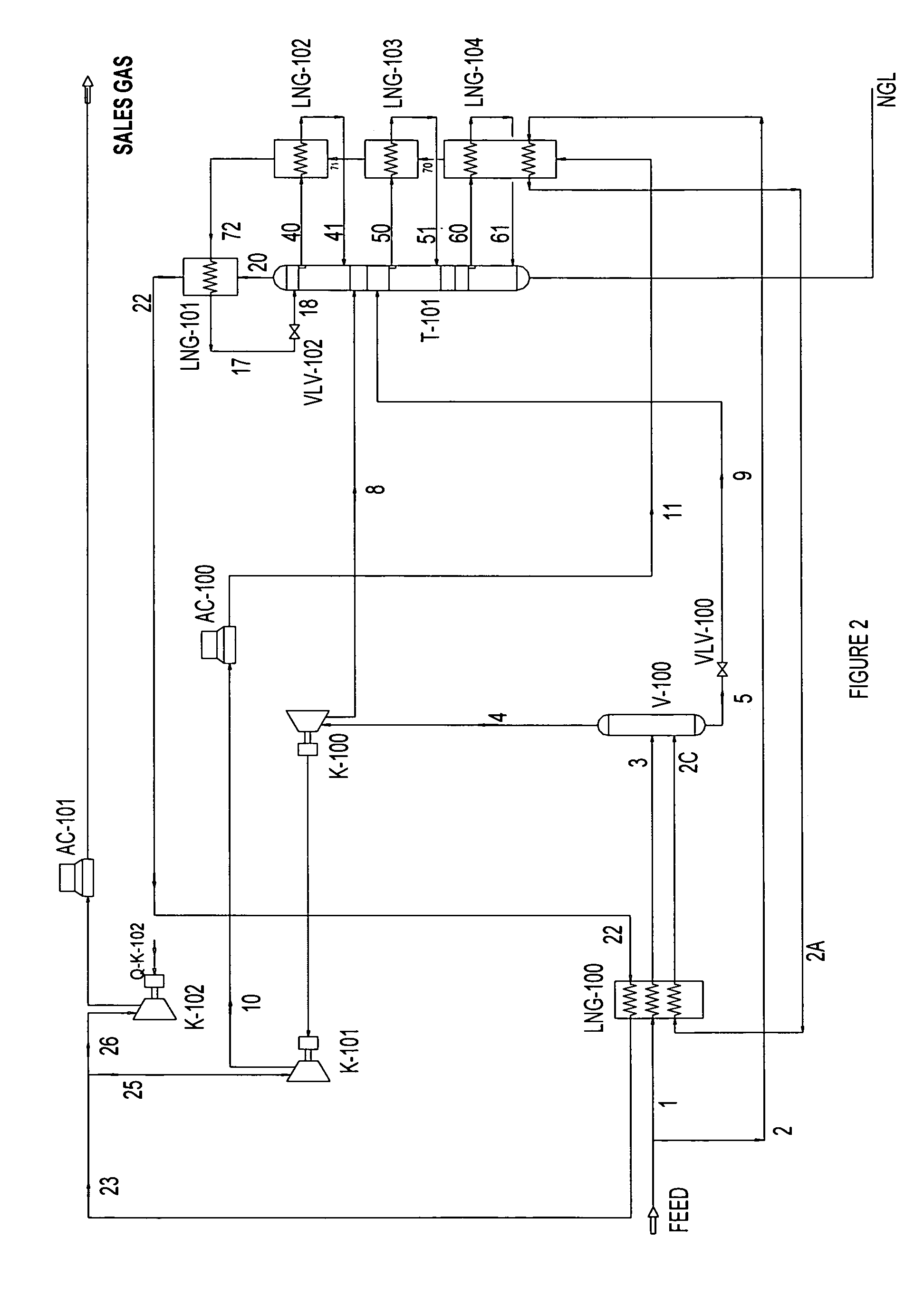

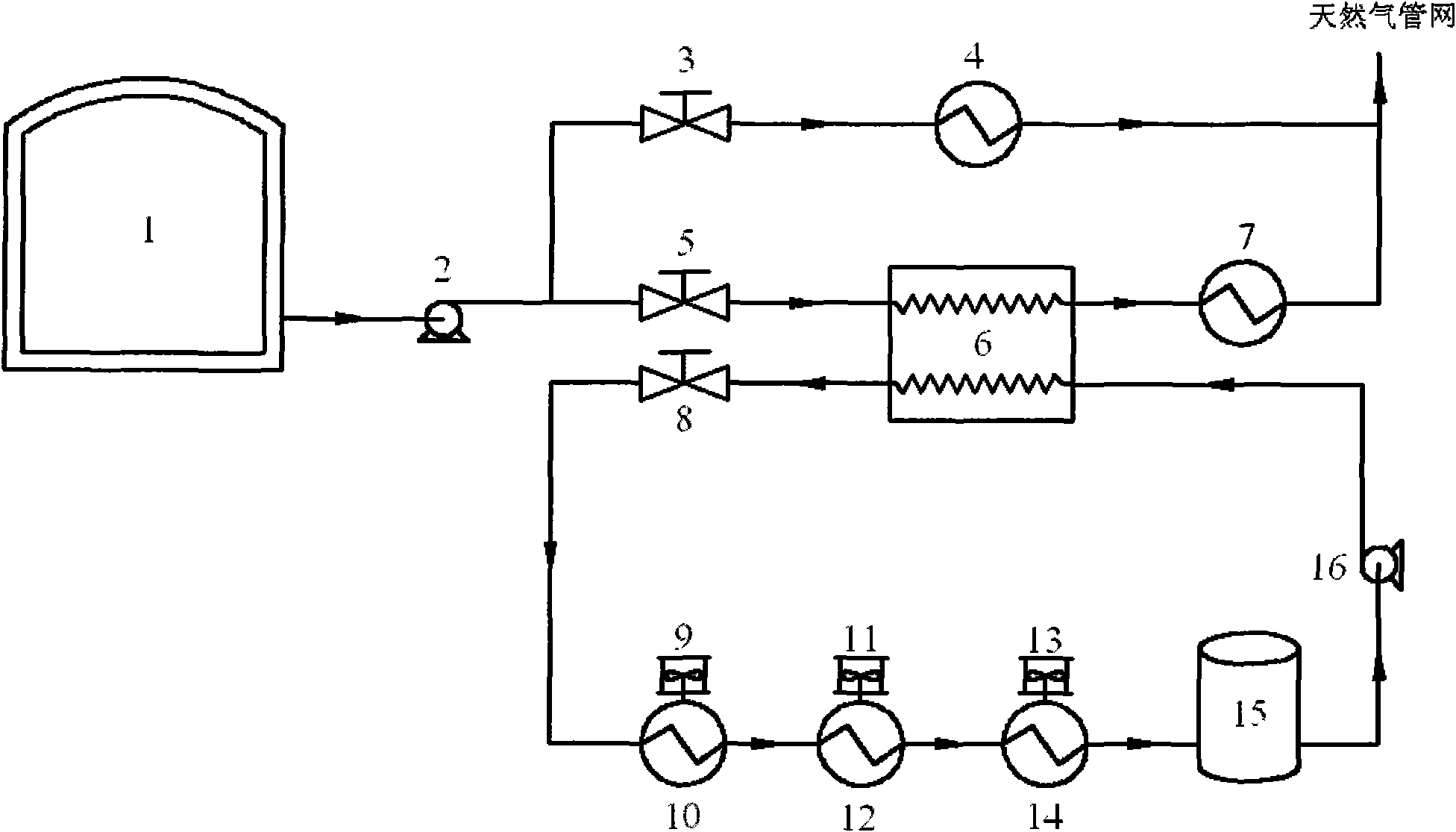

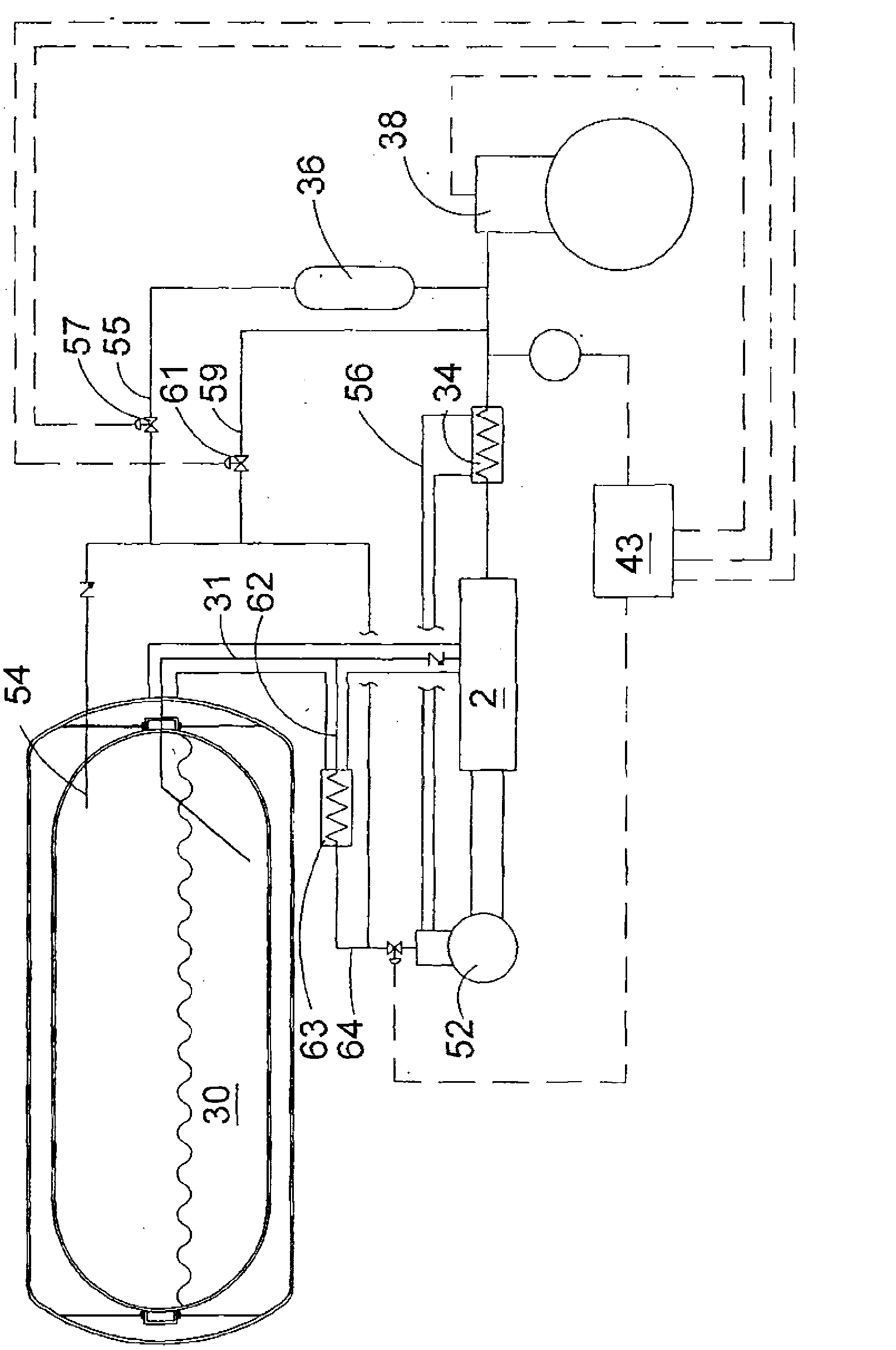

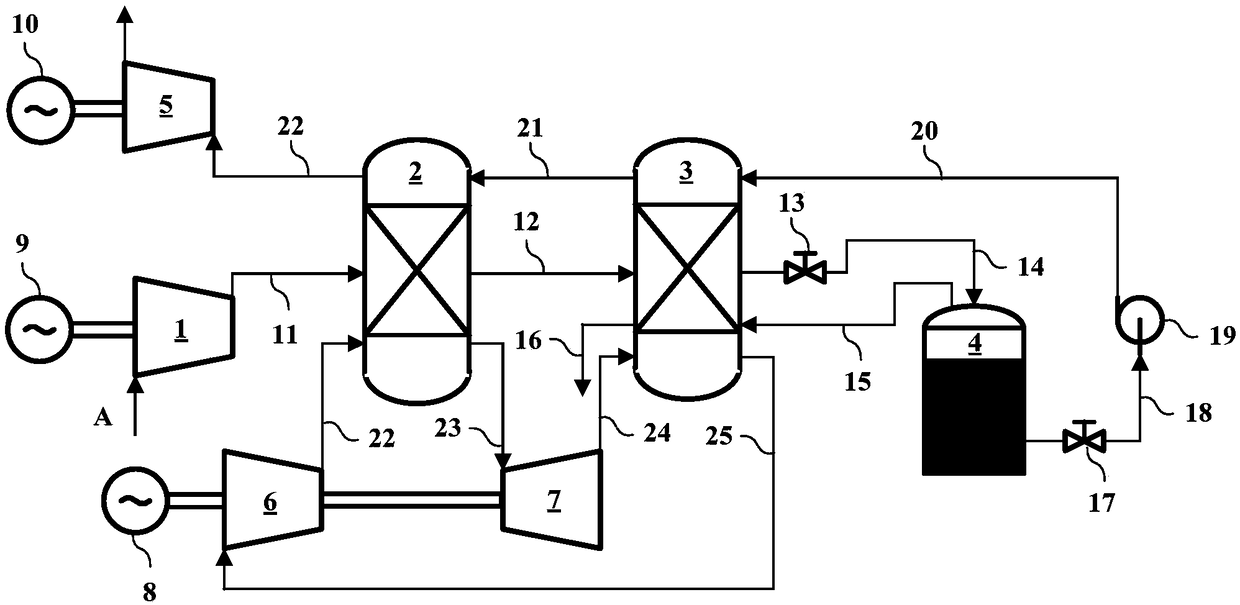

Refrigerant phase transformation-free refrigerator for recovering liquefied natural gas (LNG) cold energy

InactiveCN101619914ARealize cold energy recoveryRealize cold energy utilizationDomestic cooling apparatusLighting and heating apparatusRefrigerator carLiquid state

The invention relates to a refrigerant phase transformation-free refrigerator for recovering liquefied natural gas (LNG) cold energy, which belongs to the technical fields of energy saving and refrigeration. The refrigerant phase transformation-free refrigerator for recovering LNG cold energy comprises an LNG storage tank, an LNG cryopump, an LNG carburetor, an LNG-refrigerant heat exchanger, a refrigerator heat exchanger, a refrigerator fan, a refrigerant low-temperature storage tank, a low-temperature refrigerant pump and various flow valves. R410A is selected as refrigerant to sequentially enter all refrigerators after obtaining refrigeration amount from LNG, the refrigerant releases the refrigeration amount step by step, and the step utilization of the cold energy is realized. The refrigerant is run in a complete liquid state in the whole process and does not generate phase transformation in heat exchangers of all the refrigerators; and the refrigeration amount transformation needed by the refrigerators is realized by adjusting the rotating speed of the fan and the flow of the refrigerant. The invention has the obvious effects of saving the energy and reducing the discharge.

Owner:SHANGHAI JIAO TONG UNIV

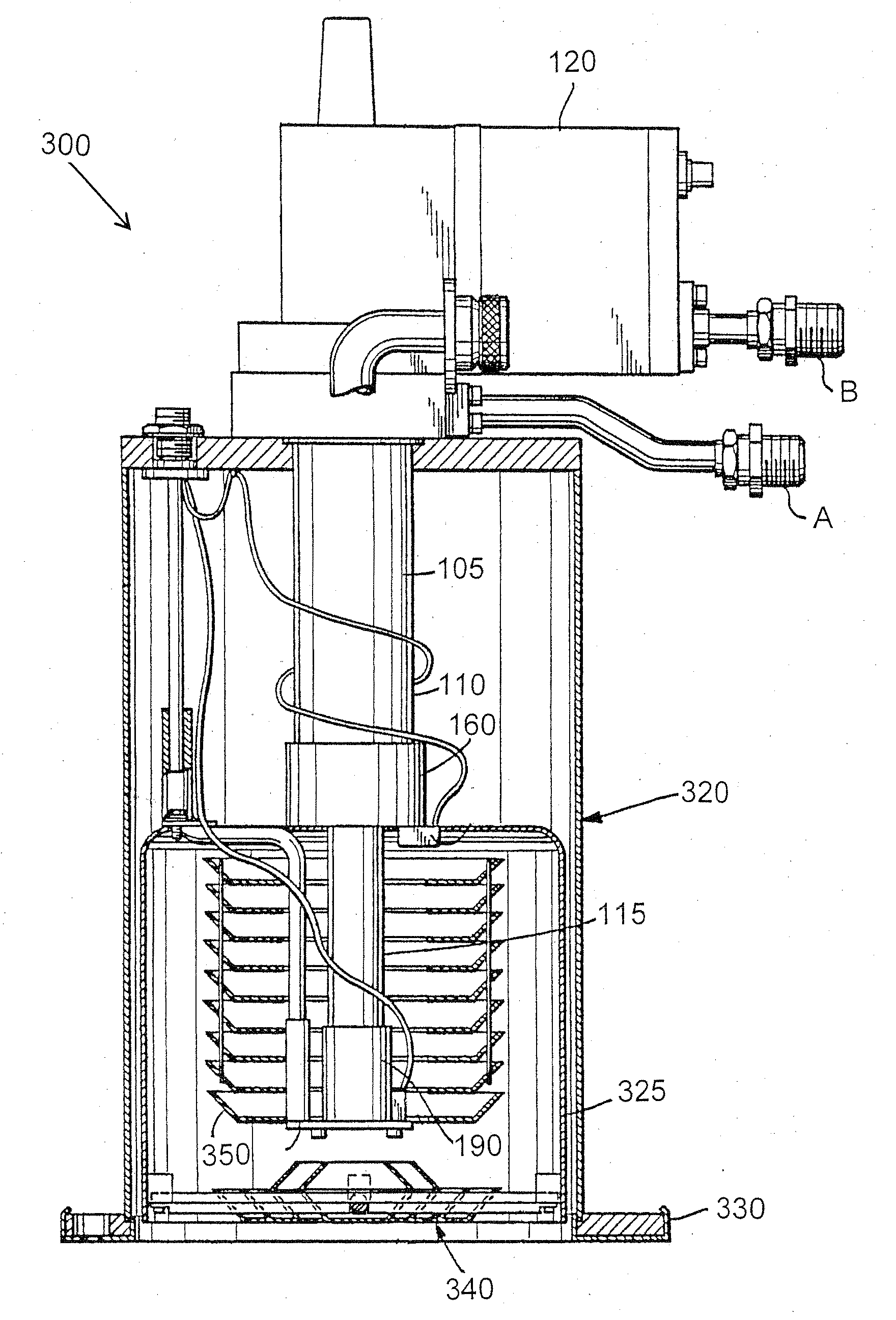

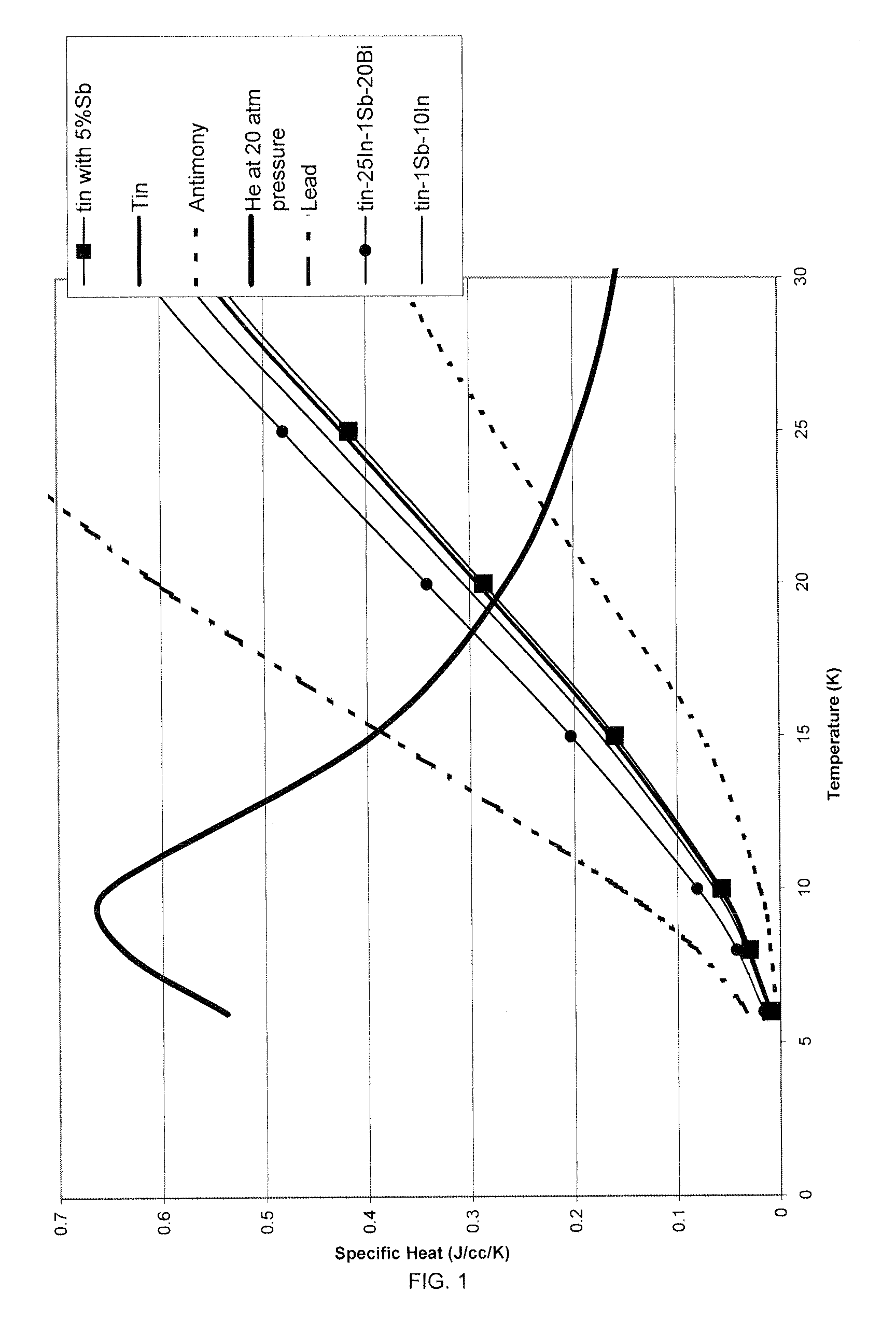

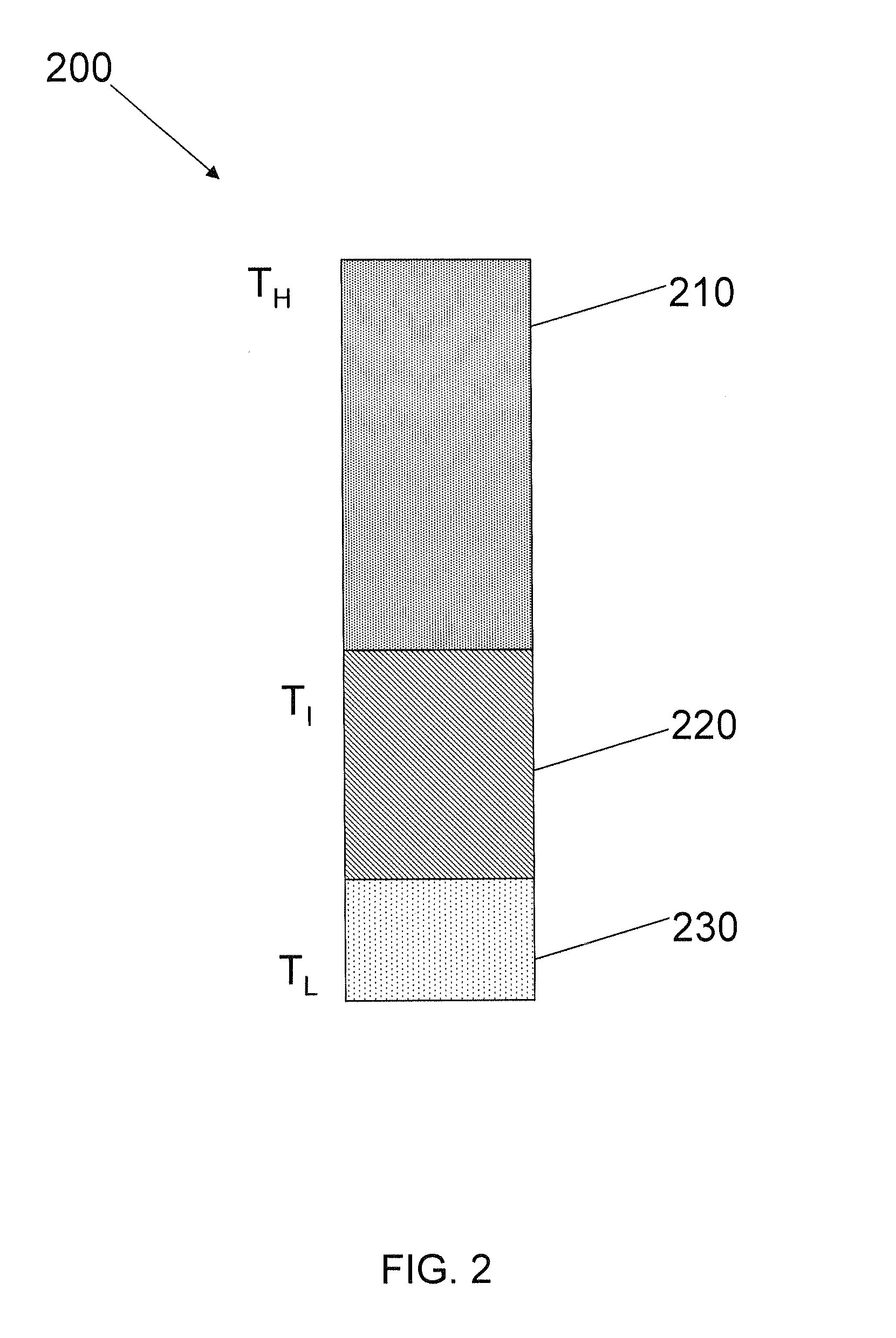

Cryogenic Pump Employing Tin-Antimony Alloys and Methods of Use

ActiveUS20110126553A1High volumetric heat capacityClean vacuum environmentPositive displacement pump componentsCompression machinesPulse tube refrigeratorRefrigerated temperature

A cryogenic refrigerator includes a regenerative heat exchanger material in thermal contact with a working gas including a tin-antimony (Sn—Sb) alloy or a tin-gallium (Sn—Ga) alloy in at least one cooling stage. The re-generative heat exchanger material can include an Sn—Sb-M alloy, with M including at least one element selected from the group consisting of Bi, Ag, Ge, Cu, La, Mg, Mn, Nd, Ni, Pd, Pt, K, Rh, Sm, Se, S, Y, Fe, In, Al, Ce, Dy, Cd, Ti, Au, P, Pr, Yb and Zn. The cryogenic refrigerator can include a Gifford-McMahon refrigerator, a pulse tube refrigerator, or a Stirling refrigerator. A cryopump includes cryopanels adapted to condense or adsorb gases and a cryogenic refrigerator.

Owner:EDWARDS VACUUM LLC

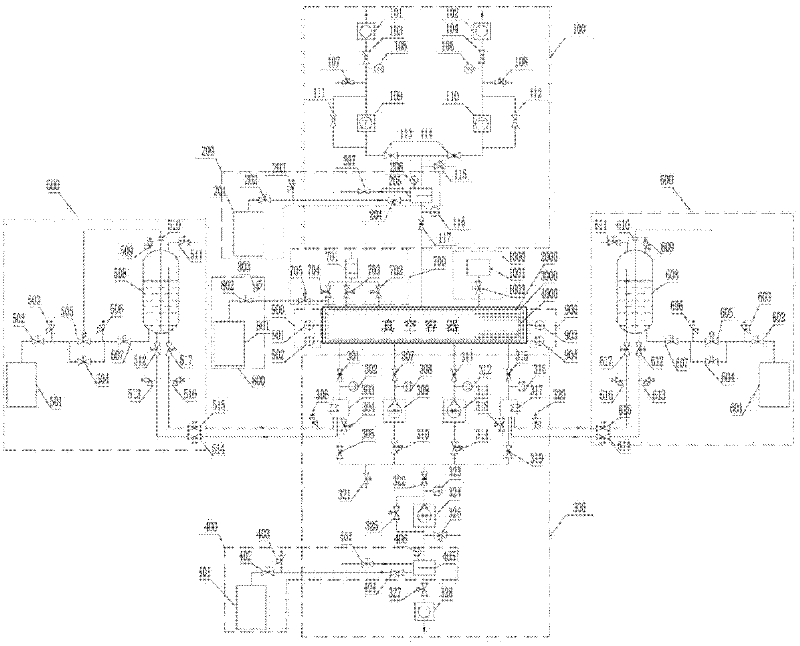

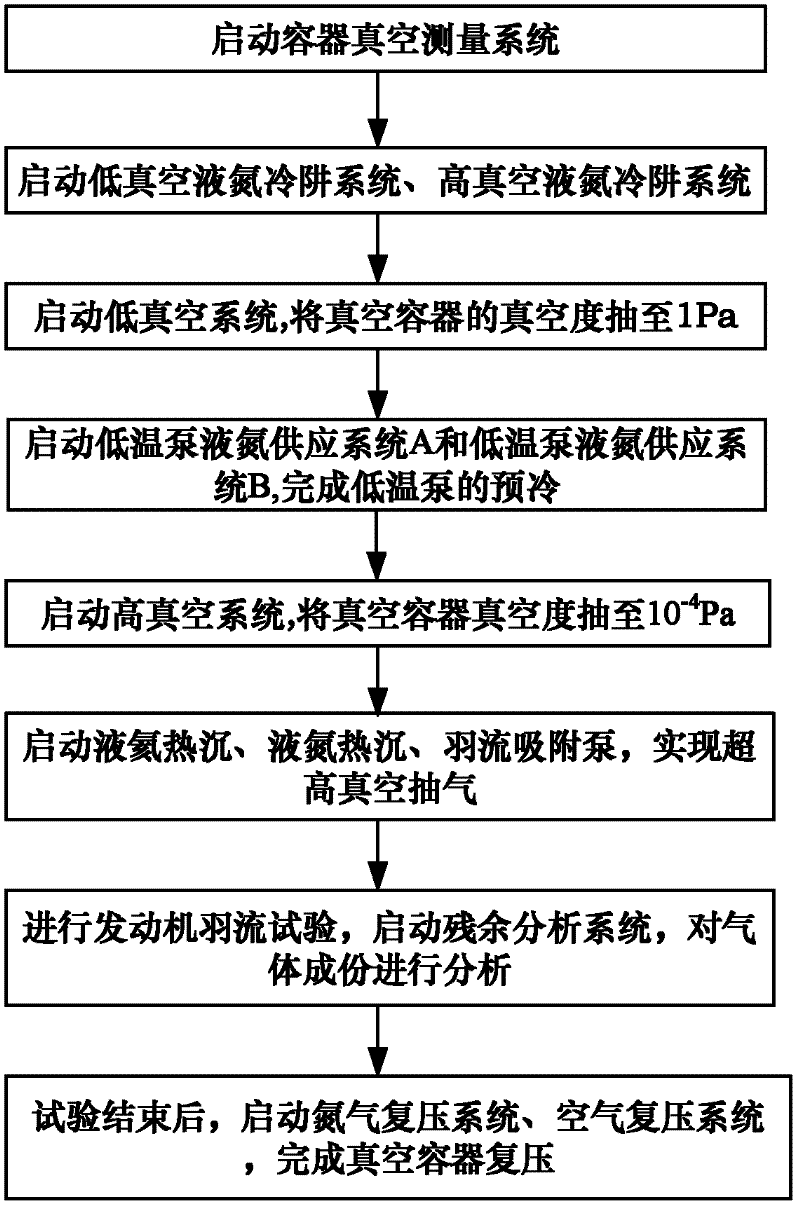

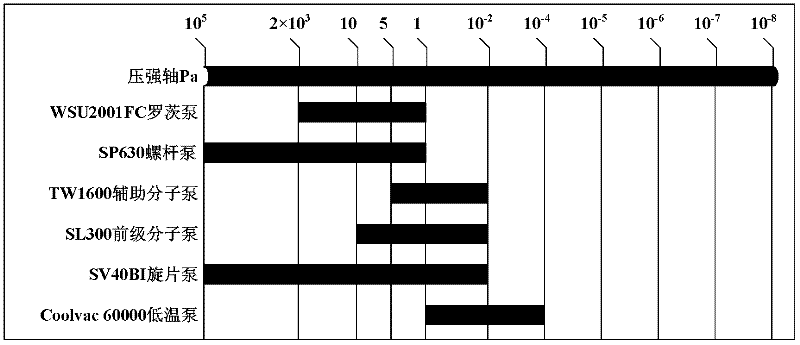

Clean vacuum system used for engine plume test research and vacuumizing and repressing method thereof

InactiveCN102359859AVarious working modesThe pumping speed is adjustableAerodynamic testingEngine testingGas analysisNitrogen

The invention provides a clean vacuum system used for engine plume test research and a vacuuminzing and repressing method thereof, belonging to the technical field of engine vacuum science. The clean vacuum system comprises a low vacuum system, a low vacuum liquid nitrogen cold trap system, a high vacuum system, a high vacuum liquid nitrogen cold trap system, a low temperature pump liquid nitrogen supply system A, a low temperature pump liquid nitrogen supply system B, an air repressing system, a nitrogen repressing system, a container vacuum measuring system, a residual gas analysis system, a liquid nitrogen heat sink, and a liquid nitrogen heat sink and plume adsorption pump. In the clean vacuum system, the vacuum is obtained mainly relying on the clean low vacuum system, the high vacuum system and the liquid nitrogen heat sink, the liquid nitrogen heat sink and plume adsorption pump; various clean vacuum degrees required by the plume test can be obtained, and the highest ultrahigh dynamic vacuum degree of 10<-6> Pa can be obtained. Both the low vacuum system and the high vacuum system are configured with the liquid nitrogen cold trap system which is used for absorbing the oil steam produced by working of a mechanical pump, so that the cleanness of the vacuum container can be ensured.

Owner:BEIHANG UNIV

Cryopump

A cryopump includes a radiation shield provided with a main inlet at one end thereof and a sub-inlet in a side thereof; and a cryopanel assembly cooled to a temperature lower than that of the radiation shield. The cryopanel assembly includes an upper structure having at least one cryopanel and a lower structure having at least one cryopanel. The upper and lower structures are arranged inside the radiation shield along a direction away from the main inlet. A frost accommodating space connected to the sub-inlet may be arranged between the upper and lower structures such that an amount of captured gas on an upper end cryopanel of the lower structure is greater than an amount of captured gas on a lower end cryopanel of the upper structure.

Owner:SUMITOMO HEAVY IND LTD

Two engine system with a gaseous fuel stored in liquefied form

ActiveCN103189618AImprove efficiencyImprove reliabilityReciprocating combination enginesInternal combustion piston enginesInjection pressureProduct gas

A gaseous fuelled two engine system is disclosed comprising a high pressure direct injection engine as the main power source and an auxiliary fumigated engine that can be fuelled with vapor removed from a storage tank that stores the gaseous fuel in liquefied form at cryogenic temperatures. The fuel supply system comprises a cryogenic pump for raising the pressure of the fuel to the injection pressure needed for the high pressure direct injection engine, and the cryogenic pump is powered by the auxiliary fumigated engine.

Owner:WESTPORT POWER

Cryopump with two-stage pulse tube refrigerator

Disclosed is a two-stage pulse tube cryopump cooling system in which the pulse tubes and valves are inline, with the hot ends of the pulse tubes at the top and the valve mechanism is at the bottom and the hot ends and buffer volume are cooled by an inline coolant line from the compressor input to the compressor output and attached in heat exchange relationship with the buffer volume.

Owner:SHI APD CRYOGENICS +1

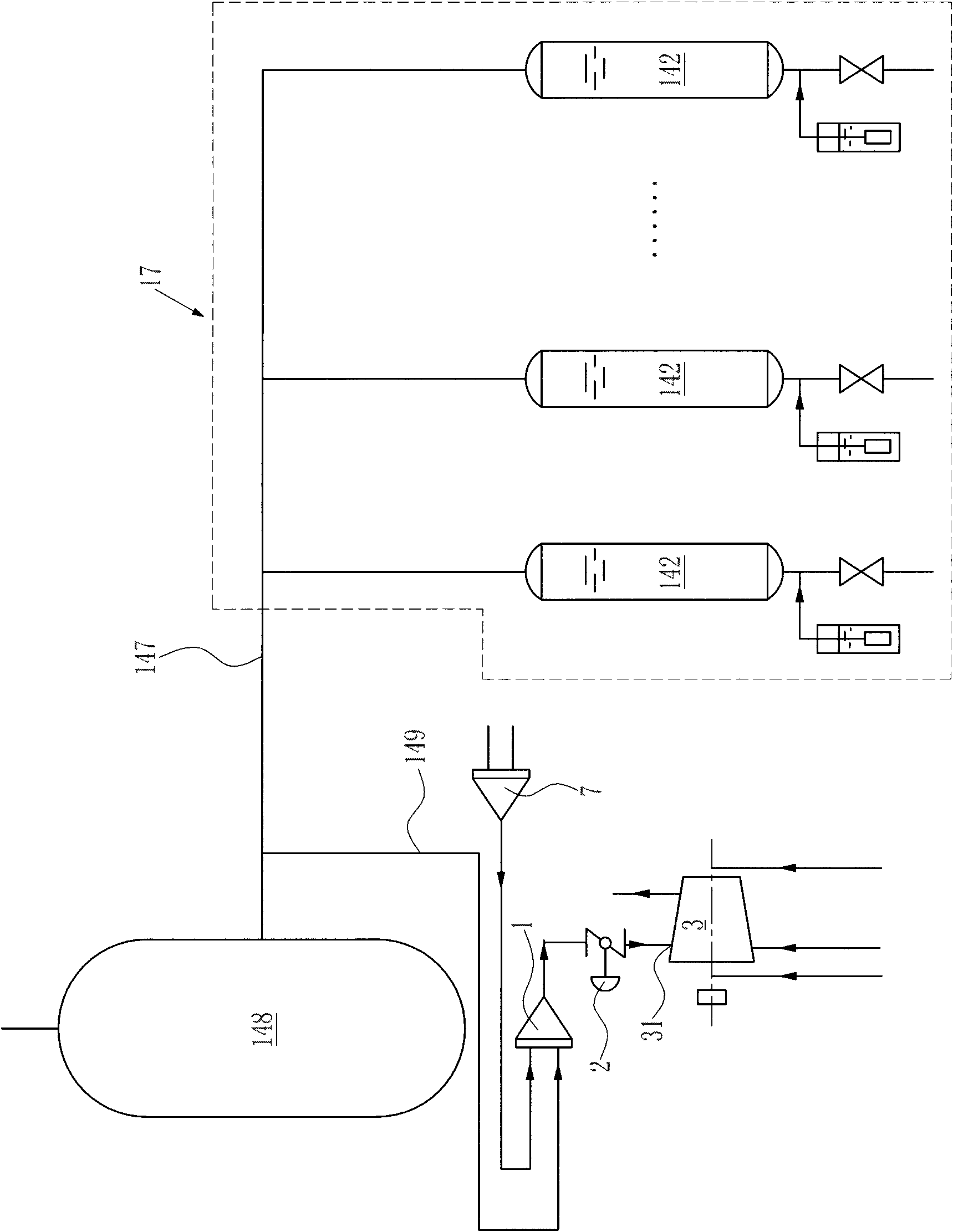

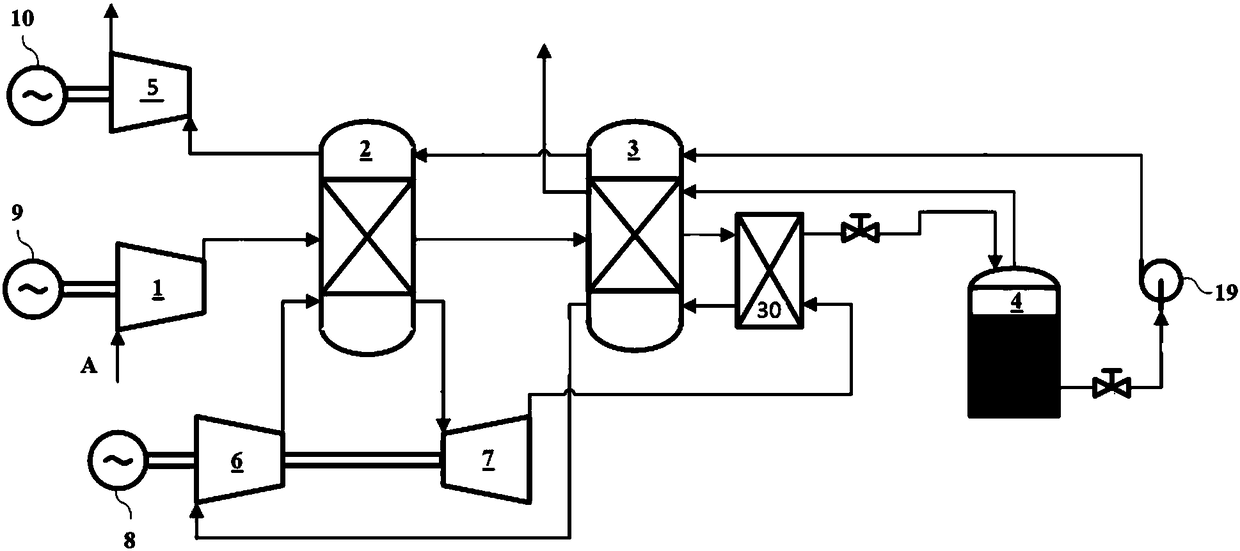

Device and method for recovery and reliquefaction of boil-off gas of liquefied natural gas

ActiveCN102182919ASimple recycling processSimplify liquefaction system processPipeline systemsEngineeringDistributor

The invention relates to a device for the recovery and reliquefaction of boil-off gas of liquefied natural gas, which comprises a storage tank with a safety valve and a low-temperature pump, wherein a first interface is formed between the storage tank and the safety valve and is connected with a recovery pipe; the low-temperature pump is provided with a second interface; the other end of the recovery pipe is communicated with a recovery compressor; an outlet of the recovery compressor is connected with a cooler, an oil-gas separator and a boil-off gas distributor, and first boil-off gas and second boil-off gas are respectively discharged from the boil-off gas distributor; the first boil-off gas is communicated with a screw expansion machine and enters a heat exchanger and a second screw compressor; the second boil-off gas is connected with the second interface of the low-temperature pump by the heat exchanger, a throttling valve and a gas-liquid separator; and the liquefied natural gas enters the storage tank. The device has the advantages that by using a screw expansion-compressor set refrigerating reliquefaction method of recovering the boil-off gas directly by the screw compressors and taking the boil-off gas as a refrigerant directly, system flow equipment is simplified, energy waste is avoided, and peripheral environmental pollution and potential safety hazards are avoided, so obvious economic and social benefits are created; and a system runs automatically, continuously and circularly, and has the excellent running work condition and high using efficiency and runningreliability.

Owner:NINGBO BAOSI ENERGY EQUIP

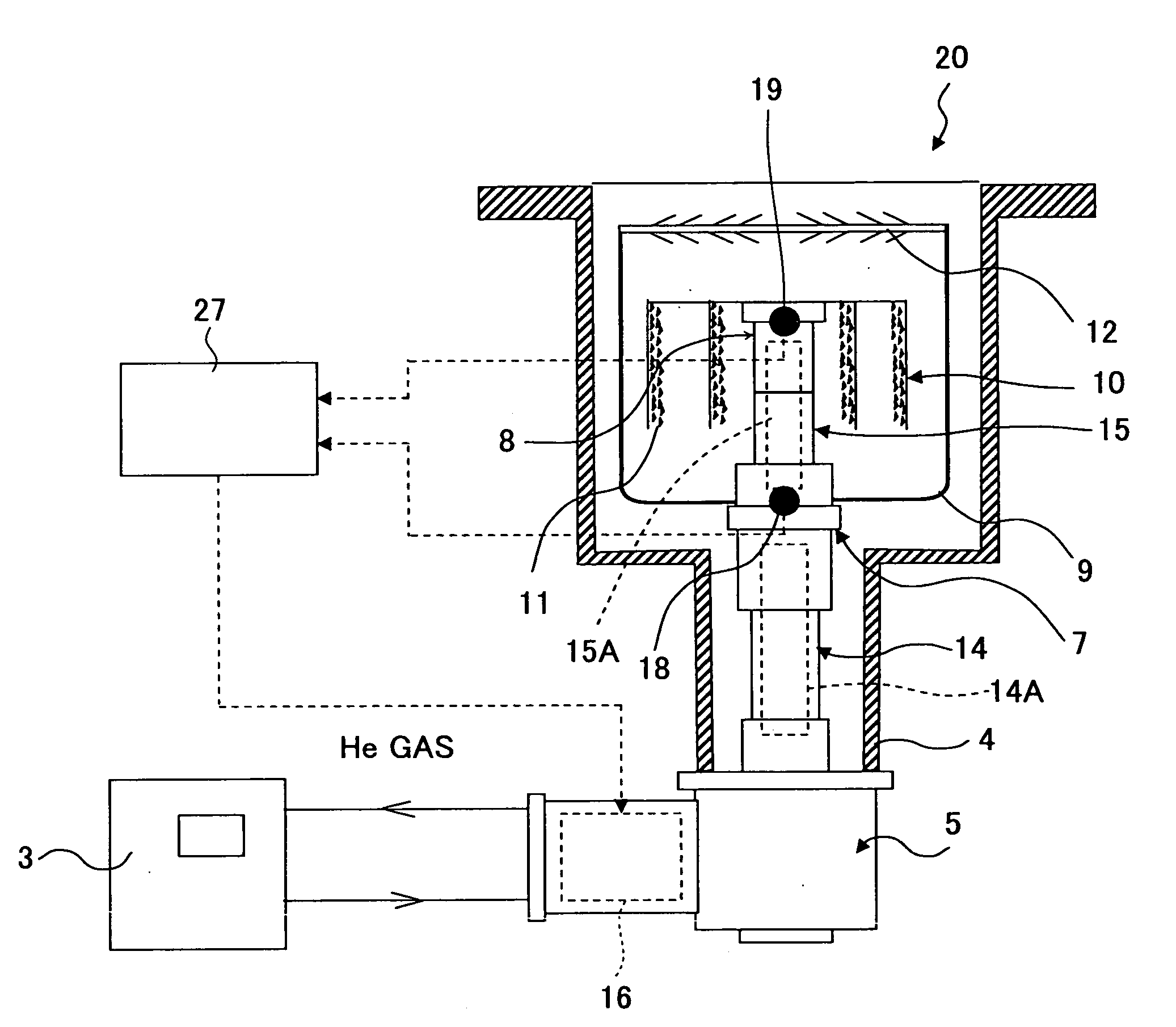

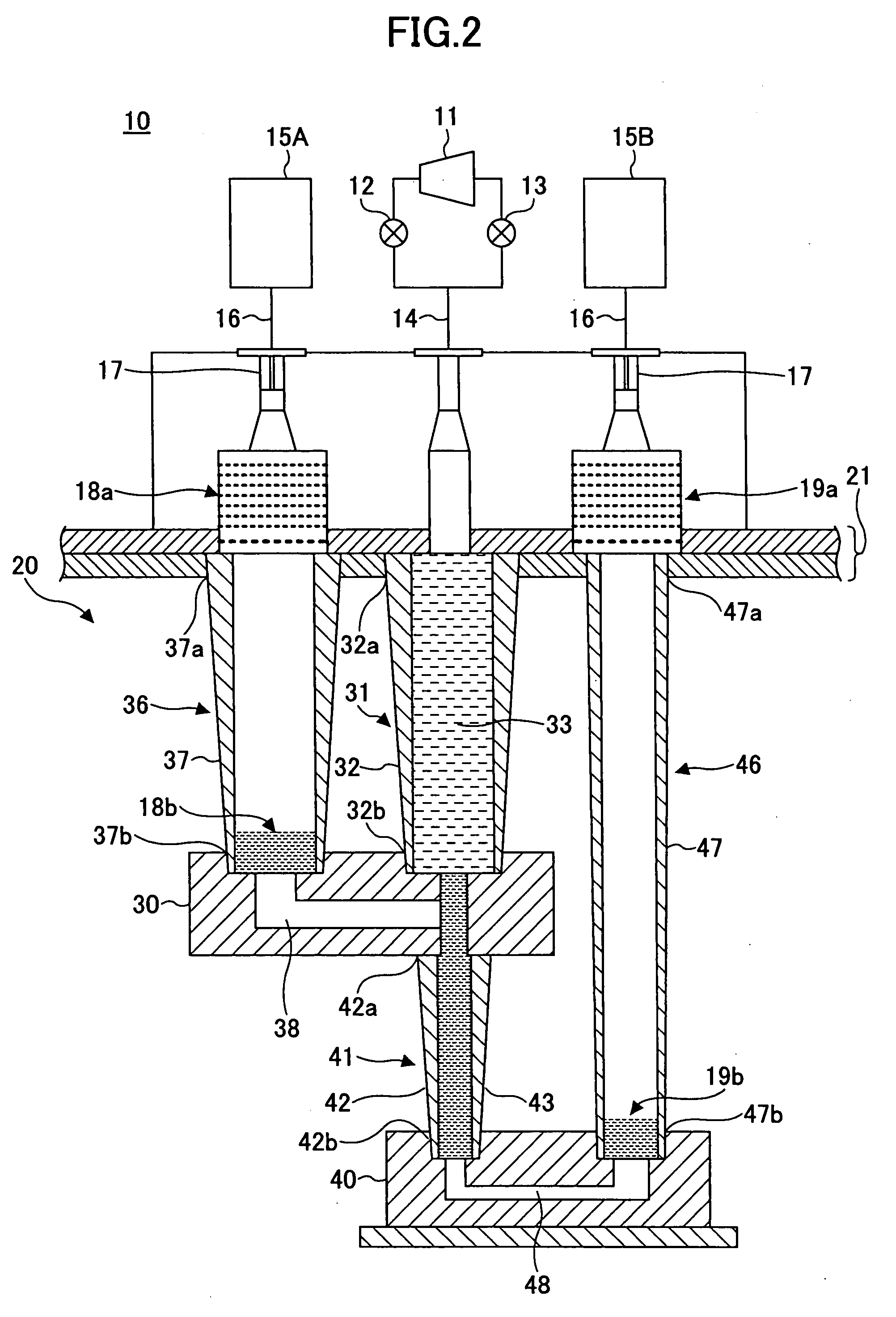

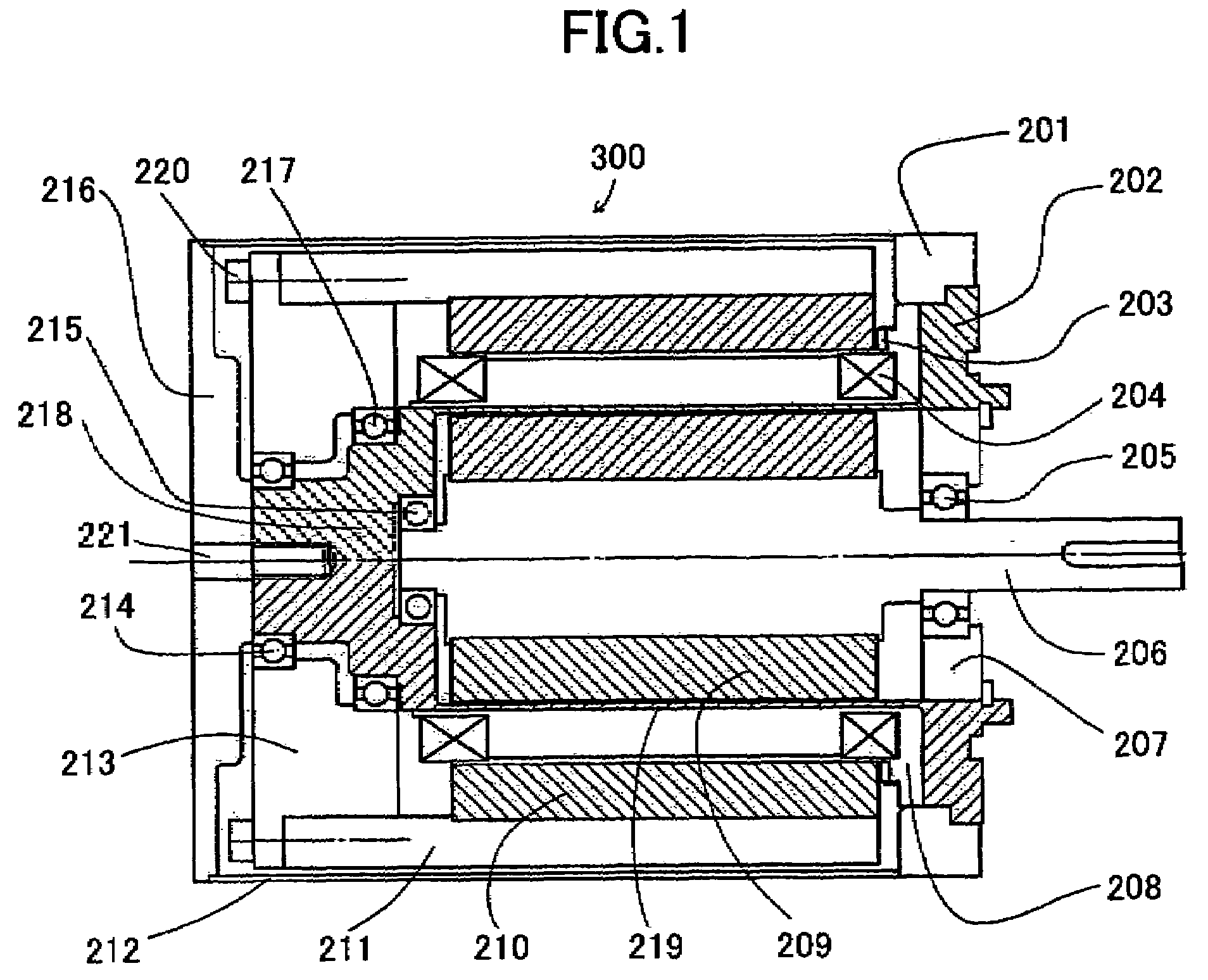

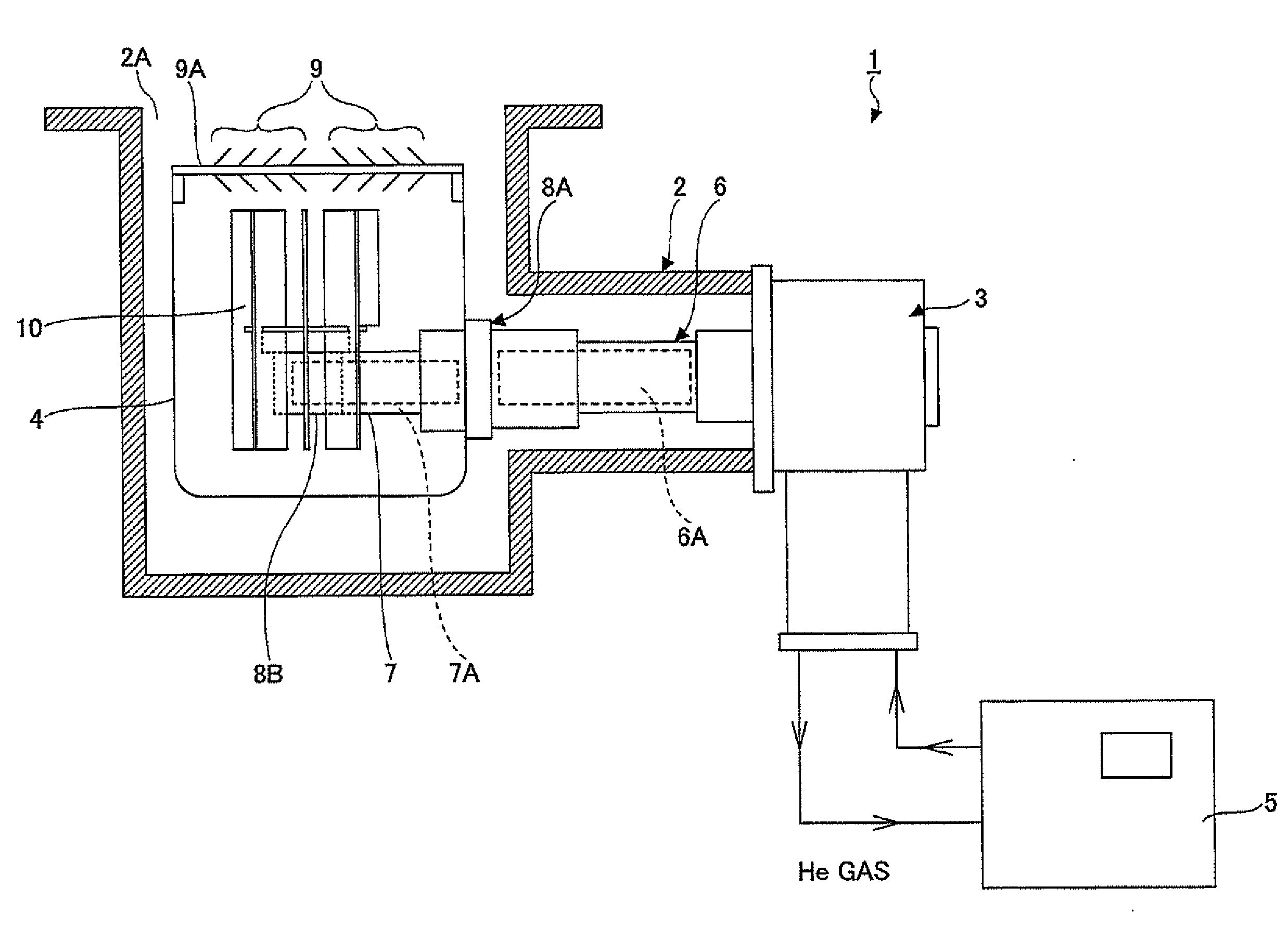

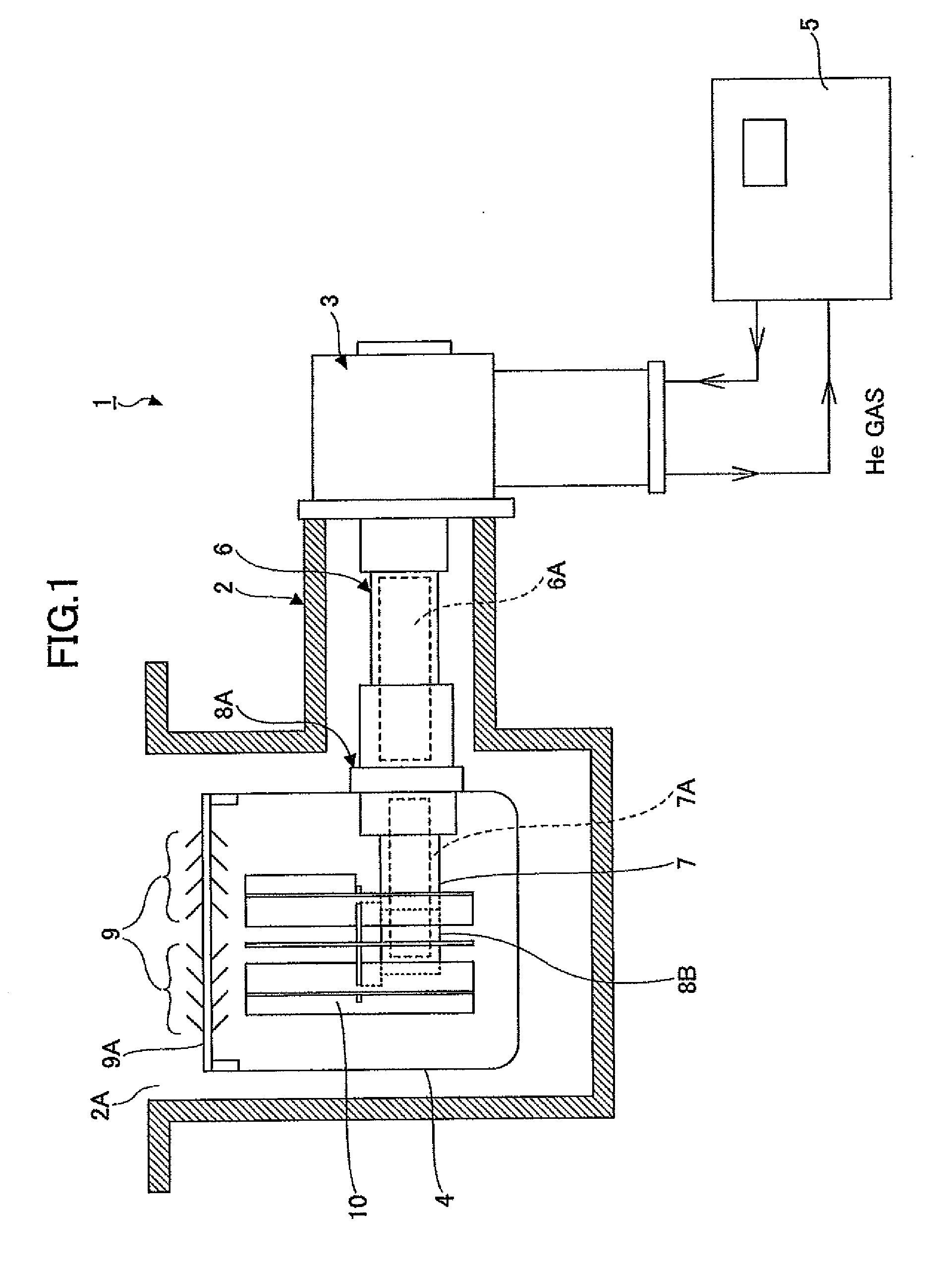

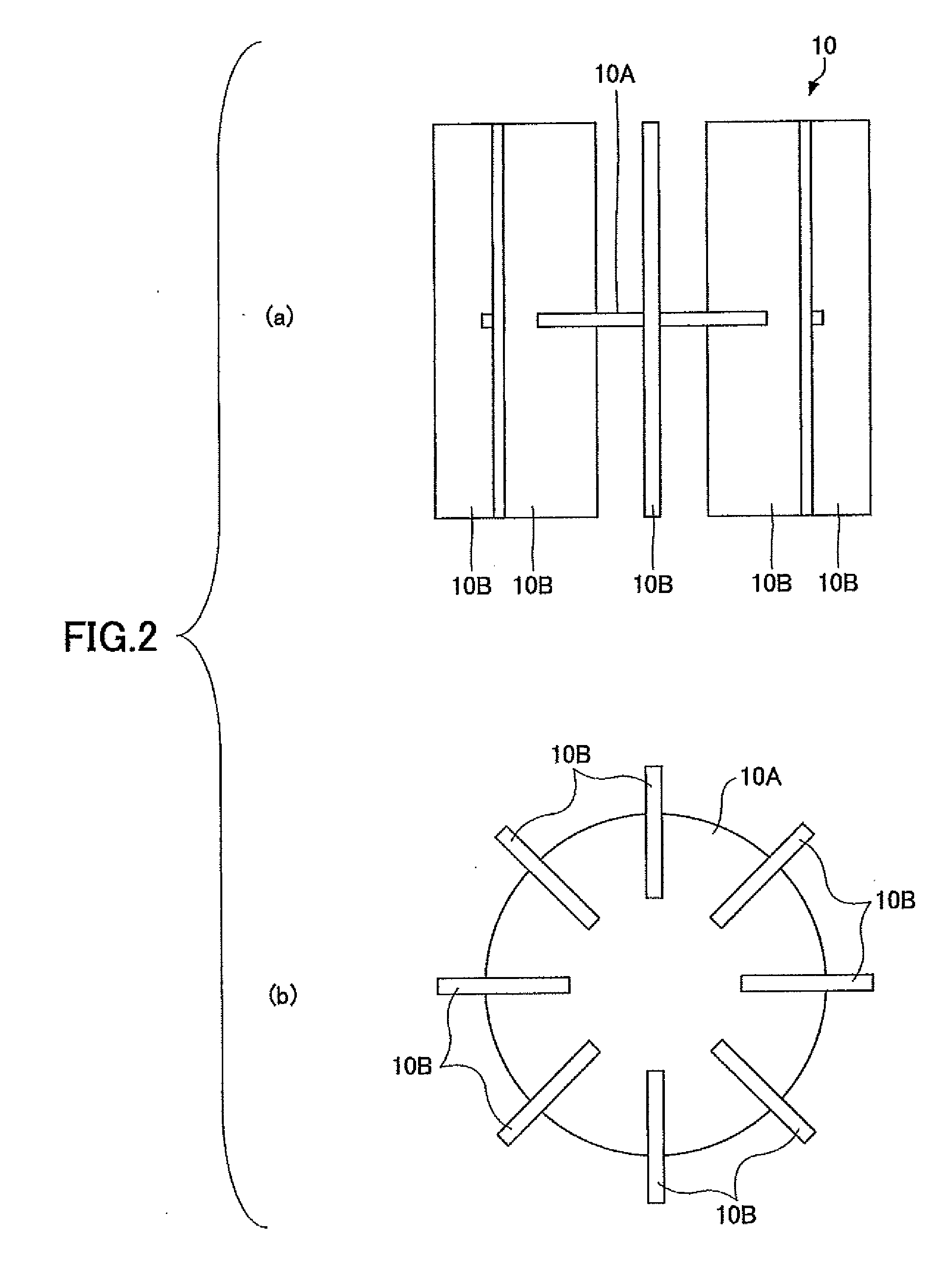

Regenerative cryocooler, cylinder used for the regenerative cryocooler, cryopump, recondensing apparatus, superconducting magnet apparatus, and semiconductor detecting apparatus

InactiveUS20080173026A1Improve cooling effectAvoid vibrationSolidificationLiquefactionSuperconducting CoilsEngineering

A cylinder used for a cold head of a regenerative cryocooler, the cylinder includes an inside having a hollow-shaped configuration for a regenerative material, wherein the thickness of the cylinder at a high temperature end is greater than the thickness of the cylinder at a low temperature end.

Owner:SUMITOMO HEAVY IND LTD

Cryopump and evacuation method

ActiveUS20090165469A1Improve pump performanceEliminate the effects ofSolidificationLiquefactionPump chamberEngineering

A cryopump includes: a cryopump chamber having an inlet port through which a gas to be pumped is introduced; a refrigerator provided with a second cooling stage provided in the cryopump chamber; an intermediate member thermally coupled to the second cooling stage; and a cryopanel having a connecting part connected to the intermediate member at a position farther from the inlet port in the direction in which the gas is introduced than the second cooling stage, and extending from the connecting part toward the inlet port. For example, a cryopump having a suspended panel structure is provided.

Owner:SUMITOMO HEAVY IND LTD

Cryopump and semiconductor device manufacturing apparatus using the cryopump

InactiveUS20070283704A1Short working hoursImprove productivitySolidificationLiquefactionEngineeringVacuum chamber

A cryopump is disclosed. The cryopump includes a cryopump main body connected to a vacuum chamber via an inlet. The cryopump main body includes a vacuum container. A shielding section, a two-stage type cryogenic cooler, a baffle, and first cryopanel and second cryopanels are provided in the vacuum container. A top surface of the first cryopanel is disposed at a position nearest to a surface of the baffle. The top surface of the first cryopanel is disposed almost parallel to the surface of the baffle.

Owner:SUMITOMO HEAVY IND LTD

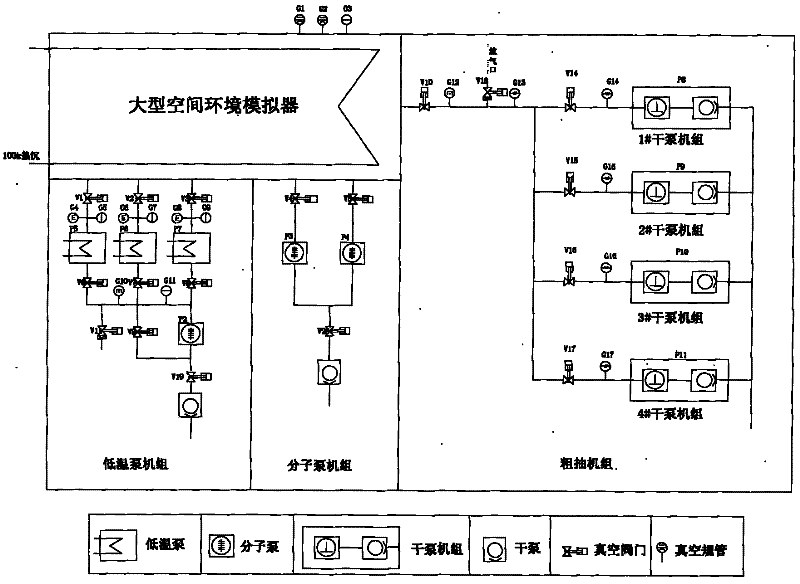

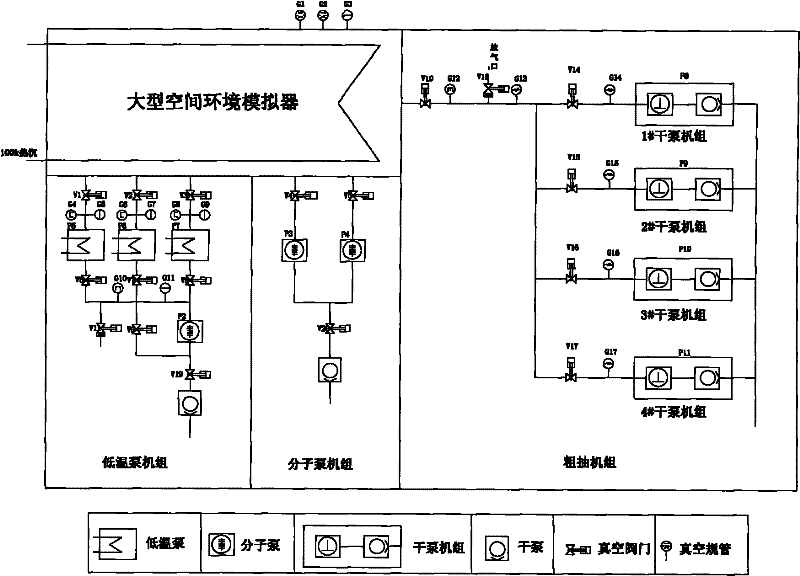

Cleaning vacuum air exhaust technology for large-sized space environmental simulator

The invention relates to cleaning vacuum air exhaust technology for a large-sized space environmental simulator, which is mainly applied to research of large-sized space environmental simulators, and provides high vacuum test conditions for tests of spacecrafts. In order to obtain high vacuum of the large-sized space simulator, at first, a novel oilless rough pumping unit of a vacuum system exhausts air in a vacuum container in a vacuum manner so that the pressure in the vacuum container is lower than 10Pa, then a turbo molecular pump is utilized to exhaust air in a transitional manner until start vacuum degree of a main pump is achieved, finally, a low-temperature pump is utilized as the main pump for realizing high vacuum air exhaust, so that working vacuum degree of equipment is higher to 1.3X10-3Pa, and the working vacuum degree is maintained until a test is finished. The high vacuum air exhaust technology realizes that cleaning high vacuum for the large-sized space environmental simulator is obtained by the aid of completely oilless vacuum air exhaust equipment.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

Compact configuration for cryogenic pumps and turbines

Owner:ELLIOTT CO

Cryopump

ActiveUS20130312431A1Increase capacityImprove isolationSolidificationLiquefactionMechanical engineeringCryopump

A cryopump has a simple-to-manufacture frontal baffle plate with improved gas distribution and has a large-area second-stage array plate to capture Type II gases. The cryopump has a first-stage frontal baffle plate having orifices and flaps bent from and attached to the orifices. The cryopump has a second-stage top plate that is larger in area than cooling baffles of the second stage array.

Owner:EDWARDS VACUUM LLC

Integral facet cryopump, water vapor pump, or high vacuum pump

A cluster tool has a transfer chamber, and a load lock chamber. An adaptor is configured to be coupled between the transfer chamber and the load lock chamber. The adaptor has an adaptor housing with an interior space including an entrance with a first valve and an exit with a second valve. The adaptor housing forms a substrate path through the interior space. The first valve connects the interior space and the load lock chamber. The second valve connects the interior space and the transfer chamber. A cryogenic surface is associated with the adaptor. Other pumps can be associated with the adaptor, such as, for example, a turbo pump, or water vapor pump. The cryogenic surface is configured to selectively evacuate the interior space. A wafer is adapted to be moved through the first valve and through the adaptor housing along the path. The wafer is moved through the exit and into the transfer chamber once the second valve is opened. This adaptor can be applied to the process chamber as well as the load lock.

Owner:EDWARDS VACUUM LLC

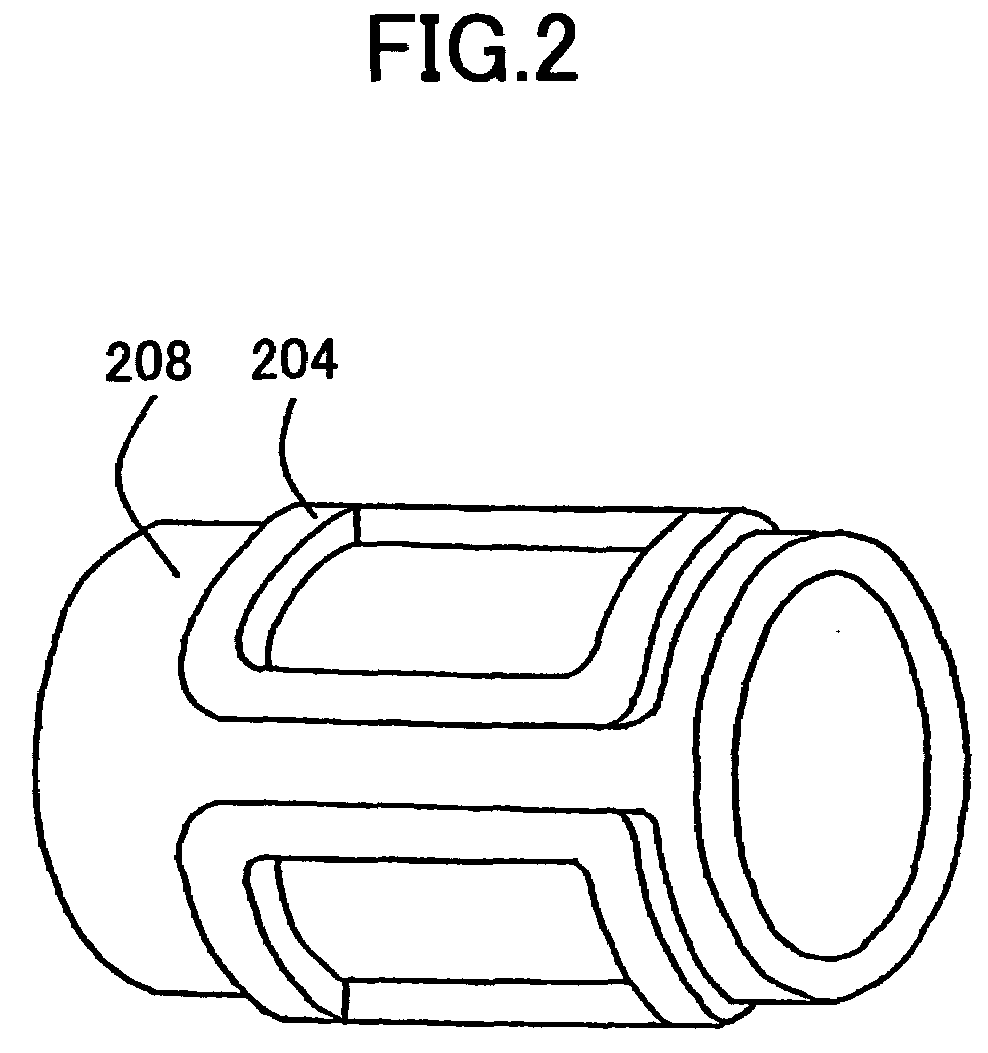

Coreless and brushless direct-current motor, Gifford McMahon (GM) cryogenic cooler, pulse tube cryogenic cooler, cryopump, Magnetic Resonance Imaging (MRI) apparatus, Superconducting Magnet (SCM) apparatus, Nuclear Magnetic Resonance (NMR) apparatus, and cryogenic cooler for cooling semiconductor

InactiveUS20080024034A1No over current loss and hysteresis lossSmall leakageMagnetic circuit rotating partsMechanical energy handlingNMR - Nuclear magnetic resonanceRotor magnets

A coreless and brushless direct-current motor includes an armature coil wound without core and formed in the shape of a saddle; an outside rotor magnet formed by a permanent magnet, the outside rotor magnet being provided at an outside of the armature coil in the shape of a cylinder so as to face the armature coil, the outside rotor magnet being rotated by the magnetic field; an inside rotor magnet formed by a permanent magnet, the inside rotor magnet being provided in the shape of a cylinder at an inside of the armature coil so that the inside rotor magnet has a pole opposite to the outside rotor magnet and a rotational shaft is independently provided; an output shaft connected to the inside rotor magnet; and a sealing part of a barrier structure which sealing part partitions the armature coil and the outside rotor magnet to an outside of the inside rotor magnet and seals the armature coil and the outside rotor magnet.

Owner:SUMITOMO HEAVY IND LTD

Pressure burst free high capacity cryopump

ActiveUS20080168778A1Avoid condensationTightly boundSolidificationLiquefactionEngineeringThermal contact

A cryopump includes a refrigerator with at least first and second stages. A radiation shield surrounds the second stage and is in thermal contact with the first stage. The radiation shield includes a drain hole to permit cryogenic fluid to traverse through the drain hole during regeneration. The cryopump also includes a primary pumping surface supporting adsorbent in thermal contact with the second stage. The second stage array assembly includes a primary condensing surface, protected surfaces having adsorbent, and non-primary condensing surfaces. A baffle is disposed over the drain hole. The baffle redirects gas from an annular space disposed between the radiation shield and the vacuum vessel that attempts to traverse through the drain hole to prevent the gas from condensing on a non-primary condensing surface. The baffle directs gas to condense on the primary condensing surface.

Owner:EDWARDS VACUUM LLC

Cryopanel and Cryopump Using the Cryopanel

A cryopanel used for a cryopump, the cryopump including a vacuum chamber having a gas flow-in opening; a stage provided in the vacuum chamber; and a cryocooler configured to cool the stage, the cryopump being configured to solidify or absorb a molecule flowing from the gas flow-in opening into the vacuum chamber, the cryopanel includes a first panel held and cooled by the stage, the first panel having a surface facing toward the gas flow-in opening; and a second panel held by the first panel and extending from the first panel in an upstream direction of a gas flow-in, the second panel having a surface where an absorption material layer is formed.

Owner:SUMITOMO HEAVY IND LTD

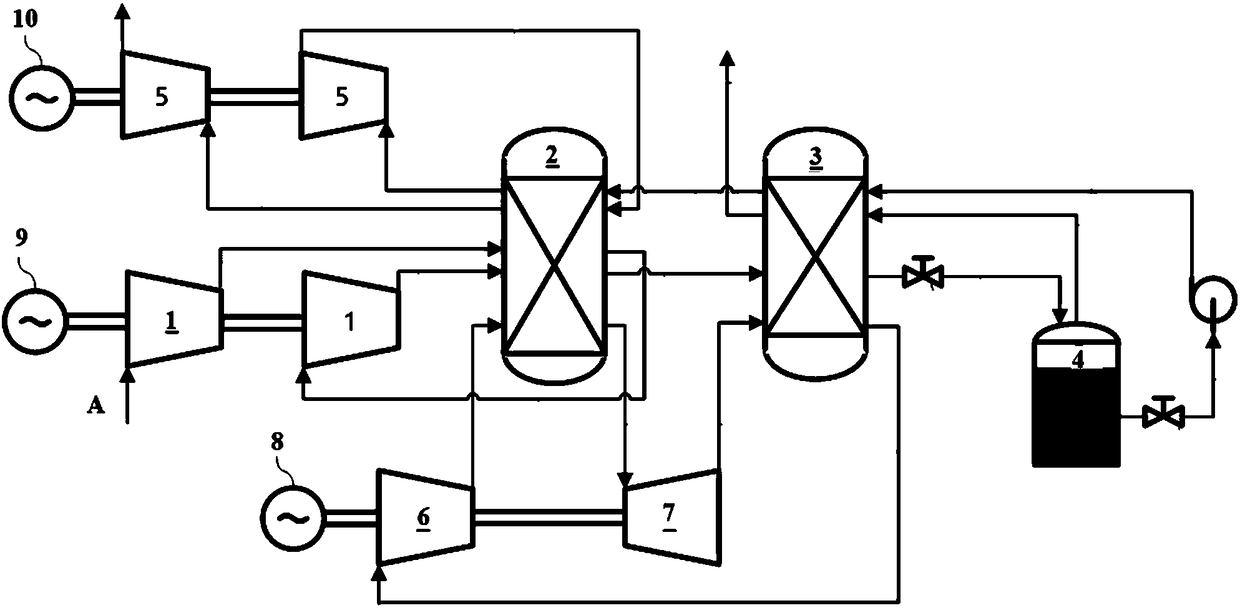

Supercritical air energy storage system of heat pump

PendingCN108533476AIncrease energy densityImprove efficiencySolidificationLiquefactionThermal energyHigh energy

The invention discloses a supercritical air energy storage system of a heat pump and belongs to the technical field of energy storage. Off-peak electricity (lowelectricity ) of a power station is adopted to condense air into a high pressure state, stored cold energy and low temperature cold energy obtained by circulation of the heat pump are used for cooling the high pressure air at the low temperature state and storing thermal energy obtained by the circulation of the heat pump, and liquid air is obtained after decompression; at the peak of electricity consumption, the high pressure liquid air is condensed by a cryopump and enters a regenerator, absorbs heat,then enters in a normal temperature high pressure state and stores the cold energy, and further, absorbs stored thermal energy including air compression heat and heat pump circulation heat to drive a motor to generate electricity through an expansion machine. The supercritical air energy storage system of the heat pump has the advantages of being high energy density, high efficiency and high flexibility, being suitable forpeak regulation of power grids and various different renewable energy power stations, and free of greenhouse gases.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Method and equipment for dynamically recycling evaporated gas of liquefied natural gas

InactiveCN104315802AReduce burning wasteEmission reductionSolidificationLiquefactionRecovery methodEvaporation

The invention discloses a method and equipment for dynamically recycling evaporated gas of liquefied natural gas. The method includes firstly, monitoring density, temperature and pressure data of the evaporated gas of the liquefied natural gas stored in a storage tank; secondly, computing and preliminarily judging super-cooling quantities required by the liquefied natural gas stored in the storage tank according to the monitored data; thirdly, enabling propane media to be in refrigerating cycles and then inputting the super-cooling quantities into the liquefied natural gas stored in the storage tank via heat exchange; fourthly, enabling the liquefied natural gas in a super-cooling state to return the storage tank by means of circulation, enabling the liquefied natural gas in the storage tank to reach new super-cooling state balance, dissolving evaporated gas generated in the liquefied natural gas into the liquefied natural gas again and reducing evaporation quantities by 80%; fifthly, starting to execute the first step, the second step, the third step and the fourth step again when the evaporated gas of the liquefied natural gas stored in the storage tank is layered. The equipment comprises the liquefied natural gas storage tank, a low-temperature pump, a heat exchanger, a refrigerating plant, a sensor and a control device. The method and the equipment have the advantages that the evaporated gas of the liquefied natural gas can be dynamically recycled, and the equipment can run stably without being frequently started and stopped and is high in safety and low emission and operating cost.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com