Xenon lamp and manufacturing technology thereof

A technology for xenon lamps and lamp holders, which is applied in the field of xenon lamps, can solve the problems of complex processing technology, shortened service life, and low manufacturing pass rate, and achieve the effects of good light transmission, high pressure leakage prevention, and high manufacturing pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

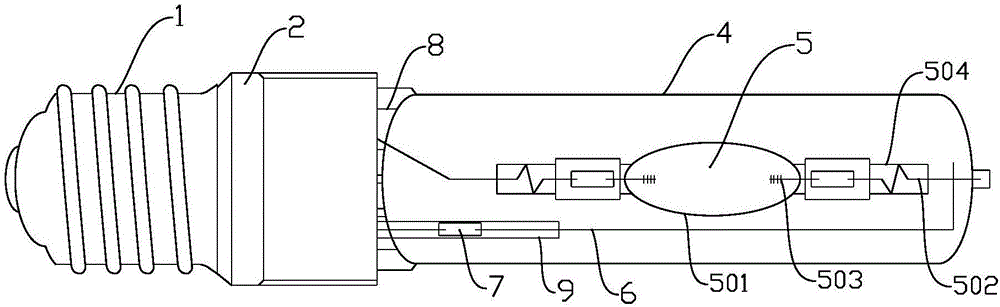

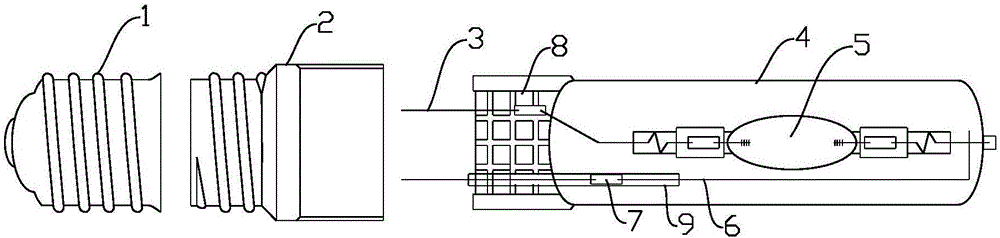

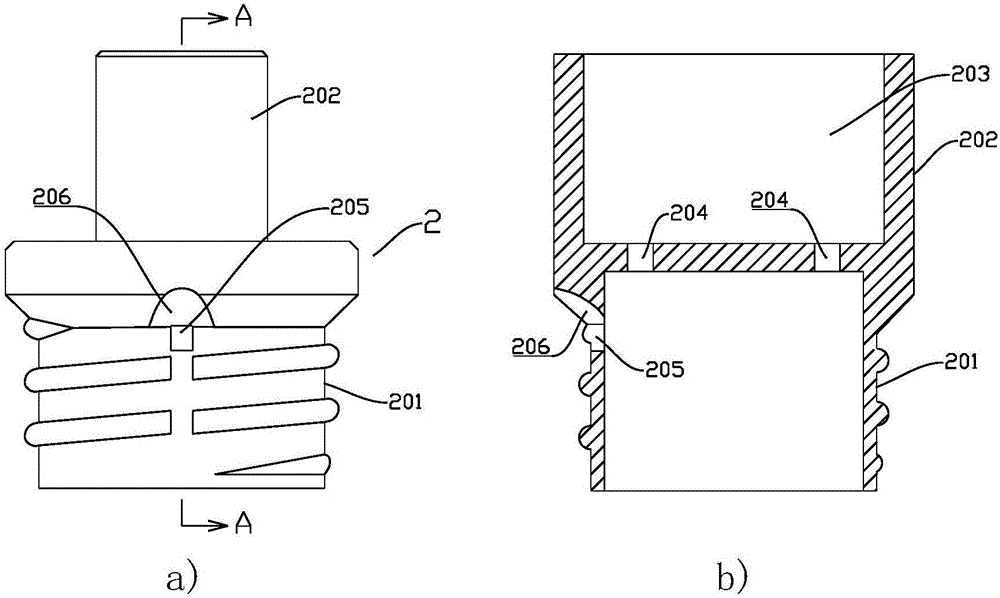

[0029] like figure 1 and 2 , the xenon lamp in this embodiment includes a lamp cap 2, a lamp tube 4 and a luminous tube 5 arranged in the lamp tube 4, a clip seal 8 is provided at the end of the lamp tube 4, and two electrode leads 3 of the luminous tube 5 pass through the clip Sealing 8, the lamp cap 2 includes a fixing seat 201 and a connecting head 202 arranged at one end of the fixing seat 201, a cavity 203 for installing a lamp tube is arranged in the connecting head 202, two connecting channels are arranged in the fixing seat 201, and the two connecting channels One end is respectively connected to the cavity 203 , and the other ends of the two connecting passages are connected to the outside of the side wall of the fixing seat 201 , and the other is connected to the lower end surface of the fixing seat 201 . like image 3 As shown, on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com