Patents

Literature

3599results about "Surface/boundary effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

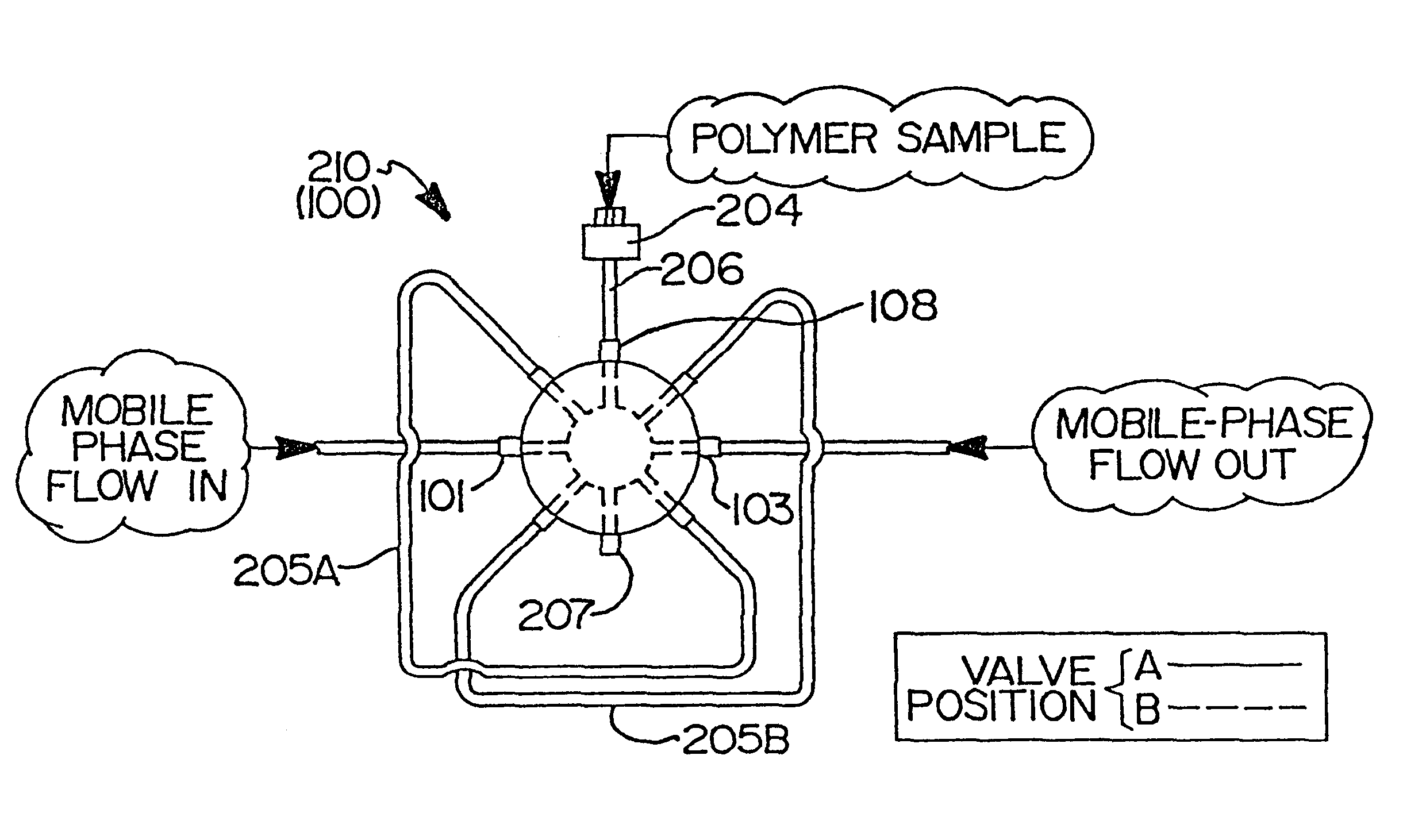

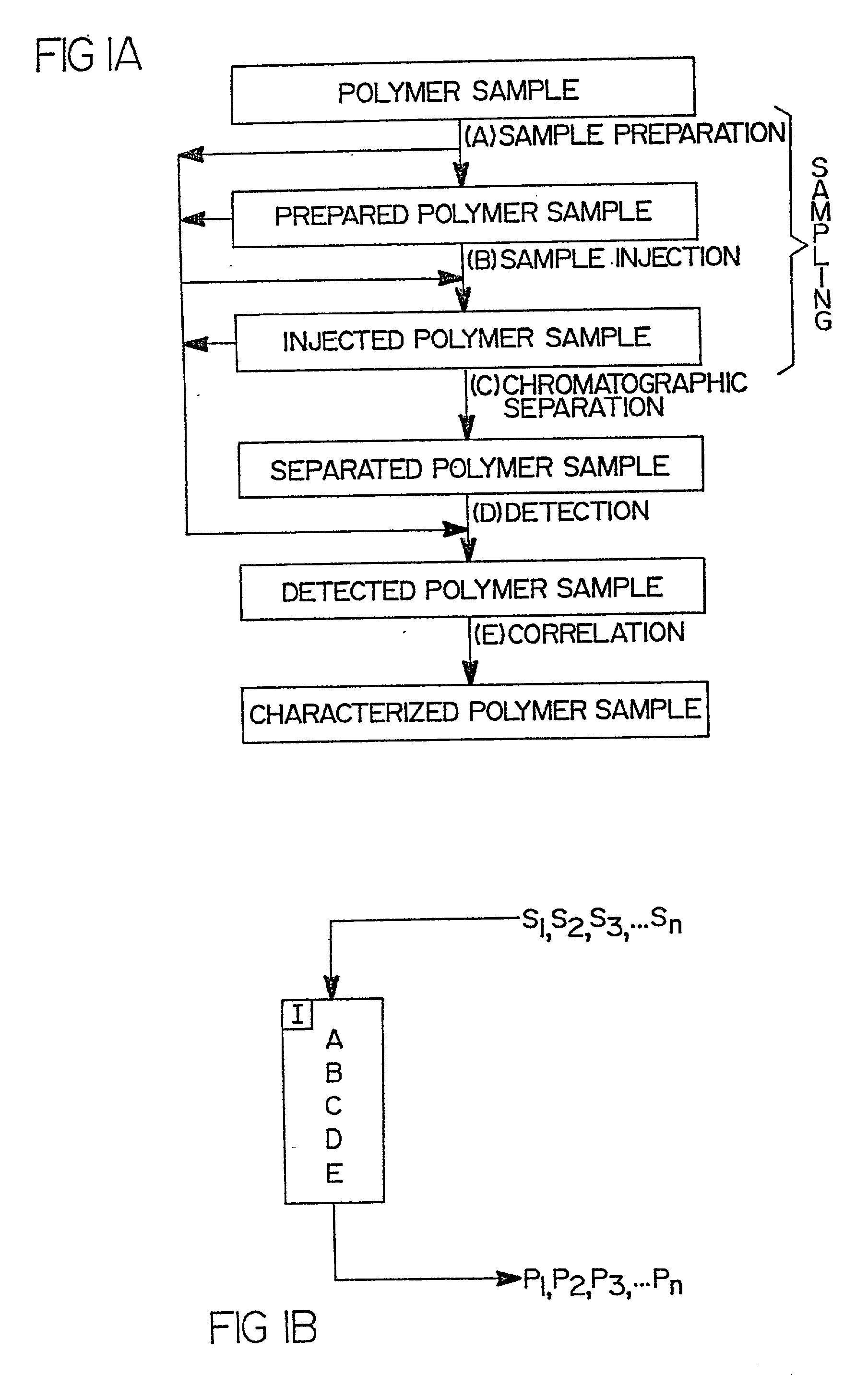

High-temperature characterization of polymers

InactiveUS6260407B1Avoid backlogImprove throughputSequential/parallel process reactionsComponent separationElutionChromatography column

Rapid characterization and screening of polymer samples to determine average molecular weight, molecular weight distribution and other properties is disclosed. Rapid flow characterization systems and methods, including liquid chromatography and flow-injection analysis systems and methods are preferably employed. High throughput, automated sampling systems and methods, high-temperature characterization systems and methods, and rapid, indirect calibration compositions and methods are also disclosed. In preferred high-temperature embodiments, the polymer sample is maintained at a temperature of not less than about 75° C. during sample preparation, loading into a liquid chromatography or flow-injection analysis system, injection into a mobile phase of a liquid chromatography or flow-injection analysis system, and / or elution from chromatographic column. The described methods, systems, and device have primary applications in combinatorial polymer research and in industrial process control.

Owner:INTERMOLECULAR

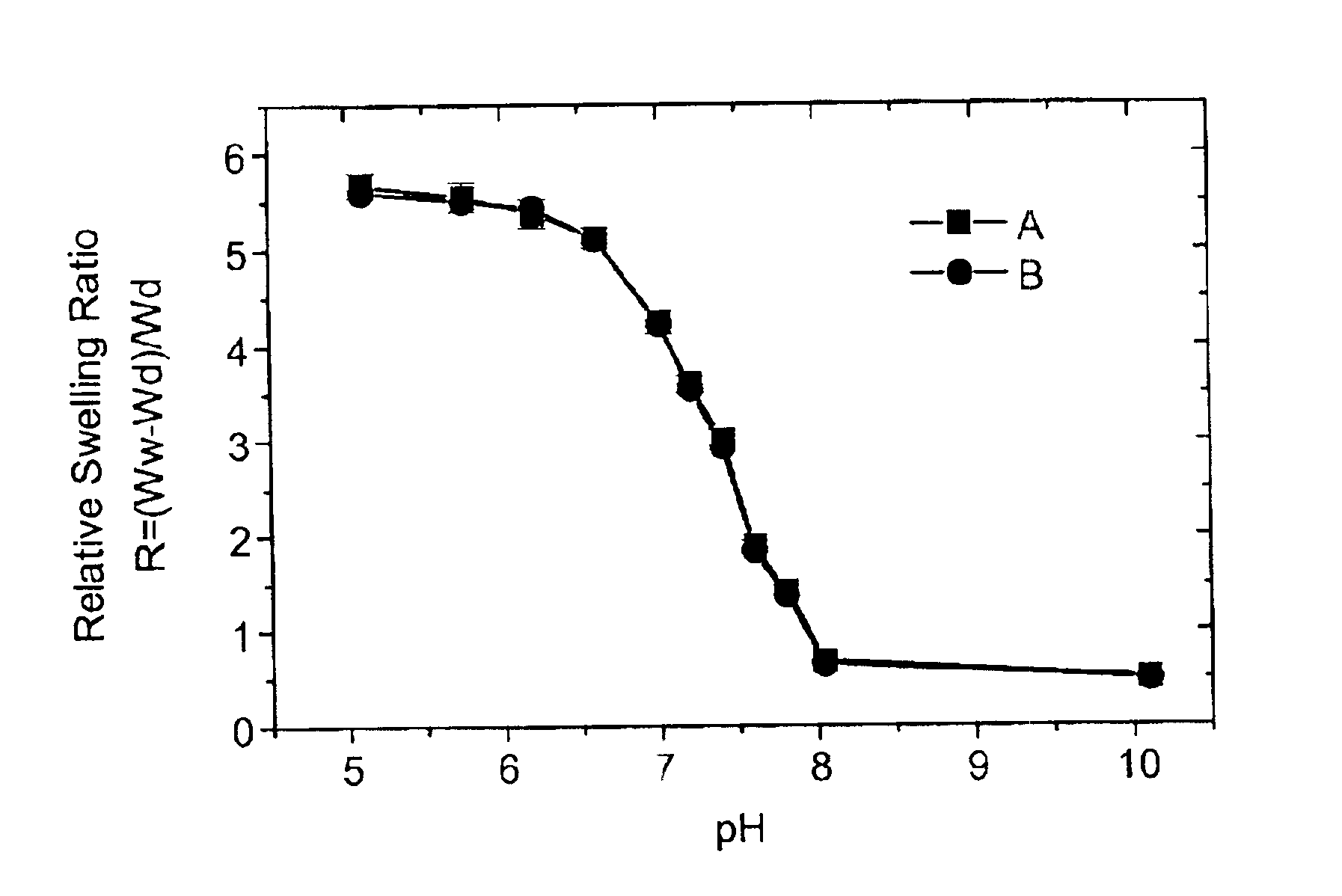

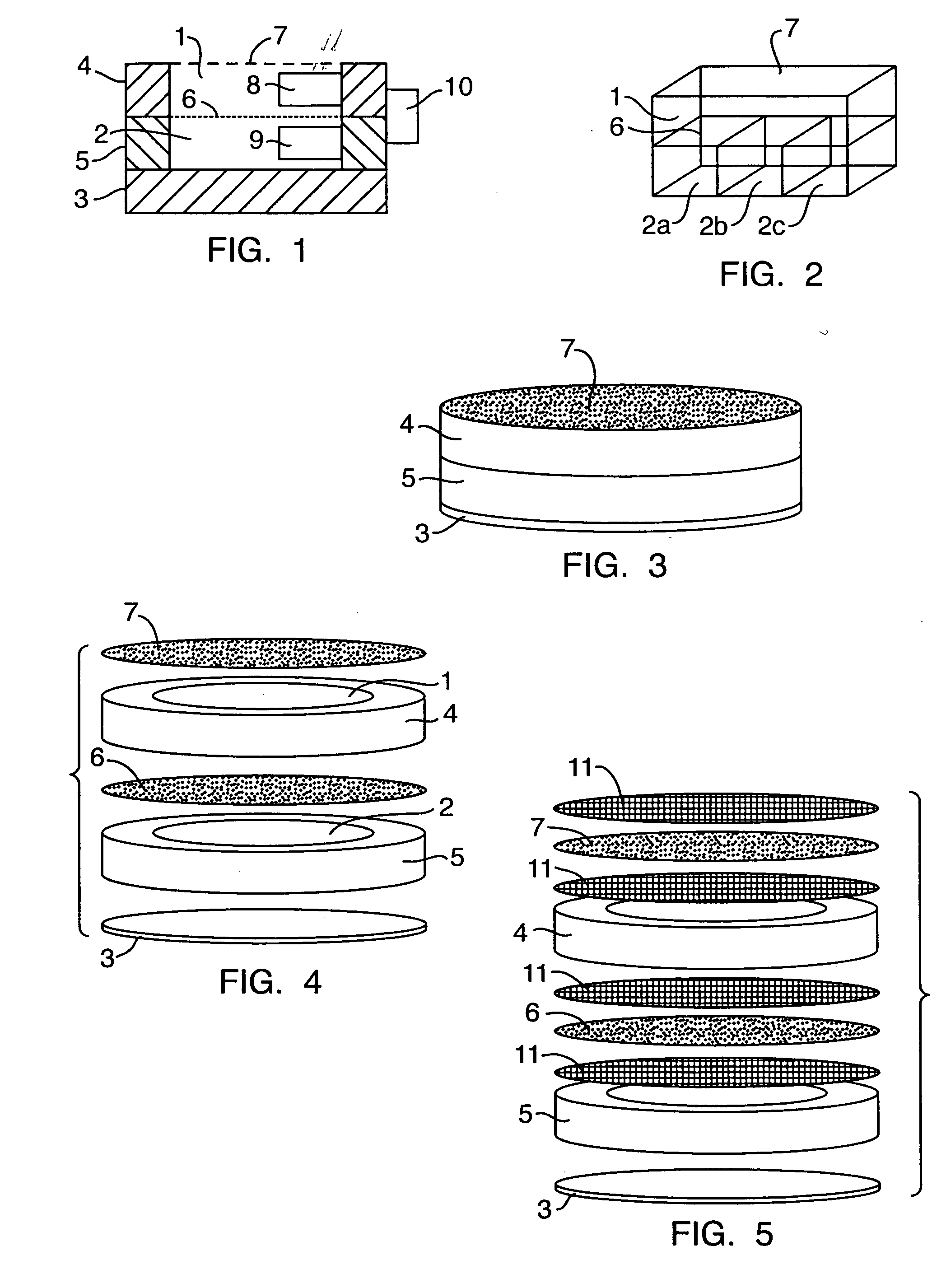

Polymer matrix containing catalase co-immobilized with analytic enzyme that generates hydrogen peroxide

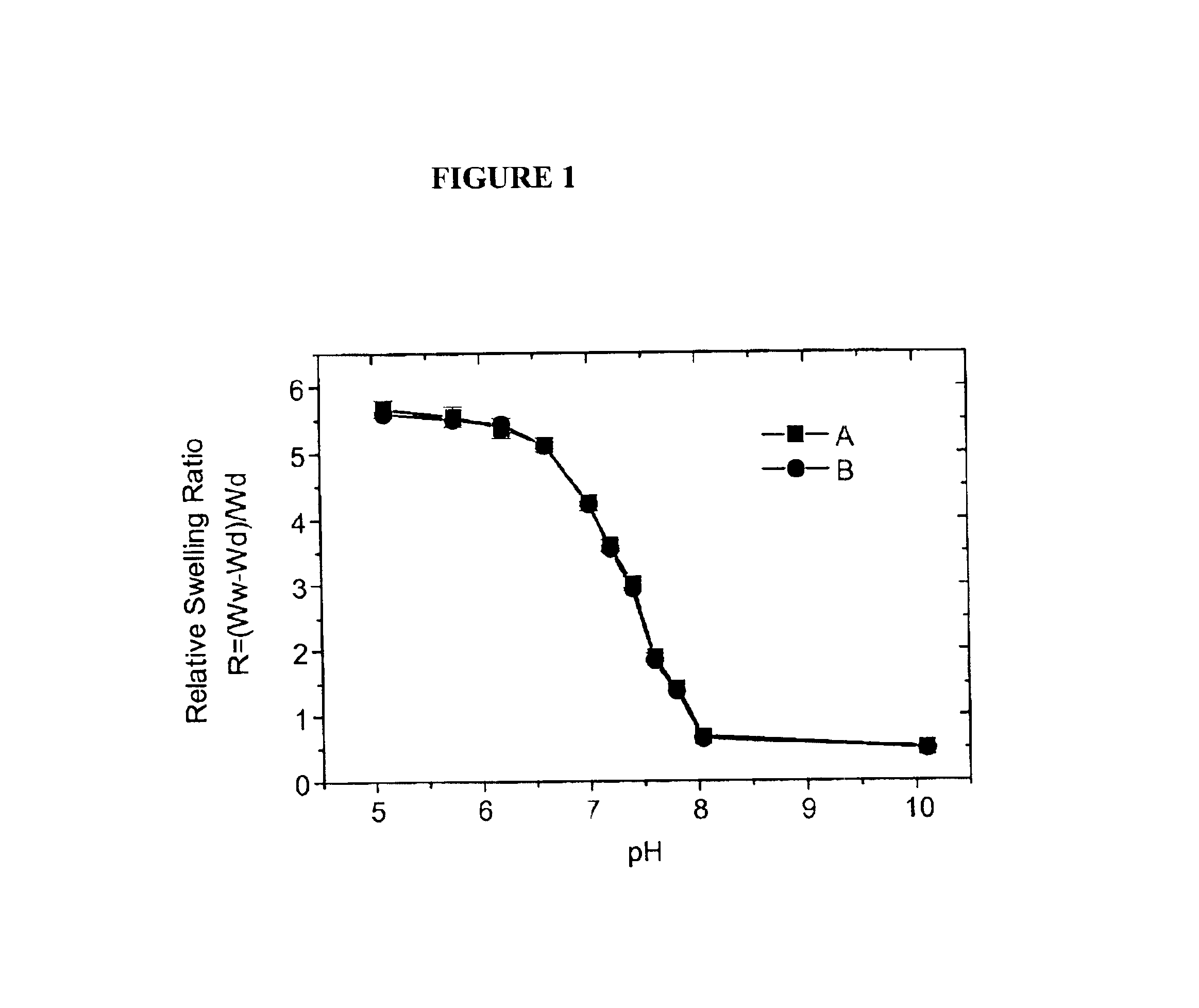

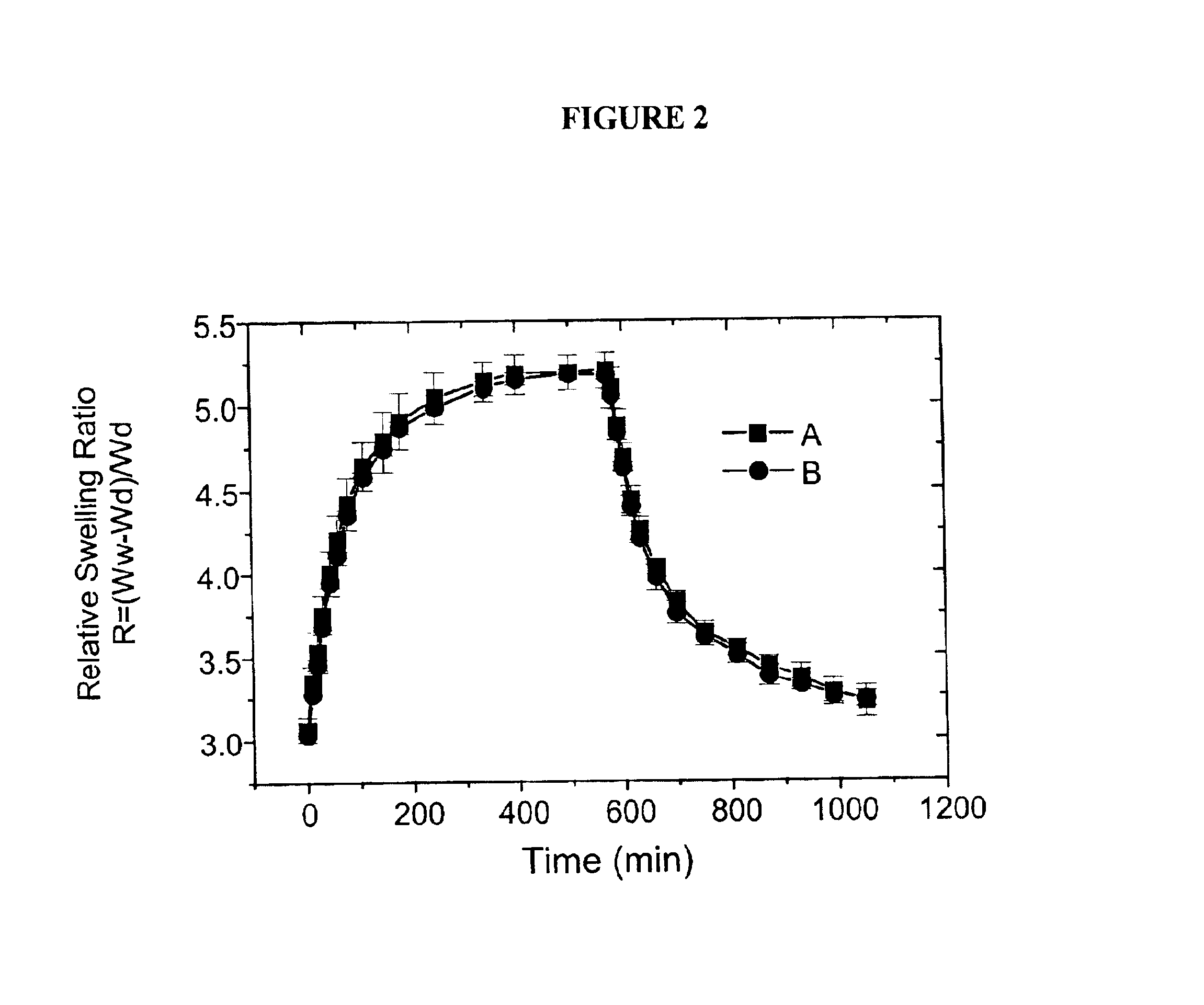

InactiveUS6858403B2Enhancing swelling kineticsLong useful lifePowder deliveryBioreactor/fermenter combinationsAnalyteHydrogen peroxide degradation

Hydrogels containing catalase co-immobilized with an analyte-sensitive enzyme such as glucose oxidase are disclosed. The hydrogels may be pH-sensitive, and preferably are thin and lightly crosslinked. The catalase is present in concentrations ranging generally from 100 units / ml to about 1000 units / ml. These hydrogels have much faster swelling response times as compared to hydrogels without catalase, and are useful in biosensors and analyte-responsive drug delivery devices. The hydrogels also have an increased useful life, due to protection of the immobilize analyte-sensitive enzyme from degradation by hydrogen peroxide.

Owner:M BIOTECH

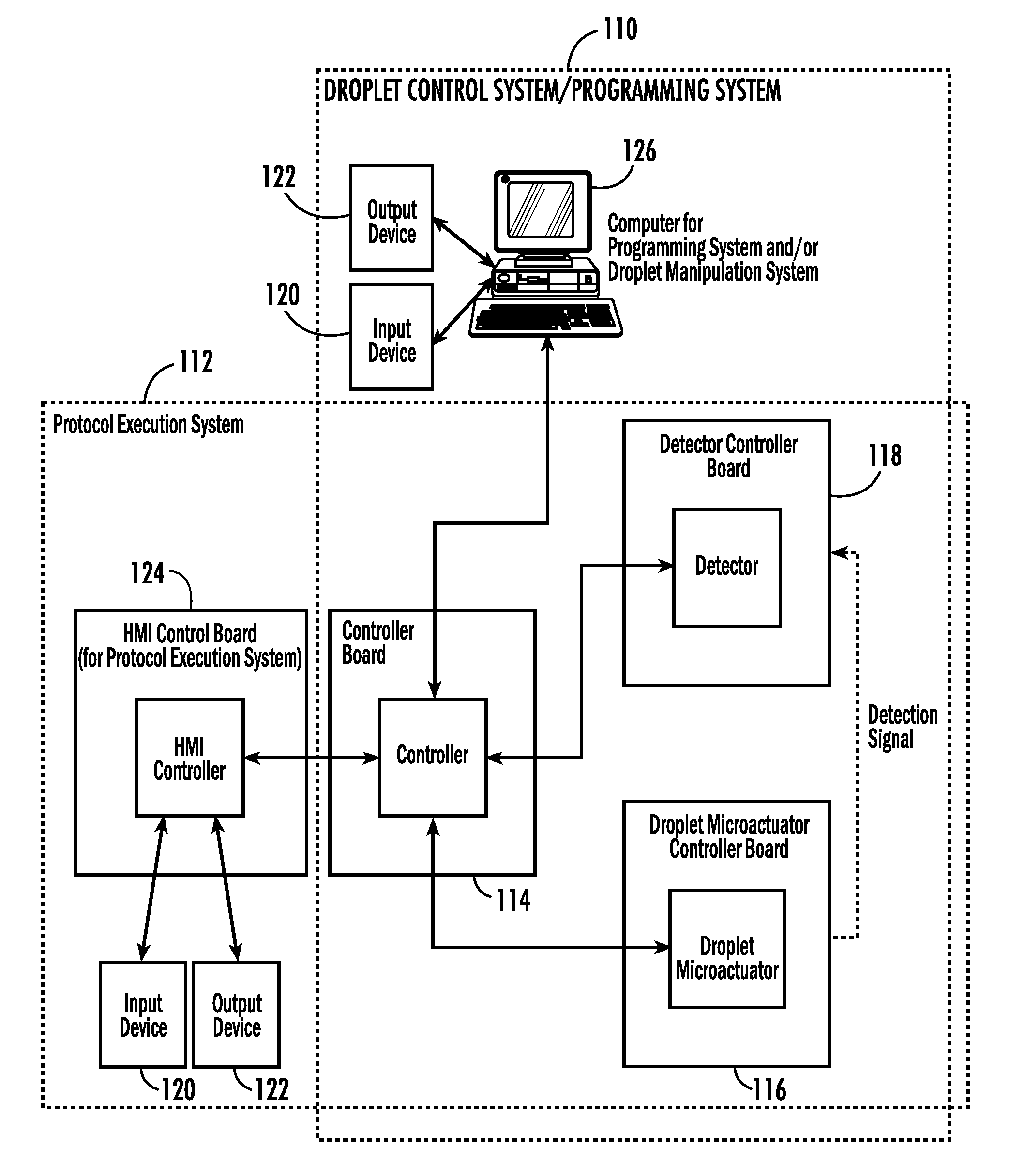

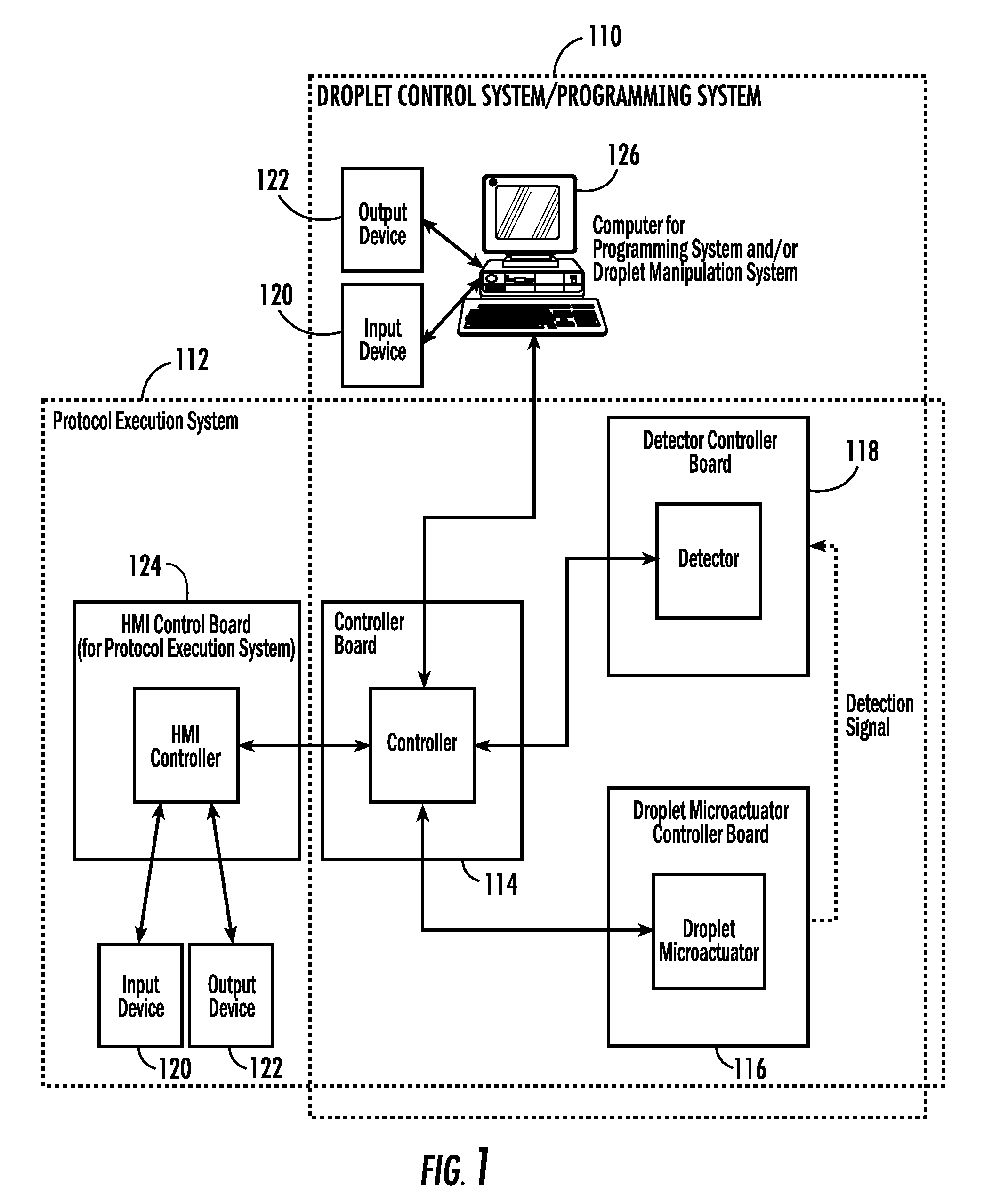

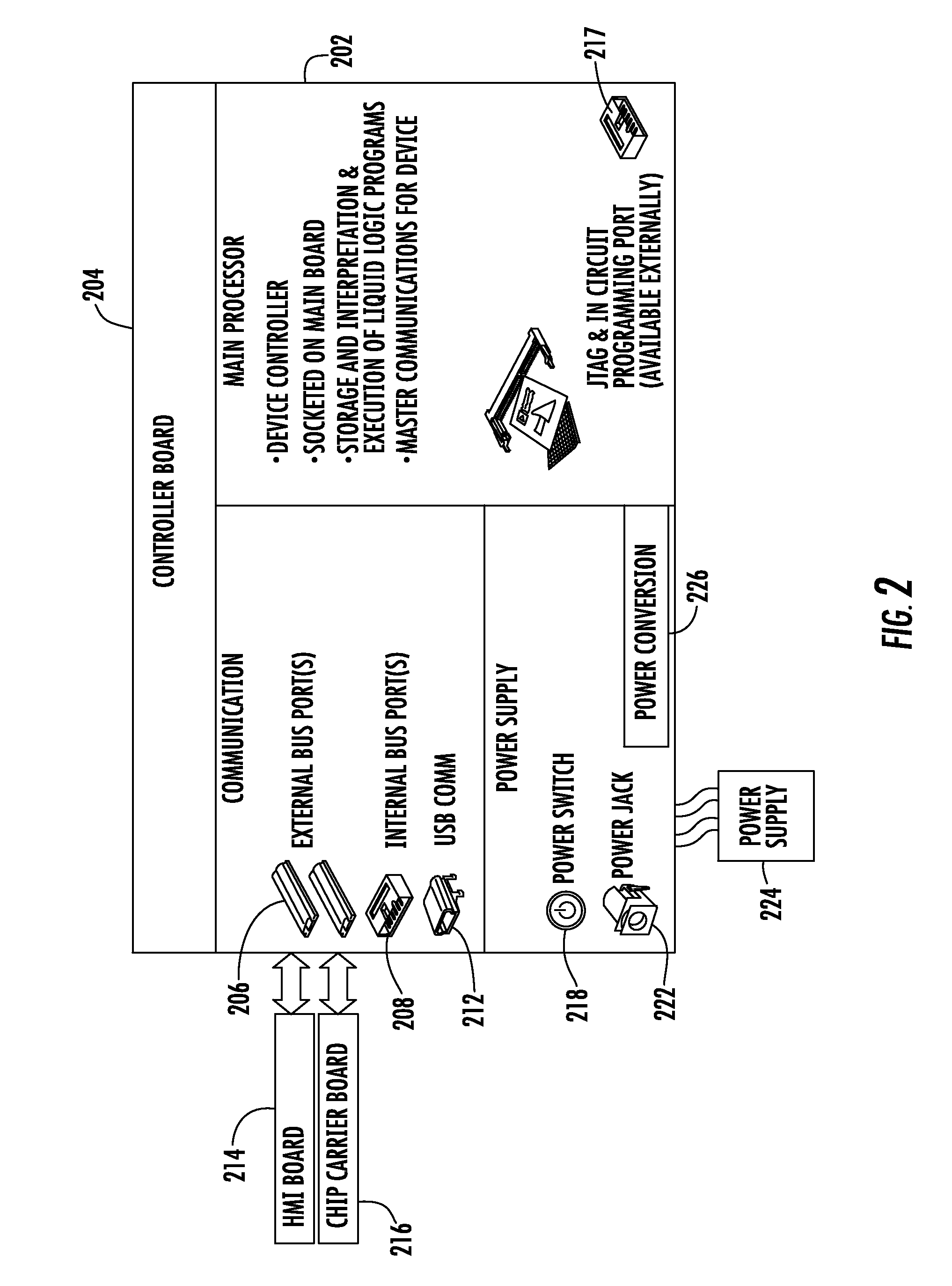

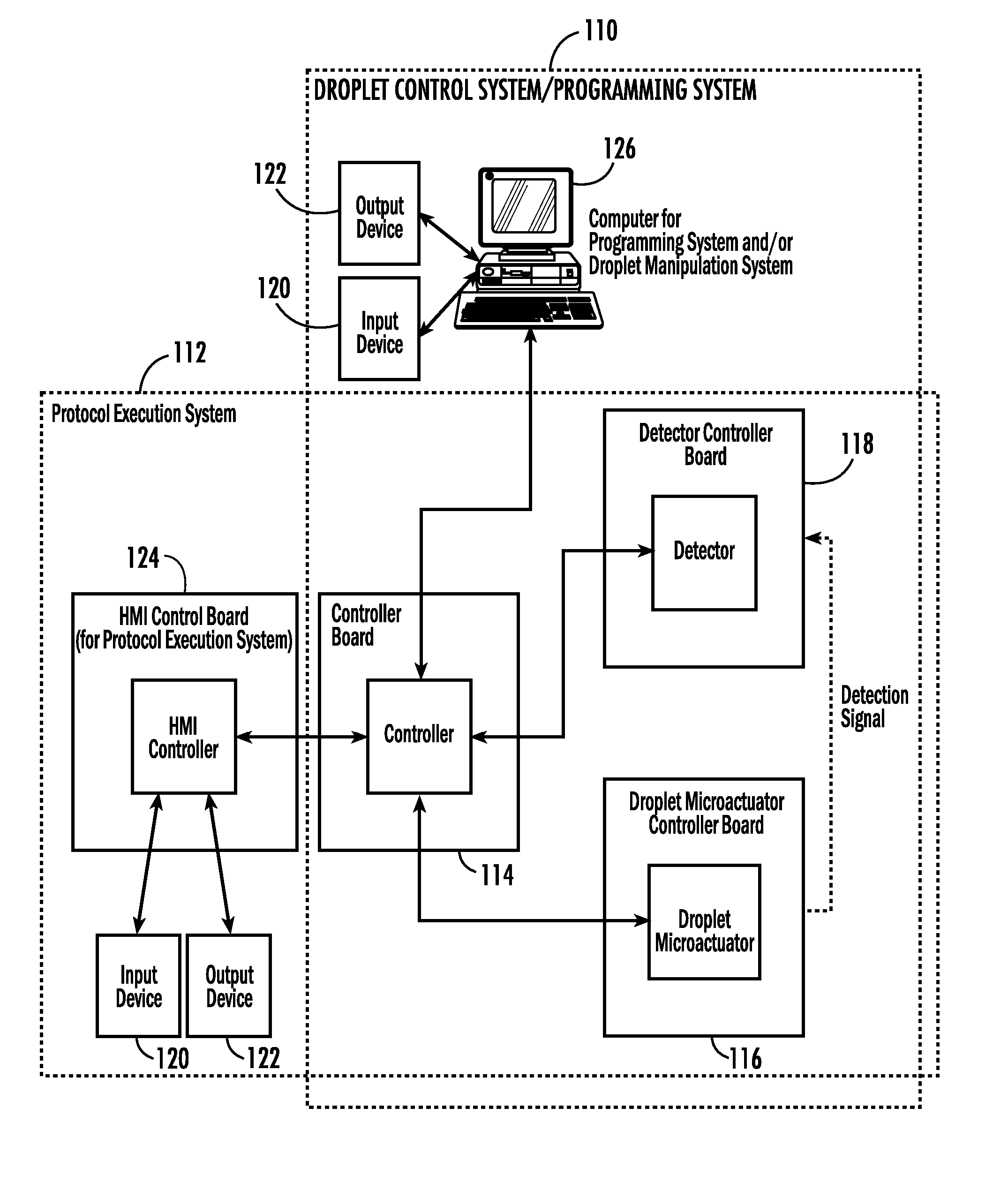

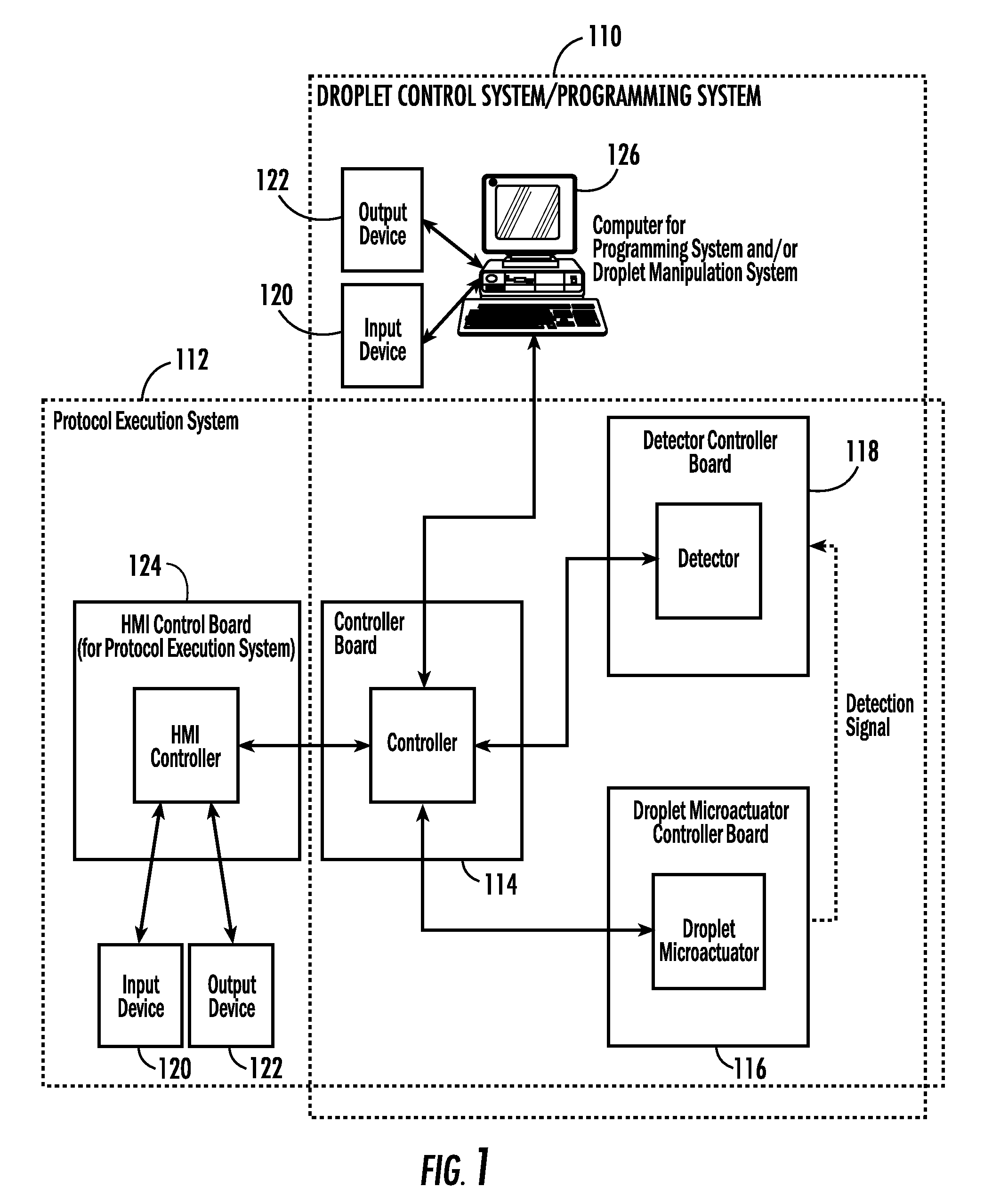

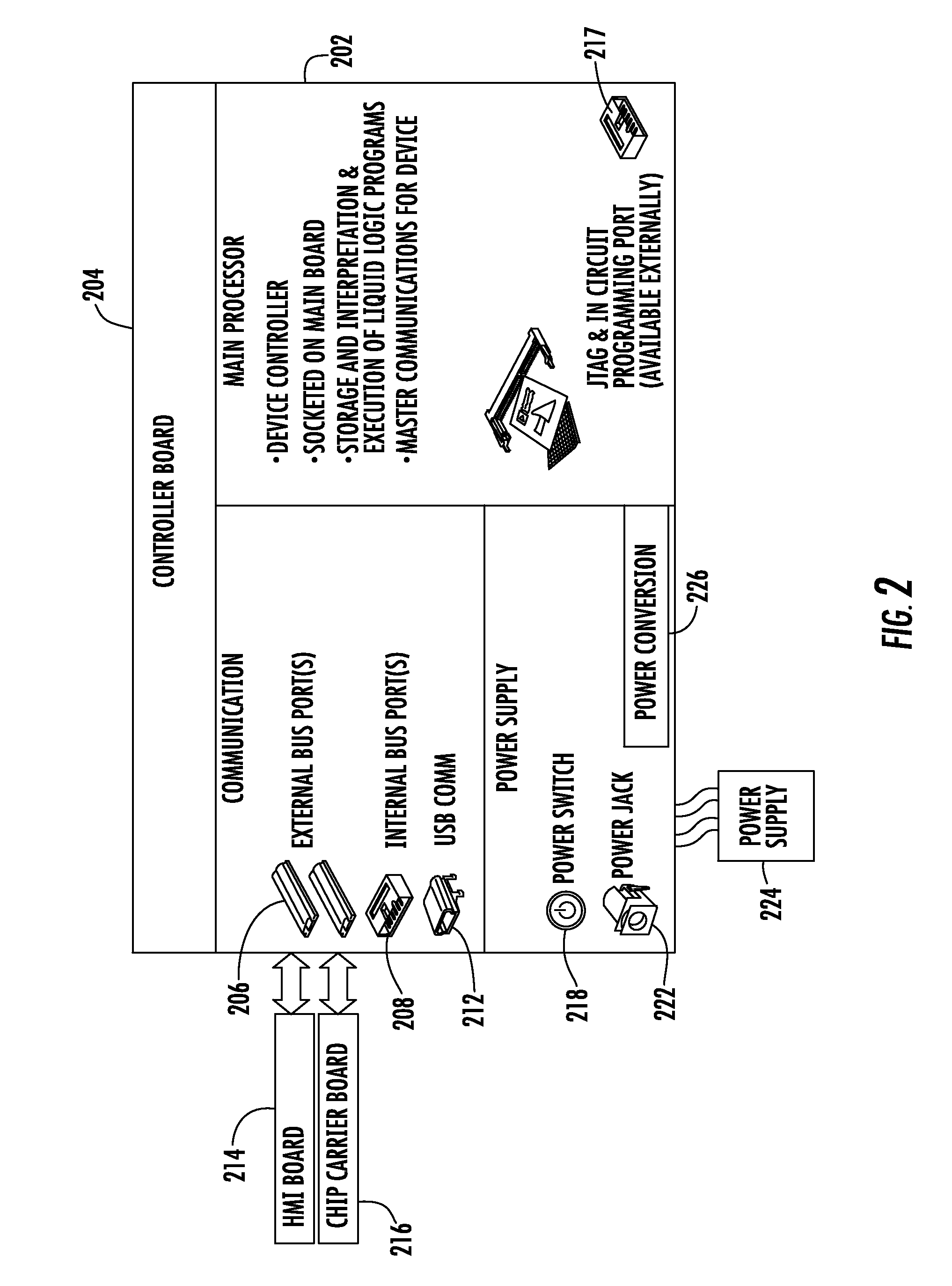

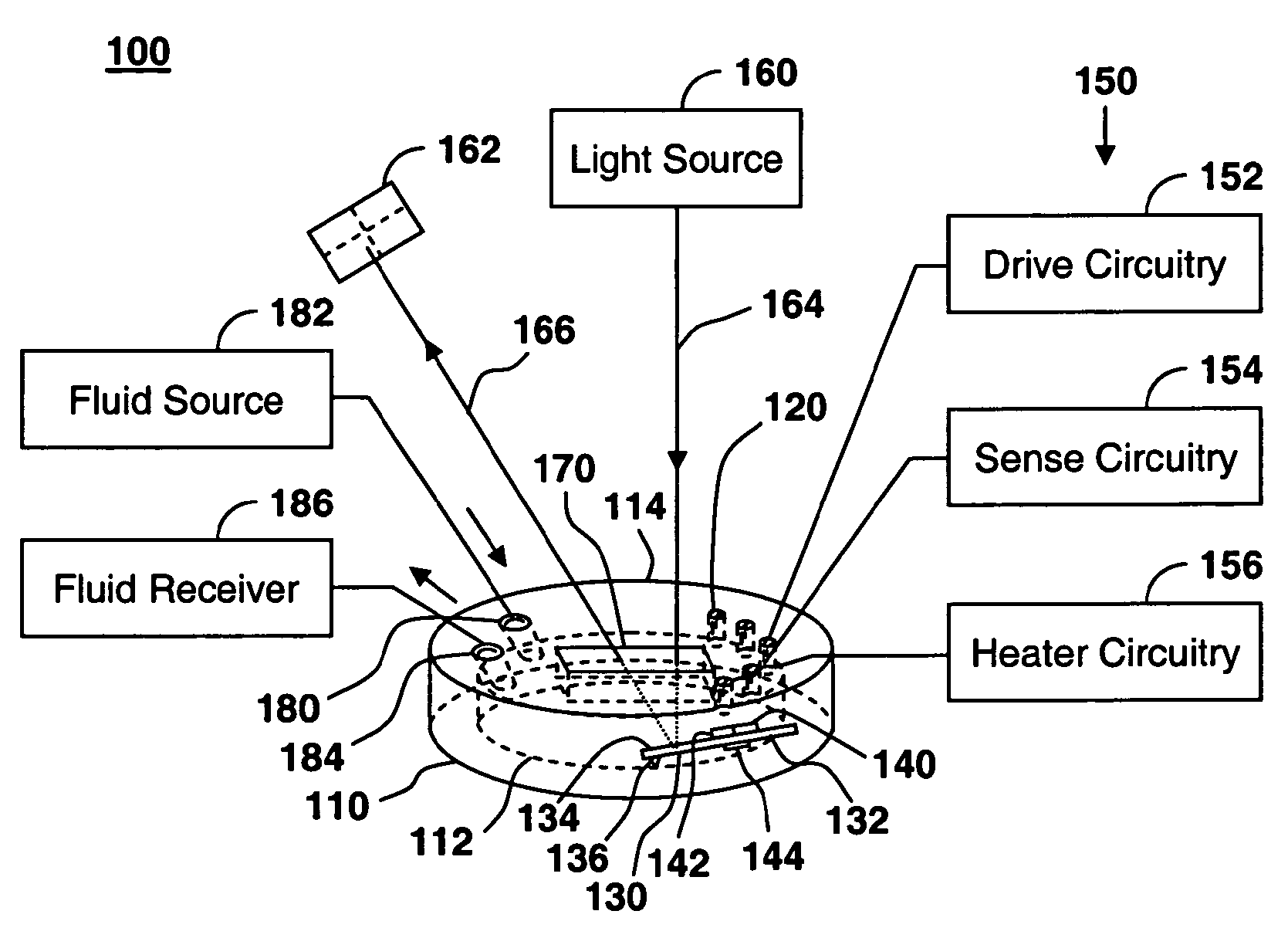

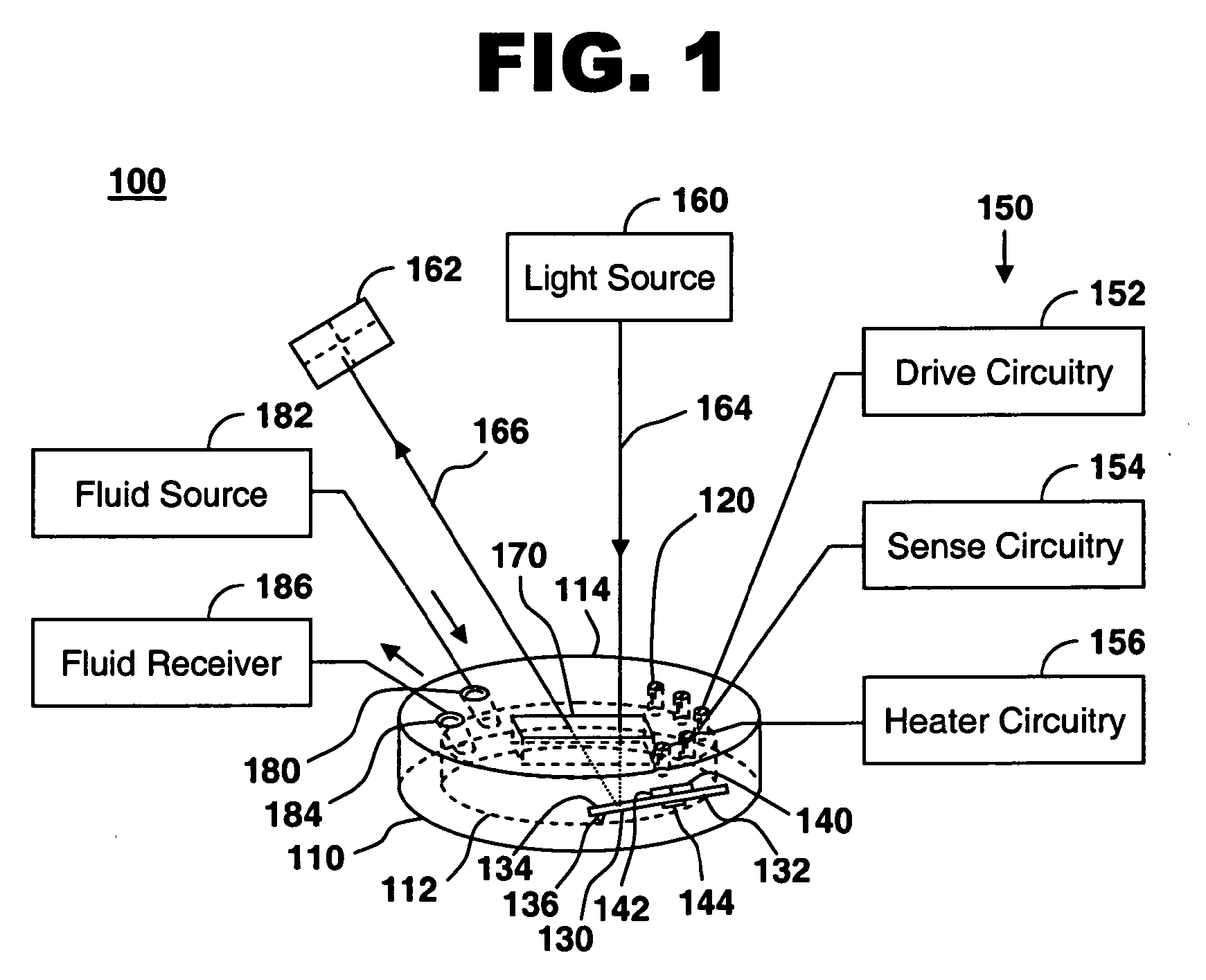

System for Controlling a Droplet Actuator

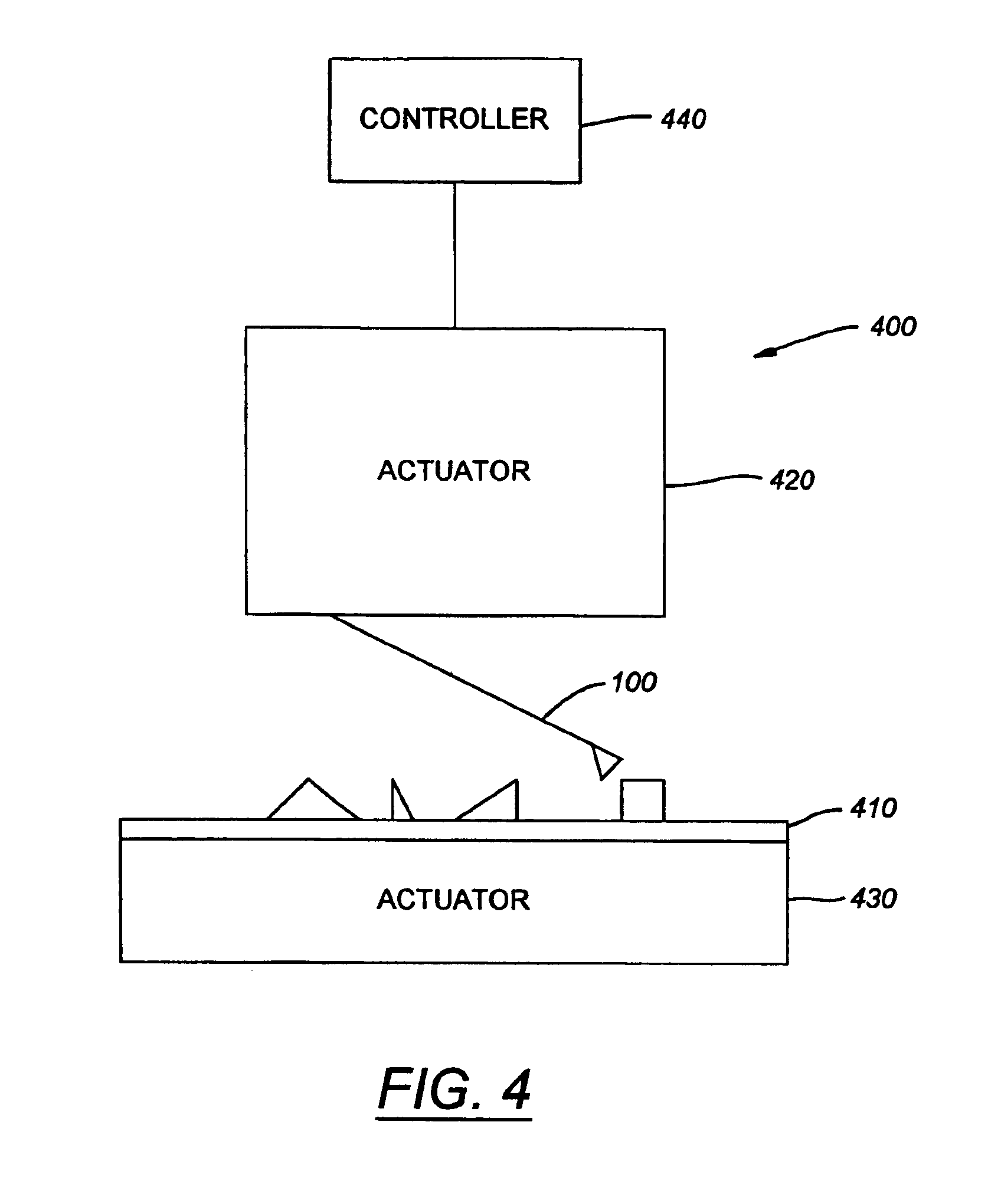

InactiveUS20080006535A1Accurate sampling volumeRestrict levelSludge treatmentLevel controlDisplay deviceEngineering

Systems for controlling a droplet microactuator are provided. According to one embodiment, a system is provided and includes a controller, a droplet microactuator electronically coupled to the controller, and a display device displaying a user interface electronically coupled to the controller, wherein the system is programmed and configured to permit a user to effect a droplet manipulation by interacting with the user interface. According to another embodiment, a system is provided and includes a processor, a display device electronically coupled to the processor, and software loaded and / or stored in a storage device electronically coupled to the controller, a memory device electronically coupled to the controller, and / or the controller and programmed to display an interactive map of a droplet microactuator. According to yet another embodiment, a system is provided and includes a controller, a droplet microactuator electronically coupled to the controller, a display device displaying a user interface electronically coupled to the controller, and software for executing a protocol loaded and / or stored in a storage device electronically coupled to the controller, a memory device electronically coupled to the controller, and / or the controller.

Owner:ADVANCED LIQUID LOGIC +1

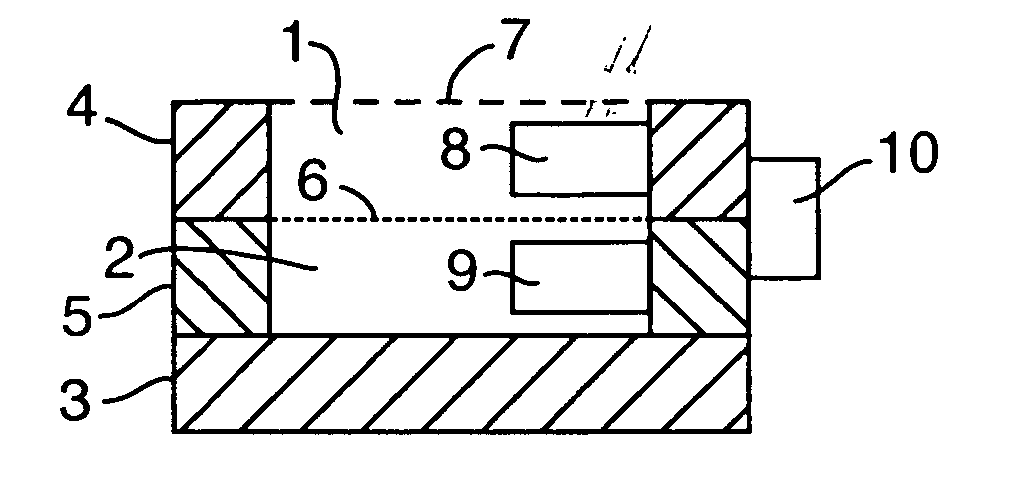

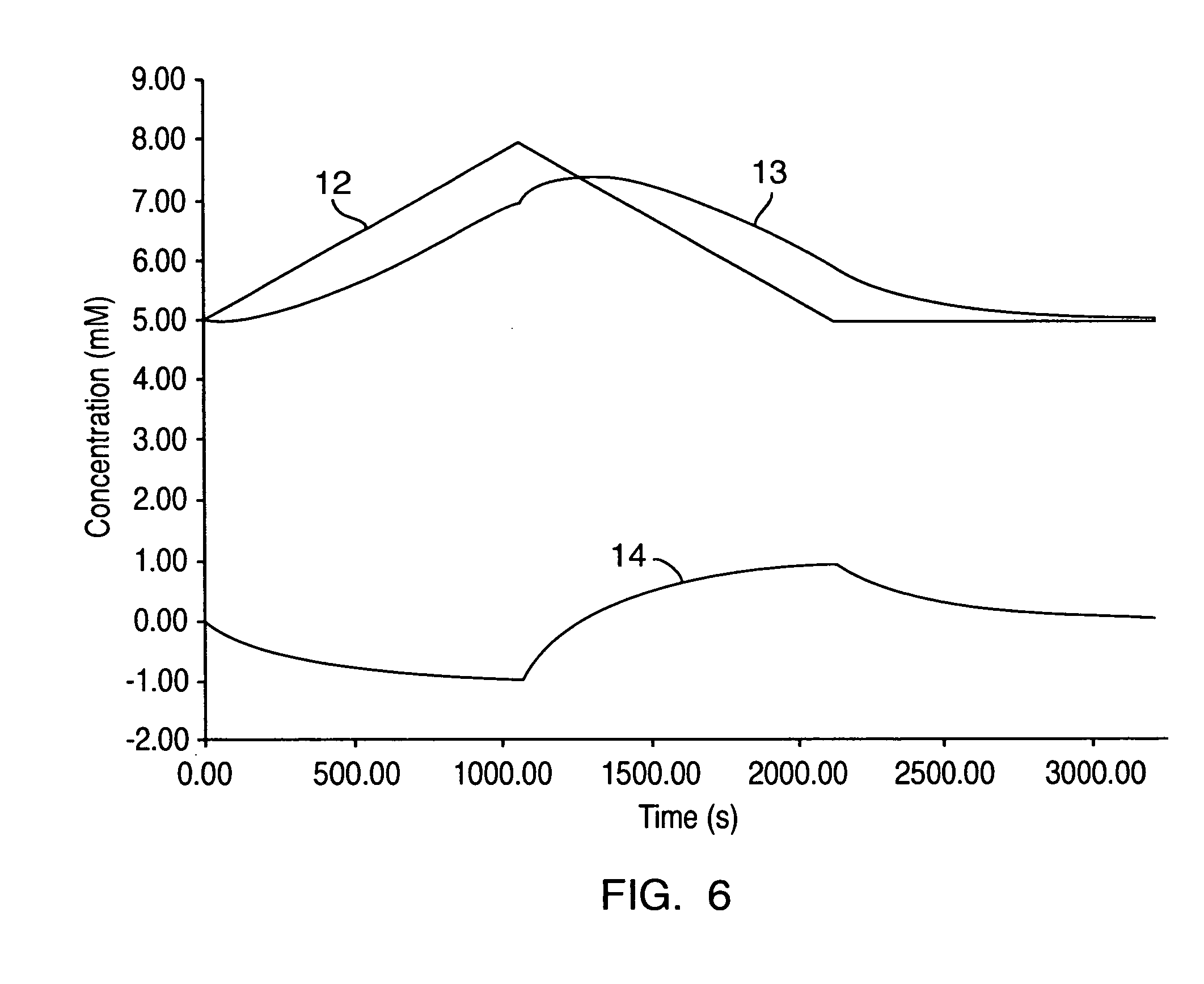

Method and device for monitoring analyte concentration by use of differential osmotic pressure measurement

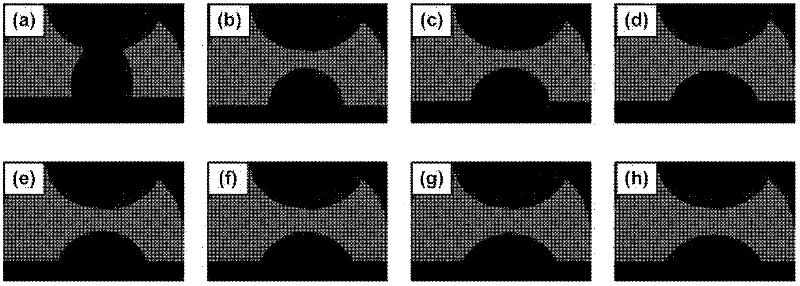

InactiveUS20050154272A1Reduce decreaseSurface/boundary effectEndoradiosondesConcentrations glucoseBlood or Tissue

A method is provided for the determination of the concentration of compounds in body tissue and fluids. The method utilises two compartments containing reference solutions, which are separated from the sample by two different semi-permeable membranes, in a serial manner, whereby a difference in osmotic pressure occurs in the two compartments due to compounds, which can permeate one of the membranes, but not the other. The difference in osmotic pressure reflects the concentration of these compounds. The method is especially suited for analysis of the concentration of glucose in blood or tissue of diabetic patients, where a device is implanted underneath the skin of the patient and where the method is carried out by using the implanted device.

Owner:DANFOSS AS

Systems, methods, and products for graphically illustrating and controlling a droplet actuator

Systems for controlling a droplet microactuator are provided. According to one embodiment, a system is provided and includes a controller, a droplet microactuator electronically coupled to the controller, and a display device displaying a user interface electronically coupled to the controller, wherein the system is programmed and configured to permit a user to effect a droplet manipulation by interacting with the user interface. According to another embodiment, a system is provided and includes a processor, a display device electronically coupled to the processor, and software loaded and / or stored in a storage device electronically coupled to the controller, a memory device electronically coupled to the controller, and / or the controller and programmed to display an interactive map of a droplet microactuator. According to yet another embodiment, a system is provided and includes a controller, a droplet microactuator electronically coupled to the controller, a display device displaying a user interface electronically coupled to the controller, and software for executing a protocol loaded and / or stored in a storage device electronically coupled to the controller, a memory device electronically coupled to the controller, and / or the controller.

Owner:ADVANCED LIQUID LOGIC +1

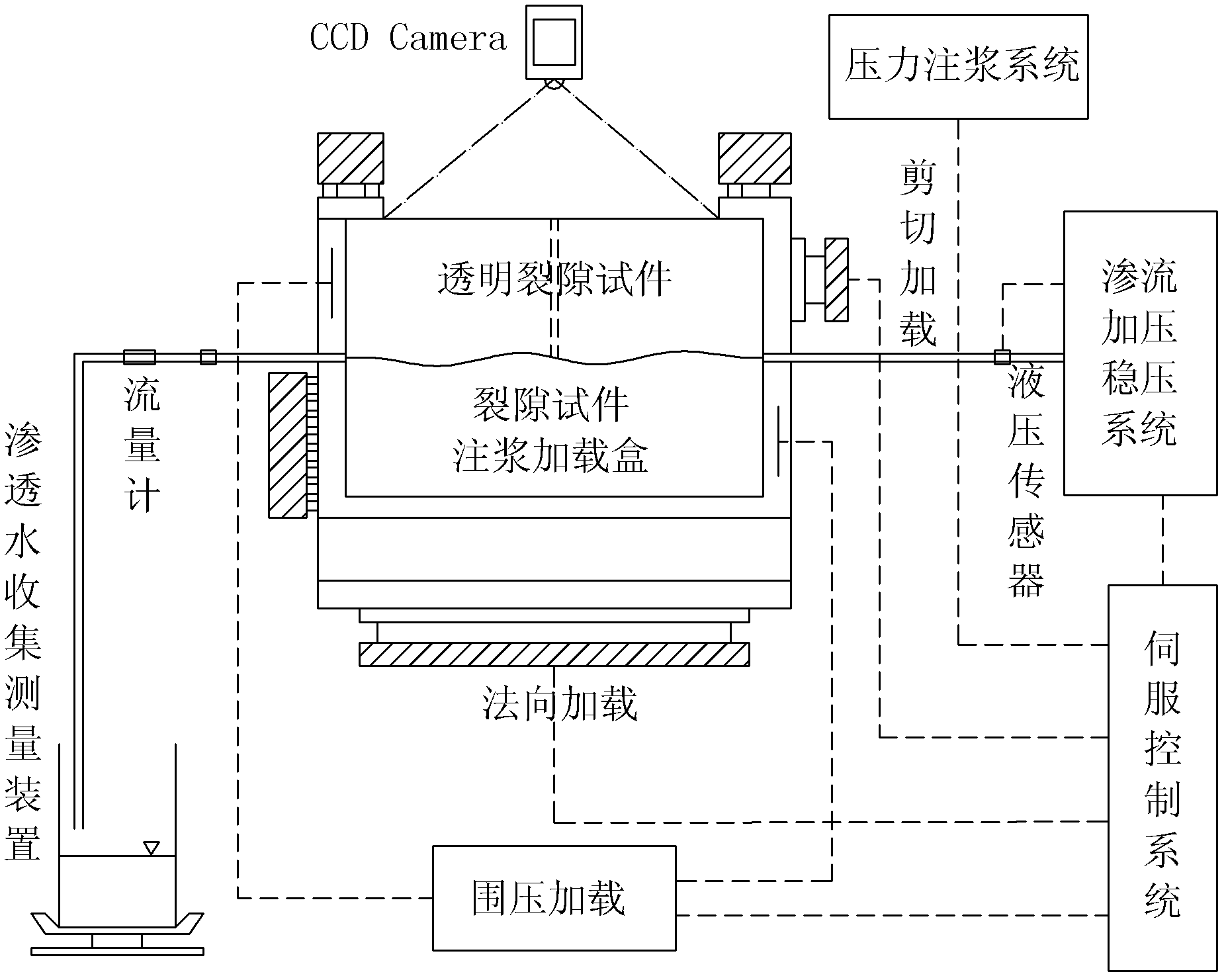

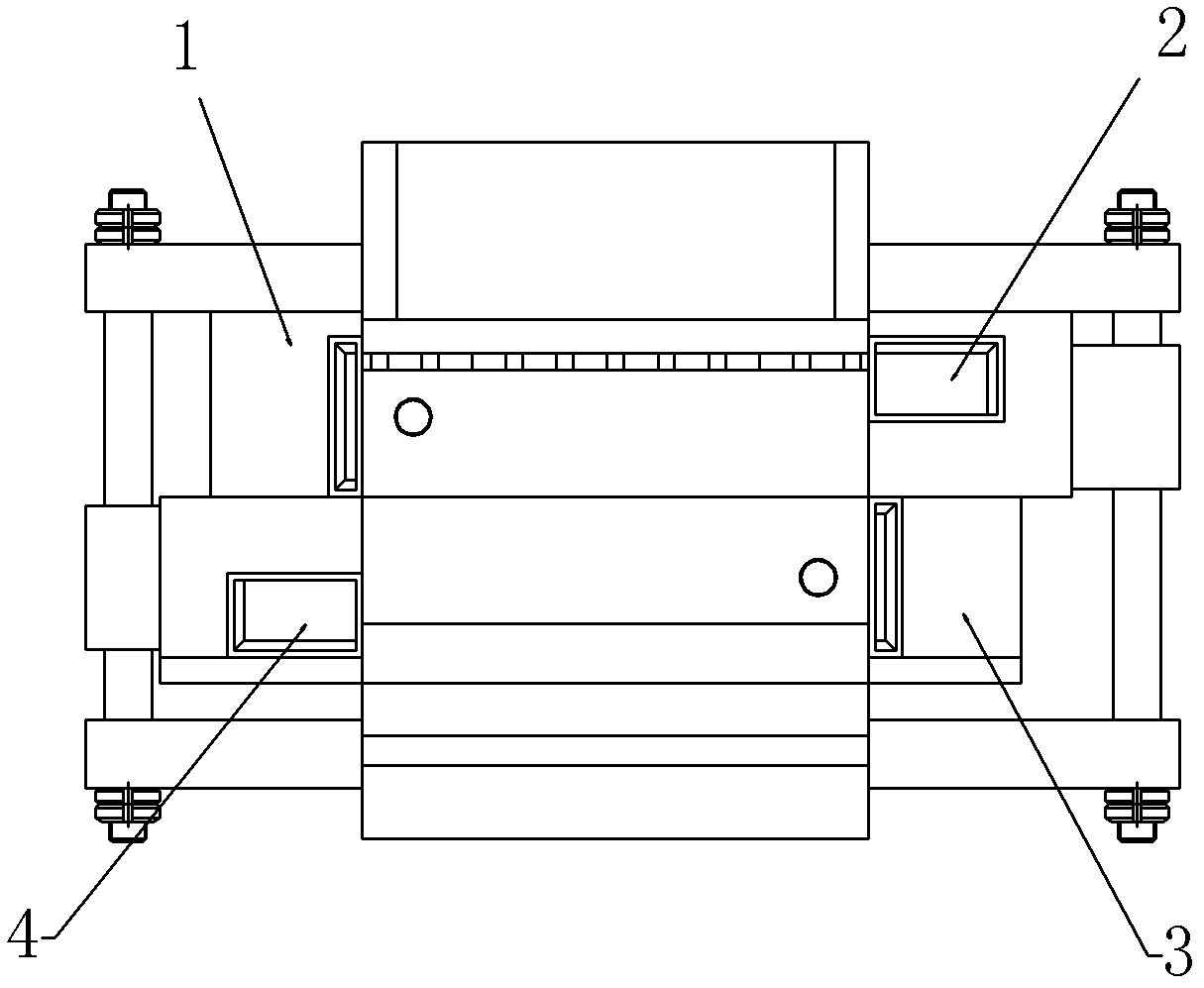

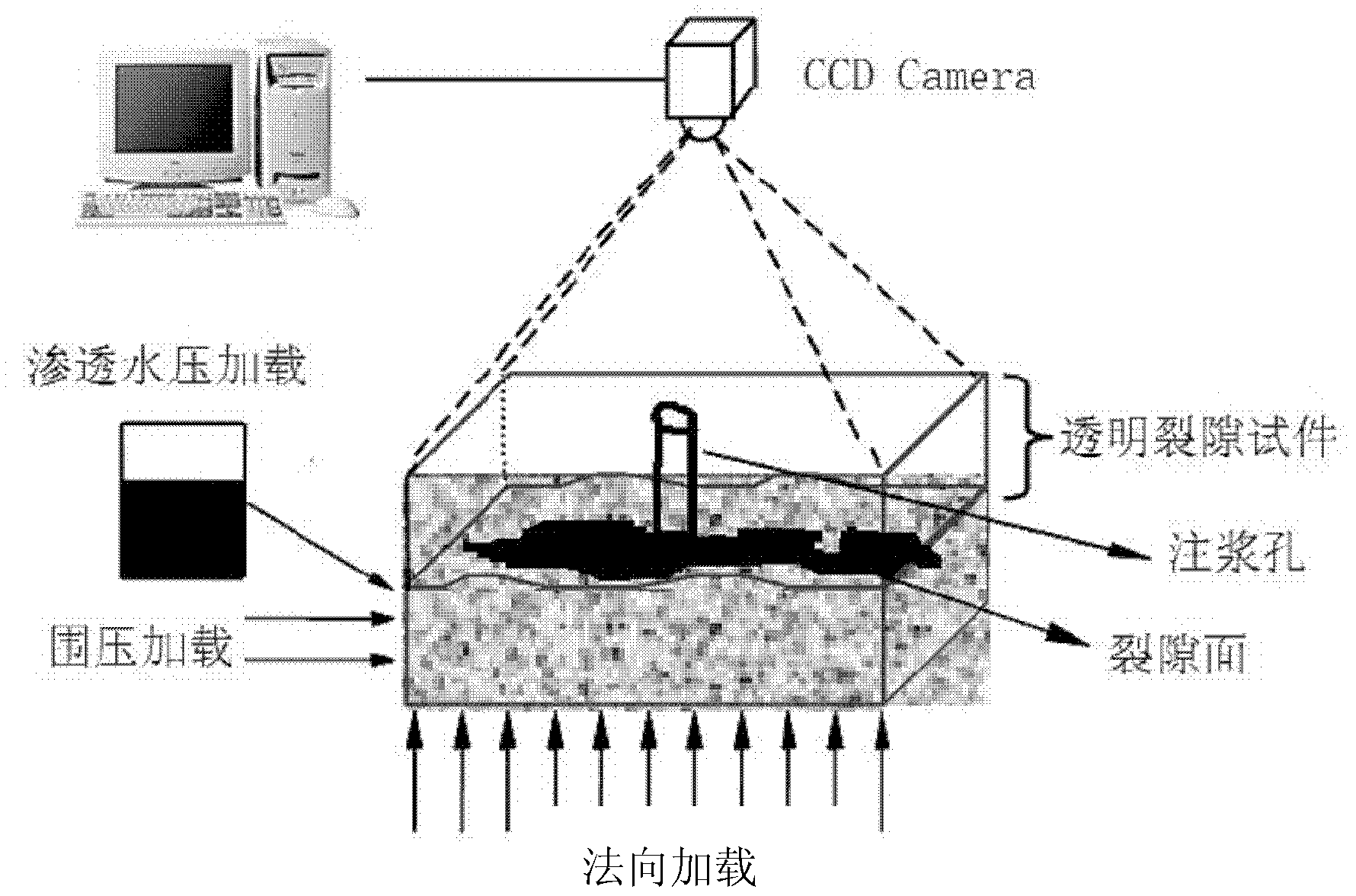

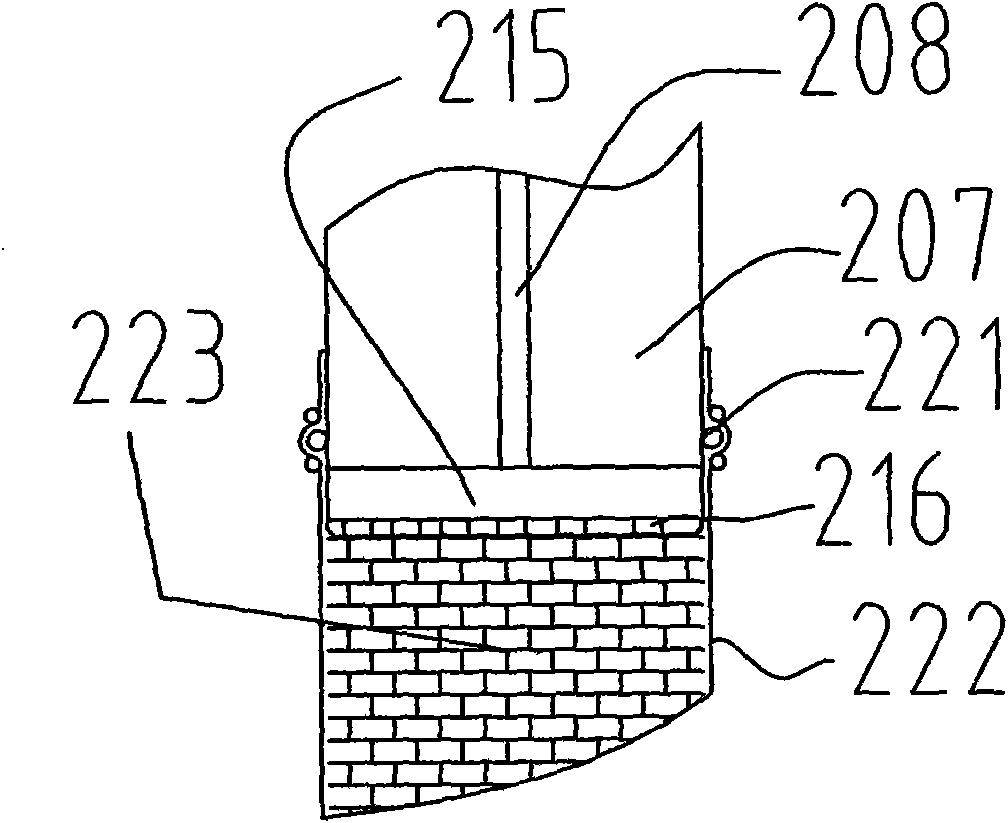

Crack grouting visualization tester under complex conditions

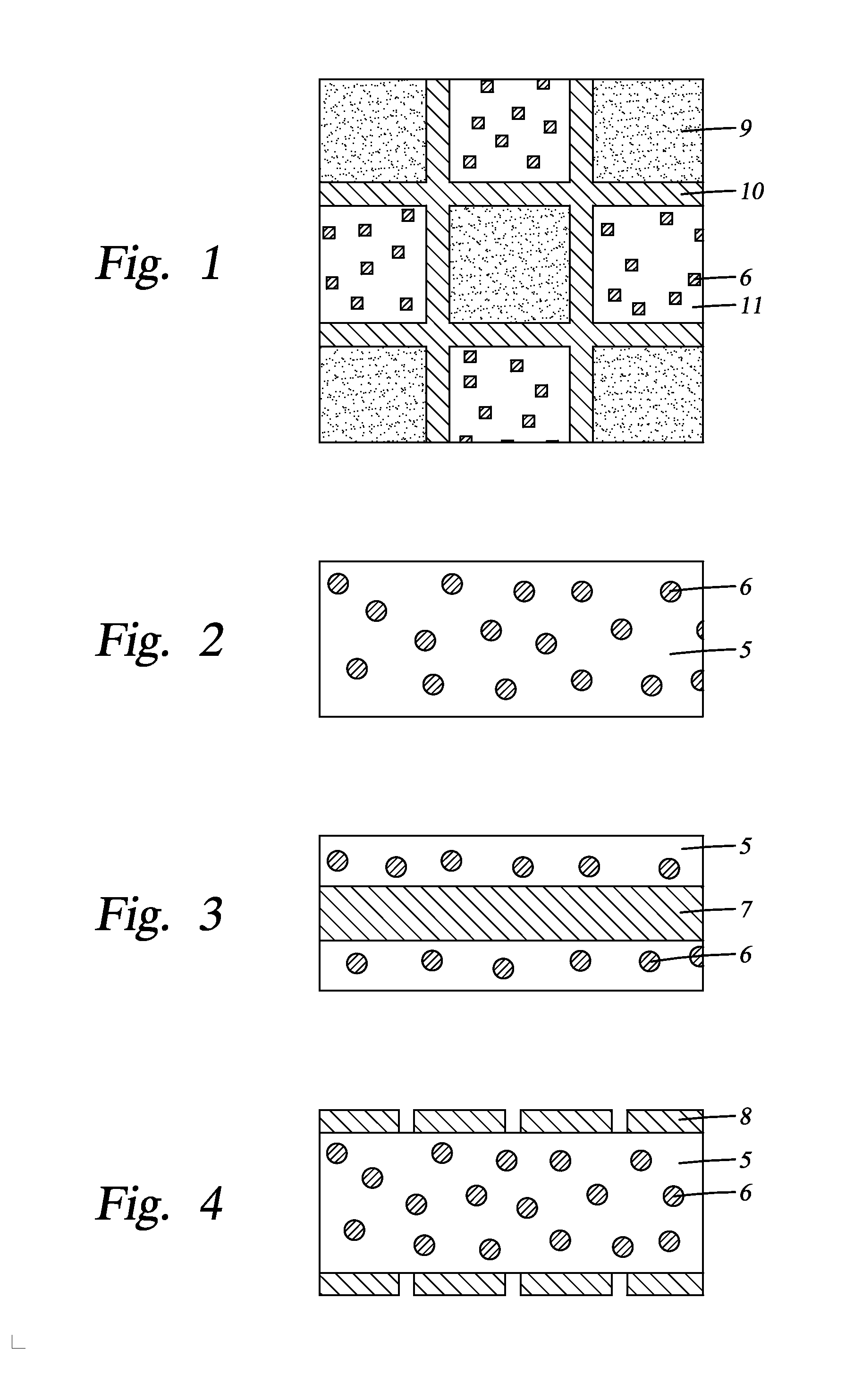

ActiveCN102419303ARealize visualizationRealize automatic controlSurface/boundary effectFoundation testingEngineeringWater collection

The invention discloses a crack grouting visualization tester under complex conditions, comprising a tester frame for testing, a crack sample grouting loading box, an axial loading mechanism, a tangential loading mechanism, a confining pressure loading mechanism, a hydraulic pressure loading mechanism, a pressure grouting system, a circulating water collection tester, and a visualization system.

Owner:SHANDONG UNIV OF SCI & TECH

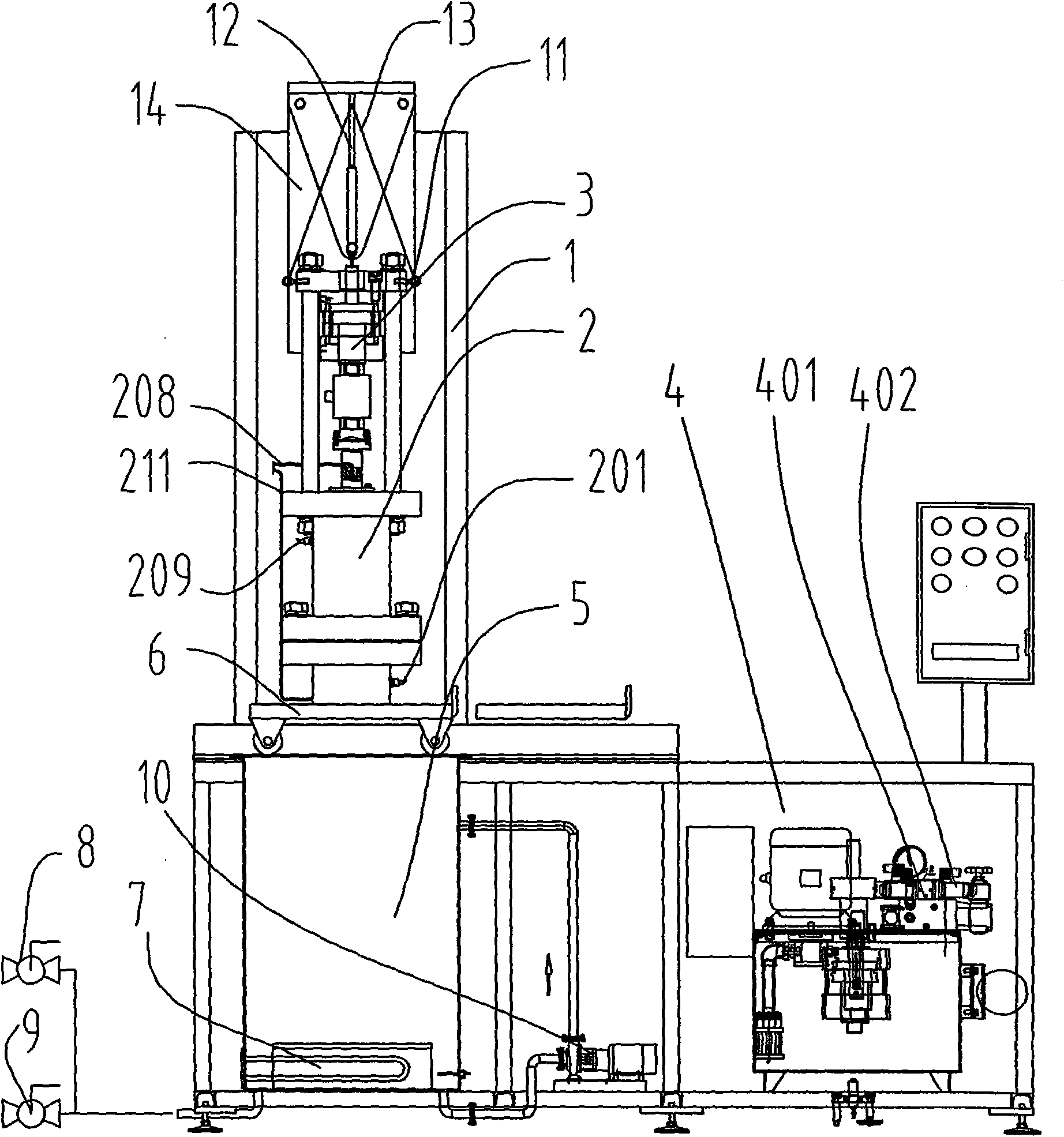

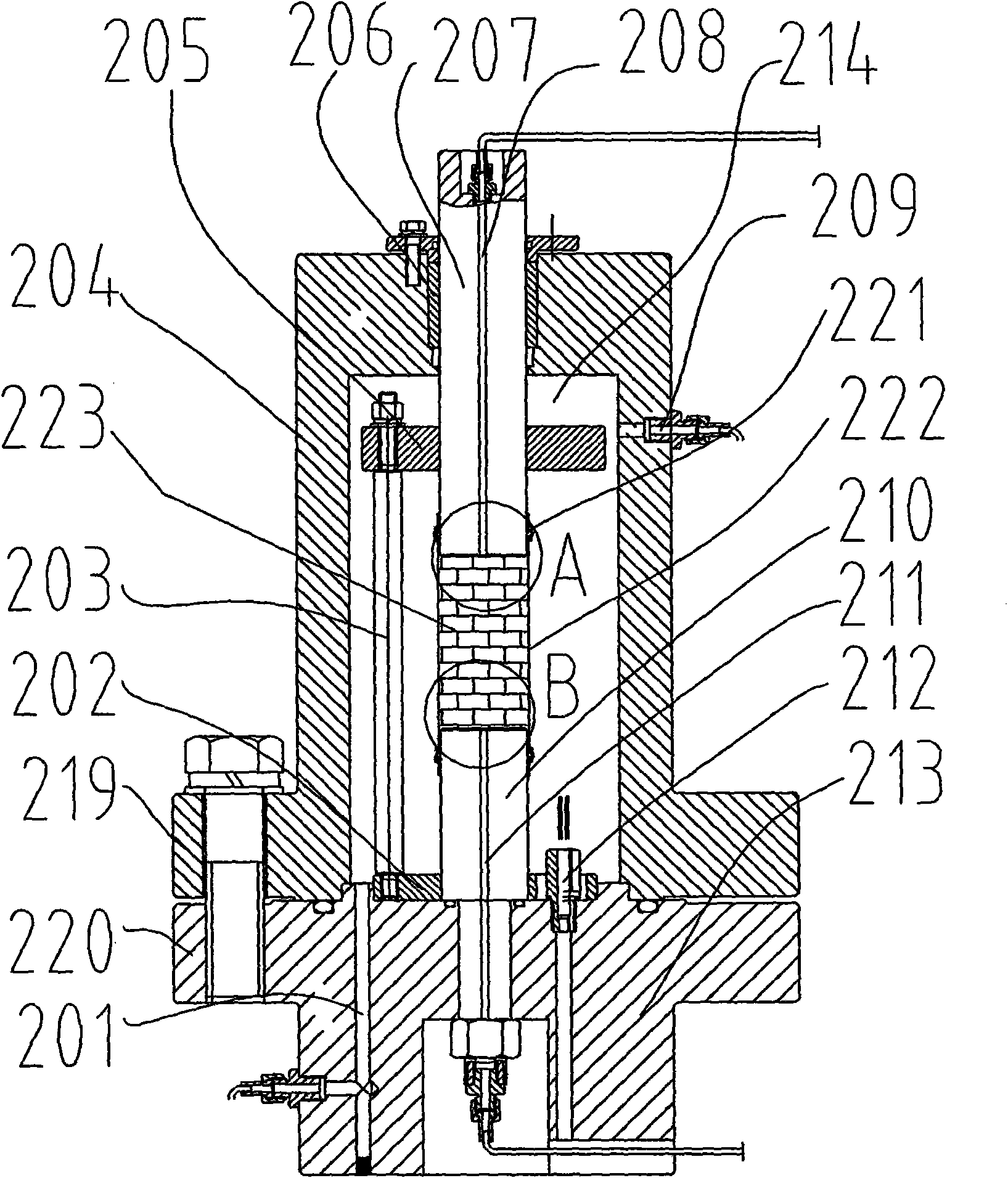

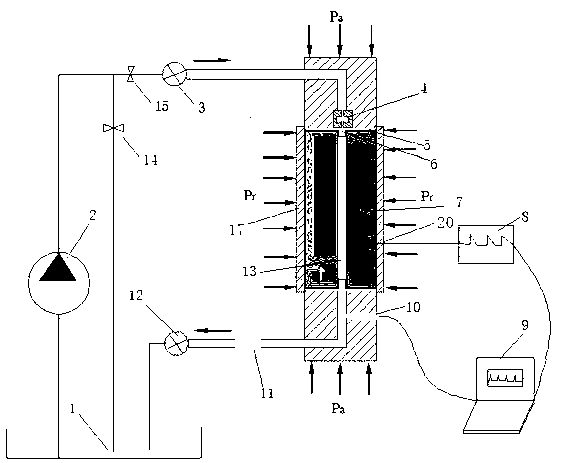

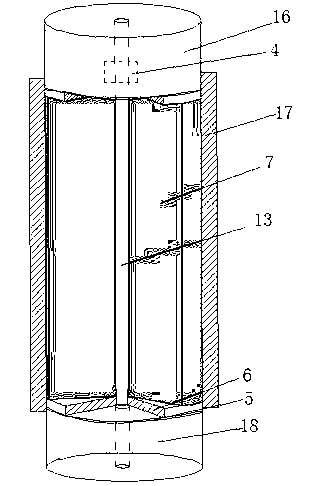

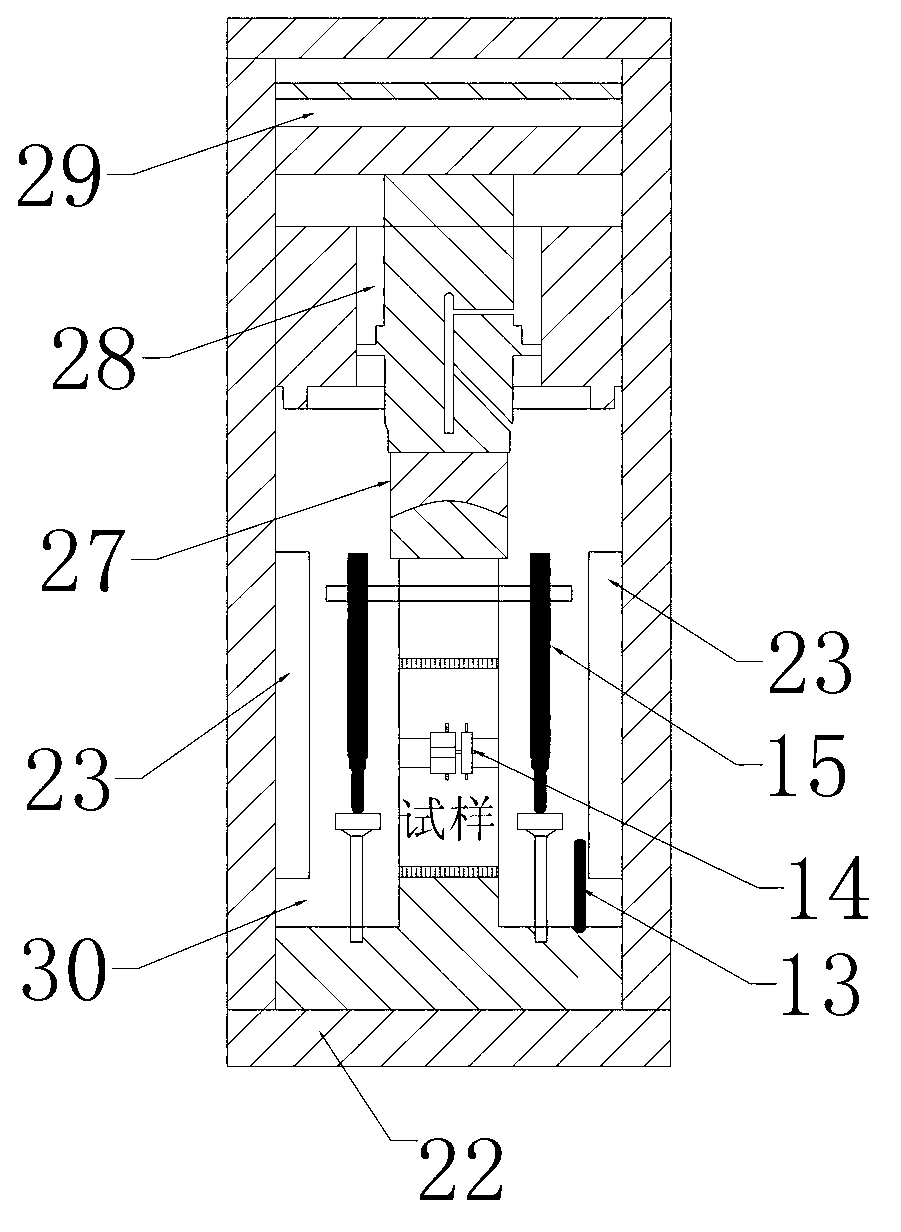

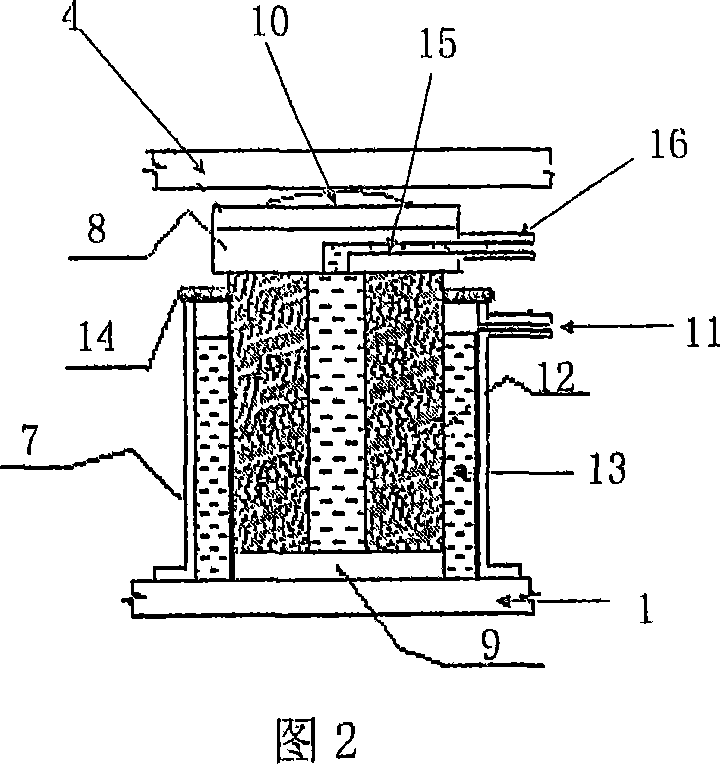

Fluid-solid-heat coupling triaxial servo percolation device for gas-contained coal

InactiveCN101634621APrecise permeability measurementImprove breathabilitySurface/boundary effectMaterial strength using tensile/compressive forcesWater bathsAxial compression

The invention discloses a fluid-solid-heat coupling triaxial servo percolation device for gas-contained coal, comprising a lifting stand, a hydraulic servo control system, an axial loading device mounted at the top of the lifting stand and a triaxial pressure chamber connected with the lower end of the axial loading device. A thermostatic water tank is arranged below the triaxial pressure chamber; a movable worktable is arranged above the thermostatic water tank; the lower end of the triaxial pressure chamber is arranged on the movable worktable; heating tubes are arranged in the thermostatic water tank; and a water inlet valve, a water drain valve and a water-bath circulating water pump are arranged outside the thermostatic water tank and are communicated with the thermostatic water tank. In the hydraulic servo control system, an axial compression loading oil pump is communicated with an oil inlet and an oil outlet by a pipeline, and a peripheral compression loading oil pump is communicated with an oil intake / drain hole by a pipeline. The fluid-solid-heat coupling triaxial servo percolation device for gas-contained coal can carry out the research of gas-contained coal percolation tests in states, such as different terrestrial stresses, different gas pressures, different temperatures, and the like and the distortion and failure characteristics of the gas-contained coal in a percolation process.

Owner:CHONGQING UNIV

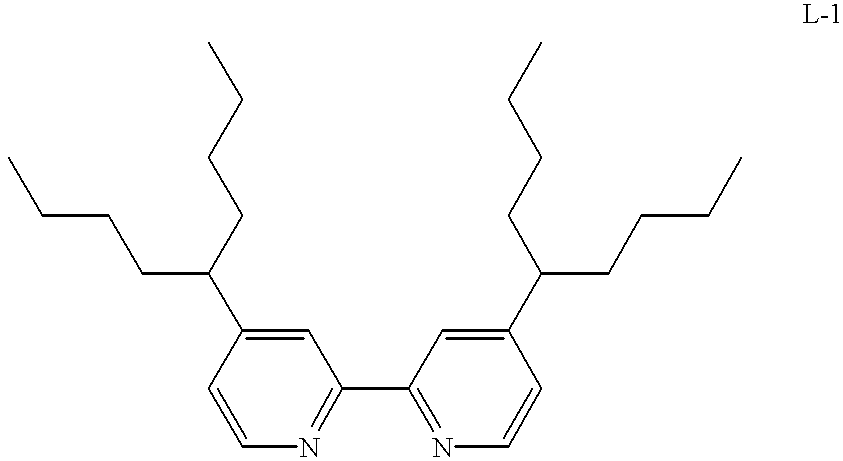

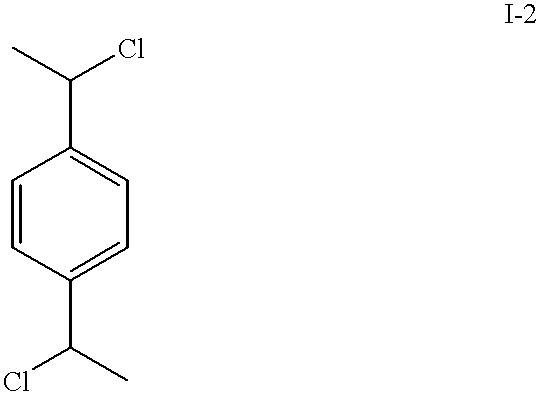

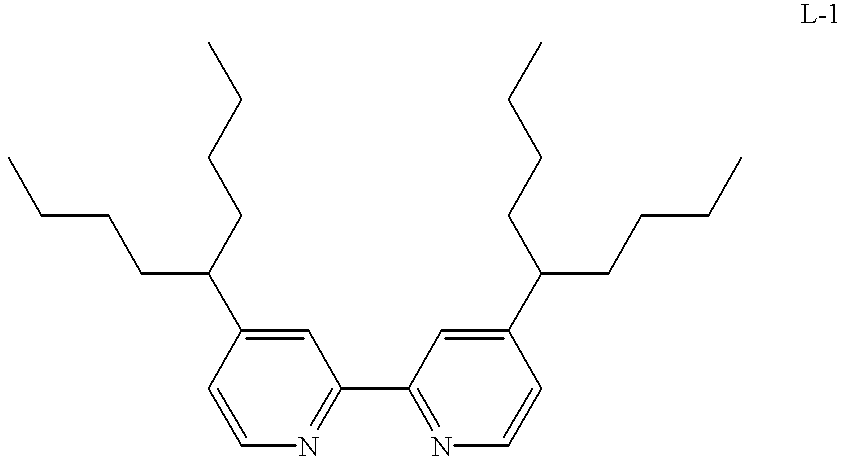

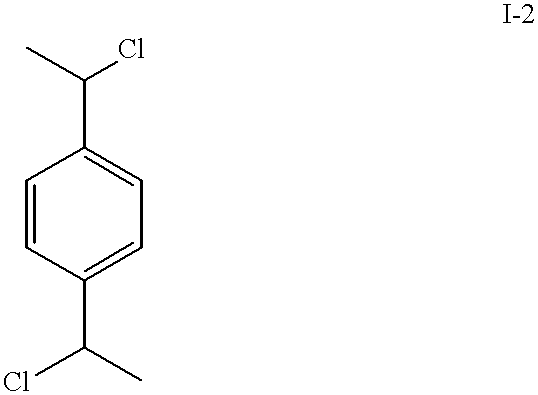

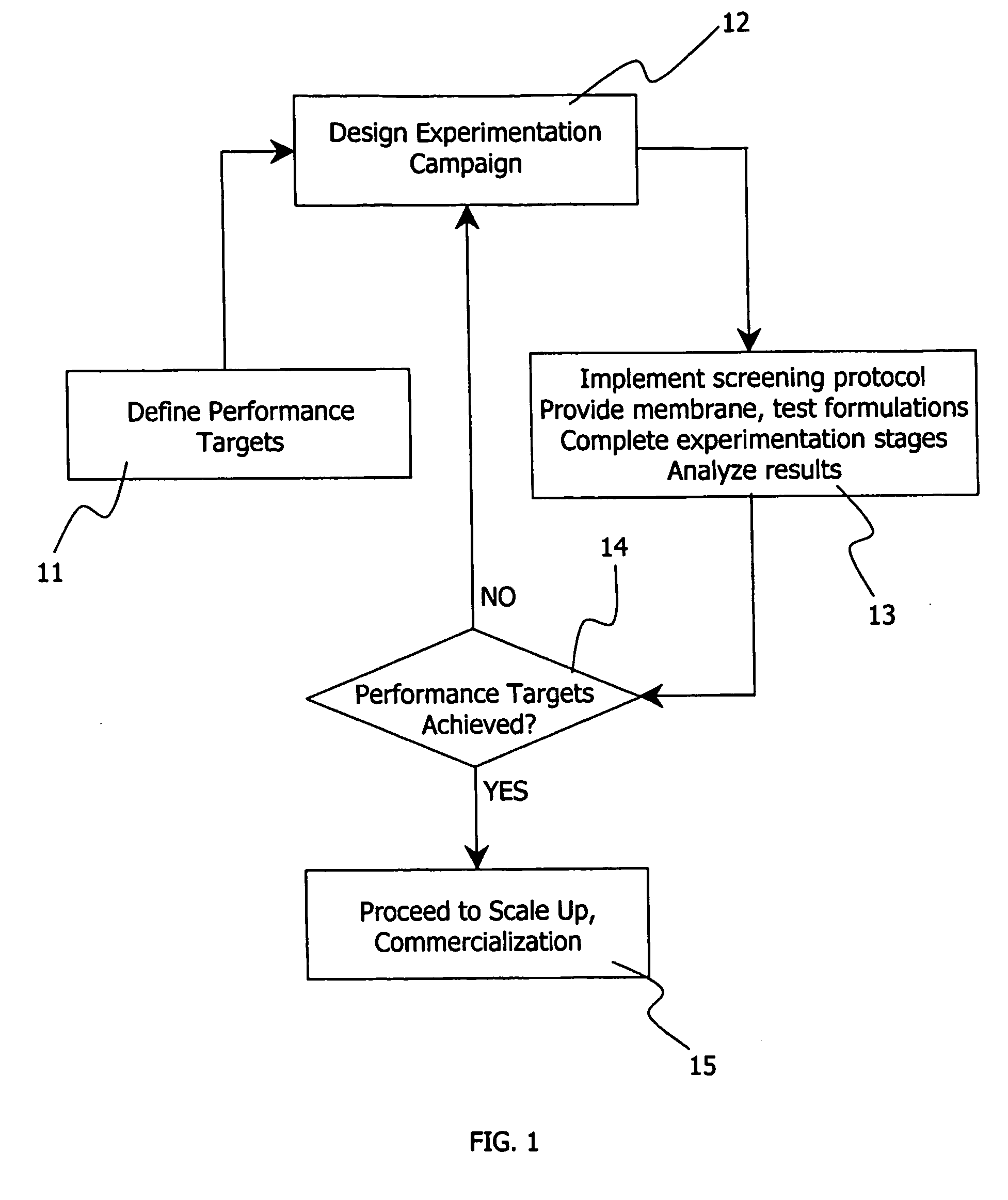

Rapid characterization of polymers for combinatorial, analytical and process control applications

InactiveUS20010027949A1Avoid backlogImprove throughputSequential/parallel process reactionsSamplingFlow injection analysisPolymer

Rapid characterization and screening of polymer samples to determine average molecular weight, molecular weight distribution and other properties is disclosed. Rapid flow characterization systems and methods, including liquid chromatography and flow-injection analysis systems and methods are preferably employed. High throughput, automated sampling systems and methods, high-temperature characterization systems and methods, and rapid, indirect calibration compositions and methods are also disclosed. The described methods, systems, and devices have primary applications in combinatorial polymer research and in industrial process control.

Owner:INTERMOLECULAR

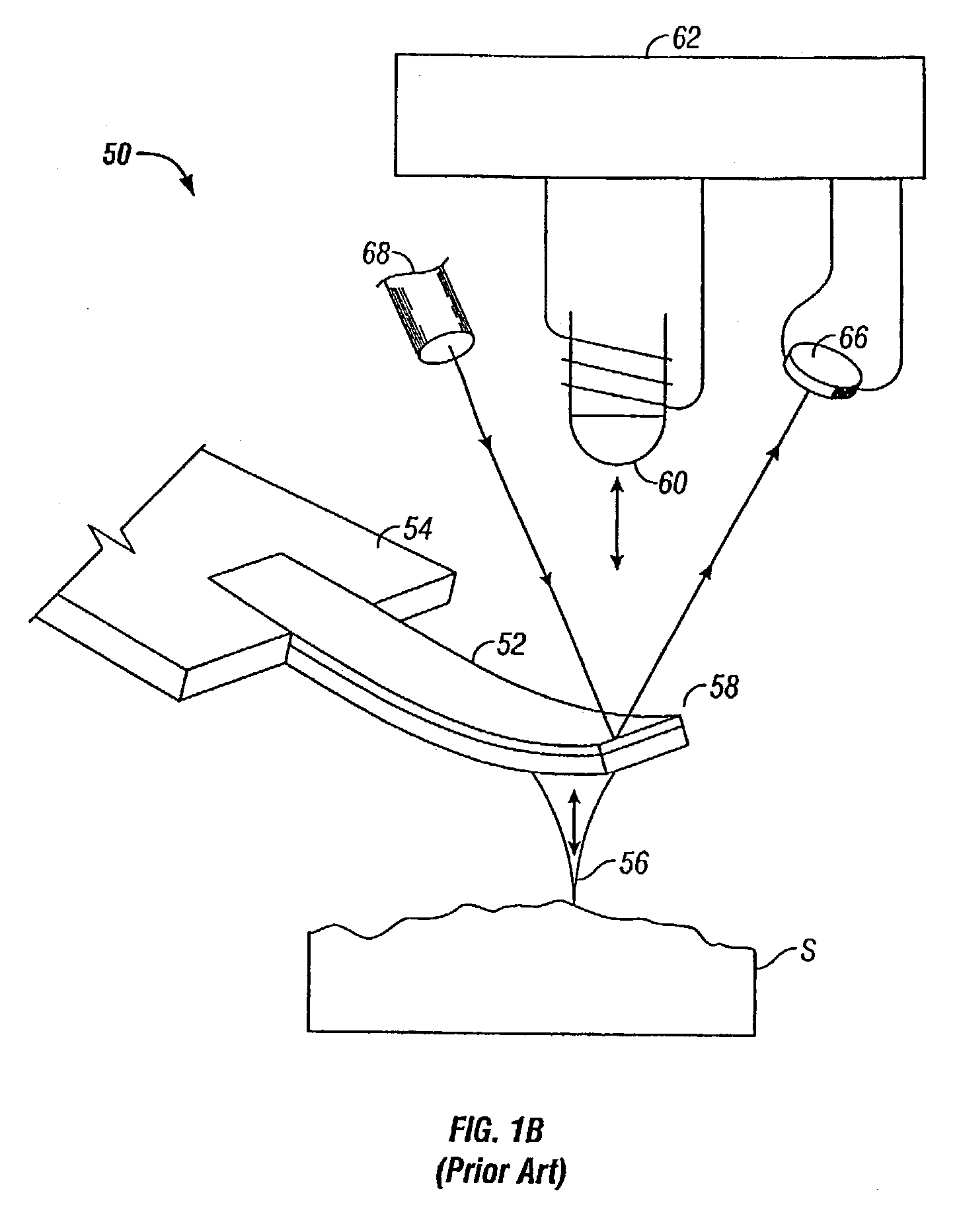

Liquid cell and passivated probe for atomic force microscopy and chemical sensing

ActiveUS20050199047A1Material analysis using sonic/ultrasonic/infrasonic wavesSurface/boundary effectAtomic force microscopyLiquid medium

The invention provides a liquid cell for an atomic force microscope. The liquid cell includes a liquid cell housing with an internal cavity to contain a fluid, a plurality of conductive feedthroughs traversing the liquid cell housing between the internal cavity and a dry side of the liquid cell, a cantilevered probe coupled to the liquid cell housing, and a piezoelectric drive element disposed on the cantilevered probe. The cantilevered probe is actuated when a drive voltage is applied to the piezoelectric drive element through at least one of the conductive feedthroughs. A method of imaging an object in a liquid medium and a method of sensing a target species with the liquid cell are also disclosed.

Owner:BOARD OF RGT NEVADA SYST OF HIGHER EDUCATION ON BEHALF OF THE UNIV OF NEVADA RENO

Experimental device and method for pulse hydrofracture transforming of shale gas storing layer

ActiveCN103196762AMonitor developments in real timeGenerating type of real-time monitoringSurface/boundary effectMaterial strength using repeated/pulsating forcesImpulse frequencyFracturing fluid

The invention relates to an experimental device and method for pulse hydrofracture transforming of a shale gas storing layer. The experimental device comprises a high pressure water pump, a fracturing fluid pond, a filtering device, a waterpower pulse generating device, a triaxial stress loading device, a pressure sensor, a sound emission device, a throttle valve, an overflow valve, a data collection recording system and a core test specimen. The device provided by the invention can simulate the operating environment of a shale sample under main operating parameter such as different pulse pressures and impulse frequencies on a certain confining pressure condition; moreover, the device can monitor a space-time developing rule of cracks and can test permeability change before and after fracture in real time; therefore, an experimental platform is provided for researching pulse hydrofracture of a shale gas storing layer. The experimental device provided by the invention has strong practicality, is easy to assemble, convenient to operate, is compact in structure, and can better imitate fracture damage and permeability change mechanism of a shale sample of the shale gas storing layer under the actions of static pressure and pulse hydrofracture.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

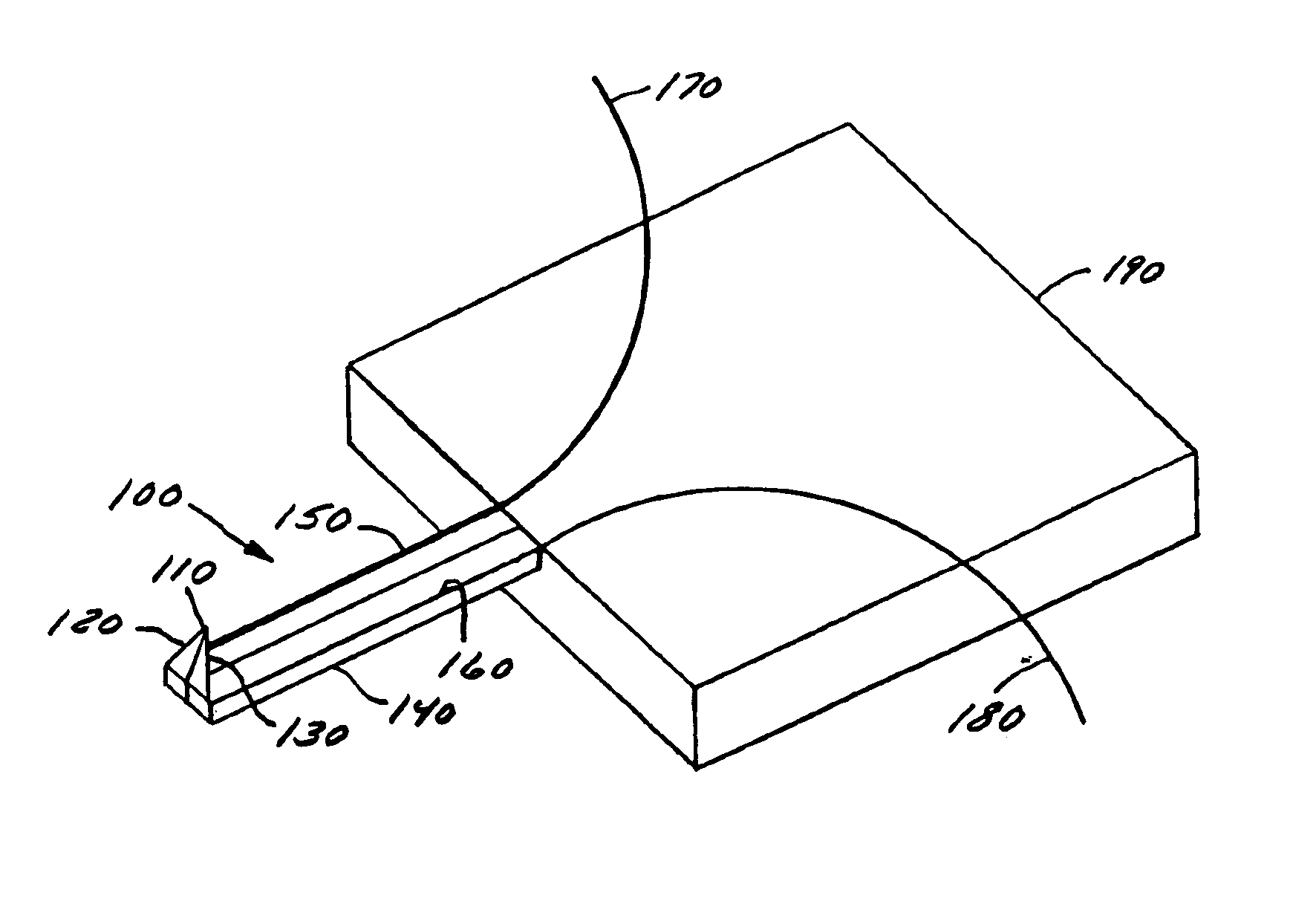

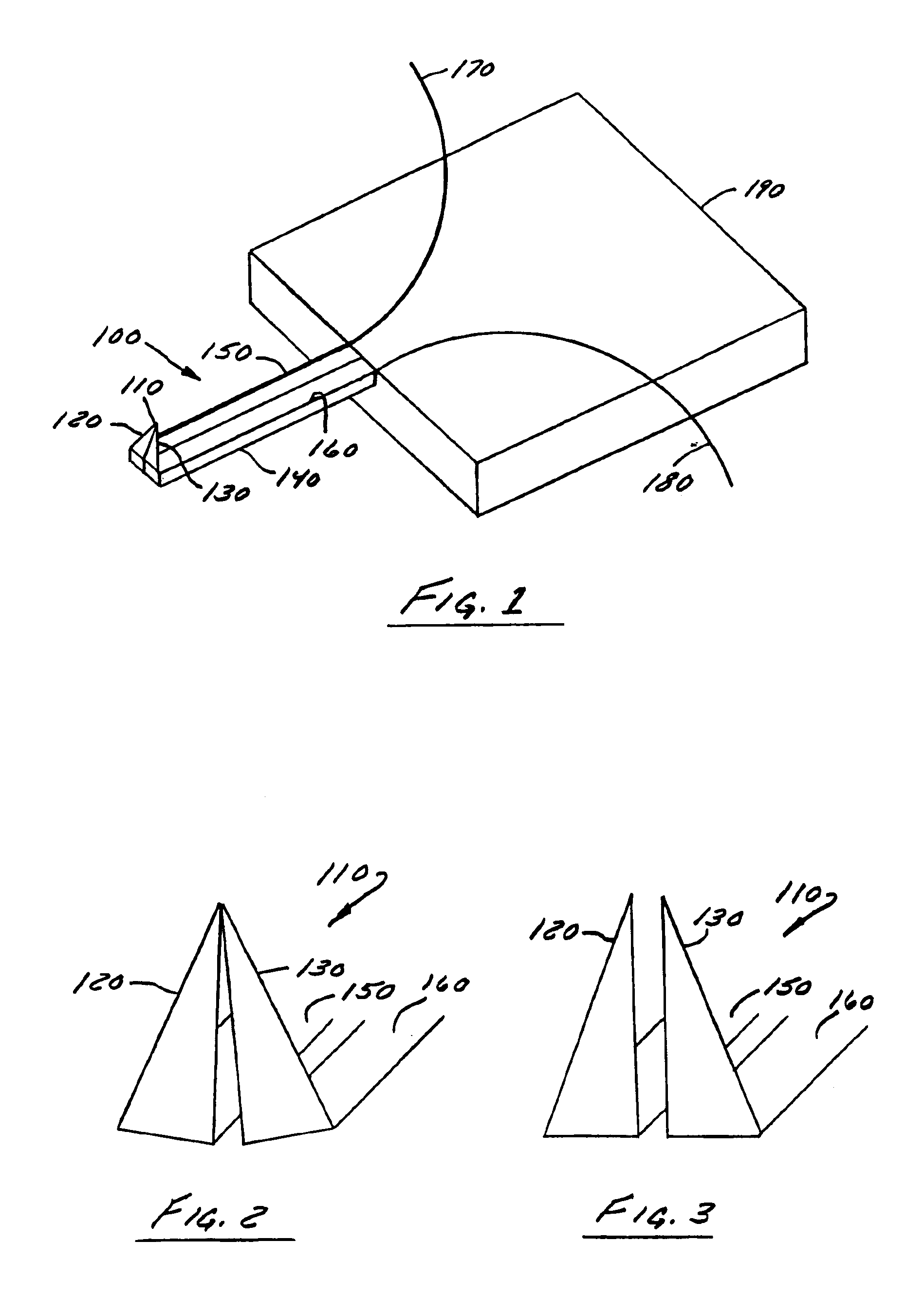

Method and apparatus for manipulating a sample

InactiveUS6862921B2Manipulation is accurateDoes not affect accuracyMaterial analysis using wave/particle radiationSurface/boundary effectCantileverBiomedical engineering

A method and apparatus for manipulating the surface of a sample including a cantilever, a first tip mounted on the cantilever, and a second tip mounted on the cantilever, the first and the second tip being configured to combine to form an imaging probe and to separate to form a manipulation probe. The first and second tips are configured to form a first position characterized in that the tips combine to form an imaging tip and the first and the second tip are configured to form a second position characterized in that the tips separate to manipulate particles on a surface of a sample. The tips can be configured to form the first position when a voltage is applied across the tips, and preferable extend downwardly from the cantilever substantially perpendicular thereto.

Owner:BRUKER NANO INC

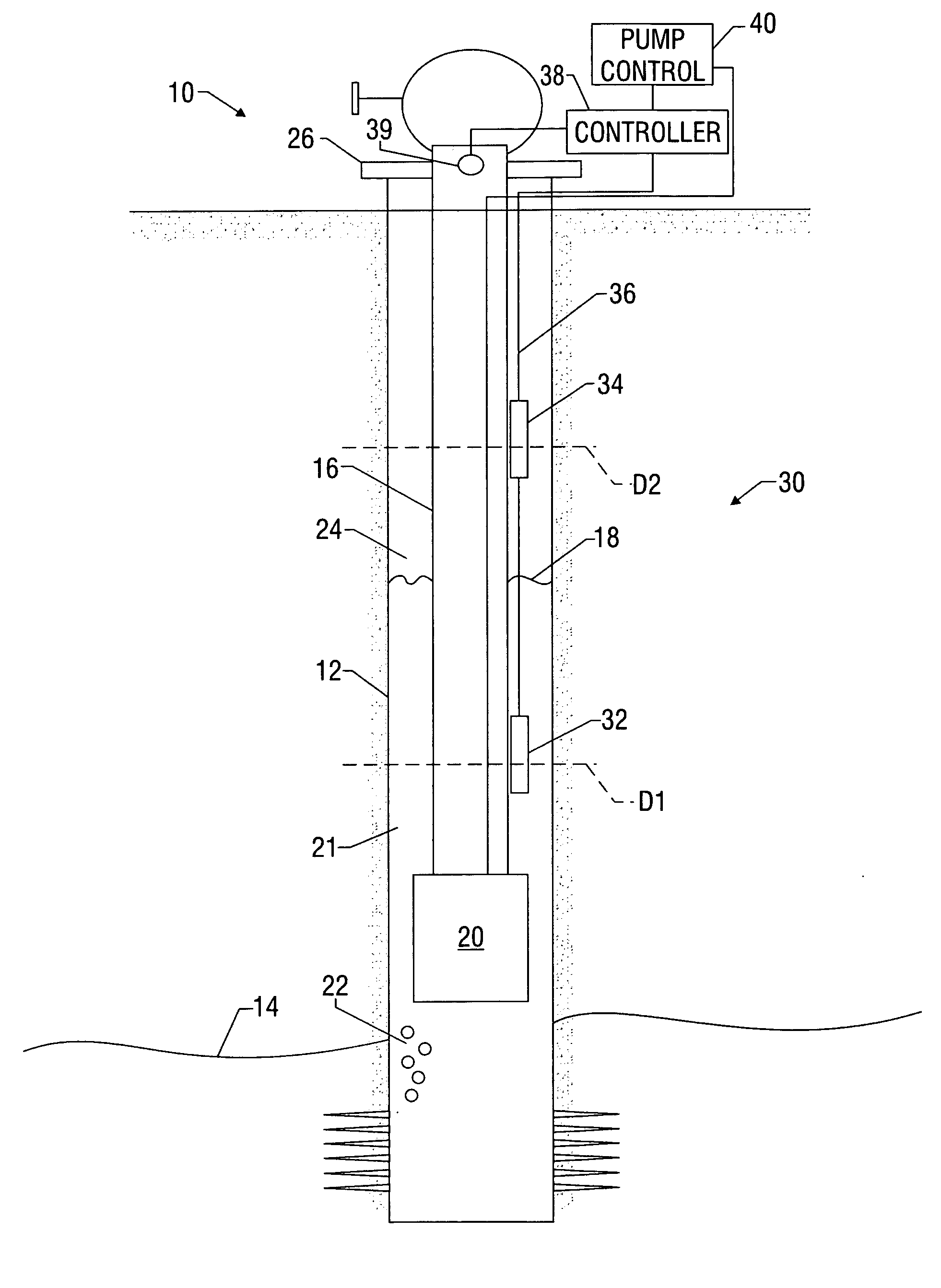

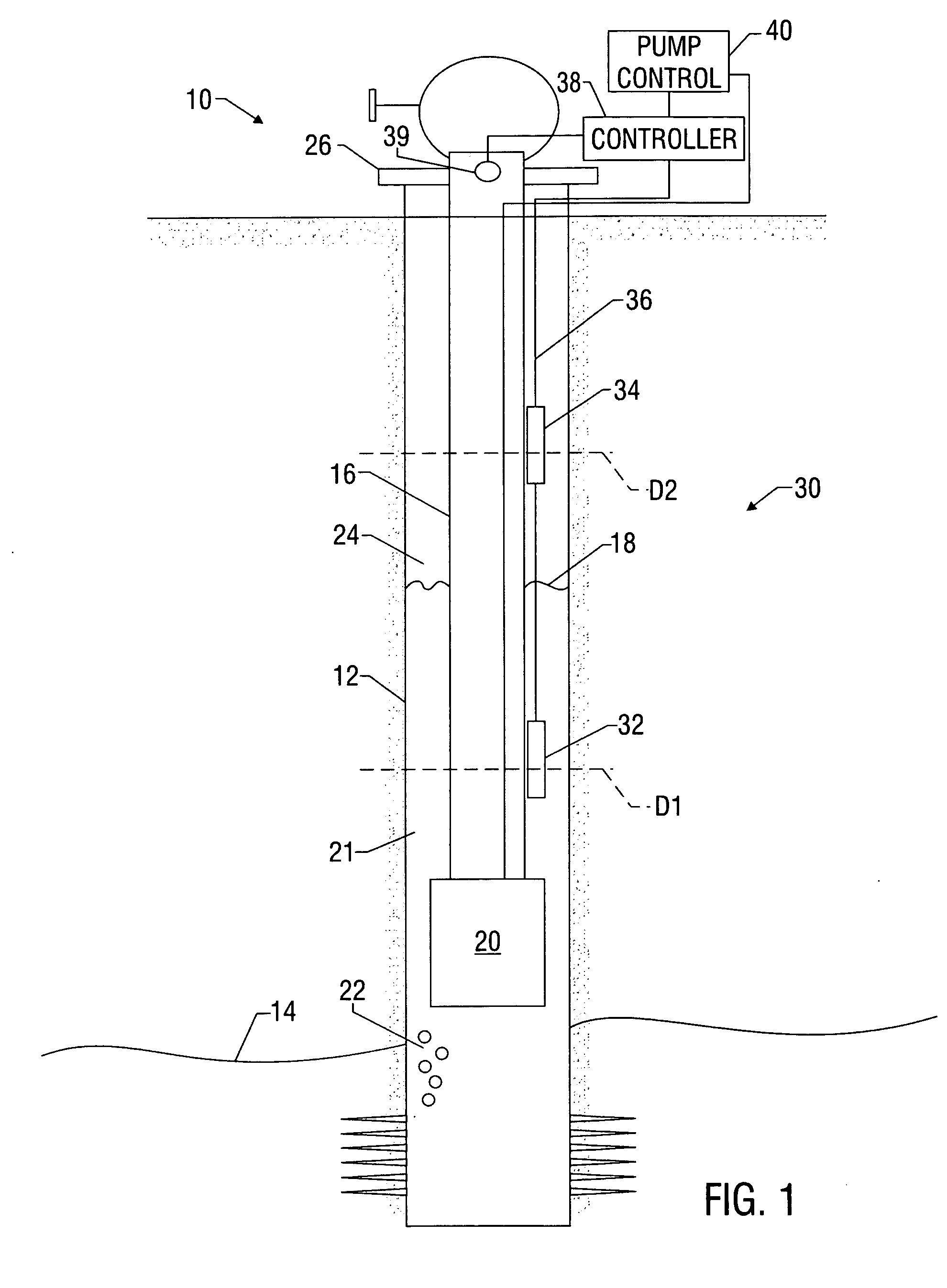

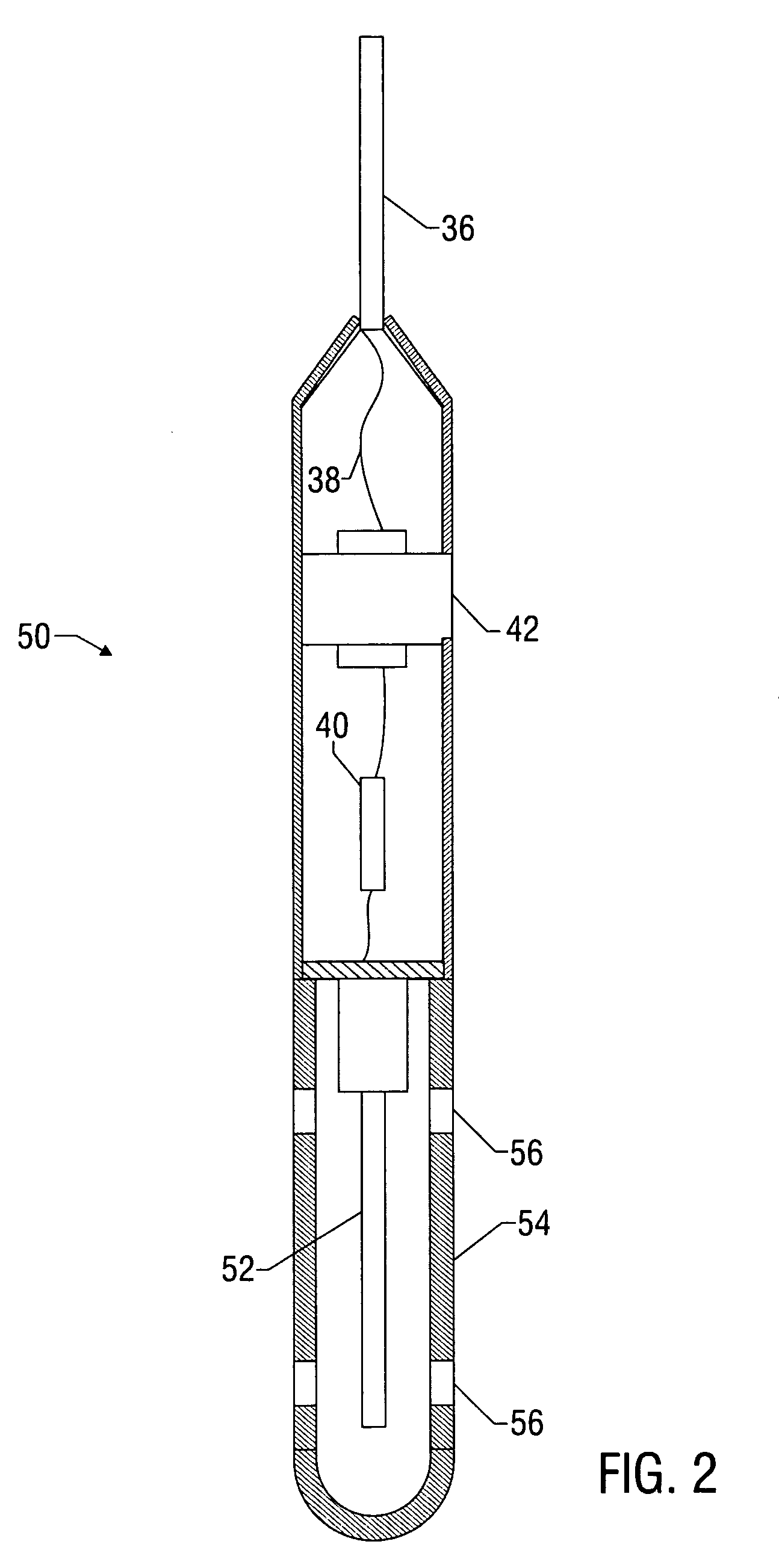

Systems and methods for controlling flow control devices

A device for determining a location of an interface between a first fluid and second fluid includes a non-mechanical sensor that measures a selected parameter of interest relating to the fluid surrounding the sensor (“the surrounding fluid”) and a processor for processing the sensor measurements. The non-mechanical sensor measures a parameter relating to the surround fluid without physically co-acting with the surrounding fluid. Exemplary parameters such as thermal properties, electrical properties, fluid properties, and magnetic properties can be measured. The processor is programmed to process the sensor measurements to identify one or more characteristics in the measurements that can indicate the nature of the fluid being measured and thereby determine the location of the interface. The determined location can be used to operate a downhole device such as a pump, to provide real-time monitoring of well conditions, to record data for long-term reservoir characterization, or to actuate an alarm.

Owner:CORE LAB CANADA

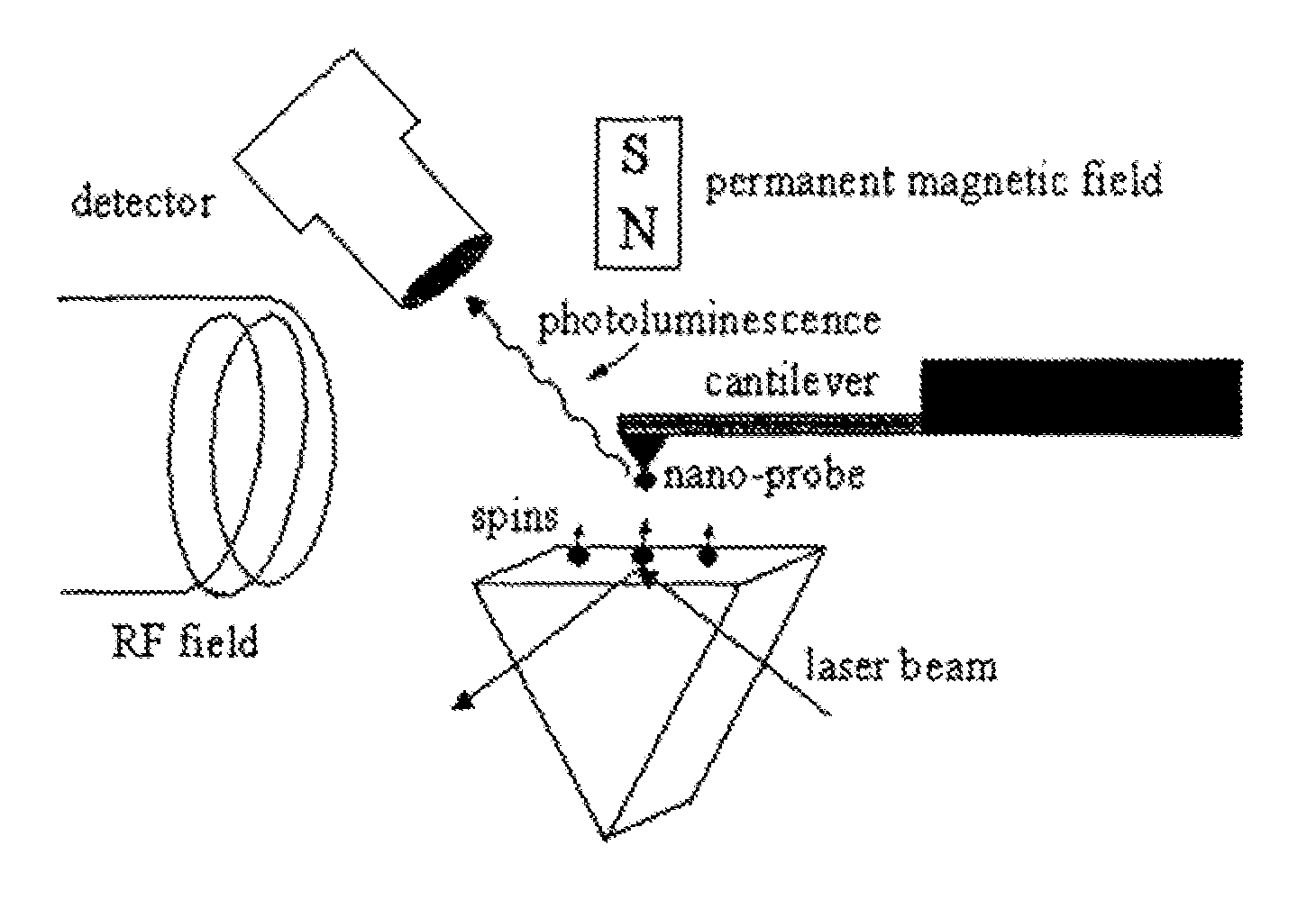

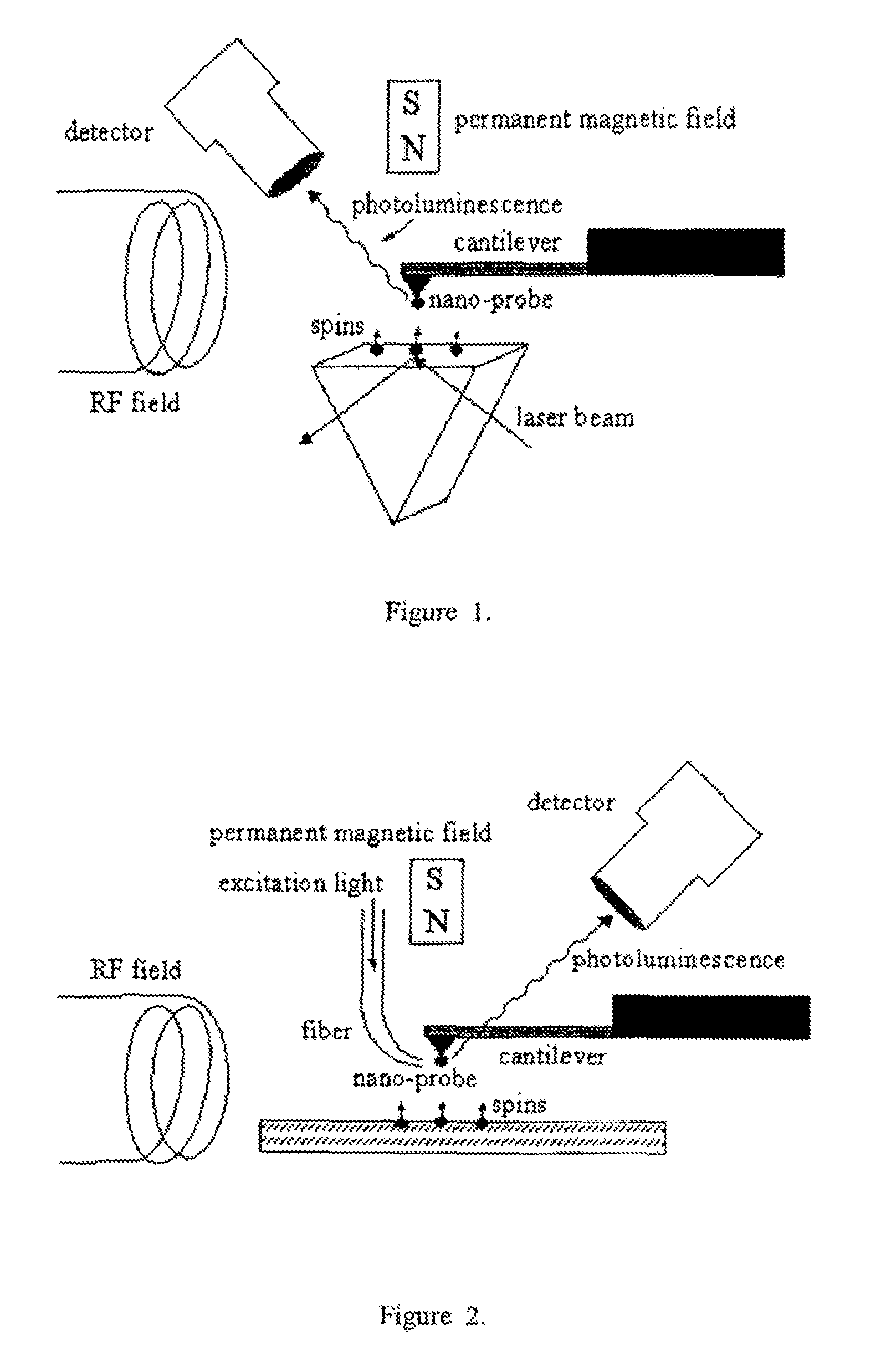

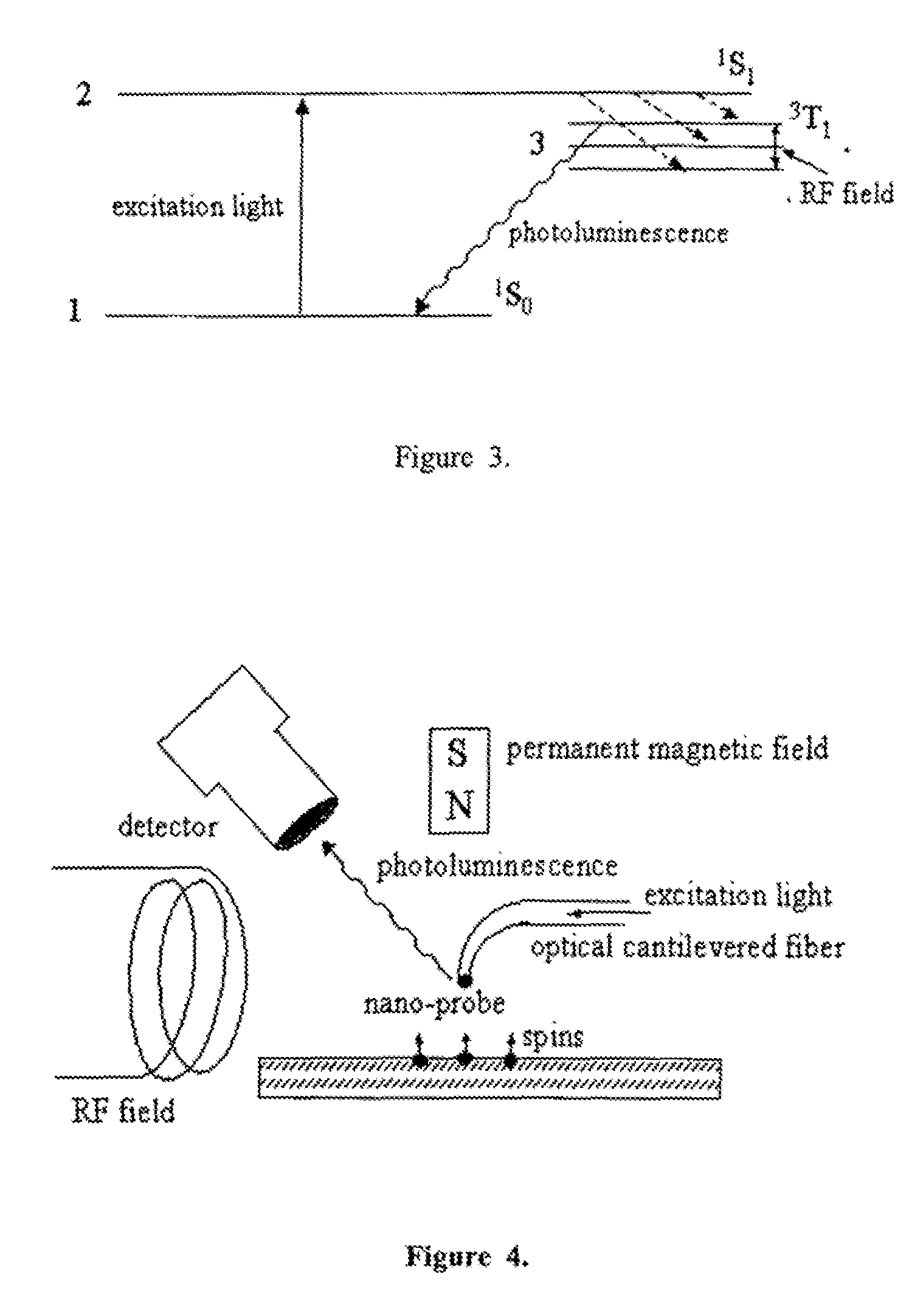

Spin microscope based on optically detected magnetic resonance

InactiveUS7608820B1NanomagnetismMaterial analysis using wave/particle radiationMagnetic force microscopePhotoluminescence

The invention relates to scanning magnetic microscope which has a photoluminescent nanoprobe implanted in the tip apex of an atomic force microscope (AFM), a scanning tunneling microscope (STM) or a near-field scanning optical microscope (NSOM) and exhibits optically detected magnetic resonance (ODMR) in the vicinity of unpaired electron spins or nuclear magnetic moments in the sample material. The described spin microscope has demonstrated nanoscale lateral resolution and single spin sensitivity for the AFM and STM embodiments.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

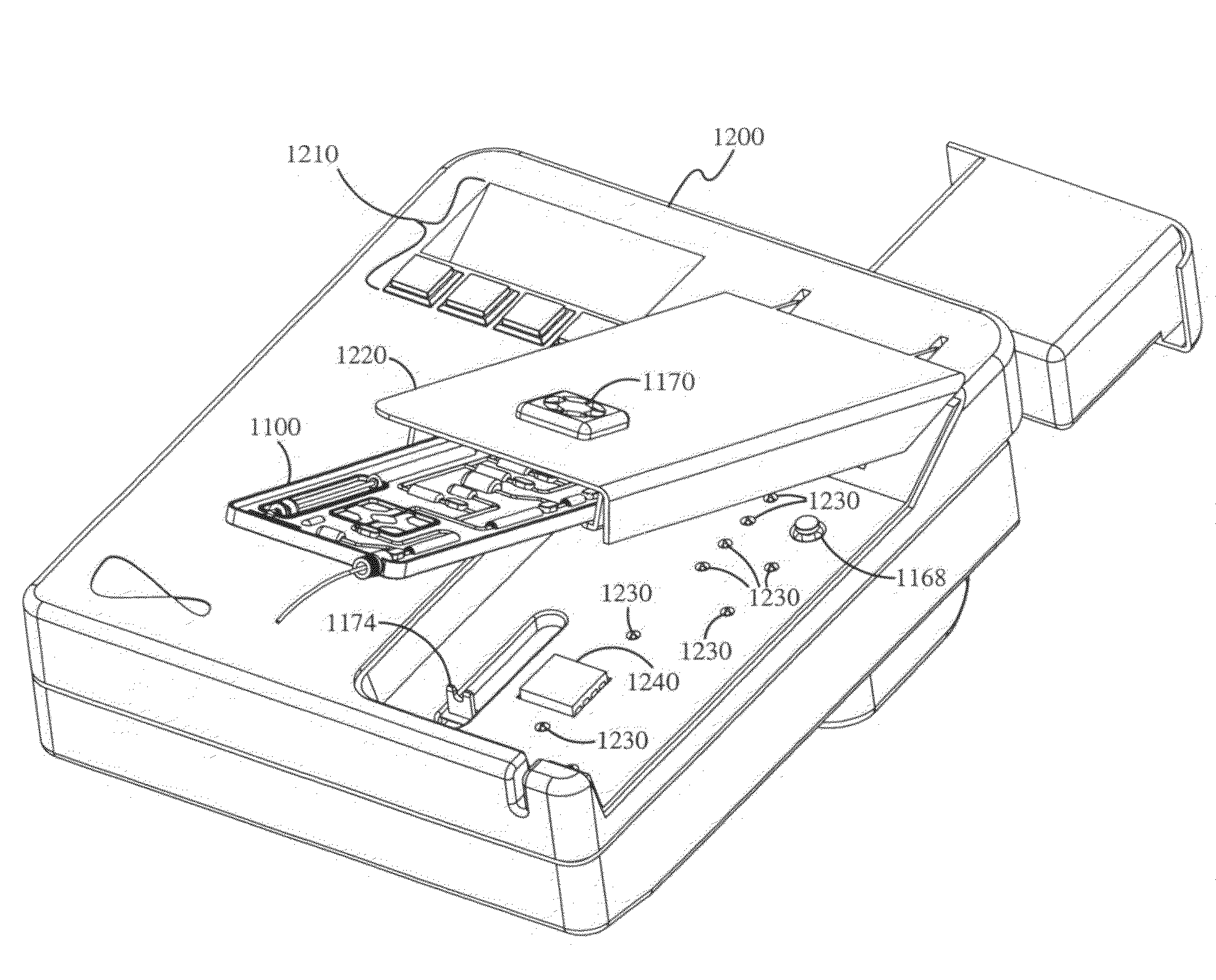

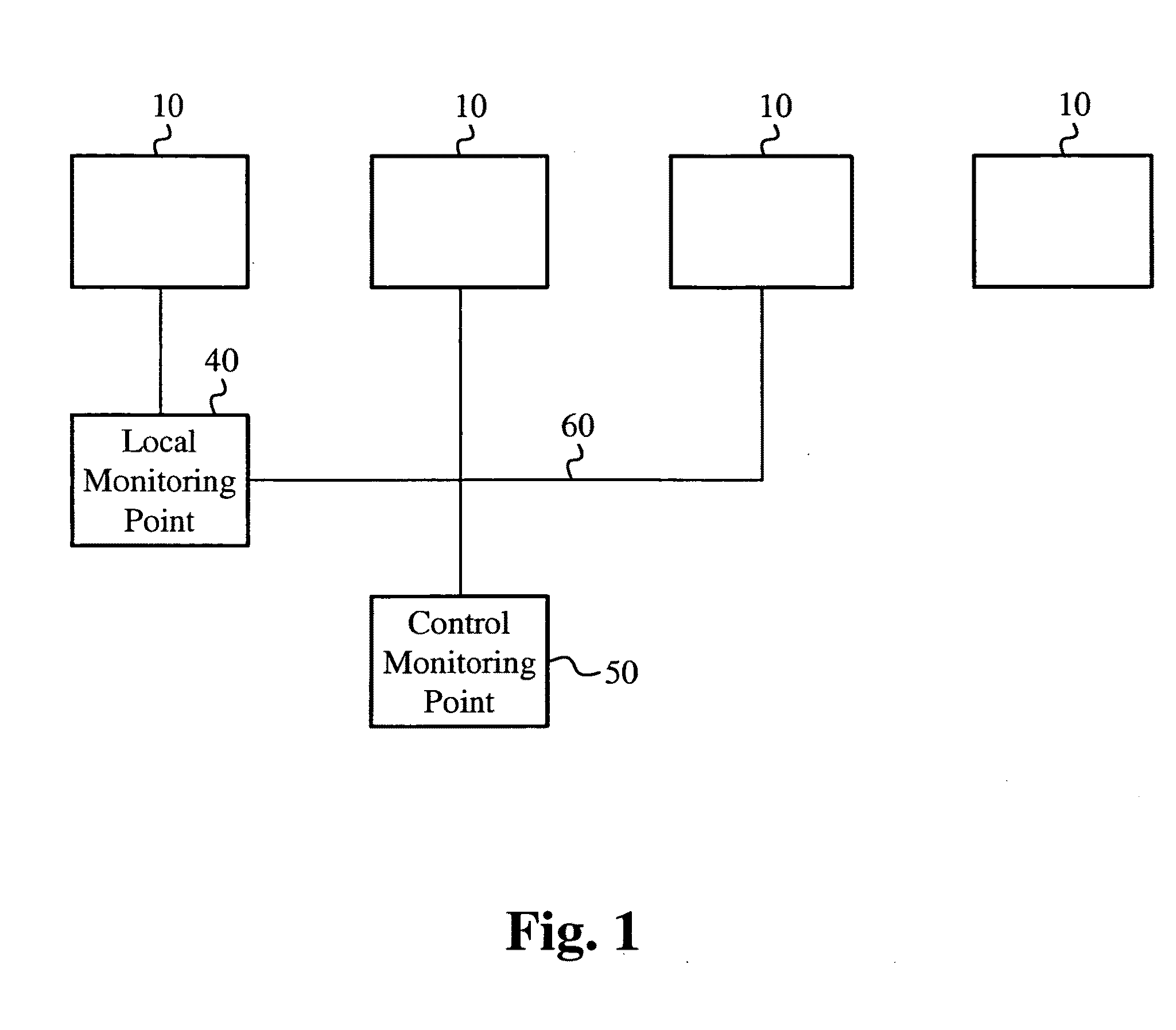

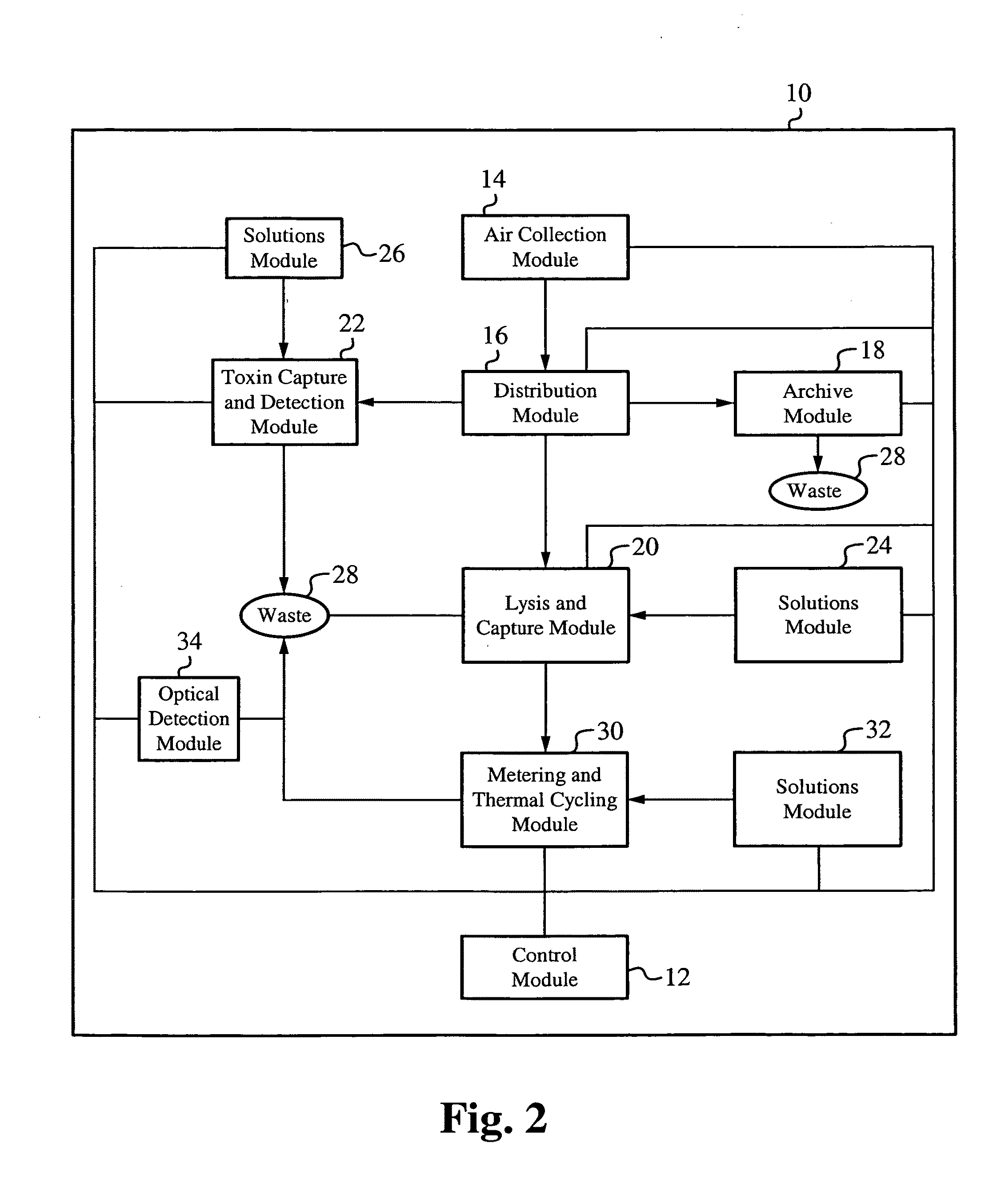

Sample preparation apparatus

InactiveUS20100050749A1Bioreactor/fermenter combinationsBiological substance pretreatmentsLysisAnalyte

A capture and purification apparatus is configured as a stand-alone apparatus or as part of a larger system. The capture and purification apparatus can be configured as a microfluidic cartridge that includes microfluidic circuitry and individually controlled valves. The microfluidic cartridge can be configured to function independently, or can be configured to be coupled to a separate instrument that provides the actuation to perform the capture and purification process. The capture and purification apparatus is configured as a volume-driven system that applies single-direction valves, a single fluid driving device, and fluid lines to control and discretely direct fluid flow within a full-loaded fluidic system. Such control enables various fluid sample processing techniques to be performed including, but not limited to, lysis, thermal cycling, and / or target analyte capture and purification, for example using a combination of ion-exchange chromatography and size-exclusion chromatography (SEC).

Owner:MICROFLUIDIC SYST

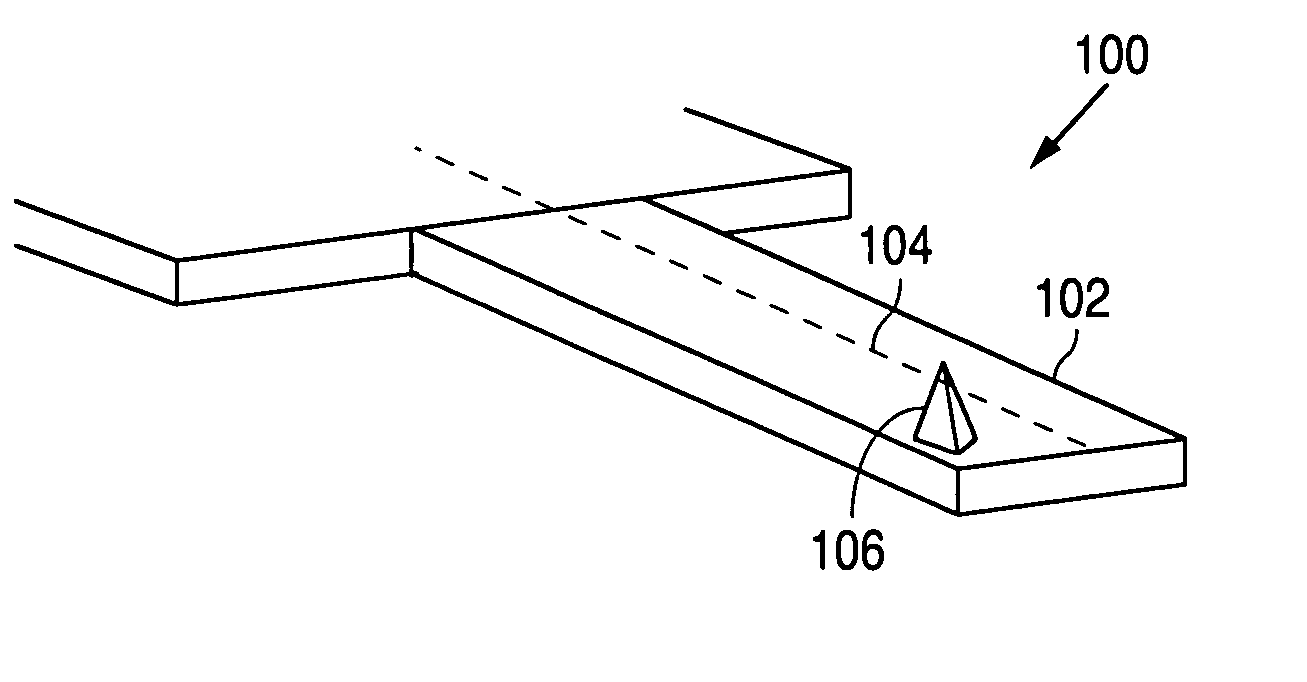

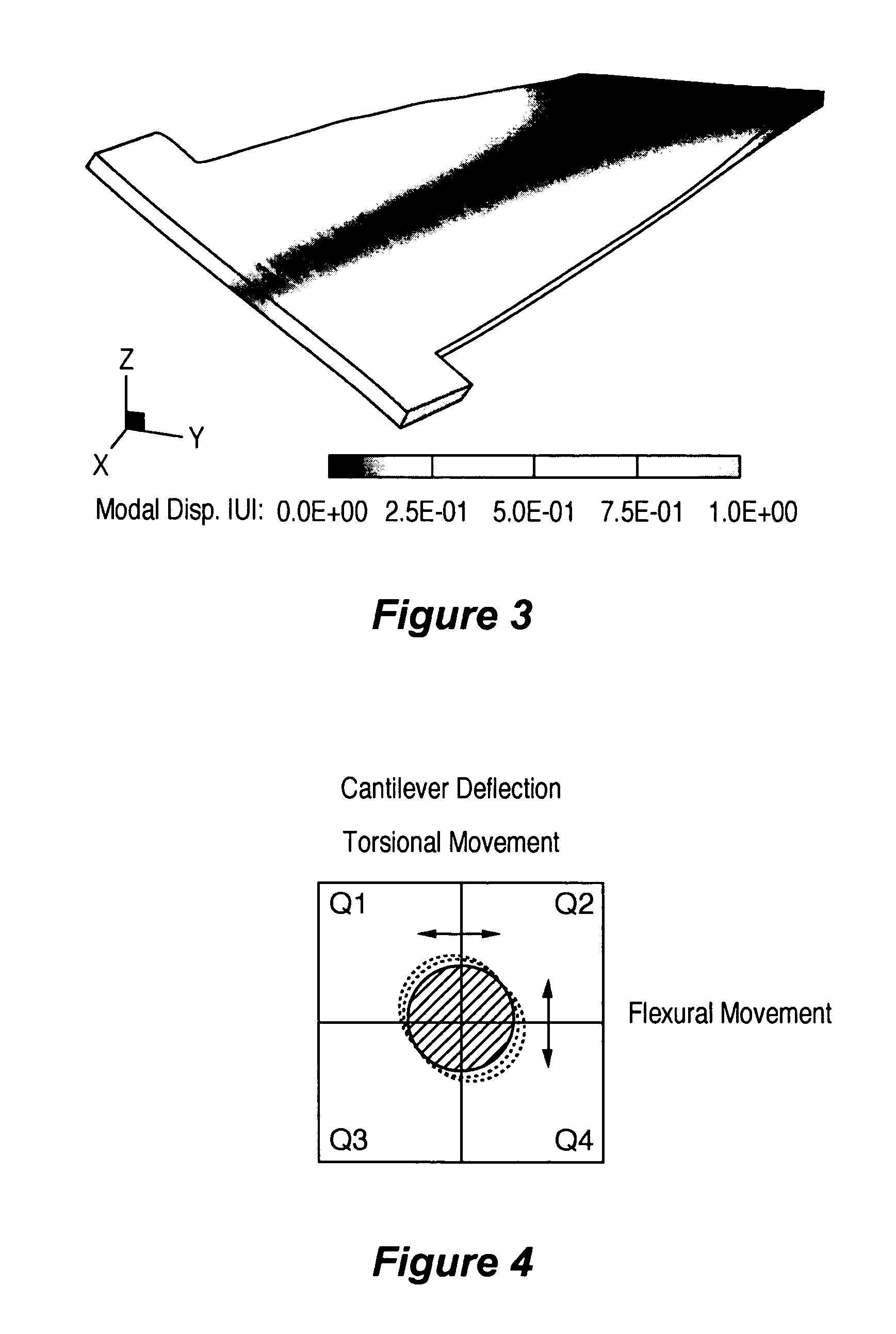

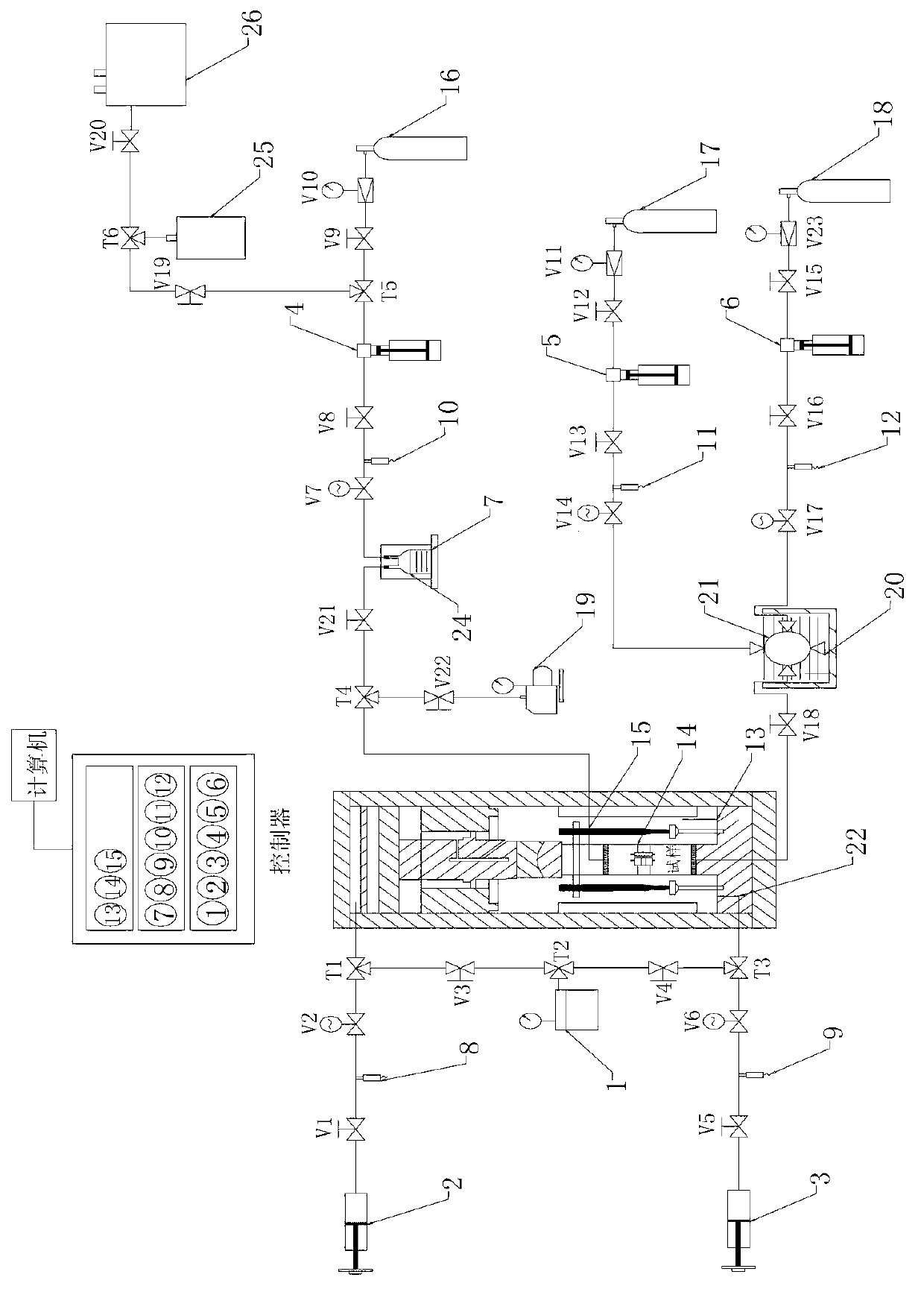

Torsional harmonic cantilevers for detection of high frequency force components in atomic force microscopy

InactiveUS7089787B2Fast response timeQuick checkForce measurement by measuring frquency variationsSurface/boundary effectAtomic force microscopyHarmonic

A cantilever for the use in atomic force microscopy includes a cantilever arm having a fixed end being attached to a base member and a free end where the cantilever arm has a first shape and an axis of torsion associated with the first shape, and a probe tip projecting from the cantilever arm near the free end where the probe tip is positioned in an offset displacement from the axis of torsion. Alternately, the cantilever arm has a first shape selected to tune a torsional resonance frequency of a selected torsional mode or the fundamental flexural resonance frequency of the fundamental mode so that the torsional resonance frequency and the fundamental flexural resonance frequency has an integer ratio. In this manner, the torsional motion of the torsional harmonic cantilever at that harmonic frequency will be largely enhanced by the corresponding torsional resonance.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

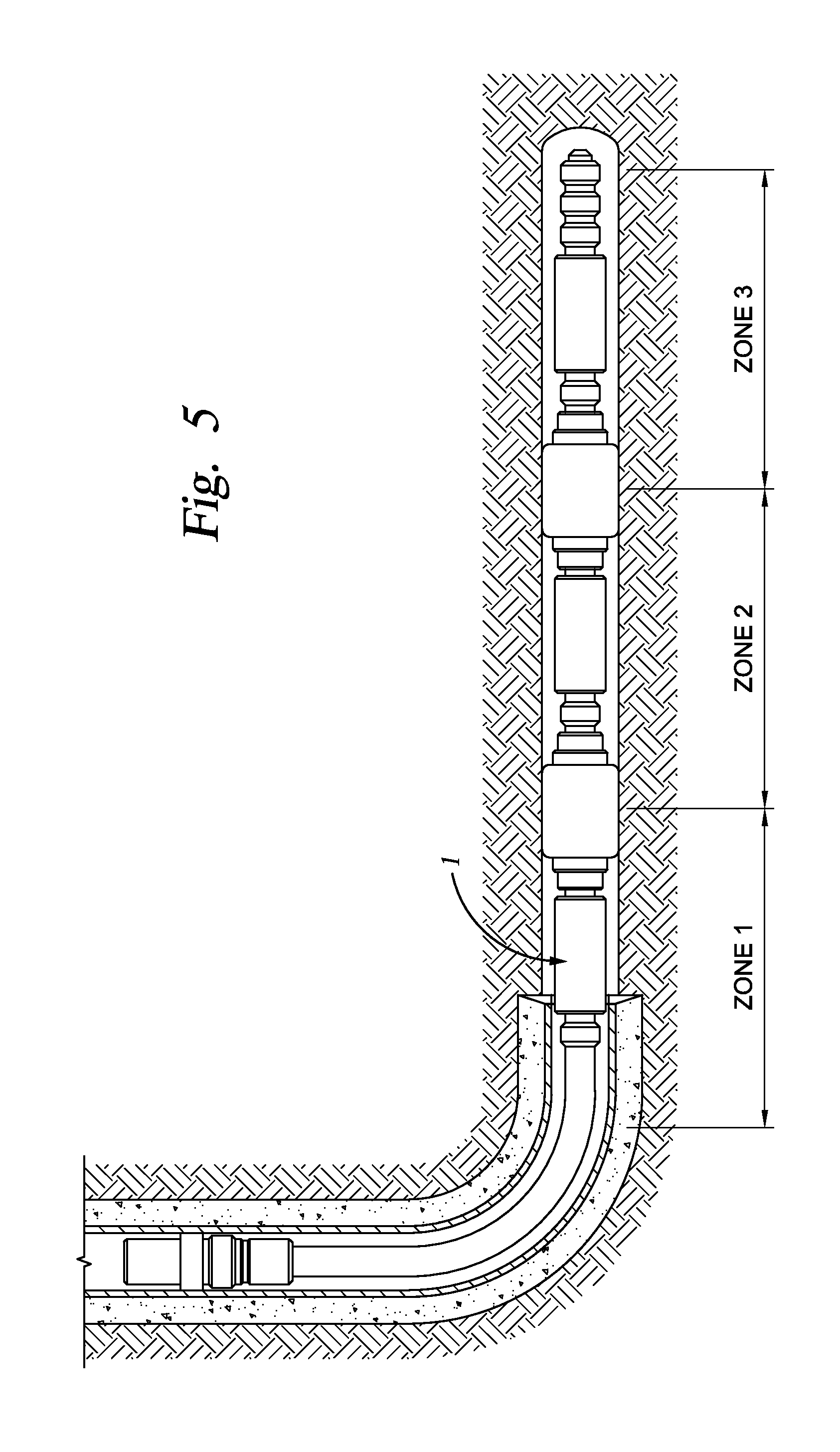

Device and method for gas bearing shale-seepage-temperature coupling and displacement experiment

ActiveCN103278428AEnables permeability determinationImprove stabilitySurface/boundary effectMaterial strength using tensile/compressive forcesRock engineeringAxial pressure

The invention belongs to the field of rock engineering, and in particular relates to a device and a method for a gas bearing shale-seepage-temperature coupling and displacement experiment. The experimental device comprises a triaxial pressure cavity, an axial pressure loading system, a confining pressure loading system, an upstream gas pressure loading system, an upstream liquid pressure loading system, a downstream gas pressure loading and collecting system, a downstream liquid collecting system, a multi-component mixed gas collecting system, a vacuumizing device, a heating system and a data collection control system. The experimental method comprises the following steps of: fixing a test piece; applying confining pressure; applying axial pressure; heating; vacuumizing; applying upstream liquid pressure (or pre-saturated methane); applying upstream gas pressure (or applying upstream gas pressure); injecting multi-phase mixed fluid (or applying another upstream liquid pressure); performing pre-adsorptive saturation by the test piece (injecting multi-component constant-proportion mixed gas); and collecting. The experimental device can be used for applying triaxial stress to the test piece according to the actual stress condition, and remolding a stress environment according to the fact.

Owner:NORTHEASTERN UNIV

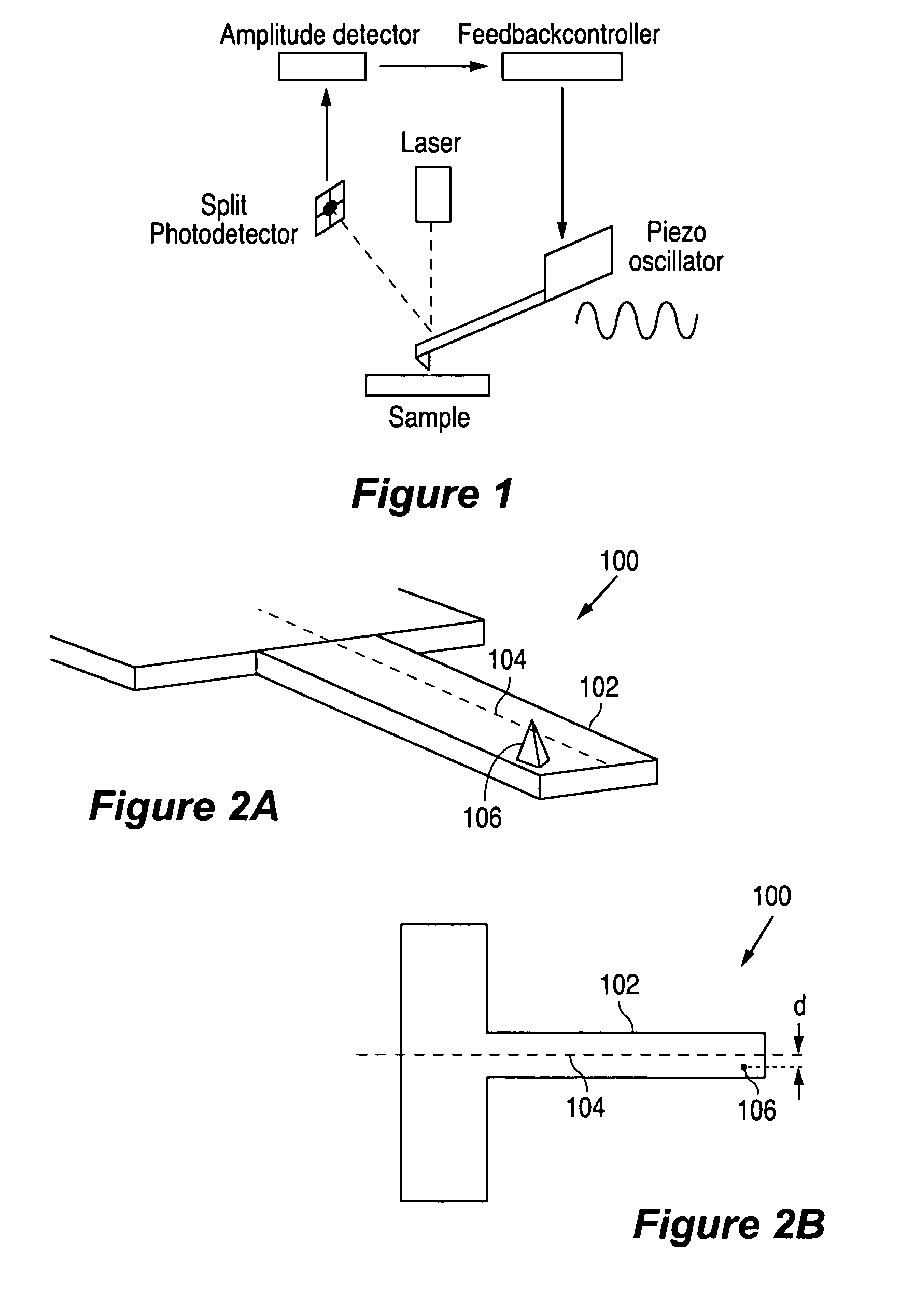

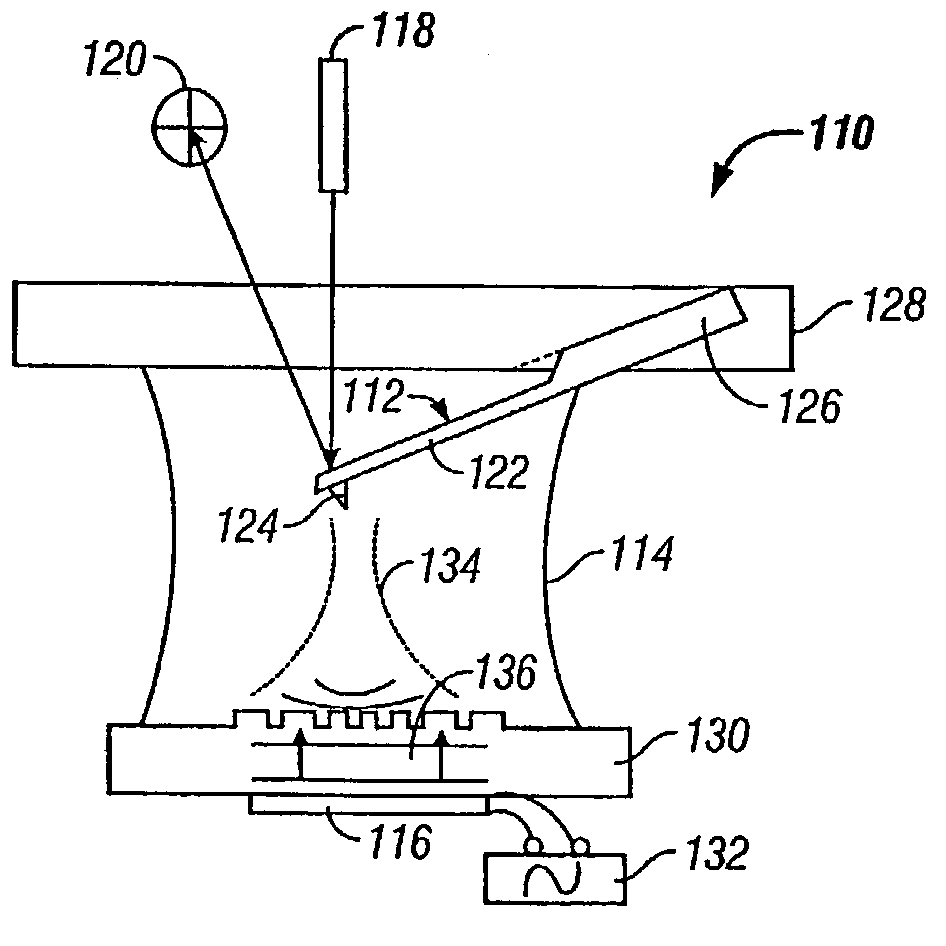

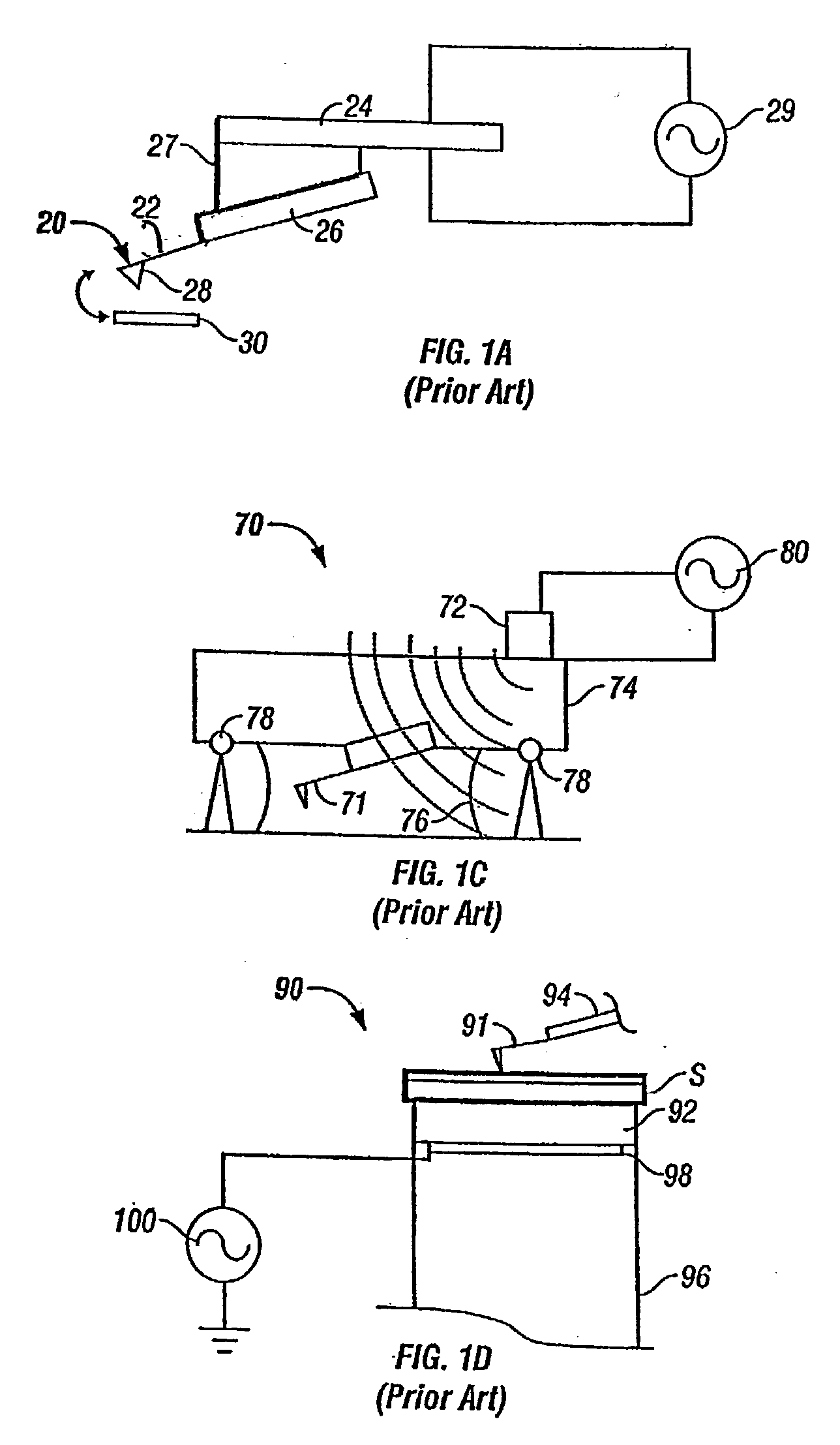

Method and apparatus for the actuation of the cantilever of a probe-based instrument

InactiveUS20040020279A1NanotechAnalysing solids using sonic/ultrasonic/infrasonic wavesResonanceCarrier signal

An electromagnetic drive causes a cantilever of a probe-based instrument to deform flexurally by transmitting a high frequency AC signal through an electromagnetic actuator located in the vicinity of the cantilever. The AC signal preferably is an RF carrier signal having a frequency that is substantially higher than the resonant frequency of the cantilever. The carrier signal may, if desired, be modulated with a lower frequency modulation signal to induce the cantilever to oscillate, preferably at resonance. Alternatively, the carrier signal may be transmitted to the electromagnetic actuator without being modulated in order to deflect the cantilever quasi-statically. Cantilever response can then be monitored either directly in response to the imposition of the electromagnetically induced deformation of the cantilever in response to probe / sample interaction to obtain measurements regarding characteristics of the sample, the environment, and / or the cantilever.

Owner:GEORGIA TECH RES CORP

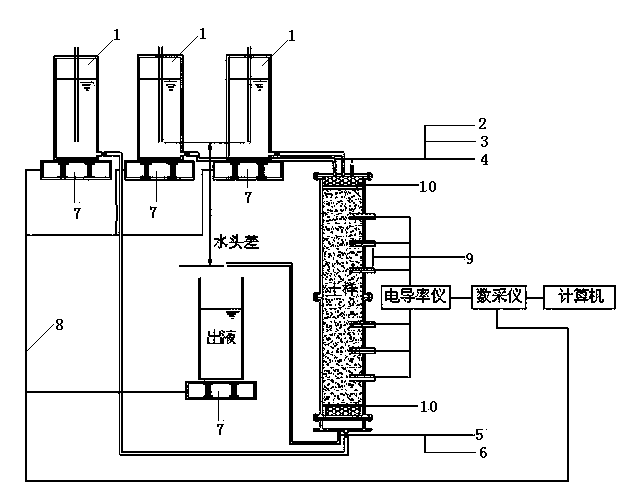

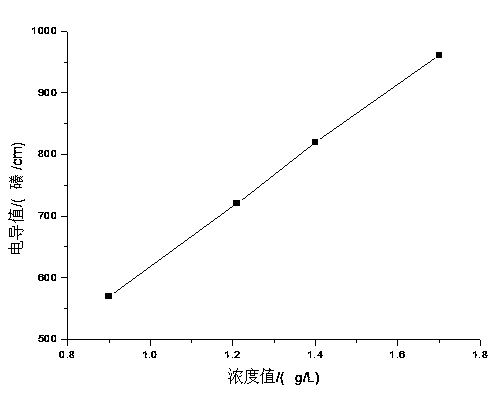

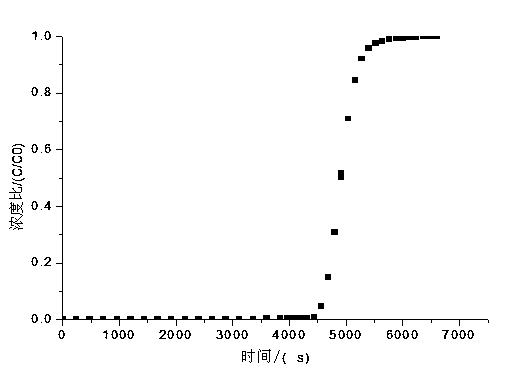

Simulator for transport of soil pollutant

InactiveCN103424341ARealize automatic collectionHigh precisionSurface/boundary effectTime changesEngineering

The invention discloses a simulator for transport of soil pollutant. The simulator comprises a solution injection system, a testing column, a measuring system, and an outlet collecting system, wherein the solution injection system comprises solution injection bottles and guide pipes; valves are arranged at two ends of the testing column, conductivity electrode mounting holes are formed in a side face of the testing column, and an air outlet hole is formed in the top of the testing column; the measuring system comprises conductivity electrodes, a conductivity meter, a pressure sensor, a date collector and a computer; the outlet collecting system comprises a water outlet pipe and an outlet collecting container. According to the simulator, the transfer behavior of pollutants in soil body can be simulated indoors; distribution condition of concentration of pollutant in time and space and the real-time changing of the outlet volume can be acquired in a real-time manner during the simulation; the automation degree is high and the precision is high; therefore, the simulator obviously keeps ahead of relative instruments at home and abroad.

Owner:HOHAI UNIV

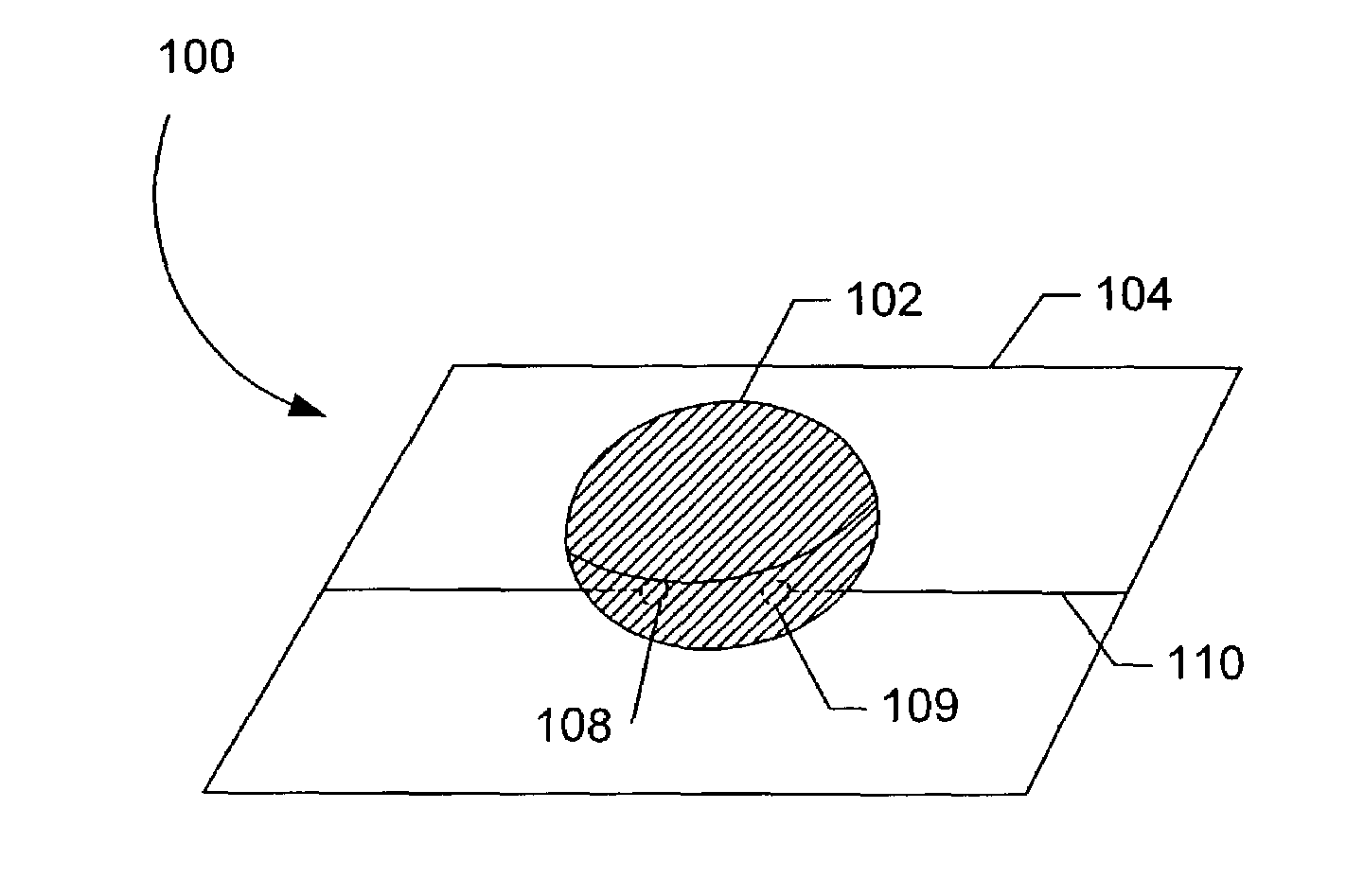

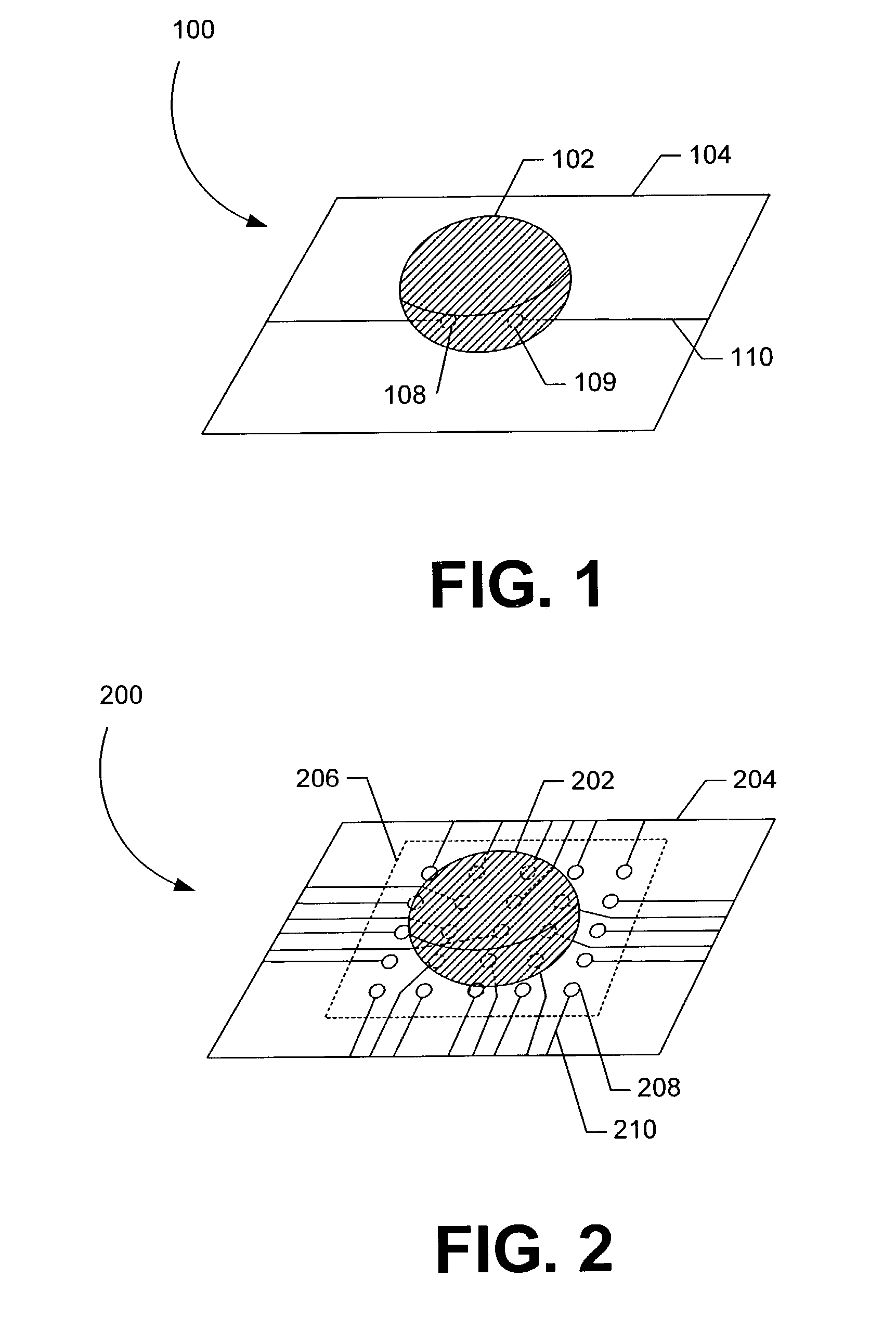

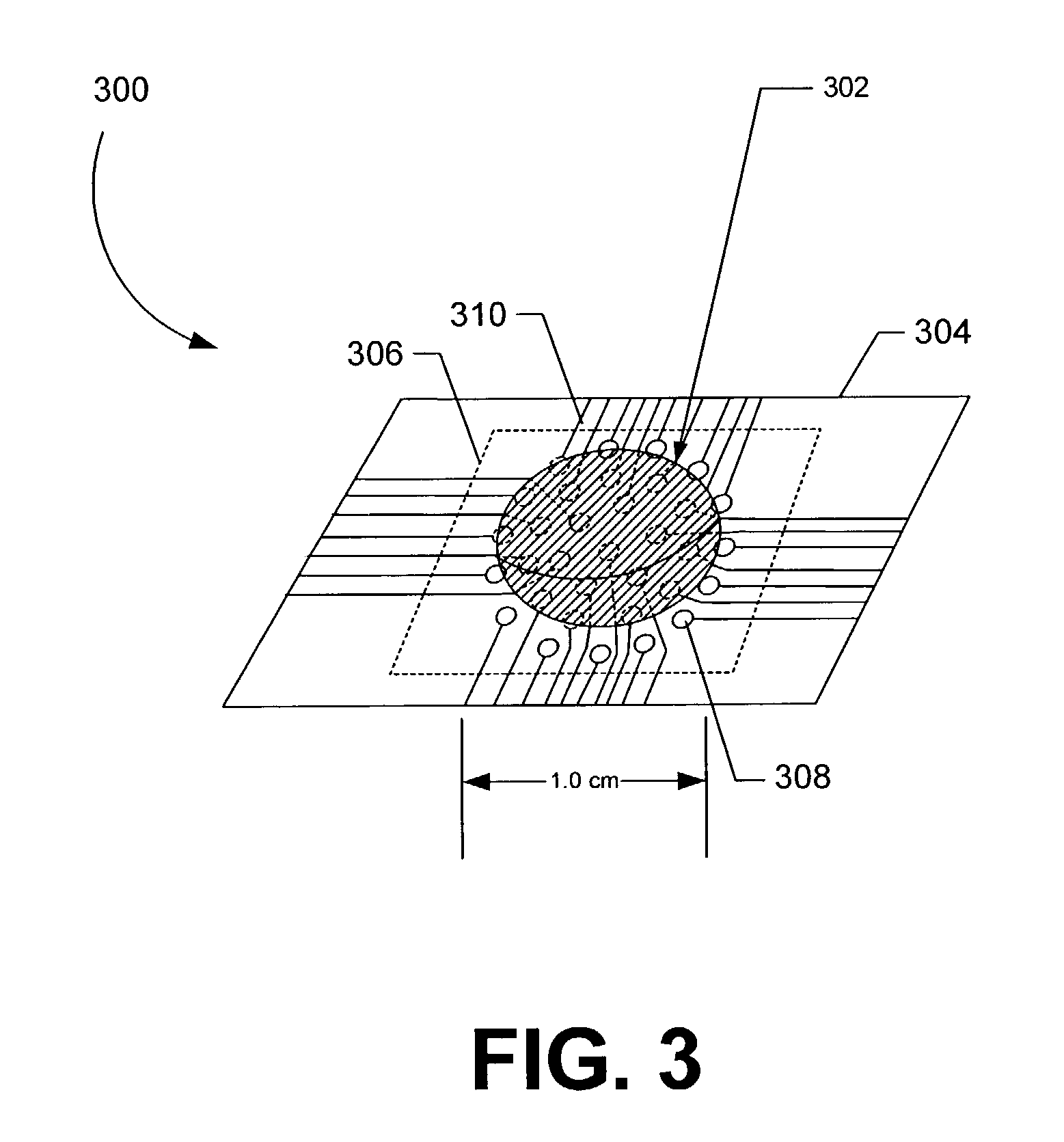

Tear film osmometry

ActiveUS7017394B2Quickly and easily obtainedAccurate measurementResistance/reactance/impedenceFlow propertiesThermal energyFluorescence

Osmolarity measurement of a sample fluid, such as tear film, is achieved by depositing an aliquot-sized sample on a sample receiving substrate. The sample fluid is placed on a sample region of the substrate. Energy is imparted to the sample fluid and energy properties of the fluid can be detected to produce a sample fluid reading that indicates osmolarity of the sample fluid. An aliquot-sized volume can comprise, for example, a volume of no more than 20 microliters (μL). The aliquot-sized sample volume can be quickly and easily obtained, even from dry eye sufferers. The imparted energy can comprise electrical, optical or thermal energy. In the case of electrical energy, the energy property of the sample fluid can comprise electrical conductivity. In the case of optical energy, the energy property can comprise fluorescence. In the case of thermal energy, the measured property can be the freezing point of the sample fluid. The substrate can be packaged into a chip, such as by using semiconductor fabrication techniques. An ex vivo osmolarity sensor system that uses the chip can detect energy from the sample region and can provide an accurate osmolarity measurement without user intervention.

Owner:RGT UNIV OF CALIFORNIA

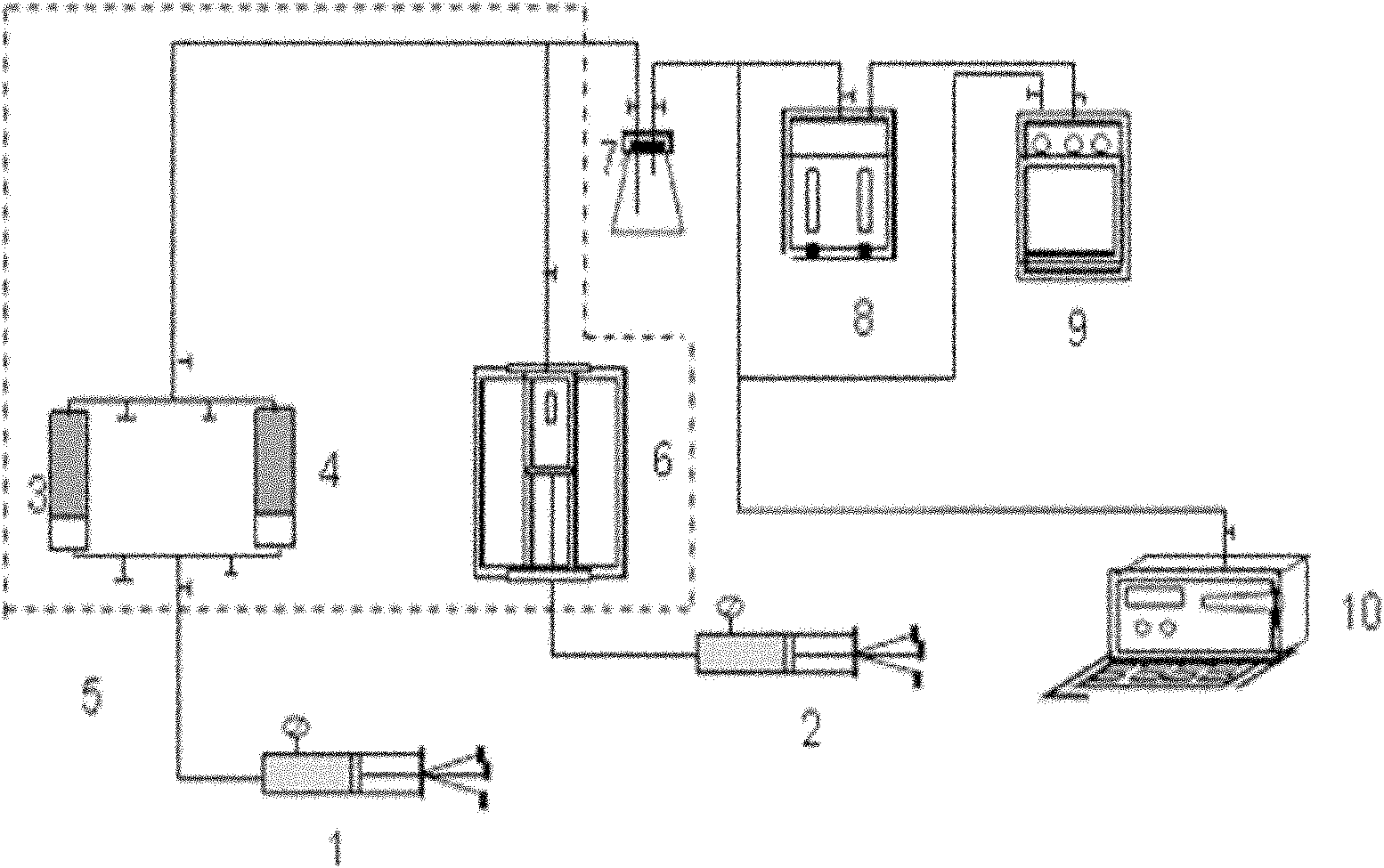

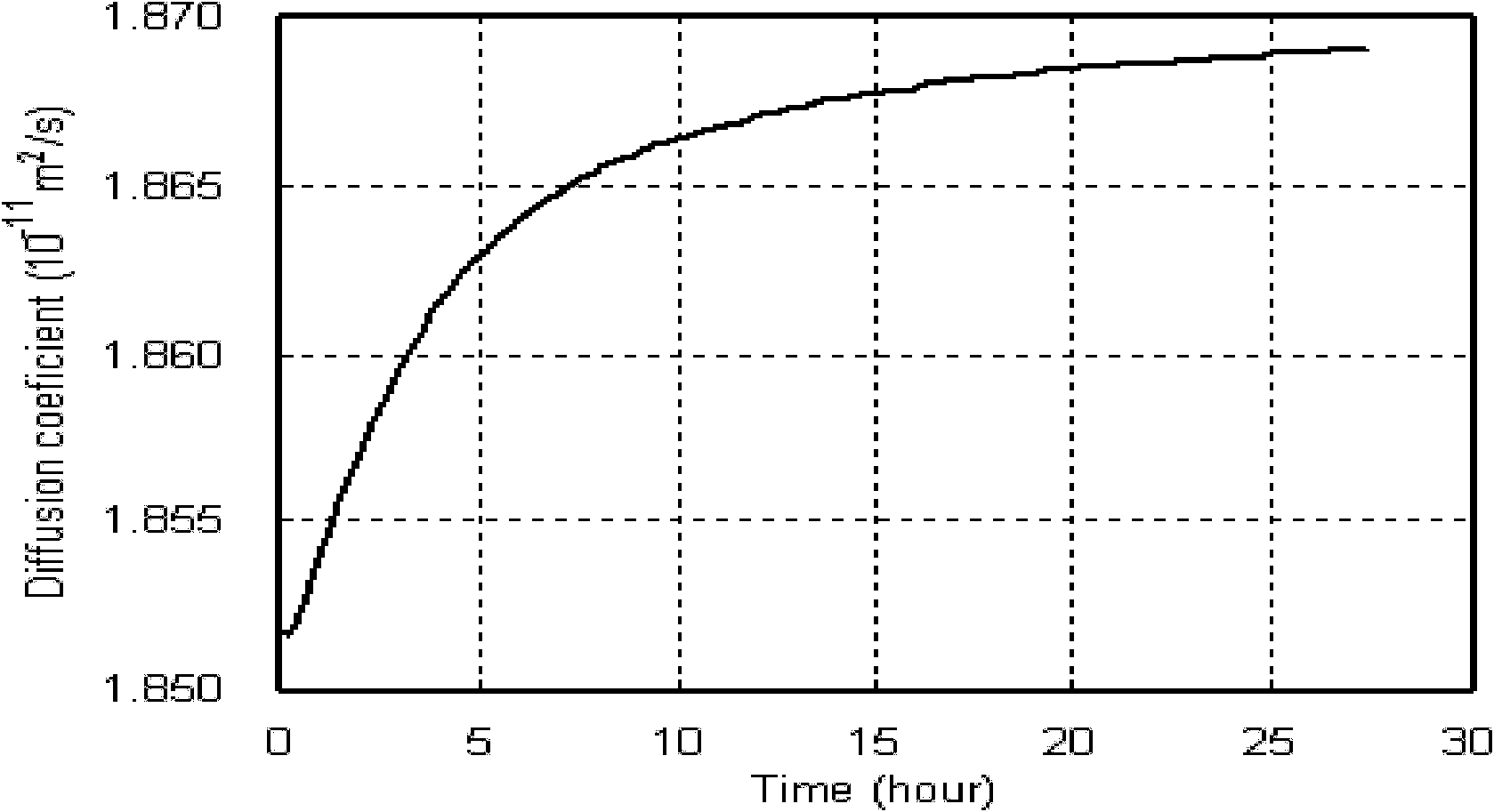

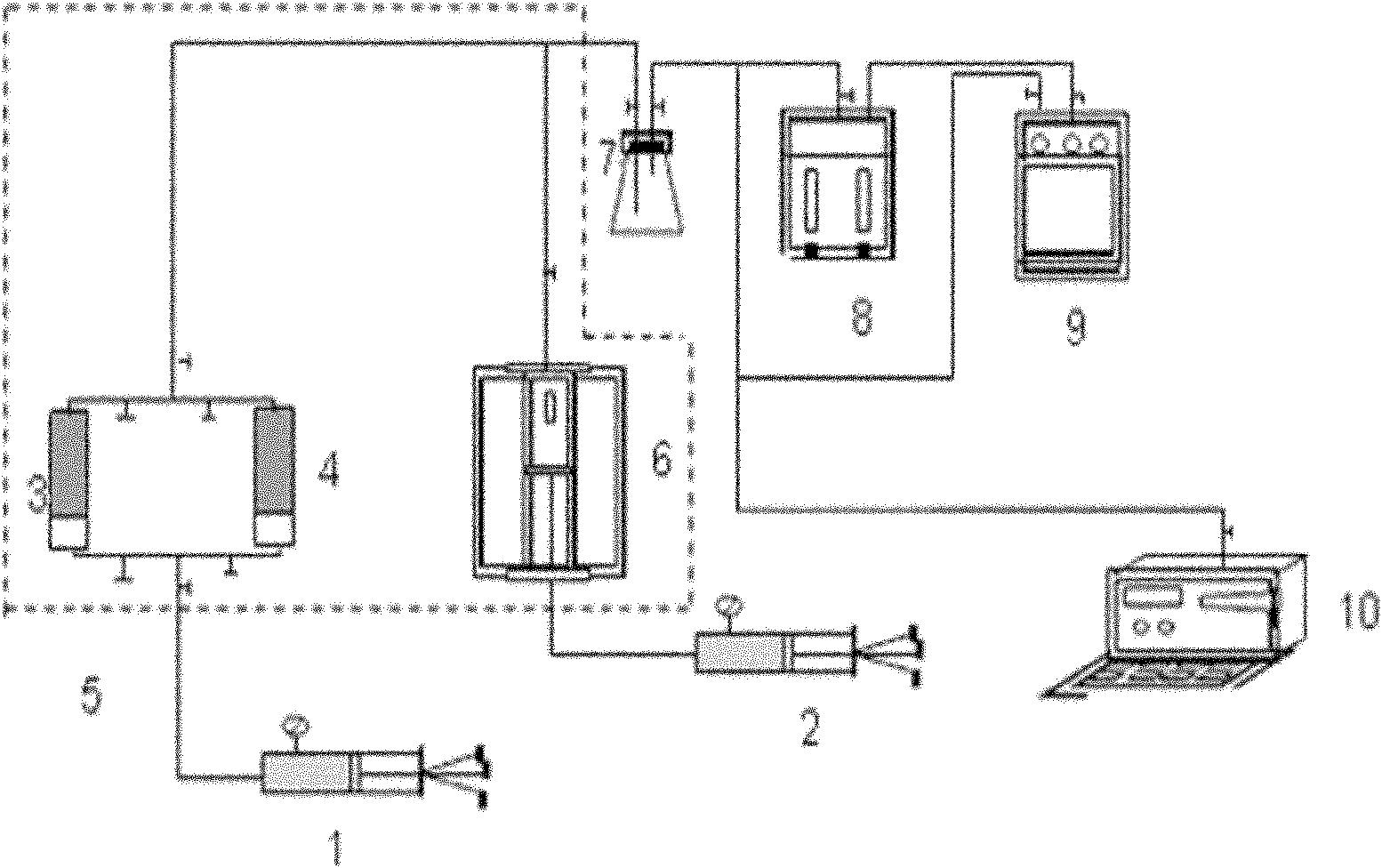

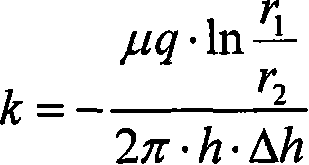

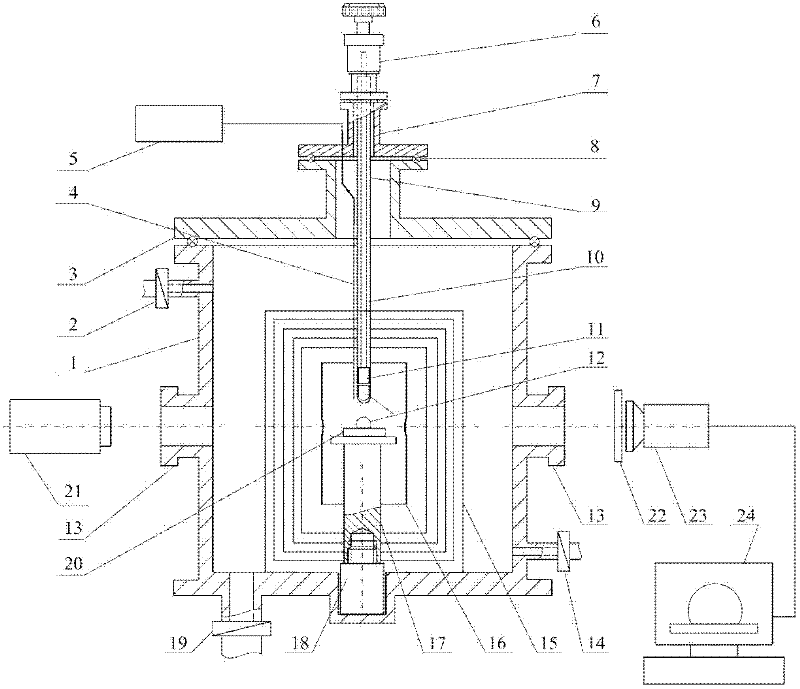

Device and method for testing molecular diffusion coefficients in multi-component oil-gas system under high temperature and high pressure

InactiveCN102121891AReliable principleGuaranteed accuracySurface/boundary effectUltra high pressureGas phase

The invention relates to a device and method for testing molecular diffusion coefficients in a multi-component oil-gas system under high temperature and high pressure. The device consists of an inlet pump 1, an outlet pump 2, an intermediate container, a PVT (pressure-volume-temperature) cylinder 6, an oil-gas separator 7, a gas volume flow meter 8, a liquid phase density analyzer 10 and a chromatographic analyzer 9, wherein, one end of the intermediate container is connected with the inlet pump 1, and the other end of the intermediate container is connected with the PVT cylinder 6; the PVT cylinder is connected with the oil-gas separator 7; the separator is connected with the gas volume flow meter 8 and the liquid phase density analyzer 10; the gas volume flow meter and the liquid phase density analyzer are respectively connected with the chromatographic analyzer 9; and the other end of the PVT cylinder is connected with the outlet pump 2. The device has the advantages of reasonable principle and simple structure, and is convenient in operation; and by utilizing the method, the molecular diffusion coefficients of each component in a multi-component injected gas and actual crude oil system in gas phase and oil phase under the conditions of different reservoir temperature and pressure can be determined, thereby providing reasonable basic data for quantitative evaluation of influence of molecular diffusion effect on the enhancement of the recovery ratio by means of gas injection.

Owner:SOUTHWEST PETROLEUM UNIV

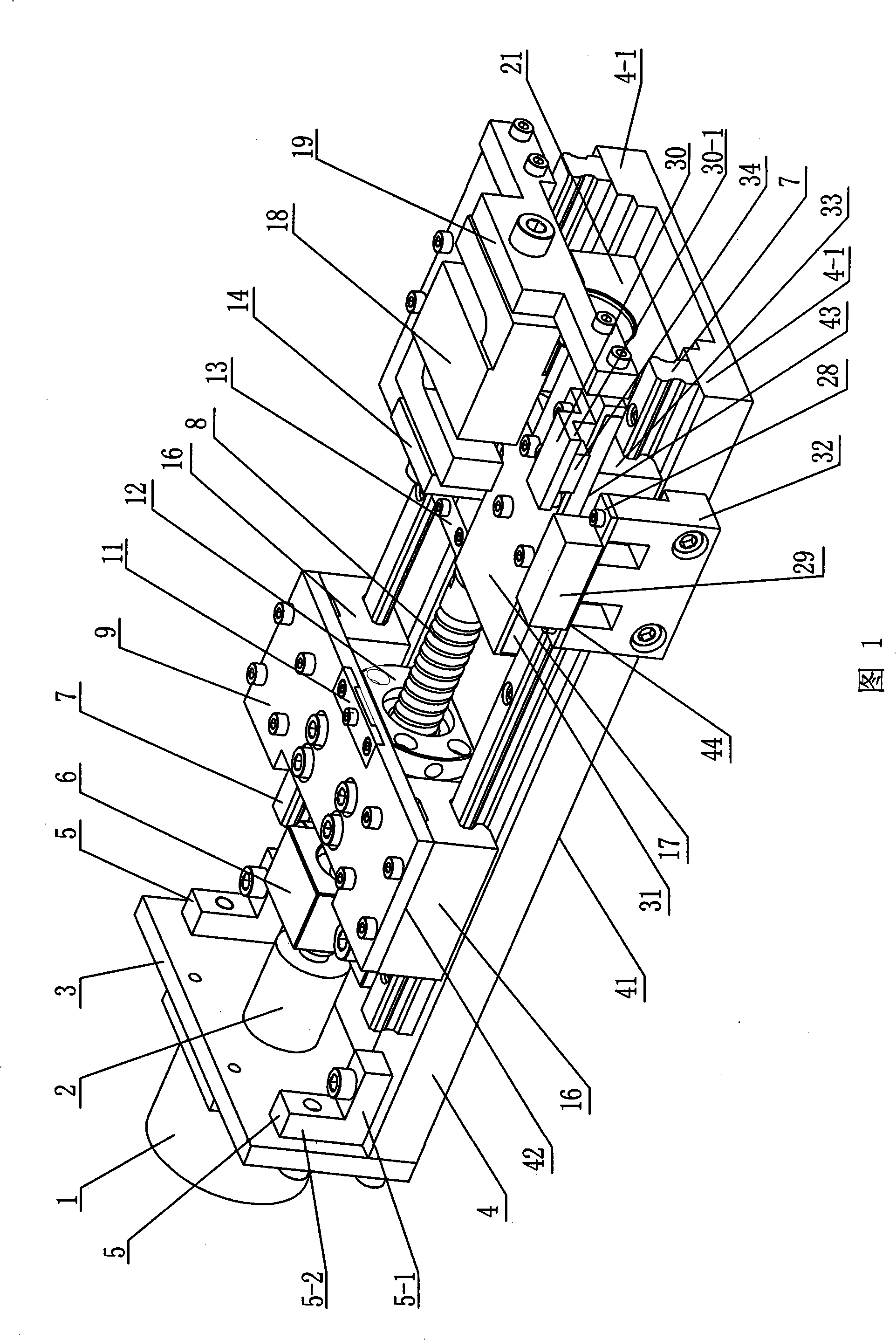

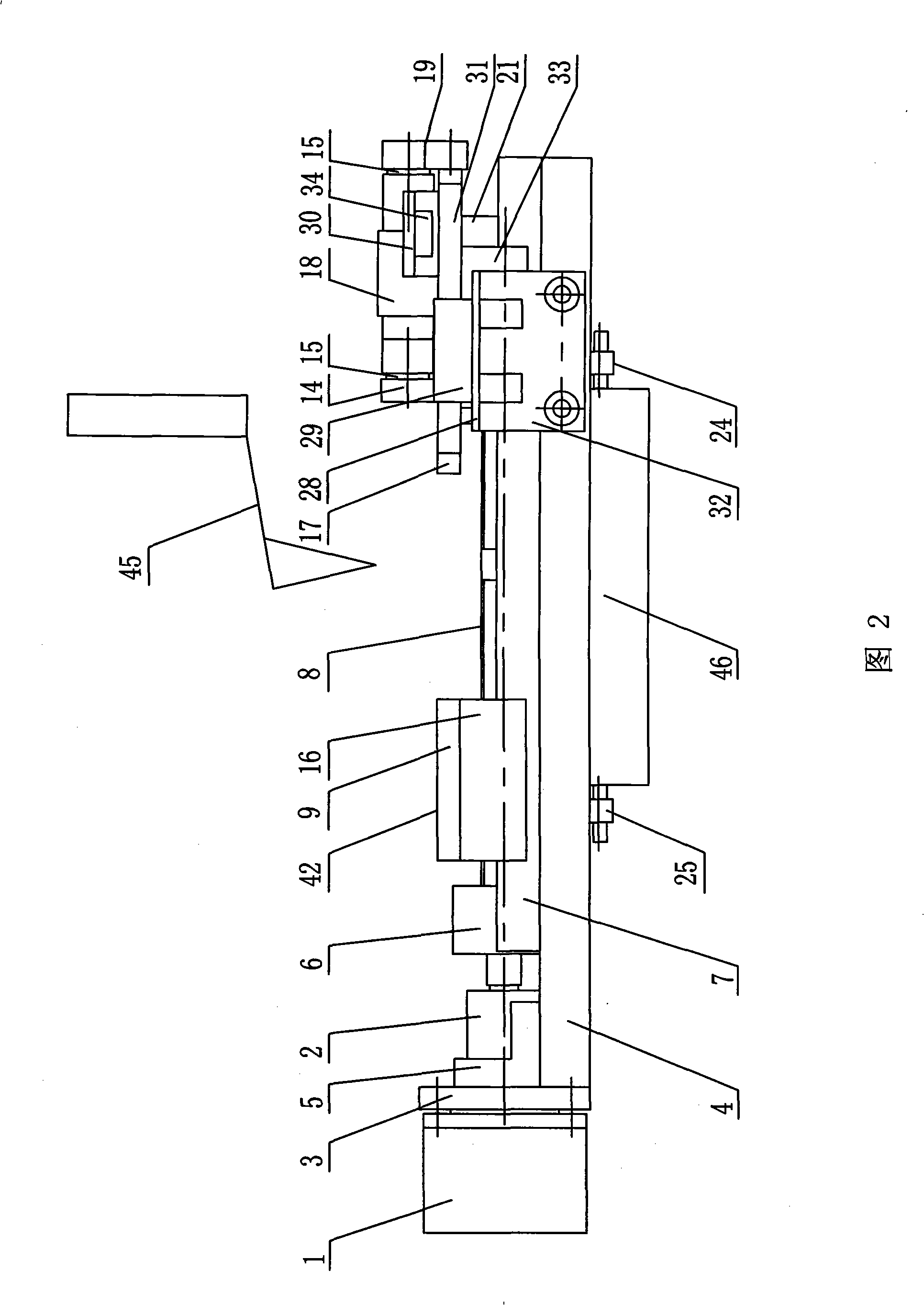

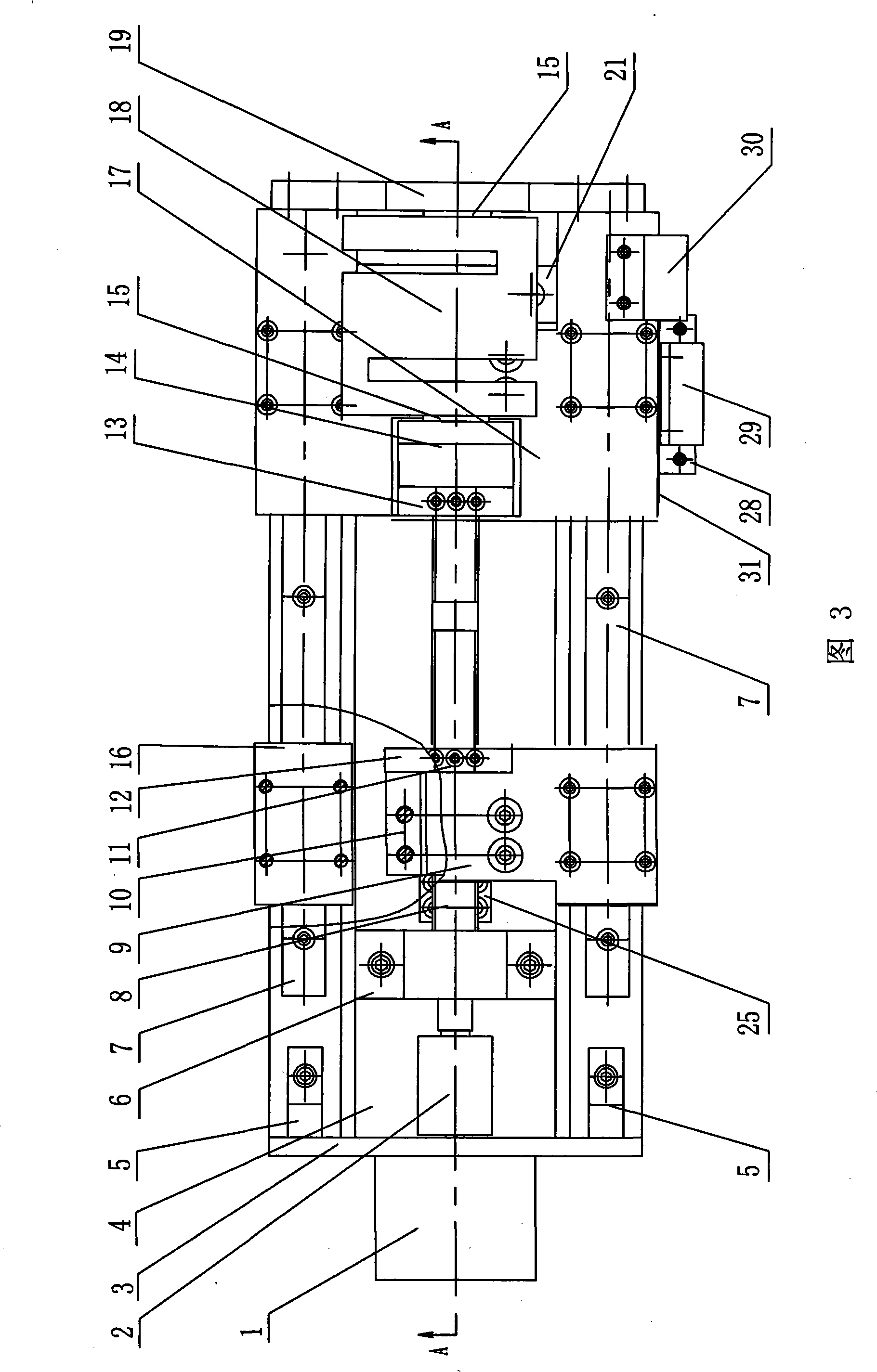

In situ nanometer stretching experiment measuring detection device

InactiveCN101285747ASurface/boundary effectMaterial strength using tensile/compressive forcesVehicle frameCoupling

The invention relates to a tension experiment measuring and detecting device, in particular to an in-situ nano tension experiment measuring and detecting device. The invention solves the problem in the prior art that measurement of mechanical properties and detection of micro-morphology are two independent and separate processes. An output shaft of a stepper motor (1) of the device is fixedly connected with a coupler (2); a guide rail (7) is fixed on a stander soleplate (4); a left frame set (42) and a right frame set (43) are arranged on the guide rail (7); both ends of a left and right rotary screw (8) are respectively connected with the coupler (2) and a bearing support (21); a left end face and a right end face of a force sensor (18) are respectively and fixedly connected with a right clamp connecting block (14) and a force sensor holder (19); a reading device (44) is arranged on the stander soleplate (4); and a tension measuring device (41) is fixed on a worktable (46) of the detection device. The in-situ nano tension experiment measuring and detecting device promotes further development of the research area of dynamic observation required on the micro-morphology variation of a sample under the state of stress, and has important theoretical significance and good application prospect on measurement of the mechanical properties and detection of the micro-morphology of composite functional nanophase materials.

Owner:HARBIN INST OF TECH

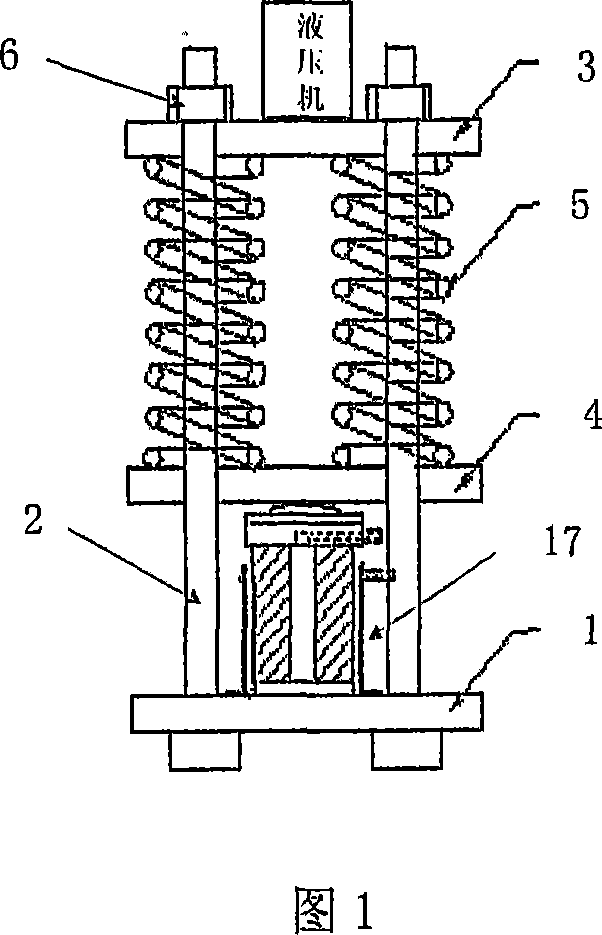

Apparatus and method for testing cement concrete penetration performance under loading action

InactiveCN101074912ASolve the problem that the continuous stability of the load cannot be guaranteedSurface/boundary effectPermeability/surface area analysisGraduated cylinderSheet steel

A device used for testing permeation performance of hydraulic engineering concrete under load action is prepared forming pressurizing unit by steel chassis, steel plate, steel vertical column, spring, nut and bolt; forming test-piece chamber by sleeve, up-pressing steel plate, down-pressing steel plate, ball base and concrete test-piece. Its testing method is also disclosed.

Owner:HOHAI UNIV

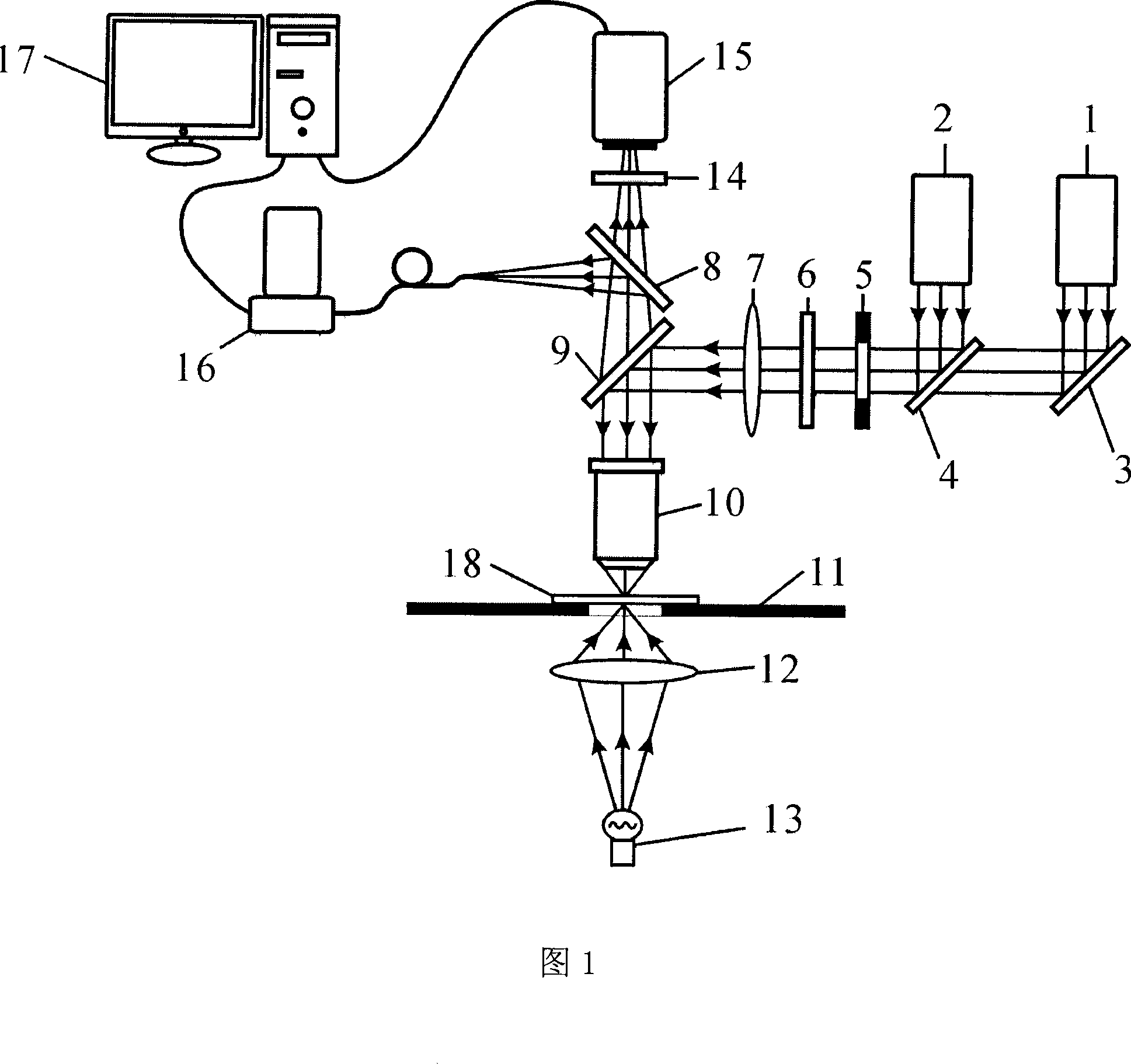

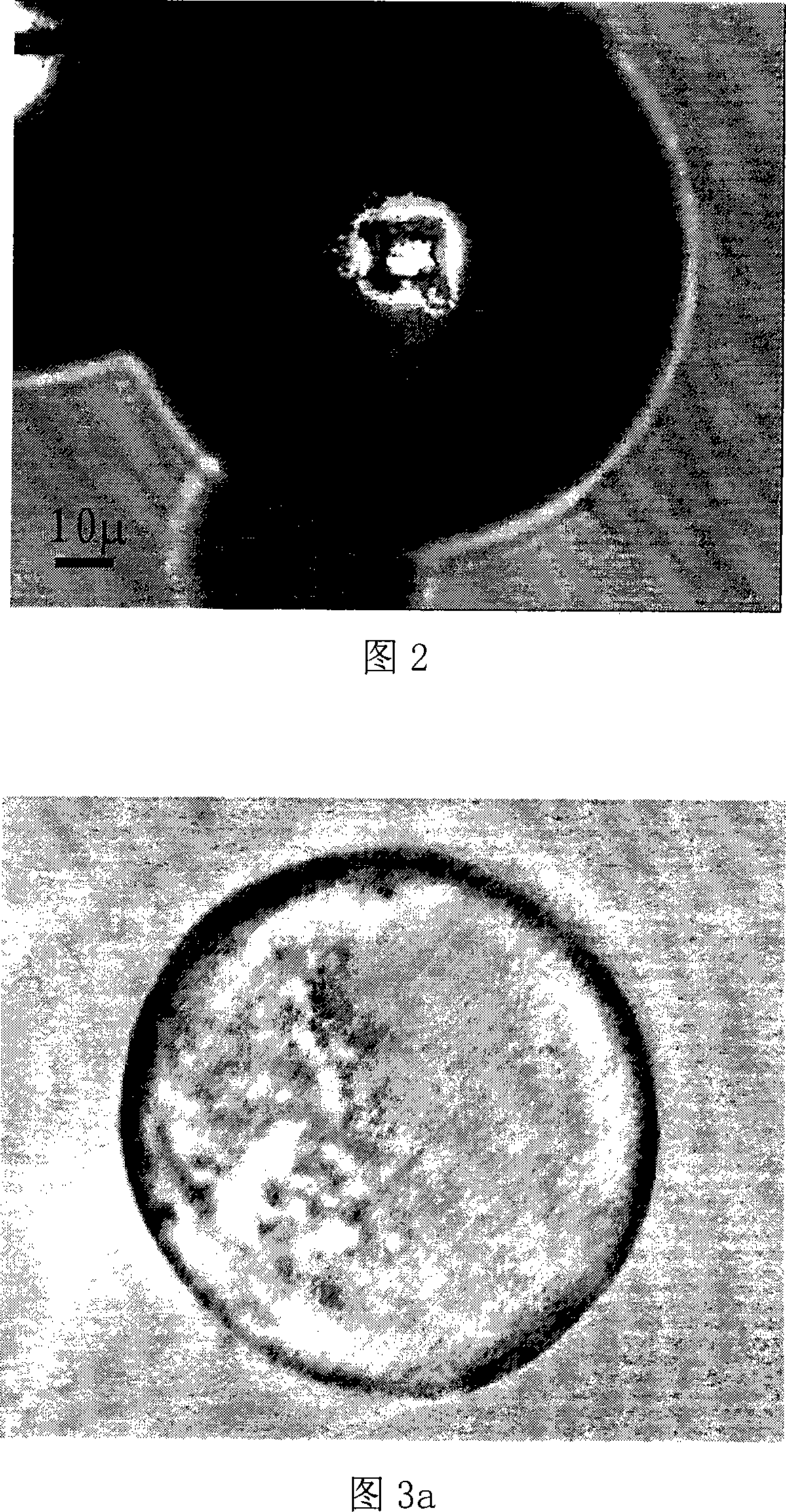

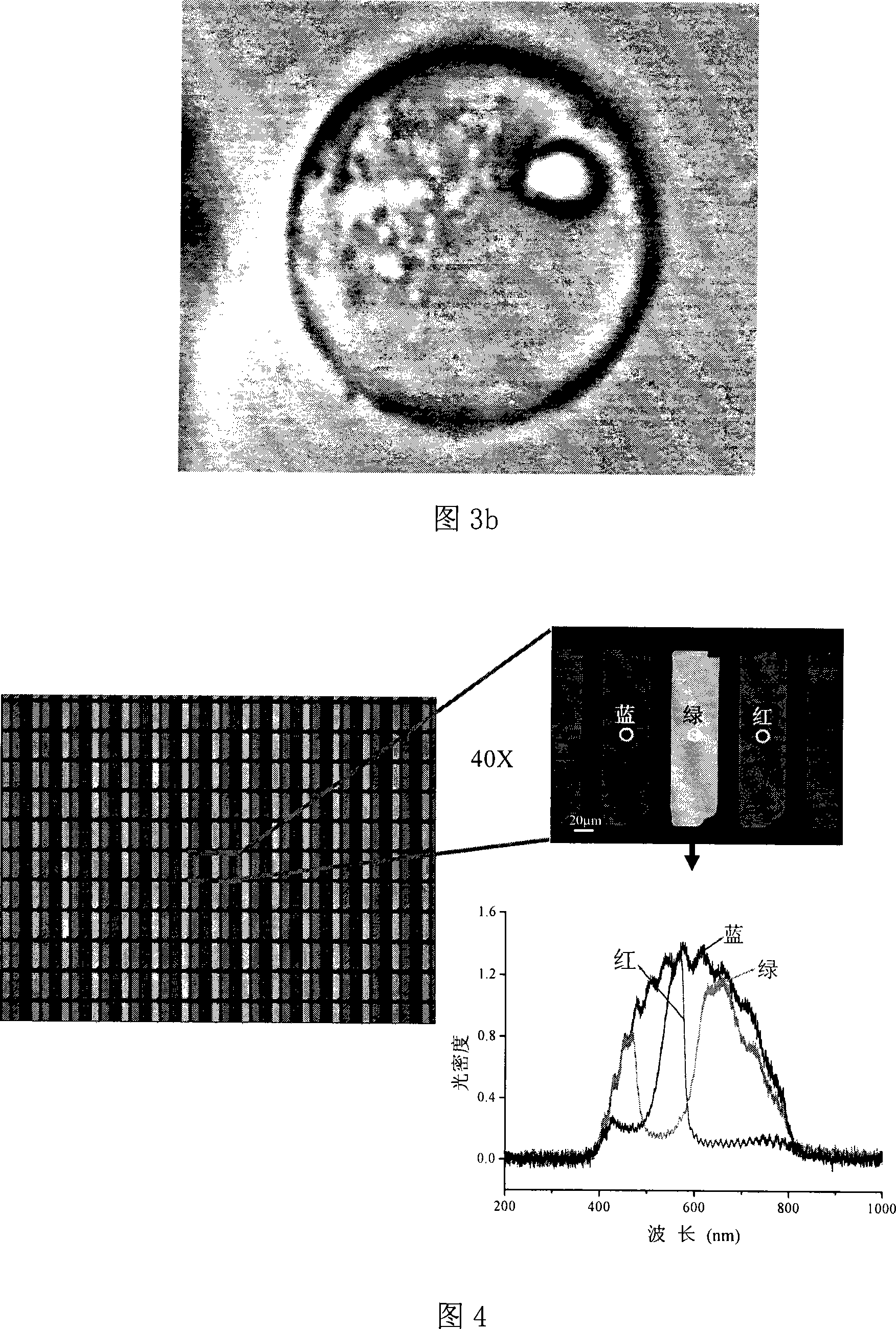

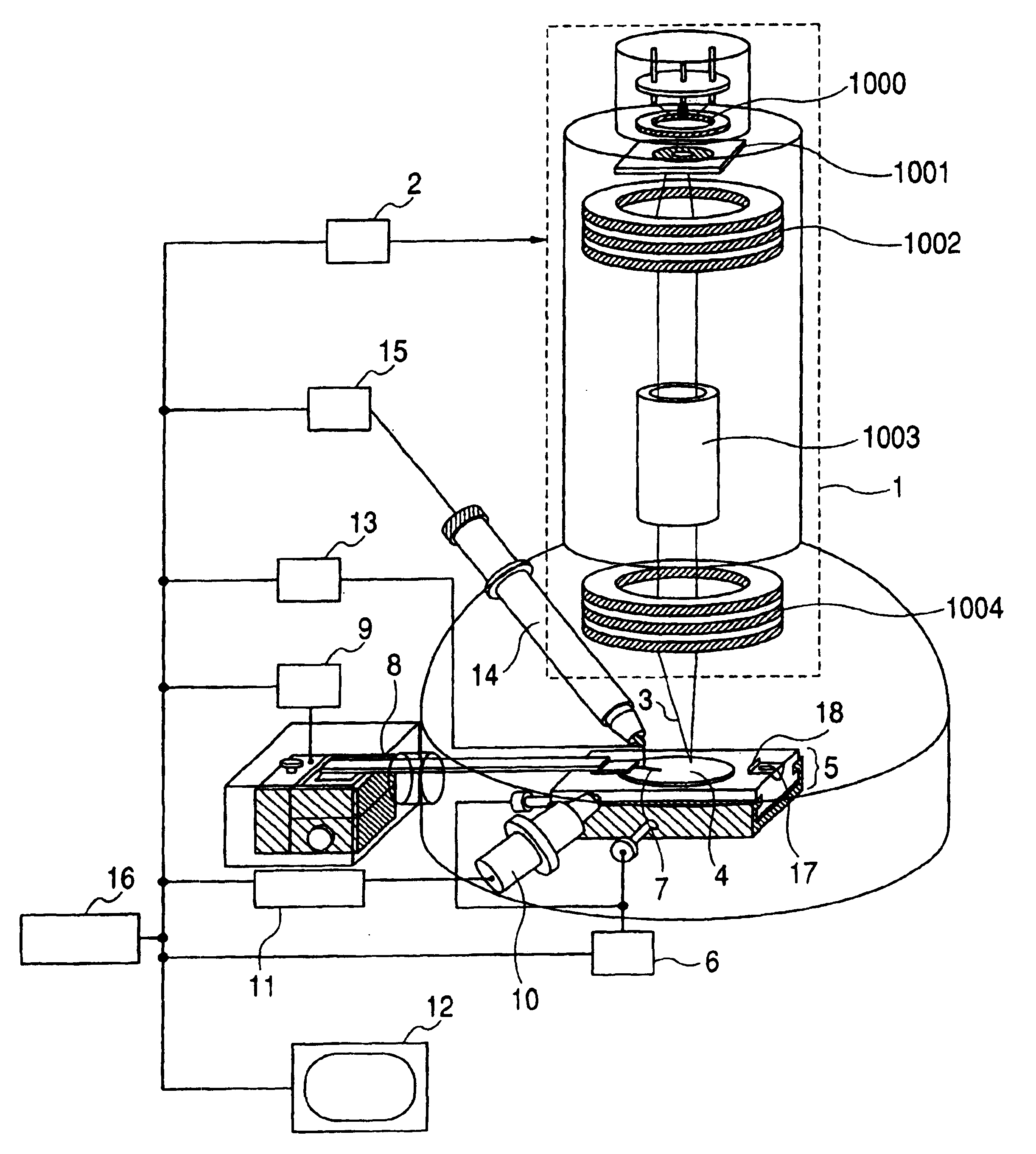

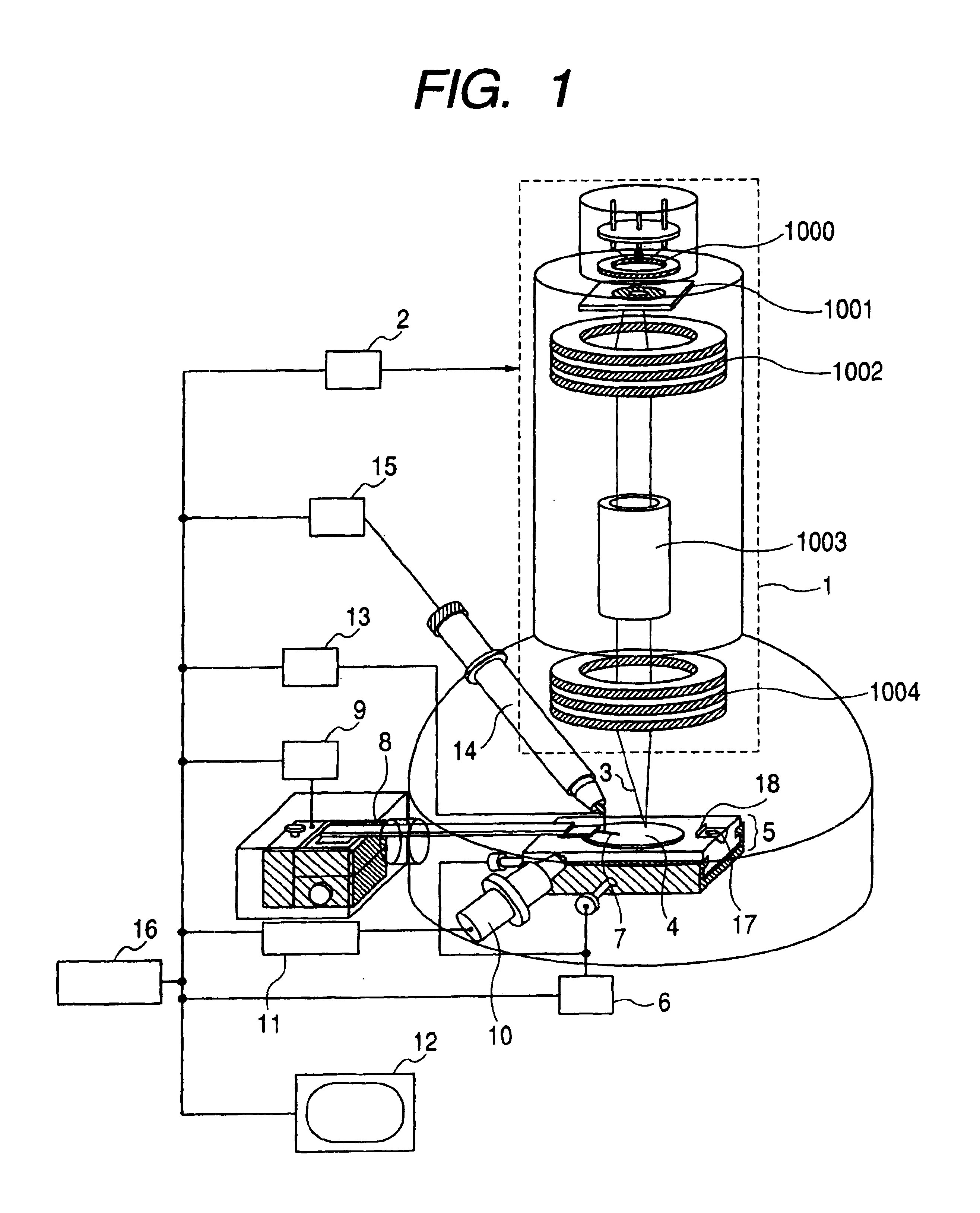

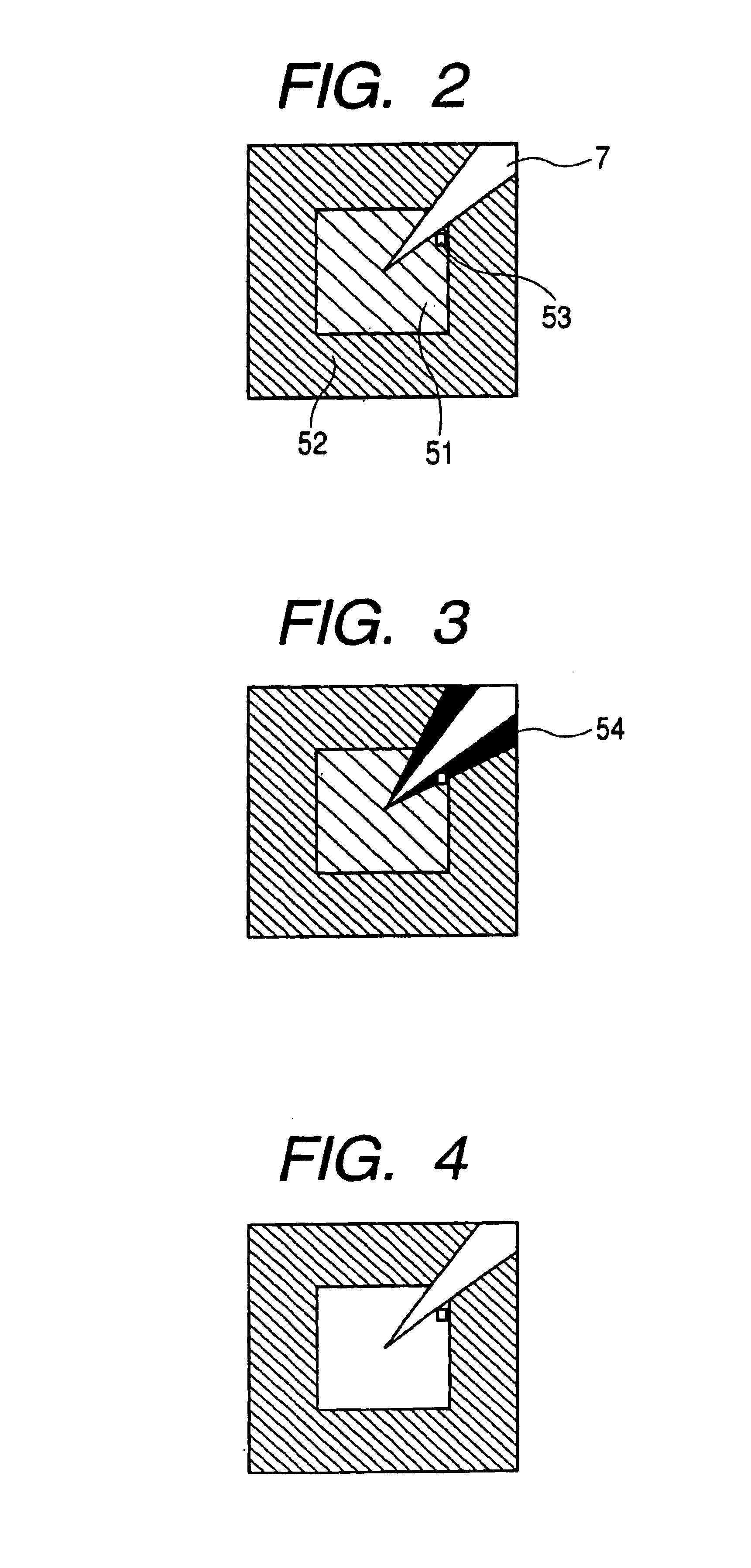

Multifunctional optical micro-control device

InactiveCN101216414AOvercome singleOvercome deficienciesSurface/boundary effectMaterial analysis by optical meansFemto second laserCcd camera

A multifunctional optical micro-manipulation device comprises a femtosecond laser, an optical tweezers laser, an optical system, a stage, a light source system, an imaging system, a spectral measurement system and a computer, wherein the optical system comprises a shutter, an attenuator, a focusing lens, a near IR reflector and a microscopic objective lens; the light source system comprises an illumination light source and a condenser lens; the microscopic objective lens is arranged on the stage for condensing a laser beam emitted by a laser generator onto a sample; the condenser lens is arranged below the stage for condensing a visible light emitted by the illumination light source onto the sample; and the imaging system includes an IR filter and CCD camera sequentially disposed on the projection light path of the near IR reflector. By integrating three functions of laser tweezers, femtosecond laser scissors and microspectrometer in one system, the invention can overcome the singleness and the disadvantages of the prior laser micro-beam technology and can be widely used for studying in biological, medical, biophysical, material chemistry and nano-technology fields.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

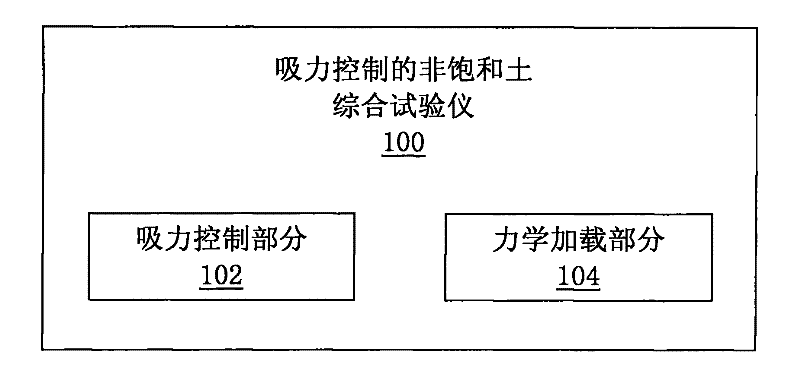

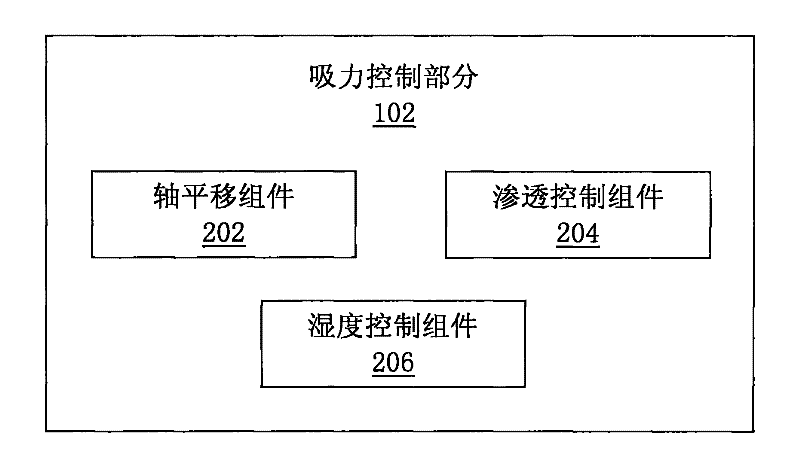

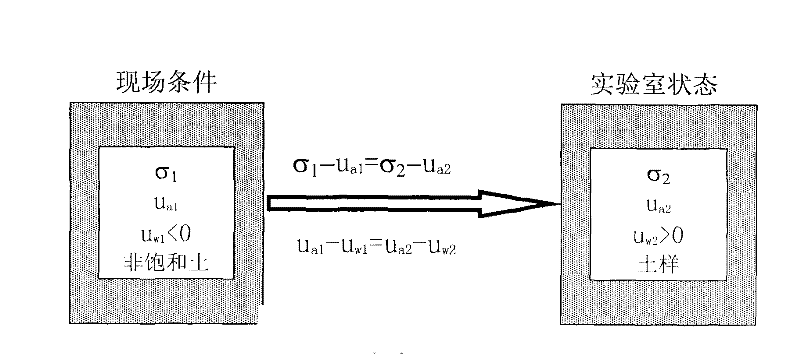

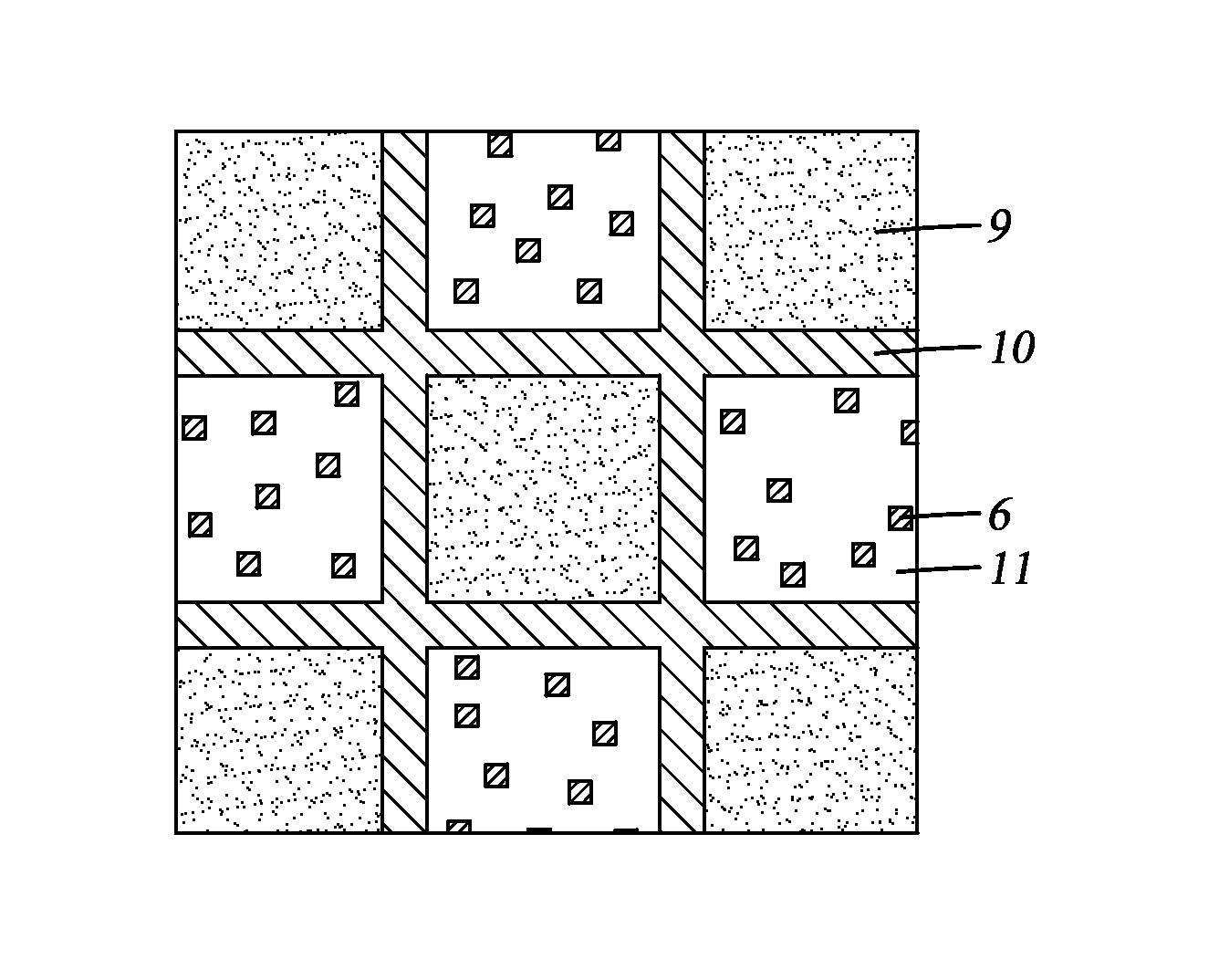

Humidity and osmotic suction-controlled box

Described herein are systems, apparatuses and methods for the design and use of a suction-controlled box for the measurement of stress-dependent soil and water characteristics, shear strength, volume changes and consolidation characteristics from a single unsaturated soil specimen. The suction-controlled box can include a suction control part and a mechanical loading part, which can apply various suctions and mechanical loadings to test a specimen for a full range of suctions. The suction-controlled box can also include a helical water compartment that can flush diffused air bubbles.

Owner:THE HONG KONG UNIV OF SCI & TECH

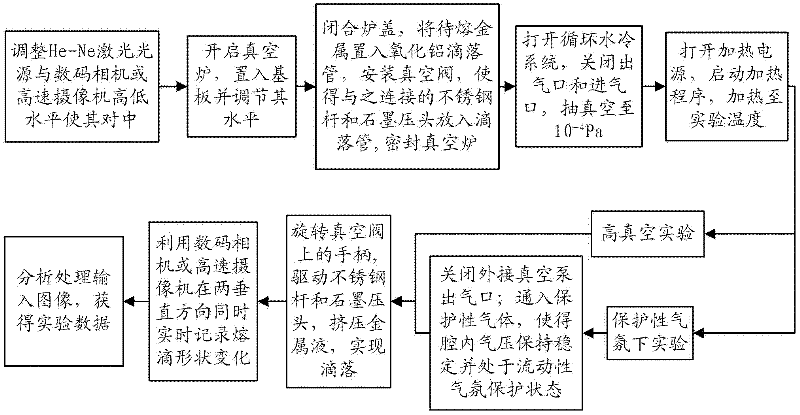

Apparatus and method for determining high temperature wettability

InactiveCN102353620ARealize separate heatingPrevent oxidationSurface/boundary effectFurnace typesRubber ringEngineering

Owner:JILIN UNIV

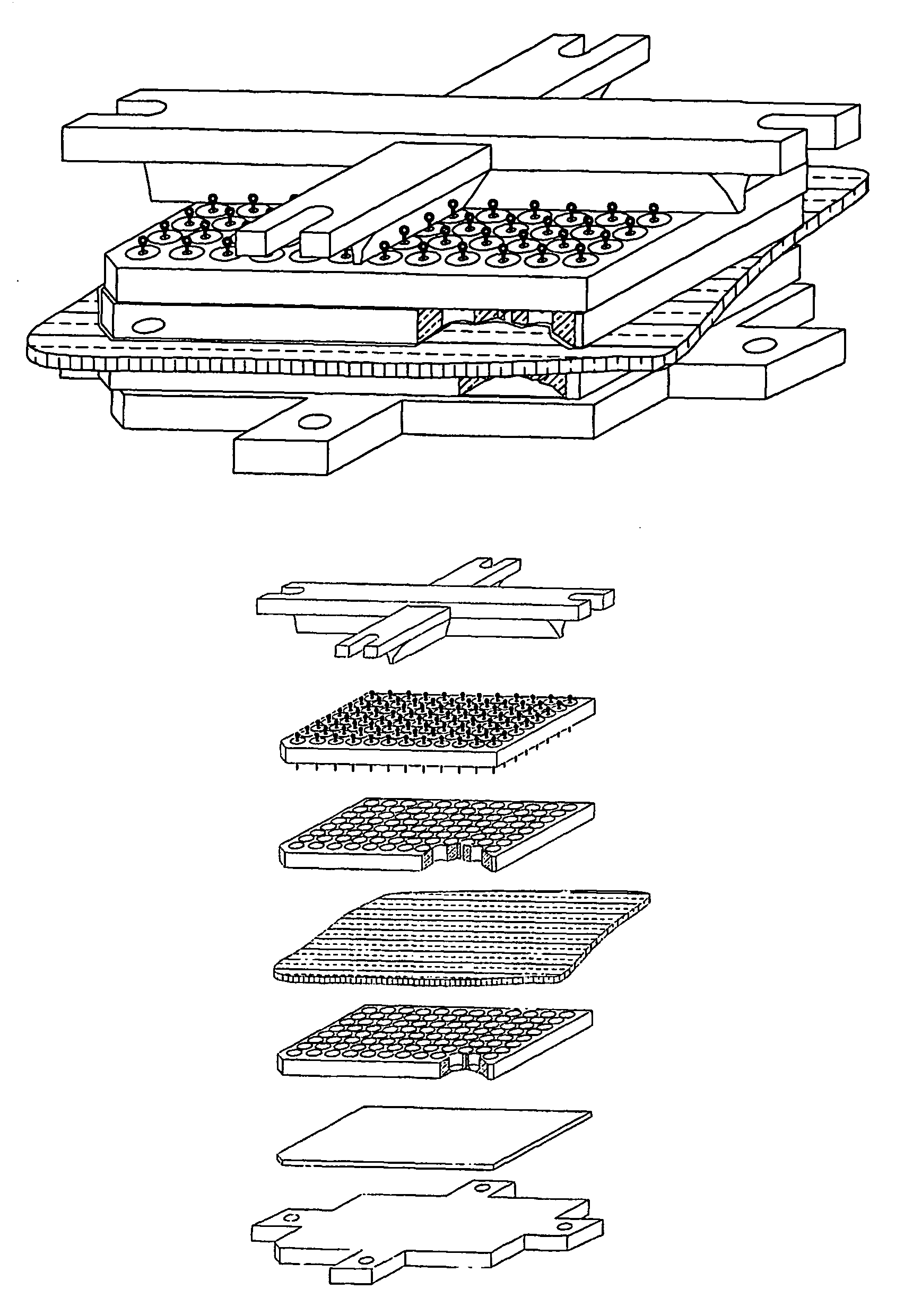

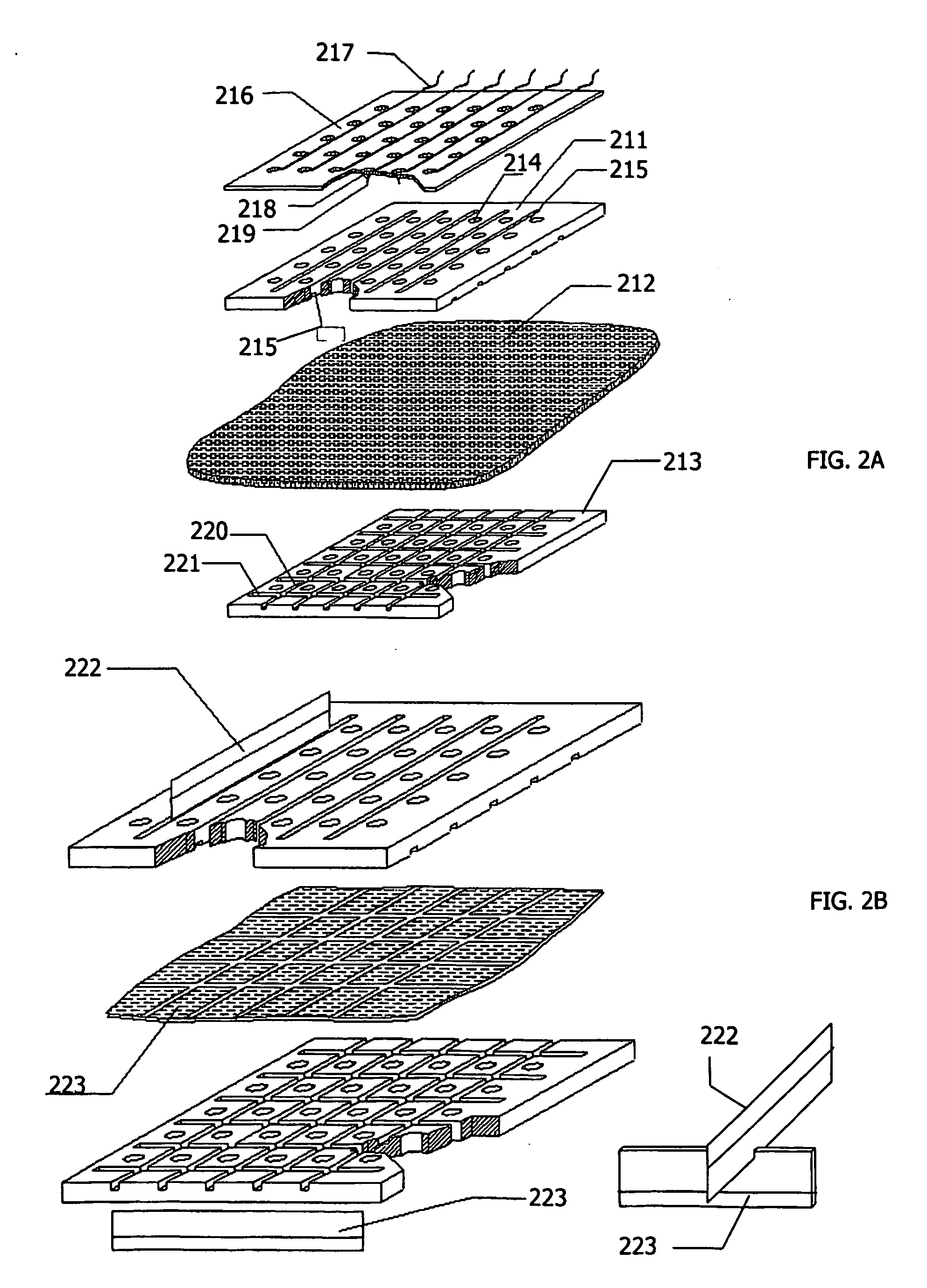

Apparatus and methods for evaluating the barrier properties of a membrane

InactiveUS20070183936A1MeasurementsSimple and robust and scalableMaterial analysis by observing effect on chemical indicatorRotary centrifugesElectricityAdditive ingredient

Owner:TIOGA RES

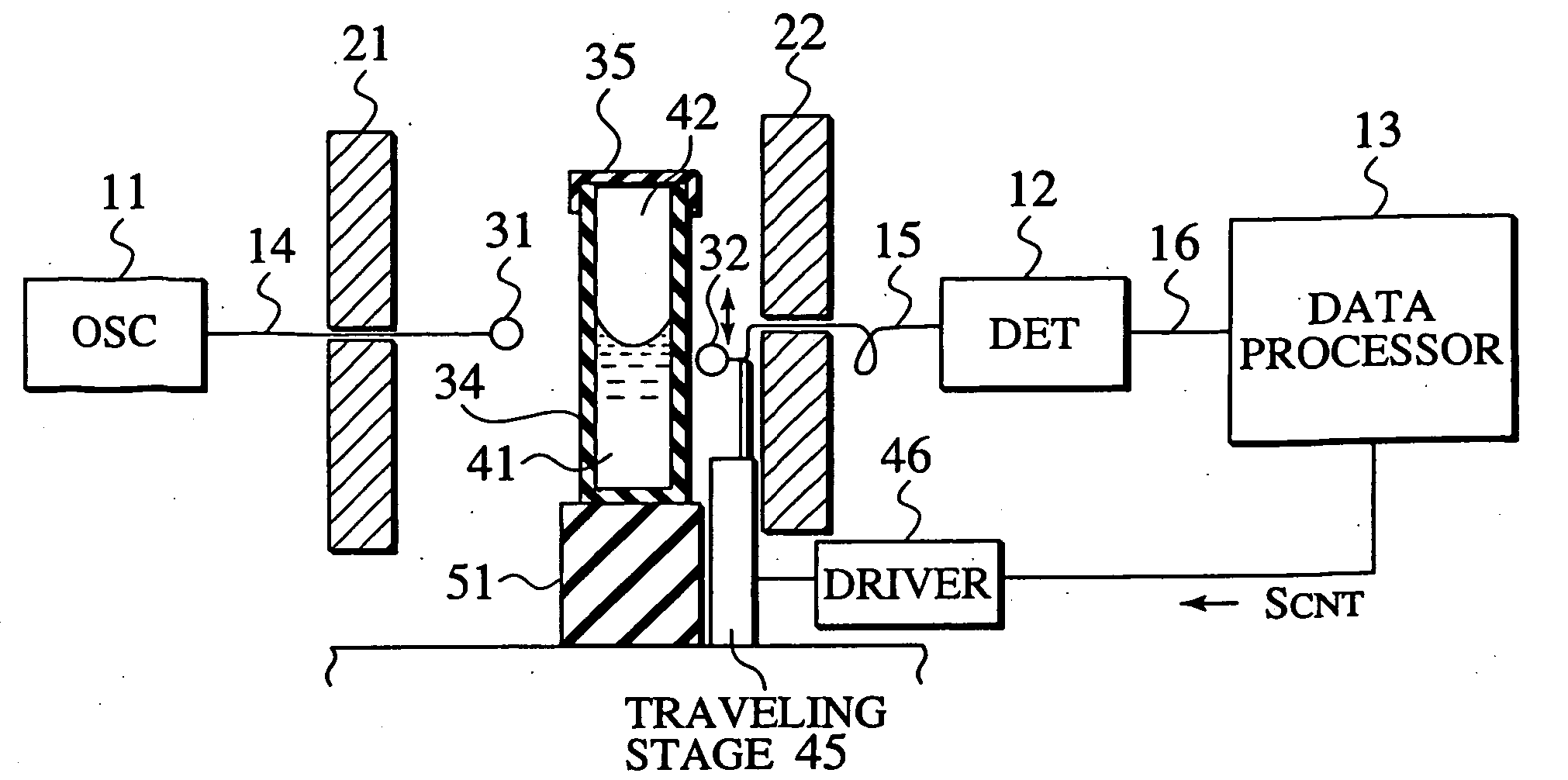

Probe driving method, and probe apparatus

InactiveUS6960765B2Easy to controlDecrease in luminanceSemiconductor/solid-state device testing/measurementInstrumental componentsIon beamSample image

A probe driving method and a probe apparatus for bringing a probe into contact with the surface of a sample in a safe and efficient manner by monitoring the probe height. Information about the height of the probe from the sample surface is obtained by detecting a probe shadow appearing immediately before the probe contacts the sample, or based on a change in relative positions of a probe image and a sample image that are formed as an ion beam is irradiated diagonally.

Owner:HITACHI LTD +1

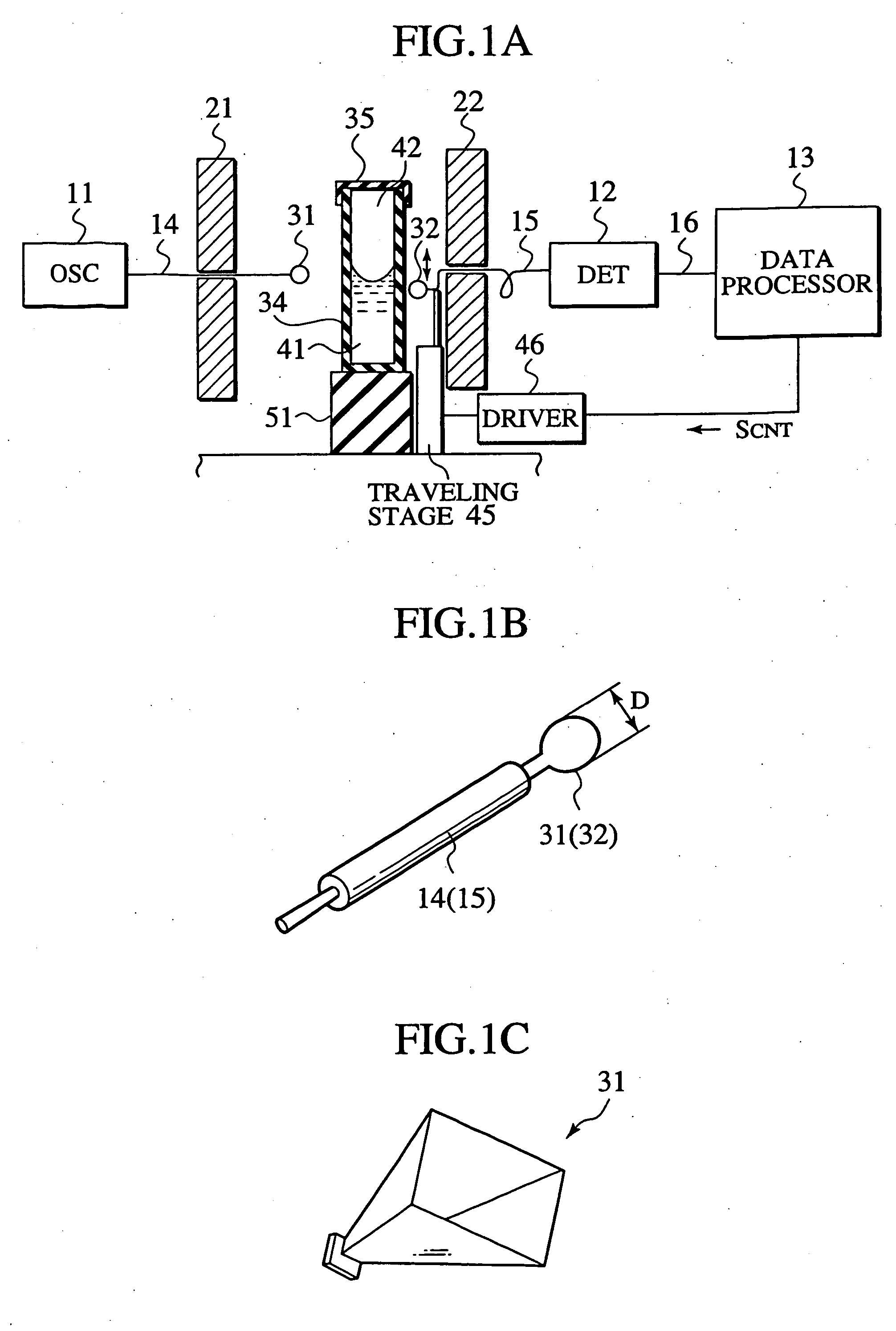

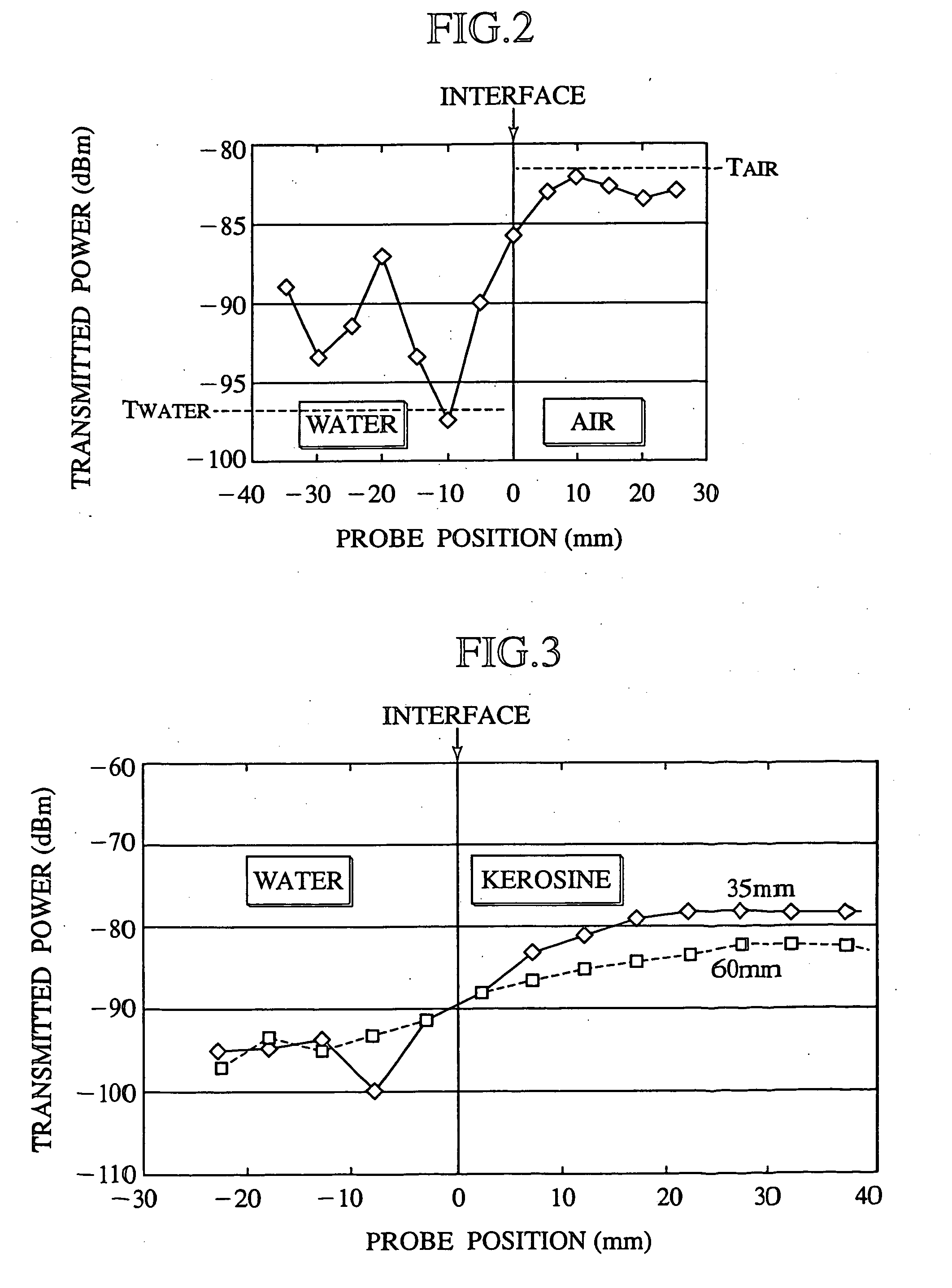

Interface detection apparatus and method for detecting hidden interface using microwave

InactiveUS20050156607A1Resistance/reactance/impedenceMaterial analysis using microwave meansEngineeringIrradiation

An interface detection apparatus detects a position of a hidden interface between first and second materials, the first material having a different physical property from the second material. The apparatus encompasses (a) an irradiation mechanism configured to irradiate an electromagnetic wave onto a sample implemented by the first and second materials, (b) a detection mechanism configured to detect the electromagnetic wave that has passed through the sample, and (c) a traveling mechanism configured to change the relative position of the hidden interface with respect to the position of the detection mechanism.

Owner:PRESIDENT OF SHIZUOKA UNIVERSITY

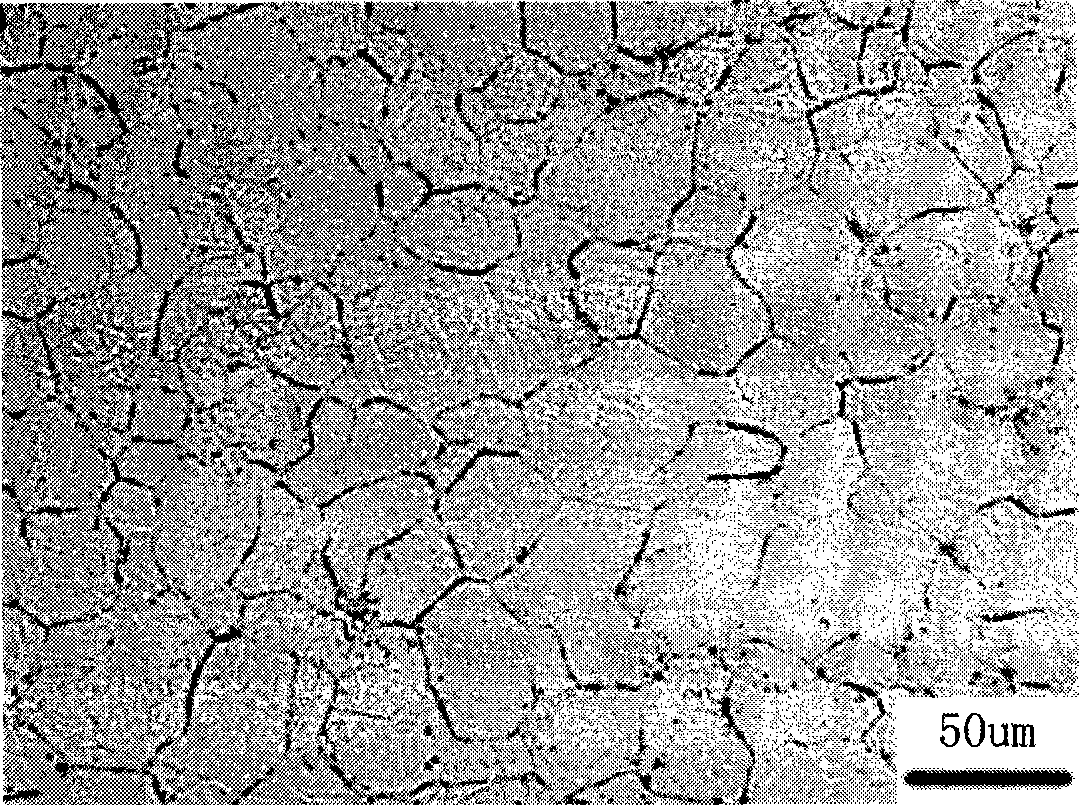

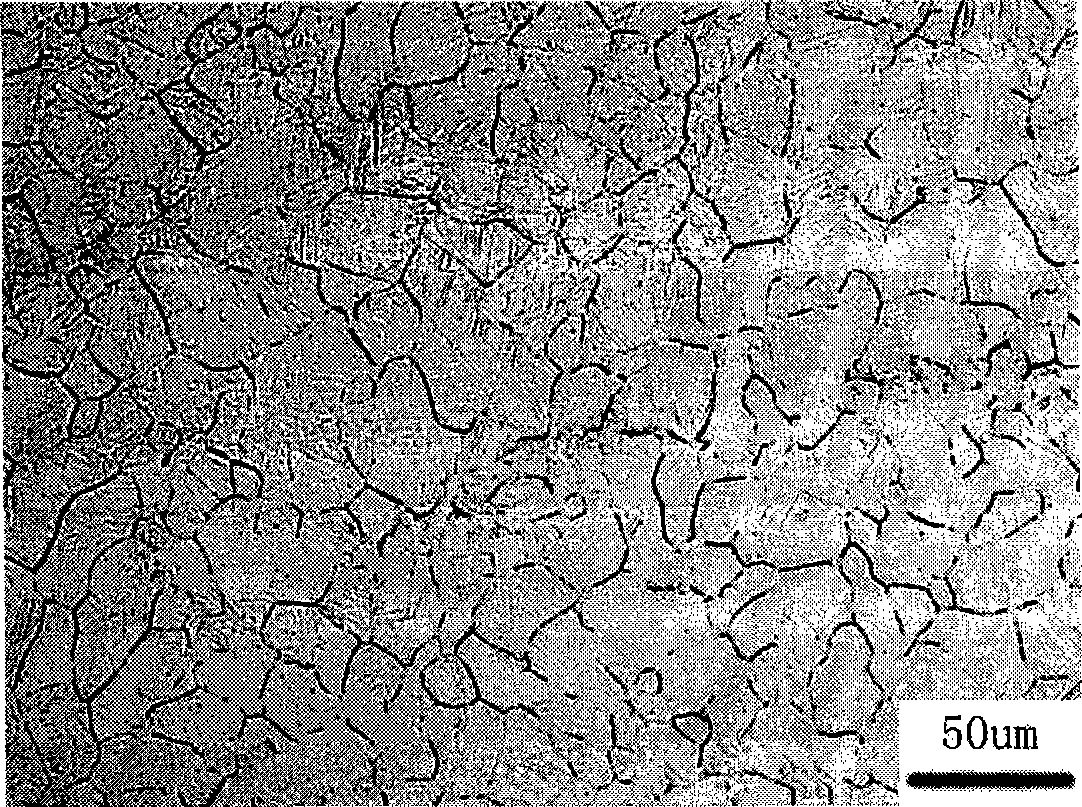

Method for displaying high-strength vessel slab original austenite crystal grain

ActiveCN101368889ADeep corrosionImprove solubilitySurface/boundary effectPreparing sample for investigationMaterials scienceDodecylbenzenesulfonic acid

The invention relates to a display method used for preparing high-intensity ship plate metallographic samples and the original austenite grains, belonging to the technical field of metallographic sample preparation. The invention has the following technological steps: coarse grinding, fine grinding, polishing and corrosion; the polished specimen is put in the etching solution at 70-80 DEG C; the formula of the etching solution comprises 100ml of distilled water, 5-7g of picric acid, 0.5-1.5ml of hydrochloric acid, 3-5g of SDBS, 5-15g of Seagull paste shampoo and 0.3-1ml of hydrogen peroxide; after being etched for 1-2 minutes, the surface of the specimen is dimmed, and the specimen is taken out, cleaned with alcohol and then dried; and the relatively clear original austenite structure can be observed under a microscope. The invention has the advantages of solving the problem of different display of the high-intensity ship plate austenite grains and clearly displaying the austenite structure; besides, the invention is easy and simple to implement.

Owner:NANTONG WANBAO IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com