Liquefied natural gas flash gas constant pressure recovery method and equipment

A liquefied natural gas and recovery method technology, applied in the field of constant pressure recovery of liquefied natural gas flash gas, can solve problems such as system overpressure and increased chance of venting, decreased operating economy of receiving stations, and increased cost of flash gas treatment, etc., to reduce noise and Effects of vibration, avoiding overpressure alarm and cold and heat air defense, and improving recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

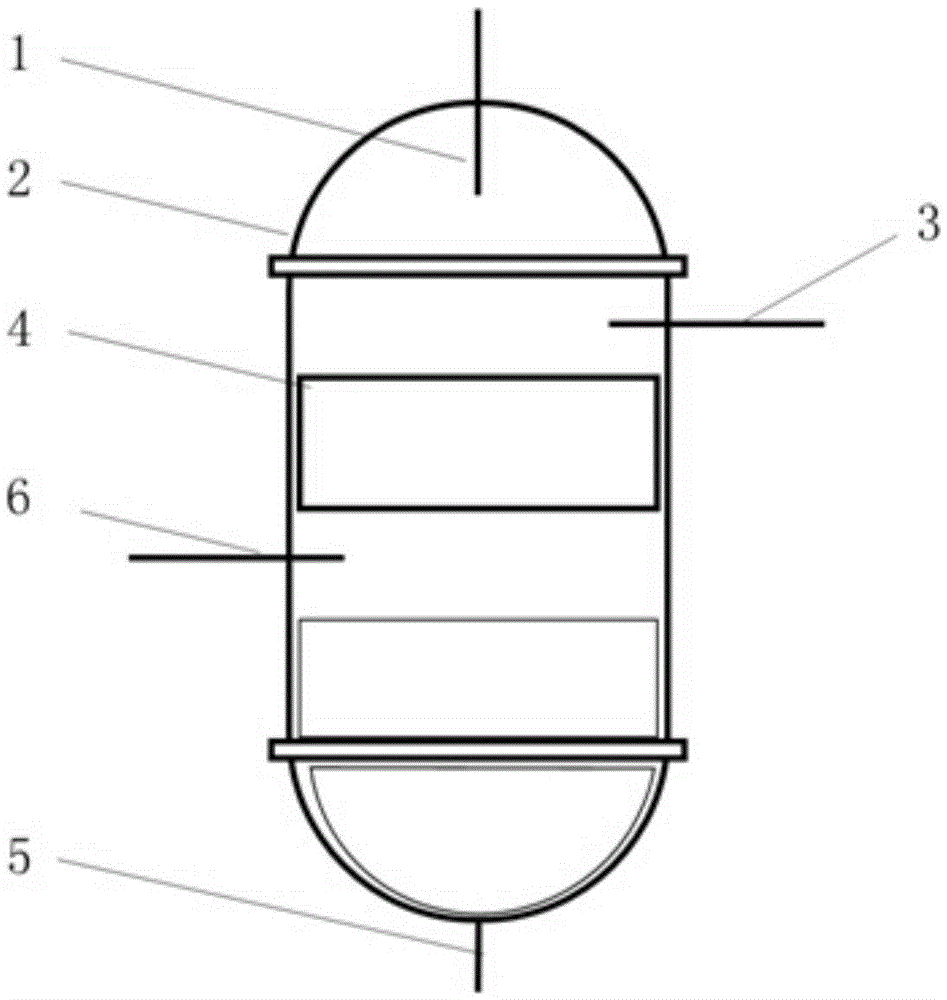

Image

Examples

Embodiment 1

[0028] A liquefied natural gas peak shaving station has an annual production capacity of 2 million tons. It uses a recondenser pressure vessel with a processing capacity of about 10 tons per hour. It uses compressed flash gas and supercooled liquefied natural gas in a structured packed bed without nitrogen supplementary pressure. The external gas is depressurized to about 1 MPa and returned to the input pressure vessel to make up the pressure. Due to the high-pressure gas make-up, the LNG is in a supersaturated state. After entering the subsequent process, it is quickly released again, and is collected by the air defense pipeline to the evaporation gas main pipe to form evaporation. In addition, due to the vibration caused by the flash gas dissolution process inside the pressure vessel, the internal parts, nozzles and auxiliary structures need to be maintained for three months, resulting in production shutdown losses. The above-mentioned total annual loss is about 25 million yu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com