Patents

Literature

188results about How to "Uniform surface temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

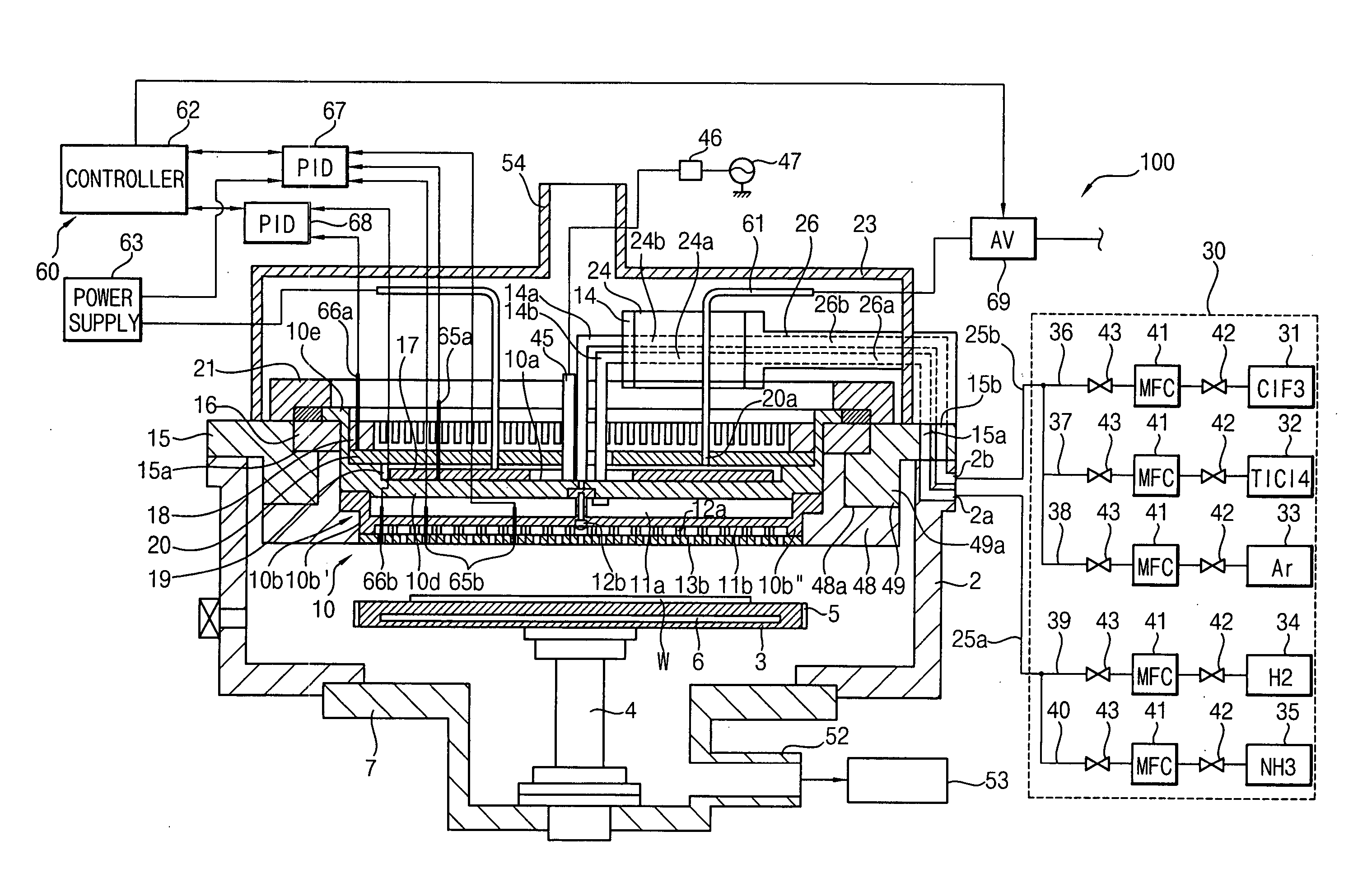

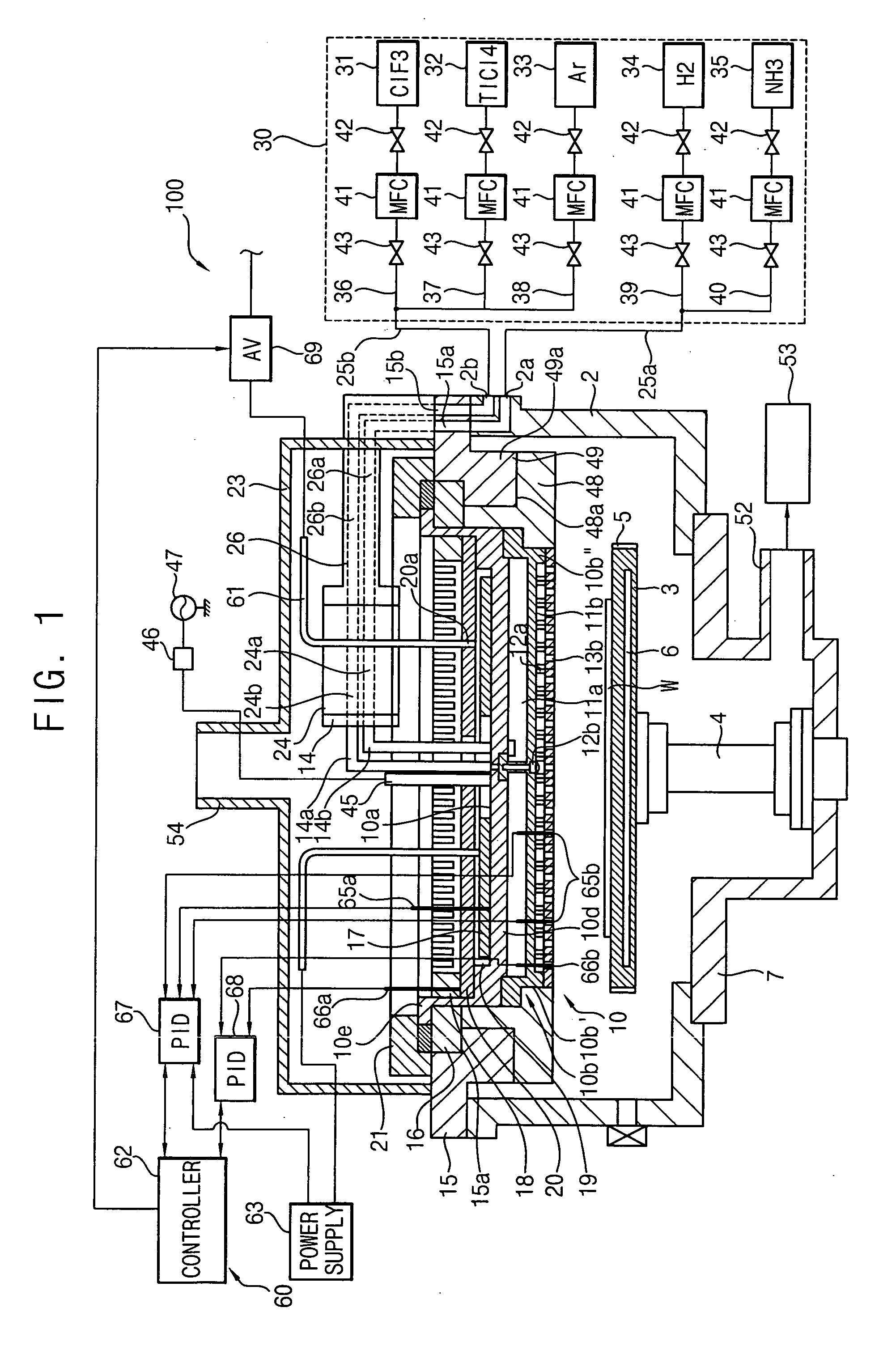

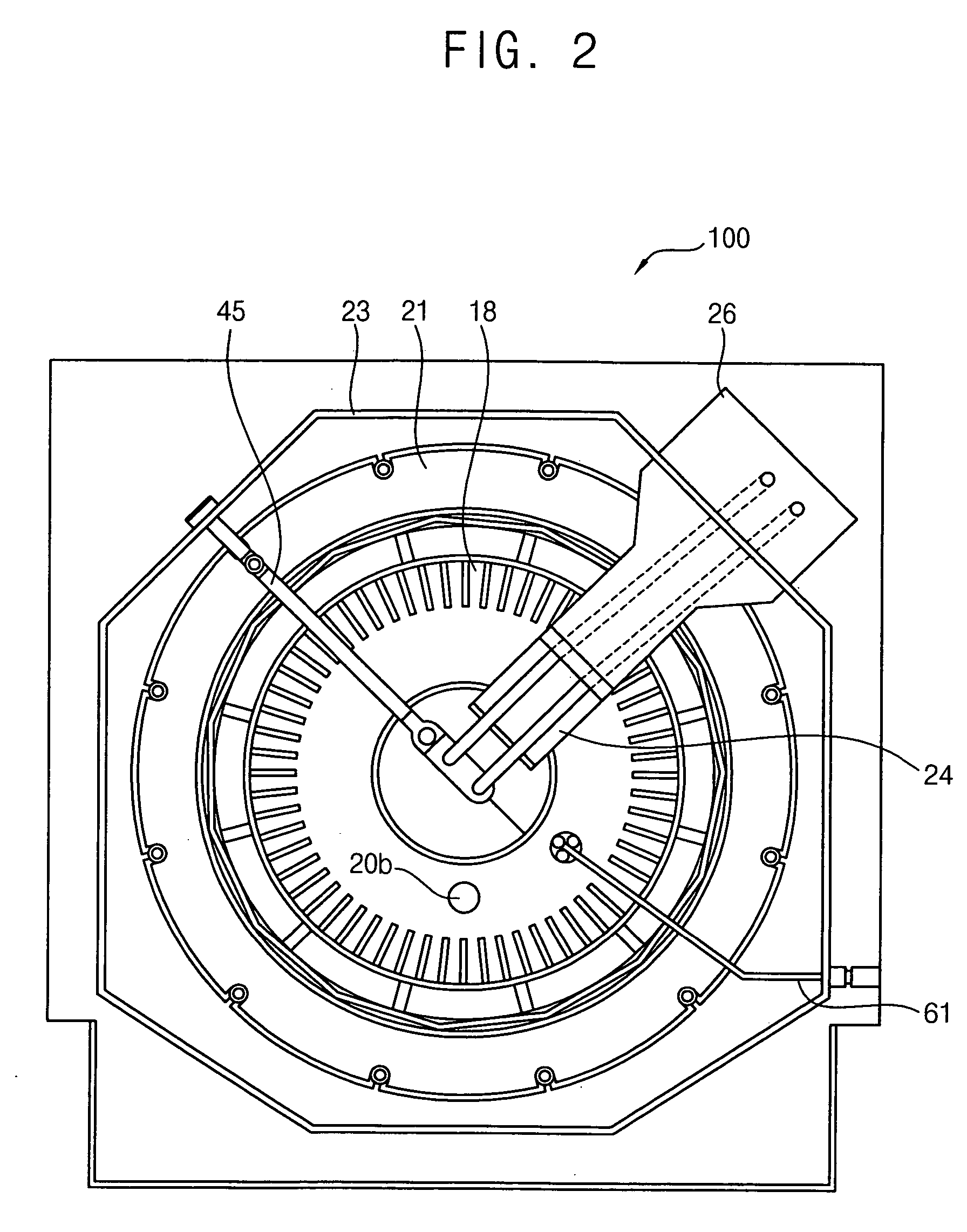

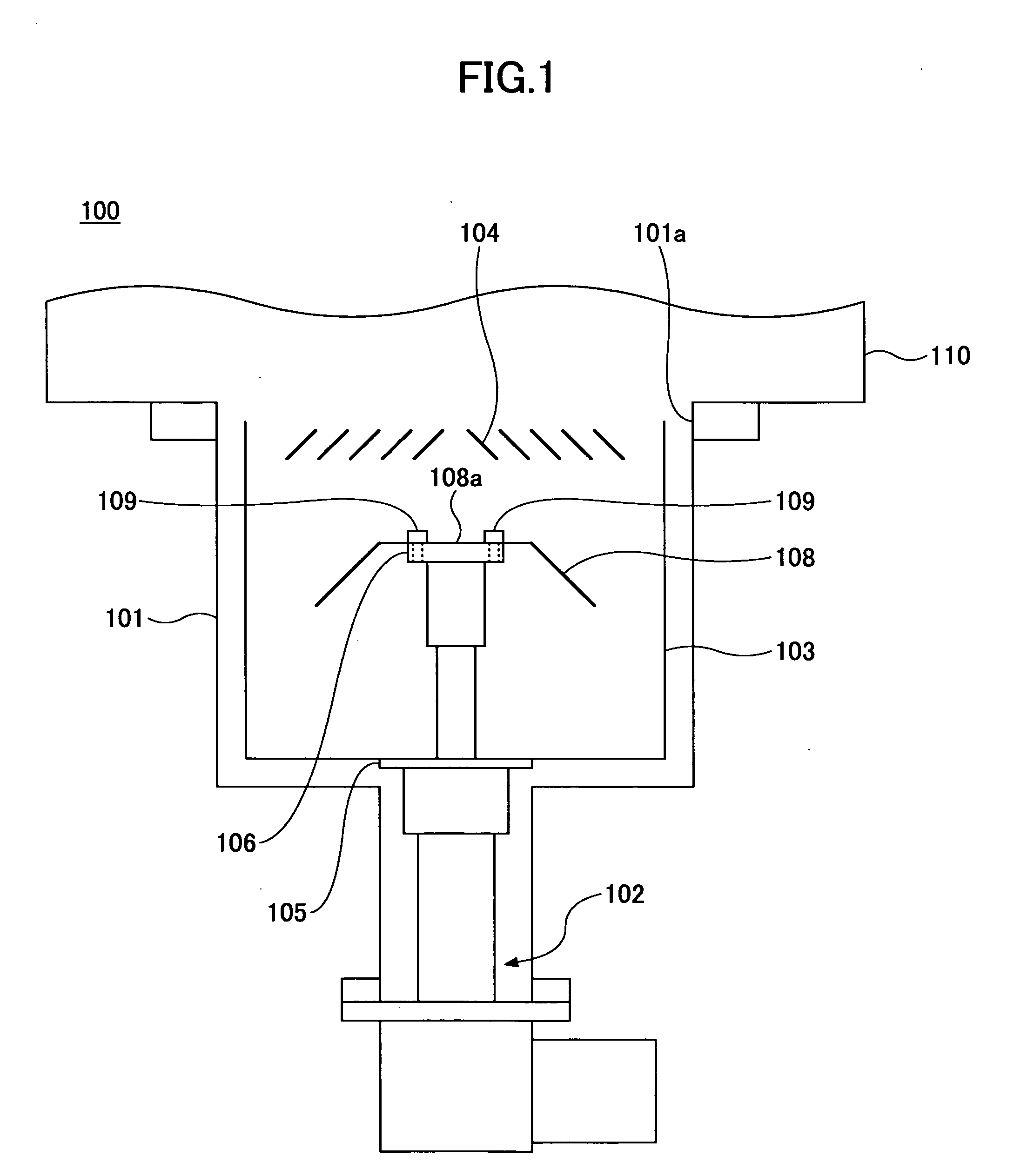

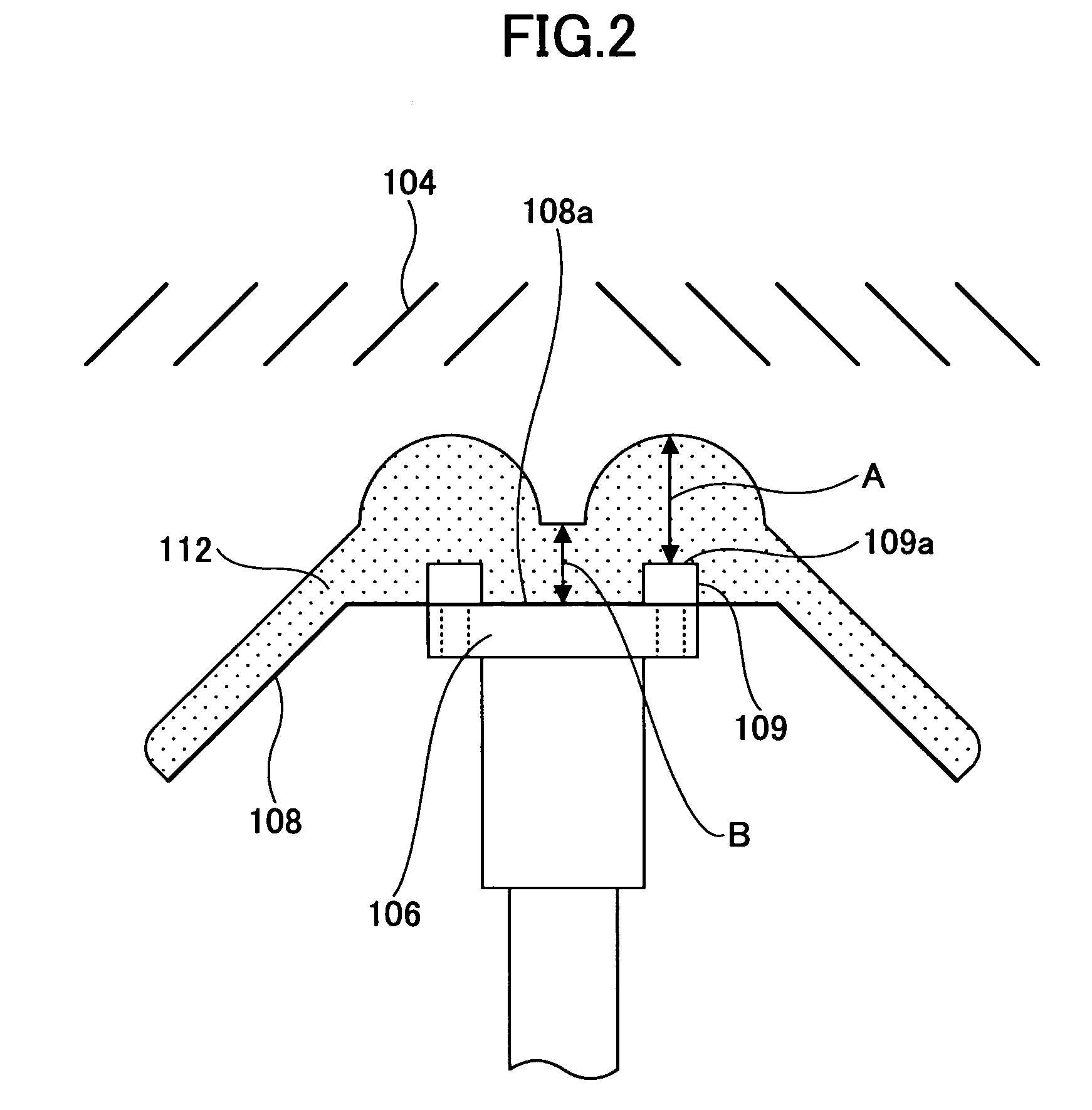

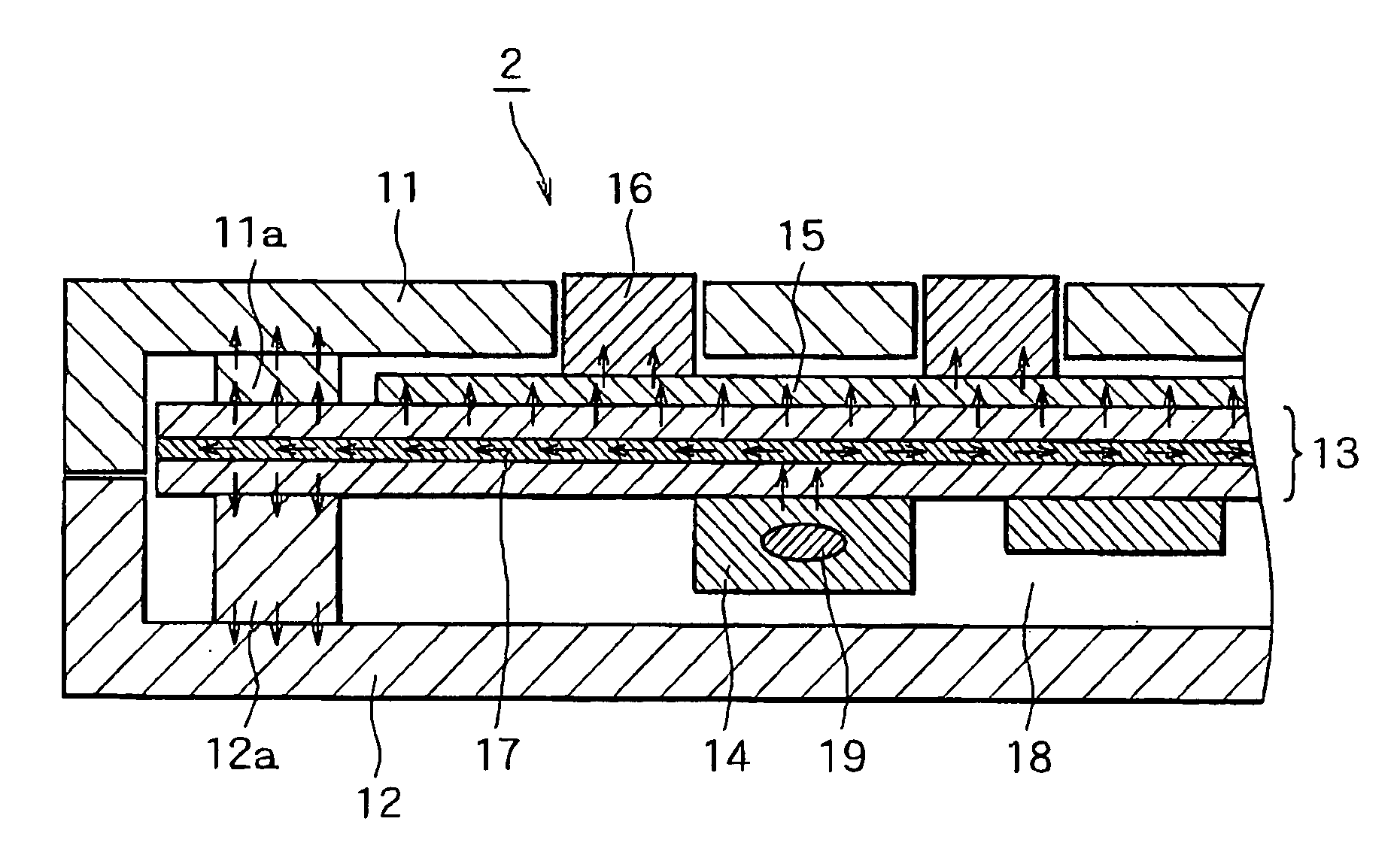

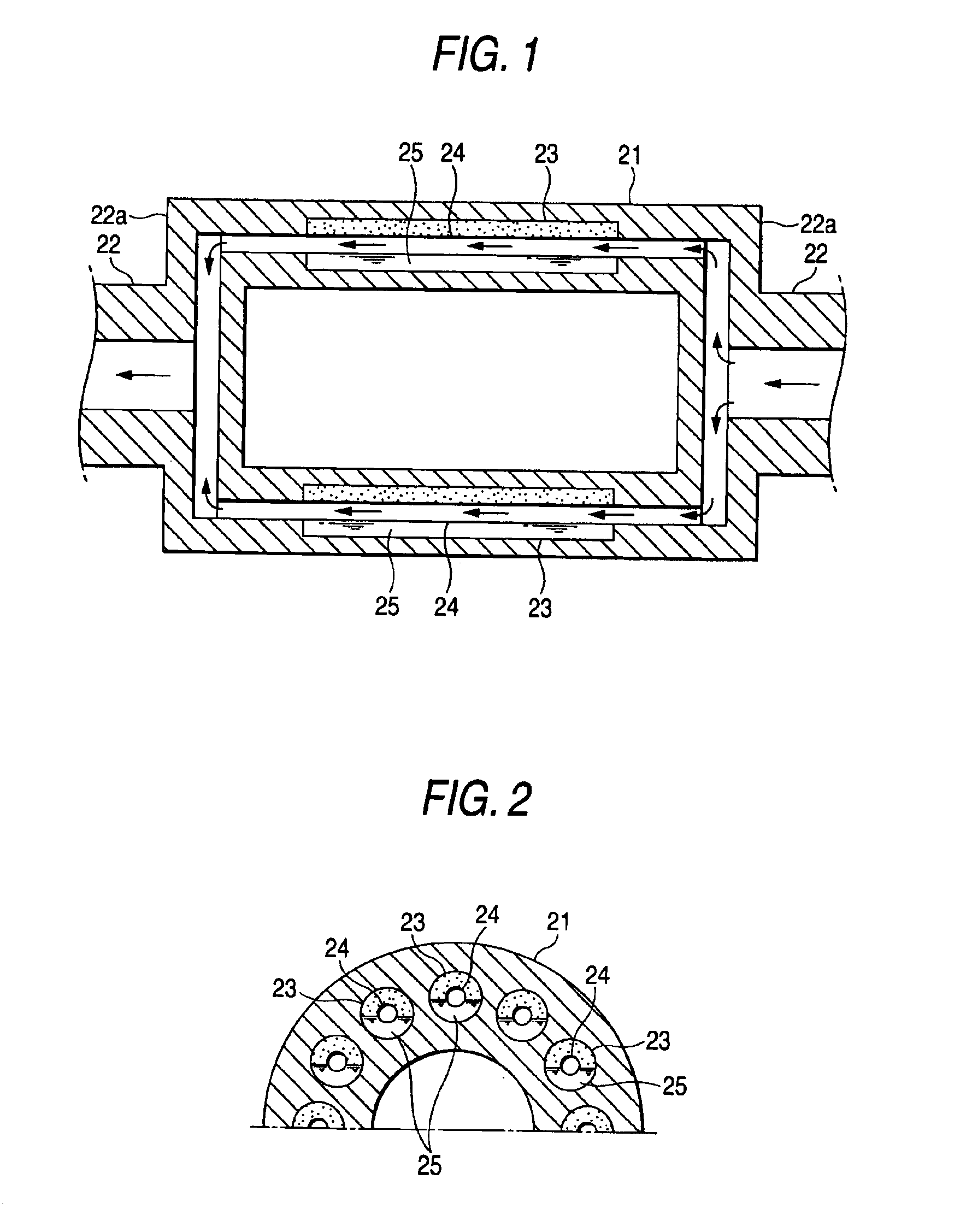

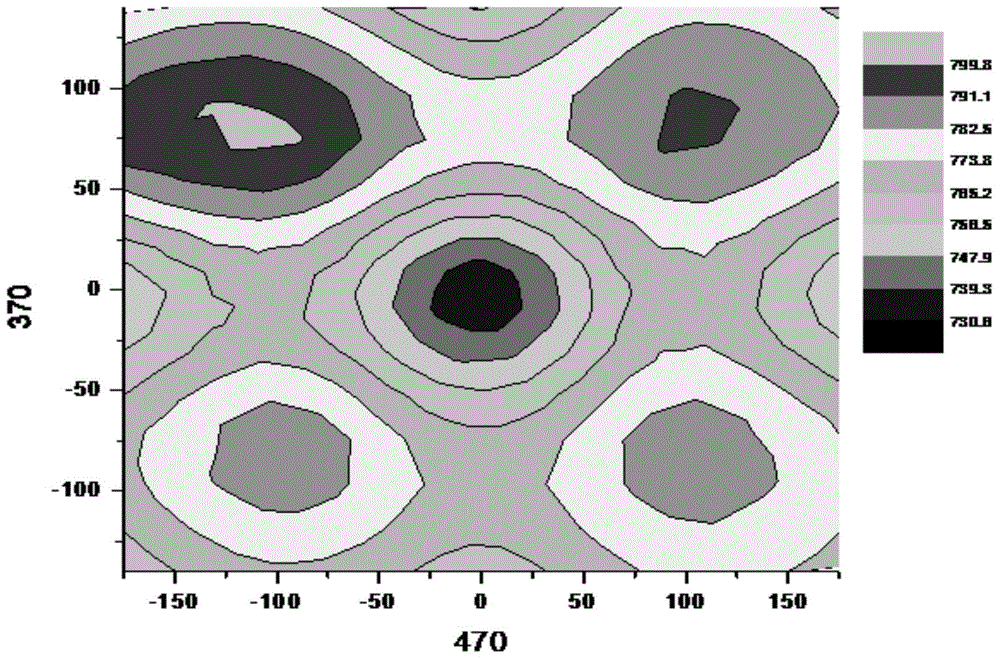

Combination of showerhead and temperature control means for controlling the temperature of the showerhead, and deposition apparatus having the same

InactiveUS20060137607A1Stable and fastUniform surface temperatureElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringTemperature control

A chemical vapor deposition apparatus has a showerhead, and temperature control apparatus including a heater and a heat dissipation plate for regulating the temperature of the showerhead. The showerhead includes a bottom plate having gas spray openings, and an upper plate. The heater is disposed on an upper plate of the showerhead. The heat dissipation plate contacts an upper portion of the upper plate of the showerhead above the heater so that heat dissipates from the showerhead through the plate. The temperature control apparatus also includes a coolant system by which coolant is fed into a space defined between the heater and the heat dissipation plate. The temperature of the showerhead is precisely controlled using the heater, the heat dissipation plate and the coolant system.

Owner:SAMSUNG ELECTRONICS CO LTD

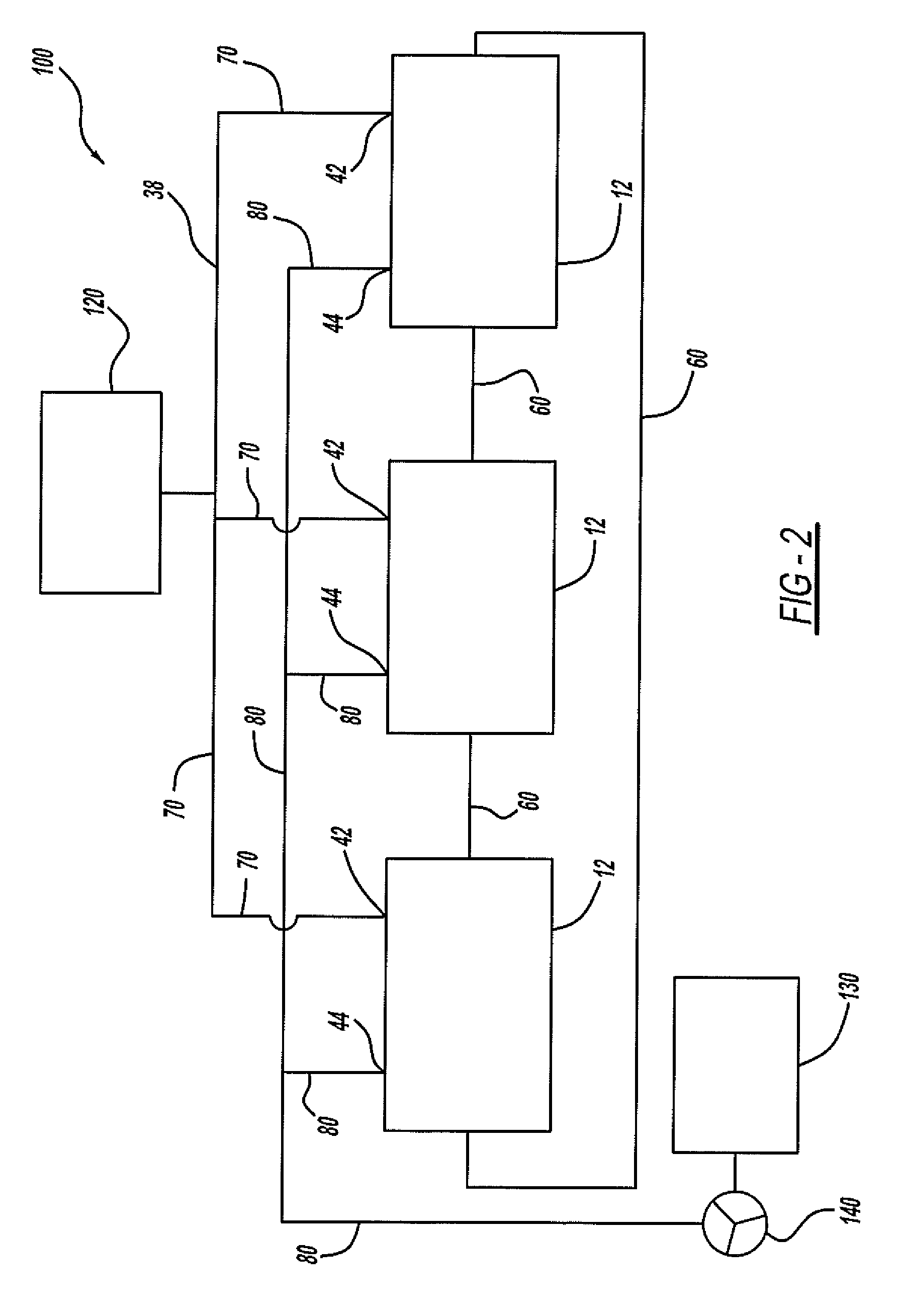

Lithium ion battery cooling system

ActiveUS20130122331A1Readily apparentUniform surface temperatureFinal product manufactureCell temperature controlDielectricInterior space

A Lithium Ion battery cooling system for use in a hybrid vehicle comprises a plurality of self-contained liquid cooling modules, each cooling module including a closed and sealed container having an interior space. Each cooling module includes a battery assembly disposed within the interior space of the container and a plurality of battery cells having at least one fluid channel formed therebetween for receiving a fluid therein. A dielectric fluid is disposed within the at least one fluid channel. The dielectric fluid substantially immerses and is in contact with the battery assembly to heat and cool the battery assembly. A heating element is disposed within the interior space and heats the dielectric fluid. A cooling element is disposed within the interior space and cools the dielectric fluid.

Owner:GM GLOBAL TECH OPERATIONS LLC

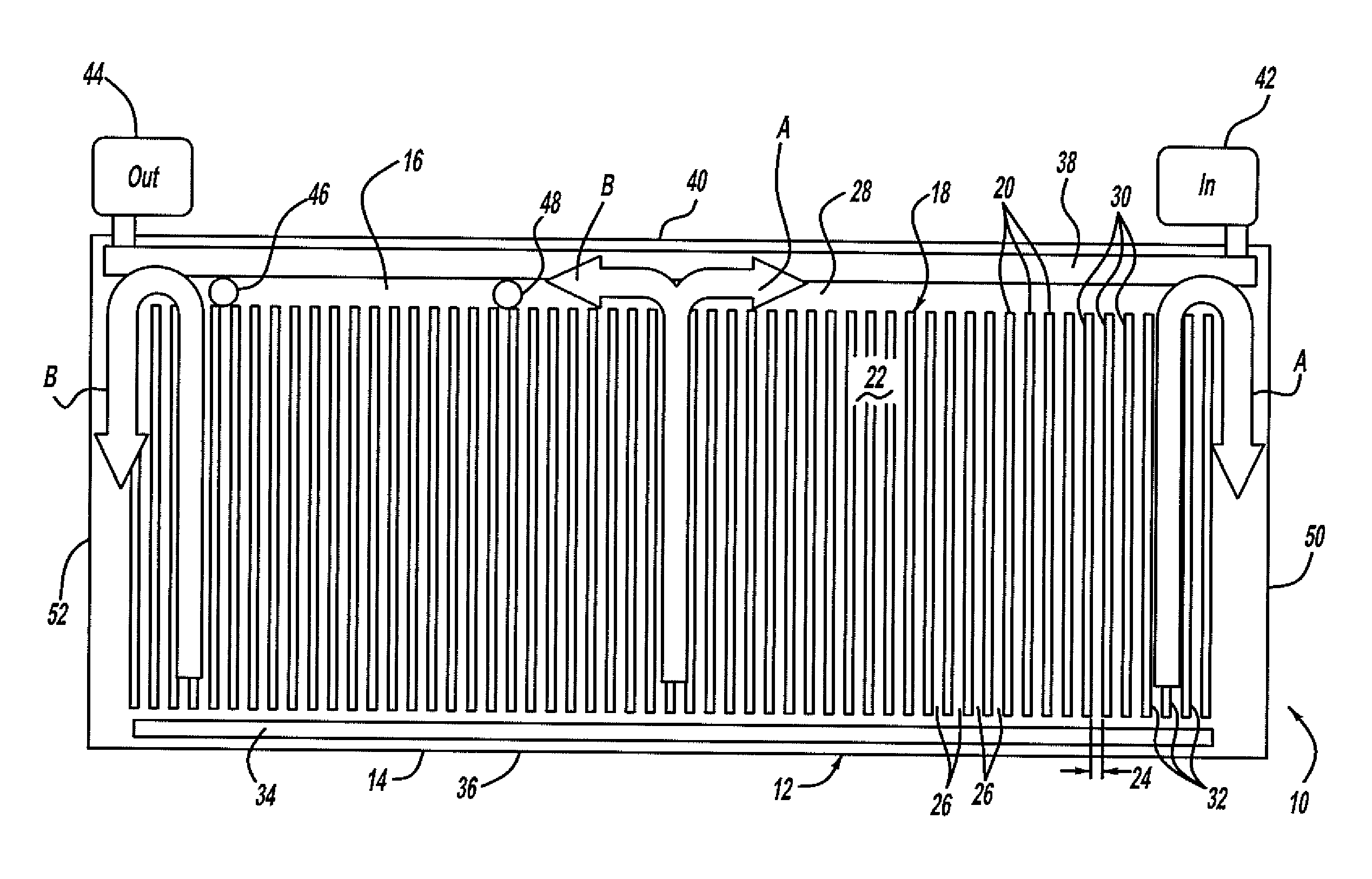

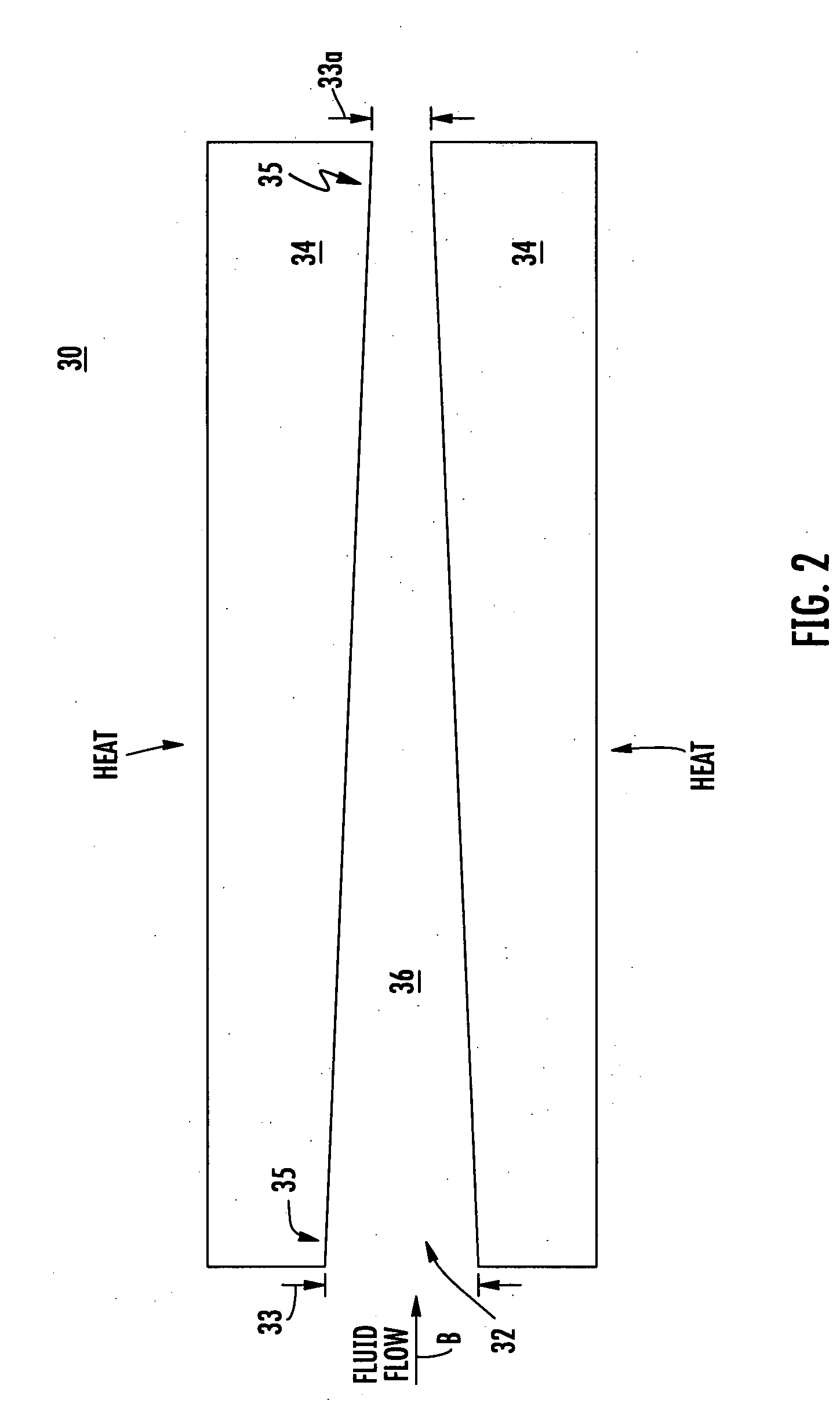

Heat sink and method of making same

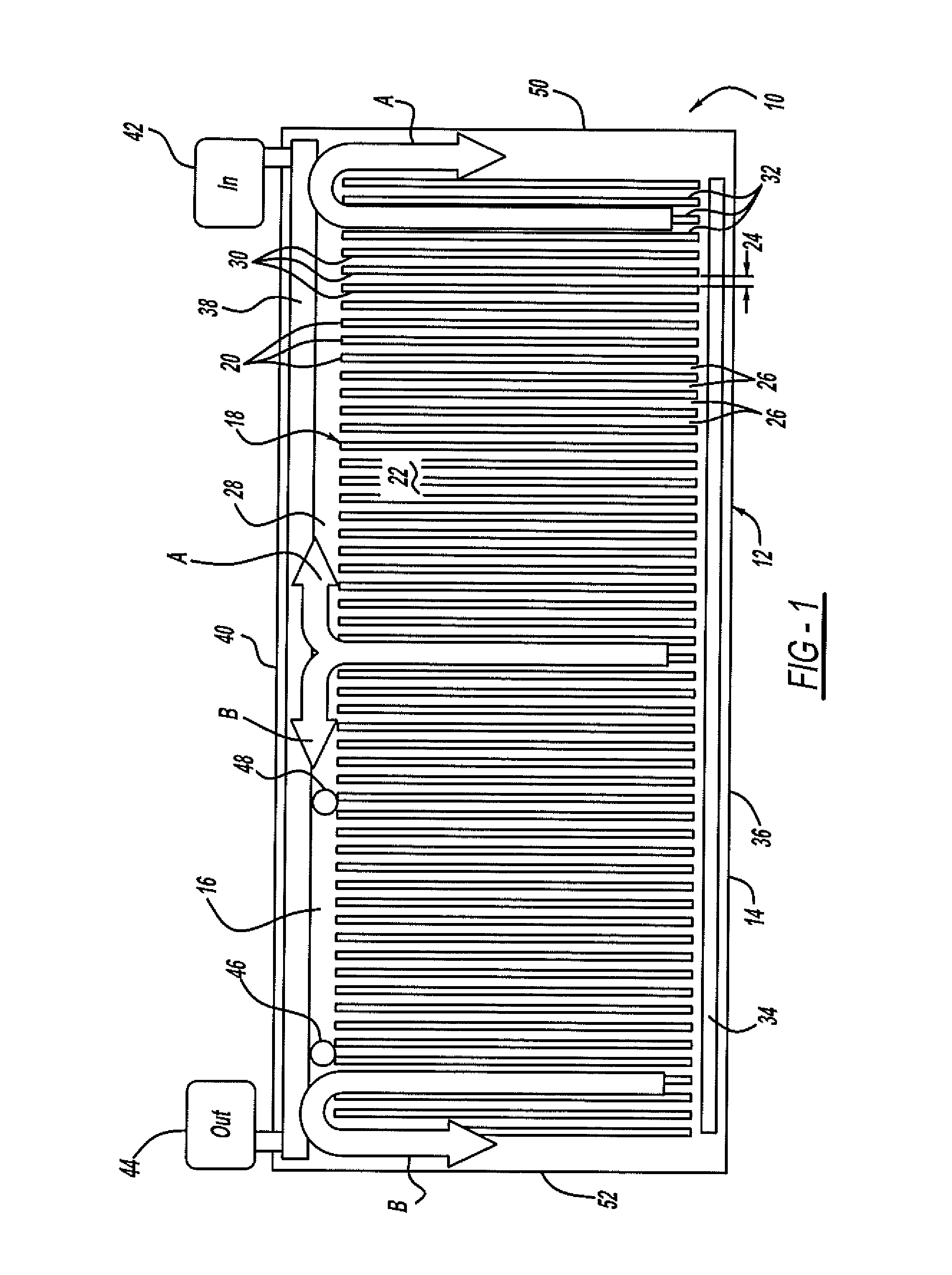

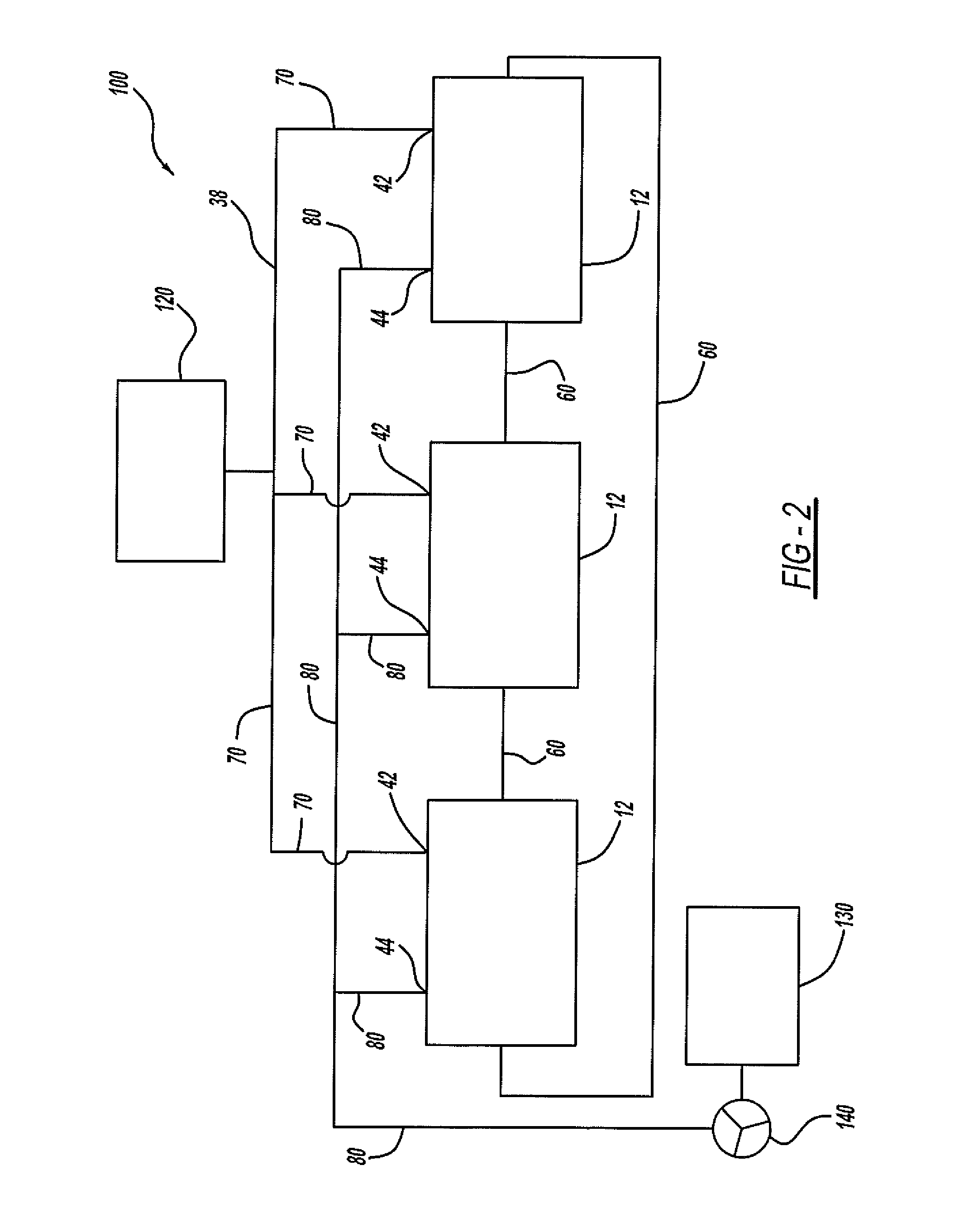

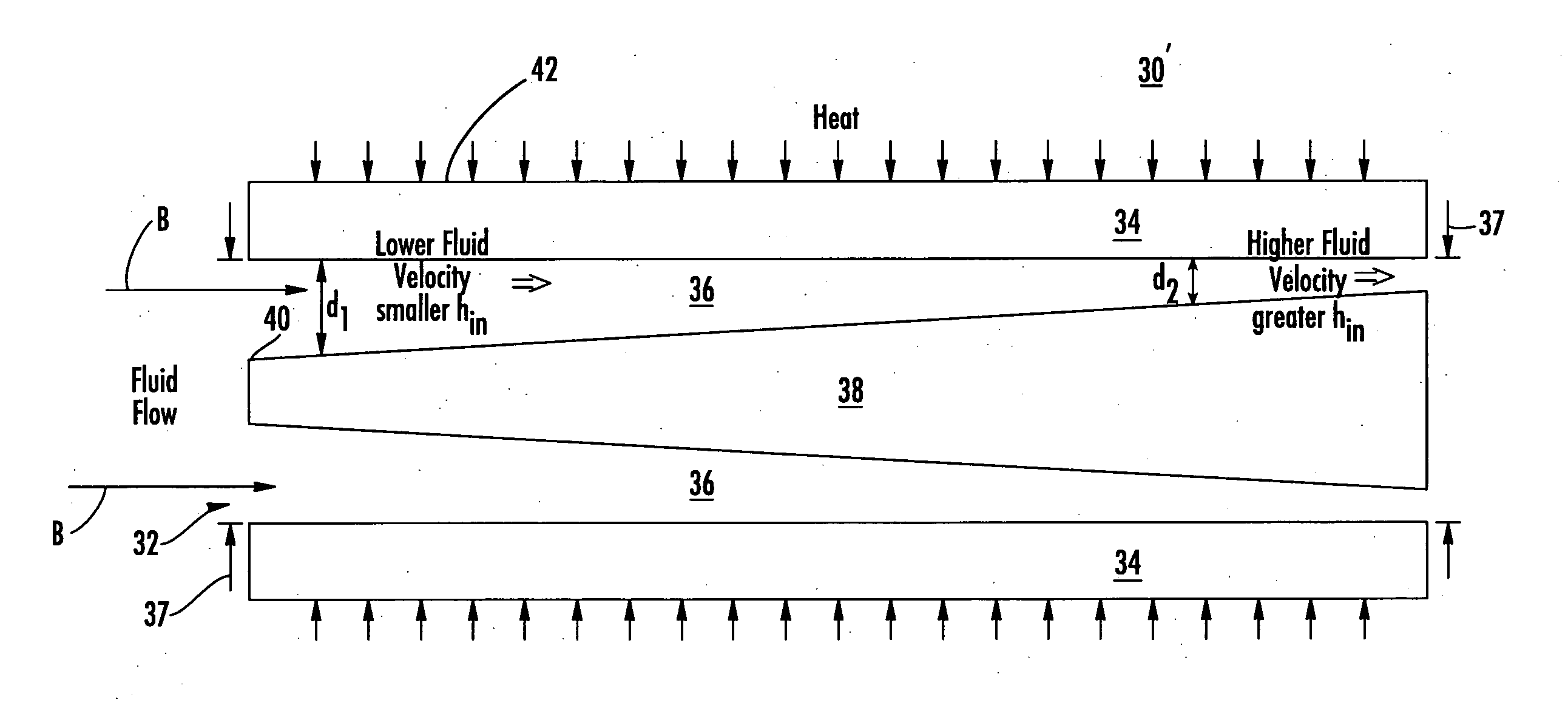

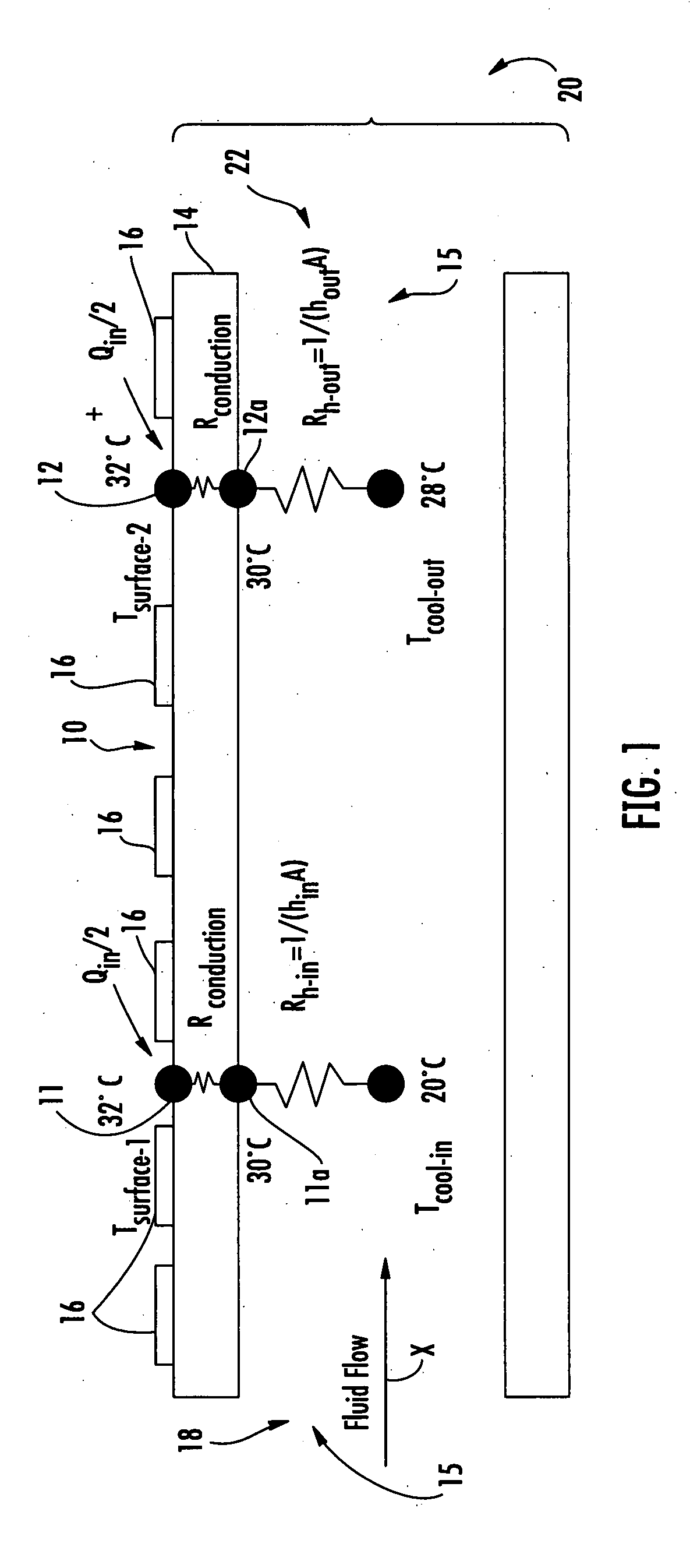

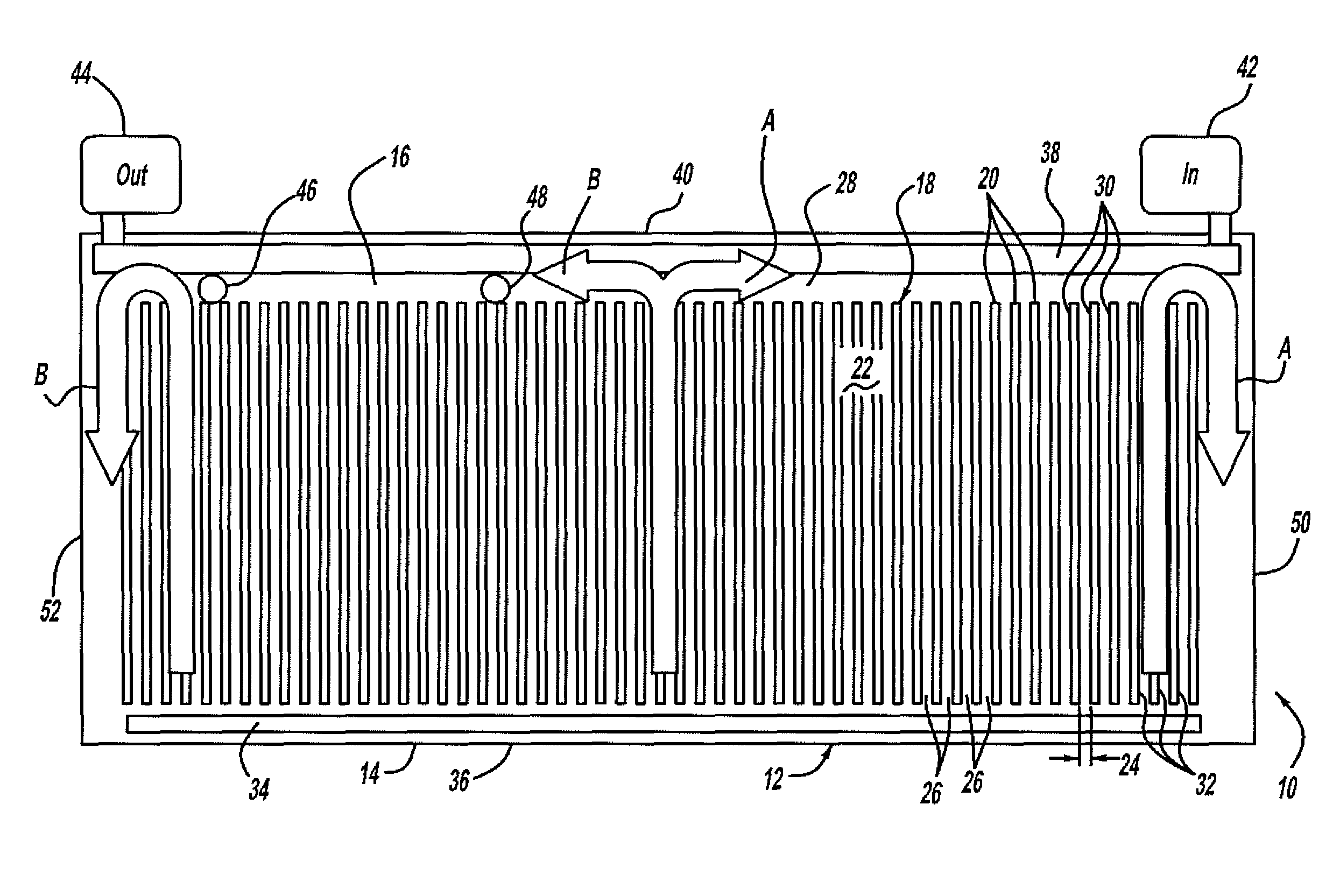

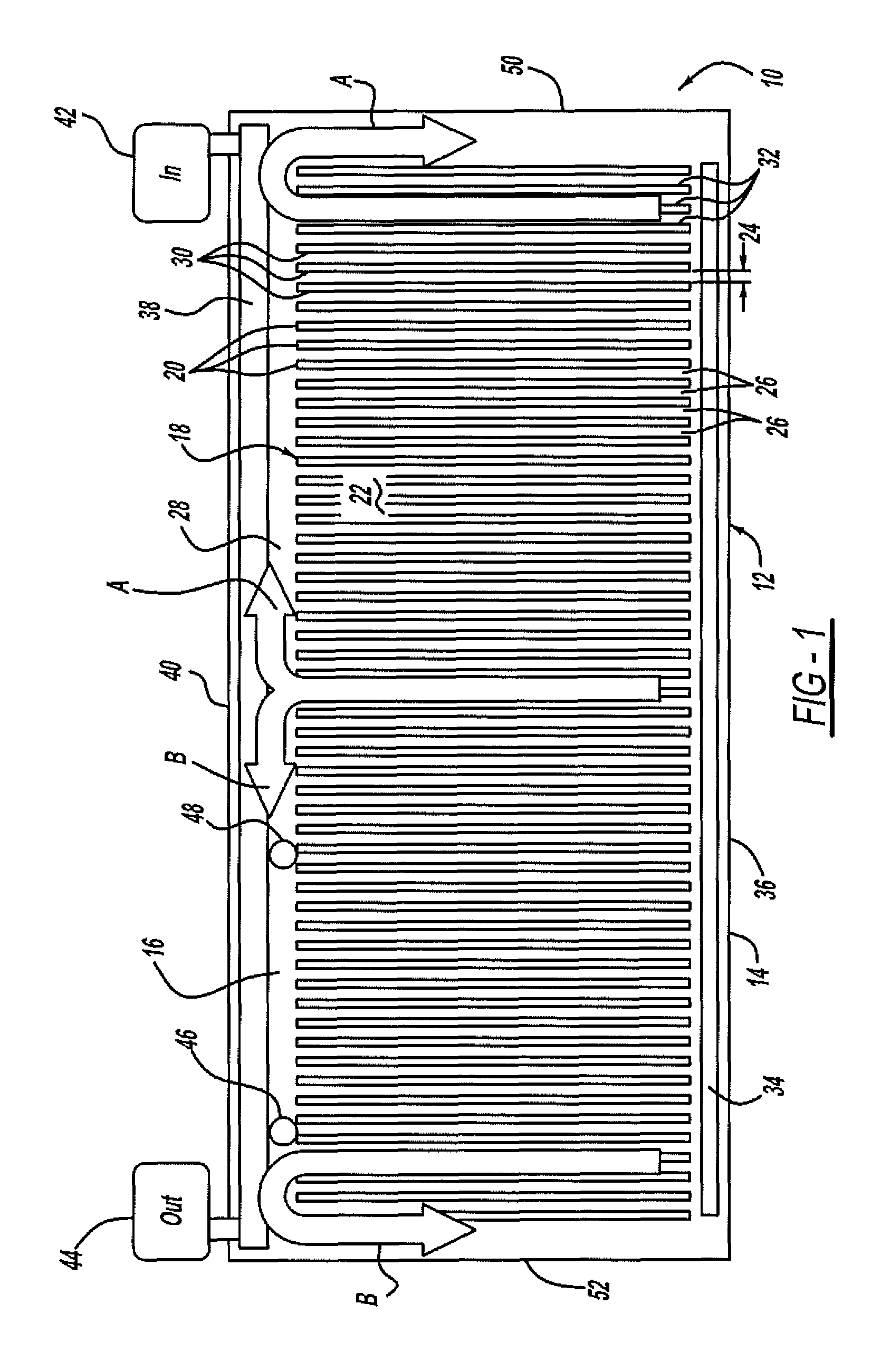

ActiveUS20070289718A1Less complexReduce riskIndirect heat exchangersHeat transfer modificationCoolant flowEngineering

A heat sink includes a fluid channel and a cooling wall in contact with coolant flowing in the fluid channel. The channel is configured to vary the velocity of coolant along the length of the fluid channel to vary the coolant's heat transfer coefficient and thereby compensate for the coolant's temperature rise along the length of the fluid channel. The result is a heat sink that is isothermal along its length.

Owner:RAYTHEON CO

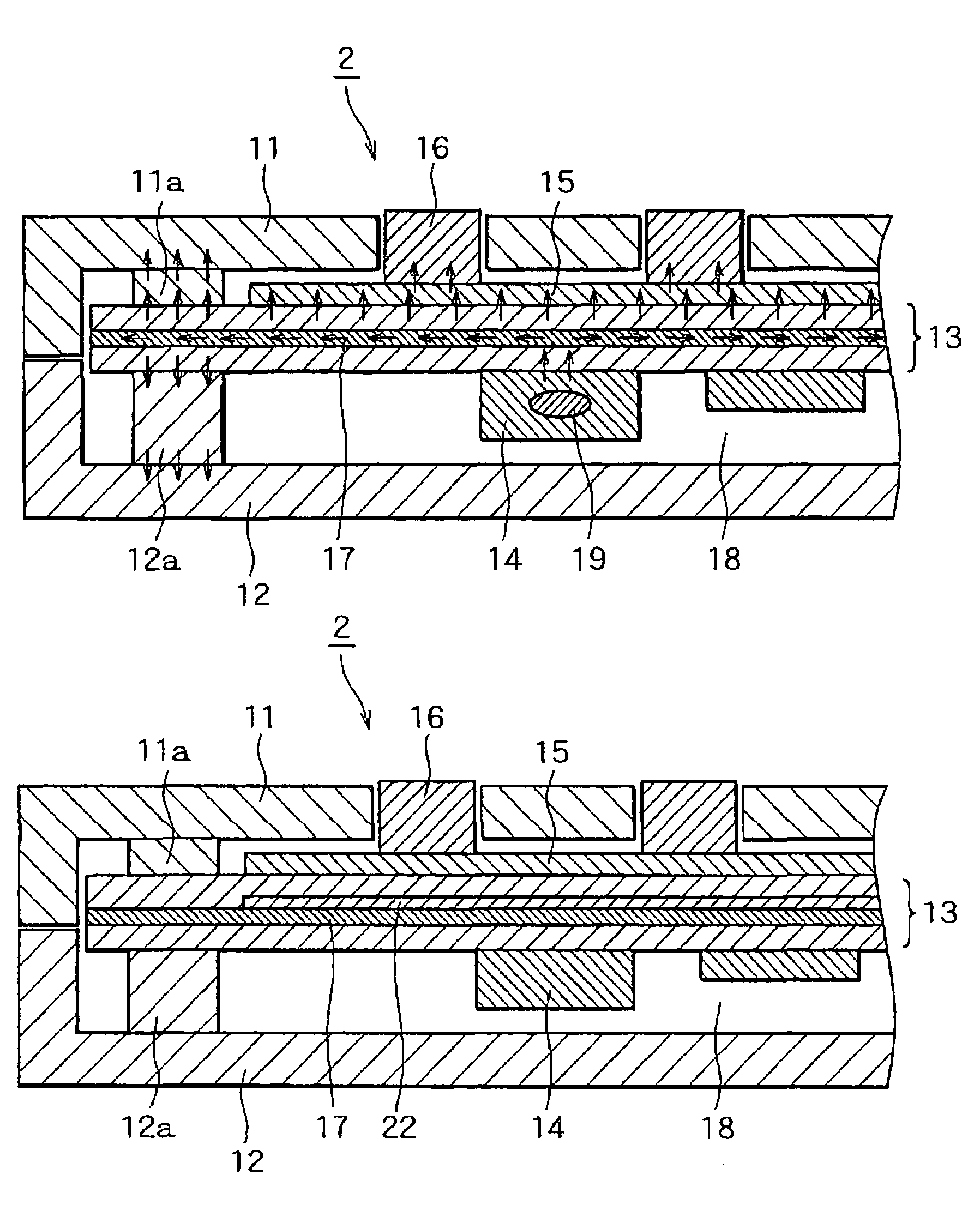

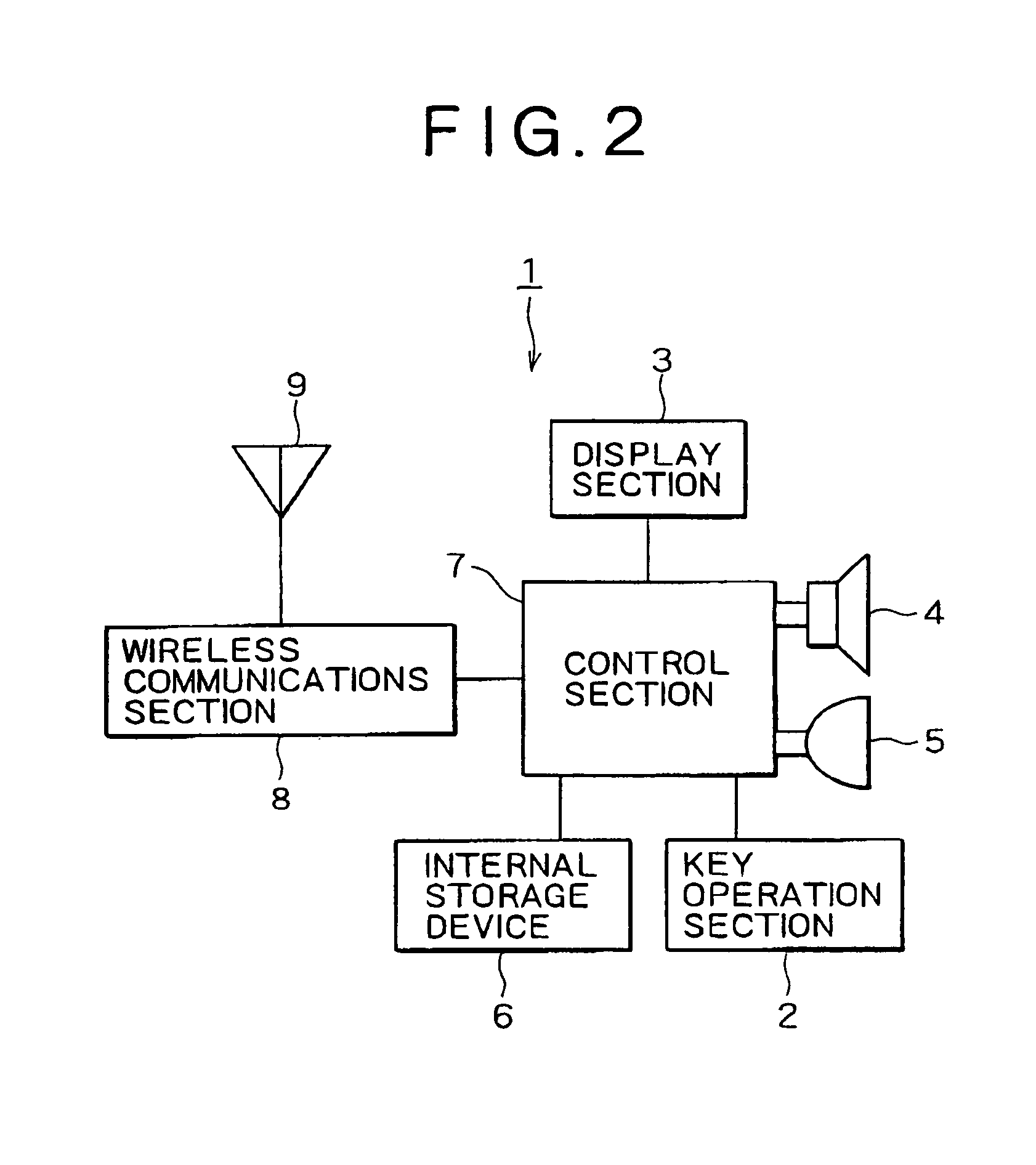

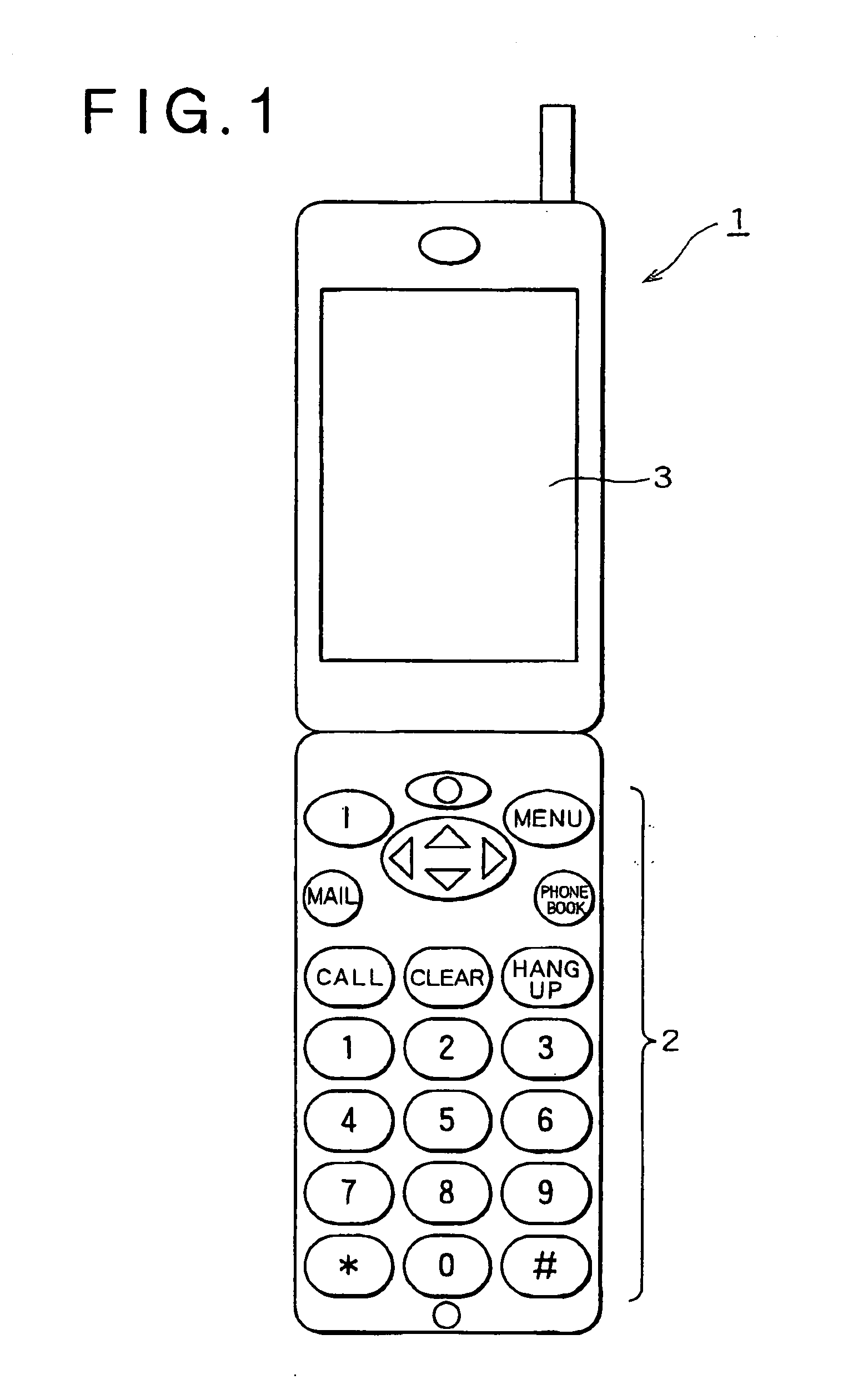

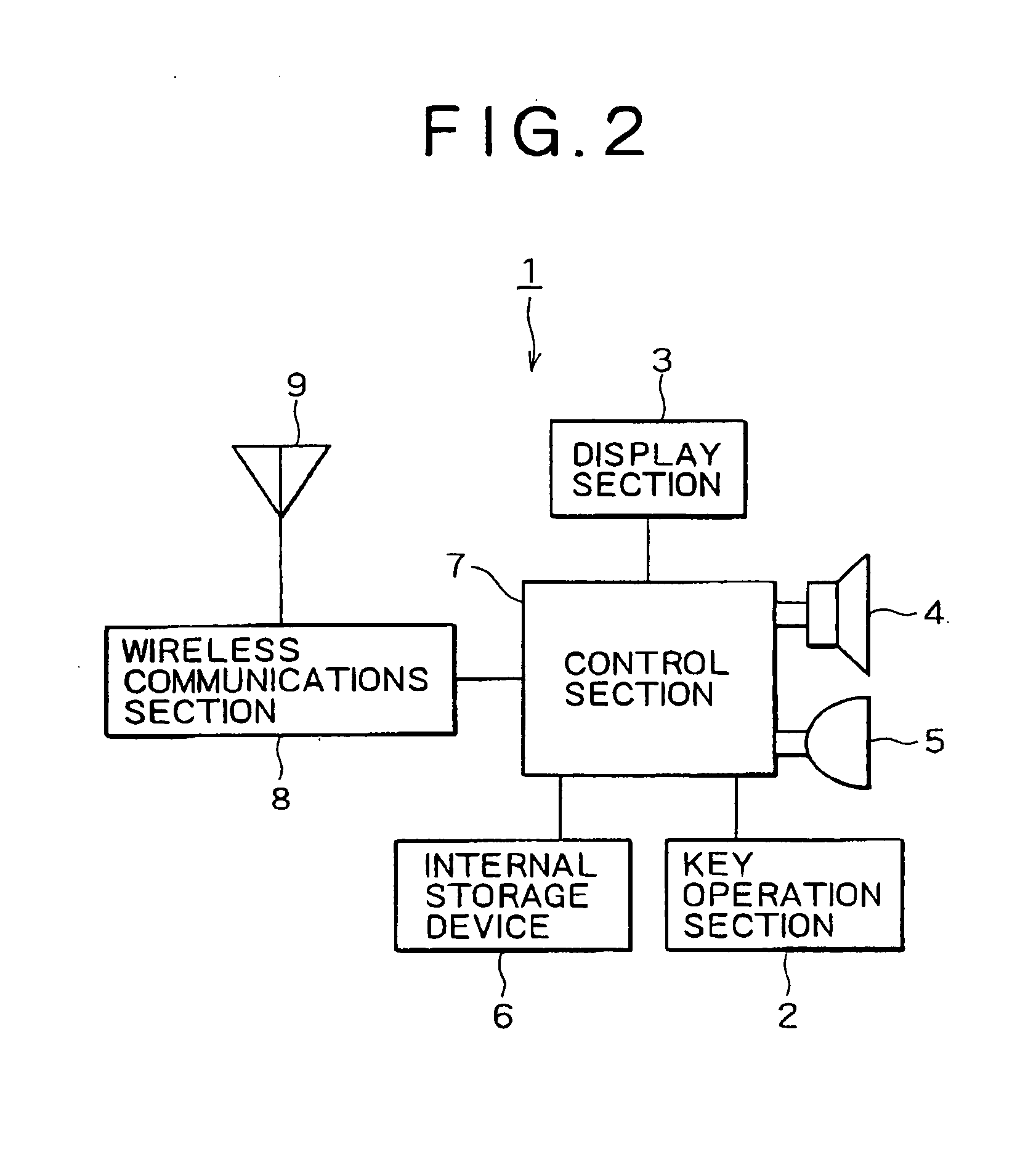

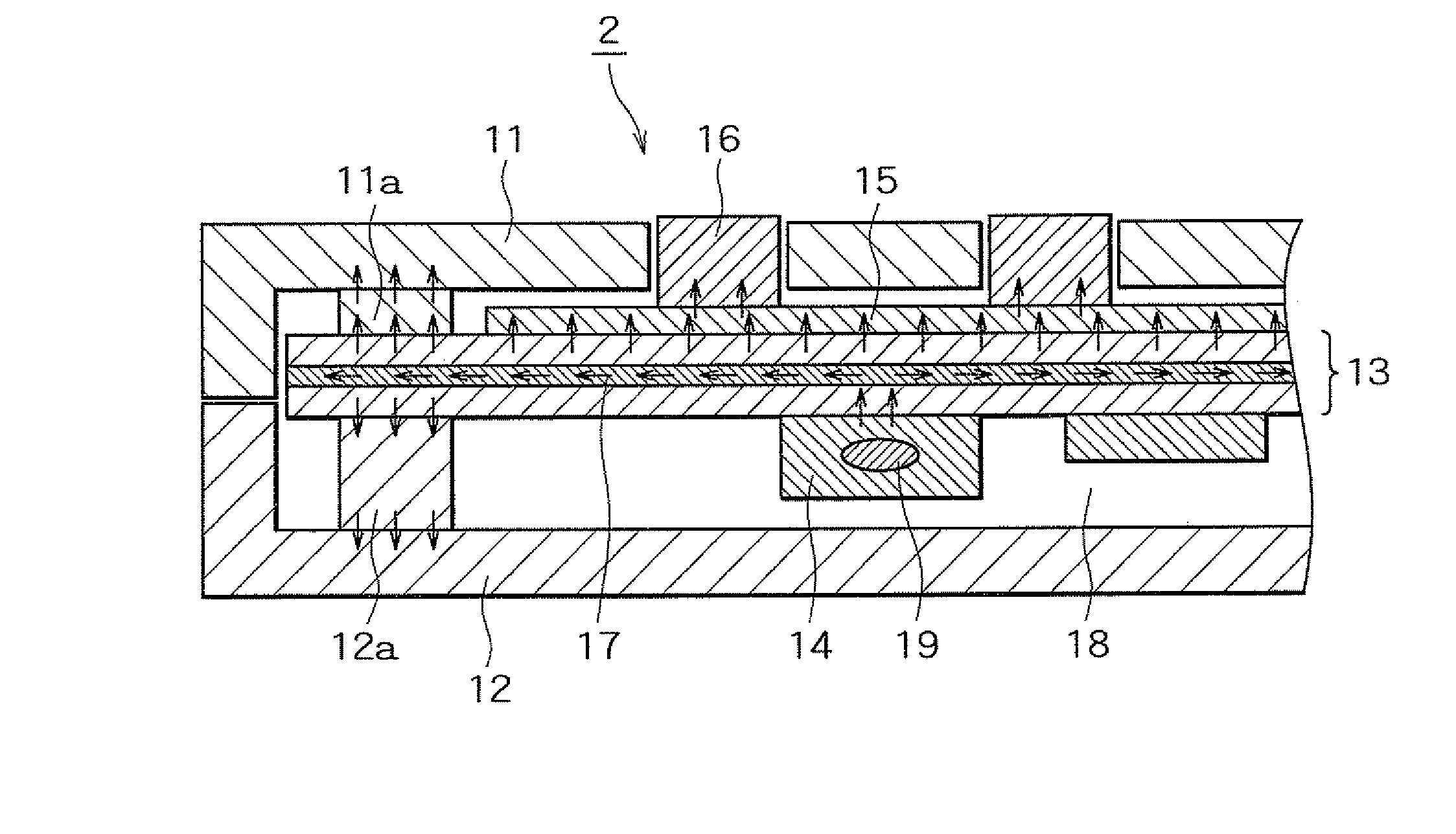

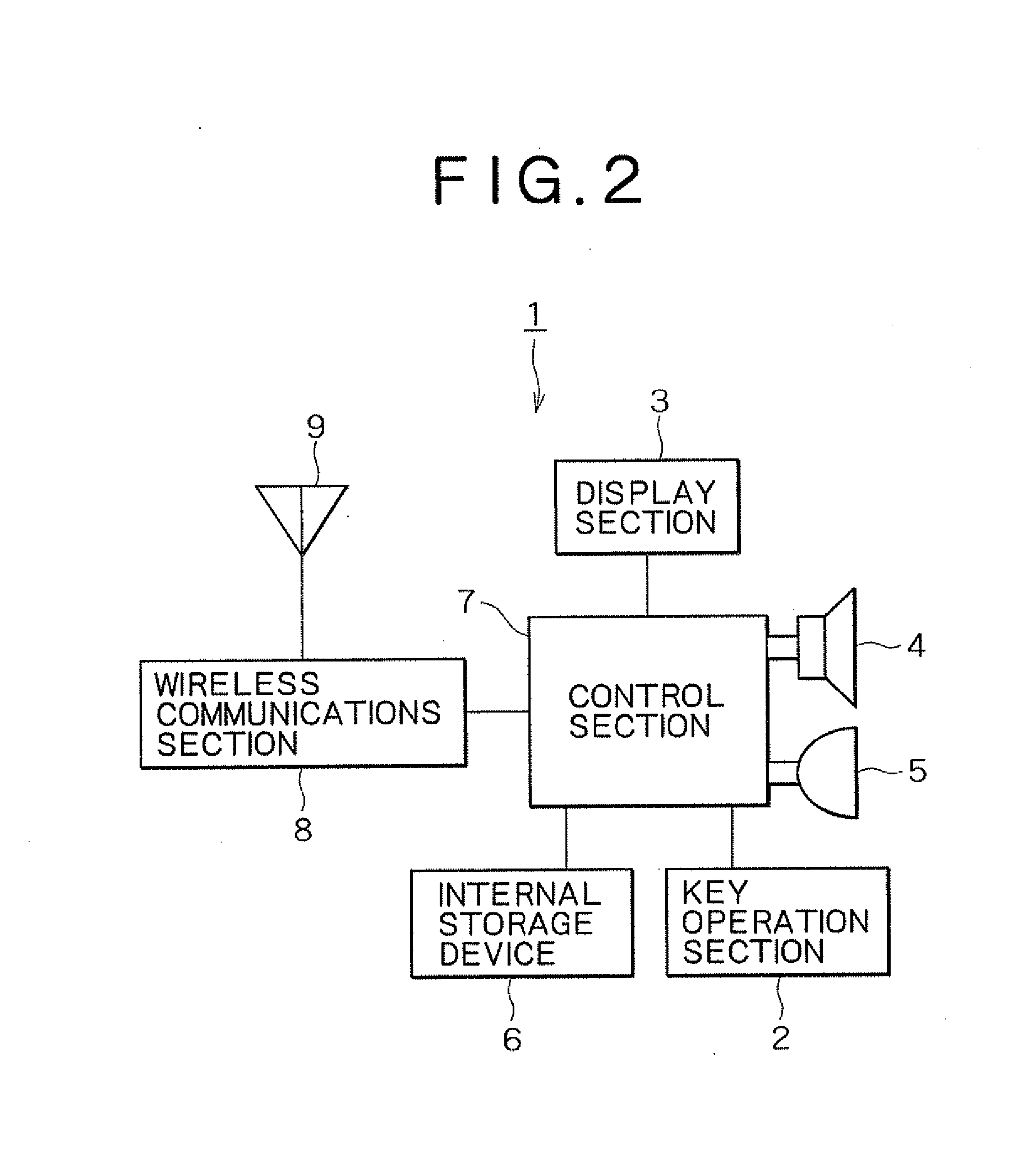

Mobile terminal device and method for radiating heat therefrom

InactiveUS7330354B2Suppresses local temperature riseEfficient executionDigital data processing detailsPrinted circuit aspectsTerminal equipmentEngineering

In a mobile terminal device, at least one heat conduction layer formed of a member, such as copper, aluminum or carbon, being excellent in heat conductivity is provided inside a circuit board on which electronic components are mounted. The heat generated in the electronic components is promptly dispersed in the direction of the face of the circuit board by the heat conduction layer, and transferred from the whole face of the circuit board to the operation member, such as keys, and the housing, and then radiated to the outside. With this structure, the local temperature rise at the operation member and the housing can be suppressed, and the temperature on the surface of the mobile terminal device can be made uniform, without significantly increasing the cost and the thickness of the mobile terminal device. In addition, high-performance electronic components can be used by adopting this structure. Furthermore, the rigidity of the circuit board can be raised, and the reliability of the mobile terminal device can be improved.

Owner:LENOVO INNOVATIONS LTD HONG KONG

Lithium ion battery cooling system comprising dielectric fluid

ActiveUS8852772B2Uniform surface temperatureFinal product manufactureCell temperature controlInterior spaceDielectric

A Lithium Ion battery cooling system for use in a hybrid vehicle comprises a plurality of self-contained liquid cooling modules, each cooling module including a closed and sealed container having an interior space. Each cooling module includes a battery assembly disposed within the interior space of the container and a plurality of battery cells having at least one fluid channel formed therebetween for receiving a fluid therein. A dielectric fluid is disposed within the at least one fluid channel. The dielectric fluid substantially immerses and is in contact with the battery assembly to heat and cool the battery assembly. A heating element is disposed within the interior space and heats the dielectric fluid. A cooling element is disposed within the interior space and cools the dielectric fluid.

Owner:GM GLOBAL TECH OPERATIONS LLC

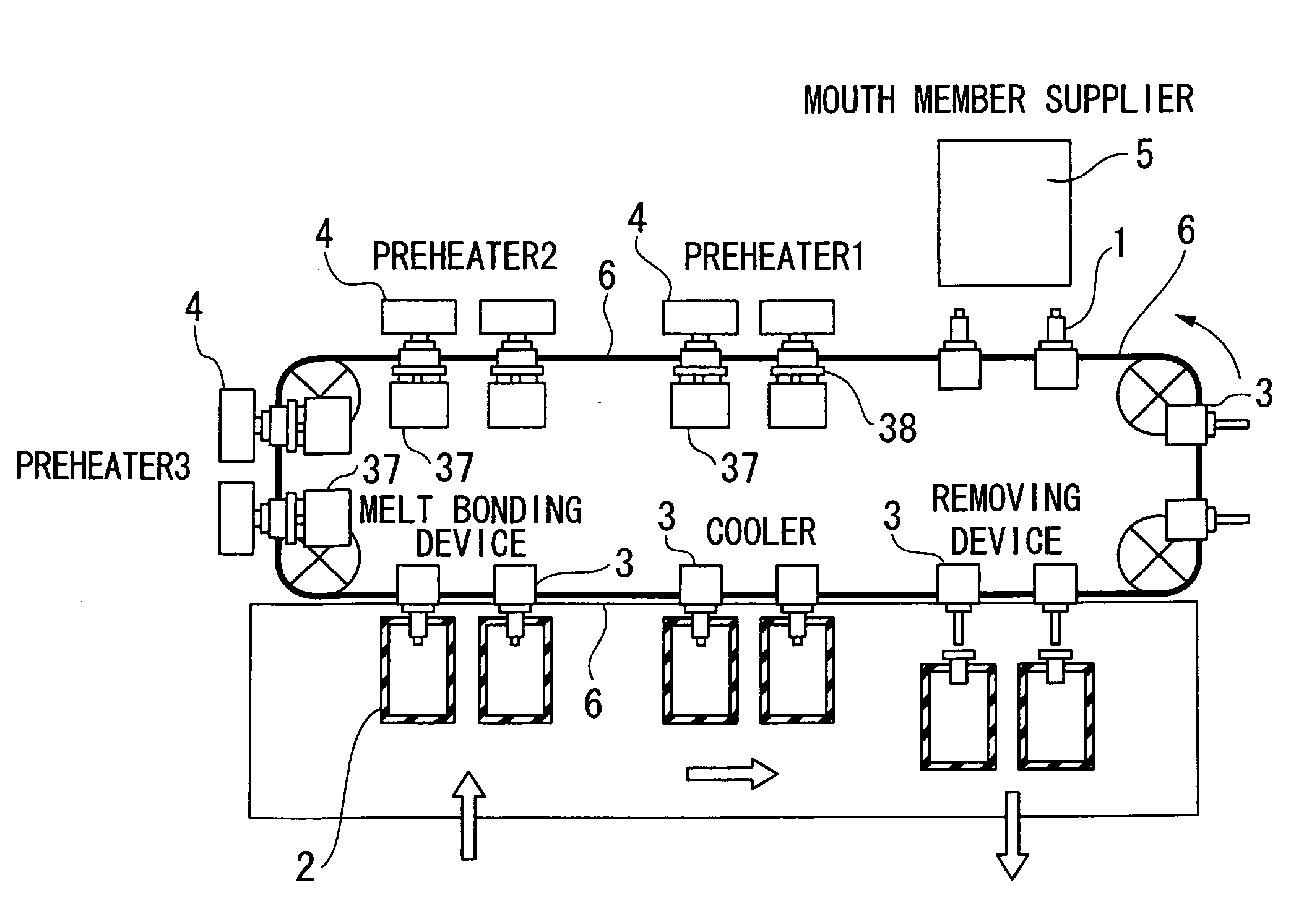

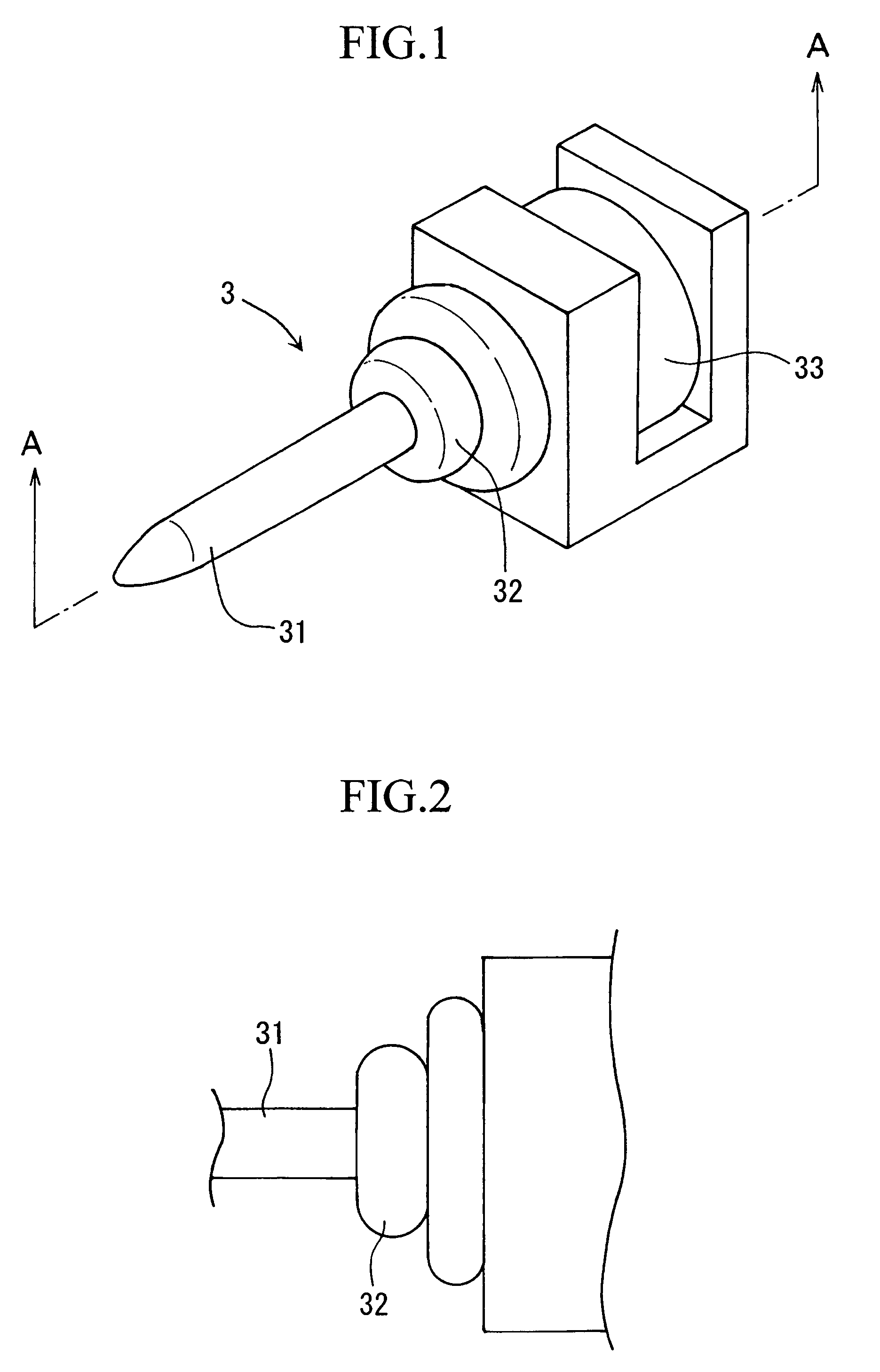

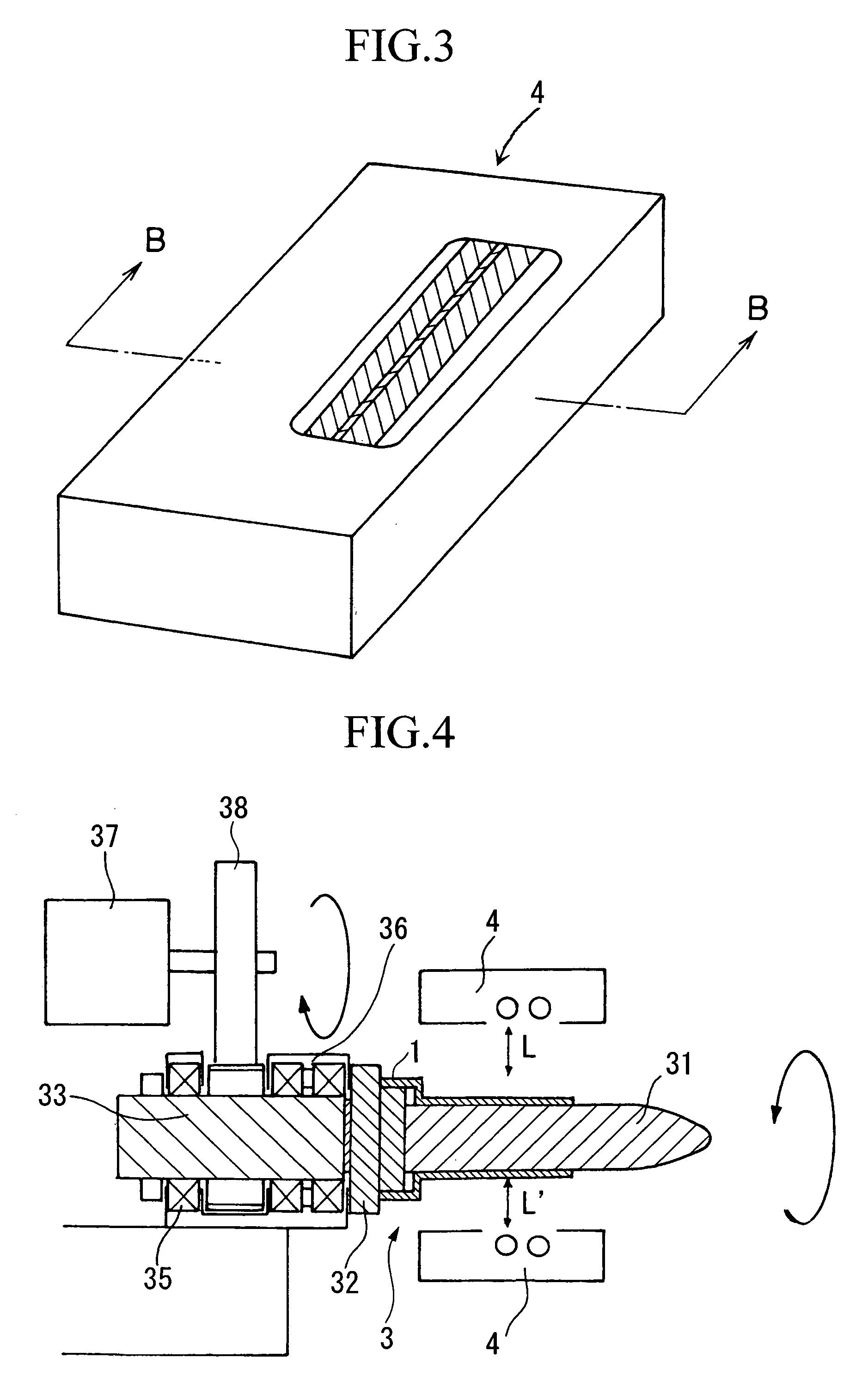

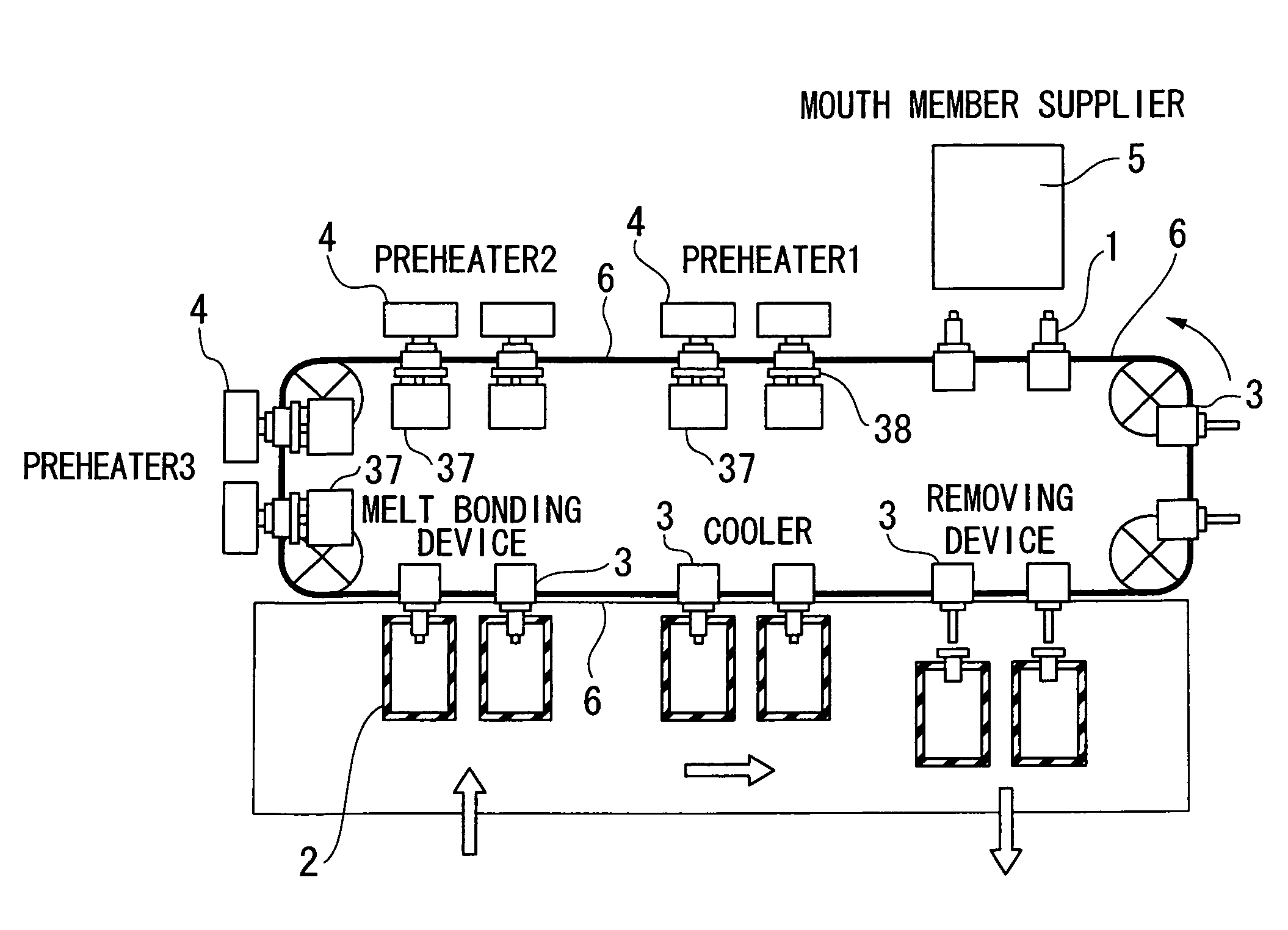

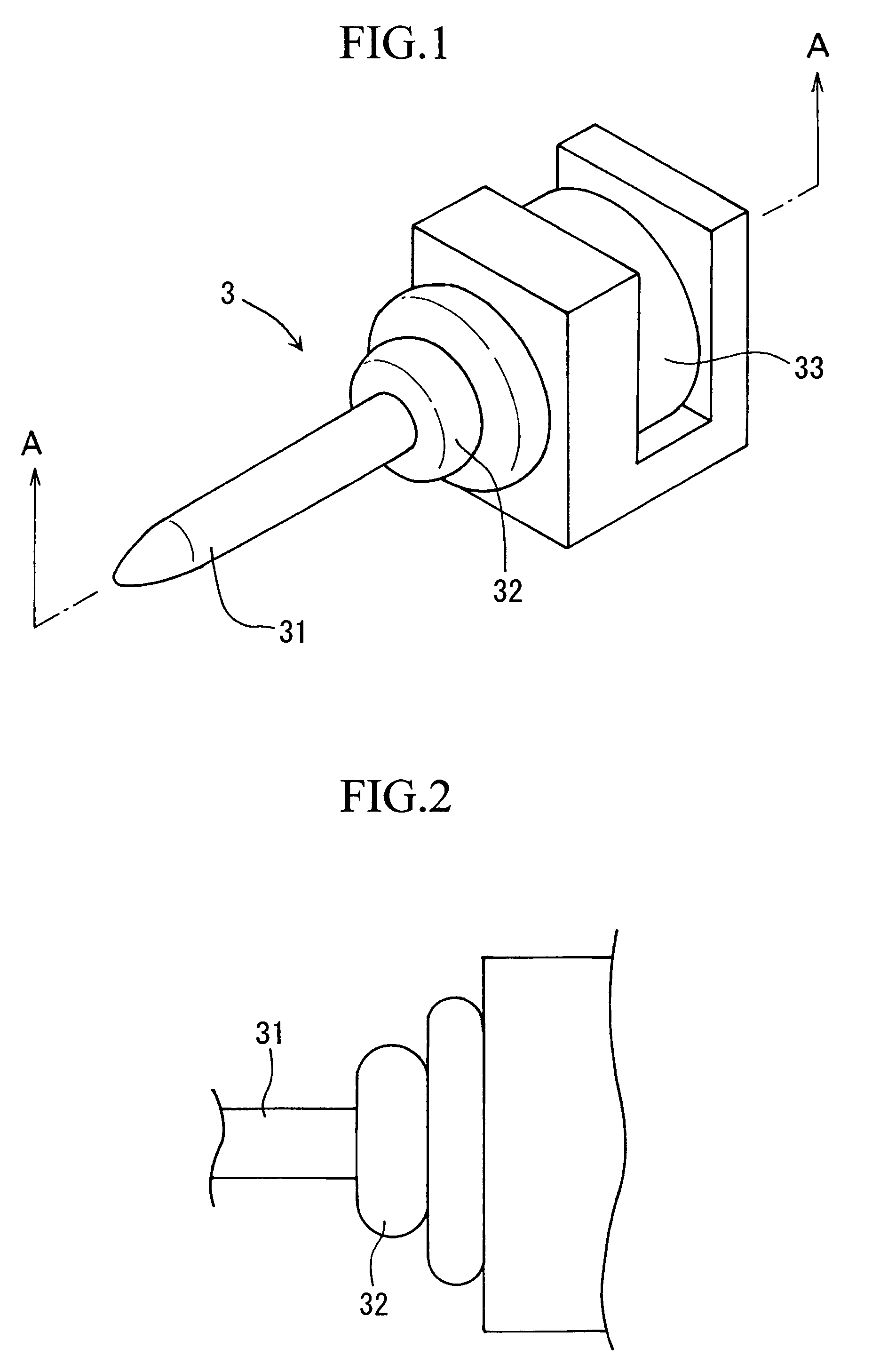

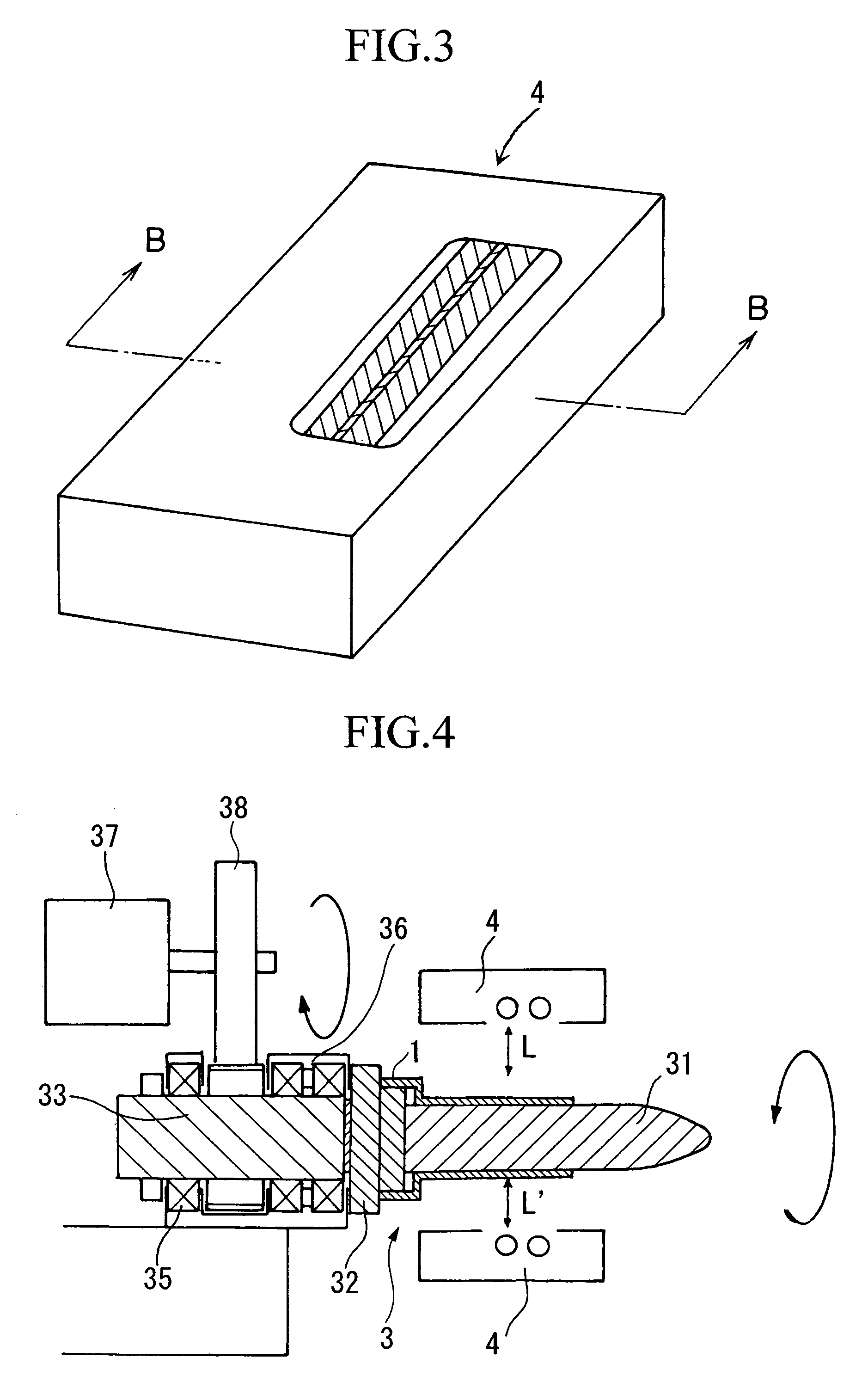

Method and Apparatus For Producing Bag With Mouth Member

InactiveUS20080254962A1Improve drop strengthEnhanced inhibitory effectEnvelopes/bags making machineryMechanical working/deformationEngineering

A method is provided for producing a bag with a mouth member by liquidtightly melt-bonding a mouth member comprising a thermoplastic resin and a bag unit comprising a relatively soft flexible film, in which uniform surface temperature of the mouth member is realized, generation of an A-shaped gap is prevented, and a bag with a mouth member excellent in the liquidtightness of the melt-bonded part between the mouth member and the bag unit is produced; and also a production apparatus therefor is provided. The method comprises a preheating step of heating a tubular mouth member while rotating it around the cylinder axis thereof, and a melt-bonding step of inserting the heated mouth member into the opening part of a bag unit and pressing, and thereby melt-bonding the mouth member to the opening part of the bag unit.

Owner:HOSOKAWA YOKO CO LTD

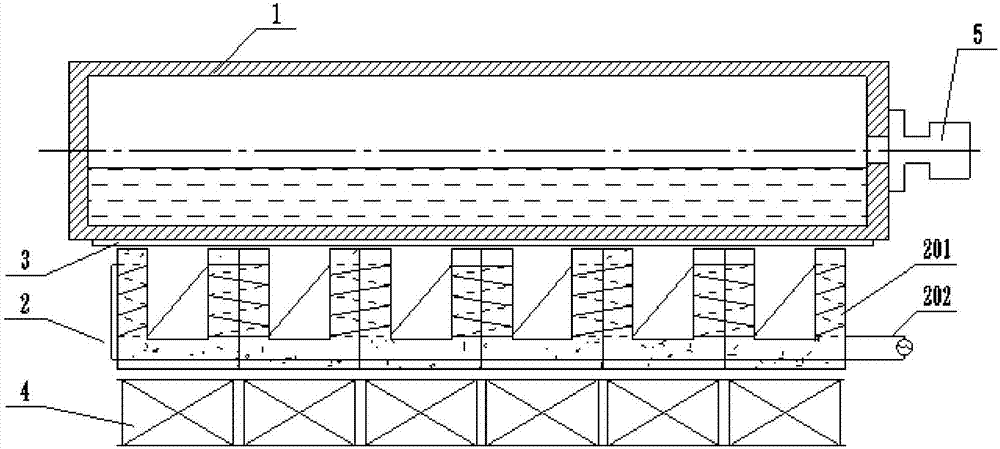

Electrothermal combined using device for solar cell

InactiveCN1988183AUniform surface temperatureImprove photoelectric conversion efficiencyPhotovoltaicsPhotovoltaic energy generationElectricityWorking fluid

This invention discloses a common use device for electricity and heat of a solar cell including a liquid container with heat collection working fluid, in which, hot tubes are set on the side walls of the container and set with phase change heat- carry working fluid, a solar cell is connected with the tubes in the container fixedly, an inlet is set at the bottom of the container and an outlet is set at the top of the container, the bottom face is transmissive, heat preservation materials are set at outside of the top and outside of the side wall of the container. This invention can carry away solar heat not changed to electricity quickly by dipping a solar cell in a heat-collection working fluid and connecting to the hot tubes.

Owner:TIANJIN UNIV

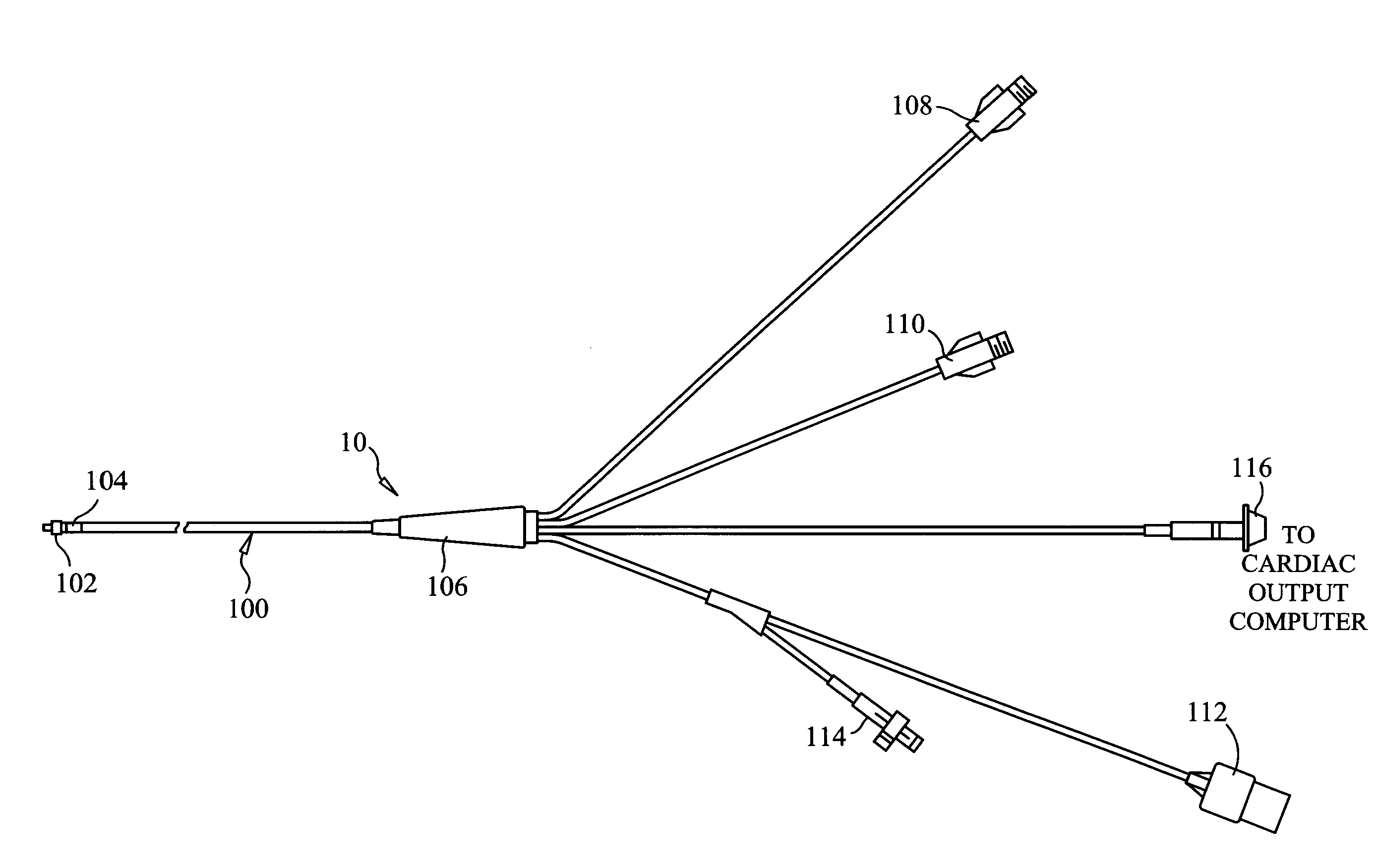

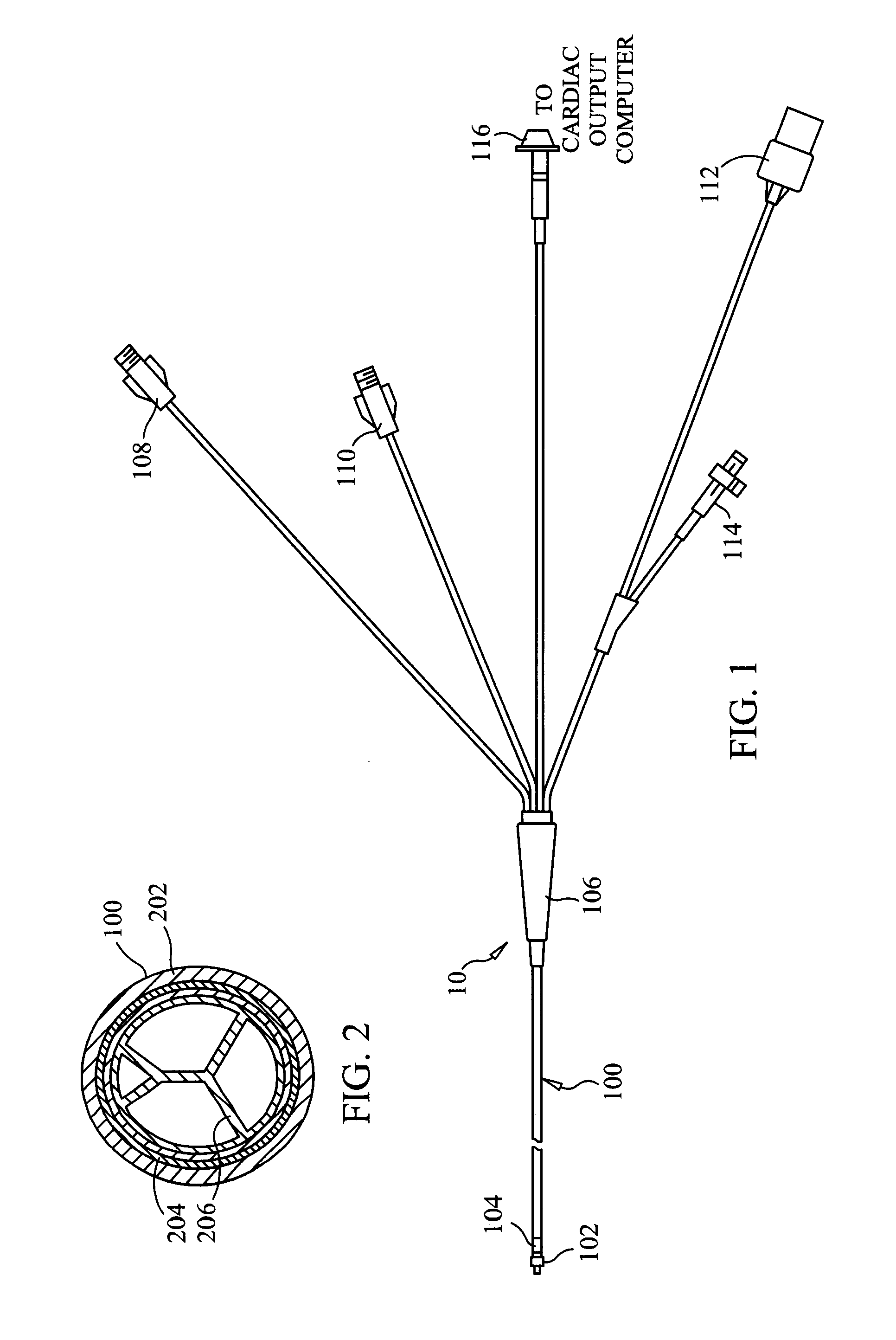

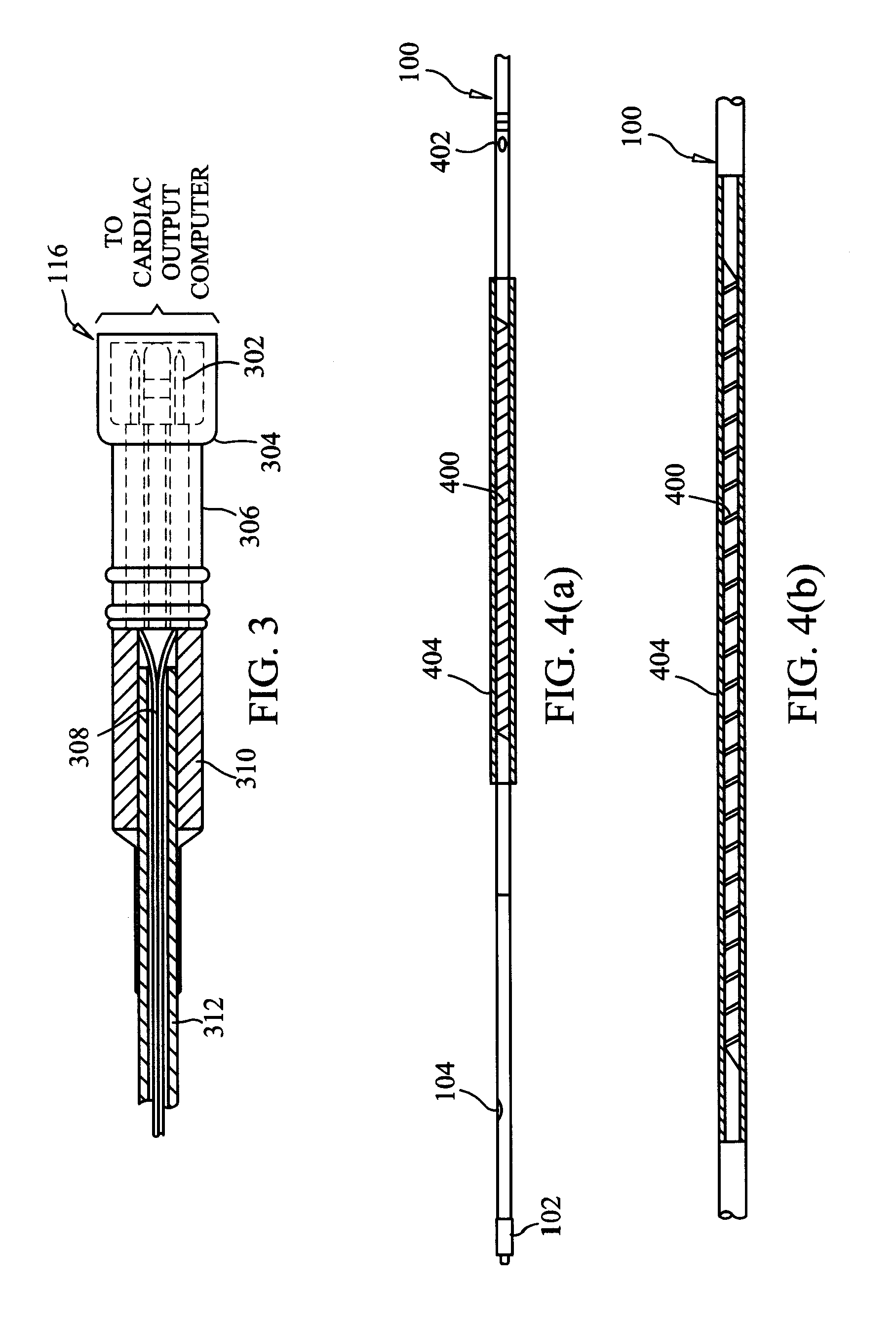

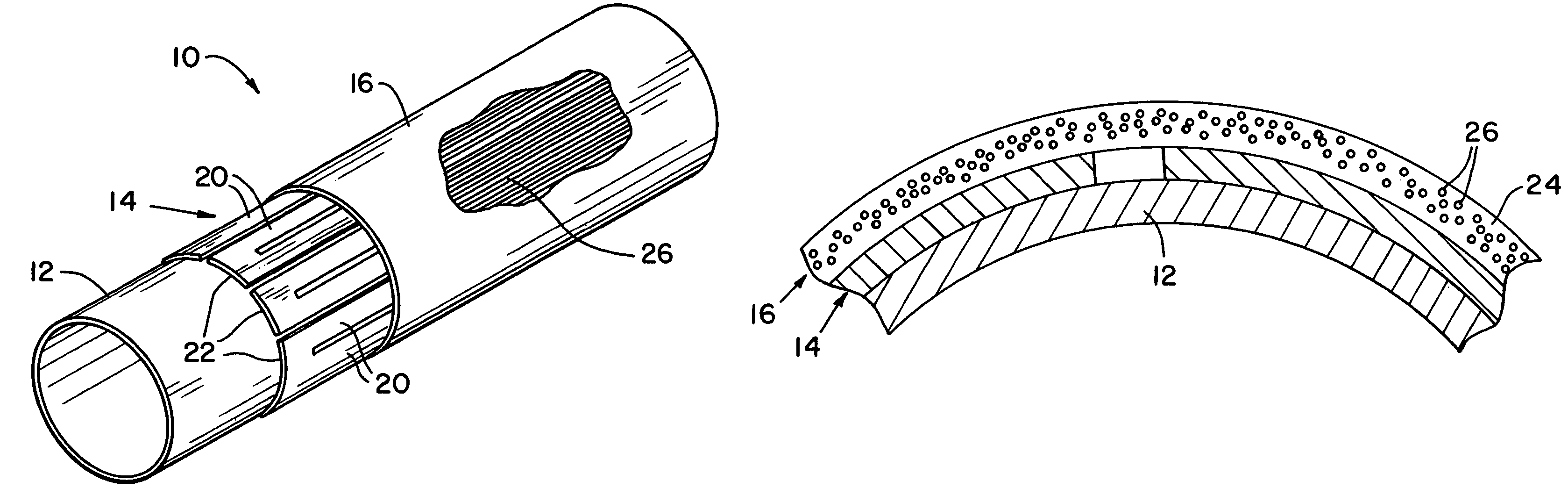

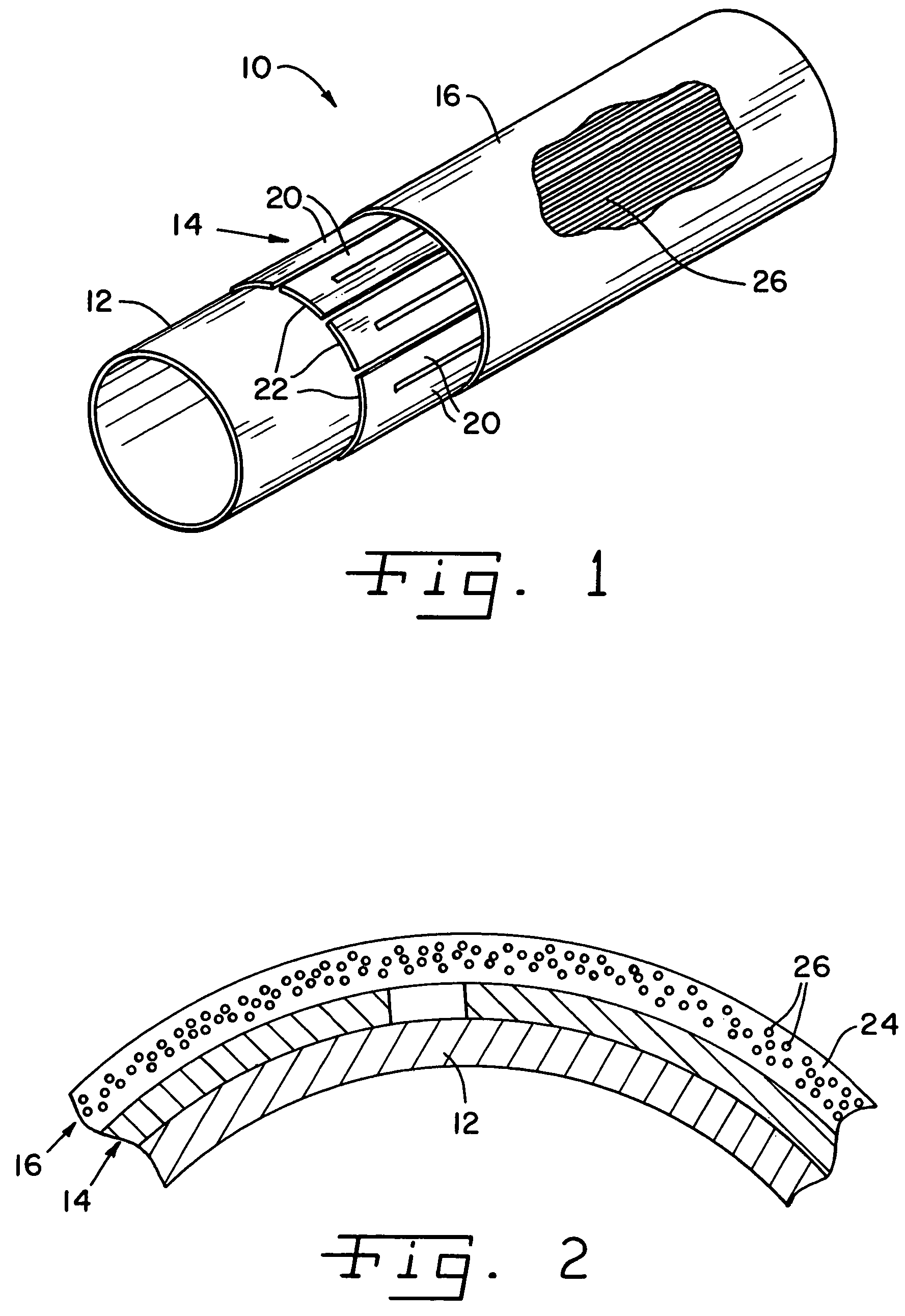

Thermodilution catheter having a safe, flexible heating element

InactiveUS7254946B1Increase the cross-sectional areaReduce the possibilityCatheterMachines/enginesProgram segmentCapacitance

A thermodilution catheter having a heating filament which is fabricated so as to be thin and flexible enough to avoid contact with the patient's blood. The heating filament is either inserted in a preformed catheter lumen, incorporated into a wall of the catheter body itself, or wrapped around the catheter body wall and surrounded by an external sheath. Generally, the covering of the heating filament is minimally thin so as to allow the heat from the heating filament to be transferred to the surrounding blood and to minimally increase the overall cross-sectional area. Since the heating filament does not directly touch the patient's blood, the outer surface may be made smooth so as to prevent inducement of blood clots. In addition, the heating filament may be maintained at a safe temperature by forming the heating element of a flexible material having a high temperature coefficient of resistance, low thermal capacitance and high thermal conductivity. Preferably, the temperature coefficient of resistance of the material forming the heater filament is greater than 0.001 Ω / Ω-° C. and the resistance of the heating filament is proportional or inversely proportional to its temperature. By monitoring this resistance, the application of power to the heating filament may be regulated to prevent overheating of the heating filament. Calibration techniques are also disclosed whereby a memory containing encoded calibration information is disposed within or connected to a connector of the catheter. This memory may also include a program segment used by a cardiac output computer having a cardiac output calculation program, whereby the portion of code stored in the memory must be input into the cardiac output computer before the determination of the cardiac output can be performed. As a result of these improvements, the invention enables the thermodilution cardiac output calculation to be performed quite safely and accurately in a clinical setting.

Owner:EDWARDS LIFESCIENCES CORP

Fouling and slagging resistance and high temperature and corrosion resistance ceramic paint and preparation and usage method thereof

InactiveCN104987032AThe composition of the formula is reasonableReasonable ratioCeramic coatingSpray coating

The invention relates to a fouling and slagging resistance and high temperature and corrosion resistance ceramic paint and a preparation and usage method thereof. The ceramic paint comprises, by mass, the components of 20-30% of filler, 23-29% of binders, 0.8-1.2% of addition agents and the balance water. According to the ceramic paint, the formula component and ratio are reasonable, the filler granularity is small, granularity matching among different filler components is reasonable, and the matching compatibility of the filler and a binder system is good. A ceramic coating prepared by spray coating can resist high temperature 1320 DEG C, is thinner, has the functions of resisting fouling and slagging and resisting high temperature and corrosion, and cannot be pulverized and fall off in a long-term high-temperature operating environment; the high emissivity above 0.95 can be still kept at high temperature and is close to the thermal expansion coefficients of metal, and heat transfer can be enhanced; the coating integrates chemical inertness and passivation protection into a body, and therefore a high-temperature corrosion environment is prevented from corroding the metal through the compact ceramic coating; meanwhile, due to the fact that the coating has the self-cleaning effect, the coating can be applied easily and conveniently.

Owner:HANGZHOU CHITIAN ENERGY TECH CO LTD

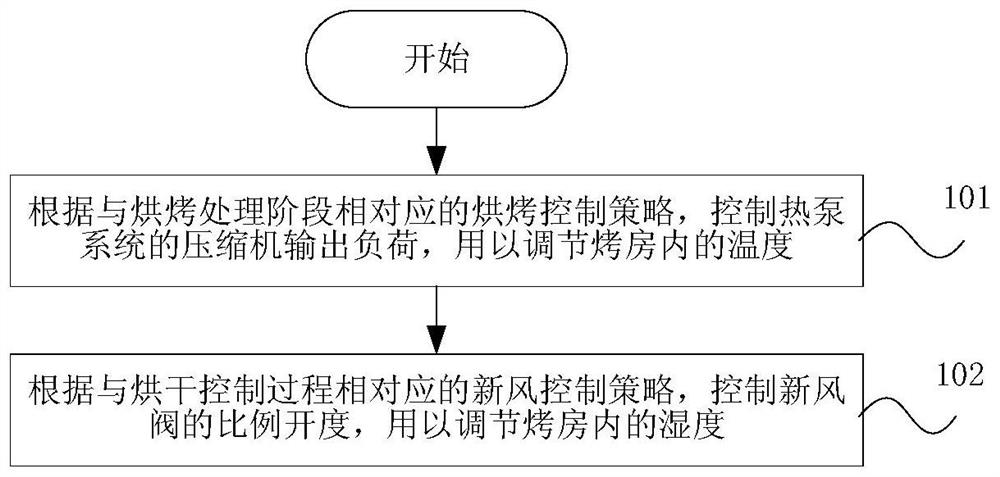

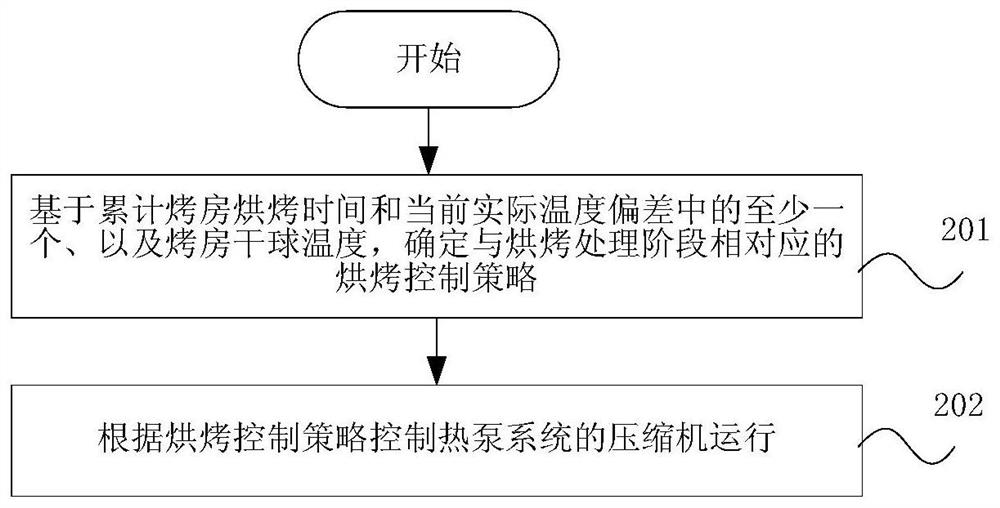

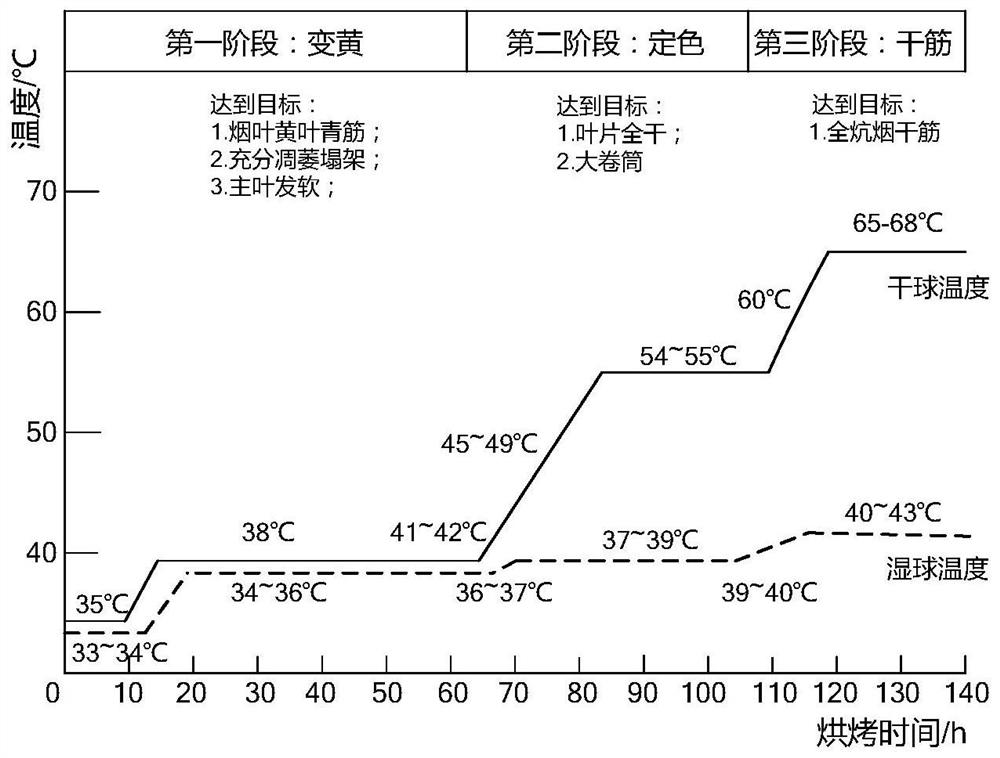

Control method and device of heat pump drying equipment and storage medium

ActiveCN112524800ATimelyUniform surface temperatureFluid heatersTobacco preparationThermodynamicsFresh air

The invention provides a control method and device of heat pump drying equipment and a storage medium, and relates to the technical field of heat pumps. The method comprises the steps that according to a baking control strategy corresponding to a baking processing stage, the output load of a compressor of a heat pump system is controlled to adjust the temperature in a baking room; and according toa fresh air control strategy corresponding to the drying control process, the proportional opening degree of a fresh air valve of a fresh air dehumidification device is controlled so as to adjust thehumidity in the baking room. According to the method, the device and the storage medium, the temperature is adjusted by controlling the load output of the compressor, the humidity is controlled by adjusting the proportional opening degree of the fresh air valve, independent temperature and humidity control and synchronous temperature and humidity adjustment can be achieved, high-precision and intelligent adjustment and control are achieved, the drying technology can be improved, and the product quality is guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

Cryopump and semiconductor device manufacturing apparatus using the cryopump

InactiveUS20070283704A1Short working hoursImprove productivitySolidificationLiquefactionEngineeringVacuum chamber

A cryopump is disclosed. The cryopump includes a cryopump main body connected to a vacuum chamber via an inlet. The cryopump main body includes a vacuum container. A shielding section, a two-stage type cryogenic cooler, a baffle, and first cryopanel and second cryopanels are provided in the vacuum container. A top surface of the first cryopanel is disposed at a position nearest to a surface of the baffle. The top surface of the first cryopanel is disposed almost parallel to the surface of the baffle.

Owner:SUMITOMO HEAVY IND LTD

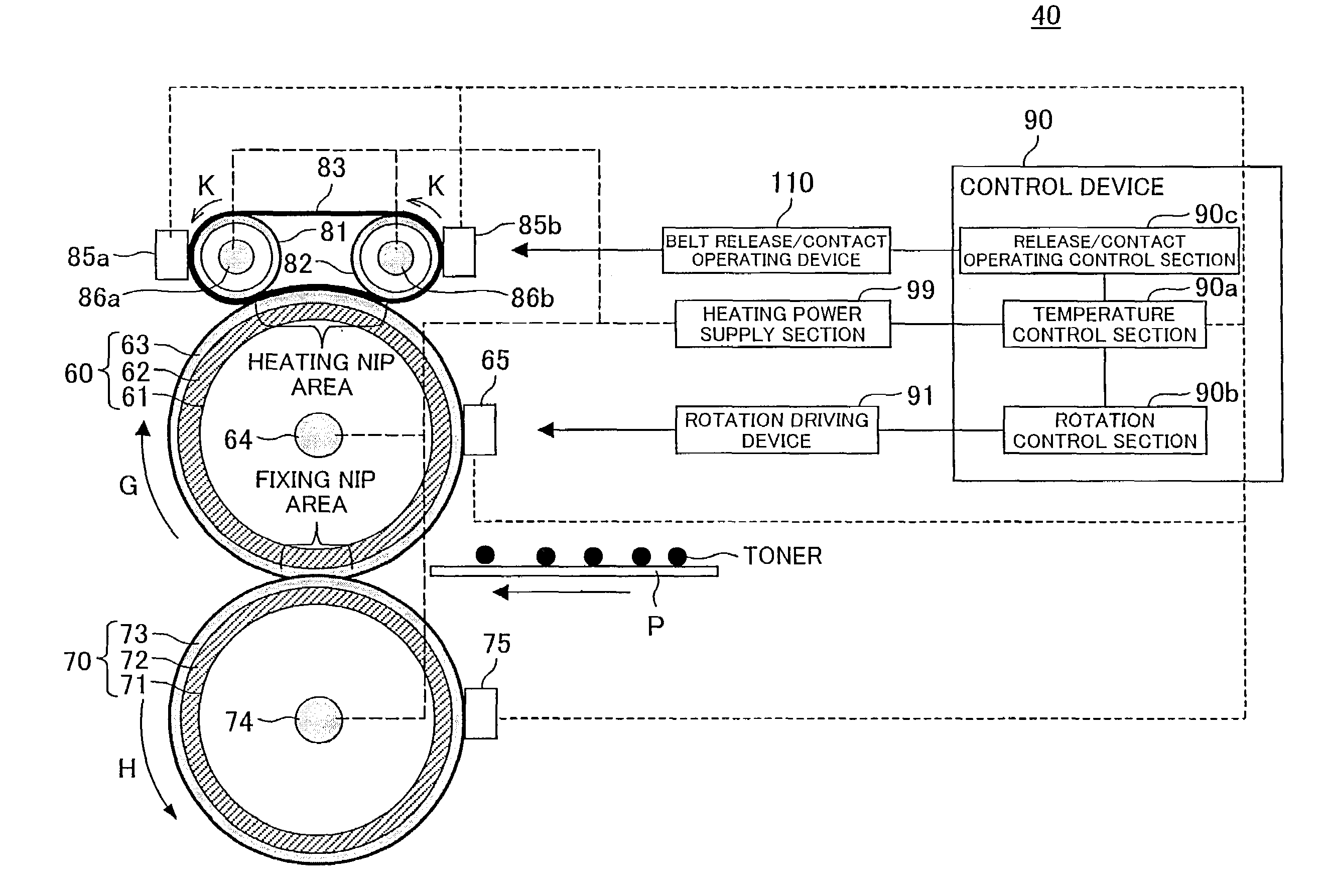

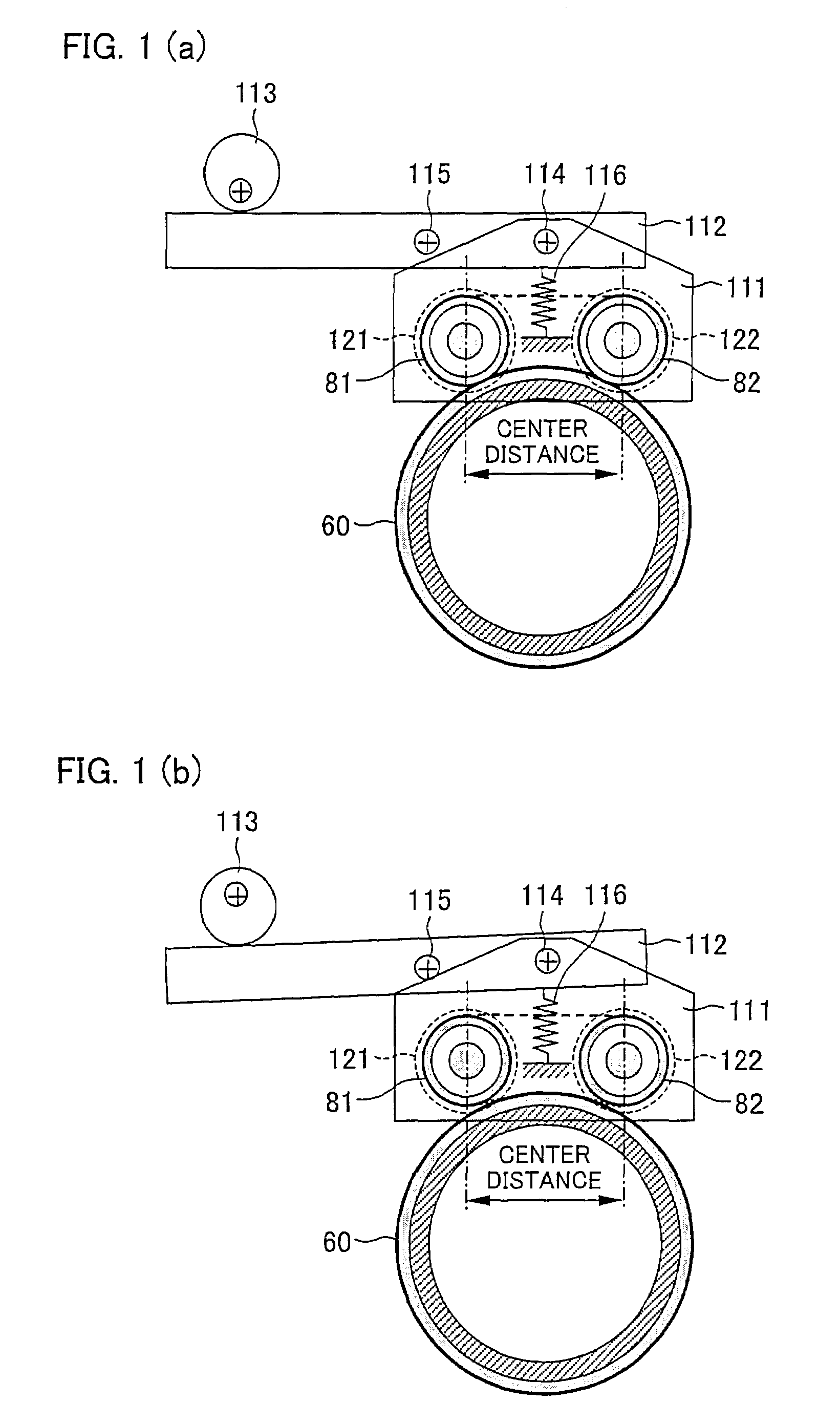

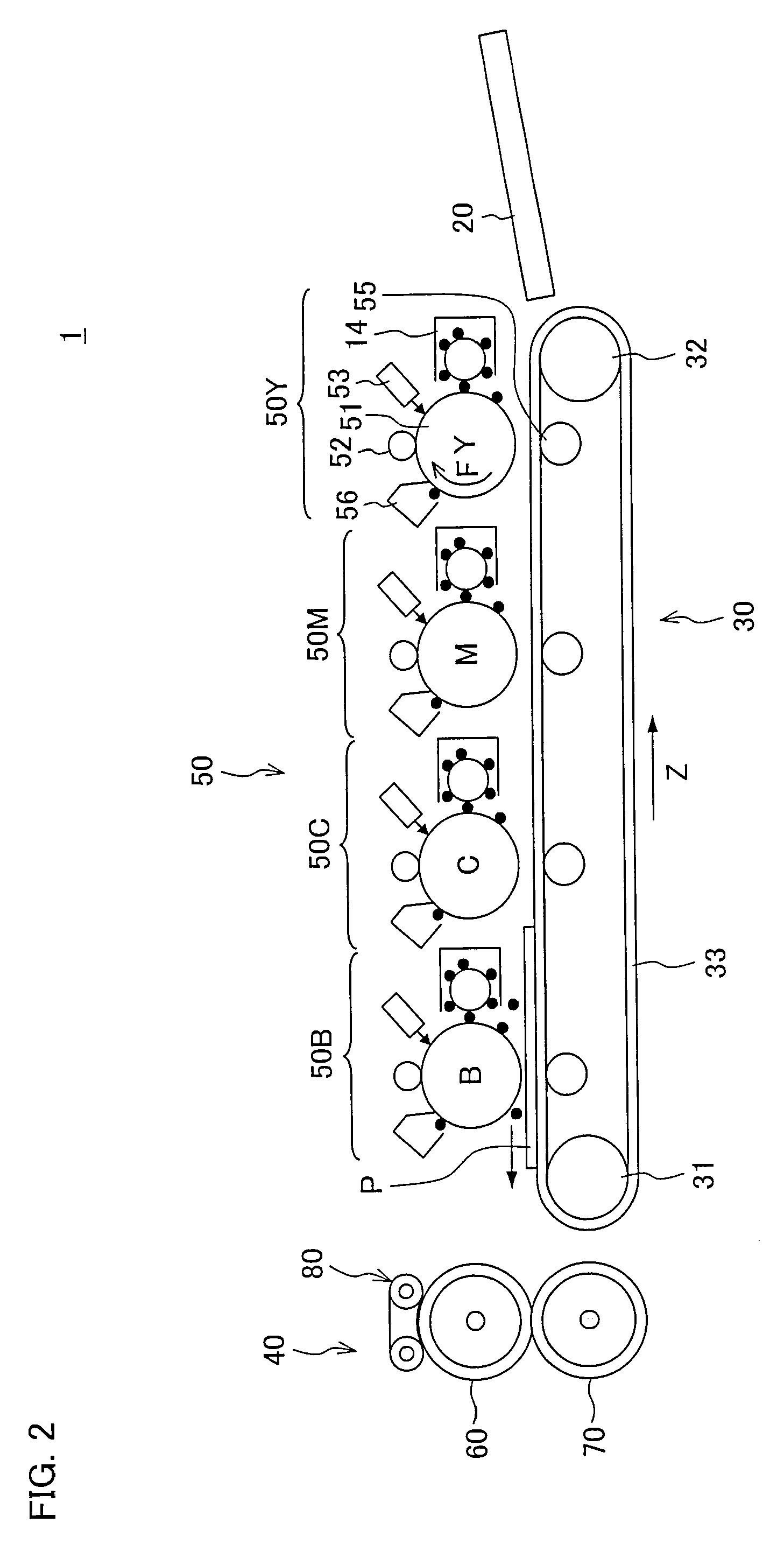

Image forming apparatus having fixing device with external heater

InactiveUS7684746B2Smooth rotationAvoid runningElectrographic process apparatusRotational axisImage formation

Owner:SHARP KK

Mobile terminal device and method for radiating heat therefrom

InactiveUS20060126310A1Suppresses local temperature riseUniform temperatureDigital data processing detailsPrinted circuit aspectsTerminal equipmentCopper

In a mobile terminal device, at least one heat conduction layer formed of a member, such as copper, aluminum or carbon, being excellent in heat conductivity is provided inside a circuit board on which electronic components are mounted. The heat generated in the electronic components is promptly dispersed in the direction of the face of the circuit board by the heat conduction layer, and transferred from the whole face of the circuit board to the operation member, such as keys, and the housing, and then radiated to the outside. With this structure, the local temperature rise at the operation member and the housing can be suppressed, and the temperature on the surface of the mobile terminal device can be made uniform, without significantly increasing the cost and the thickness of the mobile terminal device. In addition, high-performance electronic components can be used by adopting this structure. Furthermore, the rigidity of the circuit board can be raised, and the reliability of the mobile terminal device can be improved.

Owner:LENOVO INNOVATIONS LTD HONG KONG

Household wall-mounted flat solar heat-pump water heater and control method thereof

ActiveCN103453679ASolve the problem of antifreezeAchieve high efficiencyFluid heatersSolar heat devicesSolar waterEngineering

The invention discloses a household wall-mounted flat solar heat-pump water heater and a control method thereof. The household wall-mounted flat solar heat-pump water heater comprises an outdoor unit and an indoor unit, wherein the outdoor unit comprises a tube-wing heat collecting evaporator, a solar heat-pump compressor, a thermal expansion valve, a liquid storage device, a dry filter and an electromagnetic valve, wherein the tube-wing heat collecting evaporator is formed through integrating a heat collecting plate core of a flat solar heat collecting panel and an evaporator of a heat pump; the indoor unit comprises a controller, a heat-storage water tank and a coil tube type condenser which is arranged inside the heat-storage water tank; the operation of the flat solar heat-pump water heater is realized through controlling the compressor, the thermal expansion valve and the electromagnetic valve by the controller. Through the manner, the household wall-mounted flat solar heat-pump water heater has the advantages that various complicated, changeable and harsh working conditions of a solar heat collecting evaporator are overcome successfully, heat pump technologies can be applied to solar heat utilization, the efficiency is increased greatly compared with that of a solar water heater and that of an air source heat-pump water heater, and meanwhile, the problems that the flat solar water heater needs to be protected from frostbite in winter and the air source heat-pump water heater needs to be defrosted in winter are solved.

Owner:CHANGZHOU HAICA SOLAR HEAT PUMP

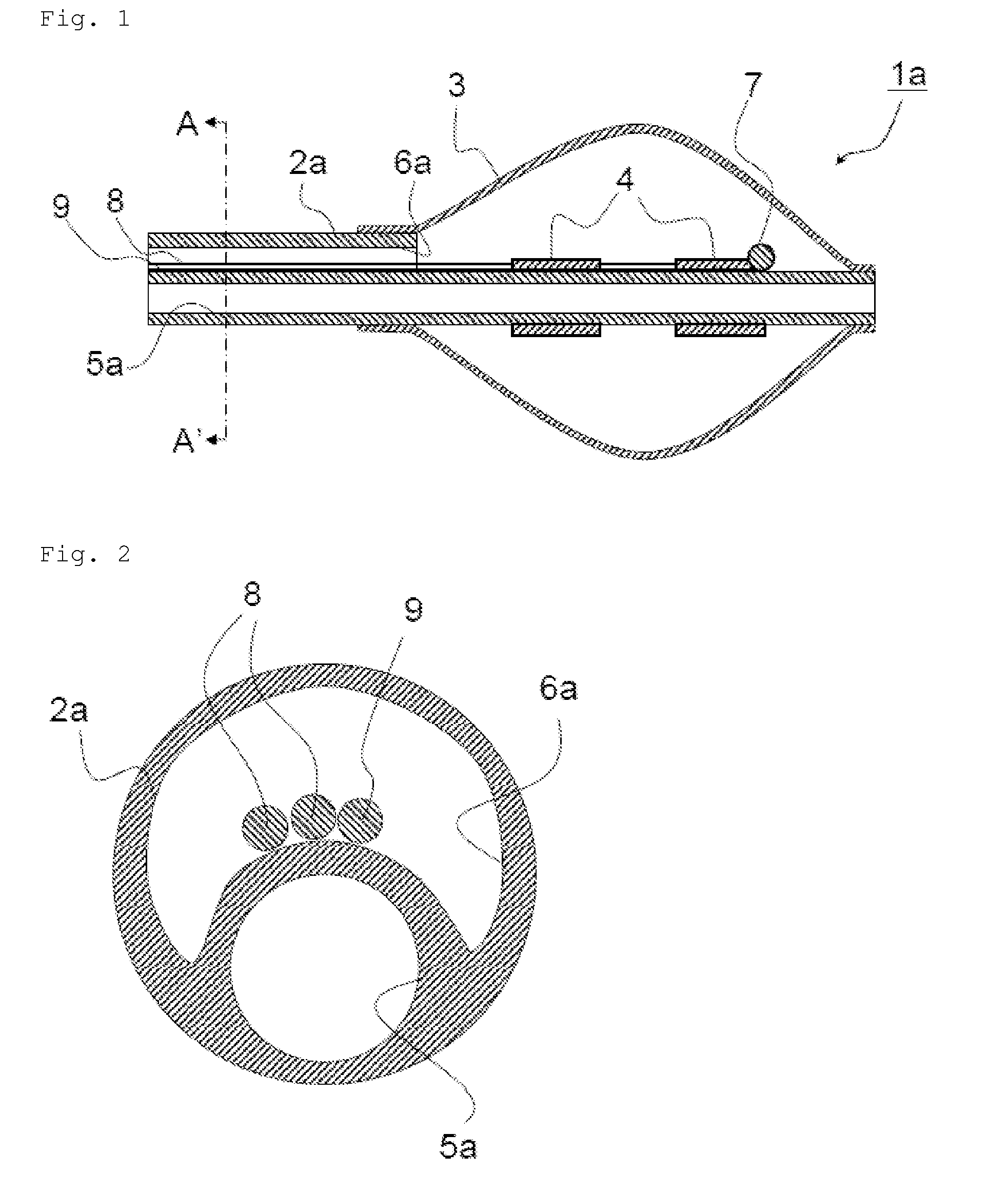

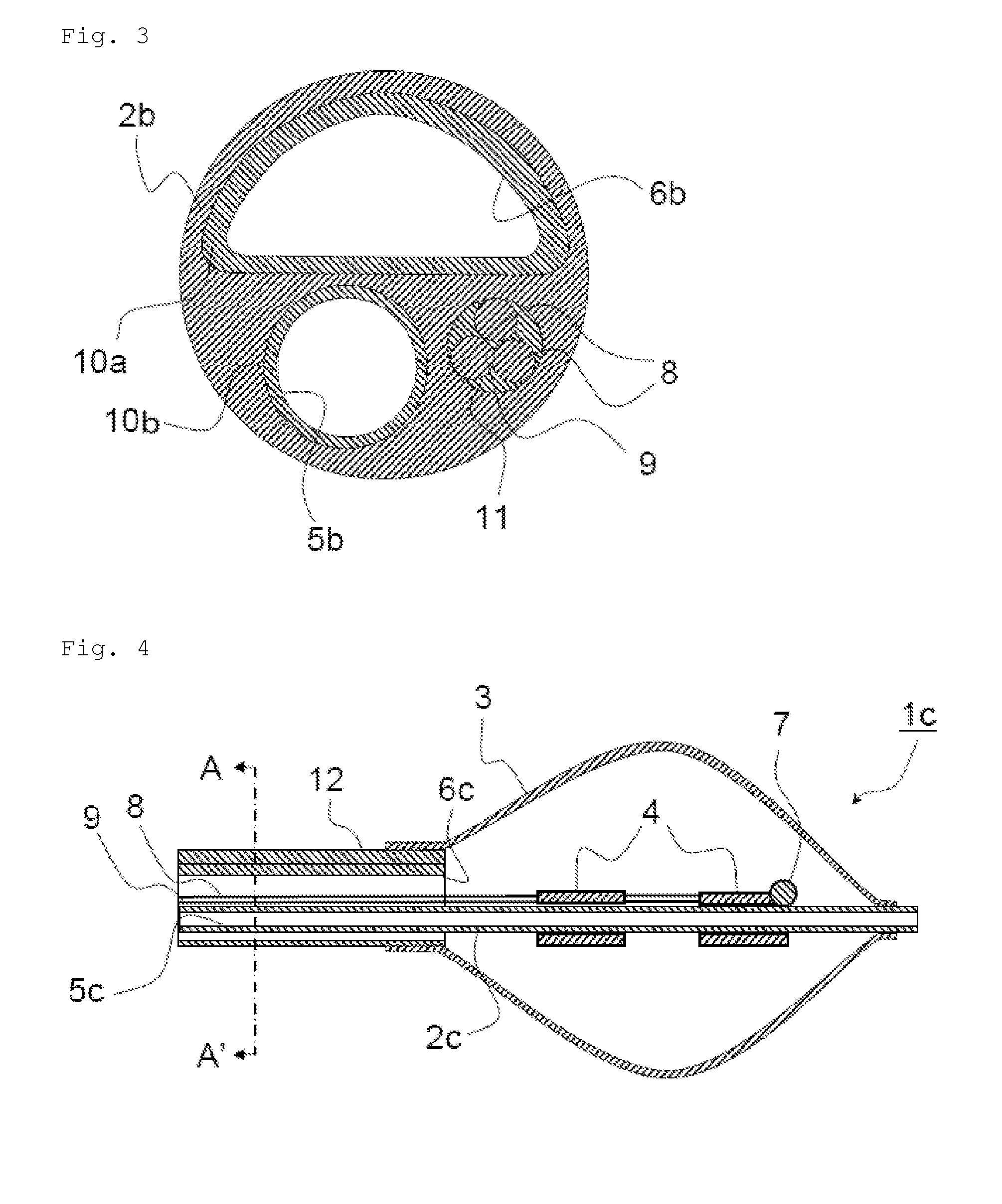

Shaft for ablation catheter with balloon

ActiveUS20120065633A1Improve mixing efficiencyReduce the burden onStentsBalloon catheterCatheterGuide wires

The stirring efficiency of a heating liquid which is supplied to the balloon of a balloon-equipped ablation catheter is increased to quickly uniformize the surface temperature of the balloon, and air is prevented from remaining in the balloon-equipped ablation catheter to enhance the safety of treatment which uses the balloon-equipped ablation catheter. A shaft for a balloon-equipped ablation catheter, consisting of a single pipe, wherein the shaft has two lumens which communicate from the distal end to the proximal end of the shaft, a first lumen being a guide wire passage lumen which is provided in order to allow a guide wire to pass therethrough, the second lumen being a liquid supply lumen which is provided in order to supply liquid to the inside of the balloon of the balloon-equipped ablation catheter.

Owner:TORAY IND INC

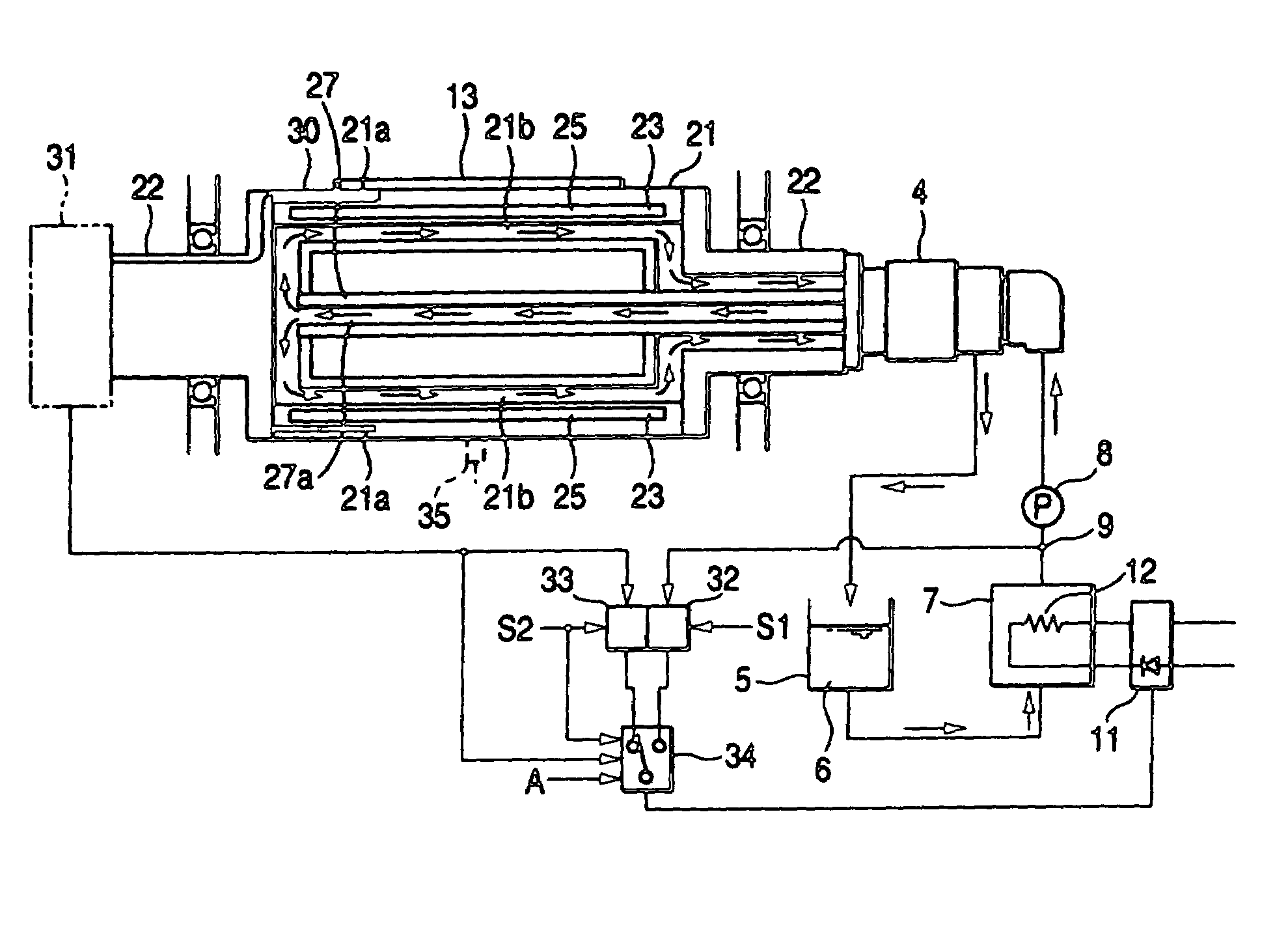

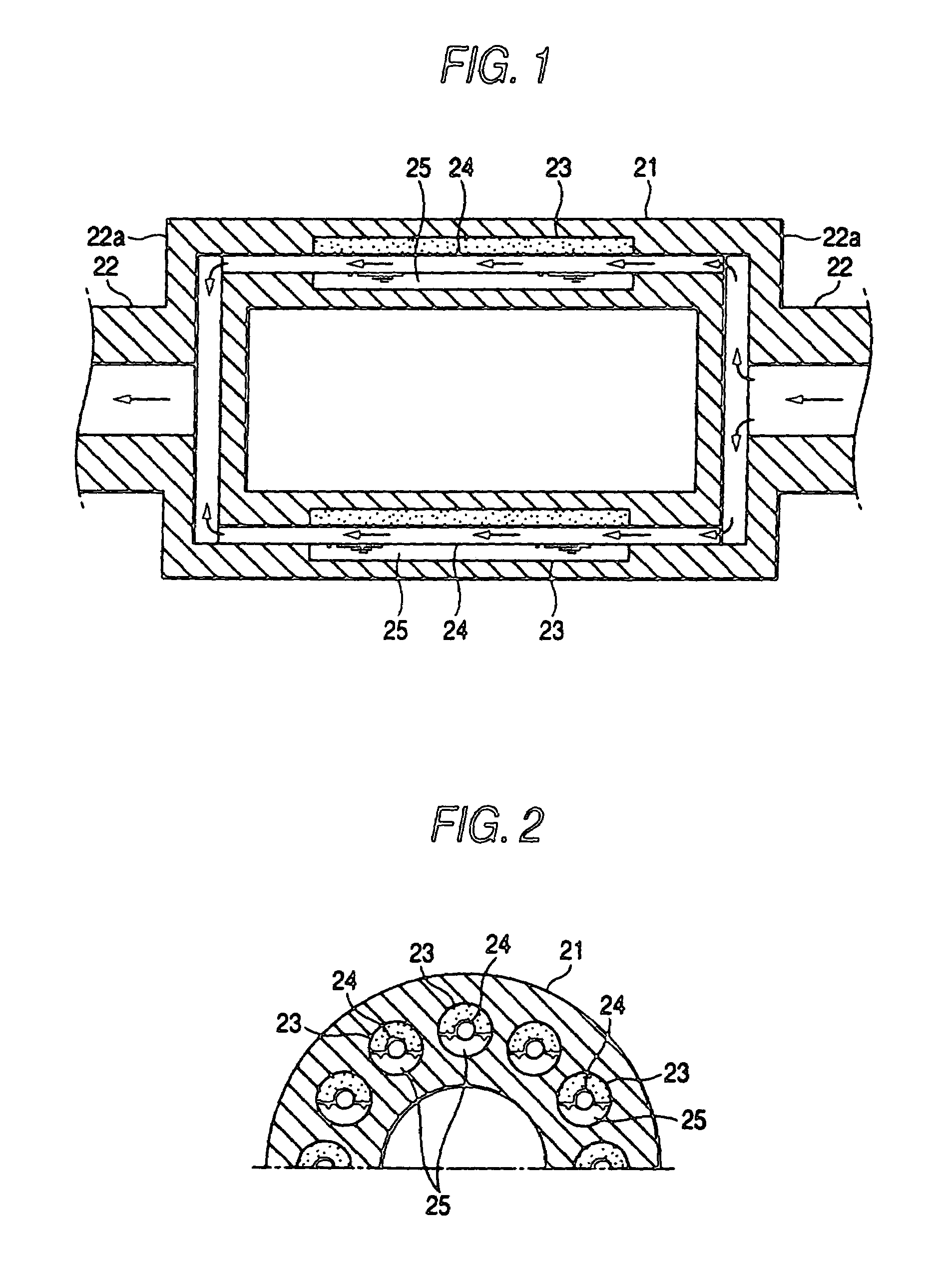

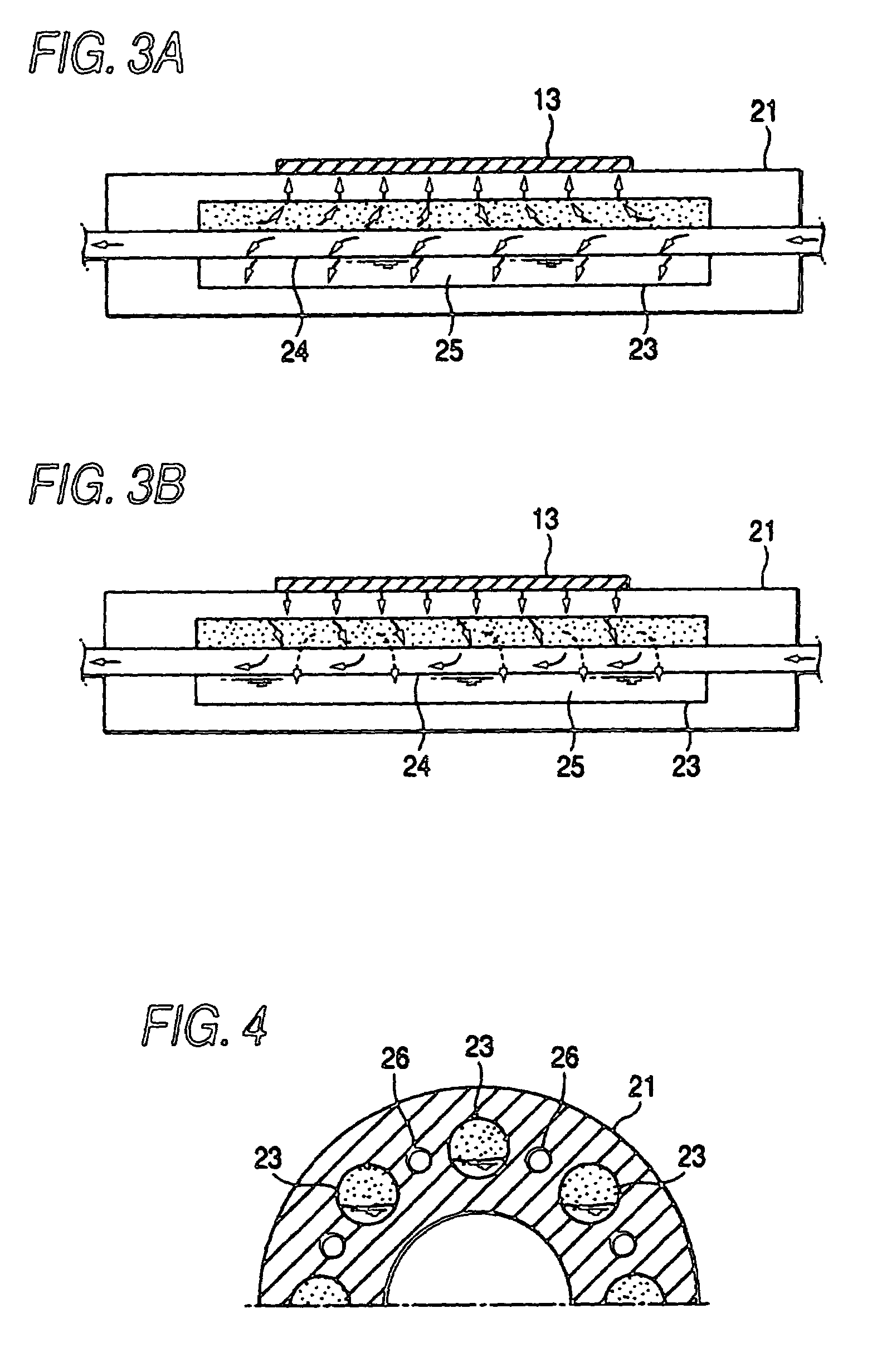

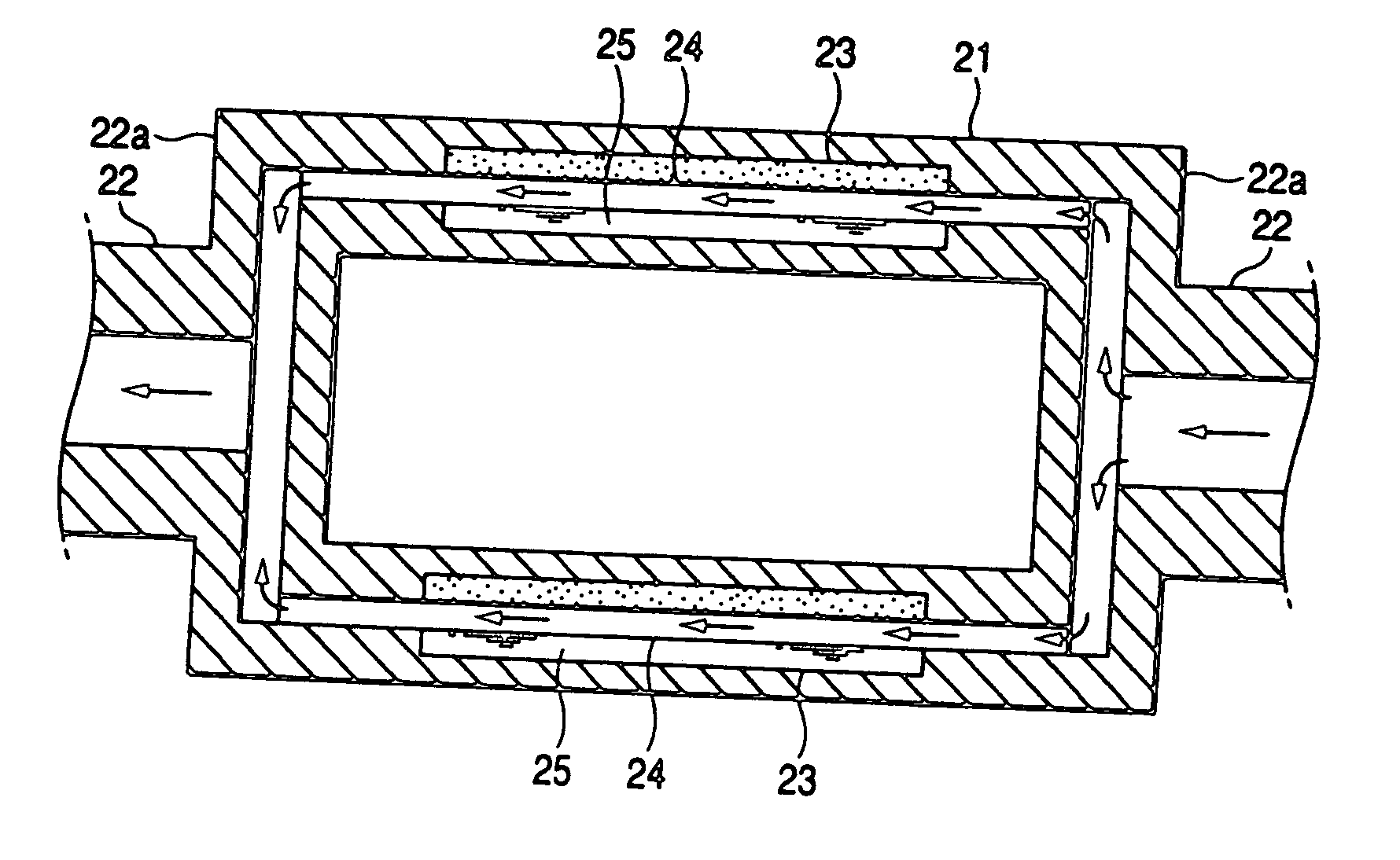

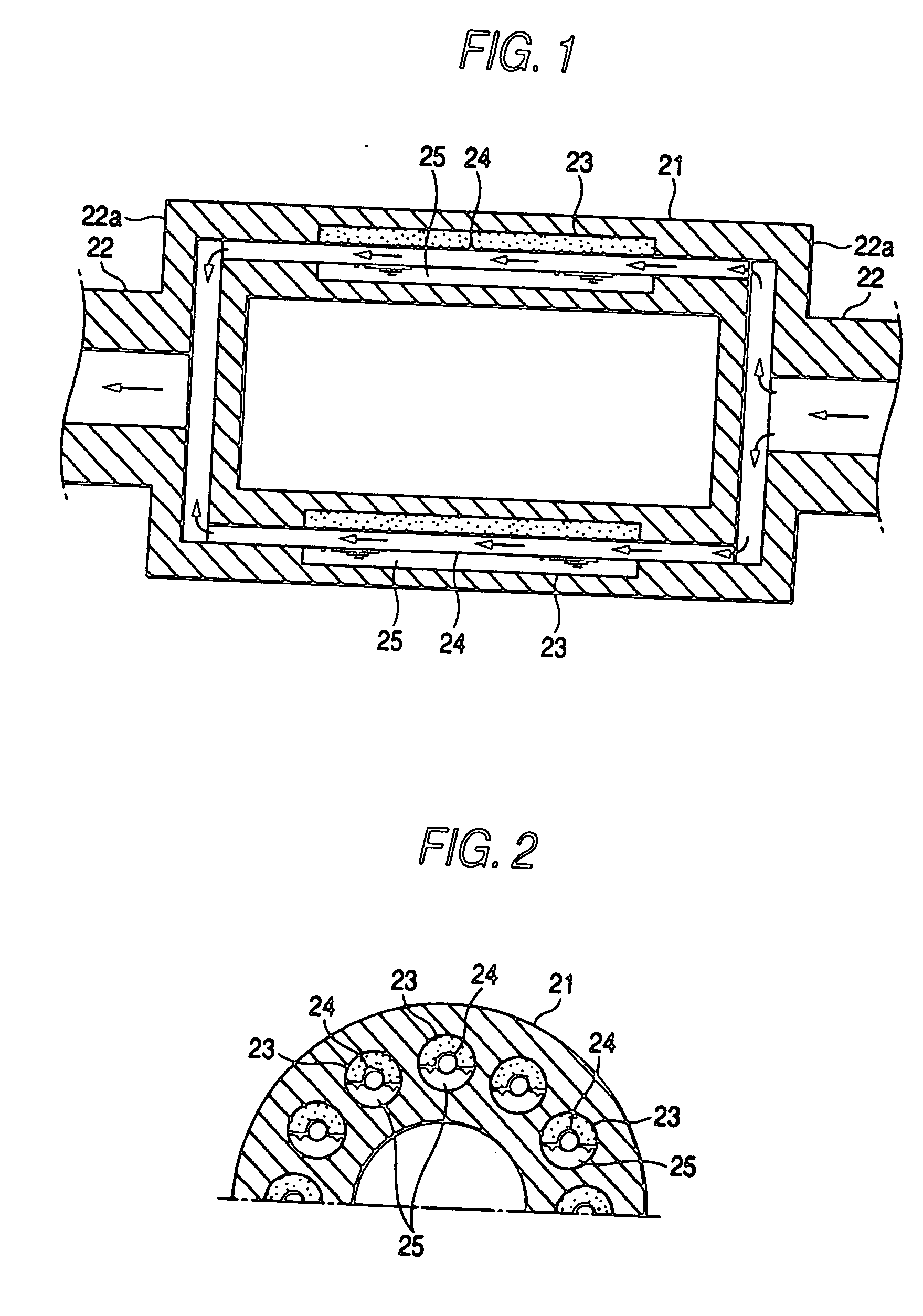

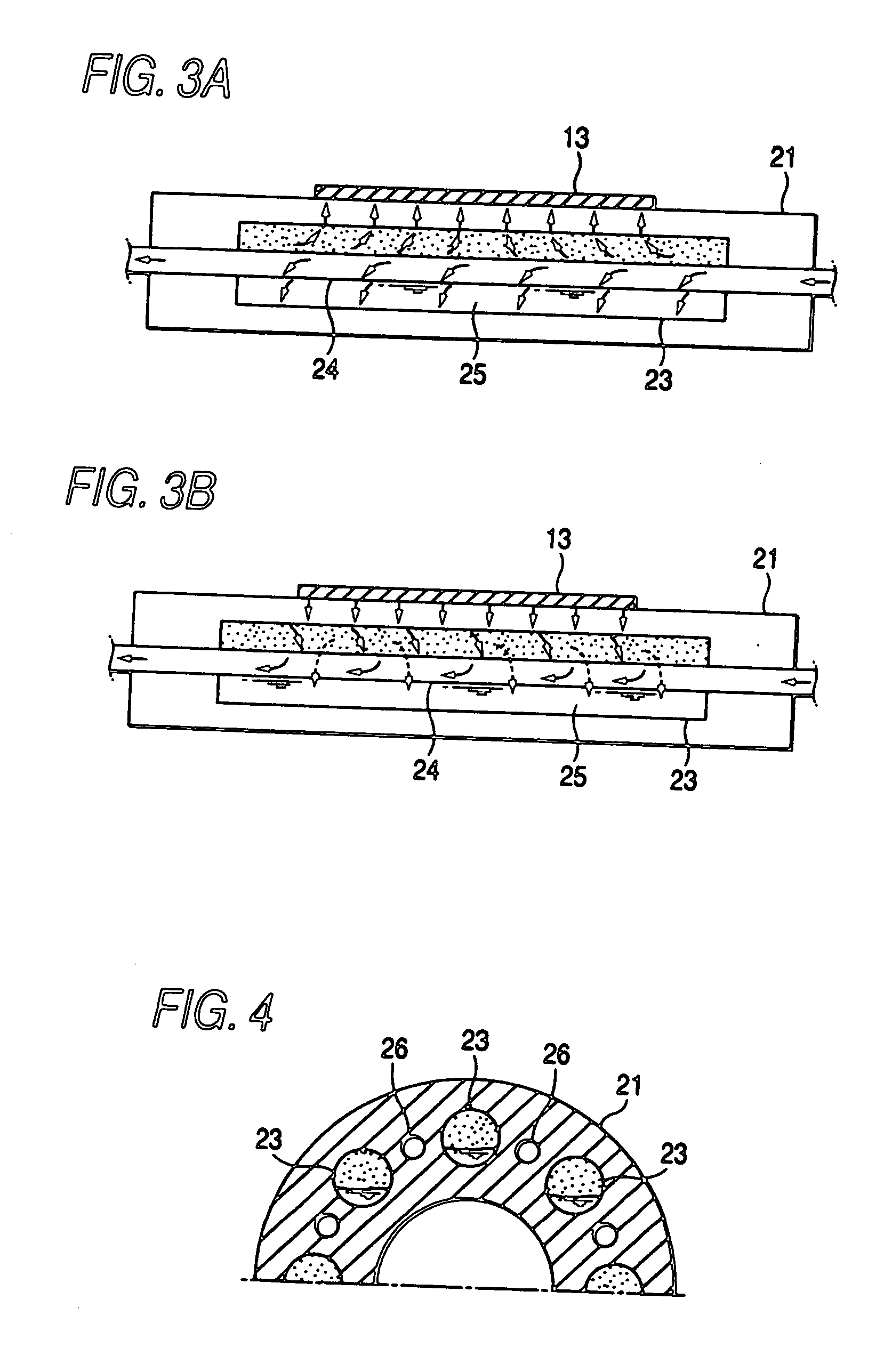

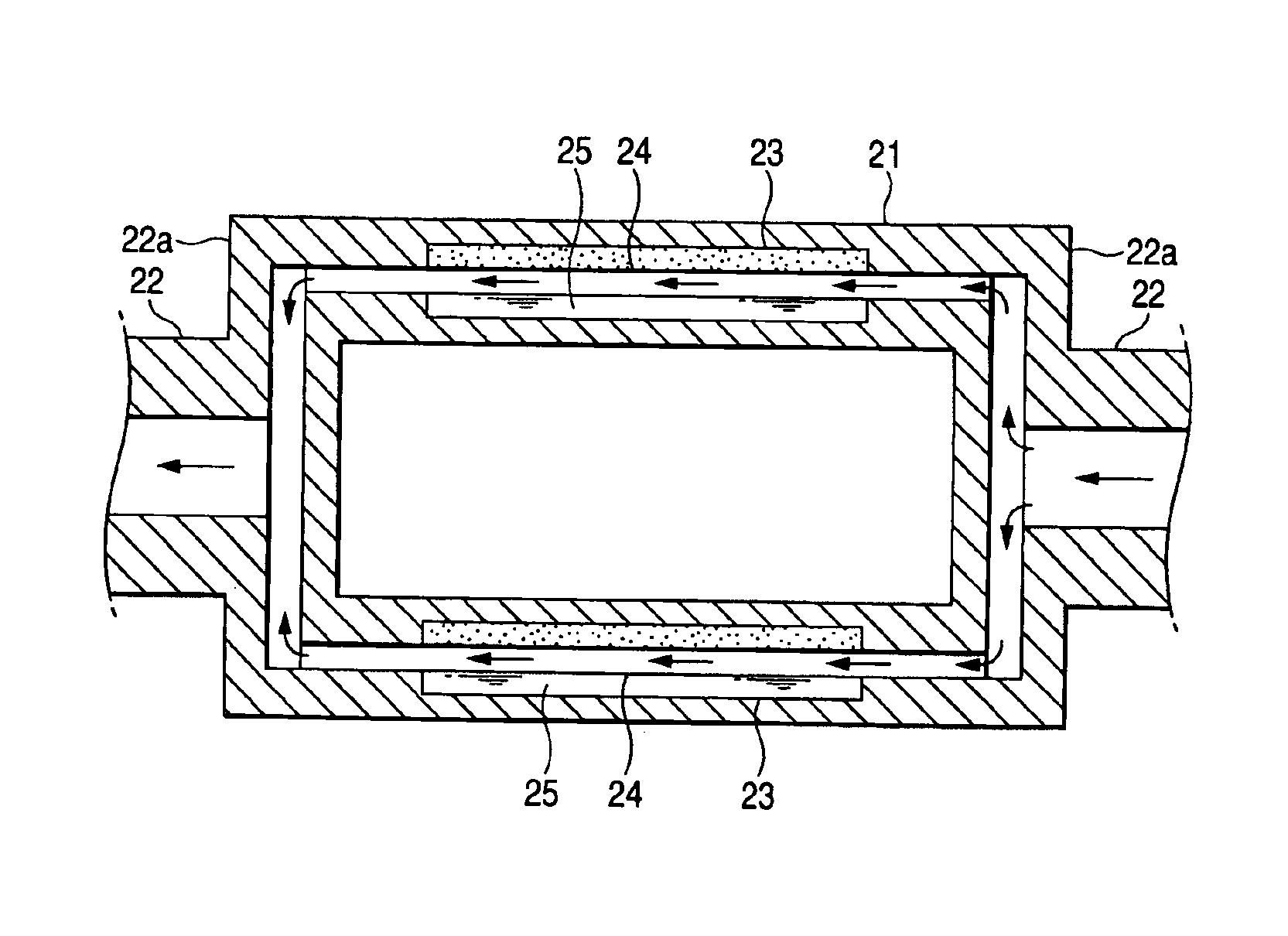

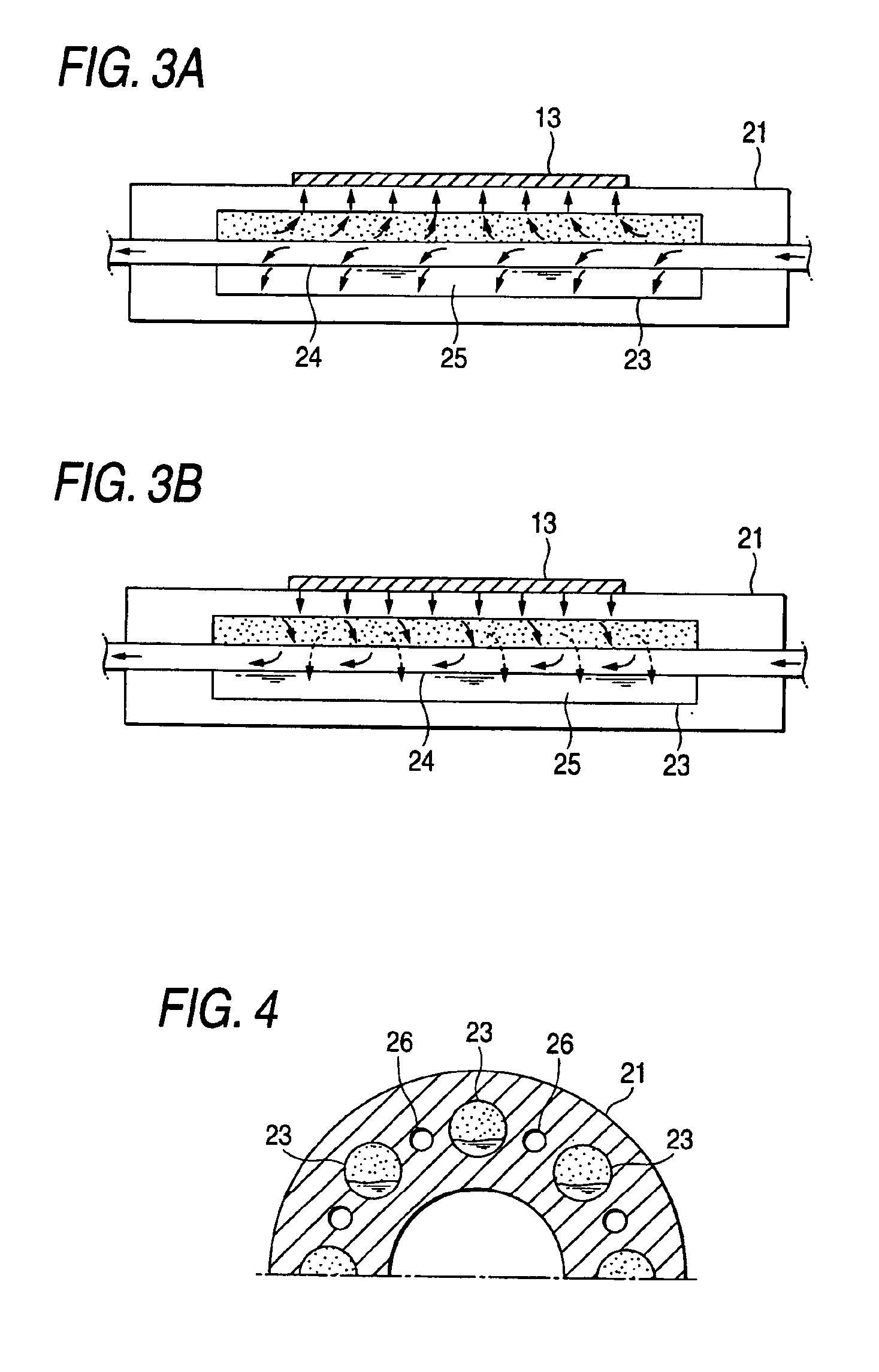

Thermal processing roller and temperature control apparatus for roller

InactiveUS7420141B2Uniform heat treatmentIncrease flow rateOhmic-resistance heating detailsRollsVapor liquidTemperature control

A thermal processing roller includes a heat transfer medium flowing path therein and heats a member to be processed abutting against a surface of the roller or absorbs heat therefrom by heat transfer fluid flowing through the heat transfer medium flowing path, wherein a sealed chamber extending in a longitudinal direction of the roller and in which heat transfer medium of vapor-liquid two phases is sealed is formed within a thick portion of the roller.

Owner:TOKUDEN CO LTD

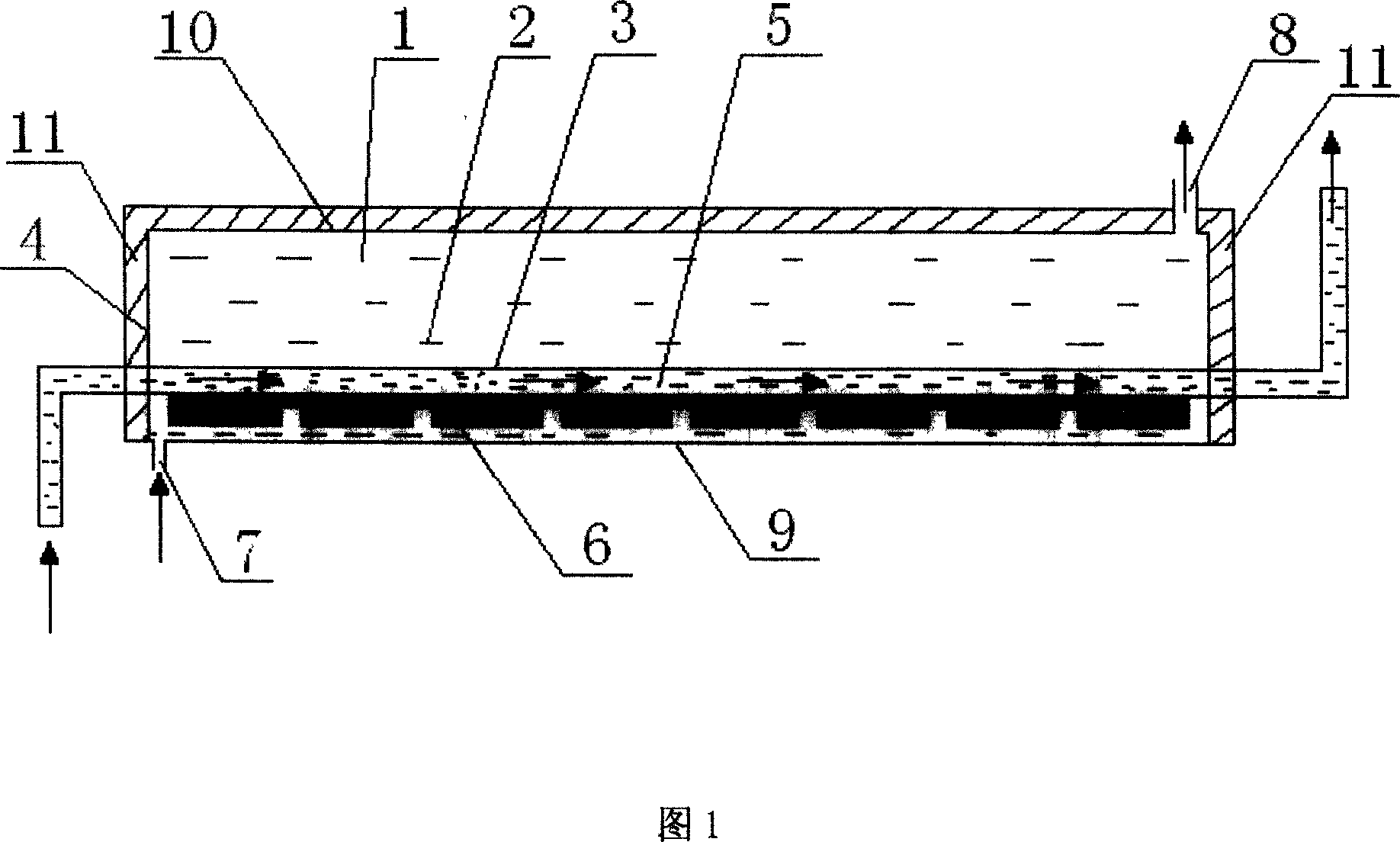

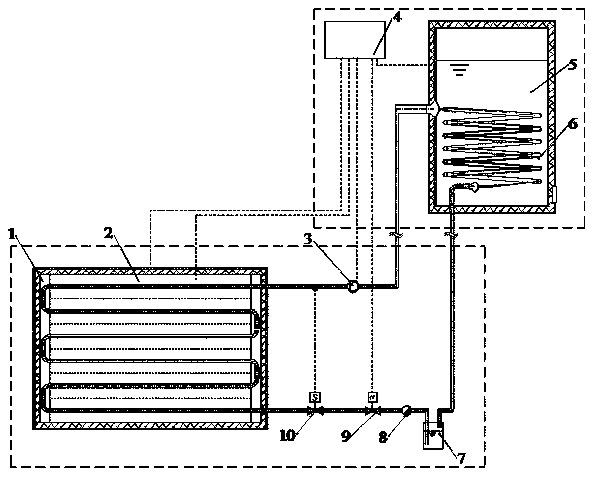

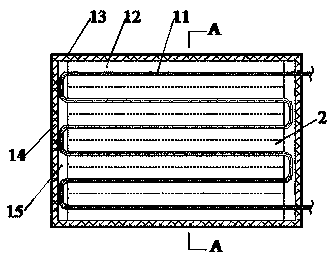

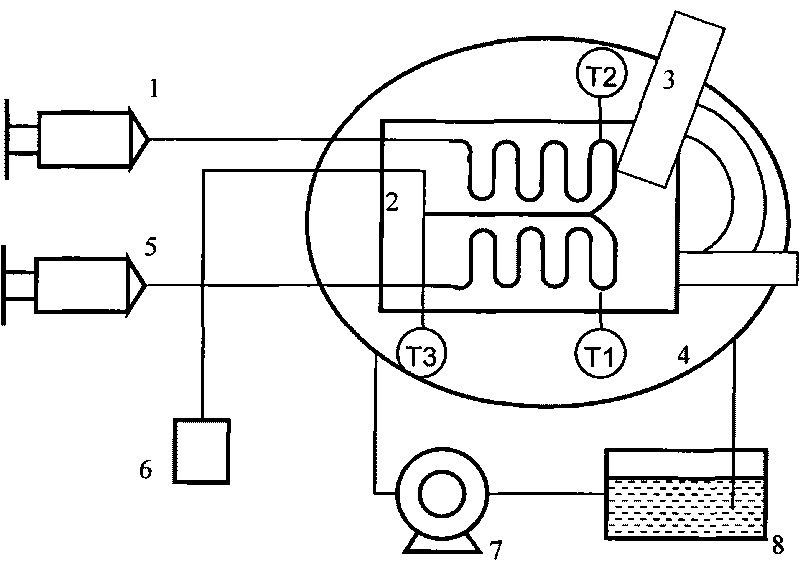

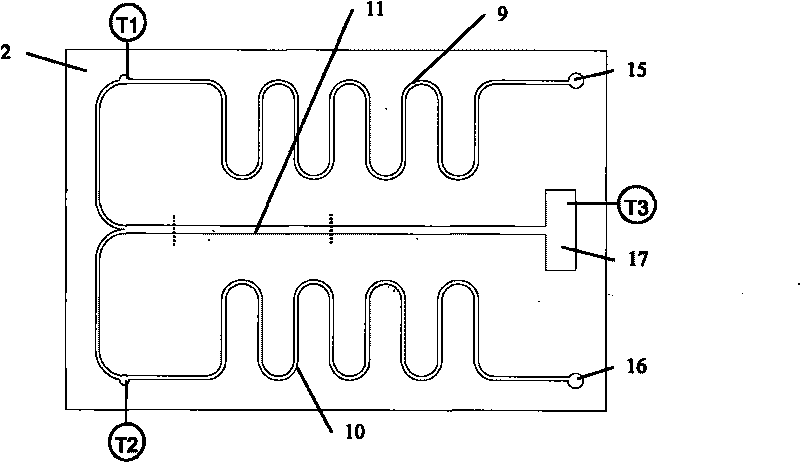

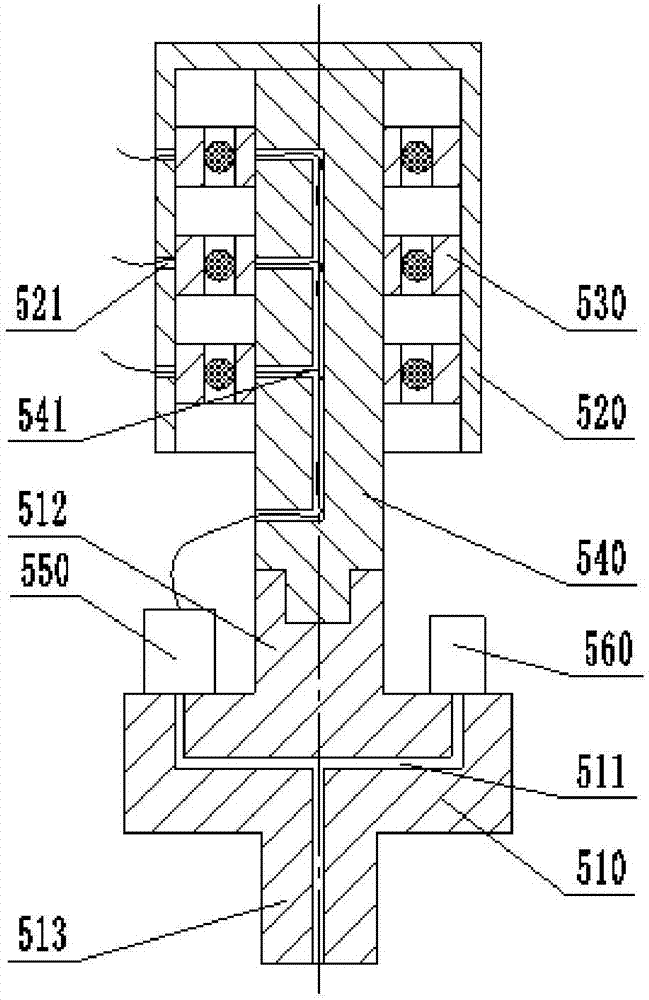

Device and method capable of measuring liquid-liquid diffusion coefficient at different temperatures

ActiveCN101701895AAchieve uniformityUniform surface temperatureSurface/boundary effectLiquid diffusionContinuous measurement

The invention relates to a device and method capable of measuring liquid-liquid diffusion coefficient at different temperatures. In the invention, solution in different concentrations is injected into a micro fluid control chip 2 by inject pumps 1 and 5, concentration distribution of mixing runner in the micro fluid control chip 2 is measured by a Raman spectroscopy, and further liquid-liquid diffusion coefficient is inverted. The micro fluid control chip is placed on a soaking block 4, and the soaking block is connected with a metering pump 7 and a thermostatic waterbath 8, so as to realize measurement at different temperatures. The micro fluid control chip 2 realizes high-accuracy measurement by design of winding micro runner structure before mixing, mixing runner section designed as a rectangle with high crown proportion and aluminizing at the bottom of runner. The device and method of the invention can realize continuous measurement of liquid-liquid diffusion coefficient at different temperatures and has the advantages of less sample usage, low cost, non contact, high sensibility, high repeatability, high efficiency, small error, safety and reliability and easy operation.

Owner:EAST CHINA UNIV OF SCI & TECH

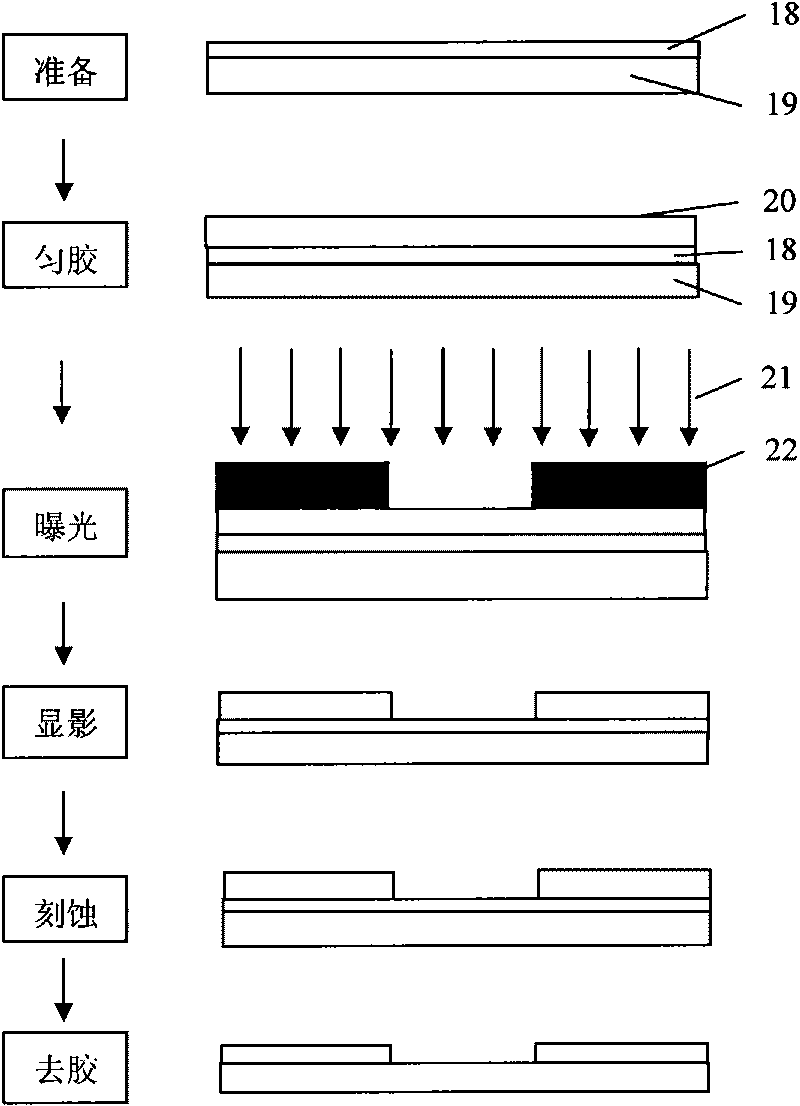

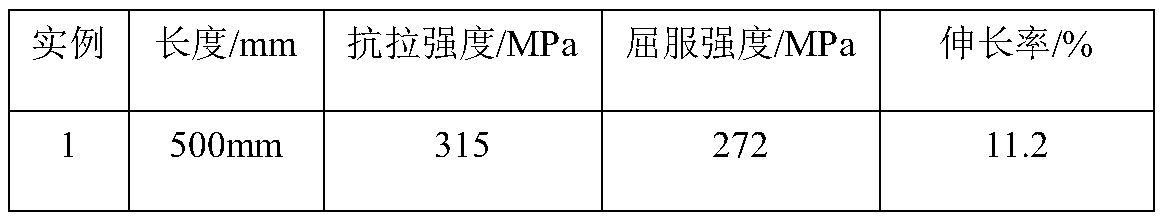

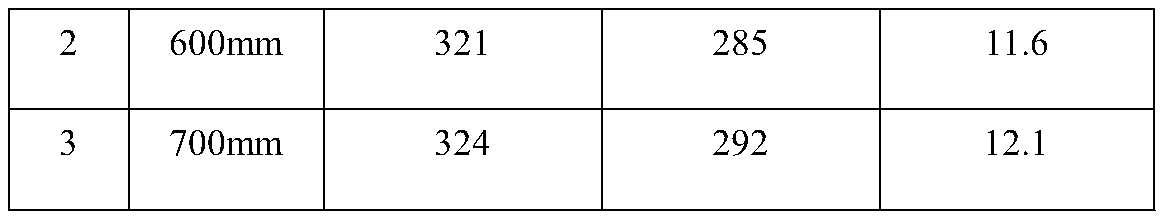

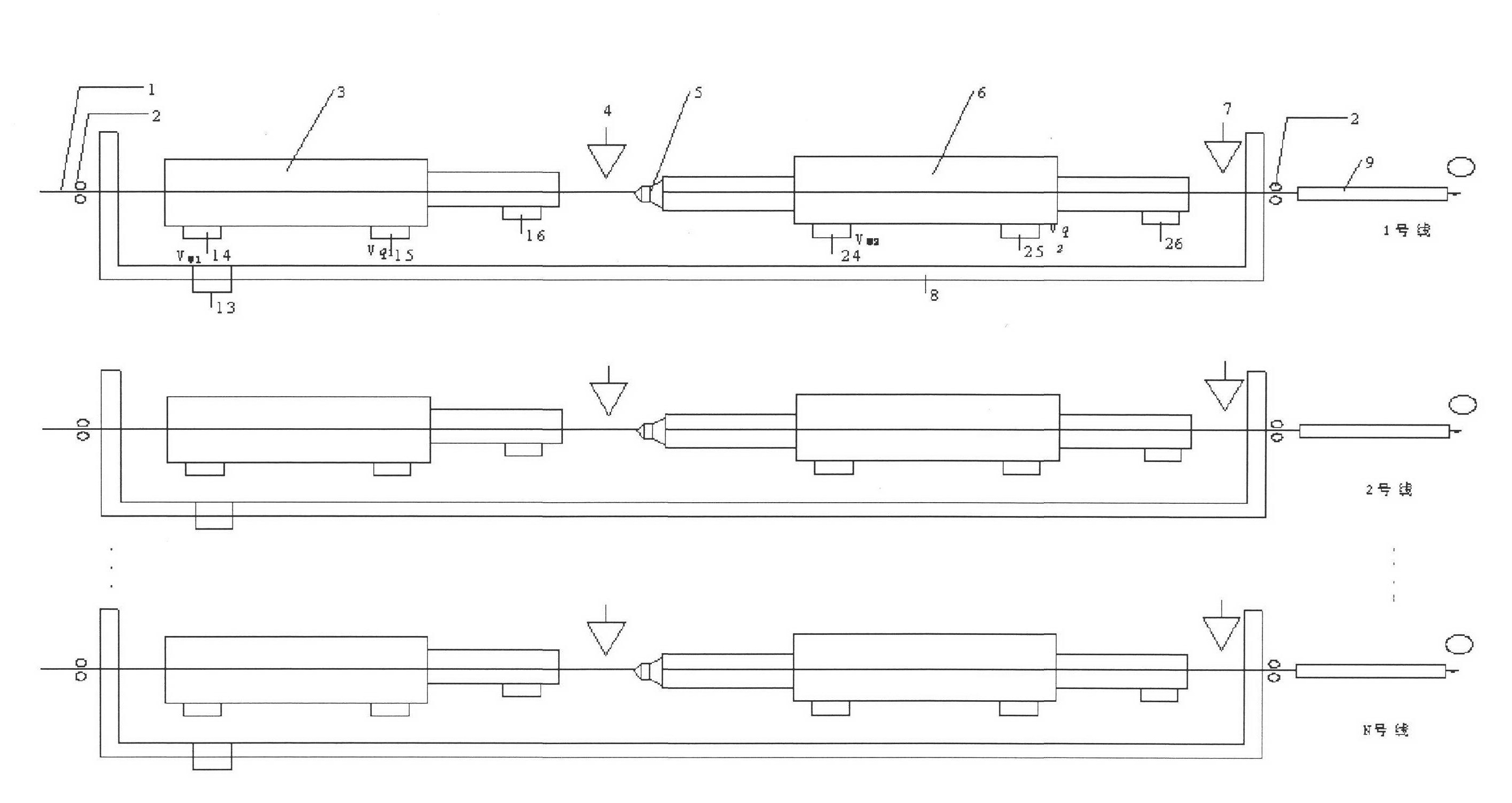

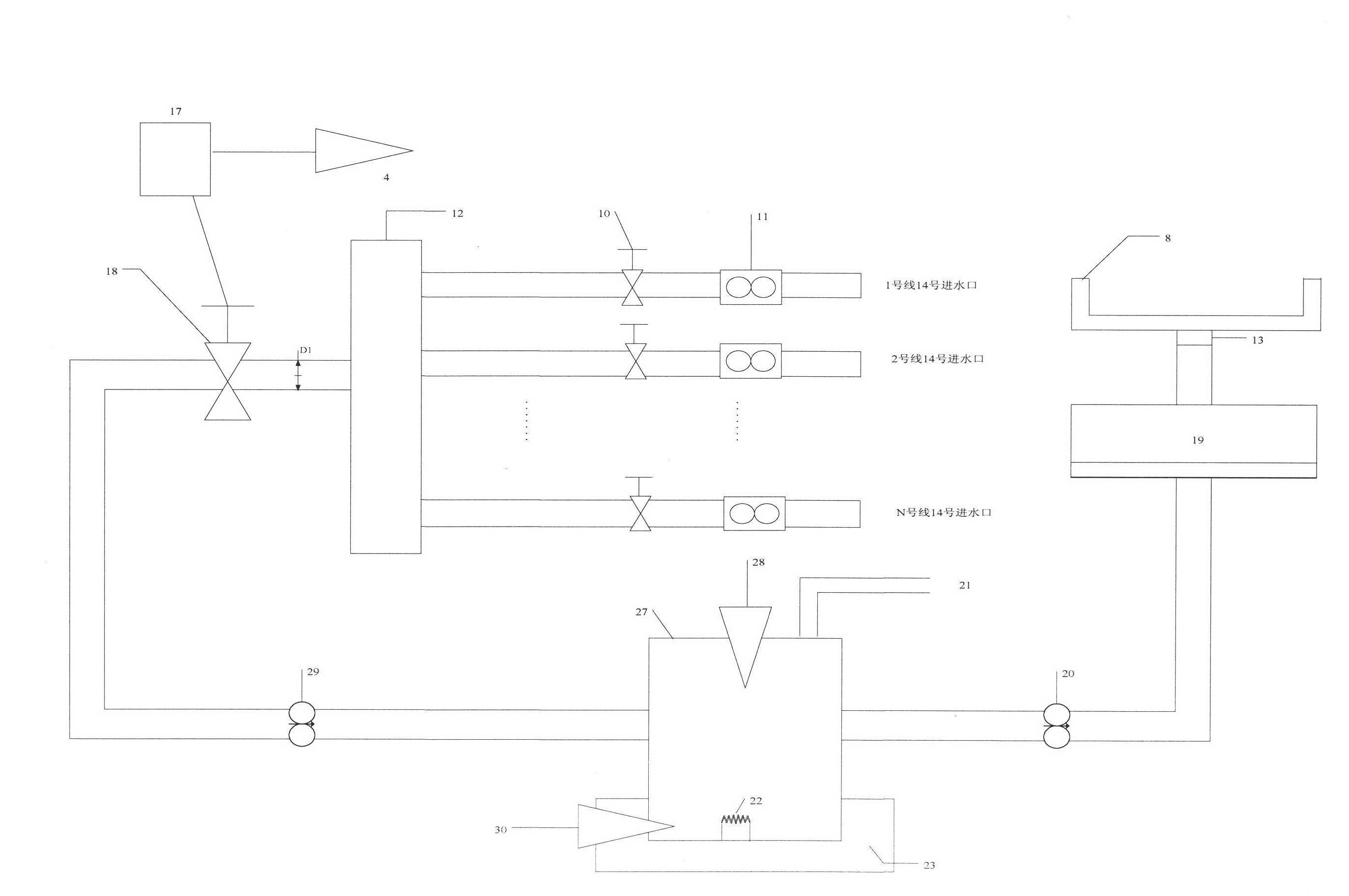

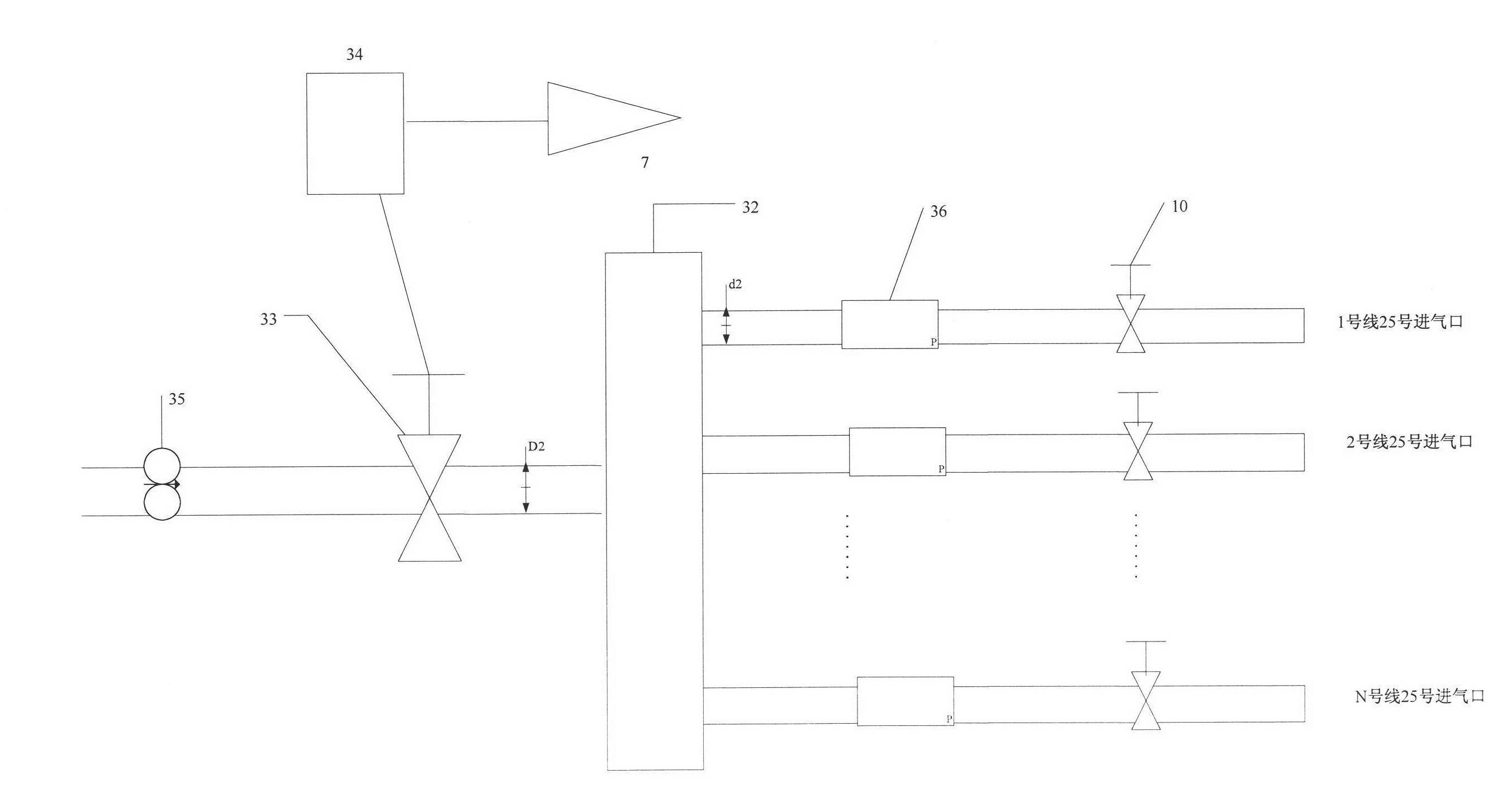

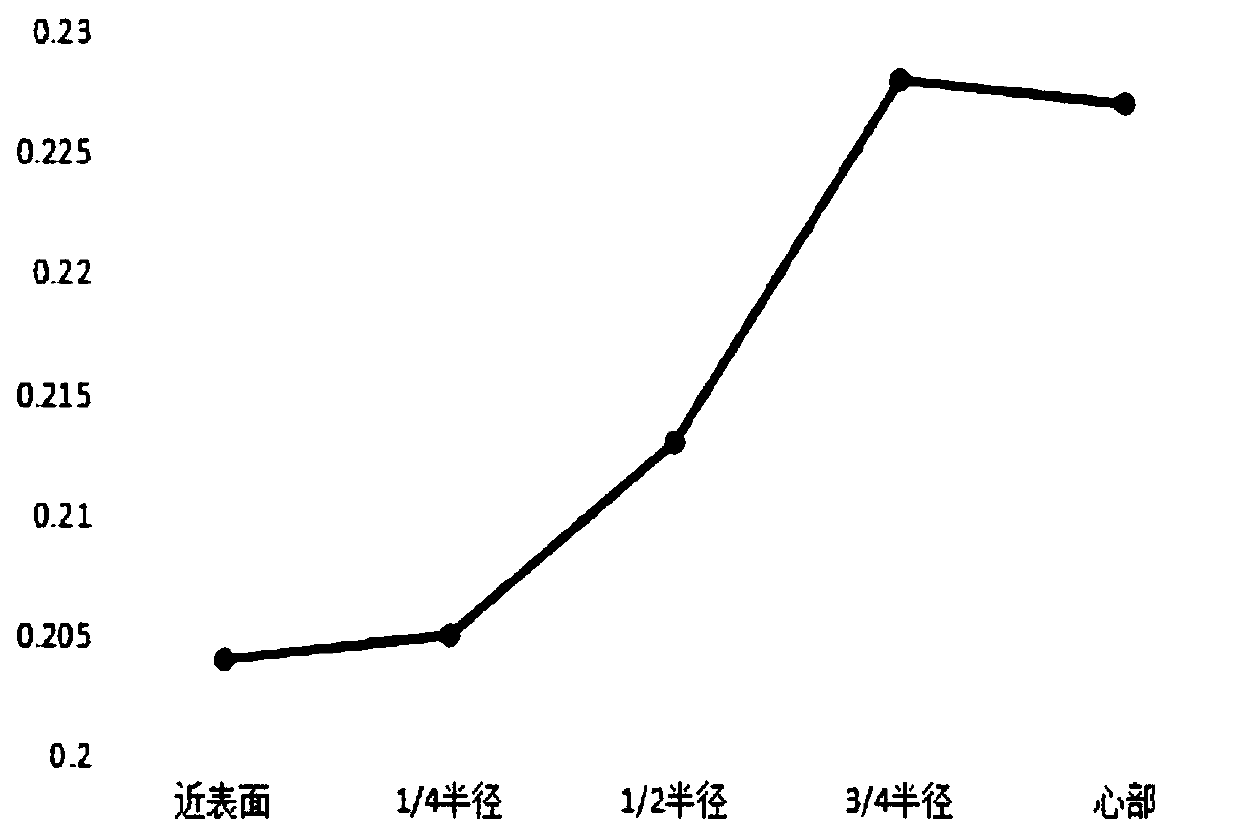

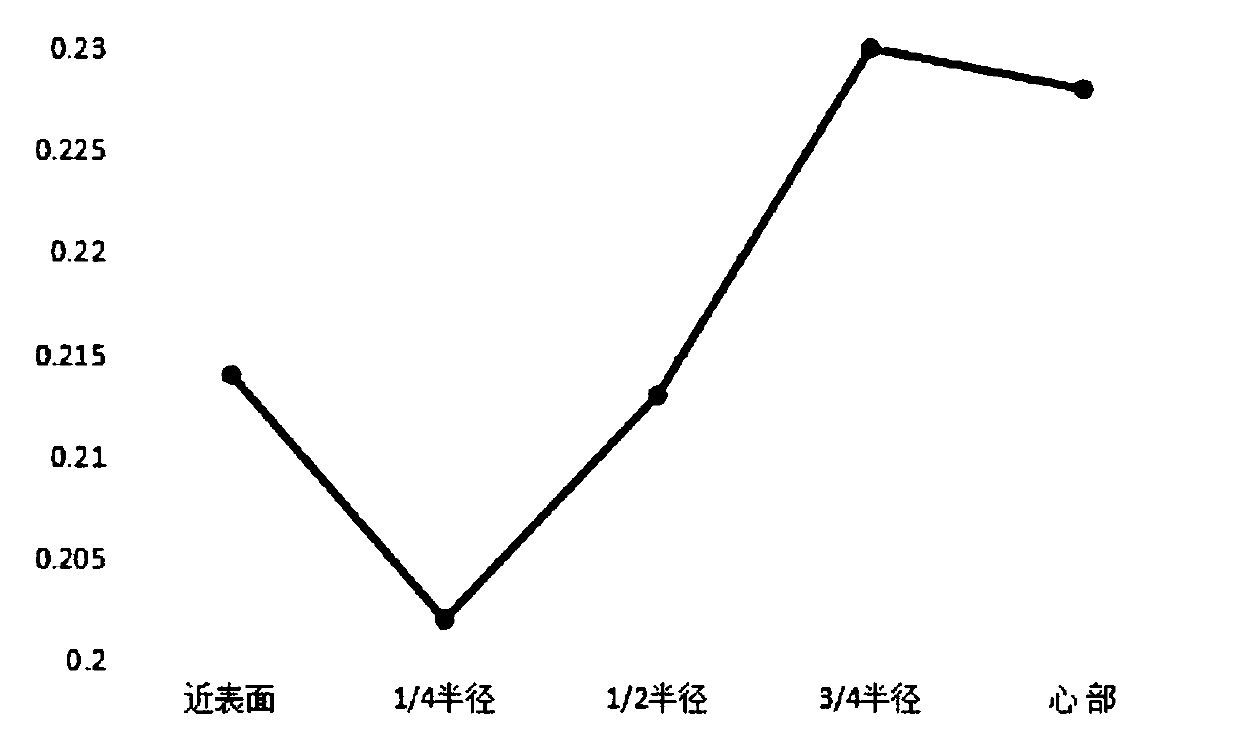

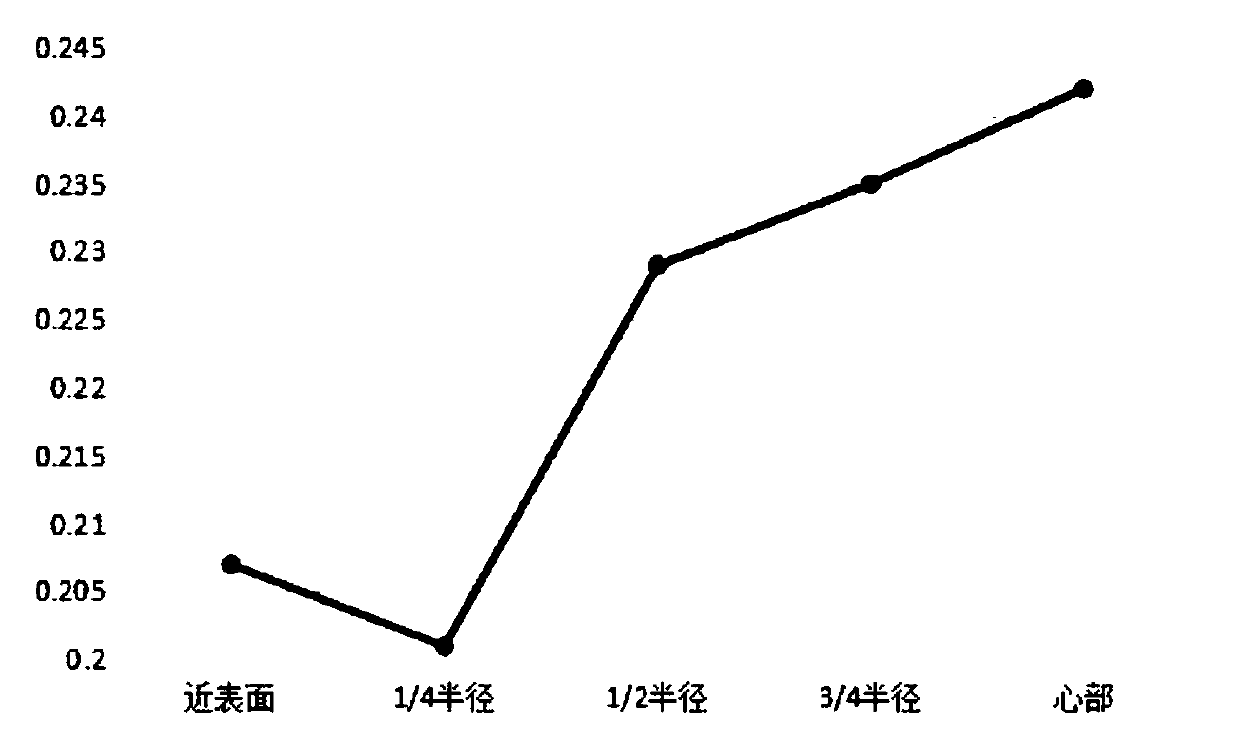

High-strength aluminum alloy section bar for battery tray of novel energy vehicle and preparation method for high-strength aluminum alloy section bar

The invention relates to a high-strength aluminum alloy section bar for a battery tray of a novel energy vehicle and a preparation method for the high-strength aluminum alloy section bar. Ingredient components are improved, and a gradient heating process is adopted for gradually reducing the temperature of a heated aluminum bar before extrusion from front to rear in the axial direction, so that temperature gradient is formed, and equal-temperature extrusion is realized; and the heated and processed product is uniform in core surface temperature, is bright in surface color and luster, and is small in mechanical performance deviation. The aluminum alloy section bar prepared by the preparation method has tensile strength of 310 MPa or higher, has yield strength of 270 MPa or higher, has elongation of 11% or higher, and greatly improves the product quality, so that the integral quality of the novel energy vehicle is improved.

Owner:JIANGYIN EAST CHINA ALUMINUM TECH

Thermal processing roller and temperature control apparatus for roller

InactiveUS20050255396A1Uniform heat treatmentIncrease flow rateOhmic-resistance heating detailsRollsTemperature controlVapor liquid

A thermal processing roller includes a heat transfer medium flowing path therein and heats a member to be processed abutting against a surface of the roller or absorbs heat therefrom by heat transfer fluid flowing through the heat transfer medium flowing path, wherein a sealed chamber extending in a longitudinal direction of the roller and in which heat transfer medium of vapor-liquid two phases is sealed is formed within a thick portion of the roller.

Owner:TOKUDEN CO LTD

Thermal processing roller and temperature control apparatus for roller

ActiveUS6992272B2Uniform heat treatmentIncrease flow rateOhmic-resistance heating detailsRollsTemperature controlVapor liquid

Owner:TOKUDEN CO LTD

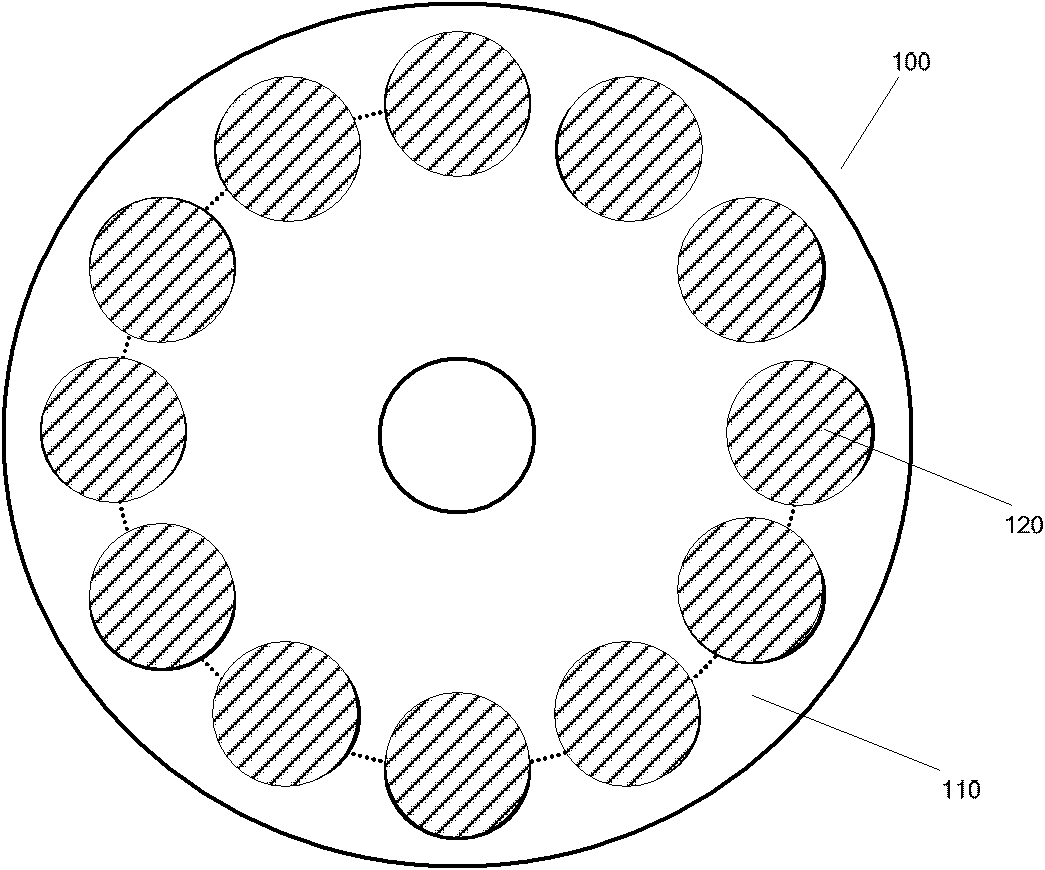

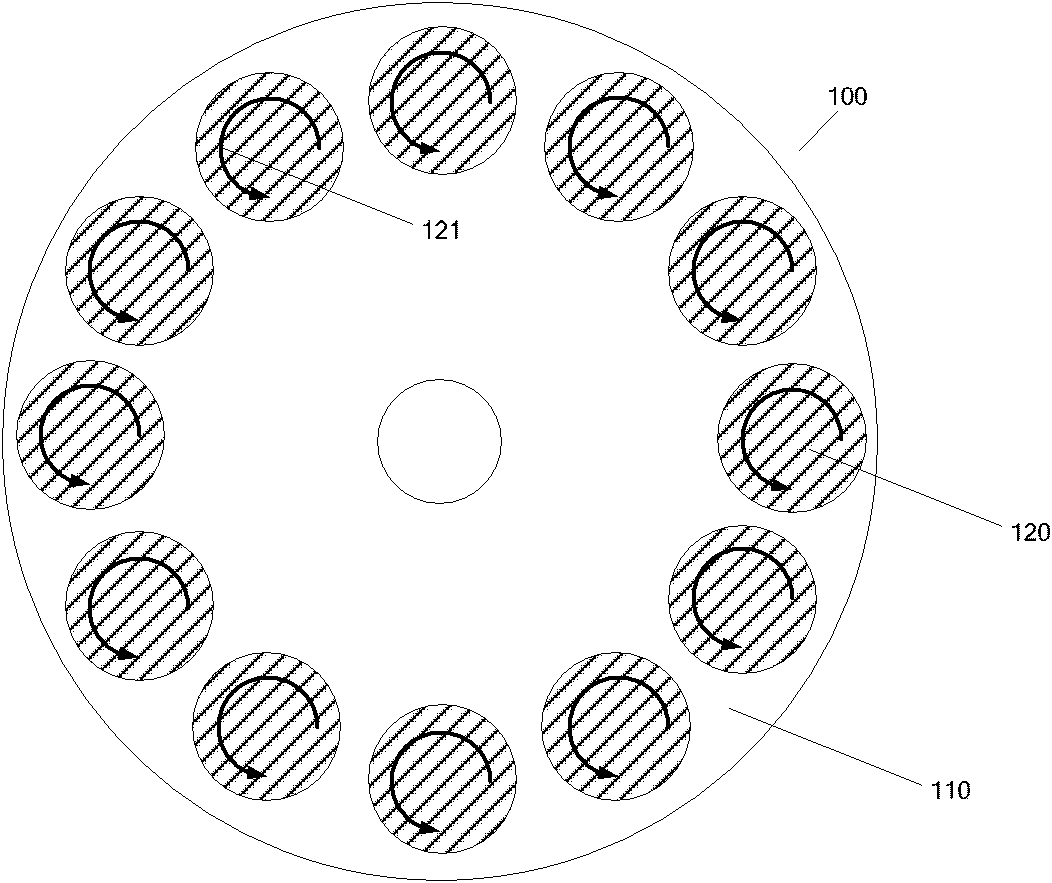

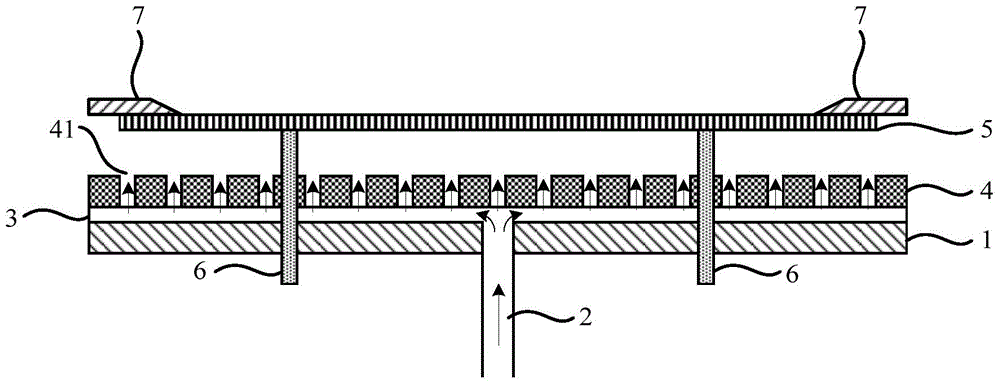

Pallet and chemical vapor deposition equipment with pallet

ActiveCN102732861AReduce temperature variabilityUniform surface temperatureChemical vapor deposition coatingGas phaseEngineering

The invention brings forward a pallet, which comprises: a pallet body; a plurality of mounting grooves which are arranged along the circumference of the pallet body; and a plurality of small pallets, each small pallet correspondingly being arranged in one mounting groove, werein the pallet body is composed of an insulating material and the plurality of small pallets are composed of a heat conduction and electrically conductive material. The invention also brings forward chemical vapor deposition equipment with the above pallet. According to the chemical vapor deposition equipment provided by the invention, as the turning radius of induced-current is becoming smaller, the surface temperature of the pallet is more uniform, thus raising temperature homogeneity of a substrate processed by the chemical vapor deposition equipment. In addition, the pallet is simply designed and is easy to realize.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Mobile terminal device and method for radiating heat therefrom

InactiveUS20080068810A1Suppression temperatureEfficient executionDigital data processing detailsPrinted circuit aspectsTerminal equipmentCopper

In a mobile terminal device, at least one heat conduction layer formed of a member, such as copper, aluminum or carbon, being excellent in heat conductivity is provided inside a circuit board on which electronic components are mounted. The heat generated in the electronic components is promptly dispersed in the direction of the face of the circuit board by the heat conduction layer, and transferred from the whole face of the circuit board to the operation member, such as keys, and the housing, and then radiated to the outside. With this structure, the local temperature rise at the operation member and the housing can be suppressed, and the temperature on the surface of the mobile terminal device can be made uniform, without significantly increasing the cost and the thickness of the mobile terminal device. In addition, high-performance electronic components can be used by adopting this structure. Furthermore, the rigidity of the circuit board can be raised, and the reliability of the mobile terminal device can be improved.

Owner:LENOVO INNOVATIONS LTD HONG KONG

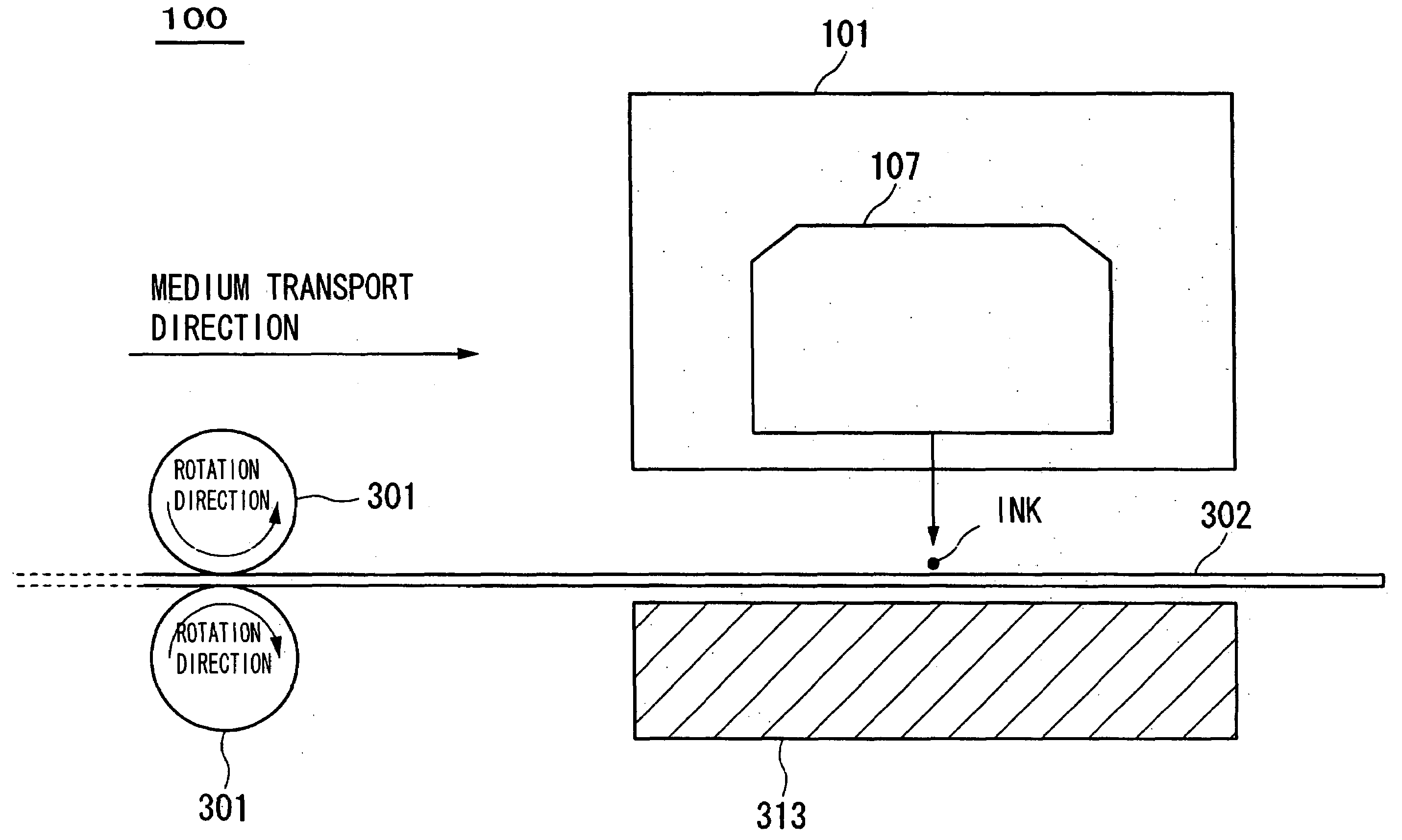

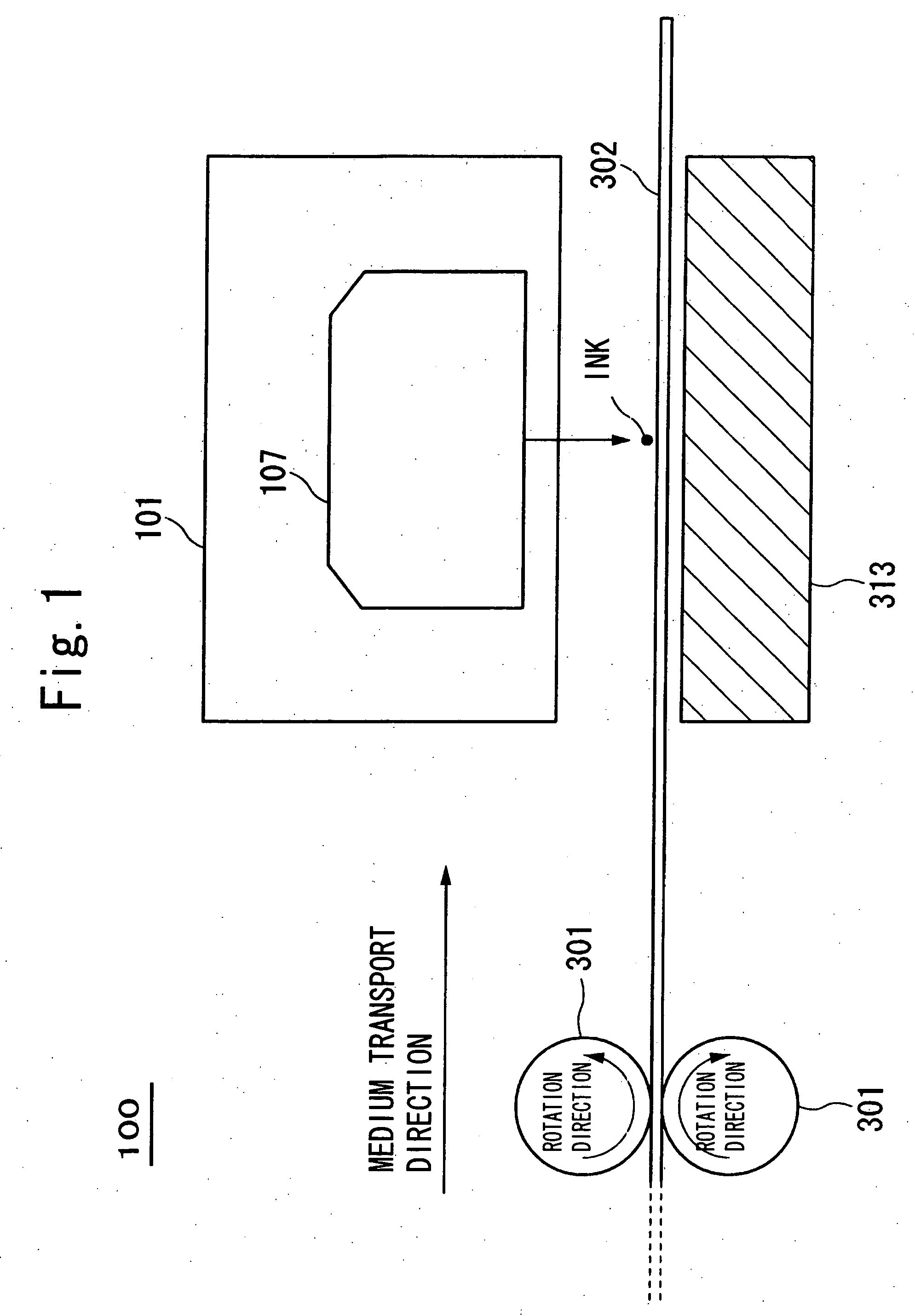

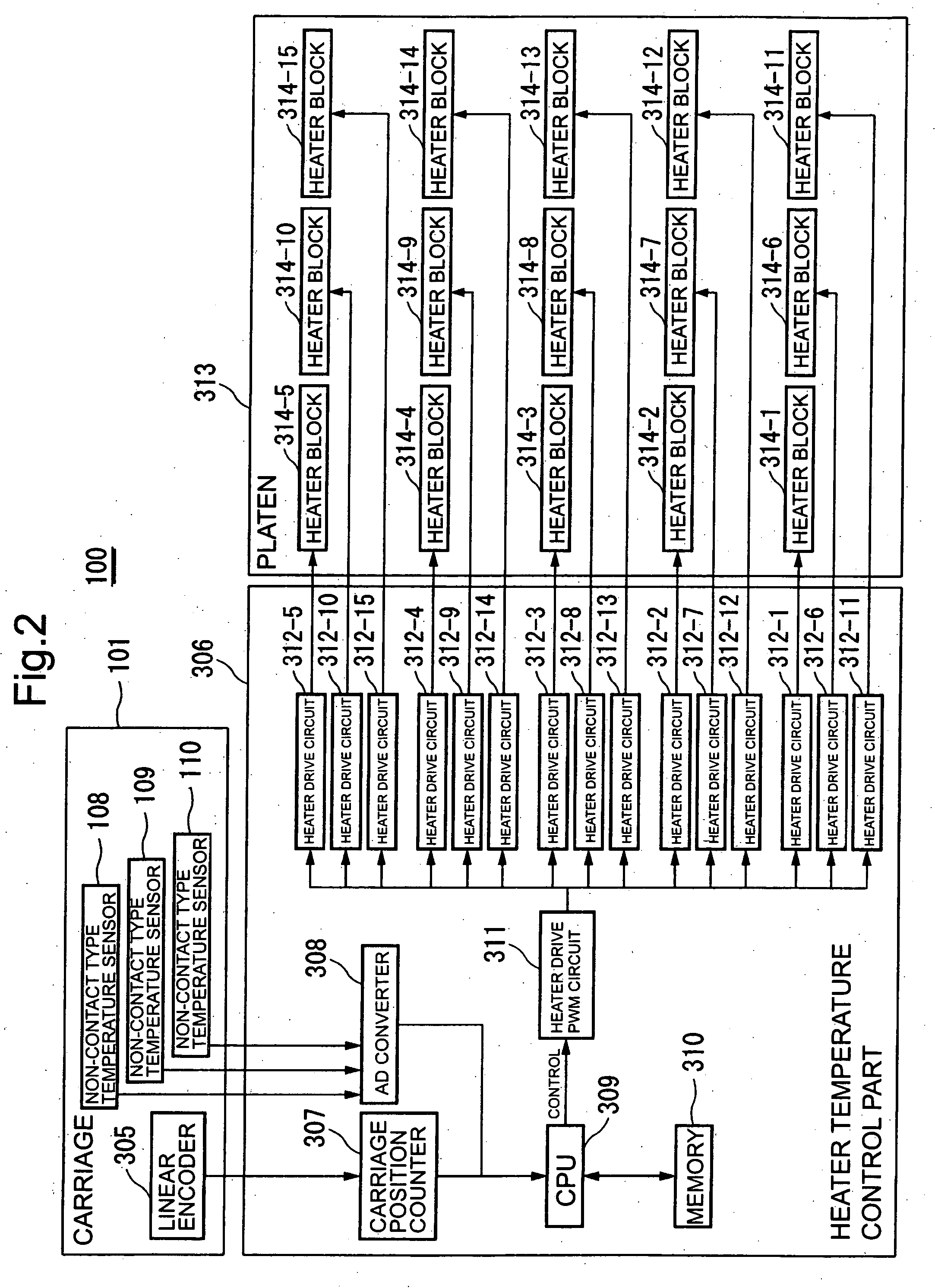

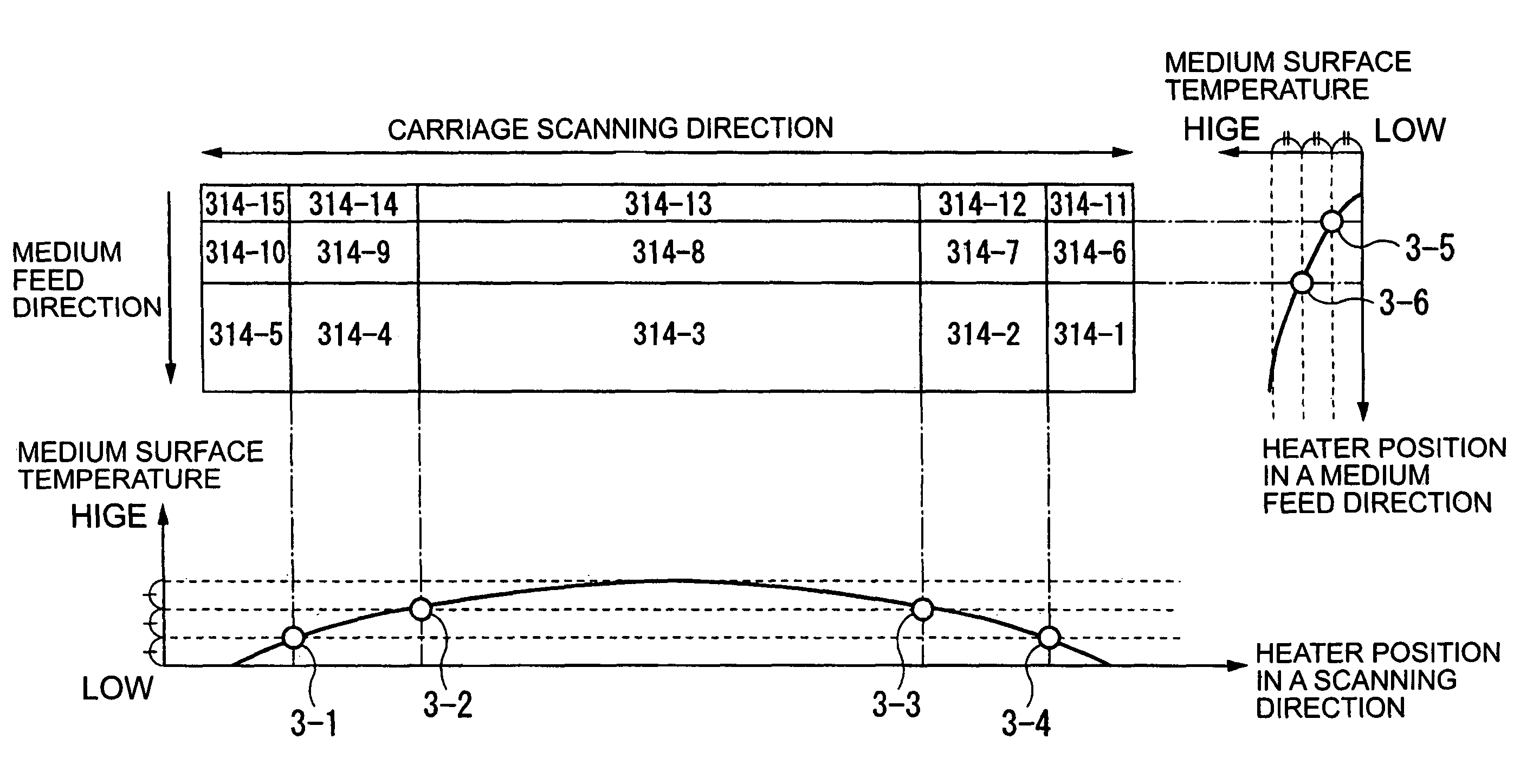

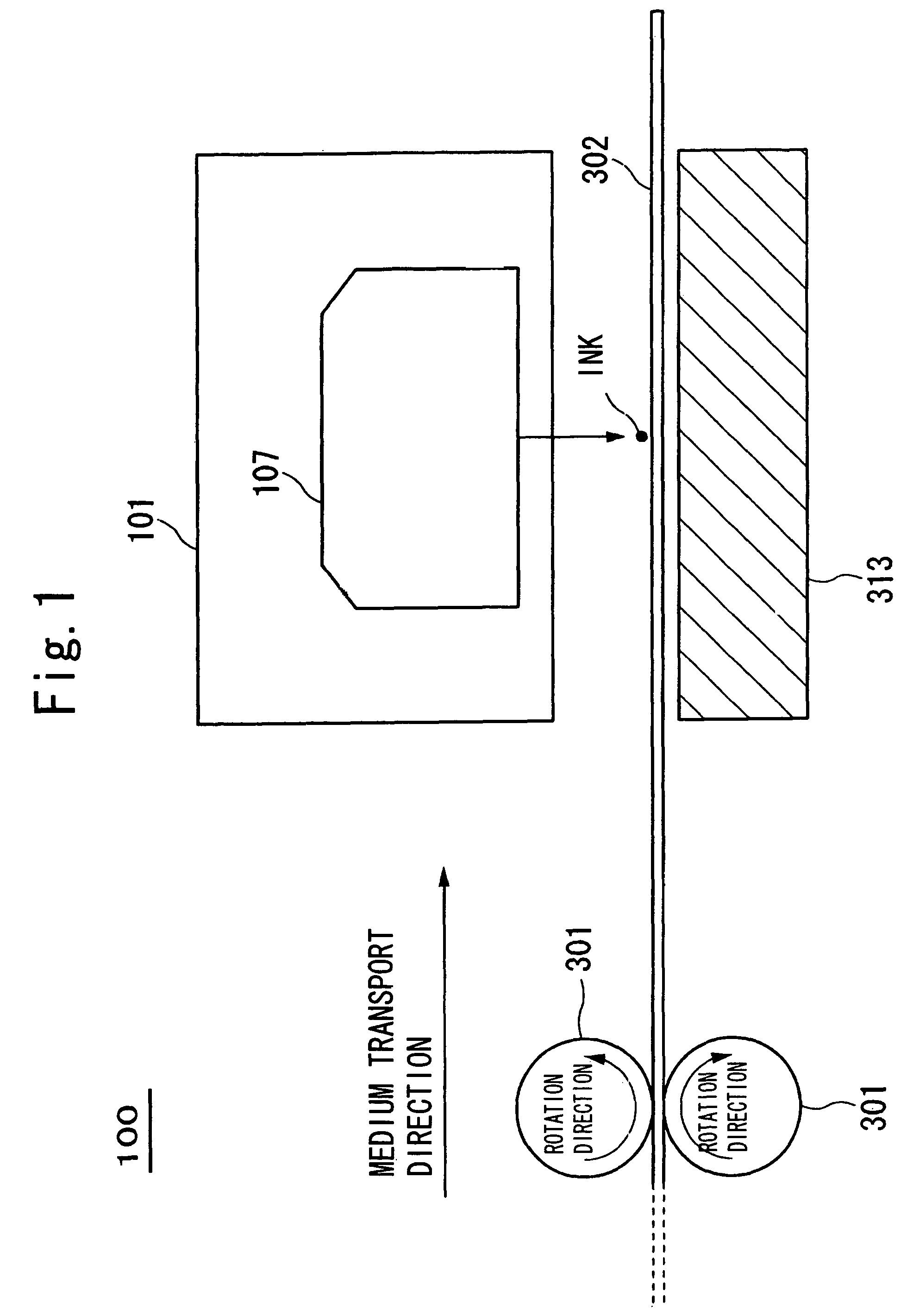

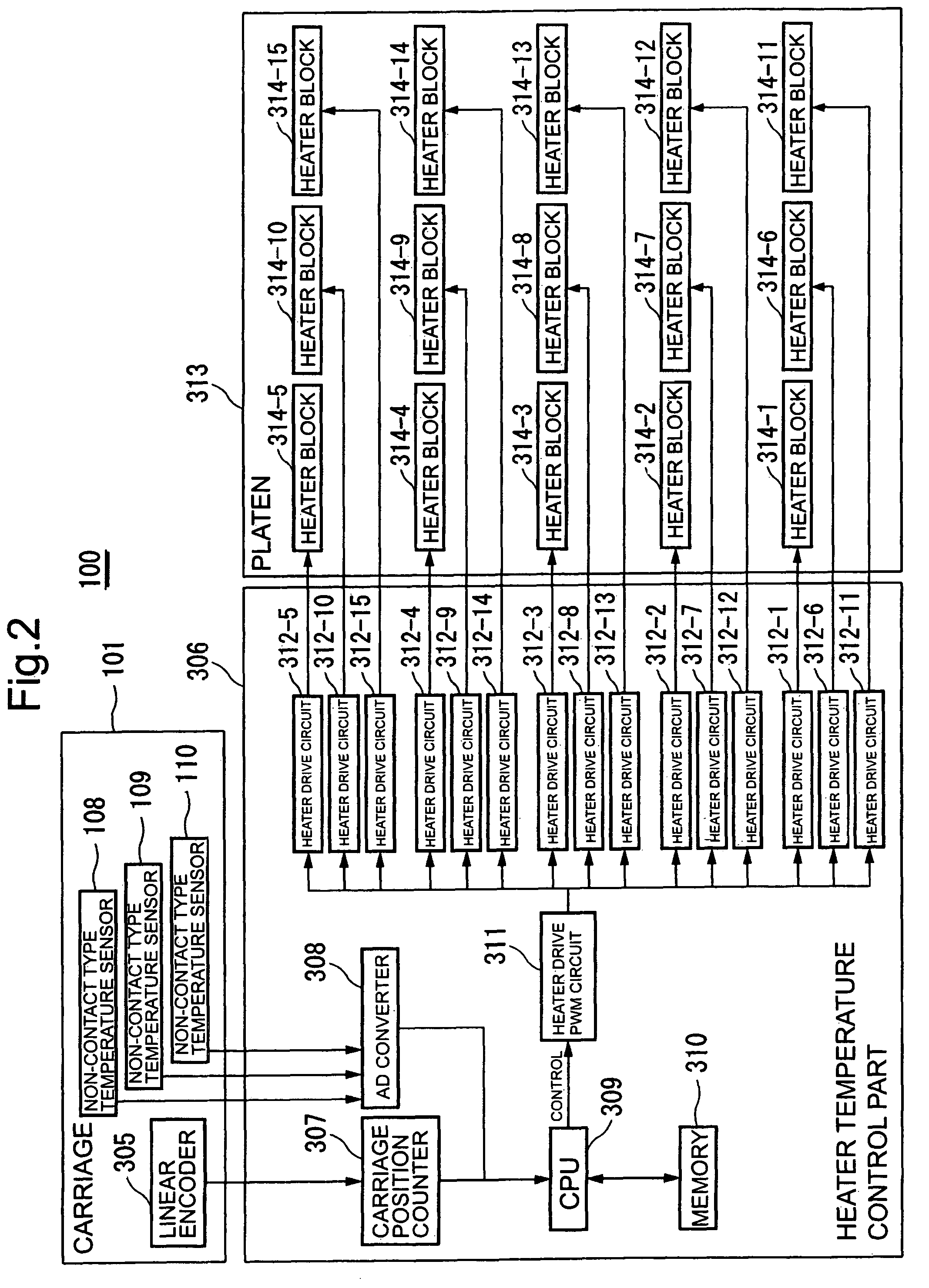

Ink-jet printer device and ink-jet printing method

InactiveUS20080204537A1Eliminate degradationReduce temperature unevennessOther printing apparatusContact typeElectrical and Electronics engineering

An ink-jet printer device equalizes a surface temperature of a print medium on the platen. In an ink-jet printer device which includes a platen having heater blocks, and a carriage having non-contact type temperature sensors each measure a surface temperature of each of a plurality of portions of the print medium on the platen. A CPU calculates an output value of each of the heater blocks for making the surface temperature of each of the plurality of portions of the print medium uniform based on the measured surface temperature, and a heater drive PWM circuit controls an output of each of the heater blocks based on the calculated output value.

Owner:OKI DATA CORP

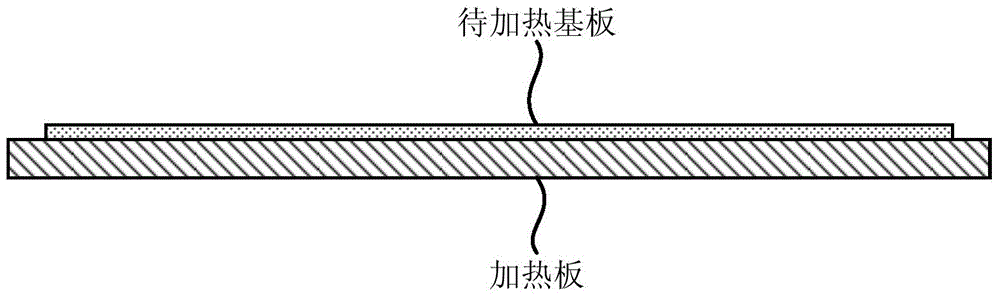

Substrate heating device and substrate heating method

ActiveCN104681402AUniform surface temperatureAvoid wastingSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingDiffusion layerMaterials science

The invention relates to a substrate heating device and a substrate heating method. The device comprises a heating layer used for conducting heat, a transmission tube used for transmitting gas to a diffusion layer, the diffusion layer arranged on the heating layer and used for enabling the gas to be uniformly distributed between a lead-out layer and the heating layer, and the lead-out layer arranged on the diffusion layer and internally and uniformly provided with a plurality of through holes, wherein the through holes are used for leading out the gas in the diffusion layer to a lower side of a to-be-heated substrate, thereby enabling the to-be-heated substrate to be uniformly heated. Through the technical scheme of the invention, the to-be-heated substrate can be uniformly and comprehensively heated, so that the temperature of an upper surface of the to-be-heated substrate is more uniform and processes such as etching, depositing and / or sputtering performed on the to-be-heated substrate are enabled to achieve better effects.

Owner:BOE TECH GRP CO LTD

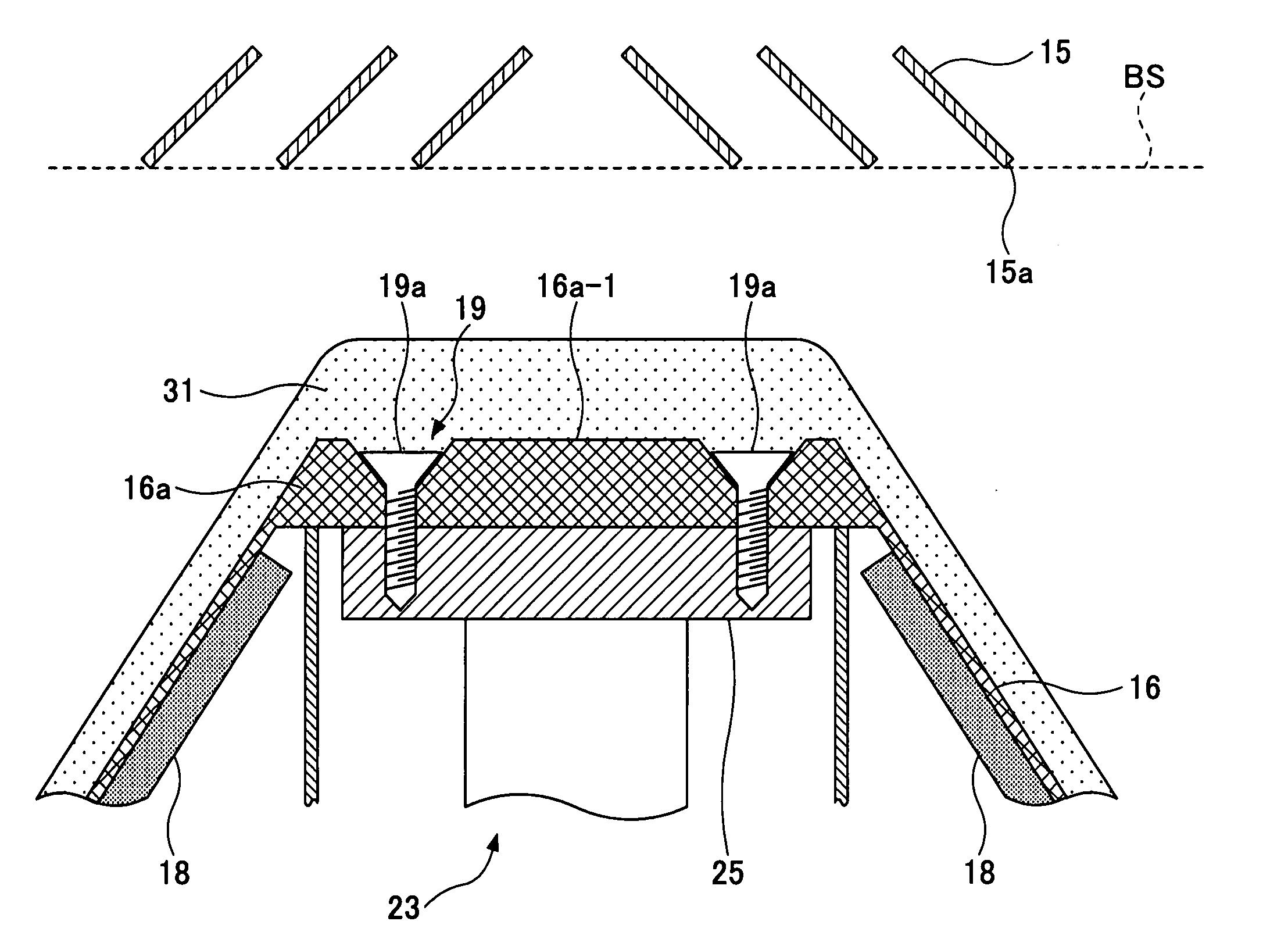

Method and apparatus for producing bag with mouth member

InactiveUS7736288B2Uniform surface temperatureAvoid it happening againEnvelopes/bags making machineryMechanical working/deformationEngineering

A method is provided for producing a bag with a mouth member by liquidtightly melt-bonding a mouth member comprising a thermoplastic resin and a bag unit comprising a relatively soft flexible film, in which uniform surface temperature of the mouth member is realized, generation of an A-shaped gap is prevented, and a bag with a mouth member excellent in the liquidtightness of the melt-bonded part between the mouth member and the bag unit is produced; and also a production apparatus therefor is provided. The method comprises a preheating step of heating a tubular mouth member while rotating it around the cylinder axis thereof, and a melt-bonding step of inserting the heated mouth member into the opening part of a bag unit and pressing, and thereby melt-bonding the mouth member to the opening part of the bag unit.

Owner:HOSOKAWA YOKO CO LTD

Electromagnetic heating roller used for corrugating machine, application of electromagnetic heating roller and corrugating machine electromagnetic heating method

PendingCN106903932AIncreased complexitySimplify complexityMechanical working/deformationStorage heatersMagnetic heatingEngineering

The invention discloses an electromagnetic heating roller used for a corrugating machine, an application of the electromagnetic heating roller and a corrugating machine electromagnetic heating method, and belongs to the technical field of electromagnetic heating. The electromagnetic heating roller comprises a roller body and an electromagnetic heater. The electromagnetic heater is used for heating the roller body. The roller body is provided with a cavity for encapsulating heat-conducting liquid. The electromagnetic heater can heat the heat-conducting liquid through the roller body, so that steam is produced in the cavity of the roller body. The electromagnetic heater comprises a plurality of U-shaped magnets and an electromagnetic wire. The multiple U-shaped magnets are arranged on a straight line side by side in the axis direction of the roller body. The electromagnetic wire is wound at the two ends of the U-shaped magnets in a single-loop wire winding mode to form a coil. Corrugated paper can be uniformly heated through the electromagnetic heating roller, moisture balance of the corrugated paper in the whole width direction is ensured, and the product quality is improved.

Owner:ANHUI RESUDA ELECTRONICS TECH

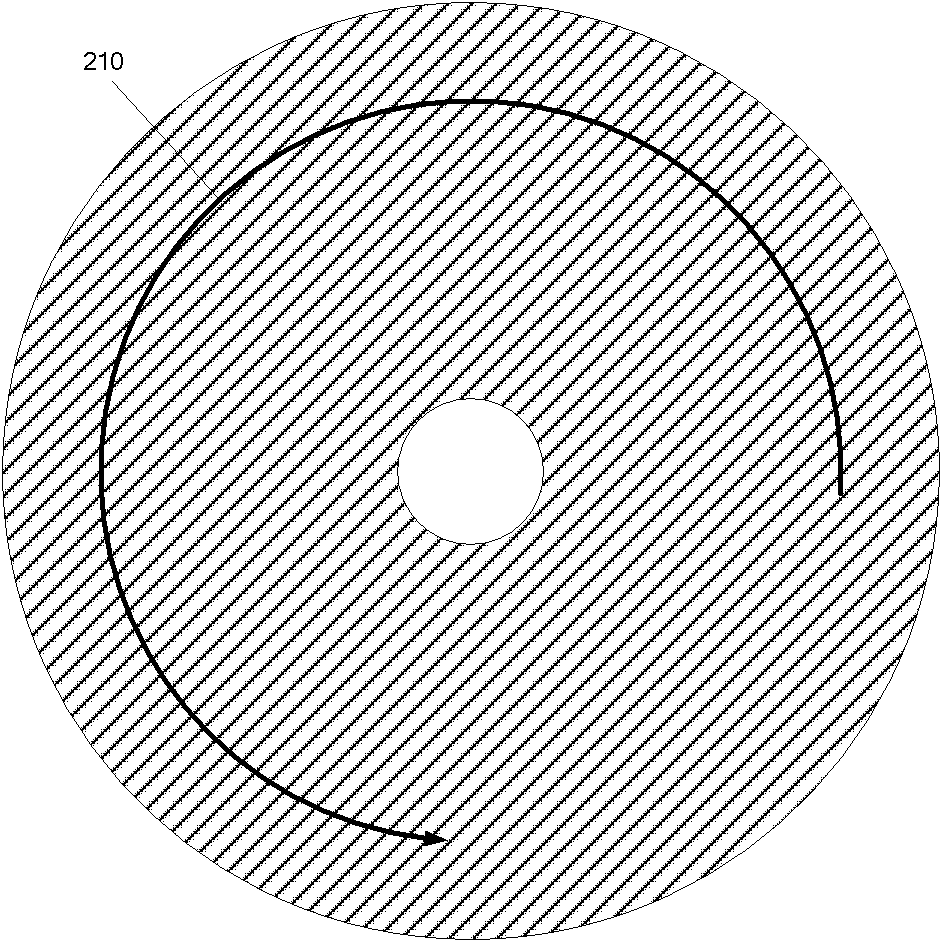

Fuser roll with improved heating performance

InactiveUS7241253B2Uniform surface temperatureEvenly heatShaft and bearingsPortable power-driven toolsSurface layerFiber

A roll cover particularly suitable for a fuser roll has an intermediate layer on the roll body and an outer surface layer including heat transfer bodies therein. The intermediate layer is a graphite sheet having legs extending along the axial extent of the roll body. The outer layer has graphite fibers embedded therein, the graphite fibers extending axially with respect to the roll.

Owner:ILLINOIS TOOL WORKS INC

Ink-jet printer device and ink-jet printing method

InactiveUS7959247B2Eliminate degradationReduce temperature unevennessOther printing apparatusTemperature controlInk printer

An ink-jet printer has a print head that performs printing on a print medium transported in a print medium transport direction by scanning in a scanning direction intersecting the print medium transport direction. A platen supports the print medium while the print medium is transported along the print medium transport direction. The platen has heater blocks that become smaller in width in the scanning direction toward both ends of the platen. A measurement section measures a surface temperature of each of portions of the print medium supported by the platen. A calculation section calculates an output value of each of the heater blocks for making the surface temperature of each of the portions of the print medium uniform based on the surface temperature measured by the measurement section. A heater temperature control section controls an output of each of the heater blocks based on the output value calculated by the calculation section.

Owner:OKI DATA CORP

Thin steel wire atomizing cooling treatment method and device

ActiveCN102220474AUniform coreUniform surface temperatureFurnace typesProcess efficiency improvementCooling capacityPollution

The invention discloses a thin steel wire atomizing cooling treatment method and a thin steel wire atomizing cooling treatment device. Steel wires of different steel numbers and diameters can be cooled simply by changing the ratio of cooling water to compressed air and the cooling capacity of a system instead of changing the cooling medium. Meanwhile, a two-stage segmental cooling method is adopted to ensure the temperatures of the core parts and surfaces of the cooled steel wires are more uniform, so the heat treatment performance of the steel wires is improved and the quality of the steel wires subjected to heat treatment is more stable. Therefore, when the method and the device are used, the process is simple, pollution is avoided, and cooling water can be utilized circularly; and the method can replace a high-temperature lead patenting process effectively.

Owner:网都河北科技服务有限公司

Banded structure control method, gear steel and formula thereof

The invention relates to the field of steel manufacturing, in particular to a banded structure control method, gear steel and a formula thereof. The banded structure control method comprises the stepsthat molten steel forms a casting blank through continuous casting by a crystallizer at constant pull speed; diffusion heating is conducted on the casting blank at the temperature of 1225-1255 DEG Ctill surface temperature and core temperature of the casting blank are even; and rolling of the down-pressing rate of 20%-30% is conducted on the casting blank obtained after diffusion heating at thetemperature of 1085-1205 DEG C. The continuous casting process, the diffusion heating process and the rolling process are controlled, austenite of the gear steel is fully deformed and homogenized fromthe surface to the core, and fine and even austenite particles are formed. Even-structure ferrite can be formed at the core and surface of the gear steel, and the banded structure is smaller than orequal to 2.0 grade.

Owner:BAOSTEEL SPECIAL STEEL SHAOGUAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com