Patents

Literature

686results about How to "Reduce flying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

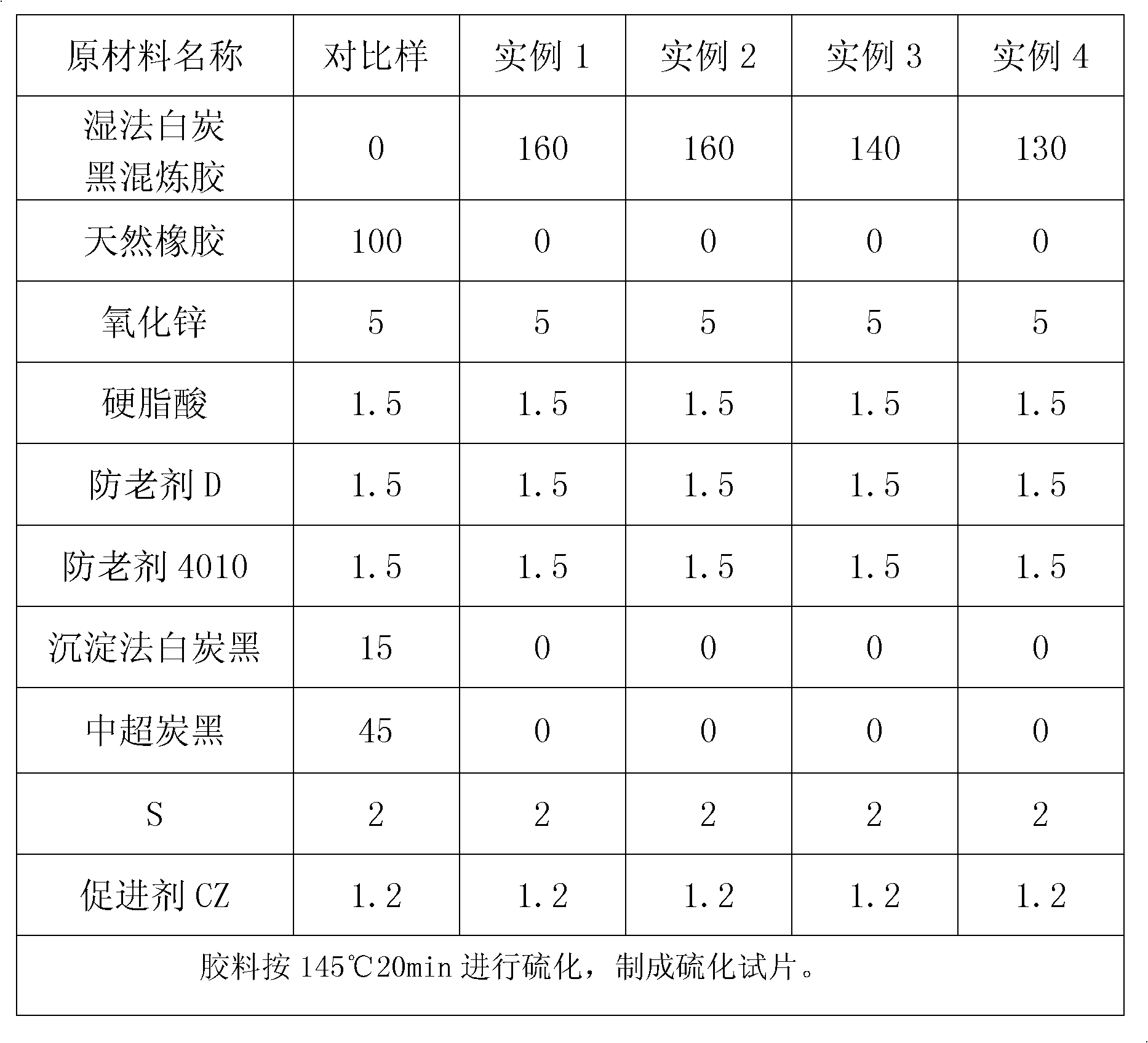

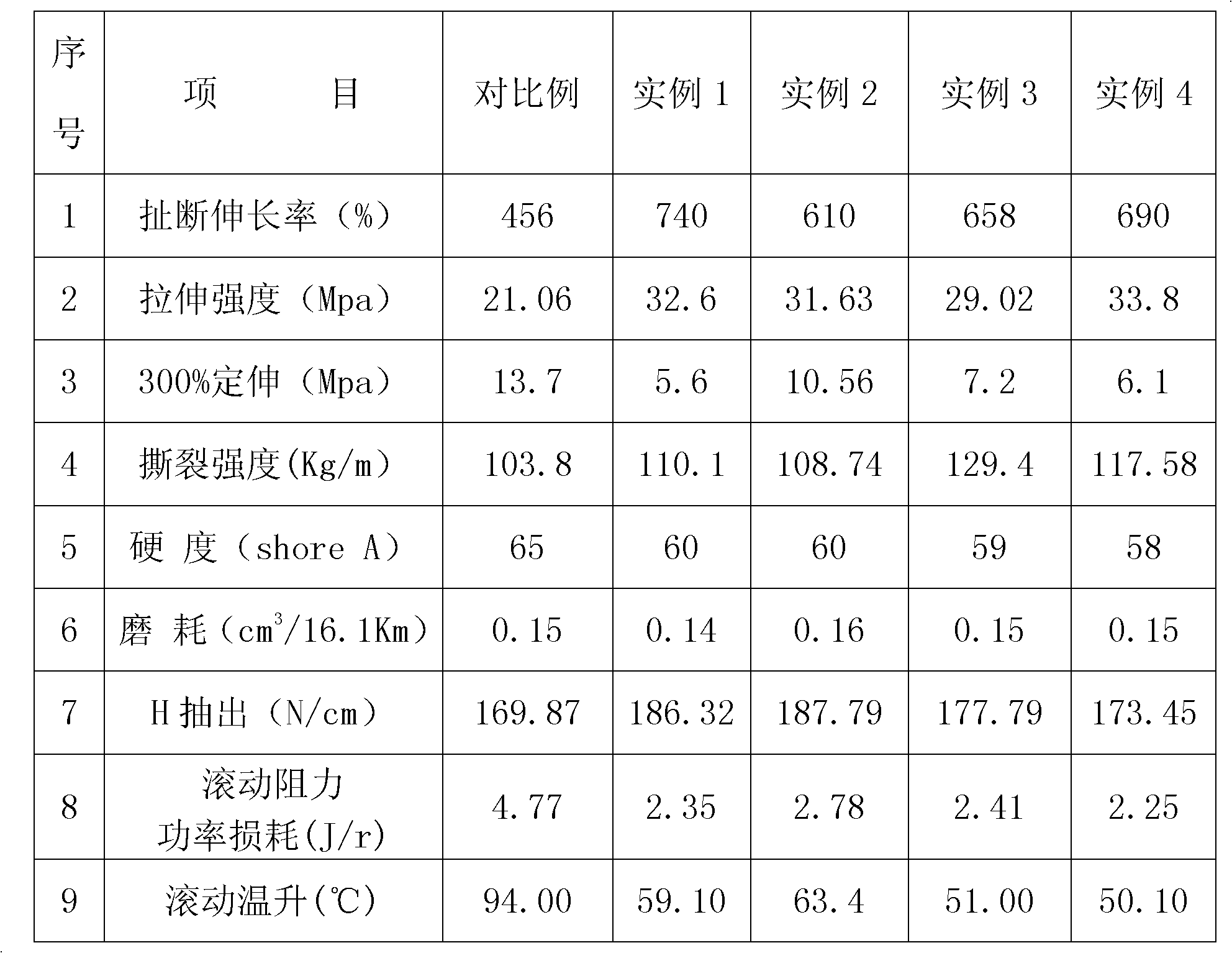

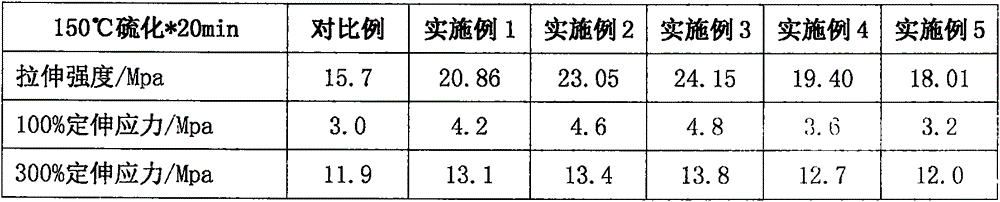

Preparation method of wet process mixed natural rubber material

ActiveCN102153792AGood dispersionImprove uniformityRolling resistance optimizationRubber materialPolymer science

The invention relates to a preparation method of a wet process mixed natural rubber material. The method comprises the following steps of: preparing slurry and soaking 15-40 percent of dry white carbon black in 60-85 percent of deionized water; adding a coupling agent and a surfactant, uniformly mixing, grinding, preparing latex mixed liquor, extracting natural latex and adding white carbon black water dispersoid into the latex; stirring and mixing to obtain a latex mixed liquor, flocculating and adding acetic acid into the mixed liquor; performing rubber washing and dehydration by using a rubber washing machine and feeding to a rubber pelletizer for pelletizing; and feeding rubber particles into a box drying cabinet for drying. The preparation method has the advantages of simple machining process, small equipment investment, realization of various ideal performances with the most ordinary white carbon black, low dust pollution in the entire production process and energy saving. A tire manufactured with the method has small rolling resistance, low heat generation, high tensile strength, high tearing strength and high rubber material ageing resistance. Mixing of the white carbon black is performed in a liquid phase, so that the dispersivity and uniformity are enhanced.

Owner:ZHUZHOU ANBAOLINFENG NEW MATERIALS

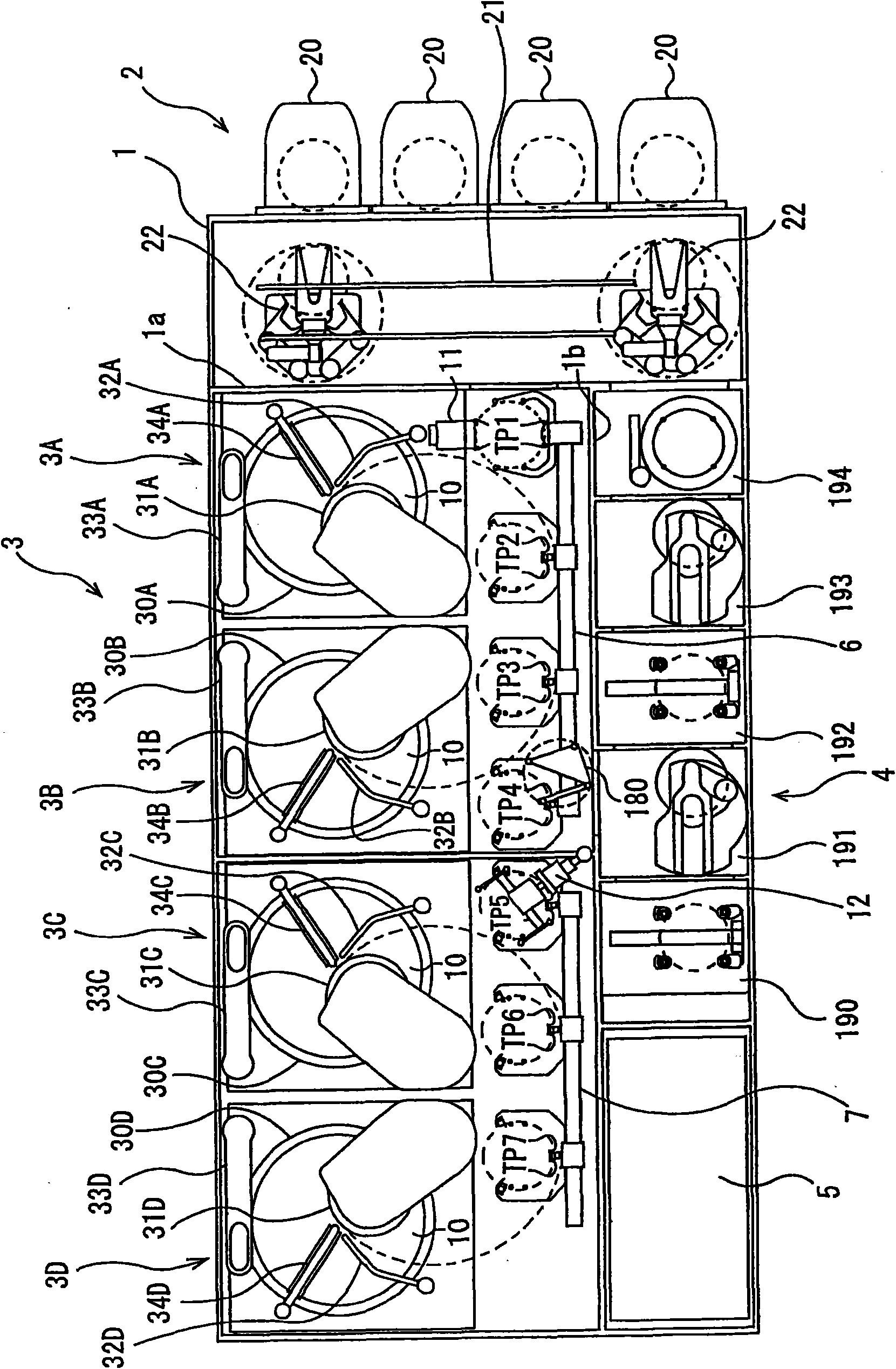

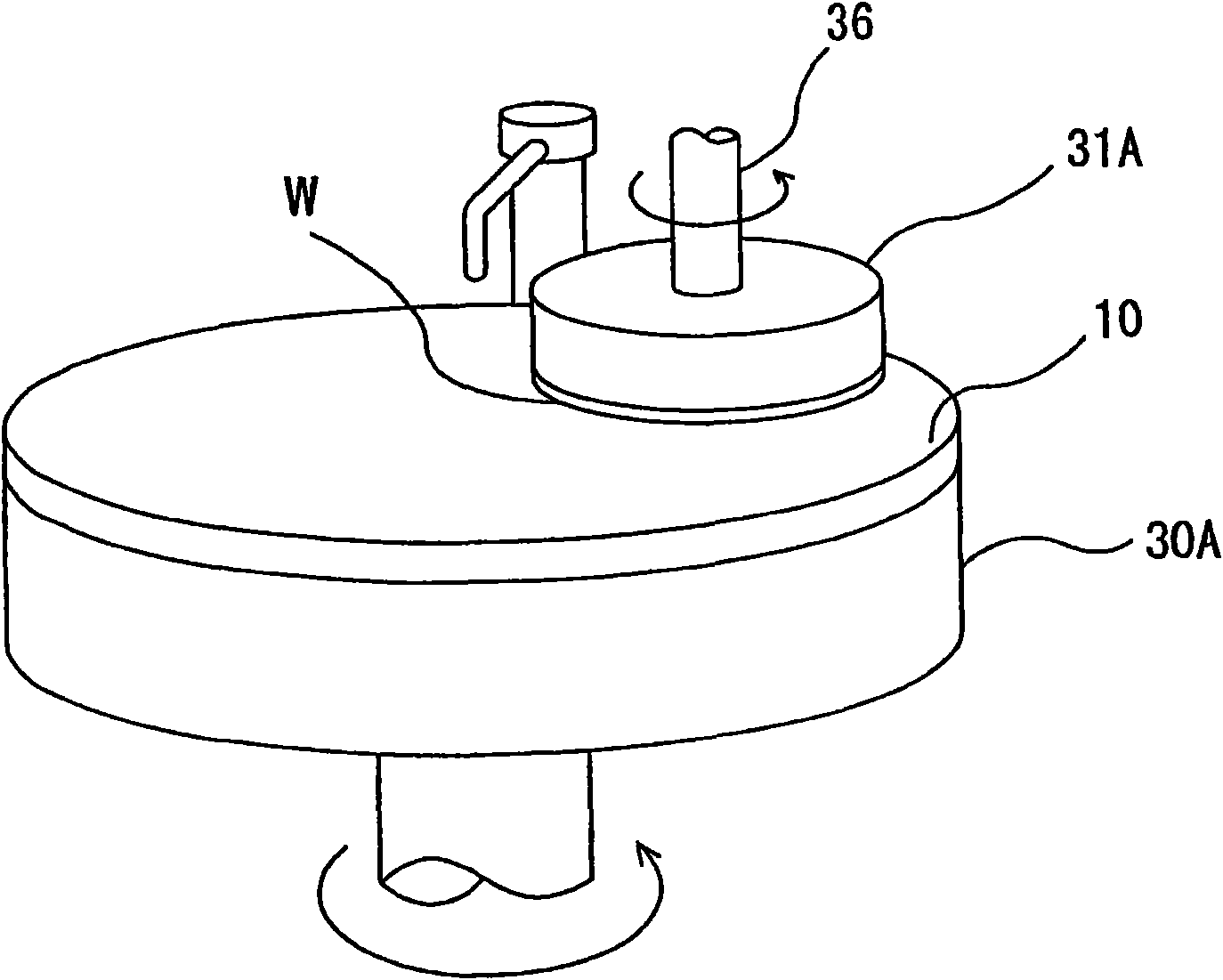

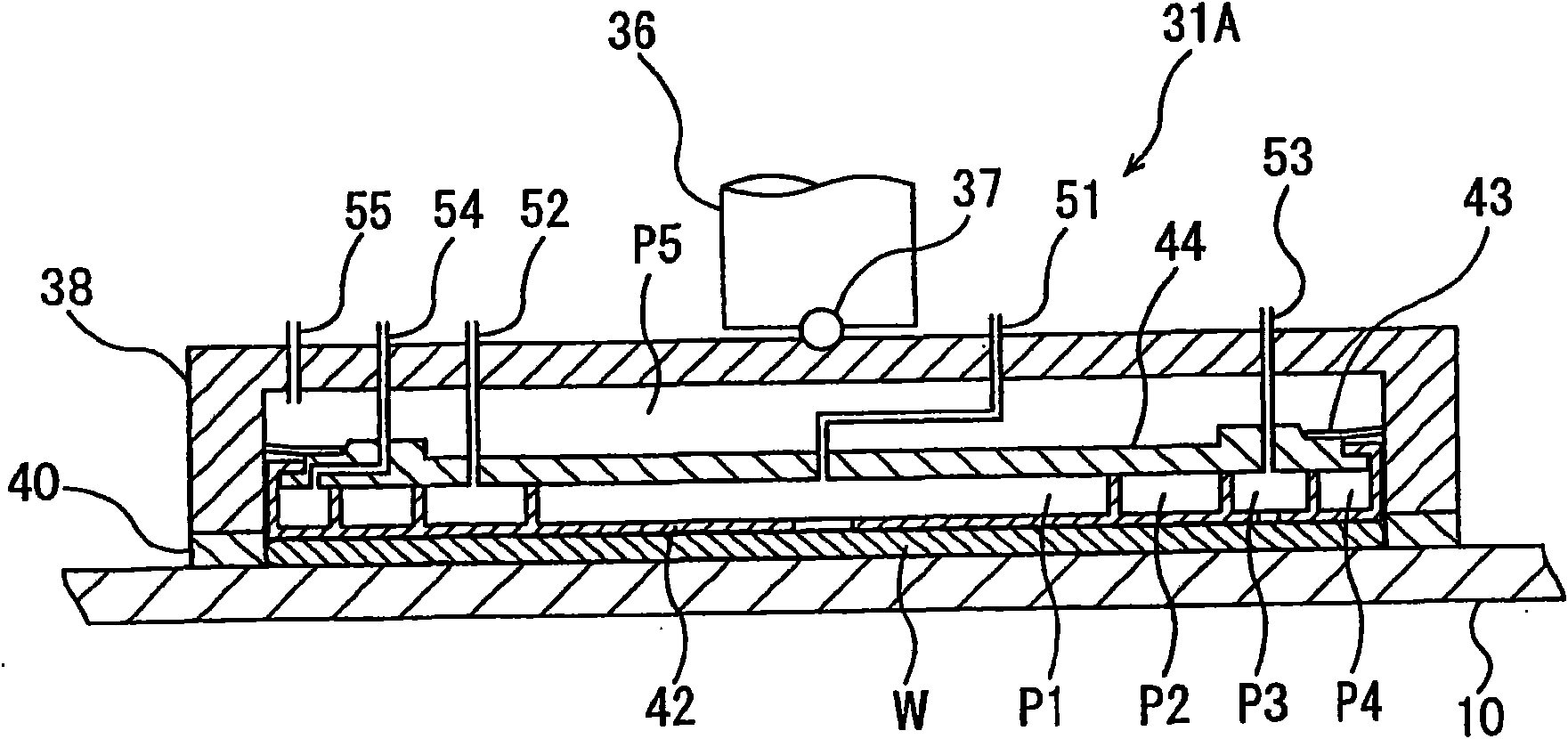

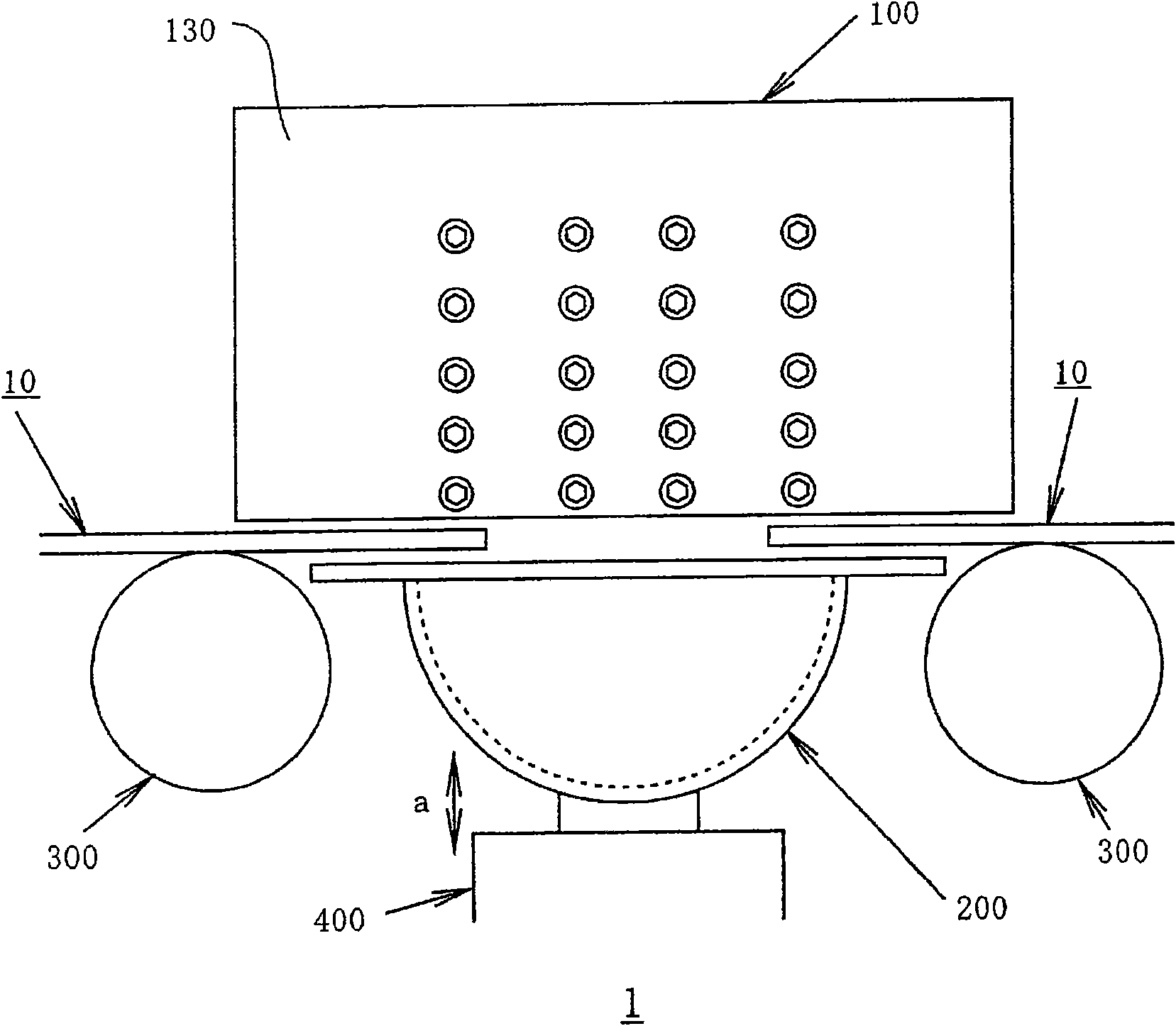

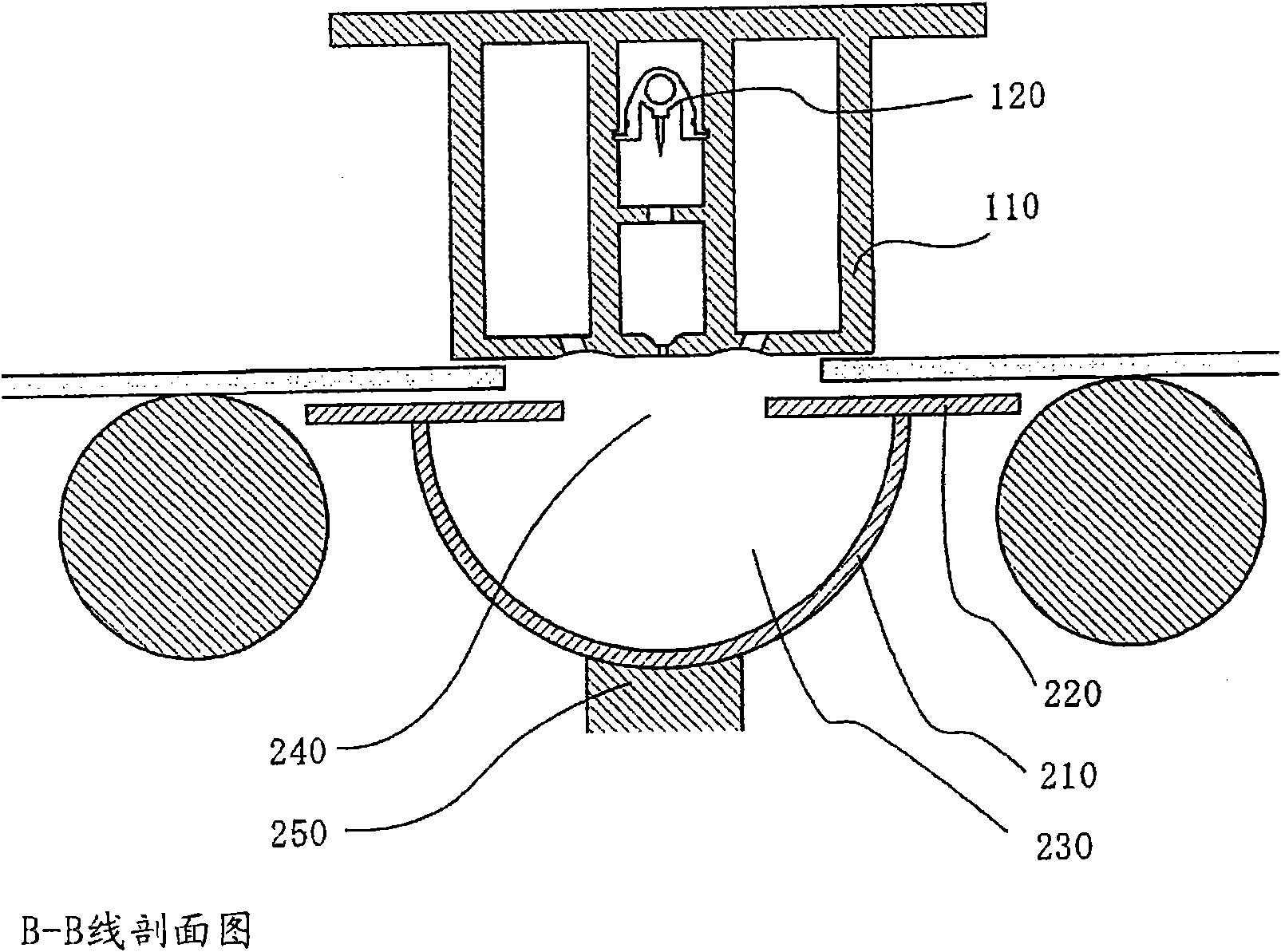

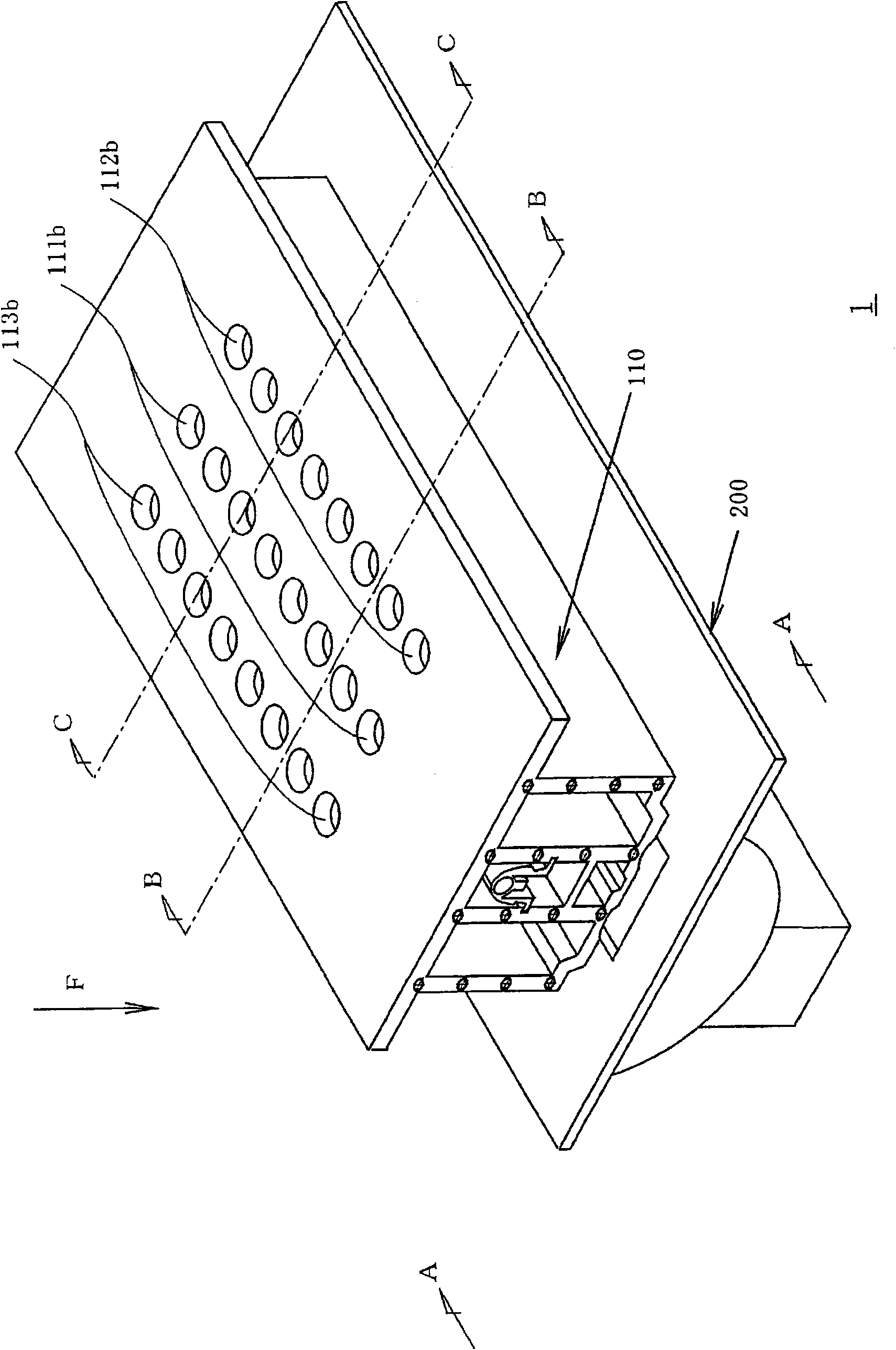

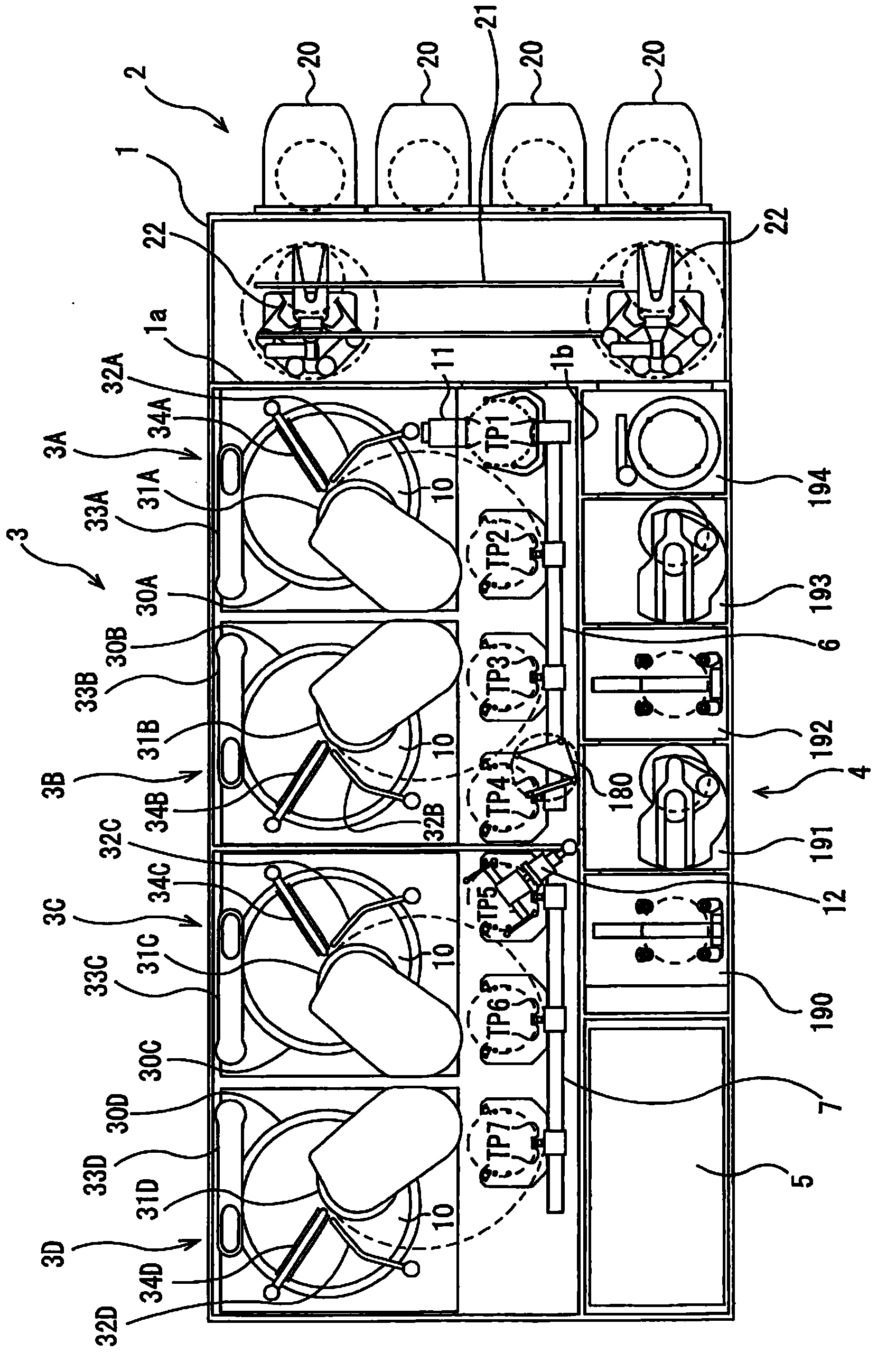

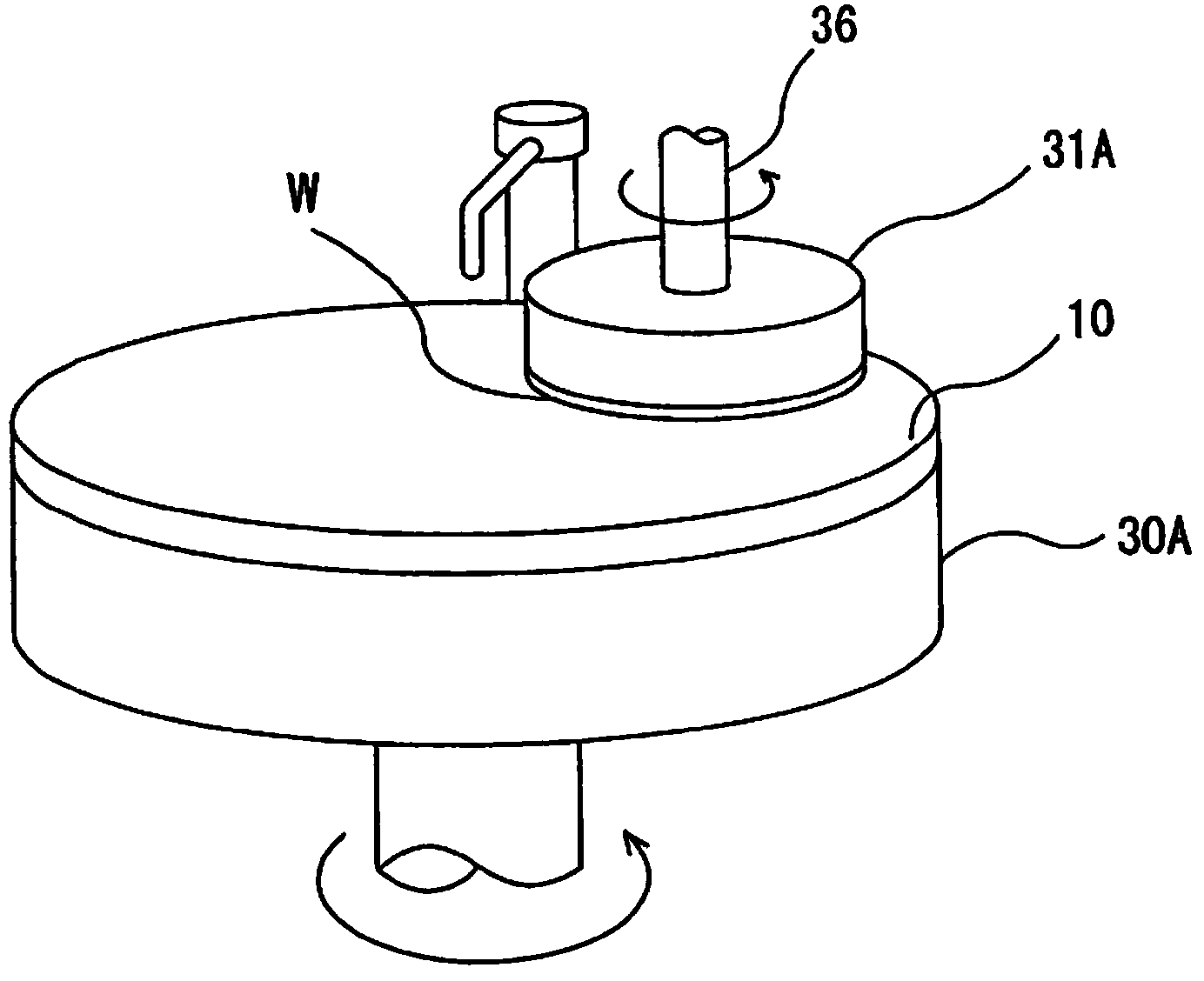

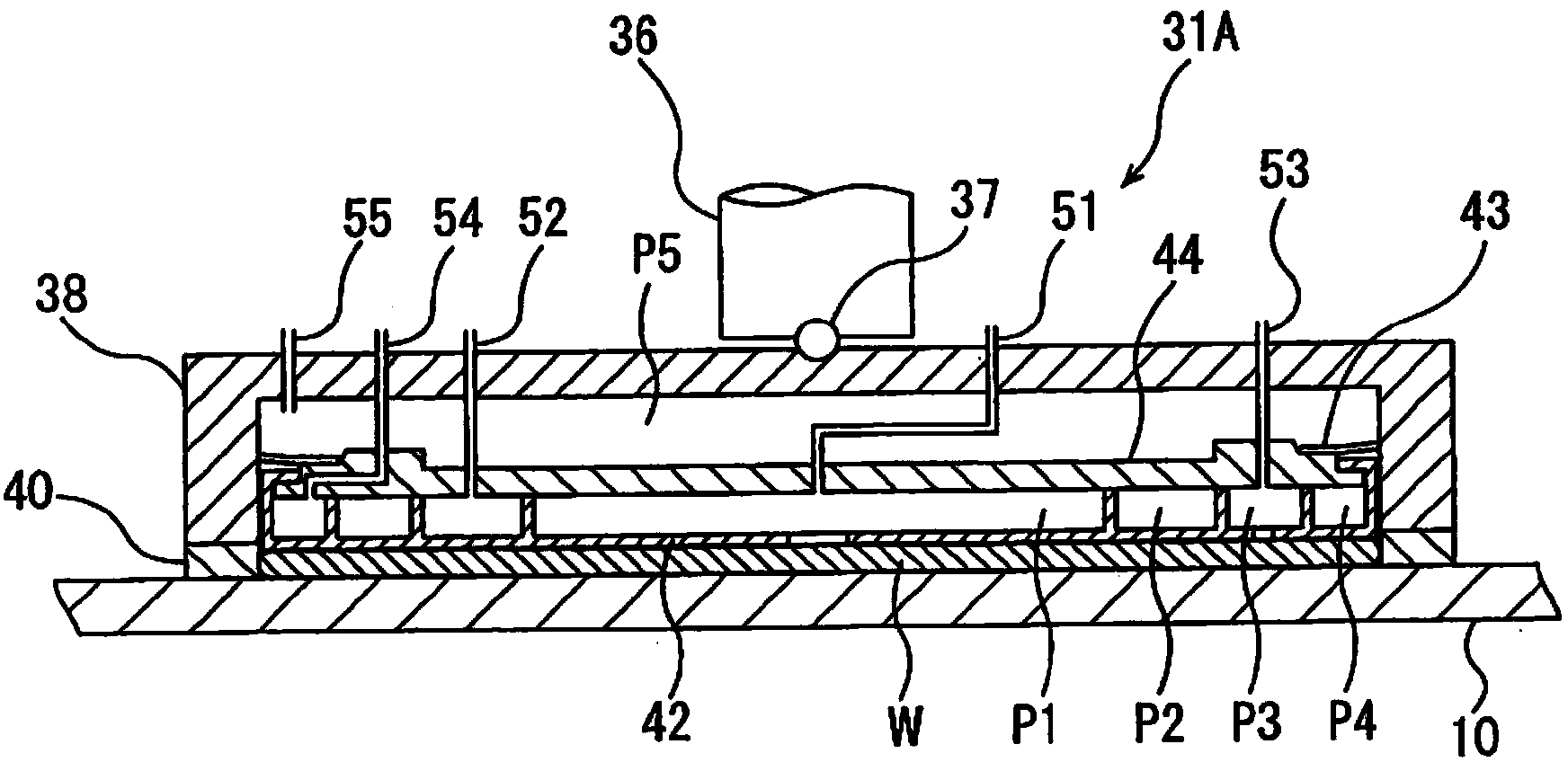

Substrate processing apparatus, substrate processing method, substrate holding mechanism, and substrate holding method

ActiveCN101599423AProcessing time equalizationImprove processing efficiencyPolishing machinesSemiconductor/solid-state device testing/measurementTransfer mechanismElectrical and Electronics engineering

A substrate processing apparatus, a substrate processing method, a substrate holding mechanism, and a substrate holding method are disclosed. The apparatus includes a polishing section configured to polish a substrate, a transfer mechanism configured to transfer the substrate, and a cleaning section configured to clean and dry the polished substrate. The cleaning section has plural cleaning lines for cleaning plural substrates. The plural cleaning lines have plural cleaning modules and plural transfer robots for transferring the substrates.

Owner:EBARA CORP

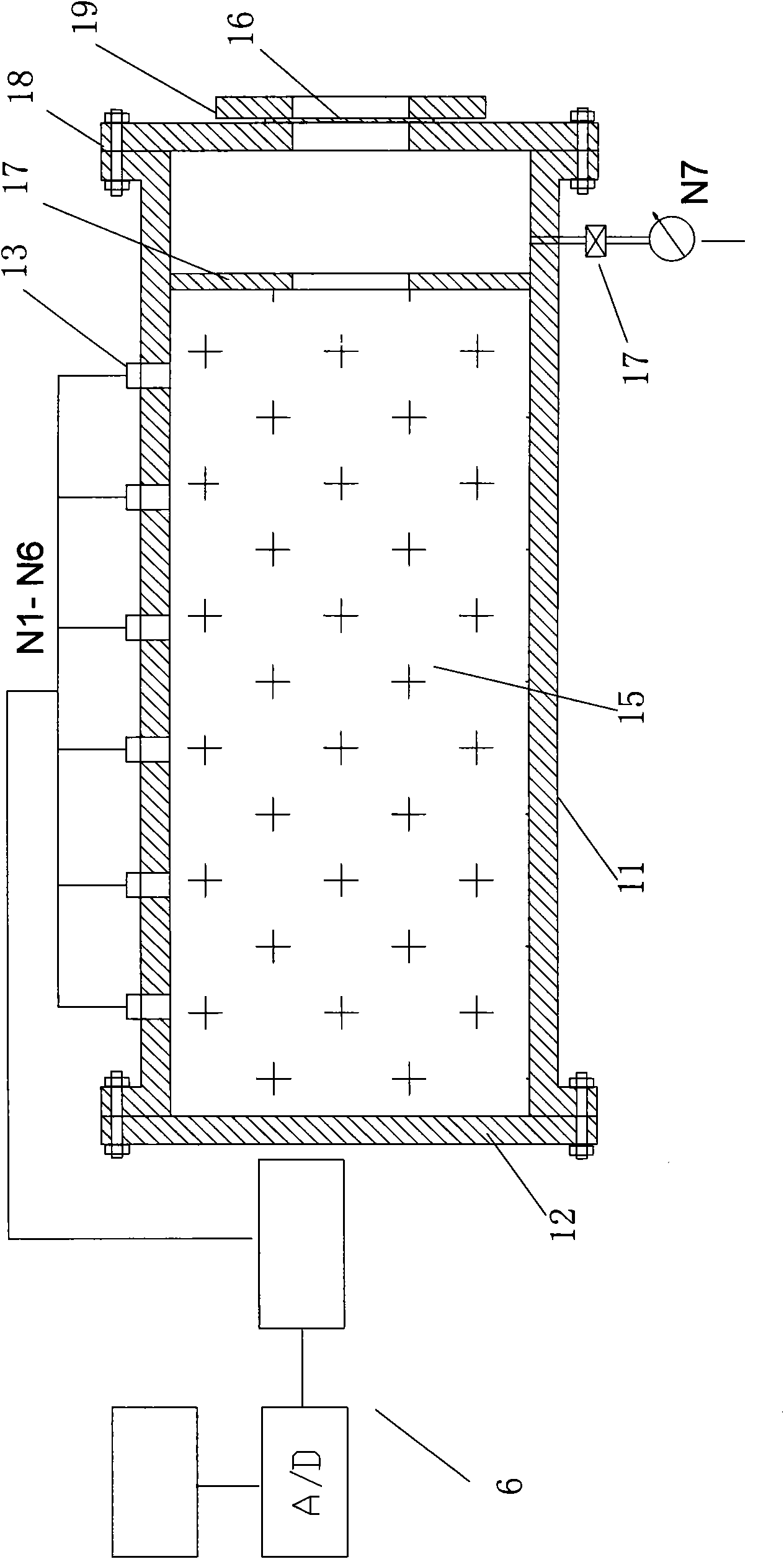

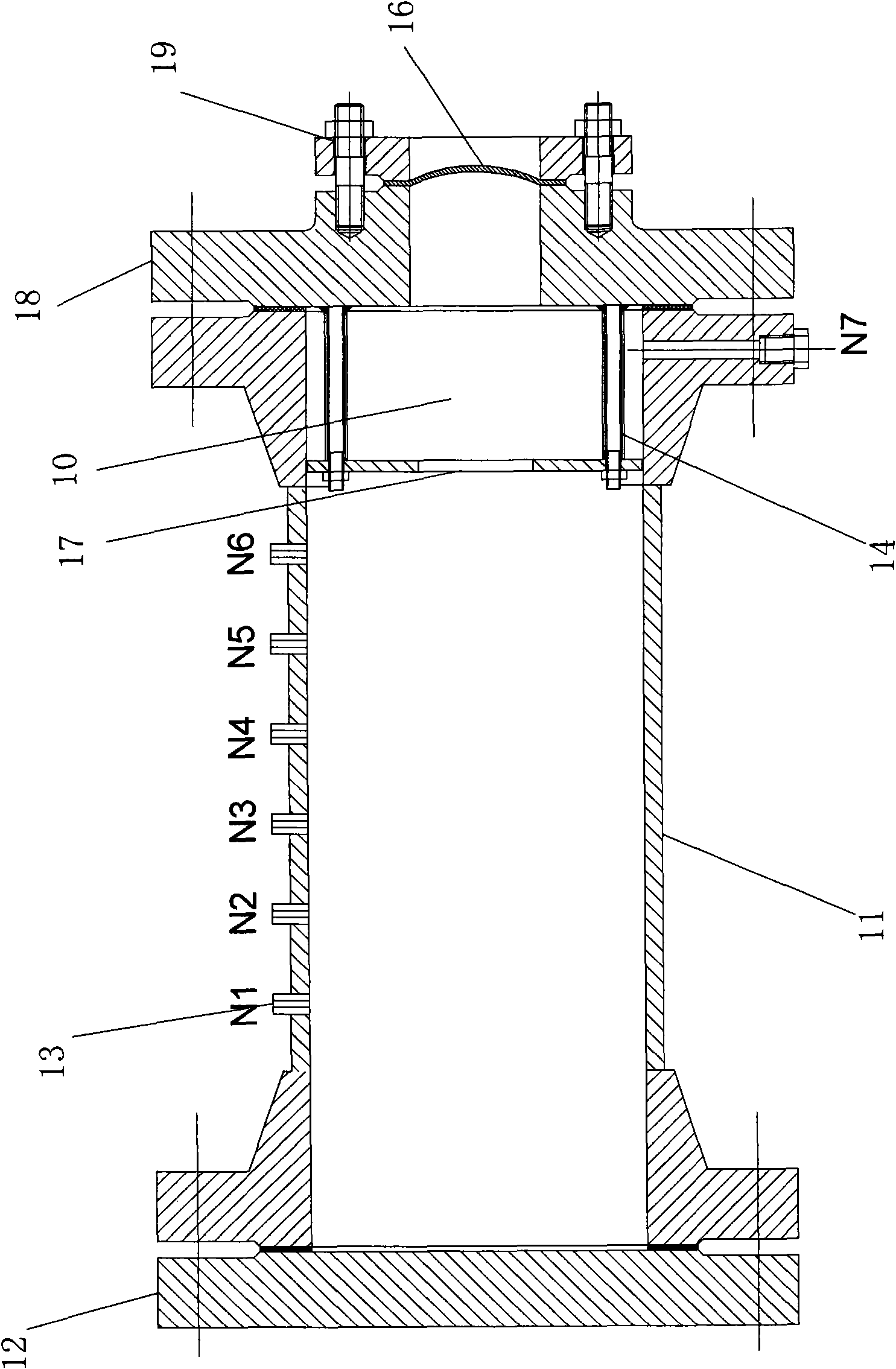

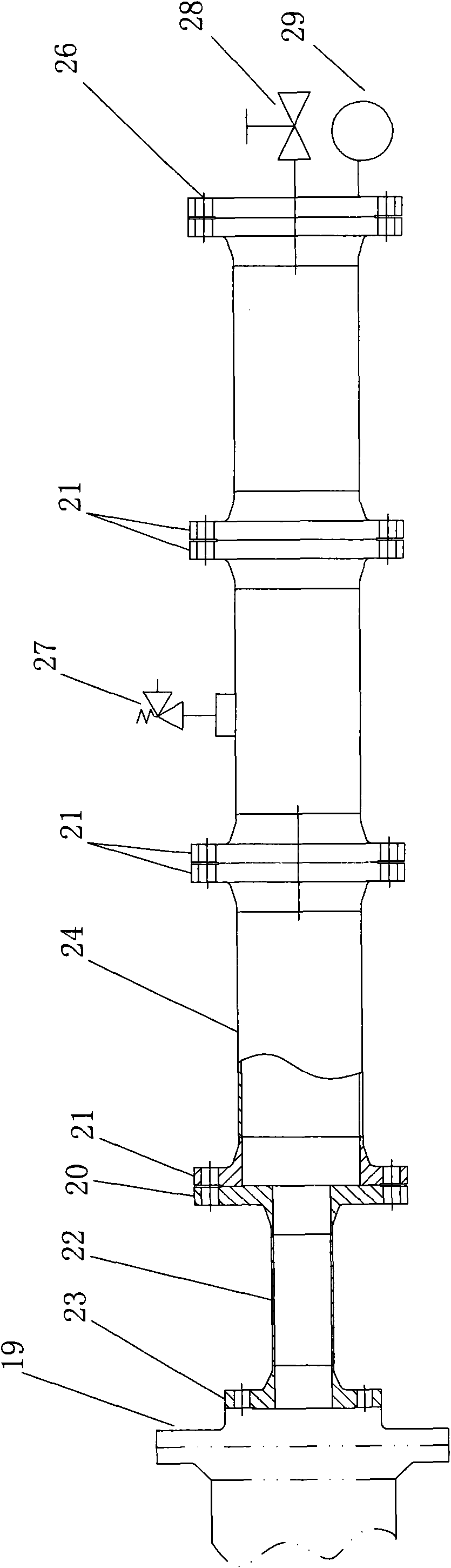

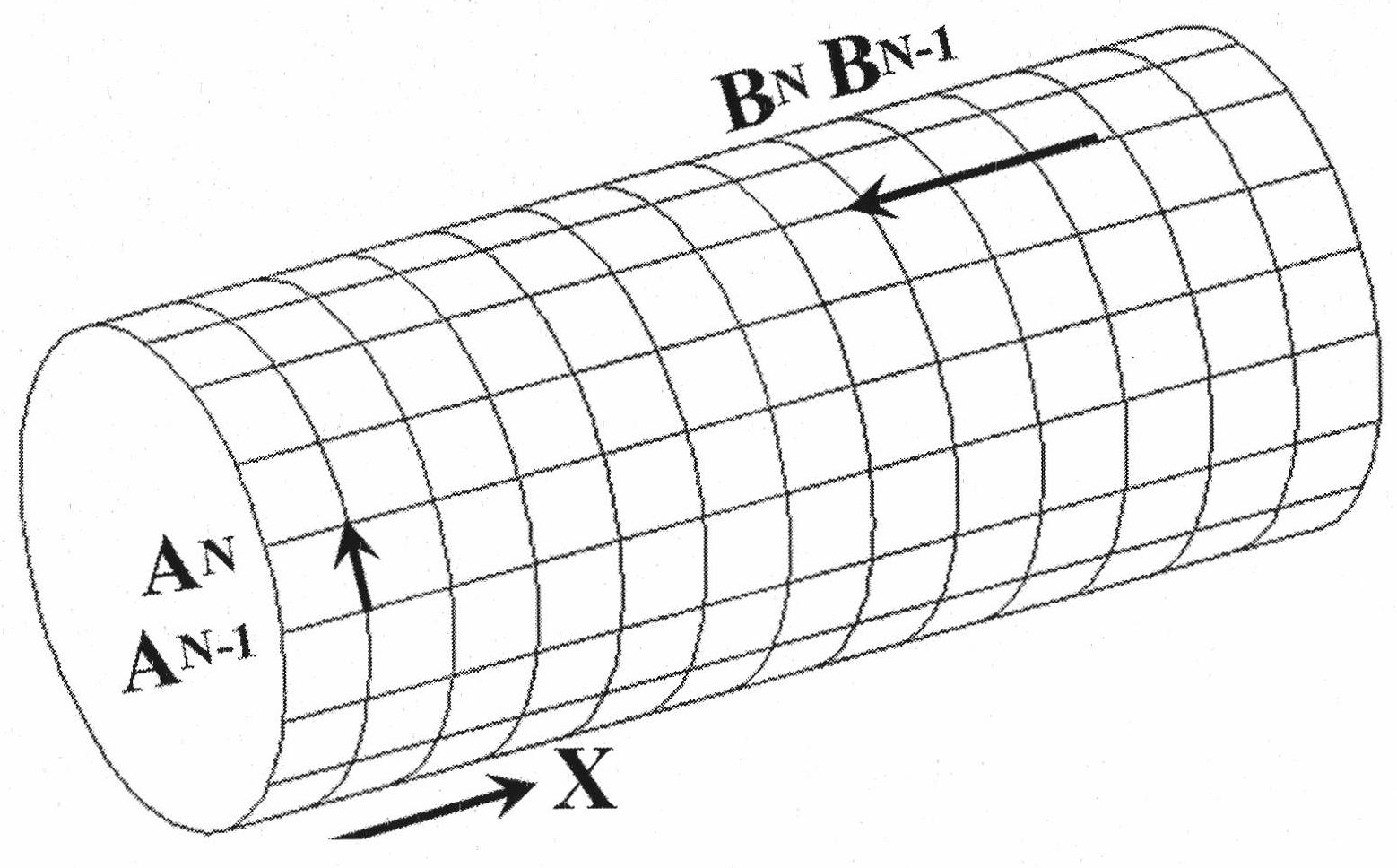

Coal and gas outburst simulation test device and protection device thereof

ActiveCN101806792AAvoid disturbanceGuaranteed strength and stabilityMaterial analysisCoalSafety valve

The invention discloses a coal and gas outburst simulation test device, which comprises a steel cylinder, flange disks arranged at two ends of the steel cylinder, an inflation system and a data acquisition system. The flange disk which is arranged at one end of the steel cylinder is a flange disk provided with a central hole, and an explosion-proof plate is arranged on a non-mounting side of the flange disk and the steel cylinder. The invention also relates to a protection device for the coal and gas outburst simulation test device, which mainly comprises a bearing flanged pipe fitting, a pressure relief cavity, an anti-overload safety valve, an air release valve and a shock-proof pressure gauge. One end of the bearing flanged pipe fitting is connected with the coal and gas outburst simulation test device, and the other end of the bearing flanged pipe fitting is connected with the pressure relief cavity through a flange disk; and the tail end of the pressure relief cavity is provided with a flange cover. The protection device can be applied to real-time measurement and safe pressure relief in the test process.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

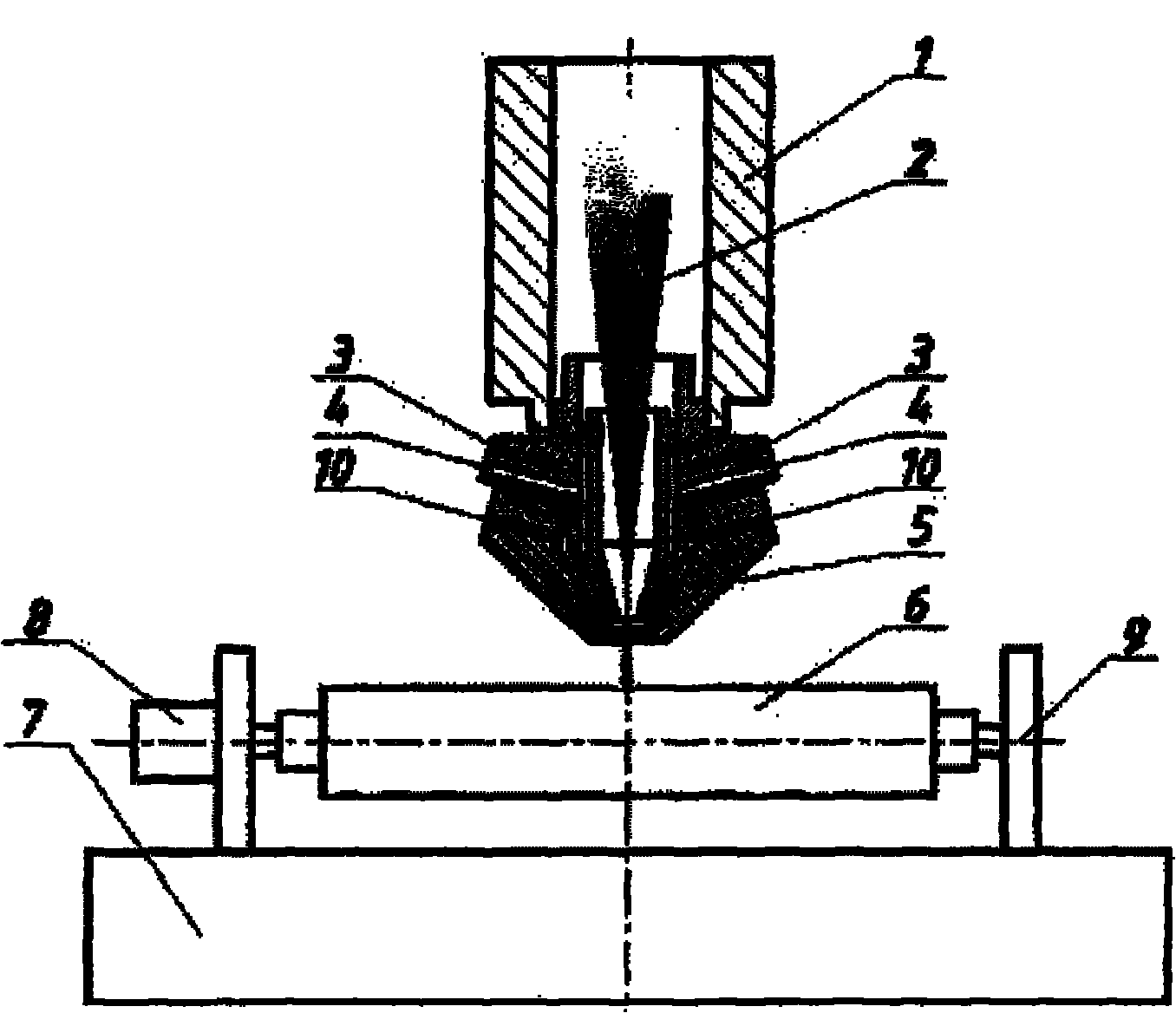

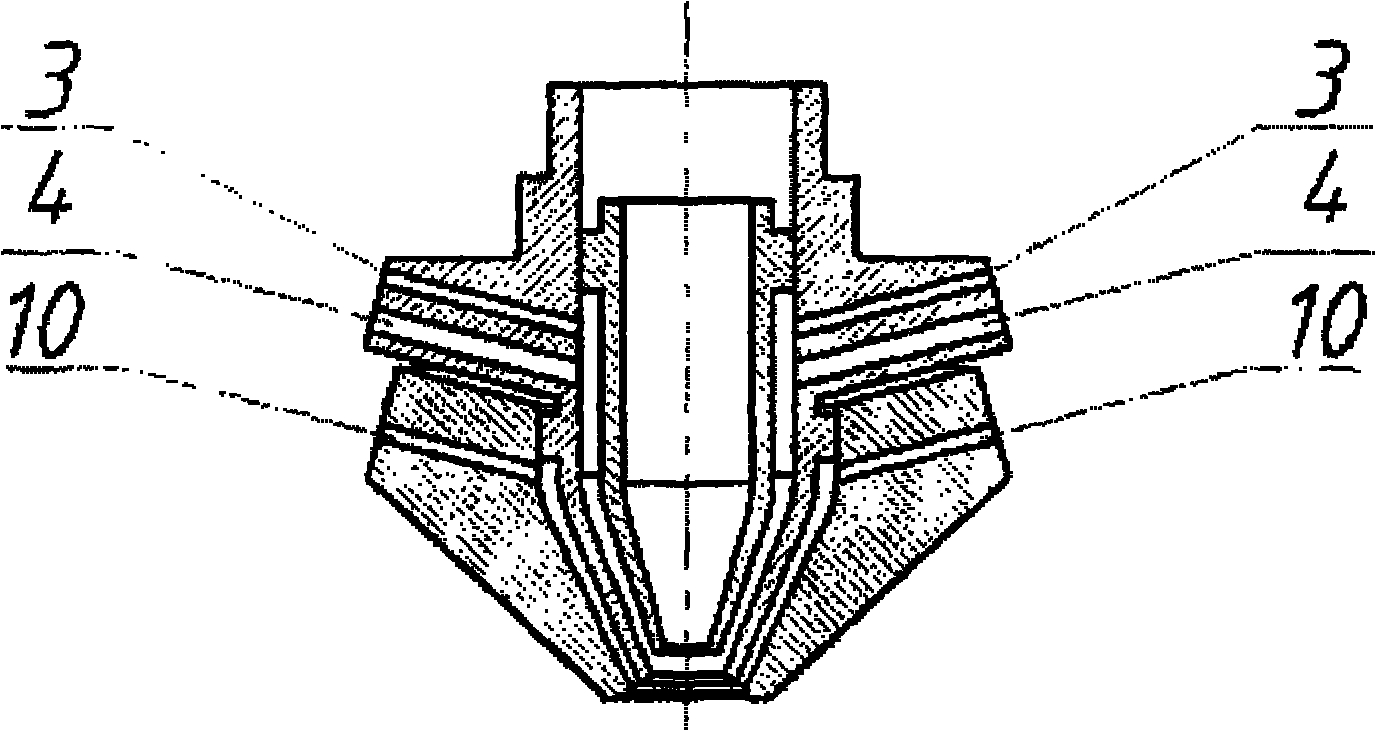

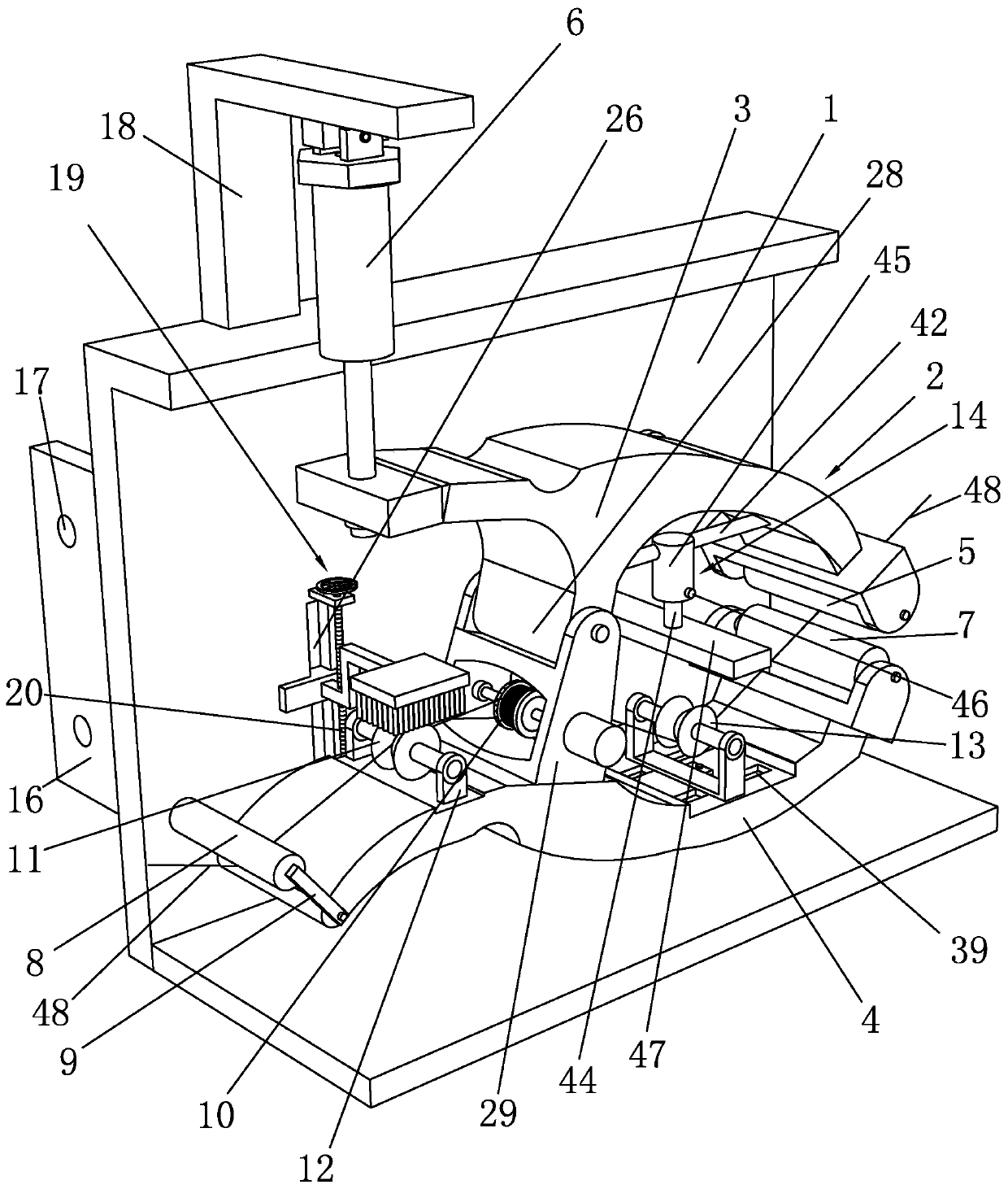

Method and device for preparing working layer of metallurgical hot roll by laser direct deposition

InactiveCN101818342ARealize direct manufacturingReduce flyingMetallic material coating processesLaser technologyAlloy composite

The invention discloses a method and a device for preparing a working layer of a metallurgical hot roll by laser direct deposition, which belong to the field of the application of laser technology. The method is characterized in that high speed steel-like powder and Co-based alloy composite powder are used as the materials for the working layer of the roll. Concretely, the method comprises: filling high speed steel-like powder or mechanically mixed powder which uses Co-based alloy and the like as a substrate material and is added with reinforcing and toughening submicron grains with different amounts into a powder supply system; and performing laser-assisted direct metal deposition on the surface of a roll core, of which the travel is controlled by a worktable, with synchronous powder supply to manufacture the working layer of the roll. A deposition method adopts an alternate deposition mode. The corresponding deposition thickness is determined according to the requirements on the thickness of the working layer. The hard phase content of the powder, in which the Co-based alloy is added as a hard phase, is increased layer by layer so as to form a gradient deposited layer. In the method, the reinforced, toughened and wear-resistance working layer is prepared on the surface of a cheap hot roll core part material by laser-assisted metal direct deposition technology under specific process conditions.

Owner:JIANGSU UNIV

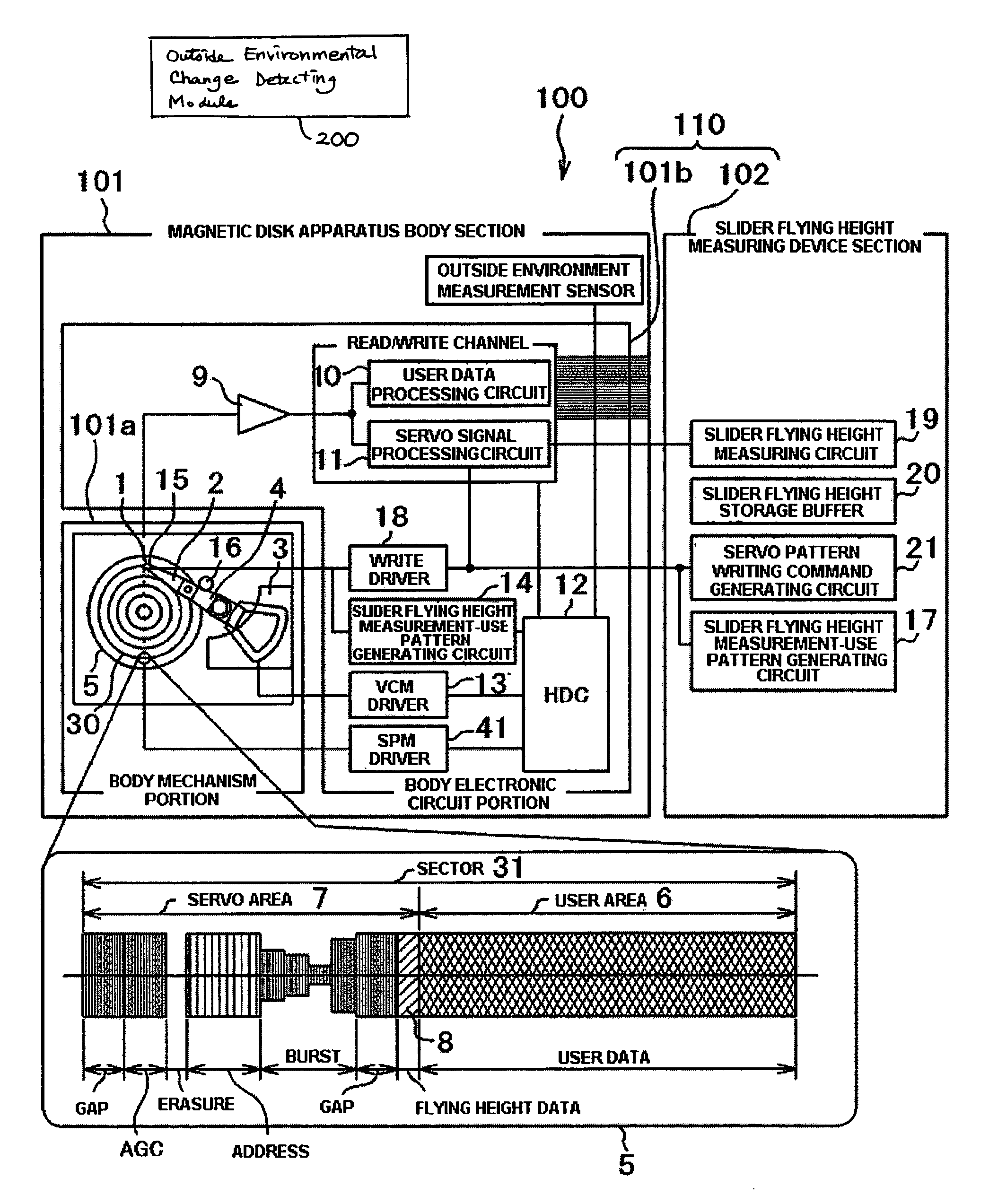

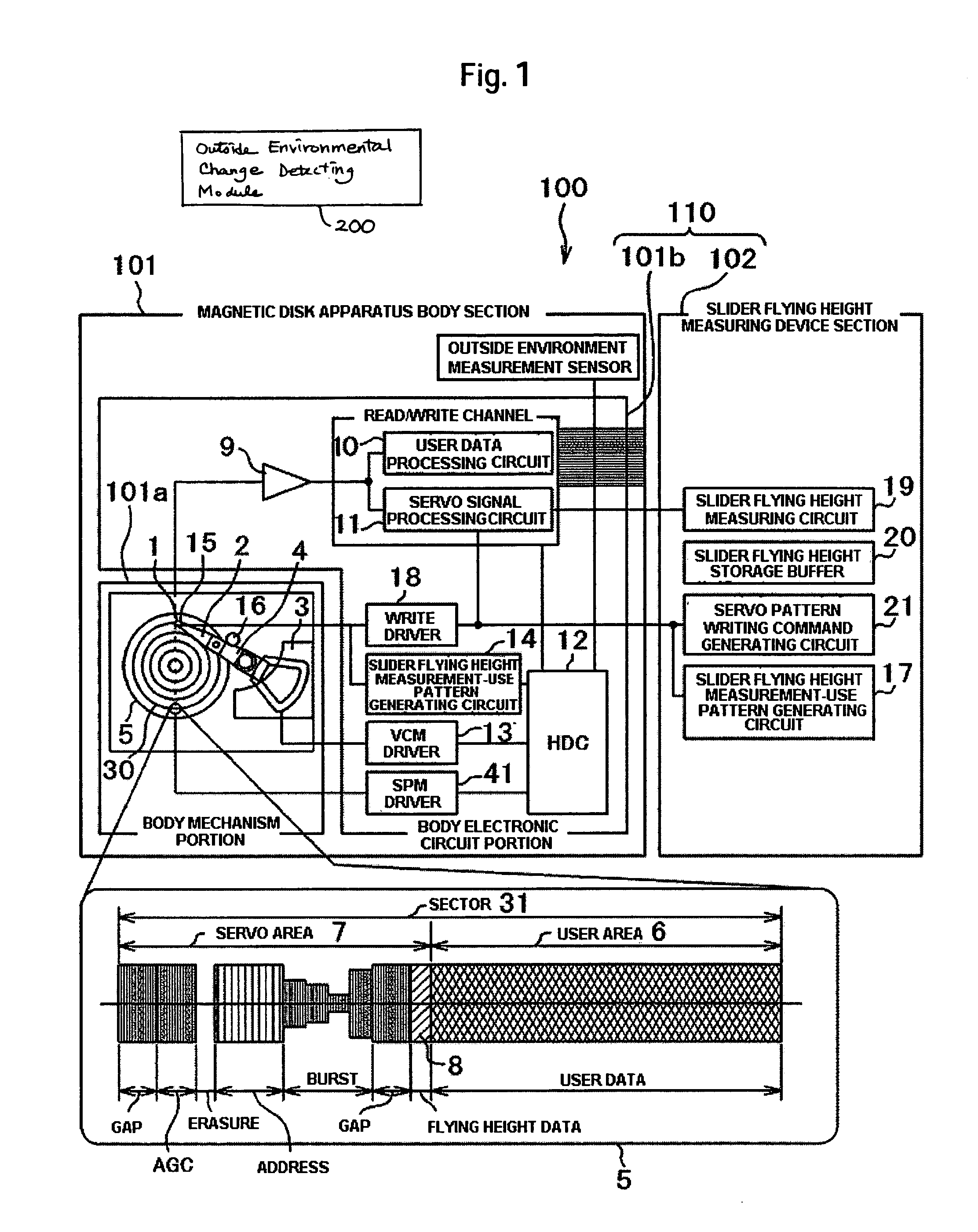

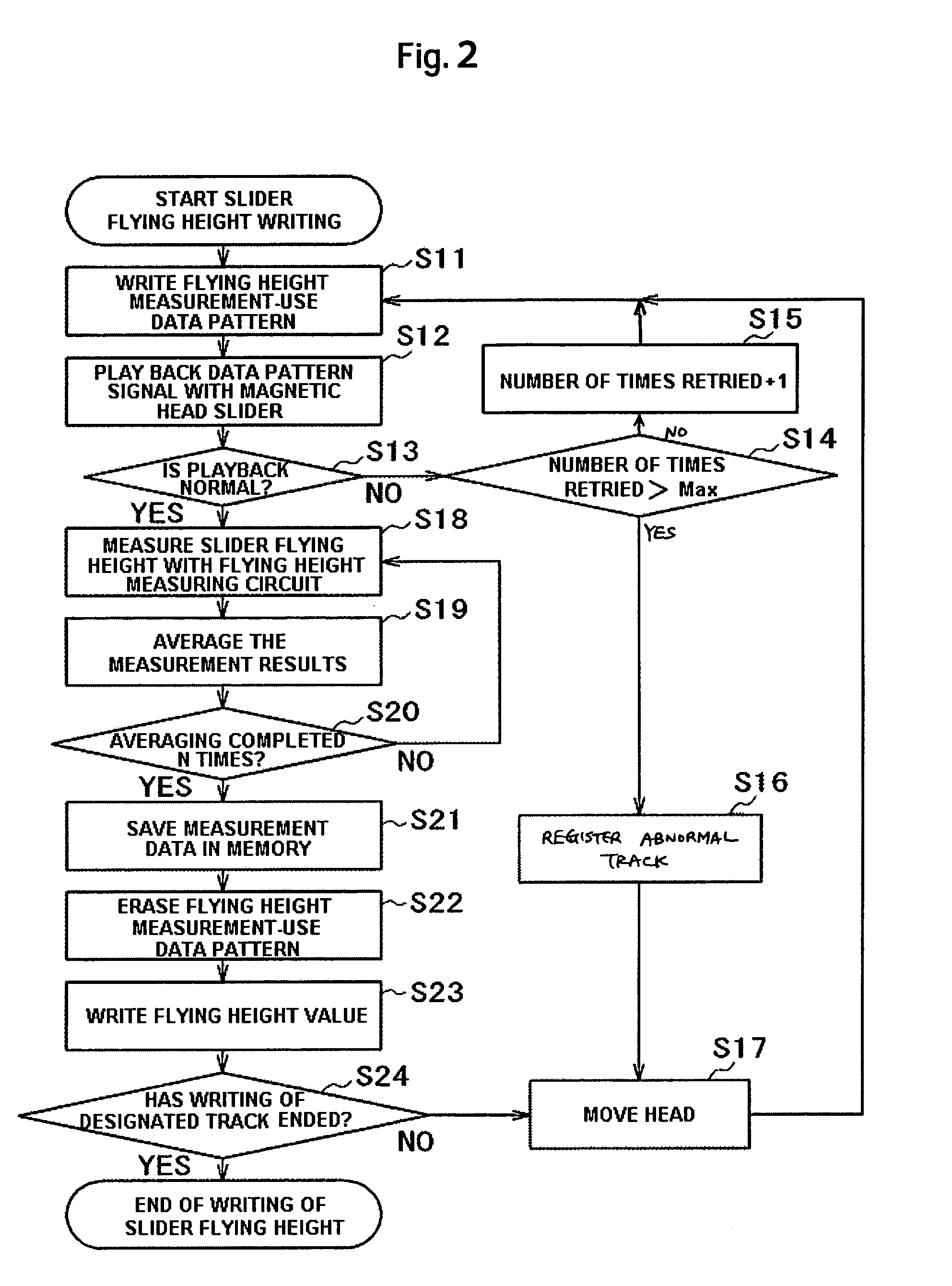

Controlling head flying height in a data storage device

InactiveUS7271975B2Reduce flyingFlying of a slider to be loweredDisc-shaped record carriersDriving/moving recording headsControl dataEngineering

Embodiments of the invention enable the flying of a slider to be lowered and increase recording density with a simple configuration in a magnetic disk apparatus. In one embodiment, a magnetic disk apparatus comprises a magnetic disk including tracks for recording data; a magnetic head slider disposed with a magnetic head that flies over the rotating magnetic disk and records data to, or plays back data from, the magnetic disk; and a control device that controls the operation of the apparatus. Slider flying height data that vary inside the tracks are prerecorded in the tracks of the magnetic disk. The control device controls the operation of the magnetic head slider with respect to the magnetic disk on the basis of the slider flying height data recorded in the tracks.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

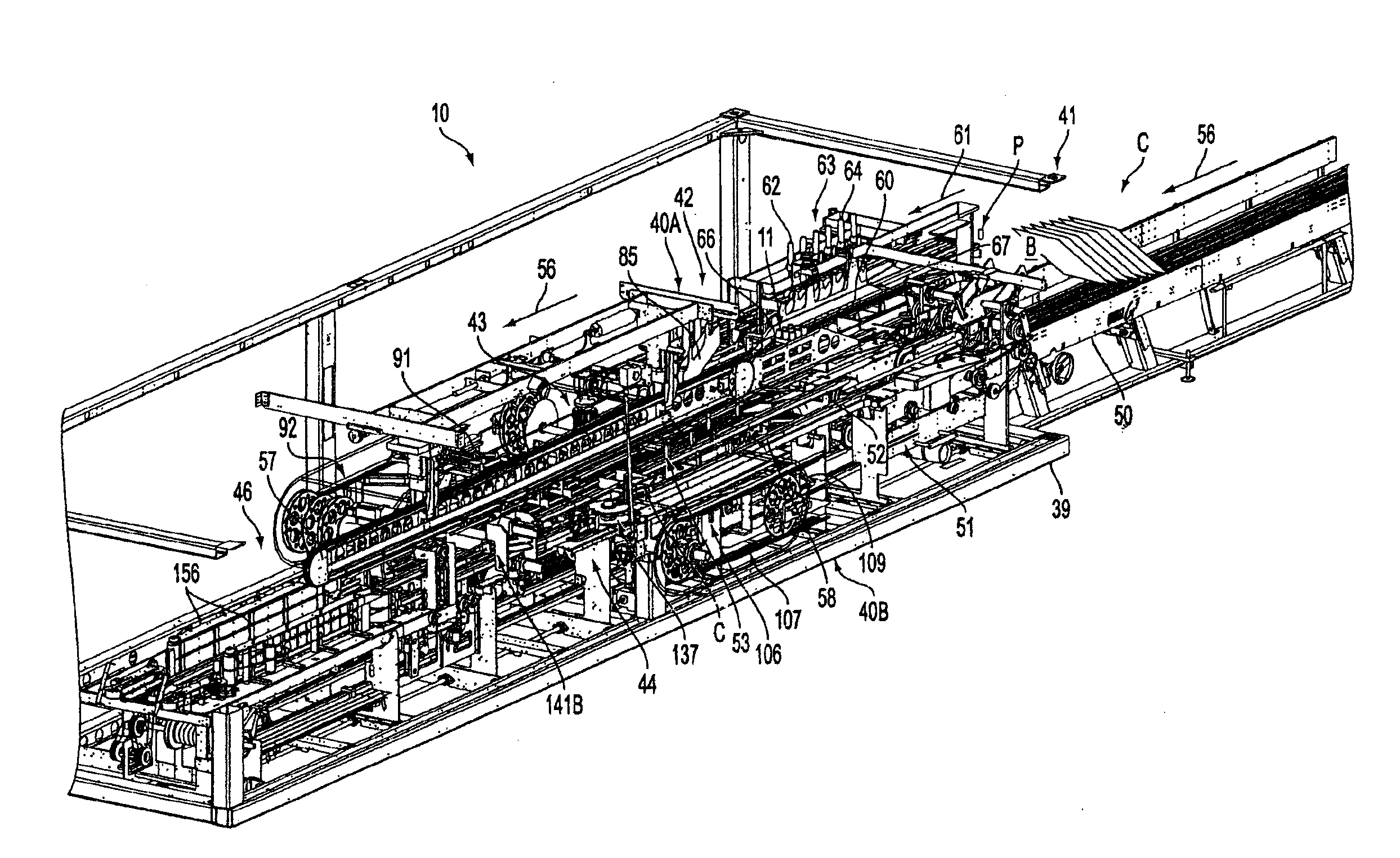

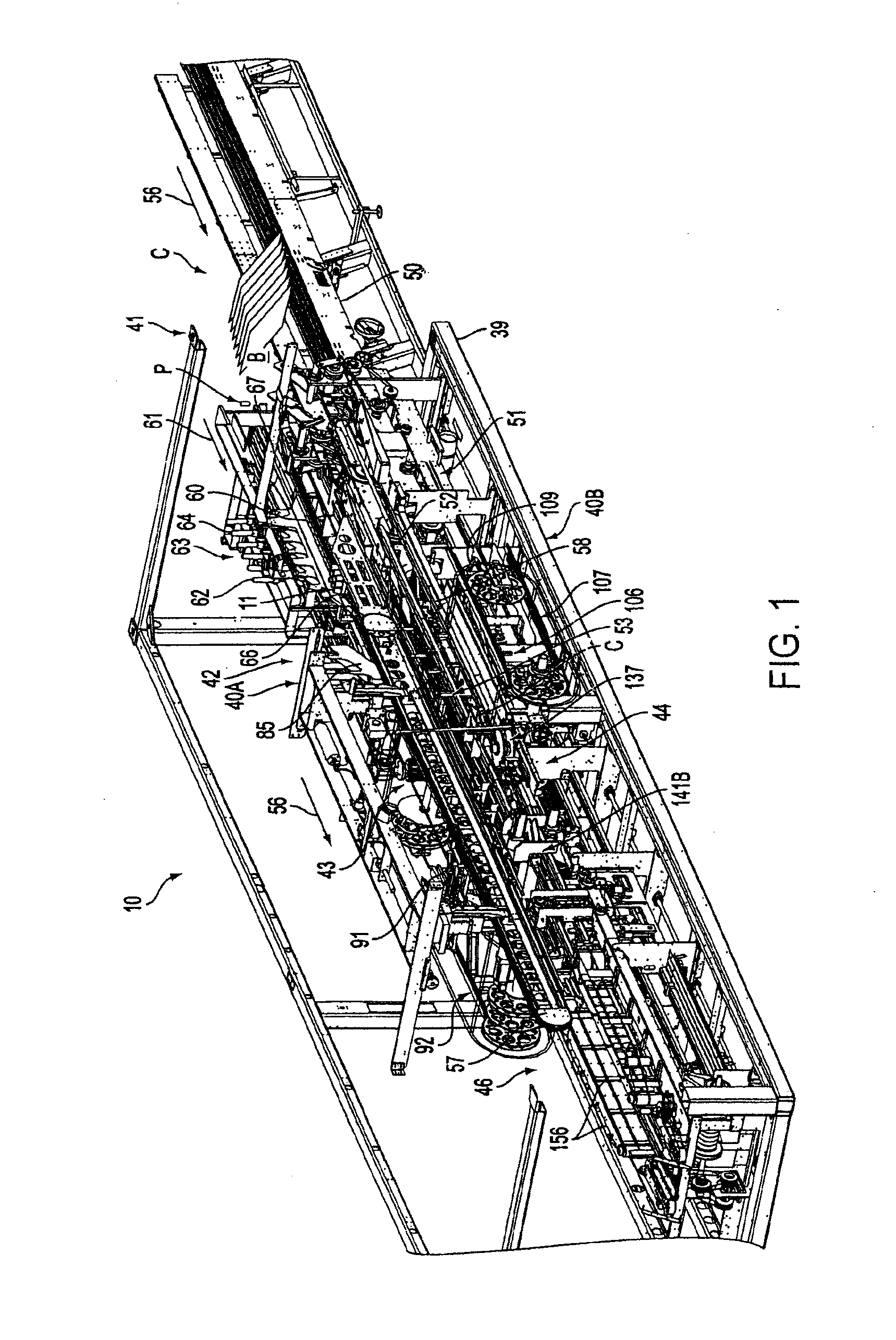

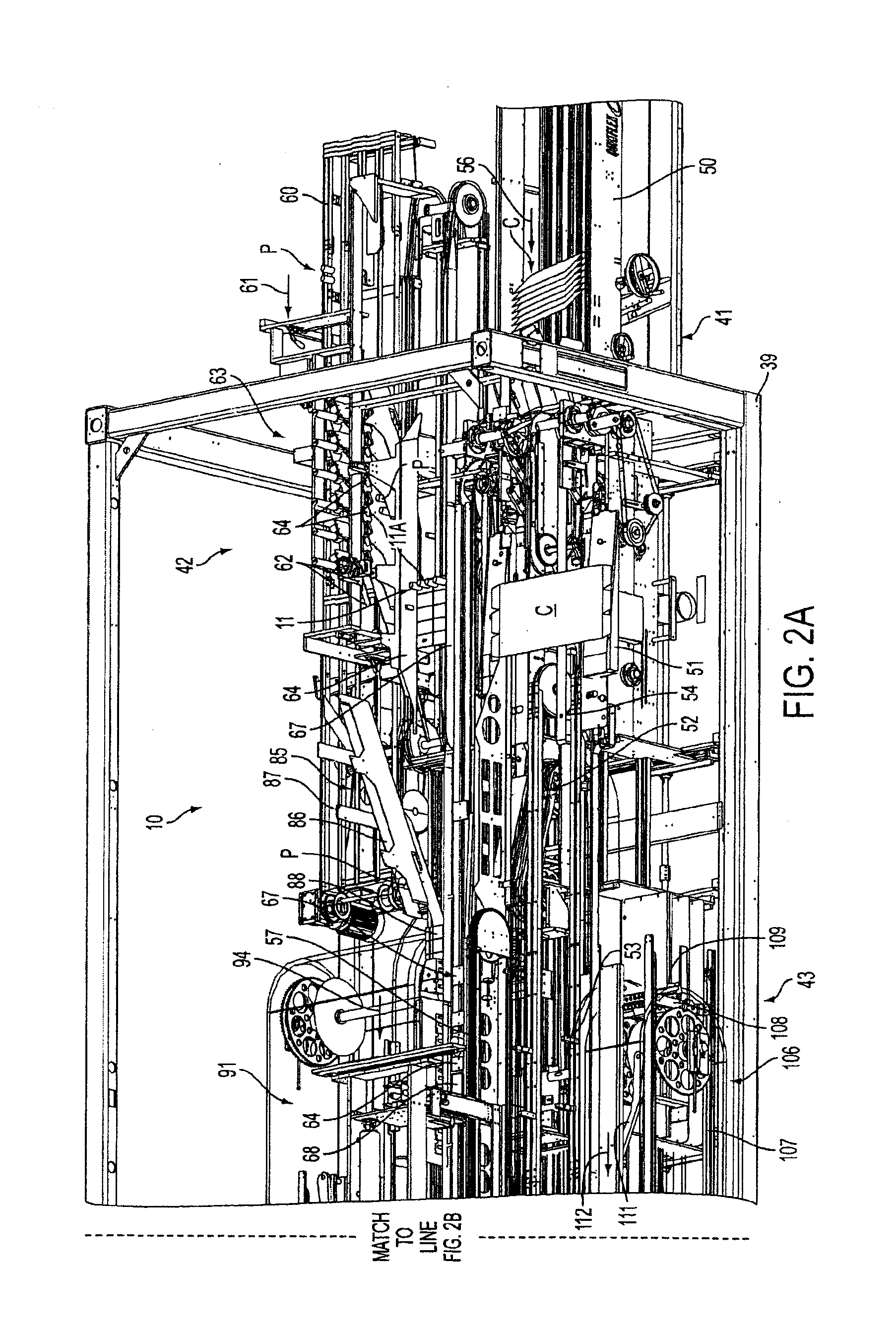

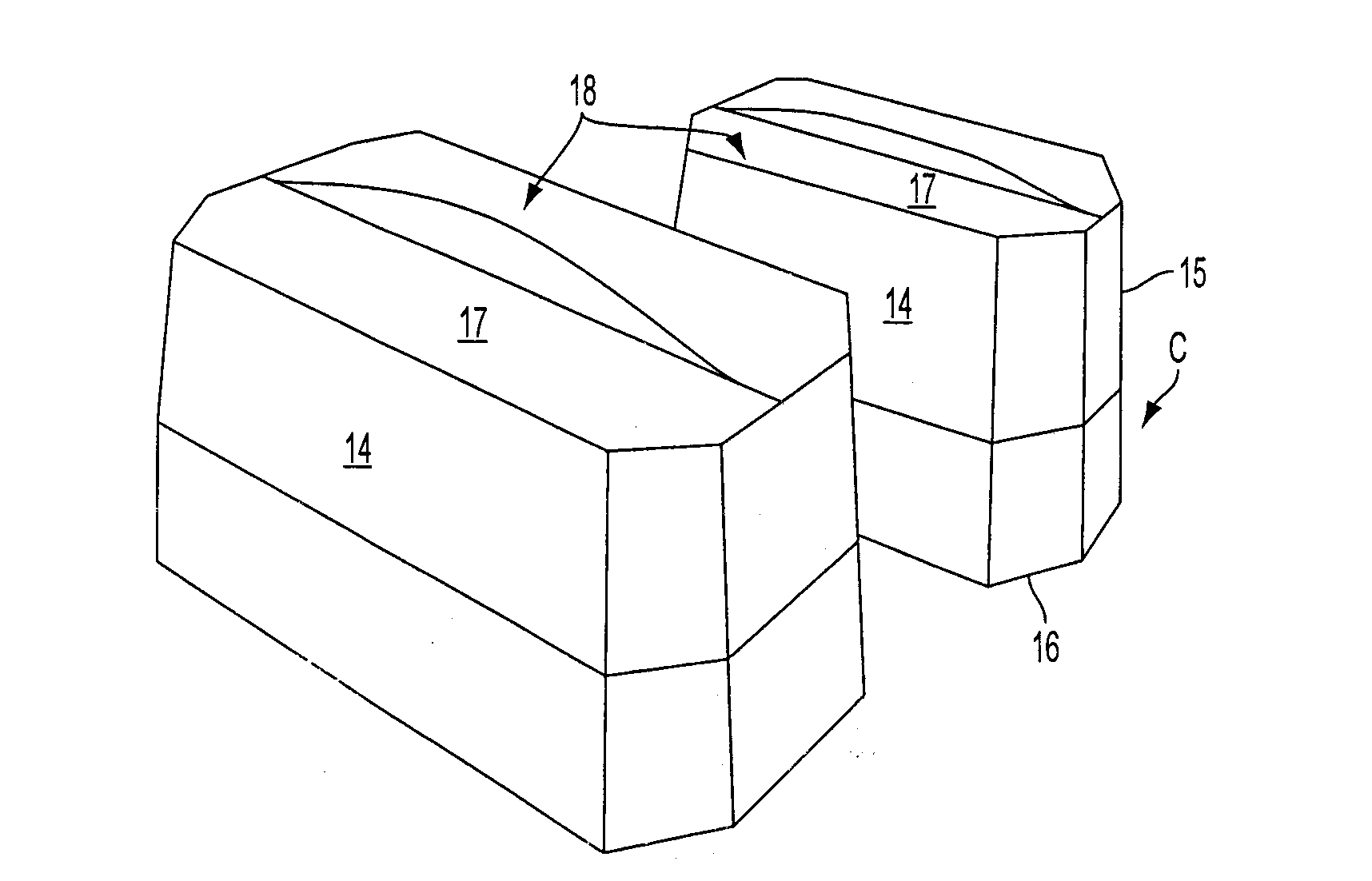

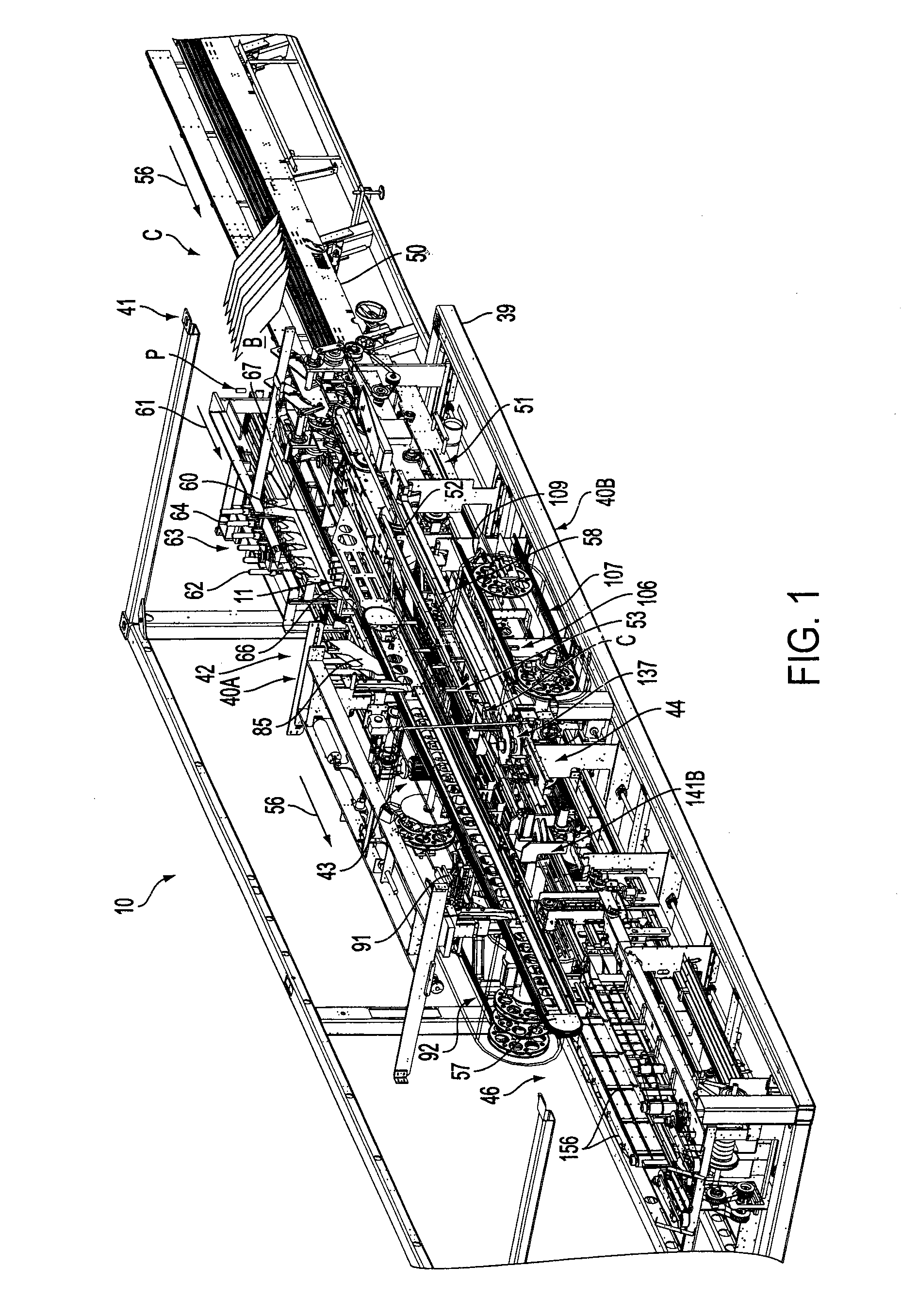

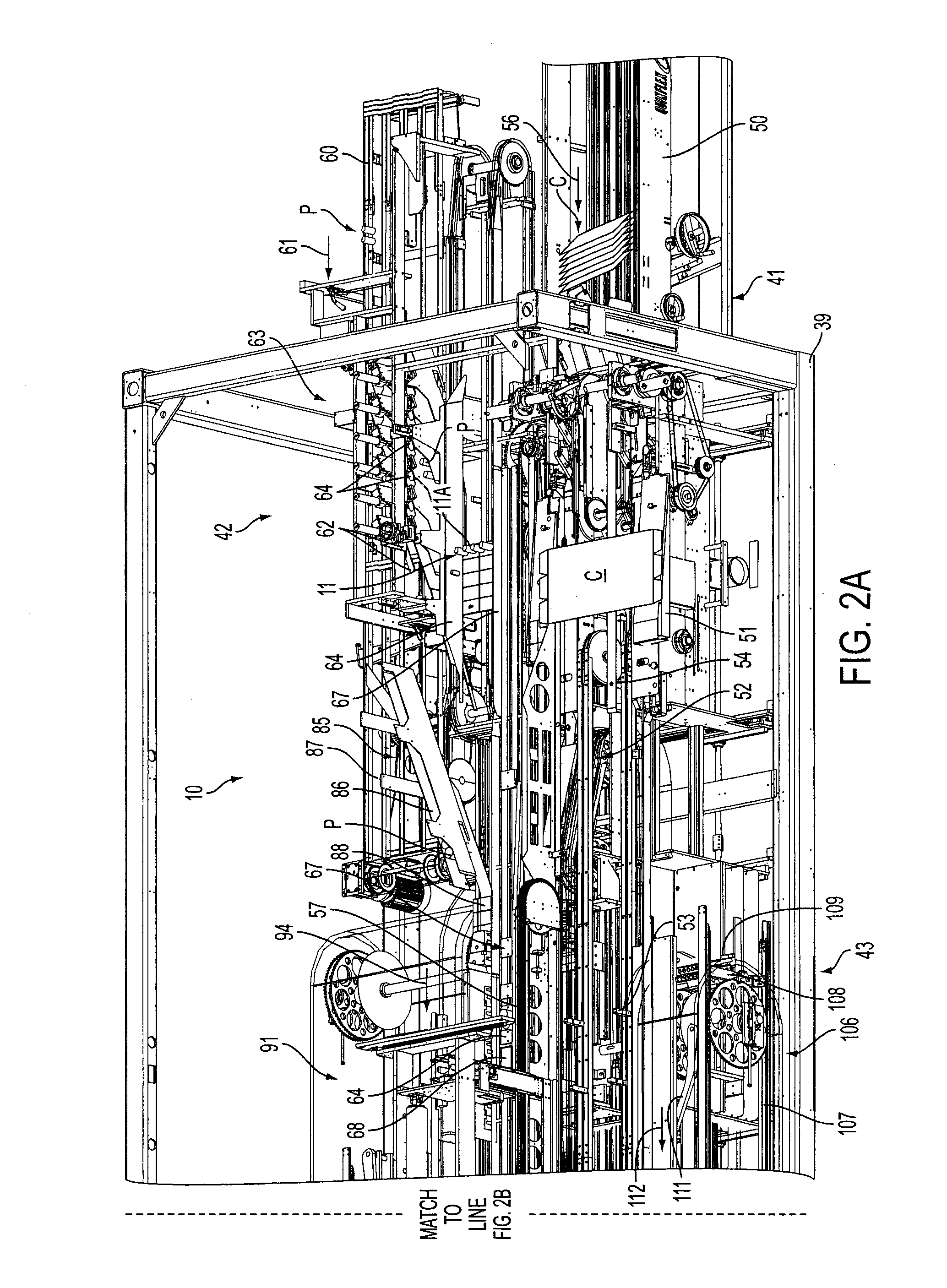

System and method for packaging of nested products

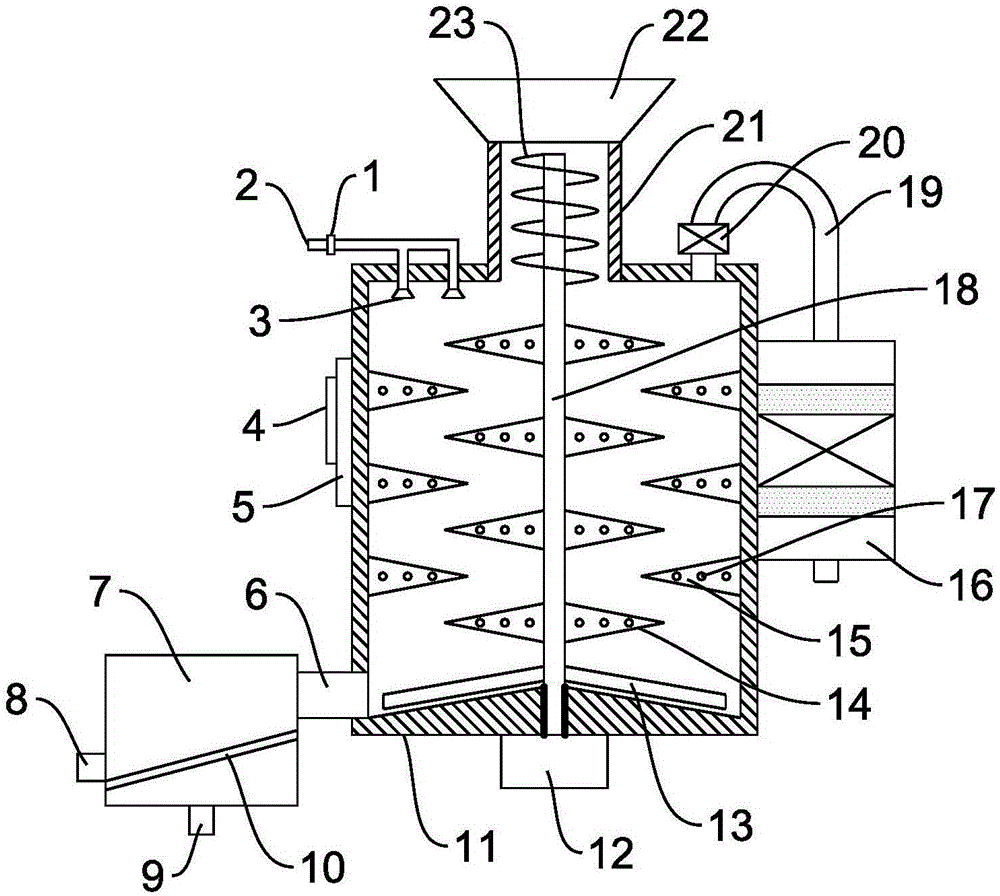

ActiveUS20150329231A1Reduce flyingReduce and tighten spacingWrapper twisting/gatheringIndividual articlesBiomedical engineeringPackaging and labeling

A packaging system for the selection, grouping and loading of varying size and / or configuration product packs into cartons as provided. The packaging system includes a selection area having a primary selector for forming an initial product pack configuration, and a secondary selector adapted to select and direct an additional grouping of products into a nested arrangement against the initial product pack so as to form a nested product pack. The nested product packs thereafter can be engaged by loader arms of a pair of opposed loading assemblies, which move the nested product packs into a series of cartons moving through the packaging machine. Thereafter, the ends of the cartons can be closed and sealed to complete the packaging of the product packs therein.

Owner:GRAPHIC PACKAGING INT

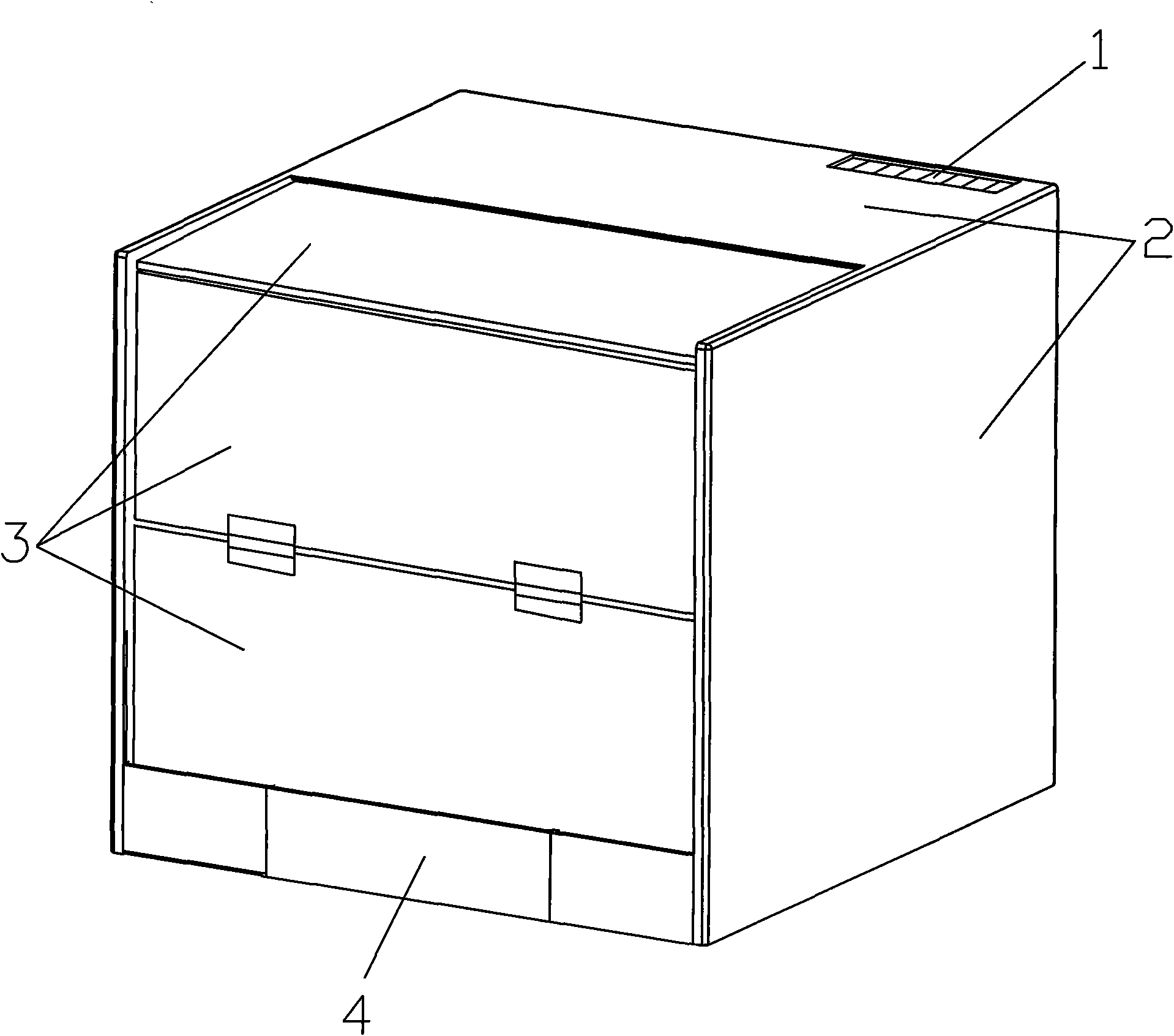

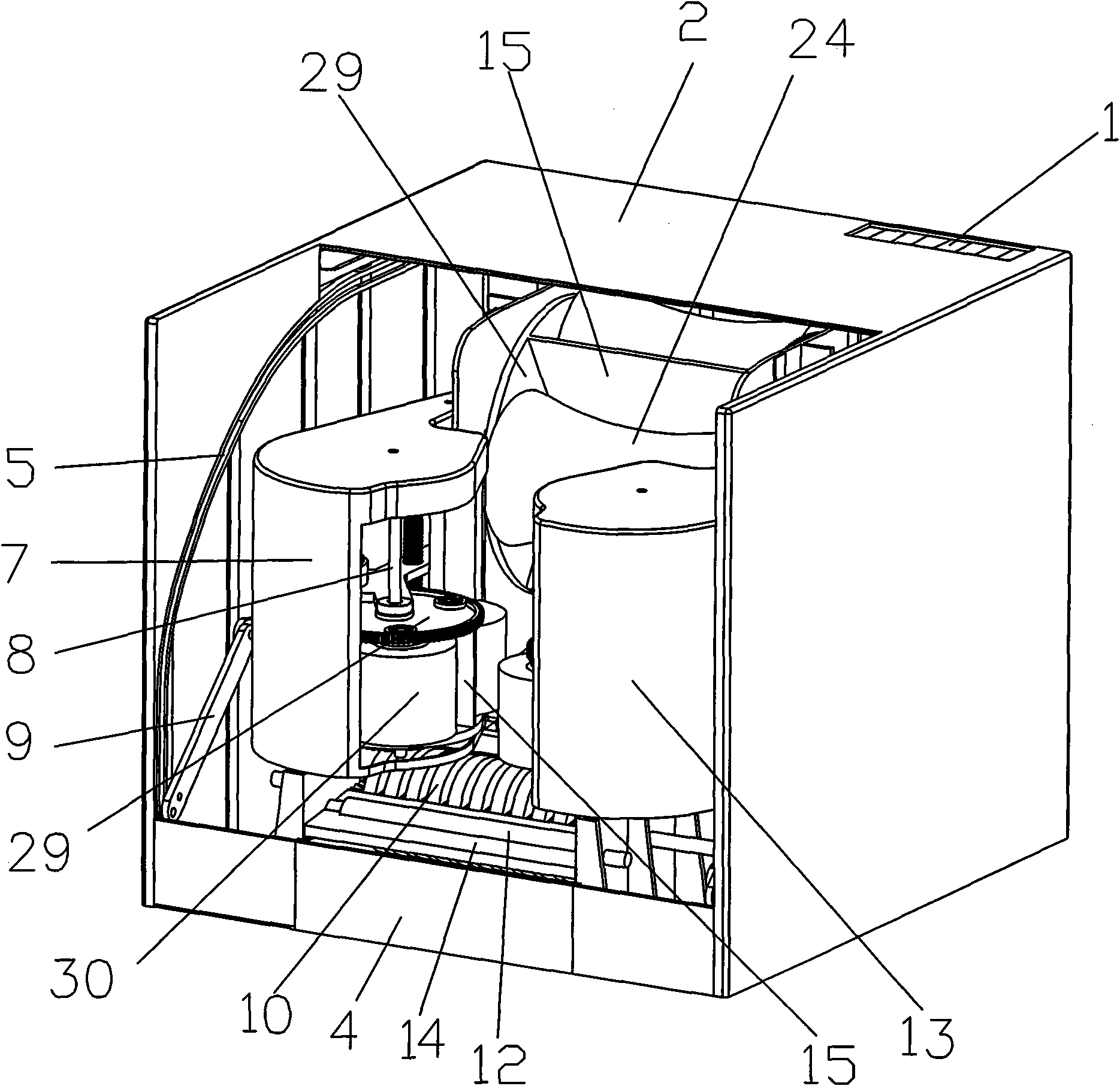

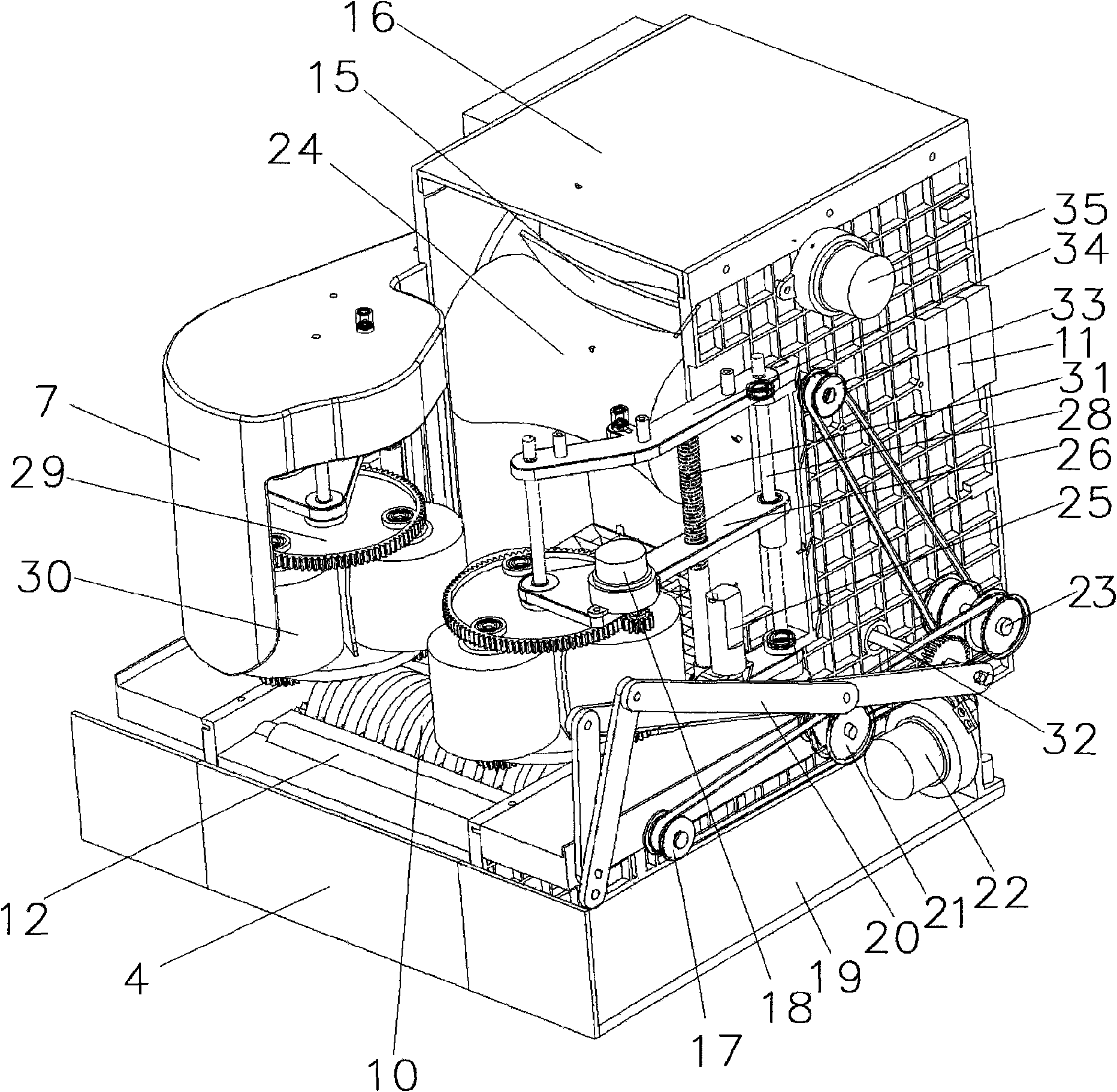

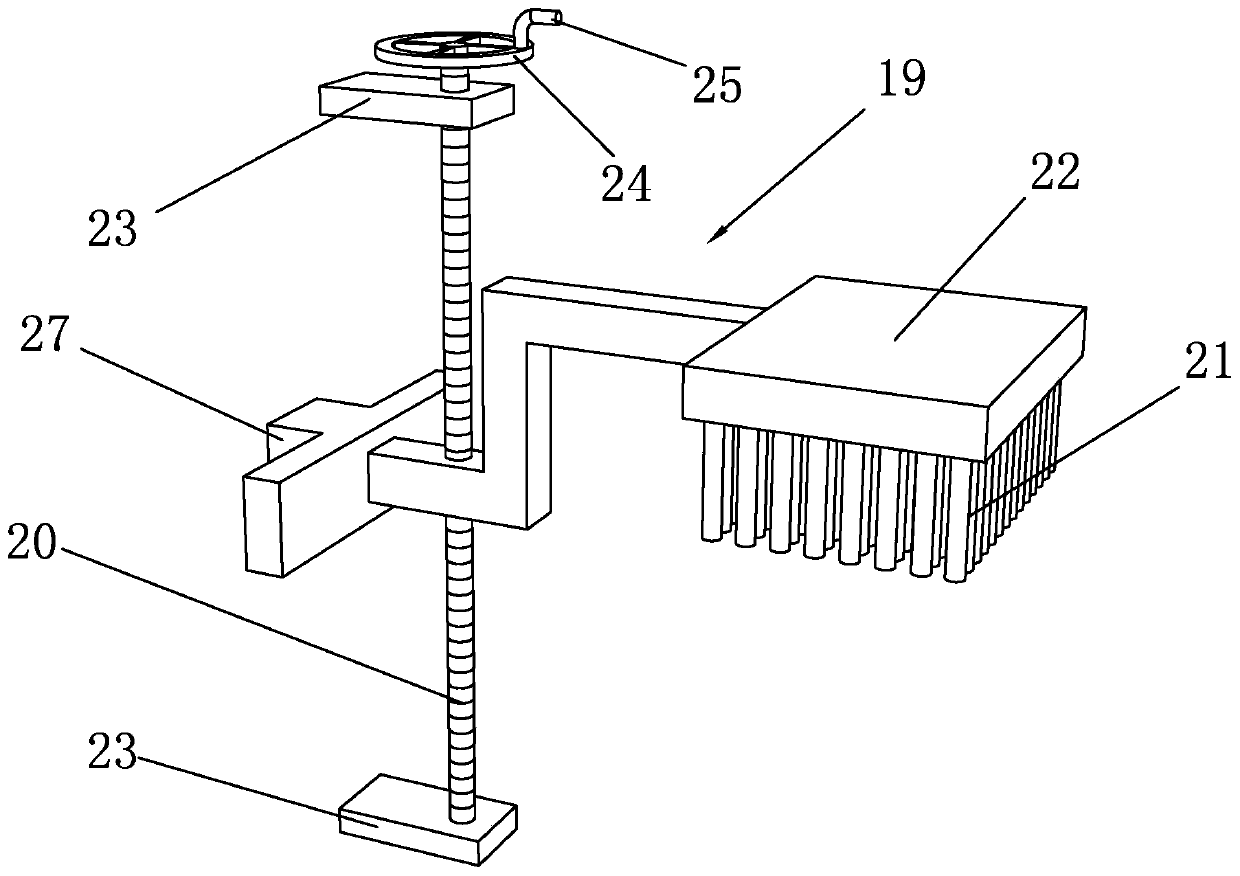

Automatic shoe polisher

The invention discloses an automatic shoe polisher comprising a base and a case cover connected on the upper part of the base. The front and top surfaces of the case cover are provided with openings.The middle of the base is provided with a dust collecting box. A grid leakage dust protective laminate is arranged on the upper part of the dust collecting box. A sole brush penetrating the grid leakage dust protective laminate is arranged on the position of the dust collecting box and the position is close to the opening. An inner box is arranged on the position inside the base and the position is next to the dust collecting box. Tri-color brush rollers with upper brushes are arranged above inside the inner box. Left and right brush carrier cover bodies extending above the sole brush are respectively connected on the middle parts of two side plates of the inner box. The tri-color brush rollers with shoe side brushes are respectively arranged in the cover bodies. The shoe polisher realizesmultidirectional cleaning of the leather shoes through cooperation of the roller brushes in four directions. The semi-closed case structure helps reduce dust scatter. The folding door can enable themachine body to be closed and to keep nice-looking and safe. The tri-color brush roller mechanism effectively realizes the function of caring with multicolor shoe polish and has the functions of all-round dedusting, polish spraying and polishing on the same position.

Owner:SHENZHEN XUNFENG TECH

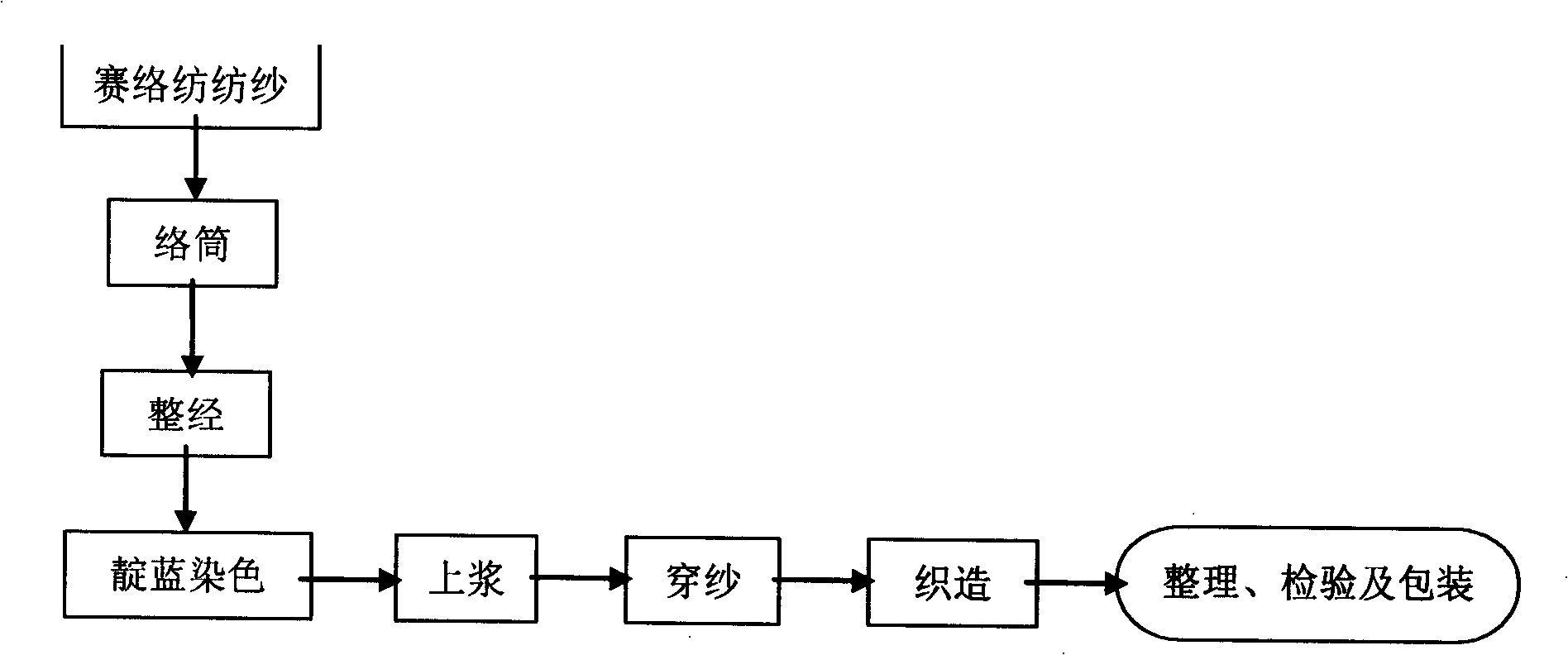

Process for manufacturing sirospun yarn jean facing material

The invention discloses a manufacture technique of a siro yarn jean fabric, in which, firstly an advanced siro yarn spinning technology is adopted to manufacture the siro yarn; the spun siro yarn is wound; then the wound siro yarn which is used as a warp is warped, dyed and starched be manufactured into a beam; then the siro yarn is used as the warp and the siro yarn, a rotor spun yarn or a ring yarn are used as an abb to be woven on a loom according to the fabric weave and the weaving technique of the jean to manufacture a grey fabric and finally the grey fabric is made into a finished product through subsequent finishing. As the siro yarn with better quality is adopted as the warp, the method has the advantages of easy yarn splitting, few broken ends, uniform colorizing, reducible sizing quality requirement as well as high heddle draft and reeding efficiency during the dyeing process, clear cut, uniform tension, few broken ends and stopping, few fly wastes in a workshop and on a machine station as well as being beneficial to the cleanness of the workshop and the maintenance of the machine station when weaving.

Owner:佛山市致兴纺织服装有限公司

Dispersable thermoplastic mineral powder particle and preparing method thereof

ActiveCN1528809AGood dispersionReduce flyingInorganic pigment treatmentGranulation with special binding agentsThermoplasticMaterials science

The invention discloses a kind of mineral powder granules which are dispersive and have thermal plasticity. The mineral powder granules are made up of 95%-99.8% weight percentage mineral powder and 0.2%-5% weight percentage thermal plasticity binder. The mineral powder granules are easy to be dispersed, it can reduces the fluffy powder in use, decreases the harm to the environment and workers, at the same time, upgrades the quality of the products, it applies to plastic, rubber, paint field. The invention also discloses the manufacturing method of above mineral powder granules.

Owner:GUANGZHOU ECHOM SCI & TECH CO LTD

High-strength meltblown polyester webs

InactiveUS7468335B2Improvements with respect to flyReduce flyingSynthetic resin layered productsFilament/thread formingFiberPolyester

A meltblown web of polymeric polyester fibers, where the polyester polymer includes an aromatic dicarboxylic acid, a butanediol, and at least one additional branched or cycloaliphatic diol compound. The webs of the invention achieve high tensile strength values, and are particularly suitable for use as filter media.

Owner:TICONA LLC

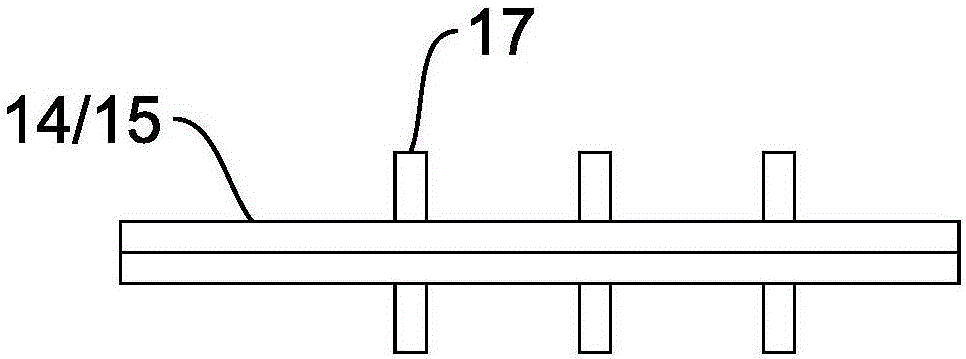

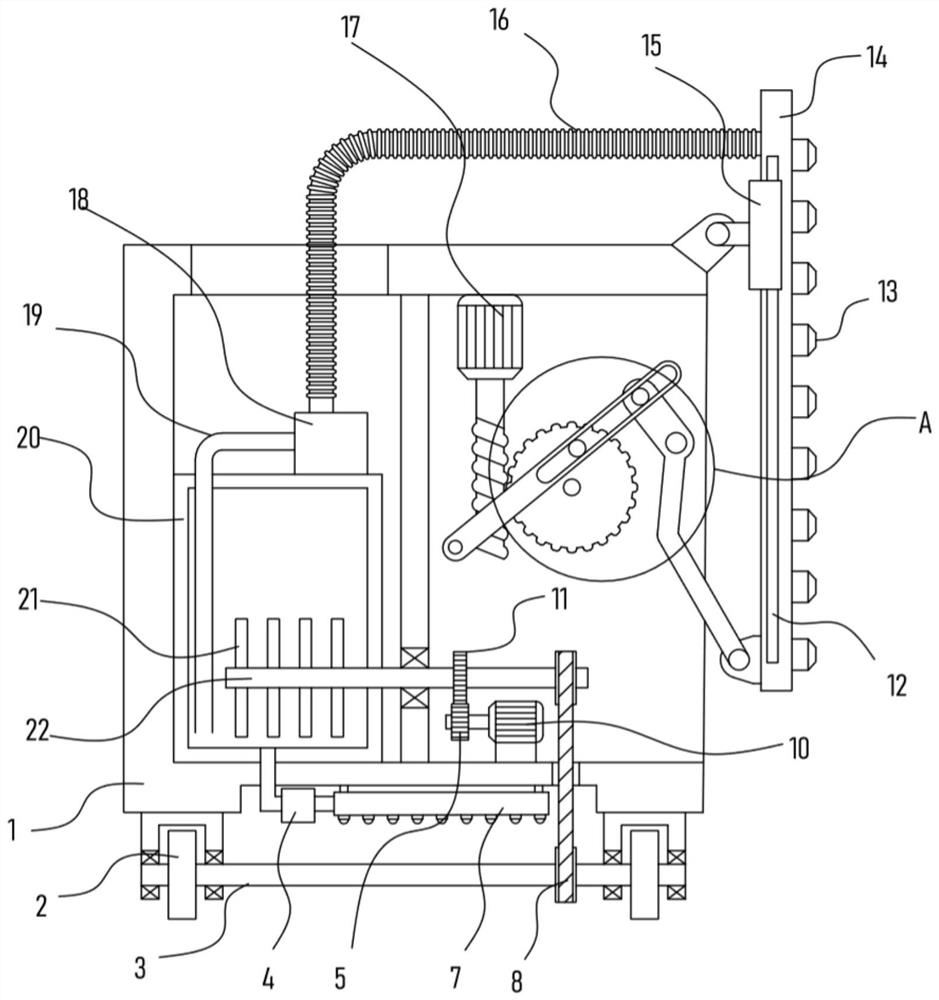

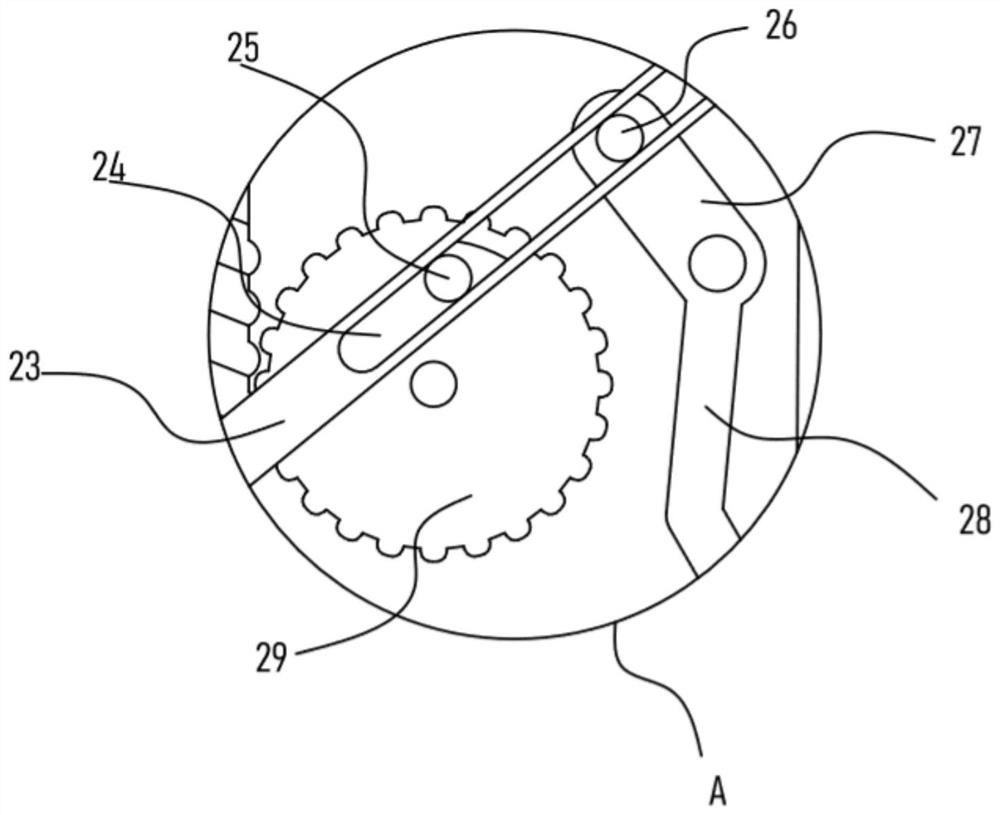

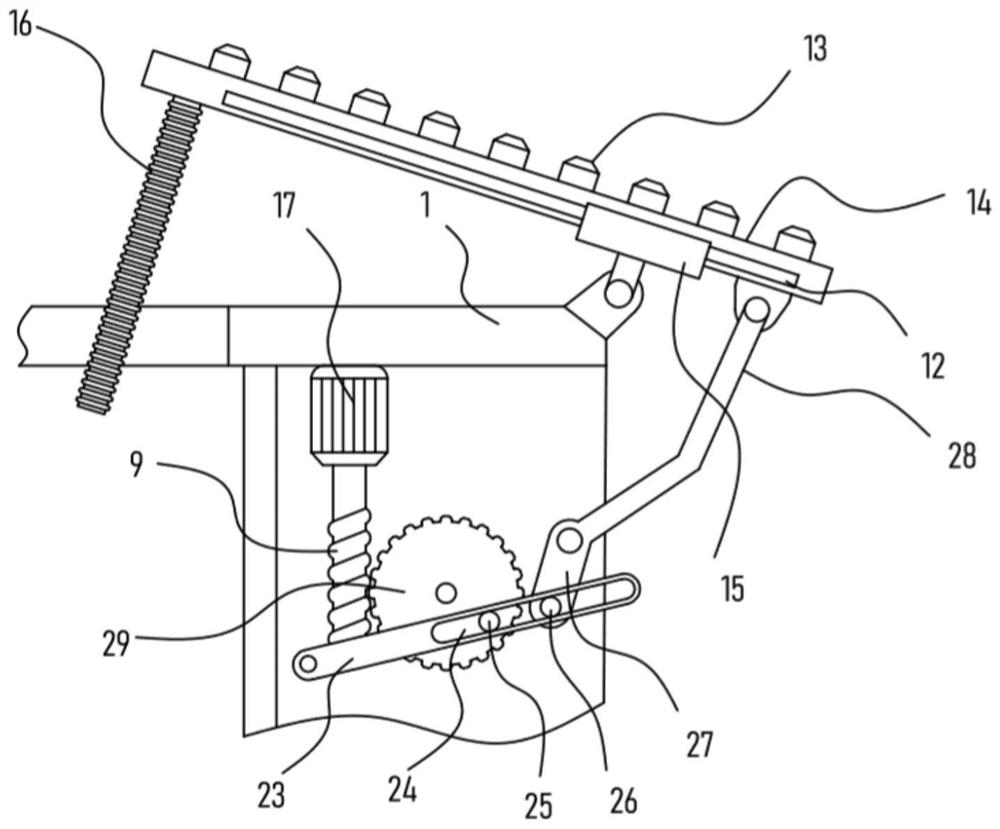

Garbage harmless and environment-friendly machining processing device

The invention discloses a garbage harmless and environment-friendly machining processing device which comprises a machine body. A material guide barrel is arranged in the middle of the top of the machine body in a through manner, a hopper is arranged at the upper end of the material guide barrel in a through manner, a center shaft is arranged at the middle portion of the inner side of the machine body, and a driving motor connected with the center shaft is further arranged at the bottom of the outer side of the machine body; a material pushing plate is arranged at the position, located on the center shaft, of the bottom of the interior of the machine body, a plurality of rotation cutter plates are arranged at the positions, located on the center shaft, of the inner side of the machine body, a plurality of fixed cutter plates arranged with the rotation cutter plates in a staggered manner are arranged on the inner wall of the machine body, and spiral blades are arranged at the positions, located on the center shaft, of the inner side of the material guide barrel; and a material discharging pipe is arranged at the bottom of the left side of the machine body, and the other end of the material discharging pipe is connected to the upper portion of the side face of a garbage storage box. By means of the garbage harmless and environment-friendly machining processing device, garbage can be rapidly smashed and processed, dust and peculiar smells in work are reduced, and popularization is facilitated.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

Dust removing apparatus

InactiveCN101664744ASimple structureReduce flyingSemiconductor/solid-state device manufacturingDirt cleaningEngineeringProduct gas

Owner:HUGLE ELECTRONICS

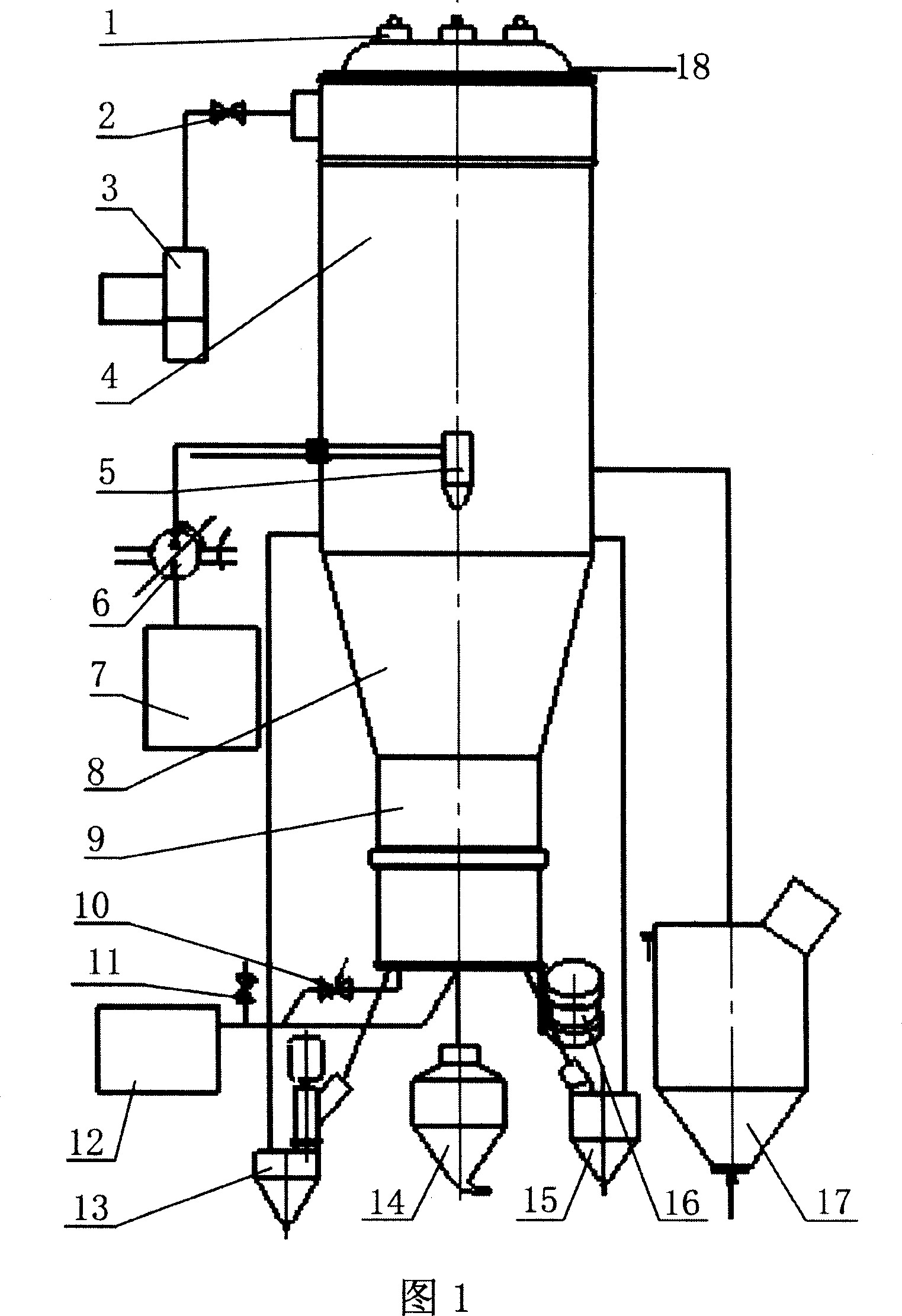

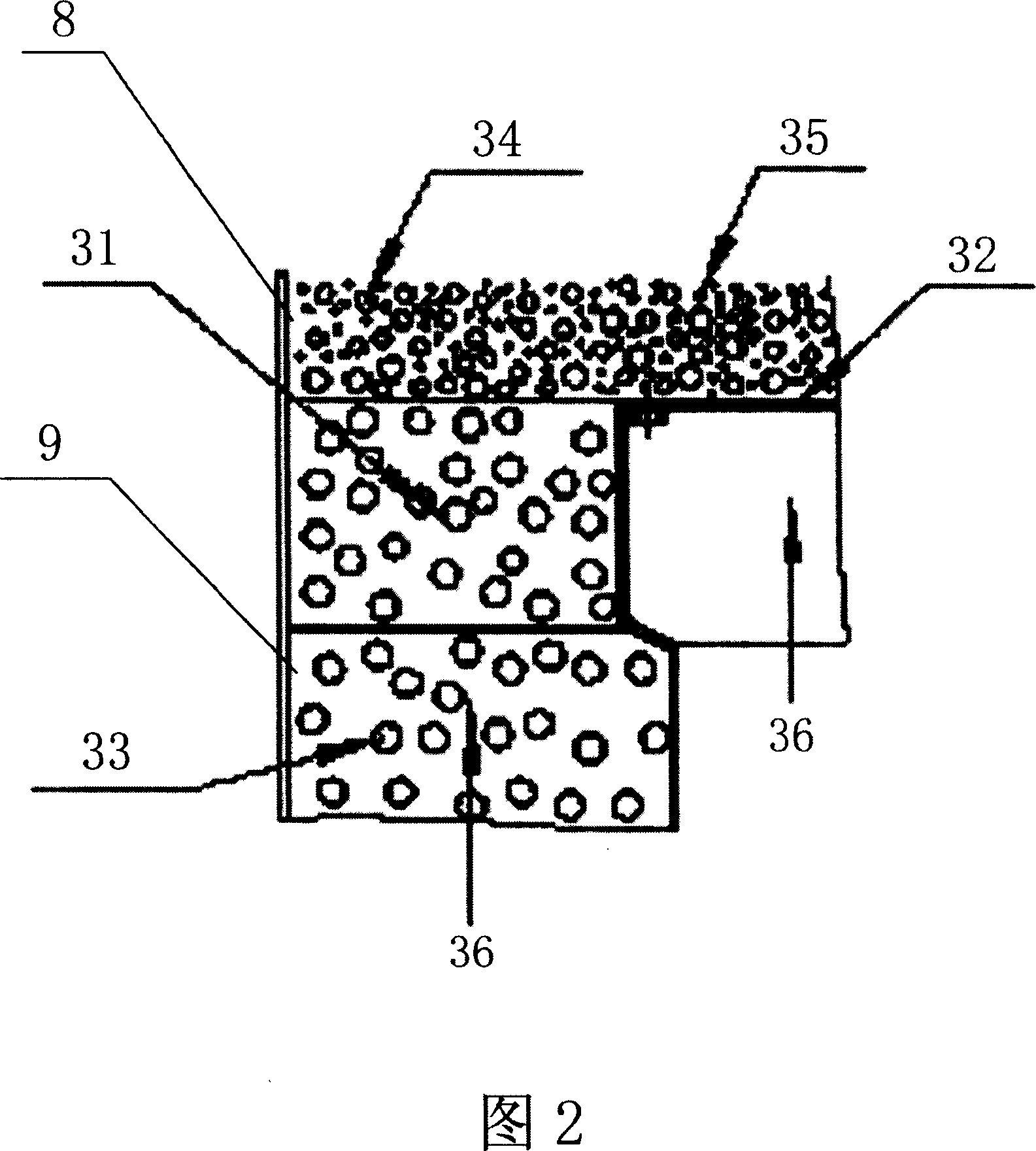

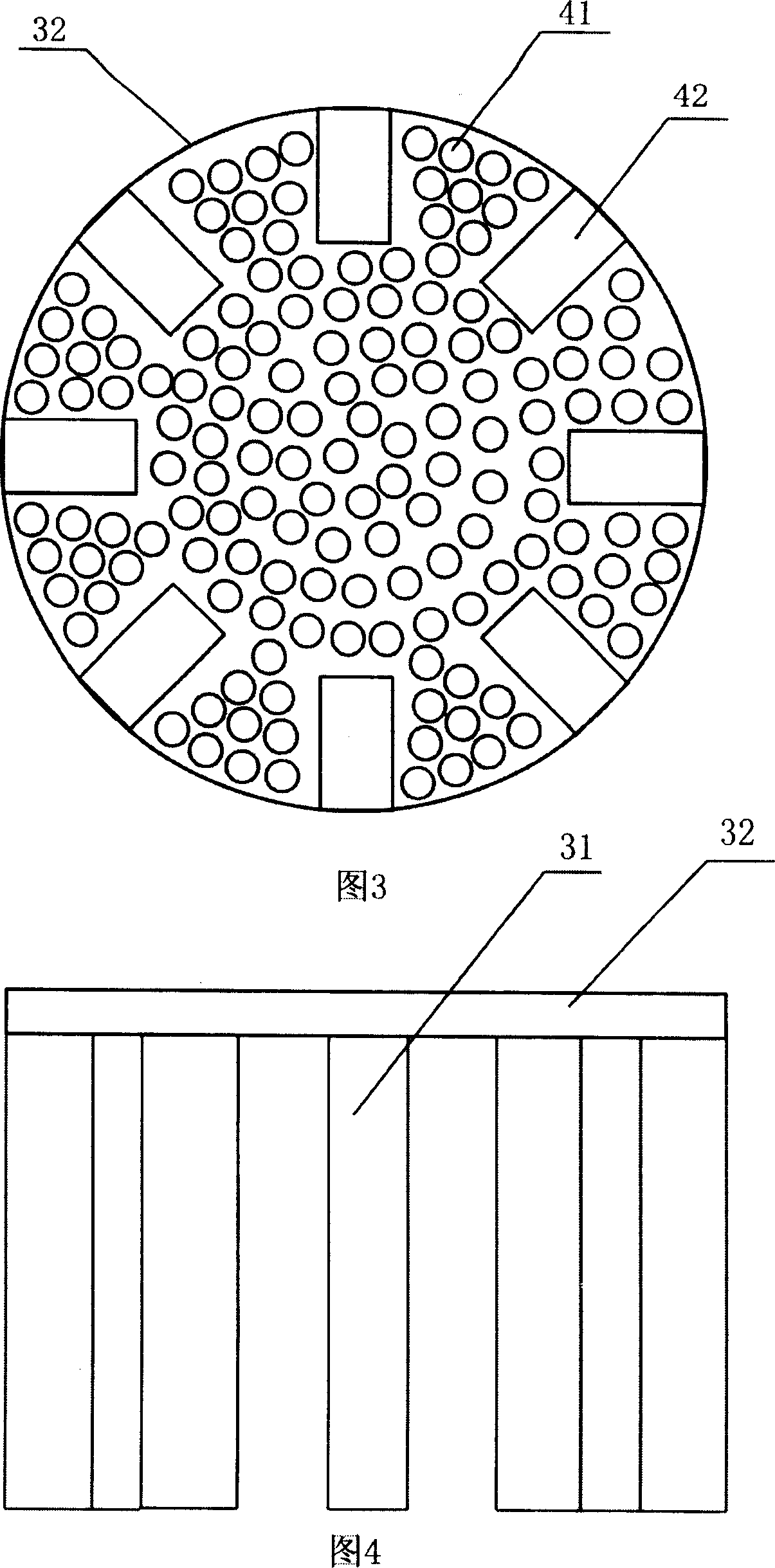

Continuous granulator and granulating method by gravity method

InactiveCN101028582ABreak through continuous granulationSolve the problem of energy consumptionGranulation by powder suspensionEngineeringDischarger

A continuous gravitational granulating apparatus is composed of powder collecting unit, granulating chamber, liquid spraying system, drying chamber, hot air system, continuous feeder, discharger, air plate, throat pipe, particle classifier and unqualified particles returning unit. Its gravitational granulating method is also disclosed.

Owner:谢麟 +1

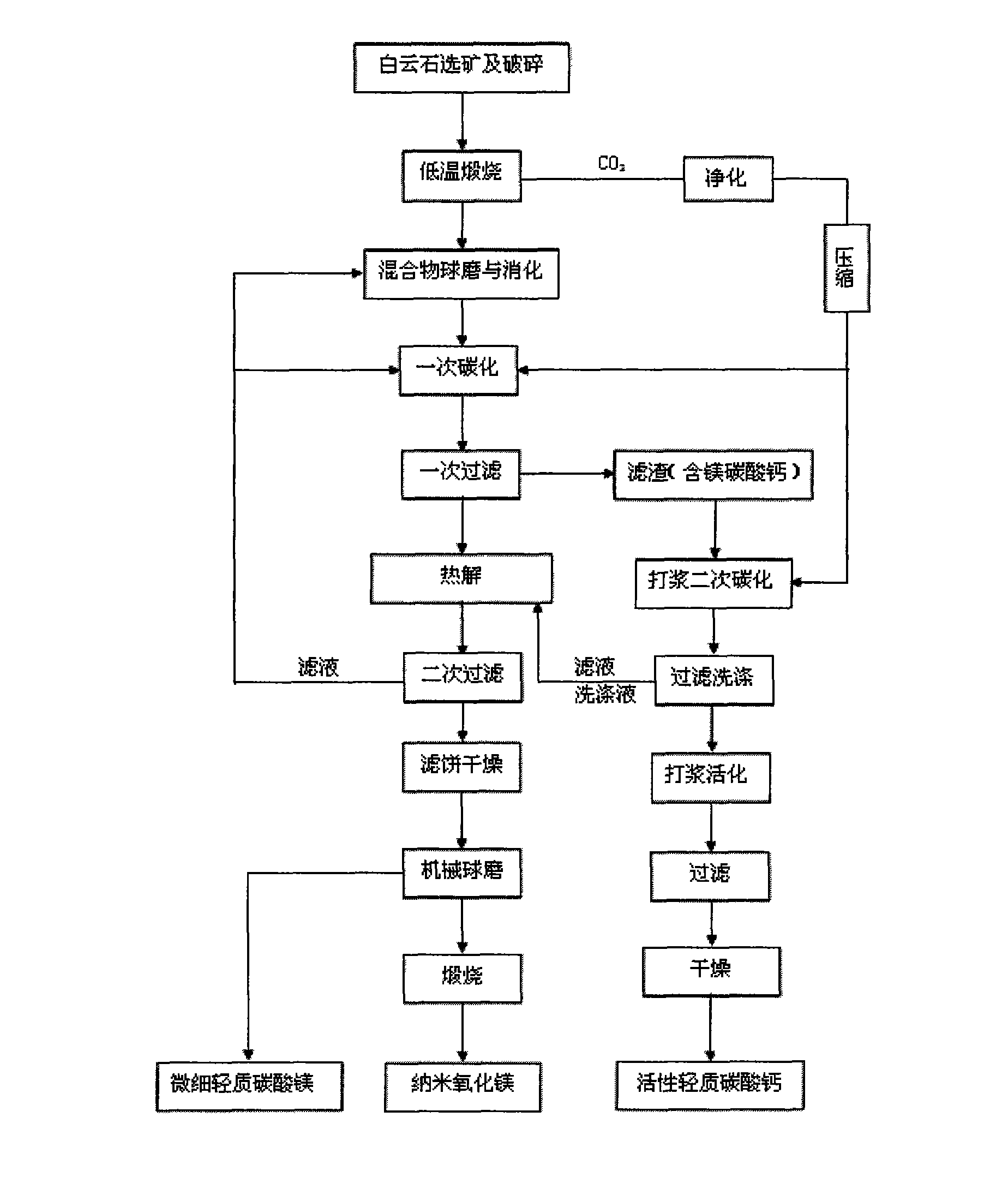

Method for preparing nanometer magnesium oxide and active light calcium carbonate

InactiveCN101648721ASave fuelReduce flyingCalcium/strontium/barium carbonatesNanostructure manufactureDolomiteHigh energy

The invention discloses a method for preparing nanometer magnesium oxide and active light calcium carbonate, aiming to solve the problems of expensive equipment, high energy consumption, material producing area limit, and the like in the prior art. The method for preparing the nanometer magnesium oxide comprises the following steps: smashing dolomites; calcining the dolomites at low temperature; ball-milling and slaking a mixture; primary carbonizing; primary filtering; pyrolyzing; secondary filtering; mechanically ball-milling; and calcining. The method for preparing the active light calciumcarbonate comprises the following steps: smashing the dolomites; calcining the dolomites at low temperature; ball-milling and slaking; primary carbonization; primary filtering; pulping filter residuesand secondary carbonizing; filtering and washing the filter residues; pulping and activating the filter residues; filtering; and drying. CO2 generated by calcining the dolomites at the low temperature is delivered to the primary carbonization and the secondary carbonization to be used; secondary filtering liquid containing magnesium, which is obtained by filtering pyrolyzed liquid, is delivered to the ball-milling and slaking process or theprimary carbonization process of the mixture to be continuously used; and the filtering liquid containing the magnesium and hot water washing liquid are delivered to the pyrolyzing process of the method for preparing the nanometer magnesium oxide to be continuously used.

Owner:JILIN UNIV

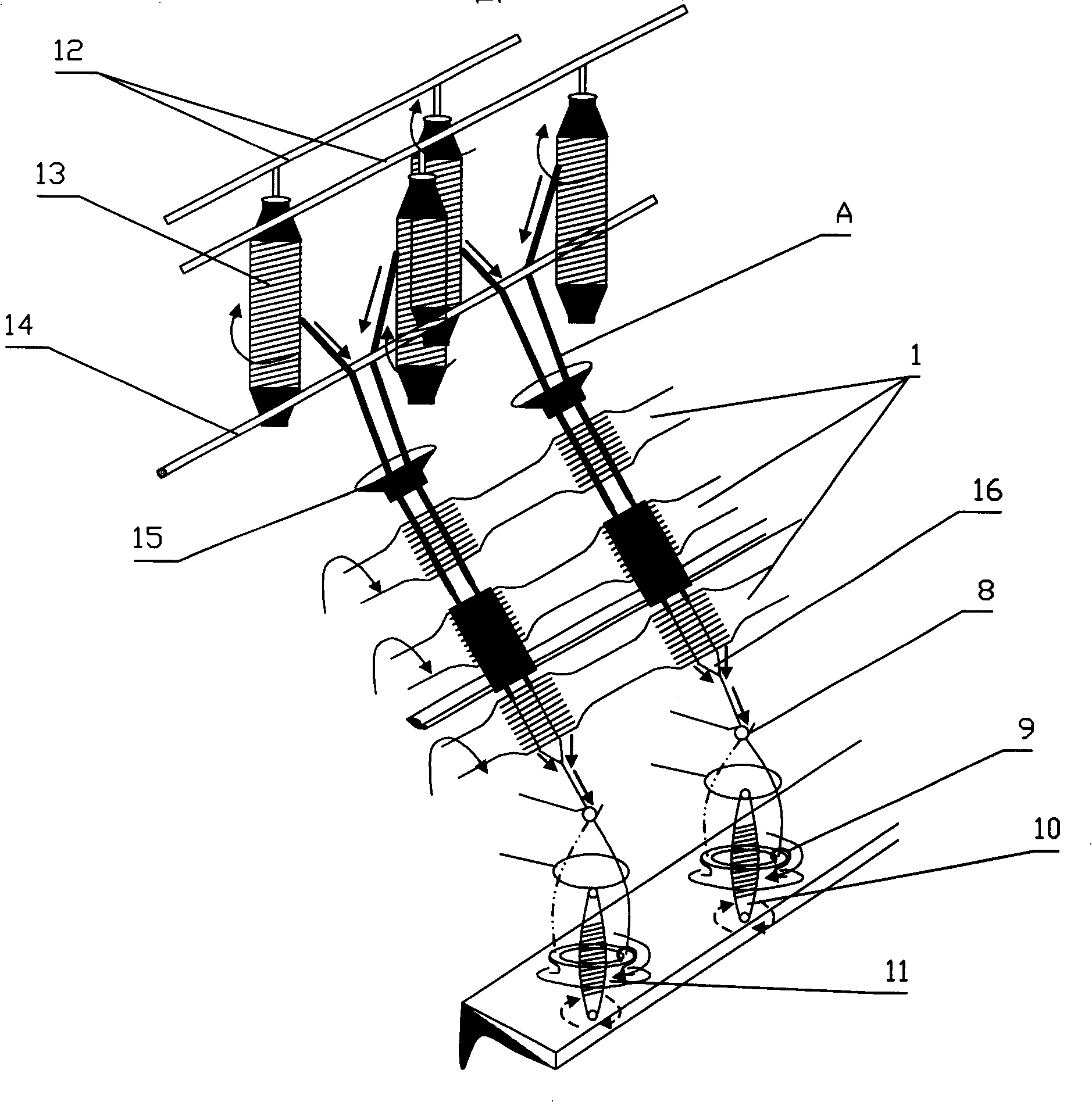

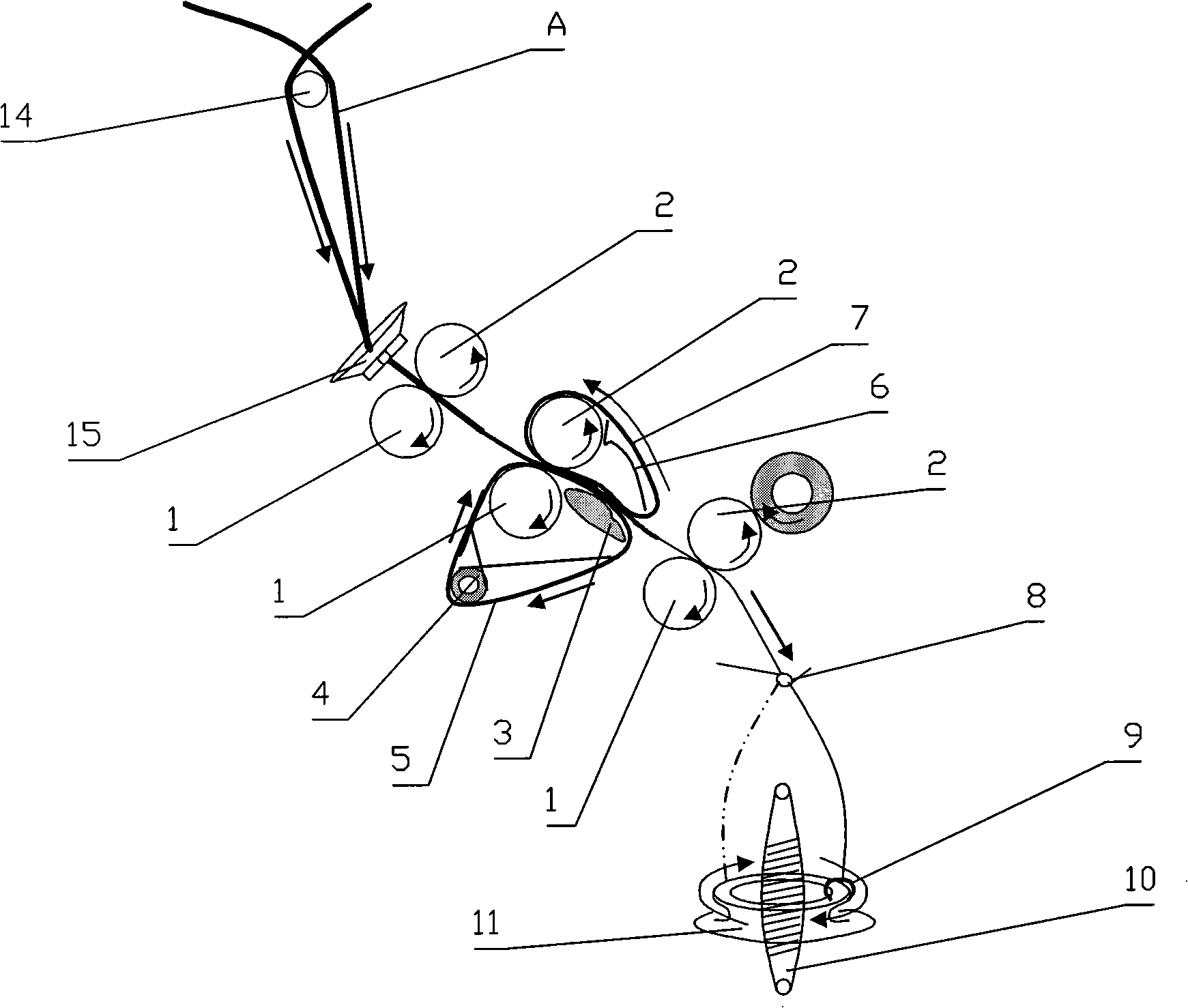

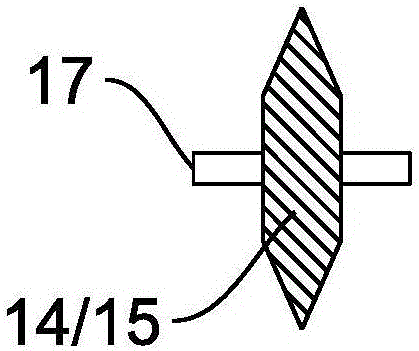

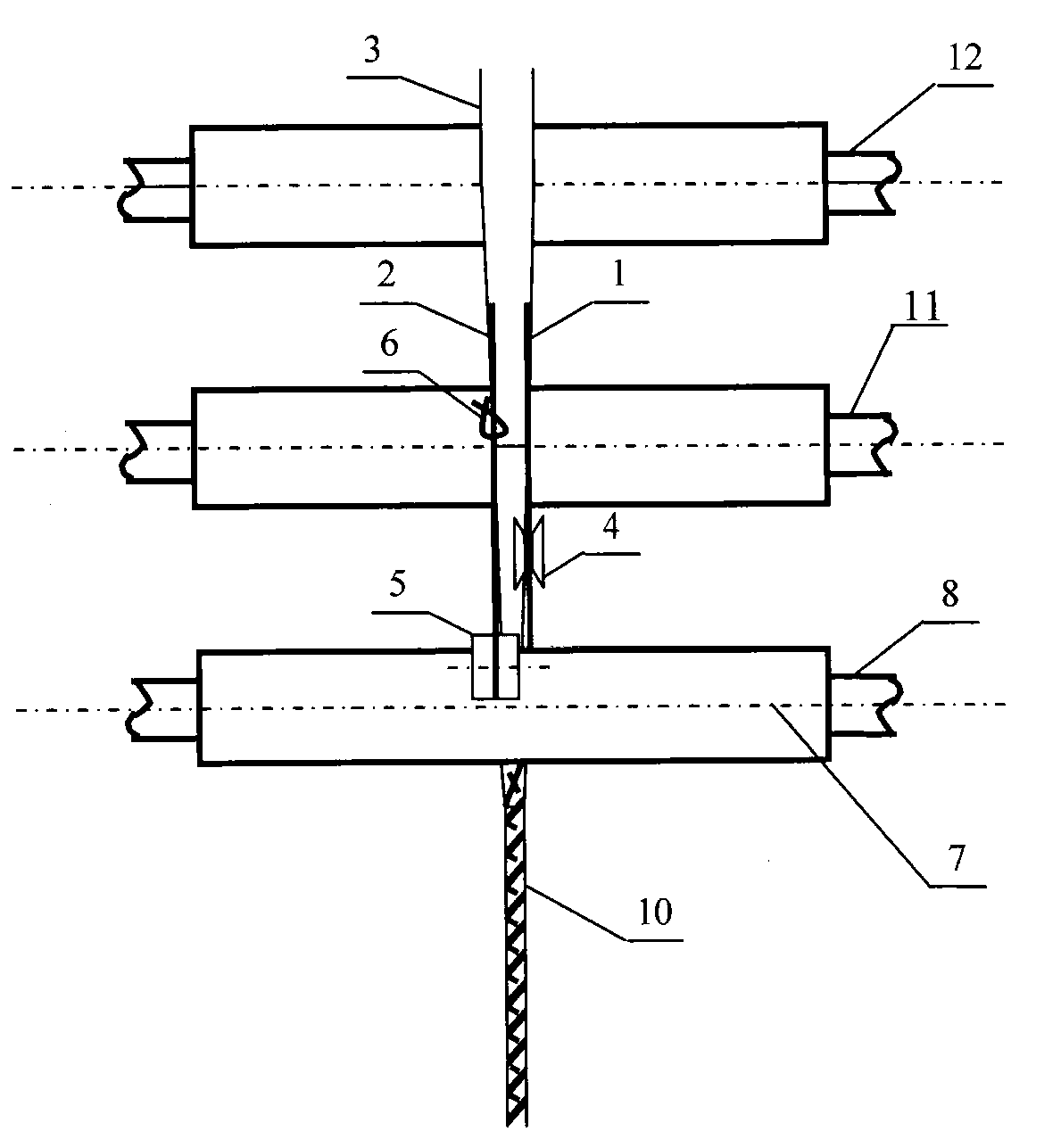

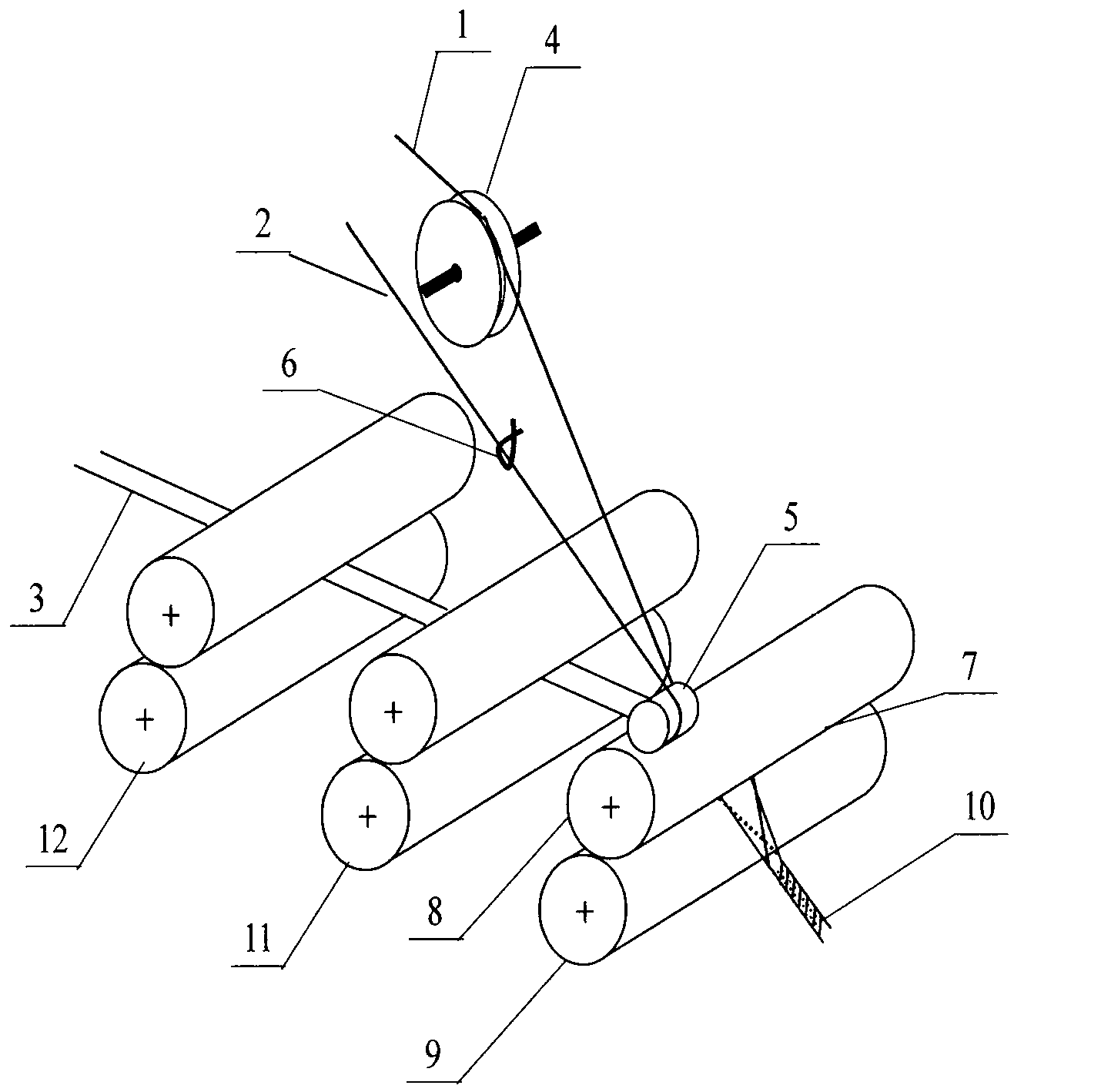

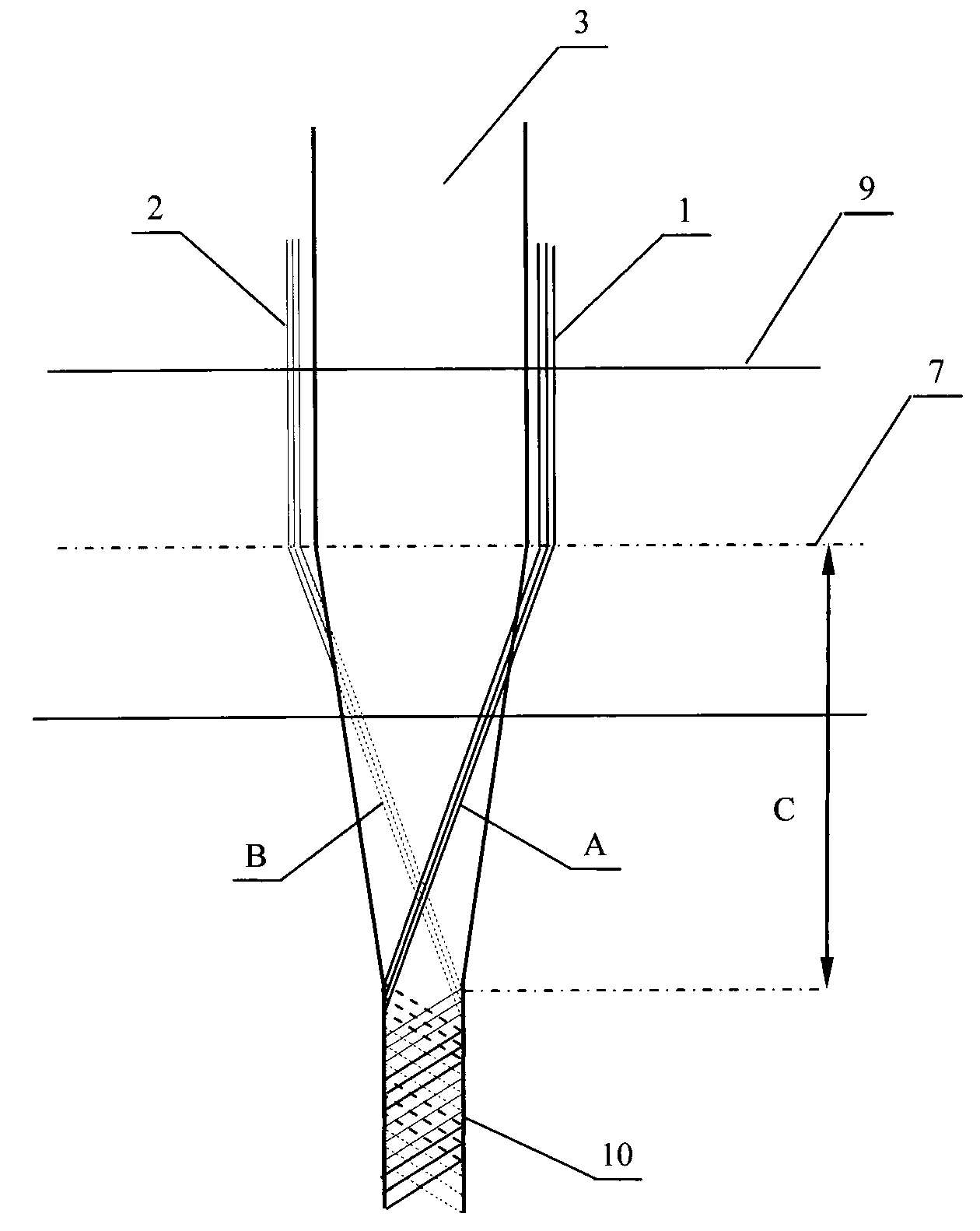

Smooth composite spinning mechanism and method of short fiber whisker strip clamped by double filaments via unequal tension

The invention relates to a smooth composite spinning mechanism, method and application of a short fiber whisker strip clamped by double filaments via unequal tension. The mechanism is composed of a tension disk used for locating a tension filament and controlling tension thereof, a yarn guide hook used for locating a low-tension filament and a holding roller used for keeping the tension. The composite spinning method comprises the steps of: synchronously feeding the tension filament, the low-tension filament as well as the short fiber whisker strip into a front roller to enable the short fiber whisker strip to be wrapped by the two filaments in a traction zone; and forming a three-shafting spinning yarn with the short fiber whisker strip covered by the tension filament from the upside and support by the low-tension filament from the downside, wherein the composite yarn is a smooth composite yarn which is formed by spirally twisting the tension filament and the short fiber whisker strip and externally coating the low-tension filament. The mechanism is light, practical, convenient to install, controllable and adjustable, can produce yarns with steady structure and is suitable for composite spinning of high-count smooth yarns and superfine yarns of short fibers.

Owner:DONGHUA UNIV

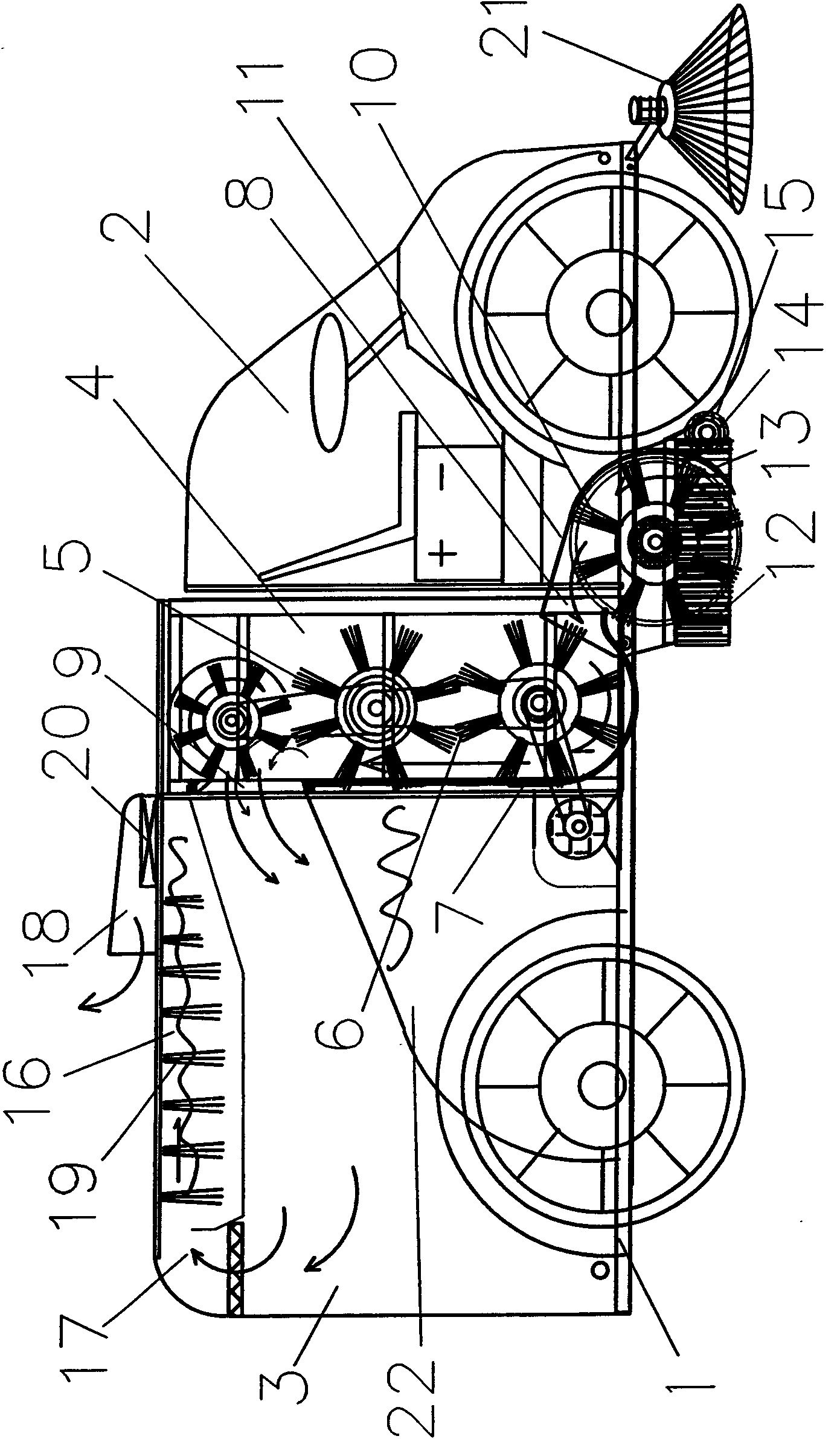

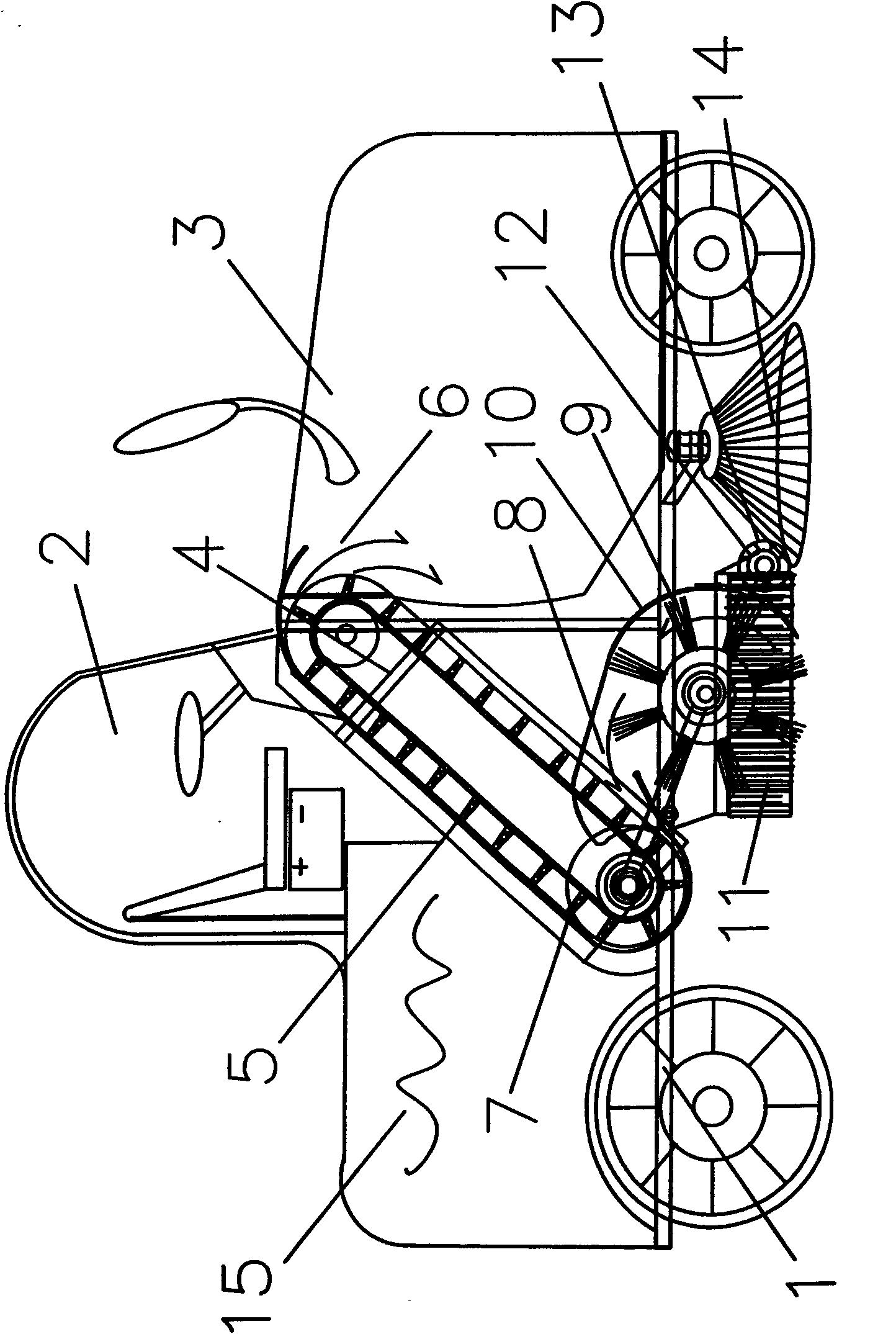

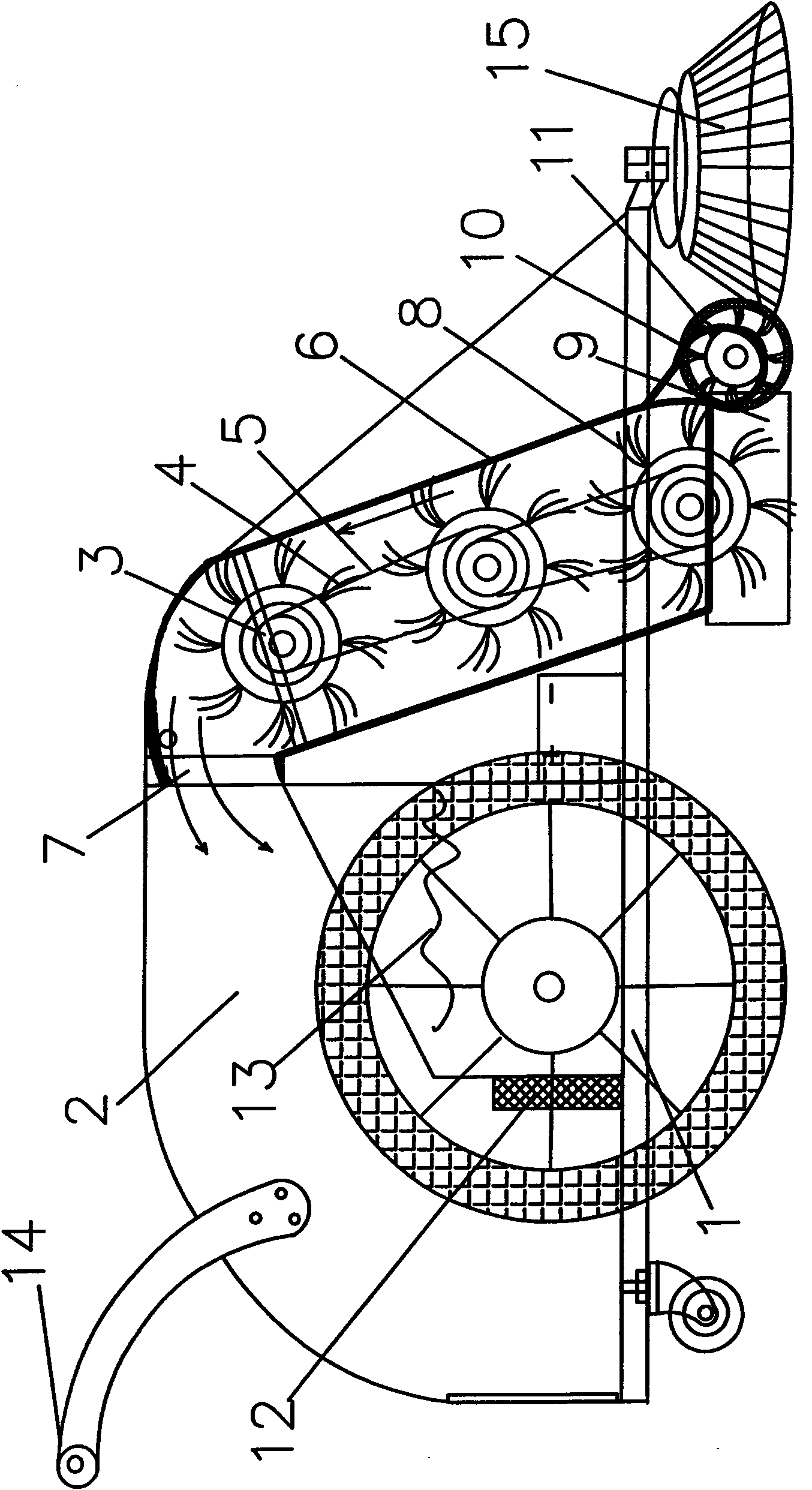

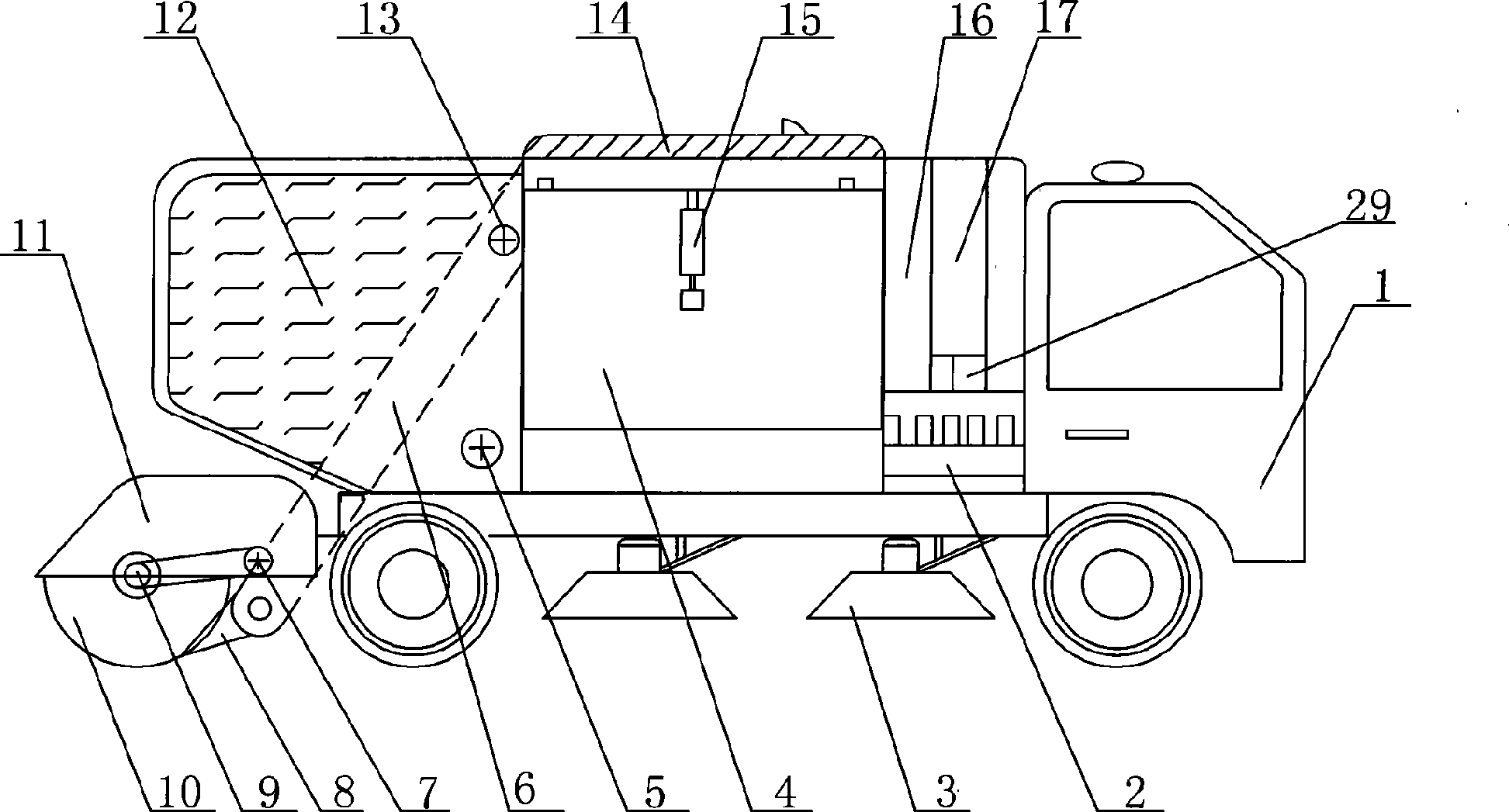

A transfer type sweeper

A transfer-type cleaning vehicle, which includes a car body, is characterized in that: several forward-rotating transfer rubbish rolling brushes are installed horizontally between the tipping garbage bin and the driver's cab; An arc-shaped guide garbage cover is formed at the lower end, and a garbage inlet is installed to facilitate the entry of the garbage to be swept; at an appropriate position above the guide garbage cover, a garbage outlet and a tipping bucket are installed backward At the proper position in front of the garbage entrance, install a reverse rotating sweeping roller brush that can move up and down freely following the height of the road; The small roller brush is equipped with a one-way rotating small tire on both sides of the small roller brush to cooperate with each other, so as to achieve the effective sweeping distance of the roller brush, and to assist the small roller brush to rotate in the same direction. The counter-rotating sweeping roller brush (5) works together to sweep the floor.

Owner:张珉

Coal composite sulfur fixing agent

The invention relates to a coal composite sulfur fixing agent, belonging to the technical field of boiler combustion desulphurization. The composite sulfur fixing agent is made of the following raw materials in parts by weight: 40-70 parts of CaO, 5-10 parts of SiO2, 5-15 parts of Al2O3, 3-5 parts of Fe2O3, 0.5-1 parts of BaS, 0.5-1 parts of BaCO3, 0.1-1.5 parts of Zn, 0.02-0.05 parts of Cu, 0.05-0.1 parts of As, 0.01-0.05 parts of Pb, 1-5 parts of CaF2, 0.05-0.2 parts of MgO, 0.5-1.0 parts of TiO2, 0.5-1.0 parts of K2O, 0.1-1.0 parts of Na2O and 0.04-0.06 parts of Ag. The coal composite sulfur fixing agent of the invention can reduce the emission of SO2, the atmospheric pollution and the formation conditions for acid rain. Since pulverized fuel ash and coal cinder are converted to modified ash and can be used in cement production technology, the clinker production of common cement can be reduced generally, the mine resources and the energy consumed during cement production are reduced, and the emission of CO2 is reduced.

Owner:河南中上环保科技有限公司

System and method for packaging of nested products

ActiveUS20140311091A1Reduce flyingReduce and tighten spacingWrapper twisting/gatheringSolid materialCartonBiomedical engineering

A packaging system for the selection, grouping and loading of varying size and / or configuration product packs into cartons as provided. The packaging system includes a selection area having a primary selector for forming an initial product pack configuration, and a secondary selector adapted to select and direct an additional grouping of products into a nested arrangement against the initial product pack so as to form a nested product pack. The nested product packs thereafter can be engaged by loader arms of a pair of opposed loading assemblies, which move the nested product packs into a series of cartons moving through the packaging machine. Thereafter, the ends of the cartons can be closed and sealed to complete the packaging of the product packs therein.

Owner:GRAPHIC PACKAGING INT

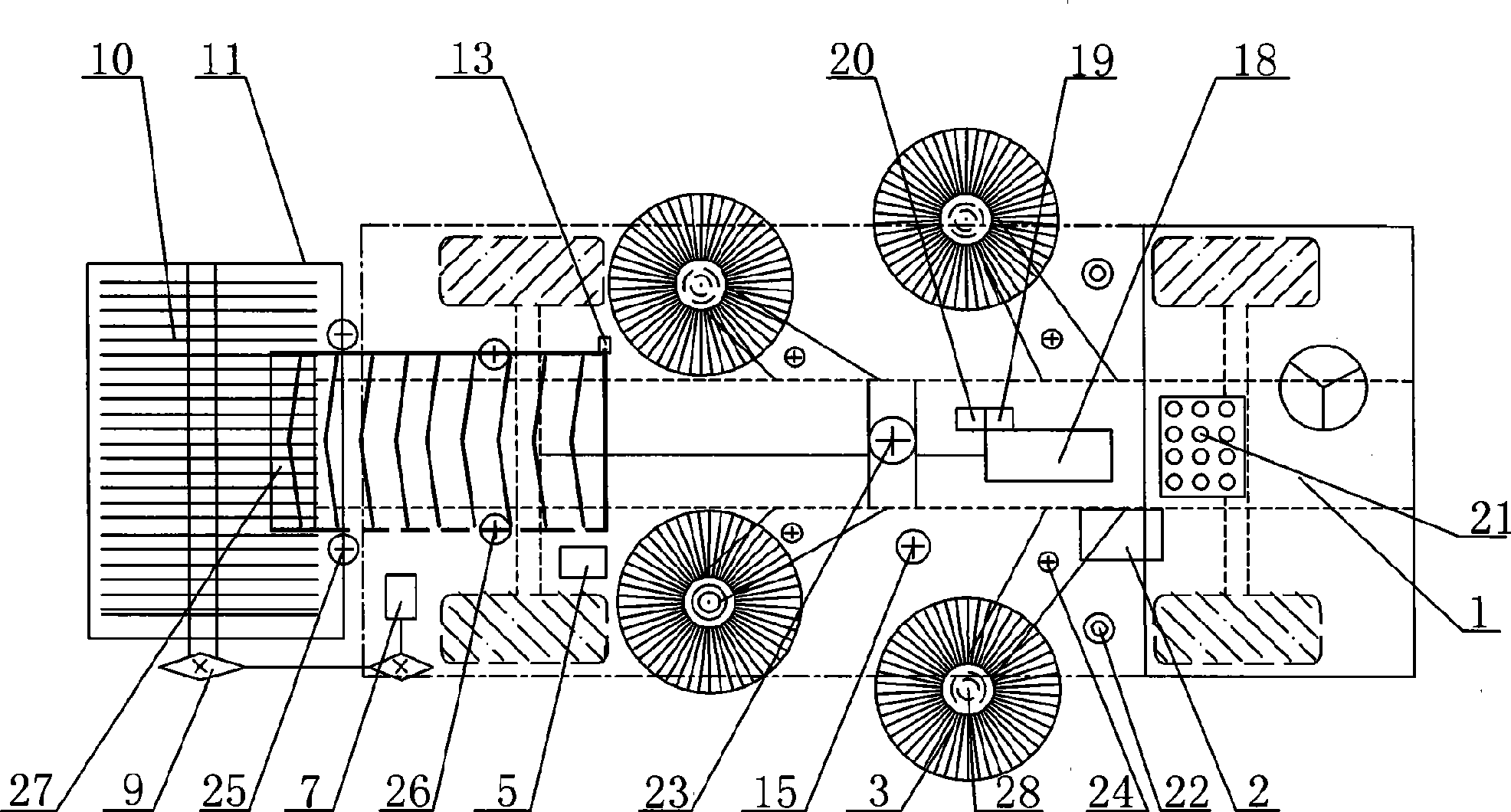

Purely sweeping type road sweeper

The invention belongs to the technical field of an environmental sanitation vehicle, in particular to a pure-sweeping typed cleaning vehicle. The cleaning vehicle comprises an automobile chassis, a middle sweeping device assembly, a garbage conveyer assembly, a garbage collecting box and a hydraulic system. The rear suspension position of the automobile chassis is fixedly provided with the middle sweeping device assembly; wherein, a roller brush is arranged on the shell of the middle sweeping device; the roller brush is connected with the hydraulic motor of the middle sweeping device by a chain wheel pair; the front part of the roller brush is provided with a feeding dustpan hole; the front part of the feeding dustpan hole is provided with a garbage feeding hole; and a lifting hydraulic cylinder of the middle sweeping device is arranged between the shell of the middle sweeping device and the automobile chassis. The pure-sweeping typed cleaning vehicle integrates collecting, sweeping and dust-pressing into a whole, has simple structure, little malfunction, is not restricted by reasons and provided with a spraying dust-pressing device, thus avoiding the secondary pollution due to dust flying during the operation process.

Owner:郑振华

Substrate processing apparatus, substrate processing method, substrate holding mechanism, and substrate holding method

ActiveCN103839857AProcessing time equalizationImprove processing efficiencySemiconductor/solid-state device manufacturingLapping machinesTransfer mechanismElectrical and Electronics engineering

A substrate processing apparatus, a substrate processing method, a substrate holding mechanism, and a substrate holding method are disclosed. The apparatus includes a polishing section 3 configured to polish a substrate W, a transfer mechanism 5, 6 configured to transfer the substrate, and a cleaning section 4 configured to clean and dry the polished substrate W. The cleaning section 4 has plural cleaning lines for cleaning plural substrates. The plural cleaning lines have plural cleaning modules 201A, 201B, 202A, 202B and plural transfer robots 209, 210 for transferring the substrates.

Owner:EBARA CORP

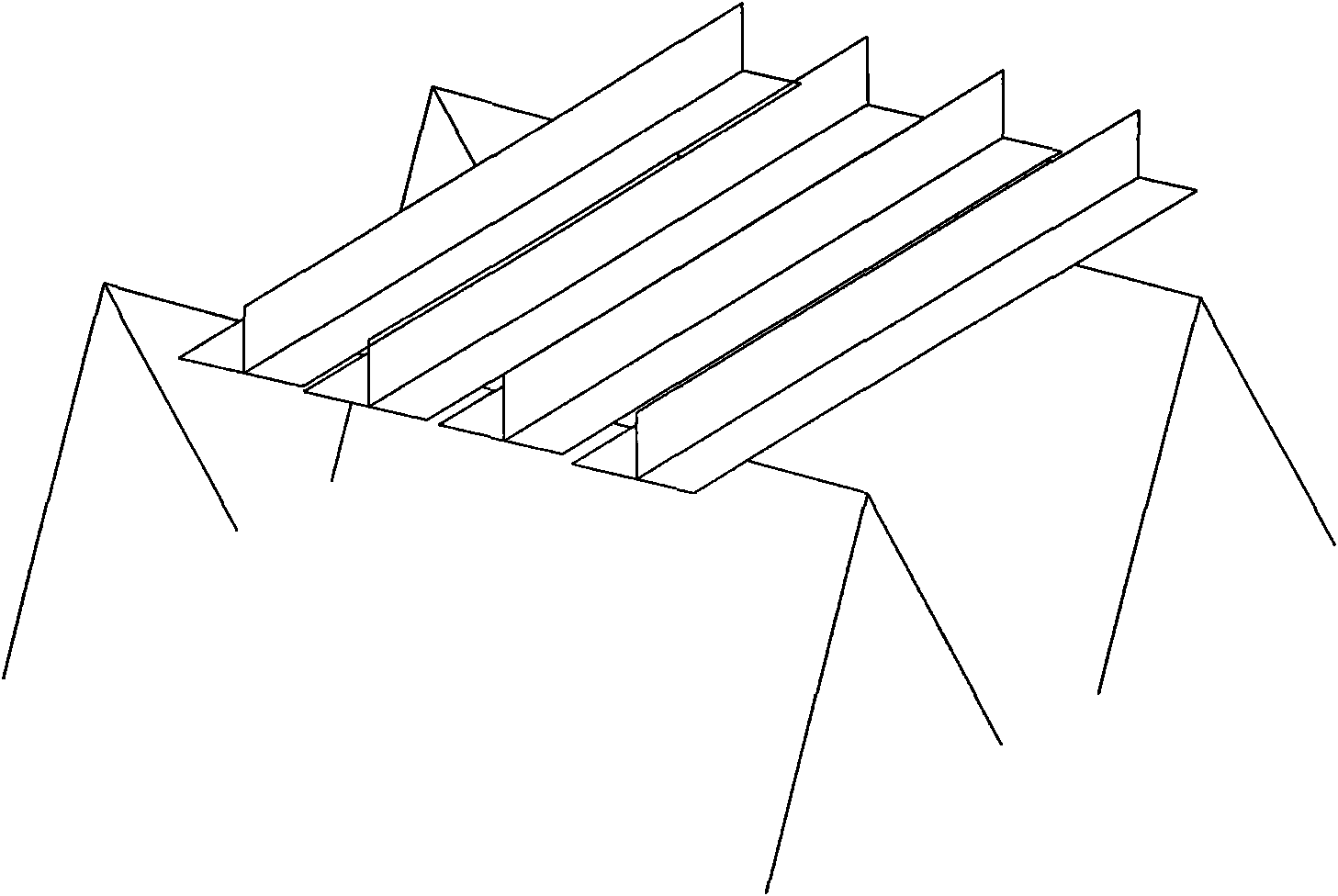

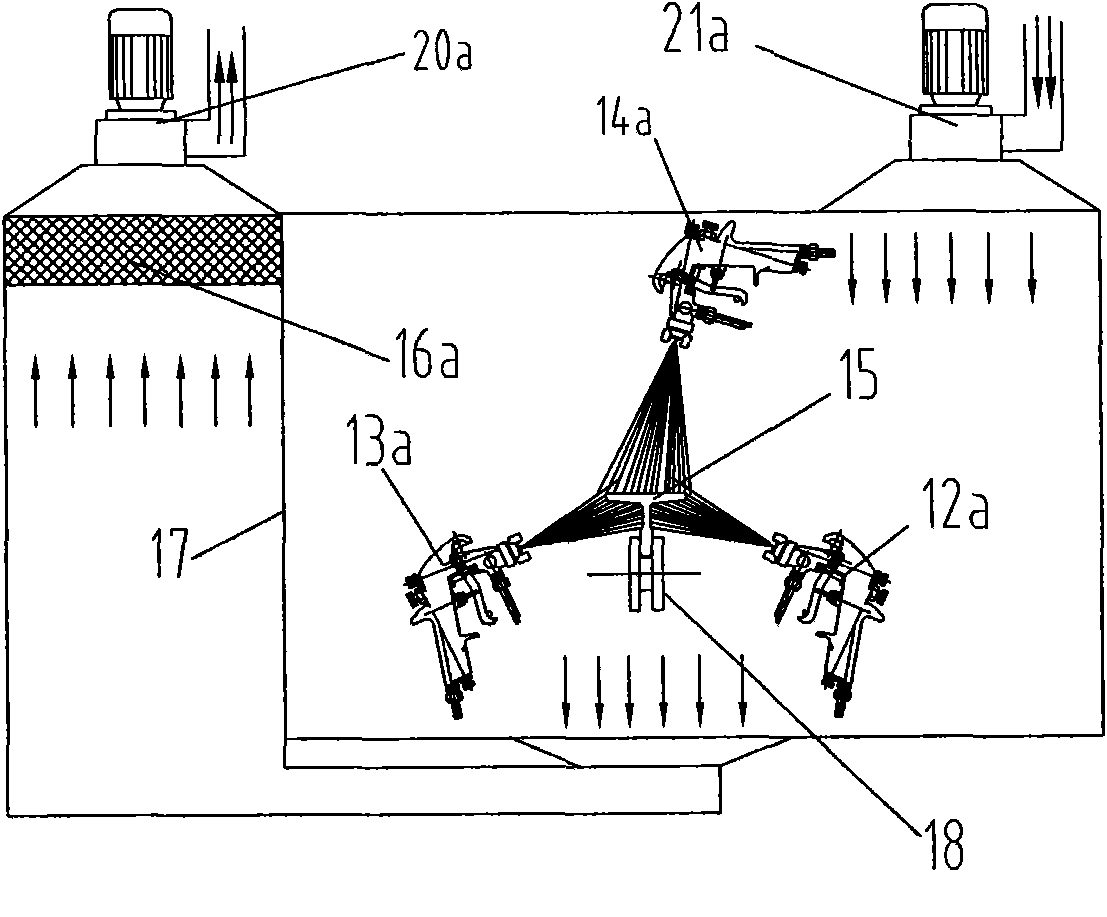

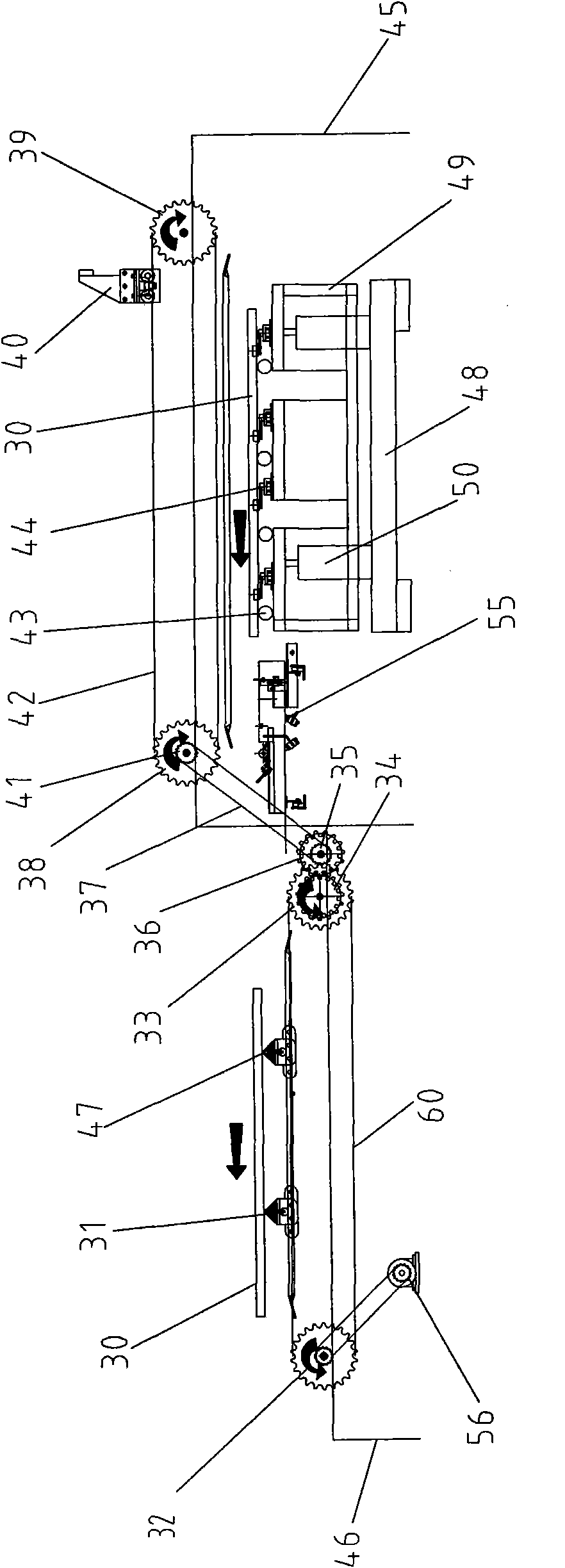

Automatic paint spraying equipment for blank of elevator guide rail

InactiveCN102463201AReduce pollutionImprove pollutionLiquid surface applicatorsSpraying apparatusBlade plateSprocket

The invention provides automatic paint spraying equipment for a blank of an elevator guide rail. The automatic paint spraying equipment is characterized by comprising a feeding frame and a receiving frame; the feeding frame and the receiving frame are arranged on the same straight line; traction chain wheels, traction chains connected with the traction chain wheels and power sources for driving the traction chain wheels are arranged on the feeding frame and the receiving frame; a pusher is arranged on the traction chain of the feeding frame, and a lifting frame is arranged below the traction chain of the feeding frame; a flexible self-centering guiding mechanism and a lifting frame roller are arranged on the lifting frame; a support mechanism is arranged on the traction chain on the receiving frame; and a spraying center is arranged between the lifting frame and the support mechanism. According to the automatic paint spraying equipment, blade plates on two sides of the front side of a guide rail are sprayed by a spray gun in a static mode; and the bottom surfaces of the guide rail blade plates are subjected to roll coating and brush coating, so that the elevator guide rail serving as the blank is sprayed and brushed on three surfaces at a time. By the automatic paint spraying equipment, the spraying environment is improved, the motion speed of guide rail workpieces is constant during spraying, the spraying is accurate and quick, the floor area is small, the efficiency is improved, and the stability of the quality is ensured.

Owner:徐胜利

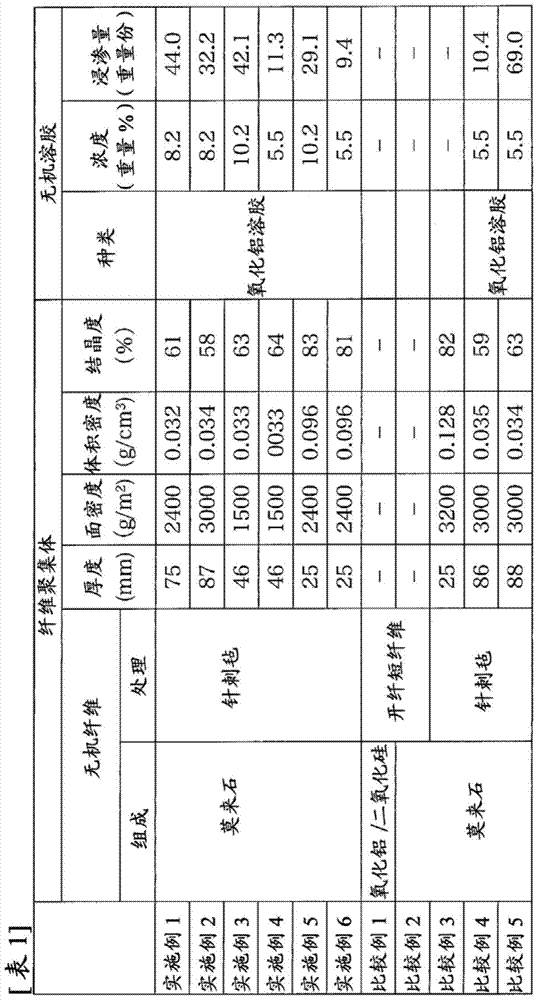

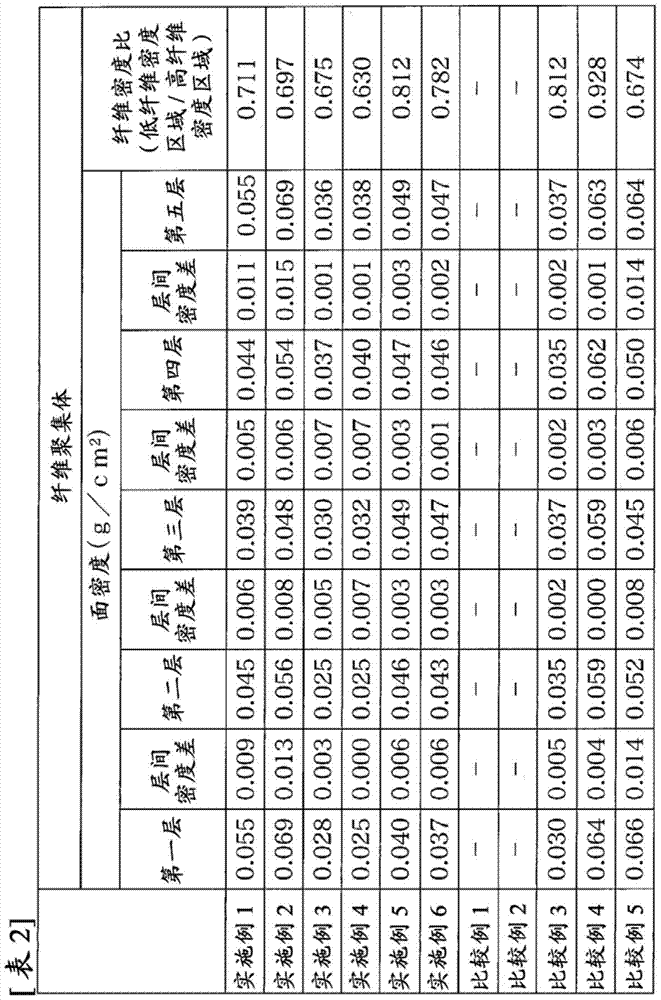

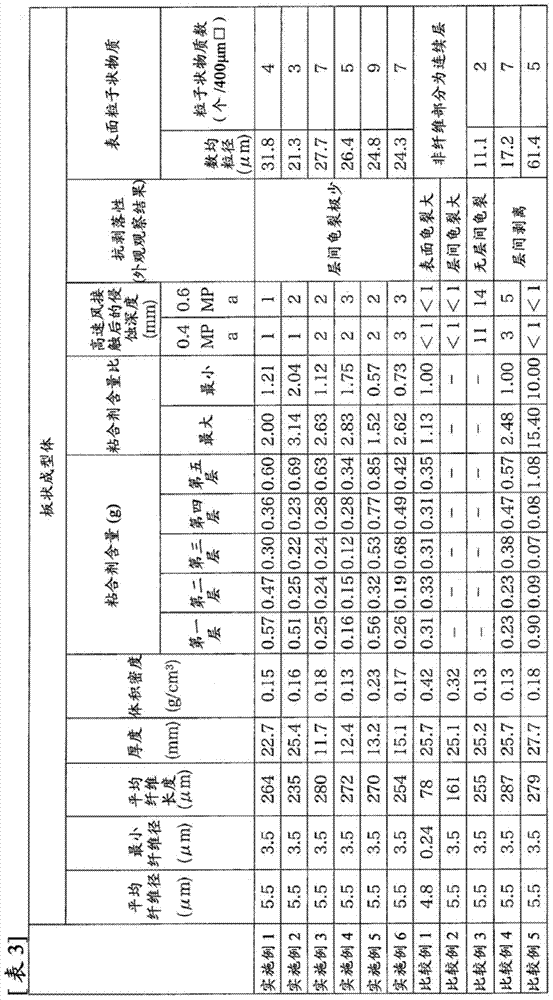

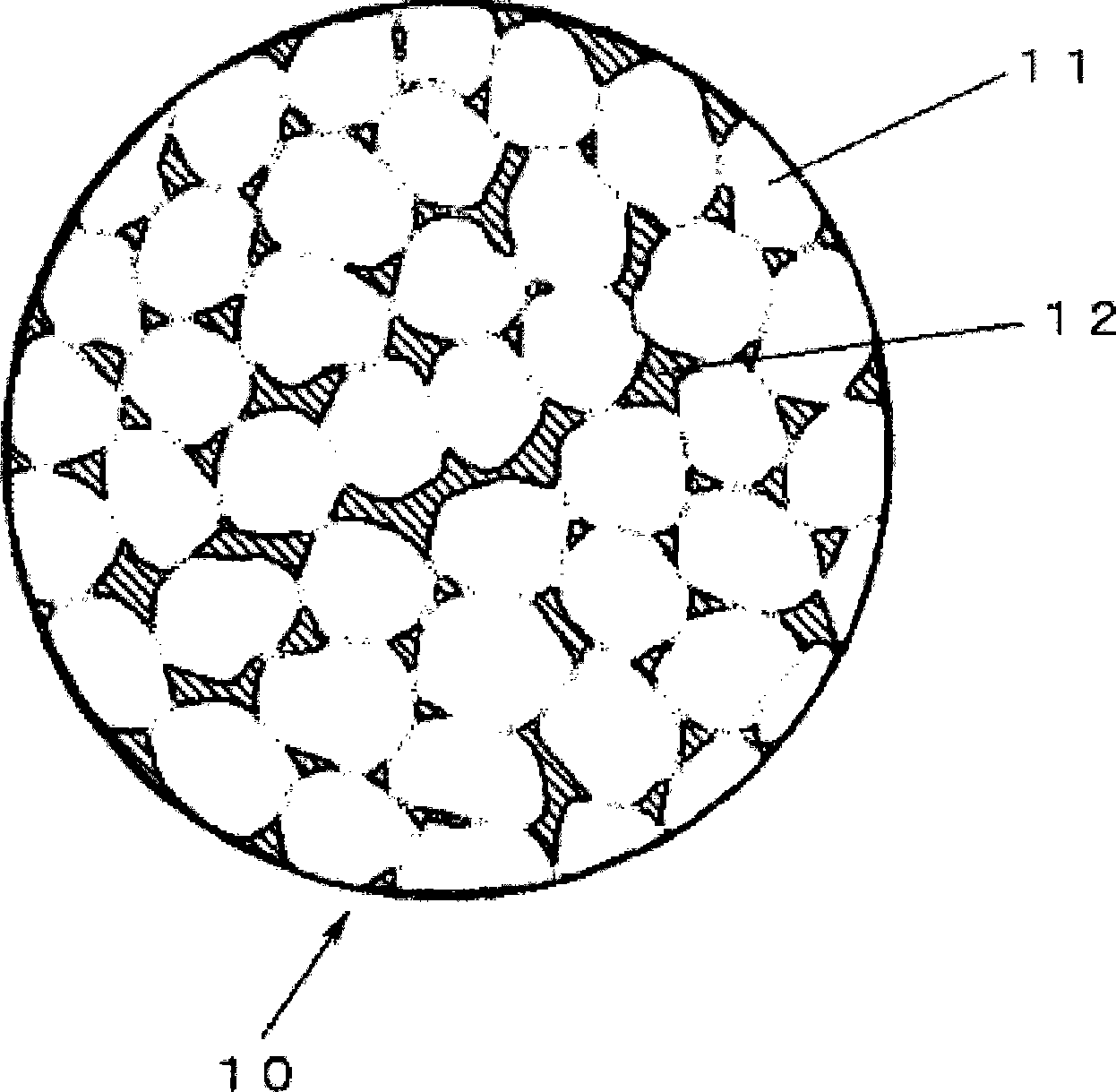

Molded inorganic-fiber object and process for producing same

ActiveCN103781954AImprove thermal shock resistanceExcellent balance of physical propertiesExhaust apparatusSilencing apparatusHazardous substanceShock resistance

Provided is a molded inorganic-fiber object which is characterized by being extremely lightweight, being reduced in flying of fibers or a particulate substance from the surface thereof, and being free from problems concerning environmental pollution, such as generation of a harmful substance. The molded object is excellent in terms of thermal shock resistance and mechanical shock resistance and of resistance to high-speed wind erosion, has an excellent balance among material properties, and can be used in various heat insulator applications. The molded inorganic-fiber object comprises inorganic fibers and inorganic binder particles and has at least a pair of regions, a high-fiber-density region and a low-fiber-density region, wherein the ratio of the content of the binder particles in the high-fiber-density region to the content thereof in the low-fiber-density region, as determined by a given method, is 0.5:1 to 5:1 and the inorganic binder particles in the outermost surface of the molded object have a number-average particle diameter, as determined by a given method, of 20-35 [mu]m, the number of the inorganic binder particles therein being less than 15.

Owner:MAFTEC CO LTD

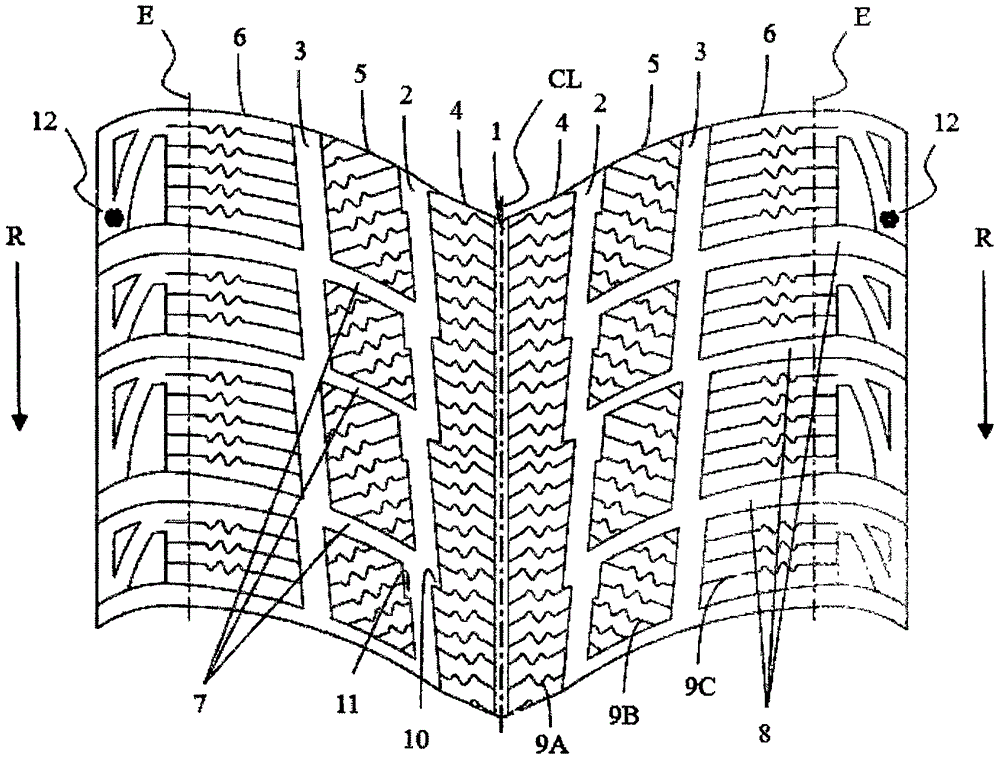

Tire tread rubber compound with low rolling resistance and tire made from tire tread rubber compound

ActiveCN106279797AFast and reliable integrationReinforced phase distributionSpecial tyresTyre tread bands/patternsRolling resistanceEngineering

The invention relates to a tire tread rubber compound with low rolling resistance and a tire made from the tire tread rubber compound. The tire tread rubber compound comprises the following raw materials in parts by weight: 50-70 parts of natural rubber STR20, 0-30 parts of solution polymerized styrene-butadiene rubber SSBR4525, 0-20 parts of neodymium butadiene rubber BunaNd22EZ, 0-10 parts of guayule, 20-35 parts of carbon black ECORAX1670, 20-35 parts of white carbon black ULTRASIL 5000GR, 1.5-3.0 parts of a silane coupling agent Si69 and 0.2-0.4 part of a silane coupling agent KH580. A preparation method comprises the following steps: preparing guayule, mixing by adopting an internal mixer and mixing by adopting an open mill, thereby acquiring the tire tread rubber compound with low rolling resistance. Through the tread pattern design for circumferential pattern, transverse pattern, siping pattern, and the like, the tire with low rolling resistance is prepared. According to the tire tread rubber compound with low rolling resistance and the tire made from the tire tread rubber compound provided by the invention, the tread formula is optimized, the mixing technique is improved, the tread pattern is improved and the tread formula, the mixing technique and the tread pattern are organically combined, so that the performances, such as road holding, abrasive resistance and wet sliding resistance of the tread, are guaranteed and the rolling resistance of the tire is reduced.

Owner:郑兴荣

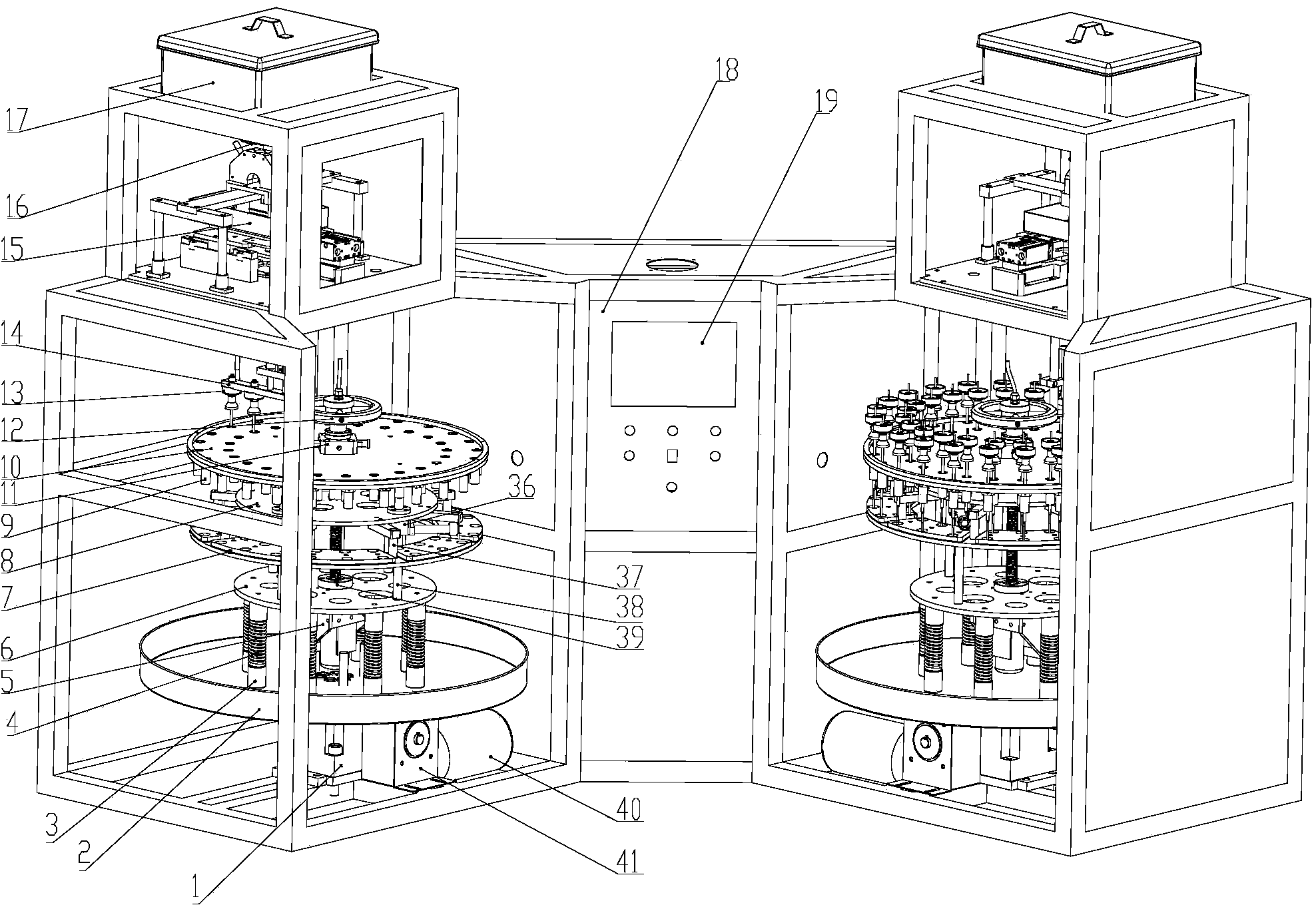

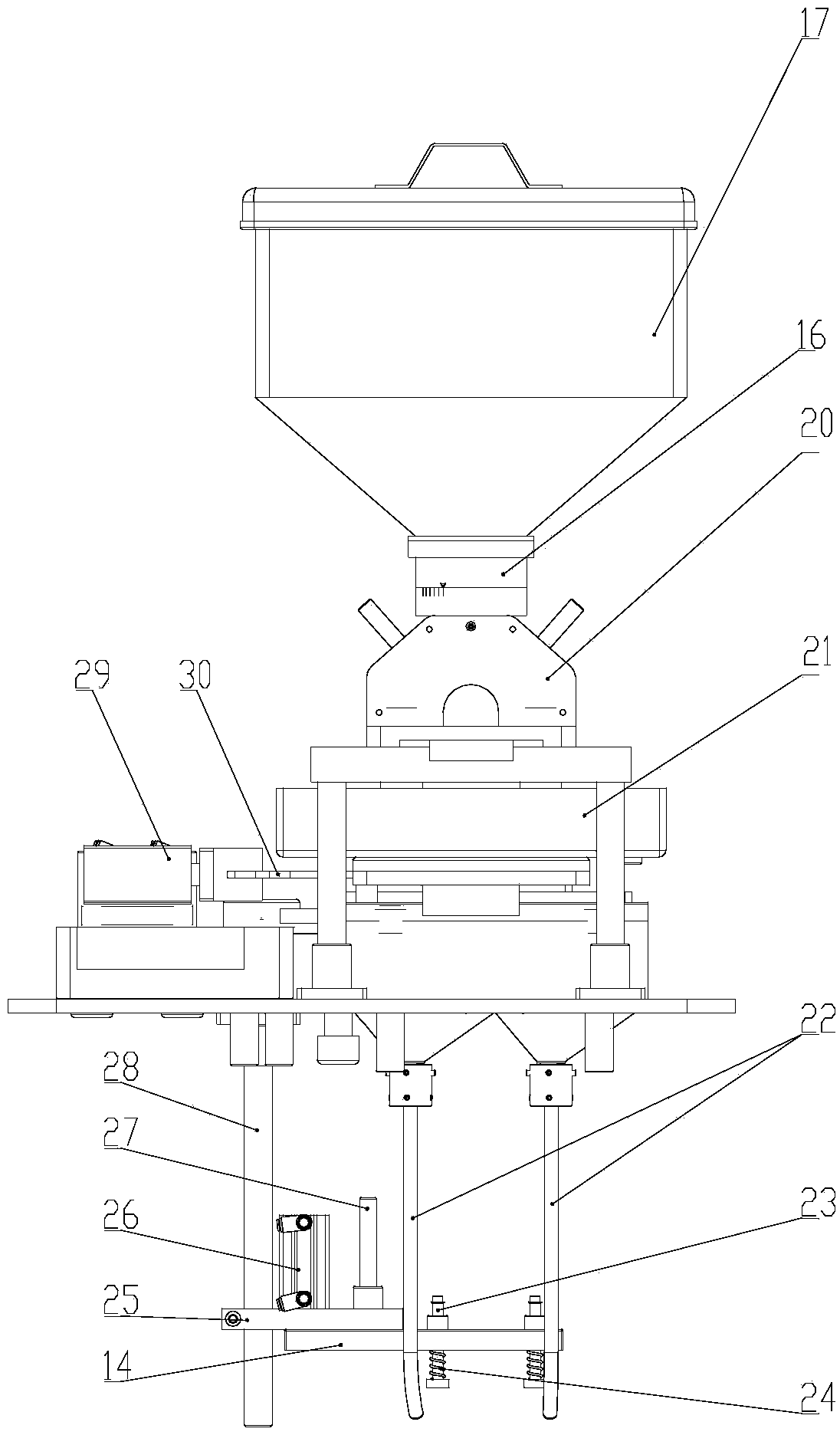

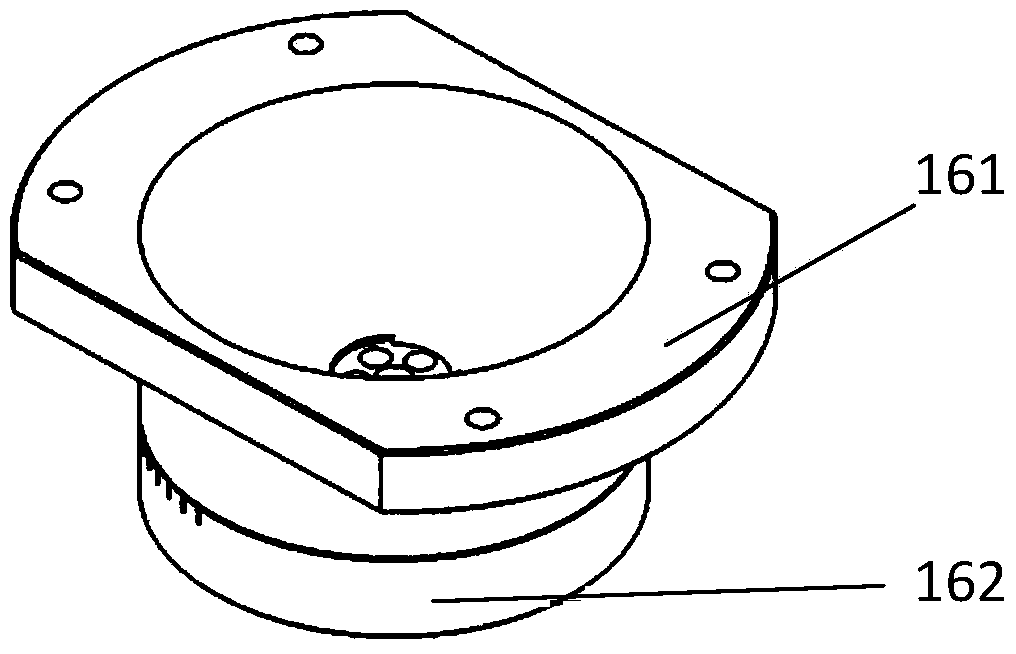

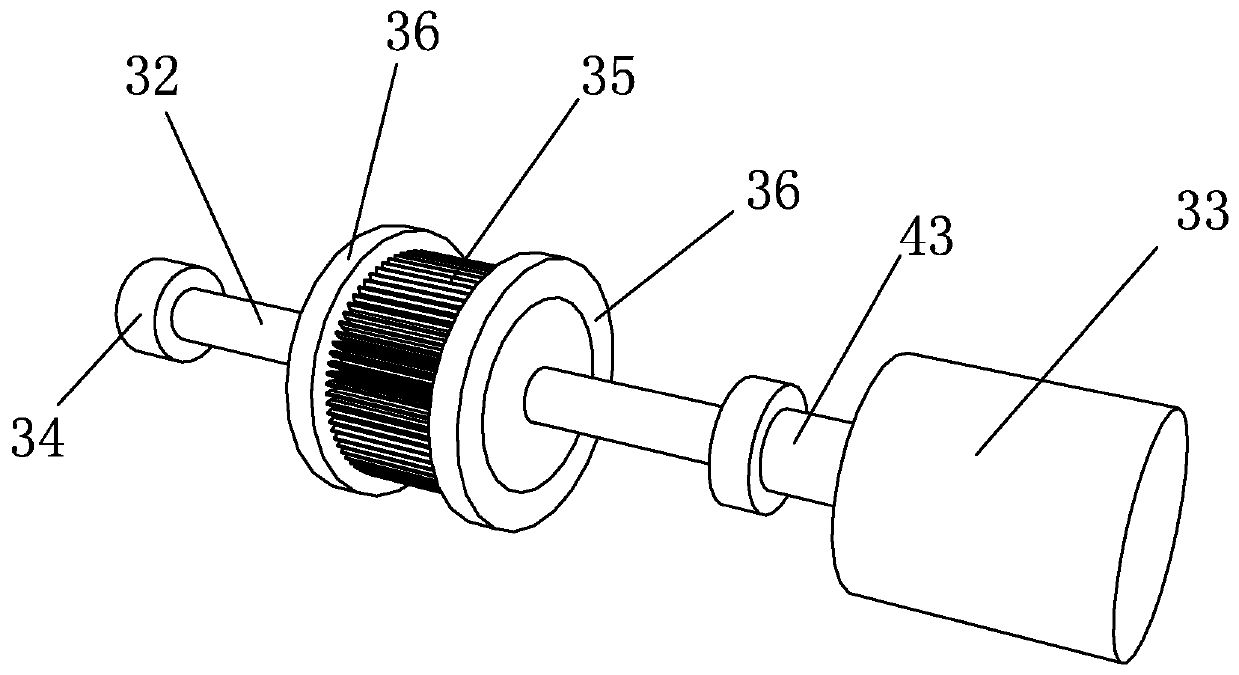

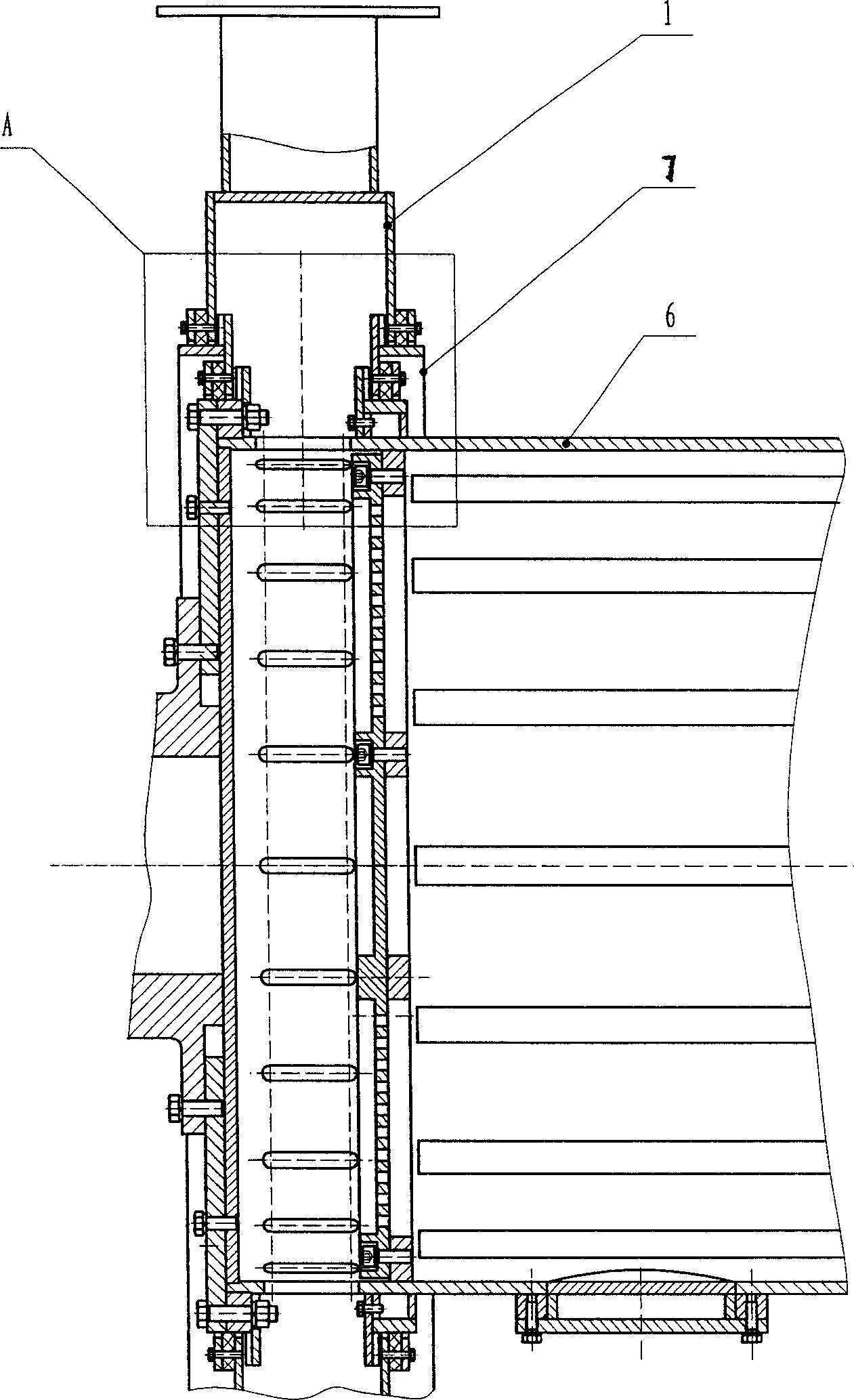

Quantitative powder-filling device for sintering-type heat pipes

The invention discloses a quantitative powder-filling device for sintering-type heat pipes. The quantitative powder-filling device comprises a bilateral symmetry V-shaped rack, a touch screen control panel, a funnel positioning device and two sets of powder-filling core mechanisms, the touch screen control panel is arranged in the middle of the rack, the two sets of powder-filling core mechanisms are arranged on the rack in a bilateral symmetry mode, the powder-filling core mechanisms comprise powder storing tanks, automatic powder inlet mechanisms, pressing mechanisms, powder-filling platform main panels, fixed middle plates, positioning plates, vibrating mechanisms and intermittent rotation devices which are sequentially arranged on the rack from top to bottom, the pressing mechanisms are used for pressing core rods, the powder-filling platform main panels are used for placing the heat pipes, and the touch screen control panel is respectively connected with the vibrating mechanisms, the intermittent rotation devices and the automatic powder inlet mechanisms in a circuit mode. The quantitative powder-filling device for the sintering-type heat pipes has the advantages that the automation degree is high, the controlling is accurate, requirements for operators are low, the labor intensity of the operators is reduced, the operation is convenient, the production efficiency is high, meanwhile, waste of raw materials such as copper powder can be reduced, flying dust is reduced, and the operating environment is improved.

Owner:SOUTH CHINA UNIV OF TECH

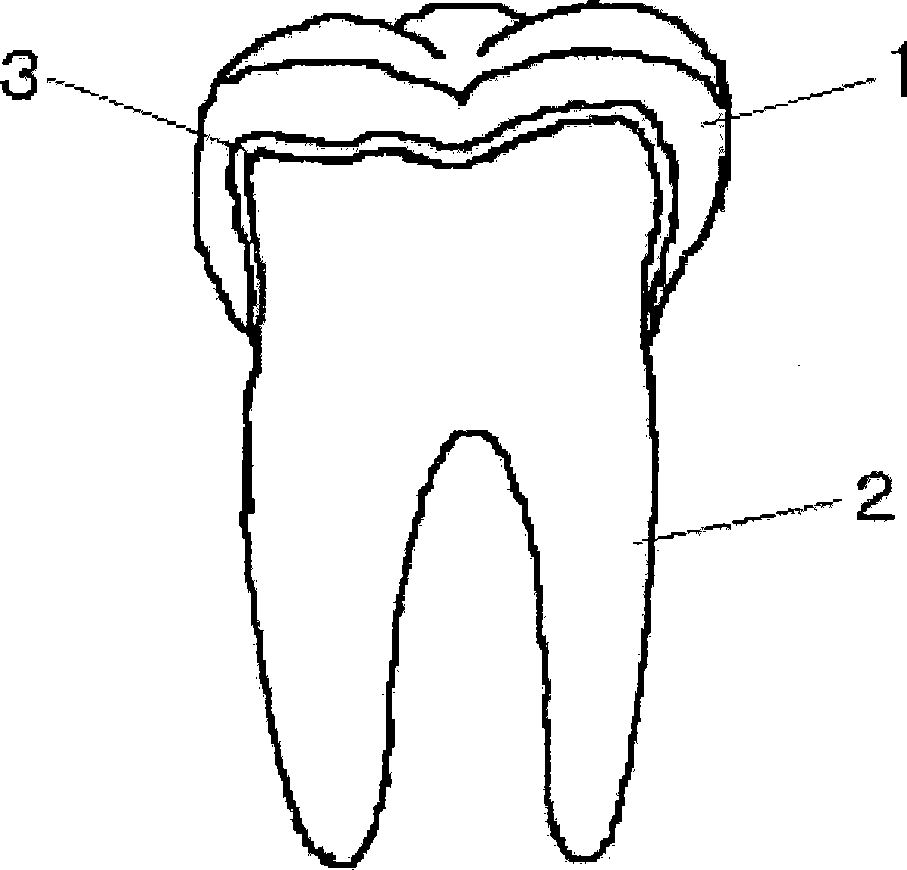

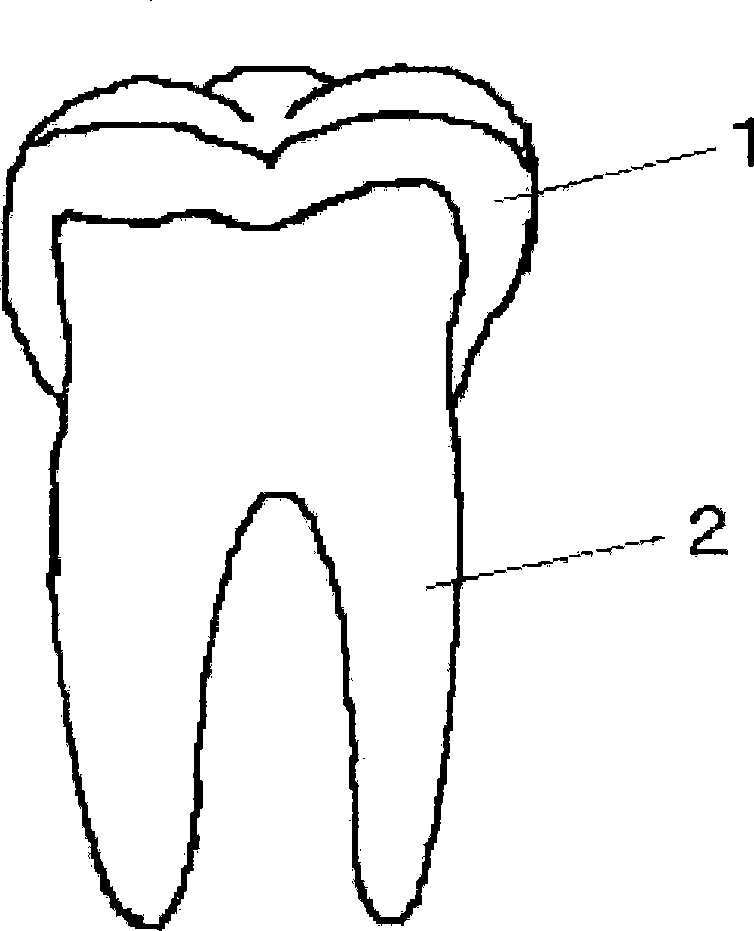

Tooth for dental arch model and method of producing the same

A tooth to be used in a dental arch model with which dental students can conduct dental works in the oral cavity and practice treatments. More specifically, a tooth composition for formation trainings such as anchor tooth formation and cavity preparation. Since conventionally used dental arch models have cutting properties different from natural teeth, dental students having completed formation trainings such as anchor tooth formation and cavity preparation by using these conventional models are frequently puzzled to have different cutting and handling properties upon dental works in the oral cavity in practice. That is, these conventional dental arch models are largely different from natural teeth in cutting properties including the slipperiness and easiness in cutting. A tooth for a dental arch model simulating the enamel texture and the dentin texture constituting a natural tooth whereby even the difference in cutting properties between the enamel texture and the dentin texture constituting a natural tooth can be reproduced by forming at least the enamel part with the use of a baked inorganic powder such as alumina.

Owner:SHOFU INC

Yarn guiding device for textile machinery yarn

ActiveCN109693971ASmooth and smooth entryEasy to handleFilament handlingFibre cleaning/openingYarnFixed frame

The invention discloses a yarn guiding device for textile machinery yarn. The yarn guiding device comprises a fixed frame and a yarn guiding frame; the yarn guiding frame comprises an arc-shaped rotating plate and an arc-shaped fixed plate; an upper pressure roller is arranged at the right end of the arc-shaped rotating plate, and the left end of the arc-shaped rotating plate is connected with anadjusting air cylinder; a lower pressure roller is arranged at the right end of the arc-shaped fixed plate, and a yarn arranging wheel is arranged on the arc-shaped fixed plate; and a first yarn guiding roller is arranged between the yarn arranging wheel and a yarn leading roller, and a second yarn guiding roller is arranged between the yarn arranging wheel and the lower pressure roller. The yarntransferred from different angles can be led, the yarn is prevented from being broken in the transferring process, burrs and impurities on the surface of the yarn can be removed in the yarn leading process through the design of the yarn arranging wheel, thus the surface of the yarn is smoother and flatter, and the quality of the yarn is improved; and meanwhile, electrostatic friction generated inthe yarn transferring process can be removed through a electrostatic eliminating assembly, and the problems of yarn fault increasing, yarn breaking and flying are reduced.

Owner:绍兴华清化纤纺织有限公司

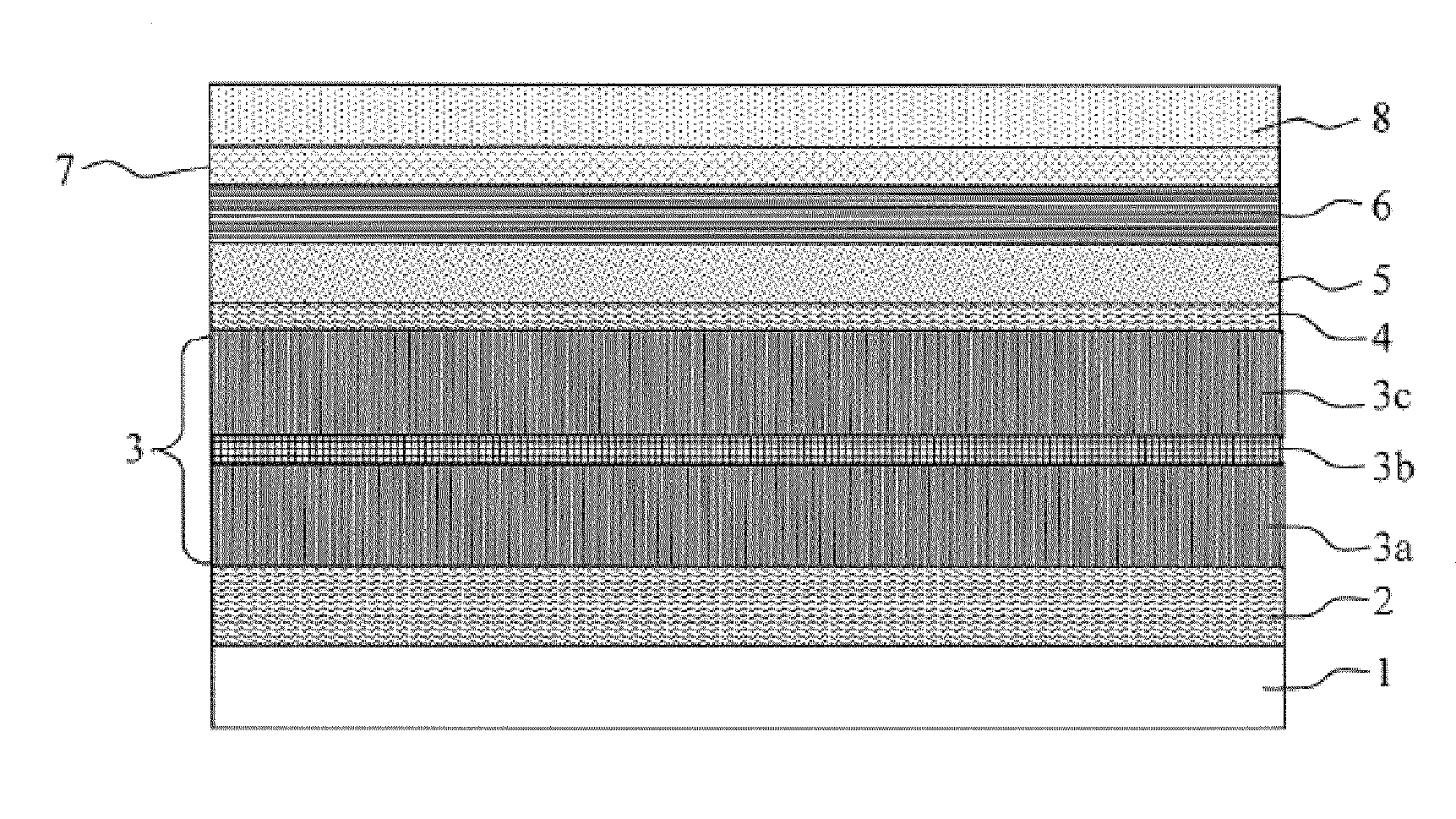

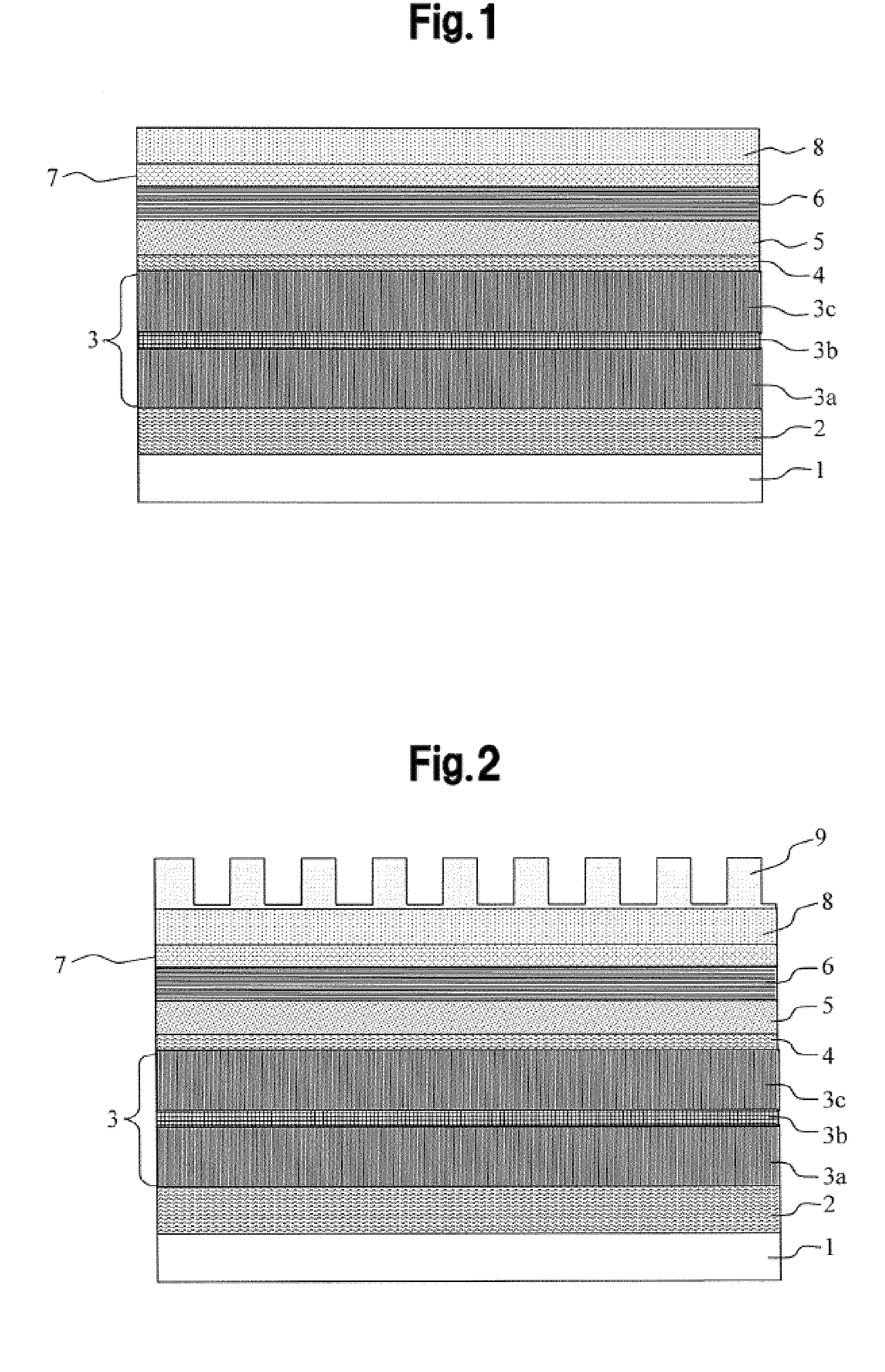

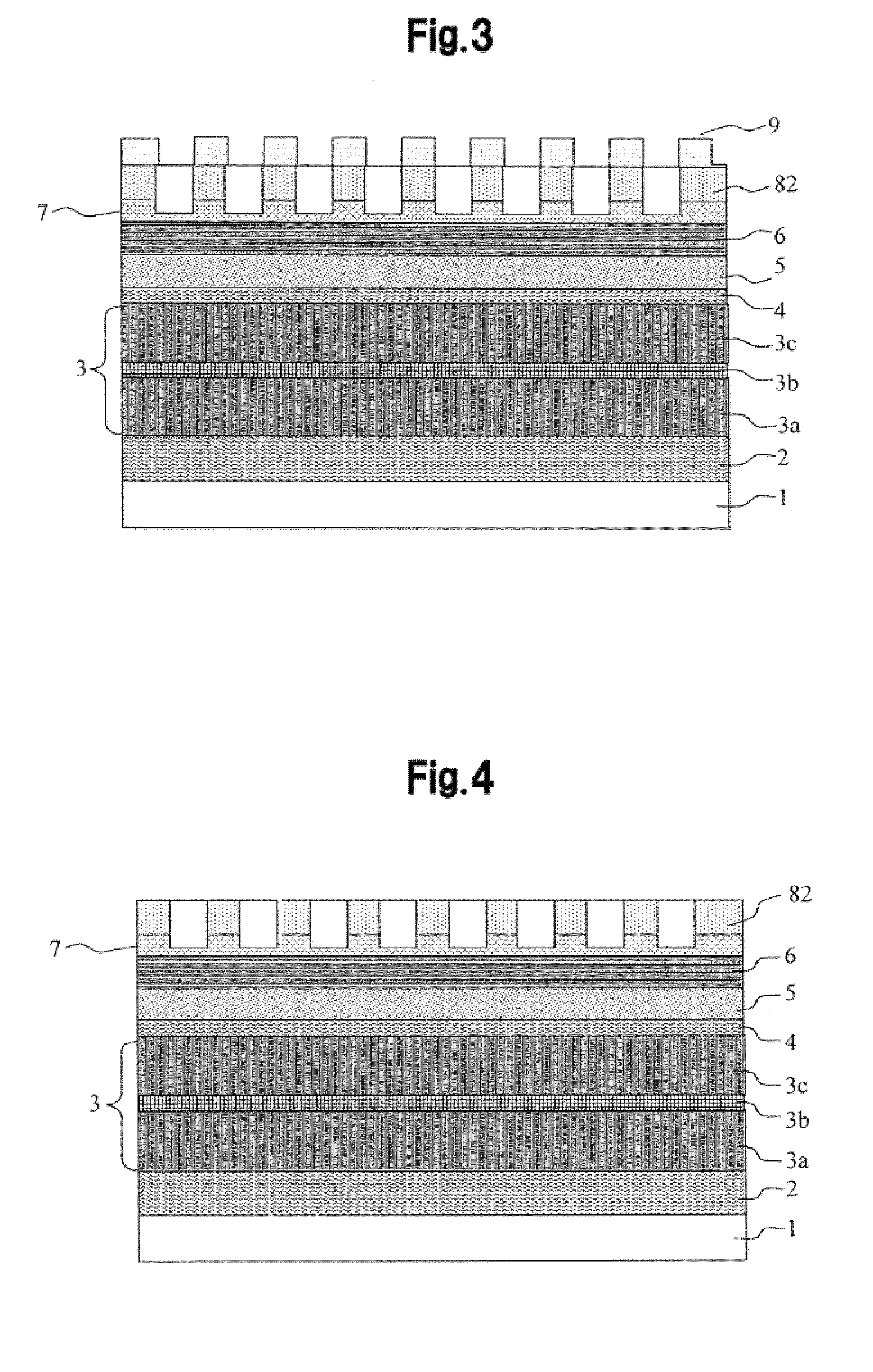

Magnetic recording medium and manufacturing method thereof

ActiveUS20090213497A1Reduce rateReduce flyingVacuum evaporation coatingSputtering coatingIn planeRecording layer

Embodiments of the present invention provide recording area separated magnetic recording media (DTMs, BPMs) allowing magnetic heads to fly lower. According to one embodiment, the recording area separated magnetic recording media are configured so that magnetic recording layers have parts with the relatively higher element ratio of a ferromagnetic material, and parts with the lower element ratio of the ferromagnetic material, occurring periodically in the in-plane direction, and the average height from the substrate surface of the parts with the relatively higher element ratio of a ferromagnetic material is higher than the average height from the substrate surface of the parts with the lower element ratio of the ferromagnetic material. In producing recording area separated magnetic recording media with the element ratio of a ferromagnetic material relatively lowered by ion implantation, preliminarily etching the part to be ion implanted makes the height after ion implantation relatively lower than the non-implanted part.

Owner:WESTERN DIGITAL TECH INC

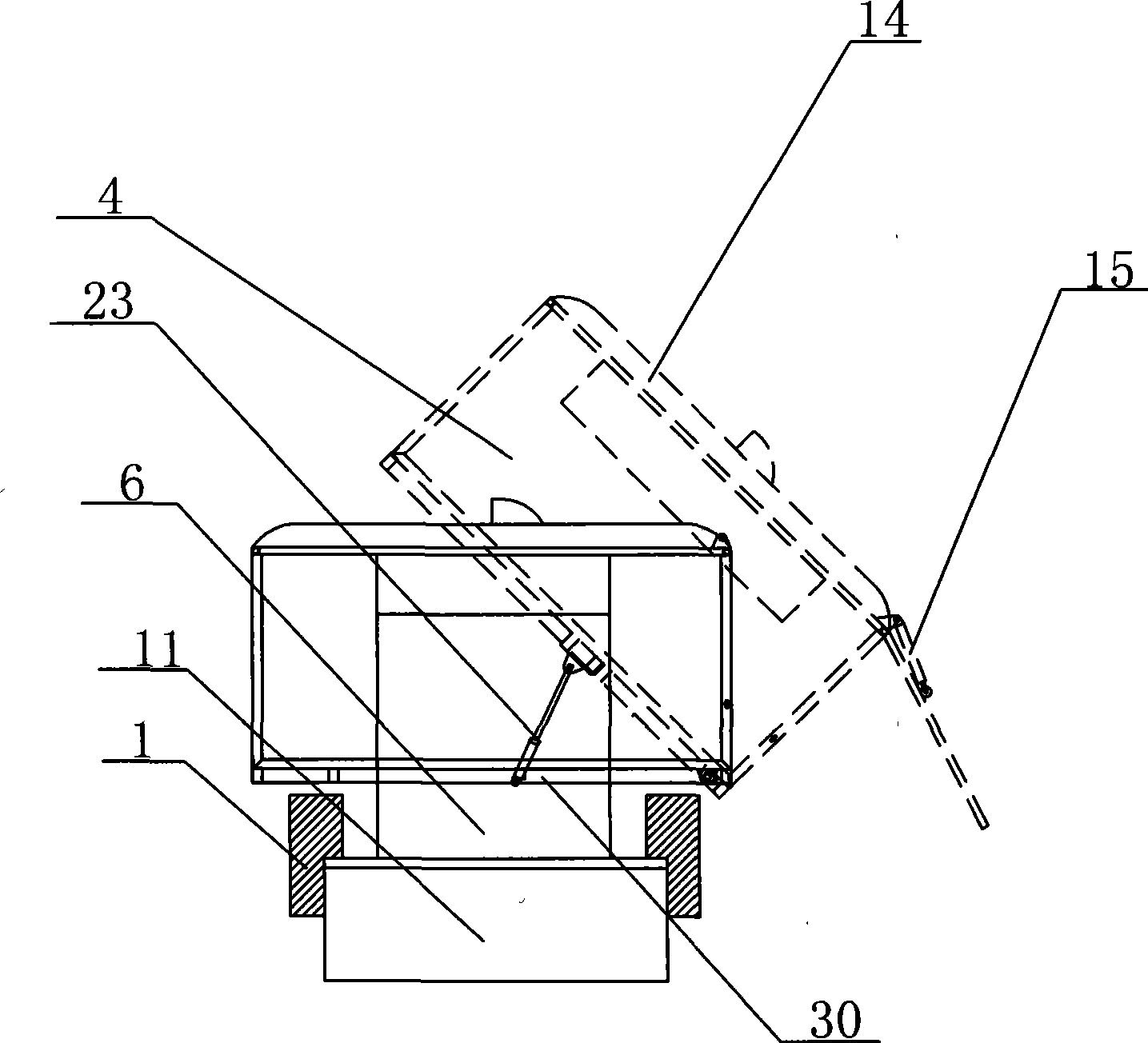

Self-propelled construction site watering and dust-settling device

InactiveCN111749182AOrientation flexible adjustmentRealize the effect of sprinkler and dust reductionUsing liquid separation agentRoad cleaningElectric machineryStructural engineering

The invention discloses a self-propelled construction site watering and dust falling device, and relates to the technical field of construction engineering. The device which comprises a moving frame,wherein a water tank is fixed in the moving frame, a limiting mechanism slidably connected with a spraying plate is hinged to the moving frame, a servo motor is in driving connection with a dispersingmechanism located in the water tank, and walking wheels are rotatably mounted at the bottom of the moving frame. According to the invention, spray heads on the spray plate are arranged to realize watering and dust falling effects on dust in the air; an arranged overturning adjusting mechanism can be driven by a driving motor to drive the spray plate to achieve the rotating adjusting effect; the orientation of the spray heads on the spray plate can be flexibly adjusted, the full spraying dust falling effect on dust in the air at different positions is achieved; the arranged walking wheels candrive the device to integrally move, so that the full dust falling effect on different position areas is achieved; and the spray plate can conduct vertical downward spraying, the water spraying dust falling effect on ground dust is achieved, and dust flying caused by device movement is effectively reduced.

Owner:高光美

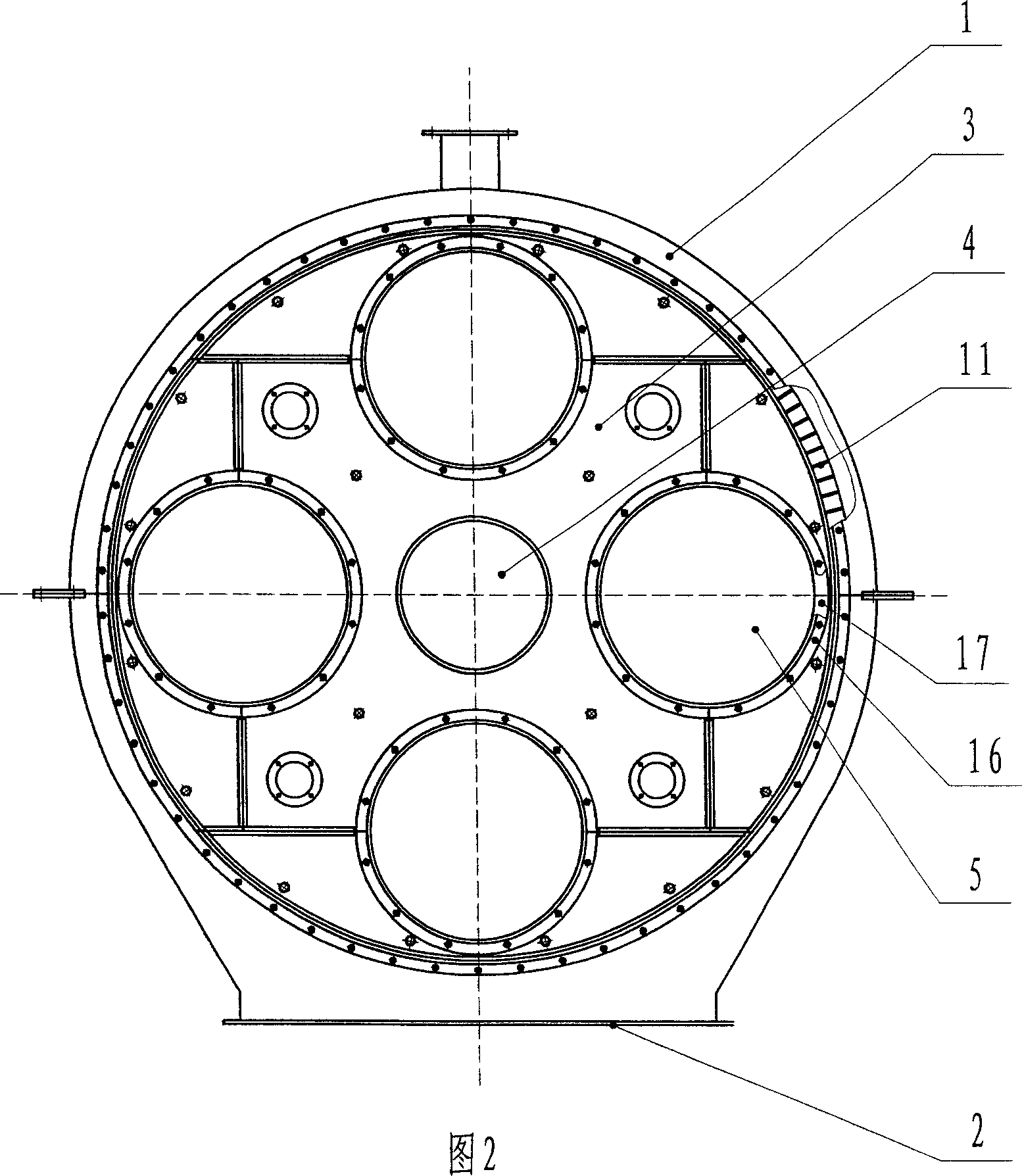

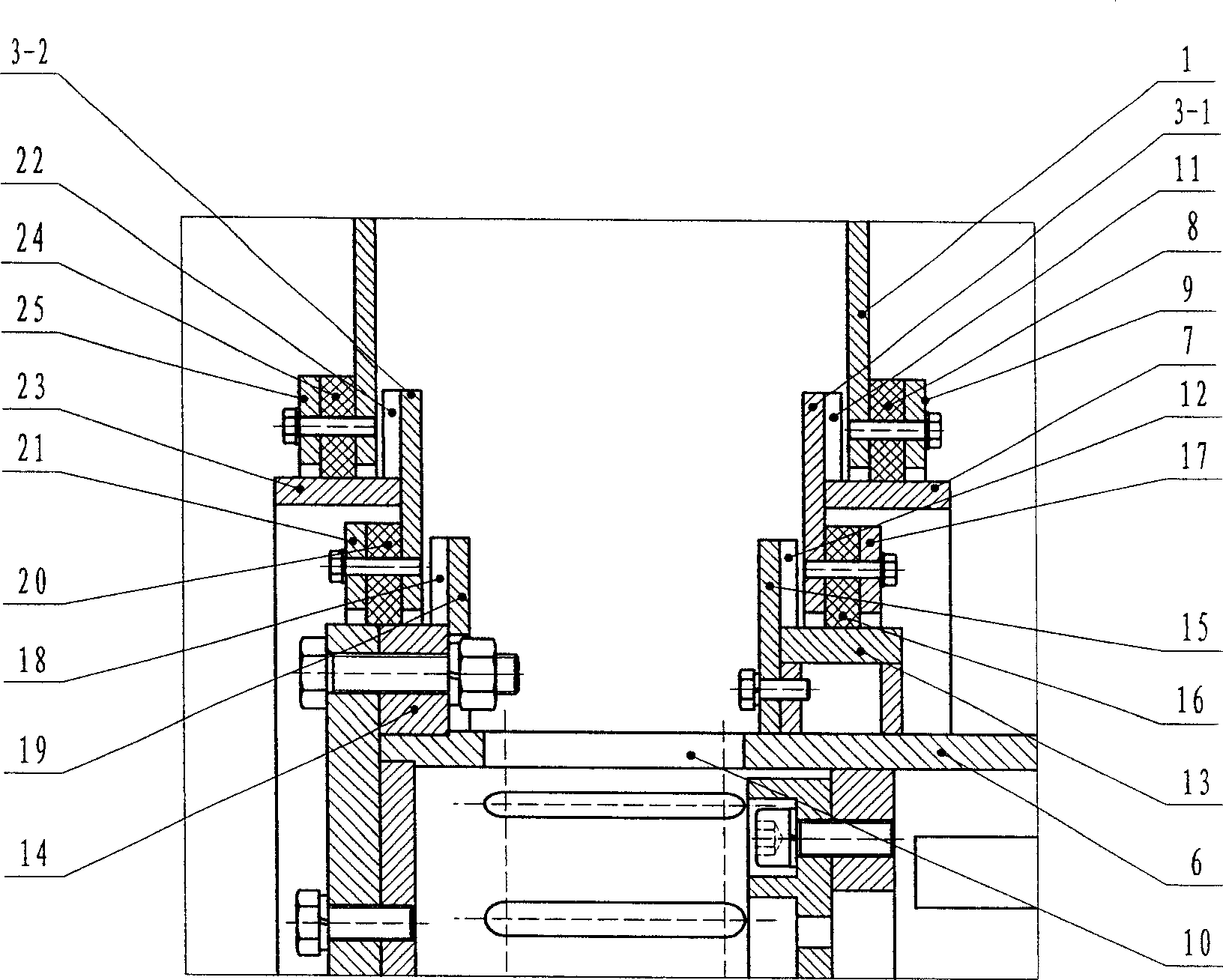

Material collecting assembly of large planetary ball mill

The present invention relates to pulverizing apparatus, and is especially material collecting assembly of large planetary ball mil. The material collecting assembly includes a material collecting cover, two material collecting turntables on the ends of the material collecting cover and with homogeneously distributed holes for the discharge bins in the back part of the grinding barrel to be set inside, blade A's set between the material collecting turntable and the material collecting cover, and blade B's set between the grinding barrel and the material collecting turntable. The hard blades forms air seal to move the material from margin to the inside to avoid material escape and flying dust. The present invention results in safe and environment friendly production and saving in material.

Owner:YANGZHOU QUNYOU POWDER MATERIALS SCI & TECH

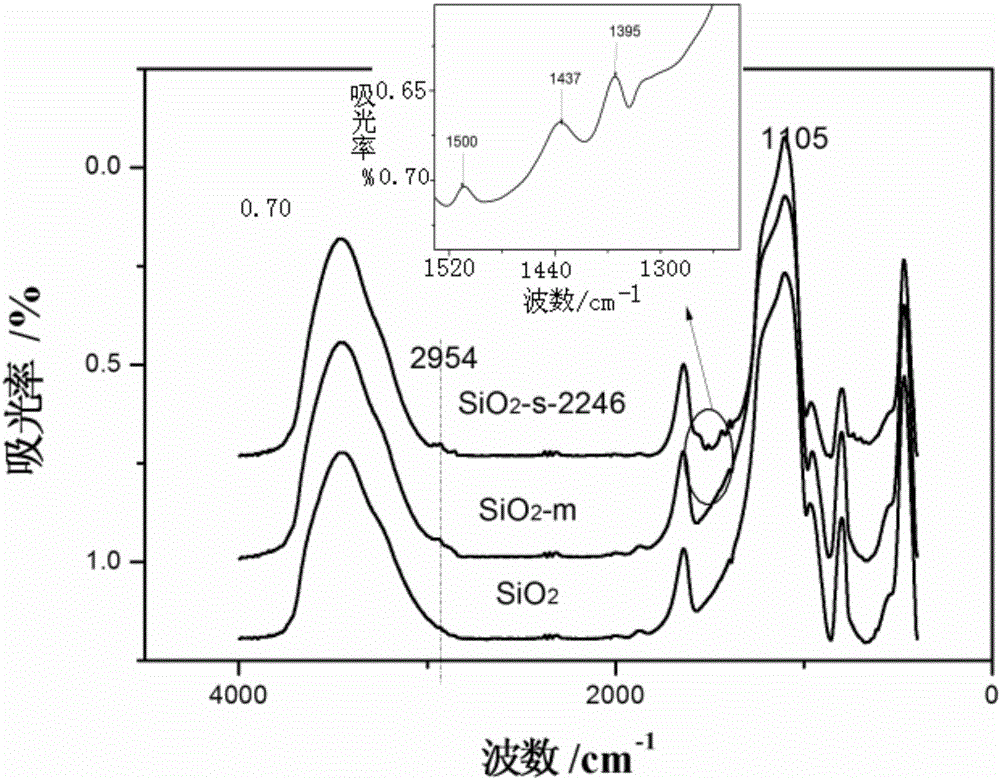

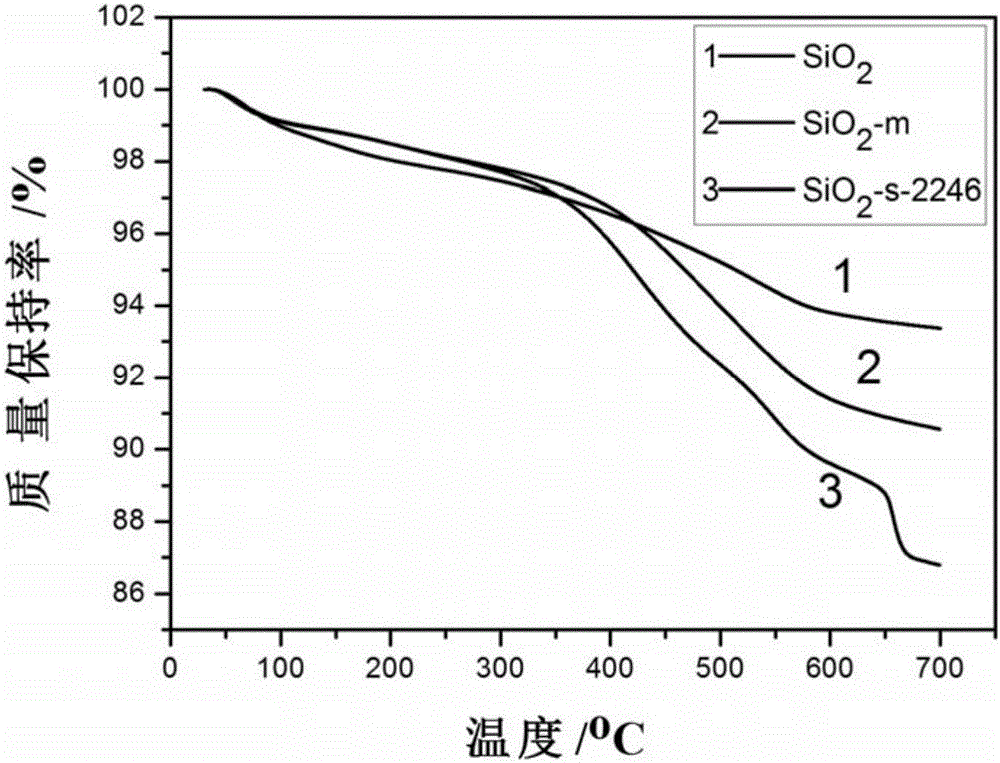

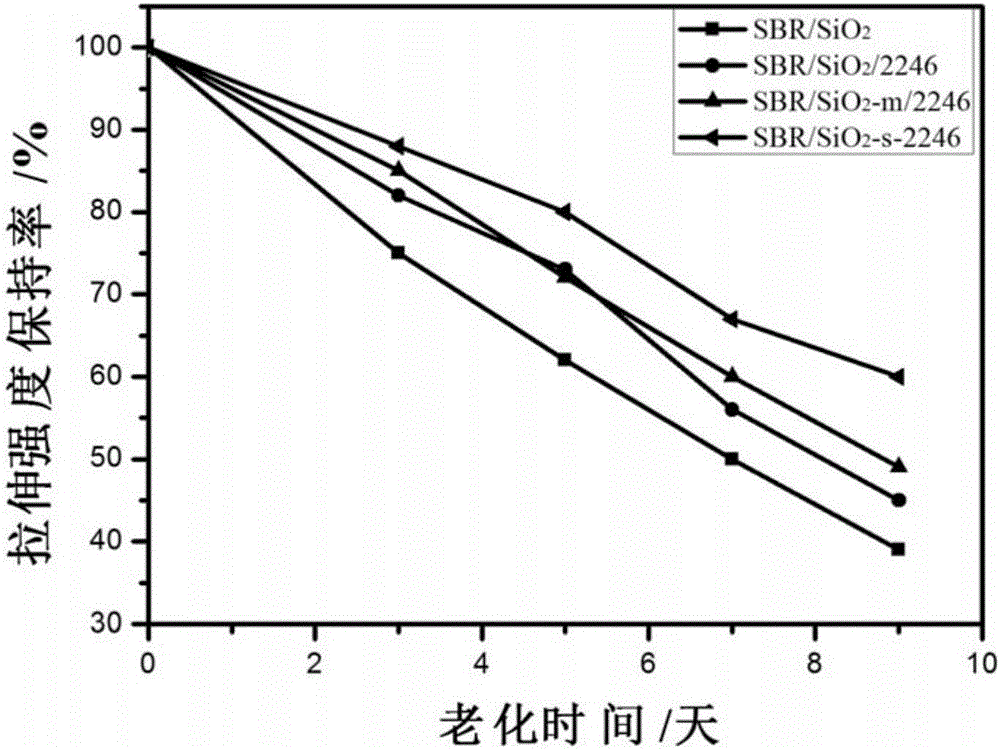

Reinforcing and anti-aging environment-friendly rubber aging inhibitor and preparation method and application thereof

The invention discloses a reinforcing and anti-aging environment-friendly rubber aging inhibitor and a preparation method and application thereof; the method comprises mixing an inorganic support and a silane coupling agent, stirring and reacting at 80-120 DEG C for 10-24 h to obtain an intermediate product; mixing the intermediate product with an aging inhibitor according to a mass ratio of (0.5-2):15, and stirring and reacting at 40-60 DEG C for 4-6 h; drying to obtain the environment-friendly rubber aging inhibitor. The aging inhibitor of the invention can improve dispersion between a rubber base and a filling material, interaction between the rubber and the filling material is improved, and mechanical properties of the base are improved; in addition, the aging inhibitor of the invention is as advantageous as an aging inhibitor prepared by direct solid-phase reaction; the aging inhibitor has the advantages of aging inhibition and reinforcing, the preparation process is simple to perform and energy-efficient and environment-friendly, the aging inhibitor is a true environment-friendly rubber aid having a promising application prospect in rubber industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com