Patents

Literature

716 results about "Rabbet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A rabbet or rebate is a recess or groove cut into the edge of a piece of machinable material, usually wood. When viewed in cross-section, a rabbet is two-sided and open to the edge or end of the surface into which it is cut.

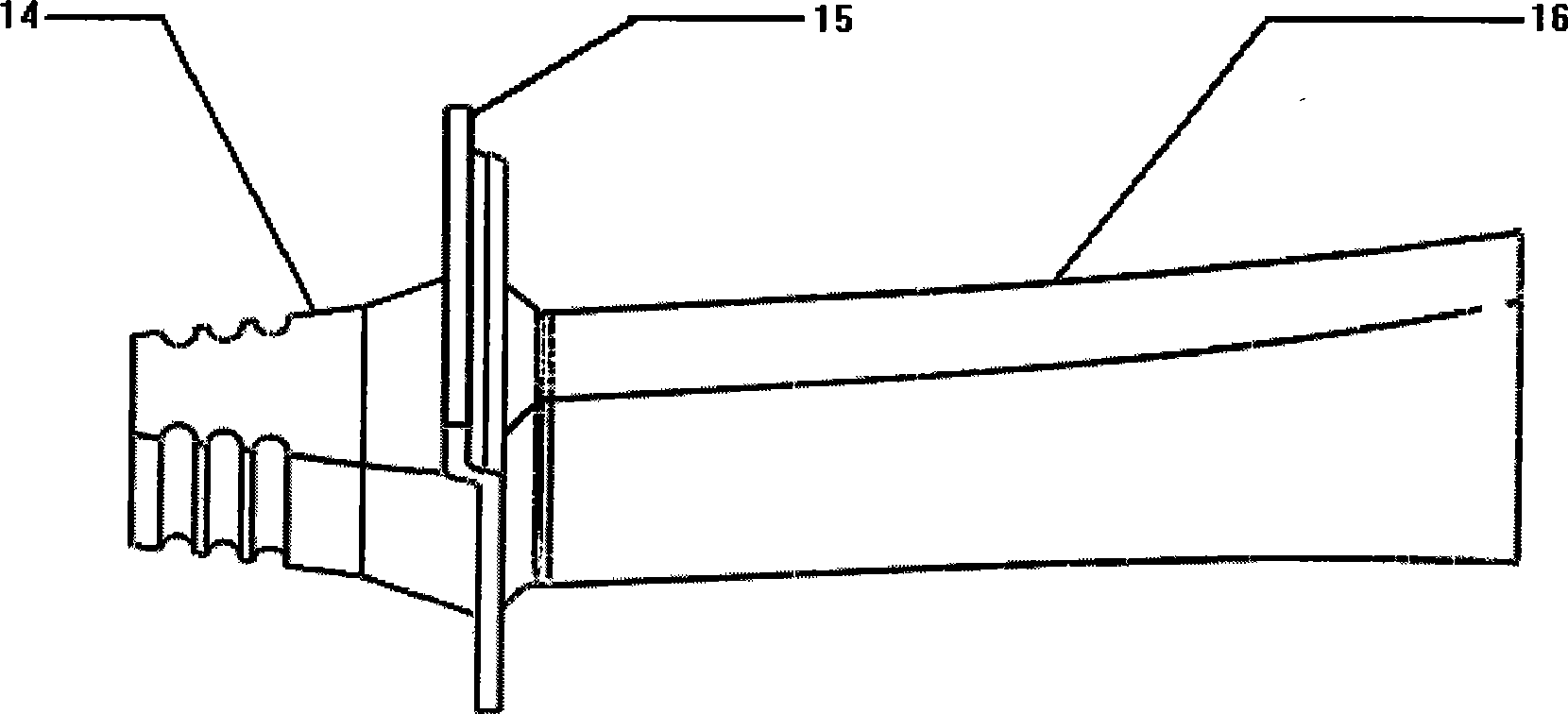

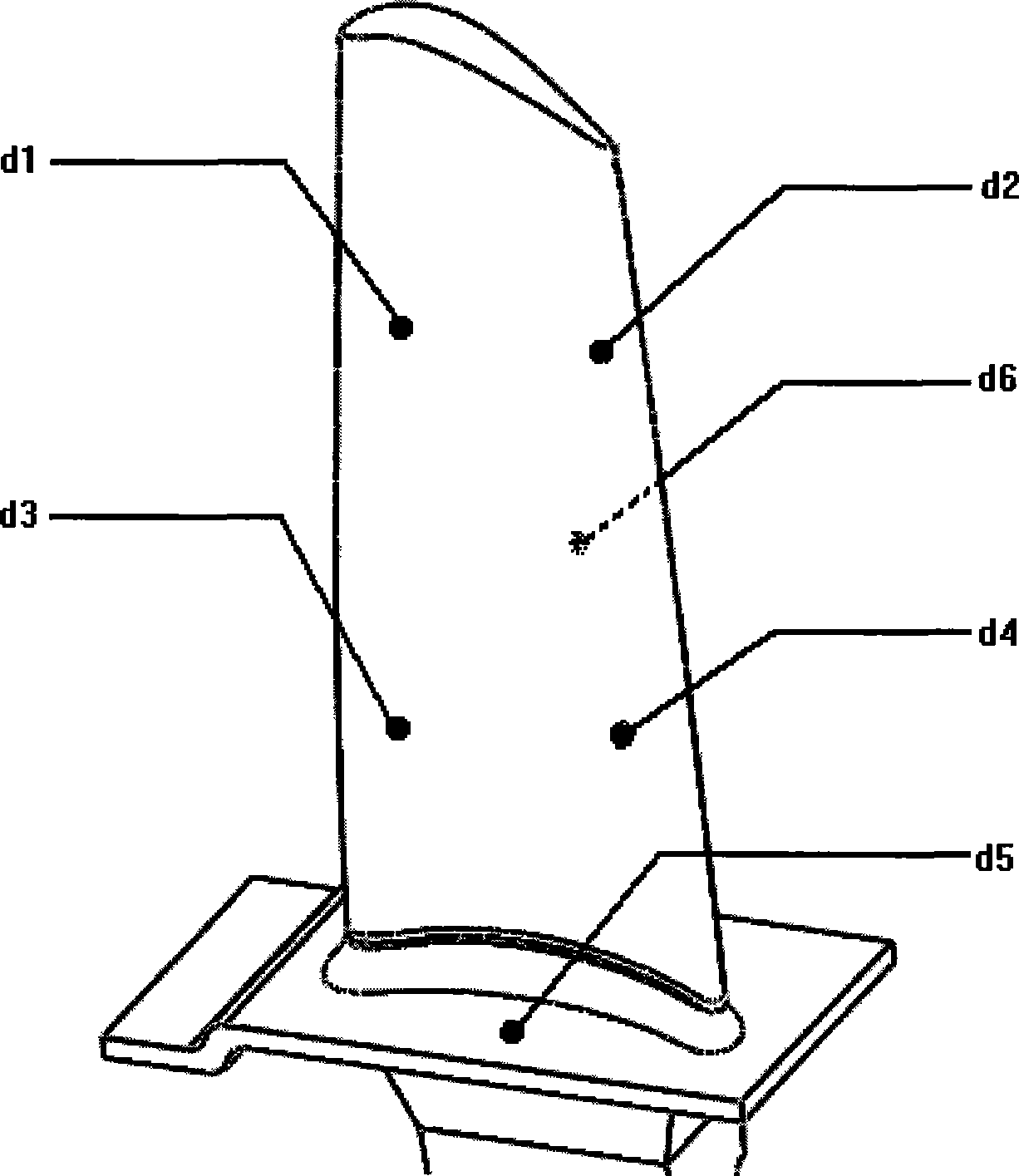

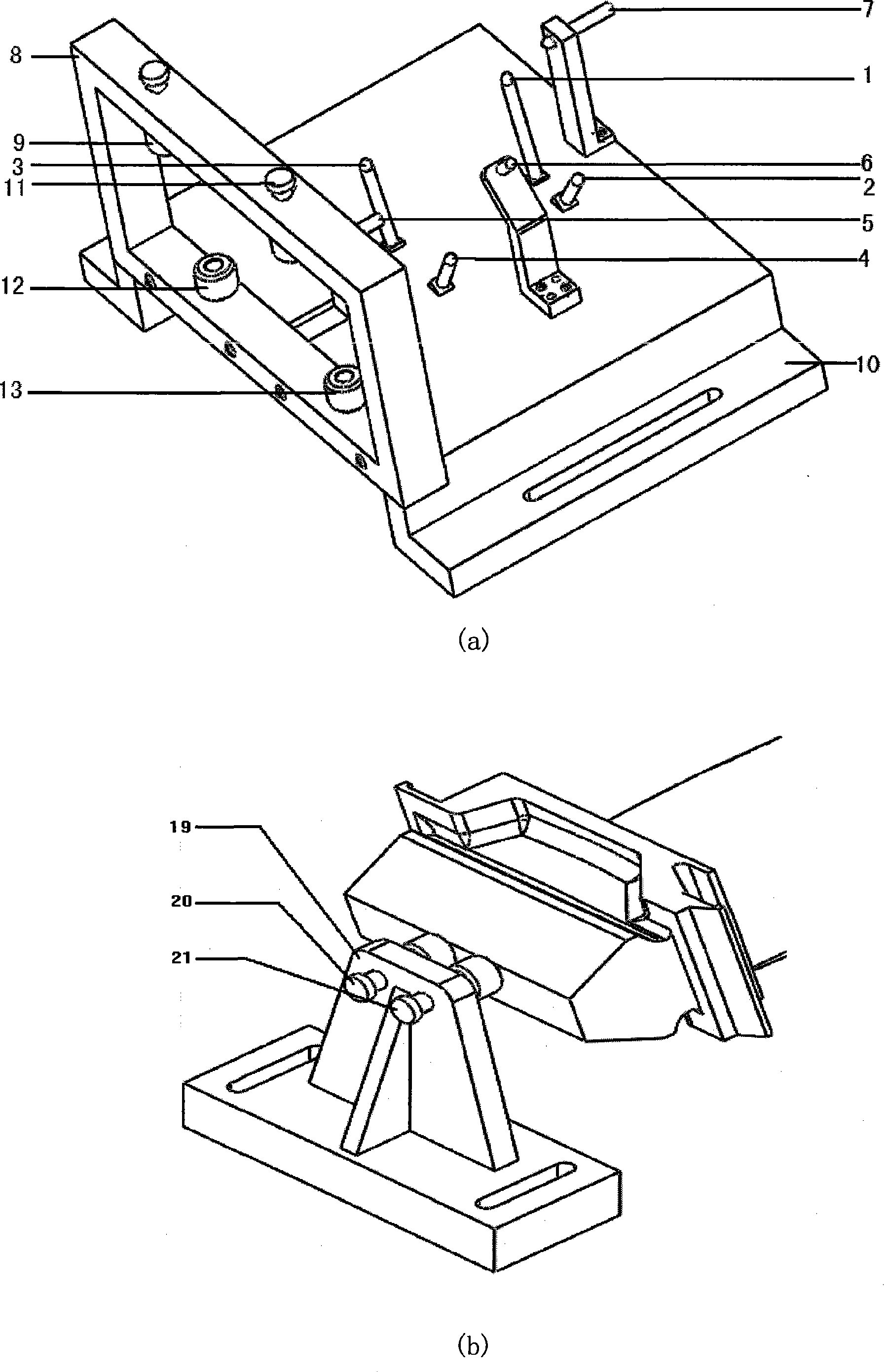

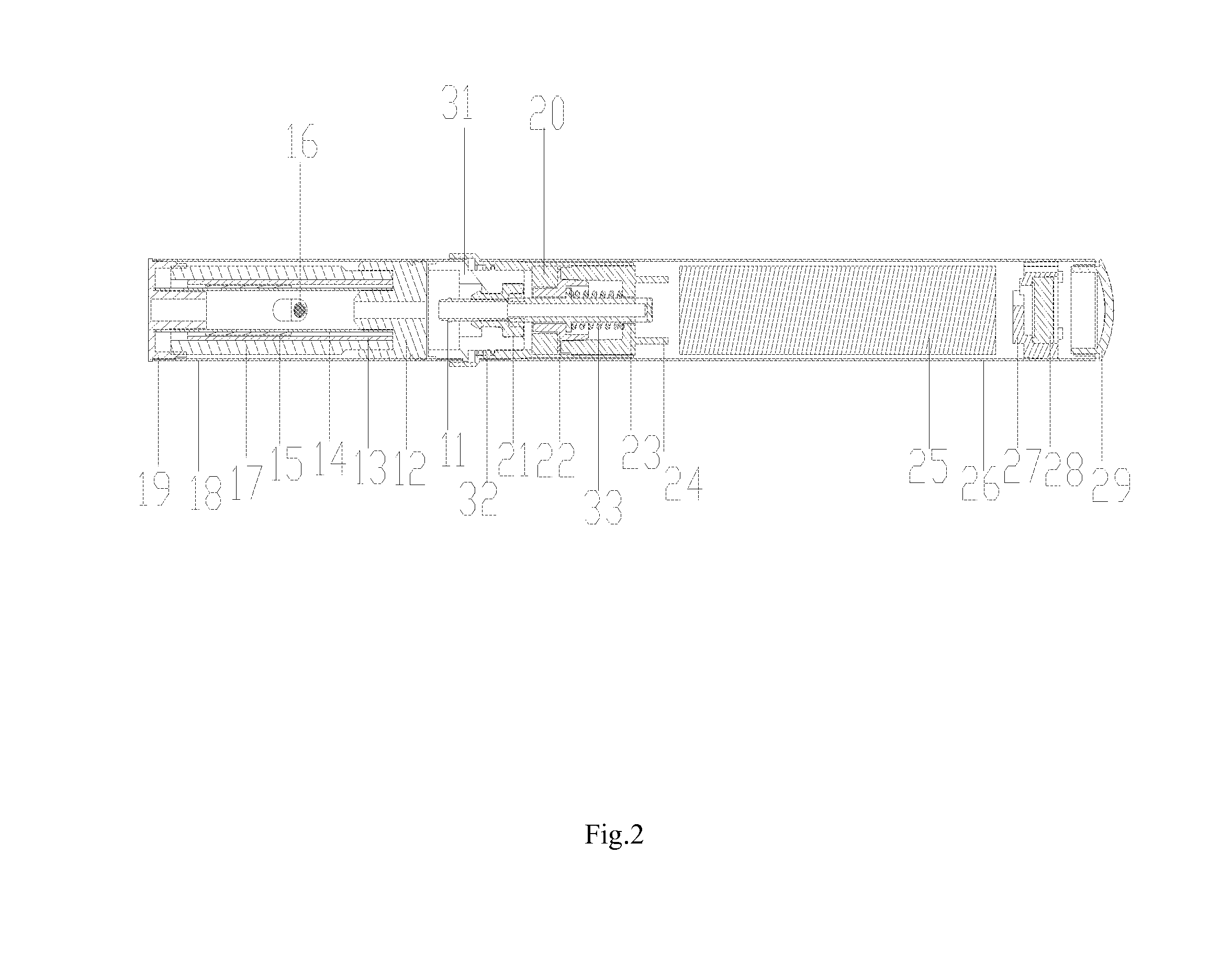

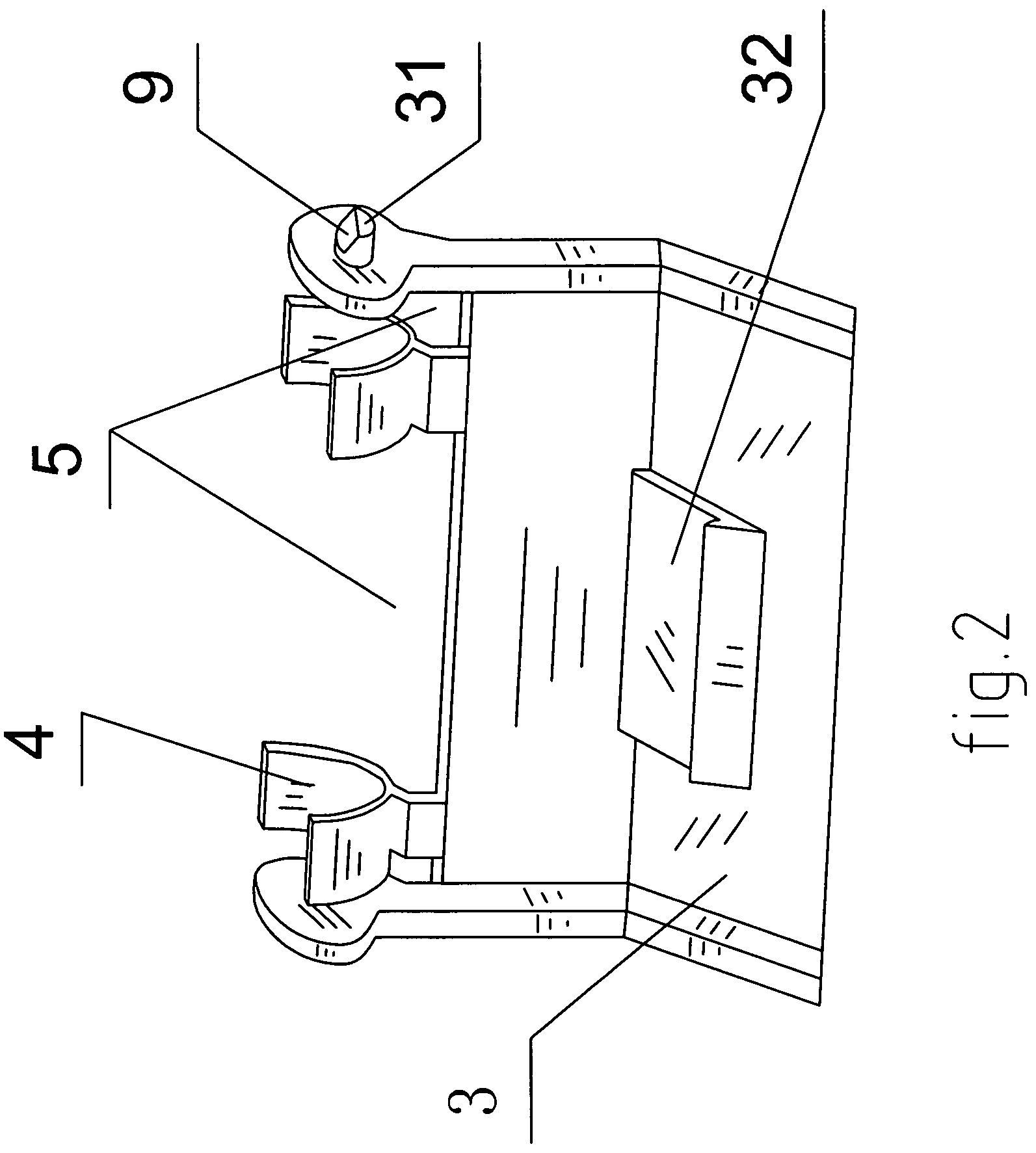

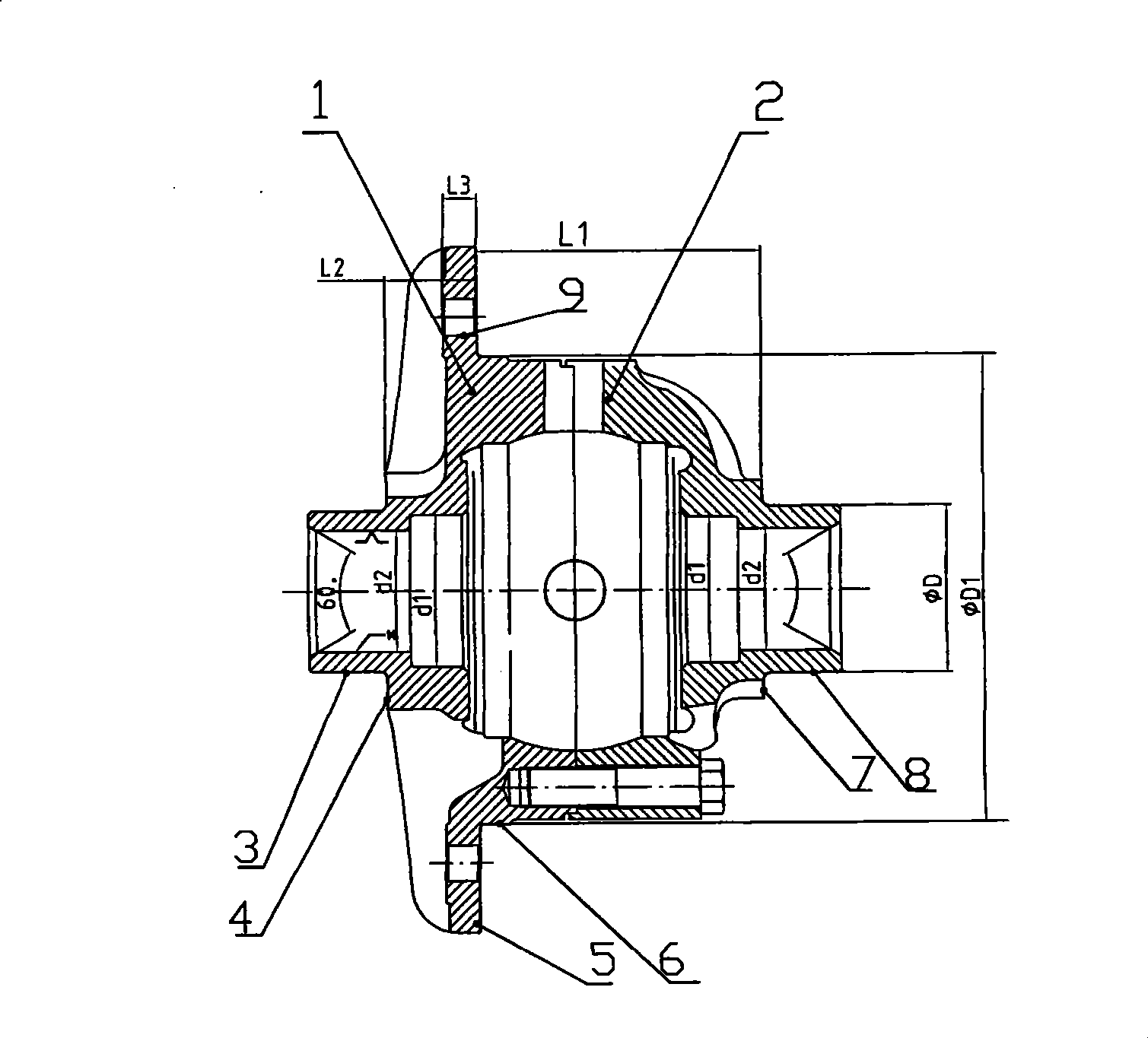

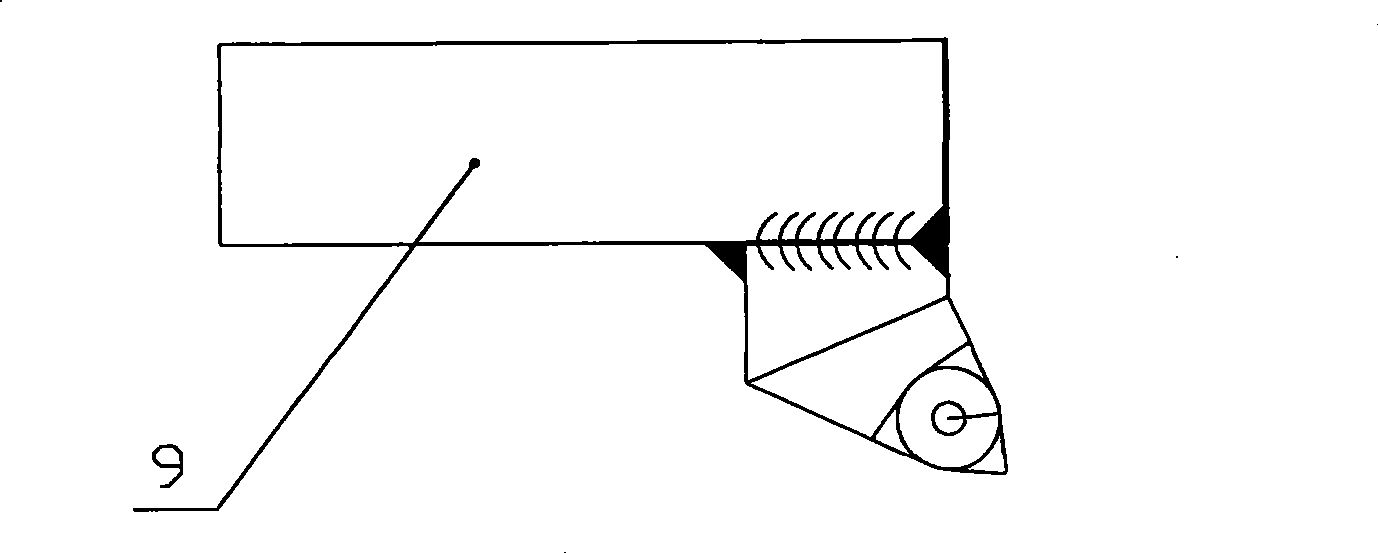

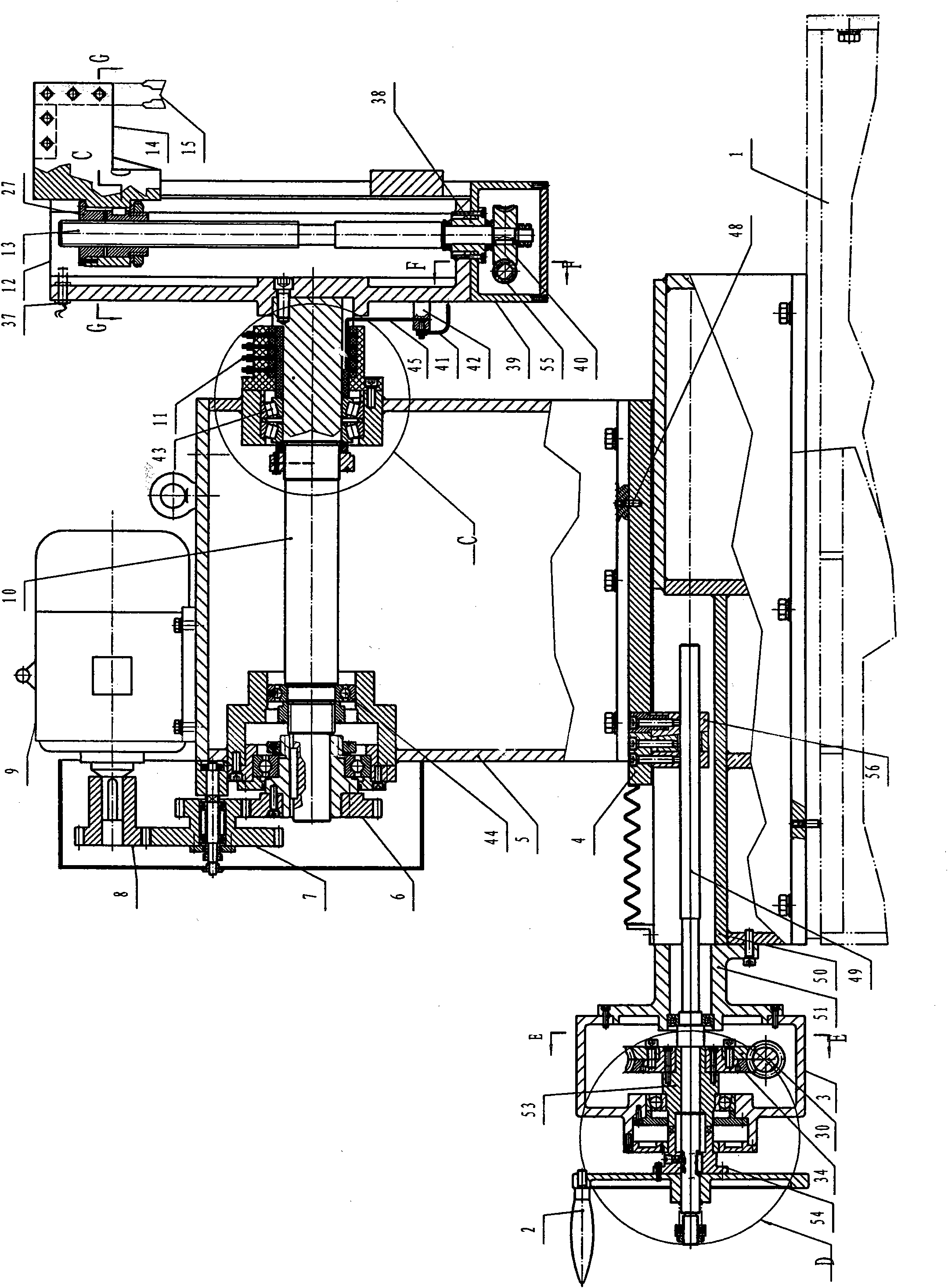

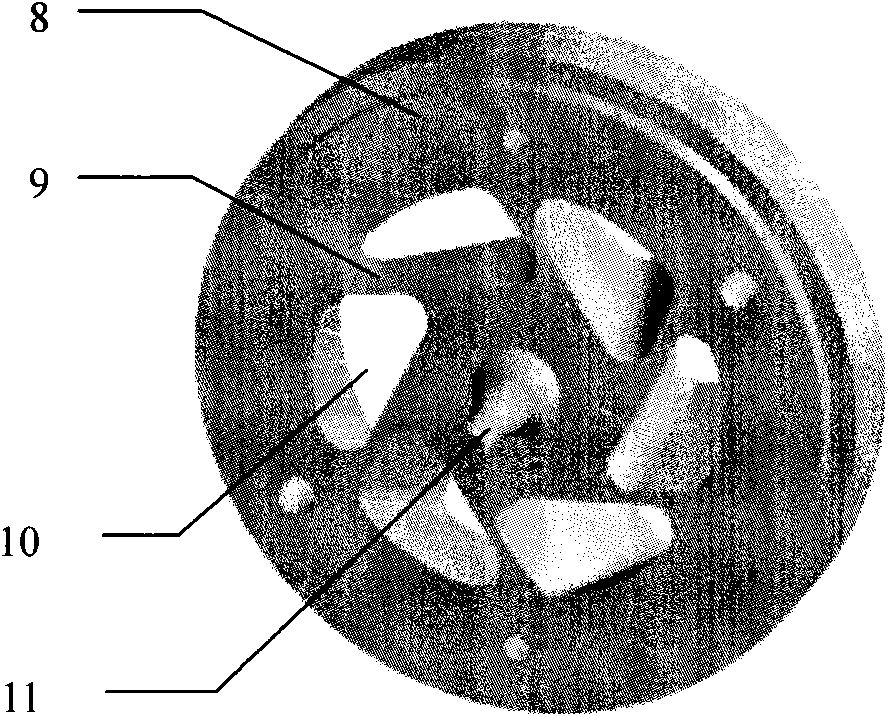

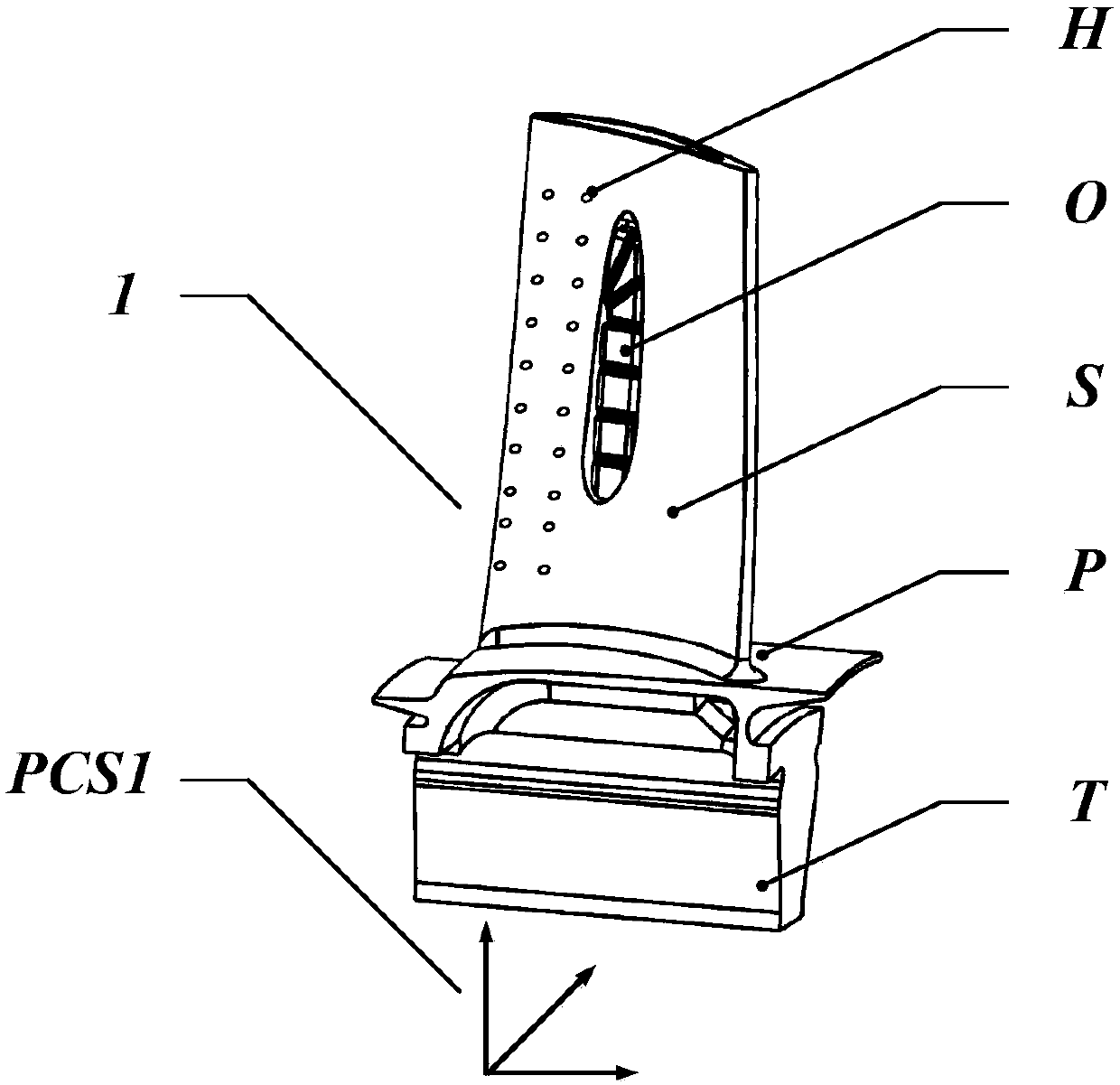

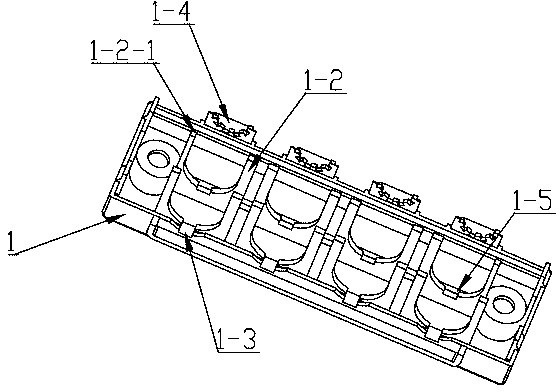

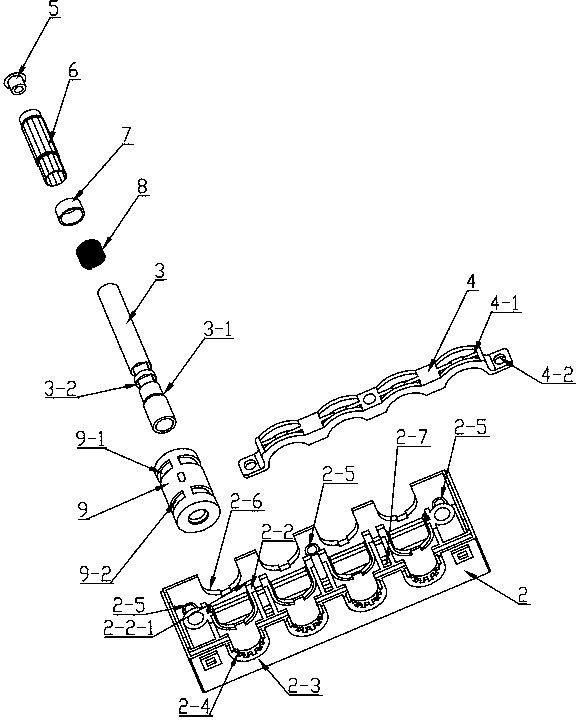

Turbine hollow blade rabbet processing locating clamping method and device

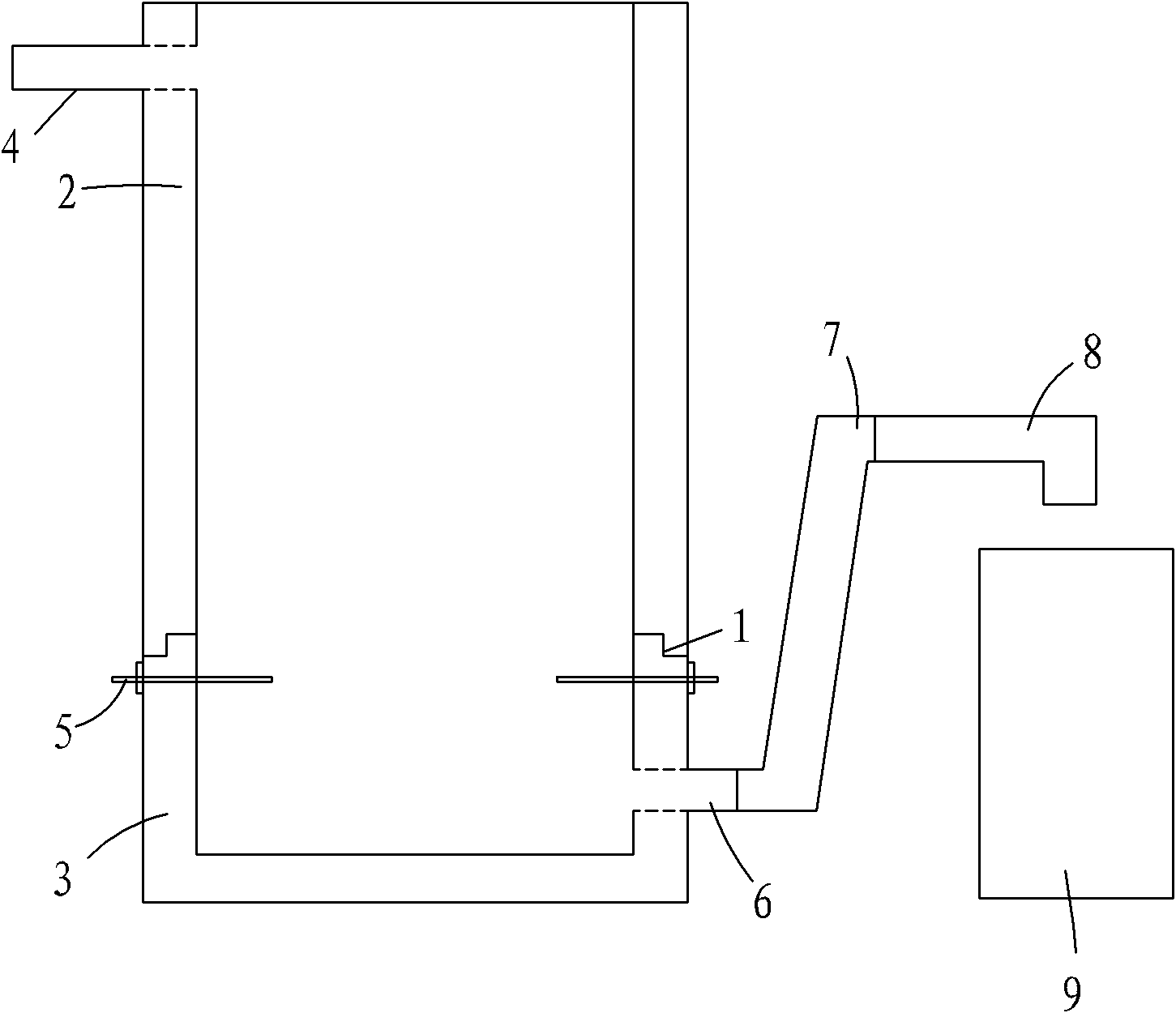

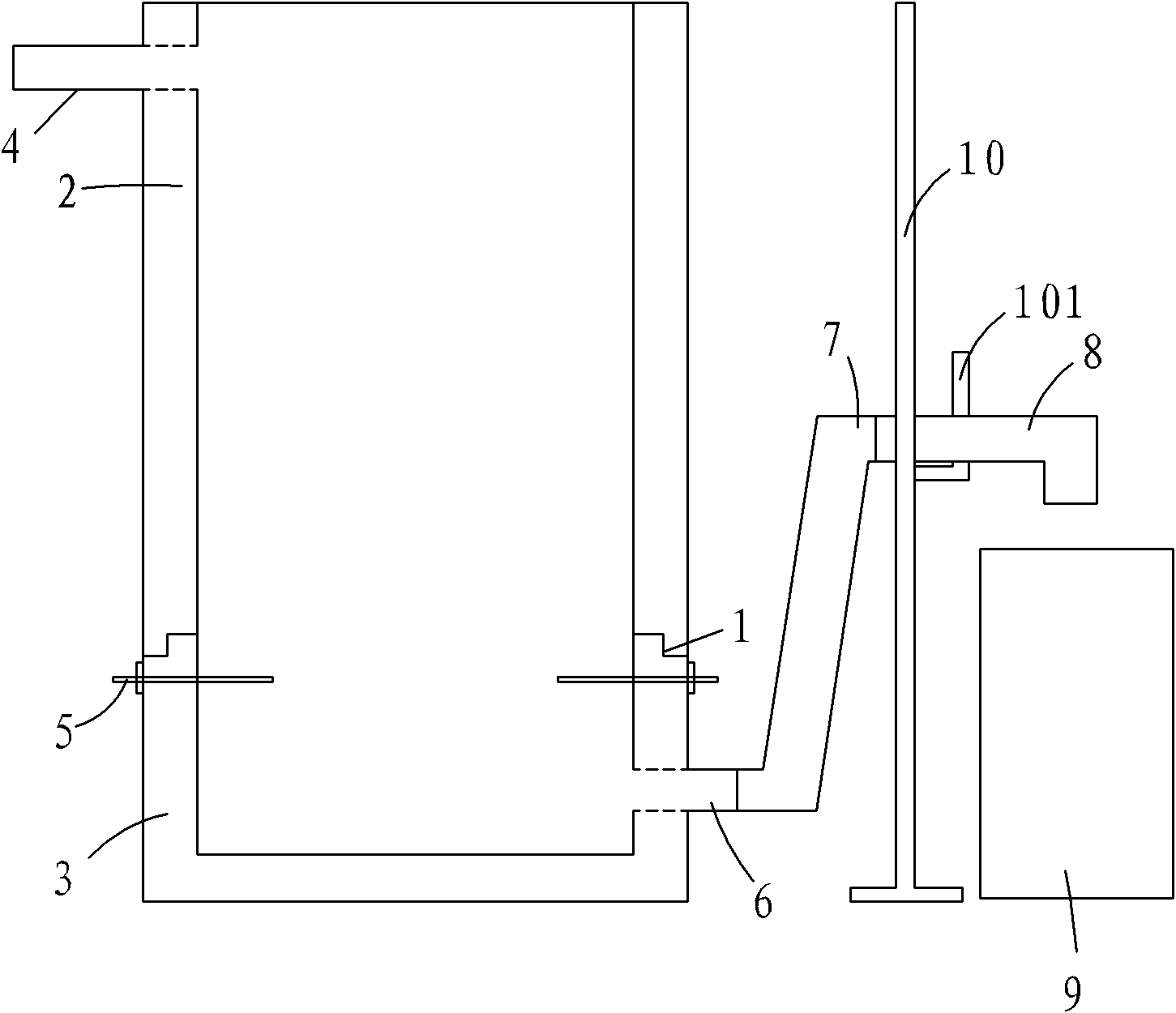

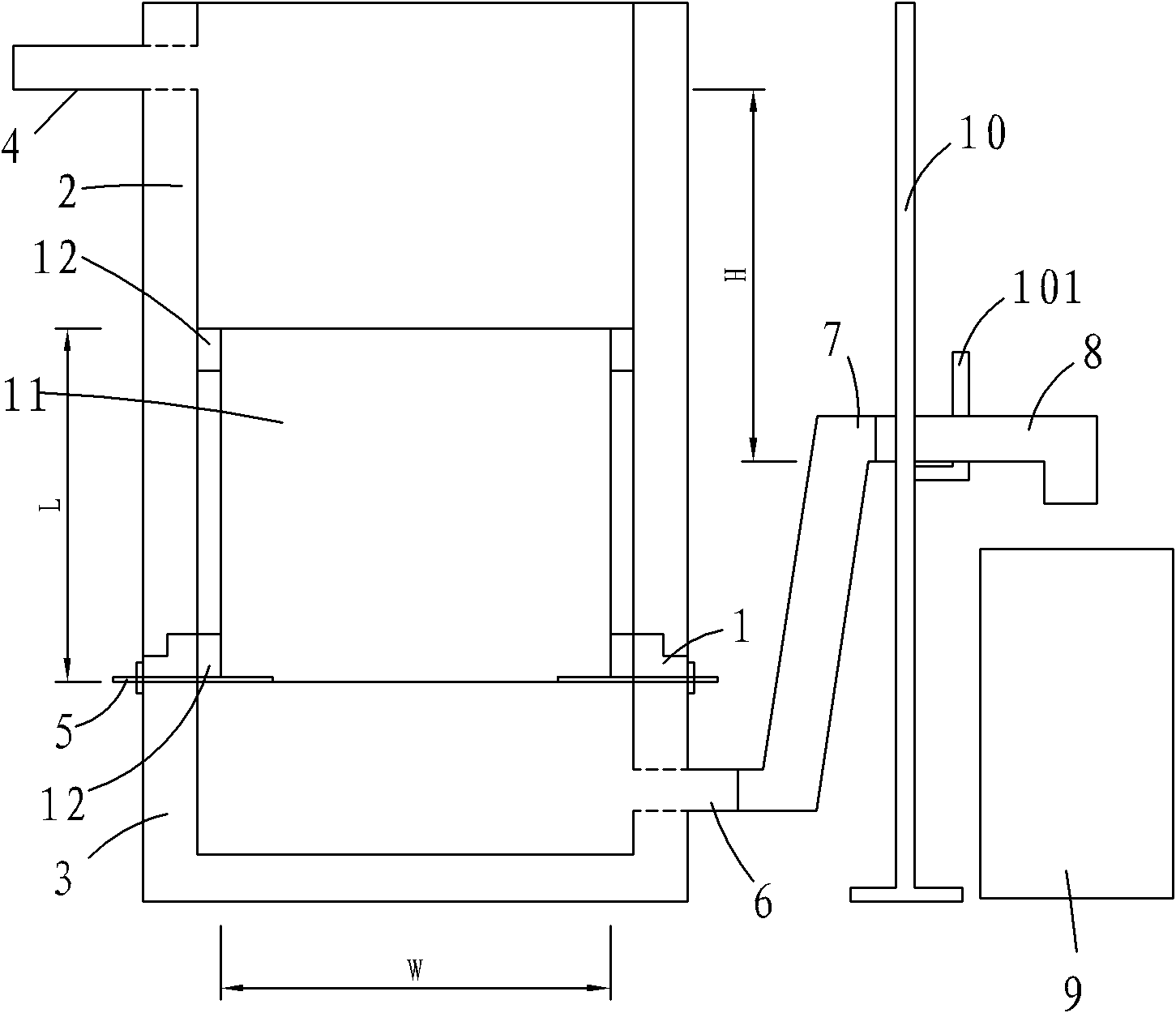

InactiveCN101417396AReduce stressReduce distortionPositioning apparatusMetal-working holdersRabbetEngineering

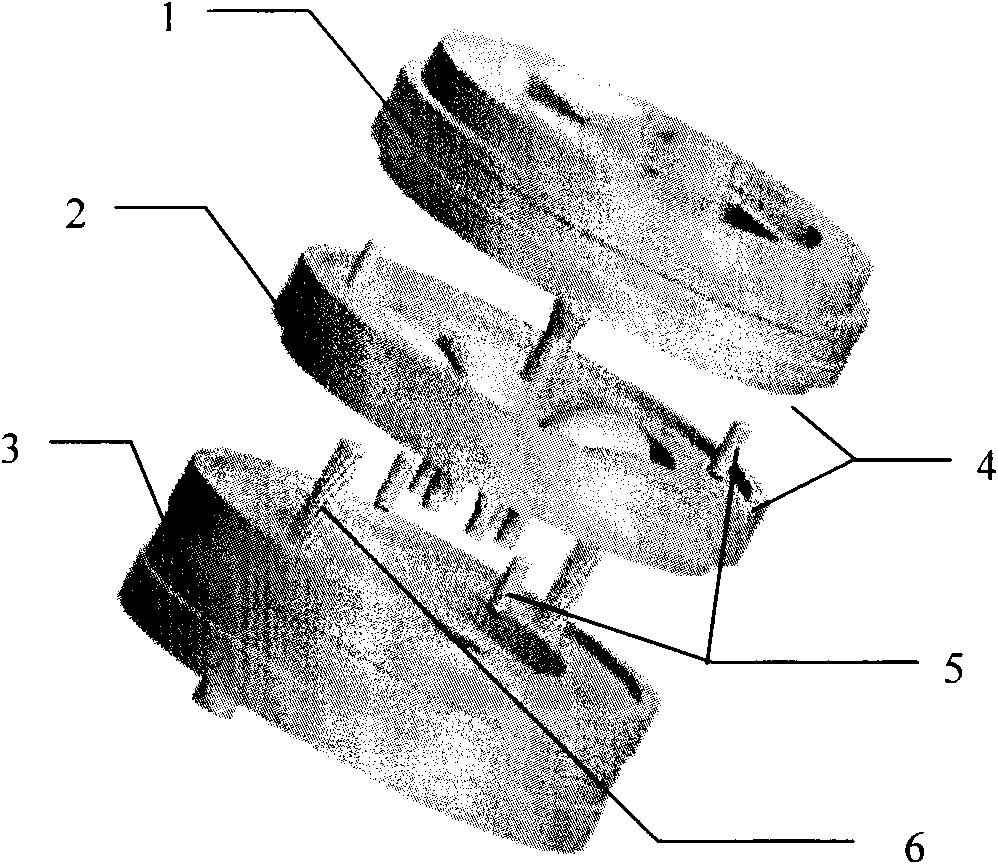

The invention discloses a clamping method and a fixture of processing and locating of a turbine hollow blade tenon. In the selection of locating points, five optimum locating points are selected by adopting a fixture precision theory based on the differential geometry, a form closure rule of locating points with the help of a blade surface three-dimensional model and so when six points comprising a benchmark are used for location, the precision of blade location is the highest; in the selection of clamping points, weak links are avoided and auxiliary clamping points are chosen on a tenon top end and a blade mounting plate which are better in rigidity and bigger in size for reducing as much stress and deformation as possible to the hollow blade. On the basis, the invention designs a special fixture for processing the blade tenon, which consists of a fixture body, a location pin, auxiliary fixtures of the tenon top end and the blade mounting plate. The fixture can ensure the accurate location and effective clamping in the processing of the turbine hollow blade tenons, improve the efficiency in the manufacturing process of complex curved hollow blades, reduce the cost and eliminate the harm to human health.

Owner:XI AN JIAOTONG UNIV

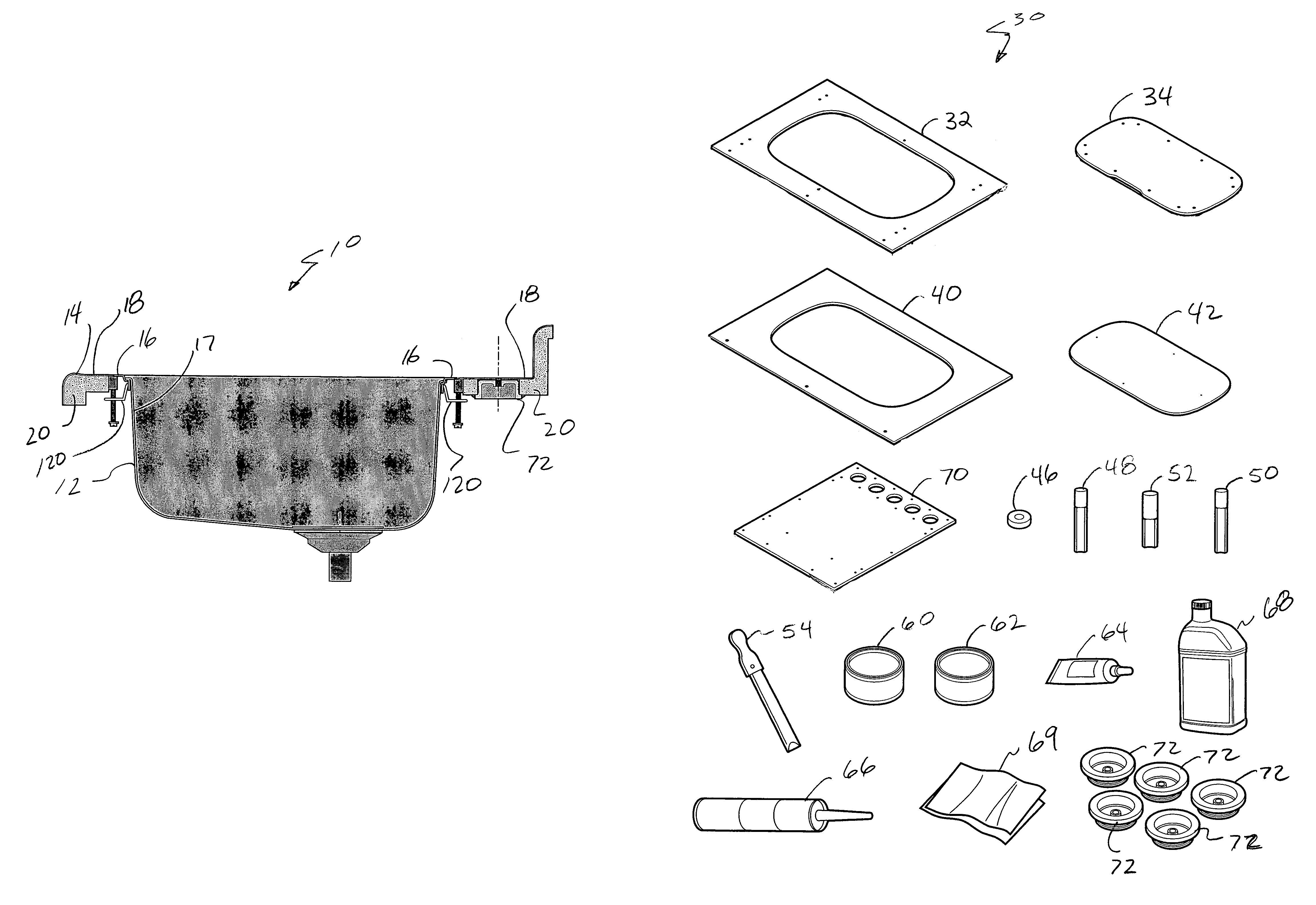

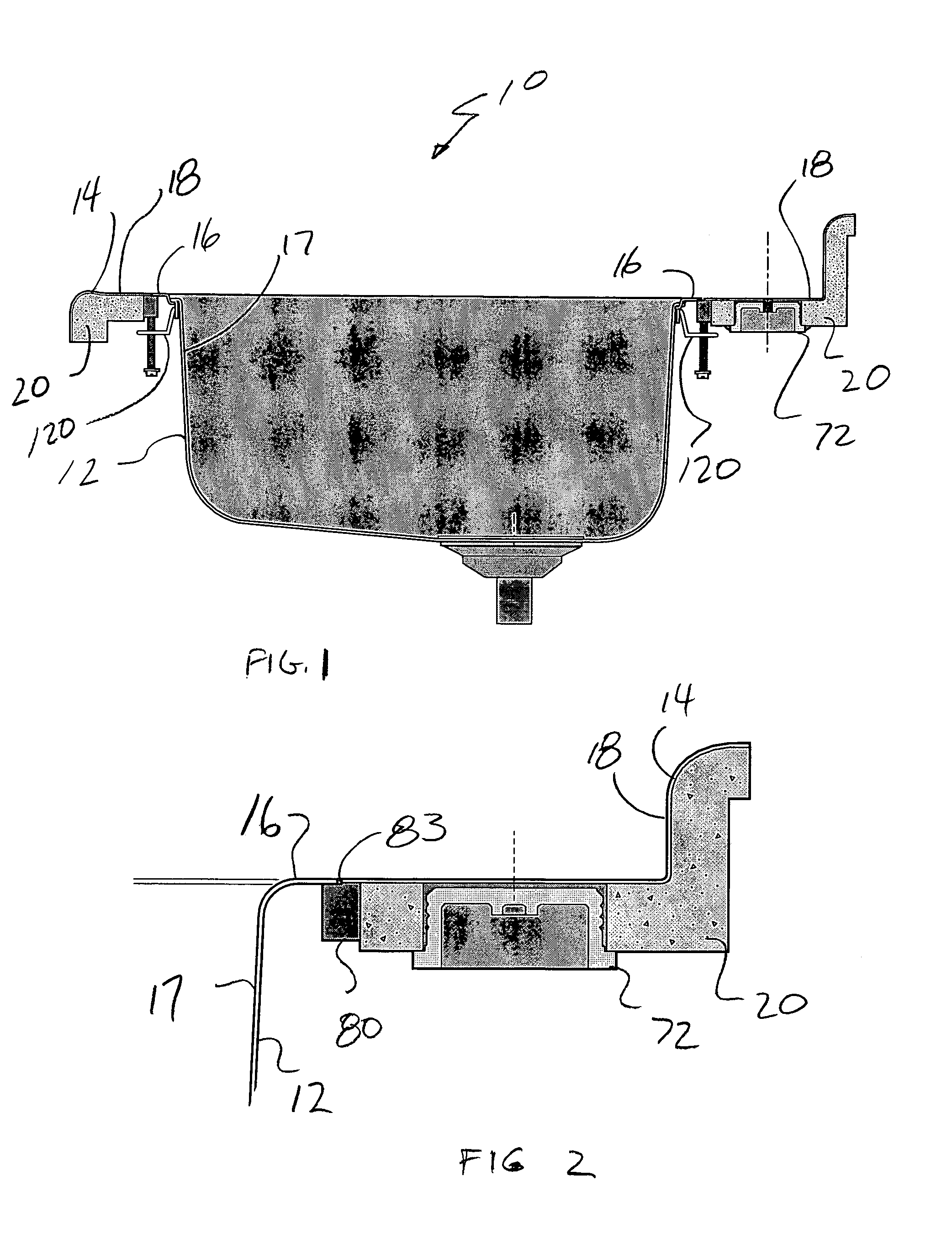

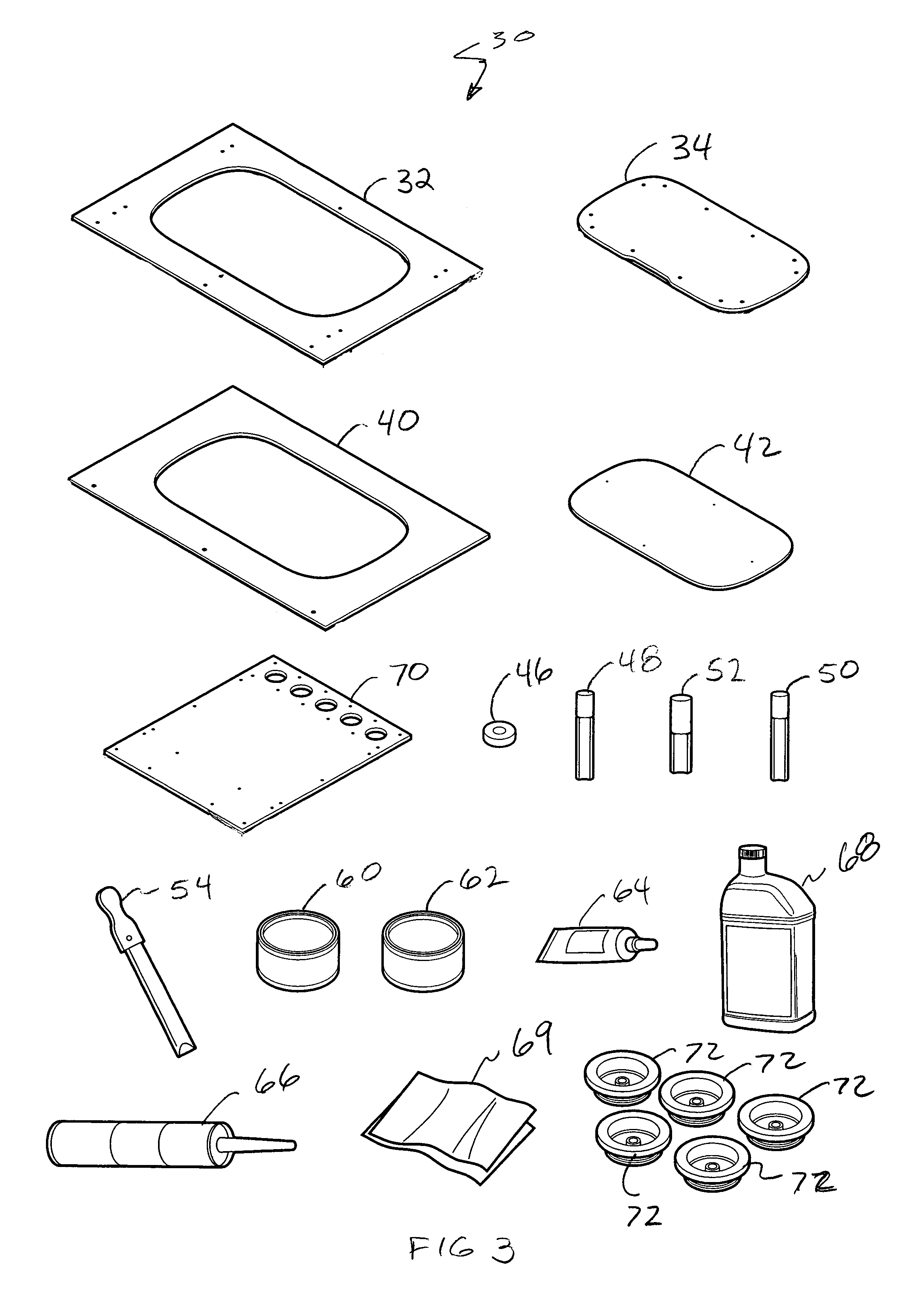

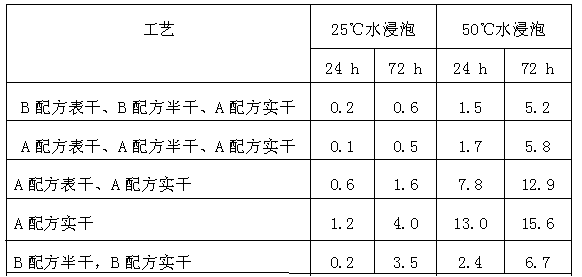

Sink/faucet flush mounting system

This invention deals with a sink having a flange can be flush mounted in a countertop where the countertop is made of a laminate upper layer supported by a wood based body such as particle board. The countertop is readied for sink mounting by ploughing out a sink channel in the supporting body of the countertop. The sink channel is filled with a hardenable plastic such as an epoxy. The upper surface of the epoxy and the laminate is machined such as by a router to create a rabbet to accommodate the flange of the sink. The sink channel is arranged so that the hardened epoxy extends under the laminate so that any water which passes under the flange of the sink will contact the epoxy and not the wood based structure. A faucet having holes to accommodate hot water, cold water, spigot and faucet accessories can be mounted using the same channel and epoxy system.

Owner:FRANKE TECH & TRADEMARK LTD

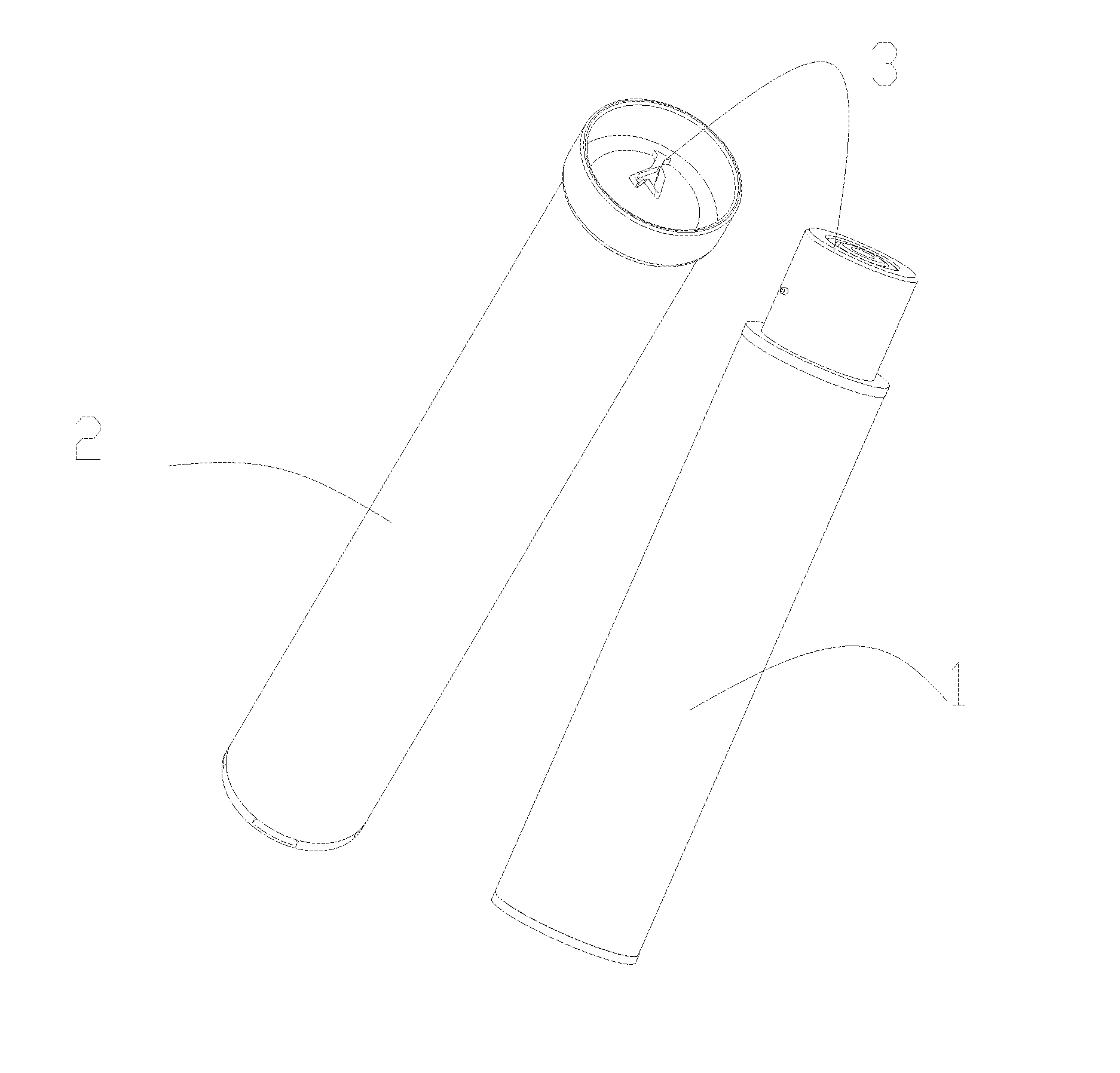

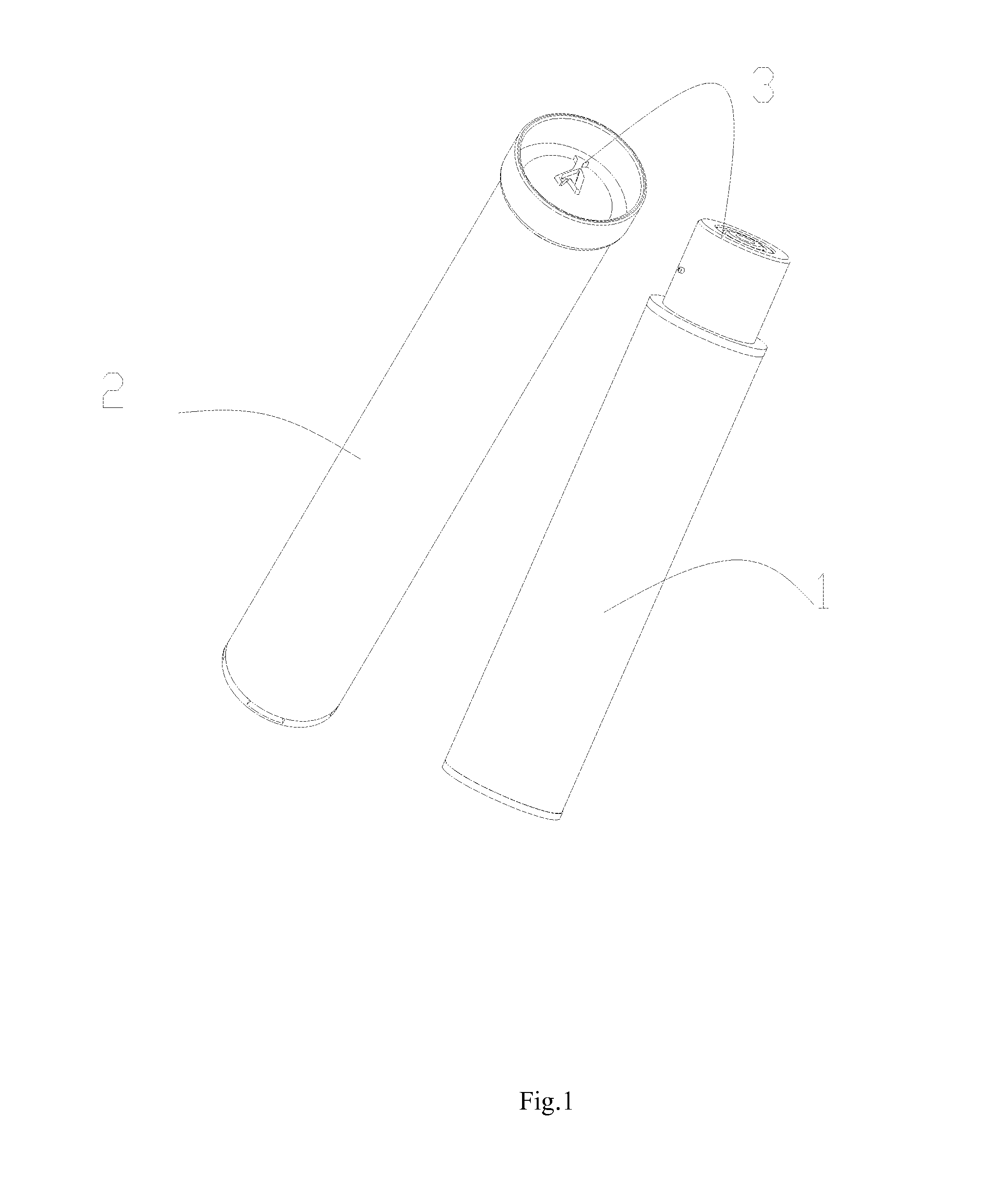

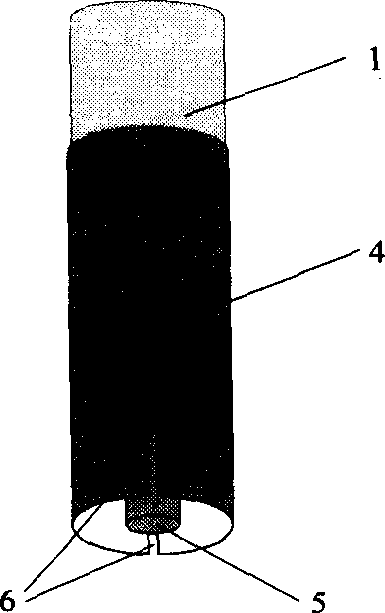

Electronic cigarette

InactiveUS20150034107A1Easy to operateImprove experienceTobacco pipesTobacco devicesButt jointEngineering

This present application discloses an electronic cigarette, comprising an atomizer and a battery rod, a connecting structure, and an elastic structure; the connecting structure includes a first connecting member and a second connecting member; the first connecting member is provided with at least one engaging portion, the second connecting member defines a butt-jointed groove, a wall of the butt-jointed groove extends away from a rabbet of the butt-jointed groove to form at least one channel structure, the channel includes an inserting guide channel, a taking-out guide channel, and a bending channel, and the bending channel forms a buckled portion; the elastic structure is configured for supplying elasticity towards the rabbet of the butt-jointed groove to the first connecting member, so that the engaging portion is engaged with the buckled portion. The non-threaded connecting structure is simple and is convenient to operate, which improves users' experience.

Owner:HUIZHOU KIMREE TECH

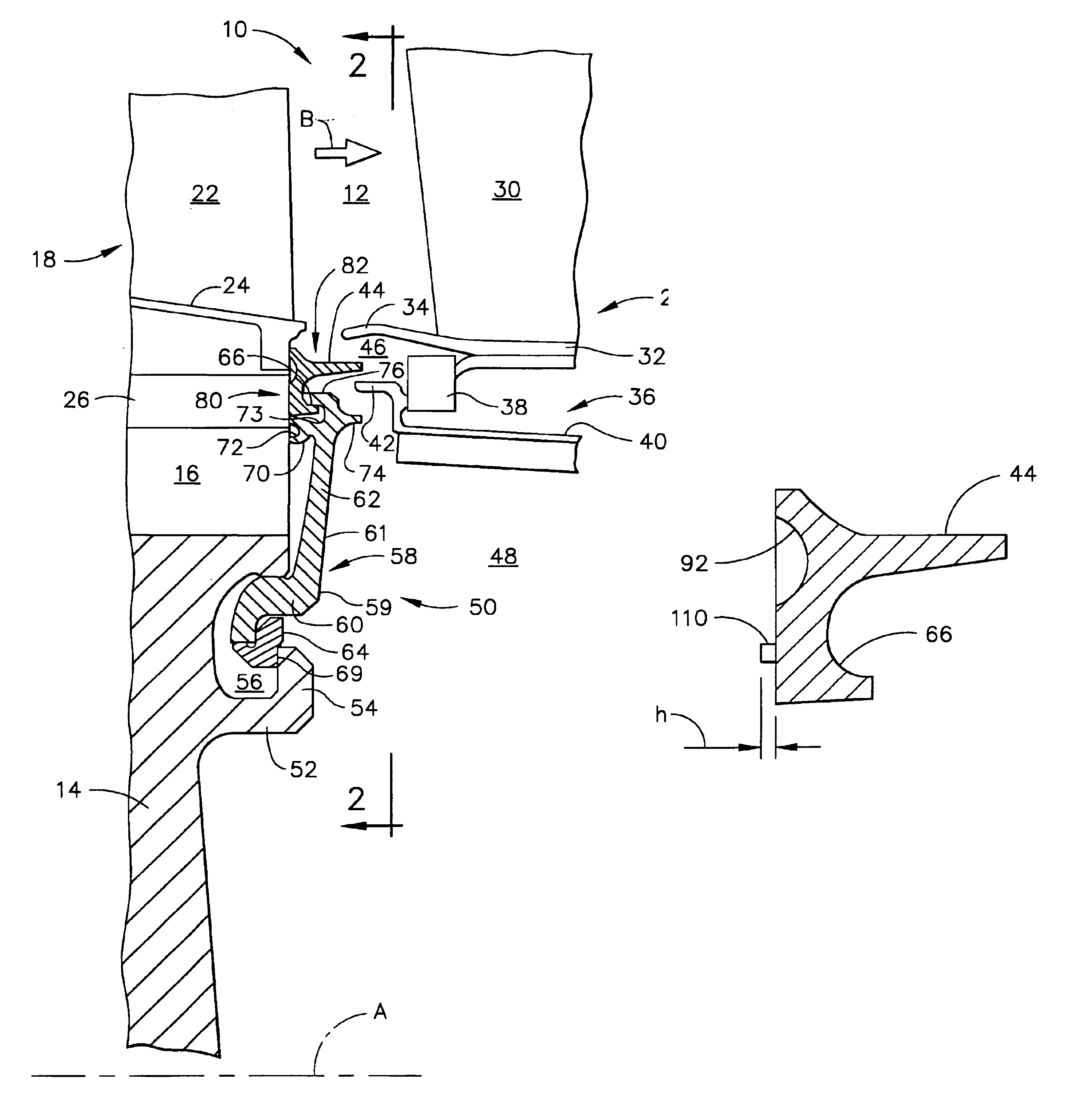

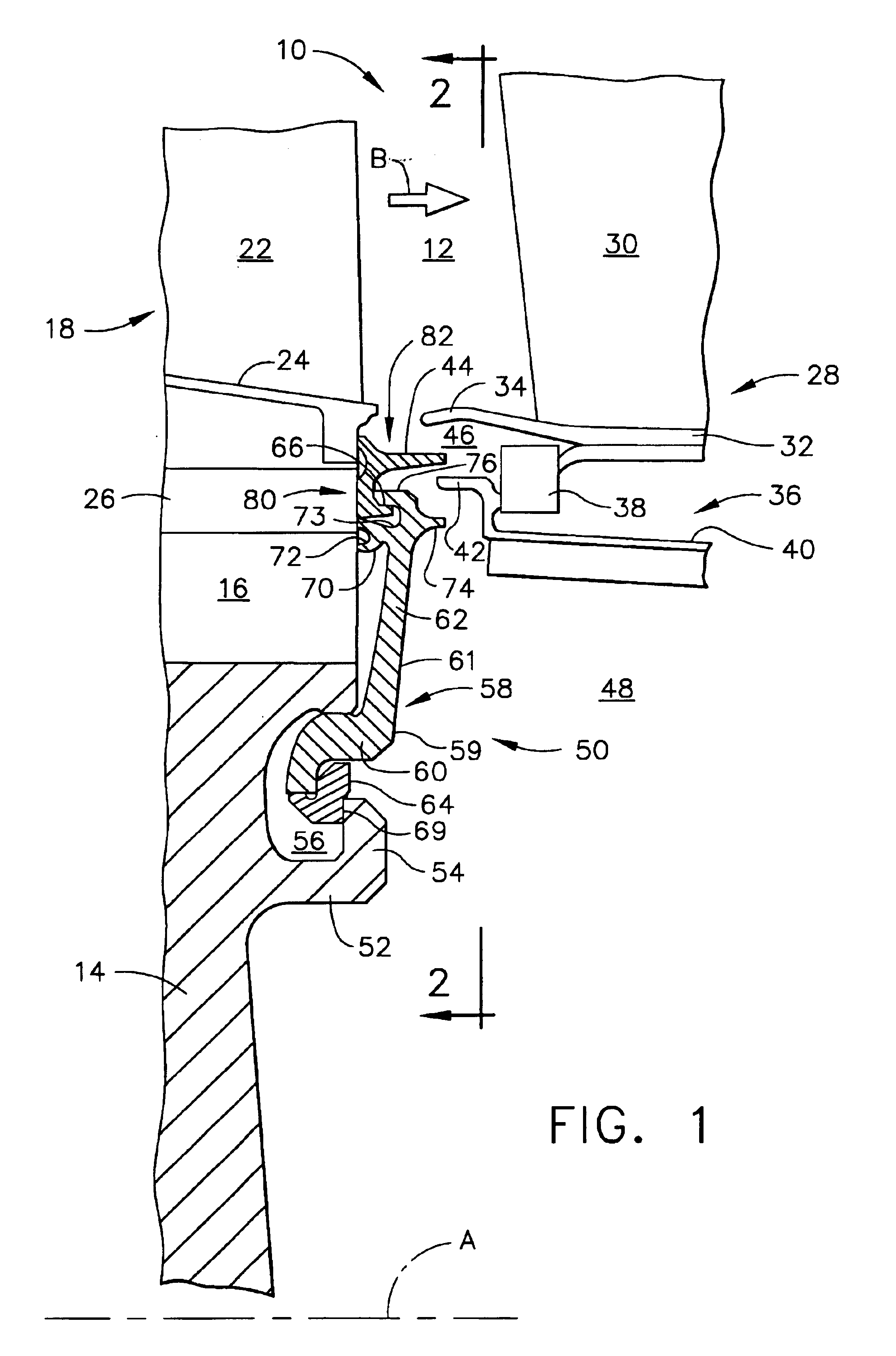

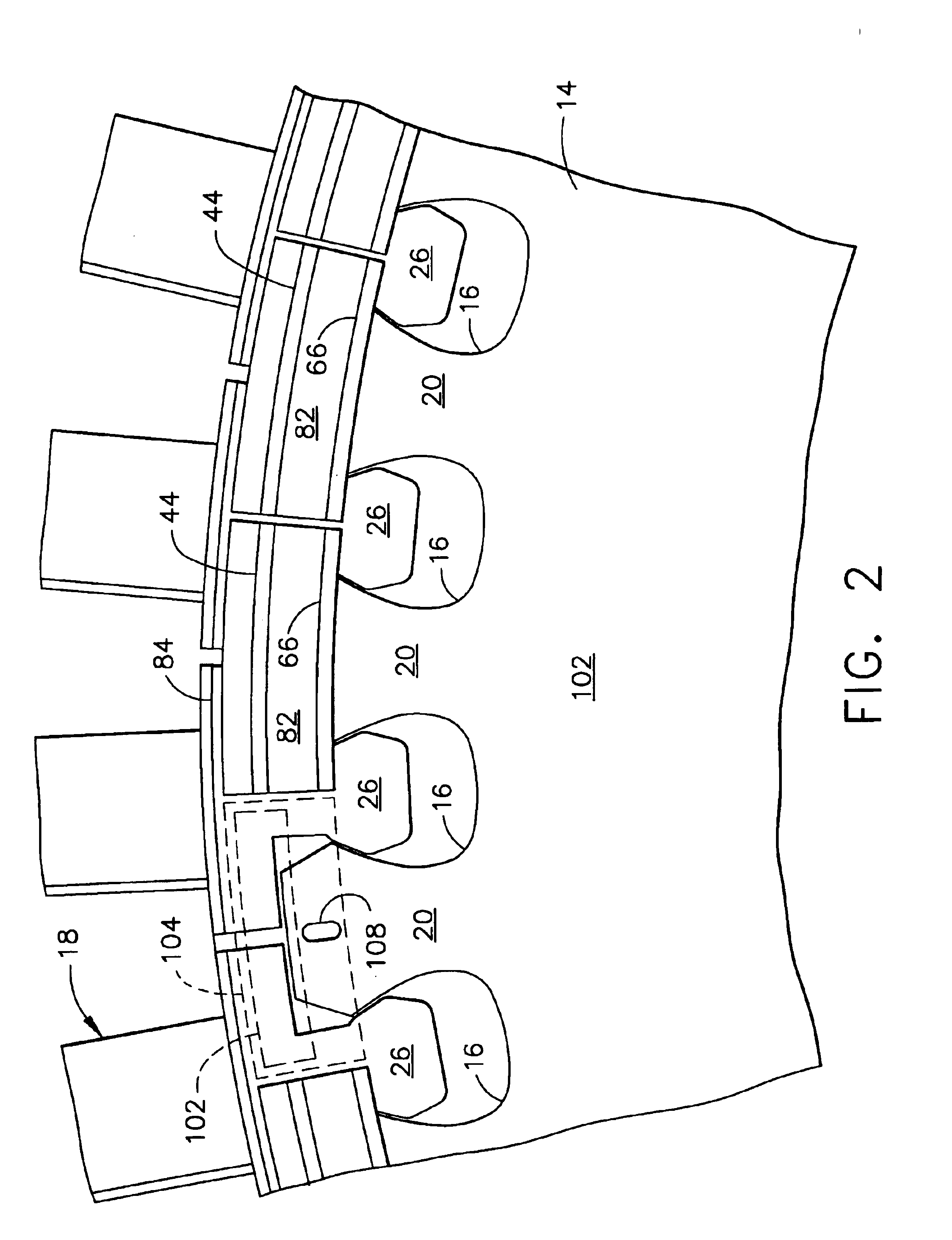

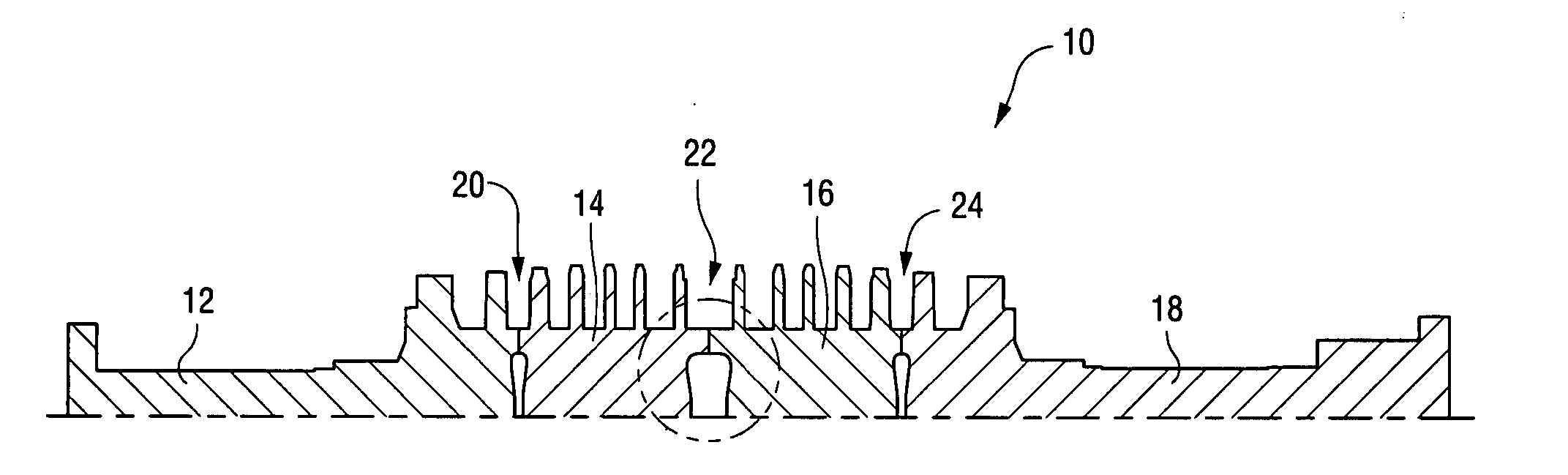

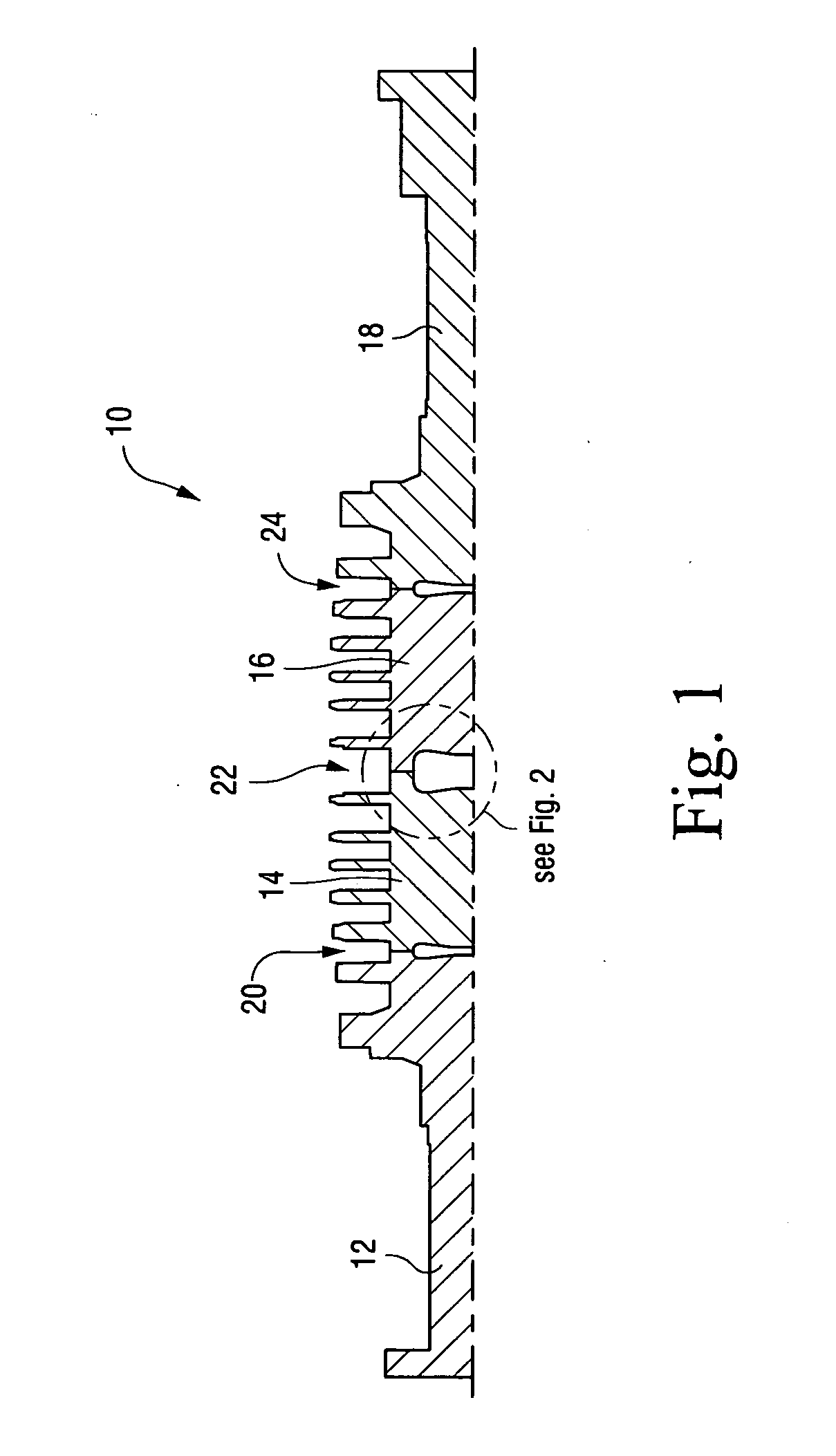

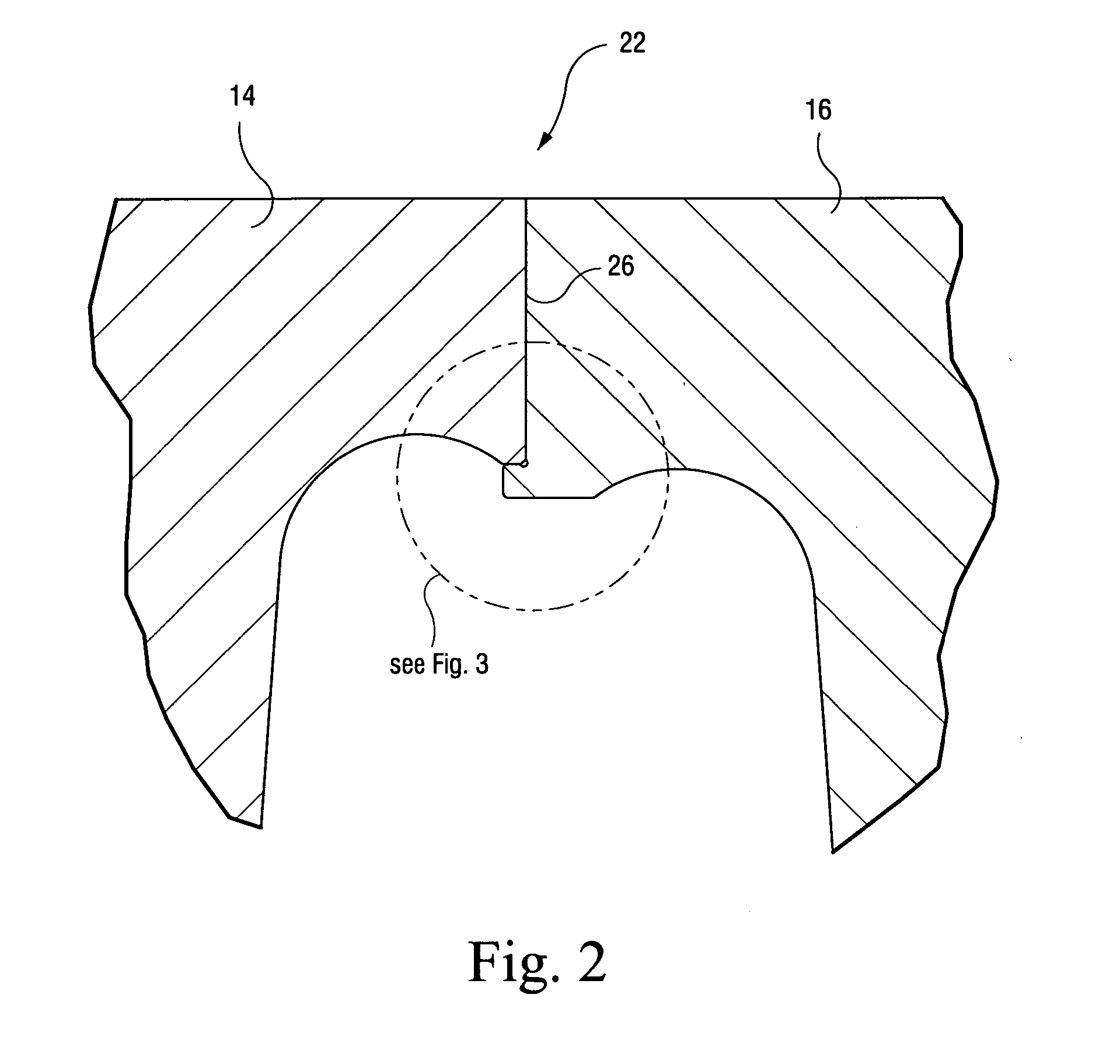

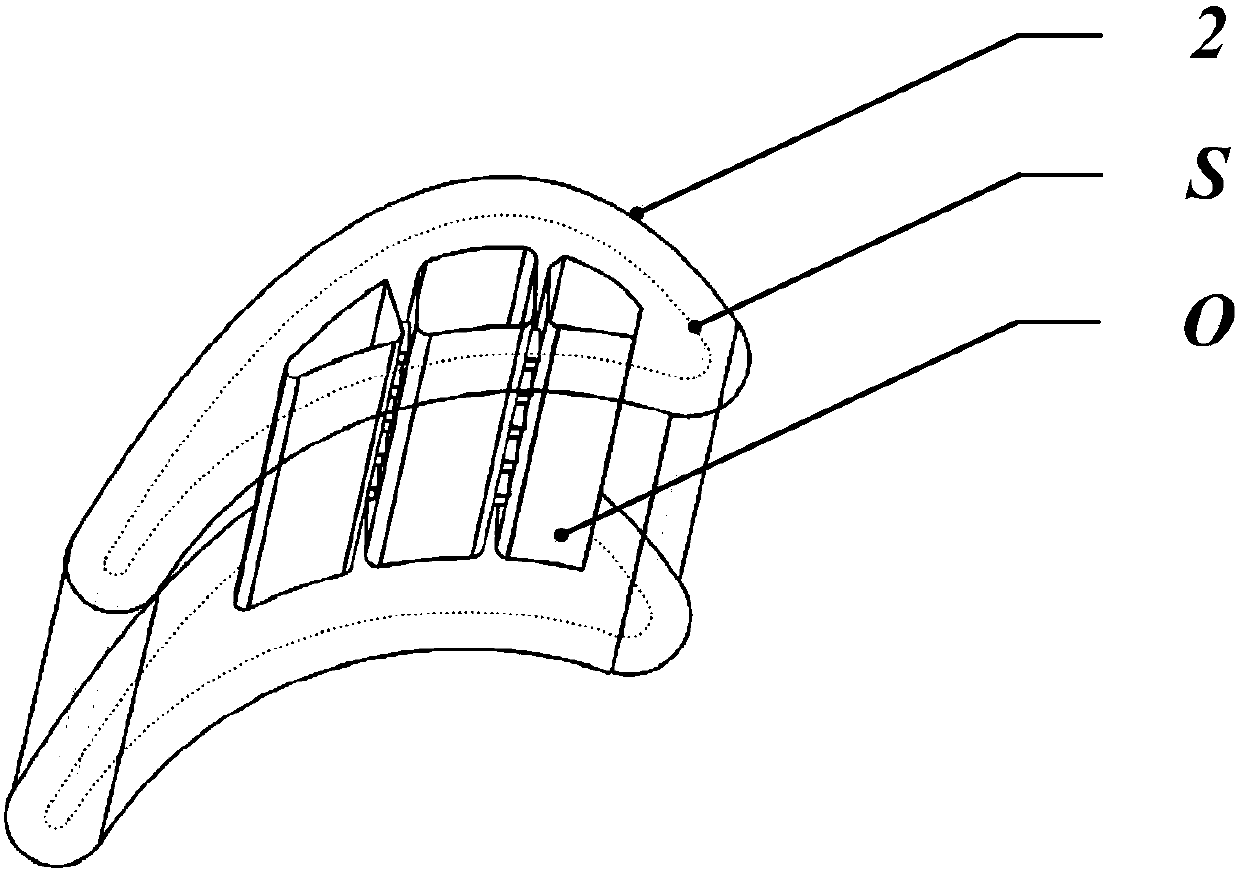

Turbomachinery blade retention system

A blade retention assembly is provided that comprises: a disk, a plurality of blades, each having a dovetail disposed in one of an array of slots formed in the outer periphery of the disk, an annular inner retainer attached to the disk, and a plurality of arcuate blade retainers, the blade retainers being secured to the inner retainer by a hooked rabbet joint. A blade retainer is also provided, comprising an arcuate body having a planar inner face having an arcuate depression formed therein defining a sealing lip, and an aft face disposed opposite the inner face which has an arcuate rim formed therein.

Owner:GENERAL ELECTRIC CO

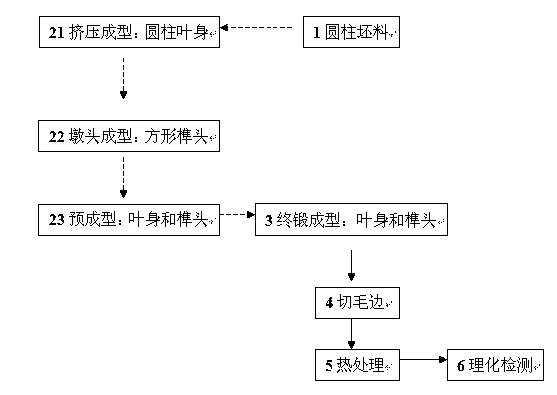

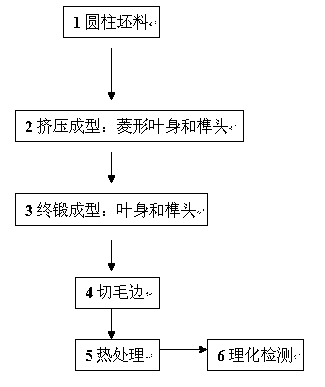

Manufacture method for ultra-fine grain and high-intensity alloy blade forged piece

ActiveCN103009018AShorten the design cycleReduce design processEngine componentsHeating/cooling devicesBarium saltMaterial consumption

The invention provides a manufacture method for an ultra-fine grain and high-intensity alloy blade forged piece. The manufacture method for the ultra-fine grain and high-intensity alloy blade forged piece comprises the following manufacture processes of extruding, finally forging, cutting burrs and carrying out thermal treatment and is characterized in that a barium salt furnace is adopted to heat before the extrusion process; an extrusion die is a ''rhombic blade body and rabbet'' split-type square frustum structure; and the throat part of the extrusion die is strengthened. According to the manufacture method for the ultra-fine grain and high-intensity alloy blade forged piece, which is disclosed by the invention, the die design period and the product technology flow are shortened, the material consumption is lowered, and the cost is saved. Meanwhile, the mean grain size of the prepared forged piece performance tissue is less than the tenth grade, and the performance achieves the level of a high-strength forged piece.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

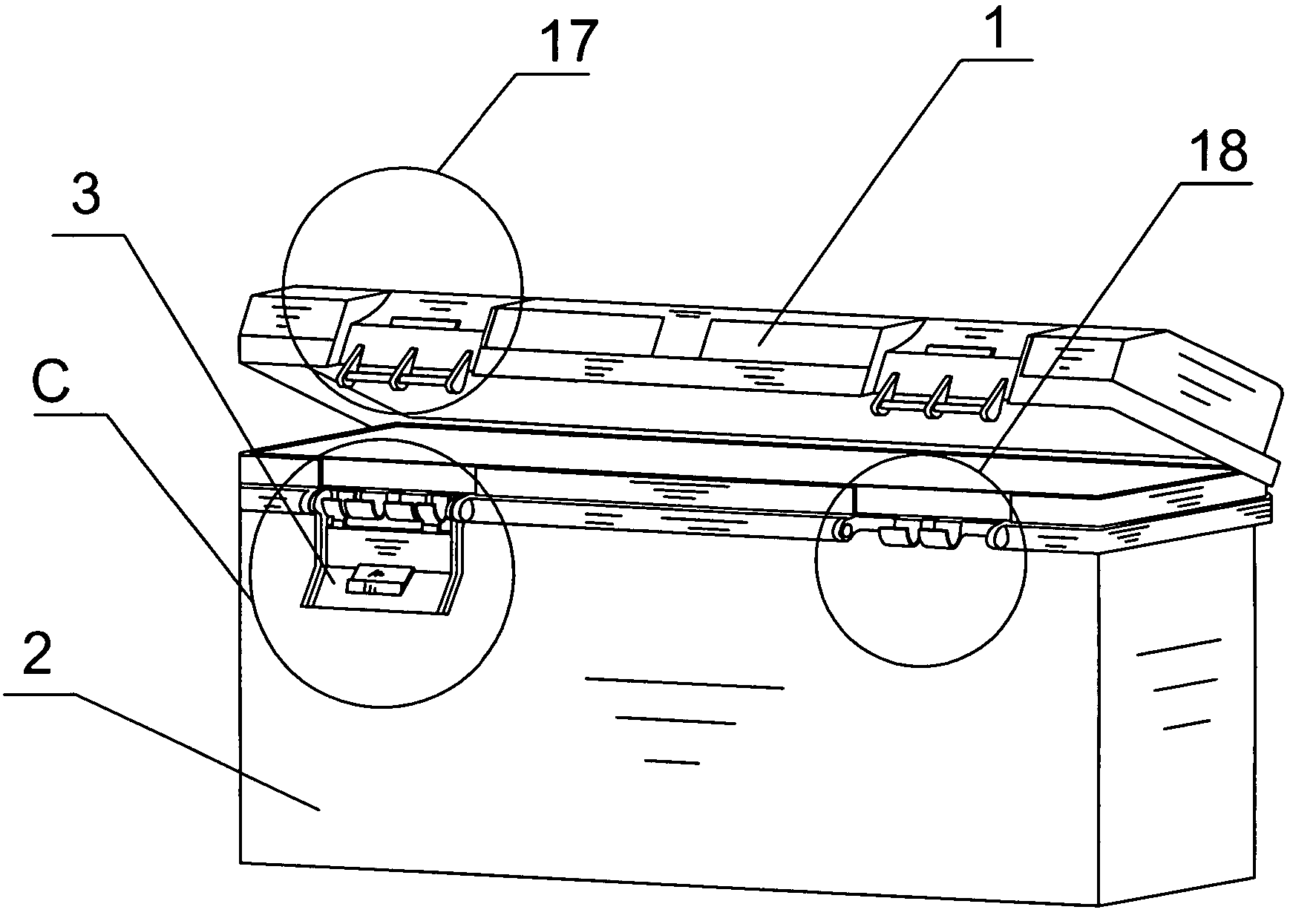

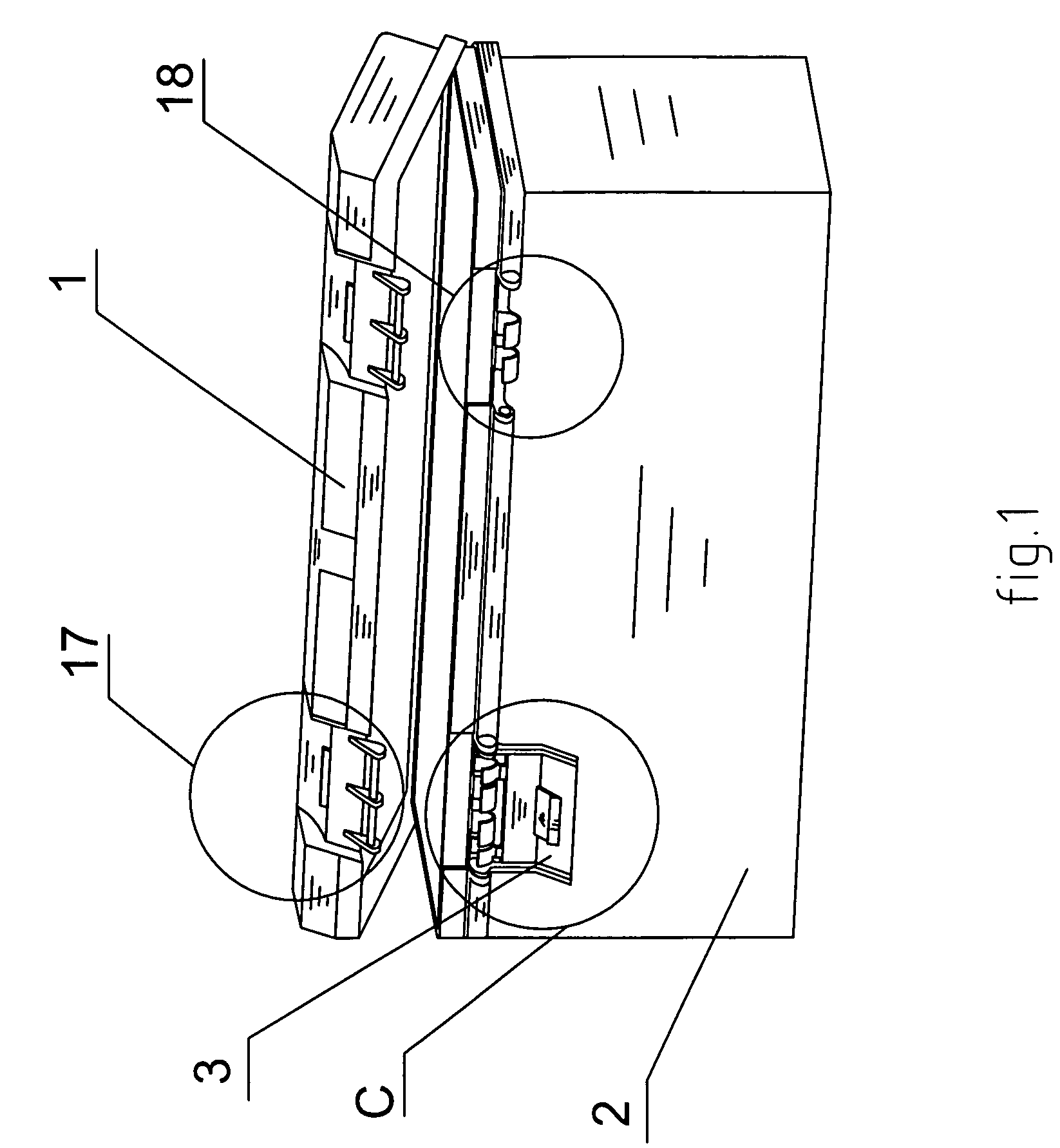

Toolbox

InactiveUS7516842B2Easy to disassembleCover of the toolbox can be disassembled from the bodyOther accessoriesContainer/bottle contructionEngineeringRabbet

Owner:NINGBO HUALEI TOOL

Processing technique of split type speed differentiator shell

InactiveCN101362279AReduce noiseFulfil requirementsAutomatic/semiautomatic turning machinesPositioning apparatusNumerical controlDifferentiator

The invention relates to a processing technique of a split type differential case, which belongs to the technical field of mechanical working. The inner cavities of a left differential case 1 and a right differential case 2 are fine-processed according to the technical requirement, and the inner cavities comprise spherical surfaces, half axle gear holes, half axle via holes, joint surfaces of the differential cases, and assembling rabbets of the left differential case and the right differential case; a surplus length of 0.4-0.5 is reserved on each excircle, a surplus length of 0.3 is reserved on the corresponding end surfaces, the left differential case 1 and the right differential case 2 are assembled, ten holes are drilled and bored, then a numerical control lathe is utilized for finish turning to each excircle and end surface of the differential case, the roughness value Ra of the excircle surface of the assembling bearing is smaller than 1.6, the roughness value Ra of the excircle surface and the end surface of the rabbet on the flange surface is smaller than 3.2, and the jump of the flange surface relative to the two axle necks is smaller than 0.06. The processing technique has the advantages that the split type differential case is processed through turning rather than grinding, the production benefit is high, the working accuracy can achieve the design requirement, the quality is obviously improved than the separated processing, the noise of the rear axle is favorable to be reduced, therefore, the requirements of the users can be met.

Owner:JIANGXI JIANGLING CHASSIS CO LTD

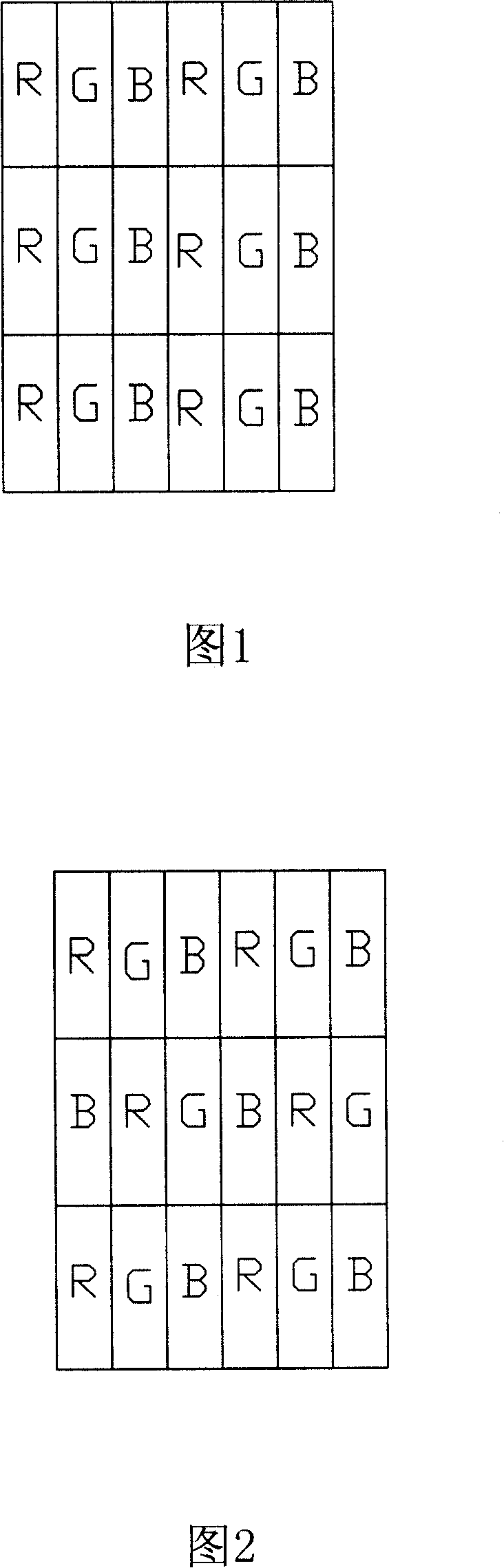

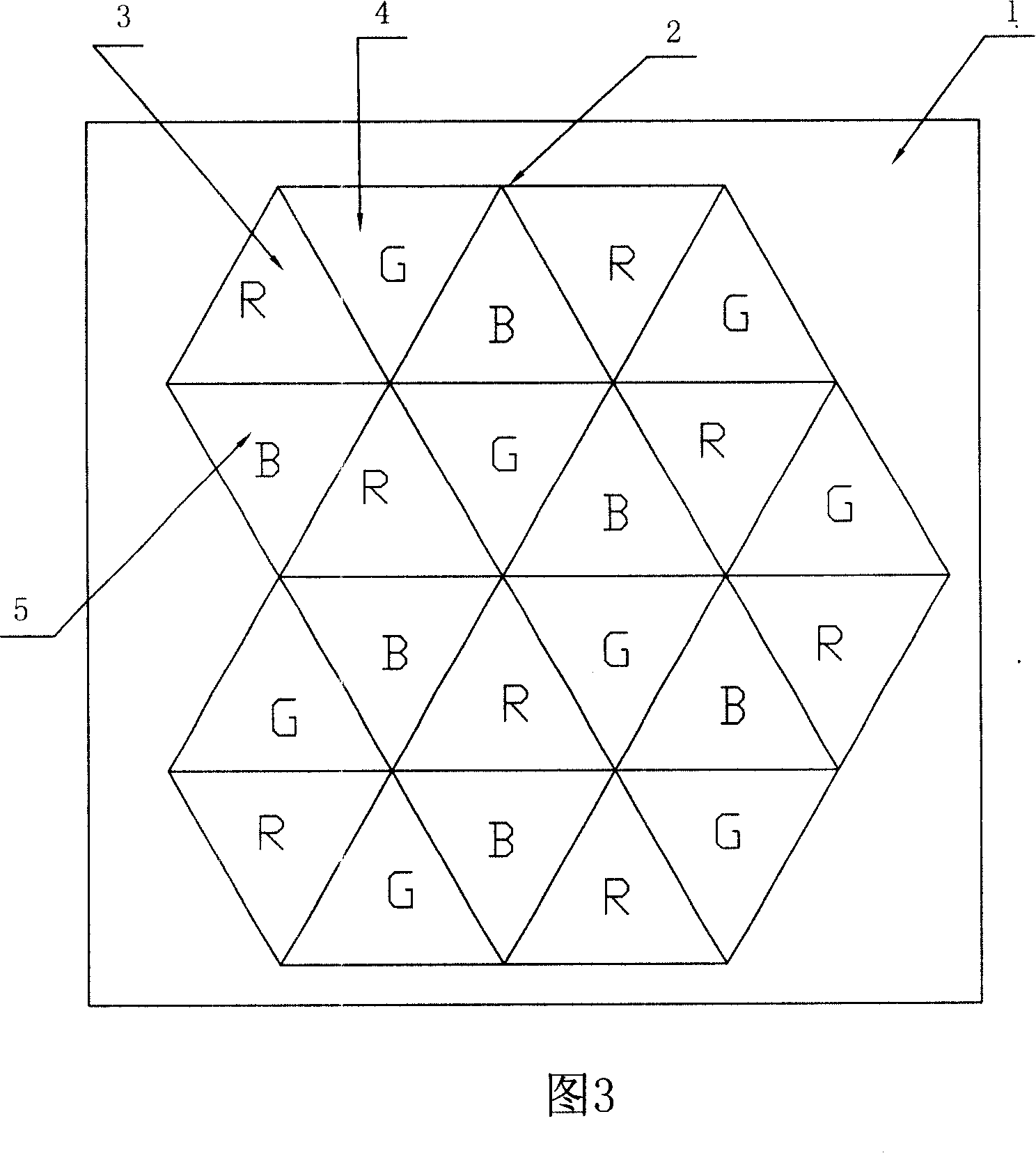

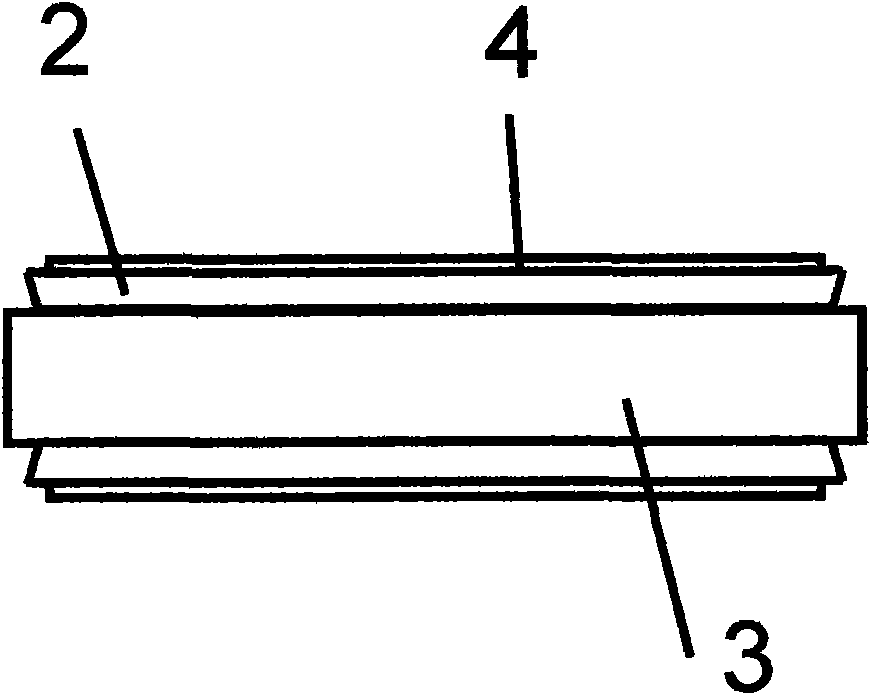

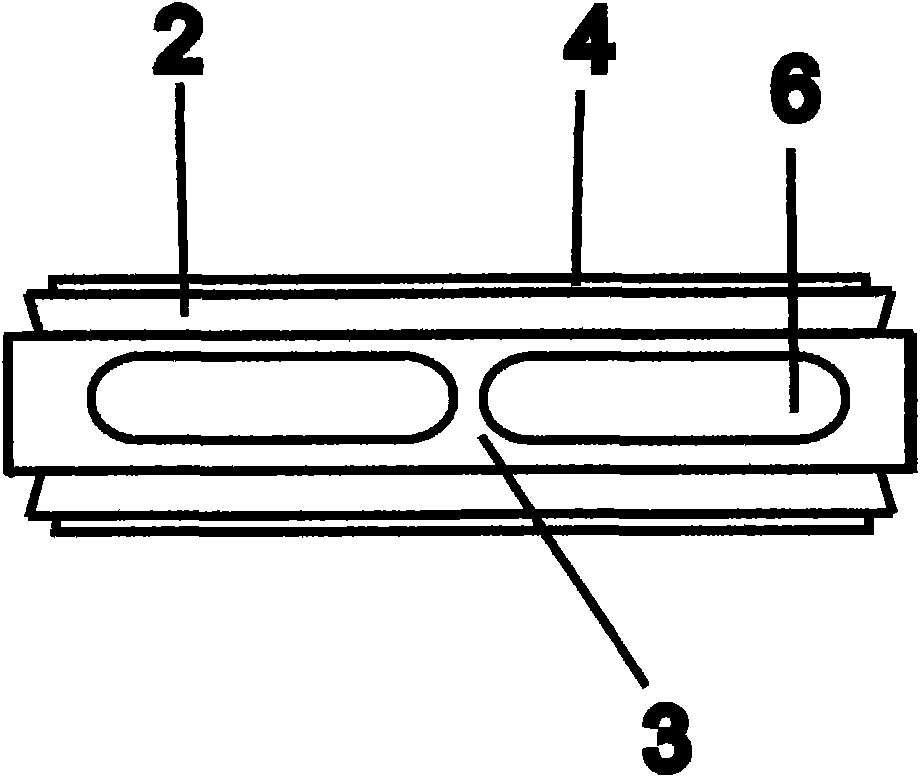

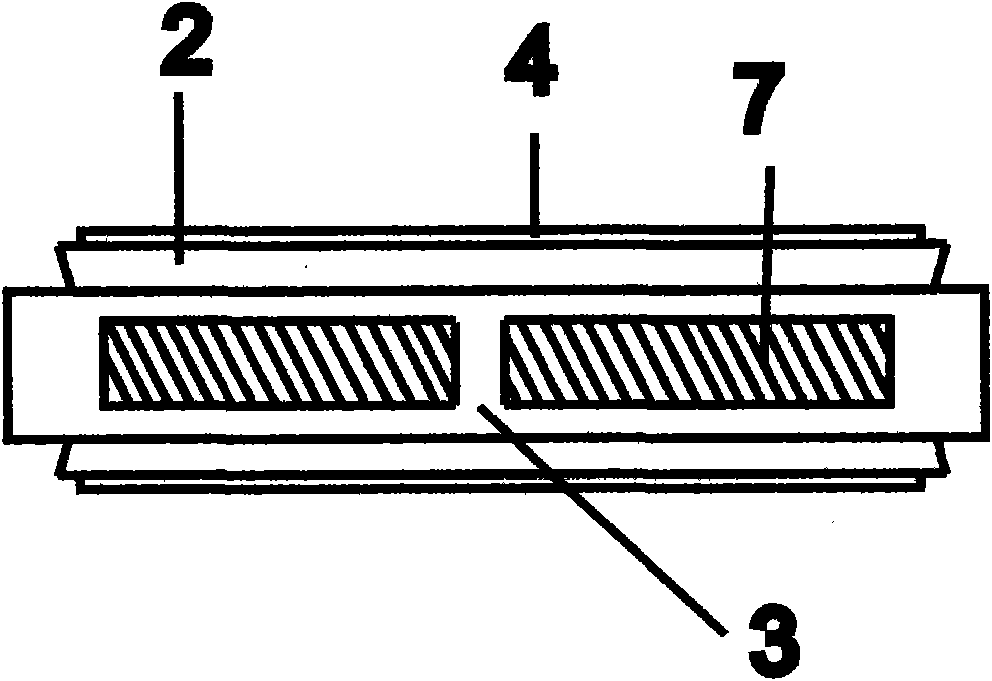

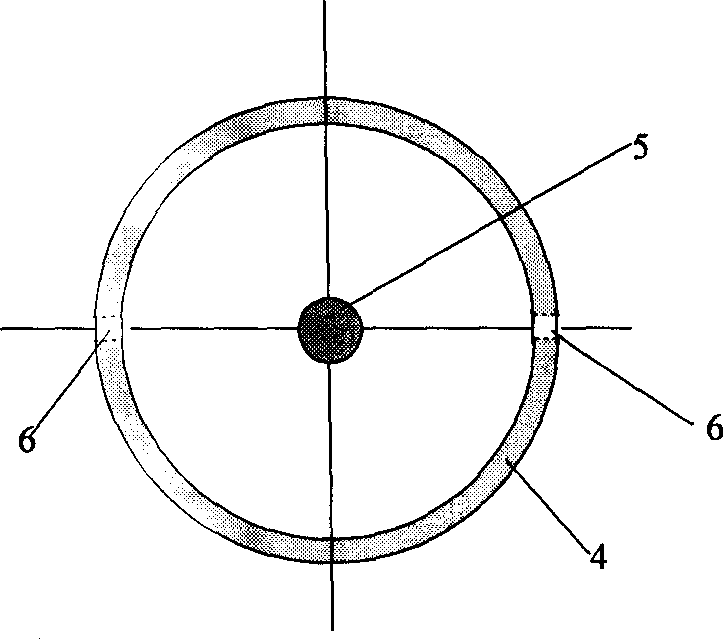

Structure of colorful spectral filter

InactiveCN101153932AScattered distributionOperableNon-linear opticsOptical elementsIsosceles trapezoidScarf joint

The present invention discloses a color filter structure which is provided with a transparent baseplate; a plurality of pixels are formed on the baseplate, wherein, each pixel is provided with a first color zone, a second color zone and a third color zone, in particular each pixel is an isosceles trapezoid; each two pixels are spliced to a regular hexagon; three identical regular triangles are in rabbet joint inside each isosceles trapezoid; three regular triangles respectively correspond to the first color zone, the second color zone and the third color zone, and after each two pixels are spliced to the regular hexagon on the transparent baseplate, with an arbitrary regular hexagon as the center, six regular hexagons spliced by other pixels in two are faveolately in scarf joint around. The color filter with the structure has good color display effect and can weaken sawtooth in the margin of image when the image is displayed obliquely.

Owner:BYD CO LTD

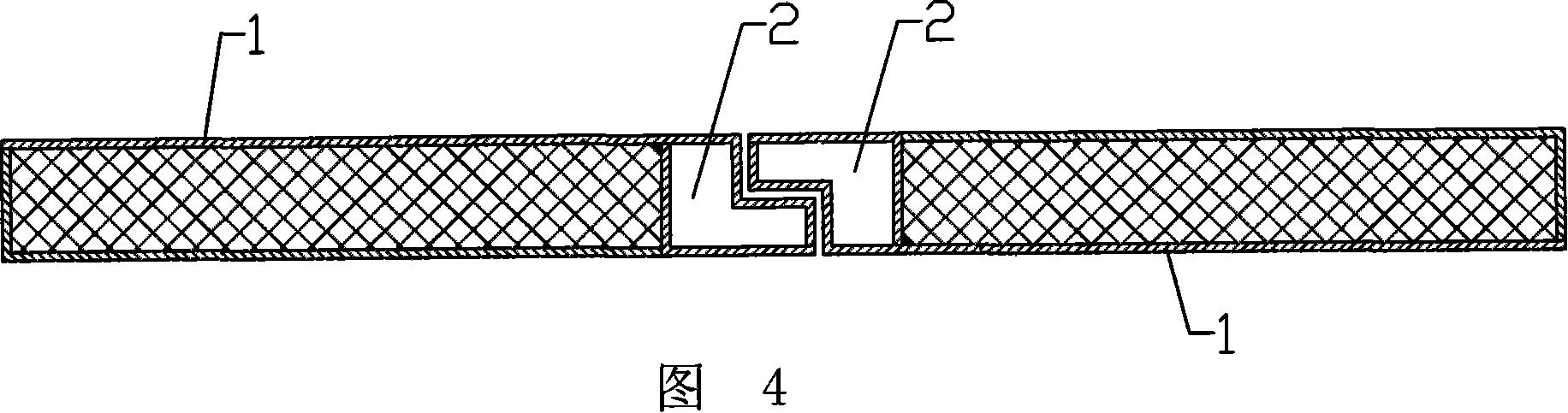

Zipper-type architectural wall plate

The invention relates to a zipper-type architectural wall plate which has the main technical characteristics that the lateral surface of the wall plate is provided with a zipper slot forming a star-shaped rabbet with a big wide exterior and small narrow interior; when installing the wall plates, the rabbets of two plates are closely spliced, and a dedicated slurry is coated to flatten the two zipper slots of the opposite rabbets to the bottom of the plate surface of an anti-cracking slot; and after the slurry is coagulated and dried, a star-shaped cylinder is formed, or the cylinders in othershapes, which have the locking function of the star-shaped cylinder, lock the joint as firm as the zipper. The wall plate fundamentally solves the problems of cracking at the plate-to-plate, plate-to-stake, plate-to-post, plate-to-beam and plate-to-other-wall bonding joints, and cold and thermal bridges at the solid bonding joints, and has the advantages of easy production and convenient construction.

Owner:内蒙古拉锁式新型建材科技有限公司

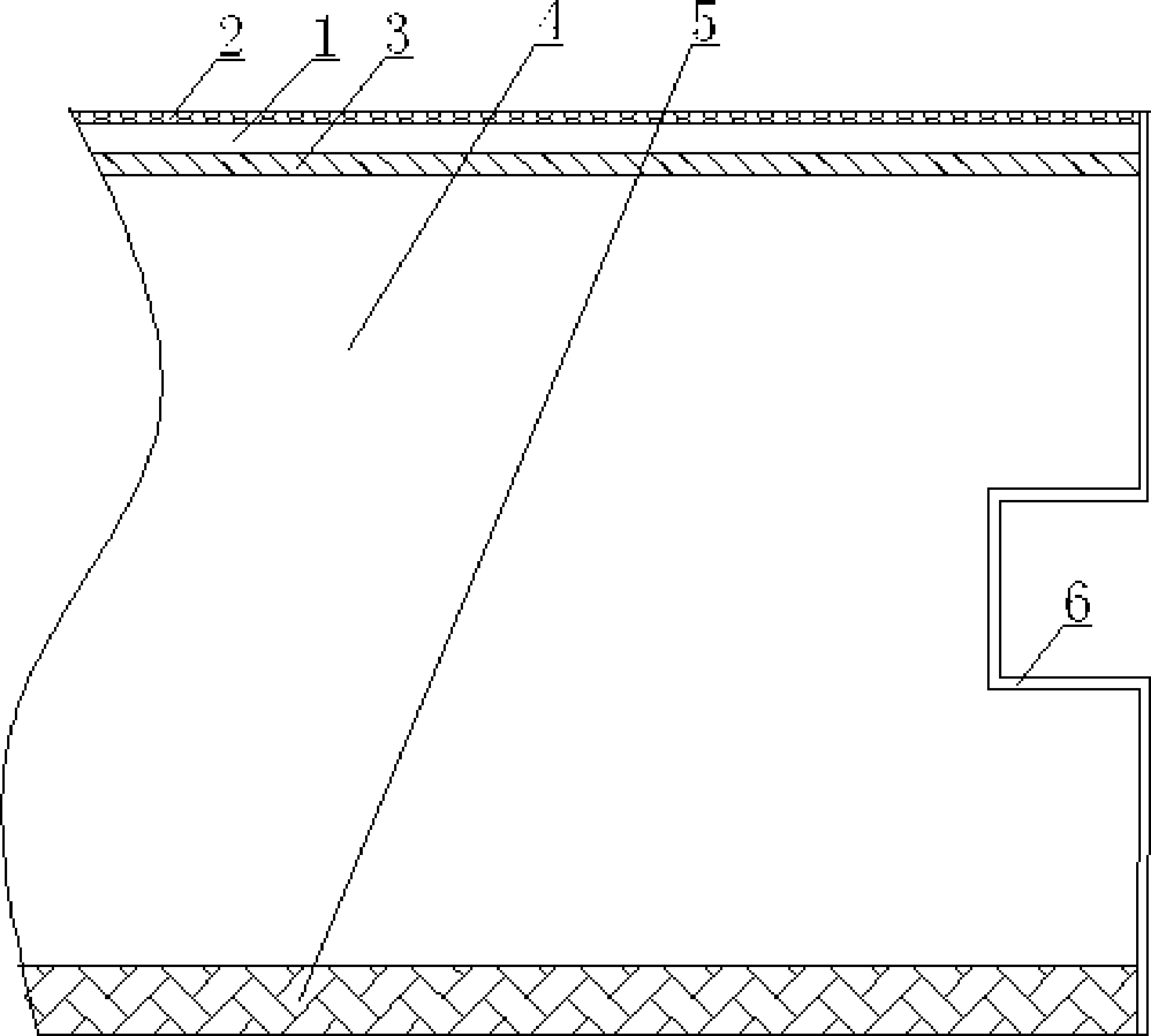

Geothermal type formaldehyde-removing solid wood composite floor and manufacturing method thereof

ActiveCN103912109APlay effectivelyImprove efficiencyWood working apparatusFlooring insulationsSolid woodRabbet

The invention discloses a geothermal type formaldehyde-removing solid wood composite floor and manufacturing method thereof and aims to increase the formaldehyde removing effect of the composite floor. The composite floor comprises floor base material. Rabbets are formed in four sections of the floor base material. The floor base material sequentially comprises a filling layer, a paint-preventing layer, a primer layer and a finishing coat layer from bottom to top. A waterproof layer is disposed at the bottom of the floor base material. The composite floor is characterized in that the finishing coat layer sequentially comprises a wear-resistant finish coating layer, a scratch-resistant finishing coat layer and a formaldehyde-removing finishing coat layer from the bottom to top. Common environment-friendly UV coatings are used on the wear-resistant finish coating layer and the scratch-resistant finishing coat layer. The geothermal type formaldehyde-removing solid wood composite floor conforms to national standards, and product quality is increased greatly.

Owner:BAROQUE WOOD IND ZHONGSHAN CO LTD

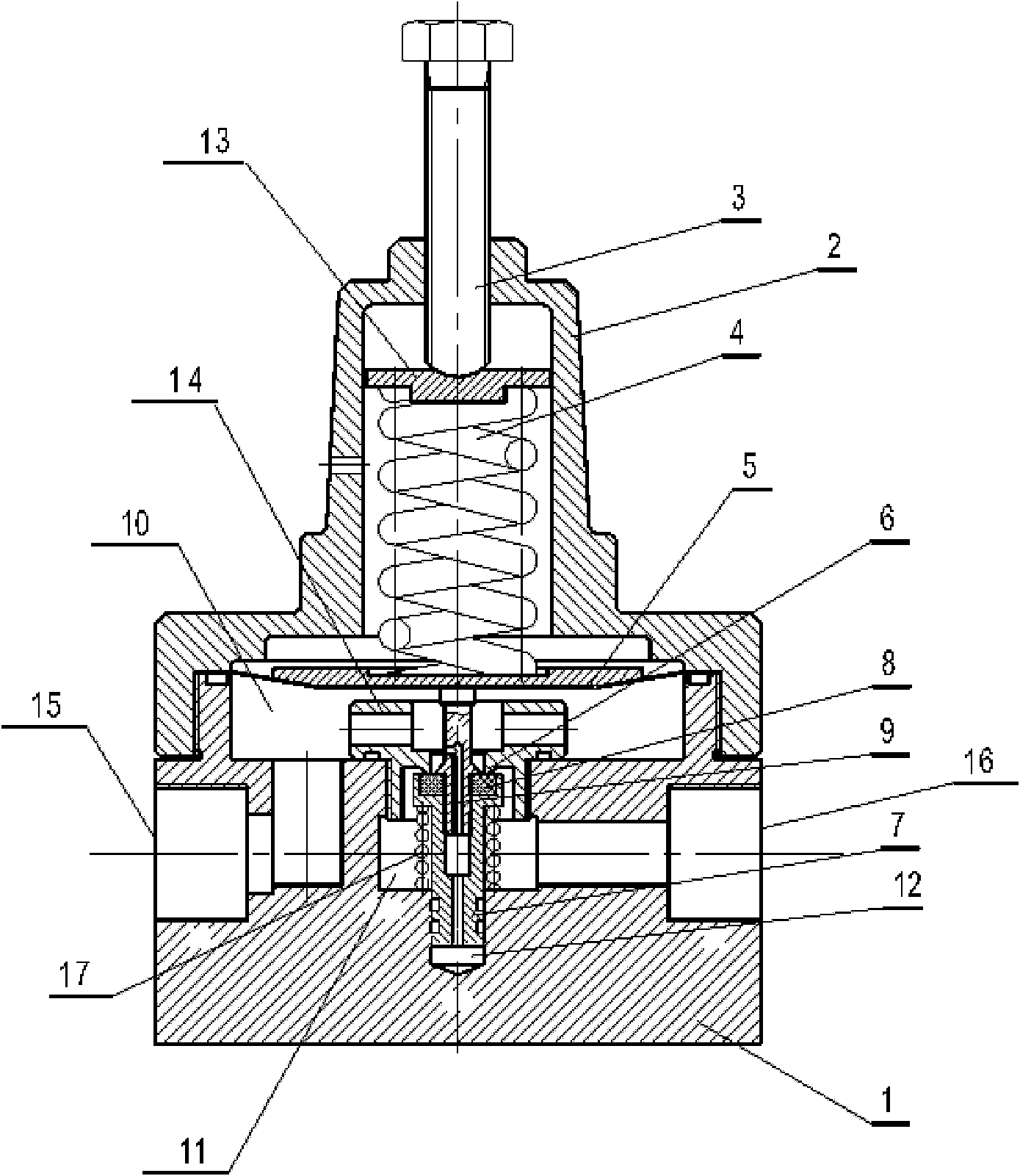

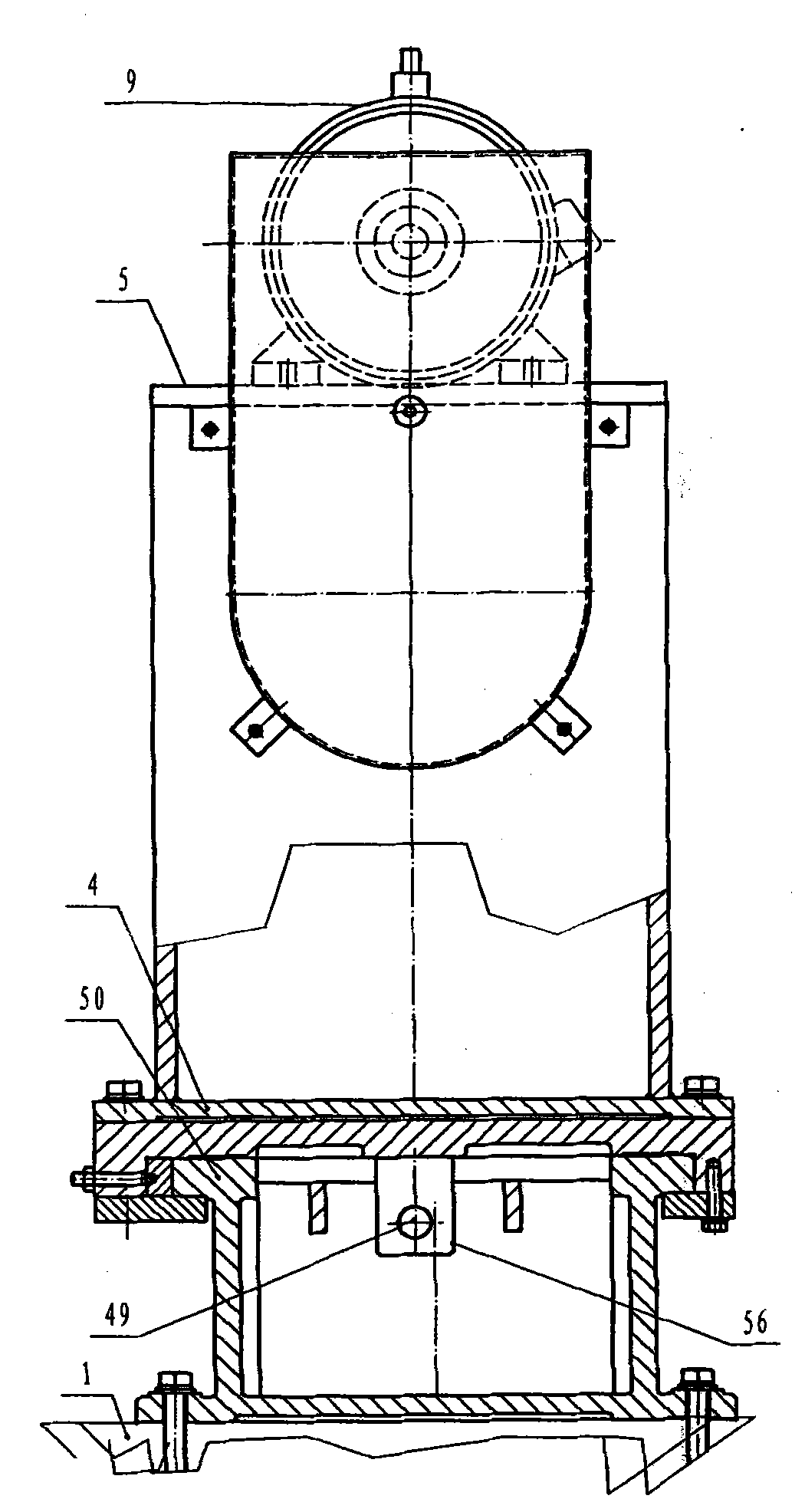

High-pressure natural gas reducing valve

InactiveCN102052495AEliminates the effects of outlet pressureRelieve stressOperating means/releasing devices for valvesEqualizing valvesCompressed natural gasAxial pressure

The invention relates to a high-pressure natural gas reducing valve which comprises a valve cover, a valve body, a pressure sensing diaphragm, a pressure preset mechanism and a valve-plug mechanism, wherein the valve-plug mechanism comprises a gas-valve connection block in which a valve port and an airflow channel are arranged and a valve clack assembly consisting of a valve-clack rod and a valve-clack ejector rod; the top of the valve-clack rod is provided with a circumferential boss, and the surface of the circumferential boss is provided with a sealing gasket; the valve-clack ejector rod passes through the valve port and is in overlap joint with the pressure sensing diaphragm; the lower part of the valve body is provided with a valve-clack groove, and a valve-clack spring is arranged between the circumferential boss of the valve-clack rod and a rabbet end face of the valve-clack groove; and a cavity is arranged in the valve clack assembly, the valve port is in the shape of cone, and the diameter of the valve port is same as that of the valve-clack rod. The high-pressure natural gas reducing valve has the advantages that because the reducing valve adopts the structure above, the axial pressure of the valve clack assembly is balanced, the pressures on the upper and lower surfaces of the valve clack assembly of the reducing valve are not affected by the pressures on a user side and a storage tank side, thereby eliminating the influence on the outlet pressure of a pressure reducing / adjusting valve when the operating pressure on the storage tank side is changed, avoiding that the valve port always produces pressures on the sealing gasket by the retraction pressure of the pressure sensing diaphragm, and prolonging the service life of the sealing gasket.

Owner:YISIDA ELECTROMECHANICAL EQUIP TIANJIN CITY

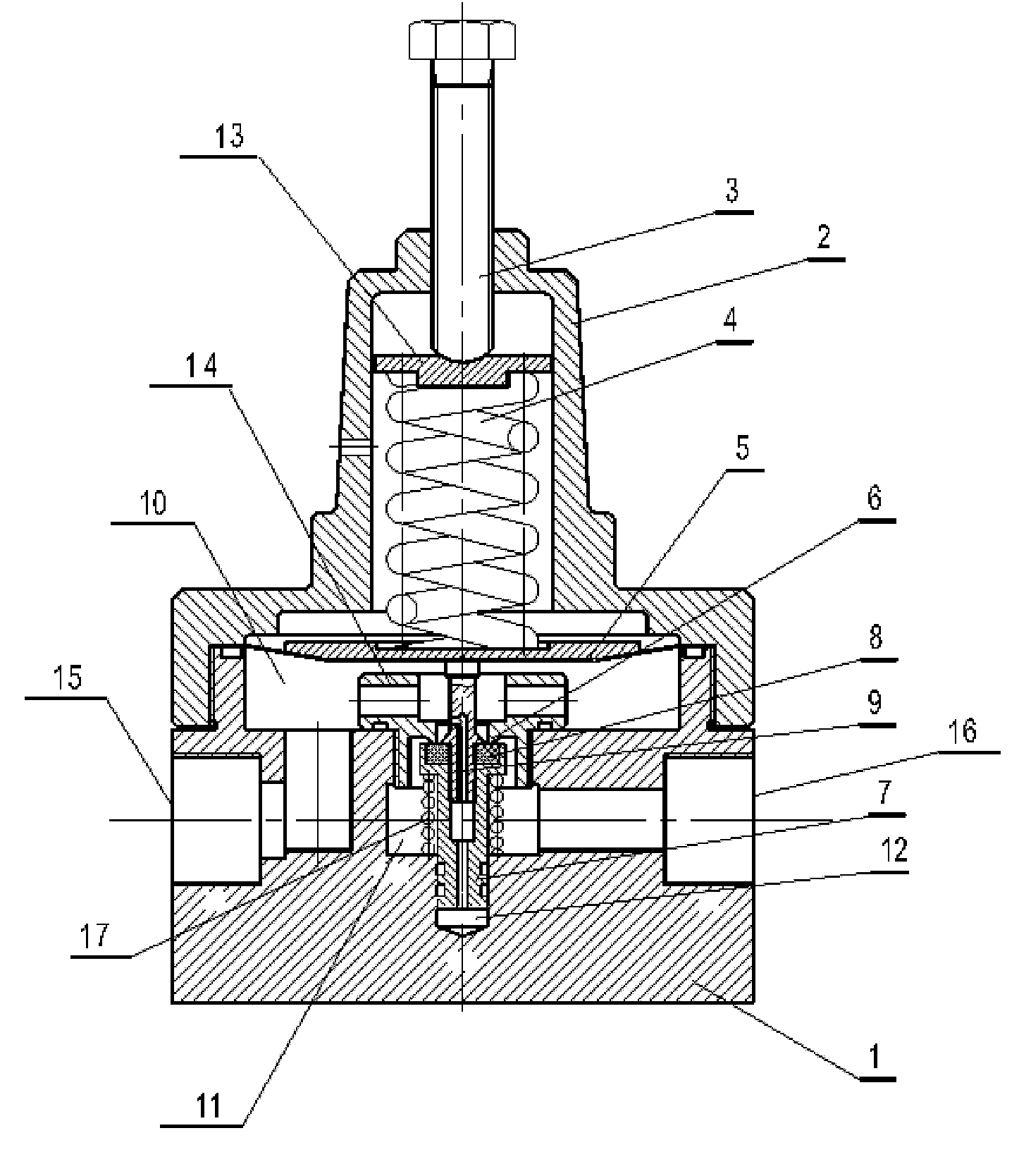

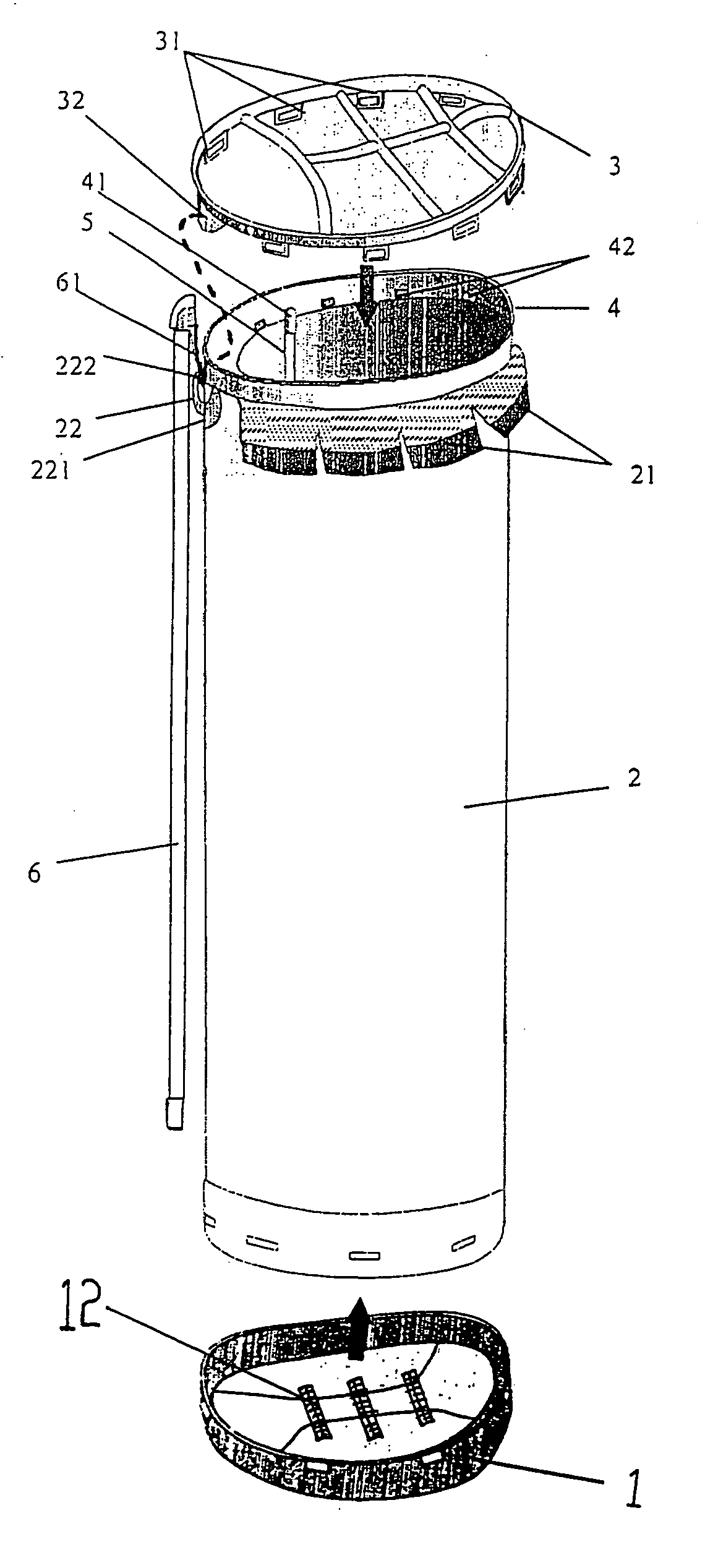

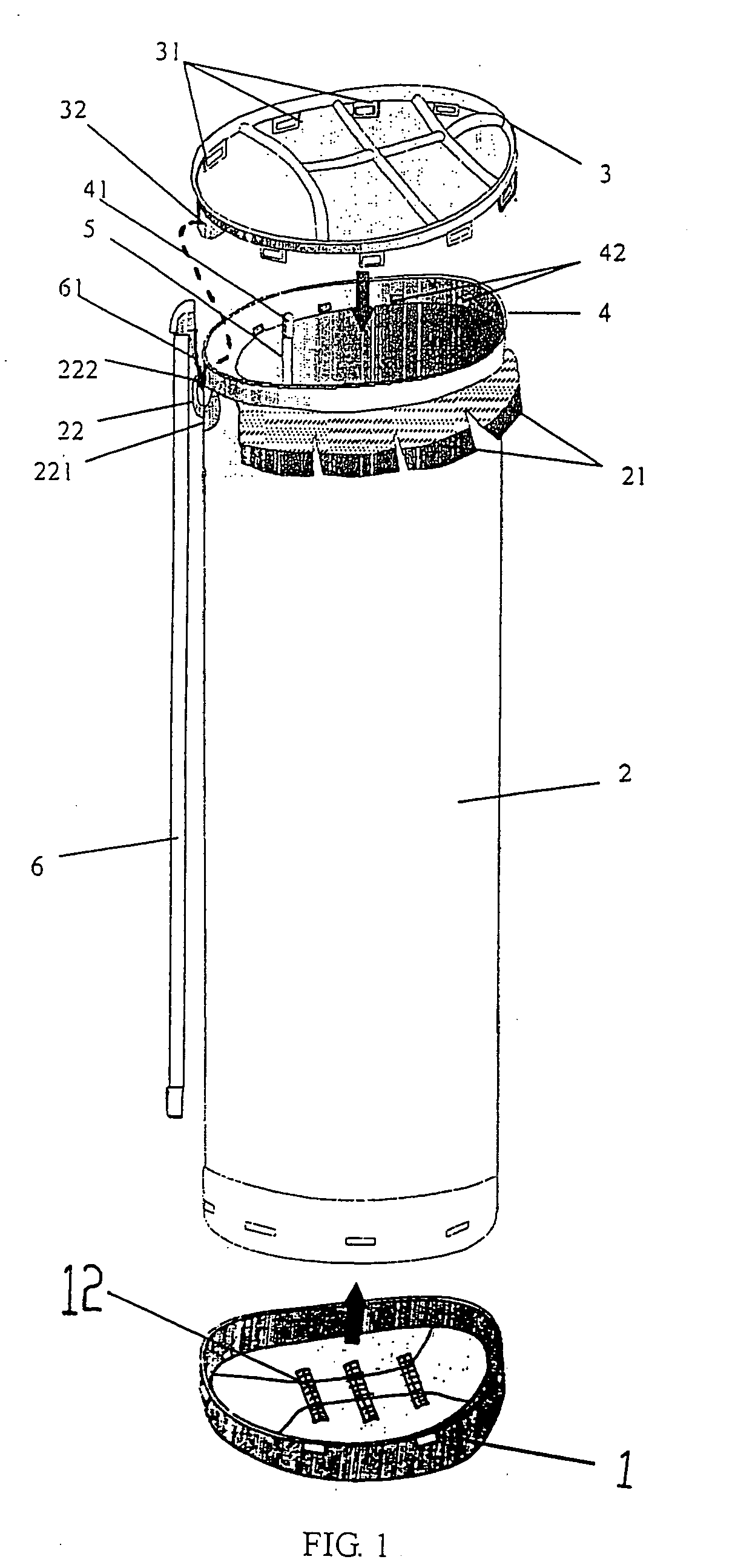

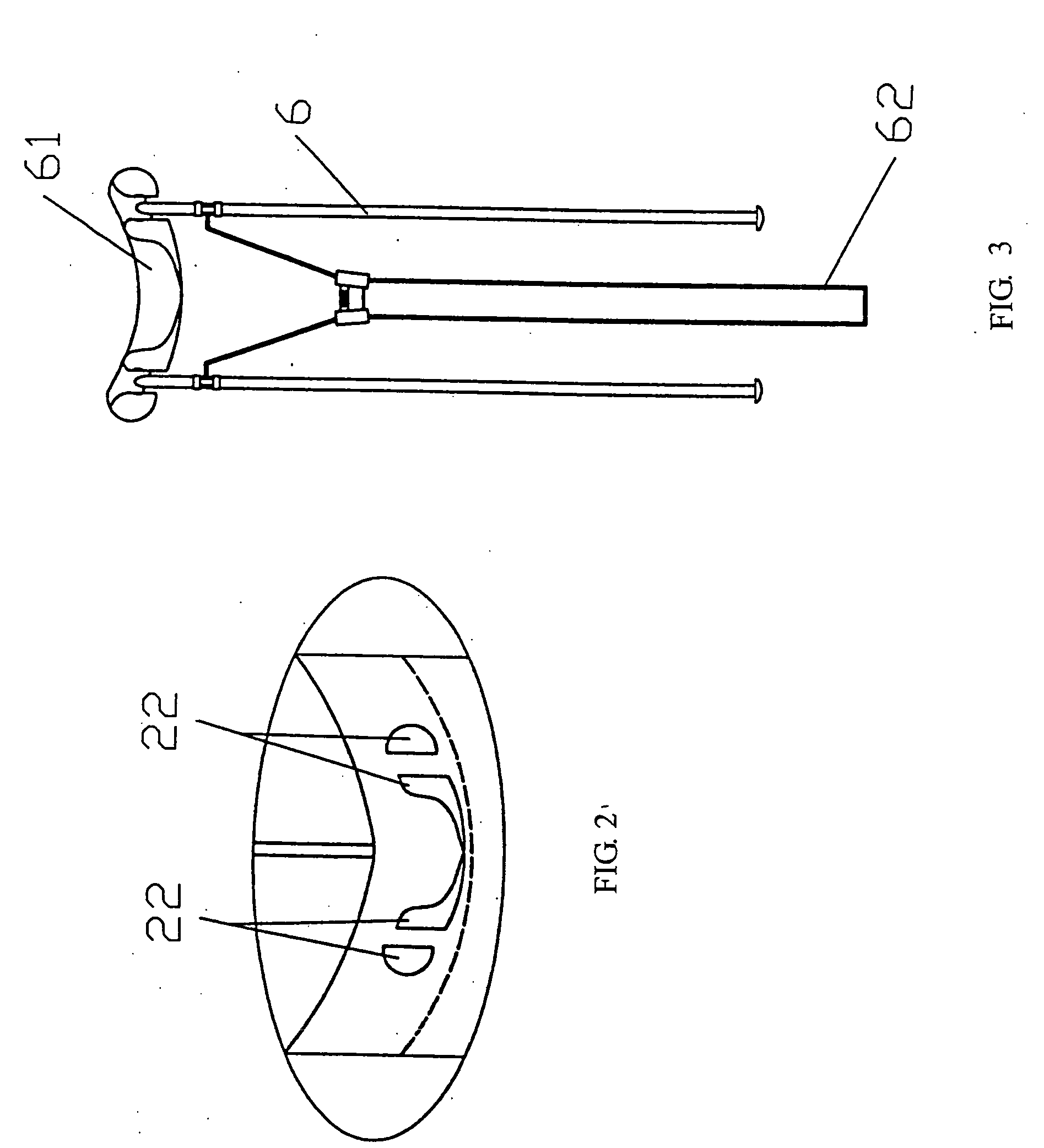

Do-it-yourself golf bag and assembly method thereof

InactiveUS20060108243A1Easy to assembleSmall footprintOther accessoriesContainer/bottle contructionRabbetGolf Ball

An do-it-yourself golf bag of the invention includes a bottom, a bag body and a head frame; wherein two frames are provided on both ends of the bag body, each of which has a rabbet for mounting a structure stay; and the two frames of the bag body are connected with the bottom and the head frame in a detachable manner. An assembly method of the above golf bag includes the steps of: (A) connecting the bottom with the frame of the bag body; (B) connecting a lower end of the stand with the bottom, and connecting a top end of the stand with the frame of the bag body; and (C) connecting the head frame with the frame of the bag body.

Owner:TAN FU HSING

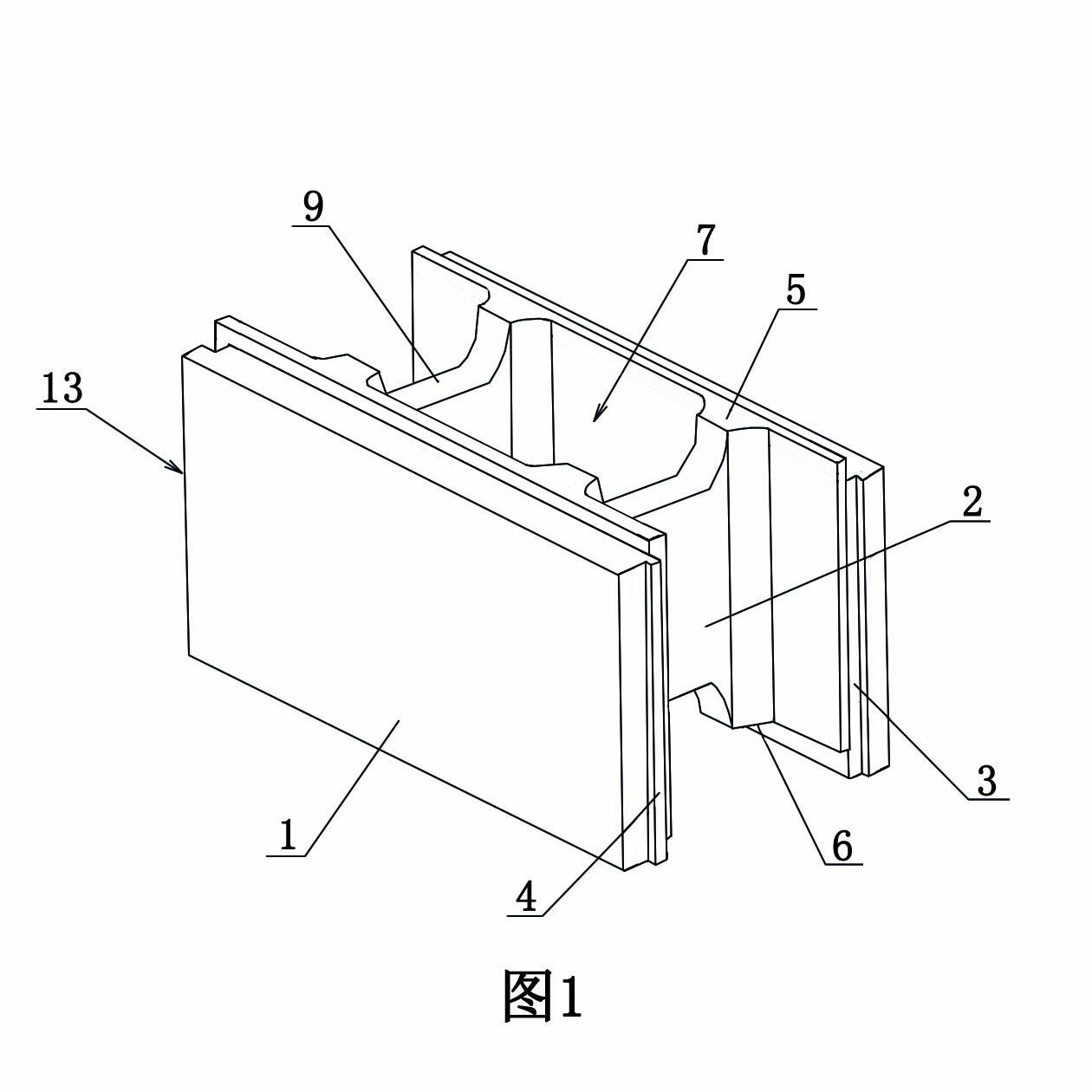

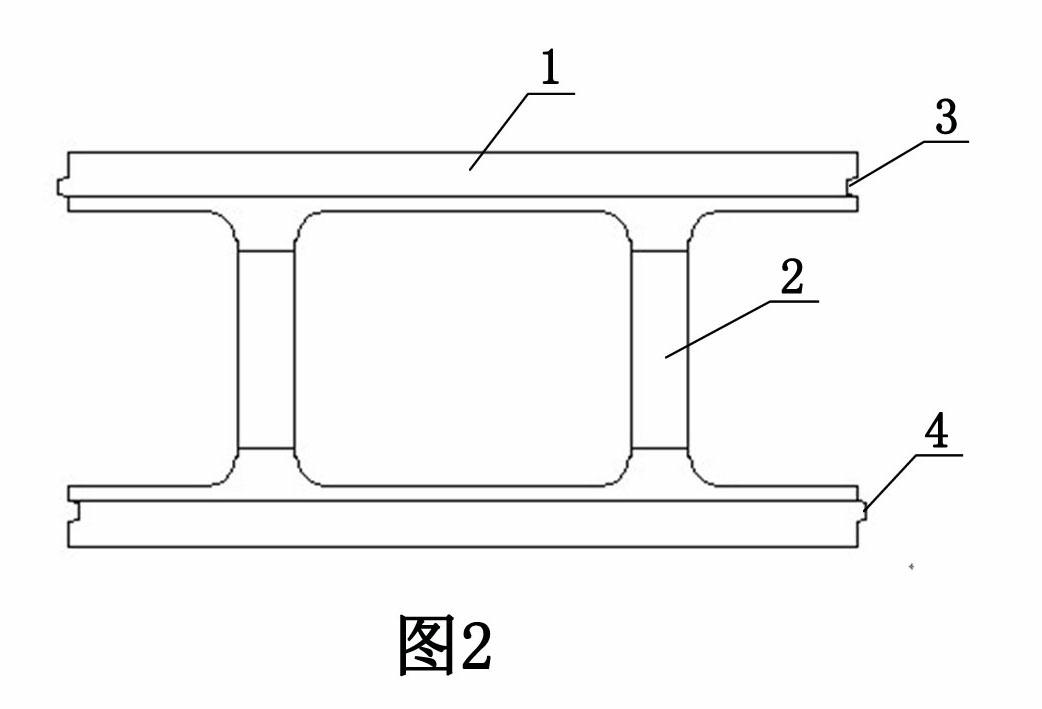

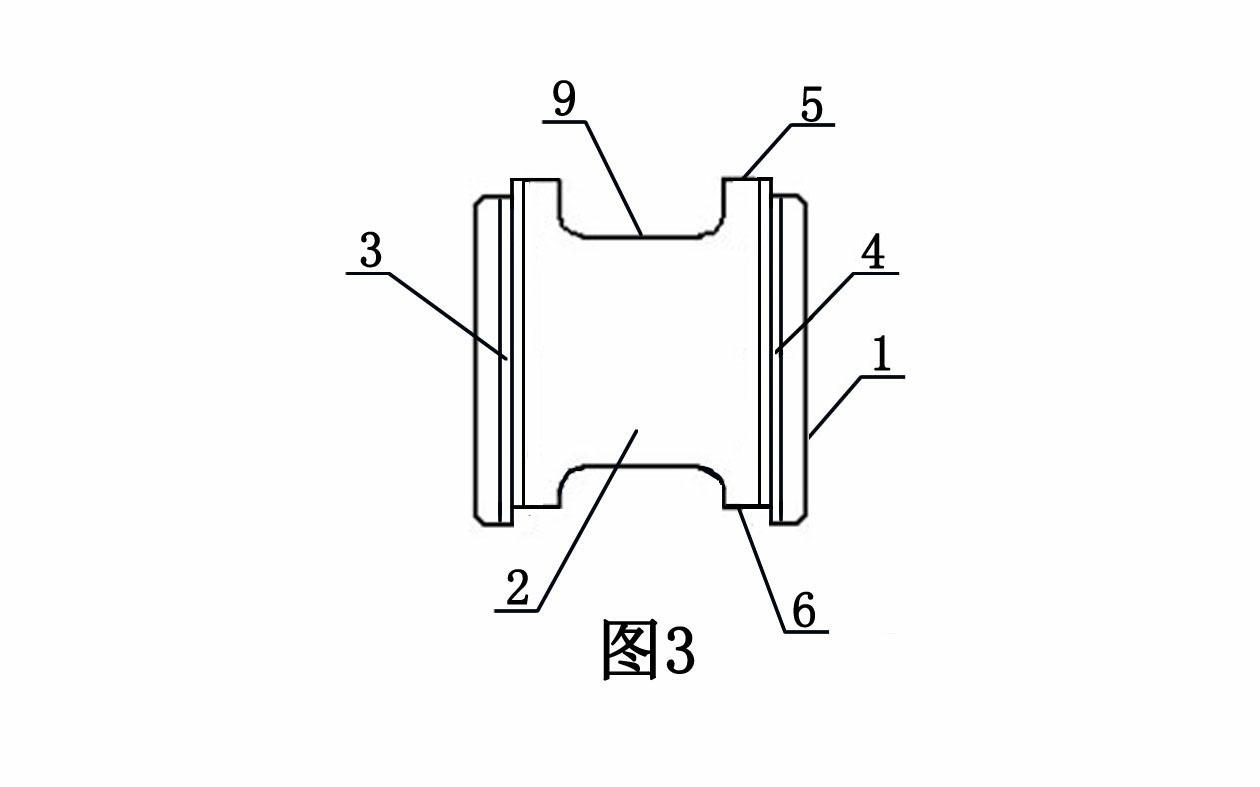

Fabricated blocks, fabricated-block building system and construction method thereof

InactiveCN102409796AImprove the seismic bearing capacityImprove anti-seepage and anti-leakage performanceWallsBuilding material handlingArchitectural engineeringRabbet

The invention discloses fabricated blocks, a fabricated-block building system and a construction method thereof. The fabricated blocks comprise a main block and auxiliary blocks, wherein the auxiliary blocks comprise 1 / 2 blocks, T-shaped node blocks, corner blocks and end blocks; the main block is composed of two parallelly-arranged long transverse ribs and at least two short longitudinal ribs perpendicularly connected between the two long transverse ribs; the two ends of the main block are both in an H-shaped open structure, the main block is in mortise-and-tenon joint with a block (horizontally adjacent to the main block) by virtue of a tenon and a rabbet, and simultaneously a vertical through hole is formed between the main block and the block (horizontally adjacent to the main block); and a horizontal through hole is formed between the main block and a block (vertically adjacent to the main block) by virtue of opposite openings of U-shaped grooves on the short longitudinal ribs. According to the invention, the relatively complex construction operation of traditional blocks bonded by using mortars is simplified, and the working efficiency, anti-permeability performance and leakage resistance of the block are improved, meanwhile, the noise and dust of an operation field also can be reduced, and energies and raw materials can be saved, thereby satisfying the green and environmentally-friendly requirements of building construction and facilitating the implementation of housing industrialization.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD +1

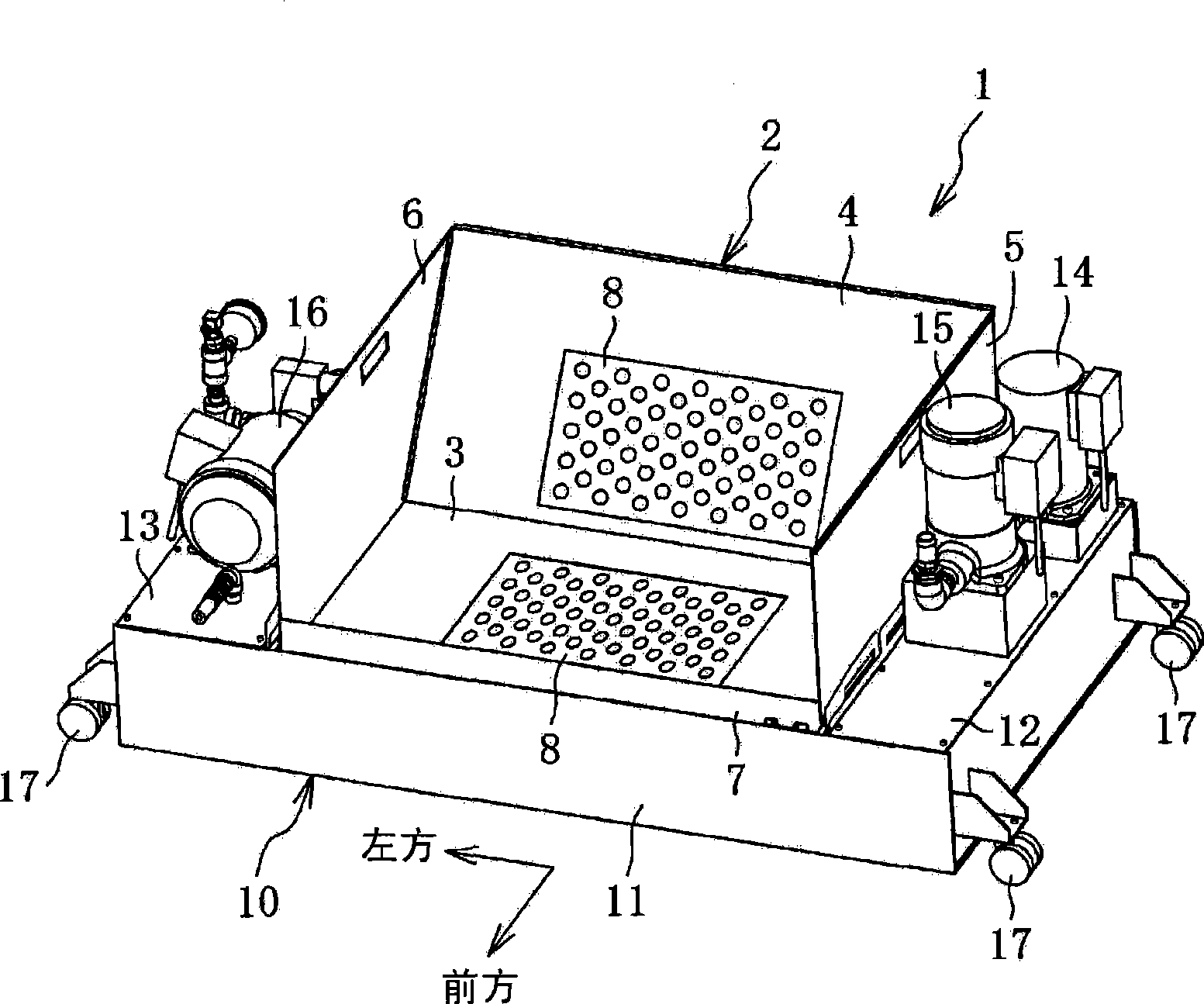

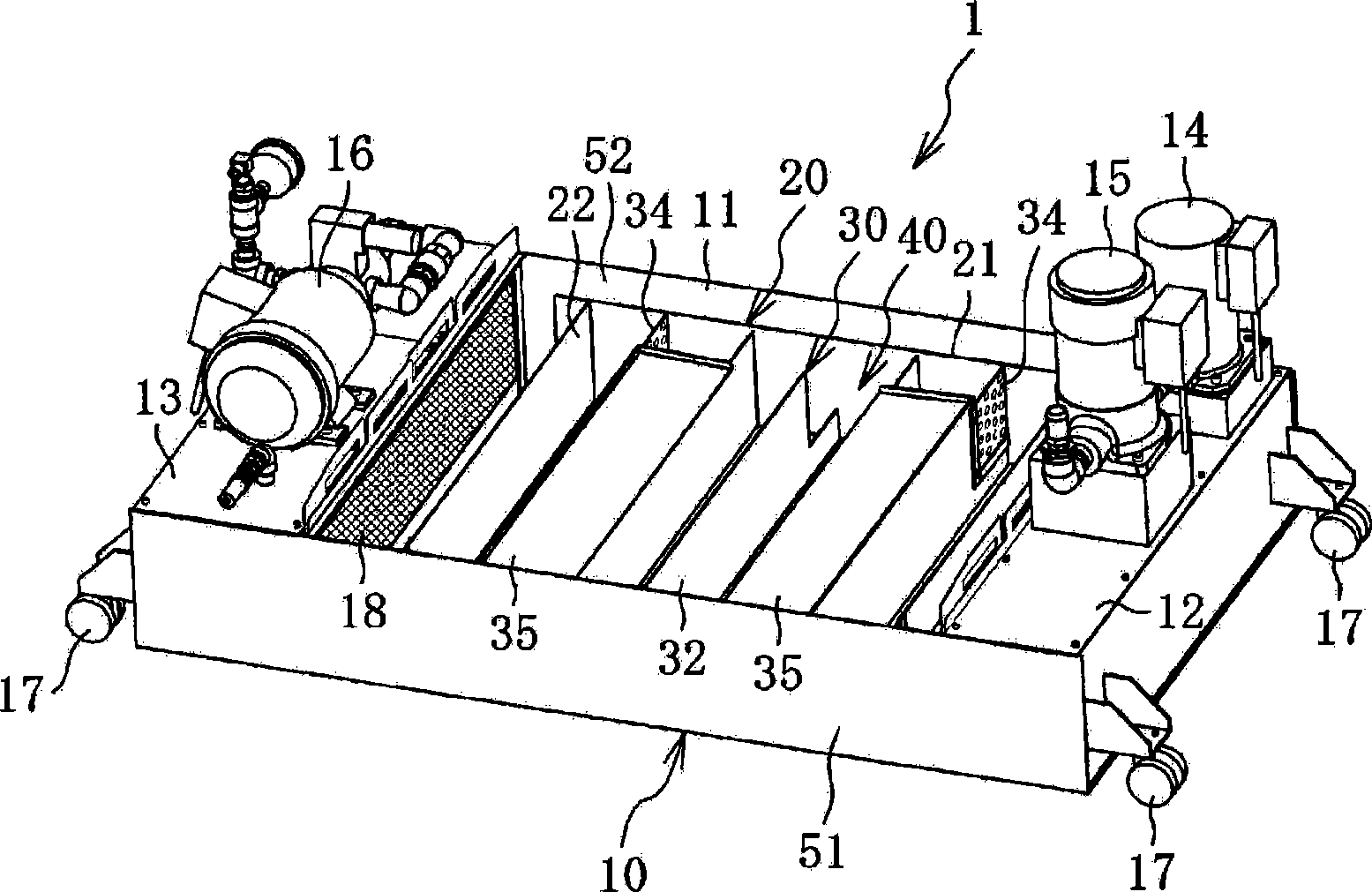

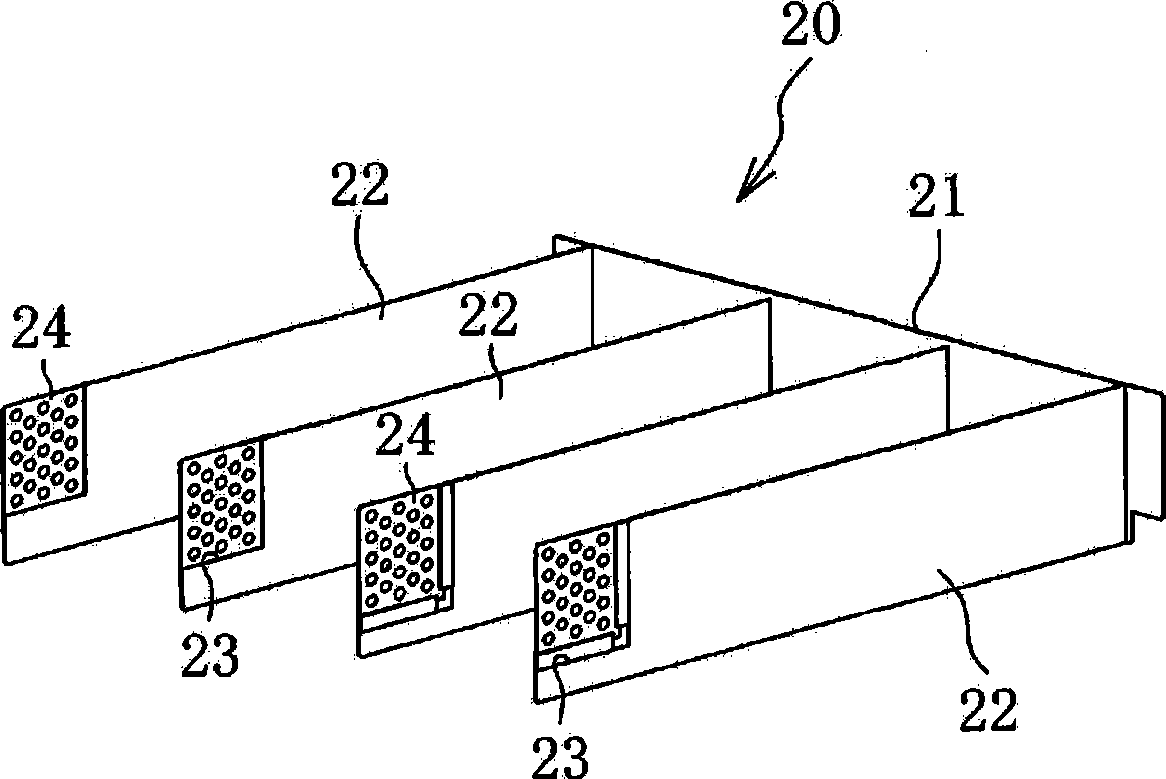

Device for filtering cutting fluid

ActiveCN101444889AImprove cleanlinessEfficient removalSedimentation separationFiltration circuitsEngineeringRabbet

The present invention provides a device for filtering cutting fluid, capable of availably separating and removing cutting waste in the cutting liquid after cutting treament, and availably cleaning the bottom of the reclaiming tank. The device includes a flow path forming body in the reclaiming tank, wherein the flow path forming body is provided with a connection plate and a plurality of baffles. The connection plate is parallel with the side wall of the reclaiming tank, and the baffles are spaced with each other by suitable distance in a parallel direction and are crossed with the connection plate on the square. The end portion of the different side of neighboring baffles is provided with a rabbet portion. In the device of the invention, due to the existing of the rabbet portion, the flow path of the cutting fluid is in serpentuate state along a horizontal direction, and the whole length of the flow path is increased, such that the cutting waste in the cutting fluid is deposited.

Owner:BROTHER KOGYO KK

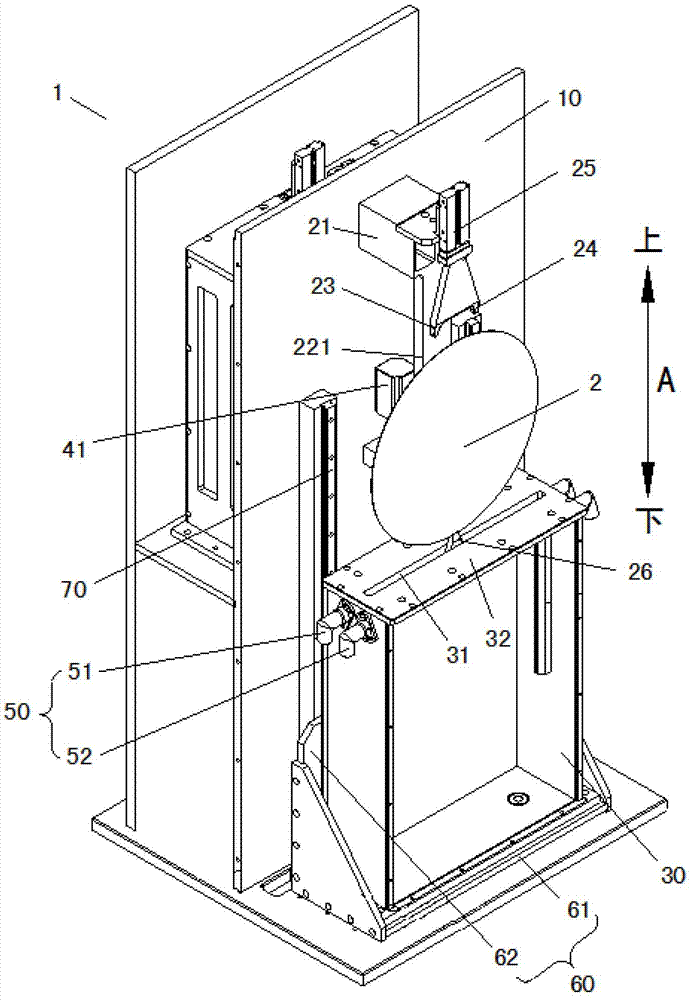

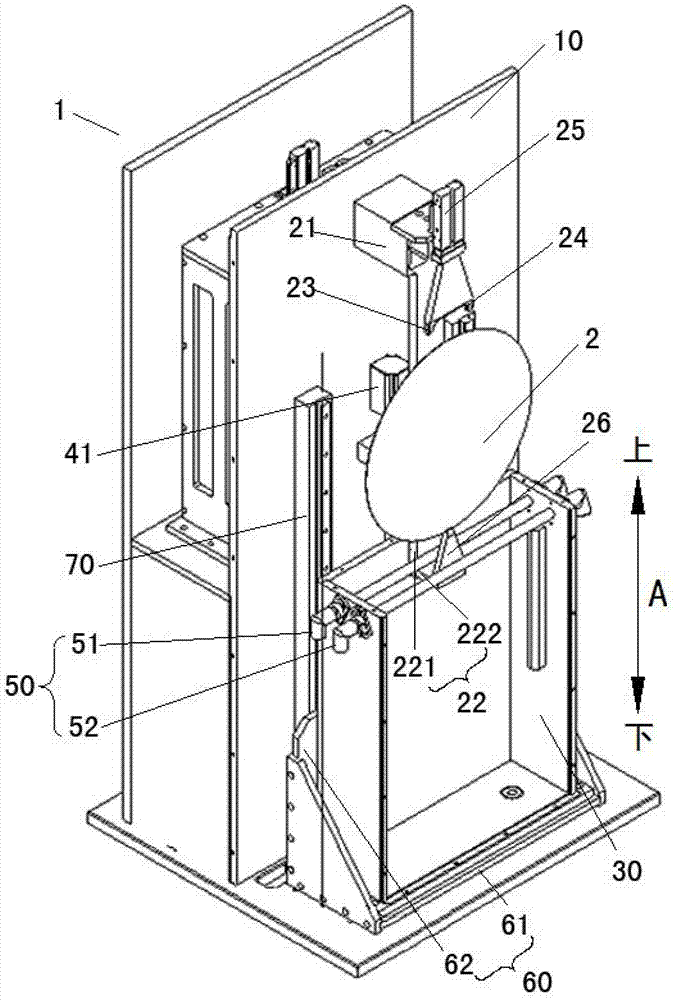

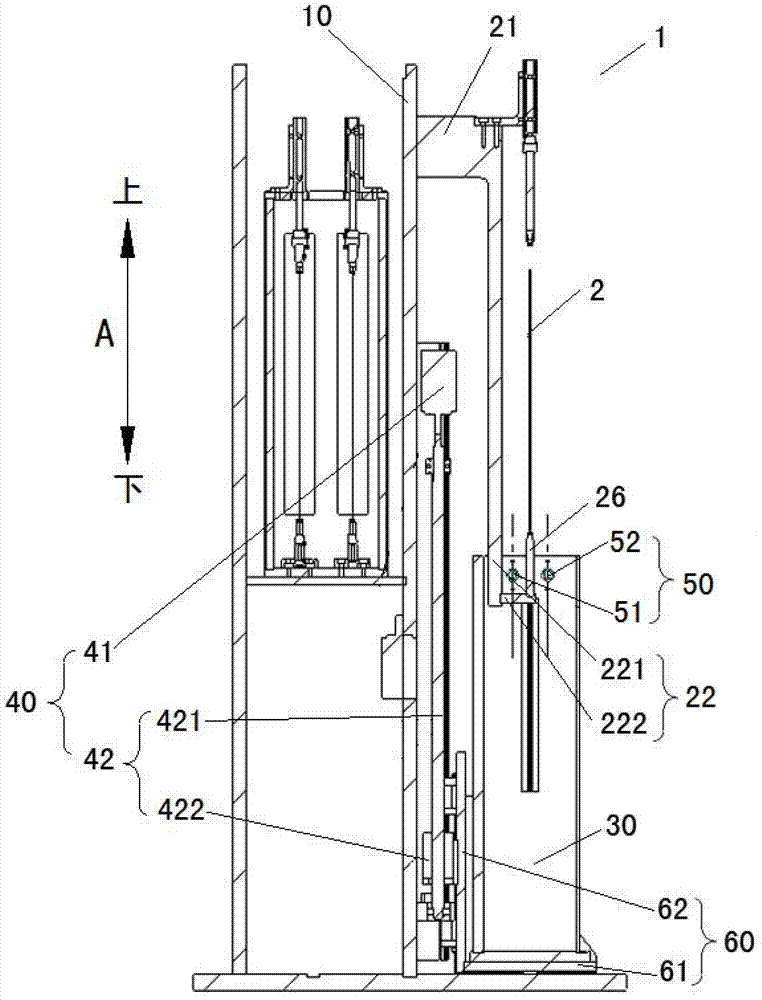

Wafer drying device

ActiveCN102768972AReduce machining accuracyReduce difficultyDrying gas arrangementsSemiconductor/solid-state device manufacturingRabbetIsopropyl alcohol

The invention discloses a wafer drying device. The wafer drying device comprises a body, a wafer clamping mechanism, a water tank, a water tank driving piece and an isopropyl alcohol (IPA) drying system, wherein the wafer clamping mechanism is arranged on the body and used for supporting a wafer which is directed along a vertical direction; the water tank is arranged on the body moveably up and down, and a rabbet which penetrates the top wall of the water tank along the vertical direction and where the wafer passes through is arranged in the top wall; the water tank driving piece is arranged on the body and connected with the water tank for driving the water tank to move up and down; and the IPA drying system is arranged on the water tank and used for drying the wafer. According to the embodiment of the invention, the wafer drying device has the advantages of small manufacturing difficulty, low manufacturing cost, high reliability and the like, and repositioning precision requirements on a mechanical arm which carries the wafer are greatly reduced.

Owner:TSINGHUA UNIV

High sensitivity liquid dielectric constant measuring probe

A high sensitivity liquid dielectric constant measuring probe, comprising a coaxial outer conductor, a coaxial inner conductor and packing filling between the inner conductor and the outer conductor,the coaxial outer conductor is cut thin partly and connected to the tunable outer conductor, the coaxial inner conductor is partly hollow, with the hollow position in in rabbet joint or cup joint with the tunable inner conductor, the length of the inner conductor and the outer conductor is all adjustable, a plurality of slots are arranged on the outer conductors.

Owner:SICHUAN UNIV

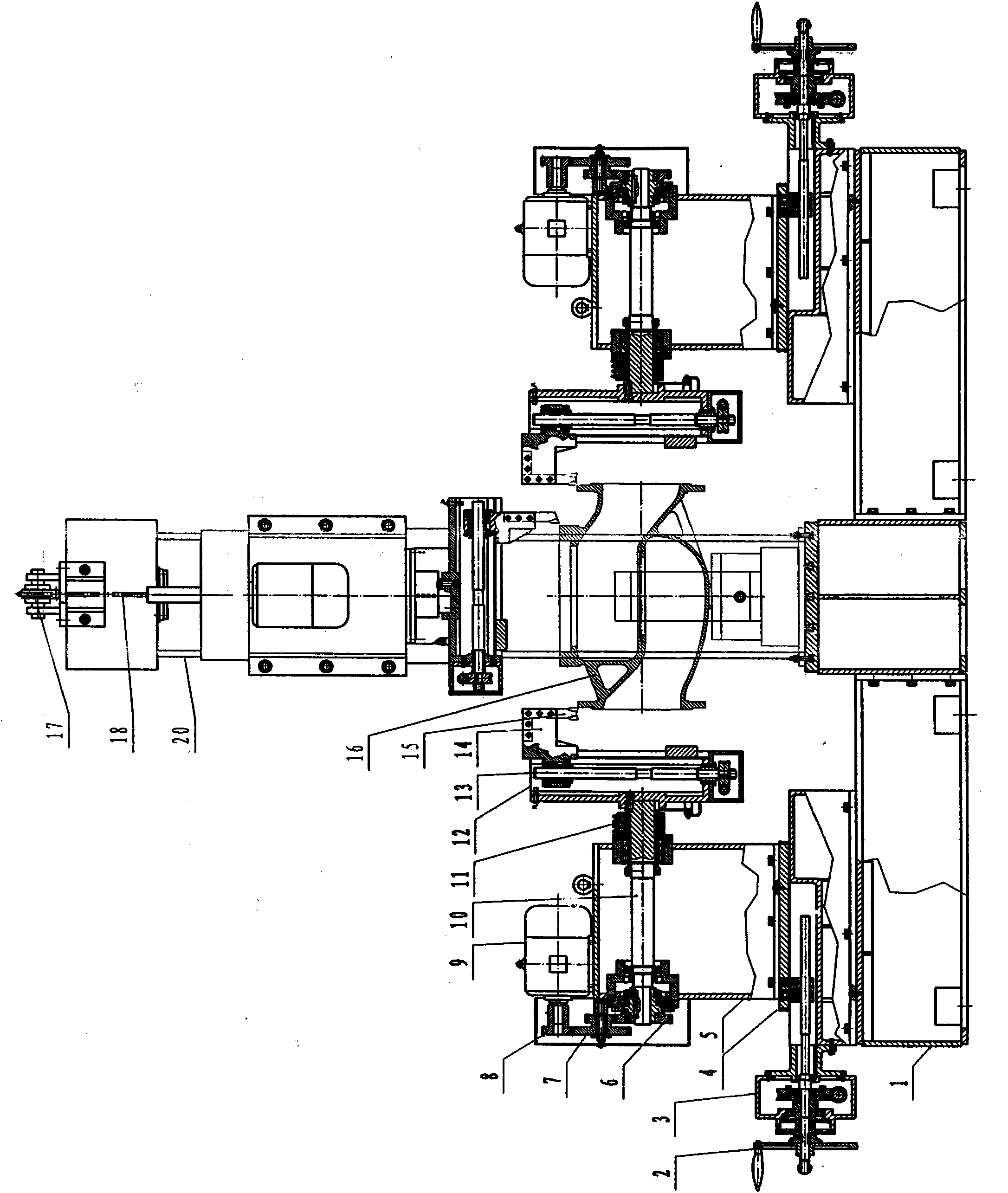

Three-station combined machining tool for valve body of valve

InactiveCN101869993APreserve machining accuracyReduce labor intensityFeeding apparatusTurning machinesControl systemEconomic benefits

The invention discloses a three-station combined machining tool for a valve body of a valve, which comprises a tool bed and three swivel stands, wherein each swivel stand mainly comprises a tool rest mechanism, a speed shifting mechanism, a main spindle box, a feeding mechanism and a control system, the tool bed is provided with a fixture, the three swivel stands are respectively arranged at the left part, the middle part and the right part of the tool bed to form a triangular structure, the left and the right swivel stands are arranged in opposite directions and are same in structure, and the middle swivel stand is vertically downwards arranged on a column. Only by single clamping and correcting, the three-station combined machining tool can simultaneously machine a left-end flange, a right-end flange and a rabbet (or a watermark trough) of a valve body workpiece of a valve as well as the surface rabbet, the inner hole and the like of a mount support at the upper end of the valve body in three three-dimensional directions, and therefore, the labor intensity of workers is reduced, time and labor are saved, the production efficiency and the product machining qualification rate are improved, and economic benefits of valve production enterprises are increased.

Owner:德阳市广泰机械科技有限公司

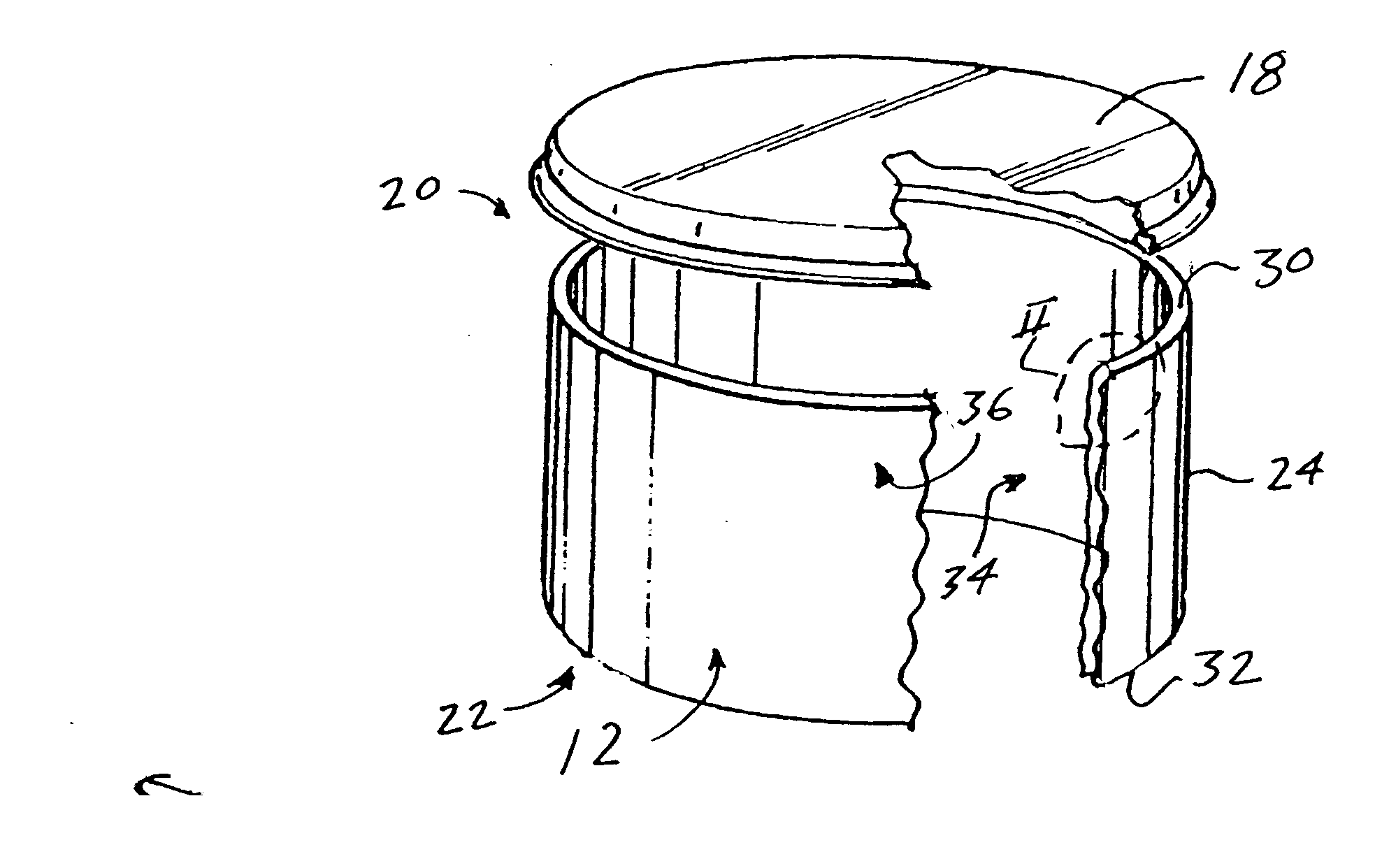

Drum with replaceable bearing edge

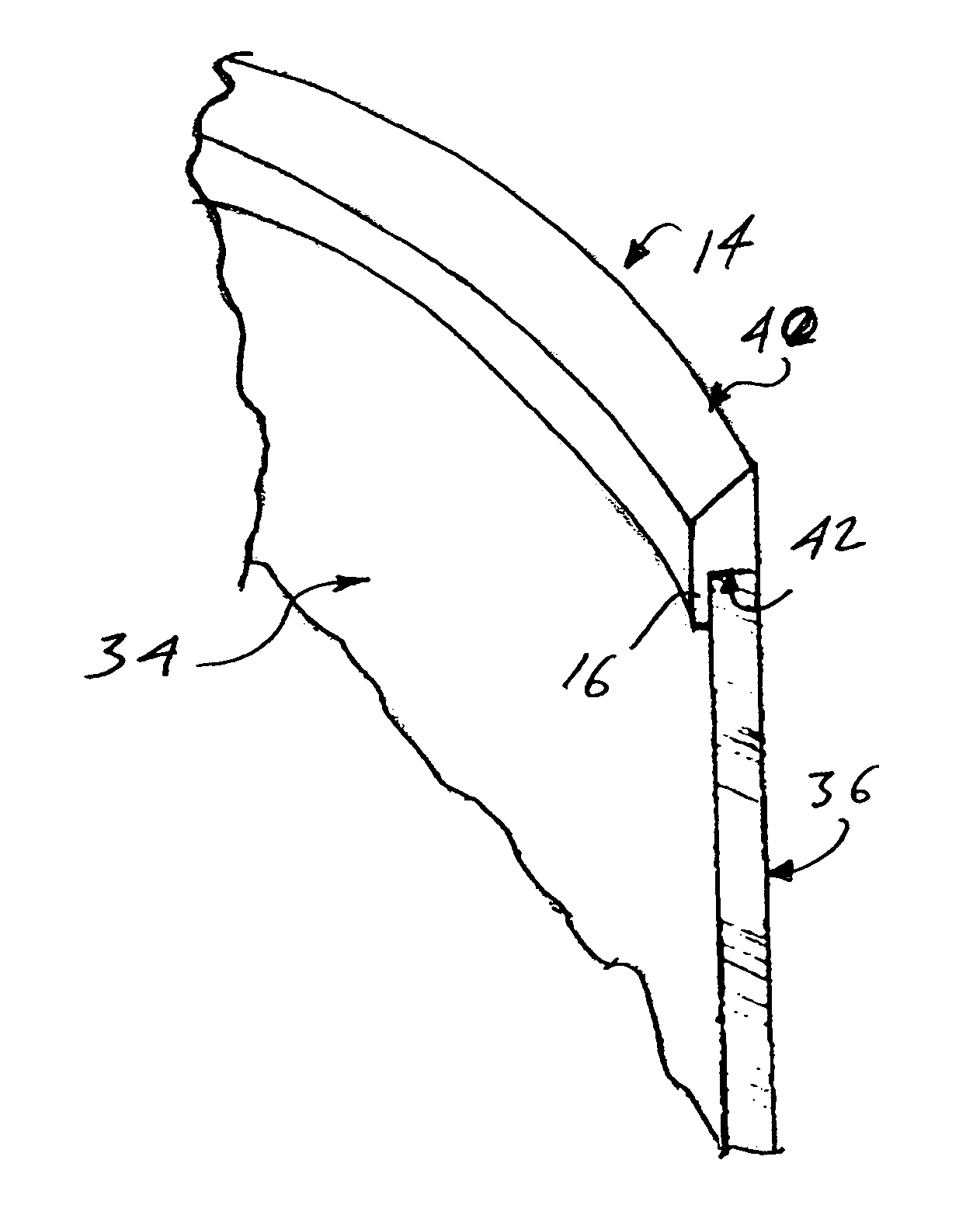

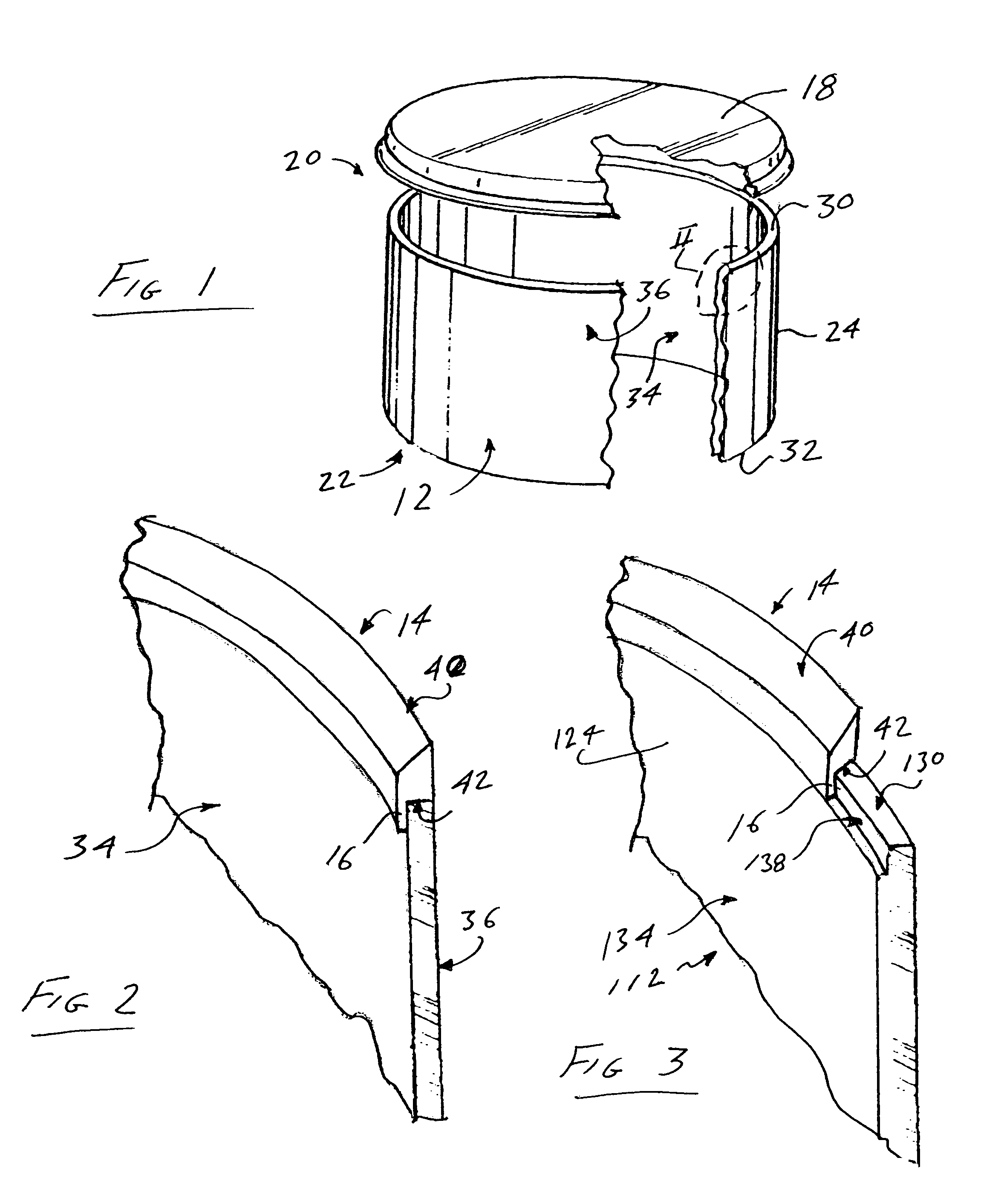

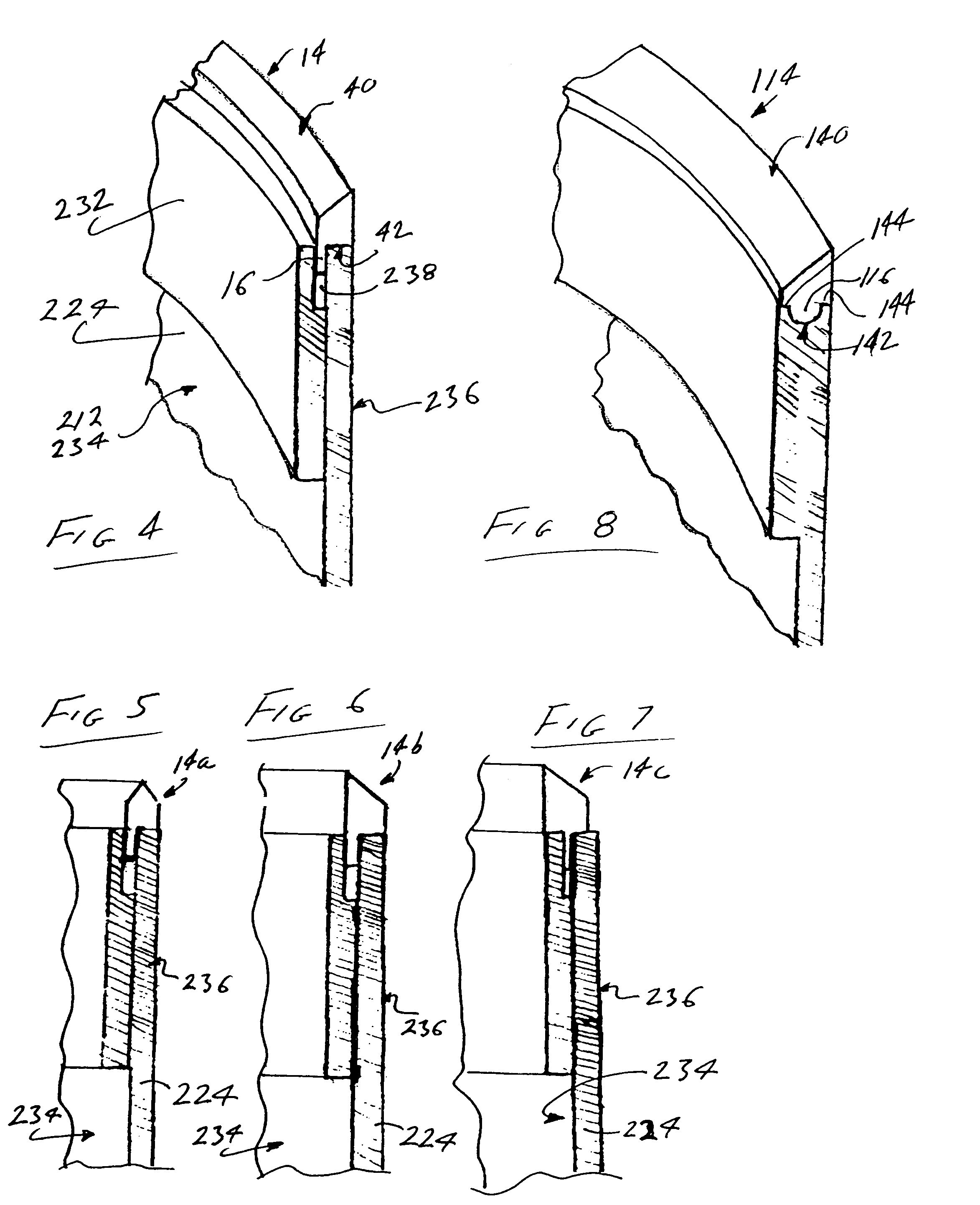

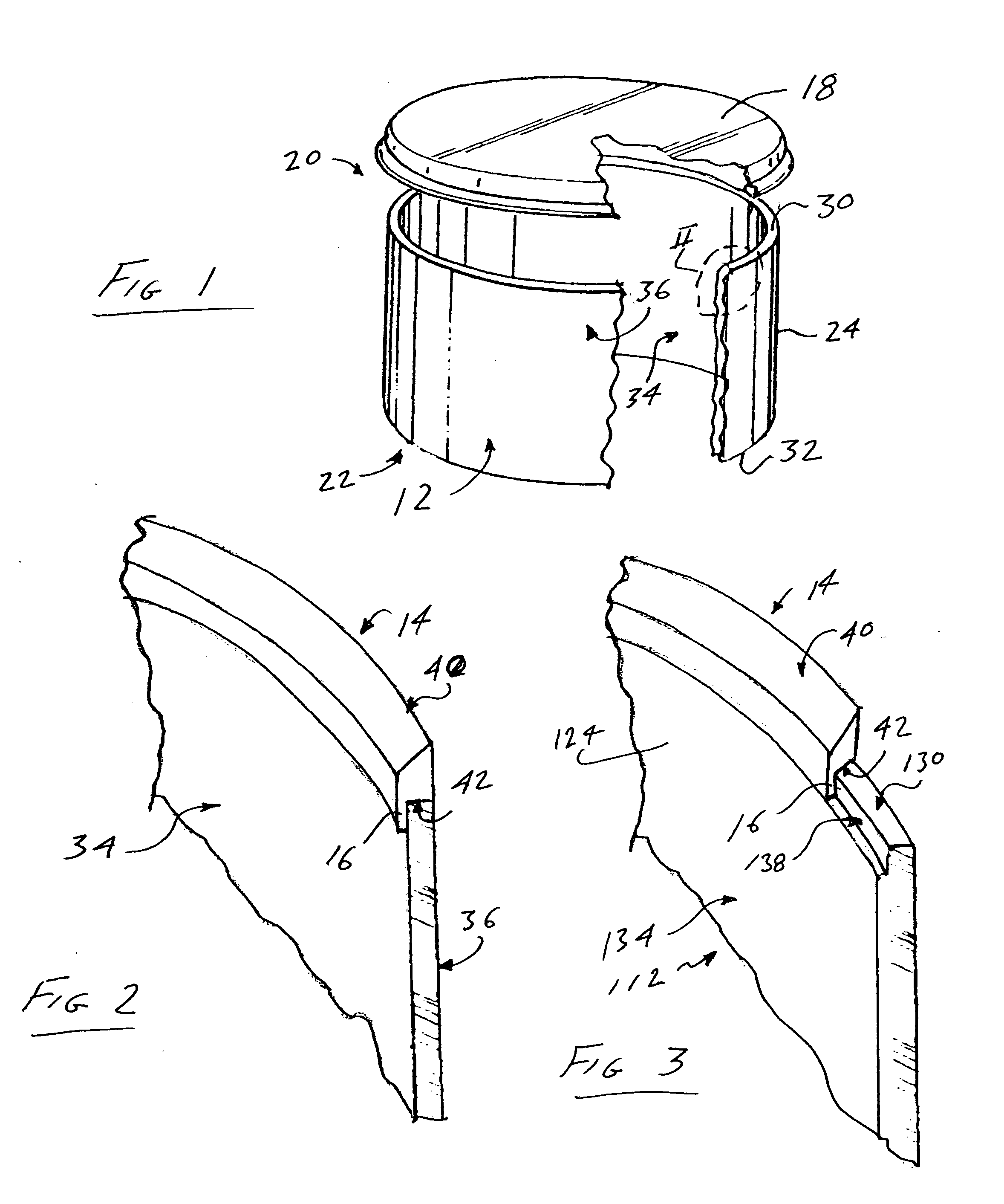

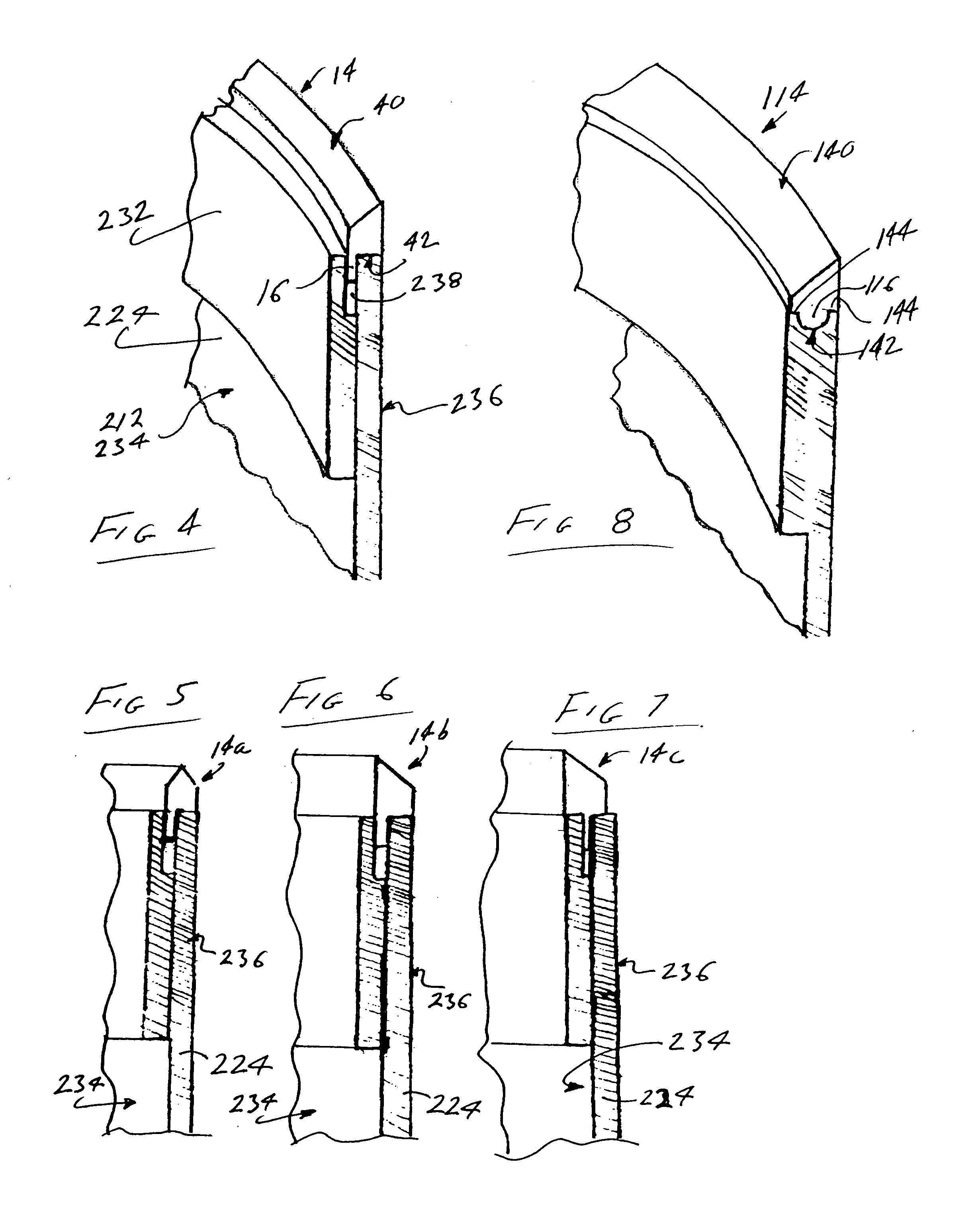

A drum of the invention has a tubular drum shell, a replaceable annular bearing edge, a spline interconnecting the shell and the bearing edge, and a membrane overlaying the bearing edge. The bearing edge may have any of various profile configurations. The bearing edge overlays a shell edge in releasable engagement. A spline extends from the bearing edge and engages a recess, including an annular rabbet between the wall edge and an inside wall surface, or an annular void, including an annular slot dado, in the shell wall, releasably coupling the bearing edge and the shell. The shell may include an aperture through the wall. An air valve may be provided to regulate passage of air through the aperture between open and closed positions. The air valve may support an audio reception device. A portion of the inside wall surface may have an acoustic pattern that influences the drum's sound. The drum may also have a flangeless hoop or arcuate portions of the hoop without a flange. A point suspension tension lug may secure the head to the shell.

Owner:RUSH MARK A

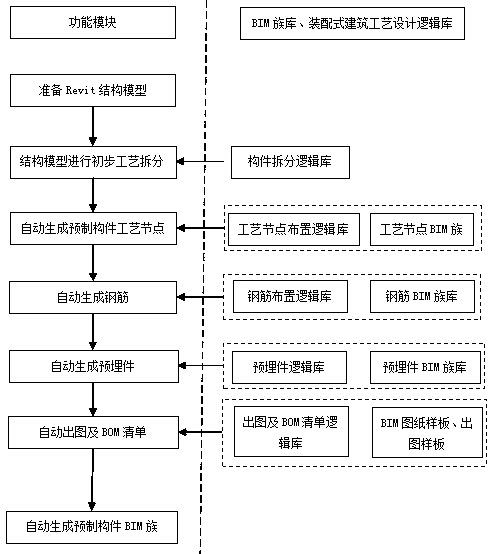

BIM-based prefabricated building quick process design method

InactiveCN108388719AQuick plotSave process design timeGeometric CADDesign optimisation/simulationRabbetSteel bar

The invention discloses a BIM-based prefabricated building quick process design method. The method comprises the seven steps of quickly splitting a prefabricated building process; parametrically automatically generating prefabricated member process nodes such as rabbets, grooves and the like of members; parametrically automatically generating reserved embedded parts of the members; parametricallyautomatically generating steel bars of the members; automatically generating a prefabricated member process design graph and a BOM; and automatically generating prefabricated member family files. Based on a Revit platform, the Revit platform is subjected to secondary development. The system, while having basic advantages of visual design, convenient modification and the like of BIM software, greatly shortens modeling time and graph generation time in a prefabricated building process design process, can at least shorten existing prefabricated building process design time by 50%, and provides convenience for subsequent process design and adjustment.

Owner:墨点狗智能科技(东莞)有限公司

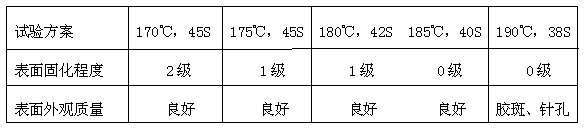

Low-formaldehyde-emission abrasion-resistant and moisture-proof laminate wood flooring and production and laying method for laminate wood flooring

ActiveCN103243892AImprove water resistanceReduced degree of water swellingLamination ancillary operationsSynthetic resin layered productsFiberPolymer science

Disclosed are low-formaldehyde-emission abrasion-resistant and moisture-proof laminate wood flooring and a production and laying method for the laminate wood flooring. The laminate wood flooring is provided with an impregnated abrasion-resistant paper layer, an impregnated separation paper layer, an impregnated decorative paper layer, a high-density fiberboard layer and an impregnated balance paper layer successively from the surface layer to the bottom layer. Impregnated balance paper, a high-density fiberboard, impregnated decorative paper, impregnated separation paper and impregnated abrasion-resistant paper which are sacked successively are subjected to hot pressing at the temperature ranging from 175 DEG C to 185 DEG C and under the pressure in a range of 5MPa to 9MPa for 40S to 45S to be produced into a large semi-manufactured plate; the large semi-manufactured plate is subjected to splitting, healthy balance treatment and rabbet machining to be manufactured into small plates; the small plates are manufactured into laminate wood flooring by coating polyurethane lacquer at peripheral rabbet positions; and sawing section fibers of the flooring is subjected to the first coating through the polyurethane lacquer during laying, the polyurethane lacquer is dried till the lacquer surface is tacky but not sticky when touched with fingers, and the flooring is laid after the second coating is performed.

Owner:圣保罗家居科技有限公司

Drum with replaceable bearing edge

A drum of the invention has a tubular drum shell, a replaceable annular bearing edge, a spline interconnecting the shell and the bearing edge, and a membrane overlaying the bearing edge. The bearing edge may have any of various profile configurations. The bearing edge overlays a shell edge in releasable engagement. A spline extends from the bearing edge and engages a recess, including an annular rabbet between the wall edge and an inside wall surface, or an annular void, including an annular slot dado, in the shell wall, releasably coupling the bearing edge and the shell. The shell may include an aperture through the wall. An air valve may be provided to regulate passage of air through the aperture between open and closed positions. The air valve may support an audio reception device. A portion of the inside wall surface may have an acoustic pattern that influences the drum's sound. The drum may also have a flangeless hoop or arcuate portions of the hoop without a flange. A point suspension tension lug may secure the head to the shell.

Owner:RUSH MARK A

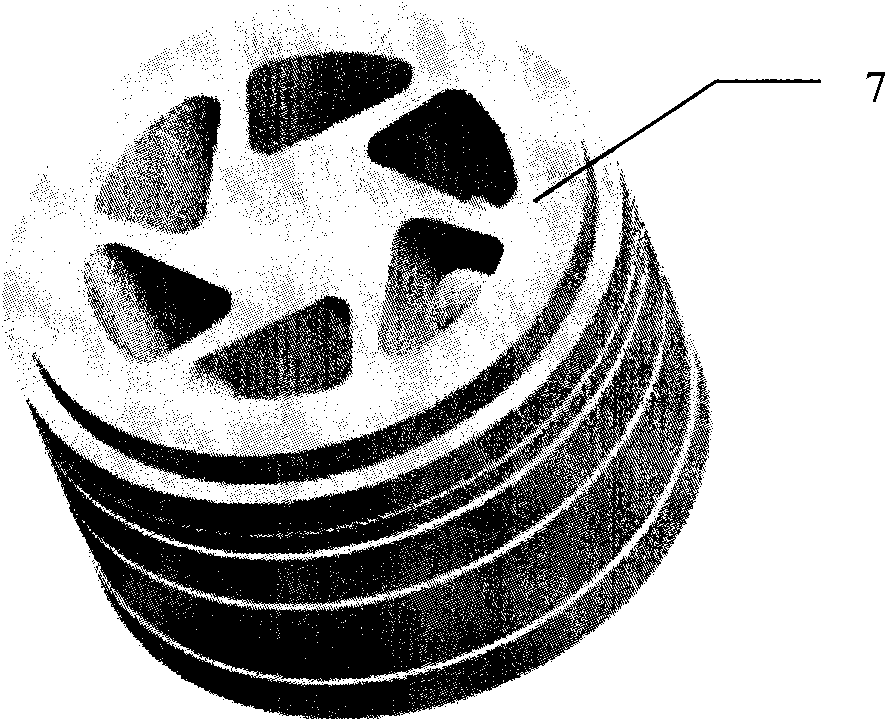

Helical tube hot-extrusion die in porous magnesium alloy

InactiveCN101633009AReduce resistanceGuaranteed dimensional accuracyExtrusion diesCircular discStructural symmetry

A helical tube hot-extrusion die in porous magnesium alloy belongs to the technical field of die processing. The helical tube hot-extrusion die comprises an upper die, a middle die and a lower die, wherein, the upper die, the middle die and the lower die are sequentially sheathed and are of disk structures, and rabbets, locating pins and bolts are respectively arranged between the upper die and the middle die as well as between the middle die and the lower die for fixation. A helical flow supply mode is adopted for the upper die of the helical tube hot-extrusion die, which significantly lowers resistance formed by helical shaping of tube blank by special helical equipment when a tubular product is extruded; and a circular welding cavity is adopted for the lower die, which is beneficial for rotary welding of a magnesium alloy material of plastic flow in the welding cavity. Meanwhile, dimensional accuracy of a metal is ensured under the action of a forming cavity working tape when the metal is extruded out of the welding cavity, and the die structure has good symmetry, thus reducing non-uniformity of feed stock flow, and avoiding cracking of tube walls when a helical aperture is formed on the magnesium alloy material. The helical tube hot-extrusion die has the advantages of high preparation and production efficiency, few waste materials, good quality and being more favorable for meeting the requirements of continuous production.

Owner:SHANGHAI JIAO TONG UNIV +1

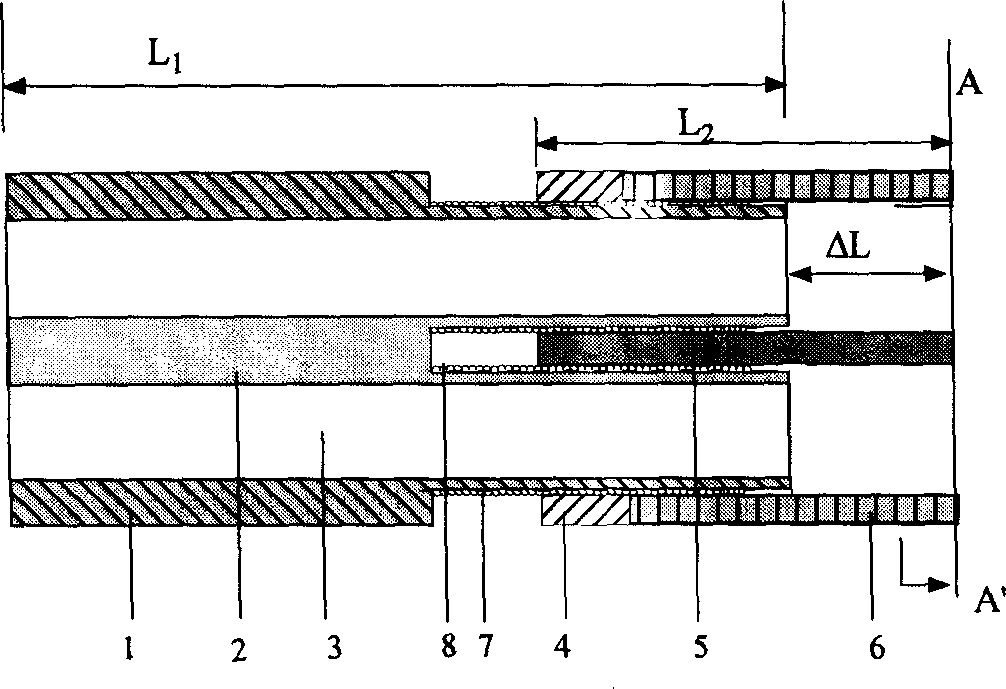

Weld prep joint for electron beam or laser welding

InactiveUS20060231531A1Preventing burn-throughRemoval from surfaceTurbinesBlade accessoriesEngineeringRabbet

A weld prep joint for welding a pair of axially aligned first and second machine rotor forgings includes a first weld joint configuration in an end of the first rotor forging including a first radial weld surface and a first axial rabbet surface; a second weld joint configuration on an end of the second rotor forging including a second radial weld surface adapted to engage the first radial weld surface, a second axial rabbet surface adapted to engage the first axial rabbet surface, and a third radial non-weld surface extending radially inwardly of the second rabbet surface and axially offset from the second radial weld surface.

Owner:GENERAL ELECTRIC CO

Instrument and method for testing permeability coefficient of water-permeable cement concrete

InactiveCN102183445AHigh measurement accuracySimple structurePermeability/surface area analysisGraduated cylinderRabbet

The invention provides an instrument for testing a permeability coefficient of water-permeable cement concrete. The instrument comprises an upper sectional water container and a lower sectional water container which are connected with each other through a rabbet; a first overflow opening is formed on the head of the upper sectional water container; a plurality of pivots for supporting a water permeability cement concrete test piece to be tested are arranged at the upper end of the lower sectional water container; a second overflow opening is formed below the pivots; the second overflow opening is connected with a water-drainage-height-adjustable water drainage pipe; and a measuring cylinder is arranged below the water drainage pipe. The invention also provides a method for testing the permeability coefficient of the water-permeable cement concrete. The method is easy in operation, and the instrument has a simple structure and is high in measurement precision; and the water permeability cement concrete test piece can be tested on any occasion.

Owner:FUJIAN UNIV OF TECH

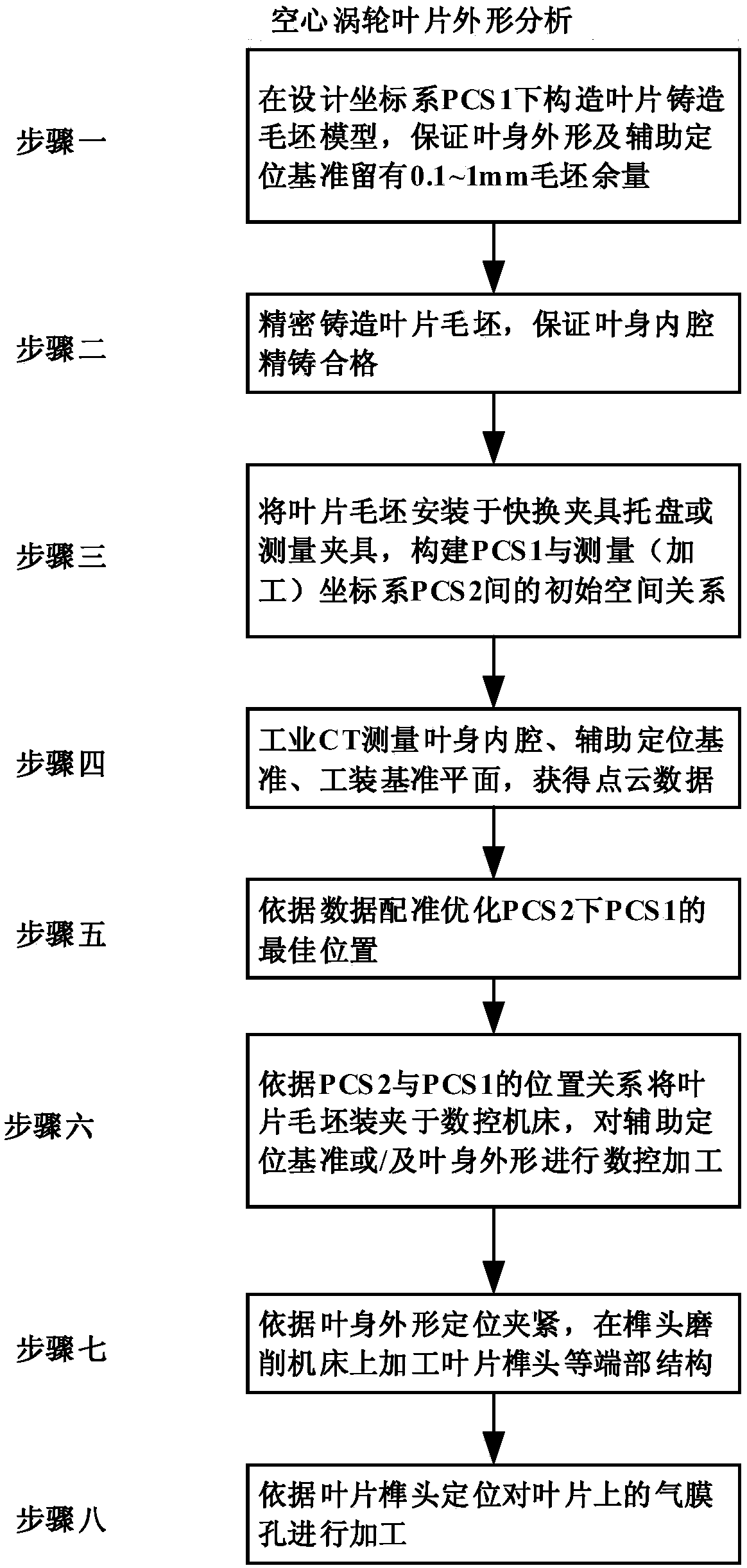

Cold-heat composite manufacturing method for machining of hollow turbine blade inner cavity precision casting appearance

ActiveCN107717364AImprove manufacturing pass rateImprove manufacturing precisionPoint cloudTurbine blade

The invention discloses a cold-heat composite manufacturing method for machining of the hollow turbine blade inner cavity precision casting appearance. The method comprises the steps that a turbine blade casting blank model is designed, a blade blank is cast, and the blade six-freedom-degree positioning datum point or the blade equivalent structure of the six-freedom-degree positioning datum pointis reserved; a rapid replacement clamp tray or a measuring clamp is arranged on a blade rabbet part, and accurate positioning of the blade is conducted; an industrial CT measuring device is used forobtaining point cloud data of a blade inner cavity, the blade inner shape and appearance, other related surfaces, auxiliary positioning datum and the like, a coordinate system is designed after fitting, and grinding machining or milling machining is conducted on the auxiliary positioning datum on the blade and the blade body appearance; the blade is positioned and clamped according to the machinedblade body appearance, and a tenon grinding machine tool is utilized for machining a blade tenon and other end portion structures; and air film holes in the blade are machined through tenon positioning. The casting process is simplified, meanwhile, the blade inner cavity and appearance manufacturing precision is guaranteed, the strict requirement for precision of the relative position of the blade inner cavity and the blade appearance is guaranteed, and the hollow turbine blade manufacturing qualification rate can be obviously increased.

Owner:枣庄北航机床创新研究院有限公司 +1

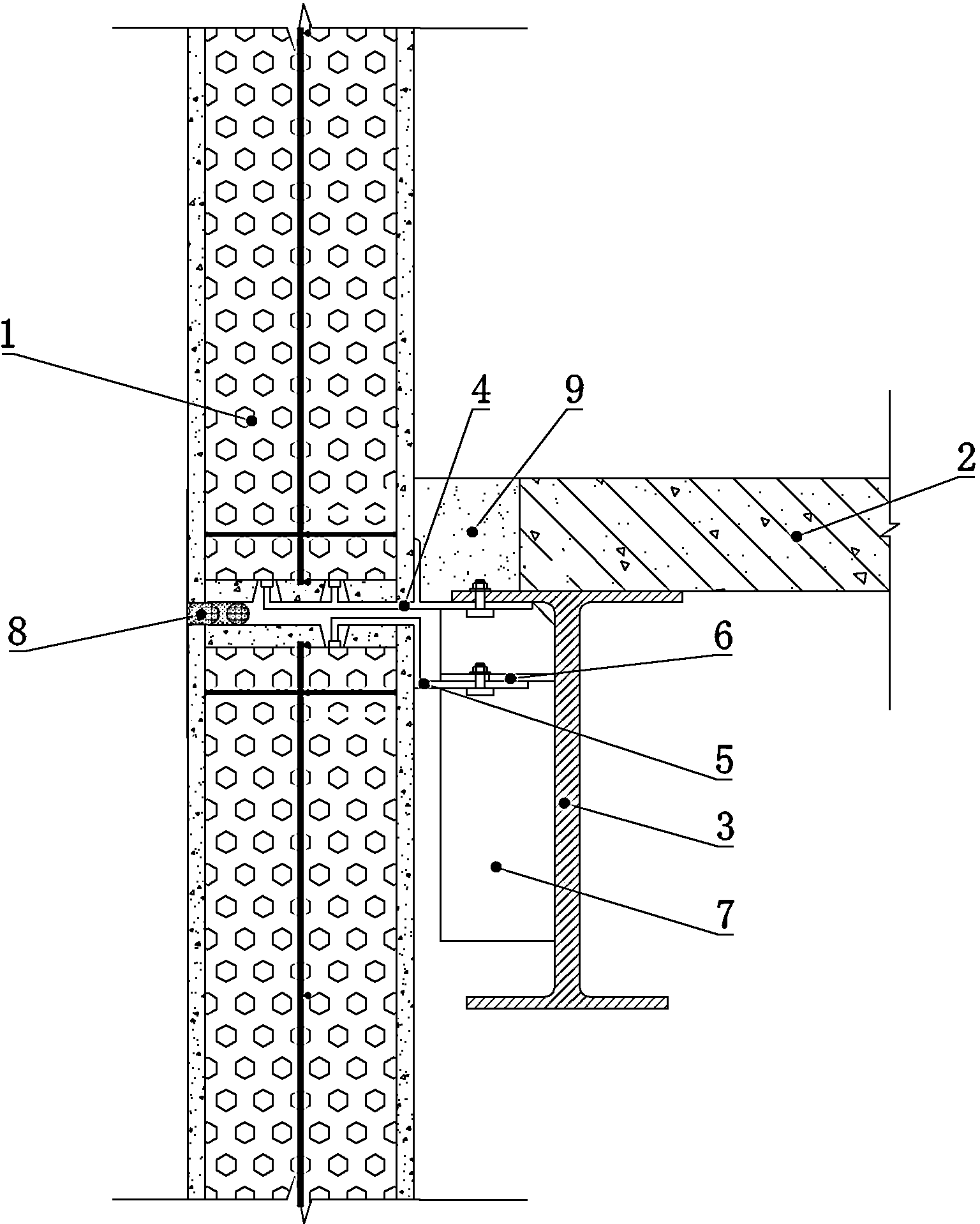

Foam concrete panel, rabbet connecting piece and wallboard externally hung structure

The invention discloses a foam concrete panel, a rabbet connecting piece and a wallboard externally hung structure. The rabbet grooves extended along the direction of a panel surface are respectively arranged on the upper end and the lower end of the foam concrete panel, the rabbet groove is a straight-through groove, the rabbet connecting pieces are respectively fixed on the upper end and lower end of the foam concrete panel body on a beam of the house, the rabbet connecting piece comprises a main part overhung to the outside of a house and a tongue protruded on an overhanging end of the main part, and the tongue is in guiding cooperation with the rabbet groove along the plane direction of the foam concrete plane body. While in use, the rabbet connecting piece is fixed on the beam of the house, the tongue on the rabbet connecting piece can form a corresponded guide rail structure at the upper side and the lower side of the installation position of the foam concrete panel, and then the foam concrete plane is introduced to slip into an area between the rabbet connecting pieces through the guiding cooperation between the tongue and the rabbet groove, so that the construction efficiency of the wallboard externally hung structure is accelerated, and the construction cycle is shortened.

Owner:河南亚鹰钢结构幕墙工程有限公司

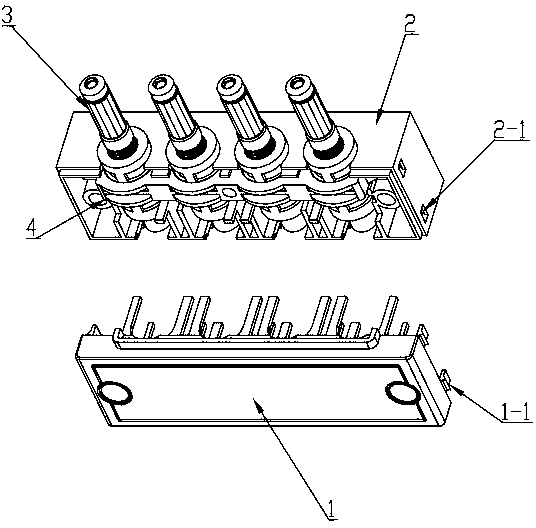

Gauge box pluggable electric energy meter installation base

The invention discloses a gauge box pluggable electric energy meter installation base which comprises a box body, fixing strips and current terminals. The fixing strips and the current terminals are all arranged inside the box body. The box body comprises an upper plastic cover and a lower plastic cover. First UR-type fixing pieces and first fixing long grooves are formed in the bottom face of the inner side of the upper plastic cover. Second UR-type fixing pieces, second fixing long grooves and thread fixing holes are formed in the bottom face of the inner side of the lower plastic cover. The front side wall and the rear side wall of the upper plastic cover and the front side wall and the rear side wall of the lower plastic cover are respectively provided with wire inlets and installation rabbets. Compression springs and installation holes are formed in the fixing strips. The current terminals are sequentially sleeved with current terminal heads, elastic copper sleeves, springs and insulation plastic rings from top to bottom. The current terminals are embedded into the second UR-type fixing pieces on the bottom face of the inner side of the lower plastic cover and the installation rabbets in the rear wall of the lower plastic cover through the insulation plastic rings, wherein the current terminals are sleeved with the insulation plastic rings. The gauge box pluggable electric energy meter installation base has the advantages of being high in current breakover rate, small in emitted heat, small in electric energy loss, flexible in application, convenient to combine and wide in application range.

Owner:浙江永信电气科技股份有限公司

Environment-friendly, flame-retardant and antibacterial laminated wood floor and manufacturing method thereof

ActiveCN105365021ATo protect the mildew, rot and other problems caused by water seepage and dampRevitalizationWood treatment detailsFlat articlesFiberHazardous substance

The invention belongs to the technical field of manufacturing of laminated wood floors and particularly relates to an environment-friendly, flame-retardant and antibacterial laminated wood floor and a manufacturing method thereof. The manufacturing method includes the steps that fibers are made through a traditional method and then dried, mixed glue having no harm to human bodies is added, the mixture forms a sheet through hot pressing, two surfaces of the sheet and a rabbet of the finished floor are processed through mixed oil, and then the environment-friendly, flame-retardant and antibacterial laminated wood floor is obtained. The laminated wood floor obtained through the manufacturing method for the environment-friendly, flame-retardant and antibacterial laminated wood floor is made of the materials containing no harmful matter like formaldehyde, and is environmentally friendly. The added mixed oil can resist bacteria, kill insects and effectively avoid bacterium breeding. The wood floor formed by adding organic amino resin and silicon dioxide has excellent flame retardant performance, and fire risks or accidents of personal injury caused when the floor catches a fire can be reduced effectively.

Owner:成都市美康三杉木业有限公司

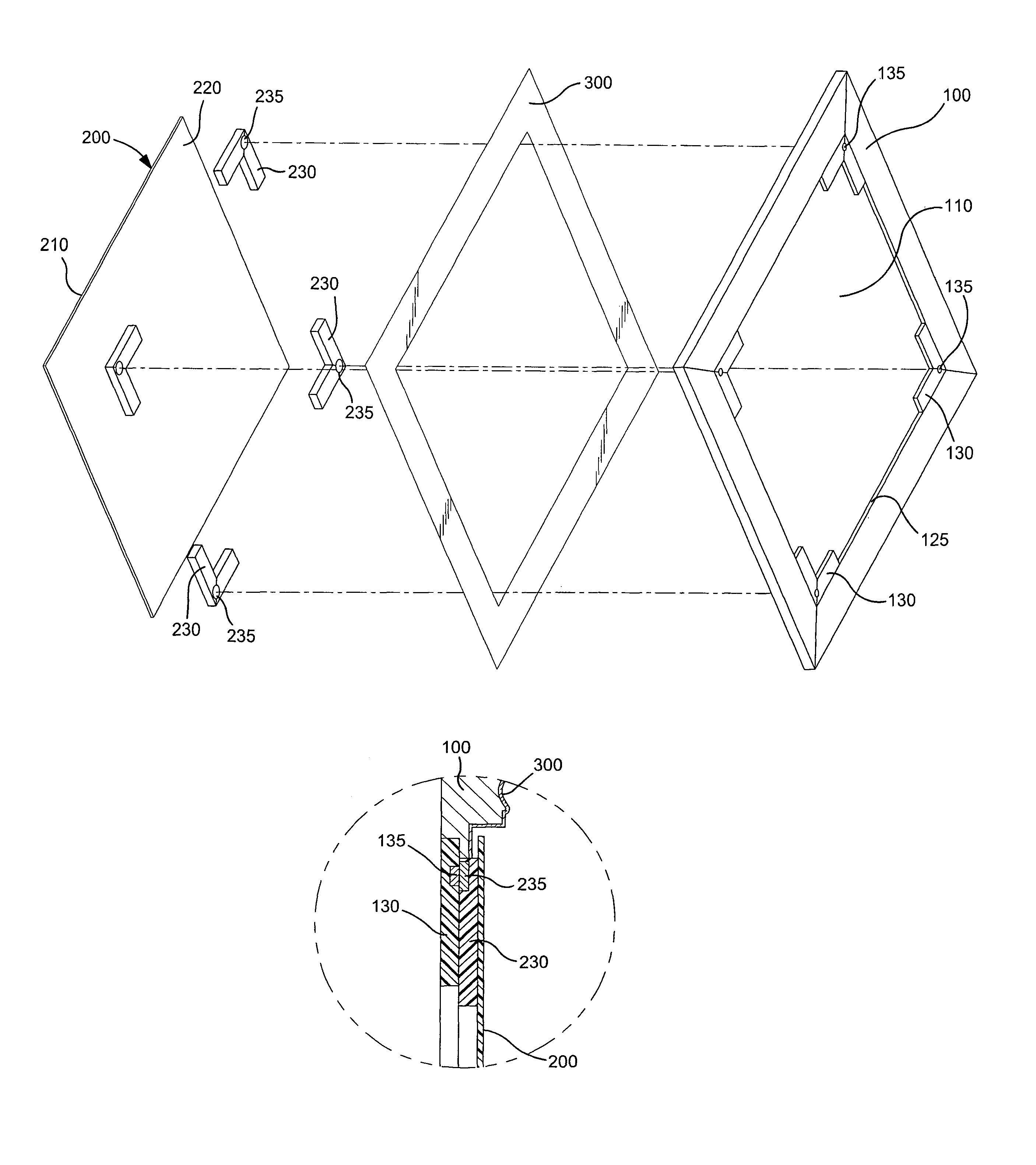

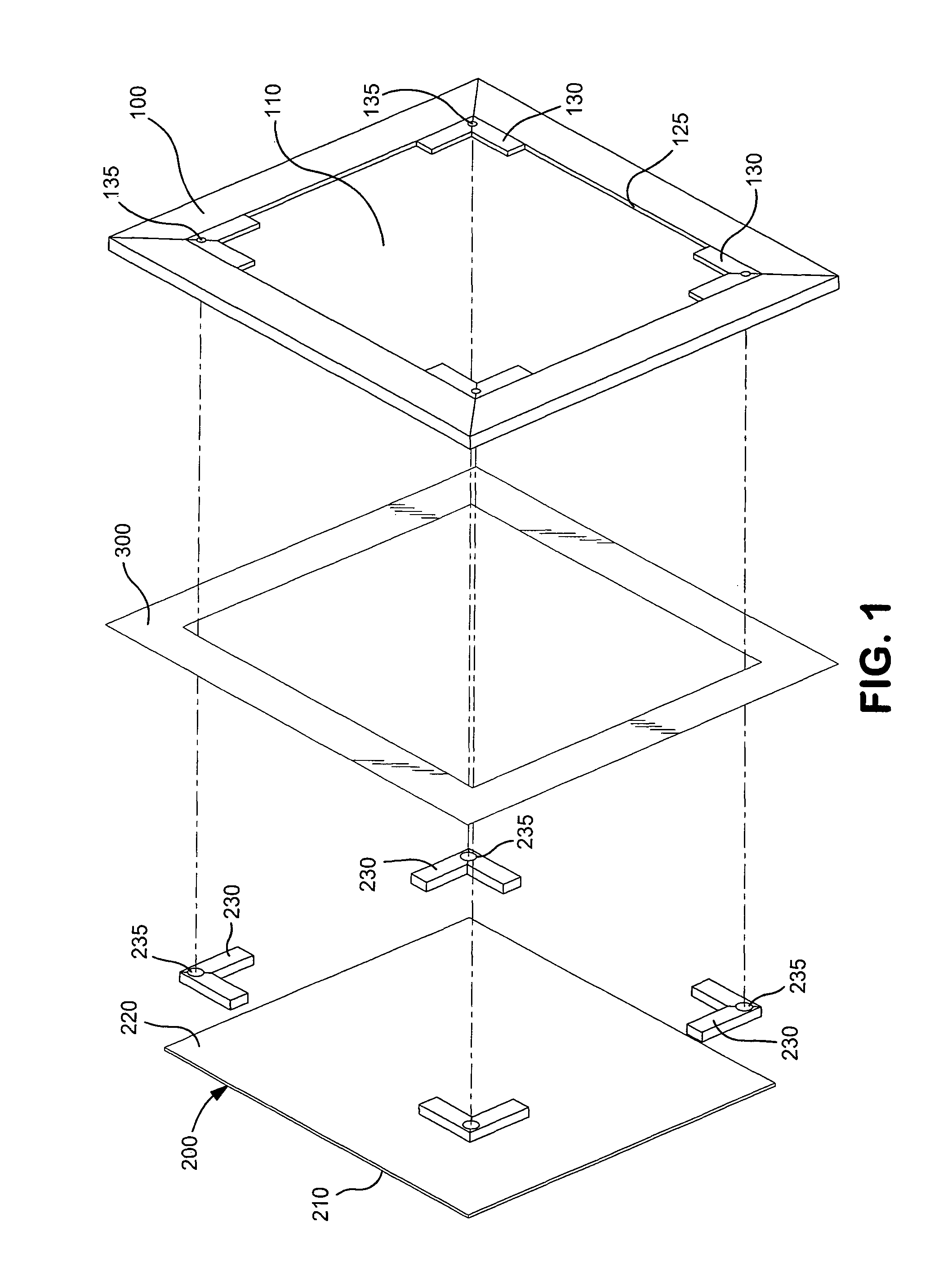

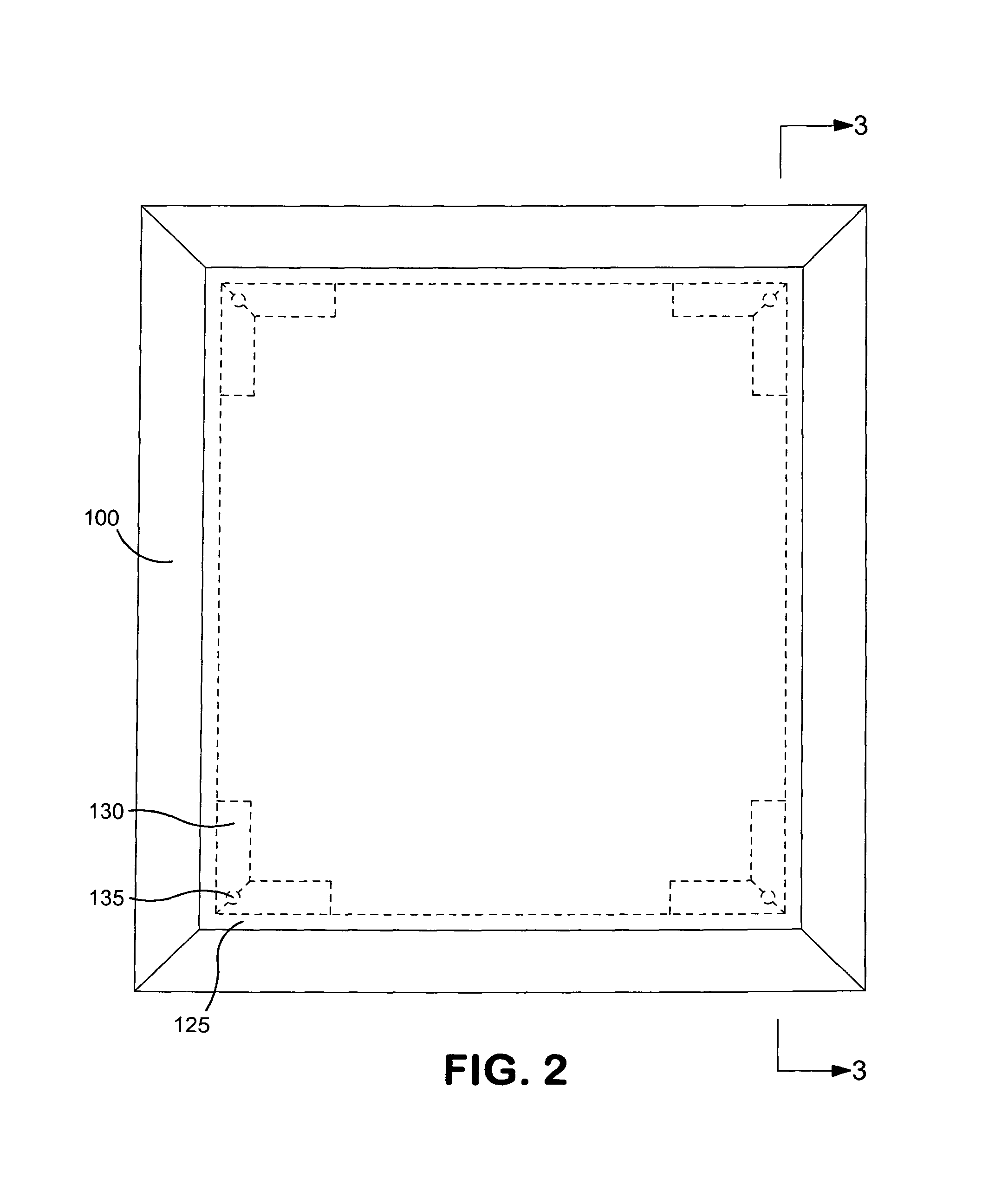

Picture frame with protective cover and interchangable canvas

A frame is adapted to hold a canvas that comprises a molding constructed and arranged to form a picture frame. The picture frame includes a front viewer facing side and rear wall facing side and a central opening defined by the molding. Additionally, a rabbet extends about the peripheral edge of the molding proximate the opening on the wall facing side. A removable protective covering covers in contacting overlying relation the molding. A canvas has a front viewer side and a rear wall facing side, the canvas being constructed and arranged to overlie and cover the opening and the protective covering when the protective covering is in place over the molding. A first magnet for detachably mounting said canvas to the front side of the frame is operatively associated with the canvas and a second magnet is operatively associated with the frame, the respective first and second magnets being constructed and arranged to cooperate with each other in magnetic attracting relation to maintain the canvas in place over the frame opening.

Owner:RUE JAMES S +1

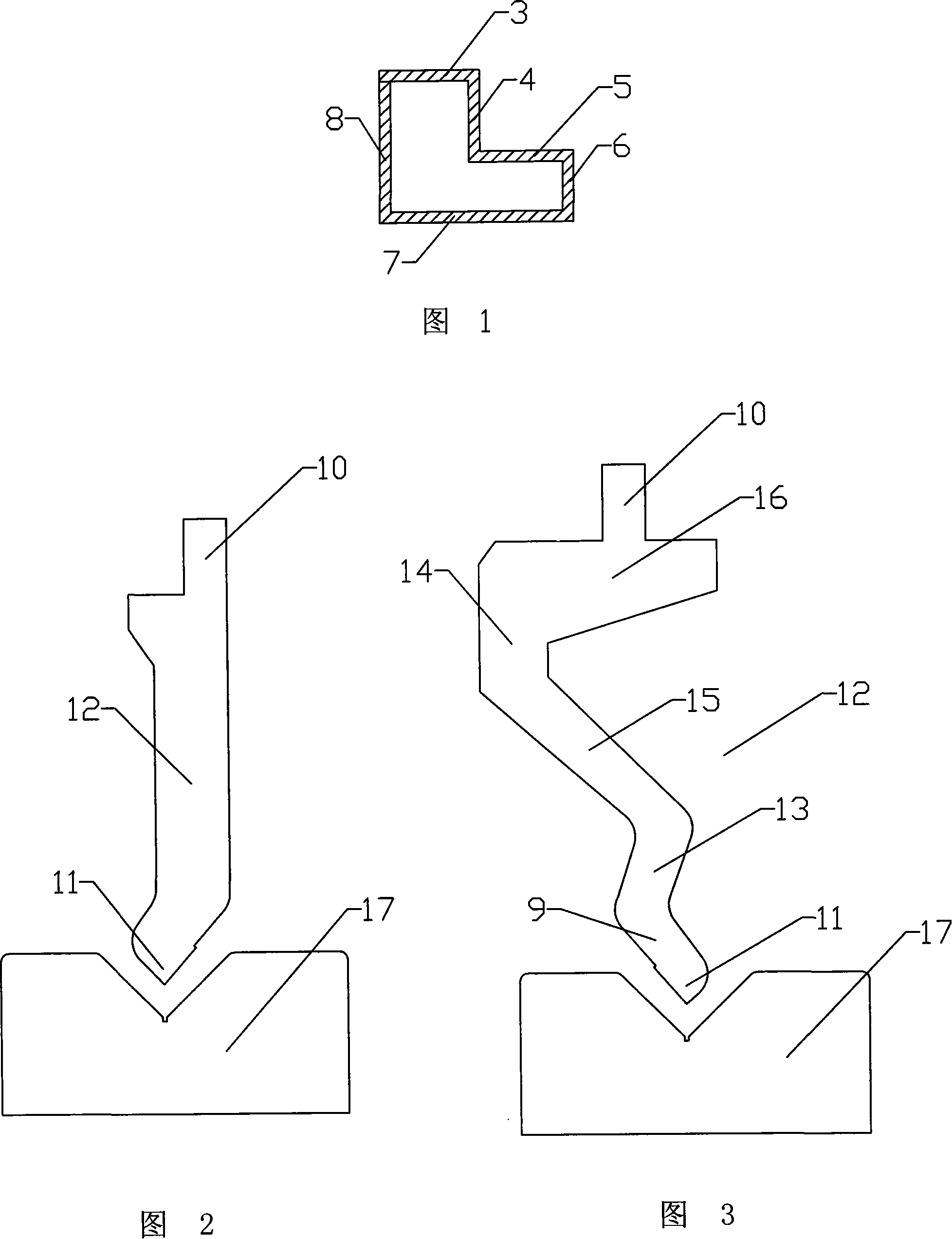

Anti-theft gate rabbet, its production method and its special mould

InactiveCN101122207AImprove structural strengthLow costBurglary protectionWar-like protectionBiochemical engineeringMetal sheet

The utility model discloses a notch of an anti-burglary door, a manufacture method of the notch and a dedicated mould of the notch. The notch is made by bending a mental sheet in an integrated way and the inside of the notch is provided with an L-shaped cavity structure. The metal sheet comprises a first rim, a second rim, a third rim, a fourth rim, a fifth rim and a sixth rim. Every two neighboring rims are bent to make them arranged in a vertical way. The sixth rim and the first rim are connected in a fixing way. In order to manufacture the notch, the dedicated bending module is used for the utility model to make all rims forming the notch be bent and form in an integrated way. Thus, the processing procedures are reduced, the production efficiency is promoted, and the manufacture cost is reduced. Moreover, the structural intensity after the assembling is enhanced.

Owner:李庆文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com