Reciprocating rack linear driving oil pumping unit

A pumping unit, reciprocating technology, applied in the field of reciprocating rack linear drive pumping unit, can solve the problems of poor oil well condition monitoring and adjustment ability, poor adaptability, difficult adjustment, etc., and achieve compact structure and low cost , the effect of smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

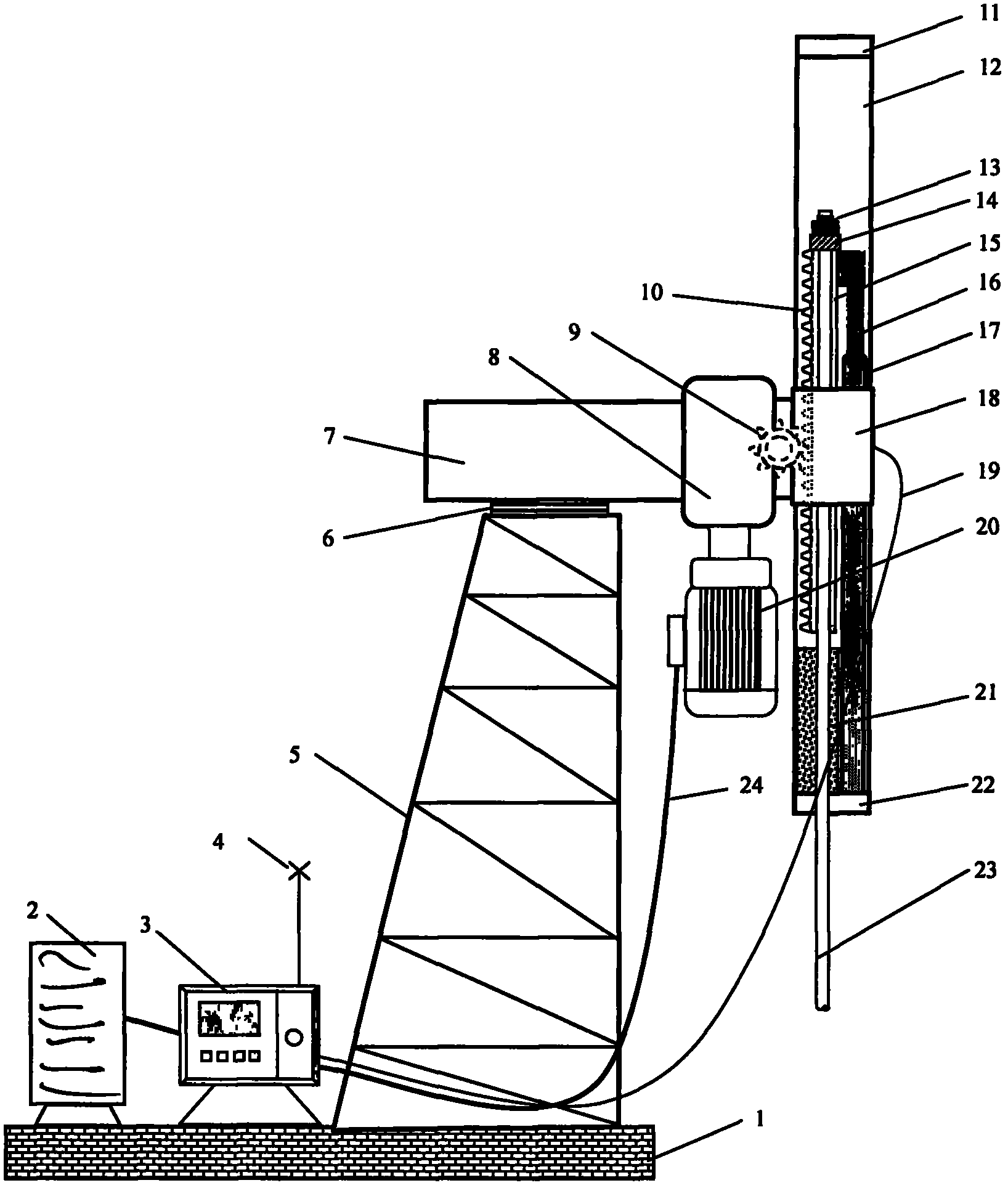

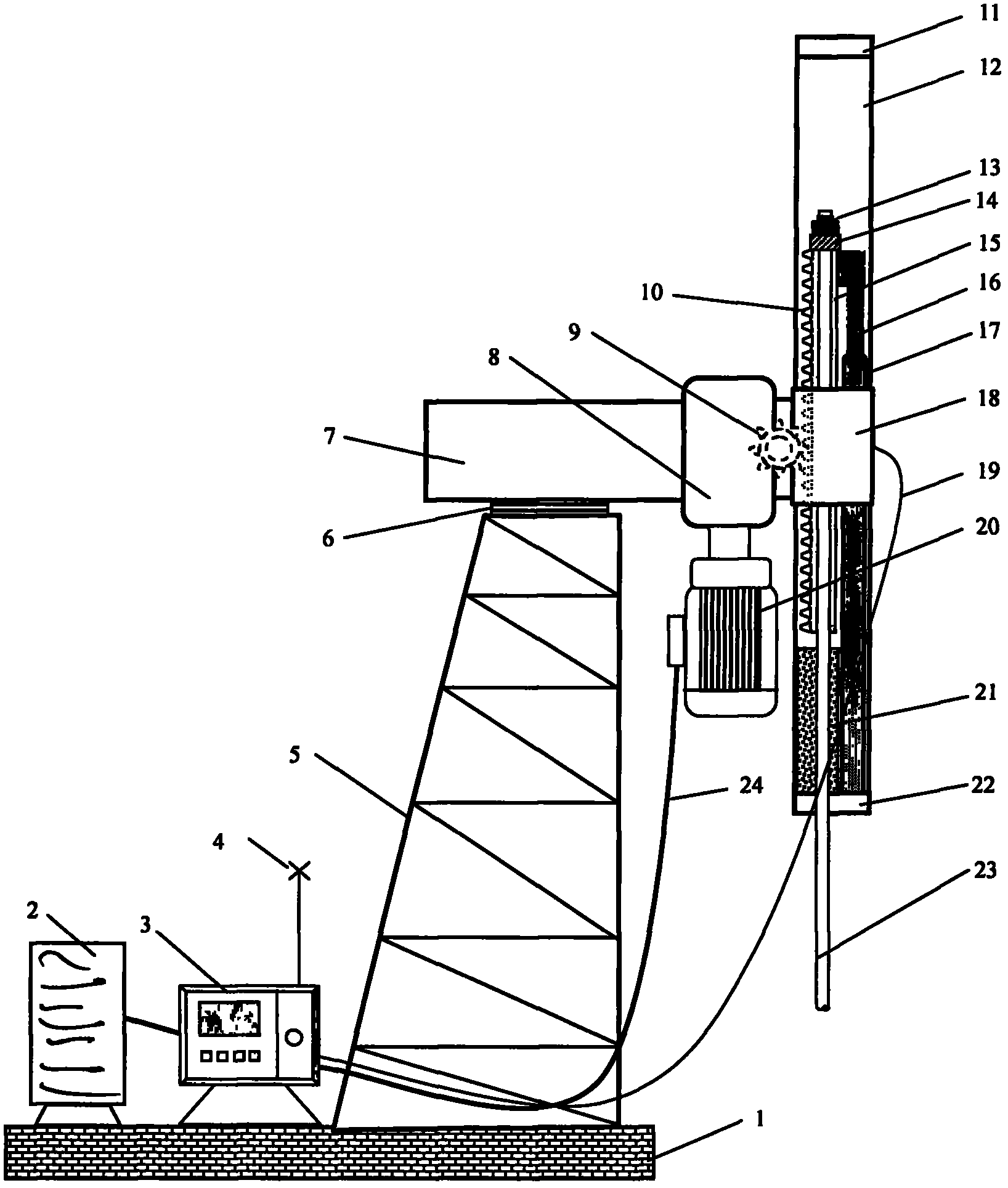

[0022] As shown in the figure, a reciprocating rack linear drive pumping unit.

[0023] Frame part: Frame 5 is fixed on the concrete base 1, and the beam base 6 is fixed on the upper part of the frame 5.

[0024] The walking beam part: the walking beam 7 is connected with the walking beam base 6, and the gear transmission box 8 and the machine body connecting body 18 are connected with the walking beam 7.

[0025] Driving and transmission part: the motor 20 is connected with the gear transmission box 8, the gear box 8 and the pumping unit casing 12 are connected through the body connecting body 18, the gear 9 is matched with the rack 10, and the rack 10 is connected to the polished rod through the polished rod clamp 13 Connected, the rack 10 slides back and forth on the rack slide 15.

[0026] Pneumatic balance part: the piston 16 is connected with the rack 10, and the piston 16 compresses the gas in the cylinder 17.

[0027] Energy storage part: The capacitor 2 is connected to the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com