Patents

Literature

2696results about How to "Reduce dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Particulate material containing thermoplastics and methods for making and using the same

ActiveUS20050019574A1Retain and enhance proppant propertyReducing dust formationPretreated surfacesDrilling compositionThermoplasticPolymer chemistry

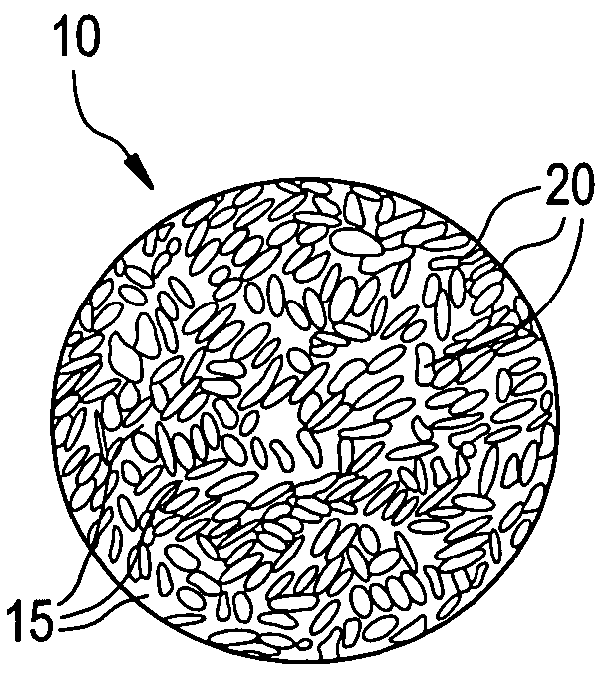

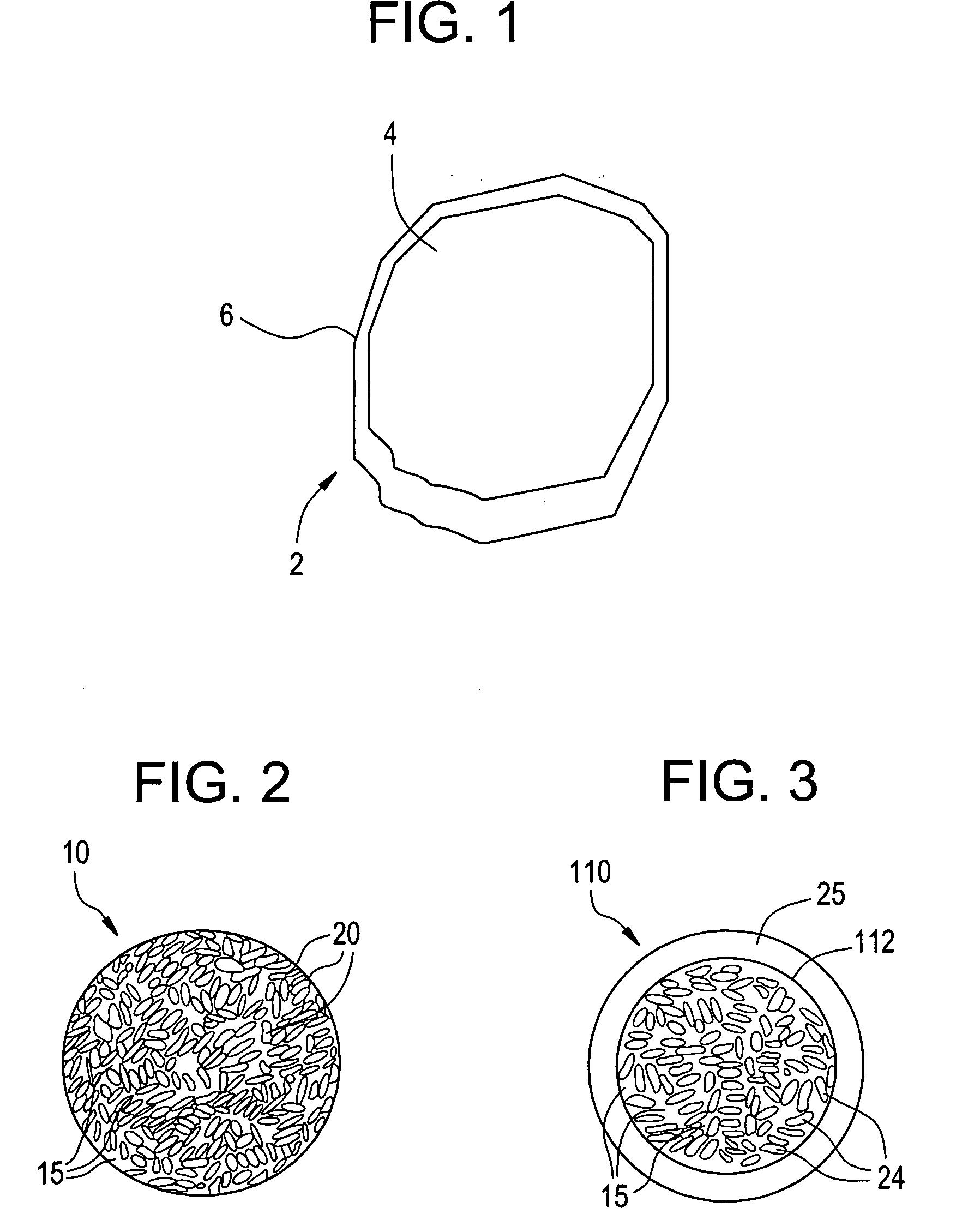

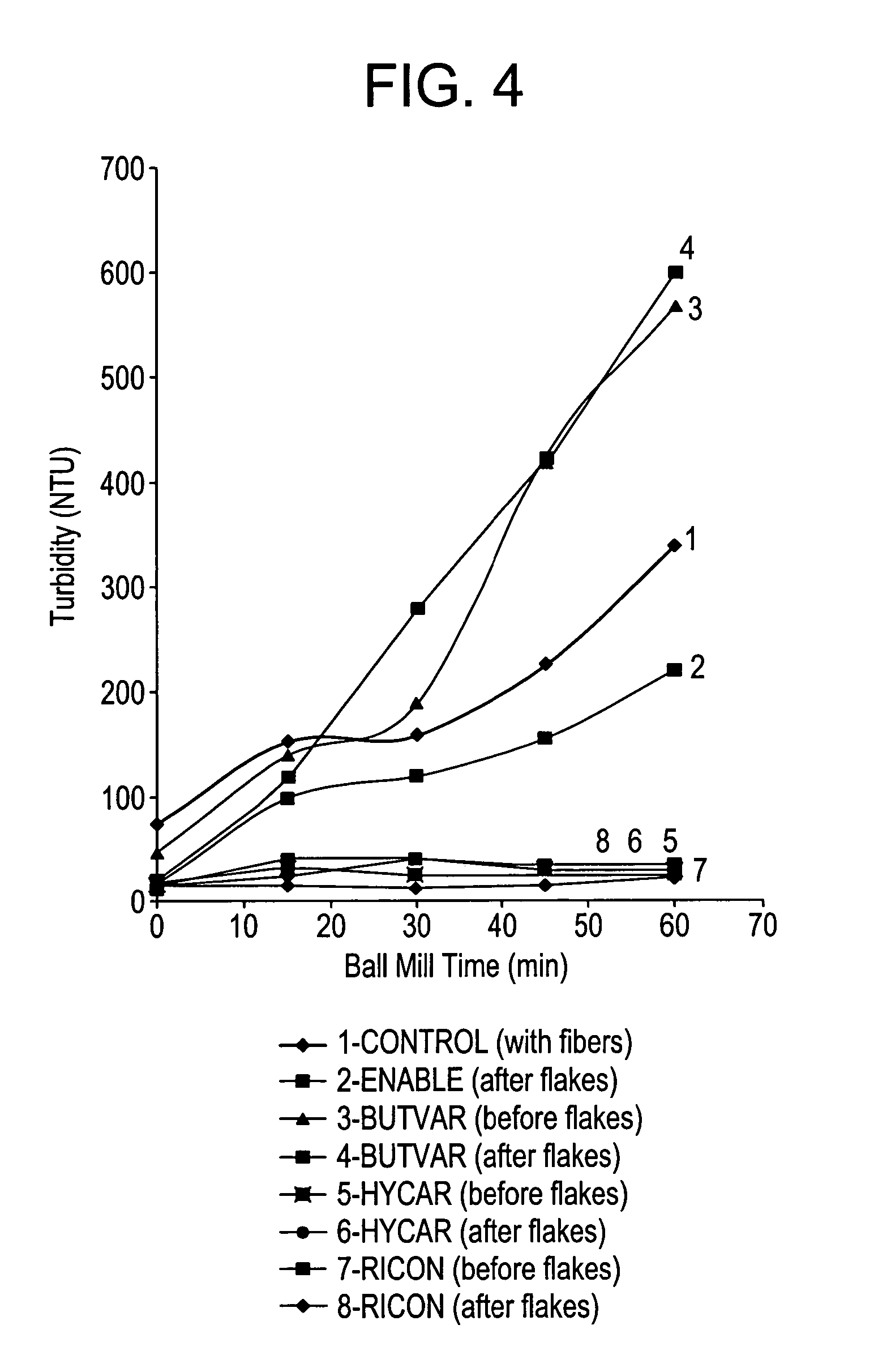

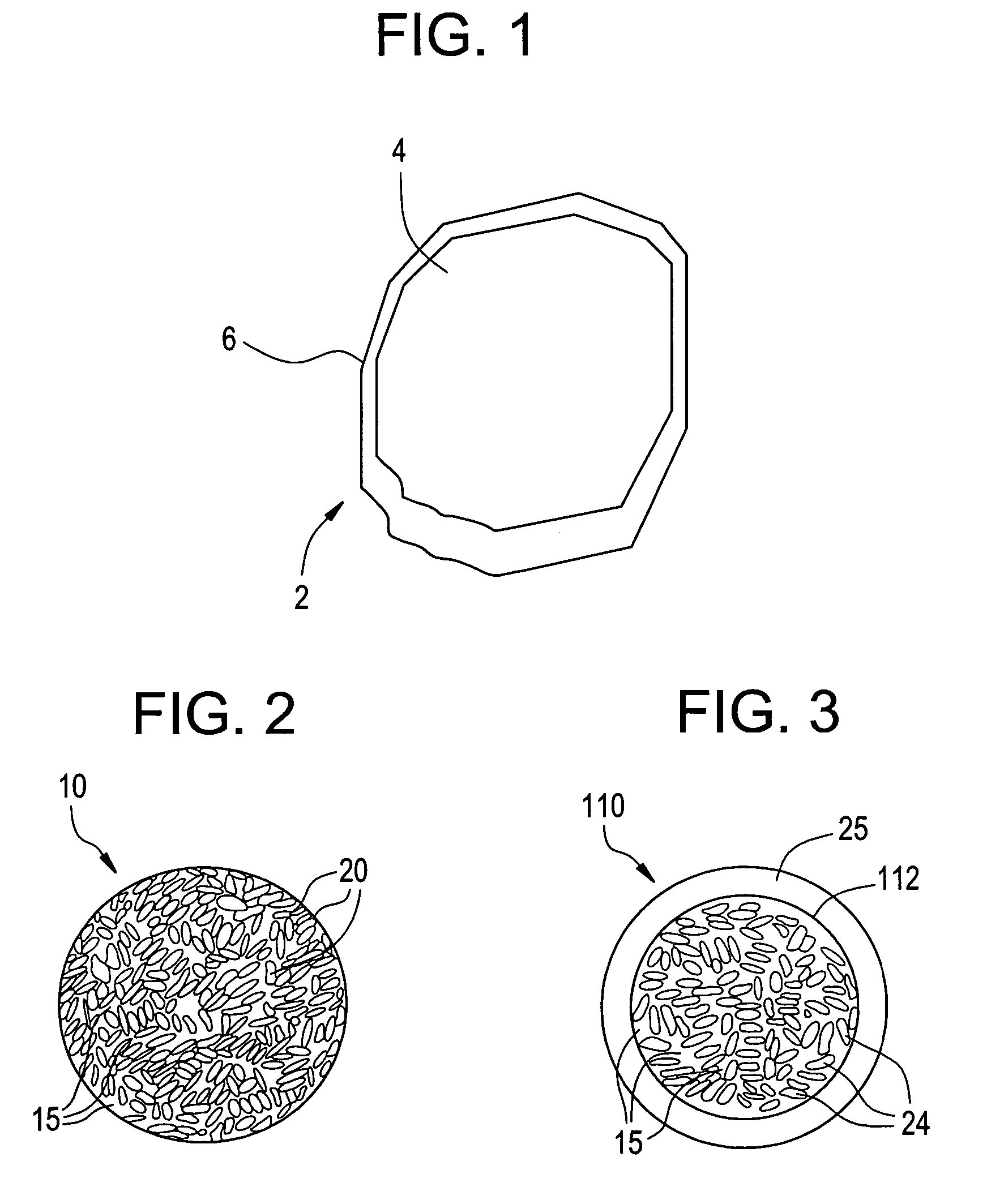

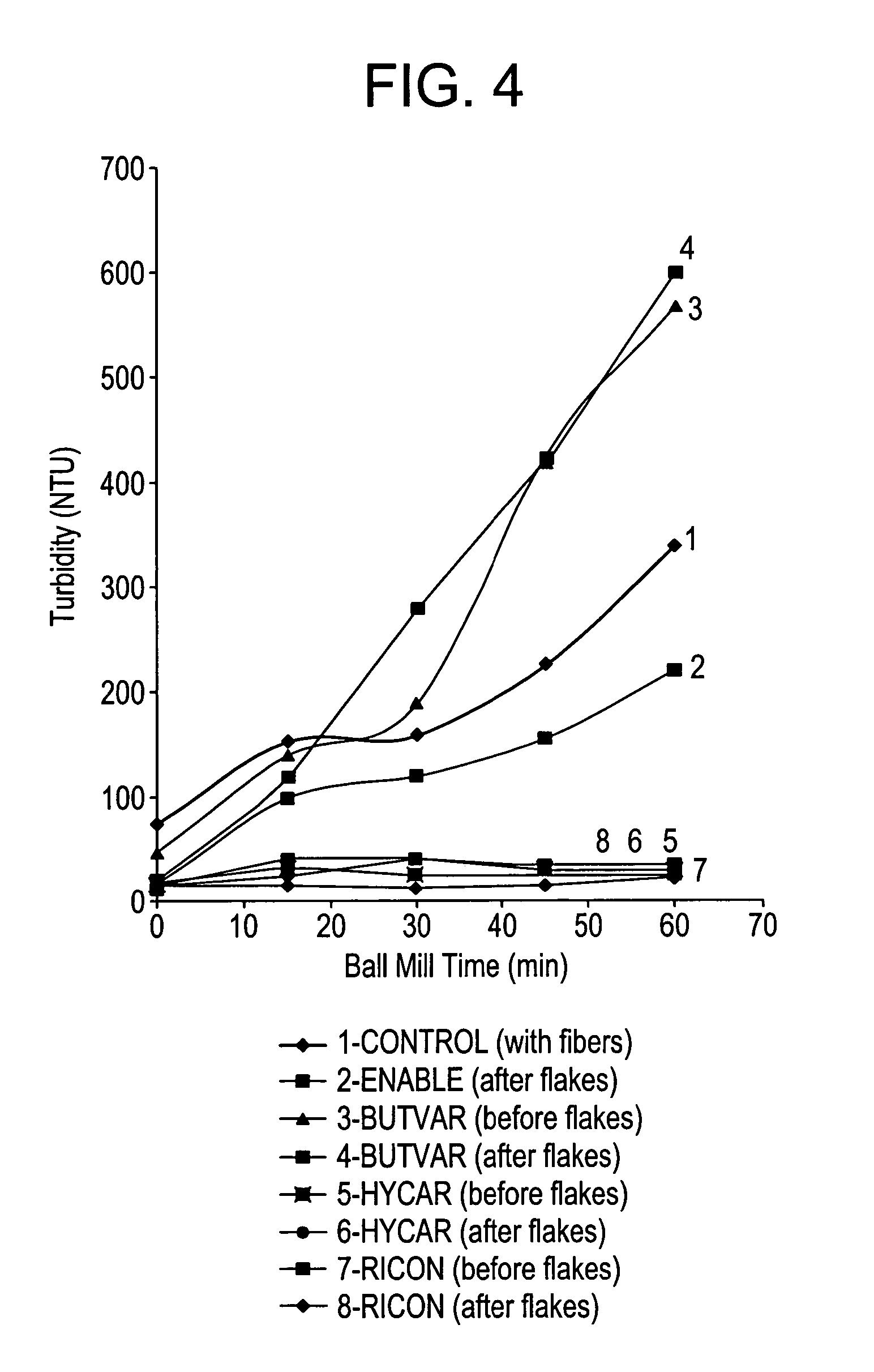

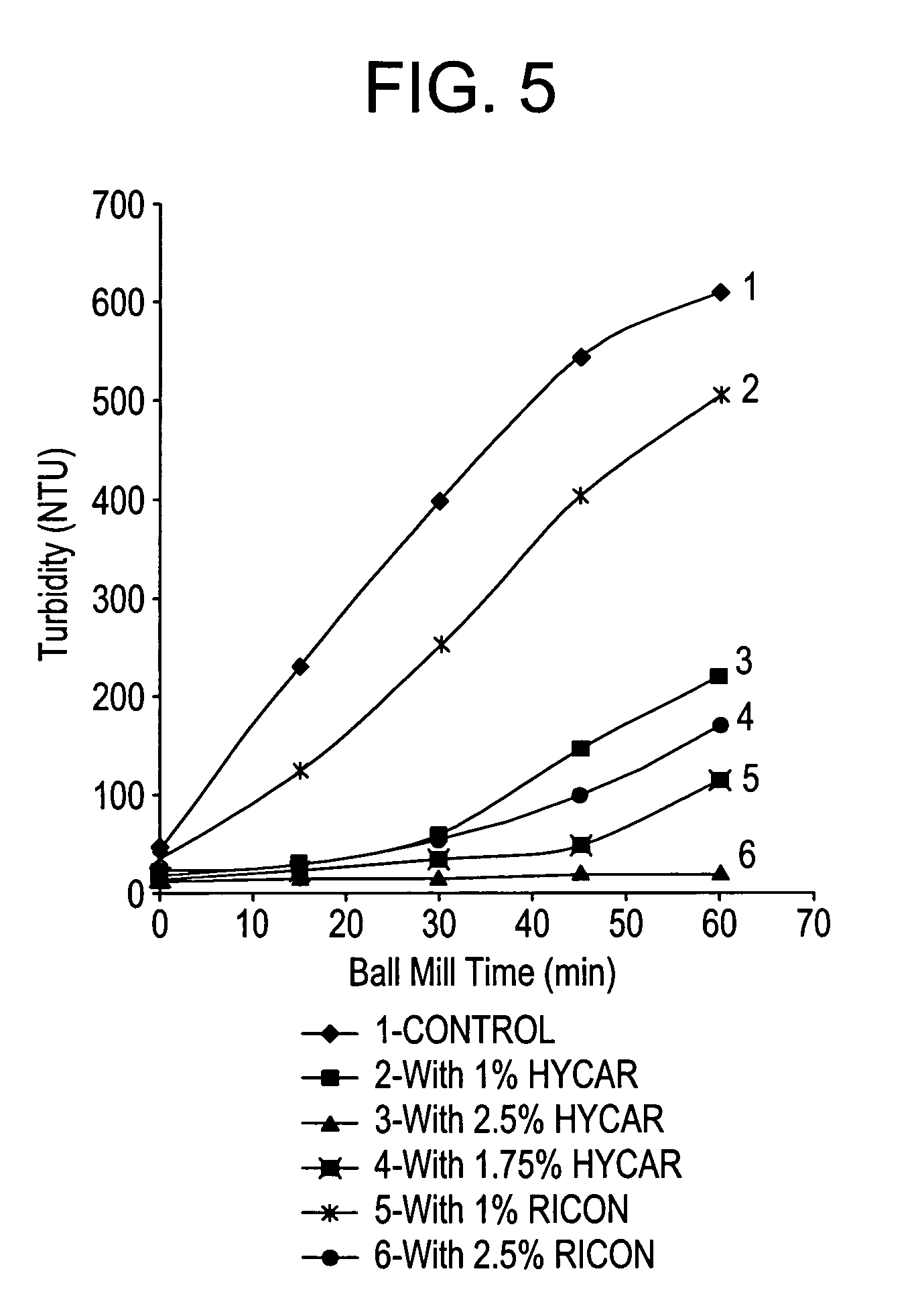

Disclosed herein is a particle comprising a particulate substrate; and a thermoplastic elastomer present on or in the substrate as an amount sufficient to improve the dust suppression of the particle above that which would occur if the thermoplastic elastomer was absent. Disclosed herein is a particle comprising a particulate substrate; and a thermoplastic elastomer, wherein the particle has a compressive strength retention of greater than about 50% as measured by a UCS test and a turbidity of about 10 to 200 NTU after a one hour ball mill test.

Owner:HEXION INC

Particulate material containing thermoplastics and methods for making and using the same

ActiveUS7270879B2Trend downImprove abilitiesPretreated surfacesGlass/slag layered productsParticulatesThermoplastic

Disclosed herein is a particle comprising a particulate substrate; and a thermoplastic elastomer present on or in the substrate as an amount sufficient to improve the dust suppression of the particle above that which would occur if the thermoplastic elastomer was absent. Disclosed herein is a particle comprising a particulate substrate; and a thermoplastic elastomer, wherein the particle has a compressive strength retention of greater than about 50% as measured by a UCS test and a turbidity of about 10 to 200 NTU after a one hour ball mill test.

Owner:HEXION INC

Cat litter prepared from dry bean dregs and preparation method thereof

The invention relates to cat litter prepared from dry bean dregs and a preparation method thereof, wherein the cat litter is used for burying excrement and urine of pets. The cat litter is prepared from the following components through a series of processes including crushing, mixing and forming according to weight ratio: 5-90 parts of dry beam dregs, 10-90 parts of plant adhesive, 20-80 parts of filling agent, 0.1-10 parts of releasing agent, 0.1-5 parts of surface active agent, 0.01-3 parts of preservative, and 1-10 parts of deodorant. According to the invention, the cat litter prepared by the preparation method provided by the invention has the advantages of being wispy and hollow in surface, low in structural density, light in weight, higher in water absorption speed and better in water absorption performance; compared with other cat litters, the cat litter has the advantages of being more saving in use amount and higher in cost performance; after being used, the cat litter can be directly washed away through a sewer and cannot be blocked; the cat litter is convenient to clean; and the cat litter provided by the invention has the advantages of being environment-friendly, non-toxic, pollution-free, strong in absorption performance, simple in production process and free from wispy dust in production and transportation processes and has a deodorization function.

Owner:王洪恩

Non-dusting roll for tft glass

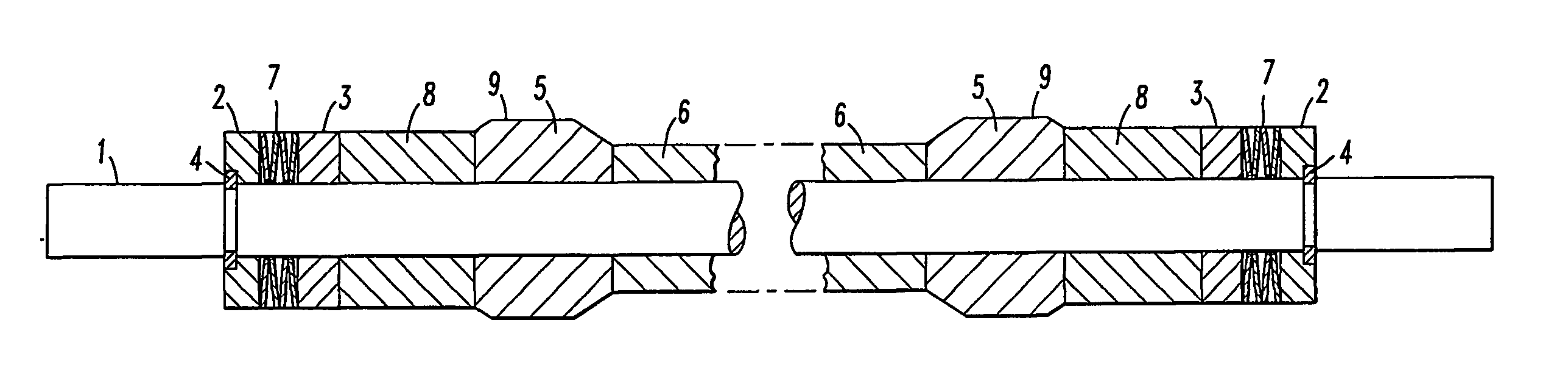

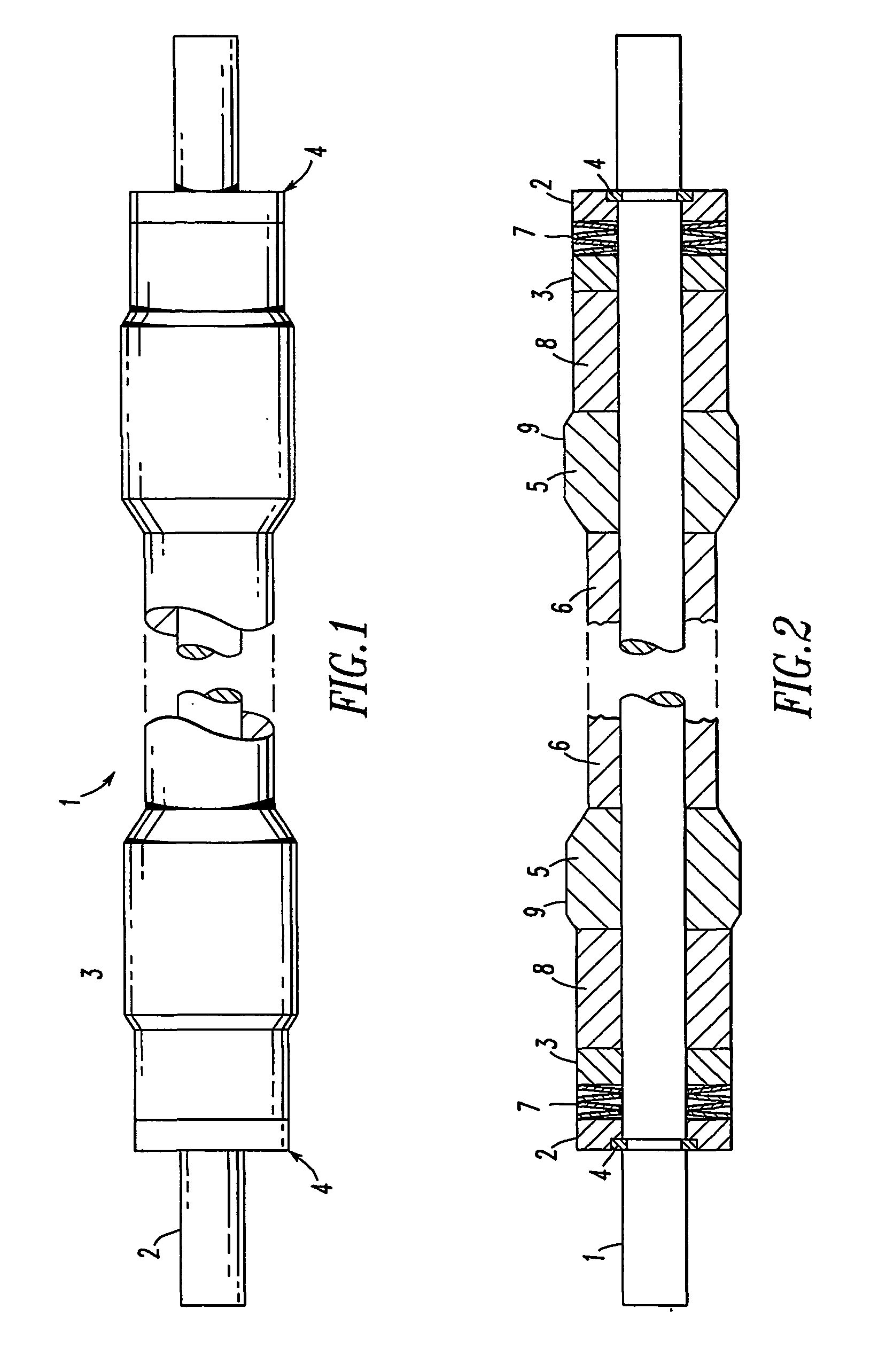

InactiveUS20070042883A1Reduce dustLow affinityShaft and bearingsGlass transportation apparatusFiberGlass sheet

A refractory roll cover is described that reduces the amount of noxious dust during the production of glass sheet. The roll cover comprises a plurality of segments, including low dusting millboard segments mechanically supported by highly rigidized compressed fiber segments. The millboard segments are adapted to contact the glass sheet. The millboard is chosen so that any dust produced has little affinity for the glass sheet or is not easily fluidized by convective currents. The highly rigidized compressed fiber has a fused surface that releases little dust. The resultant roll cover substantially eliminates dusting while providing a mechanically superior roll cover.

Owner:VESUVIUS CRUCIBLE CO

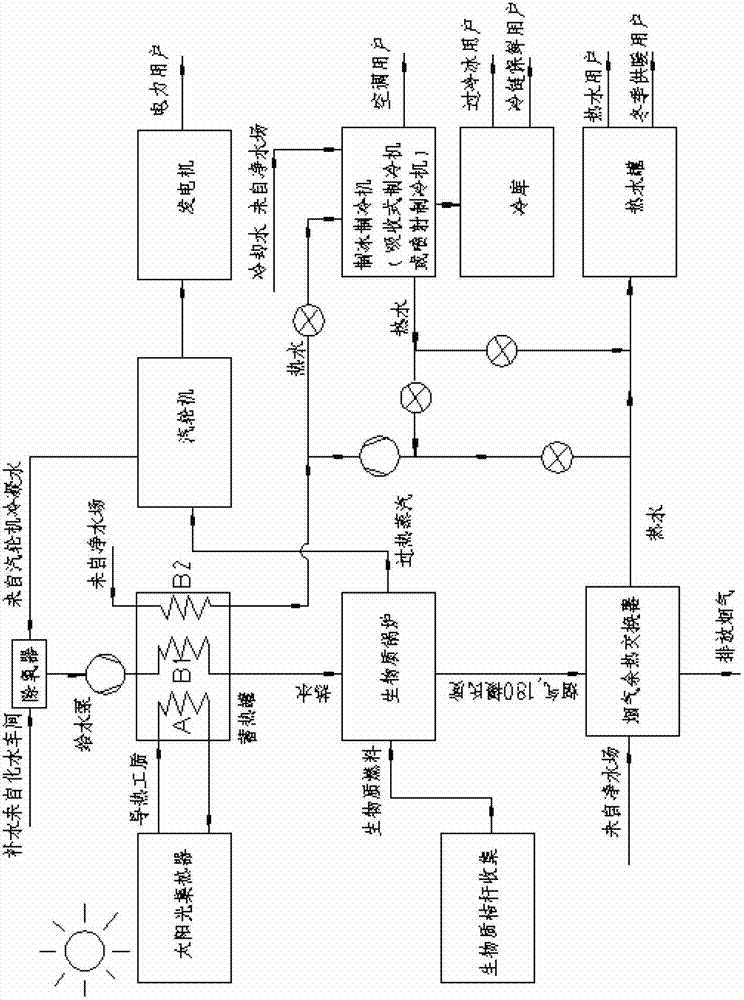

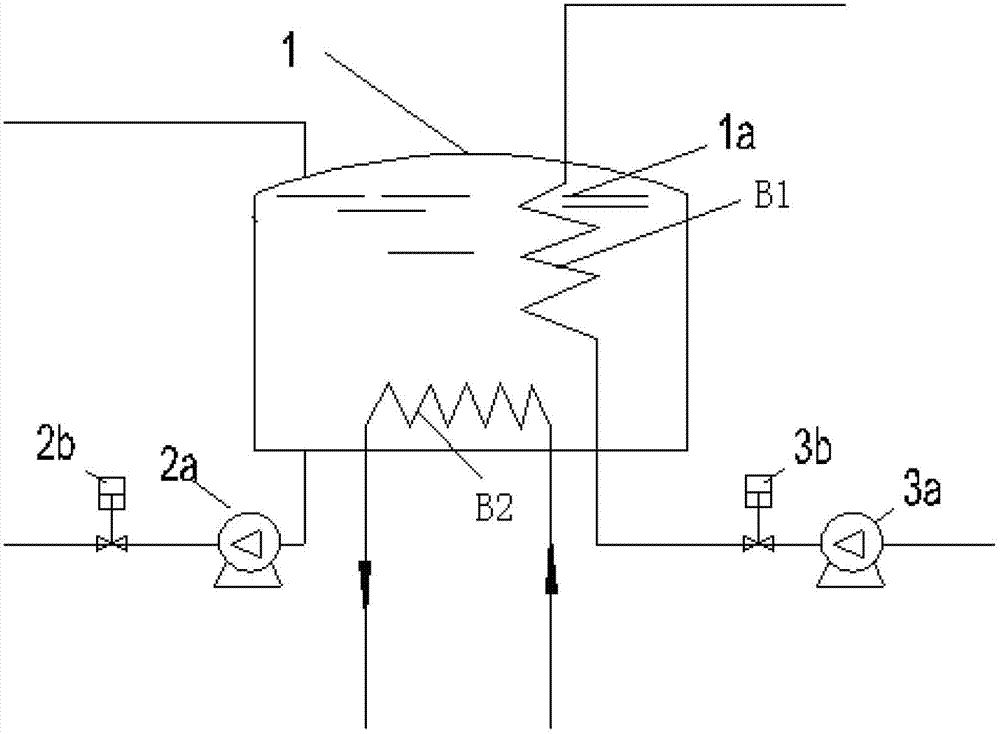

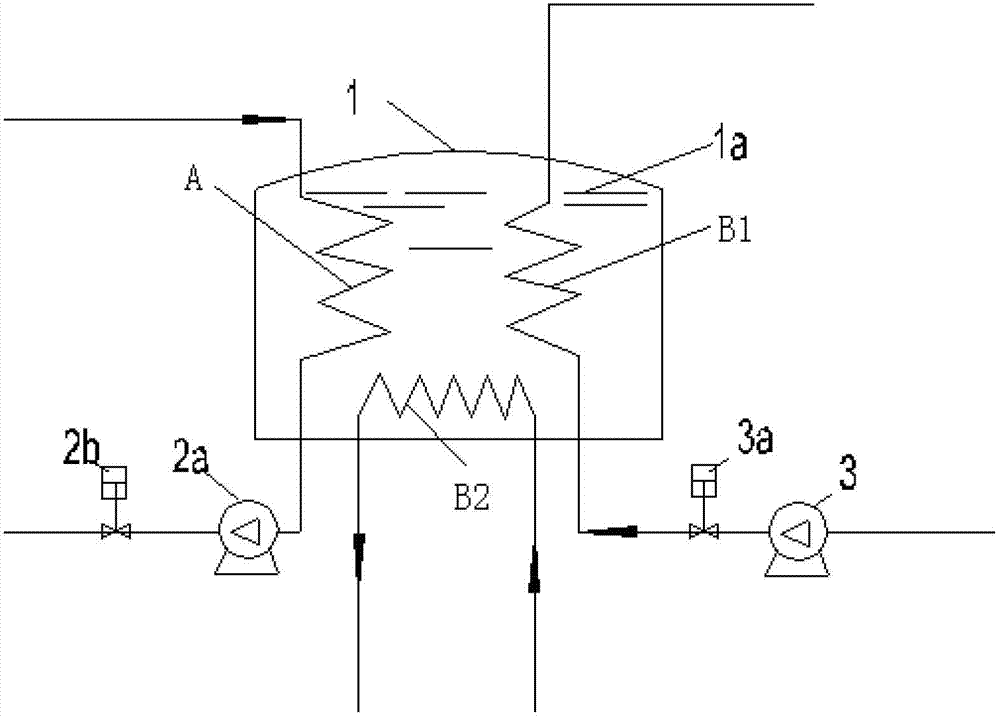

Thermal power system with complementation between solar energy and biomass energy

InactiveCN102967080AEnergy saving and environmental protection use energy modeSolve instabilitySolar heating energySpace heating and ventilationThermal energySolar light

The invention provides a thermal power system with complementation between solar energy and biomass energy. The thermal power system comprises a solar light condensing device, a solar heat storage kettle, a biomass heat power station, a combined refrigerating and icing device for intensive cooling, and a hot water system for intensive heating, wherein the solar light condensing device is connected with the solar heat storage kettle through a pipeline, the inlet of a first output heat exchanger B1 of the solar heat storage kettle is connected with the outlet of a water supply pump of a biomass boiler, and the outlet of the B1 is connected with the inlet of a water supply system of the biomass boiler; an inlet pipeline of a second output heat exchanger B2 of the solar heat storage kettle is connected with an output pipeline of a water purification plant, and the outlet of the B2 is connected with a heat input pipeline of the combined refrigerating and icing device; the heat input pipeline can supply heat for refrigerating and icing; and work cooling water of the combined refrigerating and icing device is connected to a hot water kettle of the heat supply system to intensively supply heat to users. The solar heat storage kettle is a two-medium or three-medium double-circulation heat storage kettle, and the heat storage medium is heat transfer oil and fused salt.

Owner:ZHONGYING CHANGJIANG INTERNATIONAL NEW ENERGY INVESTMENT CO LTD

Spiral composite adsorbent material

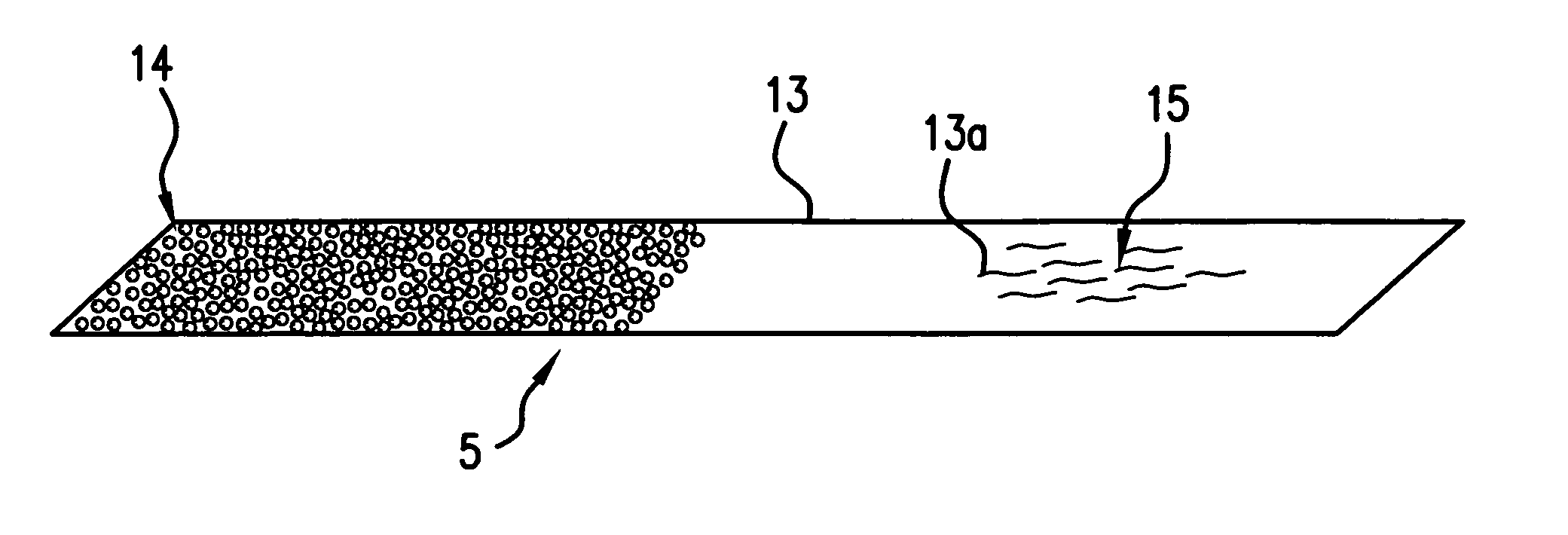

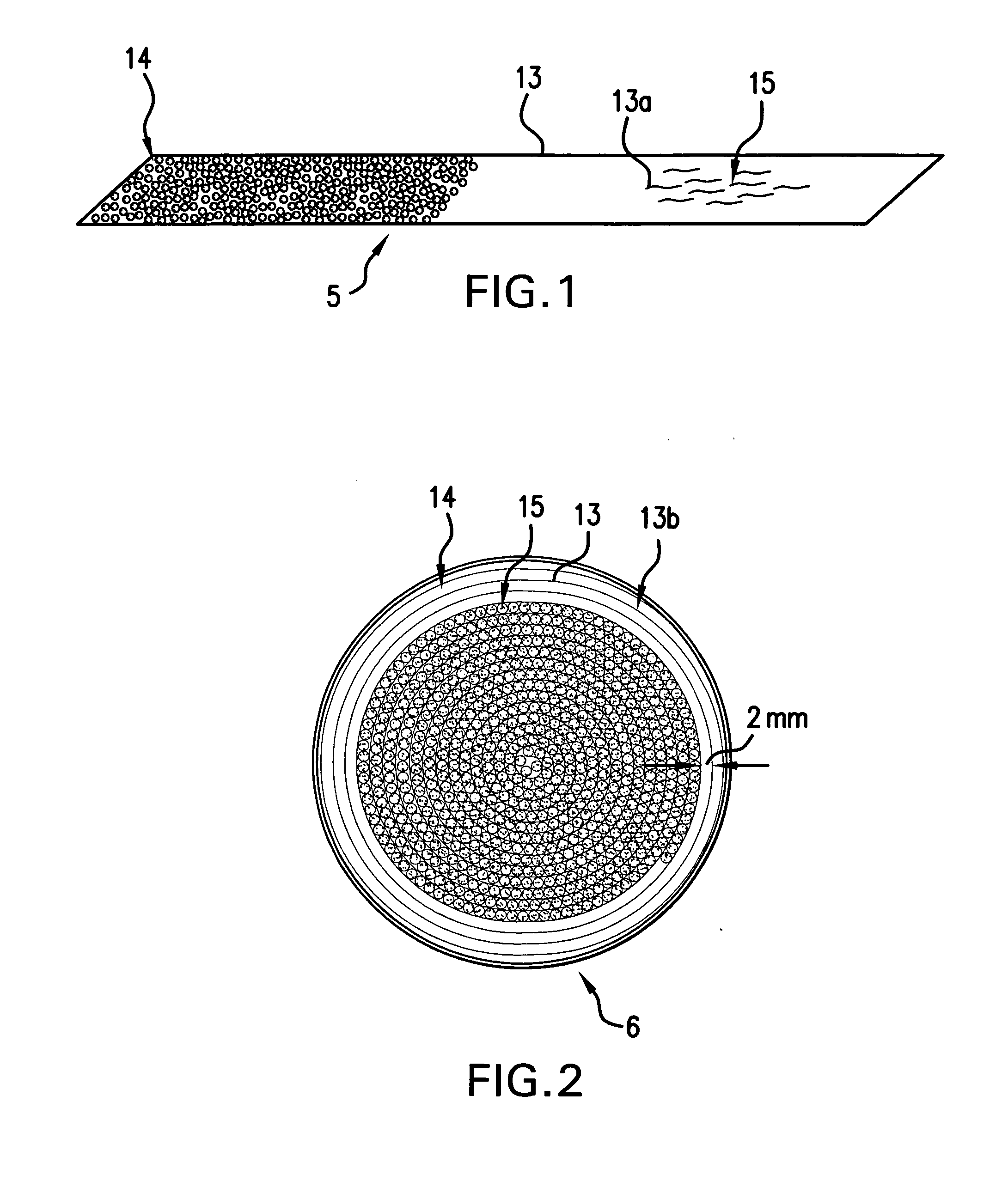

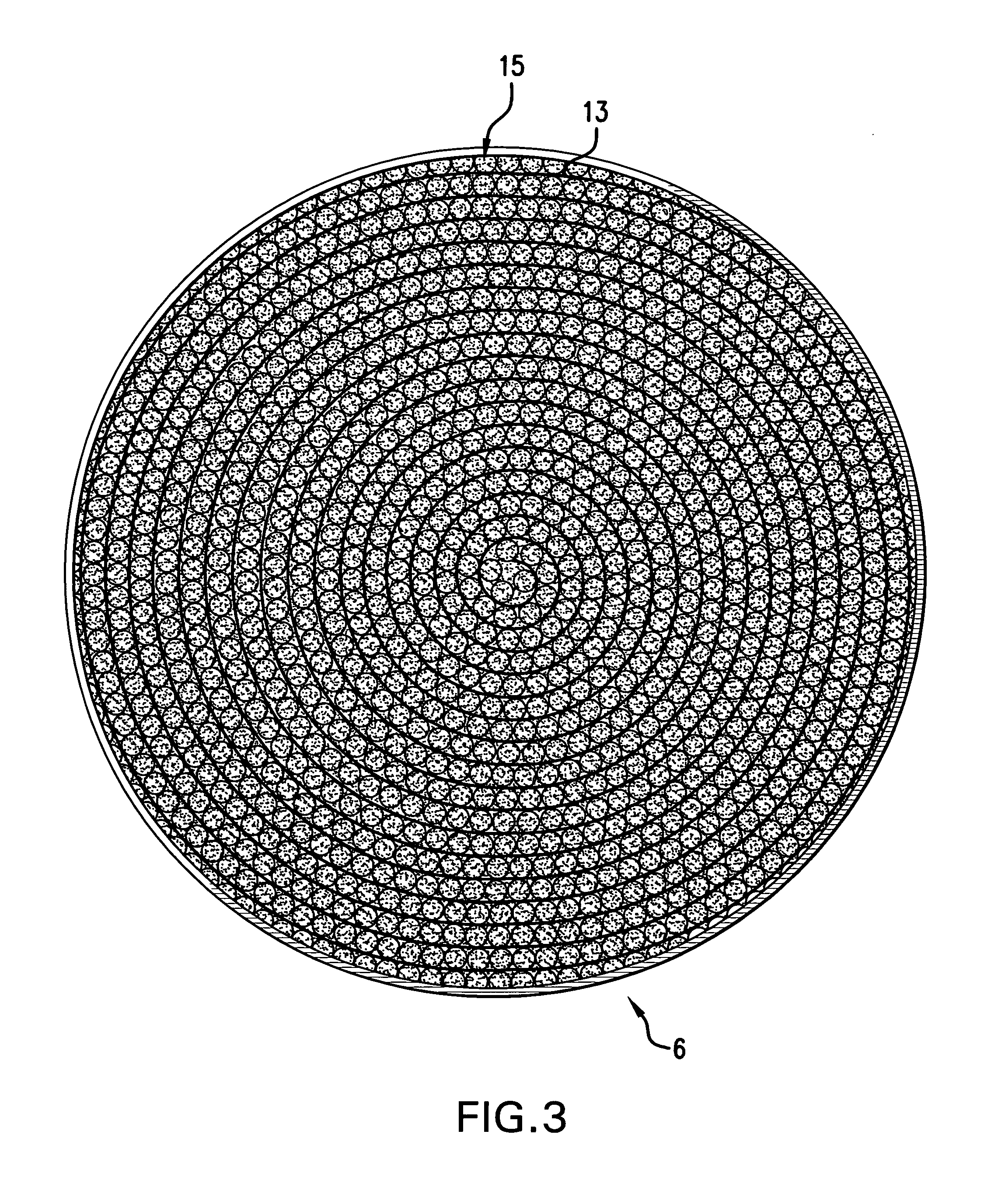

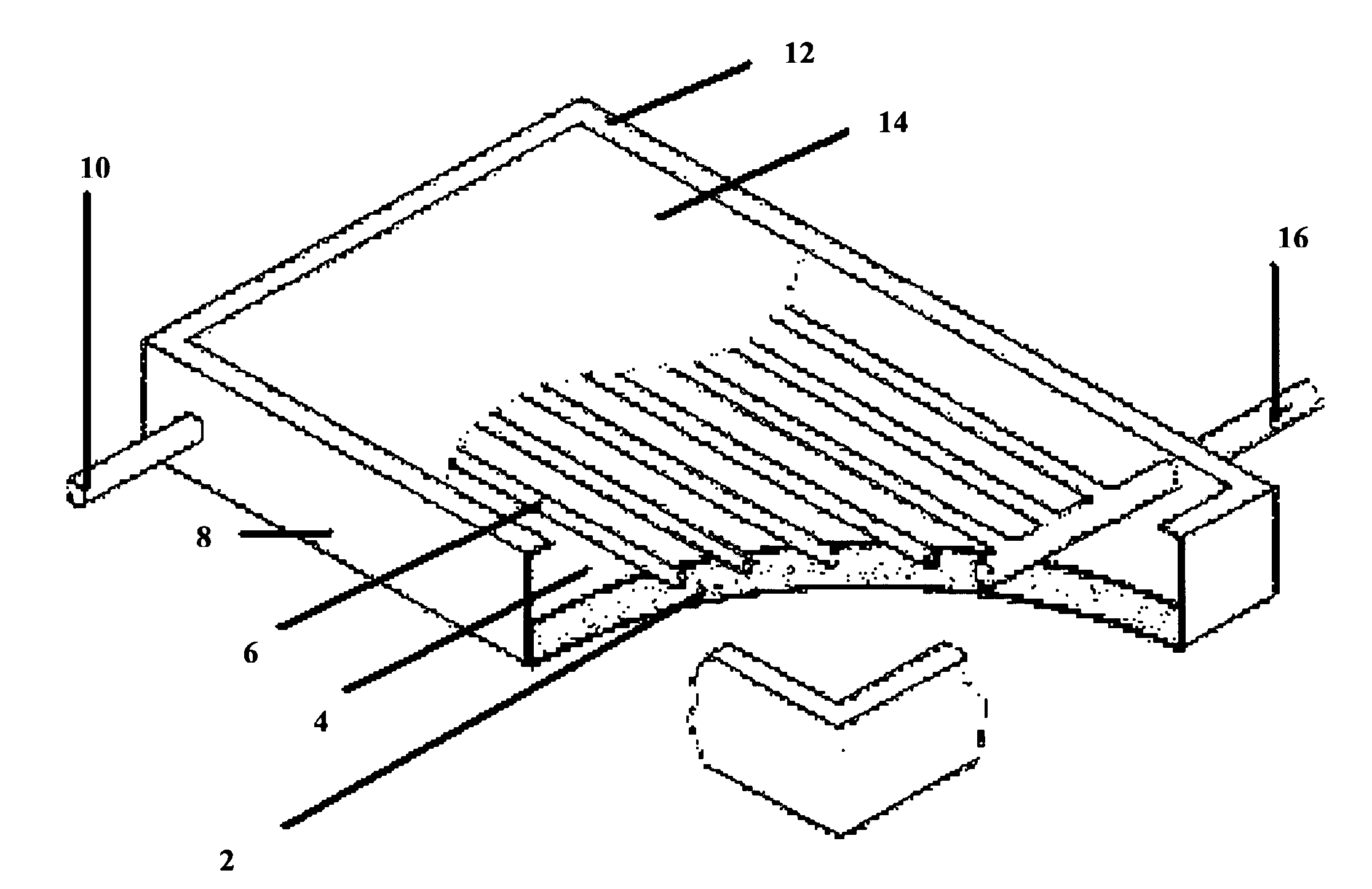

InactiveUS20050211099A1Expand accessEnhanced particle densityGas treatmentOther chemical processesSorbentGas phase

A composite adsorbent includes a shaped substrate having an adhesive film on a portion of at least one side and an adsorbent that has been immobilized as a layer on the adhesive portion of the substrate. The composite adsorbent is designed to be shaped into a form that provides a high adsorption capacity, low pressure drop, high volume capacity, and fast adsorption kinetics to effectively adsorb odors over an extended period of time. Optionally, the composite adsorbent is also used in combination with an air permeable unit wherein it is advantageously positioned to provide enhanced adsorption of contaminants found in gas phase.

Owner:CALGON CALGON

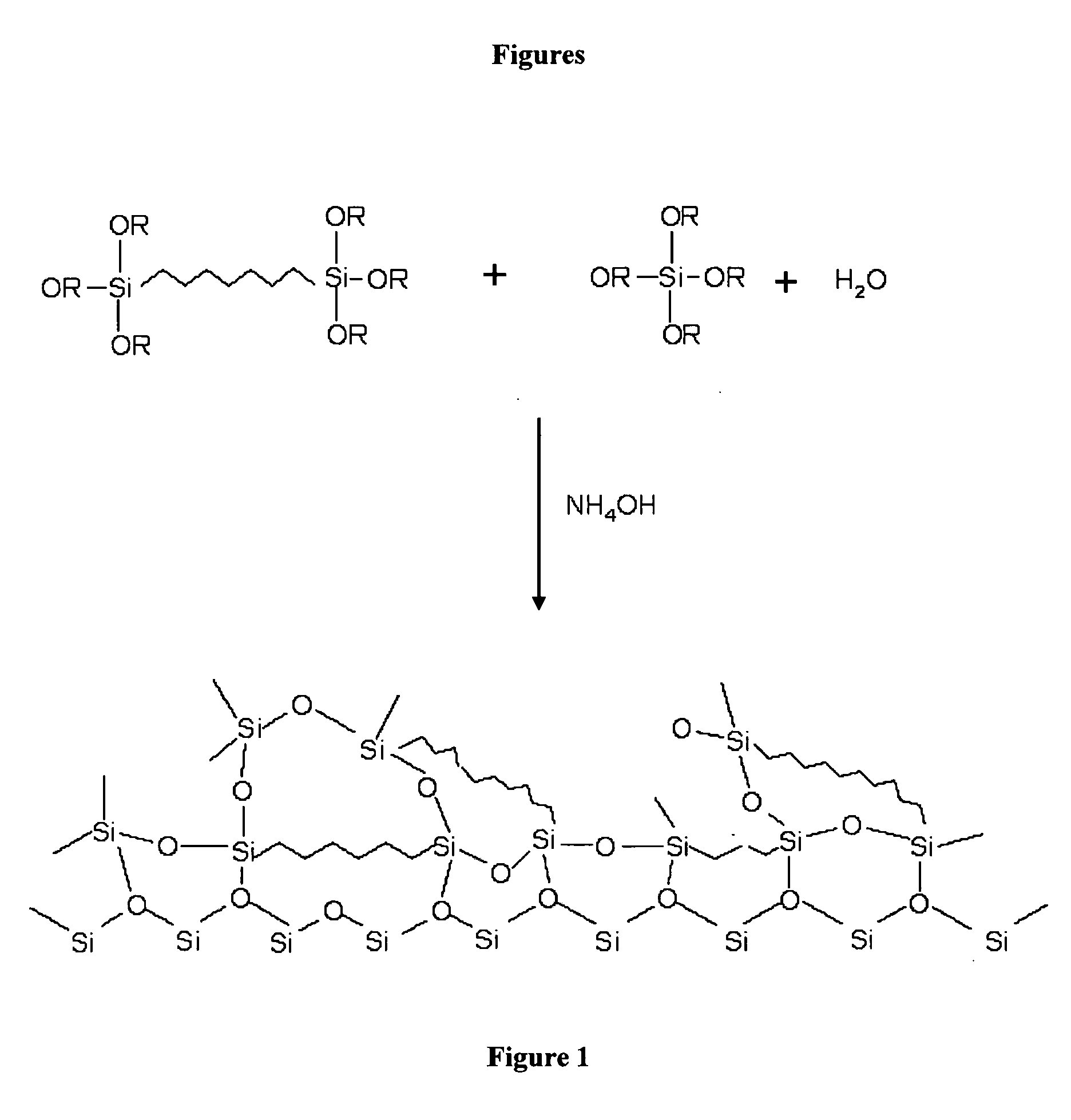

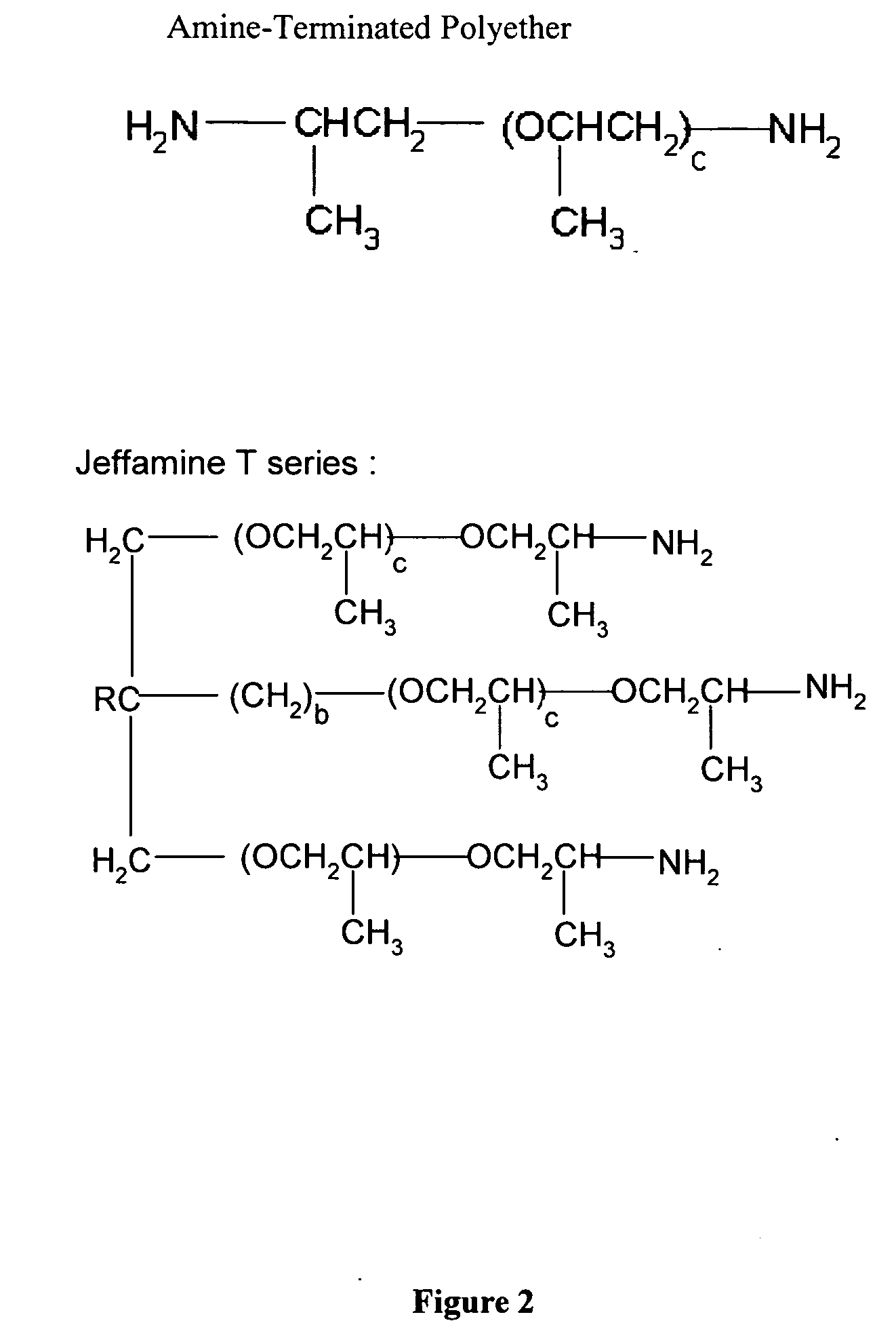

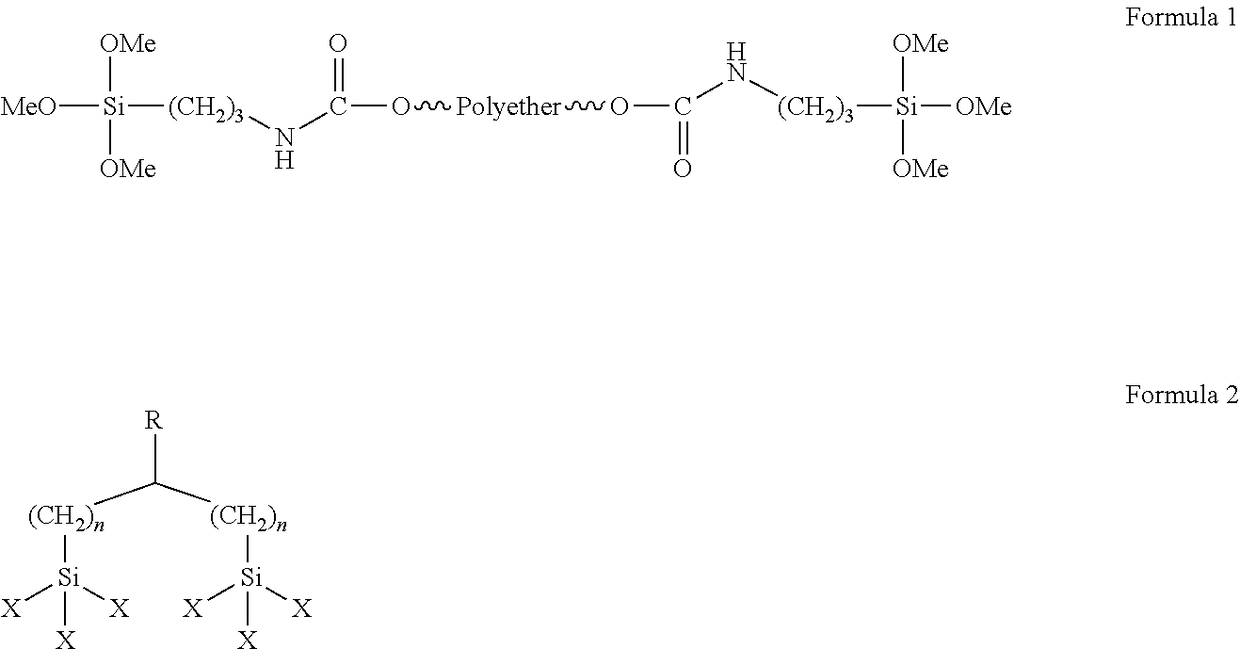

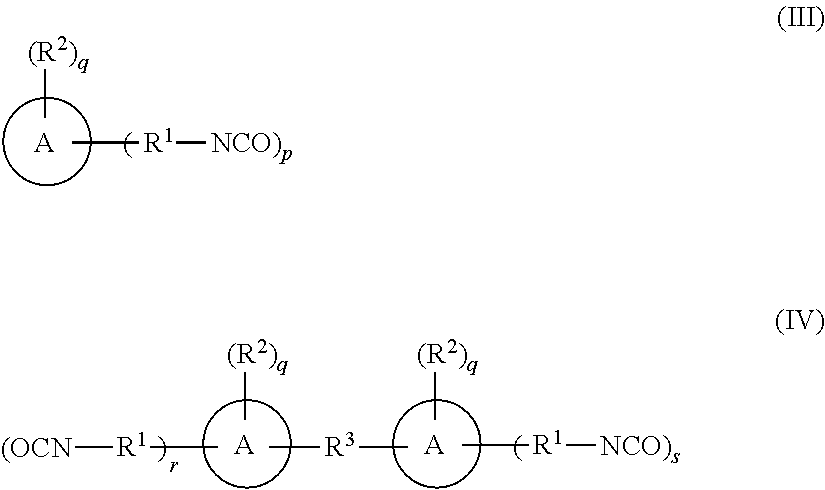

Transparent assemblies with ormosil aerogels

InactiveUS20060246806A1Good physical and mechanical propertiesImprove mechanical propertiesSolar heat devicesLayered productsPolymer scienceFiber-reinforced composite

Owner:ASPEN AEROGELS INC

Proppant with composite coating

ActiveUS9725645B2Improve the level ofIncrease resistanceFluid removalDrilling compositionParticulatesChemical Linkage

Proppants for hydraulic fracturing of oil and gas wells have a polymeric coating that is strengthened with reinforcing particulates that are reactive with, or chemically bonded to, the polymeric proppant coating. Preferably, these particulates are added into the coating during the coating process. In one embodiment, functionalized particulates are used that become grafted into the polymer of the proppant coating through the chemical functionality imparted to the particulates. If non-functionalized particulates are used, a coupling agent is preferably added to enhance the bond strength between the added particulates and the polymeric matrix of the proppant coating.

Owner:PREFERRED TECH

Unsaturated hydrocarbon hydrogenation catalyst and application thereof

ActiveCN102407118AImprove water resistanceExtended service lifeMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsUnsaturated hydrocarbonSilanes

The invention discloses an unsaturated hydrocarbon hydrogenation catalyst, belonging to the technical field of hydrogenation catalysts. For meeting the requirements of water resistance and carbon deposition resistance on the unsaturated hydrocarbon hydrogenation catalyst, the catalyst contains a carrier, a metal active ingredient loaded on the carrier and a silane group, the silane group on the catalyst is grafted by performing silylanizing treatment, and the content of the silane group is 0.05-25 percent by weight; and the carrier is made of a porous material of which the specific surface area is 2-300 m<2> / g, the pore volume is 0.05-1.2 ml / g, the average pore diameter is 9-150 nanometers, over 50 percent of pore volume is included in pores with pore diameters being greater than 9 nanometers, and the pore volume of pores with pore diameters being smaller than 5 nanometers is less than 25 percent. Compared with the conventional catalyst, the catalyst disclosed by the invention has theadvantages of high water resistance, small amount of deposited carbon, longer service life and great reduction in the powder removal phenomenon of the catalyst when the catalyst is applied to unsaturated hydrocarbon hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

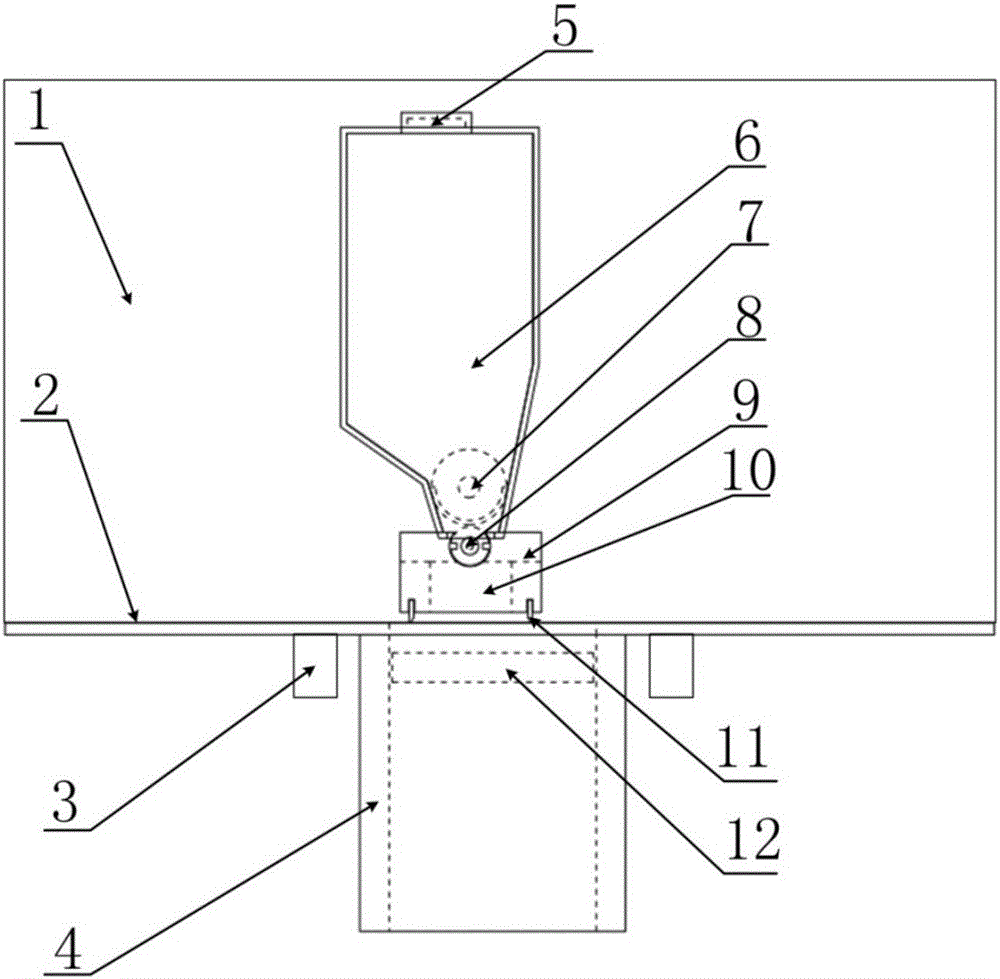

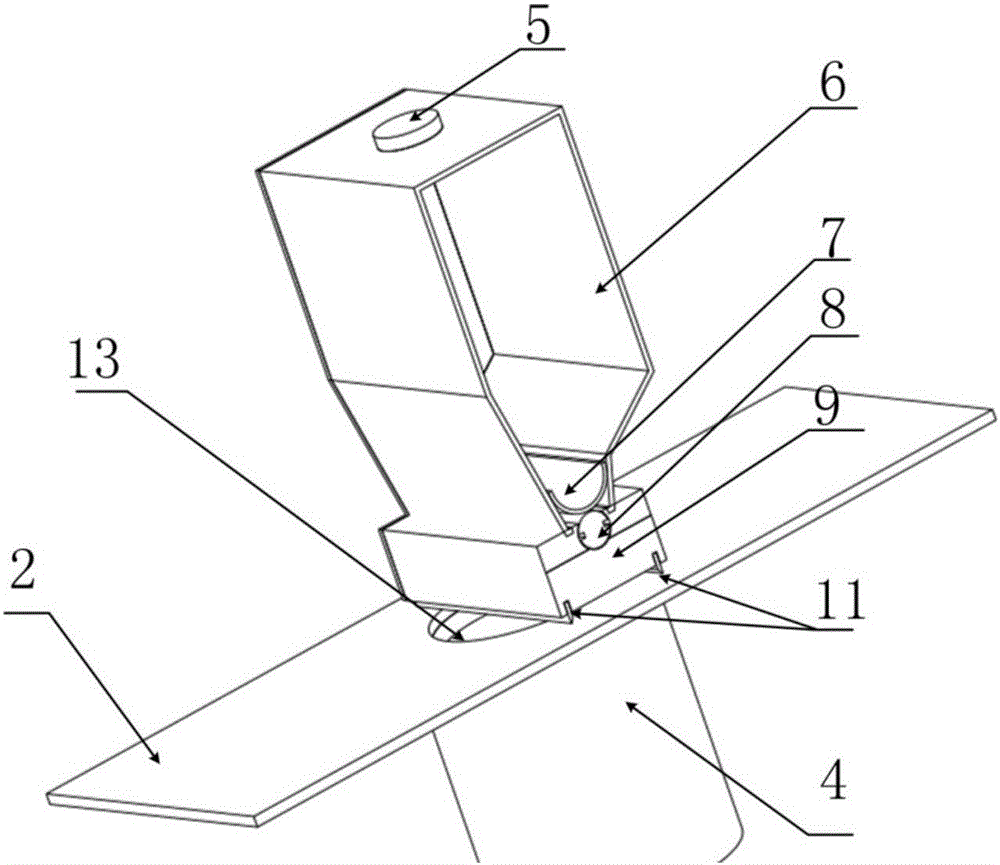

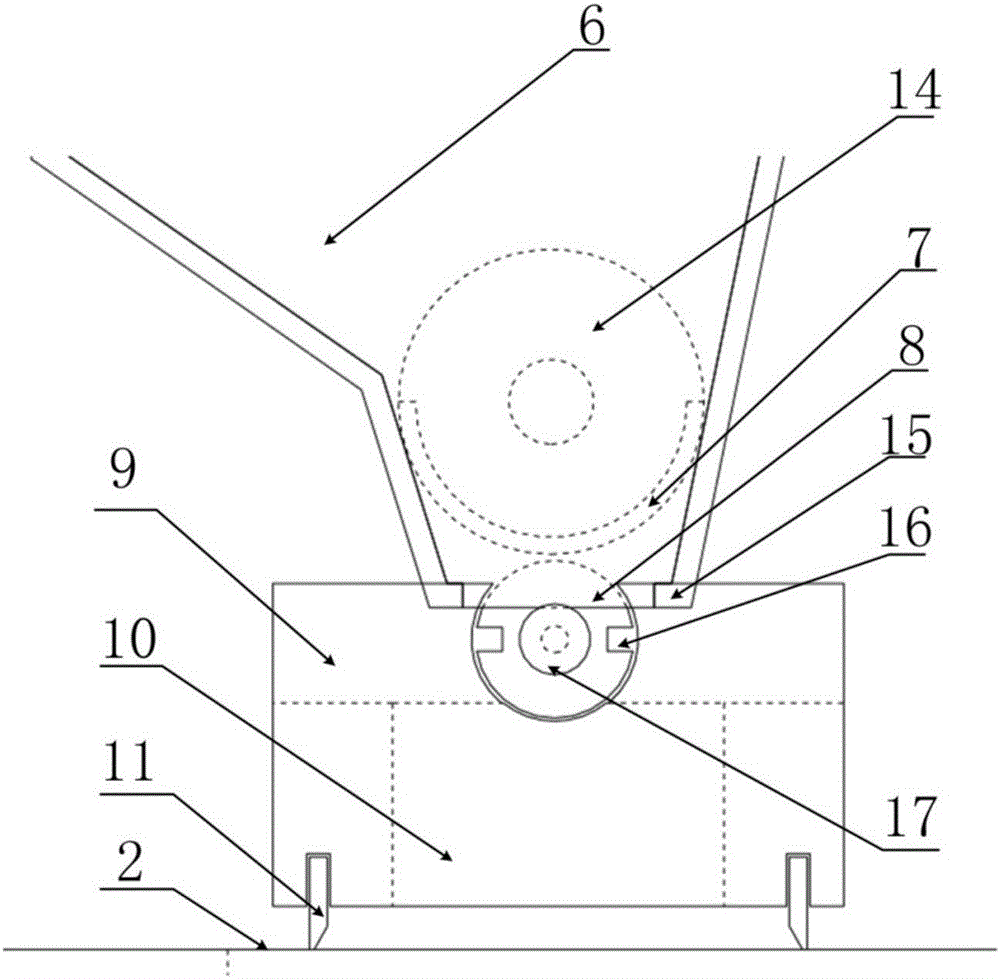

Internally-arranged automatic coating device and method based on 3D printing of precious metal

ActiveCN105903966AReduce wasteReduce pollutionAdditive manufacturing apparatusIncreasing energy efficiencyChinese charactersPowder coating

The invention discloses an internally-arranged automatic coating device and method based on 3D printing of precious metal. The device comprises a forming chamber, a powder laying mechanism and a datum horizontal plate; a closed powder storage box is arranged below a powder outlet of a powder box body, and a quantitative powder feeding mechanism is arranged between the powder outlet of the powder box body and the closed powder storage box; a structure shaped like a Chinese character 'hui' is formed by the enclosure of the peripheral side walls of the closed powder storage box, and two powder coating scrapers are installed on the front side wall and the rear side wall of a lower opening in the powder laying direction; the peripheral side walls of the closed powder storage box, the two powder coating scrapers and the datum horizontal plate form powder storage space; the powder coating scrapers flattens powder from the powder box body uniformly back and forth with the datum horizontal plate as the datum plane. The device integrates the quantitative powder feeding function and the efficient powder laying function and can effectively increase the utilization rate of the precious metal and reduce material waste when applied to the 3D printing process of the precious metal.

Owner:SOUTH CHINA UNIV OF TECH

Friction plate without asbestos and its preparation process

A non-asbestos friction disk for the brake of drilling machine, heavy machinery, etc is prepared from glass fibres, organic fibres, low-smelting-point metal powder and resin-rubber mixture. Its advantages are low hardness, high toughness, high friction coefficient, high mechanical strength, and low abrasion.

Owner:李海 +4

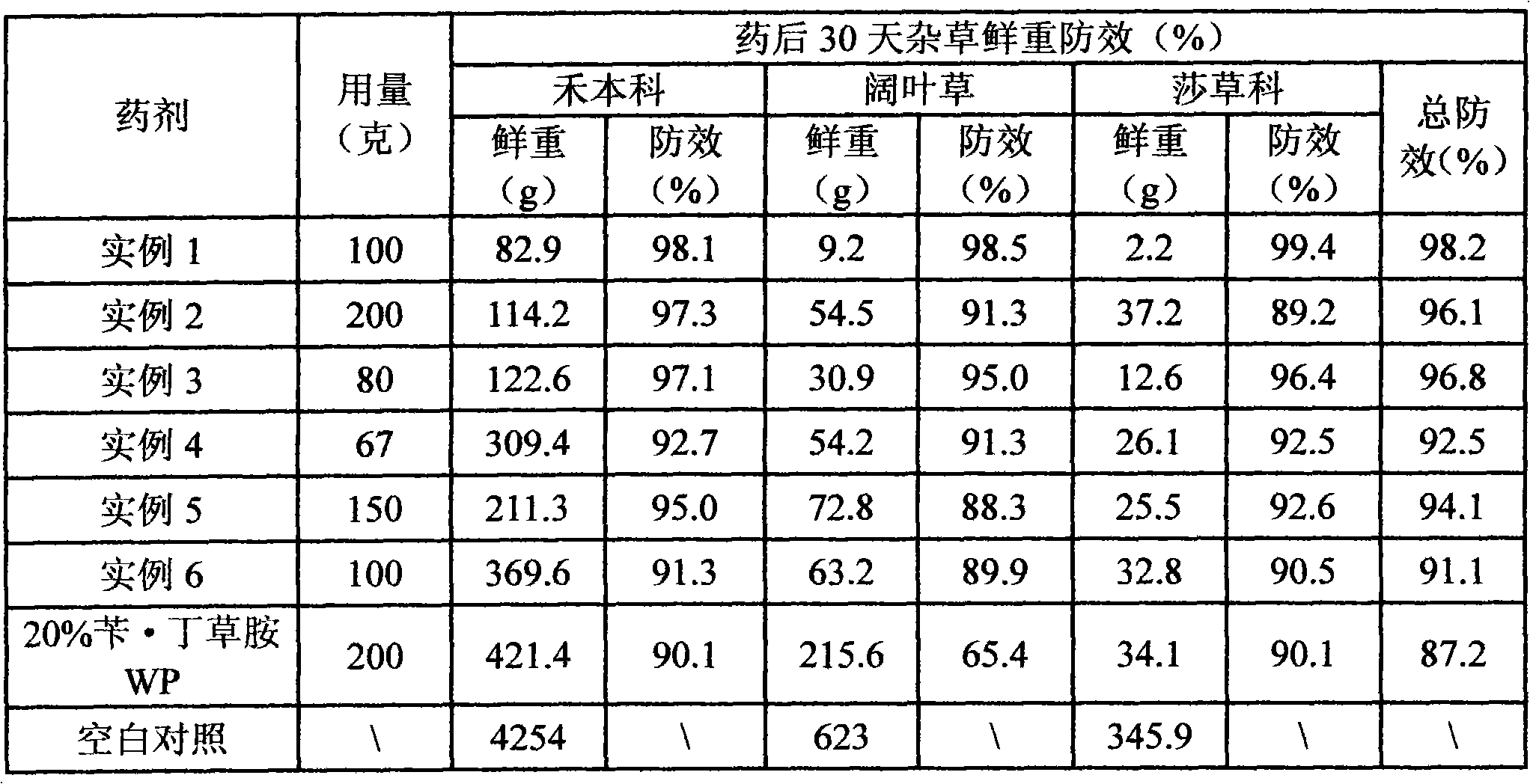

Herbicide effervescent tablets and preparation method thereof

The invention discloses herbicide effervescent tablets containing halosulfuronmethyl and pretilachlor and a preparation method thereof. The active ingredients of the herbicide effervescent tablets comprise 0.5 to 5 weight percent of halosulfuronmethyl, 10 to 25 percent of pretilachlor and the balance of an assistant. The effervescent tablets can be prepared by a direct dry-process tabletting method or a method of wet-process granulating first and then tabletting; the direct dry-process tabletting method comprises mechanically grinding the assistant, uniformly mixing with the assistant and directly tabletting the two raw material medicines; and the method of wet-process granulating first and then tabletting comprises drying the two raw material medicines and the ground assistant, mixing, adhering, granulating to prepare an acid soft material and an alkaline soft material and tabletting. The prepared effervescent tablets are new herbicide preparation products which are environment-friendly and convenient to use. The herbicide effervescent tablets can effectively prevent and control various weeds such as weed from broad leave family, grass family, cyperaceae family and the like in rice shooting fields and transplanting fields.

Owner:GUANGXI RES INST OF CHEM IND CO LTD +1

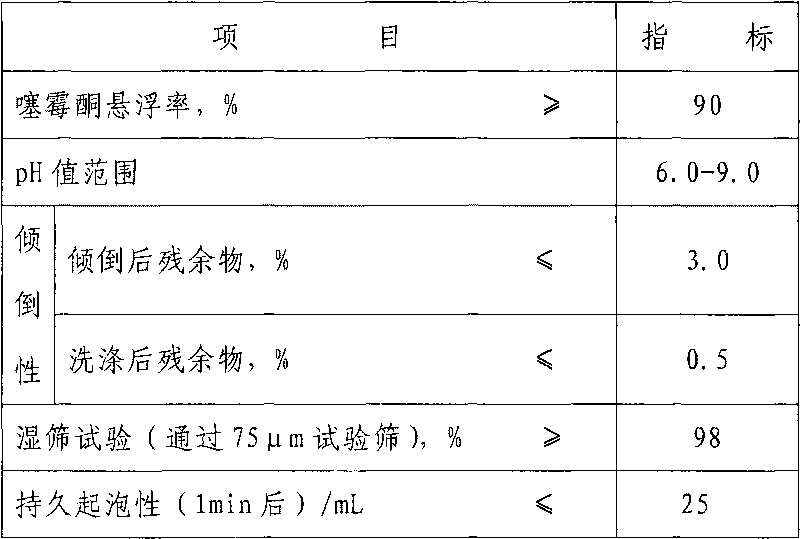

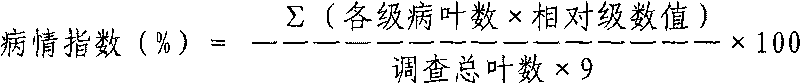

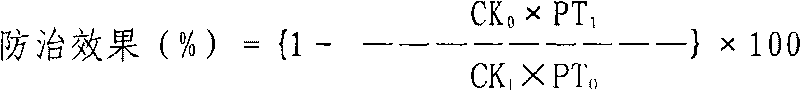

Benziothiazolinone water suspension and preparation method thereof

The invention relates to a benziothiazolinone water suspension and a preparation method thereof. The benziothiazolinone water suspension is prepared from the following components by weight percentage: 1.6-50% of benziothiazolinone, 0.3-5% of defoamer, 10-20% of wetting and dispersing agent, 0-5% of penetrating agent, 0.3-5% of thickener, 10-80% of water, 1-10% of anti-freezing agent and pH regulator which adjusts the pH value to 6.0-9.0.

Owner:陕西西大华特科技实业有限公司

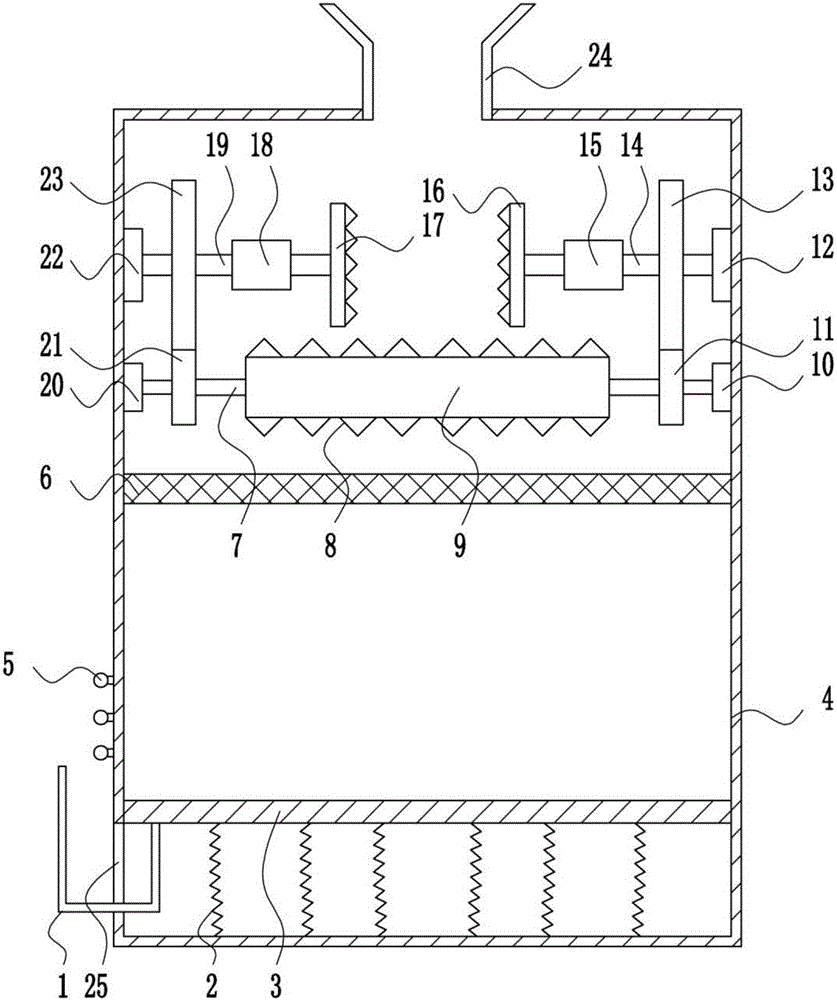

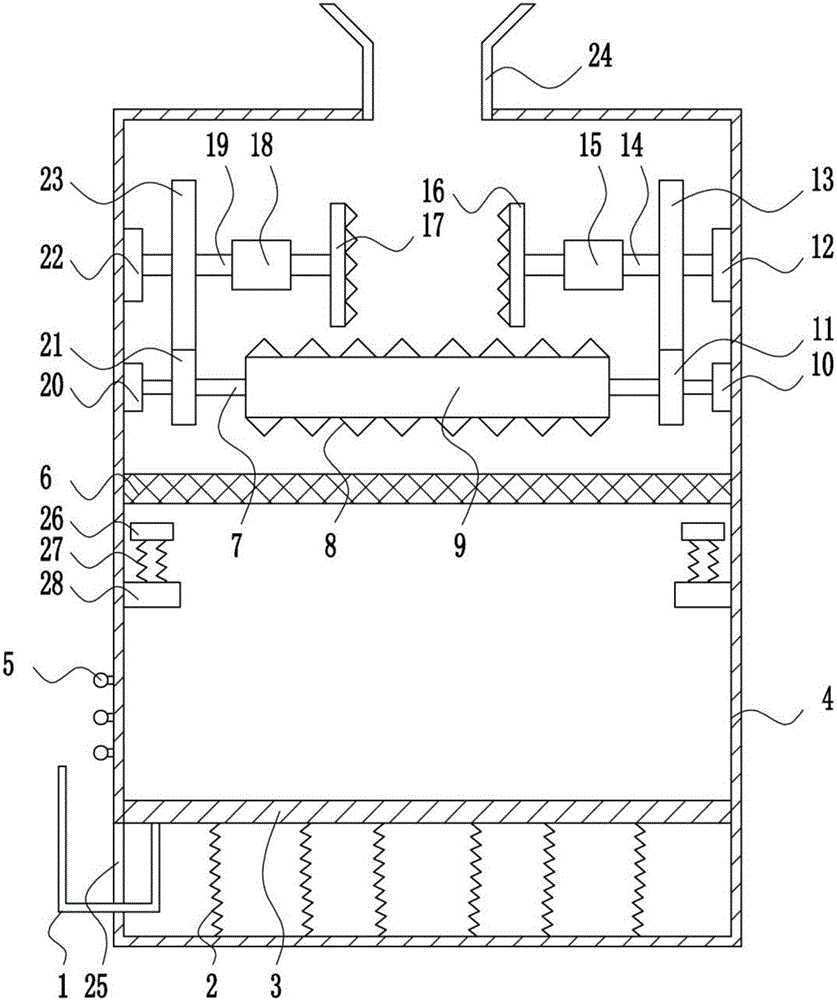

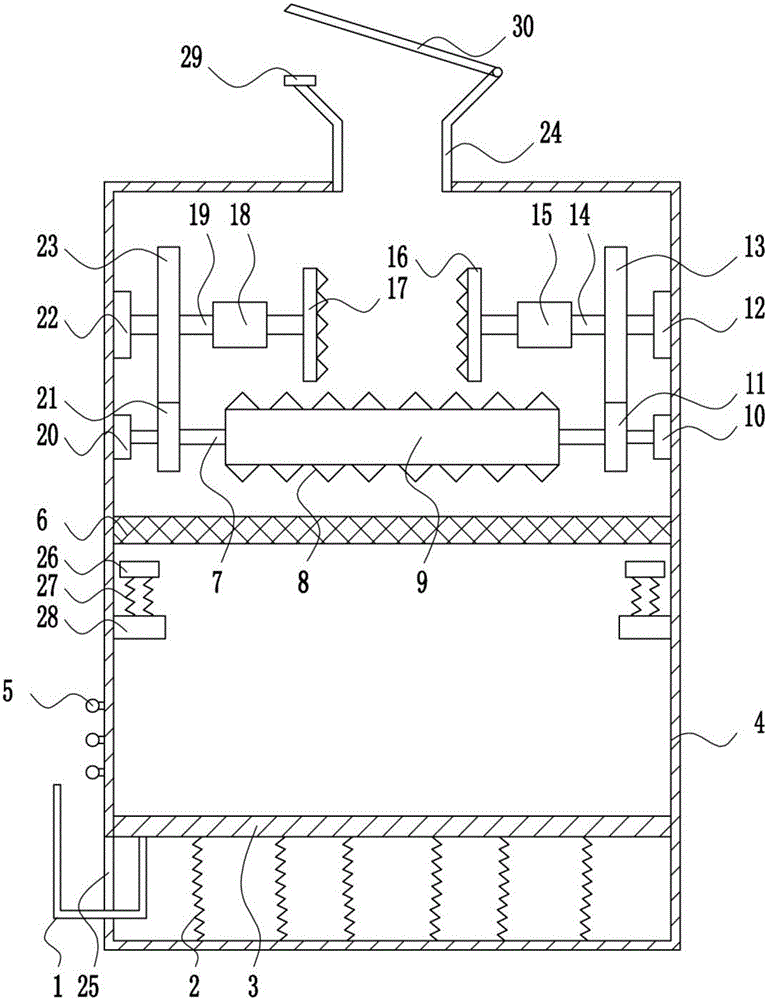

Environment-friendly treatment device for mosaic tiles

InactiveCN106269024AImprove processing efficiencyReduce dust and noiseSievingScreeningNoise pollutionMagnet

The invention relates to a treatment device, in particular to an environment-friendly treatment device for mosaic tiles. The environment-friendly treatment device for the mosaic tiles comprises a moving baffle, a first elastic part, a bearing plate, a treatment box, an indication lamp, an iron wire net, a third rotating shaft, breaking teeth, a breaking cylinder, a third bearing pedestal, a second small gear, a second bearing pedestal, a second large gear, a second rotating shaft, a second electric push rod, a second crushing plate, a first crushing plate, a first electric push rod, a first rotating shaft, a servo motor, a first small gear, a first bearing pedestal and the like. A moving hole is formed in the bottom of the inner left wall of the treatment box. The effects that the dust pollution is reduced, the noise pollution is reduced, the treatment efficiency is high, and the service life of the device is long are achieved, a magnet and an iron cover are arranged, and the treatment box can be closed.

Owner:CHONGQING RYAN PAINT CO LTD

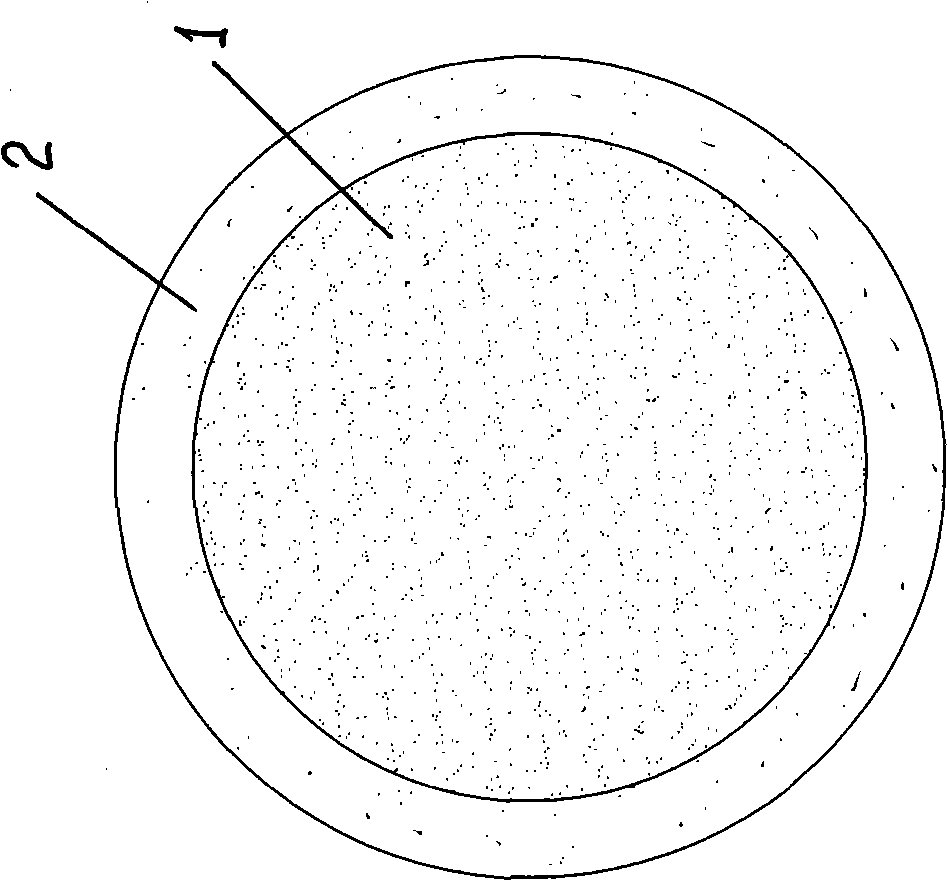

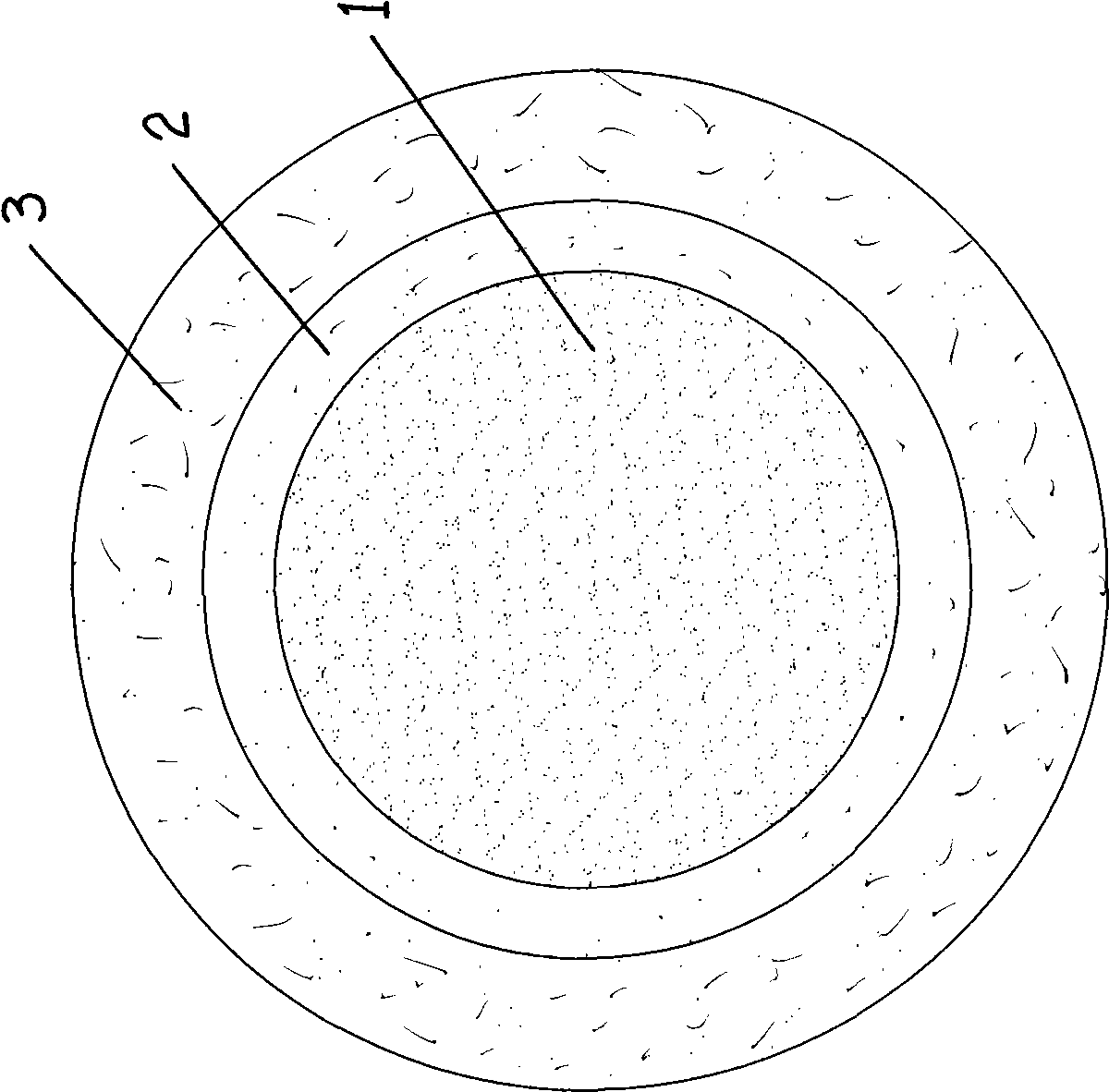

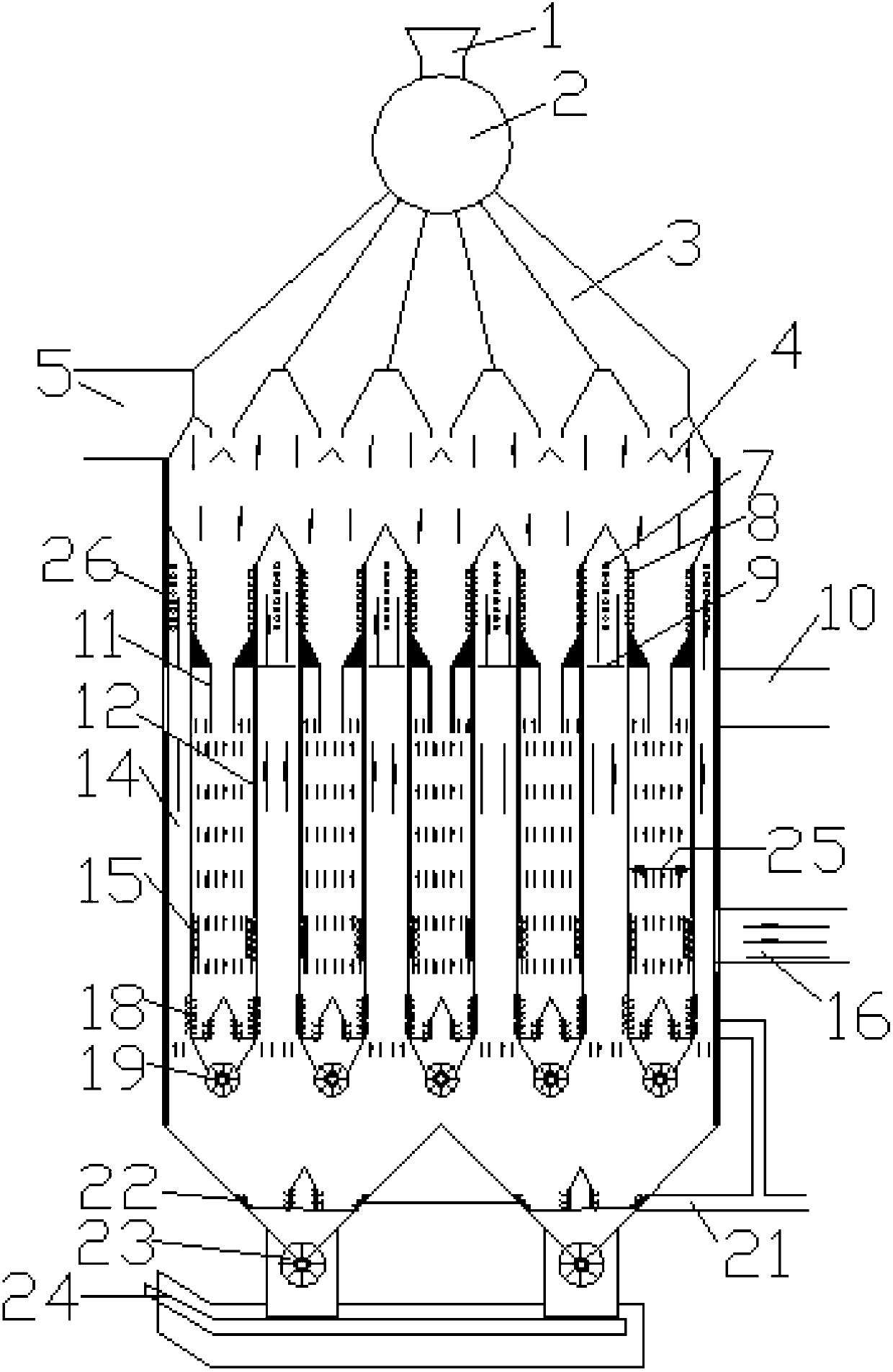

Cat litter and preparing method thereof

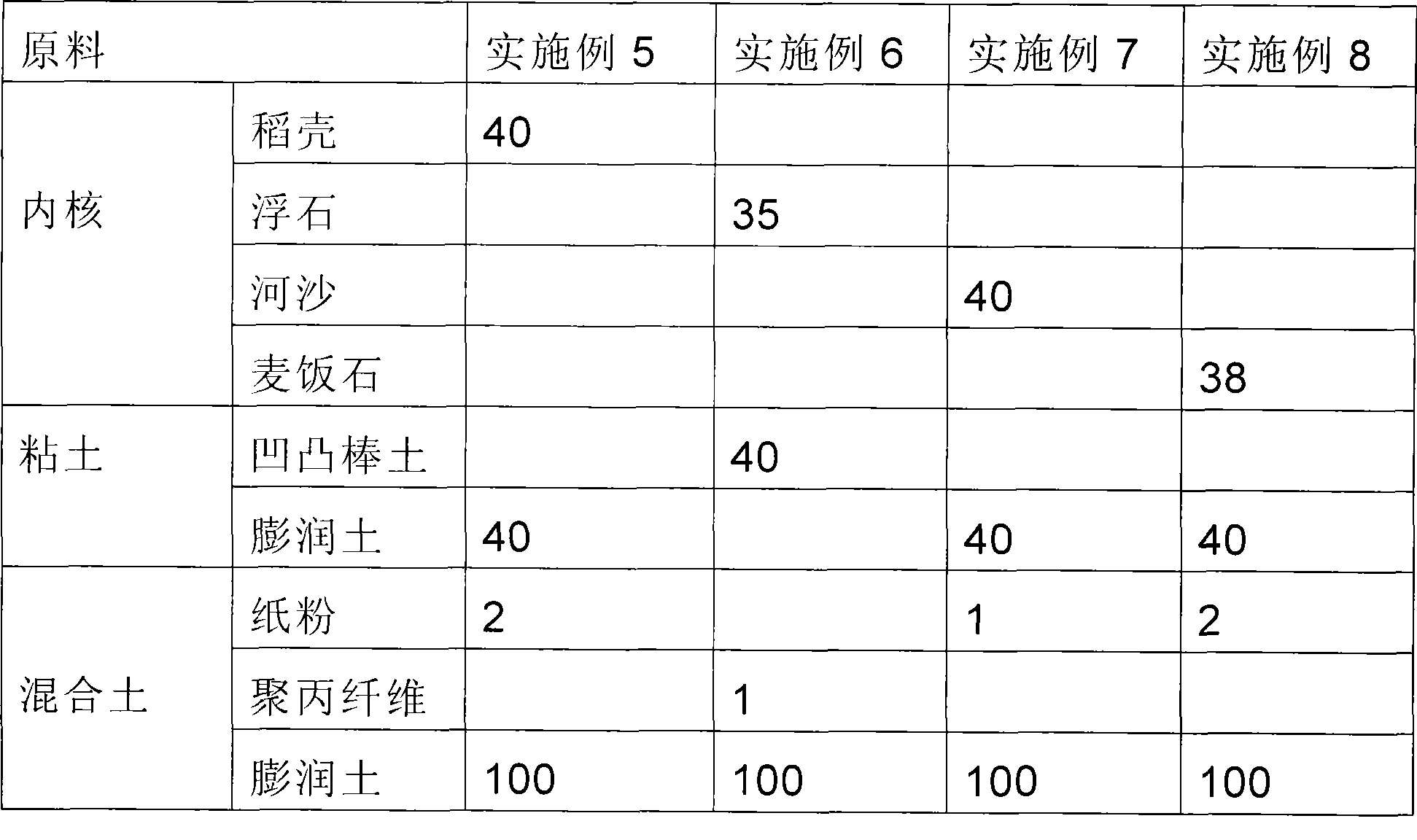

The invention relates to cat litter serving as padding for small animals. The external layer of the internal core of the cat litter is struck to a clay layer and made of perlite, pumice, river sand, rice hull or medical stone. Compared with the similar product, the cat litter has a multilayer structure, the internal core is made of light and low-price perlite, pumice or other hard materials, the clay layer and the mixed soil layer can be rapidly and easily stuck to the external layer of the internal core of the cat litter with high producing efficiency, and the water content of the product before being dried is reasonable, the product can be dried rapidly without high temperature, particularly, the cat litter with the outmost layer being stuck to the mixed clay layer contains fiber, has low dust content, improved viscosity and good utilization effect and is convenient to clean, environmental friendly and sanitary.

Owner:王春蜂

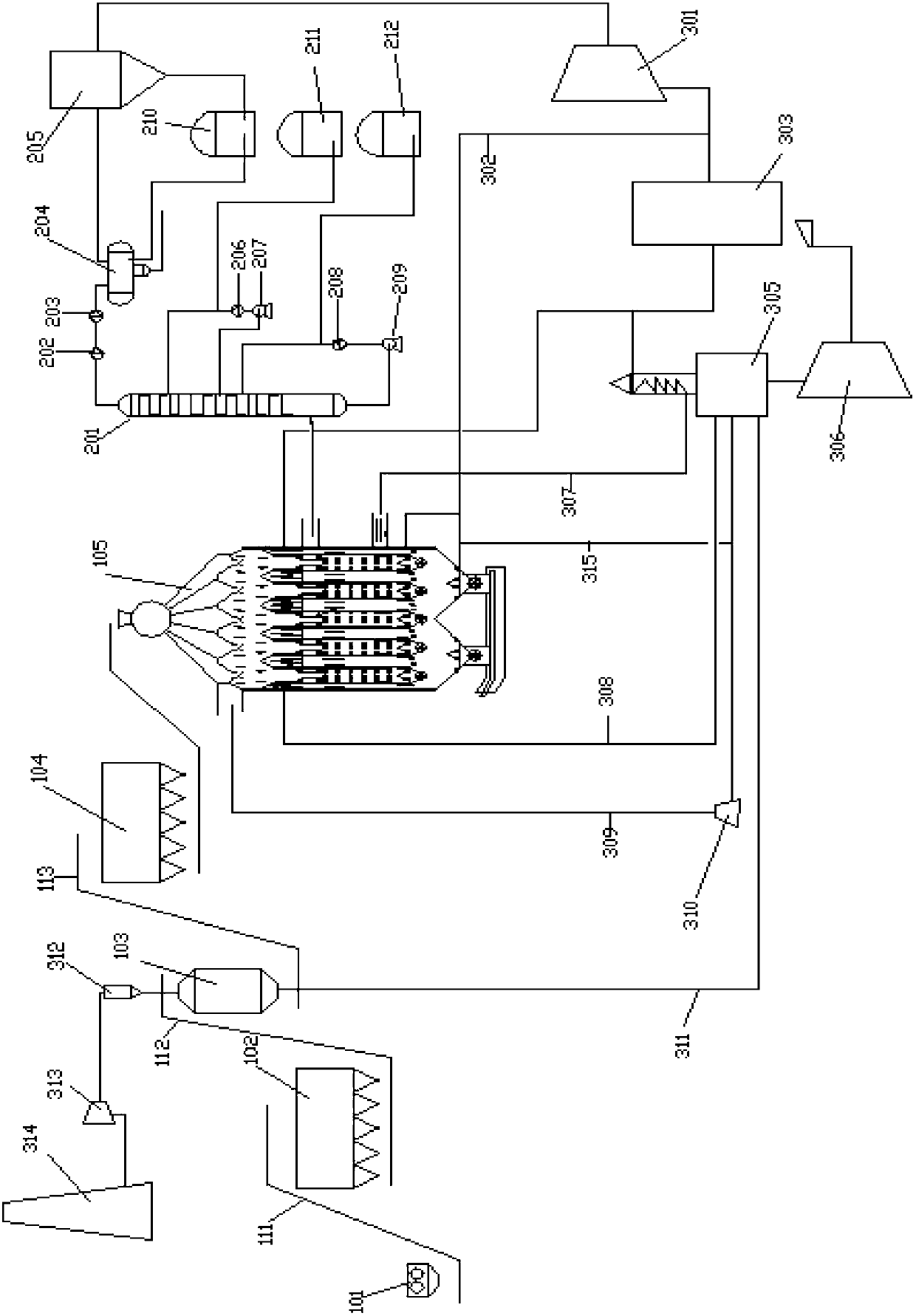

Tunnel pipe thin-layer retort for coal and oil shale and retort process thereof

InactiveCN103013544AImprove heat transfer performanceIncrease profitChemical industrySpecial form destructive distillationThin layerOil shale gas

The invention discloses a tunnel pipe thin-layer retort for coal and oil shale and a retort process thereof, relates to a retort and a process for producing coal tar and shale oil, and solves the problems that the conventional retorts and processes have large heat loss at semicoke cooling sections, the retort time is difficultly controlled accurately, the oil yield is low and the treatment capacity of the single furnace is small. The retort comprises a drying section, a retort section, a high temperature cooling section and a low temperature cooling section, wherein the semicoke cooling section is divided into two sections by a roller feeding machine, heat exchange of cooling wind is carried out at the high temperature semicoke section, the low temperature cooling section is communicated with a tunnel pipe, and drying gas enters the drying section via the tunnel pipe. According to the process, retort oil gas led out from a retort oil gas outlet of a retort furnace is purified and then used as circulation retort gas, and gas led out from a drying gas outlet of the retort furnace is used as the circulation drying gas to carry out retort. With the retort and the retort process, an addition of 20 percent of semicoke residual heat is recovered from per ton raw material, the retort time is accurately controlled, the oil yield is high, and the treatment amount of the single furnace is large; and the retort and the retort process are mainly applied to the field of coal chemical industry.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM +1

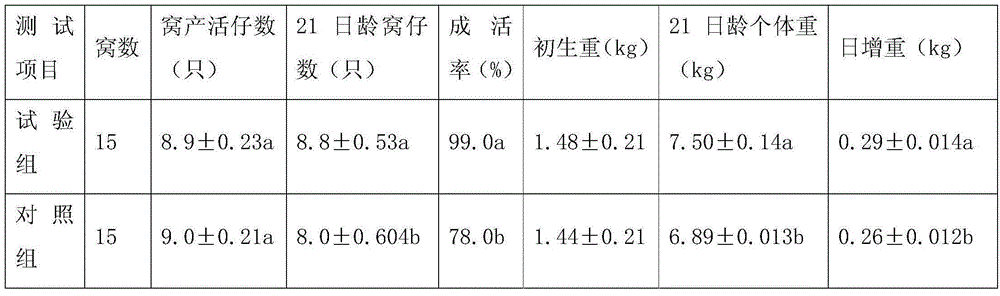

Non-resistant dust-free piglet creep formula feed and preparation method thereof

PendingCN107927384ACollocation scienceImprove digestion and absorption rateAnimal feeding stuffAccessory food factorsPhytaseSucrose

The invention discloses non-resistant dust-free piglet creep formula feed and a preparation method thereof. The feed is prepared from the following components: corns, fermented corns, soybean meal, fermented soybean meal, expanded soybean flour, expanded corn flour, imported fish meal, spray-dried plasma proteins, dried porcine solubles, powdered whey, soybean oil, sucrose, molasses, sodium glutamate, a feeding promoting agent, Yibao phospholipid, yeast autolysate, an acidifying agent, stone powder, calcium hydrogen phosphate, table salt, 98.5 percent of lysine, 98.5 percent of threonine, 10 percent of tryptophan, special compound enzyme for early-weaned piglets, phytase enzyme, a micro-ecological preparation, a Chinese herbal medicine heath preserver, antibacterial peptide, immunopotentiator, 50 percent of choline chloride and a premix. The preparation method comprises the following steps: firstly, separately preparing granulated feed products and powdery feed products; and then mixing the granulated feed products with the powdery feed products to obtain the non-resistant dust-free piglet creep formula feed. According to the feed disclosed by the invention, antibiotics are not added, a formula is scientific, the dust of the product is low, the palatability and the immunity are improved, and a diarrhea ratio of piglets is reduced.

Owner:江苏中煤长江生物科技有限公司

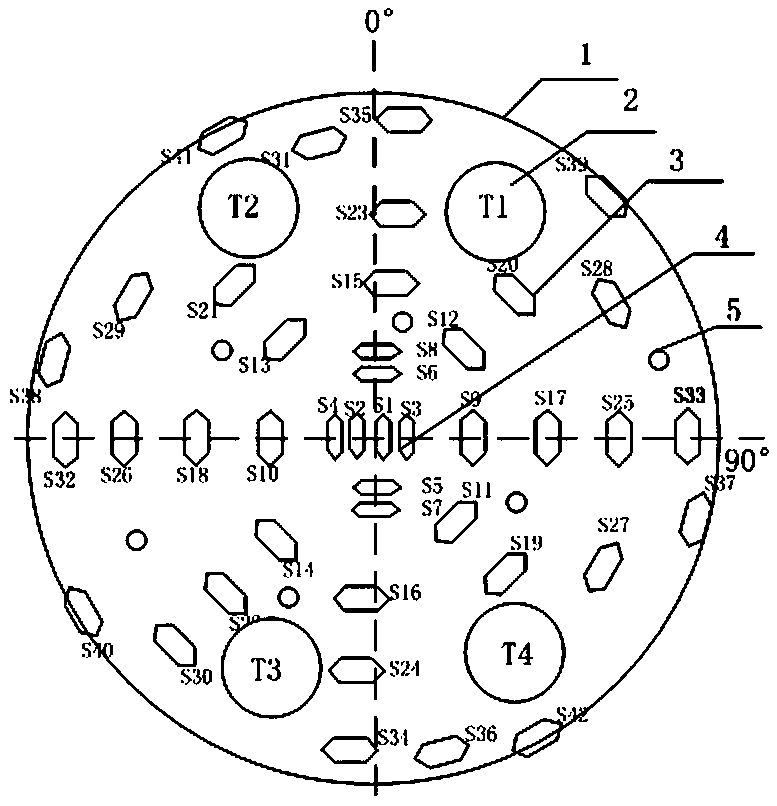

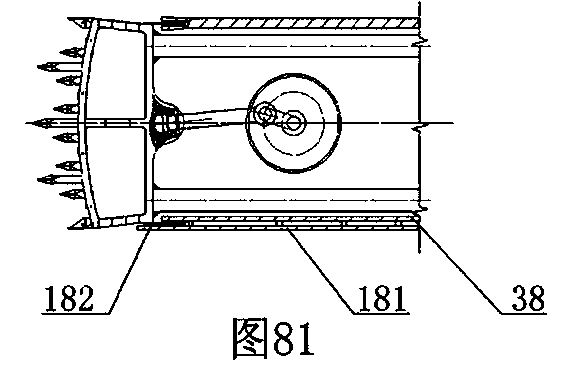

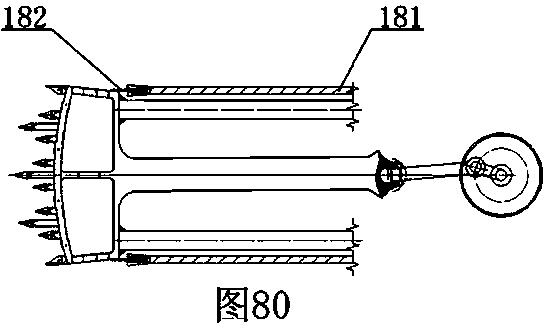

Microwave-assisted rock breaking TBM cutter head for hard rocks

PendingCN109763832AExpand coverageGood rock breaking effectDust removalFire preventionRock breakingDisc cutter

The invention discloses a microwave-assisted rock breaking TBM cutter head for hard rocks. The cutter head comprises a TBM cutter head body, wherein the TBM cutter head body mainly comprises a single-edge rock breaking hobbing cutter, a double-edge rock breaking hobbing cutter, a plurality of water injection dedusting openings and a plurality of microwave-assisted rock breaking emitters; the cutter head covers rock breaking paths in different tracks through the combination of the double-edge rock breaking hobbing cutter and the single-edge rock breaking hobbing cutter; a cutter head panel is provided with the water injection dedusting openings; the cutter head panel is provided with the microwave-assisted rock breaking emitters; each microwave-assisted rock breaking emitter comprises a microwave emitting disc, a wave guiding structure and a microwave emitting module. The cutter head has the advantages that a microwave emitting device is started in case of hard strata, rocks are rapidlyheated through microwave, mechanical properties of rocks, such as the point load strength, uniaxial compressive strength and tensile strength, are reduced, rock joint fissure assisted TBM hobbing cutter rock breaking is added, the penetration speed of disc cutters is improved, the rock breaking rate is improved, the thrust and torque of TBM equipment are reduced, abrasion of the hobbing cutters in hard rocks and cutter changing frequency are reduced, the construction period can be greatly reduced, and the construction investment can be reduced.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +2

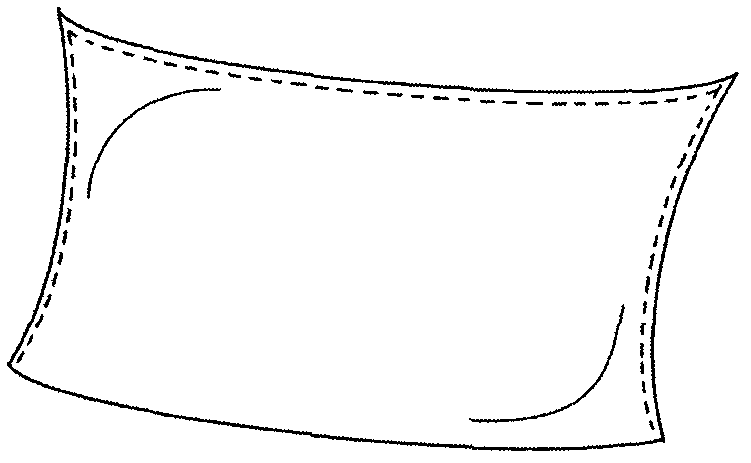

Potted plant substrate bag

InactiveCN103299854AOvercome inconvenienceOvercoming pollutionCultivating equipmentsPlastic mulchPlant cultivation

The invention discloses a potted plant substrate bag and belongs to the technical field of plant container culture and substrate culture. In order to solve various troubles and the pollution problem occurring during potting, pot change, soil utilization, watering and management of household potted plants at present, the invention provides a household material which is clean, easy, fast and happy for performing the container culture. The technical scheme disclosed by the invention is that the potted plant substrate bag is manufactured by wrapping a potted plant substrate with permeable and breathable cloth, and is characterized in that the substrate is completely wrapped by the cloth; the substrate bag is put in a potted plant container to perform the container culture; the substrate bag is soft and is deformable; the planting side of the substrate bag can be molded, and even can be made into a three-dimensional modeling and a cartoon modeling. Three-dimensional culture can be performed on the three-dimensional modeling; and a waterproof film also can cover on the planting side of the substrate bag. The potted plant substrate bag has functions of various functional mulching films. The invention also provides a culture and application method for the potted plant substrate bag.

Owner:吴晓丽 +1

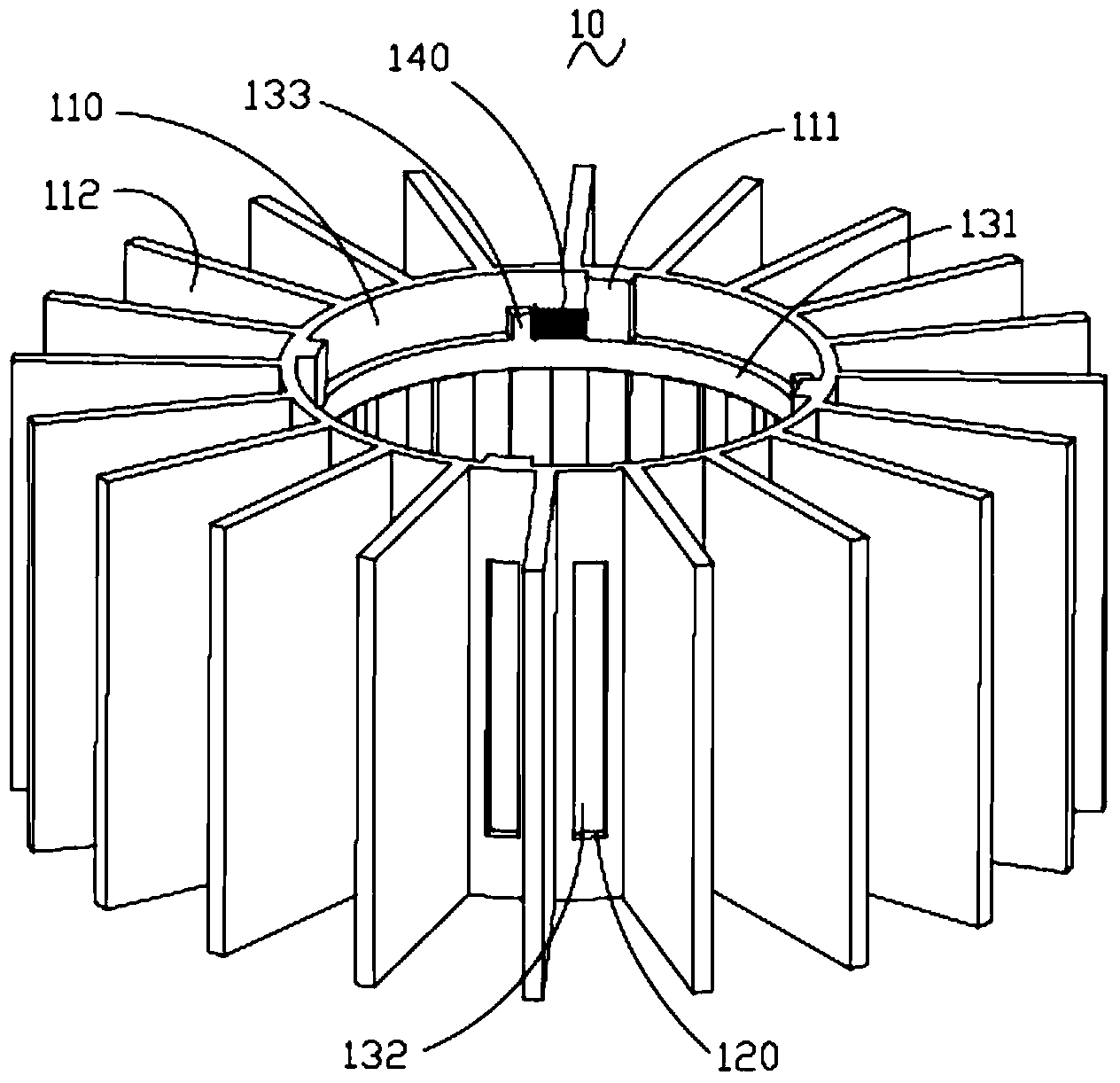

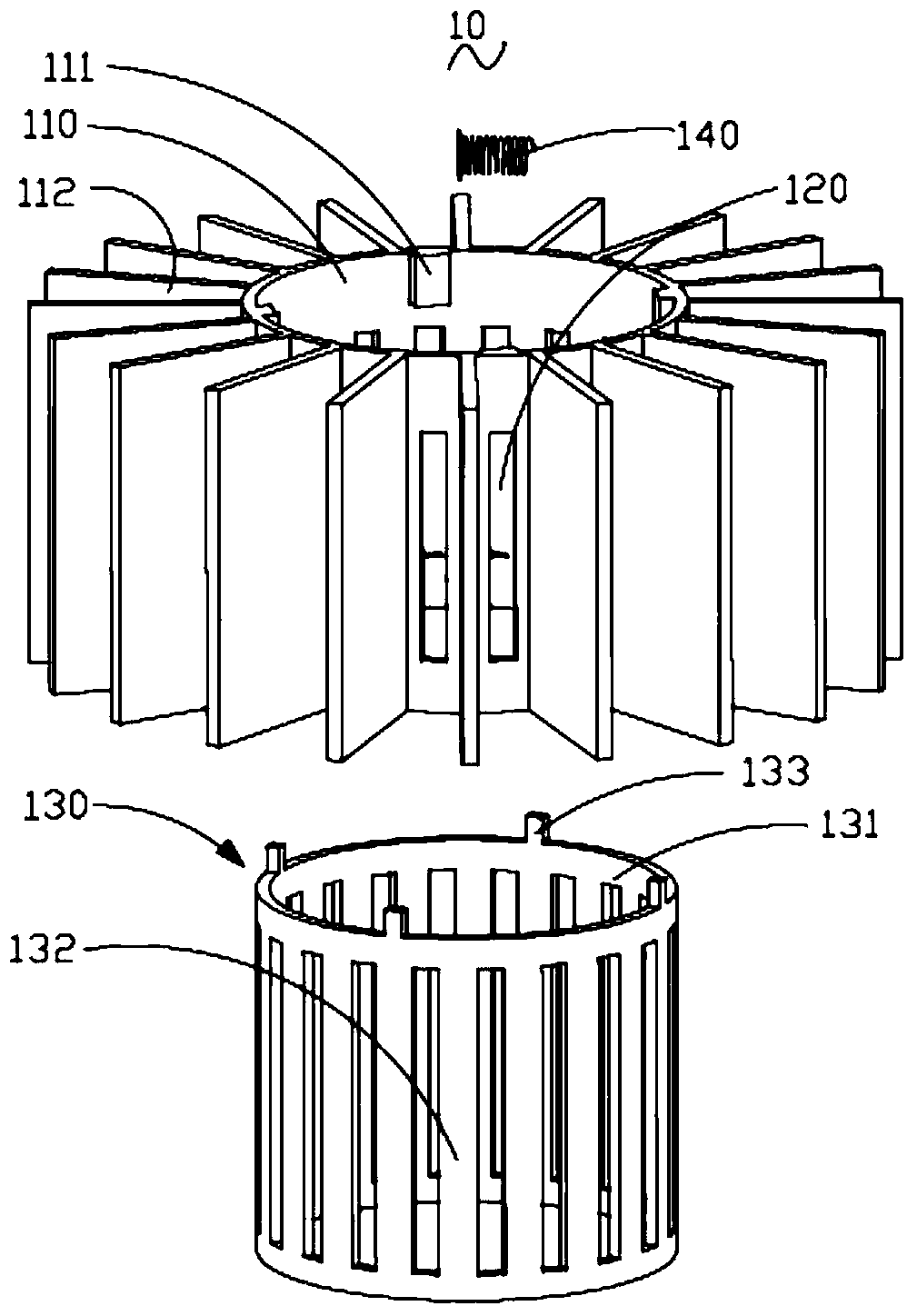

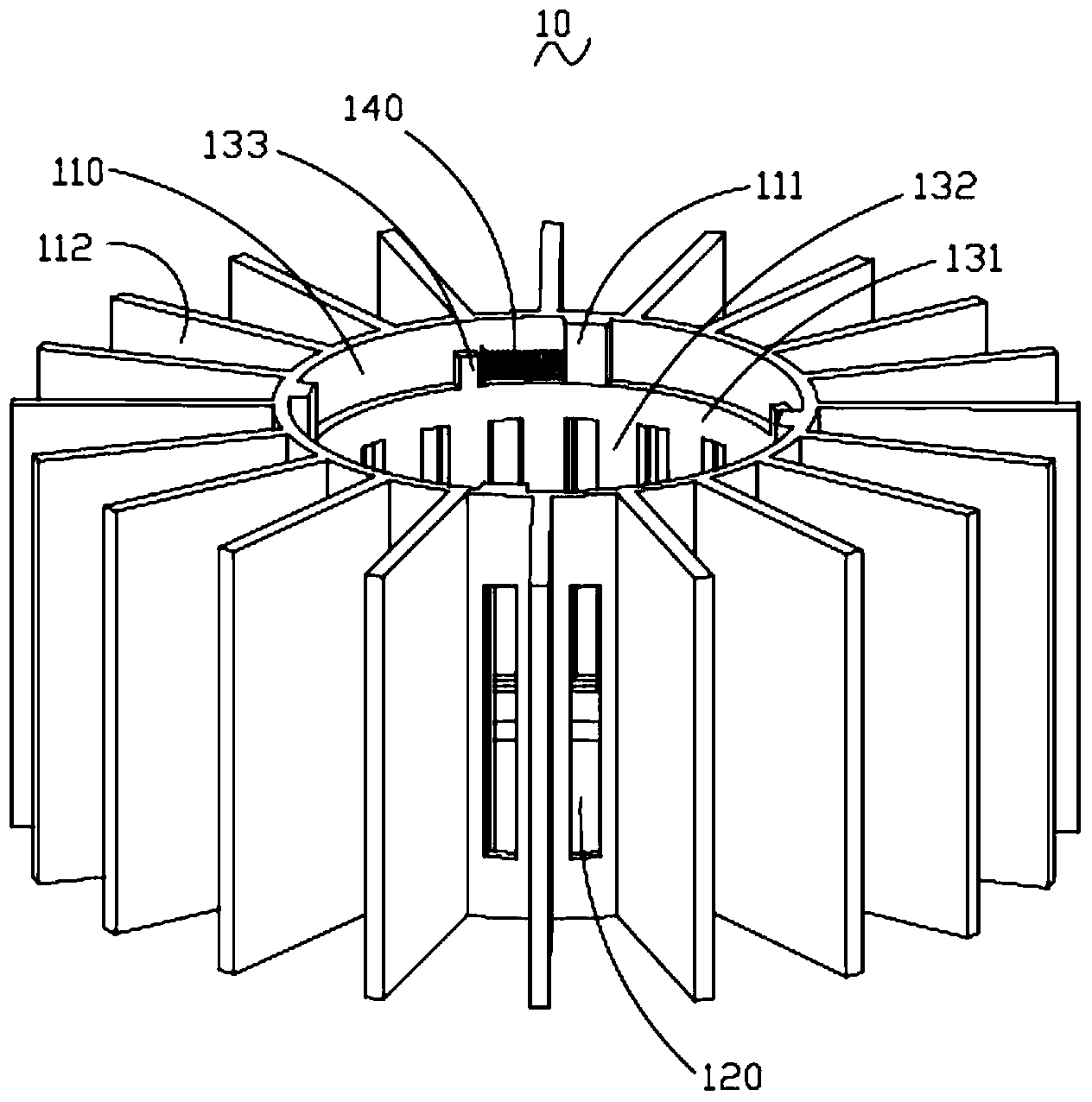

Heat dissipation device

InactiveCN104296107AImprove cooling efficiencyImprove securityPoint-like light sourceLighting heating/cooling arrangementsRoom temperatureShape-memory alloy

A heat dissipation device comprises a cylindrical heat dissipation device body, a plurality of heat dissipation holes formed in the heat dissipation device body, a blocking piece tightly attached to the heat dissipation device body, and drivers connected between the blocking piece and the heat dissipation device body. The blocking piece comprises a blocking piece body, blocking strips connected with the blocking piece body, and first connecting portions arranged on the blocking piece body. The heat dissipation device body is provided with second connecting portions matched with the first connecting portions. The drivers are connected between the first connecting portions and the second connecting portions. The drivers are made of shape memory alloy material and can deform in the circumferential direction of the heat dissipation device body when heated to reach the preset temperature value. According to the heat dissipation device, in the room temperature, the blocking piece can close the heat dissipation holes so that the heat dissipation device can be in a closed state. After the heat dissipation device is heated, the drivers made of the shape memory alloy material can be stretched out and drawn back or can be bent in the circumferential direction of the heat dissipation device body, and therefore the blocking piece is driven to rotate so as to open the heat dissipation holes, and the heat dissipation efficiency is improved.

Owner:东莞市闻誉实业有限公司

Feed for lactating sows

InactiveCN104304790APromote digestion and absorptionImprove palatabilityFood processingAnimal feeding stuffNutritional statusAdditive ingredient

The invention relates to feed for lactating sows. The feed comprises a feed main material and a traditional Chinese medicine additive, wherein the feed main material comprises the following raw material components: dried corn, distiller grains, soybean meal, barley with peel, puffed rapeseeds, wheat bran, honey, soybean oil, liquid enzymic preparation and premix. The feed for lactating sows disclosed by the invention is reasonable in formula of main material and meets physiological characteristics of lactating sows in growth; by adding traditional Chinese medicine ingredients, the feed can improve feed intake of sow, improve nutritional status of the sow, enhance body immunity, regulate gastrointestinal function, promote involution of uterus and bring about benefit for recovery of postpartum constitution of the sow; meanwhile, the feed, which contains vitamin A, vitamin B, vitamin E, etc., is favorable for synthesis of milk.

Owner:GUANGXI BOBAI YANGXIANG BAOZHONGBAO FEED

Clutch facing piece for automobile and production method thereof

InactiveCN101655128AHigh strengthHigh modulusMixing operation control apparatusCeramic shaping apparatusConductor CoilAntimony trisulfide

The invention discloses a clutch facing piece for an automobile and a production method thereof. The production method comprises the following steps: stirring 10-20% of water soluble phenolic resin, 0.5-1.5% of alumina, 4-8% of crystalline flake graphite, 0.6-1.2% of antimony trisulfide, 6-10% of ground calcium carbonate, 8-12% of chalcopyrite powder, 6-10% of magnetite powder, 3-8% of vermiculitepowder, 12-18% of barium sulfate, 6-15% of powder nitrile-butadiene rubber and water according to parts by weight of each component, preparing suspension, then dipping 15-25% of basalt fibre and obtaining a product by drying, winding, pressing, heat treatment and mechanical processing. By using the invention, the temperature resistance and the wear resistance of the clutch facing piece for the automobile are enhanced, a phenomenon of dust raising in the production and use process is reduced, and the product is more affinitive to the environment.

Owner:十堰法雷诺动力科技有限公司

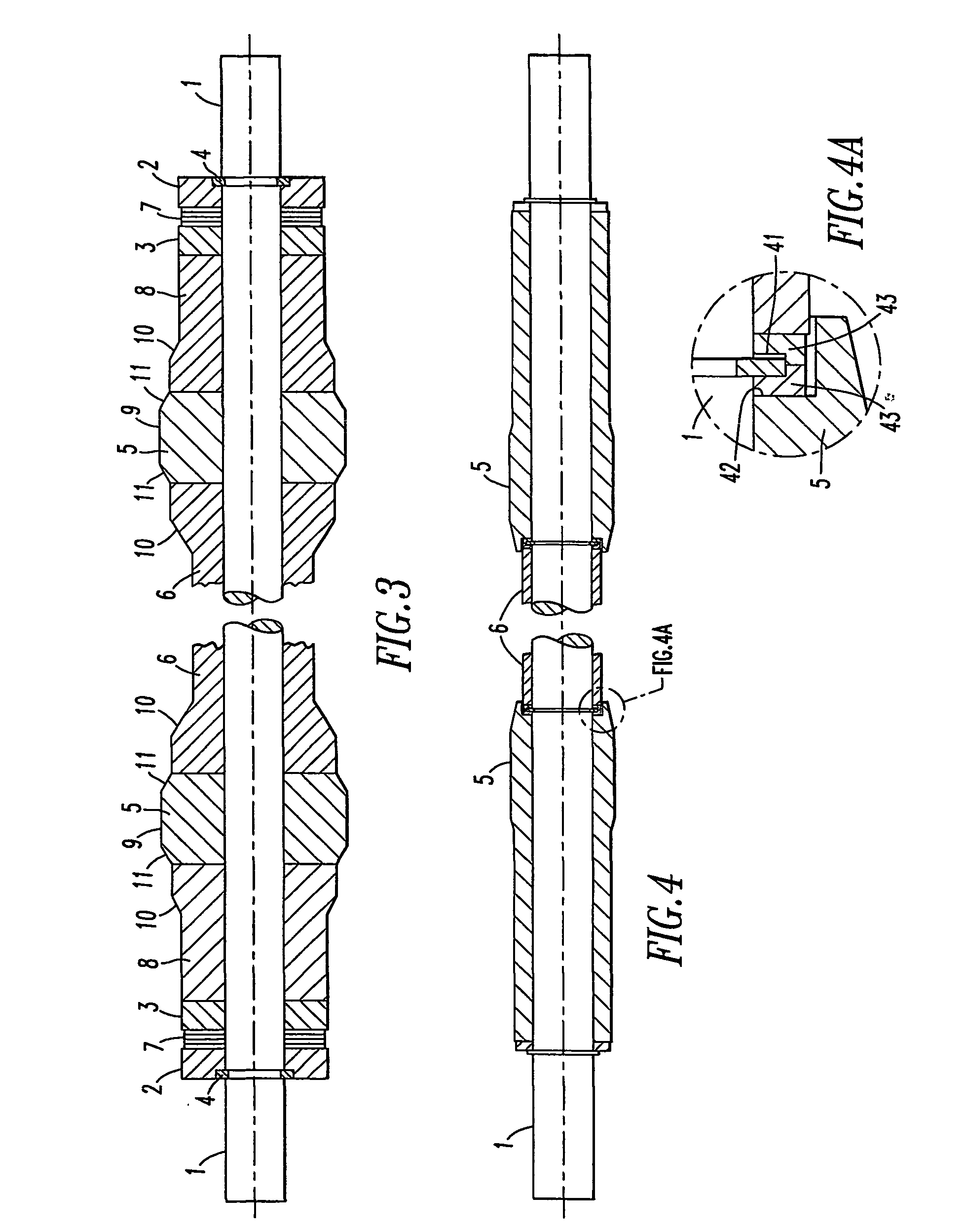

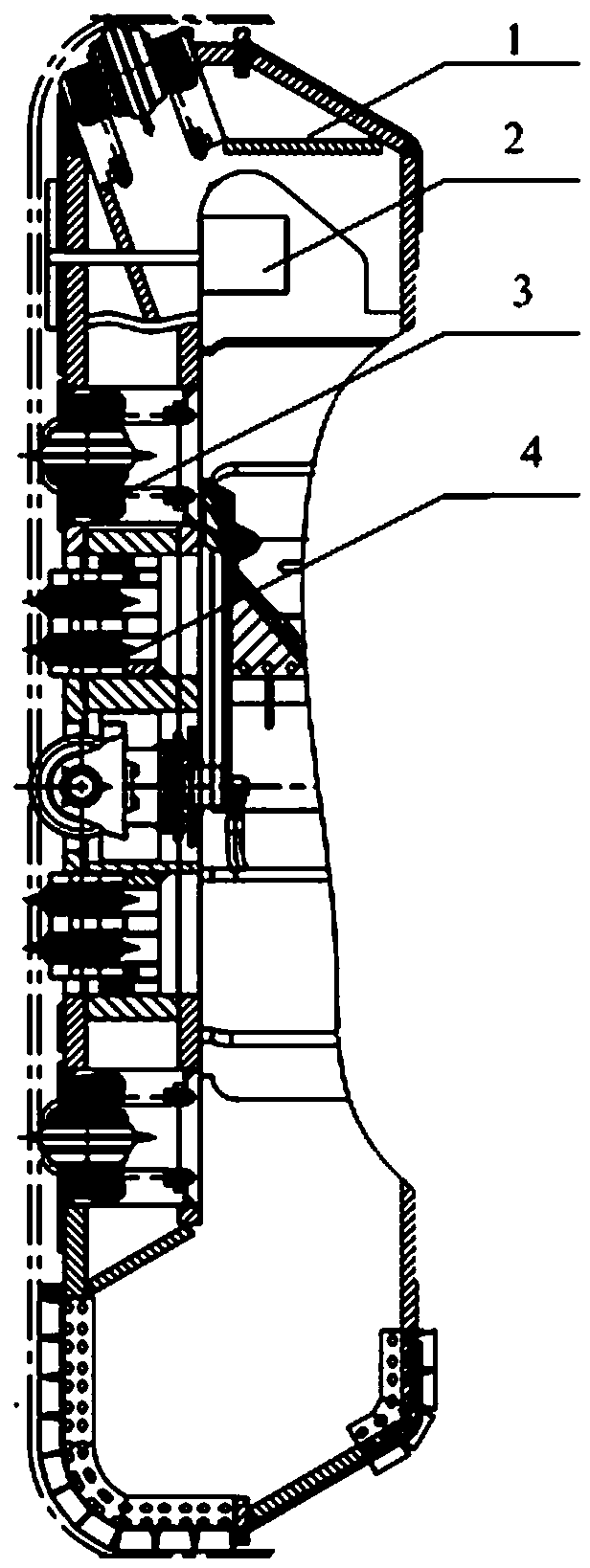

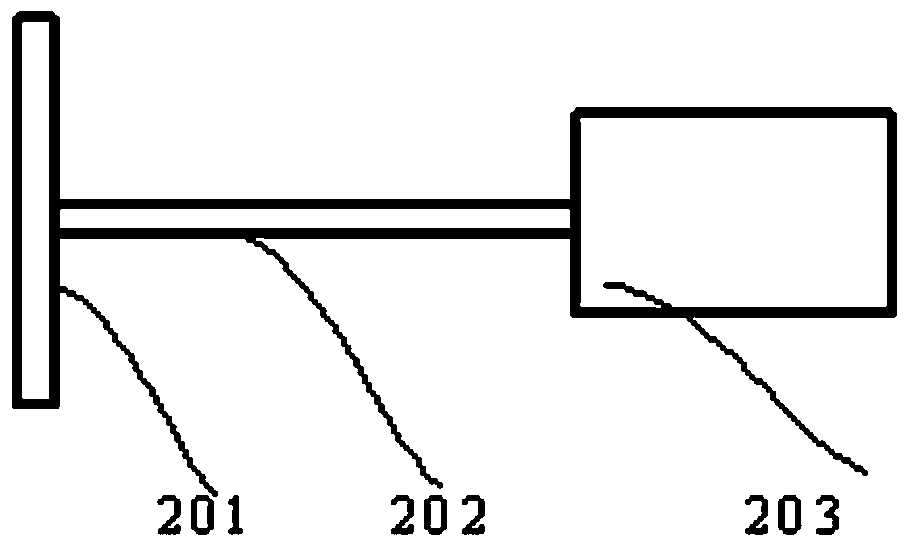

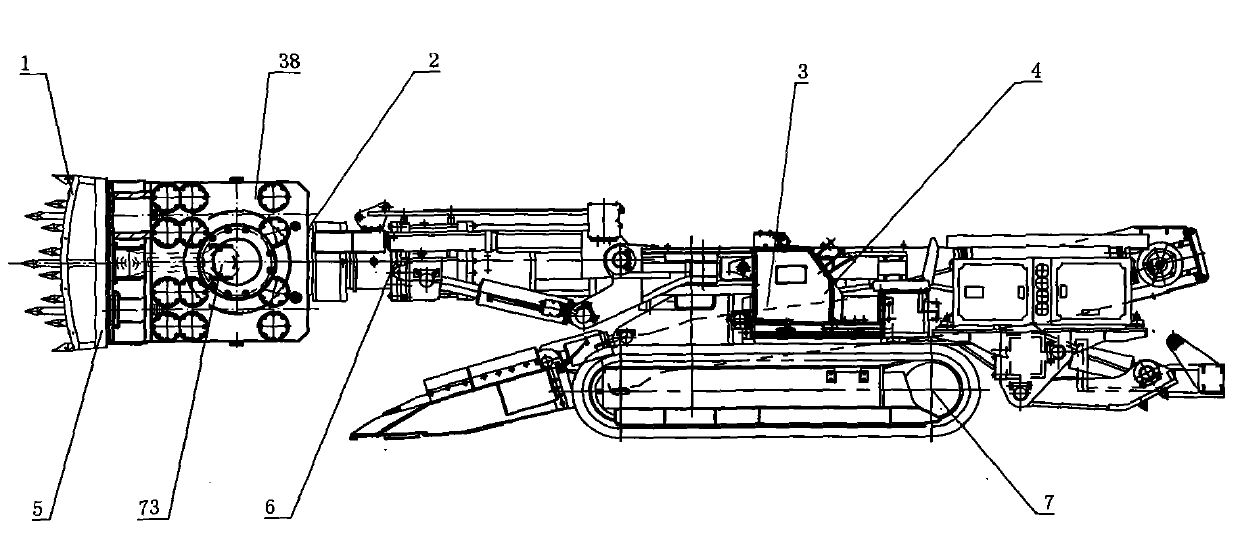

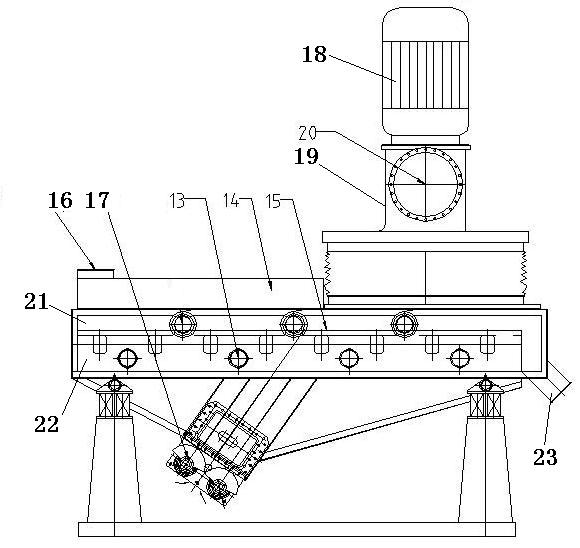

Method and apparatus for converting rotary motion into reciprocating impact motion

ActiveCN103498673APass smoothlySmooth nestingDriving meansPercussion drillingDrive shaftReciprocating motion

A method and device for converting rotary motion to reciprocating percussion motion. The device comprises a machine body (4), a travel portion (7), and a reciprocating percussion portion (5). The reciprocating percussion portion (5) comprises a percussion drive mechanism (2), a rocker arm (6), and a percussion head (1). The percussion drive mechanism (2) comprises a percussion power source member (11), a transmission component, and a crankshaft (10). The percussion power source member (11) comprises a motor, and the motor comprises a power output shaft (14). The transmission component comprises a power gear (13) and a transmission gear (12). The power gear (13) is mounted on the power output shaft (14). The transmission gear (12) drives the crankshaft (10). The transmission component comprises a transmission shaft. The power output shaft (14) is perpendicular to the rocker arm (6), and is parallel to the transmission shaft and the crankshaft (10) so that the transmission gear (12) drives the crankshaft (10) to convert rotary motion to reciprocating motion; or the power output shaft (14) is parallel to the rocker arm (6), the crankshaft (10) is driven to convert rotary motion to reciprocating motion after the power direction is changed by a power bevel gear and a transmission bevel gear. The crankshaft (10) drives the percussion head (1) to perform reciprocating percussion. The travel portion (7) drives the machine body to travel. The machine body (4) drives the reciprocating percussion portion (5) to move and work continuously. The device applies to the mining field or mechanical engineering field, and has advantages such as strong structural strength and a small amount of maintenance.

Owner:刘素华

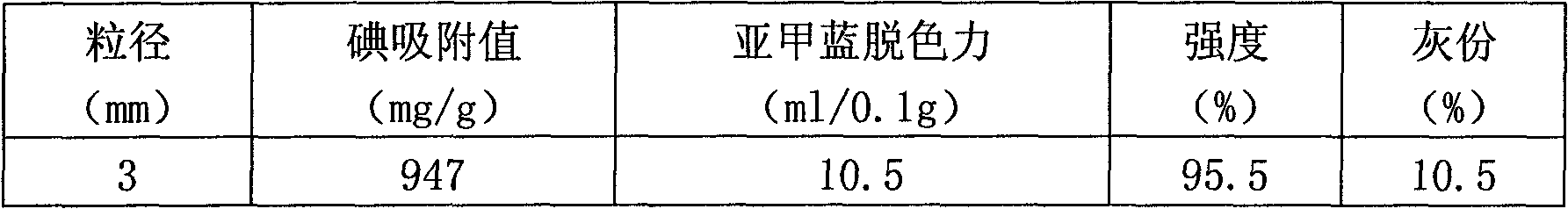

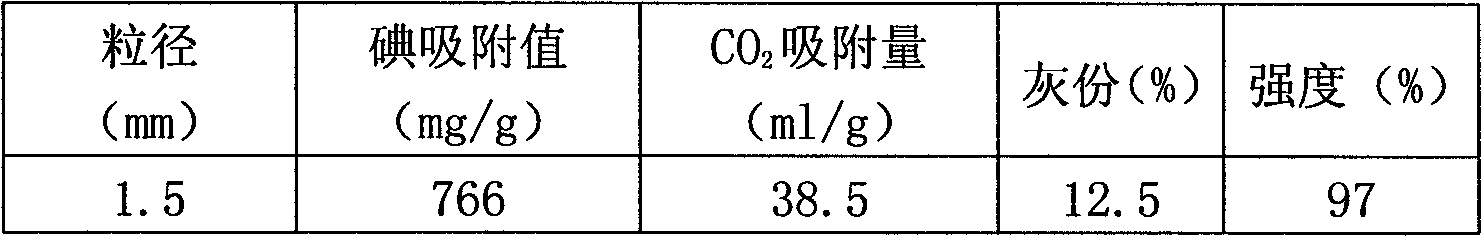

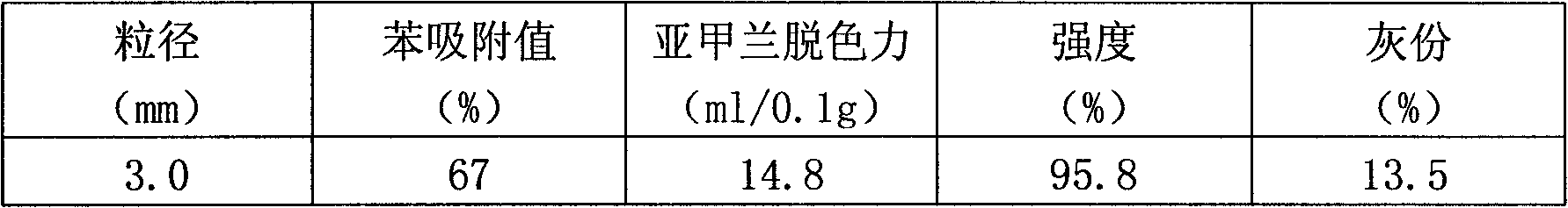

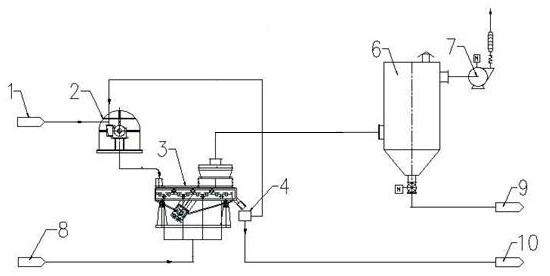

Production method for activated carbon

The invention discloses a production method for activated carbon. The production method comprises the following steps of: adding binding agents such as polyphosphates, active silicic acid and the like to raw materials such as pulverized coal and the like, and obtaining a finished product after kneading, extruding, drying and activating the mixture. According to the production method, as the binding agents formed by matching one or several compounds are used for replacing coal tar, the serious pollution caused by using the coal tar as the binding agent can be avoided, and plenty of coal tar with the high cost is saved, and the production cost is reduced. The obtained activated carbon has high strength, very few floating dust and very high adsorptive capacity and can be used for water treatment, deodorization, decolorization, a catalyst carrier, the desorption of CO2 and N2 gasses in pressure swing adsorption, gas phase adsorption, solvent recovery, a carbon catalyst and the like.

Owner:淮北市大华环保科技有限公司

Manufacturing method for flame-retardant organic mulch for landscapes and greenbelts

InactiveCN104686261ALarge water storage capacityAchieve recyclingBio-organic fraction processingExcrement fertilisersParticulatesGreening

The invention relates to a manufacturing method for a flame-retardant organic mulch for landscapes and greenbelts. The method comprises the following steps: separately collecting landscape wastes such as tree branches, tree leaves, stems and leaves of flowers and plants generated in the greening and maintaining process; crushing the tree branches and processing the tree branches into particles about 1.5-7.0 cm in length; crushing the tree leaves and the stems and leaves of flowers and plants into fine particles about smaller than 0.5 cm in diameter; then adding water, a fermentative strain and a fermentation catalysis substance, neatening the materials in piles, fermenting for 30-45 days and then paving the materials in the greenbelts; finally spraying a water-soluble flame-retardant agent to the surface of the organic mulch. According to the method, the cyclic utilization of the landscape wastes can be implemented; the rising dust is reduced; the water retention capacity of the landscapes is improved; the soil humidity is retained; the hardening of the soil is avoided; the growth of weeds is inhibited; the soil fertility is enhanced; the greenbelt landscape effect is improved; the safety of the organic mulch is improved.

Owner:沈阳市园林科学研究院(沈阳市环境卫生工程设计研究院)

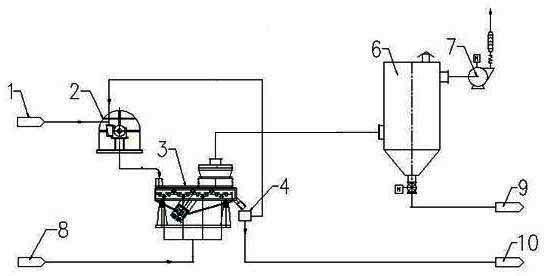

Production process of steel slag micro-powder

InactiveCN102168155ASimple production processLess investmentRecycling and recovery technologiesProcess efficiency improvementIron powderSlag

The invention relates to a production process of steel slag micro-powder, which comprises the following steps: enabling wet steel slag powder with water content of 5% and particle size of 0-20mm generated after crushing and magnetic separation of steel slag to enter a mill for powder milling, conveying obtained fine powder into a vibration drying and powder selecting machine for powder selection, enabling a micro-powder finished product to be discharged from an air outlet of the vibration drying and powder selecting machine and then enter a cloth bag dust collector for collection, then sending the micro-powder finished product into a finished product cabin, enabling the residual coarse powder to be discharged from a discharge port of the vibration drying and powder selecting machine, performing magnetic separation via a magnetic separation machine for removing iron powder, and then returning to the mill to perform the powder milling together with the wet steel slag powder. The production process has the benefits of shortening the process flow and reducing equipment investment. The closed loop circulation is adopted, the dust is little, and energy conservation and environment friendliness are realized.

Owner:TIANJIN SUMEIR ENVIRONMENTAL PROTECTION INVESTMENT

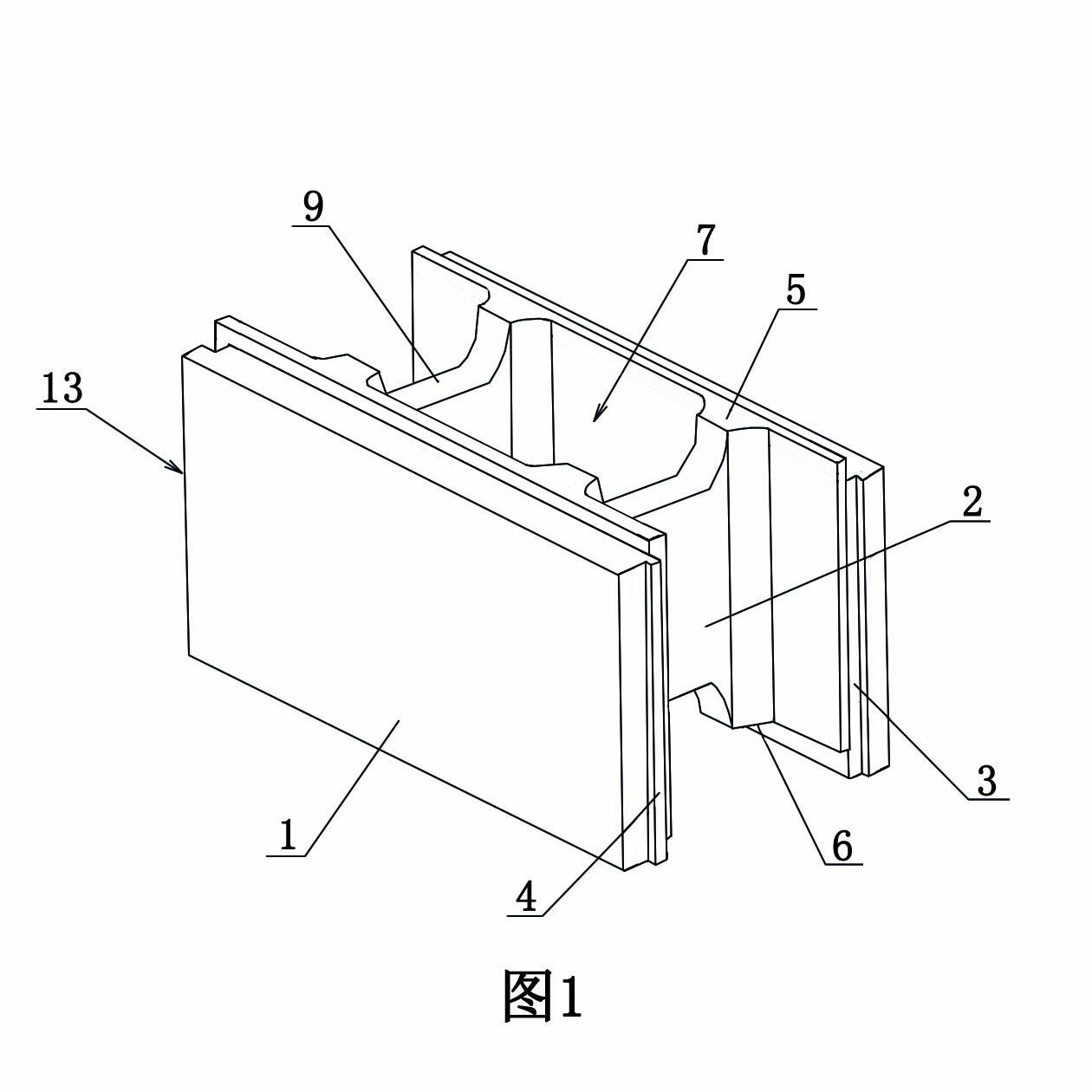

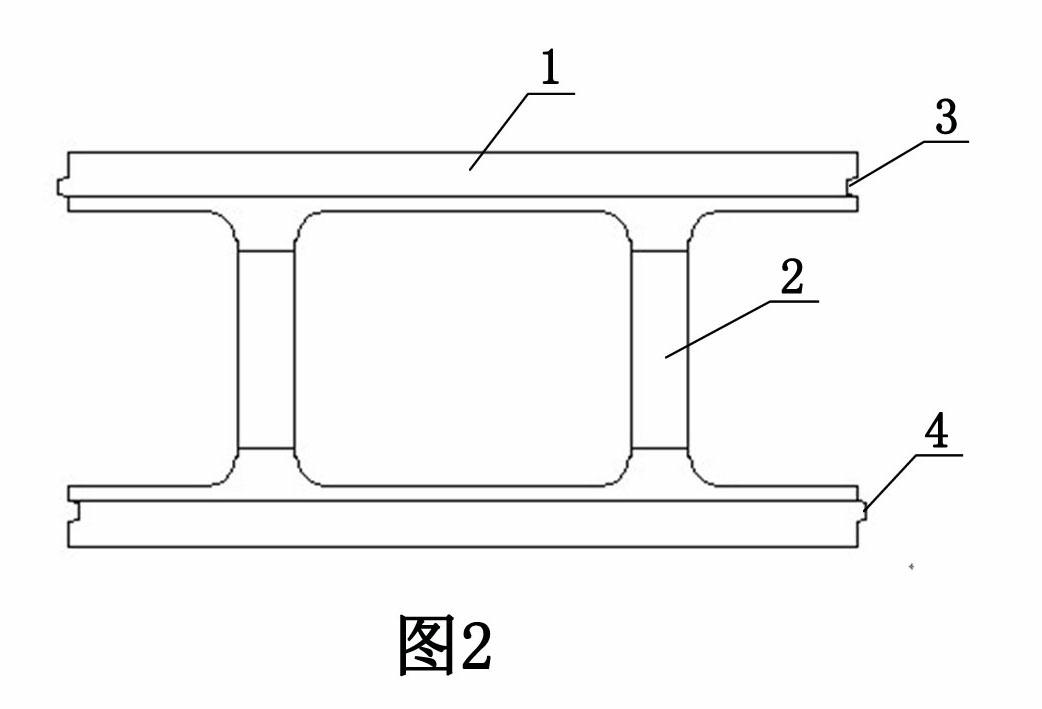

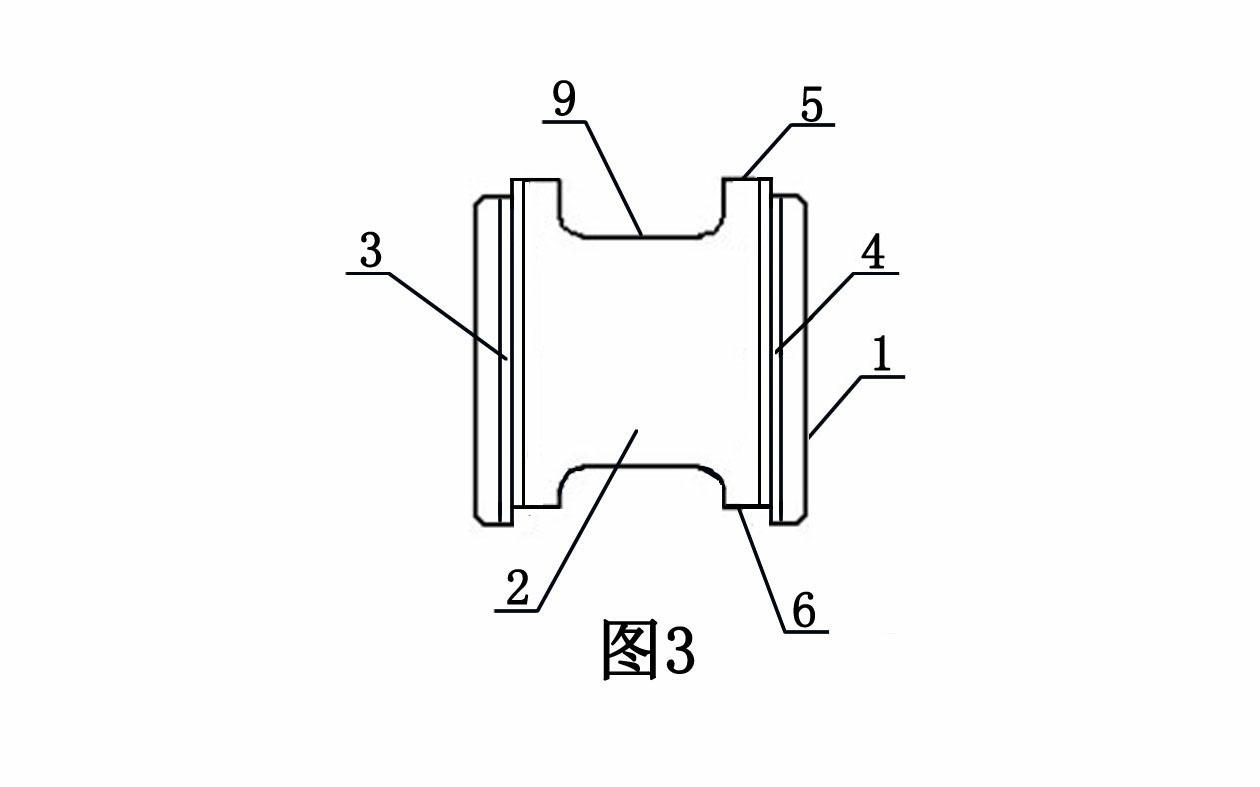

Fabricated blocks, fabricated-block building system and construction method thereof

InactiveCN102409796AImprove the seismic bearing capacityImprove anti-seepage and anti-leakage performanceWallsBuilding material handlingArchitectural engineeringRabbet

The invention discloses fabricated blocks, a fabricated-block building system and a construction method thereof. The fabricated blocks comprise a main block and auxiliary blocks, wherein the auxiliary blocks comprise 1 / 2 blocks, T-shaped node blocks, corner blocks and end blocks; the main block is composed of two parallelly-arranged long transverse ribs and at least two short longitudinal ribs perpendicularly connected between the two long transverse ribs; the two ends of the main block are both in an H-shaped open structure, the main block is in mortise-and-tenon joint with a block (horizontally adjacent to the main block) by virtue of a tenon and a rabbet, and simultaneously a vertical through hole is formed between the main block and the block (horizontally adjacent to the main block); and a horizontal through hole is formed between the main block and a block (vertically adjacent to the main block) by virtue of opposite openings of U-shaped grooves on the short longitudinal ribs. According to the invention, the relatively complex construction operation of traditional blocks bonded by using mortars is simplified, and the working efficiency, anti-permeability performance and leakage resistance of the block are improved, meanwhile, the noise and dust of an operation field also can be reduced, and energies and raw materials can be saved, thereby satisfying the green and environmentally-friendly requirements of building construction and facilitating the implementation of housing industrialization.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD +1

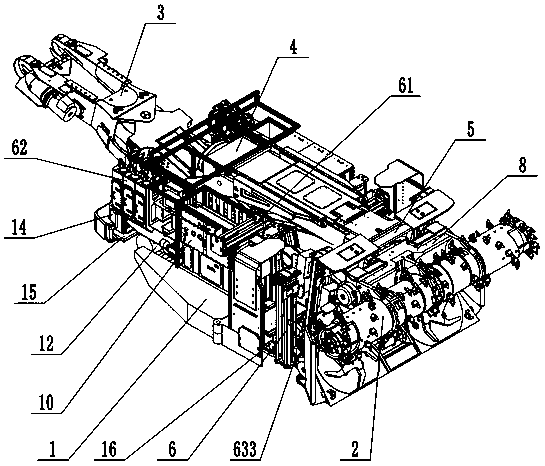

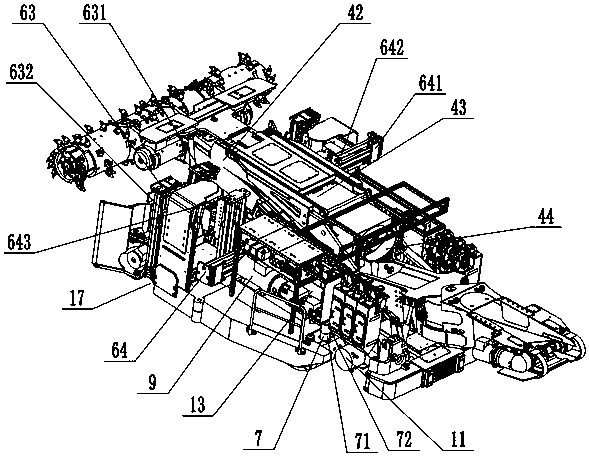

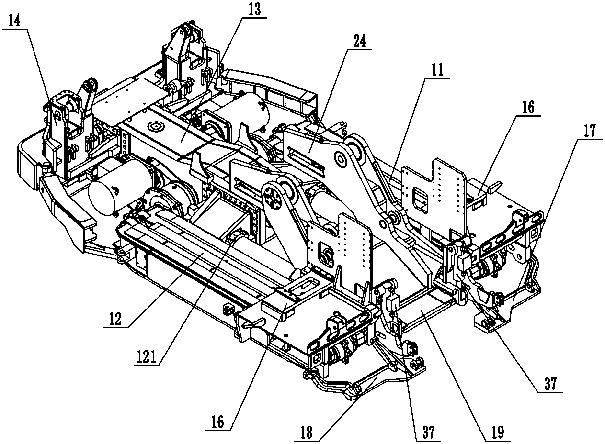

High-adaptability digging and anchoring integrated machine with dual-mode anchor drilling system

PendingCN111075444AAchieving parallel operation of anchor diggingFully automatedPropulsionAnchoring boltsSupporting systemElectric control

The invention provides a high-adaptability digging and anchoring integrated machine with a dual-mode anchor drilling system, and belongs to the technical field of underground coal mining equipment. The high-adaptability digging and anchoring integrated machine comprises a frame main body, a cutting system, a conveying system, a dust removing system, a multifunctional temporary supporting system, the dry-wet dual-mode anchor drilling system, an automatic lubricating system, a water-cooling spraying system, a hydraulic system and an electric control system, wherein a traveling mechanism adopts awide crawler design, so that the adaptability of the digging and anchoring integrated machine to a muddy bottom plate is improved; and the dry-wet dual-mode anchor drilling system has two functions of dry dust removal and wet dust removal, and real-time switching selection is carried out according to the geological conditions of the roadway bottom plate without replacing a drill box. By means ofthe high-adaptability digging and anchoring integrated machine, the problems of muddy of the bottom plate, poor stability of a top side wall and low tunneling efficiency in the rapid coal roadway tunneling under the complex geological conditions are solved; the integrated parallel operation of tunneling, anchor protection, transportation, dust removal and the like of a roadway tunneling working surface is realized; and the efficiency and safety of coal mining and transportation are improved.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

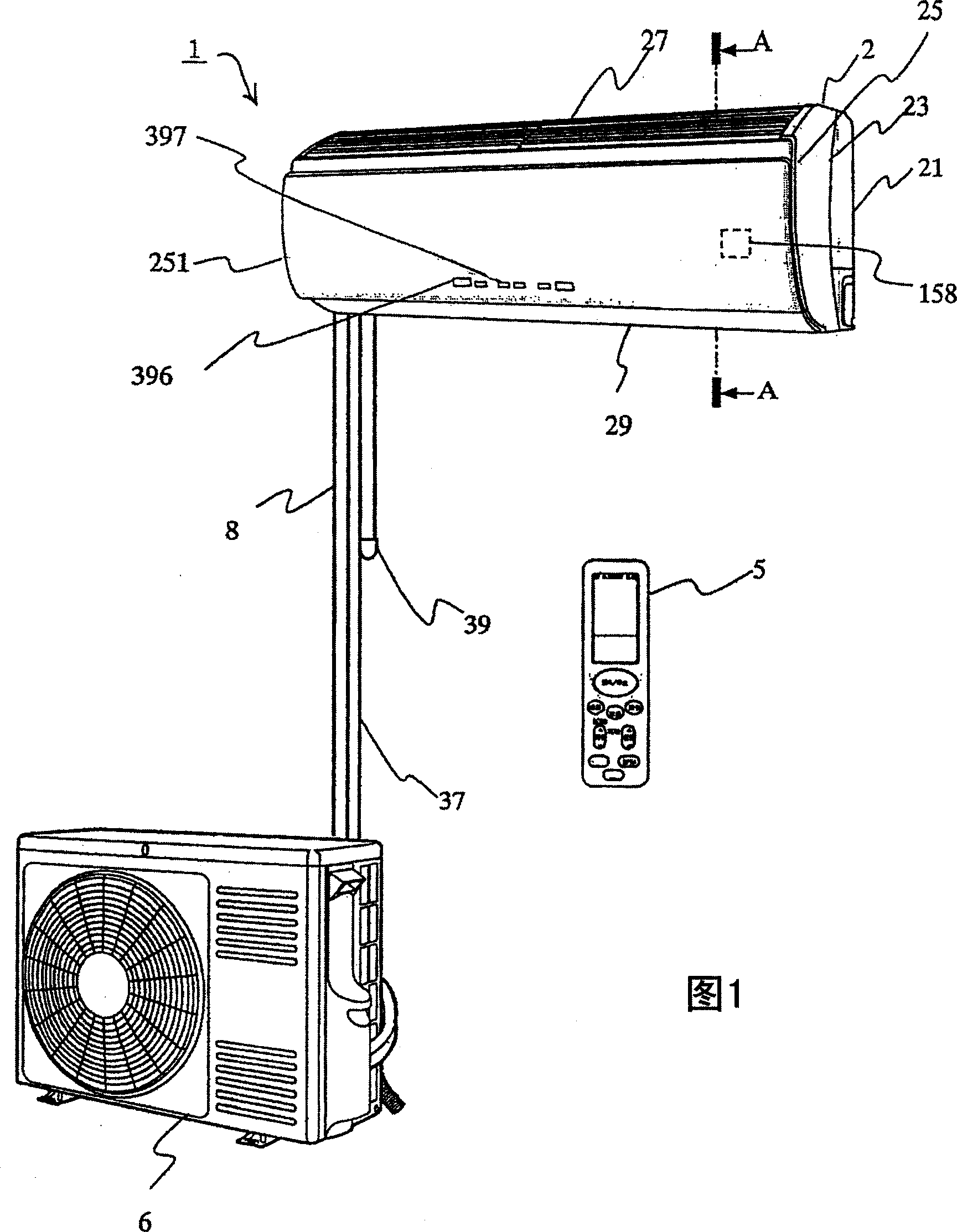

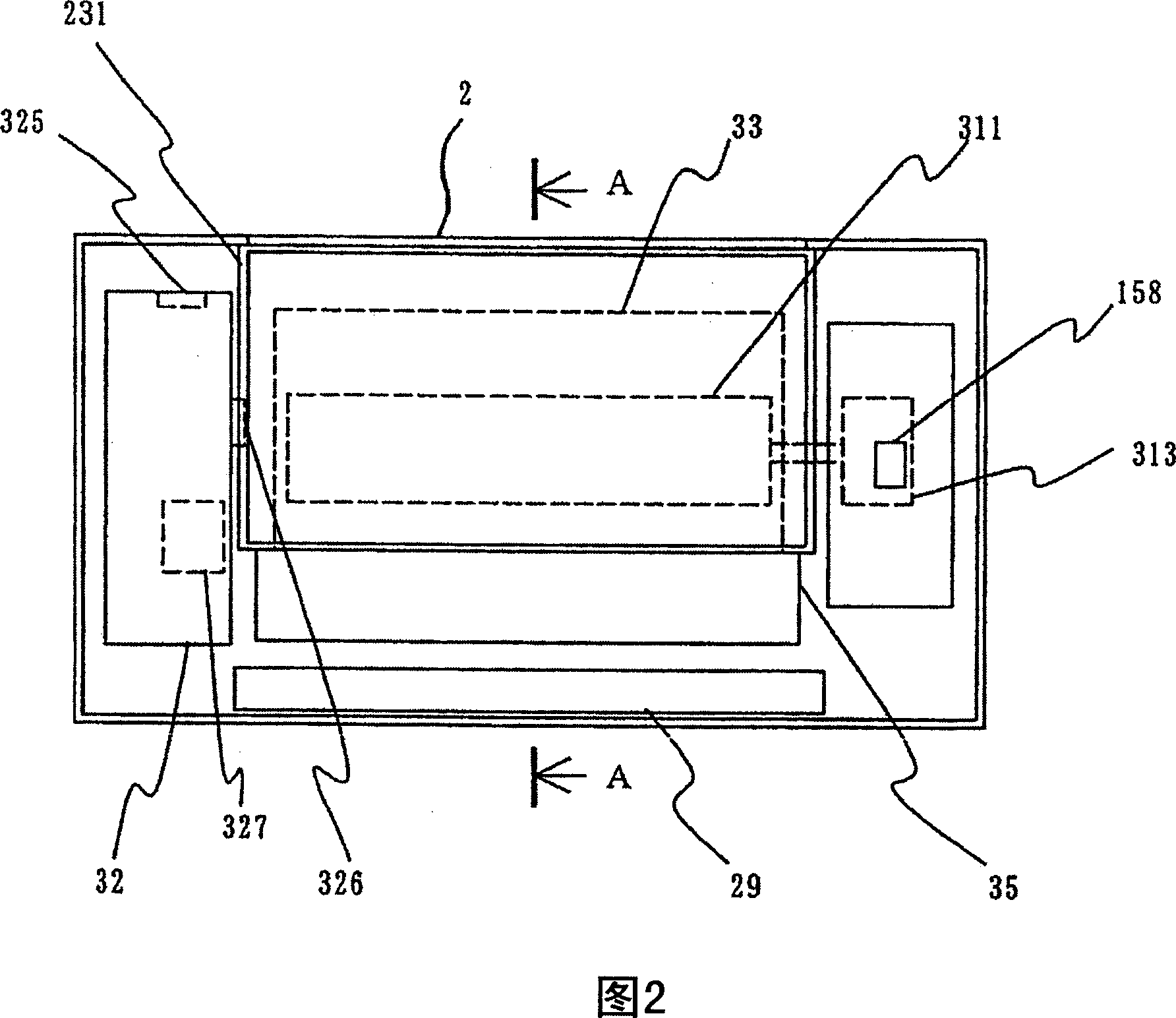

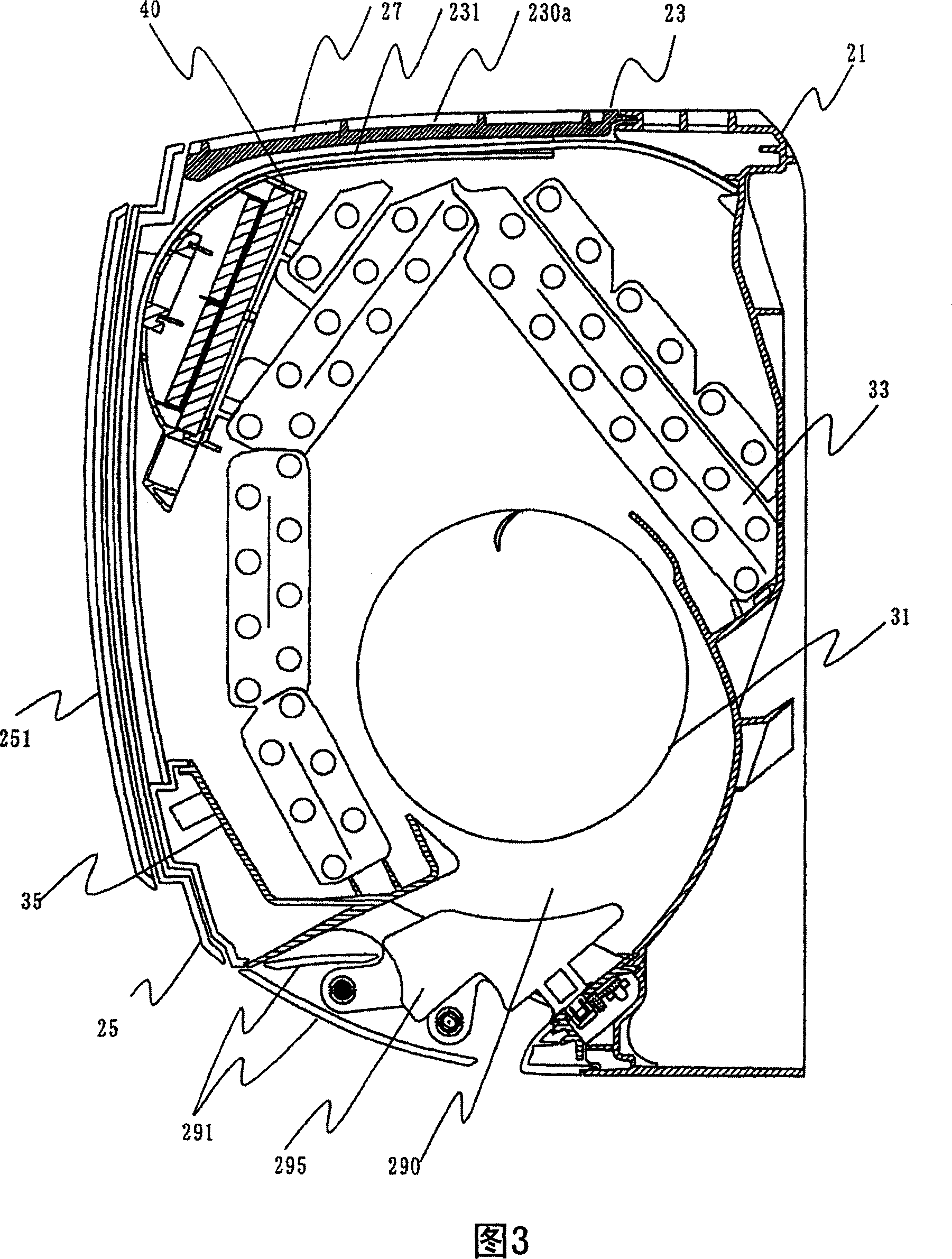

Air conditioner

InactiveCN1948840ARelaxReduce dustHuman health protectionMechanical apparatusAllergic reactionElectric power

Provided is an air conditioner, capable of maintaining the inside of a room with a dust-minimized state by detecting specific dust containing pollen that is a substance generated outdoors and causing seizures by allergic reaction or promoting the seizures, and performing dust removing operation. This air conditioner (1) comprises an indoor unit (2) including an electric dust collecting and cleaning unit provided with a dielectric filter, a ventilating device capable of performing air supply operation for taking outside air into the room, a cleaning filter provided in an suction passage of the outside air by the ventilating device, a dust sensor (158) capable of discriminating dust floating in the air. A control device of the air conditioner (1) controls, when the dust sensor detects dust of a specific group including pollen, so as to perform operation of the electric dust collecting and cleaning unit and the air supply operation of the ventilating device.

Owner:HITACHI HOME & LIFE SOLUTIONS INC

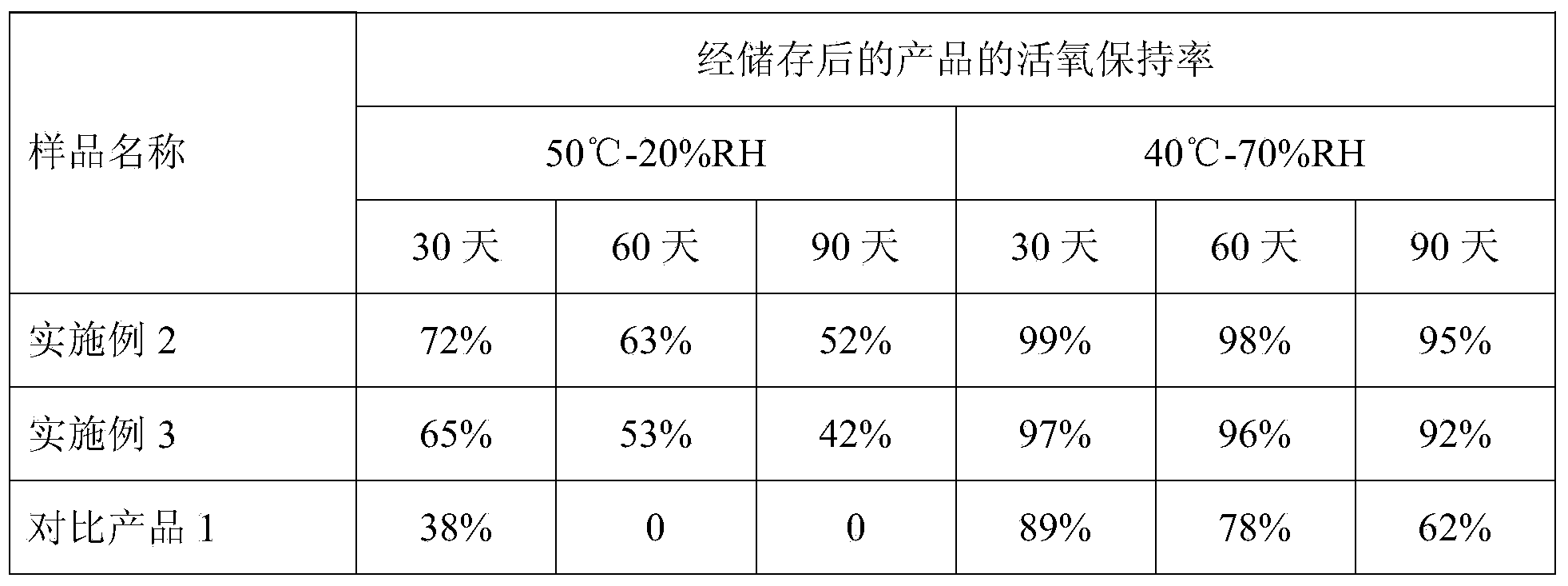

Pipeline dredging agent with stable oxygenation effect and preparation method of pipeline dredging agent

ActiveCN103937624AGood insulation performanceShort contact distanceSurface-active non-soap compounds and soap mixture detergentsOrganic non-surface-active detergent compositionsDissolutionOxygen

The invention discloses a pipeline dredging agent with a stable oxygenation effect and a preparation method of the pipeline dredging agent. The pipeline dredging agent comprises strong base, a non-volatile liquid, special powder, an oxygen bleaching agent and a chlorine bleach, and can further comprises an additive, and is prepared through a special feeding process. The combination of the non-volatile liquid and the special powder is innovatively introduced, so that the oxygenation stability and the anti-caking property of a product in a storage process are greatly improved, and the dust amount and the nose chocking feeling are reduced and alleviated. The product disclosed by the invention also has the advantages of rapid dissolution, stable heat radiation, low chloride smell, low metal corrosion, easy production and machining and the like, is applicable to dredging or cleaning and maintaining drainage pipelines, and has a good application prospect.

Owner:广州超威生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com