Method and equipment for dynamically recycling evaporated gas of liquefied natural gas

A technology of liquefied natural gas and recovery method, which is applied in the field of dynamic recovery of liquefied natural gas boil-off gas, can solve the problems of low emissions and reduced operating costs, and achieve the effects of low emissions, reduced operating costs and strong safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

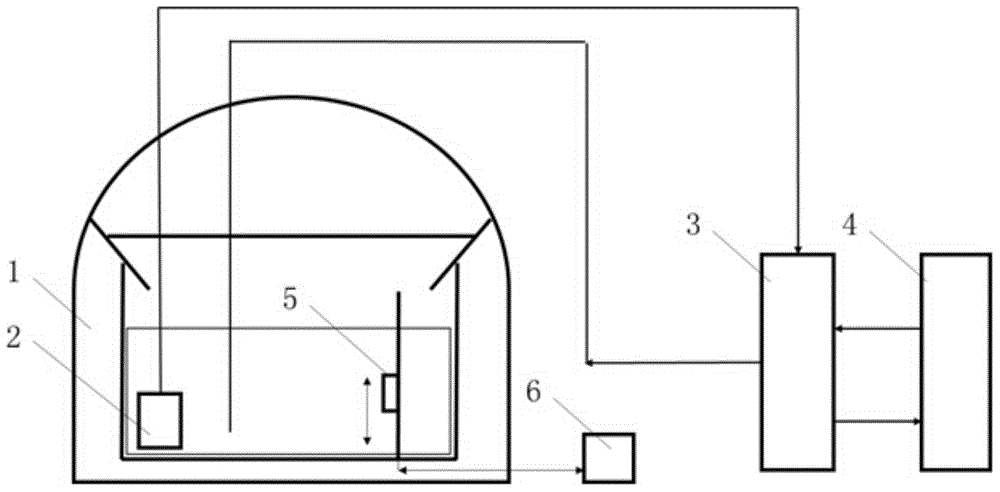

Image

Examples

Embodiment 1

[0036] Taking a medium-sized liquefied natural gas peak-shaving station as an example, the annual gaseous output capacity is 800,000 tons, and a low-temperature LNG storage tank of 80,000 m3 is installed. If the conventional recovery method is adopted, the direct loss caused by the evaporation loss is about 4,000 tons of LNG. In addition, due to the frequent start and stop during the peak shaving period and the impact of the vibration caused by the evaporation gas recovery on the structure and internal parts, additional internal Part replacement, maintenance work, etc., the overall calculation of the annual economic loss is about 12 million yuan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com