Cold-heat composite manufacturing method for machining of hollow turbine blade inner cavity precision casting appearance

A technology of turbine blade and precision casting, which is applied in the field of cold and heat composite manufacturing of precision casting shape machining of hollow turbine blade inner cavity, can solve the problems of air film hole deflection, difficult fixing of ceramic core, eccentric core, etc. The effect of manufacturing yield, improving manufacturing accuracy, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

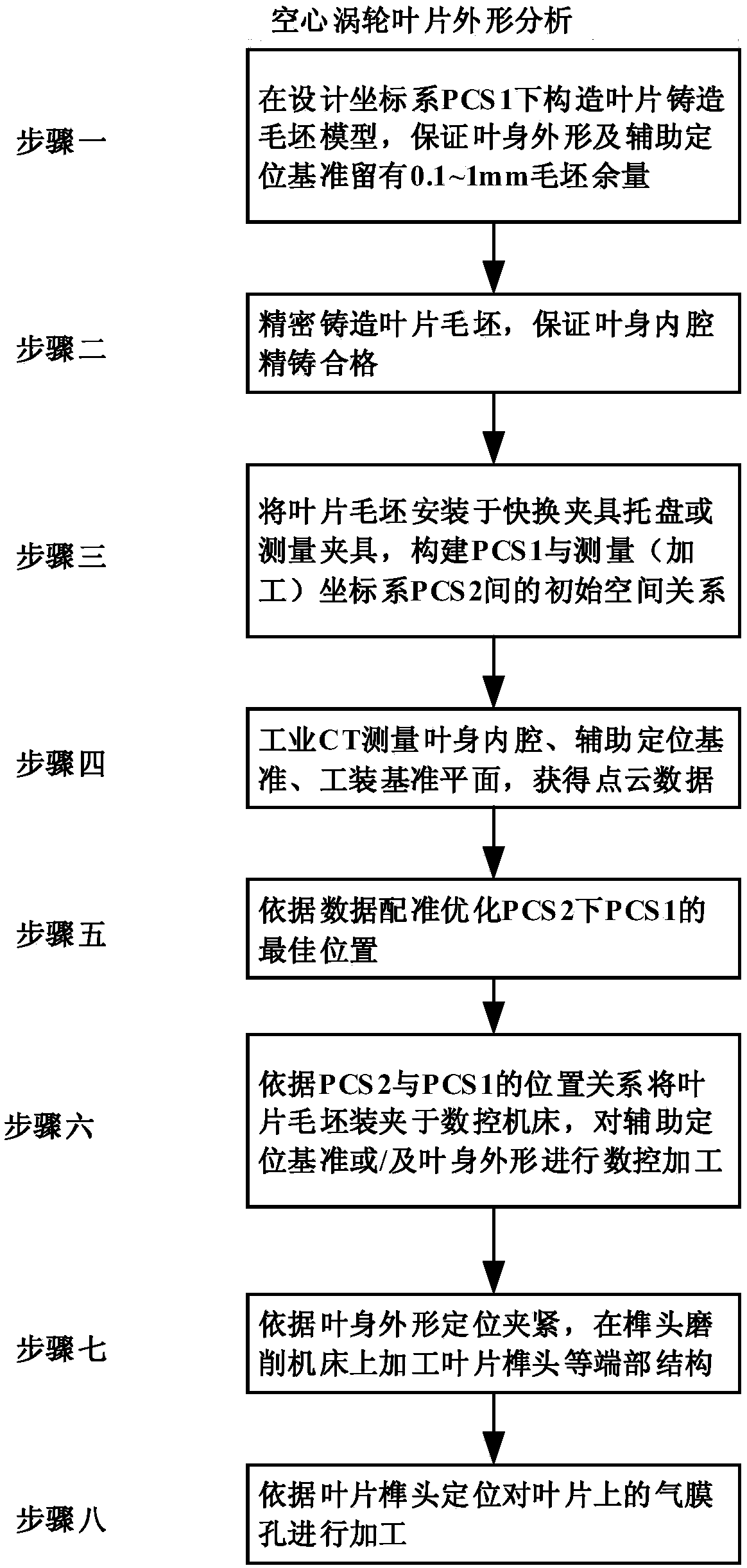

[0051] The technical process of the present invention is as figure 1 As shown, the specific implementation includes the following steps:

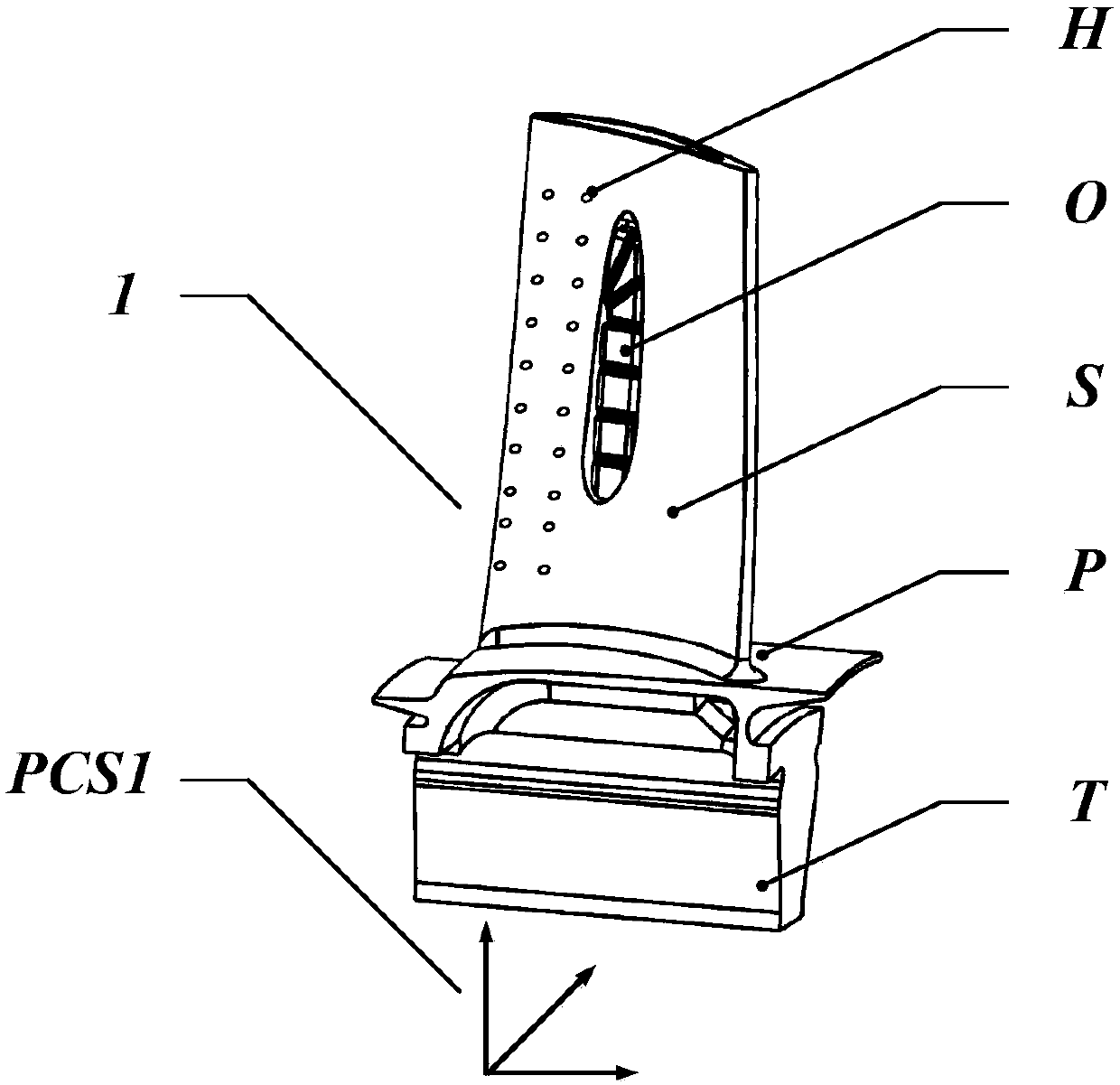

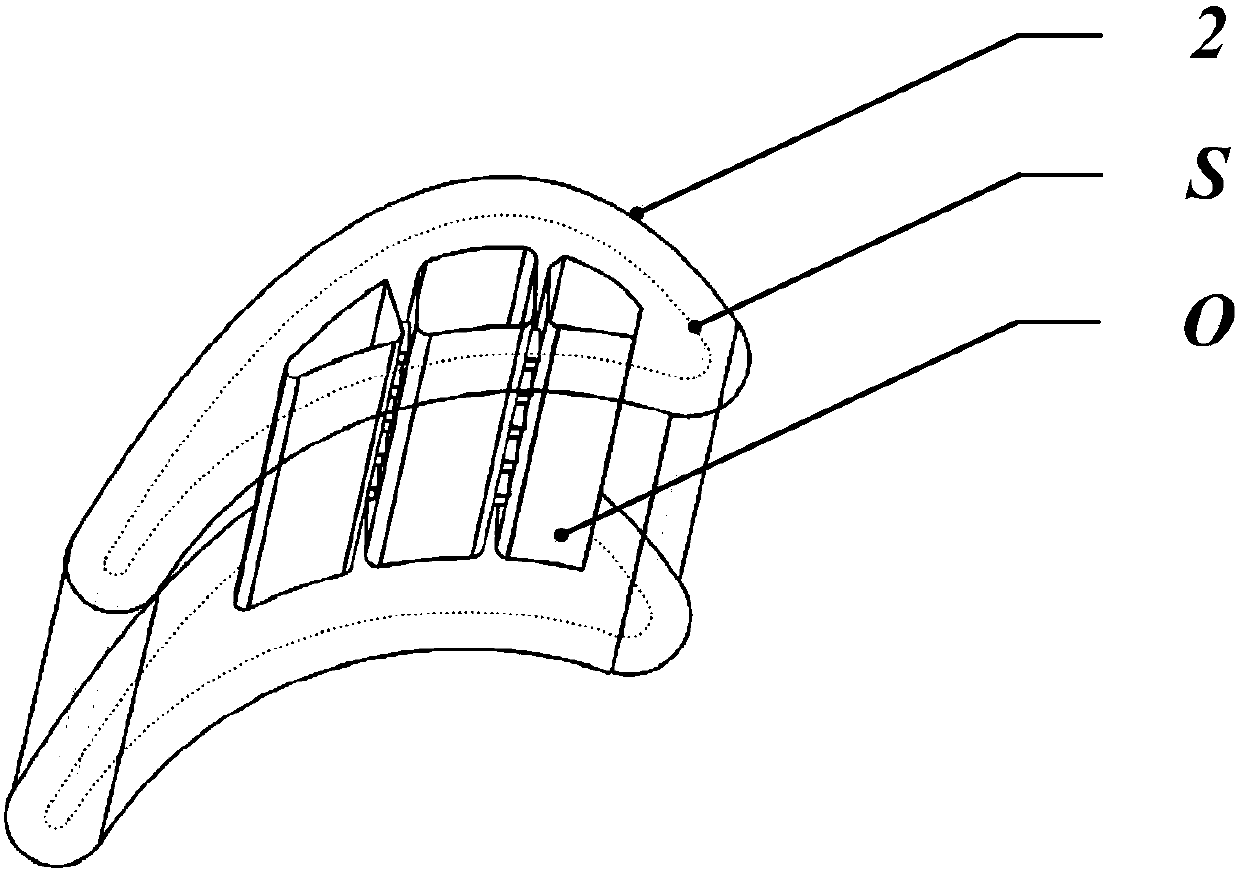

[0052] step one figure 2 It shows the front view of the hollow turbine blade design model 1 that needs to be manufactured by investment casting technology. The blade design model 1 includes tenon T, edge plate P, airfoil shape S, airfoil inner cavity O, air film hole H, blade Design model benchmark PCS1. image 3 It is the basic idea proposed by the present invention to solve the problem that the wall thickness does not meet the design requirements and the position deviation between the airfoil shape S and the airfoil inner cavity O due to the core shift caused by the investment casting process, the airfoil shape After the machining allowance d is left in S, the thickened casting blank 2 of the blade is obtained, so as to machine the shape S of the airfoil. At the same time, based on the requirements of the subsequent processing technol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com