Patents

Literature

611 results about "Mechanical sensor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Systems and methods for electrode contact assessment

ActiveUS20070100332A1Increase contact pressureReduce contact pressureCatheterDiagnostic recording/measuringElectricityDistal portion

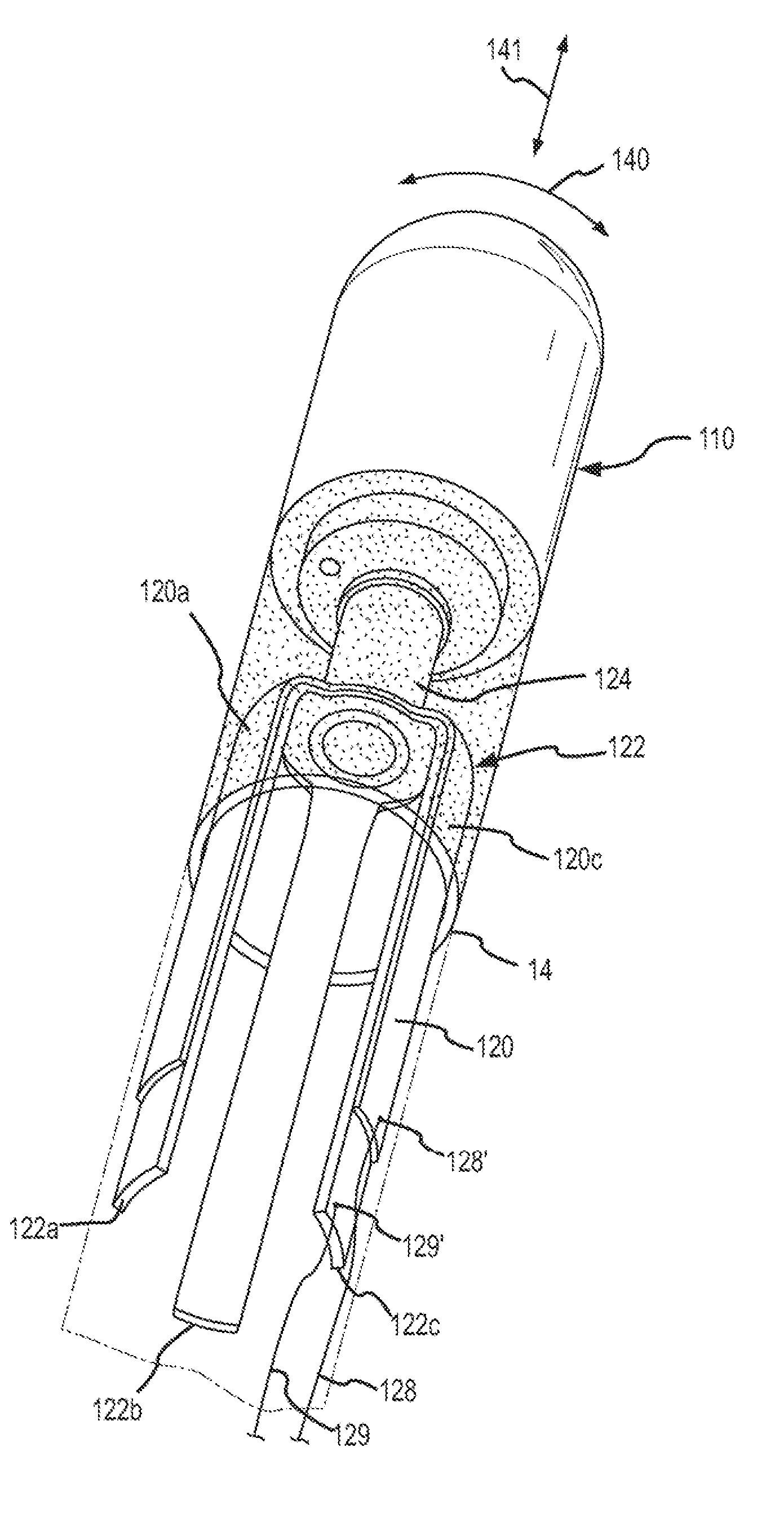

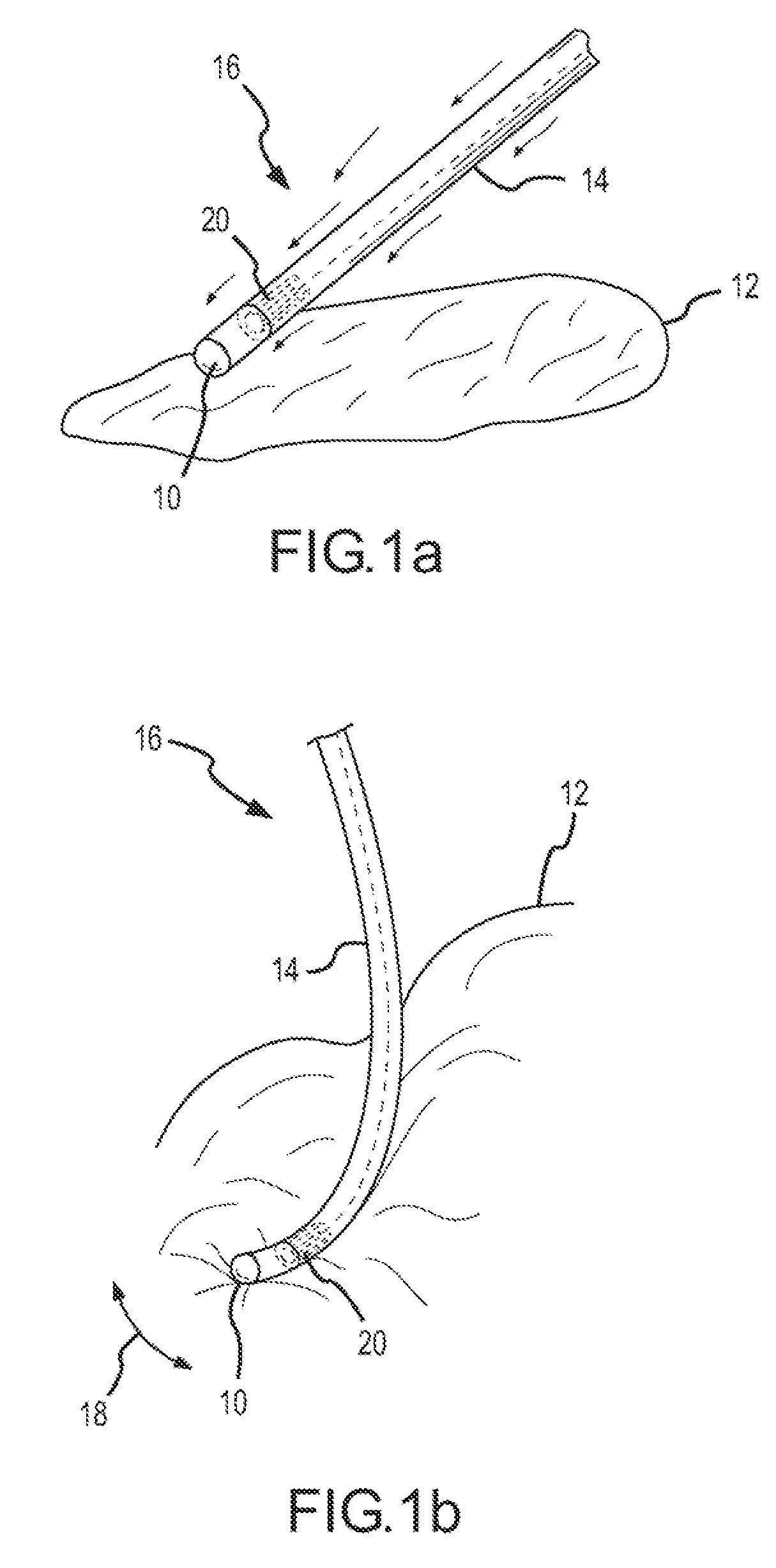

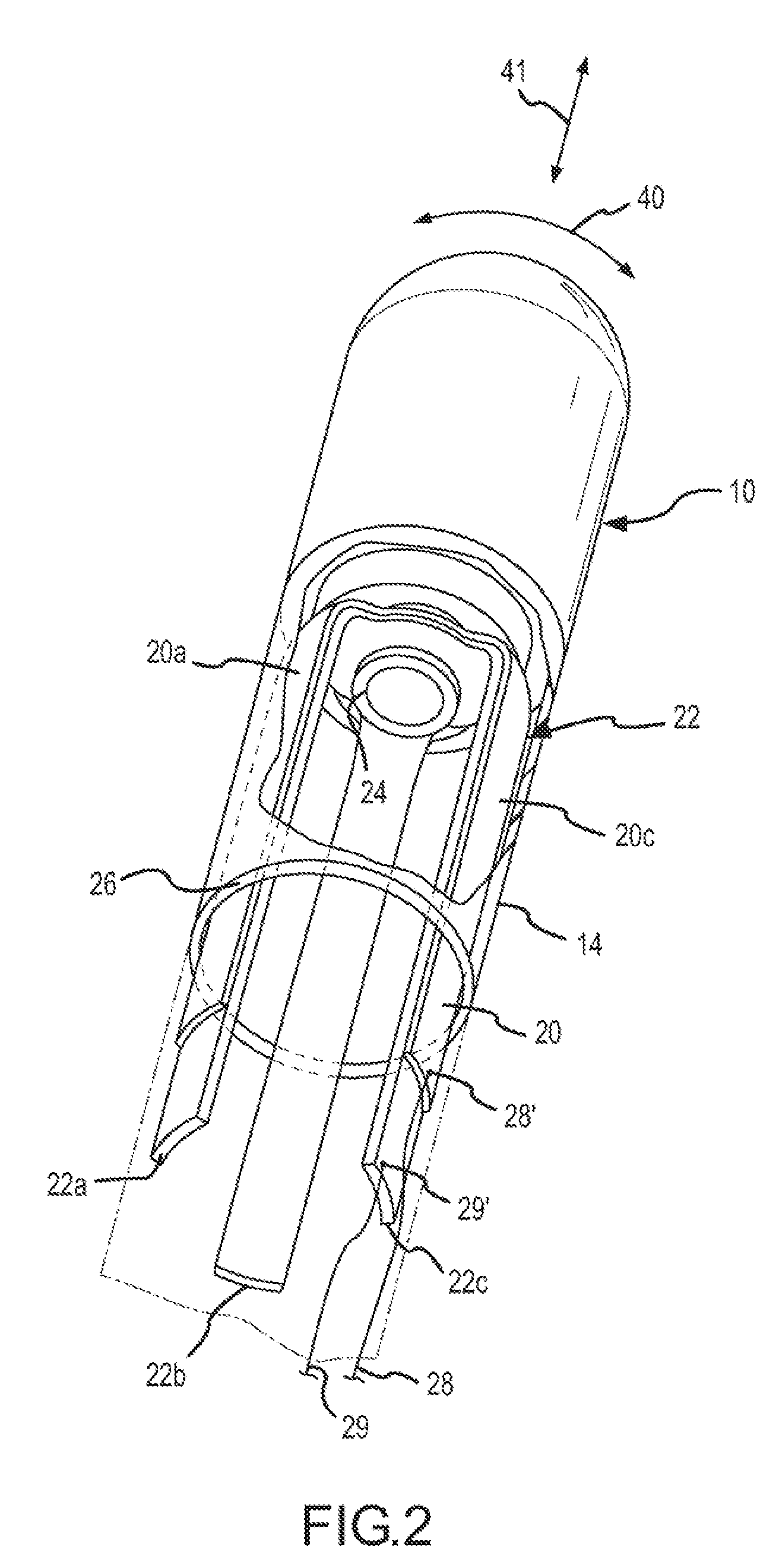

Systems and methods are disclosed for assessing electrode-tissue contact for tissue ablation. An exemplary electrode contact sensing system comprises an electrode housed within a distal portion of a catheter shaft. At least one electro-mechanical sensor is operatively associated with the electrode within the catheter shaft. The at least one electro-mechanical sensor is responsive to movement of the electrode by generating electrical signals corresponding to the amount of movement. The system may also include an output device electrically connected to the at least one electro-mechanical sensor. The output device receives the electrical signals for assessing a level of contact between the electrode and a tissue.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

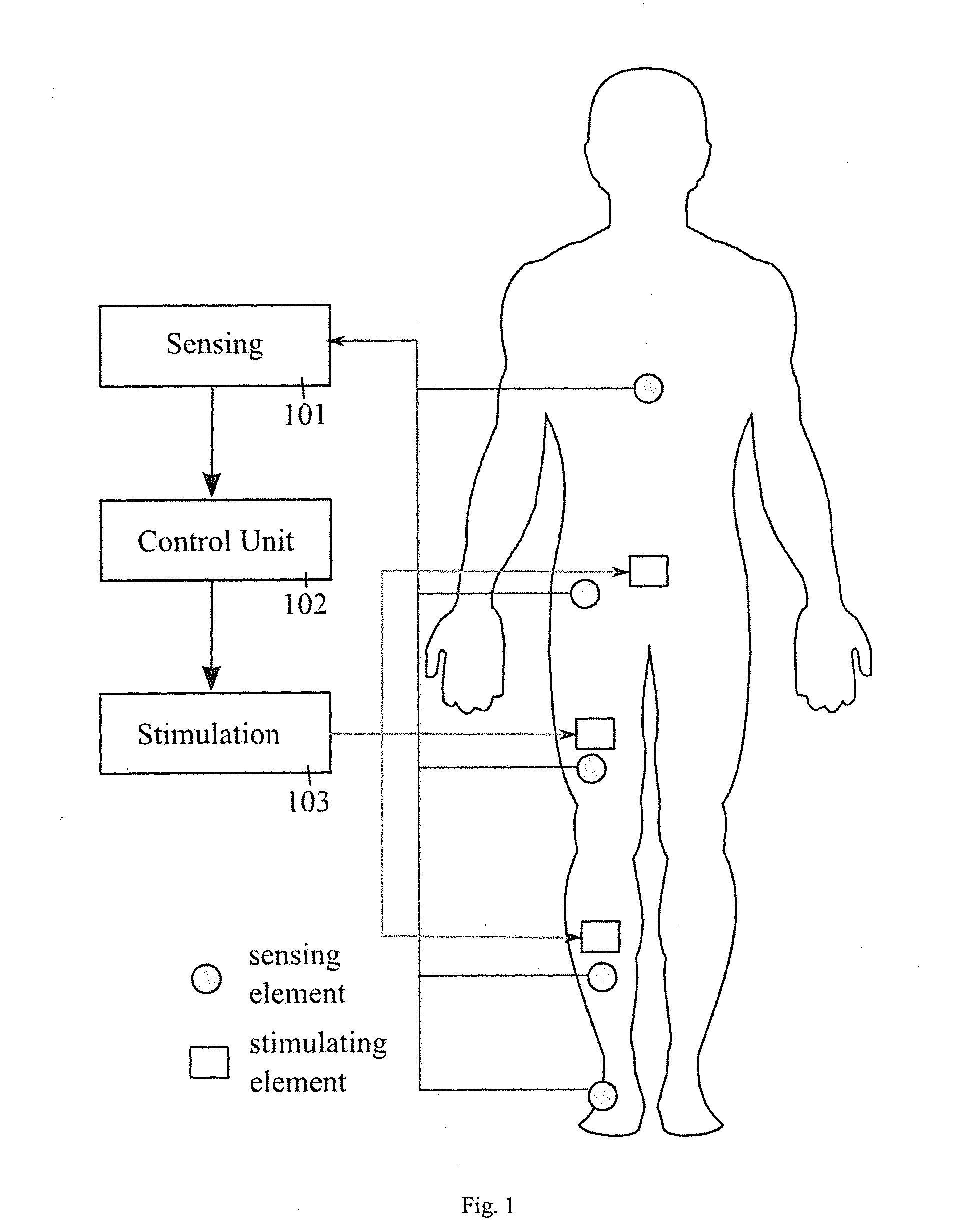

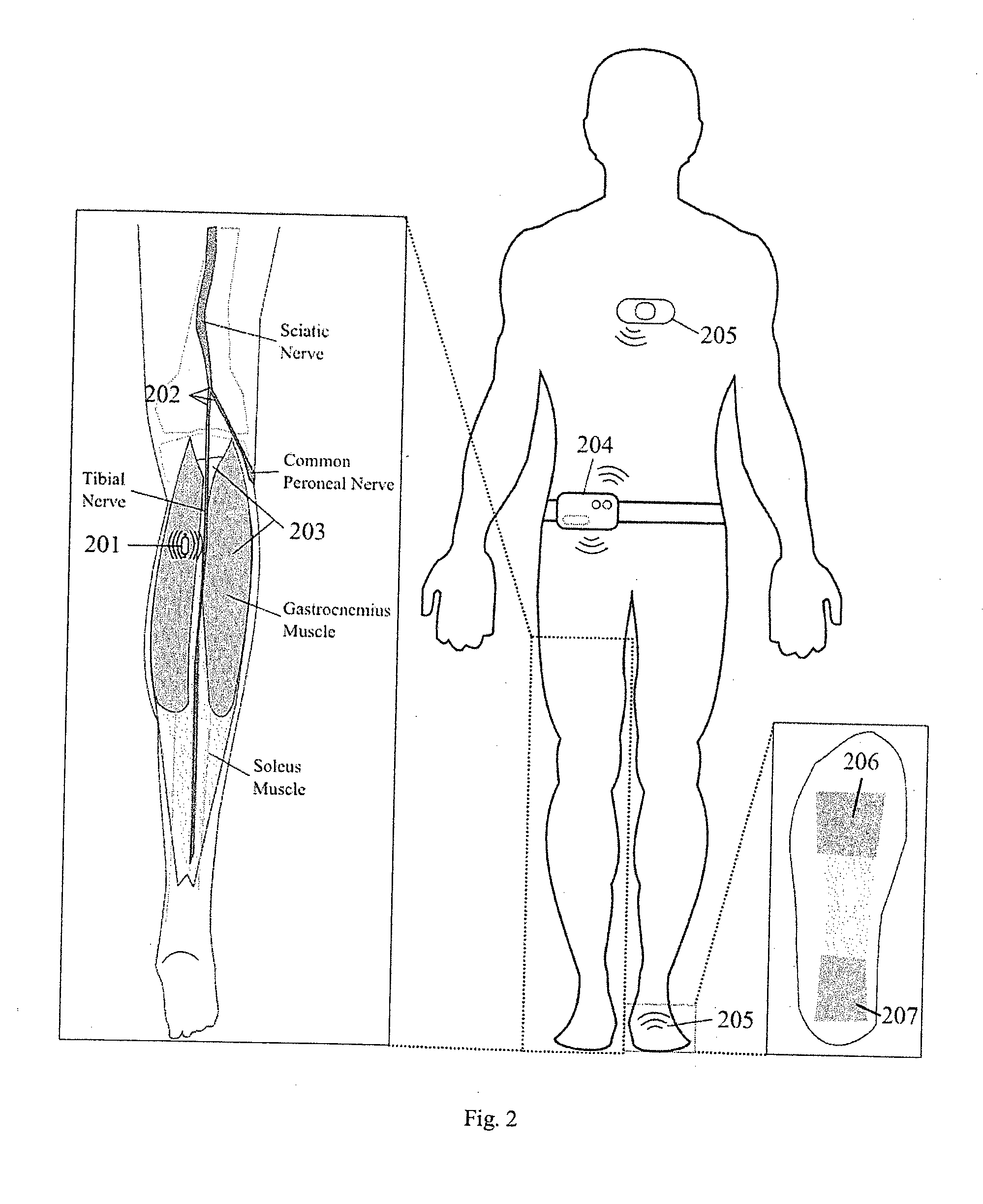

Apparatus and methods for prevention of syncope

ActiveUS20140358193A1Easy to installRemove changeSpinal electrodesElectrocardiographyMonitoring systemFinite-state machine

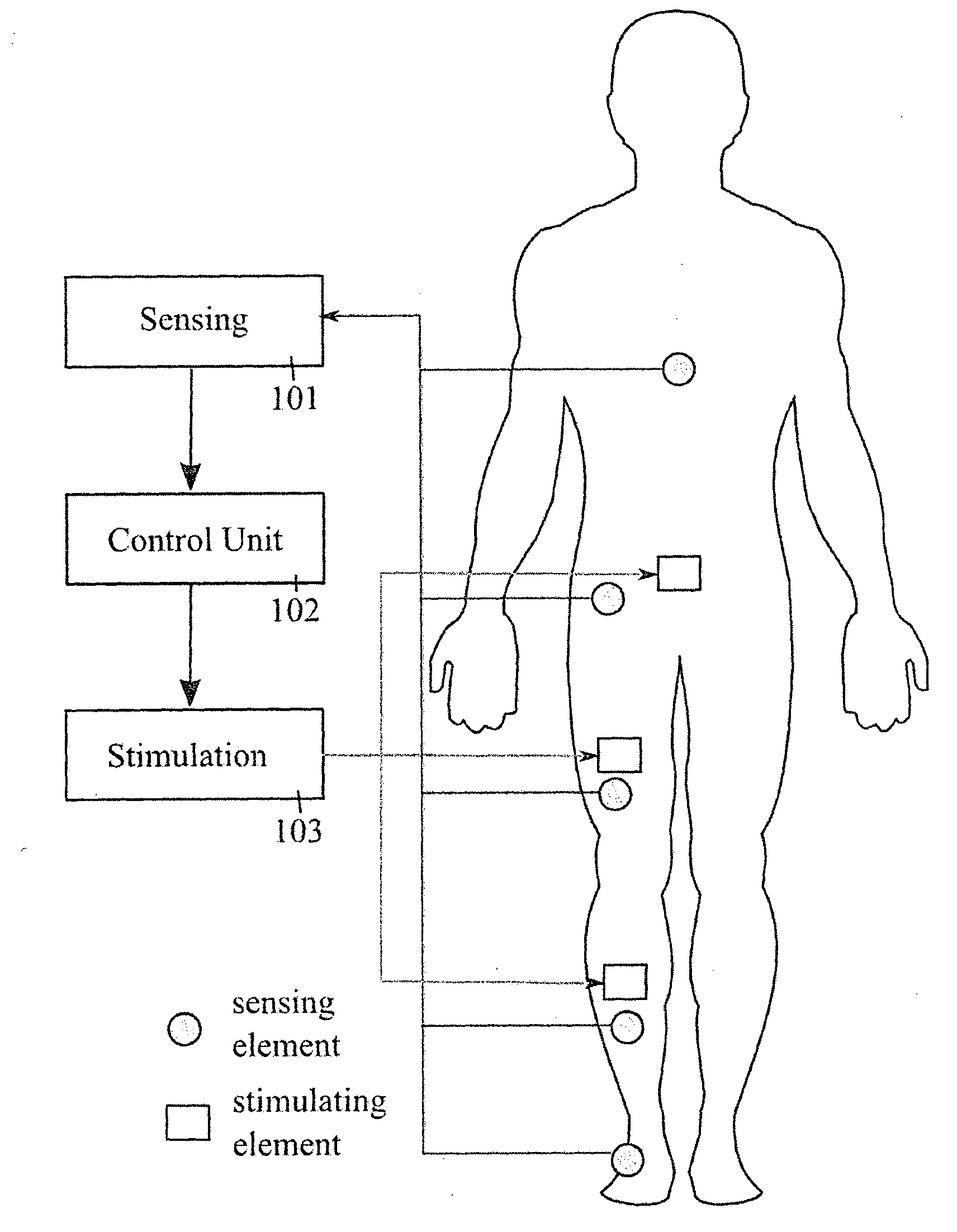

A monitoring system has biomechanical sensors, physiological sensors and a controller which receive sensory inputs from the sensors to provide output signals for the output device, and it detects from the sensory inputs risk of a syncopal event The bio-mechanical sensors include sensors arranged to allow the processor to detect a user postures and posture transitions. The processor operates a finite state machine, in which there is a state corresponding to each of a plurality of user physical postures and to each of a plurality of transitions between said postures, and the processor determines a relevant state depending on the sensory inputs. A device output may be muscle stimulation to prevent syncope, and there are stimulation permissions associated with the finite state machine states.

Owner:THE NAT UNIV OF IRELAND GALWAY +2

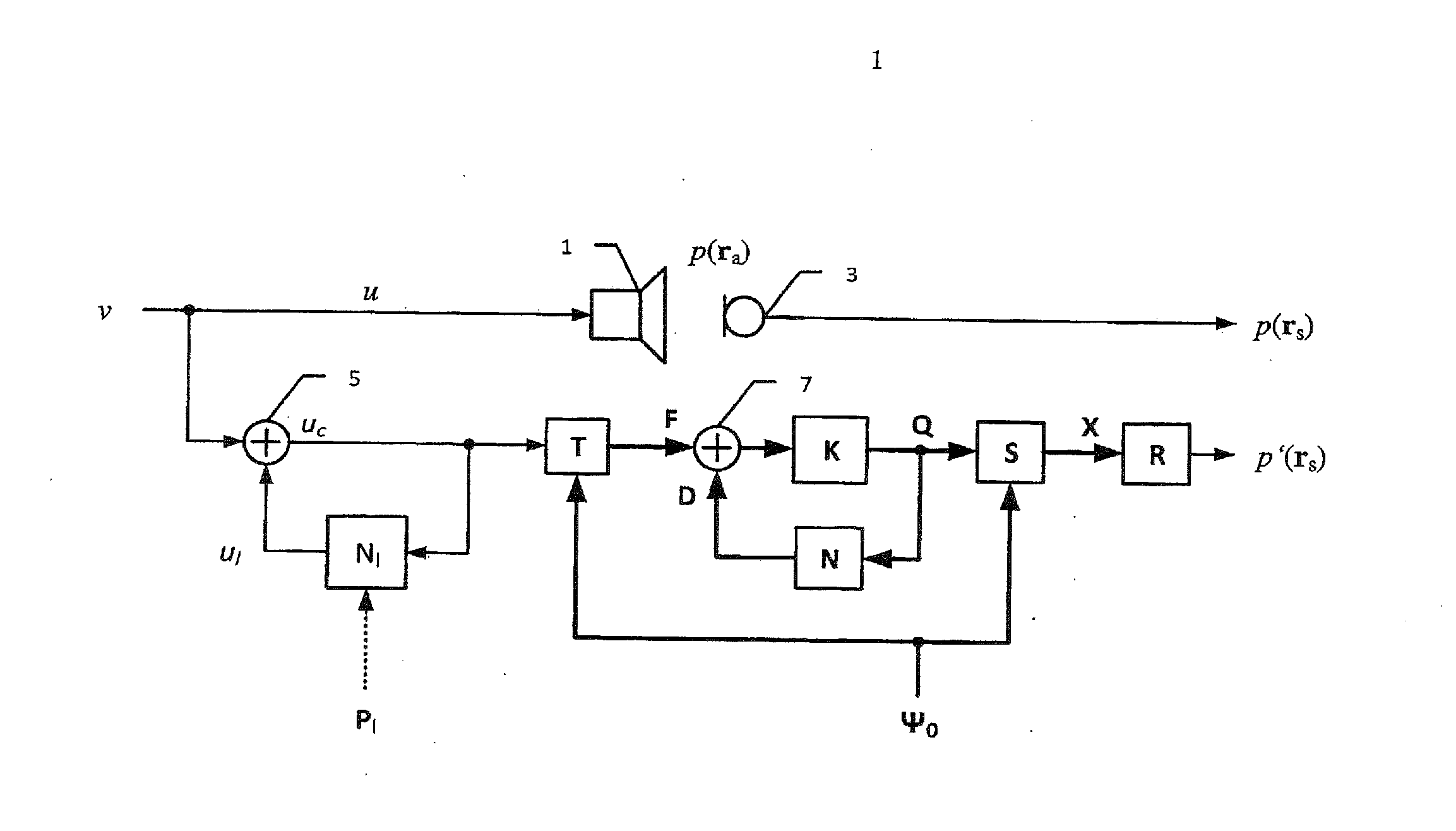

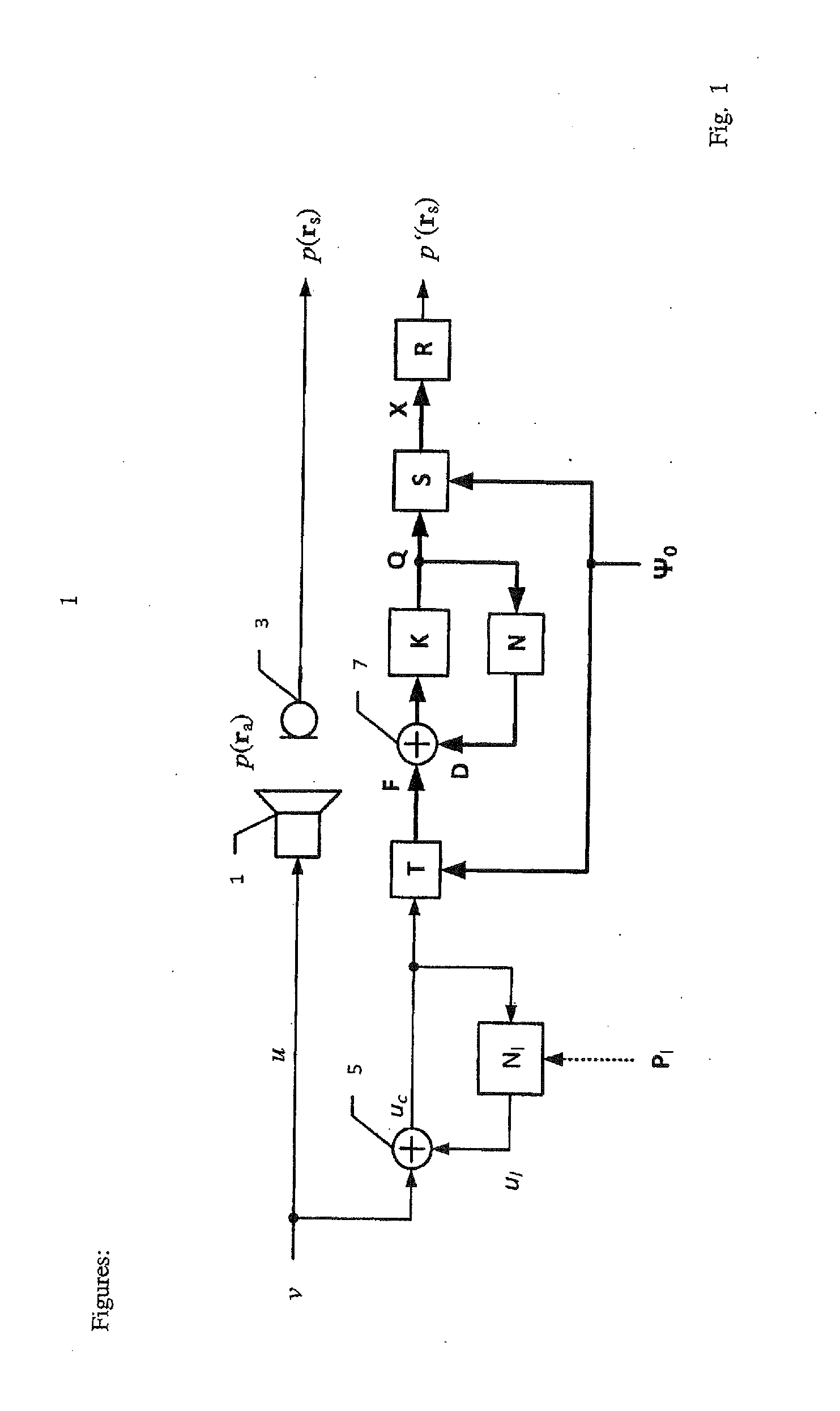

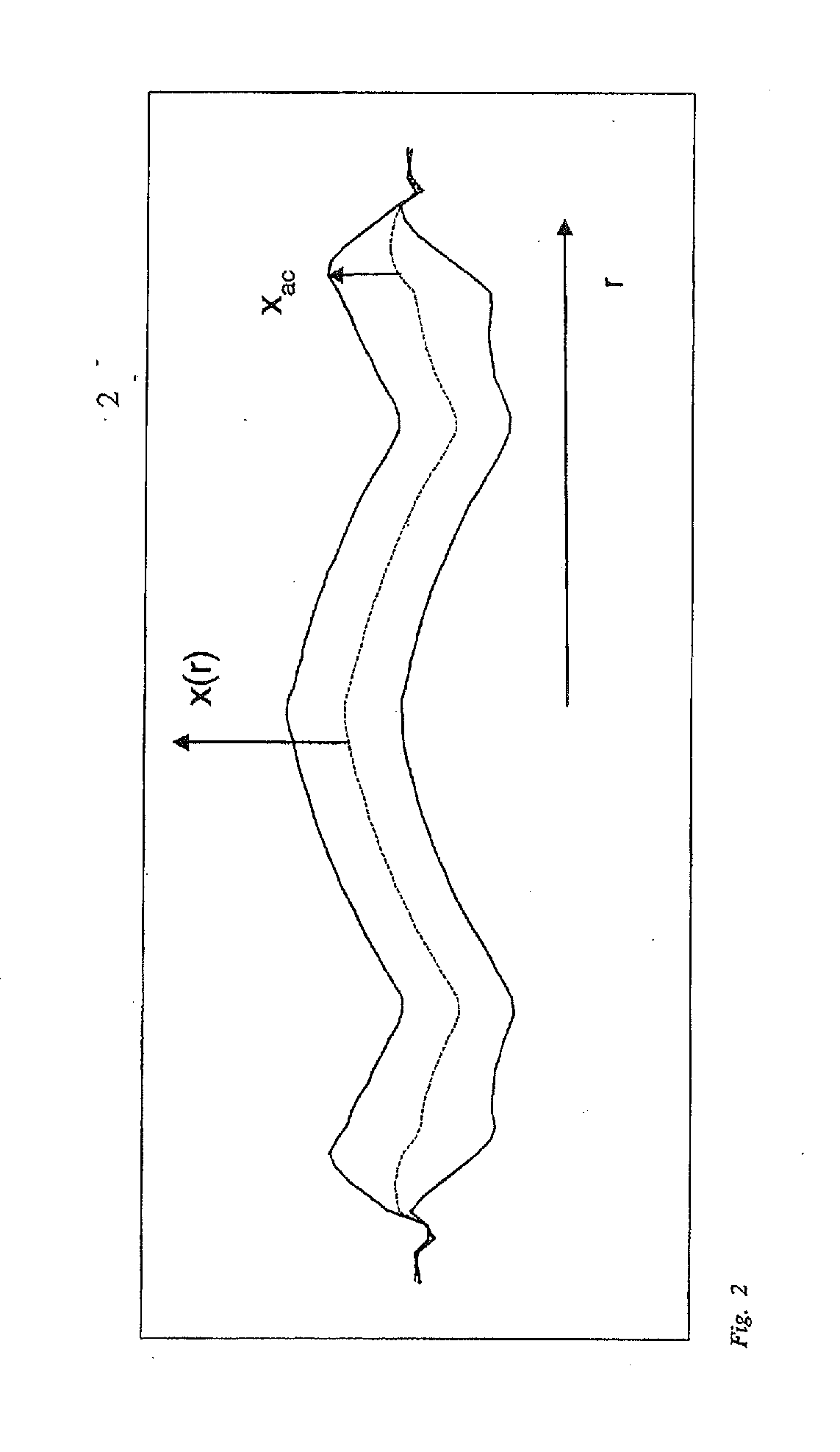

Arrangement and method for identifying and compensating nonlinear vibration in an electro-mechanical transducer

ActiveUS20150296299A1Simple structural designImprove performanceFrequency response correctionDeaf-aid setsNonlinear distortionState variable

The invention relates to an arrangement and a method for converting an input signal v into an output signal p(ra) by using an electro-mechanical transducer and for reducing nonlinear total distortion pd in said output signal p(ra), whereas the nonlinear total distortion pd contains multi-modal distortion ud which are generated by nonlinear partial vibration of mechanical transducer components. An identification system generates distributed parameters Pd of a nonlinear wave model (Nd) and lumped parameters Pl of a network model (Nl) based on electrical, mechanical or acoustical state variables of transducer measured by a sensor. The nonlinear wave model distinguishes between activation modes and transfer modes, whereas the activation modes affect the transfer modes, which transfer the input signal u into the output signal p. A control system synthesizes based on the physical modeling and identified parameters Pd and Pl nonlinear distortion signals vd and vl which are supplied with the input signal v to the transducer and compensate for the distortion signals ul and ud generated by the transducer nonlinearities.

Owner:KLIPPEL WOLFGANG

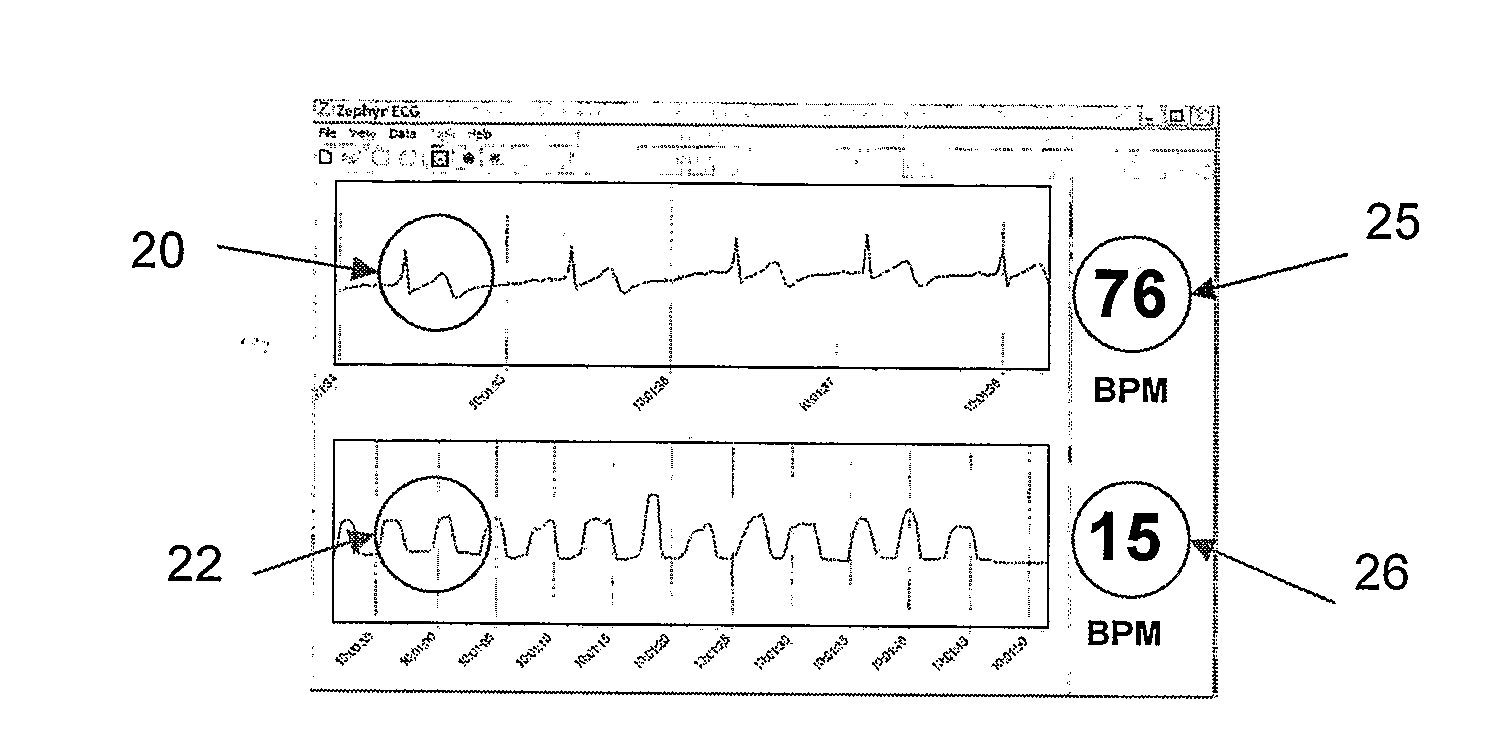

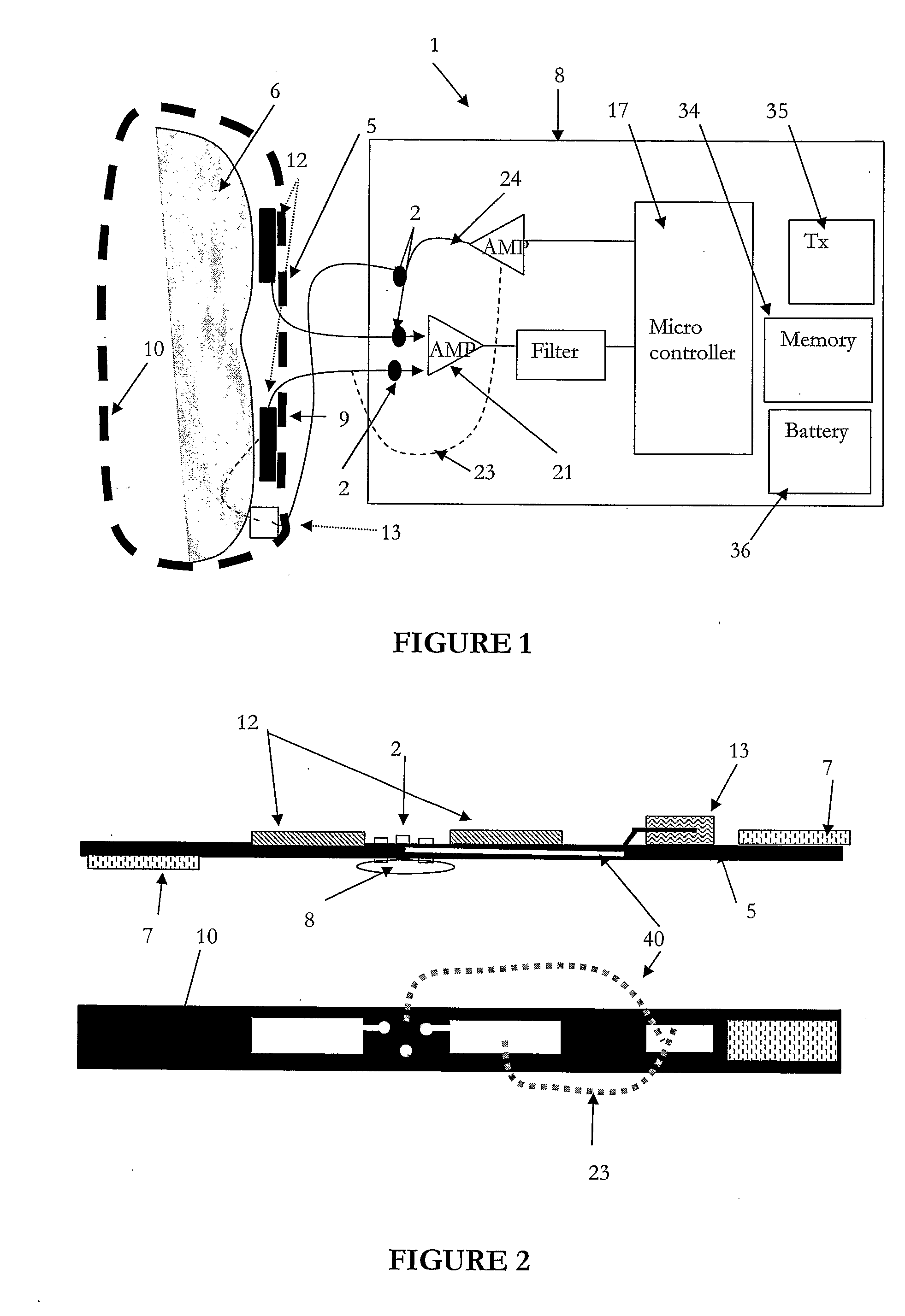

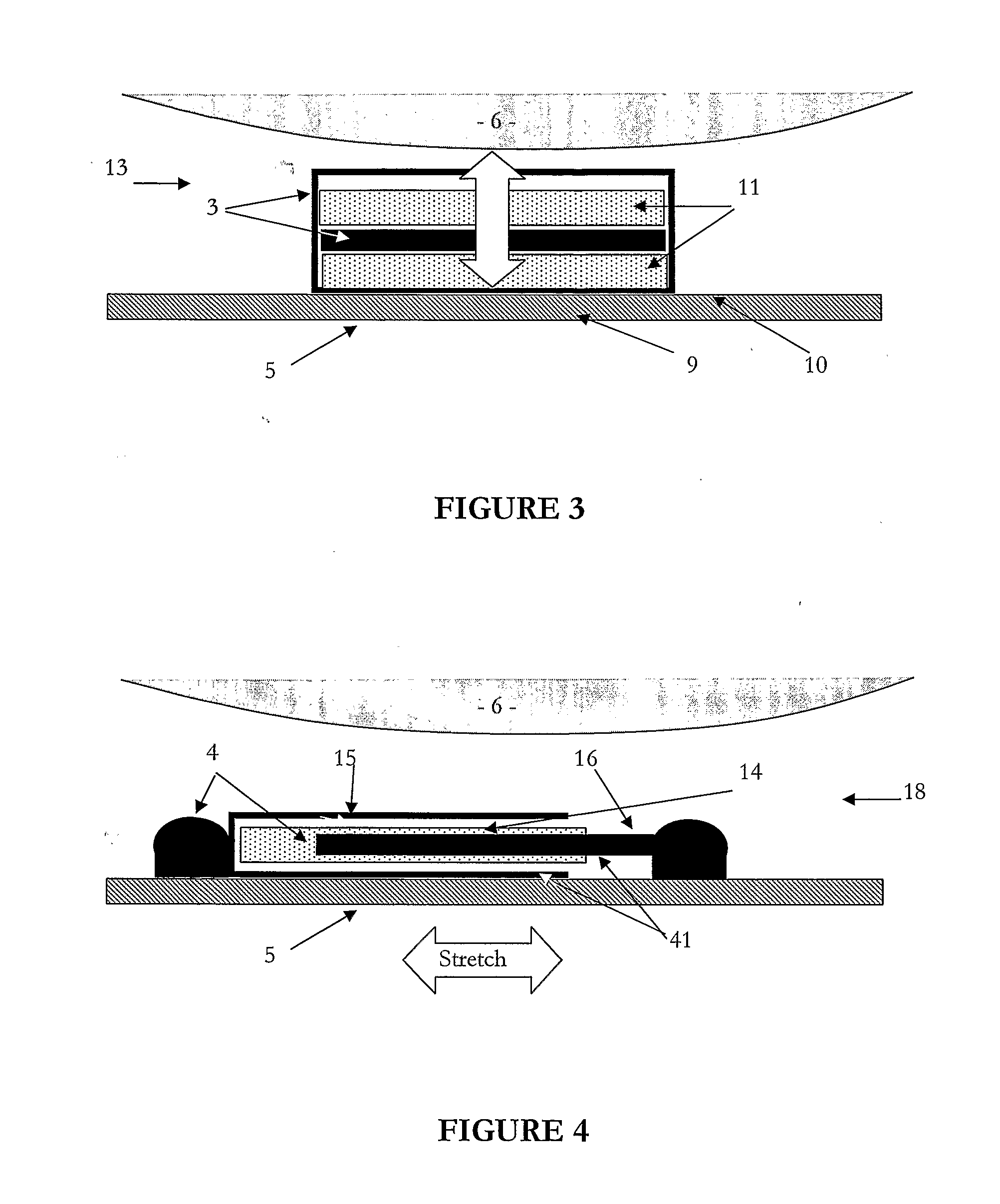

Bio-mechanical sensor system

InactiveUS20090281394A1Shorten the separation distanceSensorsTelemetric patient monitoringThird partyPulse rate

The bio mechanical sensor system is disclosed that uses conductive fabric sensors to detect, monitor and record one or more physiological parameters of a person wearing a garment that incorporates the fabric sensors such as a body harness or strap for example, that is attached to a person. The physiological parameters that can be detected include a wearer's heart rate and respiration rate plus ambient temperature and body temperature for example. The garment has a monitoring device that is attached to the garment and used to receive the detected physiological data. A processing circuit within the monitoring device then processes the data and outputs the person's physiological data to a display device in a format characteristic of the person's heart rate and respiratory rate and / or outputs the data to a third party system for review and analysis.

Owner:ZEPHYR TECH CORP

Non-contact passive temperature measuring system and method of operation using micro-mechanical sensors

InactiveUS6050722AAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesThermal energyEmissivity

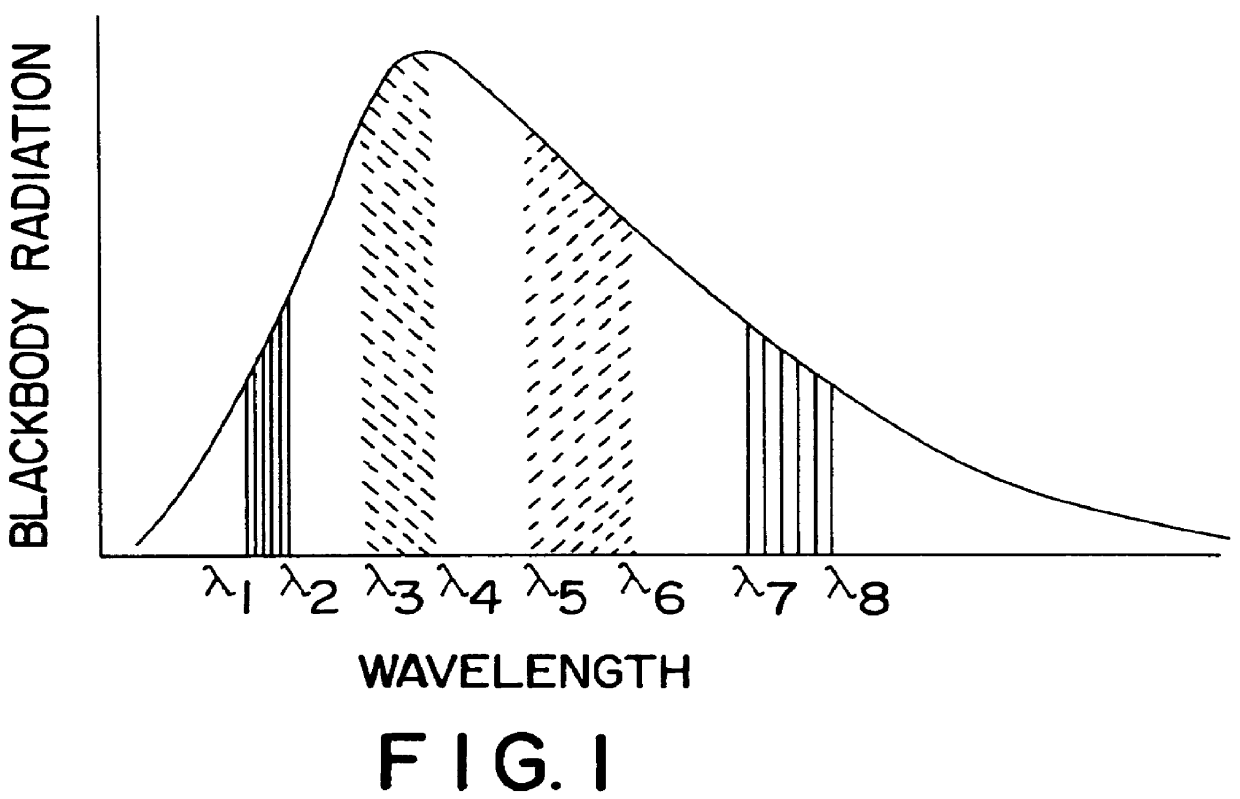

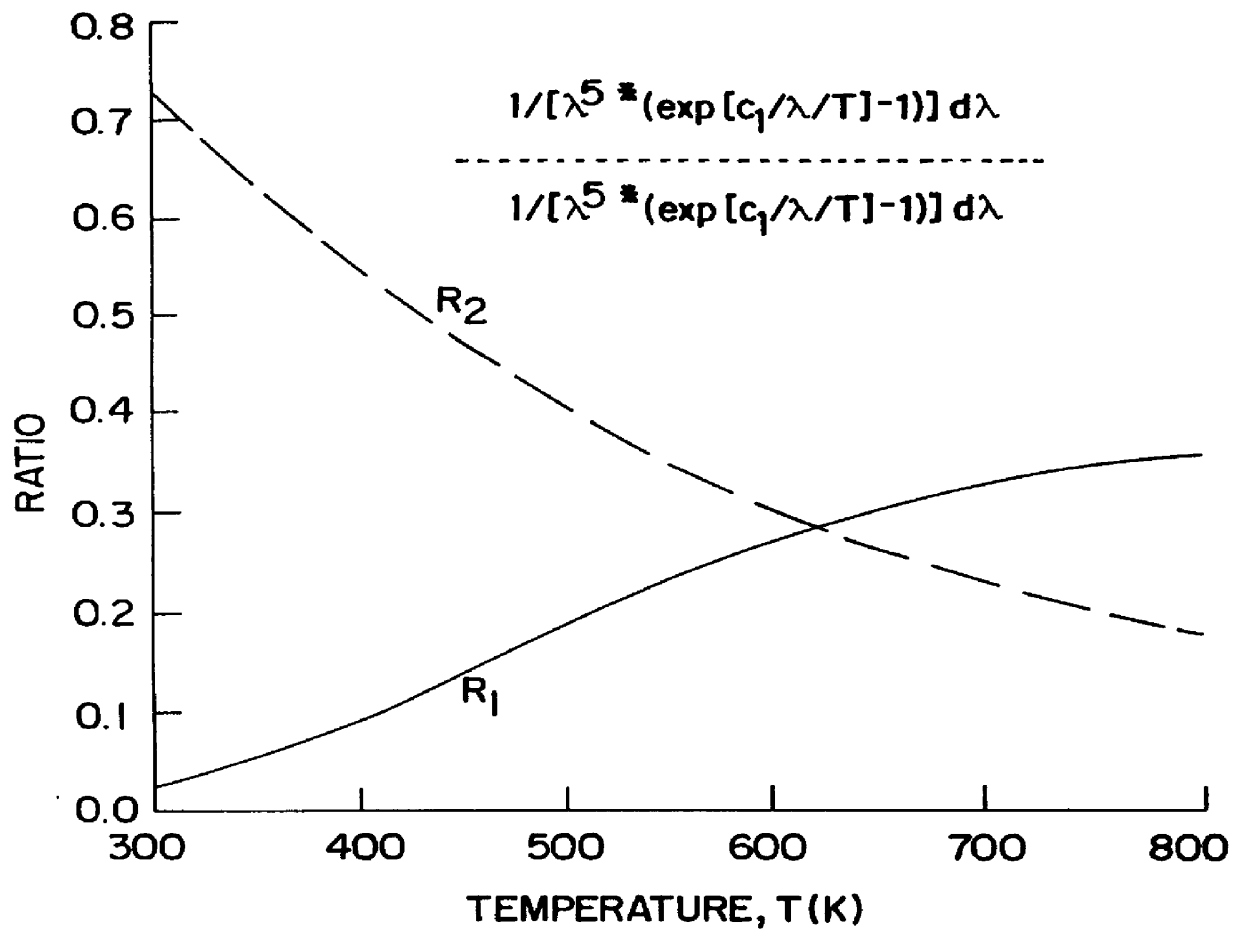

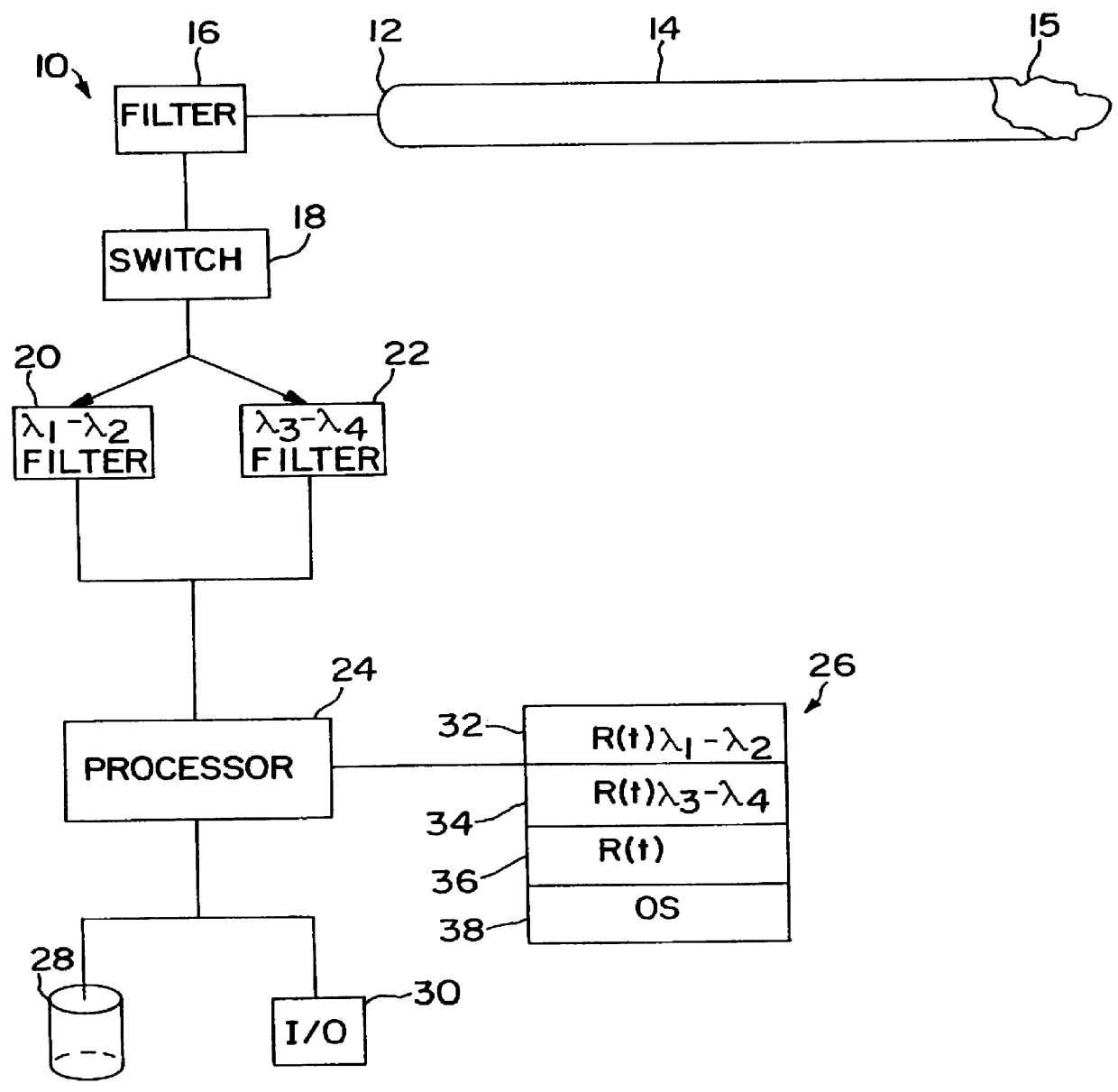

A non-contact infrared thermometer measures target temperatures remotely without requiring the ratio of the target size to the target distance to the thermometer. A collection means collects and focusses target IR radiation on an IR detector. The detector measures thermal energy of the target over a spectrum using micromechanical sensors. A processor means calculates the collected thermal energy in at least two different spectral regions using a first algorithm in program form and further calculates the ratio of the thermal energy in the at least two different spectral regions to obtain the target temperature independent of the target size, distance to the target and emissivity using a second algorithm in program form.

Owner:LOCKHEED MARTIN ENERGY SYST INC

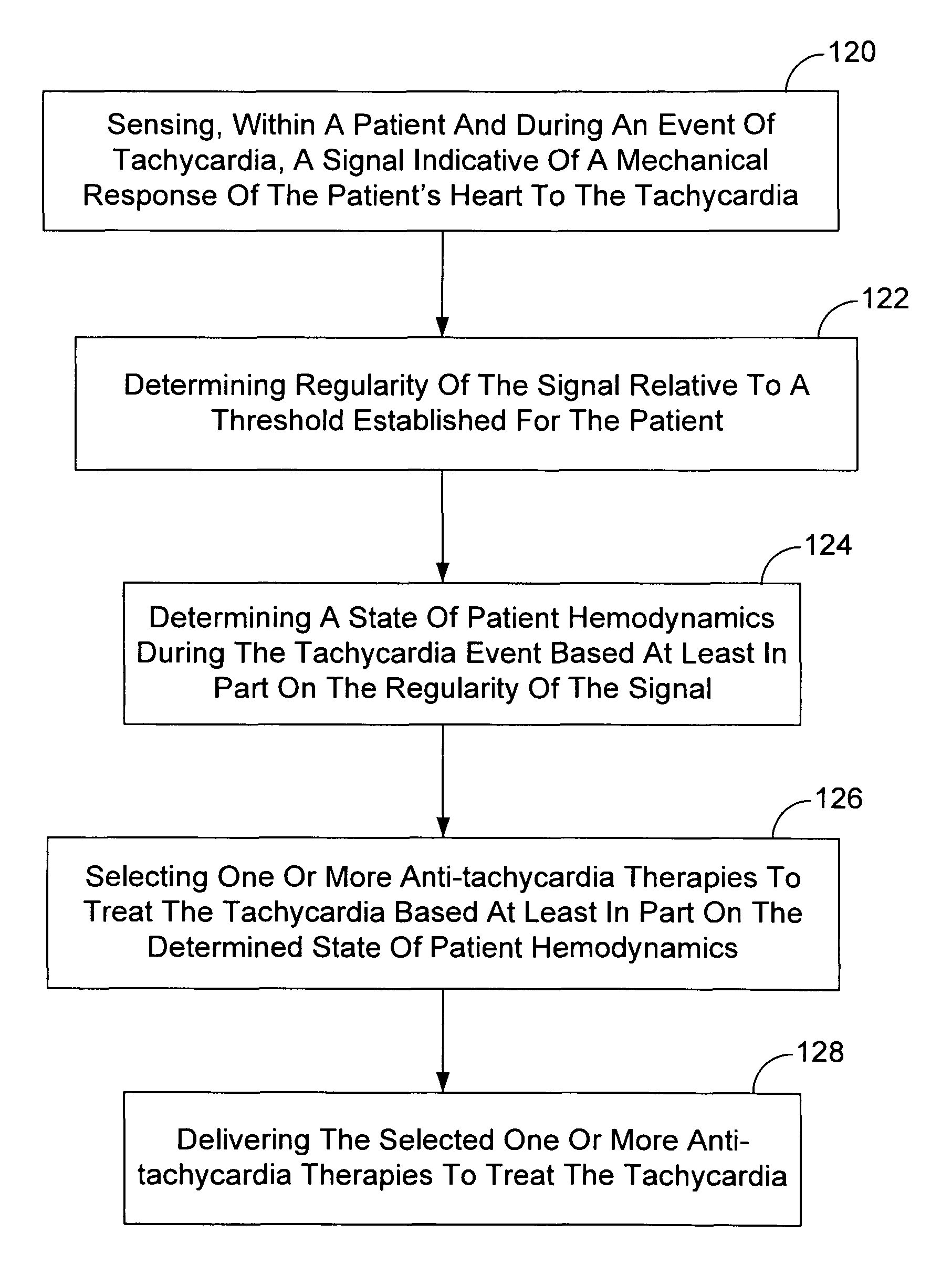

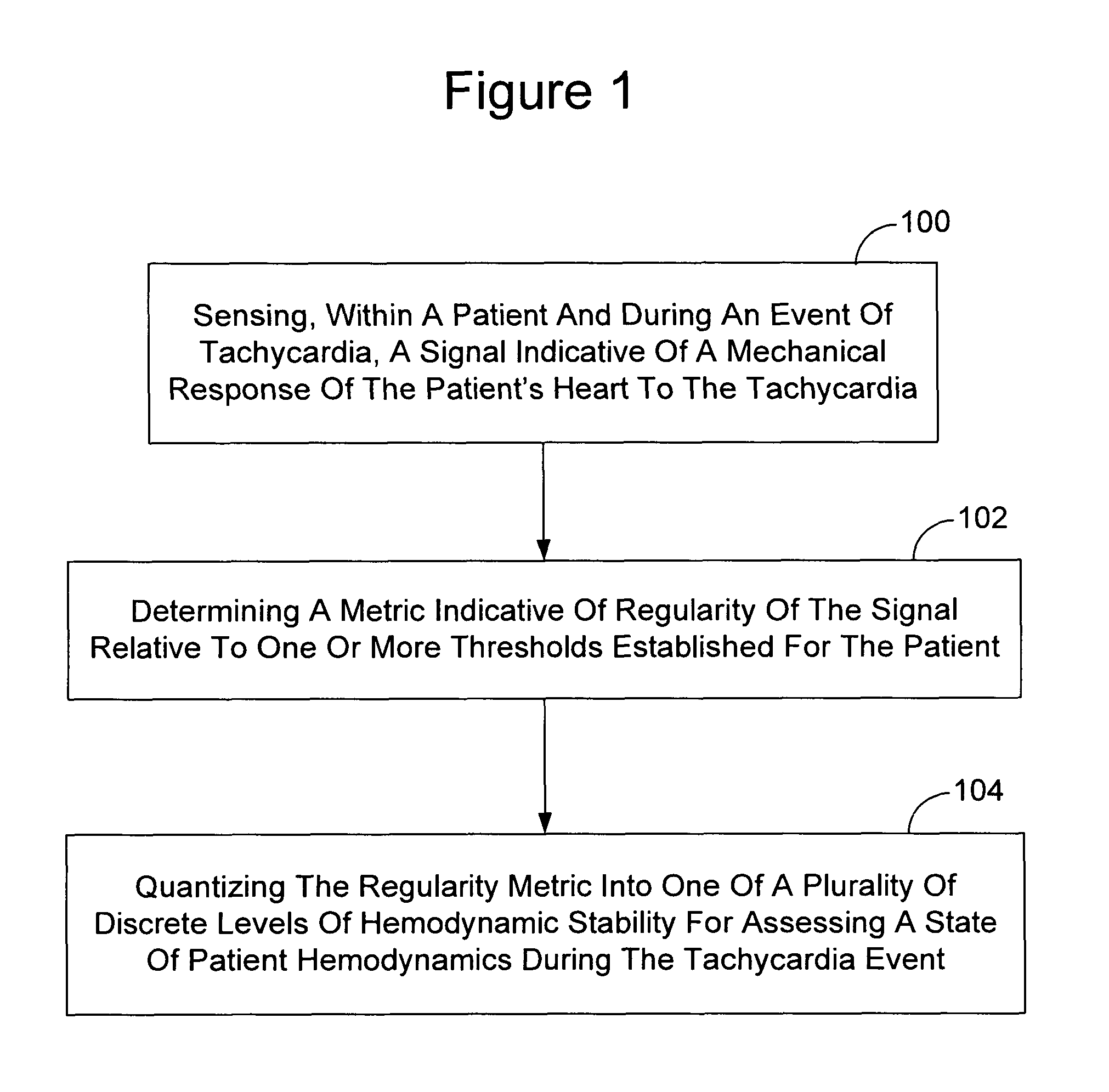

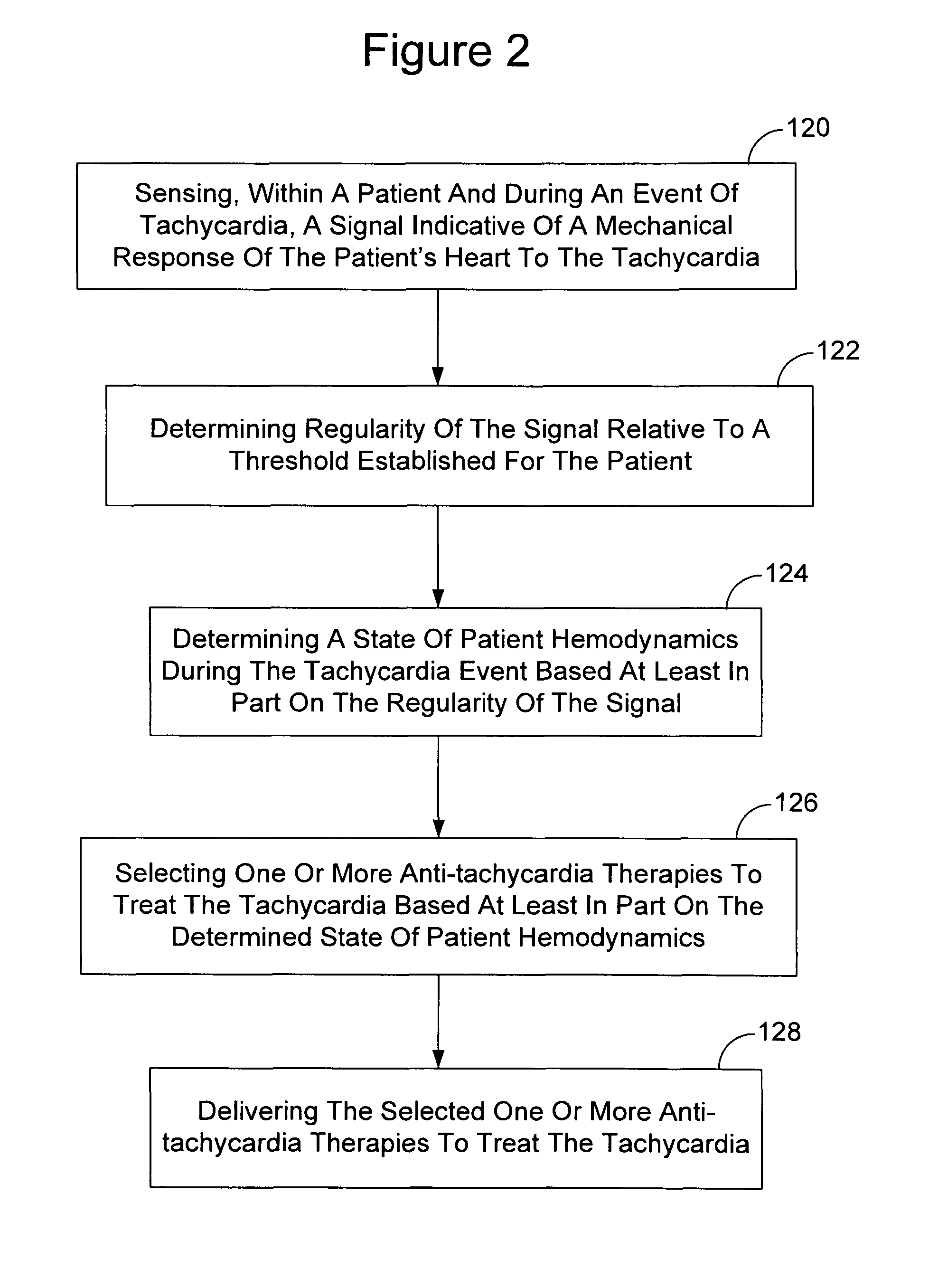

Tachycardia hemodynamics detection based on cardiac mechanical sensor signal regularity

Owner:CARDIAC PACEMAKERS INC

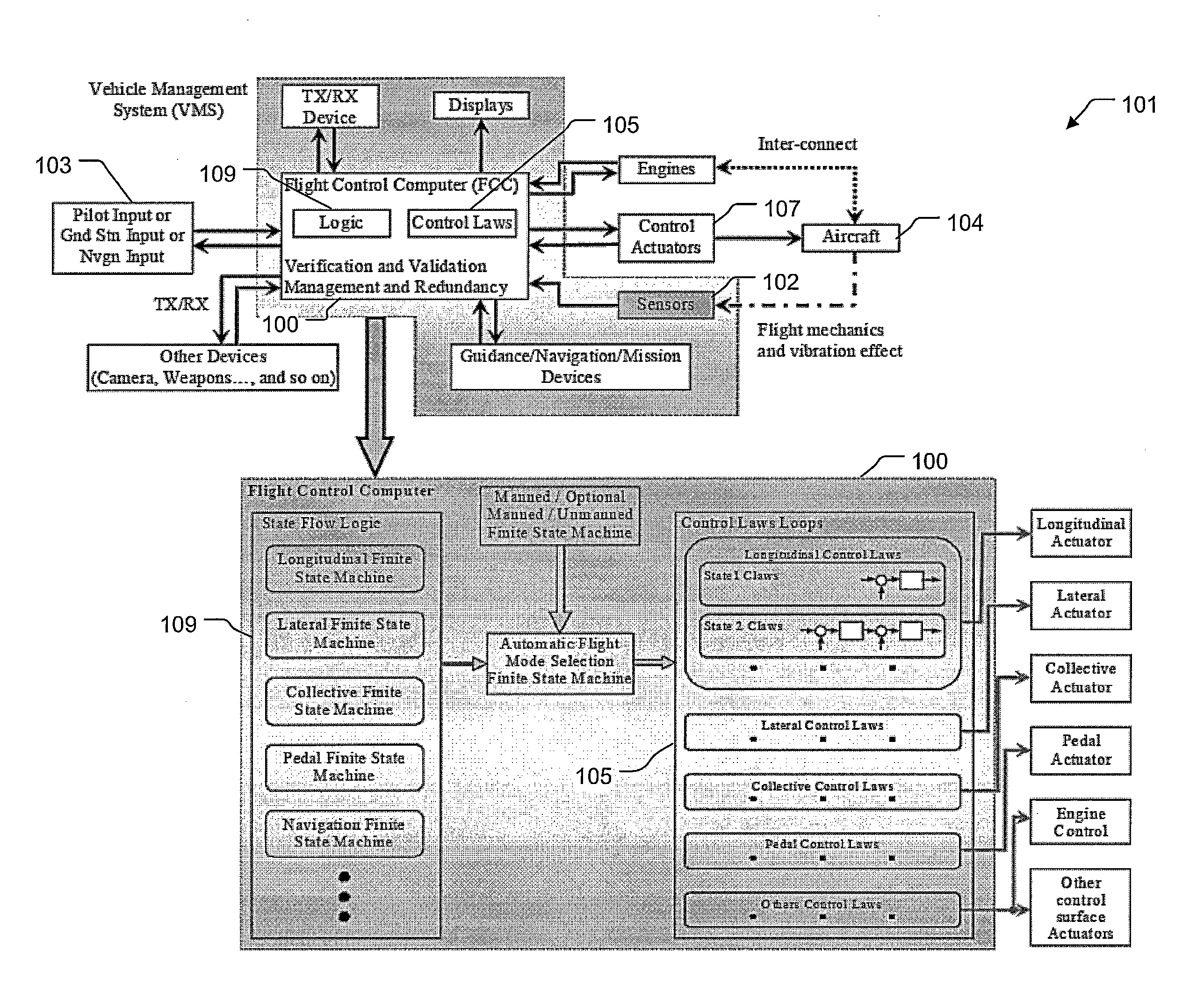

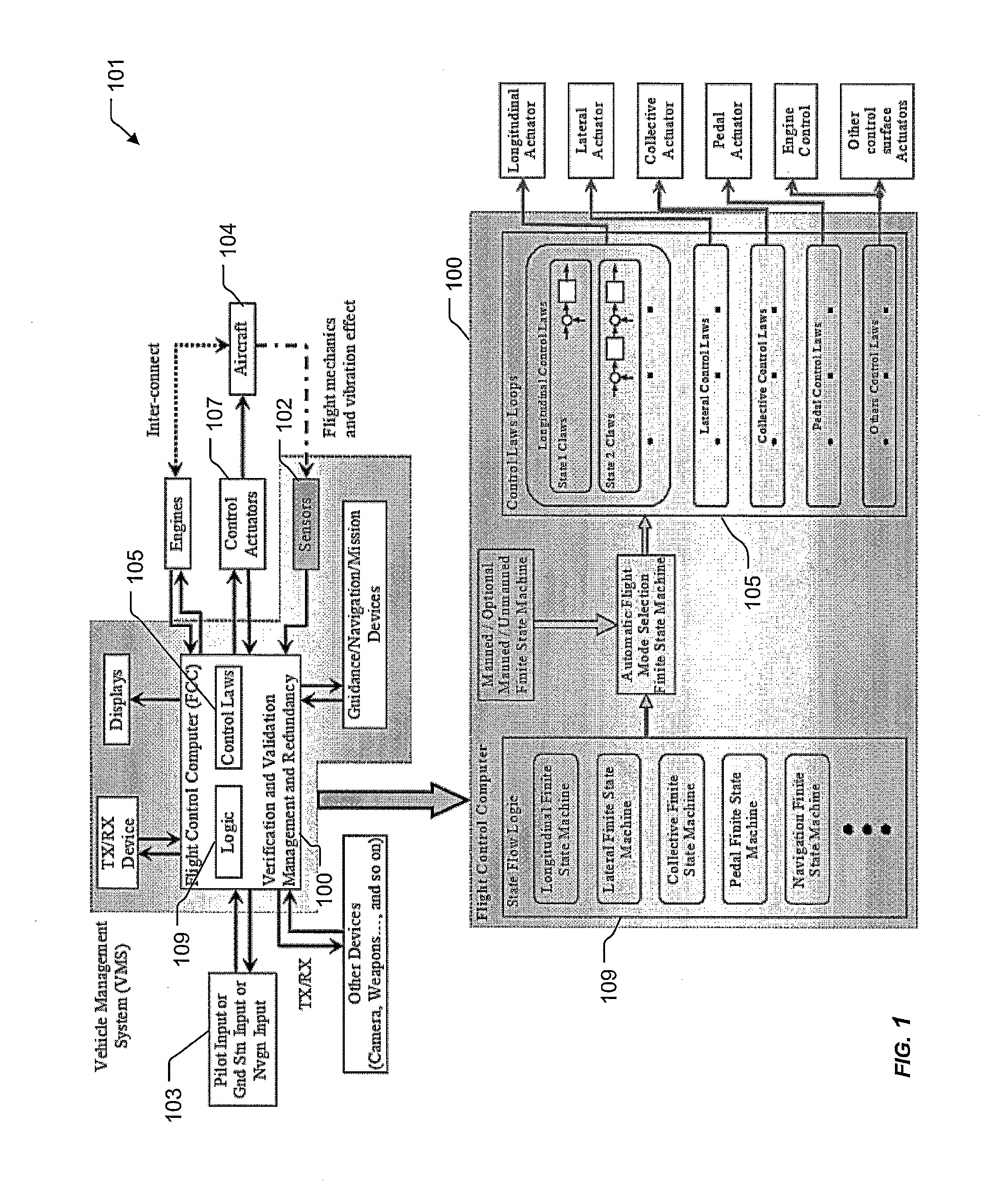

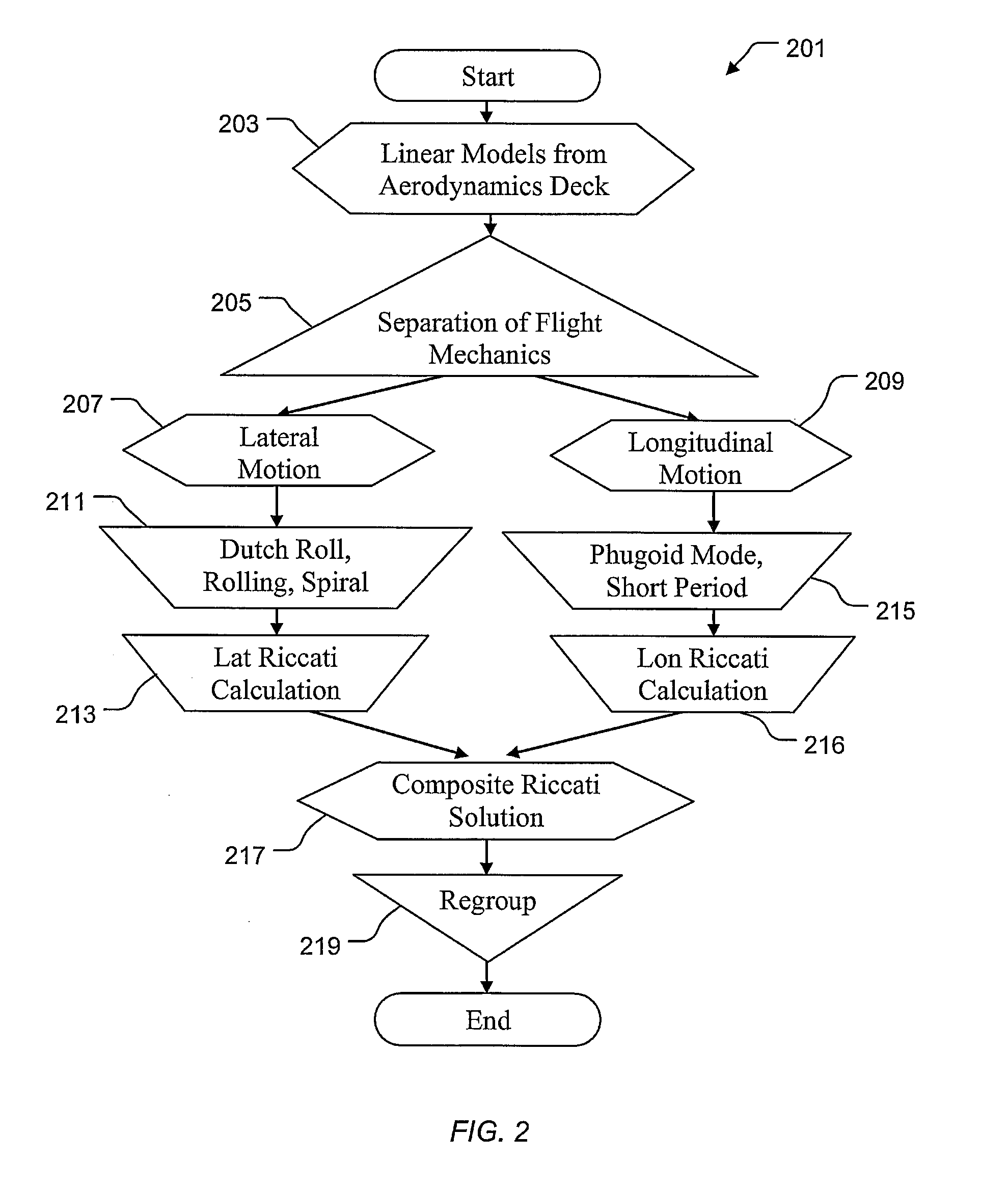

Vehicle management system using finite state machines

A system includes a plurality of actuators and a management system operably associated with the plurality electronic and mechanical devices. The management architecture includes interfaces configured to the entire electronics and mechanics to provide a parameter to a computer. The computer includes a control and management architecture using modular finite state flow designs configured to analyze the parameter. The computer with a plurality of finite state machines can conduct a plurality of control laws operably associated with one or more actuators for finite functions of mobility. The method includes matching the parameter with the finite state machine and controlling the actuator via control law operably associated with finite state machine. The method can therefore be achieved either manually, semi-autonomously and autonomously with seamless and switchless control using a central control computer with integration of electronic and mechanic sensors and devices.

Owner:TEXTRON INNOVATIONS

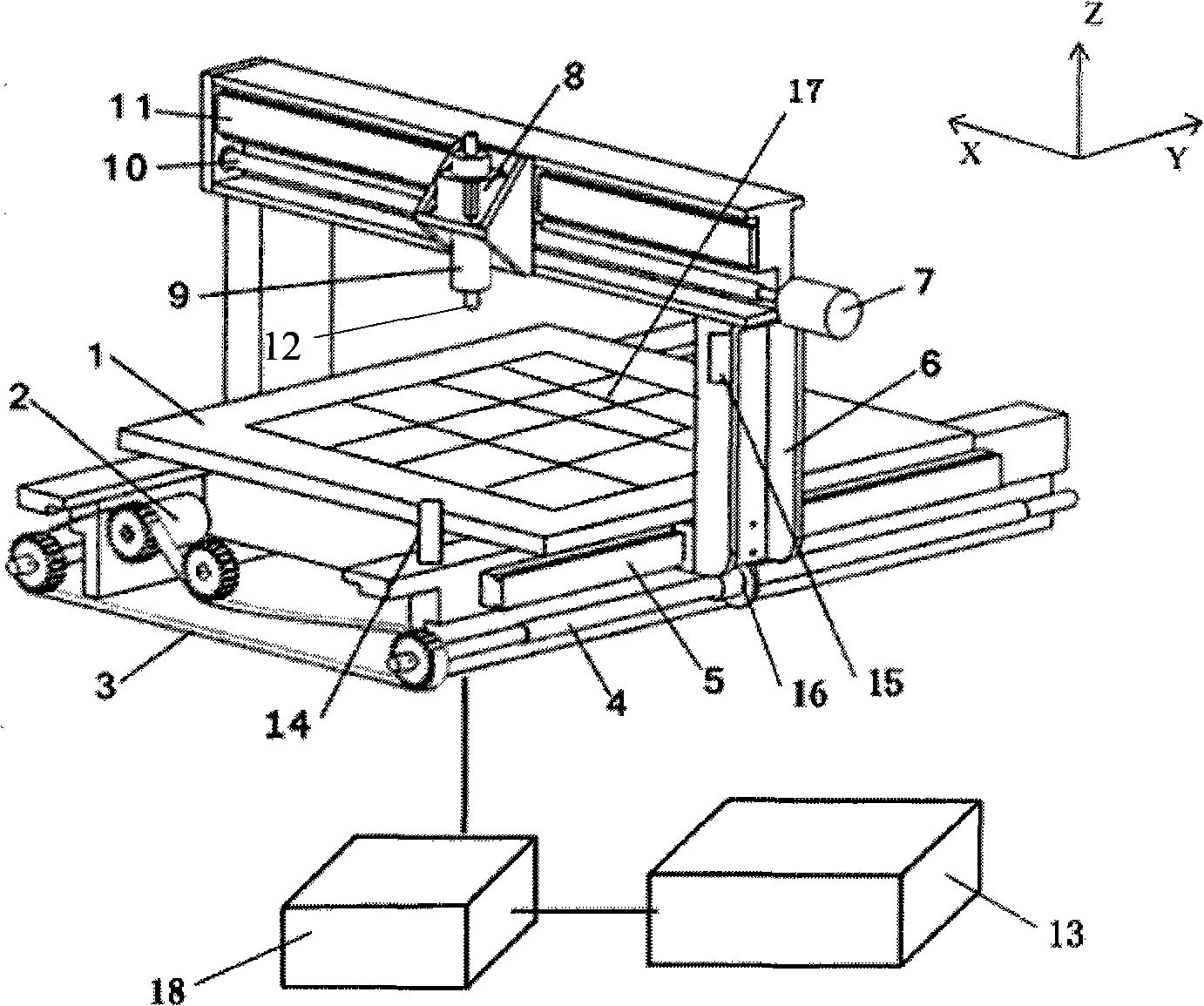

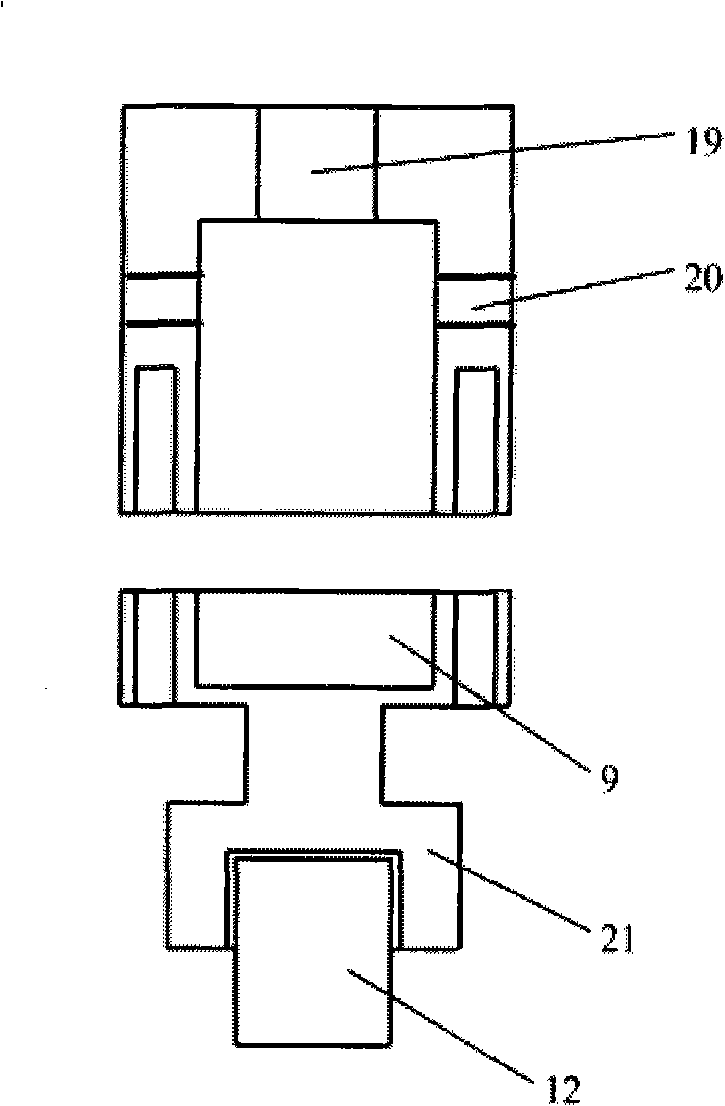

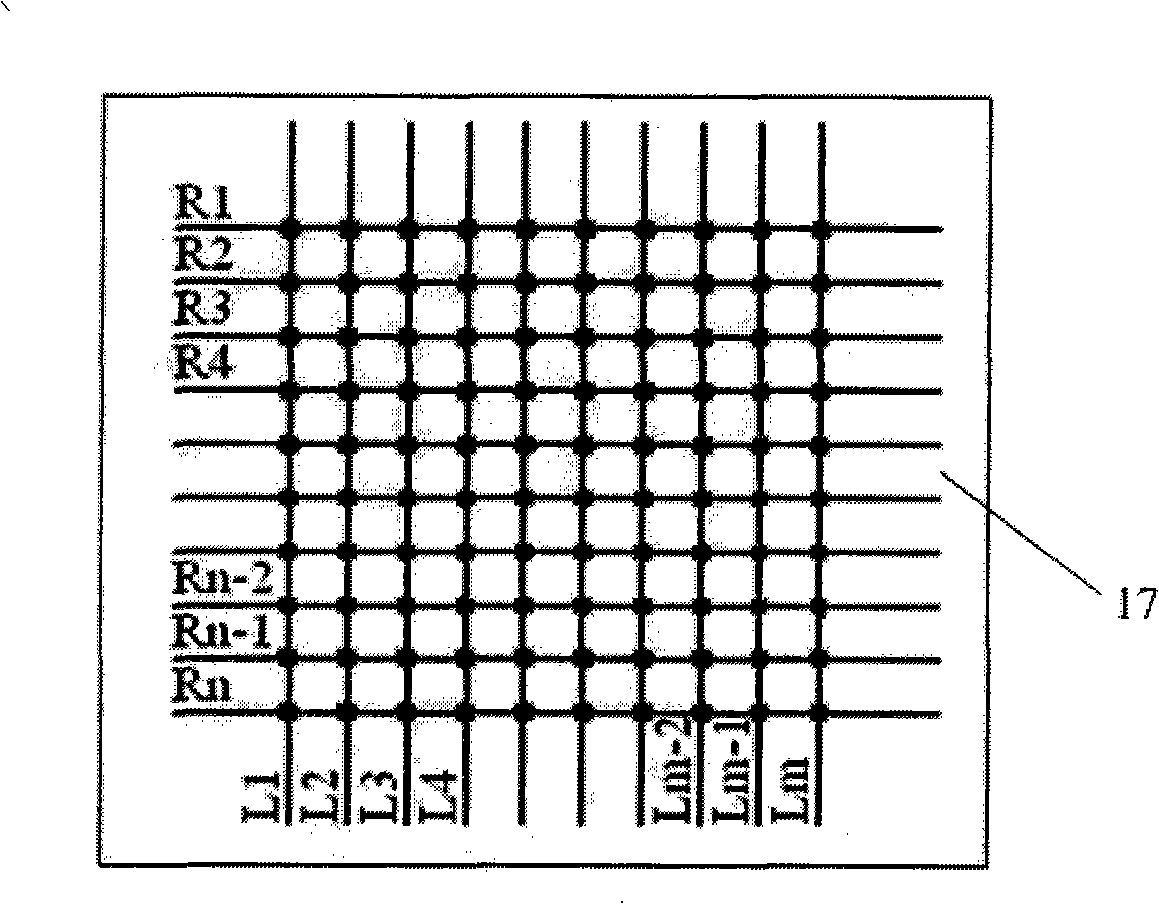

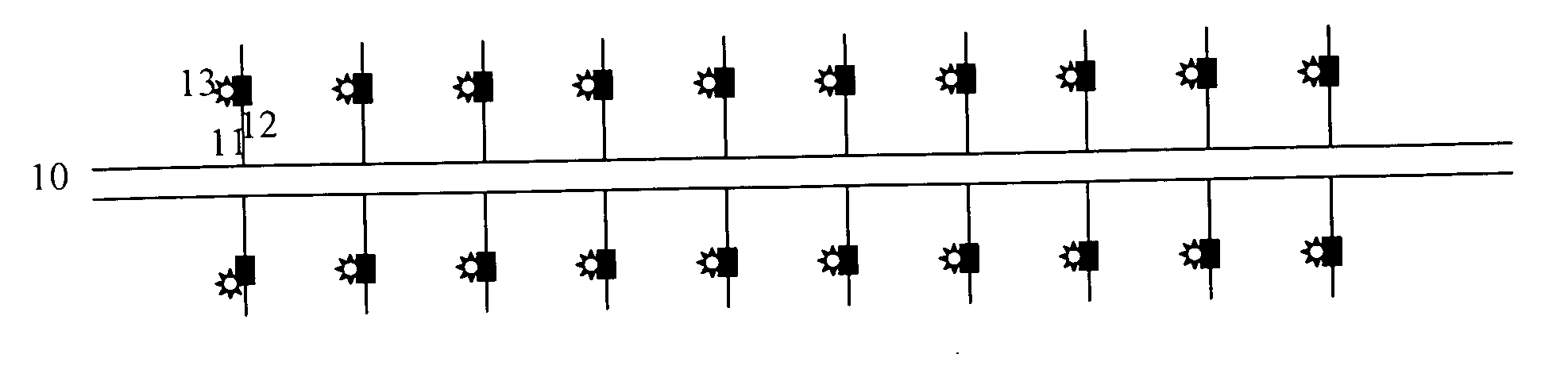

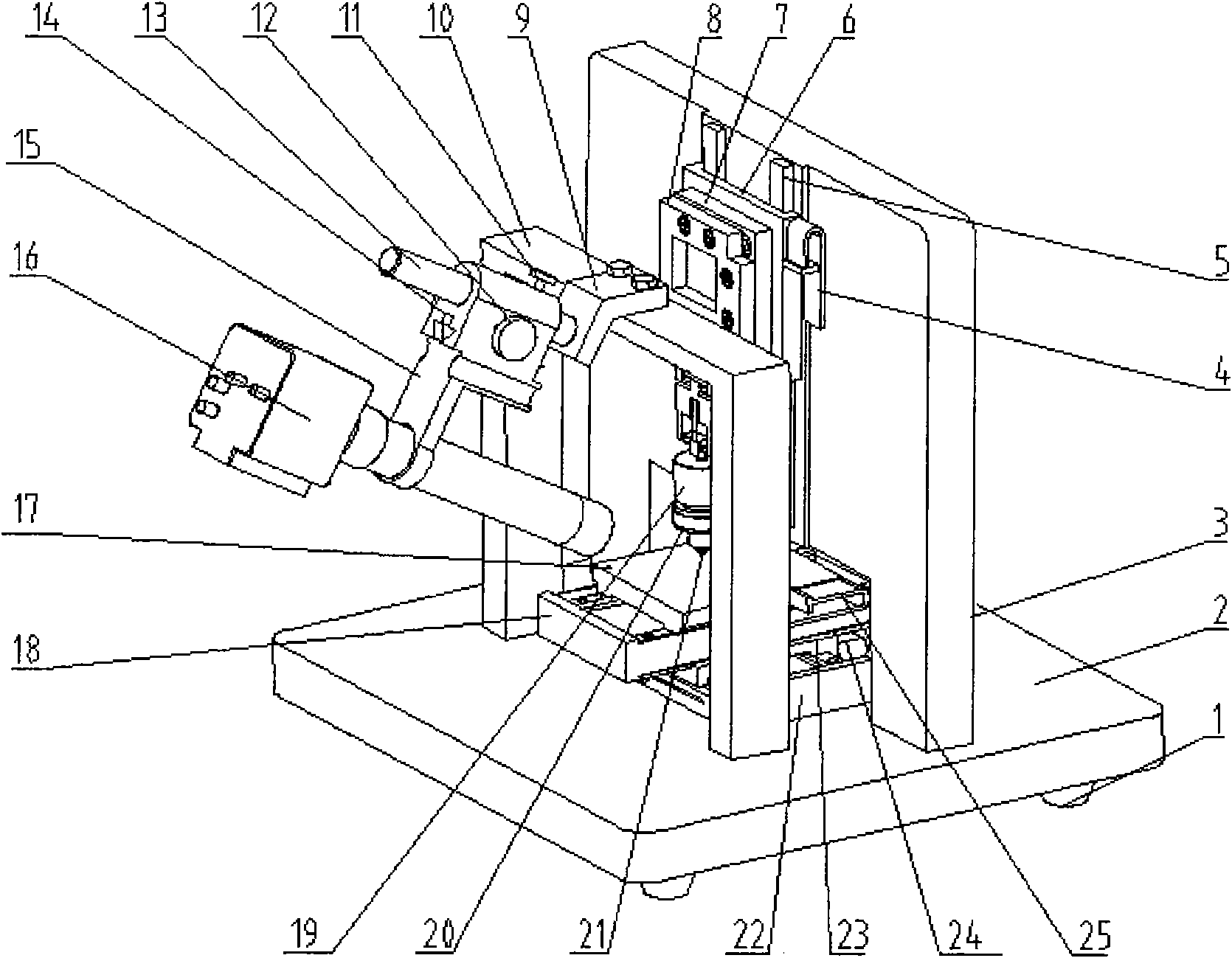

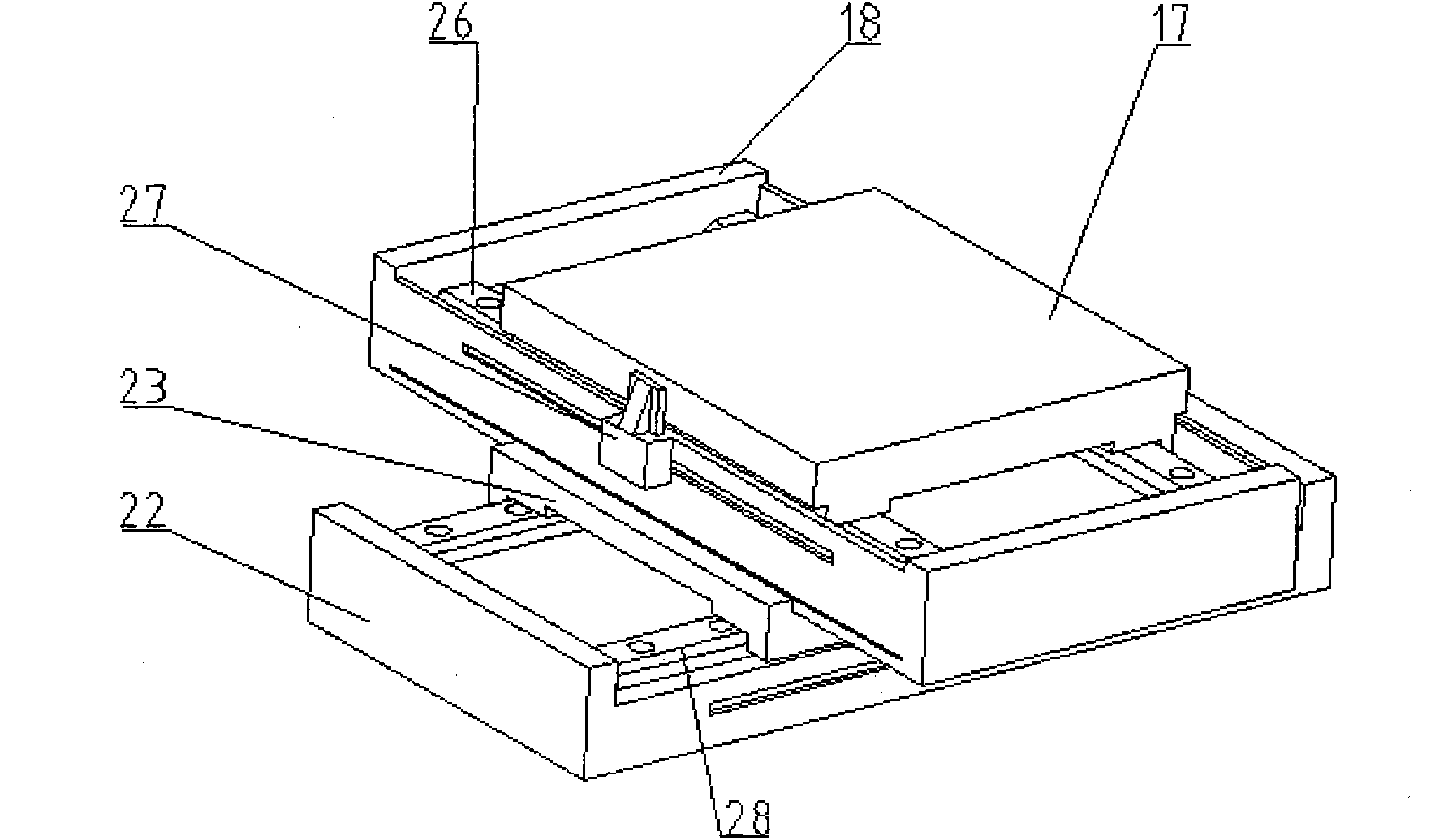

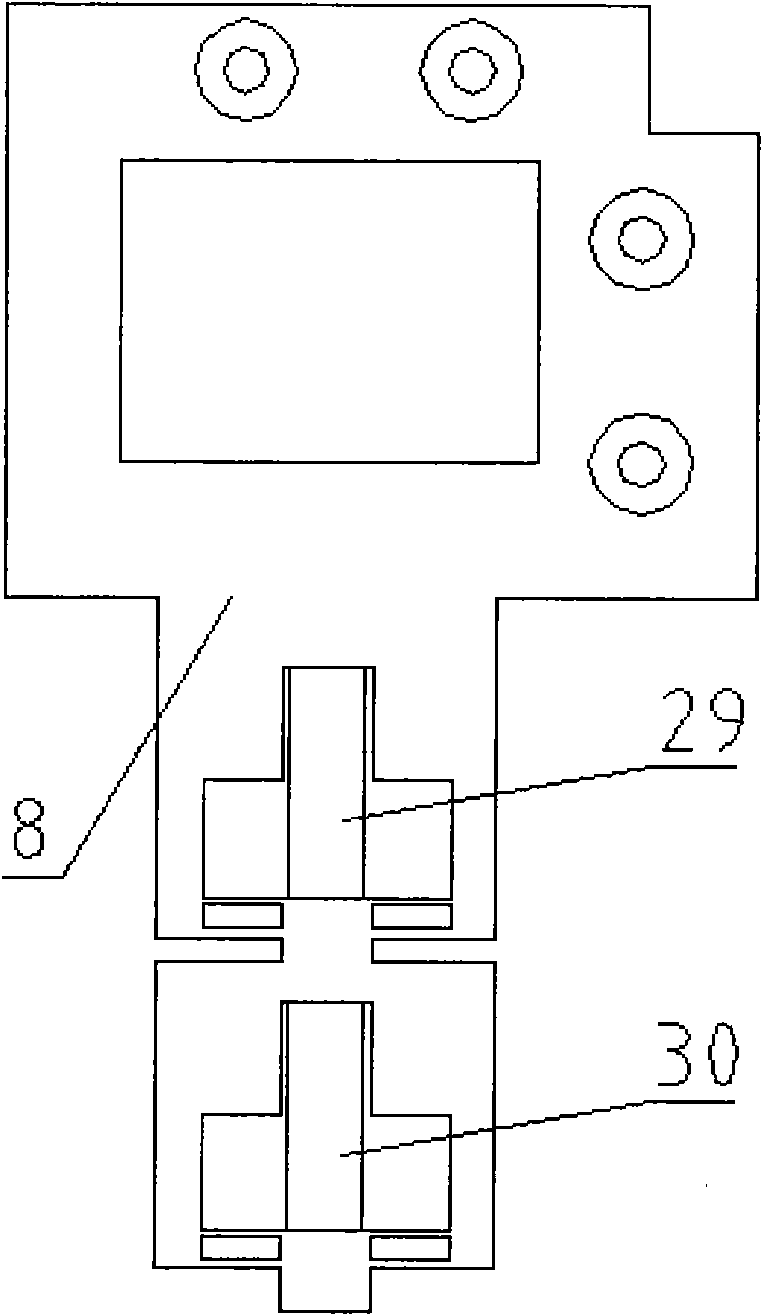

Mechanics sensor array calibrating apparatus and working method thereof

ActiveCN101281073APrecision mechanical designQuick start and stopForce/torque/work measurement apparatus calibration/testingSensor arrayElectricity

The present invention discloses a mechanical sensor array calibration device and the working method thereof. The device comprises locating transmission part and control part which is electrically connected with the locating transmission part; wherein, the locating transmission part comprises calibrated working platform and pressure head testing part; the pressure head testing part is connected with a force sensor through an extension head of a Z-directional linear stepper motor. Using the working method of the device adopts three stepper motors as the driving source; two stepper motors drive the coordinate motion of the slides on the guide rail to finish the location of coordinate point on the working platform; an extension of a linear stepper motor drives the pressure head to exert force on the tested sensor; when the force exerted by the pressure head achieves the set pressure valve, the singlechip collects the output of the tested sensor and the force sensor and the position coordinate of the tested sensor. The present invention is able to execute the choose and configuration of the calibrating mode and process according to the specific sensor array and the specific calibrating demand so as to enlarge the using range of the device.

Owner:ANHUI ZHONGKE BENYUAN INFORMATION TECH CO LTD

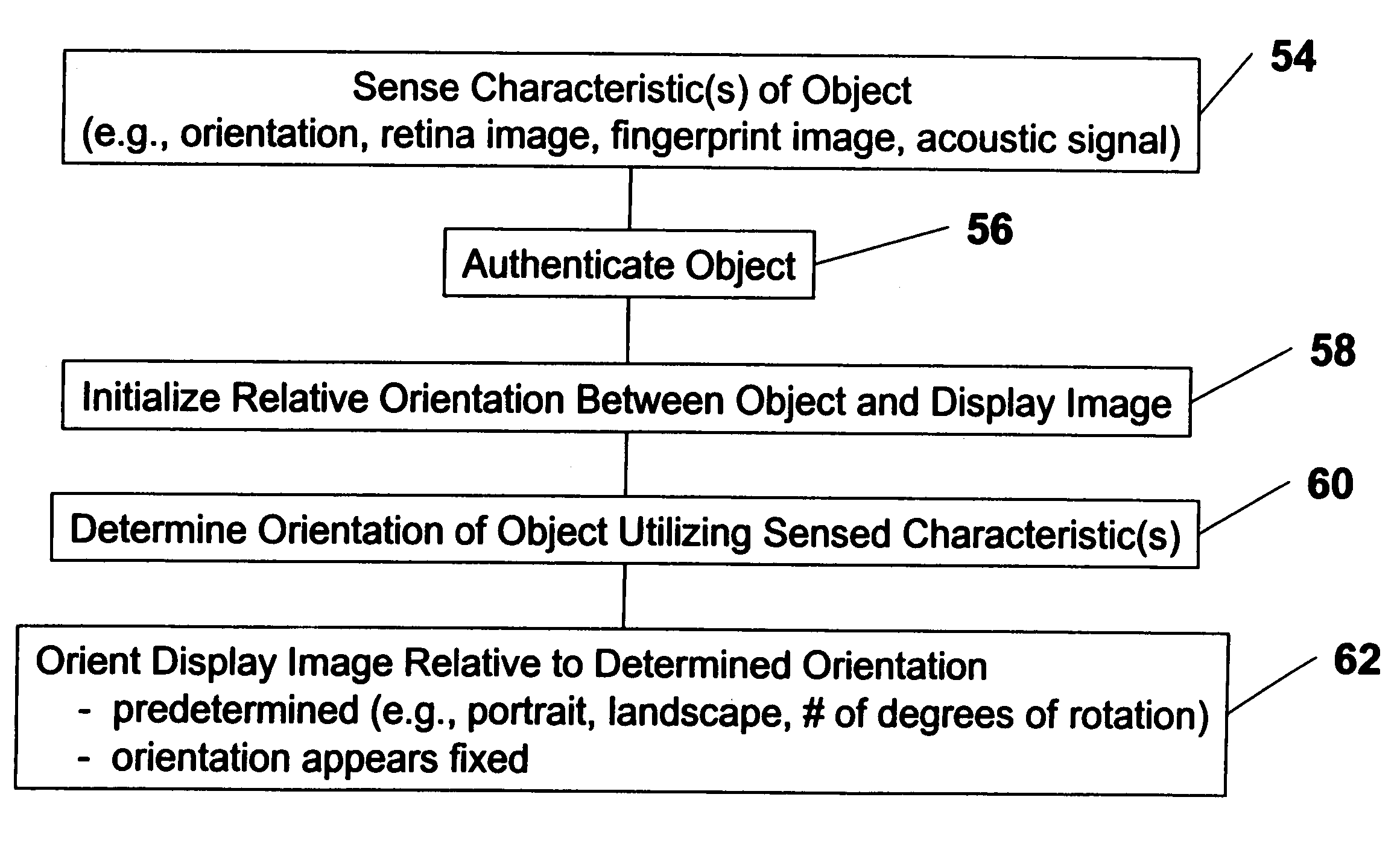

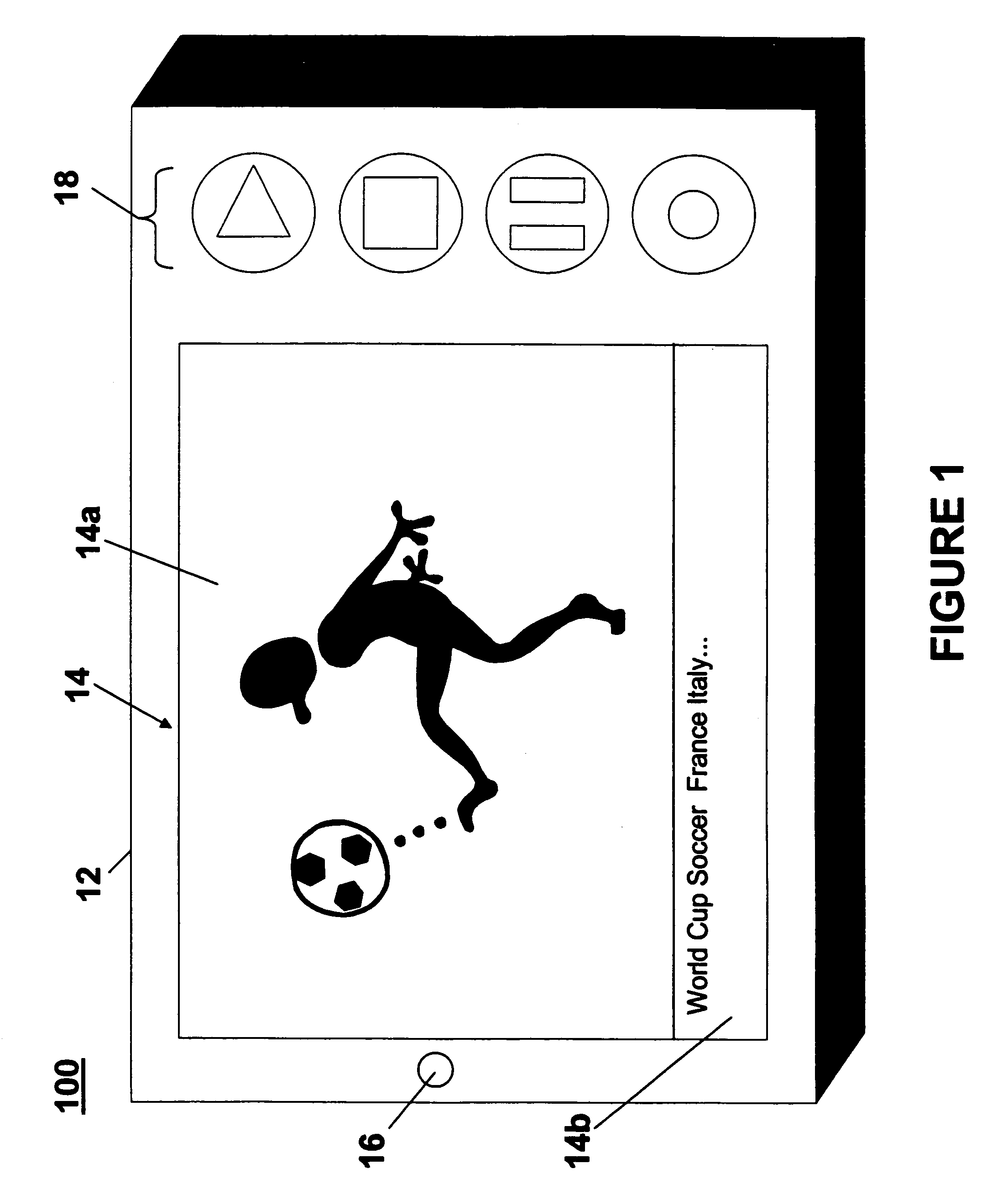

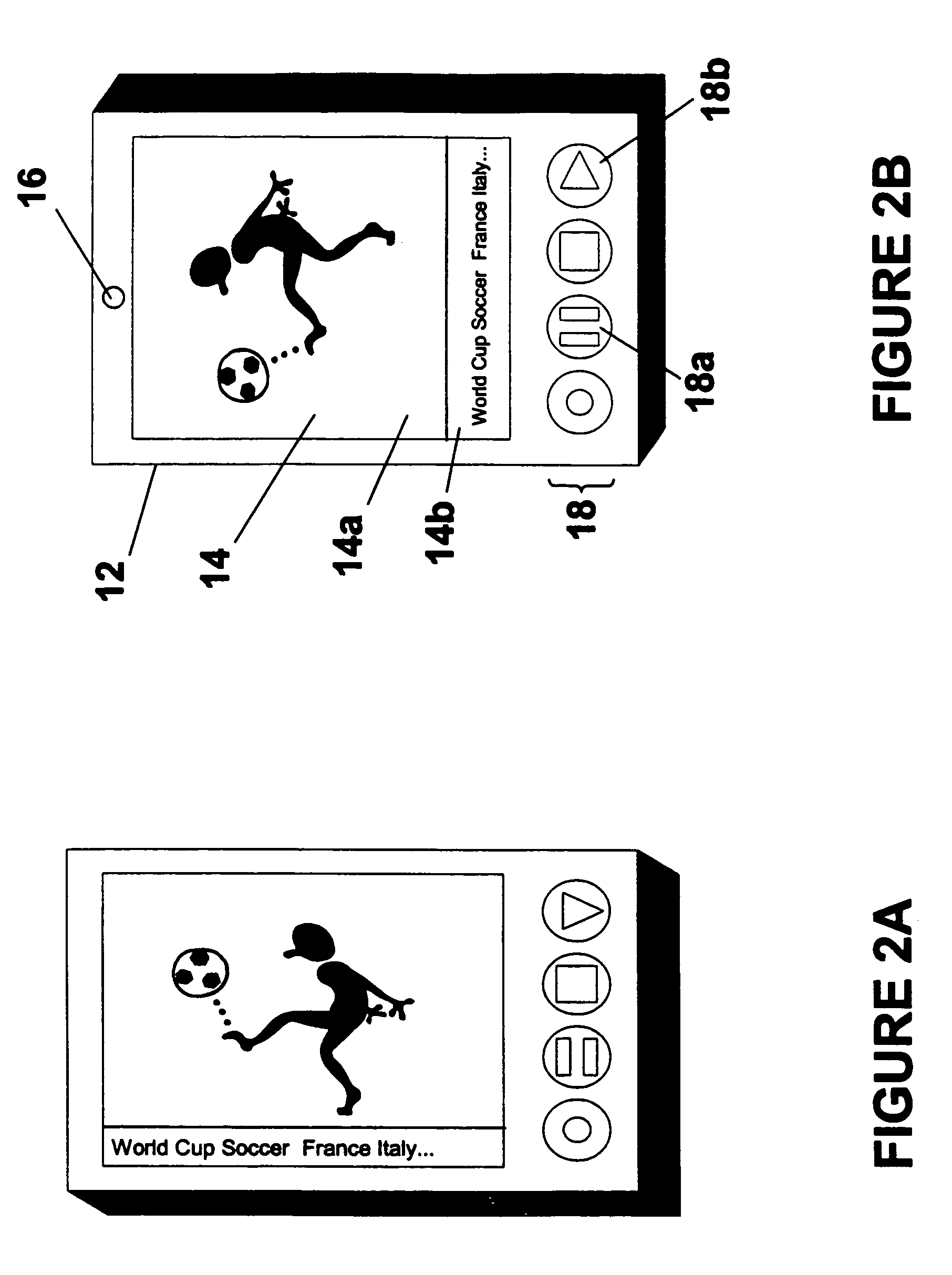

Self-orienting display

Owner:MICROSOFT TECH LICENSING LLC

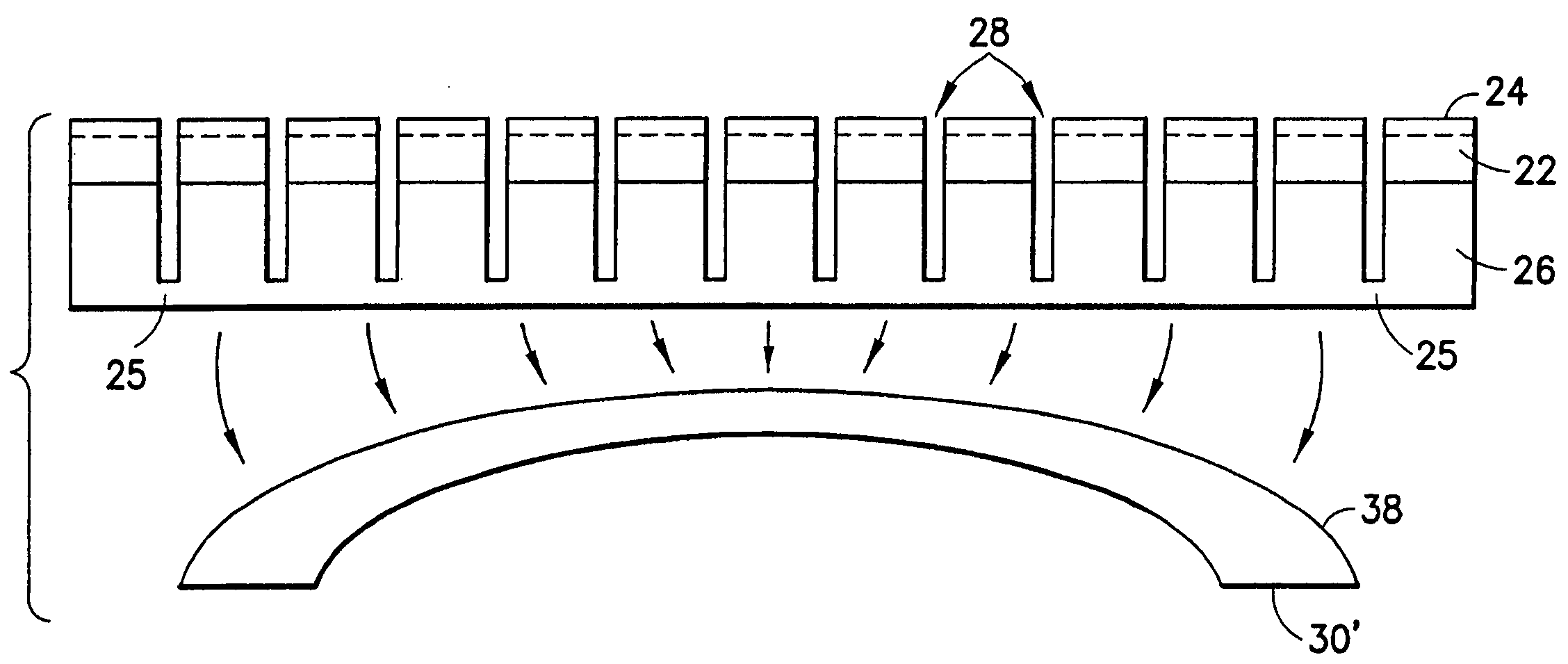

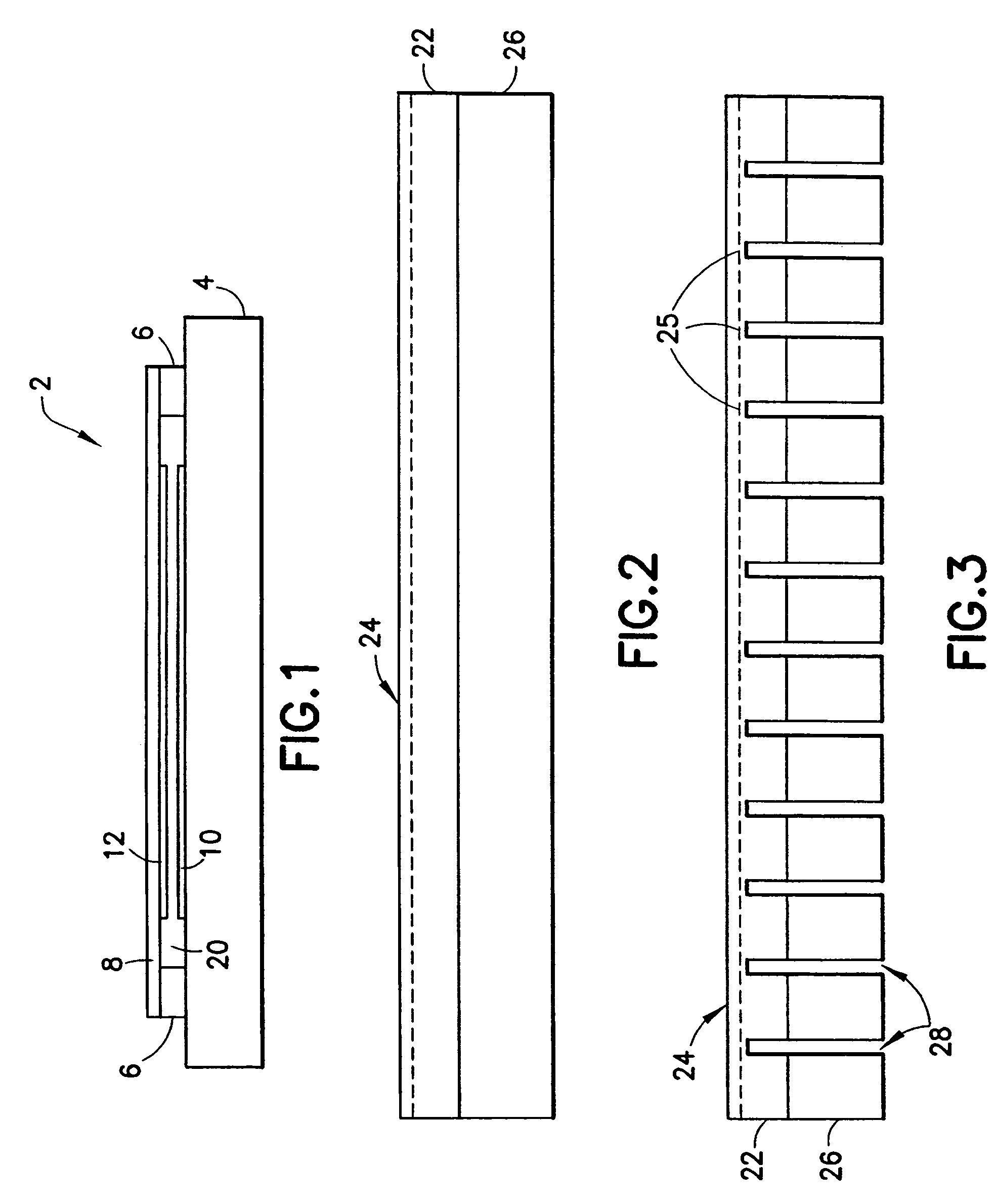

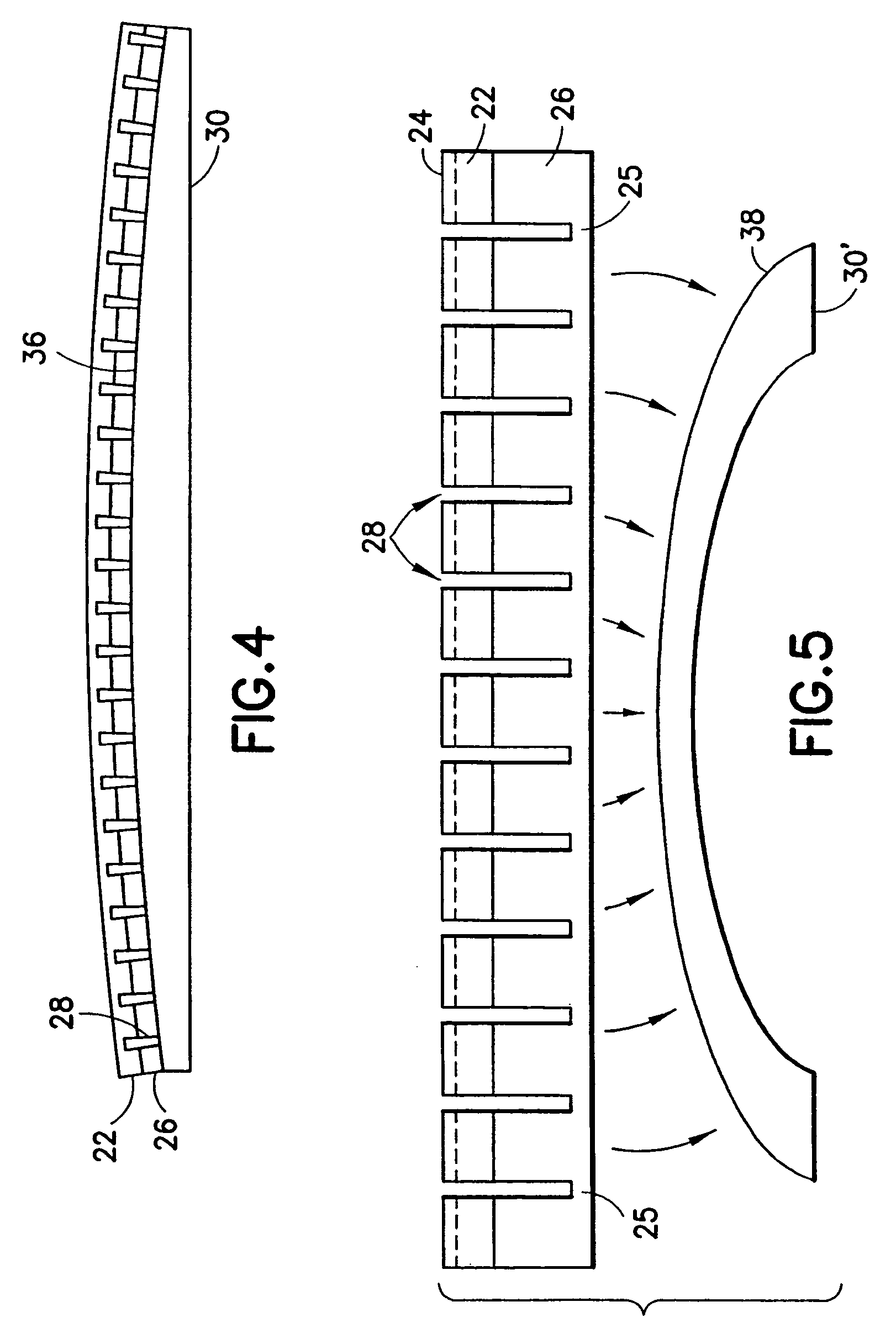

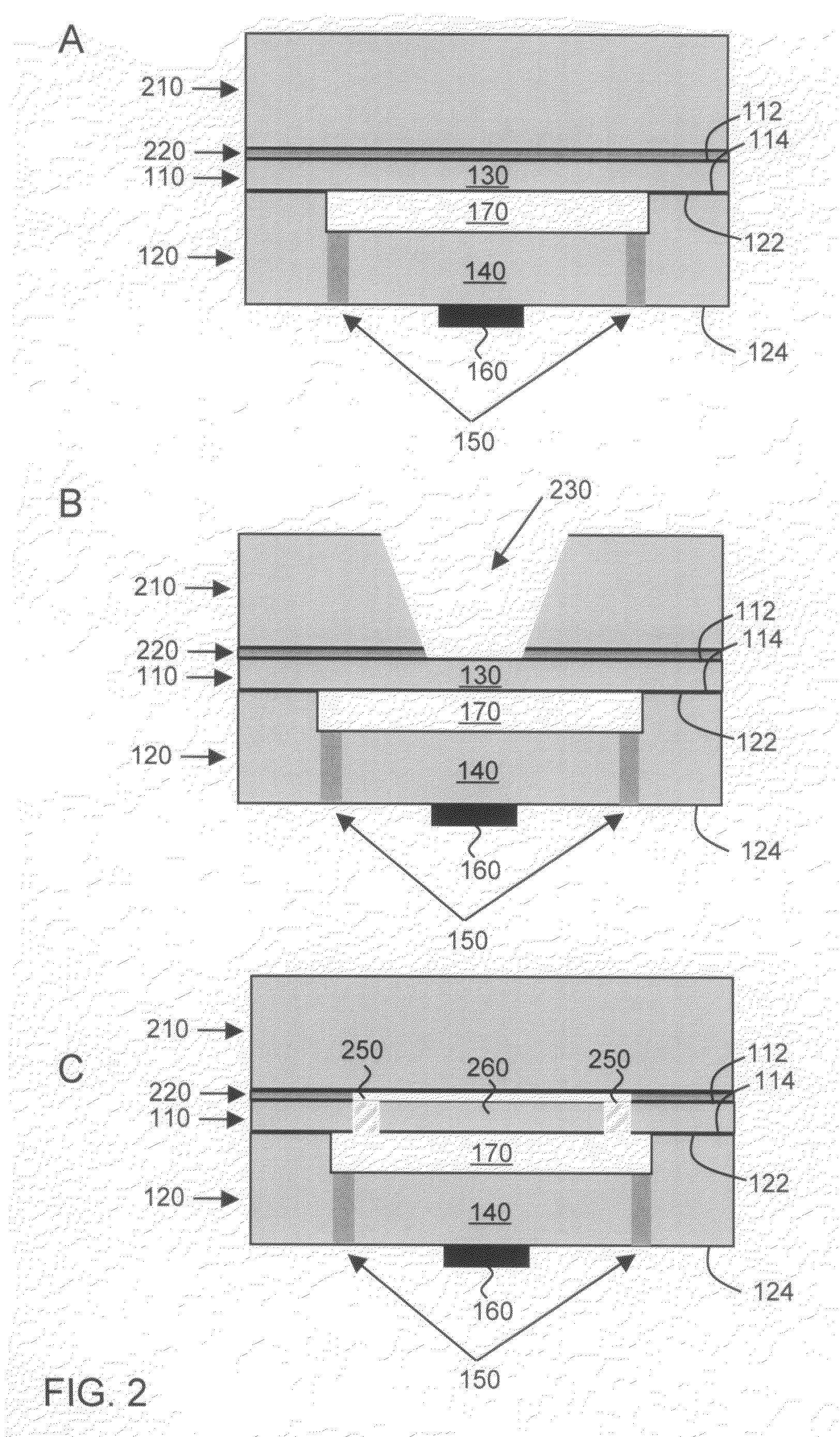

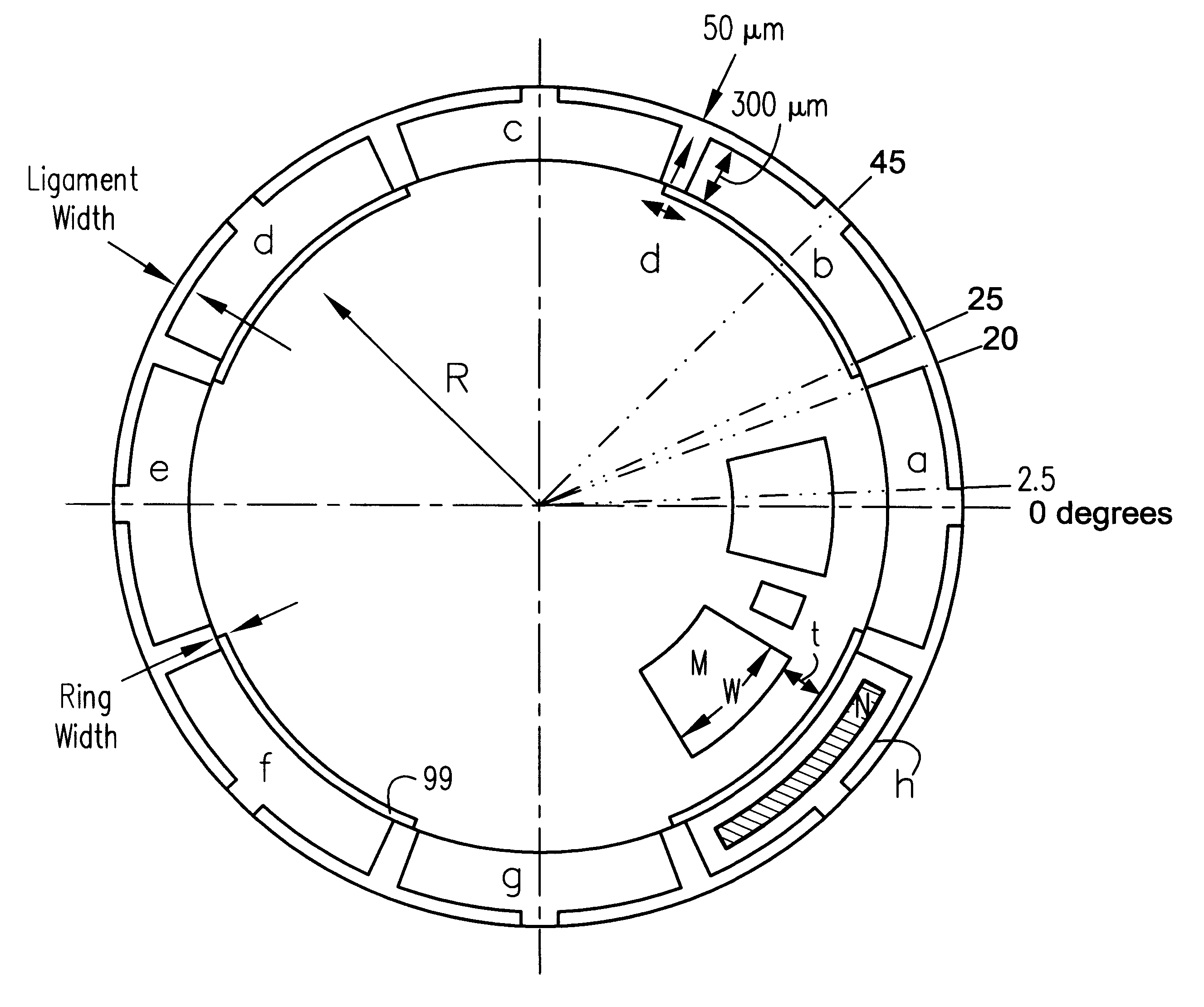

Curved micromachined ultrasonic transducer arrays and related methods of manufacture

ActiveUS7285897B2Ultrasonic/sonic/infrasonic diagnosticsFixed microstructural devicesPMUTEngineering

A curved sensor device, such as an ultrasonic transducer array, is fabricated from a flat micromachined sensor (such as cMUT or pMUT) array constructed using micromachined electro-mechanical systems (MEMS) techniques. The device comprises: a support structure comprising a spine having a profile that is generally curved and a multiplicity of teeth extending from one side of the curved spine; and a multiplicity of sensors built on the support structure. The spine can be bent forward or backward and attached to a curved front face of a support member, thereby causing the sensors to adopt a curved array.

Owner:GENERAL ELECTRIC CO

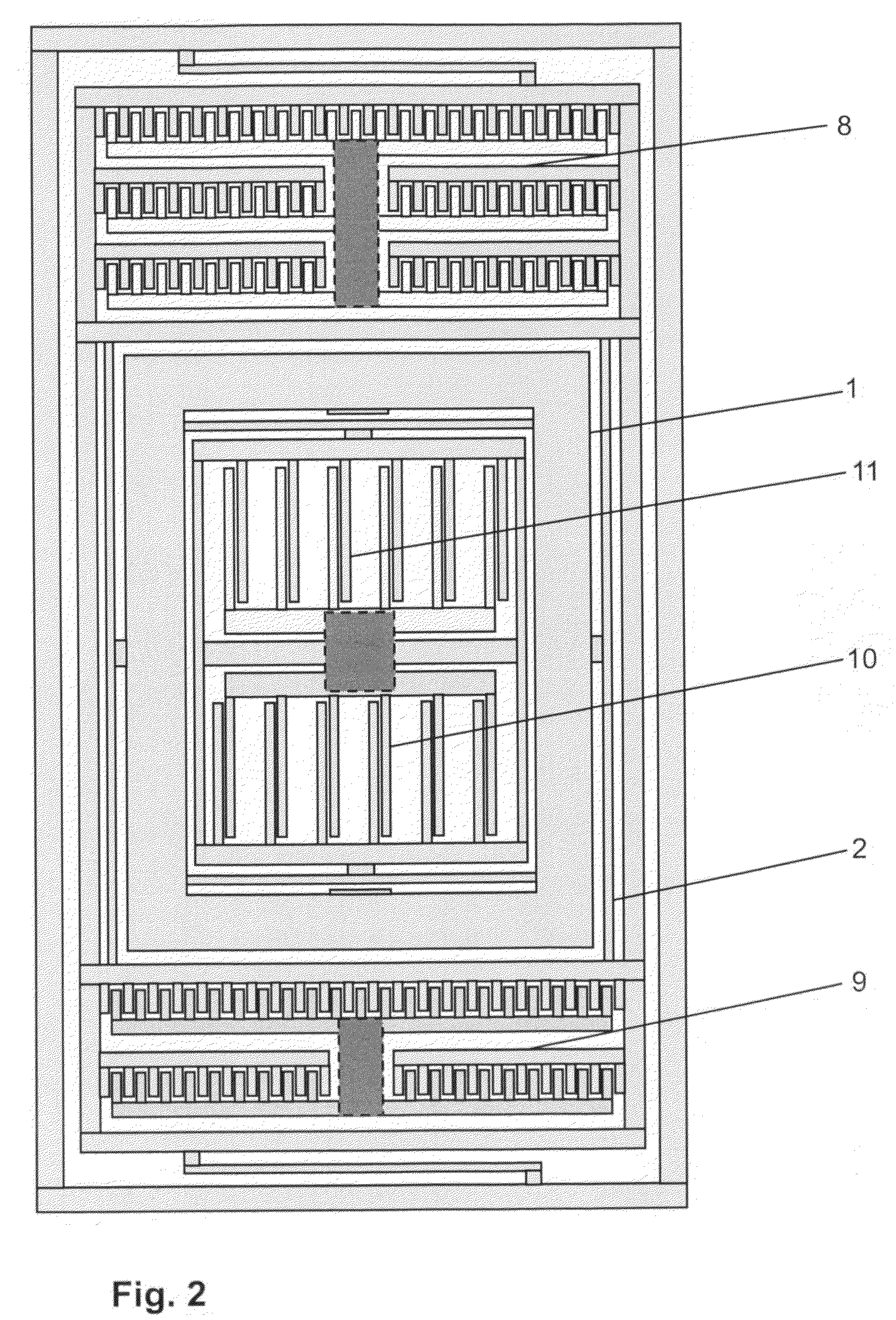

Capacitive micro-electro-mechanical sensors with single crystal silicon electrodes

ActiveUS7539003B2Mechanically variable capacitor detailsCapacitor with electrode area variationIn planeAccelerometer

The devices presented herein are capacitive sensors with single crystal silicon on all key stress points. Isolating trenches are formed by trench and refill forming dielectrically isolated conductive silicon electrodes for drive, sense and guards. For pressure sensing devices according to the invention, the pressure port is opposed to the electrical wire bond pads for ease of packaging. Dual-axis accelerometers measuring in plane acceleration and out of plane acceleration are also described. A third axis in plane is easy to achieve by duplicating and rotating the accelerometer 90 degrees about its out of plane axis Creating resonant structures, angular rate sensors, bolometers, and many other structures are possible with this process technology. Key advantages are hermeticity, vertical vias, vertical and horizontal gap capability, single crystal materials, wafer level packaging, small size, high performance and low cost.

Owner:SAMSUNG ELECTRONICS CO LTD

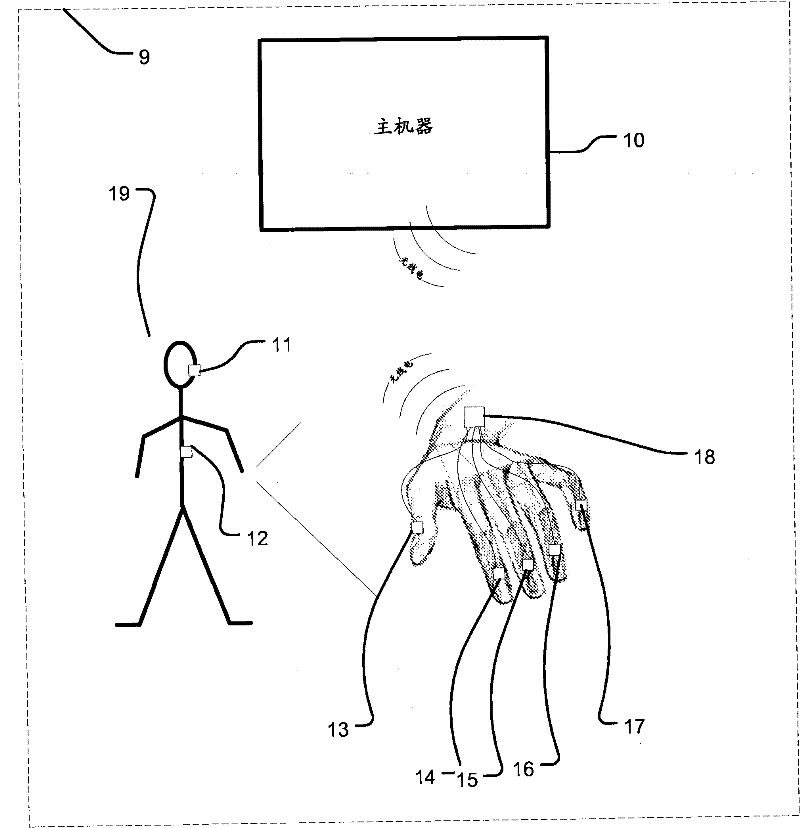

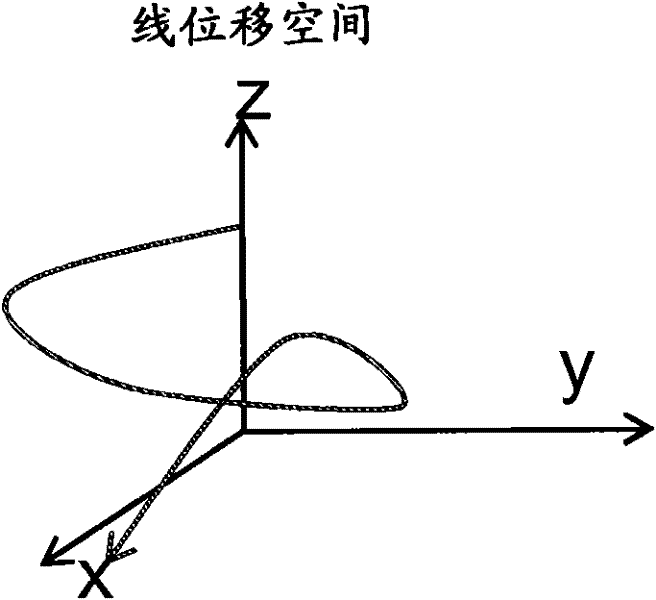

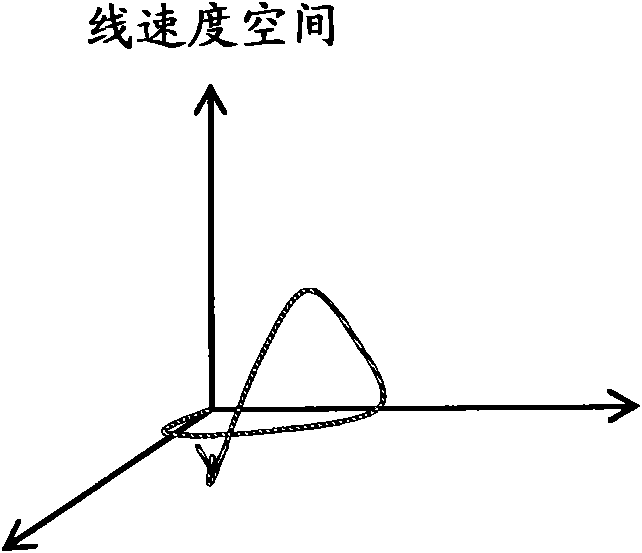

Hand-free interface based on gesture using a plurality of sensor spaces

InactiveCN101751126AInput/output for user-computer interactionGraph readingHands freeEmbedded system

A system for interpreting a gesture, comprises, preferably, at least one microelectronic mechanical sensor, which comprises a base suitable for being attached on a first position (such as a finger or a hand) of the human. A signal accumulating unit is connected to the sensor, and has another base suitable for being attached on a second position of the human. The signal accumulating unit comprises a logic for packing and / or interpreting the data about the gesture in a plurality of spaces sensing at one or more sensors. The signal accumulating unit also comprises a communication port for being communicated with a main computer, through which the interpreted data is transmitted to the main computer.

Owner:孙骏恭 +1

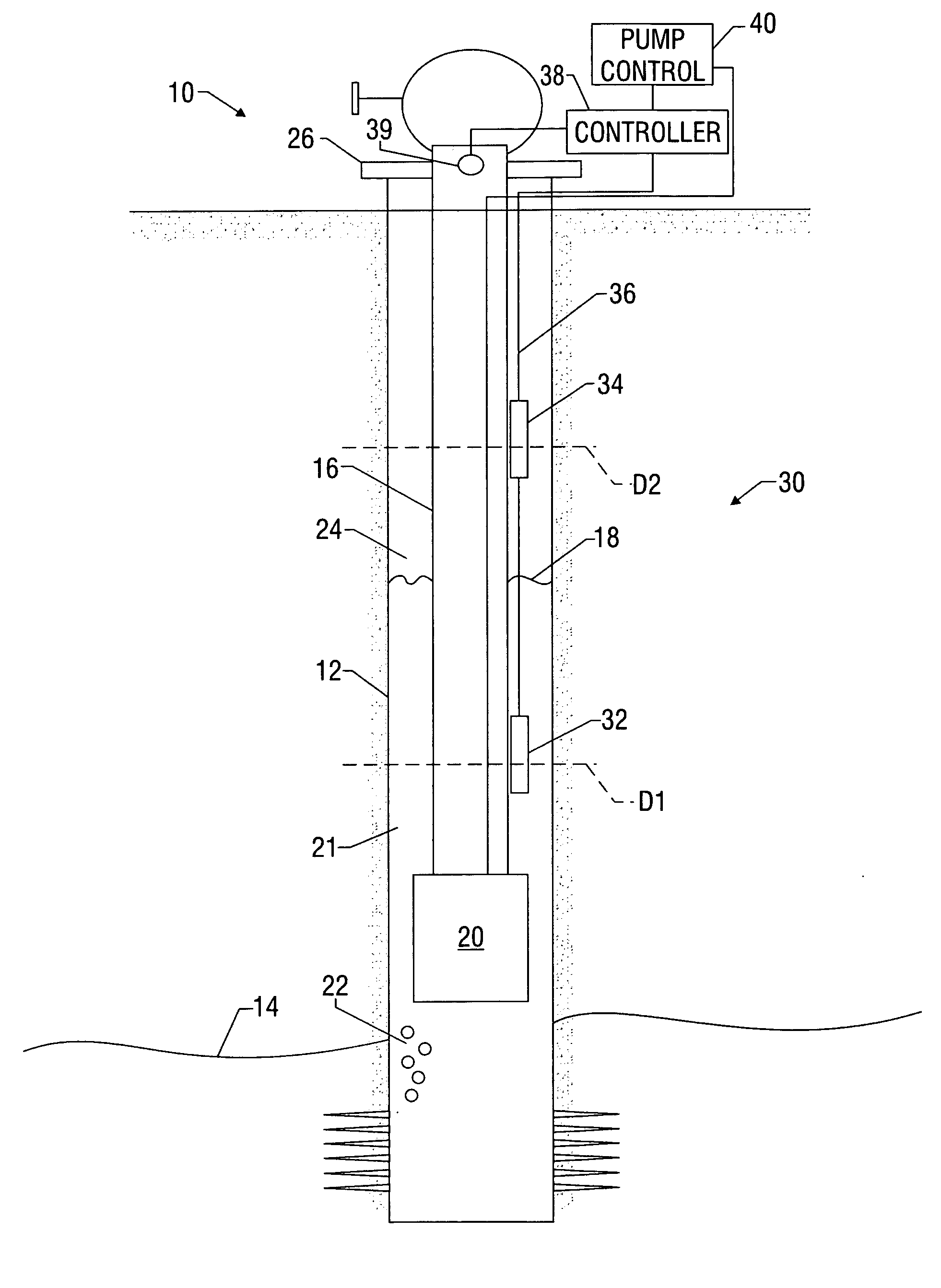

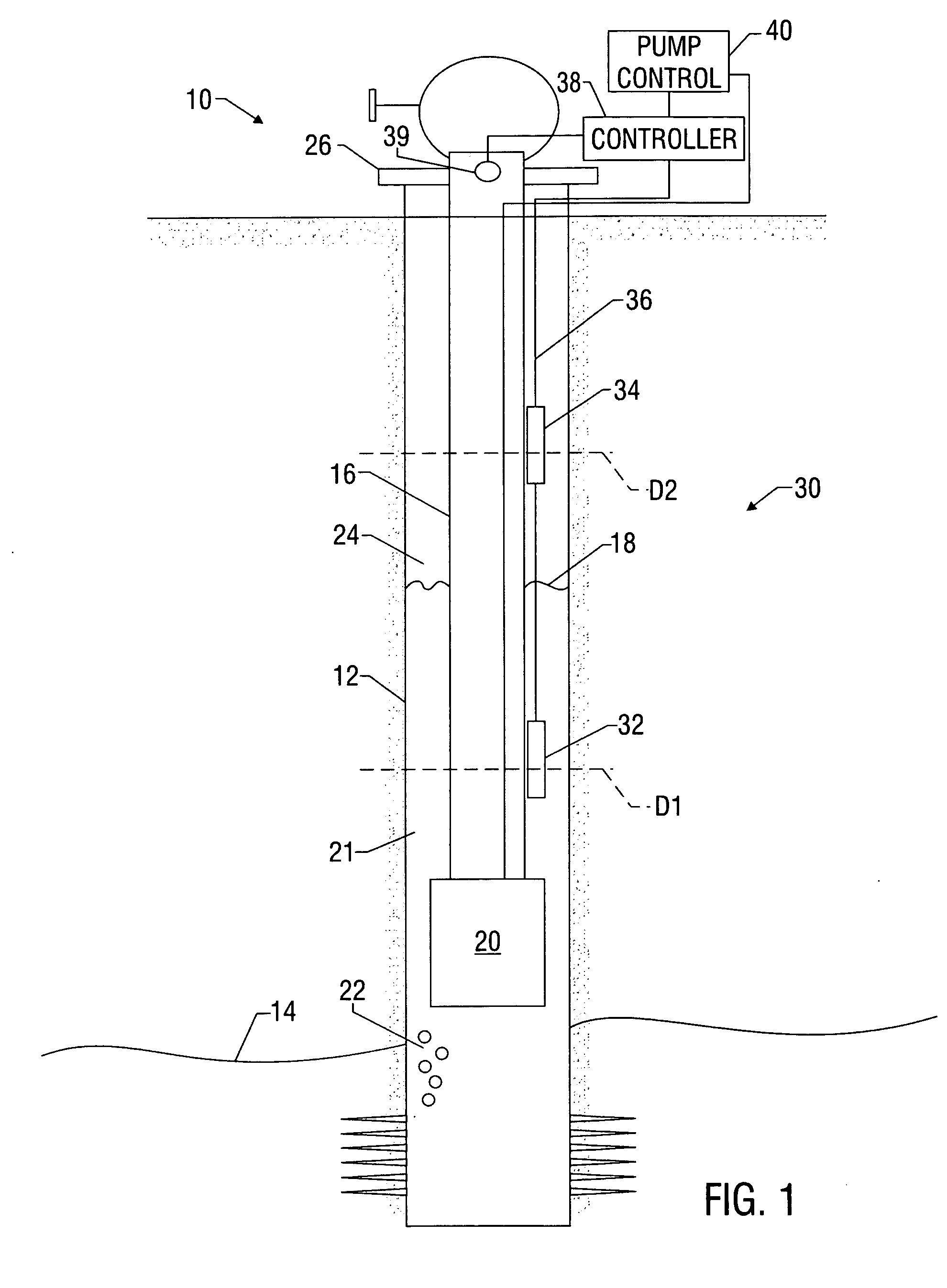

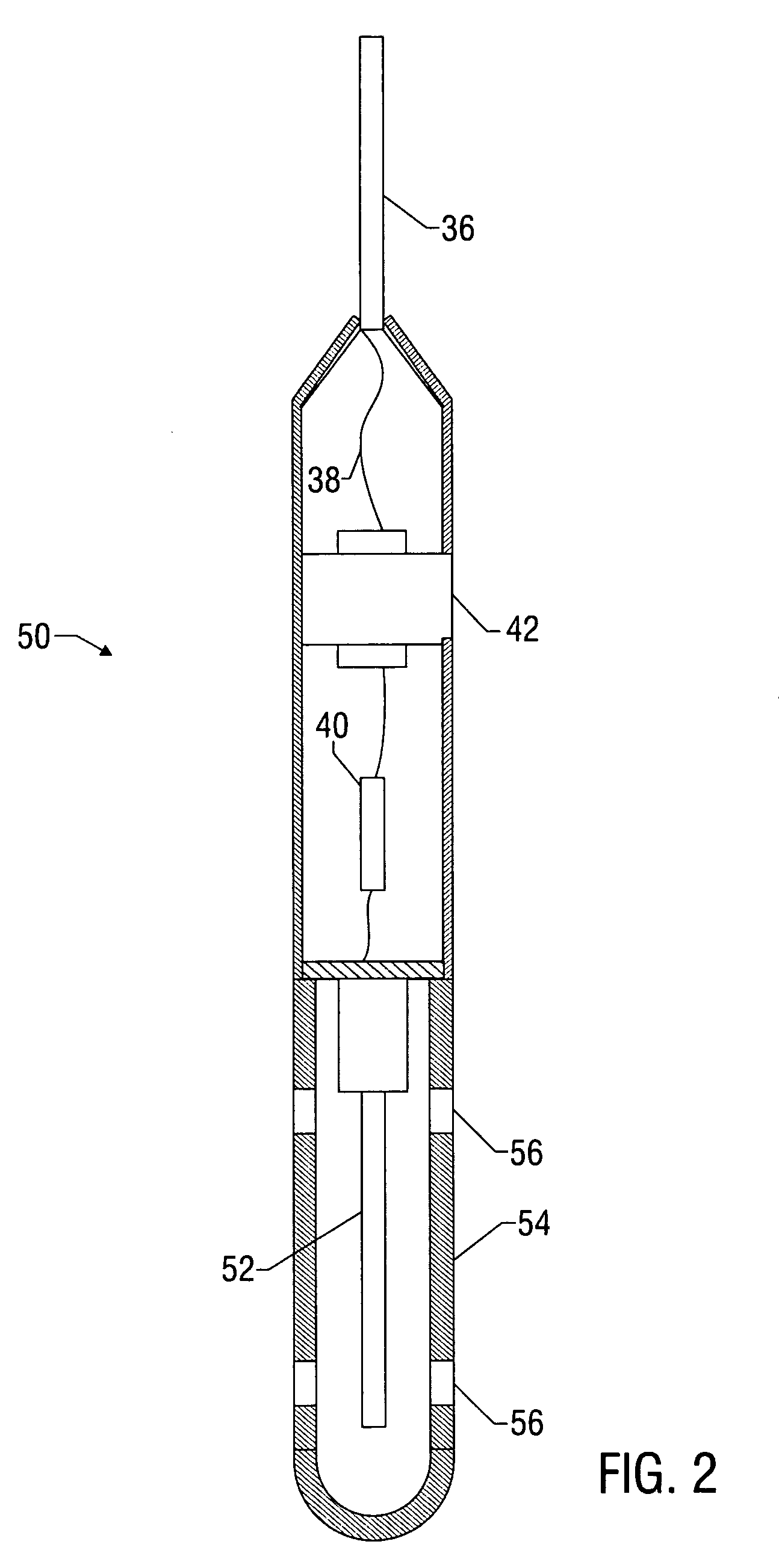

Systems and methods for controlling flow control devices

A device for determining a location of an interface between a first fluid and second fluid includes a non-mechanical sensor that measures a selected parameter of interest relating to the fluid surrounding the sensor (“the surrounding fluid”) and a processor for processing the sensor measurements. The non-mechanical sensor measures a parameter relating to the surround fluid without physically co-acting with the surrounding fluid. Exemplary parameters such as thermal properties, electrical properties, fluid properties, and magnetic properties can be measured. The processor is programmed to process the sensor measurements to identify one or more characteristics in the measurements that can indicate the nature of the fluid being measured and thereby determine the location of the interface. The determined location can be used to operate a downhole device such as a pump, to provide real-time monitoring of well conditions, to record data for long-term reservoir characterization, or to actuate an alarm.

Owner:CORE LAB CANADA

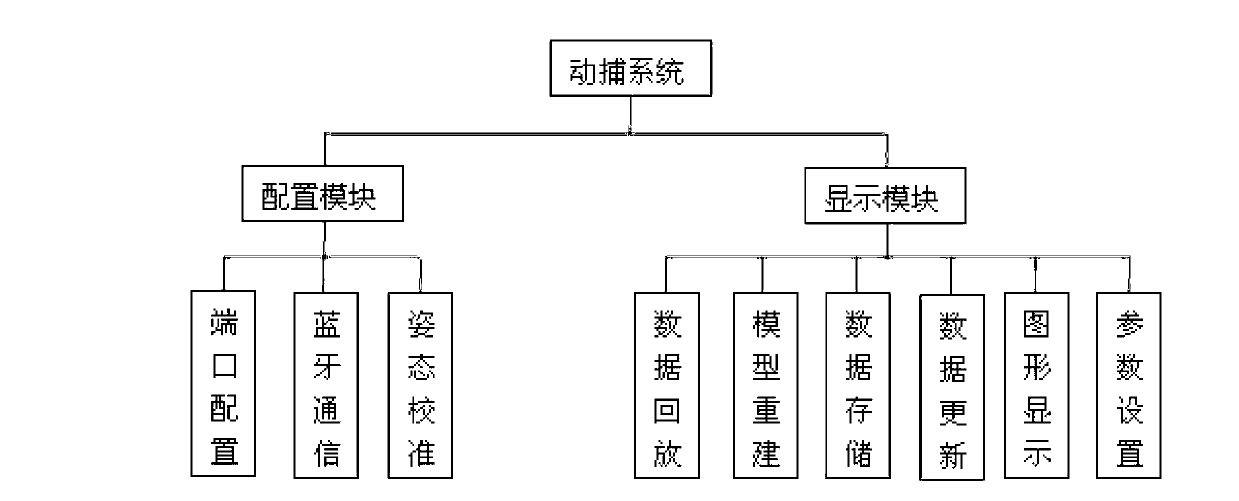

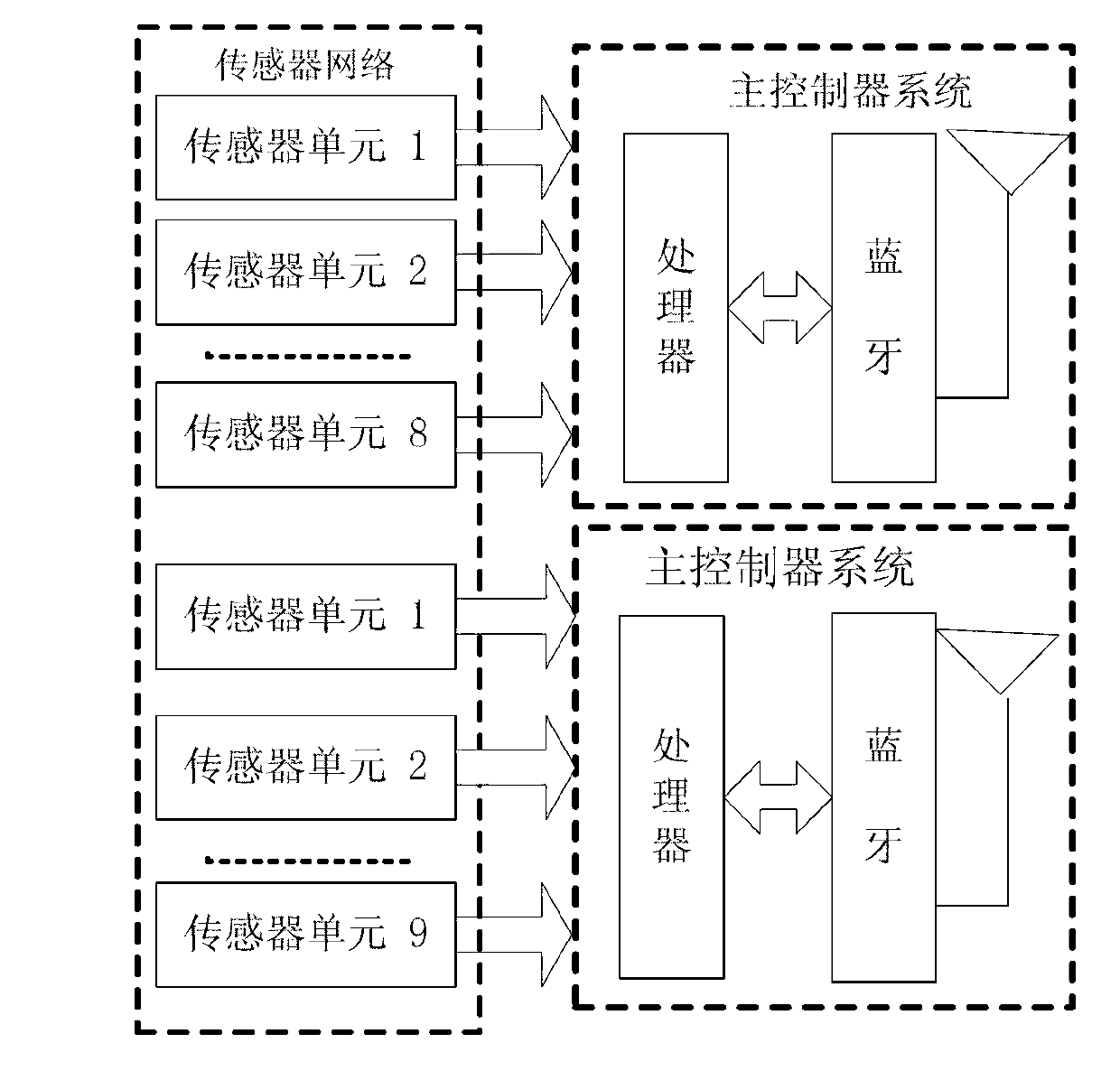

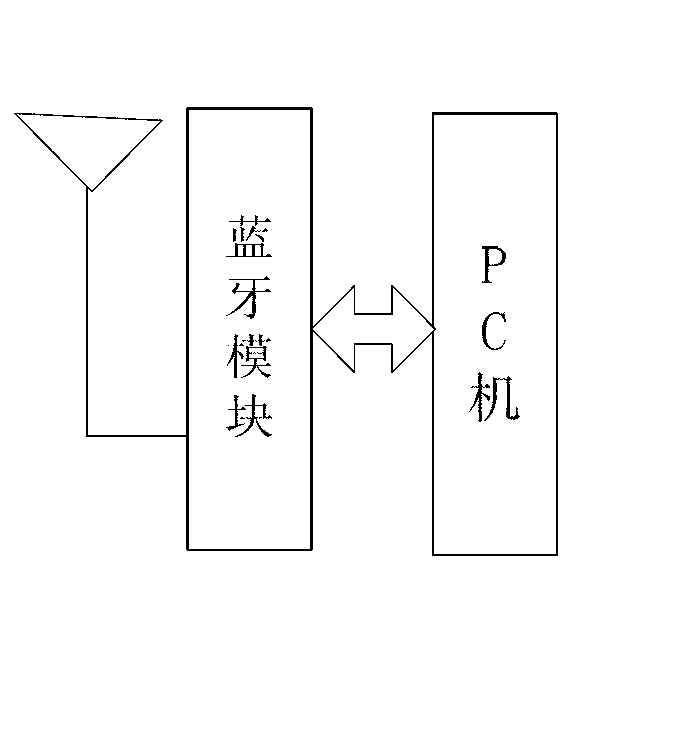

Human motion information capturing system based on micro-mechanical sensor

InactiveCN103135765AIncrease flexibilityIncrease independenceInput/output for user-computer interactionGraph readingHuman bodyWhole body

The invention discloses a human motion information capturing system based on a micro-mechanical sensor. The human motion information capturing system comprises a plurality of sensor units, a main controller system and a data processing and graph rebuilding system, wherein the plurality of sensor units are used for obtaining motion posture data of every feature point position of the human body; the main controller system is used for performing processing on the basis of the human motion posture data obtained through a corresponding sensor network sensor unit and performing data transmission in a bluetooth module wireless pass-through mode; and the data processing and graph rebuilding system is provided with personal computer (PC) software and BVH files, can perform calculation according to the motion posture data obtained by processing through the main controller system and rebuilds a human motion posture model in real time. Every sensor unit, the main controller system and the data processing and graph rebuilding system are connected in sequence. Real-time data capturing of motion of the whole human body can be achieved in a wireless mode through the human motion information capturing system based on the micro-mechanical sensor, and the human motion information capturing system can be applied to motion control of virtual characters or robots in animations and games.

Owner:LANZHOU JIAOTONG UNIV

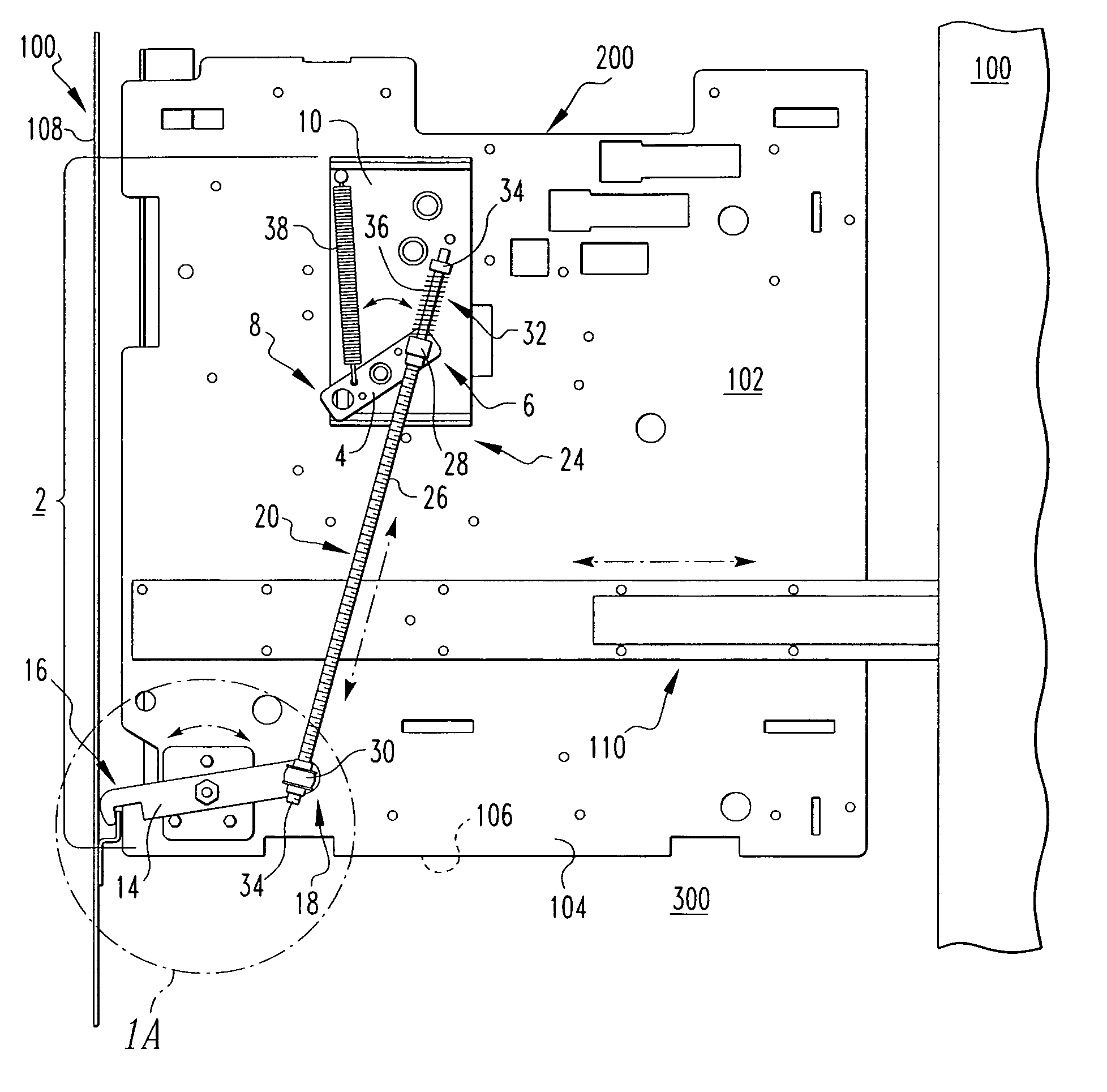

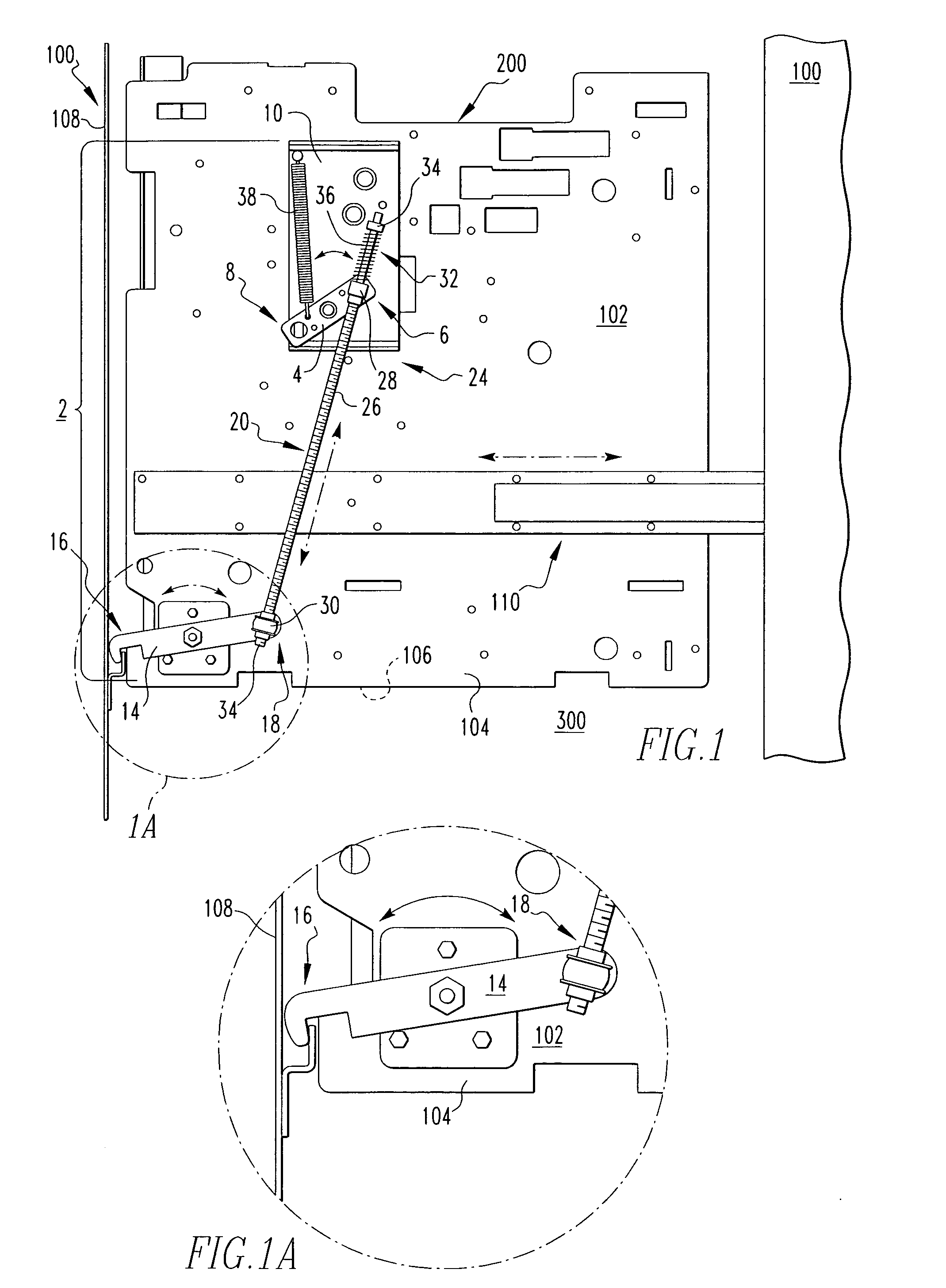

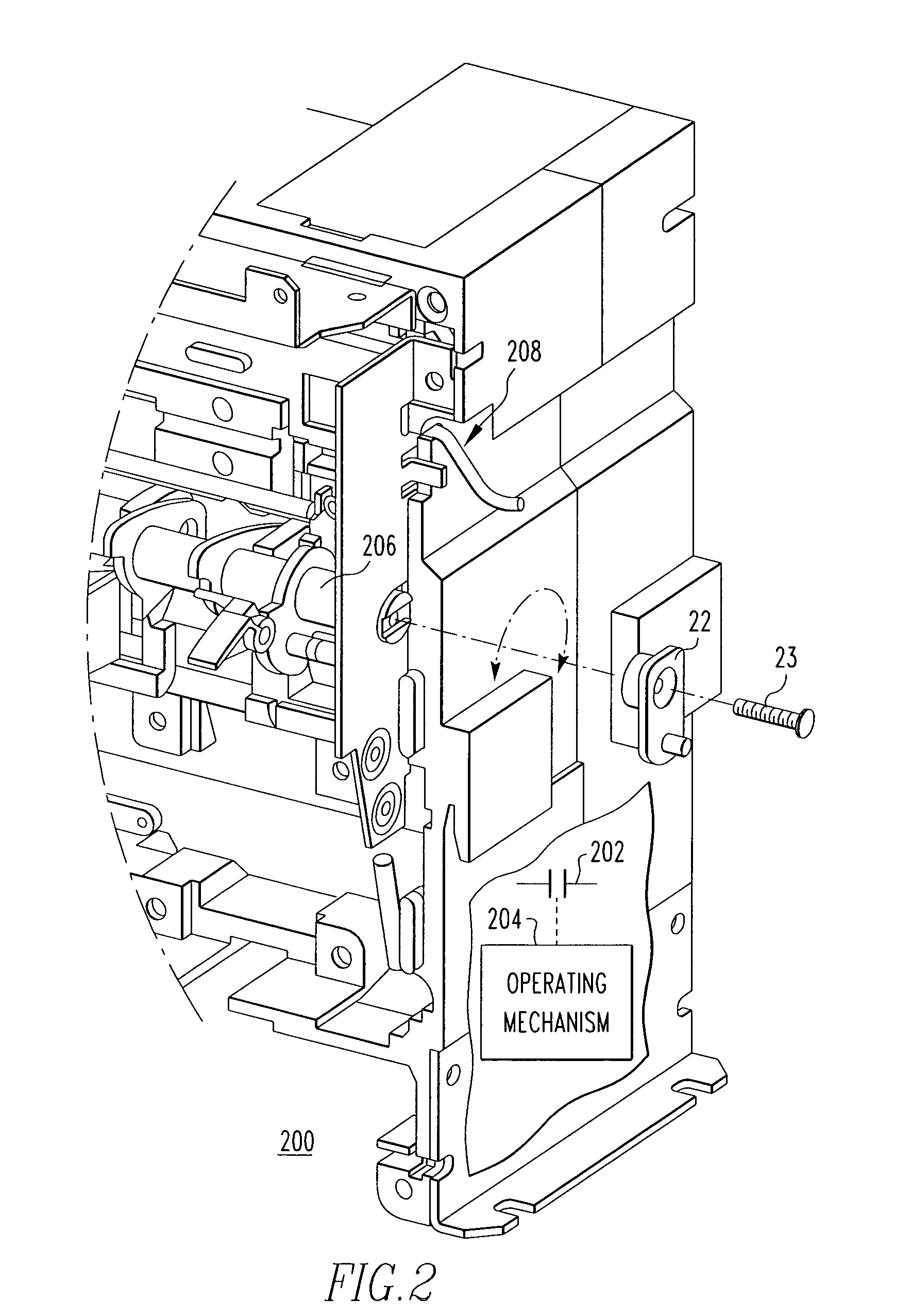

Door interlock assembly and draw-out circuit breaker assembly employing the same

ActiveUS7019229B1Non-enclosed substationsSwitchgear with withdrawable carriageEngineeringCircuit breaker

Owner:EATON INTELLIGENT POWER LTD

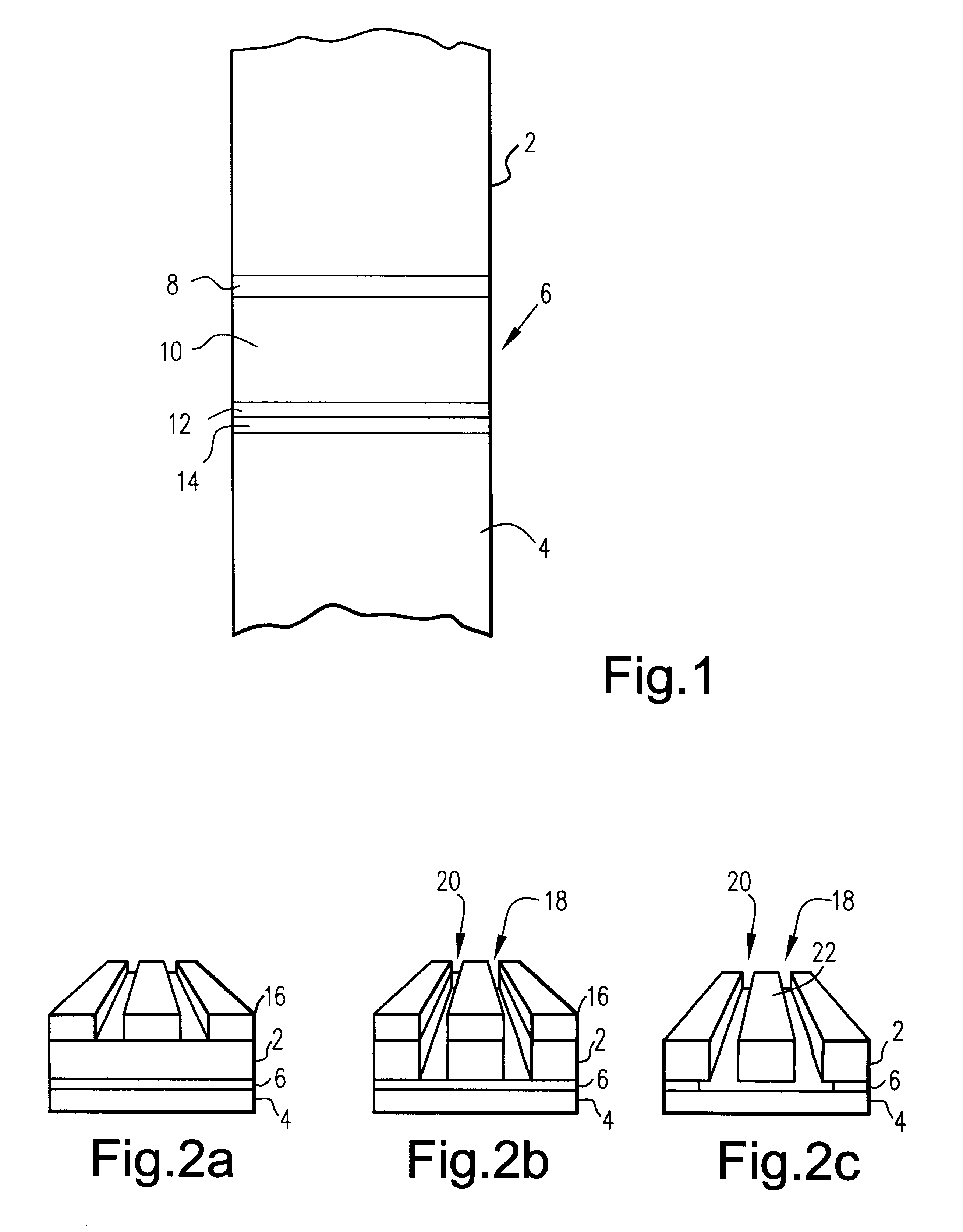

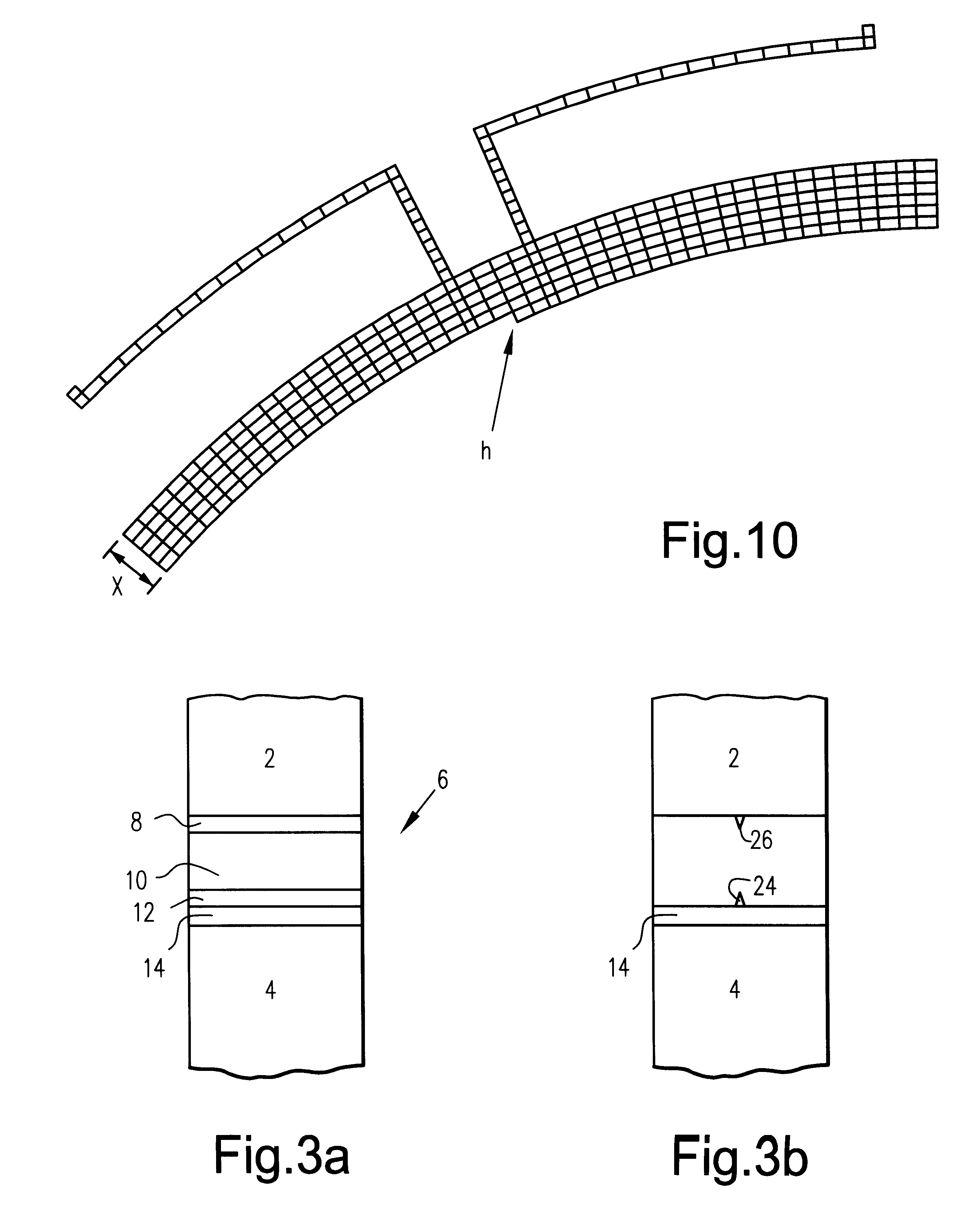

Micro-machining

InactiveUS6276205B1Offset high cost of waferAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsGyroscopeMachining

A method of fabricating a micro-mechanical sensor (101) comprising the steps for forming an insulating layer (6) onto the surface of a first wafer (4) bonding a second wafer (2) to the insulating layer (6), patterning and subsequently etching either the first (4) or second wafer (6) such that channels (18, 20) are created in either the first (2) or second (4) wafer terminating adjacent the insulating layer (6) and etching the insulating layer (6) to remove portions of the insulating layer (6) below the etched wafer such that those portions of the etched wafer below a predetermined cross section, suspended portions (22), become substantially freely suspended above the un-etched wafer. This method uses Silicon on Insulator technology. Also disclosed is a micro-mechanical gyroscope structure (101) allowing an anisotropic silicon to be used to fabricate a sensor functioning as if fabricated from isotropic silicon.

Owner:QINETIQ LTD

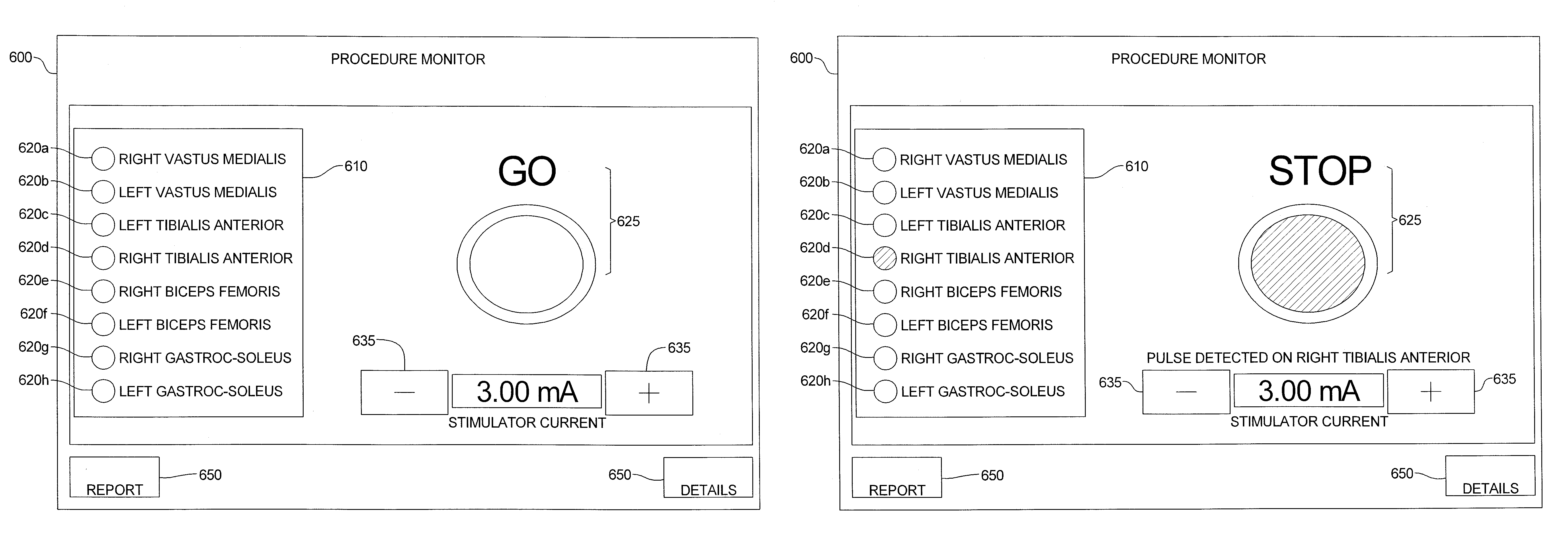

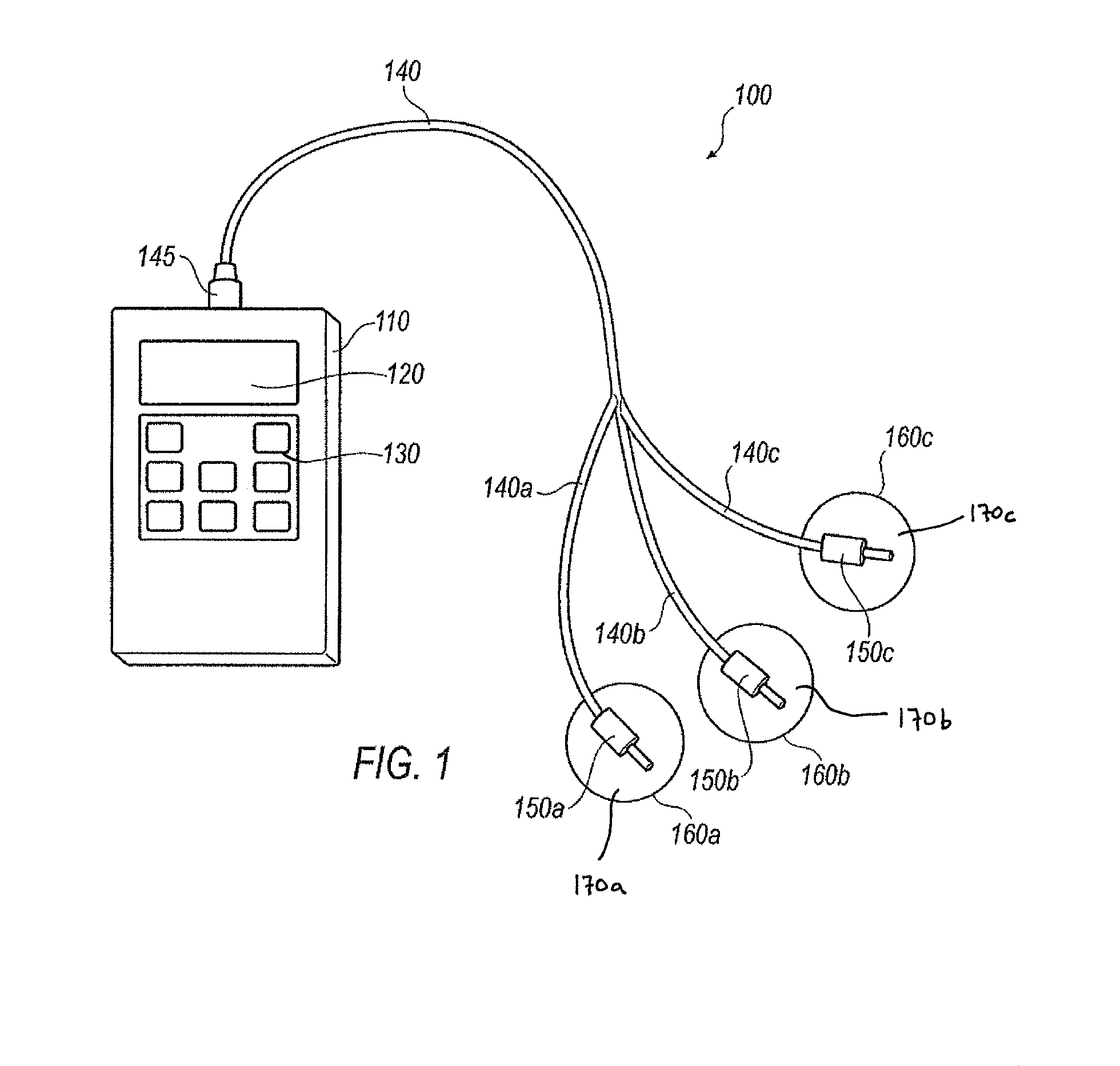

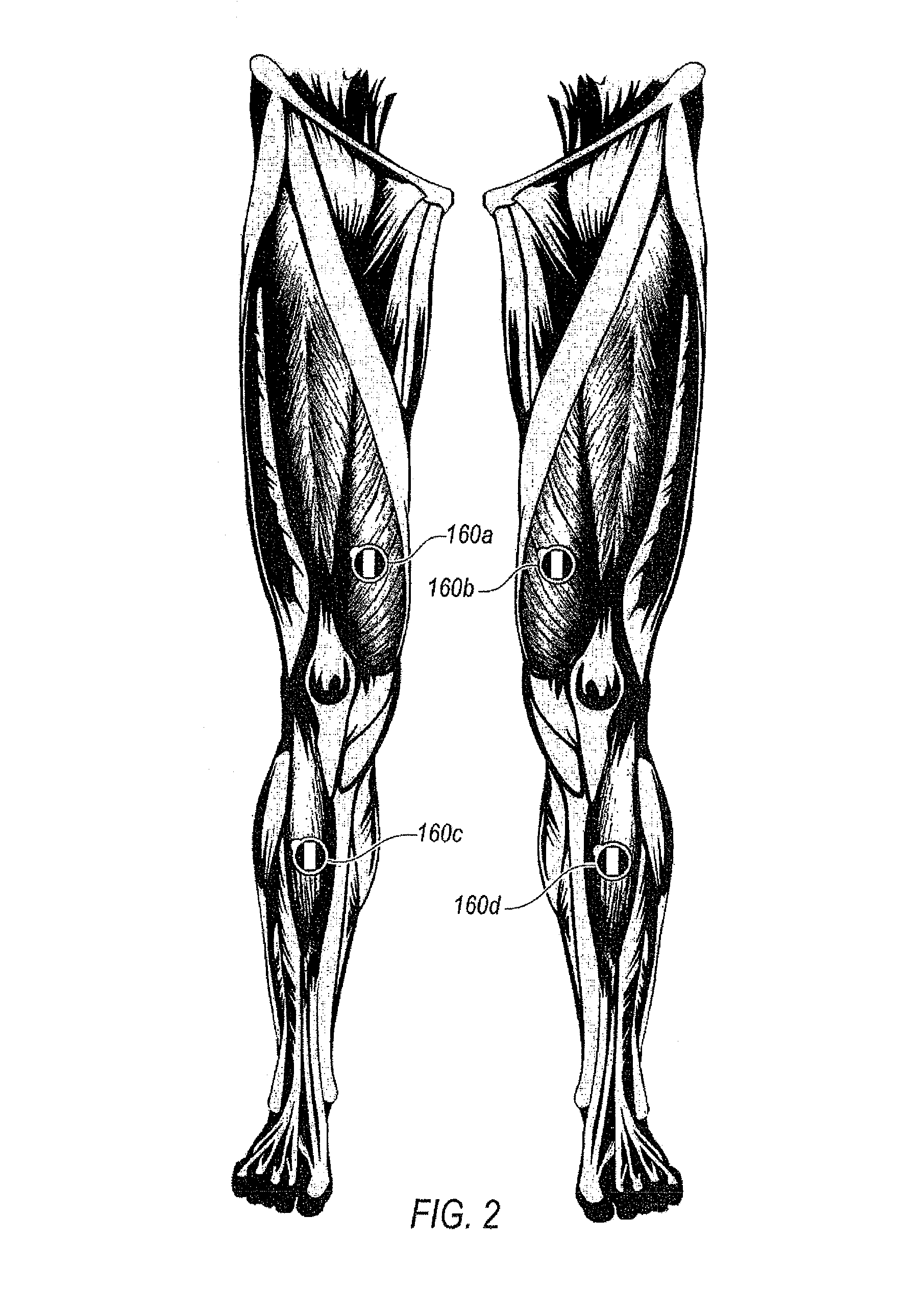

Minimally invasive nerve monitoring device and method

A neural monitoring device includes a stimulator configured to provide a stimulus, a mechanical sensor configured to generate an output signal corresponding to a sensed event, and a receiver configured to receive an output signal from the mechanical sensor and determine if the output signal corresponds to the stimulus provided by the stimulator.

Owner:INNOVATIVE SURGICAL SOLUTIONS

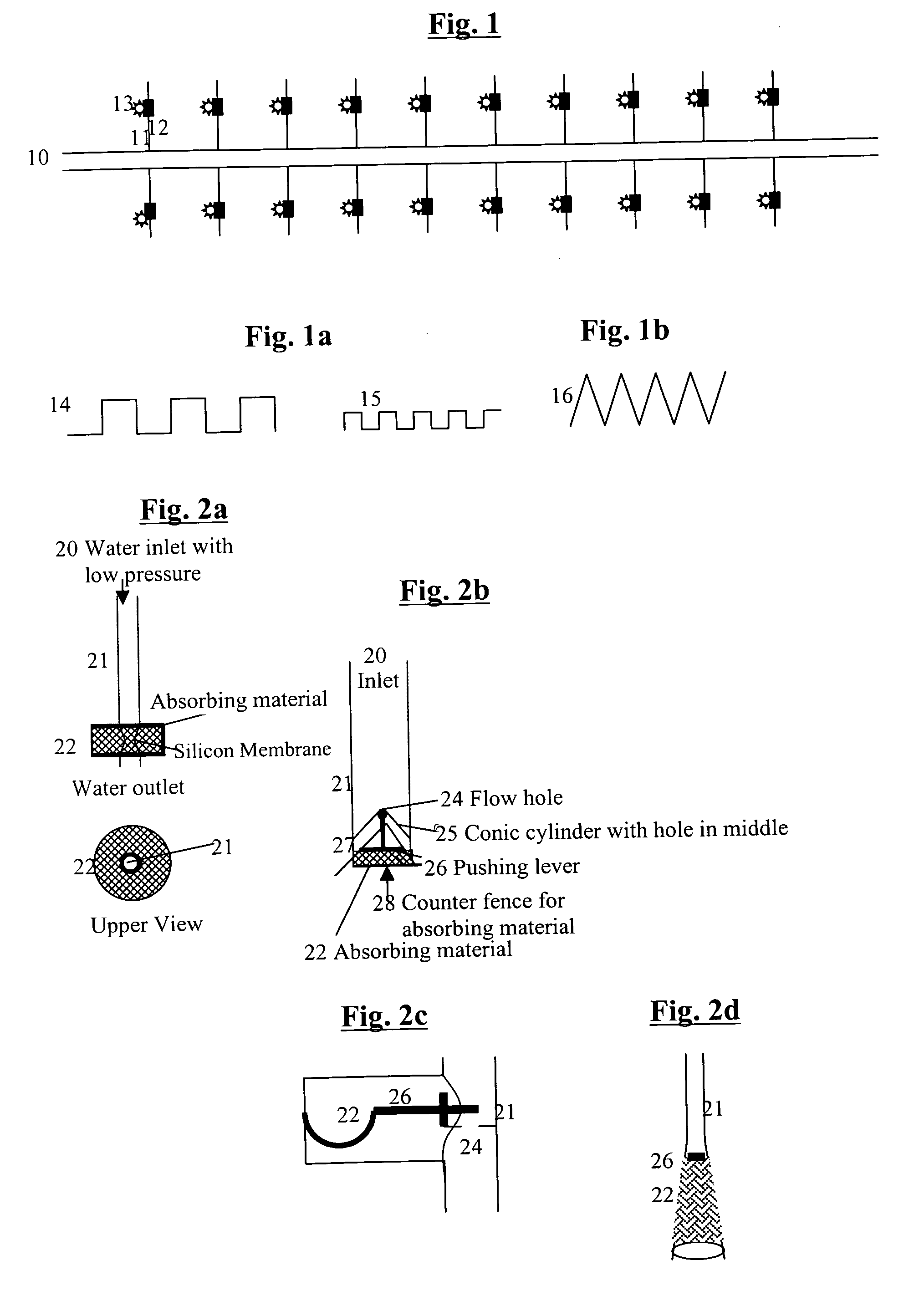

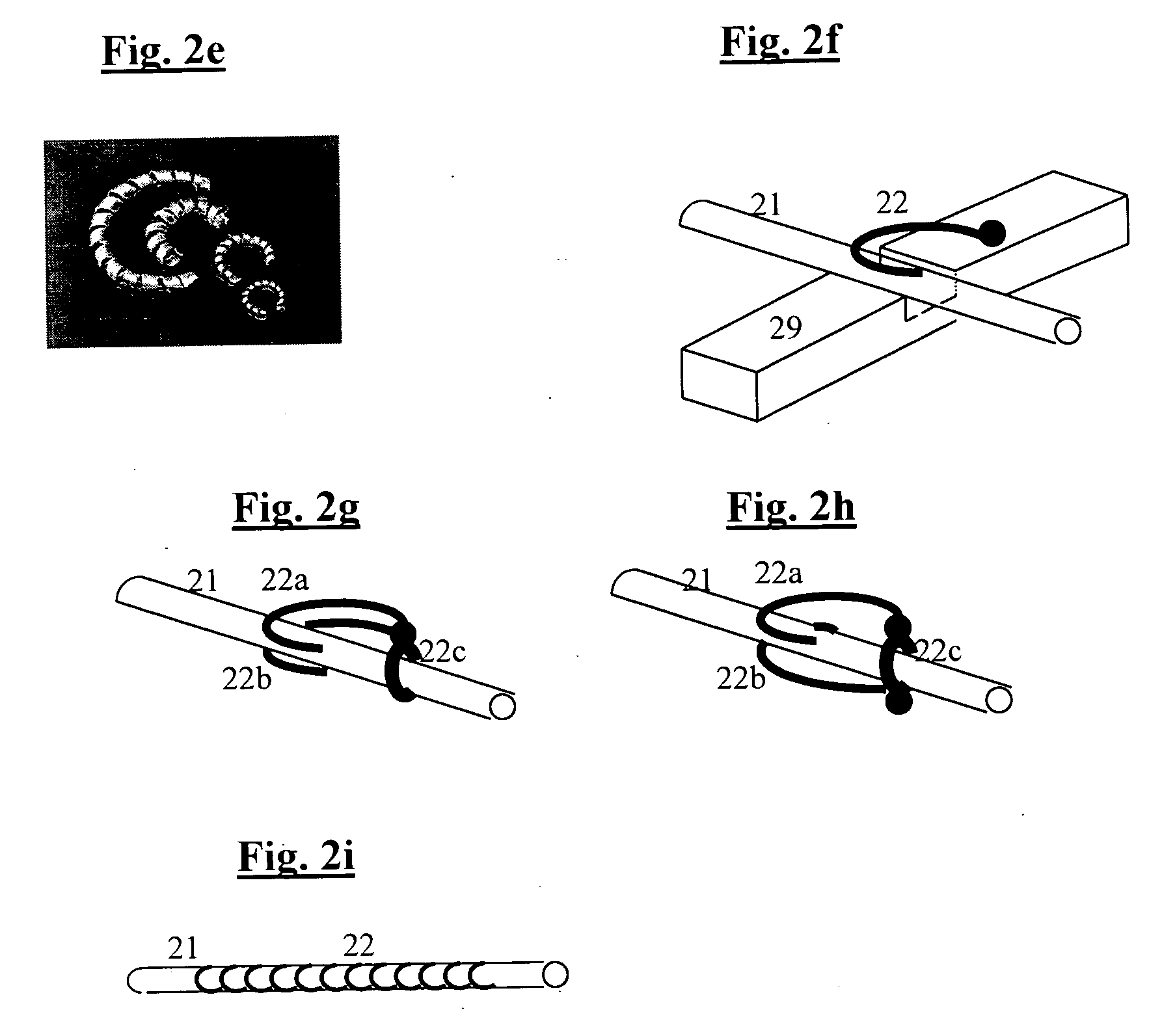

System and method for more efficient automatic irrigation based on a large number of cheap humidity sensors and automatic faucets

InactiveUS20050133613A1Control can be done more efficiently and moreProtection worksSelf-acting watering devicesWatering devicesMechanical sensorAutomatic faucet

The present invention provides an irrigation system with cheap humidity sensors and cheap automatic faucets preferably by using at the end nodes of the system low water pressure, so that much less force is needed to open and close the local waterway and then either using simple electrical valves that do not require engines, or using for example mechanical sensors based on a bi-material of two or more materials which expand differently when they become wet, thus converting the difference of the expansion into convenient movement. Another possible variation, instead of mechanical sensors and valves, is to use for example a preferably synthetic material that tends to behave like a normal root preferably at the edge of each side channel, so that the “root” counter-balances the water supply and reaches equilibrium with it when the soil becomes wet enough, based preferably on asymmetric capillary materials.

Owner:MAYER YARON +2

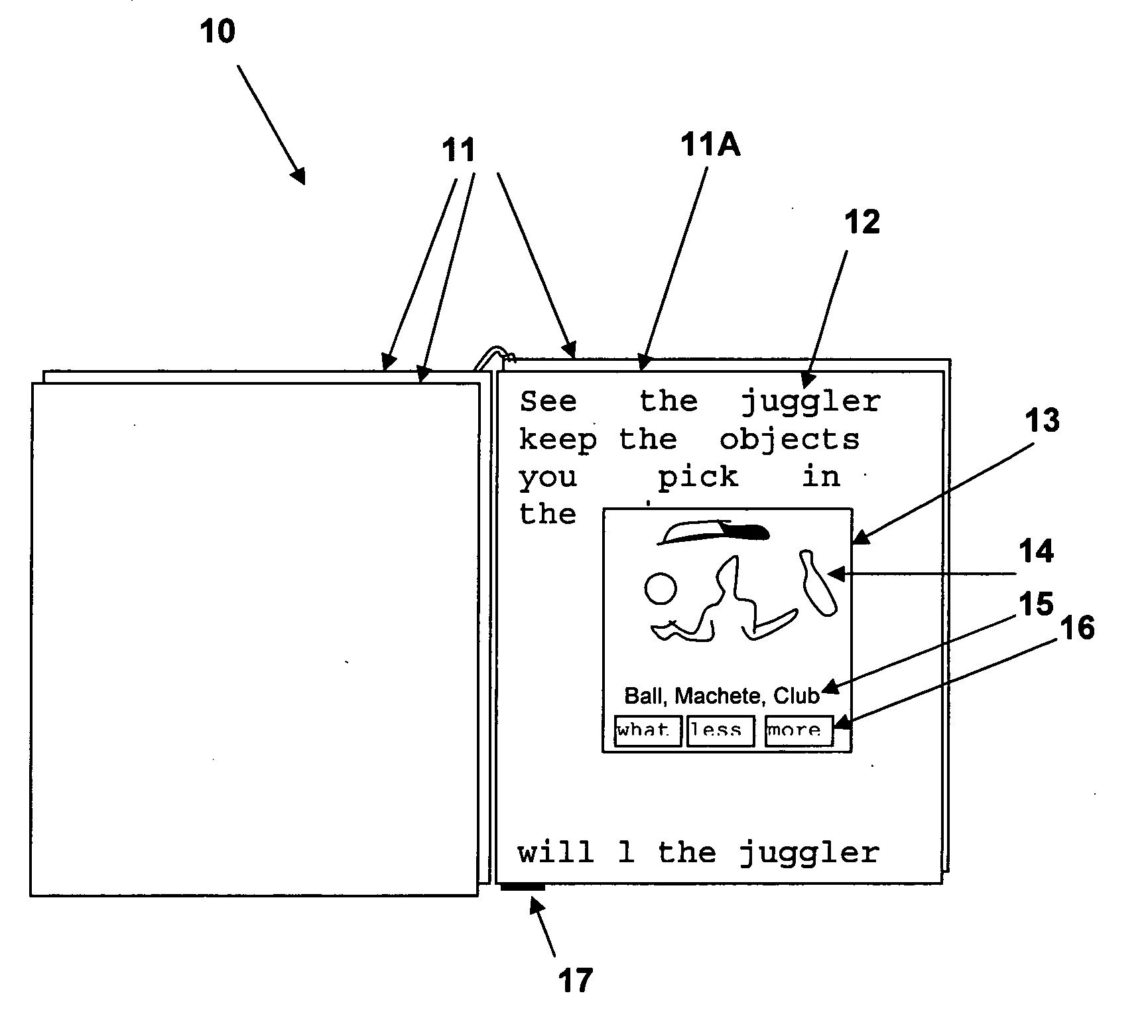

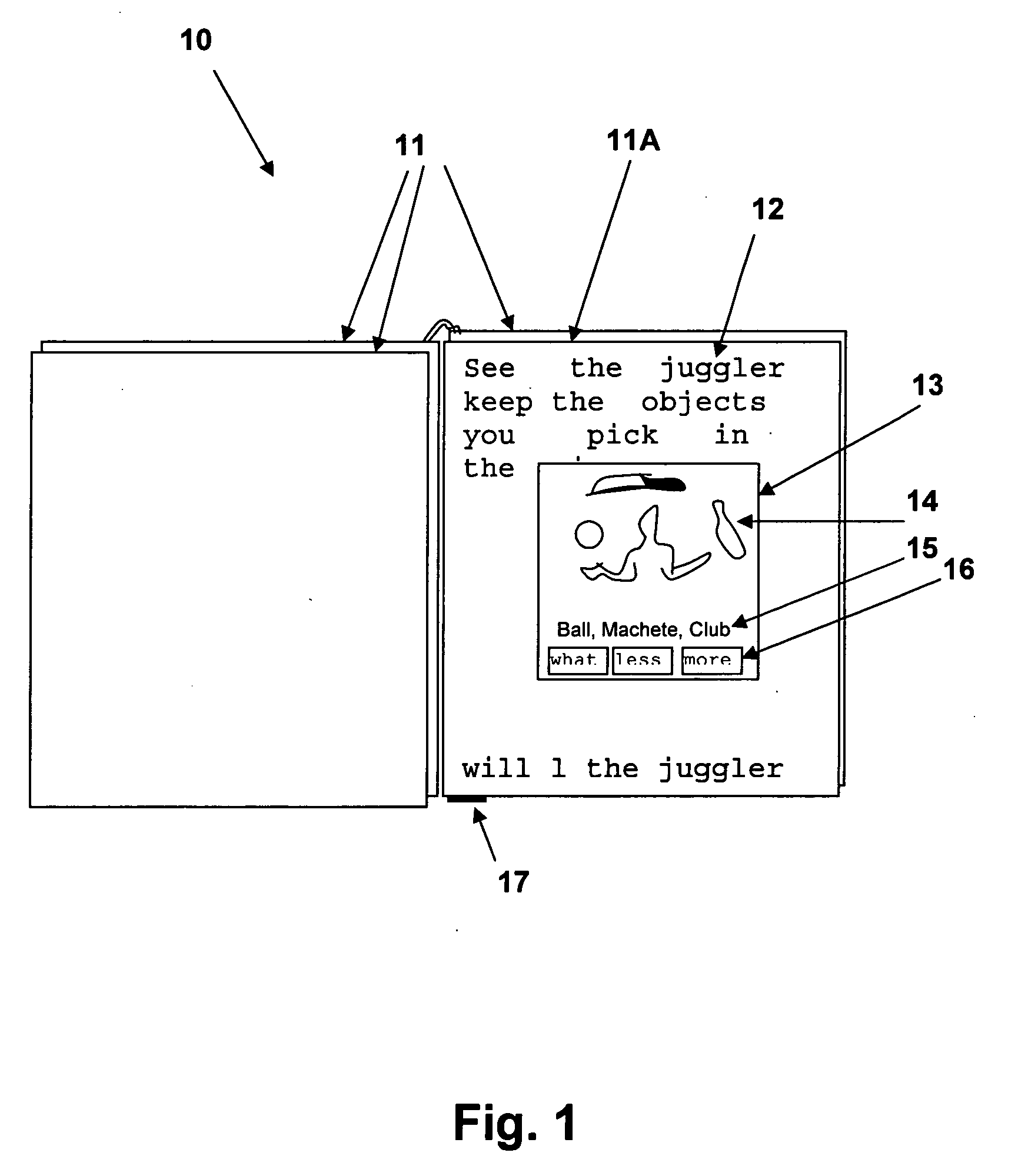

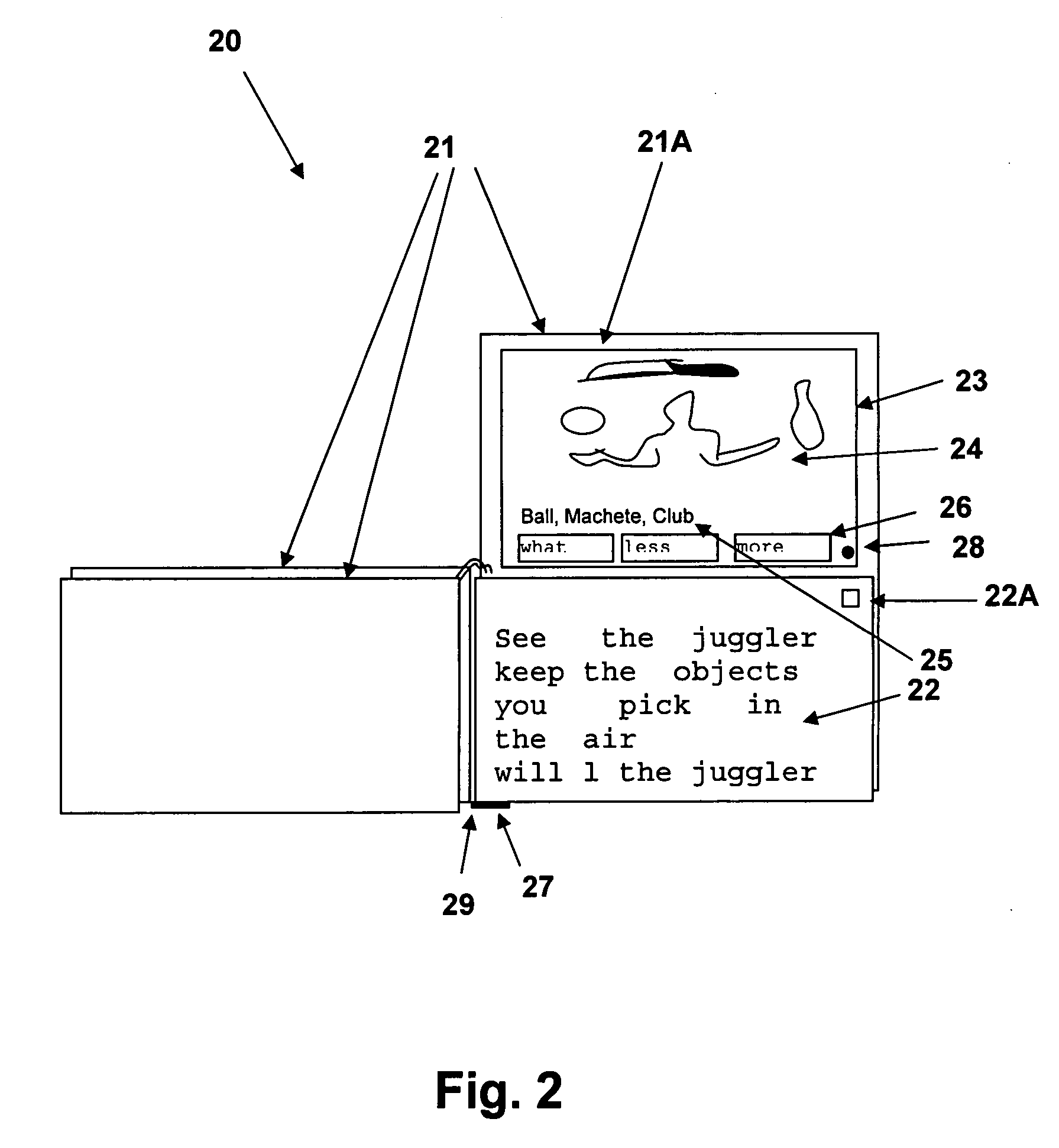

Reading book including partially electronic page display

InactiveUS20050260551A1Cost-effectiveDigital computer detailsElectrical appliancesAnimationElectronic book

A reading book including a partially electronic page display provides a system and method for implementing interactive and / or animated books without the cost associated with typical electronic books, while retaining the multiple page features of a traditional printed book. The reading book may be a split-page design, where a portion of a reader's view is provided by a fixed electronic display, while a second portion is provided by a plurality of movable pages that may be recirculating electronic pages or printed pages. Alternatively or in concert, the reading book may include partial page areas implemented with electronic displays. Page selection via turning may be detected by optical, electronic or mechanical sensors and the display contents synchronized or activated in response to detected page turning activity.

Owner:AAA DOODADS

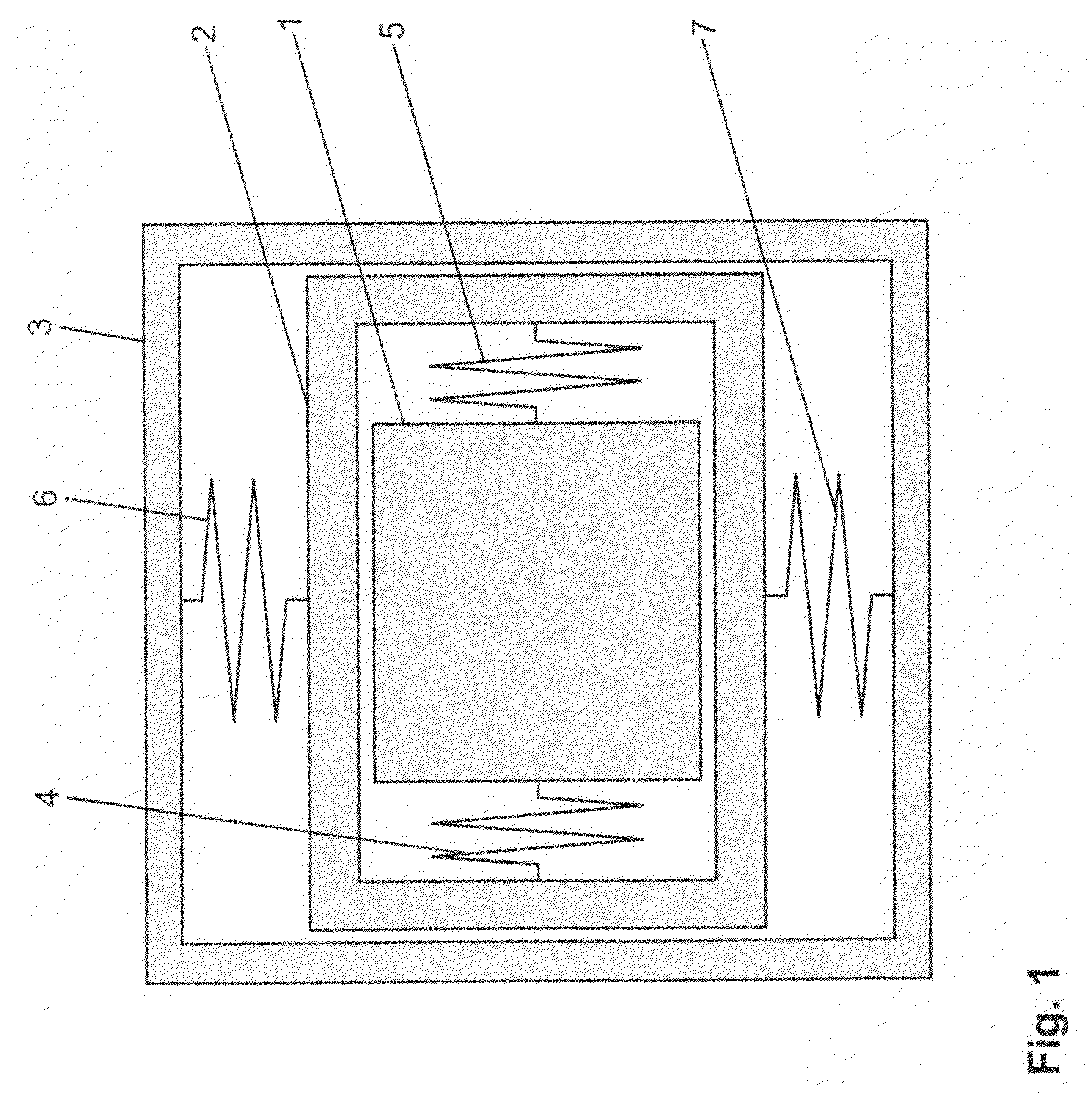

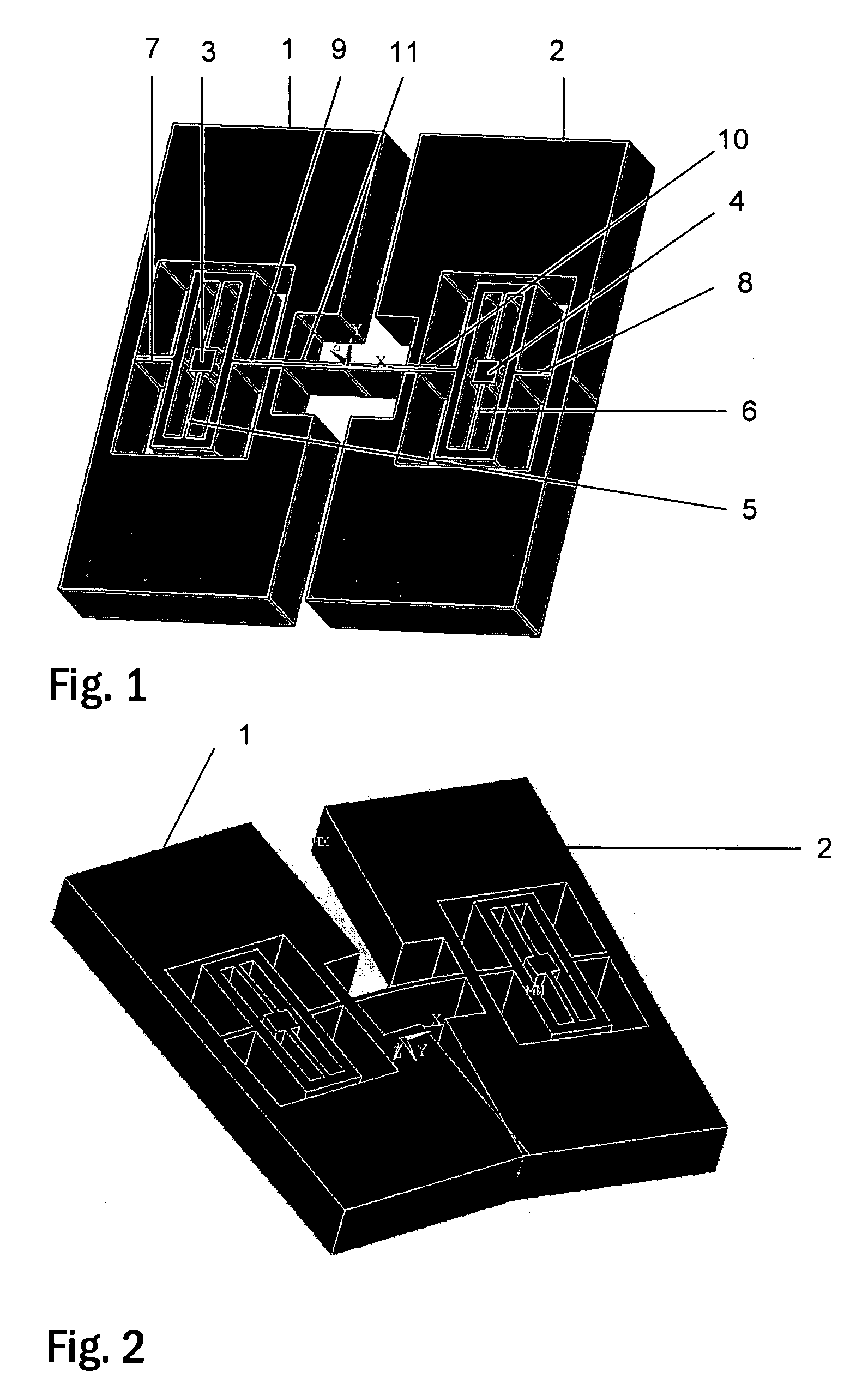

Vibrating micro-mechanical sensor of angular velocity

ActiveUS20090260437A1Reliable measurementImprove performanceAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsMechanical sensorMeasurement device

The invention relates to measuring devices used in measuring angular velocity and, more precisely, to vibrating micro-mechanical sensors of angular velocity. The sensor of angular velocity according to the invention is adapted to measure angular velocity in relation to two or three axes, and at the least two seismic masses (34-36, 52-53, 71-75) of the sensor of angular velocity are adapted to be activated into primary motion vibration by means of a common mode. The structure of the sensor of angular velocity according to the invention enables reliable measuring with good performance, particularly in small size vibrating micro-mechanical sensors of angular velocity.

Owner:MURATA MFG CO LTD

Self-locking multi-size cartridge extraction unit

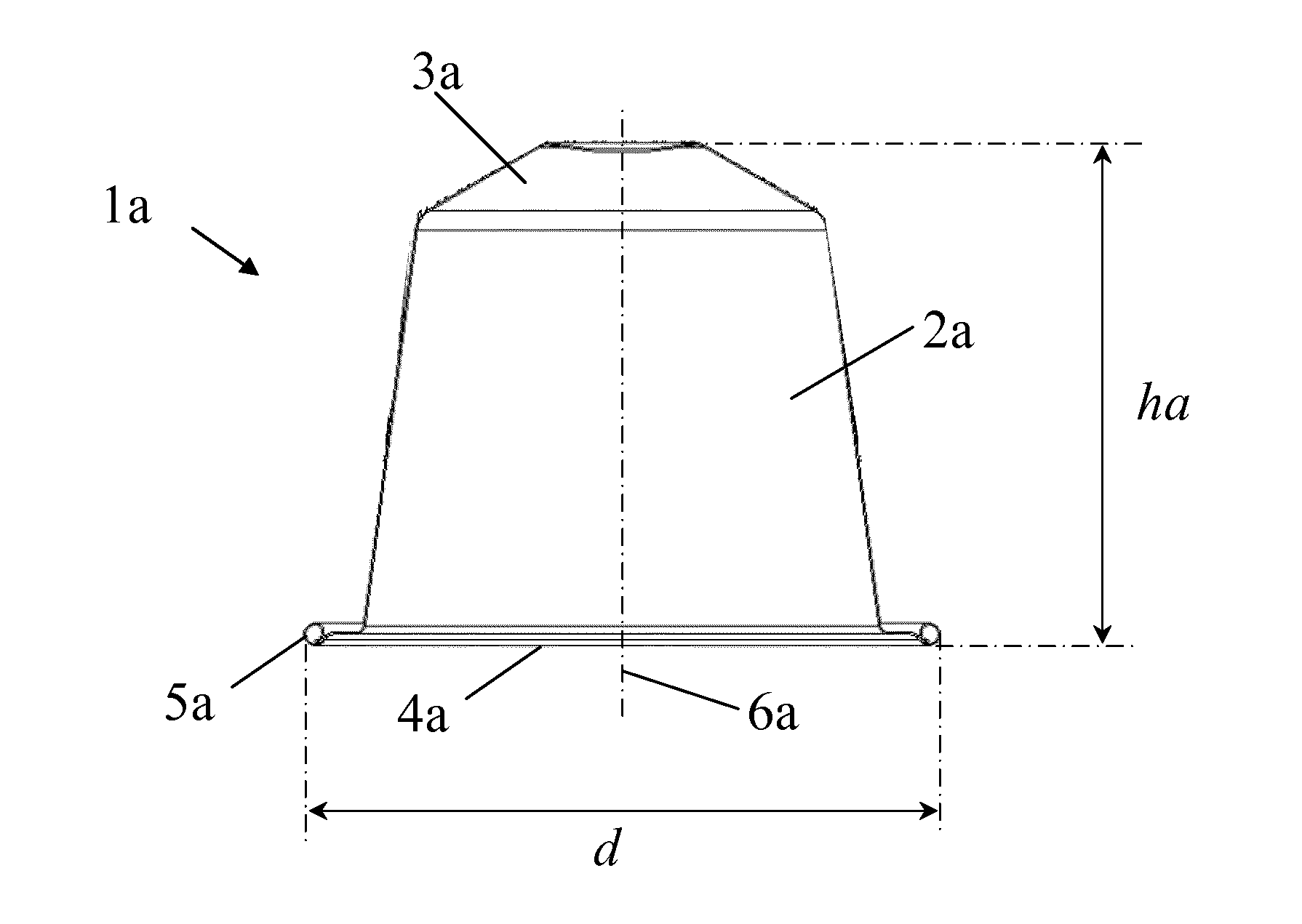

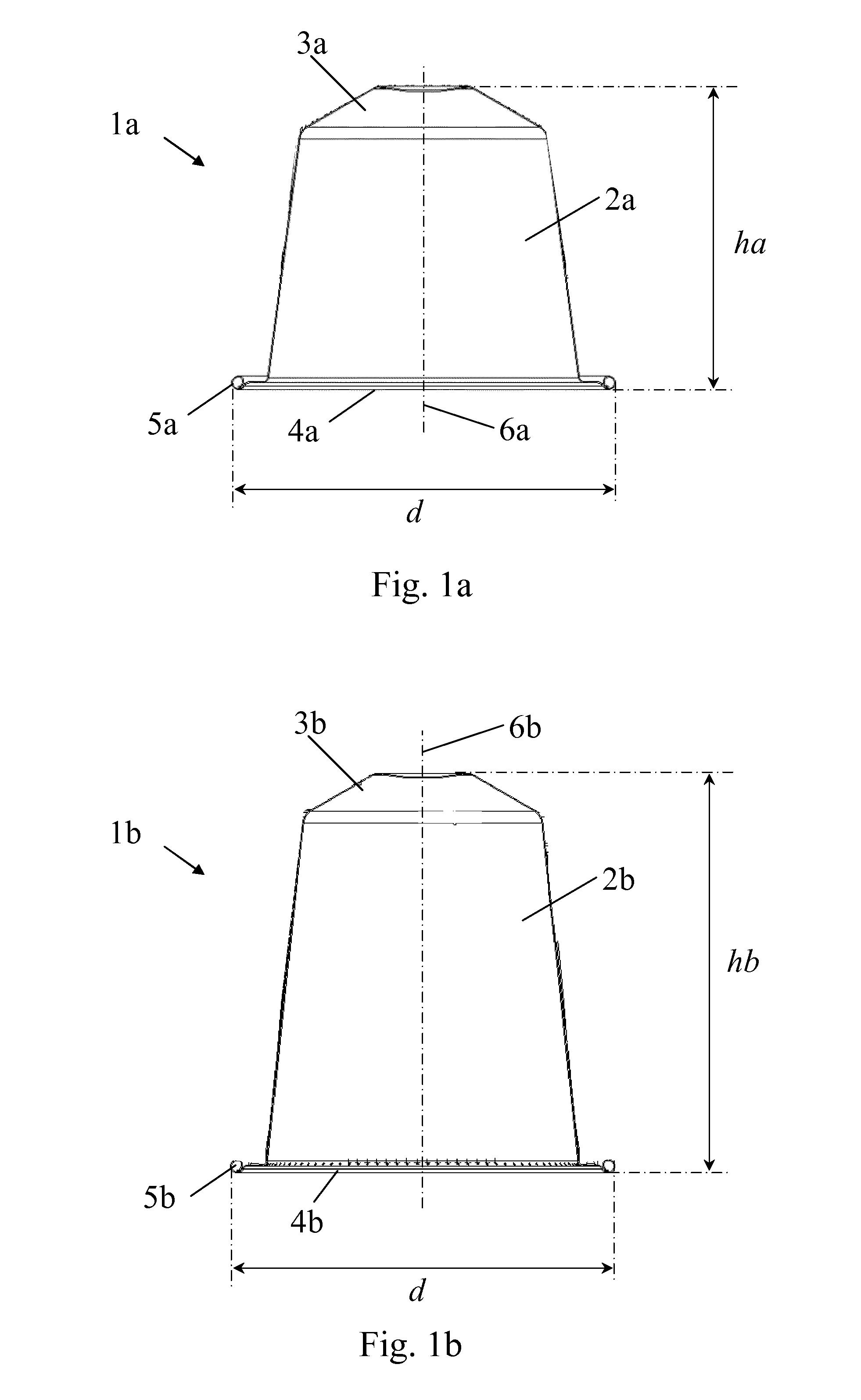

An extraction unit (10) for extracting cartridges (1a; 1b) of two different heights (ha;hb) comprises a seat (11, 12, 13; 15) for receiving any of such cartridges (1a; 1b) for extraction thereof in the seat. The seat is delimited by a first part (11,12,13) and second part (15) that are relatively movable between a cartridge extraction position and a cartridge loading and / or ejection position. The first part (11,12,13) has a first portion (11,12) and a second portion (13) that are relatively movable to delimit a cavity (12′) having selectively: —a first depth (da) for receiving a cartridge (1a) of the first height (ha); and—a second depth (db) for receiving a cartridge (1b) of the second height (hb), the first part (11,12,13) has a lock (112′, 132, 132′, 142′) for locking the first and second portions (11,12,13) when the delimited cavity (12′) has the first depth (da) or the second depth (db). Such extraction unit (10) further comprises a mechanical sensor (14) that senses the height (ha;hb) of a cartridge (1a; 1b) and that controls the lock (112′, 132, 132′, 142′) to lock or unlock the first and second portions (11,12,13) when the sensor is actuated by a cartridge of first height (ha) or of second height (hb).

Owner:SOC DES PROD NESTLE SA

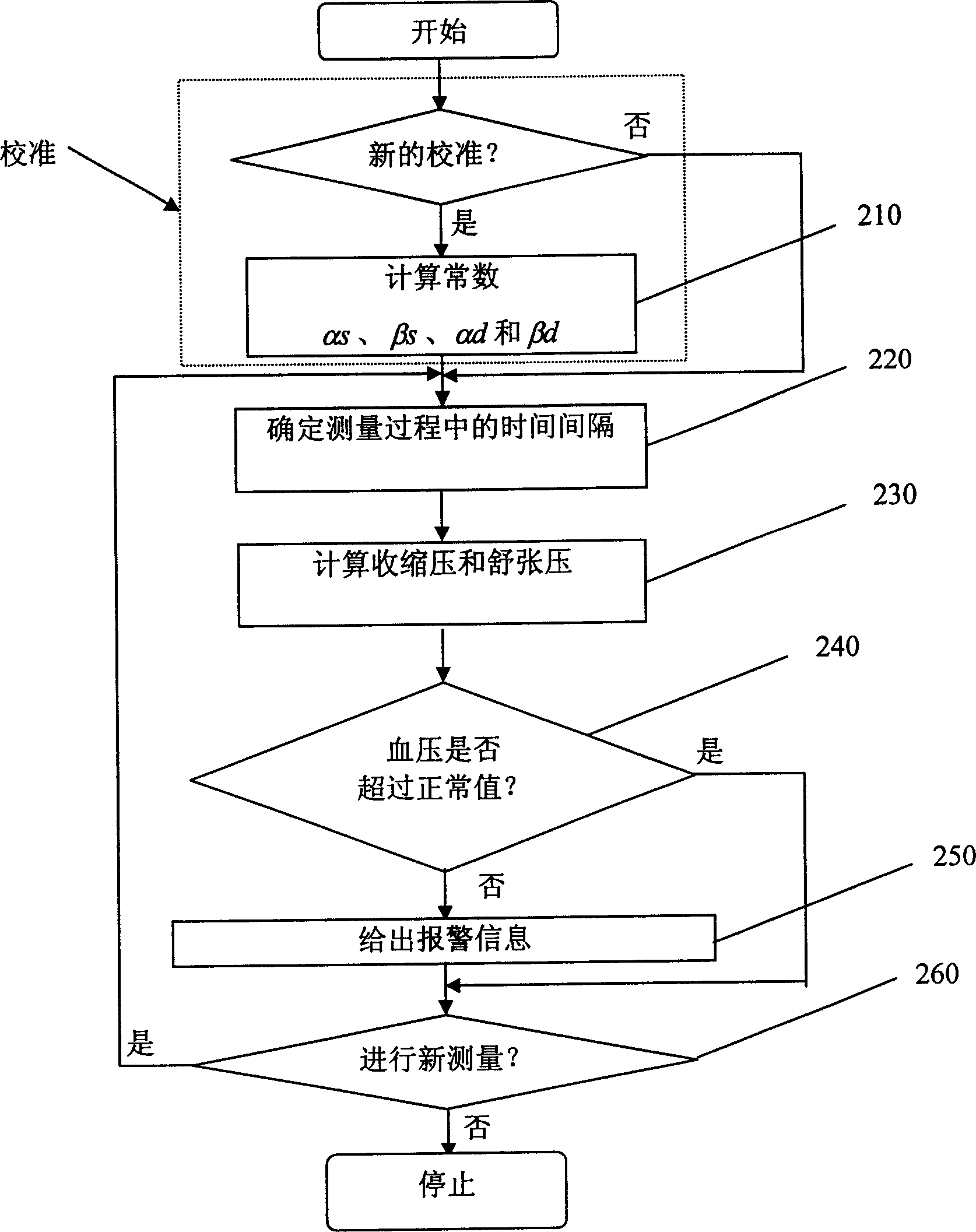

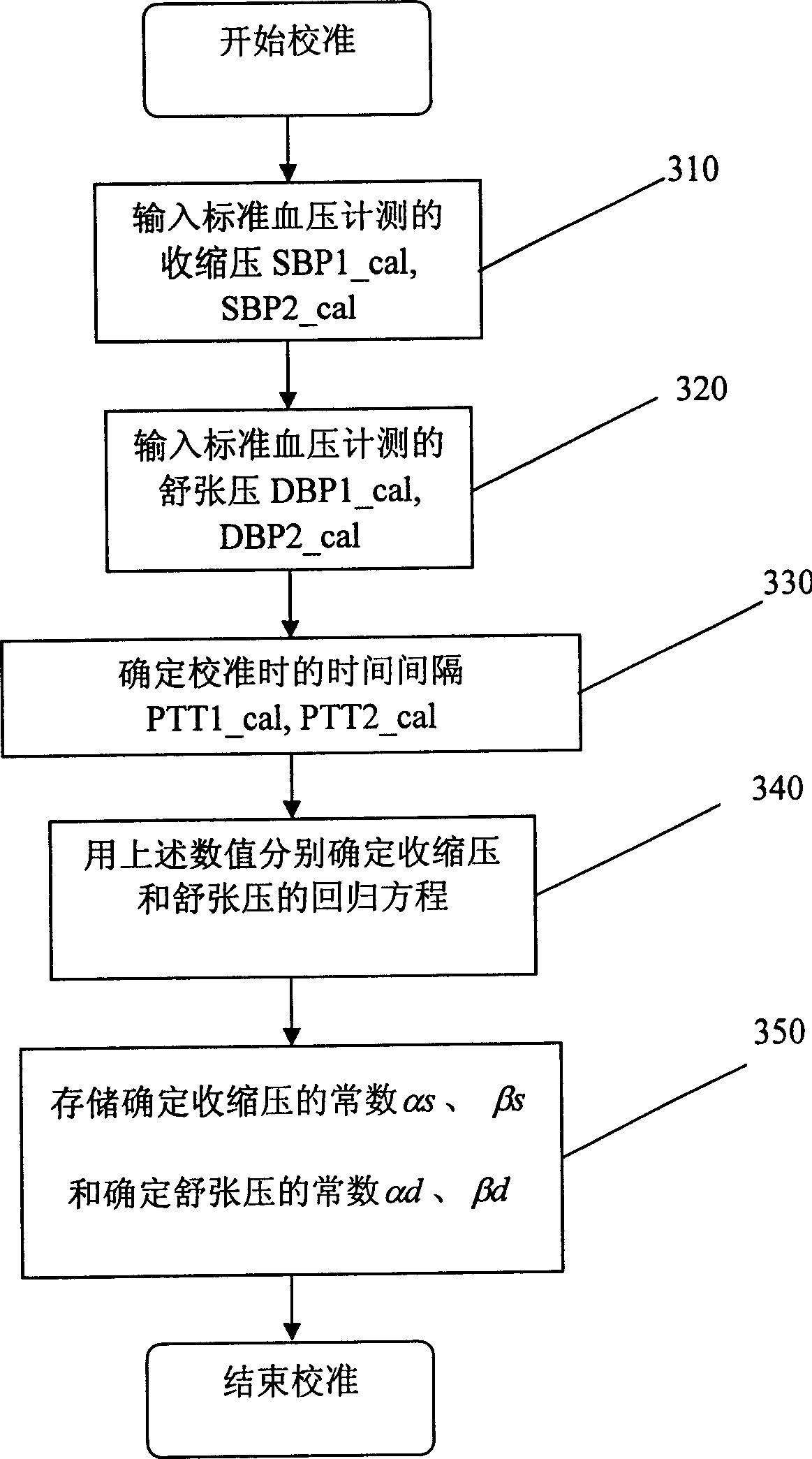

Blood pressure measuring device and method based on the pulse information of radial artery

InactiveCN1548005AEasy to wear for a long timeEasy to monitor in real timeEvaluation of blood vesselsCatheterTime informationContinuous measurement

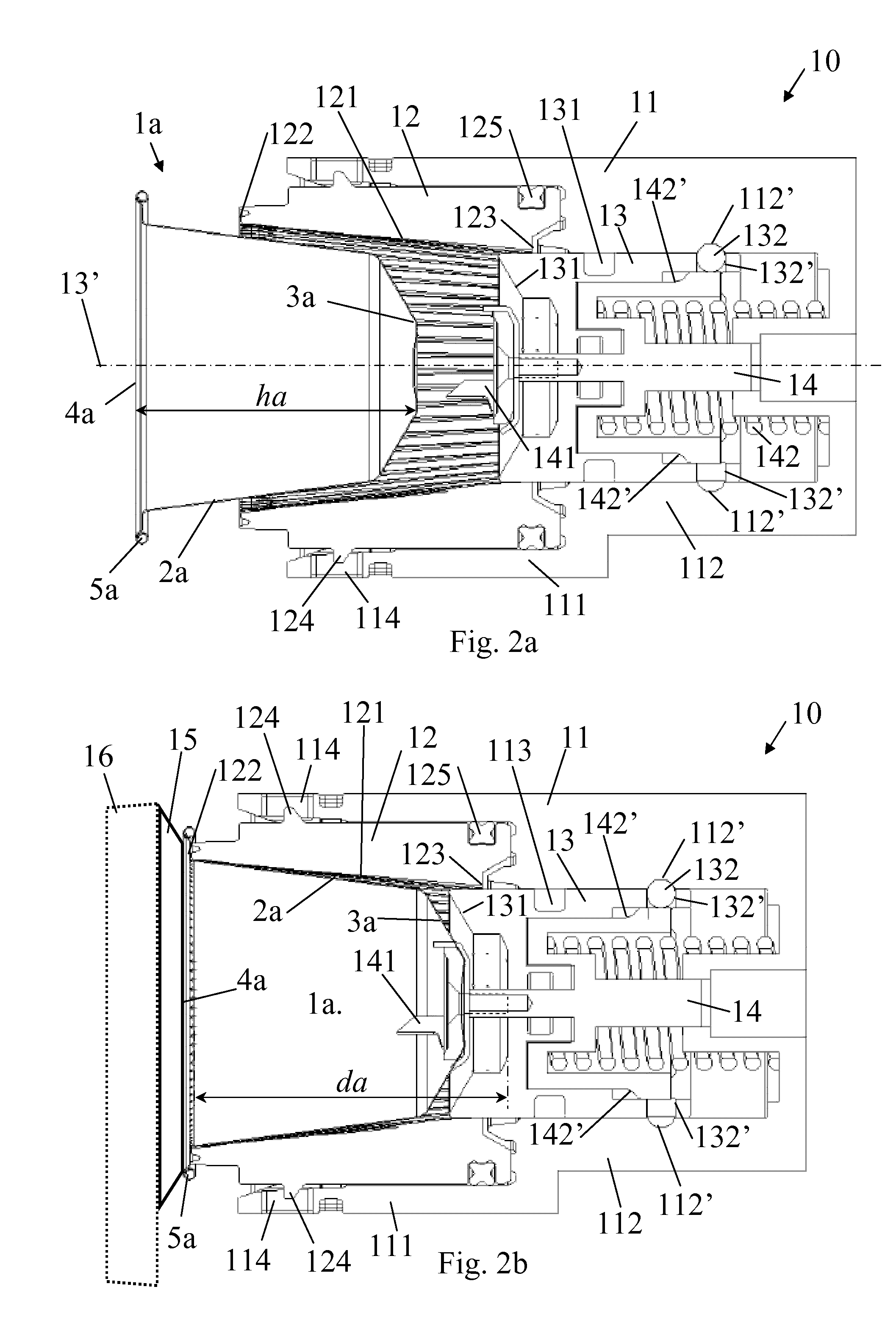

The pulse analysis is one of the important measures for Chinese medicine diagnosis. Doctor can understand the health condition of patient based on pulse condition of radial artery of the patient. The present invention provides blood pressure measuring method based on radial artery pulse information. The method includes detecting the pulse wave of radial artery in wrist with one mechanical sensor and detecting electrocardiac signal with two conducting electrode, and then determining artery blood pressure based on the time information extracted from these two signals. The device is calibrated with standard sphygmomanometer before used in continuous measurement of artery blood pressure without using sleeve belt.

Owner:THE CHINESE UNIVERSITY OF HONG KONG

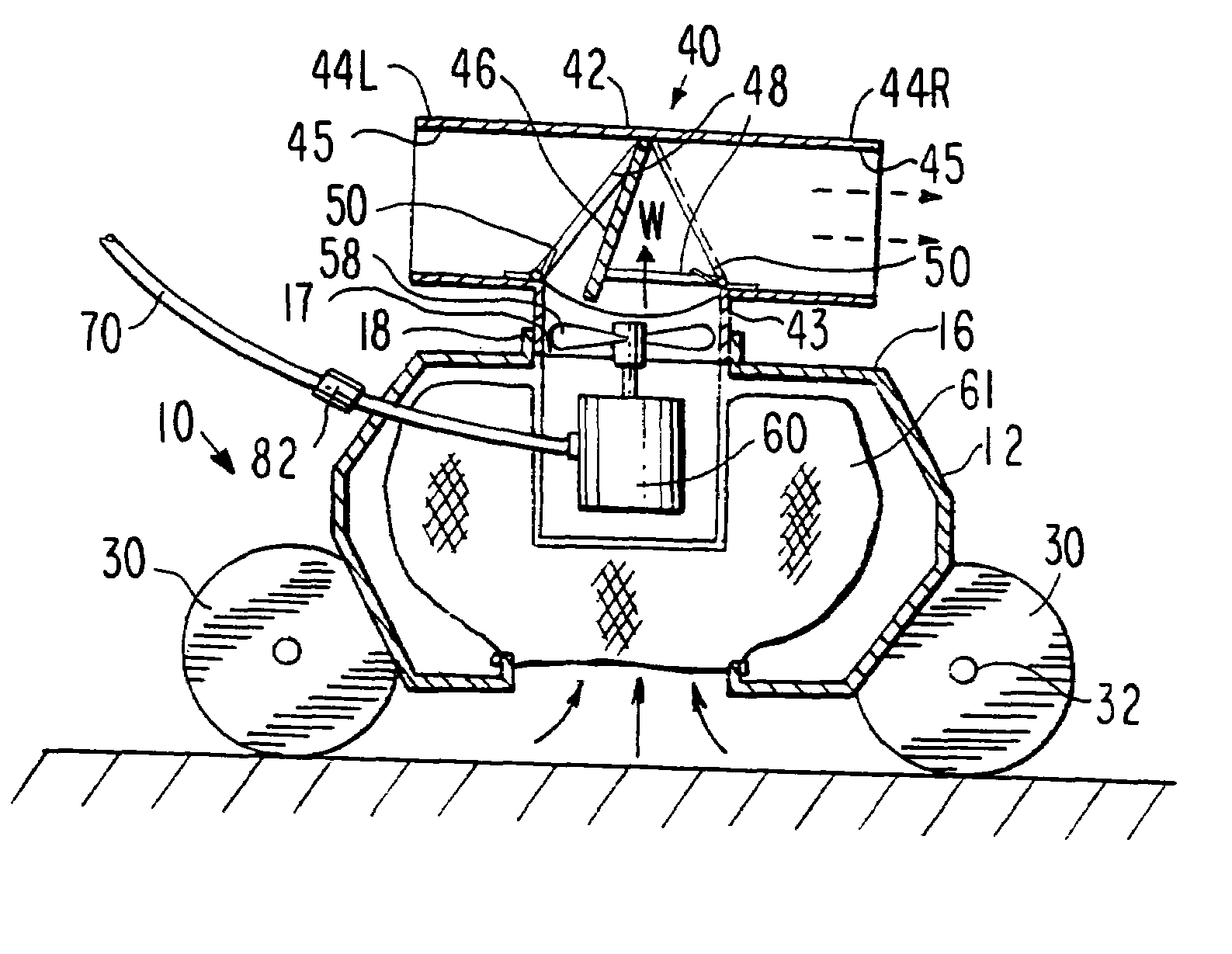

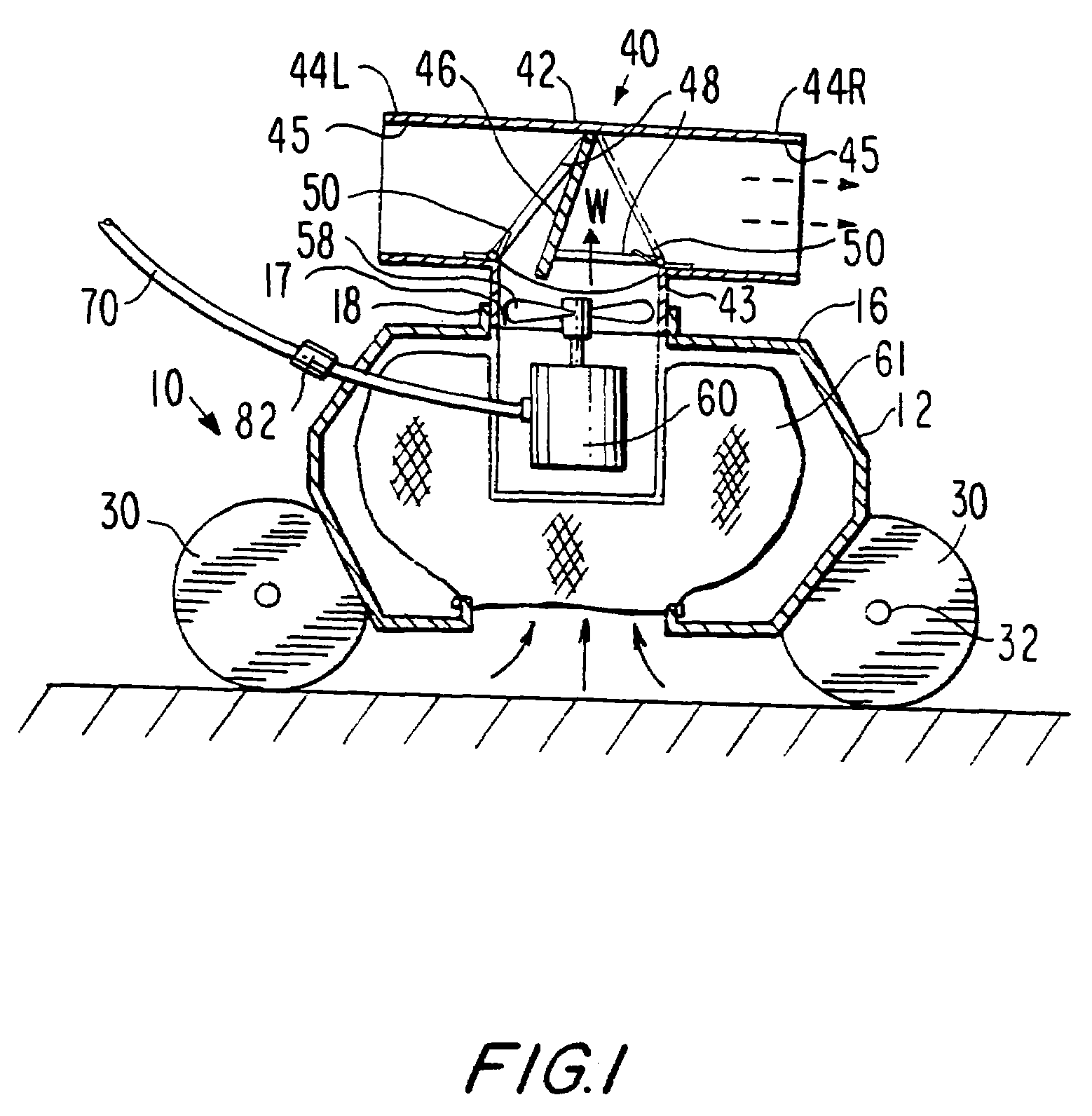

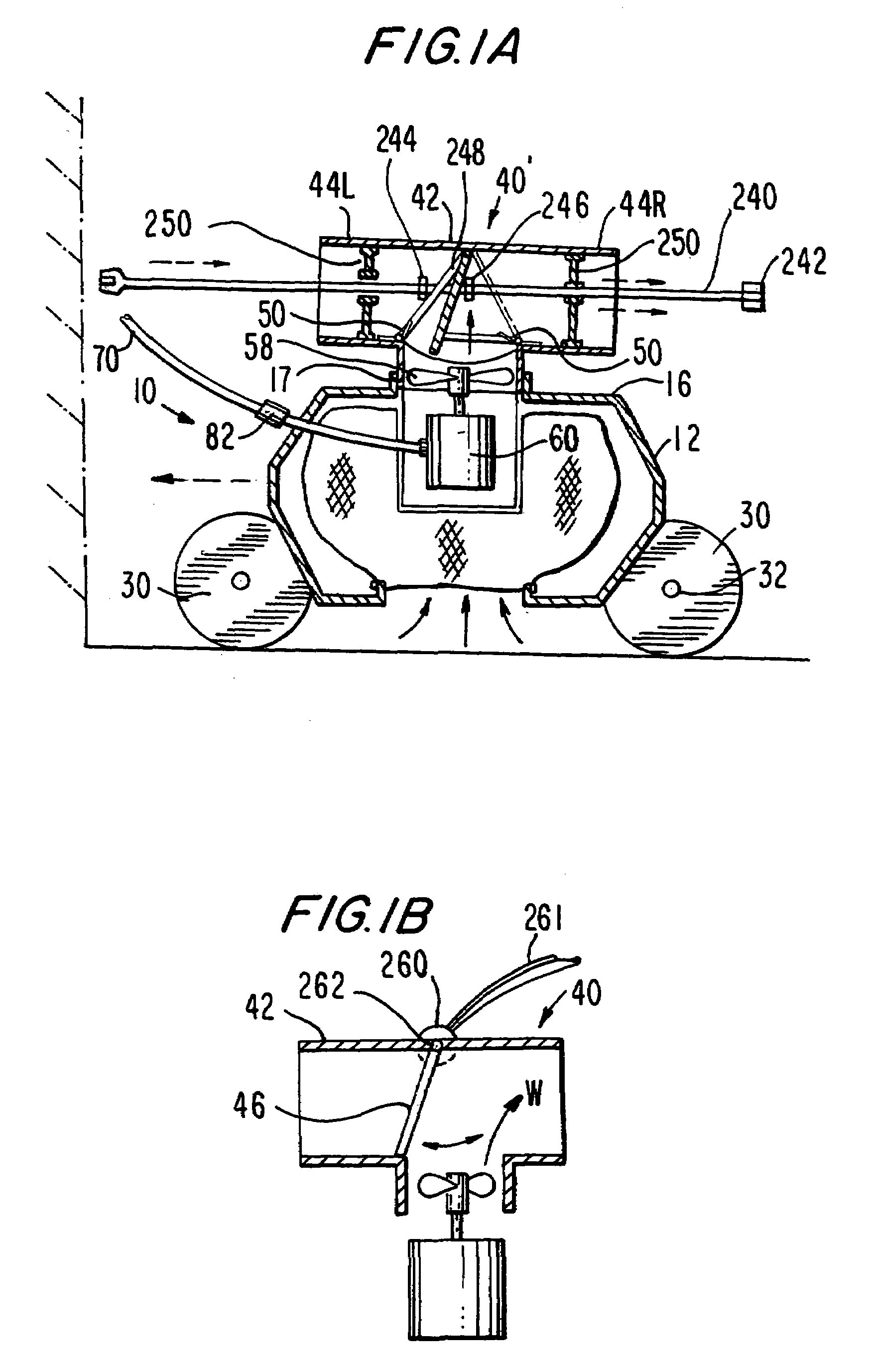

Water jet reversing propulsion and directional controls for automated swimming pool cleaners

InactiveUS7165284B2Easy to cleanReduce and eliminate interferenceGymnasiumCleaning using gasesMarine engineeringMechanical sensor

A pool or tank cleaner that is propelled by means of one or more water jets is directed in one or more predetermined systematic scanning patterns of either straight, curvilinear, or combinations of both, by an apparatus and method that controls and varies the directional discharge of one or more water jets that propel the cleaner in its translational movement. The direction of the discharge of the propelling water jet is changed by mechanical sensors, electrical sensors, or by interrupting the water pump. Further variations in the direction of translational movement of the cleaner are effected by activating at least one retractable depending member to periodically contact the pool surface below the moving cleaner, thereby causing the cleaner to pivot or otherwise change direction.

Owner:AQUA PRODS

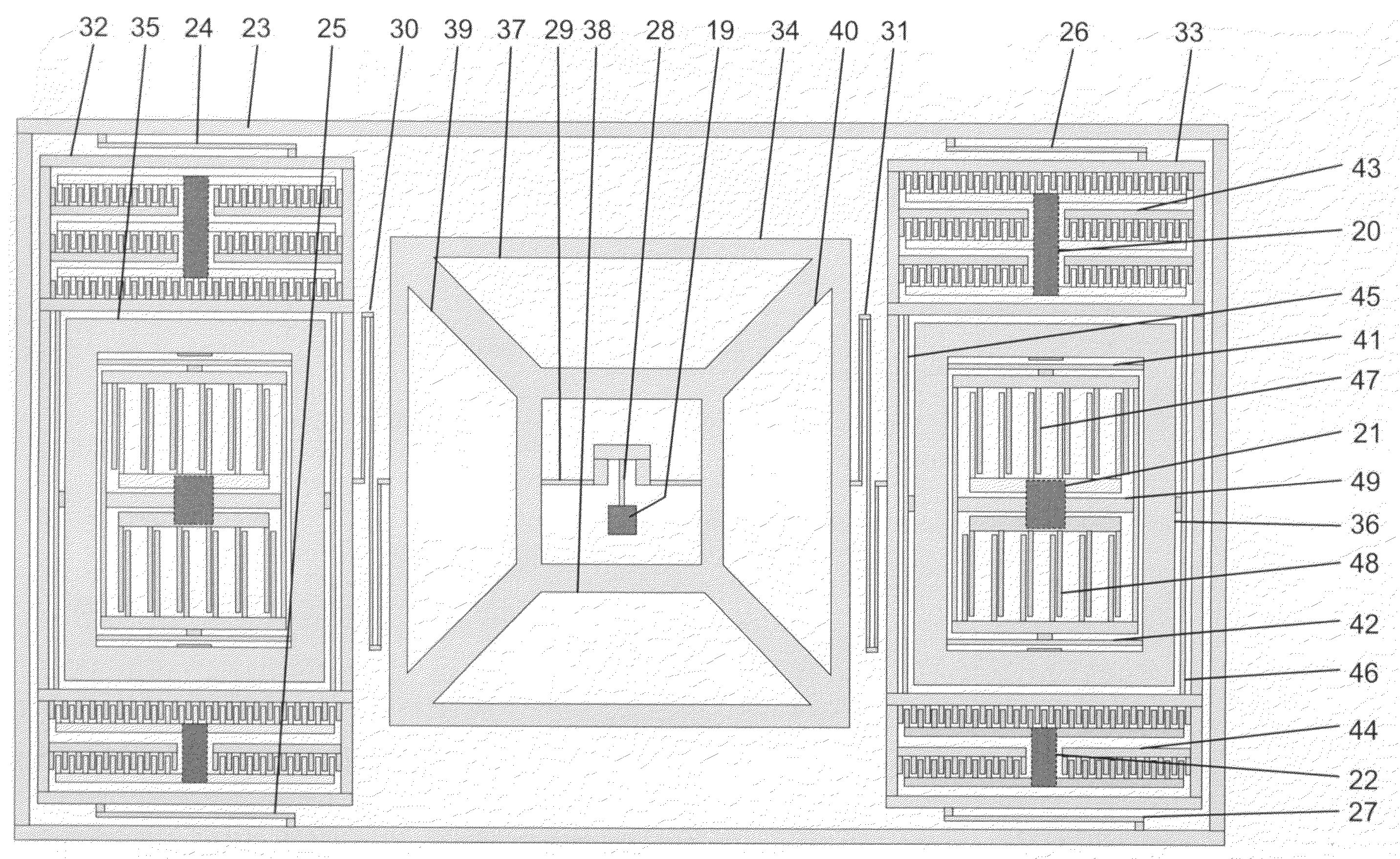

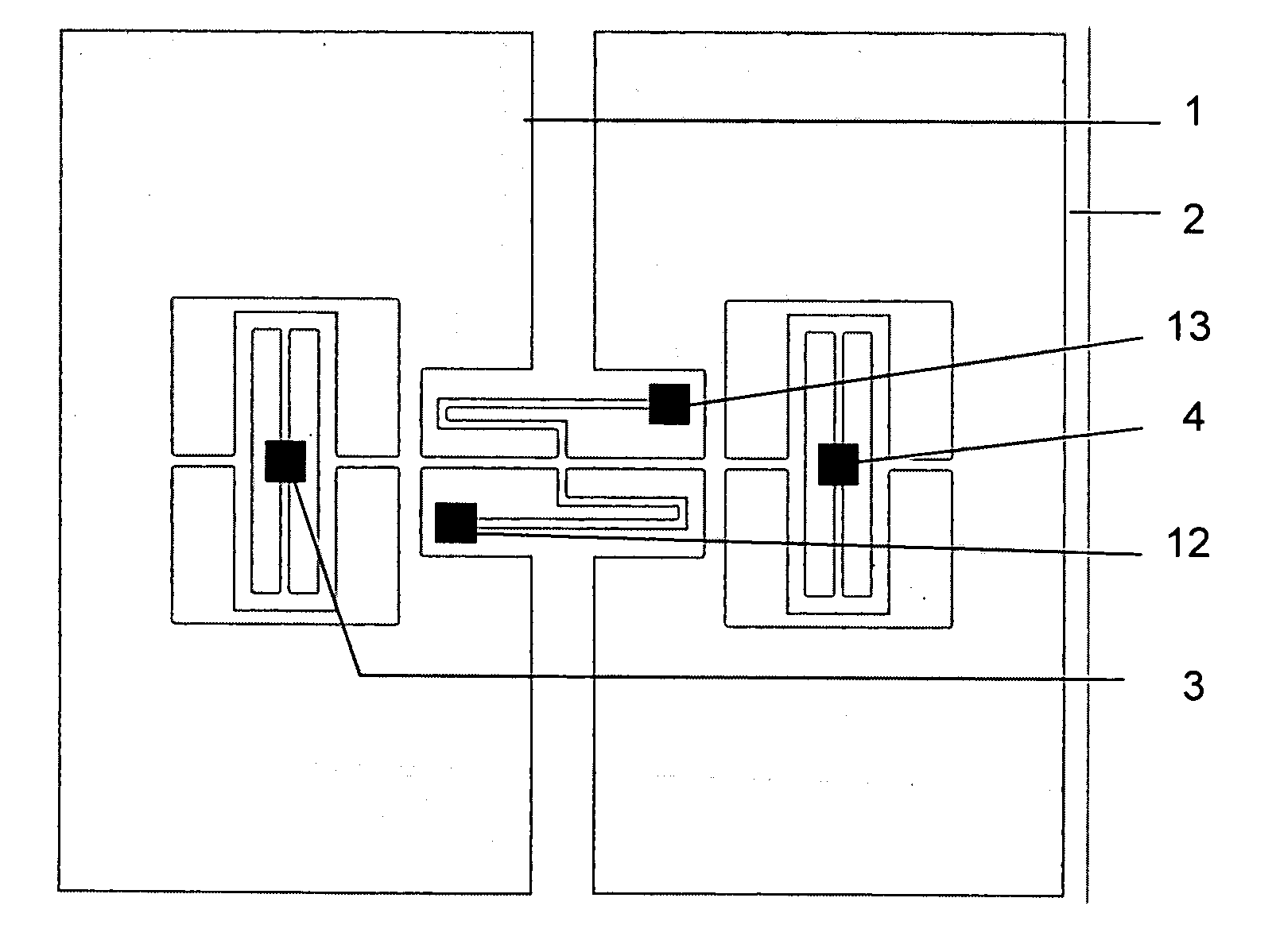

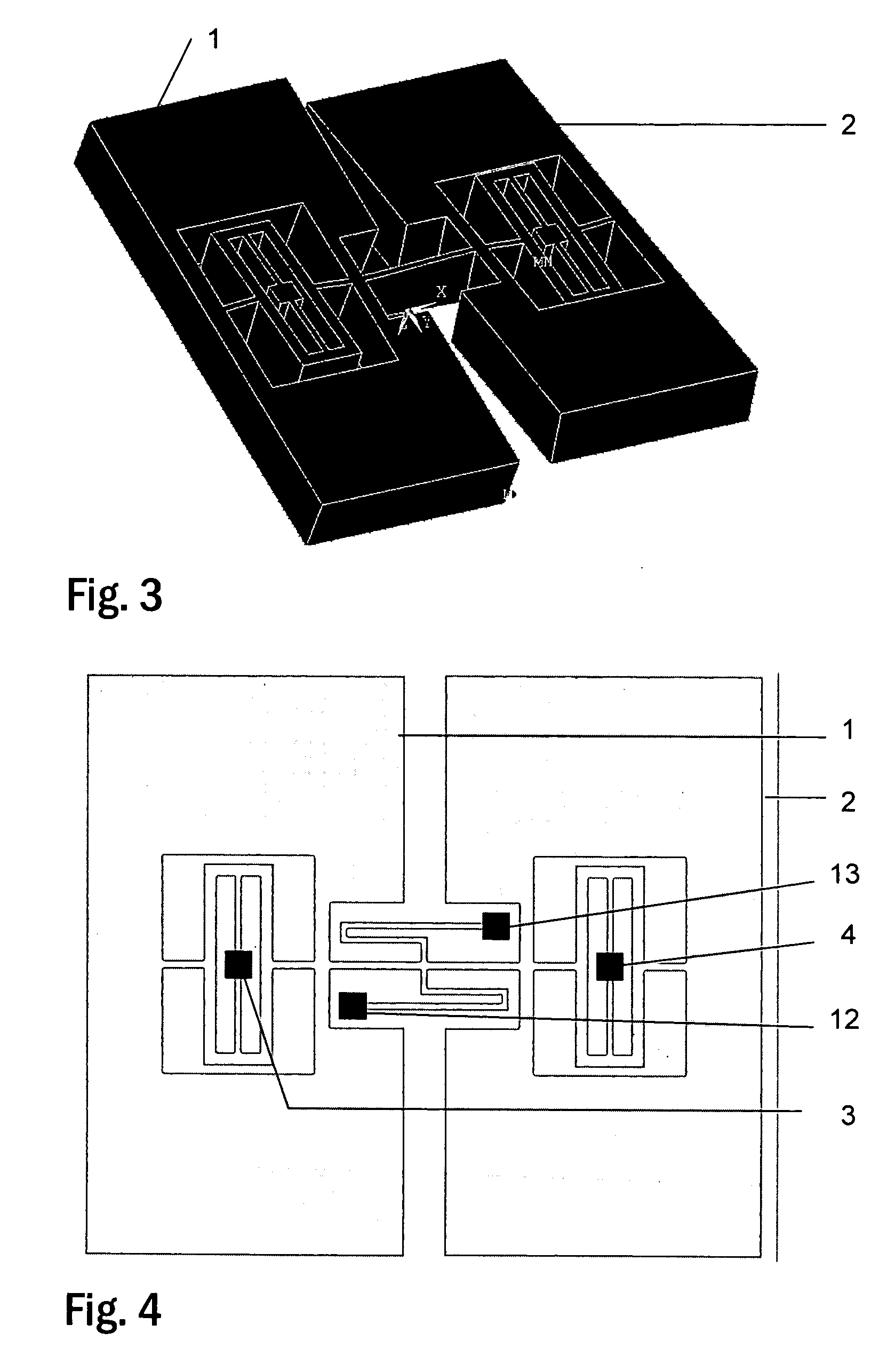

Oscillating micro-mechanical sensor of angular velocity

ActiveUS20060156814A1Reliable and efficient measuringLess sensitive to linkageAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsSeismic massMeasurement device

The invention relates to measuring devices used in measuring angular velocity, and, more specifically, to oscillating micro-mechanical sensors of angular velocity. In the sensor of angular velocity according to the present invention seismic masses (1), (2), (36), (37) are connected to support areas by means of springs or by means of springs and stiff auxiliary structures, which give the masses (1), (2), (36), (37) a degree of freedom in relation to an axis of rotation perpendicular to the plane of the wafer formed by the masses, and in relation to at least one axis of rotation parallel to the plane of the wafer. The structure of the sensor of angular velocity according to the present invention enables reliable and efficient measuring particularly in compact oscillating micro-mechanical sensors of angular velocity.

Owner:MURATA MFG CO LTD

Micron-nano scale in-situ nano indentation and scratching test system

InactiveCN101876609AThe test method is accuratePrecision equipmentUsing optical meansInvestigating material hardnessImage resolutionEngineering

The invention relates to a micron-nano scale in-situ nano indentation and scratching test system which integrates driving, precise loading and signal detection, micron-nano scale mechanics performance testing, ultraprecise scratching processing and high resolution in-situ observing as one. The system is mainly composed of a precise positioning platform at X-axis and Y-axis directions, a precise linear positioning platform at Z-axis direction, a precise indentation driving unit, a load signal and displacement signal detection unit and a high resolution digital microscopic imaging system for observing and storing material deformation and damage conditions in the test process. The precise positioning platform at the X-axis and Y-axis directions is assembled on a base, the precise linear positioning platform at the Z-axis direction is assembled on a side plate, the precise indentation driving unit, a precise mechanical sensor for detecting the indentation material pressure of a diamond tool head and a precise displacement sensor for detecting the indentation depth of the diamond tool head to along the Z-axis direction are assembled on the precise linear positioning platform at the Z-axis direction, and the high resolution digital microscopic imaging system is assembled on a beam.

Owner:赵宏伟

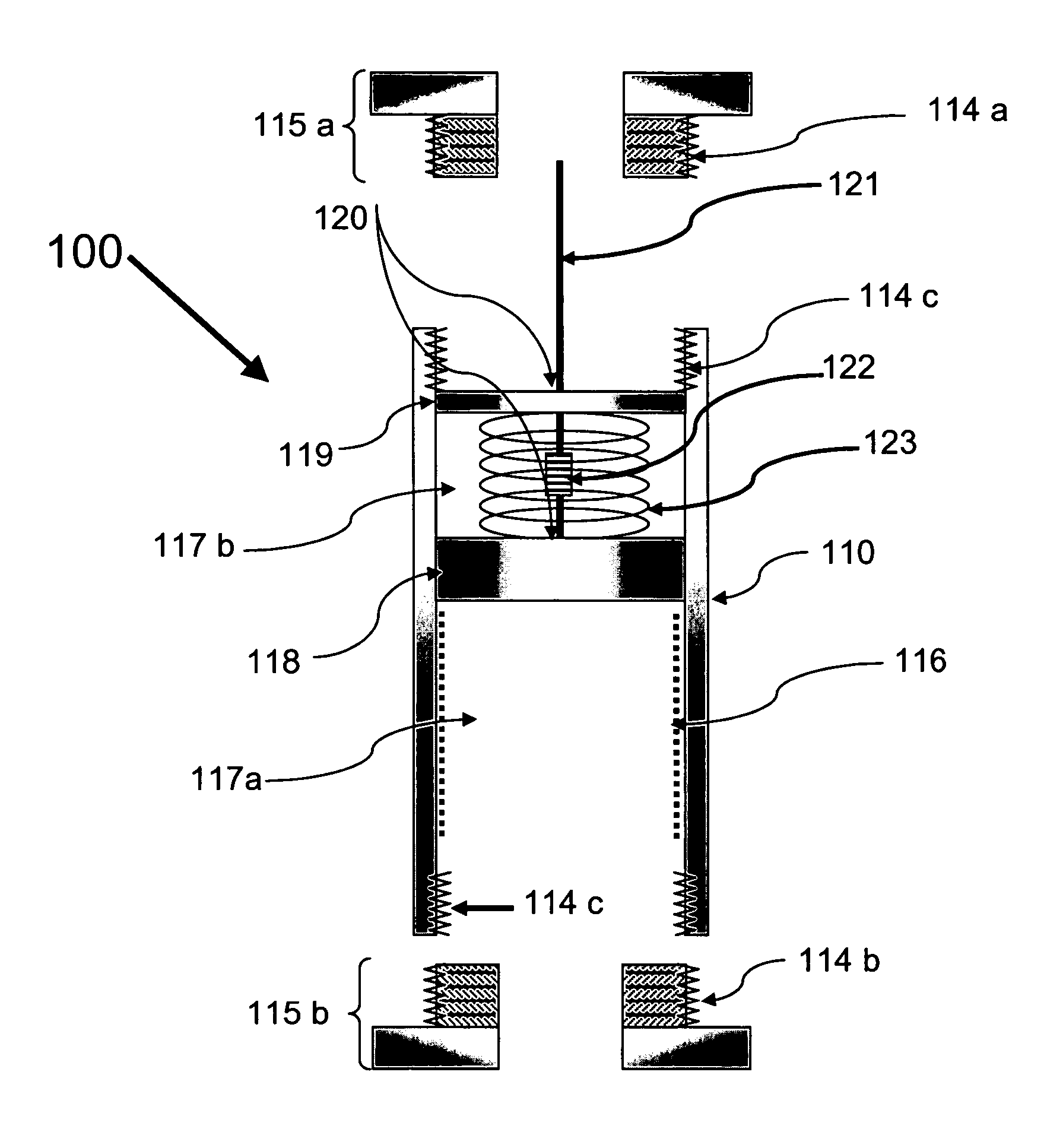

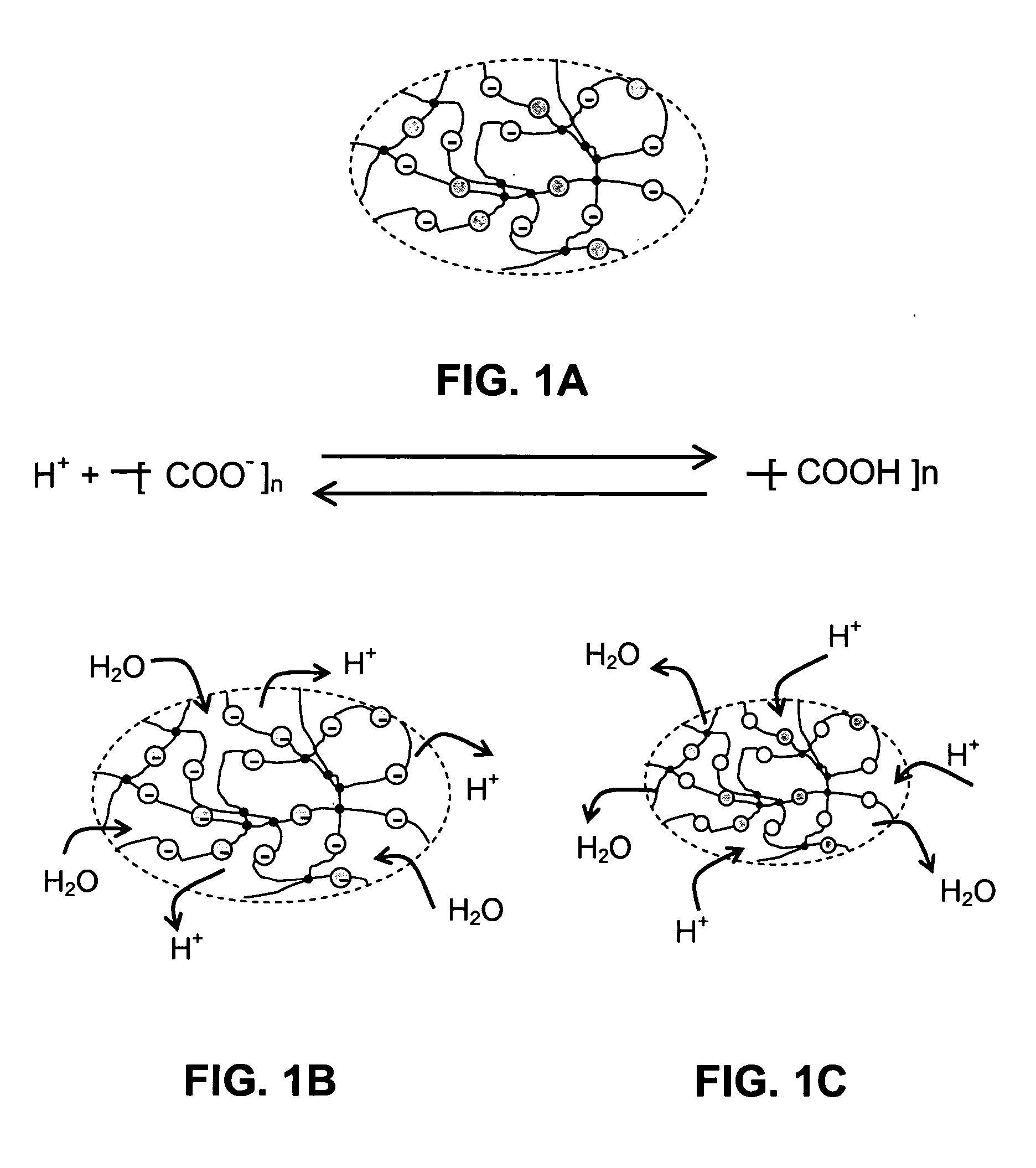

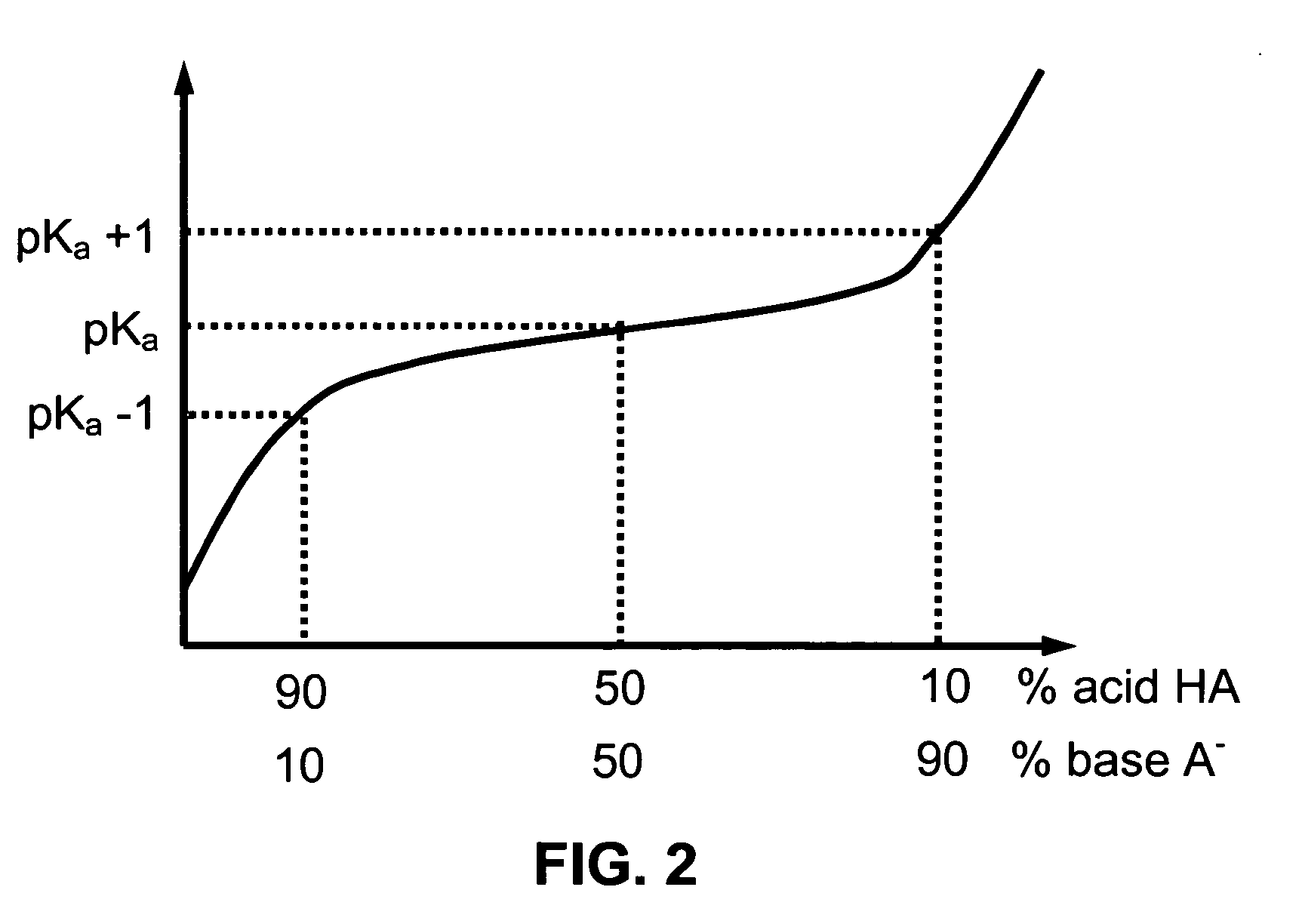

Optical fiber pH sensor

ActiveUS20050265649A1Indirect evaluationMaterial analysis by observing effect on chemical indicatorPhase-affecting property measurementsGratingTransducer

An optical fiber pH sensor 100, 200, 300 is described, where a transducer mechanically couples a Bragg grating to a pH-sensitive hydrogel, said sensor comprising a central part 110, 210, 301 where are placed the optical fiber 121 containing a Bragg grating 122, the pH-sensitive hydrogel set of discs 130, and the mechanical transducer which is a spring 123 a beam 215 or still the optical fiber itself 121, the mechanical transducer assuring the strain on the Bragg grating 122. The change in hydrogel hydrodynamic volume resulting from a change of the pH of the medium introduces a force that is sufficient to cause a strain in the Bragg grating. The measure of the pH change is retrieved using the usual techniques for wavelength measurement. The pH sensor 100, 200, 300 of the invention is useful for the indirect evaluation and control of corrosion in petroleum wells and is suitable for multiplexing with other optical fiber sensors measuring the same or different parameters.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

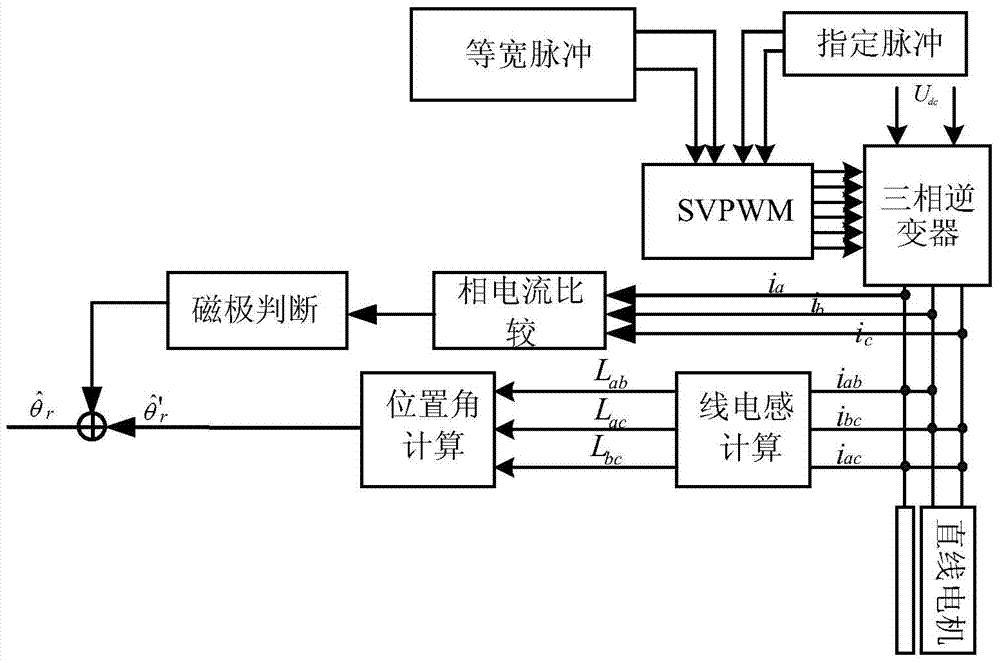

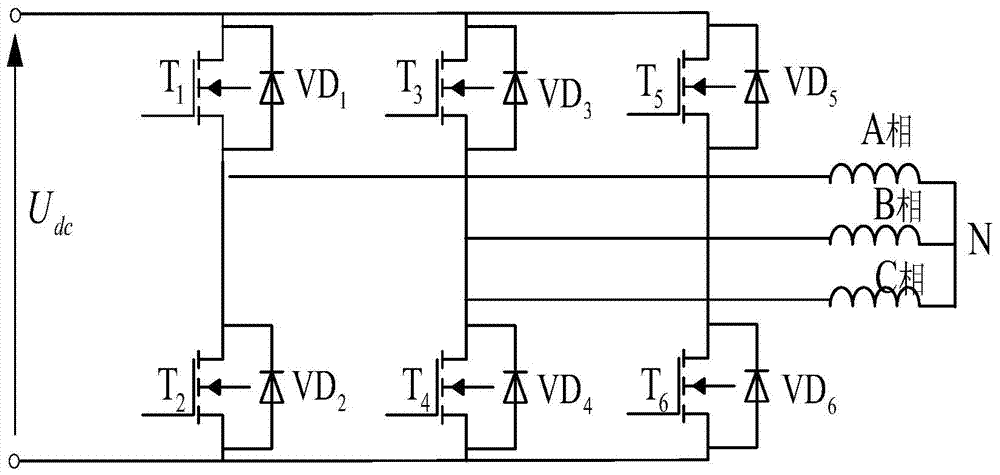

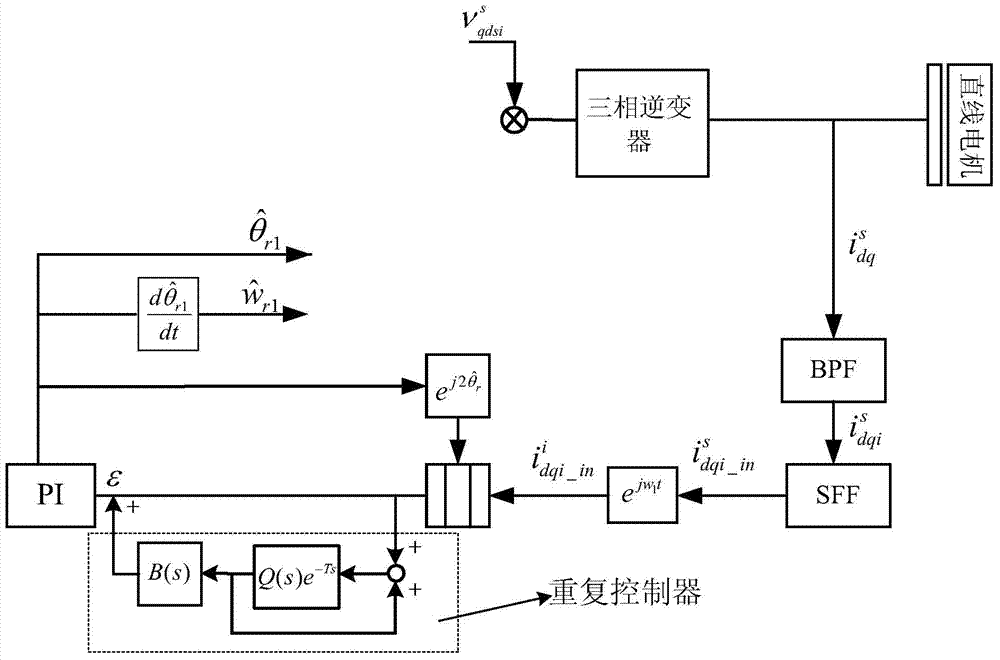

Unposition sensor for permanent magnet linear motor

InactiveCN103501151AImprove detection accuracyElectronic commutation motor controlVector control systemsLow speedMagnetic poles

The invention discloses an unposition sensor for a permanent magnet linear motor. Before a motor starts, a designated trigger signal is inputted into an inverter, a corresponding line inductance value is solved, the calculation is realized by combining the existing inductive parameters of the motor for preliminarily obtaining an initial position of a linear servo motor and then high-frequency voltage is immediately introduced to judge the direction of a magnetic pole of the rotor; after the motor starts, the position of the rotor is detected at the low-speed phase in real time by a method of combining the injection of the high-frequency voltage with the repetition of a controller; position information of the rotor is acquired at the middle-high speed phases in real time by a method of combining a sliding-mode observer based on an extended counter electromotive force model with a saturation function algorithm. According to the unposition sensor disclosed by the invention, an initial position detection method, a rotating high-frequency injection method, repeated control and the sliding-mode observer are combined together, so that the position information of the linear servo motor can be accurately and effectively detected, the defects caused by the existence of a mechanical sensor are overcome and the reliability of the system is improved.

Owner:SOUTHEAST UNIV

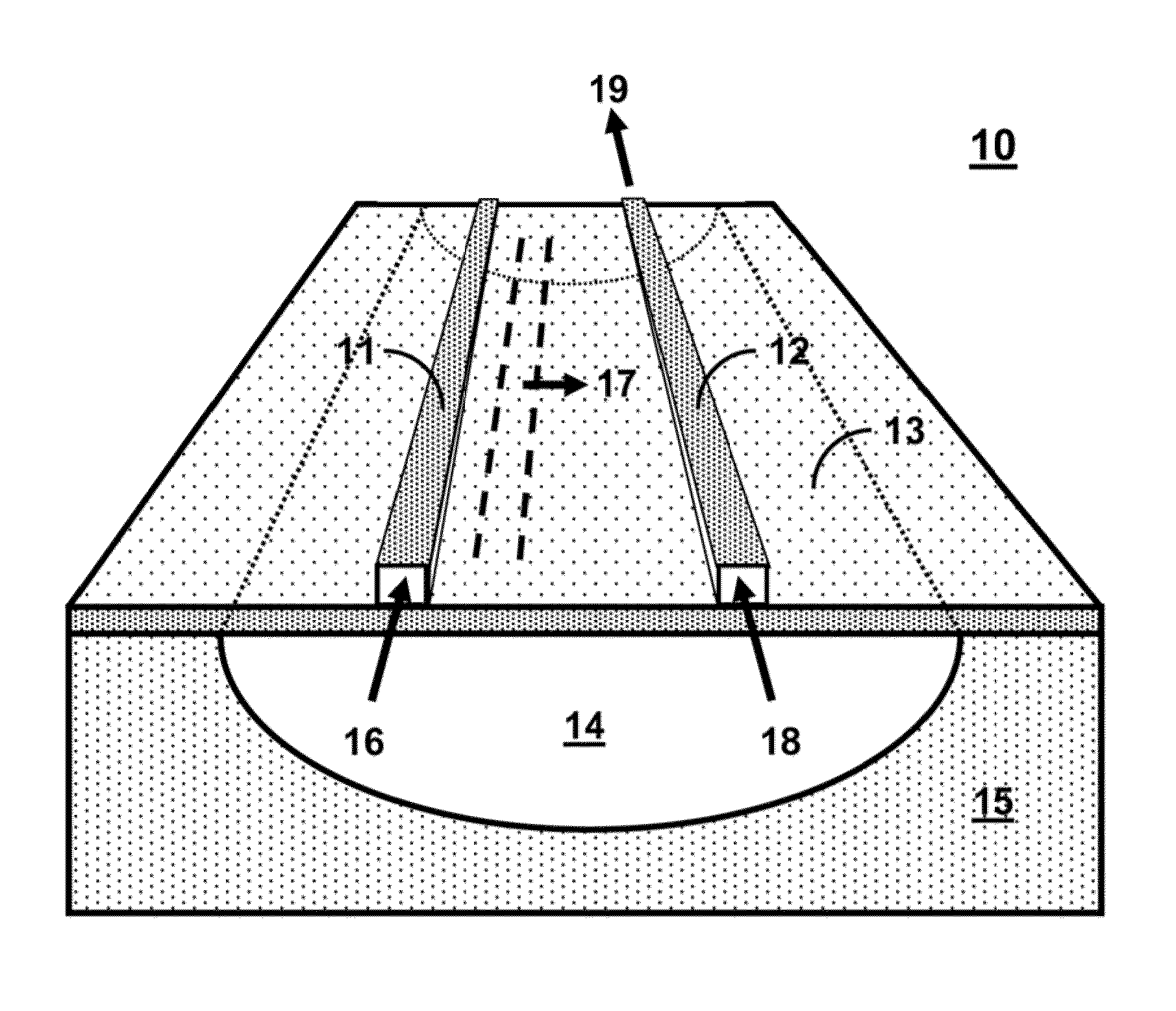

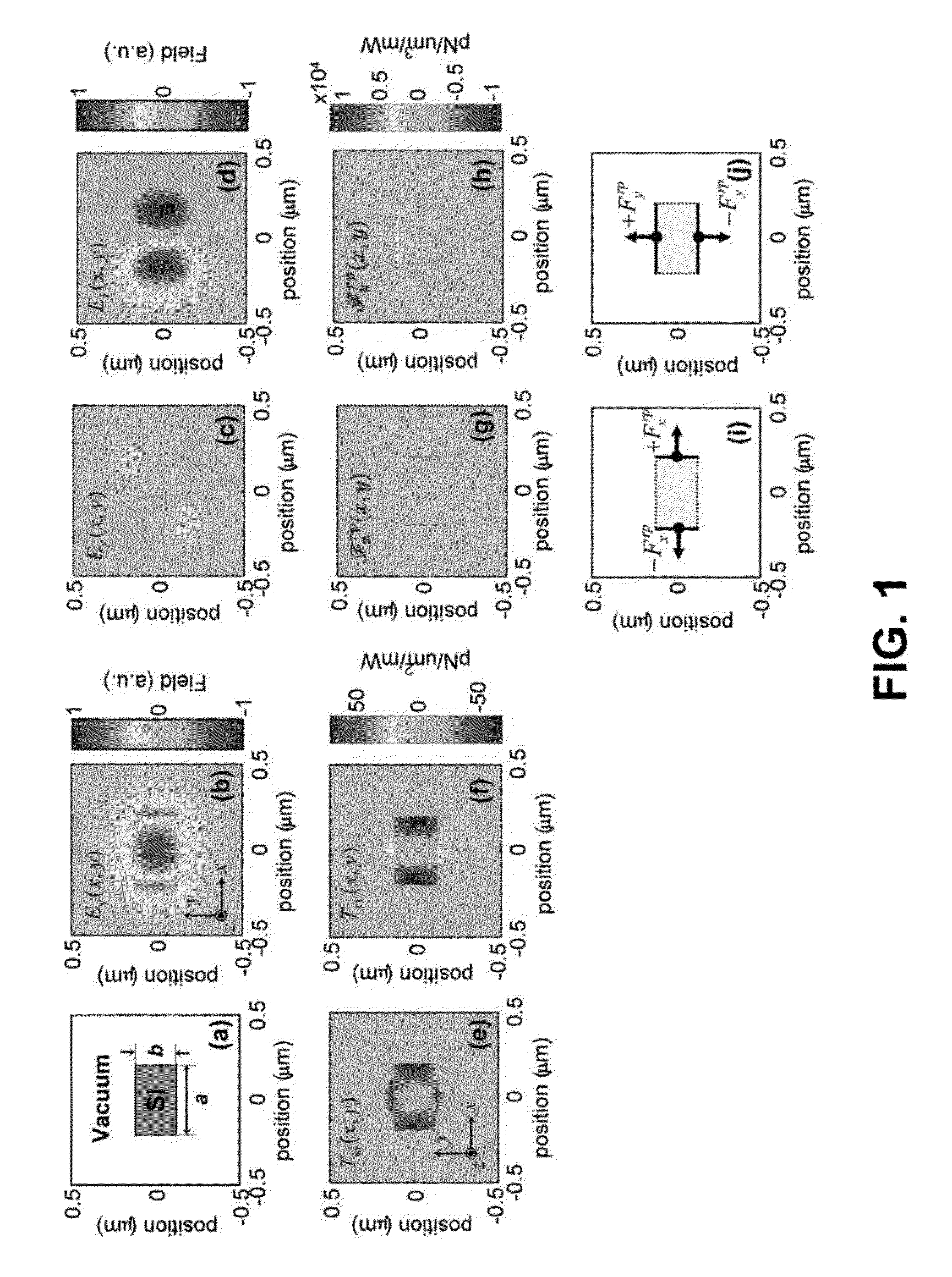

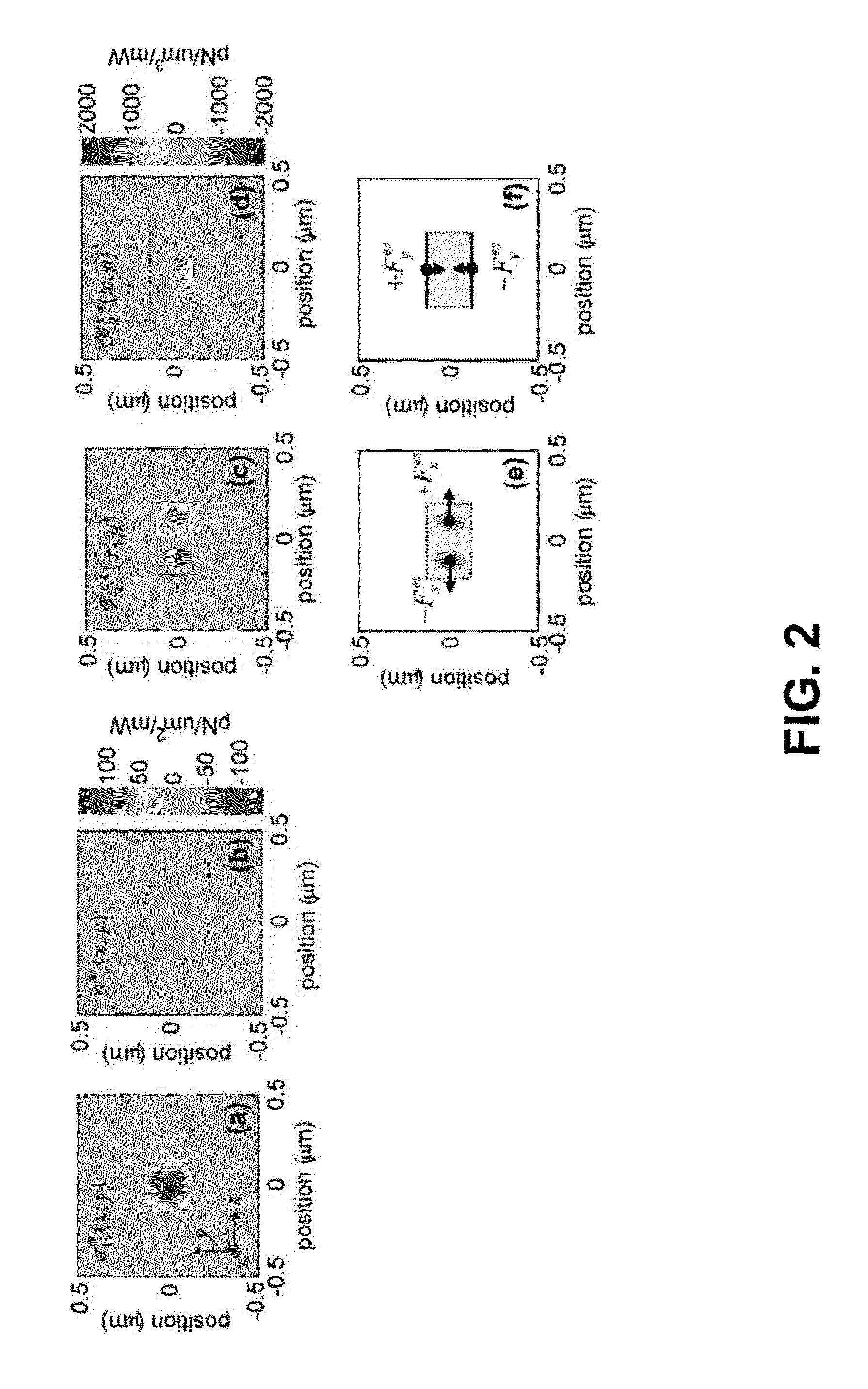

Nano-optomechanical transducer

A nano-optomechanical transducer provides ultrabroadband coherent optomechanical transduction based on Mach-wave emission that uses enhanced photon-phonon coupling efficiencies by low impedance effective phononic medium, both electrostriction and radiation pressure to boost and tailor optomechanical forces, and highly dispersive electromagnetic modes that amplify both electrostriction and radiation pressure. The optomechanical transducer provides a large operating bandwidth and high efficiency while simultaneously having a small size and minimal power consumption, enabling a host of transformative phonon and signal processing capabilities. These capabilities include optomechanical transduction via pulsed phonon emission and up-conversion, broadband stimulated phonon emission and amplification, picosecond pulsed phonon lasers, broadband phononic modulators, and ultrahigh bandwidth true time delay and signal processing technologies.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

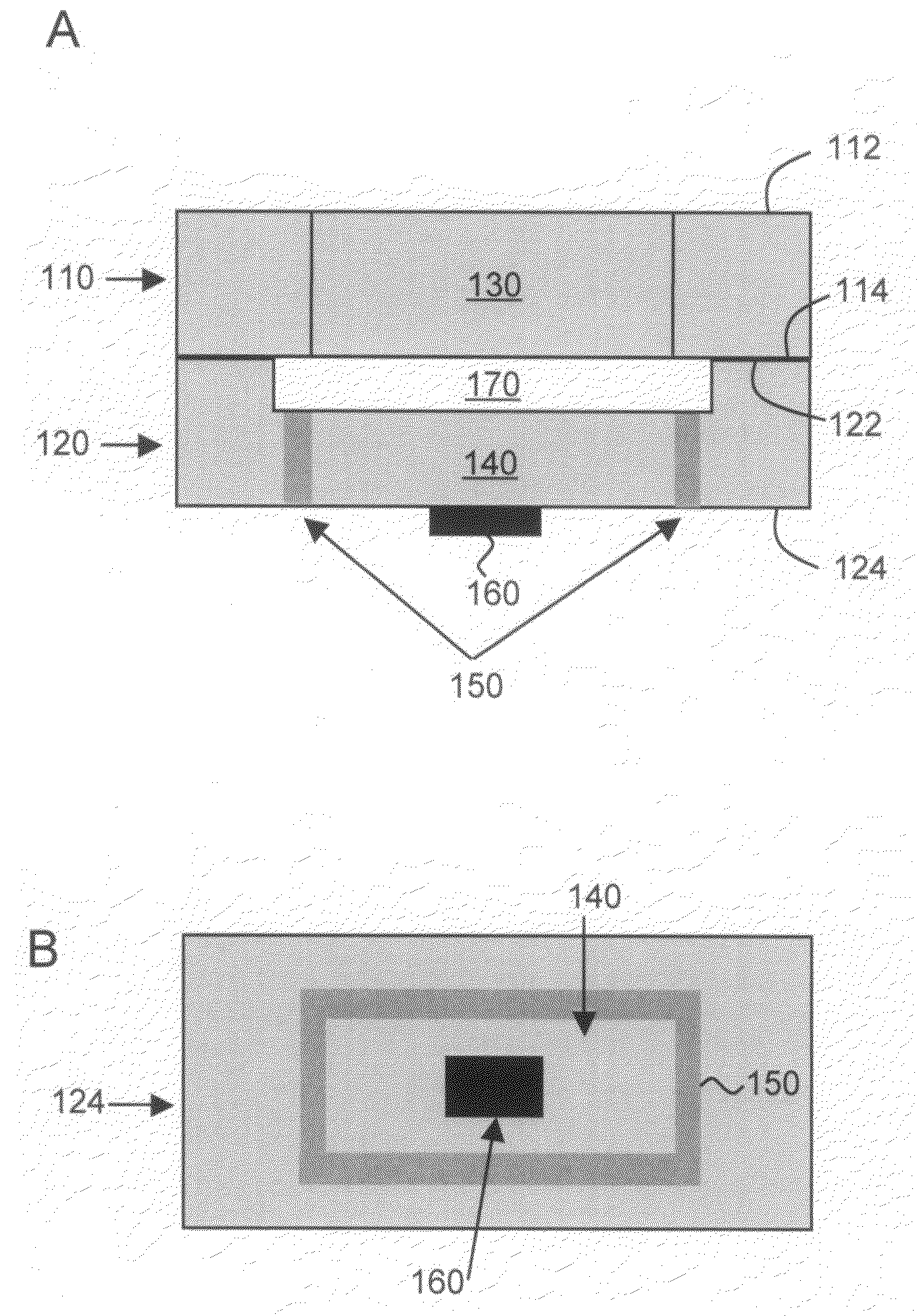

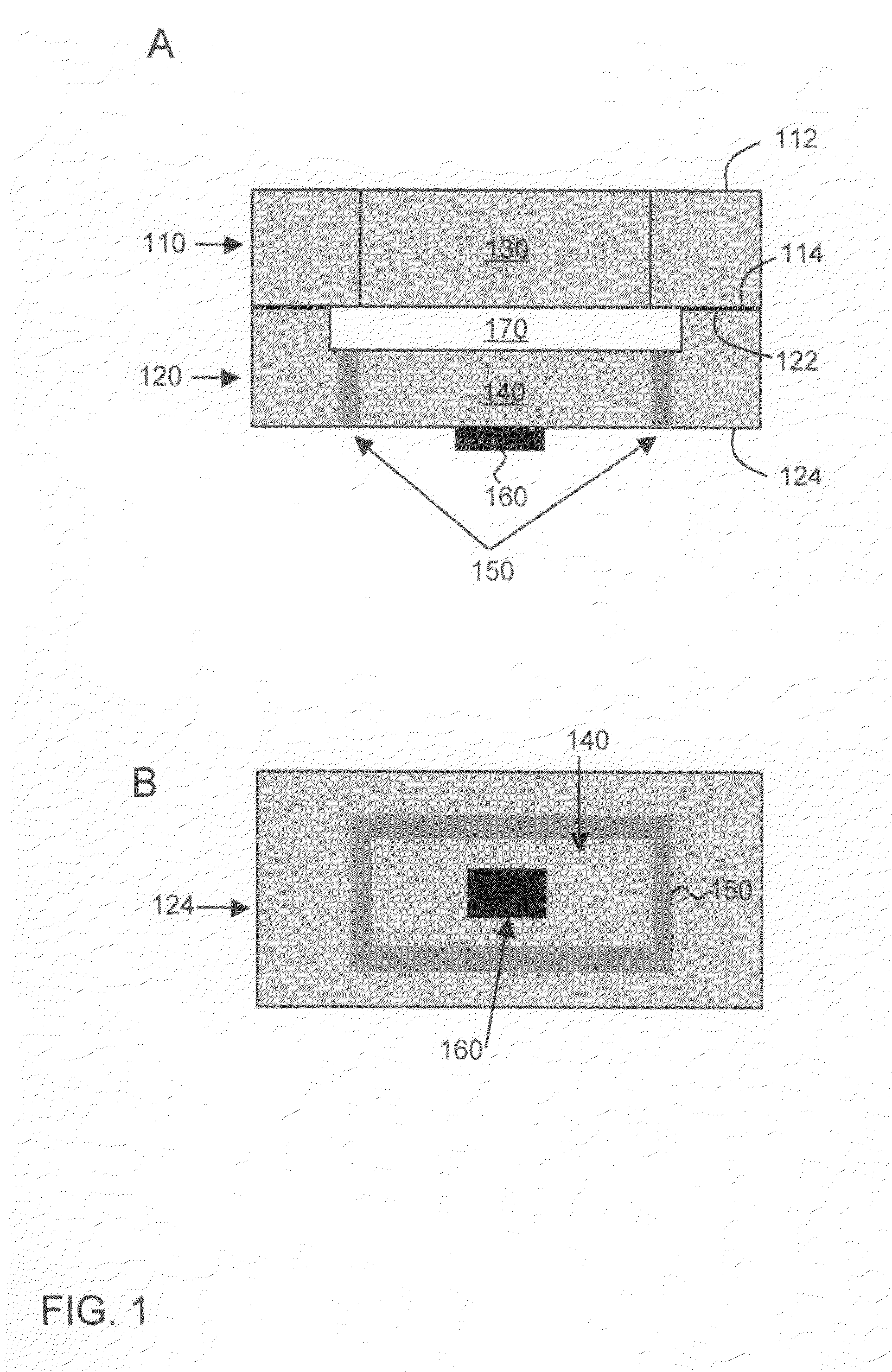

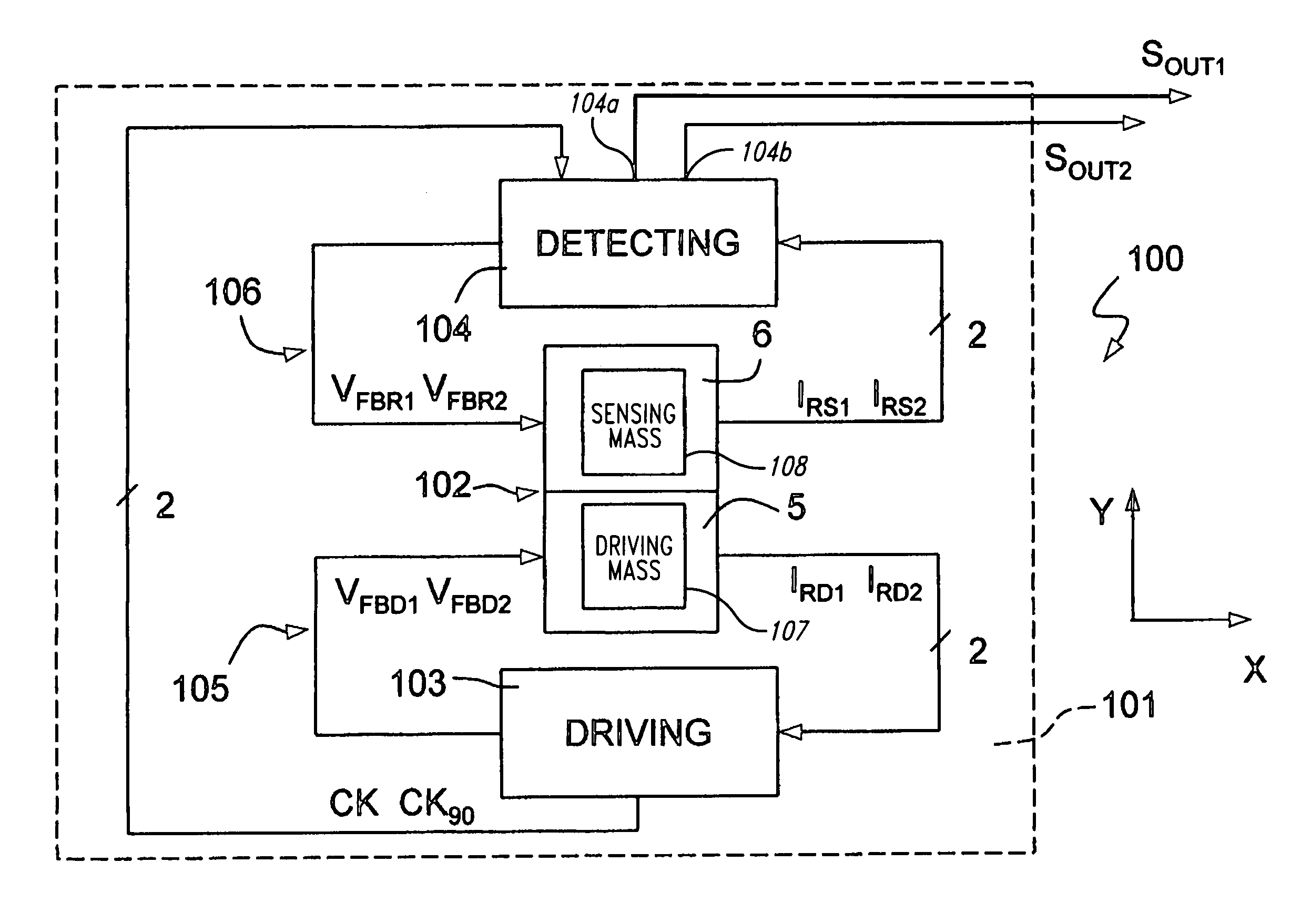

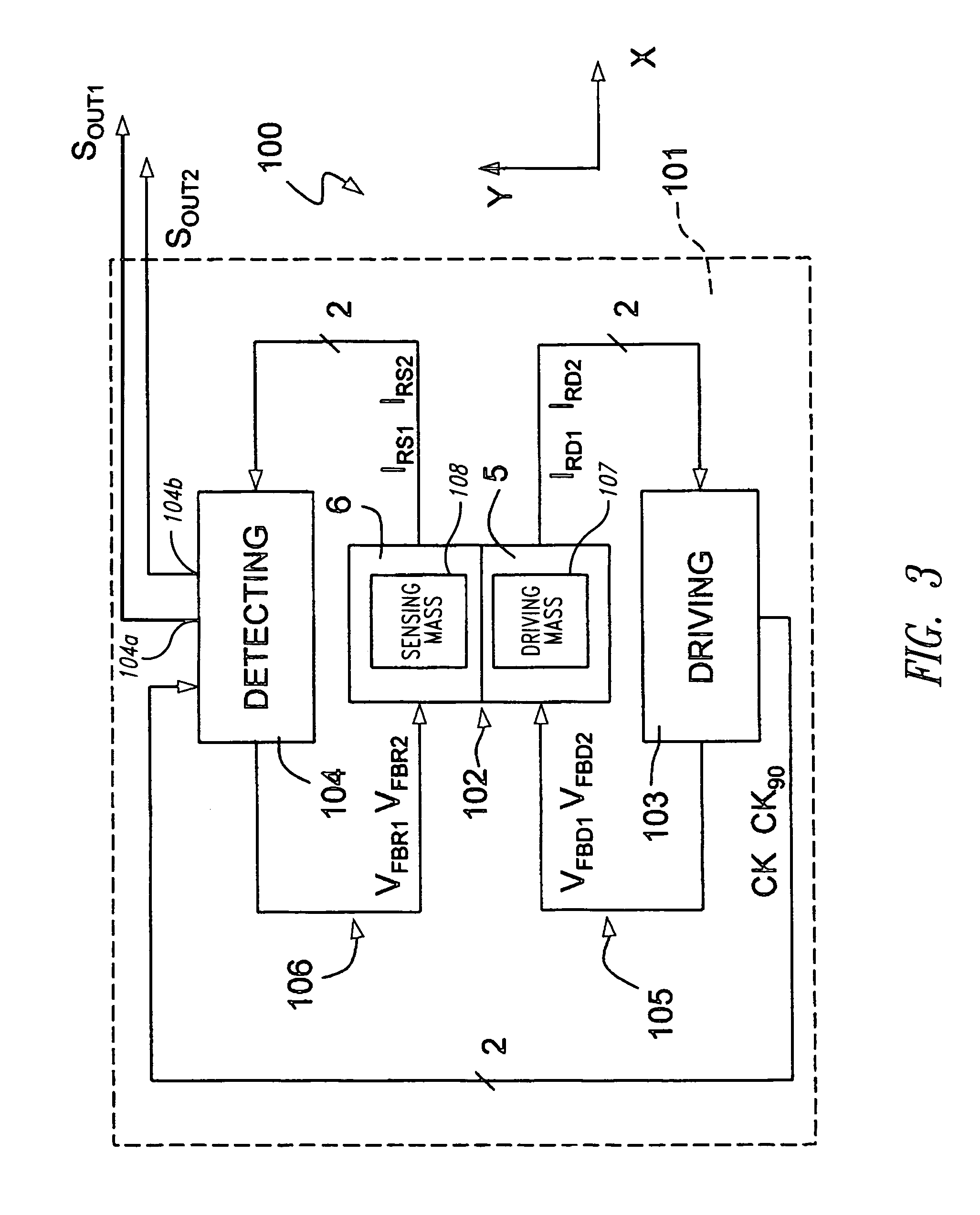

Micro-electro-mechanical sensor with force feedback loop

ActiveUS7275433B2Acceleration measurement using interia forcesSpeed measurement using gyroscopic effectsRest positionDegrees of freedom

A micro-electro-mechanical sensor includes a microstructure having a mass which is movable with respect to a rest position, according to a predetermined degree of freedom, and a displacement-detecting device for detecting a displacement of the mass according to the predetermined degree of freedom. The displacement-detecting device includes a force feedback loop of a purely analog type, which supplies electrostatic forces tending to restore the mass to the rest position in response to a displacement of the mass according to the predetermined degree of freedom.

Owner:STMICROELECTRONICS SRL

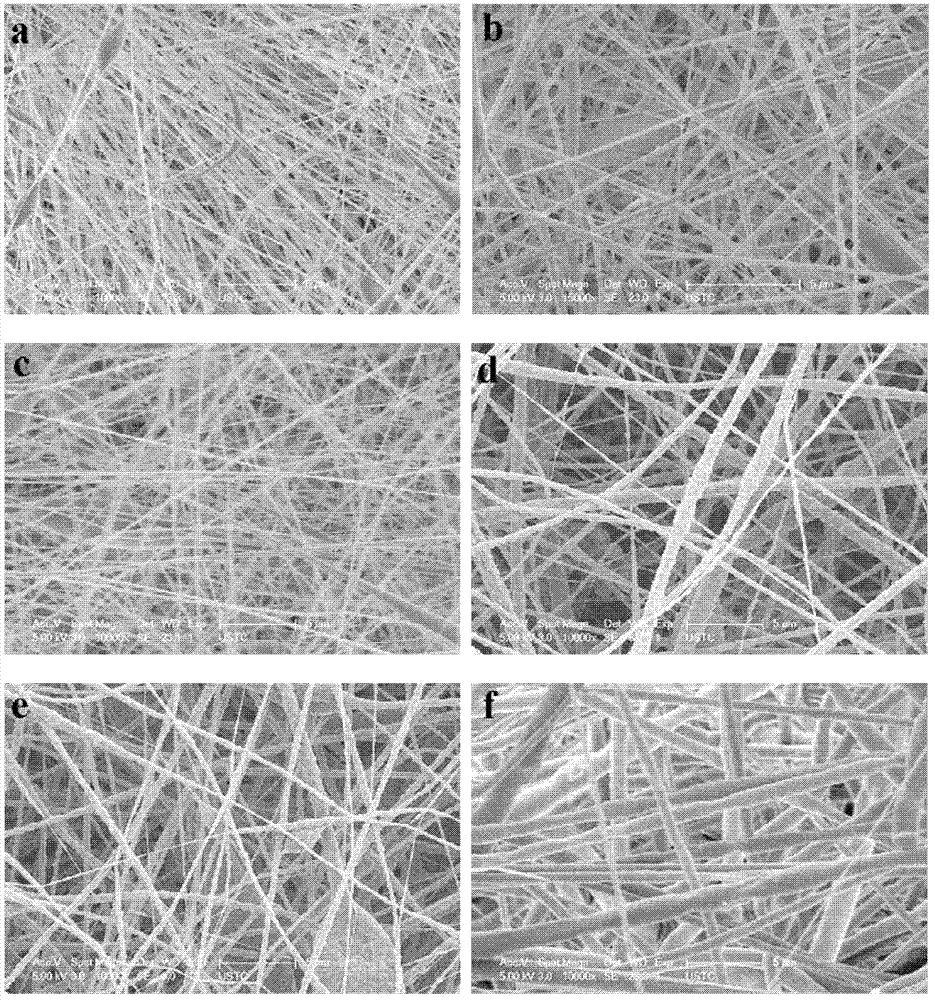

Novel flexible mechanical sensor and preparation method thereof

InactiveCN102954848AHigh sensitivityImprove featuresForce measurement using piezo-electric devicesPolyvinylidene fluorideMechanical sensor

The invention relates to a novel flexible mechanical sensor which consists of a nanofiber film layer and a conductive film electrode layer. The nanofiber film layer is made of piezoelectric material polyvinylidene fluoride or polyvinylidene fluoride-fluoro-olefine copolymer, and the molar weight of the polyvinylidene fluoride in the polyvinylidene fluoride-fluoro-olefine copolymer is 55-85% and is preferably 70-80%. The invention further provides a preparation method of the flexible mechanical sensor.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com